Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4500results about "Linear bearings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

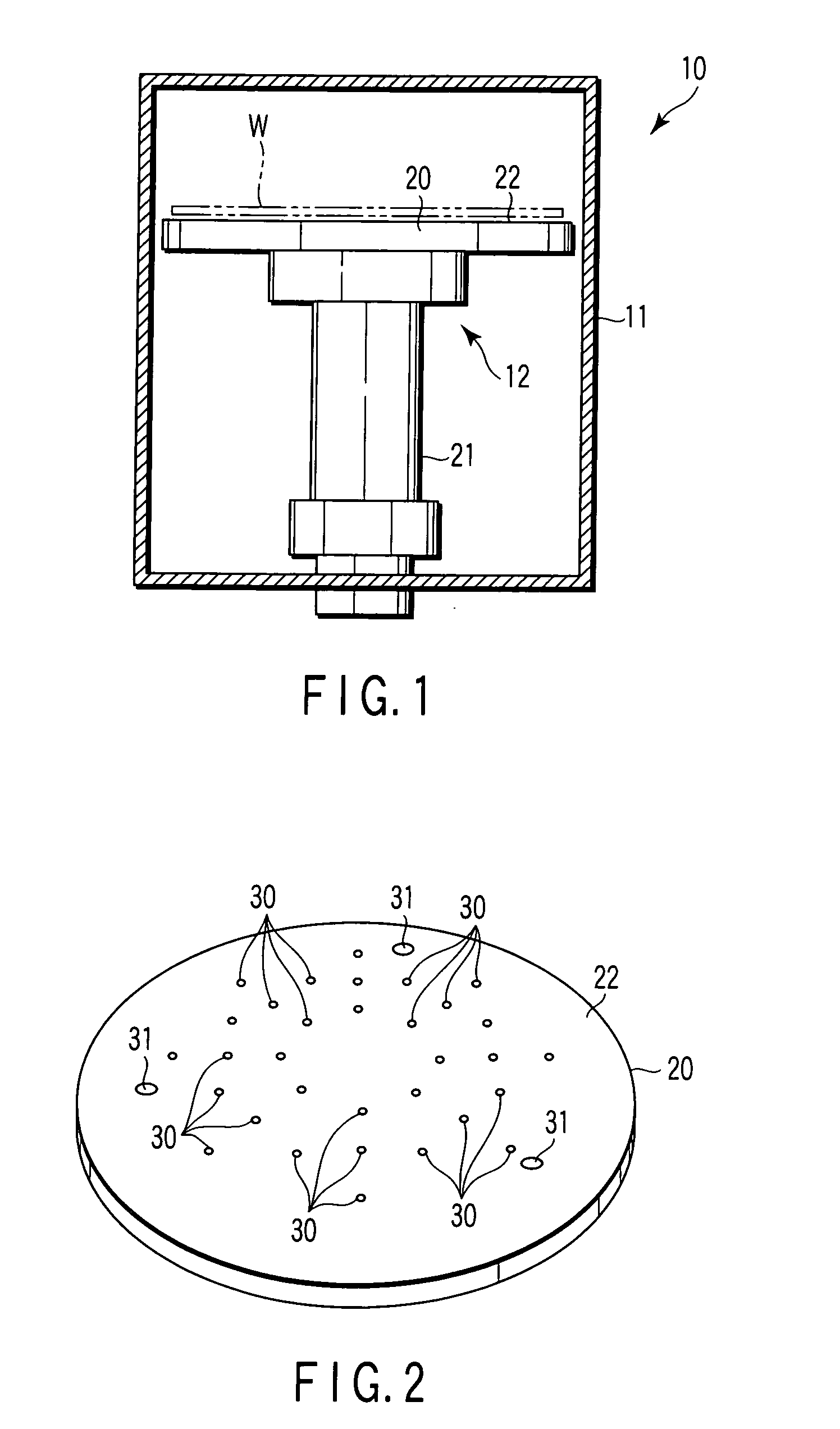

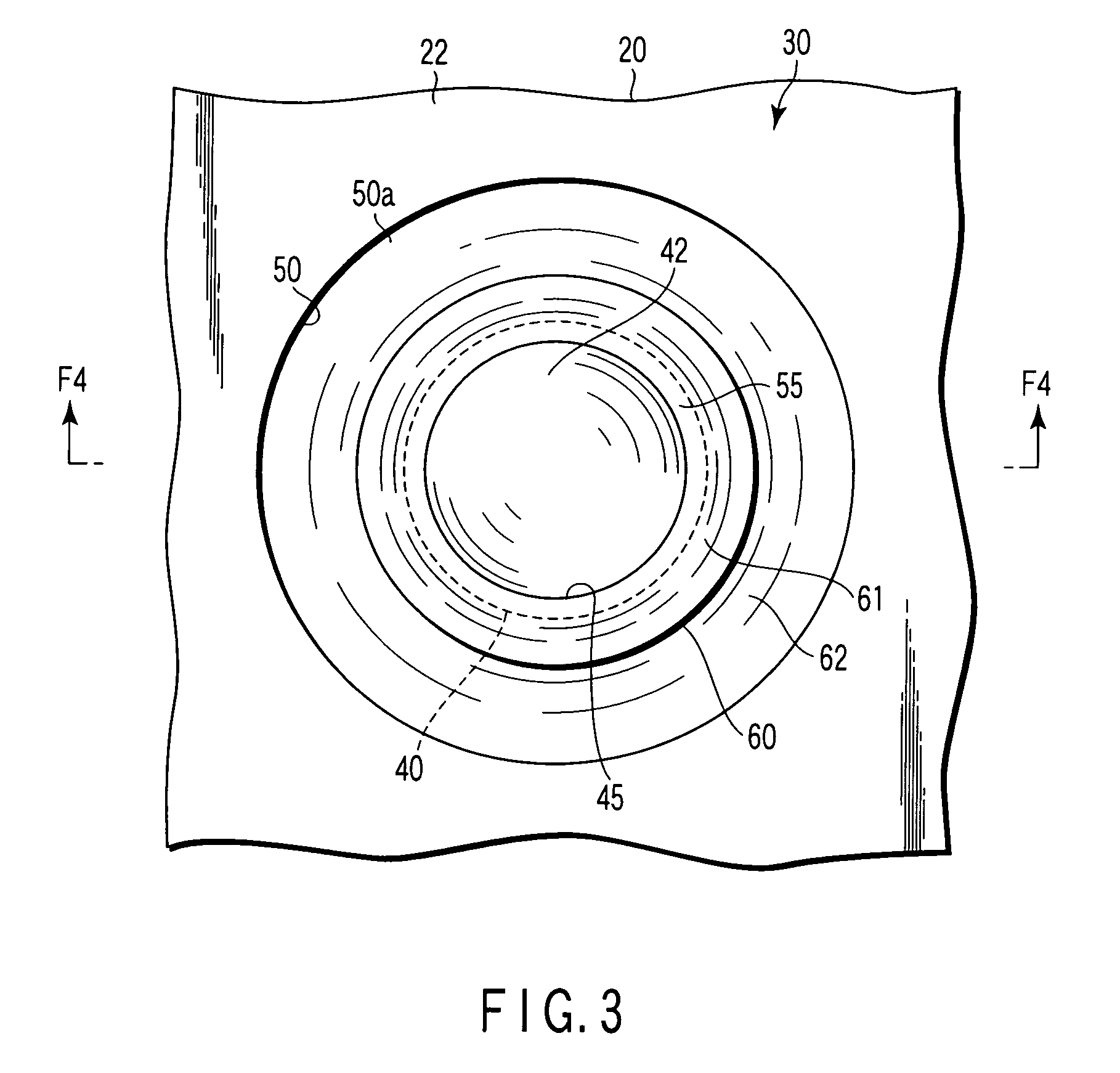

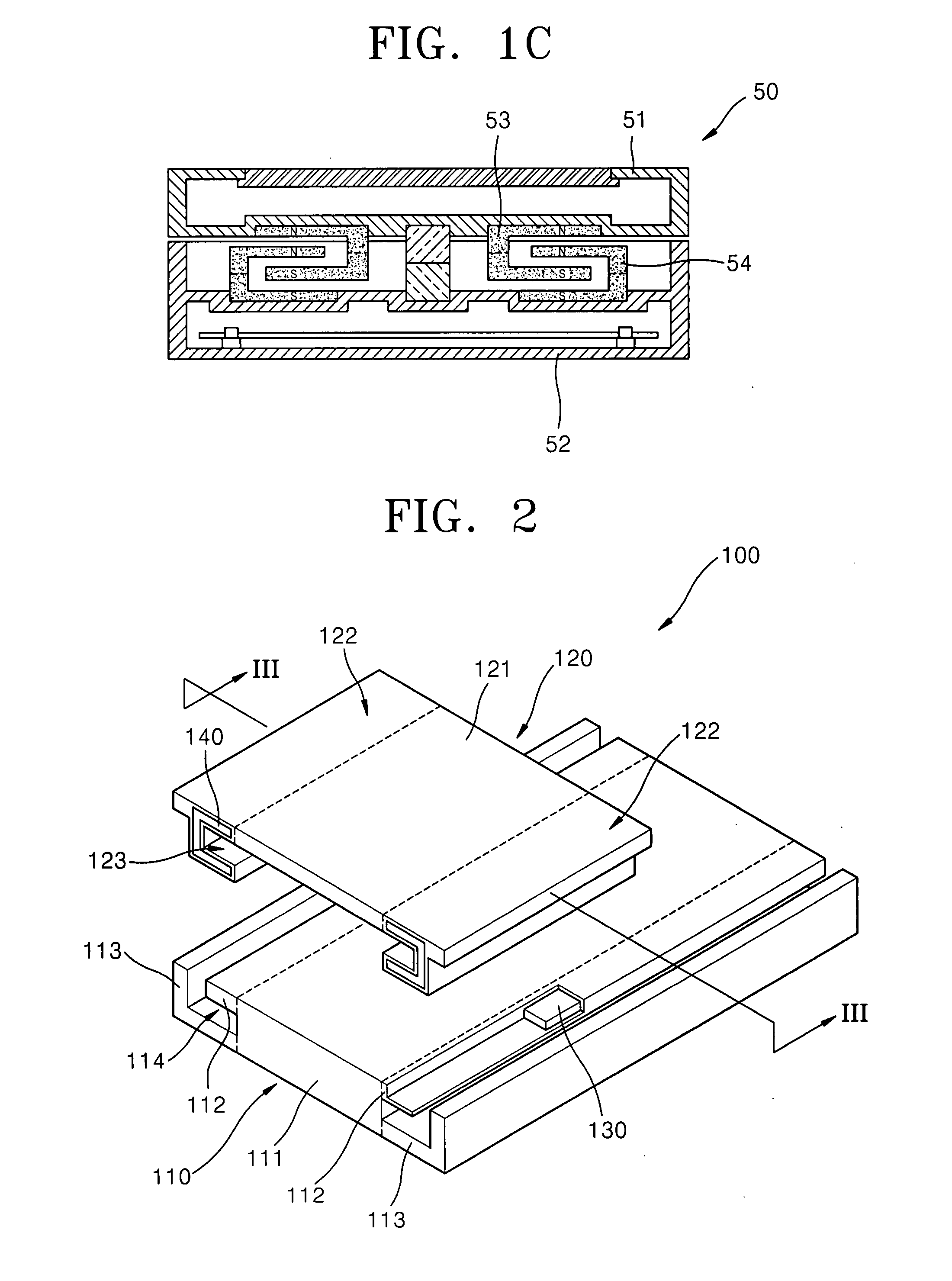

Substrate supporting apparatus

ActiveUS7503980B2Preventing slipping-off and breakageInhibit transferLiquid surface applicatorsLinear bearingsAlloyEngineering

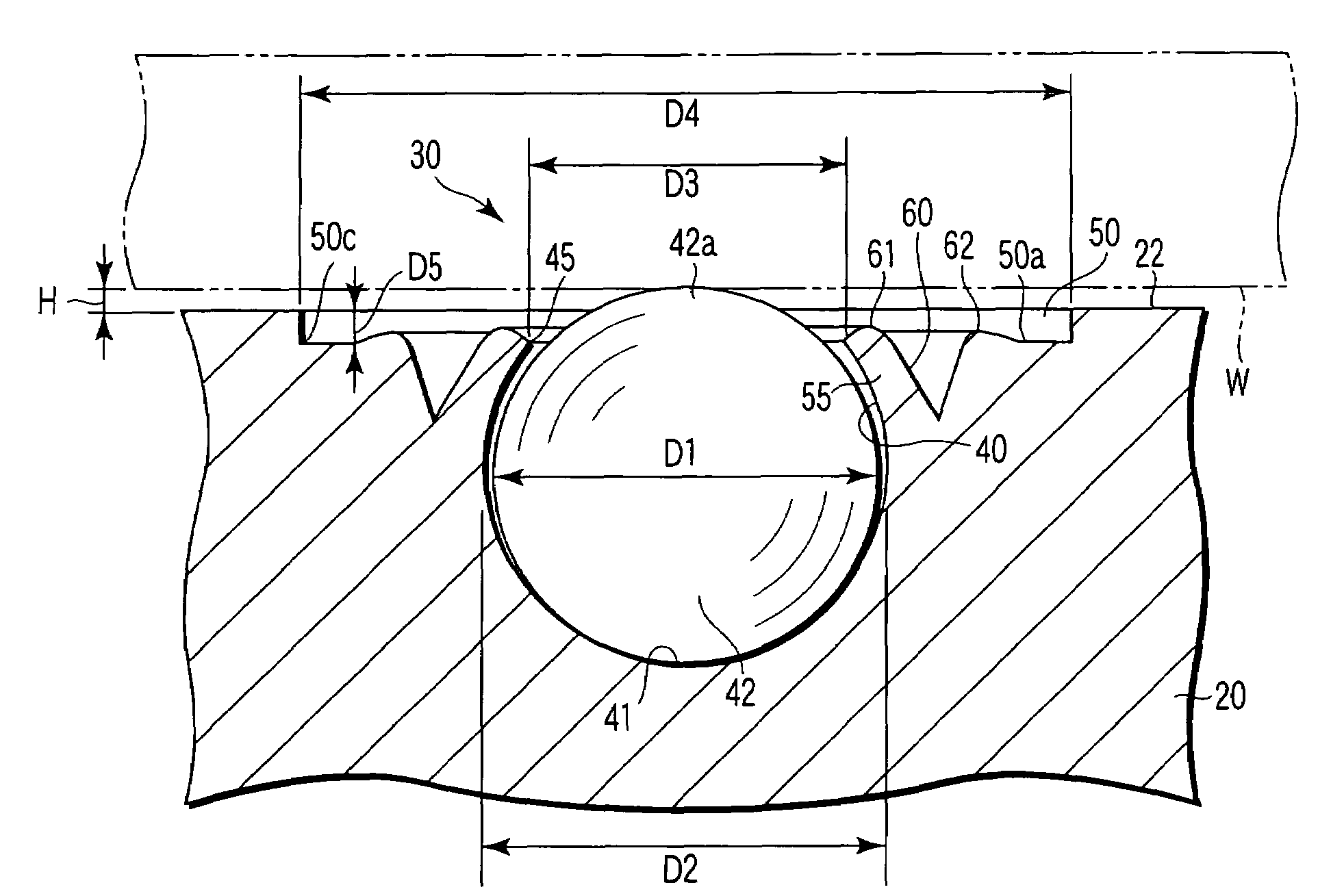

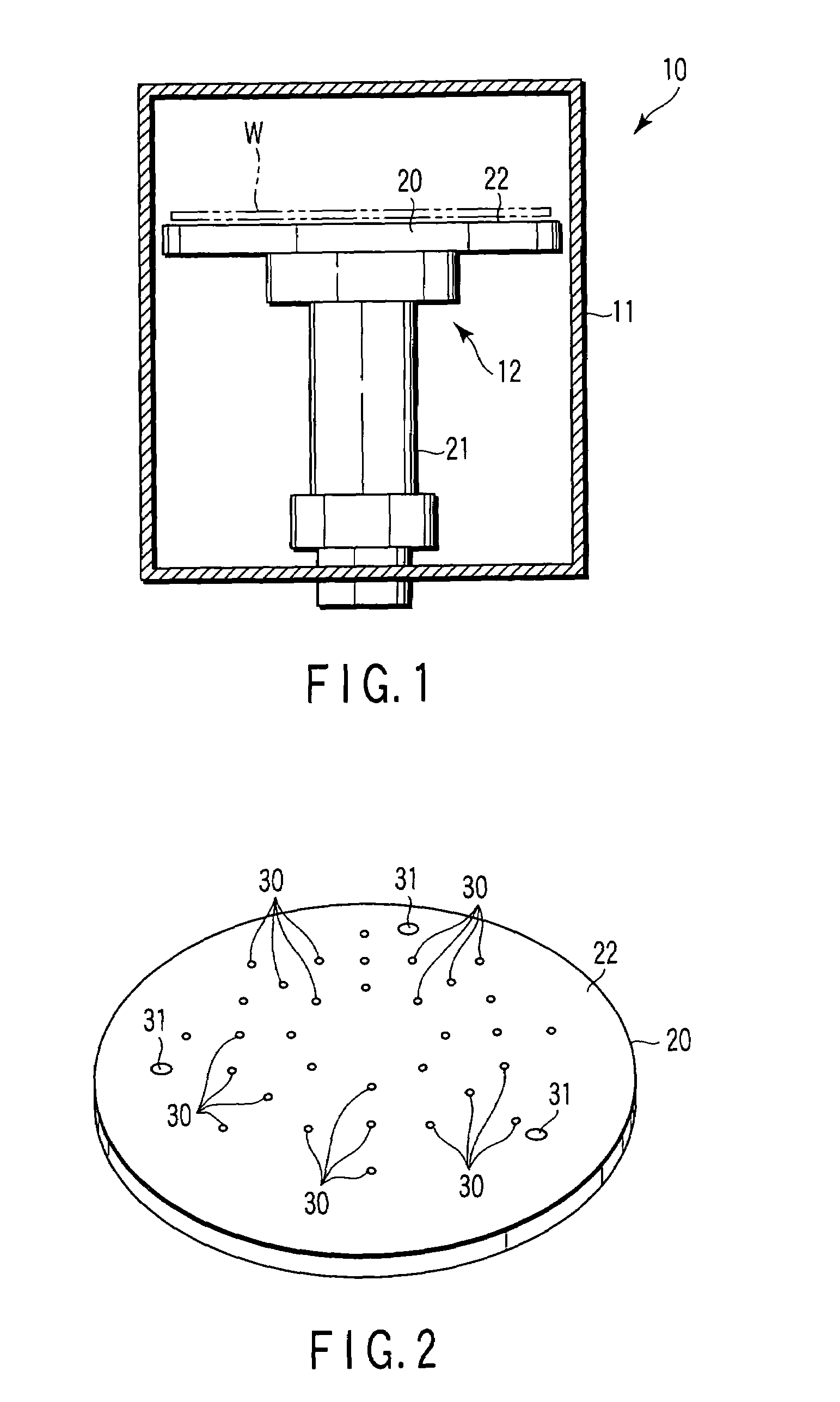

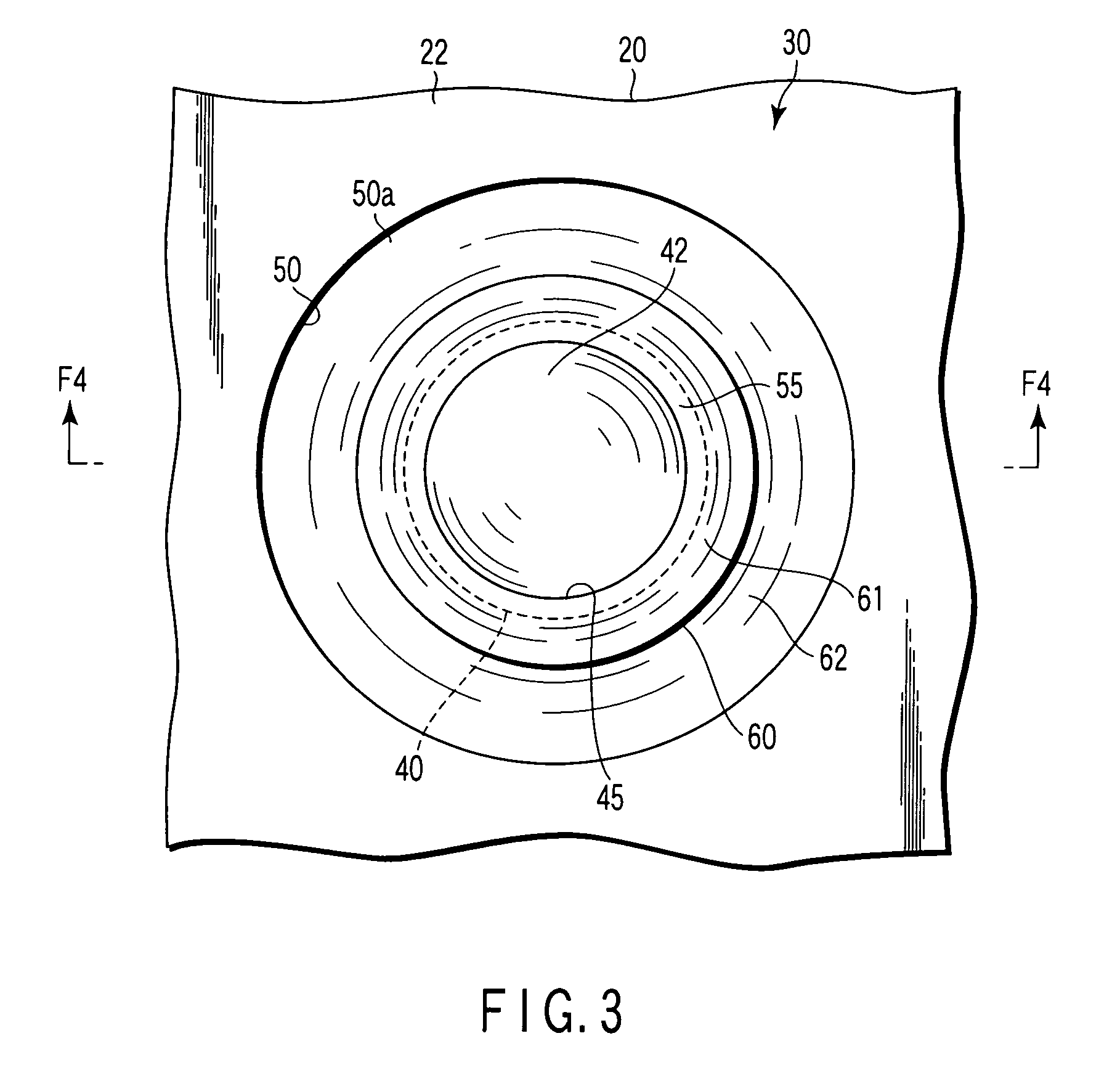

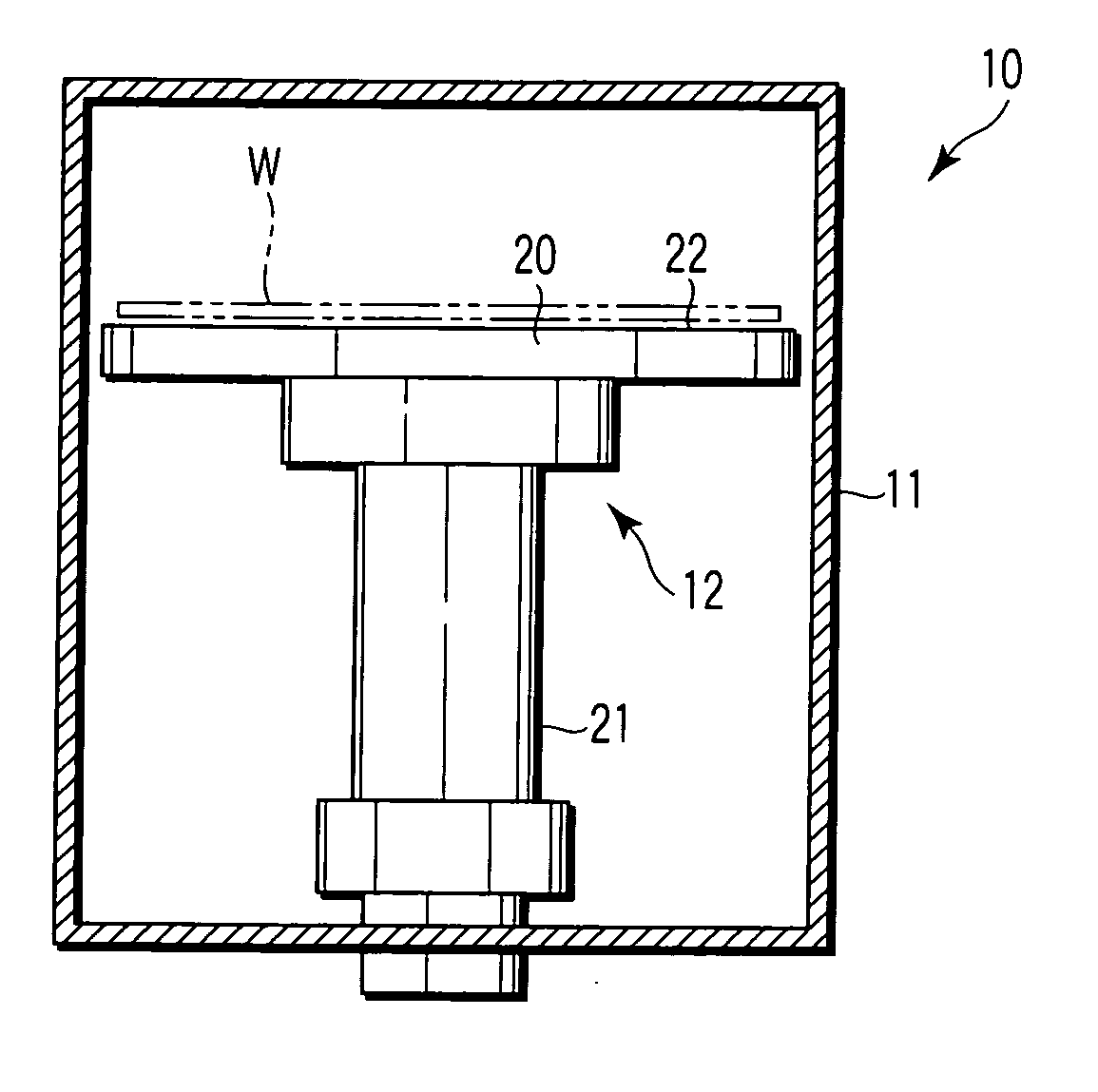

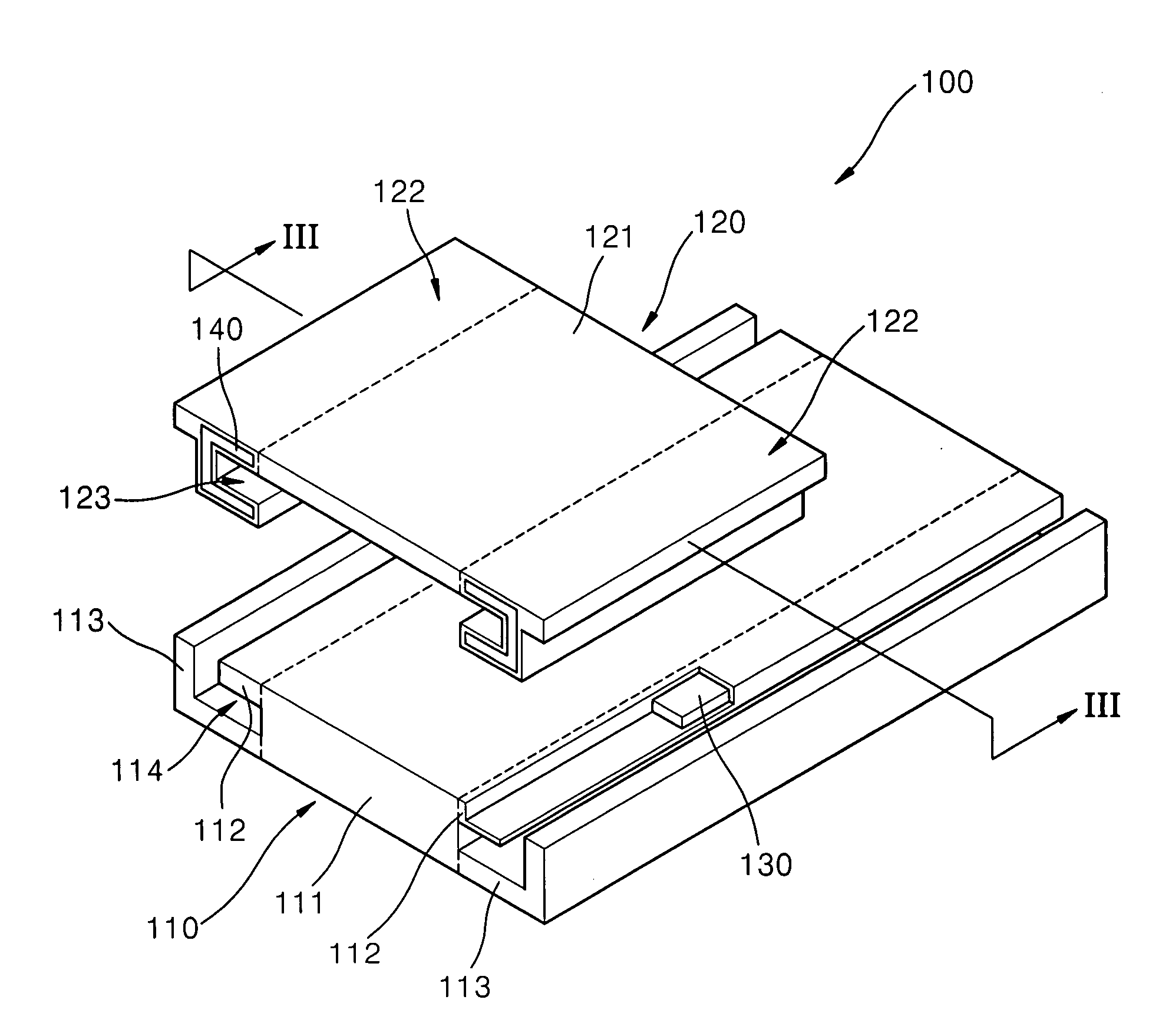

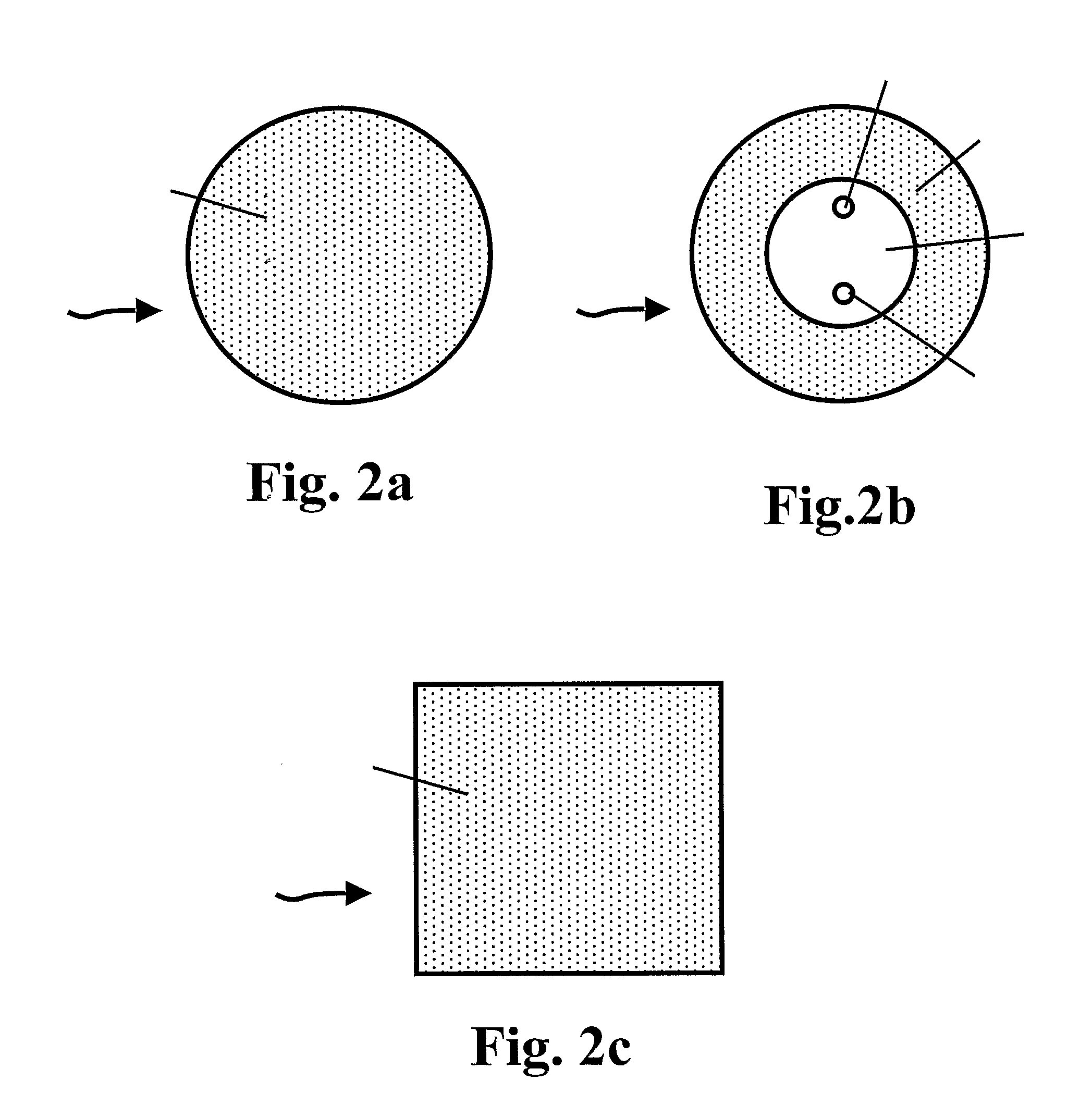

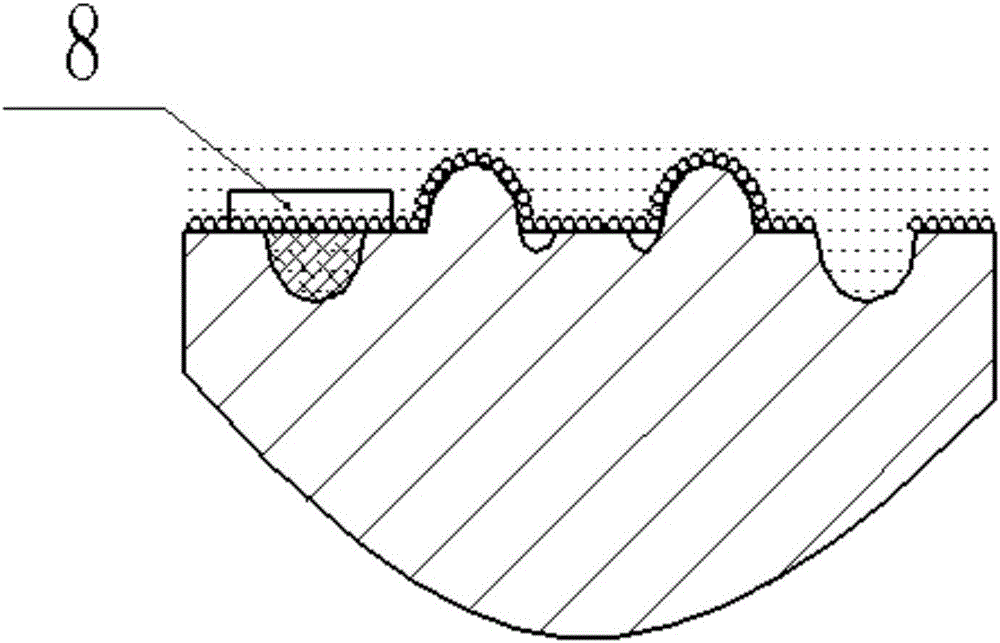

A substrate supporting apparatus includes a plate member of an aluminum alloy having a flat upper surface, bottomed pits formed in the plate member, and spacer members held in the pits, individually. The spacer members are sapphire spheres. The diameter of each spacer member is a little smaller than that of each pit. The upper end of each spacer member projects from the upper surface of the plate member. A spot facing is formed in a region that includes the open edge portion of the pit. A bending portion which is obtained by plastically deforming the open edge portion of the pit toward the spacer member is formed on a bottom surface of the spot facing. A V-shaped groove is formed behind the bending portion.

Owner:NHK SPRING CO LTD

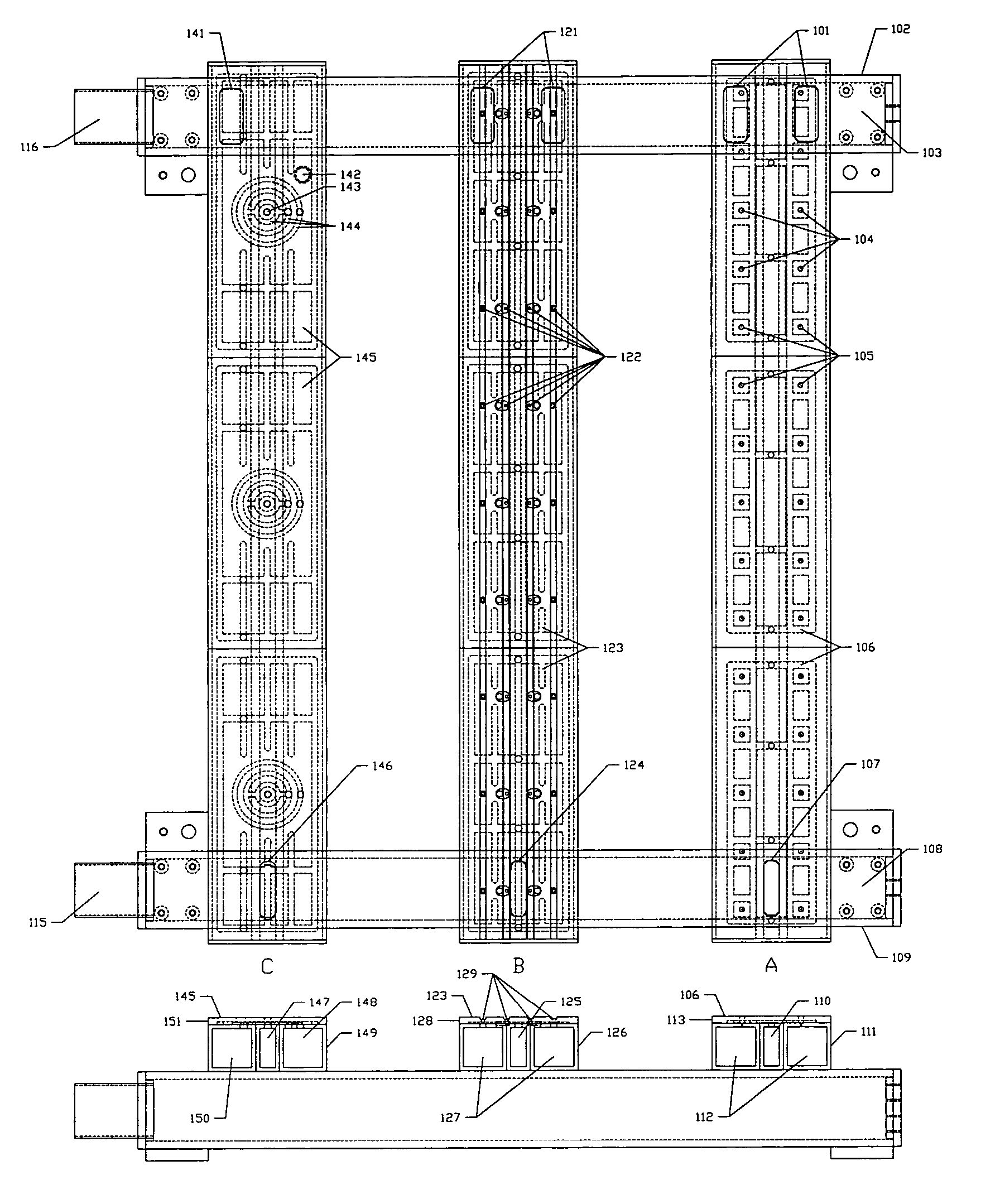

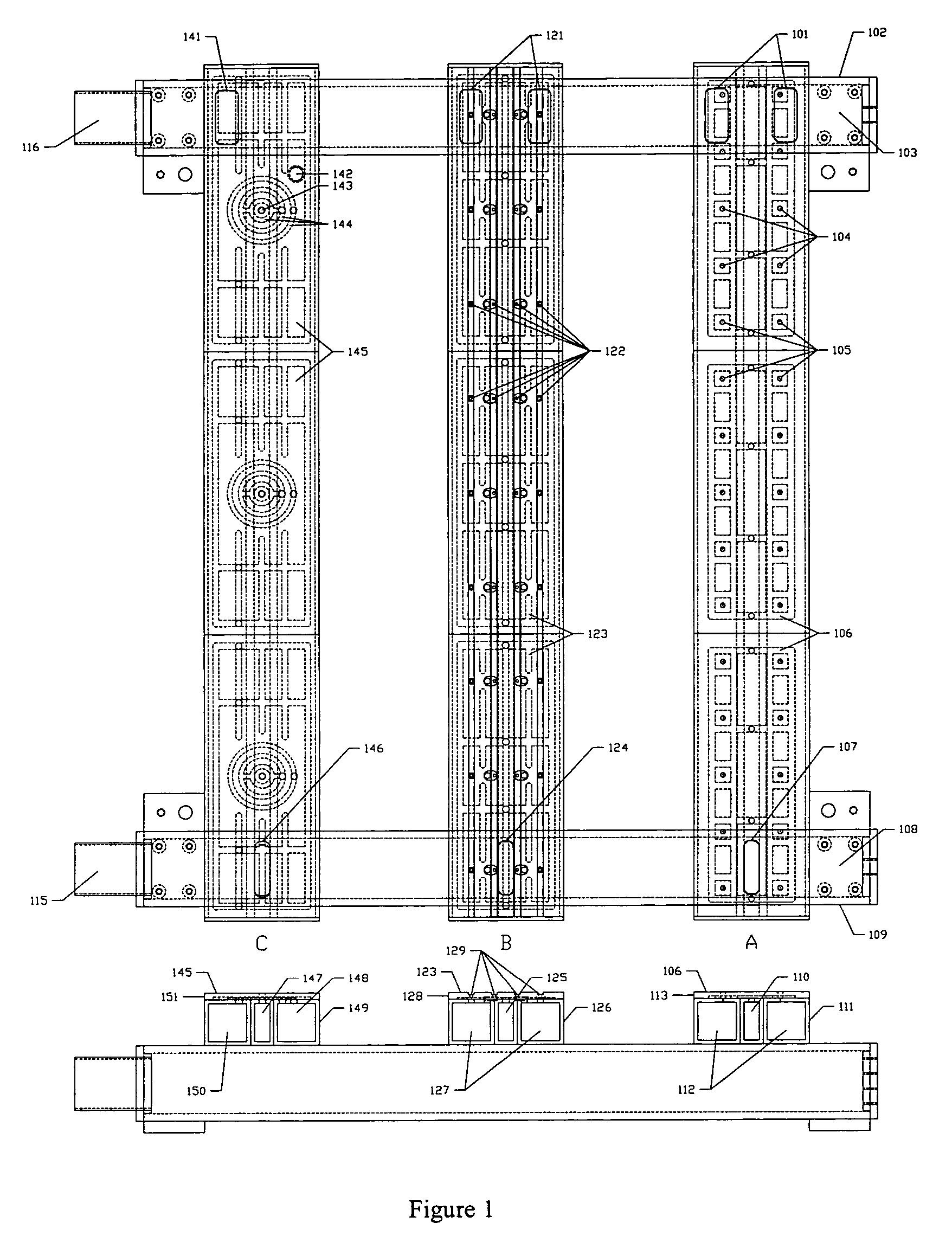

Substrate supporting apparatus and manufacturing method therefor

ActiveUS20070157466A1Preventing slipping-offAvoid breakingLiquid surface applicatorsLinear bearingsEngineeringAlloy

A substrate supporting apparatus includes a plate member of an aluminum alloy having a flat upper surface, bottomed pits formed in the plate member, and spacer members held in the pits, individually. The spacer members are sapphire spheres. The diameter of each spacer member is a little smaller than that of each pit. The upper end of each spacer member projects from the upper surface of the plate member. A spot facing is formed in a region that includes the open edge portion of the pit. A bending portion which is obtained by plastically deforming the open edge portion of the pit toward the spacer member is formed on a bottom surface of the spot facing. A V-shaped groove is formed behind the bending portion.

