Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

796results about How to "Reduce friction and wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

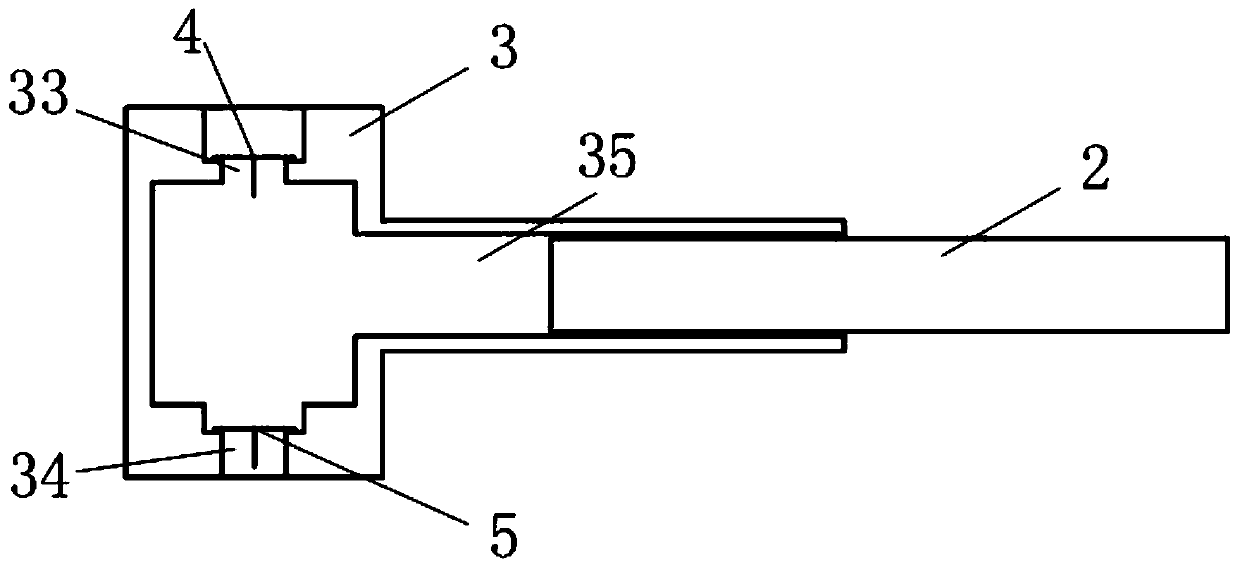

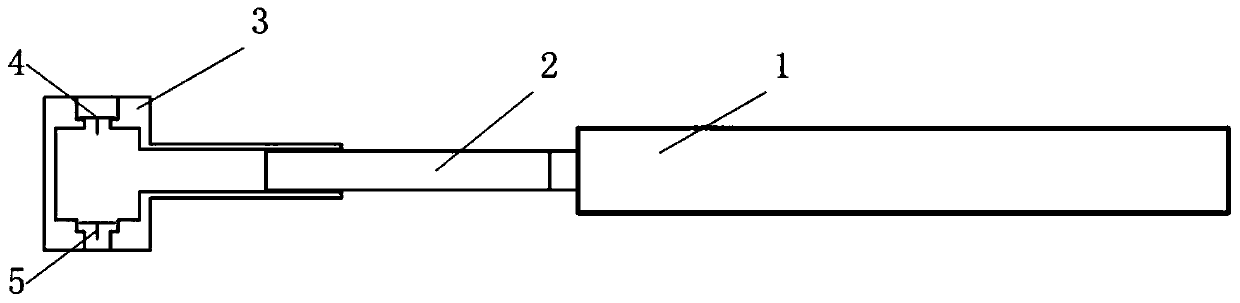

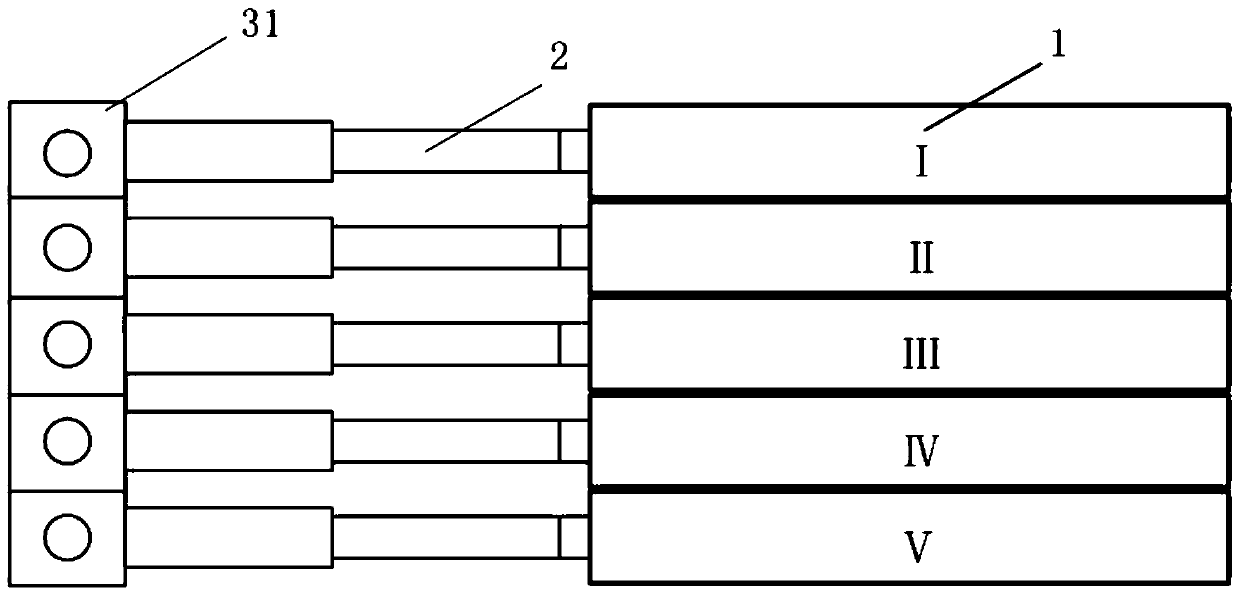

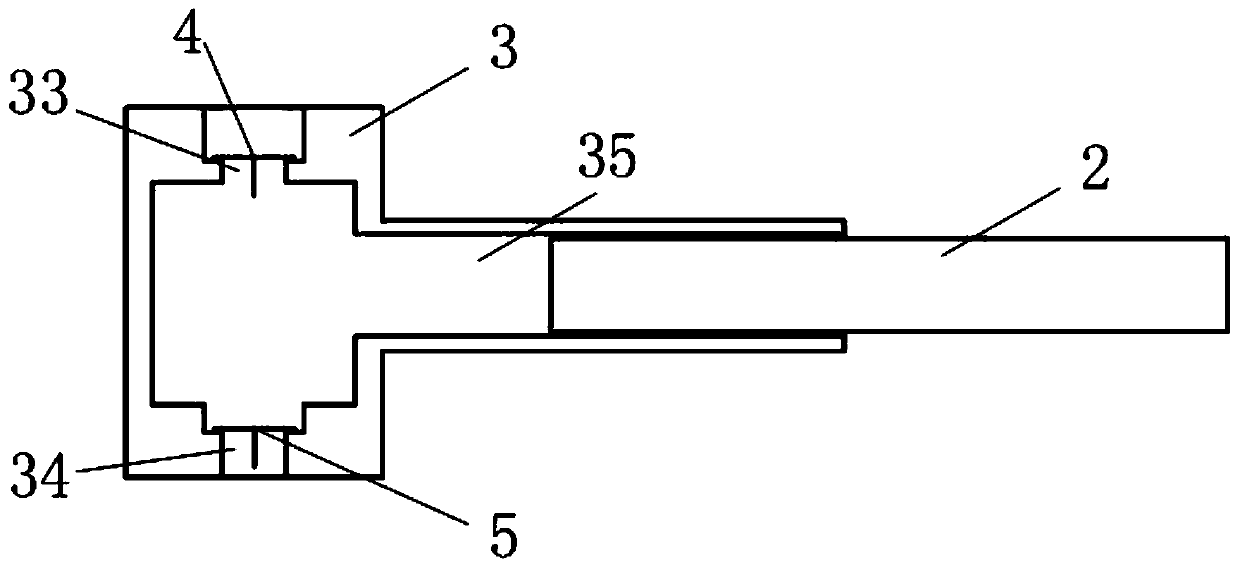

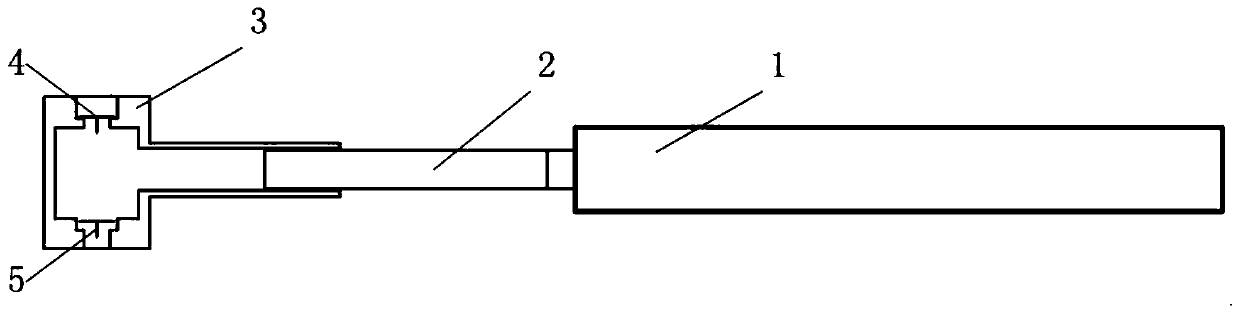

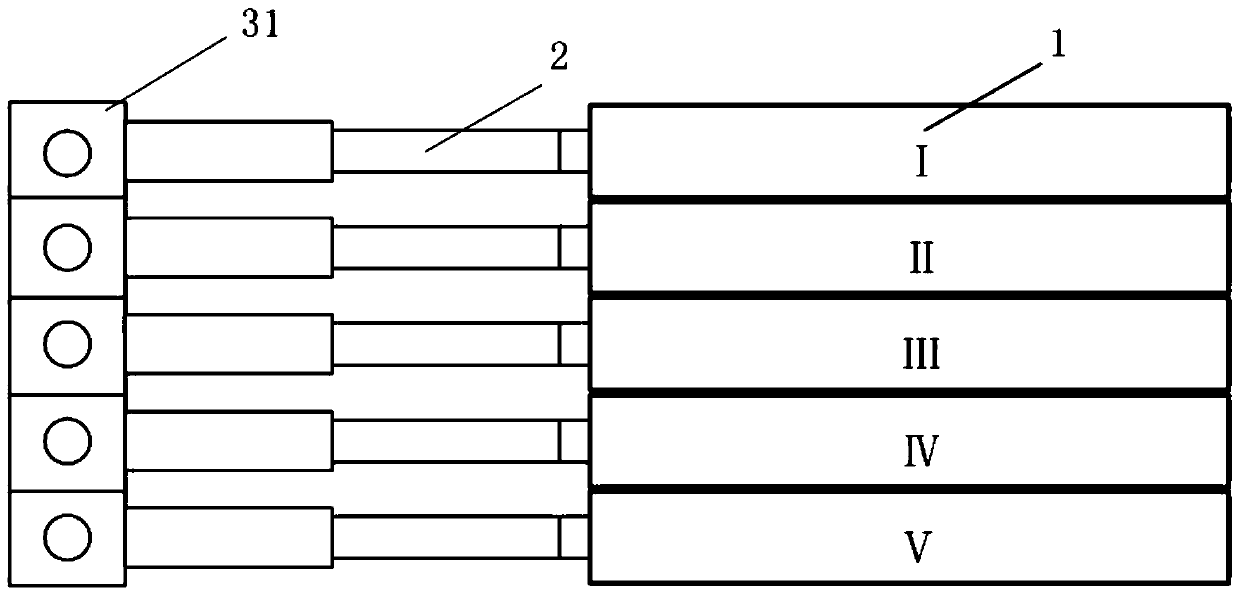

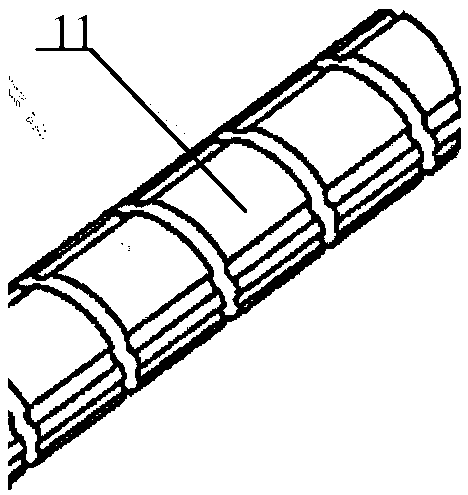

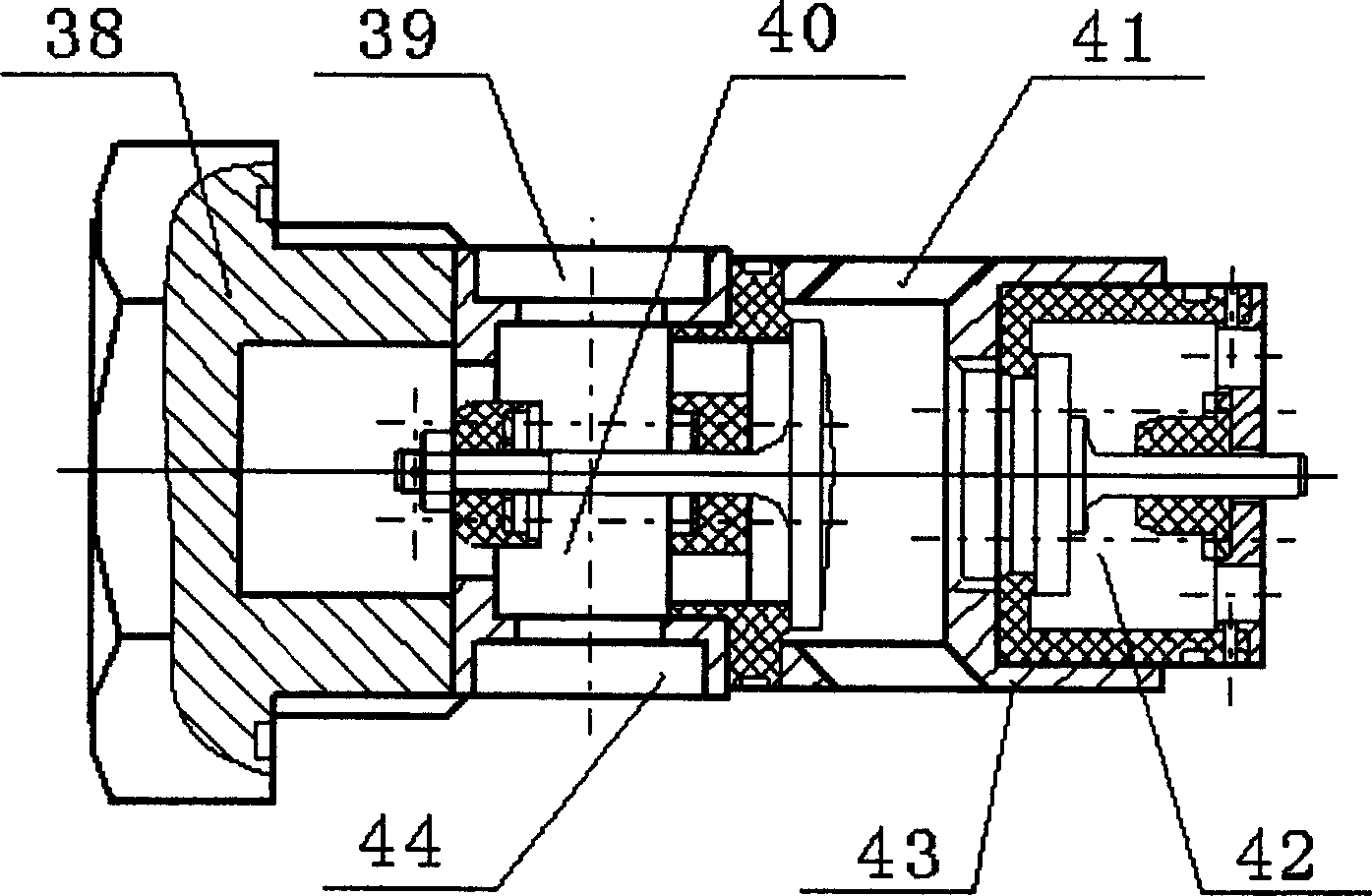

Plunger pump driven by linear motor

PendingCN110454352ASolve the real problemReduce intermediate transmission linksPositive displacement pump componentsPumpsLinear motorPlunger pump

The invention discloses a plunger pump driven by a linear motor. The plunger pump is characterized in that the plunger pump is driven by the linear motor, and the movement rule of an assembly is controlled by controlling the movement rule of the linear motor, so that the defects of an existing plunger pump are overcome, and the advantages of the plunger pump are exerted to the maximum extent.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

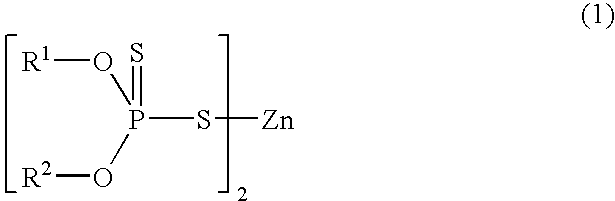

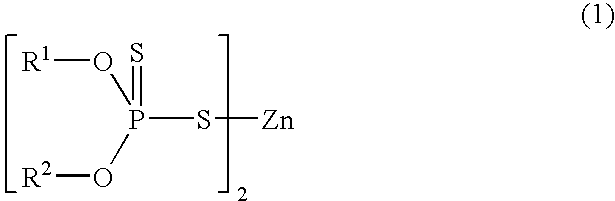

Low ash, low phosphorus and low sulfur engine oils for internal combustion engines

InactiveUS6730638B2Reduce friction and wearReduce frictionOrganic chemistryOrganic compound preparationCombustionSulfur

A lubricating composition for internal combustion engines especially useful with fuels having less than 350 ppm sulfur comprises a lubricating oil basestock, a boron containing ashless dispersant, a molybdenum containing friction reducing agent, a metal type detergent and zinc dithiophosphate.

Owner:EXXON RES & ENG CO

Linear motor plunger pump

PendingCN110425105ASolve the real problemReduce intermediate transmission linksPositive displacement pump componentsPumpsEngineeringLinear motor

The invention discloses a linear motor plunger pump. The plunger pump is driven through a linear motor, the movement rule of an assembly is controlled by controlling the movement rule of the linear motor, and therefore the defects of an existing plunger pump are overcome, and the advantages of the plunger pump are furthest developed.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

