Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

763results about "Fibrous raw materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

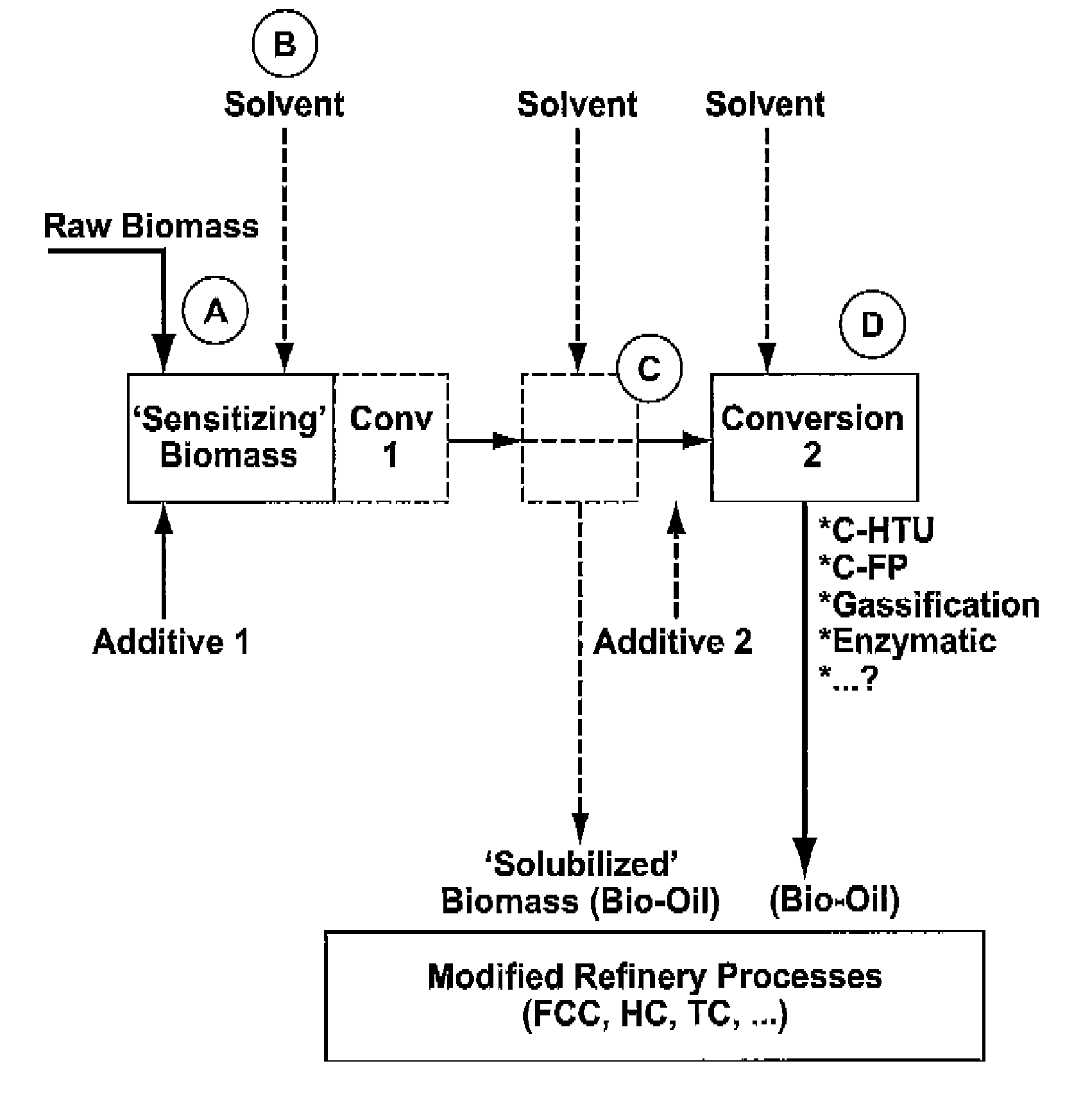

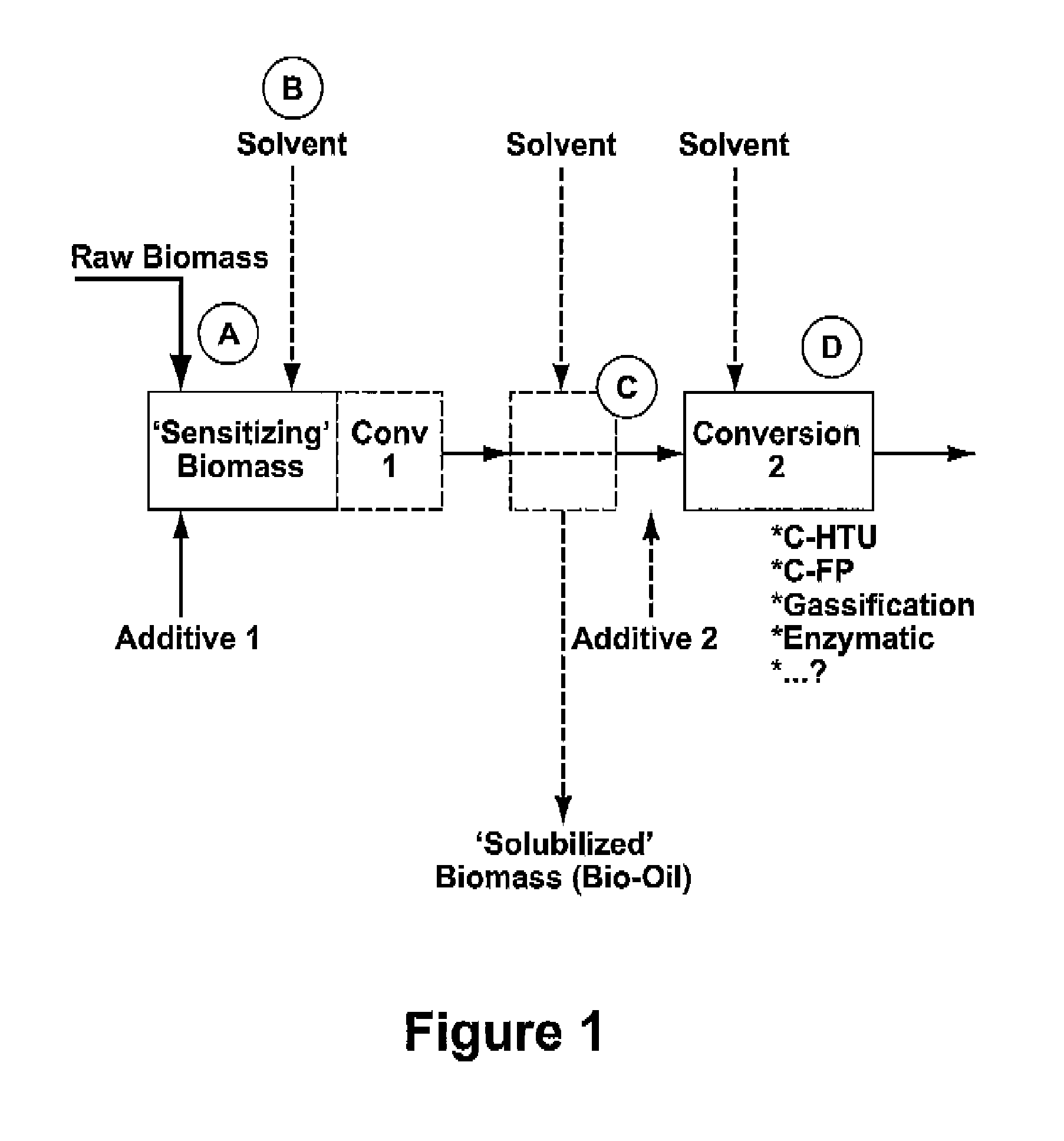

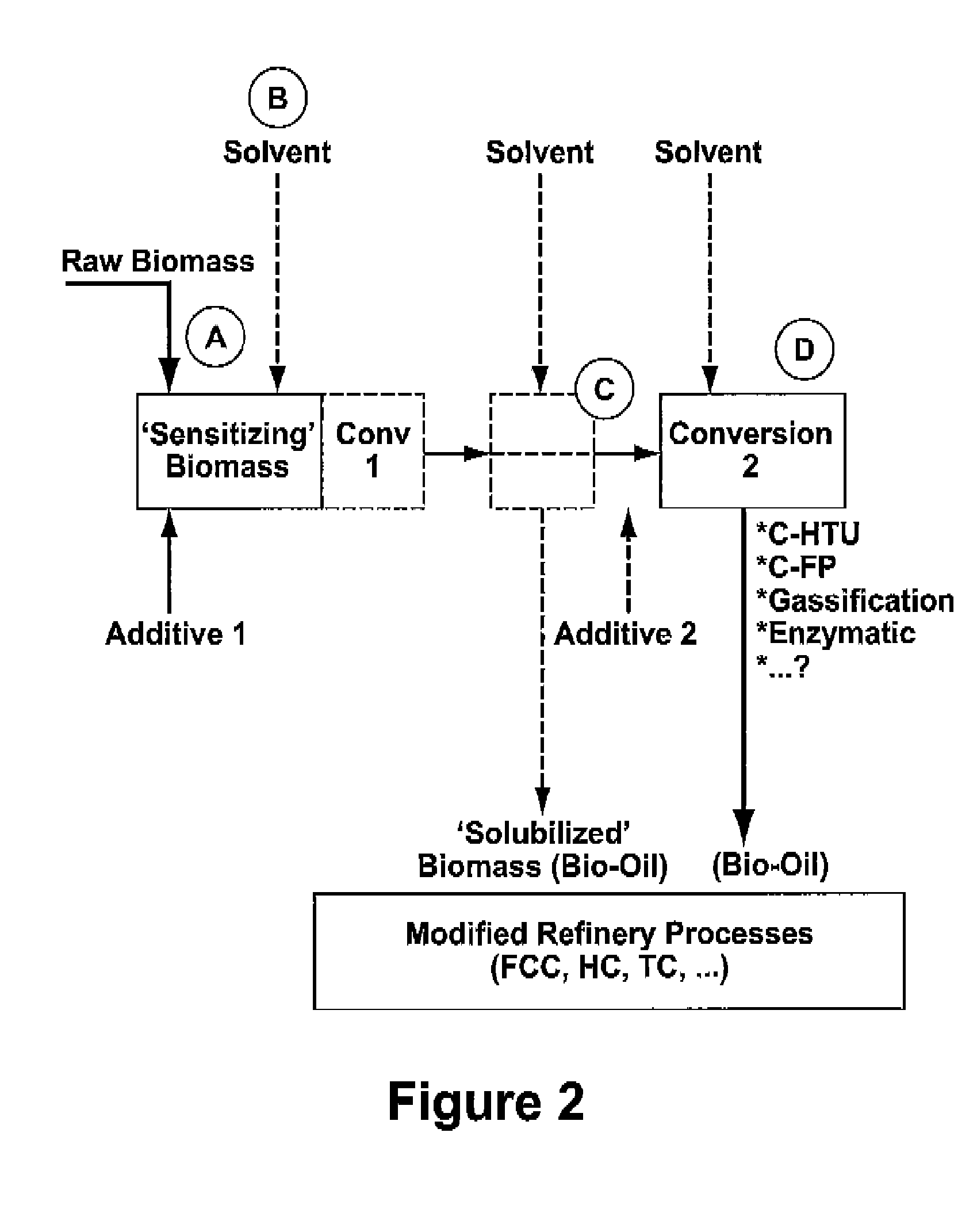

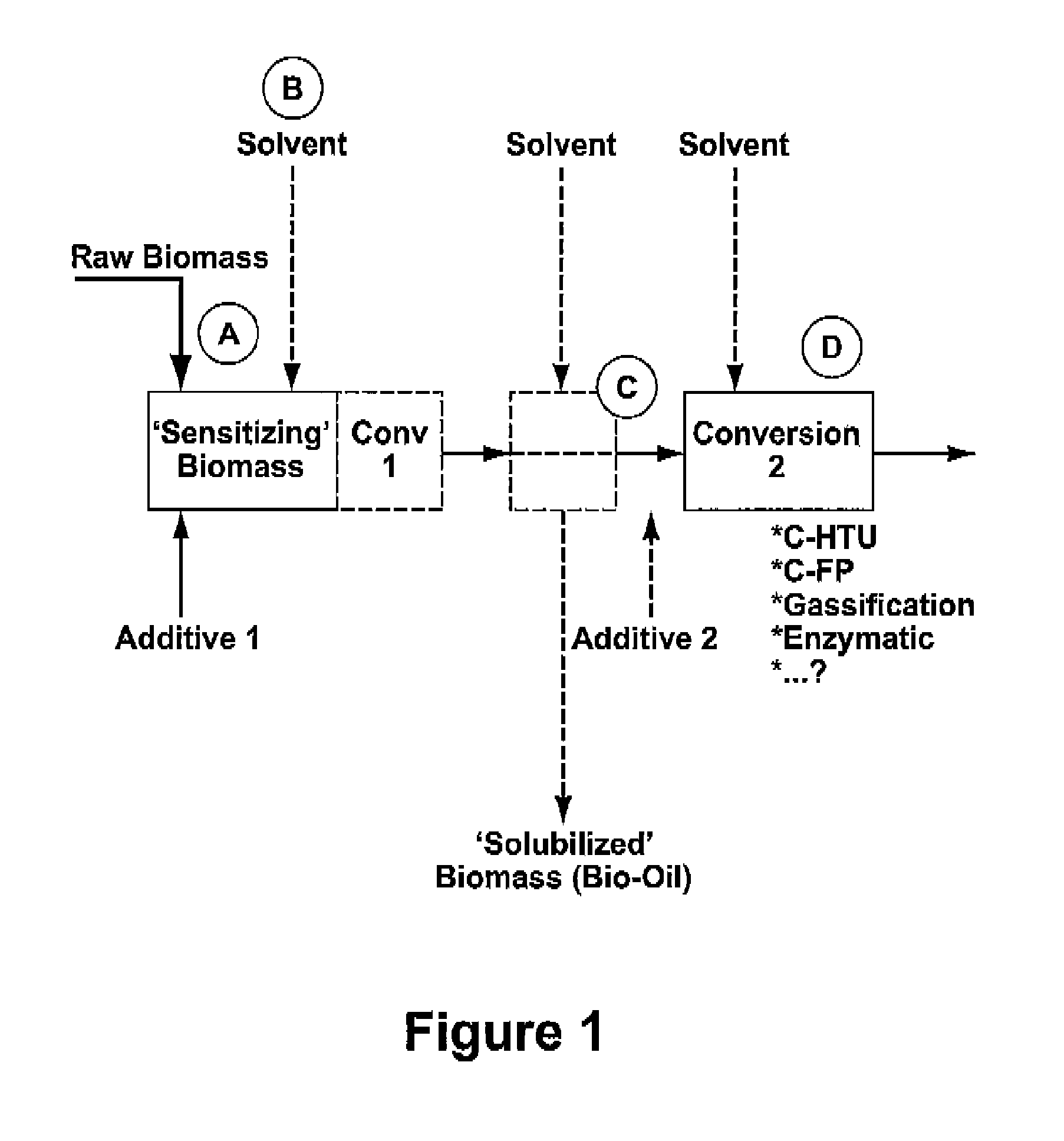

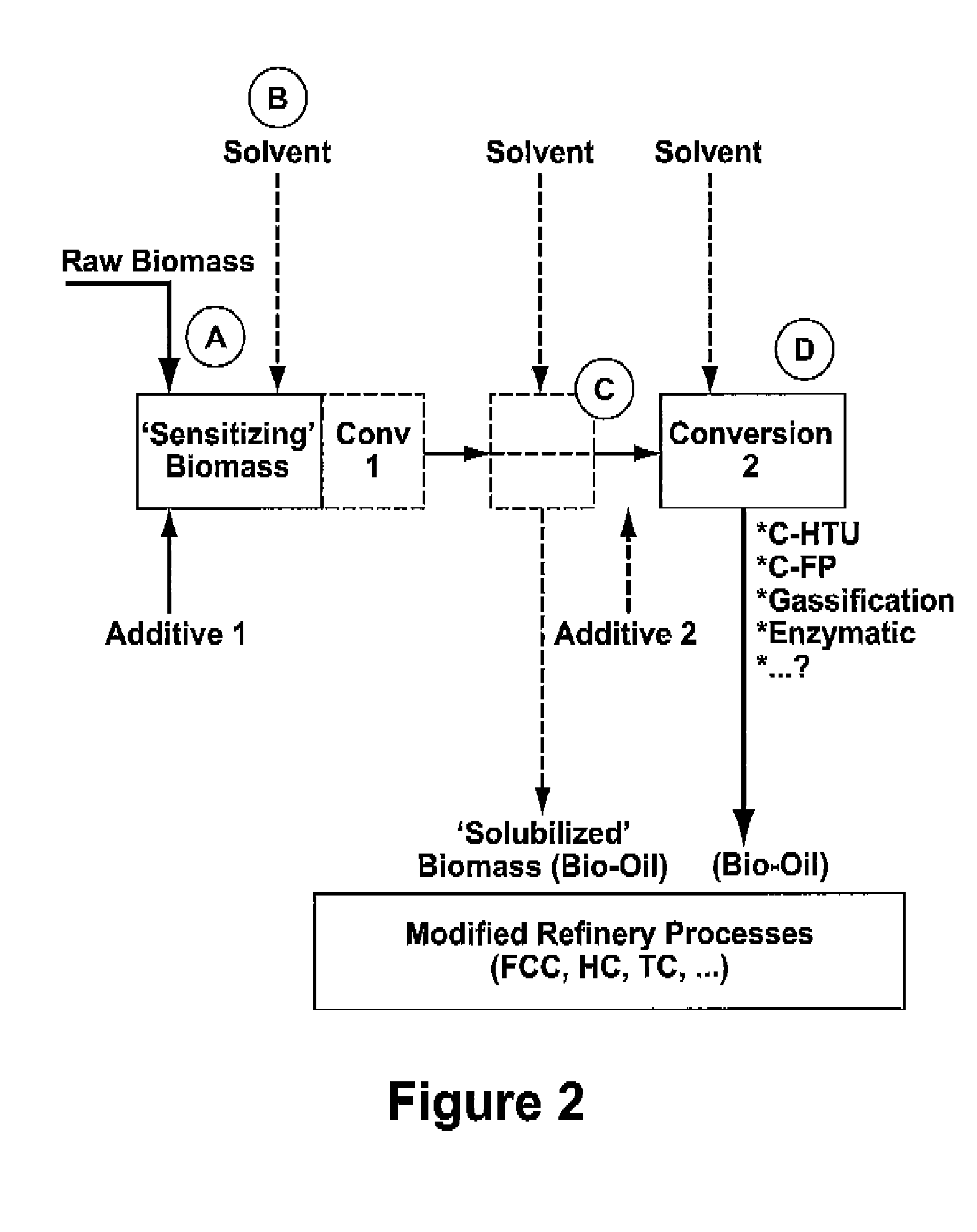

Process for the conversion of biomass to liquid fuels and specialty chemicals

Disclosed is a hydrothermal treatment process for conversion of a carbon-based energy carrier material. The process comprises a step for sensitizing or activating the carbon based energy carrier material to increase its susceptibility to hydrothermal conversion. As a result of the sensitization step, the hydrothermal conversion step itself may be carried out under relatively mild conditions.The process comprises the steps of sensitizing the carbon-based energy carrier material to increase its susceptibility to hydrothermal conversion; and subjecting the sensitized carbon-based energy carrier material to hydrothermal conversion at a temperature of less than 300 degrees centigrade in a hydrothermal treatment reactor.

