Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1748results about "Slip coupling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

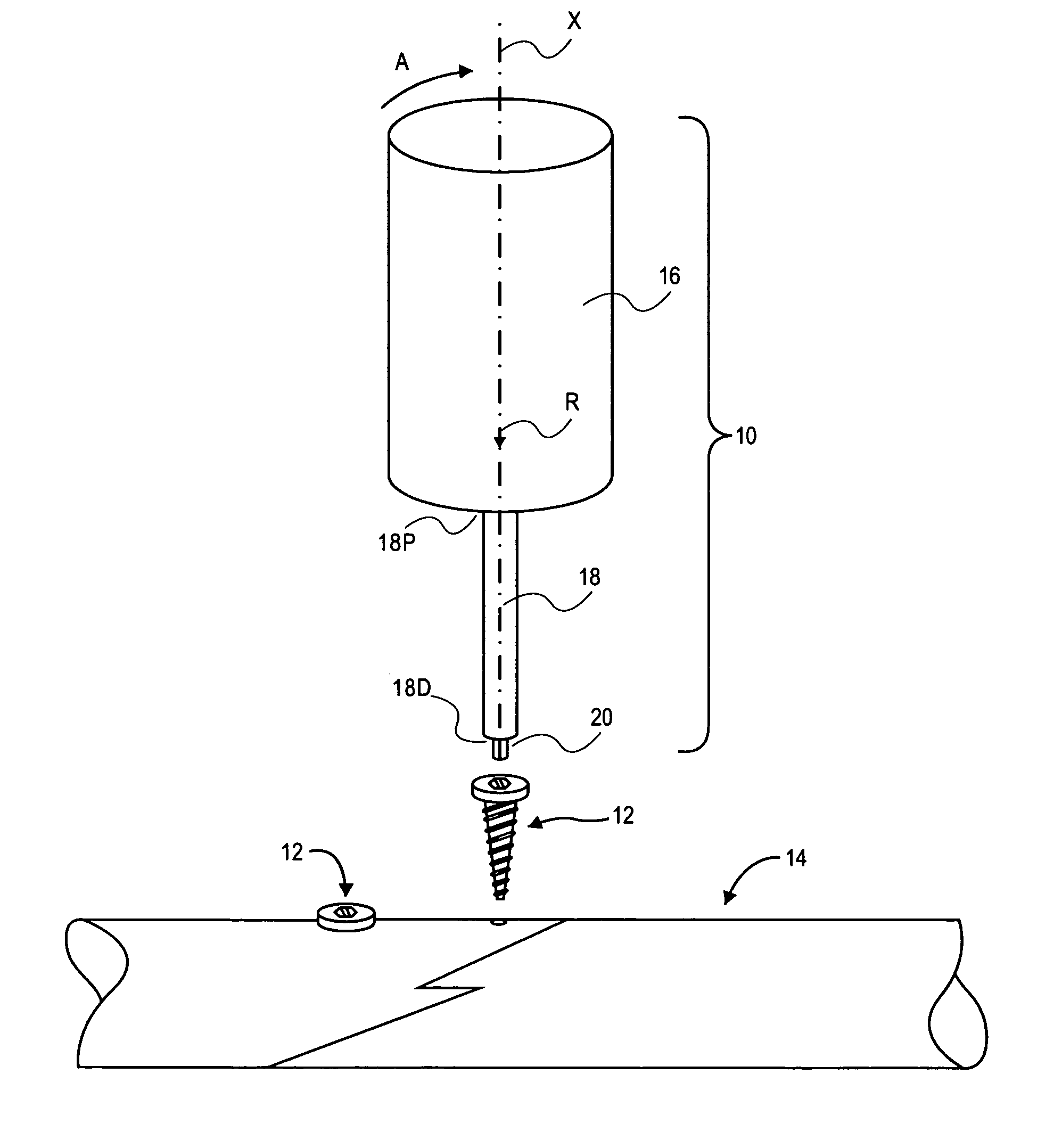

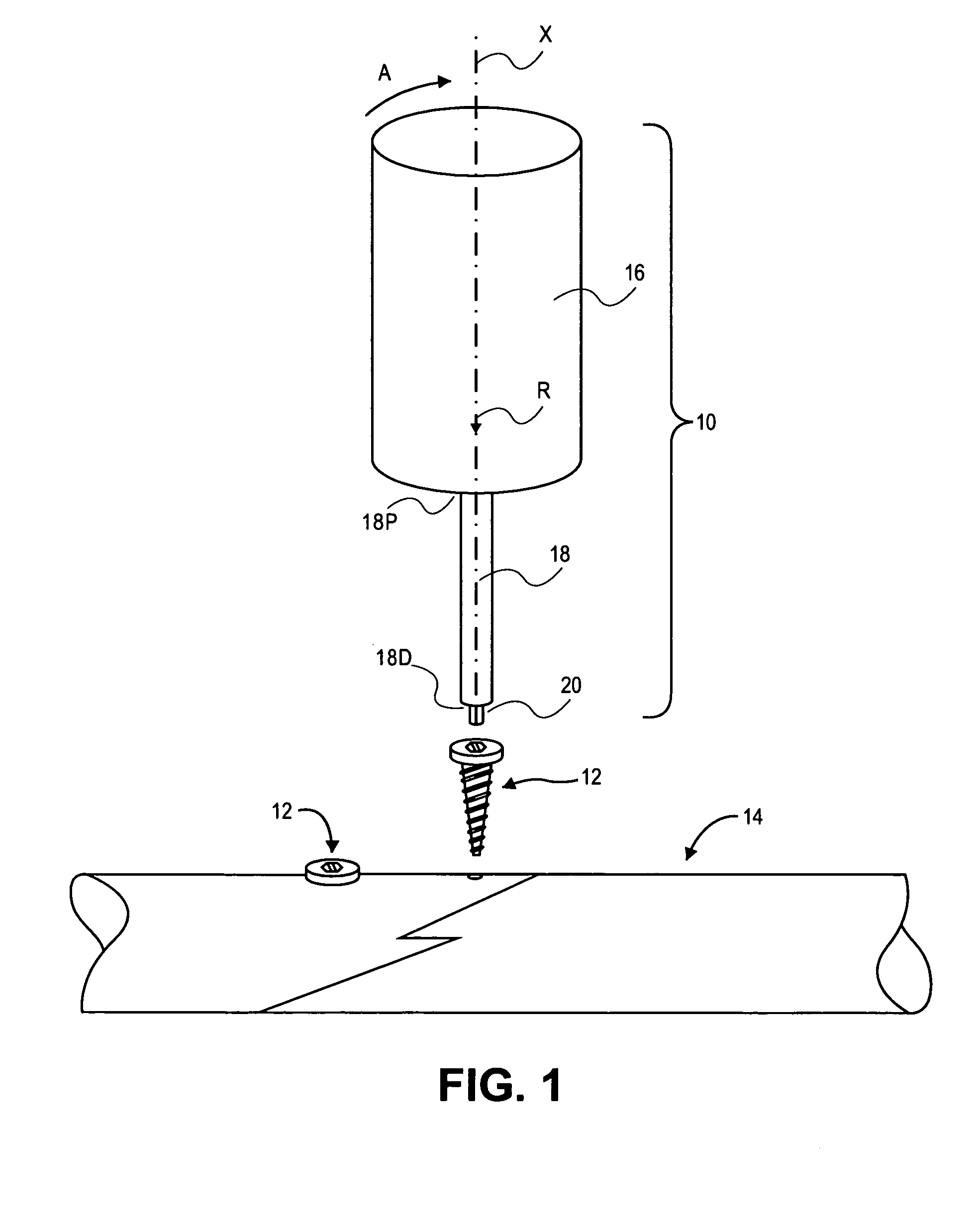

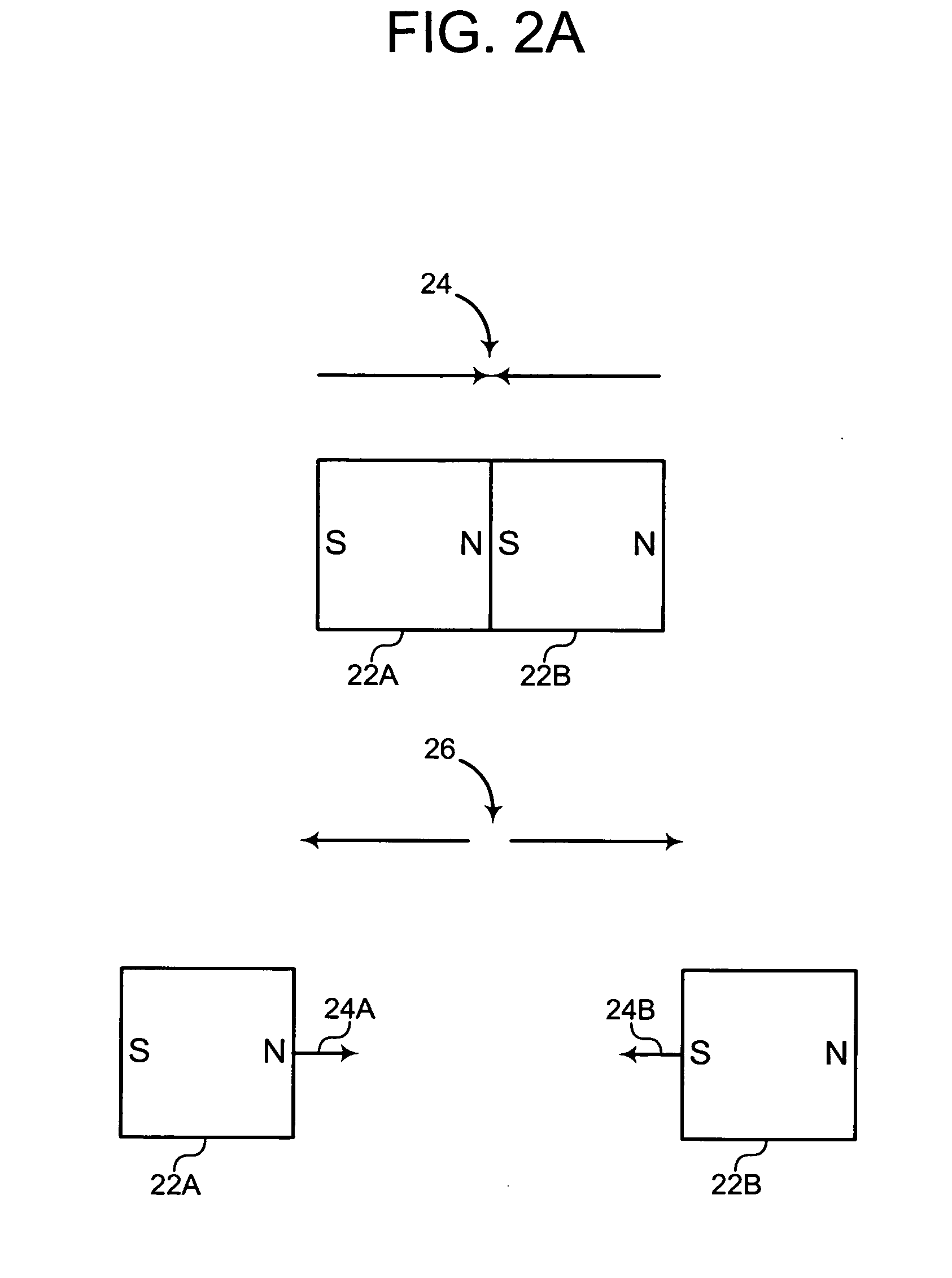

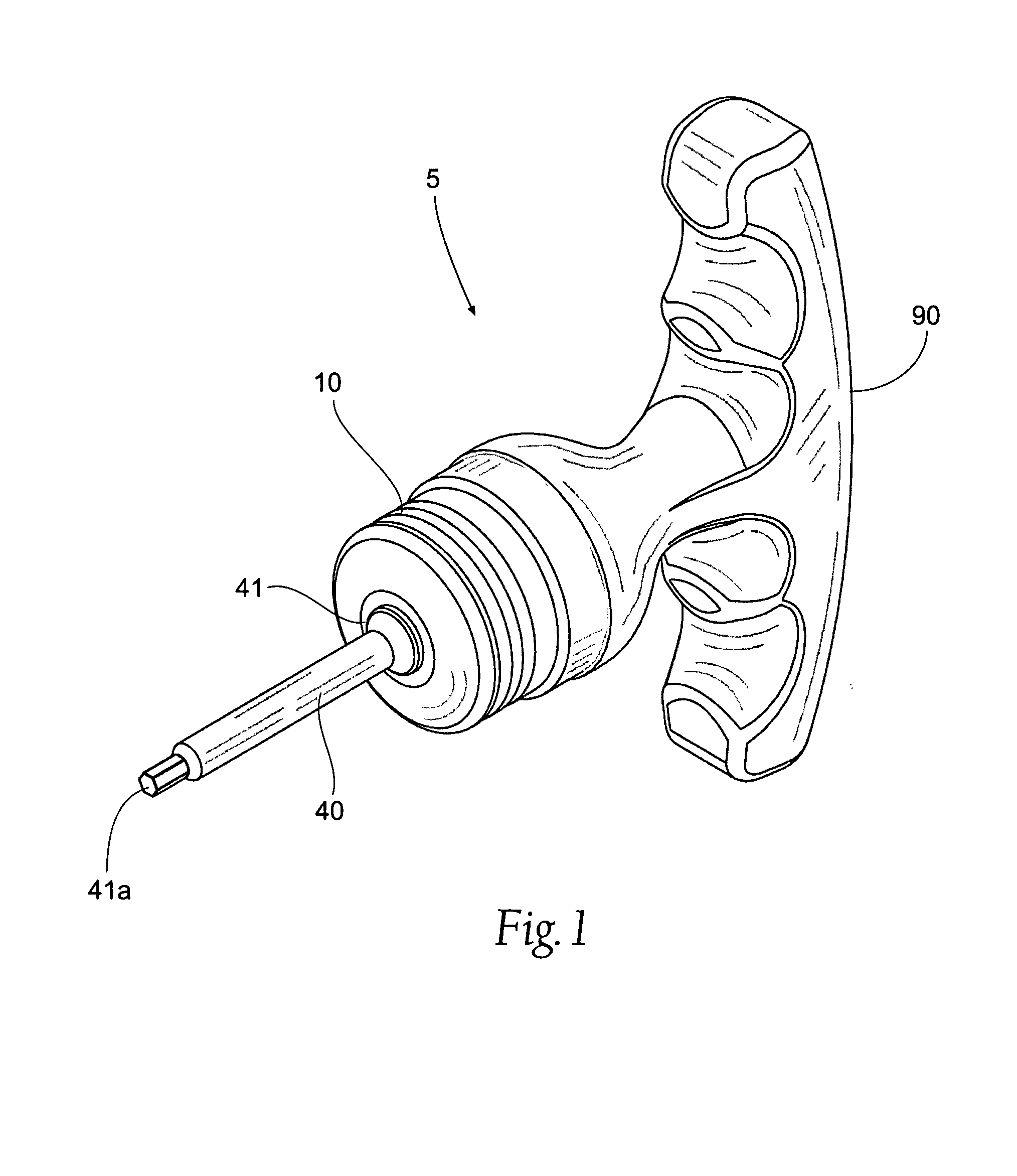

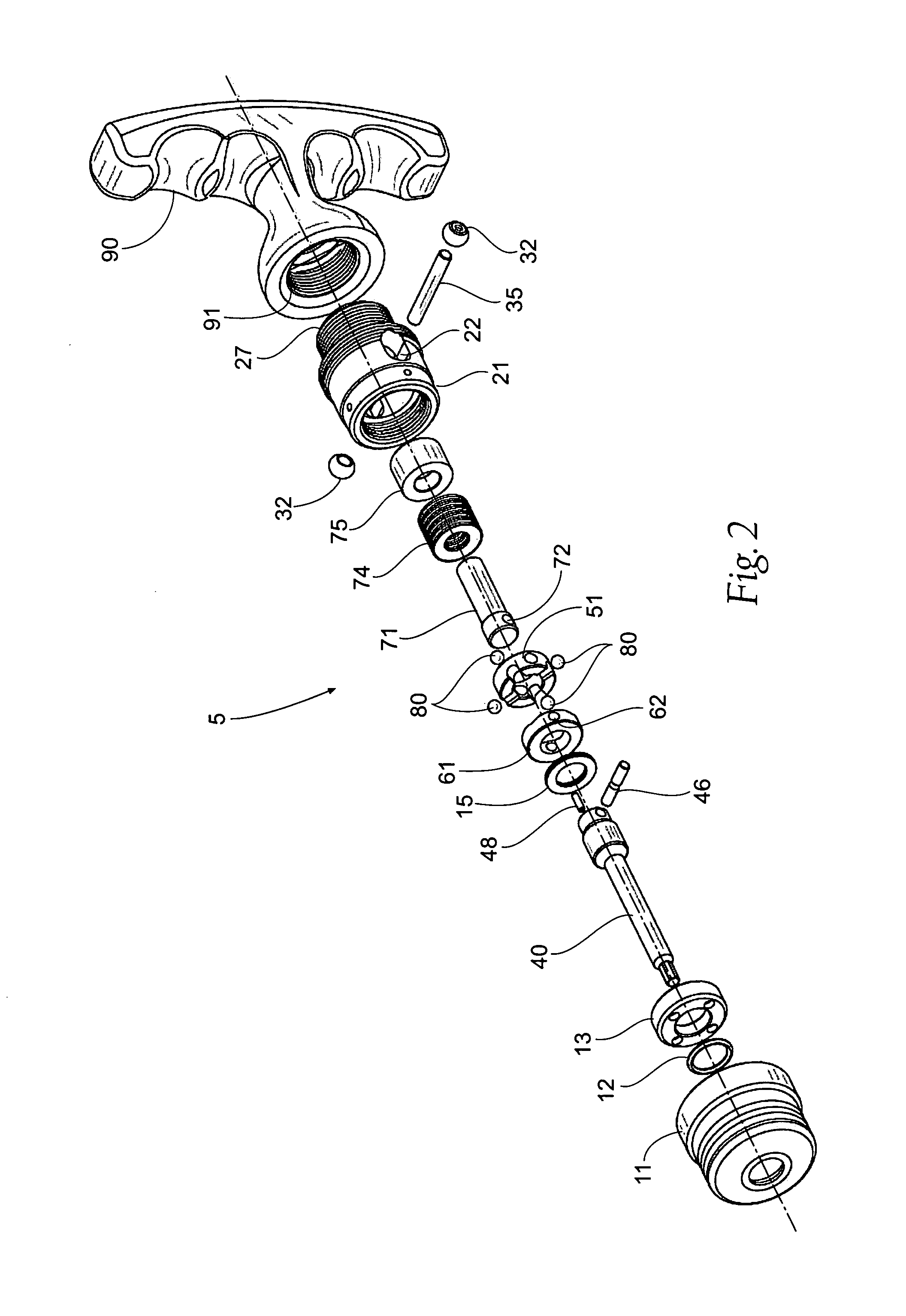

Magnetic torque-limiting device and method

In a torque-limiting device, a first end engages a fastener, a second end receives an applied torque, and a magnetic torque limiter transmits the applied torque from the second end to the first end to rotate the first end in conjunction with the second end when the applied torque is less than a predetermined limit.

