Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7973results about "Carboxylic compound separation/purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

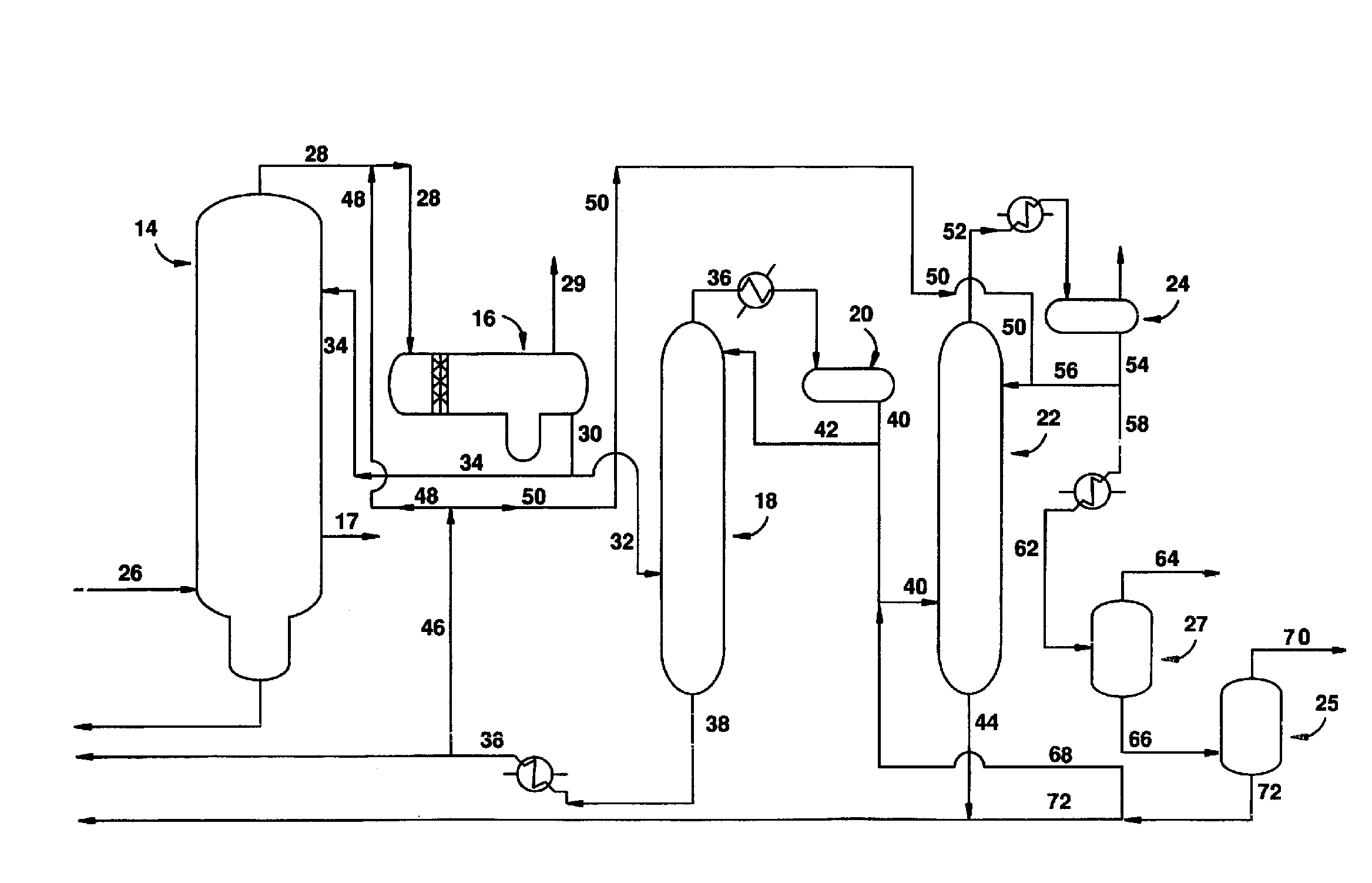

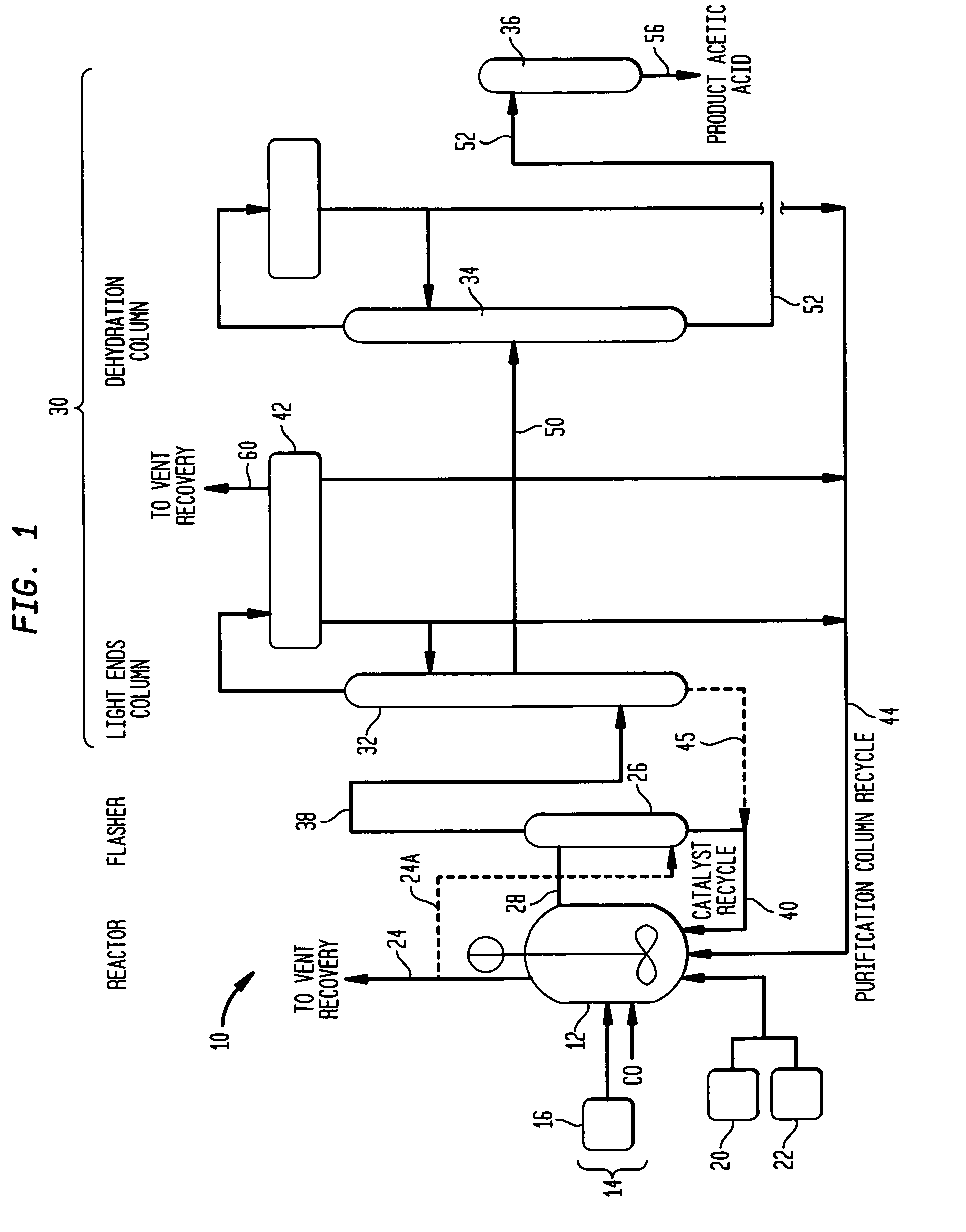

Low energy carbonylation process

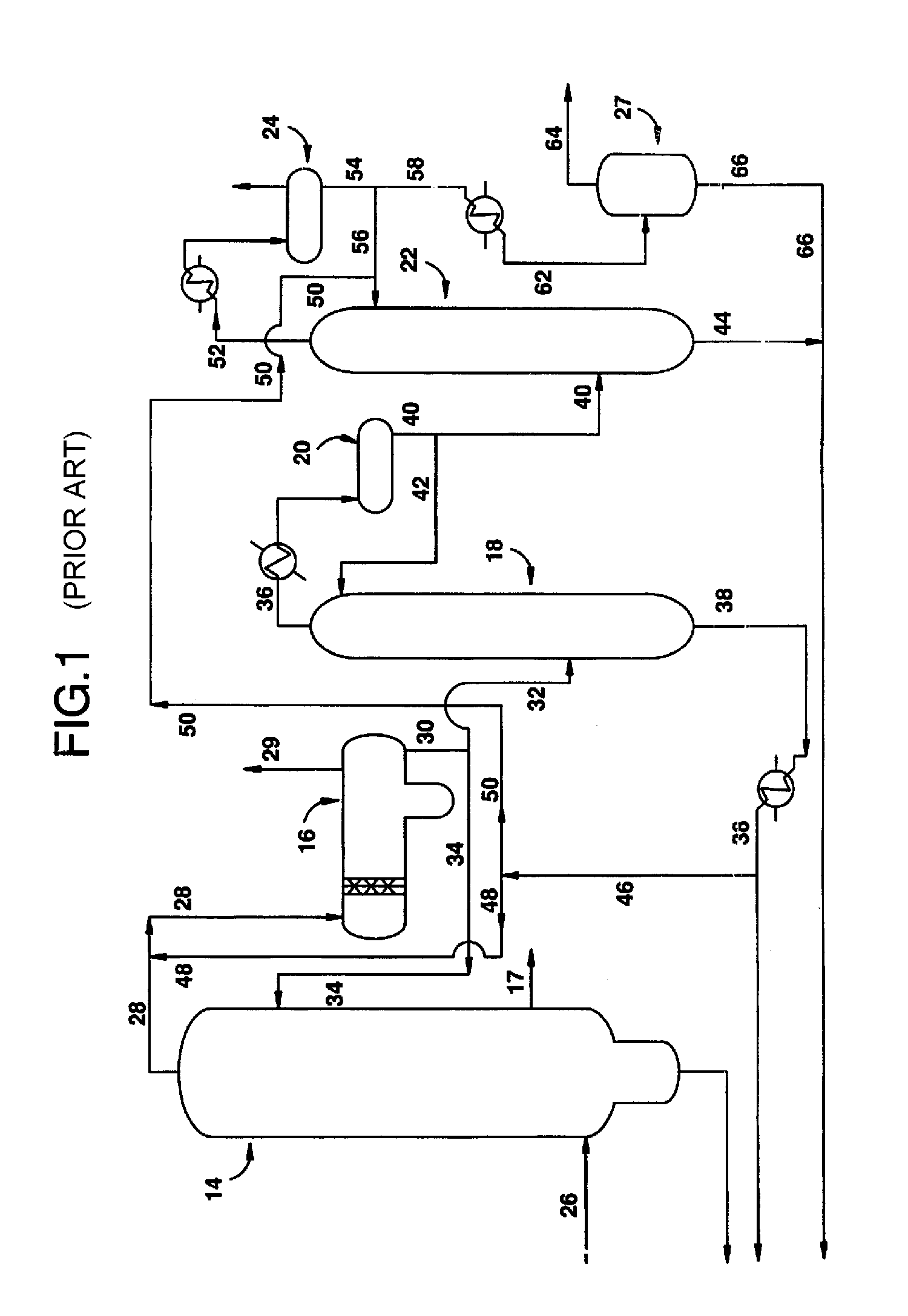

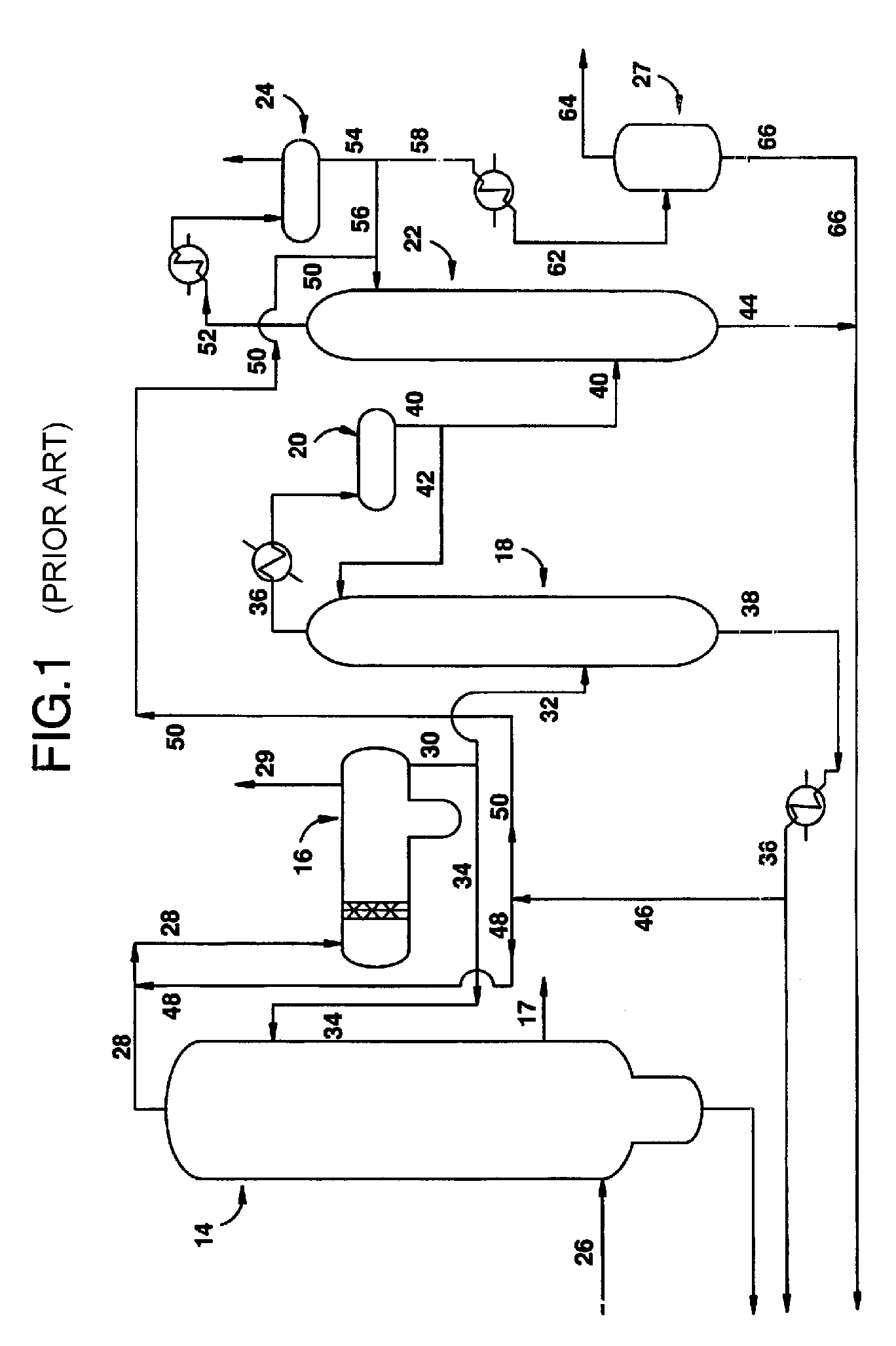

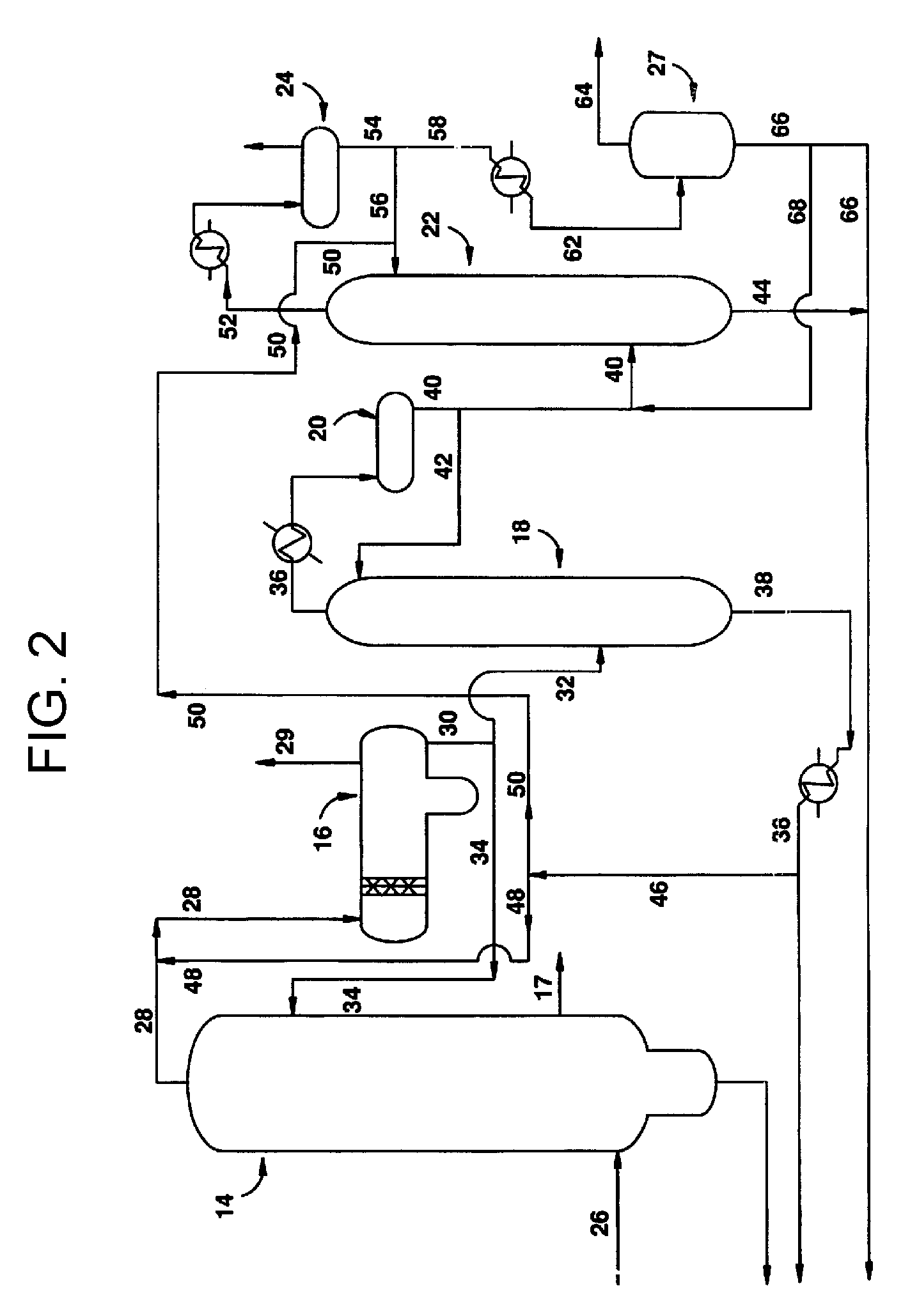

InactiveUS6657078B2Weaken energyHigh purityOrganic compound preparationOrganic chemistry methodsPropanoic acidIodide

