Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79 results about "Carboxylic acid synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carboxylic acid - Synthesis of carboxylic acids: Most of the methods for the synthesis of carboxylic acids can be put into one of two categories: (1) hydrolysis of acid derivatives and (2) oxidation of various compounds.

Extraction process for removal of impurities from an oxidizer purge stream in the synthesis of carboxylic acid

InactiveUS20050038288A1Easy to operateImprove reliabilityOrganic compound preparationOrganic chemistry methodsSingle stageMetal catalyst

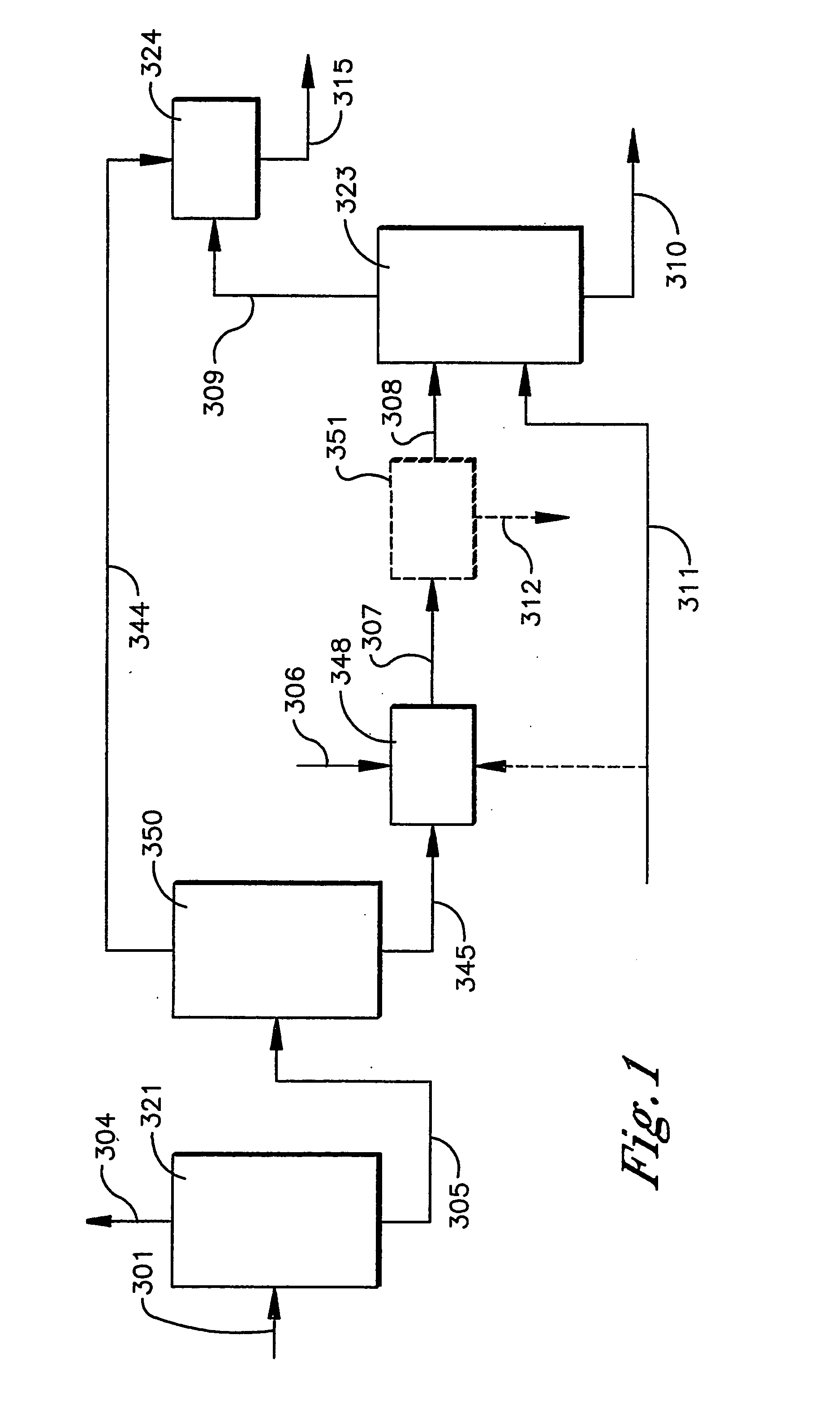

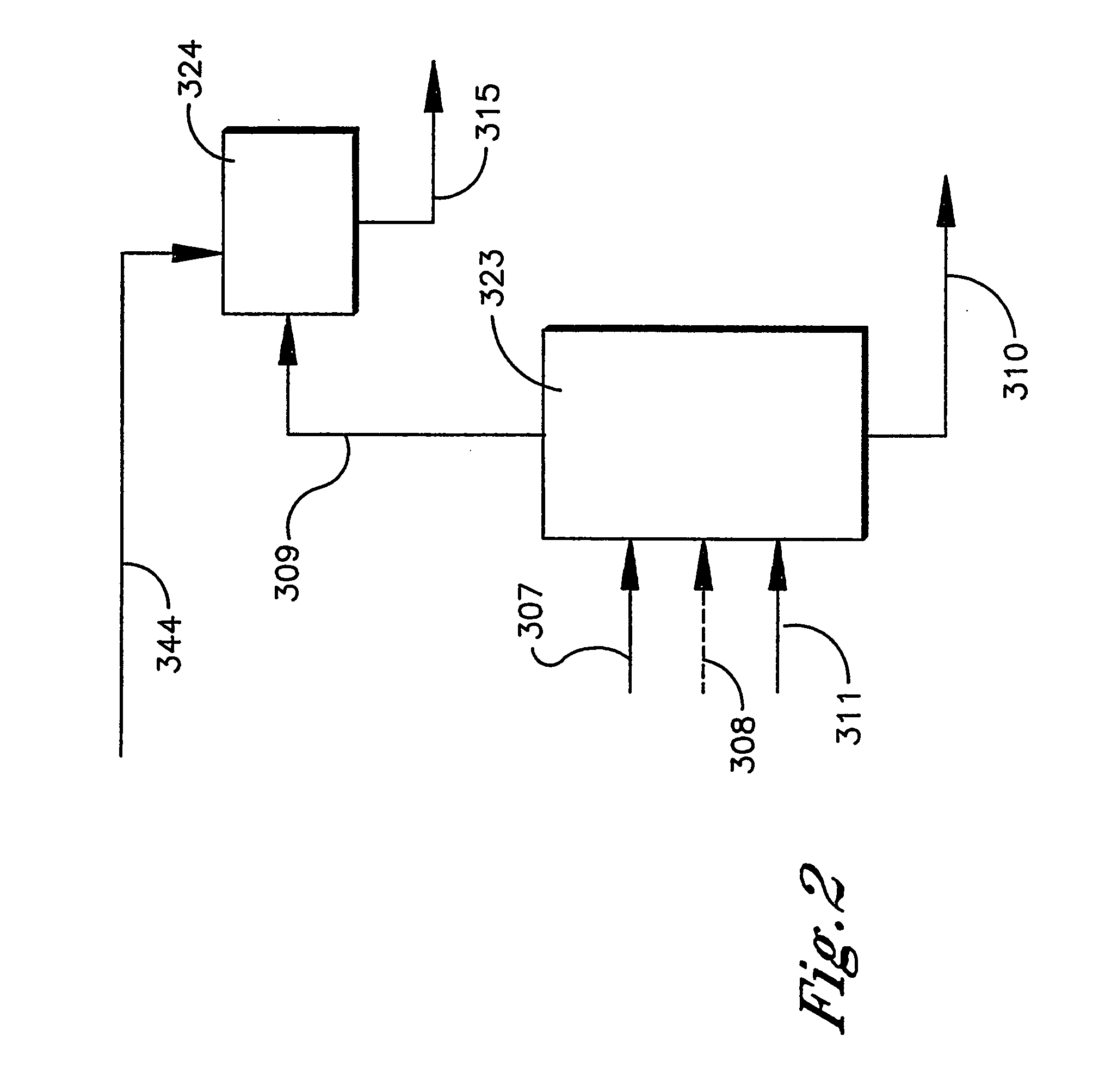