Owner:PILLING WECK INC

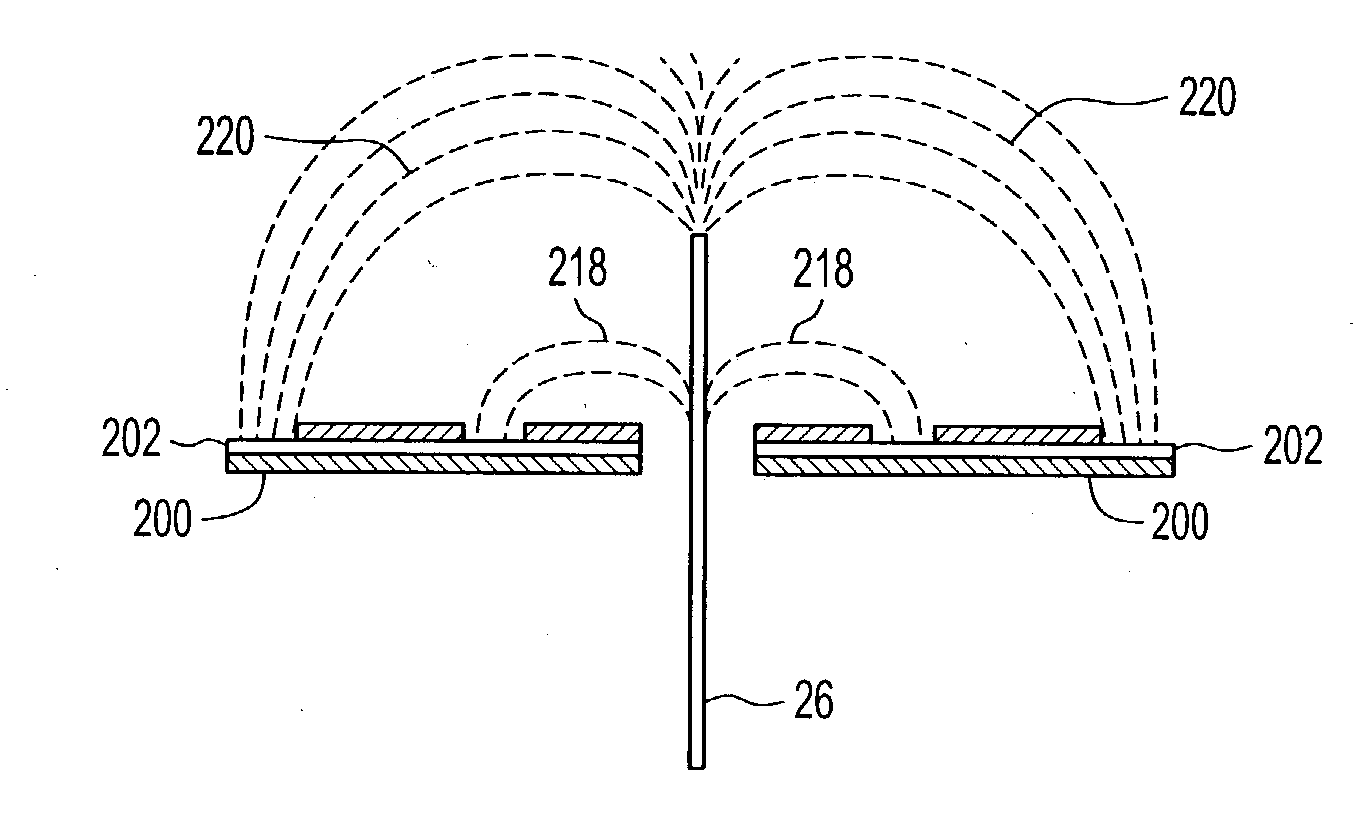

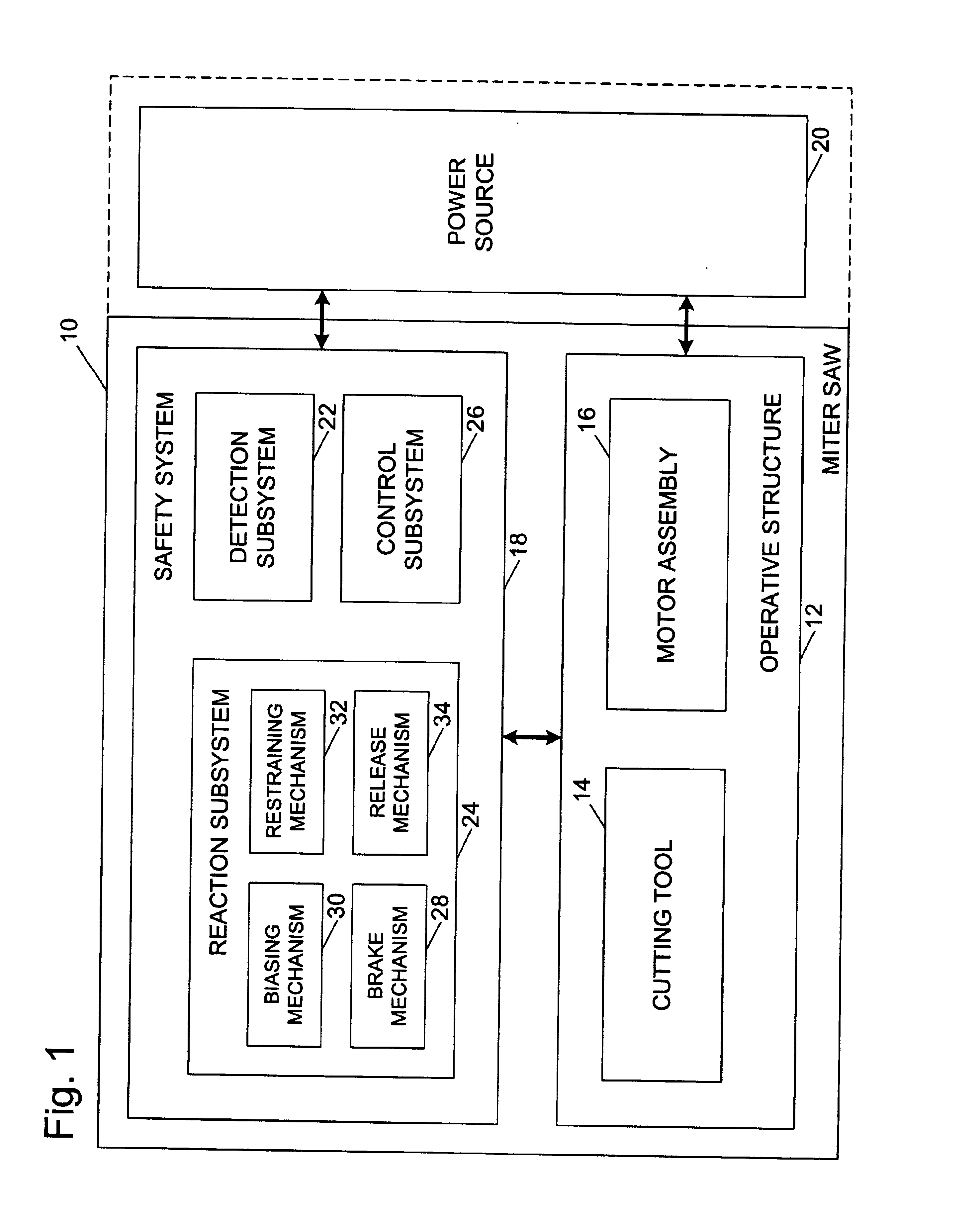

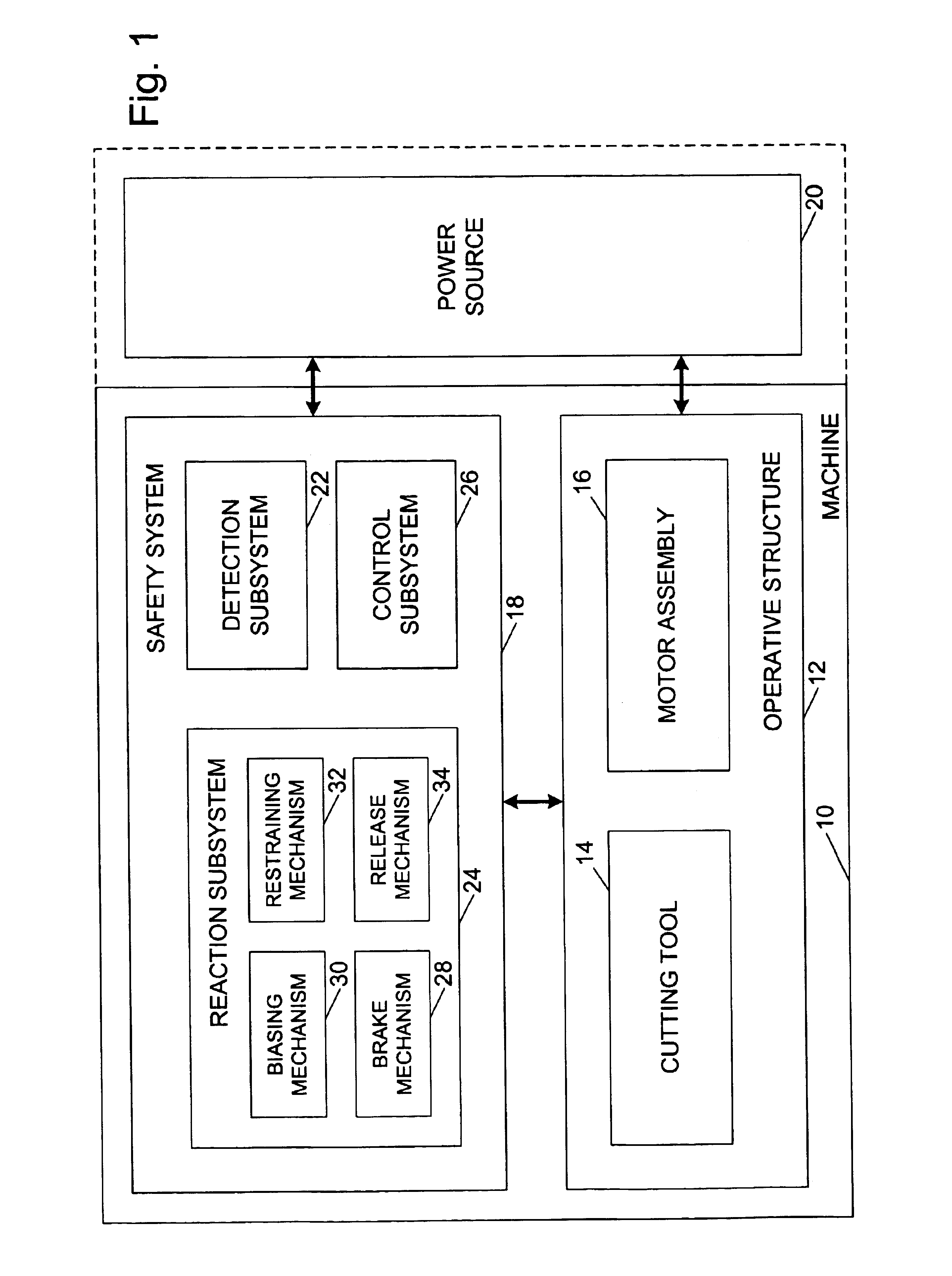

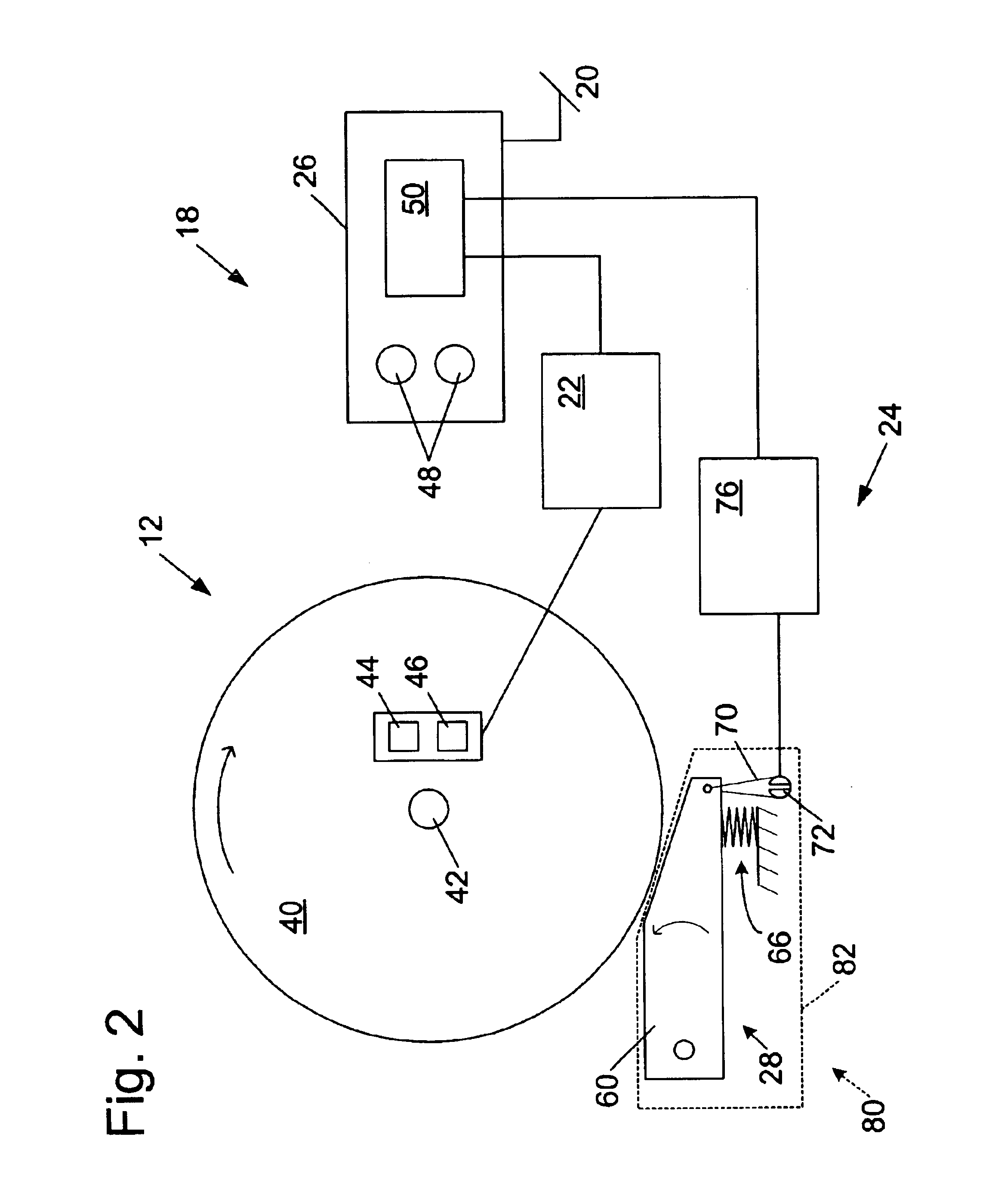

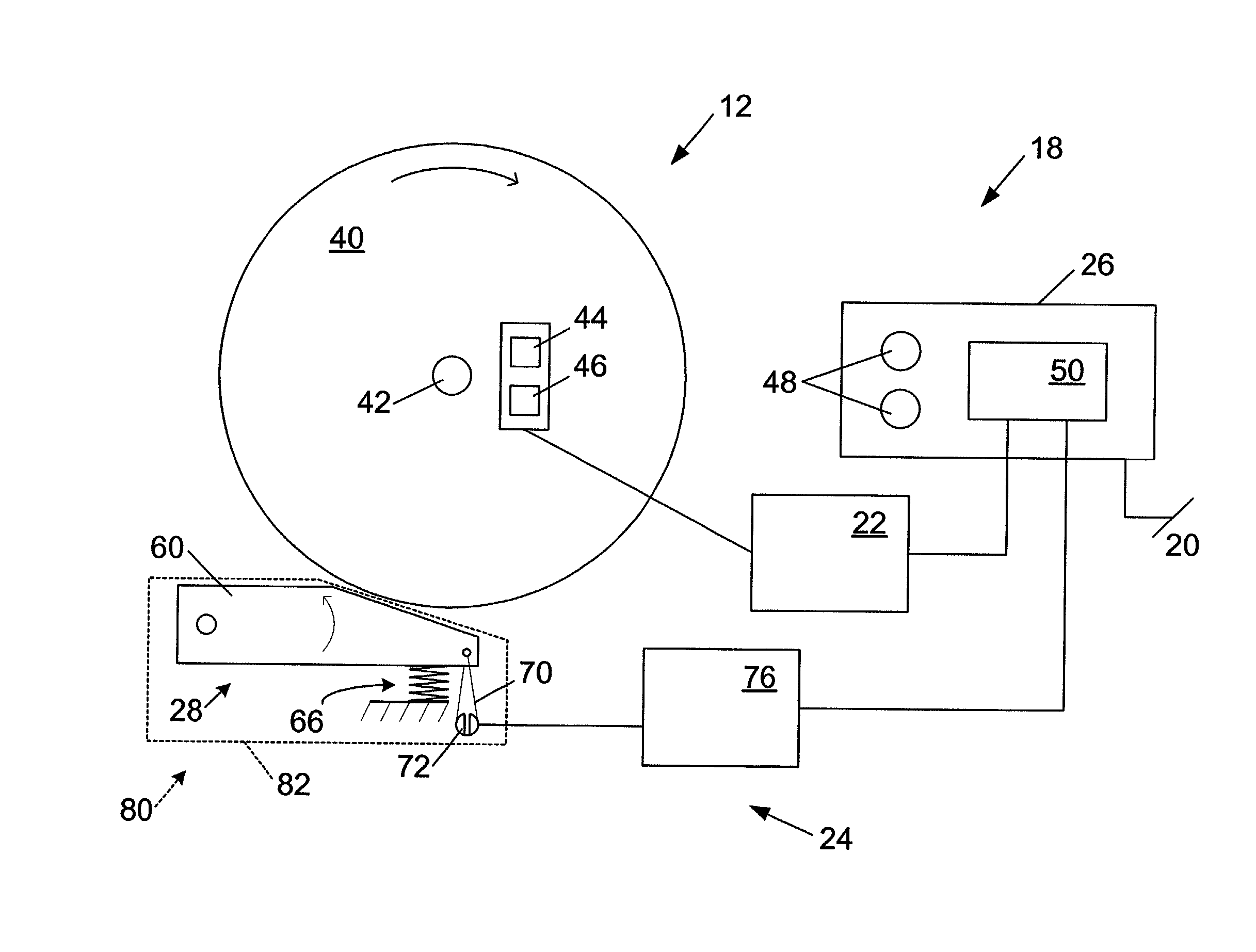

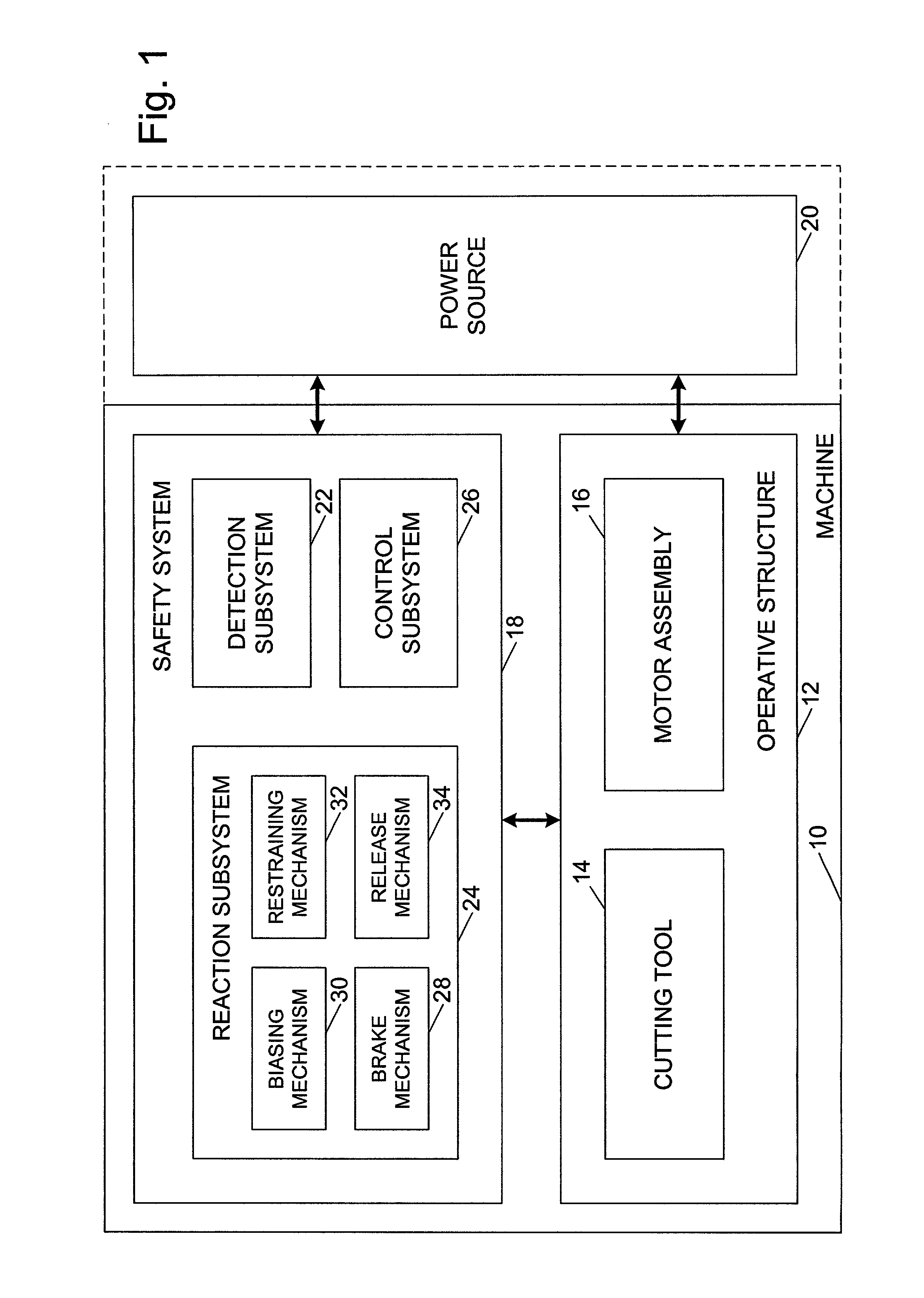

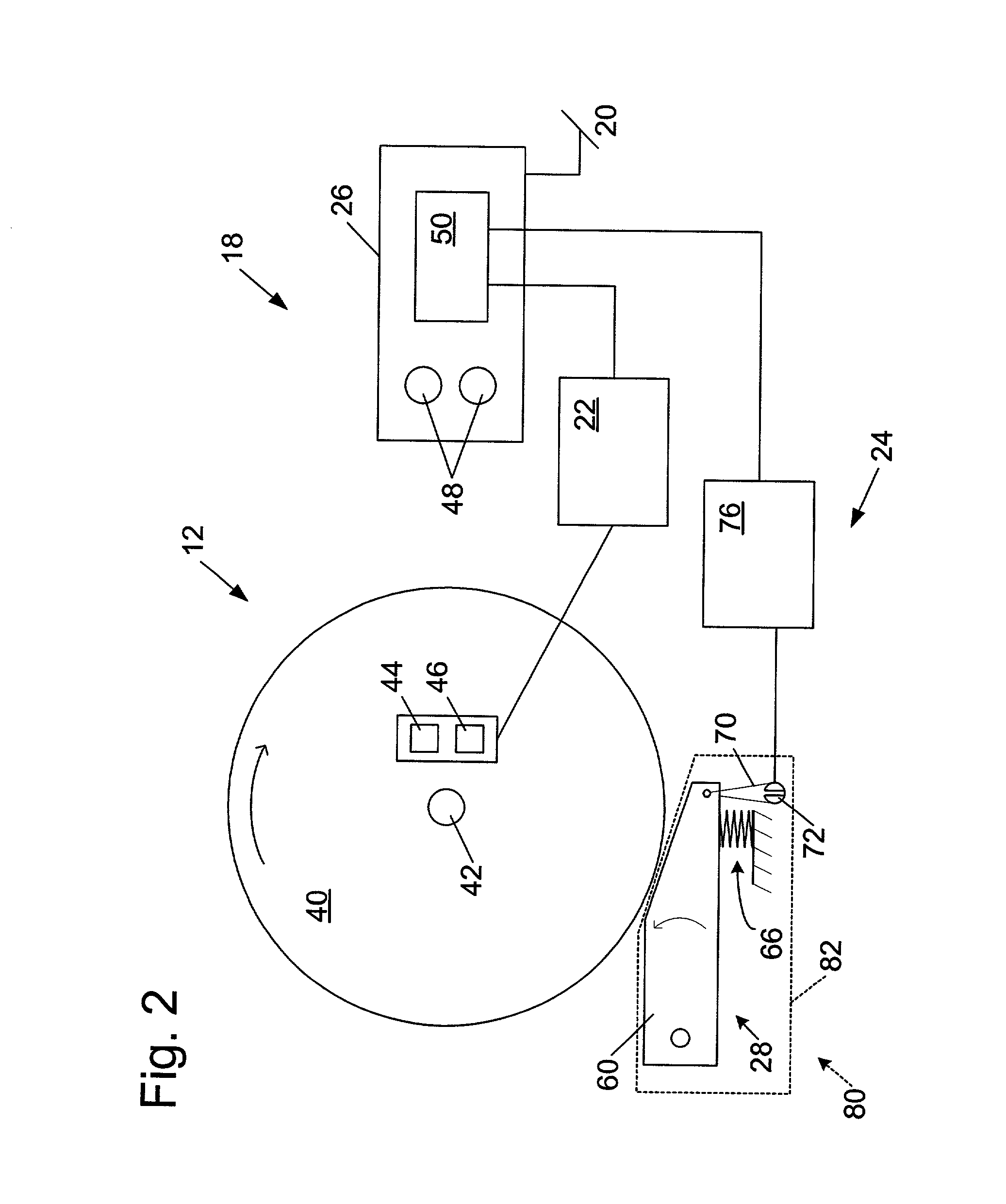

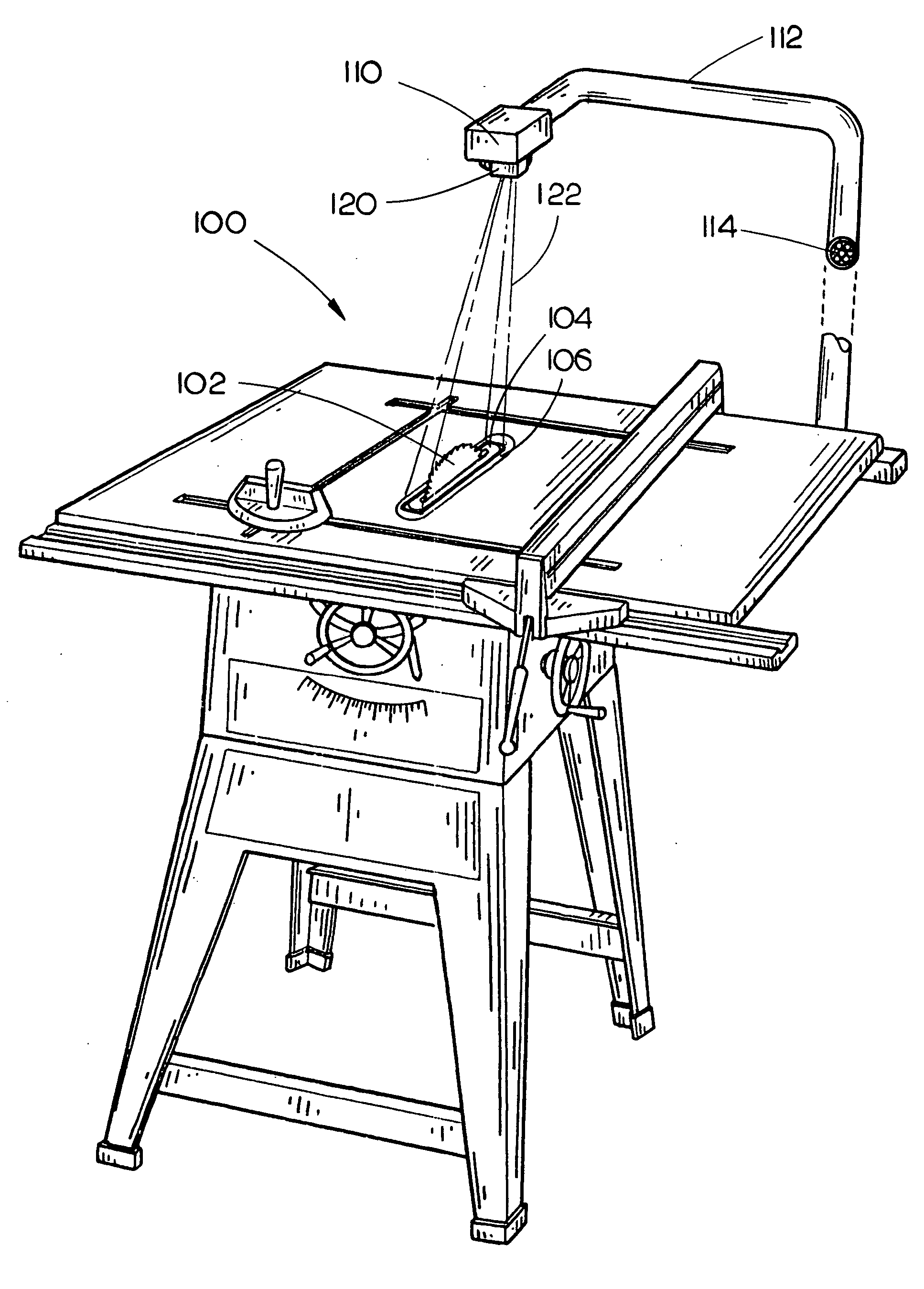

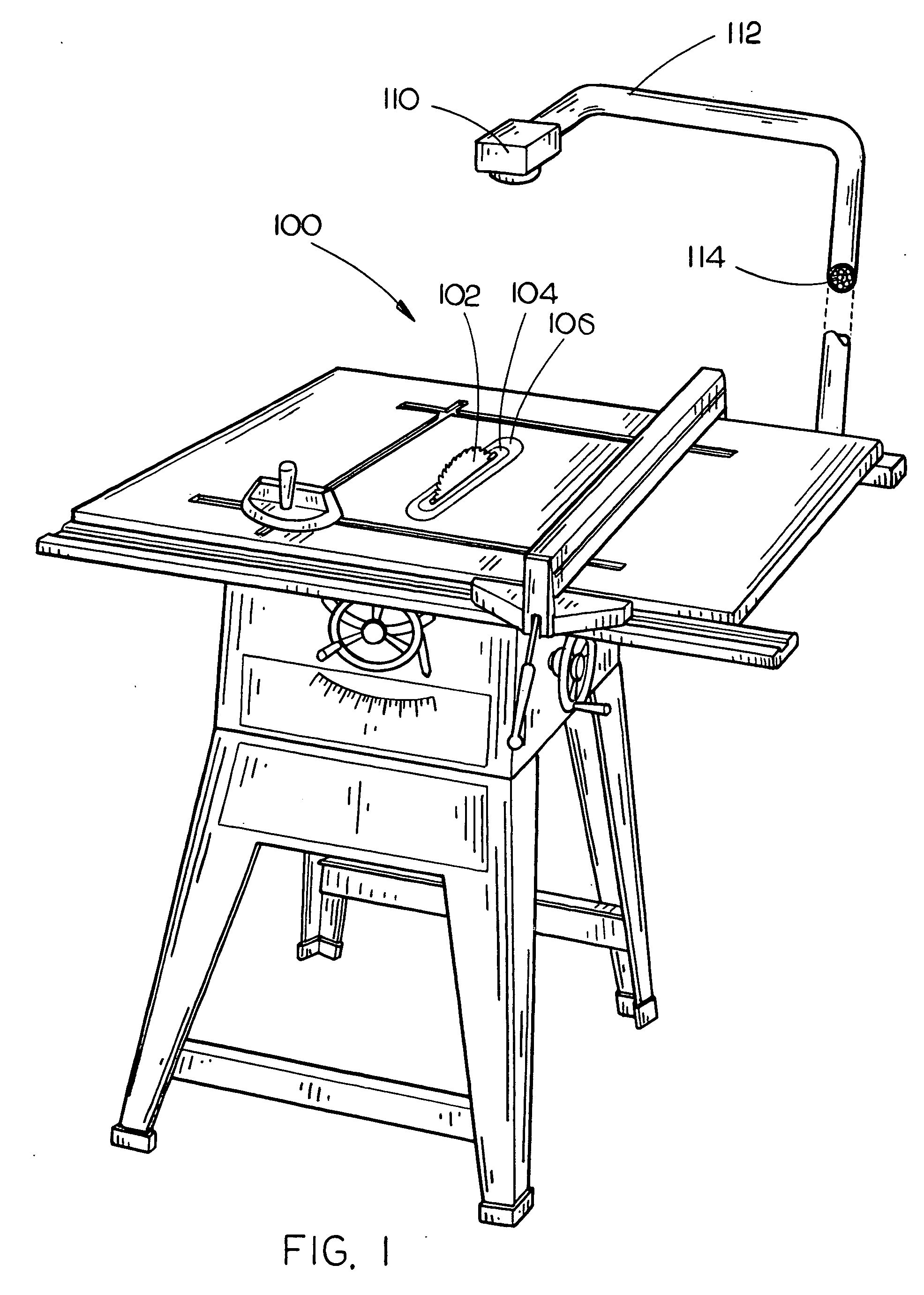

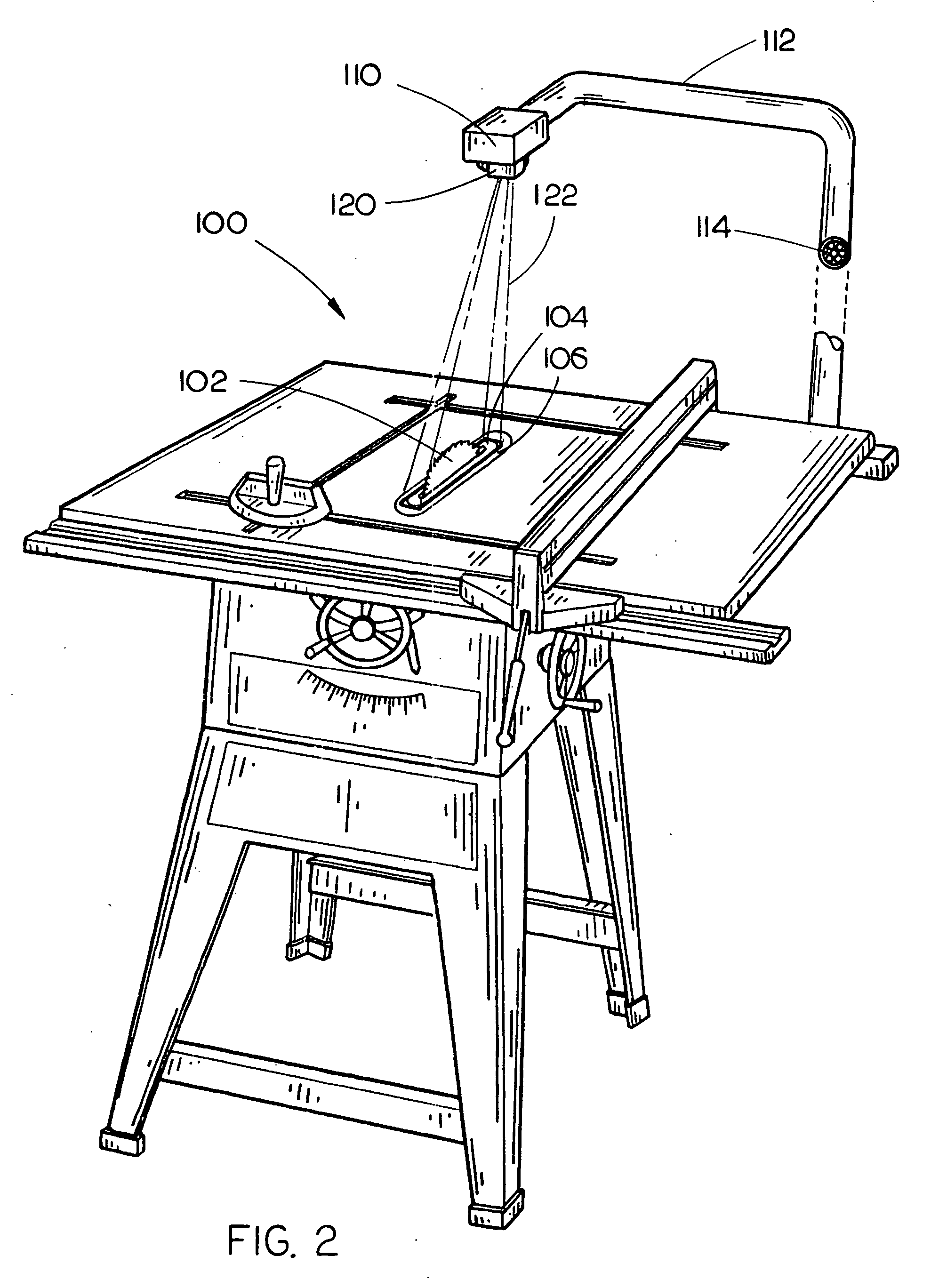

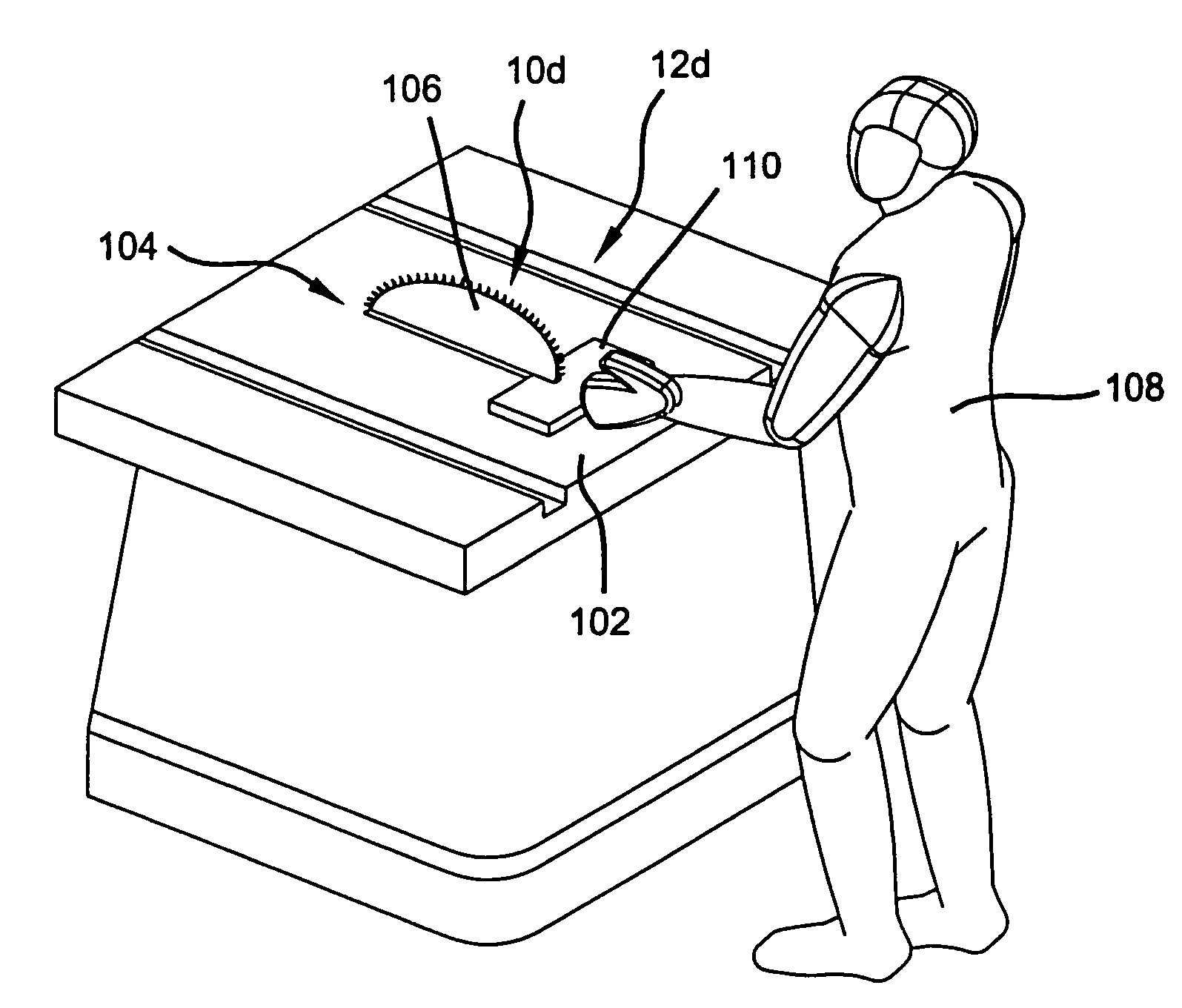

Safety detection and protection system for power tools

InactiveUS20040226800A1Quick stopQuick pullDC motor speed/torque controlEmergency protective circuit arrangementsPower toolProtection system

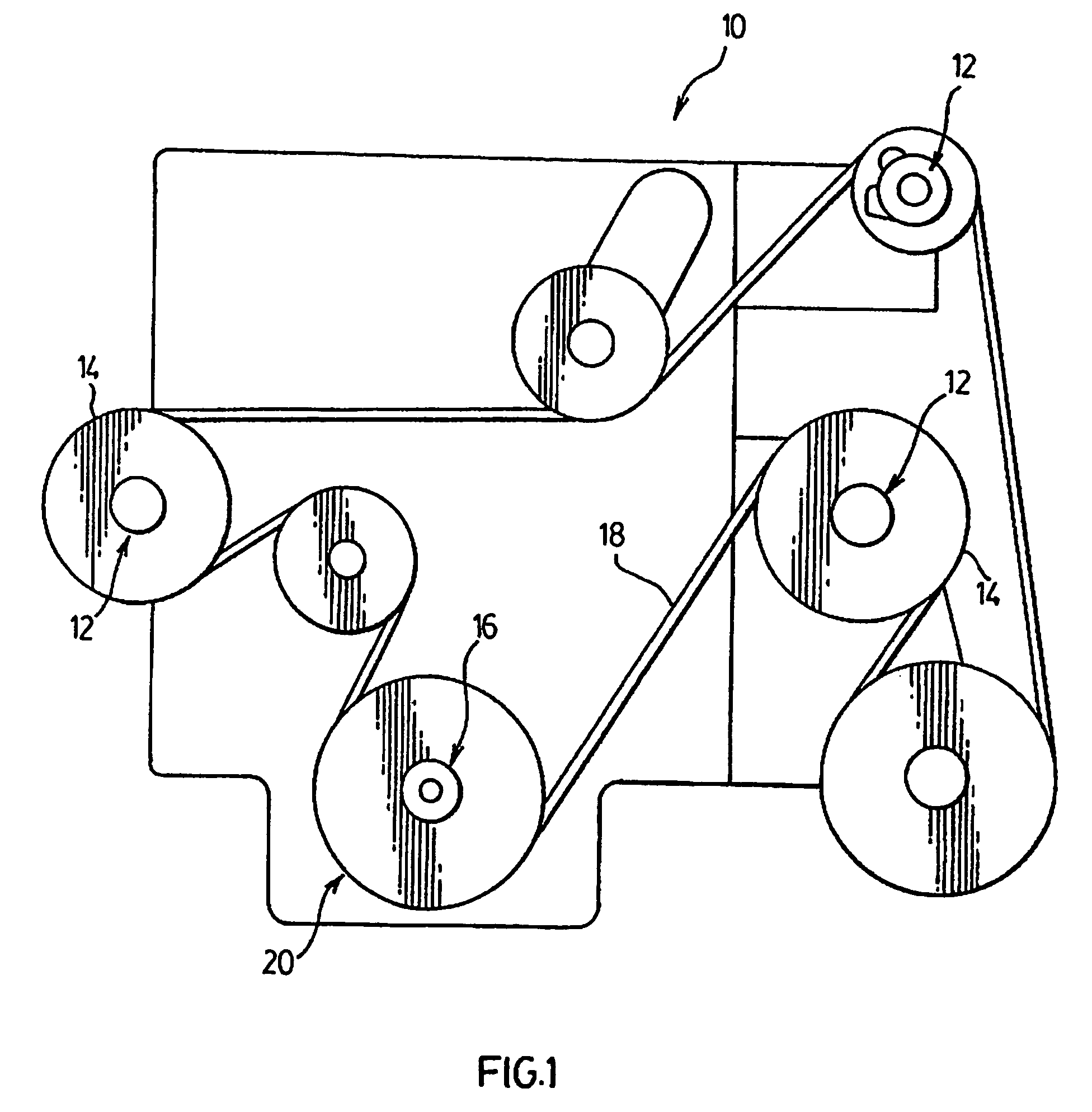

A detection system for detecting a dangerous condition for an operator using a power tool of the type which has an exposed blade relative to a work surface and a protection system for minimizing, if not eliminating the possibility of a user being injured by contacting the blade. In one preferred embodiment of the present invention, a proximity detection system is capable of detecting the presence of a user near the blade of a table saw and a protection system that can either retract the blade below the work surface of the table saw or terminate the drive torque to the blade which can result in rapid stopping of the saw blade by a work piece that is being cut.

