Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

164 results about "Dilution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dilution is the process of decreasing the concentration of a solute in a solution, usually simply by mixing with more solvent like adding more water to a solution. To dilute a solution means to add more solvent without the addition of more solute. The resulting solution is thoroughly mixed so as to ensure that all parts of the solution are identical. The same direct relationship applies to gases and vapors diluted in air for example.

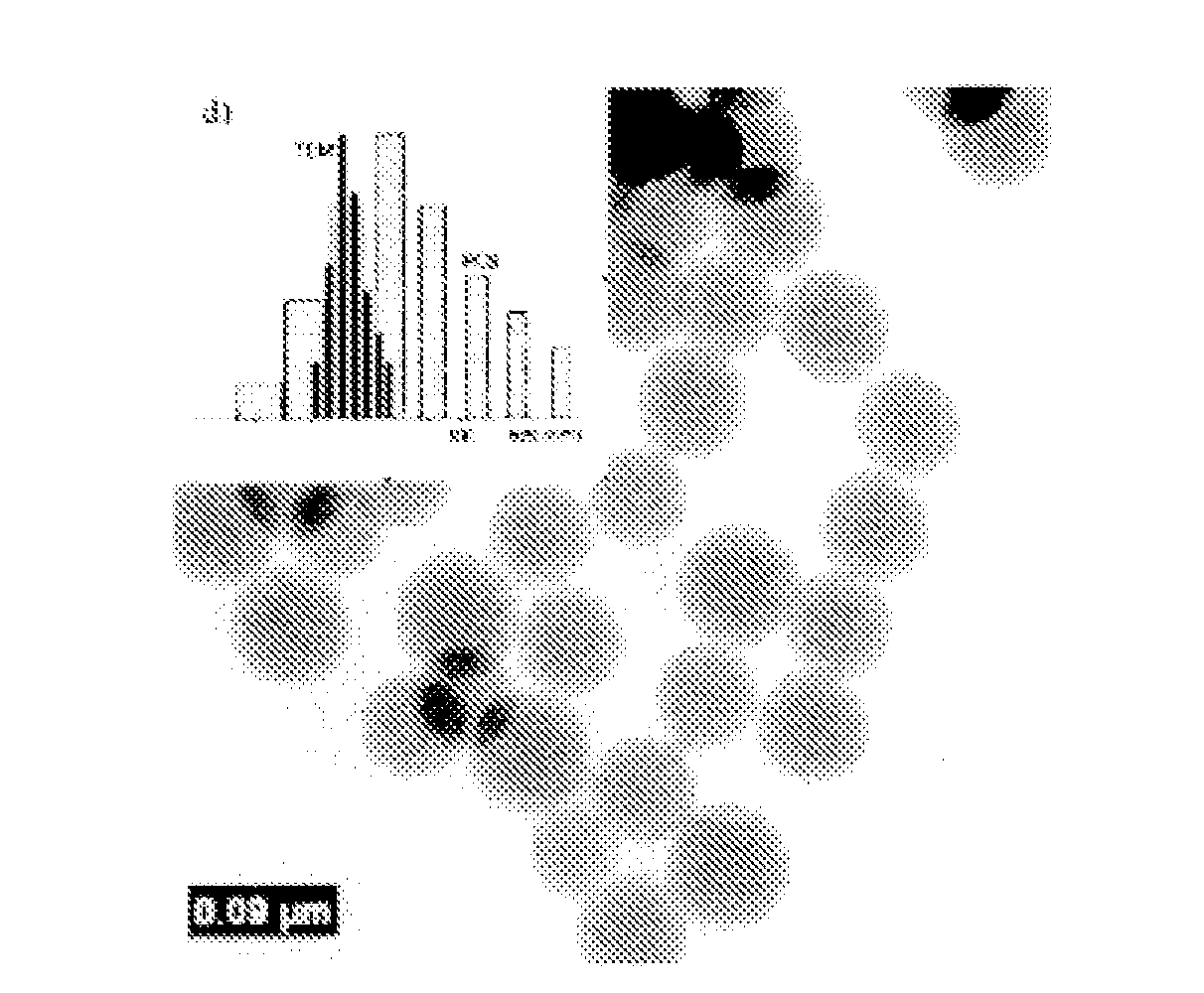

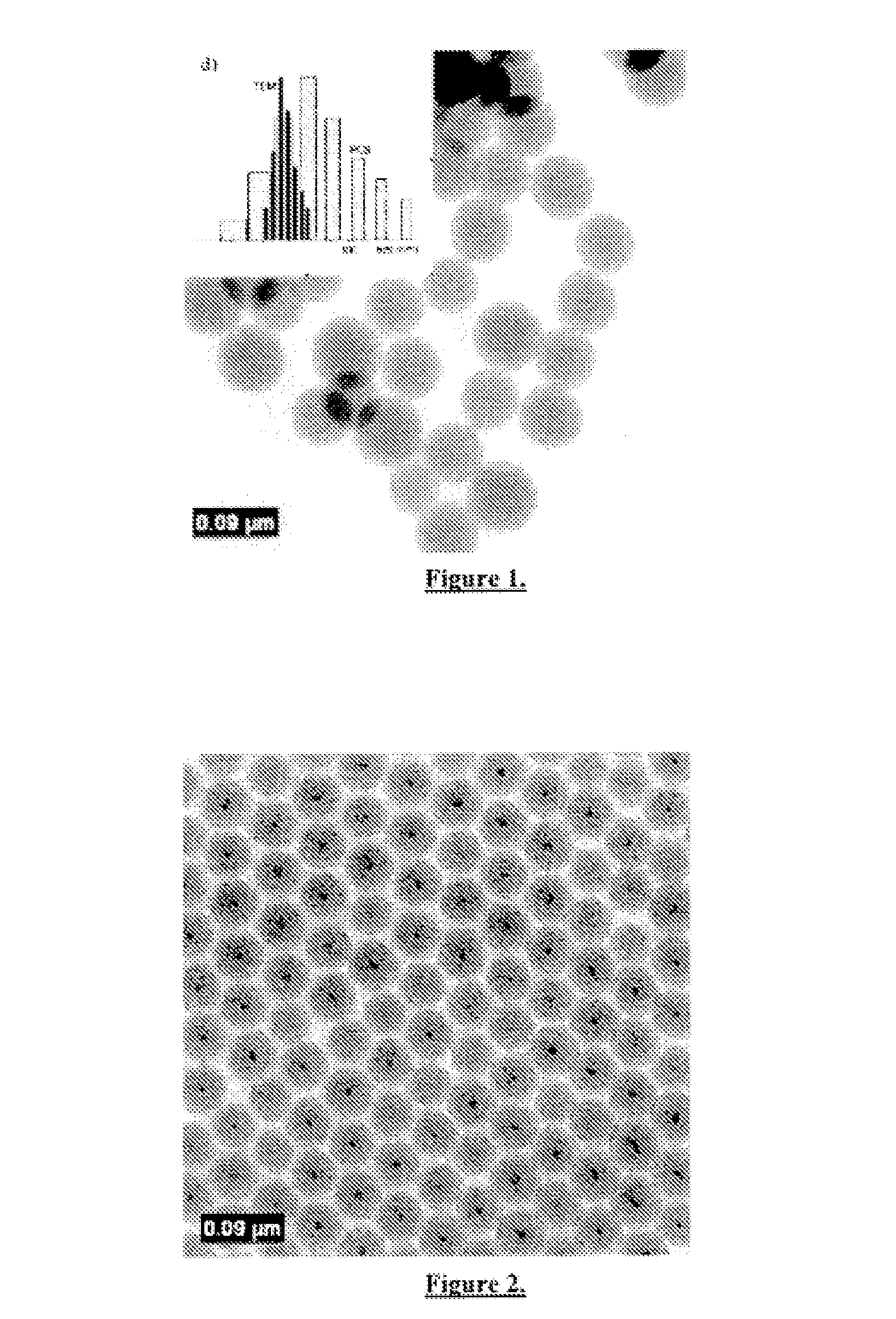

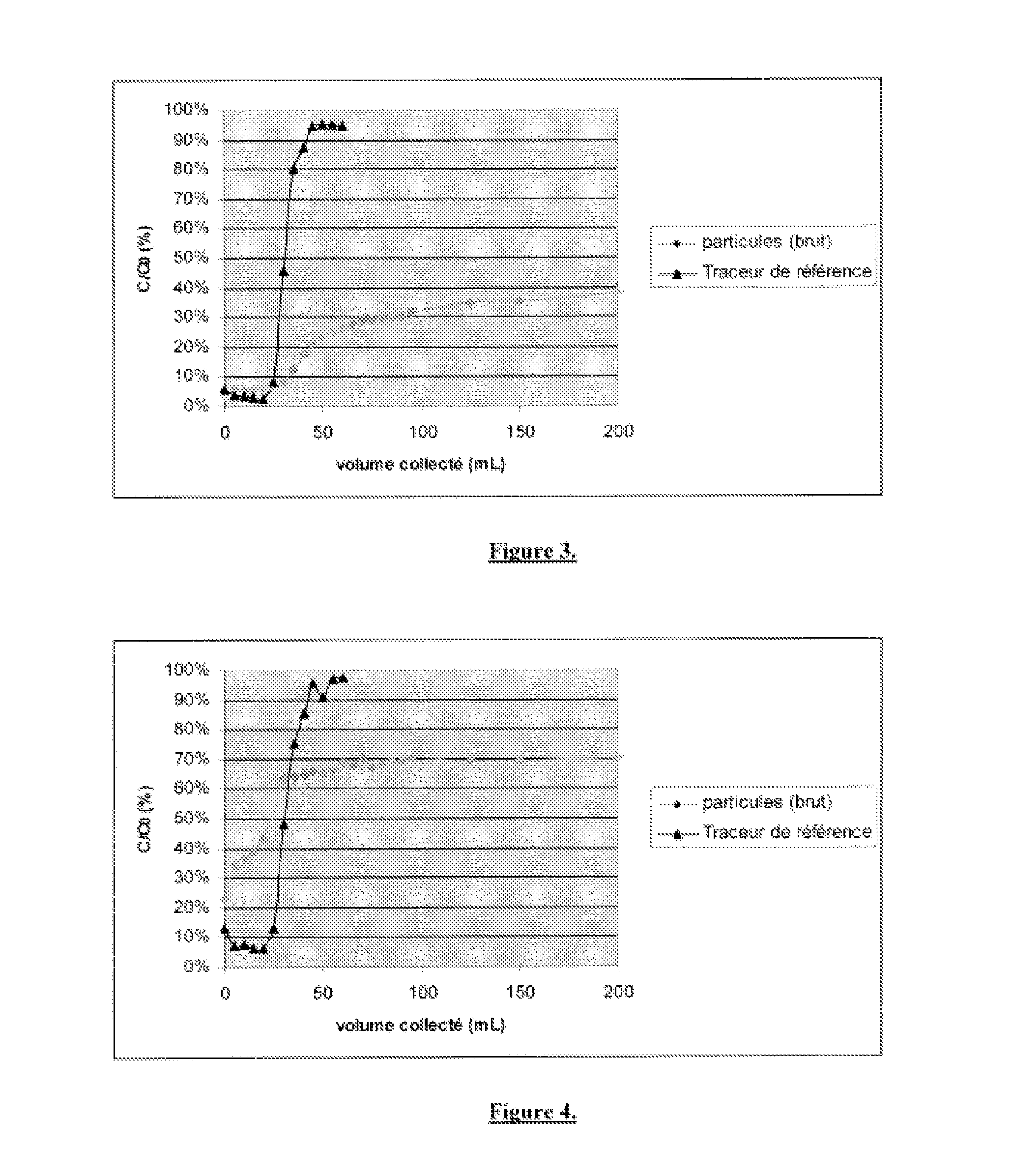

Use of nanoparticles for labelling oil field injection waters

InactiveUS20130084643A1Effective sizeEasy to implementOptical radiation measurementSurveyInjection wellOrganosilicon

The present invention relates to the development of tracer fluids, more generally, that of aqueous liquids, intended to be injected under pressure in an oil reservoir, for example from an injection well up to a production well.The object of the invention is to propose a new method of study of a solid medium, i.e. an oil reservoir, by diffusion of a liquid (i.e. injection waters) containing tracers, through said solid medium, which is simple to implement and economical and which remedies the drawbacks of the known tracers for injection waters of oil reservoirs.This method essentially consisting of injecting, in this solid medium, an injection liquid comprising a nanoparticle-based tracer having average dimensions comprised between 20 and 200 nm, detectable by means of one or several S signals at dilutions of less than or equal to 10−7, adapted to form a stable colloidal suspension in a saline medium, at least a portion of which is constituted of a core and a coating provided with an adjustable hydrophilic-lipophilic balance (HLB) and comprising at least one organic and / or organosilicon component; recovering the liquid having diffused; and analyzing this liquid having diffused to measure the quantity of tracer by detection of the signal or signals S.

