Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

887results about "Fibreboard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micronized wood preservative formulations

ActiveUS20050118280A1Material efficiencyFibreboardHeavy metal active ingredientsPreservativeMaterials science

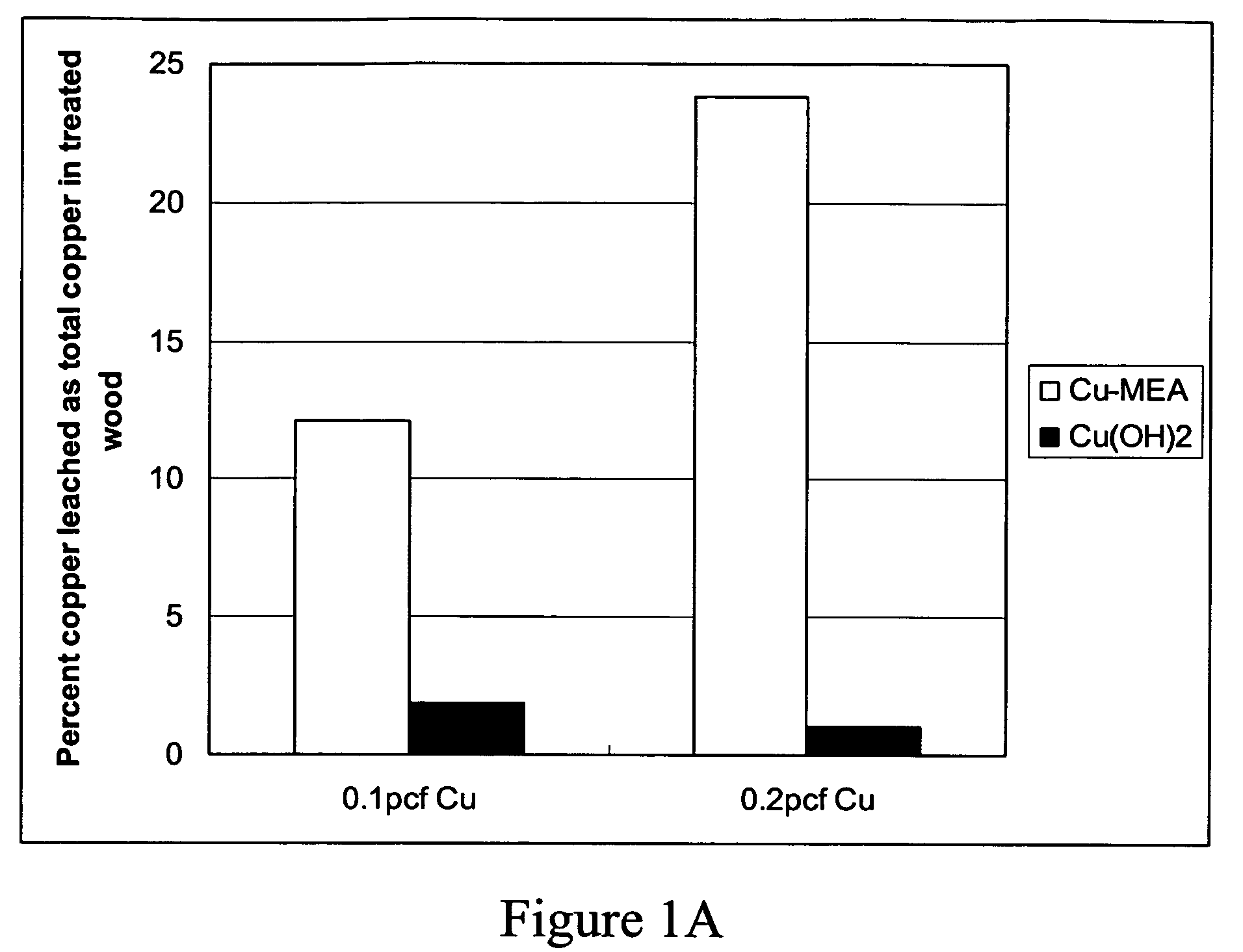

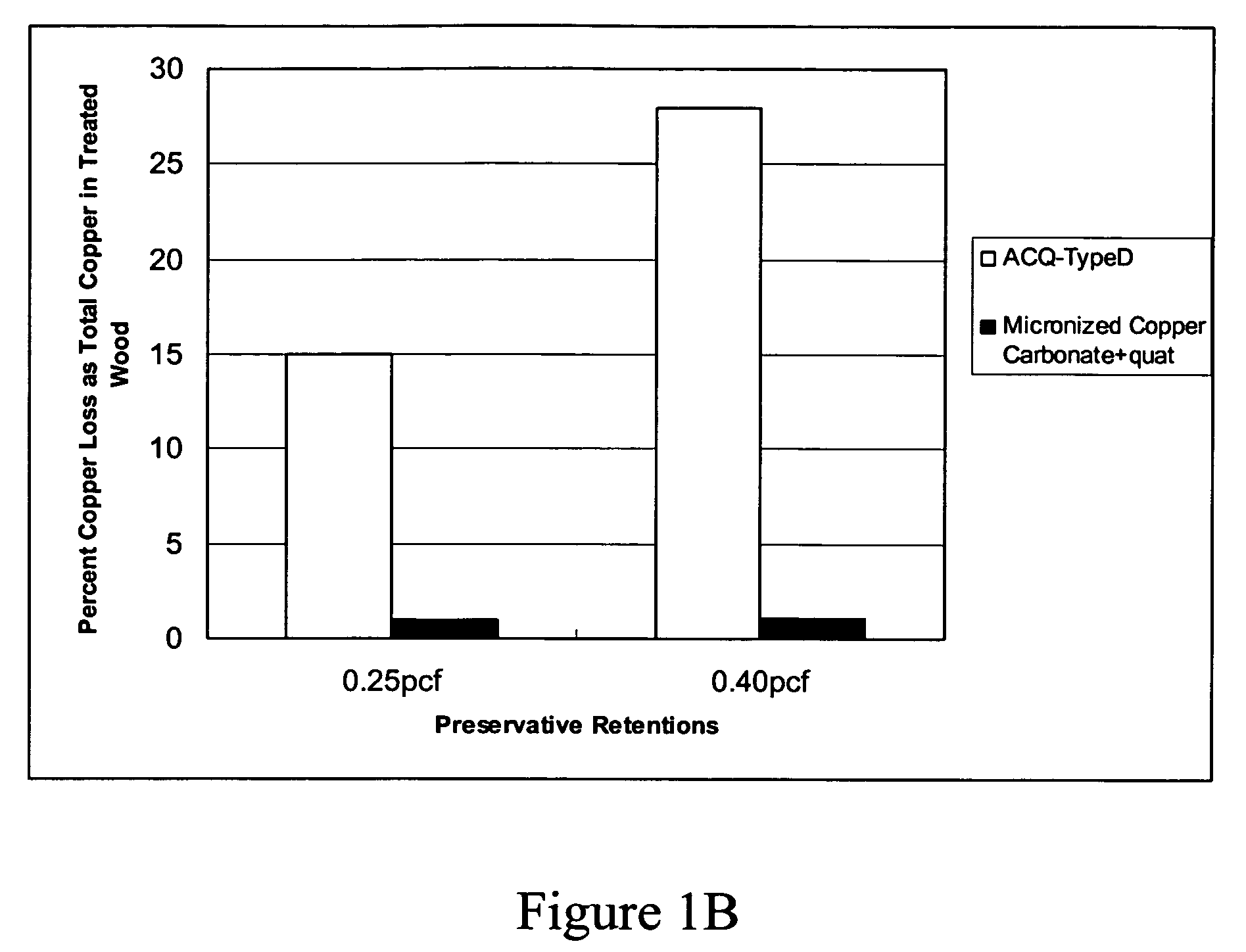

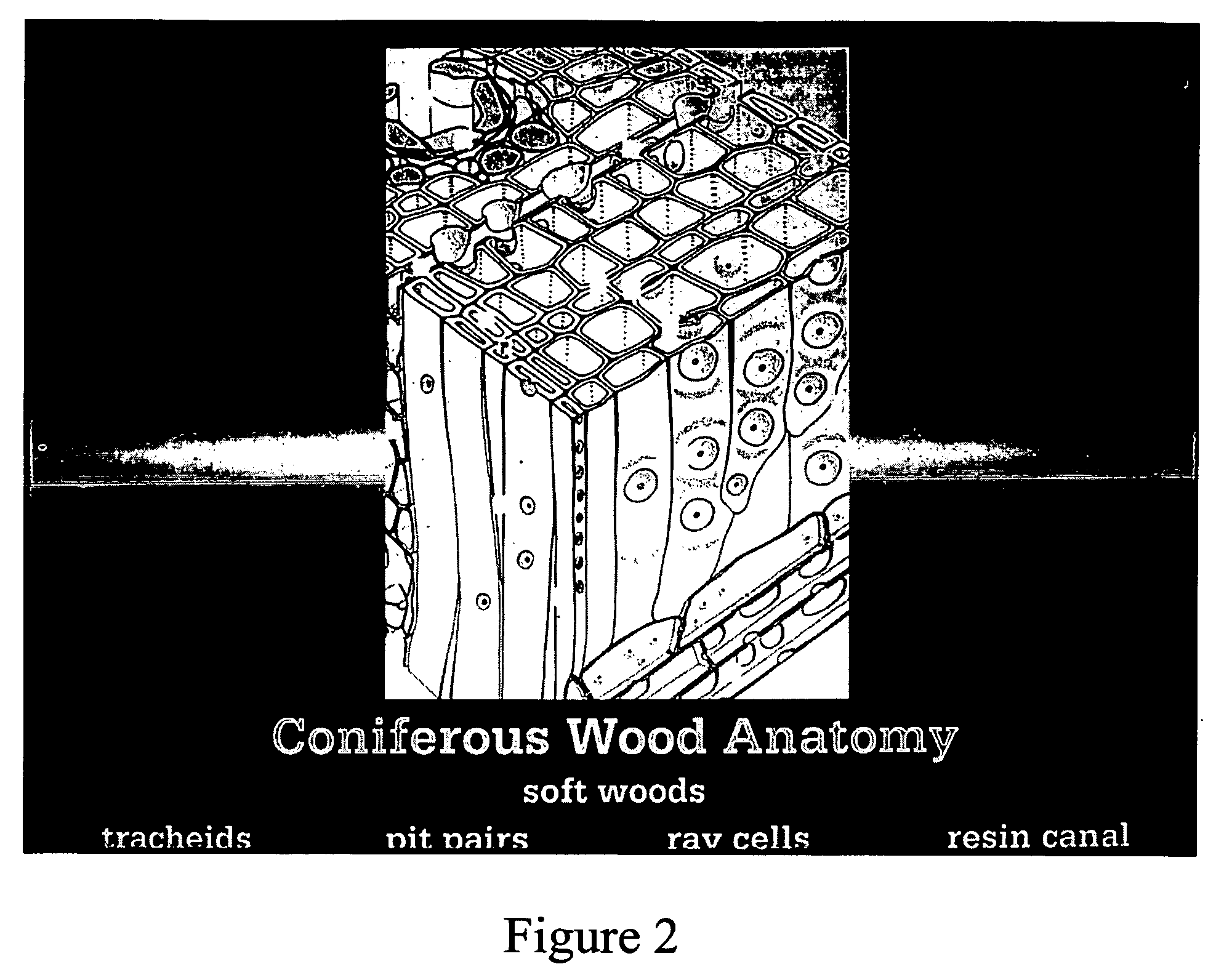

The present invention provides wood preservative compositions comprising micronized particles. In one embodiment, the composition comprises dispersions of micronized metal or metal compounds. In another embodiment, the wood preservative composition comprises an inorganic component comprising a metal or metal compound and organic biocide. When the composition comprises an inorganic component and an organic biocide, the inorganic component or the organic biocide or both are present as micronized particles. When compositions of the present invention are used for preservation of wood, the micronized particles can be observed as uniformly distributed within the wood and there is minimal leaching of the metal and biocide from the wood.