Owner:CREDO TECH CORP +1

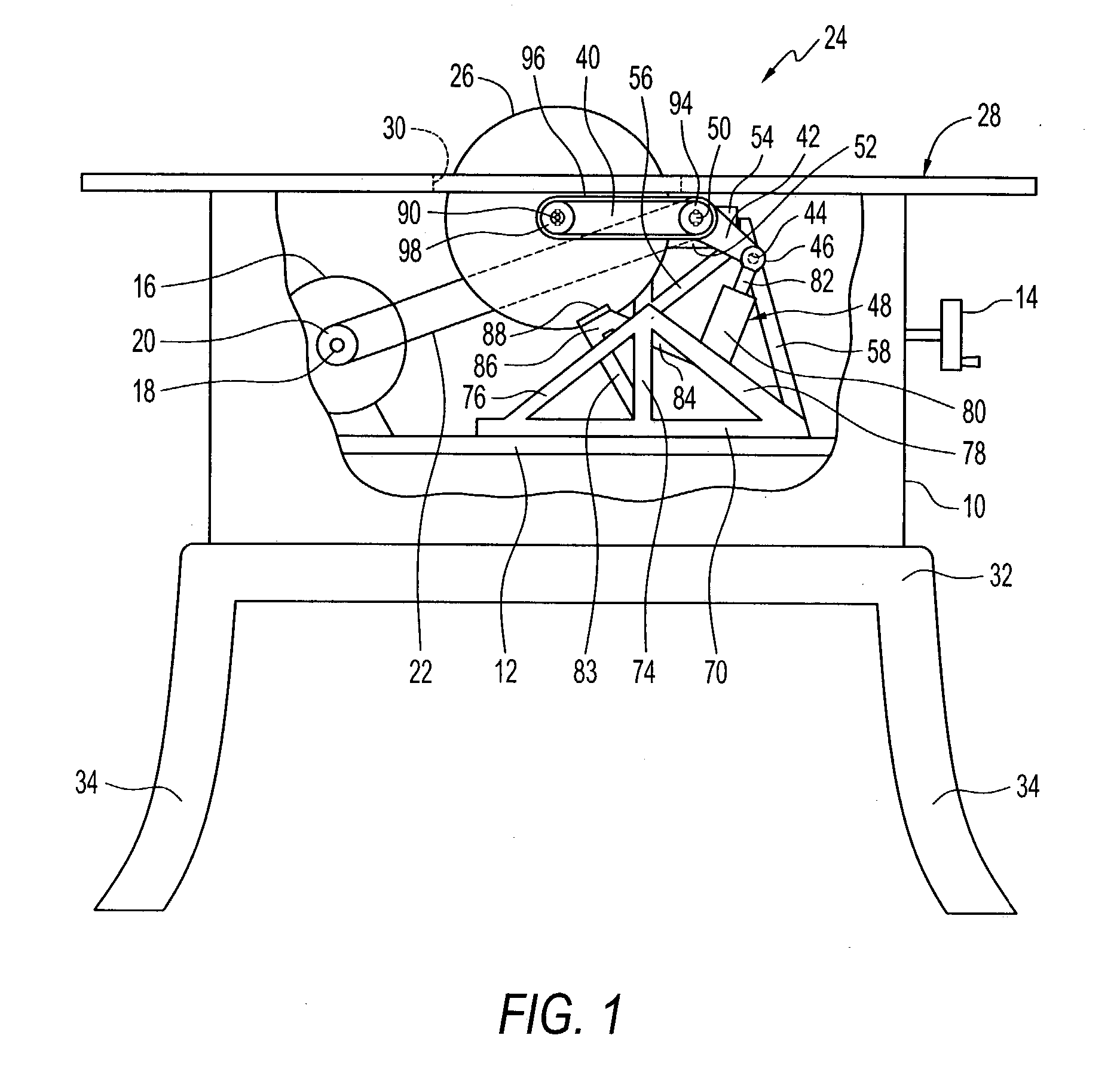

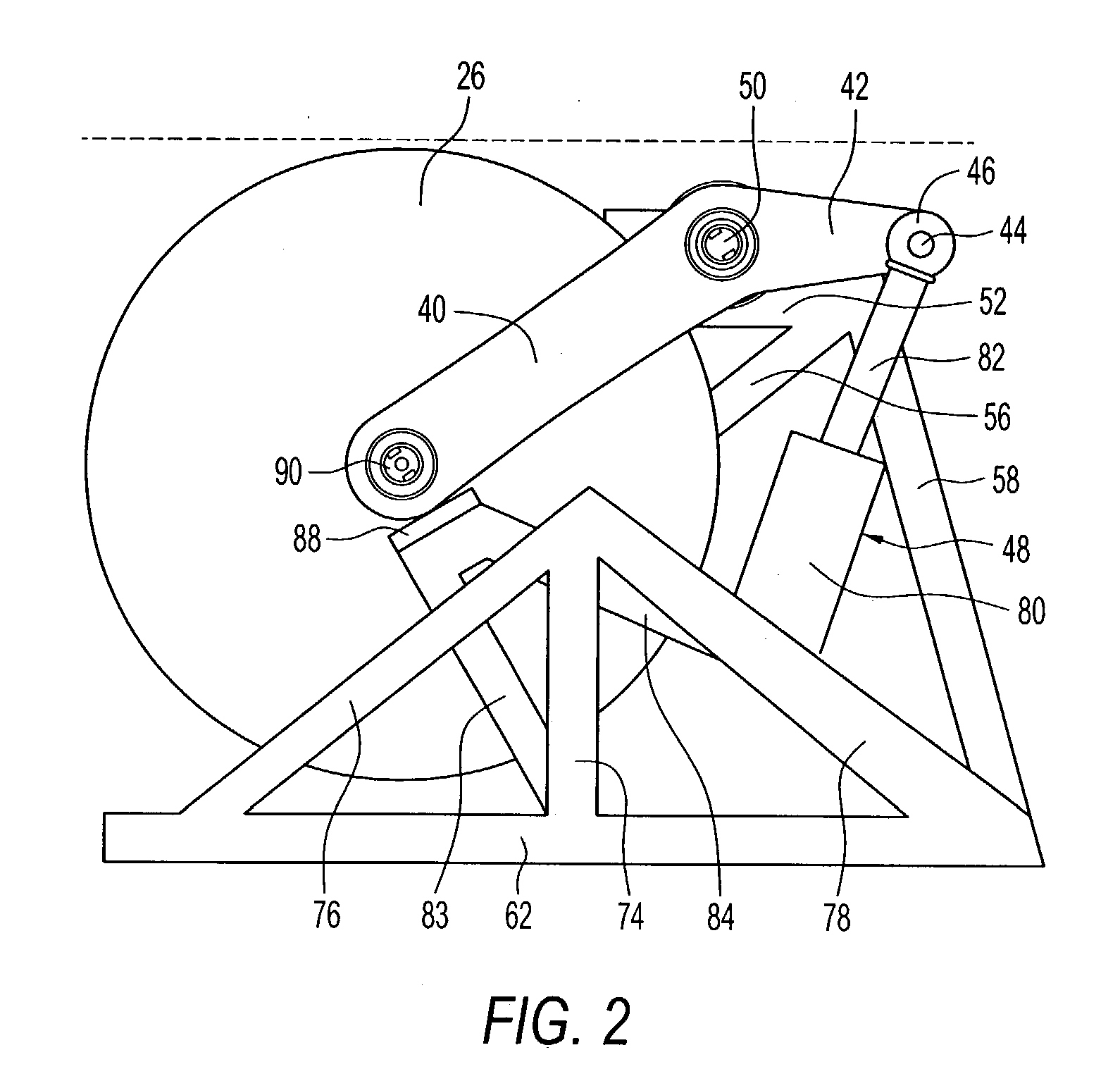

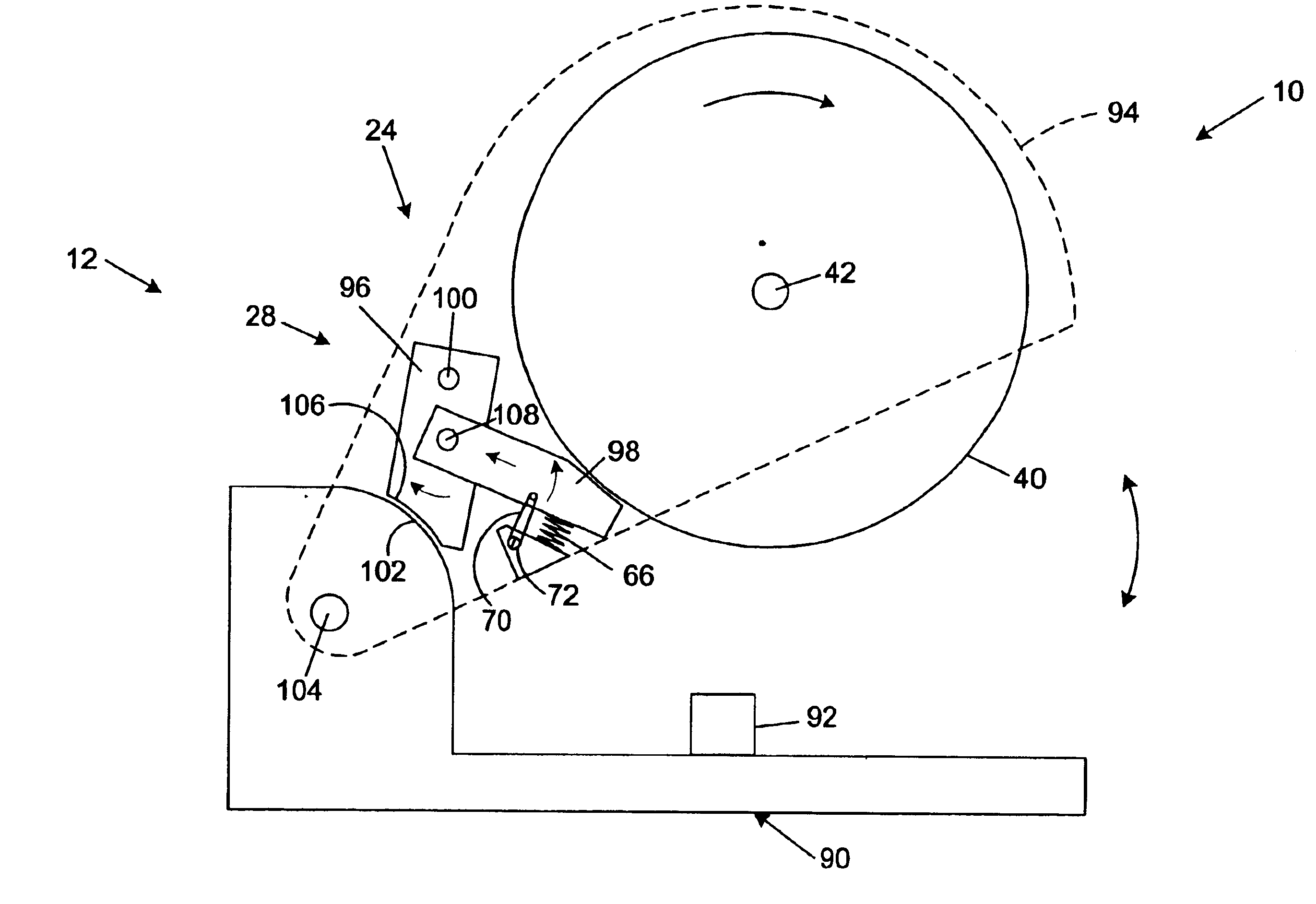

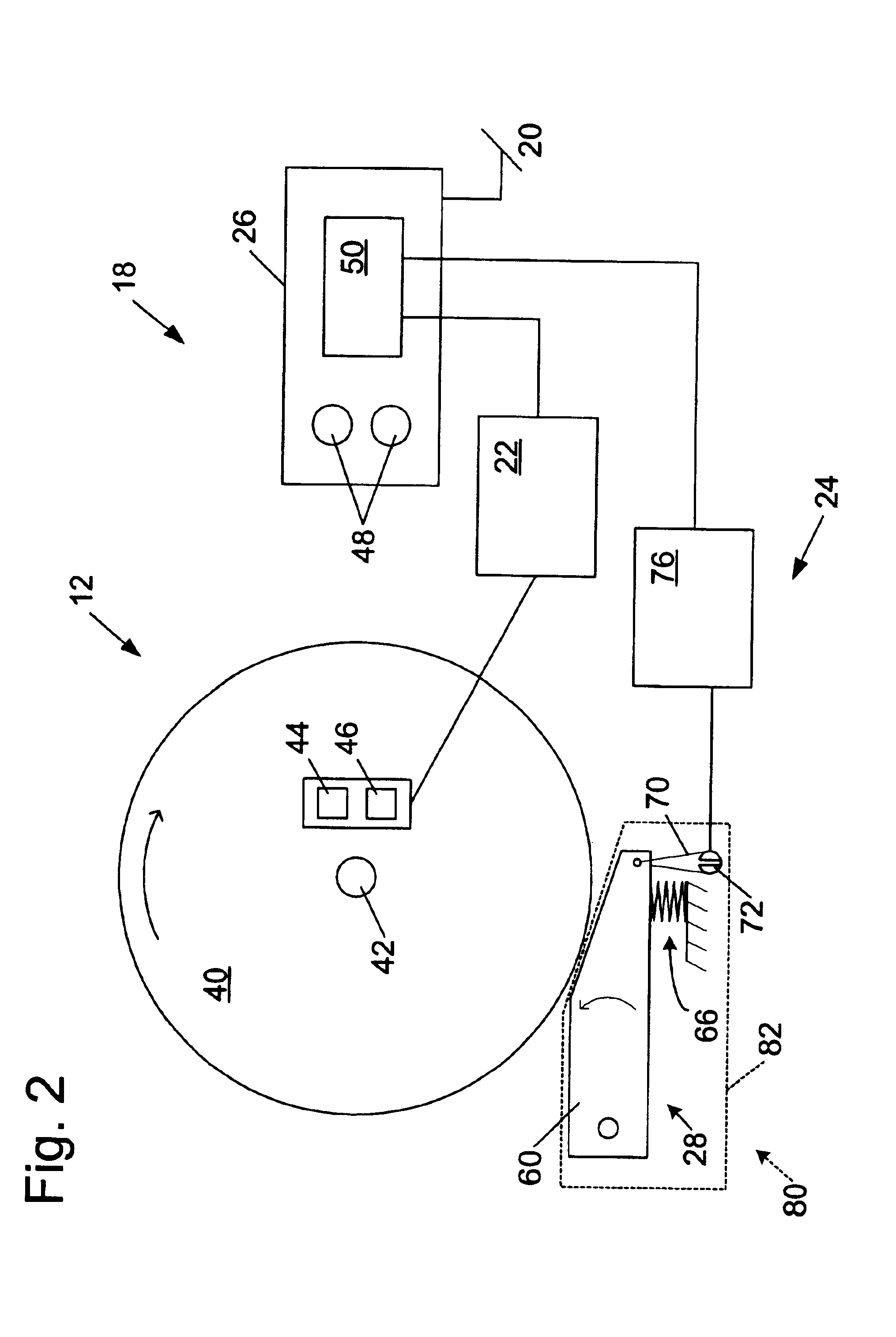

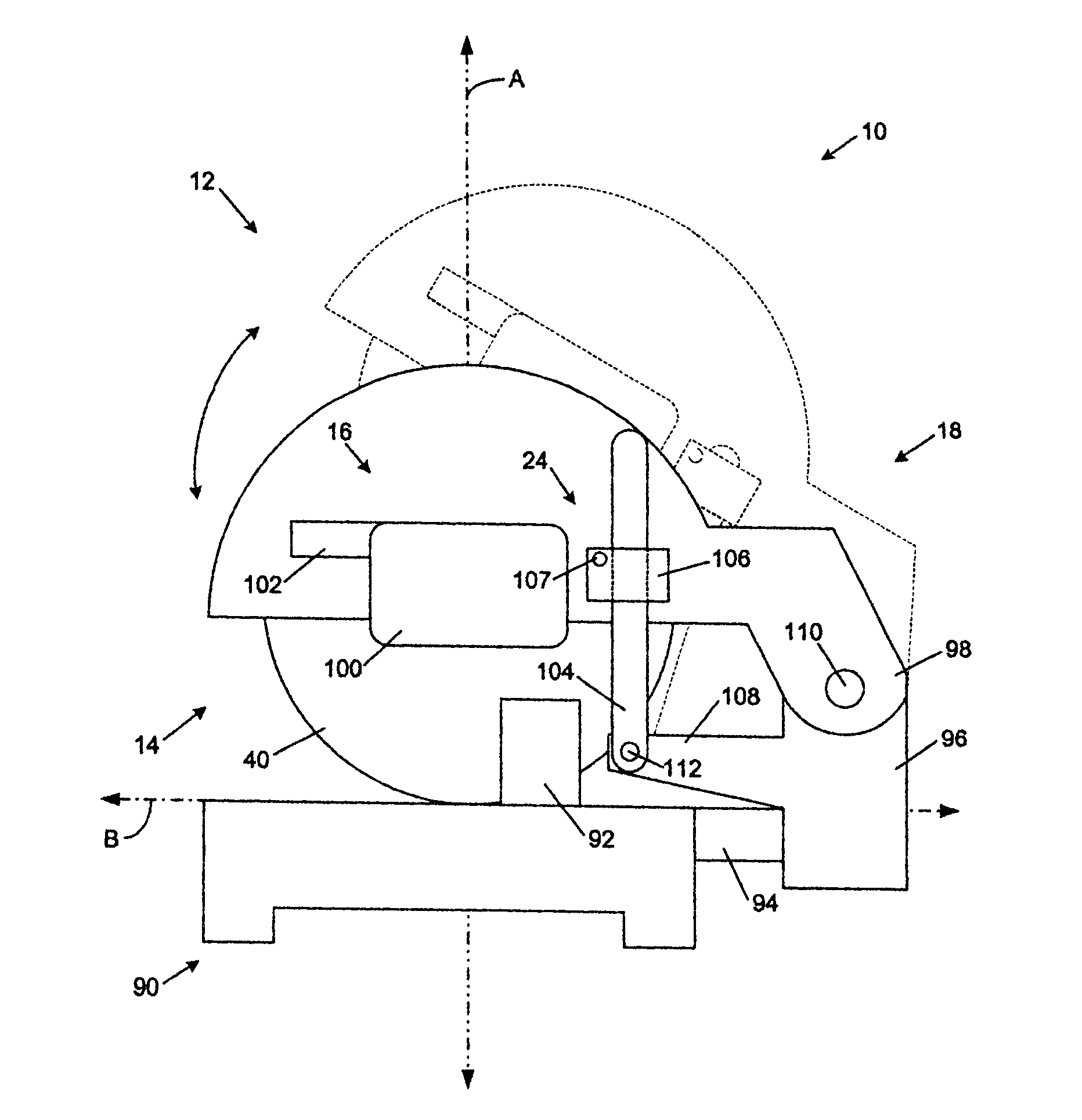

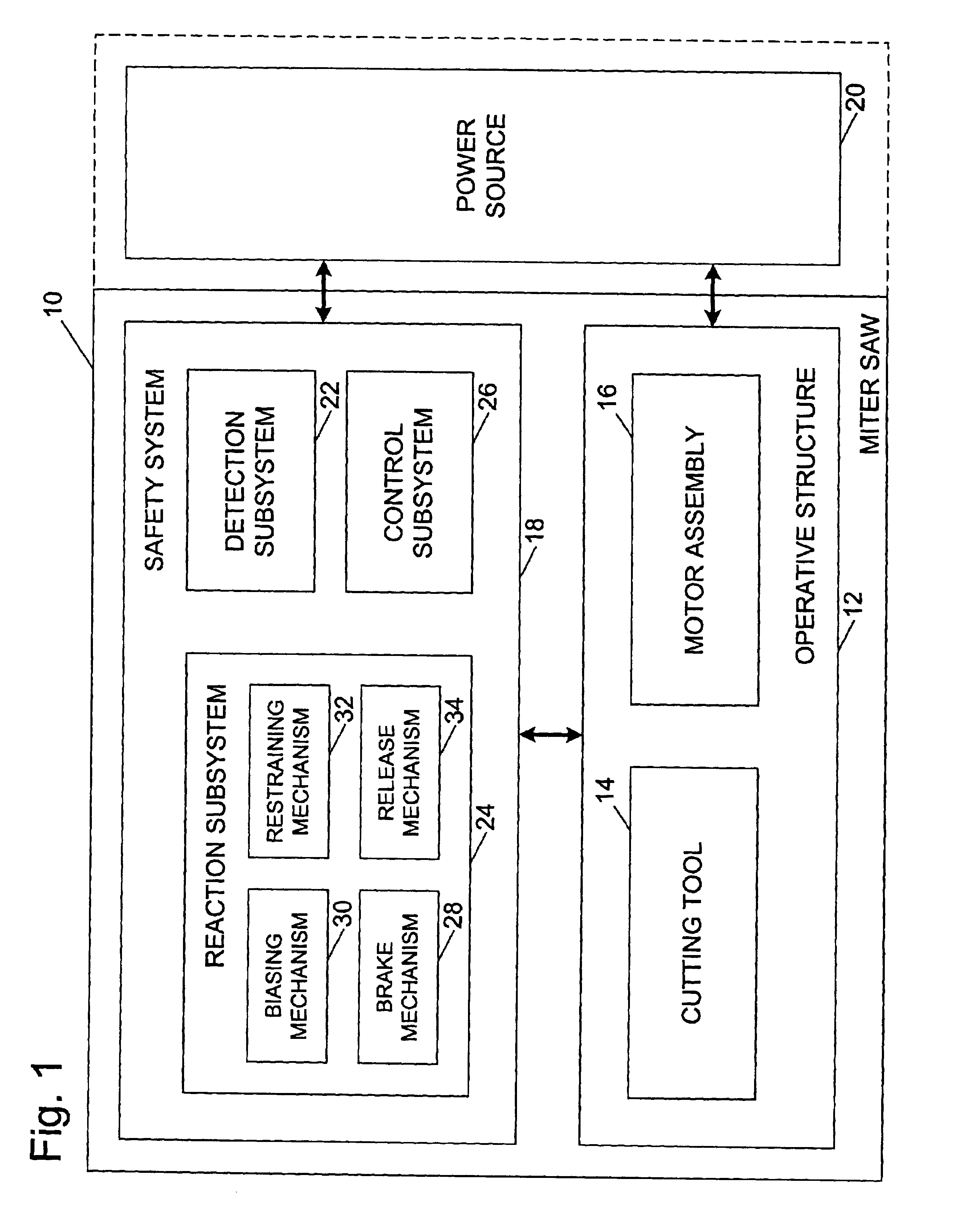

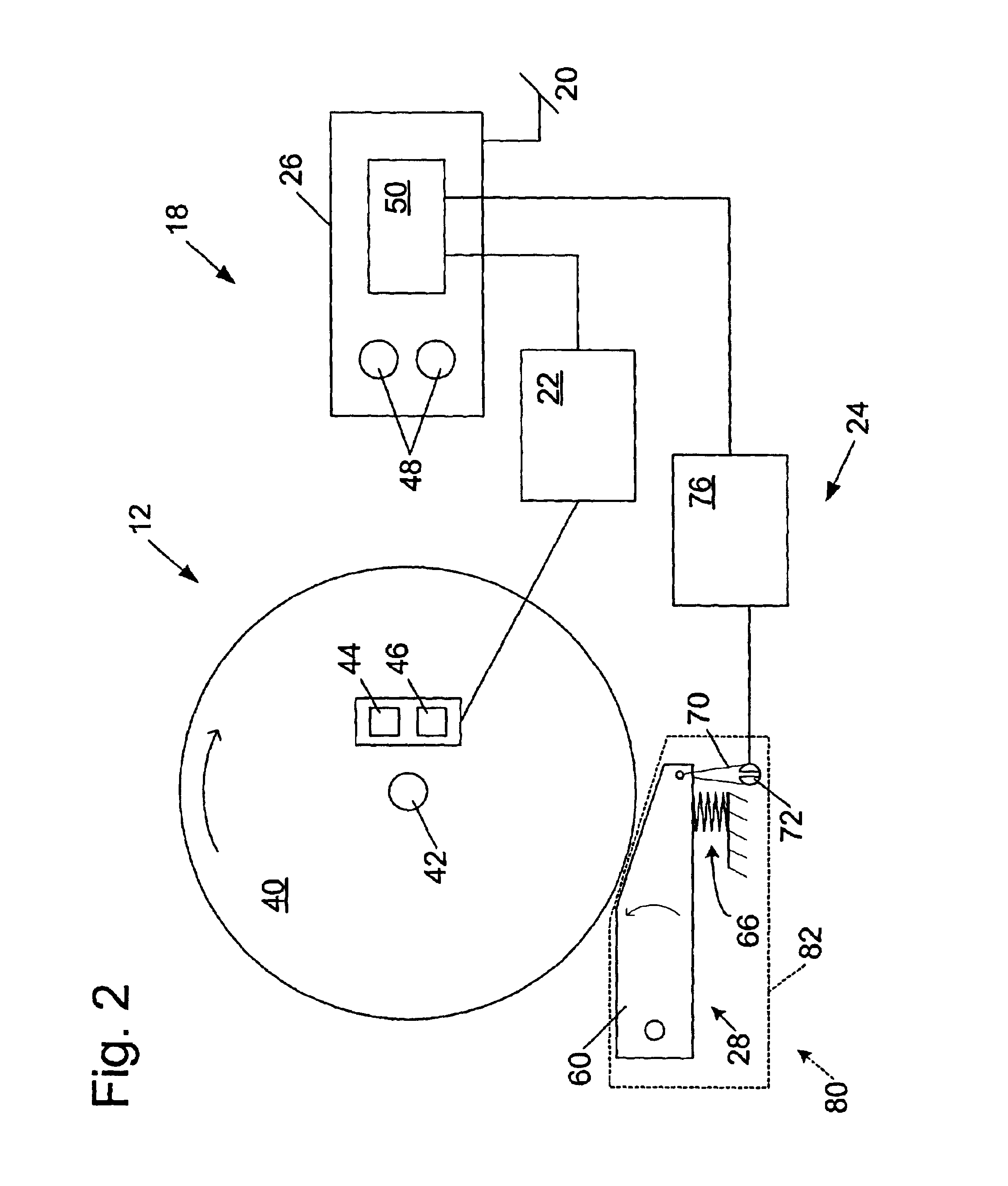

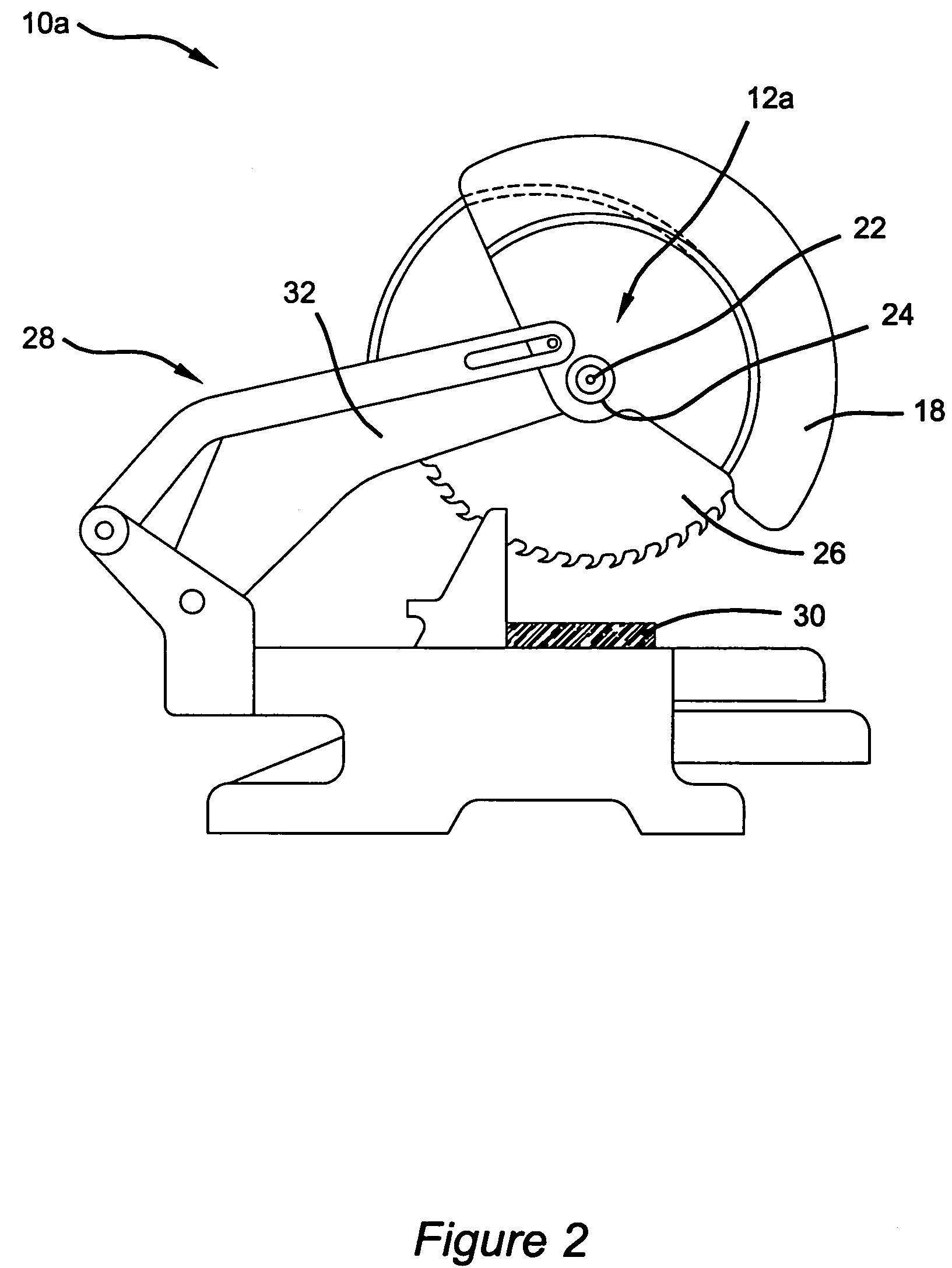

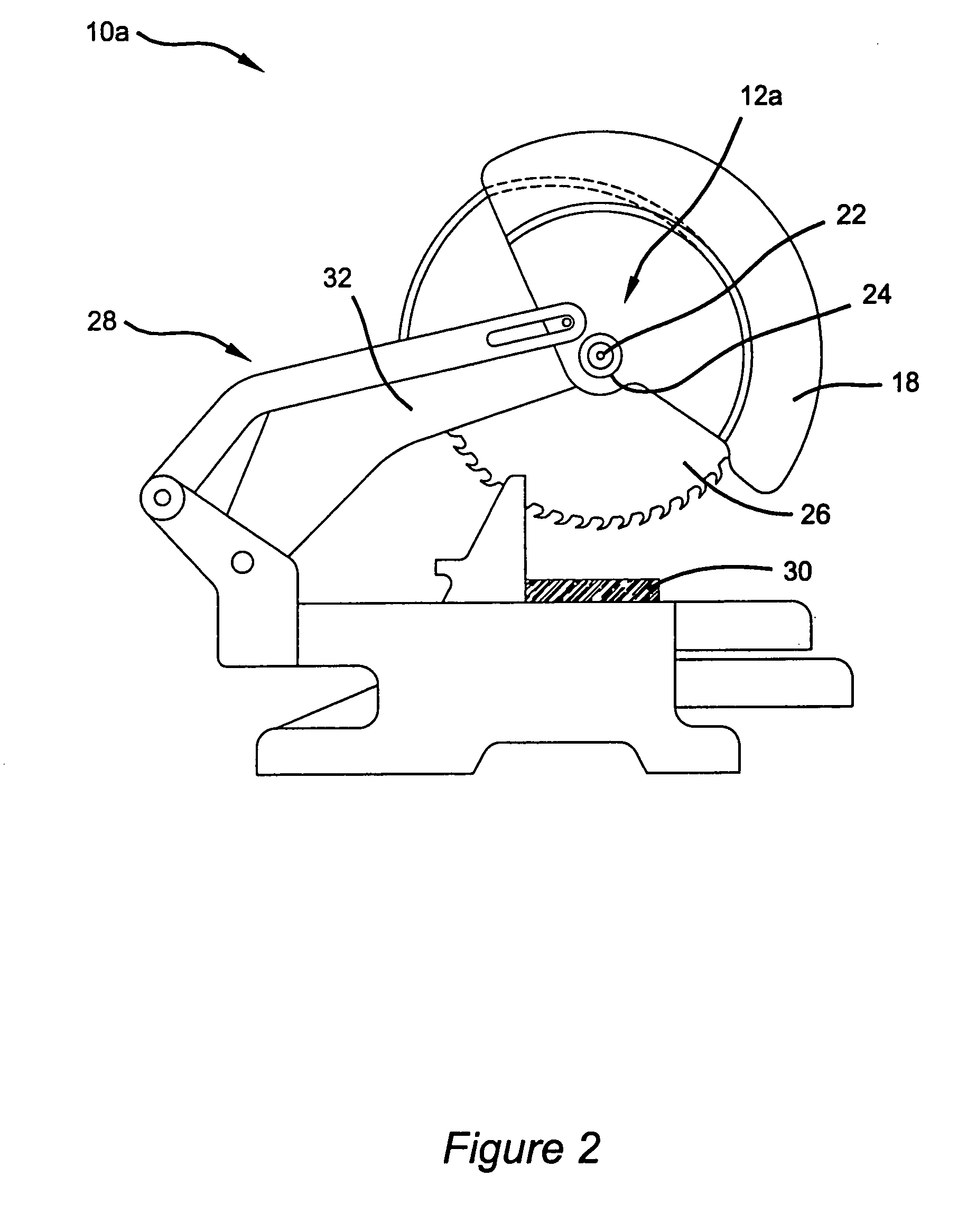

Miter saw with improved safety system

InactiveUS6826988B2Increase opportunitiesLimit and even prevent injuryEmergency protective circuit arrangementsEngineering safety devicesEngineeringWoodworking machine

A woodworking machine is disclosed having a base, a blade, a detection system adapted to detect a dangerous condition between a person and the blade, and a reaction system associated with the detection system to cause a predetermined action to take place upon detection of the dangerous condition. The blade is rotatable, and moves into a cutting zone to cut a workpiece. The predetermined action may be to stop the blade from rotating and / or to stop movement of the blade toward the cutting zone.

Owner:SAWSTOP HLDG LLC

Miter saw with improved safety system

InactiveUS6880440B2Limit and even prevent injuryImprove the security systemEmergency protective circuit arrangementsEngineering safety devicesEngineeringMechanical engineering

A miter saw having a base and an arm that pivots toward the base is disclosed. A blade is supported by the arm, and is designed to cut workpieces resting on the base when the arm and blade pivot downward. The saw includes a detection system configured to detect one or more dangerous conditions between a person and the blade, such as when a person accidentally touches the spinning blade, and the saw includes a reaction system to stop the downward movement of the blade and arm when the dangerous condition is detected.

Owner:SAWSTOP HLDG LLC

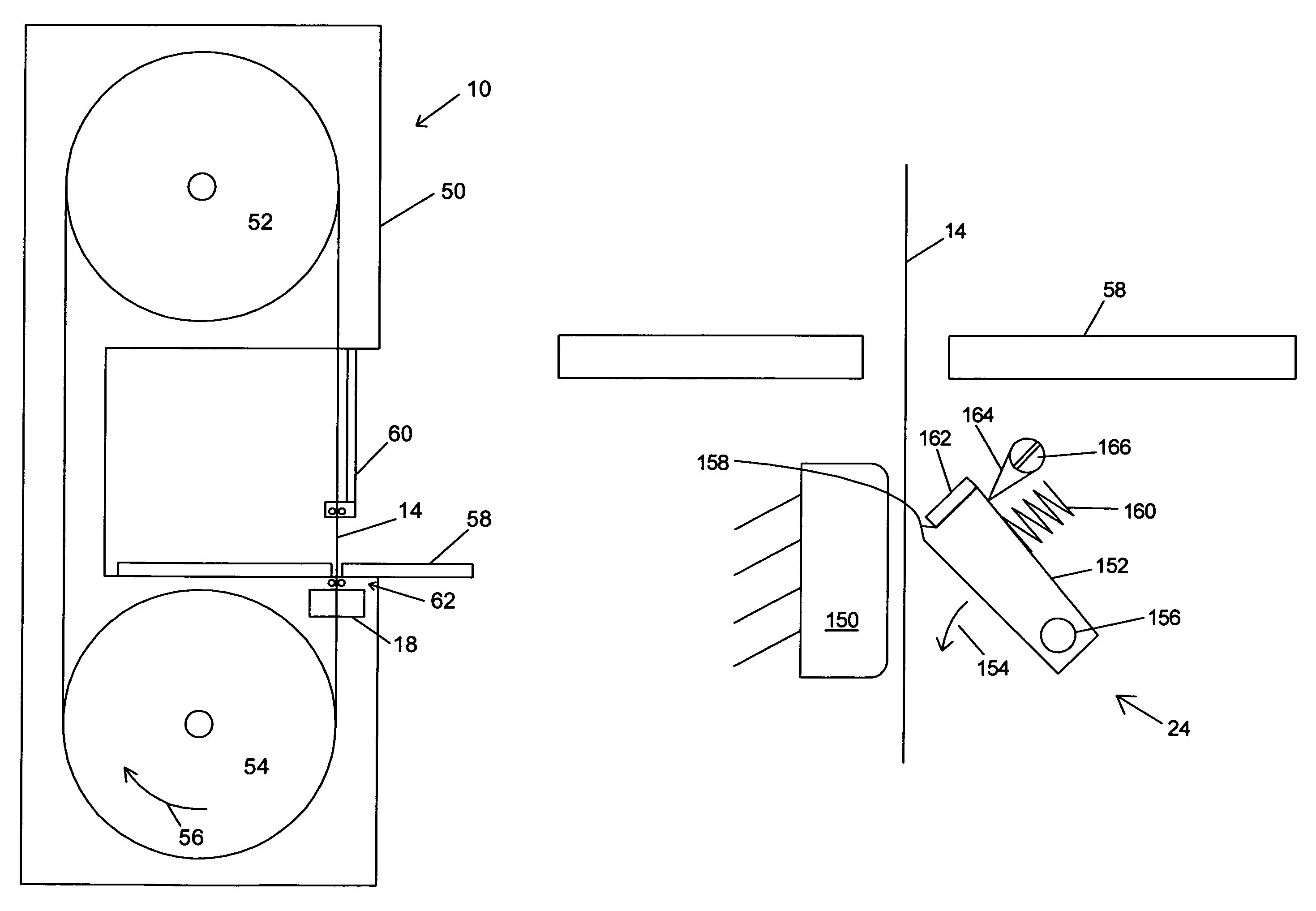

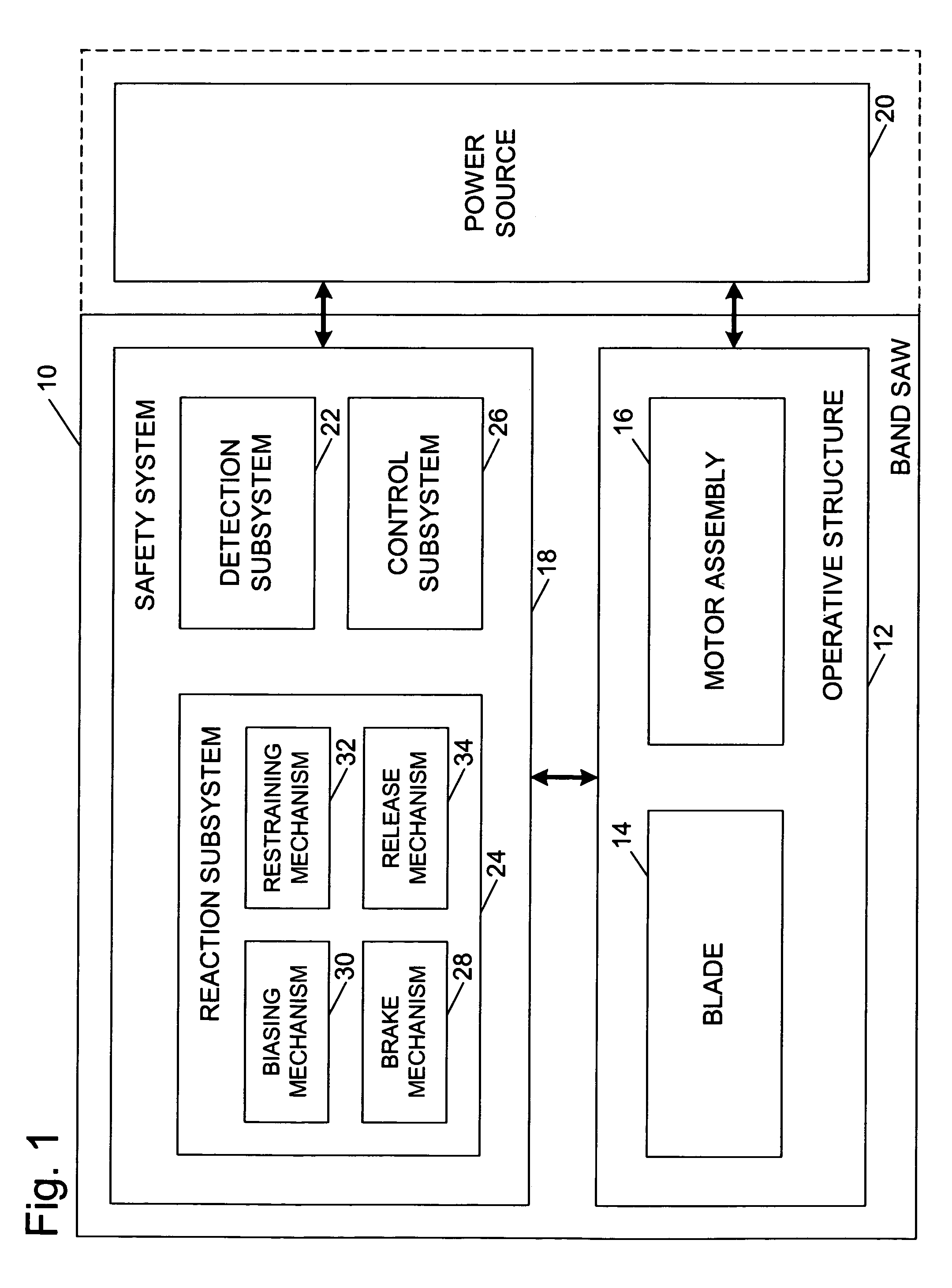

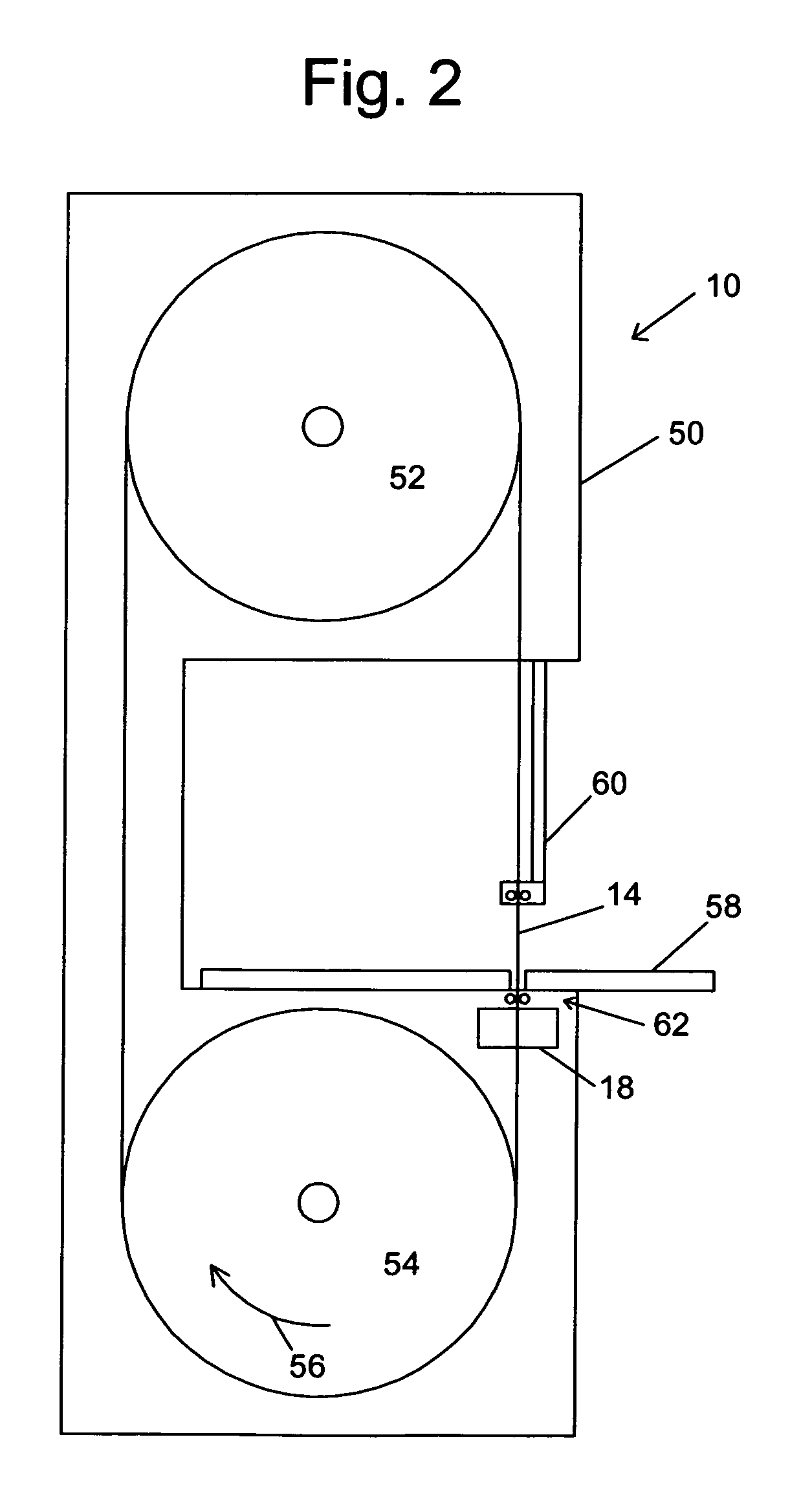

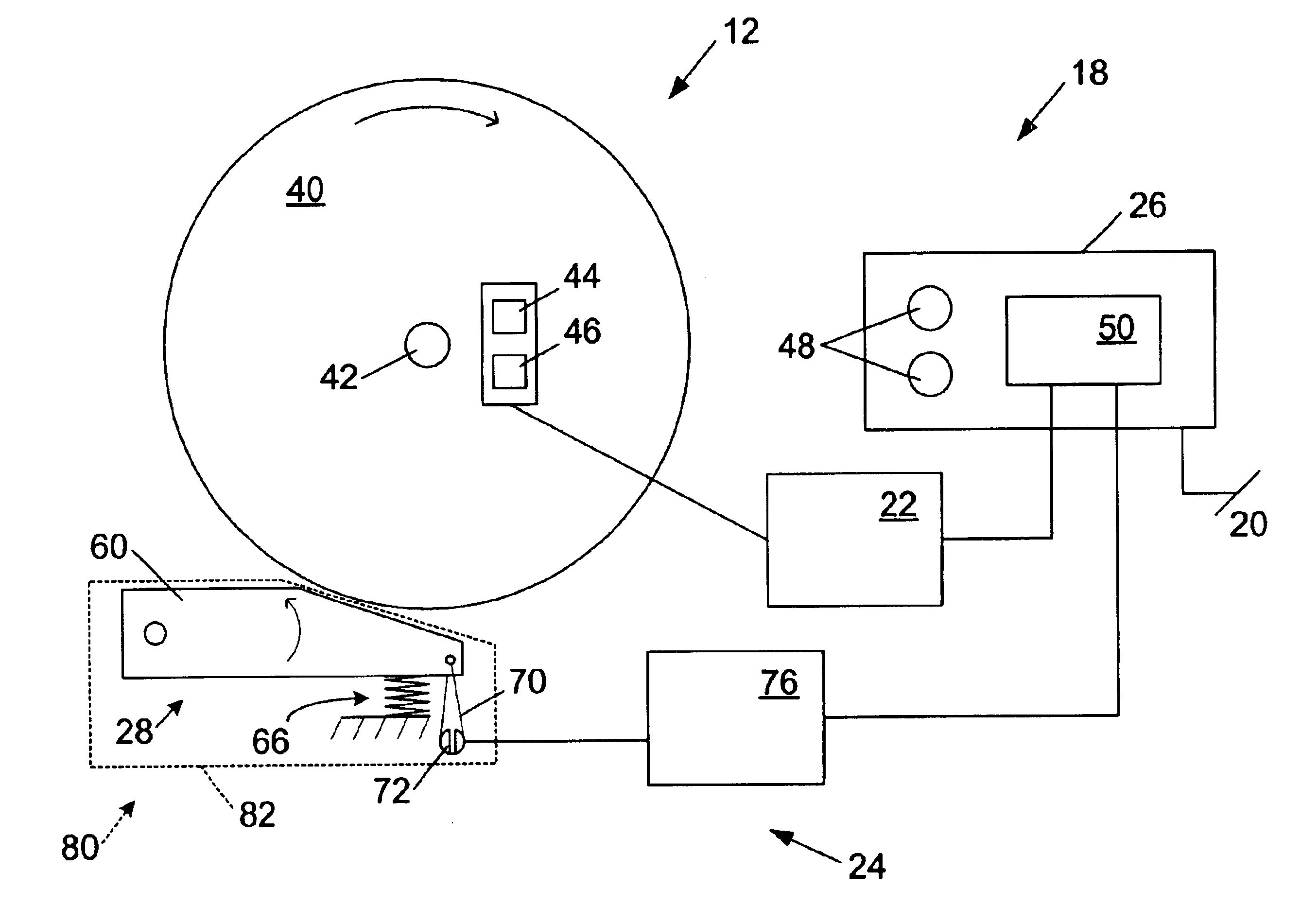

Safety systems for band saws

Owner:SAWSTOP HLDG LLC

Safety systems for power equipment

A saw with a safety system is disclosed. The safety system includes a detection system adapted to detect contact between a person and a blade while the blade is moving. The safety system further includes a brake system adapted to engage the blade and to stop the blade when the detection system detects contact between the person and the blade.