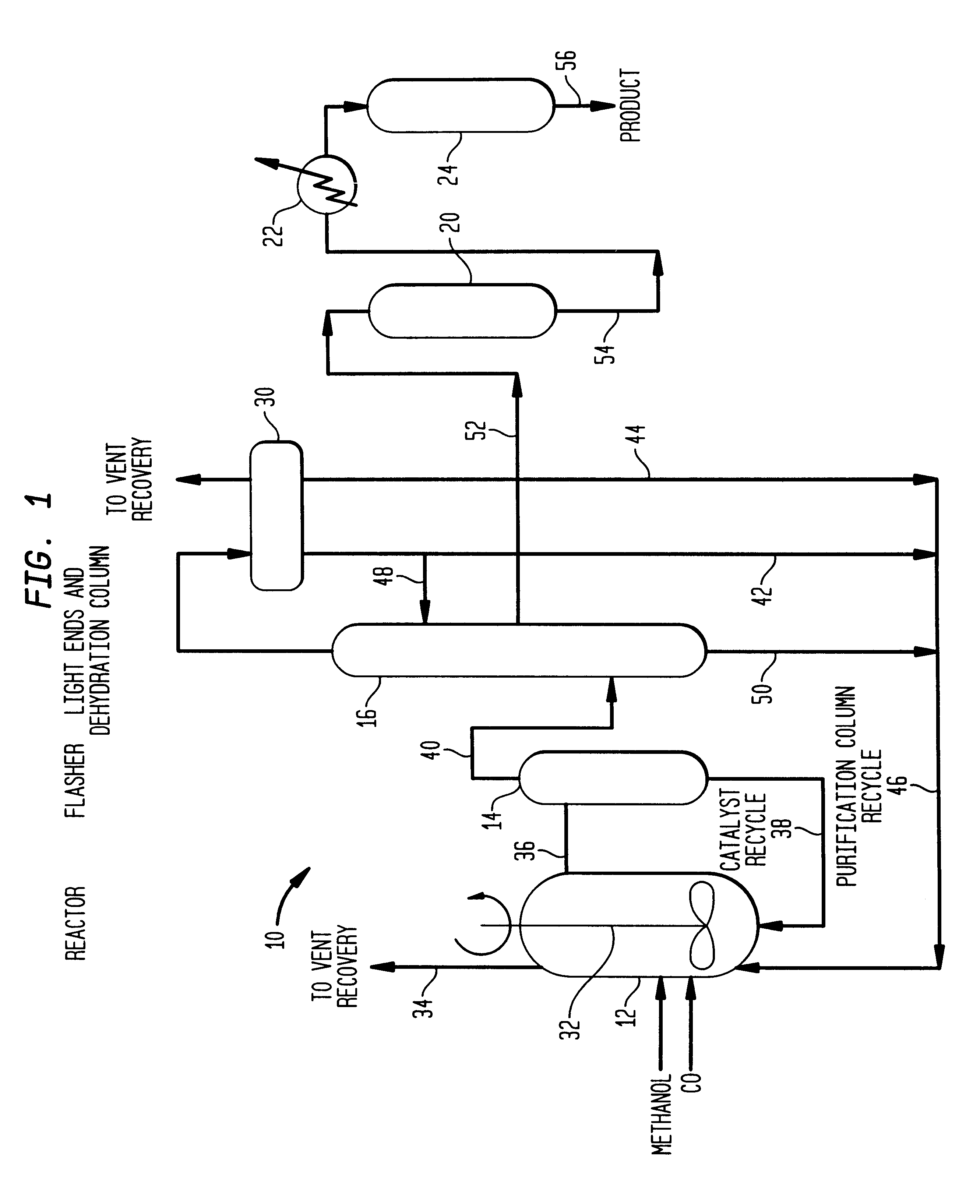

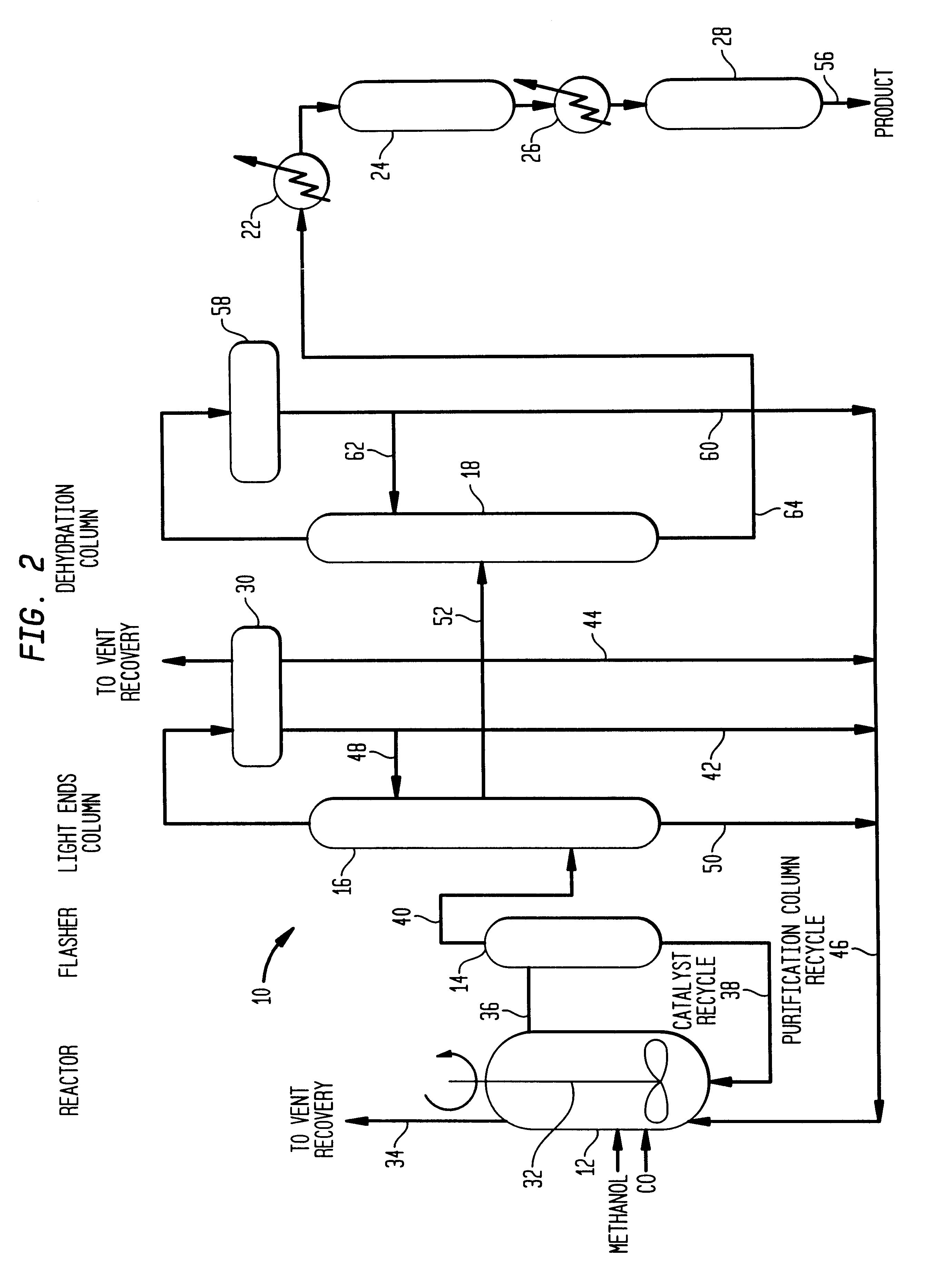

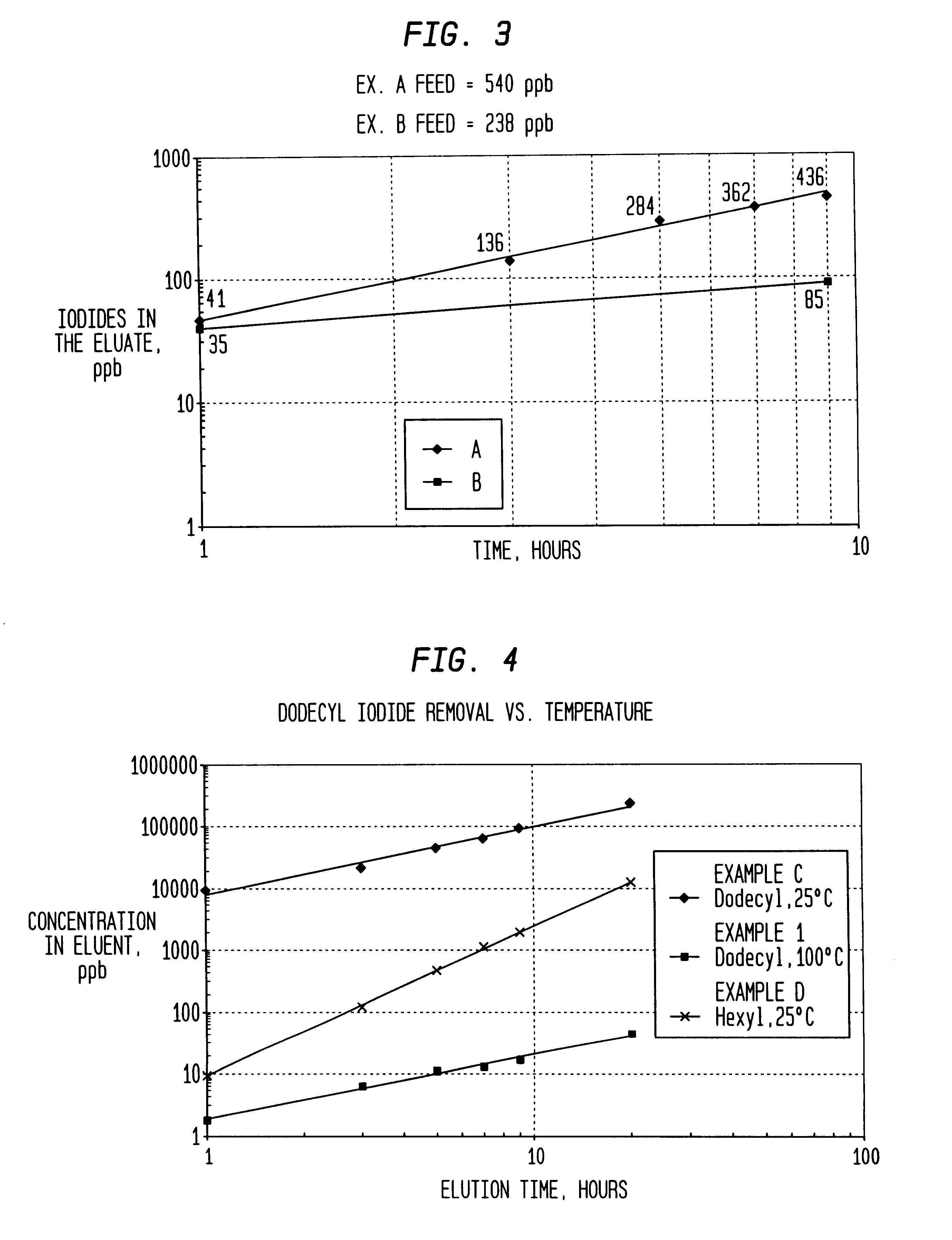

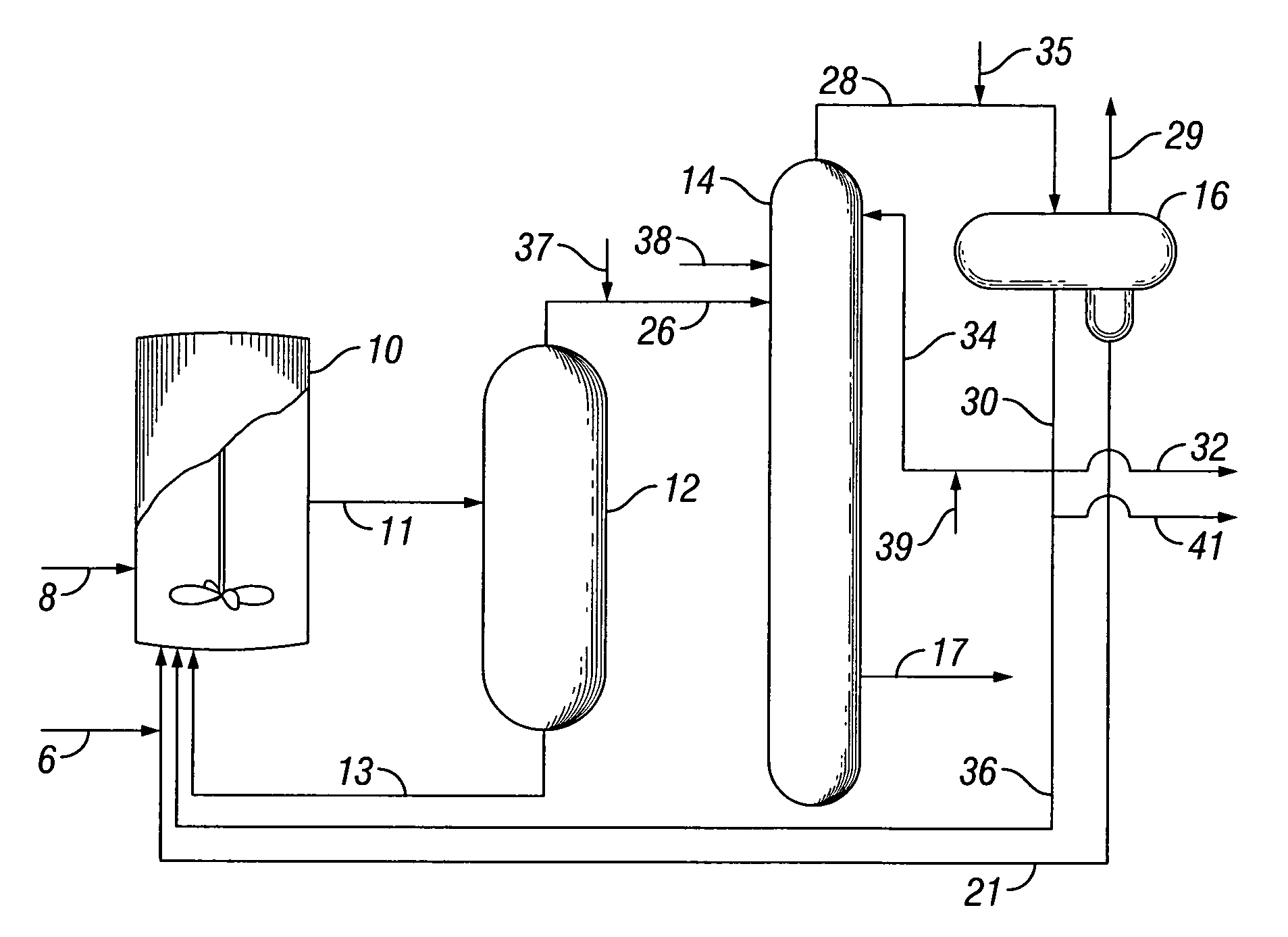

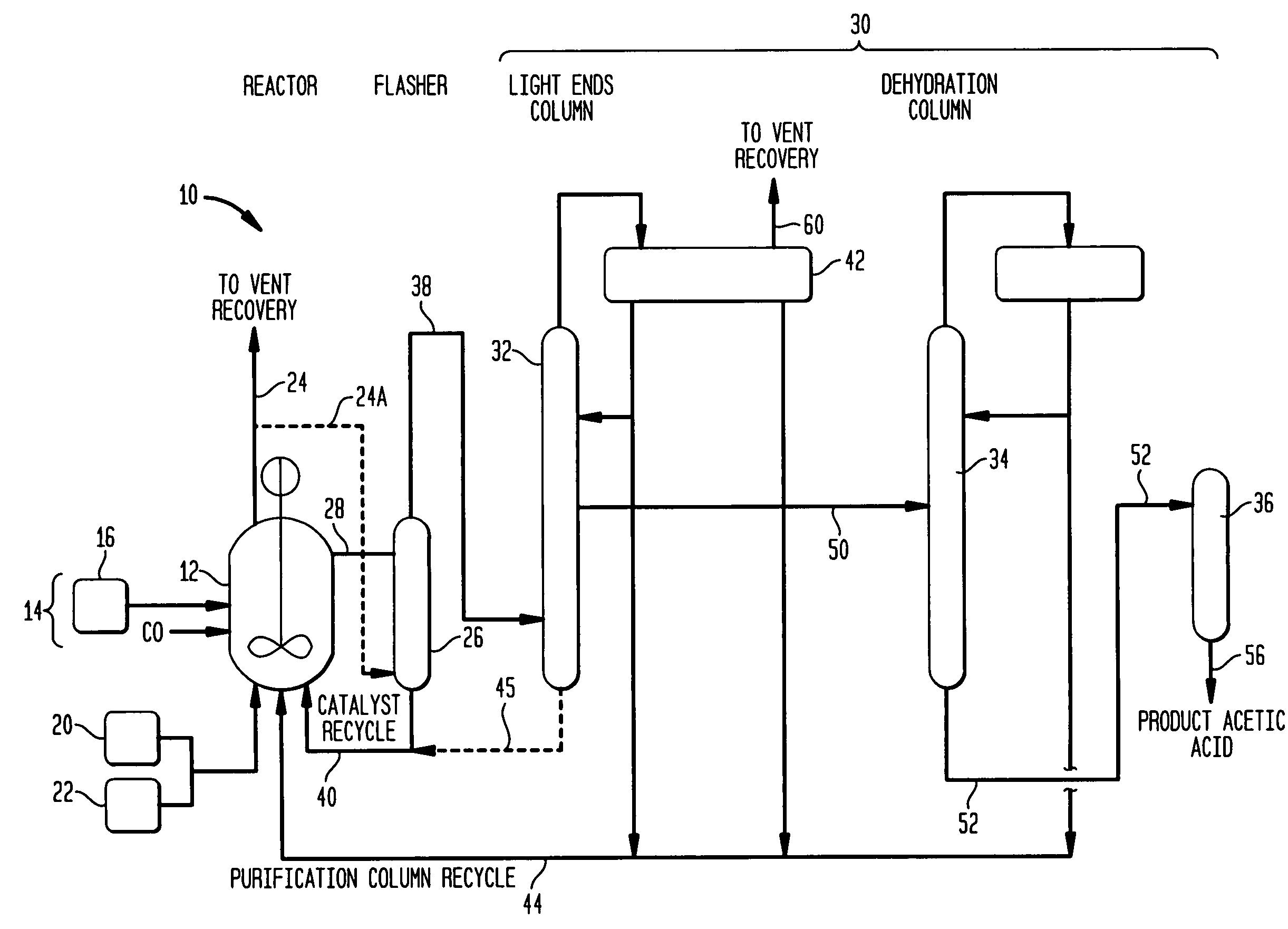

A low energy process for producing acetic acid by the carbonylation of methanol is disclosed. The process involves a rhodium-catalyzed system operated at less than about 14% water utilizing up to 2 distillation columns. The process is preferably controlled such that the product stream has a low level of propionic acid impurity and the level of aldehyde impurities is minimized by way of aldehyde removal or minimizing aldehyde generation. The level of iodides is controlled by contacting the product, at elevated temperatures, with ion exchange resins. In preferred embodiments, at least one silver or mercury exchanged macroreticular strong acid ion exchange resin is used to purify the product. The high temperature treatment provides the added benefit of controlling the Color Value (Pt-Co units) of the product stream.

Owner:CELANESE INT CORP

Low water methanol carbonylation process for high acetic acid production and for water balance control

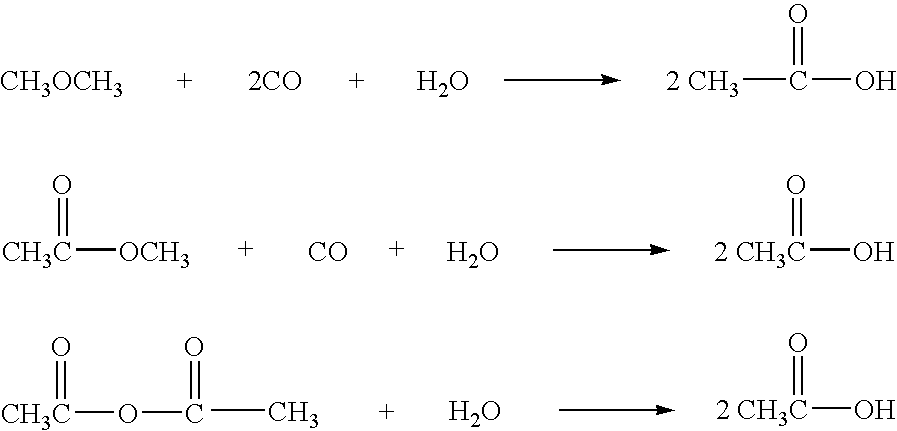

ActiveUS7005541B2High acetic acid production rateIncrease chanceOrganic compound preparationCarboxylic preparation from carbon monoxide reactionWater methanolAcetic anhydride

The invention relates to a process for the production of acetic acid by carbonylation of methanol, and reactive derivatives thereof, in a reaction mixture using a rhodium-based catalyst in low water conditions. The process is used to achieve reaction rates of at least 15 g mol / l / hr. The high rate reactions proceed at water concentrations of less than 2.0 wt. %. Under certain conditions, the water concentration in the reaction mixture of the process is maintained at a desired concentration by at least one process step including adding a compound such as methyl acetate, dimethyl ether, acetic anhydride, or mixtures of these compounds to the reaction system. The process step of adding the components to the reaction mixture may be combined with other process steps for controlling water concentrations in reaction mixtures for the carbonylation of methanol.

Owner:CELANESE INT CORP

Process for producing acetic acid

ActiveUS7208624B2Easy to separateFacilitate phase separationOrganic compound preparationCarboxylic preparation from carbon monoxide reactionMethyl acetateFormate Esters

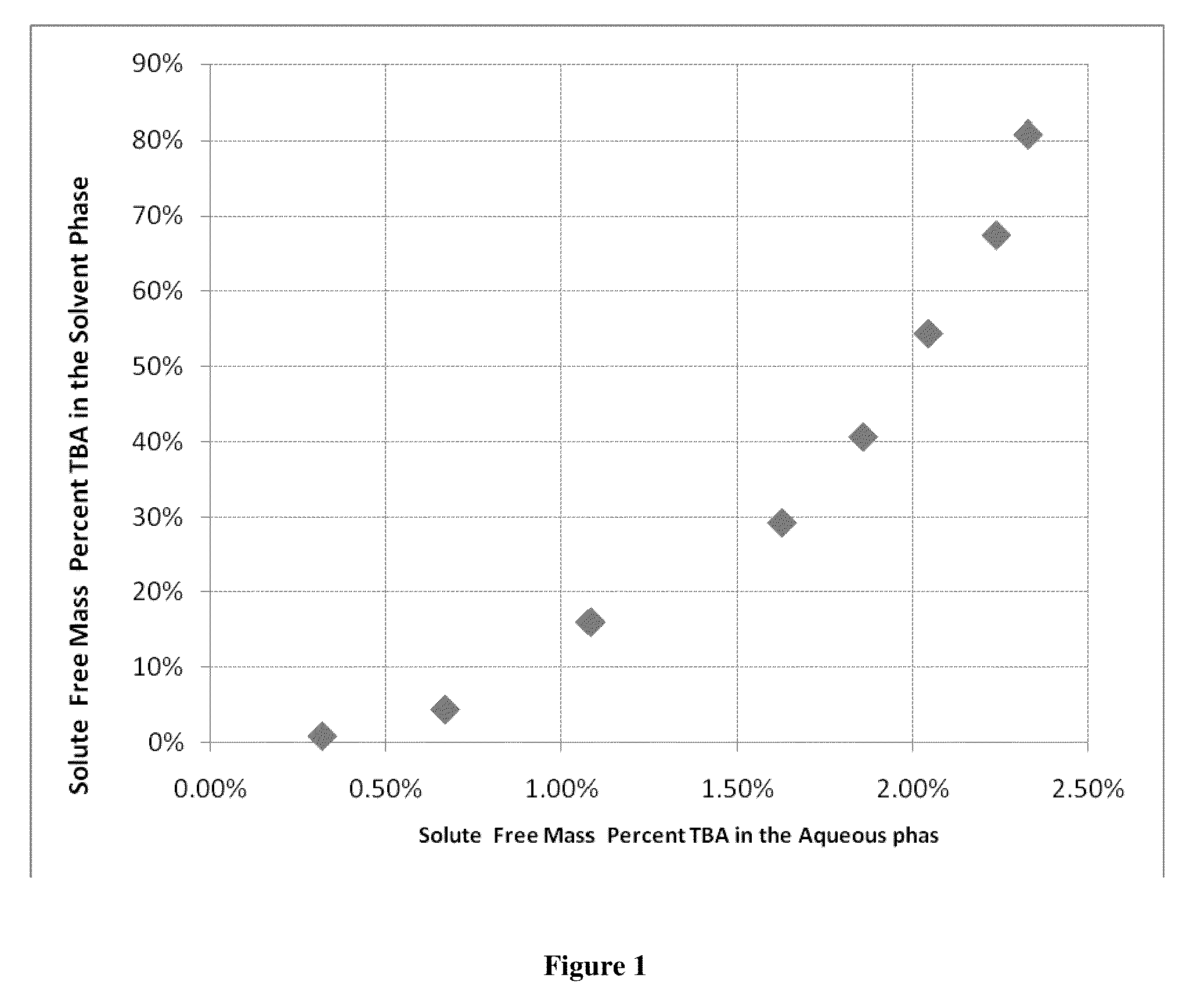

An improved process is disclosed for producing acetic acid, including the following steps: reacting a carbonylatable reactant such as methanol, methyl acetate, methyl formate or dimethyl ether with carbon monoxide in a reaction medium containing water, methyl iodide, and a catalyst to produce a reaction product that contains acetic acid; separating the reaction product to provide a volatile phase containing acetic acid, water, and methyl iodide and a less volatile phase; distilling the volatile phase to produce a purified acetic acid product and a first overhead containing water, methyl acetate, and methyl iodide; phase separating the first overhead to provide a first liquid phase containing water and a second liquid phase containing methyl iodide; and adding dimethyl ether to the process in an amount effective to enhance separation of the first overhead to form the first and second liquid phases.

Owner:CELANESE INT CORP

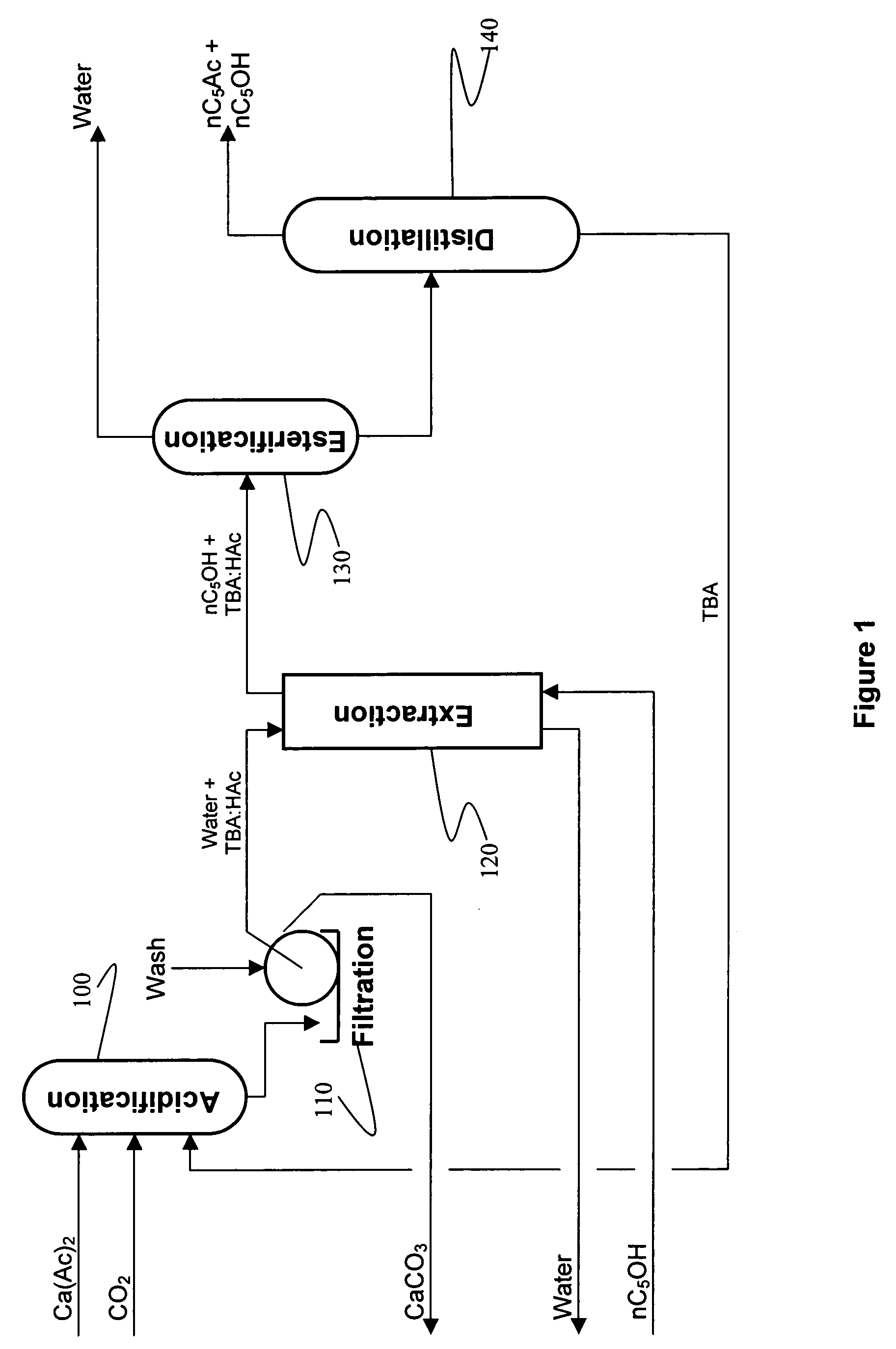

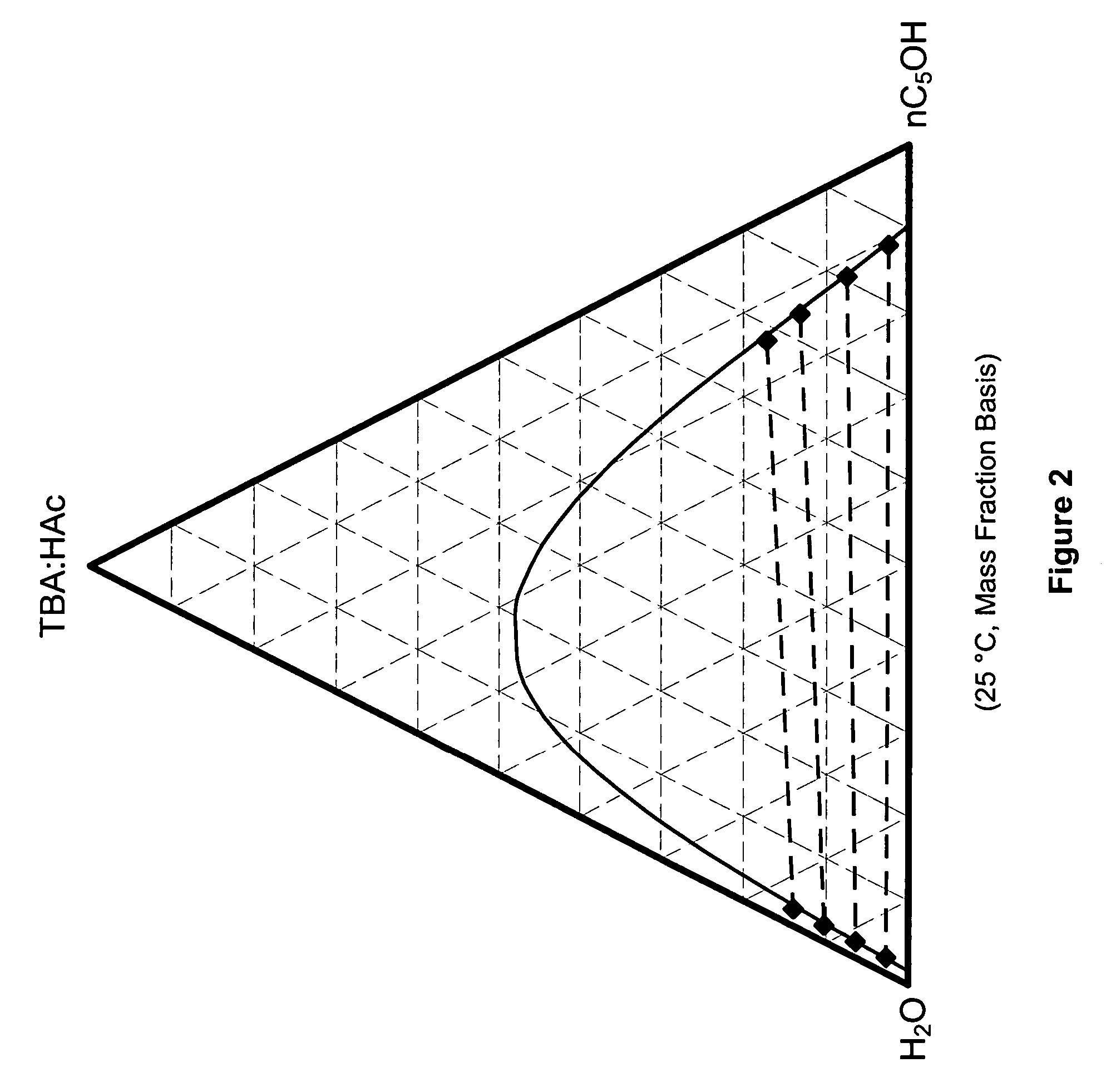

Recovery of organic acids

InactiveUS20090281354A1Promote recoveryOvercome consumptionPreparation from carboxylic acid saltsOrganic compound preparationOrganic acidReactive distillation

A method is disclosed for the recovery of an organic acid from a dilute salt solution in which the cation of the salt forms an insoluble carbonate salt. An amine and CO2 are introduced to the solution to form the insoluble carbonate salt and a complex between the acid and the amine. The acid / amine complex is thermally dissociated, or “cracked”, in the presence of a water immiscible solvent in which the amine is selectively soluble and in which the acid is not appreciably soluble. The organic acid may then be recovered from the water by any suitable means such as distillation, reactive distillation, extraction, or reactive extraction.