Owner:MARD INC

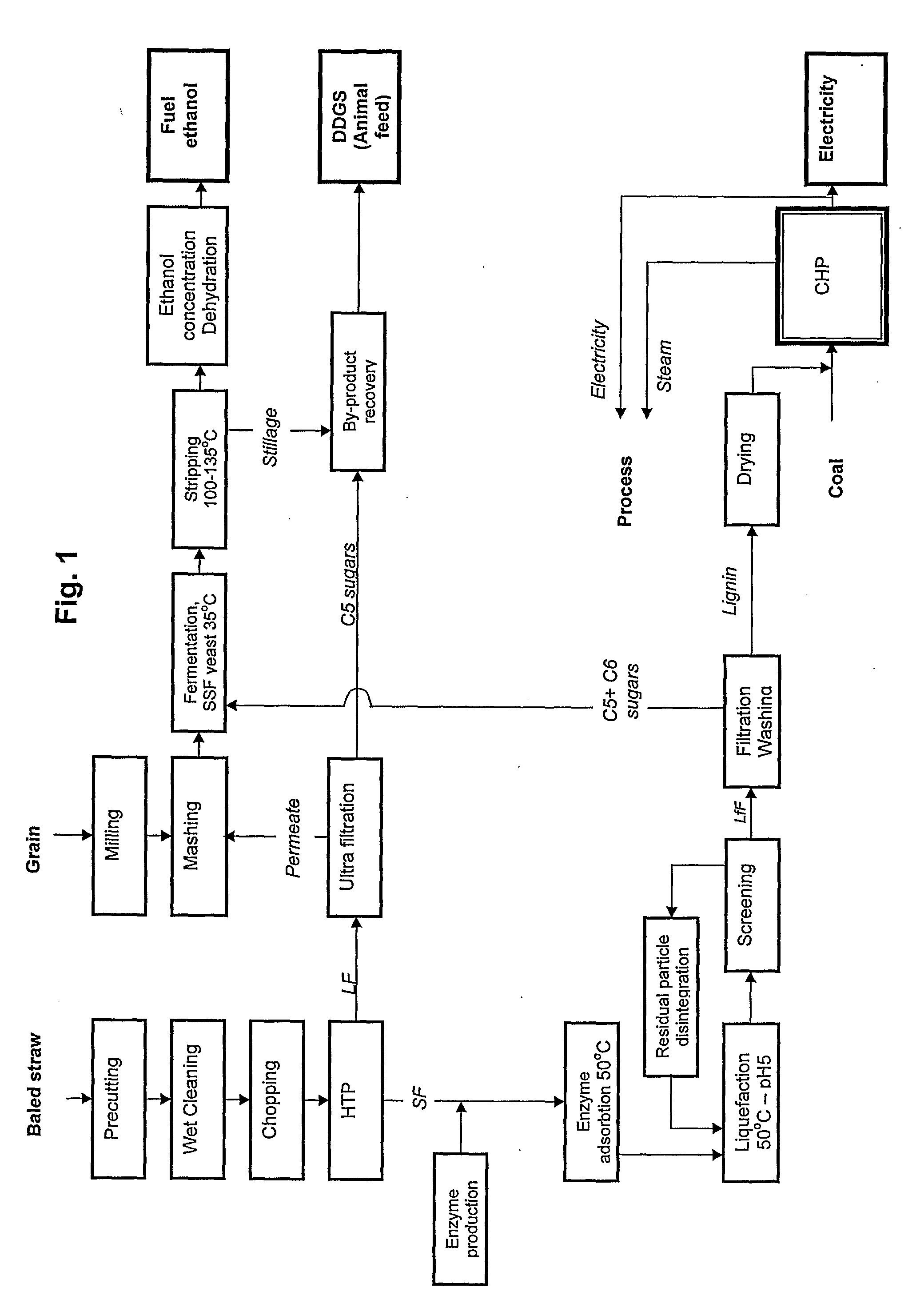

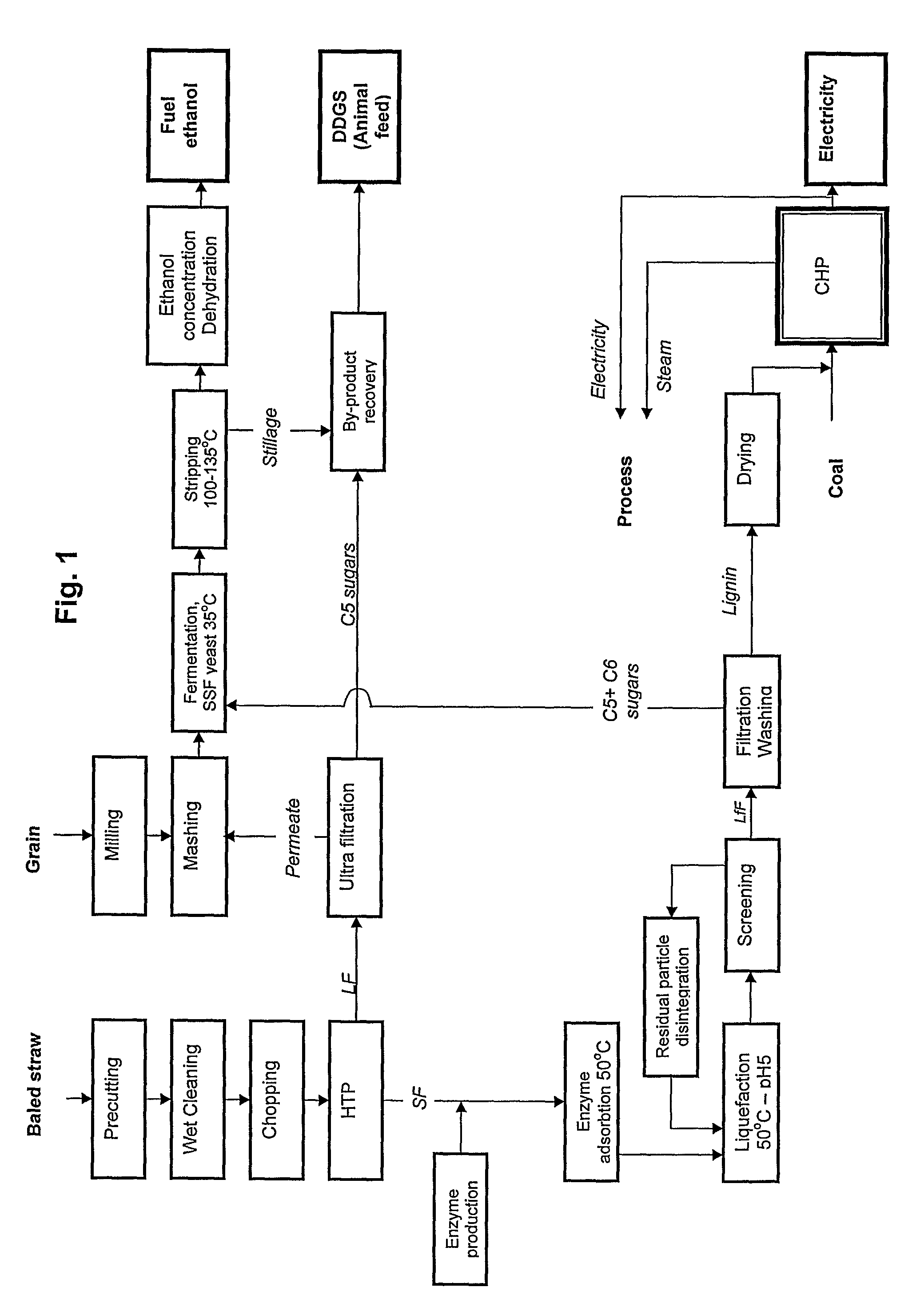

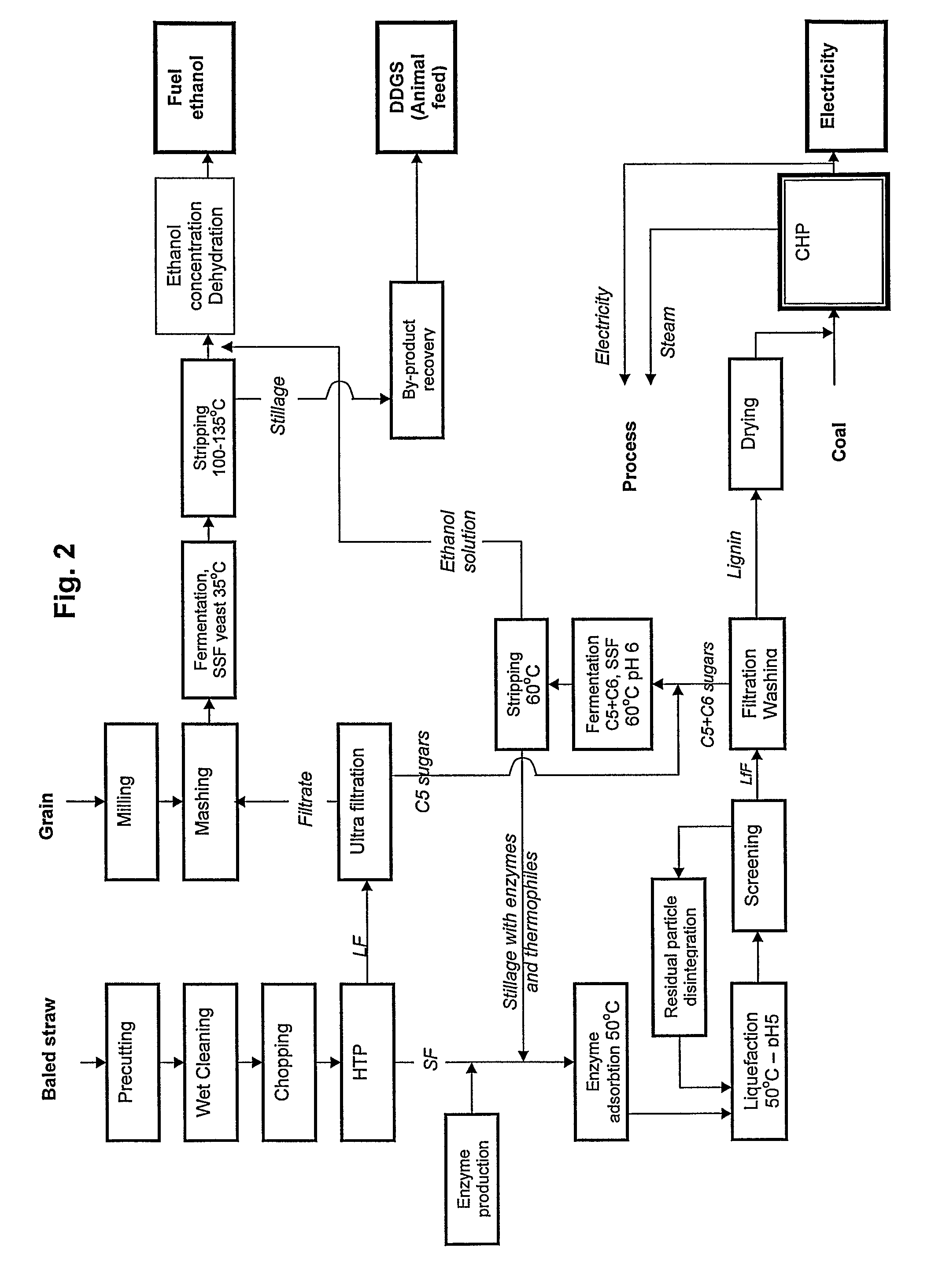

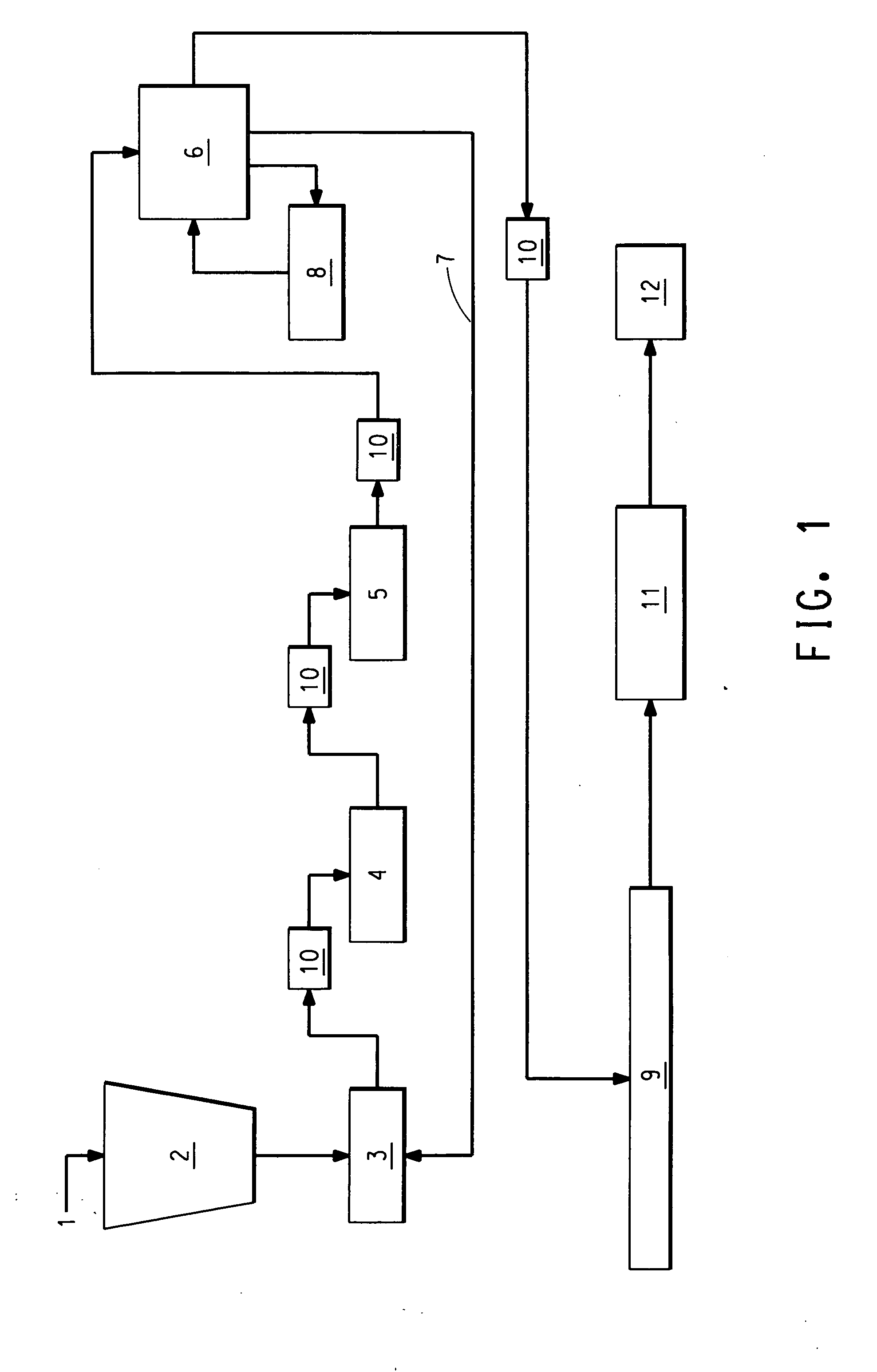

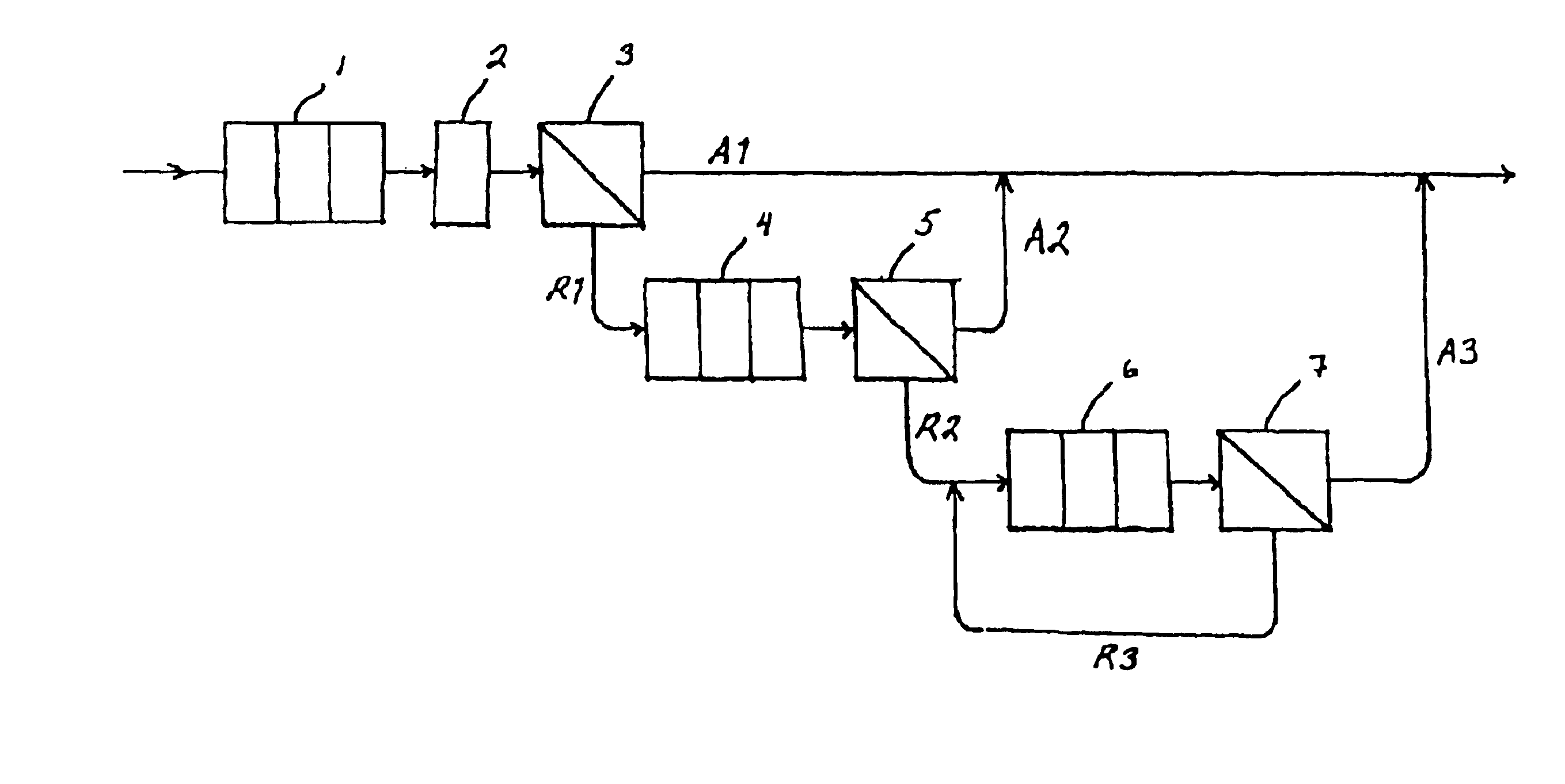

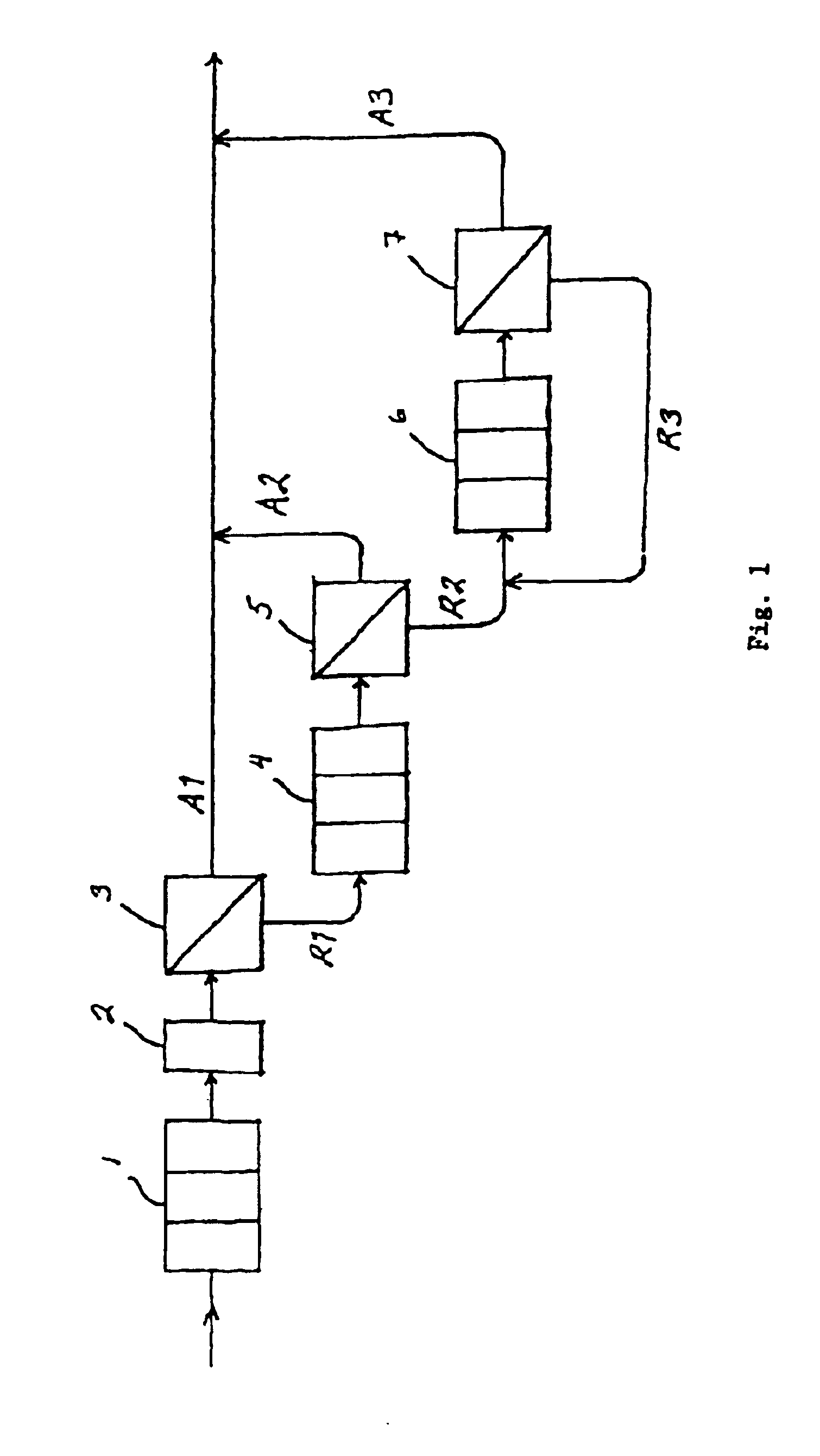

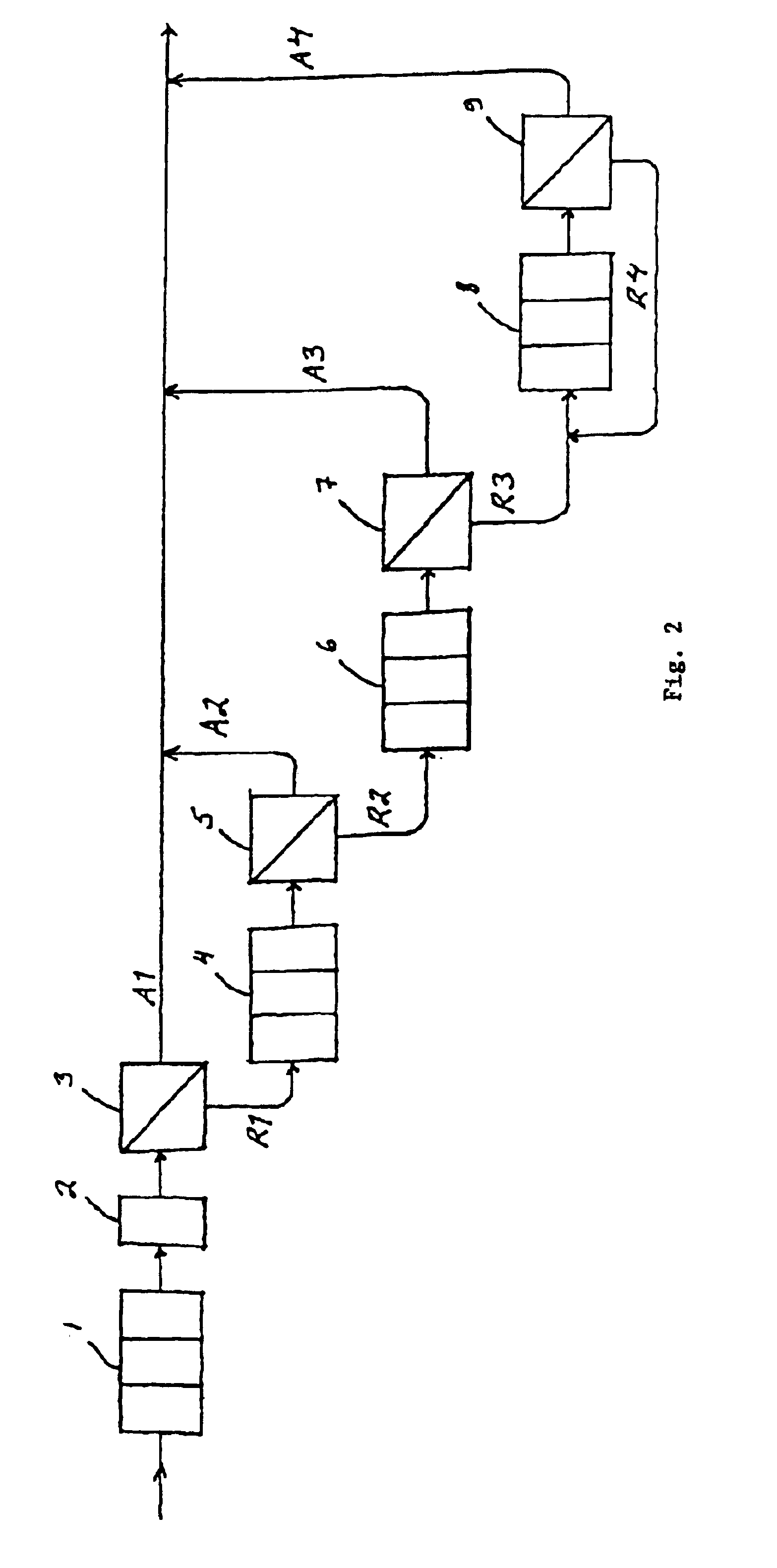

Method and apparatus for conversion of cellulosic material to ethanol

ActiveUS20100041119A1Low costDown rate of fermentationBiological substance pretreatmentsBiofuelsFiberCellulose

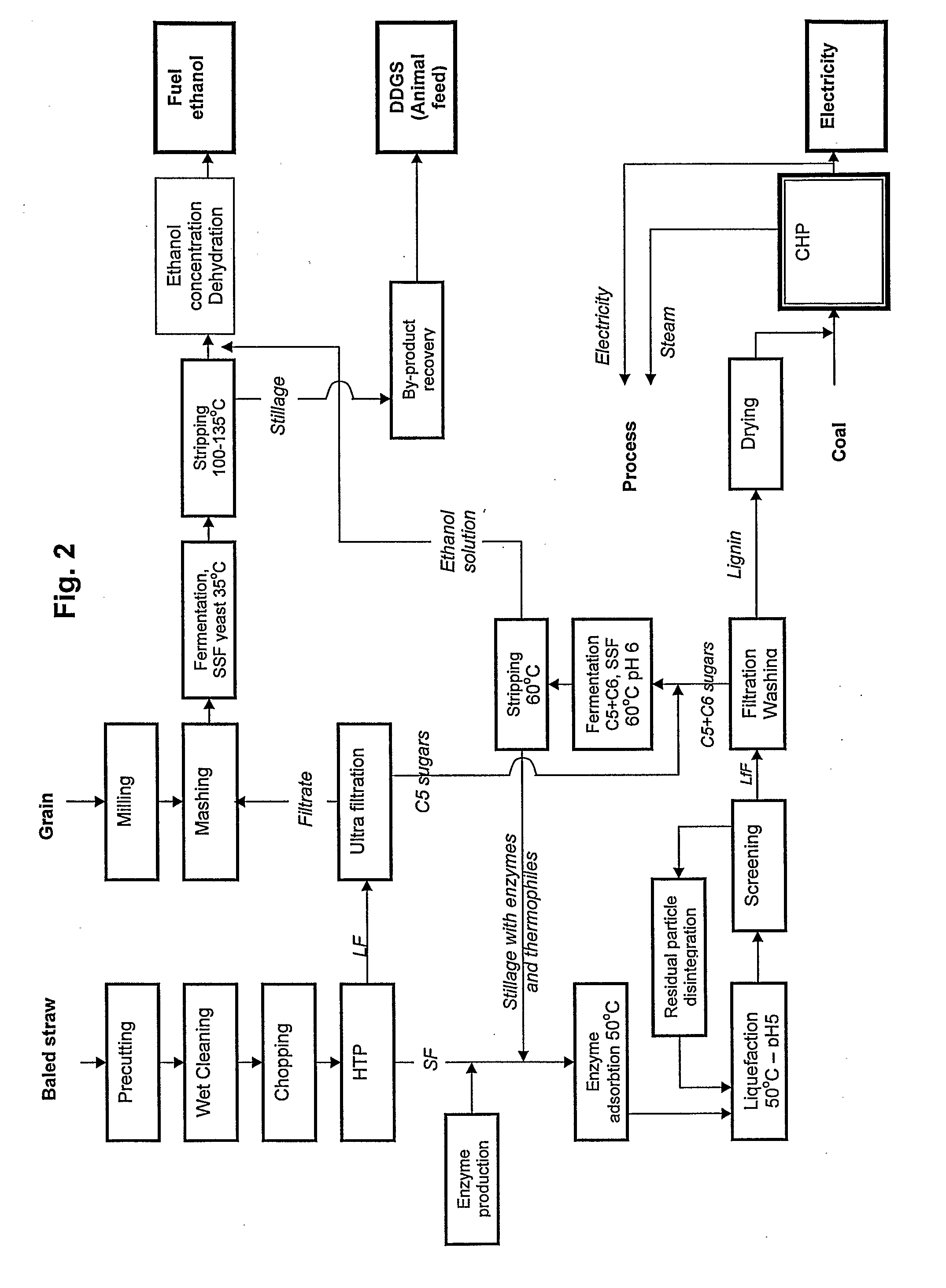

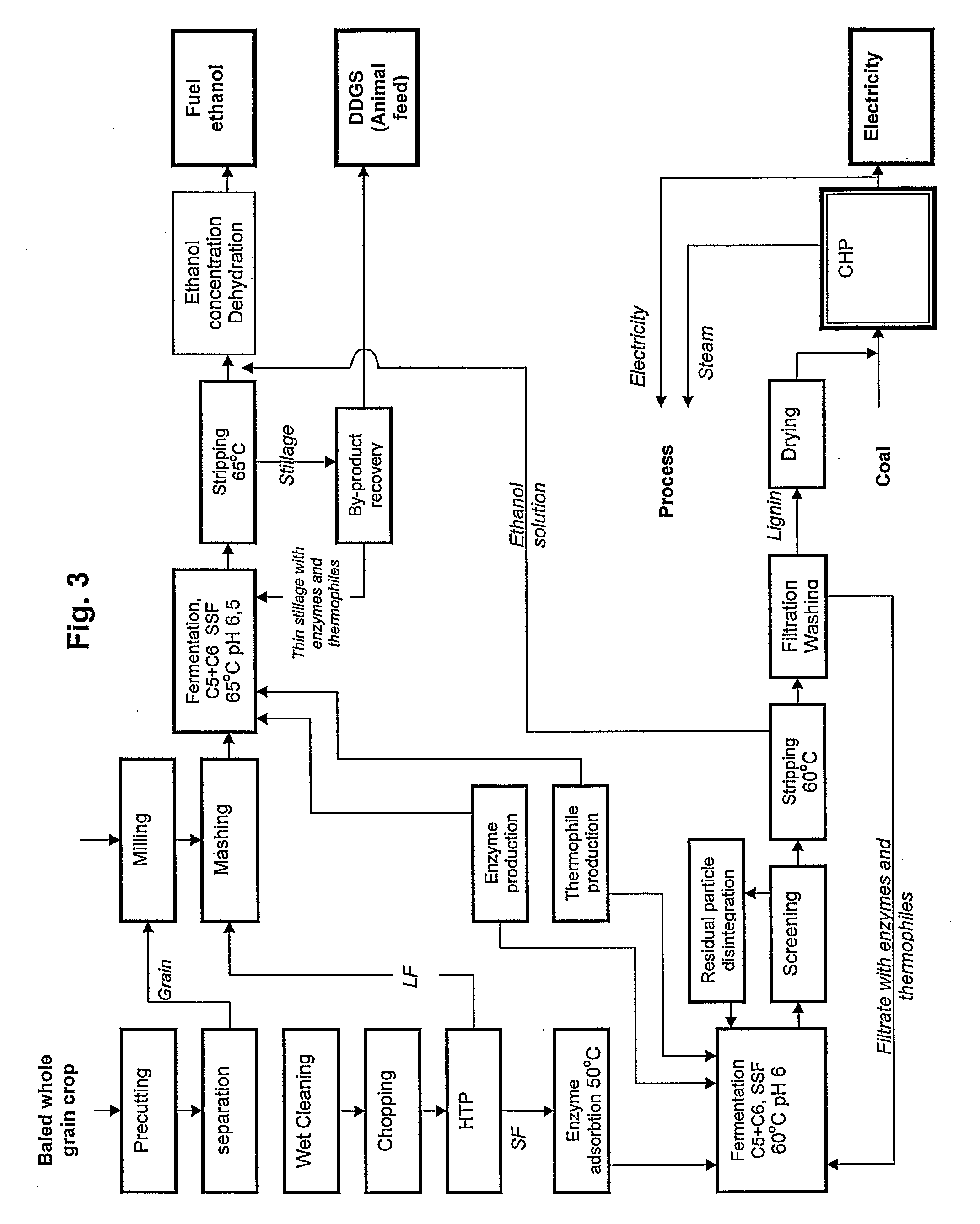

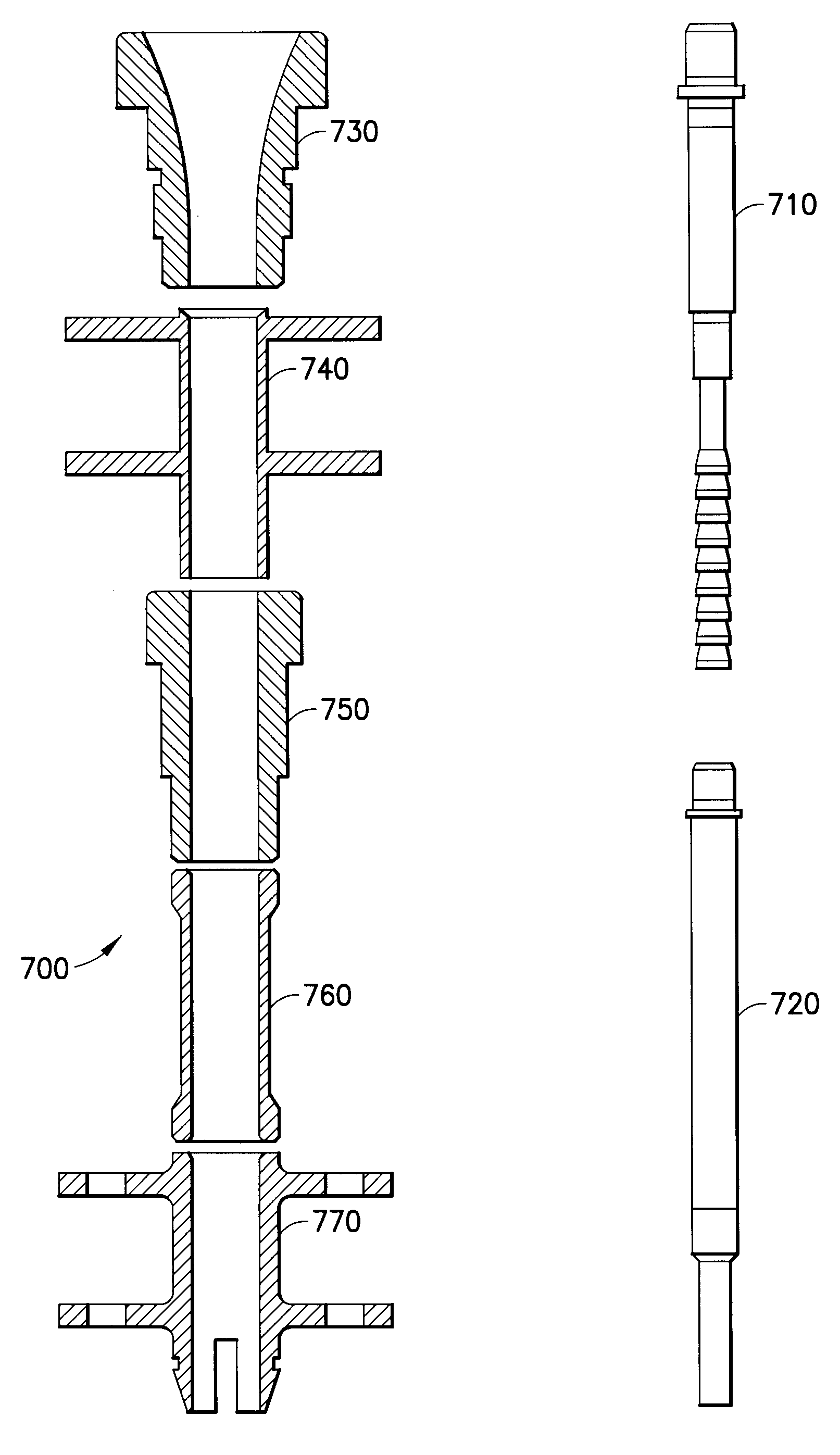

The present invention provides an apparatus and a method for conversion of cellulosic material, such as chopped straw and corn stover, and household waste, to ethanol and other products. The cellulosic material is subjected to continuous hydrothermal pre-treatment without addition of chemicals, and a liquid and a fibre fraction are produced. The fibre fraction is subjected to enzymatic liquefaction and saccharification. The method of the present invention comprises:performing the hydrothermal pre-treatment by subjecting the cellulosic material to at least one soaking operation, and conveying the cellulosic material through at least one pressurised reactor, and subjecting the cellulosic material to at least one pressing operation, creating a fibre fraction and a liquid fraction;selecting the temperature and residence time for the hydrothermal pretreatment, so that the fibrous structure of the feedstock is maintained and at least 80% of the lignin is maintained in the fibre fraction.