Owner:SAWSTOP HLDG LLC

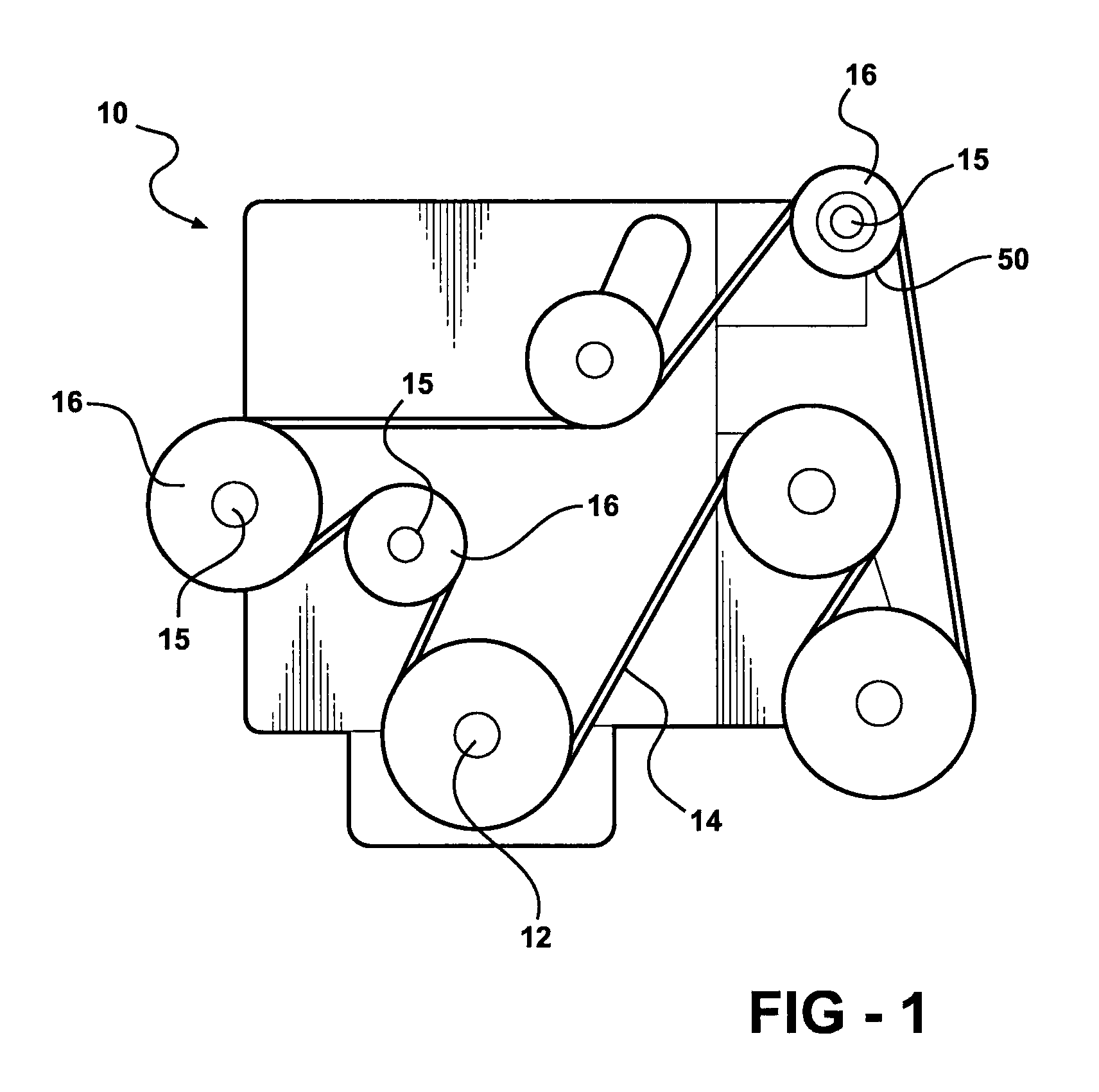

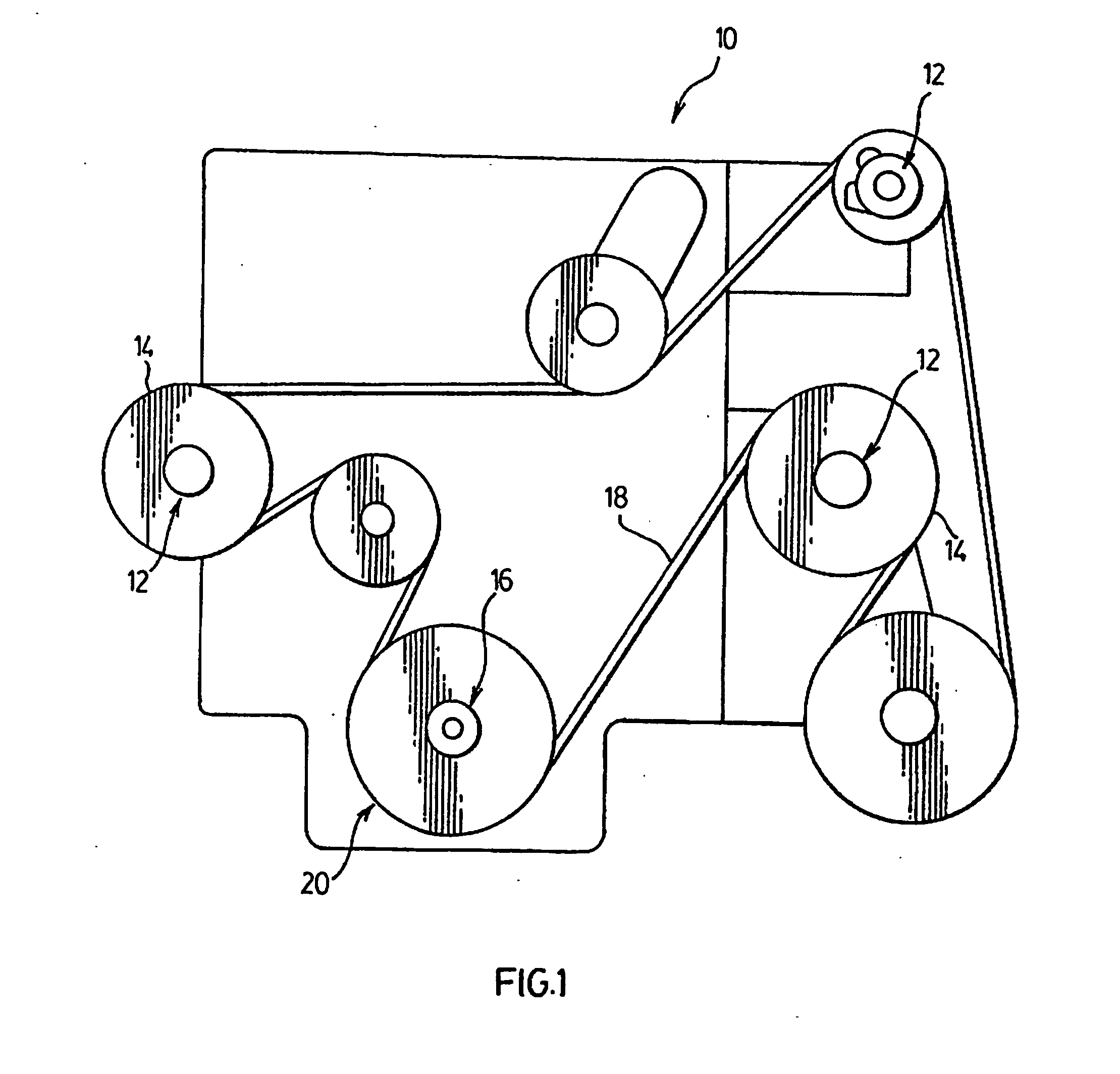

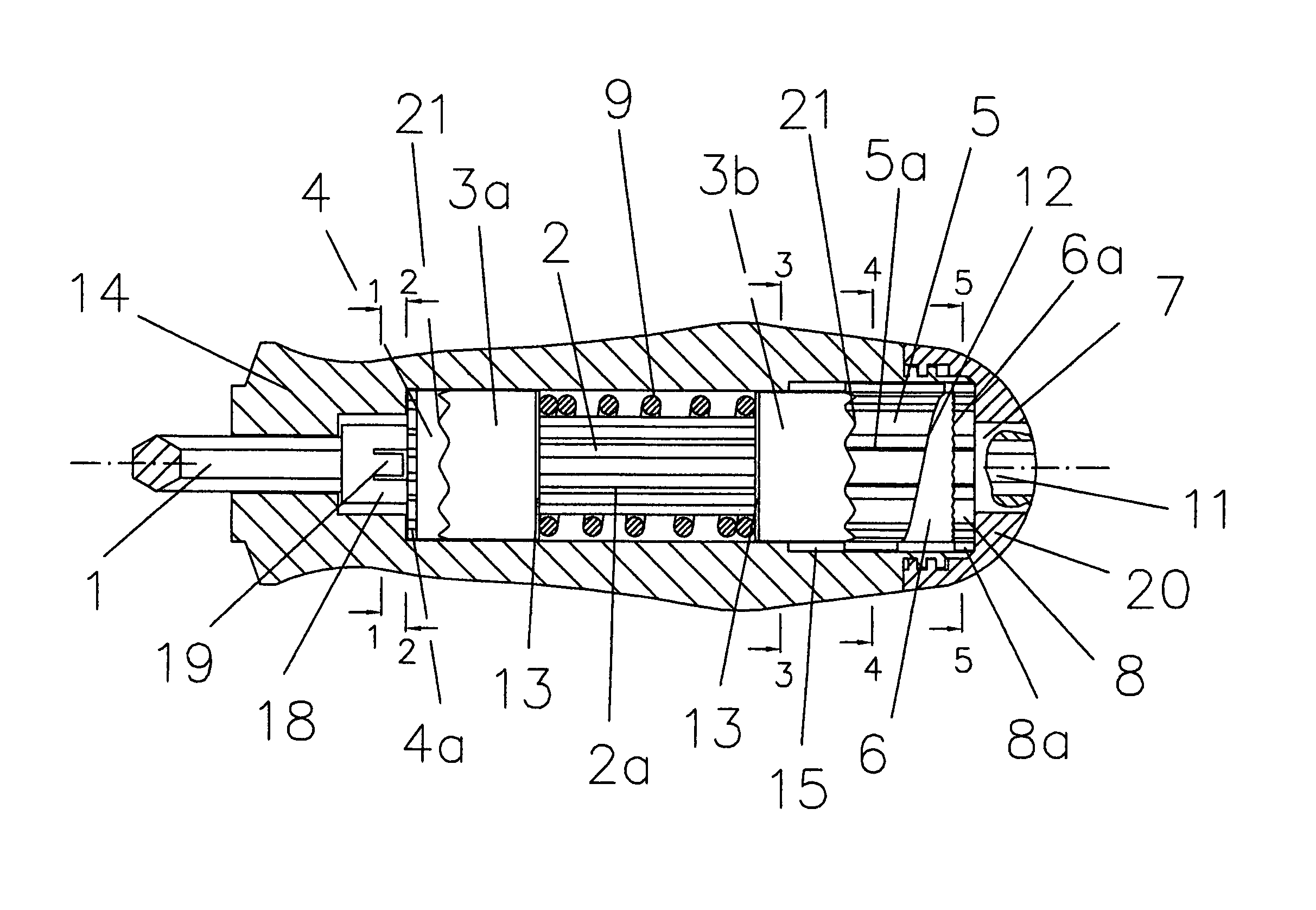

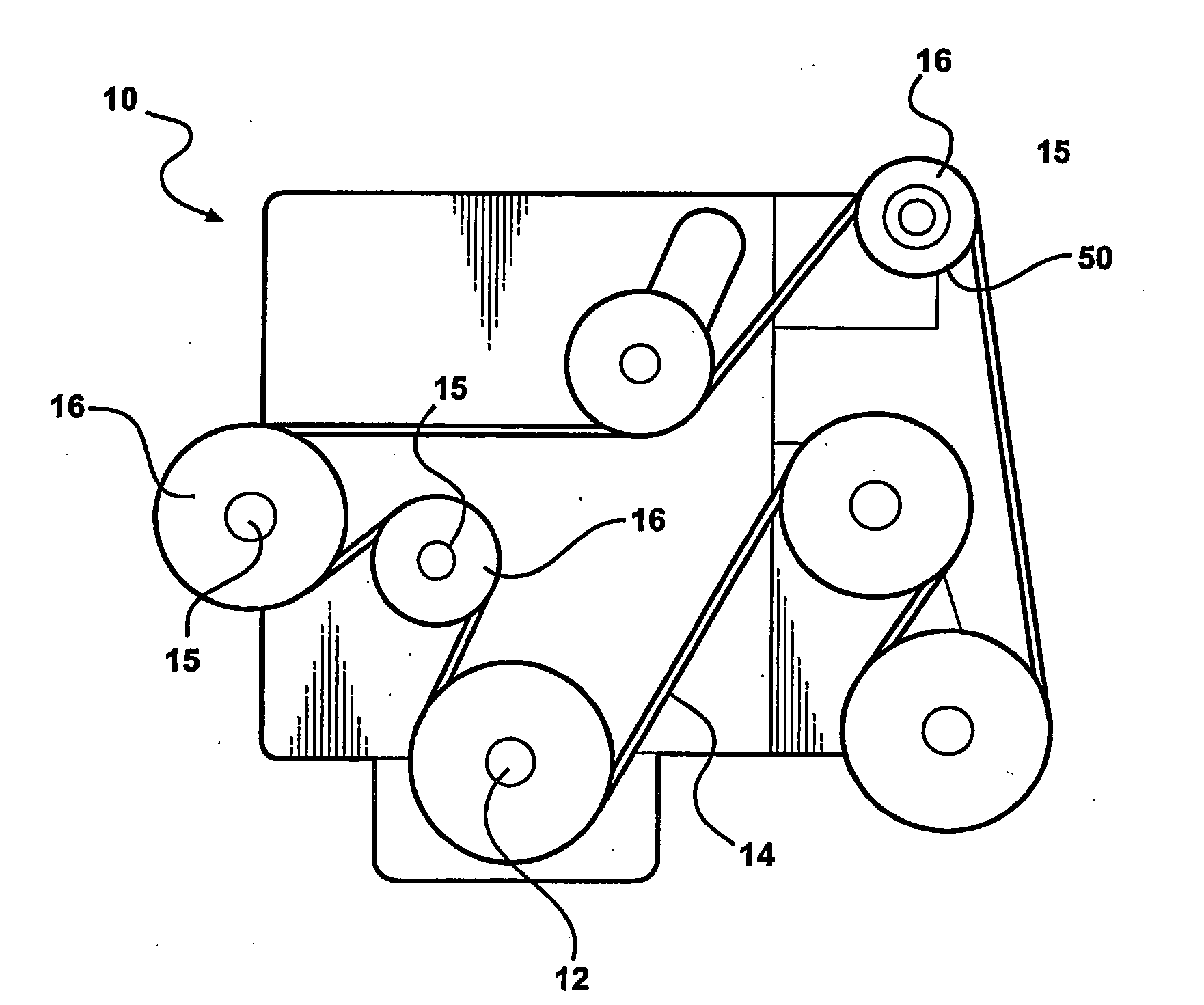

Spring travel limiter for overrunning alternator decoupler

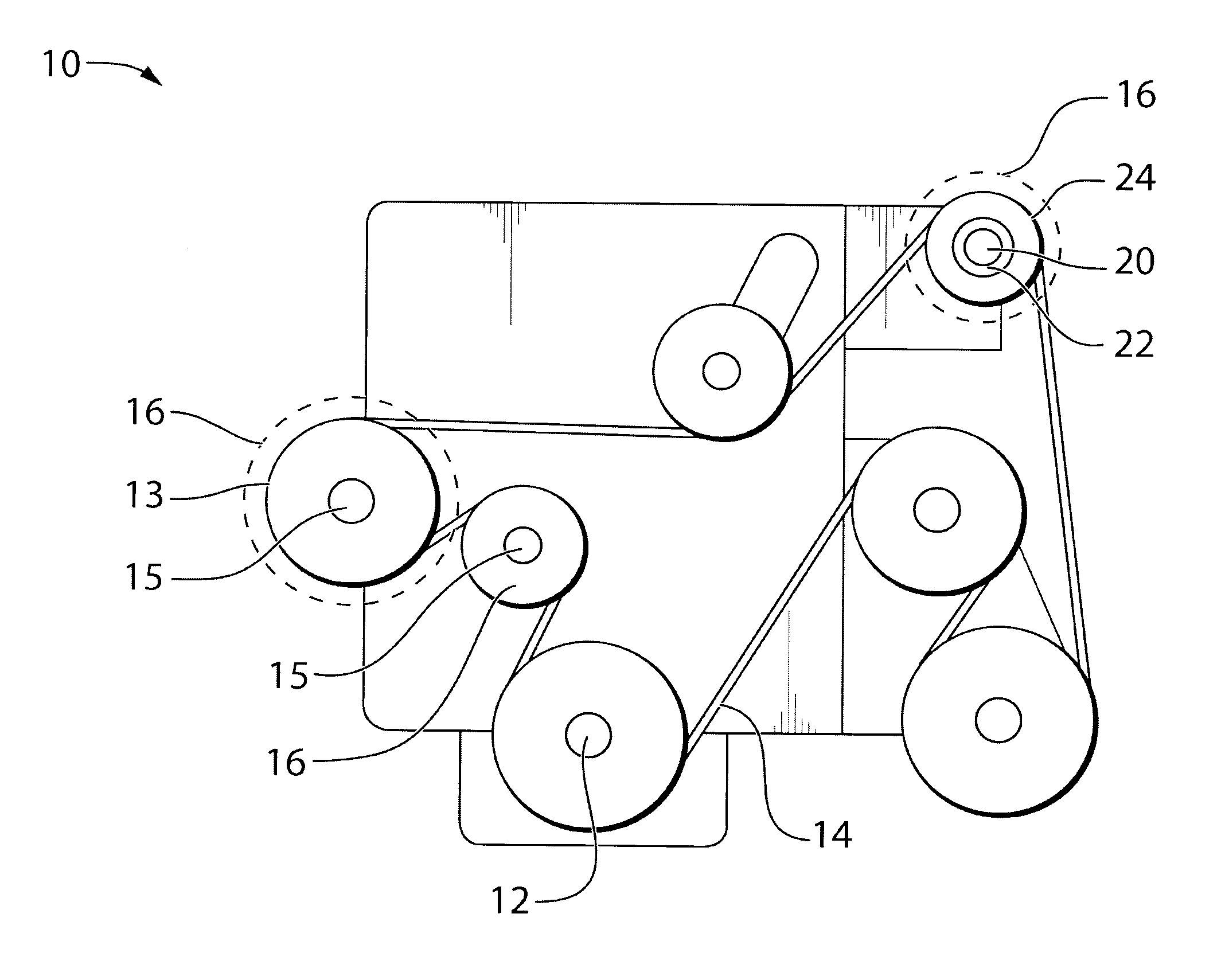

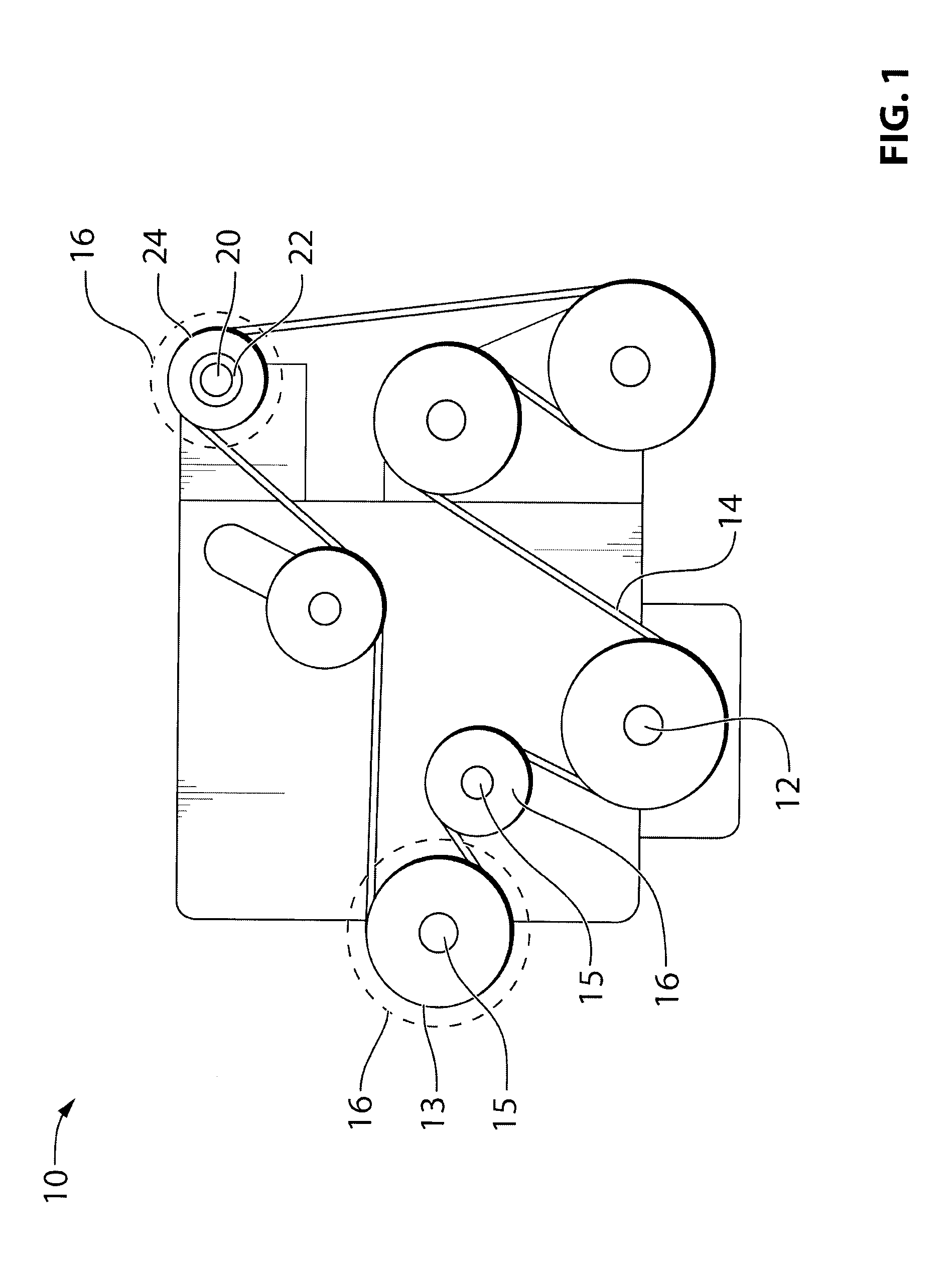

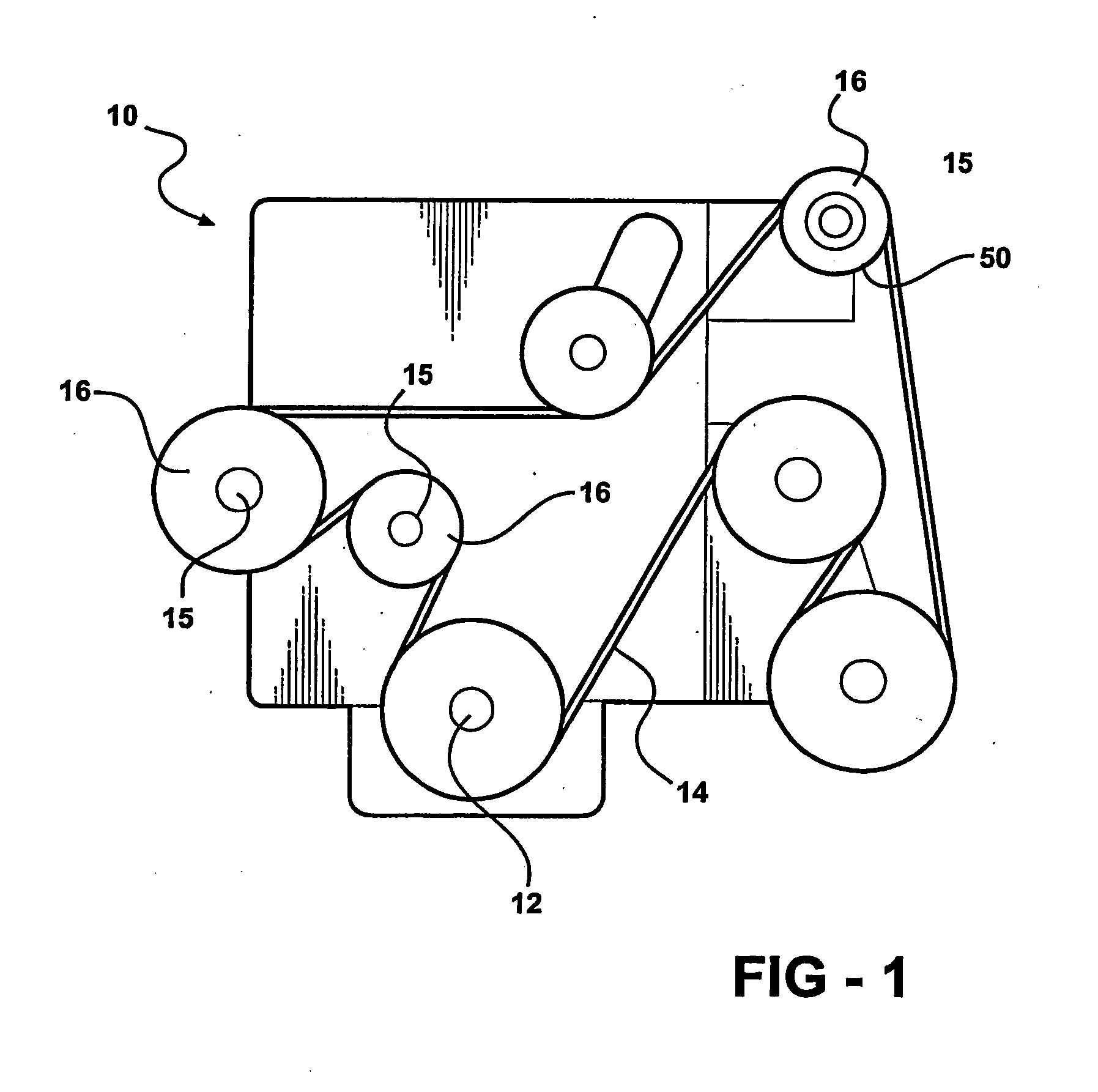

ActiveUS7712592B2Prevent movementPrevent rotationYielding couplingSlip couplingSerpentine beltAlternator

A decoupler assembly for transferring rotary movement between an engine driven shaft and a serpentine belt. The decoupler includes a hub configured to be assembled to the shaft. The hub has a helical first slot formed therein. A pulley is rotatably coupled to the hub. A carrier is mounted on the hub and includes a helical second slot formed therein, as well as an anti-ramp up boss formed thereon. A thrust plate is fixed to the hub and has a slot formed therein. A torsion spring is compressed between a hub end retained in the helical first slot and a carrier end retained in the helical second slot for transferring torque between the hub and carrier. The anti-ramp up boss travels within the slot formed in the thrust plate for limiting rotation between the carrier and thrust plate and preventing rotation of the torsion spring relative to the hub and carrier.

Owner:LITENS AUTOMOTIVE INC

Detection system for power equipment

Woodworking machines including conductive cutters adapted to cut workpieces, and motors adapted to drive the cutters are disclosed. The machines also include a contact detection system adapted to detect contact between a person and the cutter, and to distinguish contact between the person and the cutter from contact between the workpiece and the cutter. The machines further include a reaction system adapted to cause a predetermined action to take place upon detection of contact between the person and the cutter by the contact detection system.

Owner:SAWSTOP HLDG LLC

Isolator decoupler

An isolator decoupler comprising a pulley, a shaft, a bushing slidingly engaged with the pulley and slidingly engaged with the shaft, the pulley journalled to the shaft by a bearing, a one-way clutch fixed to the shaft and engaged with the bushing whereby the bushing rotates in unison with the one-way clutch, a torsion spring engaged between the pulley and the one-way clutch to resiliently couple the pulley to the shaft, and the pulley non-resiliently directly coupleable to the shaft in a temporary predetermined loaded condition.

Owner:THE GATES CORP

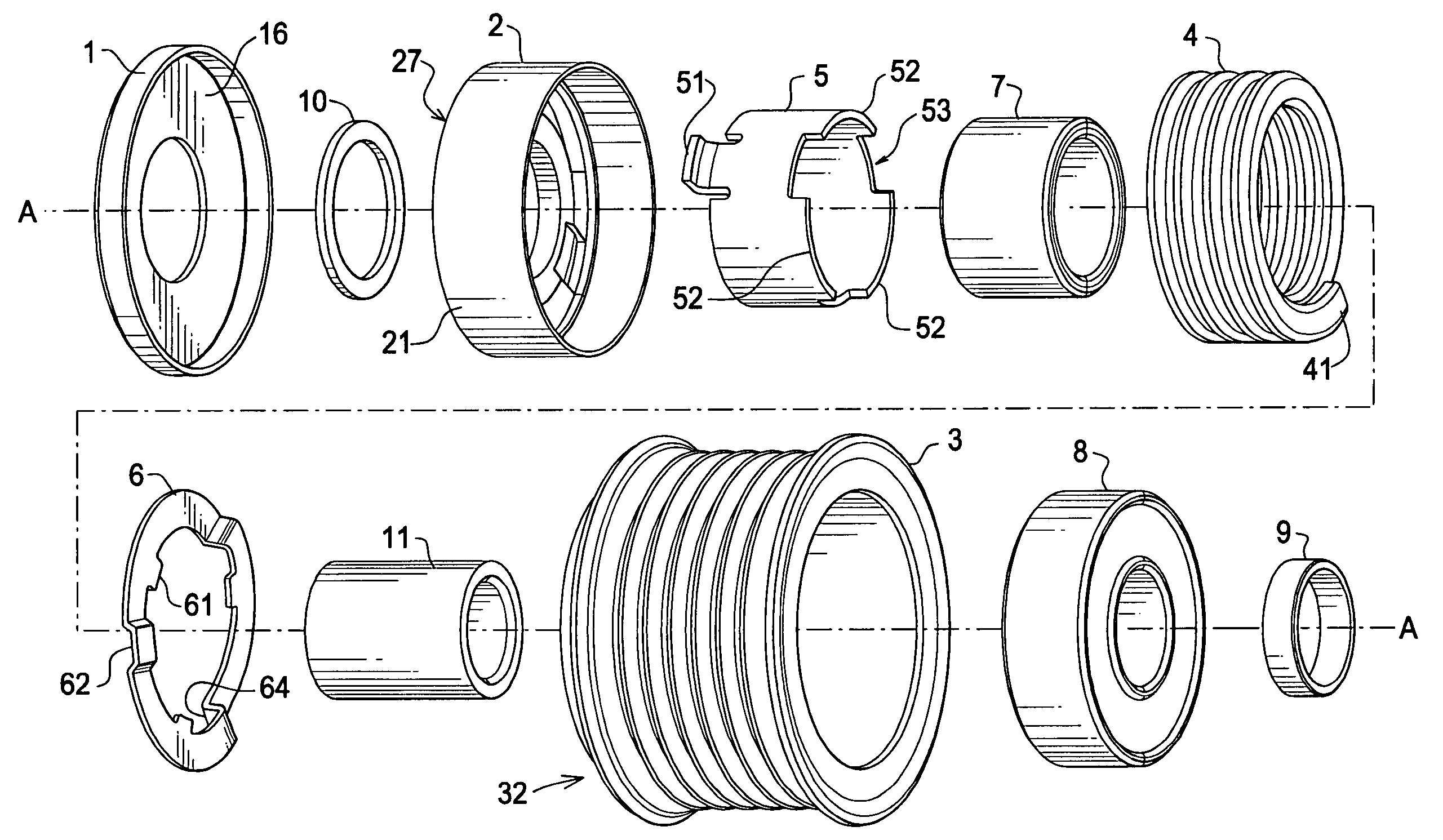

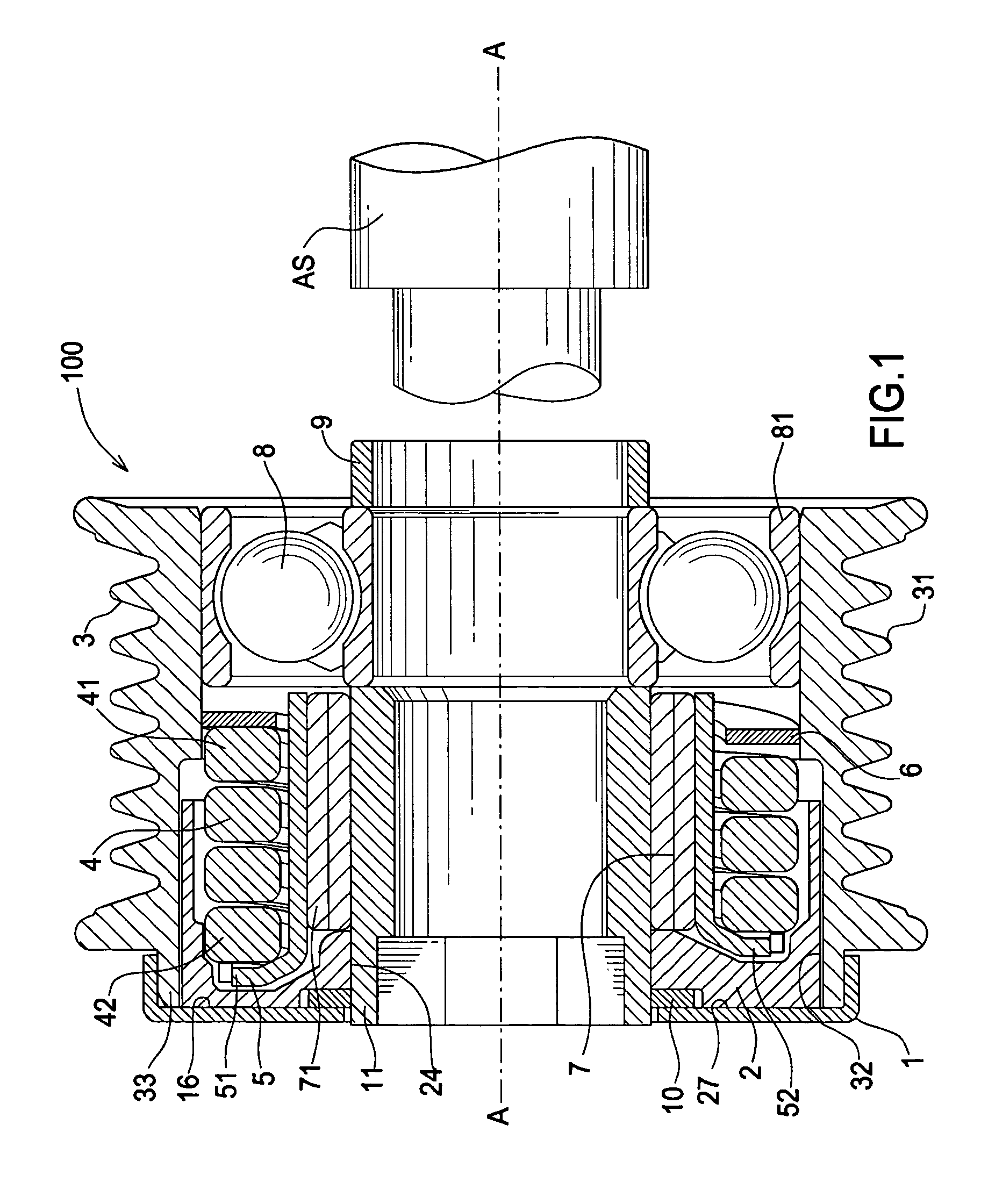

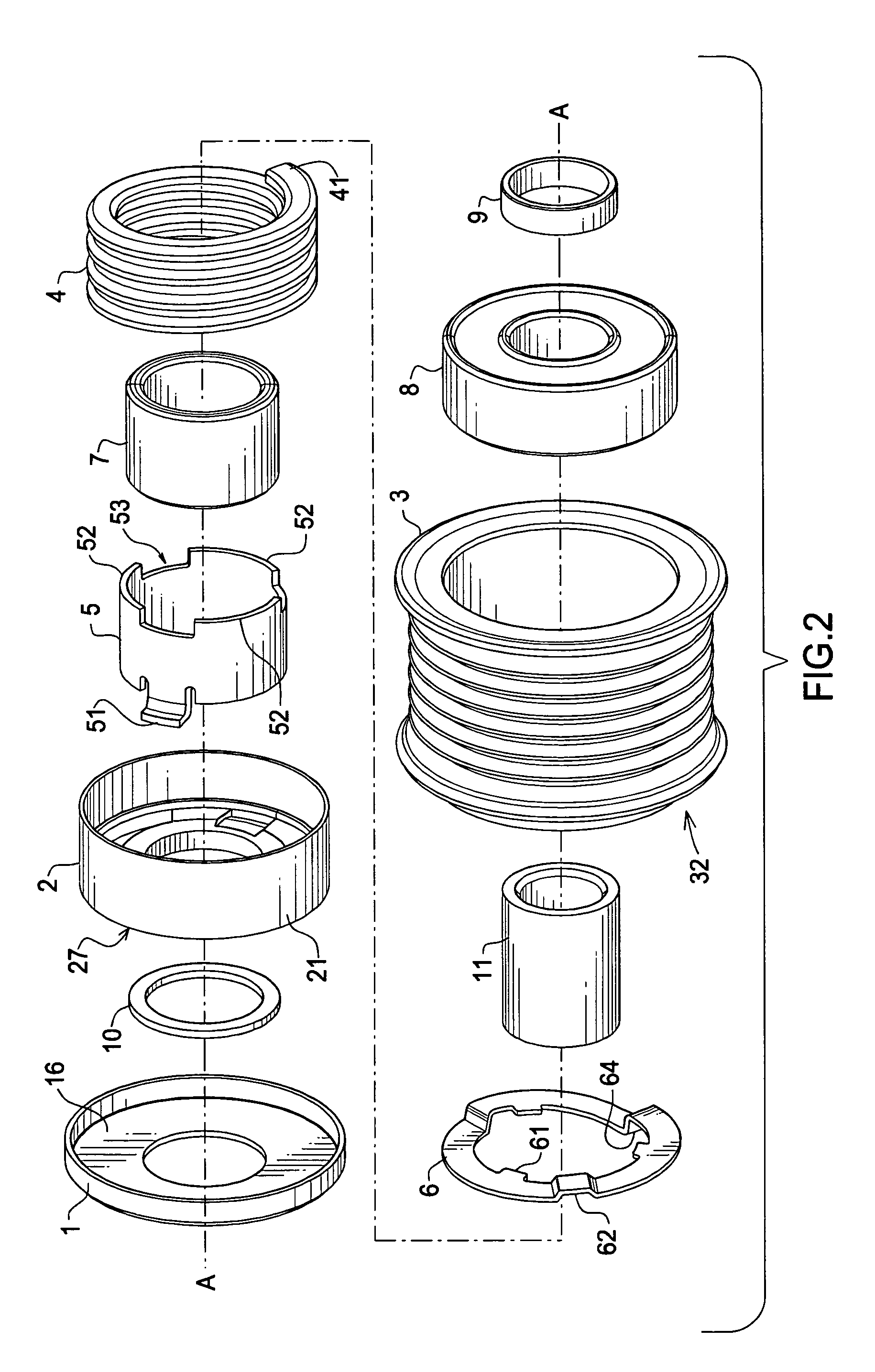

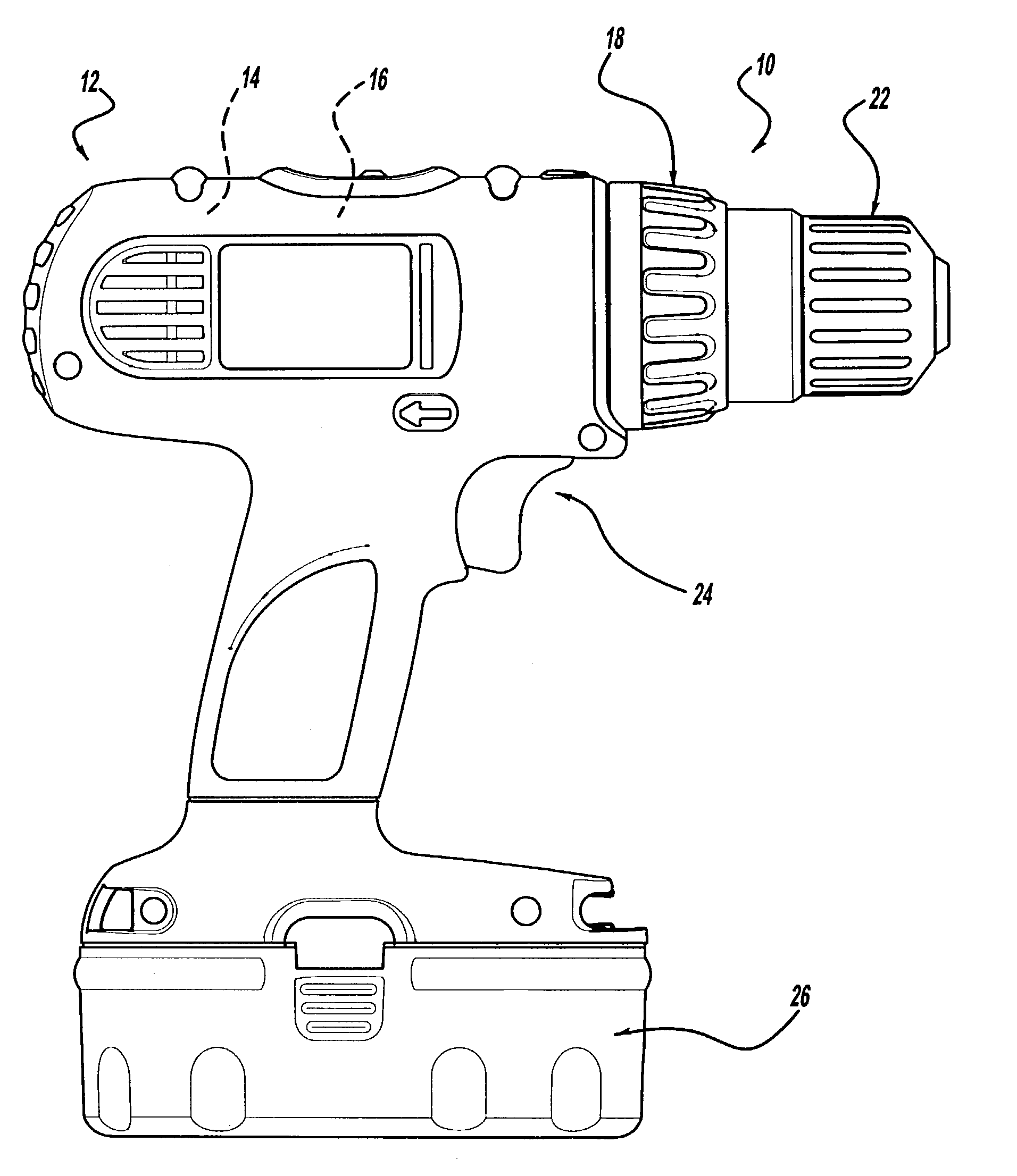

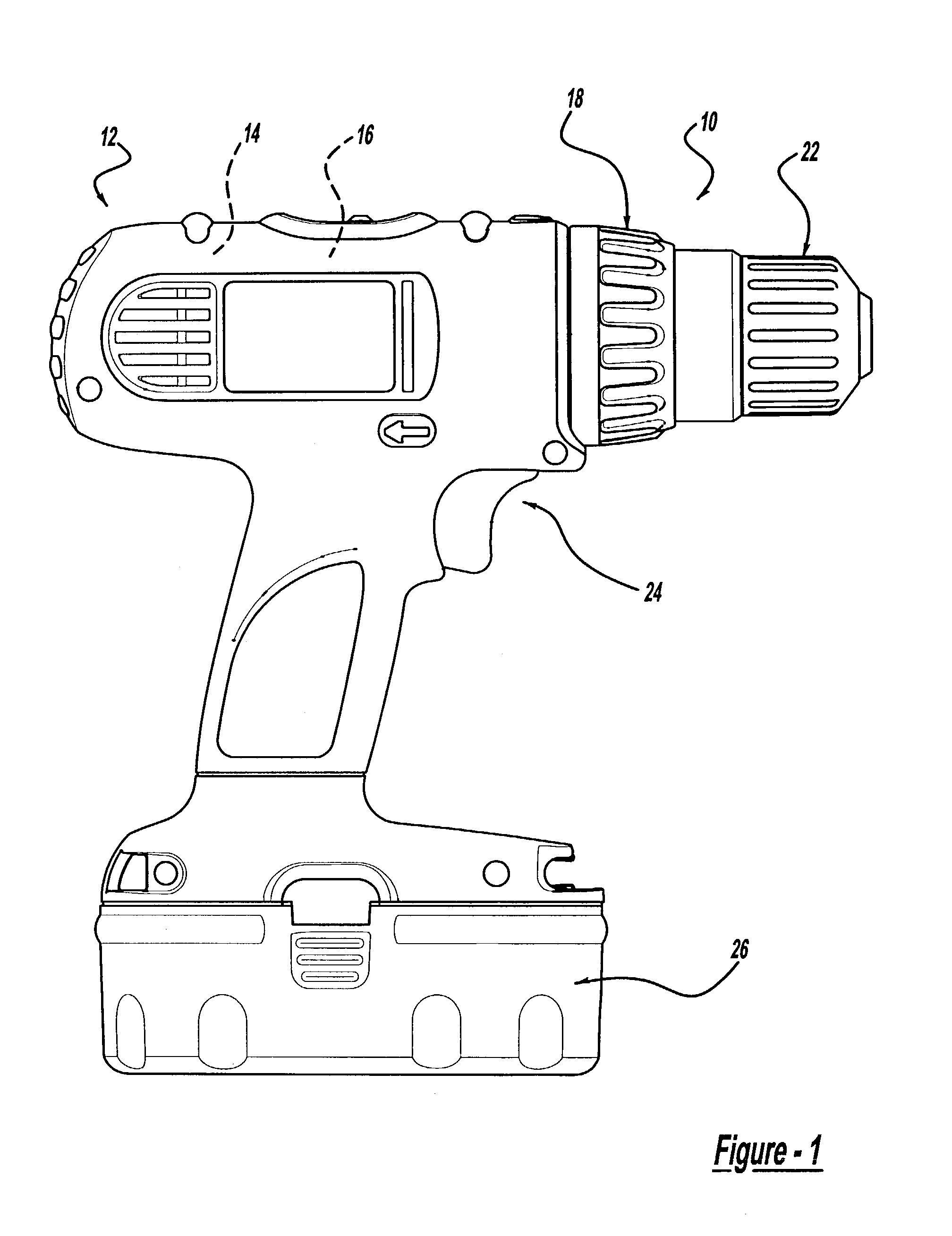

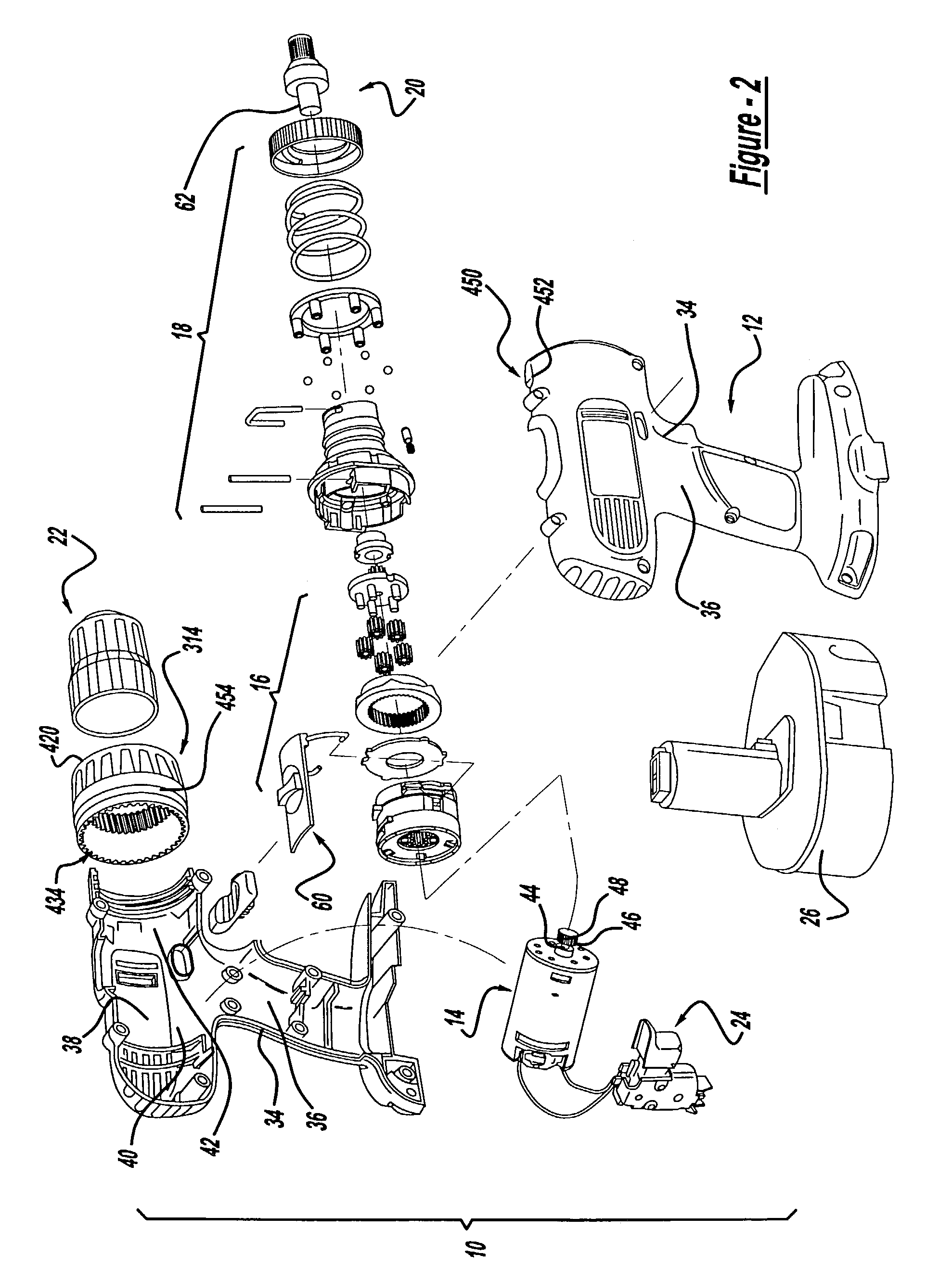

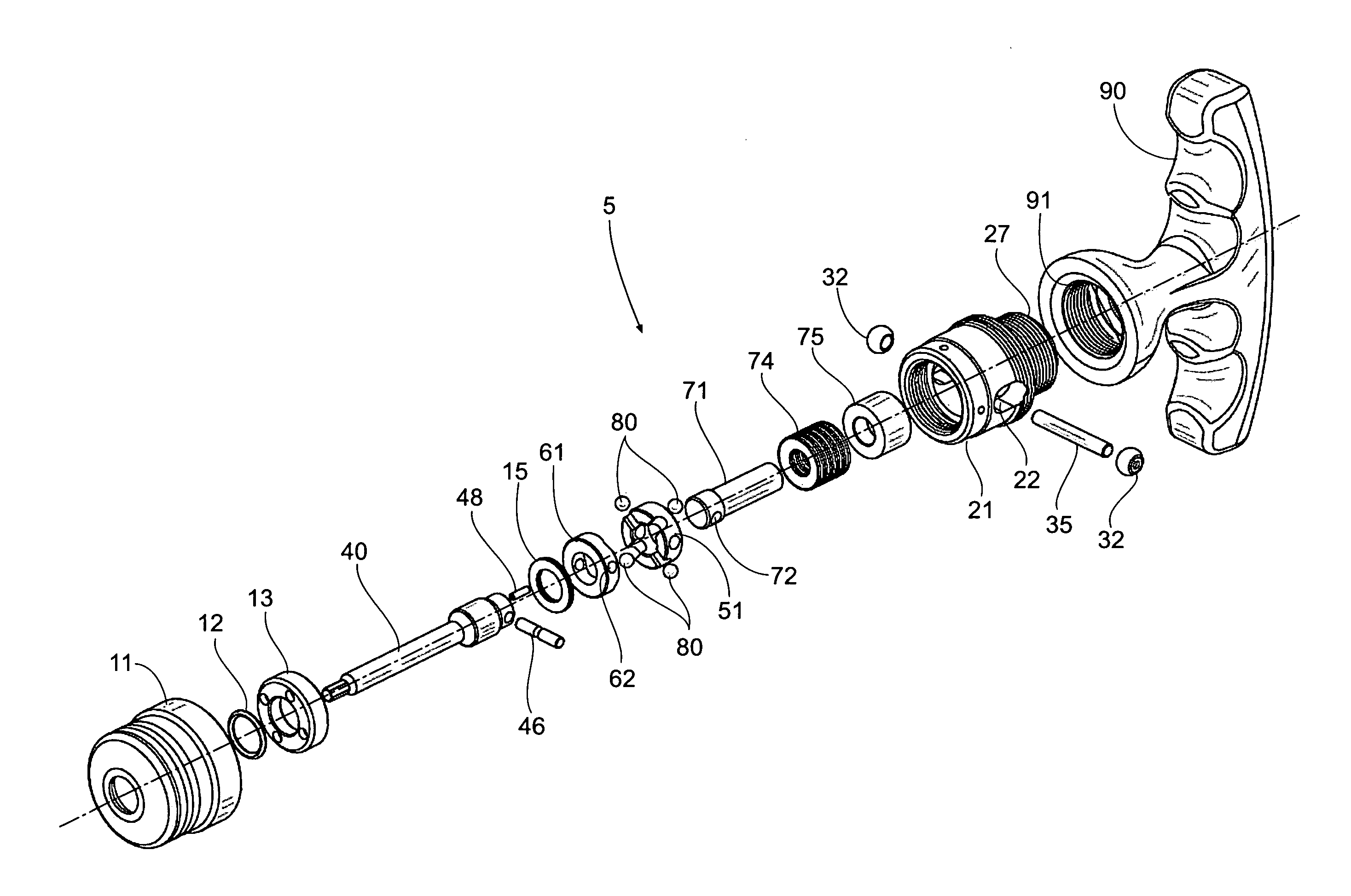

Power drill/driver

ActiveUS7066691B2Limit torsional outputOptimization mechanismThread cutting auxillary apparatusSlip couplingHand heldEngineering

A hand-held power tool having a multi-speed transmission and a clutch. The multi-speed transmission and the clutch are coupled to one another via a set of interconnecting tabs that are slidingly engaged to one another and secured with pins to inhibit the withdrawal of the tabs from one another. The clutch may include a clutch member, a unitarily formed clutch plate and a plurality of engagement members. The clutch plate includes an annular plate member and a plurality of leg members that extend generally perpendicularly from the annular plate member and which bias the engagement members into engagement with the clutch member. The clutch member may be coupled to an element of the multi-speed transmission, such as to the ring gear of a planetary gear set, so as to reduce the overall size of the power tool.

