Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

138results about How to "Improve lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanometer fuel oil addition agent

ActiveCN1737090AReduce equipment wear and tearImprove lubricationLiquid carbonaceous fuelsFuel oilEngineering

Disclosed is a nanometer fuel oil addition agent, wherein the constituents comprises (by weight percent): rare earth powder 0.1-10%, fuel synergistic agent 1-10%, dispersing agent 1-20%, oleinic acid 1-10%, castor oil 1-20%, and balancing white oil.

Owner:上海集能化工有限公司

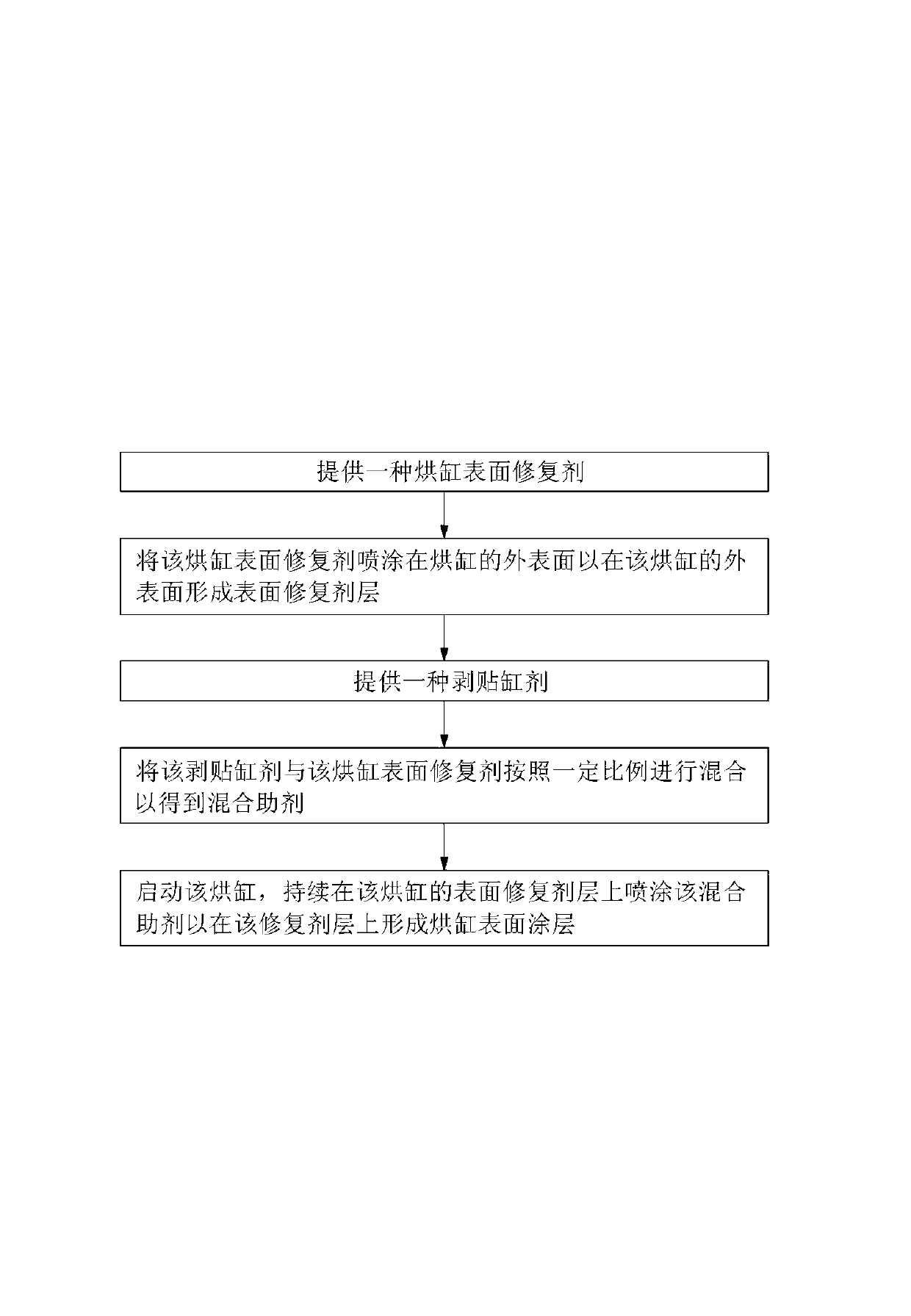

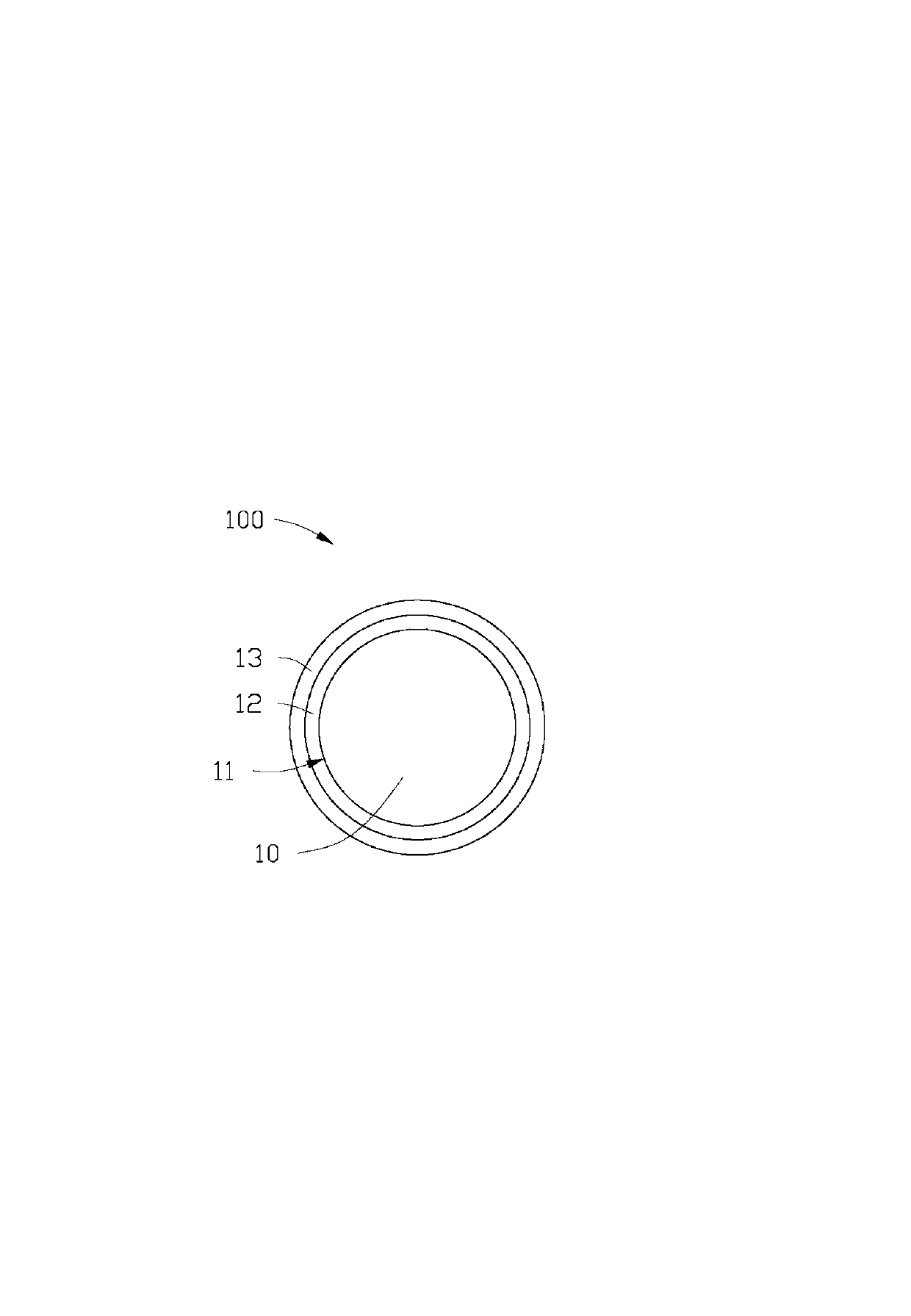

Drying cylinder surface repairing agent, drying cylinder surface repairing method and drying cylinder

ActiveCN102899955ASmooth surface structureGood adhesionDryer sectionLubricant compositionPolymerMetal

The invention relates to a drying cylinder surface repairing agent. The drying cylinder surface repairing agent comprises, by mass, from 2% to 5% of metallic compound solid lubricants, from 5% to 15% of cationic polymers and from 80% to 90% of water. The drying cylinder surface repairing agent contains the metallic compound solid lubricants, the metallic compound solid lubricants have the property that the metallic compound solid lubricants in heat automatically approach metal surfaces, accordingly, in a paper drying process after the drying cylinder surface repairing agent forms a coating on the surface of a drying cylinder, the metallic compound solid lubricants in heat can be effectively attached to the surface of the drying cylinder, and defects on the surface of the drying cylinder can be effectively filled and repaired. The invention further relates to a drying cylinder surface repairing method and a repaired drying cylinder.

