Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6047 results about "Terephthalic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Terephthalic acid is an organic compound with formula C₆H₄(CO₂H)₂. This white solid is a commodity chemical, used principally as a precursor to the polyester PET, used to make clothing and plastic bottles. Several million tonnes are produced annually. The common name is derived from the turpentine-producing tree Pistacia terebinthus and phthalic acid.

Extraction process for removal of impurities from an oxidizer purge stream in the synthesis of carboxylic acid

InactiveUS20050038288A1Easy to operateImprove reliabilityOrganic compound preparationOrganic chemistry methodsSingle stageMetal catalyst

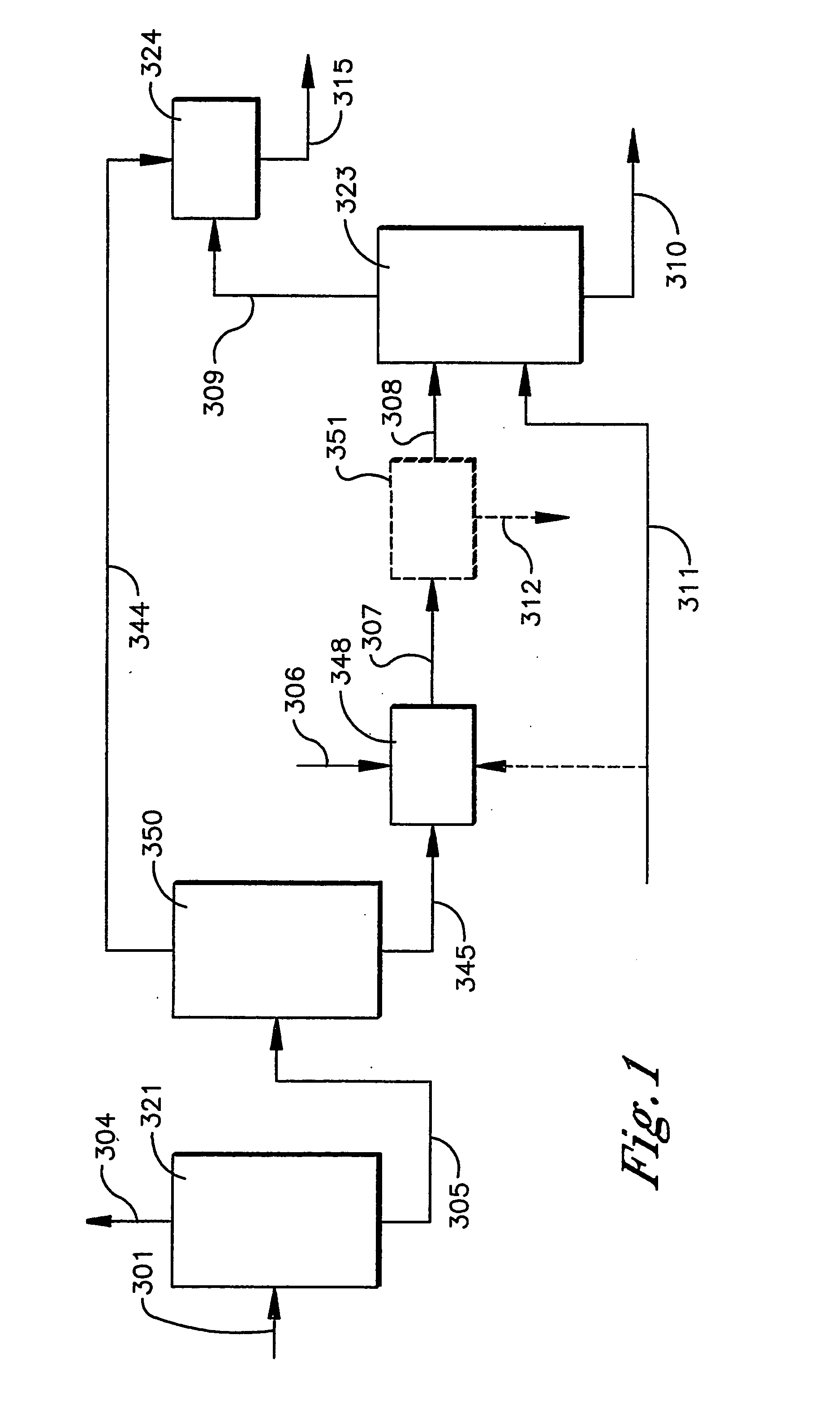

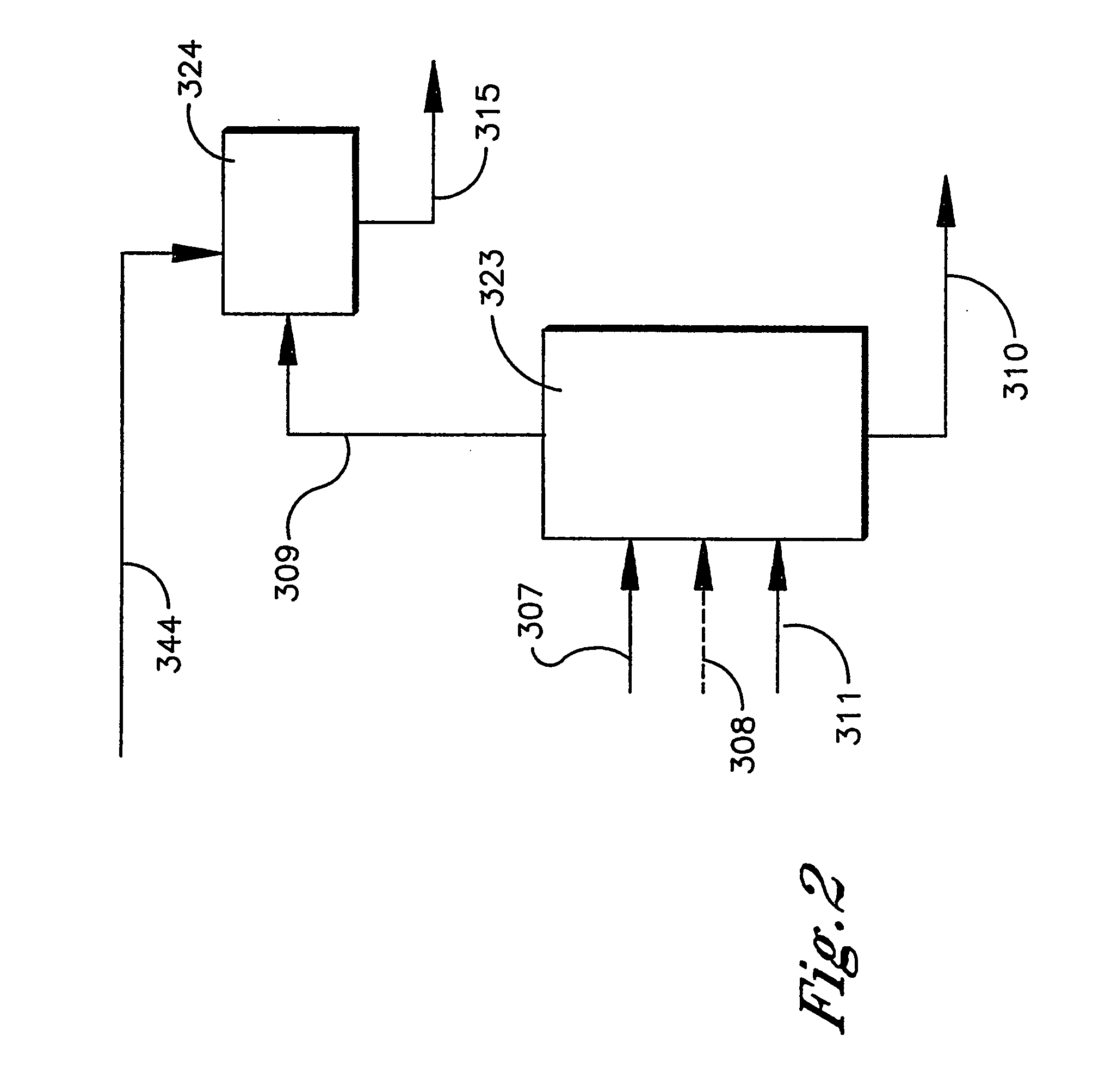

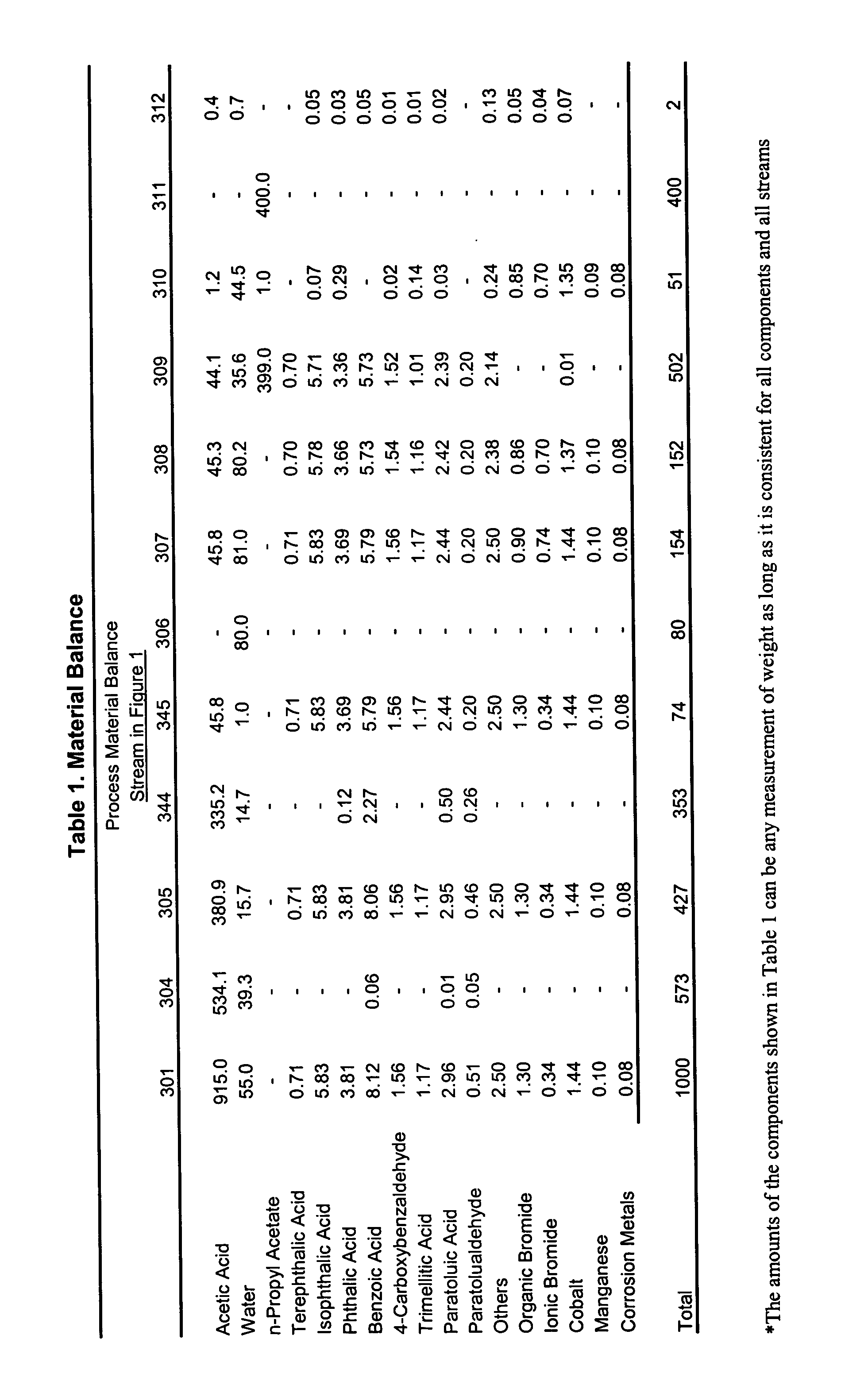

Disclosed is a process that relates to the recovery of a metal catalyst from an oxidizer purge stream produced in the synthesis of carboxylic acid, typically terephthalic acid. The process involves the addition of a wash solution to a high temperature molten dispersion to recover the metal catalyst and then subjecting an aqueous mixture or purified aqueous mixture so formed to a single stage extraction to remove organic impurities to produce an extract stream and a raffinate stream comprising the metal catalyst.

Owner:GRUPO PETROTEMEX DE C V

Semiaromatic polyamide molding compositions and their use

ActiveUS20080274355A1High strengthLow water absorptionPigmenting treatmentNon-fibrous pulp additionHexamethylenediamineAramides

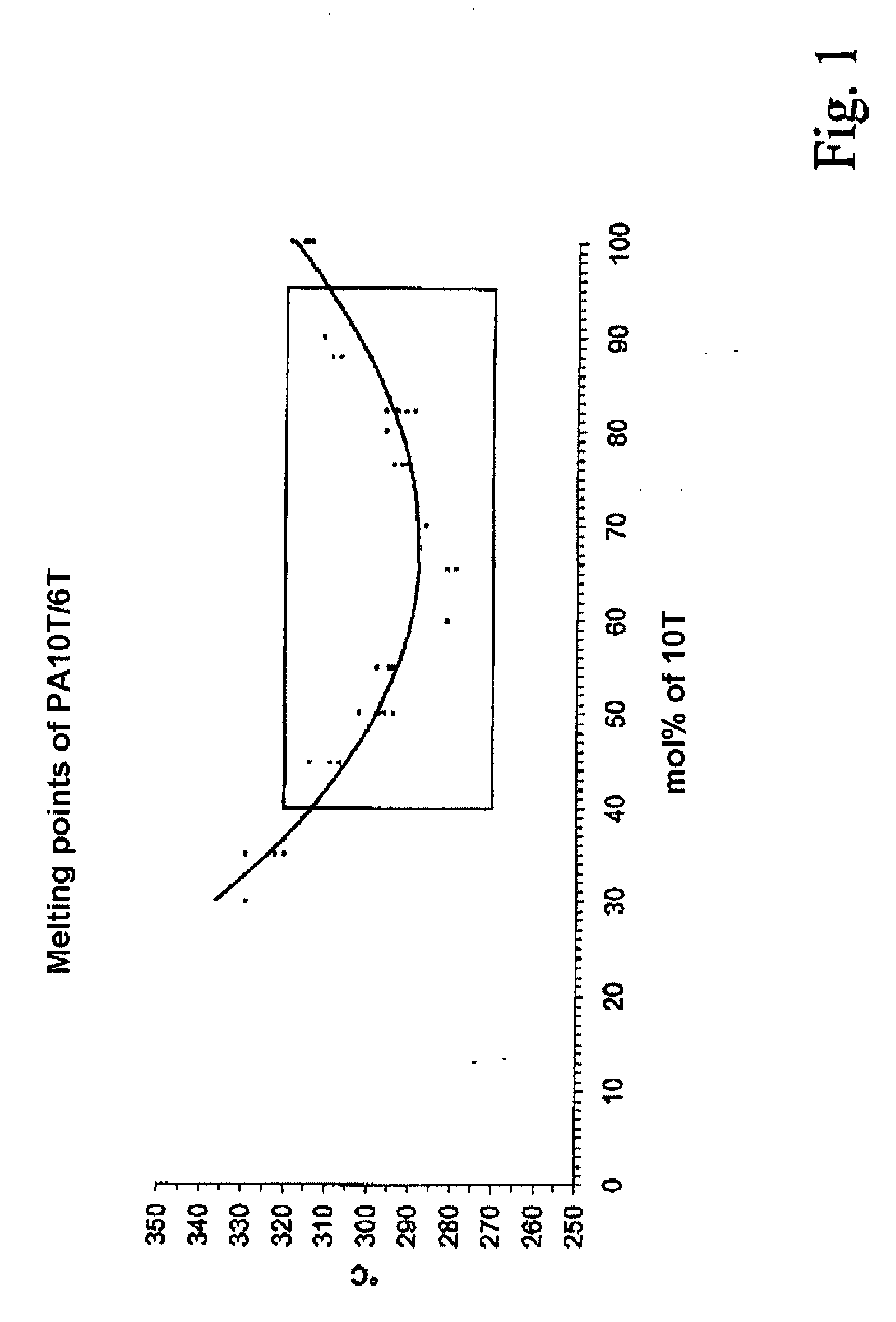

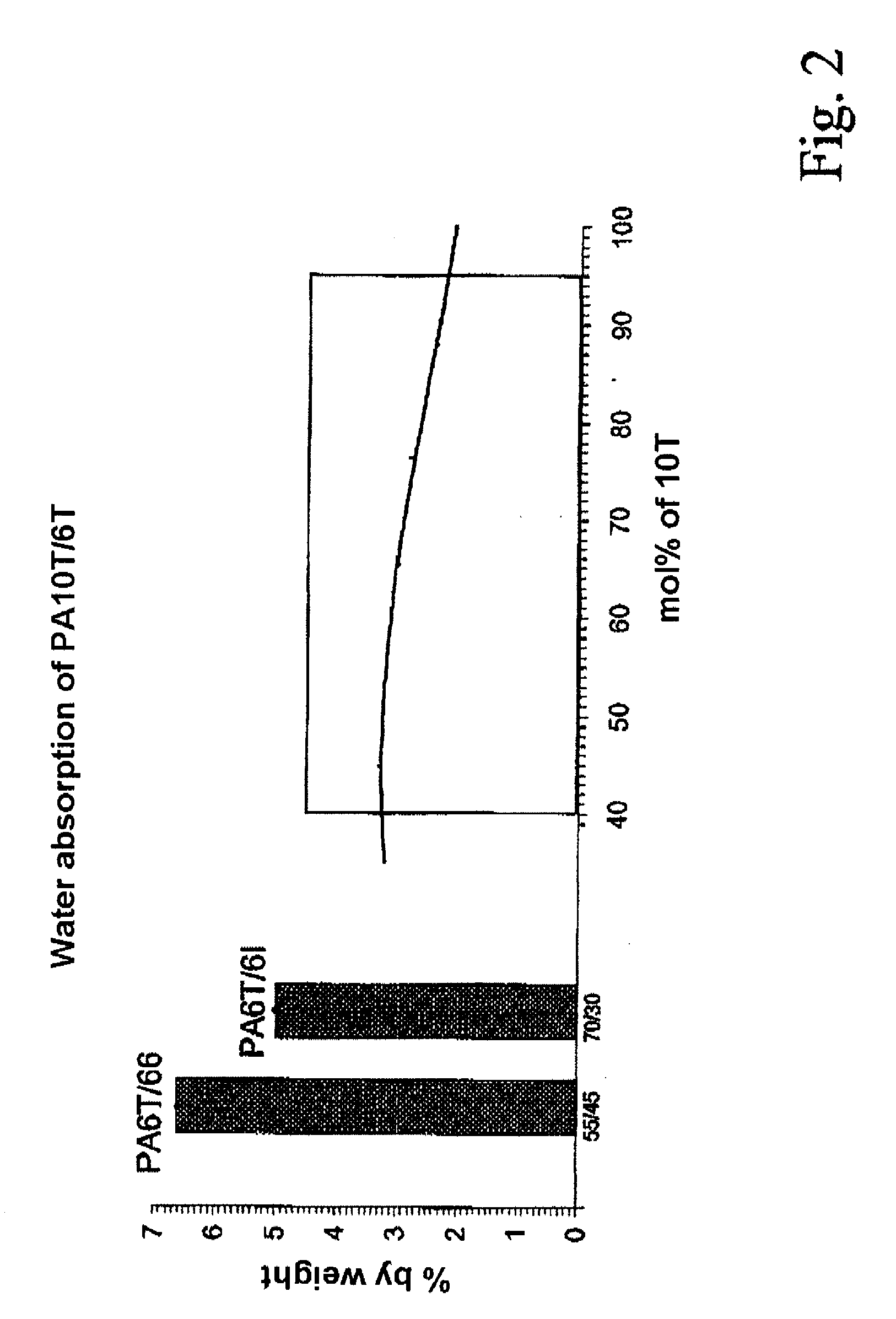

A polyamide molding composition with the following constitution is described:(A) from 30 to 100% by weight of at least one 10T / 6T copolyamide, where this is composed of(A1) from 40 to 95 mol % of 10T units, formed from the monomers 1,10-decanediamine and terephthalic acid(A2) from 5 to 60 mol % of 6T units, formed from the monomers 1,6-hexanediamine and terephthalic acid(B) from 0 to 70% by weight of reinforcing materials and / or fillers(C) from 0 to 50% by weight of additives and / or further polymerswhere the entirety of components A to C is 100%, with the proviso that in component (A) up to 30 mol %, based on the entirety of the dicarboxylic acids, of the terephthalic acid can have been replaced by other aromatic, aliphatic, or cycloaliphatic dicarboxylic acids, and with the proviso that in component (A) up to 30 mol % of 1,10-decanediamine and respectively 1,6-hexanediamine, based on the entirety of the diamines, can have been replaced by other diamines, and with the proviso that not more than 30 mol % in component (A), based on the entirety of the monomers, can have been formed via lactams or amino acids. Uses of this polyamide molding composition are moreover described, as also are processes for the preparation of these polyamide molding compositions.

Owner:EMS PATENT AG

Method to produce aromatic dicarboxylic acids using cobalt and zirconium catalysts

InactiveUS6153790AAvoid problemsEfficient removalOrganic compound preparationChemical recyclingOrganic acidWater vapor

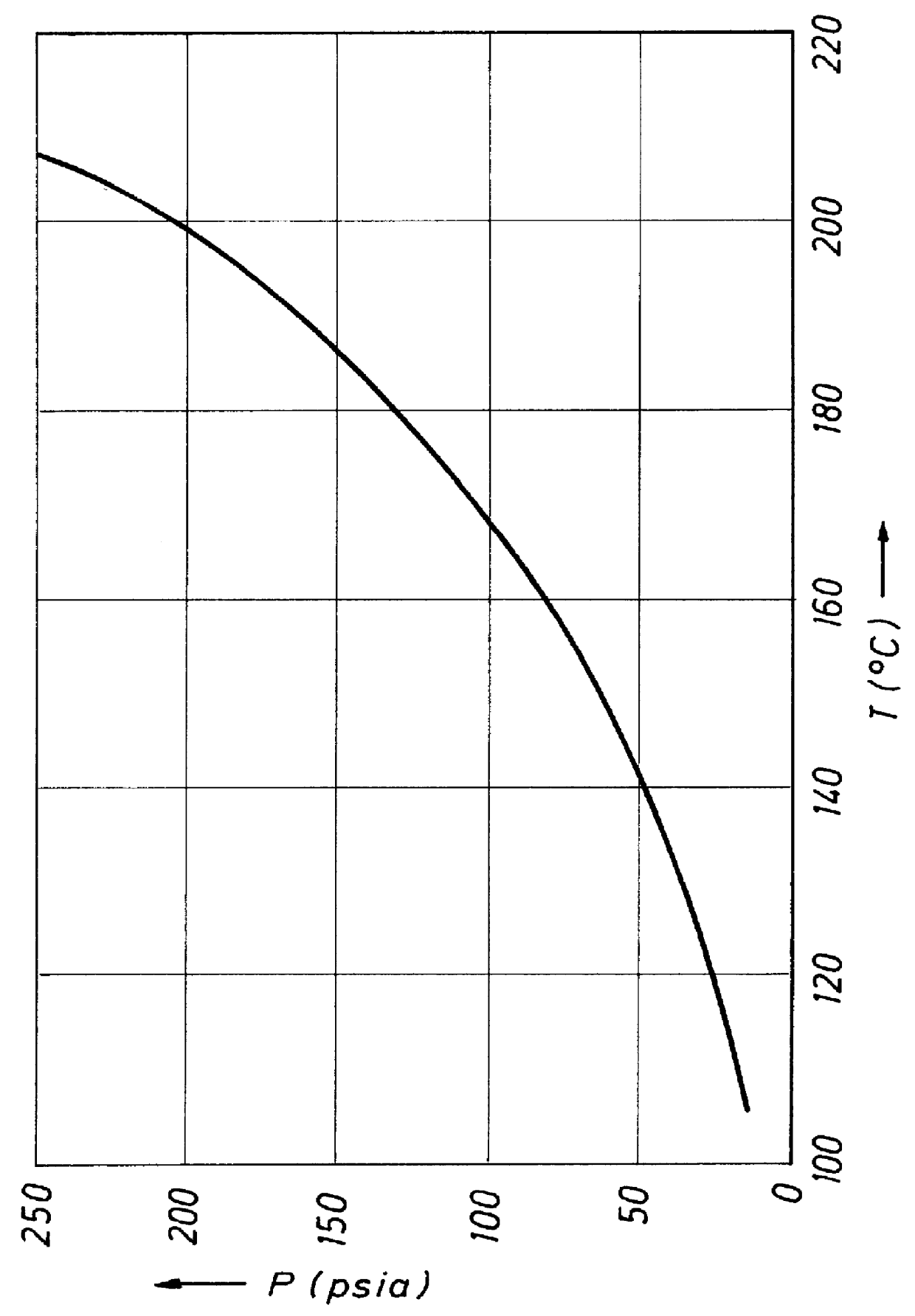

A process to produce terephthalic acid is provided, the process including the steps of: providing a feed stream comprising a dialkyl substituted aromatic and in an organic acid solvent: contacting the feed stream with an oxidant, the oxidant containing at least 50% by volume oxygen and at an oxygen partial pressure of at least 1 psia, at a temperature between about 80 DEG C. and about 130 DEG C., in the presence of a catalyst system comprising zirconium and cobalt, wherein the contacting is done in a stirred tank reactor; removing from the stirred tank reactor a vapor stream comprising the organic acid, water vapor and unreacted oxidant; condensing at least a portion of the organic acid and water from the vapor stream; separating at least a portion of the water from the organic acid back to the stirred tank reactor; returning at least a portion of the condensed organic acid back to the stirred tank reactor; continuously recovering from the stirred tank reactor a product comprising a diacid substituted aromatic; isolating solid crystals of diacid substituted aromatic from the reactor product; and recovering from the solid crystals a diacid substituted aromatic having a purity of preferably at least 97% by weight.