Owner:TOTAL PUTEAUX FR

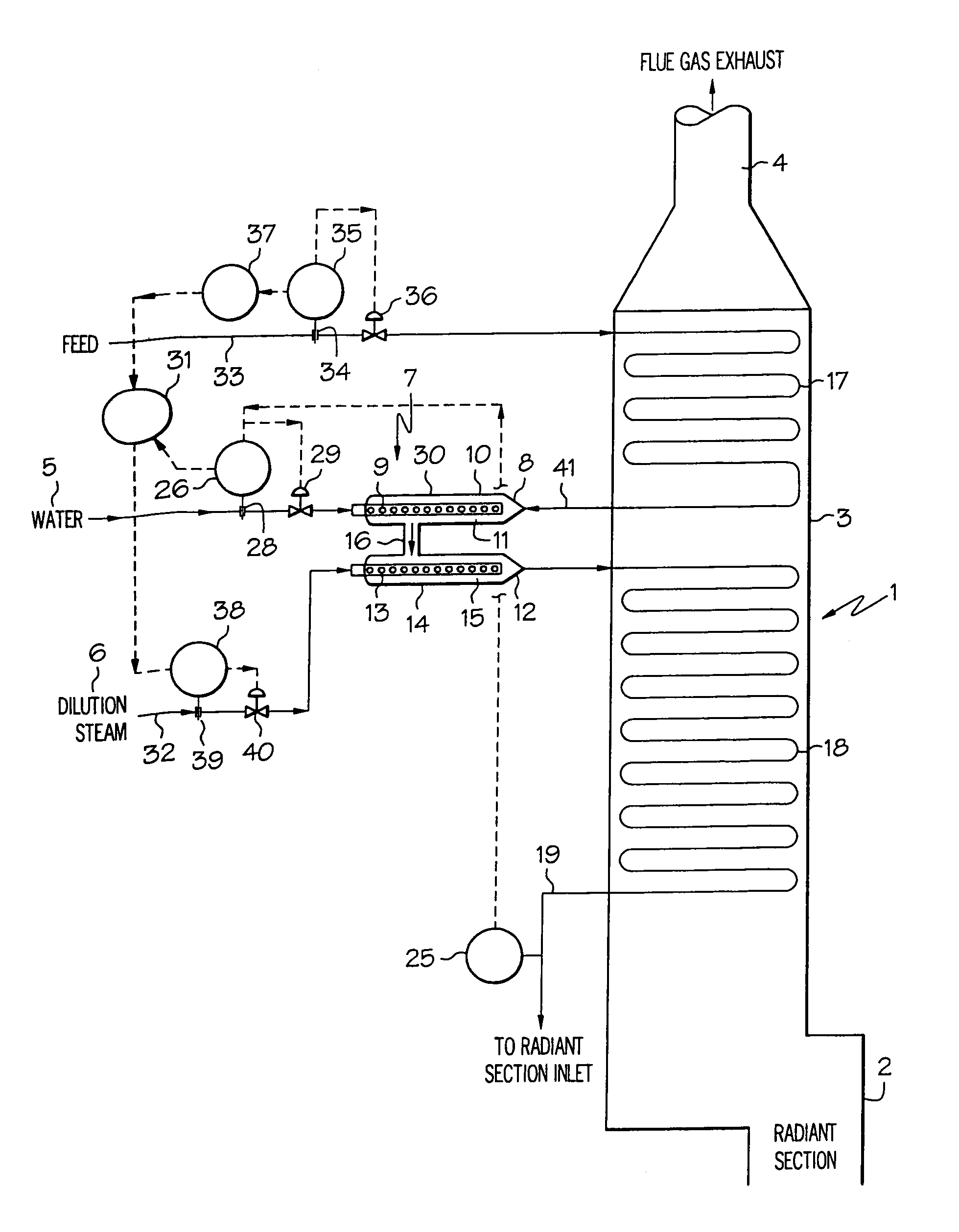

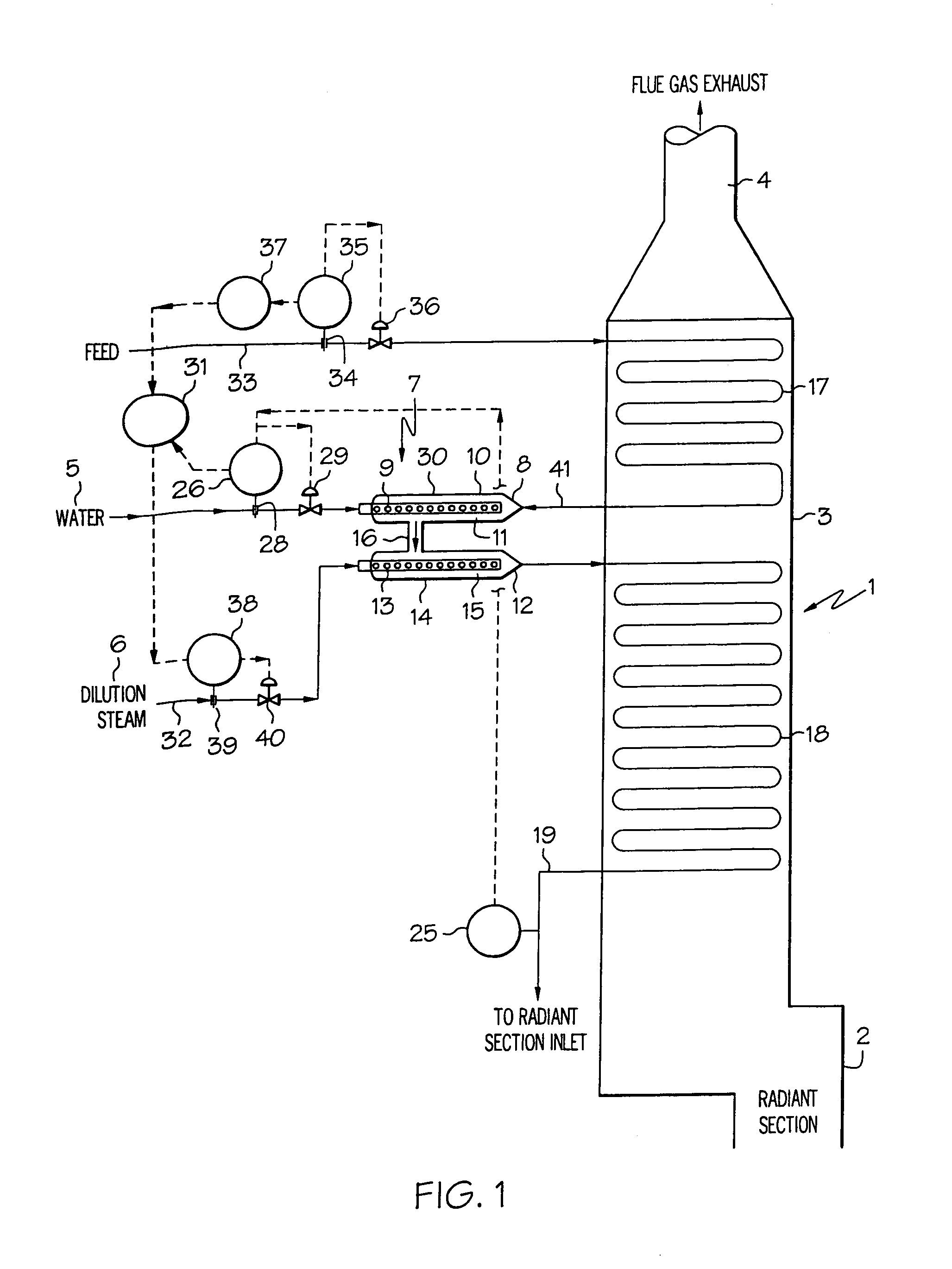

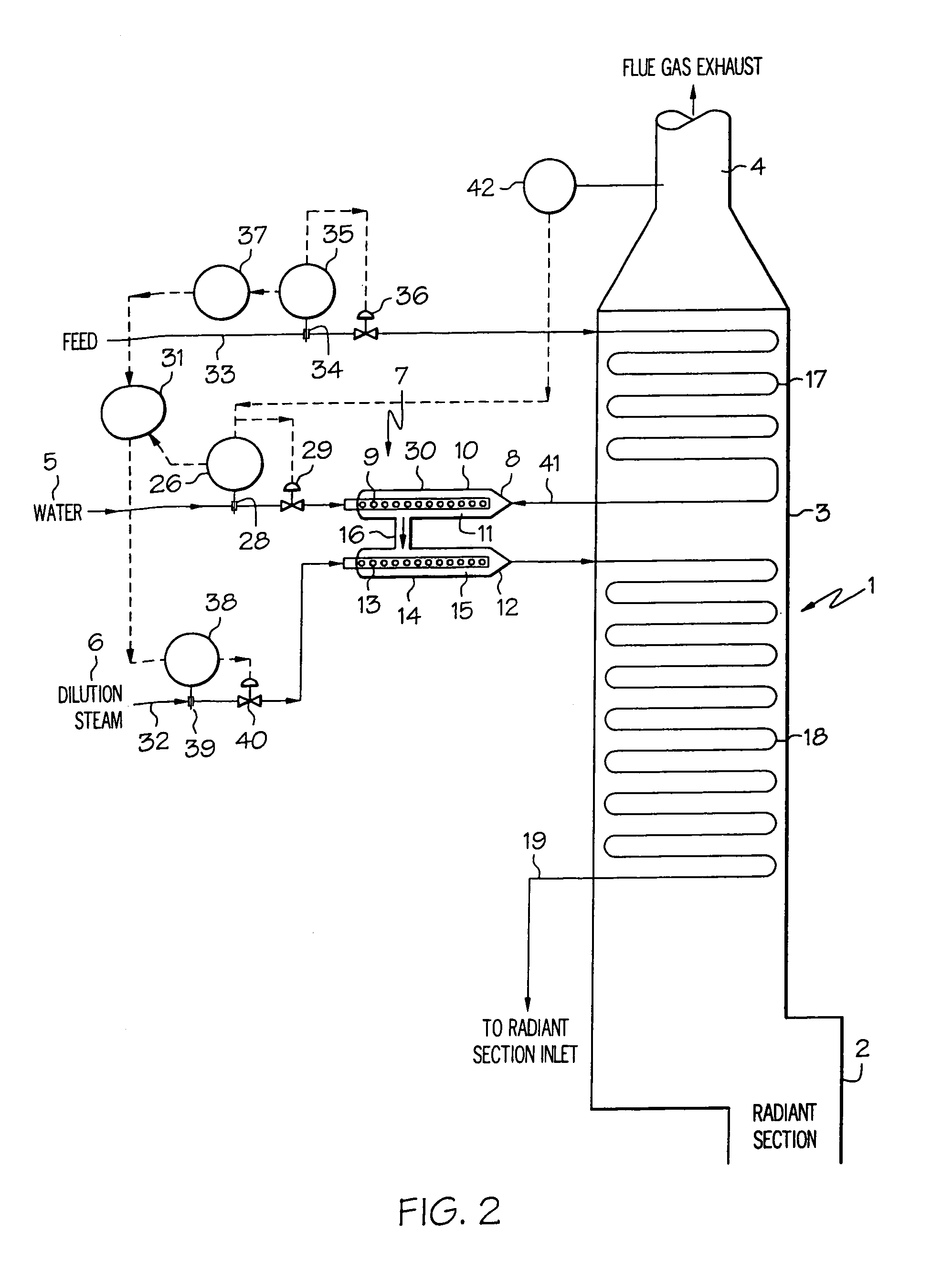

Process for cracking hydrocarbon feed with water substitution

InactiveUS7090765B2Thermal non-catalytic crackingHydrocarbon oil cracking processHydrocarbonHydrocotyle bowlesioides

A process for treating hydrocarbon feed in a furnace, the process comprising: (a) heating hydrocarbon feed, (b) adding water to the heated feed, (c) adding dilution steam to the heated feed to form a mixture, (d) heating the resulting mixture and feeding the resulting heated mixture to the furnace, wherein the water in (b) is added in an amount of from at least about 1% to 100% based on water and dilution steam by weight.

Owner:EXXONMOBIL CHEM PAT INC

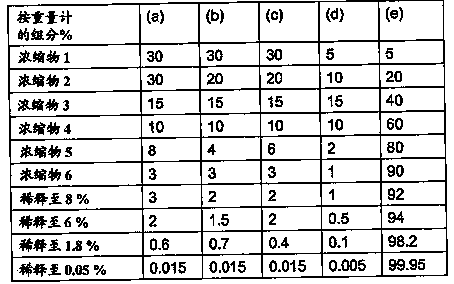

Concentrated Liquid Detergent Composition And Process For Production Thereof

InactiveUS20130053295A1Appropriate viscosityLosing qualityCosmetic preparationsNon-ionic surface-active compoundsAlcoholActive agent

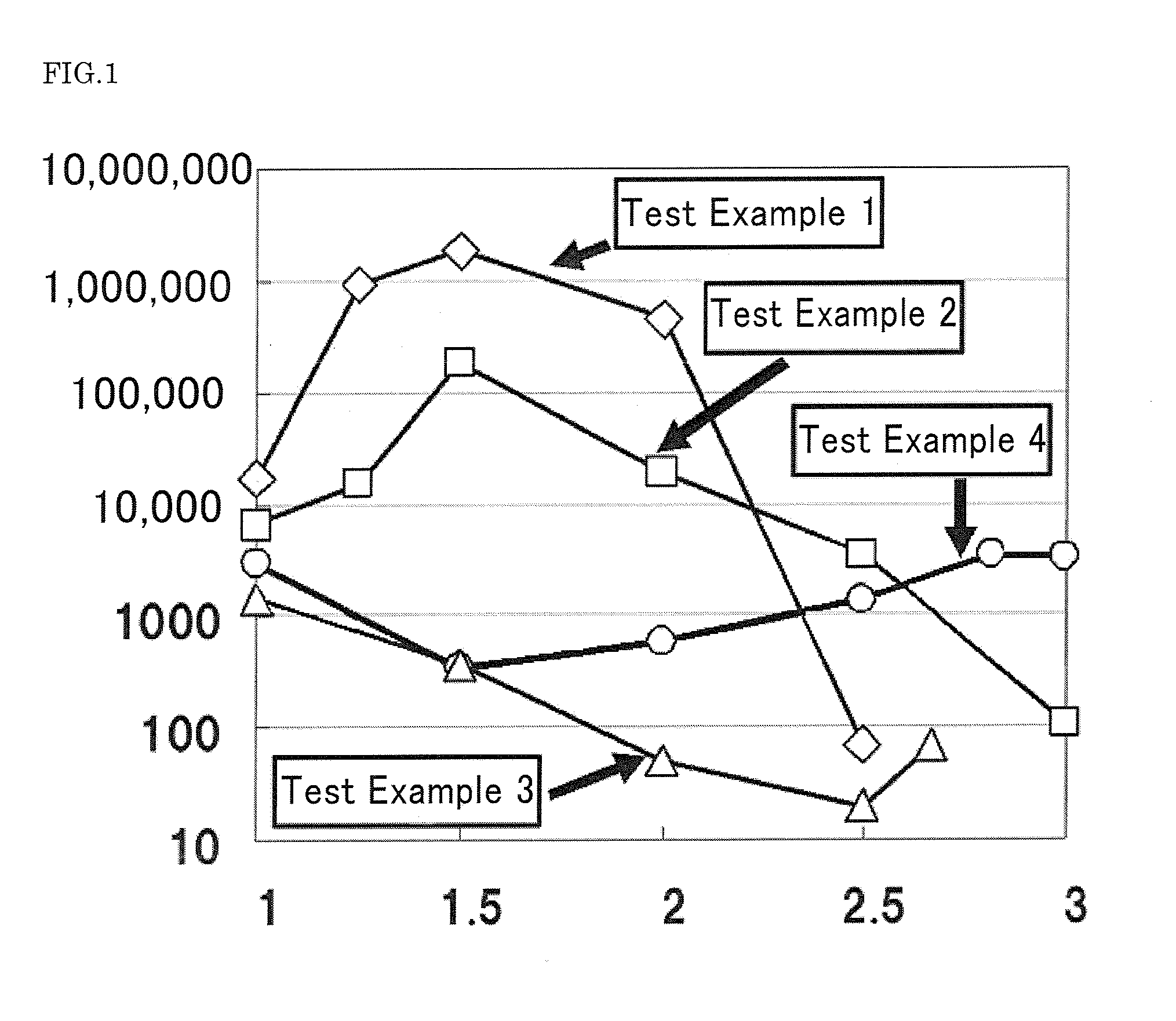

An object of the present invention is to provide an easy-to-handle, before and after dilution with water, concentrated liquid cleanser composition and a production method thereof. A concentrated cleanser composition of the present invention is characterized by comprising: (A) an anionic surfactant, (B) an amphoteric surfactant, (C) 5 to 15 mass % of a monohydric or dihydric alcohol, (D) 8 to 18 mass % of a nonionic surfactant with the IOB value of 0.8 to 1.1 and the molecular weight of 500 or lower, and (E) 45 mass % or less of water, wherein the sum of (A) and (B) is 40 to 60 mass %; wherein the blending ratio (C):(D) is 3.5:1 to 1:2.5; and wherein the viscosity at 30° C. is 300 mPa·s or higher when the composition is diluted until the concentration of (A) and (B) becomes 15 mass %.