Owner:海南金红叶纸业有限公司 +1

Biodegradable polyester composition

Owner:KINGFA SCI & TECH CO LTD +2

Special lubricating oil of bearing bush of supporting roller of rotary kiln and manufacturing method thereof

The invention discloses special lubricating oil of a bearing bush of a supporting roller of a rotary kiln and a manufacturing method thereof. The special lubricating oil contains the following components according to the content by mass percent: 49 to 69 percent of liquid paraffin chlorination and condensation synthetic oil, 15 to 35 percent of poly-alpha-alkene synthetic oil, 0.5 to 1.5 percent of tackifier, 2 to 4 percent of nano colloid molybdenum disulphide powder, 3.5 to 5.5 percent of organic molybdenum complex additive, 2.5 to 4.5 percent of borate complex additive, 1 to 3 percent of additive T406, 0.4 to 0.6 percent of antioxidant T203, 0.7 to 0.9 percent of antioxidant T531 and 0.6 to 0.8 percent of antioxidant T512. The invention has the favorable performances of extreme-pressure resistance, abrasion resistance, high-temperature resistance, water sprinkling resistance and oxidation resistance, can fully act as the functions of repairing the wire drawing of the bearing bush, decreasing the abrasion and lowering the temperature of the bearing bush, prolongs the use period of the bearing bush of the supporting roller and realizes the aims of energy saving and consumption reduction.

Owner:洛阳正本润滑材料有限公司 +1

Reinforcing ring for reversing device and preparation method thereof

The invention provides a reinforcing ring for a reversing device and belongs to the technical field of reversing devices. The reinforcing ring solves the technical problems that an existing reversing device is low in strength and poor in abrasion resistance. According to the technical scheme, the reinforcing ring for the reversing device comprises an annular body which is prepared from, by weight, 55-75 parts of epoxy resin, 5-15 parts of non-alkali glass fibers, 5-10 parts of aramid fibers, 15-30 parts of a curing agent, 3-8 parts of a toughening agent, 5-10 parts of a heat-resistant modifying agent and 4-7 parts of a lubricating agent. The reinforcing ring for the reversing device has the advantages that the glass fibers and the aramid fibers are added, so that the mechanical strength of the reinforcing ring is improved; meanwhile, the toughening agent is added, so that the toughness of the reinforcing ring is improved to a certain extent, and the reinforcing ring is not prone to breakage; the lubricating agent is added, so that the abrasion resistance of the reinforcing ring is improved, the reinforcing ring is not prone to abrasion, the integrality of the reinforcing ring is guaranteed to a certain extent; the heat-resistant modifying agent is added, so that the heat resistance of the reinforcing ring is improved, and the reinforcing ring can work in a high-temperature environment for a long time.

Owner:HUARUI ELECTRICAL APPLIANCE

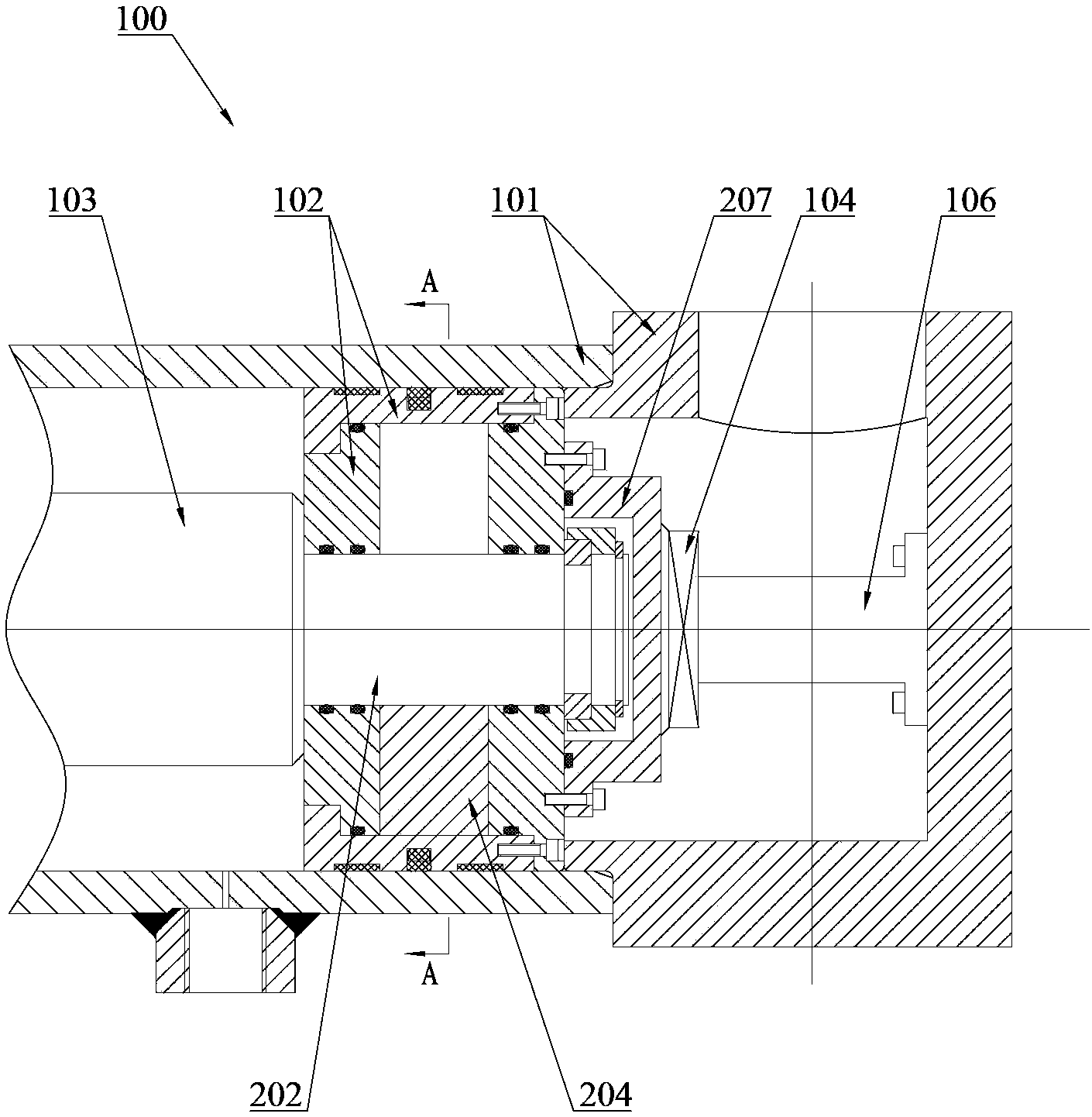

Concrete pumping device and pumping oil cylinder

ActiveCN103527548AImprove lubricationAvoid partial wearFluid-pressure actuator componentsPiston rodConcrete pump

The invention discloses a concrete pumping device and a pumping oil cylinder. The pumping oil cylinder can be used in the concrete pumping device to drive a concrete piston. The pumping oil cylinder comprises a main oil cylinder body and a rotating oil cylinder body. The main oil cylinder body comprises a first cylinder barrel, a piston and a piston rod. The rotating oil cylinder body comprises a second cylinder barrel, a rotating shaft, a first blade and a first partition plate, wherein the rotating shaft is arranged on the second cylinder barrel, the axis of the rotating shaft is overlapped with the axis of the second cylinder barrel, one end of the first blade is fixedly connected with the rotating shaft, the other end of the first blade is connected with the second cylinder barrel in a sealed mode, one end of the first partition plate is fixedly connected with the second cylinder barrel, the other end of the first partition plate is connected with the rotating shaft in a sealed mode, and a first oil opening and a second oil opening are formed in the second cylinder barrel and are formed in the two sides of the first partition plate respectively. Part of parts of the rotating oil cylinder body are selectively connected with part of parts of the main oil cylinder body, and therefore the rotating shaft of the rotating oil cylinder body can selectively drive the piston rod of the main oil cylinder body. The piston rod in the pumping oil cylinder can conduct independent linear reciprocation and rotation.