Owner:SHELL OIL CO

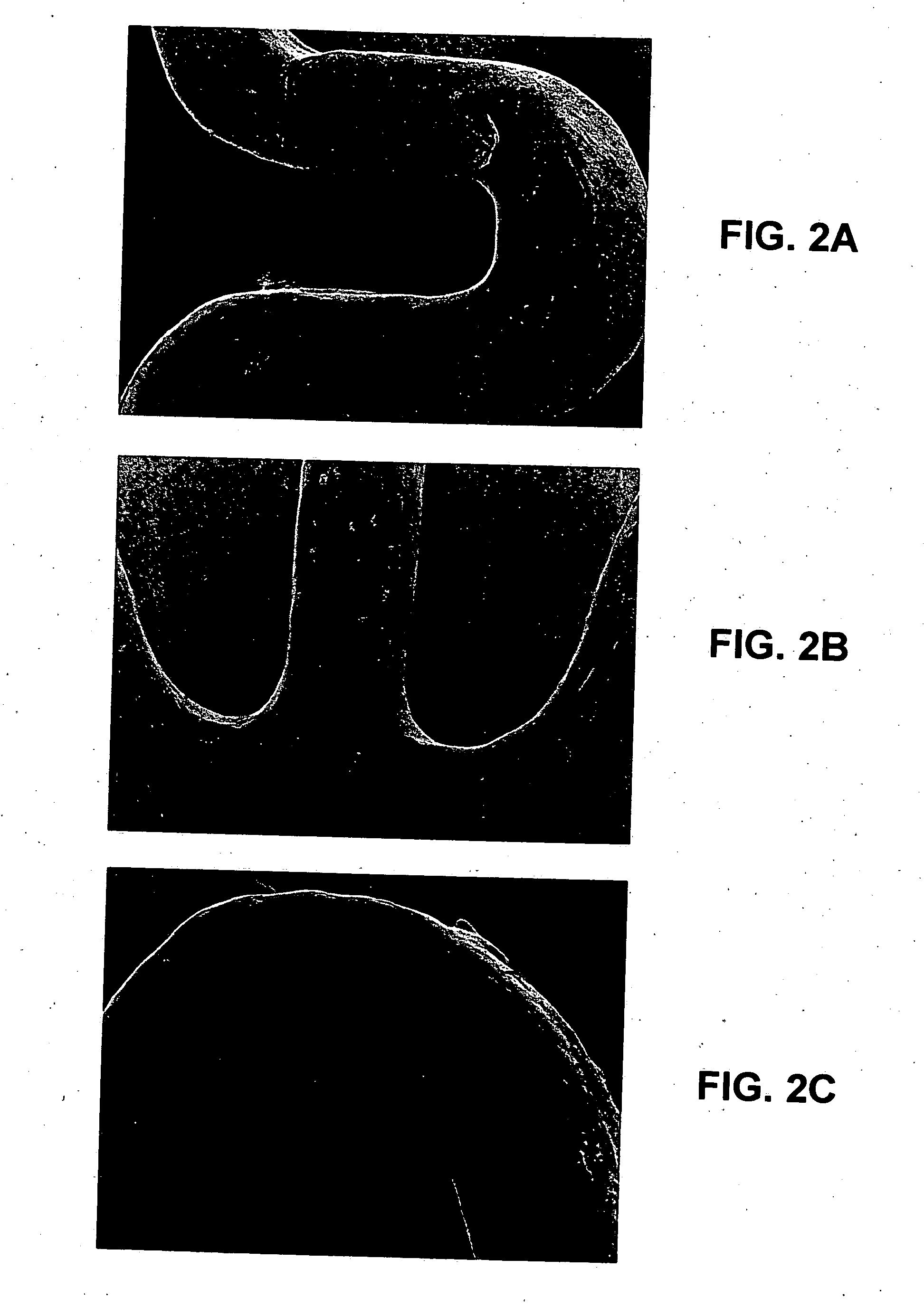

Terephthalic acid composition and process for the production thereof

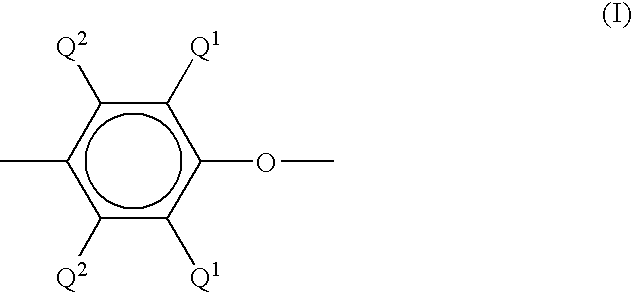

InactiveUS7385081B1Reducing and eliminating resultantOrganic compound preparationCarboxylic compound preparationEtherCarbon oxide

Terephthalic acid is prepared by reacting a 2,5-furandicarboxylate with ethylene in the presence of a solvent to produce a bicyclic ether; and then dehydrating the bicyclic ether. The process of the present invention effectively produces terephthalic acid, while reducing or eliminating the impurities, color bodies and carbon oxides produced in commercial practice by the liquid-phase oxidation of methyl-substituted benzene feedstocks.

Owner:BP CORP NORTH AMERICA INC

Method and apparatus for preparing purified terephthalic acid

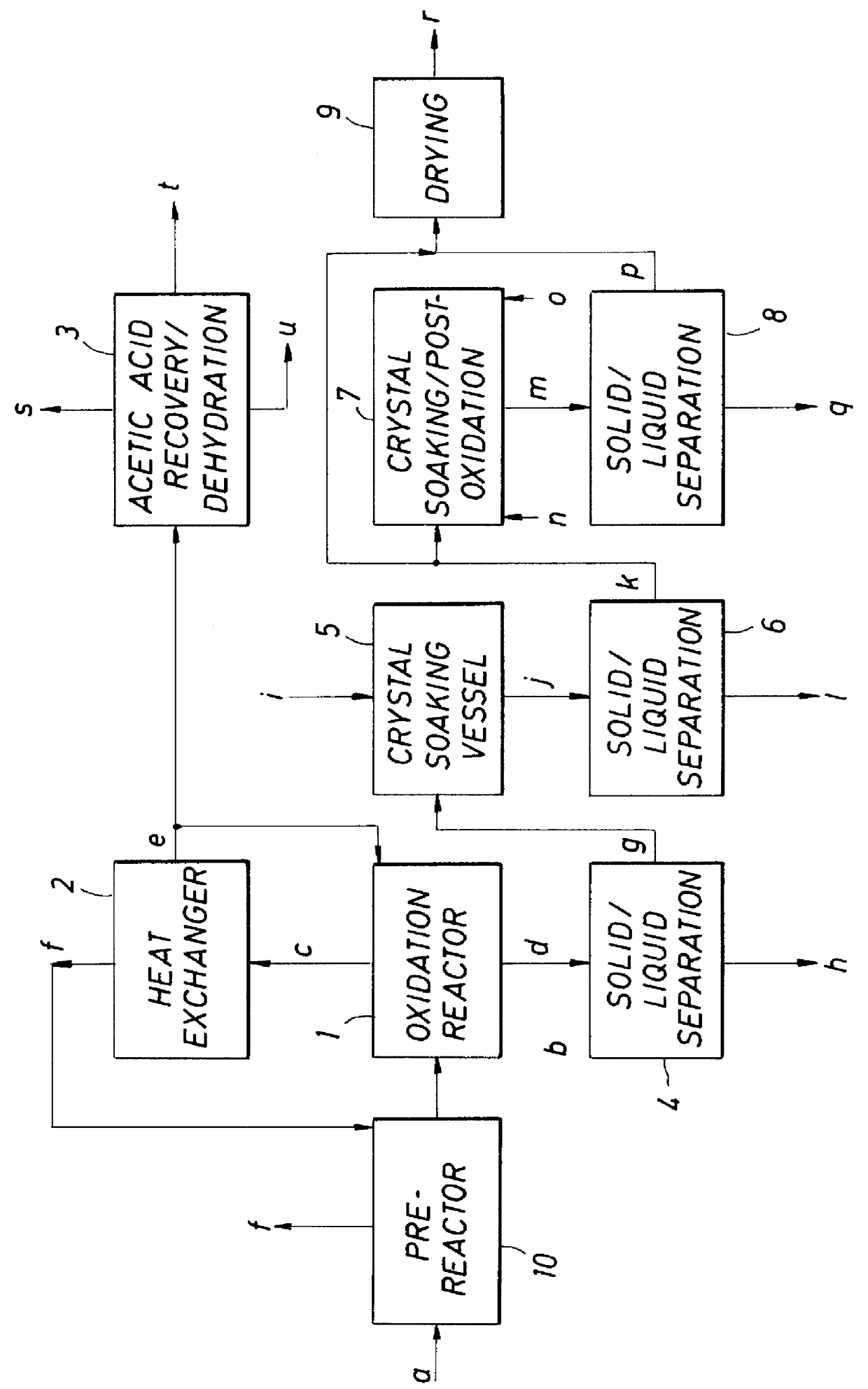

InactiveUS6013835AOrganic compound preparationCarboxylic preparation by oxidationPolyester resinSide reaction

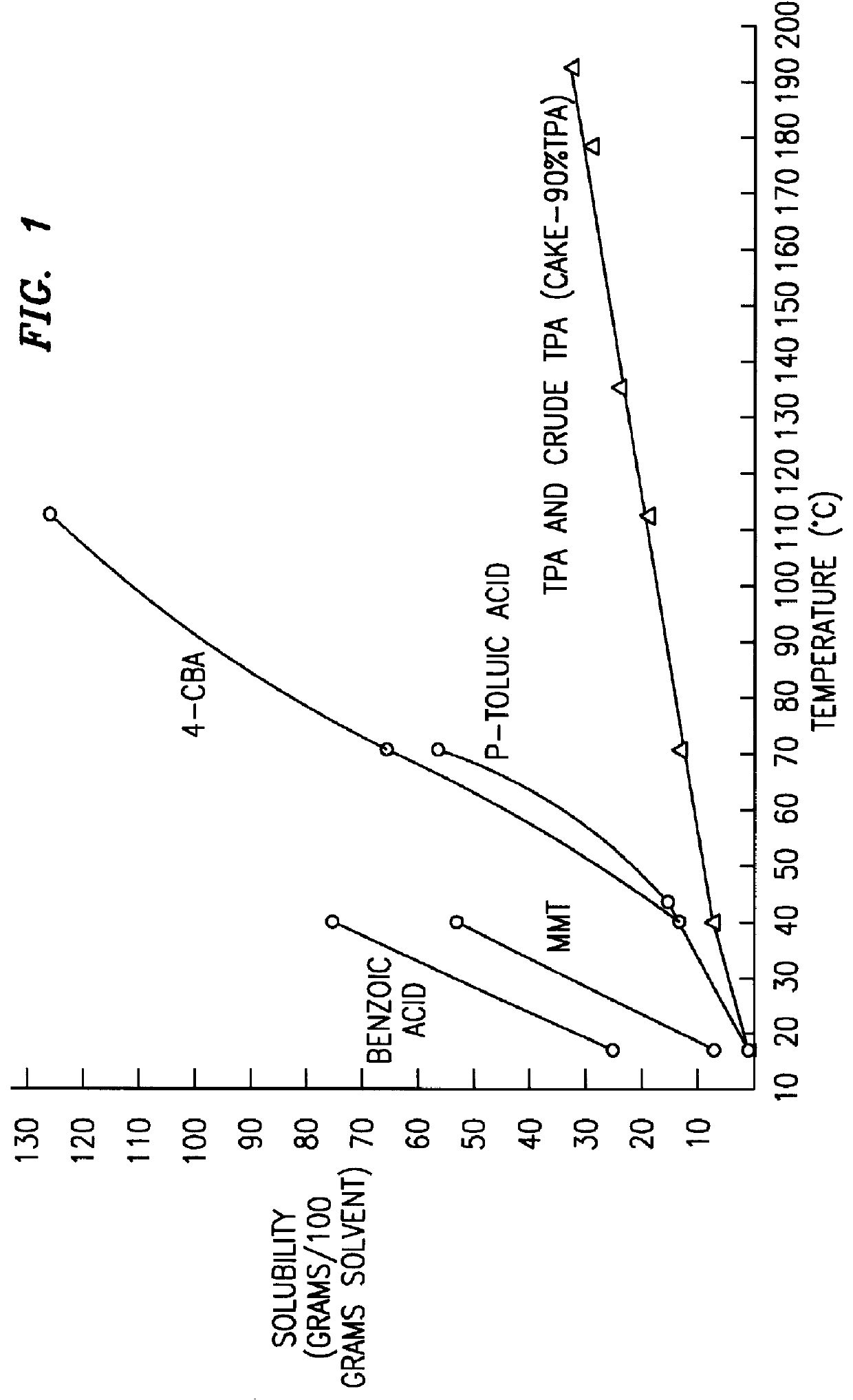

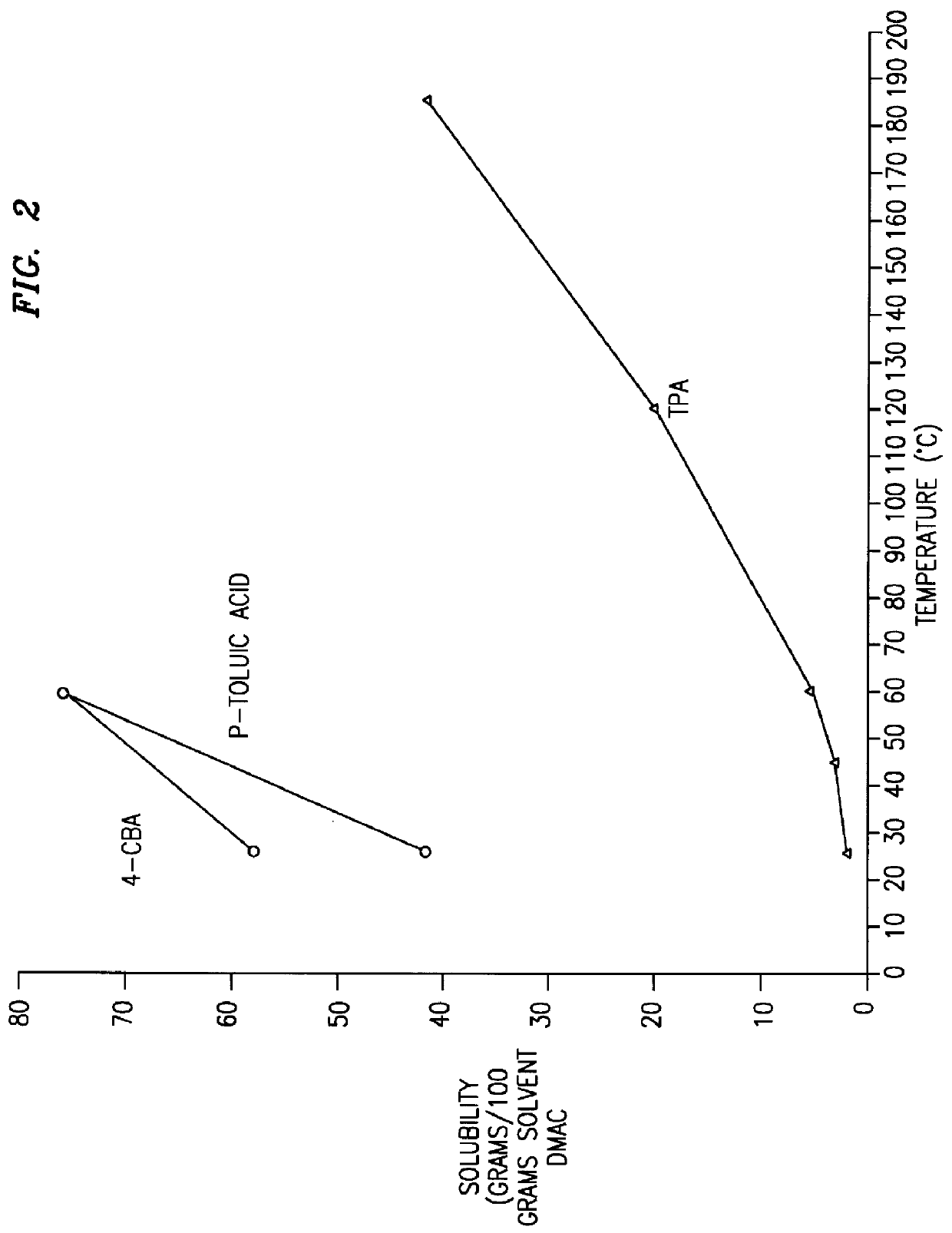

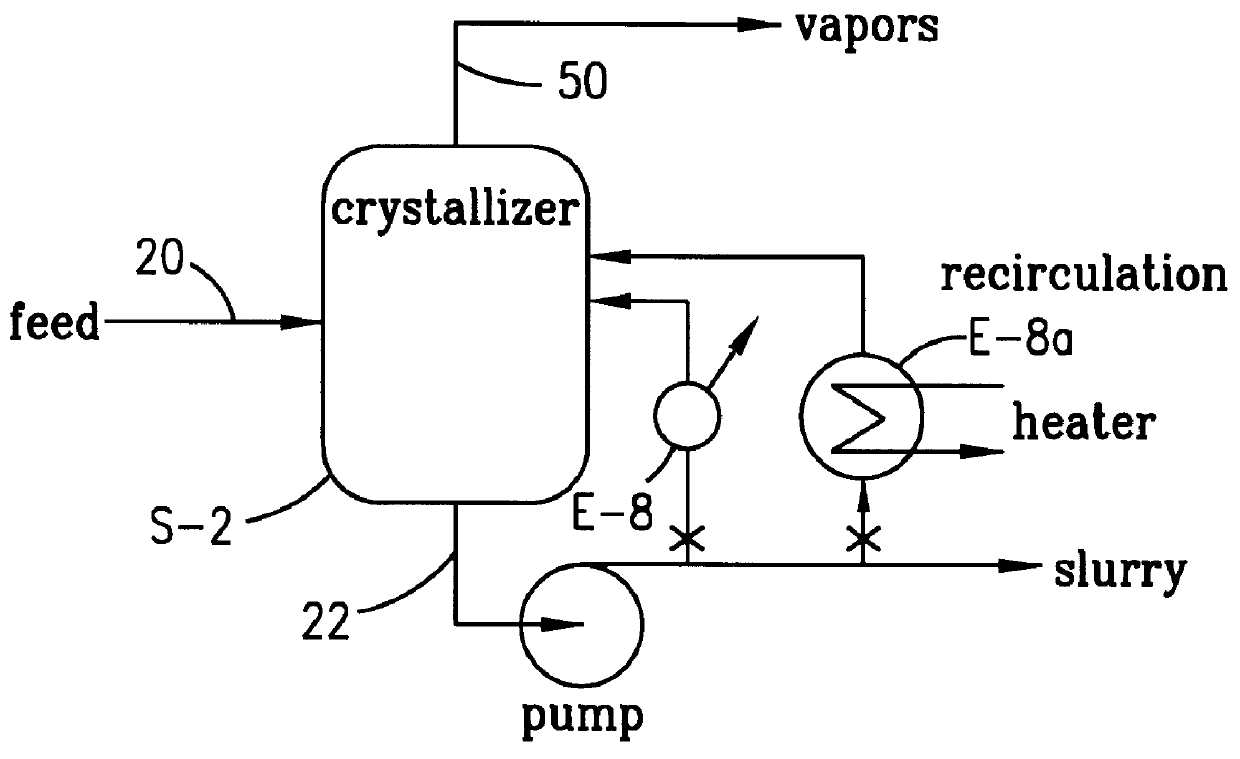

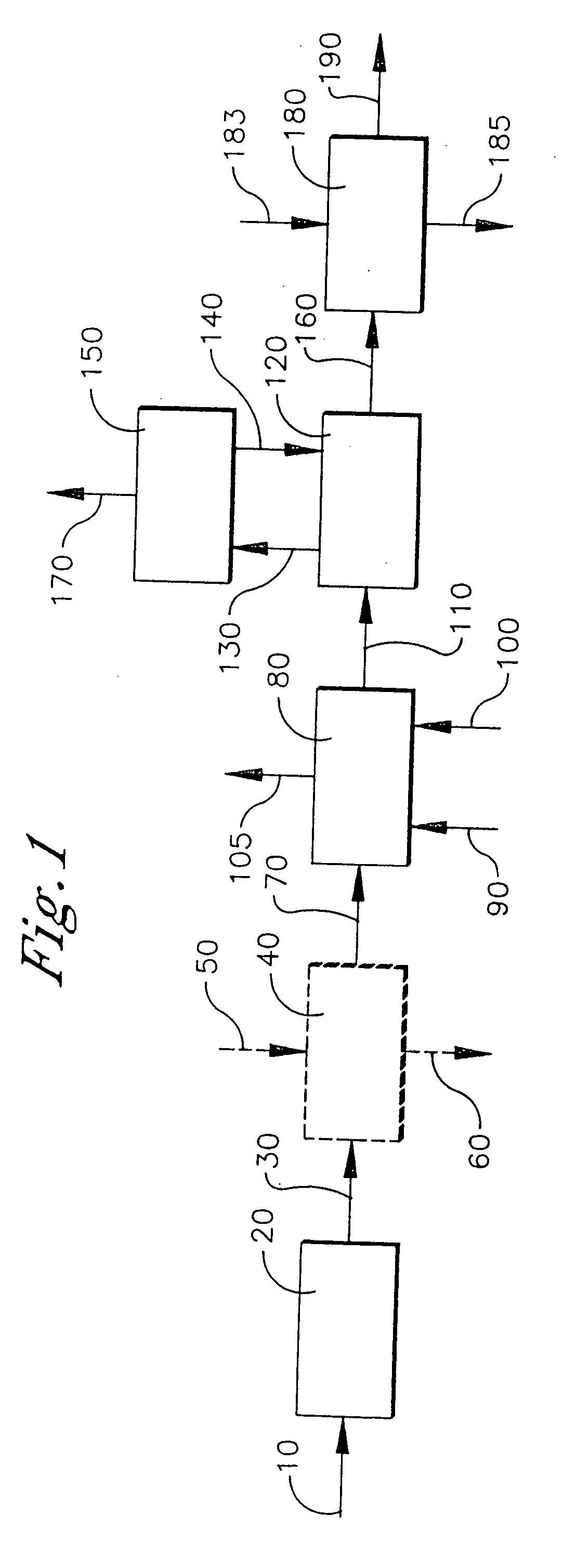

A method and apparatus for purifying crude terephthalic acid from a liquid dispersion thereof also containing impurities selected from unreacted starting materials, solvents, products of side reactions and / or other undesired materials is provided. The method comprises the steps of filtering the dispersion to form a crude terephthalic acid filter cake, dissolving the filter cake in a selective crystallization solvent at an elevated temperature to form a solution, crystallizing purified terephthalic acid from the solution in the crystallization solvent by reducing the pressure and temperature of the solution, and separating the crystallized purified terephthalic acid from the solution. According to the invention, the selective crystallization solvent is non-aqueous, non-corrosive and essentially non-reactive with terephthalic acid. Preferably, the selective crystallization solvent is N-methyl pyrrolidone. The method and apparatus produces purified terephthalic acid having a purity desired for use in forming polyester resin and other products at an economically attractive rate and at operating conditions of reduced severity which require a lower capital investment and simplified processing.

Owner:GTC TECHNOLOGY INC

Process for the oxidative purification of terephthalic acid

InactiveUS20040110980A1Organic compound preparationCarboxylic preparation by oxidationSlurryCarboxylic acid

Disclosed is a process to produce a purified carboxylic acid slurry. The process comprises removing impurities from a crystallized product in a solid liquid displacement zone to form the purified carboxylic acid slurry. The process produces purified carboxylic acid slurry having good color and low impurity levels without the use of purification steps like hydrogenation or an impurity removal process.