Owner:SHISEIDO CO LTD

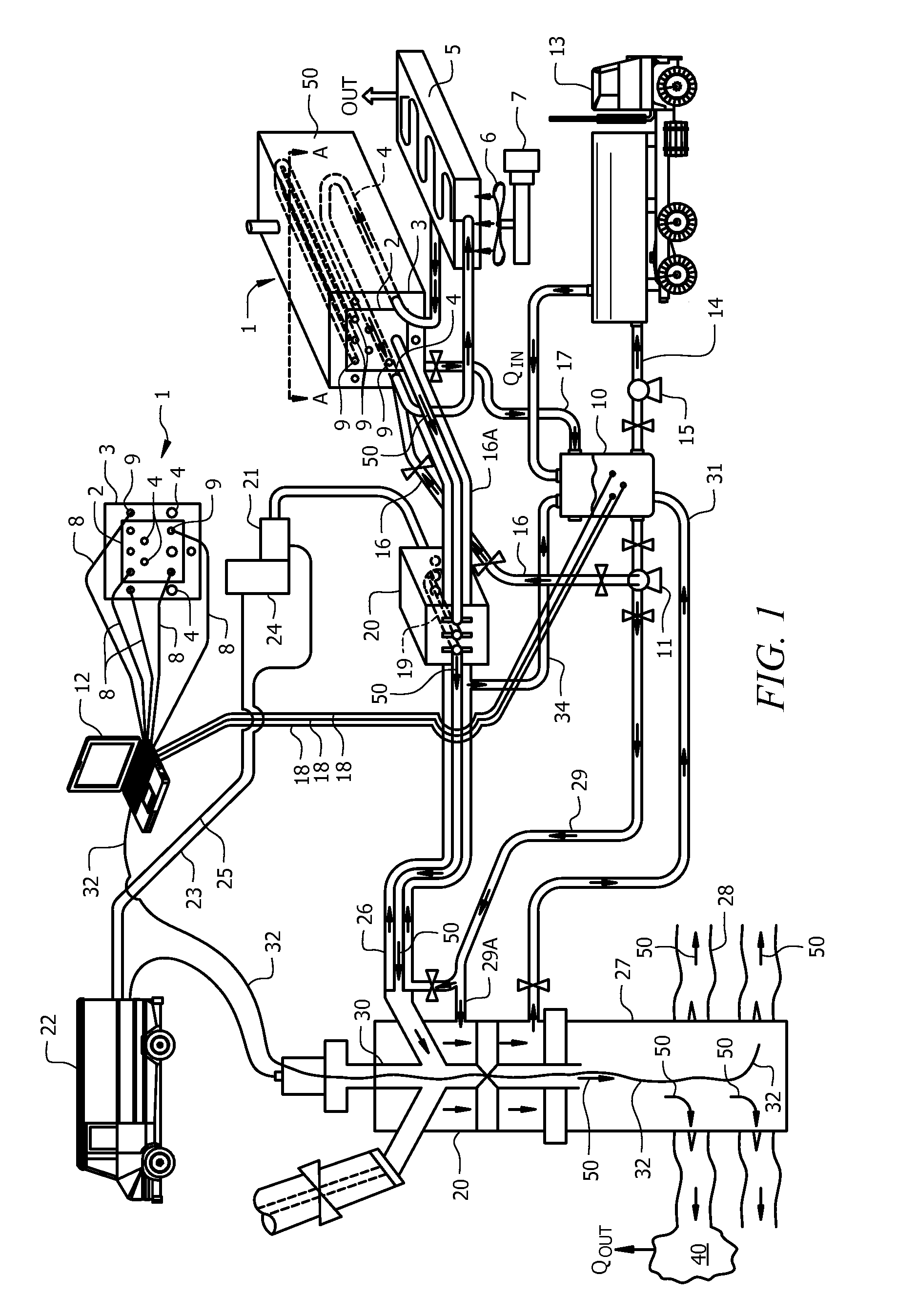

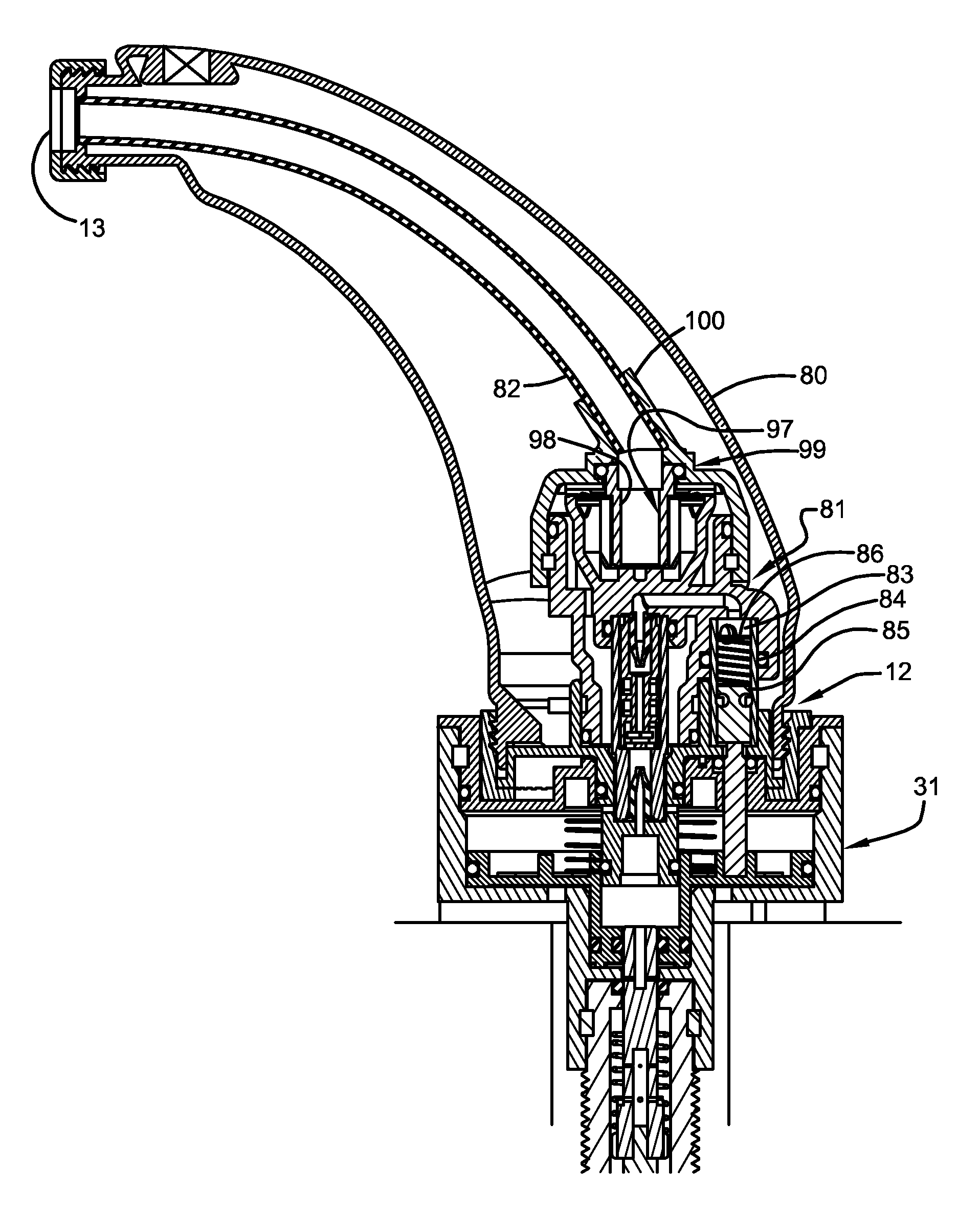

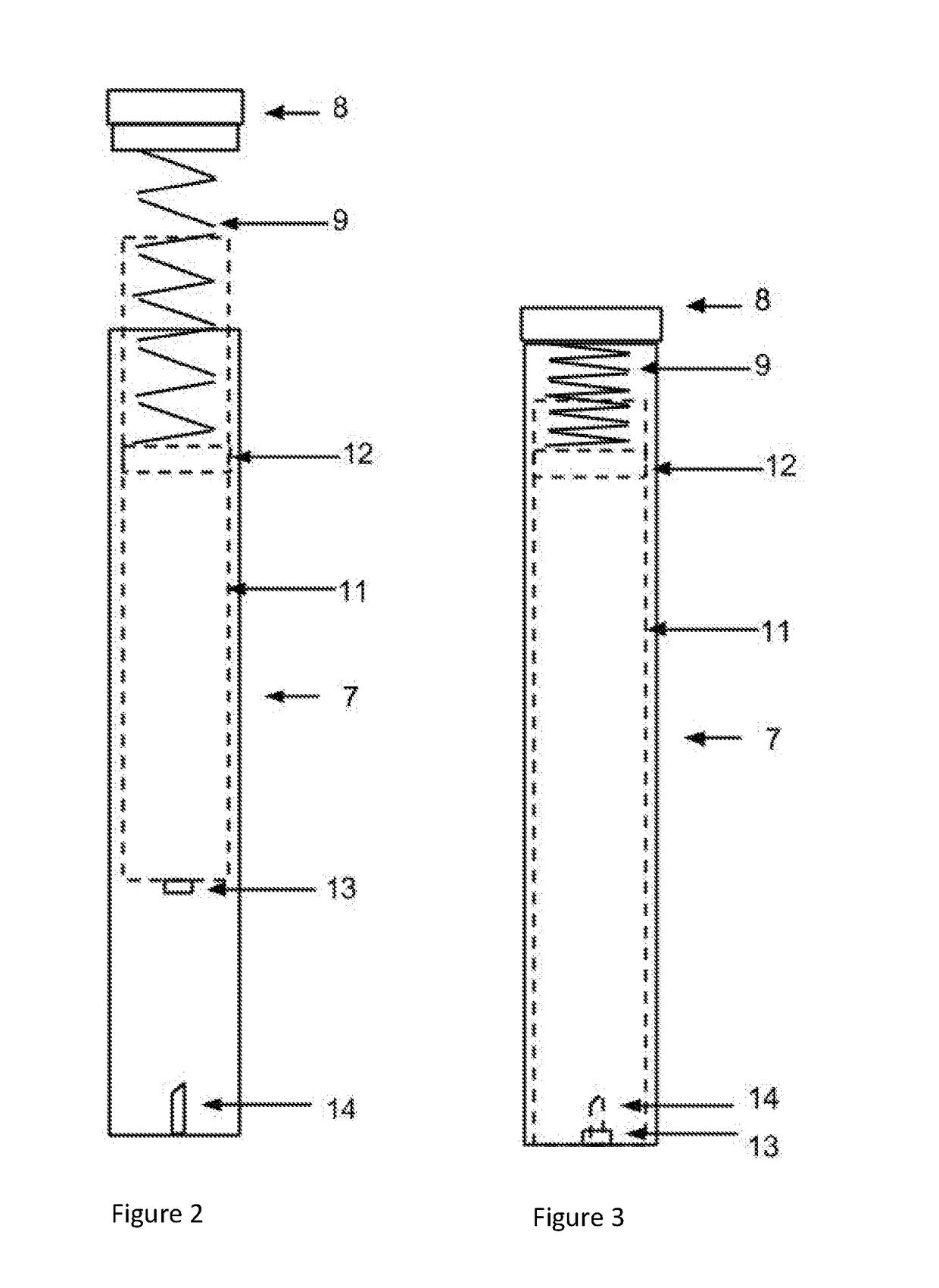

Method and apparatus to treat a well with high energy density fluid

The invention relates to methods and apparatuses for the subterranean injection of reactive substances like propellants into wellbores and subterranean reservoirs. These methods and apparatuses controls the temperature of a reactive substance for safe handling at surface and controls the decomposition rate of the substances in the subterranean environment. In addition, these methods and apparatuses provide a means for safe dilution of reactive fluids in the event of a leak or spillage of the reactive substance.

Owner:SMITH DAVID RANDOLPH

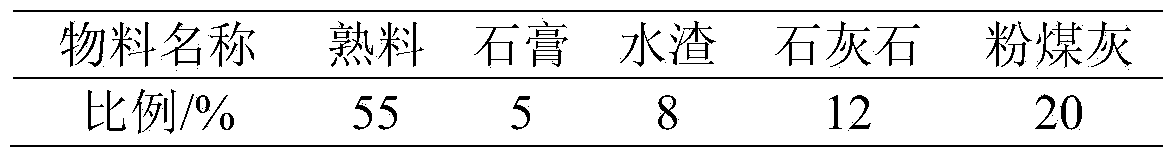

Glycerin distillation residue treatment method

The invention discloses a glycerin distillation residue treatment method. The glycerin distillation residue treatment method sequentially comprises the following steps: adding an extracting agent to glycerin distillation residues, stirring and filtering out inorganic salt; distilling so as to remove the extracting agent; adding water for dilution, heating to 60-95 DEG C; adding an acidifying agent so as to adjust the pH value to 2.5-6; standing still, and skimming; adding an alkaline solution so as to adjust the pH value to 8-10, thus obtaining a mixed liquid of glycerin, polymerization glycerin and water. The mixed liquid prepared by the method falls in the protection scope of the invention and is applied in a cement grinding-aid reinforcing agent.

Owner:JIANGSU JUWEI NEW MATERIALS

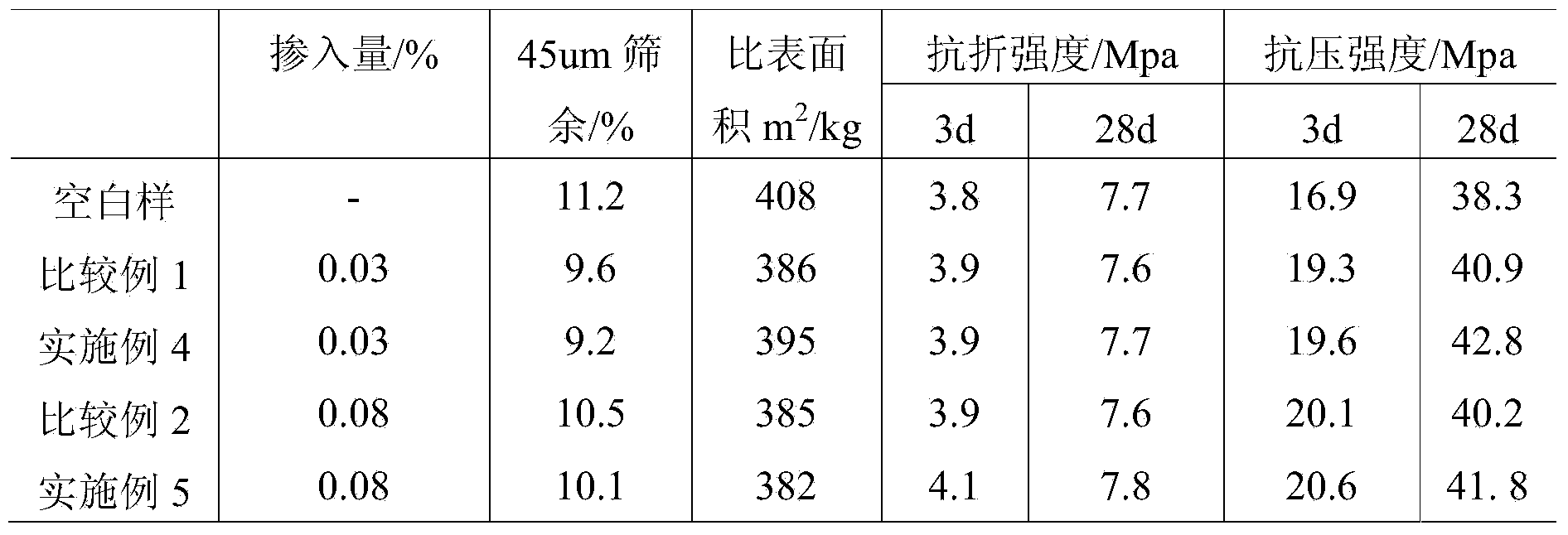

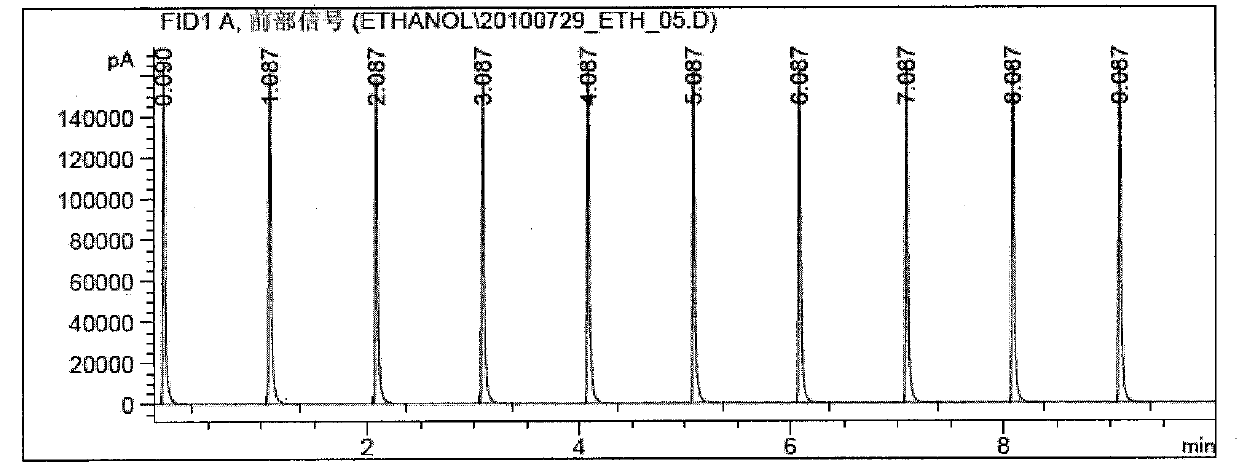

Multifunctional standard gas generator

ActiveCN105498640AThe result is accurateReliable resultsPreparing sample for investigationGas generation devicesHigh concentrationEvaporation

Owner:李圣彭

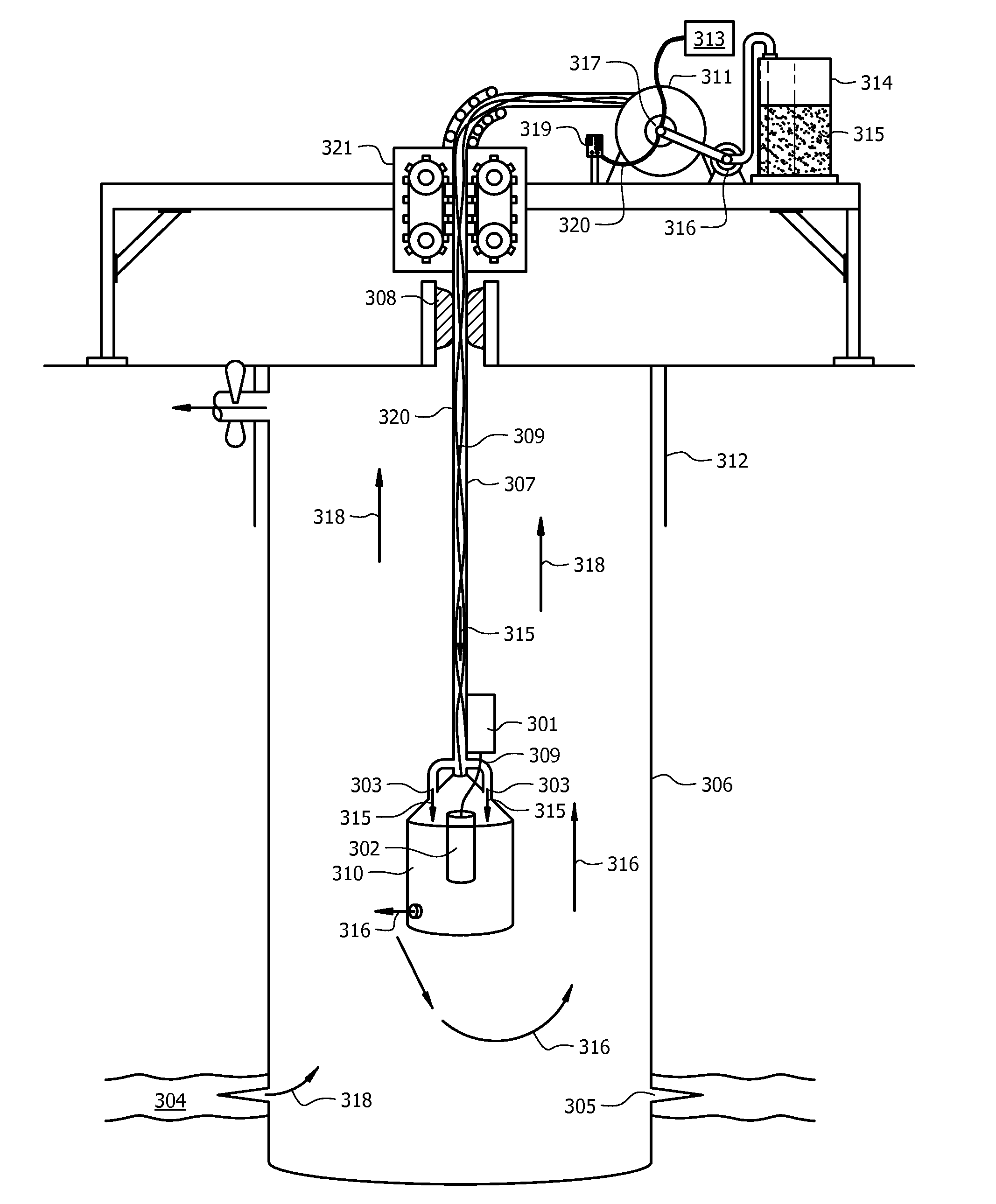

Measurement of non-aqueous phase liquid flow in porous media by tracer dilution

A method and apparatus for measuring in situ flow of non-aqueous phase liquids (NAPLs) through a porous medium is described. A tracer is introduced into a well or boring located in the medium and the tracer concentration in the well kept uniform by mixing. The rate at which the tracer is depleted from the well has been determined to be proportional to the flow rate of the NAPL through the well or boring and surrounding formation.

Owner:CHEVROU USA INC +1

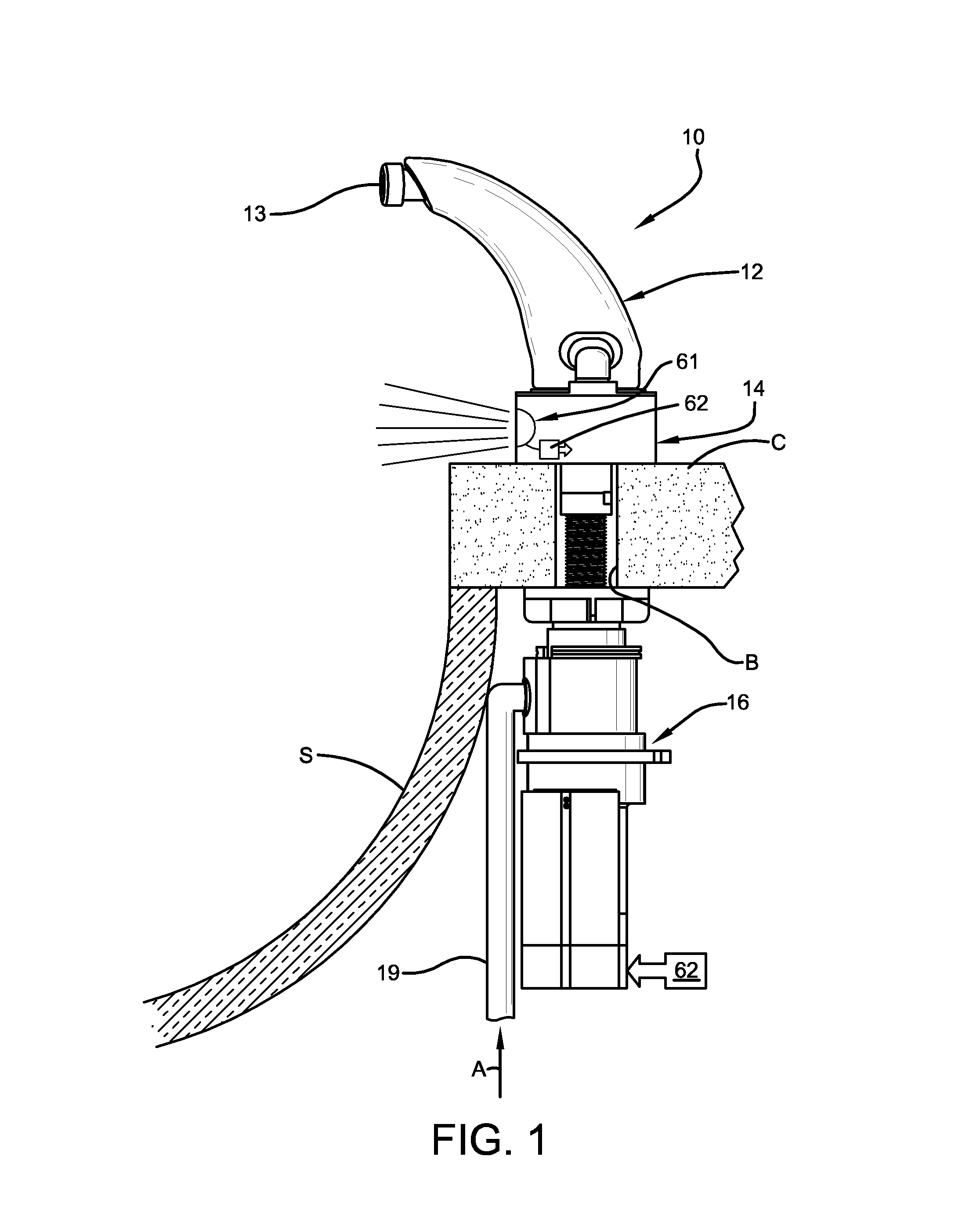

Water-driven dispensing systems employing concentrated product

A dispenser for dispensing a diluted form of a concentrated product includes: a supply of concentrated product; a dilution chamber; an actuation assembly and a product pump mechanism having a water staging chamber. The actuation assembly receives water under pressure from a pressurized water supply. In a staging state, water from the pressurized water supply is fed to the water staging chamber, increasing the volume thereof and causing the actuating of the pump mechanism thereby driving a dose of product into the dilution chamber. In a return state, (a) water within the water staging chamber exits the water staging chamber, (b) water is advanced to the dilution chamber and mixes with the dose of product to create diluted product, and (c) a dose of concentrated product is drawn from the supply of concentrated product into the product pump mechanism.