Owner:娄底市中兴液压件有限公司

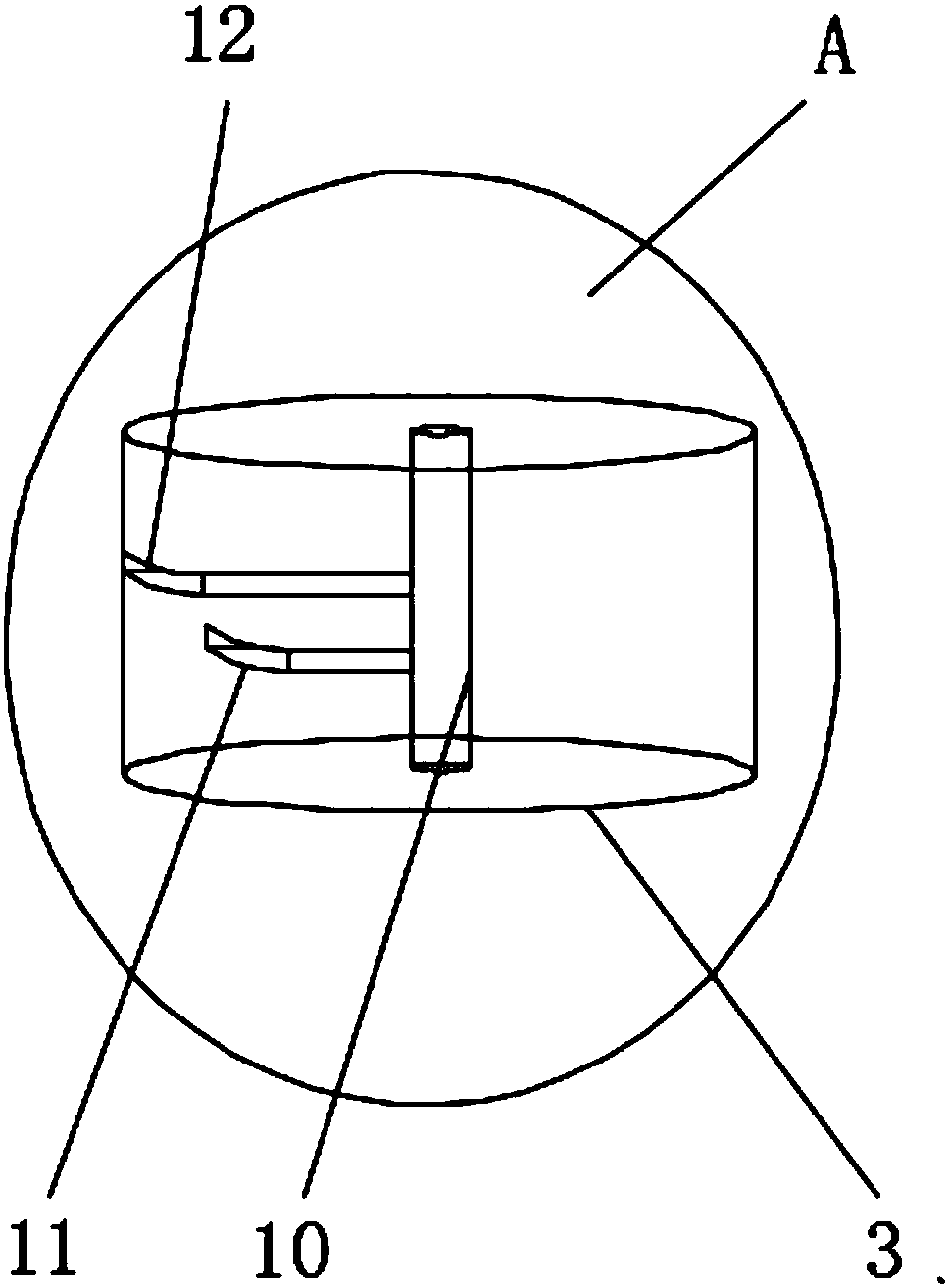

Scroll compressor

InactiveCN103089620AImprove lubricationSolve the burning problemRotary piston pumpsRotary piston liquid enginesEngineeringLubrication

The invention discloses a scroll compressor, relating to the technical field of manufacturing of fluid machinery. The scroll compressor comprises a movable scroll plate, a static scroll plate and bearings installed in a bearing carrier on the back surface of the movable scroll plate, wherein the static scroll and the movable scroll mesh with each other to form a variable-volume compression chamber. The invention is characterized in that at least two groups of through holes are drilled from the inner end of a slip ring groove at the back end surface of the movable scroll plate to the inner cavity of the bearing carrier, so that lubricating oil outside the movable scroll plate can smoothly enter the inner cavity of the bearing carrier of the movable scroll plate. Compared with the prior art, the invention can enable the lubricating oil outside the bearing carrier of the movable scroll plate to enter the inner cavity of the bearing carrier through the drilled channels, so that the bearings installed in the bearing carrier can be sufficiently cooled and lubricated, thereby greatly reducing the phenomenon of bearing burnout caused by bearing overheating due to defective lubrication or oil shortage of the bearings.

Owner:LIUZHOU YIZHOU AUTOMOBILE AIR CONDITIONER

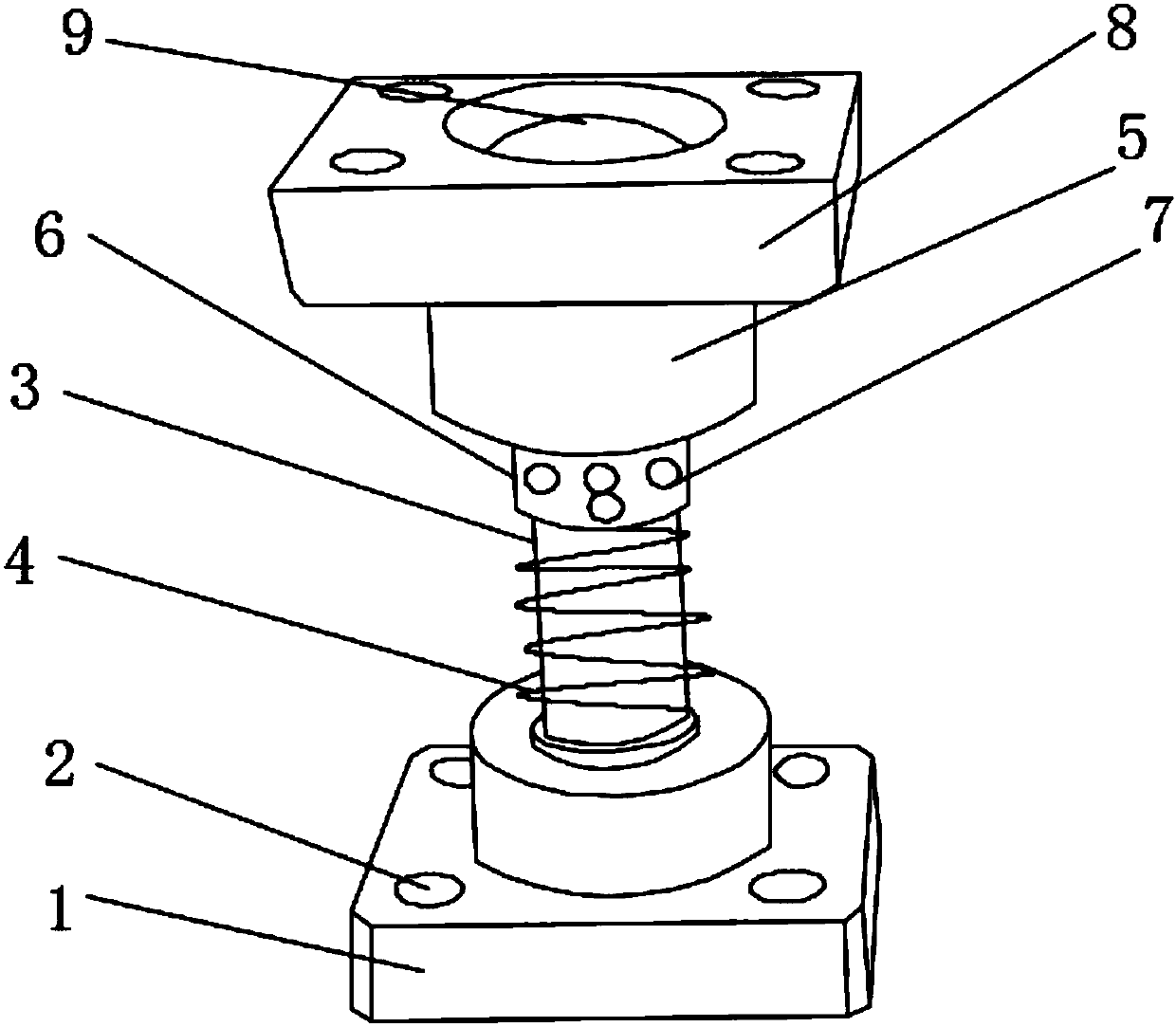

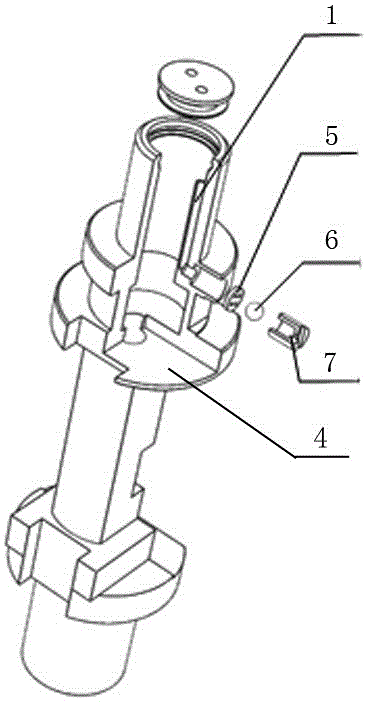

Self-lubricating type stamping mold guide column special for punching machine

InactiveCN107755543AReduce the number of manual oilingReduce difficultyShaping toolsPunch pressOil separation

The invention relates to the field of mold guide columns, in particular to a self-lubricating type stamping mold guide column special for a punching machine. The stamping mold guide column comprises alower shaft shoulder and an outer guide sleeve; mounting holes are formed in the inner side of the lower shaft shoulder, and a column body is movably installed on the outer side of the upper end of the lower shaft shoulder; a spring is arranged on the outer surface of the column body; the outer side of the lower end of the outer guide sleeve is fixedly provided with a steel ball guide sleeve, andsteel balls are movably installed on the inner surface of the steel ball guide sleeve; and an upper shaft shoulder is fixedly installed on the outer side of the upper end of the outer guide sleeve. According to self-lubricating type stamping mold guide column special for a punching machine, first oil separation outlets, second oil separation outlets, an oil guide pipe and a guide sleeve inner wall are arranged, the guide sleeve inner wall is not attached to the outer guide sleeve so that a cavity is formed, oil can be stored, oil can be discharged at the same time through the oil separation outlets which are alternately installed in a staggered mode, and therefore the lubricating effect is improved, multiple oil injection grooves are replaced by the single oil guide pipe, production costof the column body is reduced, and better application prospects are brought.

Owner:WUXI BOJIN PRECISION MACHINERY MFG

Gap filler

The invention discloses a gap filler which comprises the following components in parts by weight: 30-70 parts of quartz sand, 20-30 parts of Portland cement, 3-10 parts of antioxidant, 1-3 parts of limestone, 1-3 parts of organosilicon leveling agent, 1-2 parts of mold preventive and 5-10 parts of inorganic aluminum salt waterproofing agent. The gap filler disclosed by the invention has the advantages of favorable water resistance, mold resistance and oxidation resistance, is easy and safe for construction, and thus, is a favorable gap filler for spreading and attaching ceramic tiles.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

Method for realizing conical roller bearing low friction and structure thereof

InactiveCN101158371AReduce the number of touch pointsImprove contact conditionsRoller bearingsShaftsRetaining ringEngineering

The invention discloses a method and a structure of a taper roller bearing low friction. The invention causes the angle between a large retaining ring of the taper roller bearing and a raceway generatrix more than 90 DEG and reduces the ball diameter of the sphere at one end of the taper roller, meanwhile, the invention implements the object that the contact between the taper roller sphere and the large retaining ring is changed from crossed multi-point contact into slippery one-point contact; meanwhile, the invention presents the angle range is 90 DEG-93 DEG; furthermore, the ball diameter complies with the specific requirement of 40%-80% of the stipulated value of the existing drawing of the products. The invention is beneficial for reducing the friction, reducing the abrasion between the large retaining ring and the sphere and implementing the high-speed heavy loading of the taper roller bearing.