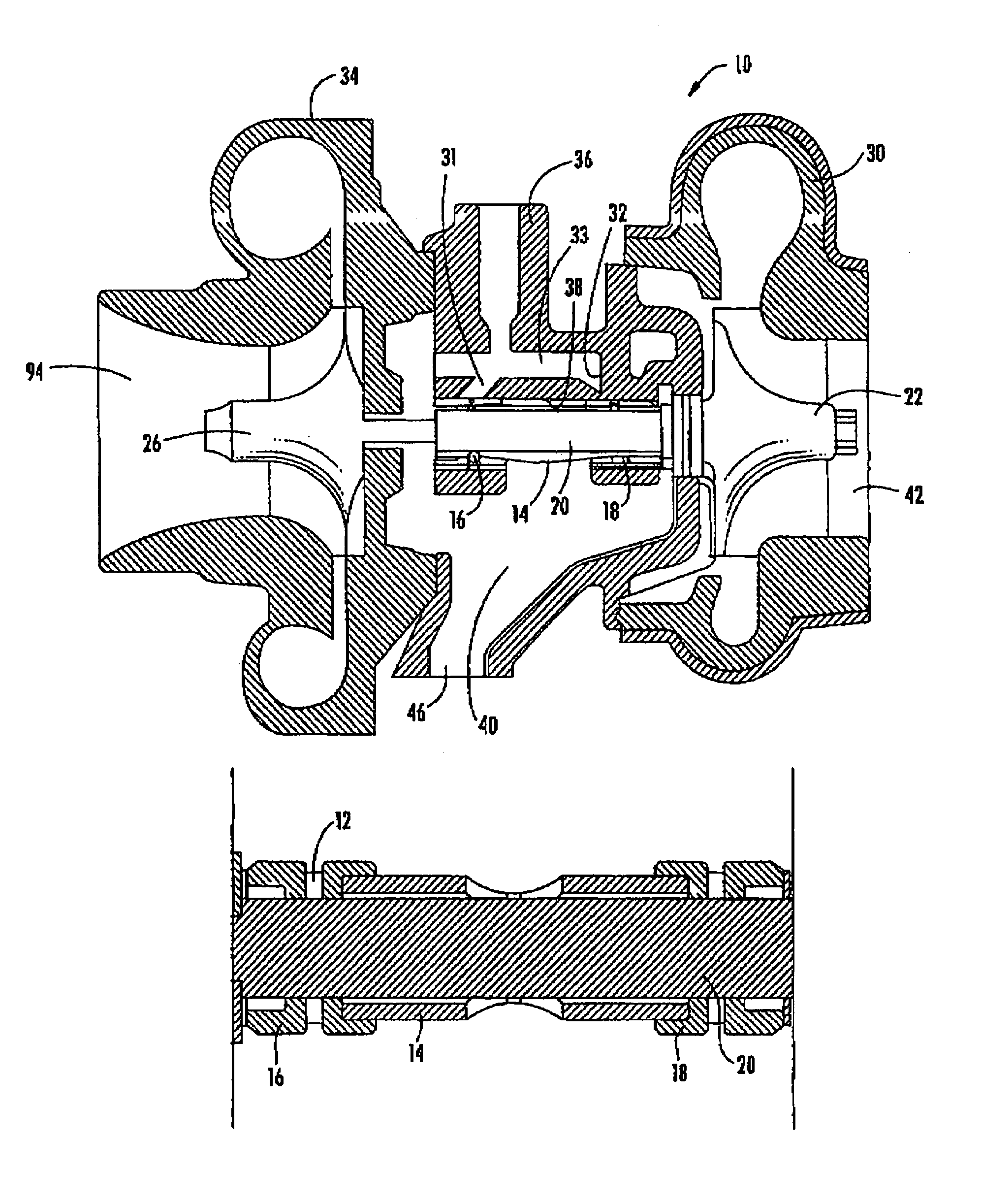

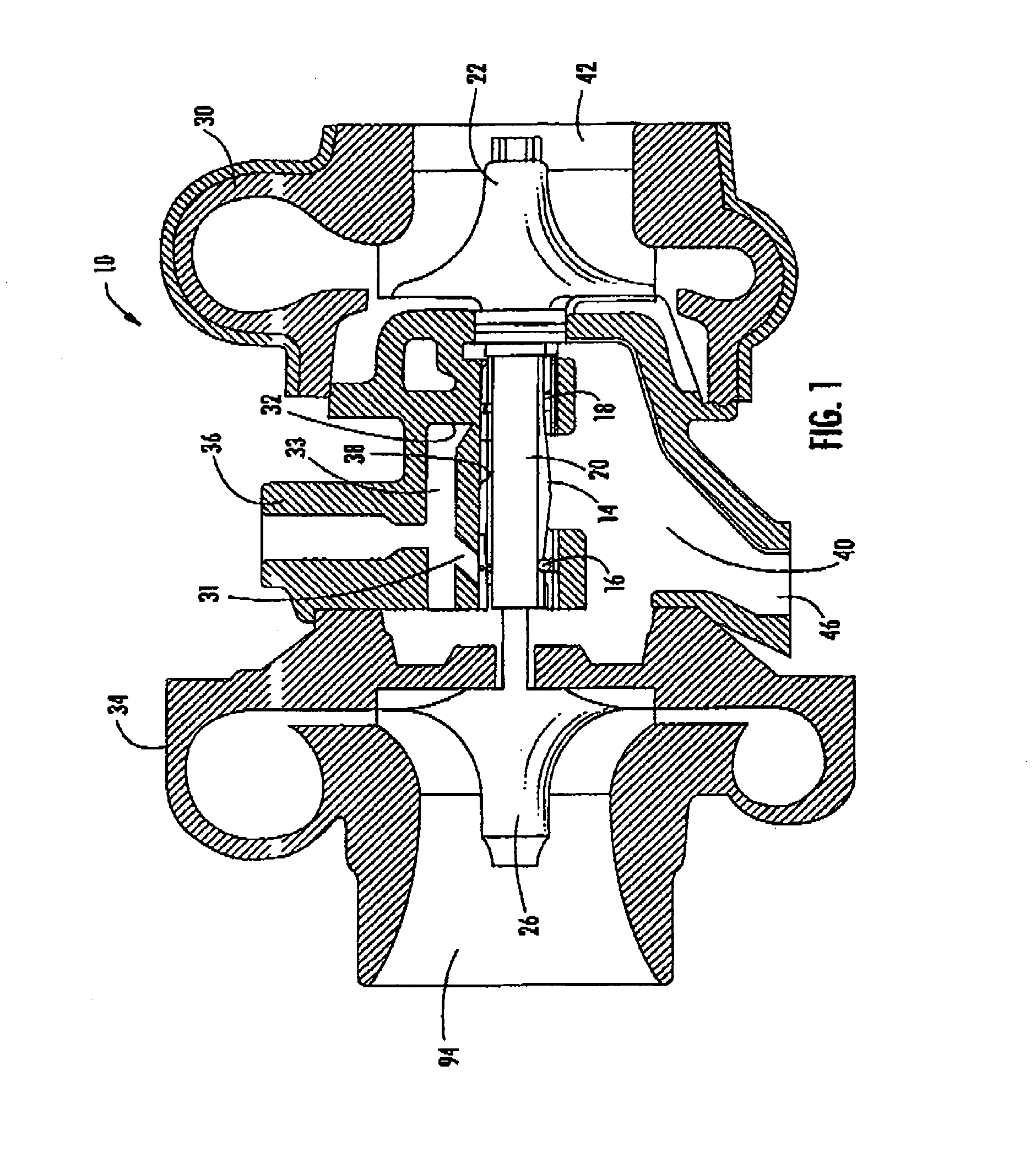

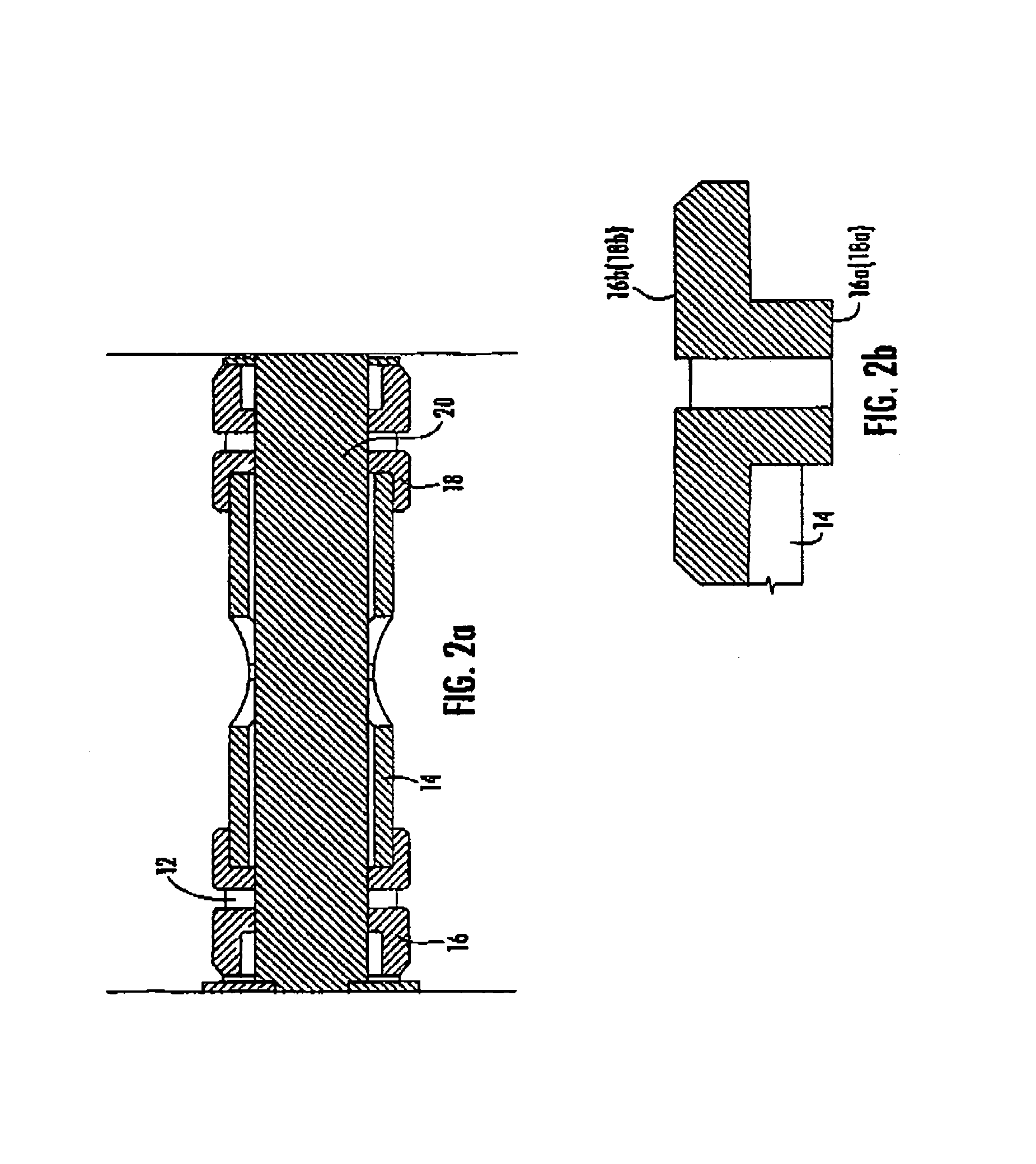

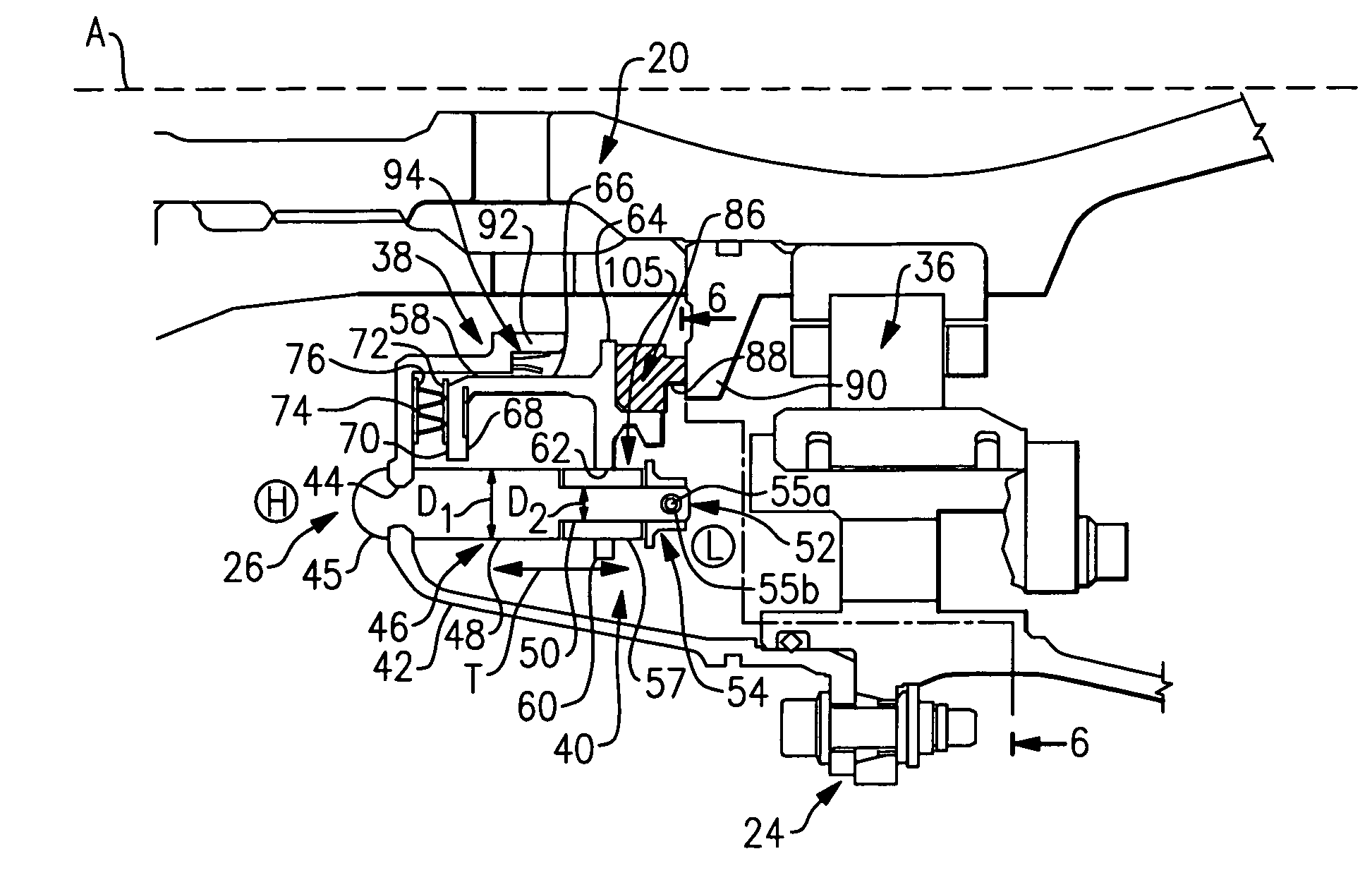

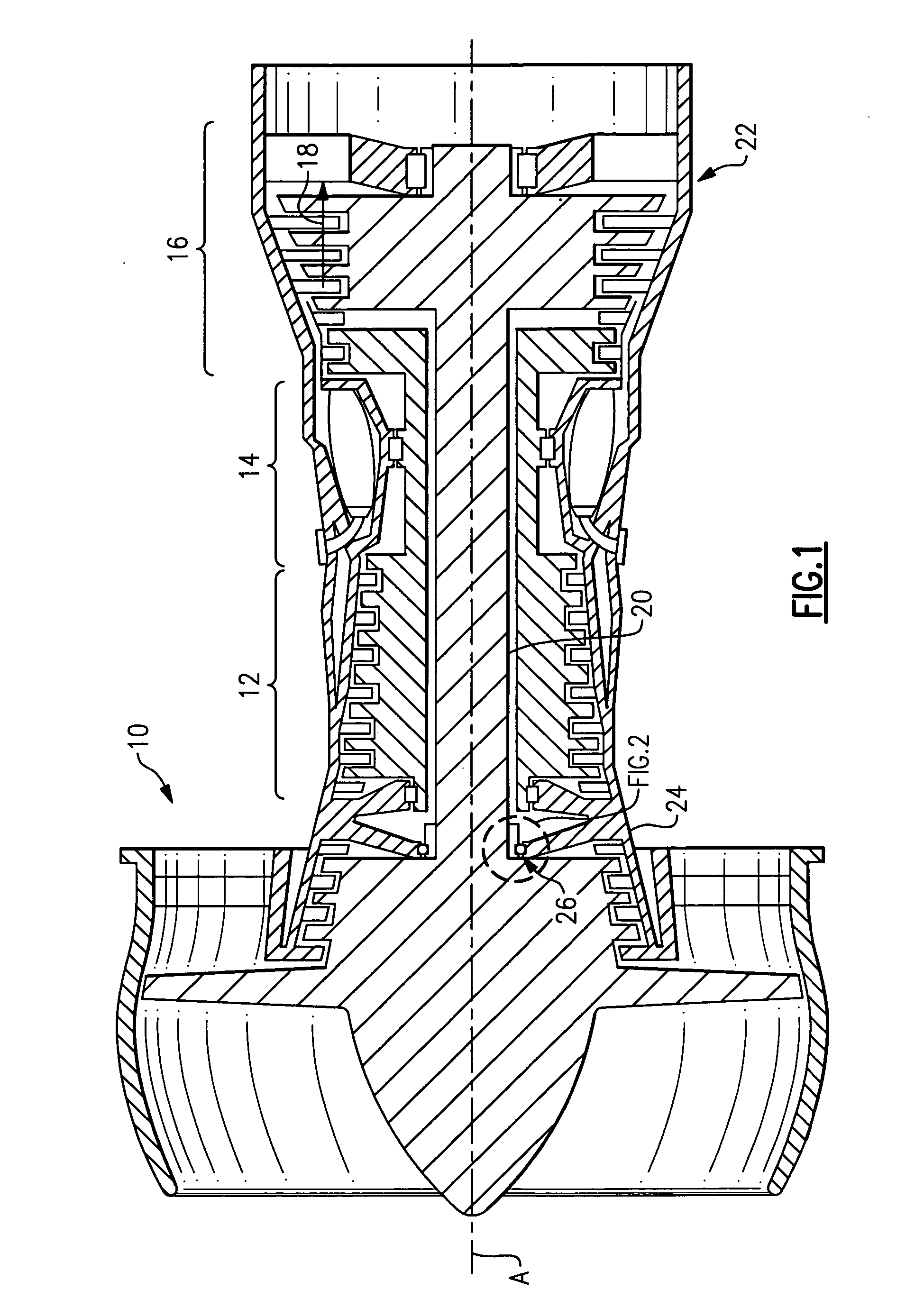

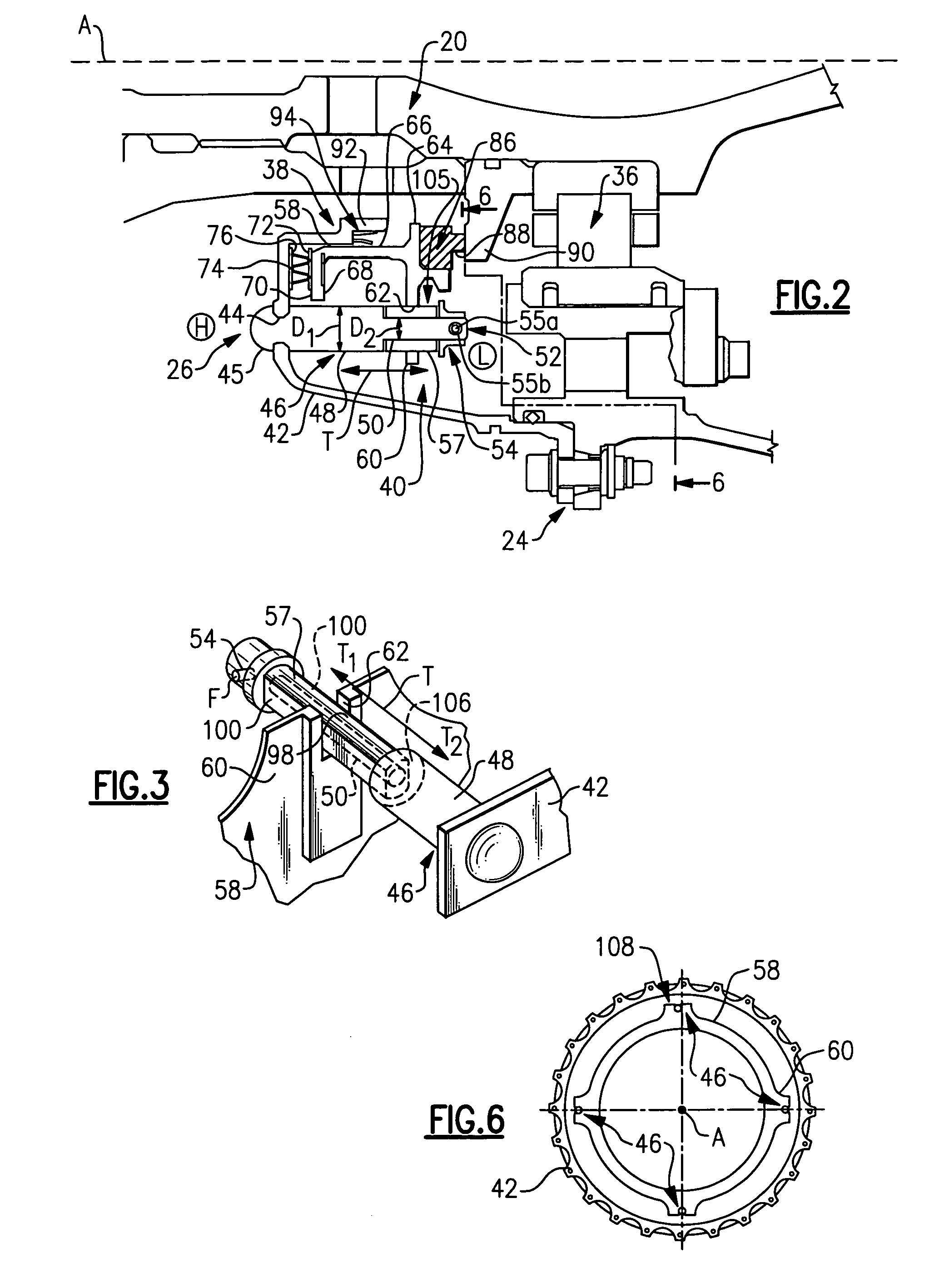

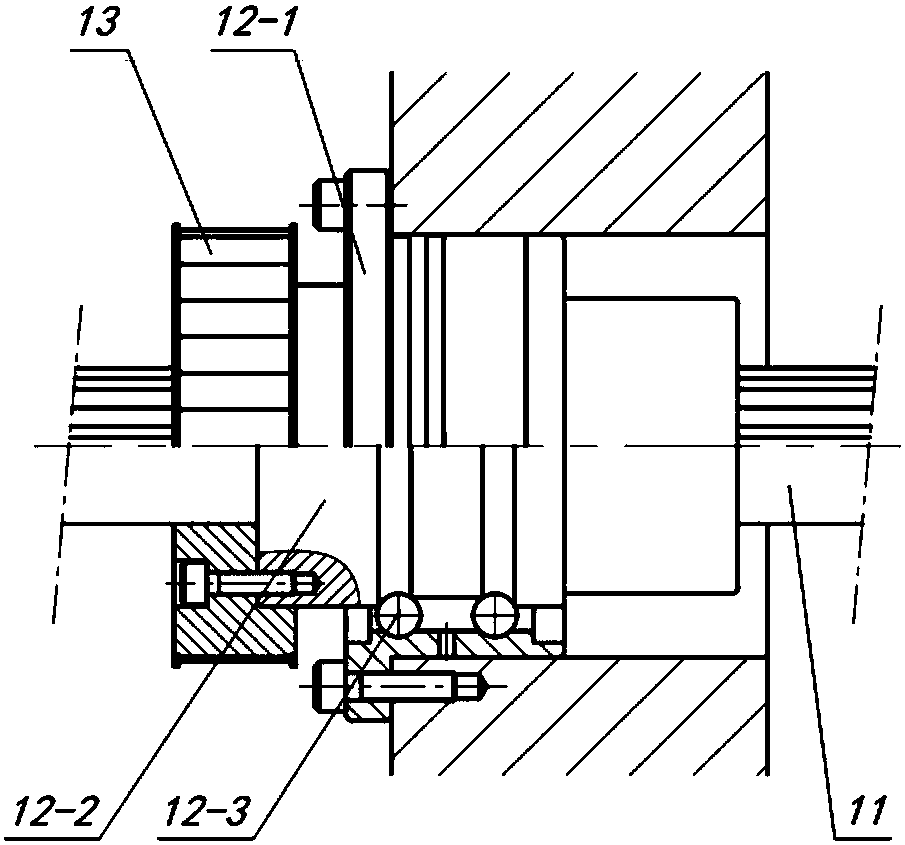

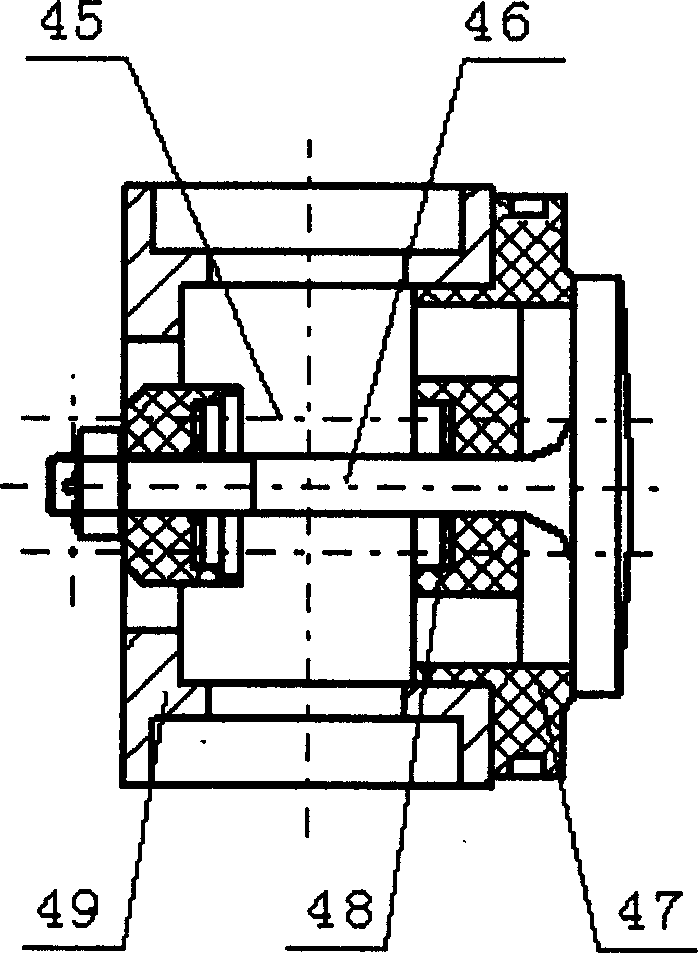

Bearing system for a turbocharger

ActiveUS7189005B2Easy to assembleReduce friction and wearEngine fuctionsShaftsTurbochargerStructural engineering

A bearing system for a turbocharger, simple in design and easy to manufacture, having desired rotational dynamics of a three piece bearing design, yet having the superior vibration damping characteristics of a one piece bearing design. The inboard end of each journal bearing includes an axial recess for receiving an outboard end of a cylindrical bearing spacer, thereby axially locating the journal bearings as well as axially and radially locating the bearing spacer.