Owner:GOJO IND INC

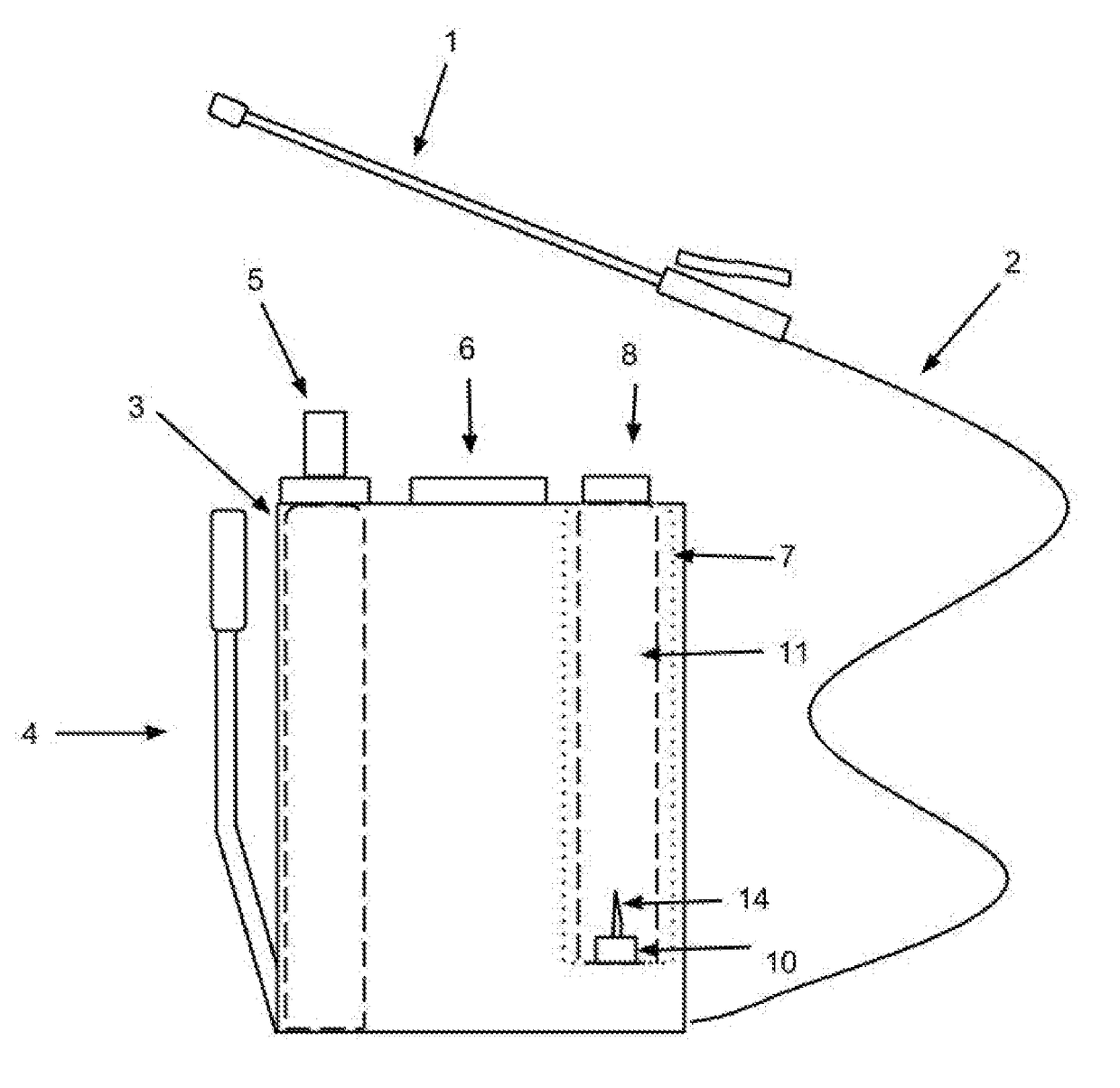

New micro spray backpack with independent mixture system through removable cartridge

InactiveUS20180236472A1Guaranteed air tightnessEasy to movePressurised distribution of liquid fertiliserLiquid spraying apparatusHybrid systemEngineering

A system for micro spray backpacks is a reusable device which has at least one cartridge that contains at least one agrochemical element or another type of concentrate which is to be dispensed separately from the dilution, performing this task at the very moment at which its application is required. The device contemplates the adjustment in the concentration of the mix, as well as the change of the cartridges without spilling the solvent contained in the tank of the backpack. The cartridge prevents oxidation of the concentrate which is to be applied due to its being isolated, reducing economic and environmental costs. The device is designed for use in agricultural and industrial sectors.

Owner:ANTONIO MENDOZA PEDRO

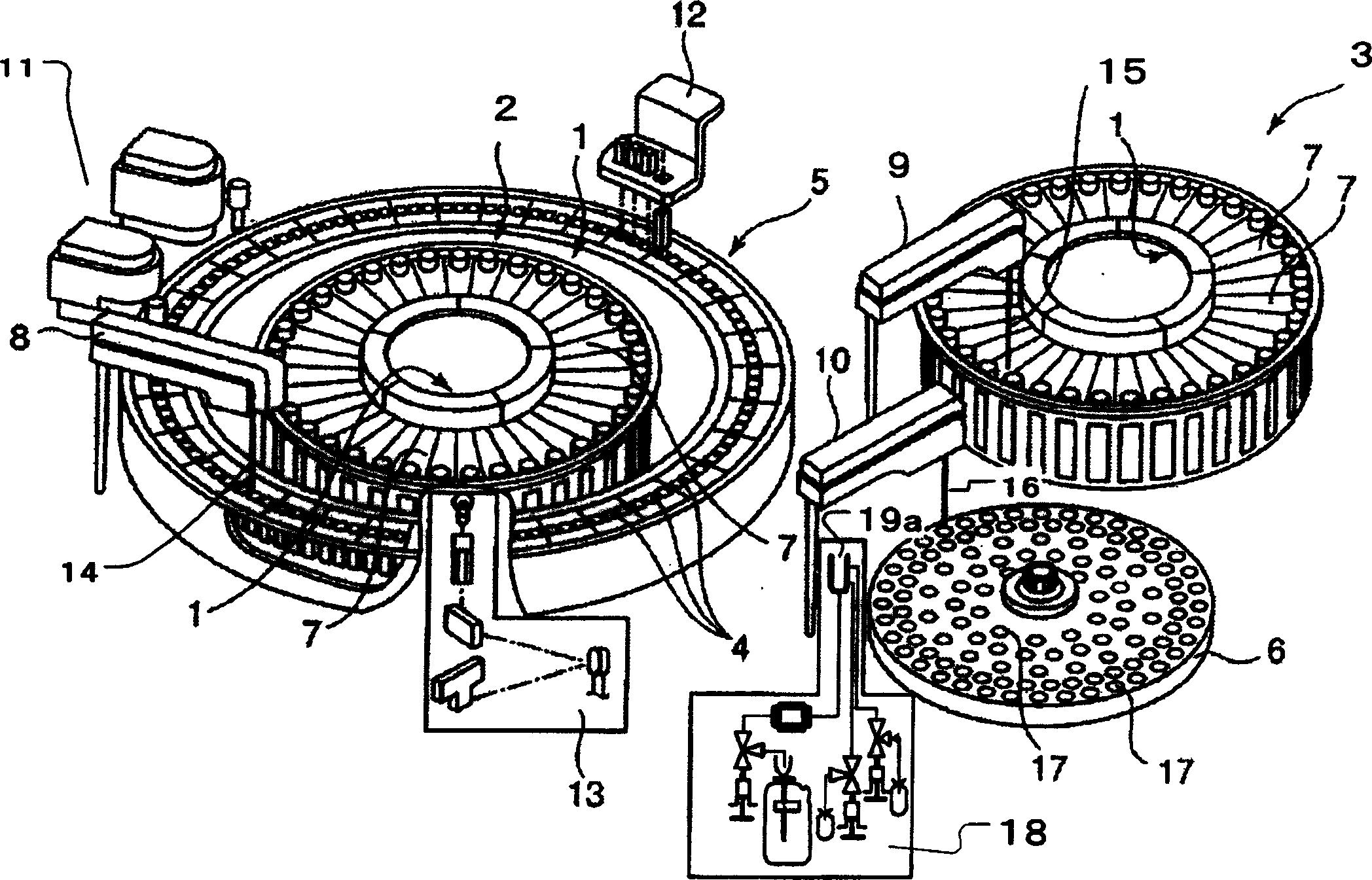

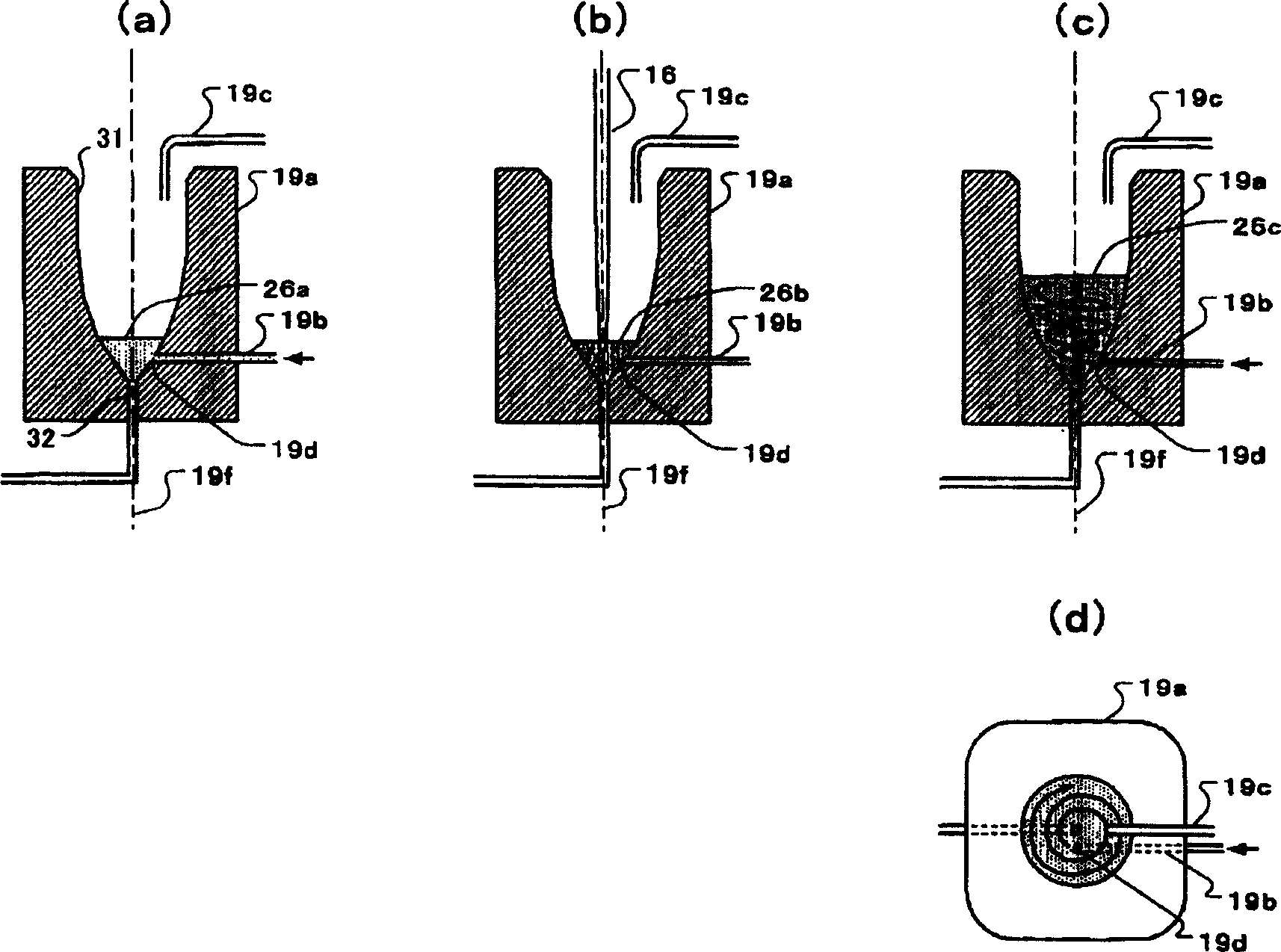

Chemical analyzer, method for dispensing and dilution cup

A dilution cup of the present invention is arranged with an inner face where a diameter of a horizontal section increases on at least one position from a bottom to a top; a sprue, locating on the top of the inner face for feeding checking sample; an outlet, setting on the bottom of the inner face for outputing the checking sample, and ensuring the checking sample as well as reagent form gyrate upwelling; a discharging port locating on the bottom of the inner face. In addition, a chemical analysis device of the present invention includes: a container for mixing the checking sample and reagent; a first component for feeding the reagent into the container; a second component for feeding the checking sample into the container; a controller for controlling the injection of the checking sample and the reagent to feed checking sample after feeding reagent from the first component.

Owner:TOSHIBA MEDICAL SYST CORP

Amine-free voc-free metal working fluid

The present application concerns an aqueous metalworking composition comprising in a concentrate or after dilution of a concentrate with water in a diluent: 0.002 to 40 % by weight of component (a) which is a lubricity agent comprising at least one water-insoluble compound (a) having at least one hydrophobic aliphatic chain and at least one polar group and having a water solubility at 20 DEG C of less than 0.1 g / liter; 0.002 to 40 % by weight of component (b)comprising at least one water-soluble corrosion inhibiting compound(b) having a water-solubility at 20 DEG C of more than 0.1g / liter; 0.002 to 45 % by weight of at least one emulsifying and dispersing agent(c)which contains at least one emulsifying and / or dispersing compound (c) which is water-soluble, water-miscible or water-dispersable and which is selected from the group consisting of non-ionic, anionic and zwitterionic surfactants; 0.002to 30 % by weight of an alkalinity agent (d) containing at least one alkaline water-soluble compound (d) selected from the group consisting of hydroxides and carbonates; and 0.004 to 99 % by weight of a transport component(e)containing predominantly water. Further on, the present application concerns a method of use of such aqueous metalworking composition as a coolant, as a lubricant, etc., and concerns further on a method to prepare an aqueous metalworking composition and a metalworking process.

Owner:CHEMETALLGMBH

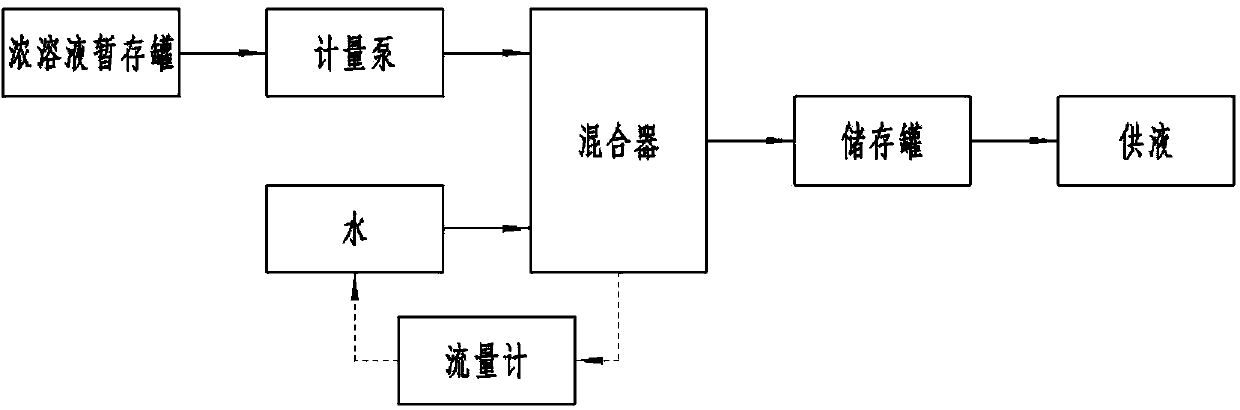

Concentrated solution dilution method

InactiveCN103418259AReduce wasteAccurate concentrationMixing methodsPhysical chemistryProcess engineering

The invention relates to a concentrated solution dilution method. The concentrated solution dilution method includes the steps: (1) measuring volume of a batch tank; (2) setting a concentrated solution level set height for the batch tank according to requirements on the concentration to be prepared, and then pumping a concentrated solution from a concentrated-solution temporary storage tank into the batch tank to the concentrated solution level set height; (3) setting a water level set height for the batch tank, adding water from a water tank into the batch tank to the water level set height, and then uniformly mixing the concentrated solution and the water in the batch tank prior to dilution; (4) enabling a dilute solution diluted in the batch tank to flow into a storage tank for storage and stand-by; (5) repeating the steps (2)-(4) until required production usage amount of the dilute solution is realized. The concentrated solution dilution method is convenient to operate, and the dilute solution obtained by dilution is accurate in concentration.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

Device and method for mixing and heat treating a liquid product

InactiveUS20120015088A1Effective recoveryAvoid product qualityMeat/fish preservation by heatingMixing methodsLiquid productProcess engineering

A device and a method for mixing and heat treating a liquid product, in particular a beverage, and having a first supply pipe for providing a product concentrate and a second supply pipe for providing an aqueous dilution liquid for diluting the product concentrate, as well as a first steam injector provided at the first supply pipe to introduce a first steam quantity flow into the product concentrate, and a second steam injector provided at the second supply pipe to introduce a second steam quantity flow into the dilution liquid. The product concentrate and the dilution liquid can be simultaneously heat treated and diluted, and the heat supply can be interrupted with an only slight delay in case of a production interruption to prevent overheating of the product.