Owner:张荣发

Latex abrasive base paper and preparation method and application thereof

InactiveCN107034720ALightweightWith wear resistanceInorganic fibres/flakesWater-repelling agents additionAlkali freePolyacrylamide

The invention provides latex abrasive base paper, which is prepared from the following raw materials in parts by weight: 30-50 parts of cornstalk fiber, 100 parts of high-density cotton linter pulp, 5-12 parts of polypropylene fiber, 20-40 parts of alkali-free glass fiber chopped strands and 3-8 parts of a ceramic fiber; the base paper is prepared from the following raw materials in parts by weight: 0.1-4 parts of amphoteric polyacrylamide, 0.2-0.8 part of modified starch light calcium carbonate, 0-0.2 part of polyoxyethylene with the molecular weight of 2500000 to 3000000, 0-0.2 part of an antifoaming agent and 5-10 parts of latex. The latex abrasive base paper has the characteristics of being good in abrasive resistance, good in flexibility and high in tensile strength.

Owner:杭州特种纸业有限公司

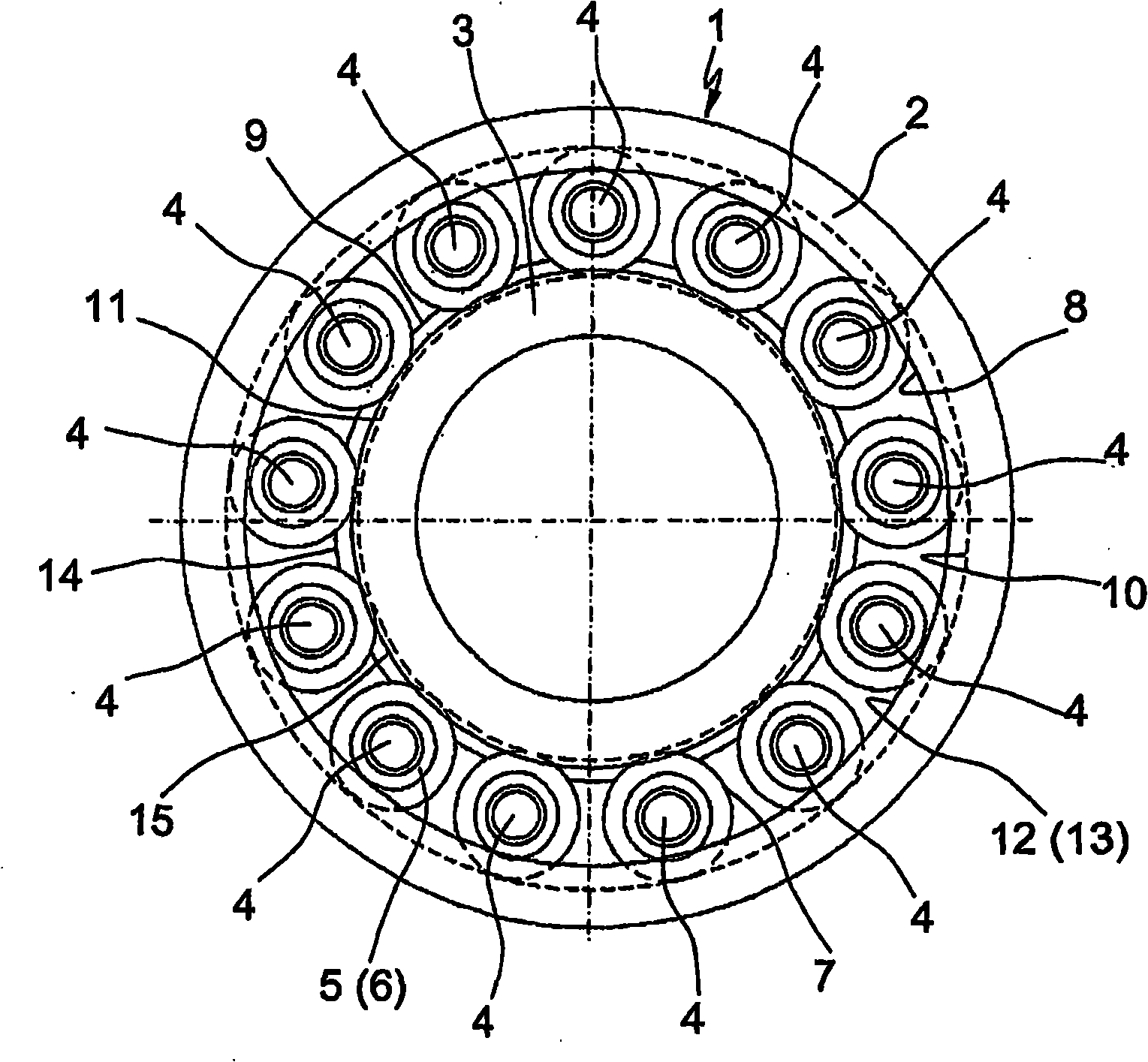

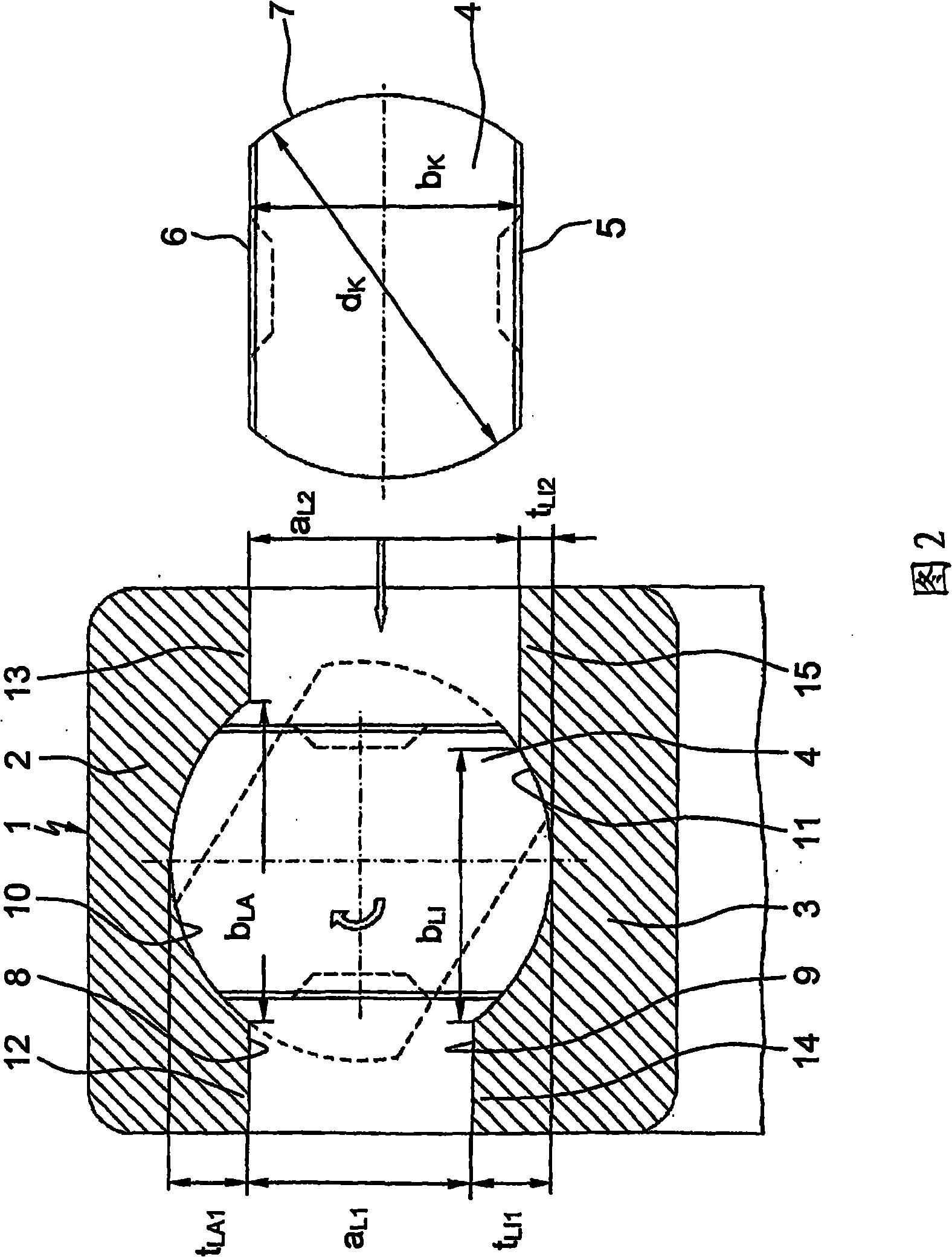

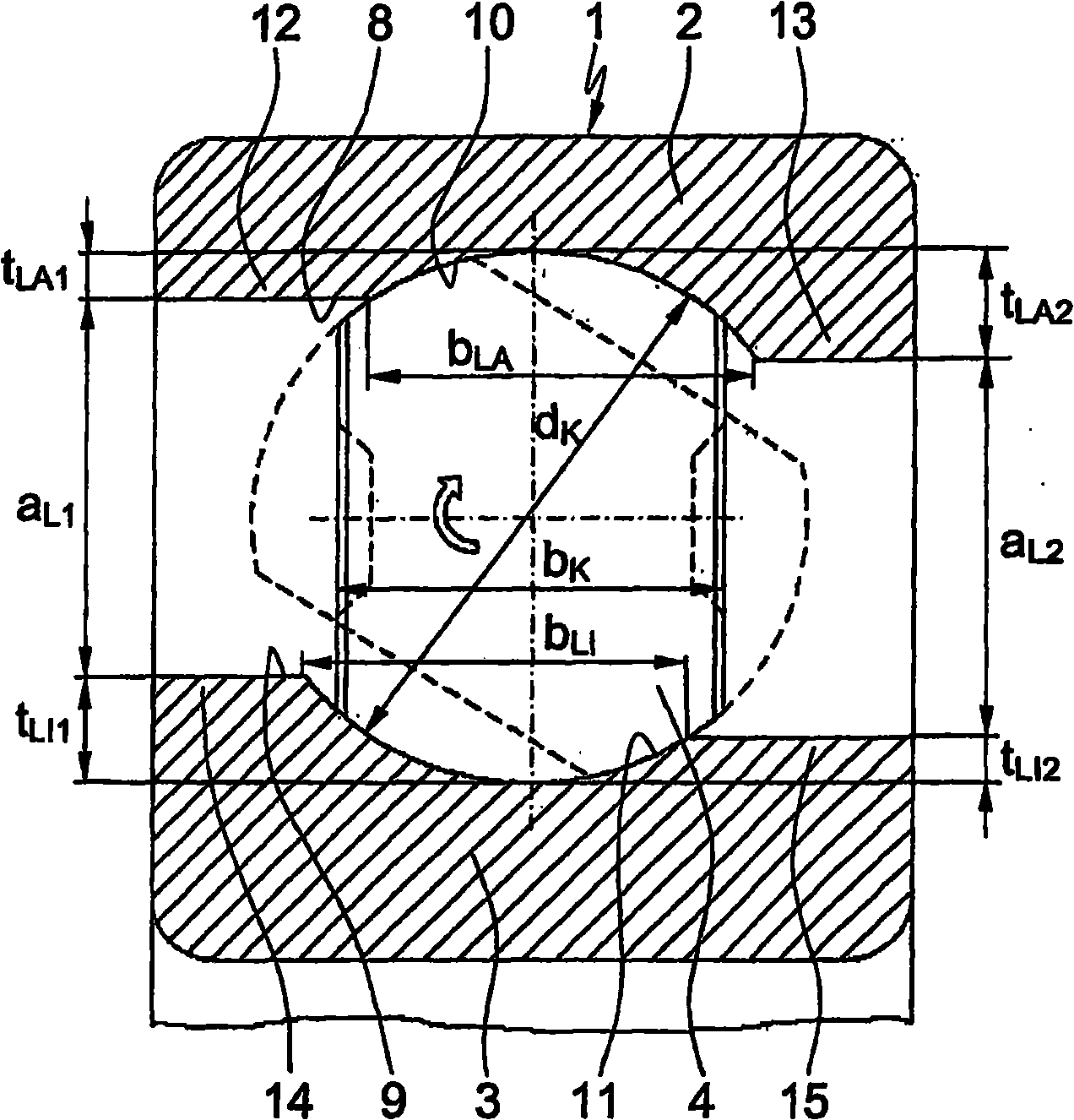

Radial rolling bearing, in particular single-row spherical-roller bearing

InactiveCN101346551AEasy to assembleLower the altitudeRoller bearingsShaftsRolling-element bearingEngineering

The invention relates to a radial rolling bearing, in particular single-row spherical-roller bearing, which is composed substantially of an outer bearing ring (2) and an inner bearing ring (3) and of a plurality of spherical rollers (4), which spherical rollers (4) are arranged between said bearing rings (2,3), which spherical rollers (4) have in each case two side faces (5,6) which are flattened symmetrically from a spherical basic shape and are arranged parallel to one another, and which spherical rollers (4) are retained with uniform spacing to one another in the peripheral direction by means of a bearing cage. Here, the spherical rollers (4) have a width (bk) between their side faces (5,6) of approximately 70% of the diameter (dk) of their spherical basic shape, and roll with their running faces (7) in two groove-shaped raceways (10,11) which are formed in the inner side (8) of the outer bearing ring (2) and in the outer side (9) of the inner bearing ring (3). According to the invention, at least one of the axial rims (12, 13, 14, 15) which delimit the groove-shaped raceways (10,11) in the bearing rings (2,3) is designed to be reduced in radial height such that the radial bearing (1) can, by means of the increased spacing (aL2) of said rim (12, 13, 14, 15) to the radially opposite rim (12, 13, 14, 15), be equipped with an increased number of spherical rollers (4) in an axial assembly process.

Owner:SCHAEFFLER KG

Main piston rod, air control valve and lubricating method for slide valve pair

ActiveCN105972296AImprove lubricationOperating means/releasing devices for valvesEngine lubricationSpool valveControl valves