Owner:KOPPERS PERFORMANCE CHEM

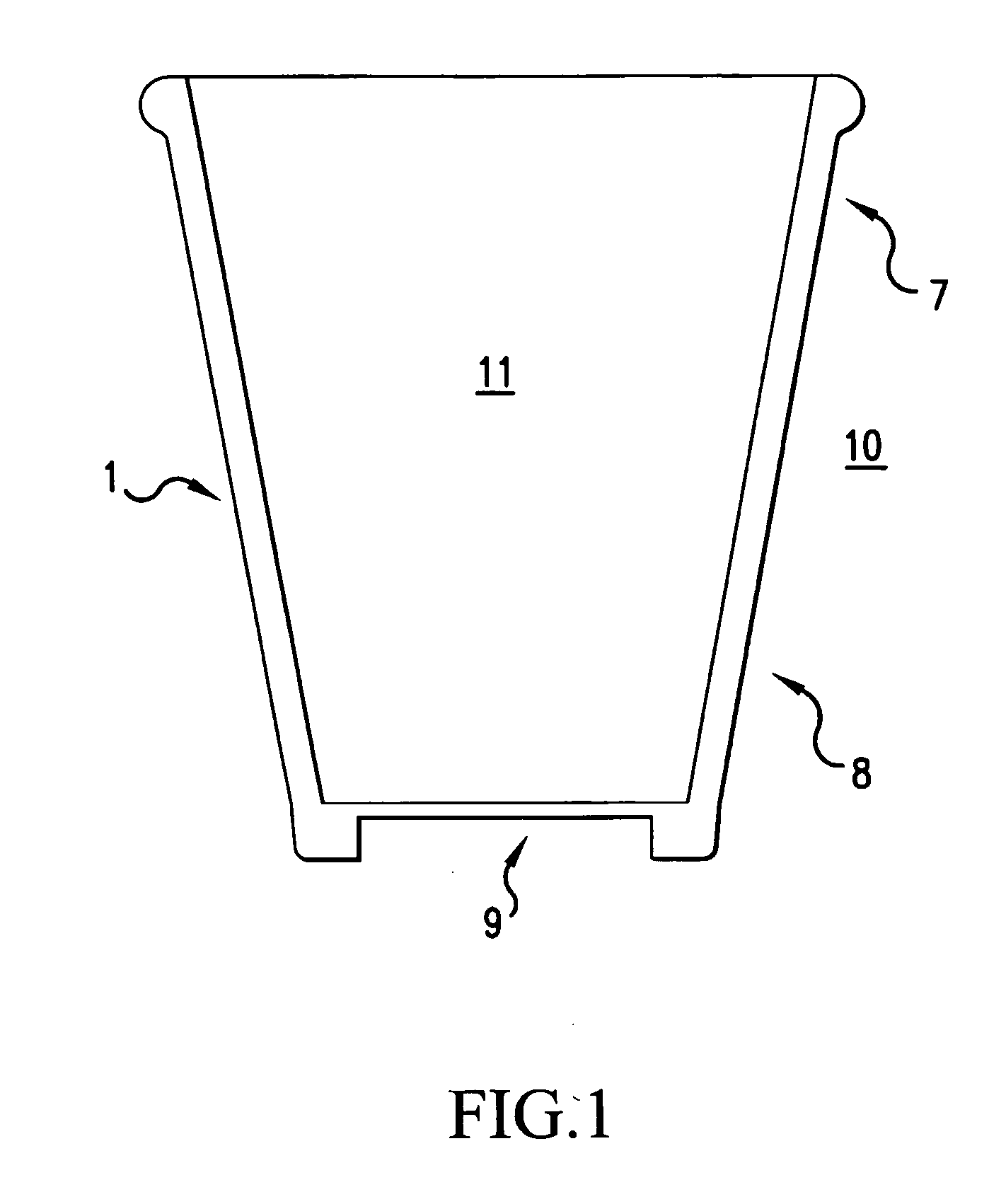

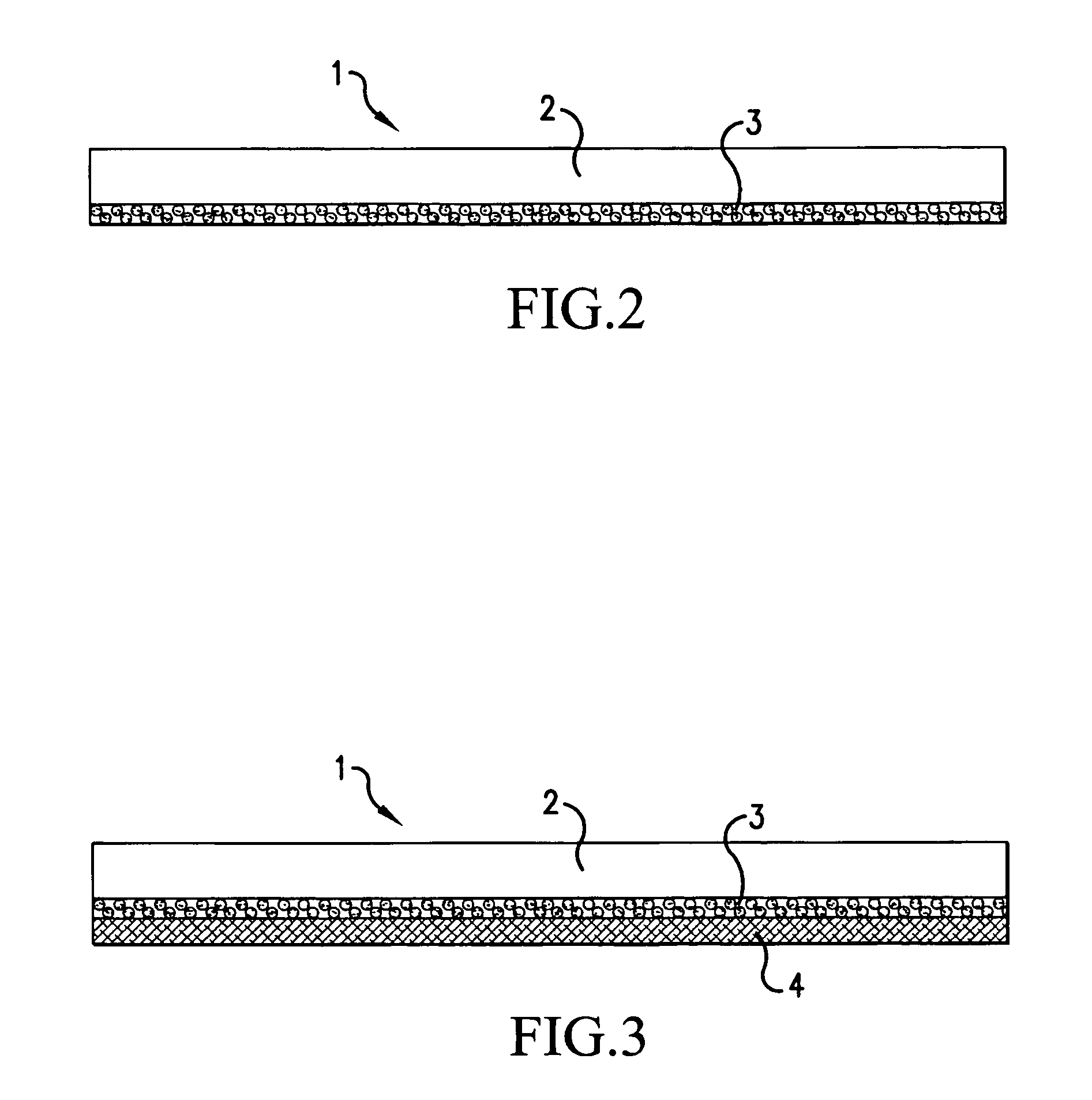

Insulated beverage or food container

InactiveUS20050003122A1Reduce energy transferImprove functionalityFibreboardWrappersEnergy transferEngineering

An insulating beverage cup or sleeve is produced with a foam layer disposed on an inner surface of a food or beverage paper stock. A polyethylene film layer is arranged in a position between a paper stock layer and an inside surface of the beverage container. The foam layer decreases the energy transfer between the beverage and the user's hands allowing the user to hold onto the cup for an extended period of time without causing user discomfort or pain, e.g. greatly extends the hold time of the paper cup. The exterior surface of the beverage cup remains highly printable and predisposed to high quality graphics both before and after cup manufacture.