Owner:KRONES AG

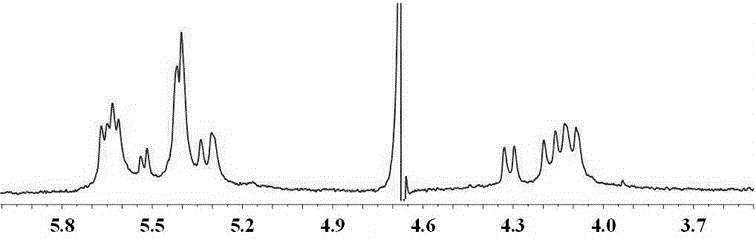

Synthesis and separation method of trans-seven-membered-cucurbituril

The invention provides a synthesis and separation method of trans-seven-membered-cucurbituril iQ[7] and belongs to the technical field of organic polymers. The method includes following steps: employing glycoluril and paraformaldehyde with concentrated hydrochloric acid as a medium; performing heating reflux for 5-8 hours; performing a cooling process; performing a dilution process with water being added step-by-step to separate eight-membered-cucurbituril Q[8], six-membered-cucurbituril Q[6], little trans-six-membered-cucurbituril iQ[6] and little ten-membered-cucurbituril with five-membered-cucurbituril Q[5] being included Q[5]@Q[10] which are poor in water dissolvability; concentrating a mother liquid containing five-membered-cucurbituril Q[5], seven-membered-cucurbituril Q[7], little trans-seven-membered-cucurbituril iQ[7] and little hinged fourteen-membered-cucurbituril tQ[14]; carrying the mother liquid onto a chromatographic colum with Dowex cationic exchange resin as an stationary phase; performing a leaching process with a solution composed of water, acetic acid and concentrated hydrochloric acid, wherein a volume ratio of the water, the acetic acid and the concentrated hydrochloric acid is 1:1:(0.01-0.3) to obtain a purified production of the trans-seven-membered-cucurbituril iQ[7]. The method is simple and quick.

Owner:GUIZHOU UNIV

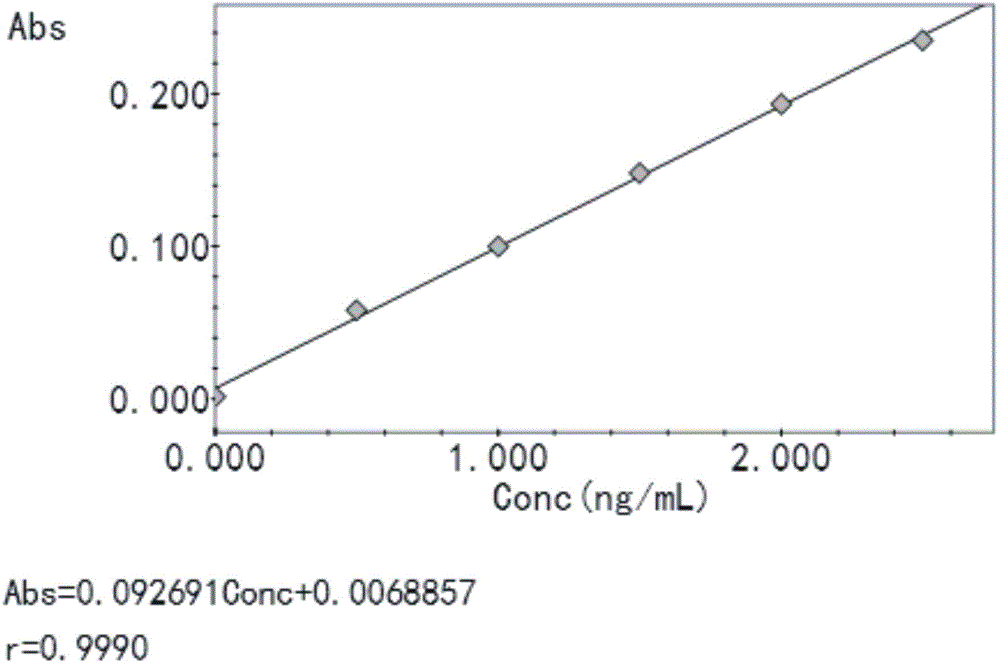

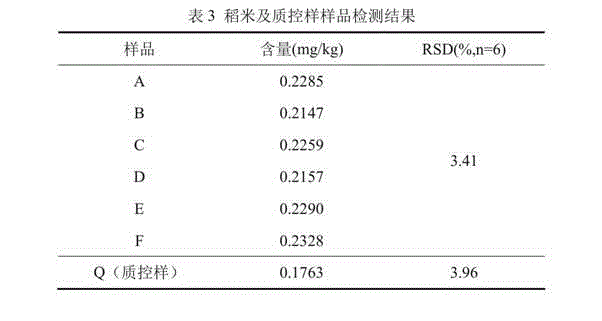

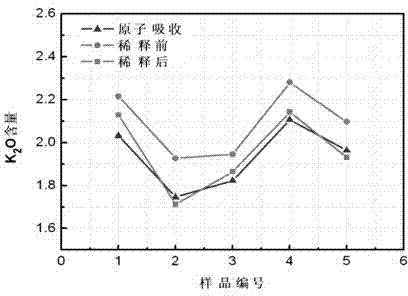

Pre-treatment and quantitative analysis method for rapid determination of content of cadmium element in rice

ActiveCN103604686AFast processEasy to operatePreparing sample for investigationColor/spectral properties measurementsRice wheatStandard solution

The invention relates to a pre-treatment and quantitative analysis method for rapid determination of the content of the cadmium element in rice. The method comprises the following steps (1) crushing rice into powder; (2) preparing an agar solution with a concentration of 0.8 to 1.5 gL; (3) weighing a plurality of parts of rice powder as parallel samples, respectively subjecting the parallel samples to suspension and volume fixation with the agar solution prepared in the step (2), carrying out dilution with dilute nitric acid so as to obtain to-be-measured sample liquids with rice concentration of 4 to 16 gL and directly diluting the agar solution obtained in the step (2) with dilute nitric acid so as to obtain a blank sample; (4) preparing cadmium standard solutions, determining the absorbance value of each cadmium standard solution by using graphite furnace atomic absorption spectrometry and drafting a cadmium element standard curve; and (5) determining the absorbance values of the to-be-measured sample liquids and the blank sample and calculating cadmium content of the to-be-measured sample liquids. The method provided by the invention is simple and fast, can rapidly detect the content of the cadmium element in rice and has good accuracy and repeatability.

Owner:SHIMADZU (CHINA) CO LTD

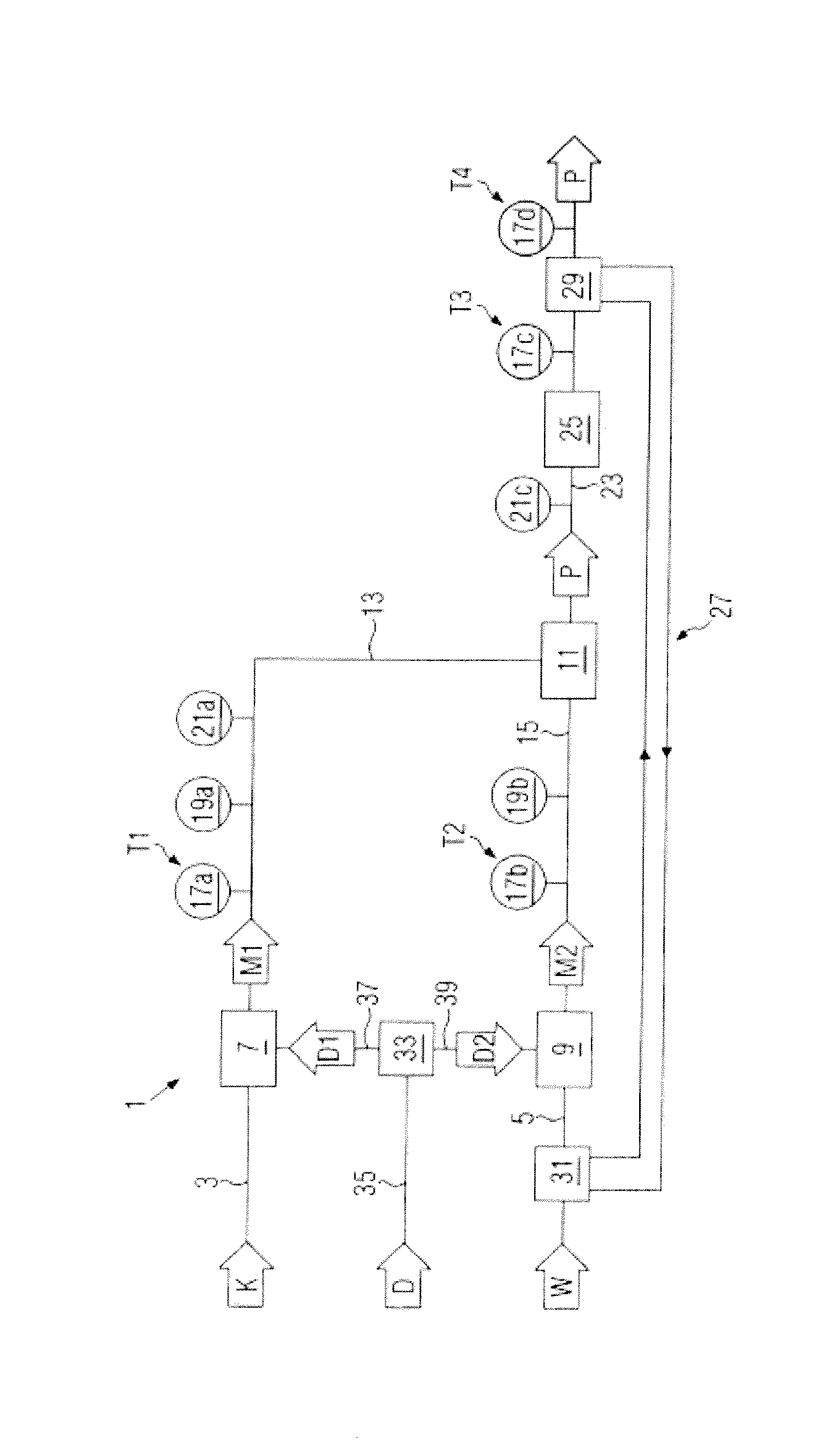

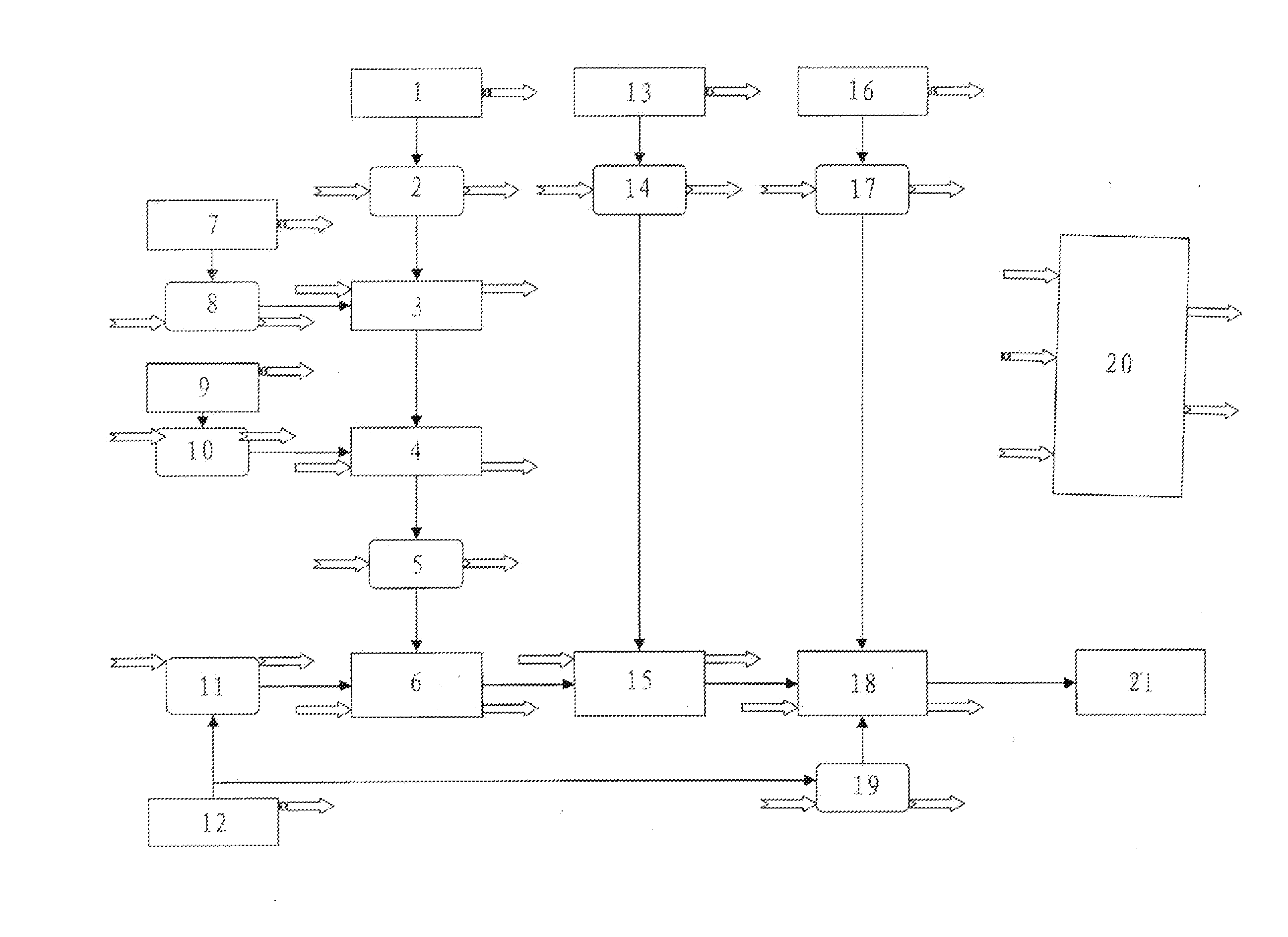

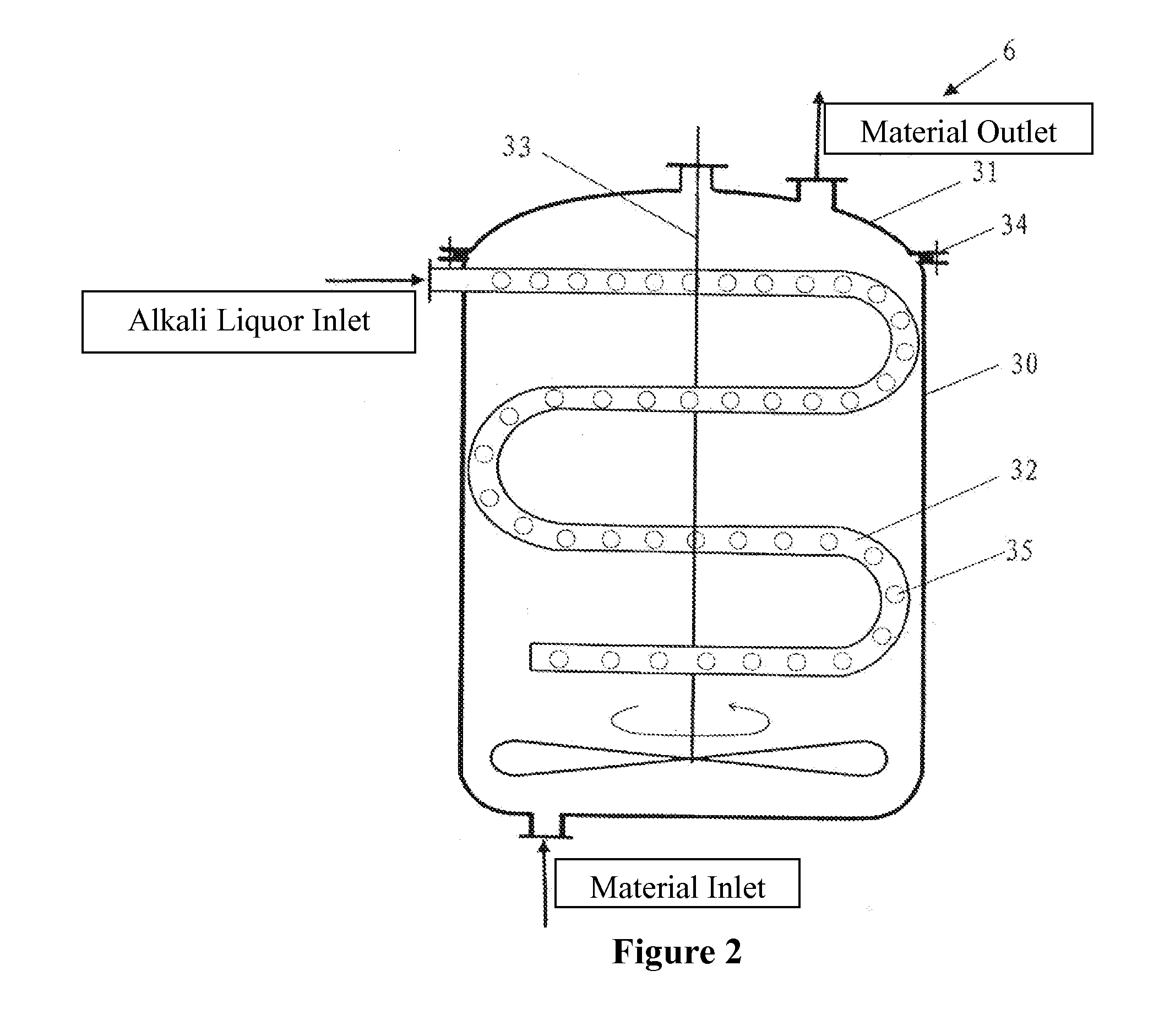

Continuous method and production device for producing hydrolysis-resistant stable ionic titanium

ActiveUS20120111074A1Shorten mixing timeEasy to controlSamplingDisinfectionWater storage tankStrong acids

A continuous method and a production device for producing hydrolysis-resistant stable ionic titanium (Ti4+) are provided. The method comprises six steps: (i) carrying out redox reaction between metal titanium and excess strong acid; (ii) carrying out primary chelation; (iii) diluting; (iv) adjusting pH value for the first time; (v) carrying out secondary chelation; and (vi) adding microelement and adjusting pH value for the second time. The device includes a reaction kettle, multiple metering pumps, a chelation kettle, dilution tank, multiple precise mixing reaction kettles, the first chelator storage tank, a pure water storage tank, an alkali liquor storage tank, the second chelator storage tank, multiple microelements storage tanks, a control center, etc. The method uses a multi-points, spiral, reverse and atomization spraying technique synchronously to carry out digital full automatic continuous production and reach the effect of elaborately mixing the material. Also, the method greatly shortens the inter-dissolving time of the materials, easily controls the pH of the solution, and improves the stability of the product.