The invention discloses a main piston rod, an air control valve and a lubricating method for a slide valve pair. Compared with the prior art, a balance valve and a balance pipe are arranged on a main piston rod body, the upper end of the balance pipe is located above the lubricating oil liquid level, and the lower end of the balance pipe is communicated with a slide valve chamber through the balance valve. Accordingly, lubricating oil stored in a main piston can be delivered to all lubricating points, in the low pressure state or zero pressure state, caused by emergency braking or long-time vehicle stopping or air braking value storing and transporting after a test is completed, of the slide valve chamber, the pressure in an oil storage cavity is discharged in a delayed mode to achieve balance with that in the slide valve chamber, therefore, the problem that a large amount of the lubricating oil is drained through the lubricating points to cause the stored oil to be exhausted in a short time due to the fact that the pressure in the oil storage cavity is kept high and the pressure in the slide valve chamber is low or zero, and particularly on the condition that the plane of the slide valve pair is damaged is avoided, and then long-time continuous lubricating is achieved.

Owner:成都海瑞斯轨道交通设备有限公司

Lubricating compensation compressor

InactiveCN104806479AImprove compression efficiencyReduce friction damagePositive displacement pump componentsPositive-displacement liquid enginesFuel tankEngineering

The invention provides a lubricating compensation compressor which comprises a plurality of pistons, a plurality of compression cylinders, an oil storage tank, an oil outlet valve, a plurality of oil charge valves, a plurality of oil supply pipes and a control module. A resistance sensor is mounted on each piston and used for detecting the movement resistance of the pistons, a gas pressure sensor is mounted in each compression cylinder and used for detecting gas pressure values, the control module is respectively connected with the pistons, the gas pressure sensors, the resistance sensors, the oil outlet valves and the oil charge valves, and operation of the oil outlet valves and the oil charge valves is controlled according to detection values of the gas pressure sensors and the resistance sensors, so that oil is applied to the pistons. By detecting the movement resistance of the pistons and the pressure intensity of an environment with the pistons, friction resistance is automatically judged, the oil outlet valves and the oil charge valves are controlled to automatically apply the oil according to the friction resistance, and efficiency and accuracy are high.

Owner:安徽寅时压缩机制造有限公司

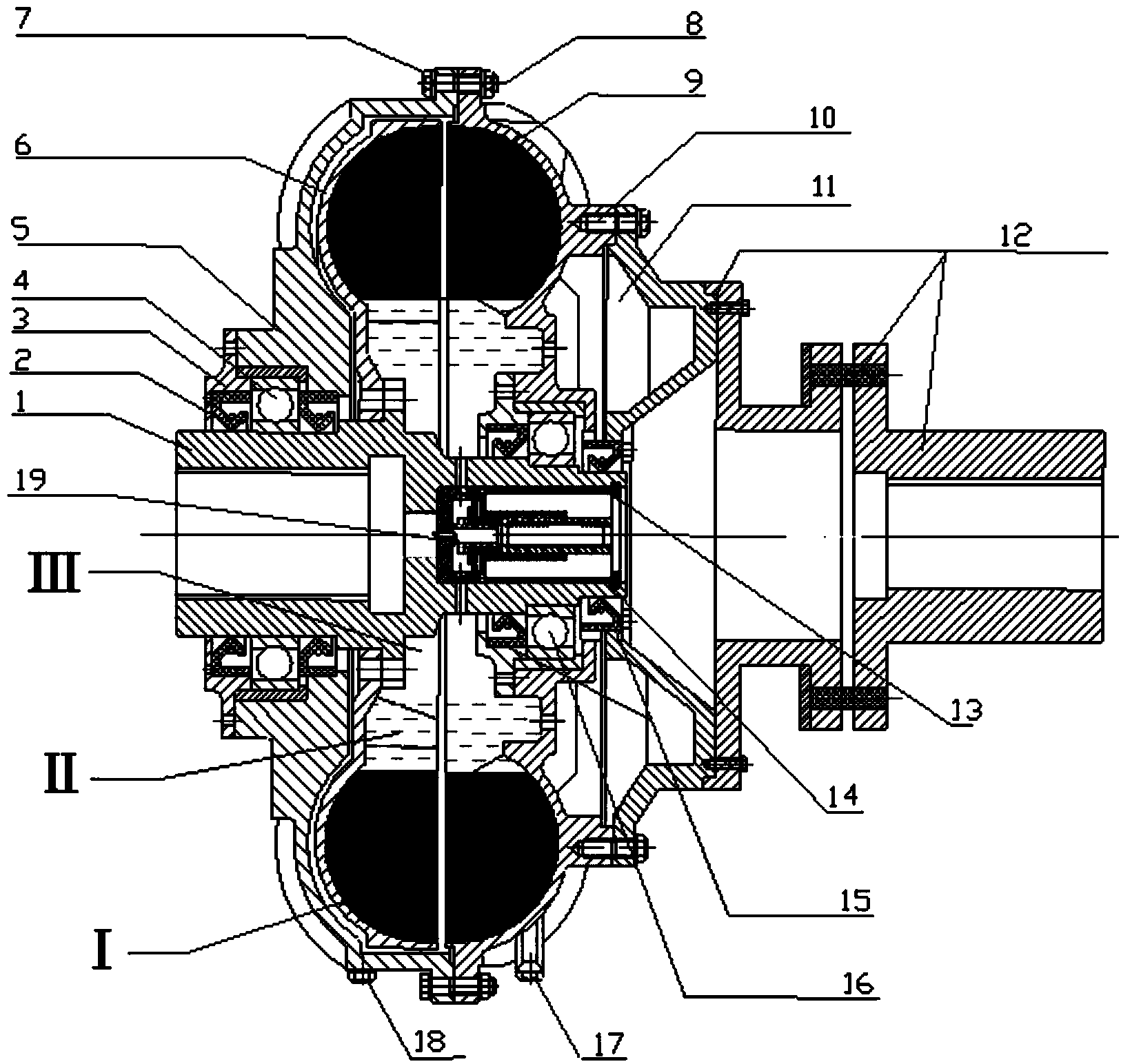

Aqueous medium coupling and internal pressure release method thereof

ActiveCN103867682AAvoid Unnatural ExplosionsImprove securityEqualizing valvesSafety valvesInternal pressurePressure rise