Owner:BORGWARNER INC

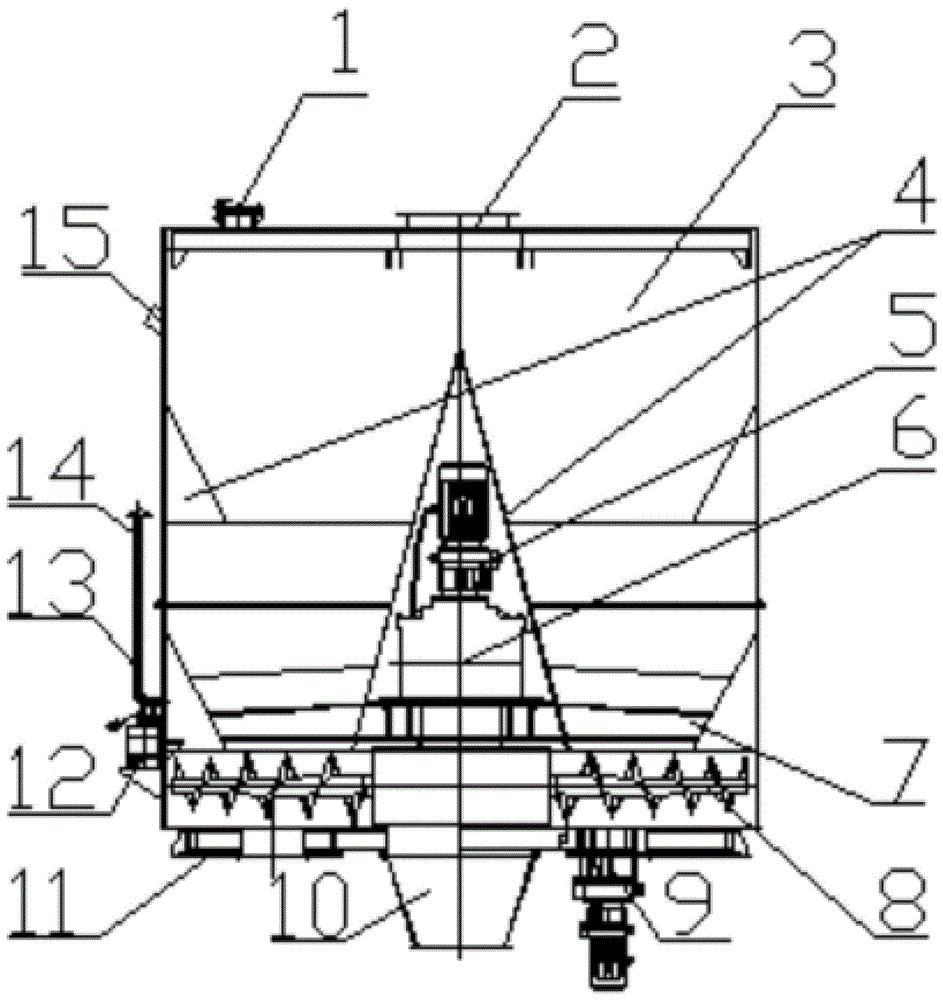

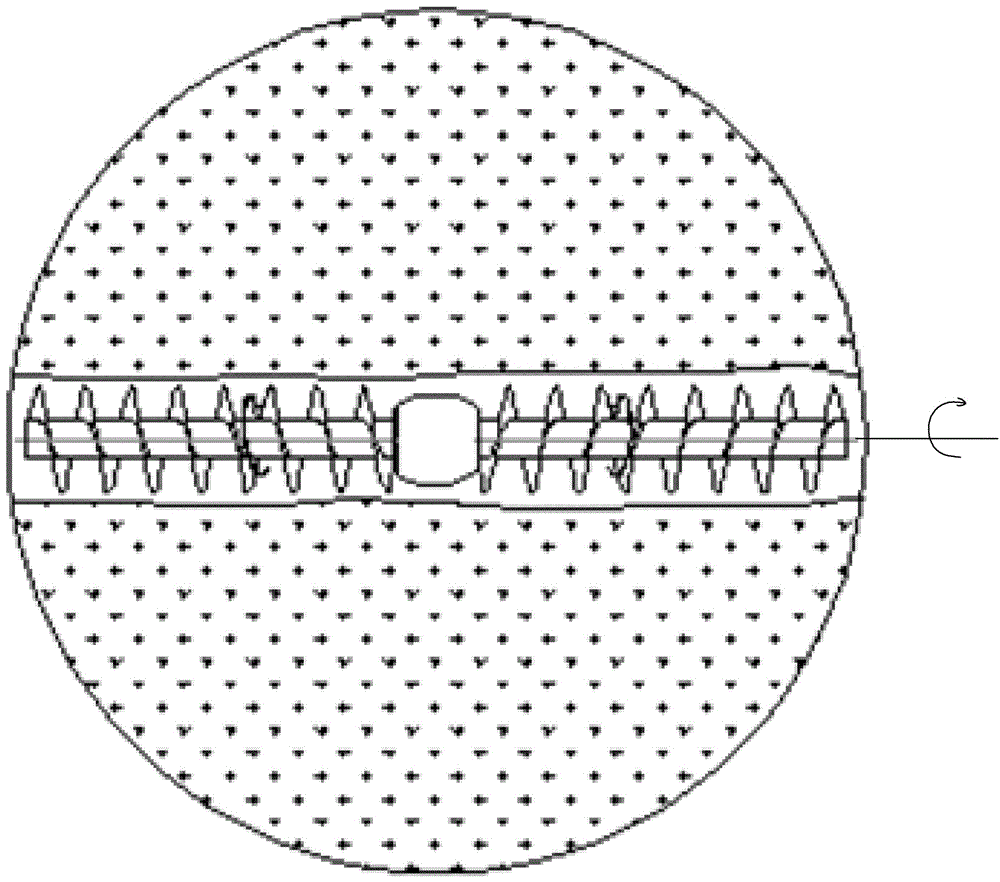

Traversing spiral discharge device for stock bin and discharging method

InactiveCN105883433ATraversal guaranteeGuaranteed uptimeLarge containersLoading/unloadingDischarge efficiencyEngineering

The invention relates to a traversing spiral discharge device for a stock bin and a discharging method. The traversing spiral discharge device comprises a round stock bin, wherein the round stock bin is fixed at the top of a mounting base; a feeding opening is formed in the center of the top of the round stock bin; an access door is arranged on a side edge of the feeding opening; a pressure relief cone cover is mounted inside the round stock bin; a primary rotating motor is mounted inside the pressure relief cone cover; the primary rotating motor and a transmission case are connected with each other and drive a spiral shaft to rotate along the axis of the spiral shaft; a discharging opening is formed in the bottom of the round stock bin; a rotational transmission system is fixedly mounted on a mounting base on the side edge of the discharging opening; the rotational transmission system drives the spiral shaft to conduct 360-degree rotational motion along the axis of the round stock bin. The traversing spiral discharge device is capable of facilitating material delivery, effectively preventing a charging basket from being blocked, boosting discharge efficiency, ensuring discharge safety and reducing the intensity of manual operation.

Owner:HUBEI YIDU YUNJI MEC & ELEC CO LTD

Friction- and wear-reducing coating

InactiveUS20100028641A1Improve tribological propertiesImprove performanceSynthetic resin layered productsVacuum evaporation coatingAlloyHardness

A coating includes a first layer of a ceramic alloy and a second layer disposed on the first layer and including carbon. The coating has a hardness of from 10 to 20 GPa and a coefficient of friction of less than or equal to 0.12. A method of coating a substrate includes cleaning the substrate, forming the first layer on the substrate, and depositing the second layer onto the first layer to thereby coat the substrate.

Owner:EATON CORP

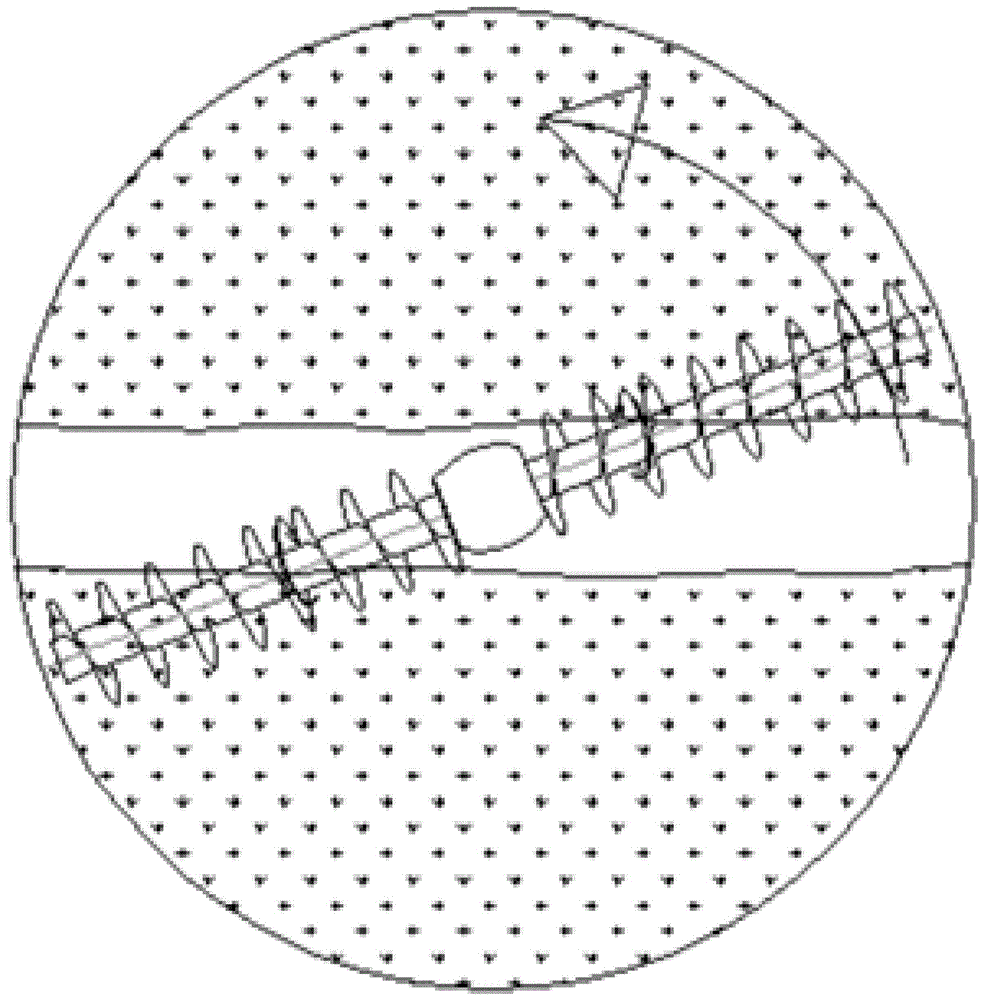

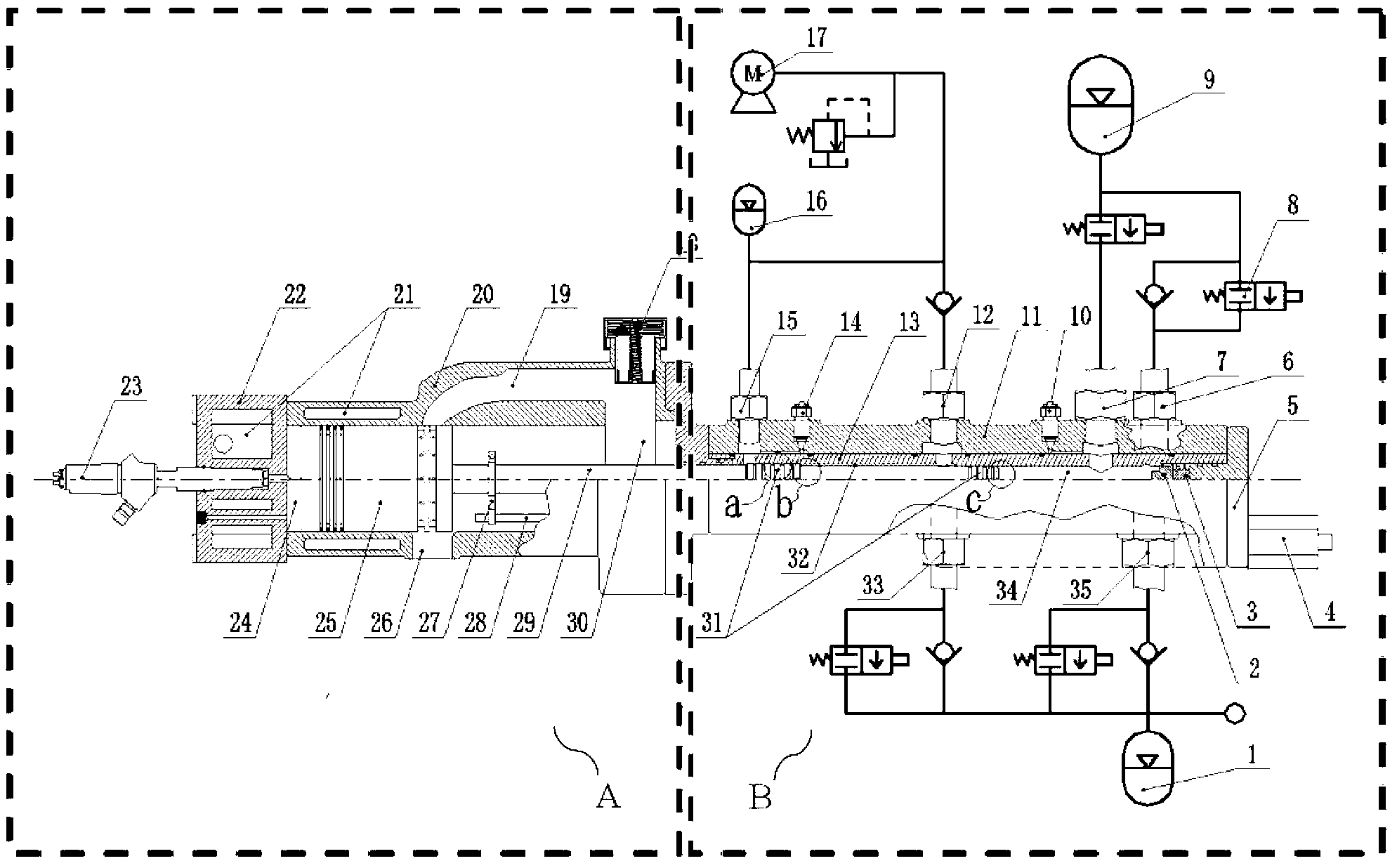

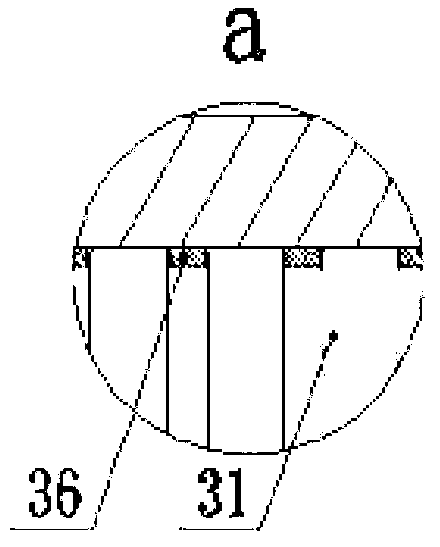

Return flow scavenging type hydraulic free piston diesel engine

InactiveCN102705076AOmit the crankshaftReduce intermediate conversion linksInternal combustion piston enginesFree piston enginesHydraulic motorHydraulic pump

The invention discloses a return flow scavenging type hydraulic free piston diesel engine, which comprises a single-cylinder two-stroke diesel engine without a crankshaft connecting rod and a valve distribution mechanism, and a hydraulic system provided with a linear hydraulic pump and a hydraulic motor, wherein a piston in the single-cylinder two-stroke diesel engine is connected with a plunger in the hydraulic system, and a space in the linear hydraulic pump in the hydraulic system is divided into a high-pressure cavity and a low-pressure cavity; the piston in the single-cylinder two-stroke diesel engine can drive the linear hydraulic pump to output high-pressure oil in an expansion travel, and the high-pressure oil is output to the hydraulic motor from a pipe joint C; the piston is pushed back to an upper dead center from a lower dead center by the low-pressure oil end, so that a compression travel of the piston is completed. According to the invention, a crankshaft in the conventional internal combustion engine is omitted, and a middle conversion step of power output is reduced, so that the heat efficiency is about 5% higher than that of the conventional internal combustion engine, the diesel engine can be operated at a variable compression ratio, the best heat efficiency of a full operation work condition is ensured, and the fuel economy is improved.

Owner:JILIN UNIV

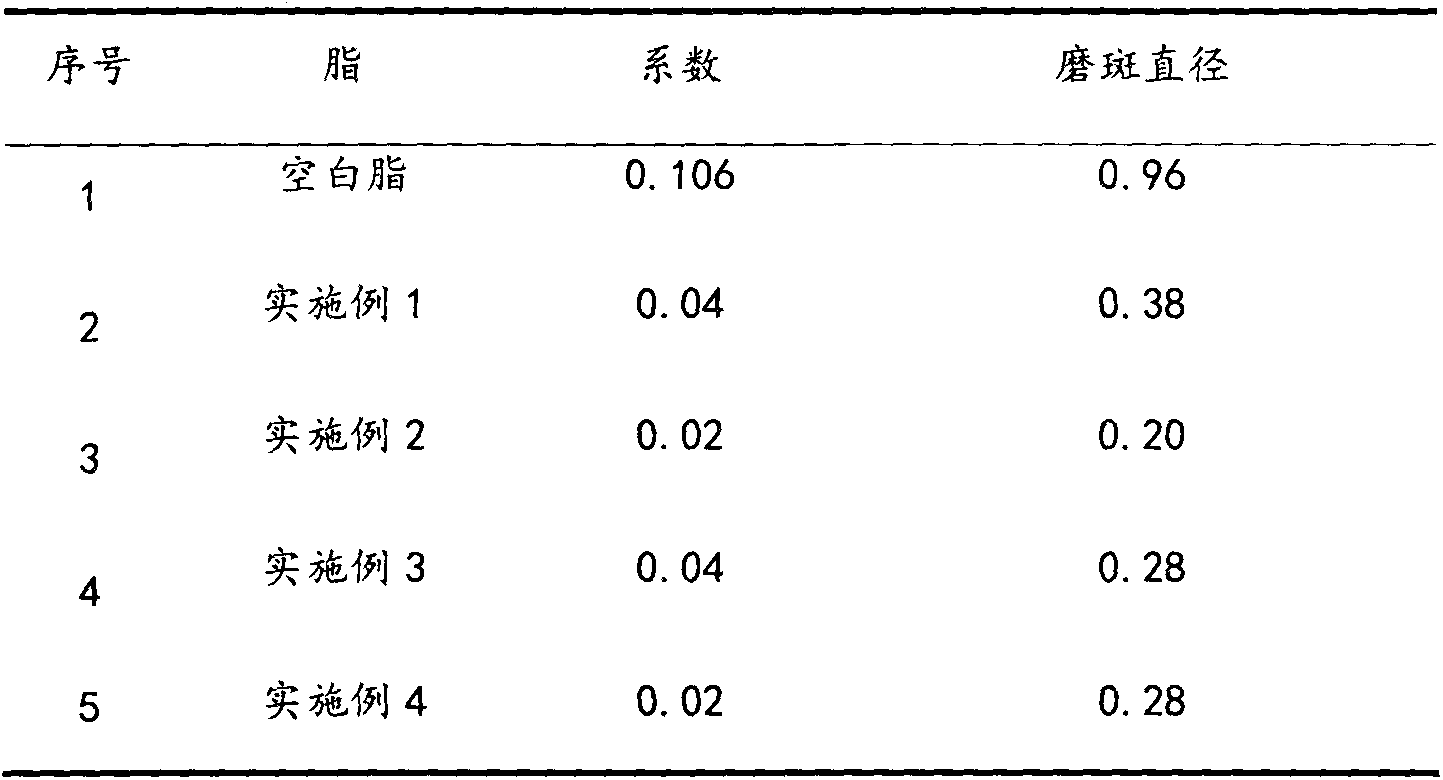

Metal/ ceramic nano composite additive of self-rehabilitation and its preparation method

The invention relates to a metal / ceramic nano complex self-repairing additive, which comprises metal nano micropowder and nano natural ore powder as main material, detergent, catalyst, antioxidant, and solvent, and can be used in lube, grease and ultrasonic medium. The advantages of this invention include: it can form rapidly high-hardness self-repairing protection layer on a plurality of metal friction surfaces with thickness adjustable to optimize gap and improve surface physical and chemical property, and has wide application in friction dual parts.

Owner:JIANGSU MOLEDN PETROCHEM

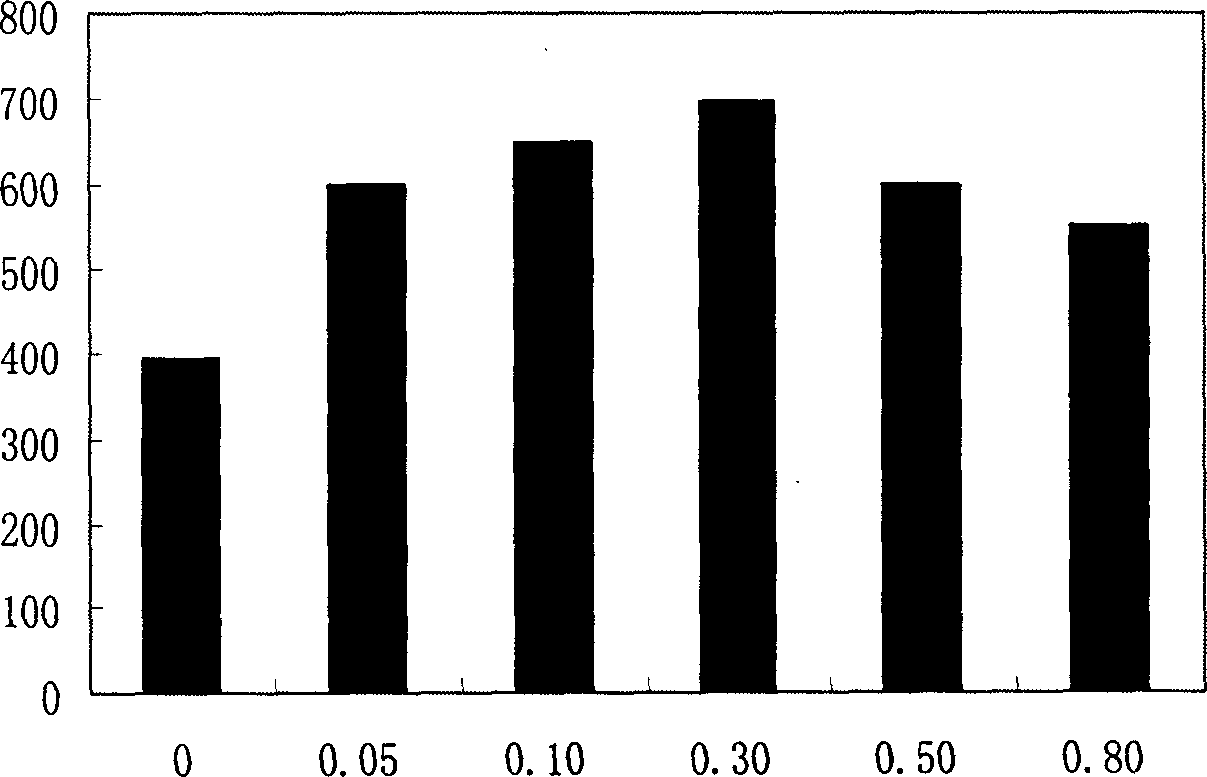

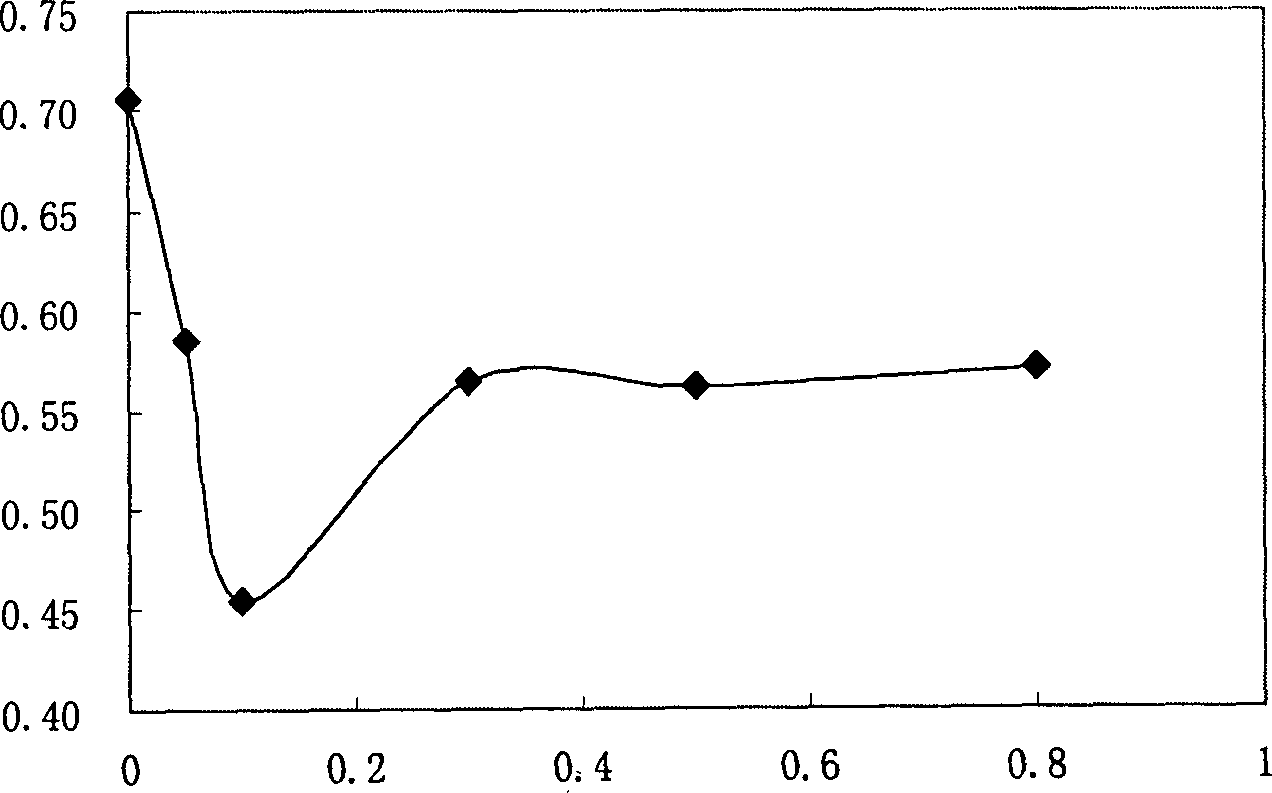

Low ash, low phosphorus and low sulfur engine oils for internal combustion engines

InactiveUS20030158048A1Reduce friction and wearLow sulfurOrganic chemistryOrganic compound preparationCombustionSulfur

A lubricating composition for internal combustion engines especially useful with fuels having less than 350 ppm sulfur comprises a lubricating oil basestock, a boron containing ashless dispersant, a molybdenum containing friction reducing agent, a metal type detergent and zinc dithiophosphate.

