High performance and low cost C/C-SiC composite brake disc, preparation method and application thereof

A technology of composite materials and brake discs, applied in the direction of brake discs, mechanical equipment, gear transmission mechanisms, etc., can solve problems such as poor heat dissipation, poor wear resistance, thermal cracks, etc., achieve strong interlayer bonding, improve Effect of creep resistance and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing a composite material brake disc, which is characterized in that it comprises the following steps:

[0029] S1: Carbonize the brake disc prefabricated body, and then use the chemical vapor deposition method to densify the carbonized brake disc prefabricated body to obtain a C / C composite material; wherein, the brake disc prefabricated body is made of polyacrylonitrile-based prefabricated Oxygen silk fibers are formed by three-dimensional needle punching; the carbonization temperature is 1000-1400°C, the time is 45-75h, and the carbonization is carried out under vacuum conditions; the chemical vapor deposition method is specifically: one of propane, natural gas and propylene or several kinds of carbon source gas, nitrogen and / or hydrogen as dilution gas, infiltration temperature is 900-1200°C, infiltration pressure is 1000-5000Pa, and infiltration time is 50-200h; among them, carbon source gas and dilution gas The volume ratio...

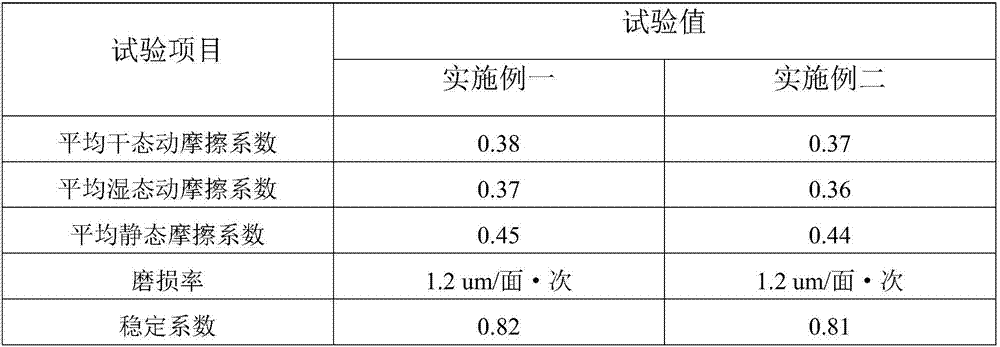

Embodiment 1

[0036] The single-layer 0° no-weft cloth, tire net, 90° no-weft cloth, and tire net are superimposed in sequence, and then the polyacrylonitrile (PAN)-based pre-oxidized silk fiber is introduced in the direction perpendicular to the lay-up direction by the relay-type needling method. , to make a brake disc prefabricated body; under vacuum conditions, the brake disc prefabricated body was carbonized at a temperature of 1200 ° C for 60 hours; and then the carbonized brake disc prefabricated body was Densification, using propane as the carbon source gas, nitrogen as the diluent gas, the volume ratio of propane to nitrogen is 1:2, the infiltration temperature is 1150°C, the infiltration pressure is 3000Pa, the infiltration time is 120h, and the obtained density is 1.3g / cm 3 C / C composite materials.

[0037] Under the protection of argon, the C / C composite material is subjected to high-temperature heat treatment at 2200 ° C for 2 hours; then it is machined, and according to the p...

Embodiment 2

[0041] The single-layer 0° no-weft cloth, tire net, 90° no-weft cloth, and tire net are superimposed in sequence, and then the polyacrylonitrile (PAN)-based pre-oxidized silk fiber is introduced in the direction perpendicular to the lay-up direction by the relay-type needling method. , to make a brake disc prefabricated body; under vacuum conditions, the brake disc prefabricated body was carbonized at a temperature of 1200 ° C for 60 hours; and then the carbonized brake disc prefabricated body was Densification, using propane as the carbon source gas, nitrogen as the diluent gas, the volume ratio of propane to nitrogen is 1:2, the infiltration temperature is 1150°C, the infiltration pressure is 3000Pa, the infiltration time is 120h, and the obtained density is 1.3g / cm 3 C / C composite materials.

[0042] Under the protection of argon, the C / C composite material is subjected to high-temperature heat treatment at 2200 ° C for 2 hours; then it is machined, and according to the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com