Owner:NHK SPRING CO LTD

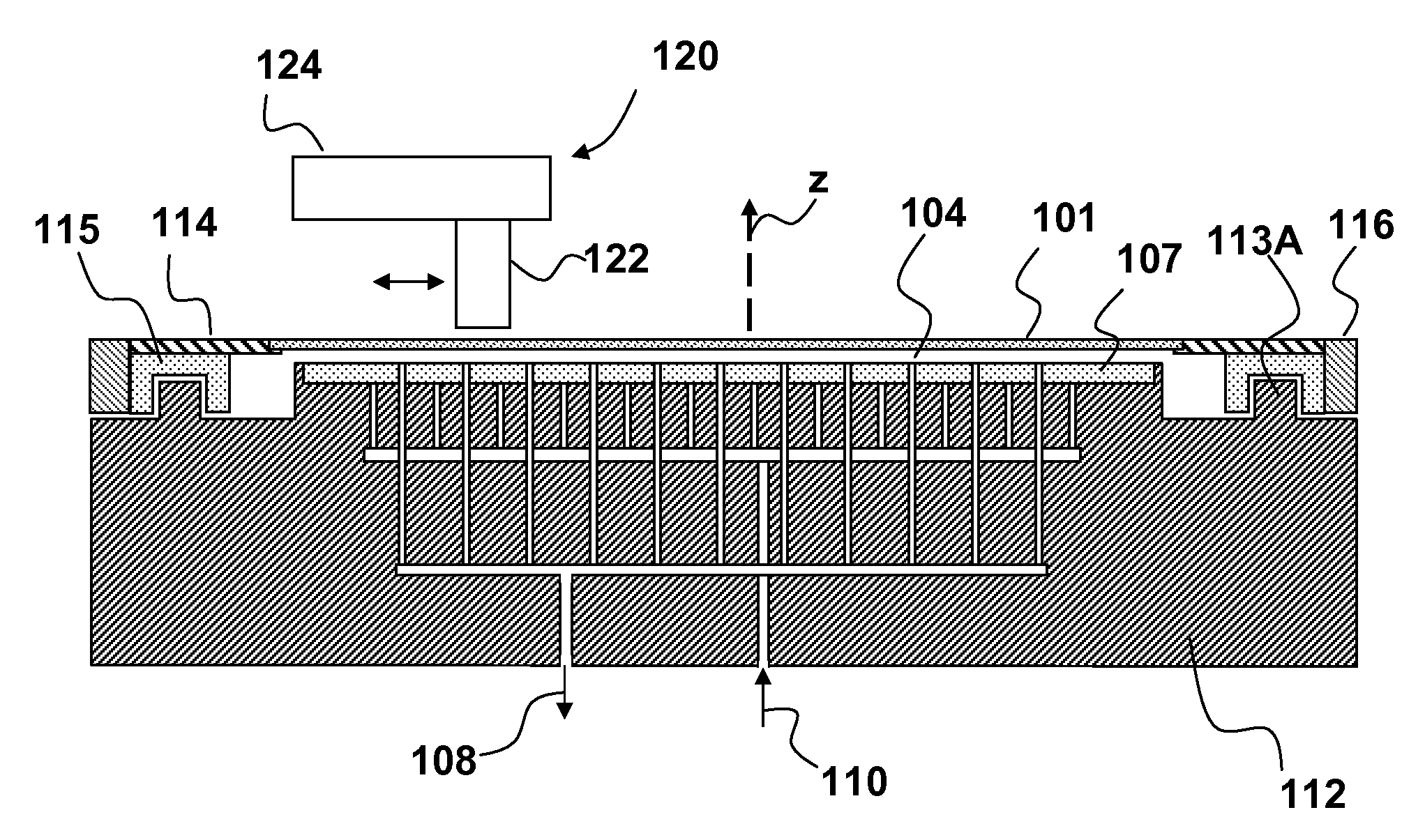

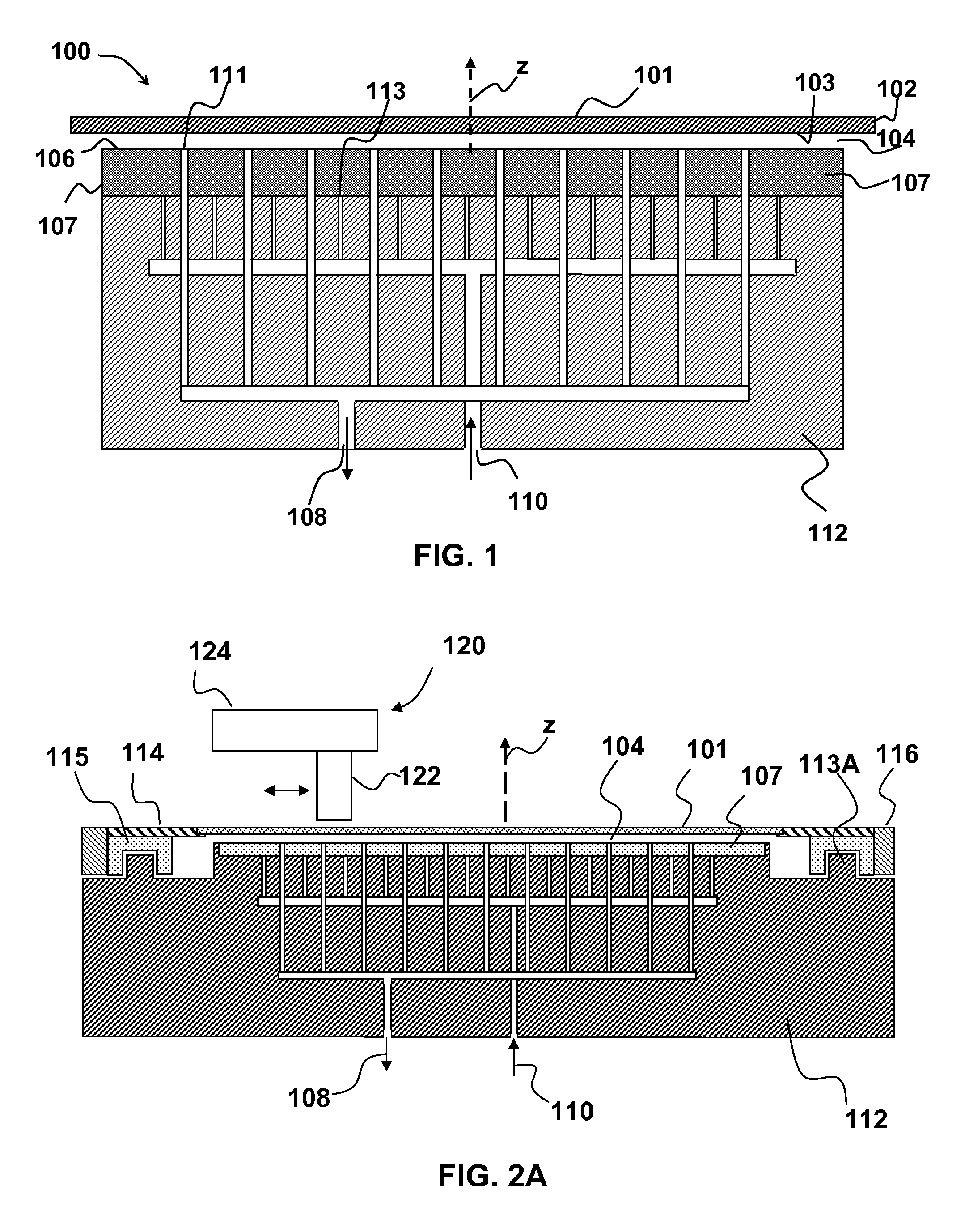

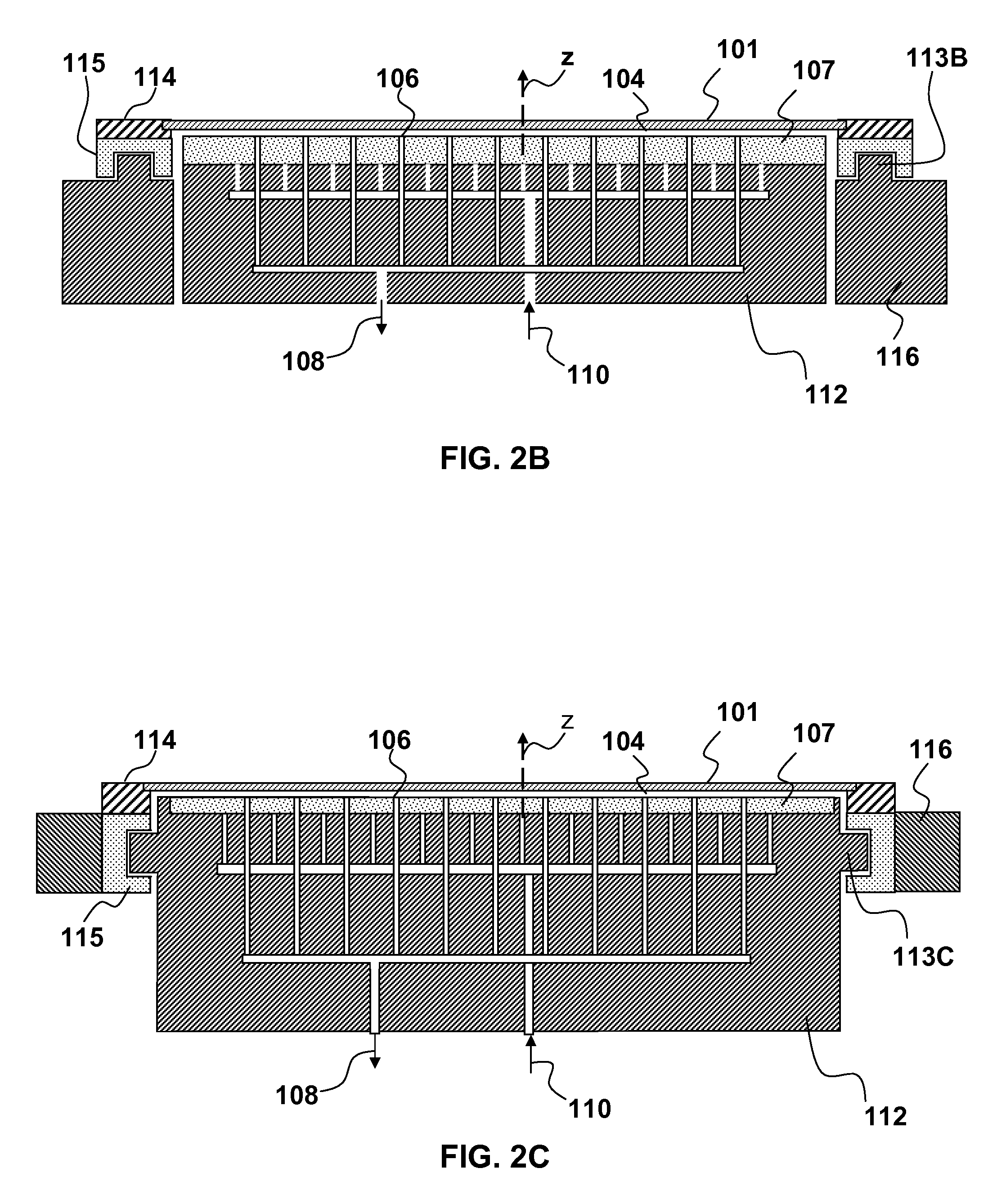

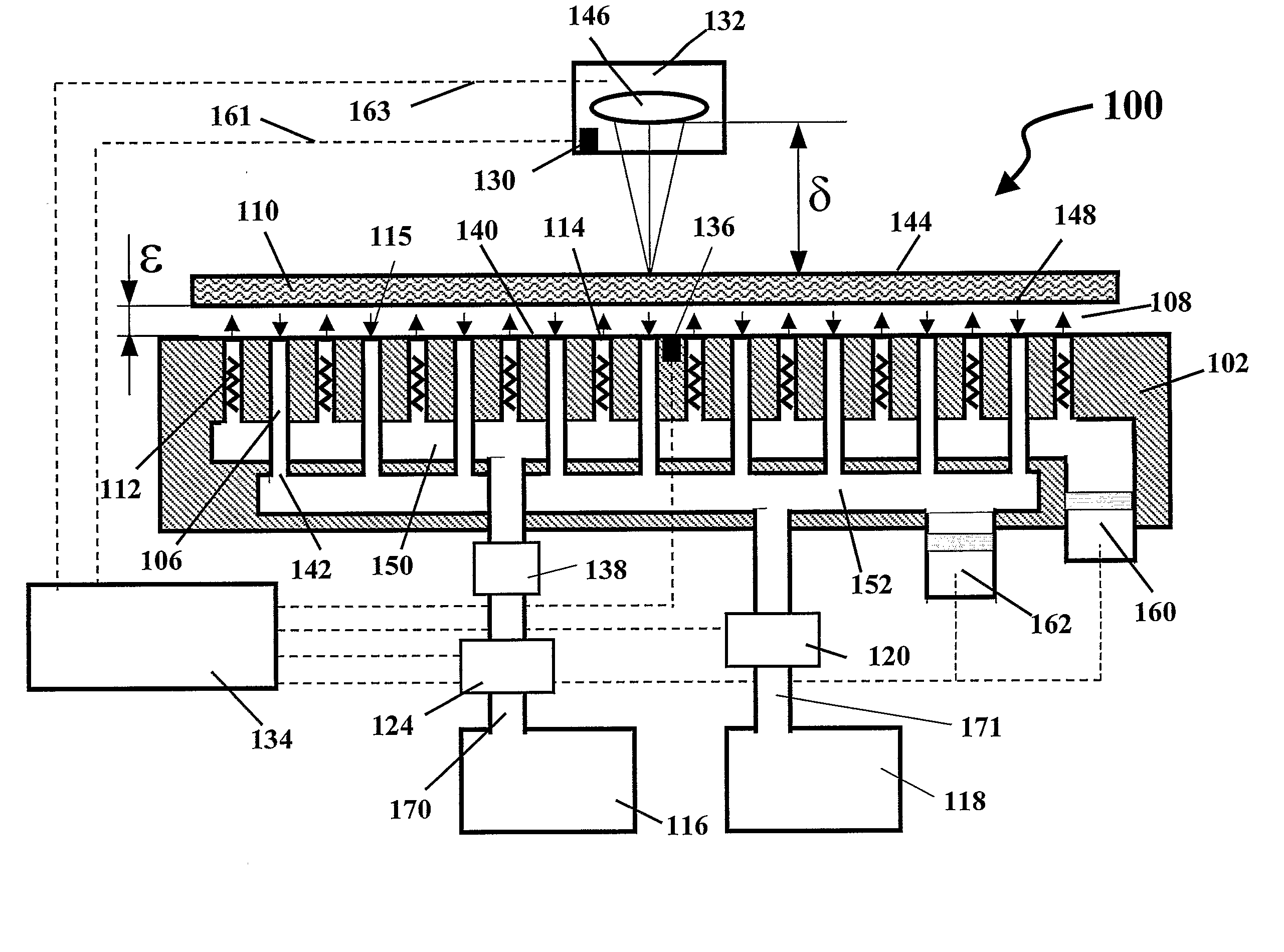

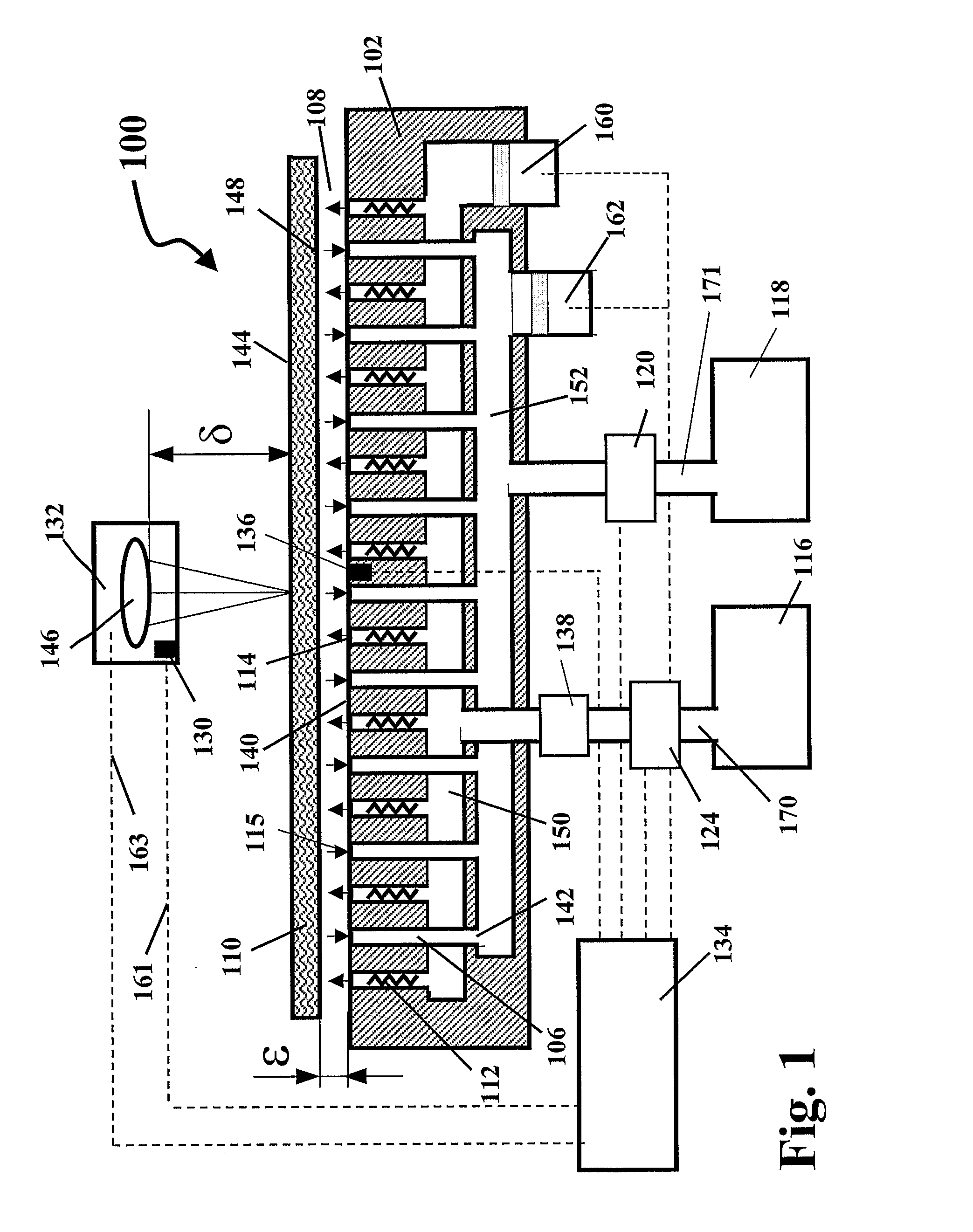

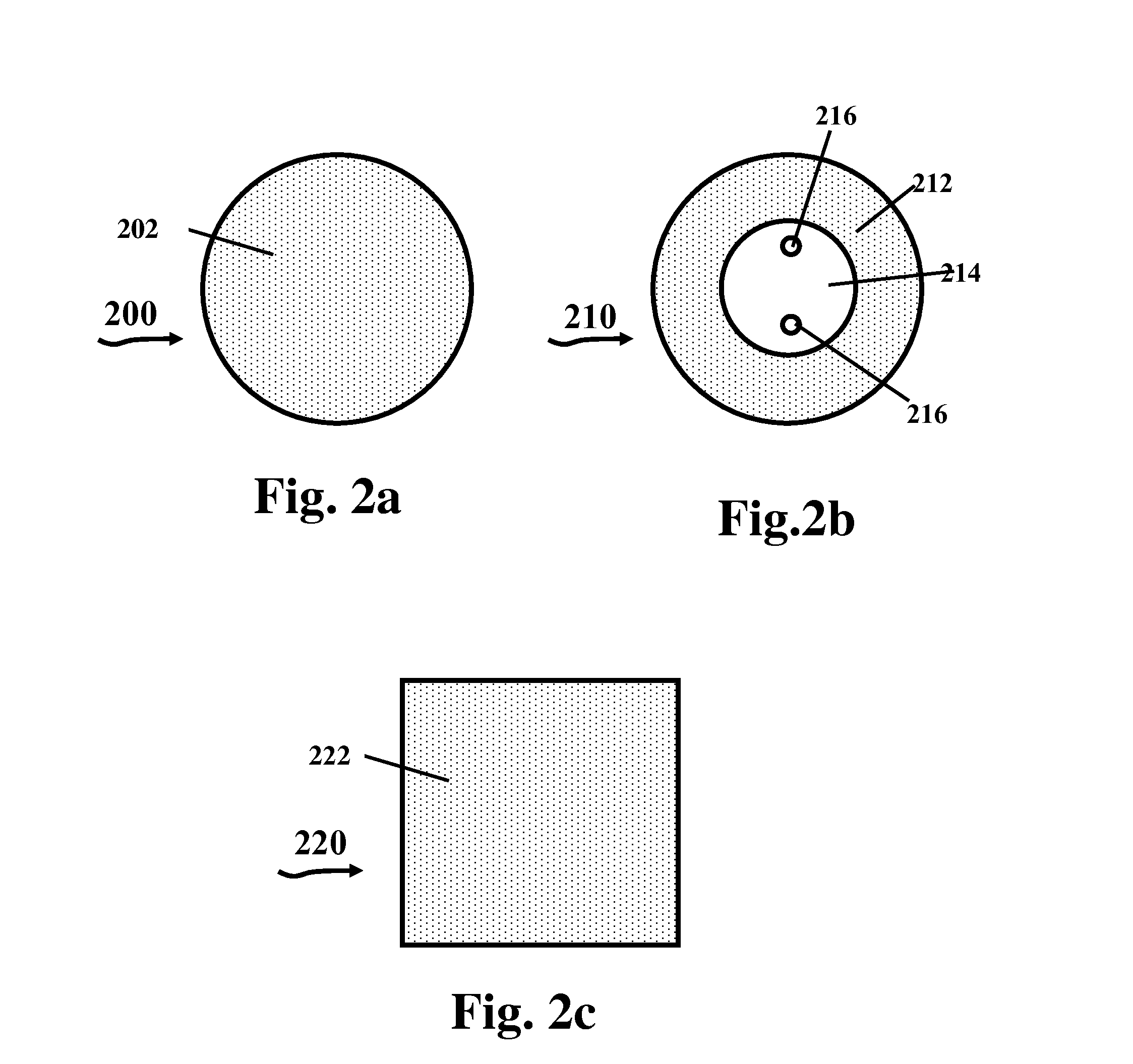

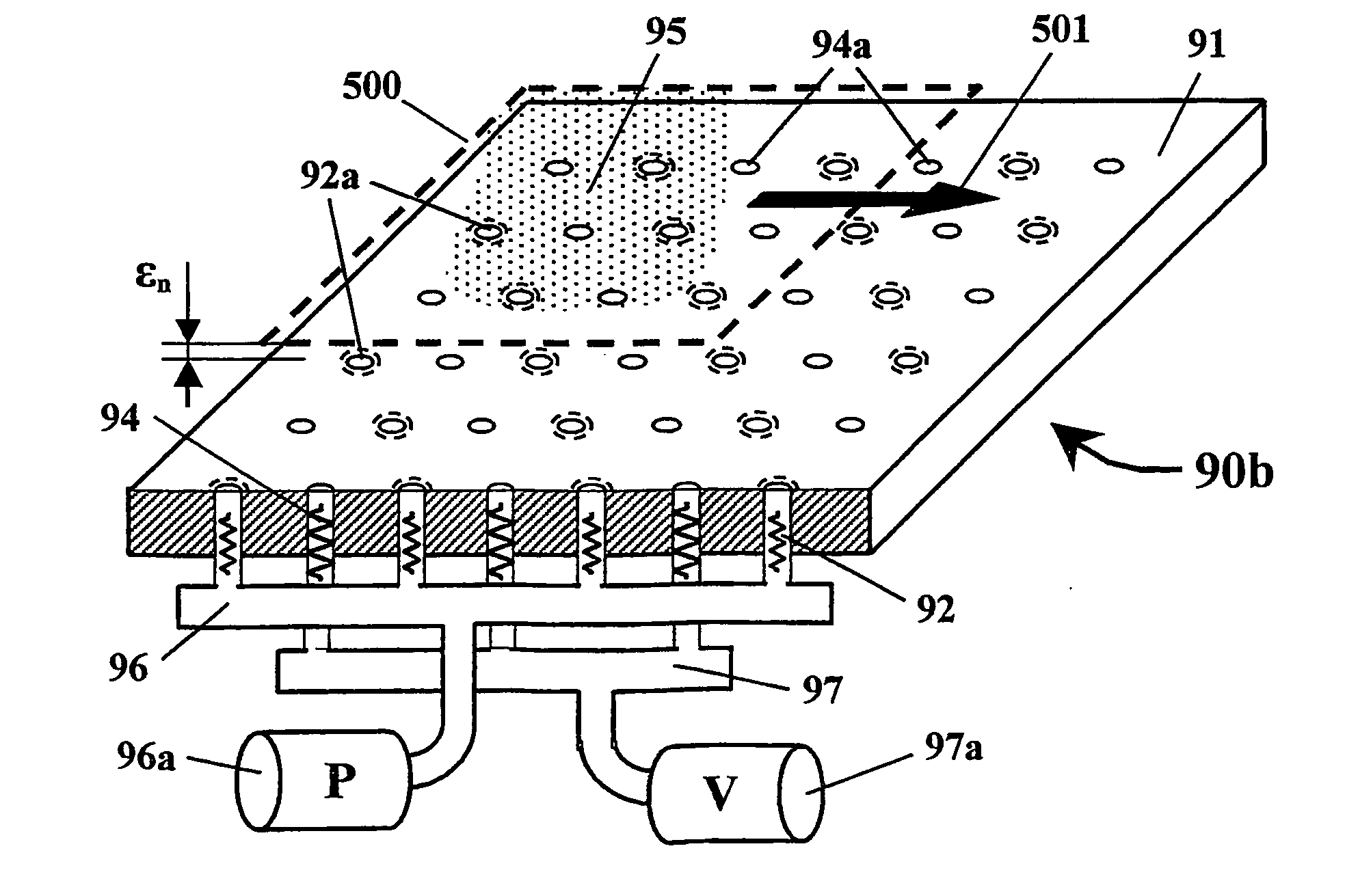

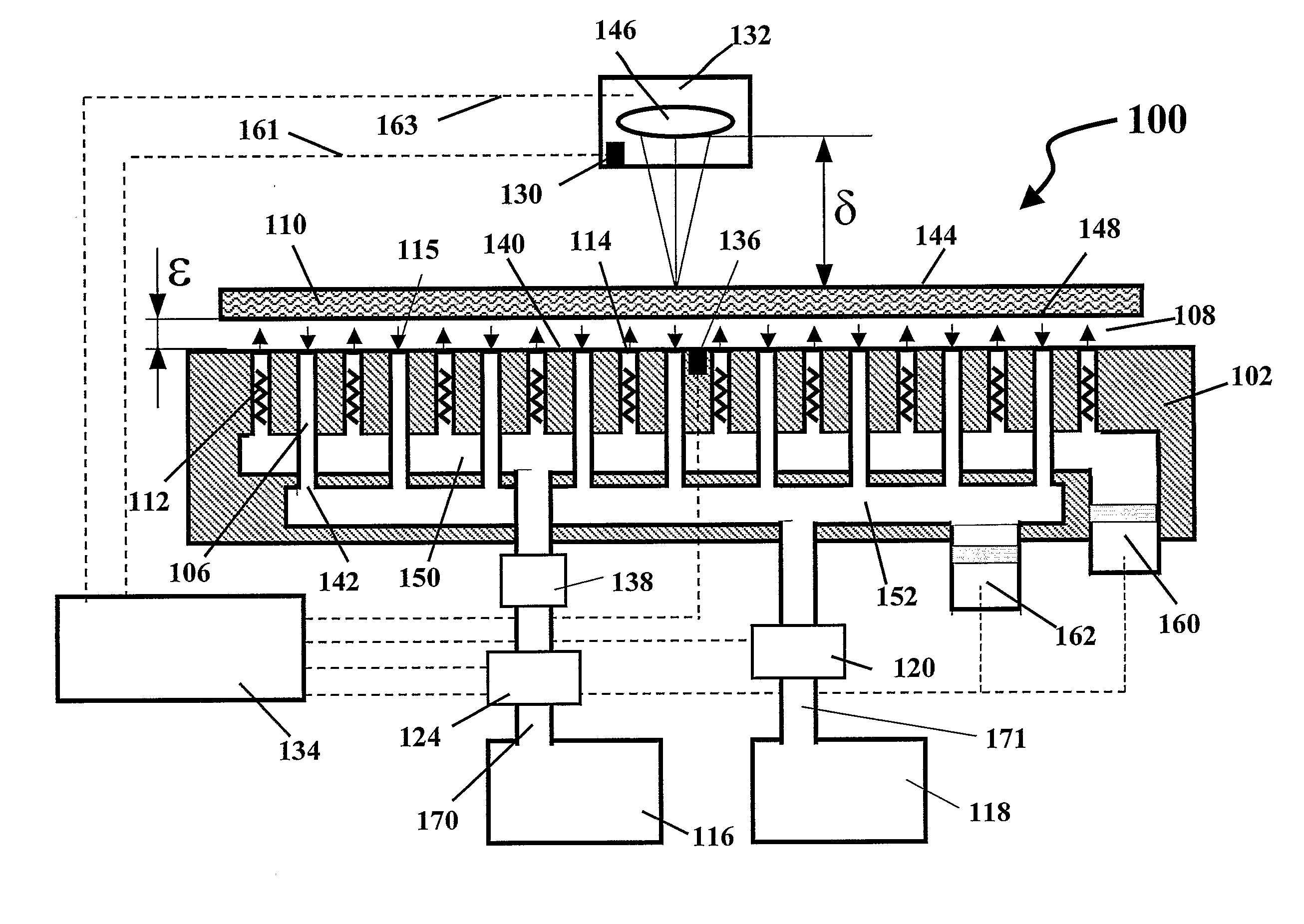

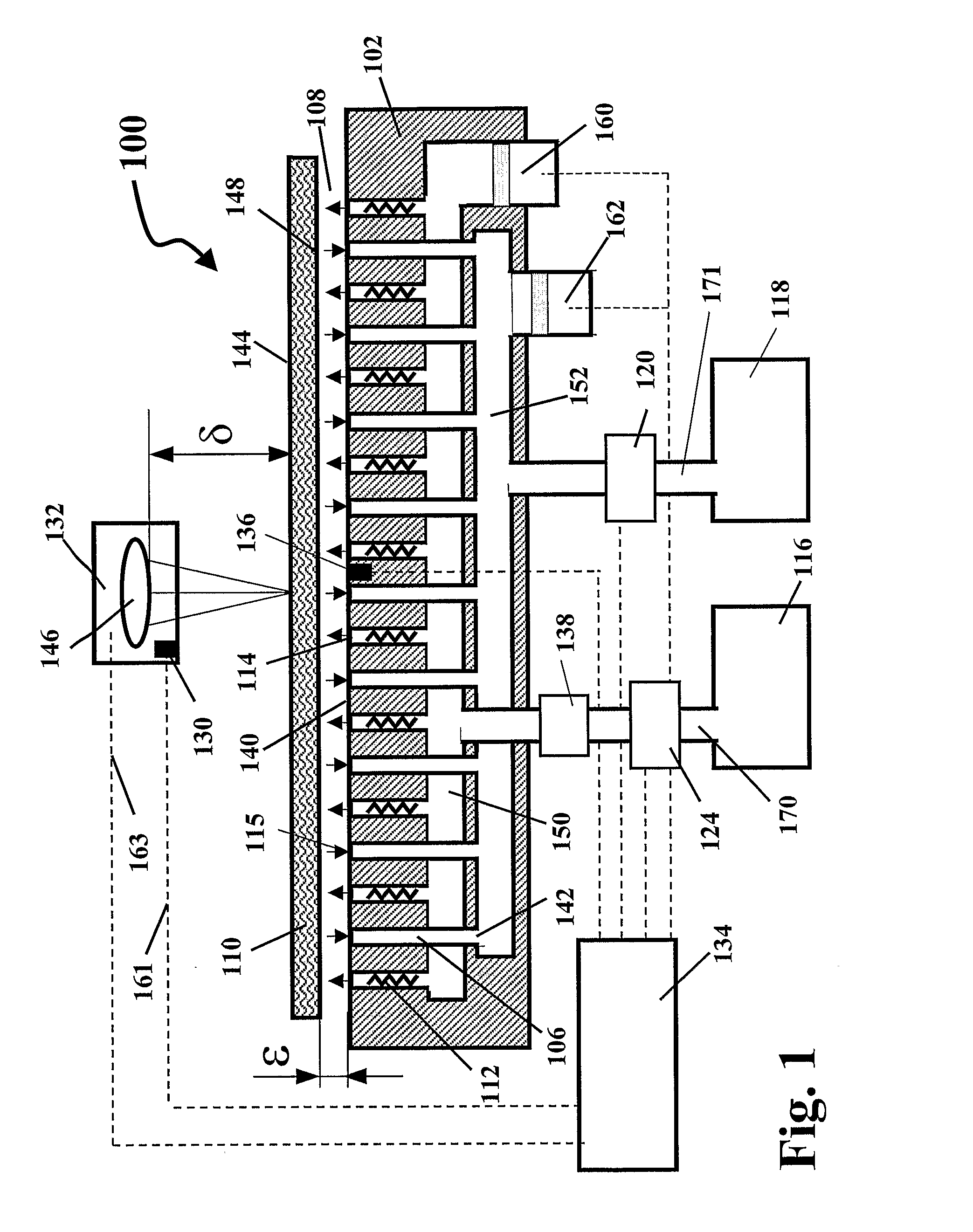

Stabilizing a substrate using a vacuum preload air bearing chuck

ActiveUS20080229811A1Improve rigidityAvoid deformationLinear bearingsGas cushion bearingsAir bearingEngineering

Substrate processing method and apparatus are disclosed. The substrate processing apparatus includes a non-contact air bearing chuck with a vacuum preload.