Owner:INBICON AS

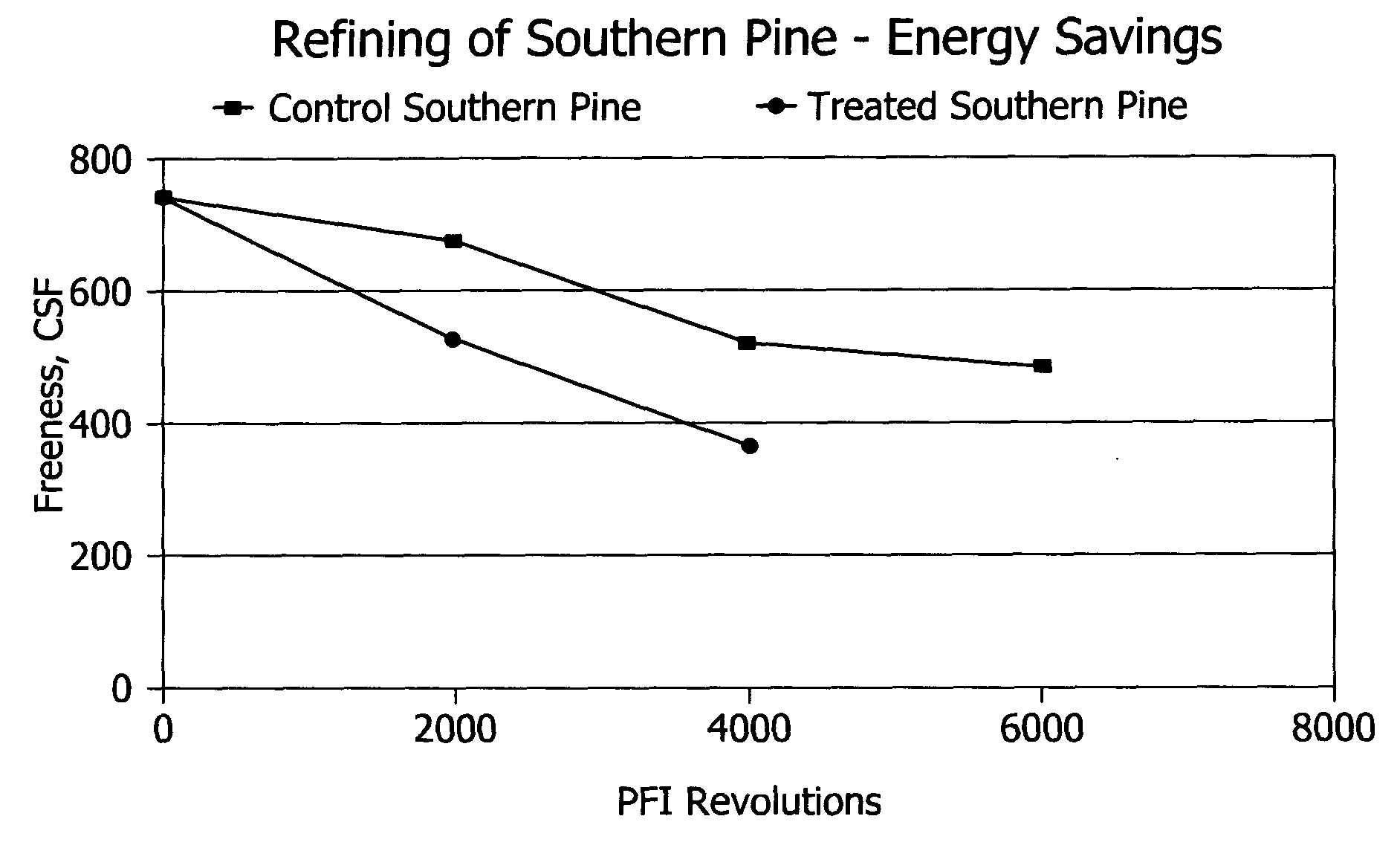

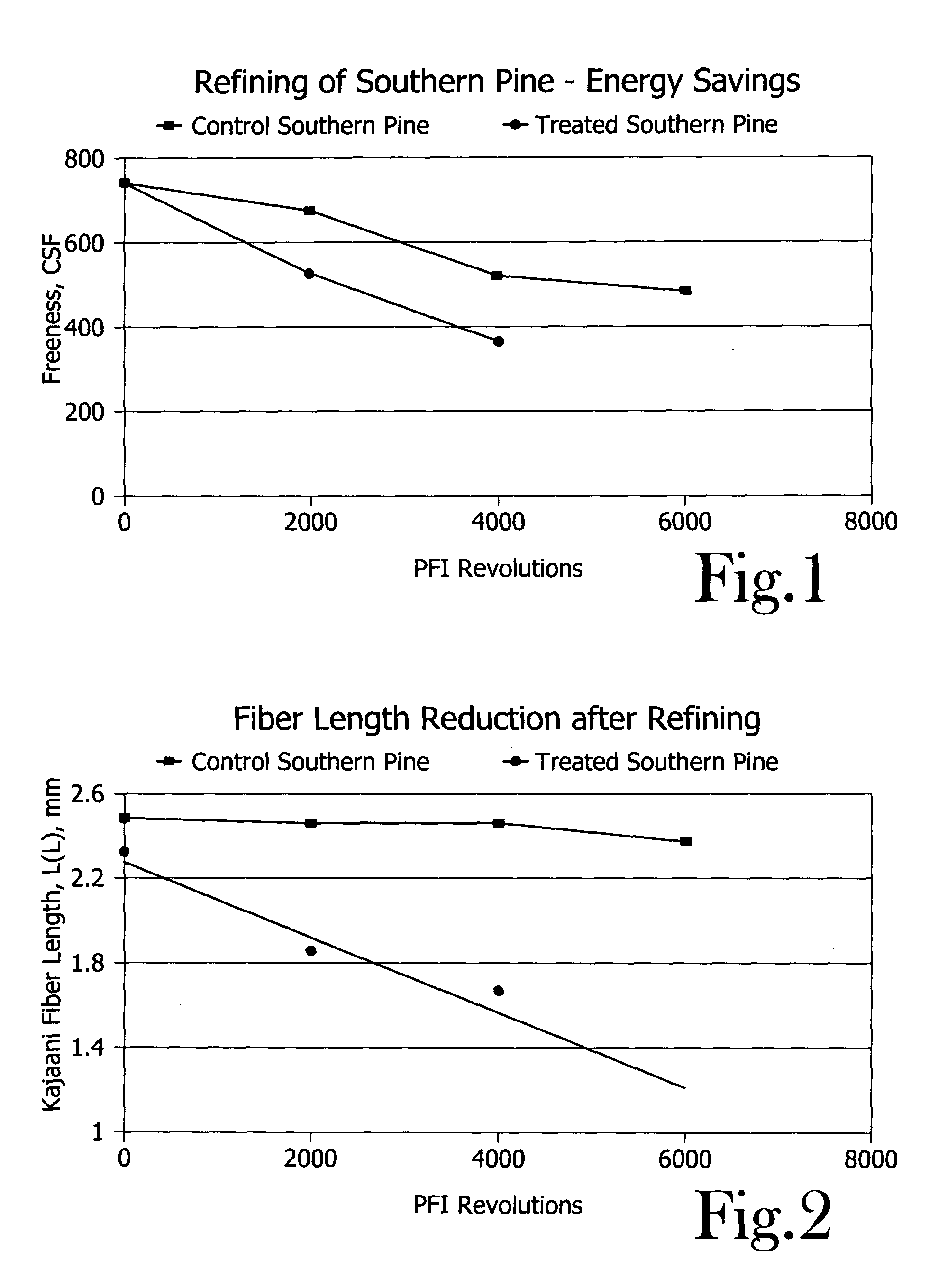

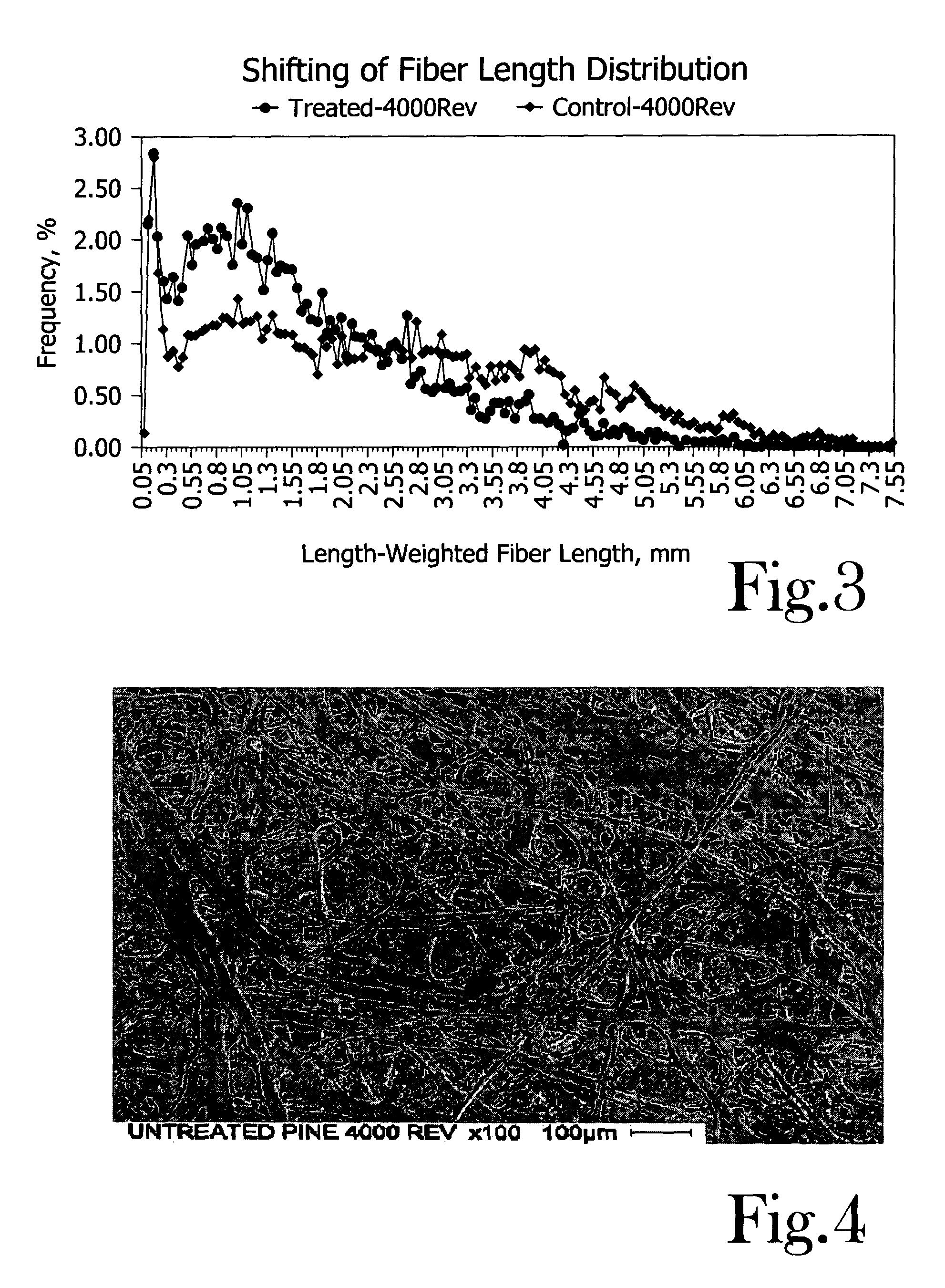

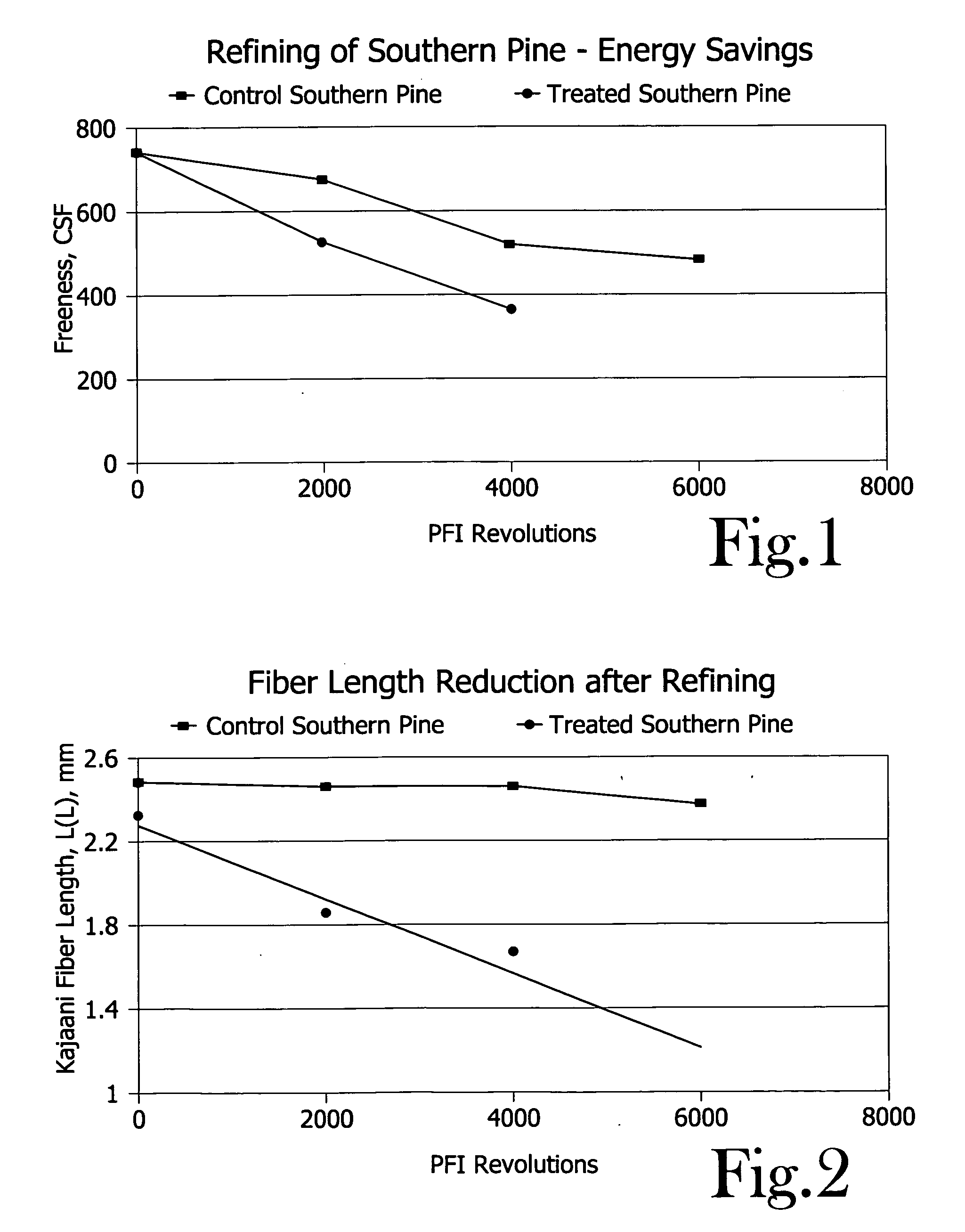

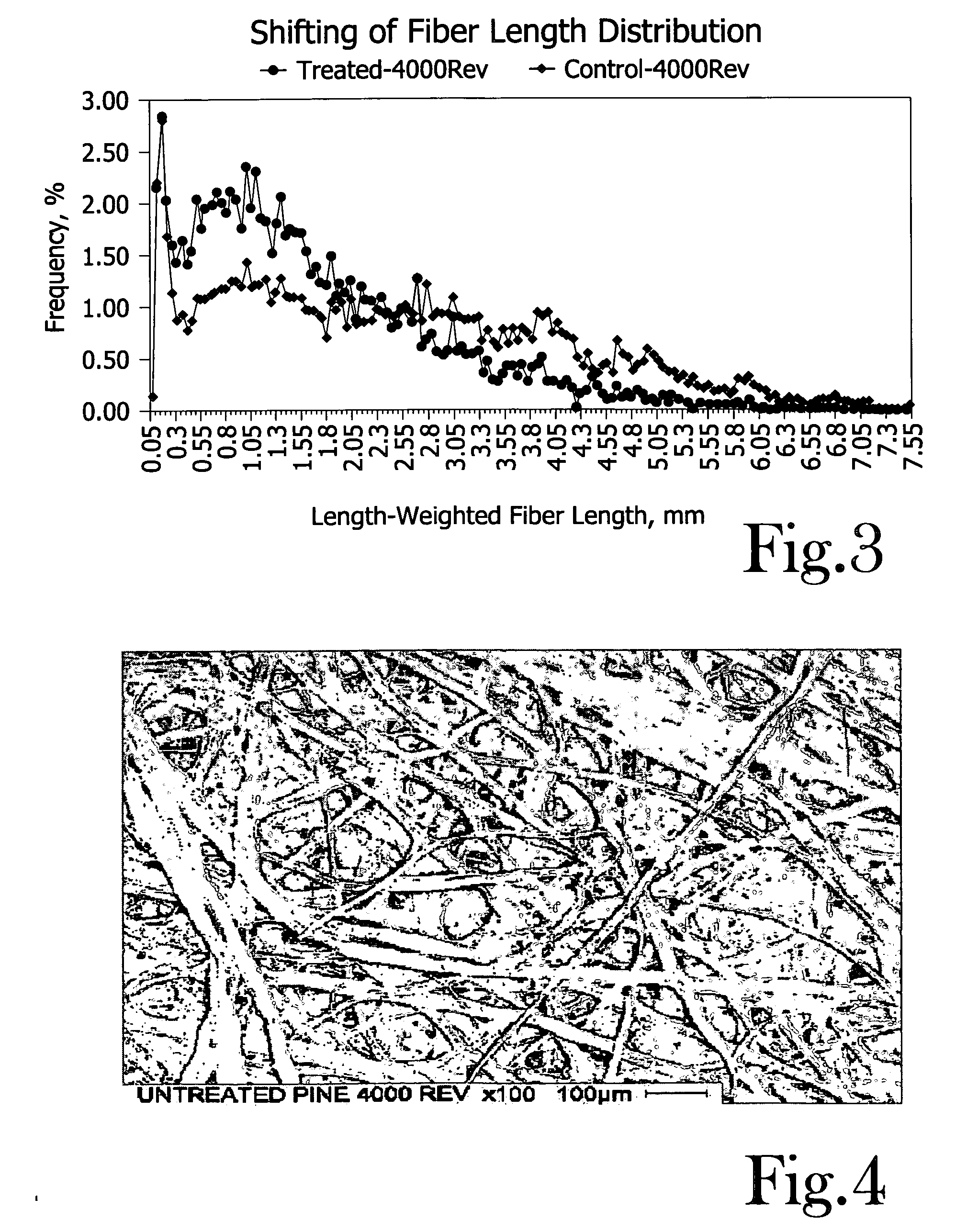

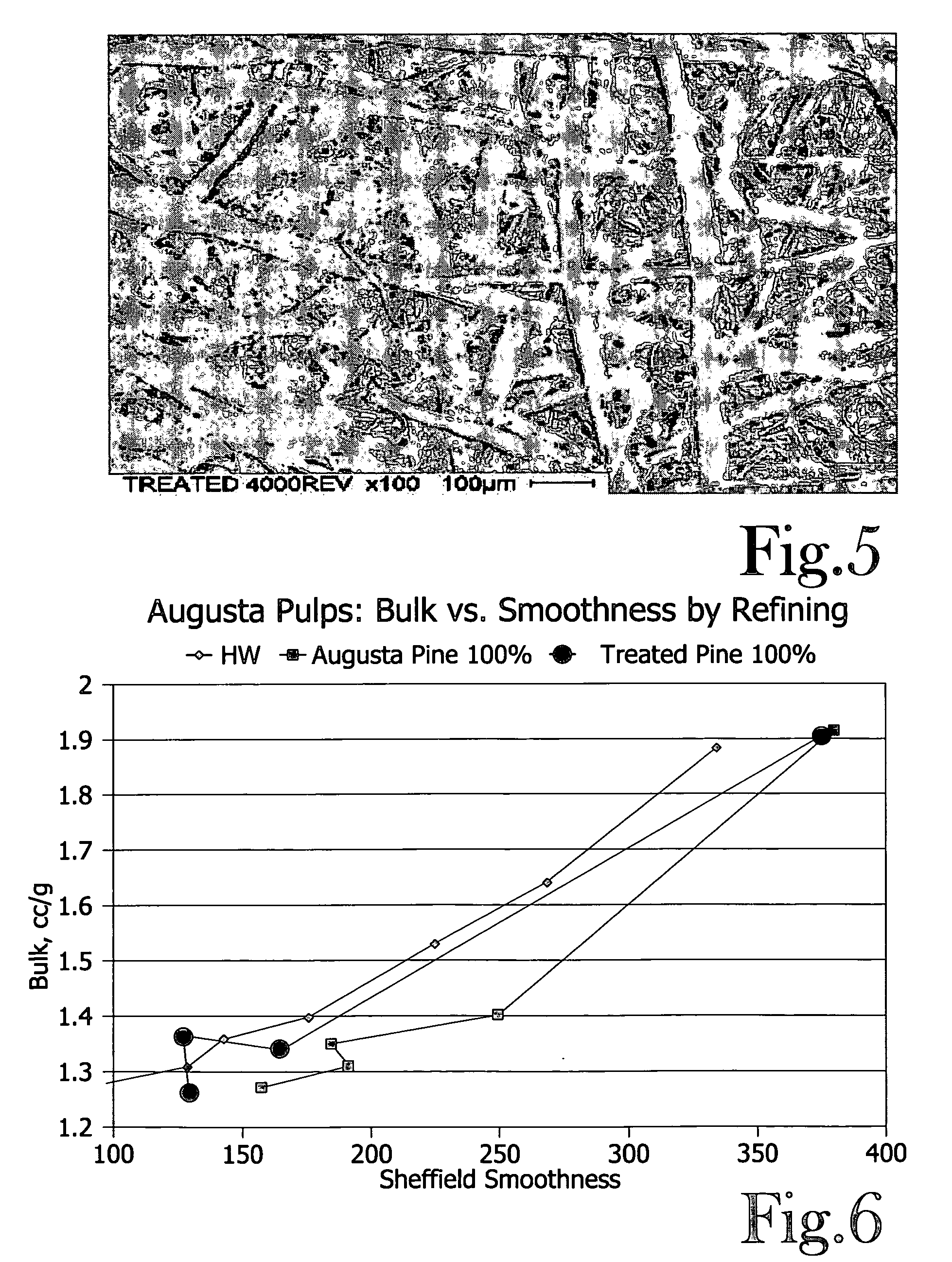

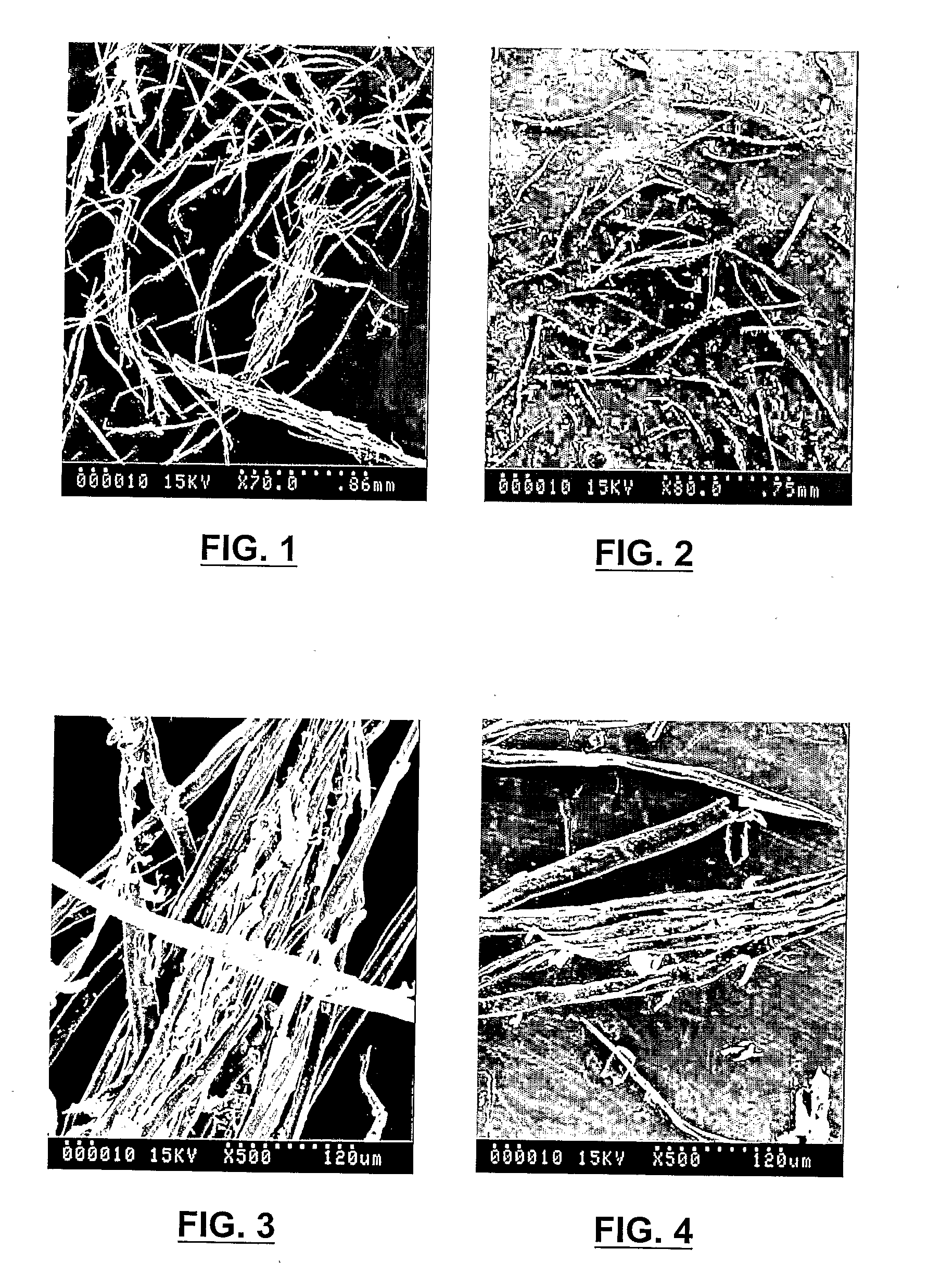

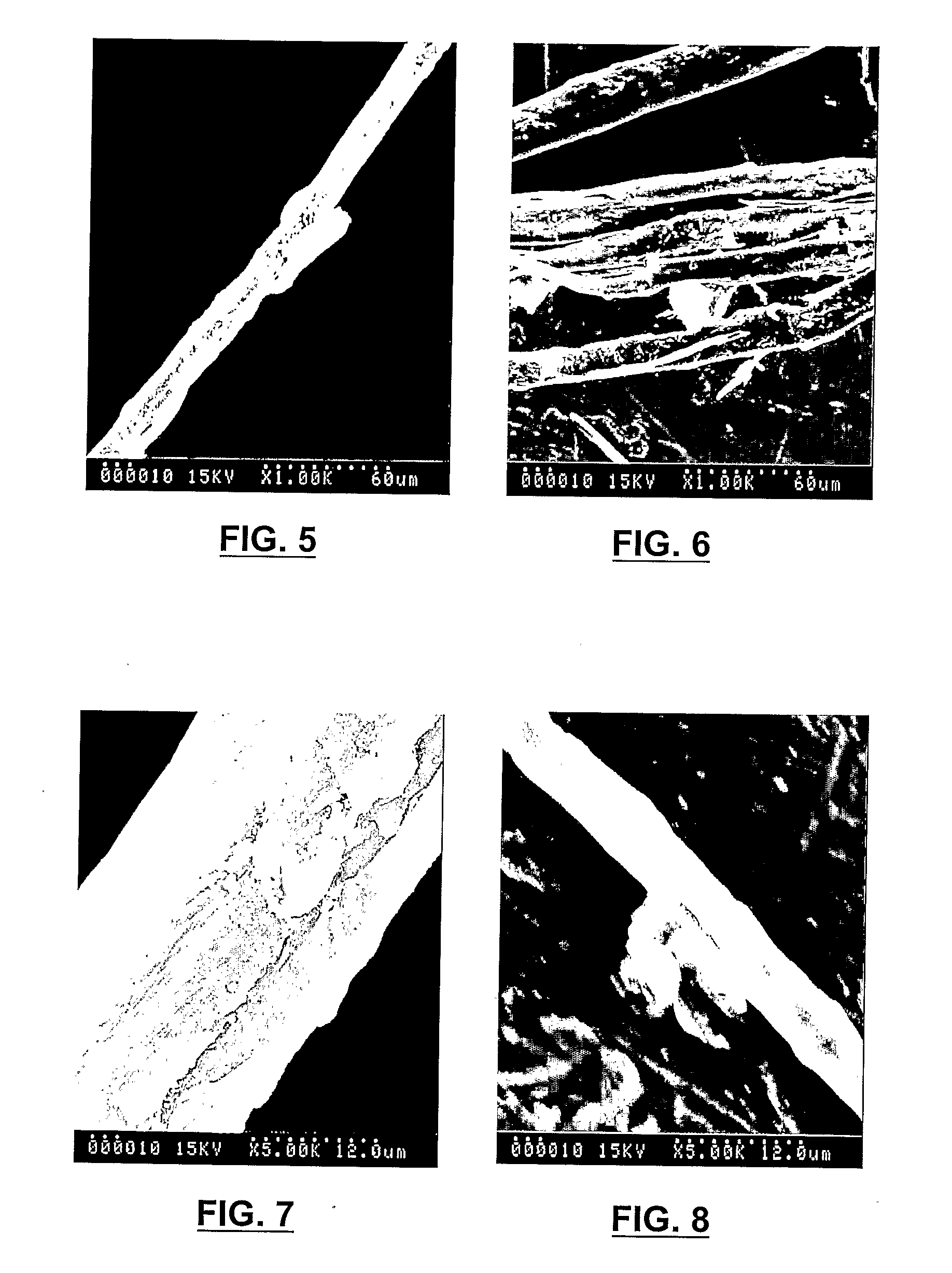

Chemical activation and refining of southern pine kraft fibers

InactiveUS20050061455A1Increase the pulp freenessEasy to drainPulp properties modificationPulp bleachingChemical treatmentCellulose fiber

A method for alteration of the morphology of cellulose fibers, particularly softwood fibers, by (a) subjecting the fibers to a metal ion-activated peroxide treatment carried out at a pH of between about 1 and about 9, preferably between 3 and 7, and (b) subjecting the treated fibers to a refining treatment thereby converts SW fibers to HW-like fibers in many respects. The metal ion-activated peroxide treatment has been noted to act on pulp cellulose and hemi-cellulose, causing oxidation and oxidative degradation of cellulose fibers. The chemical treatment of the pulp, taken alone, is not sufficient to attain the desired modification of the morphology of the fibers, however, subsequent refining or like mechanical treatment of the chemically-treated fibers to achieve a given degree of refinement of the fibers requires dramatically less refining energy to achieve a desired end point of refinement and to impart other desirable properties to the pulp. A pulp of modified SW fibers and a mixture of HW fibers and modified HW fibers are disclosed.

Owner:INT PAPER CO

Method and apparatus for conversion of cellulosic material to ethanol

ActiveUS8123864B2Low costDown rate of fermentationBiological substance pretreatmentsBiofuelsFiberCellulose