Owner:ZHANG XIAOHUI

Concentrate for preparing a disinfectant and methods for its preparation and use

ActiveUS7951404B2Improve long-term stabilityExtended shelf lifeBiocideAntisepticsDecompositionDisinfectant

A storage-stable aqueous concentrate for the preparation of a disinfectant and a disinfectant obtainable from such a concentrate by dilution are disclosed. The concentrate comprises hydrogen peroxide, colloidal silver, a biopolymeric stabilizer such as gum arabic, and phosphoric acid. In order to improve long-term stability and to reduce initial decomposition of the hydrogen peroxide in the first few days after preparing the concentrate, the concentrate further comprises sodium nitrate or sodium sulfate. The concentrate is free of any synthetic organic complexing agents, thus rendering the concentrate suitable for food- and drinking water applications. Also disclosed are methods of preparing and using the concentrate.

Owner:SANOSIL

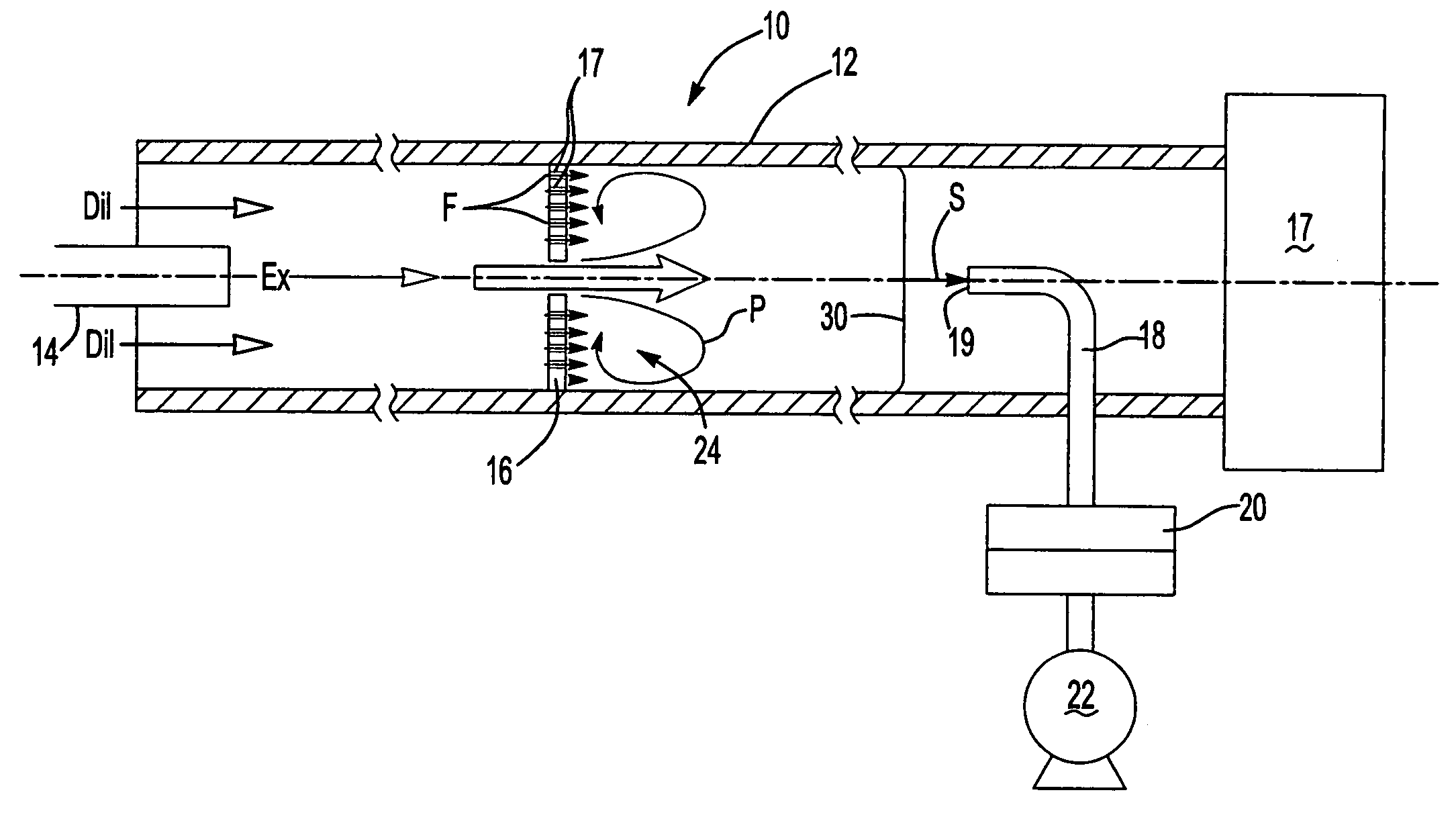

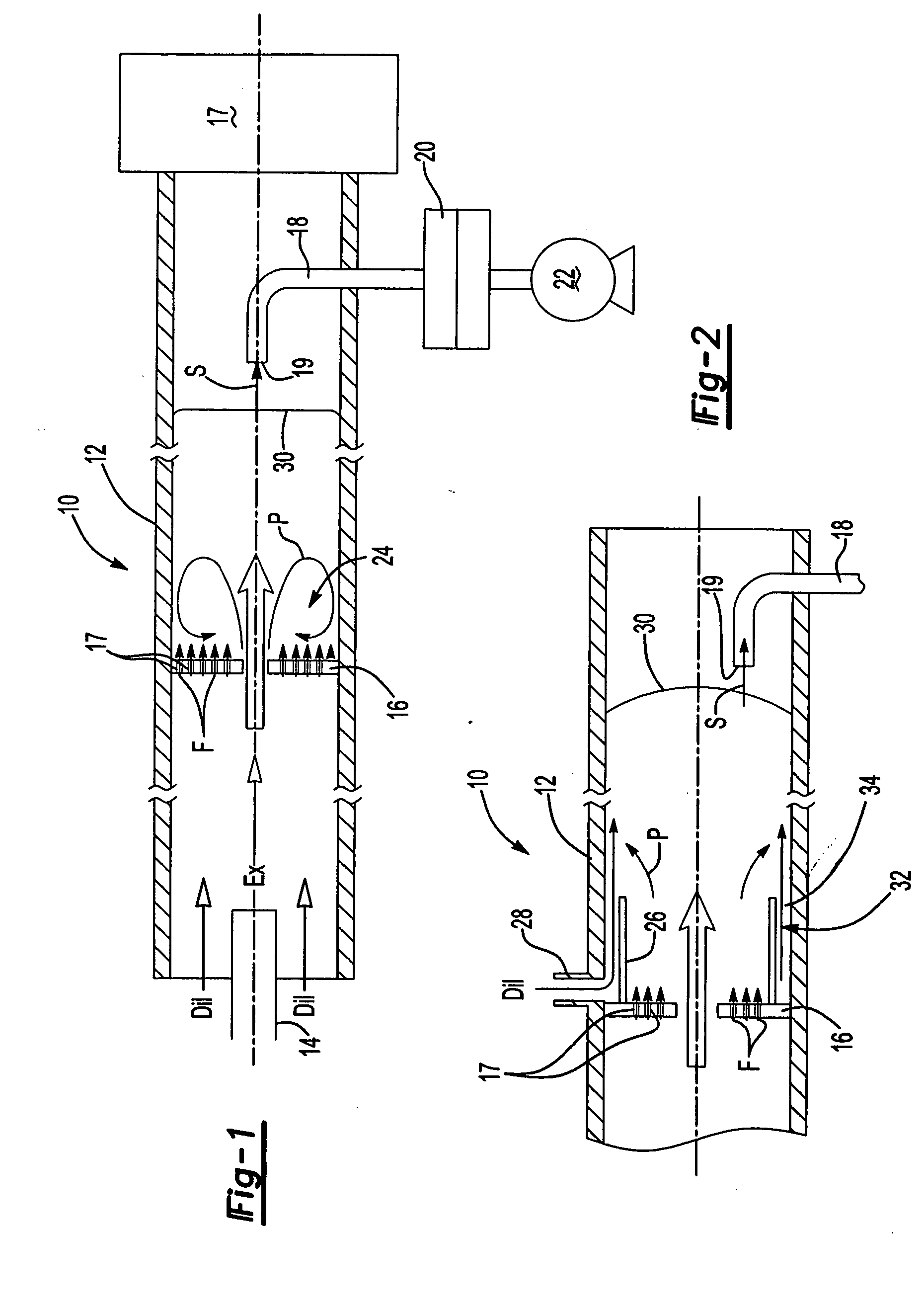

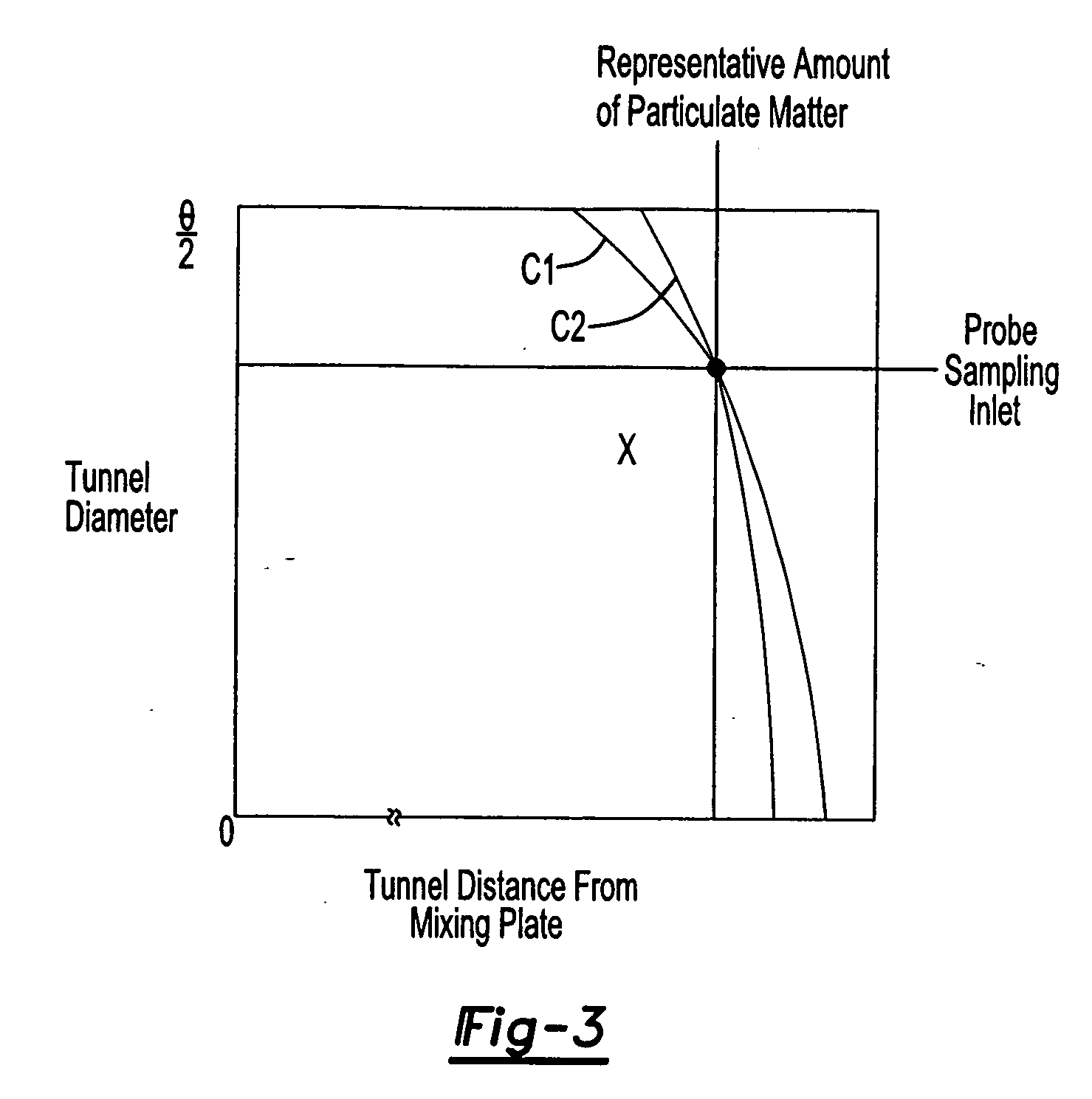

Particulate deposit avoidance and probe positioning

InactiveUS20050109129A1Reduce tunnel lengthAvoid collectingWithdrawing sample devicesPreparing sample for investigationParticle depositionEnvironmental geology

A perforated mixing plate and is fluid passage are used in conjunction with a dilution tunnel to prevent particulate matter from collecting on the sampling system components. An inlet of a sampling probe is offset from the centerline of the dilution tunnel to a location corresponding to an average particulate matter concentration along a flow profile of a sample mixture to reduce the length of the dilution tunnel.

Owner:AVL TEST SYST

Dilution treatment method for concentrated sulfuric acid industrial application

InactiveCN111068533APrevent splashReduced service lifeShaking/oscillating/vibrating mixersRotary stirring mixersElectric machineDiluent

The invention relates to a dilution treatment method for concentrated sulfuric acid industrial application. Equipment comprises a workbench, a motor, a stirring device and a conveying device, whereina motor is fixedly installed at the upper end of the workbench through a motor base; a stirring device is mounted on an output shaft at the upper end of the motor through a coupler; a conveying deviceis mounted at the right end of the stirring device; the stirring device comprises a liquid tank, an upper end cover, an inverted L-shaped frame, a heat transfer pipe, a double-acting cylinder and a stirring column. The motor is matched with the stirring device; the centrifugal force and the stirring device are used for uniformly stirring diluent, heat generated in the diluting process is recycledthrough the heat transfer pipe and the double-acting air cylinder, and the speed of concentrated sulfuric acid entering water is controlled through the conveying device so as to prevent the concentrated sulfuric acid from splashing due to a too high flow speed and from corroding equipment, so that the service life of equipment is shortened.

Owner:陈卫

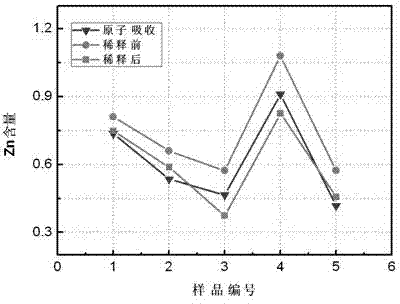

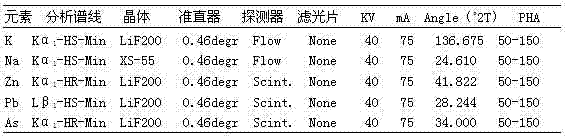

Rapid analysis method of high-content harmful element in blast furnace iron material

ActiveCN104730098APrevent cyclic enrichmentReduce dosageMaterial analysis using wave/particle radiationPreparing sample for investigationOptical spectrometerFluorescence

The invention provides a rapid analysis method of a high-content harmful element in a blast furnace iron material. The method comprises the following steps: determining an instrument analysis condition; searching a standard sample drawing working curve; analyzing a sample; determining the sample which is out of an analysis range of the working curve during detection of the sample to be a harmful element sample with high content; determining a dilution standard sample from a harmful element sample with low content; mixing, diluting and melting the harmful element sample with high content by using the dilution standard sample to be made into plates; detecting through an X-ray fluorescence spectrophotometer, and calculating to acquire the content of the harmful element in the harmful element sample with high content. Compared with the traditional atomic absorption spectrometry, the rapid analysis method has the advantages that the sample is not needed to be dissolved in water solutions, and the dilution for many times is not needed, and therefore, the method is easy to operate and accurate in evaluation; moreover, the using mount of high-pure reagents is saved, and the cost is greatly reduced. Poor and impure iron materials are reasonably added for enterprises so as to prevent circulating enrichment of the harmful elements in a furnace, thus reducing the production cost and improving the economic benefit.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Sodium bicarbonate/sodium chloride micronized slurry

A slurry comprising (a) sodium bicarbonate, (b) sodium chloride, and (c) water, in a weight ratio of (a) / (b) of about 2.5:1 to about 3.5:1, wherein upon further dilution of said slurry with additional water, the amount of sodium bicarbonate and sodium chloride which dissolves into said additional water is in the same ratio as said of (a) / (b) in said slurry before said additional dilution.