Owner:EXXON RES & ENG CO

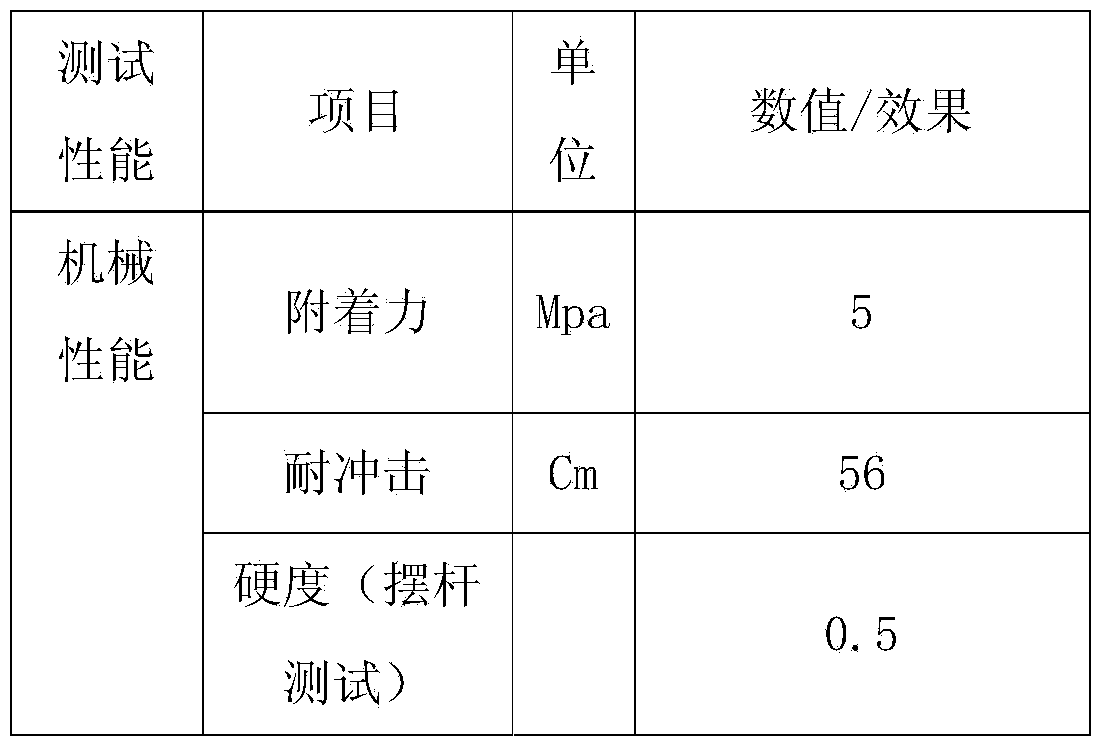

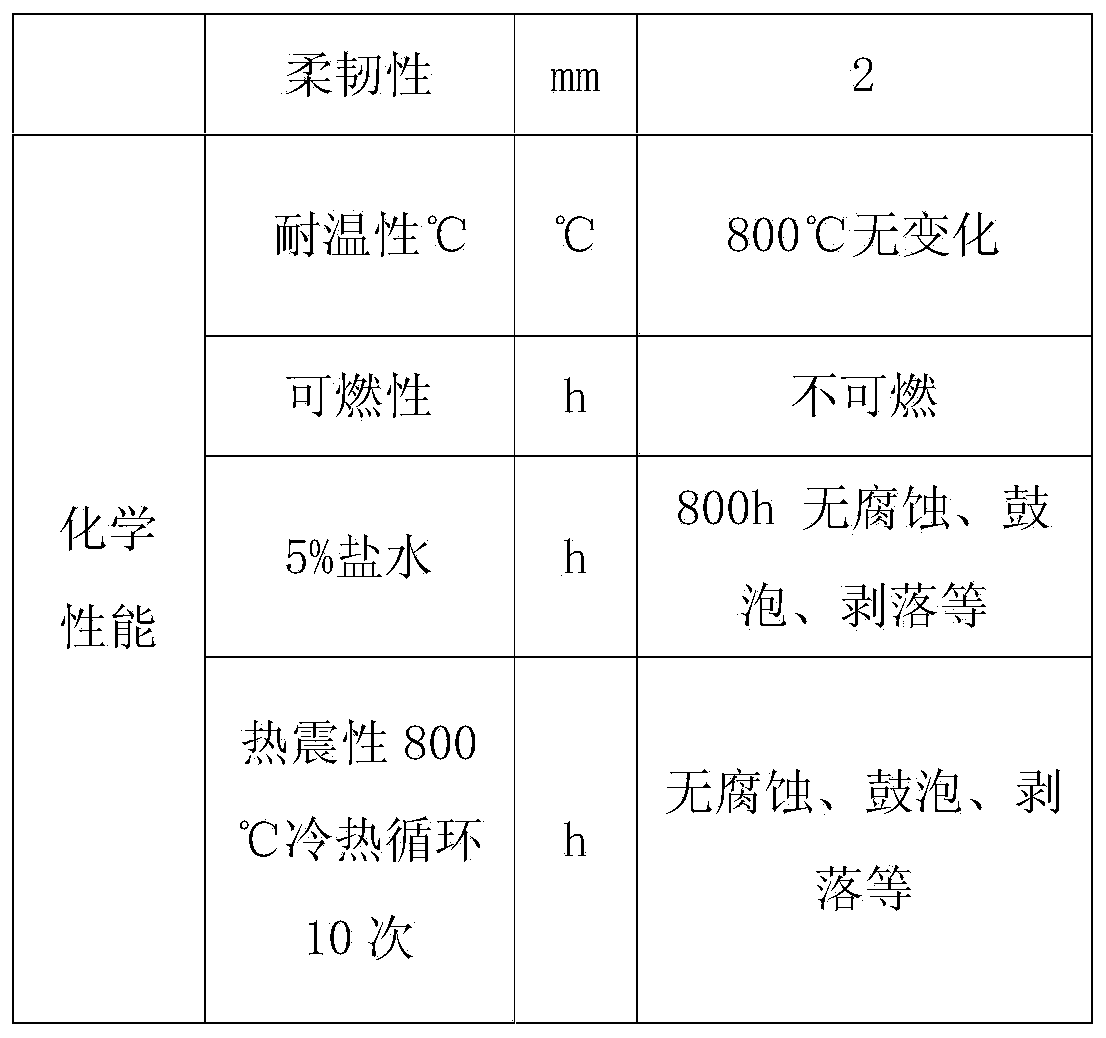

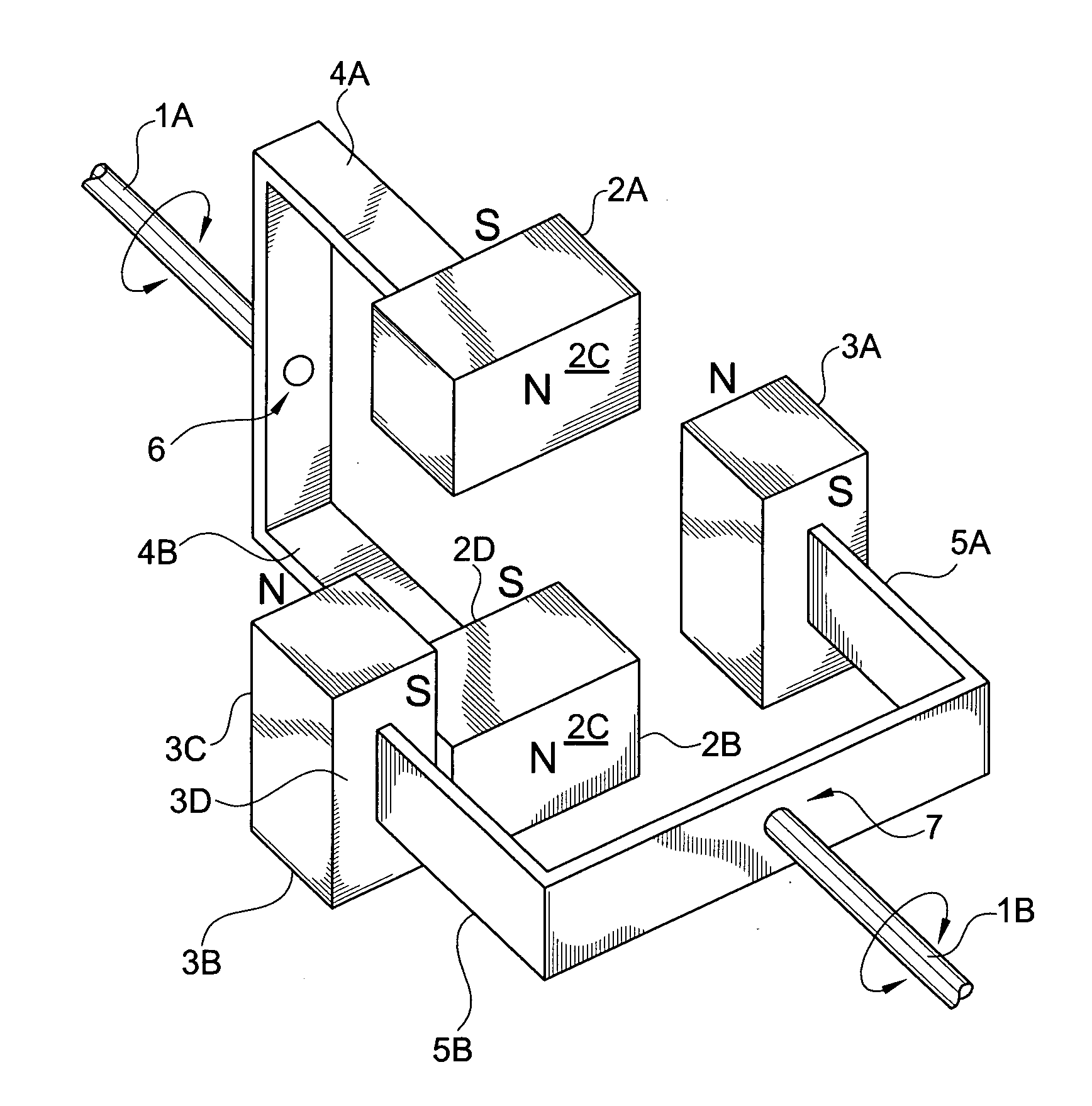

Boron-modified organic silicon resin high-temperature-resistant coating and preparation method thereof

The invention discloses a boron-modified organic silicon resin high-temperature-resistant coating which comprises the following components in percentage by mass: 45%-58% of boron-modified organic silicon resin, 35%-45% of heat-resisting pigment fillers and 2%-4% of auxiliary agents, wherein the boron-modified organic silicon resin is boric-acid-modified organic silicon resin or epoxy-modified silicon-boron resin; and the mass ratio of nanometer silicon dioxide to barrier function fillers to aluminum powder which are contained in the heat-resisting pigment fillers is 1.5:1:1. The invention also discloses a preparation method of the boron-modified organic silicon resin high-temperature-resistant coating. The preparation method disclosed by the invention can be implemented on an existing coating preparation production line without increasing equipment investment; the prepared high temperature-resistant organic silicon coating can be coated by adopting a spray coating process and constructed by adopting a roll coating process, can be subjected to high temperature of 800 DEG C for a long time and has corrosion-resistant property.

Owner:JIANGSU MARINE VICTORY COATING

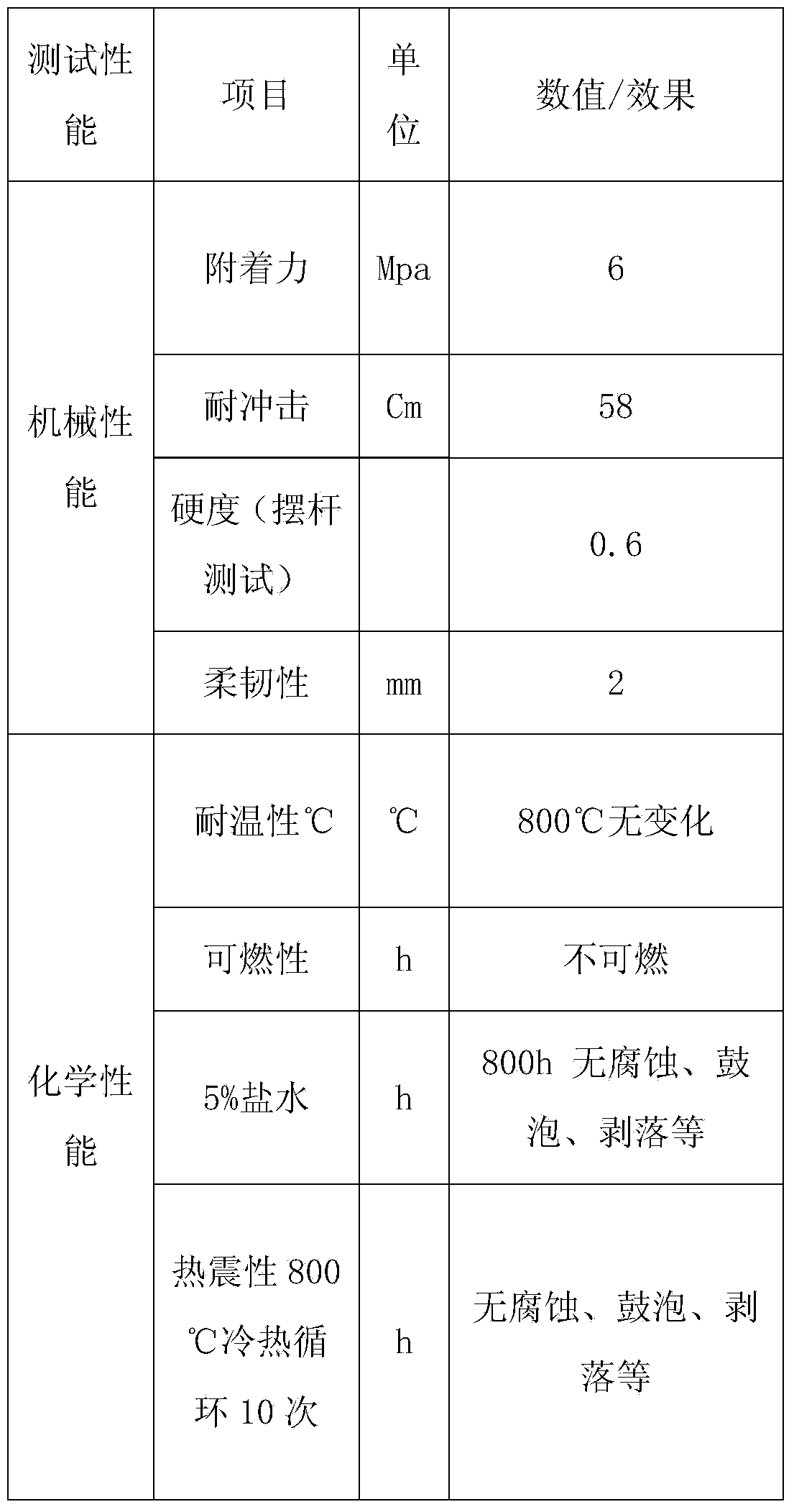

Power generating systems

InactiveUS20070007835A1Reduce friction and wearPermanent-magnet clutches/brakesMechanical energy handlingTransfer systemEngineering

A power generating system includes a torque converter system receiving a rotational motion having a first torque from a source and producing a rotational output having a second torque different from the first torque, a transfer system having a first portion coupled to the rotational output of the torque converter system and a second portion magnetically coupled to the first portion, and a generator system coupled to the transfer system to produce and electrical output.

Owner:CAMEL CLUB

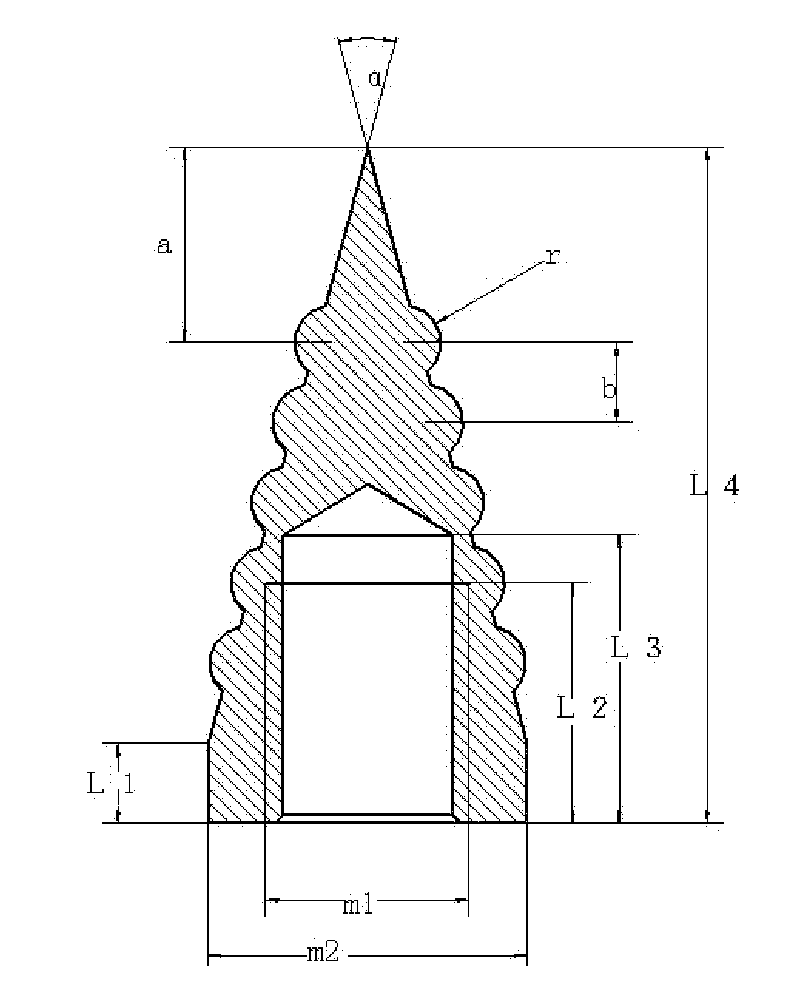

Conical soil-engaging component with abrasion-resistant geometric structural surface

InactiveCN101839906AReduce friction and wearImprove wear resistanceEarth material testingEngineeringMoisture

The invention relates to a geometric structure of a workpiece of a vehicular sensor used for measuring soil moisture and compactness, in particular to a conical soil-engaging component with an abrasion-resistant geometric structural surface. The component consists of a substrate and bionic geometric structure units distributed on the surface of the substrate and is characterized in that: the bionic geometric structure units comprise a convex hull type, a concave pit type, an annular convex rib type, an annular concave rib type, a spiral convex hull type, a spiral concave pit type, a spiral convex rib type and a spiral concave rib type. The component aims to solve the problem of the abrasion of a conical head of a sensor when the soil moisture and the compactness are measured. The bionic geometric structure units and the substrate are of an integrated structure. The component is made of 1Cr18Ni9Ti, Cr15 or Si60Mn2.

Owner:JILIN UNIV

High performance and low cost C/C-SiC composite brake disc, preparation method and application thereof

ActiveCN106966751ALow priceLow cost of preparationBraking discsActuatorsMolten siliconThermal conductivity

The invention relates to a high performance and low cost C / C-SiC composite brake disc, a preparation method and application thereof. The preparation method includes: carbonizing a brake disc prefab, and densifying the carbonized brake disc prefab by chemical vapor infiltration method to obtain a C / C composite material; then performing heat treatment in an inert atmosphere to improve the graphitization degree of the composite material; then conducting machining to obtain a C / C composite blank; treating the C / C composite blank by molten silicon infiltration method to obtain a C / C-SiC composite brake disc; then treating the C / C-SiC composite brake disc by means of chemical vapor infiltration or precursor infiltration pyrolysis; and machining the obtained product into a final design size, thus obtaining a composite brake disc finished product. The C / C-SiC composite brake disc and the preparation method thereof provided by the invention can reduce the preparation cost and improve the mechanical performance, thermal conductivity and friction and wear performance of the brake disc.