The present invention provides an apparatus and a method for conversion of cellulosic material, such as chopped straw and corn stover, and household waste, to ethanol and other products. The cellulosic material is subjected to continuous hydrothermal pre-treatment without addition of chemicals, and a liquid and a fiber fraction are produced. The fiber fraction is subjected to enzymatic liquefaction and saccharification. The method of the present invention comprises:performing the hydrothermal pre-treatment by subjecting the cellulosic material to at least one soaking operation, and conveying the cellulosic material through at least one pressurized reactor, and subjecting the cellulosic material to at least one pressing operation, creating a fiber fraction and a liquid fraction;selecting the temperature and residence time for the hydrothermal pretreatment, so that the fibrous structure of the feedstock is maintained and at least 80% of the lignin is maintained in the fiber fraction.

Owner:INBICON AS

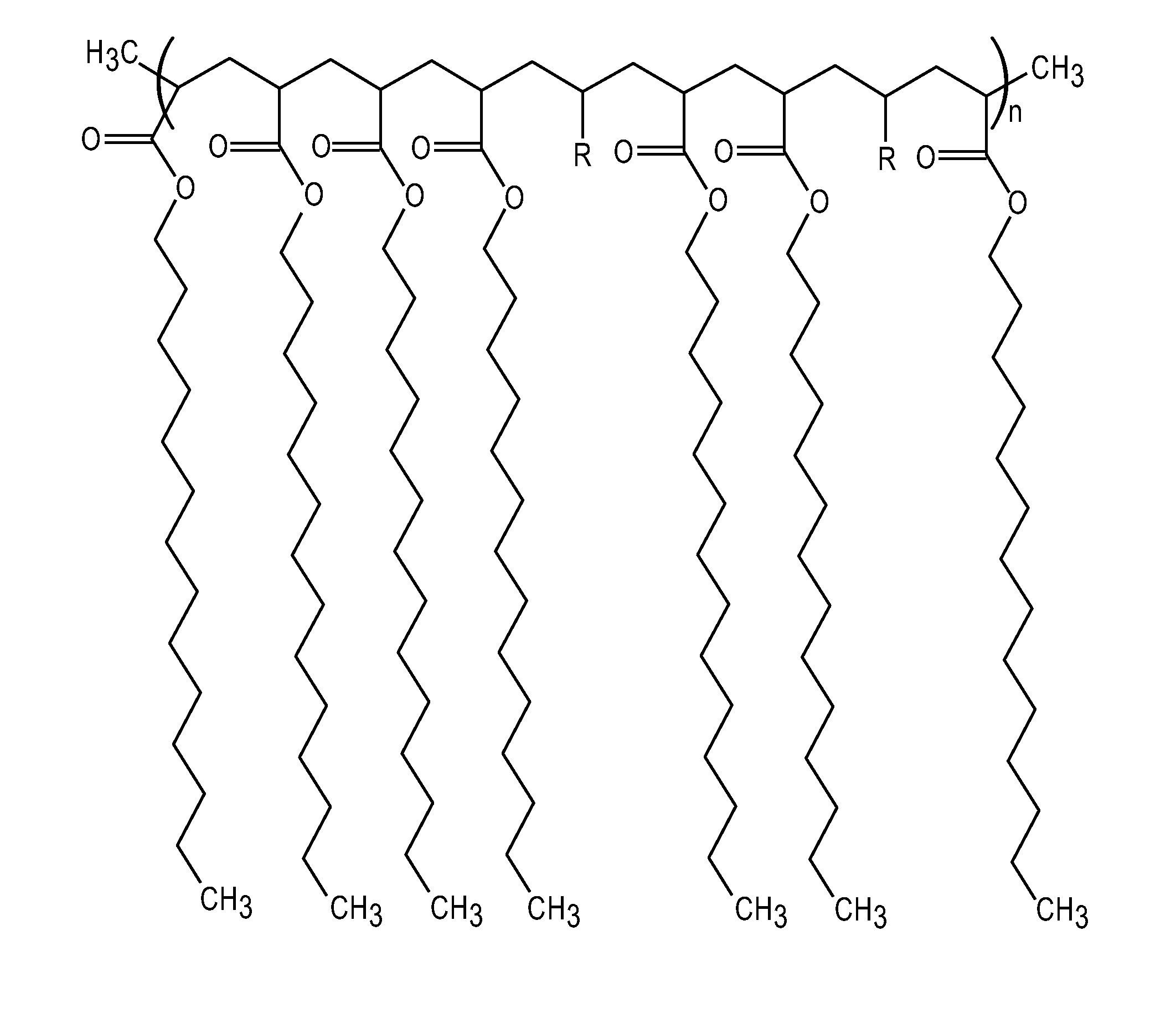

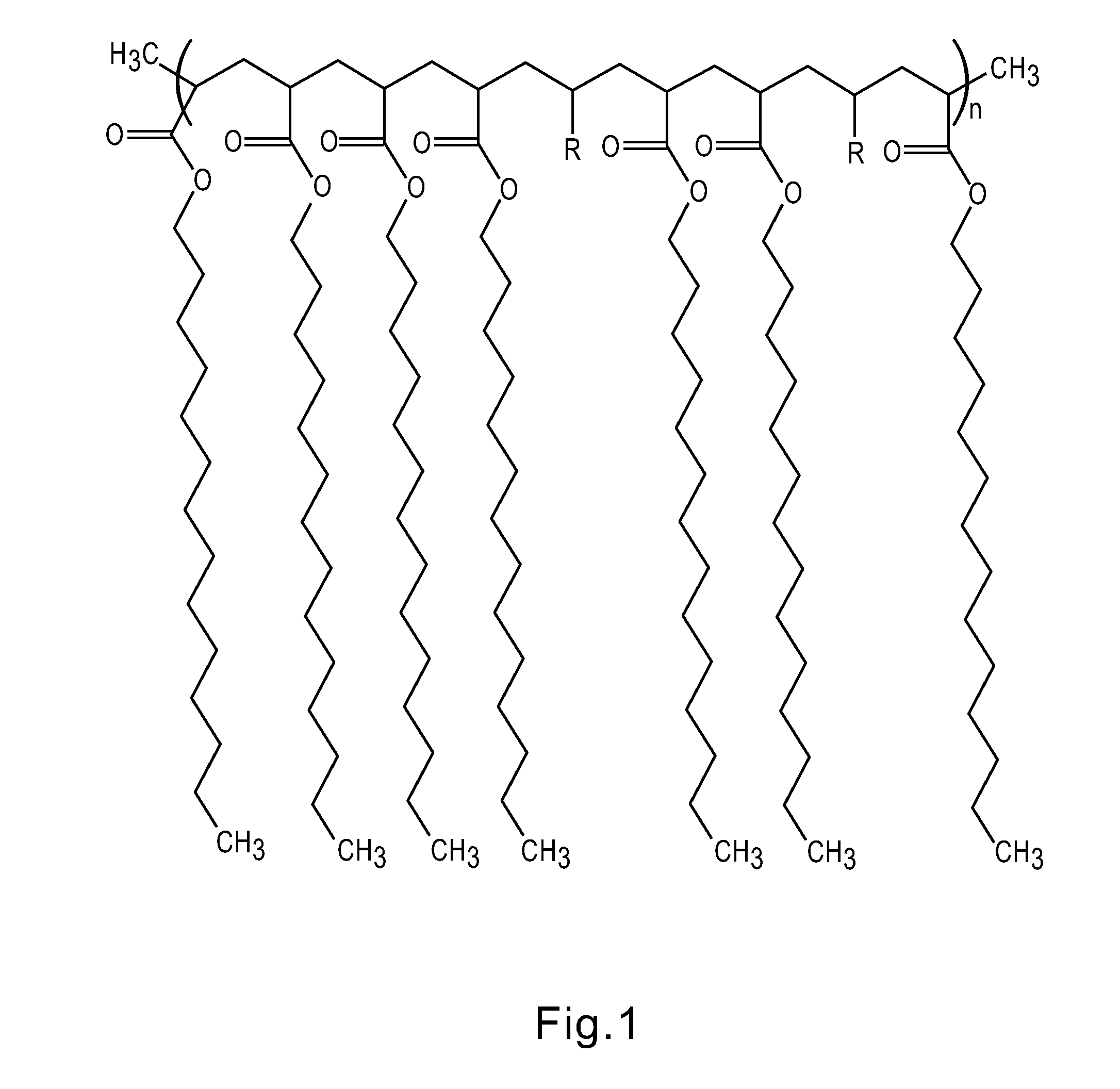

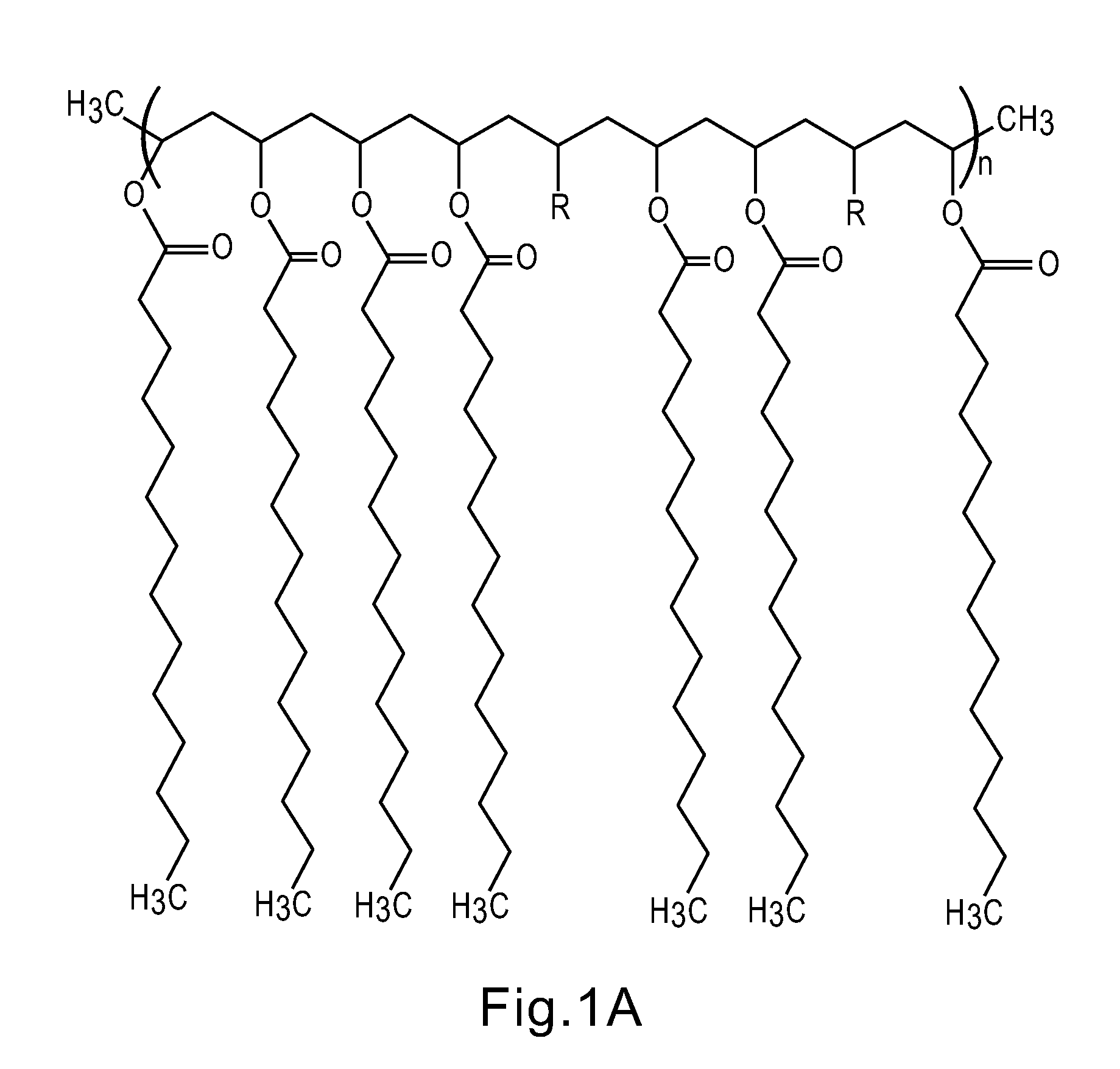

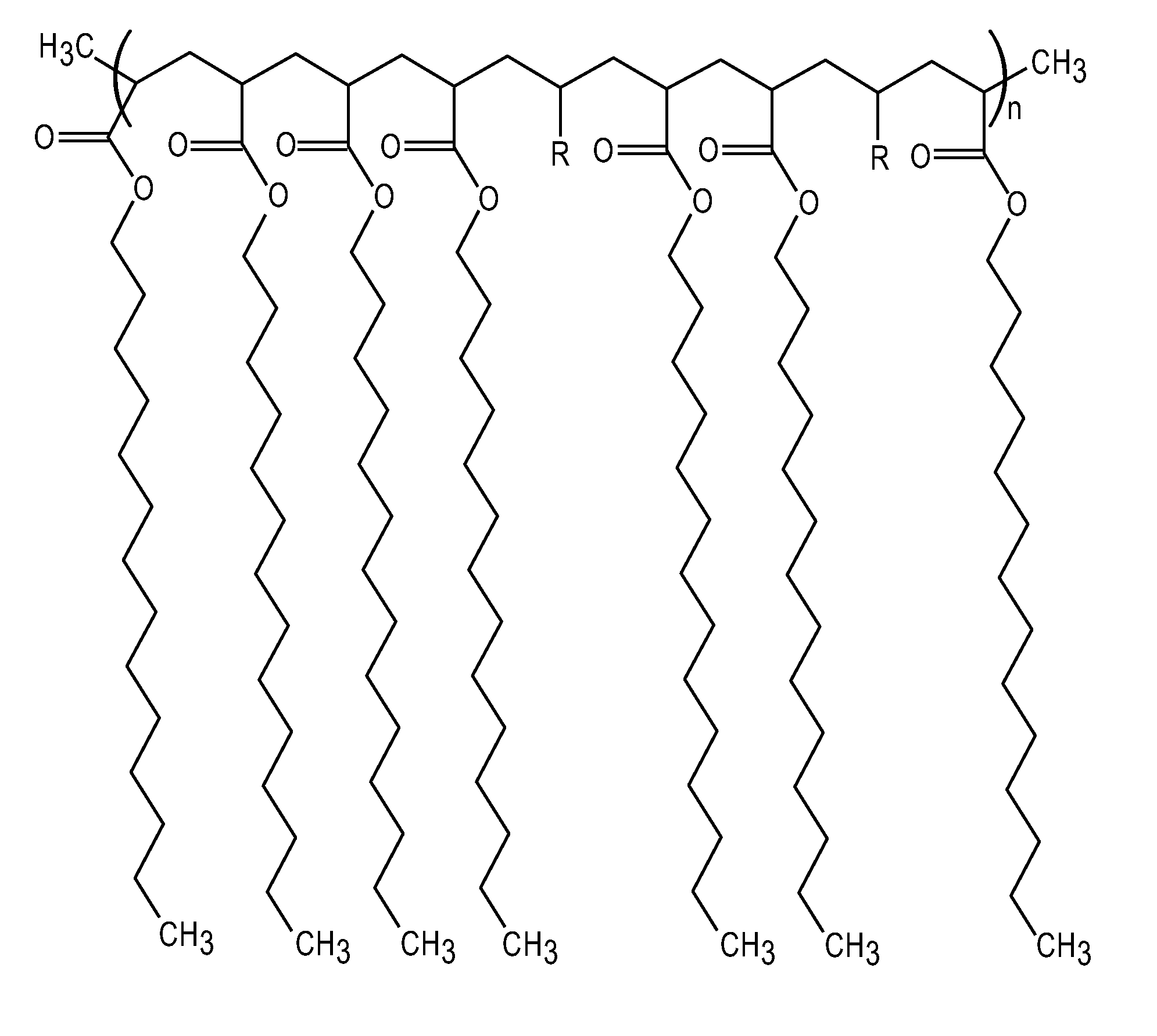

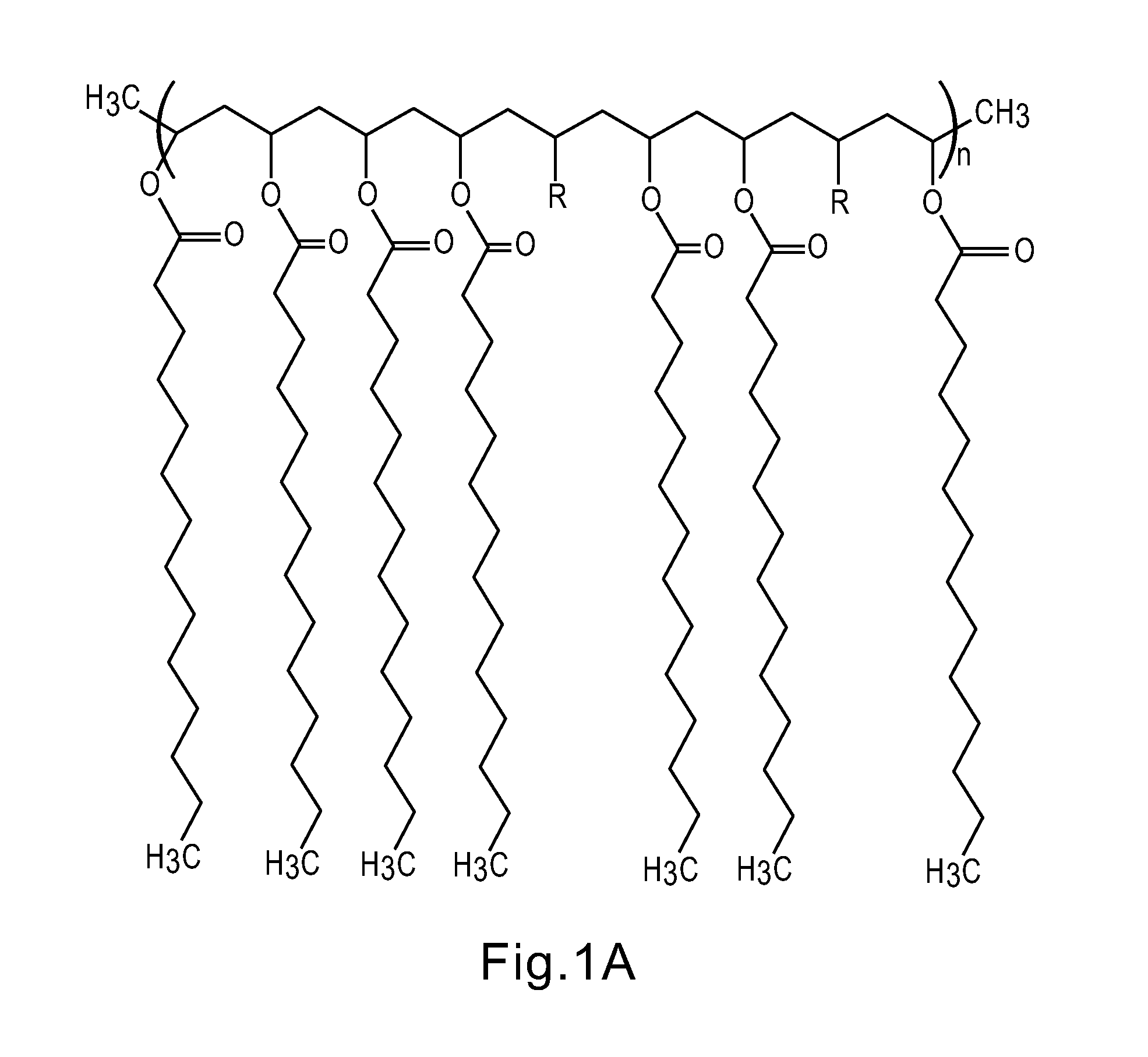

Thermal regulating building materials and other construction components containing polymeric phase change materials

In accordance with one aspect, a thermally regulating construction material comprises a base material and a polymeric phase change material bound to the base material, wherein the base material provides reversible temperature regulation properties to the building construction material. In accordance with another aspect, an insulation material for use in building construction comprises a base material and a polymeric phase change material bound to the base material, wherein the base material provides reversible temperature regulation properties to the insulation material. The base material may be selected from the group consisting of foam insulation, loose fill insulation, and batted insulation.