Owner:CHURCH & DWIGHT CO INC

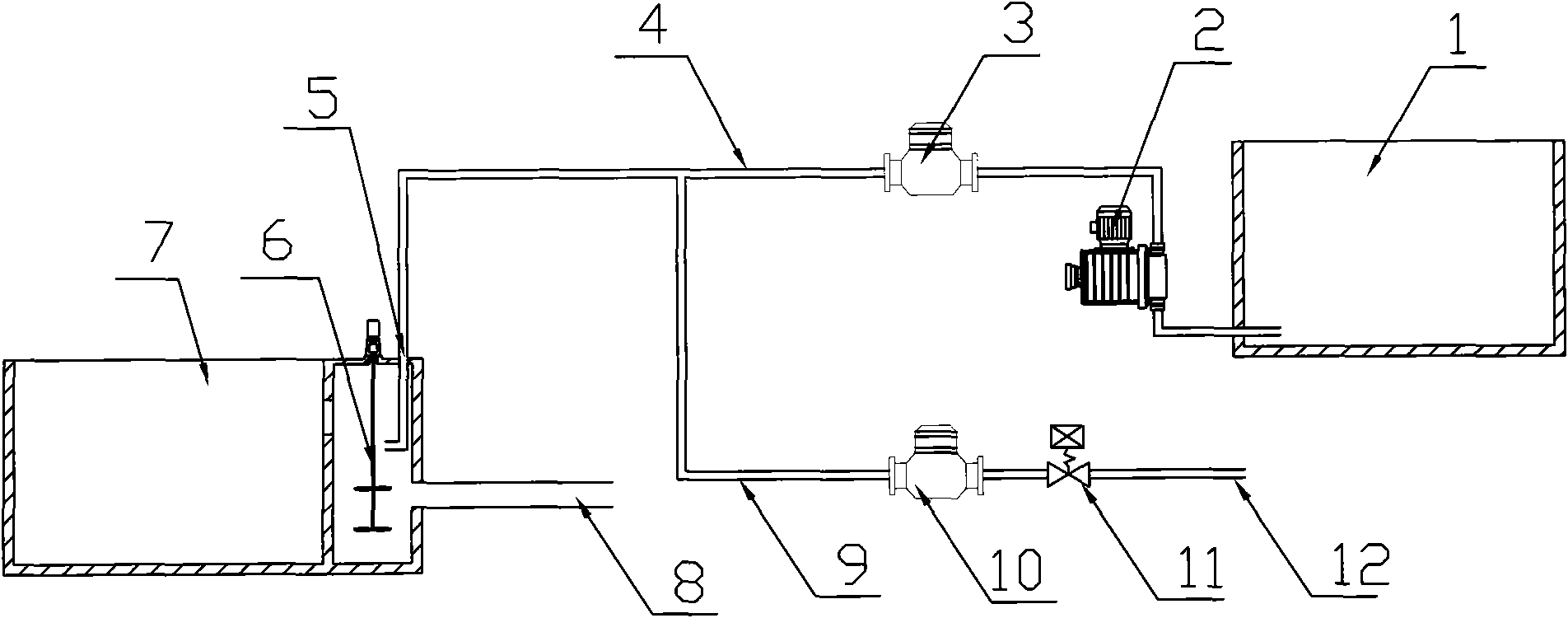

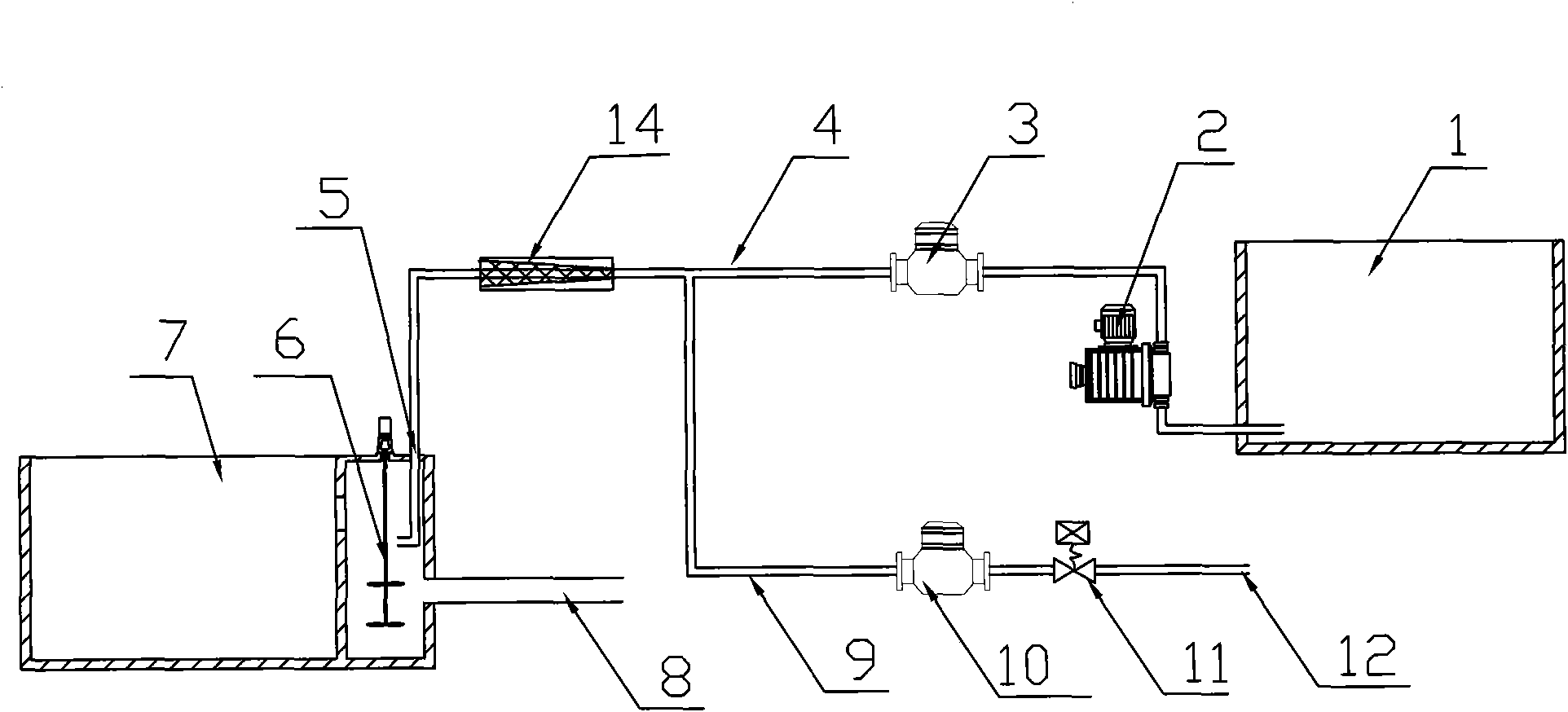

Method and device thereof for secondarily diluting and feeding coagulant

ActiveCN101602532ADilution achievedReduce mass concentrationWater/sewage treatment by flocculation/precipitationFlocculationDiluent

The invention relates to a method and a device thereof for secondarily diluting and feeding coagulant. The device comprises a diluting tank, a flocculation reaction tank, a mixing device, an infusion pipe, an infusion pump and a diluent flow meter, a water pipe, an adjusting valve and a water flow meter; the infusion pipe is connected to the flocculation reaction tank through the infusion pump and the diluent flow meter; and the water pipe is connected to the infusion pipe through the adjusting valve and the water flow meter. The primary dilution of the coagulant is finished in the diluting tank, and then the primary diluent is conveyed to a diluent feeding point by the infusion pump through the infusion pipe; simultaneously, the water for diluting is injected to the infusion pipe by the water pipe to realize secondary dilution of the coagulant; and the secondary diluent is fed to the water to be treated at the diluent feeding point, and undergoes a flocculation reaction in the flocculation reaction tank after full mixing so as to finish the purification treatment for the water. By implementing the method, the mass concentration of the coagulant is reduced to 0.5 to 2 percent through the secondary dilution, so that the utilization efficiency is improved, and the using amount is reduced.

Owner:上海艾晟特环保科技股份有限公司

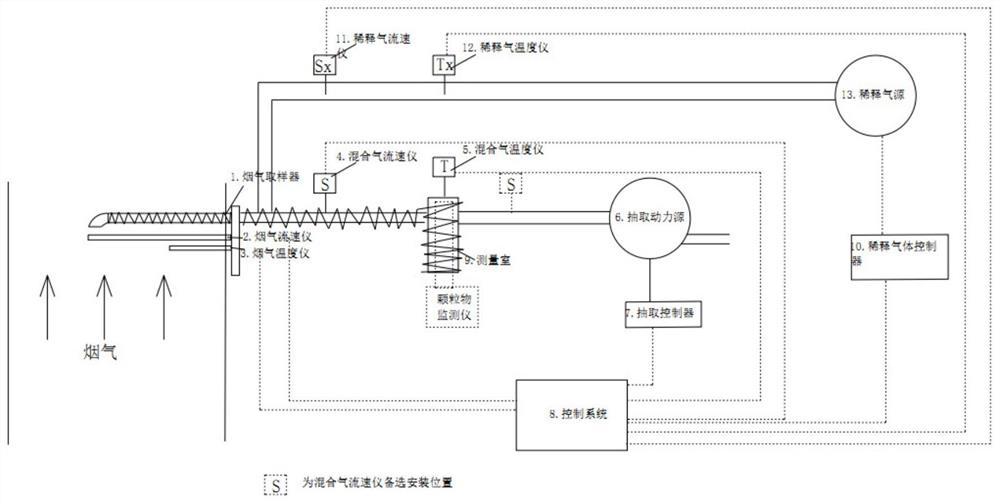

Dilution heating type particulate matter constant-speed sampling device with temperature compensation function

InactiveCN112611610AAccurate contentWithdrawing sample devicesPreparing sample for investigationParticulatesFlue gas

The invention discloses a dilution heating type particulate matter constant-speed sampling device with a temperature compensation function. The dilution heating type particulate matter constant-speed sampling device comprises a flue gas sampler, a diluent gas mechanism, a mixed gas mechanism, an extraction power source and an extraction controller. The flue gas sampler consists of a flue gas sampling pipe, a flue gas flow meter and a flue gas temperature meter; the diluent gas mechanism is composed of a diluent gas flow meter, a diluent gas temperature meter, a diluent gas source and a diluent gas controller, the diluent gas source is other gases such as nitrogen and air for diluting the sample gas, and compressed gas or a gas pump can be used; the mixed gas mechanism consists of a mixed gas flow meter and a mixed gas temperature meter; the particulate matter monitor is mounted in the measuring chamber; the extraction power source is equipment used for extracting sample gas and generating extraction power, and can be an extraction pump, a jet pump and the like; and the extraction controller is equipment for controlling sample gas extraction. The device has the advantages that the flue gas temperature, the diluent gas temperature and the mixed gas temperature are measured, compensation calculation is carried out according to the temperatures to obtain the flow velocity of the mixed gas needing to be extracted finally, and the extraction controller and the dilution controller are controlled to complete constant-speed tracking sampling according to the data.

Owner:NANJING BORY AUTOMATION TECH CO LTD

Test method of a high-purity aluminum alloy

PendingCN111751251AShort corrosion timeReduced Possibility of ContaminationPreparing sample for investigationParticle size analysisPhysical chemistryParticle counter

The invention discloses a test method of a high-purity aluminum alloy. The test method of the high-purity aluminum alloy comprises the following steps: 1) cutting a high-purity aluminum alloy sample into pieces, and carrying out impurity removal pretreatment; 2) weighing the pretreated high-purity aluminum alloy sample, adding a corrosive liquid for corrosion, standing, and adding water for dilution to form a mixed sample solution; 3) weighing the mixed sample solution, adding water to dilute the mixed sample solution, detecting the granularity of the sample solution through a liquid particlecounter for at least three times, and taking an average value S1; and 4) adding water into hydrochloric acid to form a hydrochloric acid solution with the same proportion as the mixed sample solutionin the step (3), taking the hydrochloric acid solution, adding water to dilute, detecting through a liquid particle counter, detecting for at least three times, taking an average value S2, and calculating the granularity of the sample. According to the test method of the high-purity aluminum alloy, the corrosion time of a high-purity aluminum alloy sample is shortened, the detection efficiency isimproved, the possibility that sample liquid is polluted is reduced, and data are more stable.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

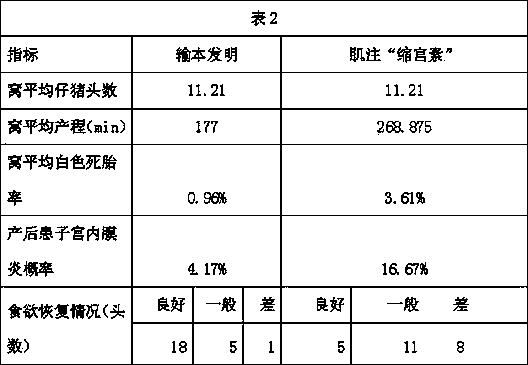

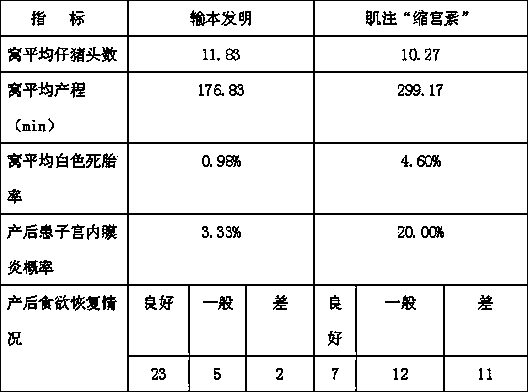

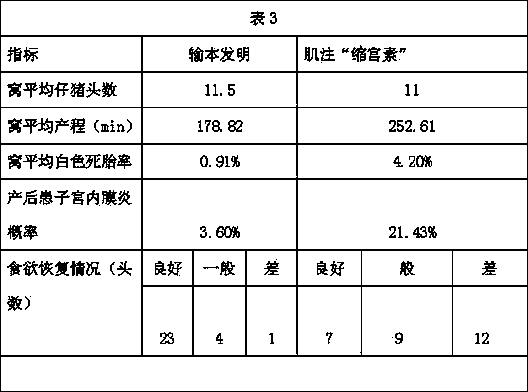

Drug for shortening sow labor process and preparation method thereof

ActiveCN103385906ANormal physiological functionReduce laborAntibacterial agentsDigestive systemFiltrationPhosphoric acid

The invention discloses a drug for shortening a sow labor process and a preparation method thereof. The preparation method comprises the following steps of adding 88.8806-88.8810% of injection water into a concentration tank, carrying out stirring, slowly adding 0.1-0.3% of metronidazole into the concentration tank, carrying out heating boiling, adding 9-11% of weighed glucose, 0.008-0.012% of triphosadenine, 0.006-0.01% of dexamethasone and 0.8-1.0% of common salt into the boiling solution until complete dissolution, adding active carbon of which humidity is pre-adjusted into the mixed solution for decoloration, filtering the hot mixed solution by a concentration and filtration titanium rod, collecting the filtrate by a dilution tank, carrying out stirring by the dilution tank, diluting the filtrate by injection water until the diluent filtrate volume is 90% of the total dilution tank volume, adjusting a pH value to 6.0-7.0 by a sodium hydroxide solution having the content of 0.1mol / L, carrying out dilution until the diluent filtrate volume is equal to the total dilution tank volume, adding active carbon of which humidity is pre-adjusted into the diluent filtrate for decoloration, carrying out filtration by a filter membrane until the filtrate is clear and transparent, feeding the filtrate to a soft bag liquid-conveying production line by a delivery pump, and carrying out loading.

Owner:福建奥姆龙生物工程有限公司

Dilution thickening, liquid cleansing compositions

The invention provides a liquid cleansing composition comprising: (i) 1 to 30% by weight, based on the total weight of the composition, of anionic surfactant; (ii) up to 5% by weight, based on the total weight of the composition, of amphoteric surfactant; (iii) up to 2% by weight, based on the total weight of the composition, of electrolyte; (iv) at least 0.5% by weight, based on the total weight of the composition, of monoalkanolamide surfactant, and (v) from 50 to 94.5% by weight, based on the total weight of the composition, of water, wherein the composition has a viscosity upon dilution which is greater than its viscosity prior to dilution.

Owner:CONOPCO INC D B A UNILEVER

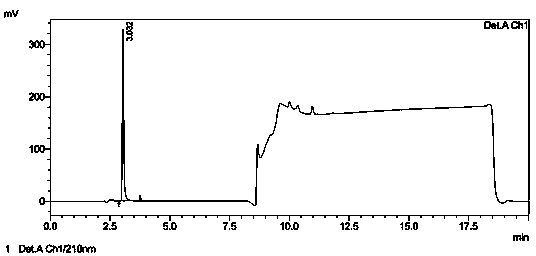

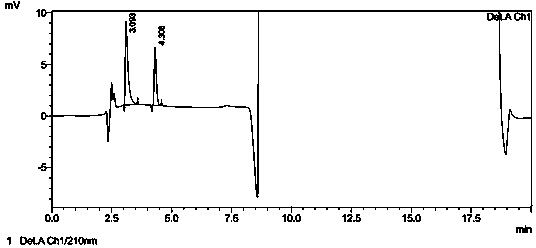

Method for measuring residual acetic acid in flubendazole crude drug by high performance liquid chromatography method

InactiveCN103983728AQuality improvementEasy to operateComponent separationSolubilityO-Phosphoric Acid

The invention discloses a method for measuring residual acetic acid in a flubendazole crude drug by a high performance liquid chromatography method. The method disclosed by the invention specifically comprises the following step: carrying out gradient elution by adopting an HPLC (high performance liquid chromatography) method and a ZORBAXSB-C18 chromatographic column, taking phosphoric acid solution and methanol of 950 to 50 as a mobile phase A, and adopting methanol as a mobile phase B, wherein detection wavelength is 210 nm, flow speed is 1.2mL.min<-1>. The acetic acid has good linearity (r=0.99999, n=6) within a range of 2.5 mu g.mL<-1>-1014.9 mu g.mL<-1>, a recovery rate of 99.2% and precision RSD (Relative Standard Deviation) of 1.1%. The method for measuring residual acetic acid in flubendazole crude drug by the high performance liquid chromatography method is simple and quick to operate, and accurate and reliable in measured result, so that quality of the drug can be effectively controlled. Gradient elution is adopted on selecting the mobile phases, so that trailing or shoulder peak due to overlong sample peak appearance time is avoided. On selection of a dilution solvent of the main drug, the method disclosed by the invention has the advantage that formic acid as a co-solvent in consideration of a fact that the flubendazole crude drug is not easy to dissolve in water and a normal organic solvent, but better in solubility in acid, so that good effect is achieved.