Owner:BEIHANG UNIV

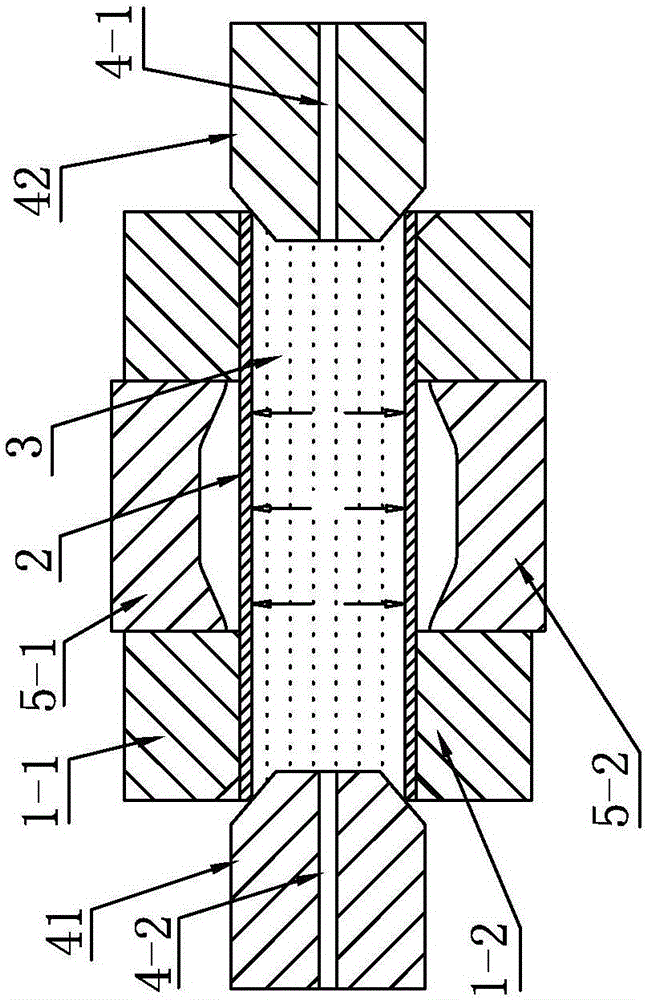

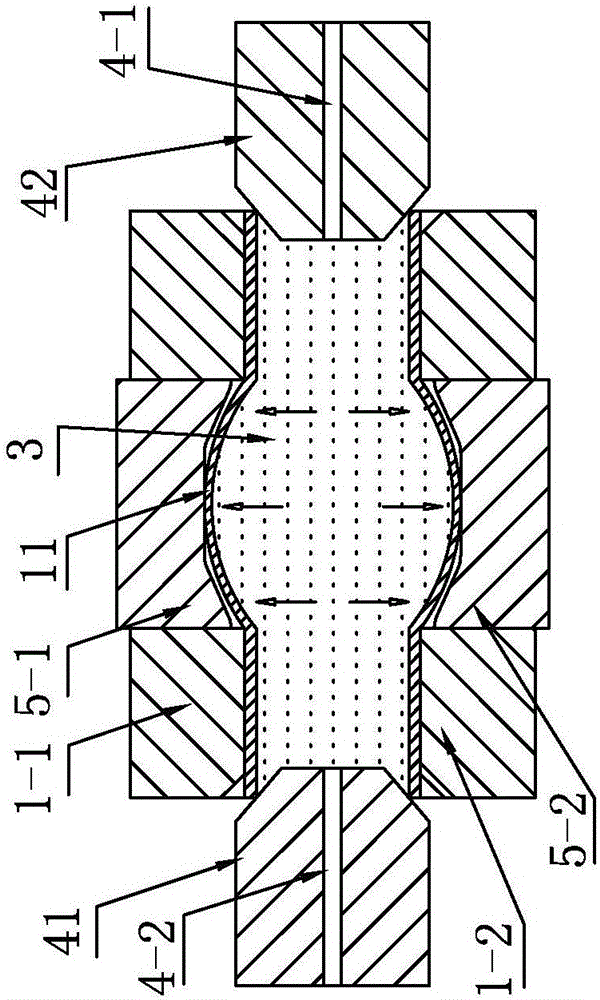

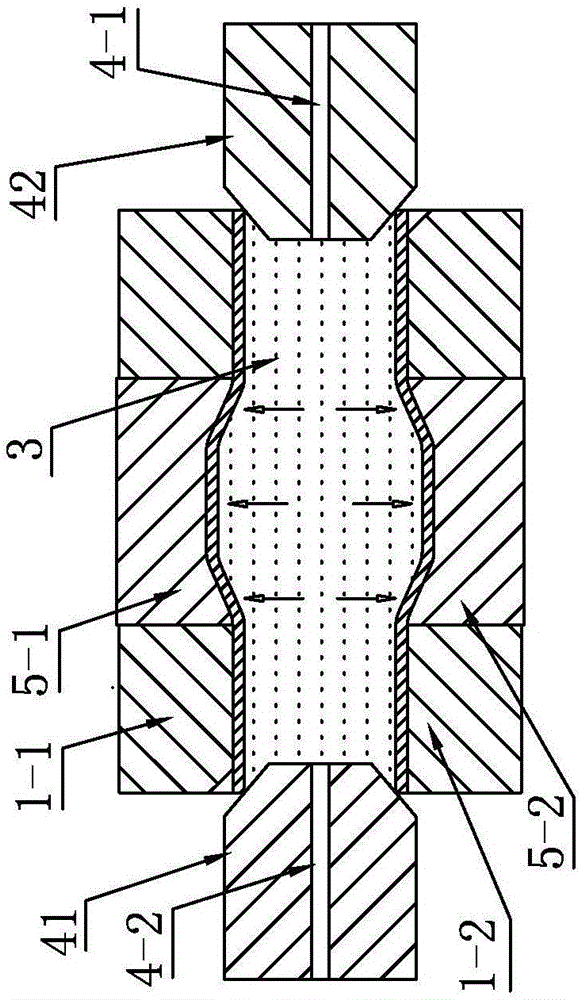

Swelling pressure composite forming method for large-section-difference special-shaped section pipe fitting

The invention provides a swelling pressure composite forming method for a large-section-difference special-shaped section pipe fitting and relates to a forming method for a large-section-difference special-shaped section pipe-shaped part. The swelling pressure composite forming method comprises the main steps that 1, the perimeters and the equivalent diameters of a plurality of cross sections on the to-be-formed large-section-difference special-shaped section pipe fitting are determined, and the structure of a swelling pressure composite forming mold and the inner cavity size and initial position of a side extrusion mold are determined; 2, an equal-diameter circular-section pipe blank with a certain length is cut and put into the swelling pressure composite forming mold; 3, the equal-diameter circular-section pipe blank is filled with a pressure medium with a certain pressure through a pressure medium inlet, and a variable-diameter circular-section pipe blank is obtained through swelling; 4, the side extrusion mold is driven to extrude the variable-diameter circular-section pipe blank, and the large-section-difference special-shaped section pipe fitting is obtained; and 5, the pressure is released, and after the swelling pressure composite forming mold is opened, the formed pipe fitting is taken out. The swelling pressure composite forming method is used for forming large-section-difference special-shaped section pipe fittings.

Owner:HARBIN INST OF TECH

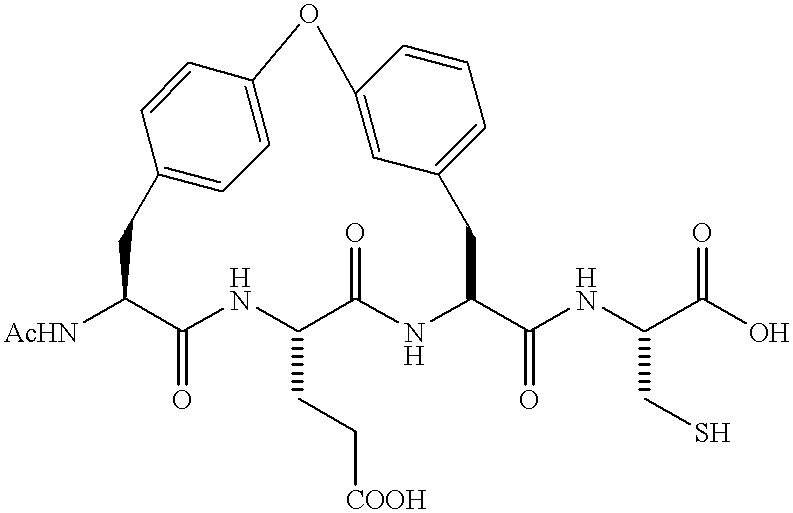

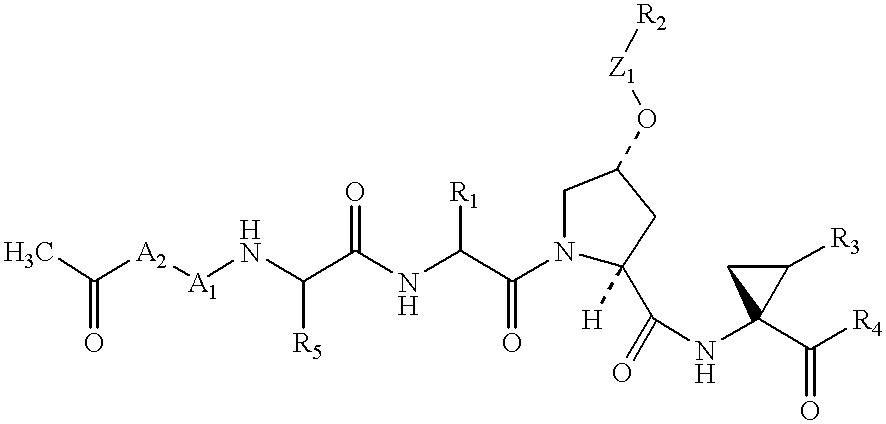

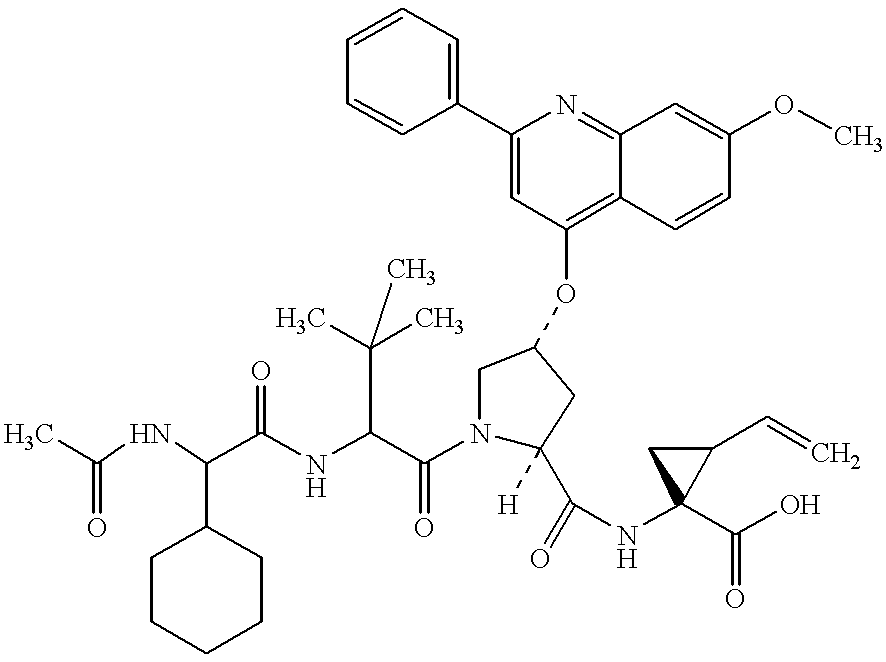

Novel imidazolidinones as NS3-serine protease inhibitors of hepatitis C virus

InactiveUS20020102235A1Reduce friction and wearHigh melting pointOrganic active ingredientsBiocideDrugHcv protease

The present invention discloses novel imidazolidinones which have HCV protease inhibitory activity as well as methods for preparing such compounds. In another embodiment, the invention discloses pharmaceutical compositions comprising such imidazolidinones as well as methods of using them to treat disorders associated with the HCV protease.

Owner:SCHERING CORP

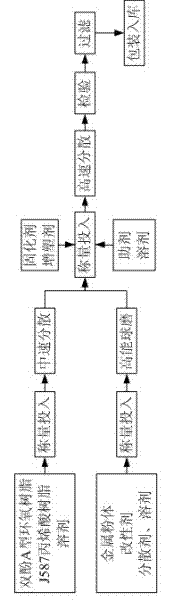

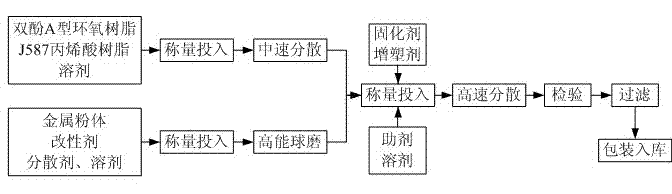

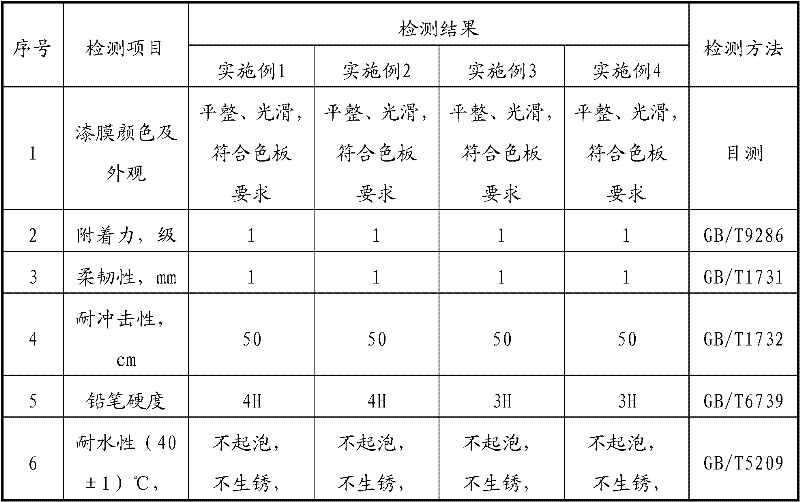

Anticorrosive wear-resistant paint for magnesium alloy and preparation method thereof

InactiveCN102352168AImprove wear resistanceImprove the lubrication effectAnti-corrosive paintsEpoxy resin coatingsAcrylic resinWear resistant

The invention relates to an anticorrosive wear-resistant paint for magnesium alloy. The paint provided by the invention is made from the following components of: a modified epoxy resin liquid which is prepared by dissolving and dispersing bisphenol A-type epoxy resin, J587 acrylic resin and the balance solvent, a metal nanometer polymer formed by Ti, Al2O3, MoS2 and the like, and a curing agent, a plasticizer, an auxiliary agent and a solvent which are commonly used for paints. The preparation method comprises the following steps of: adding the metal nanometer polymer into the modified epoxy resin liquid for dispersion, adding the curing agent, the plasticizer, the auxiliary agent and the solvent with fully stirring and uniformly dispersing, filtering and standing to prepare the anticorrosive wear-resistant paint. The preparation technology and operation are both simple with each step carried out at normal temperature and normal pressure, and are convenient for industrial production. The prepared paint is widely applied, has strong bonding force between the coating layer and the matrix and good anticorrosive and abrasion resistant performance, and has a long-acting effect of protecting magnesium alloy member.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Mechanical face seal stop pin

A mechanical face seal arrangement includes a seal member having an annular seal element for sealing against a rotatable seal surface. The seal member includes guide slots that cooperate with the guide member to establish a direction of seal member movement. The guide member includes stops to establish a range of movement of the seal member along the direction of seal member movement.

Owner:RAYTHEON TECH CORP

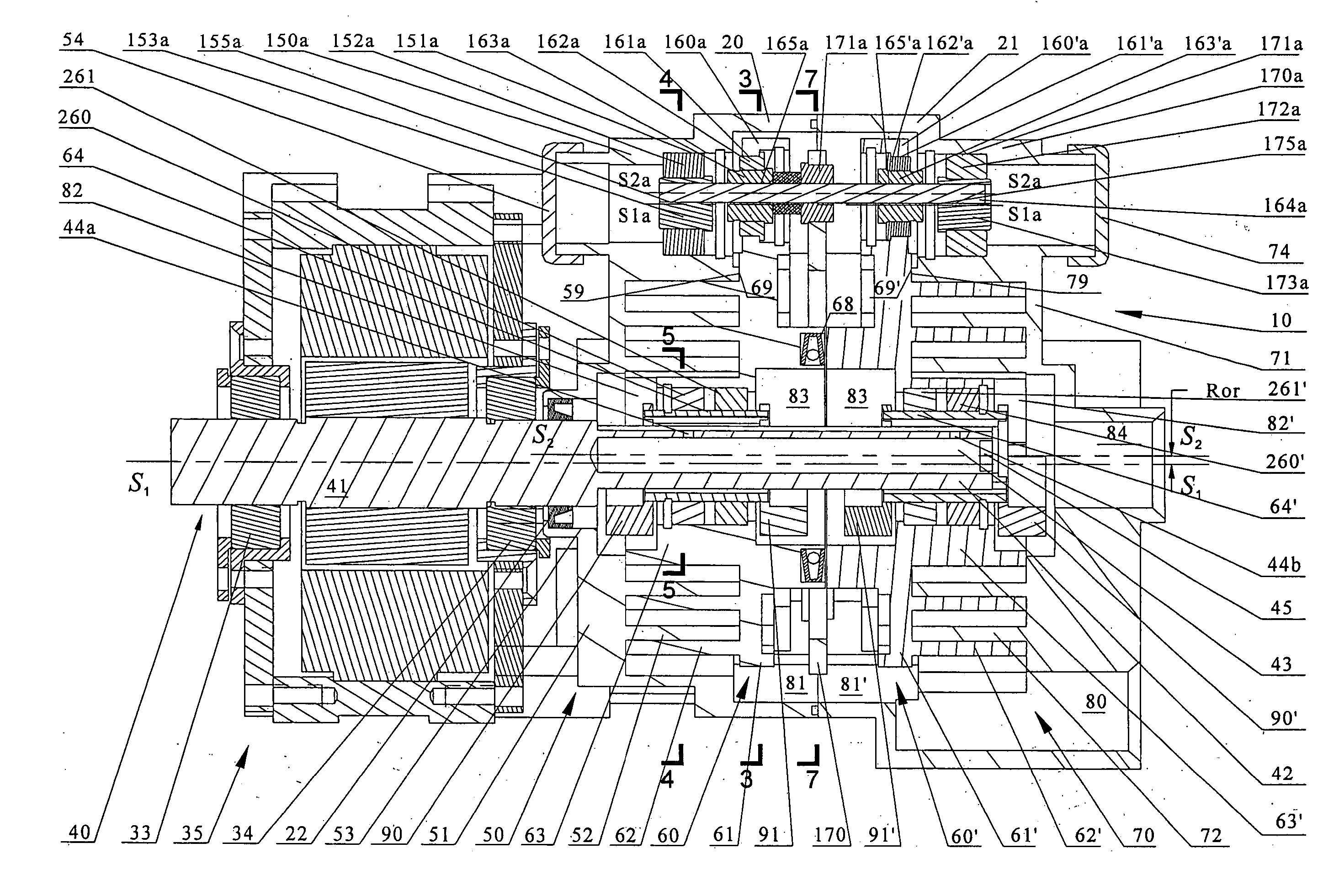

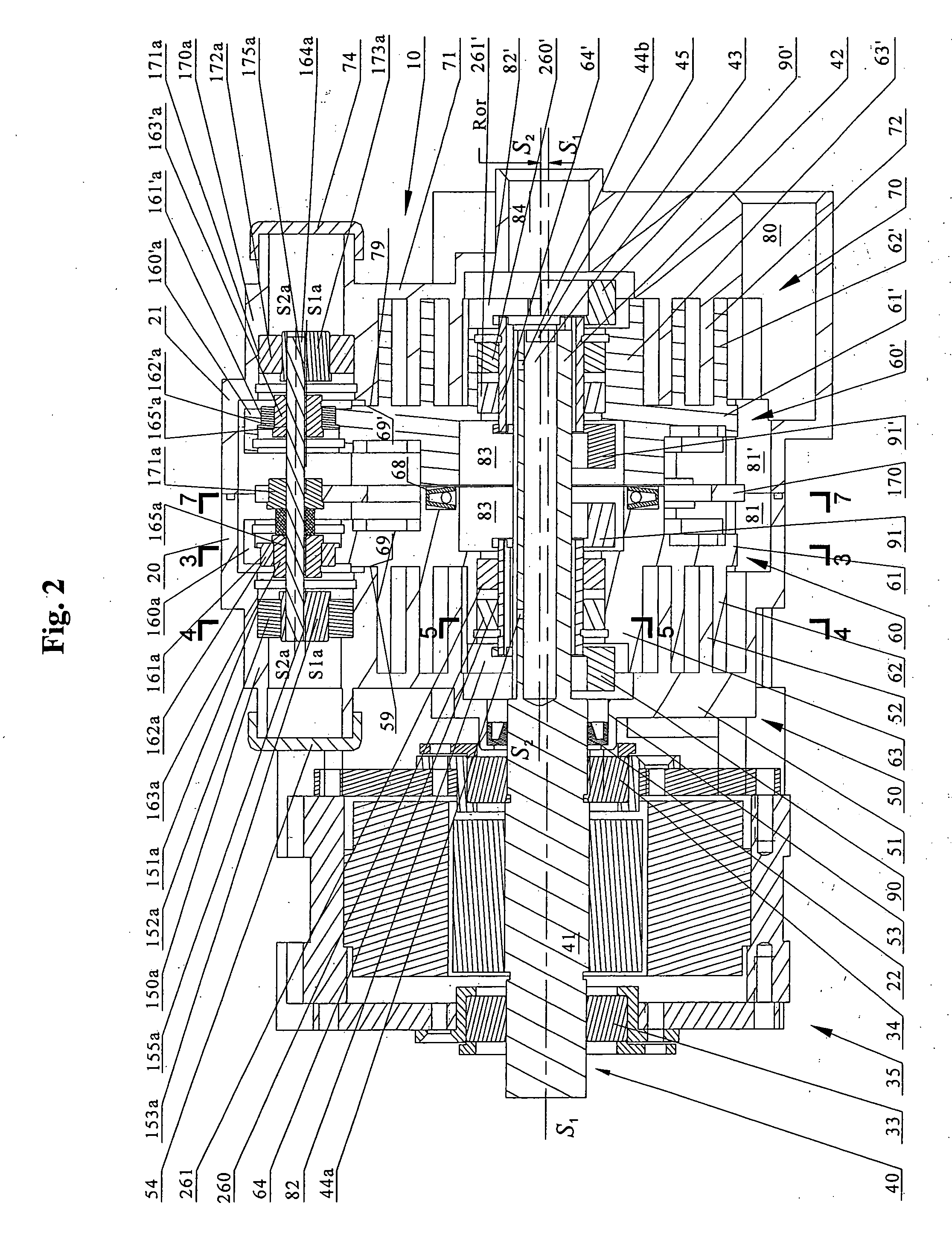

Scroll-type fluid displacement apparatus with fully compliant floating scrolls

ActiveUS20070172373A1Improve bearing lifeReduce friction and wearRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeBall bearingDrive shaft

A central drive shaft-sliding knuckle combined with a peripheral crank pin-swing link mechanism (CSPS) to provide an orbiting scroll with radial and axial compliant capability. The CSPS mechanism can be applied to both dual floating scroll and single floating scroll structures to improve performances of scroll devices, particularly in oil-free operations. In addition, an orbiting dual thrust ball bearing mechanism is provided to take thrust load in, for example, a floating scroll compressor with a CSPS mechanism.