Owner:LATENT HEAT SOLUTIONS LLC

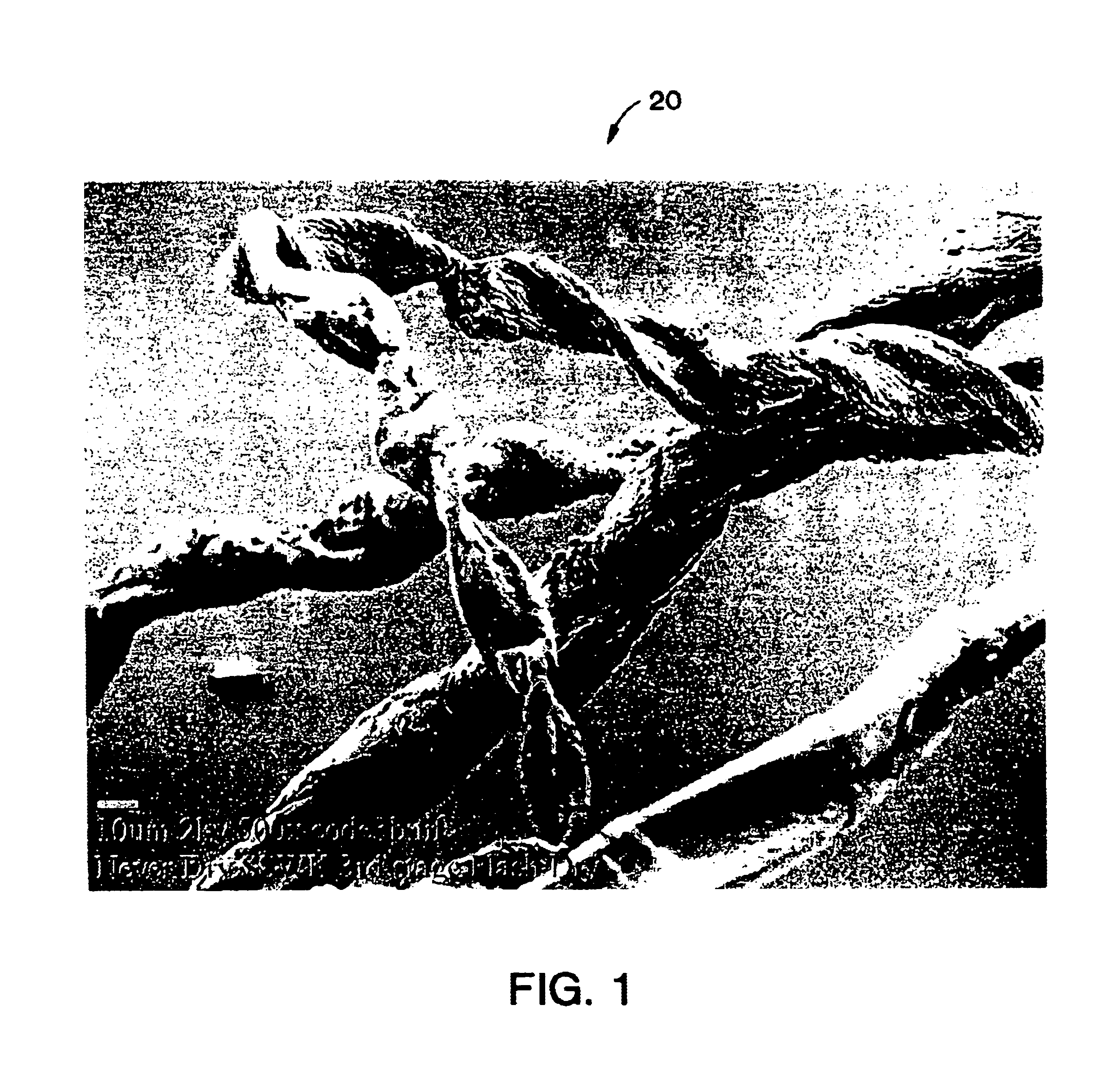

Wood pulp fiber morphology modifications through thermal drying

InactiveUS6837970B2High degreeIncreased formationPulp properties modificationPaper/cardboardFiberCross linker

A method of modifying a two-dimensional, flat fiber morphology of a never-been-dried wood pulp into a three-dimensional twisted fiber morphology without the aid of a chemical cross-linker. The method includes the steps of treating a never-been-dried wood pulp fiber slurry with a drying aid and thermally drying the wood pulp fiber slurry. The method may alternatively, or additionally, include the steps of spray drying a wood pulp fiber slurry and / or a slurry of a hydrophilic material, and flash drying the spray dried wood pulp fiber slurry and / or slurry of hydrophilic material.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Process for the conversion of biomass to liquid fuels and specialty chemicals

The present invention relates to the conversion of solid biomass to liquid fuels and specialty chemicals. The process utilizes an activating step to make the biomass more susceptible to conversion, that is the biomass is broken down such that the components of the biomass are dissociated. Subsequently, the activated biomass undergoes a reaction to convert it to a bio-oil.

Owner:MARD INC

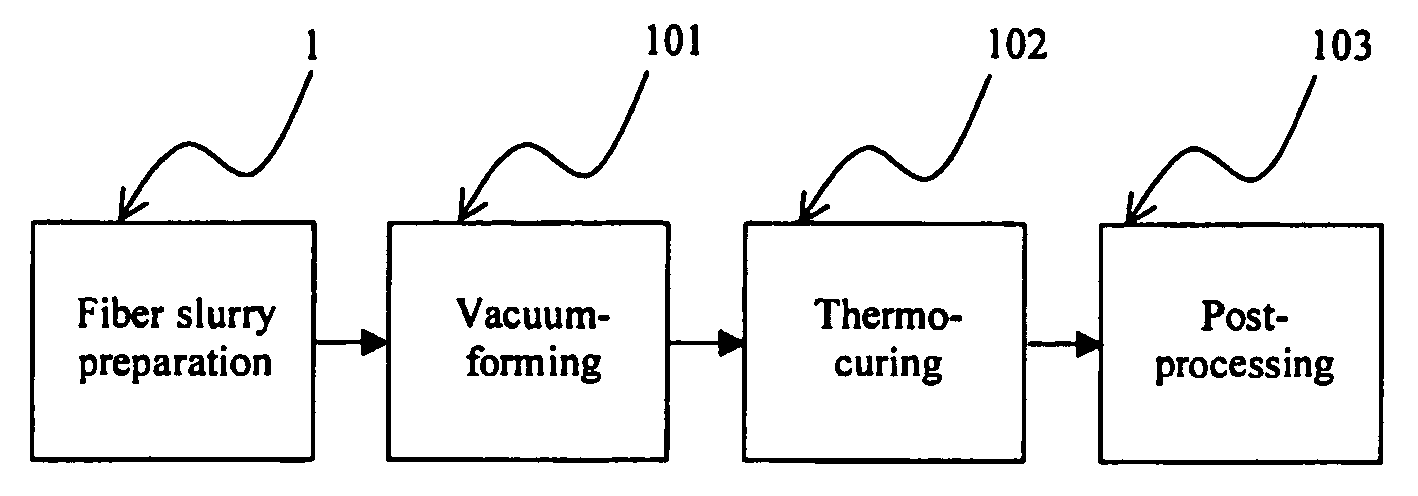

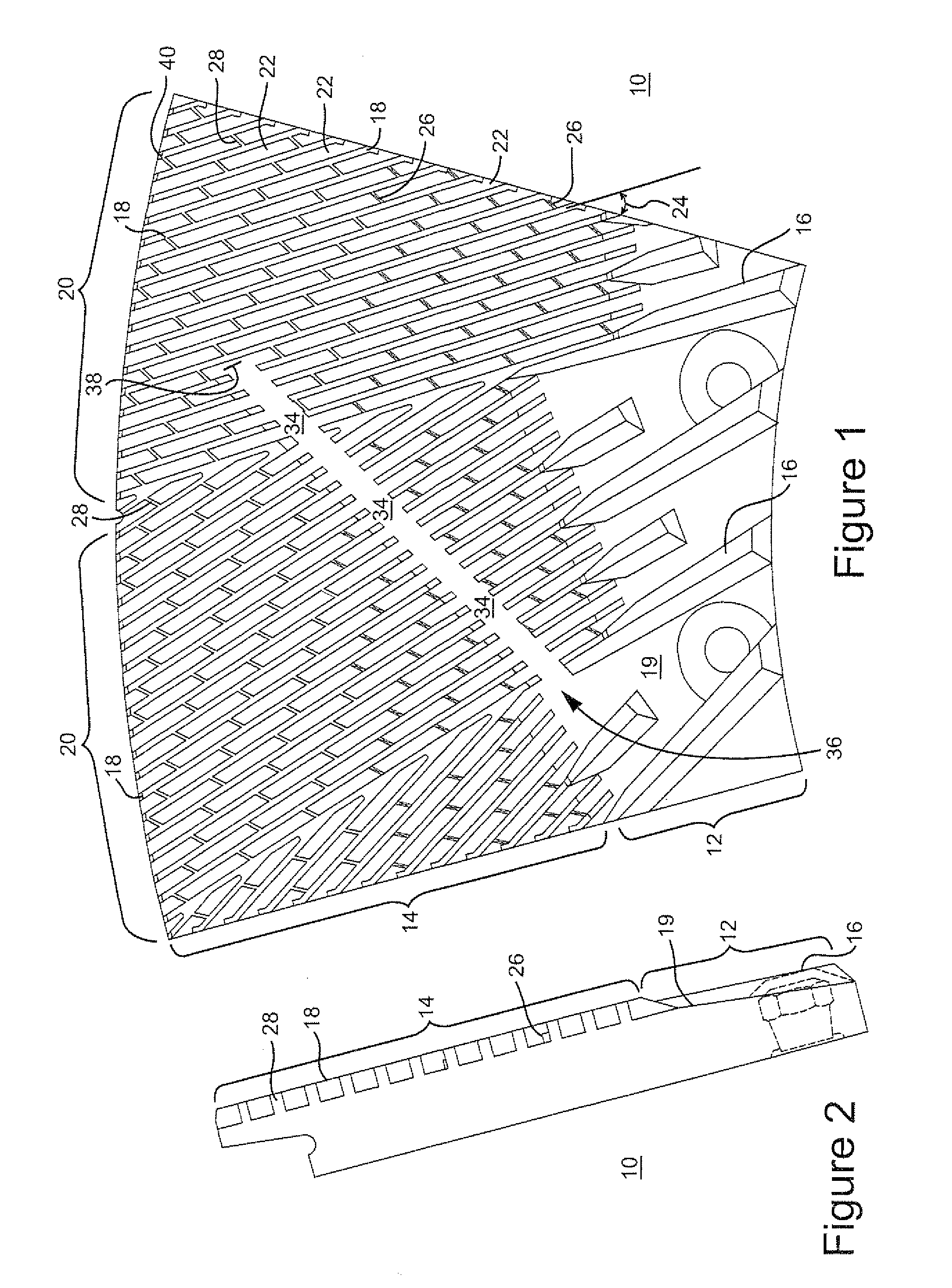

Molded fiber manufacturing

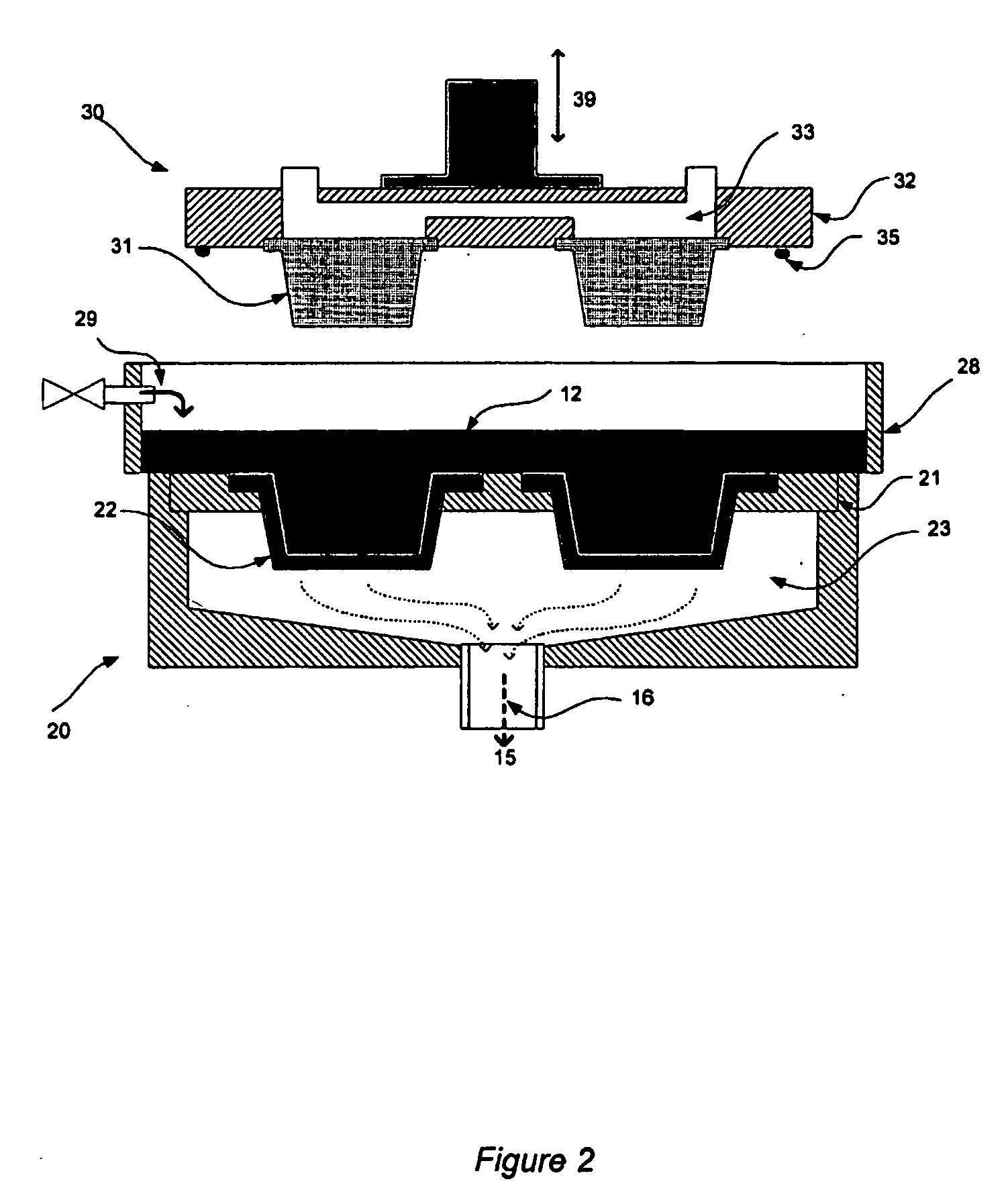

InactiveUS20050150624A1Reduce energy consumptionPrevent air infiltrationFibreboardWater-repelling agents additionFiberMolded pulp

Molded fiber products using agriculture residues are economical and environmentally beneficial. Molded fiber manufacturing is different from molded pulp. The present invention discloses a method of and an apparatus for the manufacturing of molded fiber shaped body (10) using low consistency fiber slurry (12) subject to vacuum-forming and thermo-curing. The use of porous material as mold inserts for both vacuum-forming (101) and thermo-curing (102) stations provides improved productivity and enables ease of mold release. The incorporation of self-cleaning techniques further ensures consistent performance of the manufacturing system.

Owner:GRENIDEA TECH PTE

Organic biomass fractionation process

InactiveUS20030041982A1Economical and efficientLow costPretreatment with acid reacting compoundsWaste based fuelFractionationNitration

A method for fractionating fibrous biomass comprising cellulose, hemicellulose and lignin components to separate said lignin, cellulose and hemicellulose from one another comprises: (a) shredding said fibrous biomass; (b) concurrently with or subsequent to said shredding, contacting said biomass with an aqueous solution of a nitrate ion source at a concentration of about 0.1-0.3% at a temperature in the range of about 60° to about 80° C. to initiate nitration of the lignin component of said biomass; (c) submerging said partially nitrated biomass in an aqueous solution of a nitrate ion source in the presence of an aluminum compound at a temperature within the range of about 75-100° C. for a time sufficient to complete the nitration of said lignin component; (d) contacting the nitrated biomass produced in step (c) with an alkaline extraction liquor comprising NH4OH at an initial concentration sufficient to solubilize said nitrated lignin component and said hemicellulose component from said cellulose component of said biomass; e) recovering said cellulose from said extraction liquor containing said solubilized nitrated lignin and hemicellulose components, wherein said cellulose comprises at least about 88% alpha cellulose; (f) treating said extraction liquor with an acid to precipitate lignin contained therein, and (g) separating said lignin from soluble hemicellulose in said extraction liquor. The recovered cellulose component comprises at least 88% alpha cellulose and is useful as a starting material for the production of ethanol.

Owner:PRIOR ERIC S

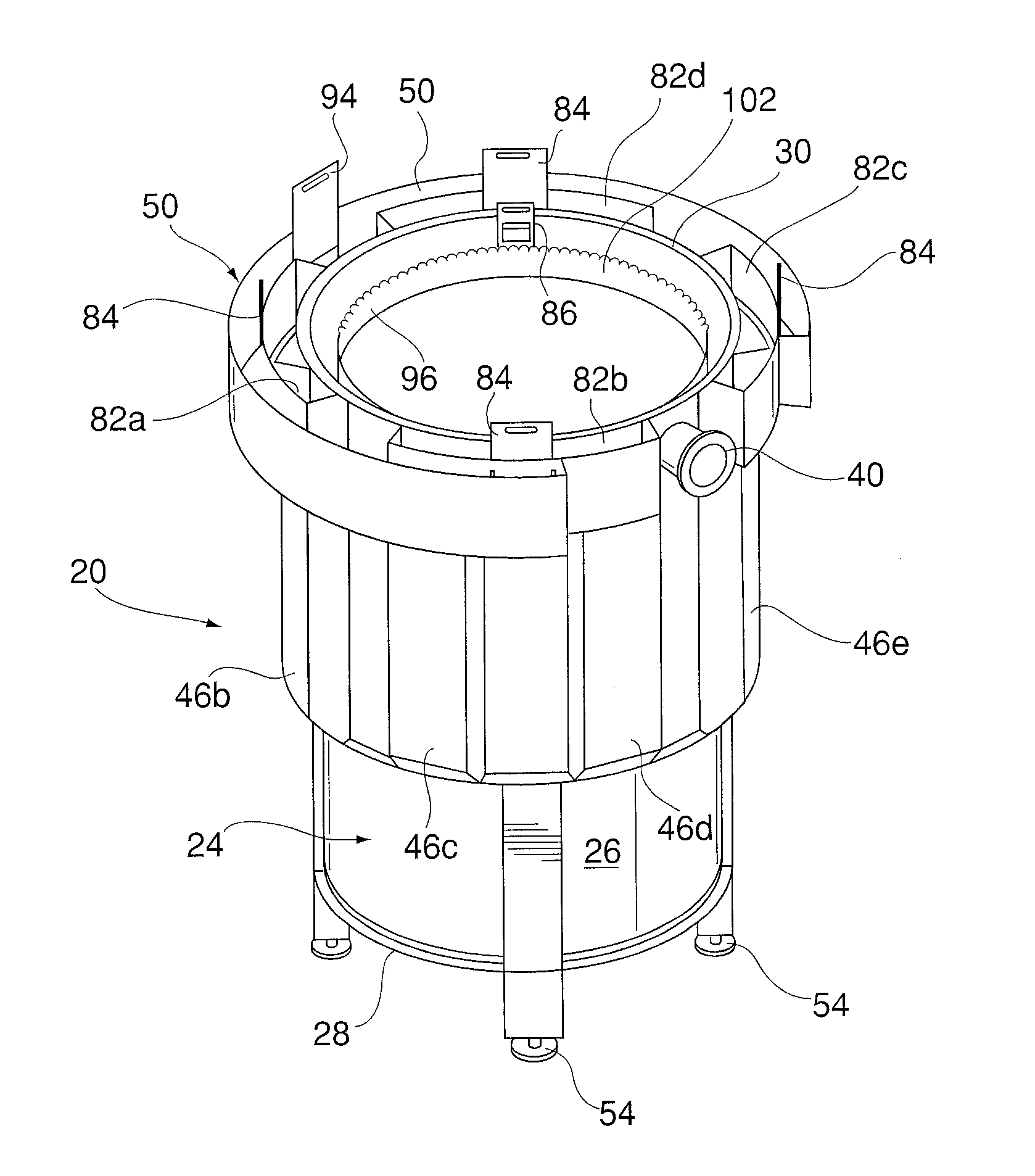

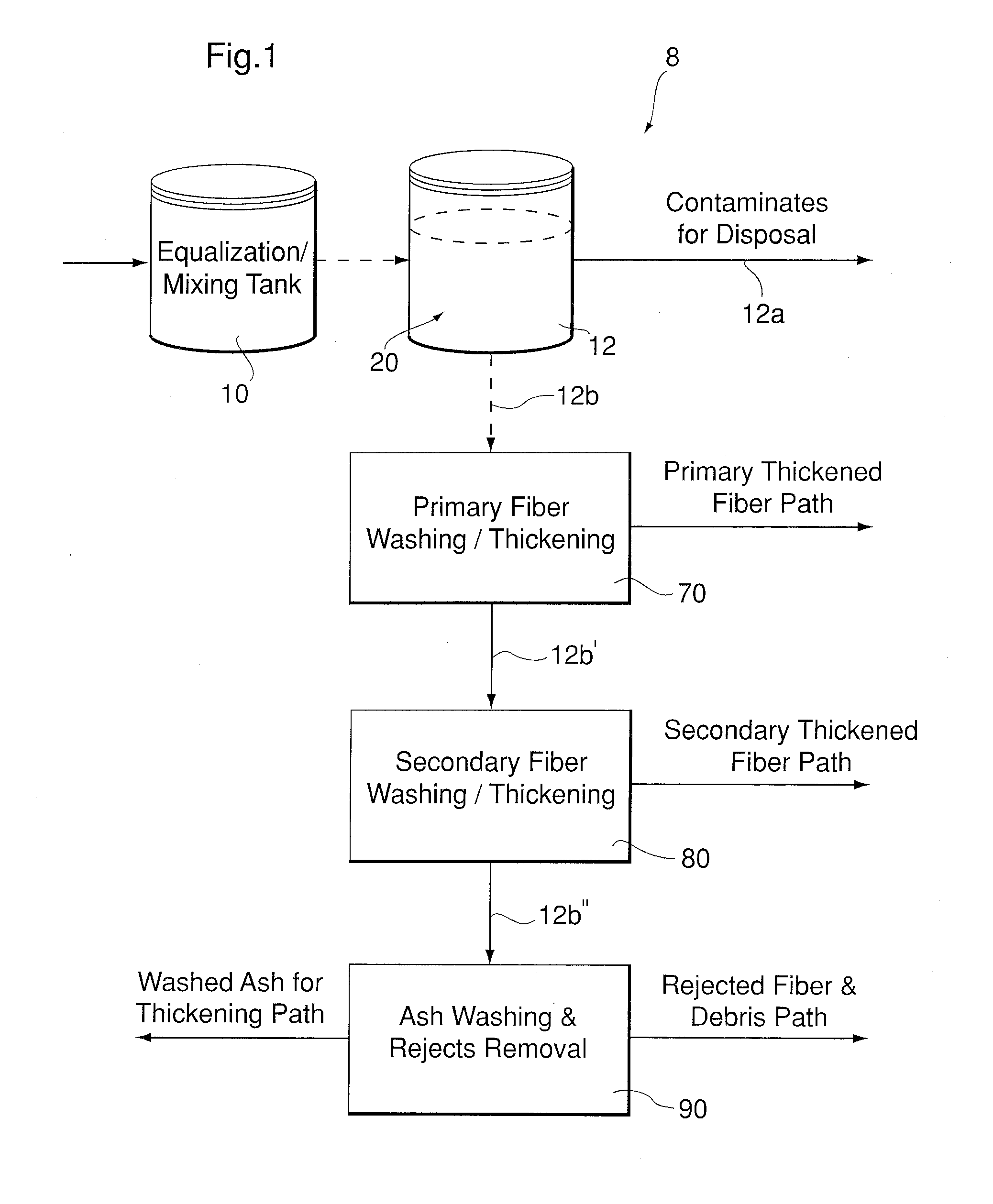

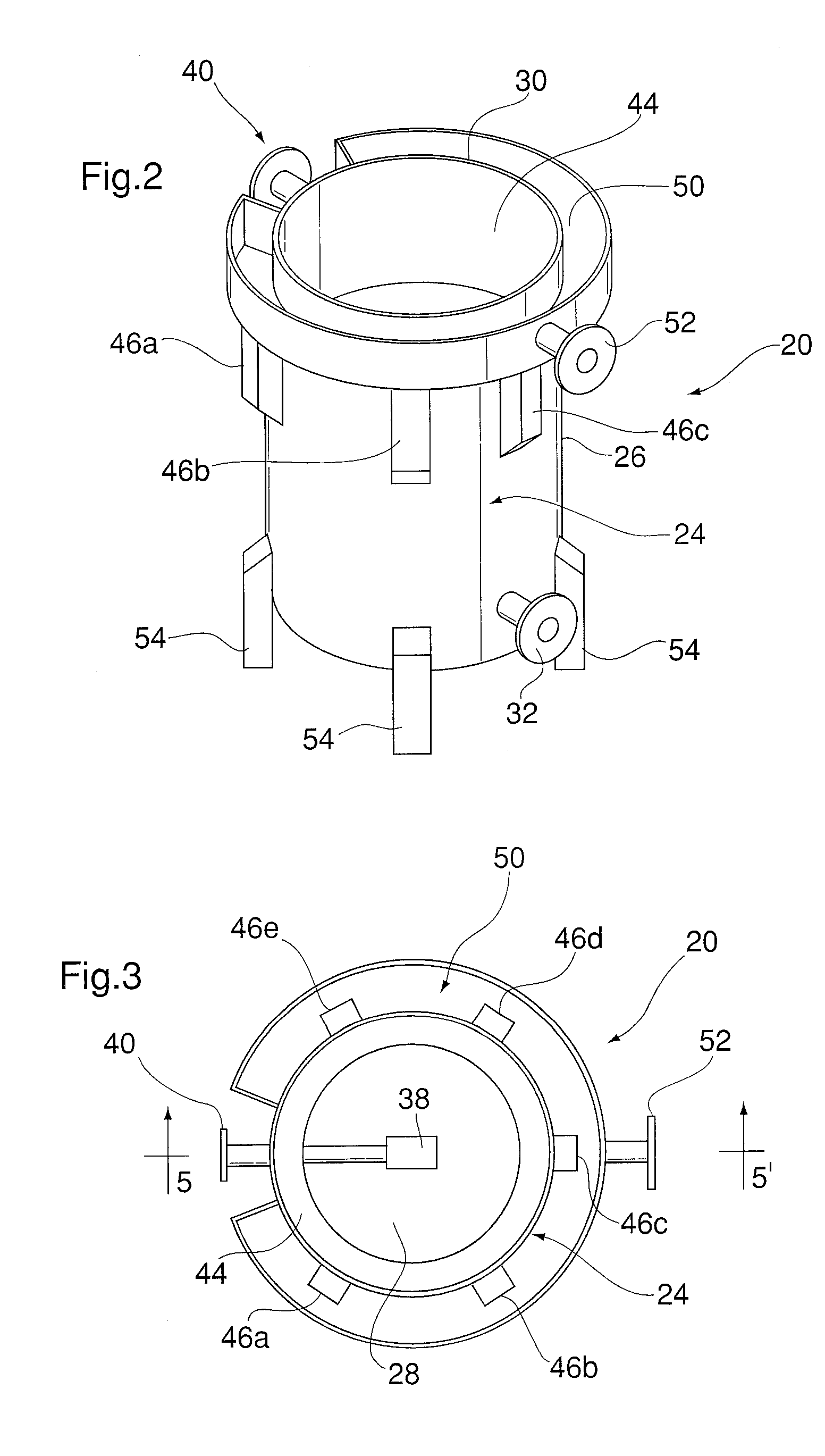

Apparatus for separating waste from cellulose fibres in paper recycling processes

InactiveUS20100133197A1Economically manufacturedEconomically usedLoose filtering material filtersFibrous raw materialsCyclic processWax

A contaminate separation apparatus for use in separating contaminant materials from cellulose and / or paper fibres in a paper recycling process includes a reservoir for receiving a waste paper slurry therein. The reservoir is provided with an inlet opening for the input of the slurry, one or more fibre discharge outlets or passages, and at least one waste outlet positioned vertically above the fibre discharge outlet opening. An agitator provided in a lower portion of the reservoir generates differential flow currents within the reservoir, to selectively divert plastics, waxes, adhesives and / or other sticky waste materials outwardly towards the waste outlet, while providing a flow of suspended paper and / or cellulose fibres to one or more of the fibre discharge outlets.