Owner:KLA TENCOR TECH CORP

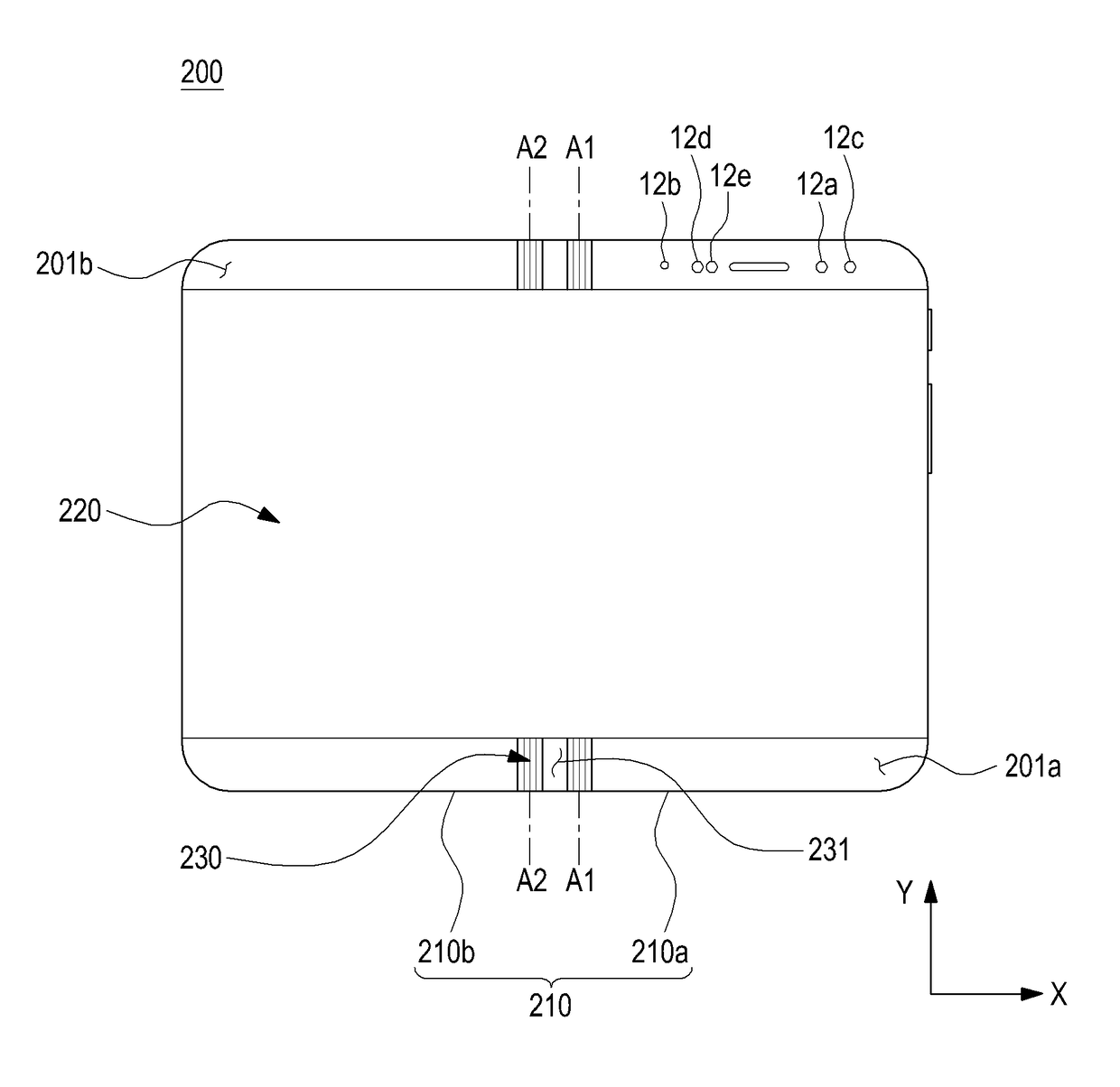

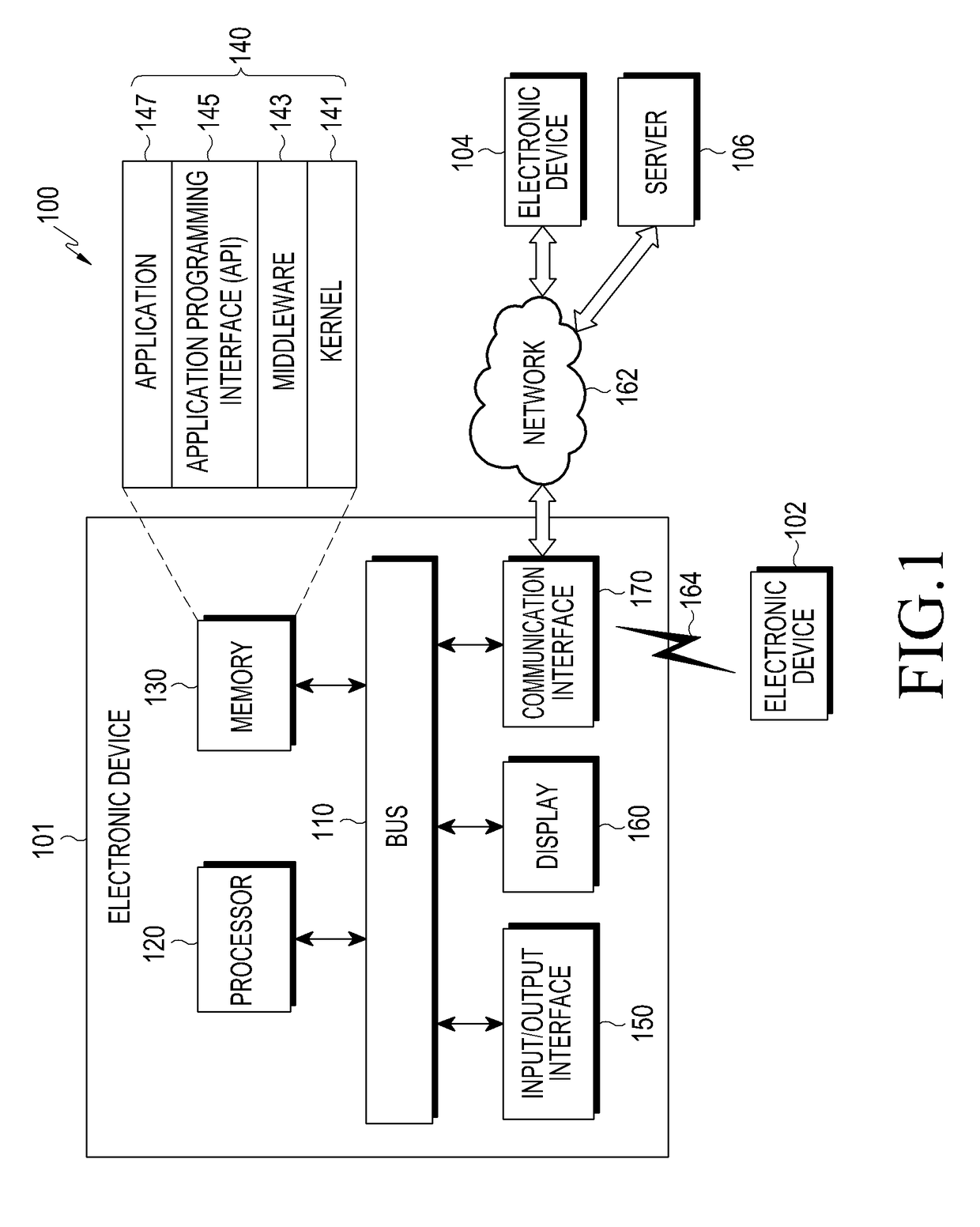

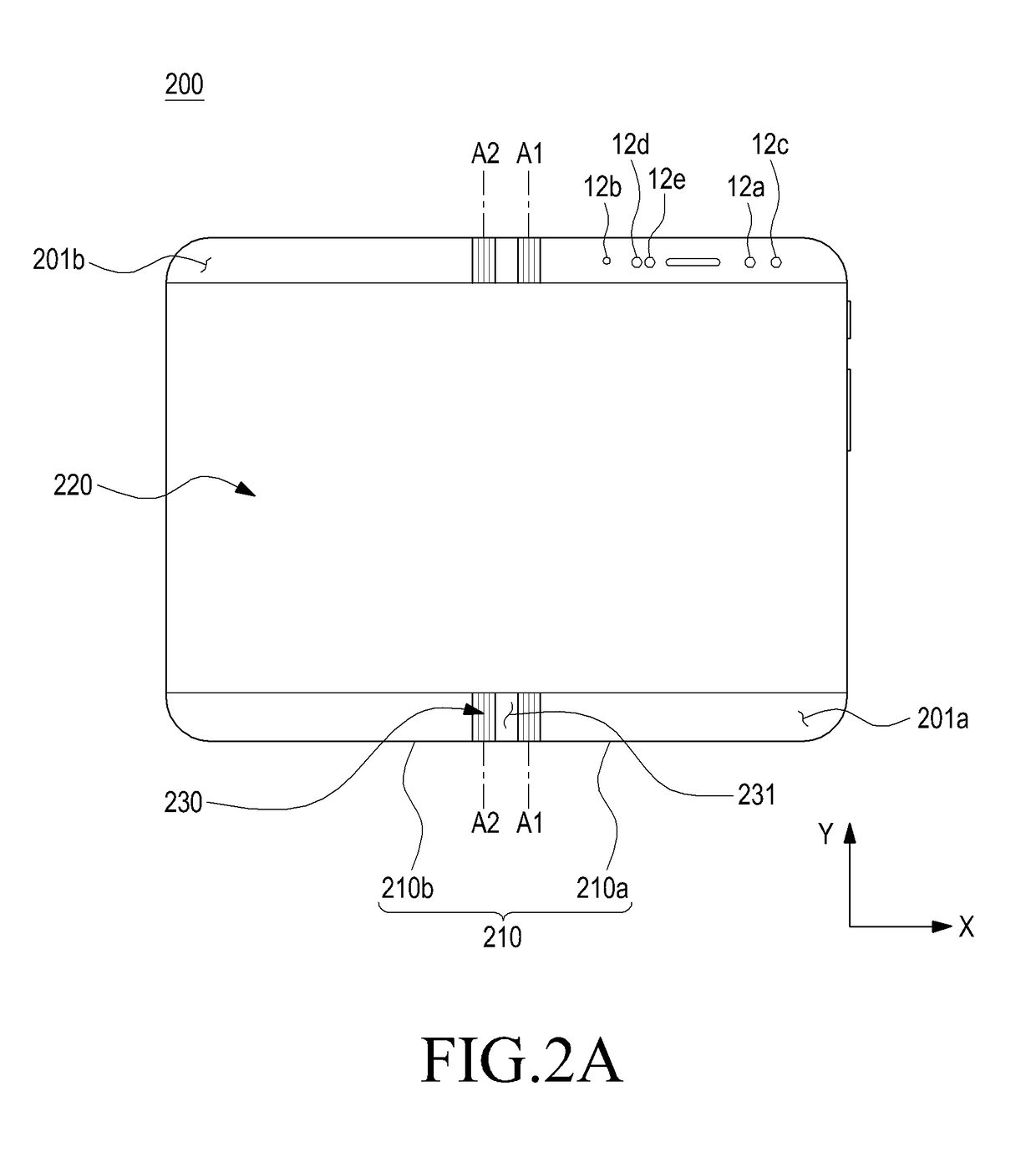

Electronic device including flexible display

ActiveUS20180324964A1Linear bearingsCasings with display/control unitsRotational axisFlexible display

According to an embodiment of the present disclosure, an electronic device may comprise a first housing including a first surface and a second surface facing in a direction opposite the first surface, a second housing including a third surface and a fourth surface facing in a direction opposite the third surface, a hinge disposed between the first housing and the second housing configured to provide rotational motion between the first housing and the second housing, and a flexible display disposed from the first surface of the first housing across the hinge to the third surface of the second housing, at least part of the flexible display configured to form a curved surface as the hinge structure is folded, wherein the hinge may include dual-axis hinges configured to provide a first rotational axis allowing the first housing to rotate about the second housing and a second rotational axis allowing the second housing to rotate about the first housing and slides coupled with the first housing and the second housing and configured to provide sliding motion perpendicular to a lengthwise direction of the first housing and the second housing.

Owner:SAMSUNG ELECTRONICS CO LTD

High-Performance non-contact support platforms

InactiveUS7530778B2Improve performanceLinear bearingsSemiconductor/solid-state device manufacturingAmbient pressureEngineering

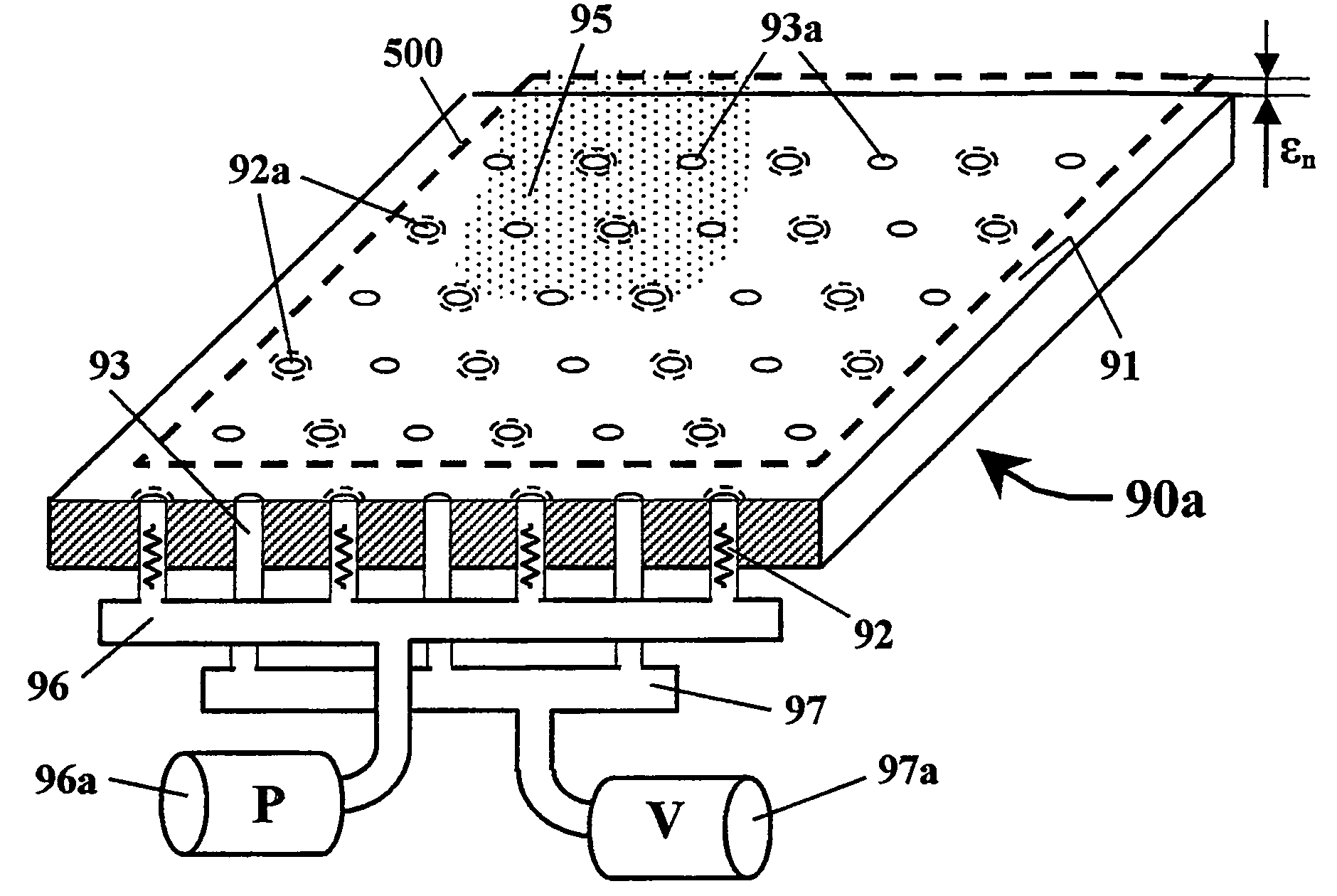

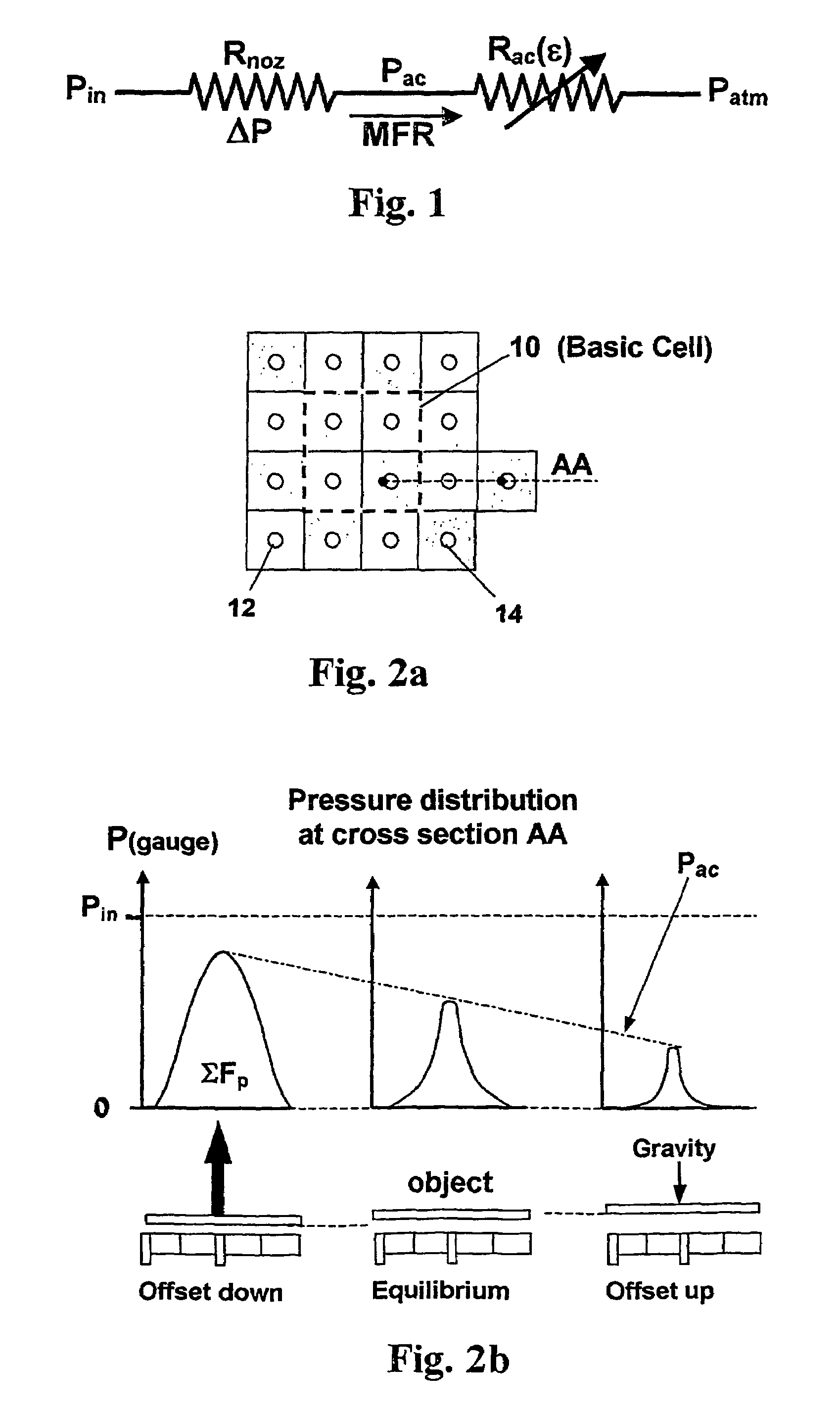

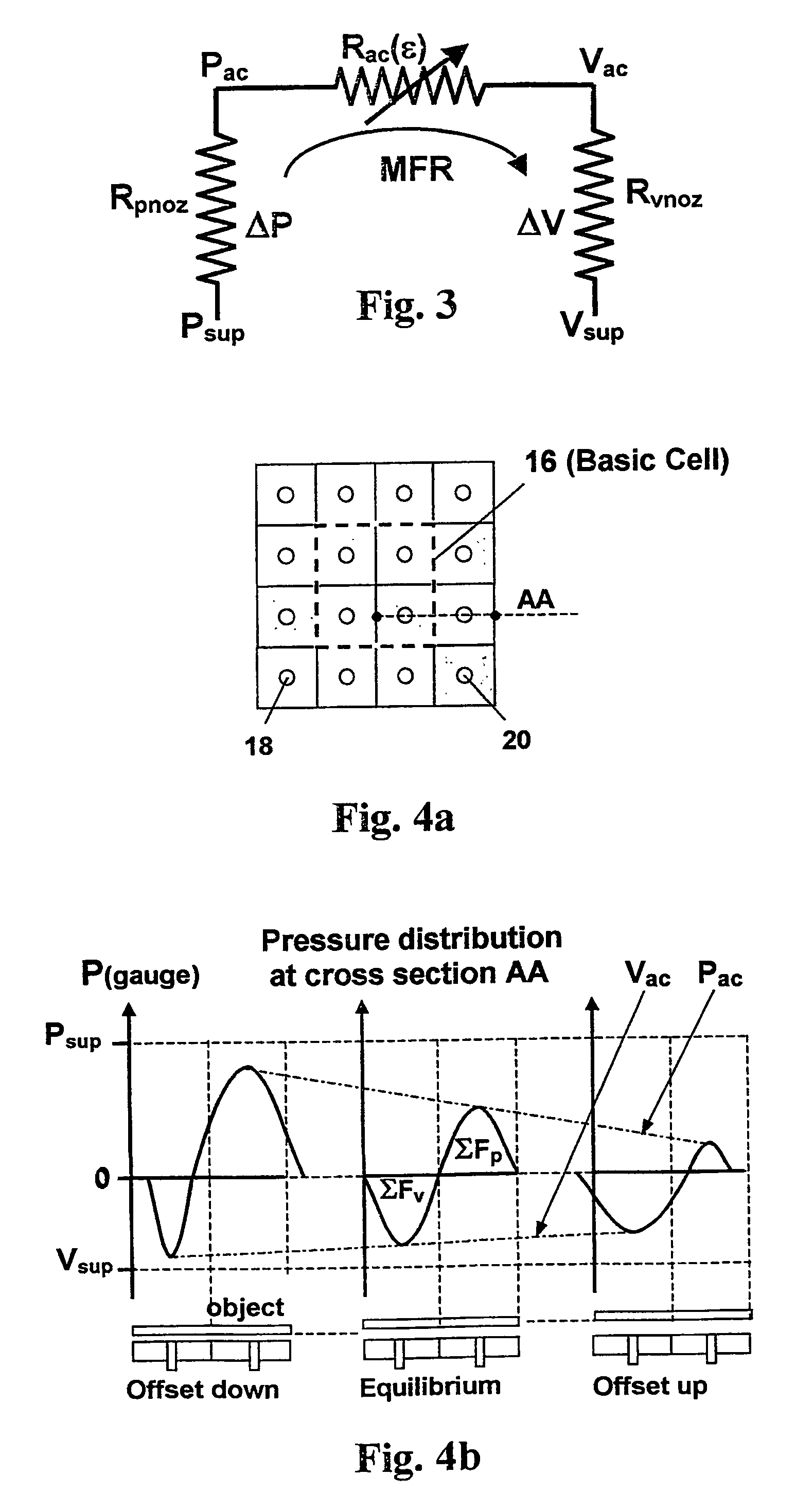

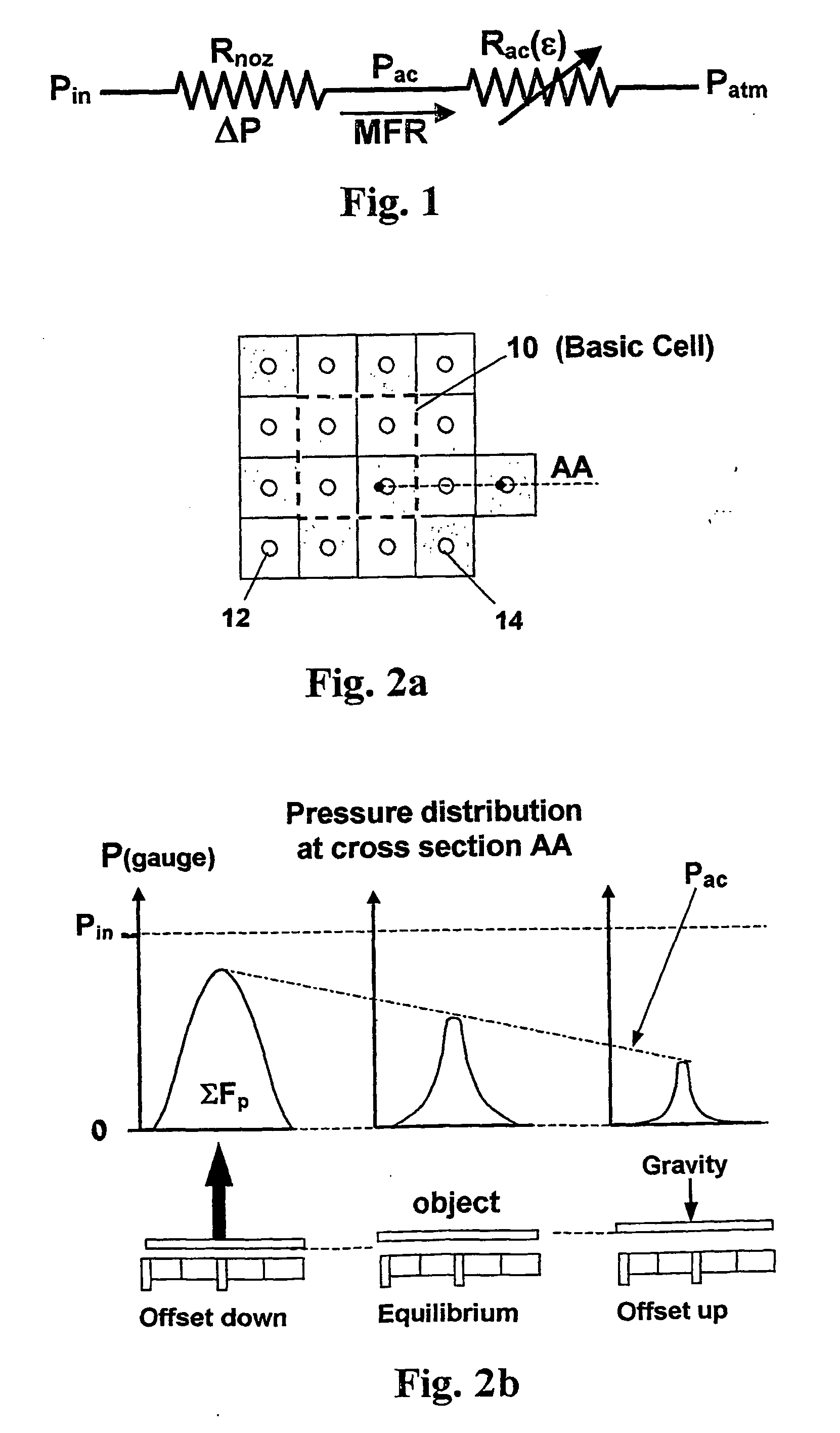

A non-contact support platform for supporting without contact a stationary or traveling object by air-cushion induced forces, the platform comprising at least one of two substantially opposite support surfaces, each support surfaces comprising at least one of a plurality of basic cells each having at least one of a plurality of pressure outlets and at least one of a plurality of air-evacuation channels at least one of a plurality of outlets, and one of a plurality of air-evacuation channels, each of the pressure outlets fluidically connected through a pressure flow restrictor to a high-pressure reservoir, the pressure outlets providing pressurized air for generating pressure induced forces, maintaining an air-cushion between the object and the support surface, the pressure flow restrictor characteristically exhibiting fluidic return spring behavior; each of said at least one of a plurality of air-evacuation channels having an inlet and outlet, the inlet kept at an ambient pressure or lower, under vacuum condition, for locally discharging mass flow, thus obtaining uniform support and local nature response.

Owner:COREFLOW

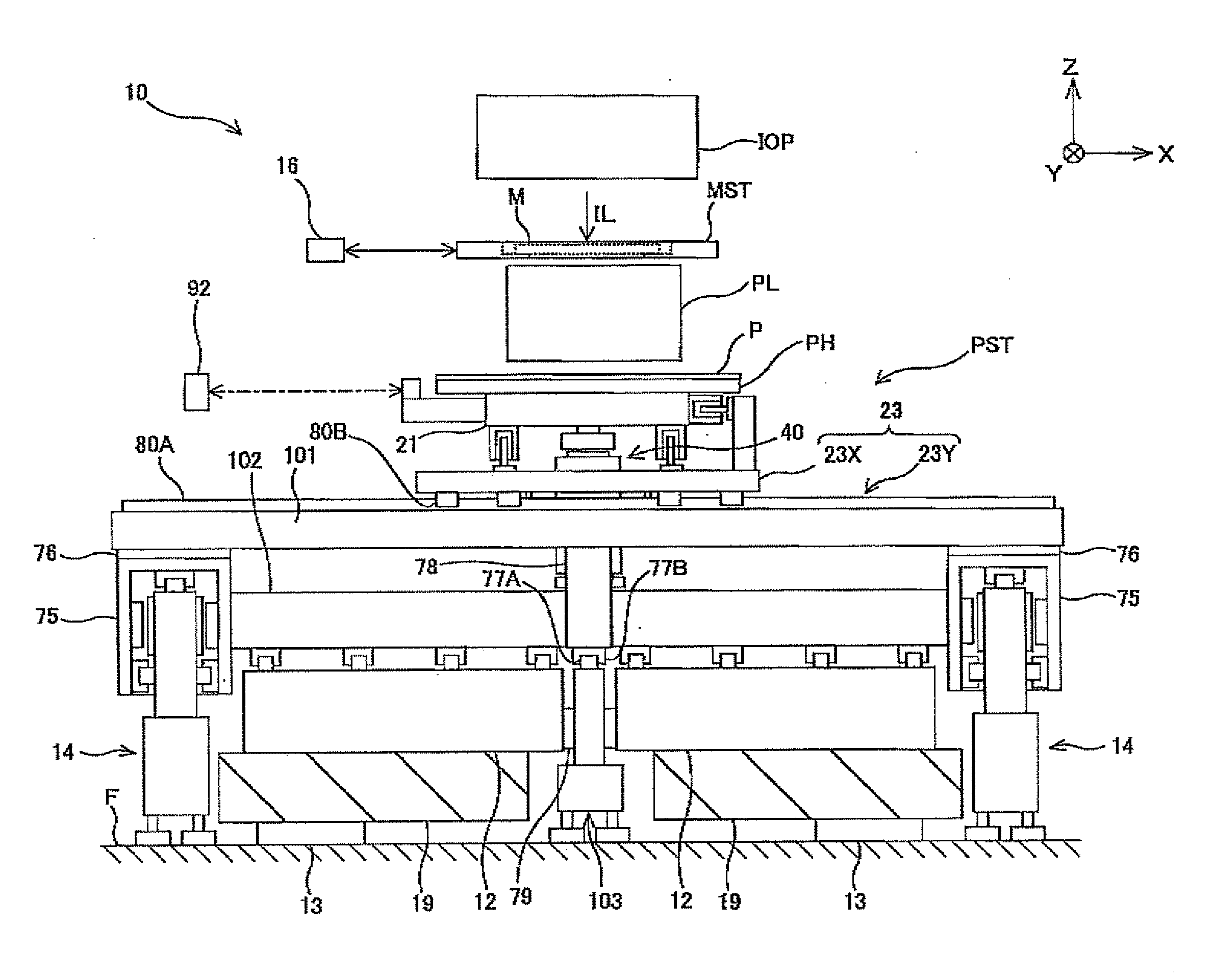

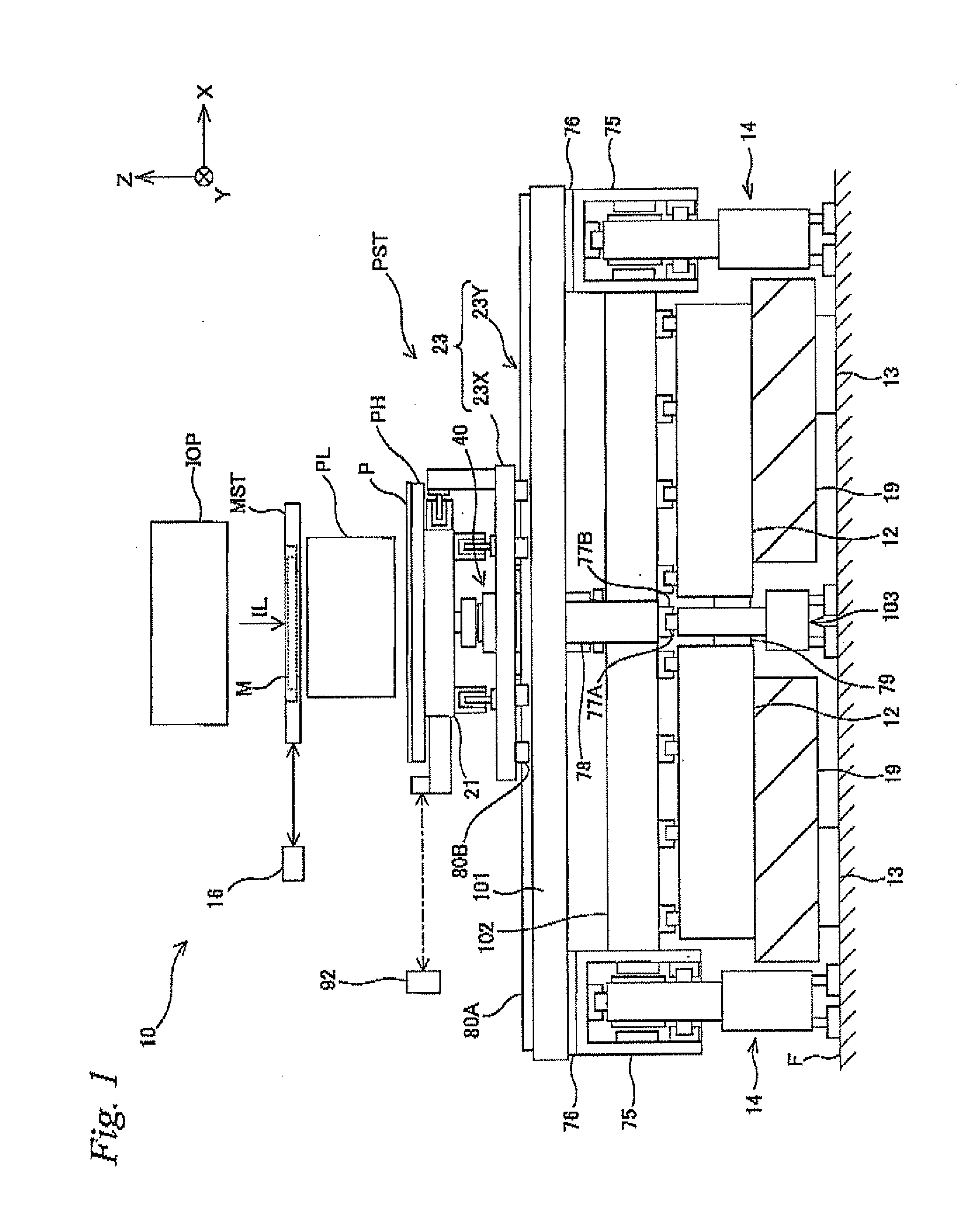

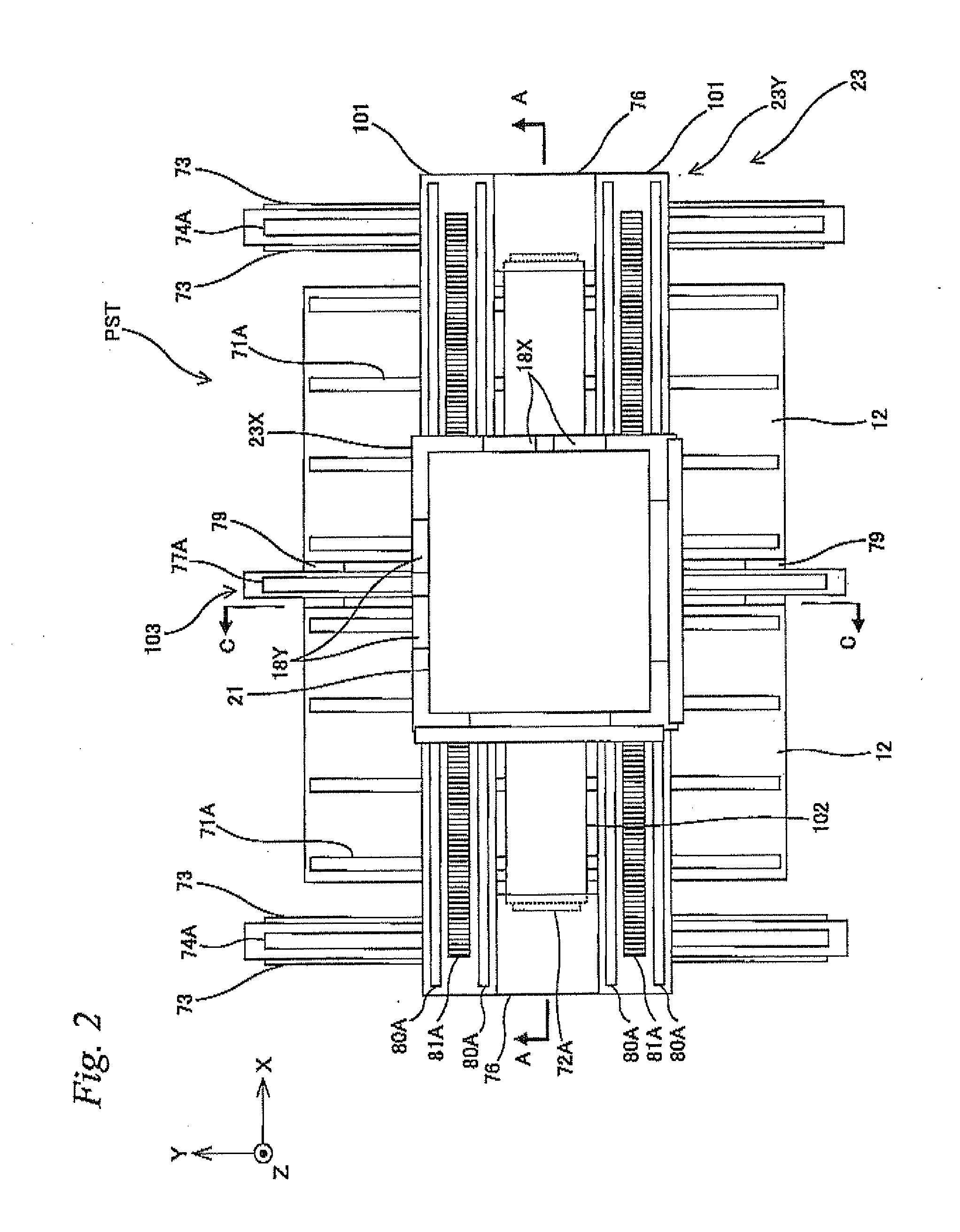

Exposure apparatus, movable body apparatus, flat-panel display manufacturing method, and device manufacturing method

In a substrate stage, when a Y coarse movement stage moves in the Y-axis direction, an X coarse movement stage, a weight cancellation device, and an X guide move integrally in the Y-axis direction with the Y coarse movement stage, and when the X coarse movement stage moves in the X-axis direction on the Y coarse movement stage, the weight cancellation device moves on the X guide in the X-axis direction integrally with the X coarse movement stage. Because the X guide is provided extending in the X-axis direction while covering the movement range of the weight cancellation device in the X-axis direction, the weight cancellation device is constantly supported by the X guide, regardless of its position. Accordingly, a substrate can be guided along the XY plane with good accuracy, even if a member (for example, a surface plate and the like) that has a guide surface large enough to cover the total movement range of the weight cancellation device is not provided.

Owner:NIKON CORP

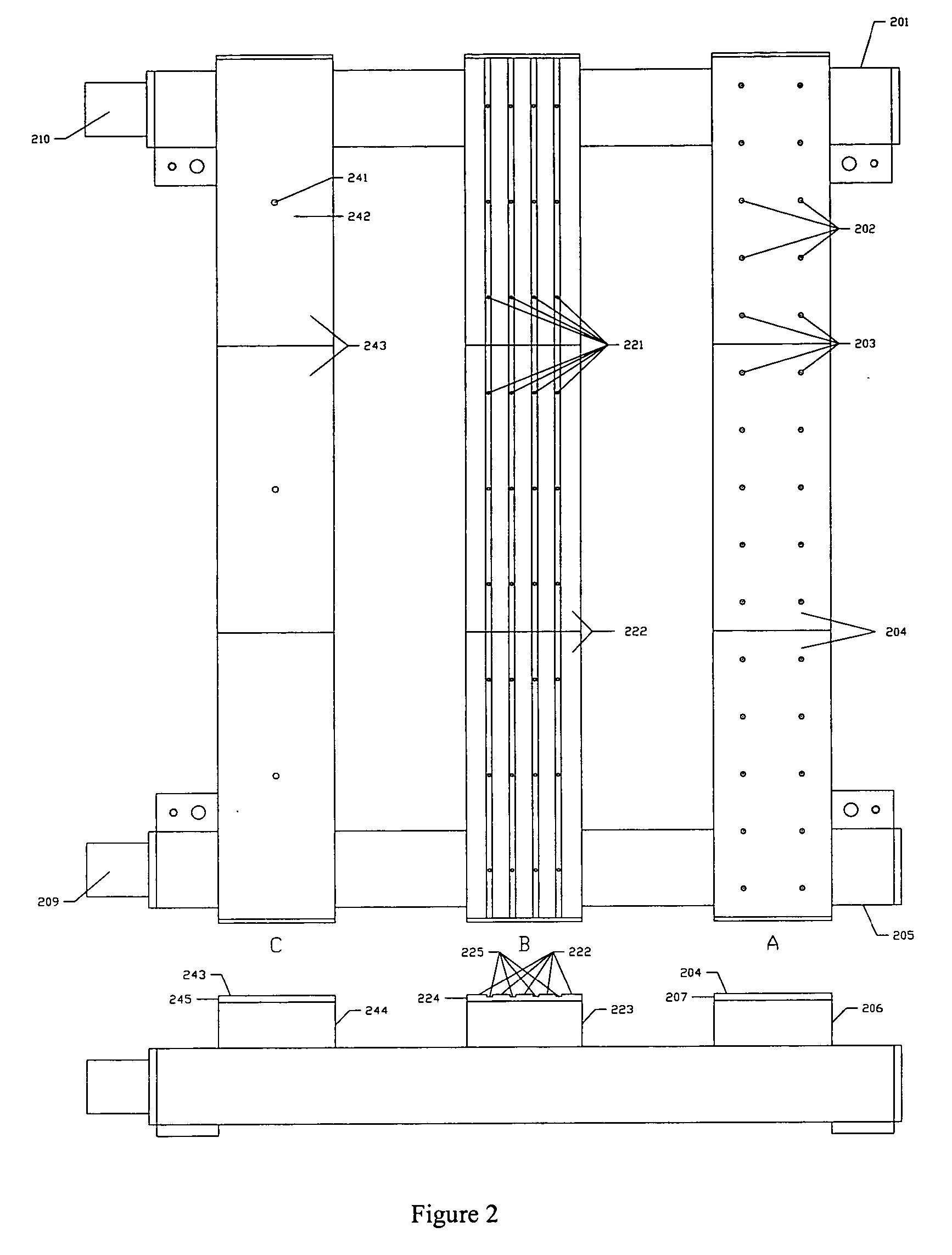

Non-contact support platforms for distance adjustment

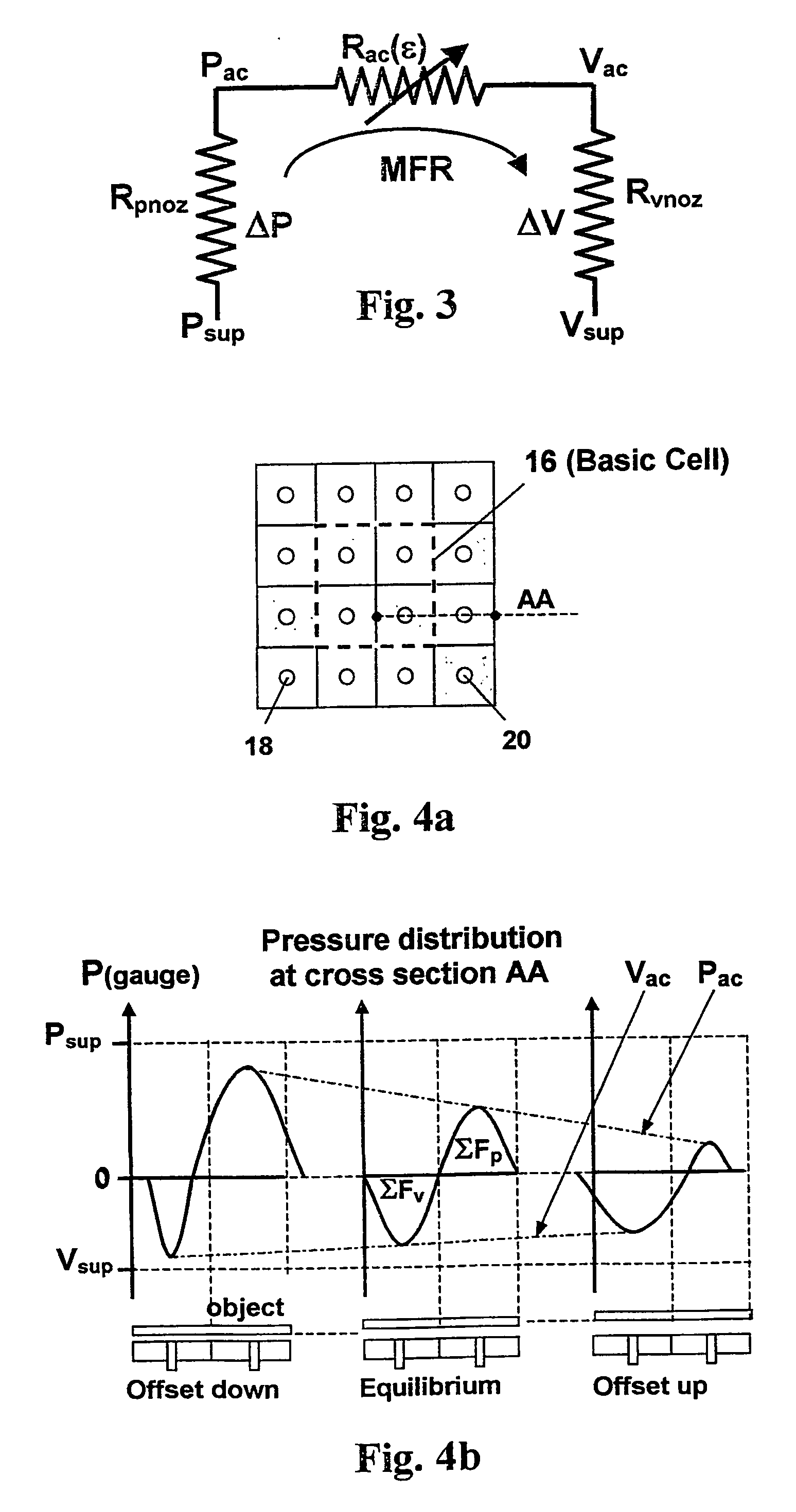

An apparatus for supporting a stationary or moving substantially flat object without physical contact on an fluid-cushion. The object floats on a fluid cushion gap, the apparatus aimed for globally or locally adjusting the gap. The apparatus comprising: a first platform for supporting the object without contact, the platform having a substantially flat active surface comprised of one or more sectors, each sector comprising at least one of a plurality of basic cells, each basic cell having at least one of a plurality of pressure outlets fluidically connected through a pressure flow restrictors to a higher-pressure manifold associated with the sector in which the basic cell lies, the higher-pressure manifold is fluidically connected through main supply pipeline to pressurized fluid supply and at least one of a plurality of fluid-evacuation channels fluidically connected to a lower-pressure manifold associated with the sector in which the basic cell lies having main evacuation pipeline; wherein the flow restrictor characteristically exhibiting fluidic return spring behavior; and wherein at least one pressure control valve is interposed with at least one of the two main pipelines of at least one sector for controlling pressure levels of at least one of the two manifolds of that sector.