Owner:APPLETON PAPERS INC

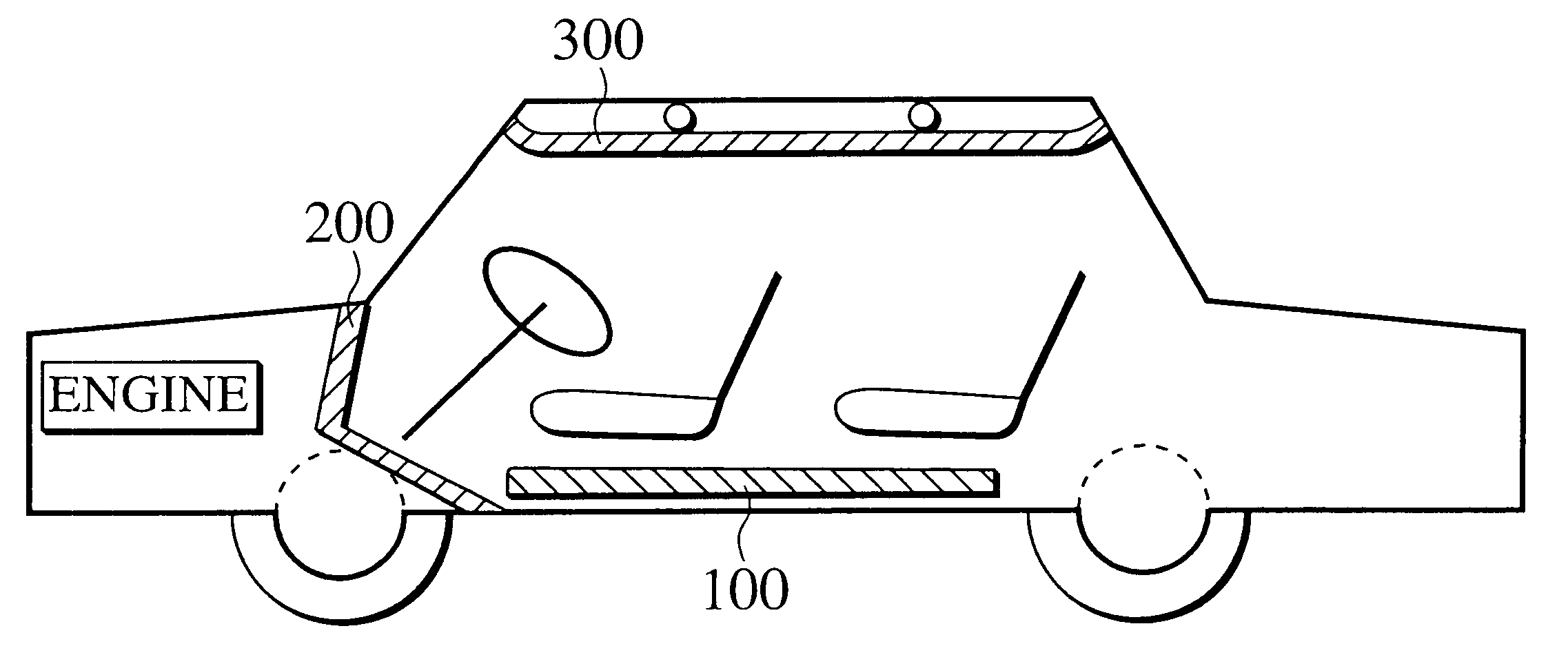

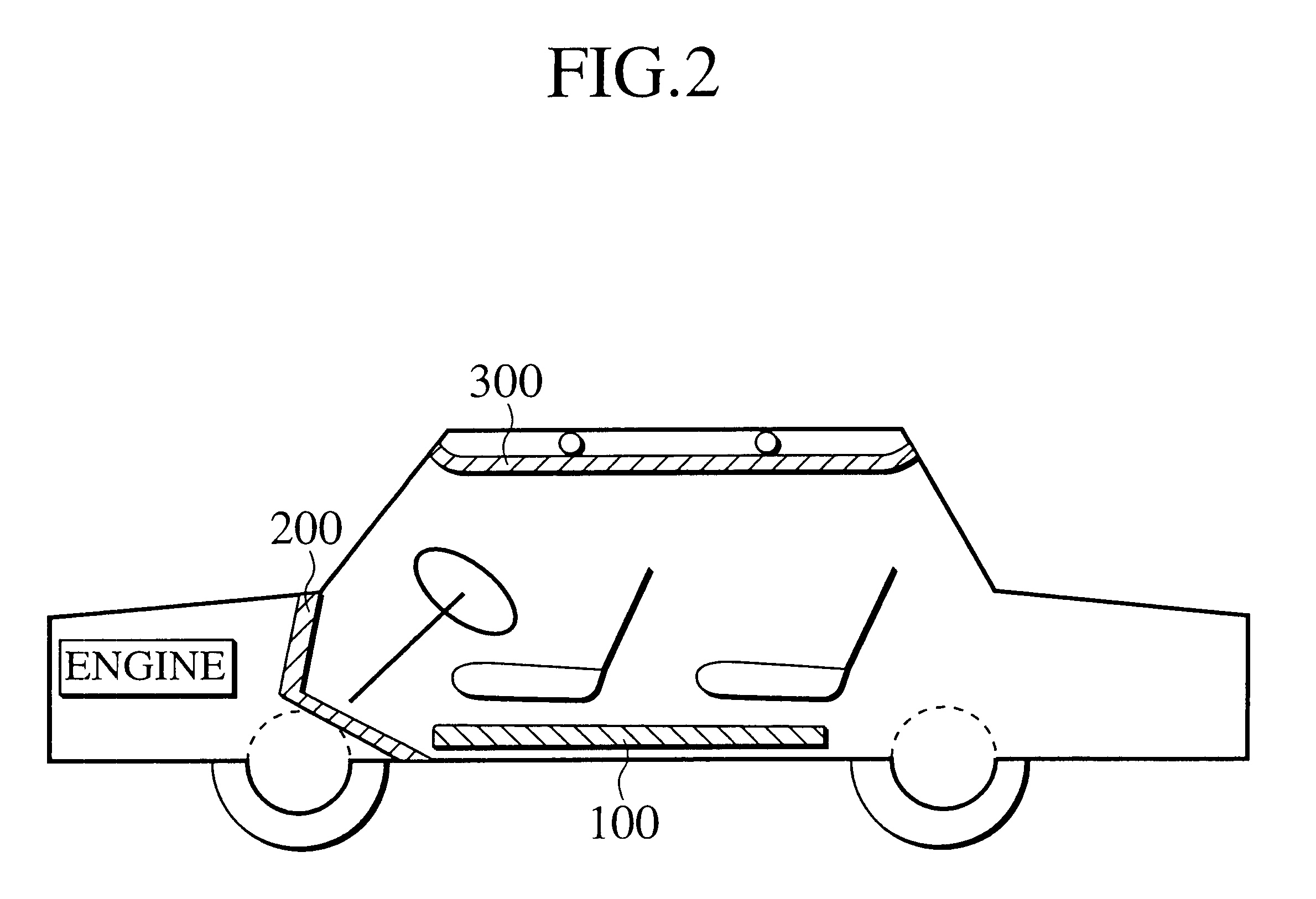

Sound absorbing-insulating structure for vehicles

InactiveUS6524691B2Improve sound absorptionLow costFibreboardWallsCellulose fiberVolumetric Mass Density