Owner:ALPEK POLYESTER SA DE CV

Preparation of poly(trimethylene terephthalate)

In one embodiment, the invention is a process for the preparation of poly(trimethylene terephthalate) comprising (a) contacting terephthalic acid with 1,3-propanediol in the presence of an organic tin catalyst to form a bis(3-hydroxypropyl)terephthalate monomer; and (b) polymerizing said monomer in the presence of organic titanate polycondensation catalyst to obtain the poly(trimethylene terephthalate). In another embodiment, the invention is a process for the preparation of poly(trimethylene terephthalate) containing less than 1.6 mol % of DPG said process comprising contacting terephthalic acid with a 1.6 to 1 to 2:1 molar amount of 1,3-propanediol in the presence of 20 to 120 ppm (as tin), by weight of the poly(trimethylene terephthalate), of a organic tin catalyst, to form a bis(3-hydroxypropyl)terephthalate monomer and polymerizing said monomer to obtain the poly(trimethylene terephthalate). The invention is also directed to poly(trimethylene terephthalate) produced by the processes.

Owner:DUPONT IND BIOSCIENCES USA LLC

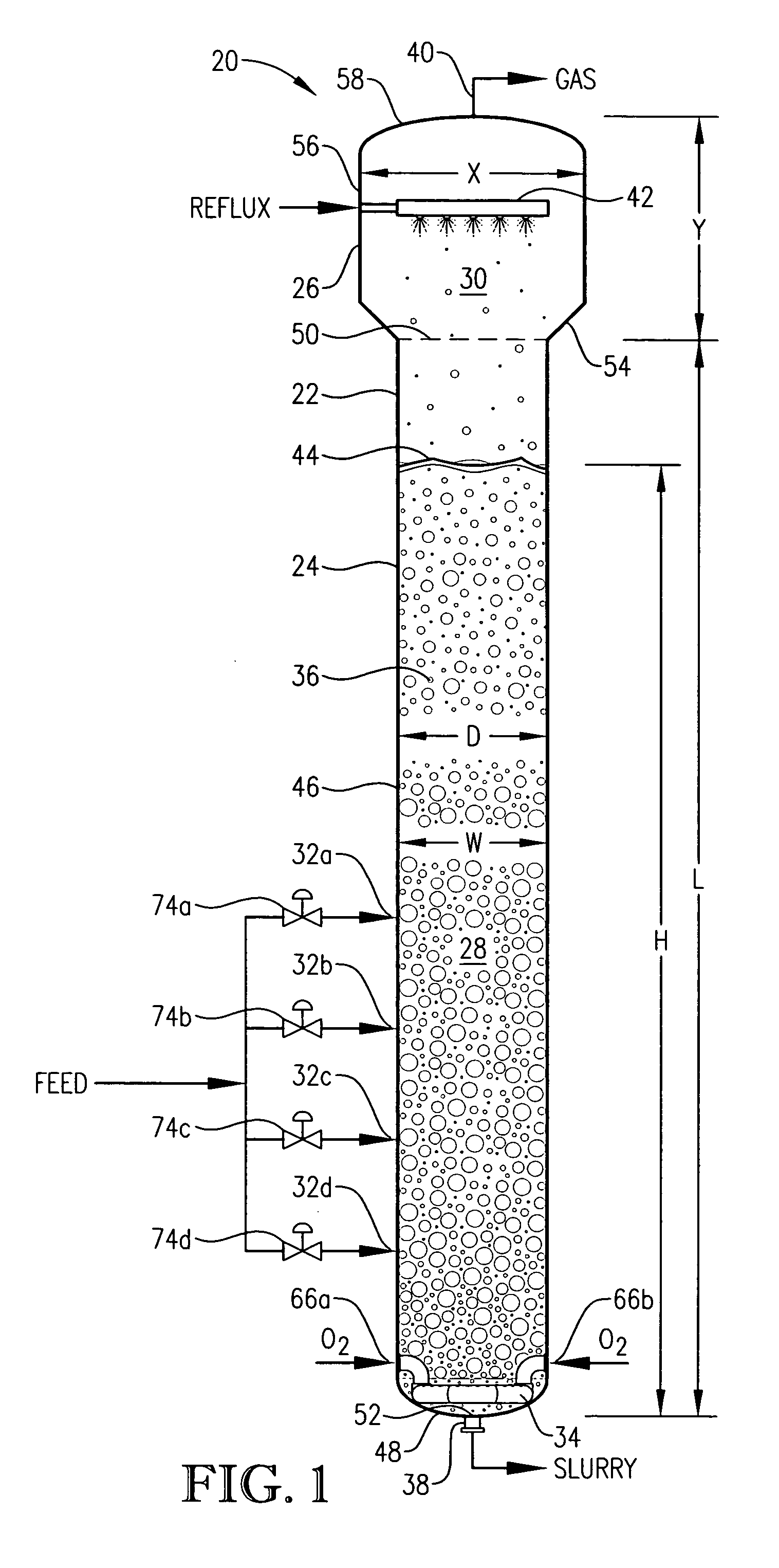

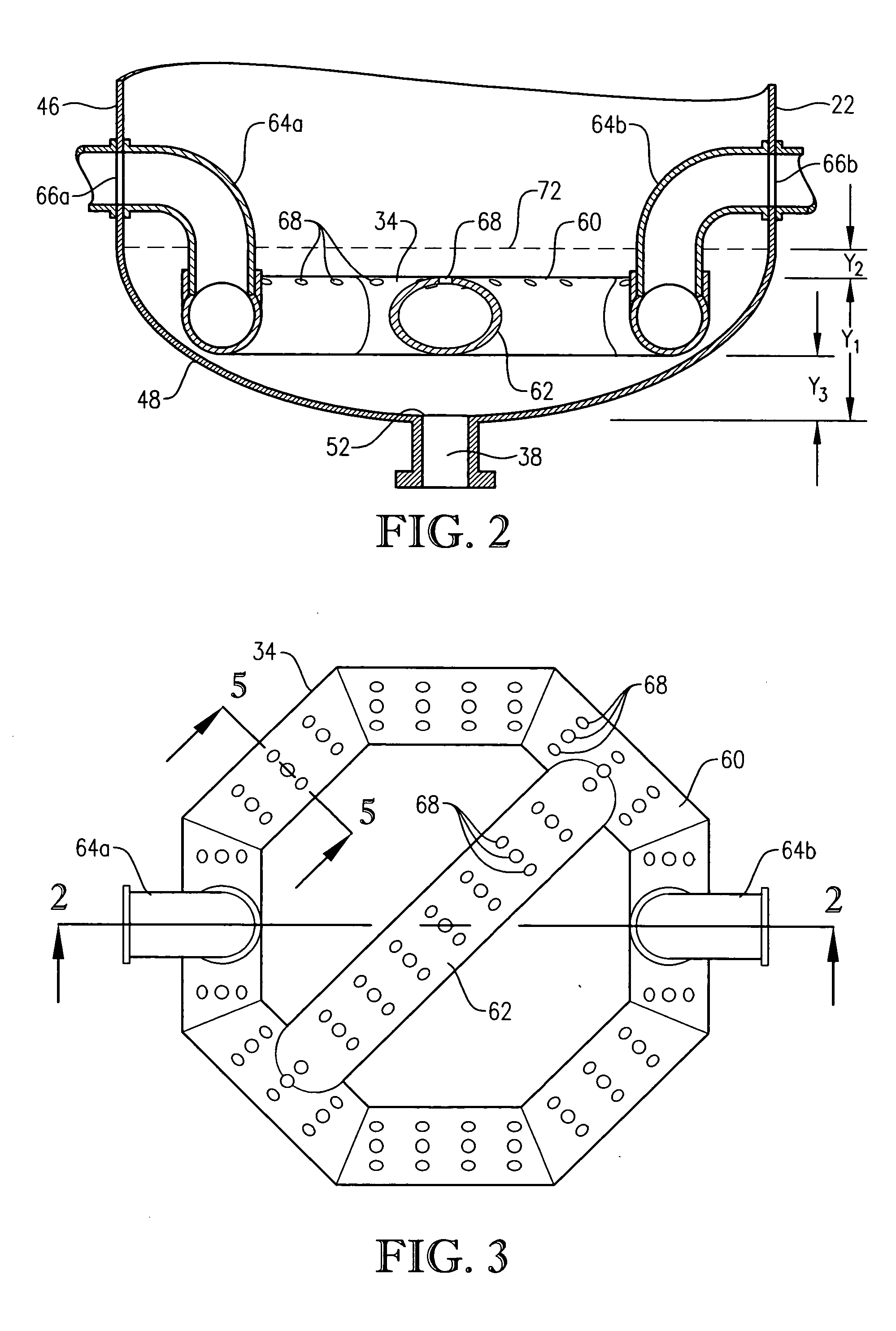

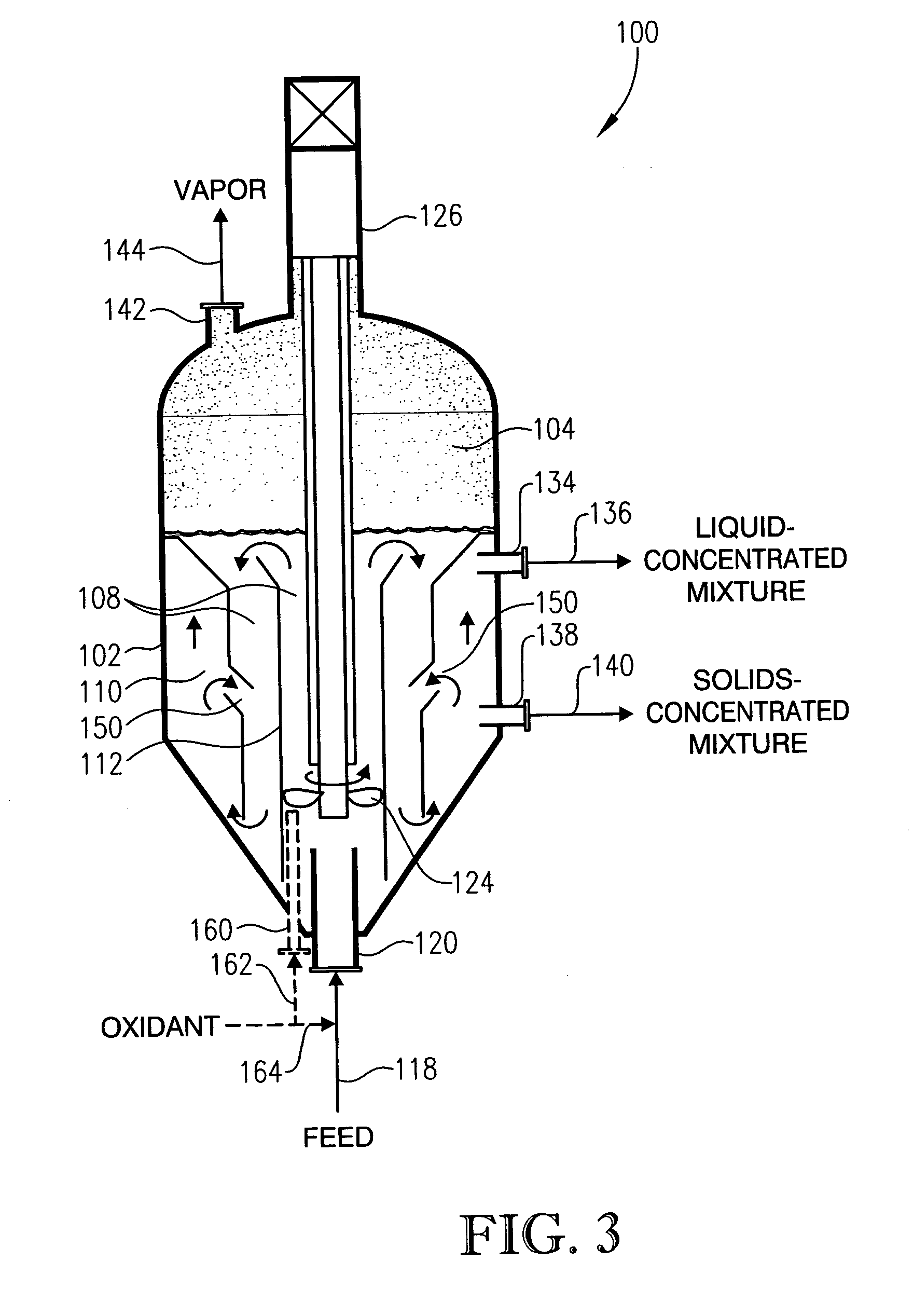

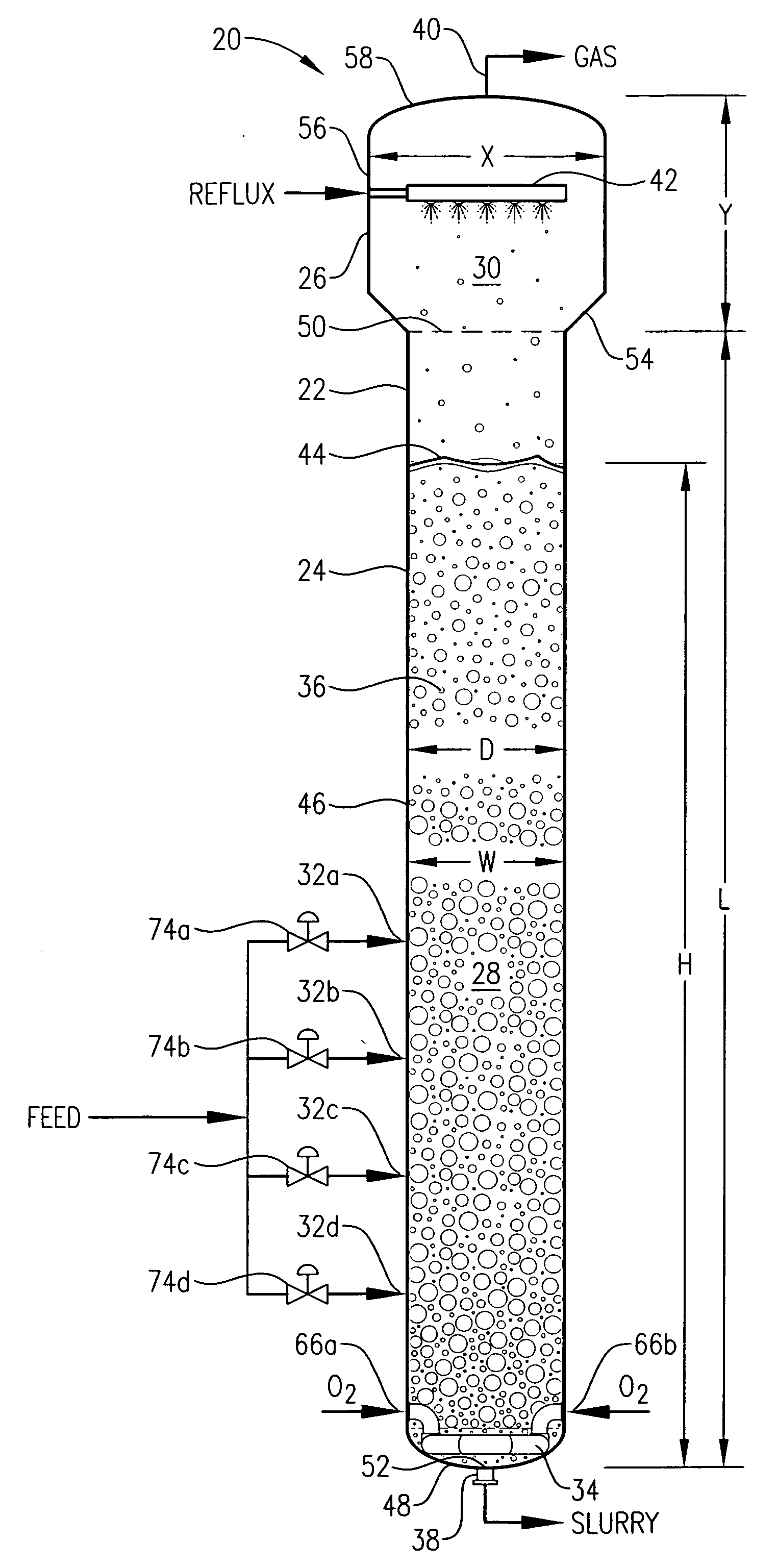

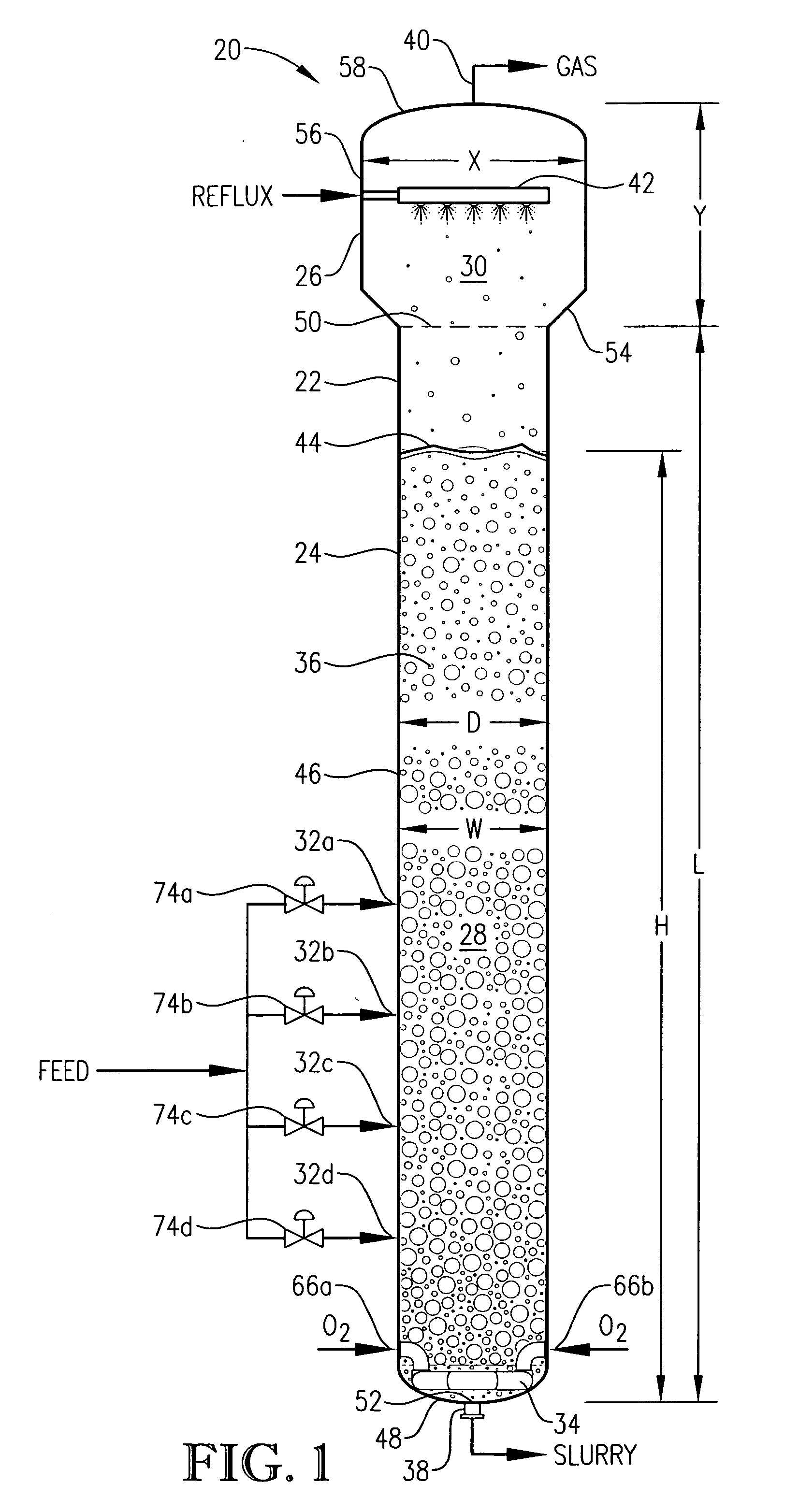

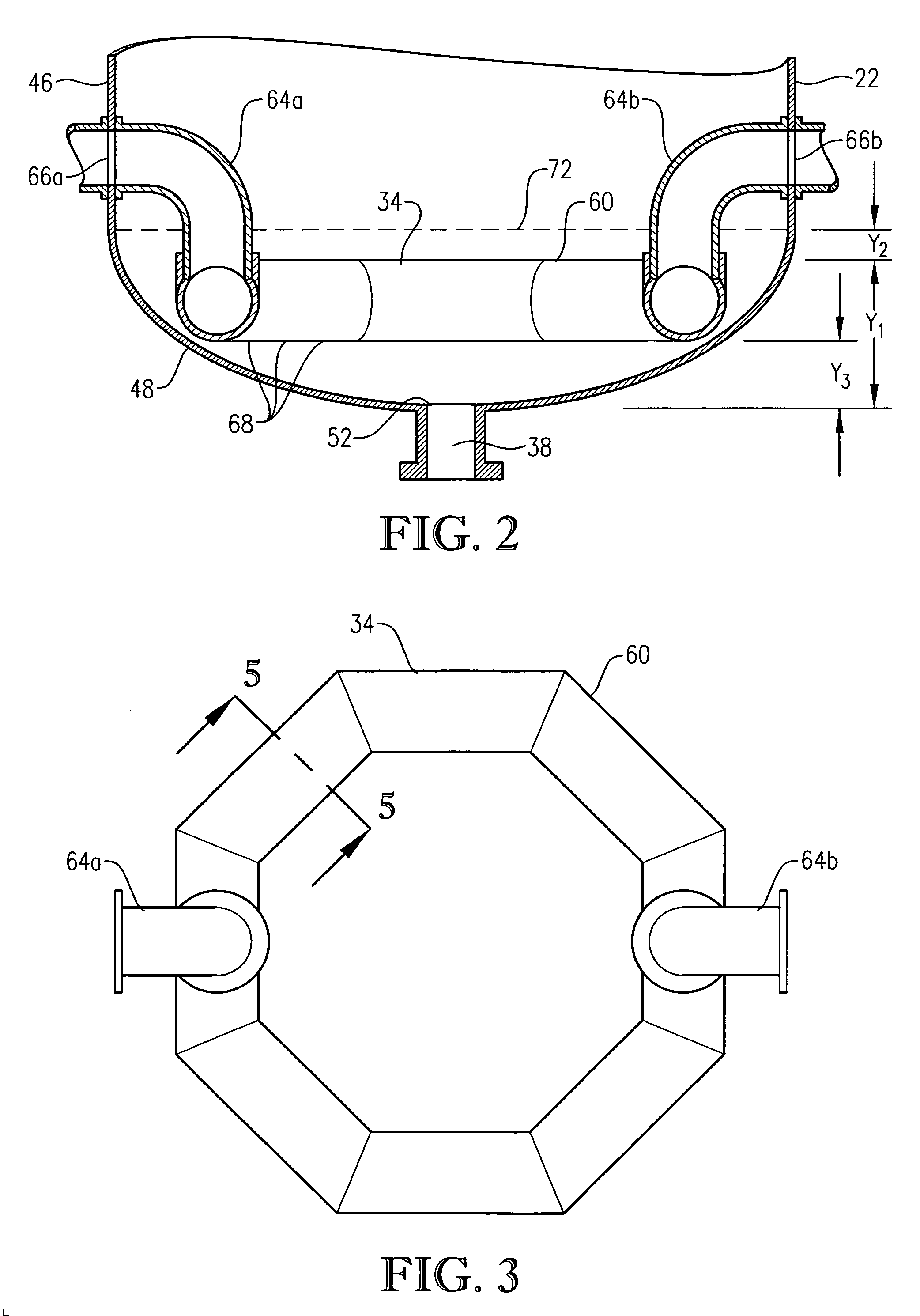

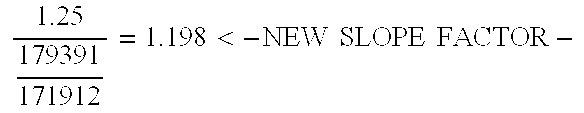

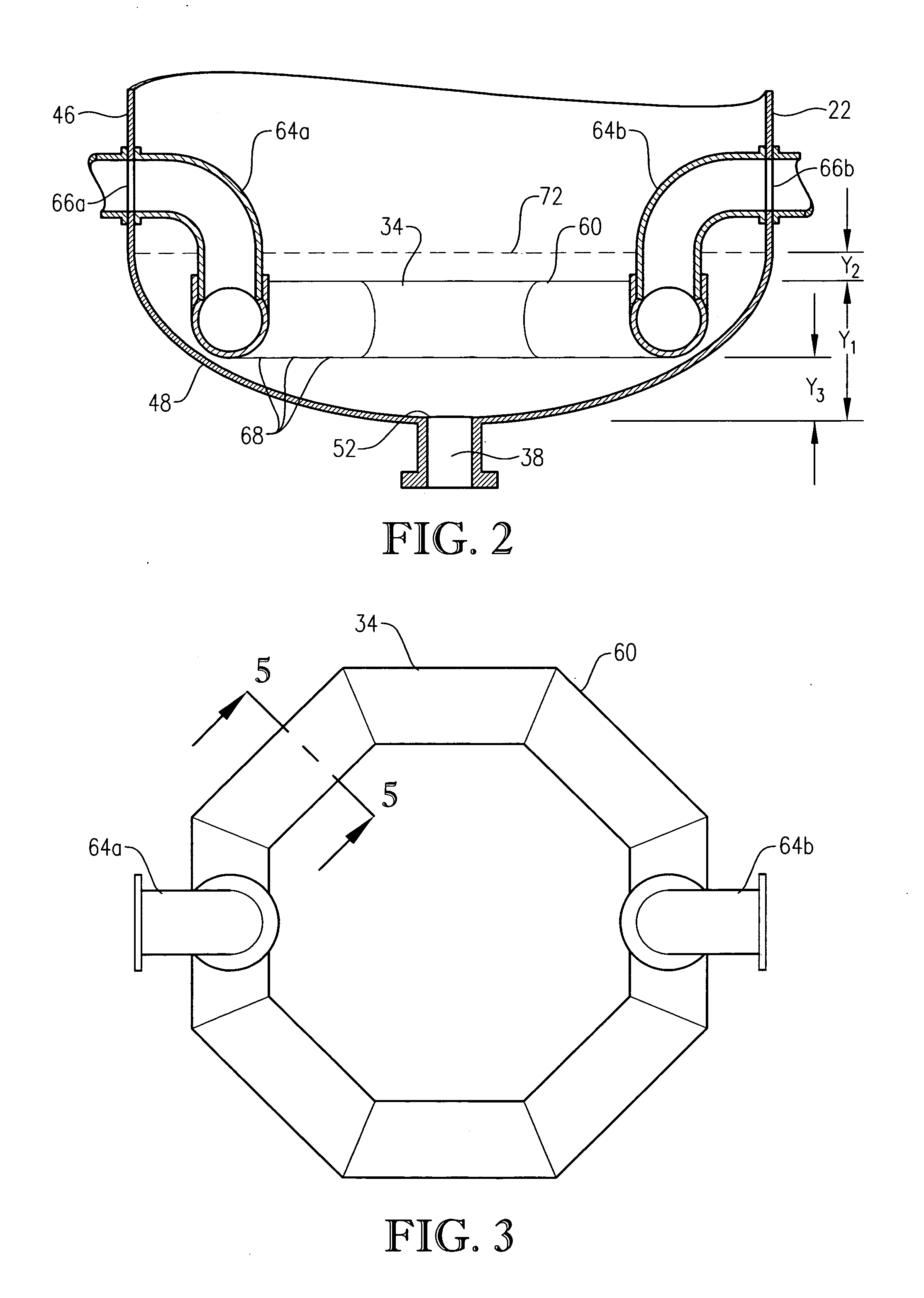

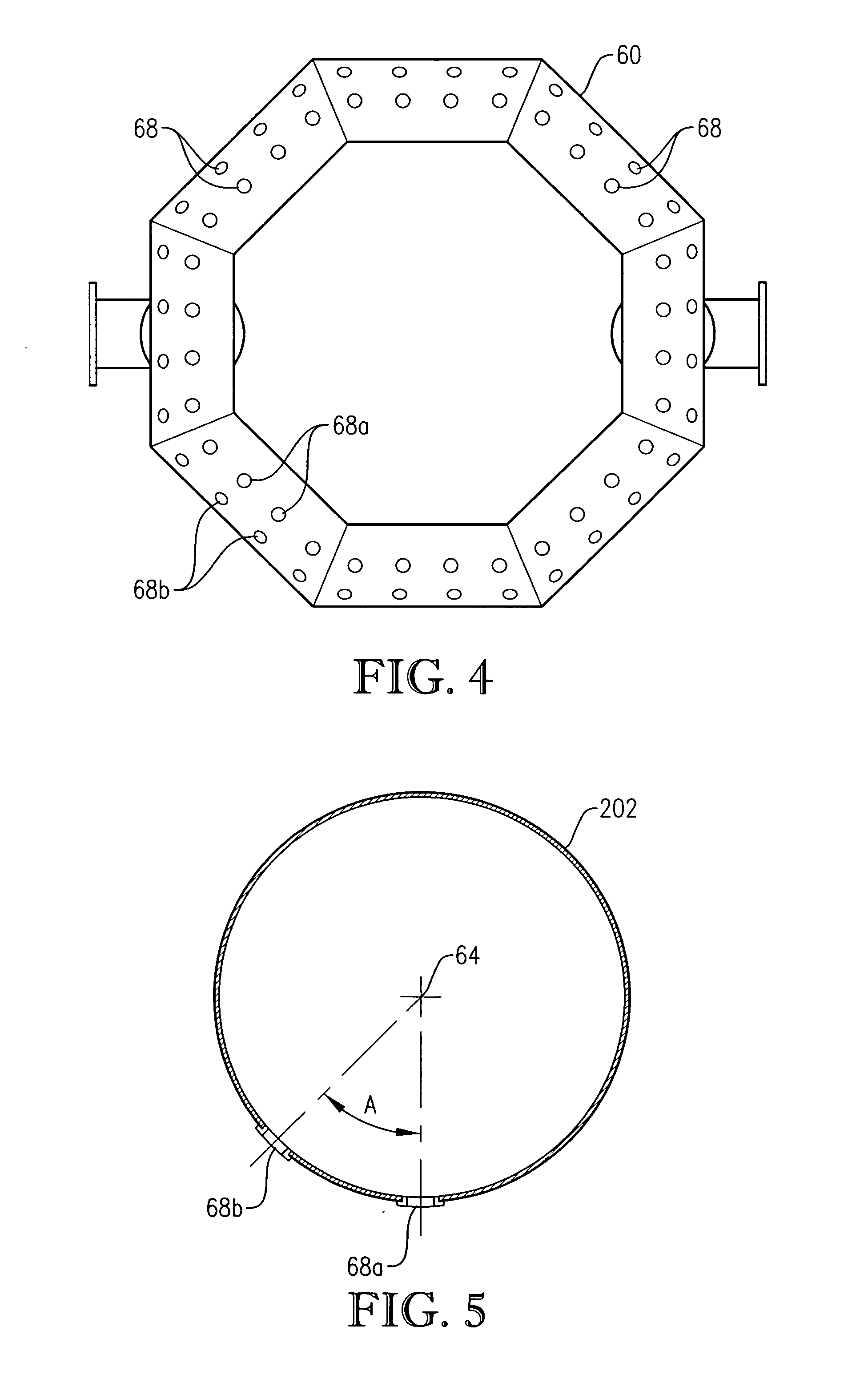

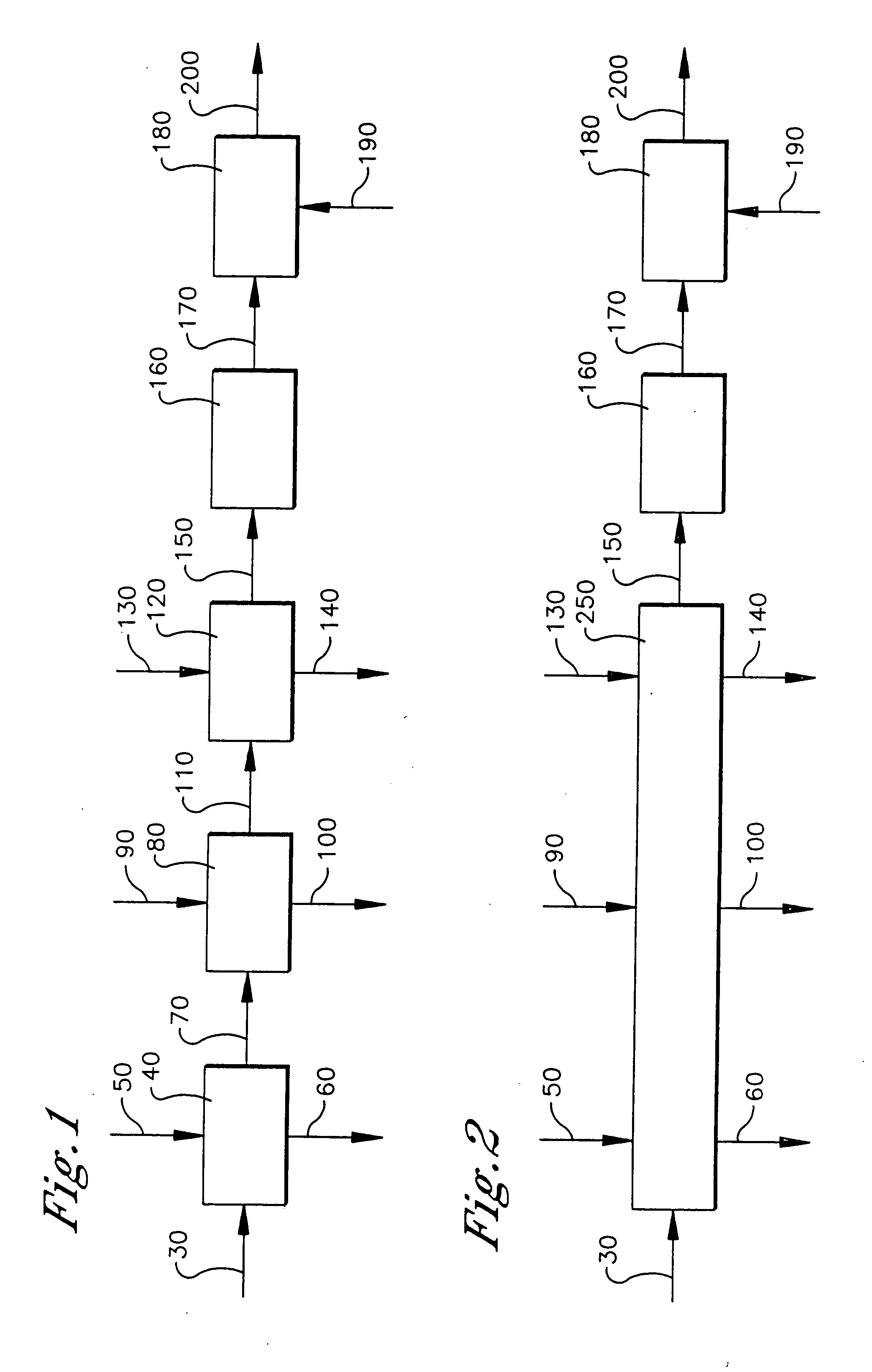

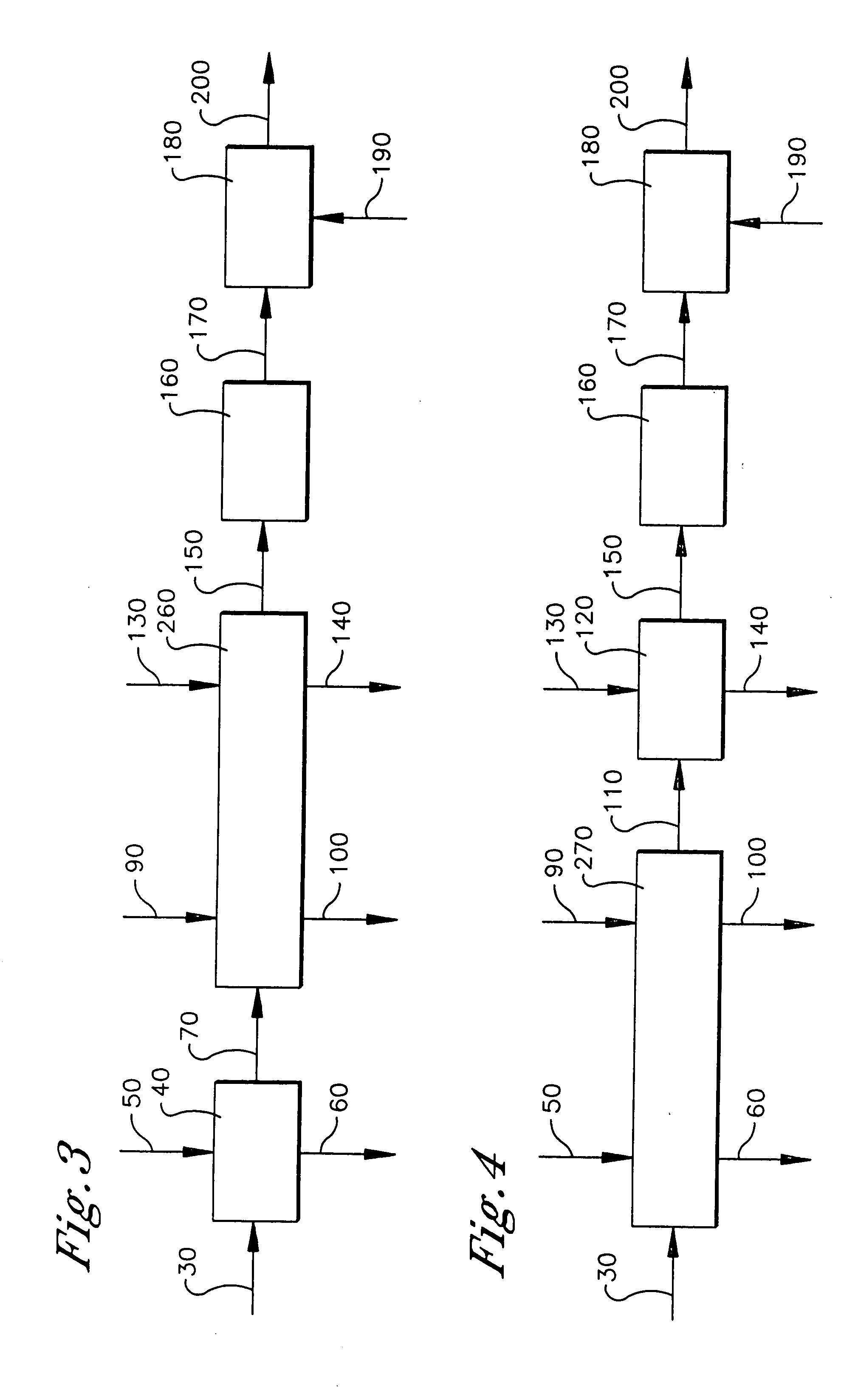

Optimized liquid-phase oxidation

ActiveUS20060047163A1Effective and economicalReduce formationOrganic oxidationOrganic compound preparationOrganic chemistryTerephthalic acid