Owner:BLACK & DECKER INC

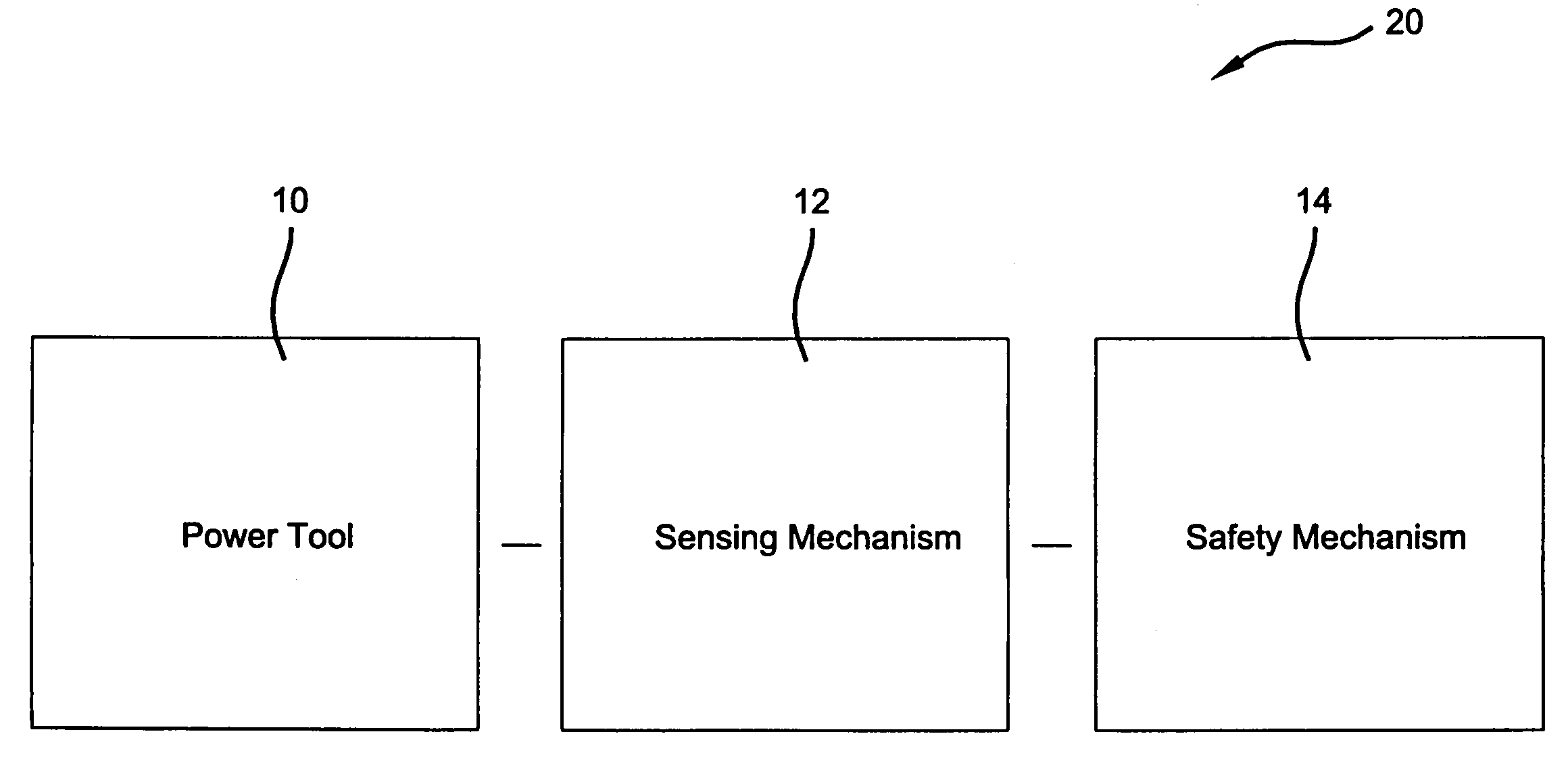

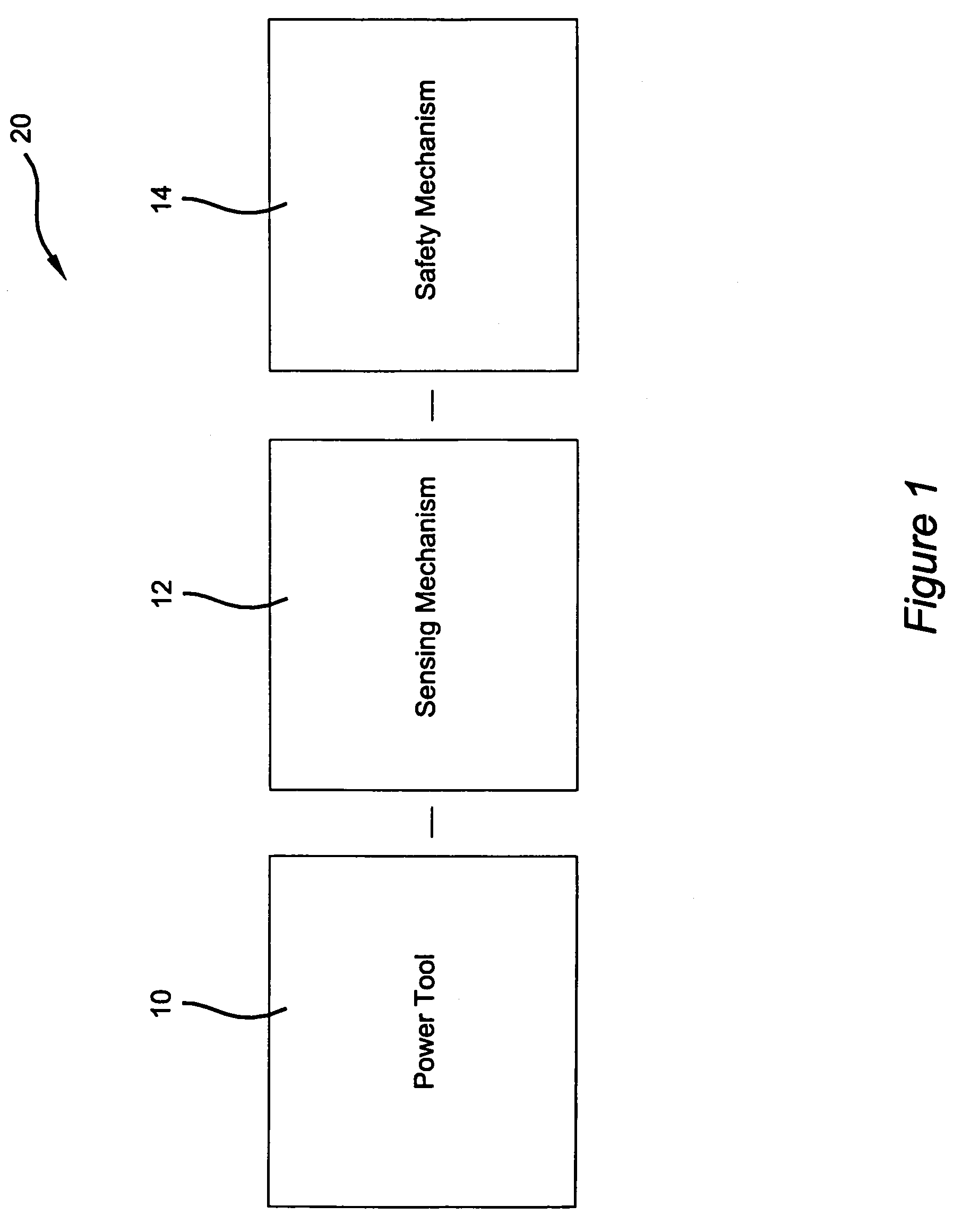

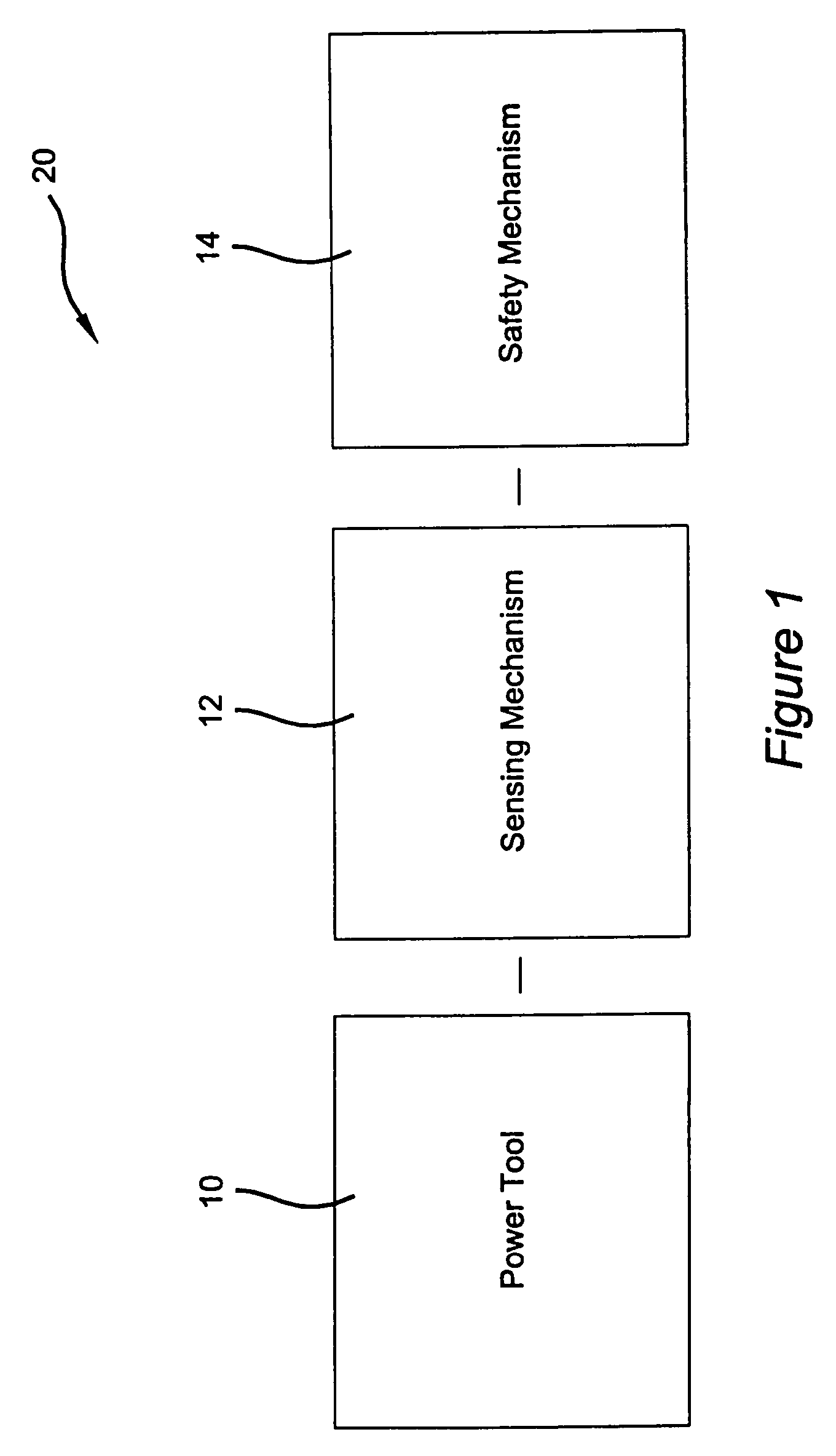

Power tool safety mechanisms

A sensing mechanism (12) for detecting user contact with an active portion (26) of the power tool (10) is provided. In addition, a safety mechanism (14) for preventing prolonged user contact with the active portion (26) of a power tool (10) is provided. The safety mechanism (14) is configured to actuate upon receipt of a signal from the sensing mechanism (12). According to a first aspect, the safety mechanism (14) is arranged to rapidly displace the active portion (26) away from a user extremity. Alternatively, according to a second aspect, the safety mechanism (14) is arranged to rapidly urge an extremity of the user away from the active portion (26) of the power tool (10).

Owner:BLACK & DECKER INC

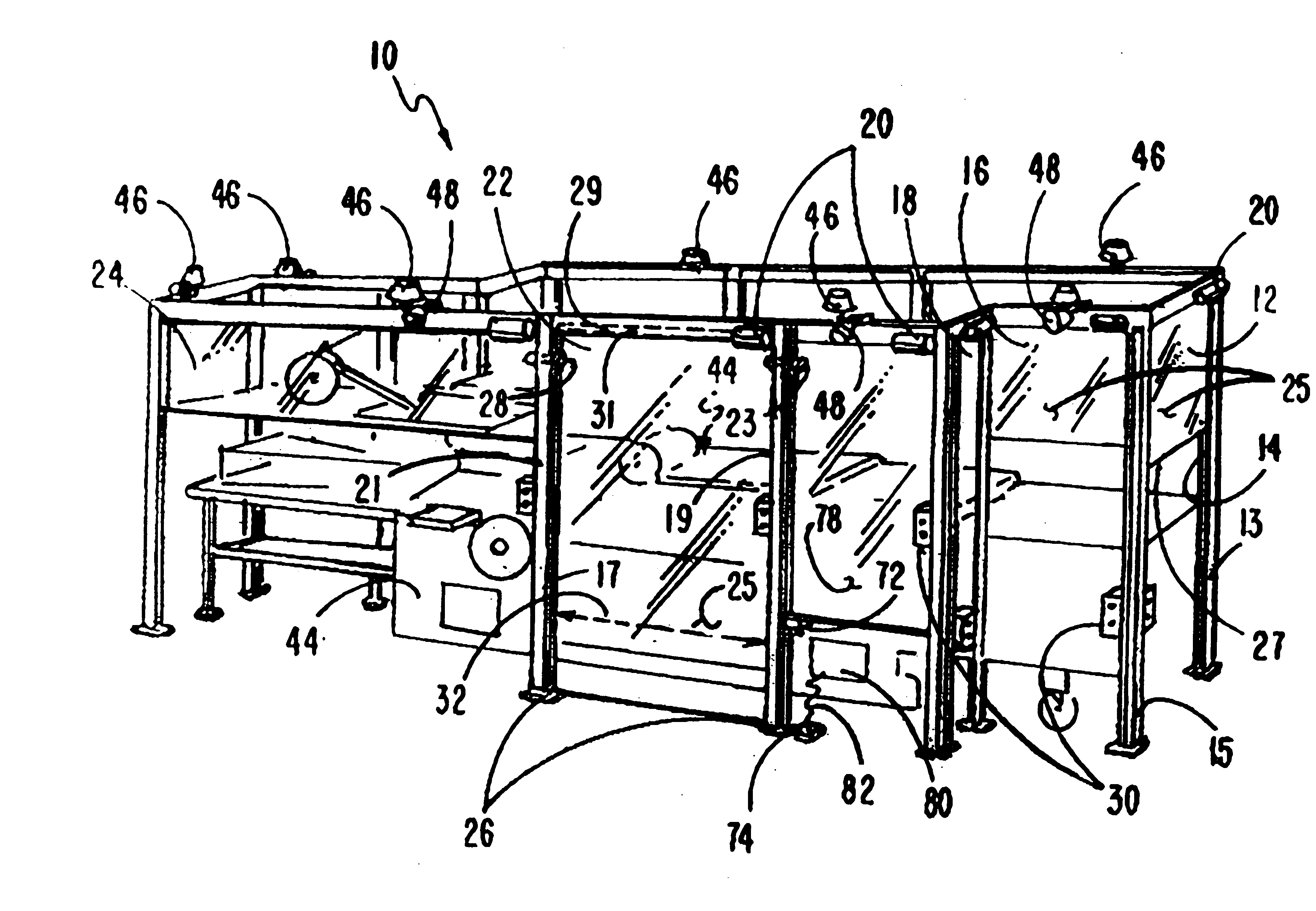

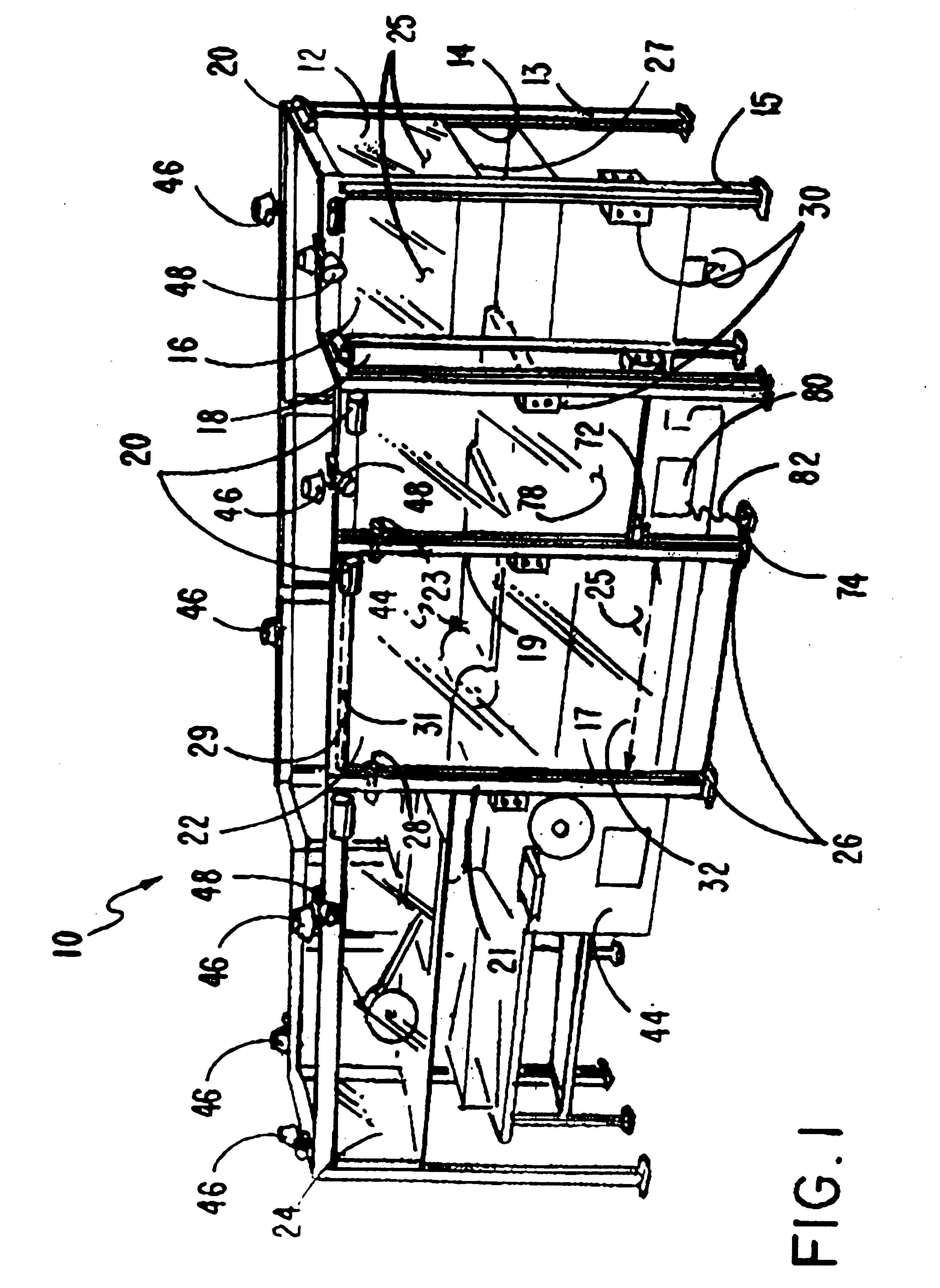

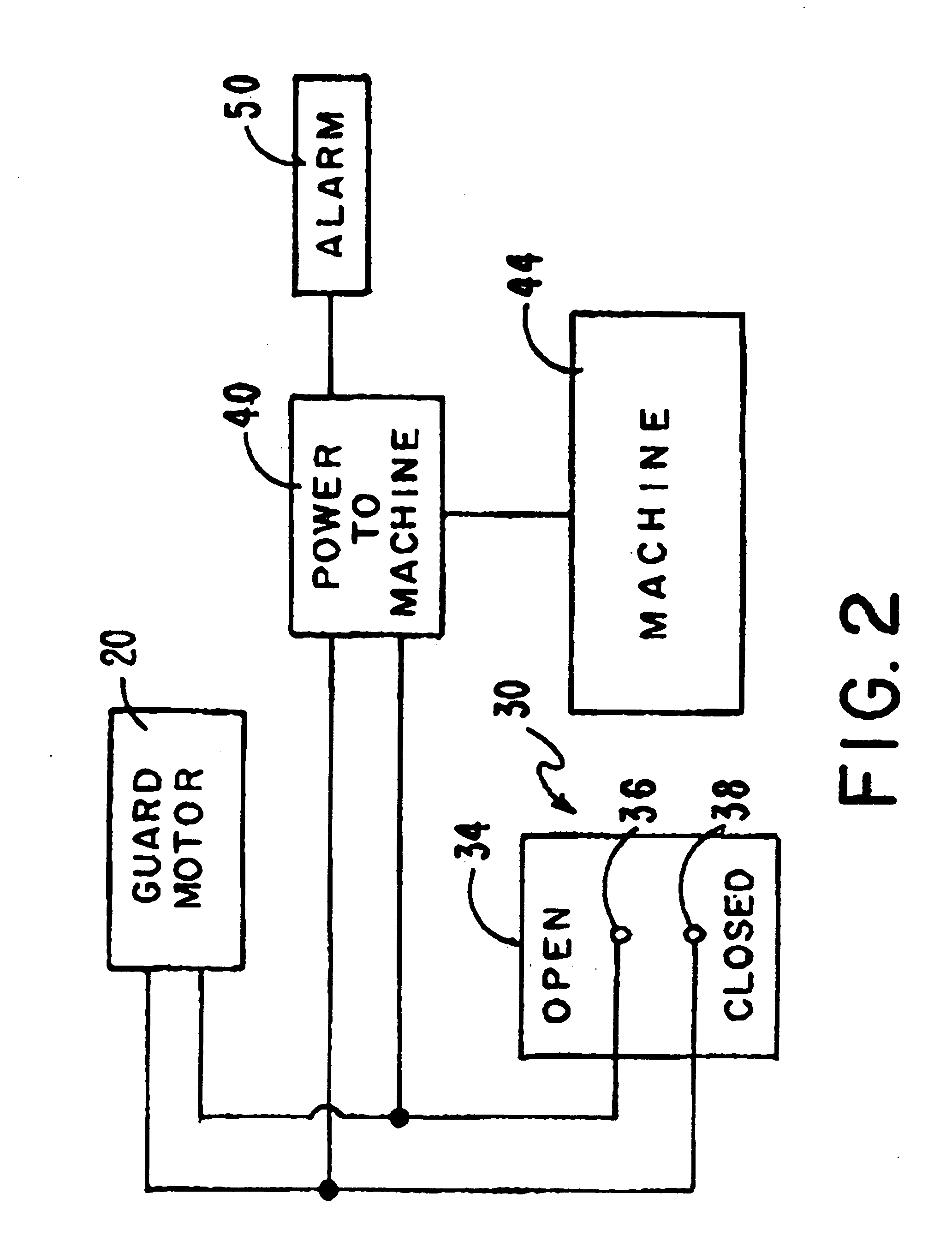

Machine safety guard

InactiveUS6325195B1Easy to operateProvide securityYielding couplingShutters/ movable grillesUnit systemEngineering

A machine safety guard unit system having a flexible panel moved upwards and downwards between track members with the system positioned between the operative parts of a machine and a machine operator, such panel when closed protecting the machine operator and when moved upwards into its open mode, allowing access to the machine and preventing the machine from operating. In some embodiments more than one of such units can be disposed around a machine with alarm means; and in yet other embodiments, with interengagement means connecting such units.

Owner:RITE HITE HLDG CORP

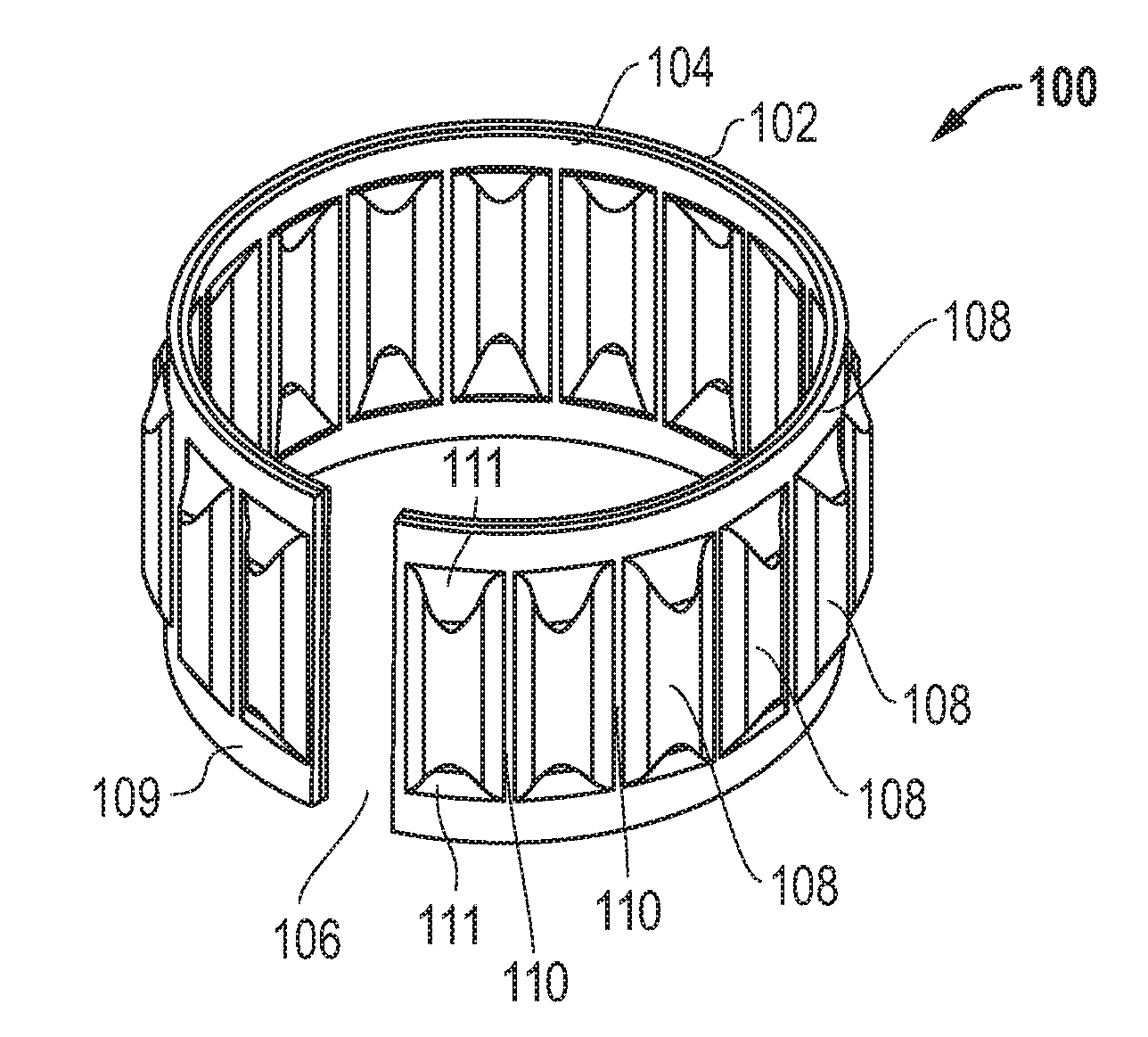

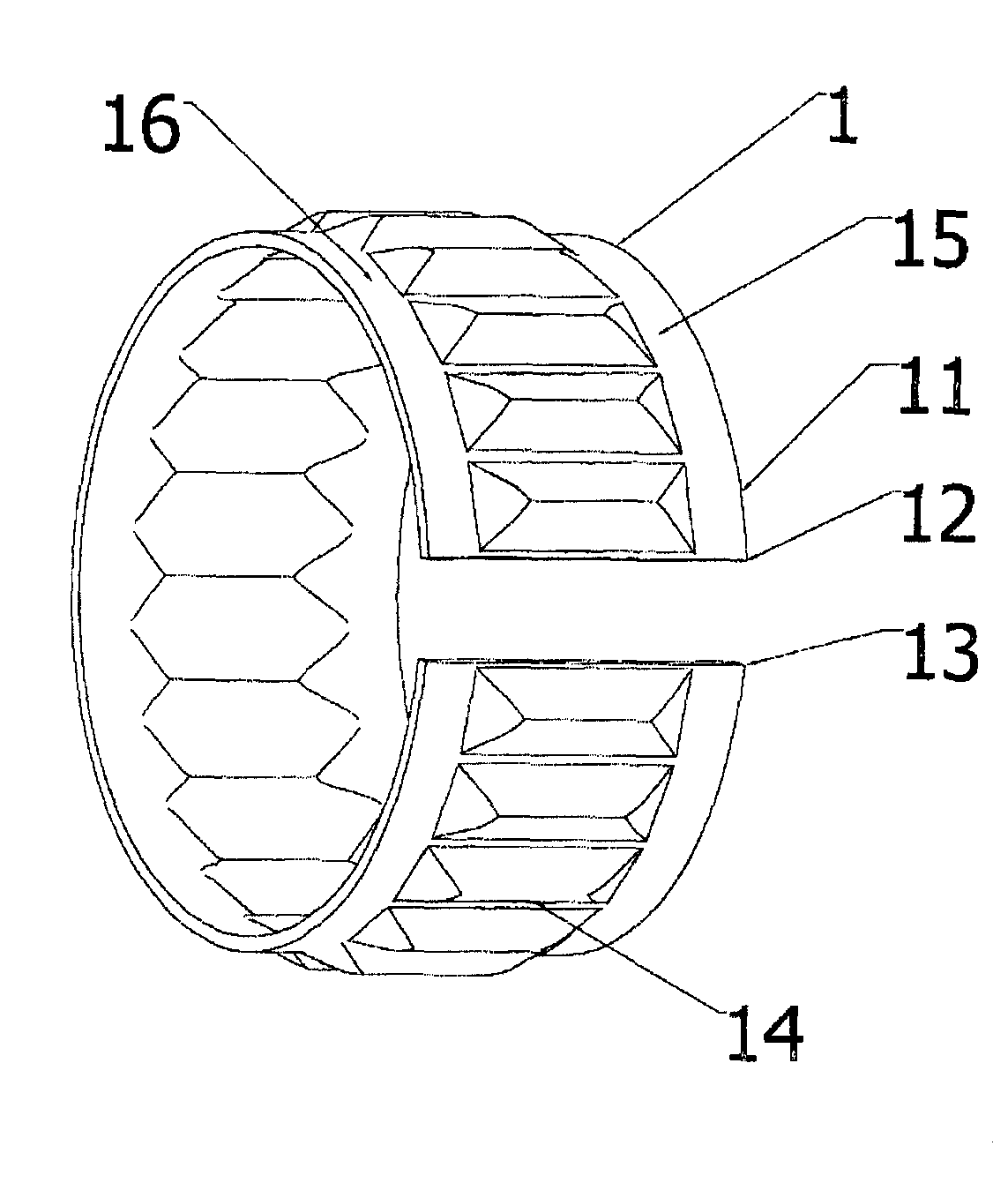

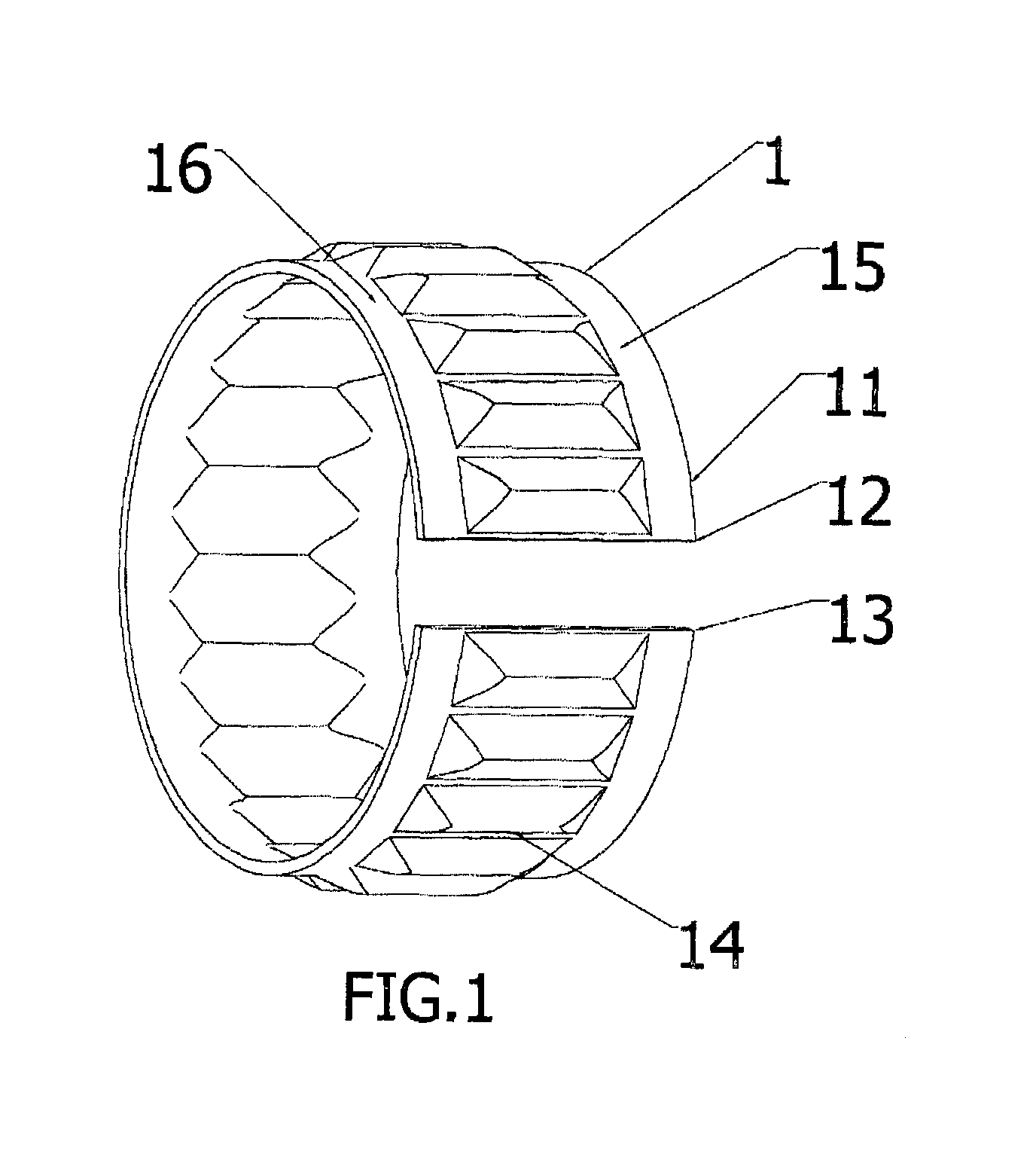

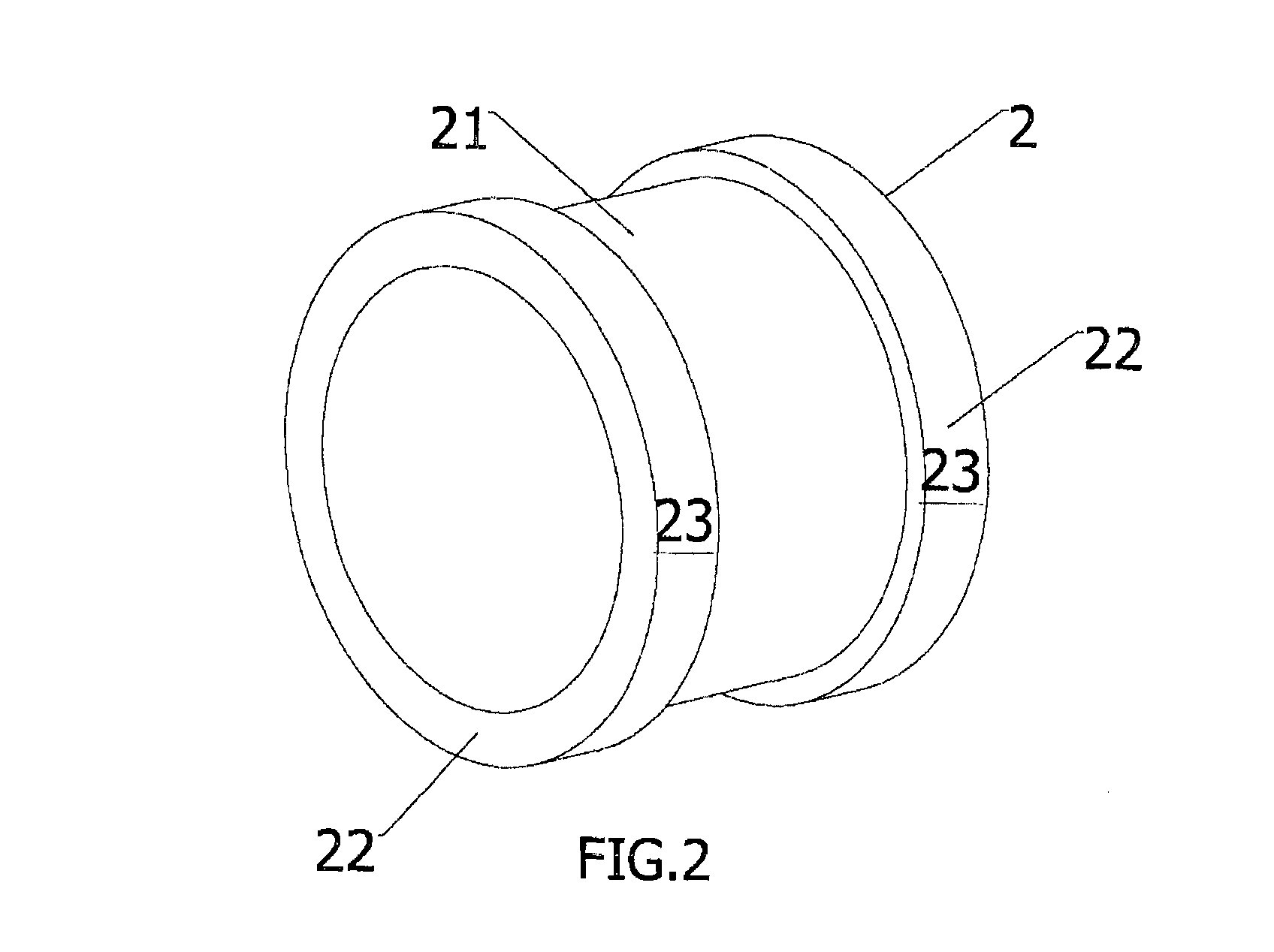

System, method and apparatus for tolerance ring control of slip interface sliding forces

InactiveUS20110076096A1Reduce radial stiffnessLower resistanceYielding couplingLinear bearingsAxial forceEngineering

A tolerance ring comprising a metallic band for spring features and a complementary low friction material for frictional considerations is disclosed. The tolerance ring is designed to operate within a precisely controlled torque or axial force band to provide a defined amount of resistance and sliding force control between components that move relative to each other. Isolated portions of the tolerance ring form regions of contact with adjacent ones of the components. Other surfaces of the tolerance ring comprise portions with spring features that have geometry suitable for their spring rate, rather than conforming to mating surfaces of the adjacent components.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS RENCOL