Owner:LANGNER HERBERT GUNTHER JOACHIM

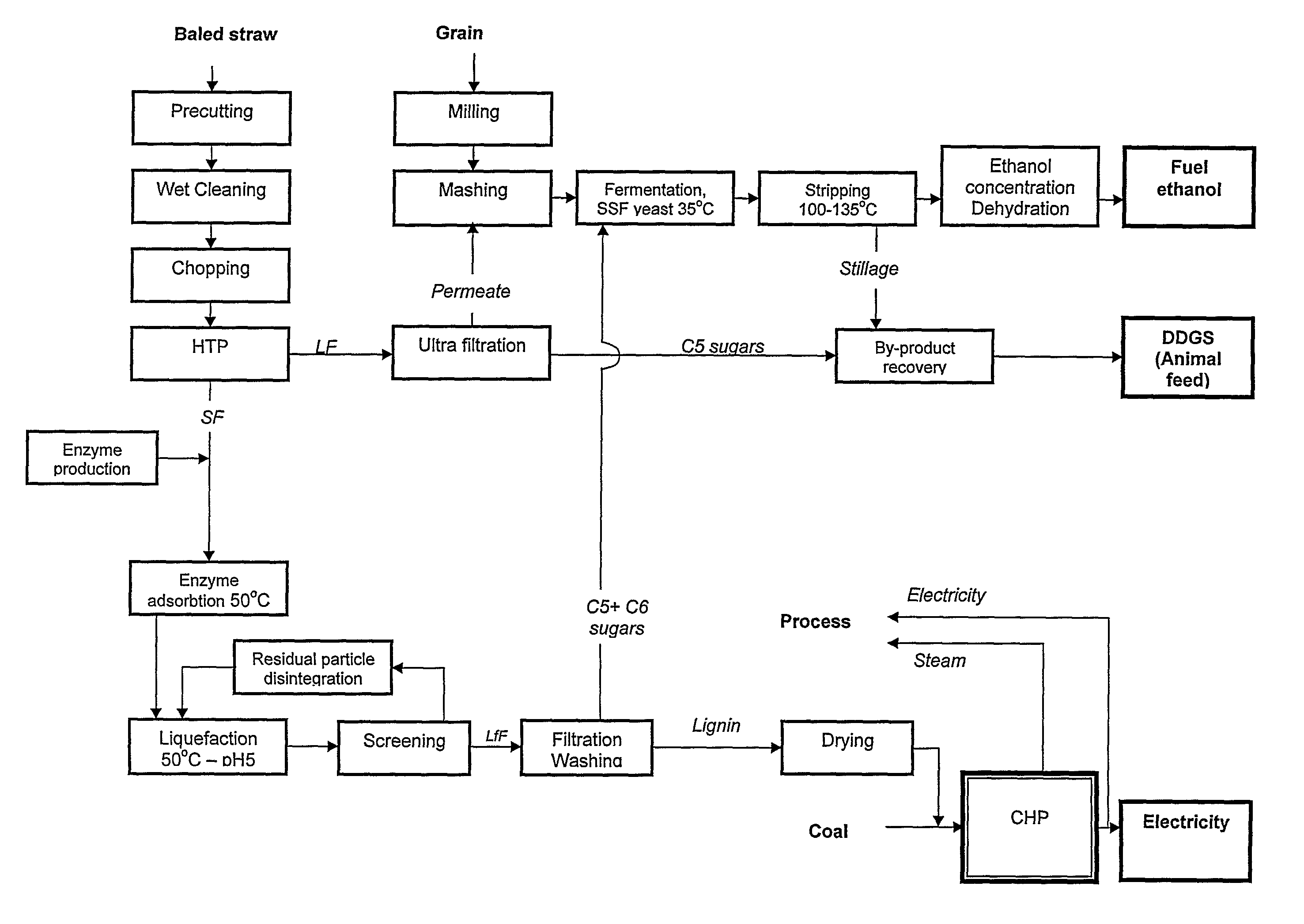

Chemical activation and refining of southern pine kraft fibers

InactiveUS20070119556A1Increase the pulp freenessEasy to drainPulp properties modificationPulp bleachingChemical treatmentCellulose fiber

A method for alteration of the morphology of cellulose fibers, particularly softwood fibers, by (a) subjecting the fibers to a metal ion-activated peroxide treatment carried out at a pH of between about 1 and about 9, preferably between 3 and 7, and (b) subjecting the treated fibers to a refining treatment thereby converts SW fibers to HW-like fibers in many respects. The metal ion-activated peroxide treatment has been noted to act on pulp cellulose and hemi-cellulose, causing oxidation and oxidative degradation of cellulose fibers. The chemical treatment of the pulp, taken alone, is not sufficient to attain the desired modification of the morphology of the fibers, however, subsequent refining or like mechanical treatment of the chemically-treated fibers to achieve a given degree of refinement of the fibers requires dramatically less refining energy to achieve a desired end point of refinement and to impart other desirable properties to the pulp. A pulp of modified SW fibers and a mixture of HW fibers and modified HW fibers are disclosed.

Owner:INT PAPER CO

Para-aramid pulp including meta-aramid fibrids and processes of making same

Owner:DUPONT SAFETY & CONSTR INC

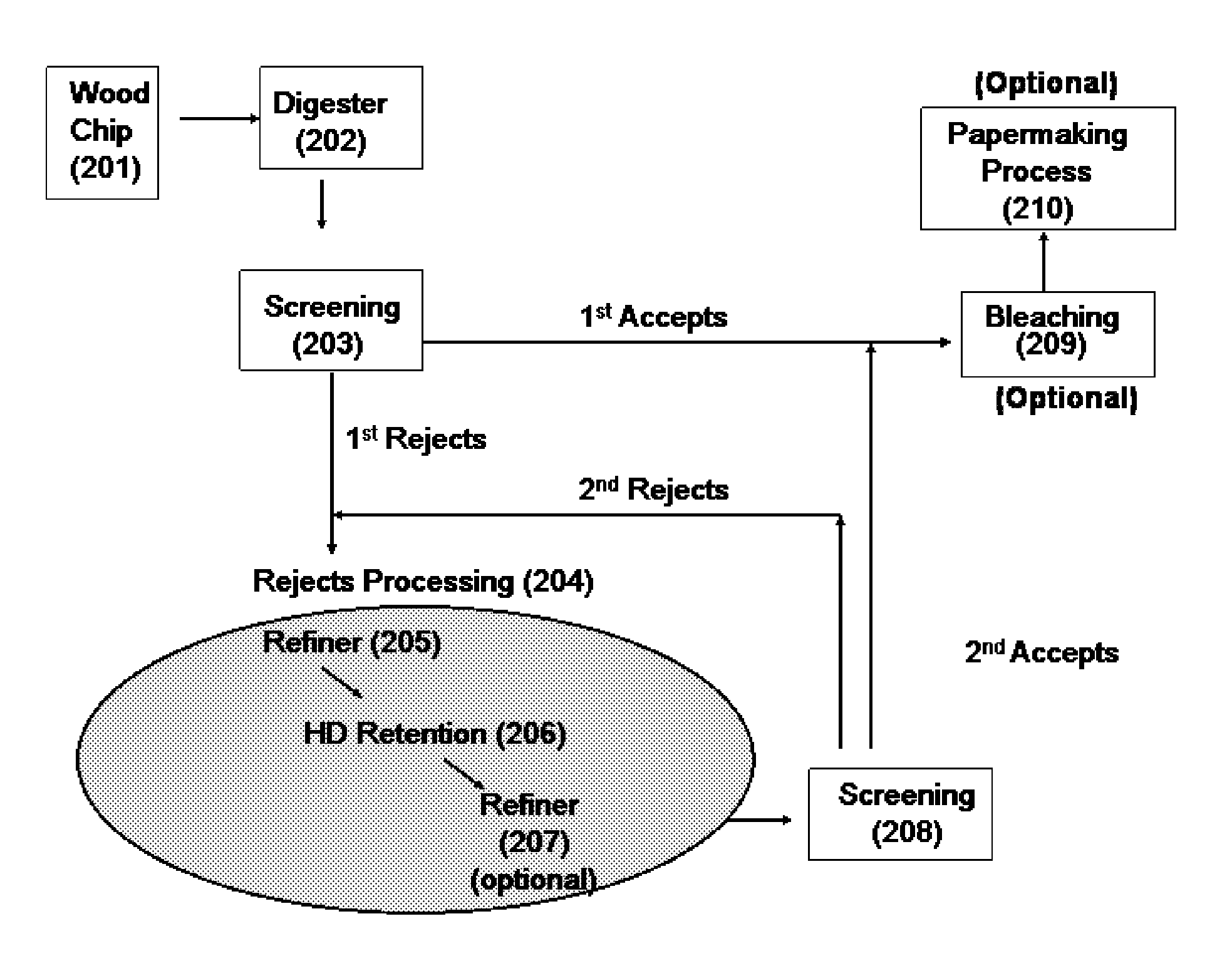

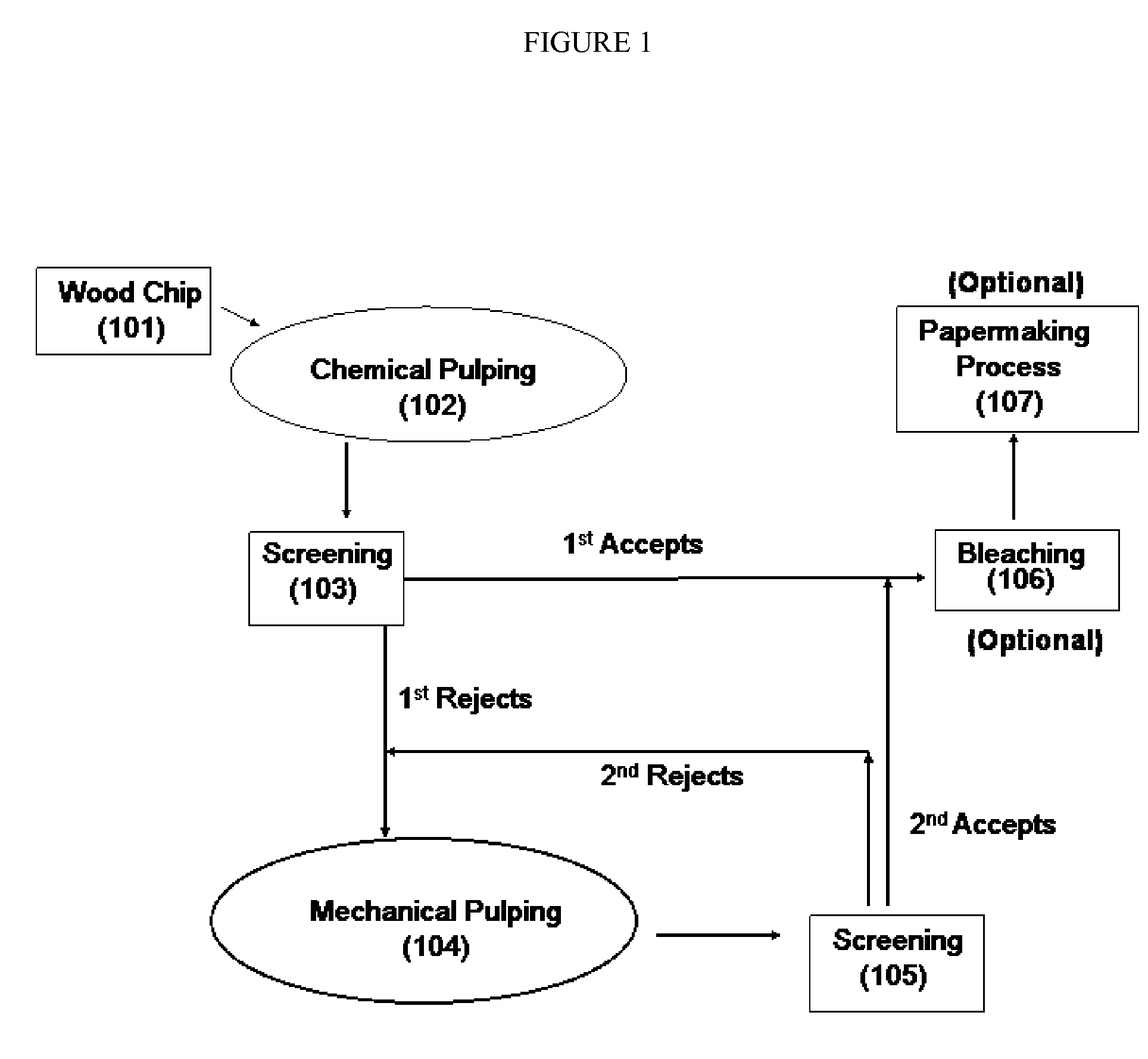

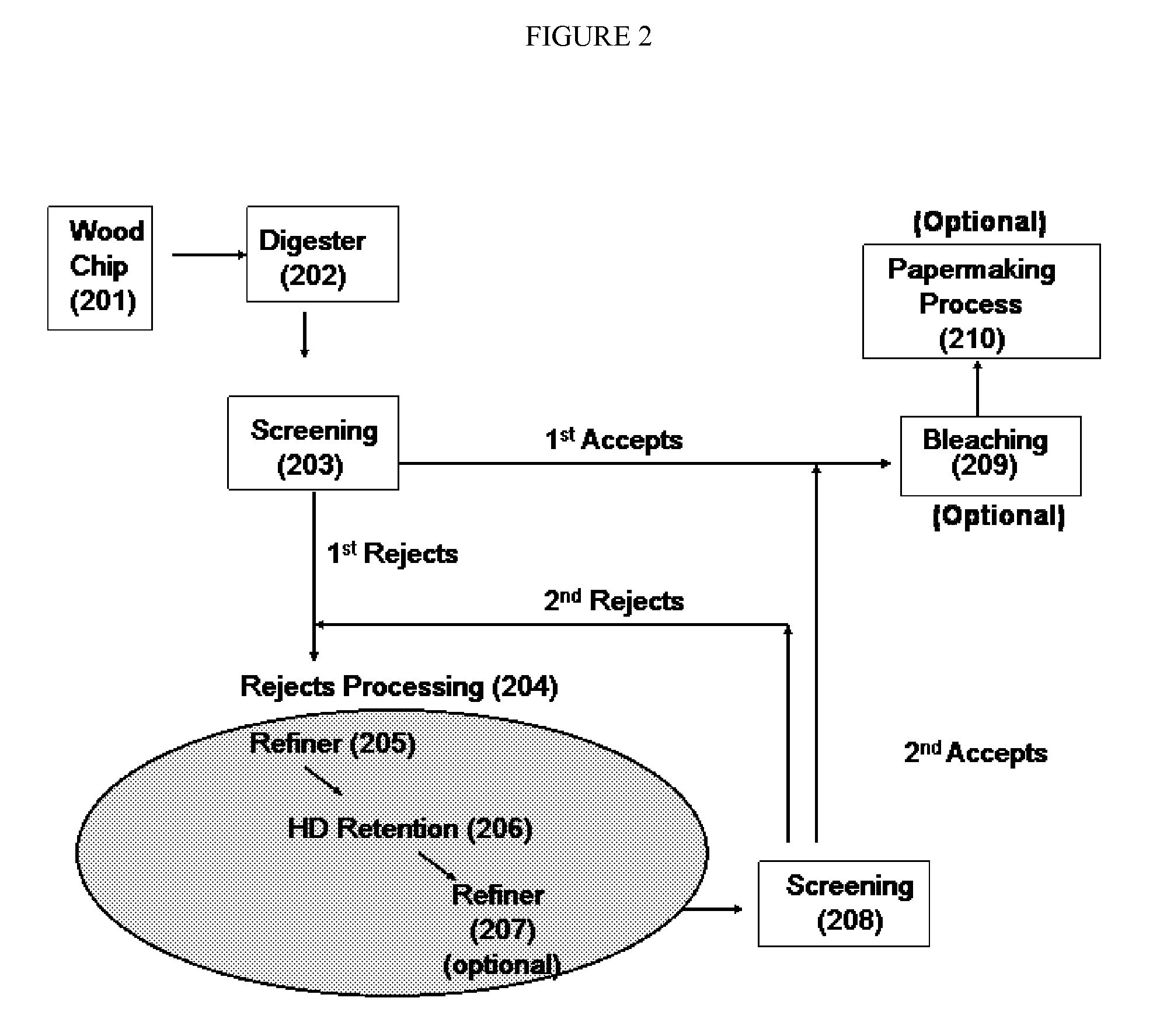

Fiber blend having high yield and enhanced pulp performance and method for making same

InactiveUS20080308239A1Increase stiffnessHigh strengthFibreboardPulp properties modificationFiberKappa number

The present disclosure relates to producing paper or paperboard having improved stiffness and strength, compared to the conventional paperboard at the same basis weight. It also discloses a method of wood pulping having a significantly increased yield and providing fiber pulps with enhanced properties such as strength and stiffness. Wood chips are chemically pulped to a high kappa number, providing a rejects component and an accepts component. The rejects component is subjected to a substantially mechanical pulping process, optionally in a presence of bleaching agent, prior to blending back into the accepts component. The resulting fiber blend is washed, optionally bleached, and subjected to a papermaking process to provide paper or paperboard with enhanced strength and stiffness at low basis weight.

Owner:MEADWESTVACO CORP

ASA emulsification with ultrasound

The invention provides a method and apparatus for optimally feeding an ASA emulsion into a papermaking process. An intense transmission of ultrasonic energy rapidly and efficiently forms an ASA emulsion. Nearly simultaneous to forming the emulsion, the emulsion is fed into a high-speed dual conduit feeding apparatus, which quickly mixes the ASA emulsion with other chemicals and feeds the mixture directly into a papermaking process. The invention operates so fast that virtually no hydrolysis of the ASA occurs. This both prevents damage to the papermaking machinery and improves the quality of the produced paper. The invention operates 10-20 times faster than mechanical based emulsion methods and requires 1 / 7 as much energy to operate. The invention also self-monitors the process and can automatically correct any detected problems with the fed ASA emulsion.

Owner:ECOLAB USA INC

Printing paper

InactiveUS6923889B2Increase coverageGood printabilityNon-fibrous pulp additionSpecial paperFiberSurface roughness

The invention relates to coated printing paper which contains mechanical pulp and whose opacity is at least 89%, brightness at least 65% and surface roughness not more than 4.5 μm. The printing paper contains mechanical pulp at least 90 weight-% of the total fiber content of the paper.

Owner:UPM-KYMMENE OYJ

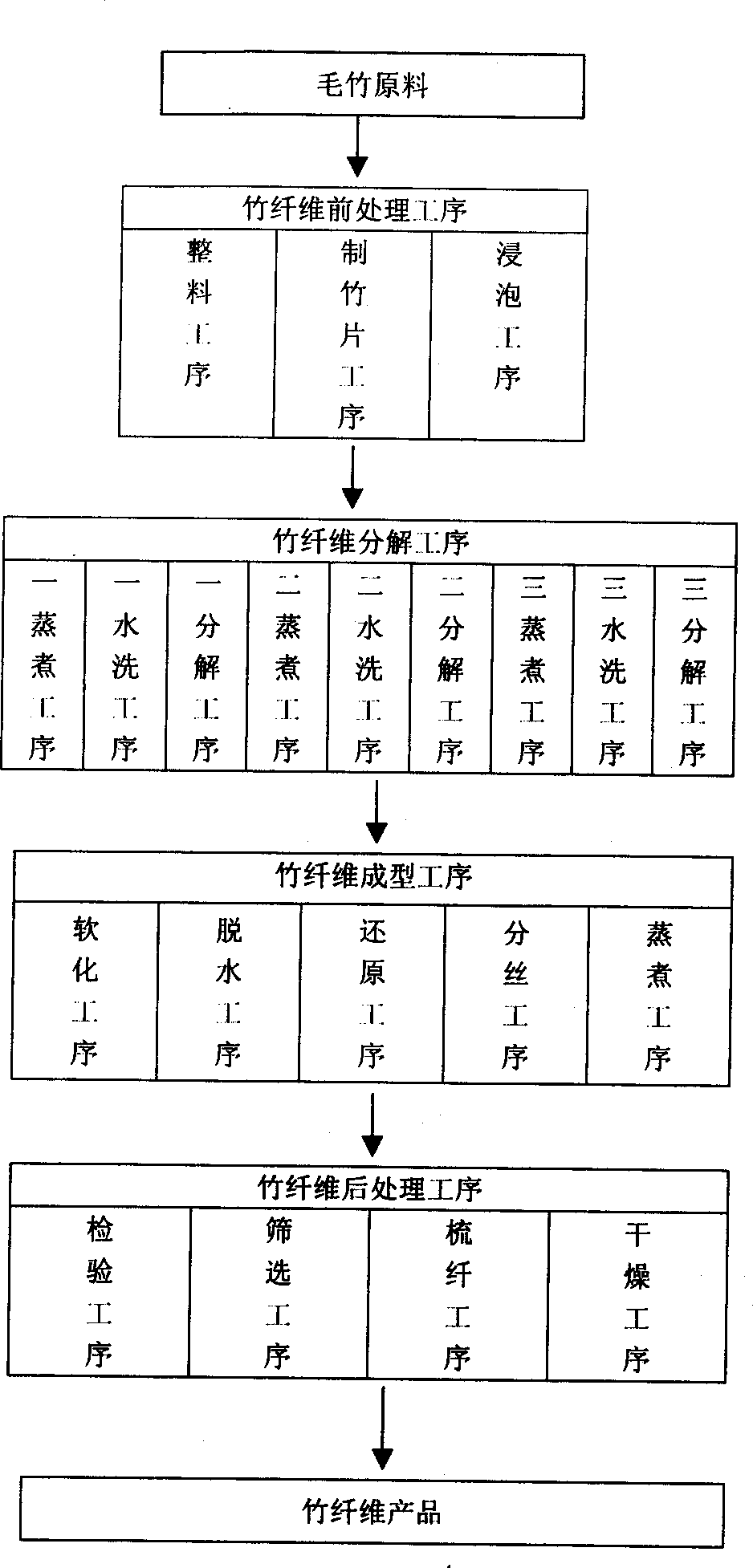

Bamboo fiber and its making process

InactiveCN1375578AGood flexibilityHigh folding resistanceVegetable fibres from other vegetable matterFibrous raw materialsAfter treatmentDecomposition

The present invention uses clustered bamboo as raw material and is aimed at providing a kind of raw material for making shell fabric instead of cotton, chemical fibre, hemp and silk, and its production method incldues the procedures of bamboo fibre pretreatment, bamboo fibre decomposition, bamboo forming and its after treatment, in which it adopts a degumming softening agent made up according to a natural formula, it is neutral in acidity-alkalinity and has no environmental pollution. Said shell fabric made of bamboo fibre is good in flexibility and permeability and is uvioresistant.

Owner:赵子群

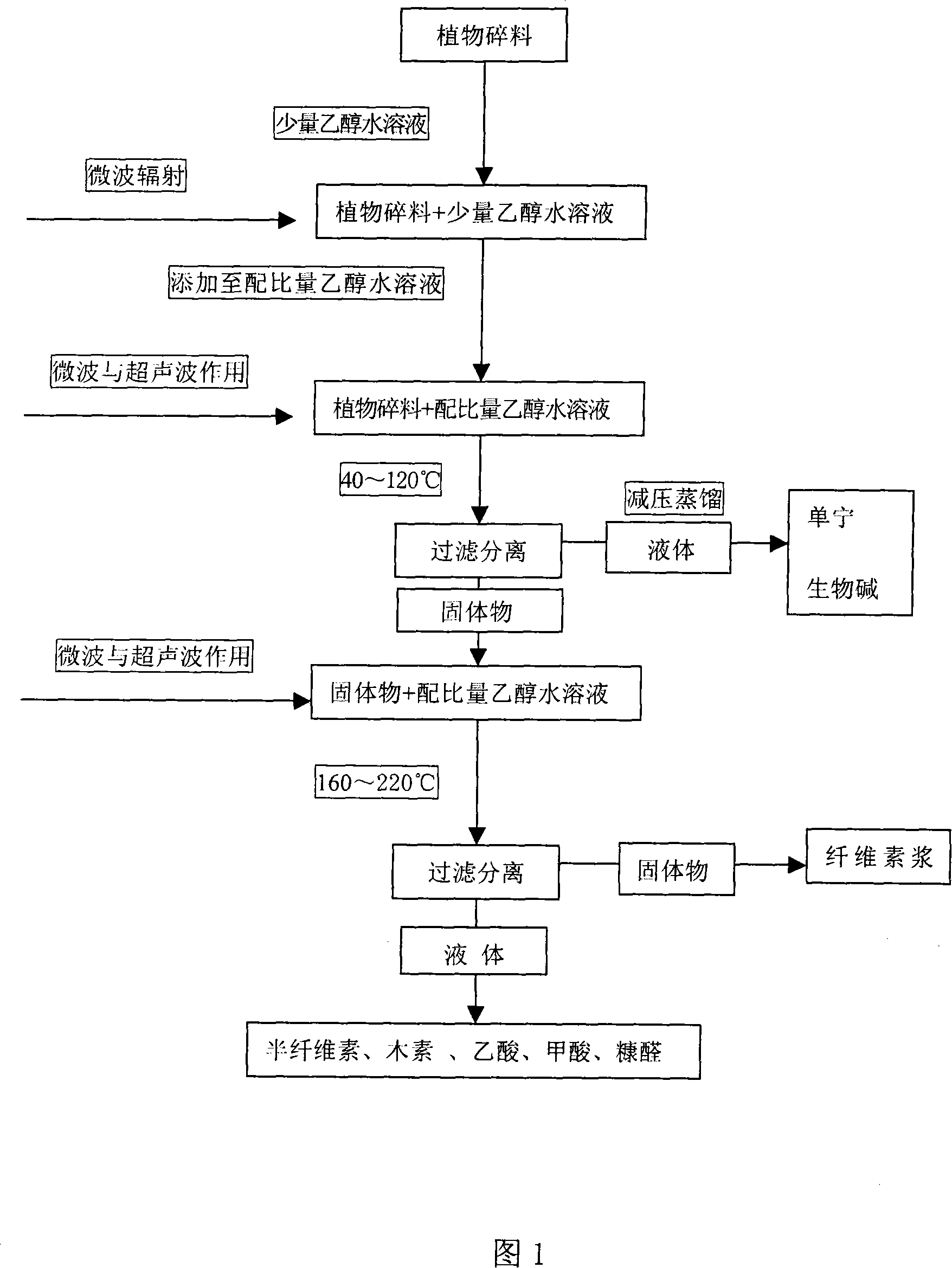

Technical method for separating organic constituent of biomass

ActiveCN101092435ATake advantage ofEasy to separateSugar derivativesLignin derivativesReaction temperatureHigh pressure

This invention discloses a method for separating biomass organic components. The method comprises: washing classified raw materials, decomposing in a high-pressure reactor under the actions of microwave and ultrasonic wave, and extracting organic components from biomass with 20-70 vol. % aqueous solution of an organic solvent. The separation process comprises: (1) extracting low-temperature-soluble organic component from biomass at 40-120 deg.C under 0.4-0.6 MPa; (2) separating cellulose pulp at 160-220 deg.C; (3) separating acetic acid, lignin and furfural from the liquid (separated by solid-liquid separation) by centrifuge and precipitation. According to different plants, the powers and frequencies of microwave and ultrasonic wave, as well as the reaction temperature and time can be adjusted. The method has such advantages as low organic molecule loss, little change, no harm of the products, high cellulose purity (higher than 95%), low lignin residue (not higher than 2%), and no environmental pollution.