Owner:ZEACHEM

Process for the manufacture of diesel range hydrocarbons

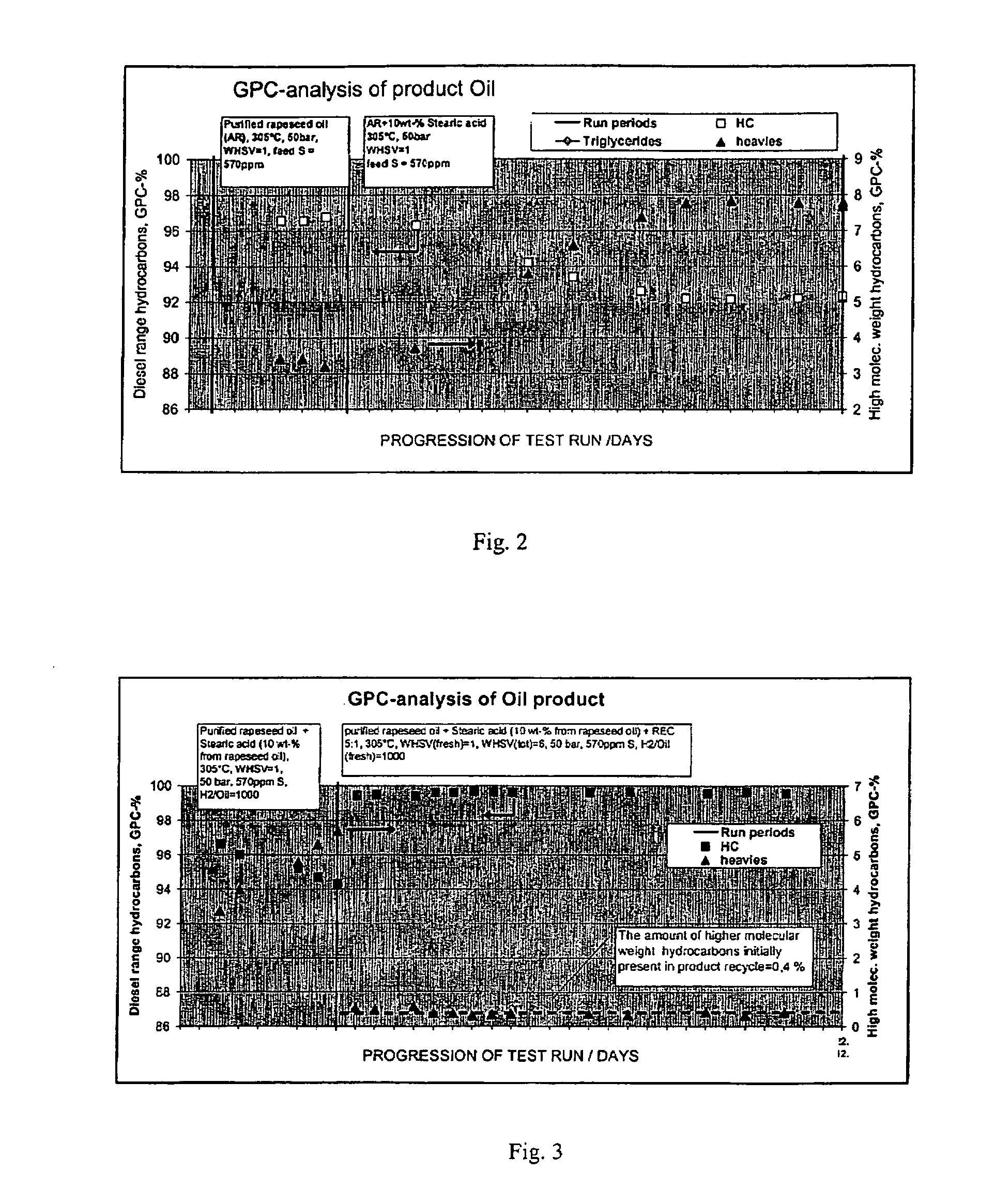

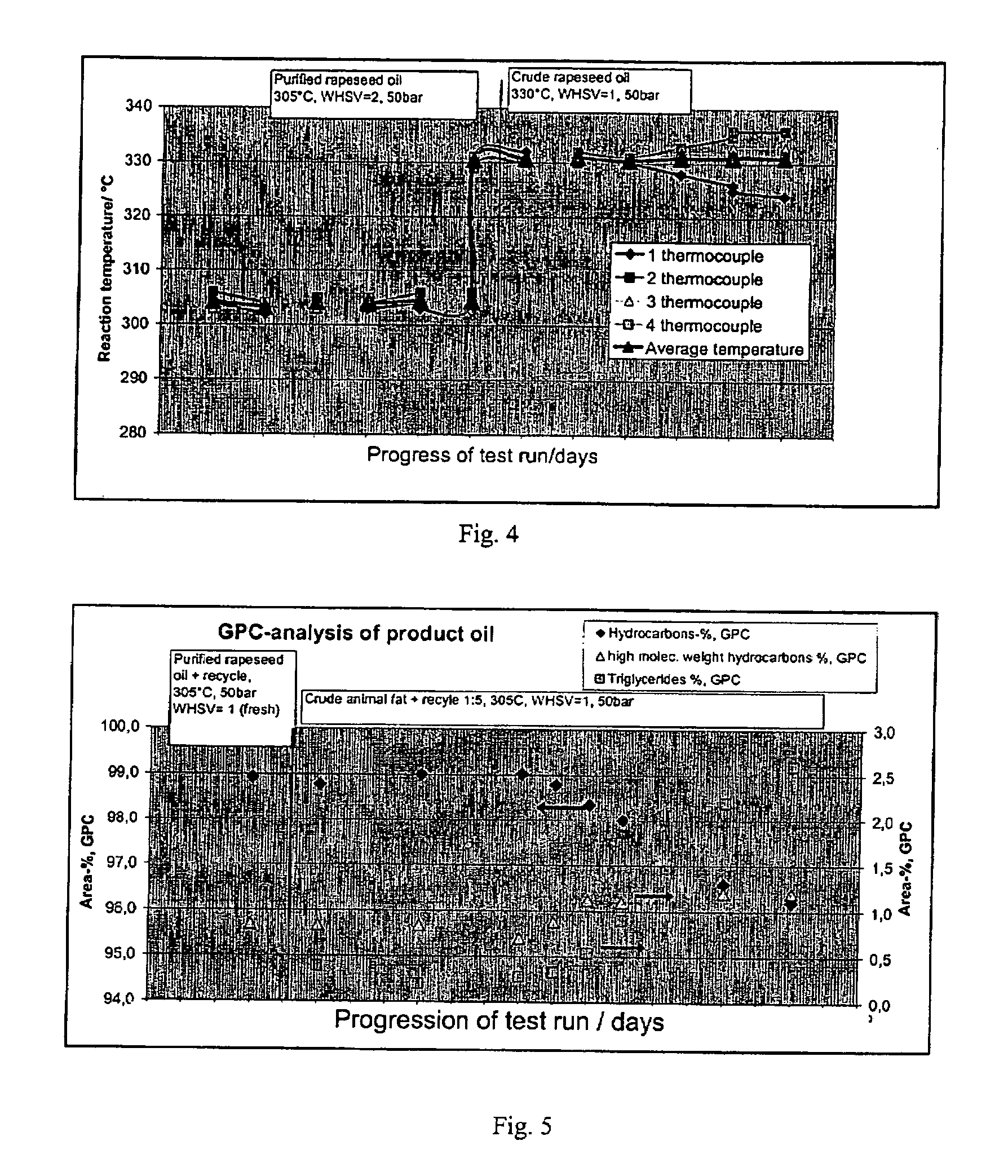

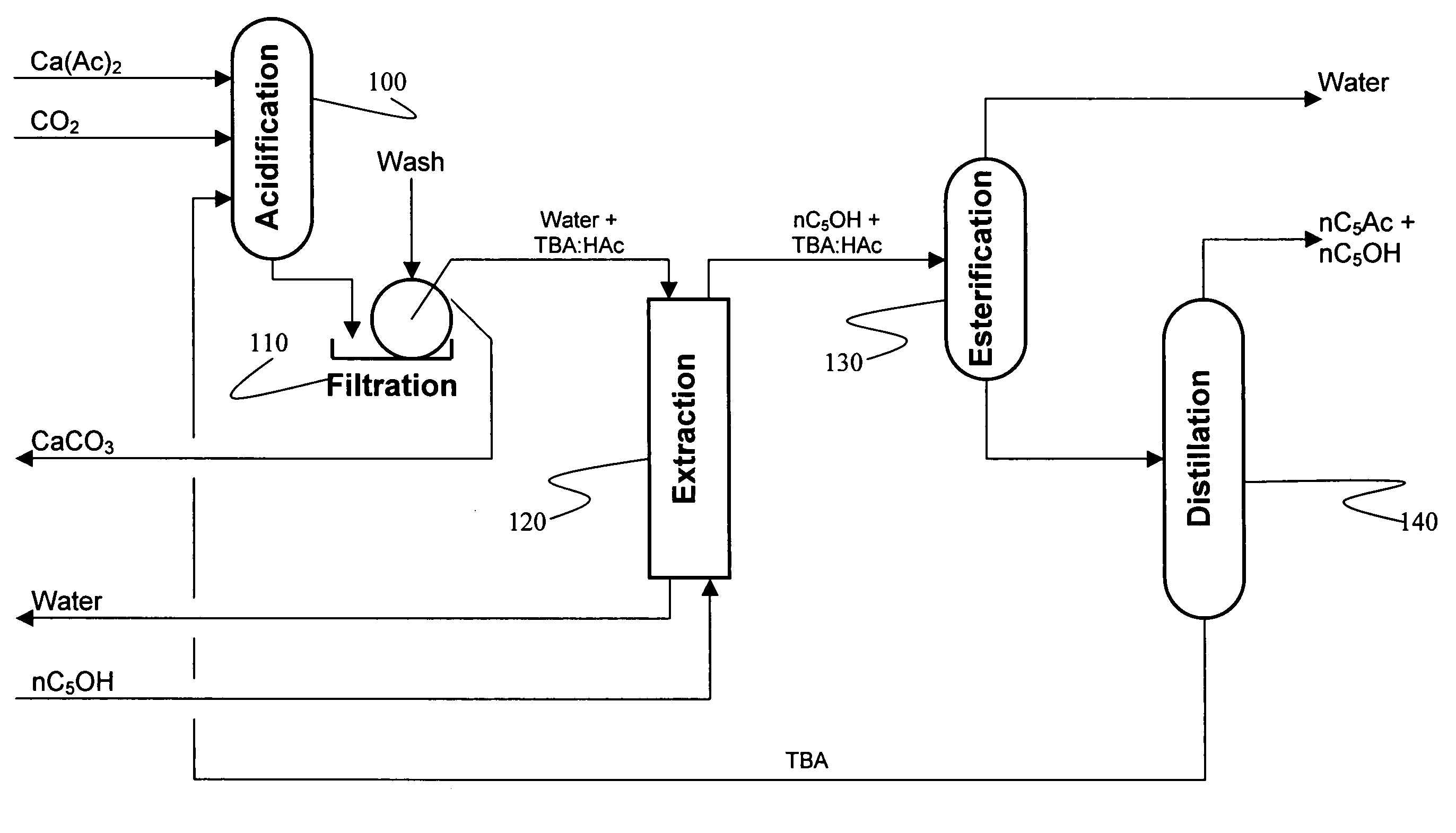

ActiveUS20070010682A1Fatty oils/acids recovery from wasteHydrocarbon by isomerisationIsomerizationReaction temperature

The invention relates to a process for the manufacture of diesel range hydrocarbons wherein a feed is hydrotreated in a hydrotreating step and isomerised in an isomerisation step, and a feed comprising fresh feed containing more than 5 wt % of free fatty acids and at least one diluting agent is hydrotreated at a reaction temperature of 200-400° C., in a hydrotreating reactor in the presence of catalyst, and the ratio of the diluting agent / fresh feed is 5-30:1.

Owner:NESTE OIL OY

Recovery of organic acids

InactiveUS7601865B2Promote recoveryOvercome consumptionPreparation from carboxylic acid saltsOrganic compound preparationOrganic acidAlcohol

Owner:ZEACHEM

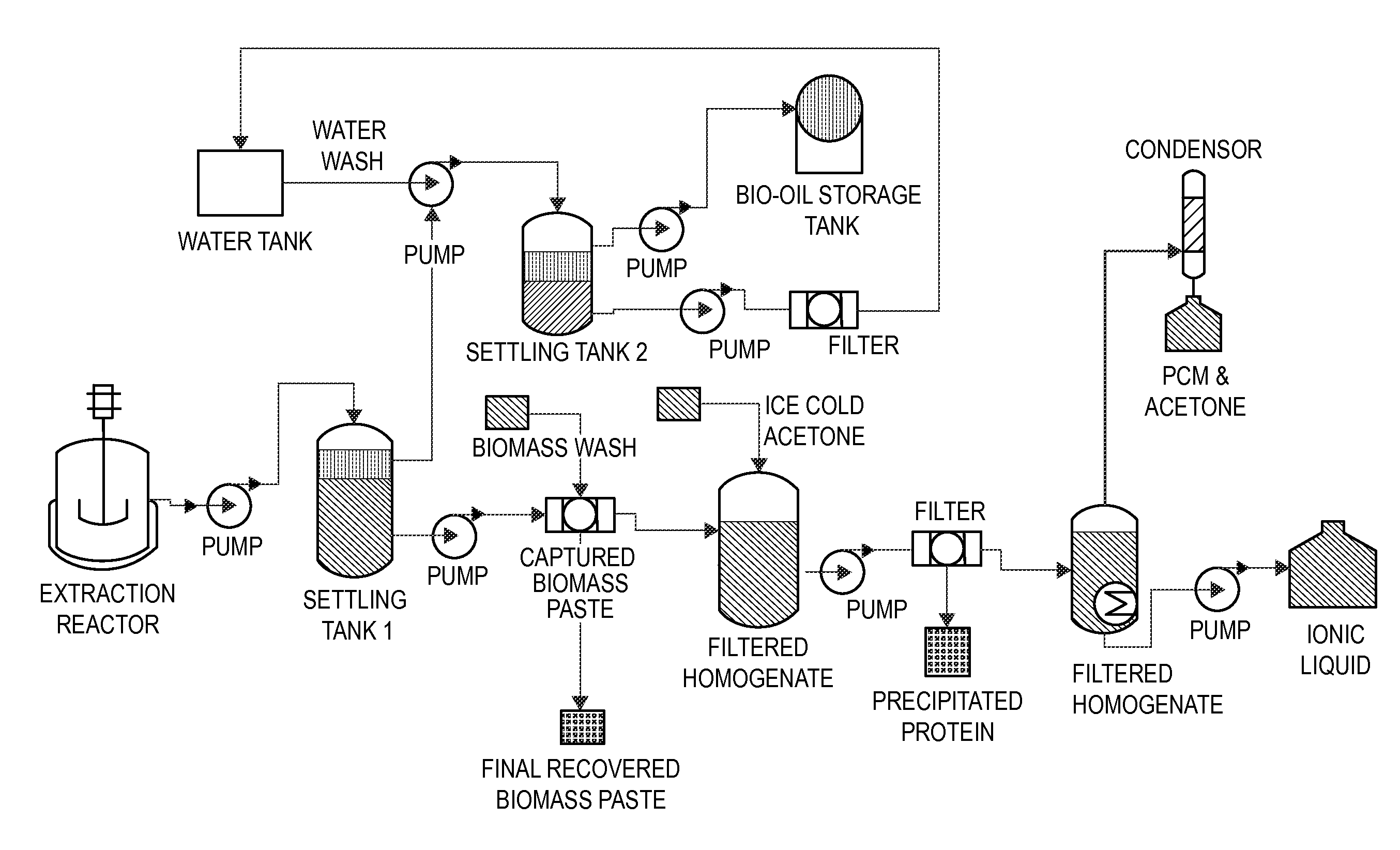

Methods and compositions for extraction and transesterification of biomass components

InactiveUS20090234146A1Fatty oils/acids recovery from wasteFatty acid esterificationTransesterificationBiofuel

Methods and compositions are disclosed for the direct transesterification and extraction of bio-lipids and bio-oils in the production of biofuel, particularly fatty acid methyl ester products.

Owner:UNIV OF HAWAII

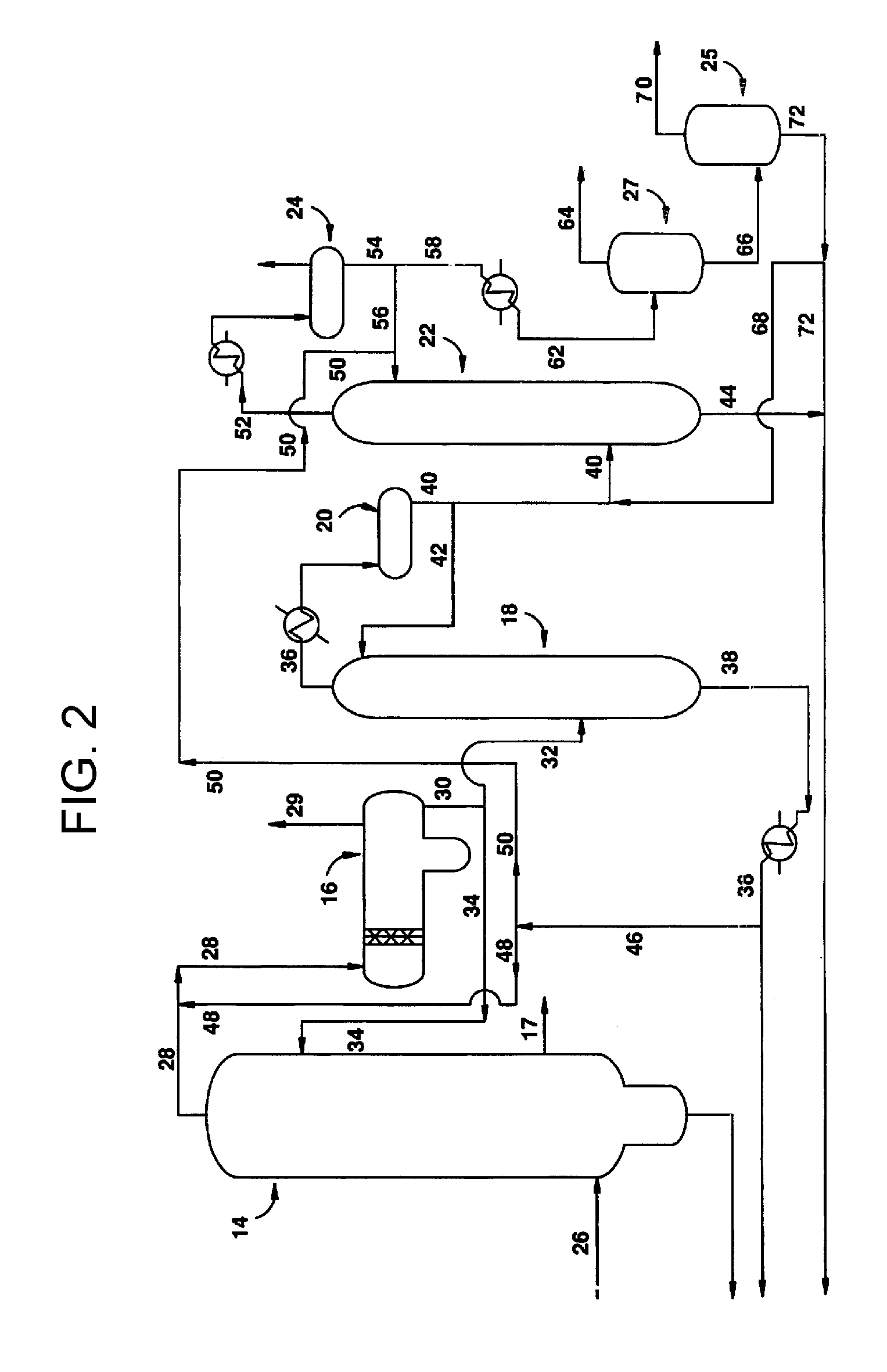

Removal of permanganate reducing compounds from methanol carbonylation process stream

ActiveUS7223886B2Reduce solubilitySimple methodOrganic compound preparationPreparation by carbon monoxide or formate reactionAcetic acidIodide

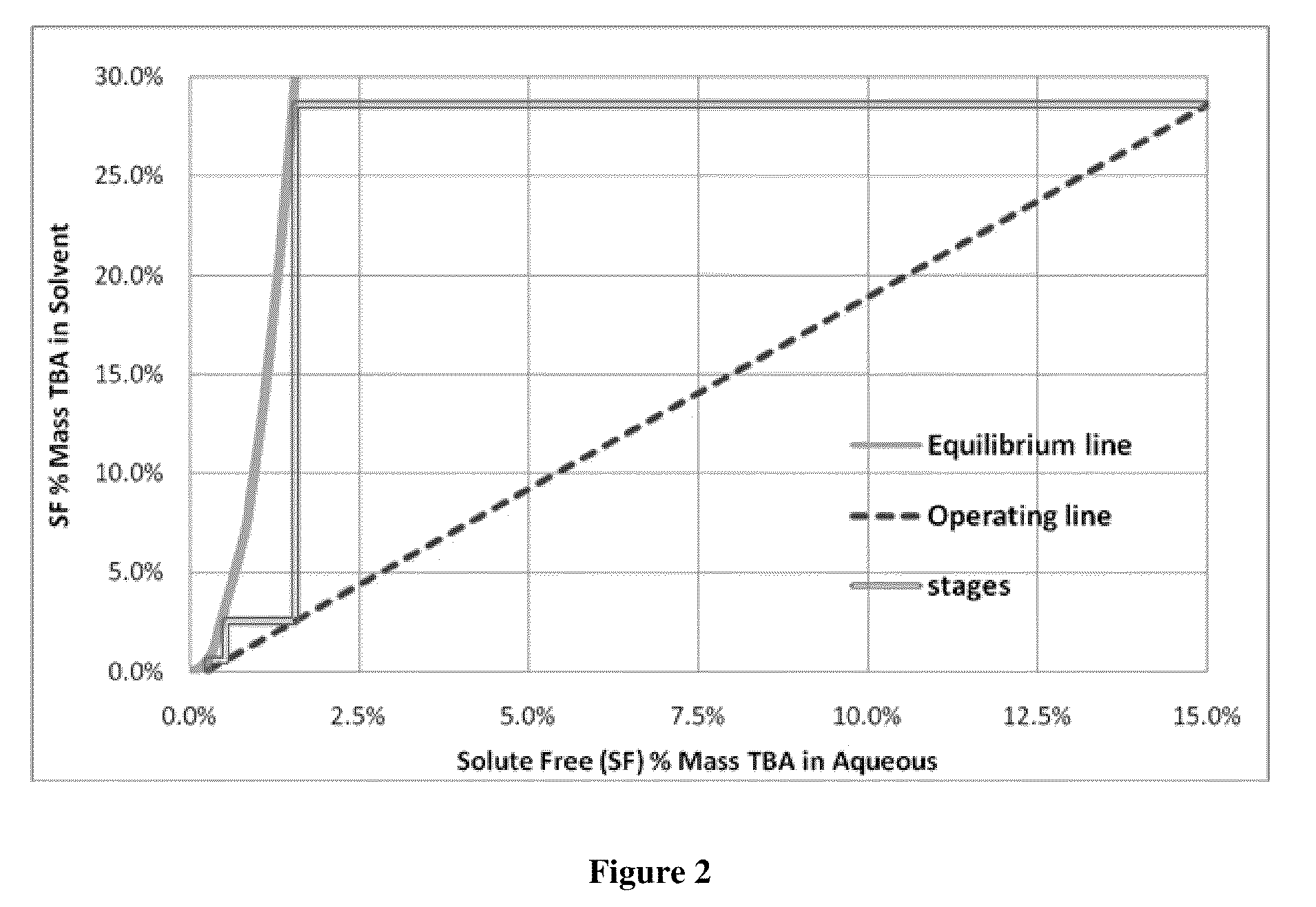

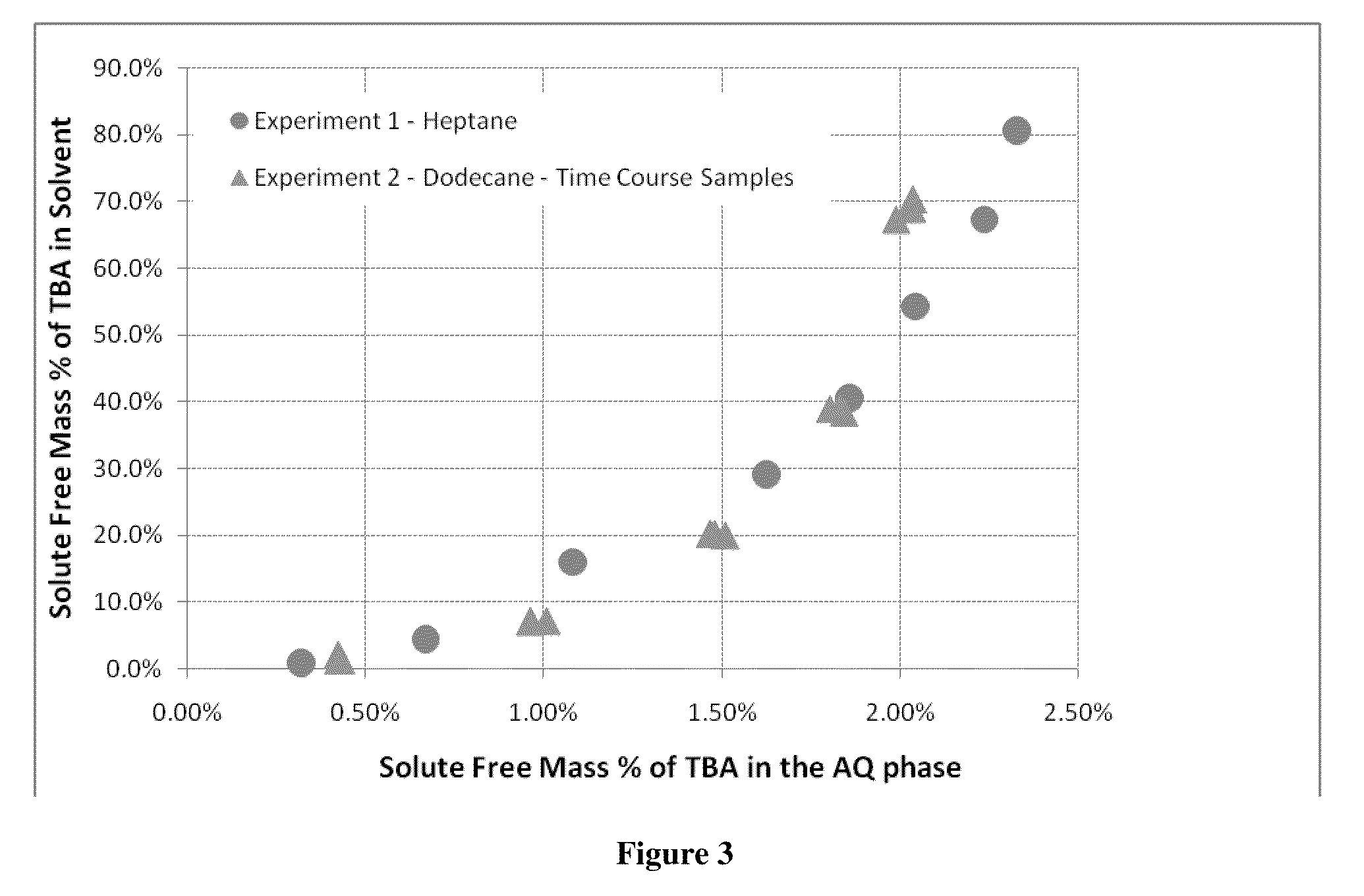

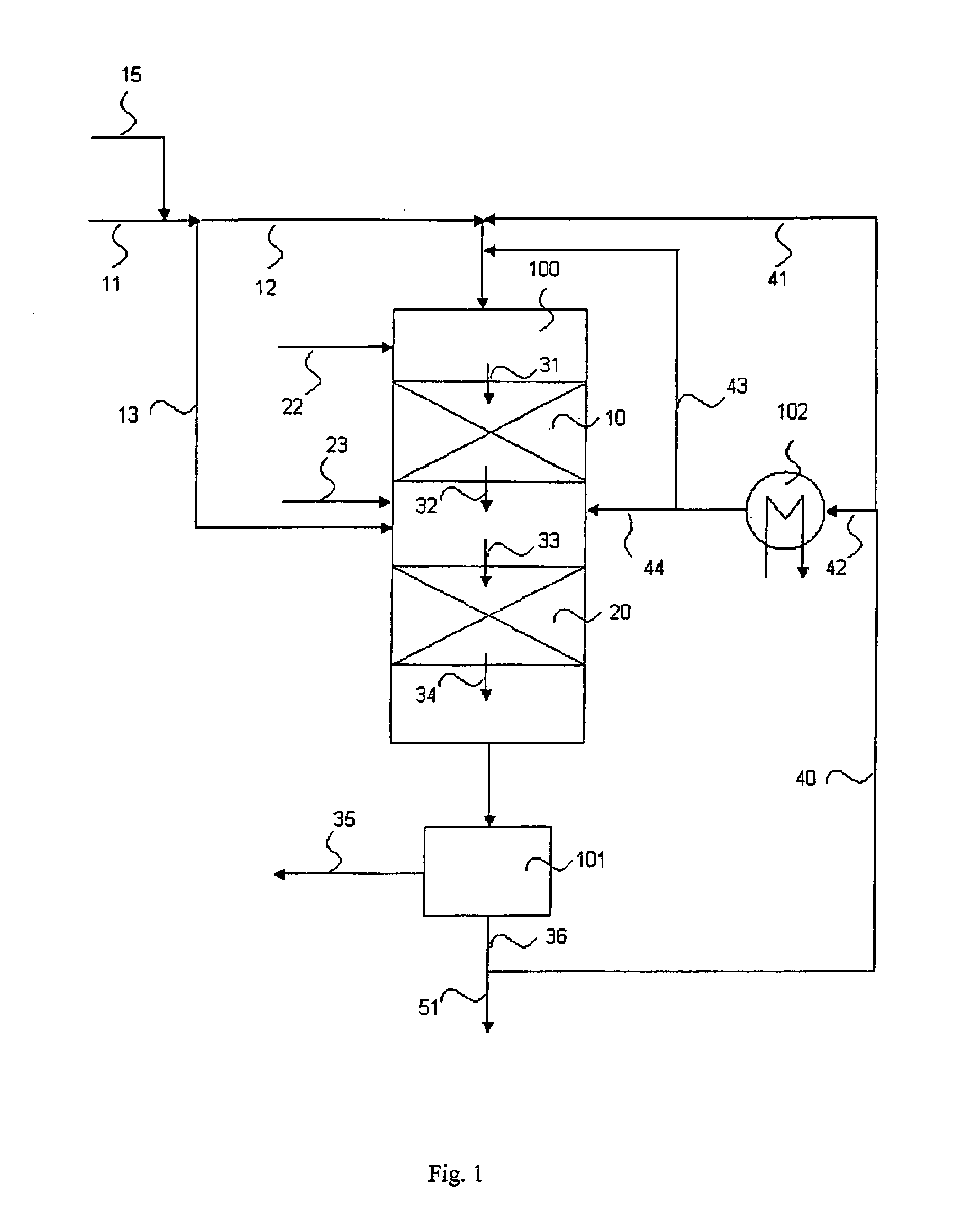

An improvement of the methanol carbonylation process for manufacturing acetic acid is disclosed. Specifically disclosed is a method for reducing the formation of alkyl iodides and C3-8 carboxylic acids by removing permanganate reducing compounds (“PRC's”) from the light phase of the condensed light ends overhead stream, including (a) distilling the light phase to yield a PRC enriched overhead stream; and (b) extracting the third overhead stream with water in at least two consecutive stages and separating therefrom one or more aqueous streams containing PRC's.