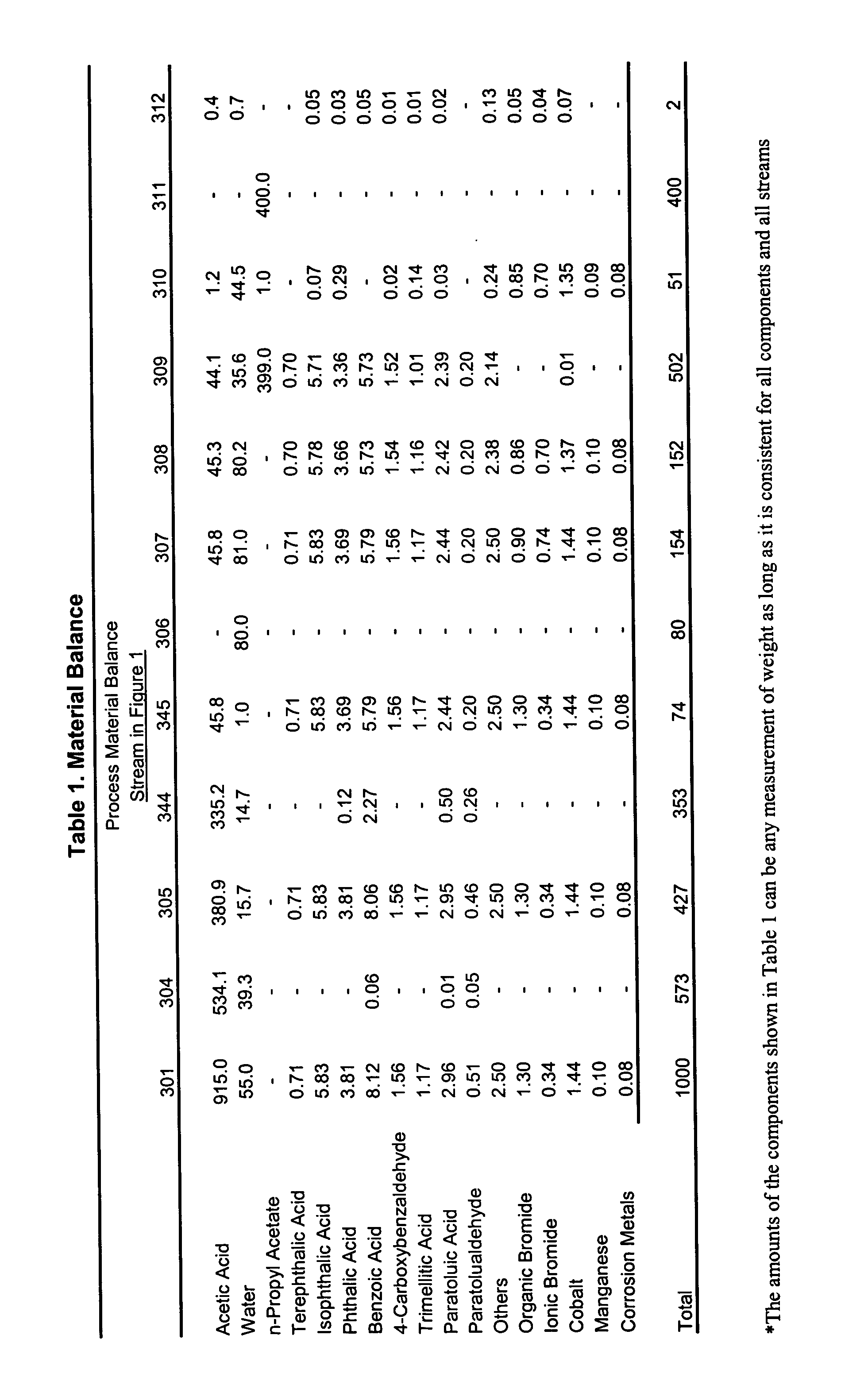

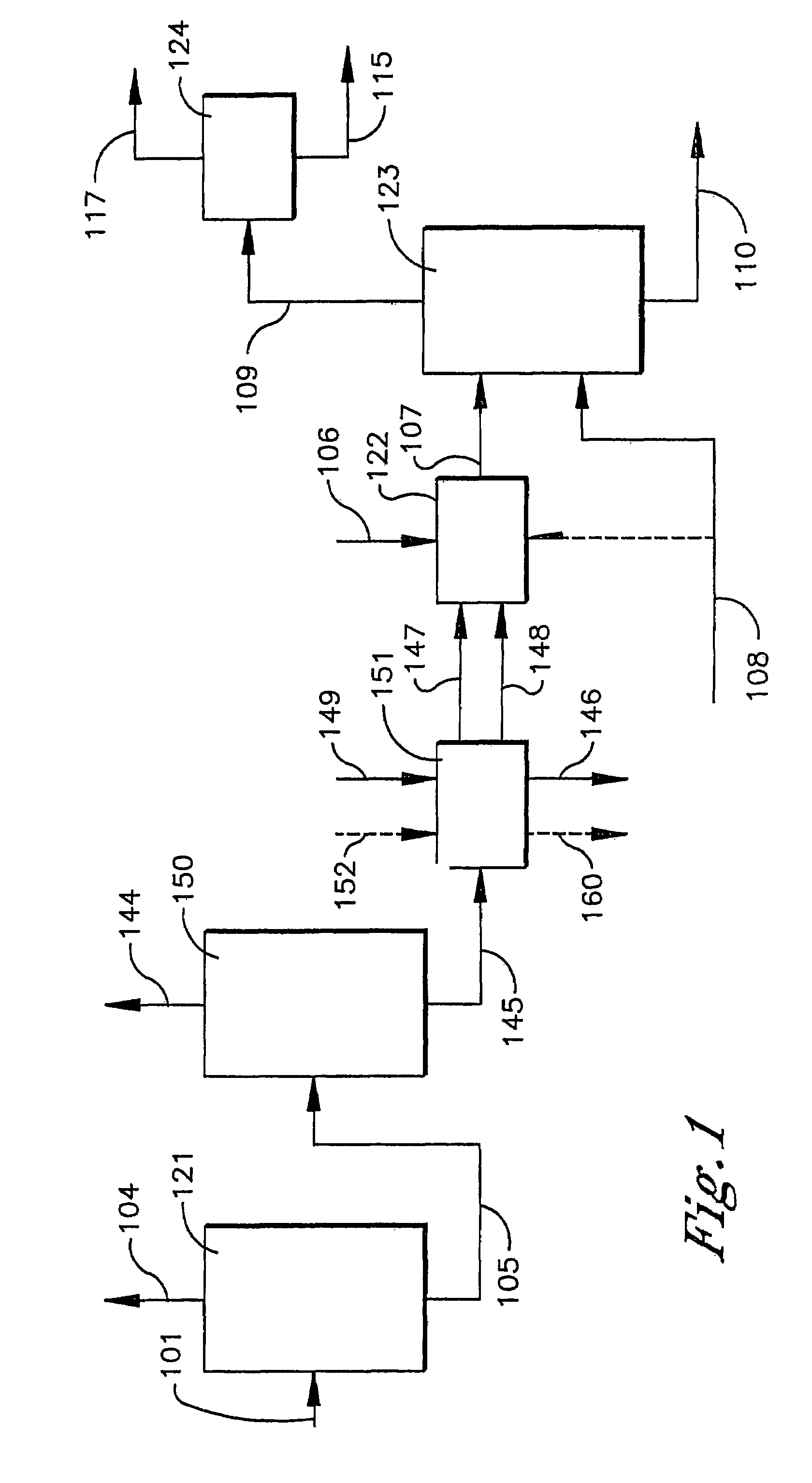

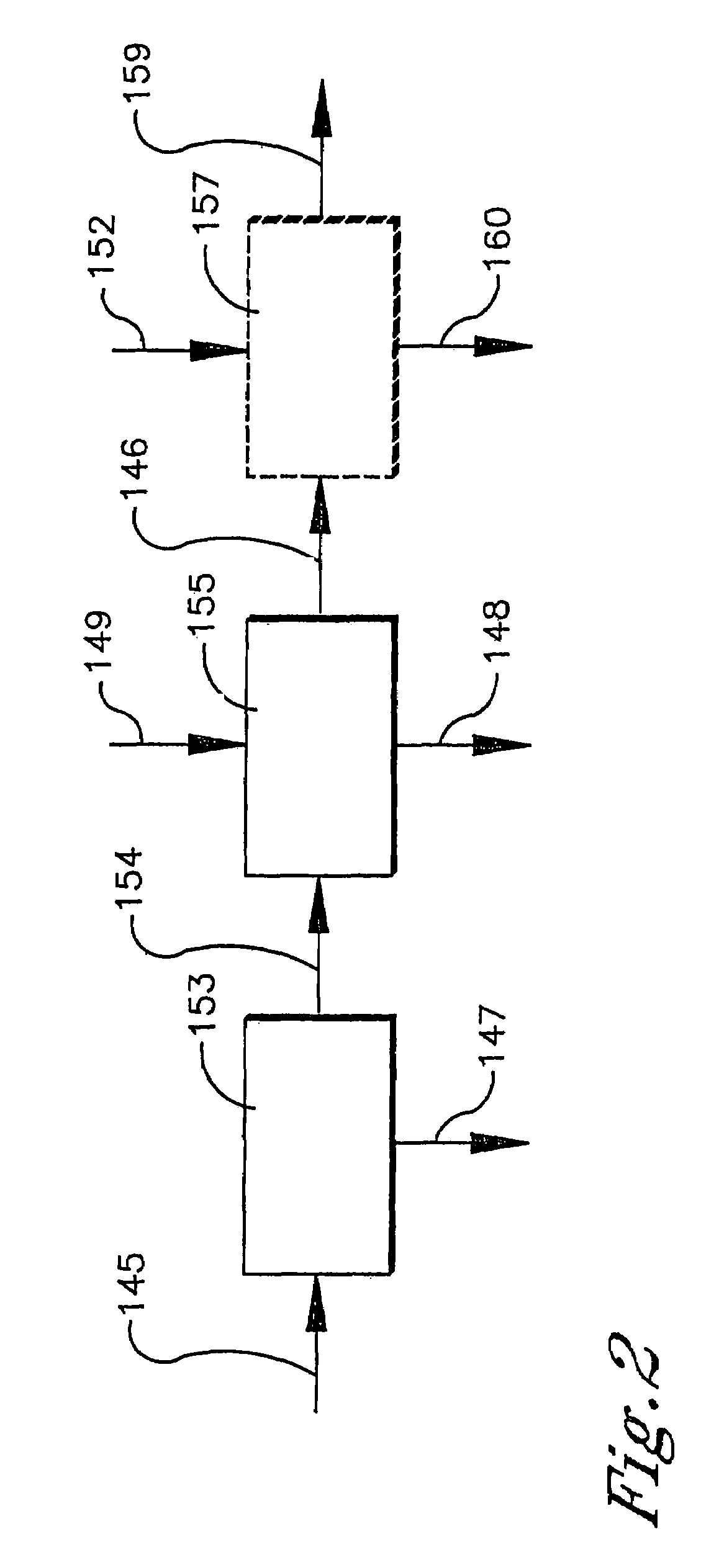

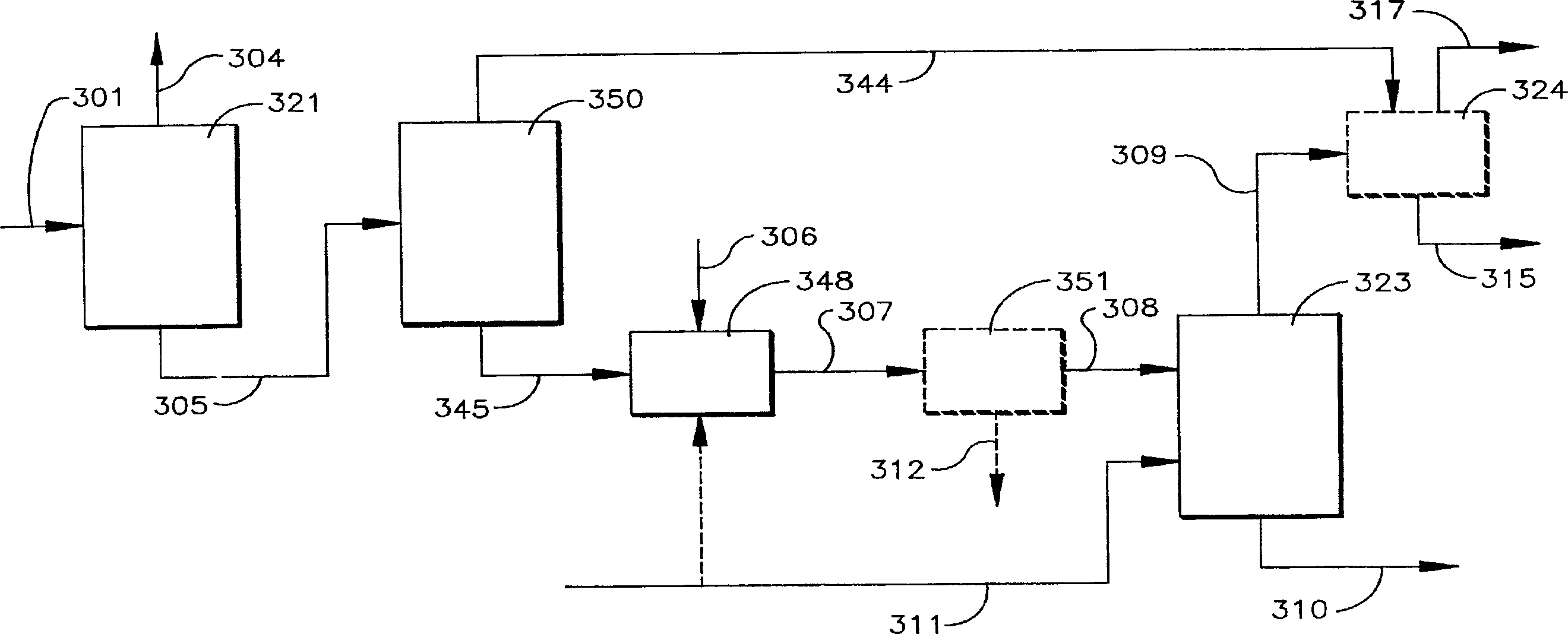

Disclosed is a process that relates to the recovery of a metal catalyst from an oxidizer purge stream produced in the synthesis of carboxylic acid, typically terephthalic acid. The process involves the addition of a wash solution to a high temperature molten dispersion to recover the metal catalyst and then subjecting an aqueous mixture or purified aqueous mixture so formed to a single stage extraction to remove organic impurities to produce an extract stream and a raffinate stream comprising the metal catalyst.