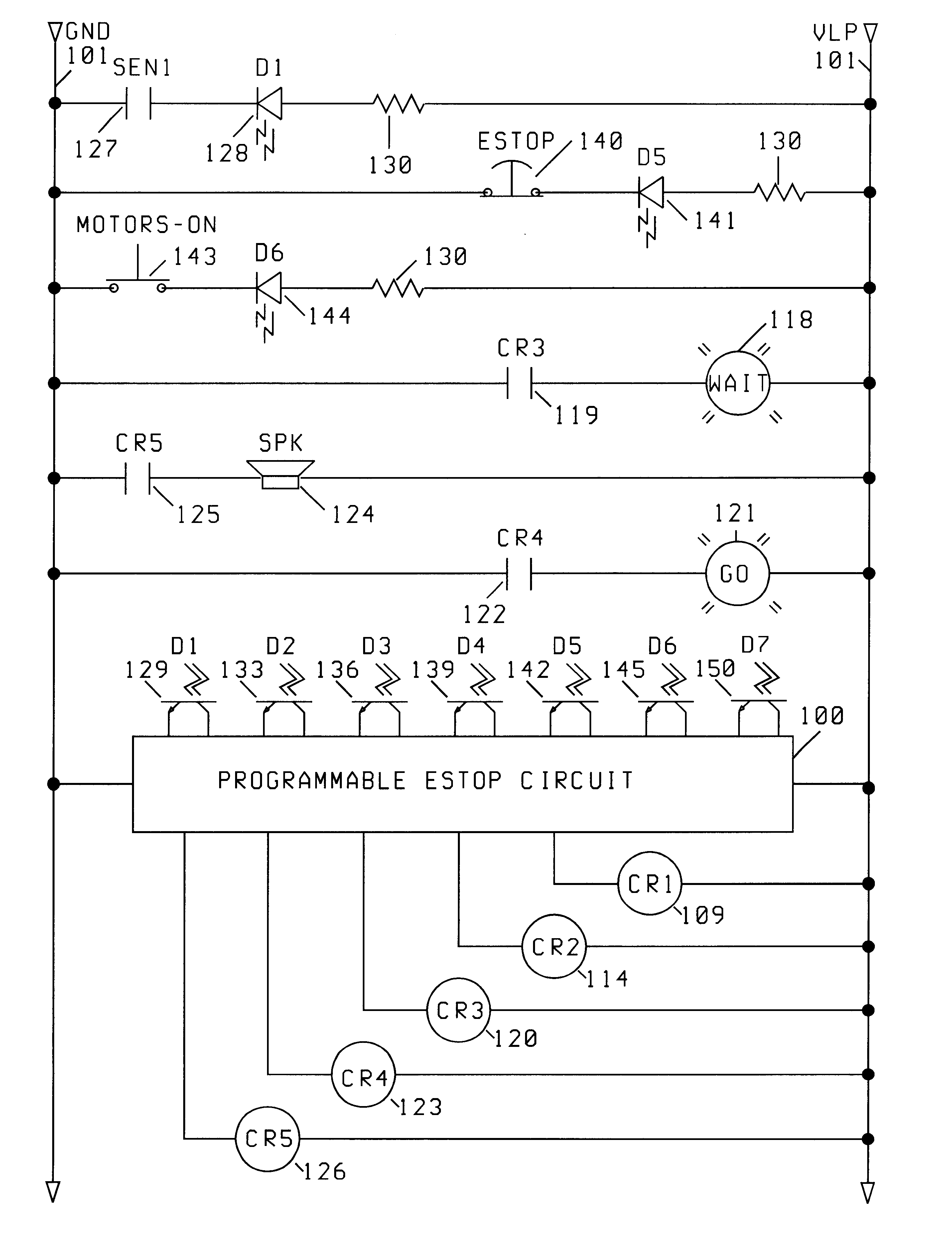

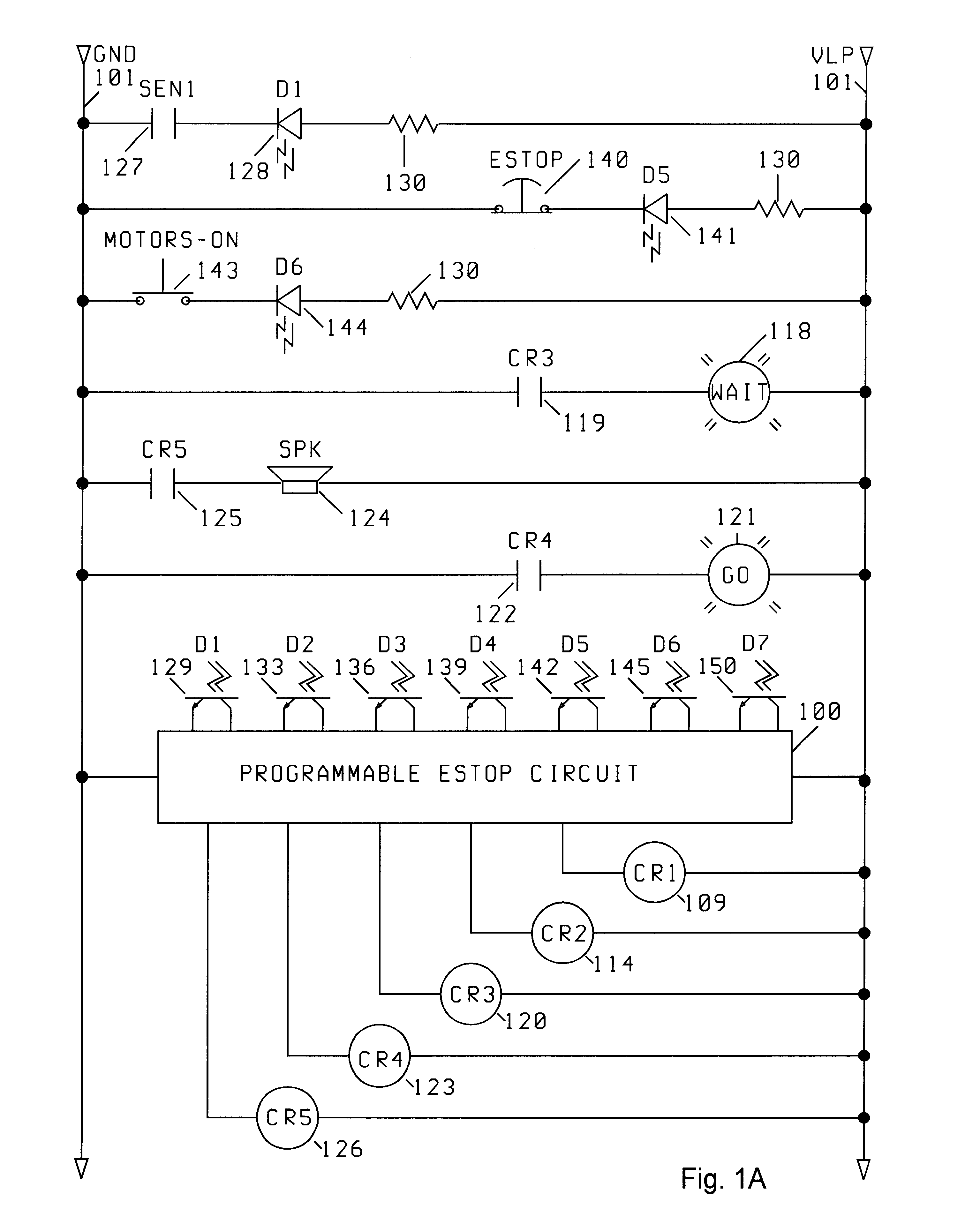

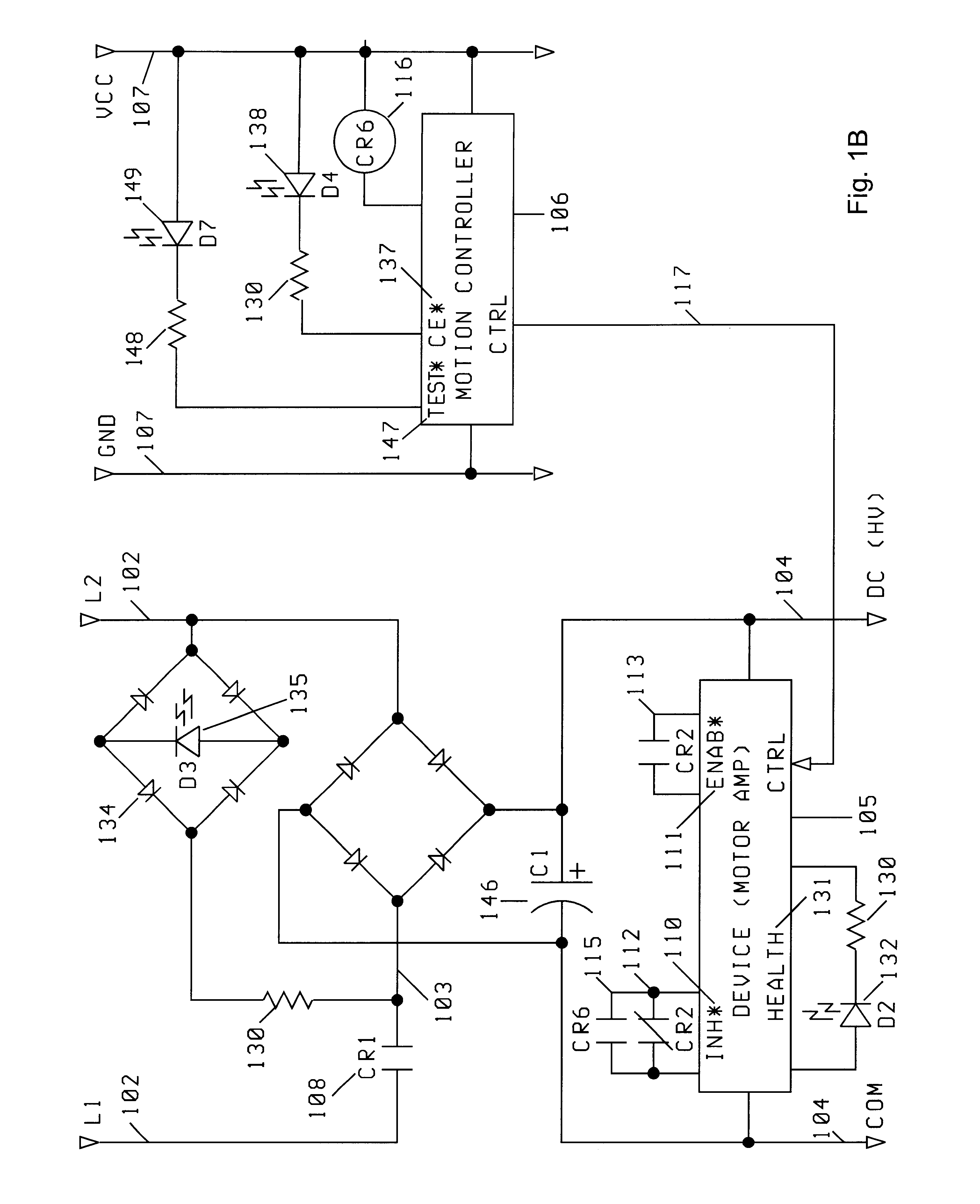

Programmable emergency-stop circuit with testing

InactiveUS6734581B1Safely incorporatedReduce sensitivityBatteries circuit arrangementsEmergency protective circuit arrangementsTest inputKill switch

The invention includes a programmable emergency-stop circuit apparatus and method that provides advanced function not found in other systems. The circuit centralizes the control of high voltage motor power into one place, by providing connections for, in its minimum configuration, several different kill switches, a motors-on button, and an AC motor power relay coil. In the present invention, kill switches, test inputs, emergency-stop and motors-on buttons, computer ready and watchdog signals are all conveniently connected in one location, alongside the AC motor power relay coil driver. Programmable options exist for testing kill inputs online, while the emergency stop is energized.

Owner:EIGENPOINT

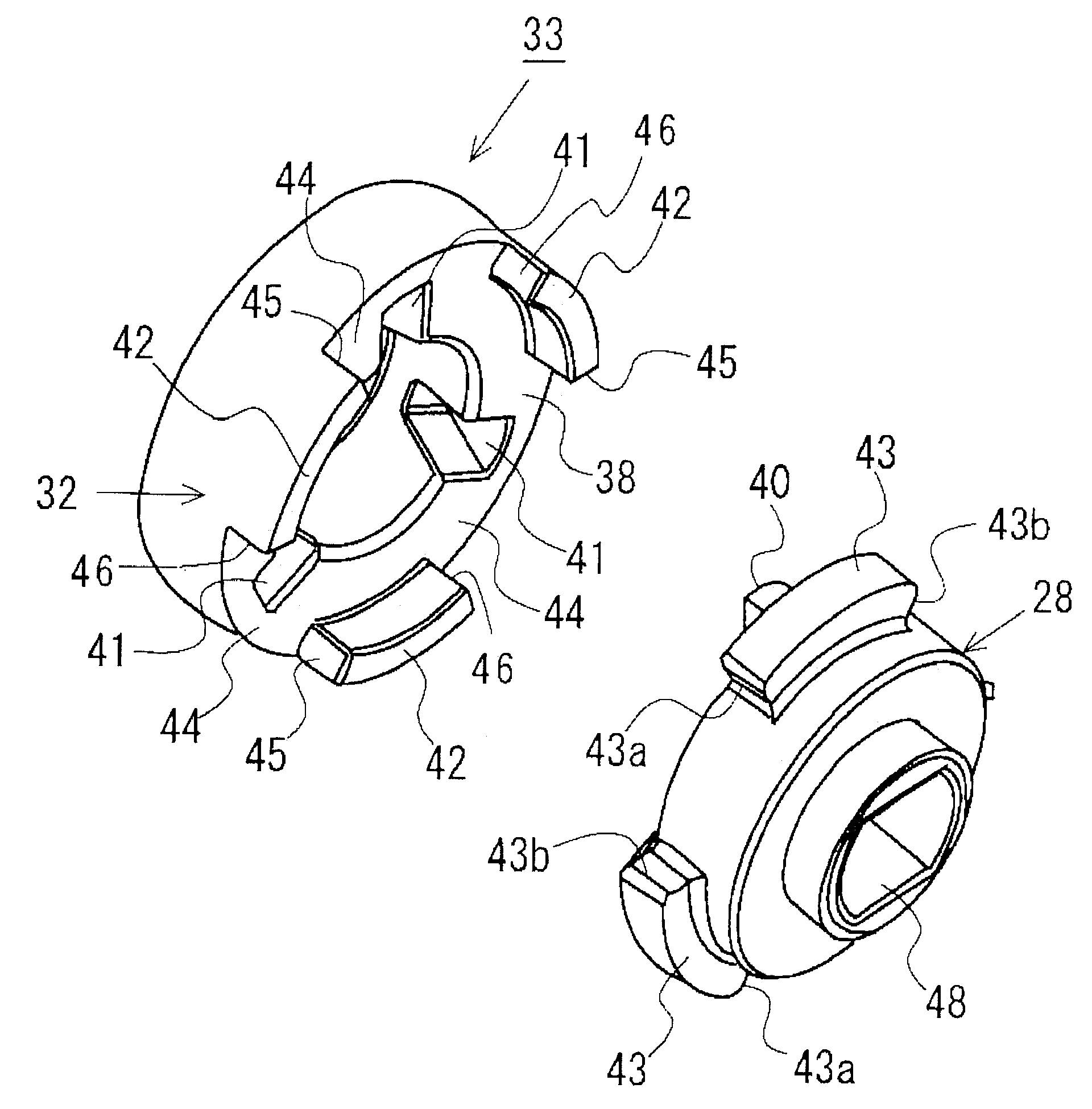

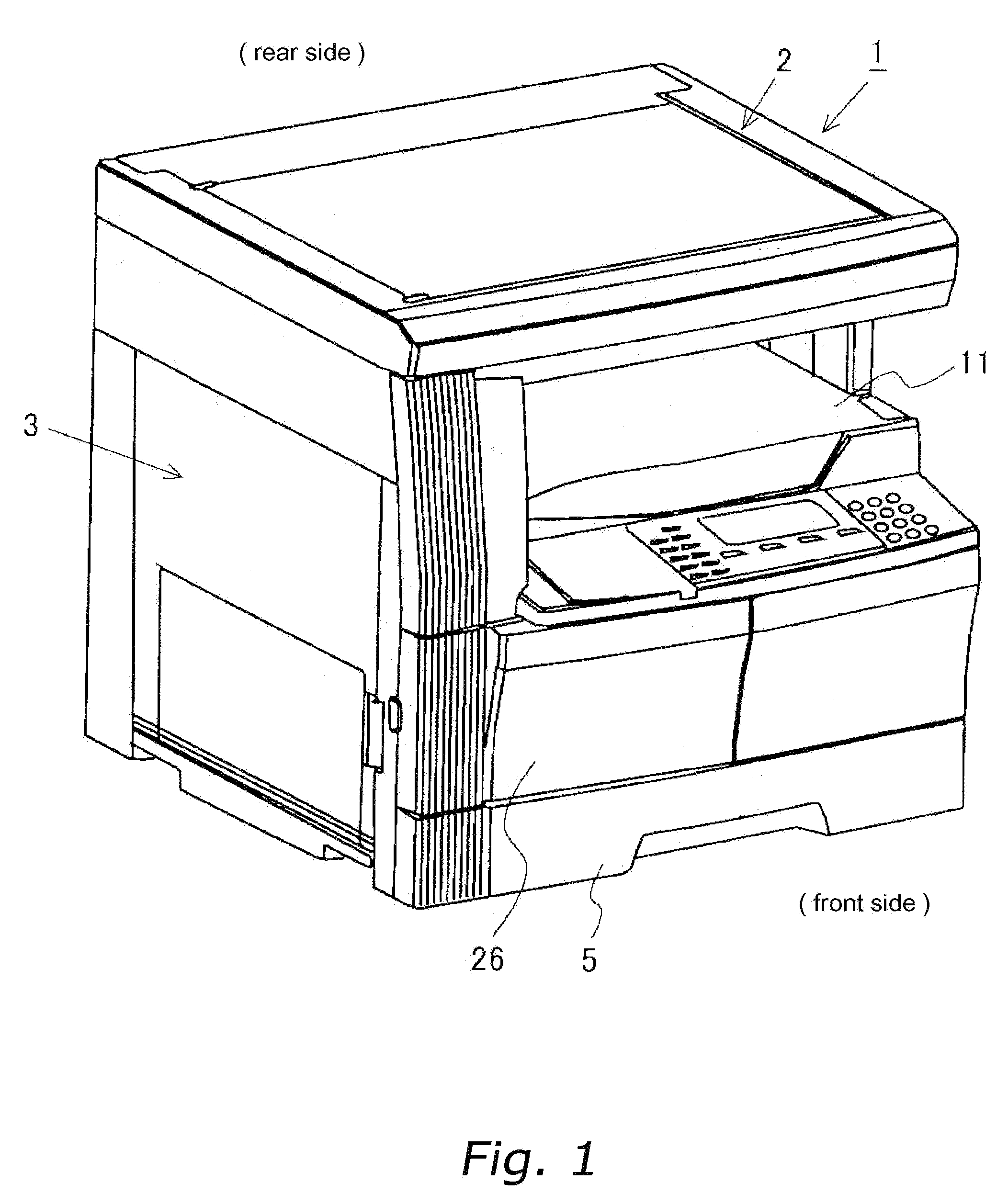

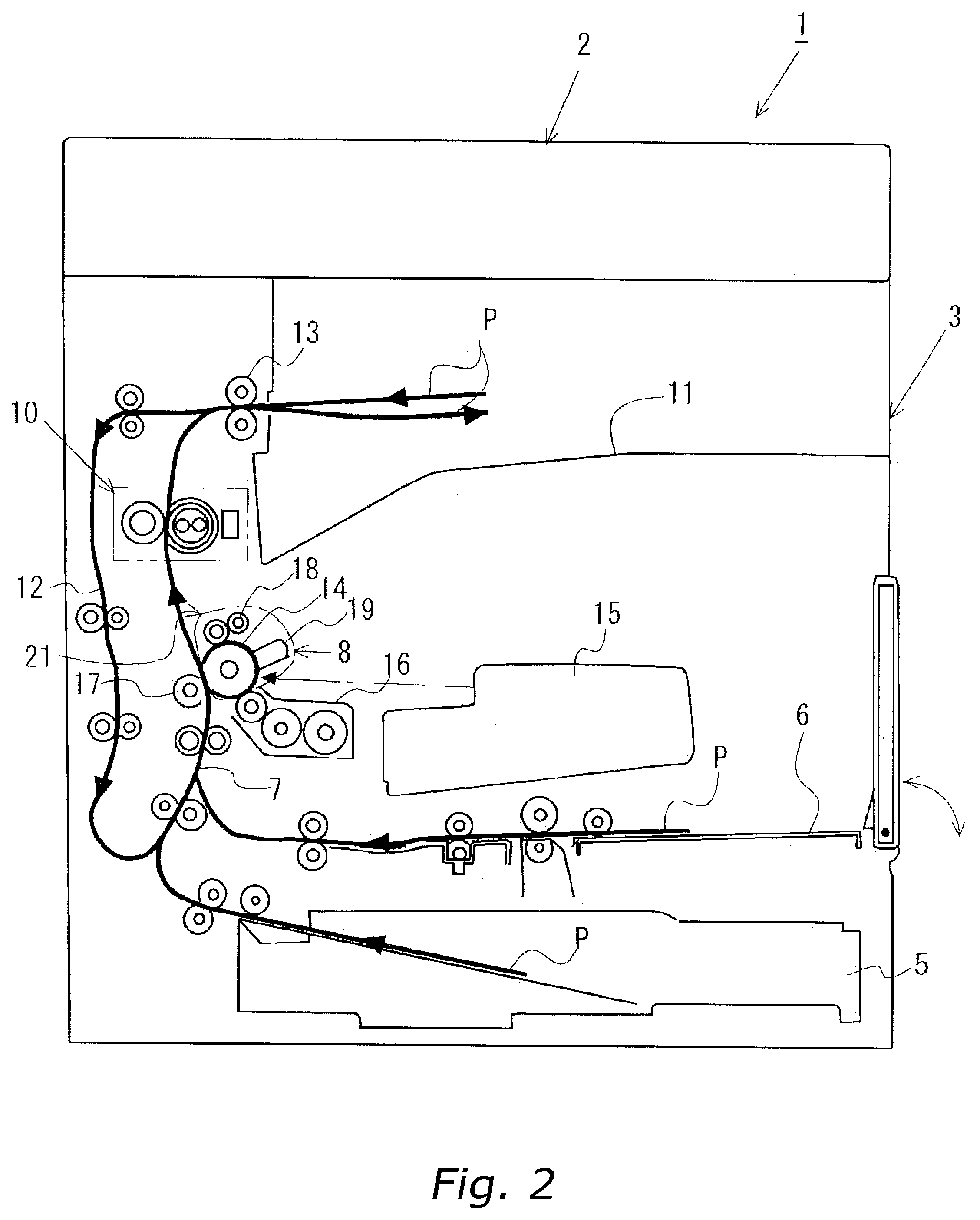

Shaft coupling, and function unit drive device for an image forming device comprising the same

InactiveUS7603059B2Suppress couplingReliable transmissionFriction grip releasable fasteningsCorona dischargeCouplingImage formation

Inner circumference projections of a driven coupling are engaged with inner circumference recesses of a drive coupling. Outer circumference projections of the driven coupling are engaged with outer circumference recesses of the drive coupling. A chamfered portion formed at each tip of the rotational leading-side side surface of the inner circumference projections is capable of contact with the leading-side side surface of each inner circumference recess. A rotational trailing-side circumferential end face of each outer circumference projection and a rotational trailing-side circumferential end face of each outer circumference recess are in surface-to-surface contact with each other. As a result, the drive coupling and the driven coupling can rotate integrally without rattling in the rotational direction.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

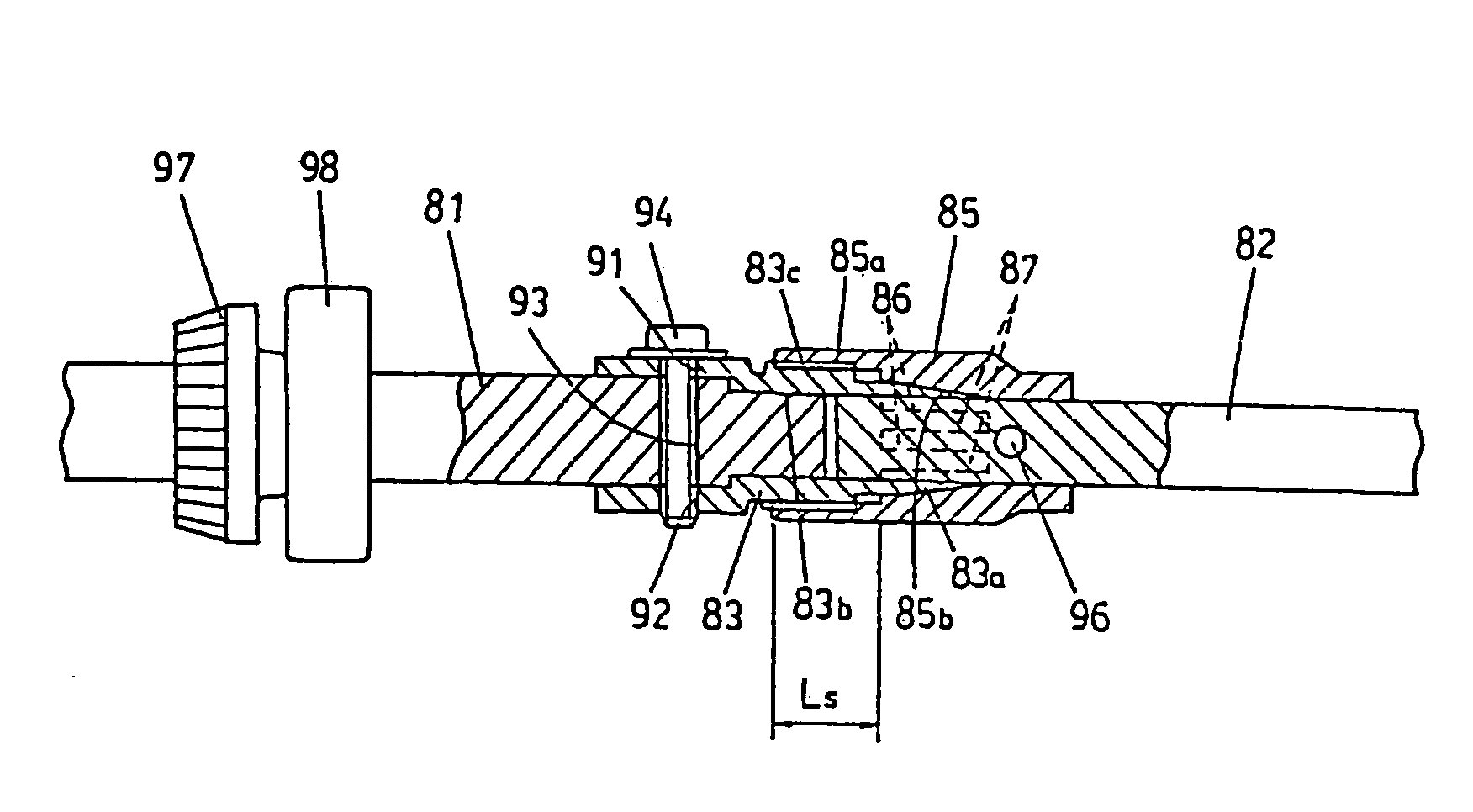

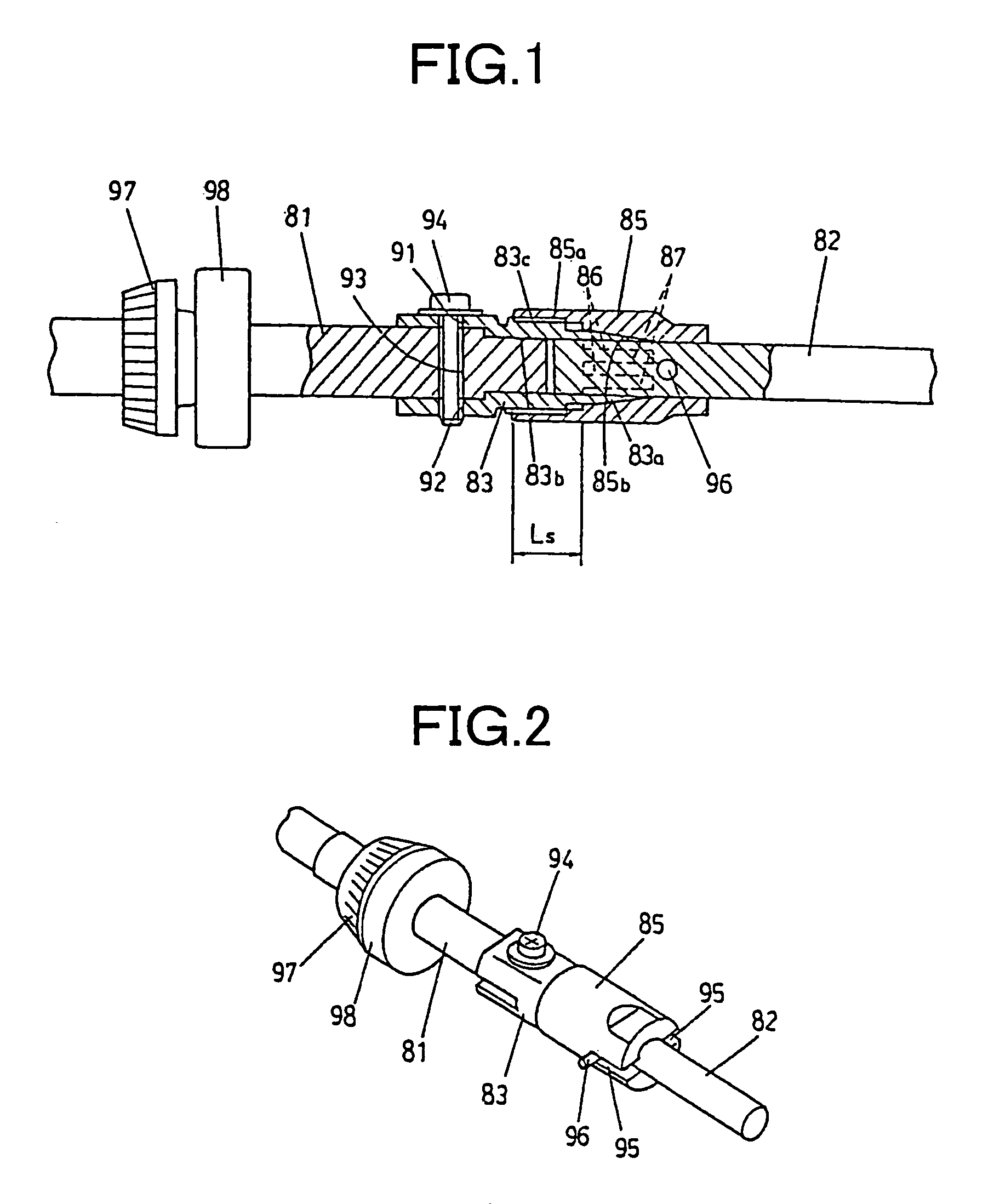

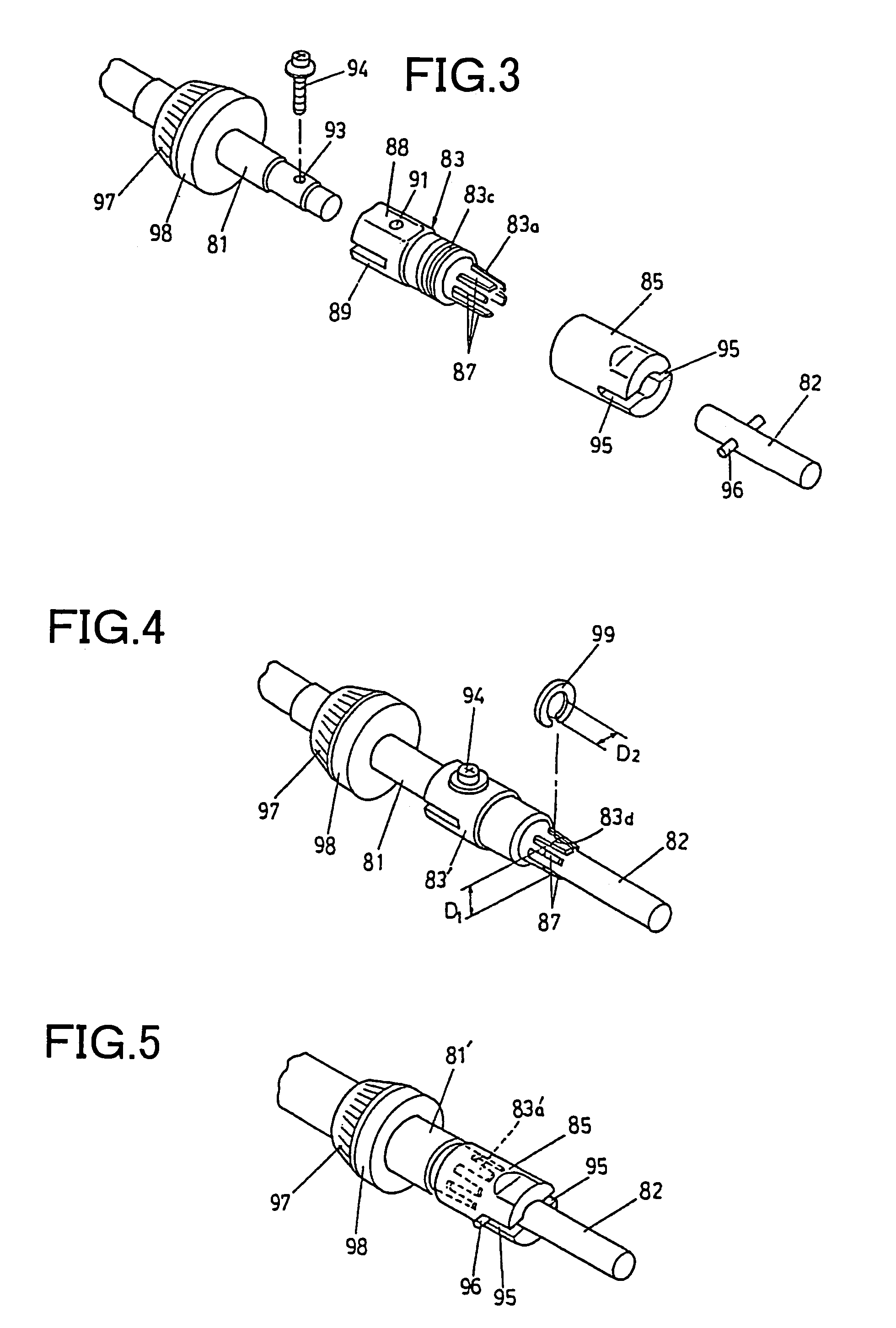

Device for and method of coupling shafts, image formation apparatus, process cartridge, and belt unit

A shaft coupling device for coupling a first shaft and a second shaft together includes a grip unit to be attached to the first shaft and including a grip portion configured to grip the second shaft, the grip portion having an end with notches of a length being parallel with an axial direction of the first shaft. The shaft coupling device also includes a grip force acting unit to be attached to the second shaft and configured to cause a grip force for gripping the second shaft to act on the grip portion by moving the grip portion in a radial direction of the second shaft.

Owner:RICOH KK

Torque limited decoupler

A decoupler assembly is provided for allowing an alternator to be rotatably driven by a serpentine belt in an engine of an automotive vehicle and for allowing the speed of the belt to oscillate relative to the alternator. A hub is fixedly carried by a drive shaft from the alternator for rotation therewith. A pulley is rotatably journaled to the hub by a ball bearing assembly. A bare, helical clutch spring is operatively coupled between the hub and pulley for transferring rotational movement from the pulley to the hub during acceleration of the pulley relative to the hub by the serpentine belt and for allowing the hub to overrun the pulley during deceleration of the pulley relative to the hub. A torque limiter, preferably a spring or sleeve, is wrapped about the torsion limiting outward expansion of the torsion isolating the torsion spring from torques above a predetermined limit.