Owner:CELANESE INT CORP

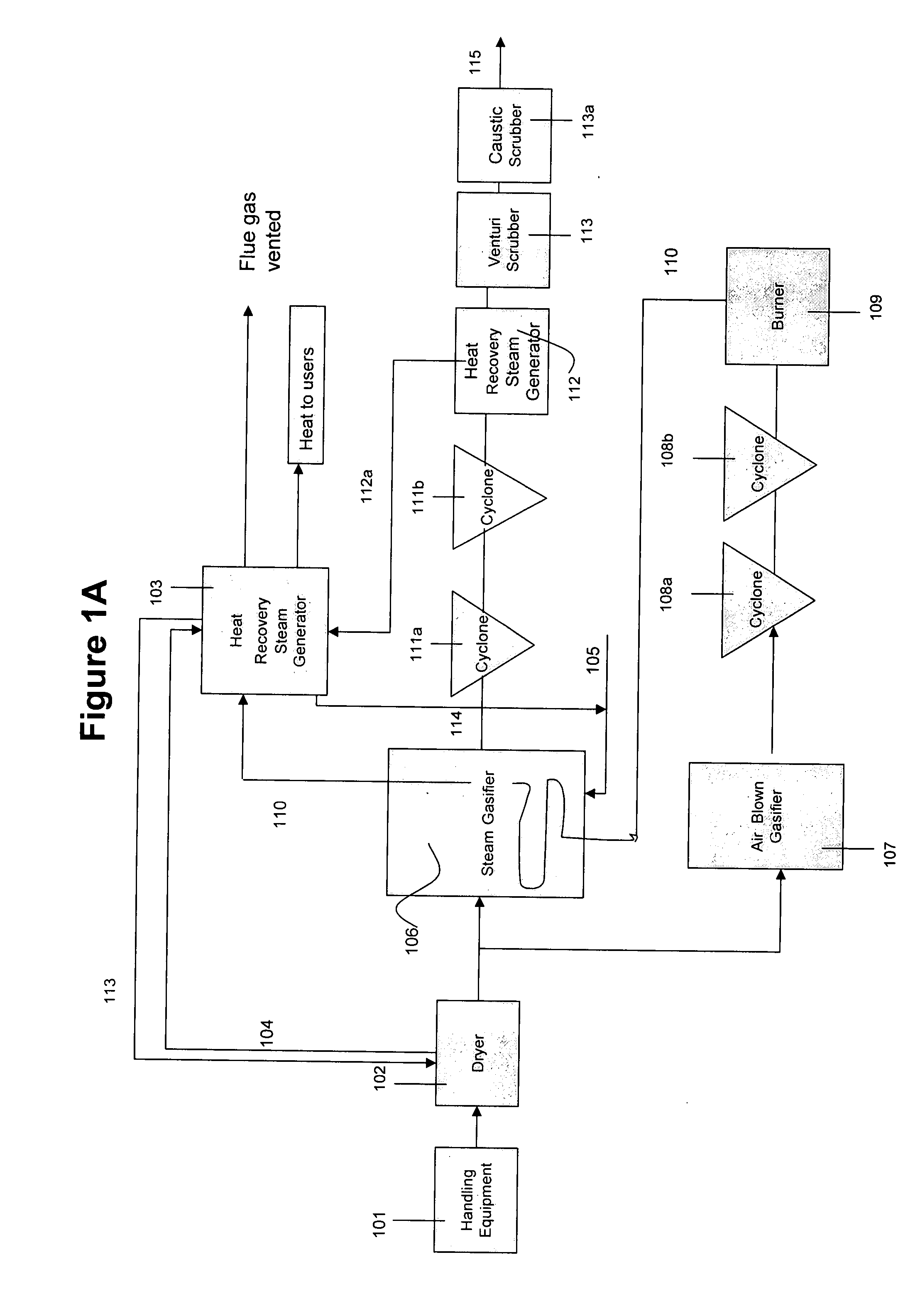

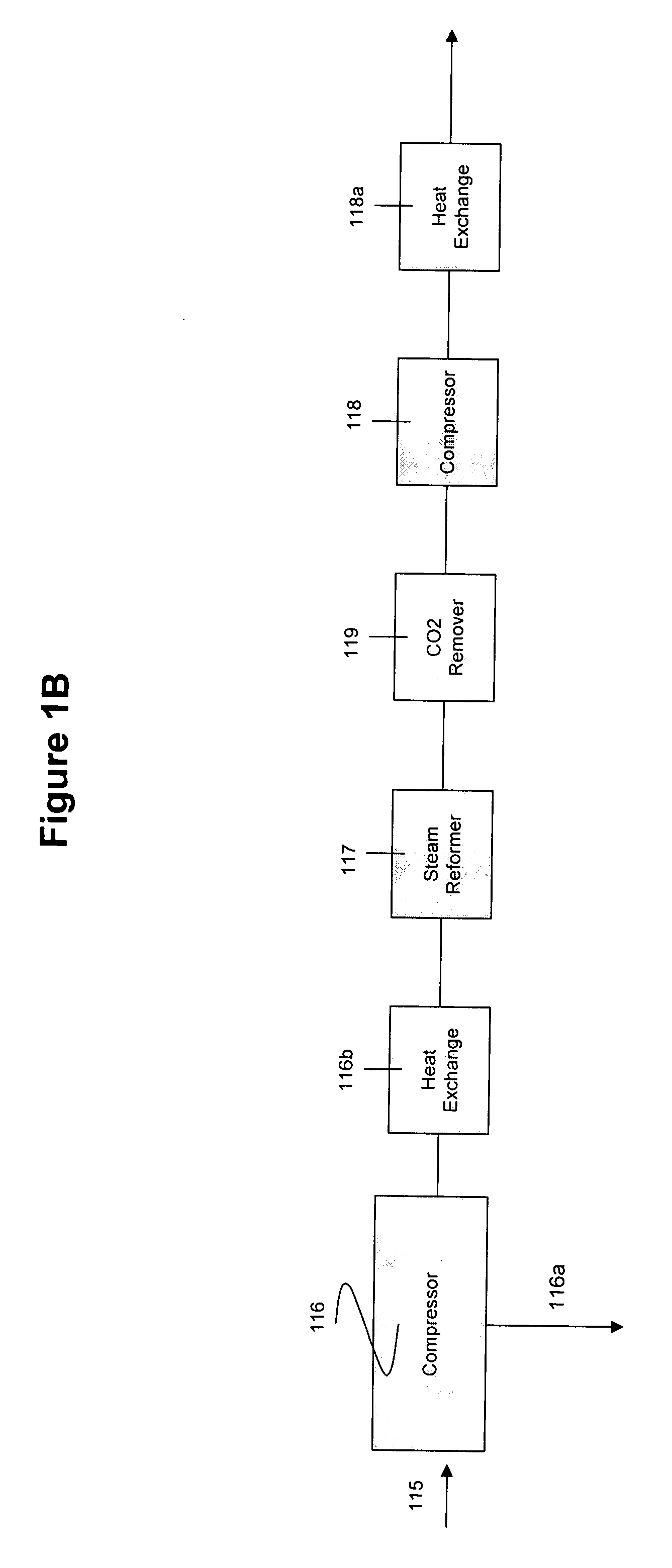

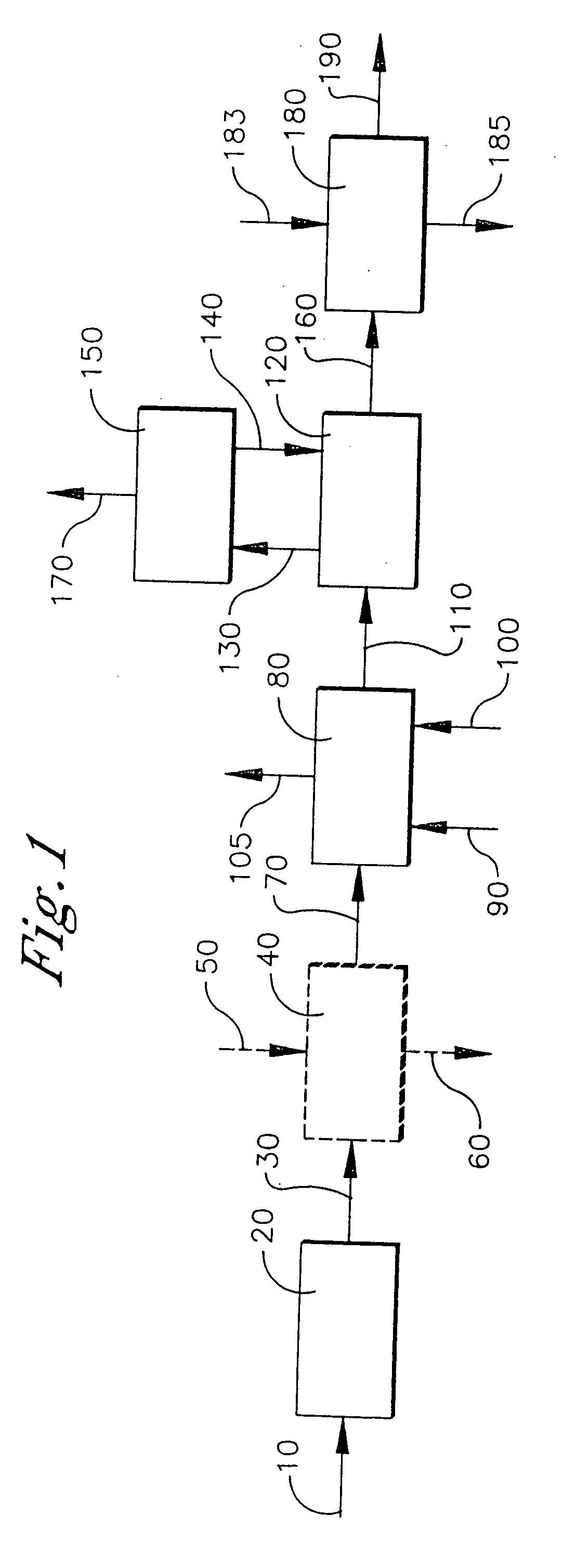

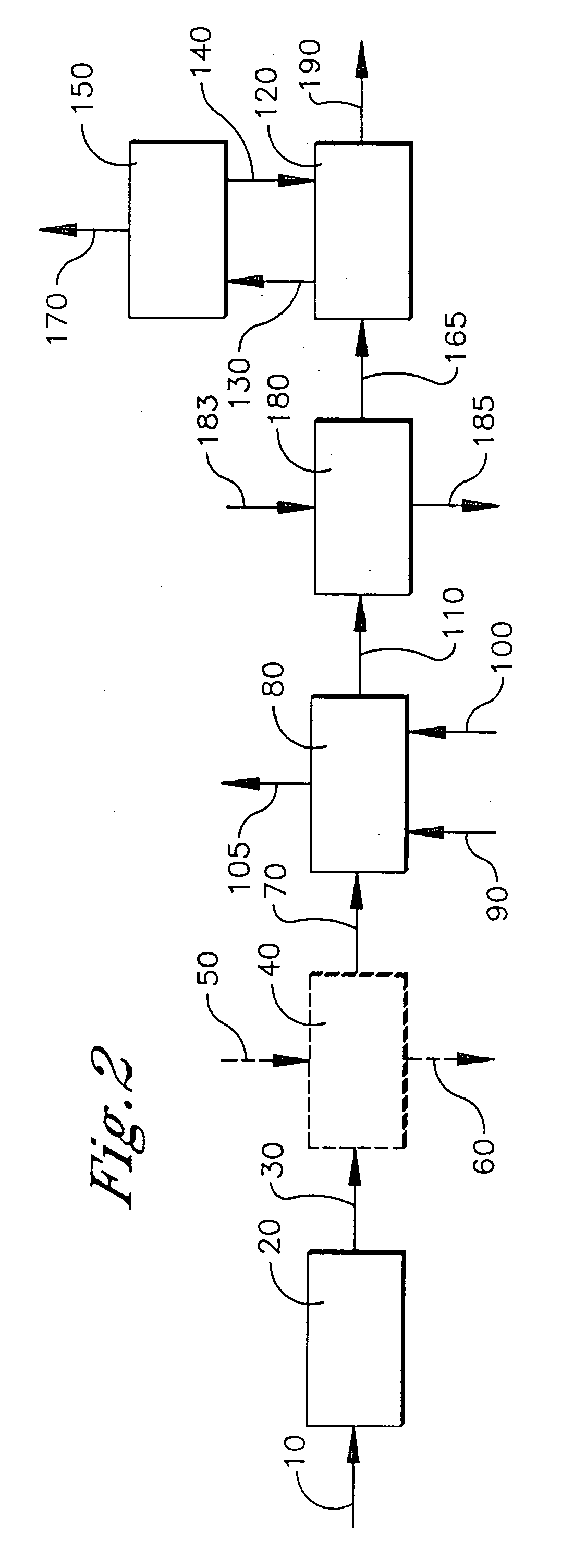

System and method for converting biomass to ethanol via syngas

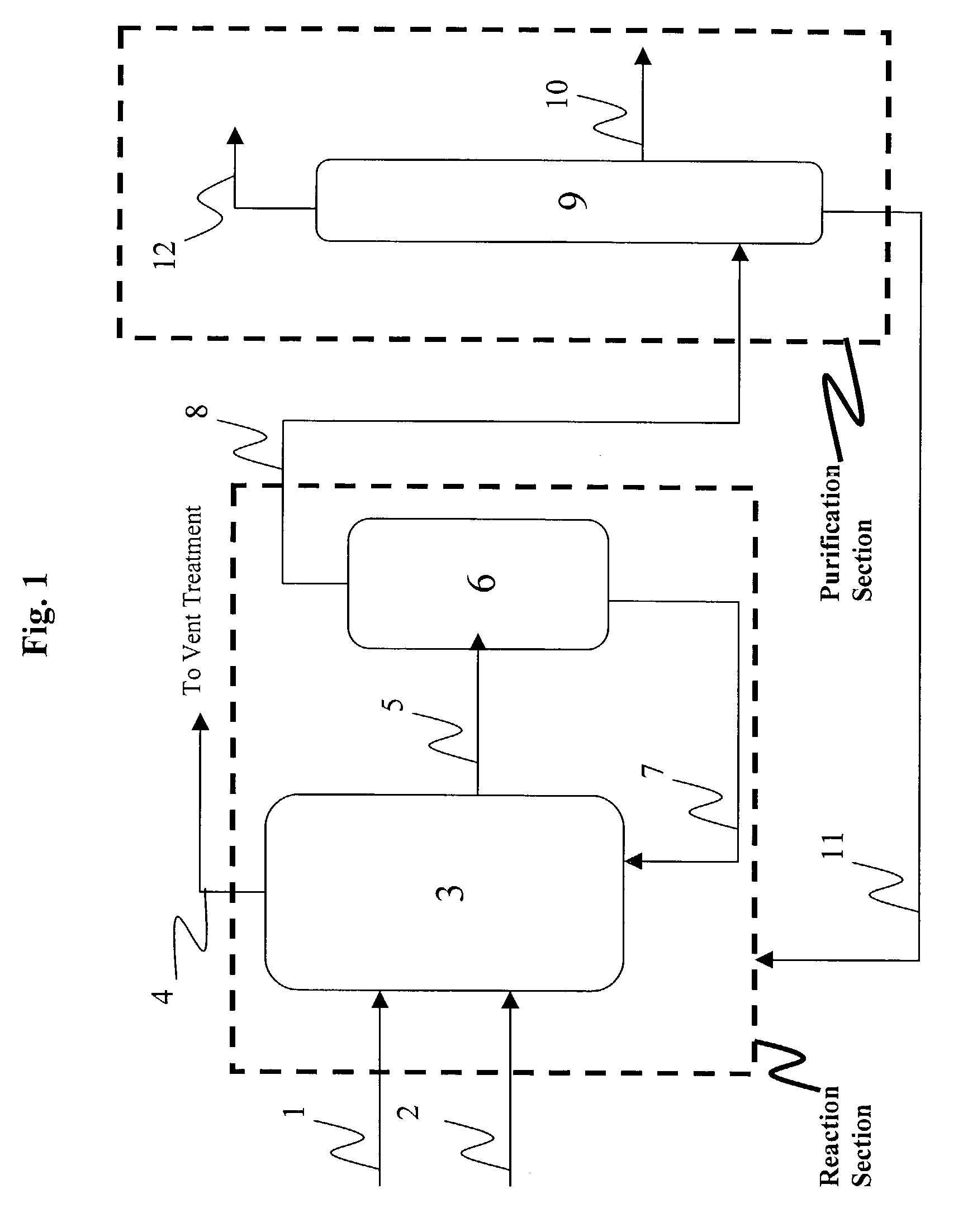

A method and apparatus for synthesizing ethanol using synthetic routes via synthesis gas are disclosed. A method and apparatus for gasifying biomass, such as biomass, in a steam gasifier that employs a fluidized bed and heating using hot flue gases from the combustion of synthesis gas is described. Methods and apparatus for converting synthesis gas into ethanol are also disclosed, using stepwise catalytic reactions to convert the carbon monoxide and hydrogen into ethanol using catalysts including iridium acetate.

Owner:WOODLAND BIOFUELS

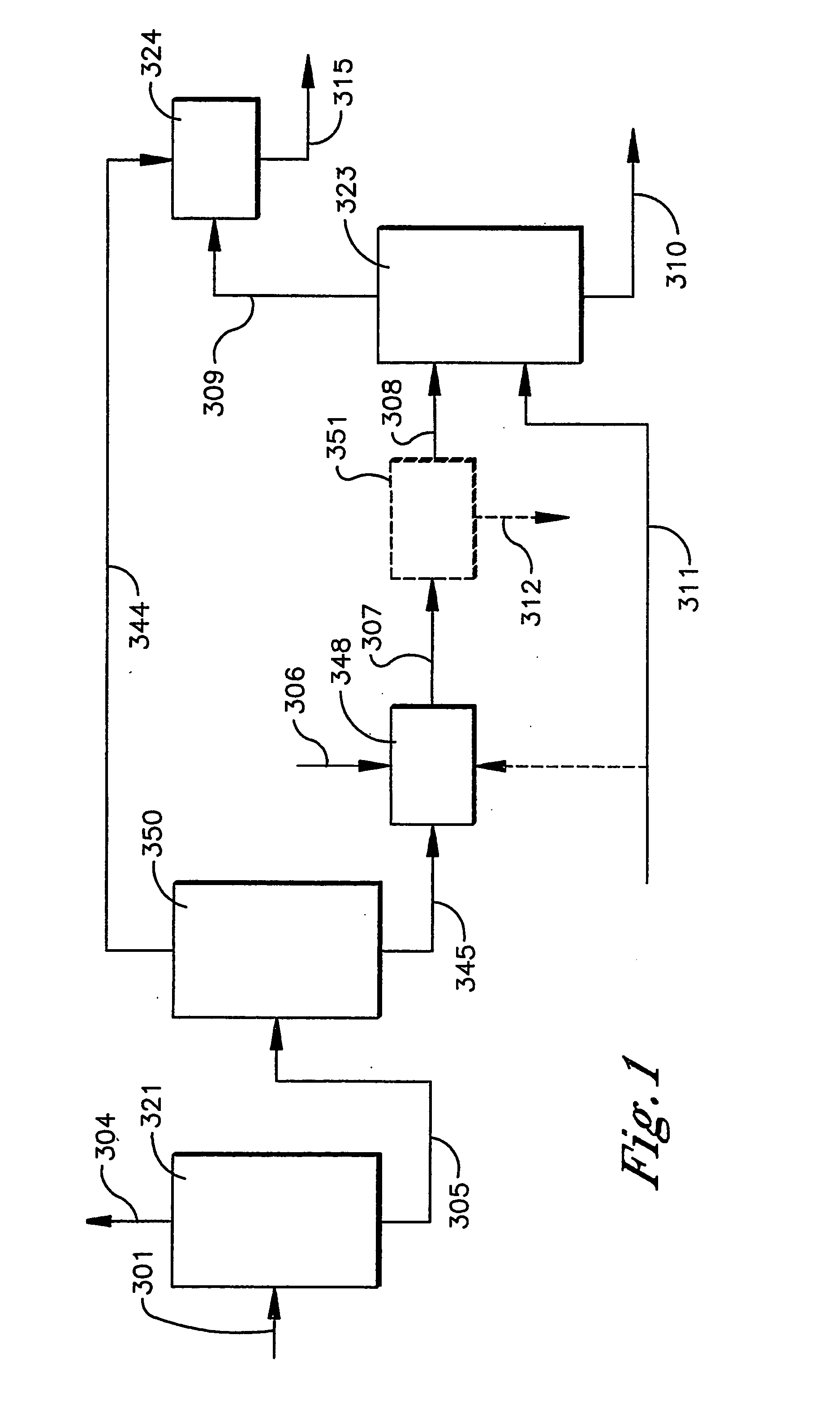

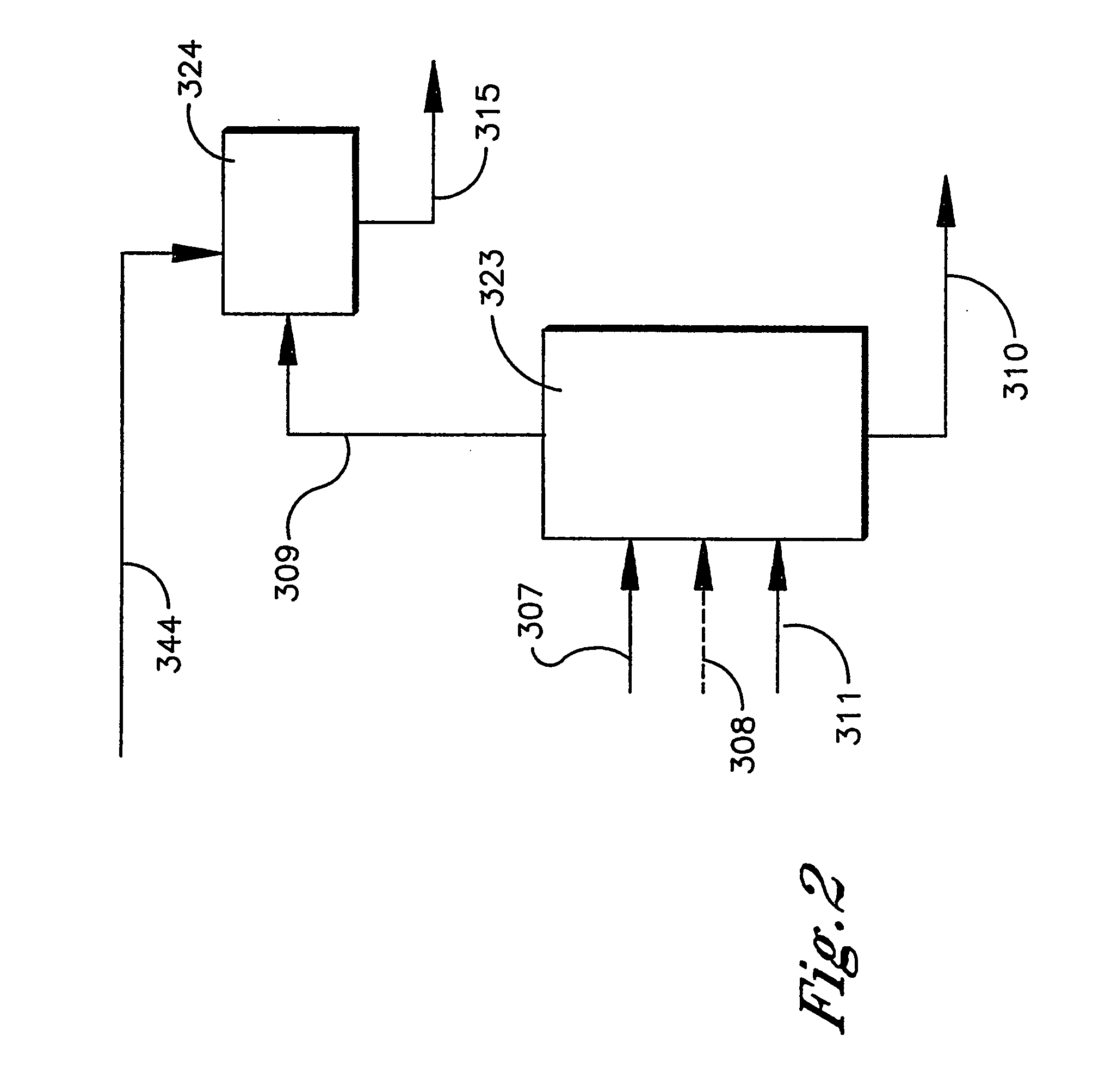

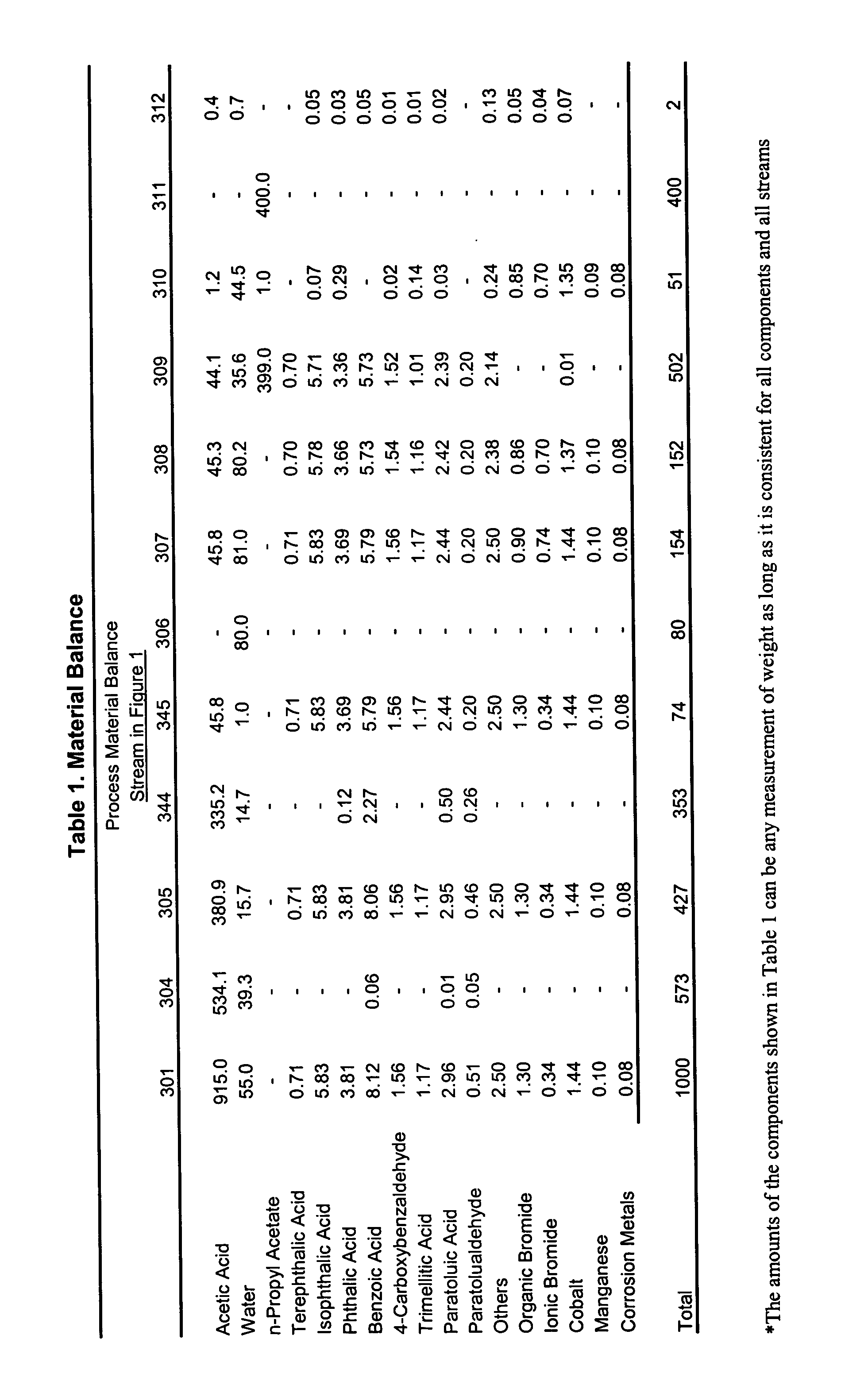

Extraction process for removal of impurities from an oxidizer purge stream in the synthesis of carboxylic acid

InactiveUS20050038288A1Easy to operateImprove reliabilityOrganic compound preparationOrganic chemistry methodsSingle stageMetal catalyst

Disclosed is a process that relates to the recovery of a metal catalyst from an oxidizer purge stream produced in the synthesis of carboxylic acid, typically terephthalic acid. The process involves the addition of a wash solution to a high temperature molten dispersion to recover the metal catalyst and then subjecting an aqueous mixture or purified aqueous mixture so formed to a single stage extraction to remove organic impurities to produce an extract stream and a raffinate stream comprising the metal catalyst.

Owner:GRUPO PETROTEMEX DE C V

Process for the purification of a crude carboxylic acid slurry

InactiveUS20050065373A1Organic compound preparationCarboxylic preparation by oxidationFiltrationCarboxylic acid

Disclosed is a process to produce a purified carboxylic acid product. The process comprises removing impurities from a crude carboxylic acid slurry in a solid-liquid displacement zone to form a slurry product. The slurry product if further treated in a staged oxidation zone and a crystallization zone to from a crystallized product. The crystallized product is further cooled in a cooling zone and subsequently filtered and dried in a filtration and drying zone. The process produces purified carboxylic acid product having good color and low impurity levels without the use of purification steps like hydrogenation.