Owner:COREFLOW SCI SOLUTIONS

Stabilizing a substrate using a vacuum preload air bearing chuck

ActiveUS7607647B2Improve rigidityAvoid deformationLinear bearingsGas cushion bearingsAir bearingEngineering

Substrate processing method and apparatus are disclosed. The substrate processing apparatus includes a non-contact air bearing chuck with a vacuum preload.

Owner:KLA TENCOR TECH CORP

Non-contact porous air bearing and glass flattening device

Thin substrates, such as flat glass panels, are levitated on a porous media air bearing creating a pressurized film of air and preloaded against the air film by negative pressure areas. The pressure can be distributed most uniformly across the pressure areas by defusing the pressure through a porous medium. Such a bearing can be used for glass flattening by holding the glass such that the unevenness is migrated to the side opposite the side to be worked on.

Owner:NEW WAY MACHINE COMPONENTS

High-performance non-contact support platforms

InactiveUS20060054774A1Improve performanceLinear bearingsSemiconductor/solid-state device manufacturingAmbient pressureEngineering

A non-contact support platform for supporting without contact a stationary or traveling object by air-cushion induced forces, the platform comprising at least one of two substantially opposite support surfaces, each support surface comprising at least one of a plurality of basic cells each having at least one of a plurality of pressure outlets and at least one of a plurality of air-evacuation channels at least one of a plurality of outlets, and one of a plurality of air-evacuation channels, each of the pressure outlets fluidically connected through a pressure flow restrictor to a high-pressure reservoir, the pressure outlets providing pressurized air for generating pressure induced forces, maintaining an air-cushion between the object and the support surface, the pressure flow restrictor characteristically exhibiting fluidic return spring behavior; each of said at least one of a plurality of air-evacuation channels having an inlet and outlet, the inlet kept at an ambient pressure or lower, under vacuum condition, for locally discharging mass flow, thus obtaining uniform support and local nature response.

Owner:COREFLOW

Magnetic levitation sliding structure

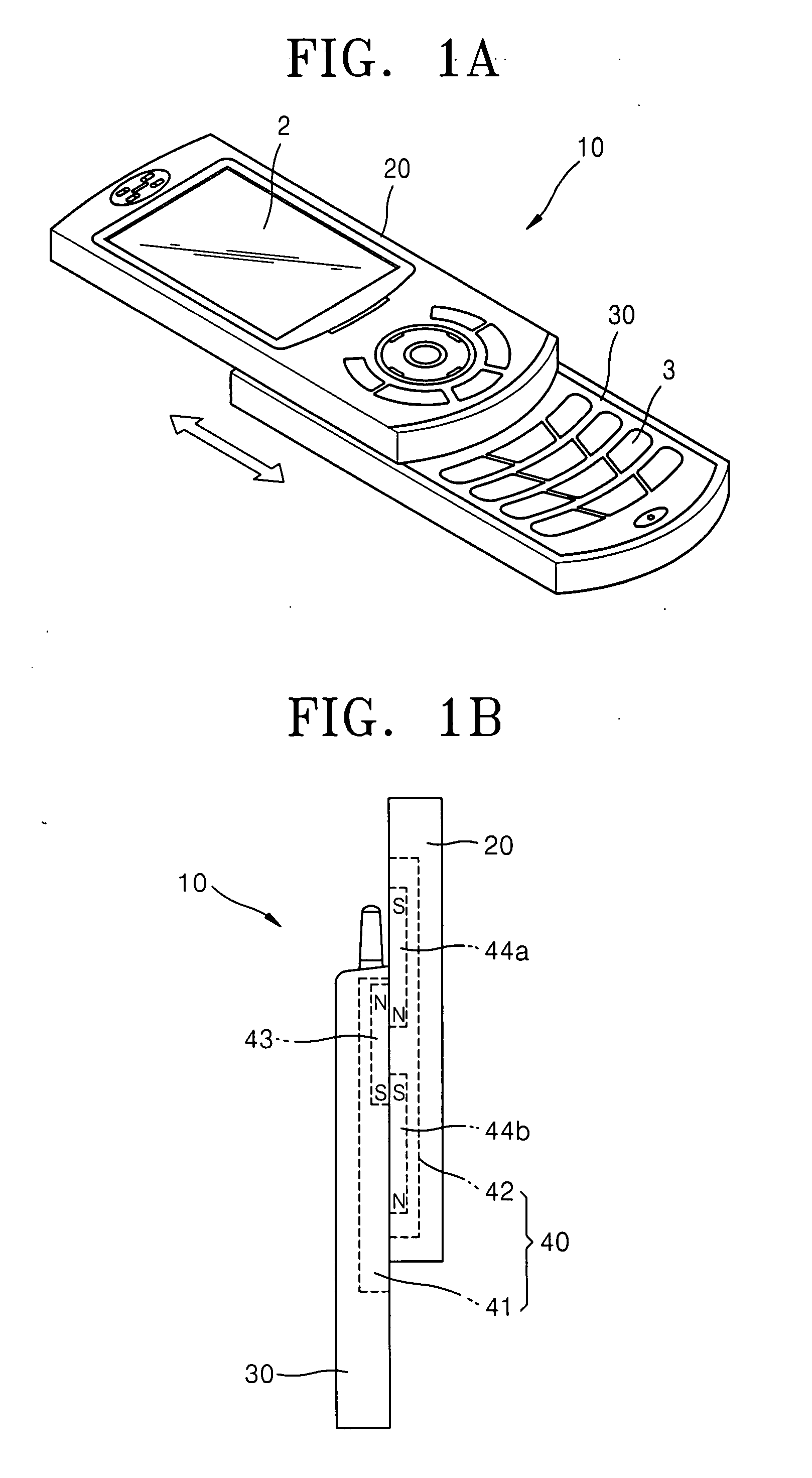

InactiveUS20080139261A1Facilitate movement of firstEasy to moveElectromagnets without armaturesLinear bearingsElectronic equipmentMagnetic levitation

A magnetic levitation sliding structure is provided. The sliding structure includes a first slider member including a guide portion with a first magnet, a second slider member including a receiving portion with a channel-shaped second magnet, the receiving portion being configured to receive the guide portion so as to slide on the first slider member. The first and second magnets are configured so that a repelling force can act there between for facilitating the sliding operation. In some embodiments the sliding structure includes at least one attraction member configured at an initial and / or final position of one of the first and second slider members. A portable electronic device including the magnetic levitation sliding structure is also provided.

Owner:SAMSUNG TECHWIN CO LTD

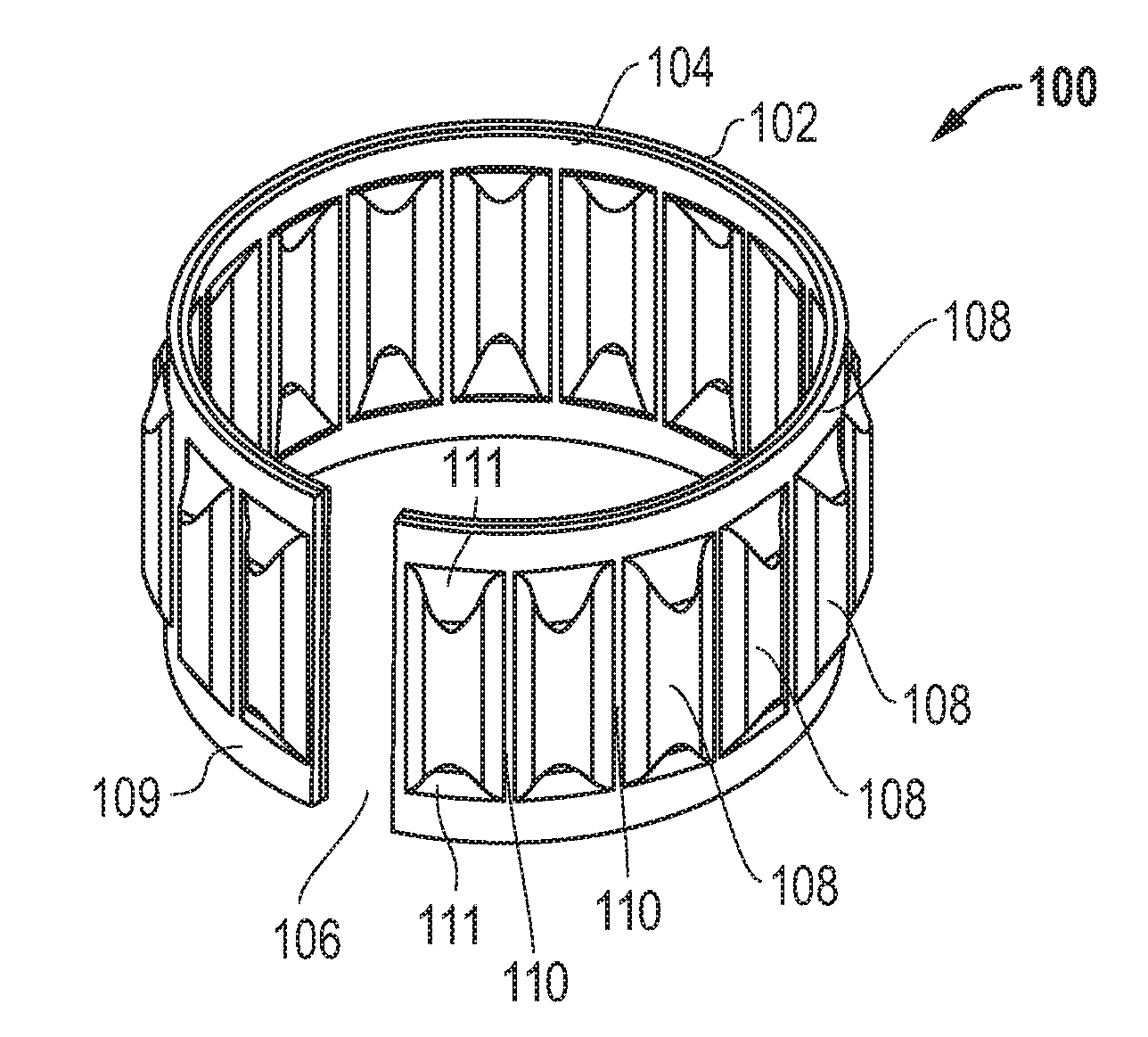

System, method and apparatus for tolerance ring control of slip interface sliding forces

InactiveUS20110076096A1Reduce radial stiffnessLower resistanceYielding couplingLinear bearingsAxial forceEngineering

A tolerance ring comprising a metallic band for spring features and a complementary low friction material for frictional considerations is disclosed. The tolerance ring is designed to operate within a precisely controlled torque or axial force band to provide a defined amount of resistance and sliding force control between components that move relative to each other. Isolated portions of the tolerance ring form regions of contact with adjacent ones of the components. Other surfaces of the tolerance ring comprise portions with spring features that have geometry suitable for their spring rate, rather than conforming to mating surfaces of the adjacent components.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS RENCOL

Non-contact support platforms for distance adjustment

ActiveUS20070195653A1Effectively rigidCombination recordingLinear bearingsHigh pressurePressure control

An apparatus for supporting a stationary or moving substantially flat object without physical contact on an fluid-cushion. The object floats on a fluid cushion gap, the apparatus aimed for globally or locally adjusting the gap. The apparatus comprising: a first platform for supporting the object without contact, the platform having a substantially flat active surface comprised of one or more sectors, each sector comprising at least one of a plurality of basic cells, each basic cell having at least one of a plurality of pressure outlets fluidically connected through a pressure flow restrictors to a higher-pressure manifold associated with the sector in which the basic cell lies, the higher-pressure manifold is fluidically connected through main supply pipeline to pressurized fluid supply and at least one of a plurality of fluid-evacuation channels fluidically connected to a lower-pressure manifold associated with the sector in which the basic cell lies having main evacuation pipeline; wherein the flow restrictor characteristically exhibiting fluidic return spring behavior; and wherein at least one pressure control valve is interposed with at least one of the two main pipelines of at least one sector for controlling pressure levels of at least one of the two manifolds of that sector.

Owner:COREFLOW SCI SOLUTIONS

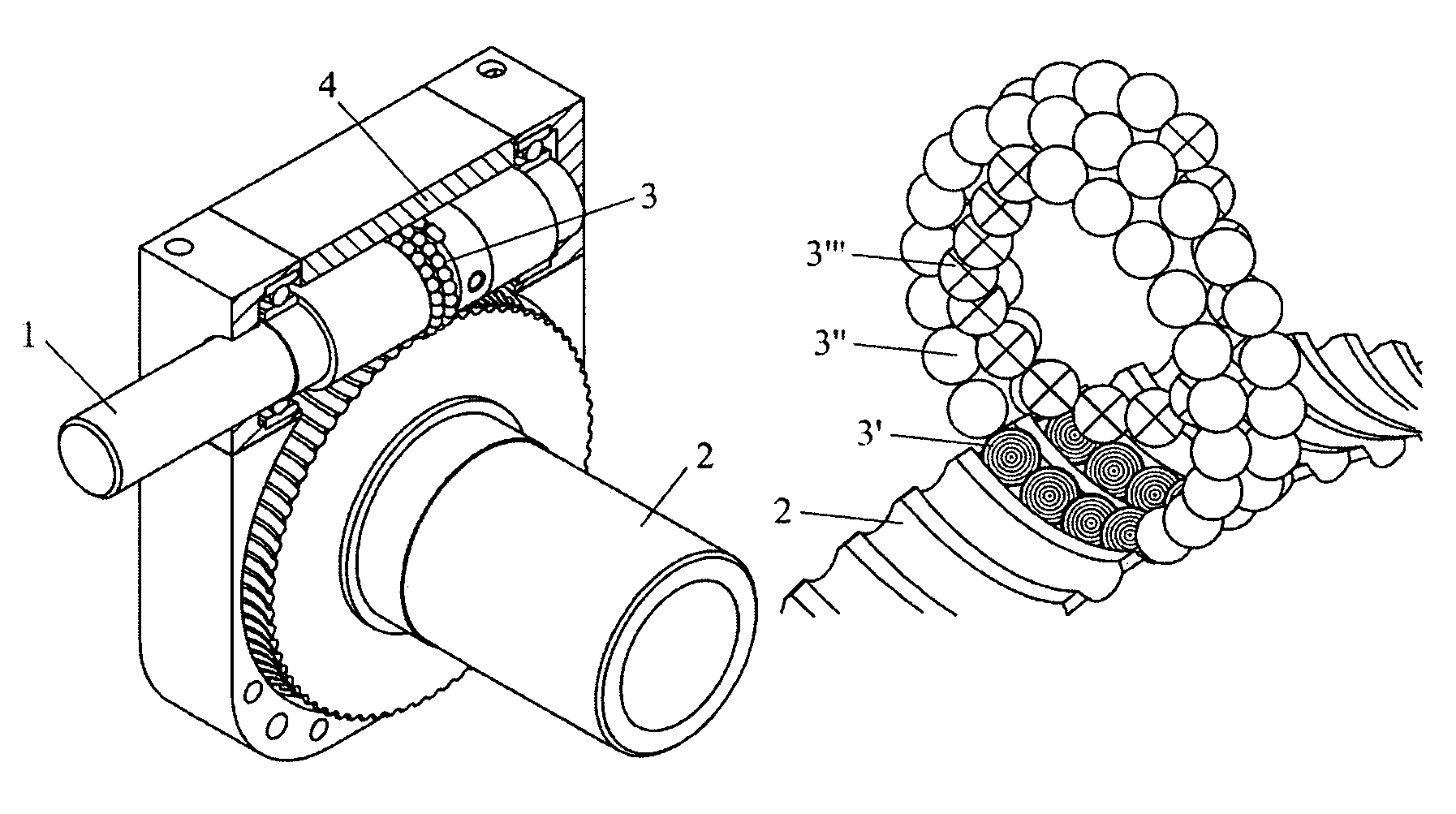

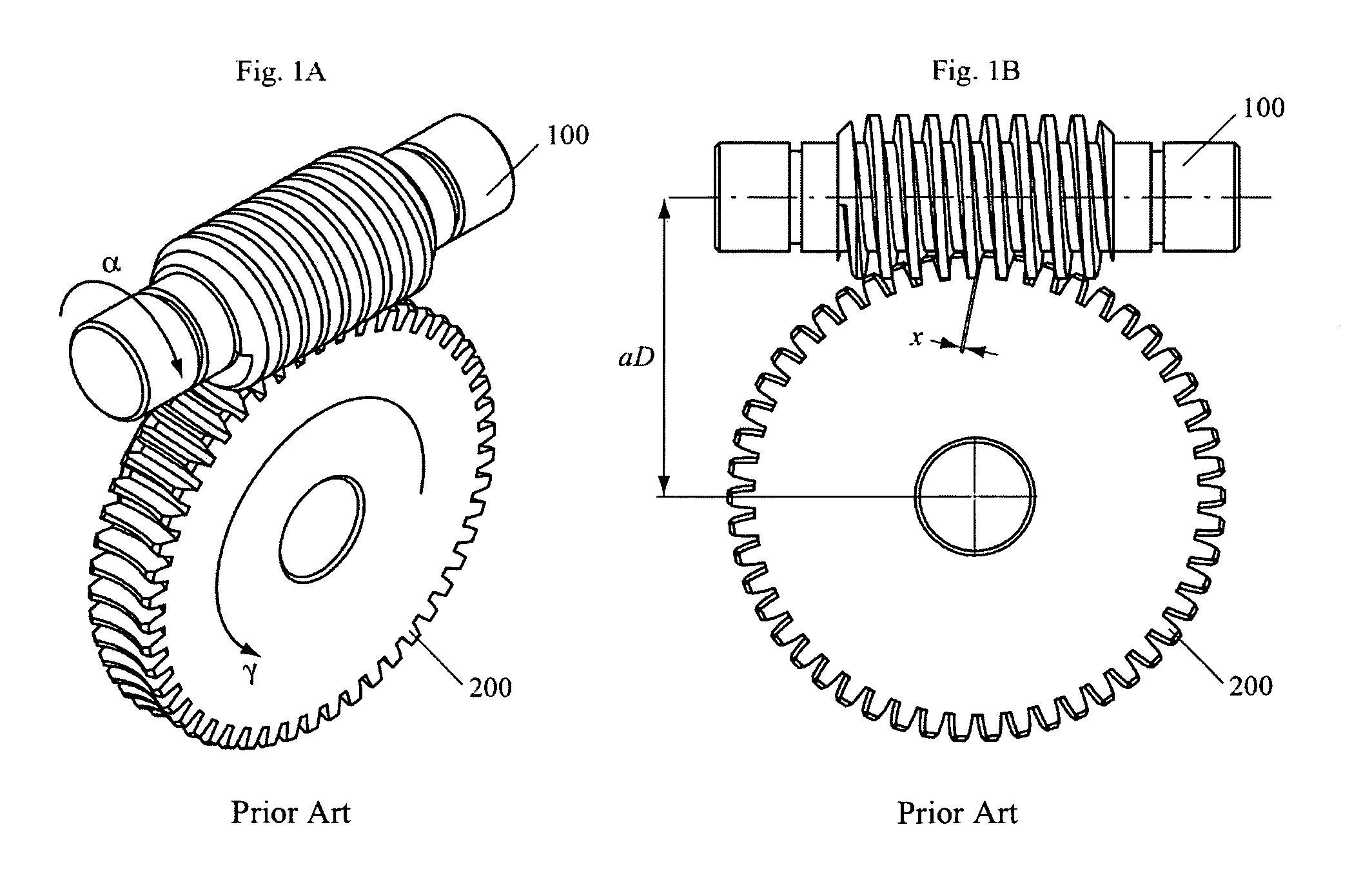

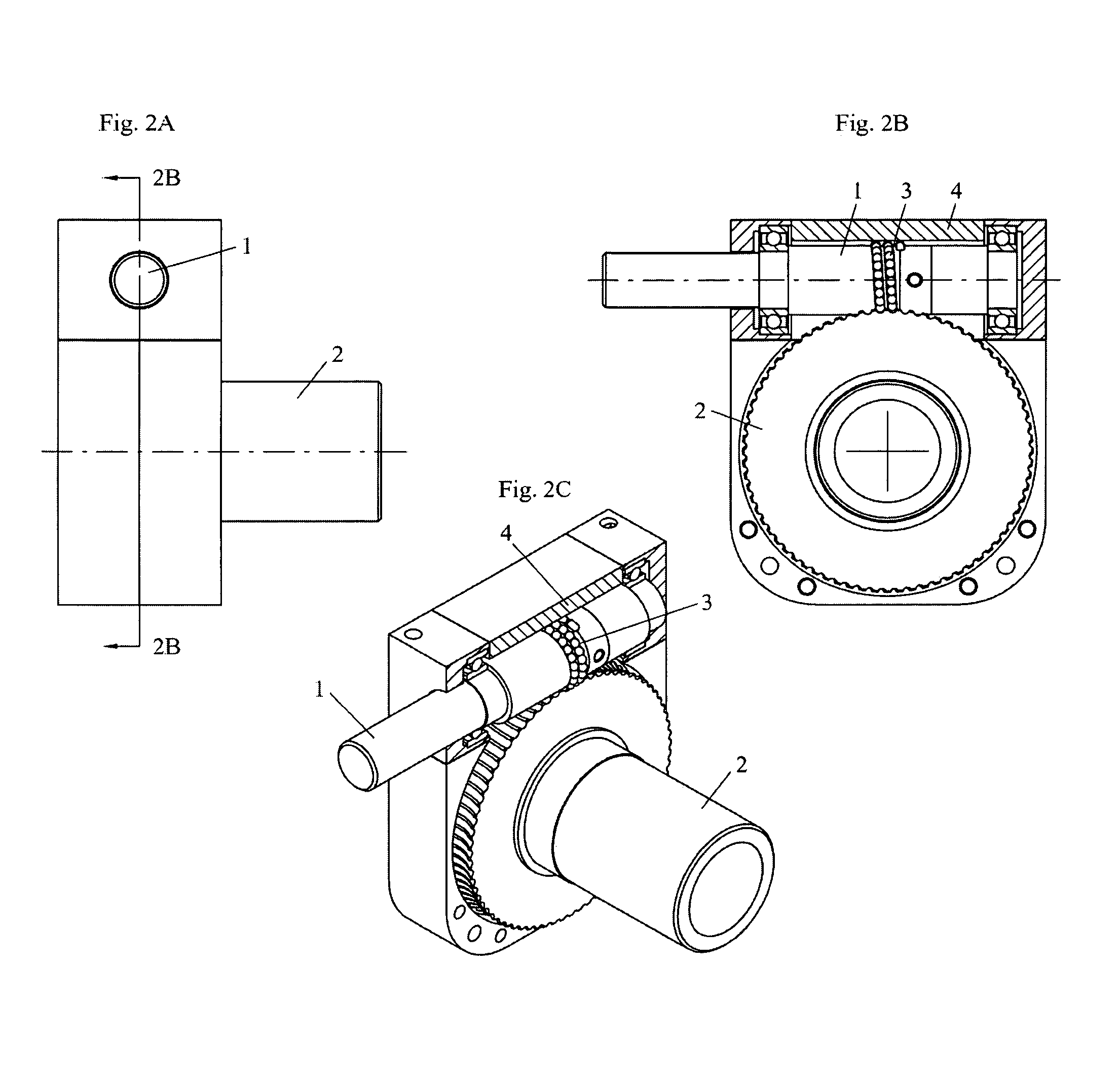

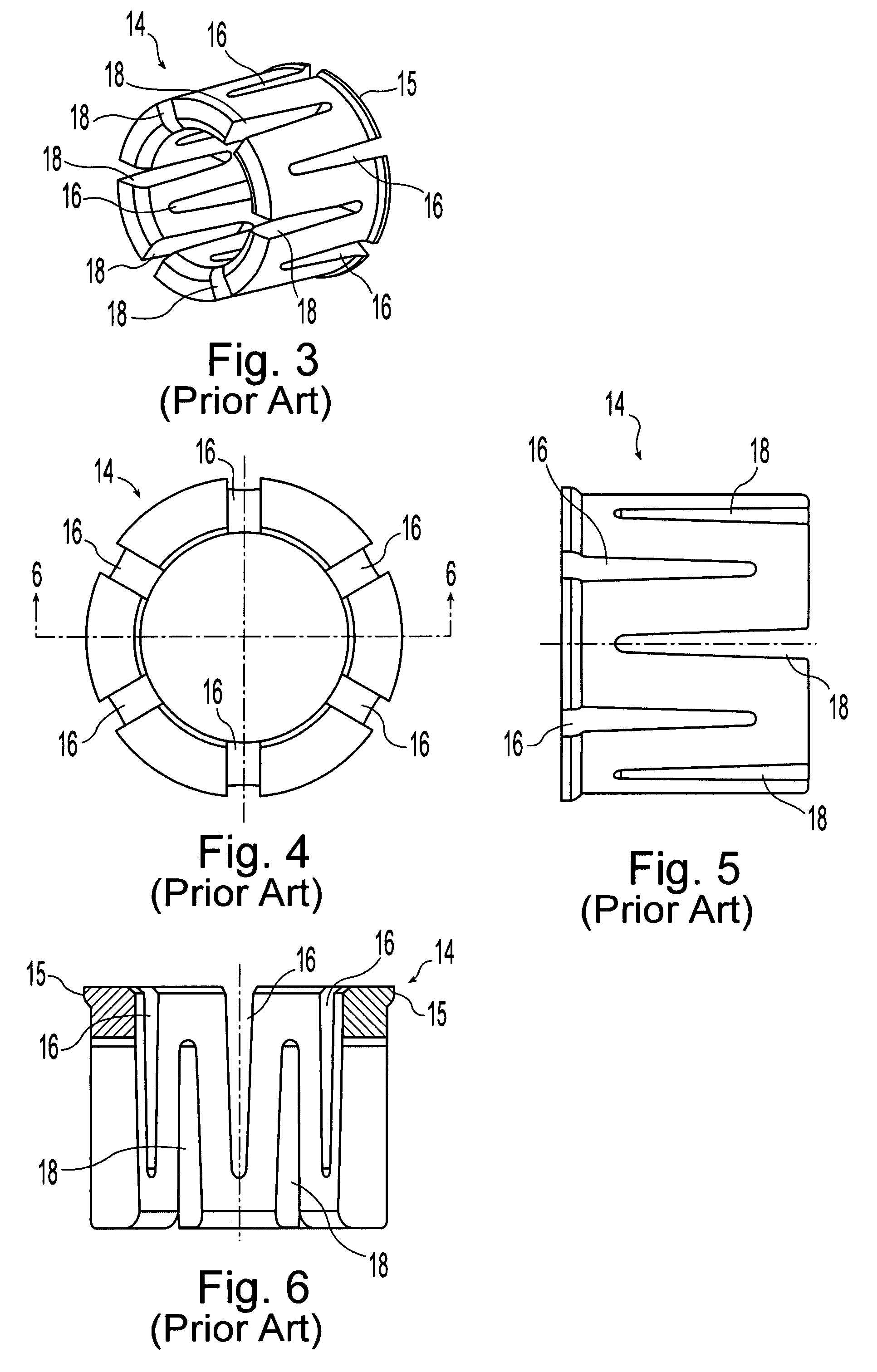

Ball-worm transmission

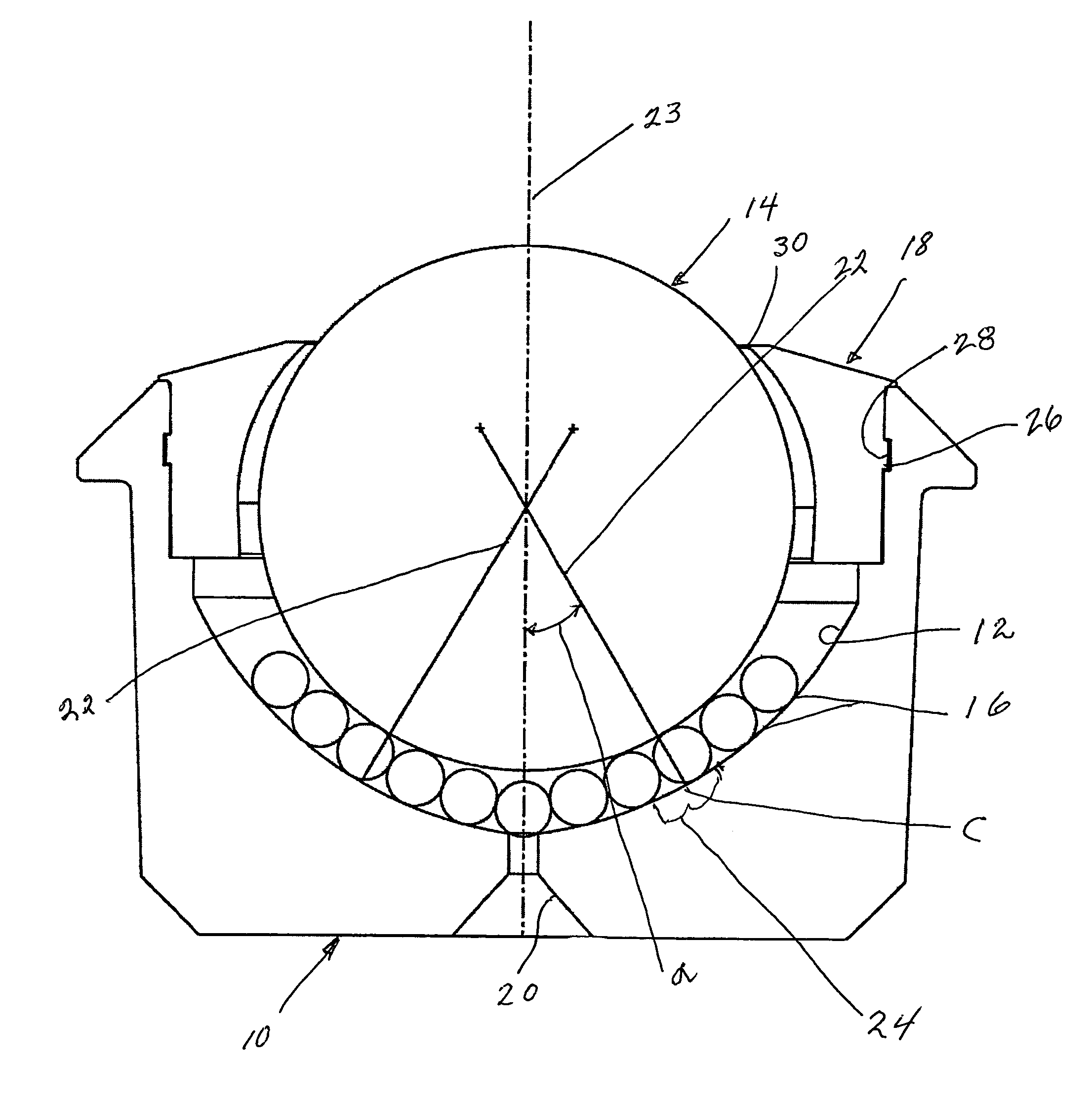

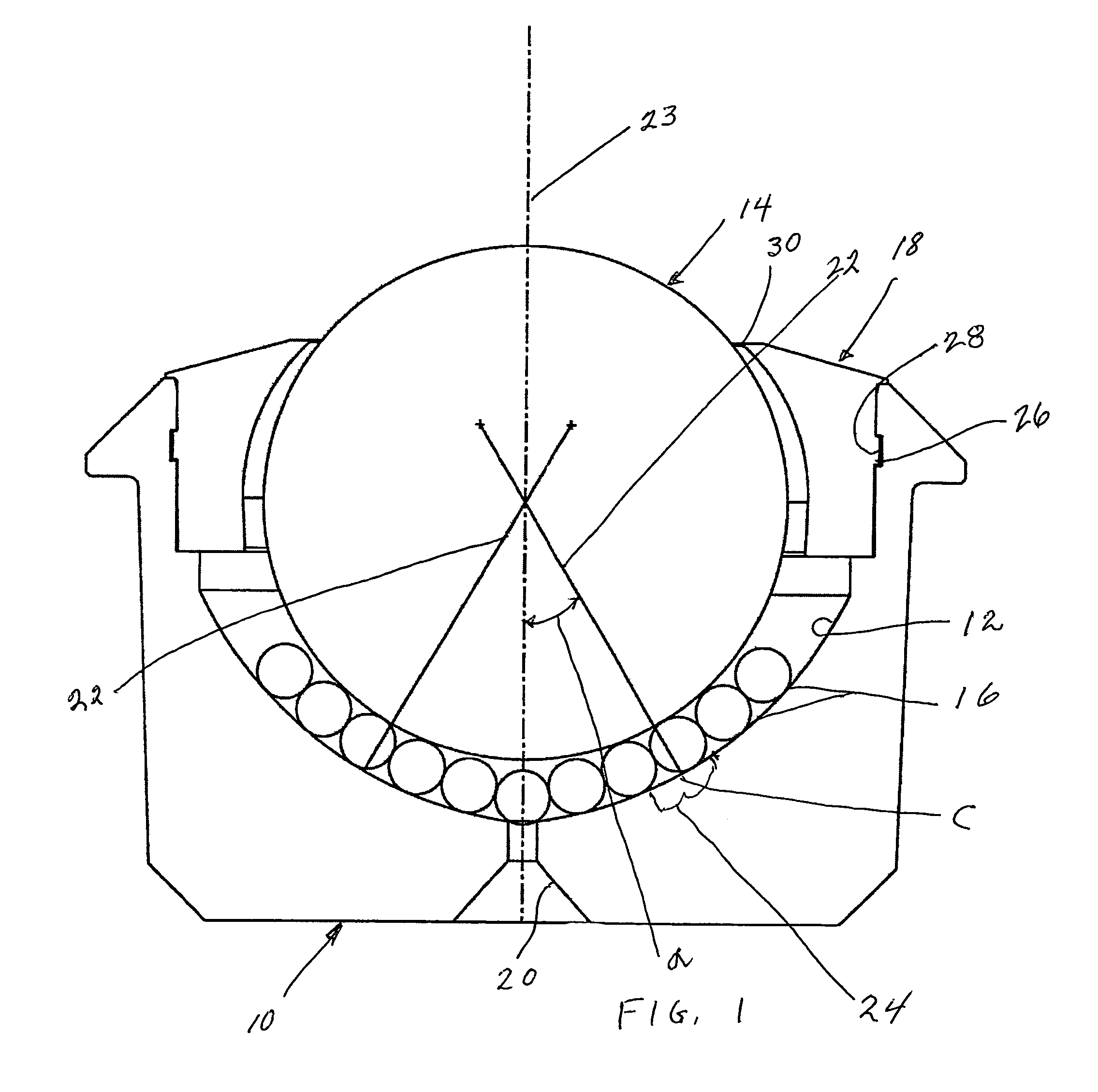

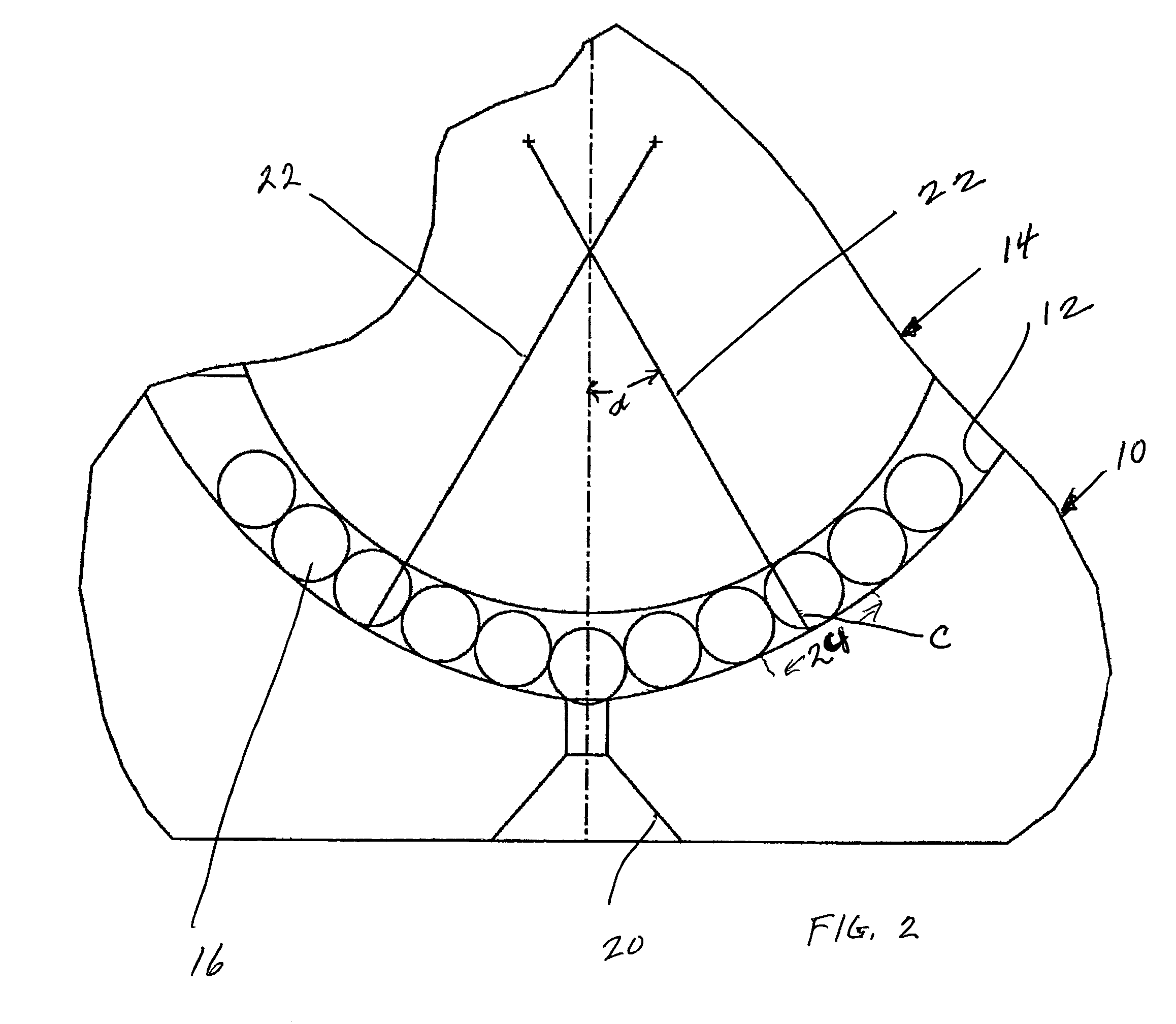

InactiveUS7051610B2Improve performanceAugments a number of ballsLinear bearingsToothed gearingsGear wheelEngineering

A ball-worm transmission is provided which replaces the sliding friction of the classic worm mechanism with the rolling friction of spherical balls. The ball-worm transmission assembly includes a worm which defines a recirculation path, and a gear coupled to the worm via a plurality of spherical balls. The gear includes a plurality of teeth each having a thickness in a central plane of the gear and a lesser thickness towards both sides of the gear, so that a gap is defined between the teeth is larger towards both sides of the gear than in the central plane of the gear.