Owner:NI & ASSOC

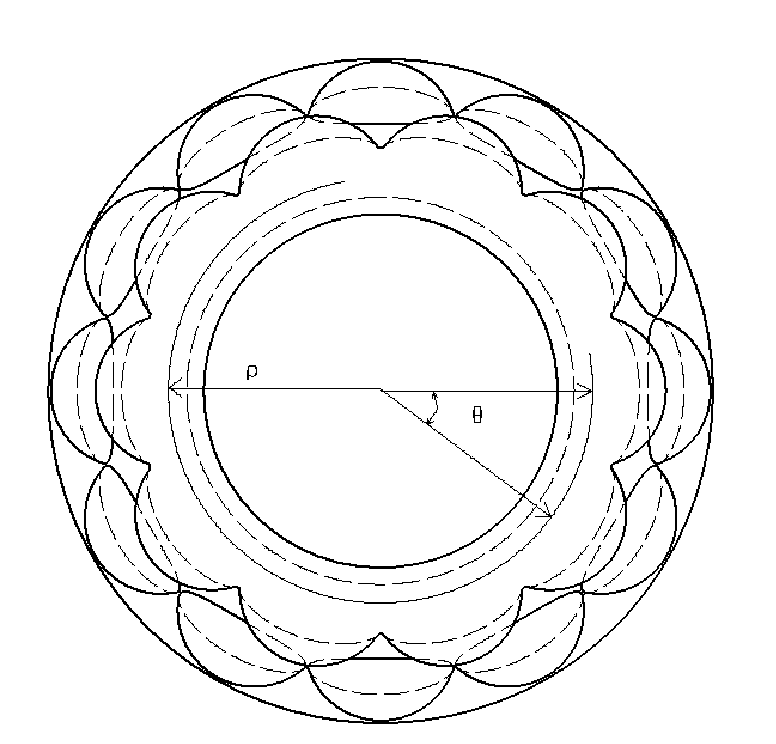

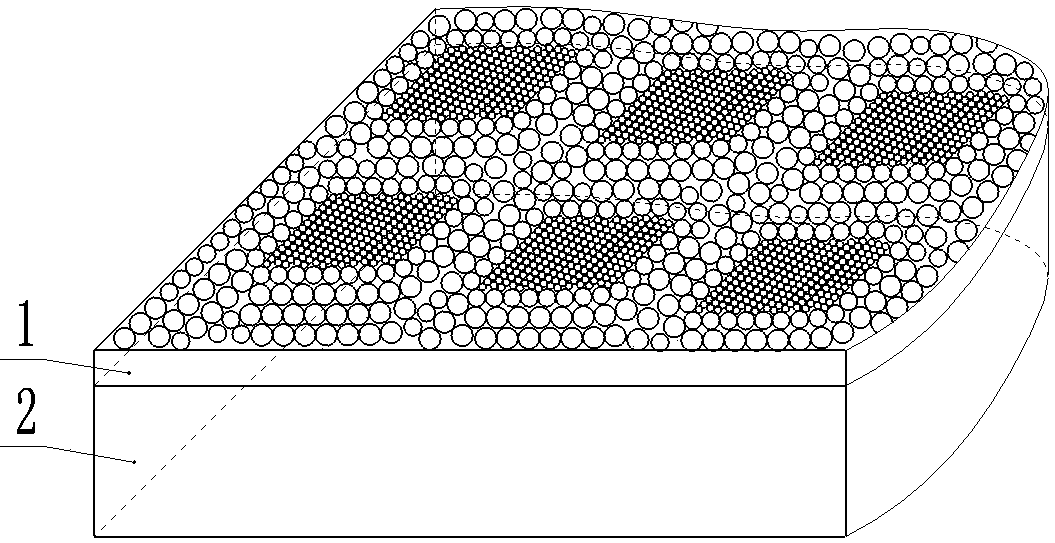

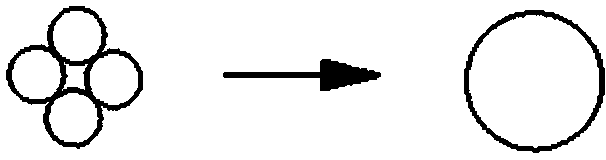

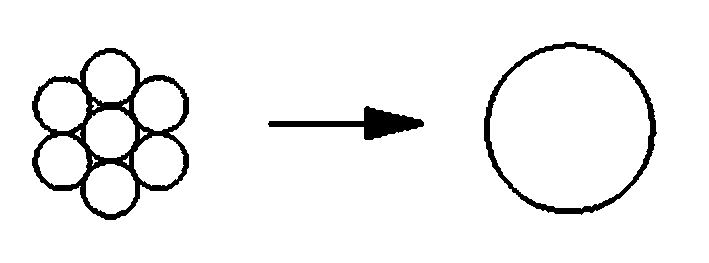

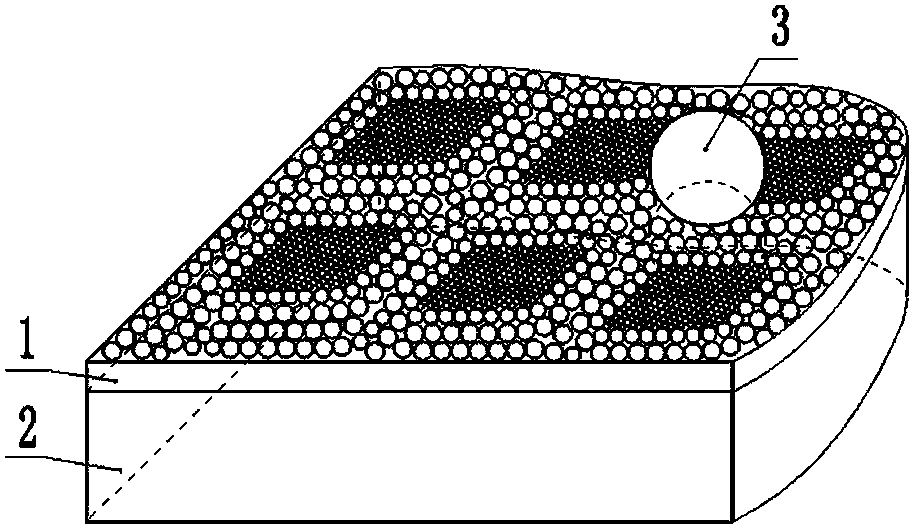

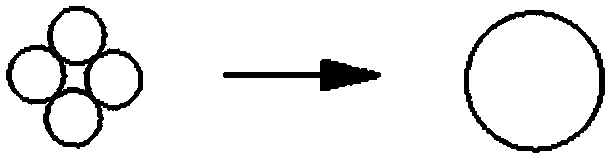

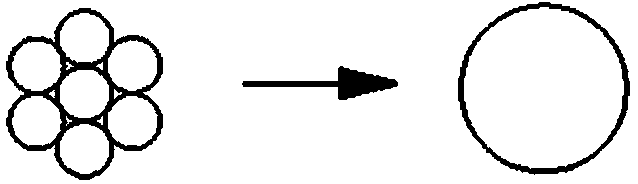

Indium-iron grid-shaped spherical composite microcrystal composite layer

InactiveCN104228206AReduce friction and wearReduces fretting fatigueLamination ancillary operationsLaminationIndiumSingle crystal

The invention discloses an indium-iron grid-shaped spherical composite microcrystal composite layer. A surface material layer is arranged on a part and mainly comprises larger indium-iron composite spherical microcrystal units of which the indium content exceeds 50% (Wt%) and the total content of indium and iron exceeds 55% (Wt%), each larger indium-iron composite spherical microcrystal unit is formed by close connection of at least four spherical crystal grains or nearly-spherical crystal grains, the larger indium-iron composite spherical microcrystal units are distributed regularly to form a grid, multiple single crystal grains or smaller indium-iron microcrystal units are closely distributed in the grid, and each smaller indium-iron microcrystal unit is formed by close connection of at least two spherical crystal grains or nearly-spherical crystal grains; the surface material layer and a base body material of the part are integrated to form the indium-iron grid-shaped spherical composite microcrystal composite layer.

Owner:FUJIAN CHUANZHENG COMM COLLEGE

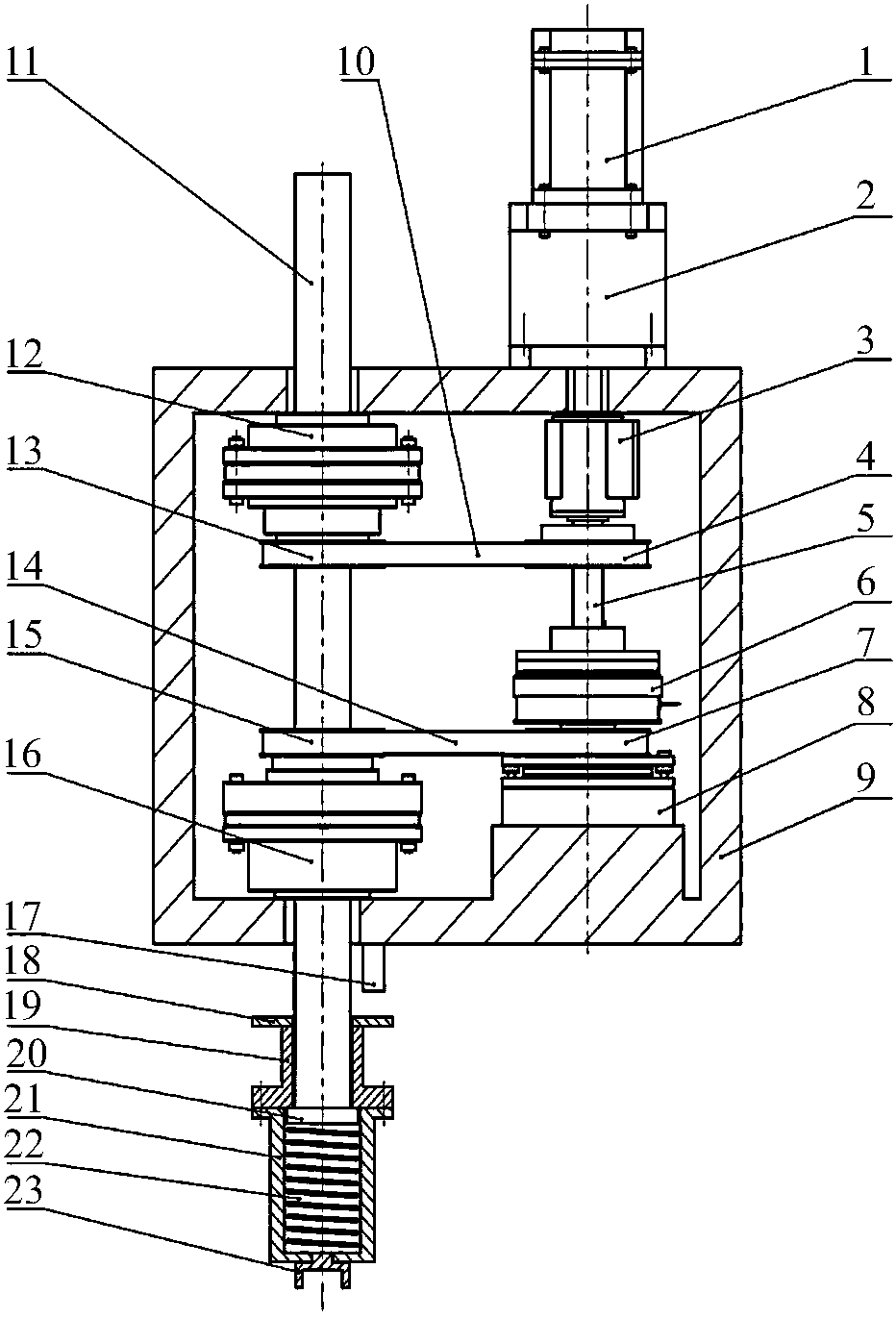

Automatic single-drive double-movement bolt tightening device and bolt tightening method thereof

InactiveCN107584274AReduce friction and wearImprove efficiencyMetal working apparatusProduction lineElectromagnetic clutch

The invention discloses an automatic single-drive double-movement bolt tightening device. The device comprises a motor, a speed reducer, a torque sensor, a drive tooth-shaped belt wheel A, a transmission shaft, an electromagnetic clutch, a drive tooth-shaped belt wheel B, an electromagnetic brake, a frame, a tooth-shaped belt A, a ball screw rod spline shaft, a rotation type ball nut component, adriven tooth-shaped belt wheel A, a tooth-shaped belt B, a driven tooth-shaped belt wheel B, a rotation type ball spline sleeve component, a non-contact displacement sensor, a reflection plate, a flange-type ball spline sleeve, a limit ring, a connection component, a compression spring and a spanner component. The automatic single-drive double-movement bolt tightening device is single-drive, full-automatic, high in efficiency, compact in structure, and suitable for being used on an automatic production line. The automatic single-drive double-movement bolt tightening device has the coupling ability, has wide application range, and can be used for tightening bolts with different screw pitches. The invention further provides a bolt tightening method of the automatic single-drive double-movement bolt tightening device.

Owner:赵阳

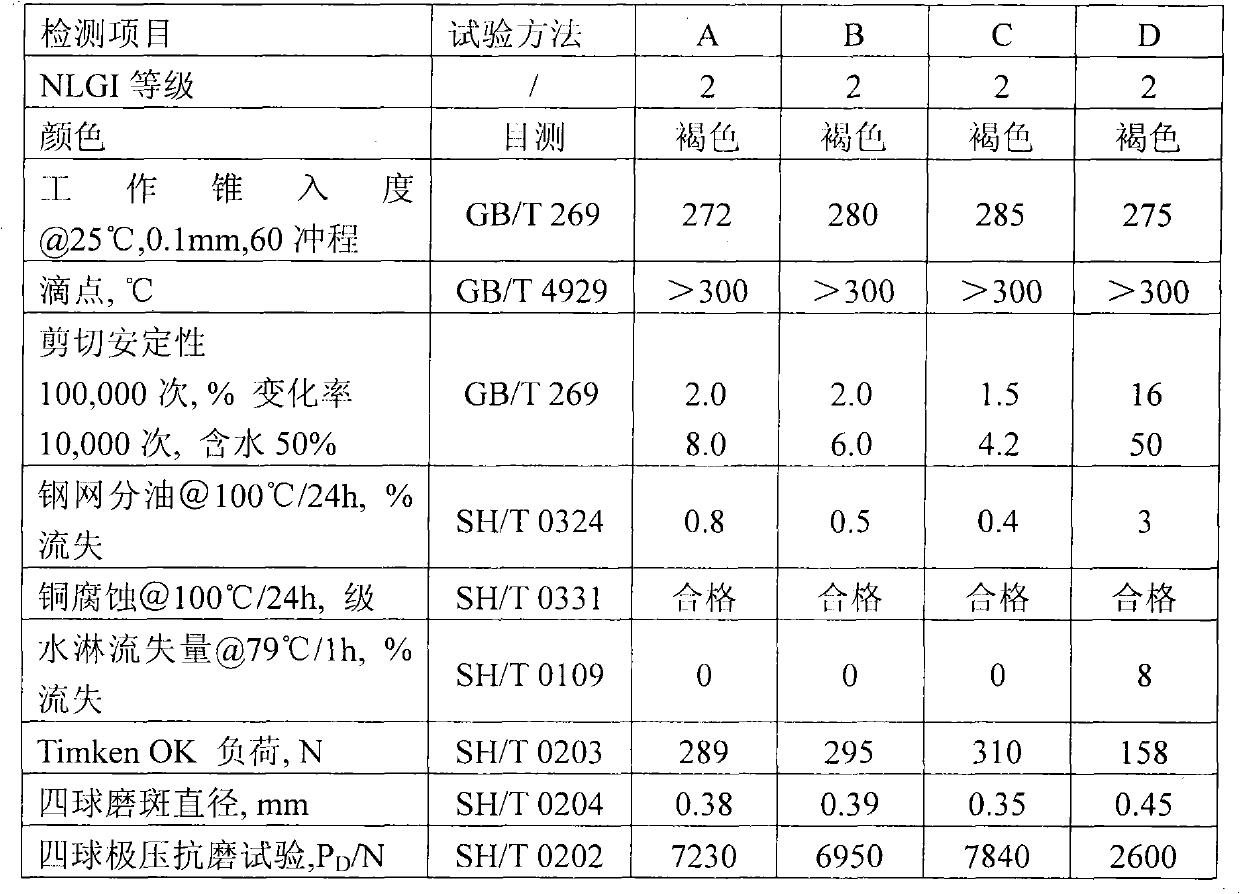

Synthetic high-temperature lubricating grease and preparation method thereof

ActiveCN101921653AGood high temperature performanceSmall oil separationLubricant compositionAntioxidantHydroxystearic Acid

The invention relates to synthetic high-temperature lubricating grease and a preparation method thereof, in particular to lubricating grease generated by taking high-base number compound calcium sulfonate as a thickening agent and high-viscosity synthetic oil as base oil. The synthetic high-temperature lubricating grease comprises the following components in percentage by mass: 30%-80% of the synthetic base oil, 15%-30% of high-base number compound calcium sulfonate, 2%-10% of 12-hydroxyl stearic acid, 1%-5% of boric acid, 1%-4% of acetic acid, 0.5%-2% of water, 1%-3% of calcium hydroxide and0.1%-0.5% of antioxidants. The produced high-temperature lubricating grease has the advantages of excellent high temperature and water spraying resistance, very well extreme pressure abrasion resistance, cutting safety, rust protection, and the like and is very suitable for the production parts of steel mills, cement plants, power plants, and the like, which have high temperature, heavy loads andlarge quantities of cooling water.

Owner:北京奥力助兴石化科技有限公司

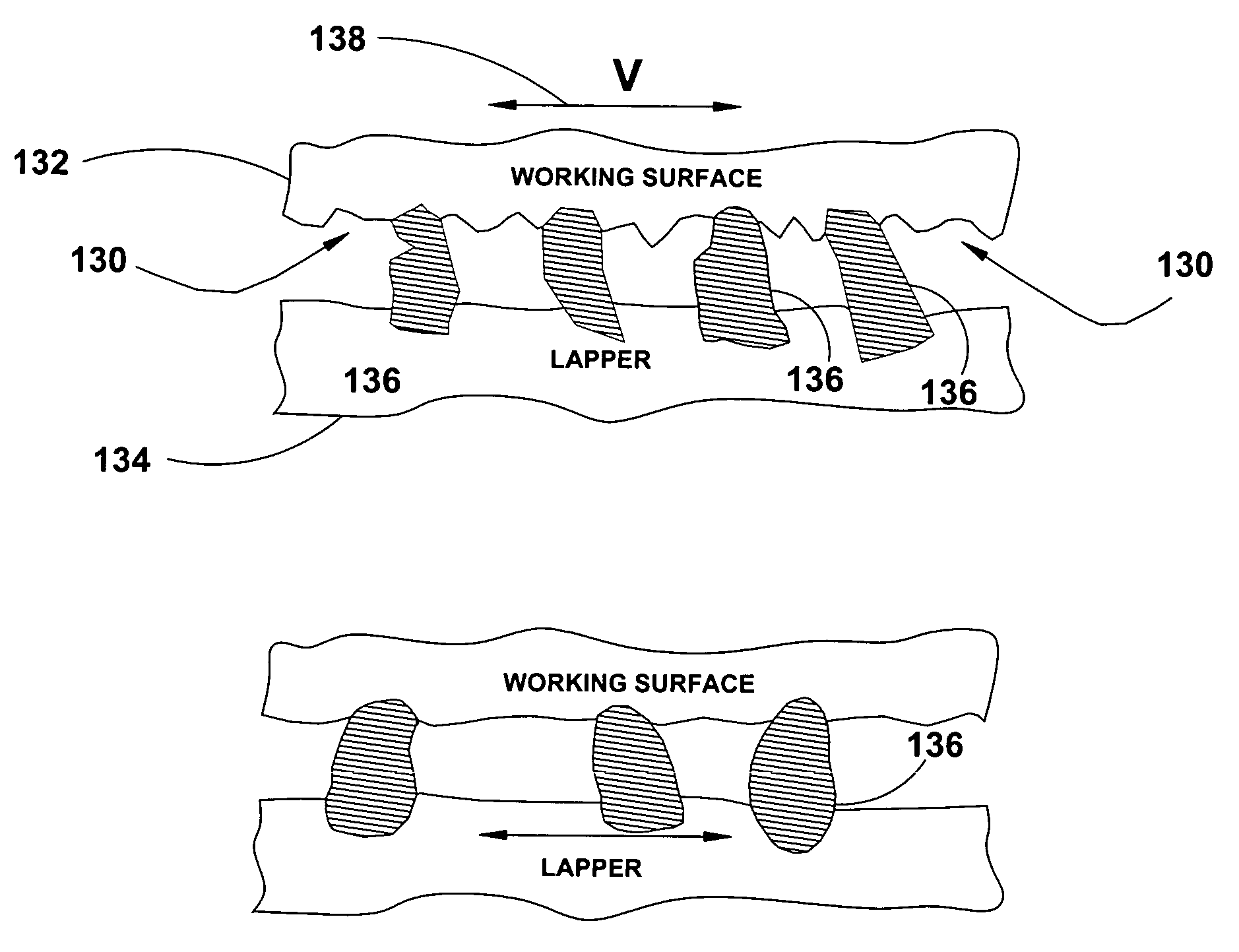

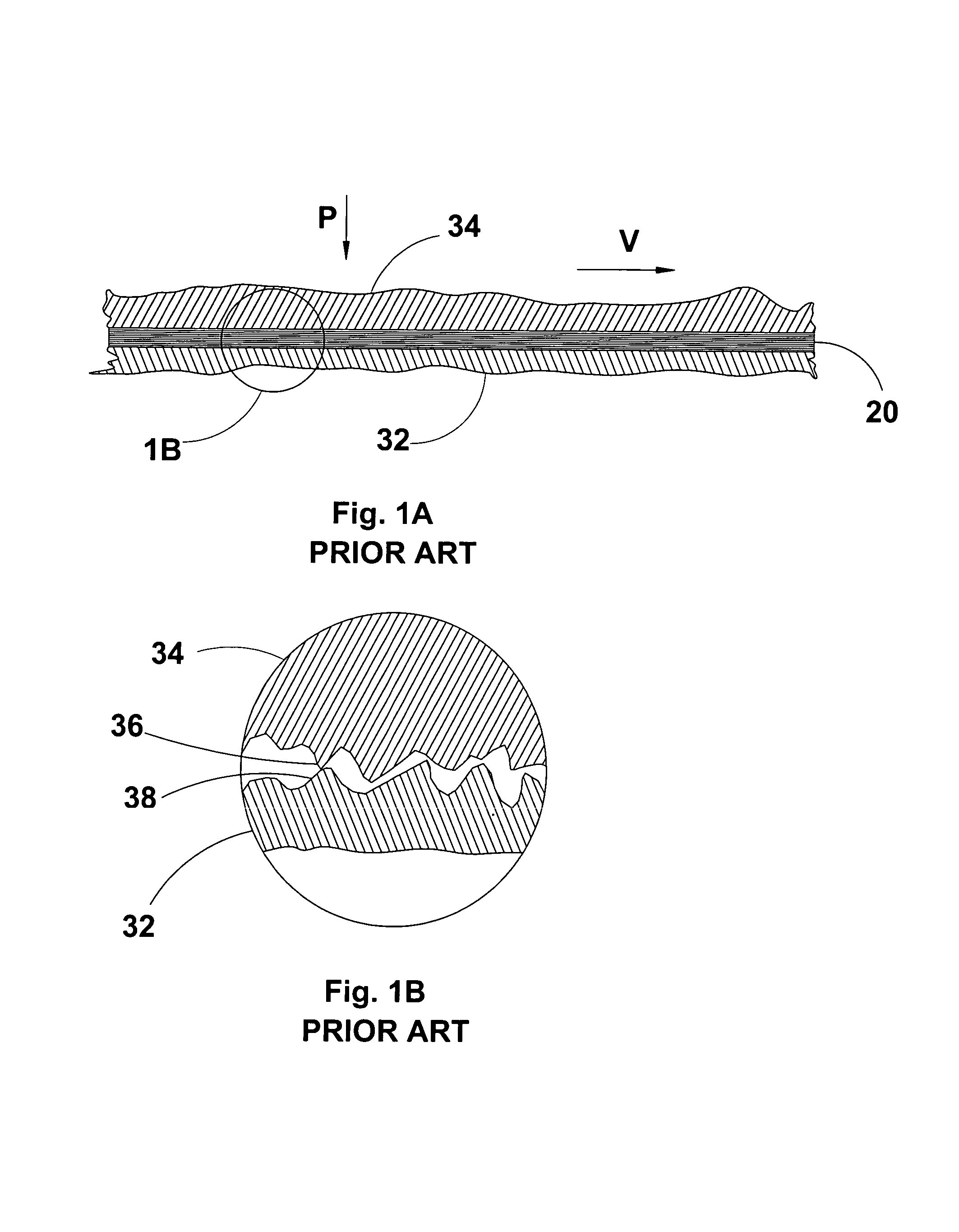

Method for reducing wear of mechanically interacting surfaces

InactiveUS7134939B2Reduce friction and wearProlong lifeLapping machinesBearing componentsEngineeringLubricant

The invention is about reducing friction and wear and risk of seizure of mechanically interacting lubricated surfaces. A working surface of a mechanical piece engaged with another piece in relative sliding movement is processed for reduced friction. Two distinctly separate zones are allocated on the surface, one attractive to a lubricant used and the other repelling to the lubricant. The repellency may be conveyed to the repelling zone by either a mechanical modifying process or by a chemical change. In a preferred embodiment of the invention the repellency is obtained by lapping. The lubricant attractive layers are associated in a preferred embodiment of the invention with an assembly of recessed microstructures.

Owner:FRICSO

Method for preparing modified graphene oxide anti-wear agent

ActiveCN104017627AImprove lubrication performanceReduce friction and wearAdditivesSolventRare-earth element

The invention relates to a method for preparing a modified graphene oxide anti-wear agent. The method disclosed by the invention comprises the following steps: adding graphene oxide and a compound containing boron, molybdenum, calcium, copper and rare earth elements into a three-mouth flask, adding an organic solvent into the container, stirring, heating, adding concentrated sulphuric acid serving as a catalyst to react, heating to the boiling point temperature of the solvent to evaporate the solvent, putting the product into a vacuum drying oven to obtain the modified graphene oxide anti-wear agent. The method disclosed by the invention has the advantages that the problems that oily lubricants and solid lubricants are high in cost, strict in service condition, troublesome in replacement, not friendly to environment due to produced wastes and the like are solved; by utilizing the characteristics that the graphene oxide is ultrathin, ultrahard, ultra lubricative and resistant to corrosion and high temperature, the novel anti-wear agent with excellent performances is prepared through the surface modification of the elements with the anti-wear property; by means of the product, the lubricating property of the lubricants can be remarkably improved, the friction and the wear of the mechanical movement surface are reduced by a big margin and the efficacies of saving material and energy are provided.