Owner:GRUPO PETROTEMEX DE C V

Process for removal of impurities from mother liquor in the synthesis of carboxylic acid using pressure filtration

ActiveUS7282151B2Drying using combination processesSolid sorbent liquid separationSingle stageMetal catalyst

A process is disclosed that relates to the recovery of a metal catalyst from an oxidizer purge stream produced in the synthesis of carboxylic acid, typically terephthalic. More particularly, the process involves recovery of a metal catalyst from an oxidizer purge stream through the use of a pressure filter, the combining of water with a mother liquor to recover the metal catalyst and then subjecting an aqueous mixture so formed to a single stage extraction with an extraction solvent to produce an extract stream comprising organic impurities and a raffinate stream comprising the metal catalyst.

Owner:ALPEK POLYESTER SA DE CV

Flame-retarding ultraviolet curing aqueous polyurethane coating and preparation method thereof

ActiveCN102250309ALittle impact on performanceMultiple flame retardant ingredientsPolyurea/polyurethane coatingsPolyesterPolymer science

The invention discloses a method for preparing flame-retarding ultraviolet curing aqueous polyurethane coating and belongs to the technical field of ultraviolet curing aqueous polyurethane coating. The preparation method comprises: synthesizing phosphorized polyester polyol by using dicarboxylic acid, diol and phosphonate polycarboxylic acid; mixing the obtained phosphorized polyester polyol, diisocyanate and a catalyst, reacting to obtain isocyanate-terminated phosphorized polyurethane prepolymer, directly adding polyhydroxyl carboxylic acid, and performing chain extension reaction to obtainphosphorized polyurethane prepolymer; and terminating the phosphorized polyurethane prepolymer by using hydroxyethyl methacrylate or hydroxypropyl acrylate, neutralizing by using an amine compound, diluting with water, stirring, emulsifying and adding photoinitiator to obtain the flame-retarding ultraviolet curing aqueous polyurethane coating. When the method is used, the aqueous polyurethane dispersion has internal flame-retarding performance and radiation curing performance and the application range of the aqueous polyurethane is expanded greatly.

Owner:XINFENG JIANWEI CHEM INDAL

Amide/imide structure polycarboxylate superplasticizer and preparation method thereof

ActiveCN107652405AProcess operation is easy to controlThe synthesis process is safe and environmentally friendlyImideSuperplasticizer

The invention discloses an amide / imide structure polycarboxylate superplasticizer and a preparation method thereof. The amide / imide structure polycarboxylate superplasticizer is synthesized by amidation / imidization of amine-terminated polyether to obtain polymerizable polyether amine, and then copolymerization reaction with active monomers. The preparation method of the polycarboxylate superplasticizer provided by the invention has the advantages of simple and easily controllable technological operation, safe and environment-friendly synthetic process, low cost, energy saving and consumption reduction. Also the obtained amide / imide structure polycarboxylate superplasticizer has the advantages of high water-reducing rate, good flowing retention performance, long storage period, significantreduction of slurry viscosity under a low water-binder ratio and the like, thus solving the problems of great difficulty, difficultly available raw materials, many side reactions, harsh conditions, high cost and the like in the amide / imide polycarboxylate synthesis process.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

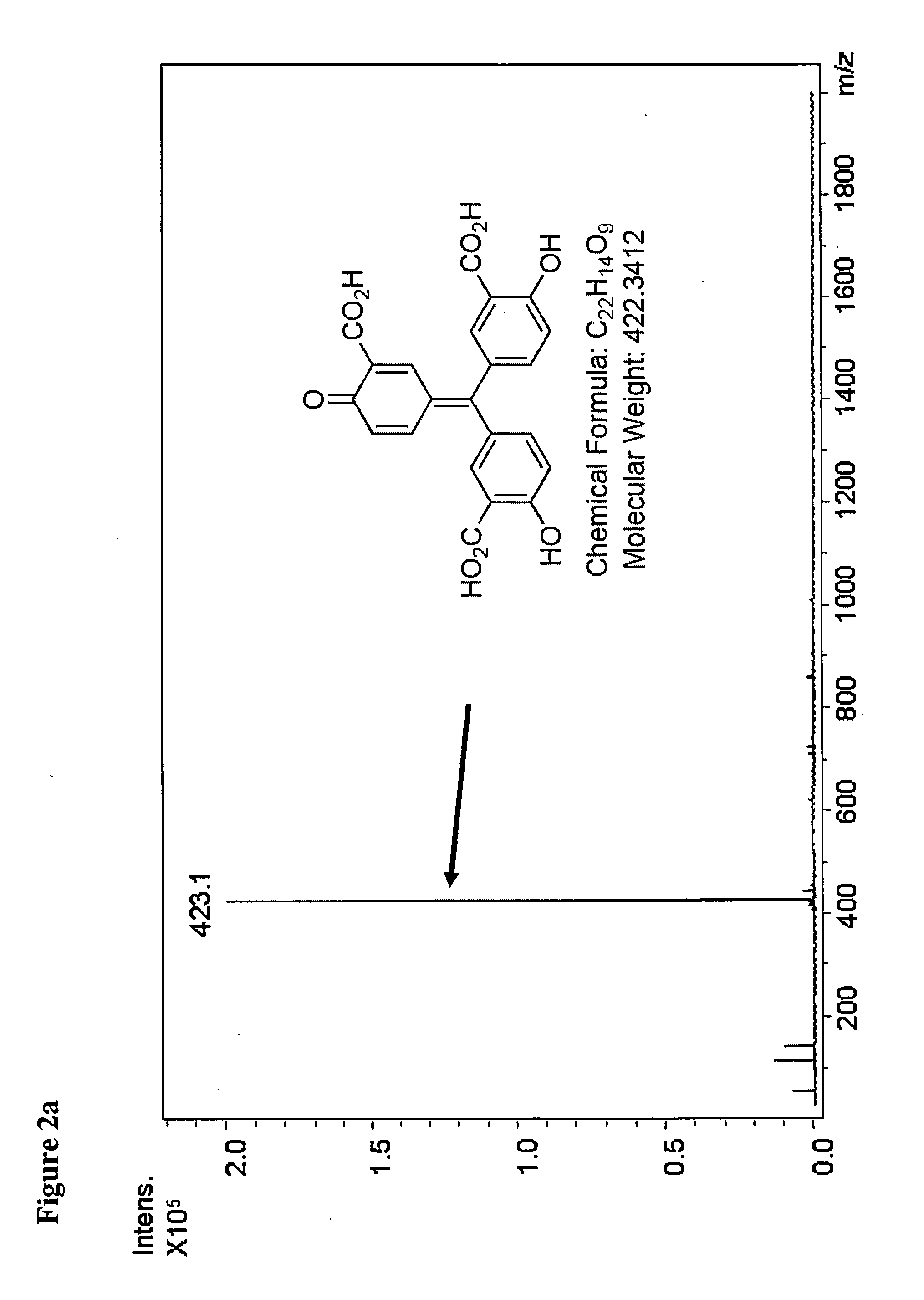

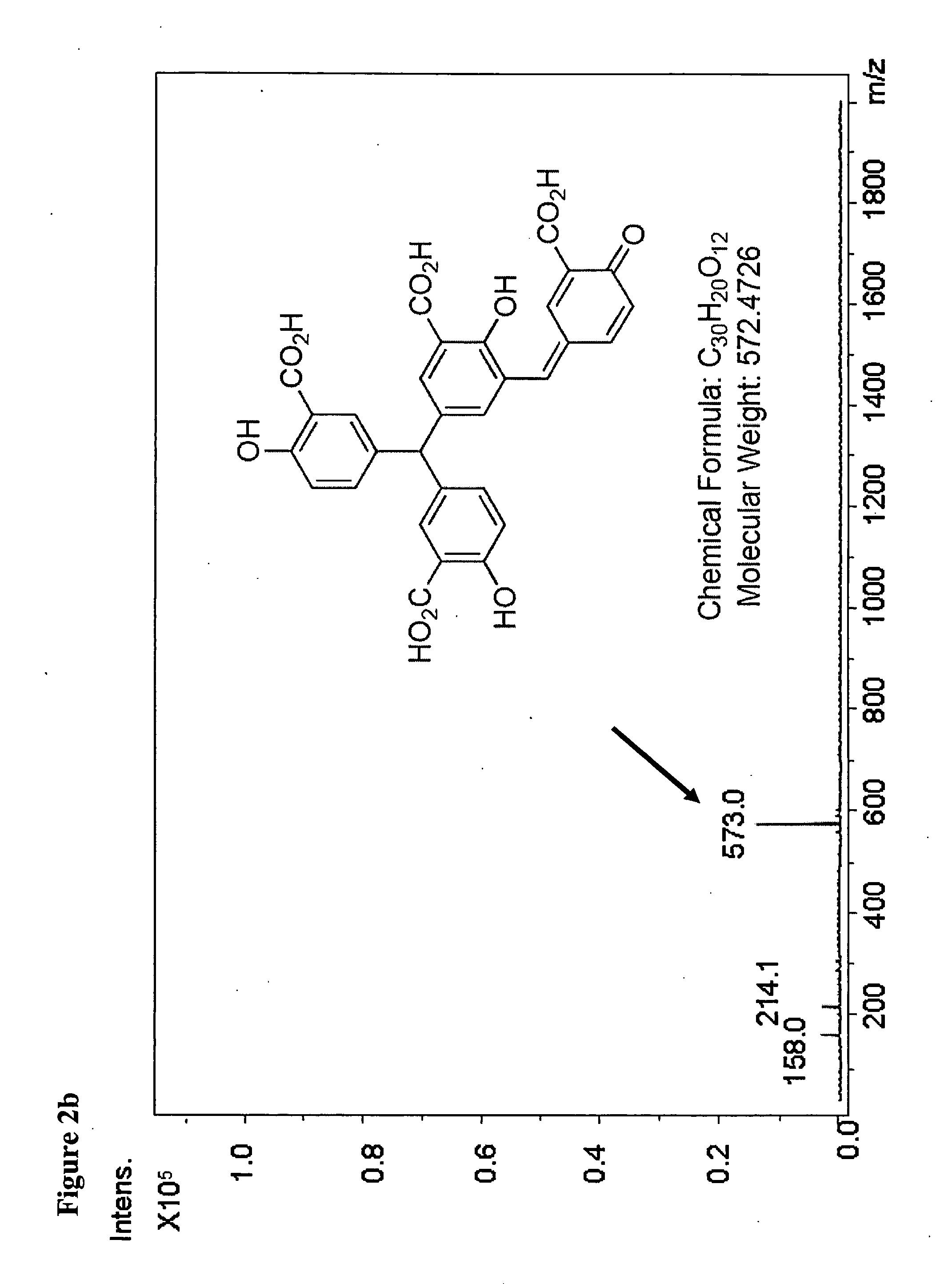

Selective inhibition of the membrane attack complex of complement by low molecular weight components of the aurin tricarboxylic acid synthetic complex