Owner:HOLTZ DOUGLAS

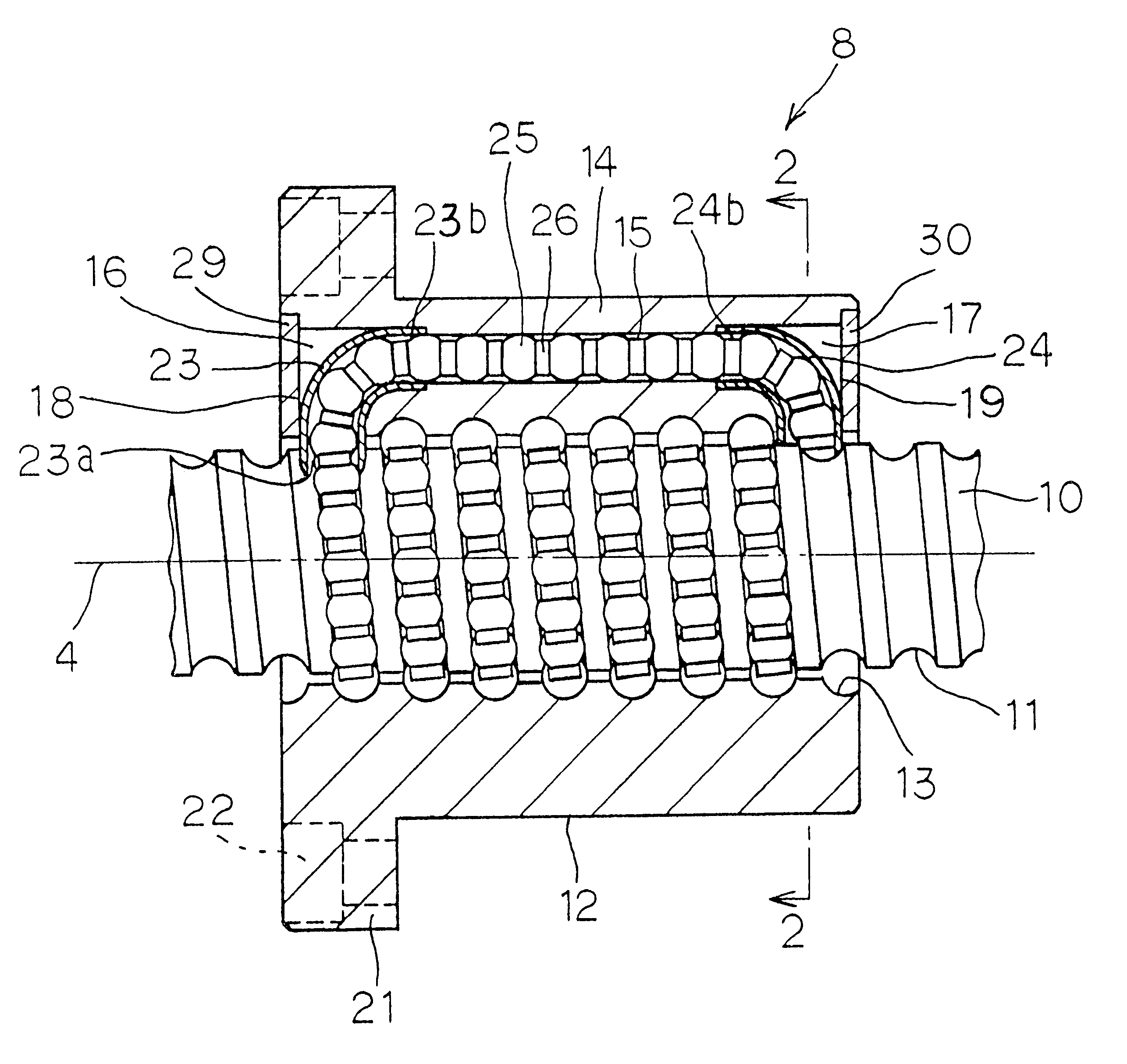

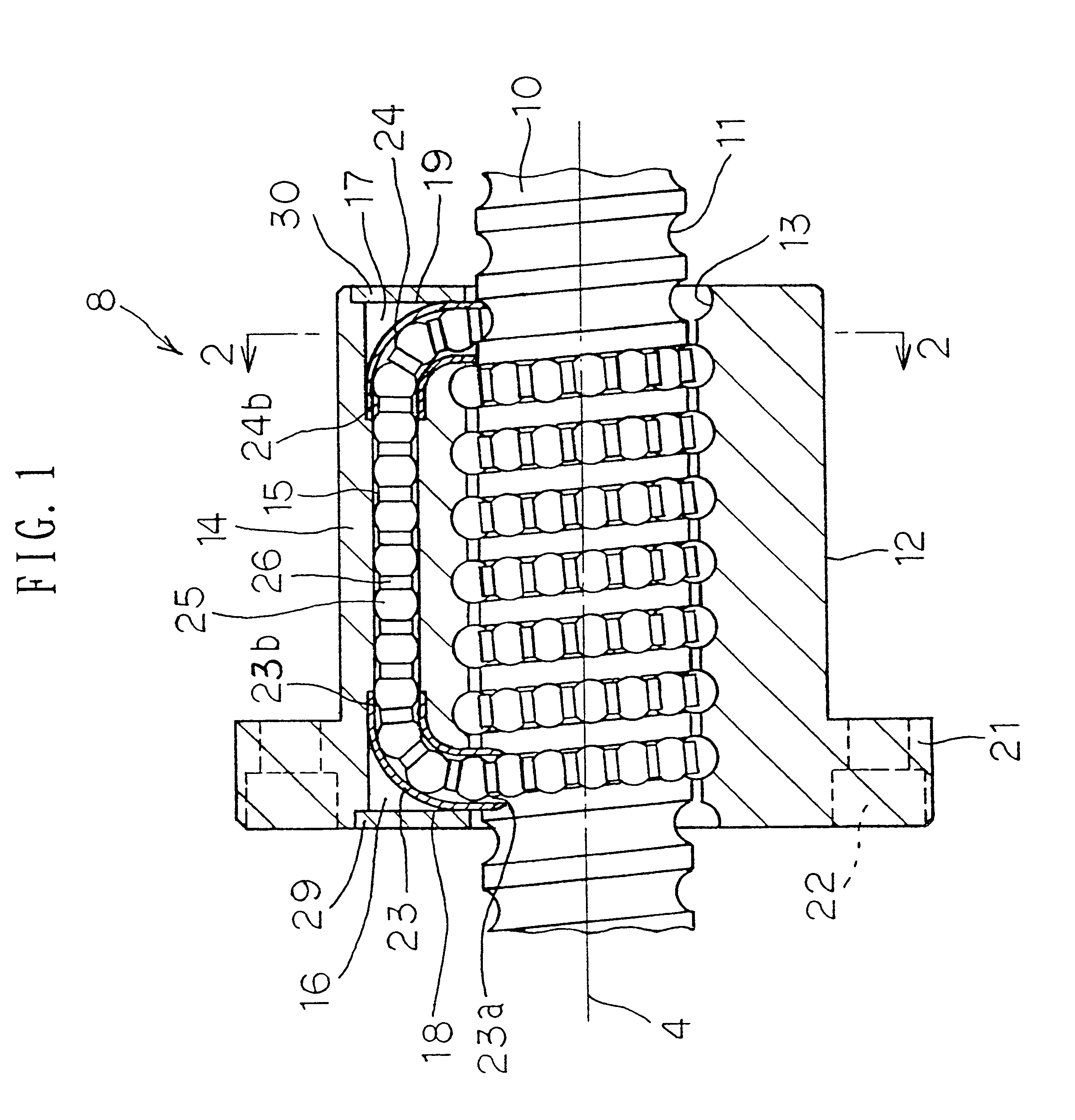

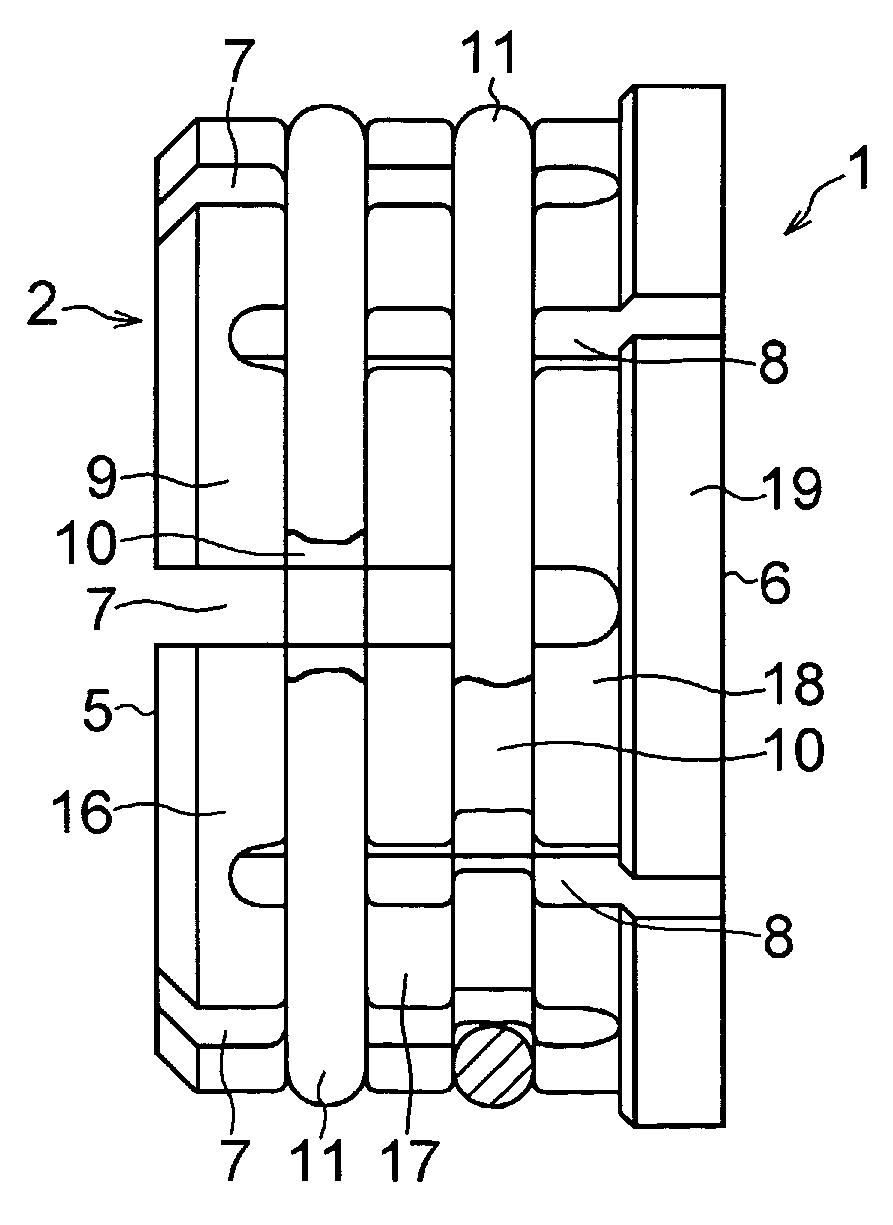

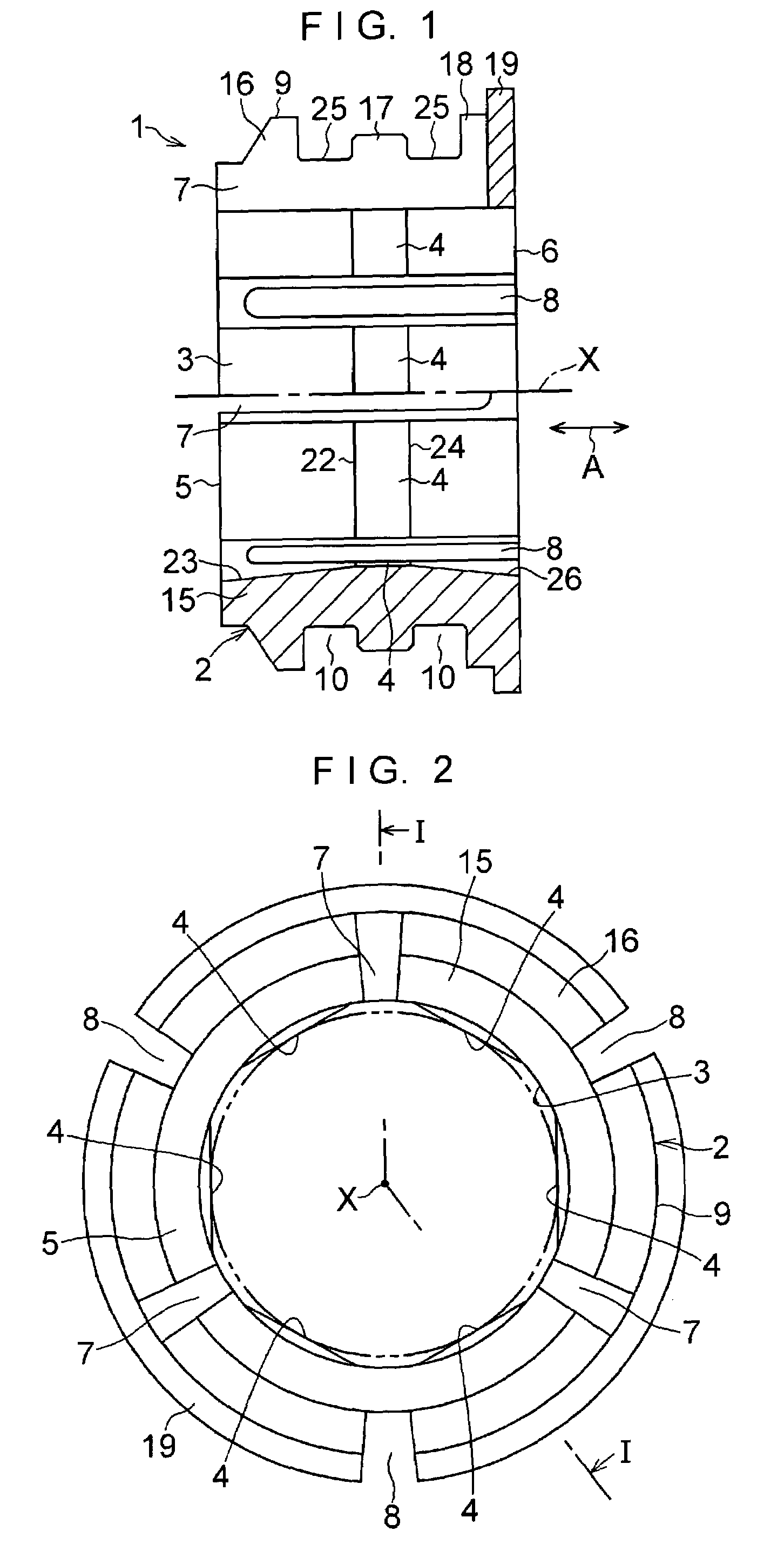

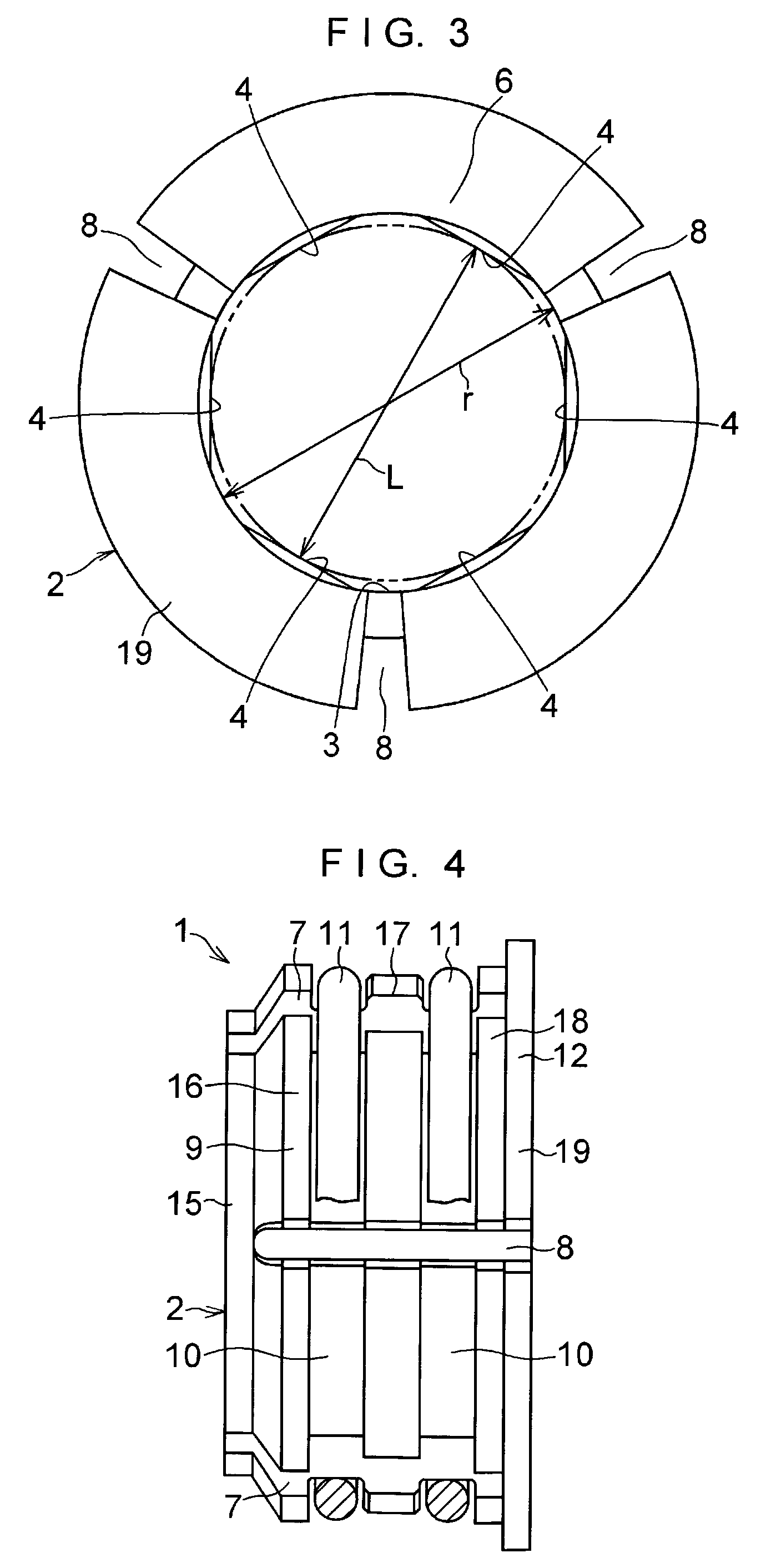

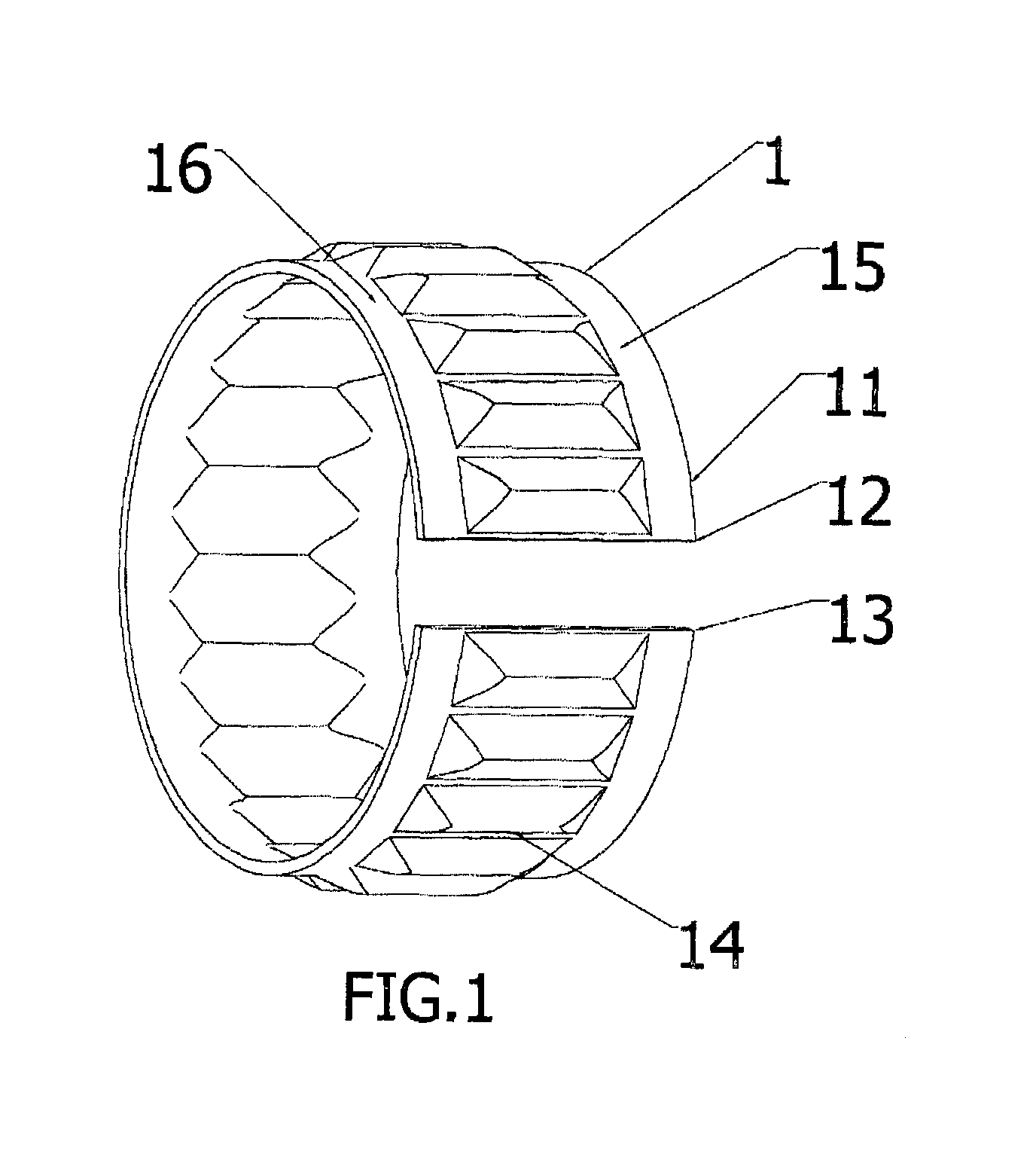

Ball screw having spacers

InactiveUS6176149B1Improve carrying capacityIncrease stiffnessControlling membersLinear bearingsCarrying capacityReciprocating motion

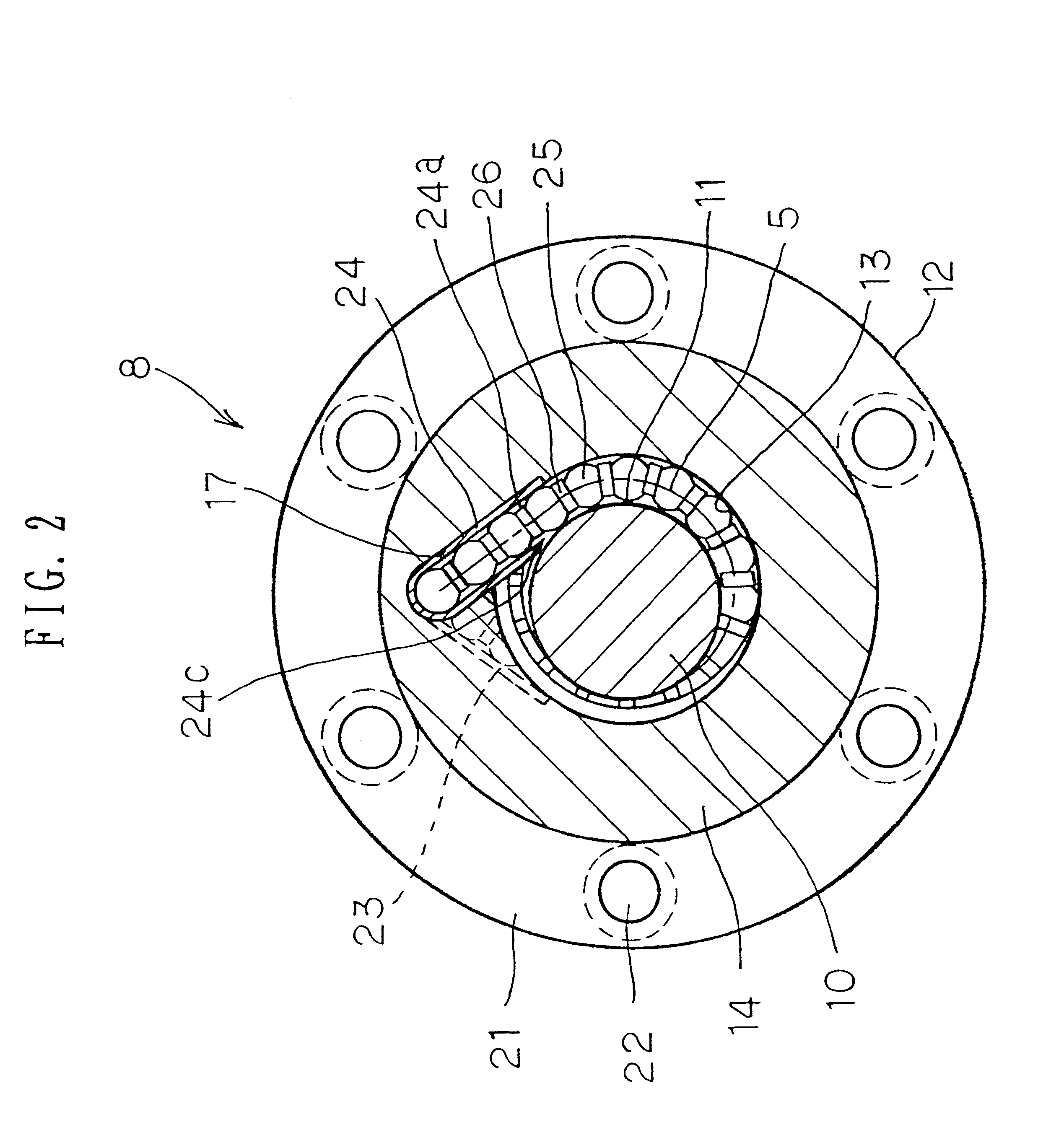

Spacers 26 each of which has a concave surface 27 complementary to the spherical surface of a ball 25 at each end thereof are disposed at areas between the adjacent balls 25, 25. A ball circulation mechanism comprises; a through hole 15 which extends in parallel to an axial line 4 of the ball nut 12 inside a thick wall part 14 of the ball nut 12; and adapters 23, 24 having open ends 23a, 24a provided with tongue portions 23c, 24c for scooping up or returning balls 25 between a ball screw groove 11 of a ball shaft 10 and a ball screw groove 13 of the ball nut 12, and the other open ends 23b, 24b being connected to be in communication with the through hole 15, and each adapter being fitted into recesses 16, 17 provided on both axial ends in the thick wall part 14 of the ball nut 12. Therefore, there is no need of upsizing a ball screw, and thus a compact ball screw which has a high load-carrying capacity and is suitable for a reciprocating movement can be provided.

Owner:TSUBAKI NAKASHIMA

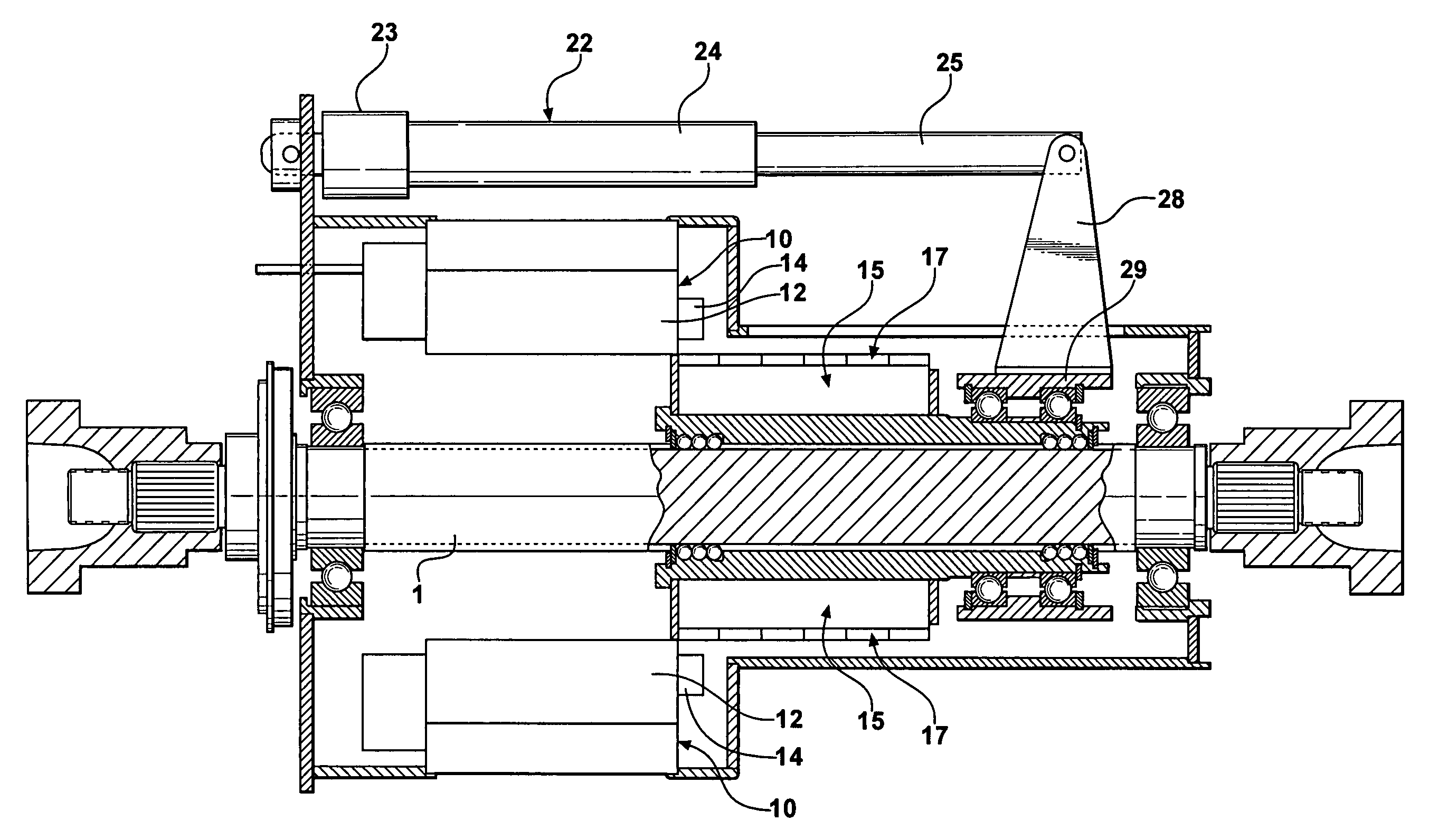

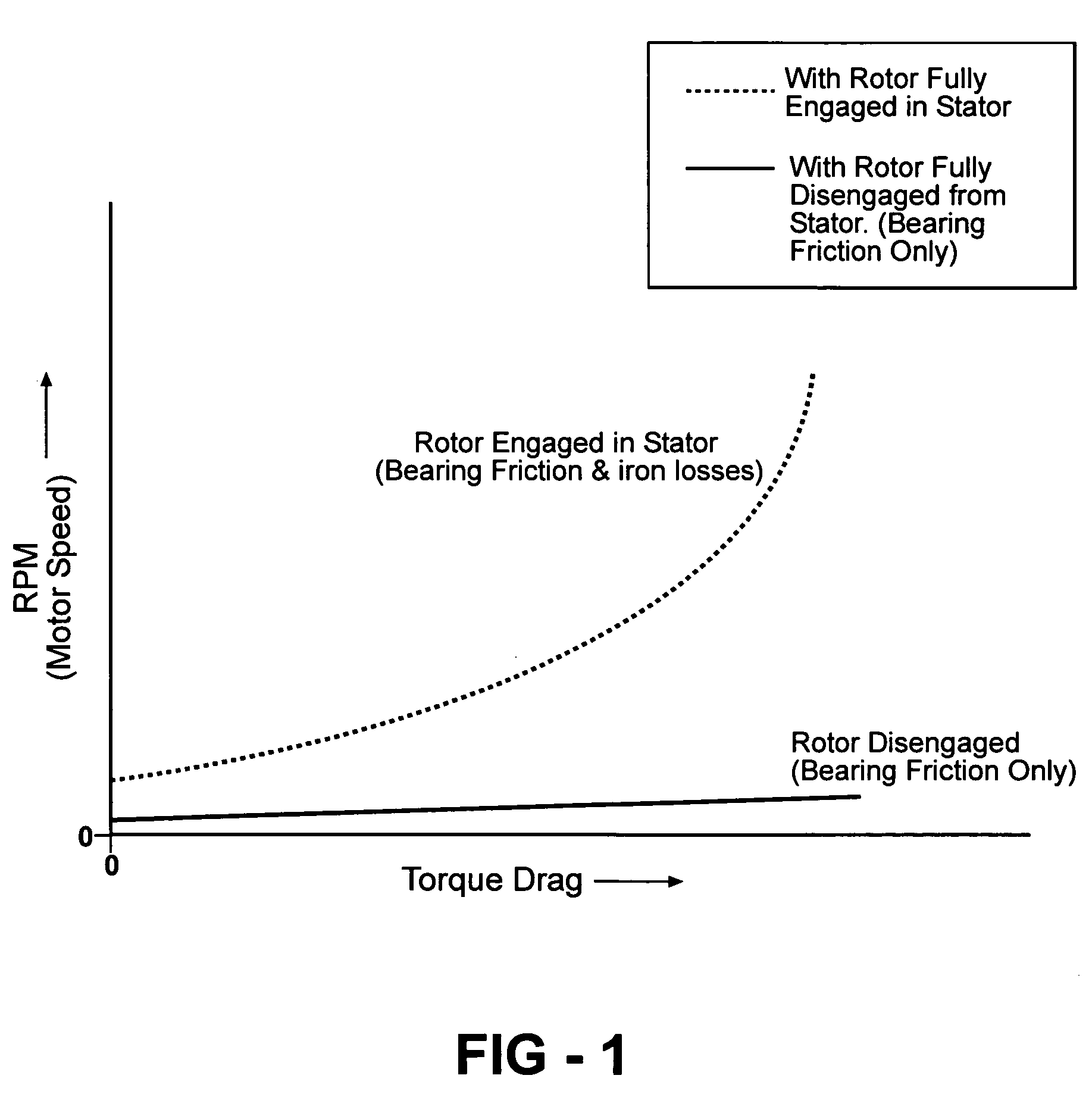

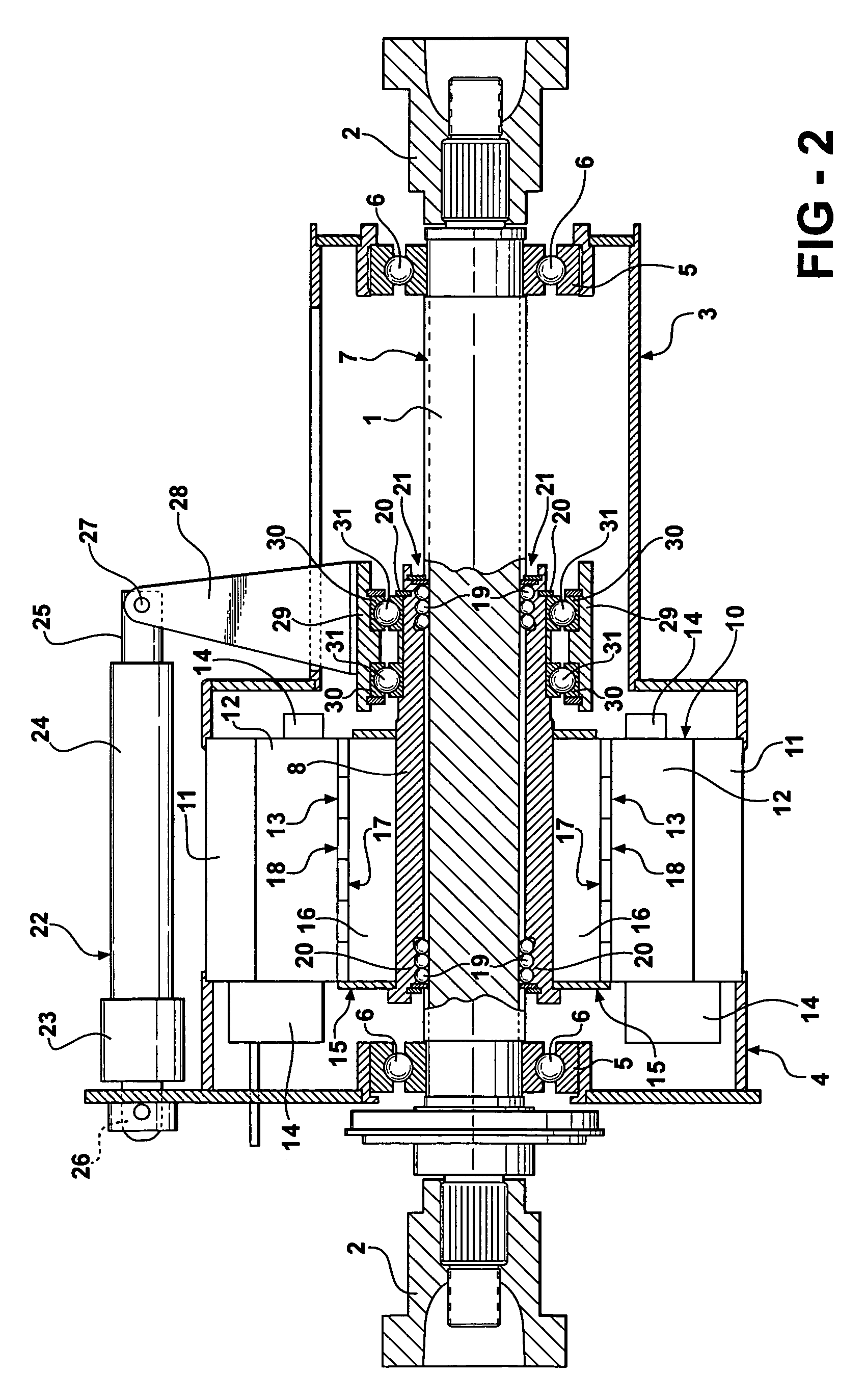

Brushless permanent magnet motor/generator with axial rotor decoupling to eliminate magnet induced torque losses

ActiveUS7863789B2Eliminate magnet induced torque dragSynchronous generatorsWindingsEngineeringPermanent magnet motor

A permanent magnet motor / generator that includes a stator, a rotor provided with a plurality of permanent magnets at a peripheral surface thereof and having a central axis which coincides with the central axis of the stator, a rotatable shaft upon which the rotor is coupled, and an actuator for moving the rotor with respect to the stator axially along the rotatable shaft a sufficient distance to completely decouple the rotor from the stator so as to eliminate magnet induced torque drag. When the permanent magnet / generator is used in parallel hybrid vehicles, the ability to completely decouple the rotor from the stator greatly improves range and efficiency. In addition, by progressively engaging the rotor with the stator a desired voltage output can be obtained upon deceleration.