Owner:LITENS AUTOMOTIVE INC

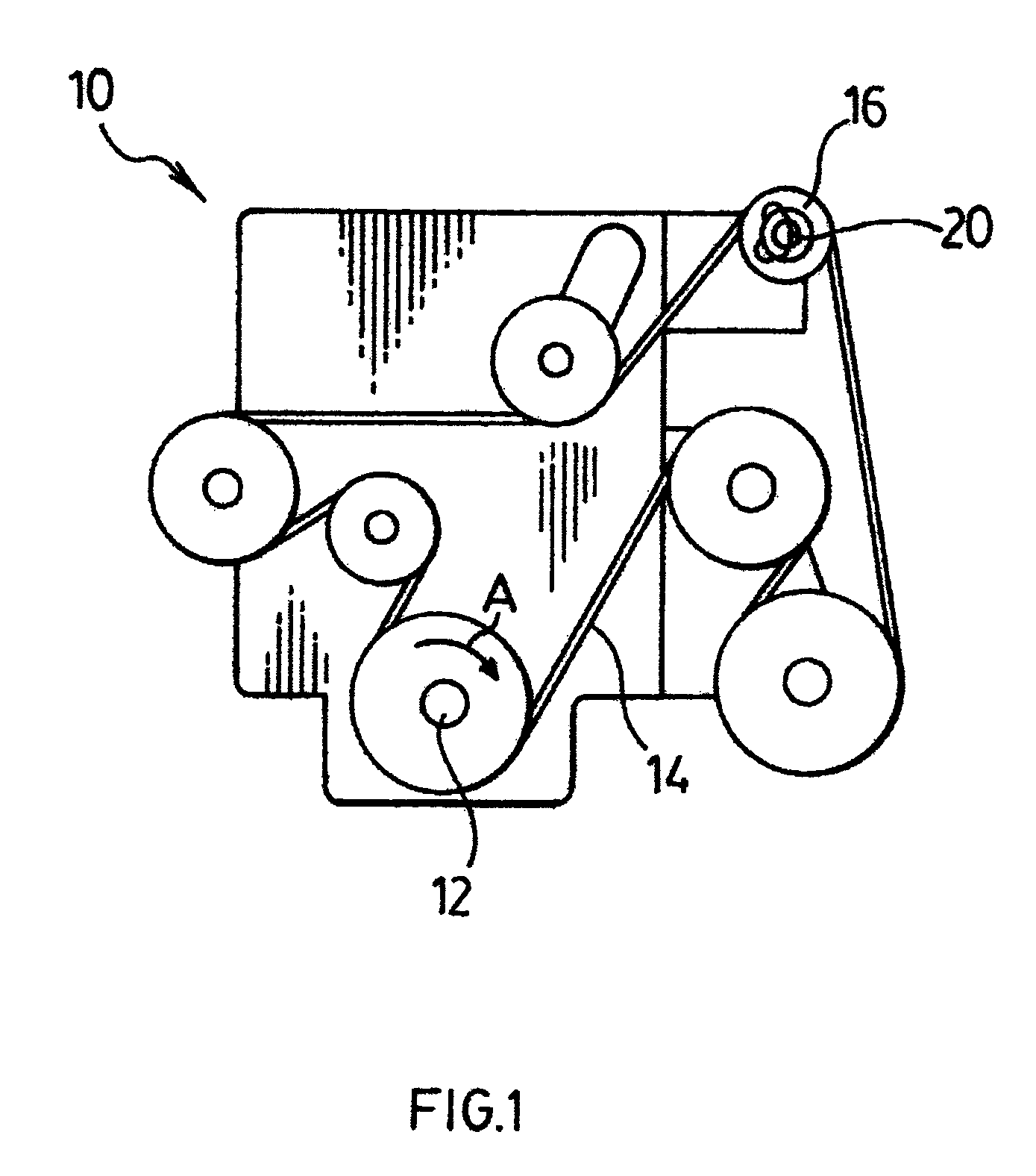

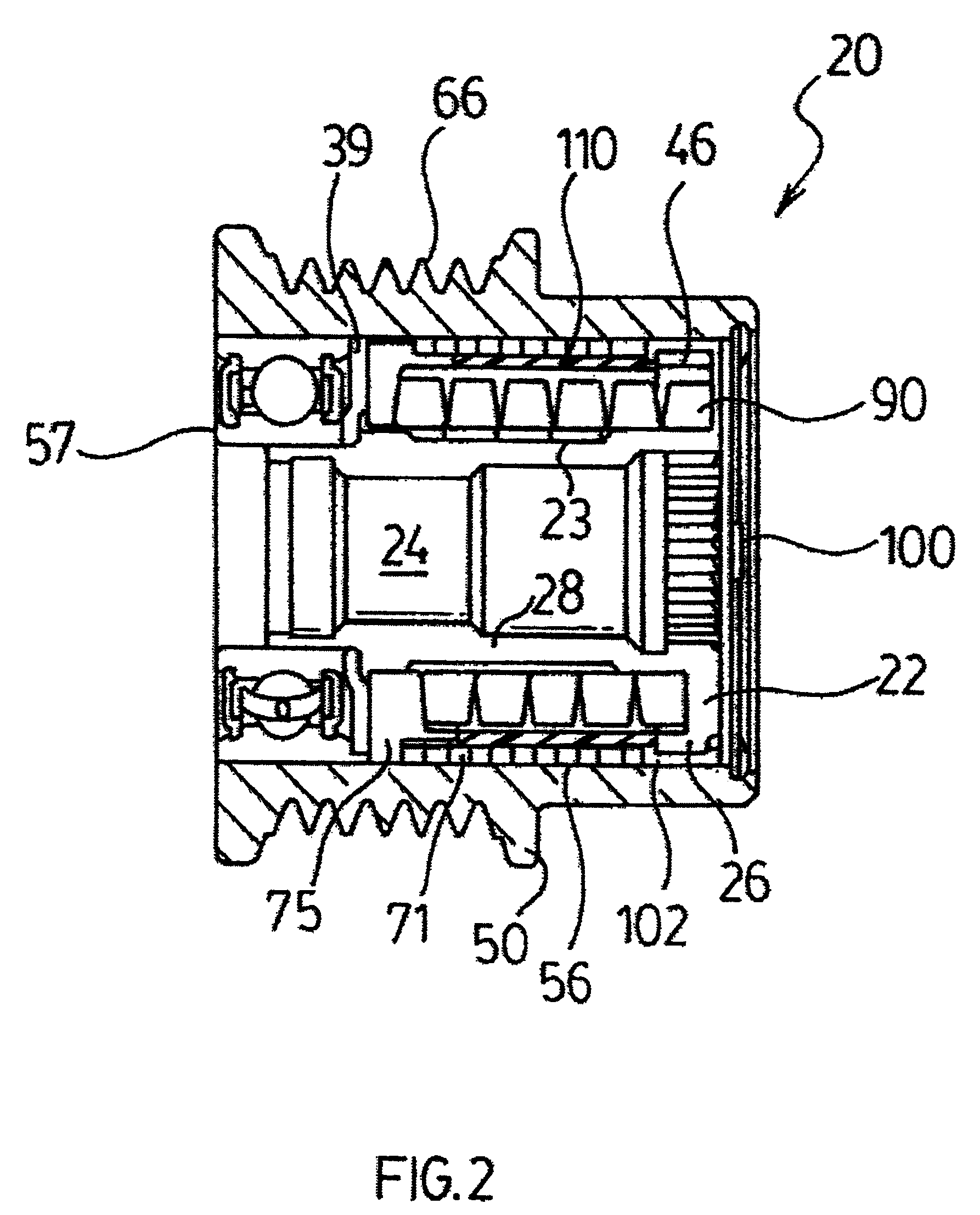

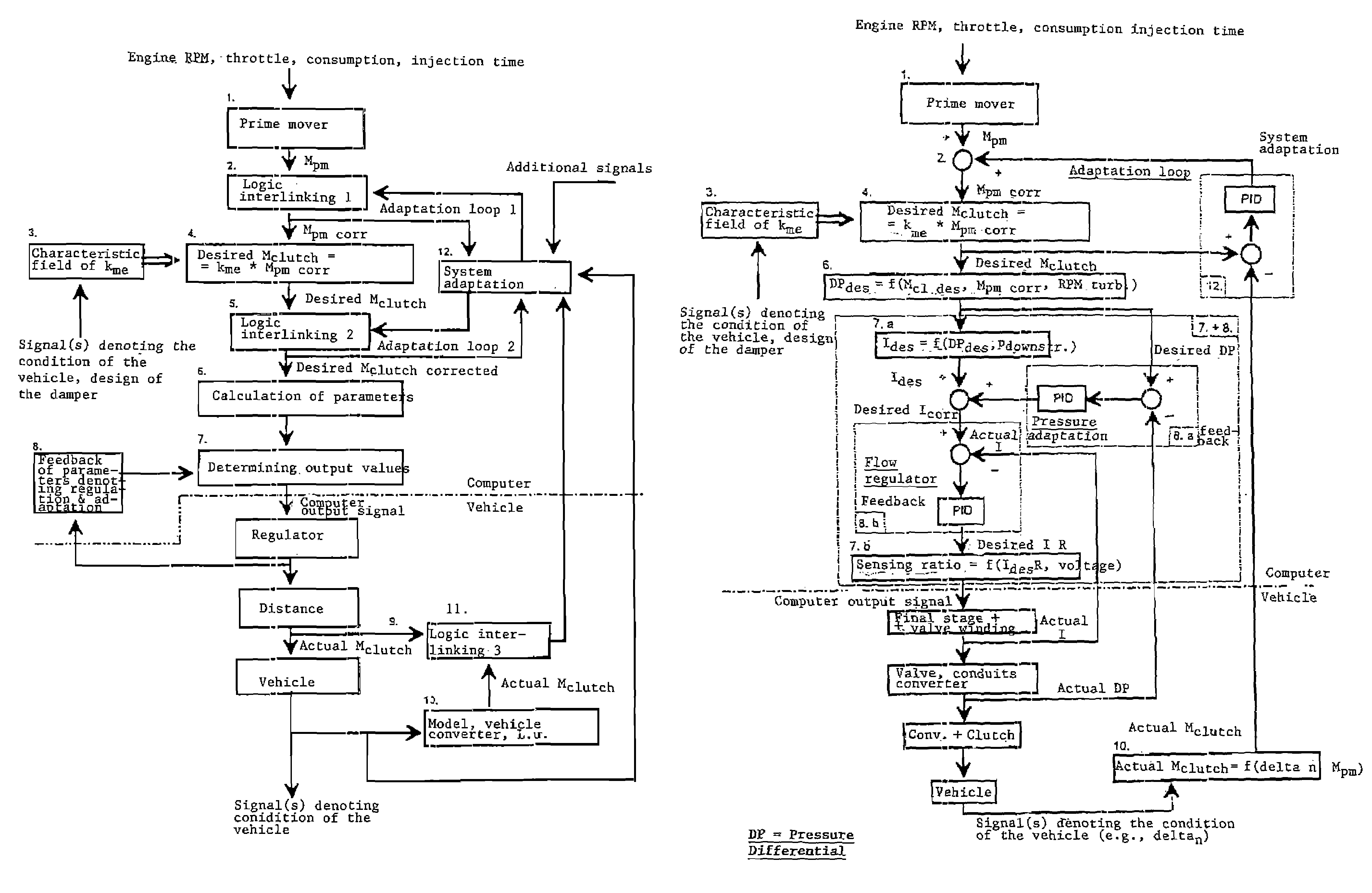

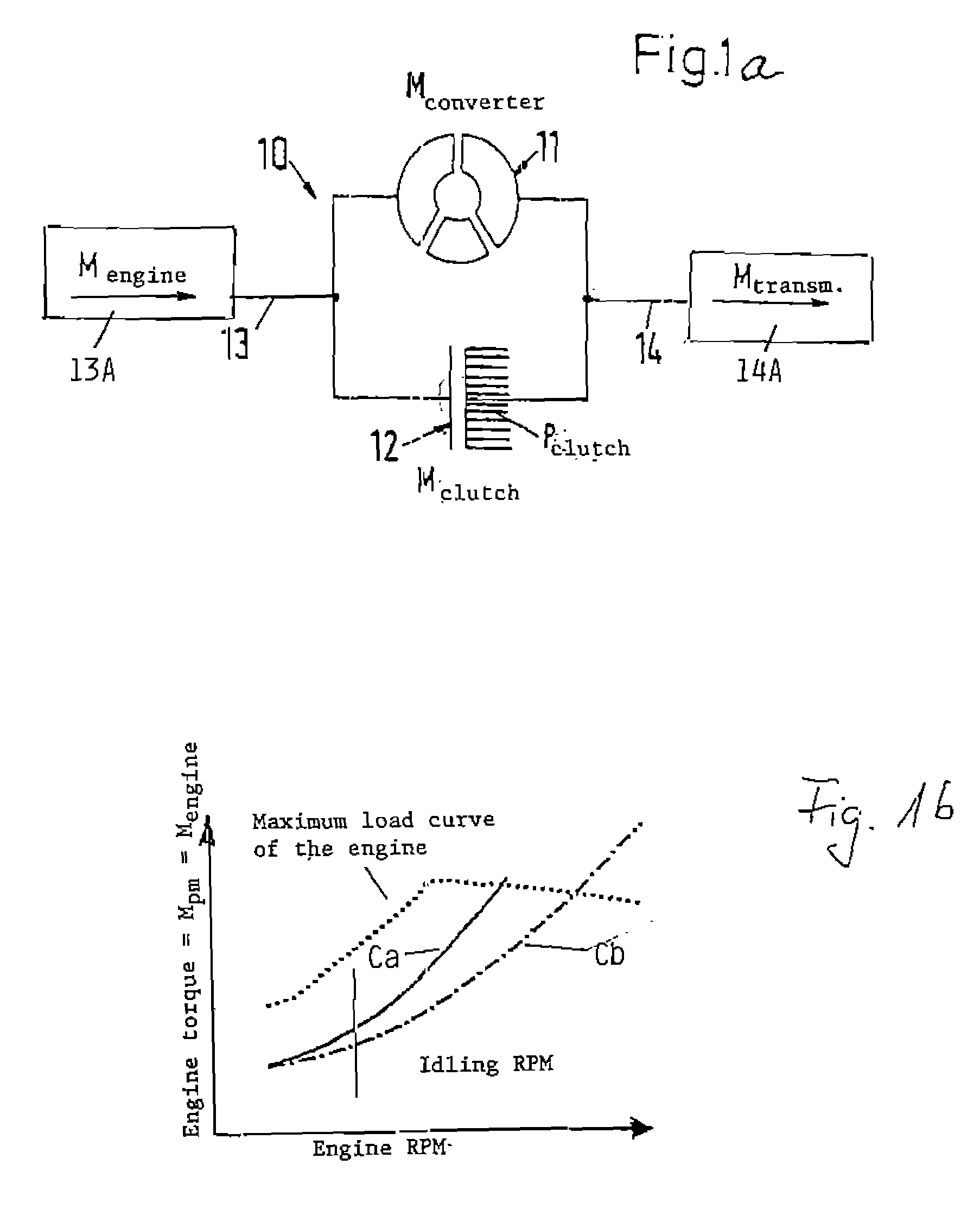

Method of and apparatus for transmitting torque in vehicular power trains

InactiveUS7286922B1Reduce capacityMechanical actuated clutchesDigital data processing detailsMobile vehicleAutomatic transmission

The magnitude of torque which can be transmitted by a bypass clutch between the housing and the turbine of a torque converter between a prime mover, such as an engine, and an automatic transmission in the power train of a motor vehicle is selectively regulatable by a computerized regulating unit. The regulation involves the transmission of torque by the clutch in dependency upon the magnitude of the torque being transmitted by the output element of the engine and ascertaining as well as adaptively applying to the clutch a variable force so that the clutch can transmit a predetermined torque. This entails automatic selection of a minimum slip between a torque receiving and a torque transmitting part of the power train. Compensation, particularly long-range compensation, is carried out for the existence of possible differences between the predetermined and actual torques being transmitted by the clutch.

Owner:LUK GETRIEBE SYST

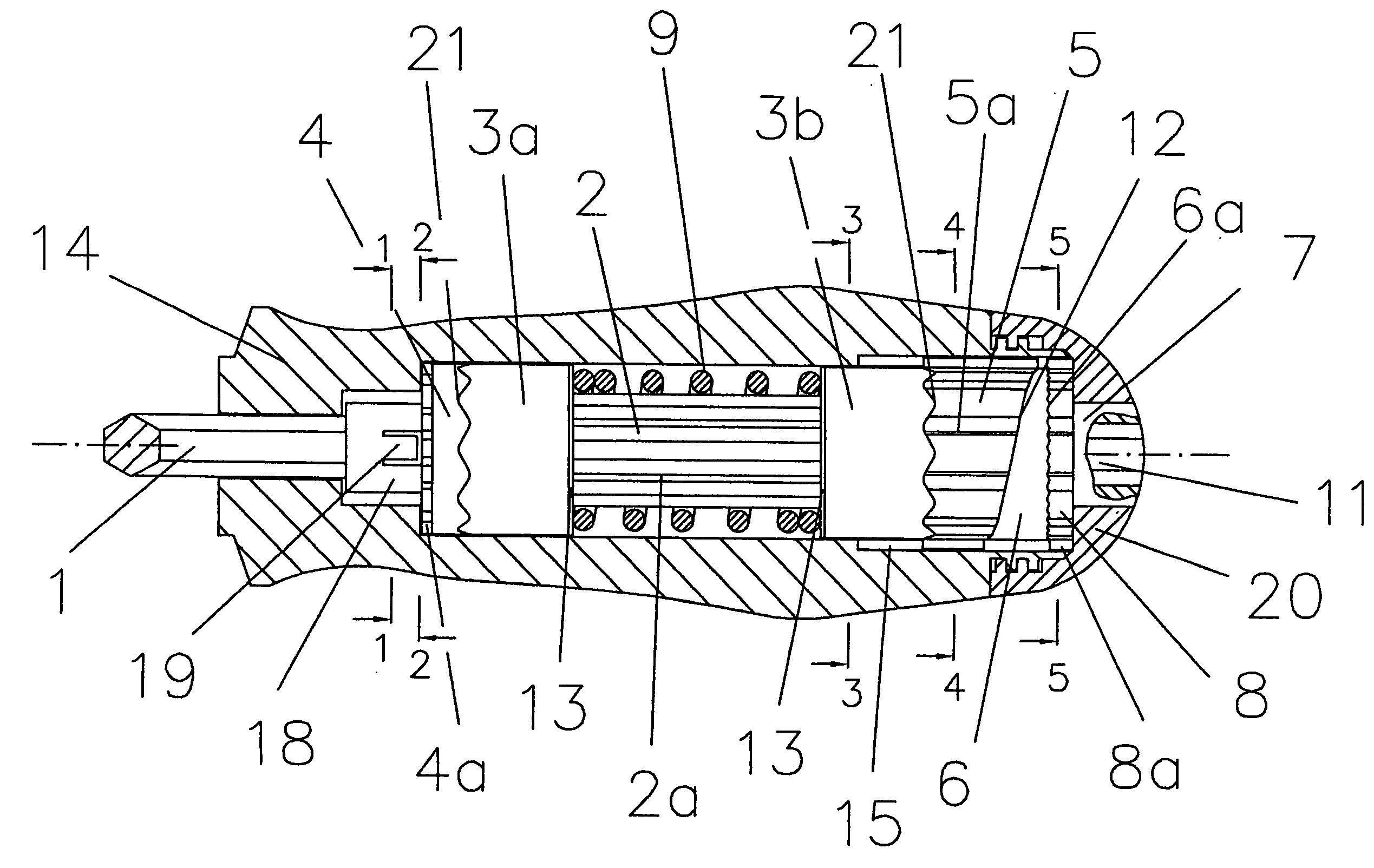

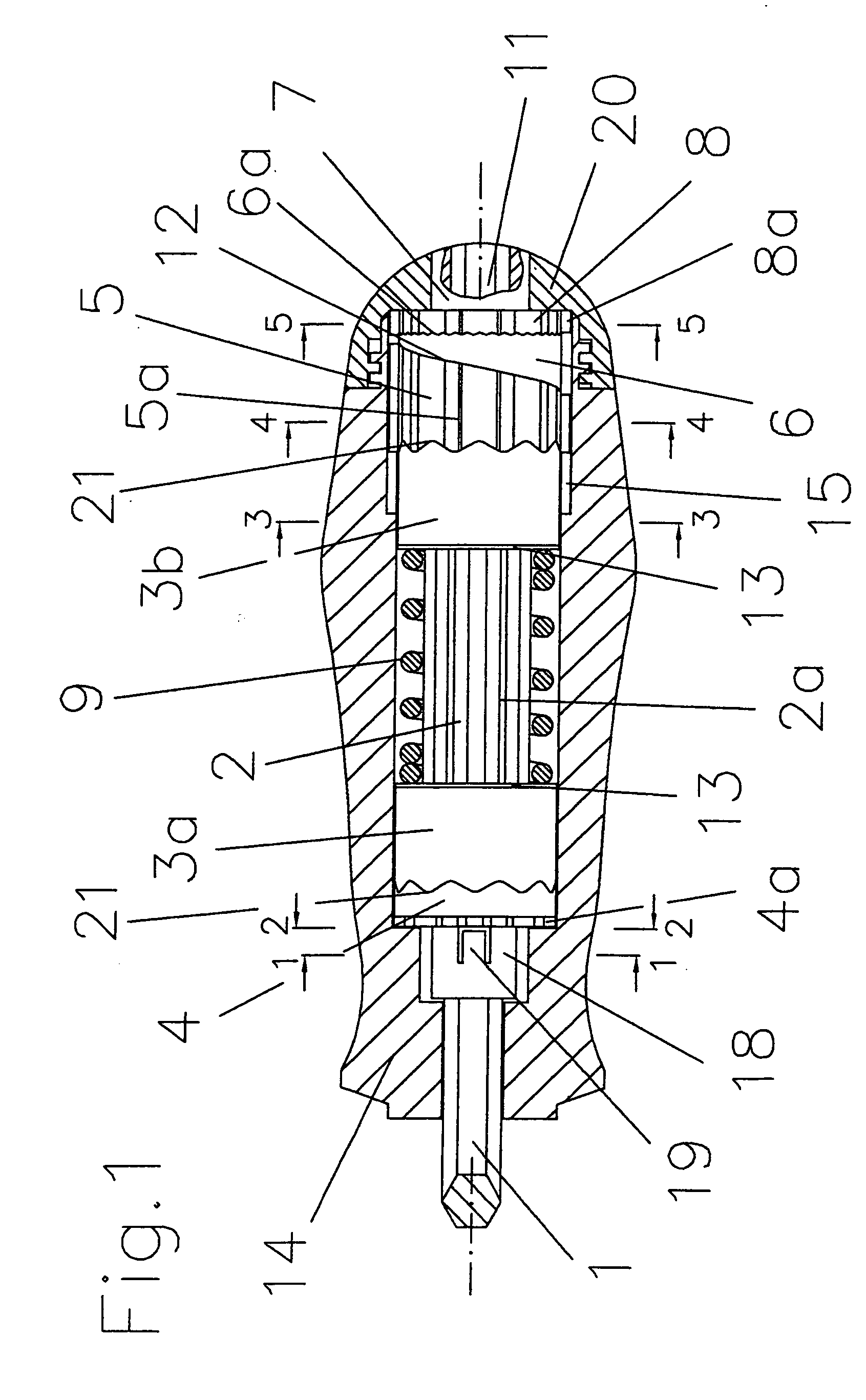

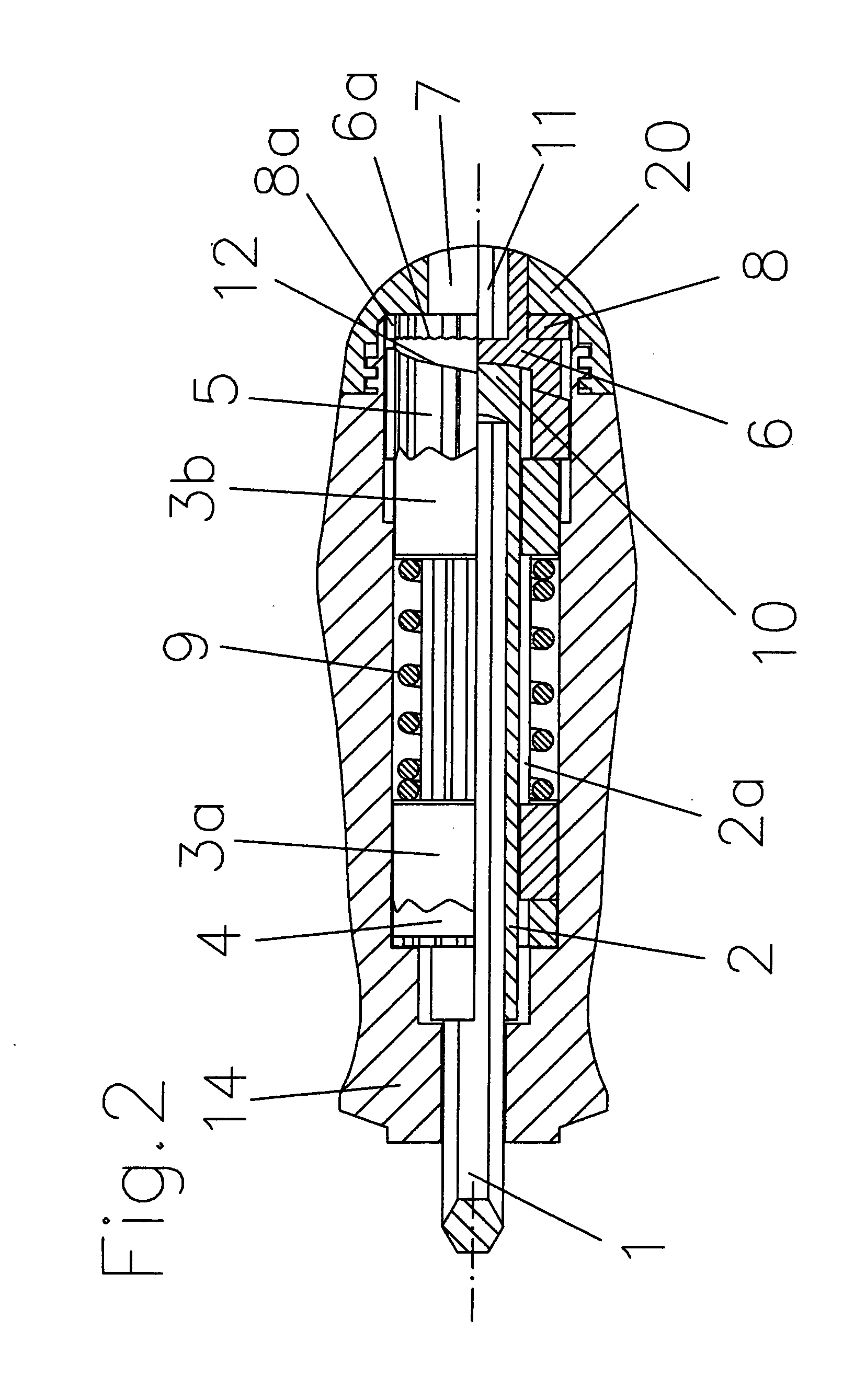

Screwdriver with adjustable device to limit transmitted torque

A screwing-tool with a device to adjust transmitted torque consists of a handle to introduce a torque to the device, which is borne in the hollow of the handle and a driver-shaft as outpout element of the torque. On the driver-shaft inside the handle two separate couplings are assembled, between them a compression spring exerting a spring force onto the two couplings. Each coupling consist of a first and second socket engaging each other by gearings at their opposing faces. The maximum torque at which the torque-transmission will be interrupted cab be adjusted in that way, that by an adjustment-element the distance between the couplings can be changed resulting in a change of the tension of the spring exerting a load on the couplings. The teeth of the gearings slide and the sockets rotate relatively to each other and interrupt the torque-transmission if a pre-adjusted torque is exceeded.