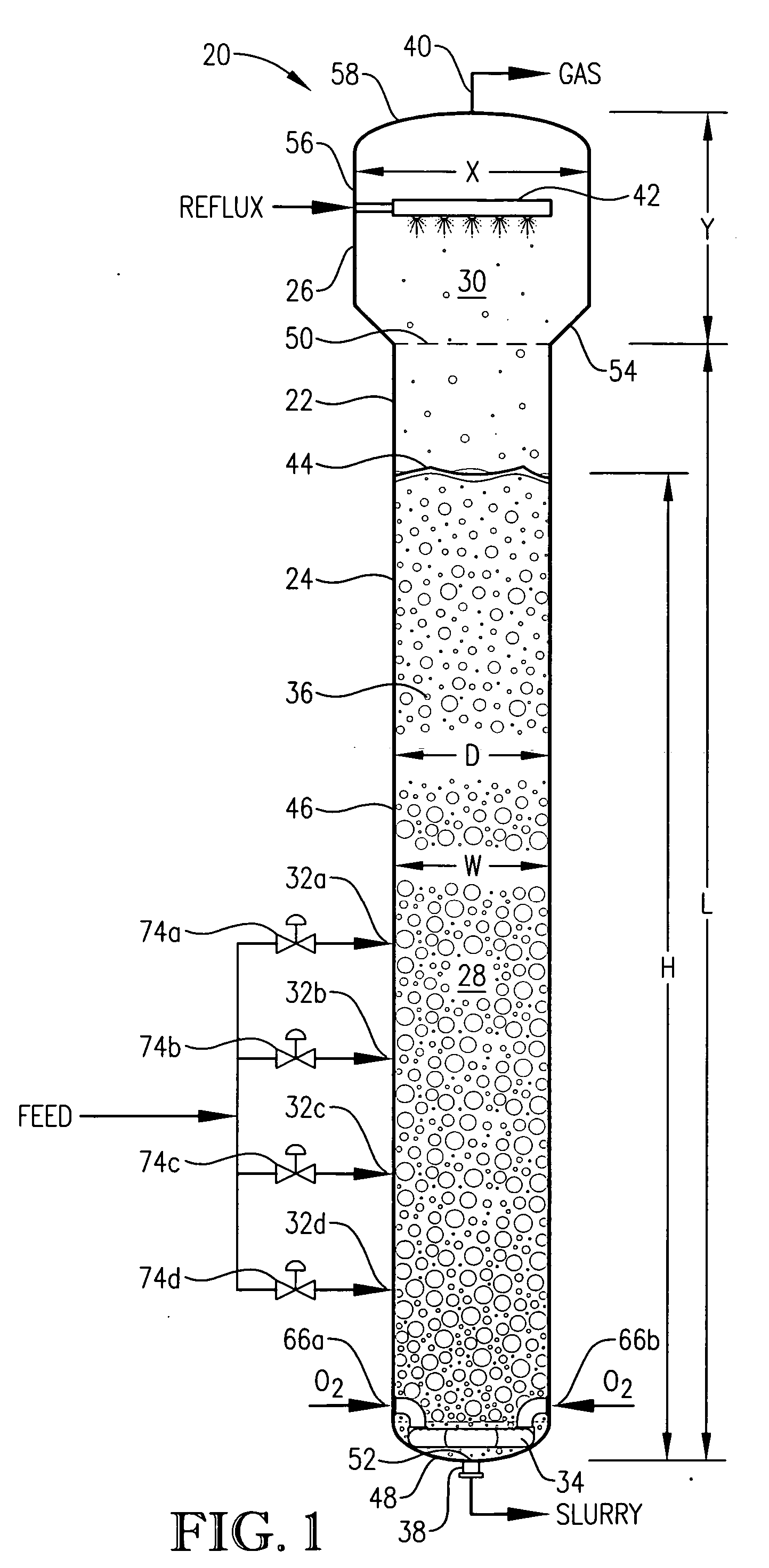

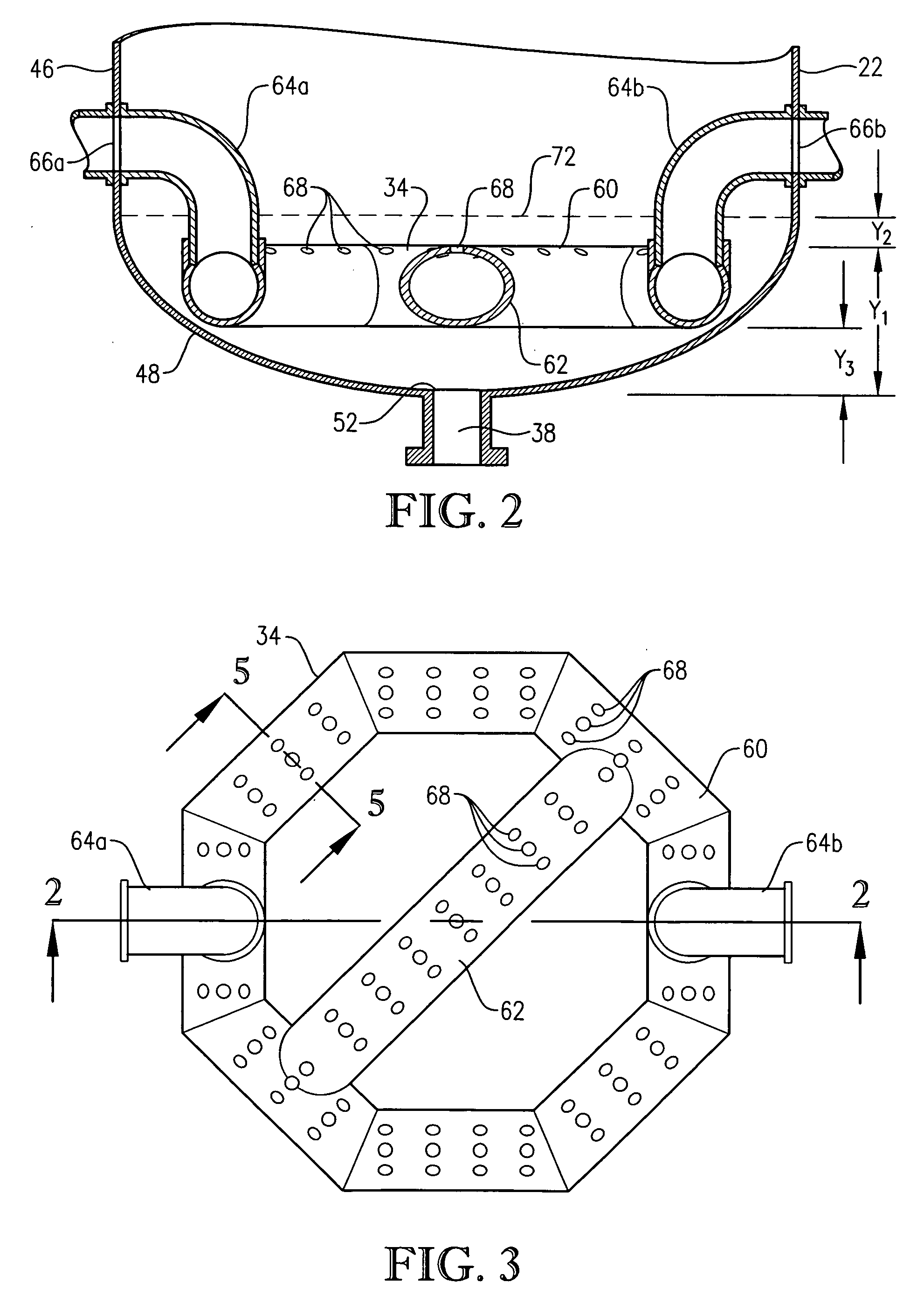

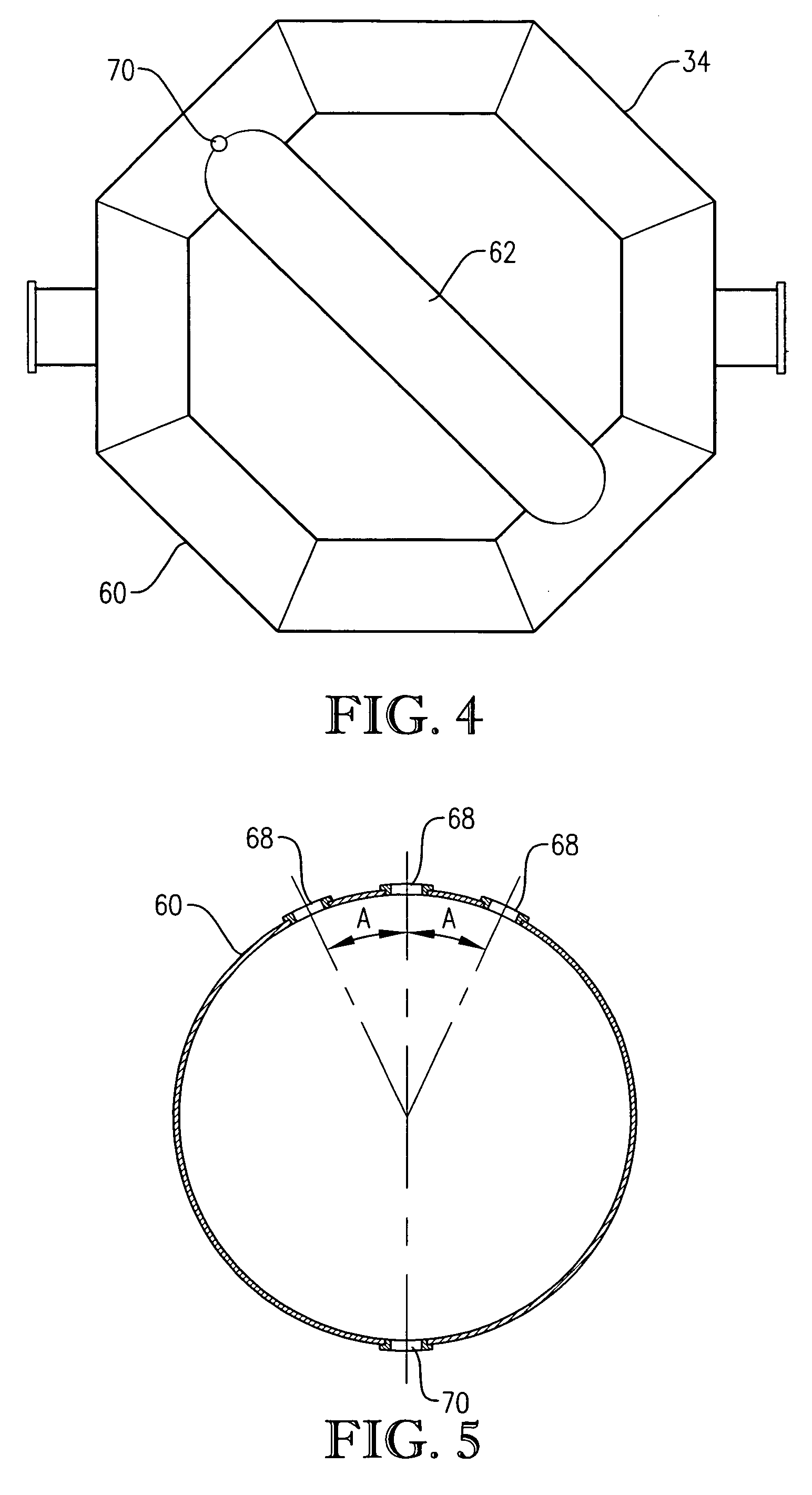

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

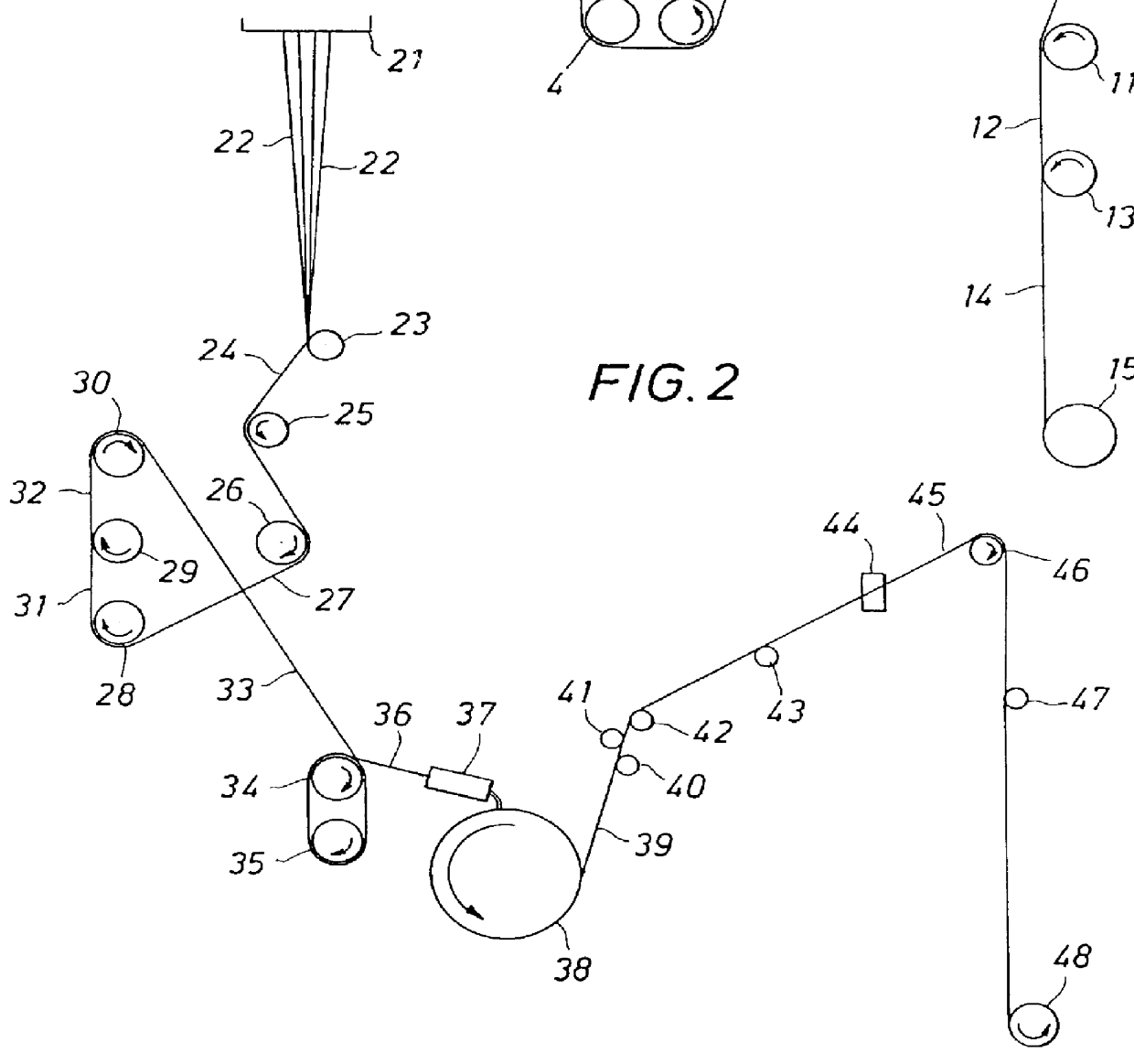

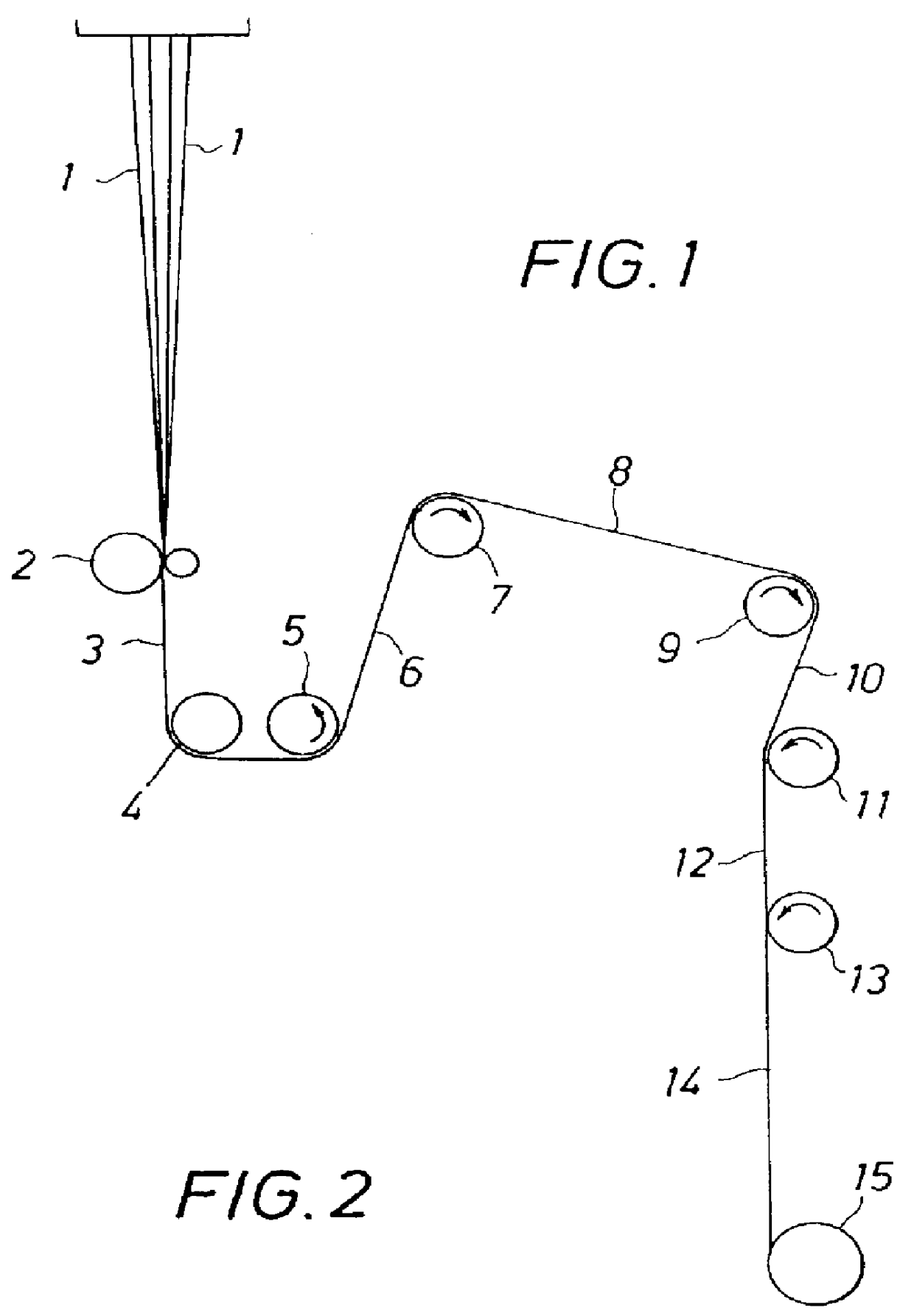

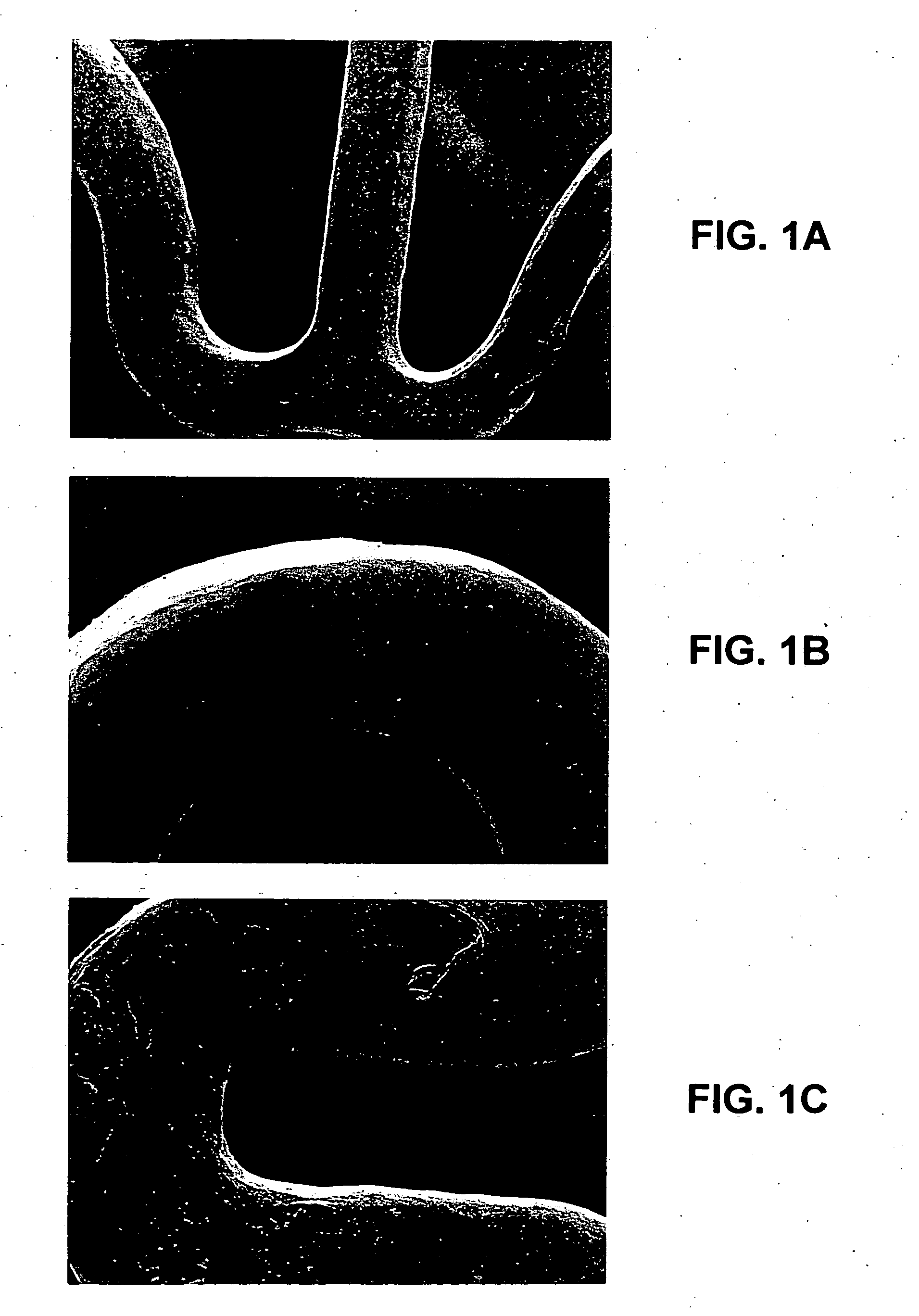

Process for preparing poly(trimethylene terephthalate) carpet yarn

Poly(trimethylene terephthalate) is formed into a bulk continuous filament yarn by melt-spinning poly(trimethylene terephthalate) at a temperature of 240 to 280.degree. C. to produce a plurality of spun filaments, cooling the spun filaments, converging the spun filaments into a yarn, drawing the yarn at a first draw ratio of 1.01 to about 2 in a first drawing stage defined by at least one feed roller and at least one first draw roller wherein at least one feed roller is operated at less than 100.degree. C. and each of the draw rollers is heated to a temperature greater than that of the feed roller and between 50 and 150.degree. C., subsequently drawing the yarn at a second draw ratio of at least about 2.2 times that of the first draw ratio in the second drawing stage defined by at least one first draw roller and at least one second draw roller, wherein at least one second draw roller is heated to a temperature greater than that of the first draw roller and within the range of 100 to 200.degree. C., and texturing the drawn yarn and cooling the textured filaments.

Owner:PTT POLY CANADA

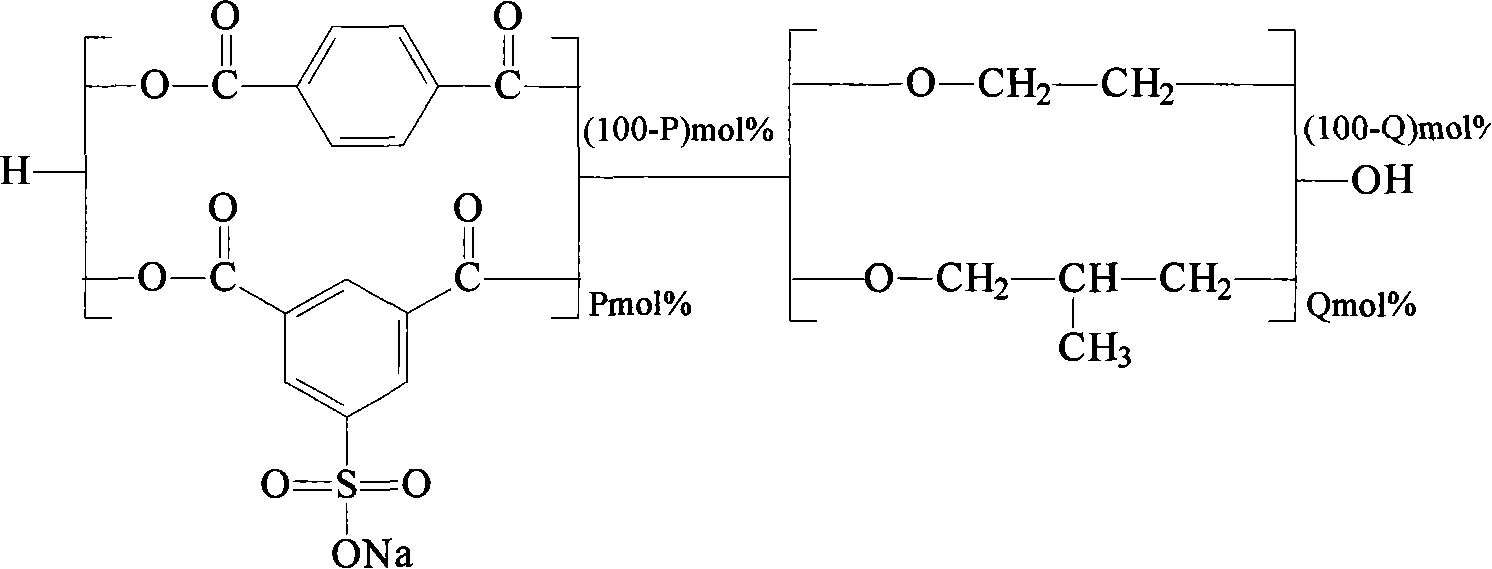

Modified copolyester slicer or fabric and method for making same

InactiveCN101063236ASoft lusterImprove shrinkageMonocomponent polyesters artificial filamentFiberAlcohol

The invention relates to a modified copolyester slice or fiber and a relative preparation, wherein the slice is copolymerized from terephthalic acid, ethandiol, isophthalate esters of sulfonic acid sodium (or potassium), and fatty group dibasic alcohol (or relative alkylate) with side chain. And the preparation comprises that (1), mixing the ethandiol and the fatty group dibasic alcohol (or relative alkylate) into a mixed alcohol, adding catalyzer and stabilizer to esterify the terephthalic acid under 220-260Deg. C, (2), adding 1-9%mol isophthalate esters of sulfonic acid sodium (or potassium) relative to the terephthalic acid for polycondensation at 250-300Deg. C, (3), drying, fusing, spinning, and drawing to obtain the modified copolyester filament. The inventive product can dye anion paint and disperse paint into deep color at normal pressure, with better feeling, high contraction, hidden micro coiled property, simple preparation, low cost and batch production support.

Owner:DONGHUA UNIV

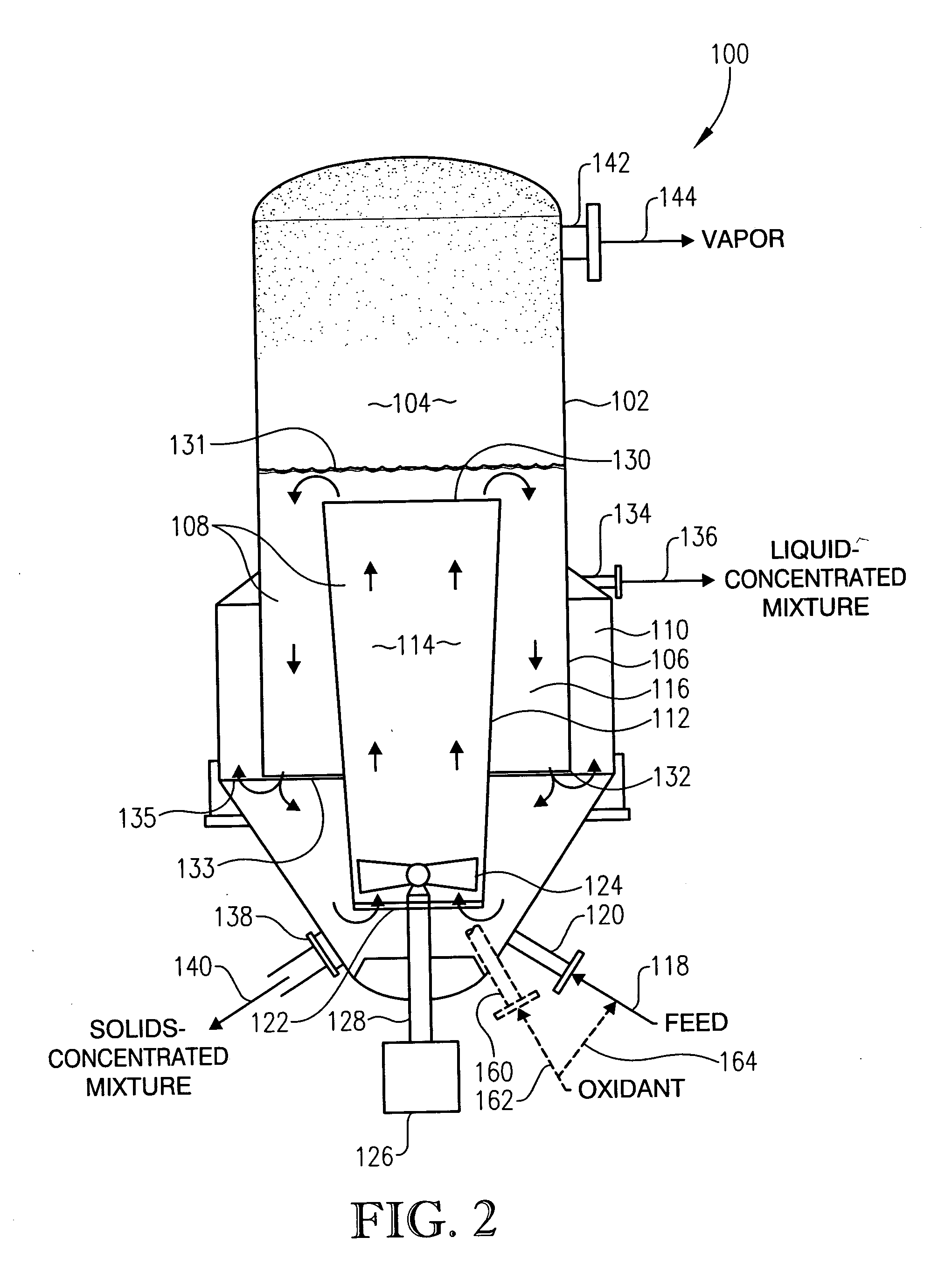

Optimized production of aromatic dicarboxylic acids

ActiveUS20060047166A1Organic compound preparationCrystallization by component evaporationDicarboxylic acidCarboxylic acid

Disclosed is an optimized process and apparatus for more efficiently producing and purifying aromatic dicarboxylic acids (e.g., terephthalic acid). The optimized system employs at least one zoned slurry concentrator to enhance purification of the aromatic dicarboxylic acid.