The invention provides an aqueous medium coupling and an internal pressure release method thereof. The aqueous medium coupling comprises an input coupling assembly arranged at the input end and connected with a motor. A rotary shell is connected with a pump wheel so that a turbine can be arranged in the rotary shell to form an annular sealed chamber between the rotary shell and the pump wheel. The coupling also comprises a hollow turbine shaft, and aqueous media are used in a coupling cavity which is a space formed by the pump wheel and the inside of the rotary shell. The coupling is characterized in that the turbine shaft is hollow, an internal pressure release valve is arranged in the hollow portion of the turbine shaft, when the coupling is overloaded and heated, water is heated and vaporized, and when pressure rises and exceeds a preset value, the internal pressure release valve automatically releases gas or steam to prevent the gas pressure from further rising. The aqueous medium coupling and the internal pressure release method are particularly suitable for scraper conveyers, belt conveyers, reverse loaders, coal ploughs, crushing machines and the like with high flame-proof and anti-explosion requirements for couplings in mine enterprises and the like.

Owner:SHANGHAI TIANJIAO ELECTROMECHANICAL SCI & TECH

Method for producing products of tubular meta casing body

ActiveCN1562559AGood physical propertiesExtended service lifeOther manufacturing equipments/toolsBiomedical engineeringMachining

Owner:CHANGZHOU RANTO METALWORK

Self-lubricating composite material layer, preparation method and component with self-lubricating function

ActiveCN106191619AImprove wear resistanceImprove antioxidant capacityMolten spray coatingMachines/enginesMo elementInlet valve

The invention discloses a self-lubricating composite material layer, a preparation method and a component with a self-lubricating function. The self-lubricating composite material layer is prepared from, by mass, 5-20% of graphite powder, 5%-20% of MoS2, 3%-10% of W powder, 1%-5% of Ti powder, 40%-60% of Ni powder and 10%-15% of Cr powder. In the laser cladding process of the particle mixture, on the one hand, part of graphite reacts with W, Cr and Ti so that new phase carbide can be formed, and besides, through solution strengthening of the Mo element, the strength of a coating is improved; on the other hand, MoS2 and chrome generate sulfide of a high-temperature solid lubricating agent, and excellent lubricating performance is achieved at high temperature; and in addition, the residual simple substance graphite not involved in the reaction serves as an excellent room temperature solid lubricating agent. Thus, an intake valve has excellent abrasion resistance and oxidation resistance and further has excellent lubricating function at both high temperature and low temperature, and the lubricating condition of the intake valve is greatly improved.

Owner:WEICHAI POWER CO LTD

Qualitative filtration paper, preparation method and applications thereof

InactiveCN107190556AGood filtration and absorption performanceHigh strengthDefoamers additionPaper coatingFiltrationPolyacrylamide

The present invention provides qualitative filtration paper, which comprises, by weight, 30-50 parts of corn straw fiber, 5-12 parts of polypropylene fiber, and 30-50 parts of high density cotton linter pulp, wherein 0.05-2 parts of amphoteric polyacrylamide, 0.2-0.8 part of modified starch light calcium carbonate, 0.05-3 parts of polyoxyethylene having a molecular weight of 2500000-3000000, and 0-0.2 part of a defoamer are used during the preparation, and an impregnant is a modified phenol formaldehyde resin. The qualitative filtration paper of the present invention has advantages of good filtration absorption performance, long service life, good water resistance, and high compressive strength.

Owner:杭州特种纸业有限公司

Scuffing detection

ActiveCN102027219AReduce loadStable temperatureElectrical controlInternal combustion piston enginesEngineeringCountermeasure

A method for detection of pre-scuffing events in a large multicylinder two-stroke diesel engine by recognizing the characteristic temperature fluctuations of pre-scuffing events. The temperature fluctuations are characterized by the time span between their peaks and the magnitude of the fluctuations. Automatic countermeasures may be initiated after detection of the pre-scuffing event. The countermeasures may automatically be ended.

Owner:曼能解决方案(曼能解决方案德国股份公司)分公司

Gear drive with integrated torque limiting coupling

InactiveUS7018296B2Improve lubricationUniform and constant friction behaviourGearboxesSlip couplingBending momentGear drive

A gear drive has a drive housing (1, 2) with a driveshaft (3) exiting the drive housing (1, 2) through a bore (10). The driveshaft 13 is rotatably supported in the drive housing (1, 2) around an axis of rotation X—X. A connecting shaft (7) is arranged inside the drive housing (1, 2). The connecting shaft (7) is connected in a rotationally fast way to a drive gear (35). A torque limiting coupling (4) is arranged inside the drive housing (1, 2). The input end of the torque limiting coupling (4) is connected to the driveshaft (3). The output end of the torque limiting coupling (4) is connected to the connecting shaft (7). The driveshaft (3) and the connecting shaft (7) are supported relative to one another by a radial bearing (30). The gear drive ensures that the driveshaft (3) and the connecting shaft (7) can more easily accommodate bending moments and transverse forces.

Owner:GKN WALTERSCHEID GETRIEBE

Metal self-lubrication piston ring

The invention belongs to the field of fluid motive sealing and particularly relates to a metal self-lubrication piston ring. A plurality of arc grooves are evenly formed in the front sealing face and the back sealing face of a piston ring body respectively, and accordingly a thermal fluid dynamic force wedge effect is generated, the sealing performance of the piston ring is improved, sealing face lubricating performance is improved, liquid flows in a circulating mode along with the arc grooves, and radiating performance is good. In addition, the piston body is made of CuSn95C5 materials, the elasticity, the fatigue resistance, the abrasive resistance, the machinability and the self-lubricating anti-attrition performance of the piston ring body are greatly improved.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