Owner:NISSAN MOTOR CO LTD

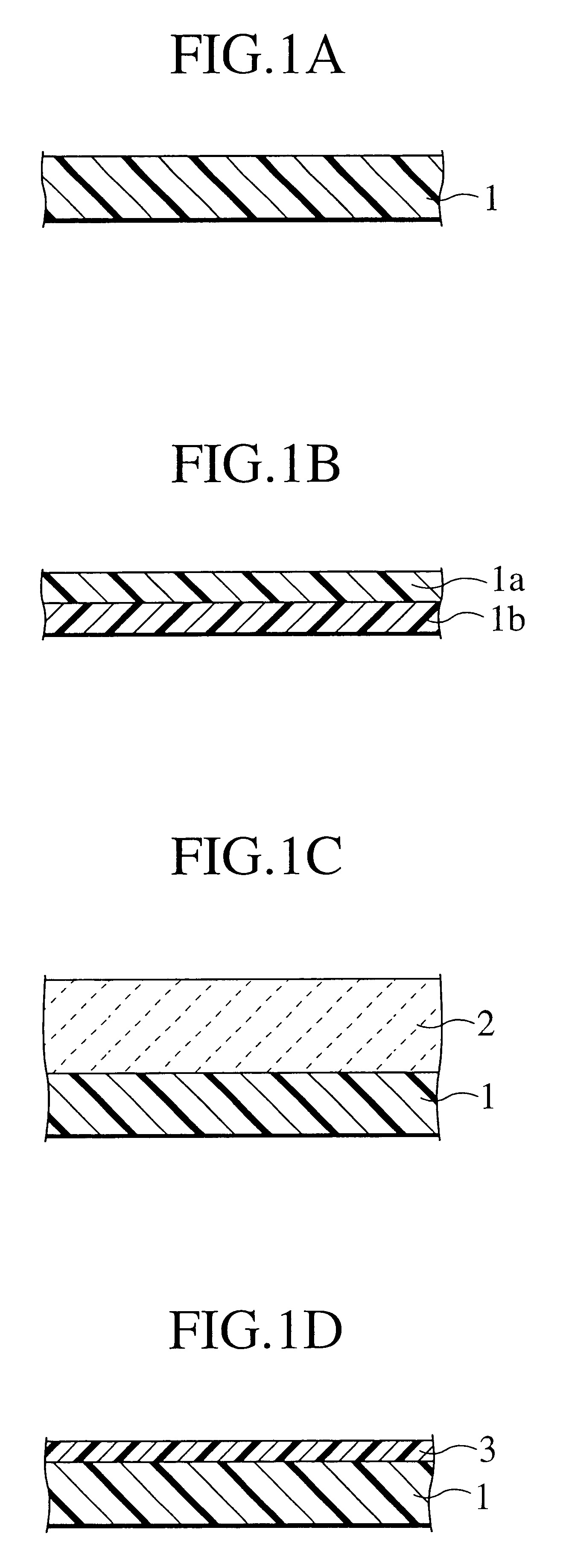

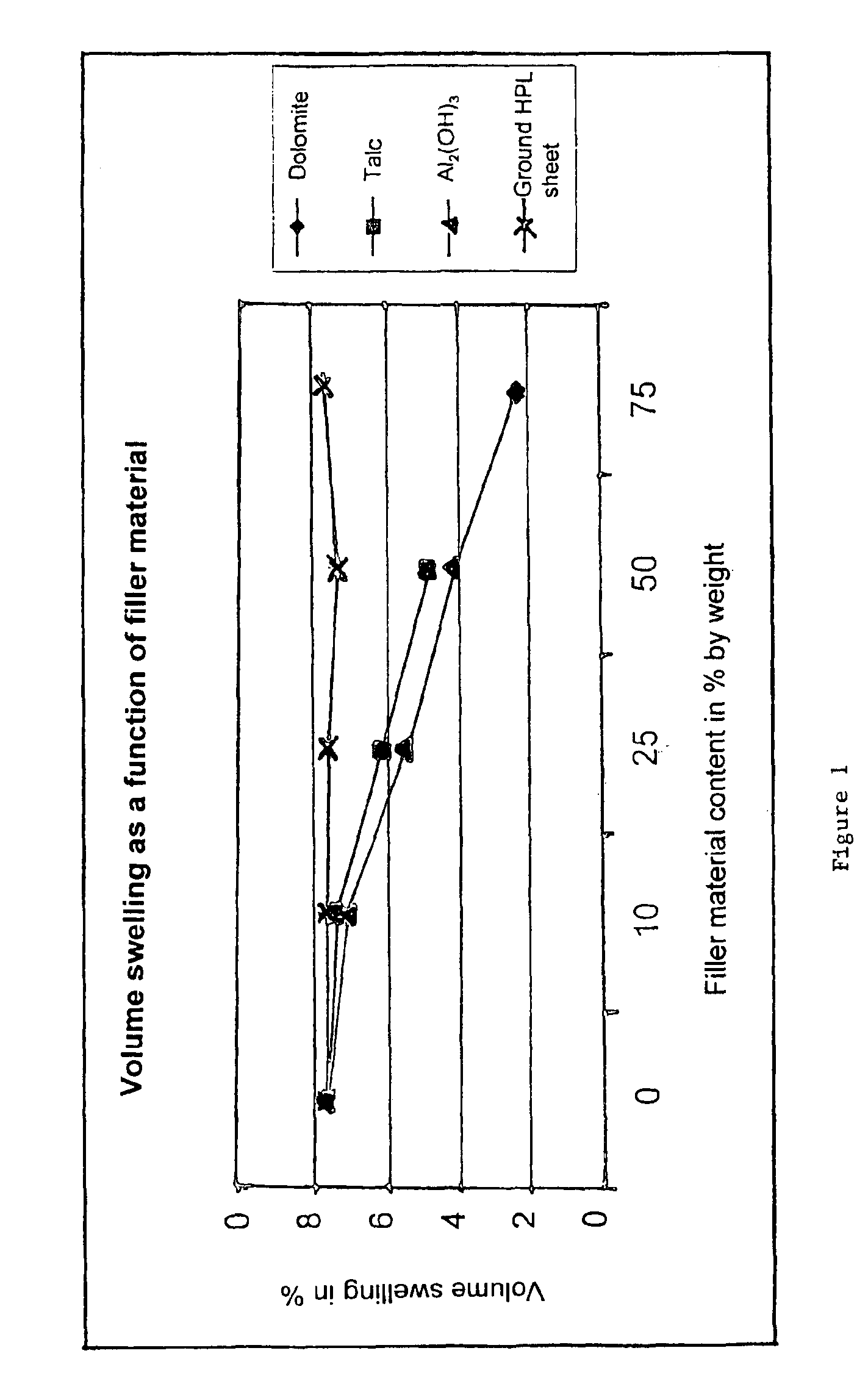

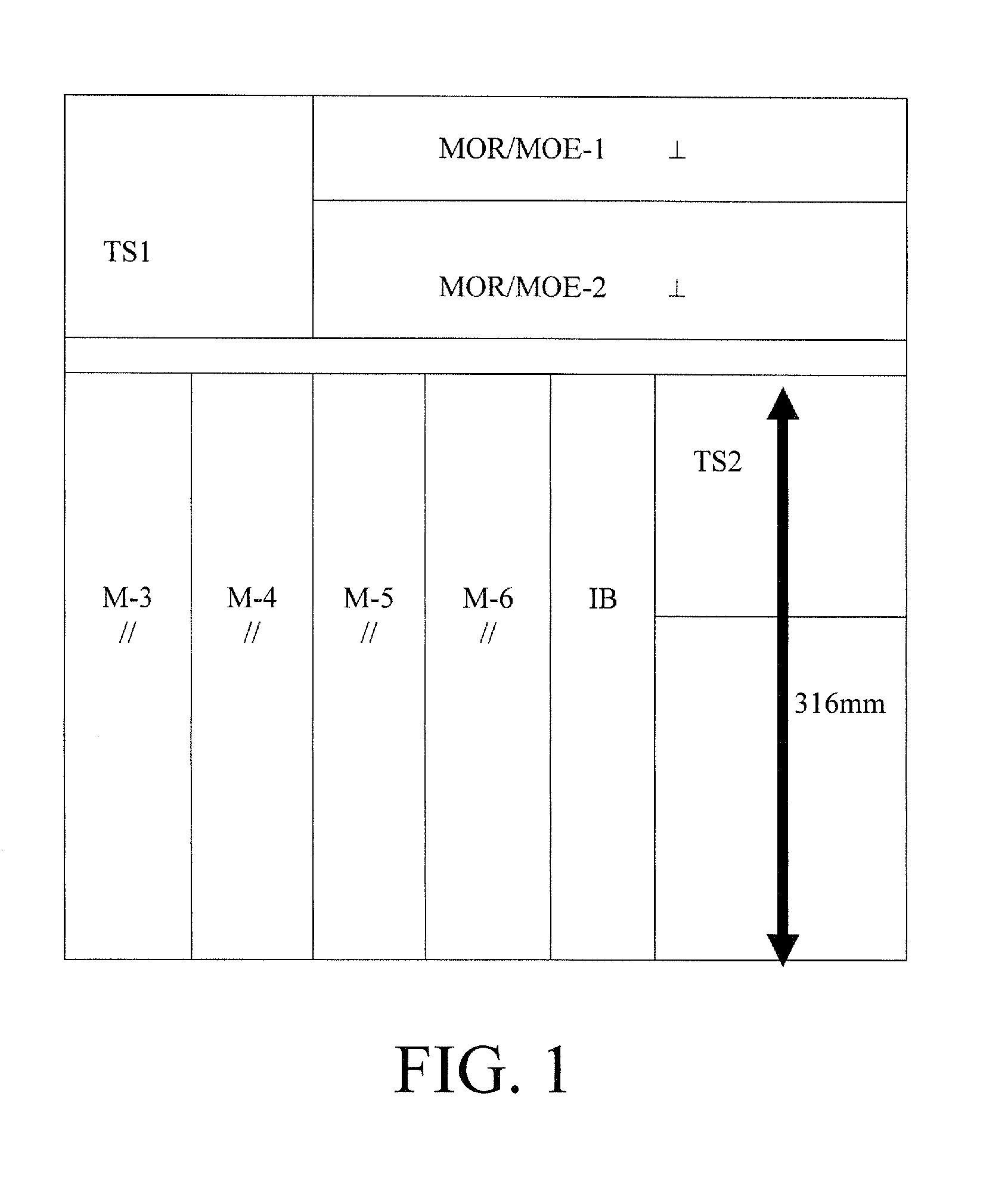

Decorative sheet or molding comprising fibers and fillers and process for its production

A decorative sheet or a molding, in particular suitable for indoor or outdoor applications on buildings, is in each case composed of a single- or multi-layer core, monolaterally or bilaterally laminated with decorative layer(s) The core layer(s) comprise(s) wood fibers, cellulose fibers, or timber sawdust products and also an organic or inorganic filler material, and a hot-curing resin. The particle size of the filler material is smaller than the thickness of the fibers or of the timber sawdust products in the core layer(s). These core layer(s) are composed of from 15 to 80% by weight of fibers or of timber sawdust products, from 10 to 75% by weight of filler material, and from 10 to 50% by weight of resin, based in each case on the total weight of the core layer(s).

Owner:TRESPA INT

Wood Adhesives Containing Reinforced Additives for Structural Engineering Products

The present disclosure relates to additives used in conjunction with adhesives to give enhanced performance. Engineered composite wood materials and methods of making such materials are also provided by the subject application. A reinforced adhesive includes an adhesive and an additive material comprising nanoscopic and microscopic materials.