Owner:ALPEK POLYESTER SA DE CV

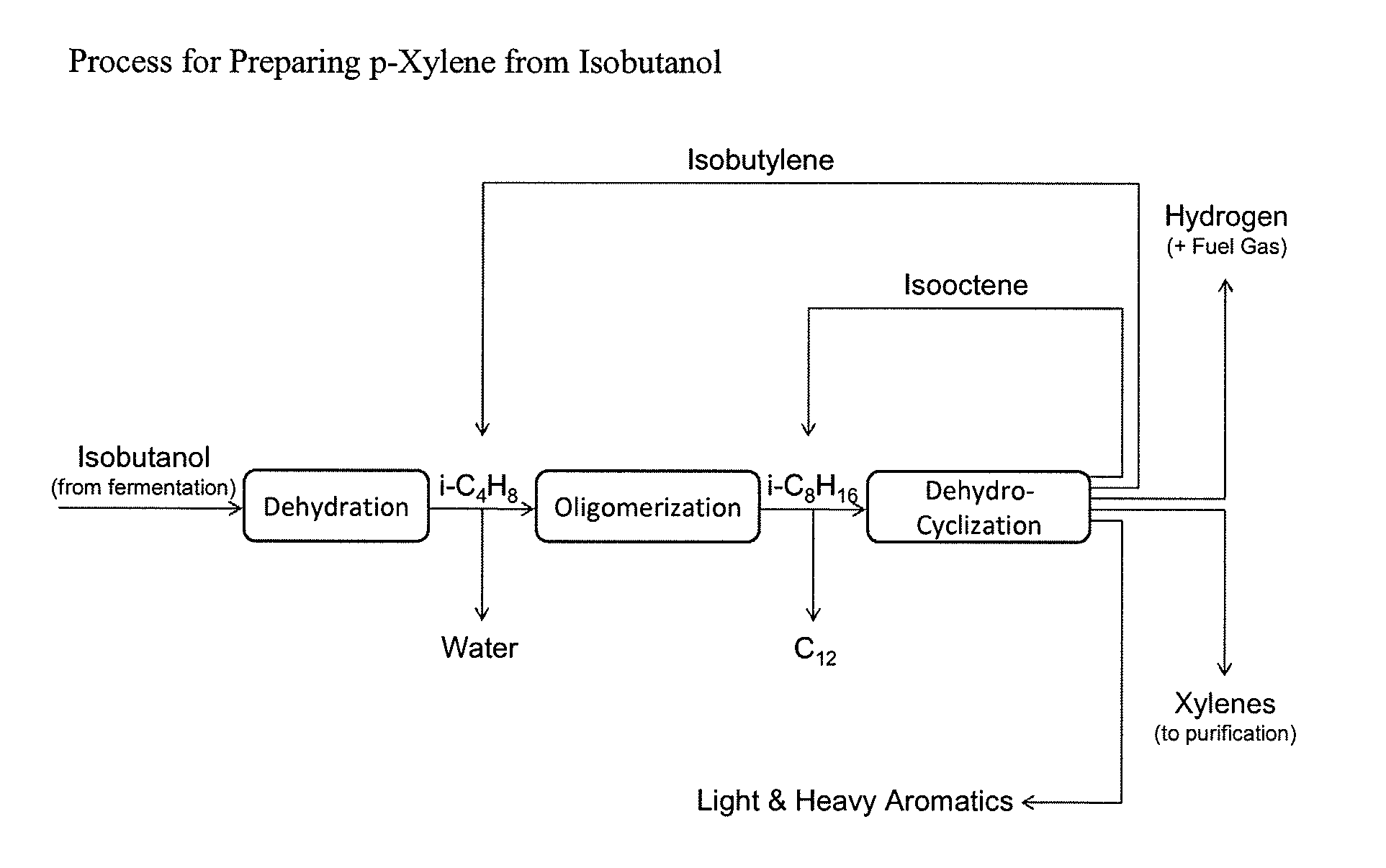

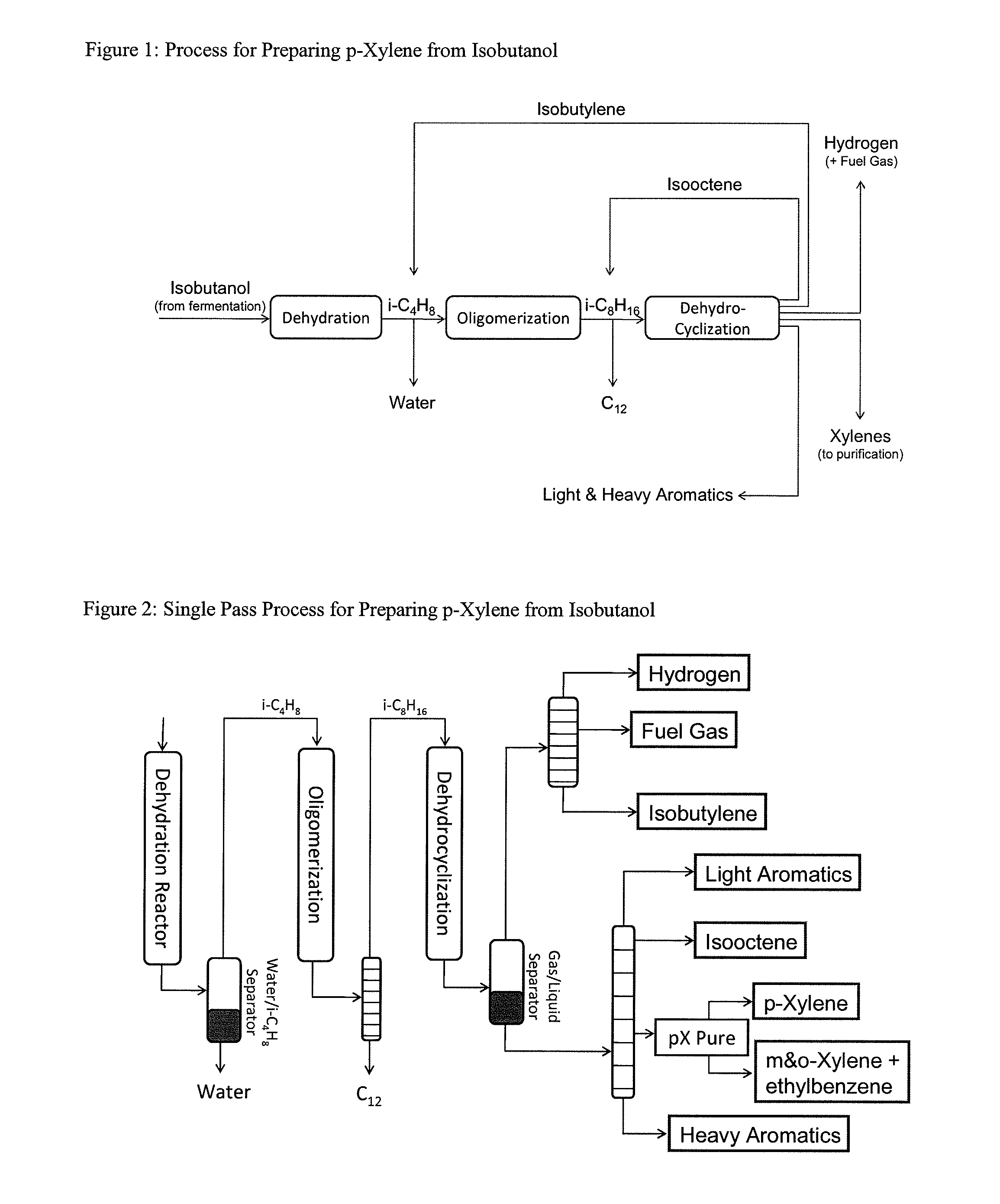

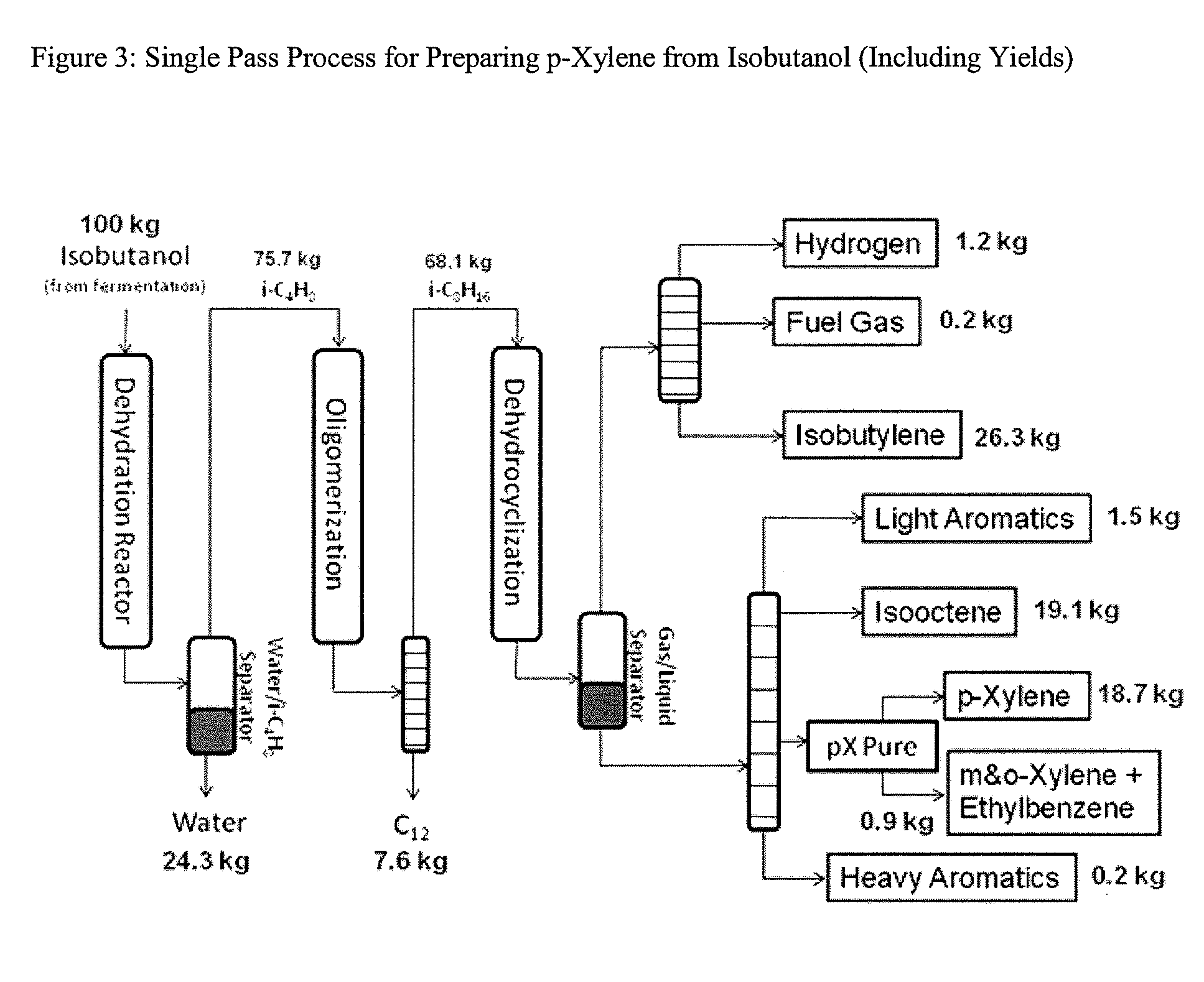

Integrated Process to Selectively Convert Renewable Isobutanol to P-Xylene

The present invention is directed to a method for preparing renewable and relatively high purity p-xylene from biomass. For example, biomass treated to provide a fermentation feedstock is fermented with a microorganism capable of producing a C4 alcohol such as isobutanol, then sequentially dehydrating the isobutanol in the presence of a dehydration catalyst to provide a C4 alkene such as isobutylene, dimerizing the C4 alkene to a form one or more C8 alkenes such as 2,4,4-trimethylpentenes or 2,5-dimethylhexene, then dehydrocyclizing the C8 alkenes in the presence of a dehydrocyclization catalyst to selectively form renewable p-xylene in high overall yield. The p-xylene can then be oxidized to form terephthalic acid or terephthalate esters.

Owner:GEVO INC

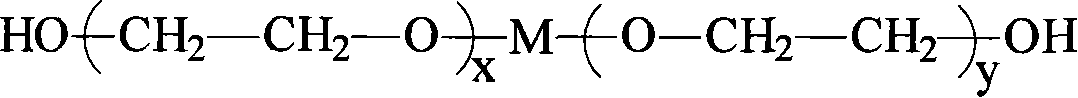

Copolyester as well as preparation method and application thereof

InactiveCN102030893AImprove dyeing effectLow investment costMonocomponent copolyesters artificial filamentDisperse dyeSide chain

The invention discloses copolyester and a preparation method and application thereof. The copolyester comprises binary acid components and binary alcohol components, wherein in the binary acid components, the content of the terephthalic acid structural unit is more than 90mol%; and in the binary alcohol components, the content of the ethylene glycol structural unit is 70-99mol%, and the content of the aliphatic dihydric alcohol structural unit which contains side chains and less than 6 carbon atoms is 1-30mol%. The copolyester also comprises a polyethylene glycol structural unit. Because the aliphatic dihydric alcohol structural unit which contains side chains and less than 6 carbon atoms and the polyethylene glycol structural unit are added to the copolyester, the copolyester can be made into fiber with the known method, and the fiber can be made into fabric. The prepared finished product has good dyeing property on disperse dye at normal temperature and pressure, thus the high equipment investment and operation cost resulted from high-temperature and high-pressure dying can be reduced.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Optimized liquid-phase oxidation

ActiveUS20060047147A1Effective and economicalReduce formationOrganic compound preparationChemical/physical/physico-chemical stationary reactorsOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

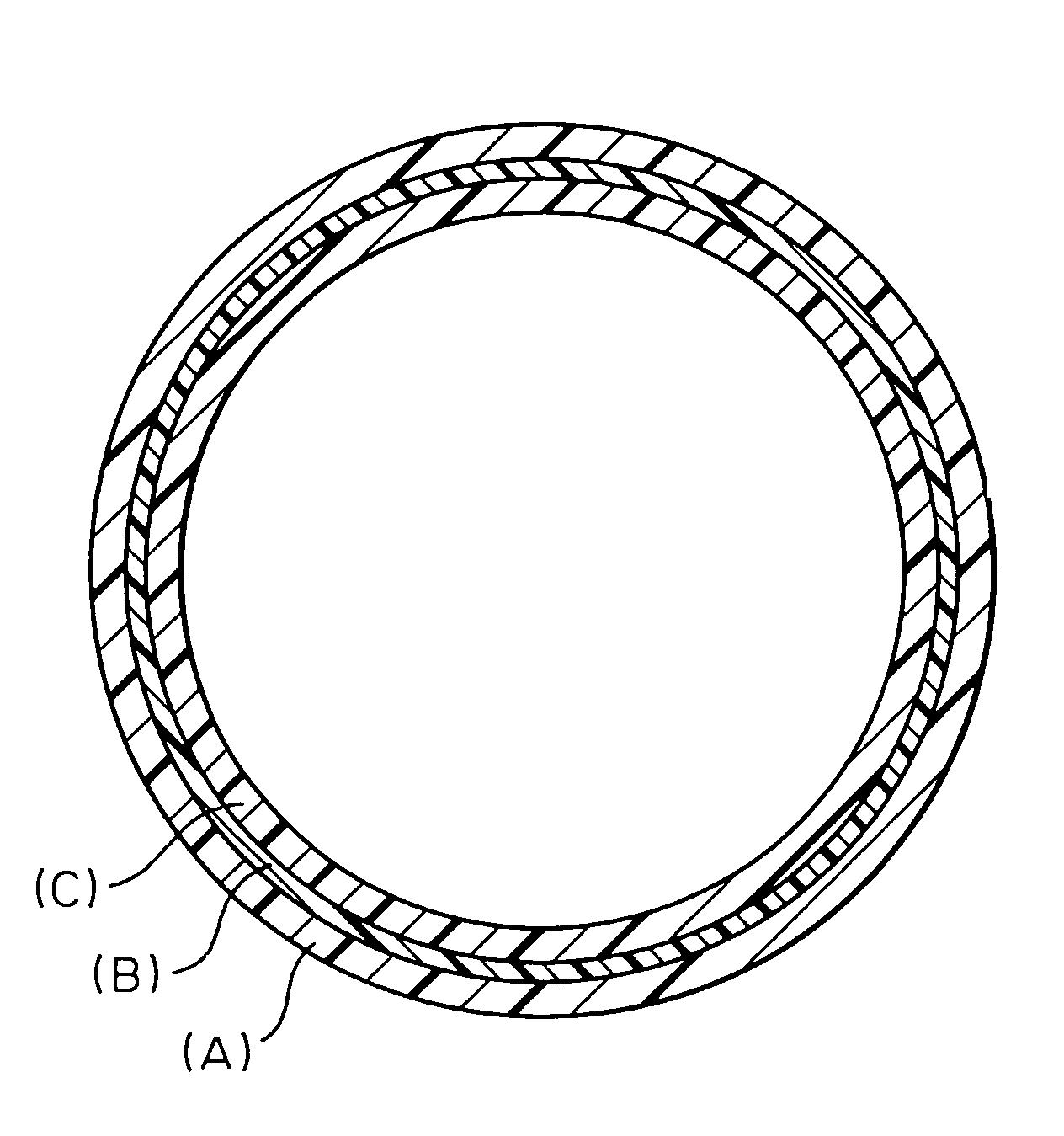

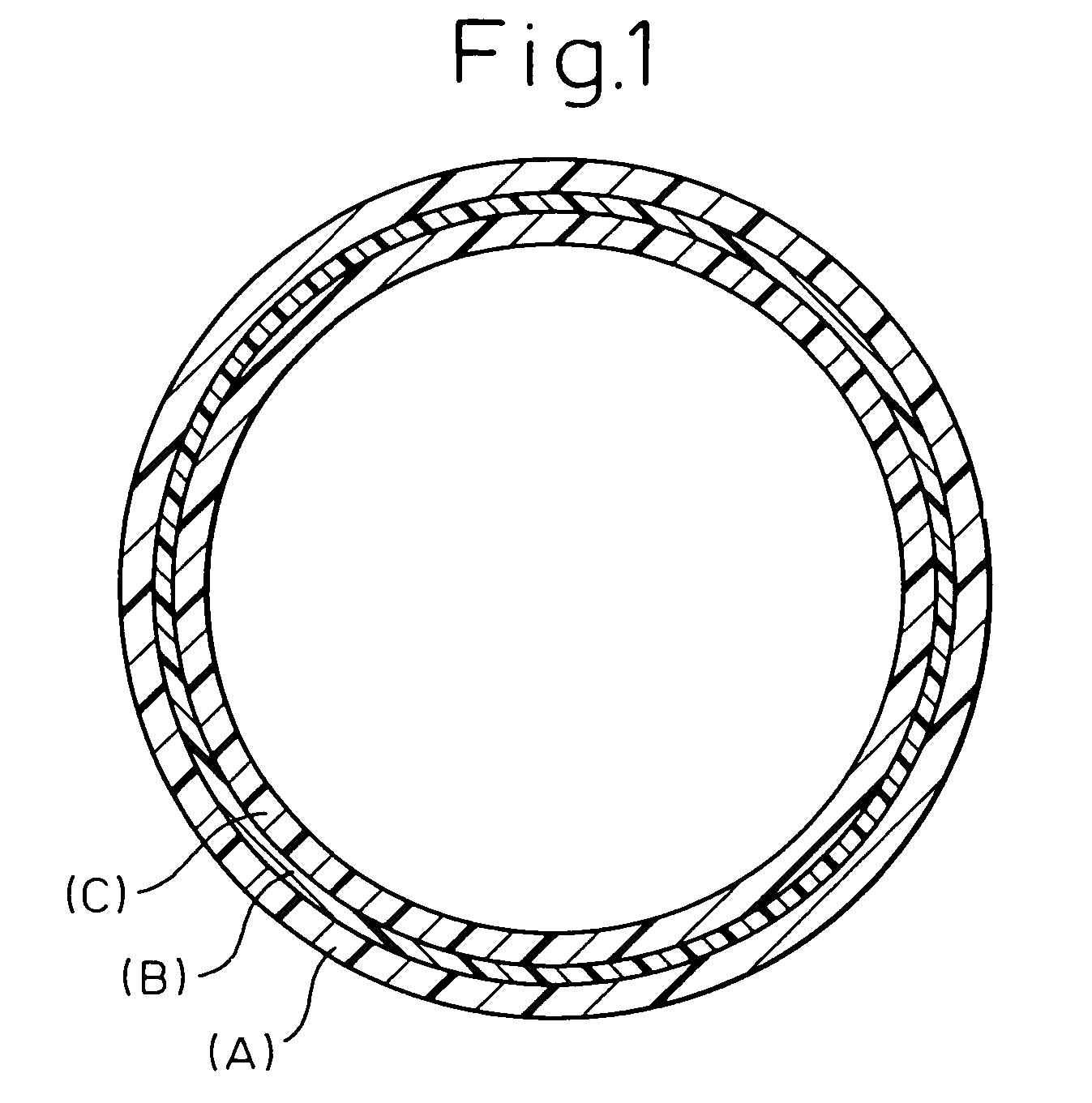

Multi-layer structure

ActiveUS6989198B2Improve penetration resistanceLarge containersRefuse receptaclesCarboxylic acidNylon 11

A multi-layer structure excellent in the barrier properties against alcohol gasoline, particularly hydrocarbon components, and also excellent in the interlayer adhesion, low-temperature impact resistance, heat resistance and chemical resistance is provided. The stractive is a multi-layer structure comprising two or more layers including at least a layer (a) comprising (A) nylon 11 and / or nylon 12 and a layer (b) comprising (B) a polyamide resin (nylon 9T) consisting of a dicarboxylic acid component and a-diamine component, with 60 to 100 mol % of the dicarboxylic acid component being a terephthalic acid and 60 to 100 mol % of the diamine component being a diamine component selected from 1,9-nonanediamine and 2-methyl-1,8-octanediamine, and preferably further including a layer (c) comprising (A) nylon 11 and / or nylon 12 or (C) nylon 6.

Owner:KURARAY CO LTD +1

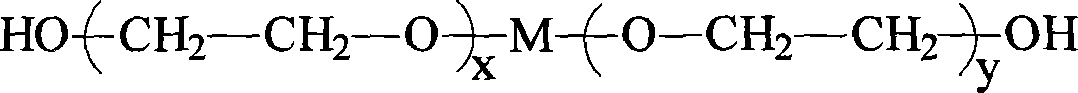

Biologically beneficial coatings for implantable devices containing fluorinated polymers and methods for fabricating the same

Coatings for an implantable medical device and a method of fabricating the coatings are disclosed. The coatings comprise a fluorinated polymer and a biologically beneficial polymer, an example of which includes poly(ethylene-glycol)-block poly(butylene terephthalate)-block poly(ethylene-glycol). A biologically active agent can be additionally conjugated to the biologically beneficial polymer.

Owner:ABBOTT CARDIOVASCULAR

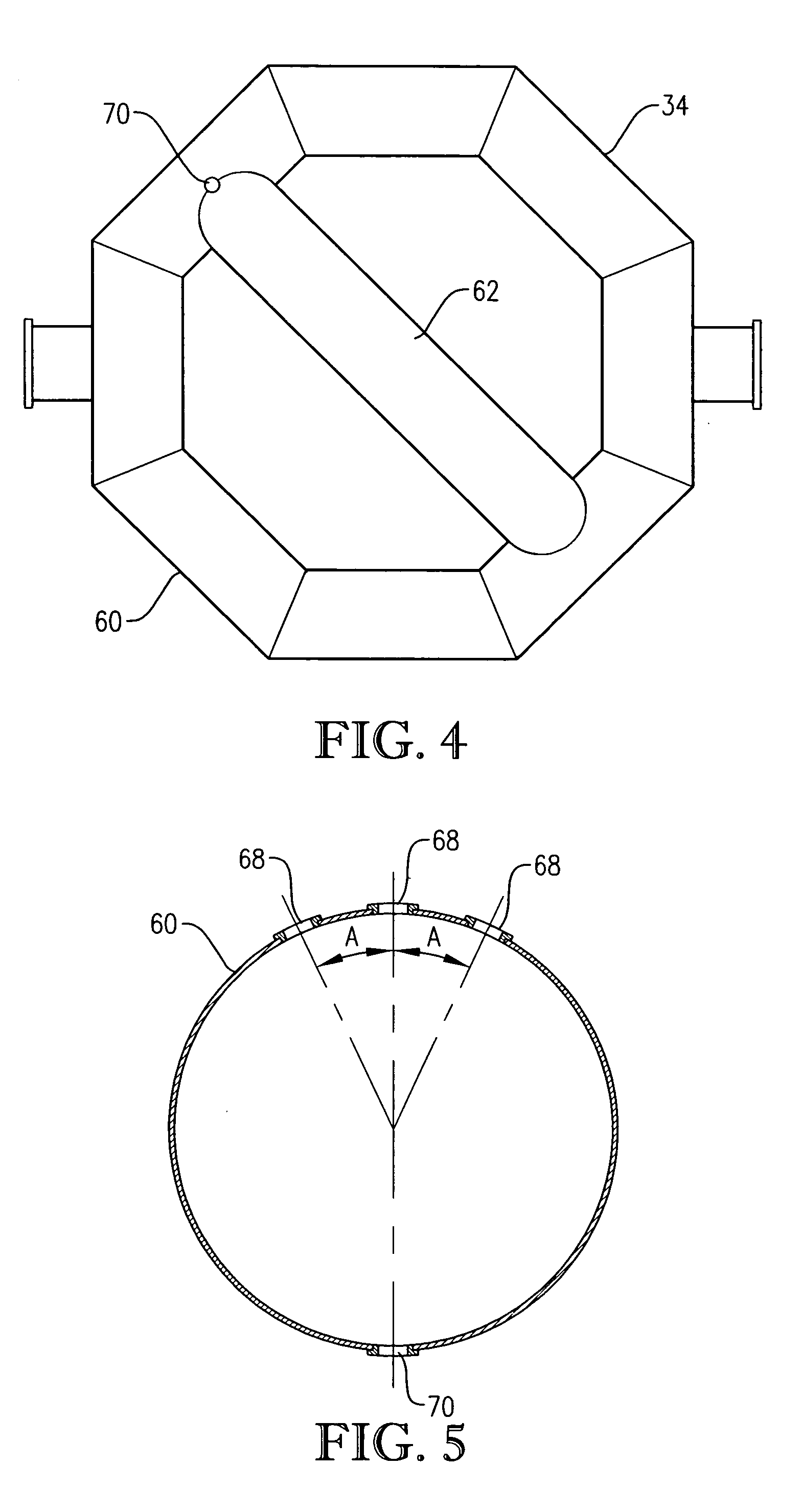

Oxidation system with internal secondary reactor

ActiveUS20070155985A1Effective and economicalReduce formationLiquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationOrganic chemistryTerephthalic acid

Disclosed is an optimized process and apparatus for more efficiently and economically carrying out the liquid-phase oxidation of an oxidizable compound. Such liquid-phase oxidation is carried out in a bubble column reactor that provides for a highly efficient reaction at relatively low temperatures. When the oxidized compound is para-xylene and the product from the oxidation reaction is crude terephthalic acid (CTA), such CTA product can be purified and separated by more economical techniques than could be employed if the CTA were formed by a conventional high-temperature oxidation process.

Owner:ALPEK POLYESTER SA DE CV

Preparation of poly(trimethylene terephthalate) with low level of di(1,3-propylene glycol)

A process of preparing poly(trimethylene terephthalate) containing less than 2.0 mole % of DPG comprising:(a) providing a molar amount of 1,3-propanediol:C1 to C4 dialkyl ester of terephthalic acid of 1.2:1 to 1.9:1,(b) reacting the 1,3-propanediol with the C1 to C4 dialkyl ester of terephthalic, acid to form bis(3-hydroxypropyl)terephthalate monomer in the presence of 10-100 ppm (as titanium metal) of an organic titanate catalyst, by weight of the poly(trimethylene terephthalate), and(c) polymerizing the bis(3-hydroxypropyl)terephthalate monomer to obtain the poly(trimethylene terephthalate); andpoly(trimethylene terephthalate) produced by the process.

Owner:DUPONT IND BIOSCIENCES USA LLC

Terephthalic Acid Composition and Process for the Production Thereof

ActiveUS20090124829A1Reducing and eliminating resultantOrganic compound preparationCarboxylic compound preparationEtherCarbon oxide

Terephthalic acid is prepared by reacting a 2,5-furandicarboxylate with ethylene in the presence of a solvent to produce a bicyclic ether; and then dehydrating the bicyclic ether. The process of the present invention effectively produces terephthalic acid, while reducing or eliminating the impurities, color bodies and carbon oxides produced in commercial practice by the liquid-phase oxidation of methyl-substituted benzene feedstocks.