Owner:AURIN BIOTECH

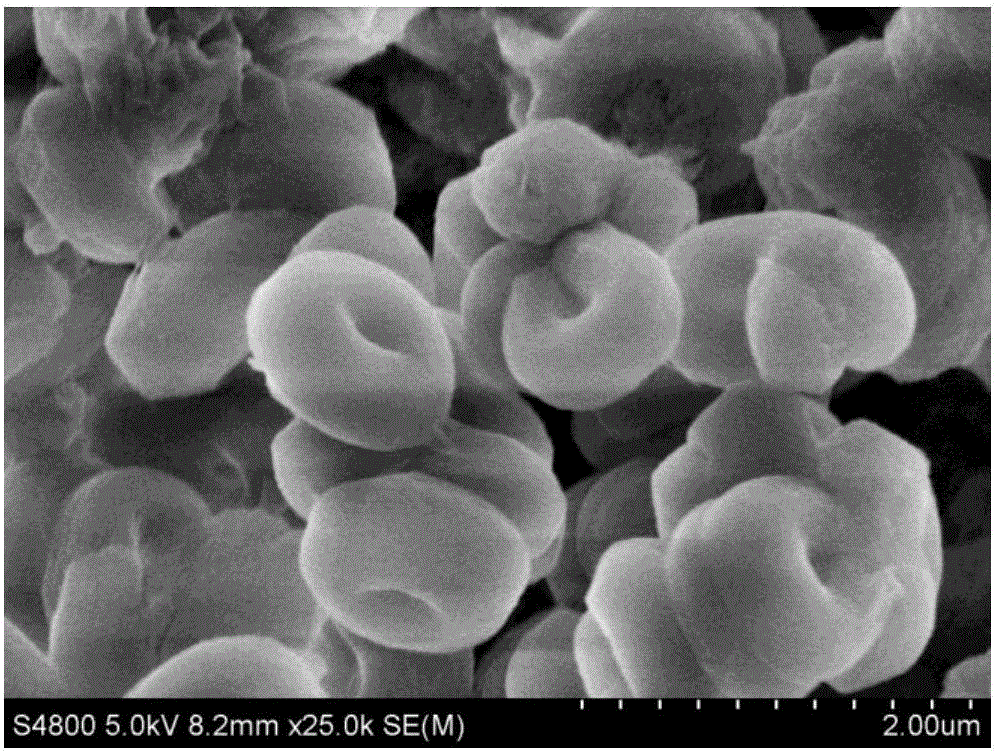

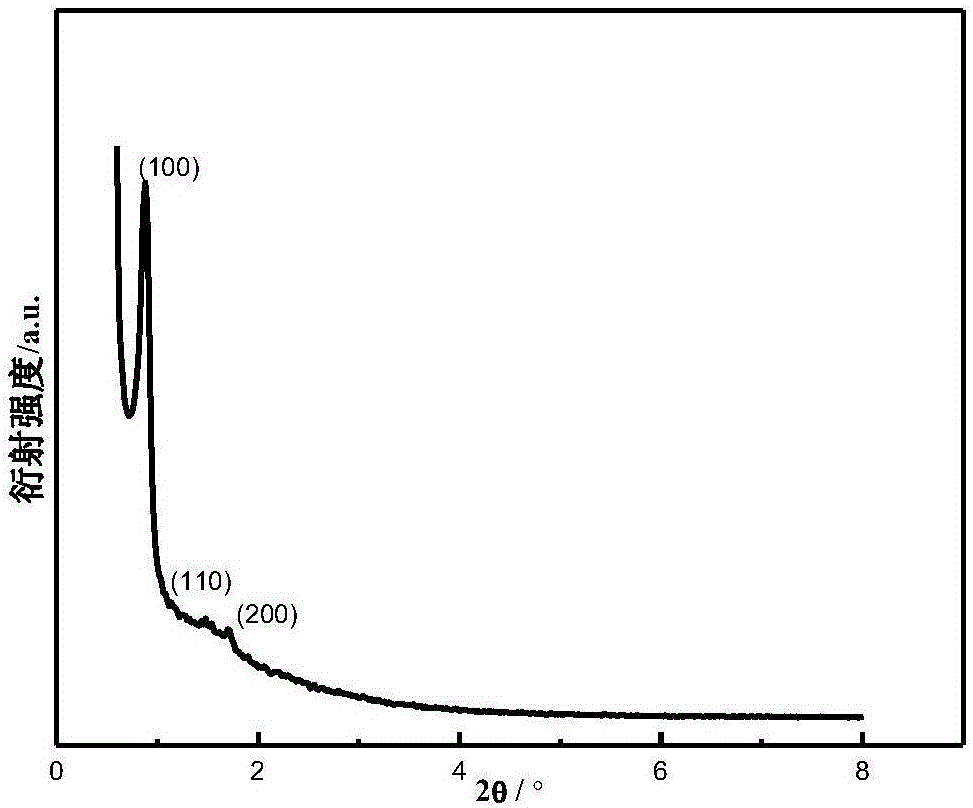

SO3H-SBA-15 molecular sieve catalyst for catalyzing isobutene and carboxylic acid to synthesize carboxylic acid tert-butyl ester and preparation method and application thereof

ActiveCN106040282AEfficient and stable synthesisReduce separation energy consumptionMolecular sieve catalystsOrganic compound preparationMolecular sieveCarboxylic acid

The invention discloses a SO3H-SBA-15 molecular sieve catalyst for catalyzing isobutene and carboxylic acid to synthesize carboxylic acid tert-butyl ester. The molecular sieve catalyst is prepared by adopting a template agent, a morphology regulator, a silicon source, a sulfonic acid source and an oxidizing agent through a one-step co-condensation method or a two-step sulfonic acid group post-synthesis method. In the SO3H-SBA-15 molecular sieve catalyst, by the molar ratio of a sulfonic acid group to silicon oxide, the sulfonic acid group supporting amount accounts for 30%-50%. The invention further discloses a method of using the SO3H-SBA-15 molecular sieve catalyst to catalyze the isobutene and the carboxylic acid for carboxylic acid tert-butyl ester synthesis. The molecular sieve catalyst is adjustable in shape, orderly in mesoporous pore passage and capable of efficiently and stably catalyzing the isobutene and the carboxylic acid to selectively synthesize the carboxylic acid tert-butyl ester under the conditions of higher temperature and polymerization inhibitor absence, meanwhile the separation energy consumption and equipment investment of reaction products are reduced, and the SO3H-SBA-15 molecular sieve catalyst has an important significance on development and utilization of atomic economic reaction.