Owner:DURA TRAC MOTORS INC

Non-contact porous air bearing and glass flattening device

Owner:NEW WAY MACHINE COMPONENTS

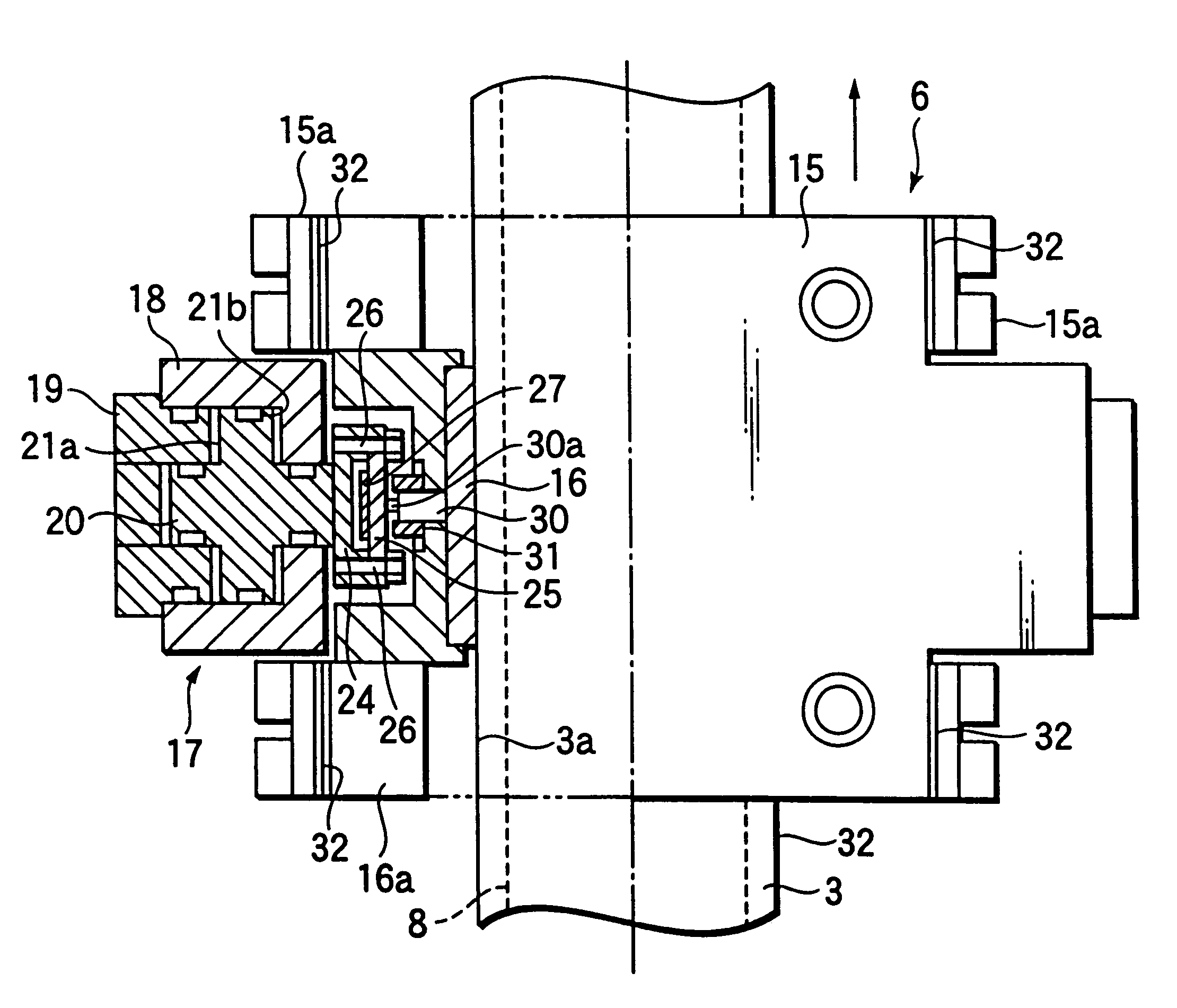

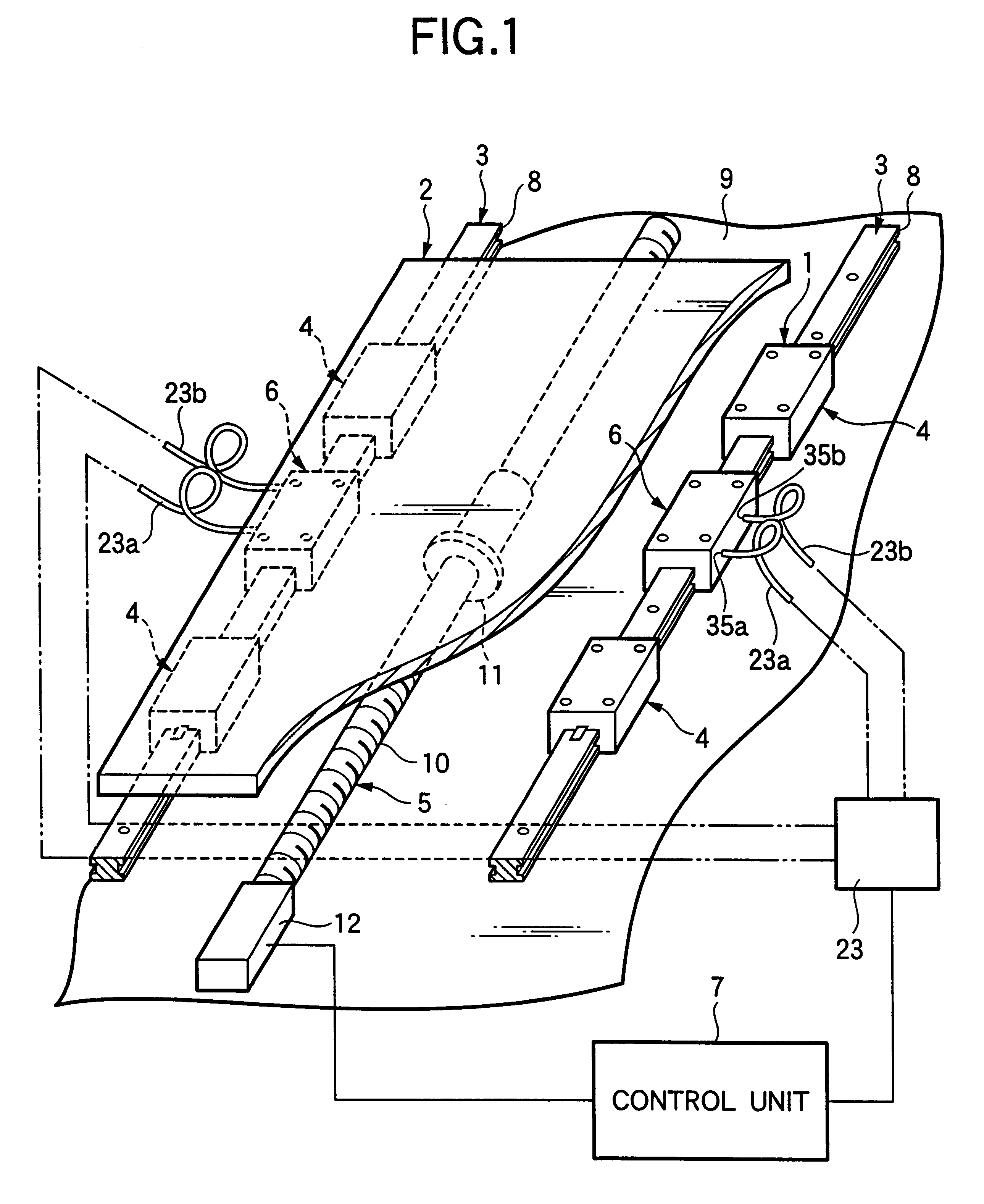

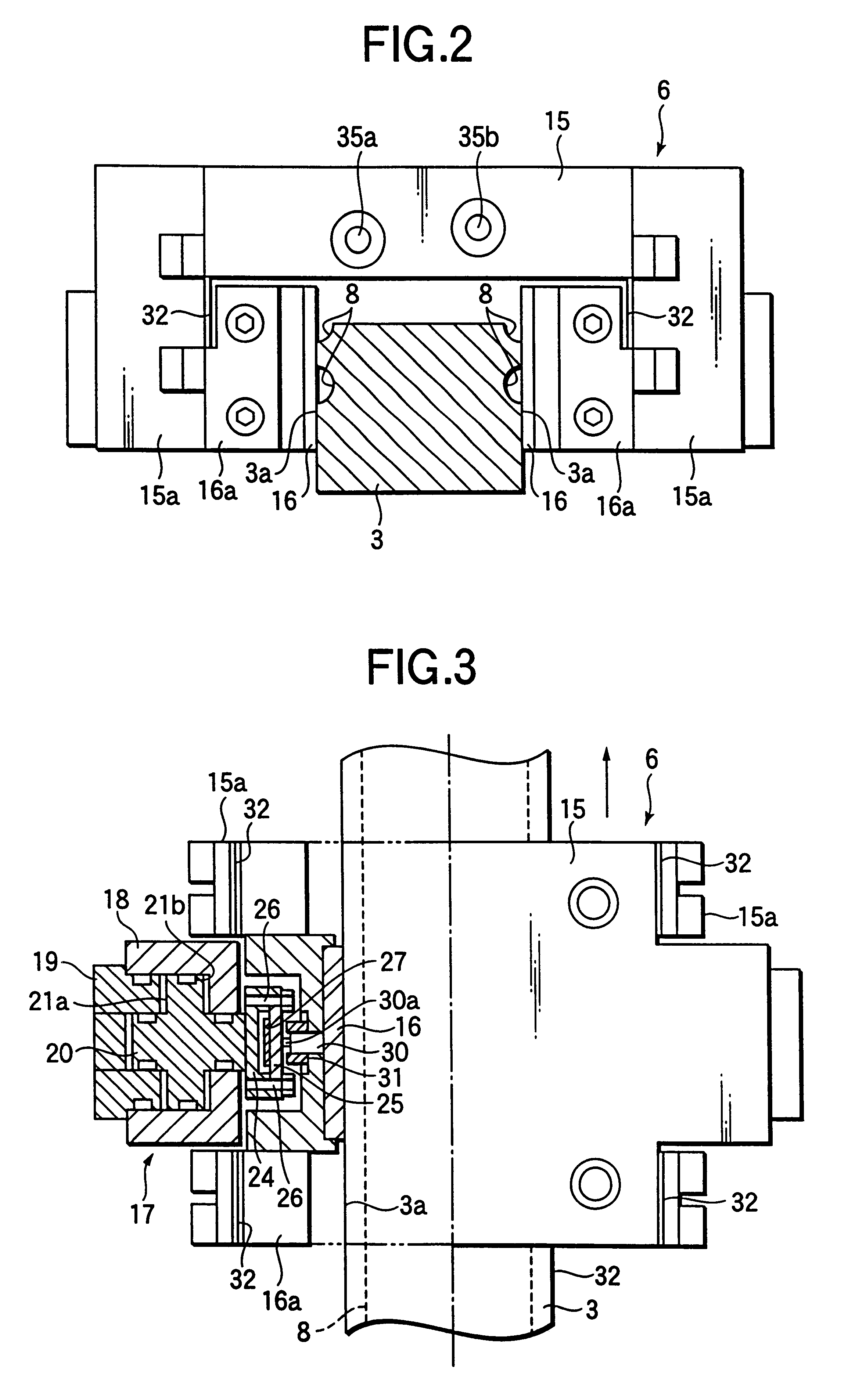

Linear guide apparatus

The linear guide apparatus includes a guide rail 3 including a rolling body rolling groove 8 and a friction apply unit 6 assembled to the guide rail 3. The friction apply unit 6 includes a unit main body 15, a brake member 16, an oil pressure cylinder 17 and a plate spring 32. The brake member 16 is disposed so as to face the side surface 3a of the guide rail 3 and can be contacted with the other portions of the side surface 3a than the rolling body rolling groove 8 thereof. The oil pressure cylinder 17 includes a piston member 20 which is structured to be driven in a positive direction to thereby press the brake member 16 against the side surface 3a of the guide rail 3 and also the piston member 20 can be driven in the opposite direction to thereby remove the pressure of the brake member 16 from the side surface 3a.

Owner:NSK LTD

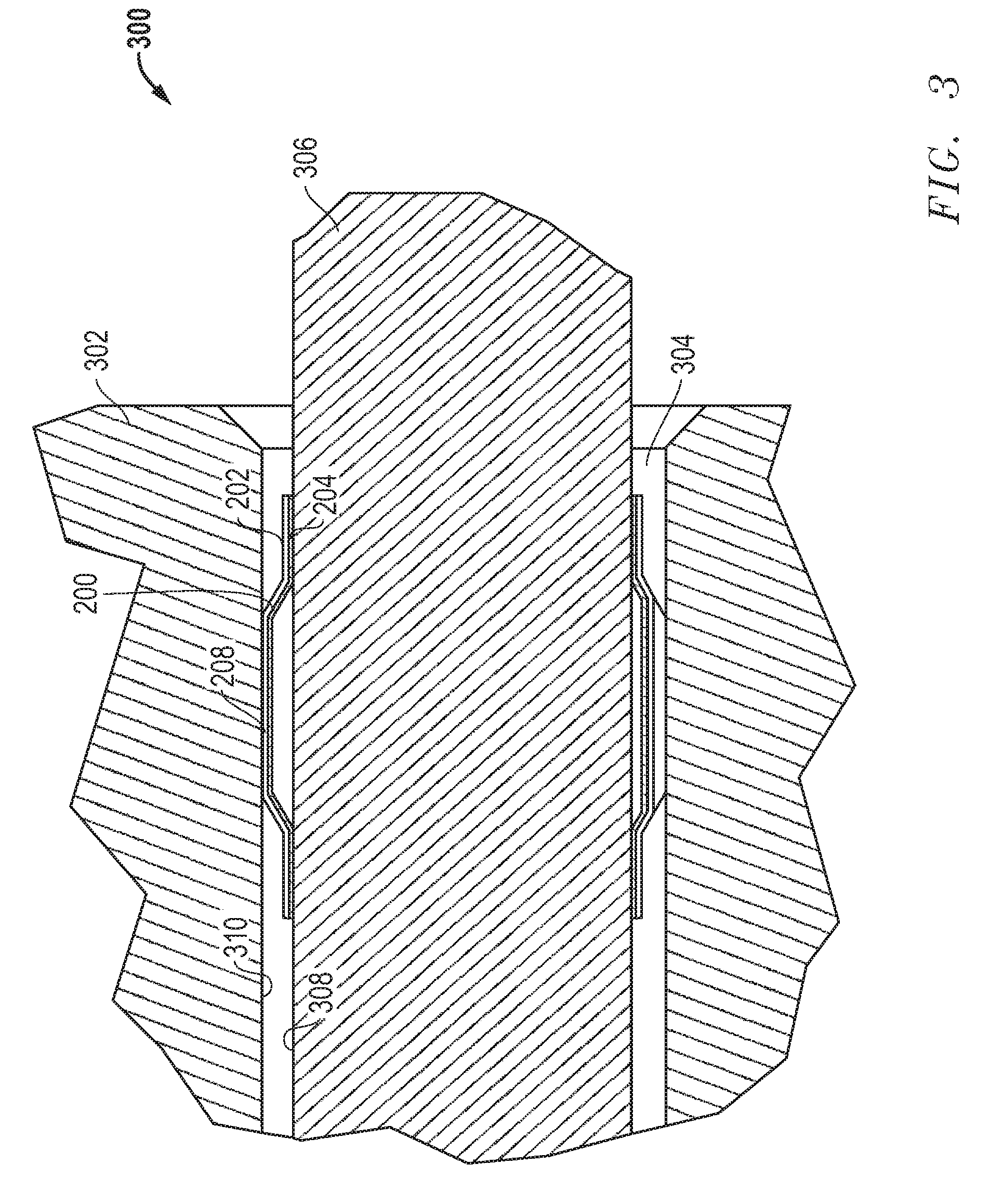

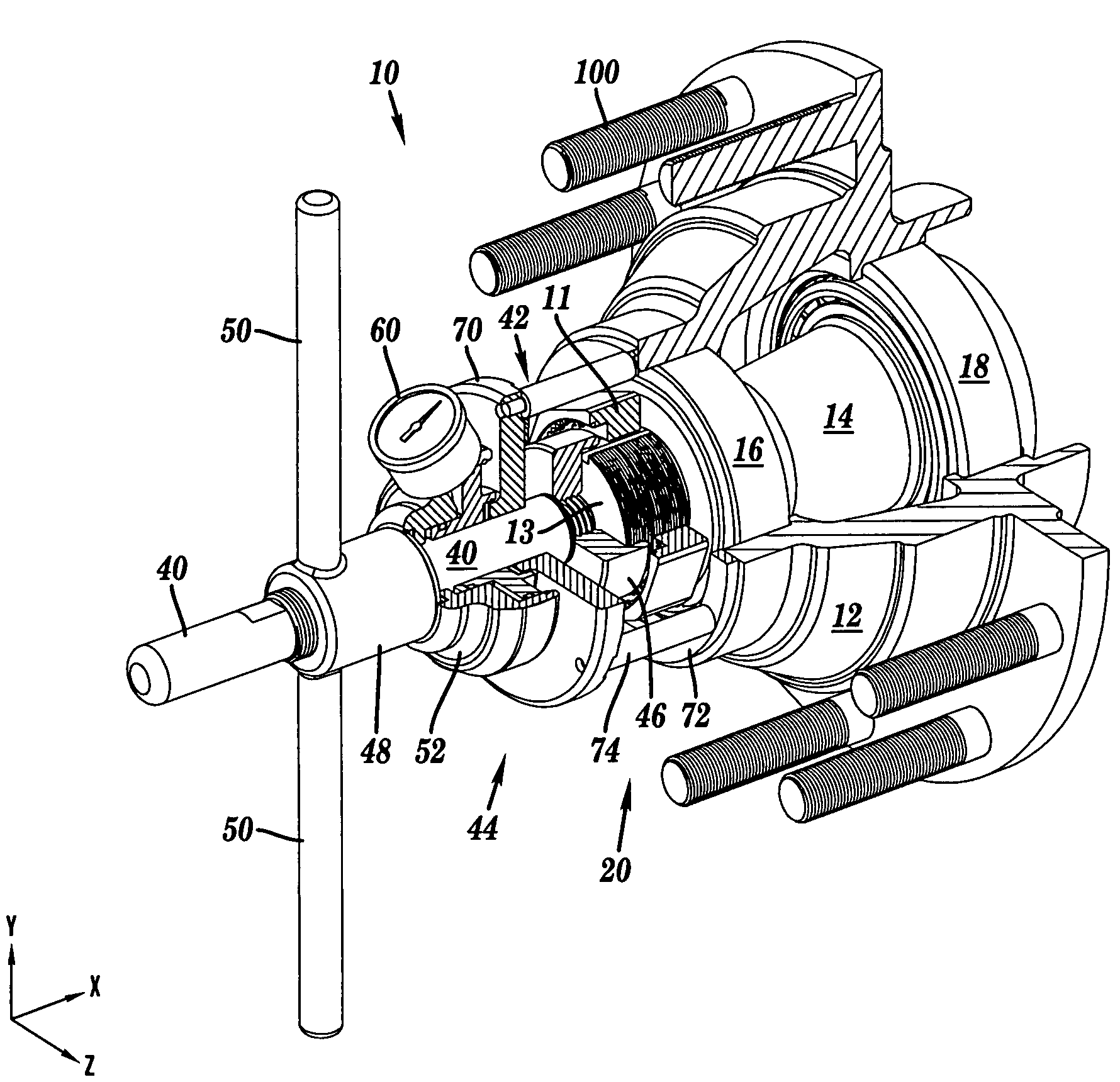

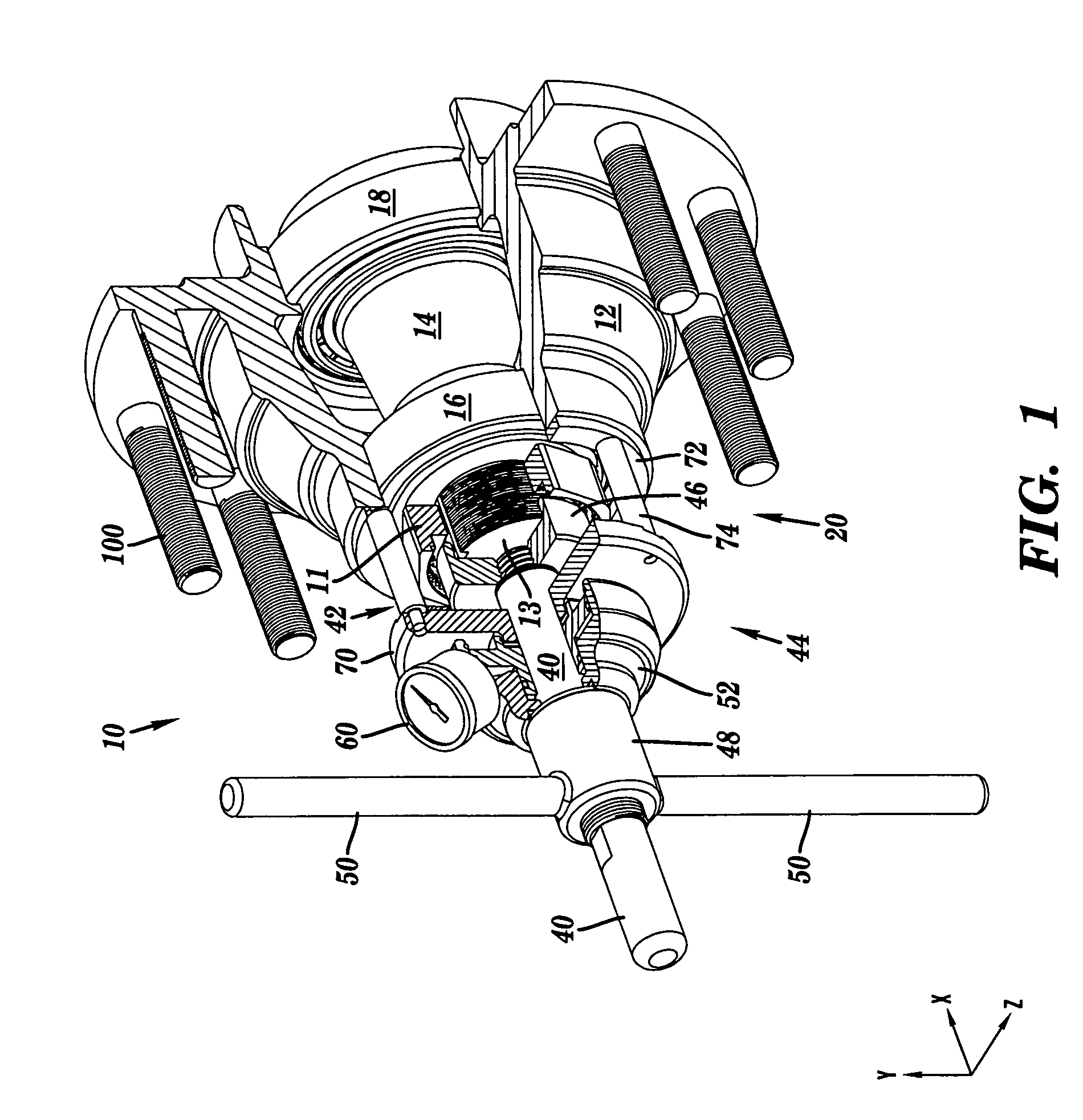

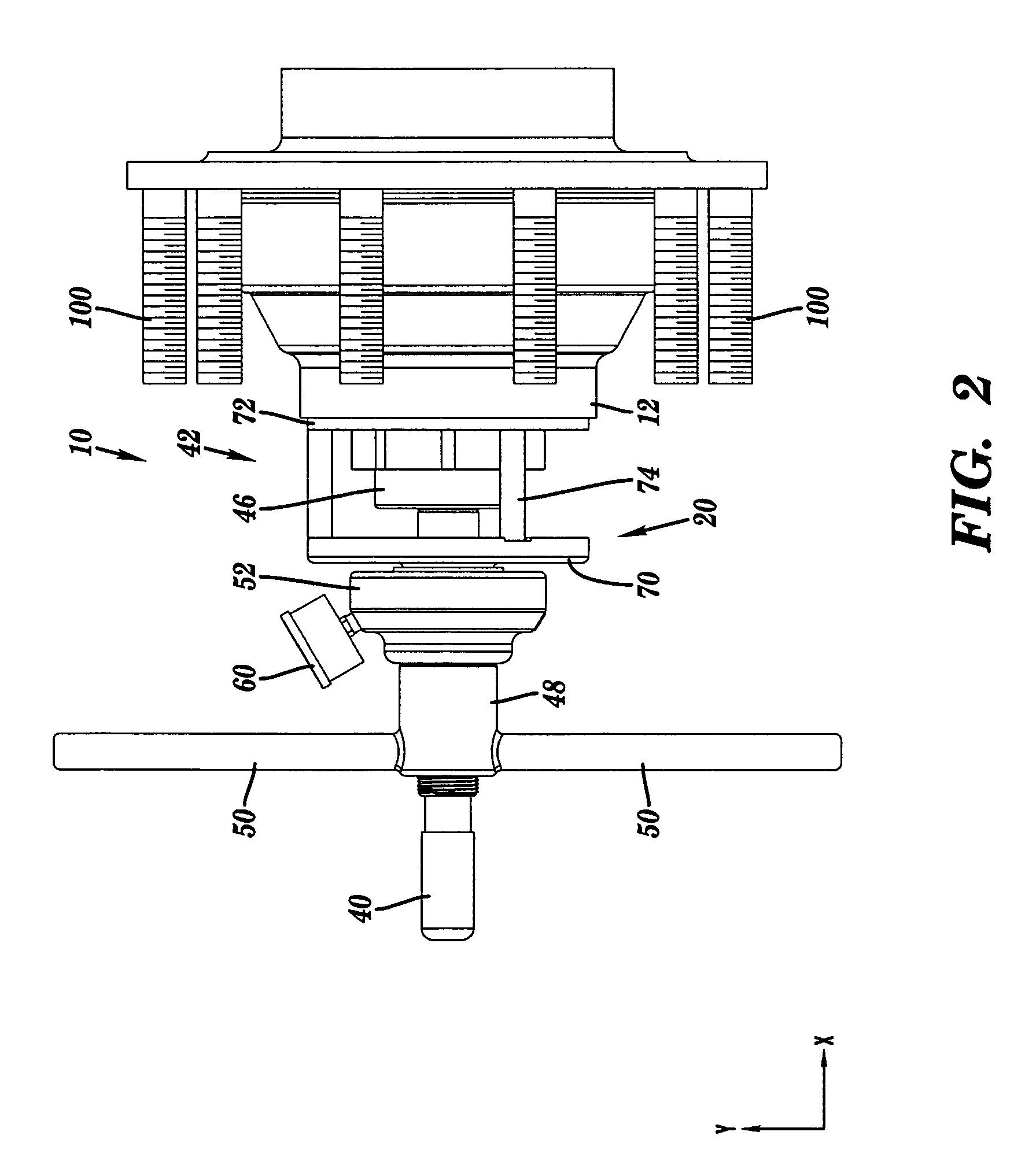

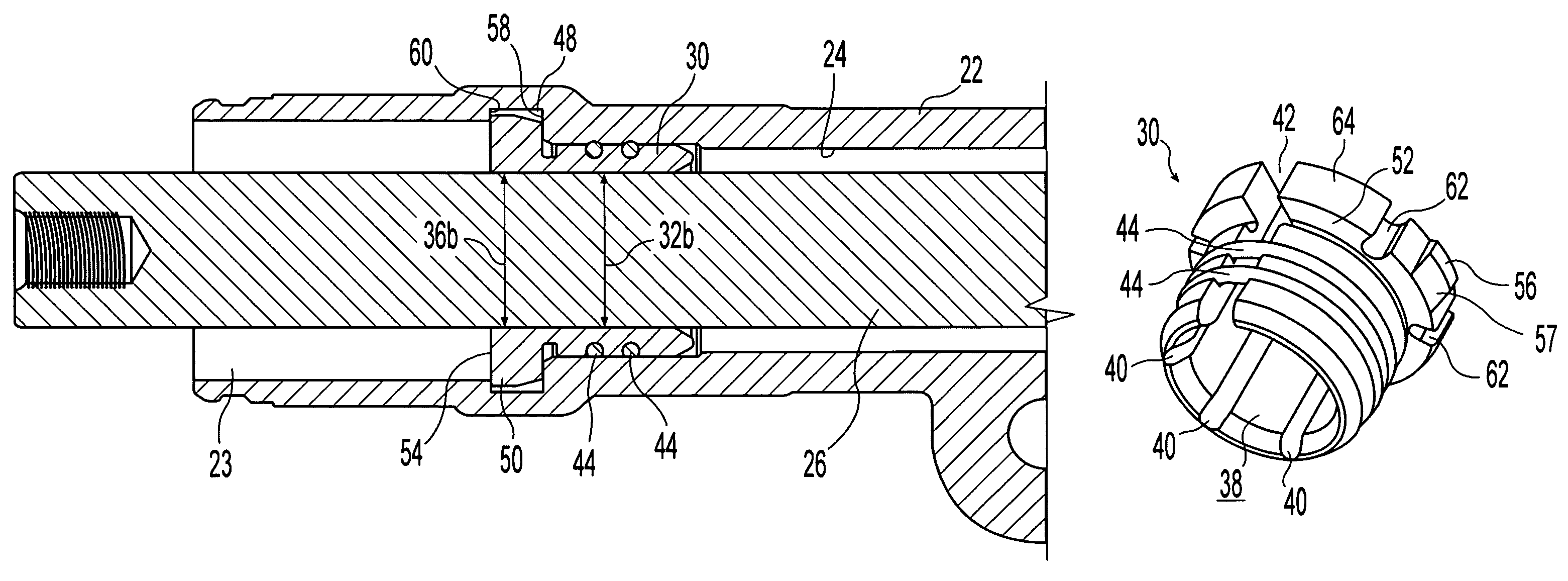

Method and apparatus for preloading a bearing

Methods and apparatus for preloading a bearing are provided. The apparatus includes a rod having a first end and a second end adapted to be removably mounted to a shaft; a device for compressing a hub against the outer race of a bearing to provide the preload to the bearing; and a cylindrical frame positioned between the device for compressing the hub and the hub. These methods and apparatus include preload monitoring devices whereby the mechanic can accurately monitor and regulate the preload to a bearing or bearing assembly. Aspects of the invention may also be used to adjust the endplay on a bearing or a bearing assembly. In one aspect, the preload to the bearing is transmitted through a housing having a fluid whose pressure can be detected and monitored. An apparatus for precisely rotating a nut and a tool for precisely rotating a nut are also provided.