Owner:BP CORP NORTH AMERICA INC

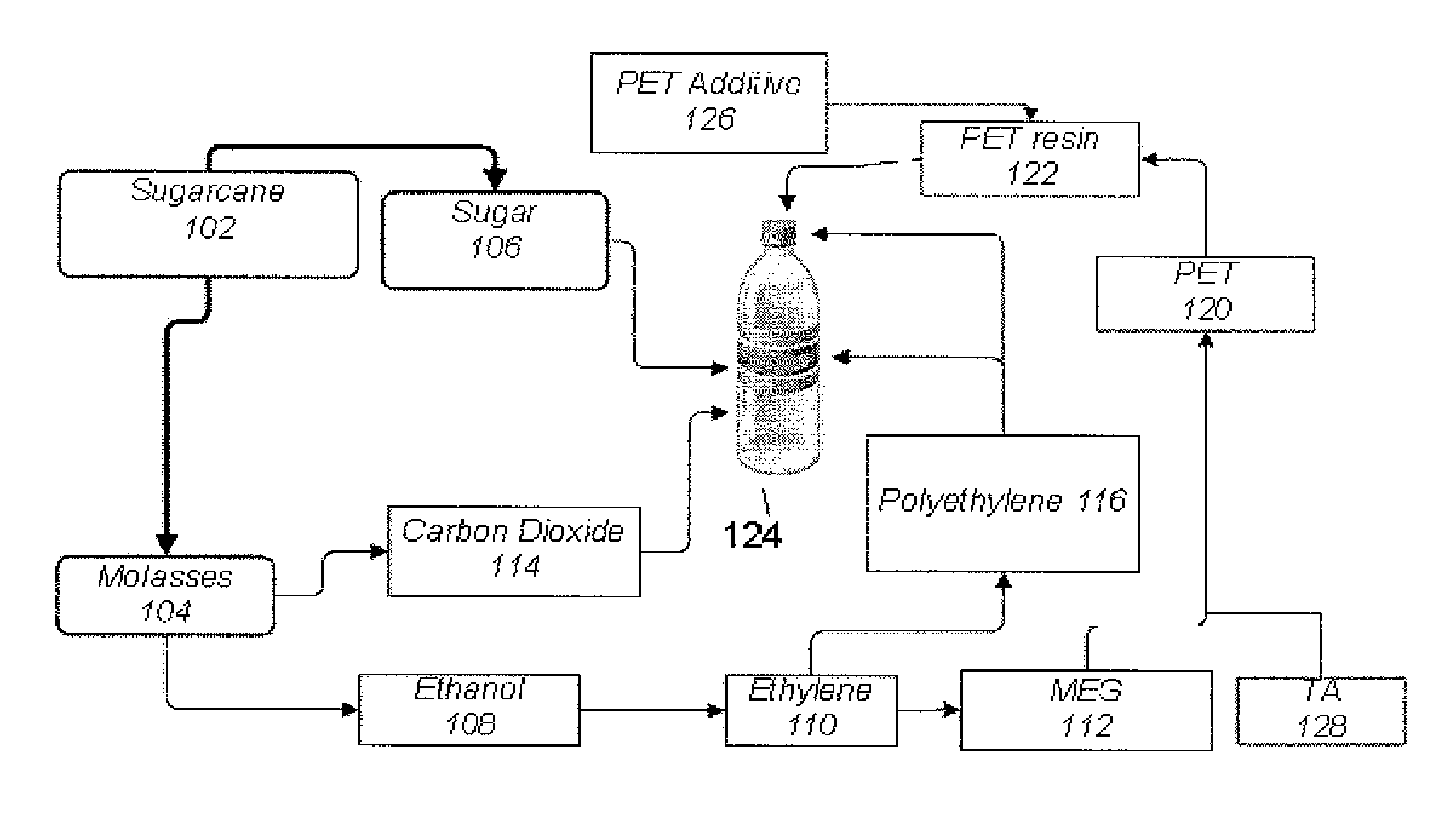

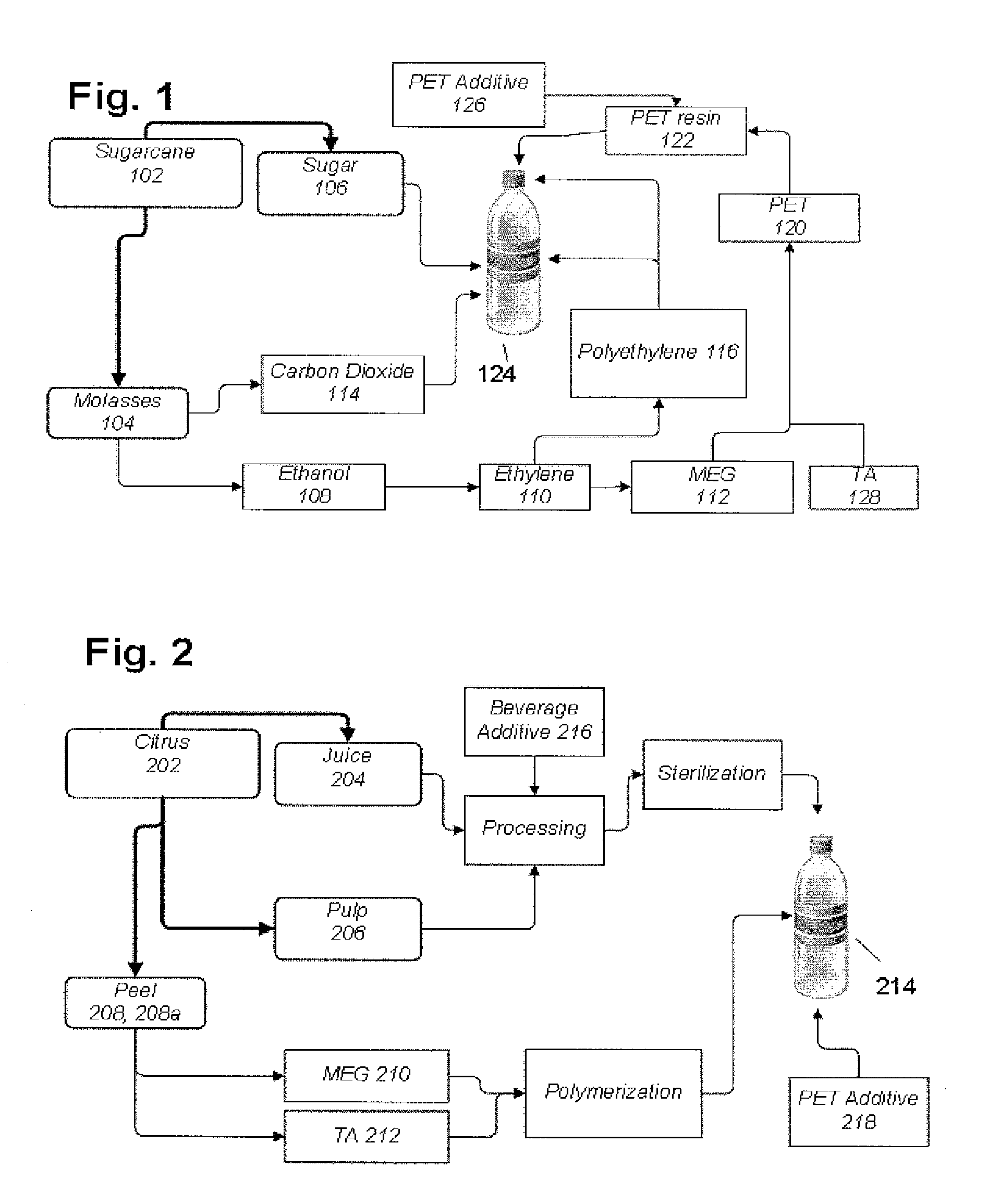

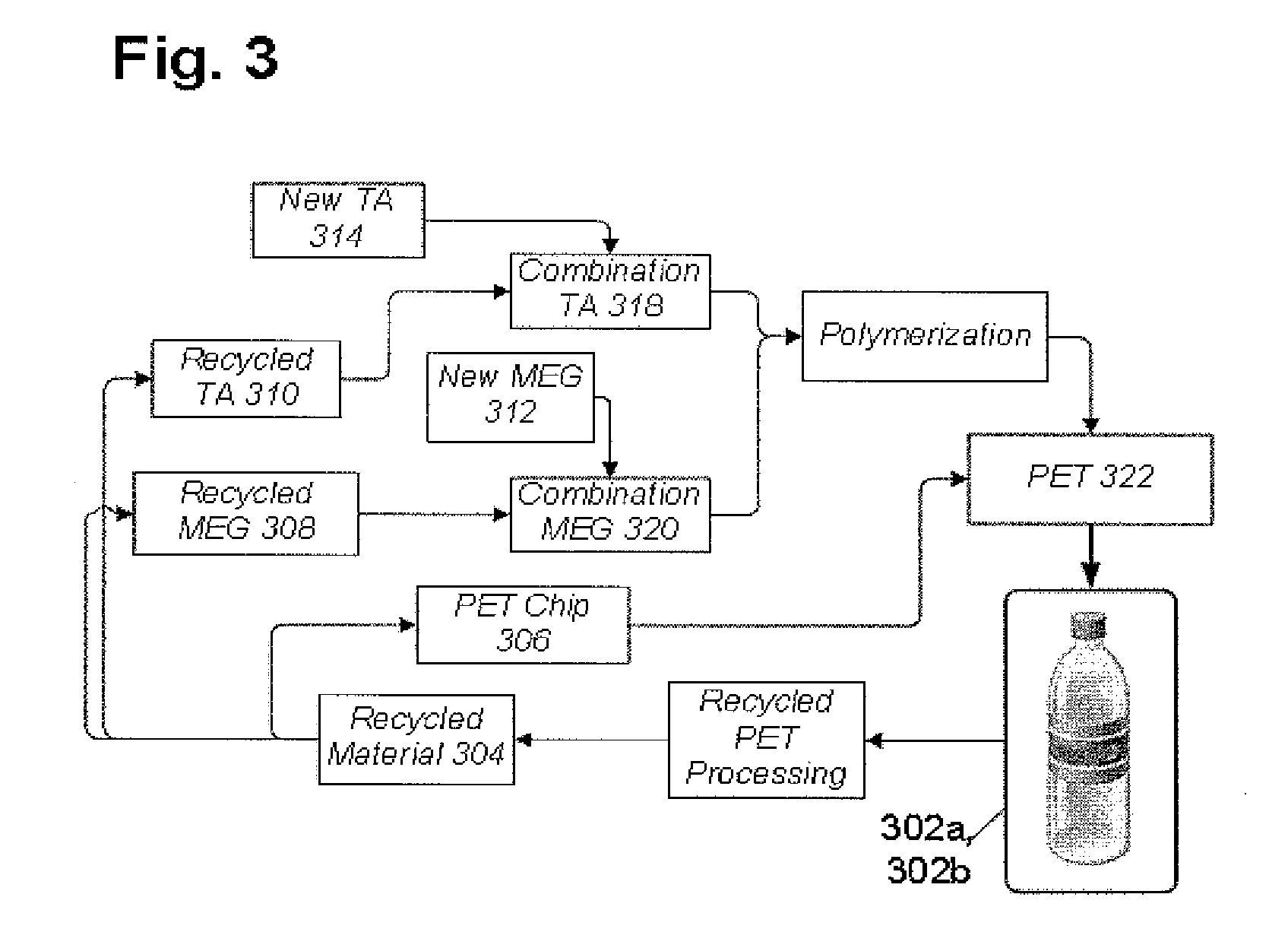

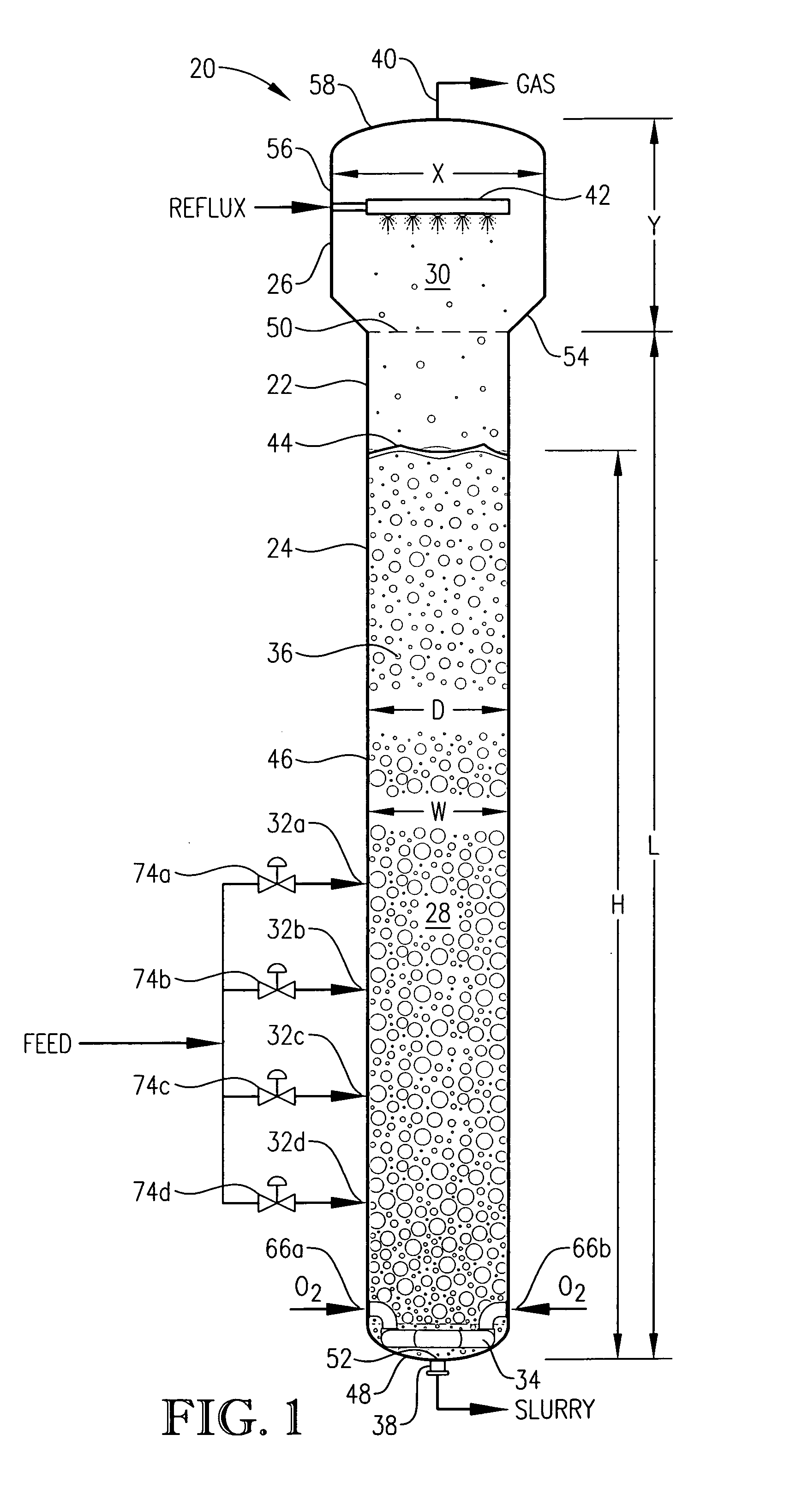

Bio-based polyethylene terephthalate packaging and method of making thereof

InactiveUS20100028512A1Flexible coversWrappersPolyethylene terephthalatePolyethylene terephthalate glycol

This invention relates to a method of making a bio-based PET packaging and particularly to a method of producing a bio-based PET from at least one bio-based material comprising: a) forming at least one PET component from at least one bio-based material, wherein the at least one PET component is selected from a monoethylene glycol (“MEG”), a terephthalic acid (“TA”), and combinations thereof; (b) processing said bio-based PET component into a bio-based PET.

Owner:THE COCA-COLA CO

Oleochemical Plasticizers with Thermal and Ultraviolet Radiation Stabilizing Activity for PVC Molding Resins and Process for Obtaining Thereof

The present invention is related with bioplasticizers or primary oleochemical plasticizers and the improved process for obtaining thereof. It refers primarily to epoxydized oleochemical plasticizers produced from vegetable oils, as substitute of traditional petrochemical plasticizers. The process starts with the epoxydized product of natural oils, such as sunflower, linseed, Jatropha curcas, soybean, etc., which are transesterified with an alcohol such as ethylic or methylic, in the presence of a catalyst such as sodium methoxide or sodium hydroxide in order to produce an alkylic esters mixture of the fatty acids that were present in the oil or oil mixture used as raw material in the epoxydized oil production. When the plasticizer obtained by the process already mentioned is used for the formulation of moldable poly(vinyl chloride), PVC, resins; the resulting plastic films get adequate hardness, static and dynamic thermal stability, and plasticizer extractability by solvents, such as n-hexane, gasoline and oil. Besides, when the PVC resin is formulated with a phthalic or terephthalic plasticizers mixture and the bioplasticizer, the bioplasticizer presents a full range solubility and or compatibility with the remainder of the resin compounds. The oxyrane chemical ring of the bioplasticizer is an excellent chemical neutralizer of the HCL that might be formed from the PVC, due to the action or interference of thermal or UV radiation.