Owner:NANJING UNIV OF TECH +1

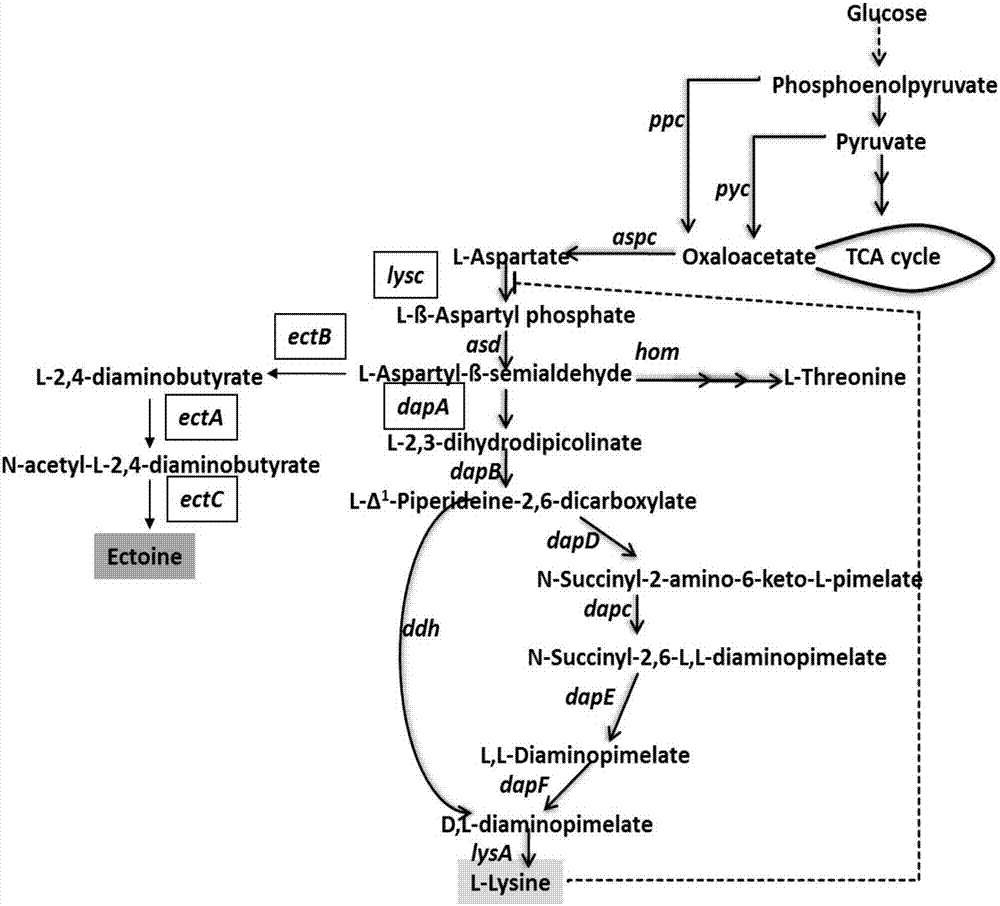

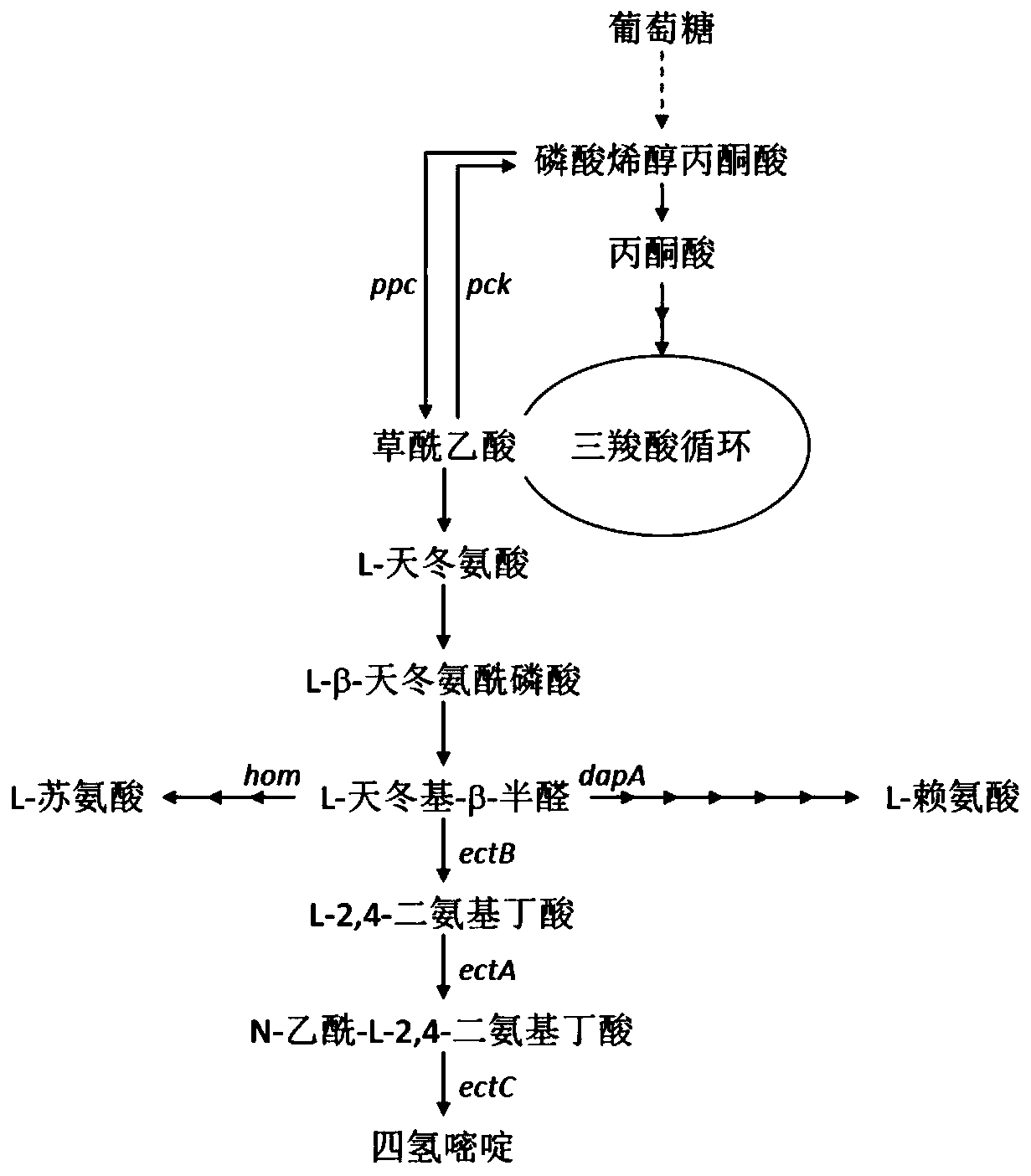

Method of producing tetrahydropyrimidine by fermenting recombinant corynebacterium glutamicum

ActiveCN107142234ALow costAddressing Biosecurity IssuesCarbon-nitrogen lyasesBacteriaBacterosiraFermentation

The invention provides a method of producing tetrahydropyrimidine by fermenting recombinant corynebacterium glutamicum. The recombinant corynebacterium glutamicum is obtained by the steps of performing overexpression in corynebacterium glutamicum to relieve an aspartokinase gene lysC of feedback inhibition; then replacing a promoter of a dihydropyrimidine dicarboxylic acid synthetase in the recombinant bacteria to weaken the activity of the dihydropyrimidine dicarboxylic acid synthetase; and then transferring tetrahydropyrimidine synthetic path related gene ectABC into the recombinant bacteria to obtain the recombinant corynebacterium glutamicum. The recombinant corynebacterium glutamicum provided by the invention can use different cheap raw materials to produce tetrahydropyrimidine by fermentation under a low salt condition, and cheap corn slurry can be also used as a nutritional component which replaces expensive yeast powder, so that the cost of the raw materials is further lowered. Meanwhile, the recombinant corynebacterium glutamicum provided by the invention solves the problem of biosafety, simplifies the post-extraction process and has a good market application prospect.

Owner:北京绿色康成生物技术有限公司

Synthetic multiple-effect lubricant additive and preparation method thereof

The invention relates to a synthetic multiple-effect lubricant additive and a preparation method thereof and in particular relates to a fully-synthetic multiple-effect lubricant additive which does not contain S and Cl and takes a metal processing lubricant as a main product. The fully-synthetic multiple-effect lubricant additive is a mixture containing glycerol single ricinoleate, a carboxylic acid synthetic ester lubricant, iso-tridecanol polyoxyethylene ether, an antirust agent, amine phosphate, a non-ferrous metal corrosion inhibitor and a carboxyl hexyl-2-cyclohexene-1-octadeca-carbonic acid. The fully-synthetic multiple-effect lubricant additive has the advantages of good wear resistance, good anti-rust performance, good synergy and environmental friendliness. The fully-synthetic multiple-effect lubricant additive is applicable to blending emulsified oil, micro-emulsifying liquid, fully-synthetic metal working fluid, metal rolling liquid and metal molding working fluid as well as lubricating oil products such as water-based fire-resistant hydraulic oil.

Owner:GUANGDONG AOLIDAN IND

Ceftezole acid preparation method

The present invention discloses a ceftezole acid preparation method, which comprises four steps such as 7-amino-8-oxo-3-[(1,3,4-thiadiazol-2-ylthio)methyl]-5-thia-1-azabicyclo[4.2.0]oct-2-ene-2??-carboxylic acid synthesis, carboxyl protection, anhydride preparation and ceftezole acid generation. The ceftezole acid preparation method has the following advantages that: the carboxyl of the synthesized 7-amino-8-oxo-3-[(1,3,4-thiadiazol-2-ylthio)methyl]-5-thia-1-azabicyclo[4.2.0]oct-2-ene-2??-carboxylic acid is protected, such that complex impurity formation during ceftezole acid generation through the reaction of the 7-amino-8-oxo-3-[(1,3,4-thiadiazol-2-ylthio)methyl]-5-thia-1-azabicyclo[4.2.0]oct-2-ene-2??-carboxylic acid and the anhydride is avoided so as to increase yield and reduce cost, wherein the total yield (calculated as a mass ratio of ceftezole acid to 7-ACA) is 130% ( the total yield=the mass of ceftezole acid / the mass of 7-ACA).

Owner:江苏德峰药业有限公司

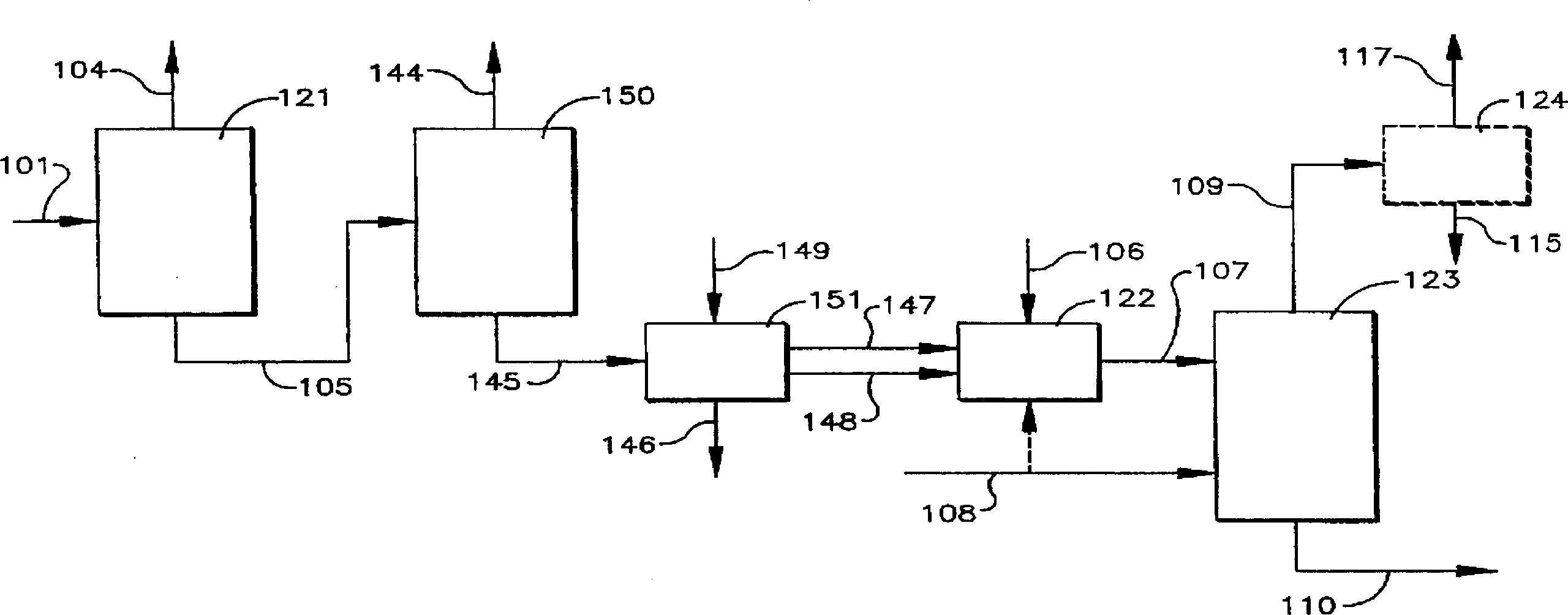

Extraction process for removal of impurities from mother liquor in the synthesis of carboxylic acid

ActiveCN1572765AReduce congestionEasy to operateInorganic chemistryOrganic compound preparationMetal catalystCarboxylic acid

A method for removing impurities from a mother liquor comprising a carboxylic acid, a metal catalyst, impurities by (a) evaporating the mother liquor comprising a carboxylic acid, the metal catalyst, impurities, water and a solvent in a first evaporator zone to produce a vapor stream and a concentrated mother liquor stream;(b) evaporating the concentrated mother liquor stream in a second evaporator zone to form a solvent rich stream and a super concentrated mother liquor stream;(c) separating organic impurities with a water-solvent solution from the super concentrated mother liquor in a solid-liquid separation zone to form an aqueous stream and a second aqueous stream; (d) mixing in a mixing zone water and optionally and extraction solvent with the aqueous stream and second aqueous stream to form an aqueous mixture; and (e) adding an extraction solvent to the aqueous mixture in an extraction zone to form an extract stream and a raffinate stream.