Owner:TEMPER +1

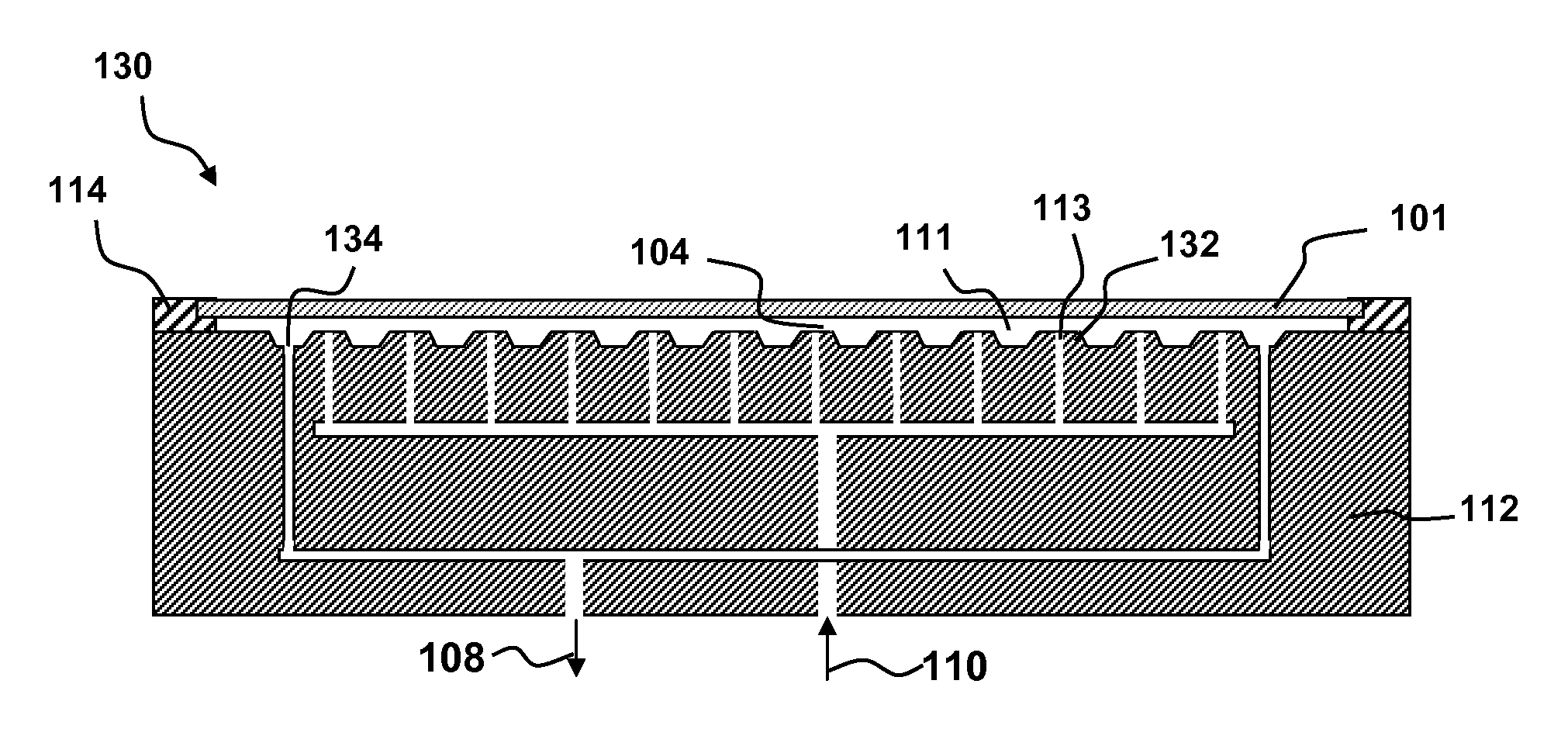

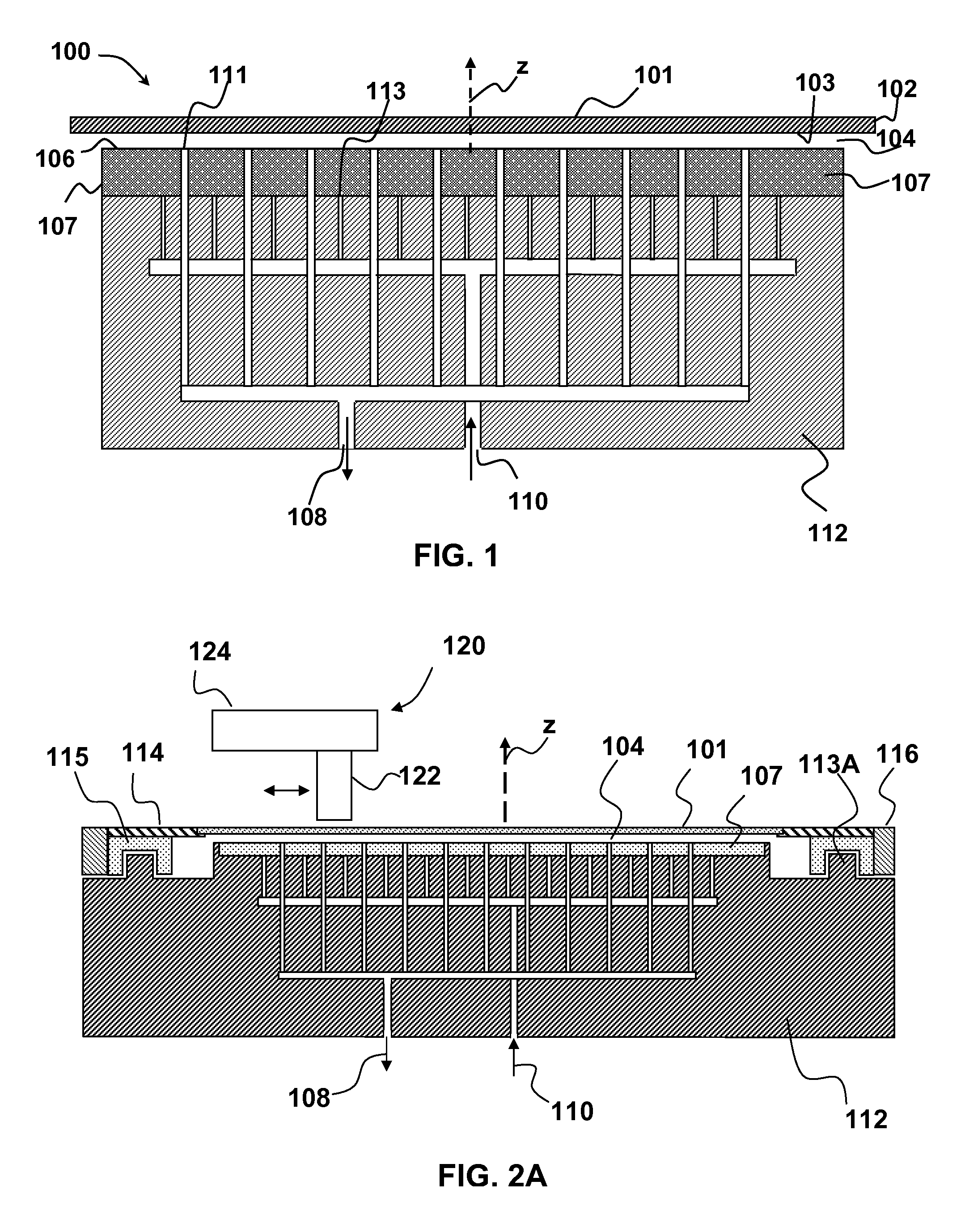

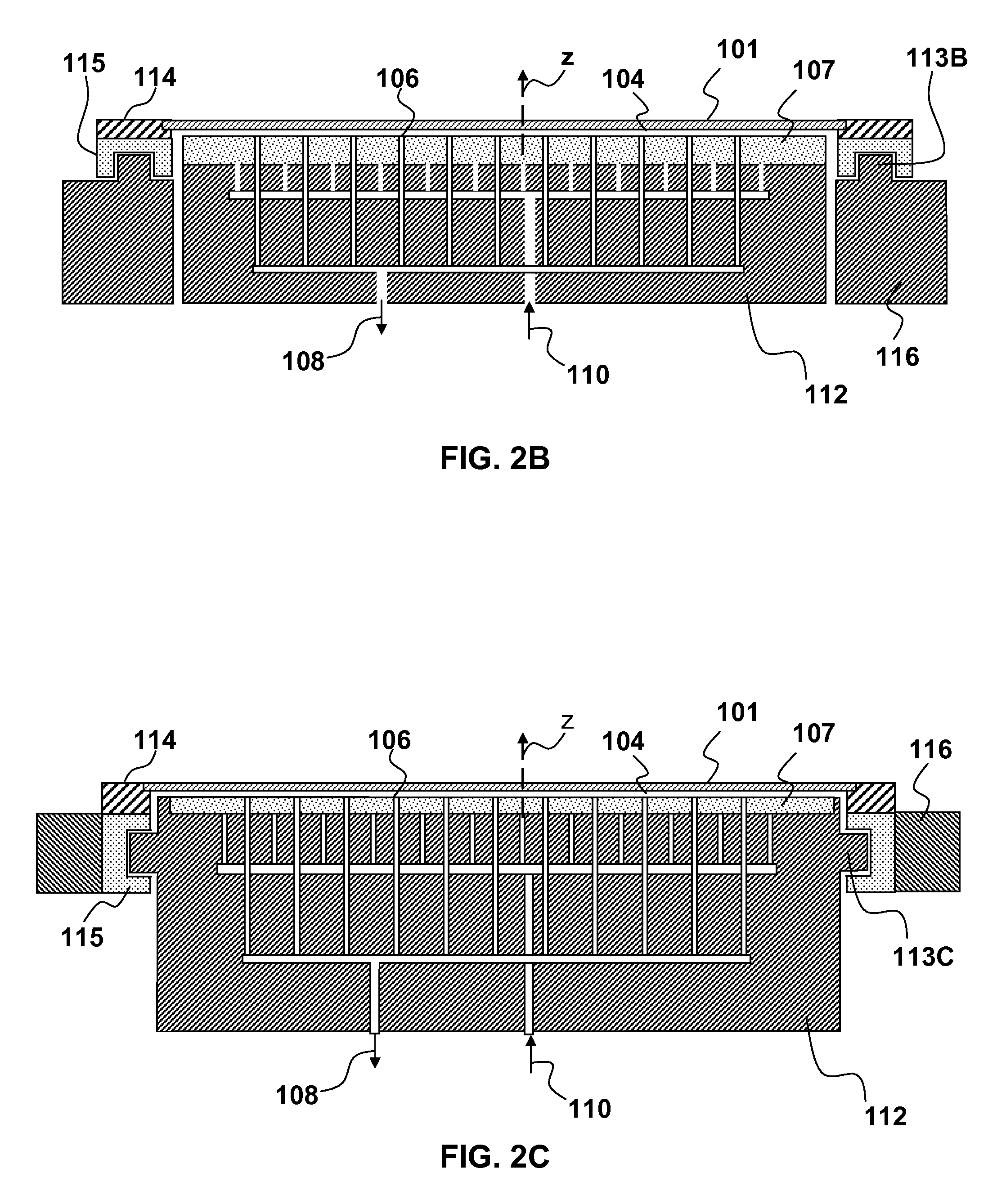

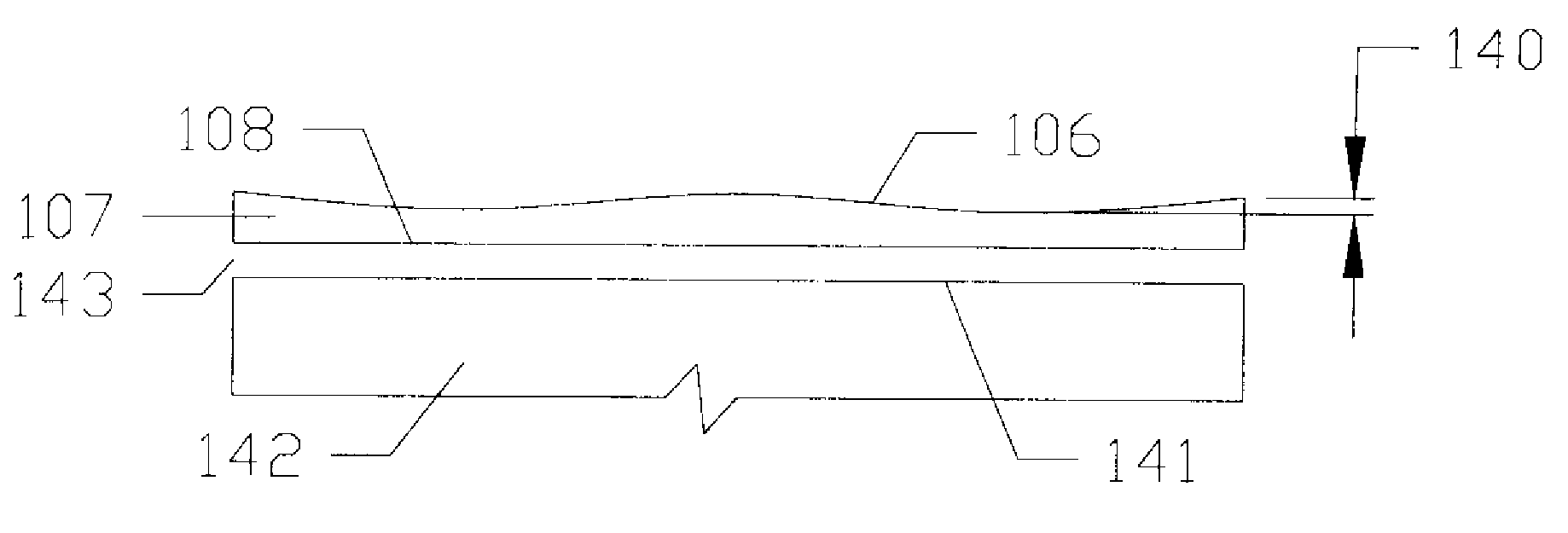

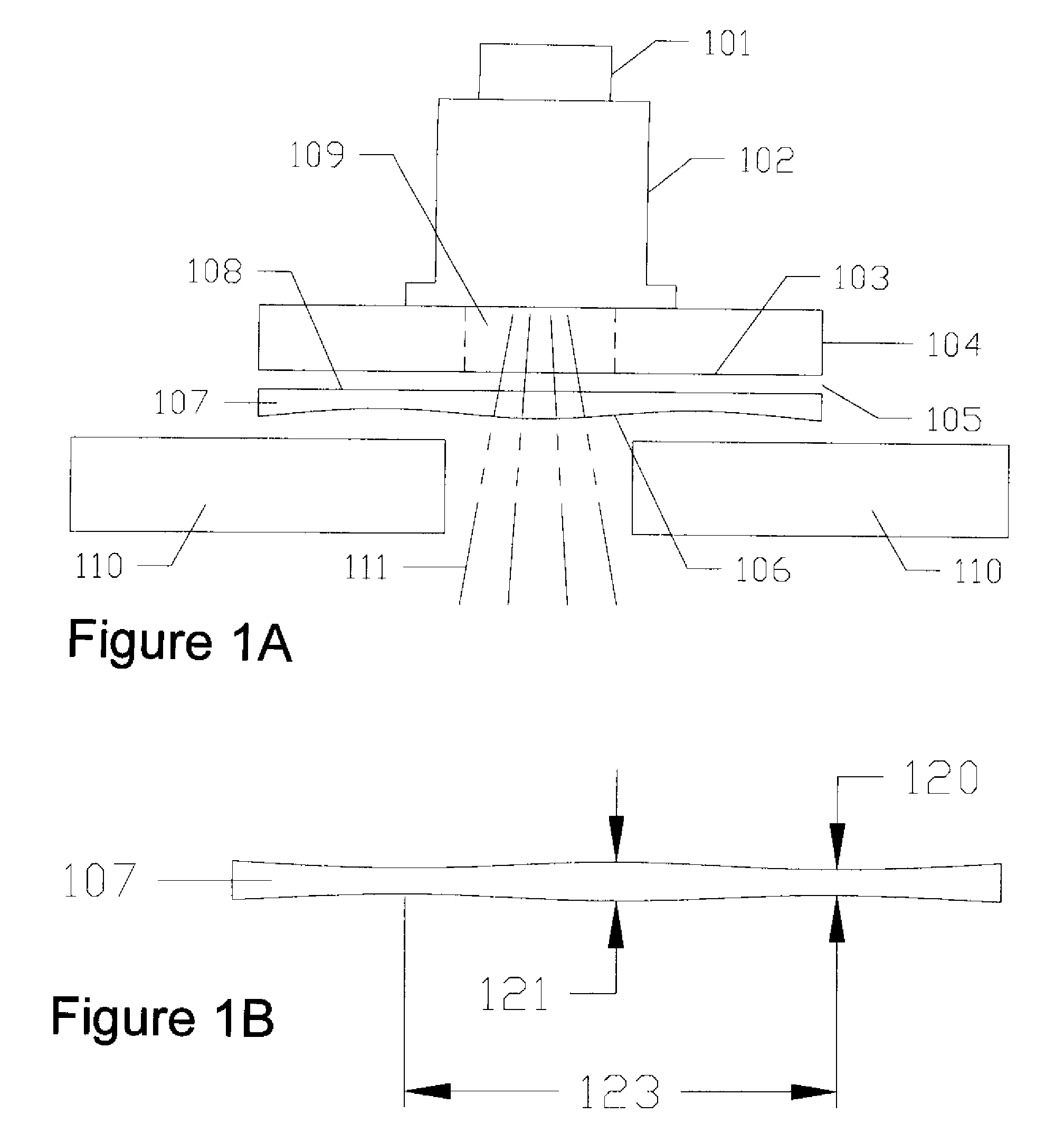

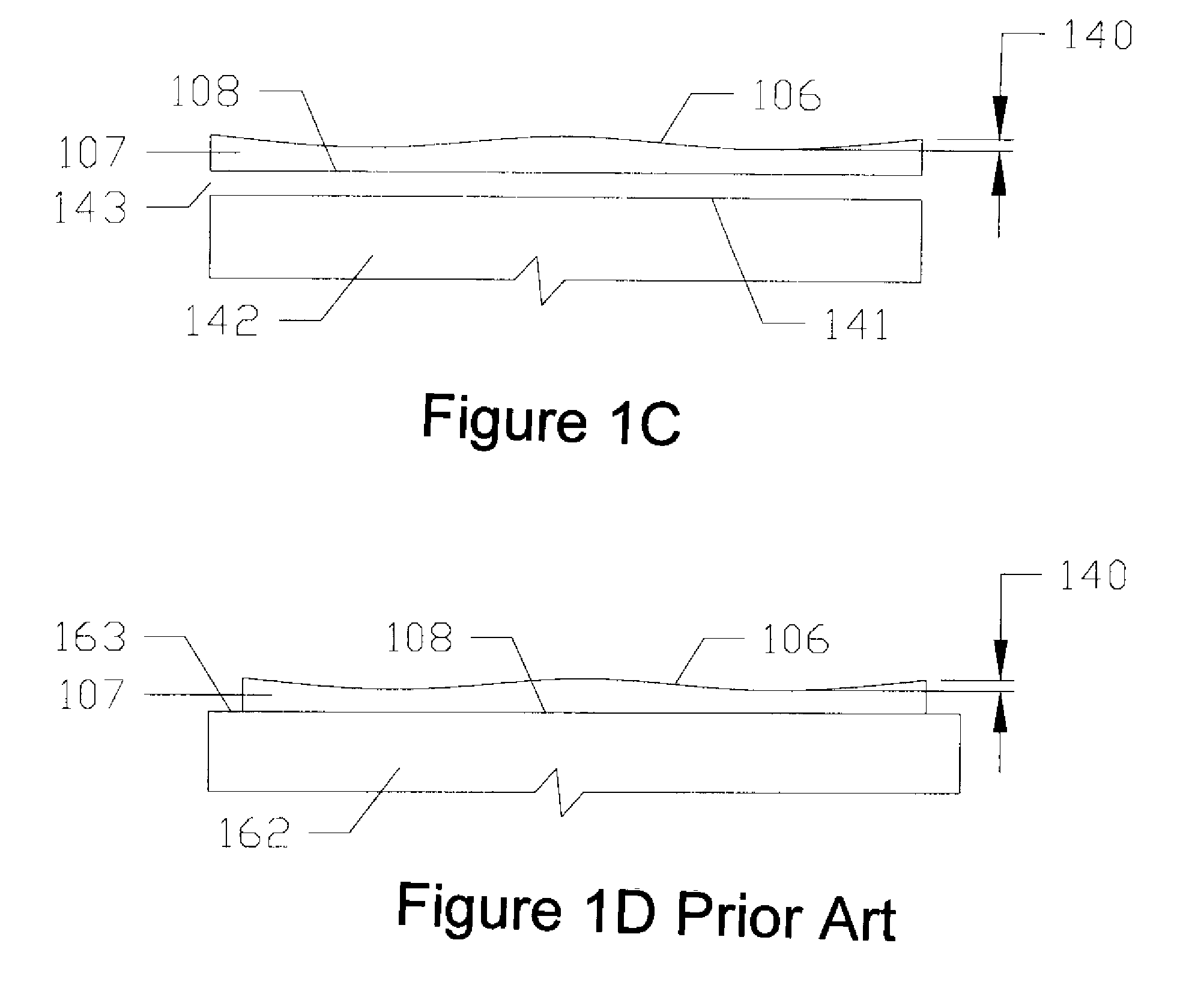

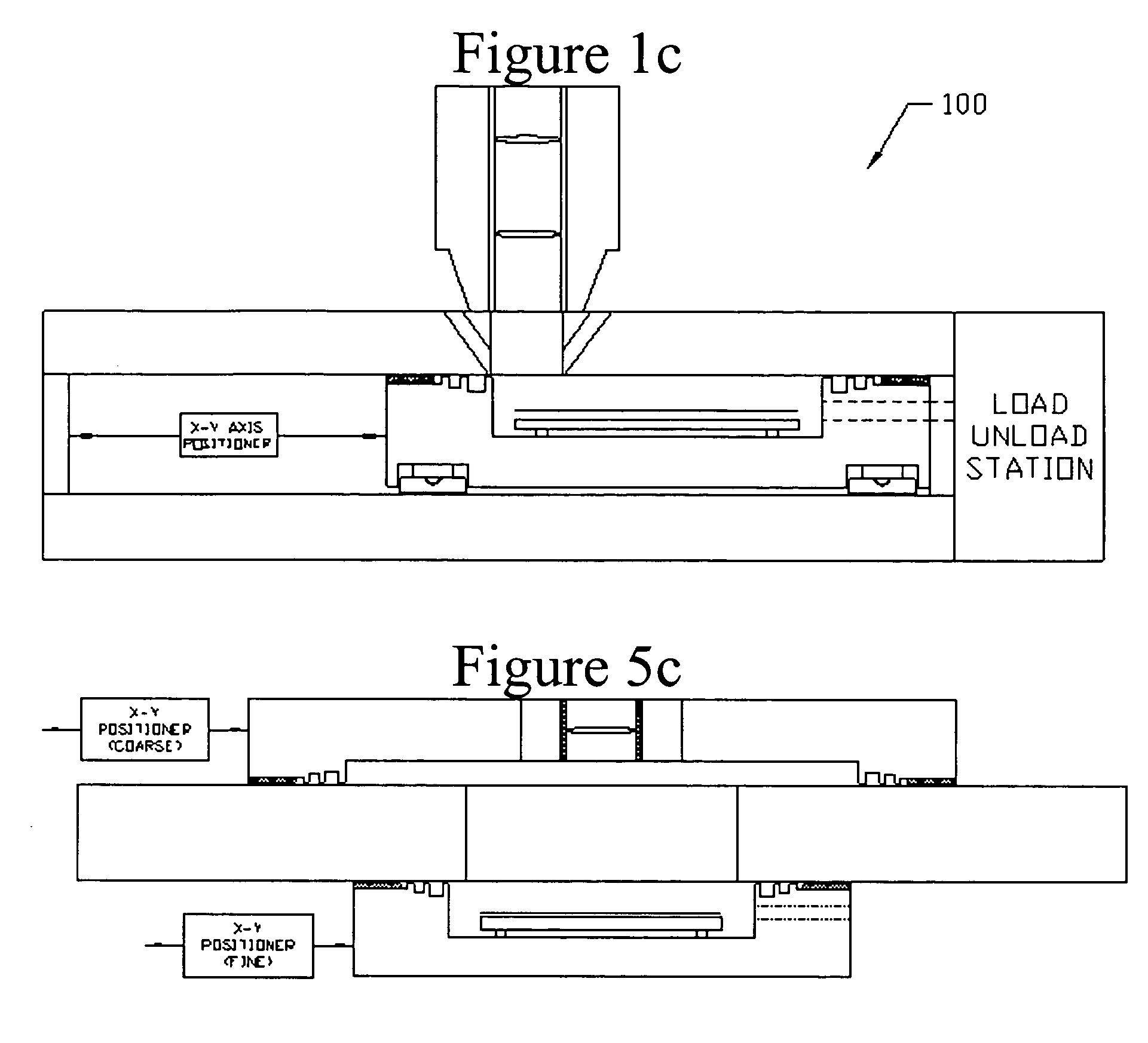

Moving vacuum chamber stage with air bearing and differentially pumped grooves

InactiveUS20060060259A1Structural loopSimple structureSemiconductor/solid-state device manufacturingPretreated surfacesAir bearingMechanical engineering

A stage for processing a substrate, especially useful for vacuum applications, has a recess just large enough to hold a substantially flat substrate and a chuck or holder but not much more. The perimeter of the recessed side has an air bearing surface separated from the recess by differentially pumped groves and seal lands. The air bearing lands are urged against a reference plate guide surface and the seal lands being substantially coplanar create a resistance to flow between the groves and recess, on the other side of the base reference plate mounts the radiation source. The VCS may operate in a vacuum environment itself, or in another preferred embodiment, it provides the possibility for multiple stages moving between process or inspection steps within the same tool or process sequence.

Owner:NEW WAY MACHINE COMPONENTS

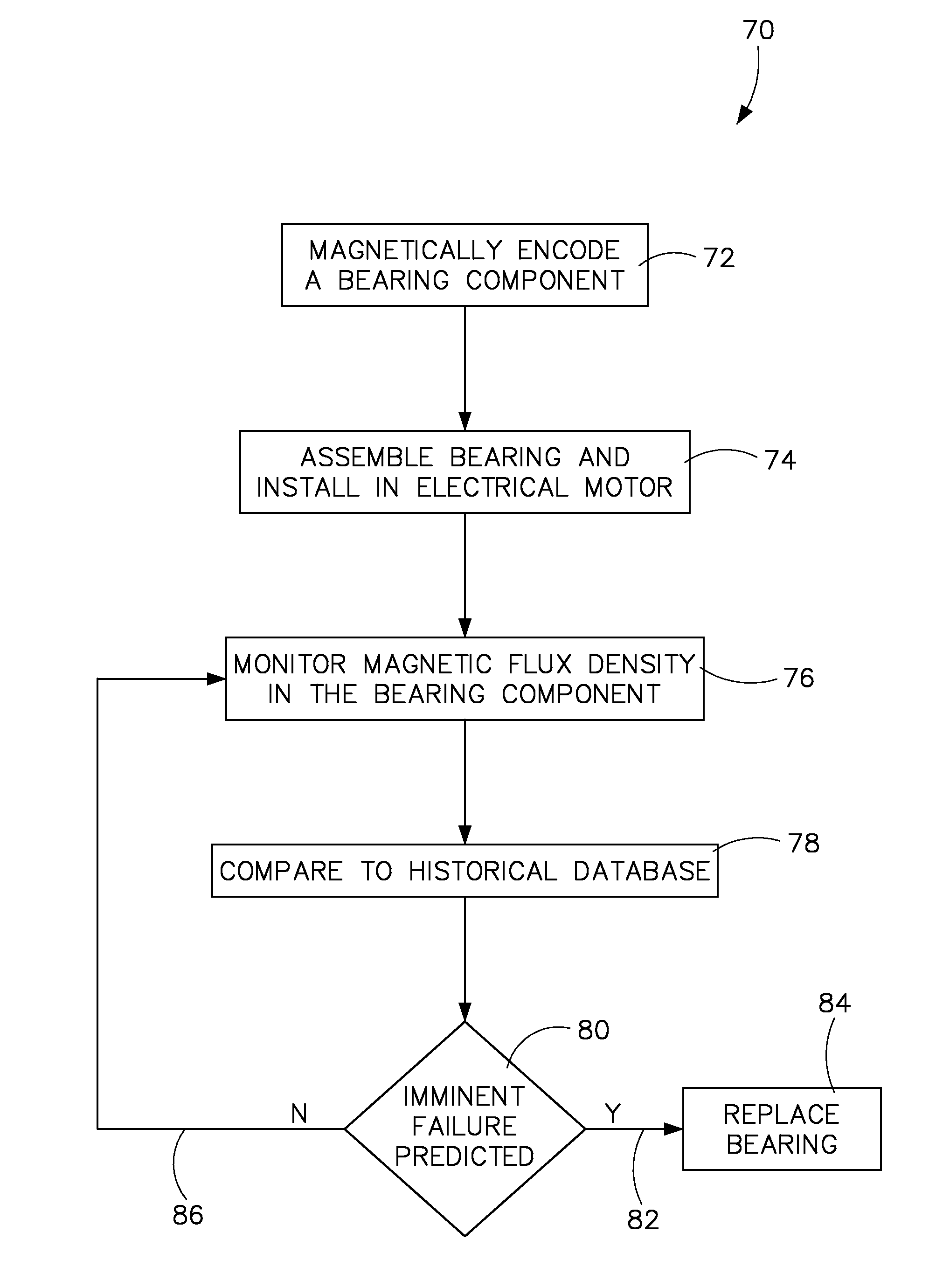

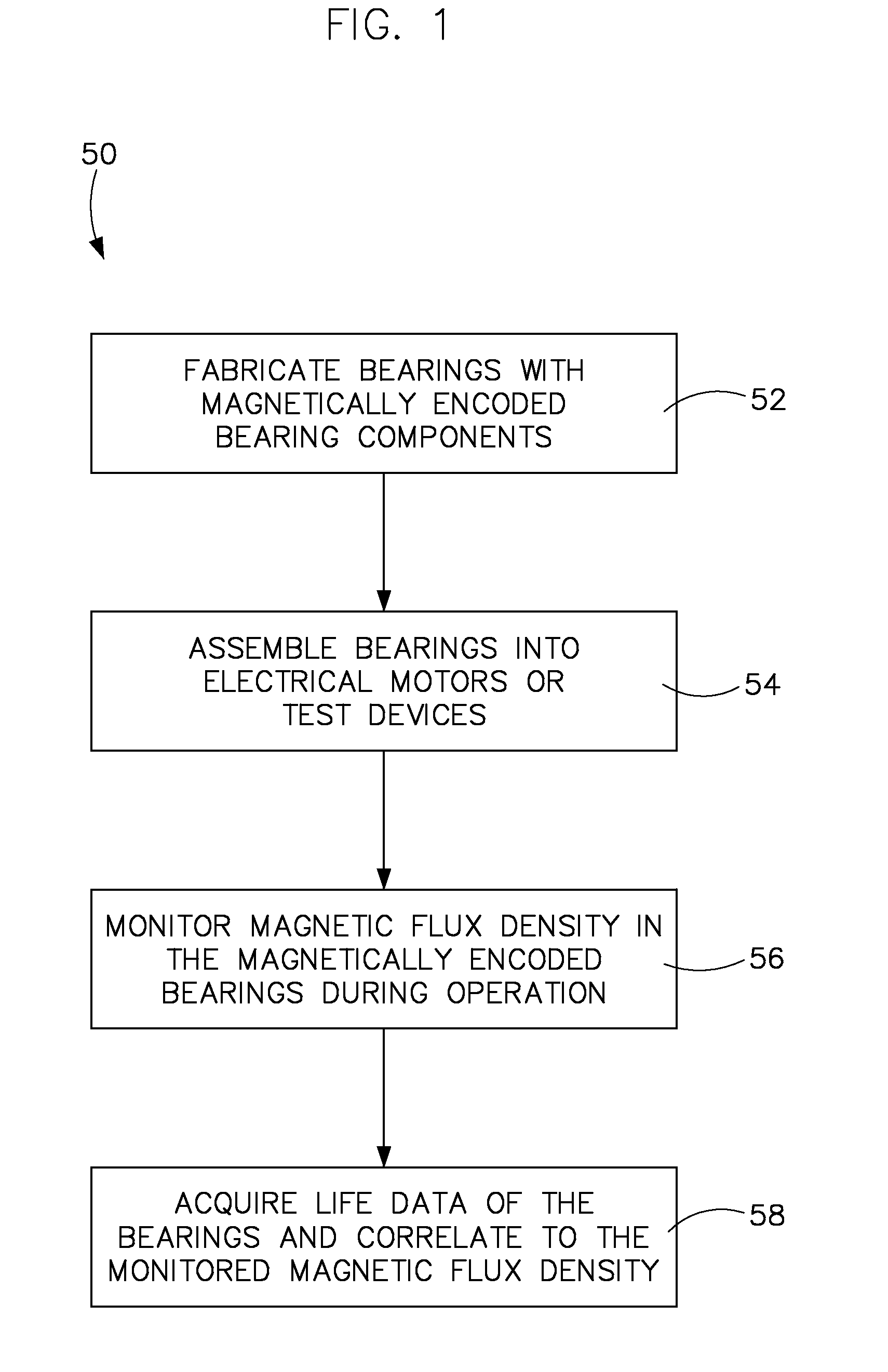

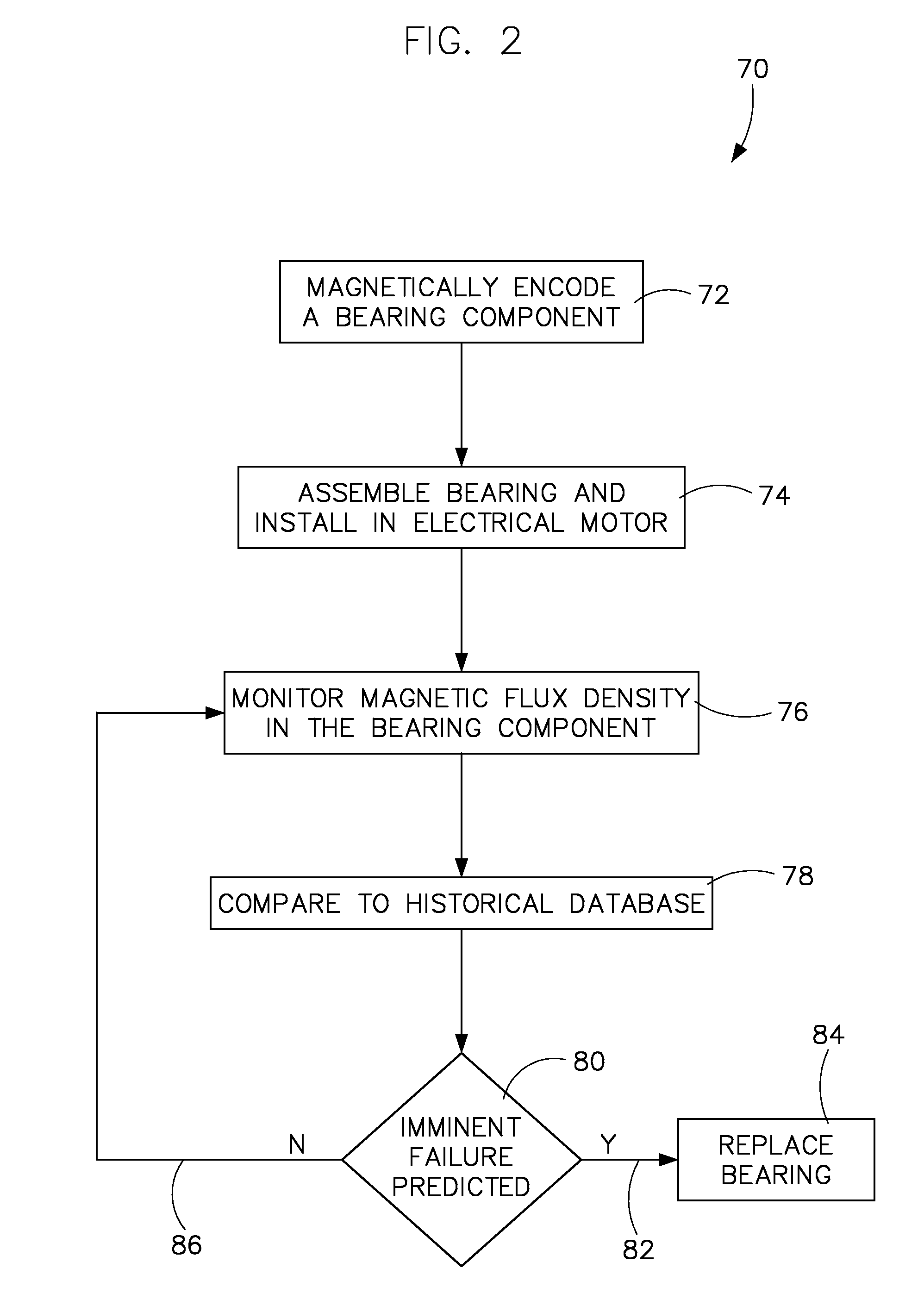

Apparatus and method for bearing condition monitoring

Owner:GENERAL ELECTRIC CO

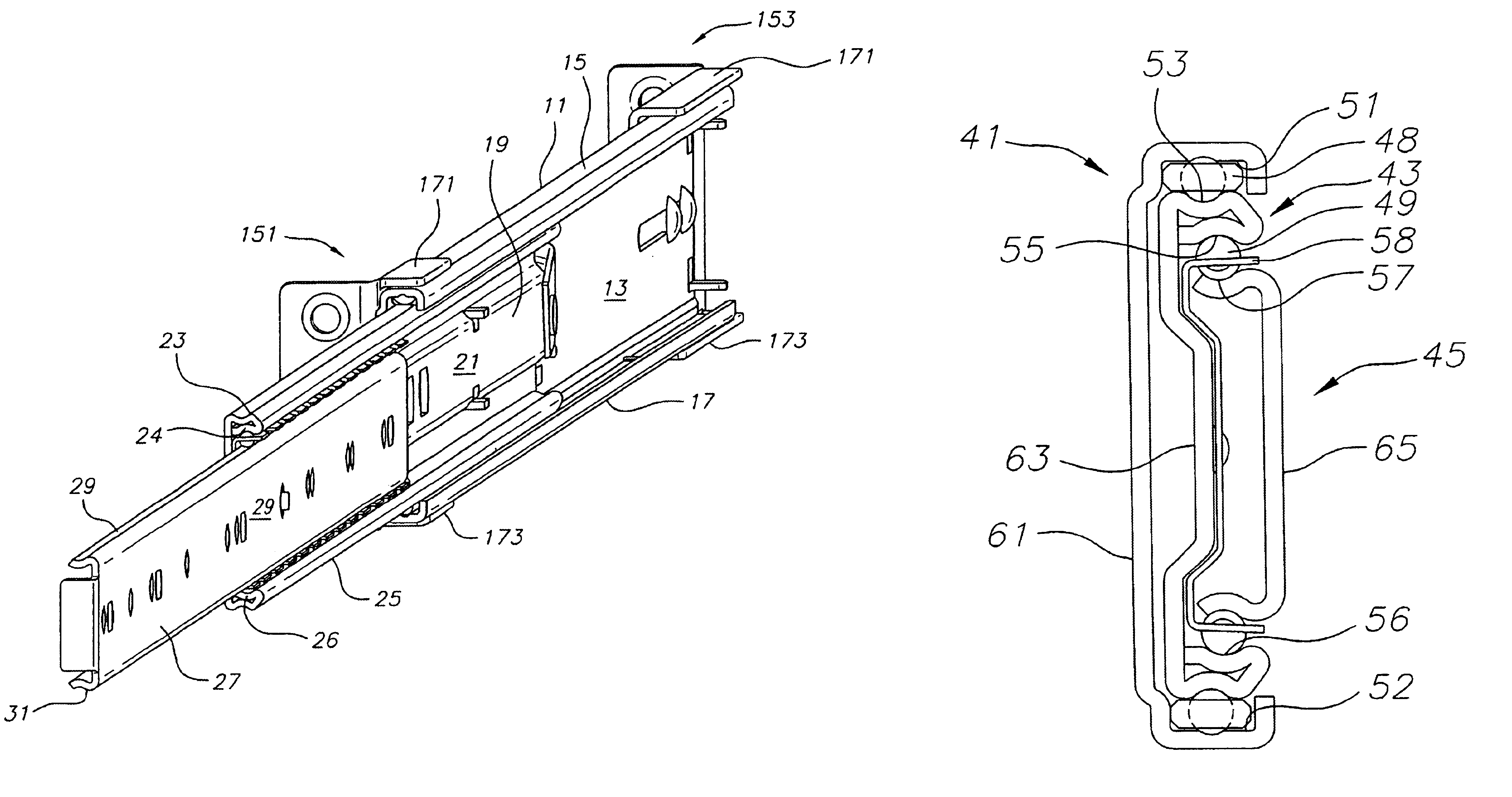

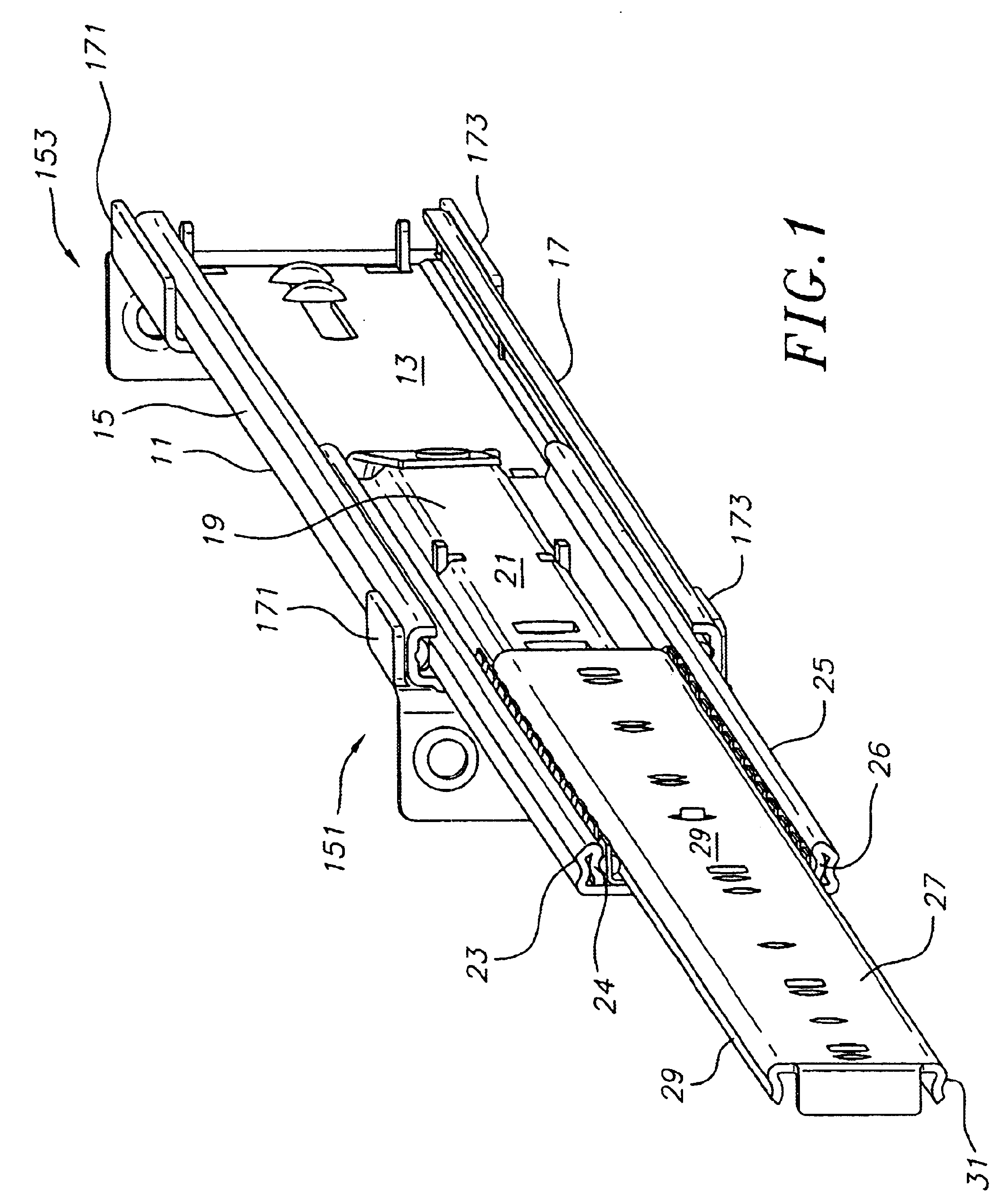

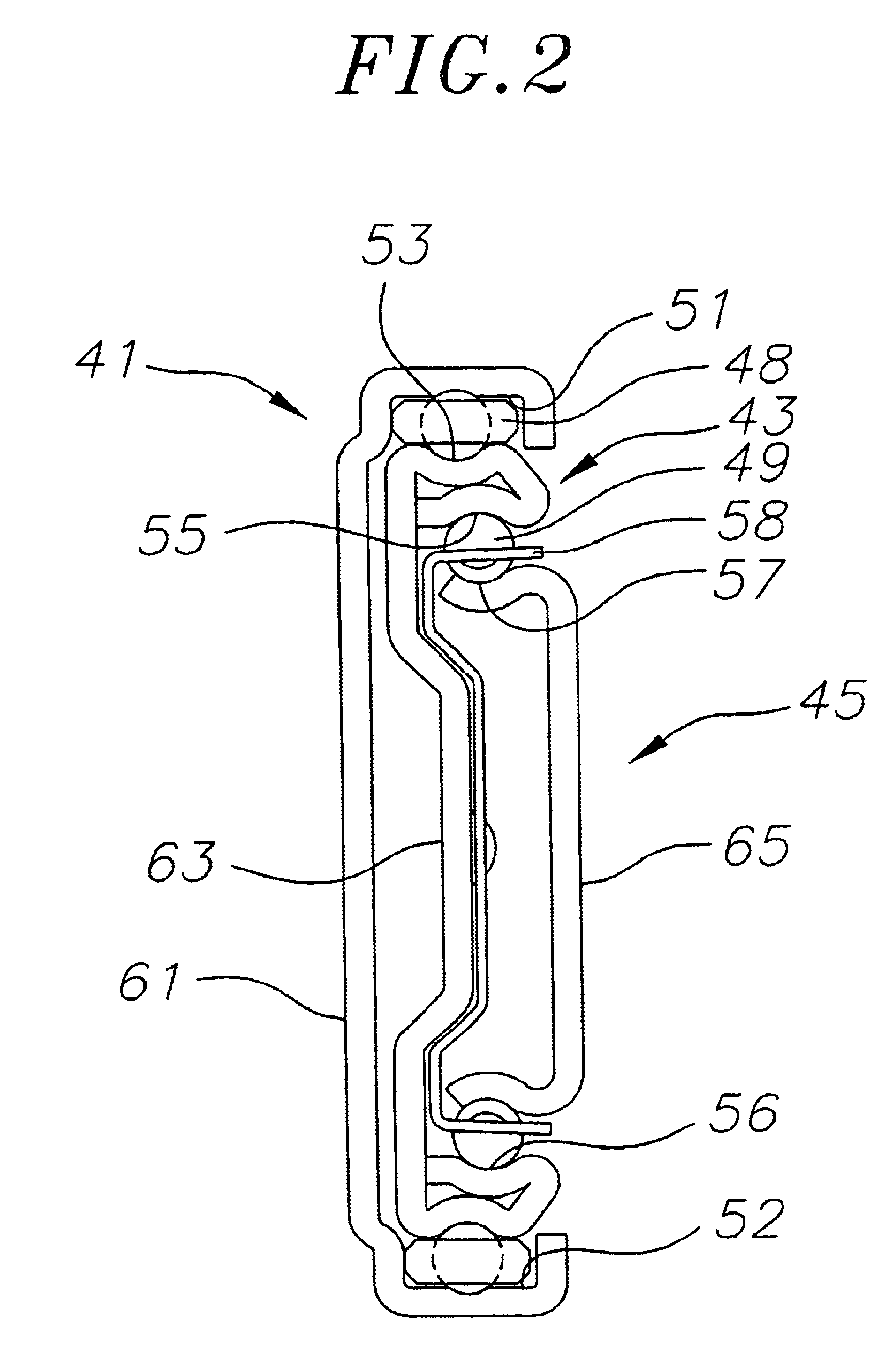

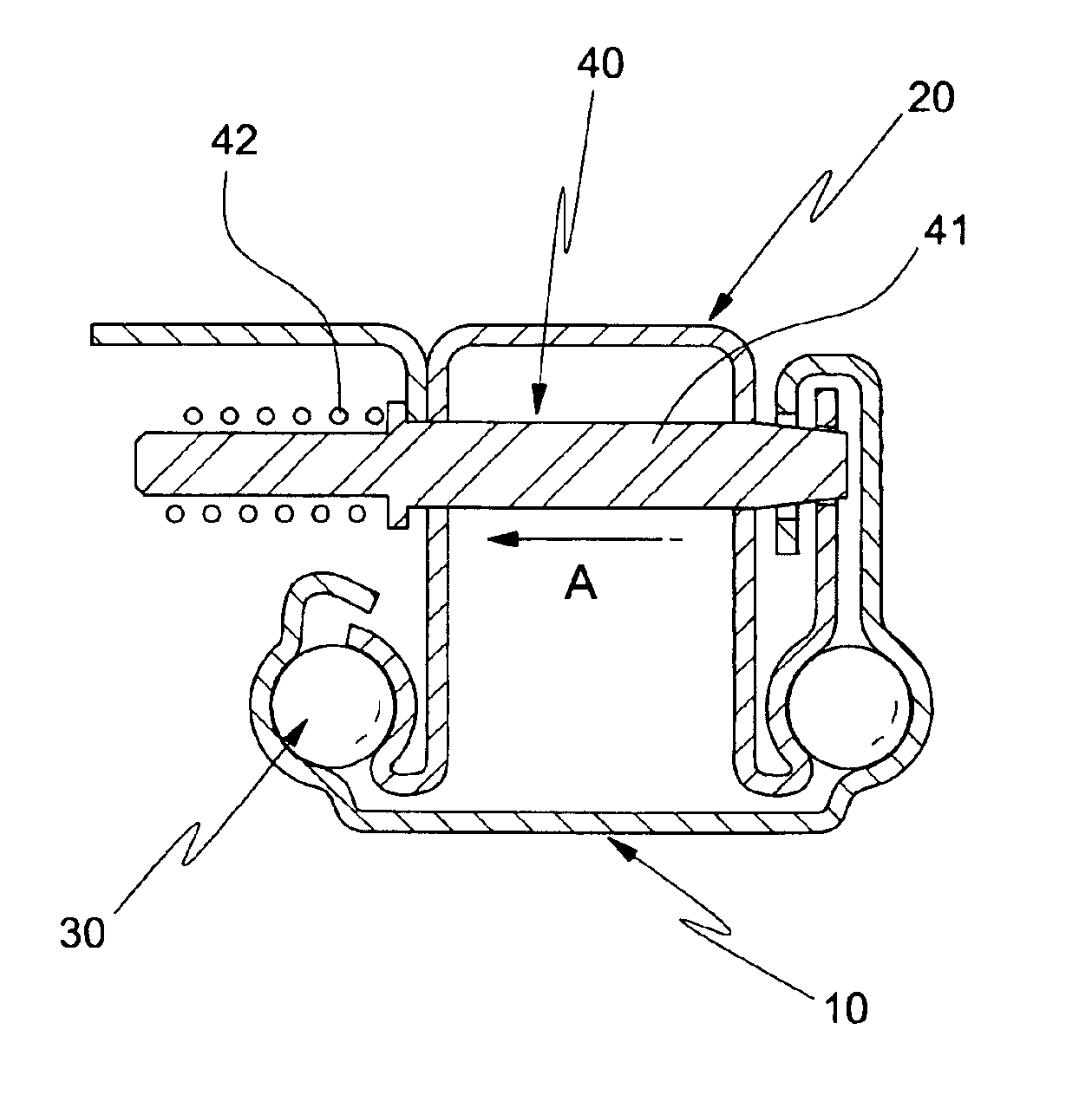

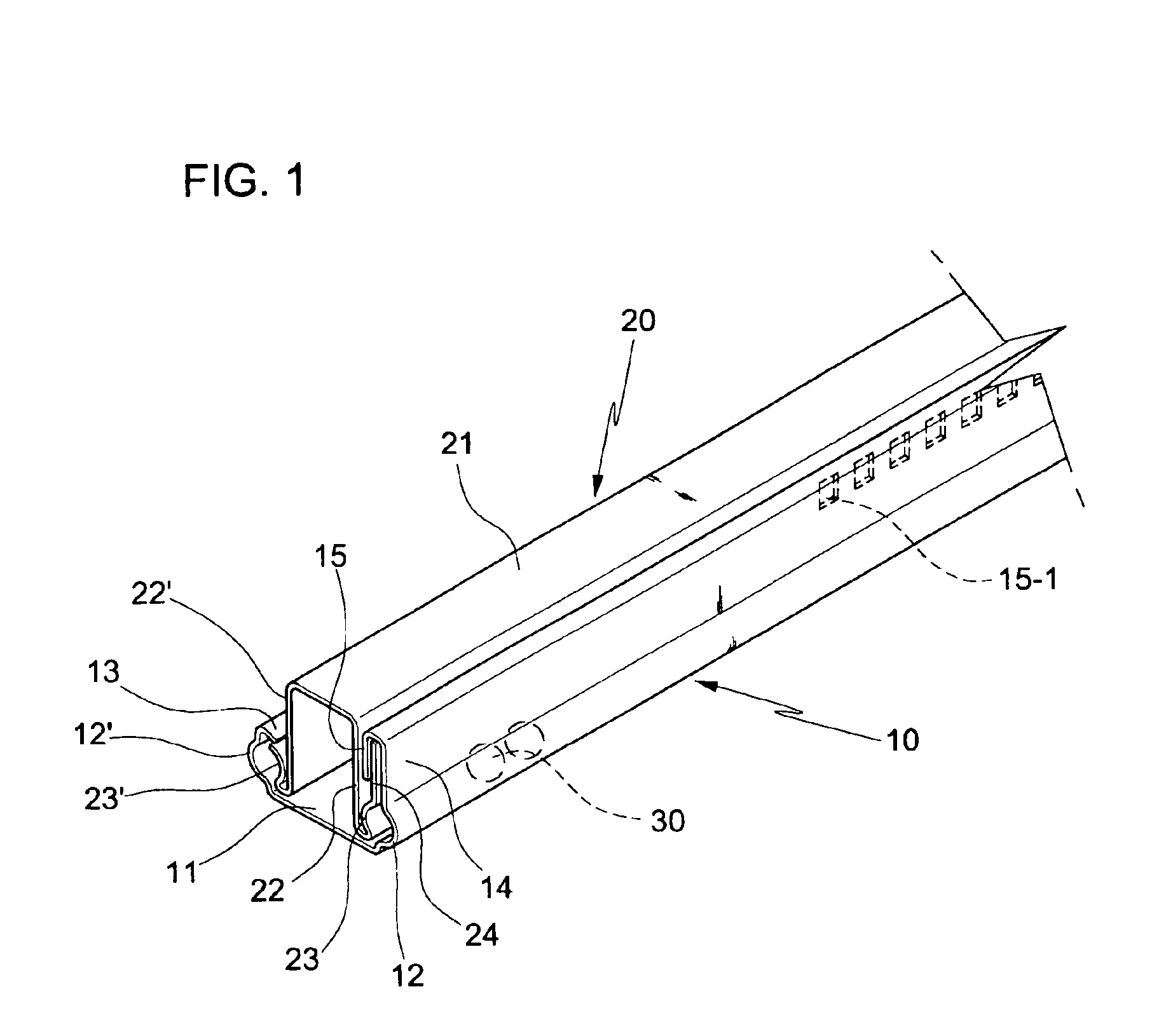

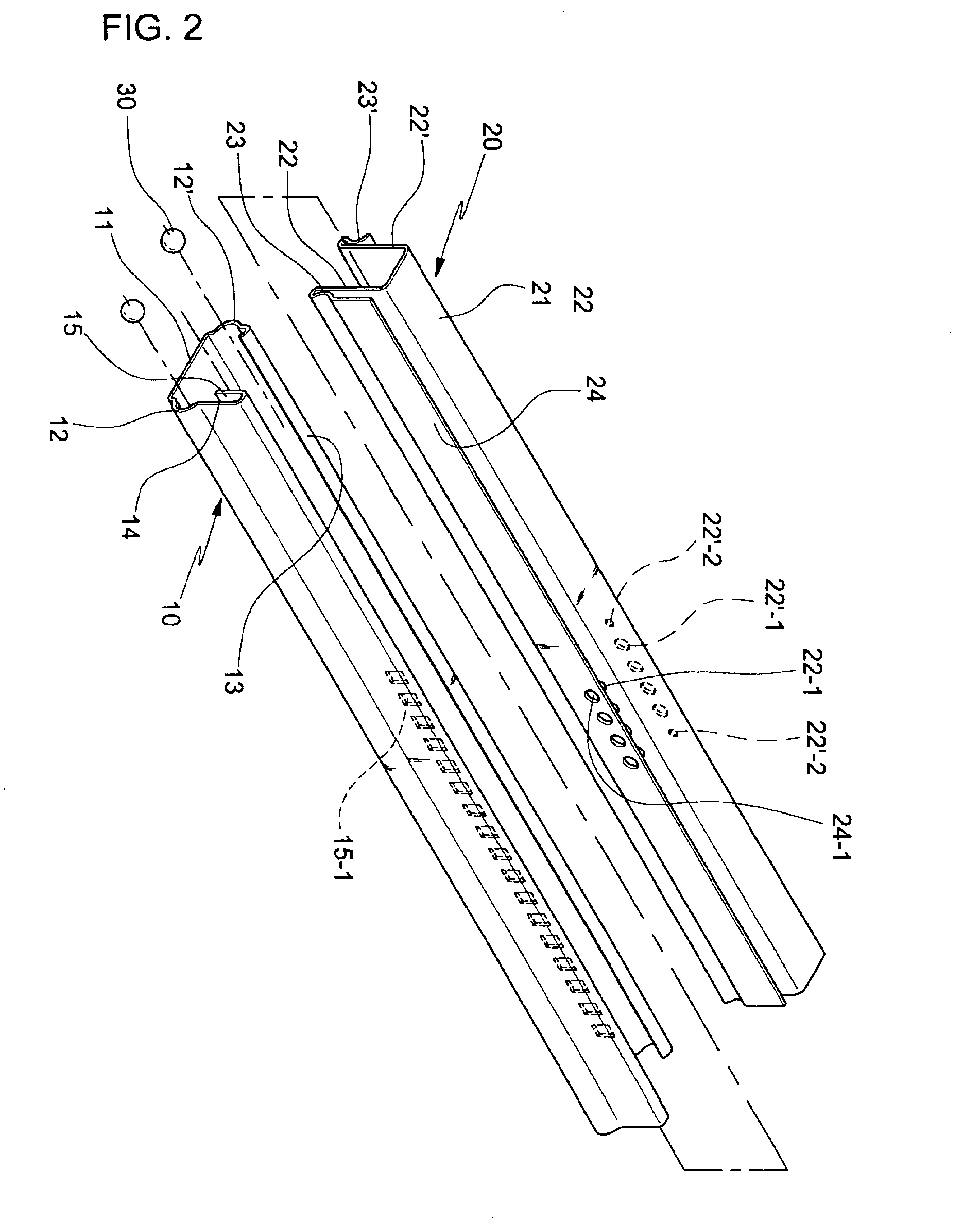

Three member thin drawer slide

A drawer slide assembly with an outer slide member with an elongate planar web including a parallel offset portion, having upper and lower bearing raceways along the length of the web, an intermediate slide member with a elongate planar web, having inner and outer upper and lower bearing raceways along the length of the web, and an inner slide member having an elongate planar web with upper and lower bearing raceways along the length of the web, with bearings disposed between and in rolling engagement with the respective outer and intermediate slide members, and intermediate and inner slide members.