Owner:FELO WERKZEUGFAB HOLLAND LETZ

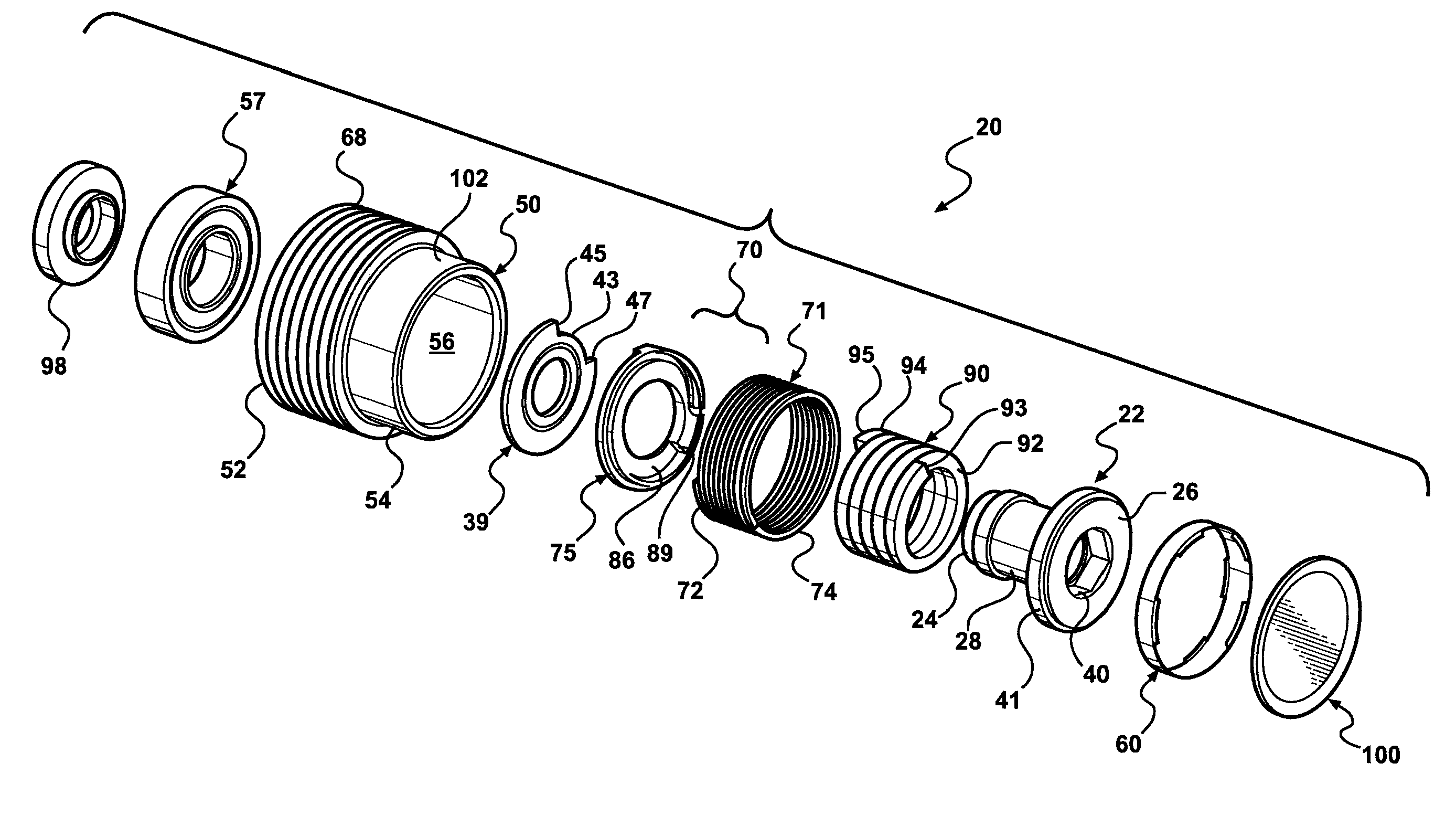

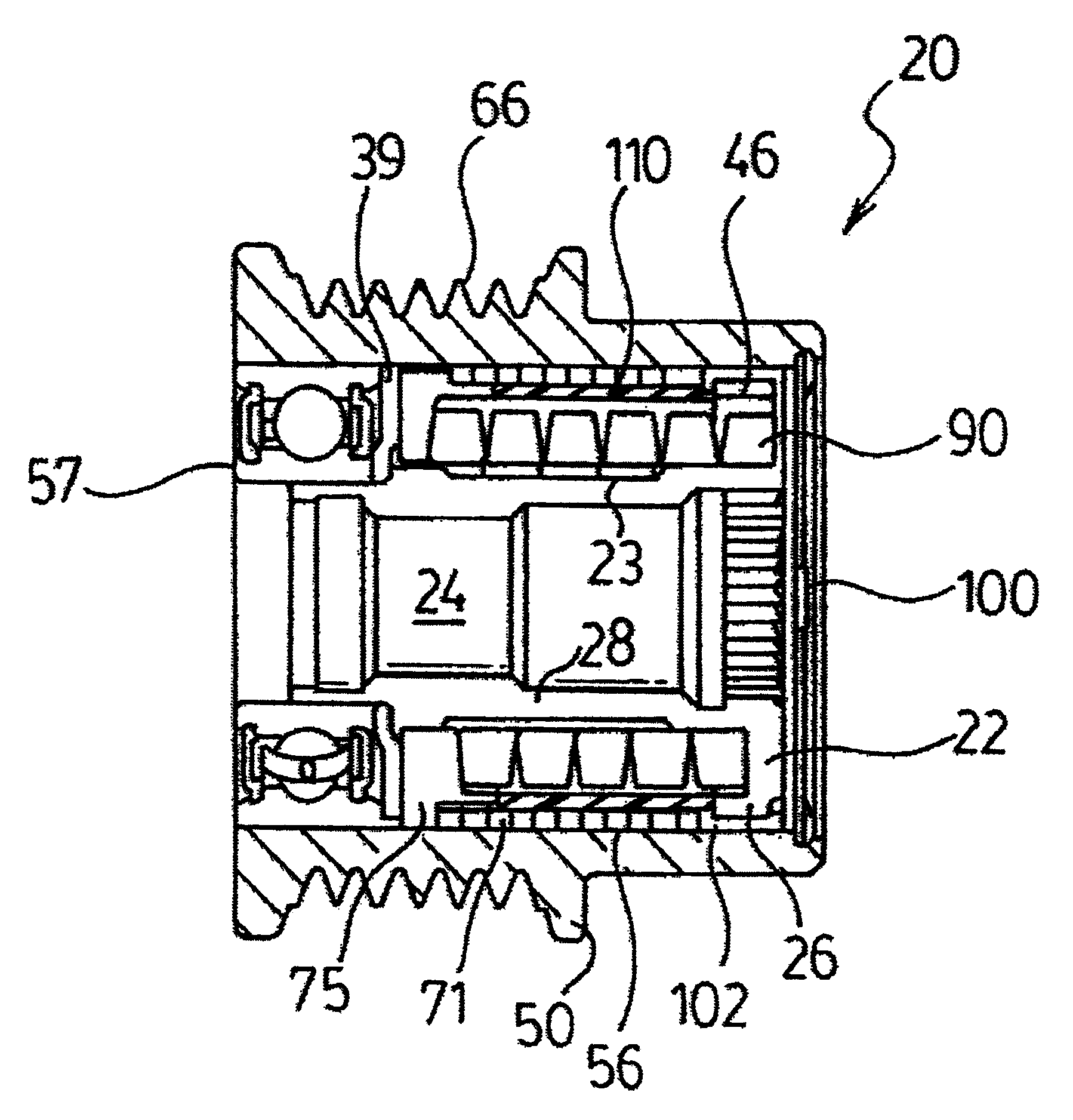

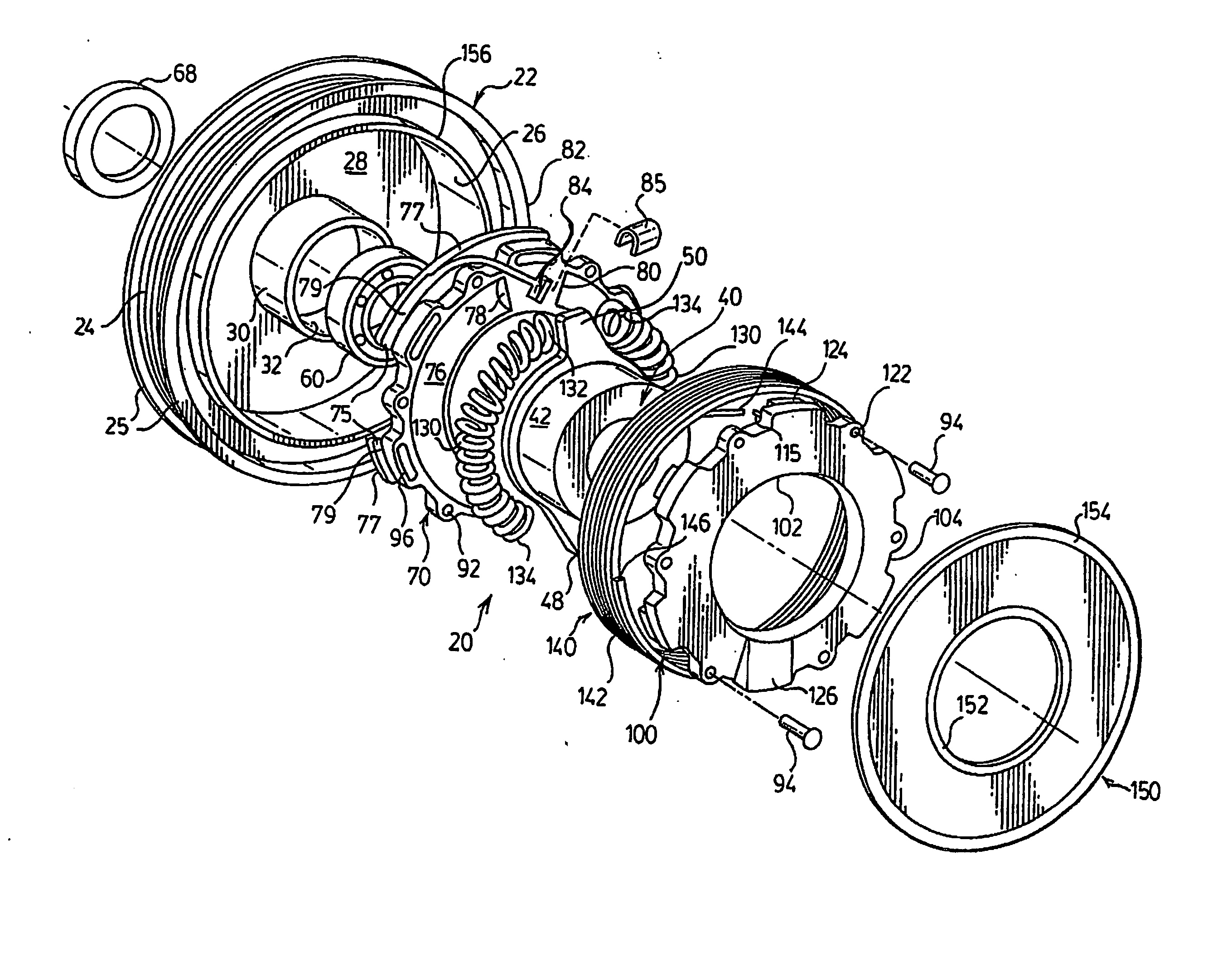

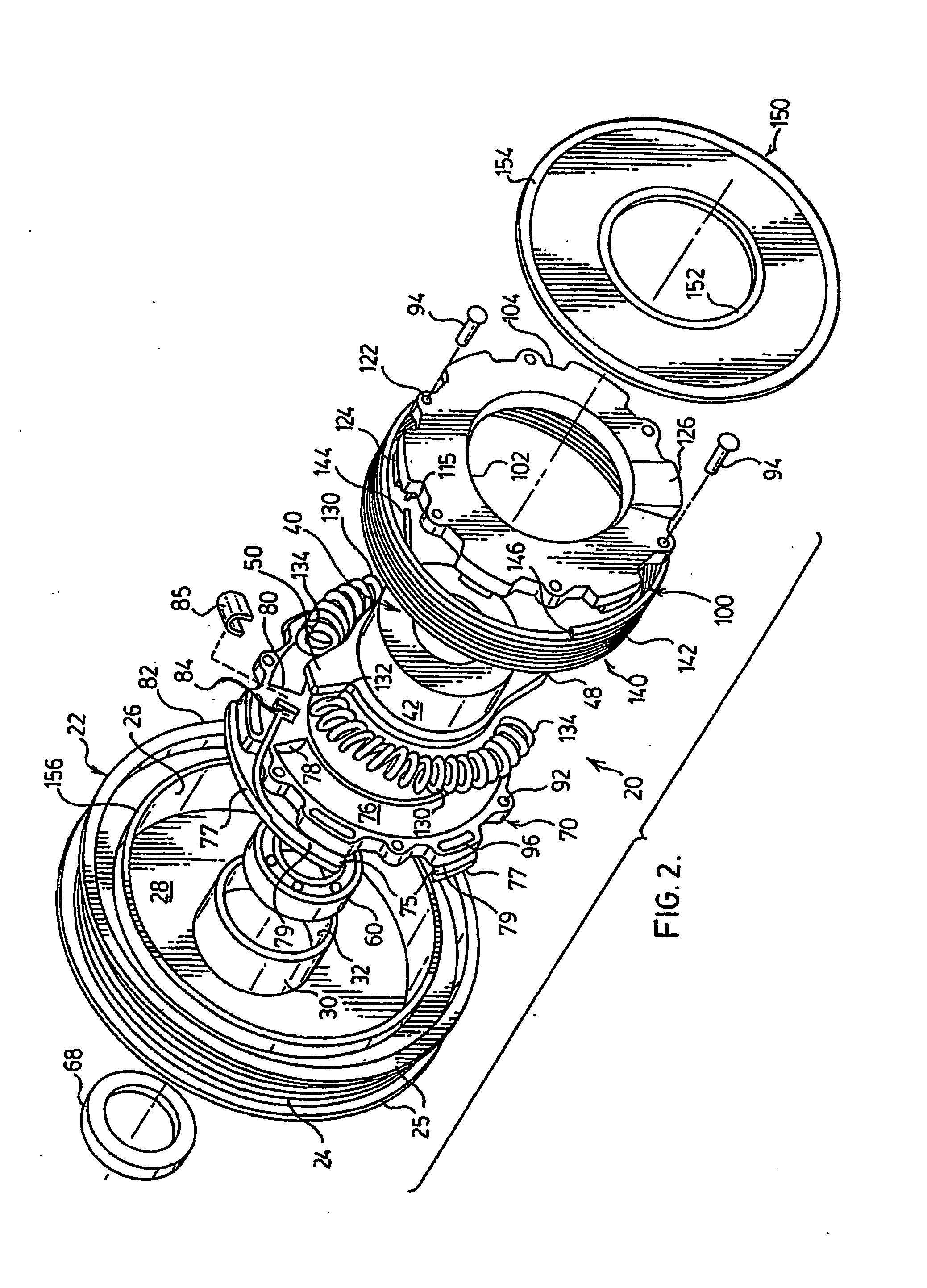

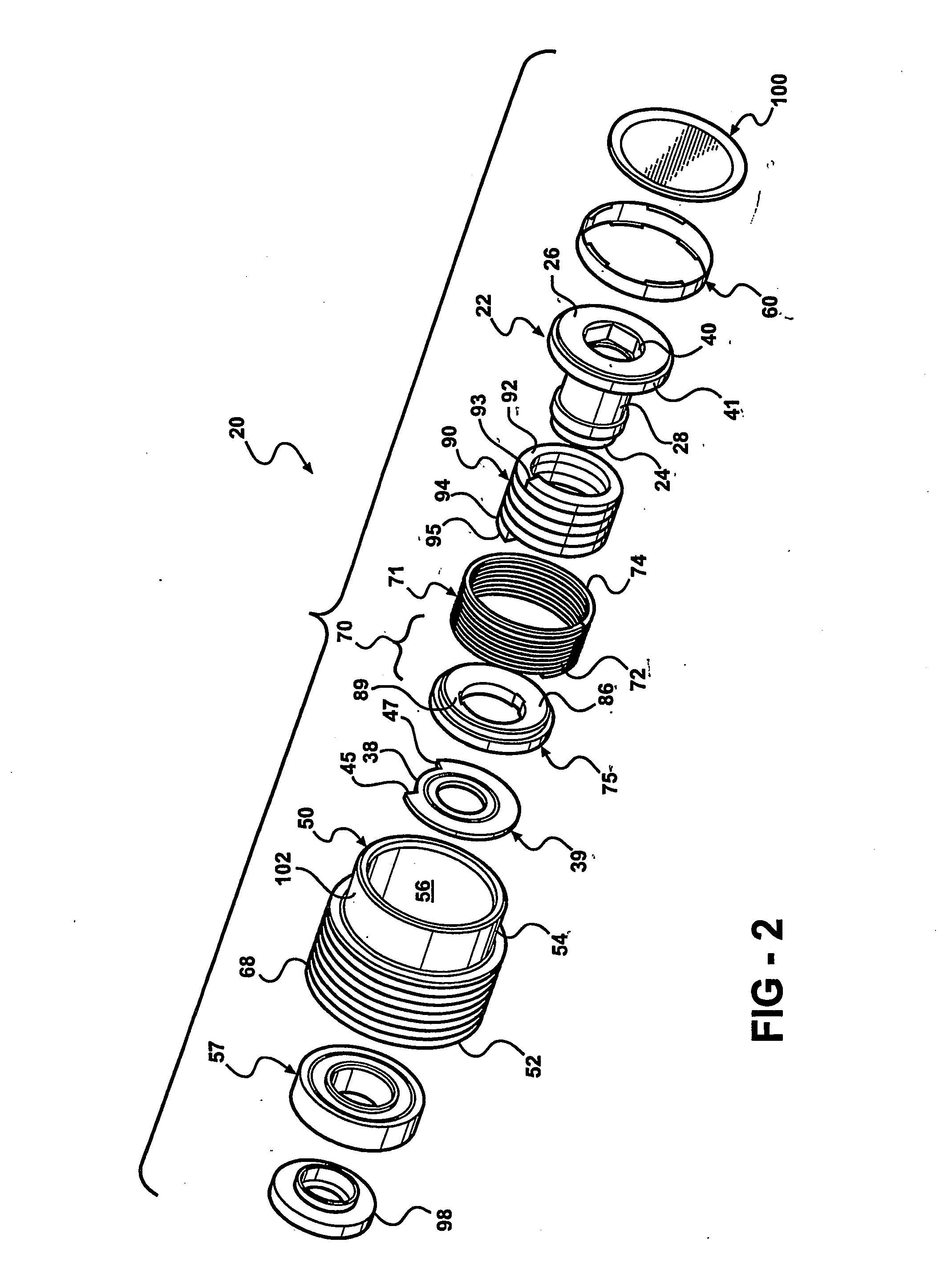

Crankshaft decoupler

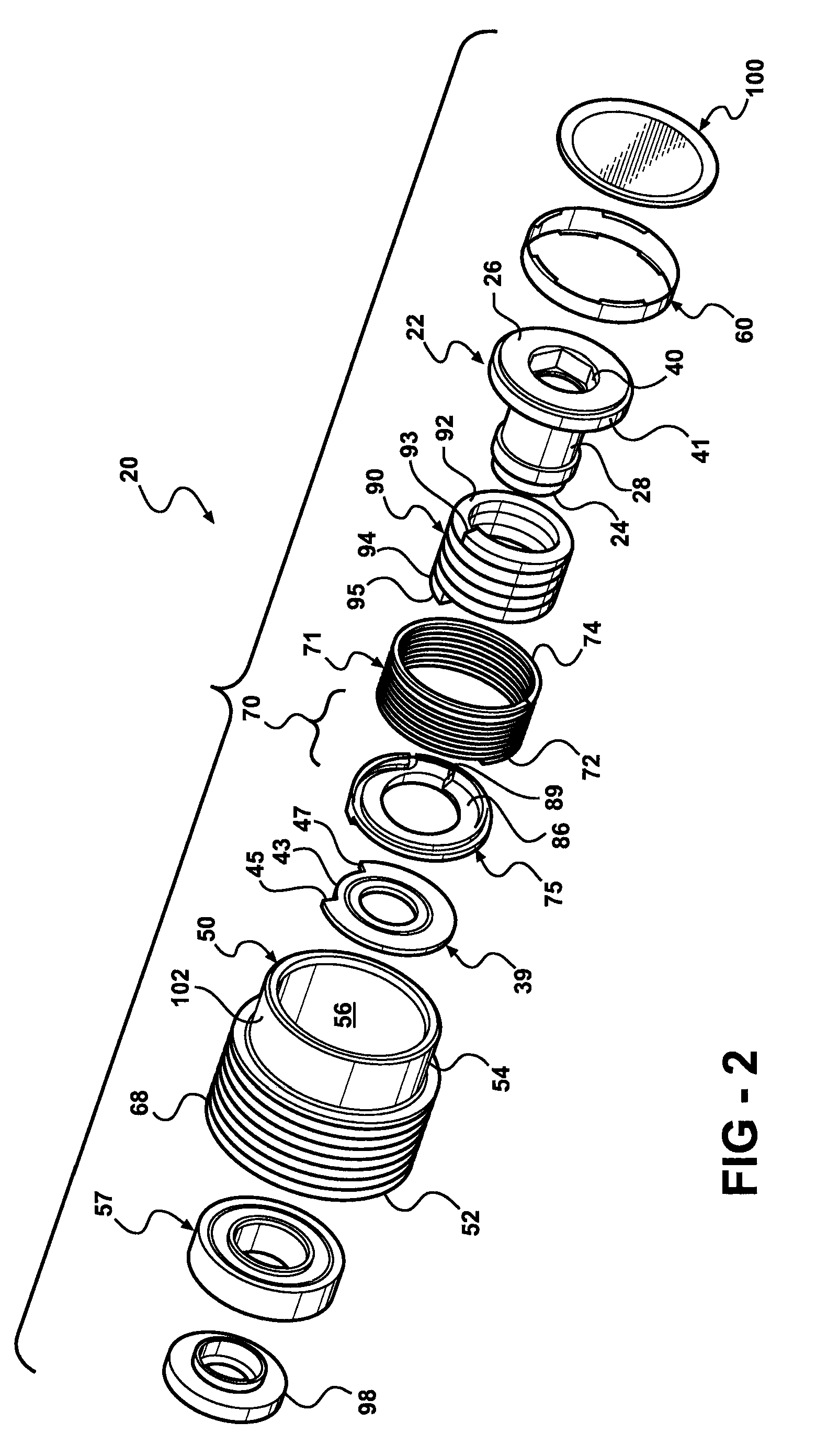

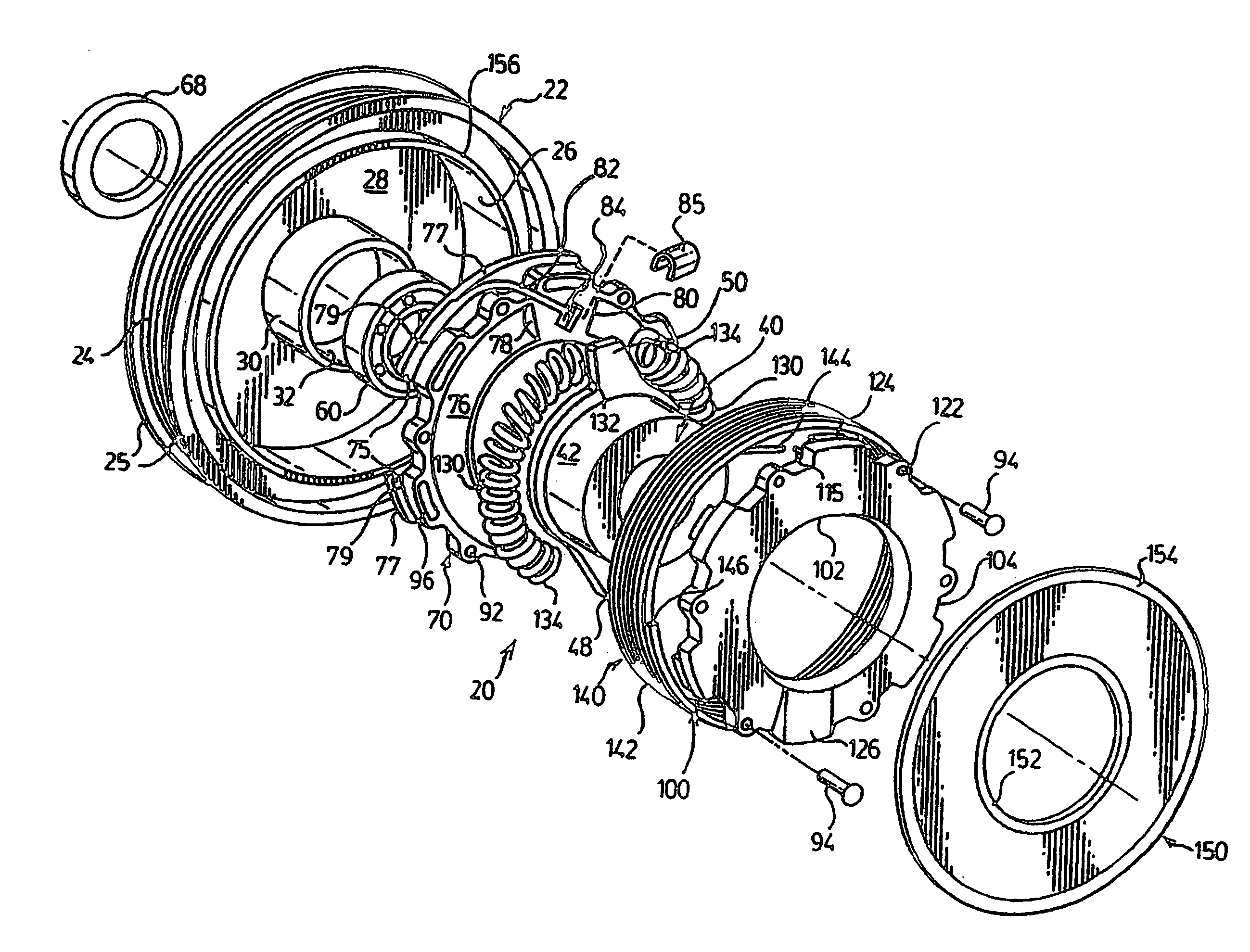

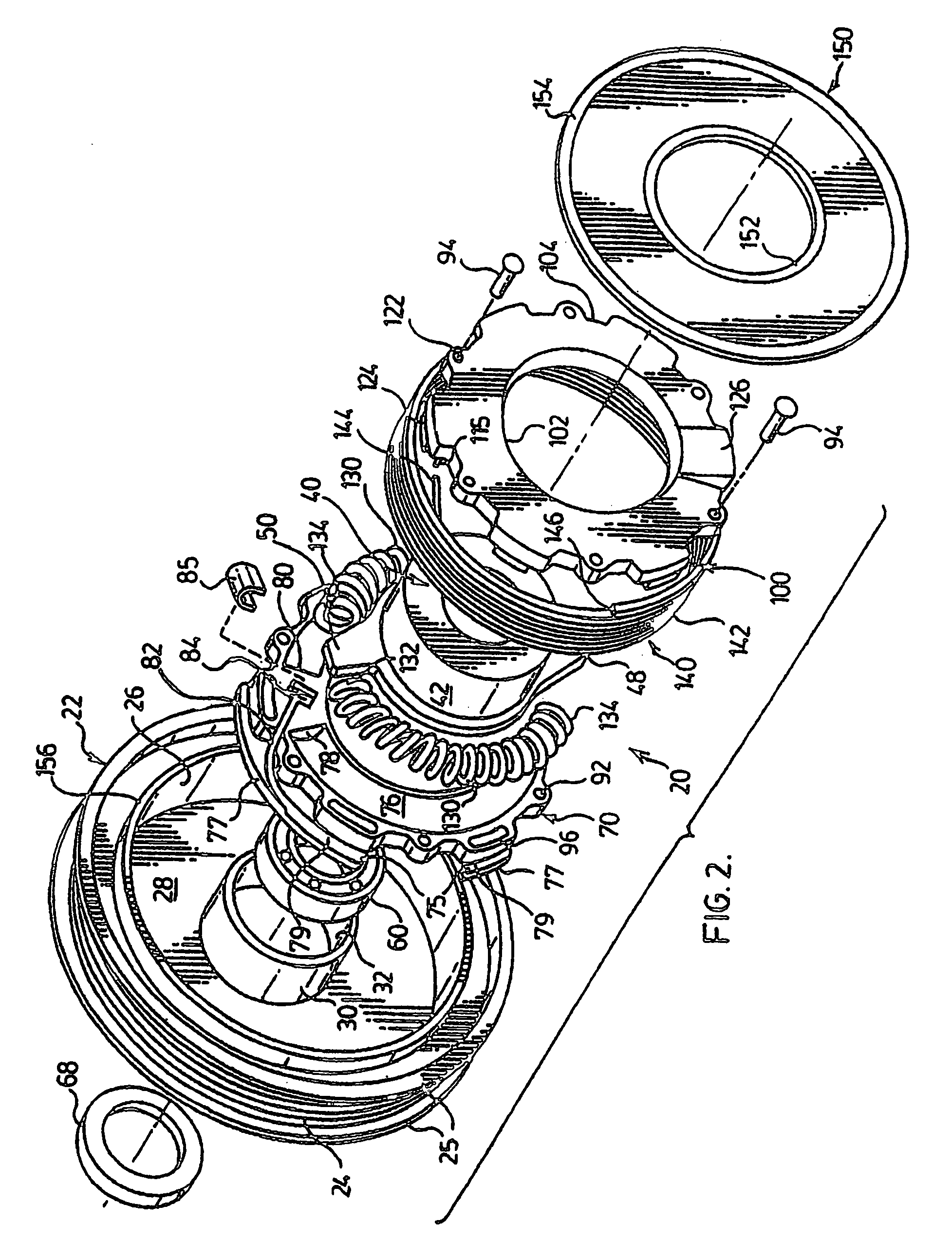

A decoupler assembly (20) is provided for transferring rotational torque between a drive shaft (16) and a drive belt (18) of an automotive engine. The decoupler assembly includes a drive hub (40) configured to be fixedly secured to the drive shaft. A pulley (22) is rotatably coupled to the drive hub (40) and adapted to be drivingly engaged with the belt (18). A spring shell (70, 100) is operatively coupled between the drive hub and the pulley for selective rotation therewith and a biasing member (130) is operatively coupled between the spring shell and the drive hub for isolating oscillatory vibrations between the drive hub and the pulley caused by rotation of the drive shaft. A clutch element (140) is seated between the spring shell (70, 100) and the pulley (22) for selectively transferring rotational torque from the drive hub to the pulley. The pulley (22) includes an inner clutch surface (26) and the clutch element includes a plurality of coils in frictional engagement with the inner clutch surface and an end coupled to the spring shell for expanding the coils against the inner clutch surface upon rotation of the spring shell with the drive hub to selectively transfer torque between the drive hub (40) and the pulley (22).

Owner:LITENS AUTOMOTIVE INC

System and method for rapidly stopping a spinning table saw blade

A system for stopping a spinning table saw blade is comprised of a pin assembly disposed adjacent to a saw blade assembly for stopping a spinning saw blade. A receiving block is disposed on a side of the saw blade opposing the pin assembly for receiving the tip of the pin assembly. A driving assembly is coupled to the pin assembly for driving the pin assembly into the spinning saw blade into the receiving block. Finally, a sensing assembly is coupled to at least one of the saw blade assembly and the driving assembly for sensing encroachment of a user's hand in a pre-defined zone. In use, upon sensing a user's hand the sensing assembly signals the driving assembly to stop the spinning saw blade by driving the pin assembly through the saw blade and into the receiving block.

Owner:CHANG TYPE INDAL

Crankshaft decoupler

A decoupler assembly (20) is provided for transferring rotational torque between a drive shaft (16) and a drive belt (18) of an automotive engine. The decoupler assembly includes a drive hub (40) configured to be fixedly secured to the drive shaft. A pulley (22) is rotatably coupled to the drive hub (40) and adapted to be drivingly engaged with the belt (18). A spring shell (70, 100) is operatively coupled between the drive hub and the pulley for selective rotation therewith and a biasing member (130) is operatively coupled between the spring shell and the drive hub for isolating oscillatory vibrations between the drive hub and the pulley caused by rotation of the drive shaft. A clutch element (140) is seated between the spring shell (70, 100) and the pulley (22) for selectively transferring rotational torque from the drive hub to the pulley. The pulley (22) includes an inner clutch surface (26) and the clutch element includes a plurality of coils in frictional engagement with the inner clutch surface and an end coupled to the spring shell for expanding the coils against the inner clutch surface upon rotation of the spring shell with the drive hub to selectively transfer torque between the drive hub (40) and the pulley (22).

Owner:LITENS AUTOMOTIVE INC

Fixed torque limiting driver

A clutch assembly for use with a torque limiting driver. The clutch assembly comprises two relatively rotatable clutch plates, a driving plate and a camming plate, that face one another, with a plurality of rolling members housed between the two members. The driving clutch member has a face comprising a plurality of radially spaced flat areas and a plurality of recesses interposed between the flat areas, with the recesses comprising a curvilinear base area. The second camming clutch member has a face comprising a plurality of radially spaced flat areas and a plurality of opposing downwardly sloped planar surfaces interposed between said flat areas, with the planar surfaces forming an angle. The rolling members are movable from an engaged position with the clutch members to an override position. When the rolling members are in the override position, the recesses form individual housings for the rolling members that include a gap located between the rolling members and a respective curvilinear base area.

Owner:BRADSHAW MEDICAL

Power tool safety mechanisms

A sensing mechanism (12) for detecting user contact with an active portion (26) of the power tool (10) is provided. In addition, a safety mechanism (14) for preventing prolonged user contact with the active portion (26) of a power tool (10) is provided. The safety mechanism (14) is configured to actuate upon receipt of a signal from the sensing mechanism (12). According to a first aspect, the safety mechanism (14) is arranged to rapidly displace the active portion (26) away from a user extremity. Alternatively, according to a second aspect, the safety mechanism (14) is arranged to rapidly urge an extremity of the user away from the active portion (26) of the power tool (10).

Owner:BLACK & DECKER INC

Screwdriver with adjustable device to limit transmitted torque

A screwing tool with a device to adjust transmitted torque comprises a handle to introduce a torque to the device, which is borne in the hollow of the handle and a drive shaft as an output element of the torque. On the drive shaft inside the handle, two separate couplings are assembled, having between them a compression spring exerting a spring force against the two couplings. Each coupling comprises a first and a second socket engaging each other by gearings at their opposing faces. The maximum torque at which the torque transmission will be interrupted can be adjusted by an adjustment element wherein the distance between the couplings can be changed, thereby resulting in a change of the tension of the spring exerting a load on the couplings. The teeth of the gearings slide and the sockets rotate relatively to each other and interrupt the torque-transmission if a pre-adjusted torque is exceeded.

Owner:FELO WERKZEUGFAB HOLLAND LETZ

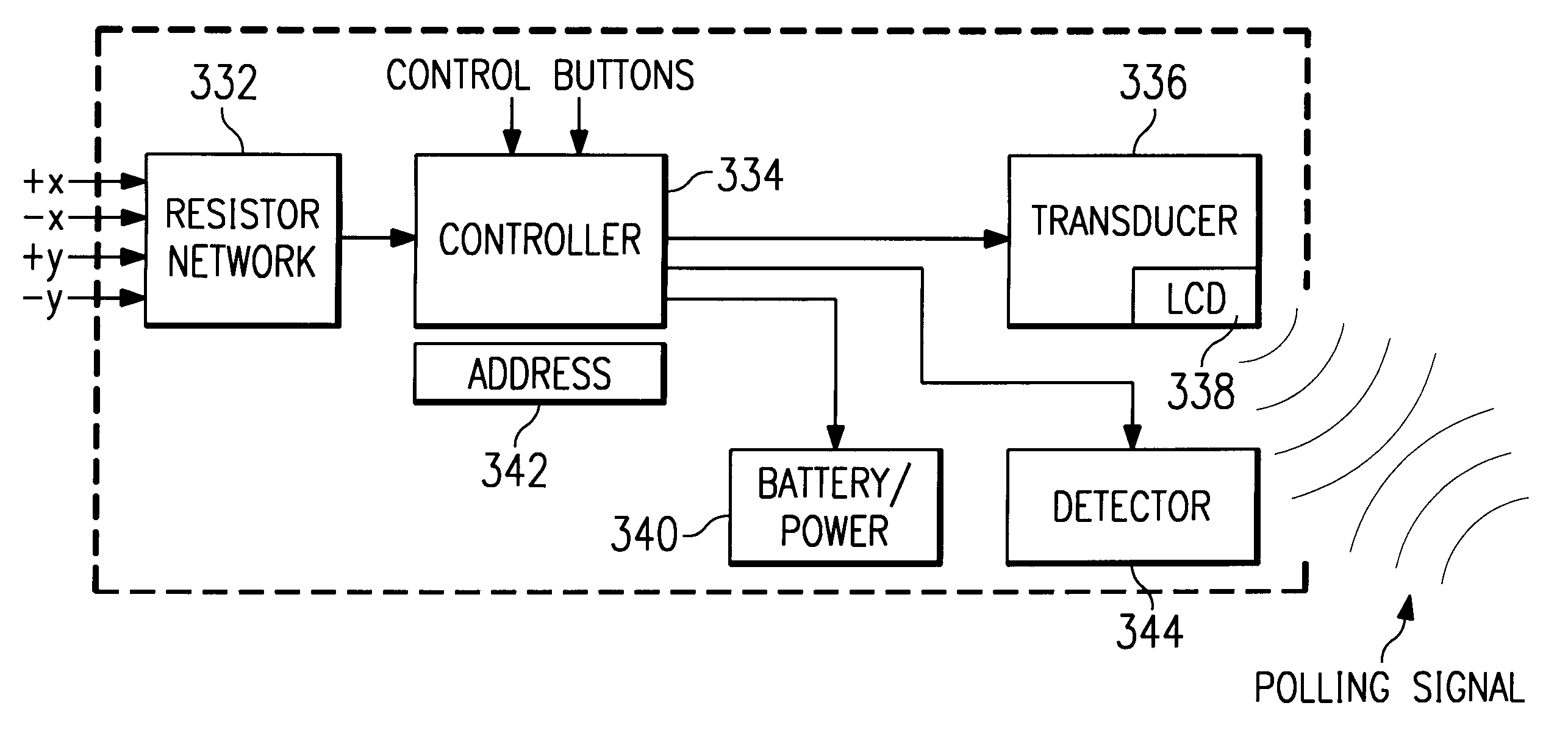

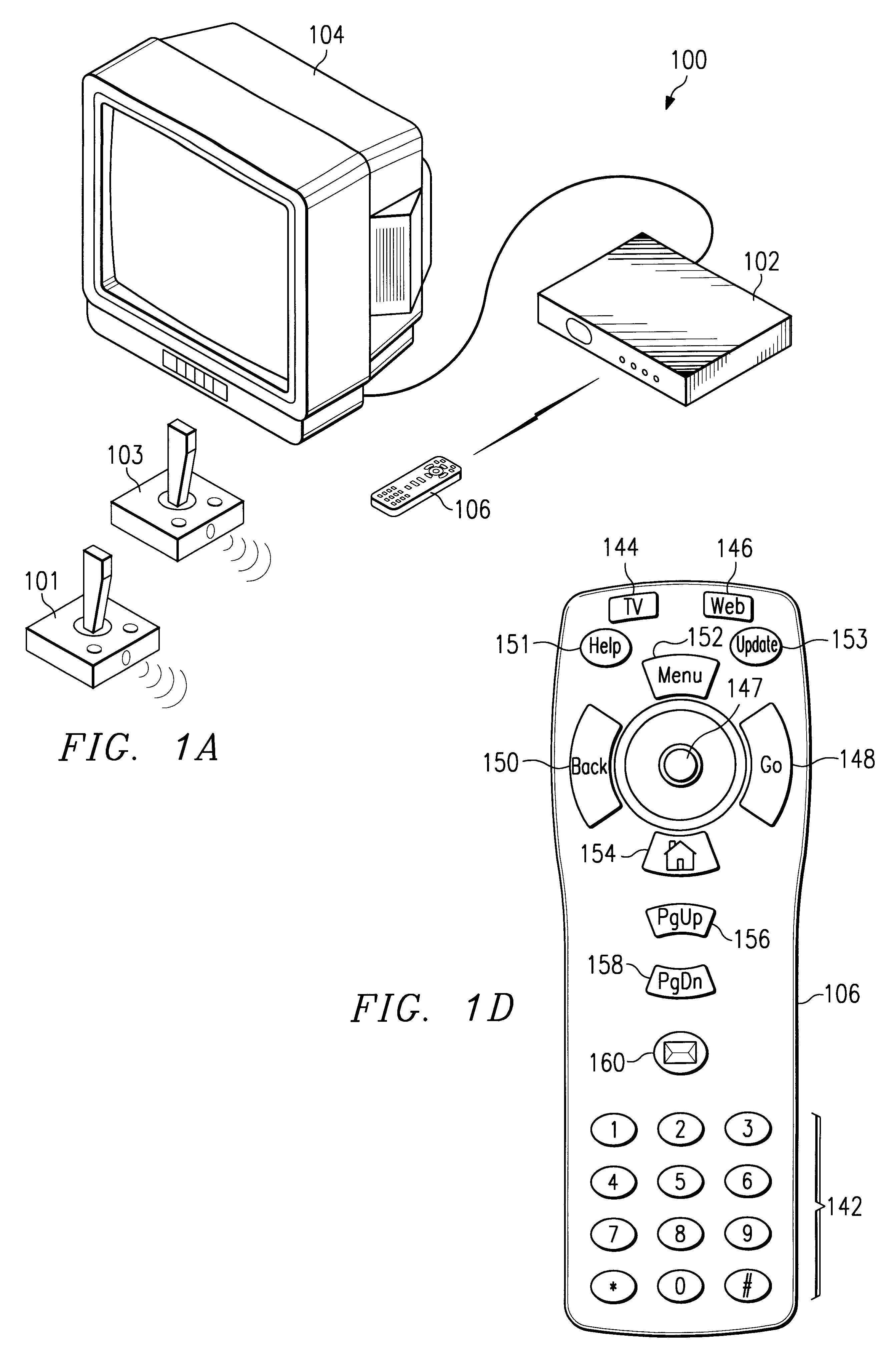

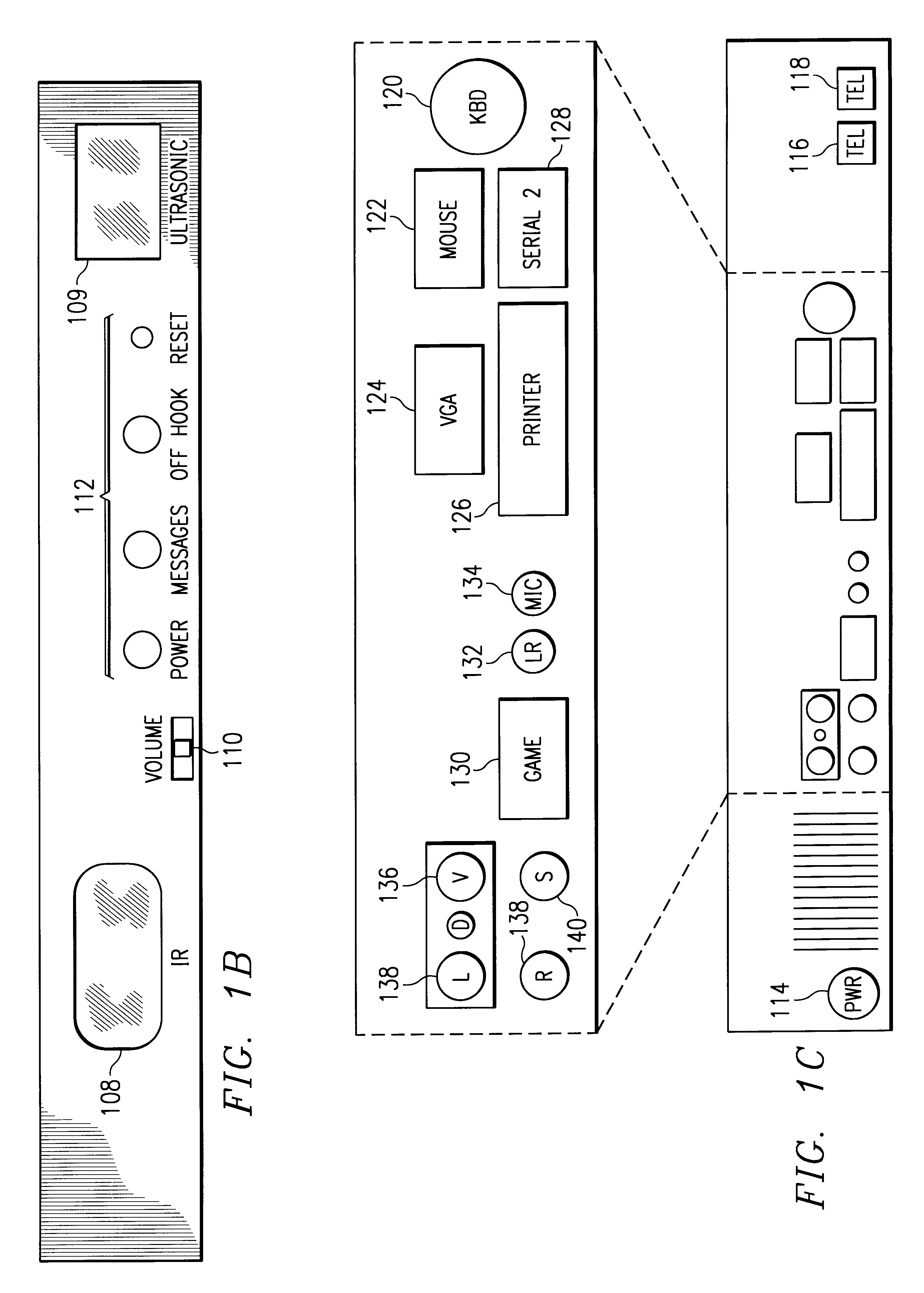

Method and system for simultaneous operation of multiple handheld IR control devices in a data processing system

InactiveUS6229526B1Increases entertainment valueSimple and cost-effectiveManual control with multiple controlled membersSlip couplingData processing systemControl signal

A method and system for controlling a display of a data processing system uses first and second wireless position control devices, and a control base unit. The first wireless position control device includes a transducer for transmitting a first signal upon which X-Y position control and / or action control signals generated by the device are imposed. A second wireless position control device includes a transducer for transmitting a second signal upon which X-Y position control and / or other action control signals generated by the second control device are imposed. The first and second signals and second different frequencies. To prevent the control devices from interfering with each other, the control base is associated with the data processing system and includes circuitry for issuing polling signals to the control devices. Only one of the control devices is polled at a particular time. The control base circuitry also receives and decodes the carrier signals to generate decoded display control signals. The display control signals are then used to drive the display device. Two users may thus control the display device simultaneously.

Owner:IBM CORP

Decoupler assembly having limited overrunning capability

In one aspect, a decoupler assembly is provided for use between a shaft and an endless drive member that is used to drive the shaft. The decoupler assembly includes a pulley, a hub and an isolator spring that is preferably a coiled torsion spring. The two ends of the spring are engageable, at least indirectly, with the pulley and the hub for the transfer of torque therebetween. At least one of the ends of the spring engages an engagement structure (on either the pulley or the hub) that includes a helical axial shoulder and a driver wall. The spring transfers torque in one direction through the driver wall (e.g. when the pulley overruns the hub), but the spring end is not fixedly connected to the driver wall. When the hub overruns the pulley, there is relative rotation between the spring and whichever of the hub and pulley it is not fixedly connected to. Accordingly, there is relative rotation between the spring end and the helical axial shoulder and the driver wall. This causes the spring end to separate from the driver wall and ride up the helical axial shoulder. This causes the spring to compress axially. The spring coils have a selected amount of spacing so that the spring can be compressed by a selected amount axially. This sets the amount of relative rotation (and the amount of overrun) that is available between the pulley and the hub in the situation when the hub overruns the pulley.

Owner:LITENS AUTOMOTIVE INC

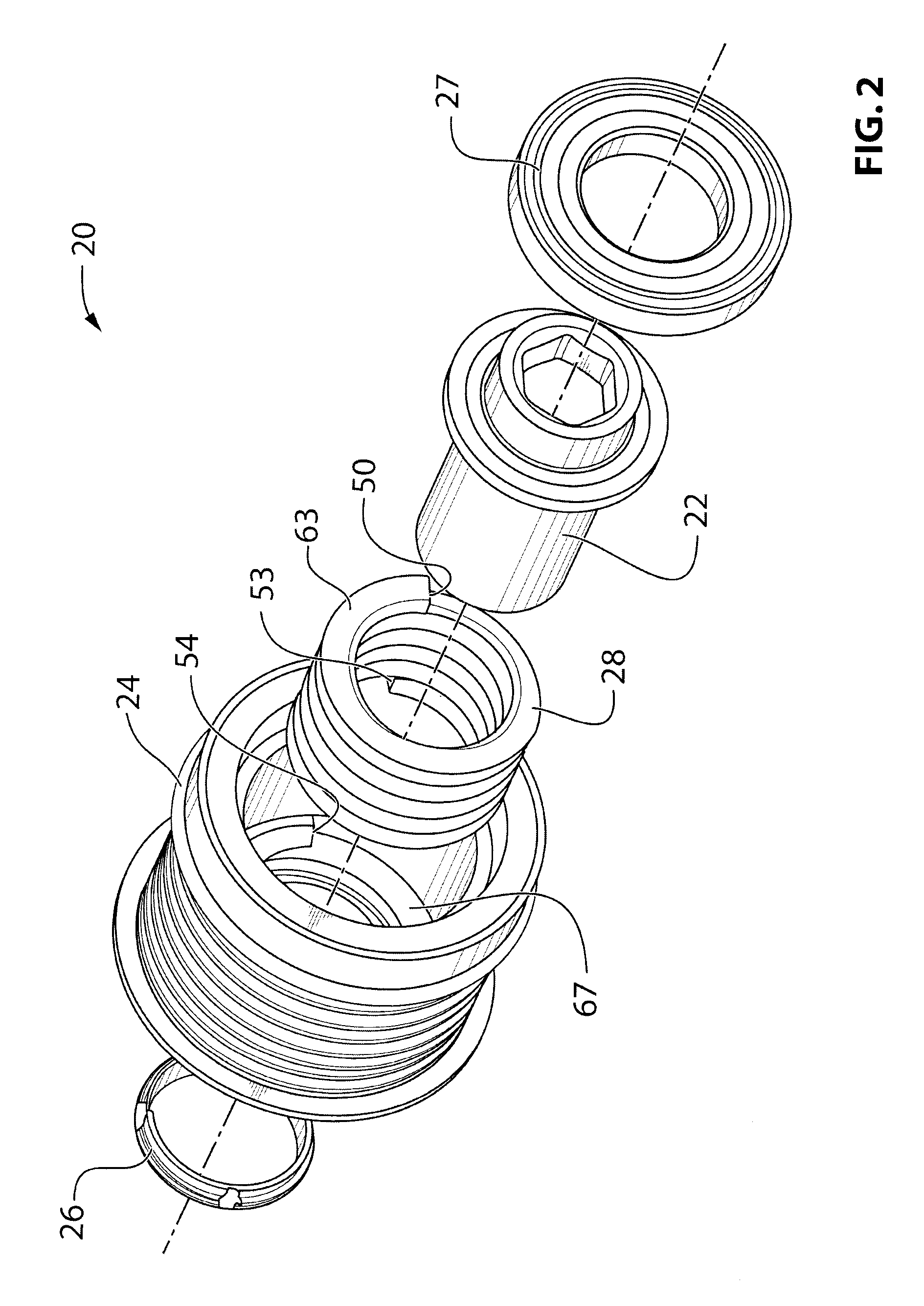

Drive assembly for locking one or several operating units of an agricultural implement or of a self-propelled implement

InactiveUS7464526B2Quick stopAgricultural machinesMechanical actuated clutchesCouplingElectrical and Electronics engineering

A drive assembly driven by a drive unit locks one or several operating units (6) of an agricultural implement (1) or of a self-propelled implement. The operating unit (6) can be locked when switching off the drive unit or upon reaction of an overload coupling (4). The drive assembly (3) has an overload coupling (4) connected to the drive unit and driven by the drive unit in one driving direction of rotation. The overload coupling (4) is also connected to the operating unit (6). The drive assembly (3) further has a brake unit (5) connected to the overload coupling (4). The brake unit (5) is intended to be arranged in the driveline between the overload coupling (4) and the operating unit (6). Actuating mechanism (10) actuates the brake unit (5) when the operating unit is running so that the operating unit is braked and locked. Thereafter, the overload coupling is disconnected.

Owner:JEAN WALTERSCHEID GMBH

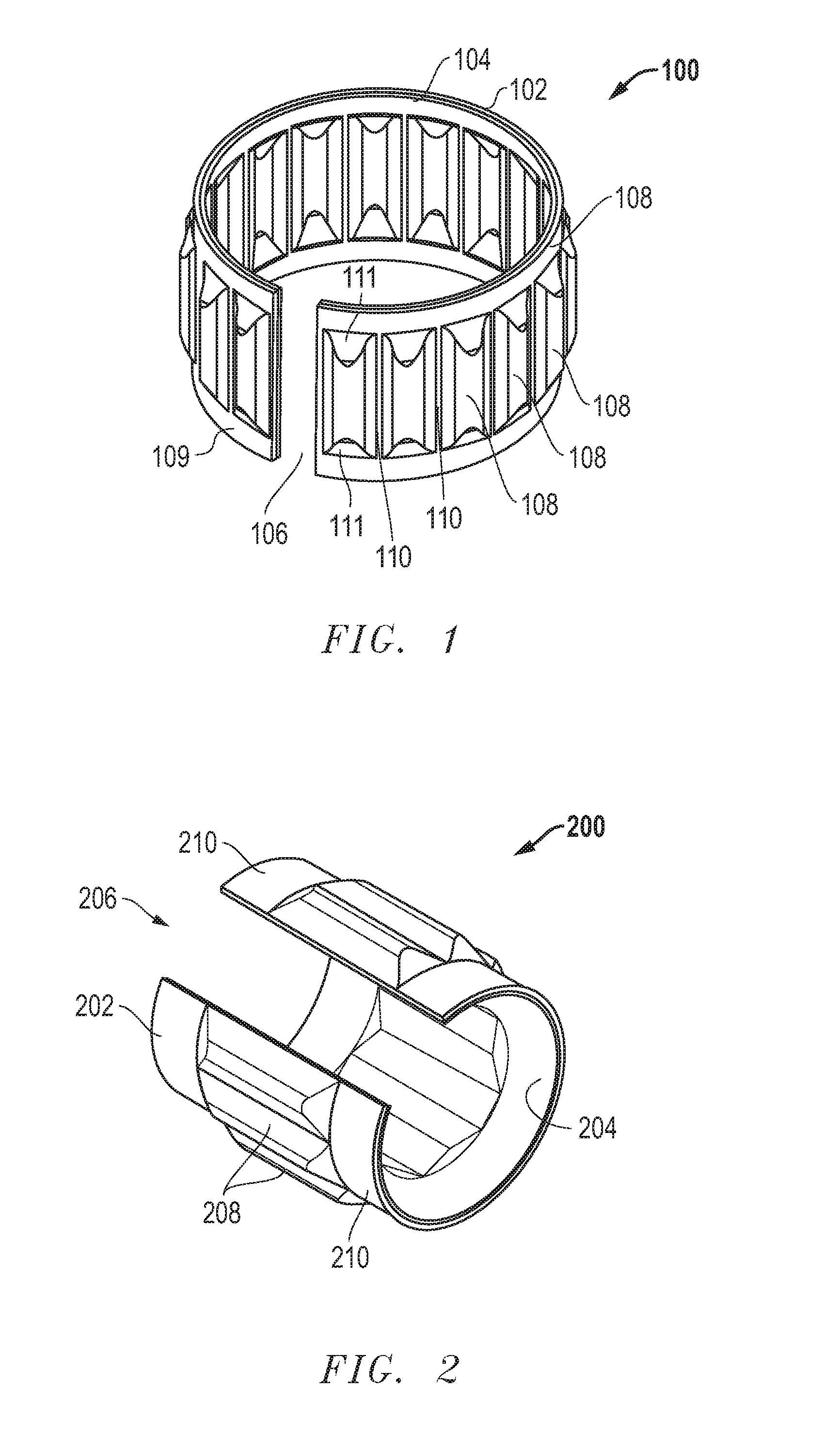

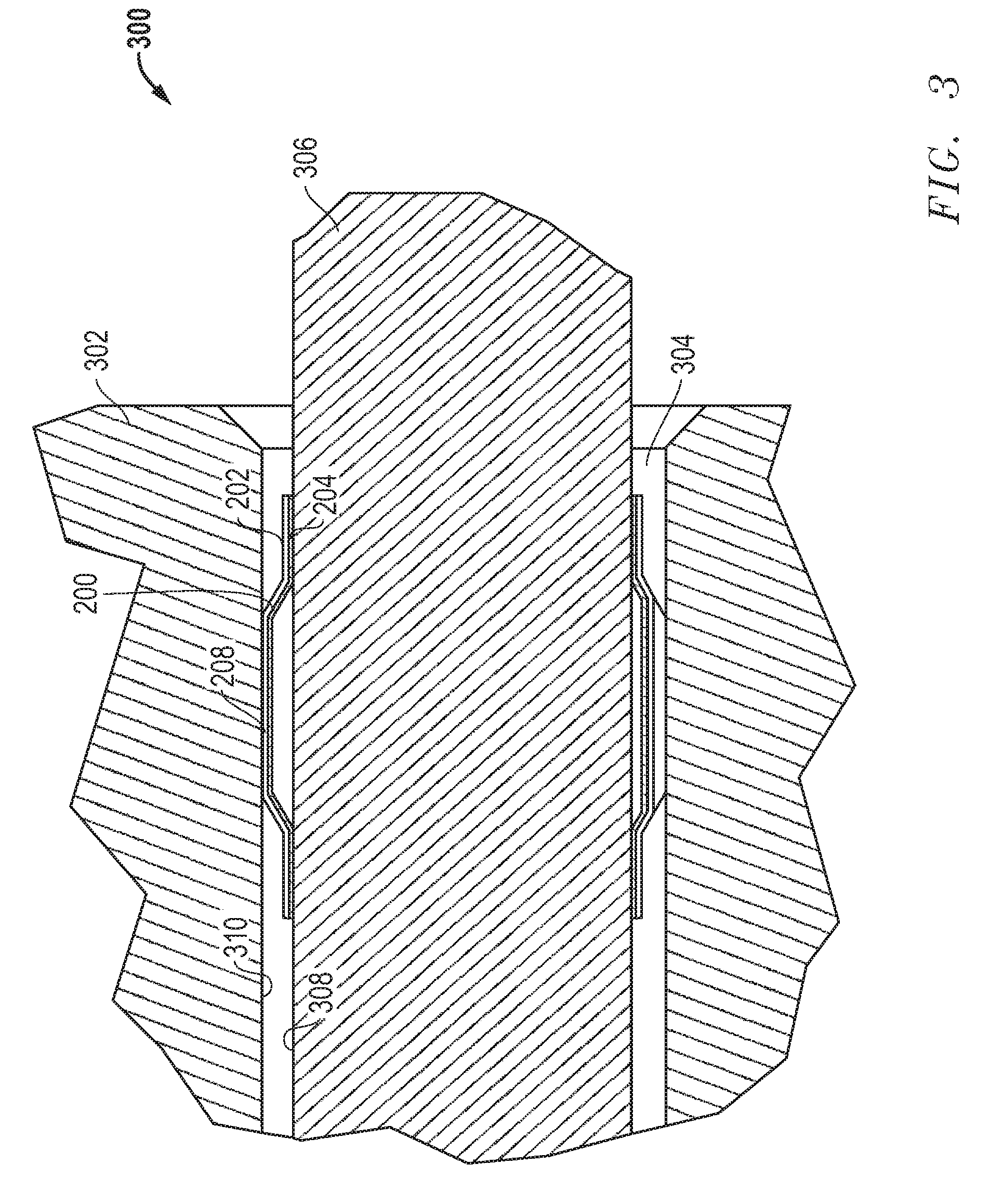

Force limiting assembly

An apparatus is shown which comprises first and second mating components with a force limiter located between them. The force limiter includes a band of resilient material, with protrusions therealong, and a slip element. The band and the slip element are secured to the first mating component with the band arranged to apply a radial force against the slip element so as to press it against the second mating component. The frictional force between slip element and the second mating component is insufficient to separate the slip element and the band from the first mating component, so any slipping that occurs between the mating components happens at the boundary of the slip element and the second mating component. A desired slip force can be obtained by choosing a slip element with an appropriate coefficient of friction, rather than by varying the dimensions of the components.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS RENCOL

Spring Travel Limiter For Overrunning Alternator Decoupler

ActiveUS20080108442A1Prevent movementPrevent rotationYielding couplingSlip couplingSerpentine beltAlternator

A decoupler assembly for transferring rotary movement between an engine driven shaft and a serpentine belt. The decoupler includes a hub configured to be assembled to the shaft. The hub has a helical first slot formed therein. A pulley is rotatably coupled to the hub. A carrier is mounted on the hub and includes a helical second slot formed therein, as well as an anti-ramp up boss formed thereon. A thrust plate is fixed to the hub and has a slot formed therein. A torsion spring is compressed between a hub end retained in the helical first slot and a carrier end retained in the helical second slot for transferring torque between the hub and carrier. The anti-ramp up boss travels within the slot formed in the thrust plate for limiting rotation between the carrier and thrust plate and preventing rotation of the torsion spring relative to the hub and carrier.

Owner:LITENS AUTOMOTIVE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com