Owner:ALPEK POLYESTER SA DE CV

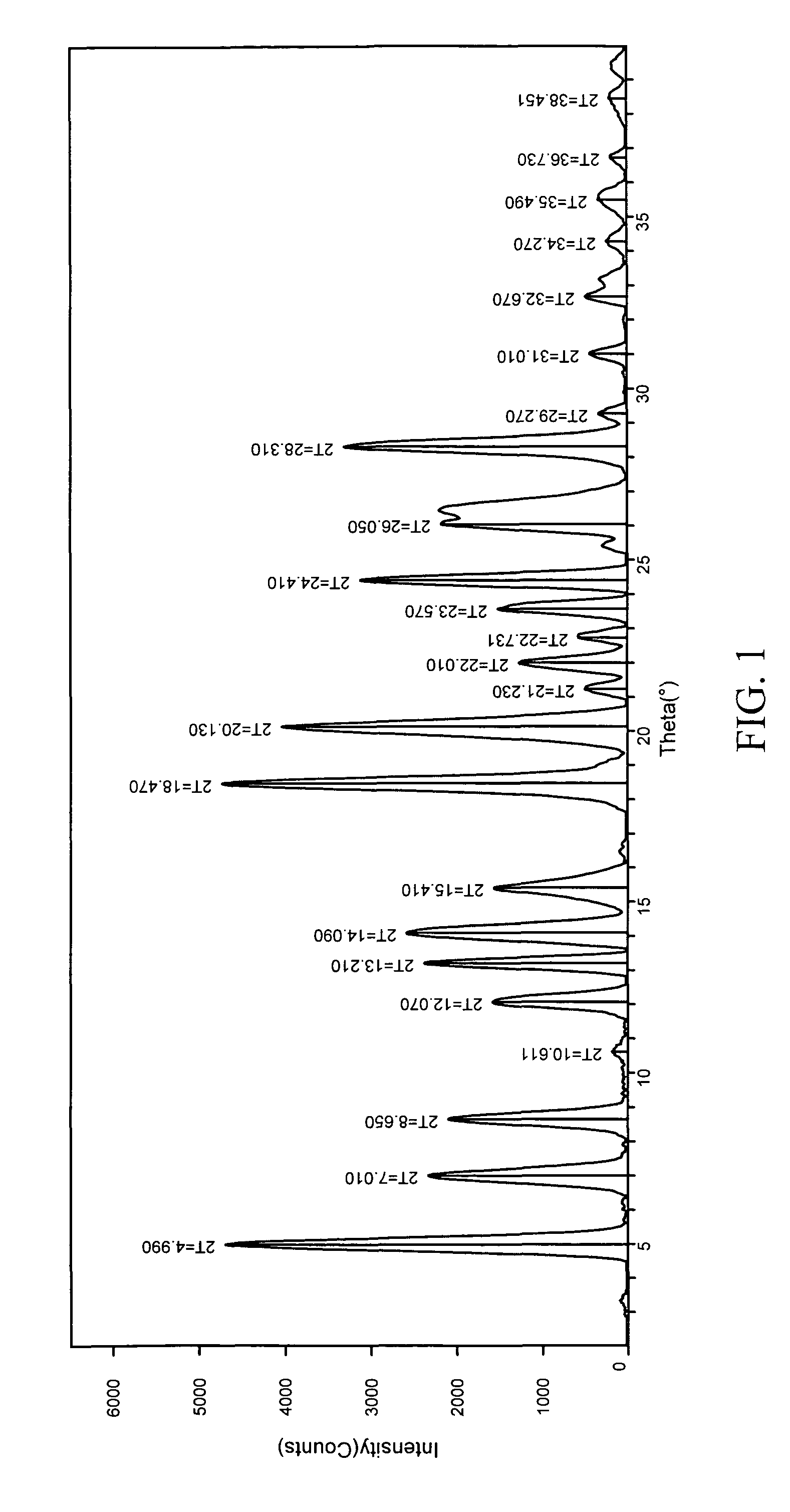

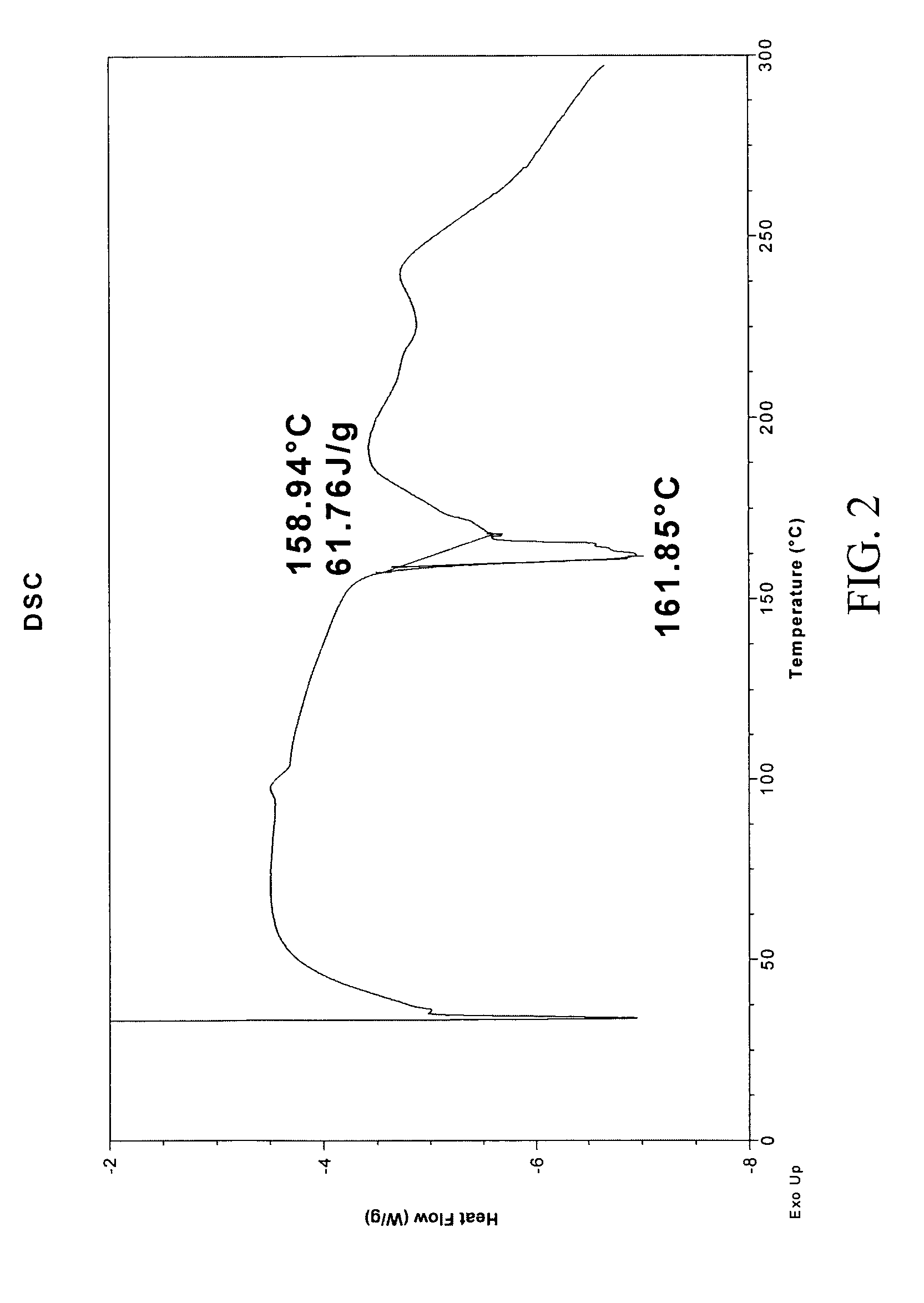

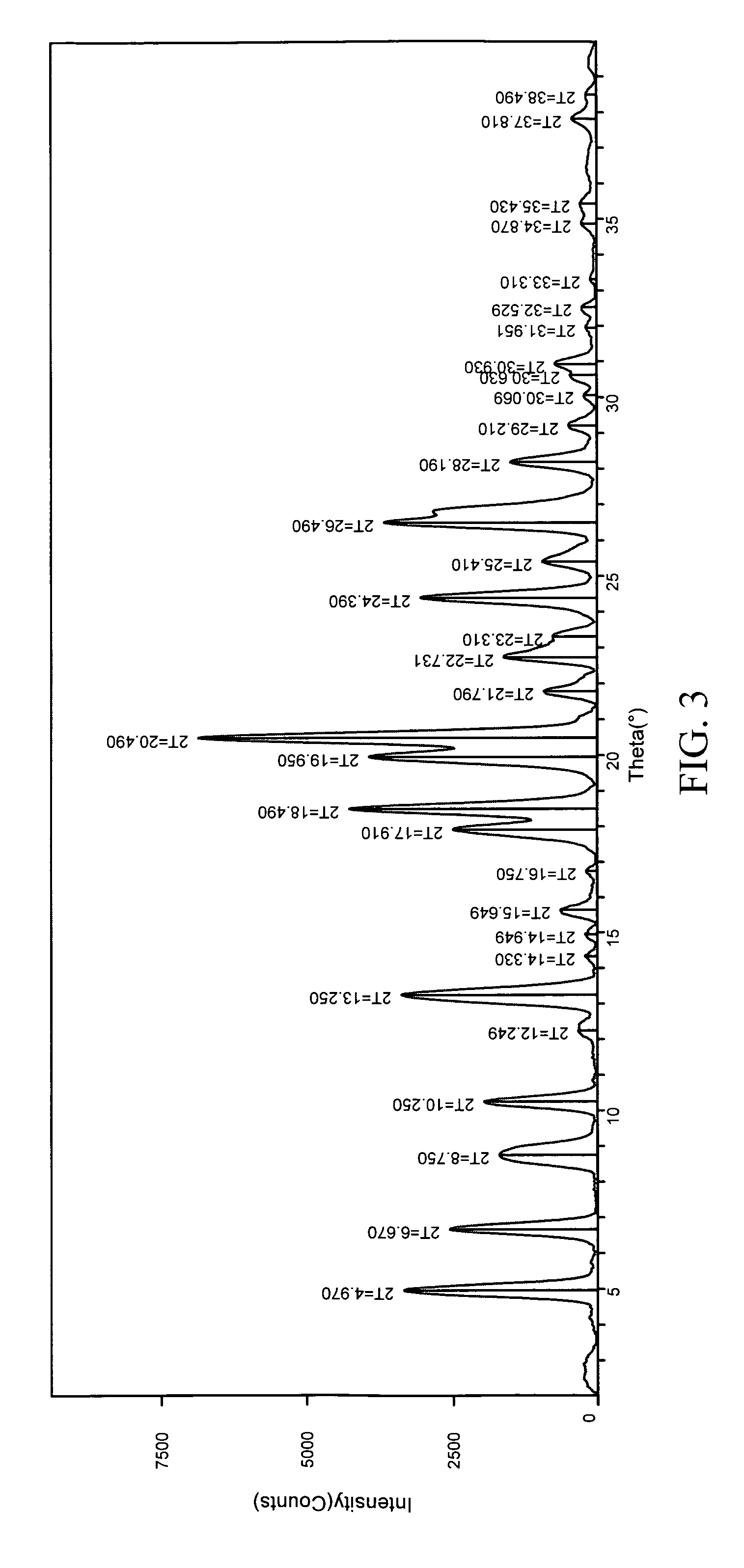

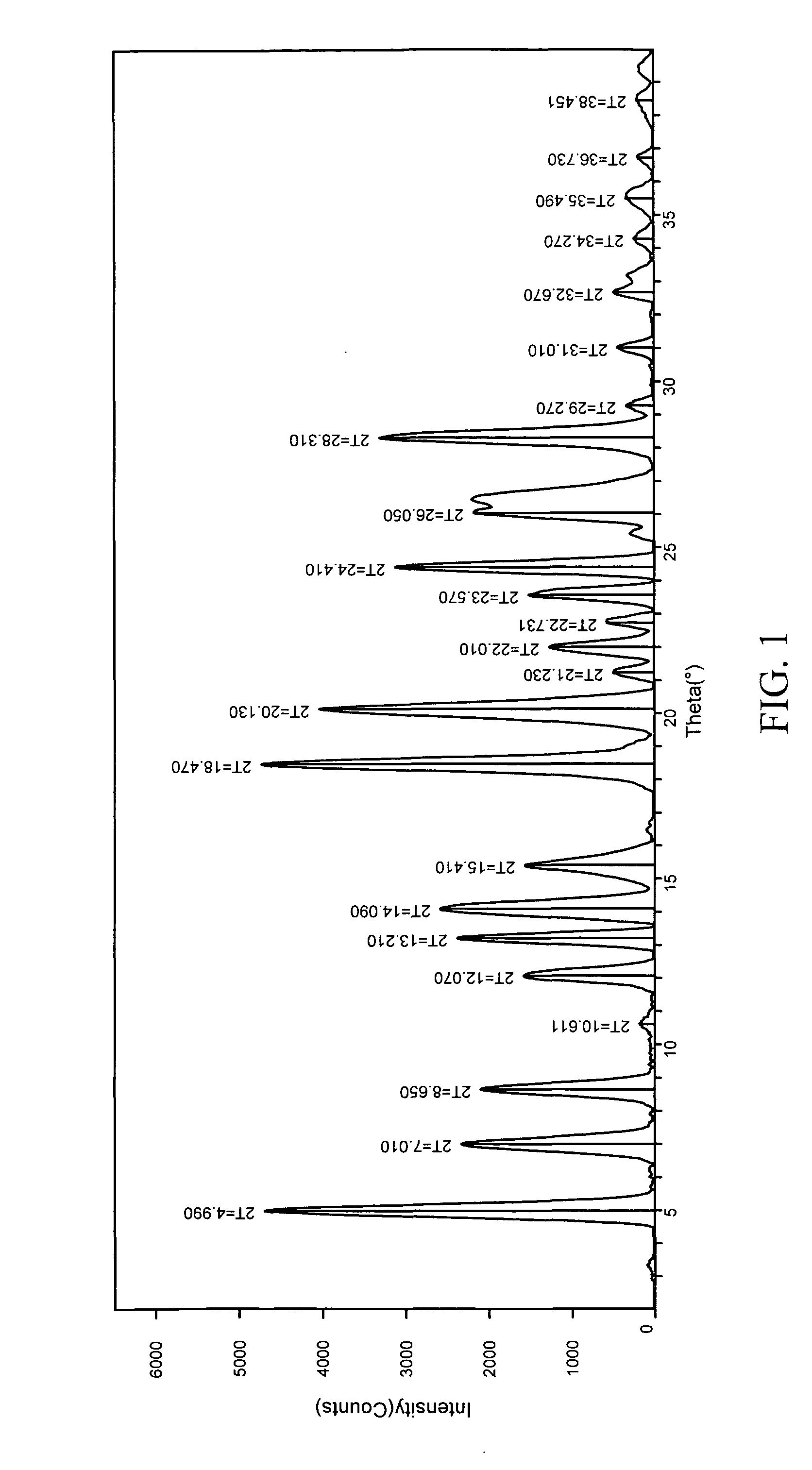

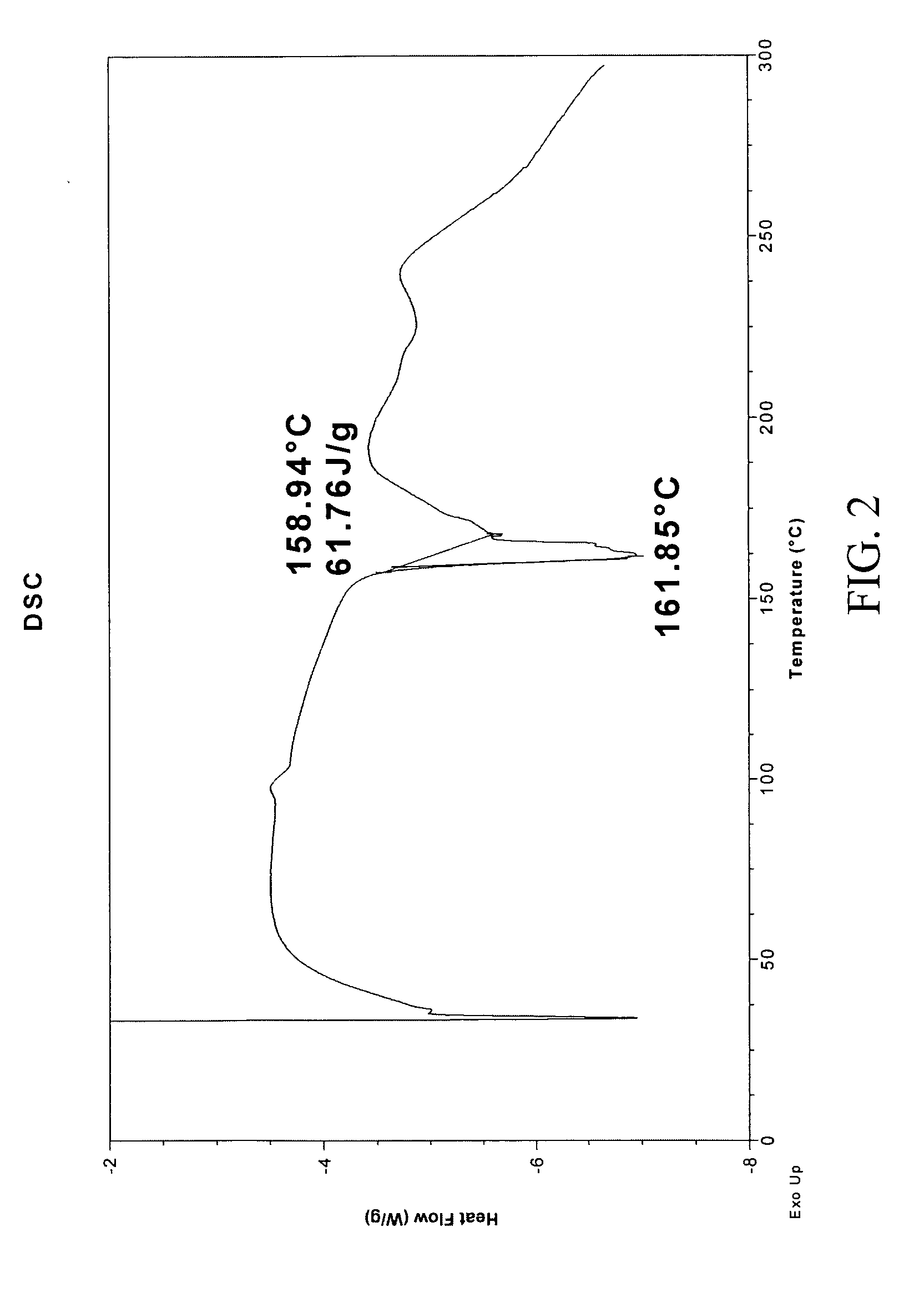

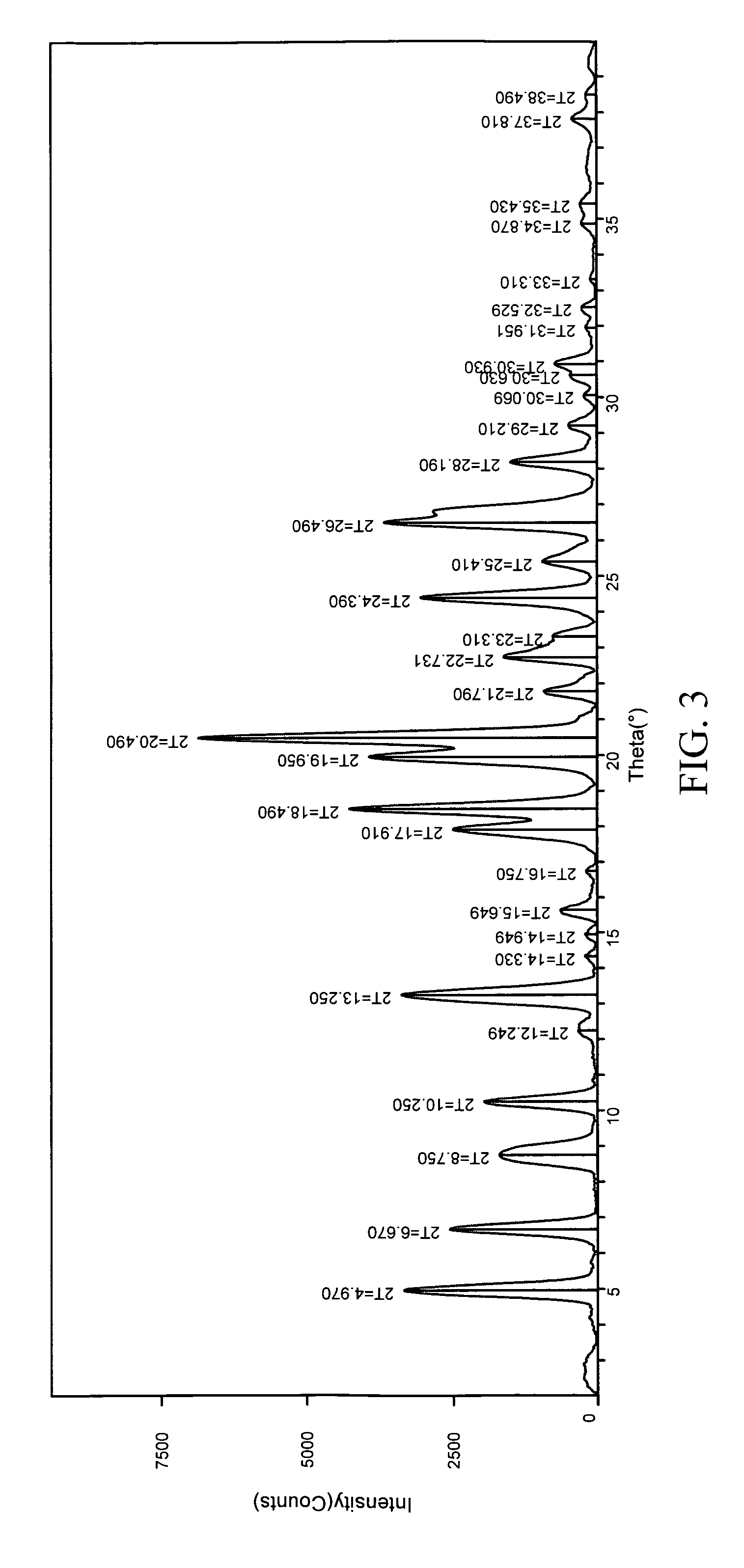

Pharmaceutical co-crystal compositions

A pharmaceutical composition comprising a co-crystal of an API and a co-crystal former; wherein the API has at least one functional group selected from ether, thioether, alcohol, thiol, aldehyde, ketone, thioketone, nitrate ester, phosphate ester, thiophosphate ester, ester, thioester, sulfate ester, carboxylic acid, phosphonic acid, phosphinic acid, sulfonic acid, amide, primary amine, secondary amine, ammonia, tertiary amine, sp2 amine, thiocyanate, cyanamide, oxime, nitrile diazo, organohalide, nitro, s-heterocyclic ring, thiophene, n-heterocyclic ring, pyrrole, o-heterocyclic ring, furan, epoxide, peroxide, hydroxamic acid, imidazole, pyridine and the co-crystal former has at least one functional group selected from amine, amide, pyridine, imidazole, indole, pyrrolidine, carbonyl, carboxyl, hydroxyl, phenol, sulfone, sulfonyl, mercapto and methyl thio, such that the API and co-crystal former are capable of co-crystallizing from a solution phase under crystallization conditions.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES +2

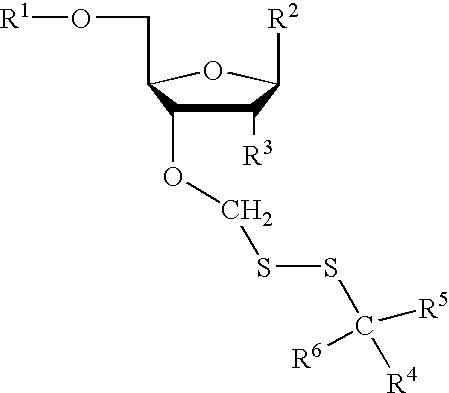

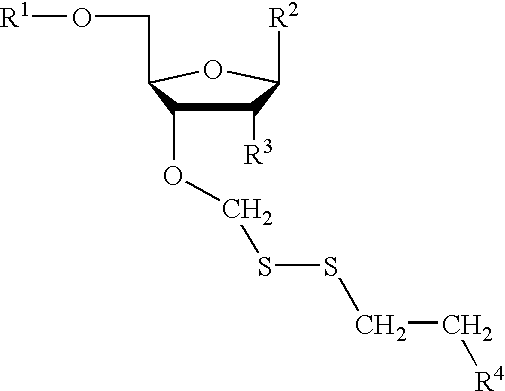

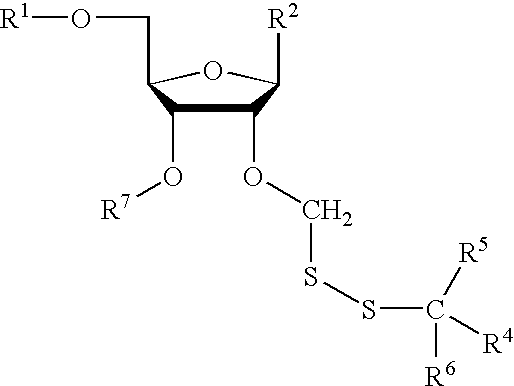

Compounds for protecting hydroxyls and methods for their use

InactiveUS7279563B2Sequencing is facilitatedEasy to implementSugar derivativesOrganic compound preparationChemical synthesisNucleotide

A hydrocarbyldithiomethyl-modified compound of the Formula:R1—O—CH2—S—S—R2or a salt thereof wherein R1 is an organic molecule and R2 is a hydrocarbyl is useful for protecting and / or blocking hydroxyl groups in organic molecules such as nucleotides. The hydrocarbyldithiomethyl-modified compounds can also be used for chemically synthesizing oligonucleotides and for sequencing nucleic acid compounds.

Owner:FLUIDIGM CORP

Oil of Brassica napus

InactiveUS6169190AOrganic compound preparationFatty substance preservation using additivesBrassicaAntioxidant

Oil produced from the seed of Brassica napus plant has an oleic acid content of 71.4-77.4% and a linoleic acid content of no more than 3%. The oil is useful in food and industrial applications. The oil has substantially improved oxidative stability relative to normal rapeseed oil, when both are identically treated with antioxidant.