Owner:GRUPO PETROTEMEX SA

Tert-carboxylic acid synthesis method

ActiveCN105218354ASimple processImprove economyPreparation from carboxylic acid anhydridesChemical recyclingCarboxylic acidAlkene

The invention discloses a tert-carboxylic acid synthesis method. According to the method, olefin and carbon monoxide serve as raw materials, and a tert-carboxylic acid product is obtained through catalyzed synthesis under normal pressure or low pressure in the presence of strongly acidic ionic liquid-metal carbonyl complex catalyst. Corrosion is avoided, catalyst consumption is low, three-waste discharge is low, the tert-carboxylic acid product and the catalyst can be separated easily after reaction ends, and the defects of existing technologies that separation effect is poor and dilute sulphuric acid recovery is hard are overcome.

Owner:WANHUA CHEM GRP CO LTD

Extraction process for removal of impurities from mother liquor in the synthesis of carboxylic acid

ActiveCN1572767AReduce congestionEasy to operateOrganic compound preparationOrganic chemistry methodsPtru catalystMetal catalyst

A method for removing impurities from a mother liquor comprising a carboxylic acid, a metal catalyst, impurities by (a) evaporating the mother liquor comprising a carboxylic acid, a metal catalyst, impurities and a solvent in a first evaporator zone to produce a vapor stream and a concentrated mother liquor stream;(b) evaporating the concentrated mother liquor stream in a second evaporator zone to form a solvent rich stream and a super concentrated mother liquor stream; (c) mixing in a mixing zone a water-solvent solution and optionally an extraction solvent with the super concentrated motherliquor stream to form an aqueous mixture;(d) optionally separating organic impurities from the aqueous mixture in a solid-liquid separation zone to form a purified aqueous mixture; and (e) extractingthe aqueous mixture or purified aqueous mixture with an extraction solvent in an extraction zone to form an extract stream and the raffinate stream.

Owner:GRUPO PETROTEMEX SA

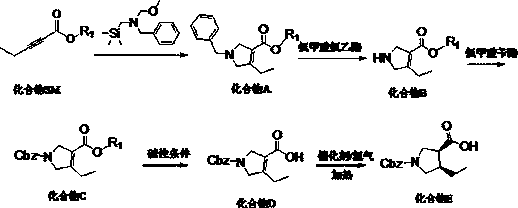

(3R,4S)-1-carbobenzoxy-4-ethylpyrrole-3-carboxylic acid synthesis method suitable for industrialization

InactiveCN110183367AEasy to operateHigh purityOrganic chemistry methodsBenzyl chloroformateCarboxylic acid

The invention discloses a (3R,4S)-1-carbobenzoxy-4-ethylpyrrole-3-carboxylic acid synthesis method suitable for industrialization. The method comprises the steps: adopting 2-pentynoate and N-methoxymethyl-N-(trimethylsilylmethyl)benzylamine as starting materials, performing a condensation cyclization reaction in a solvent under the catalysis of an acid so as to prepare an intermediate condensationproduct, adding the intermediate to chloroethyl chloroformate, performing a reaction so as to obtain another intermediate, performing an acylation reaction between the intermediate and benzyl chloroformate so as to obtain an N-protected intermediate product, performing an ester hydrolysis reaction, and performing an asymmetric reduction reaction between the hydrolyzed product and hydrogen so as to obtain (3R,4S)-1-carbobenzoxy-4-ethylpyrrole-3-carboxylic acid. The (3R,4S)-1-carbobenzoxy-4-ethylpyrrole-3-carboxylic acid with high purity and high yield can be prepared through five steps of thereactions, the problem of difficult control on the quality and yield in the prior art is solved, and sufficient raw material intermediates are provided for synthesis of upadacitinib.

Owner:南京新酶合医药科技有限公司

Method for synthesizing alpha-hydroxycarboxylic acid metallic soap by hydrolysis of alpha-halogenated carboxylic acid

ActiveCN102690184AHigh selectivityHigh yieldCarboxylic acid salt preparationSimple Organic CompoundsCarboxylic acid

The invention discloses a method for synthesizing alpha-hydroxycarboxylic acid metallic soap by hydrolysis of an alpha-halogenated carboxylic acid and belongs to the field of organic compound synthesis. The method is characterized in that a cheap and easily available alpha-halogenated carboxylic acid especially such as an alpha-chlorinated fatty acid undergoes a hydrolysis reaction in the presence of a neutral or alkalescent solid acid-binding agent and a catalyst under hydro-thermal conditions so that the corresponding alpha-hydroxycarboxylic acid metallic soap is synthesized. The method has simple and environmentally friendly processes, adopts cheap and easily available raw materials, reduces less side reactions and has a high product yield.

Owner:JIANGNAN UNIV

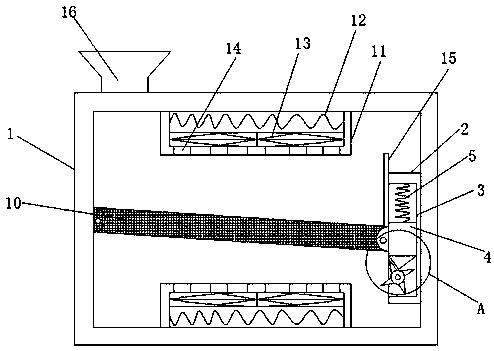

Raw material stirring device for cyclopropanecarboxylic acid synthesis

PendingCN108855380ASimple structureEasy to operateRotary stirring mixersTransportation and packagingCouplingEngineering

The invention discloses a raw material stirring device for cyclopropanecarboxylic acid synthesis. The raw material stirring device for cyclopropanecarboxylic acid synthesis comprises a stirring box. The upper part of the stirring box is connected with a screening pipe. The upper part of the screening pipe is connected with a feed hopper. The screening pipe is internally provided with a screening plate. One side of the screening pipe is connected with a material guide pipe. The stirring box is internally connected with a fixing plate. The fixing plate is provided with a grinding device. The bottom of the screening plate is vertically connected with a connection rod. One end of the connection rod is connected with a push block. The stirring box is internally and vertically provided with a guide rod. The guide rod is sleeved with the push block. The exterior of one side wall of the stirring box is fixedly provided with a stirring motor through screws. An output shaft of the stirring motoris connected with a rotating rod through a coupling. The raw material stirring device for cyclopropanecarboxylic acid synthesis is simple in structure and reasonable in design, raw materials can be screened before the cyclopropanecarboxylic acid raw materials are mixed, relatively large screened raw material particles can be automatically processed, it does not need to additionally exert power inthe process, resources are saved, and operation is easy.

Owner:兰州鸿瑄科技有限公司

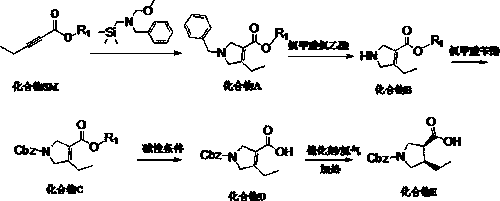

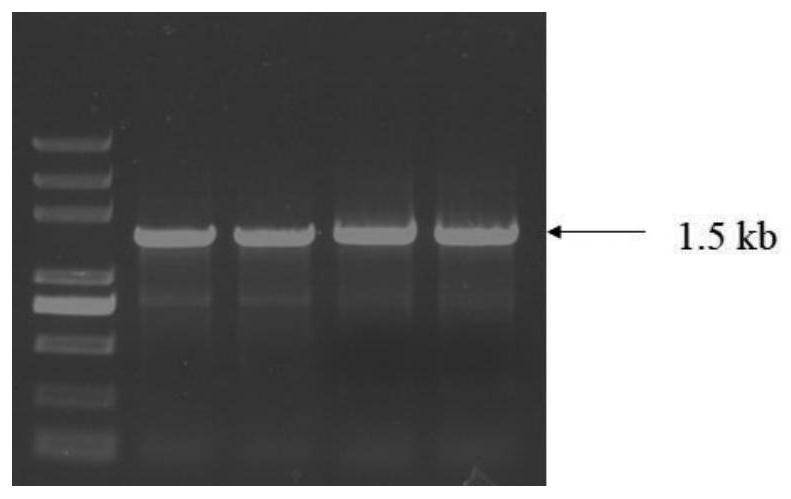

Recombinant corynebacterium glutamicum, construction method thereof and method for producing tetrahydropyrimidine by same

ActiveCN111394288AAvoid Biosecurity ConcernsReduce cumbersome stepsBacteriaMicroorganism based processesPhosphoenolpyruvate carboxylaseSerine dehydrogenase

The invention relates to recombinant corynebacterium glutamicum, a method for constructing the recombinant corynebacterium glutamicum and a method for producing tetrahydropyrimidine by using the recombinant corynebacterium glutamicum. Compared with wild corynebacterium glutamicum, the recombinant corynebacterium glutamicum has phosphoenolpyruvate carboxylase, homoserine dehydrogenase and dihydropyrimidinedicarboxylate synthetase with reduced expression level, and also has a gene expression cassette for expressing phosphoenolpyruvate carboxylase and a gene expression cassette for expressing ectA enzyme, ectB enzyme and ectC enzyme, so that tetrahydropyrimidine can be efficiently produced. The tetrahydropyrimidine produced by using the recombinant corynebacterium glutamicum has high yield, the safety of tetrahydropyrimidine products is improved, the production cost is greatly reduced, and the recombinant corynebacterium glutamicum has good market application prospect.

Owner:BEIJING BIOINNO BIOTECHNOLOGY CO LTD

A kind of method of synthesizing tertiary carbonic acid

ActiveCN105218354BImprove solubilityLow reaction pressurePreparation from carboxylic acid anhydridesChemical recyclingCarboxylic acidAlkene

The invention discloses a method for synthesizing tertiary carbonic acid. Using olefins and carbon monoxide as raw materials, in the presence of strongly acidic ionic liquid-metal carbonyl complex catalysts, catalyzed synthesis of tertiary carbonic acid products at normal or low pressure. The method disclosed by the invention has no corrosion, less catalyst loss, less discharge of three wastes, and easy separation of the tertiary carbonic acid product and the catalyst after the reaction, avoiding the defects of poor separation effect and difficult recovery and utilization of dilute sulfuric acid in the prior art.

Owner:WANHUA CHEM GRP CO LTD

Methods of removing rust from a ferrous metal-containing surface

InactiveUS20120189485A1Detergent mixture composition preparationDetergent compounding agentsLithiumPhysical chemistry

Disclosed are methods for removing rust from a ferrous metal-containing surface. These methods include contacting the surface with a composition that includes a carboxylic acid, a synthetic hectorite clay, and water.