Owner:贾海涛

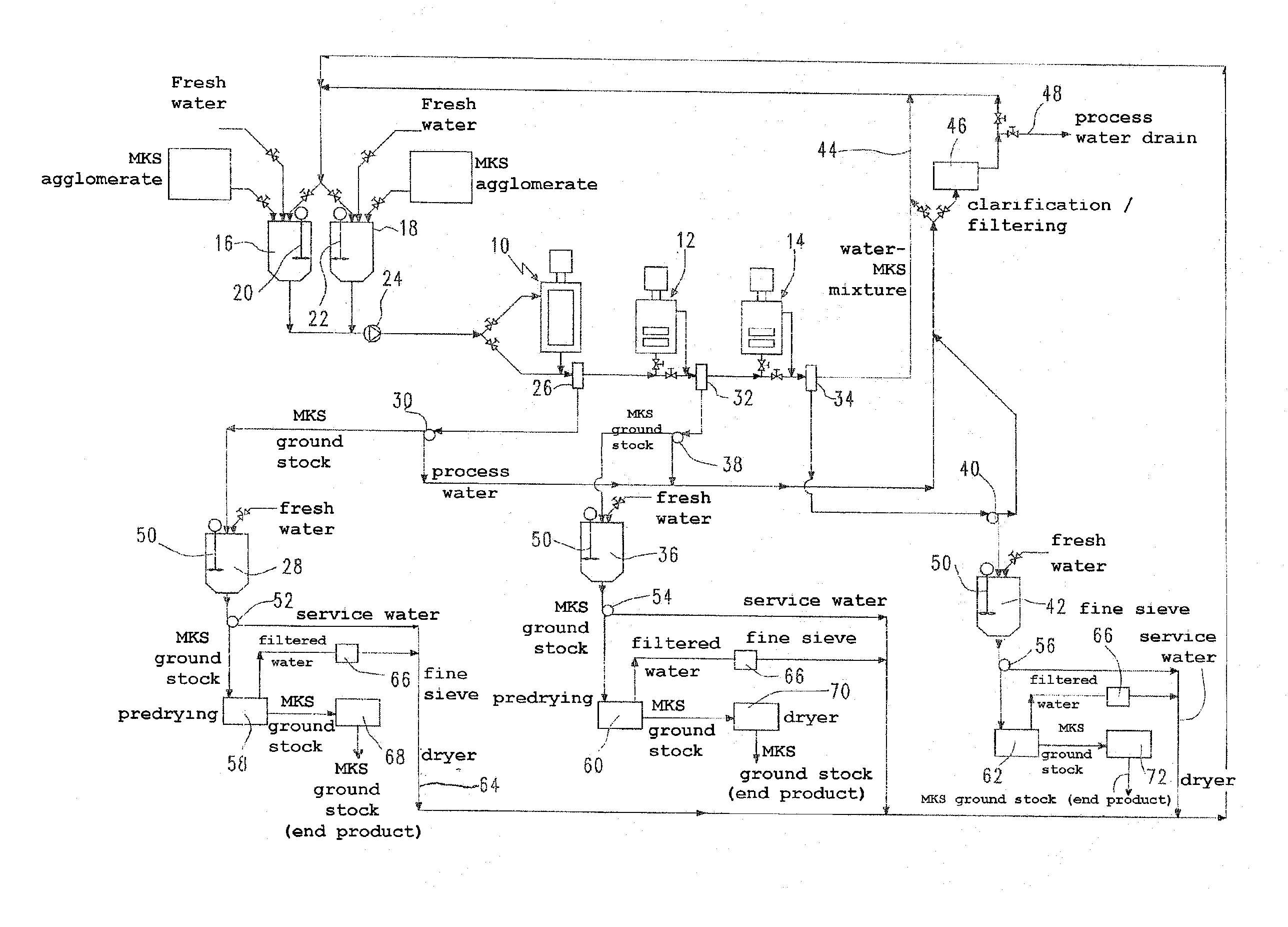

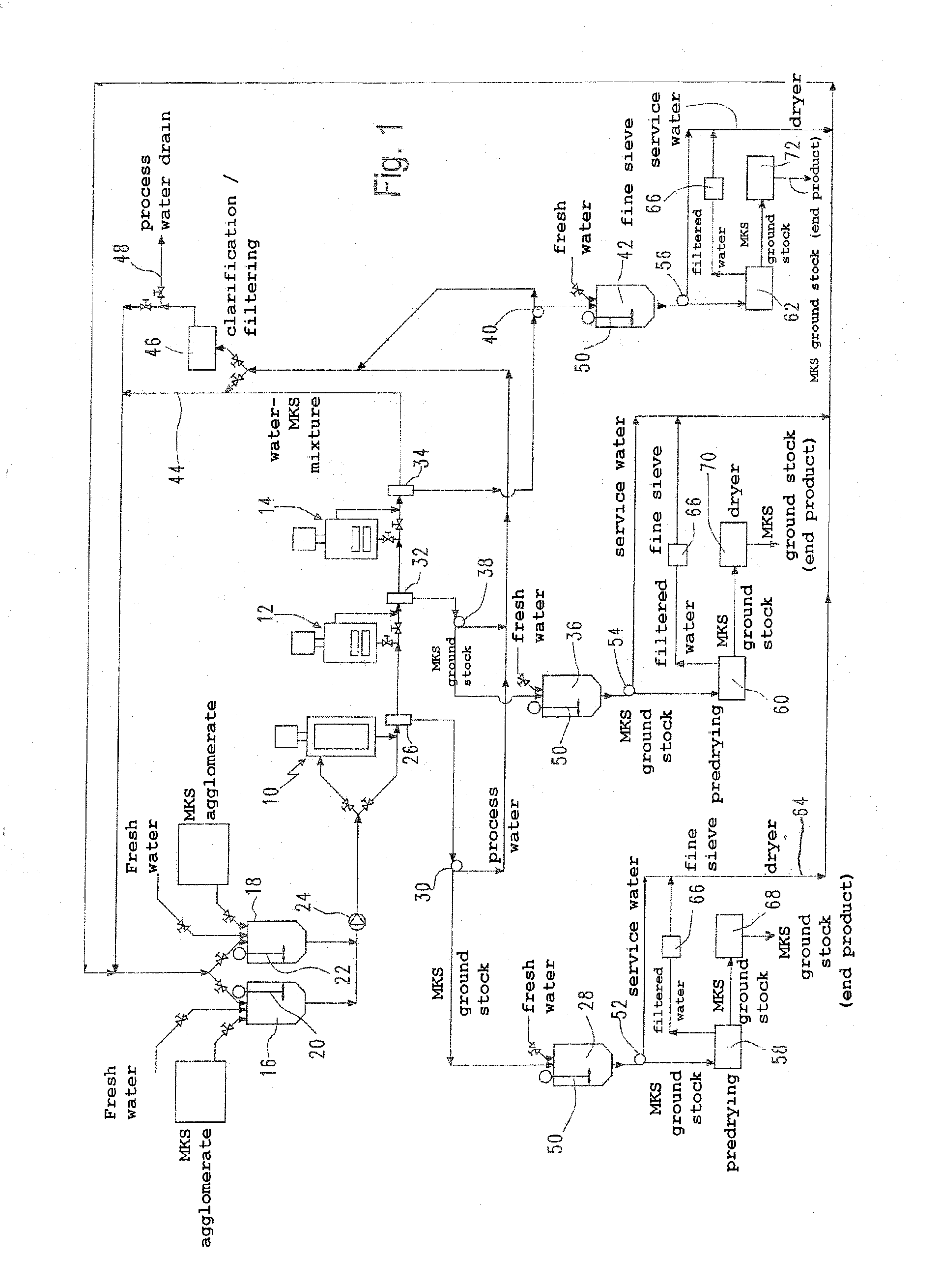

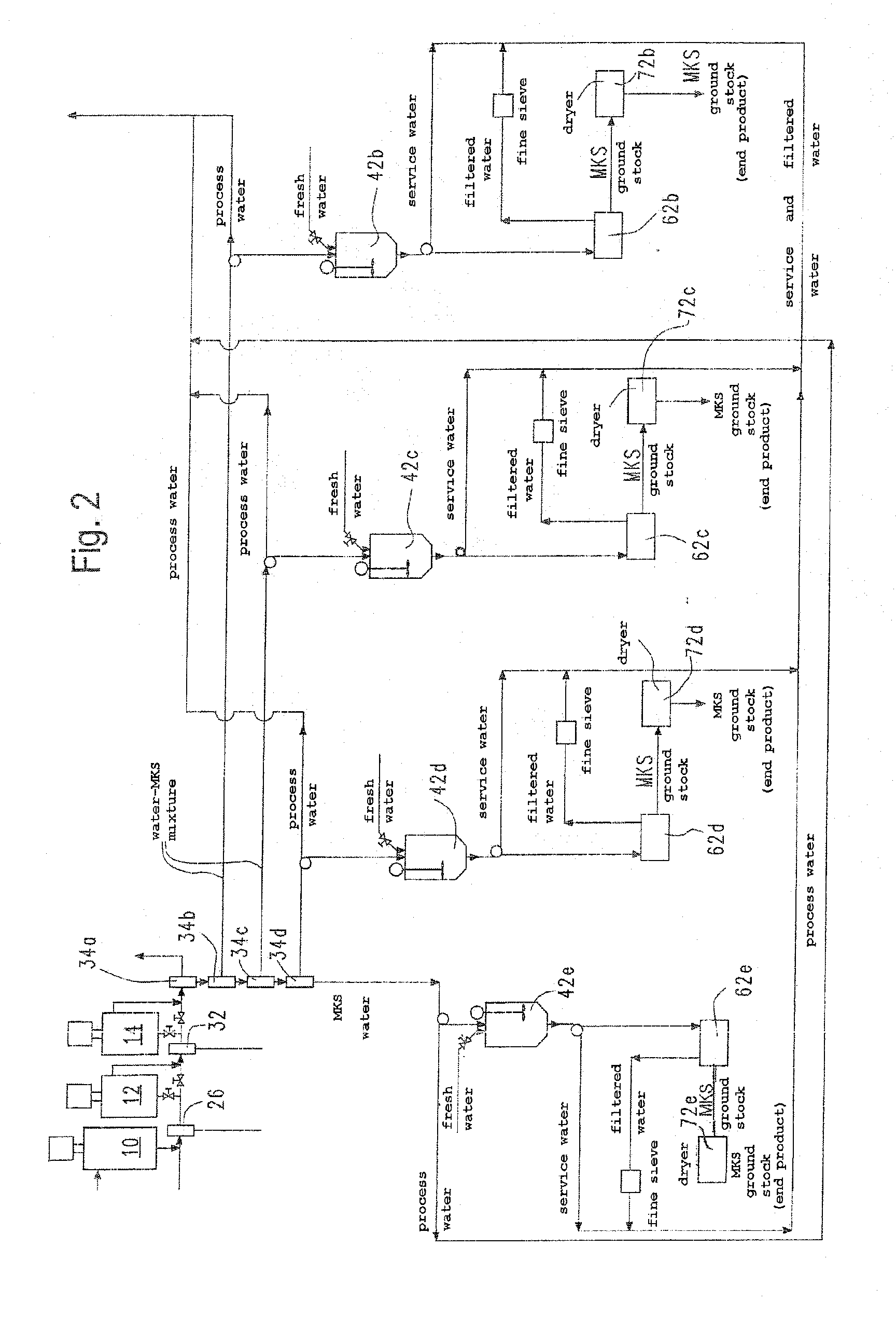

Method and Apparatus for Comminuting and Cleaning of Waste Plastic

InactiveUS20080191069A1Improve consistencyHigh material yieldSolid waste disposalWood working apparatusThick wallFine grain

Method for comminuting and cleaning waste plastic, in particular, mixed plastic (MKS) with the following steps: a compacted material, especially, an agglomerate is produced from film scraps or film remnants comminuted into flakes and / or thick-walled plastic parts chopped up into chips, the compacted material is introduced into a disc or drum refiner and is ground therein in the presence of water, wherein the portion of compacted material of the goods located in the refiner amounts to at least 10 percent by weight, a fine grain fraction is removed from the ground stock exiting from the refiner, the remaining ground stock is washed and either mechanically dewatered and dried, or pulverized again in a further refiner stage in the presence of water, and subsequently dewatered and dried.

Owner:CVP CLEAN VALUE PLASTICS GMBH

Manufacturing process for high performance lignocellulosic fibre composite materials

InactiveUS20090065975A1Structure moreStrict requirementsRotary stirring mixersLaminationDecompositionFlexural strength

The present invention relates to a process for the manufacture of composite materials having lignocellulosic fibres dispersed in a thermoplastic matrix, while generally maintaining an average fibre length not below 0.2 mm. The process comprises defibrillation of the lignocellulosic fibres using a mixer and at a temperature less than the decomposition temperature of the fibres in order to separate the fibres and generate microfibres, crofÊbres, followed by dispersion of the fibres in the thermoplastic matrix by mechanical mixing to get the moldable thermoplastic composition, followed by injection, compression, extrusion or compression injection molding of said composition. The process produces high performance composite materials having a tensile strength not less than about 55 MPa, a flexural strength not less than about 80 MPa, a stiffness not less than about 2 GPa, notched impact strength not less than about 20 J / m, and un-notched impact strength not less than about 100 J / m. The composite materials of the present invention are well-suited for use in automotive, aerospace, electronic, furniture, sports articles, upholstery and other structural applications.

Owner:SAIN MOHINI M +2

Tampon including crosslinked cellulose fibers and improved synthesis processes for producing same

InactiveUS20090227975A1Promote absorptionImprove wettabilityPulp properties modificationArtificial filaments from viscoseCellulose fiberGlyoxal

A tampon pledget includes crosslinked cellulose fibers having microstructures treated to provide improved absorbency and higher wet strength. The fibers are treated with a crosslinking agent to provide at least one of a molecular weight between crosslinks of from about 10 to 200 and a degree of crystallinity of from about 25% to 75%. The crosslinking agent includes citric acid in 1% by weight. The crosslinking agent may further include sodium hypophosphite in 1% by weight. In another embodiment, the crosslinking agent may be a difunctional agent including a glyoxal or a glyoxal-derived resin. In still another embodiment, the crosslinking agent is a multifunctional agent including a cyclic urea, glyoxal, polyol condensate. The crosslinking agent is added in an amount from about 0.001% to 20% by weight based on a total weight of cellulose fibers to be treated and, preferably, in an amount of about 5% by weight.

Owner:EVEREADY BATTERY CO INC

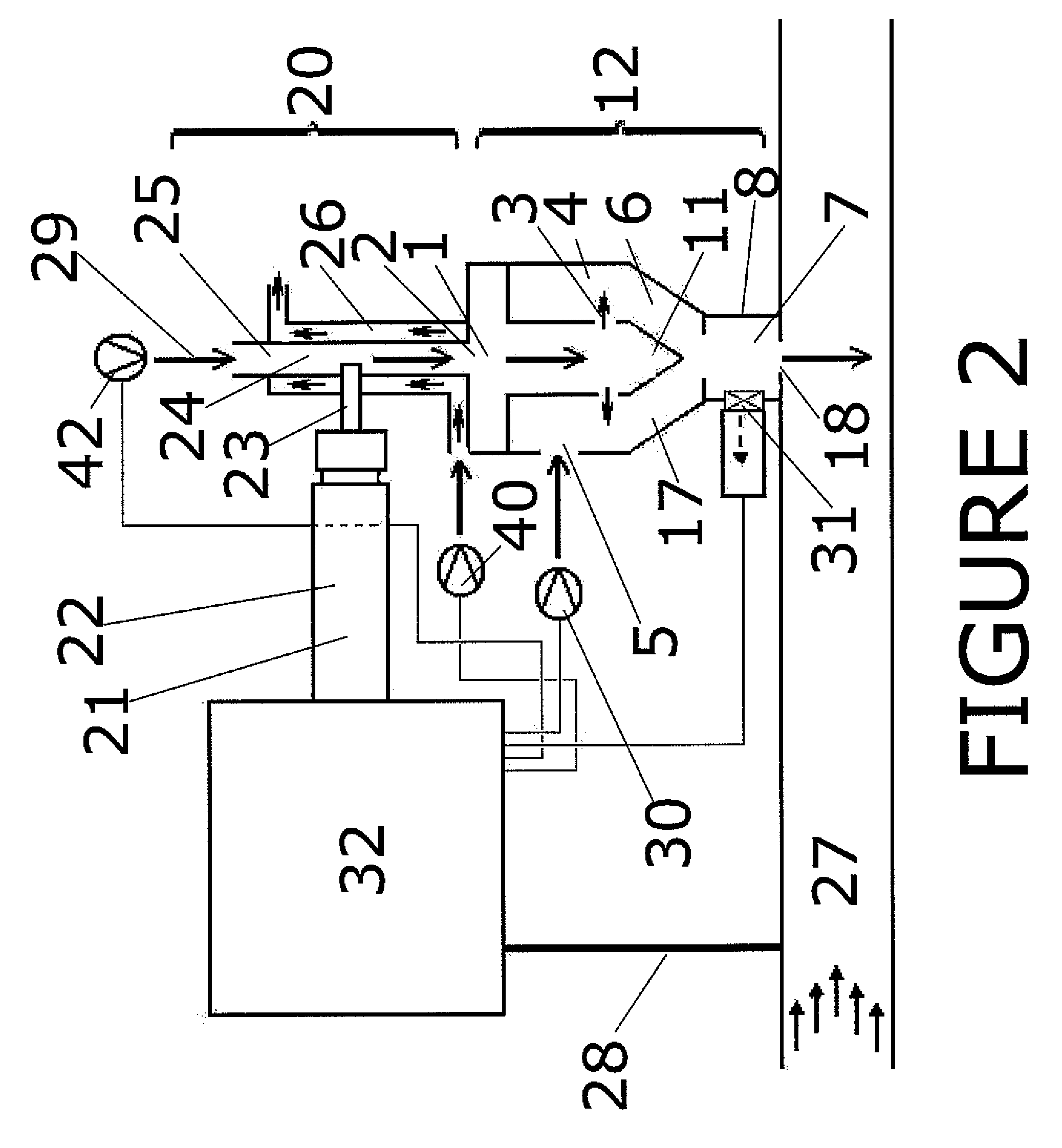

Method and arrangement for feeding chemicals into a papermaking process

A method for feeding one or more chemicals into a papermaking process is disclosed. More specifically, a method for feeding chemistry into a thick stock of a papermaking process is disclosed.

Owner:ECOLAB USA INC

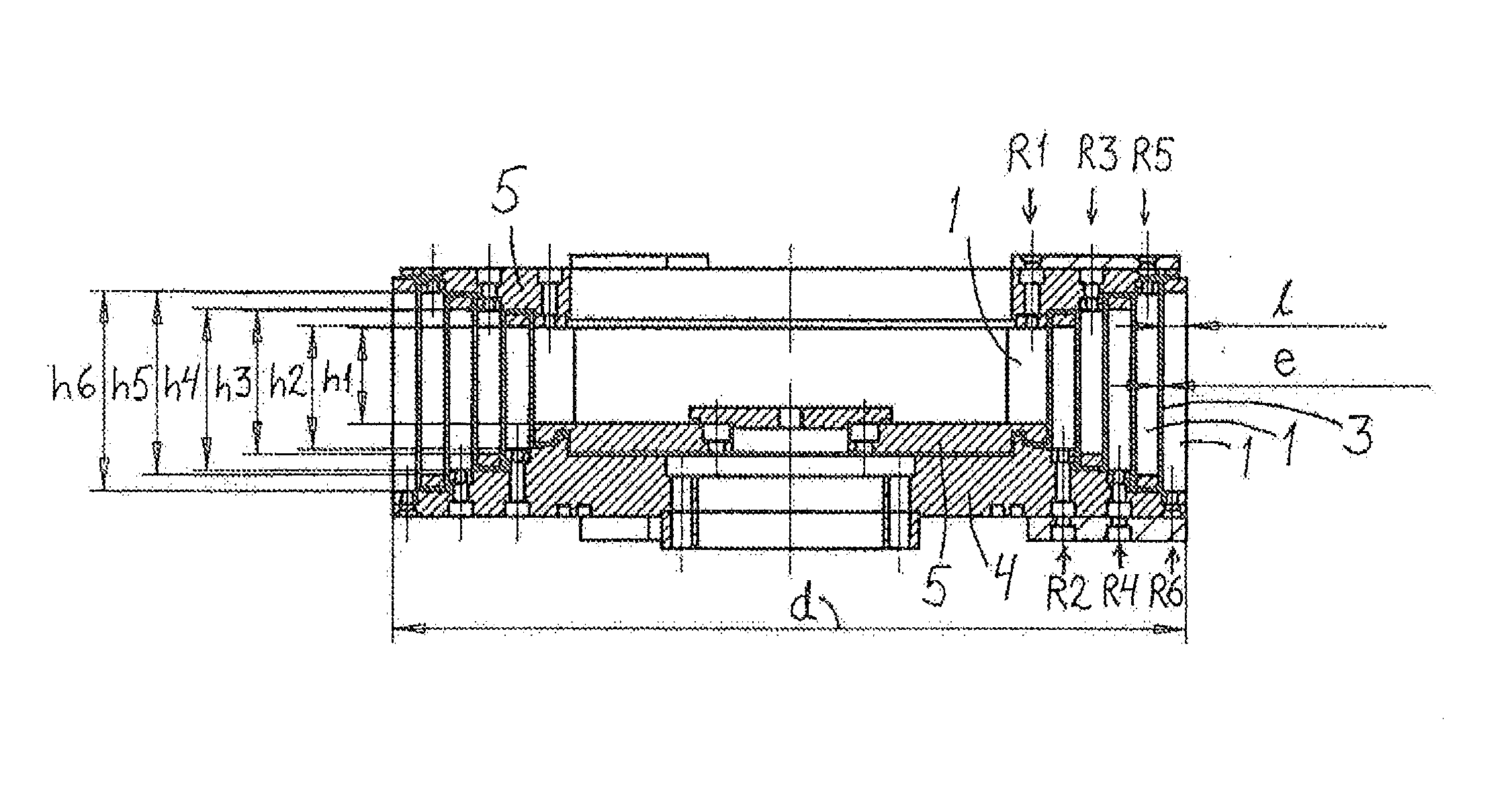

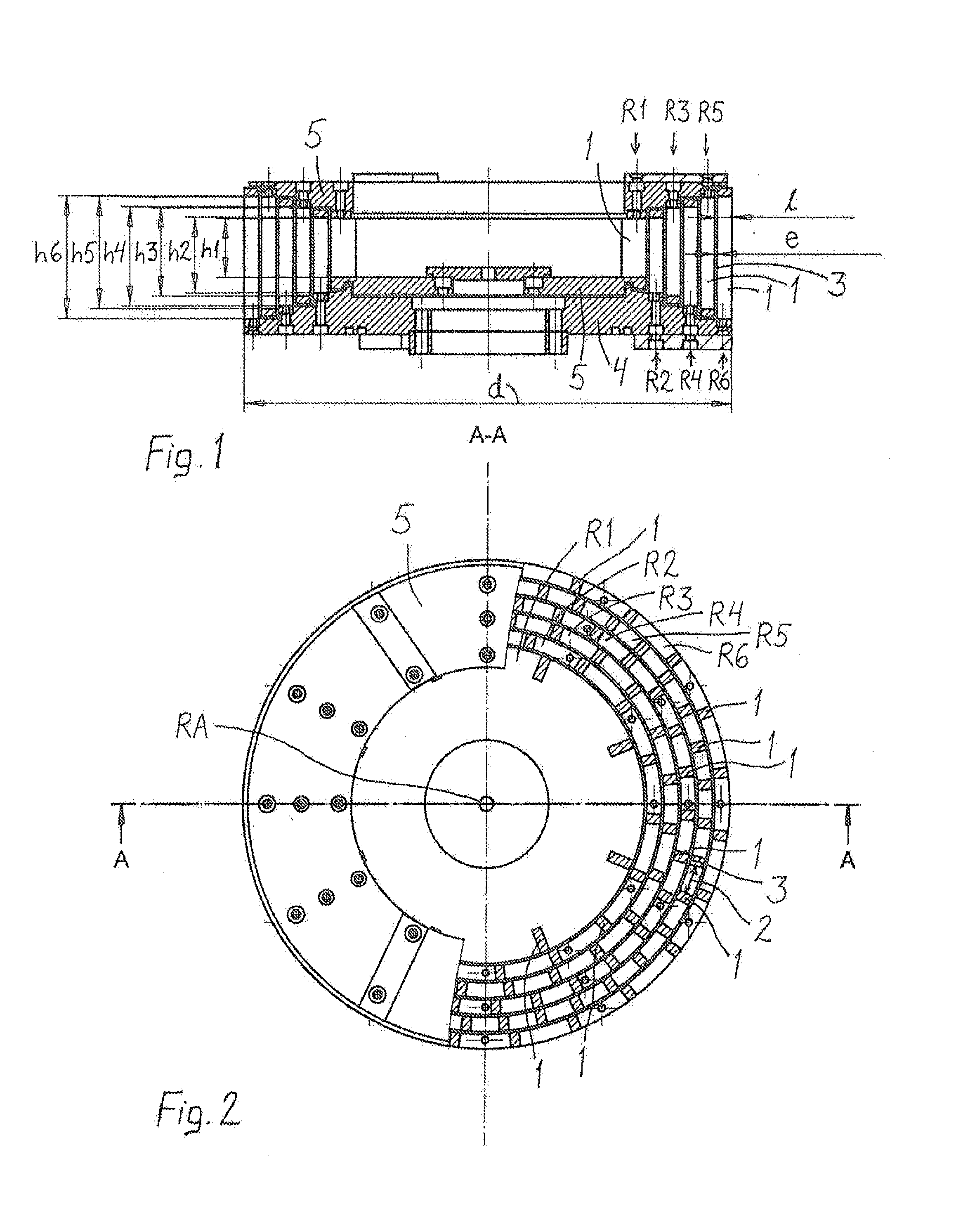

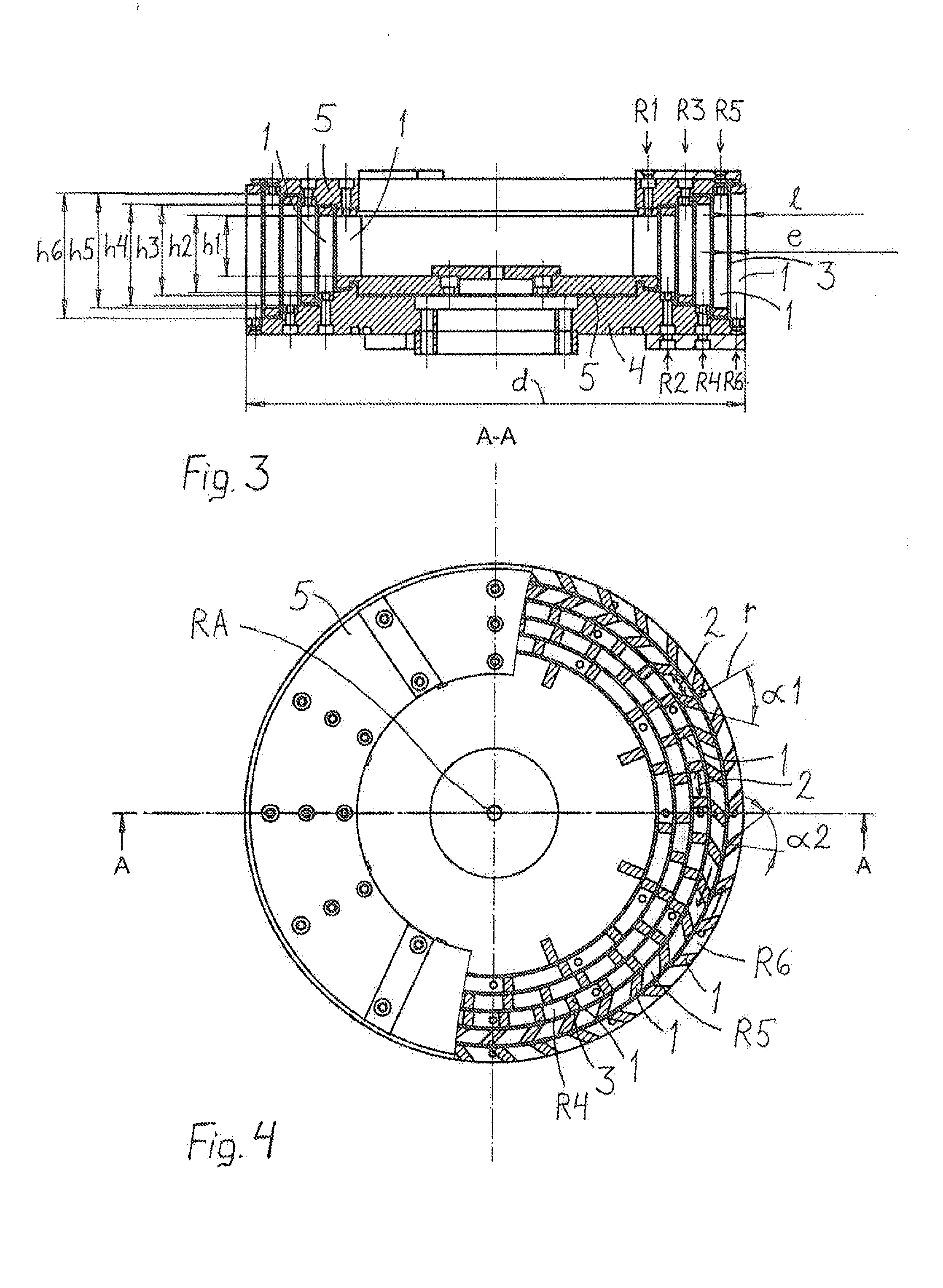

Refiner plates having steam channels and method for extracting backflow steam from a disk refiner

ActiveUS20080296419A1Reduce the amount requiredHigh energy costReed/straw treatmentCocoaGroove widthMechanical engineering

A refining plate for refining lignocellulosic material including: a radially outer peripheral edge and a substrate surface; a refining zone having a plurality of substantially radially disposed bars and grooves between the bars, wherein the bars protrude upward from the substrate surface and the grooves each have a groove width, and a steam channel traversing the bars and grooves of the refining zone, wherein the steam channel has a radially outer end radially inward of the outer peripheral edge of the plate and the steam channel has a width substantially greater than the groove width.