Owner:LANUZA JUAN ENRIQUE ROMERO +1

Integrate chemical processes for industrial utilization of seed oils

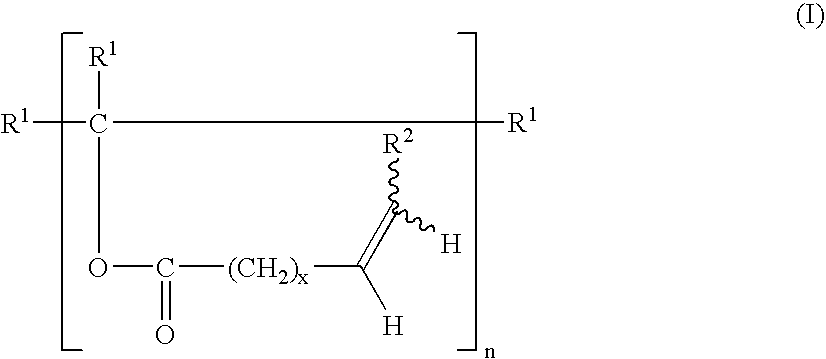

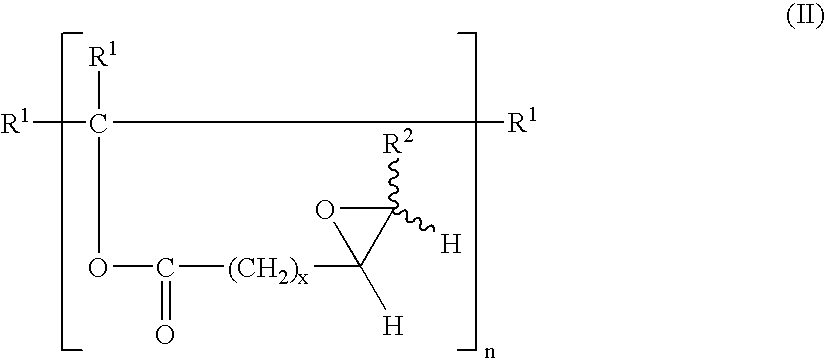

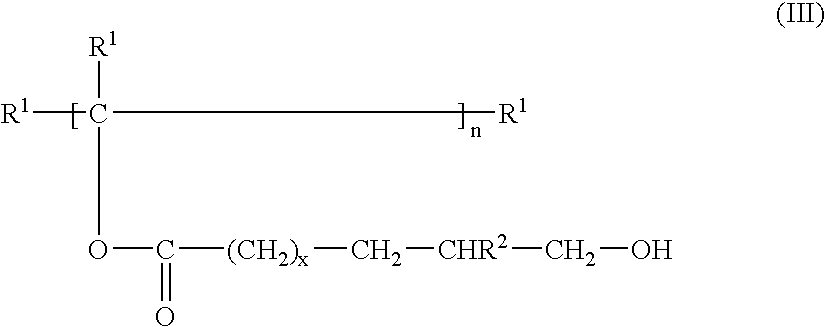

ActiveUS20050154221A1Easy to operateHigh olefin conversionFatty oils/acids recovery from wasteOxygen-containing compound preparationPolyesterAmino esters

Integrated processes of preparing industrial chemicals starting from seed oil feedstock compositions containing one or more unsaturated fatty acids or unsaturated fatty acid esters, which are essentially free of metathesis catalyst poisons, particularly hydroperoxides; metathesis of the feedstock composition with a lower olefin, such as ethylene, to form a reduced chain olefin, preferably, a reduced chain α-olefin, and a reduced chain unsaturated acid or ester, preferably, a reduced chain α,Ω-unsaturated acid or ester. The reduced chain unsaturated acid or ester may be (trans)esterified to form a polyester polyolefin, which may be epoxidized to form a polyester polyepoxide. The reduced chain unsaturated acid or ester may be hydroformylated with reduction to produce an α,Ω-hydroxy acid or α,Ω-hydroxy ester, which may be (trans)esterified with a polyol to form an α,Ωpolyester polyol. Alternatively, the reduced chain unsaturated acid or ester may be hydroformylated with reductive amination to produce an α,Ω-amino acid or α,Ω-amino ester, which may be (trans)esterified to form an α,Ωpolyester polyamine.

Owner:DOW GLOBAL TECH LLC

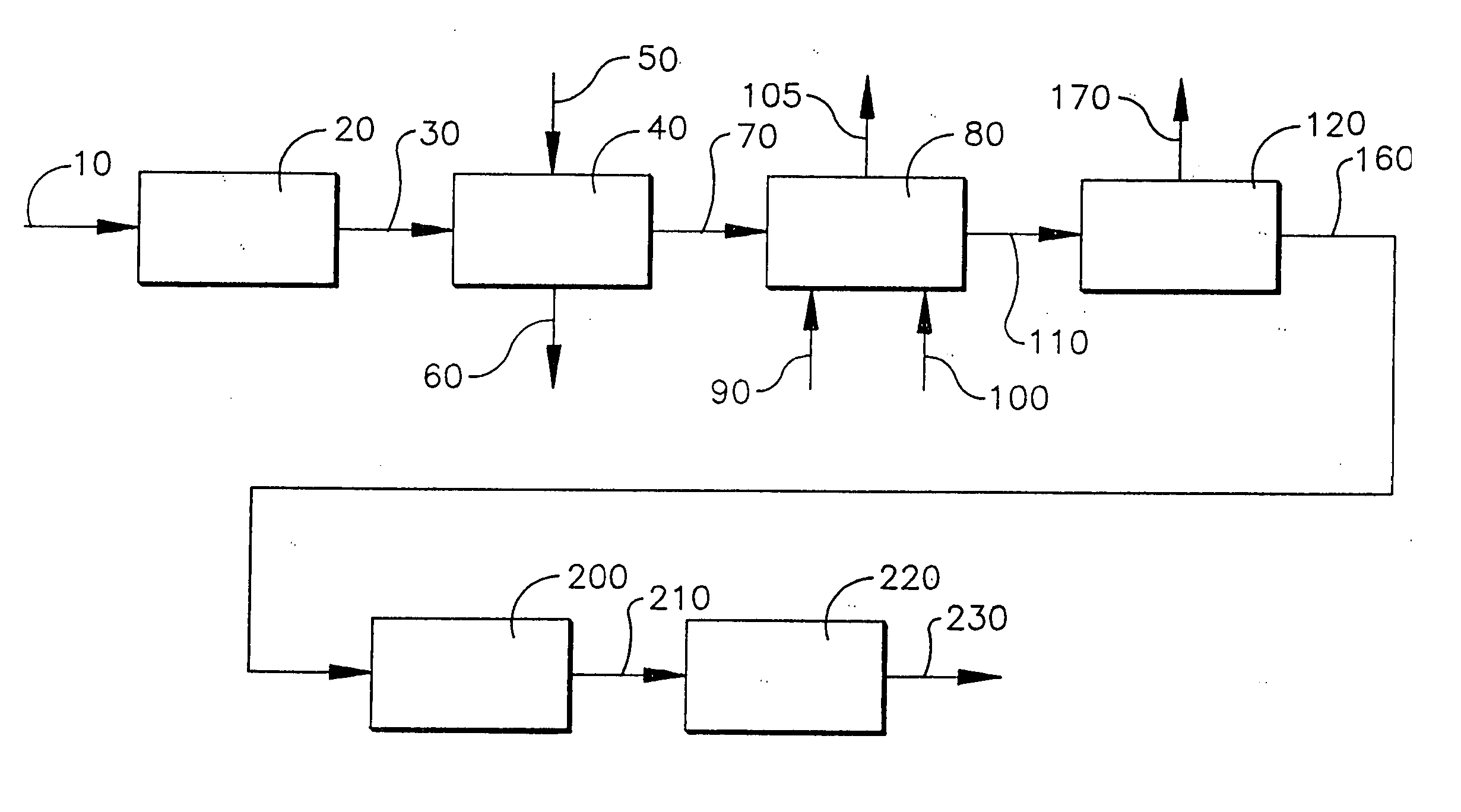

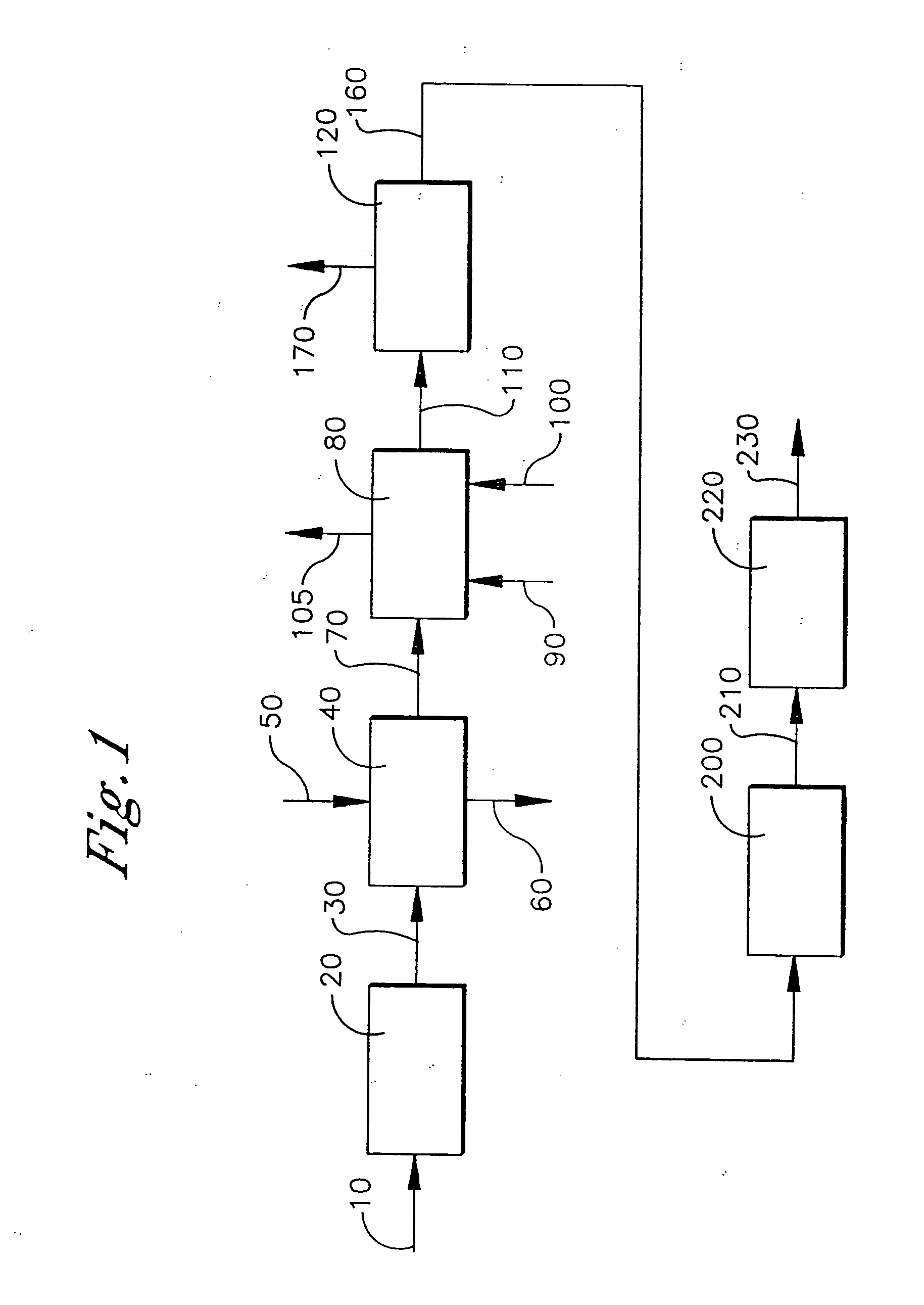

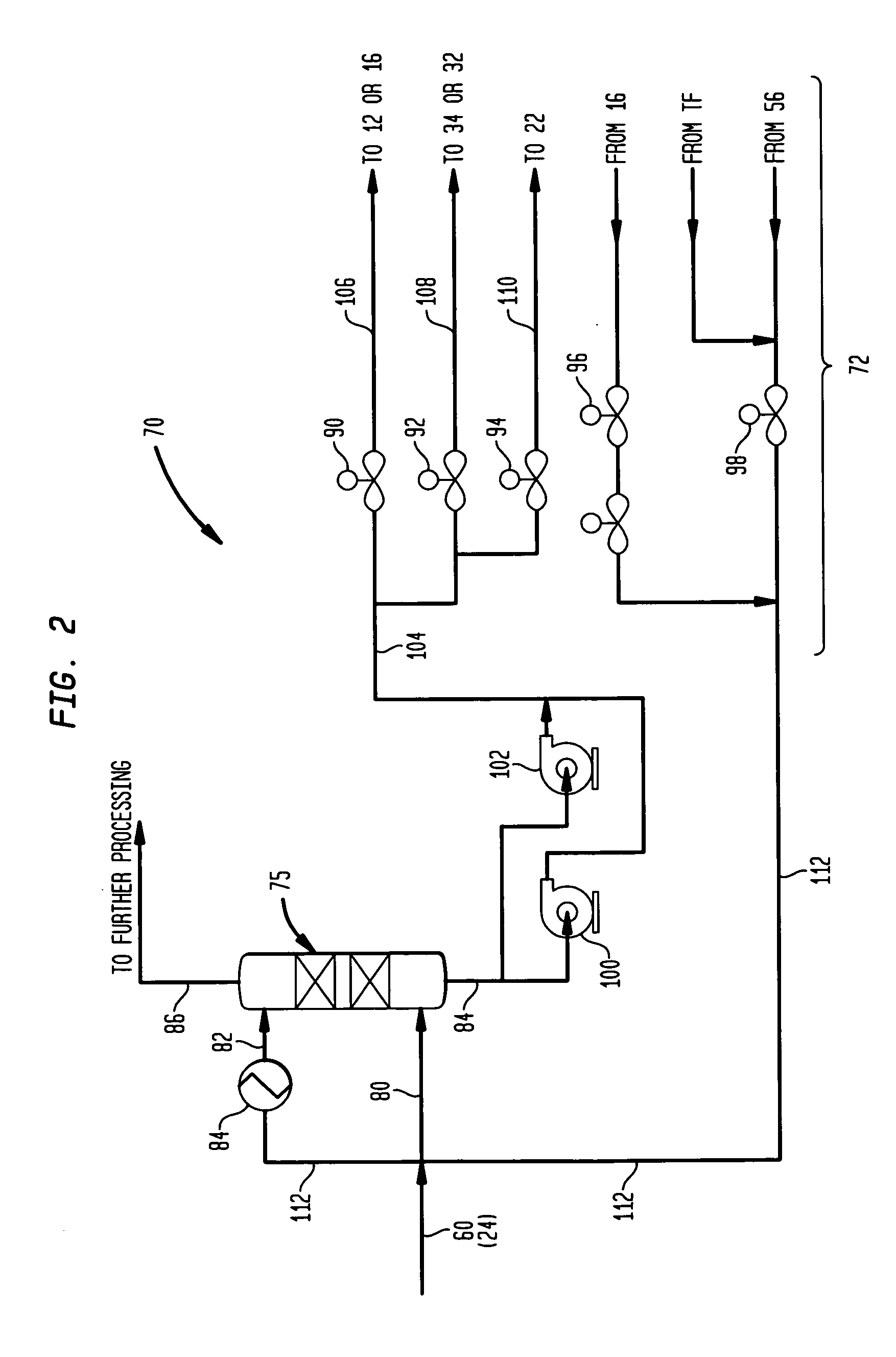

Methanol carbonylation system having absorber with multiple solvent options

A methanol carbonylation system 10 includes an absorber tower 75 adapted for receiving a vent gas stream and removing methyl iodide therefrom with a scrubber solvent, the absorber tower being coupled to first and second scrubber solvent sources 16, 56 which are capable of supplying different first and second scrubber solvents. A switching system including valves 90, 92, 94, 96, 98 alternatively provides first or second scrubber solvents to the absorber tower and returns the used solvent and sorbed material to the carbonylation system to accommodate different operating modes.

Owner:CELANESE INT CORP

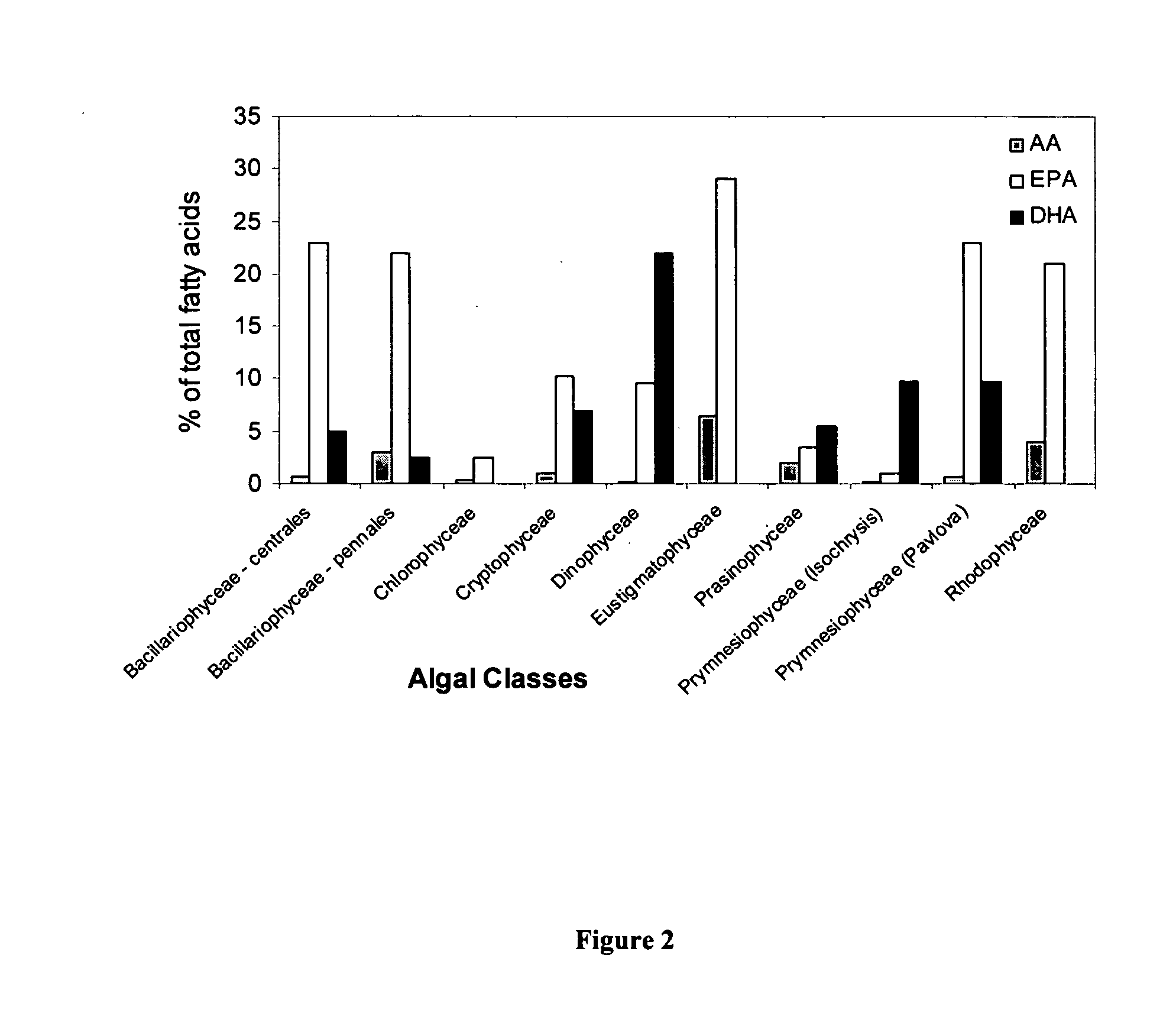

Method for preparing pure EPA and pure DHA

InactiveUS6846942B2Easy to disassembleSimple procedureFatty oils/acids recovery from wasteFatty acids production/refiningSolubilitySolvent

Pure DHA and pure EPA can be obtained from a mixture of EPA and DHA in a solution by forming salts of DHA and EPA which have different solubilities in the solvent, cooling the solution until the salt of EPA is formed, filtering the solution to recover the salt of EPA, and acidifying the EPA salt and the DHA salt to obtain pure EPA and pure DHA.

Owner:RUBIN DAVID

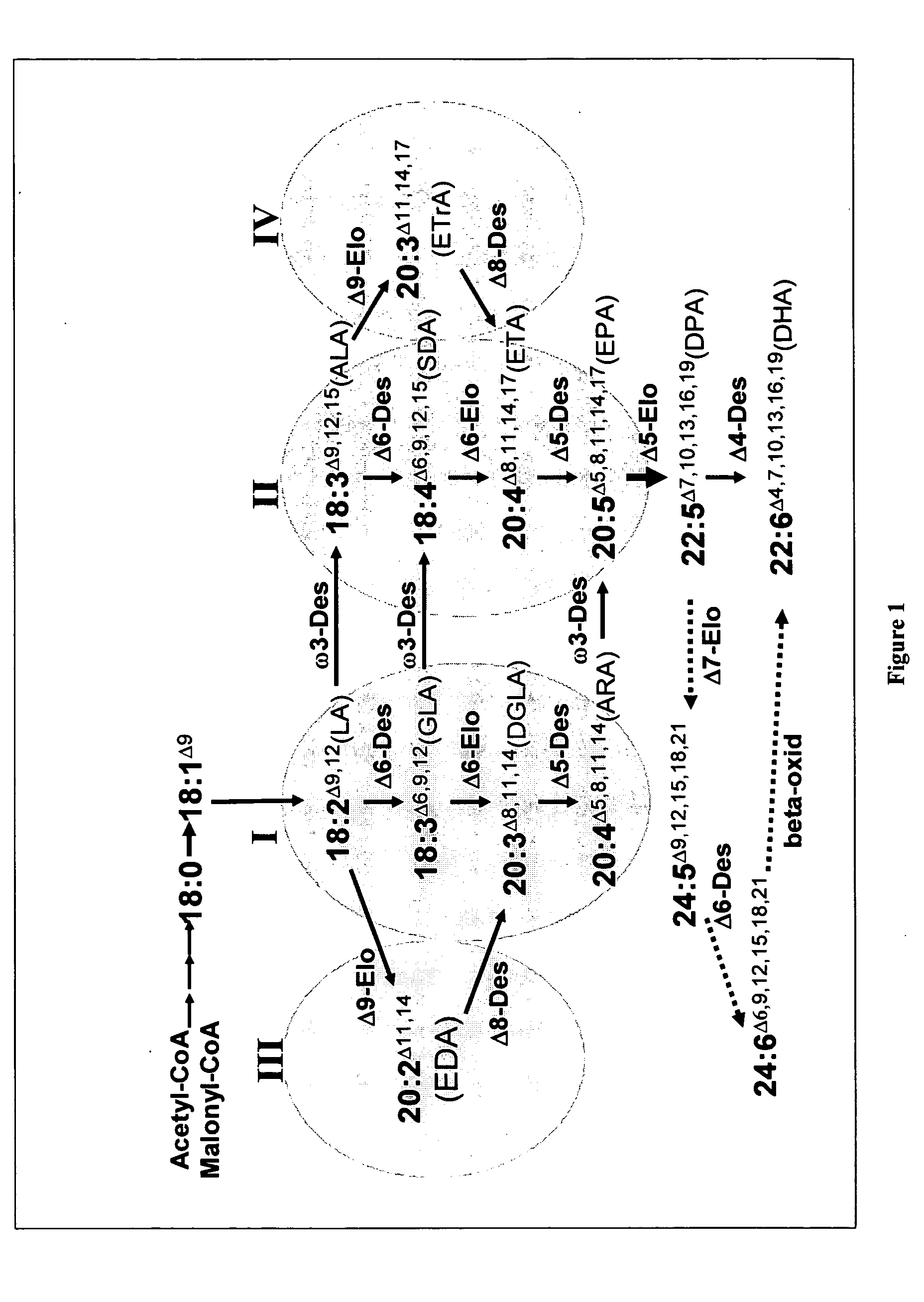

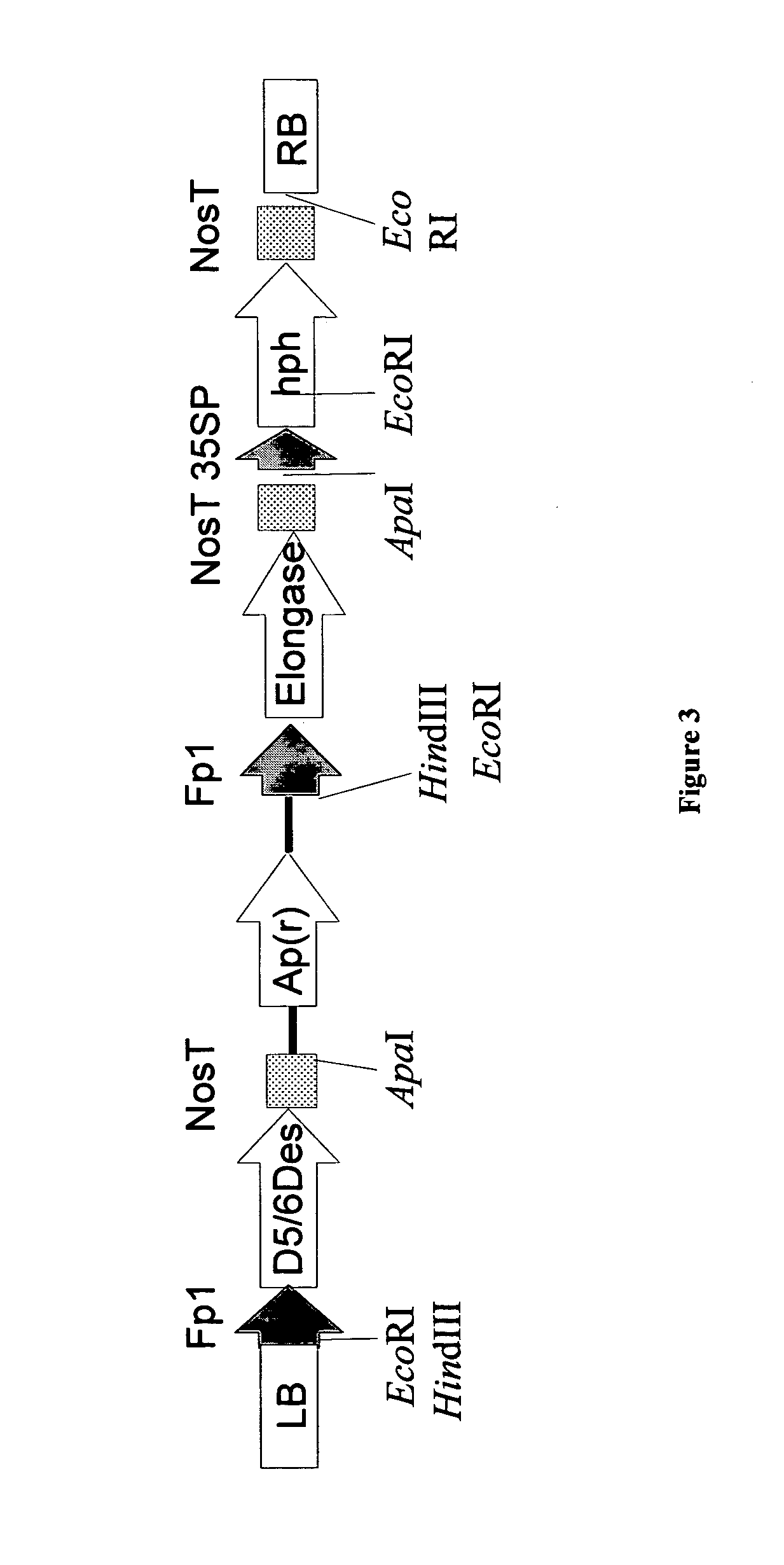

Synthesis of long-chain polyunsaturated fatty acids by recombinant cells

ActiveUS20050273885A1Reduce enzyme activityImprove efficiencyNervous disorderAntipyreticYeastPlant cell

The present invention relates to methods of synthesizing long-chain polyunsaturated fatty acids, especially eicosapentaenoic acid, docosapentaenoic acid and docosahexaenoic acid, in recombinant cells such as yeast or plant cells. Also provided are recombinant cells or plants which produce long-chain polyunsaturated fatty acids. Furthermore, the present invention relates to a group of new enzymes which possess desaturase or elongase activity that can be used in methods of synthesizing long-chain poly unsaturated fatty acids.