Owner:扬州智创企业运营管理服务有限公司

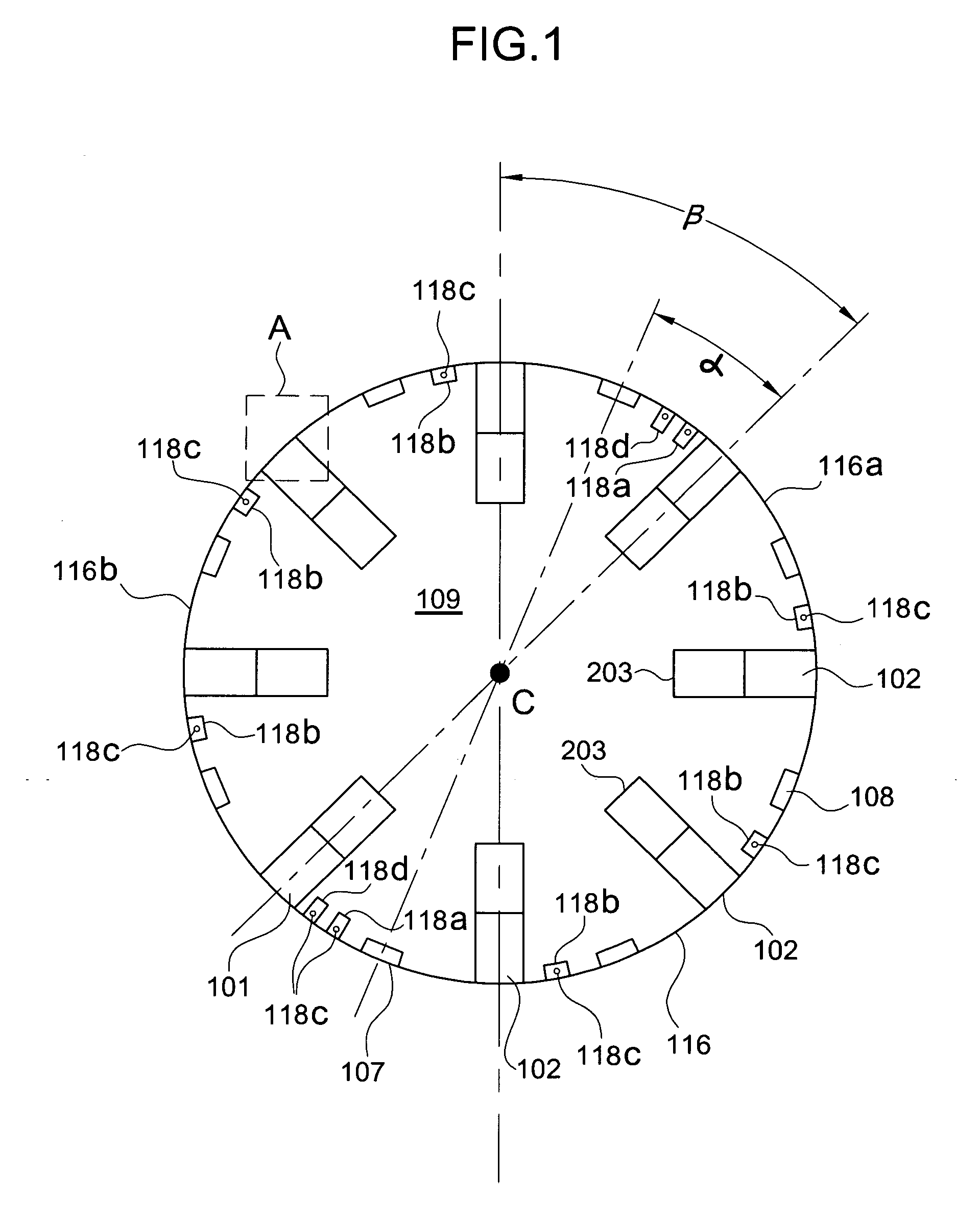

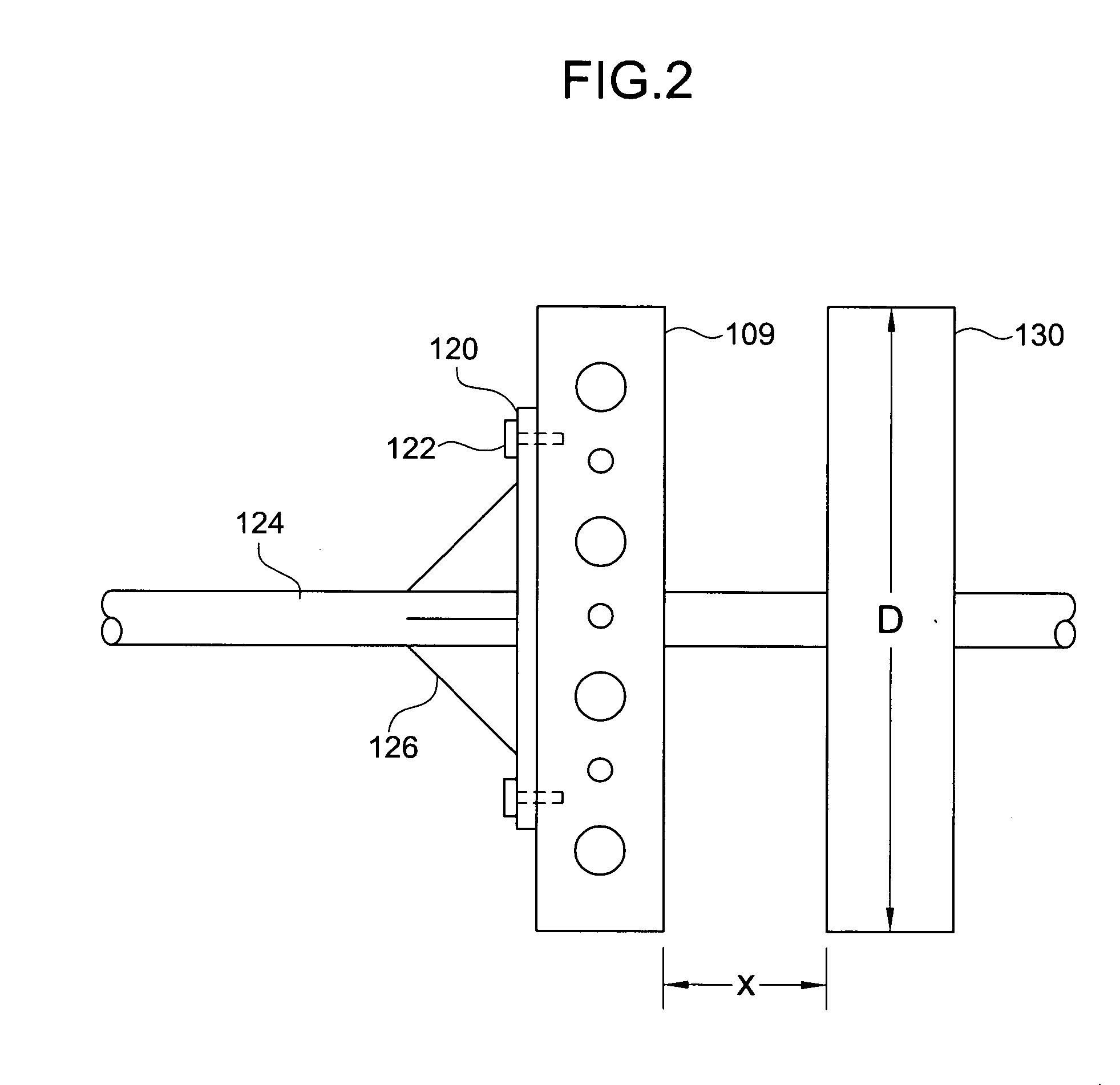

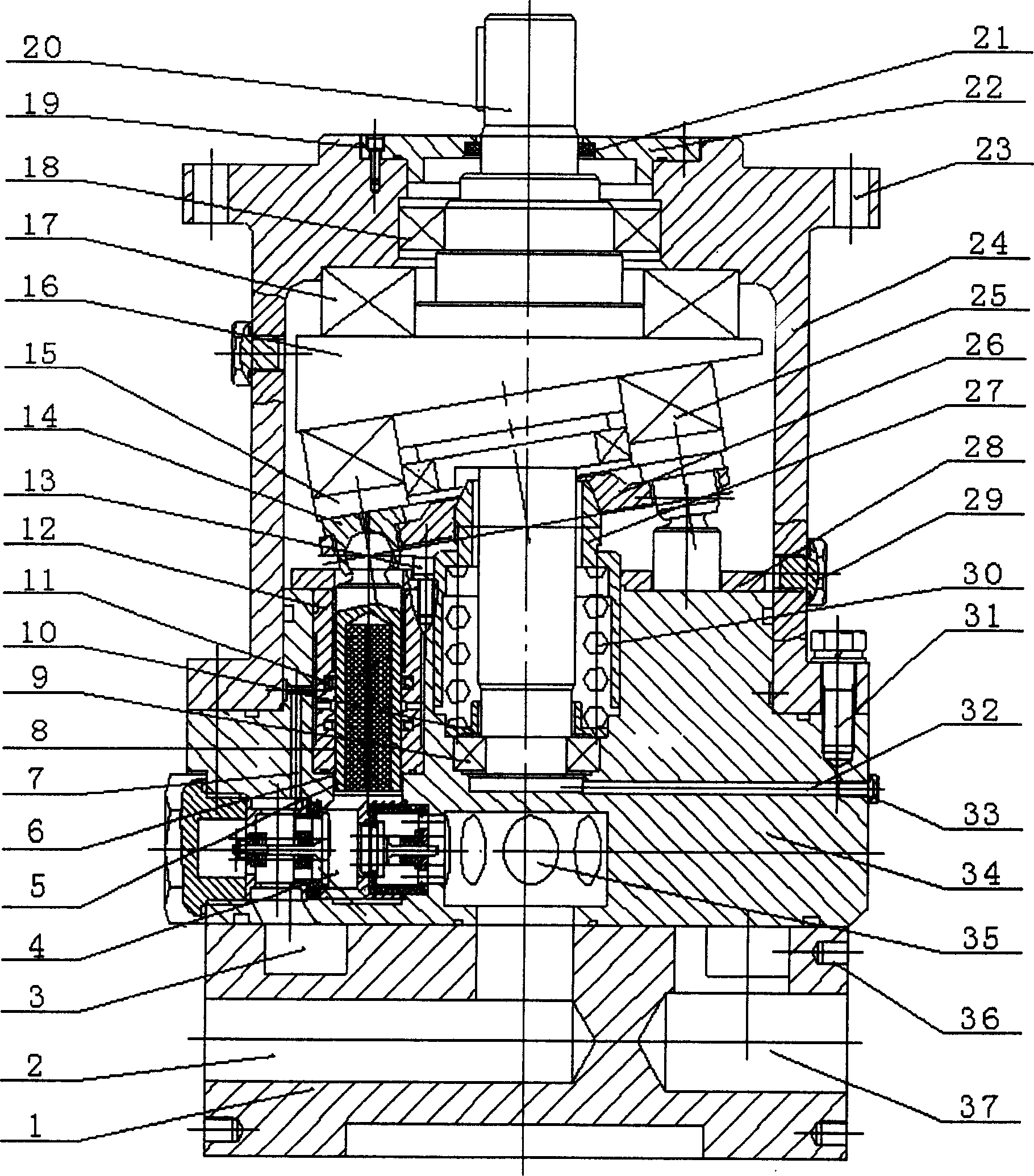

Radial valve orificing axial hydraulic pressure plunger pump

InactiveCN1904359AAvoiding Bearing Selection DilemmasImprove maintainabilityPositive displacement pump componentsPositive-displacement liquid enginesEngineeringCylinder block

In the invention, an inclined disk is bound on the mainshaft disk at the bottom of the mainshaft and on the inclined disk are uniformly set piston shoes in the flexible connection with the plunger. The plunger hole uniformly set on the cylinder is fitted with the plunger. On the central shaft of the cylinder are disposed a central spring, a spherical hinge and a return disk the piston shoes are close up to the inclined disk. The back-end cap has a radial water outlet and a radial water inlet and the central hole of the back-end cap is in communication with the water outlet. There is a ring groove around the central hole in communication with the water inlet. The mounting hole on the cylinder is corresponding to each plunger hole and in communication with the cylinder central notch. In the mounting hole is mounted a valve body. The cylinder central notch is in communication with the back-end cap central hole and each mounting hole is in communication with the back-end cap ring groove.

Owner:HUAZHONG UNIV OF SCI & TECH

High-carbon gray cast iron automobile brake disk and production method thereof

ActiveCN103225037AShorten the lengthConvenient lengthBraking discsFriction liningChemical compositionHigh carbon

The invention relates to a high-carbon gray cast iron automobile brake disk and a production method thereof. The high-carbon gray cast iron automobile brake disk comprises the following chemical components in percentage by weight: 3.7-3.8% of C, 0.5-0.8% of Mn, 0.3-0.5% of Cu, 0.1-0.2% of Cr, 0.2-0.4% of Mo, 1.6-2.0% of Si, 0.1-0.2% of N, 0.01-0.12% of P, 0.05-0.12% of S and the balance of Fe. The brake disk provided by the invention has the outstanding characteristics of small brake temperature rise, abrasion resistance, favorable heat fatigue resistance effect and the like; the performance of an automobile brake system can be obviously improved, and the service life can be obviously prolonged; and meanwhile, the potential safety hazard caused by ineffective brake due to high temperature can be effectively eliminated. Thus, the high-carbon gray cast iron automobile brake disk has high economic value.

Owner:河南淮海精诚工业科技有限公司

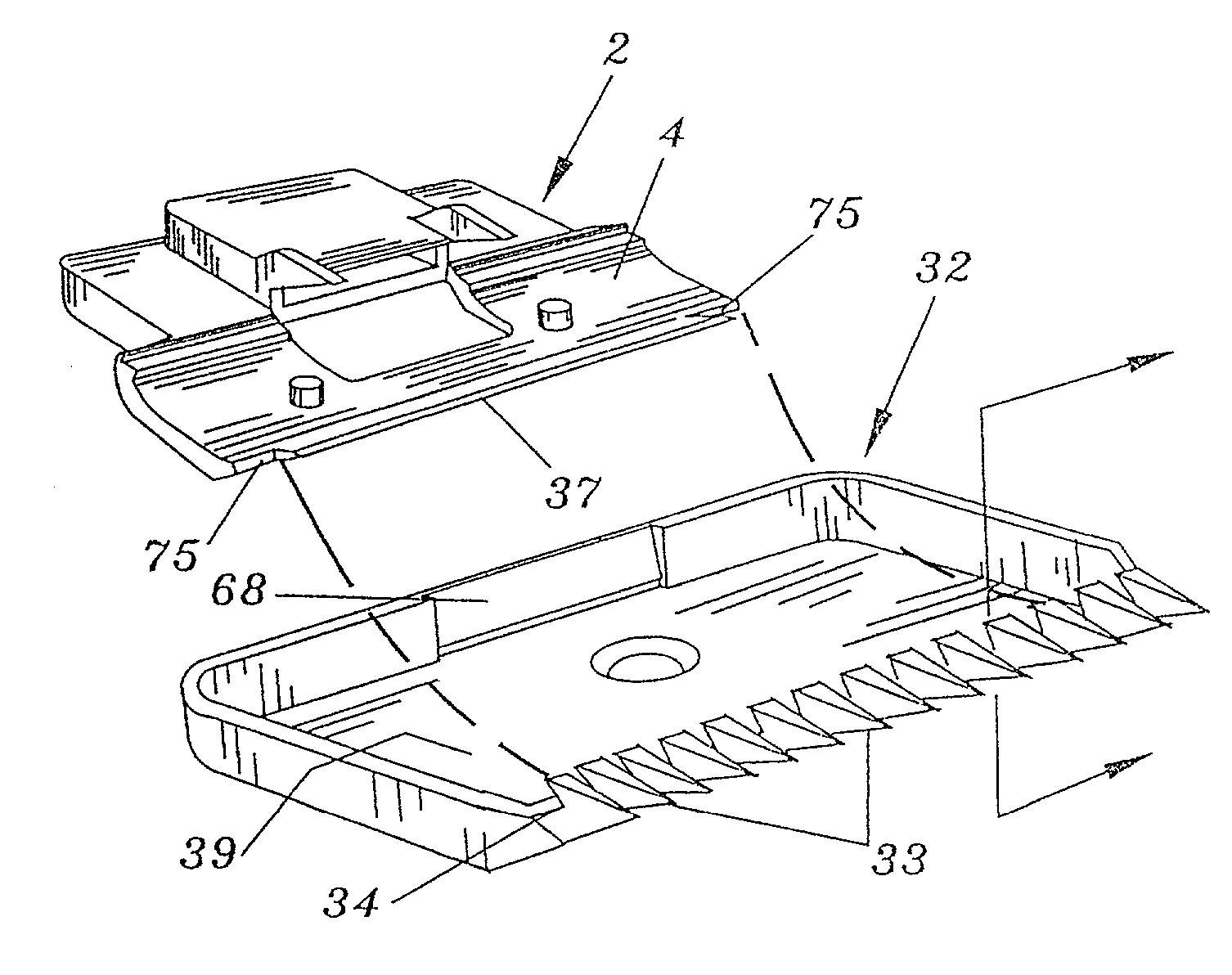

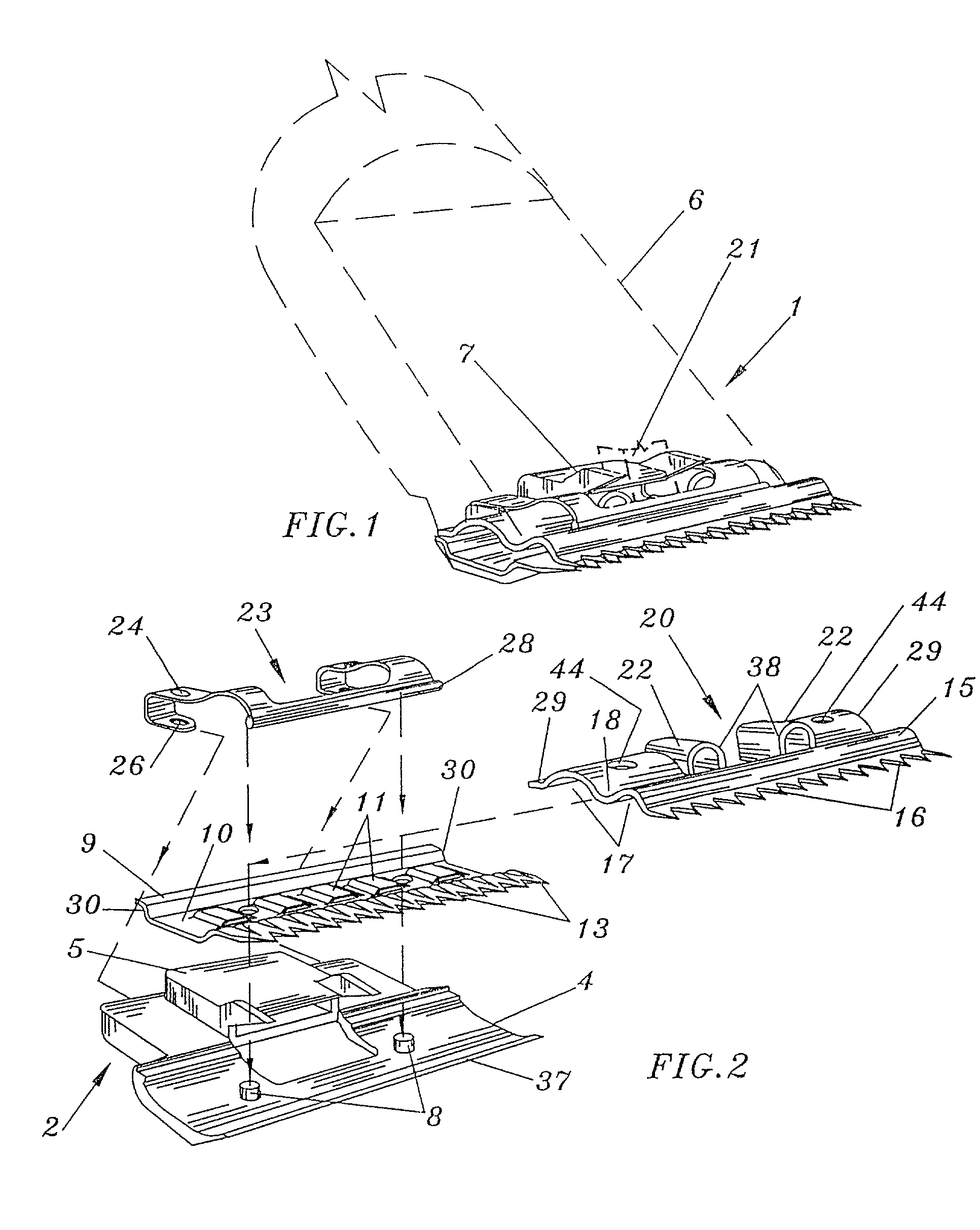

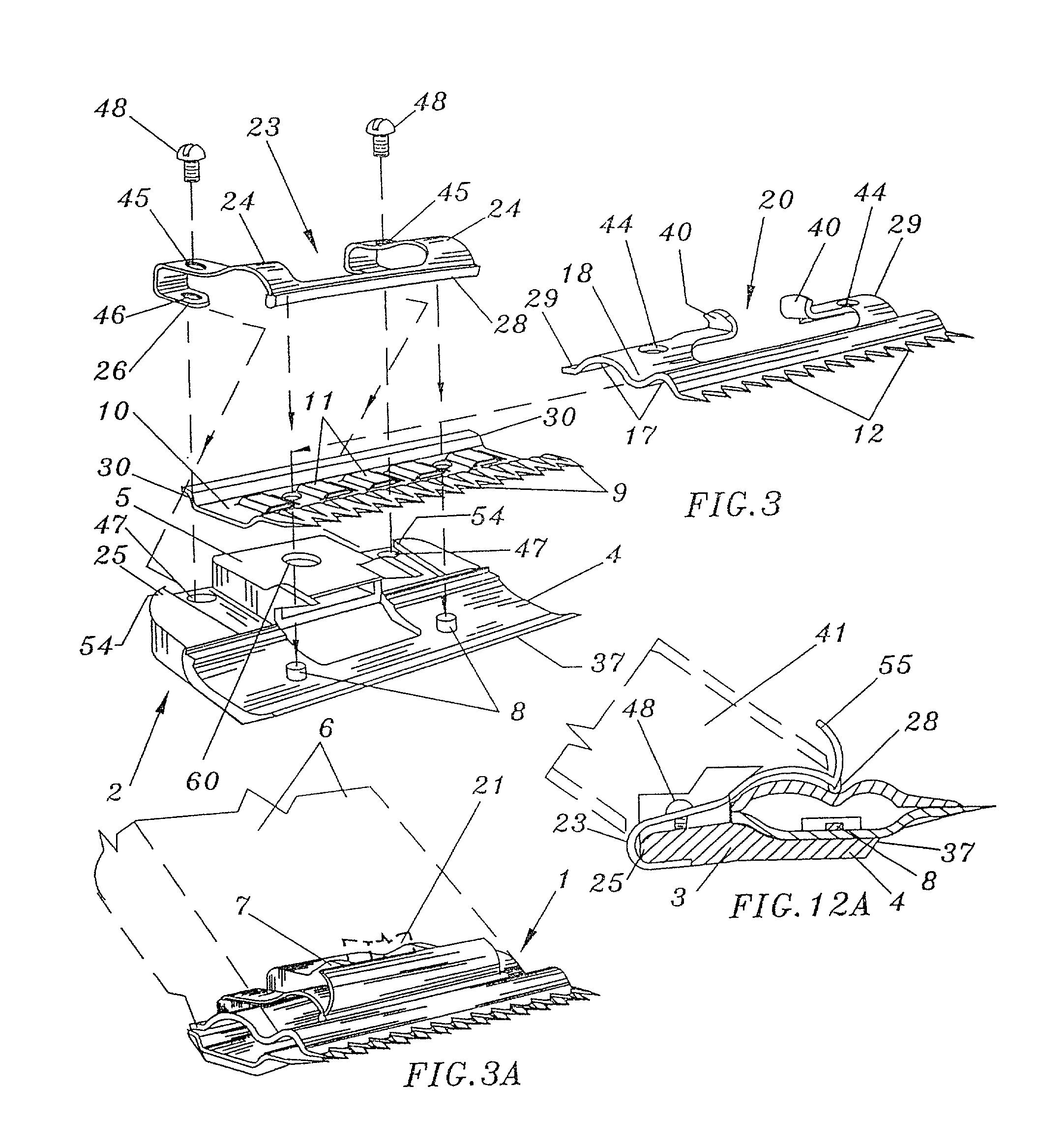

Disposable cutting head for clippers

InactiveUS7010859B2Lower frictionReduce frictional wearReciprocating piston enginesMetal working apparatusEngineeringKnife blades

The disposable cutting head is basically a four element clip together assembly with a base, lower and upper cutting blades, and spring. The base serves as the support for the entire assembly and incorporates the attachment elements for retention to a clipper. The spring holds the elements together, forces the cutting blades together and includes the runner under which the upper blade slides. The entire assembly is such that the head assembly with blades is of the disposable type, but uses metal blades. If desired the blades alone may be disposed and the head assembly reused; however, the structure is not intended for long wear and use. The head and blades are constructed such that the common problems encountered with existing removable / disposable heads and blades as for example heat retention in the blades and head and the catching and pulling of hair are minimized. Use with clipper comb elements is also accommodated.