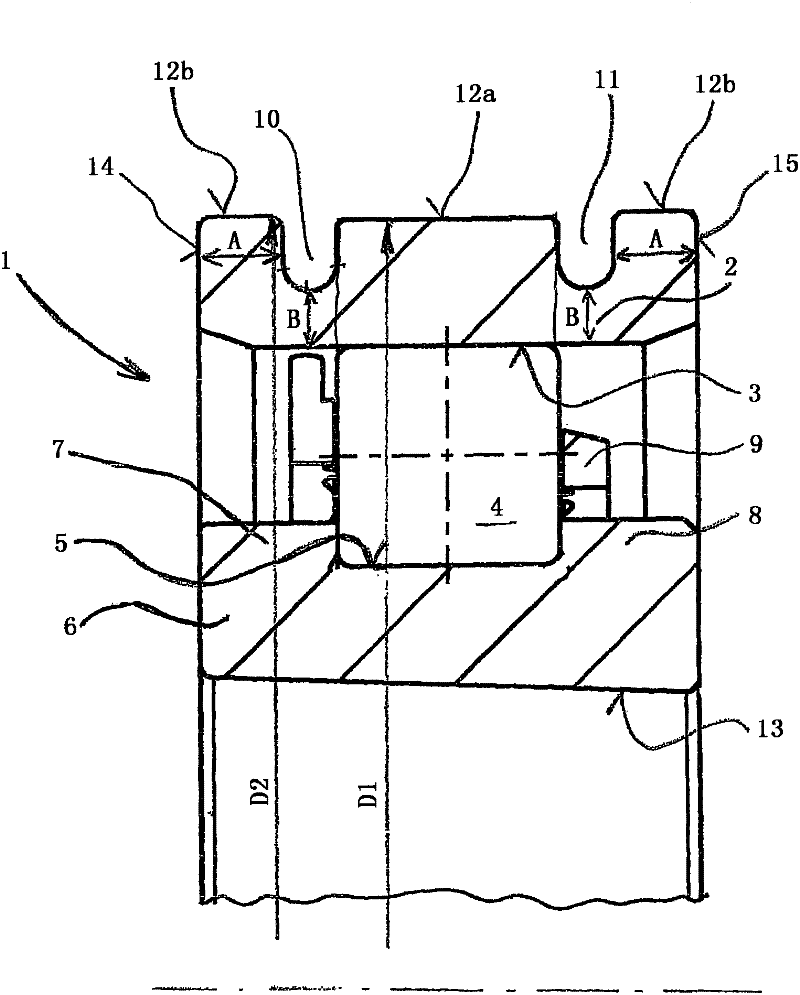

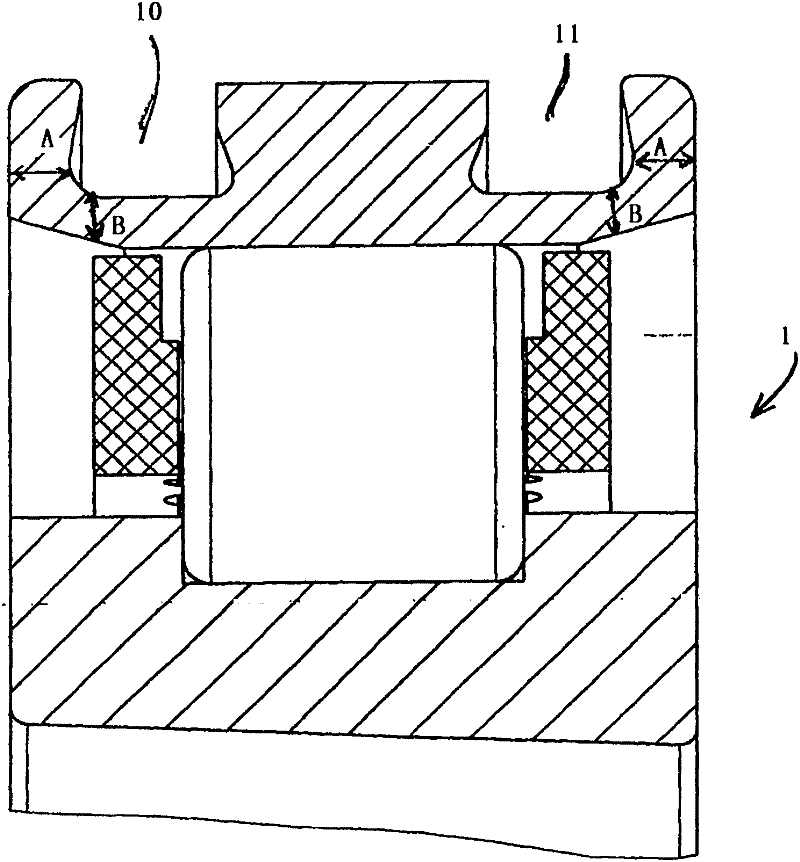

Rolling bearing having optimized outer race

ActiveCN102239339ASimple and more reliable hardeningRapid coolingRoller bearingsShaftsRolling-element bearingEngineering

The invention relates to a rolling bearing (1), comprising rolling elements (4) and an outer race (2), wherein an outer shell (12a, 12b) of the outer race (2) comprises two circumferential grooves (10, 11) axially spaced at least by the amount of the axial extent of the rolling elements (4), and wherein a first part of the outer shell (12b) axially between the two grooves (10, 11) is radially retracted relative to a second part of the outer shell (12b) axially outside of the grooves (10, 11), and wherein the outer race comprises a substantially constant thickness in the area of the first part of the outer shell (12a). In order to provide a simple rolling bearing that is inexpensive to produce and fits in a standard installation space, the invention proposes that the ratio for each groove between a radial wall thickness (B) of said groove and an axial wall thickness (A) of said groove is in the range from 0.5 to 1.5, wherein the radial wall thickness (B) corresponds to the smallest radial wall thickness of the outer race, and wherein the axial wall thickness (A) corresponds to the smallest axial distance of the groove from an adjacent end face (14, 15) of the outer race.

Owner:SCHAEFFLER TECH AG & CO KG

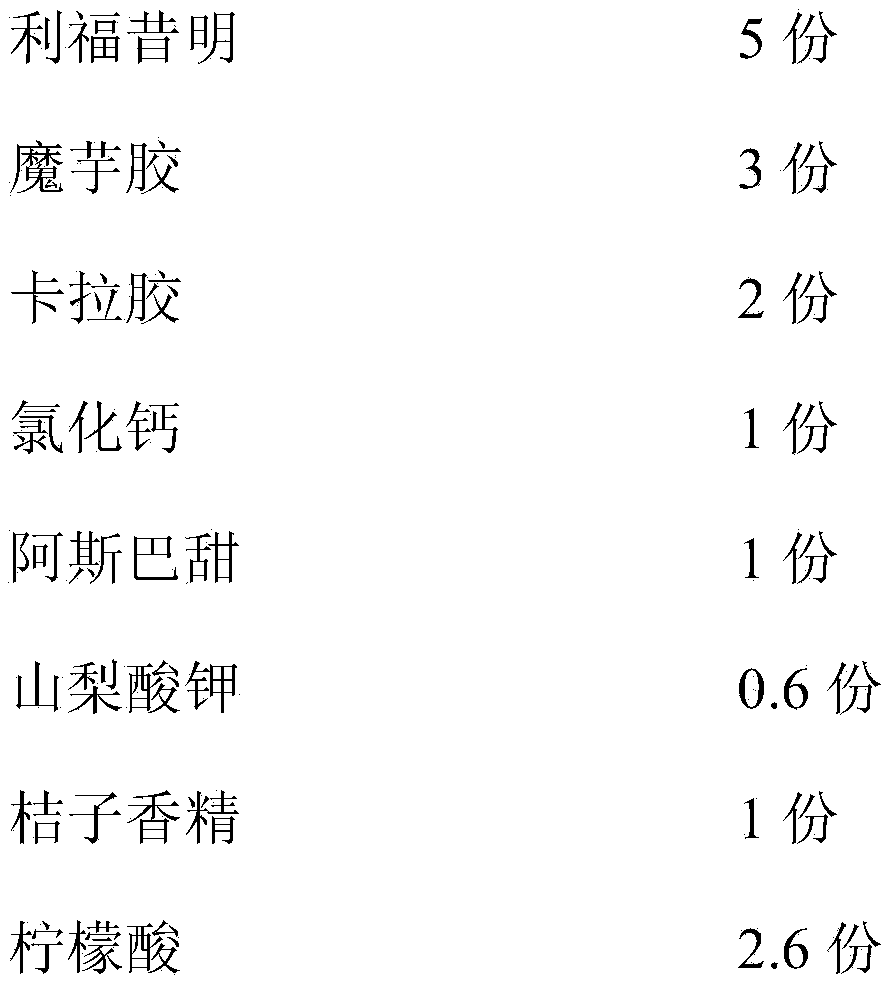

Rifaximin-containing pharmaceutical preparation

ActiveCN104274391APromote infectionReduce the fear of taking drugsAntibacterial agentsOrganic active ingredientsOral medicationMass ratio

The invention discloses a pharmaceutical preparation containing rifaximin gel and rifaximin oral emulsion and a preparation method thereof, wherein the gel comprises rifaximin and a gel matrix, the mass ratio of the rifaximin to the gel matrix is (2-80):(5-64), and the gel matrix comprises 2-30 parts by weight of a water-soluble gel matrix and 0.5-2 parts by weight of a modifier; and the rifaximin oral emulsion comprises 1-40 parts by weight of rifaximin, 50-350 parts by weight of an oil phase, 1-300 parts by weight of an emulsifier, and 0-150 parts by weight of a co-emulsifier. In the preparation, on the premise of guaranteeing that the dose of a main drug is appropriate, through the selection of auxiliary materials and preparation methods, rifaximin is prepared into gel or oral emulsion, thereby facilitating the oral administration and absorption of drugs, and achieving relatively high bioavailability. Meanwhile, a newer and better dosage form choice is provided for clinic.

Owner:黑龙江童医生儿童生物制药有限公司

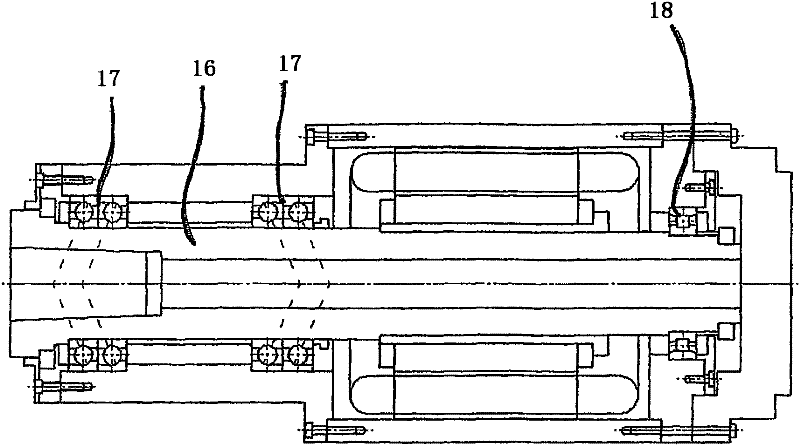

Novel lubricating and sealing structure for copper bush of press balance cylinder

The invention discloses a novel lubricating and sealing structure for a copper bush of a press balance cylinder, and belongs to the technical field of presses. The novel lubricating and sealing structure consists of a balance cylinder block 7, a piston, a bearing block 2, the copper bush 3 and a piston rod 5, wherein the bearing block 2 is fixed on a lower cover 6 of the balance cylinder block 7; the jointed part of the bearing block 2 and the lower cover 6 is provided with a corresponding step; a sealing ring 10 is arranged in a stepped hole of the jointed part of the bearing block 2 and the lower cover 6; the bearing block 2 is connected with and fixed on the lower cover 6 of the balance cylinder through a screw; the copper bush 3 is fixed in a hole of the bearing block 2 through a set screw; the lower part of the interior of the bearing block 2 below the copper bush 3 is provided with a seal groove; an oil seal 1 is arranged in the seal groove; the bearing block 2 and the copper bush 3 are provided with an oil feed hole 8 and an oil return hole 9; and lube oil enters the copper bush 3 from the oil feed hole 8 of the bearing block 2 to be stored in an oil tank 4 and flows out from the copper bush 3 through the oil return hole 9 of the bearing block 2 after the oil tank is full to form circulating lubrication.