Owner:PPG IND OHIO INC

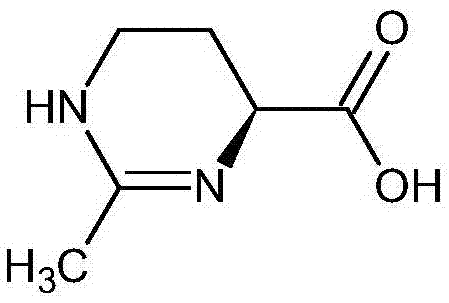

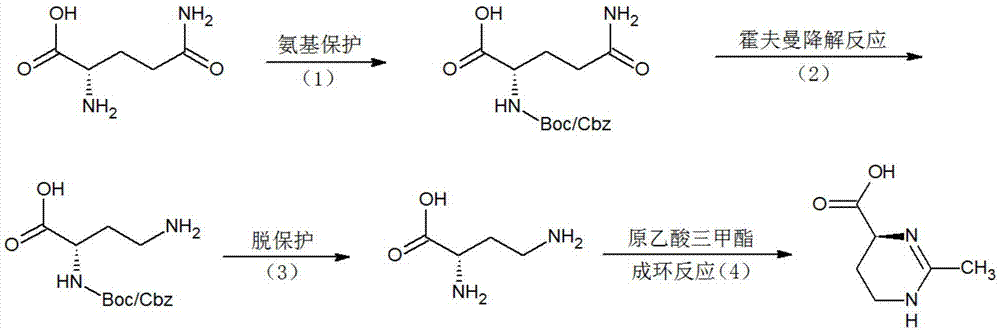

(S)-2-methyl-1,4,5,6-tetrahydromethylpyrimidine-4-carboxylic acid synthesis method

InactiveCN106916111ALow yieldThe synthesis method is simpleOrganic chemistry methodsBulk chemical productionChemical synthesisAcetic acid

The present invention relates to a (S)-2-methyl-1,4,5,6-tetrahydromethylpyrimidine-4-carboxylic acid synthesis method. According to the method, L-glutamine is used as a raw material, the alpha-amino of the L-glutamine is protected with a protection group, a decarbonylating agent is added, a Hofmann degradation reaction is performed to remove the carbonyl group attached to the remaining amino, the protection group is removed to obtain L-2,4-diaminobutyric acid, and finally the prepared L-2,4-diaminobutyric acid and trimethyl orthoacetate are subjected to a ring forming reaction to obtain the (S)-2-methyl-1,4,5,6-tetrahydromethylpyrimidine-4-carboxylic acid. Compared to the method in the prior art, the method of the present invention has the following characteristics that the chemical synthesis route is provided, the steps of the synthesis process are simple, the raw materials are easy to obtain, the product purity is high, and the method is suitable for large-scale industrial production.

Owner:上海予利生物科技股份有限公司

Raw material drying device for 7-chloro-6-fluoro-1-cyclopropyl-1,4-dihydro-4-oxo-3-quinoline carboxylic acid synthesis

PendingCN108800803AQuick drying processEvenly heatedDrying gas arrangementsDrying solid materialsQuinolineElectric machinery

The invention discloses a raw material drying device for 7-chloro-6-fluoro-1-cyclopropyl-1,4-dihydro-4-oxo-3-quinoline carboxylic acid synthesis. A drying box is included, and a fixed plate is weldedto the inner wall of one side of the drying box; the side wall of one side of the fixed plate is provided with a groove; the side wall of one side of the groove is connected with a slider in a slidingmanner; a spring connected with the side wall of the top end of the groove is installed at the top end of the slider; a filtering net is hinged to the side wall of one side of the slider; the other end of the filtering net is hinged to the inner wall of the drying box; a triangular plate is welded to the bottom end of the slider; a driving motor connected with the side wall of the groove is installed below the triangular plate; the output end of the driving motor is connected with a rotating shaft; a rotating disk is welded to the end, away from the driving motor, of the rotating shaft; and aconical plate is welded to the side wall of the rotating disk in the axis direction array direction of the rotating disk. Due to the raw material drying device for 7-chloro-6-fluoro-1-cyclopropyl-1,4-dihydro-4-oxo-3-quinoline carboxylic acid synthesis, drying treatment can be fast performed on raw materials for 7-chloro-6-fluoro-1-cyclopropyl-1,4-dihydro-4-oxo-3-quinoline carboxylic acid synthesis, drying can be performed on the two sides of the raw materials at the same time, the raw materials can be shaken in drying, the raw materials are heated uniformly, and the drying effect and efficiency are improved.

Owner:兰州鸿瑄科技有限公司

Organic liquid crystal friction modifiers with alkyl end chains and preparation method thereof

ActiveCN111454761AIncrease contactImprove lubricationOrganic compound preparationCarboxylic acid esters preparationBenzoic acidCarbon number

The invention discloses organic liquid crystal friction modifiers with alkyl end chains and a preparation method of the organic liquid crystal friction modifiers. According to the preparation method,p-hydroxybenzoic acid and hydroquinone are subjected to an esterification reaction to obtain an intermediate product A, and the intermediate product A is subjected to an esterification reaction with straight-chain carboxylic acids having different carbon chain lengths (wherein a carbon number is in a range of 5 to 21) to obtain compounds as shown in the formula (I). The series of phenyl terephthalate compounds with the alkyl end chains having different lengths are synthesized from three benzene rings connected via ester groups and long-chain n-carboxylic acid; and through the synergistic effect of the polarity of the ester groups, the oil solubility of long-chain alkyl groups, the rigidity influence of the three benzene rings of the compounds and the specific lubricating properties of liquid crystal materials of the compounds, the series of compounds have the performance suitable for being used as lubricating grease additives.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

Preparation method of lactide

PendingCN114315788AIncrease the number ofIncrease the speed of crackingOrganic chemistryPolymer scienceLactide

The invention discloses a lactide preparation method which comprises the following steps: performing dehydration oligomerization on a lactic acid monomer, a polyethylene glycol polymer and polycarboxylic acid under the action of a catalyst to obtain hyperbranched oligomeric lactic acid, and then cracking to generate lactide. According to the process disclosed by the invention, the polyethylene glycol polymer and the polycarboxylic acid are added during lactic acid oligomerization to synthesize hyperbranched oligomeric lactic acid with a random structure, the number of terminal groups is increased, the cracking speed of the oligomeric lactic acid is increased, and meanwhile, due to the addition of the polyethylene glycol polymer, the viscosity of the oligomeric lactic acid can be reduced when the viscosity is relatively high in the later stage of dehydration; and the melting point of the polylactic acid with the random structure is low, so that the cracking temperature of the polylactic acid is reduced, the carbonization rate of the polylactic acid is reduced, the contact area of the polylactic acid can be increased, and the mass transfer and heat transfer efficiency of the polylactic acid is improved.

Owner:普立思生物科技有限公司

Process And Microorganism For Synthesis Of Adipic Acid From Carboxylic Acids

A method for biosynthesis of polymer precursors, including, adipic acid, 1,6-hexanediol, 6-hydroxyhexanoic and 6-aminocaproic acids from carboxylic acids is provided. A method for biosynthesis of adipic acid from six-carbon dicarboxylic acids having α, β-enoate reductase activity by treatment with an enzyme is provided. The biocatalytic conversion of aliphatic and hydroxycarboxylic acids to corresponding aldehydes, alcohols, and amines using novel carboxylate reductases, aldehyde reductases, and aminotransferases is described. Also provided are genetically engineered microorganisms for use in the biosynthetic processes.

Owner:THE GOVERNINIG COUNCIL OF THE UNIV OF TORANTO

Preparation method of reversible covalent cross-linked reprocessable epoxy resin containing thioester bonds

ActiveCN110804162AImprove mechanical propertiesExcellent reworkabilityOrganic chemistryPlastic recyclingPolymer scienceFirming agent

The invention relates to a preparation method of reversible covalent cross-linked reprocessable epoxy resin containing thioester bonds. The preparation method comprises the following steps: firstly, synthesizing an epoxy curing agent containing a reversible covalent bond-thioester bond by utilizing acid anhydride and mercaptocarboxylic acid, then mixing the epoxy curing agent with an epoxy monomer, and curing epoxy at a specific temperature to obtain the epoxy resin capable of being reprocessed for multiple times. The epoxy curing agent is simple to synthesize, easy to operate and wide in rawmaterial source. And the synthesized epoxy curing agent can be used for various epoxy monomers. Because the dynamic covalent bond thioester bond can be subjected to dynamic exchange reaction, the cured epoxy resin not only has excellent mechanical properties, but also has excellent reprocessing properties.