Owner:LAUBE KIM

Surface texture of indium-iron grid-shaped spherical composite microcrystal composite layer

The invention discloses a surface texture of an indium-iron grid-shaped spherical composite microcrystal composite layer. A surface material layer is arranged on a part and mainly comprises larger indium-iron composite spherical microcrystal units of which the indium content exceeds 50% (Wt%) and the total content of indium and iron exceeds 55% (Wt%), each larger indium-iron composite spherical microcrystal unit is formed by close connection of at least four spherical crystal grains or nearly-spherical crystal grains, the larger indium-iron composite spherical microcrystal units are distributed regularly to form a grid, multiple single crystal grains or smaller indium-iron microcrystal units are closely distributed in the grid, each smaller indium-iron microcrystal unit is formed by close connection of at least two spherical crystal grains or nearly-spherical crystal grains, and the surface material layer and a base body material of the part are integrated to form the indium-iron grid-shaped spherical composite microcrystal composite layer; then a surface texture is machined on the part surface provided with the indium-iron grid-shaped spherical composite microcrystal composite layer and consists of multiple surface texture units, and the surface texture of the indium-iron grid-shaped spherical composite microcrystal composite layer is formed.

Owner:FUJIAN CHUANZHENG COMM COLLEGE

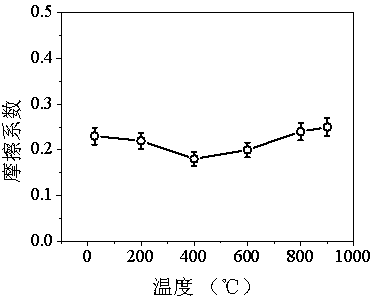

Preparation method for high-intensity nickel-based high-temperature self-lubricating composite material

The invention discloses a preparation method for a high-intensity nickel-based high-temperature self-lubricating composite material. The composite material is prepared by a hot-press sintering technology. The composite material has the characteristics of low friction abrasion and high intensity under low temperature of 900 DEG C. The material is suitable for manufacturing high-temperature mechanism lubricating components, such as a high-temperature bearing, a bushing, a sliding block and a sealing piece, which can be used at the low temperature of 900 DEG C and has a wide application prospect in the fields of aviation, metallurgy, machinery and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

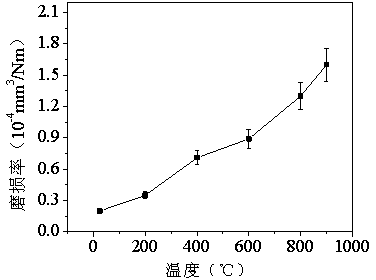

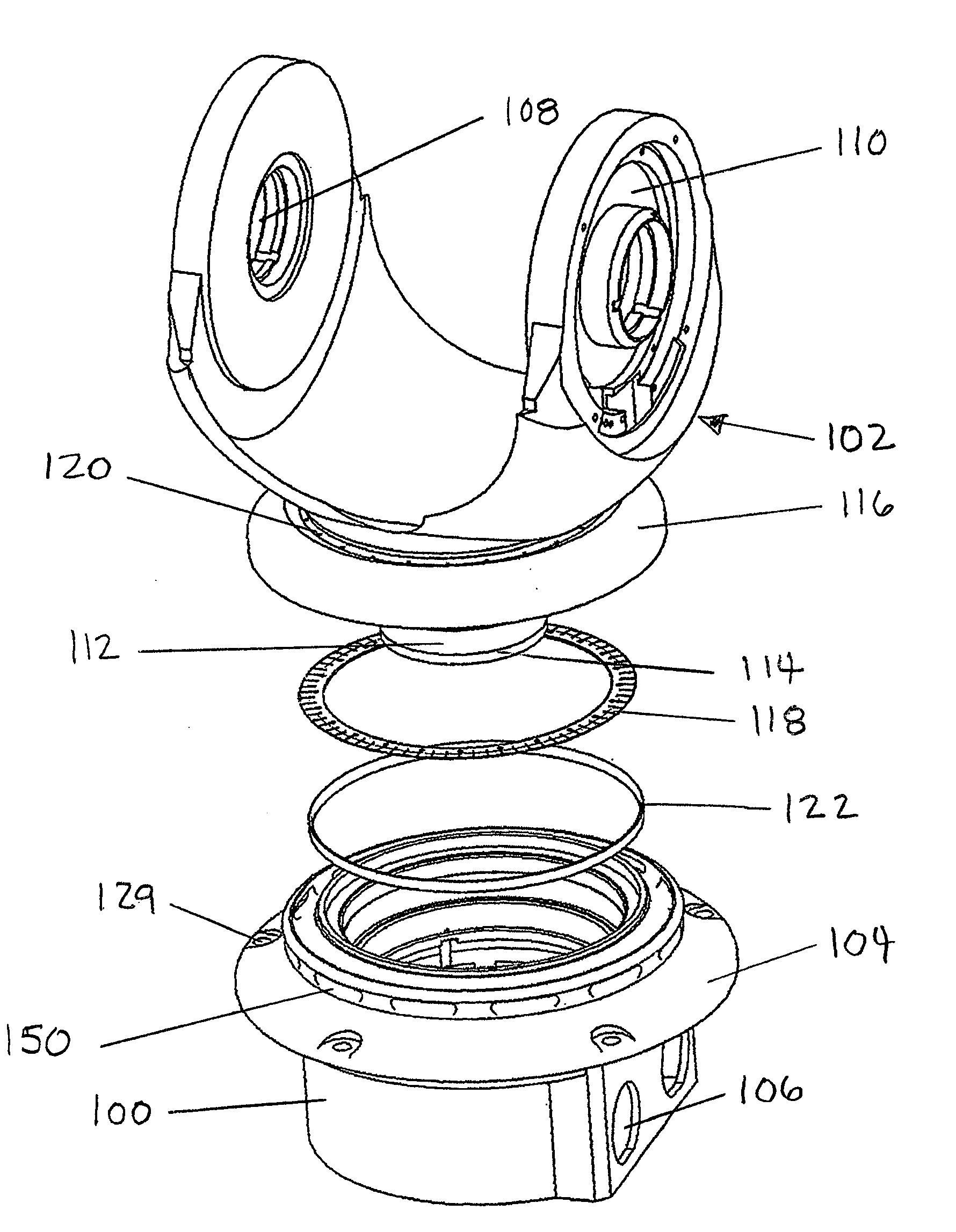

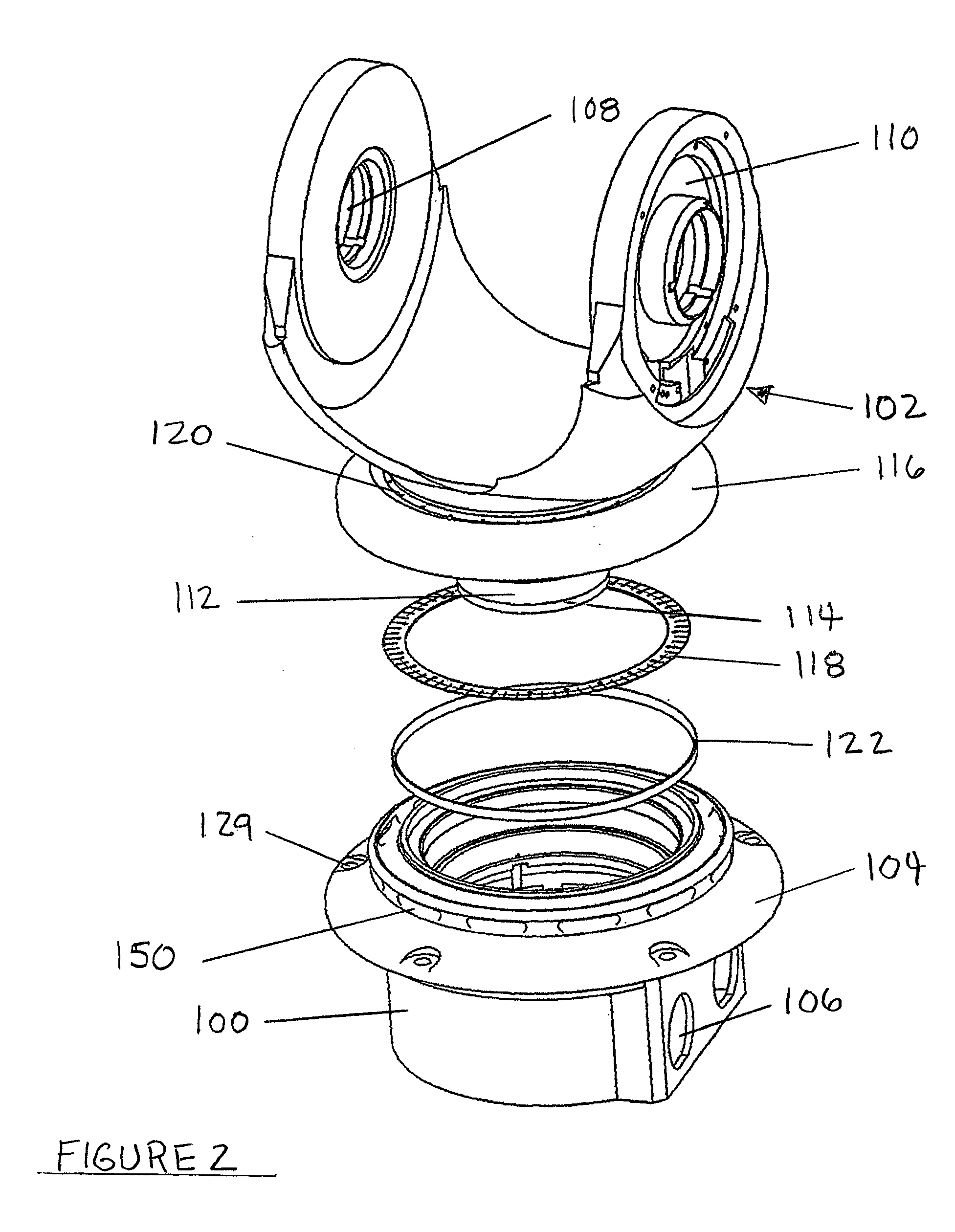

Sealed rotary joint for turret rotator

ActiveUS20060033288A1Reduce friction and wearEngine sealsMagnetically actuated clutchesEngineeringGravitational force

A rotatable payload support turret for operation in a potentially hazardous environment includes a fixed element attached to a vehicle or fixed structure and a rotatable element, supported for rotation with respect to the fixed element. The turret includes a camera payload having a pointing direction configured to be upwardly pointing. An annular clearance gap formed between the fixed element and the rotatable element is sealed by a conventional gas tight magnetic fluid seal element. A wiper seal is also provided in the clearance gap between the location of the magnetic fluid and the external environment to prevent breakdown of the magnetic fluid by elements of the potentially hazardous environment. The clearance gap may also form a labyrinth seal having up to three legs that are oriented to oppose a gravitational force direction. In addition, the fixed element may include a fluid repelling feature for repelling streams of incoming fluids thereby deflecting elements of the potentially hazardous environment away from an outer opening of the clearance gap.

Owner:TELEDYNE FLIR LLC

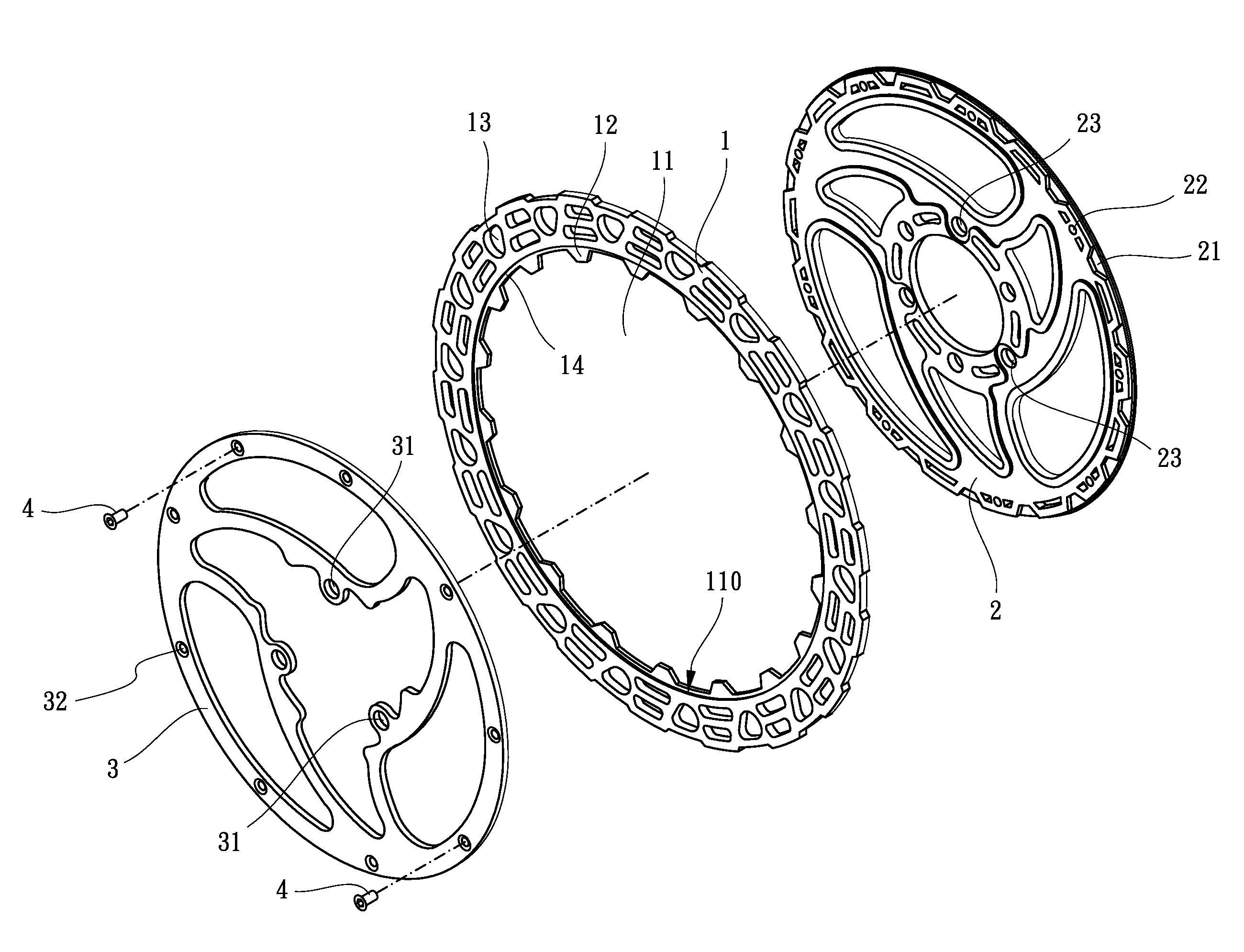

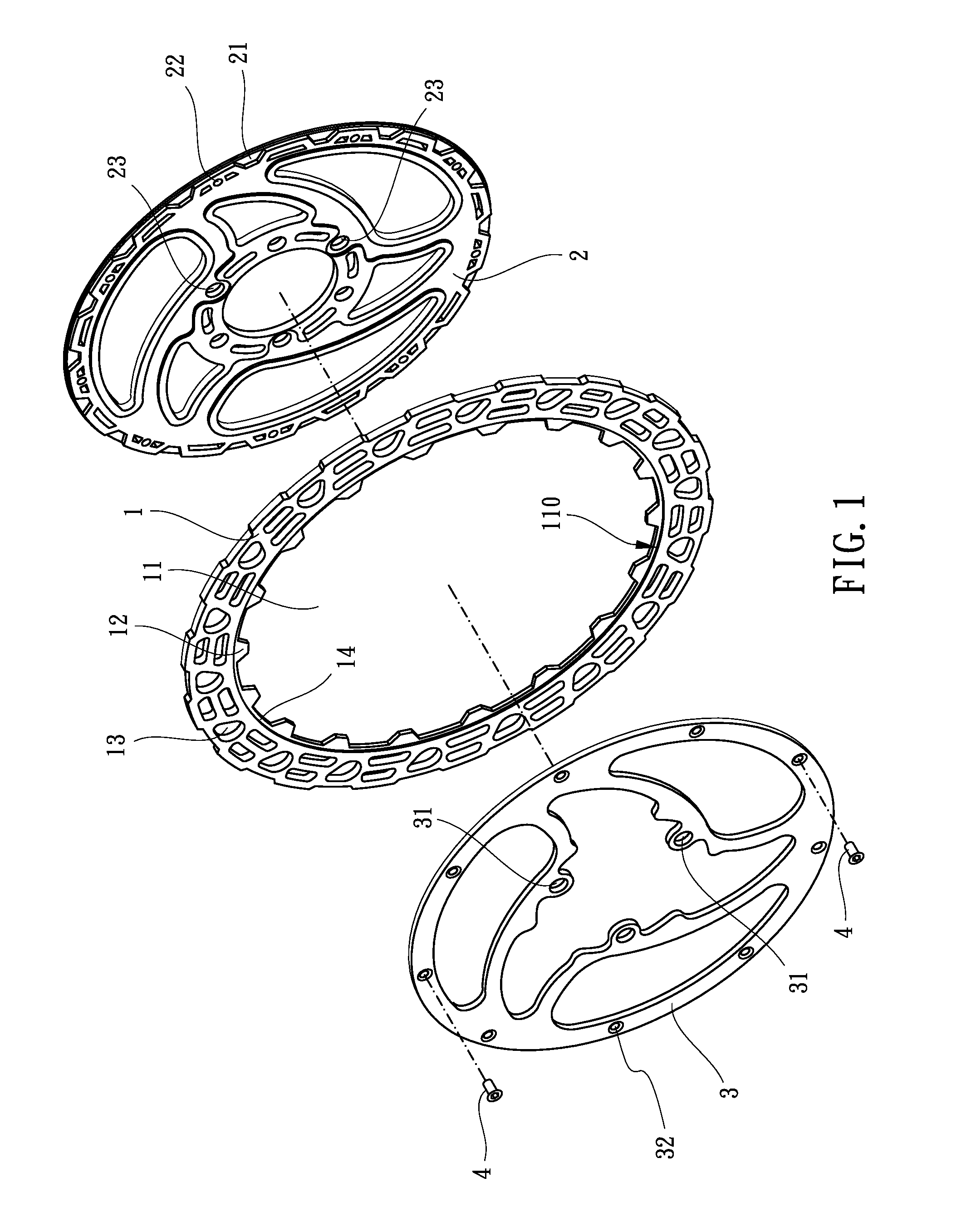

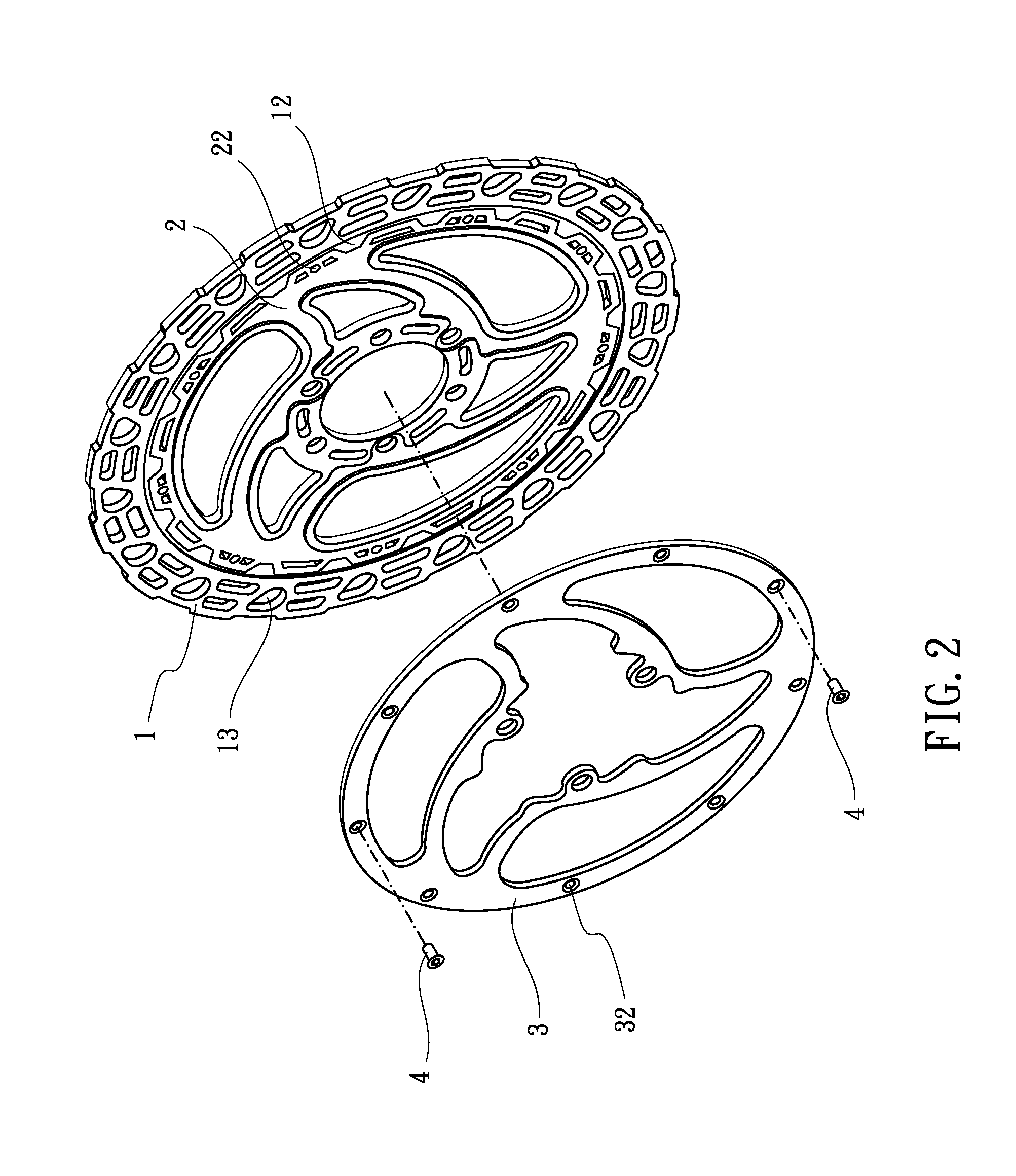

Brake Disk Assembly

InactiveUS20130240309A1Improve cooling effectReduce friction and wearBraking discsFriction liningPulp and paper industry

A brake disk assembly includes a friction disk clamped between the supporting plate and the fixing plate. The friction disk is axially movable relative to the supporting plate and the fixing plate. The contact area between the friction disk and either one of the supporting plate and the fixing plate is increased to firmly connect the friction disk and the supporting plate and the fixing plate.

Owner:ASHIMA LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com