Owner:STANDARD PURISHIJIYAN

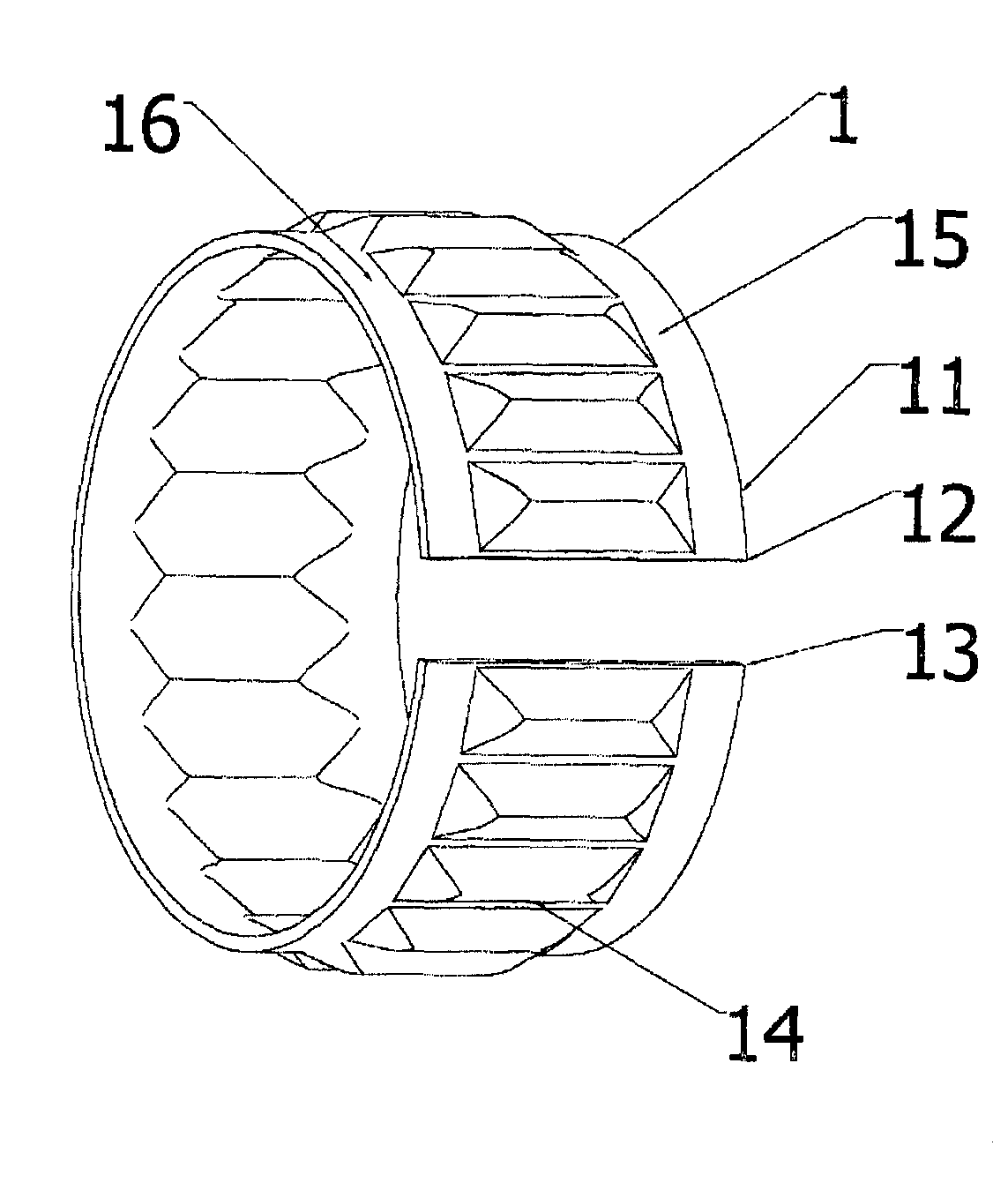

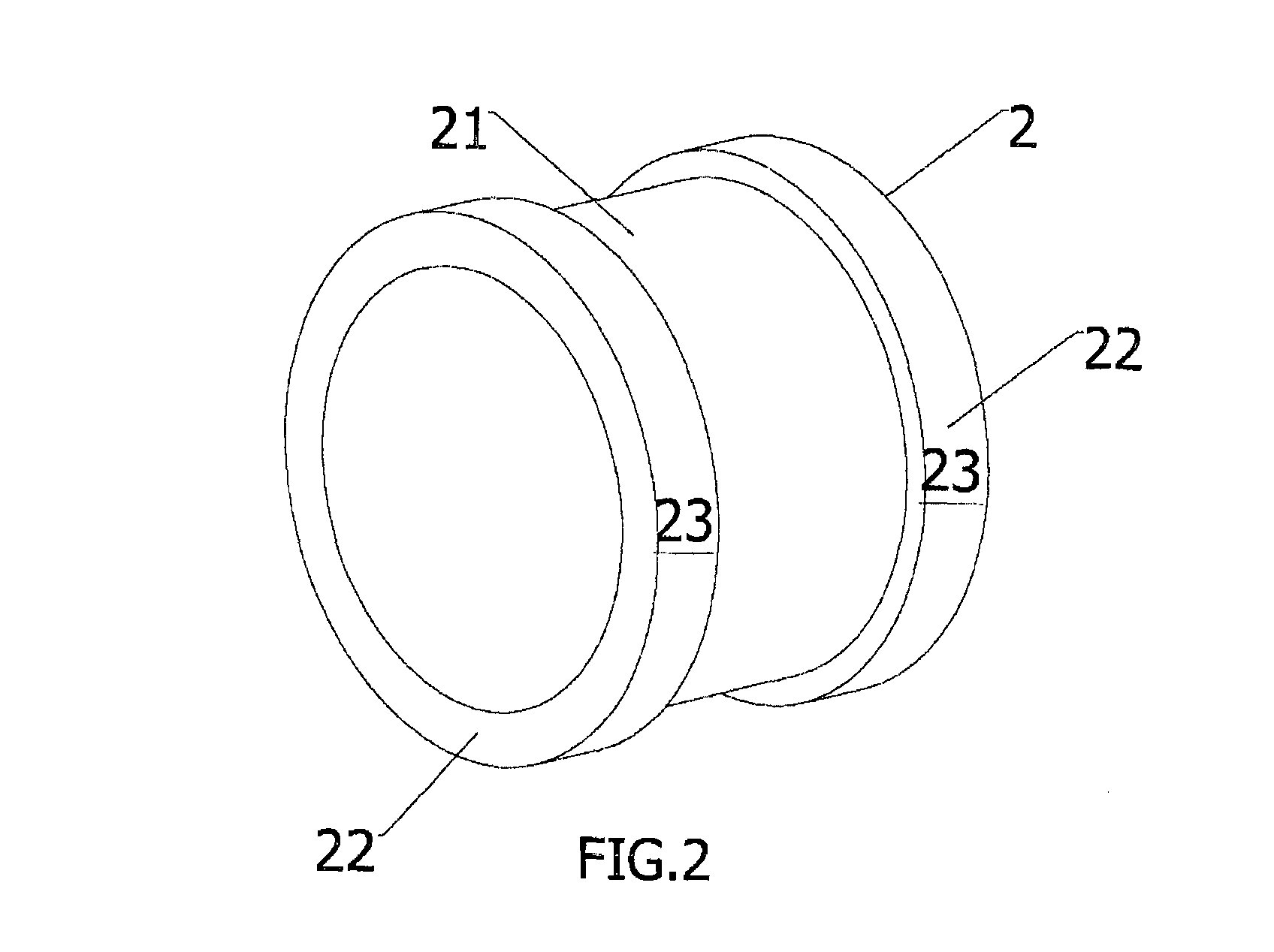

Sliding bearing and bearing mechanism having the same

ActiveUS7220056B2Cancel noiseReduce linear-motion frictional resistanceLinear bearingsShaftsSteering columnEngineering

A sliding bearing for a steering column includes: a cylindrical bearing body; flat surfaces formed integrally on an inner peripheral surface of the bearing body; first slits extending from one end face of the bearing body to this side of the other end face of the bearing body; second slits extending from this side of the other end face of the bearing body to the one end face of the bearing body; grooves formed in an outer peripheral surface of the bearing body; and elastic rings which are respectively fitted in the grooves in such a manner as to project from the outer peripheral surface of the bearing body and to reduce the diameter of the bearing body.

Owner:OILES CORP

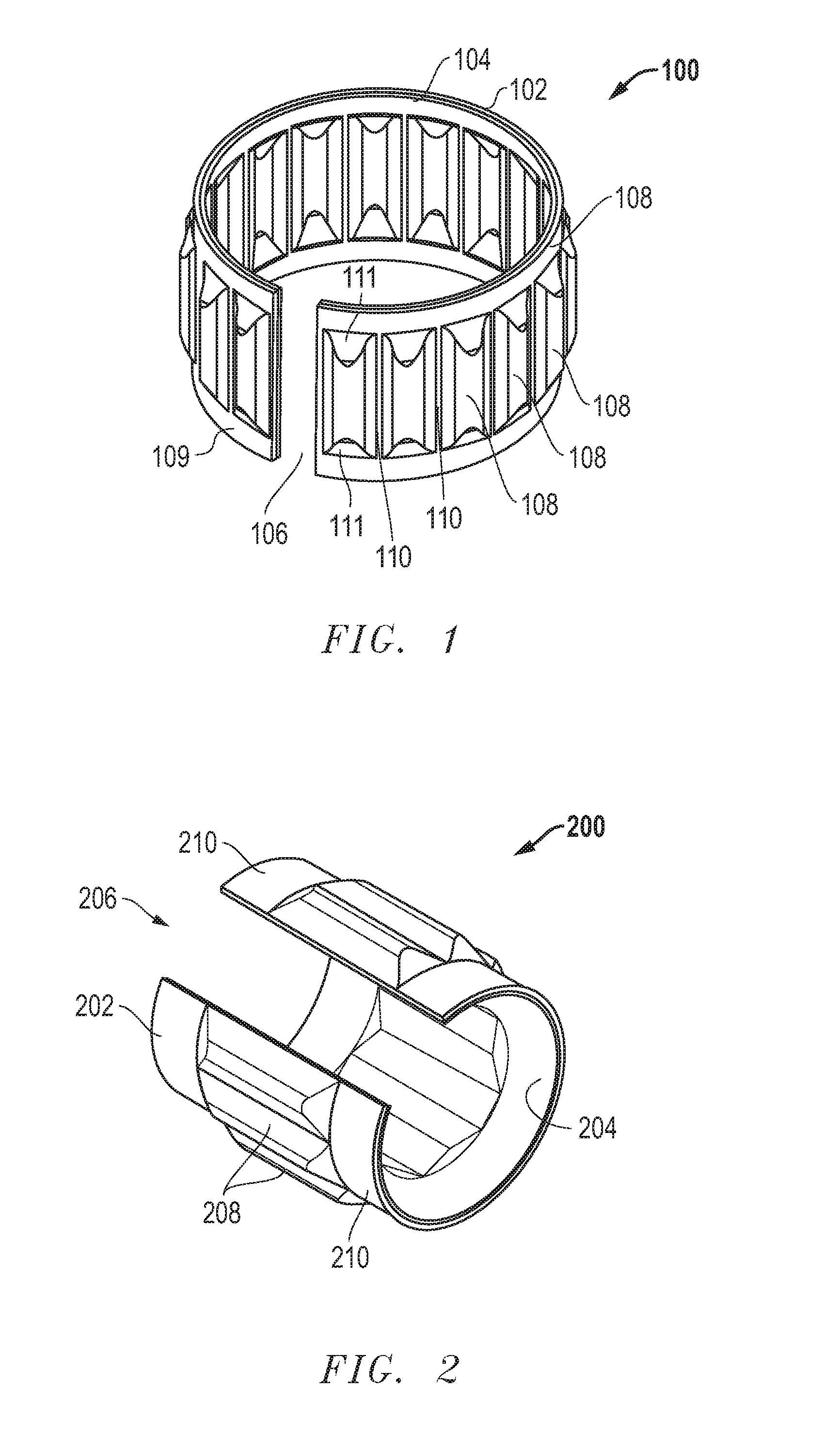

Force limiting assembly

An apparatus is shown which comprises first and second mating components with a force limiter located between them. The force limiter includes a band of resilient material, with protrusions therealong, and a slip element. The band and the slip element are secured to the first mating component with the band arranged to apply a radial force against the slip element so as to press it against the second mating component. The frictional force between slip element and the second mating component is insufficient to separate the slip element and the band from the first mating component, so any slipping that occurs between the mating components happens at the boundary of the slip element and the second mating component. A desired slip force can be obtained by choosing a slip element with an appropriate coefficient of friction, rather than by varying the dimensions of the components.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS RENCOL

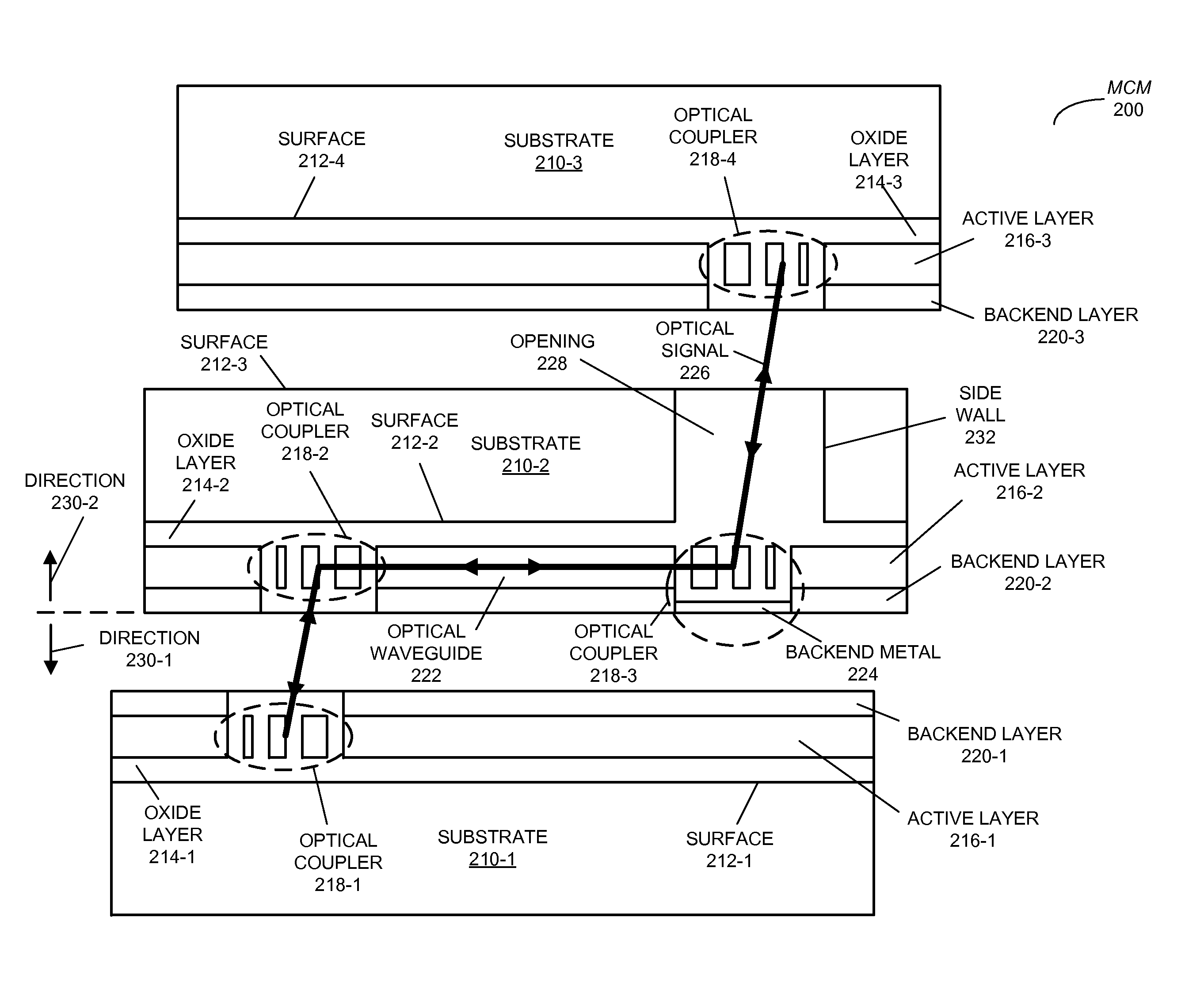

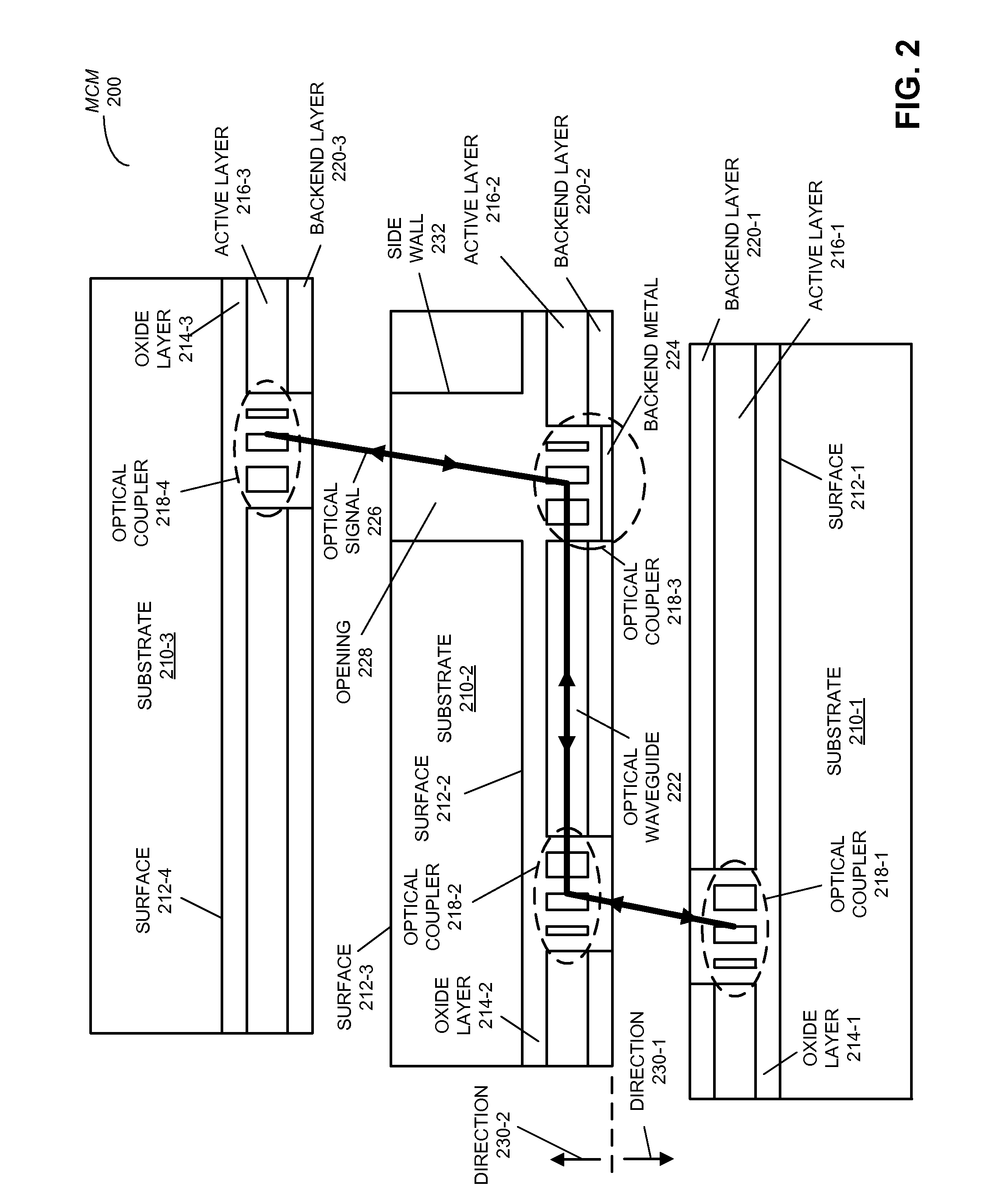

Three-dimensional macro-chip including optical interconnects

ActiveUS8267583B2Reduce expensesShorten the timeLinear bearingsCoupling light guidesOptical couplingWaveguide

A multi-chip module (MCM), which includes a three-dimensional (3D) stack of chips that are coupled using optical interconnects, is described. In this MCM, disposed on a first surface of a middle chip in the 3D stack, there are: a first optical coupler, an optical waveguide, which is coupled to the first optical coupler, and a second optical coupler, which is coupled to the optical waveguide. The first optical coupler redirects an optical signal from the optical waveguide to a first direction (which is not in the plane of the first surface), or from the first direction to the optical waveguide. Moreover, the second optical coupler redirects the optical signal from the optical waveguide to a second direction (which is not in the plane of the first surface), or from the second direction to the optical waveguide. Note that an optical path associated with the second direction passes through an opening in a substrate in the middle chip.

Owner:ORACLE INT CORP

Seat track for vehicles

ActiveUS6874747B2Reduce frictionImprove the immunityLinear bearingsStands/trestlesAcute angleEngineering

Disclosed herein is a seat track for vehicles. The fixed rail includes a horizontal bottom fixed piece, a pair of first and second grooves formed by bending both side portions of the fixed piece at a right angle and rounding a center portion of each of the resulting vertical bent portions to have an outwardly convex semi-circular form for allowing balls to be inserted therein, a first end piece formed by downwardly bending a vertical end portion of the second groove by an acute angle, a vertical piece extending upwardly from an upper end of the first groove by a relatively long length, and a second end piece formed by twice bending an upper end portion of the vertical piece at a right angle.

Owner:AUSTEM CO LTD

Steering gear assembly having rack bushing

InactiveUS7665747B2Reduce manufacturing costEasy to installLinear bearingsGearingEngineeringRack and pinion

A rack and pinion steering gear assembly including a housing, a rack that is translatably moveable relative to the housing along an axis and a bushing operably disposed between the rack and housing. The bushing defines a gap which extends the entire axial length of the bushing. At least one compressible member may be disposed between the bushing and the housing with the compressible member extending across the gap in the bushing and fully encircling the bushing. The bushing may also include a radial flange that acts as a travel stop. The bushing may also be formed of an acetal material wherein the flange and a tubular portion of the bushing are axially separated by an intermediate portion having a relatively thin radial thickness. Axially extending recesses may be provided to enhance the flexibility of the bushing.

Owner:STEERING SOLUTIONS IP HLDG +1

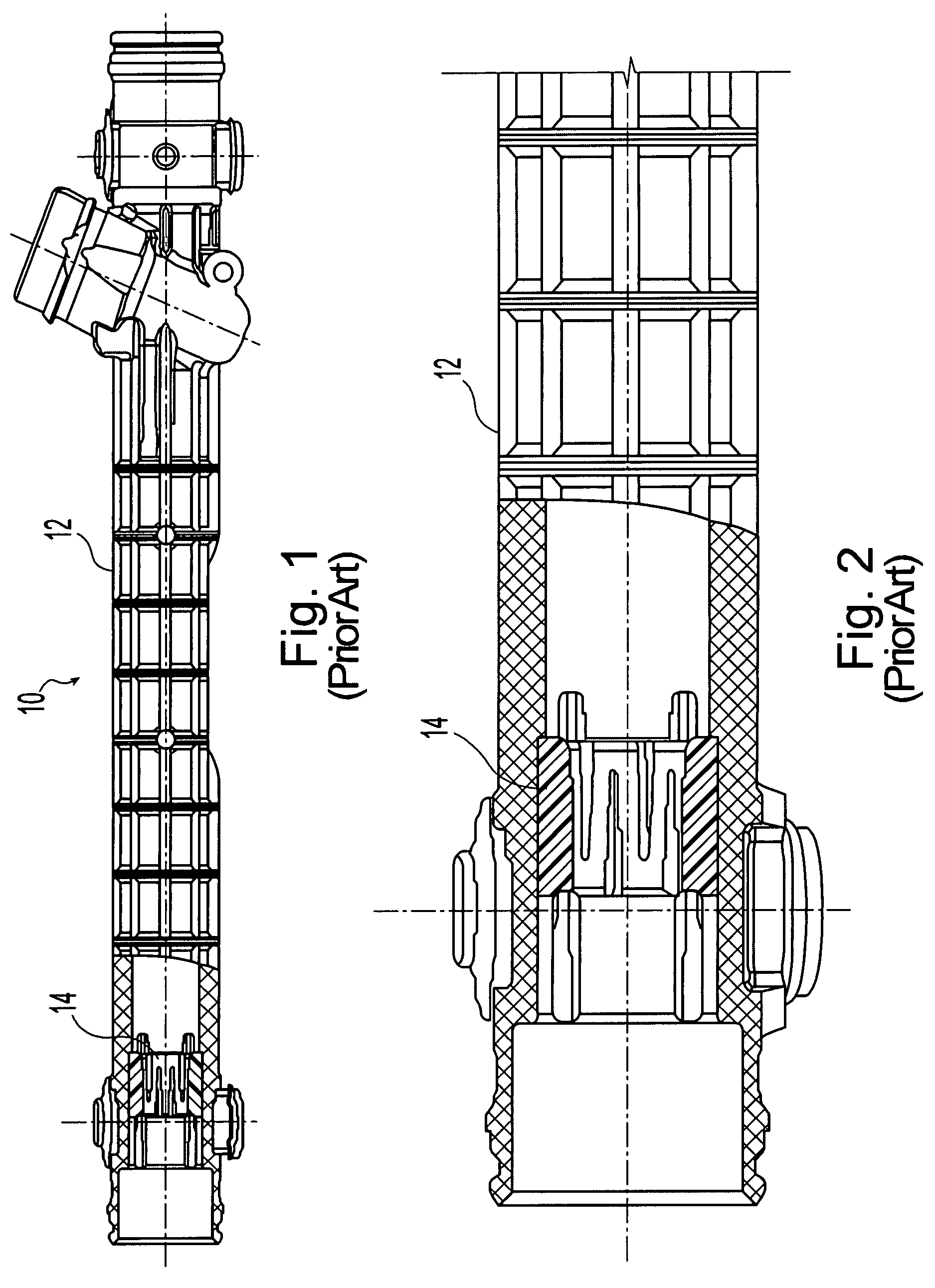

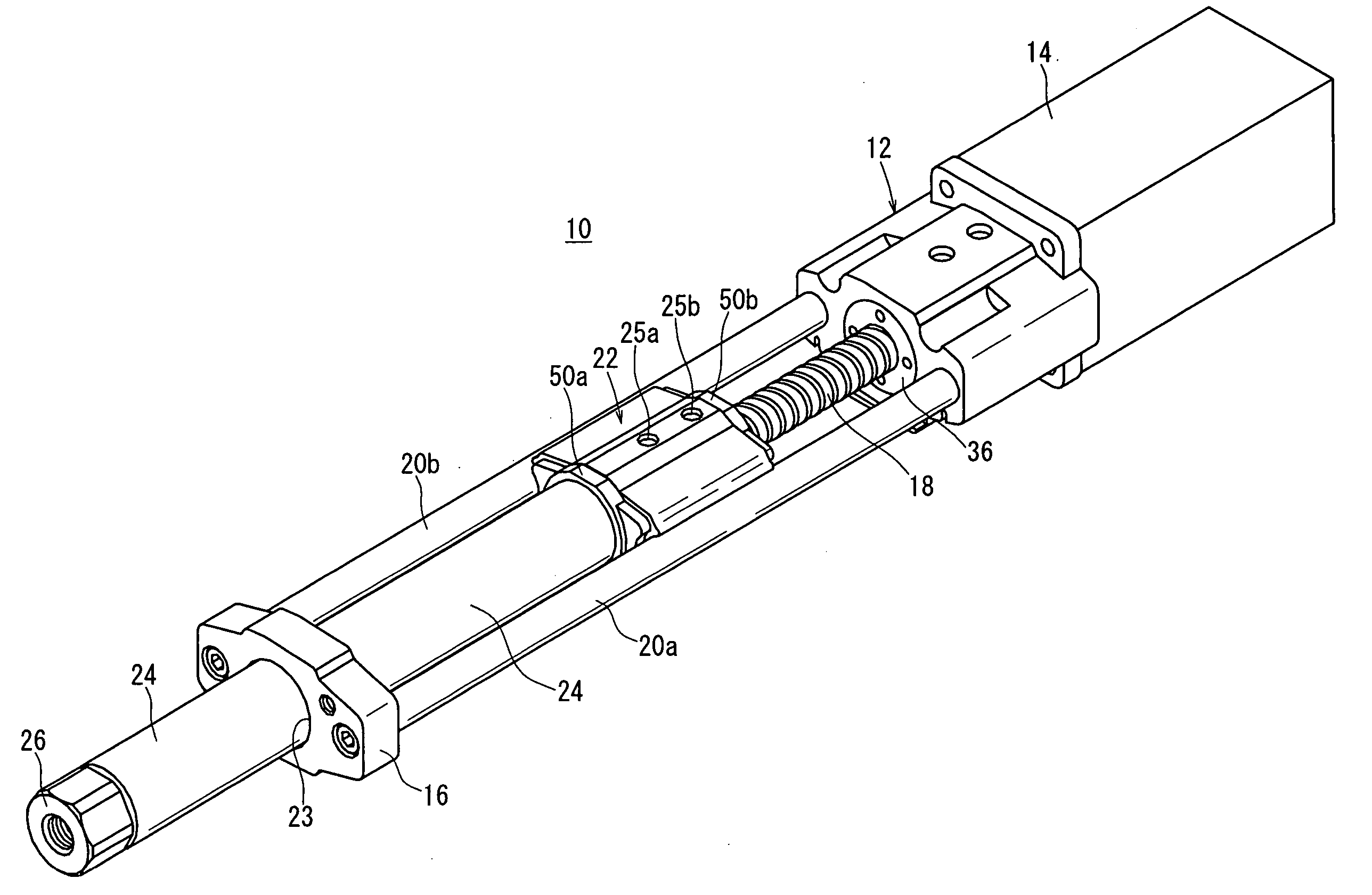

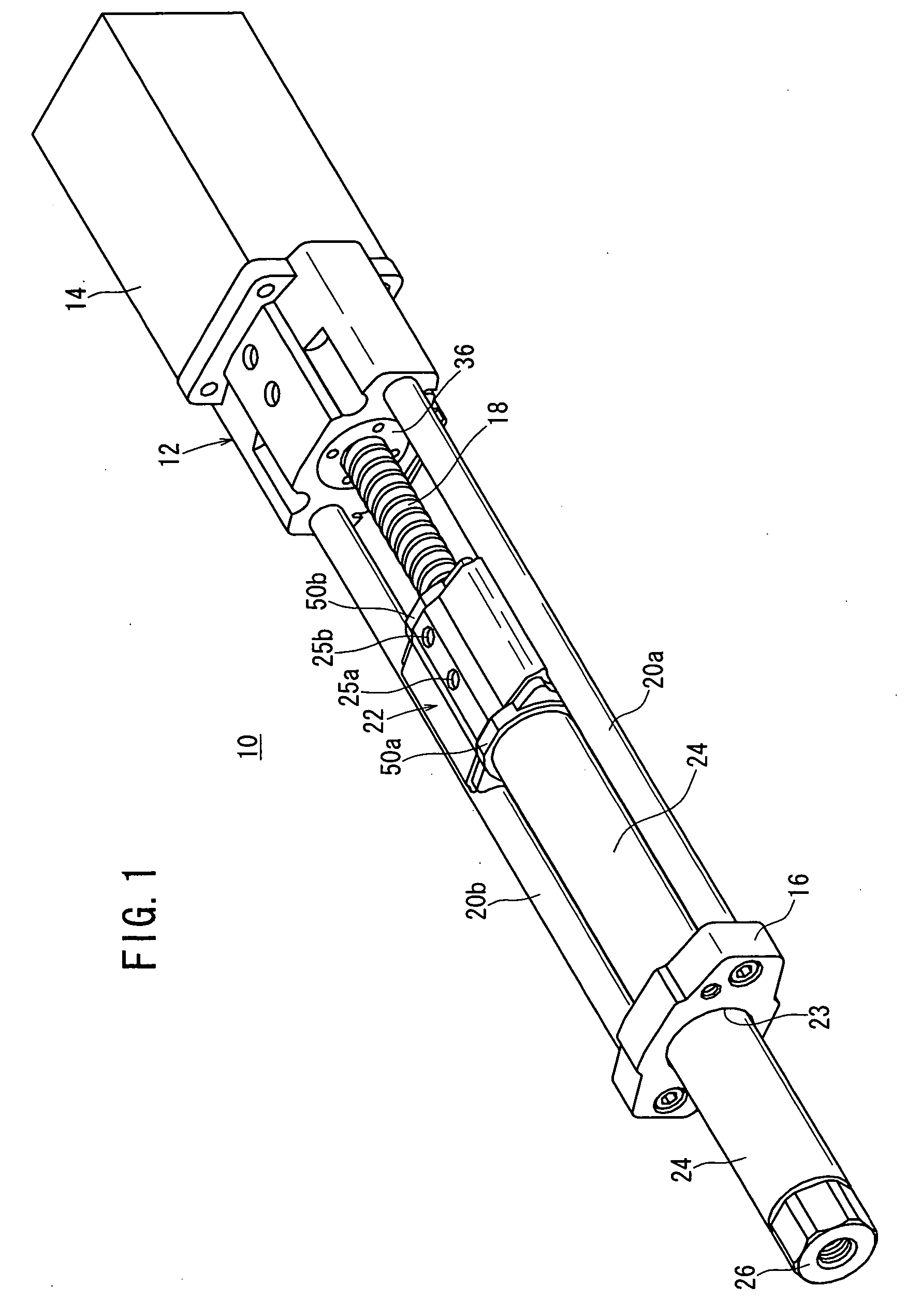

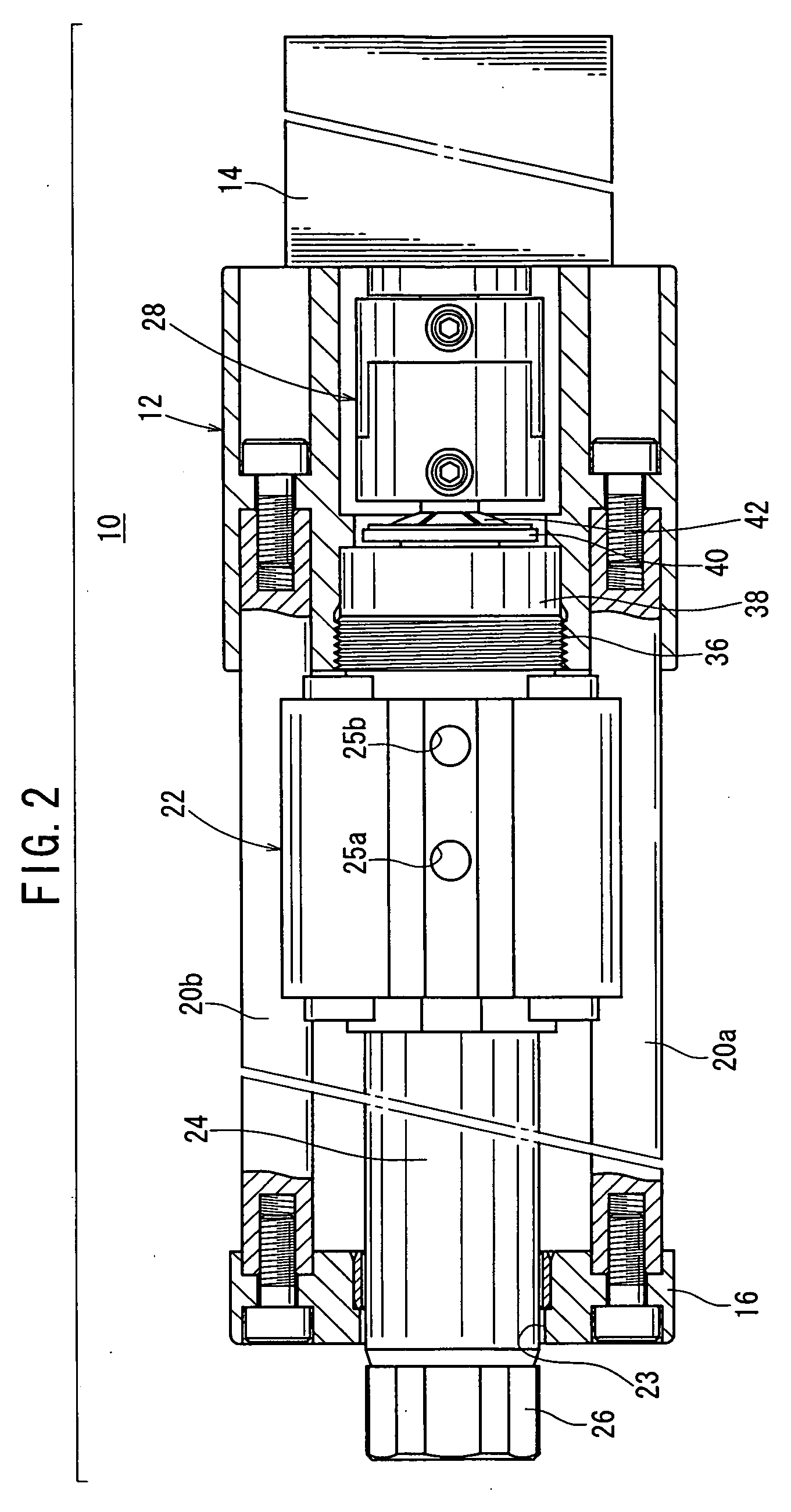

Electric actuator

InactiveUS20050011291A1Reduce in quantityReduce weightLinear bearingsToothed gearingsReciprocating motionEngineering

An electric actuator comprises a feed screw shaft which allows a piston and a piston rod to make rectilinear reciprocating motion by converting the rotary driving force of a rotary driving source into rectilinear motion to transmit to the piston and the piston rod, a rod cover which separated from a housing at a predetermined distance in the axial direction, and a pair of guide rods each of which has one end connected to the rod cover and the other end connected to the housing and which are parallel to one another with the piston intervening therebetween to guide the piston.

Owner:SMC CORP

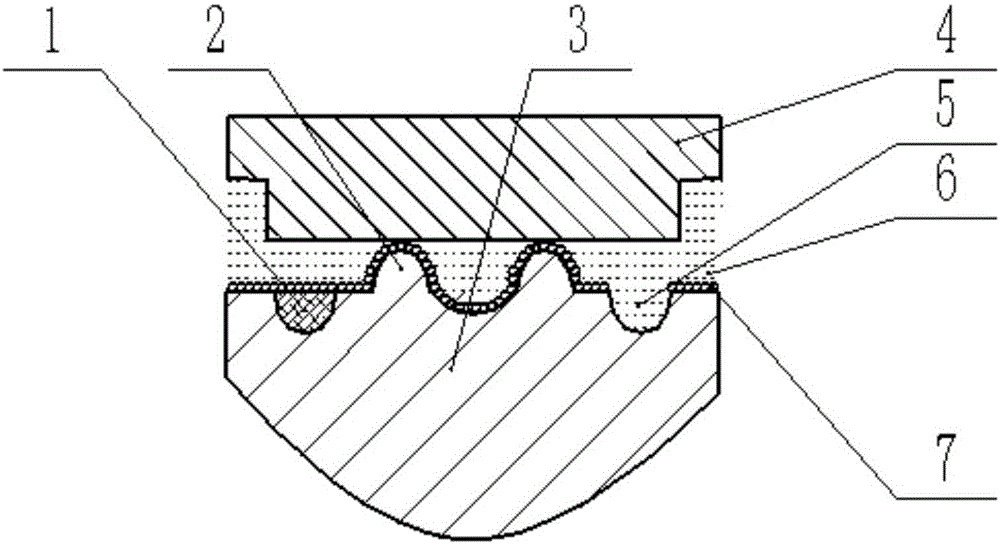

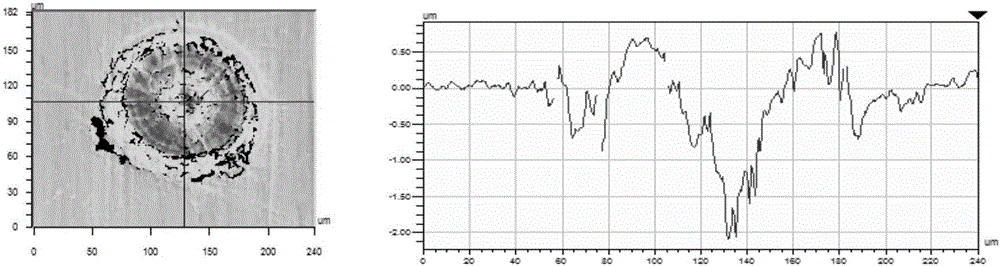

Guiding sliding friction pair of multi-element composite texture, processing method and application of guiding sliding friction pair

ActiveCN106090001AReduce friction and wearInhibit crawling phenomenonLinear bearingsShaftsLow speedMicro texture

The invention provides a guiding sliding friction pair of a multi-element composite texture, a processing method and application of the guiding sliding friction pair. Composite micro-texture morphology with orderly and uniformly distributed miniature pits and miniature protrusions is processed on a working plane of the friction pair through a laser device, and the miniature pits are filled with composite nanometer solid lubricants through a filling-pressing process. The laser micro-texture method is adopted to carry out non-contact processing and nanometer composite material filling and coating on a working plane of a guide rail, the creeping phenomenon of the machine tool guide rail can be effectively suppressed, the guide rail can be effectively lubricated under complex working conditions of a low speed, heavy load and the like, and the effects of reducing friction and resisting bonding are achieved.

Owner:JIANGSU UNIV

High endurance high capacity ball transfer unit

Owner:ROLLER BEARING OF AMERICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com