Owner:COMMONWEALTH SCI & IND RES ORG

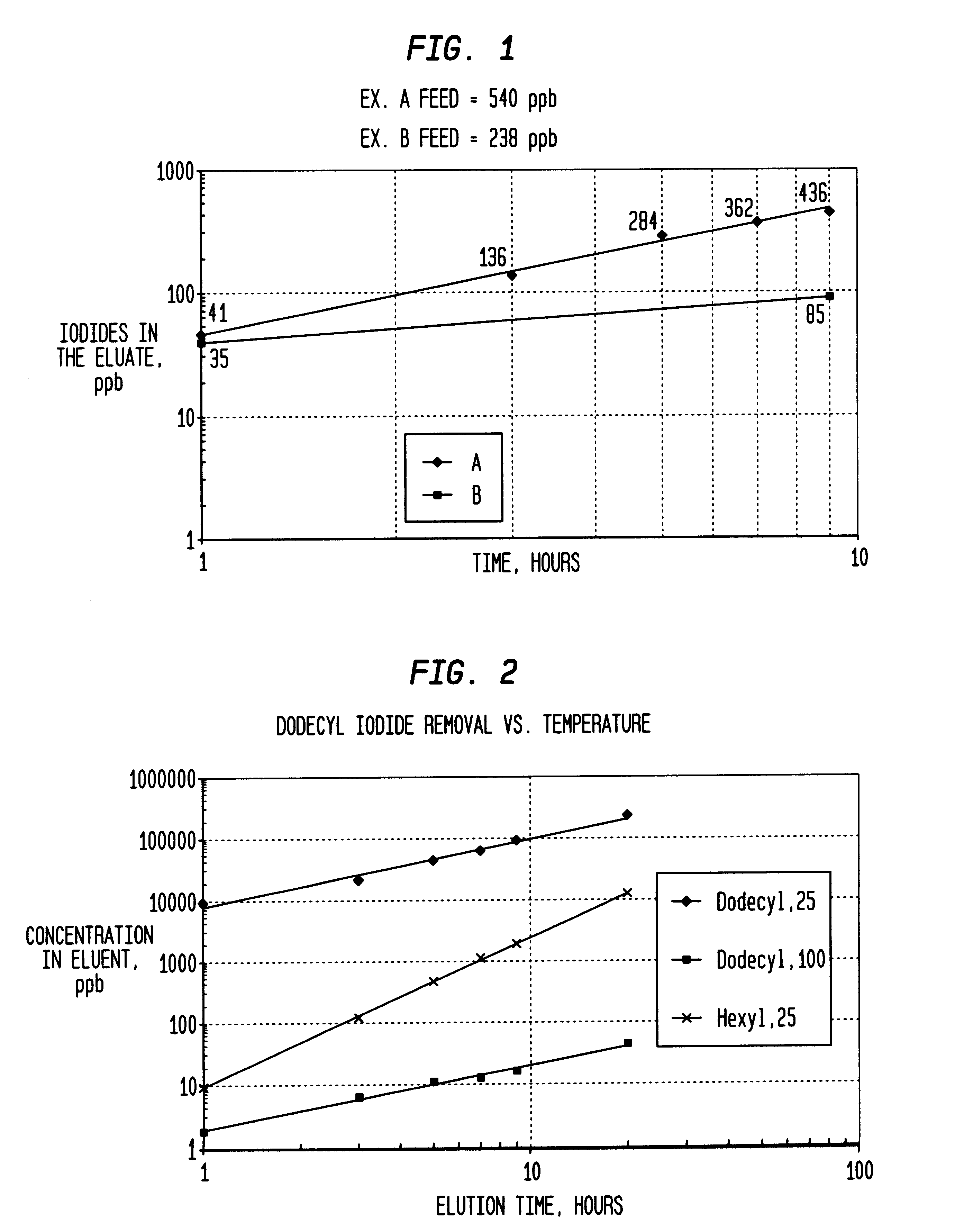

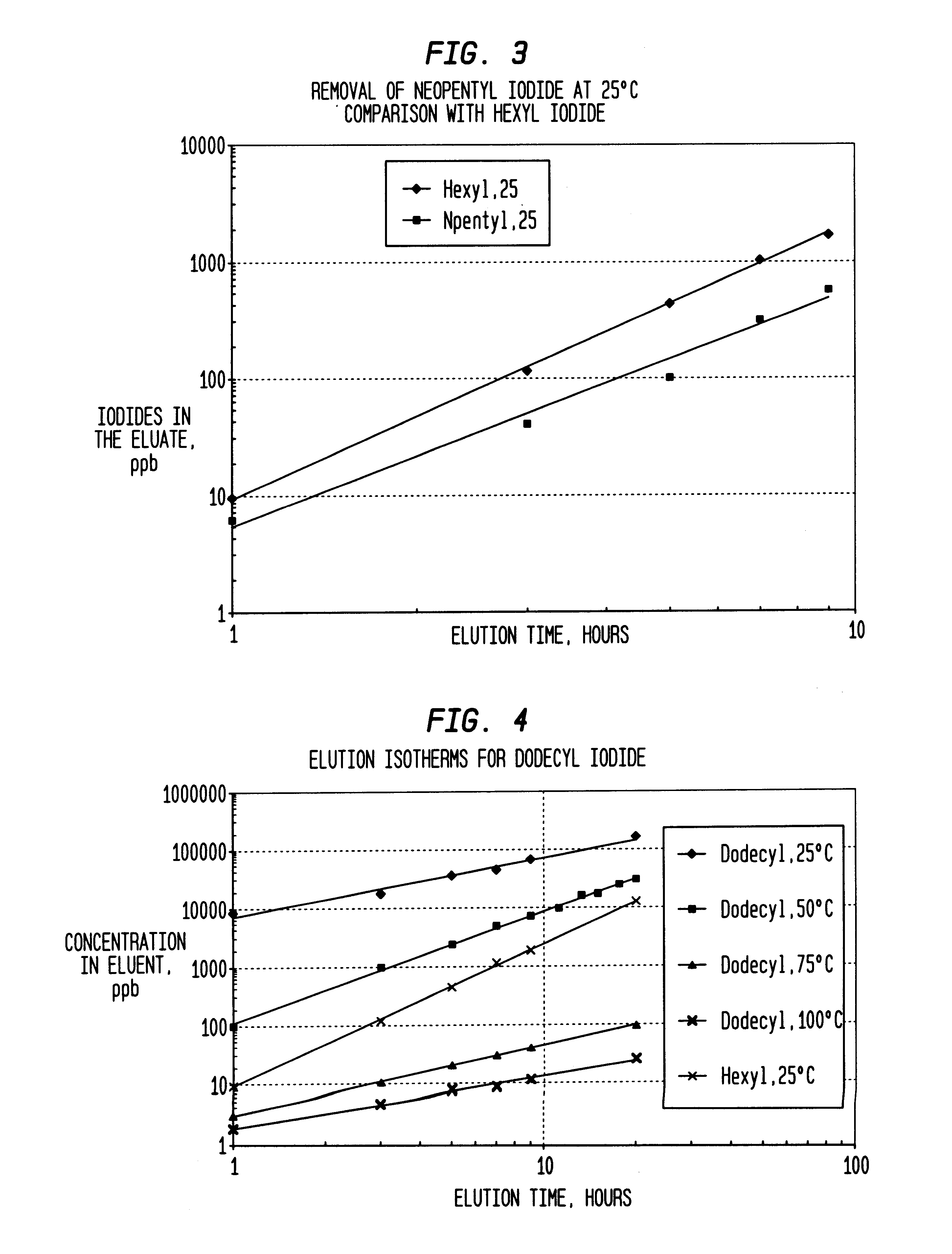

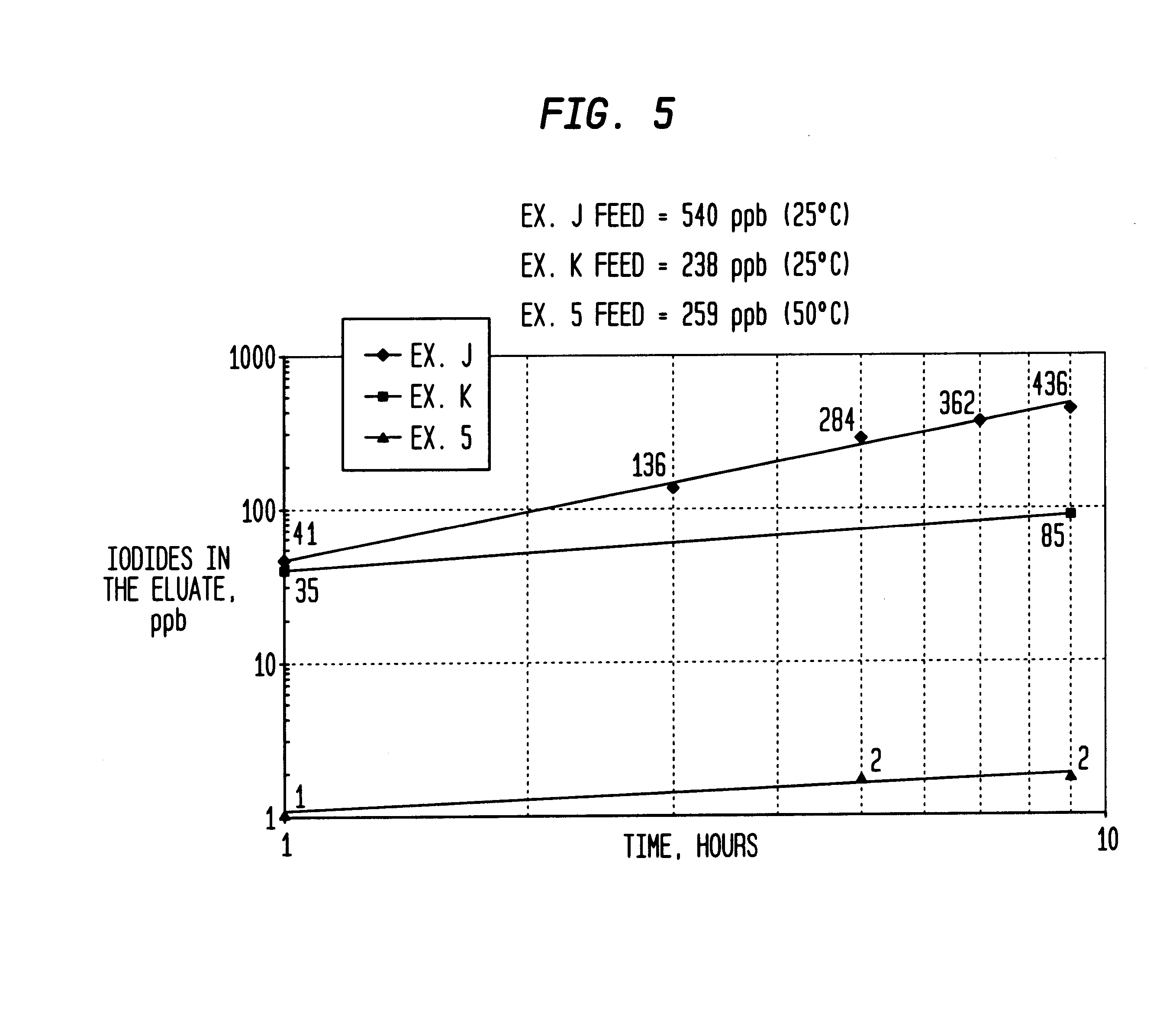

Method of removing organic iodides from organic media

InactiveUS6225498B1Efficient removalCation exchanger materialsOrganic compound preparationAcetic acidAcetic anhydride

Owner:CELANESE INT CORP

Process for the production of acetic acid

Owner:CELANESE INT CORP

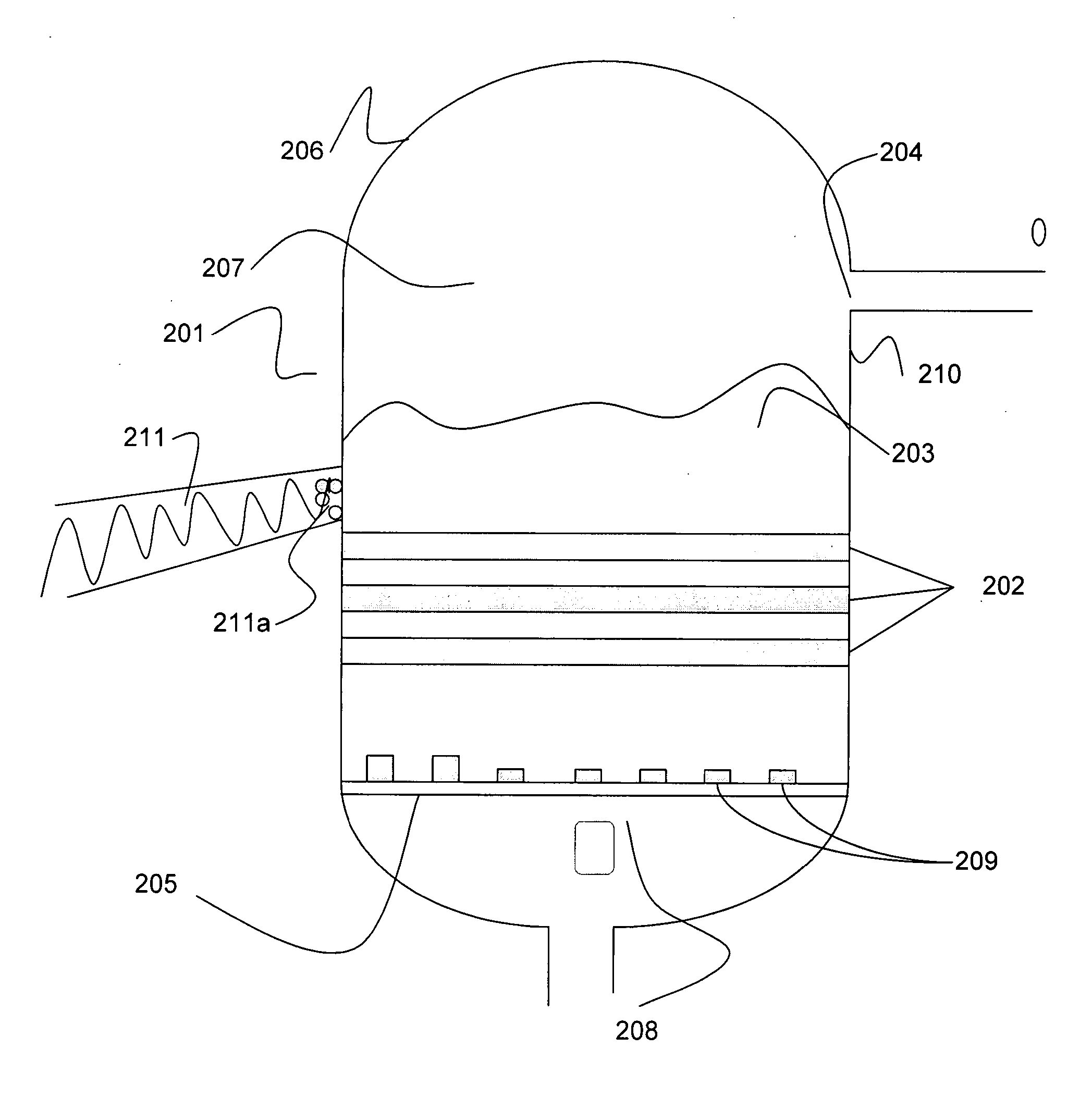

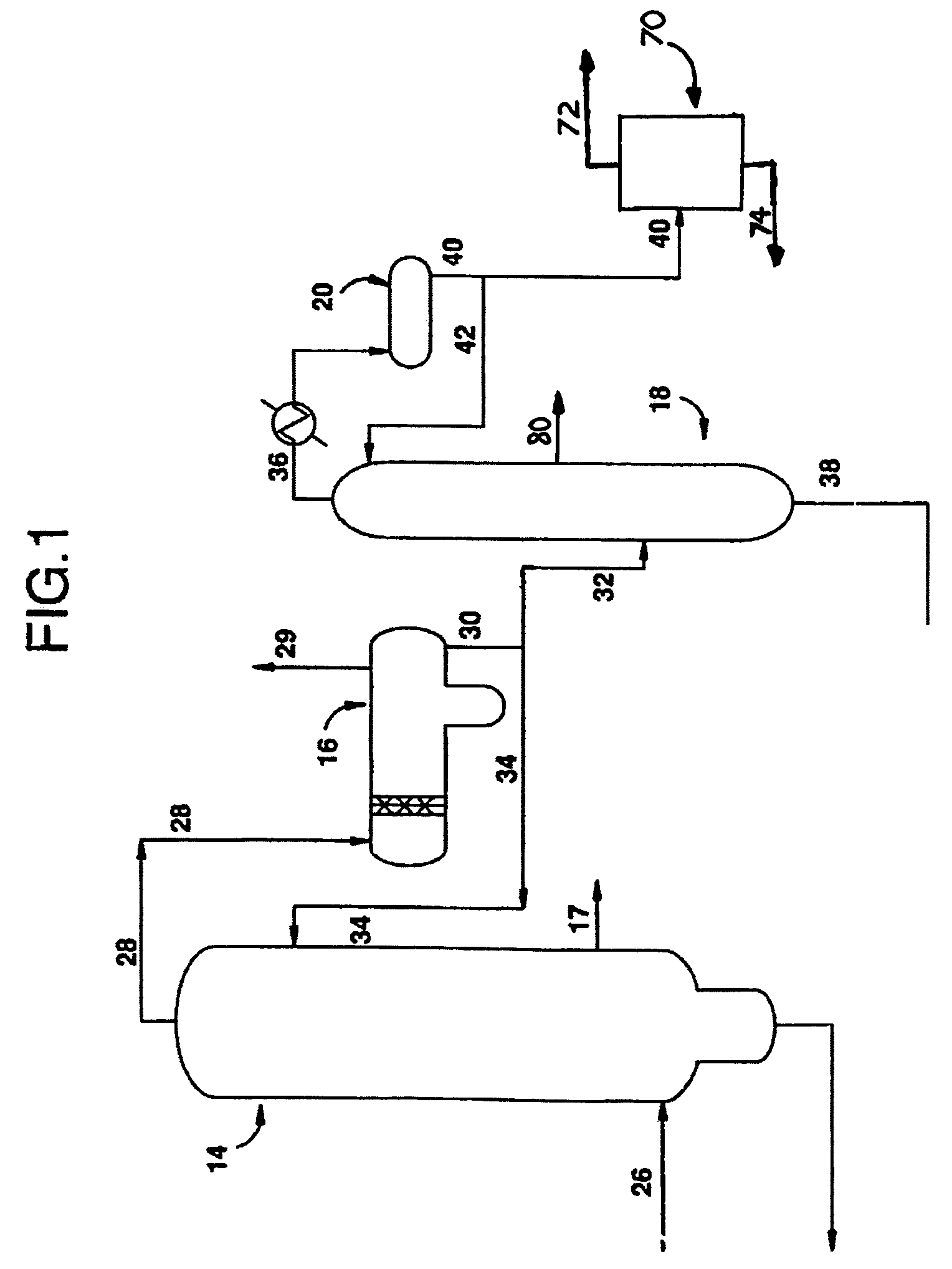

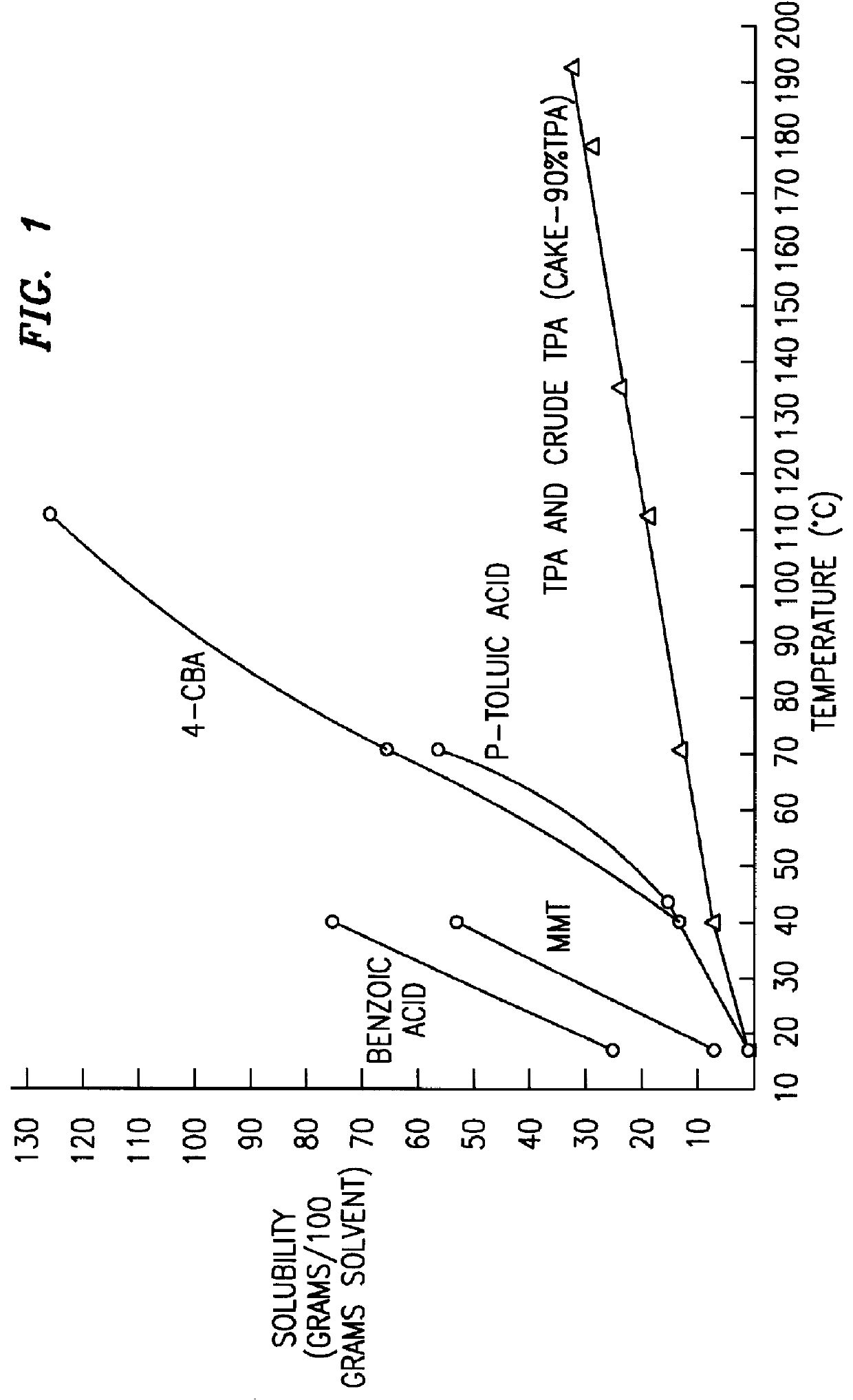

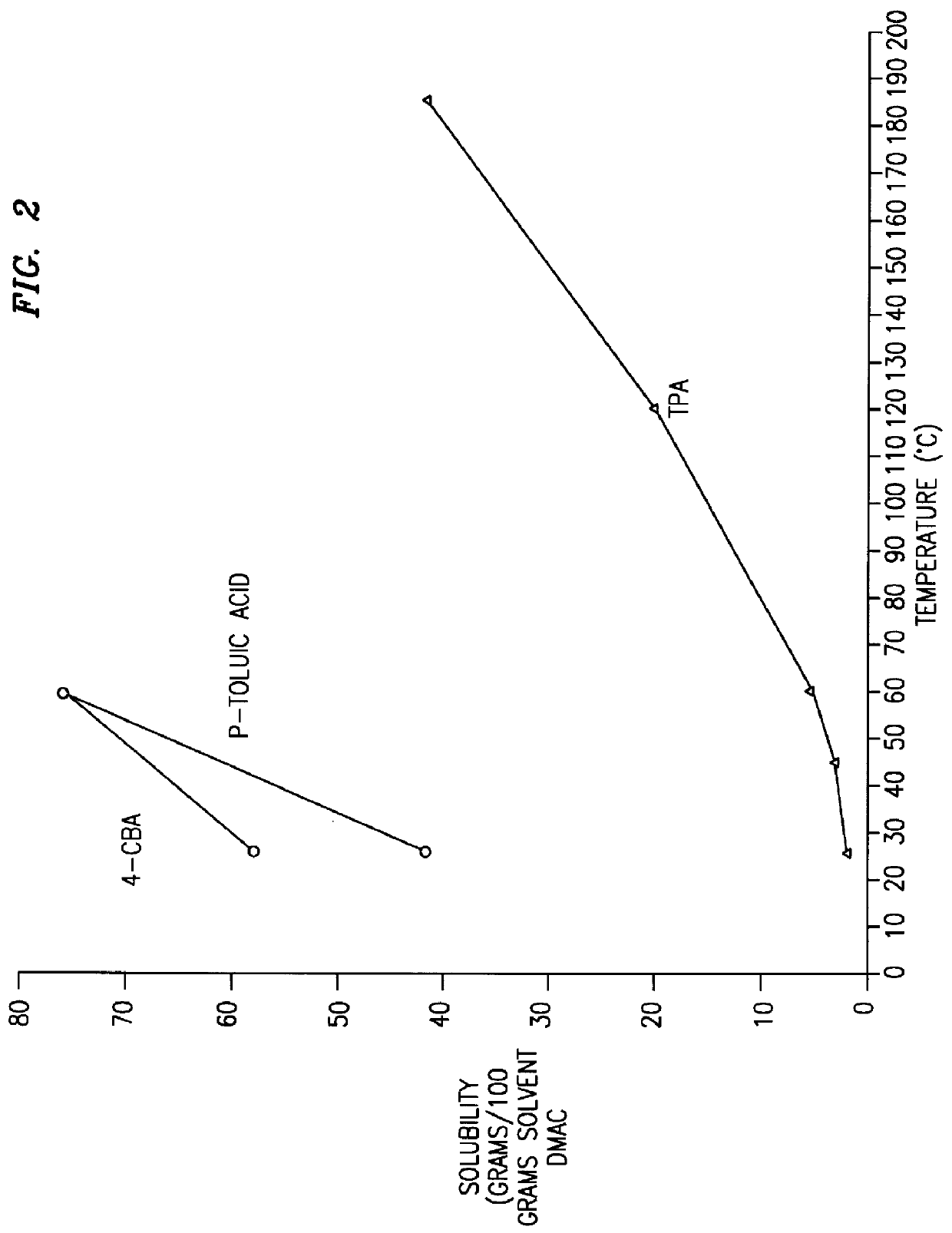

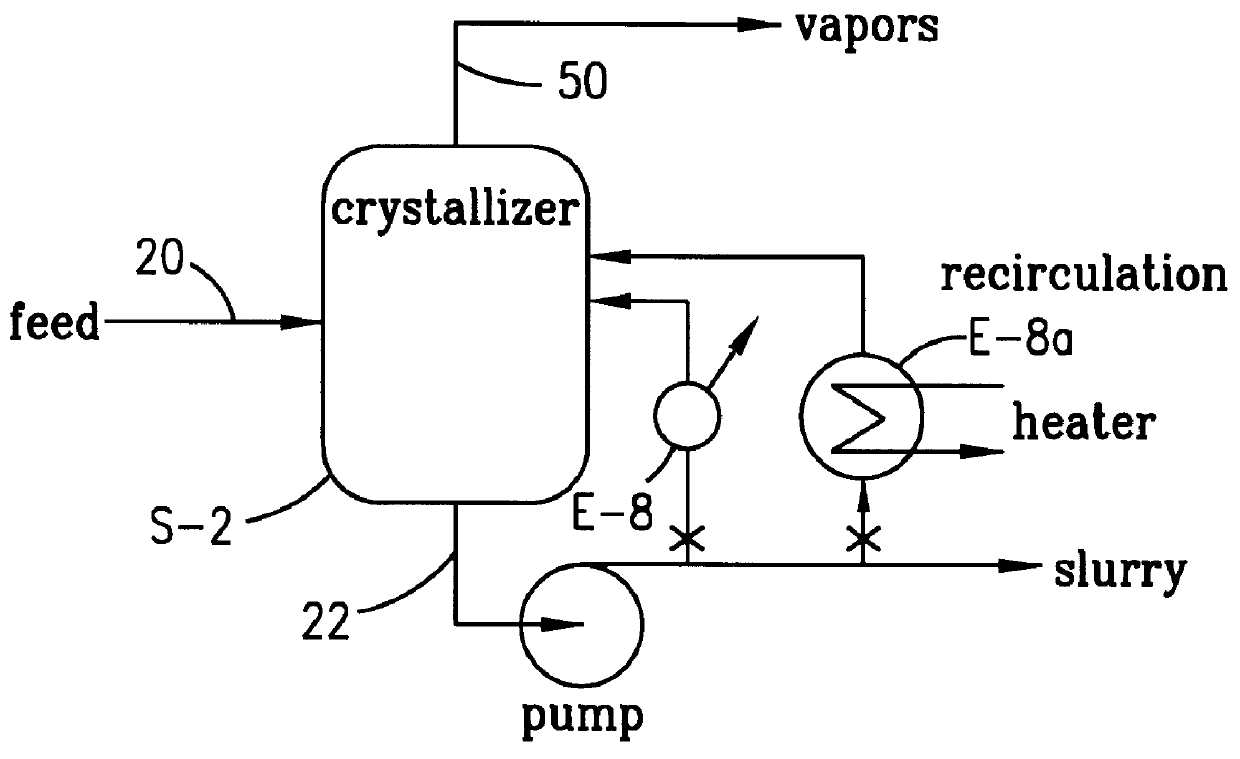

Method and apparatus for preparing purified terephthalic acid

InactiveUS6013835AOrganic compound preparationCarboxylic preparation by oxidationPolyester resinSide reaction

A method and apparatus for purifying crude terephthalic acid from a liquid dispersion thereof also containing impurities selected from unreacted starting materials, solvents, products of side reactions and / or other undesired materials is provided. The method comprises the steps of filtering the dispersion to form a crude terephthalic acid filter cake, dissolving the filter cake in a selective crystallization solvent at an elevated temperature to form a solution, crystallizing purified terephthalic acid from the solution in the crystallization solvent by reducing the pressure and temperature of the solution, and separating the crystallized purified terephthalic acid from the solution. According to the invention, the selective crystallization solvent is non-aqueous, non-corrosive and essentially non-reactive with terephthalic acid. Preferably, the selective crystallization solvent is N-methyl pyrrolidone. The method and apparatus produces purified terephthalic acid having a purity desired for use in forming polyester resin and other products at an economically attractive rate and at operating conditions of reduced severity which require a lower capital investment and simplified processing.