Owner:UNIV OF TENNESSEE RES FOUND

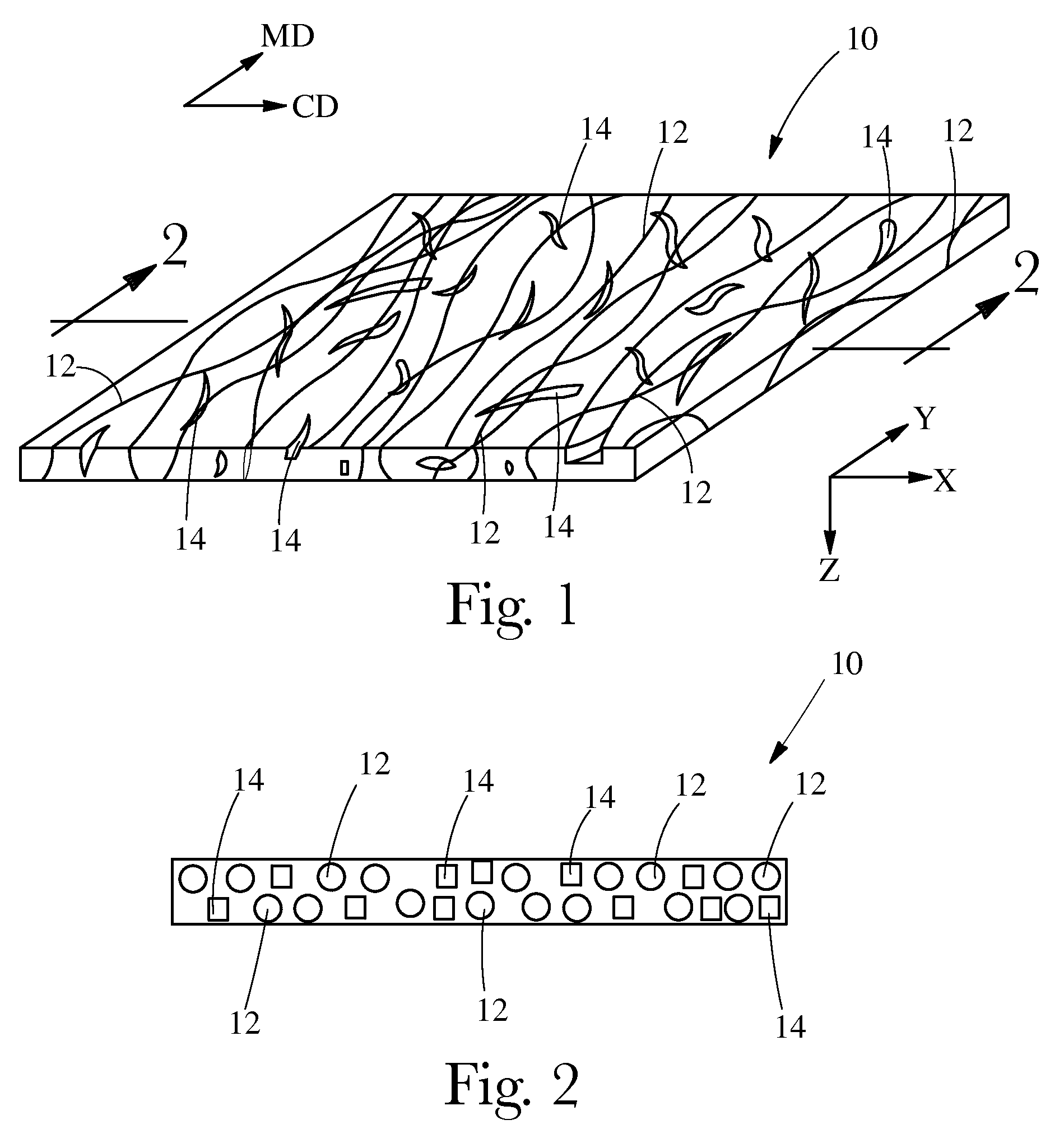

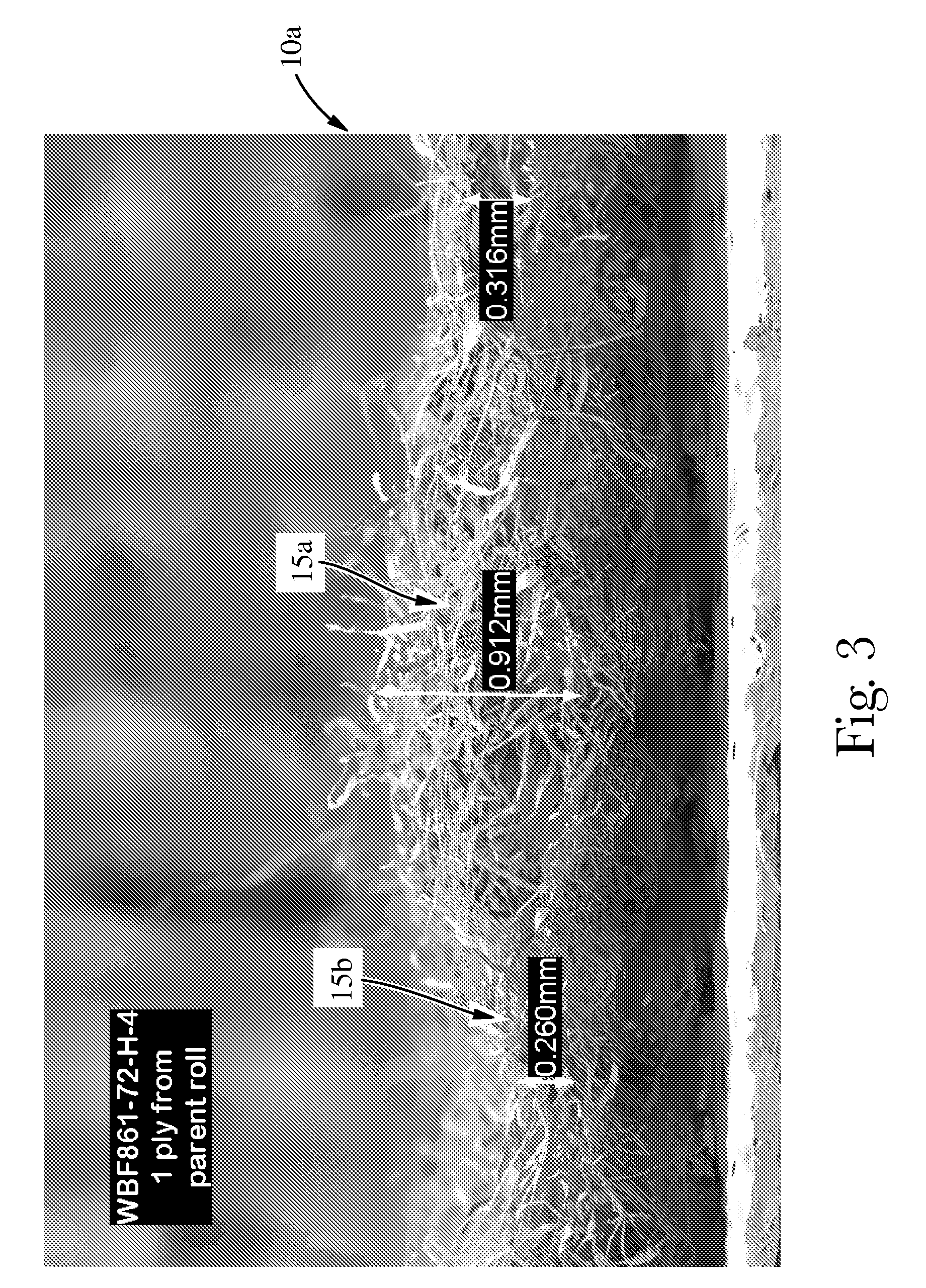

Low lint fibrous structures and methods for making same

Fibrous structures that exhibit low dry lint scores, and more