Owner:张朝明

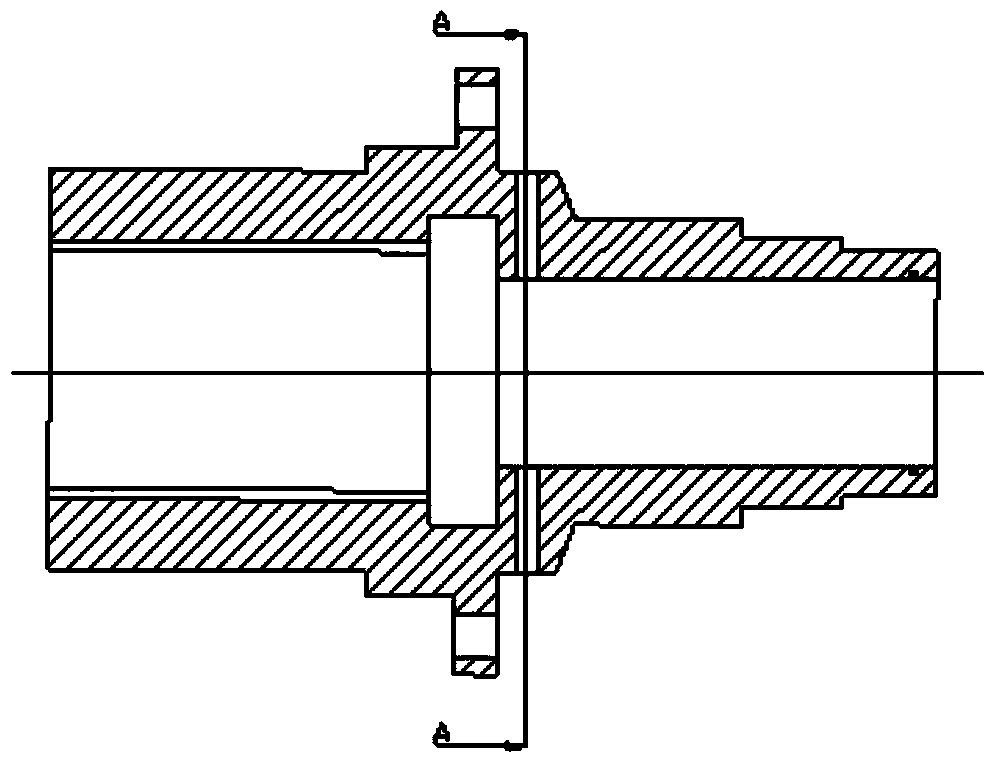

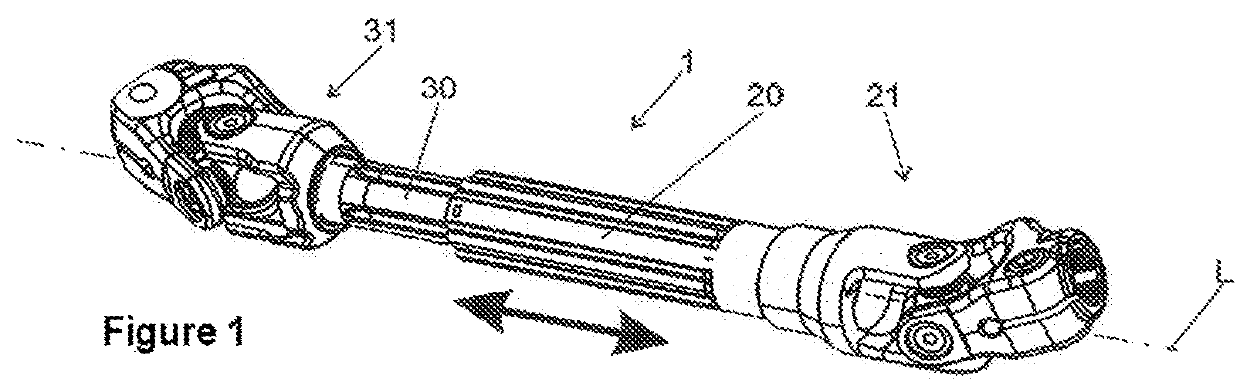

Steering shaft for a motor vehicle

ActiveUS20200189647A1Improve lubricationOperational reliability be increaseEngine sealsYielding couplingMotorized vehicleOperational reliability

A steering shaft for a motor vehicle includes a hollow shaft and an inner shaft which is arranged coaxially in the hollow shaft. The inner shaft is configured to be telescoped relative to the hollow shaft in the direction of the longitudinal axis of the steering shaft and is connected in a torque-transmitting manner to the hollow shaft via at least one rolling body. The rolling body is received in a rolling body cage such that it can roll in the direction of the longitudinal axis between the inner shaft and the hollow shaft. In order to achieve a high operational reliability with a relatively low manufacturing complexity, the rolling body cage has at least one seal element which bears sealingly against the hollow shaft and / or the inner shaft.

Owner:THYSSENKRUPP PRESTA AG +1

Laser cleaning head capable of rotating based on circular wedge-shape prism and using method

PendingCN109365413AMeet application needsSmall sizeCleaning processes and apparatusOptical elementsOptical axisLight beam

The invention discloses a laser cleaning head capable of rotating based on a circular wedge-shape prism and a using method. The laser cleaning head comprises a shell fixedly connected with optical fiber, a beam shaping part arranged in the shell, at least one circular wedge-shape prism driven to rotate around an optical axis, and a driving component for driving the circular wedge-shape prism, wherein the light extraction point of the optical fiber, the beam shaping part and the circular wedge-shape prism are arranged on the same optical axis. The circular wedge-shape prism rotates to scan, andthe laser cleaning head reduces the system size, is adapted to the light beam with a larger diameter, improves the stability and the capacity of resisting disturbance and reduces the driving controldifficulty. In addition, the invention further provides a unique cleaning scanning path, and the unique cleaning scanning path meets the application demand and has certain practical significance.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

Gap filler

The invention discloses a gap filler which comprises the following components in parts by weight: 30-70 parts of quartz sand, 3-10 parts of antioxidant, 1-3 parts of limestone, 1-3 parts of organosilicon leveling agent, 1-2 parts of mold preventive and 10-30 parts of magnesium silicate. The gap filler disclosed by the invention has the advantages of favorable wear resistance, low cracking tendency, mold resistance and oxidation resistance, is easy and safe for construction, and thus, is a favorable gap filler for spreading and attaching ceramic tiles.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

Two-stage compressor

ActiveCN105909489AGood effectSimple structurePositive displacement pump componentsMulti-stage pumpsAir compressionGas compressor

The invention discloses a two-stage compressor which comprises a shell, a film, a first connecting pipe, a second connecting pipe, a first one-way valve, a second one-way valve, a mounting rack, a rotation shaft, a driving unit, a first runner, a second runner, a first piston rod, a second piston rod, a first piston and a second piston; an air inlet, a connecting hole and an air outlet are formed in the shell; a first mounting hole and a second mounting hole are formed in the top wall of the shell; a first accommodating cavity and a second accommodating cavity are formed in the shell; the air inlet, the connecting hole and the first mounting hole communicate with the first accommodating cavity; the connecting hole, the air outlet and the second mounting hole are communicated with the second accommodating cavity; the film is arranged in the second accommodating cavity; the first end of the film is hinged to the side wall of the shell; the second end of the film is a free end; one end of the first connecting pipe is connected with the air inlet; one end of the second connecting pipe is connected with the air outlet. The two-stage compressor is excellent in air compression effect.

Owner:BENGBU JINPENG GAS EQUIP MFG

Coupling

PendingCN109707755AReduce alignment requirementsExtended service lifeYielding couplingScrapEngineering

The invention provides a coupling. The coupling comprises a first half-coupling and a second half-coupling which are connected with each other, wherein the first half-coupling comprises a first drum-shaped tooth connecting shaft part and a first transition part, and a first drum-shaped tooth of the first drum-shaped tooth connecting shaft part is matched with a first inner tooth groove of the first transition part; and the second half-coupling comprises a second drum-shaped tooth connecting shaft part and a second transition part, and a second drum-shaped tooth of the second drum-shaped toothconnecting shaft part is matched with a second inner tooth groove of the second transition part. After the installation is completed on equipment, a sealed inner cavity is formed between the first transition part and the second transition part, the inner cavity is filled with lubricating oil, and it is guaranteed that the lubricating oil fully lubricates all tooth groove surfaces. A magnetic rod is arranged in the sealed inner cavity, iron scraps in the lubricating oil can be effectively adsorbed by the magnetic rod, and the oil is purified. The whole coupling is simple and reasonable in structure, convenient to maintain and use, long in service life and great in significance for the development of the couplings.

Owner:SHANDONG IRON & STEEL CO LTD

Drilling hydraulic propulsion equipment for geological exploration

ActiveCN111425151AReasonable structureHigh degree of automationDrilling rodsConstructionsMud systemsMarine engineering

The invention discloses drilling hydraulic propulsion equipment for geological exploration. The drilling hydraulic propulsion equipment comprises a carrying platform, a drilling mechanism and a mud supply mechanism, wherein the carrying platform is a traction type flat plate transport vehicle, and the flat plate transport vehicle is provided with a pair of rollers connected through a roller. The drilling hydraulic propulsion equipment has the beneficial effects that the structure is reasonable, the automation degree is high, an electrically-driven hydraulic pump is adopted as rotating and vertical power of the drilling mechanism, thus the equipment is enabled to complete drilling by means of hydraulic power, the noise is low, and the running friction is small; meanwhile, the running trackof a drill rod is limited in cooperation with a stabilizing ring and a stabilizing semi-ring to keep the drill rod rotating stably, noise and friction caused by shaking are reduced, and a matched mudsystem is arranged, so that the lubrication degree of drilling is increased, the noise is low, and the loss is reduced; and the noise and the loss in the operation process are reduced to the maximum extent through mutual cooperation of the structures, and the operation stability of the equipment is improved in multiple aspects.

Owner:孔令智

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com