Owner:JIANGSU BAOZONG & BAODA PHARMACHEM

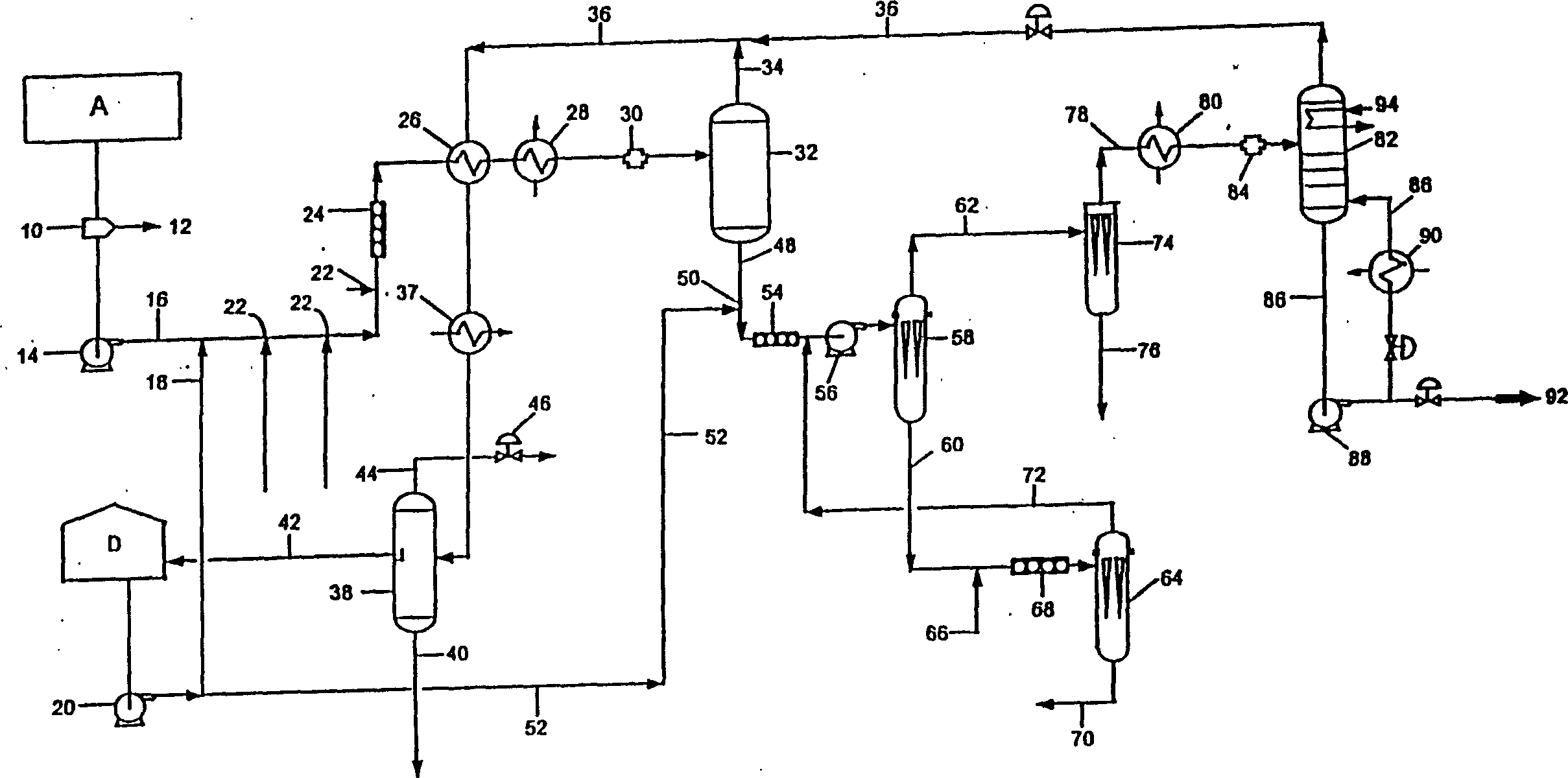

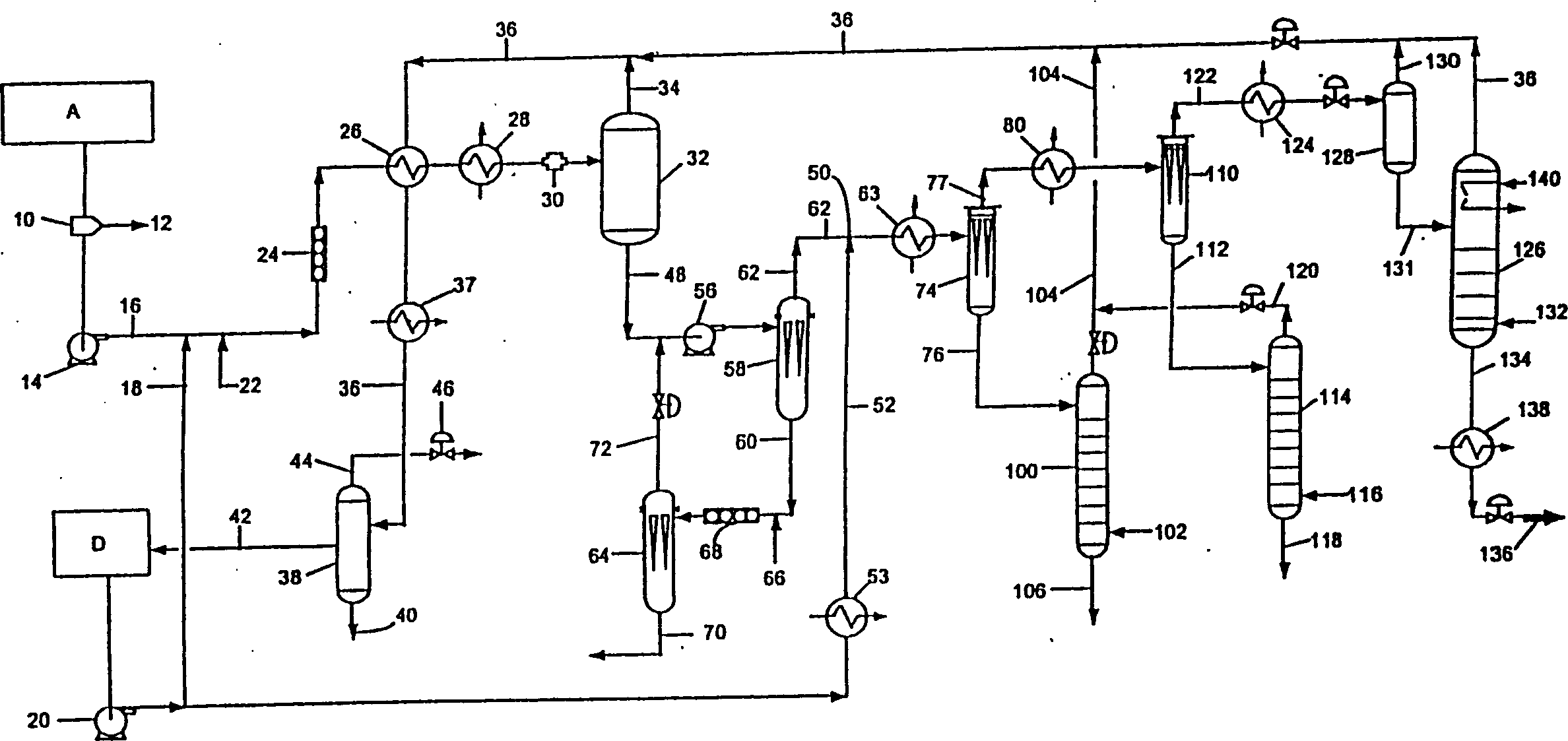

Process for upgrading heavy crude oil production

InactiveCN1152118CLow viscosityImprove performanceDewatering/demulsification with chemical meansTreatment with plural serial refining stagesSolventSpecific gravity

A process for upgrading heavy crude oil production is described which involves adding a diluent, or solvent, which is a light hydrocarbon to reduce the viscosity and specific gravity of the crude oil being processed. After dilution, the emulsions in the crude are broken and the separation of the crude into the components follows, aided by a second injection of diluent. This upgrades the crude and enhances the amount recovered for processing at a refinery. A high asphalt content of a heavy crude can also be tolerated in the practice of this invention resulting in environmentally-benign solids and water exiting a process which due to the modularization of equipment can be practiced at the well-head itself.

Owner:QUADRANT MANAGEMENT

Growth regulator concentrate and use thereof

ActiveUS11134682B2High concentrated liquid formulationsBiocideDead animal preservationSolubilityVegetable oil

The invention relates to a liquid dispersion comprising (i) at least one growth regulator which has a solubility in vegetable oil of about 0.1 wt % or less; (ii) an organic hydrophobic carrier, preferably a vegetable oil, hydrocarbon oil or paraffin oil, or a derivative thereof; wherein the at least one growth regulator which is insoluble or unstable in water, is present in the liquid dispersion in an amount exceeding 0.1 wt %; and wherein more than 90% of the particles of said growth regulator has a particle size of between 1-7 μm; wherein the dispersion further comprises (iii) an emulsifier which stabilizes the dispersion in the organic carrier, and which causes the concentrate to be water miscible and self-emulsifying when diluted in water in a suitable dilution, such as for example a 1:50 dilution or higher dilution; wherein the dispersion is essentially water free.

Owner:FINE AGROCHEMICALS LTD

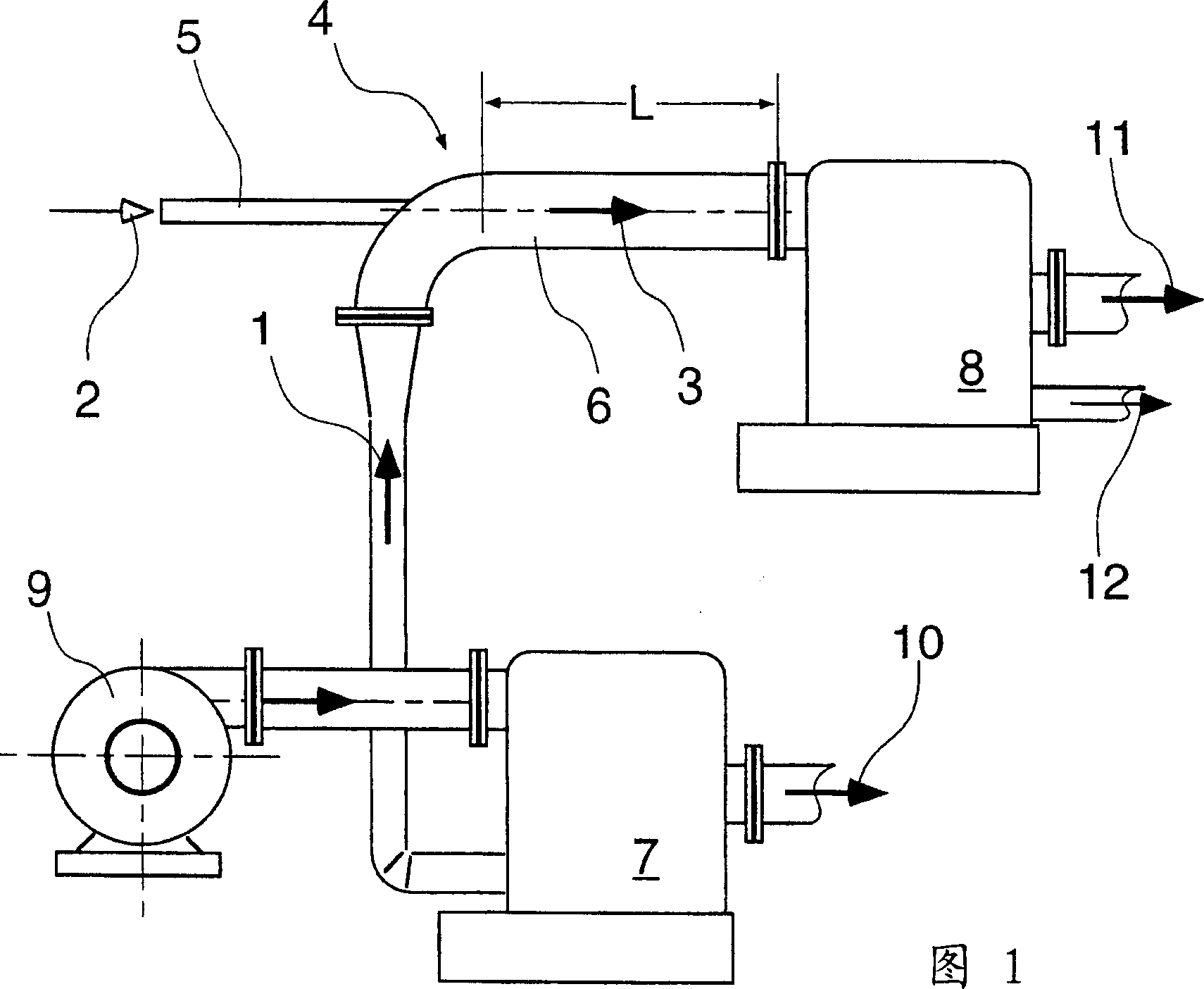

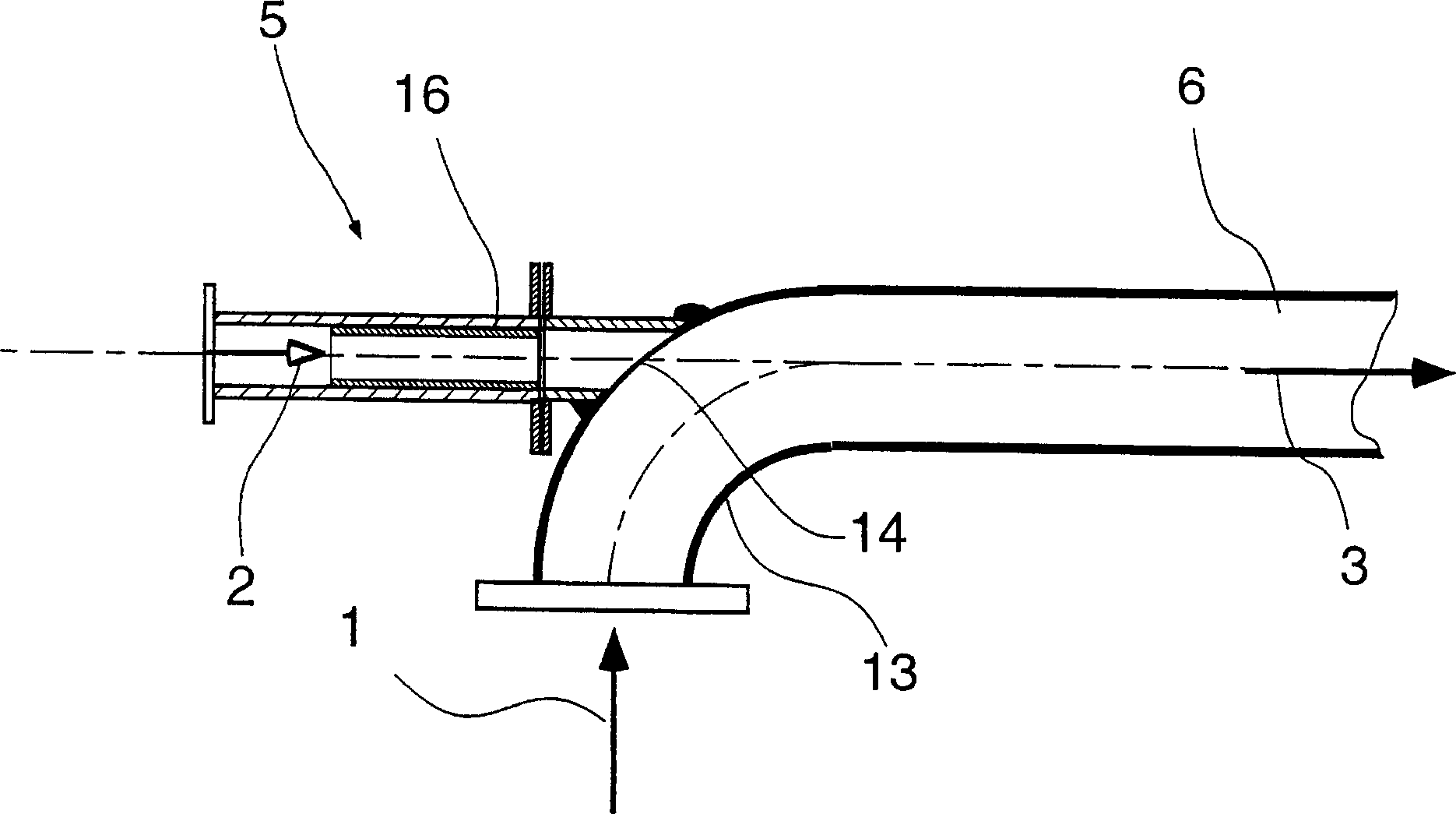

Method and device for mixing suspensions

InactiveCN1773012ALow costImprove the mixing effectMachine wet endFibrous raw materialsFiberMechanical drive

A watery dilution fluid (2), e.g. recycled papermaking water, is mixed with thicker fibrous suspension (1) arising as reject material (12) from suspension preparation. A closed mixer (4) is used. This has no mechanically-driven components to assist mixing. Its mixing tube includes at least two inlets and at least one outlet. The thick suspension (1) feed, flows more slowly into the watery dilution fluid. The latter enters at a velocity which is at least 5 m / s, preferably at least 10 m / s greater than the main flow velocity. After mixing-in the dilution fluid, the flow enters a straight cylindrical pipe section (6) with a length 5 times its diameter. The dilution fluid is fed along the axis of the pipe as a central driving jet, into the flow of thicker suspension. No pump is used to transfer the mixture into the next processing stage, which takes place in closed apparatus. The diluted suspension is fed to a pressurized screen (7, 8) without using a further pump. The thicker fibrous suspension is supplied to a cleaning plant (e.g. cyclones removing heavy contaminants) using a pulp suspension pump (9). It is fed for dilution into the mixing unit and thence to a further cleaning plant. In neither of these cases is a further pump used. An independent claim is included for the corresponding mixing equipment.

Owner:VOITH PATENT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com