Owner:ANDRITZ INC

Bleached polyacrylic acid crosslinked cellulosic fibers

ActiveUS7513973B2Increase in sizeHigh whitenessCellulosic pulp after-treatmentNon-fibrous pulp additionBleachCellulose fiber

Bleached polyacrylic acid crosslinked cellulosic fibers, methods for making the fibers, and products including the fibers. The bleached polyacrylic acid crosslinked cellulosic fibers are polyacrylic acid crosslinked cellulosic fibers that have been treated with one or more bleaching agents to provide crosslinked cellulosic fibers having improved whiteness.

Owner:INT PAPER CO

Method for preparing cellulose nano-fibril film by utilizing wood powder

InactiveCN102899949AReduce hydrogen bondingHelp removeFibrous raw materialsFibrilPotassium hydroxide

The invention relates to a method for preparing a cellulose nano-fibril film by utilizing wood powder, which comprises the following steps: 1) chemically pre-processing; 2) mechanically separating; and 3) preparing a film. The method has the advantages: the acid-base pre-processing is combined with wood powder grinding and is adopted for preparing; the lignin in the wood powder is removed by mainly utilizing sodium chlorite under an acidic condition; the half-fibril is removed by using the diluted potassium hydroxide and the remained substrate is cellulose; and the diluted hydrochloric acid is used for splitting the cellulose. The acting force of hydrogen bonds in the fibril is reduced by adopting the splitting treatment, so that the biomass cellulose nano-fibril at high length-diameter ratio is obtained; the mineral substance in the fiber is removed by utilizing HCl treatment, the alkali insoluble half-cellulose in the purified cellulose is influenced and the effect of purifying the cellulose fiber is achieved; the chemical constituents are detected through Fourier transform infrared; the grinding treatment is simple and easy to operate and the mass production is performed; the modulus of elasticity is 3105.27MPa; and the tensile strength is 64.24MPa.

Owner:襄垣县鑫瑞达连氏塑木制造有限公司 +1

Thermal regulating building materials and other construction components containing polymeric phase change materials

Owner:LATENT HEAT SOLUTIONS LLC

A method for producing nanofibrillar cellulose

ActiveUS20140284407A1Large capacityImprove consistencyFibrous raw materialsGrain treatmentsCelluloseFiber

In a method for producing nanofibril cellulose, cellulose based fibre material, in which internal bonds in the cellulose fibre have been weakened by chemical modification, are supplied, for separating fibrils, through several counter-rotating rotors outwards in the radial direction with respect to the rotation axis of the rotors in such a way that the material is repeatedly subjected to shearing and impacting forces by the effect of the blades of the different counter-rotating rotors, whereby it is simultaneously fibrillated.

Owner:UPM-KYMMENE OYJ

Paper-making grade softwood pulp plate modifying production technique

ActiveCN101158125AMeet production requirementsReduce pollutionPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpTO-18Cooking methods

The invention provides a denaturizing production technique of paper making needle wood pulp plate, which solves the problems of uneven dipping, slow hemicelluloses stripping, difficult accumulation descending, uneven cooking, single cooking method, single bleaching method and violent conditions existing in denaturizing production technique of wood pulp in the prior art. The invention comprises the following steps: wood pulp plate paging, alkali soaking, pressing, untwining and dispersion, cooking, washing, impurity removal, bleaching, a secondary washing and pulping; wherein, the wood pulp plate paging, alkali soaking, pressing, untwining and dispersion are to send papers into a alkali dipping barrel with concentration of 6 percent to 18 percent after the paper making bleaching wood pulp plates are separated by a paging device. When the wood pulp plates are changed into pulp with concentration of 3 percent to 6 percent, the pulp with concentration of 3 percent to 6 percent is sent to a squeezer to be squeezed and to untwine and disperse fiber. By adopting the invention, the quality of the dissolved viscose fiber wood pulp can be better and more stable; furthermore, the invention provides wider selection range of raw material.

Owner:YIBIN GRACE GROUP CO LTD

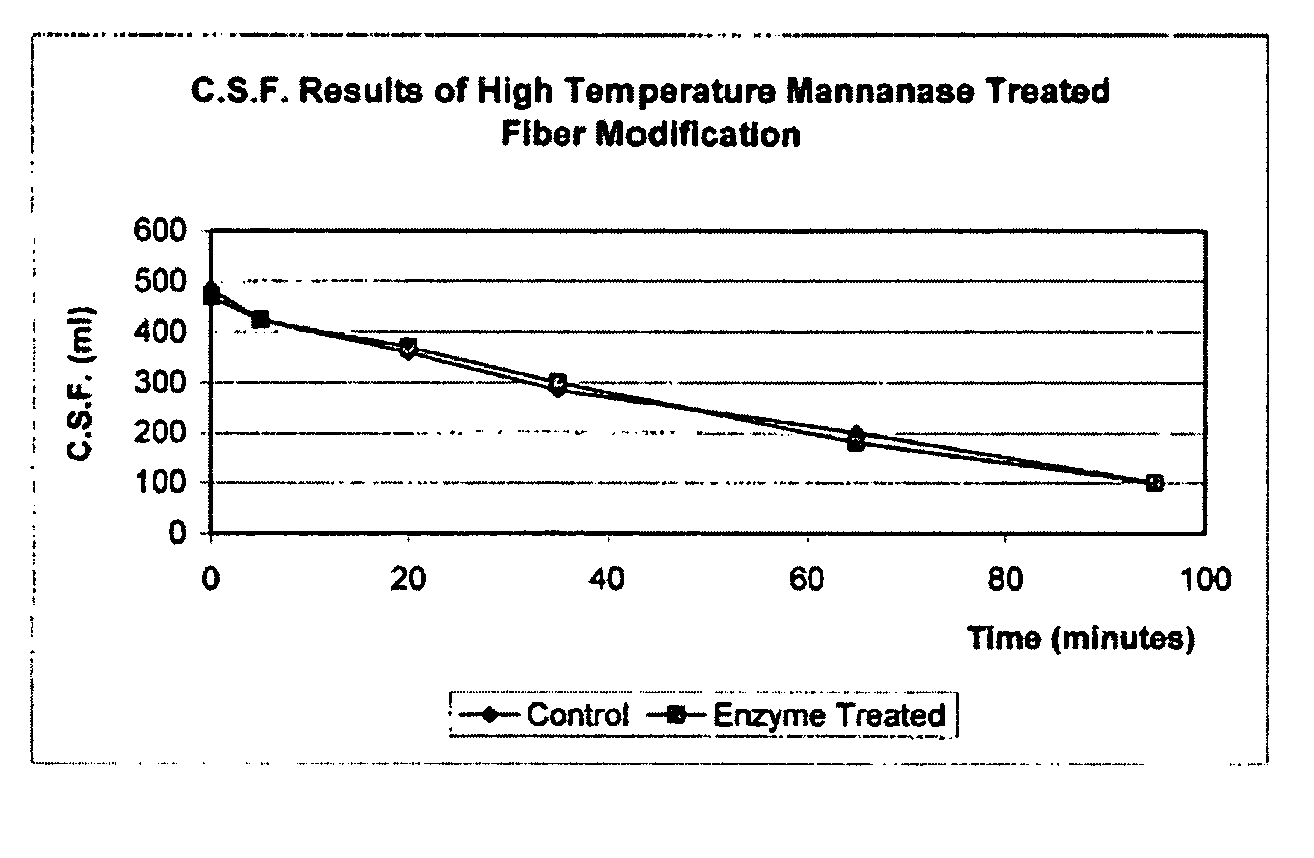

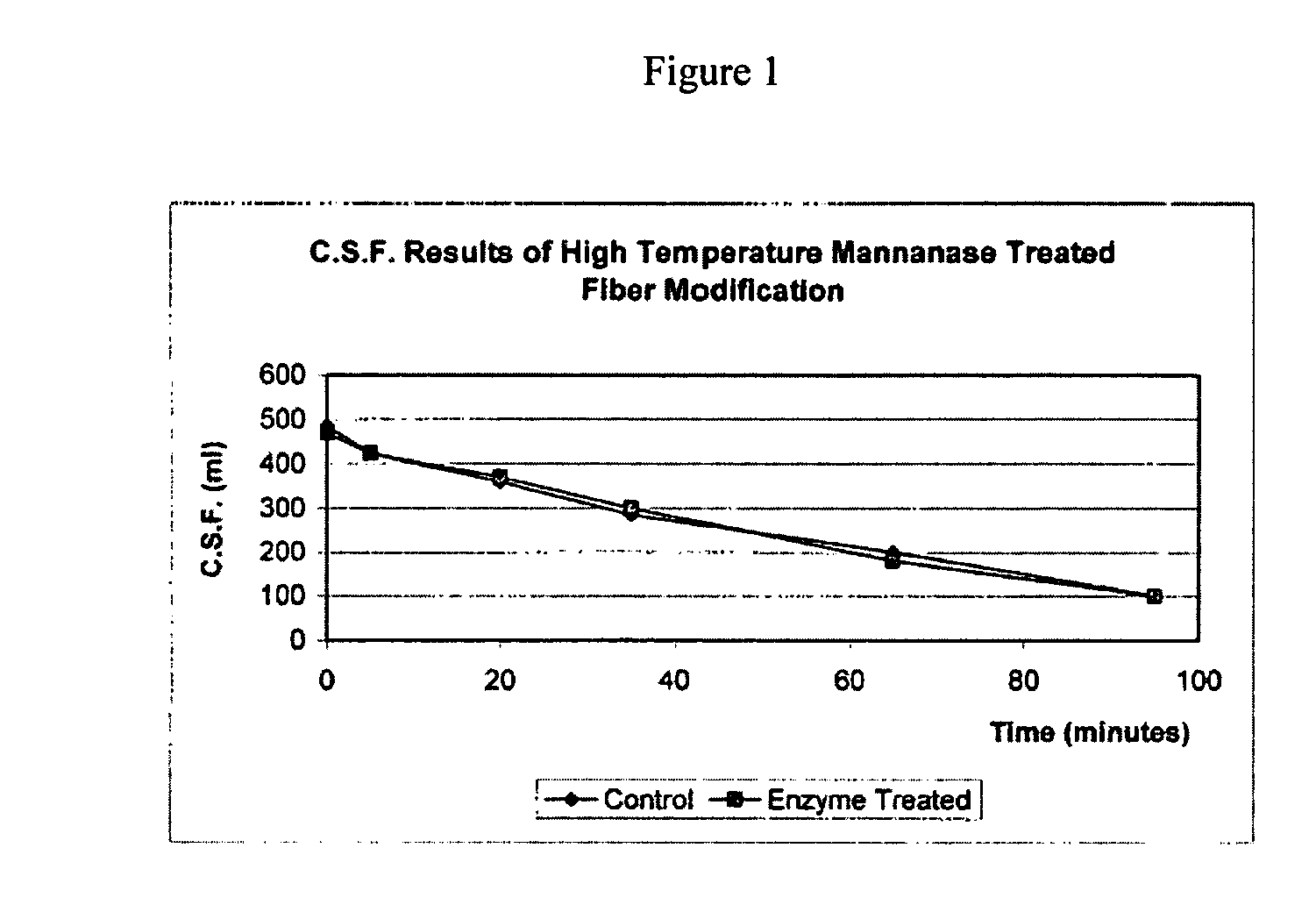

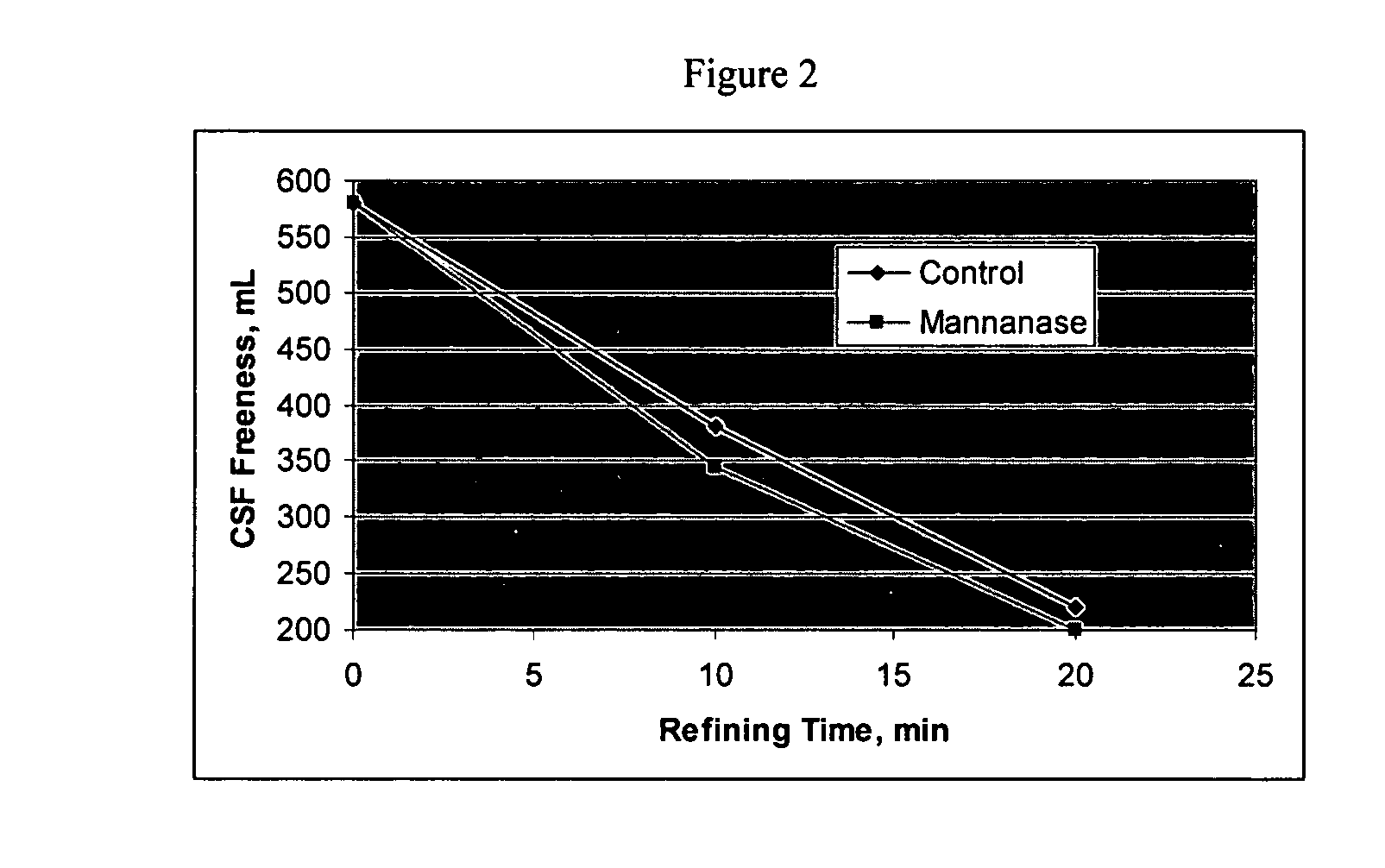

Use of hemicellulase composition in mechanical pulp production

InactiveUS20050000666A1High strengthLess energyFibrous raw materialsPulp beating/refining methodsPulp and paper industryHemicellulose

Owner:BUCKMAN LAB INT INC

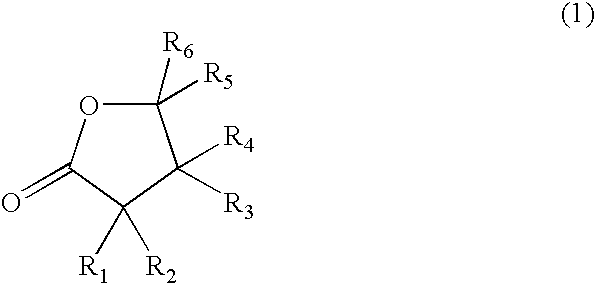

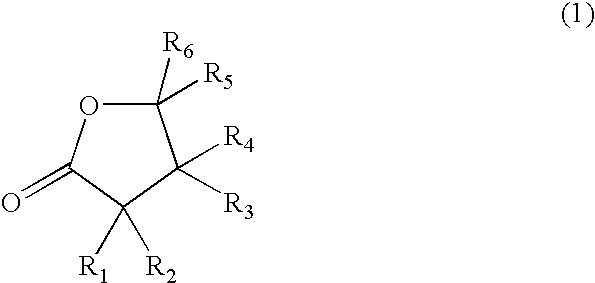

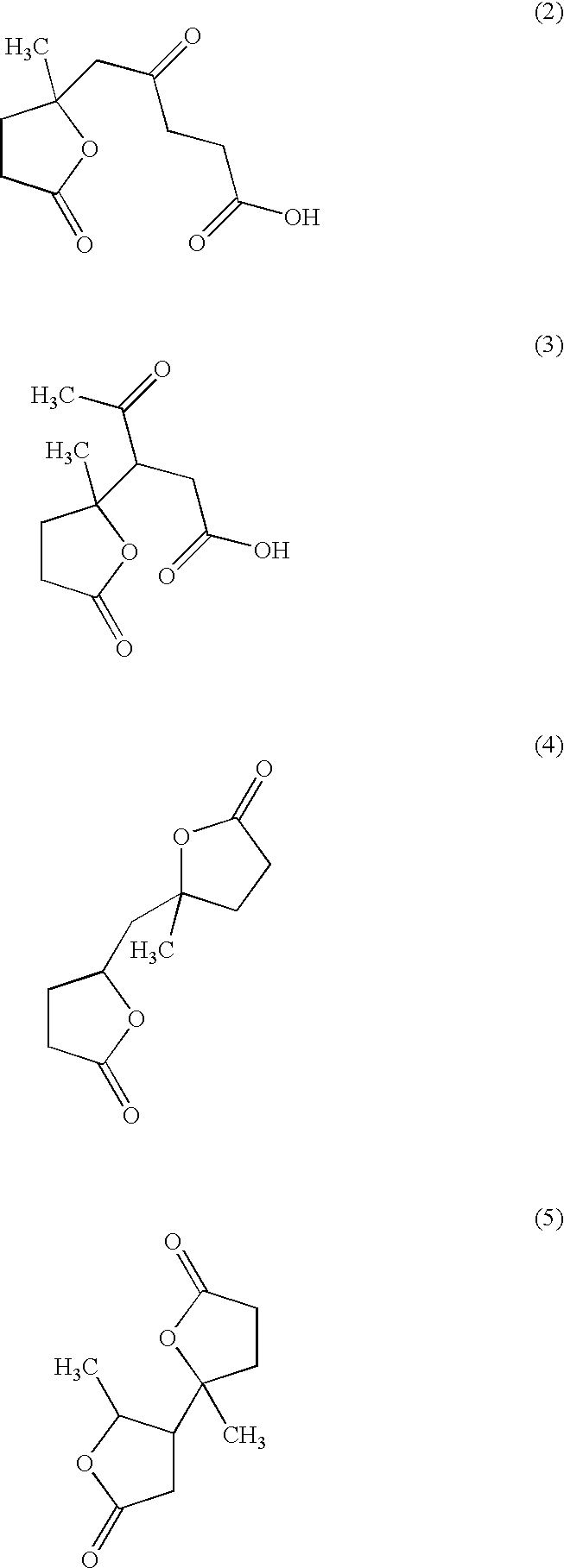

Process for organosolv pulping and use of a gamma lactone in a solvent for organosolv pulping

InactiveUS20070034345A1High boiling pointReduce stressPulp properties modificationPulp bleachingHydrogen atomOrganic group

The invention provides a process for organosolv pulping, wherein solid lignocellulosic feed material is heated at a temperature in the range of from 50 to 210° C. in a solvent to obtain a solid cellulosic fraction comprising at least 50 wt % of the cellulose present in the feed material and a liquid fraction, wherein the solvent comprises at least 10 wt % of a compound according to general molecular formula wherein R1 to R6 each represent, independently, a hydrogen atom or an organic group connected with a carbon atom to the lactone group. The invention further provides the use of a compound according to general molecular formula (1) in a solvent for organosolv pulping.

Owner:SHELL OIL CO

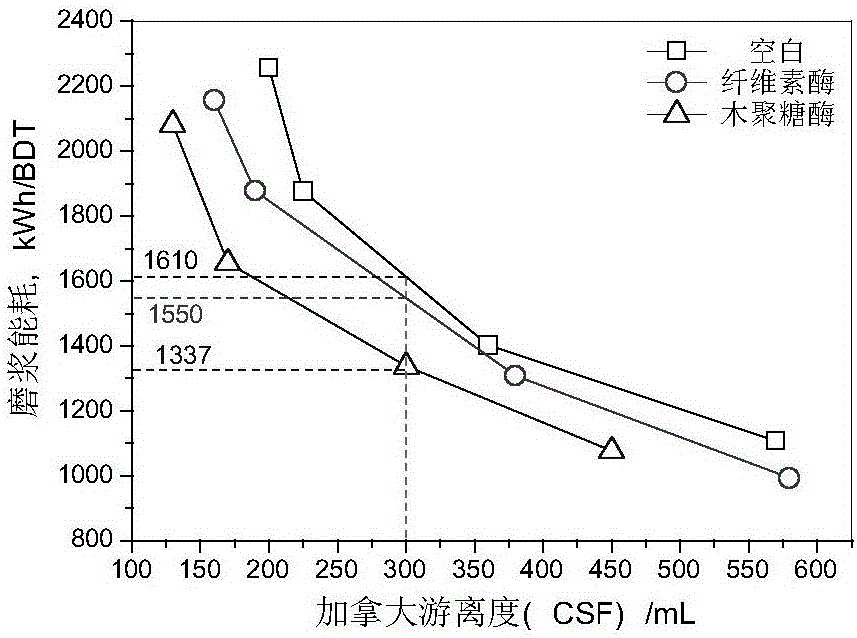

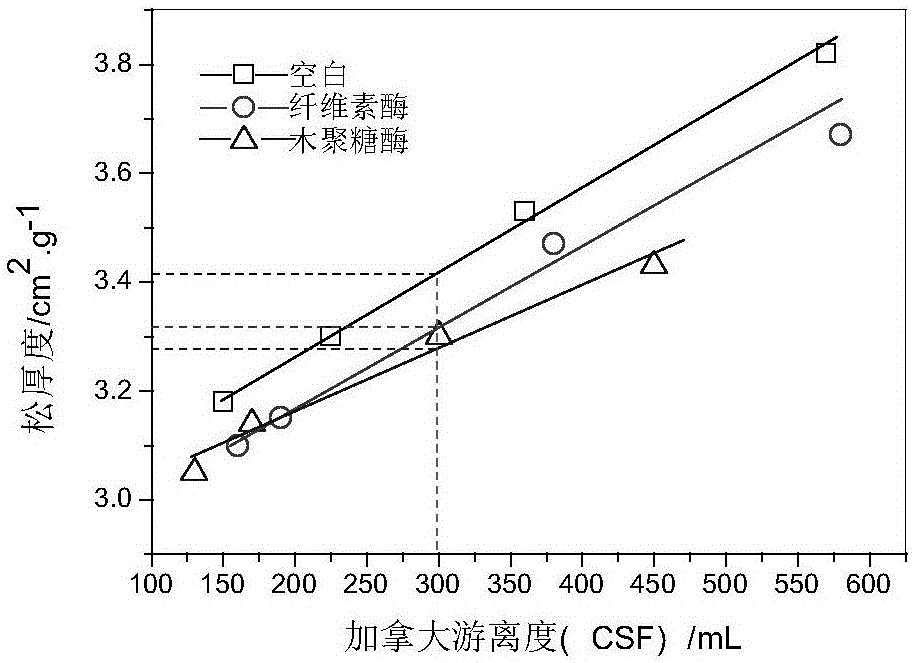

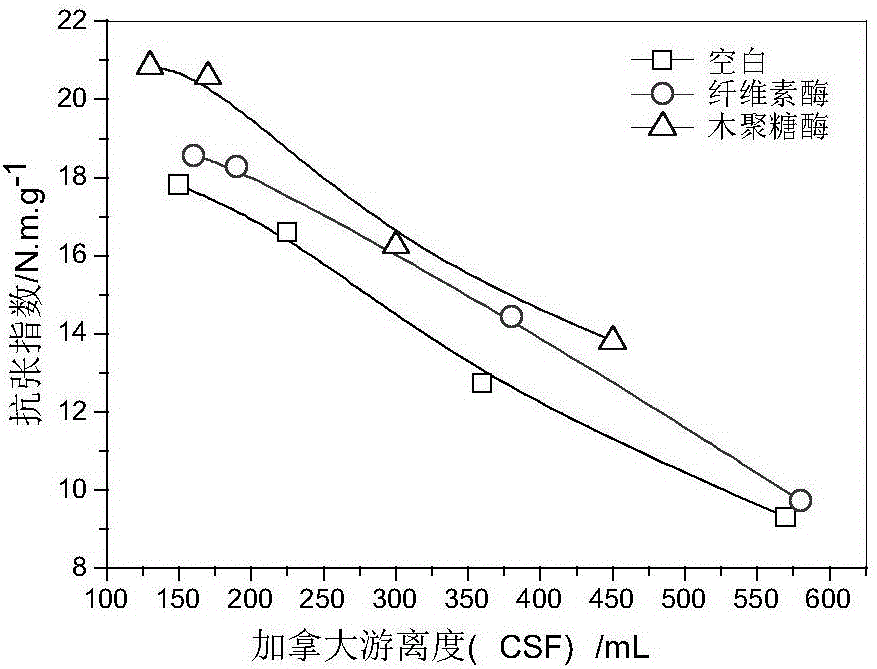

Bamboo chemimechanical pulp bioenzyme pretreatment method

ActiveCN106381741AReduce physical strengthHigh whitenessFibrous raw materialsCellulose treatment using microorganisms/enzymesPretreatment methodPre treatment

The invention discloses a bamboo chemimechanical pulp bioenzyme pretreatment method. The bamboo chemimechanical pulp bioenzyme pretreatment method comprises the following steps: feeding bamboo pieces into a steaming cabin for normal-pressure pre-steaming after screening the bamboo pieces, and then carrying out first-stage screw extrusion; adding bioenzyme in an extruded material for pretreatment, then carrying out high-temperature deactivation, washing and dewatering, then carrying out first-stage and second-stage chemical pre-impregnating in sequence, then carrying out first-stage high-consistency normal-pressure pulp grinding by using a high-consistency disc refiner of which rho is 300, and completing bleaching reaction by enabling pulp to stay in a high-consistency reaction cabin for about 50 to 60 minutes; then carrying out follow-up pulp grinding by using a disc refiner, preparing pulp samples in different Canadian freeness degrees by controlling and inputting different pulp grinding energy consumptions, respectively recording the pulp grinding energy consumption needed for preparing each pulp sample, and using the different pulp samples for paper pulp performance testing after respectively carrying out latent elimination, acidification, washing, screening and dewatering concentration. According to the bamboo chemimechanical pulp bioenzyme pretreatment method disclosed by the invention, by carrying out pretreatment on bamboo bioenzyme, compared with a traditional PRC (Preconditioning Refiner Chemical)-APMP (Alkaline Peroxide Mechanical Pulping) technology, the difference in respects of pulp grinding energy consumption and pulp performance can be observed, and a reference technology is provided for preparing chemimechanical pulp by using bamboos as raw materials.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com