Owner:RESINAS & MATERIALES

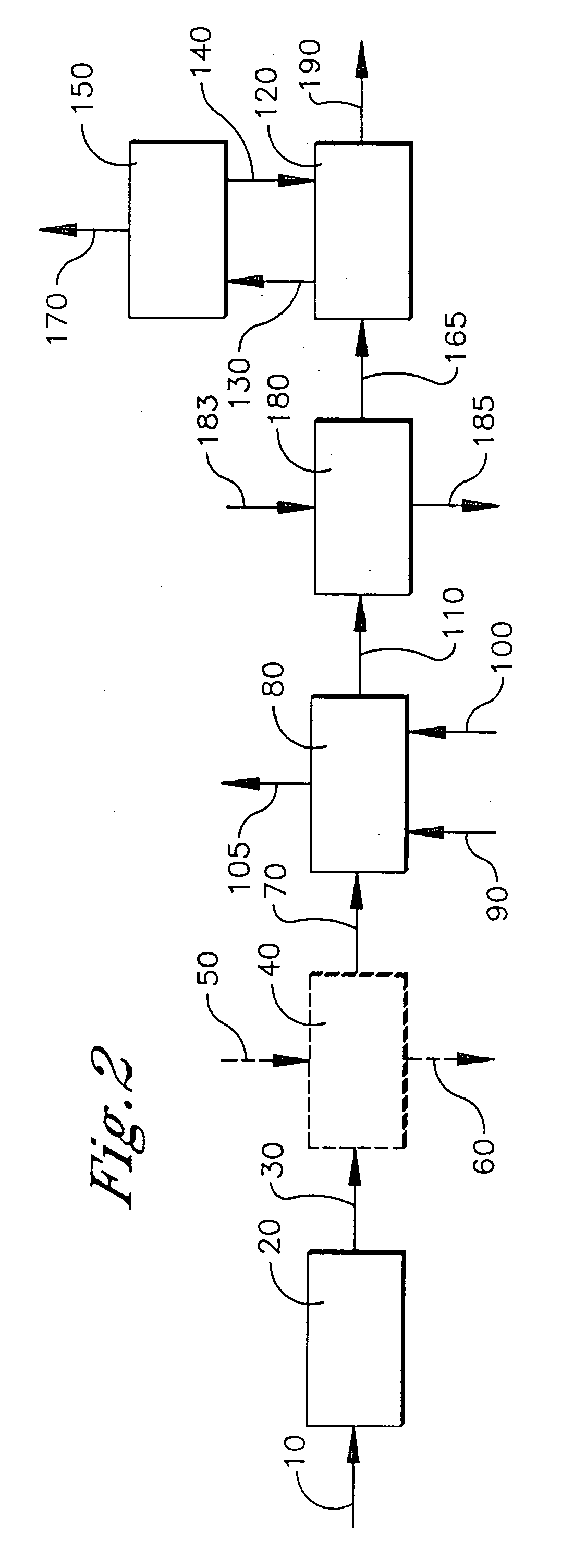

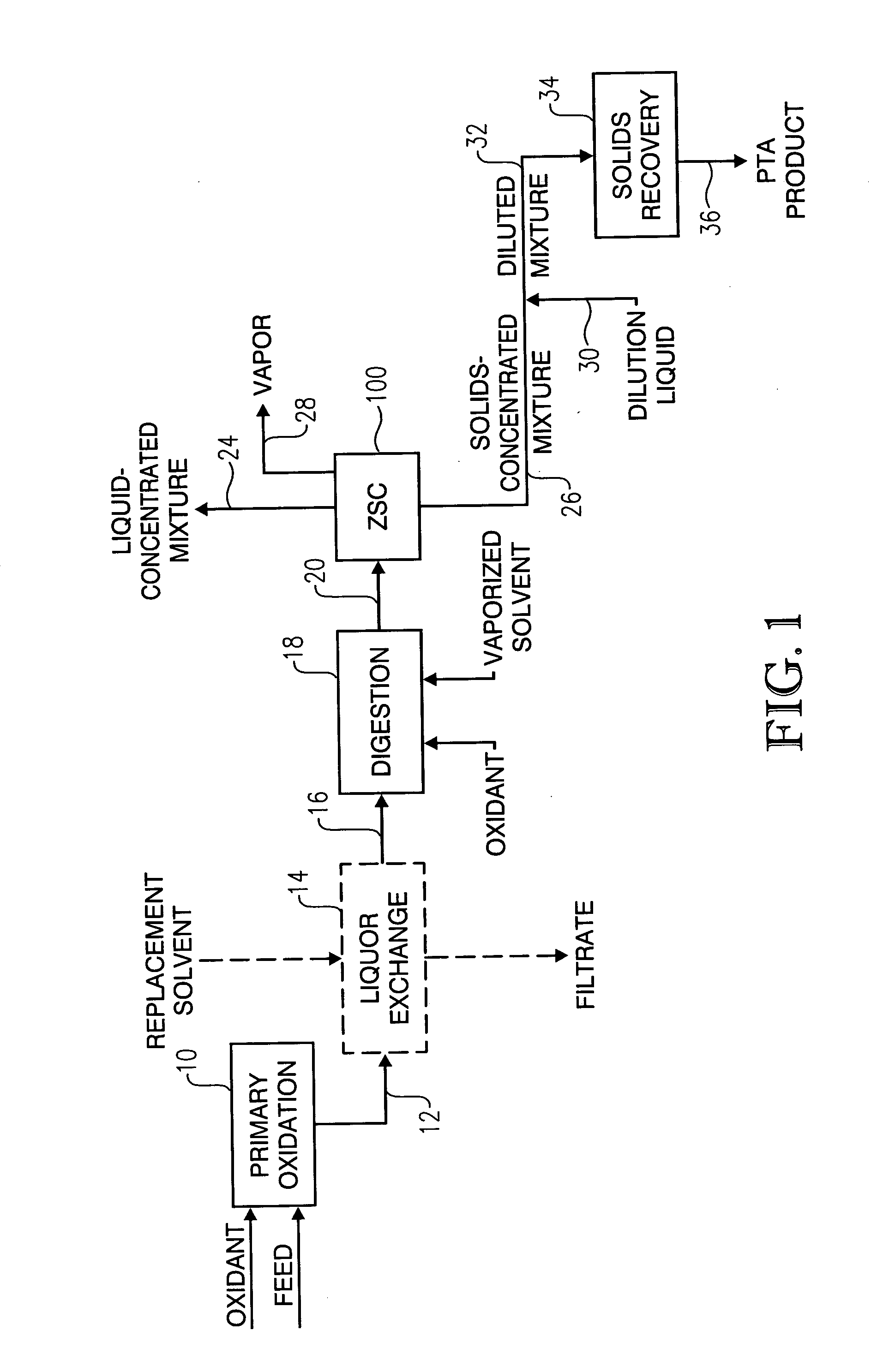

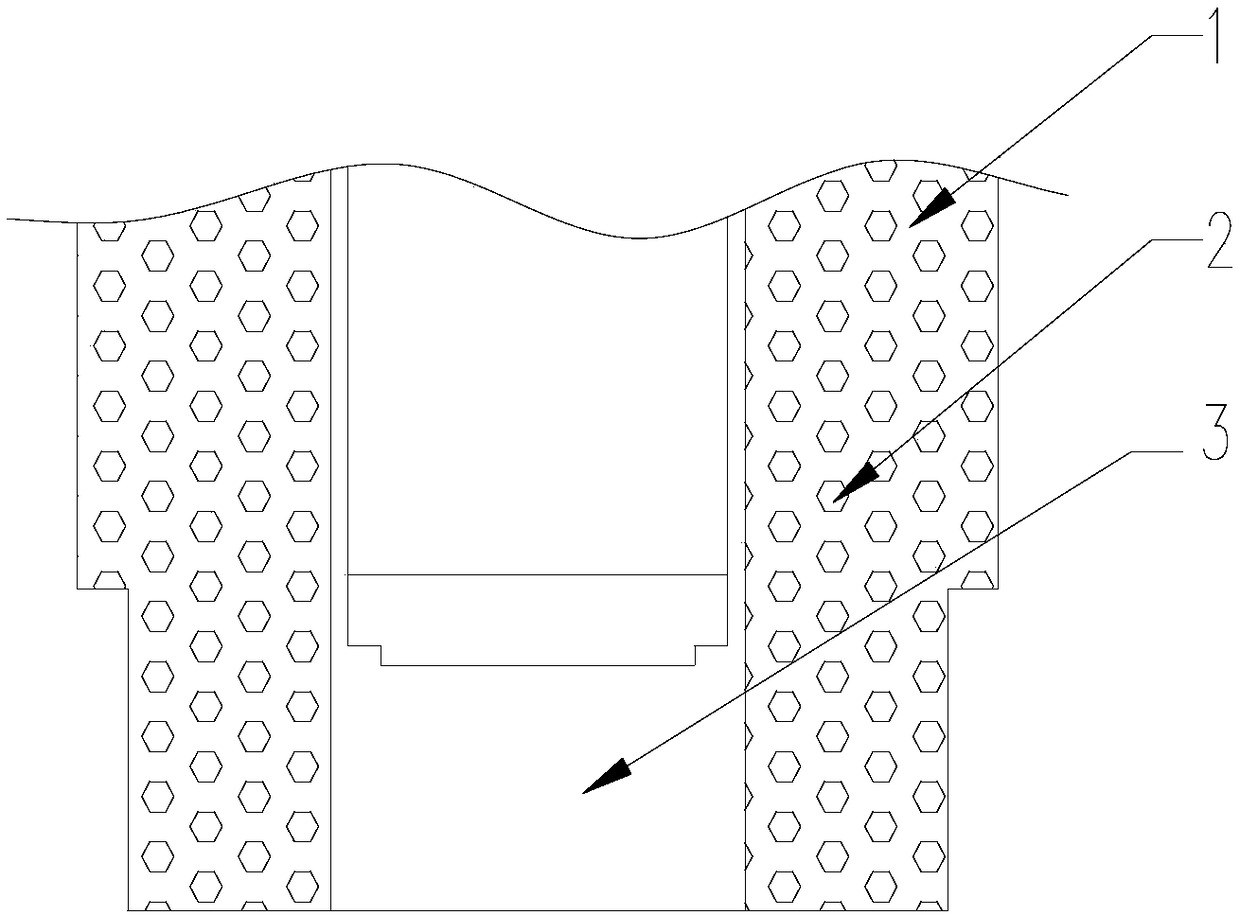

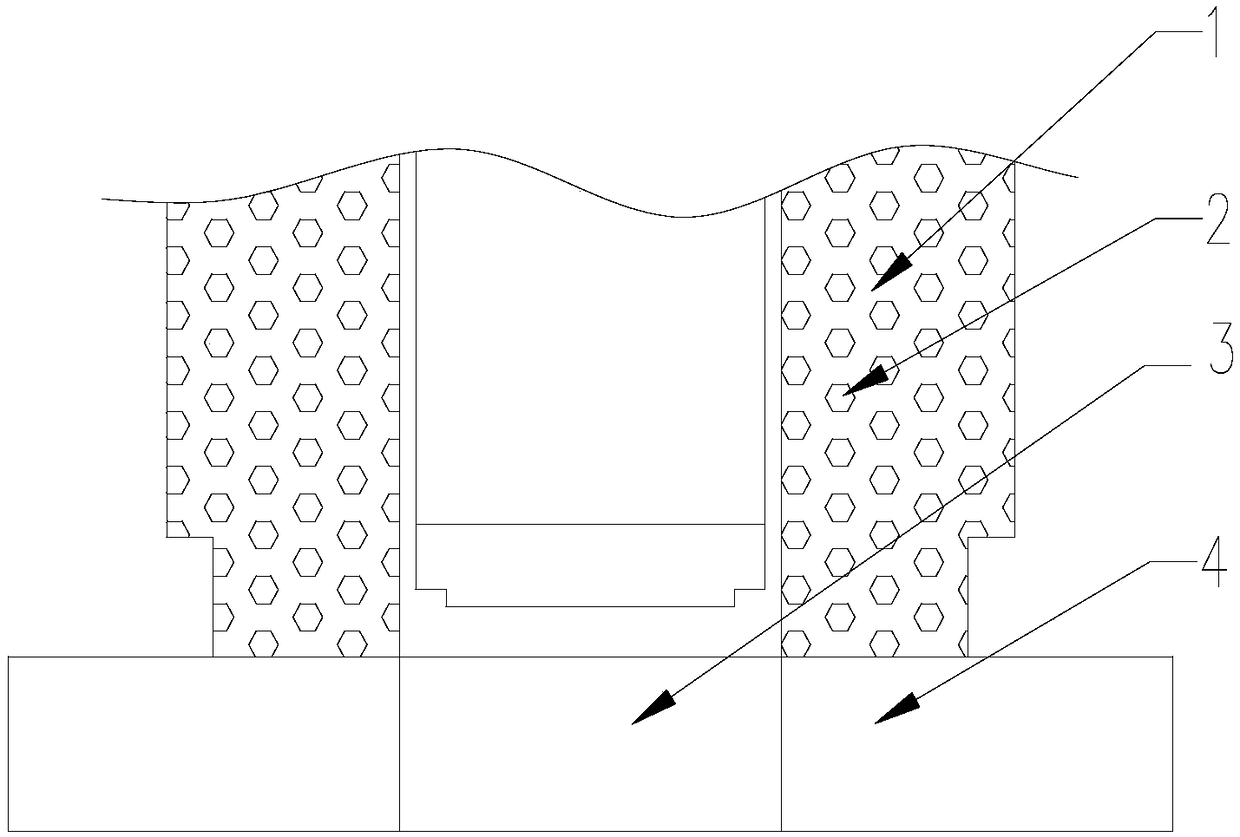

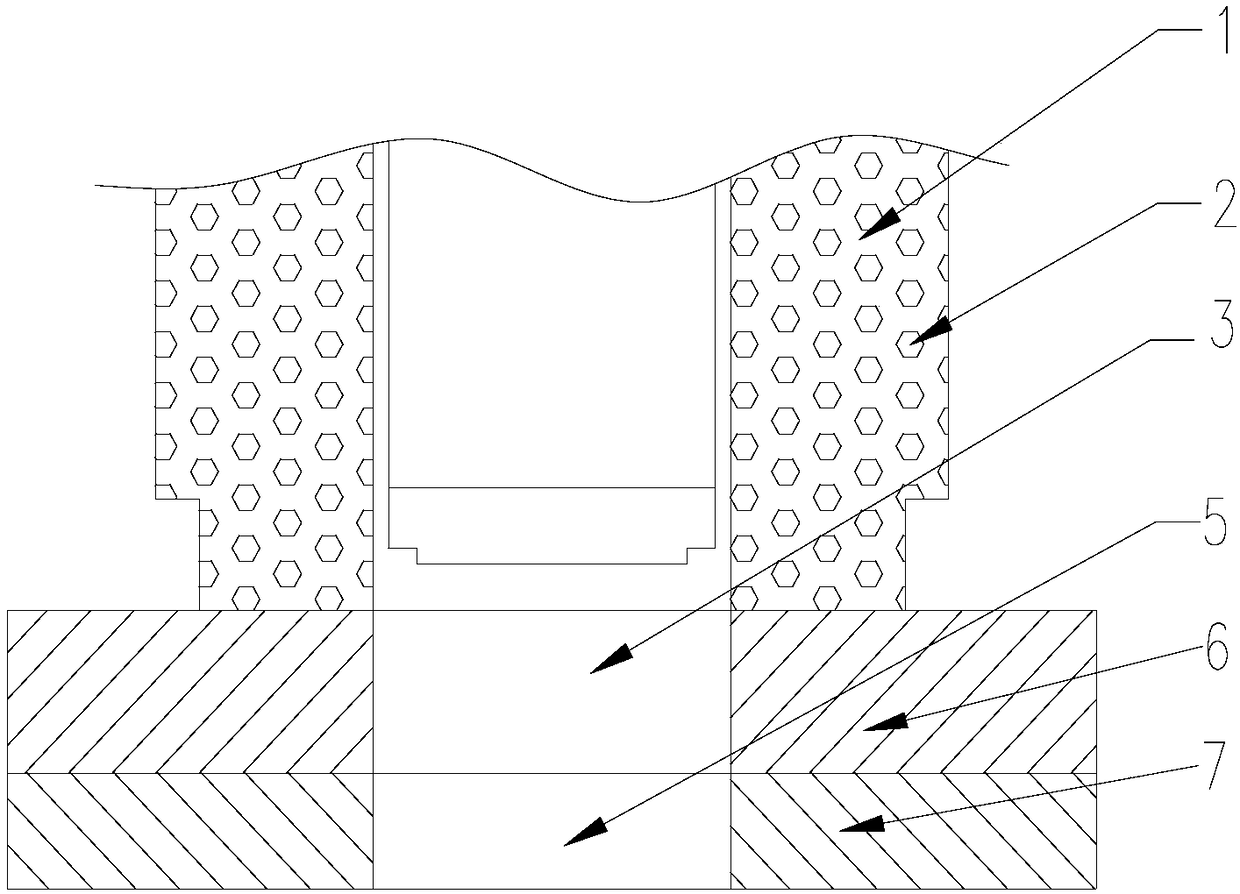

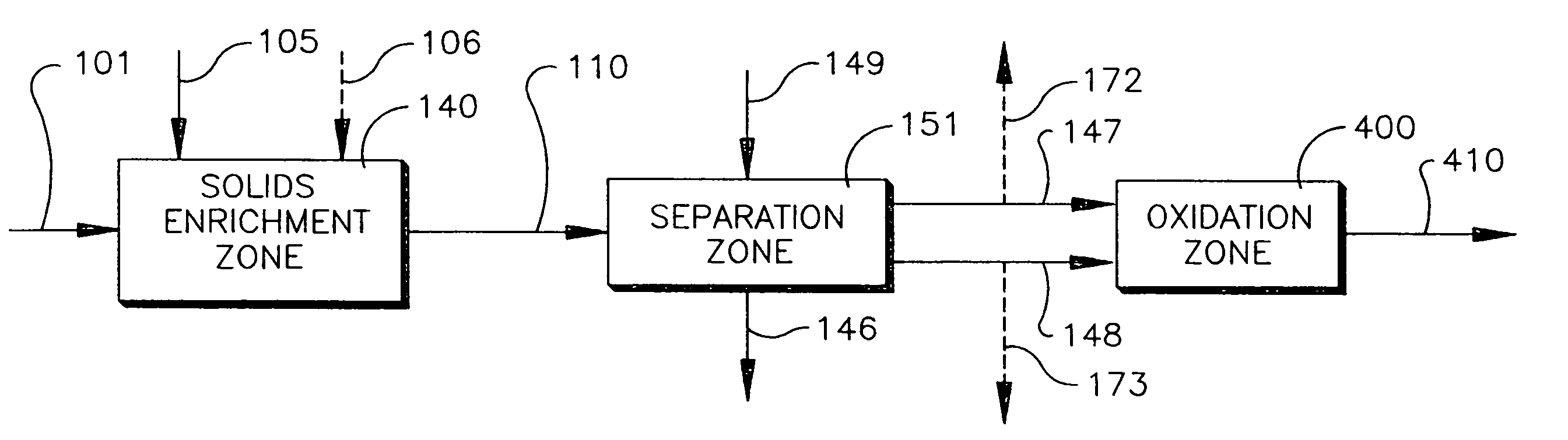

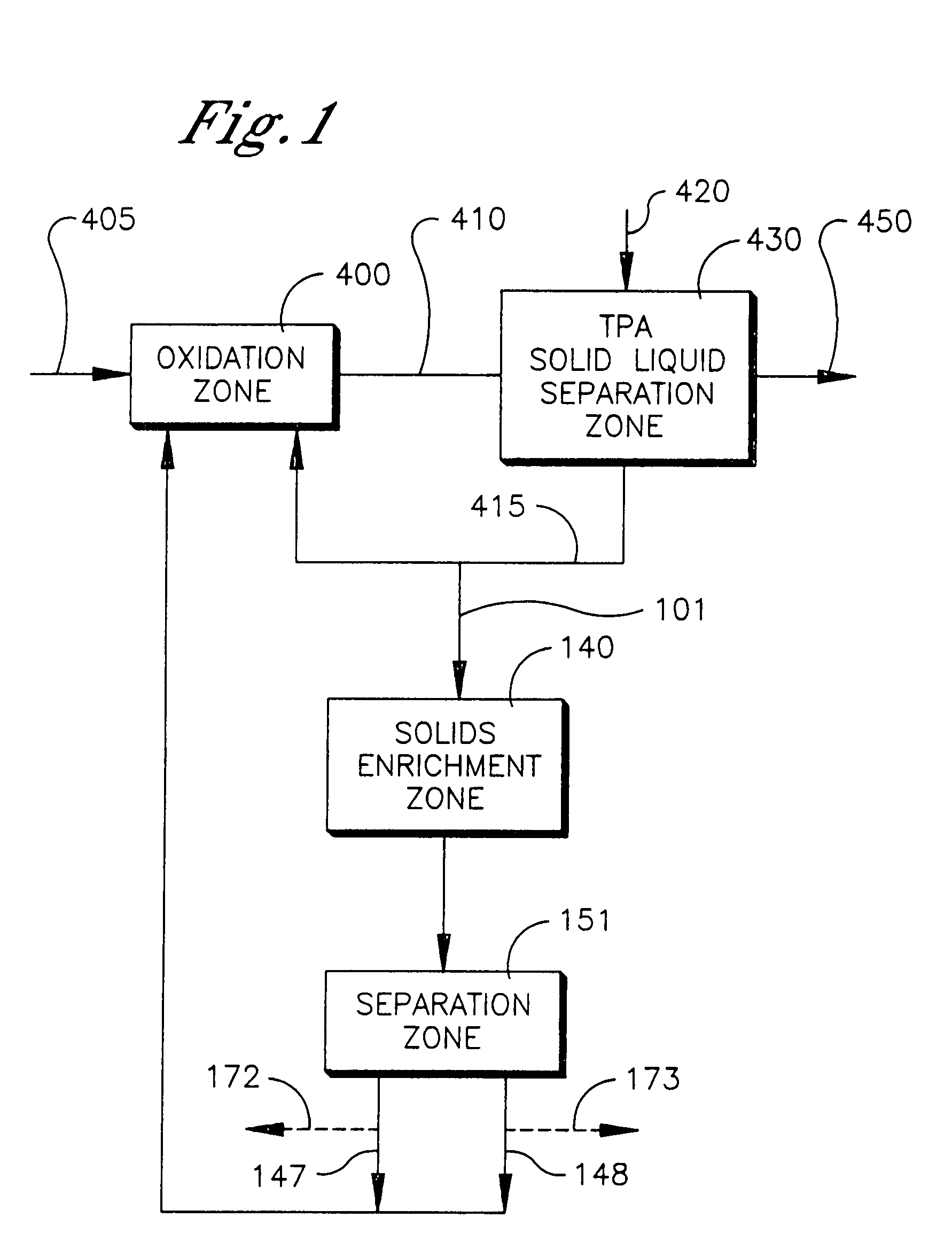

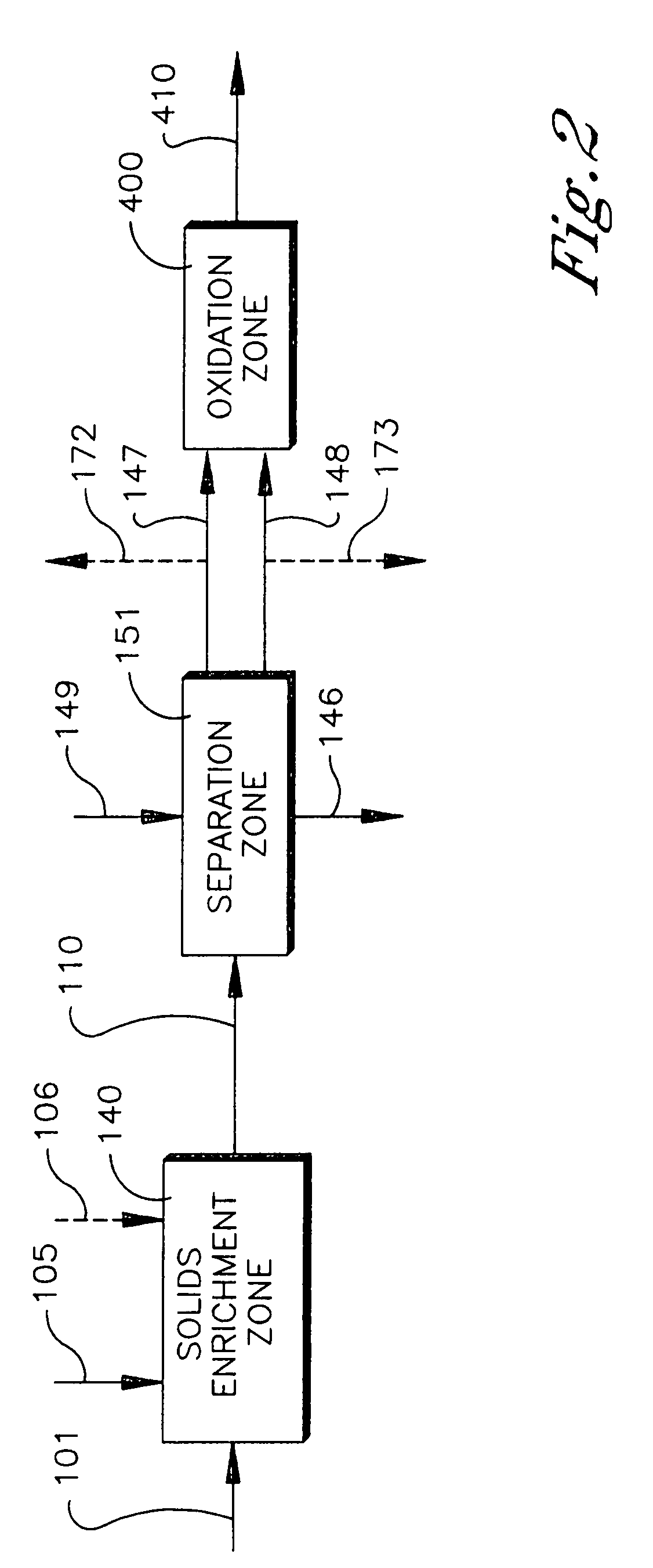

Polycarboxylic acid production system employing oxidative digestion with reduced or eliminated upstream liquor exchange

ActiveUS20070208190A1Reduce formationPromote oxidationOrganic compound preparationCarboxylic preparation by oxidationCarboxylic acidSlurry

Disclosed is an optimized system for more efficiently and economically producing terephthalic acid. The system minimizes or eliminates the need for liquor exchange upstream of oxidative digestion and / or upstream of substantial cooling of the TPA-containing slurry.

Owner:ALPEK POLYESTER SA DE CV

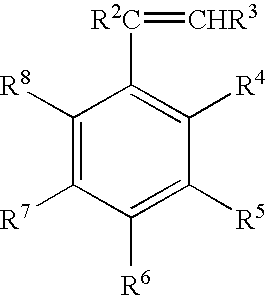

Polyester DTY fiber and preparation method thereof

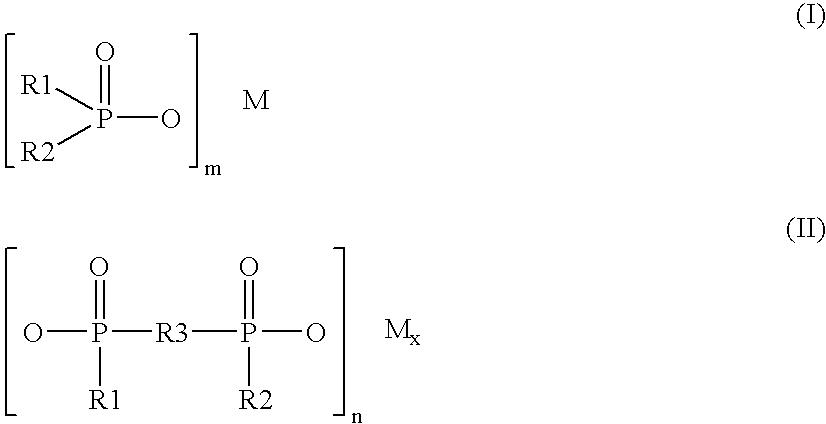

ActiveCN108385186AHigh molecular weightNarrow molecular weightSpinning head liquid feederFilament/thread formingFiberThermal insulation

The invention relates to polyester DTY fiber and a preparation method thereof. The preparation method comprises: metering a modified polyester melt, extruding, cooling, oiling, and winding to preparethe polyester POY fiber. According to the present invention, during the cooling, the longitudinal height is maintained, and the cross section area of the slow cooling chamber is increased while the plate surface temperature of the spinning plate is maintained by using the thermal insulation method; the material of the fiber is the modified polyester, the molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the structure formula of the diol chain segment having the branched chain is defined in the specification, R1 and R2 are respectively and independently selected from straight chain alkylidene with a carbon atom number of 1-3, R3 is selected from alkyl with a carbon atomnumber of 1-5, and R4 is selected from alkyl with a carbon atom number of 2-5; the chromatic aberration [delta]E of the prepared fiber is less than 0.200; and the preparation process is simple and reasonable, and the obtained fiber has excellent performance.

Owner:JIANGSU HENGLI CHEM FIBER

Reinforced poly(arylene ether)/polyamide composition

A composition comprises greater than or equal to 20 weight percent glass fiber, based on the total weight of the composition, and a compatibilized blend of a poly(arylene ether) and an aliphatic-aromatic polyamide. The polyamide is composed of dicarboxylic acid units comprising 60 to 100 mol % of terephthalic acid units and diamine units comprising 60 to 100 mol % of 1,9-nonanediamine units and / or 2-methyl-1,8-octanediamine units. The polyamide has an amine end group content greater than 45 micromoles per gram of polyamide. The composition has a heat distortion temperature (HDT) greater than or equal to 230° C. when measured according to ASTM D 648 at 1.8 megapascals (MPa)

Owner:SABIC INNOVATIVE PLASTICS IP BV

Process of preparing PDT copolyester fiber

InactiveCN101046007ASpinning high speedHigh speed spinning equipmentMonocomponent copolyesters artificial filamentFiberAlcohol

The process of preparing PDT copolyester fiber includes the following steps: 1. saccharifying and catalytically hydrogenating corn starch to prepare sorbitol, catalytically hydrogenating to prepare multicomponent mixed alcohol, and fractionating in a fractionating tower at 182-212 deg.c to obtain corn-base ethylene glycol product of 89-99 % content and with ethylene glycol as main component and other diols; 2. detecting the contents of component diols in the ethylene glycol product and adding insufficient components for content fluctuation controlled within 10-30 %; and 3. adding nanometer titania in 0.05-1 wt% into the corn-base ethylene glycol product, and copolymerizing together with terephthalic acid at 280-288 deg.c for 5-7 hr to prepare PDT copolyester. The process is suitable for industrial production.

Owner:DONGHUA UNIV

Process for production of a carboxylic acid/diol mixture suitable for use in polyester production

ActiveUS20050159578A1Save energyFew stepsOrganic compound preparationTransportation and packagingCarboxylic acidSlurry

The present invention relates to a process by which a carboxylic acid / diol mixture is obtained from a slurry or cake carboxylic acid product without isolation of a substantially dry carboxylic acid solid. More specifically, the present invention relates to a process by which a terephthalic acid / ethylene glycol mixture suitable as a starting material for polyester or co-polyester production is obtained from a slurry or cake terephthalic acid product without isolation of a substantially dry terephthalic acid solid.

Owner:ALPEK POLYESTER SA DE CV

Polyamide composition

InactiveUS7009029B2Excellent surface-reflectancePigmenting treatmentNon-fibrous pulp additionHeat resistancePolyamide

Provided is a polyamide composition comprising 100 parts by weight of (A) a polyamide having dicarboxylic acid units containing 60 to 100 mol % of terephthalic acid units, and diamine units containing 60 to 100 mol % of 1,9-nonanediamine units and / or 2-methyl-1,8-octanediamine units, and 5 to 100 parts by weight of (B) a titanium oxide with an average particle size of 0.1 to 0.5 μm. The polyamide composition shows excellent heat resistance enough to withstand the SMT process, and gives a molded article with excellent whiteness and surface-reflectance.

Owner:KURARAY CO LTD

Elastic polyester fibre and preparation method thereof

InactiveCN101126180AIncrease elasticityConvenient careFilament/thread formingMonocomponent polyesters artificial filamentFiberPolymer science

The invention relates to a springy polyester fiber and the preparing method. The technical problem of the invention to be solved is that the invention provides a springy fiber and the preparing method to make up the disadvantages of the capability of the spandex and the applying arrange. The springy fiber of the invention adopts the method of the compound filature and uses two screw extrusion machines to respectively melt the two components, and the product is obtained through the extrusion of the compound filature component. The invention is characterized in that the components of the springy fiber comprise two of the following high polymers which have heat shrinking capability difference: the high fasculation PETP, the PET, the PBT, the PTT with the weight proportion of 30-70:50.

Owner:ZHEJIANG HENGYI GRP CO LTD

Polyamide composition

ActiveUS20040034152A1Reduce heat resistance requirementsEasy applicabilityPigmenting treatmentNon-fibrous pulp additionHeat resistancePolyamide

Owner:KURARAY CO LTD

Process for removal of impurities from an oxidizer purge stream

ActiveUS7273559B2Organic compound preparationSedimentation separationEnvironmental engineeringCarboxylic acid

A process is disclosed that relates to the removal of impurities and the recovery of a mother liquor and wash filtrate from an oxidizer purge stream produced in the synthesis of carboxylic acid, typically terephthalic. More particularly, the process involves the removal of impurities and the recovery of a mother liquor and wash filtrate from an oxidizer purge stream and then routing the mother liquor and or wash filtrate to an oxidation zone.

Owner:ALPEK POLYESTER SA DE CV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com