Owner:GTC TECHNOLOGY INC

Multimetal oxide materials

Owner:BASF SE

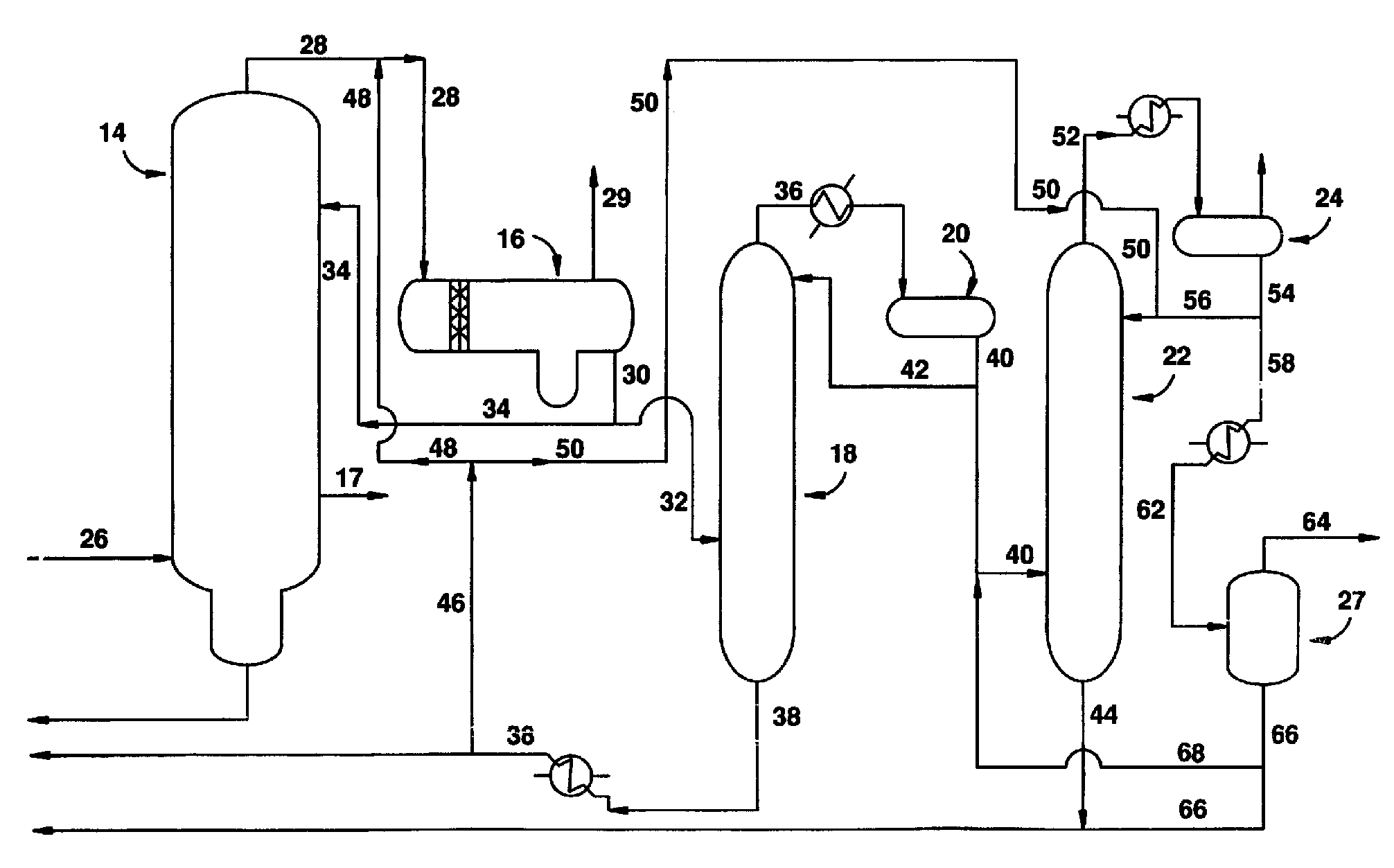

Process for producing biodiesel, lubricants, and fuel and lubricant additives in a critical fluid medium

InactiveUS6887283B1Limited mass transferImprove reaction speedFatty oils/acids recovery from wasteFatty acid esterificationBiodieselVegetable oil

A process for producing alkyl esters useful in biofuels and lubricants by transesterifying glyceride- or esterifying free fatty acid-containing substances in a single critical phase medium is disclosed. The critical phase medium provides increased reaction rates, decreases the loss of catalyst or catalyst activity and improves the overall yield of desired product. The process involves the steps of dissolving an input glyceride- or free fatty acid-containing substance with an alcohol or water into a critical fluid medium; reacting the glyceride- or free fatty acid-containing substance with the alcohol or water input over either a solid or liquid acidic or basic catalyst and sequentially separating the products from each other and from the critical fluid medium, which critical fluid medium can then be recycled back in the process. The process significantly reduces the cost of producing additives or alternatives to automotive fuels and lubricants utilizing inexpensive glyceride- or free fatty acid-containing substances, such as animal fats, vegetable oils, rendered fats, and restaurant grease.

Owner:BATTELLE ENERGY ALLIANCE LLC

Extraction process of tanshin general phenolic acid and its prepn and use

InactiveCN1384090ASimple processSimple regenerationPowder deliveryOrganic active ingredientsSalvia miltiorrhizaVascular disease

The present invention relates to extraction process of total tanshin phenolic acid, the preparation process and application of its preparation. The total tanshin phenolic acid and its preparation mayuse in preparing medicine for preventing and treating cardiac and cerebral vascular diseases, senile dementia and hypomnesia caused by cerebral ischemia. The total tanshin phonelic acid prepared based on the process of the present invention has rich active components of tanshin and obvious pharmacological effect, stable performance and les stoxicity and is safety and reliable.

Owner:INST OF MATERIA MEDICA AN INST OF THE CHINESE ACAD OF MEDICAL SCI +1

Process for the oxidative purification of terephthalic acid

InactiveUS20040110980A1Organic compound preparationCarboxylic preparation by oxidationSlurryCarboxylic acid

Disclosed is a process to produce a purified carboxylic acid slurry. The process comprises removing impurities from a crystallized product in a solid liquid displacement zone to form the purified carboxylic acid slurry. The process produces purified carboxylic acid slurry having good color and low impurity levels without the use of purification steps like hydrogenation or an impurity removal process.

Owner:ALPEK POLYESTER SA DE CV

Pharmaceutical co-crystal compositions

InactiveUS20070026078A1Improve solubilityLow hygroscopicityBiocidePowder deliveryThioketoneHydroxamic acid

A pharmaceutical composition comprising a co-crystal of an API and a co-crystal former; wherein the API has at least one functional group selected from ether, thioether, alcohol, thiol, aldehyde, ketone, thioketone, nitrate ester, phosphate ester, thiophosphate ester, ester, thioester, sulfate ester, carboxylic acid, phosphonic acid, phosphinic acid, sulfonic acid, amide, primary amine, secondary amine, ammonia, tertiary amine, sp2 amine, thiocyanate, cyanamide, oxime, nitrile diazo, organohalide, nitro, s-heterocyclic ring, thiophene, n-heterocyclic ring, pyrrole, o-heterocyclic ring, furan, epoxide, peroxide, hydroxamic acid, imidazole, pyridine and the co-crystal former has at least one functional group selected from amine, amide, pyridine, imidazole, indole, pyrrolidine, carbonyl, carboxyl, hydroxyl, phenol, sulfone, sulfonyl, mercapto and methyl thio, such that the API and co-crystal former are capable of co-crystallizing from a solution phase under crystallization conditions.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES +2

Process for the purification of a crude carboxylic acid slurry

Disclosed is a process to produce a purified carboxylic acid product. The process comprises removing impurities from a crude carboxylic acid slurry in a solid-liquid displacement zone to form a slurry product. The slurry product if further treated in a staged oxidation zone and a crystallization zone to from a crystallized product. The crystallized product is further cooled in a cooling zone and subsequently filtered and dried in a filtration and drying zone. The process produces purified carboxylic acid product having good color and low impurity levels without the use of purification steps like hydrogenation.

Owner:ALPEK POLYESTER SA DE CV

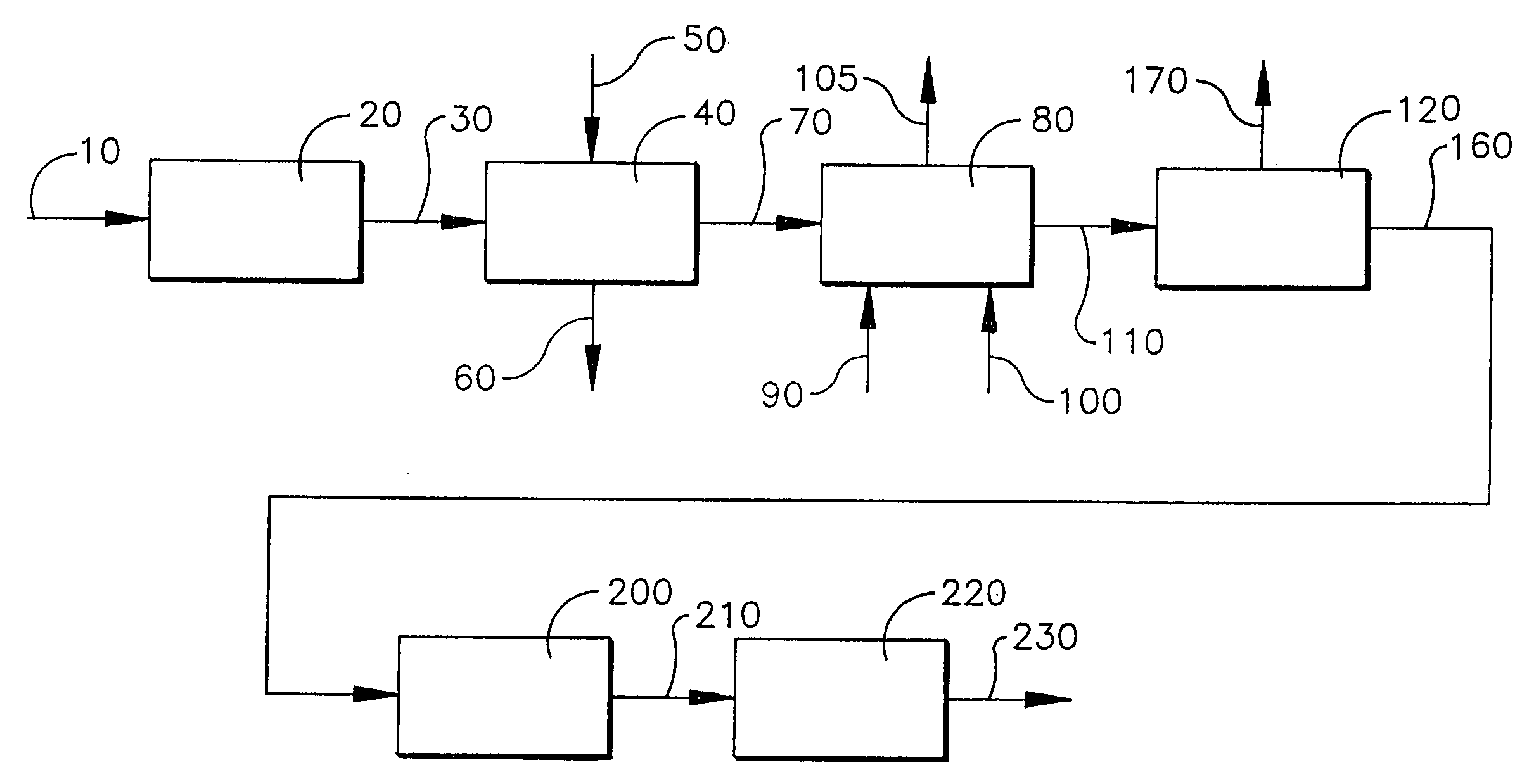

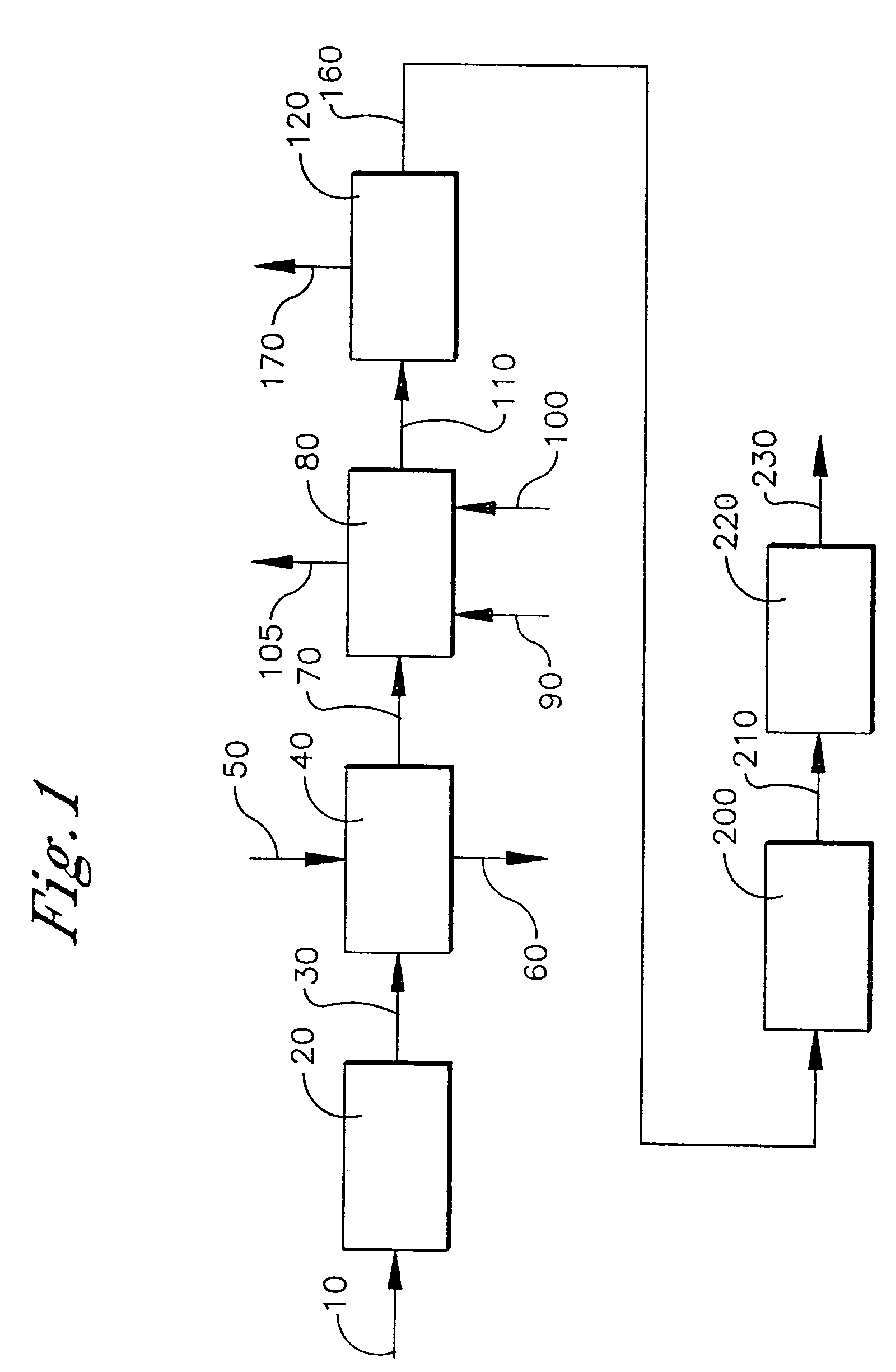

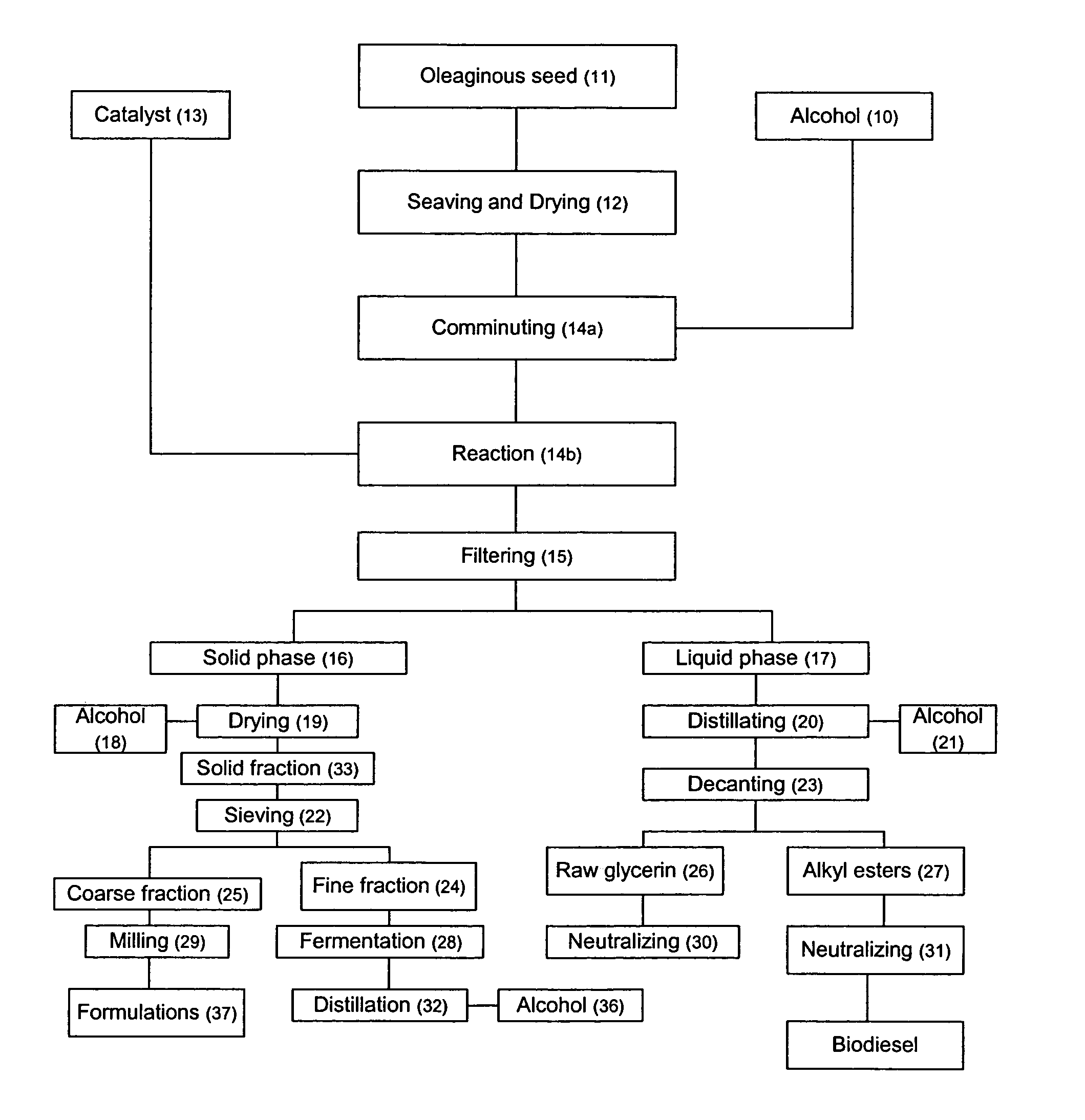

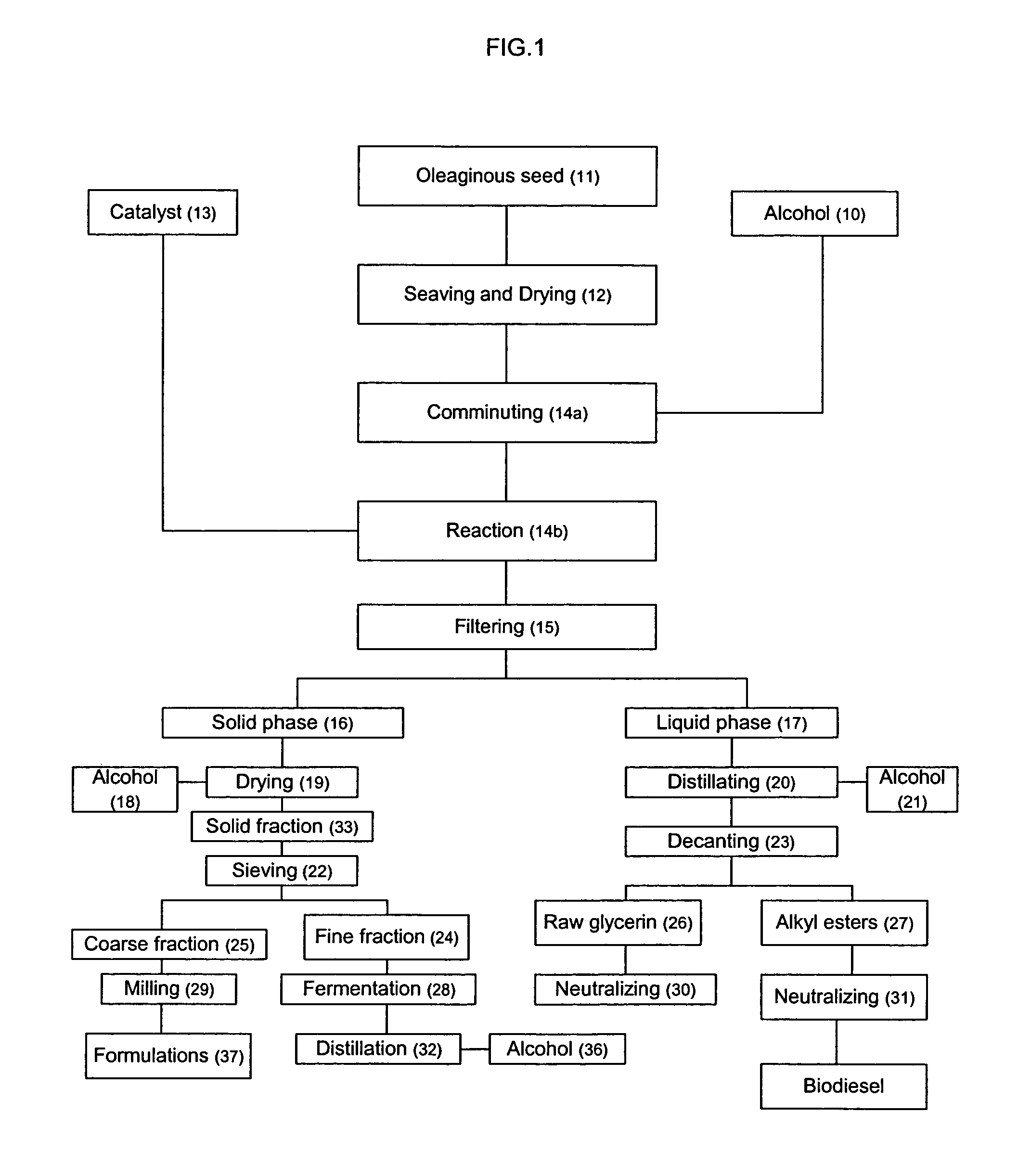

Process for producing biodiesel fuel using triglyceride-rich oleagineous seed directly in a transesterification reaction in the presence of an alkaline alkoxide catalyst

InactiveUS7112229B2Fatty oils/acids recovery from wasteFatty acid esterificationOil and greaseBiodiesel

An integrated process is described for producing biodiesel from oleaginous seeds, preferably castor bean seeds. The inventive process includes a transesterification reaction where the seeds themselves react with anhydrous ethyl alcohol in the presence of an alkaline catalyst. The resulting ethyl esters are then separated by decantation and neutralized and used as fuel for diesel engines, co-solvents for diesel and gasoline mixtures with anhydrous or hydrated ethyl alcohol. The solid fractions may be used as fertilizers, for feeding cattle and as a raw material for producing ethyl alcohol.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

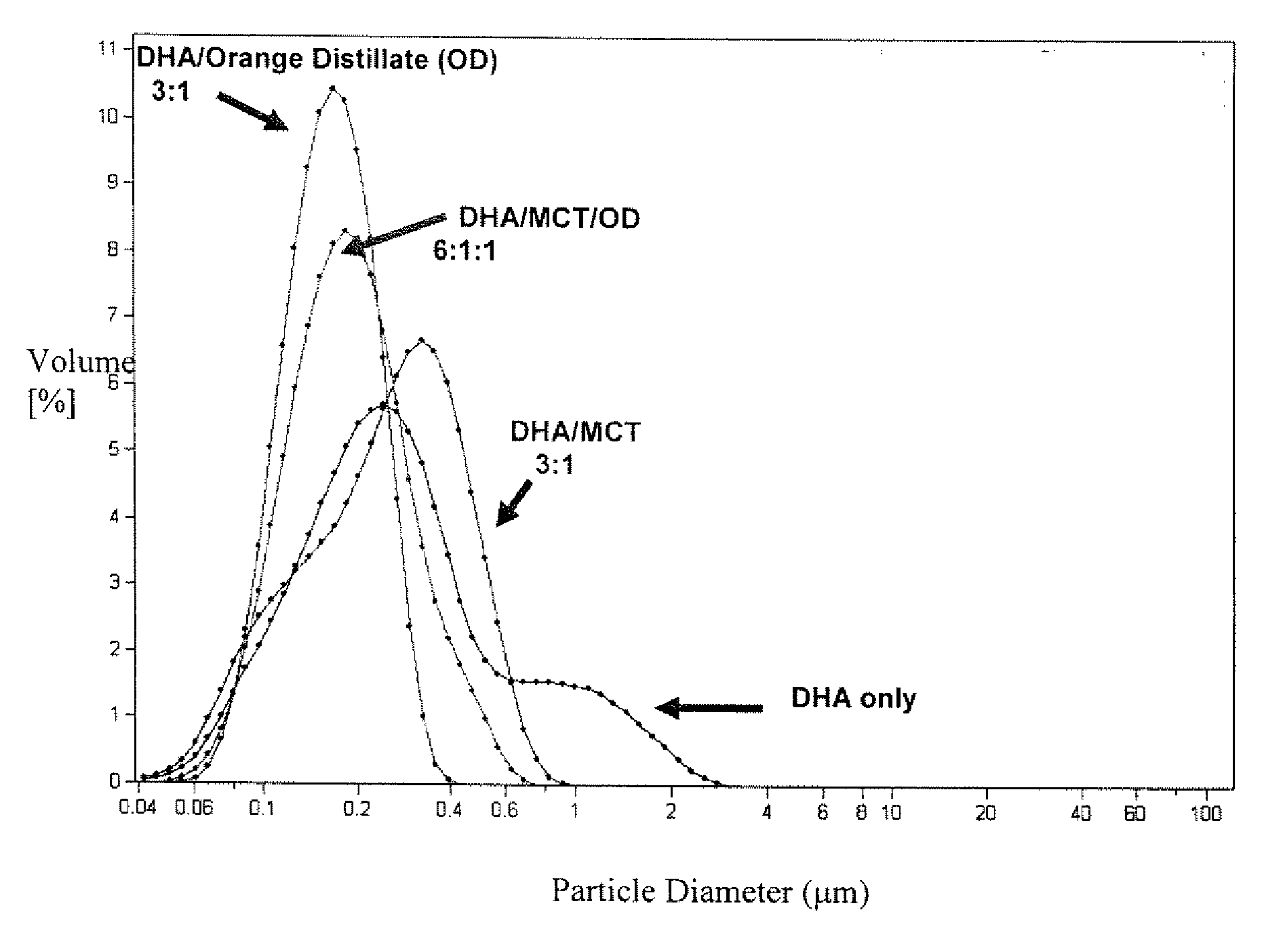

Stable polyunsaturated fatty acid emulsions and methods for inhibiting, suppressing, or reducing degradation of polyunsaturated fatty acids in an emulsion

InactiveUS20080058418A1Inhibiting and suppressing and reducingBiocideHydroxy compound active ingredientsEmulsionAntioxidant

An emulsion comprising a continuous liquid phase, an emulsifier, and a discontinuous liquid phase comprising a blend including a polyunsaturated fatty acid source and a dispersing agent. The polyunsaturated fatty acid source comprises at least one polyunsaturated fatty acid and the weight ratio of the fatty acid source to the dispersing agent in the blend ranges from about between 9:1 and 1:10. A method for making an emulsion. The stability of the emulsion can be protected by antioxidants such as tea polyphenols.

Owner:THE COCA-COLA CO

Removal of permanganate reducing compounds from methanol carbonylation process stream

ActiveUS7223883B2Reduce solubilityOrganic compound preparationCarboxylic preparation from carbon monoxide reactionAcetic acidCarbonylation

Owner:CELANESE INT CORP

Popular searches

Carboxylic compound separation/purification Chemical industry Refining to change hydrocarbon structural skeleton Hydrocarbon by hydrogenation Fatty-oils/fats refining Fatty-oils/fats separation Liquid hydrocarbon mixture production Treatment with hydrotreatment processes Bio-feedstock Hydrocarbon oils treatment products

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com