Owner:西安智聚复合材料科技有限公司

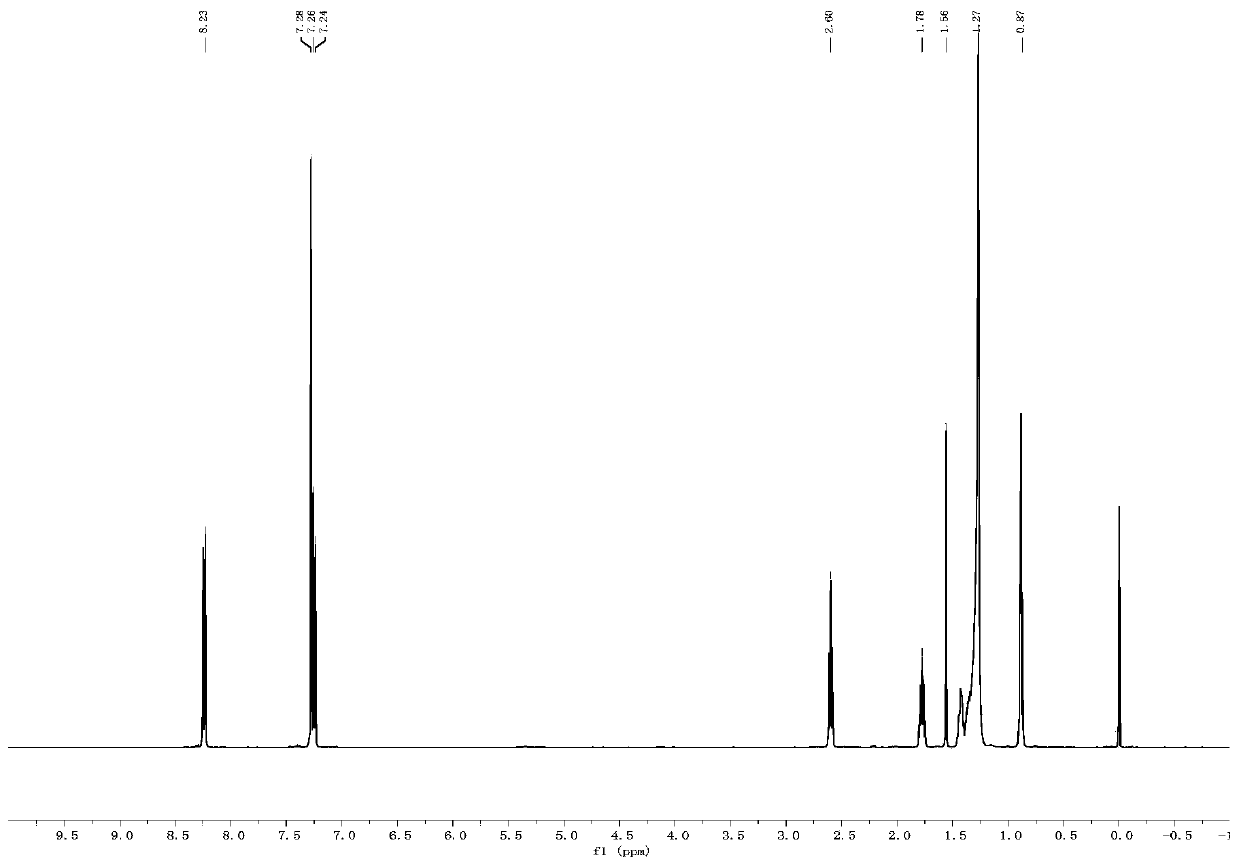

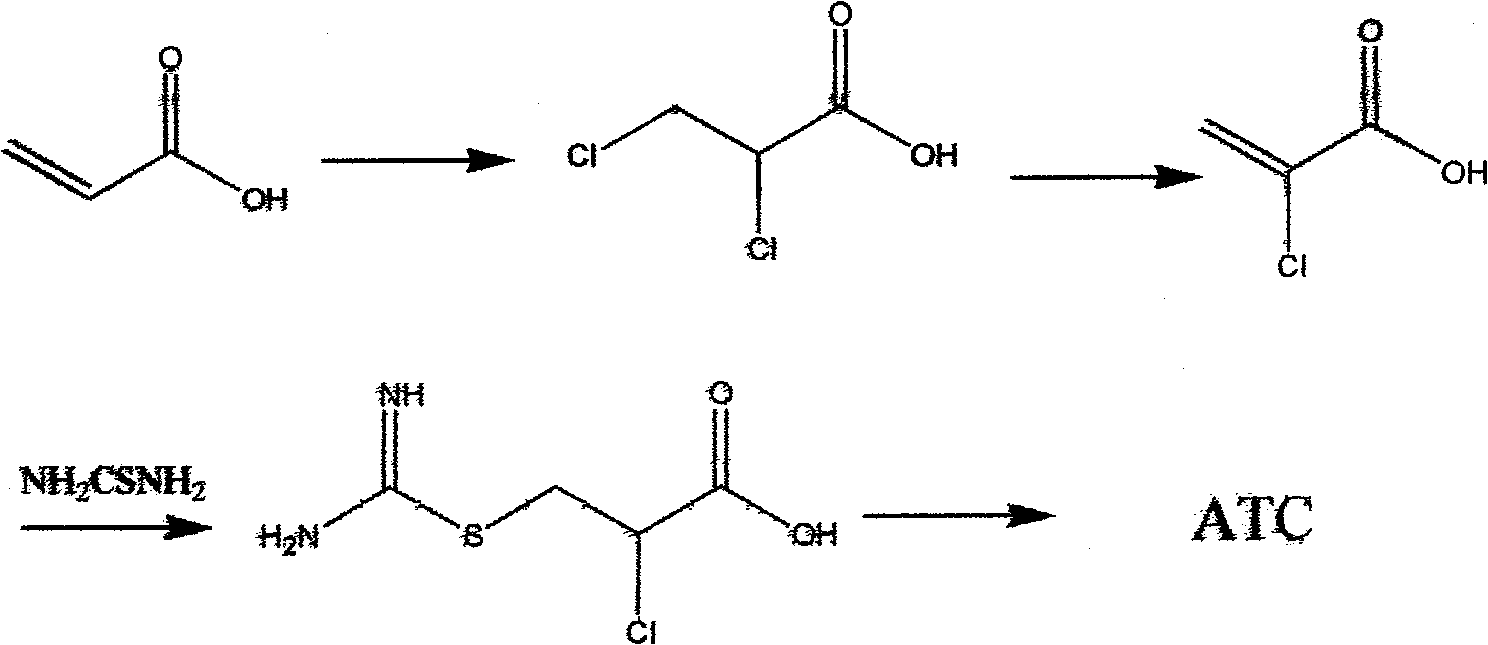

Novel method for synthesizing 2-amino-2-thiazoline-4-carboxylic acid

The invention discloses a method for preparing 2-amino-2-thiazoline-4-carboxylic acid. 3-X-lactamine hydrochloride and sodium sulfocyanate react in medium water to generate 3-X-2-thioureido monoprop, and the 3-X-2-thioureido monoprop has a ring-closure reaction to prepare the 2-amino-2-thiazoline-4-carboxylic acid. The method is simple, convenient to operate, has high yield coefficient which is more than 95 percent, and greatly enhances the quality of products.

Owner:山东祥维斯生物科技股份有限公司

Method for synthesizing raw medicine dihydroindene-1-carboxyl acid for clidabac

InactiveCN101397247ASynthesis fastEasy to synthesizeOxygen-containing compound preparationOrganic compound preparationCarboxylic acidActive ingredient

The invention relates to a synthetic method of indan-1-carboxylic acid which is a pharmaceutical raw material for clidanac. The synthetic method comprises the following steps: (1) o-bromobenzyl bromide is taken as a starting raw material and reacted with zinc powder, thereby obtaining o-bromobenzyl zinc bromide; (2) the carbon cyclization reaction is carried out on the o-bromobenzyl zinc bromide and an acrylic acid ester compound under the action of a catalyst, thereby obtaining an indan-1-carboxylic acid compound; and (3) the indan-1-carboxylic acid compound is hydrolyzed under the alkaline condition, thereby obtaining the indan-1-carboxylic acid which is the important pharmaceutical raw material for synthesizing the clidanac. The synthetic method can rapidly and simply synthesize the indan-1-carboxylic acid, thereby shortening the synthesis route of the clidanac and further reducing the production cost of the clidanac.

Owner:TIANJIN UNIV

Lycoris aurea 1-aminocyclopropane-1-carboxylic acid synthetase as well as coding gene and application thereof

The invention relates to lycoris plant lycoris aurea 1-aminocyclopropane-1-carboxylic acid synthetase as well as a coding gene and application thereof. The lycoris plant lycoris aurea 1-aminocyclopropane-1-carboxylic acid synthetase is disclosed for the first time, and has good enzymatic activity and can catalyze adenosyl methionine to synthesize the 1-aminocyclopropane-1-carboxylic acid. The invention also discloses a polynucleotide for coding the 1-aminocyclopropane-1-carboxylic acid synthetase, a vector and a host cell for expressing the 1-aminocyclopropane-1-carboxylic acid synthetase, and a method for producing the 1-aminocyclopropane-1-carboxylic acid by using a whole-cell transformation method.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

Methods of removing rust from a ferrous metal-containing surface

InactiveCN103415651ADetergent mixture composition preparationDetergent compounding agentsLithiumPhysical chemistry

Disclosed are methods for removing rust from a ferrous metal-containing surface. These methods include contacting the surface with a composition that includes a carboxylic acid, a synthetic hectorite clay, and water.

Owner:PPG IND OHIO INC

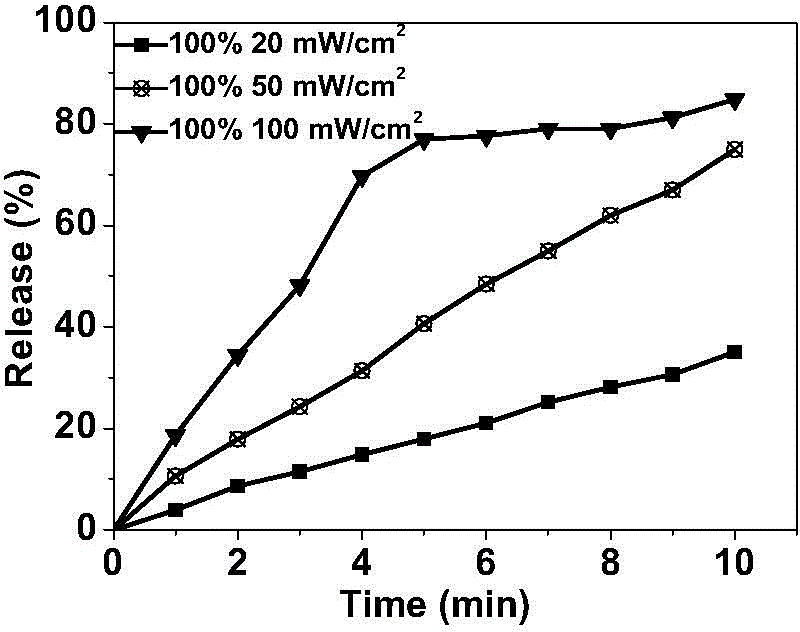

Photosensitive carboxylic acid molecule and preparation thereof, and application of photosensitive carboxylic acid molecule in drug sustained release

ActiveCN104860827ALow costThe synthesis process is simpleOrganic chemistryOrganic compound preparationCarboxylic acidFatty acid

The invention relates to a preparation method for a carboxylic acid molecule, specifically to a photosensitive carboxylic acid molecule, and a preparation method and application thereof. According to the invention, 5-hydroxyl-nitrobenzaldehyde is used as a starting material to prepare o-nitrobenzyl-containing fatty acid through simple unit synthesis; light-degradable-unit-containing carboxylic acid is prepared through simple standard organic unit reactions like etherification, reduction and esterification; meanwhile, the method in the invention uses cheap raw materials and has simple synthetic process, so the photosensitive carboxylic acid molecule with different structures can be prepared with low cost; and an obtained target product can reach a level of hectogram and realize the purity of more than 98% through simple crystallization. In addition, the invention also discloses the application of the photosensitive carboxylic acid molecule in drug sustained release; meanwhile, drug-loading and photocontrolled release capacities of photosensitive phospholipid vesicles synthesized from light-degradable carboxylic acid prove that the photosensitive carboxylic acid molecule has good photoresponse performance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for synthesis of keto acids or amino acids by hydration of acetylene compound

InactiveUS8153839B2Easy to synthesizeWithout usingOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolvent moleculeHalogen

An object of the present invention is to provide a method for synthesis of keto acids by hydration of an acetylene compound (acetylene-carboxylic acids) under mild conditions free from harmful mercury catalysts and a method for synthesis of amino acids from acetylene-carboxylic acids in a single container (one-pot or tandem synthesis). In one embodiment of the method according to the present invention for synthesis of keto acids, acetylene-carboxylic acids is hydrated in the presence of a metal salt represented by General Formula (1),where M1 represents an element in Group VIII, IX, or X of the periodic table, and X1, X2, or X3 ligand represents halogen, H2O, or a solvent molecule, and k represents a valence of a cation species, and Y represents an anion species, and L represents a valence of the anion species, and each of K and L independently represents 1 or 2, and k×m=L×n.

Owner:JAPAN SCI & TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com