particularly fibrous structures containing filaments and solid additives that exhibit low dry lint scores and methods for making such fibrous structures are provided.

Owner:THE PROCTER & GAMBLE COMPANY

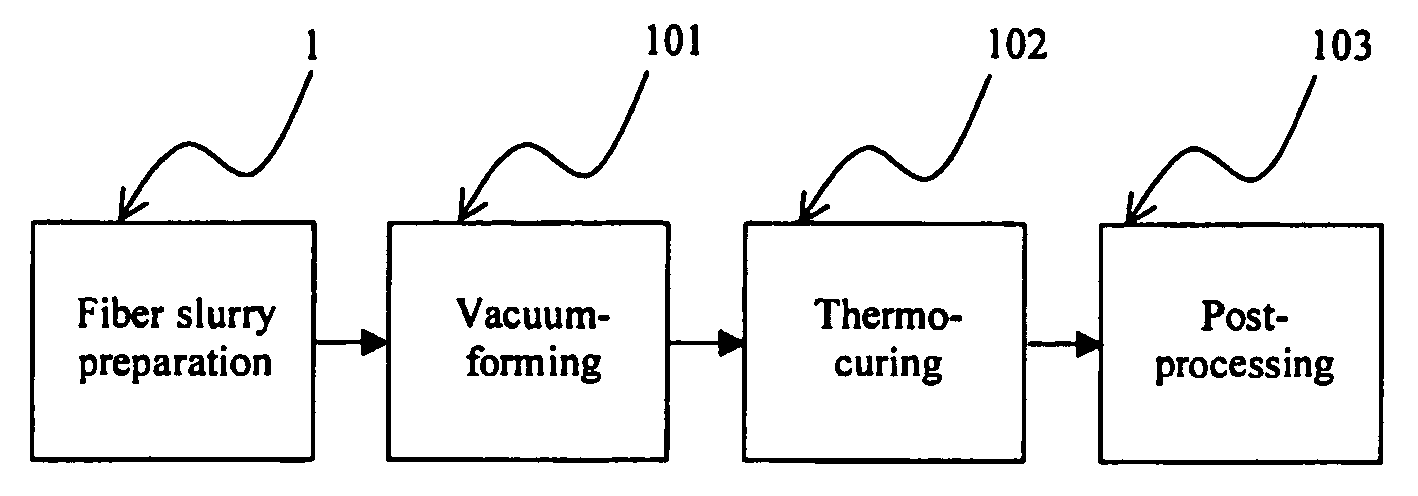

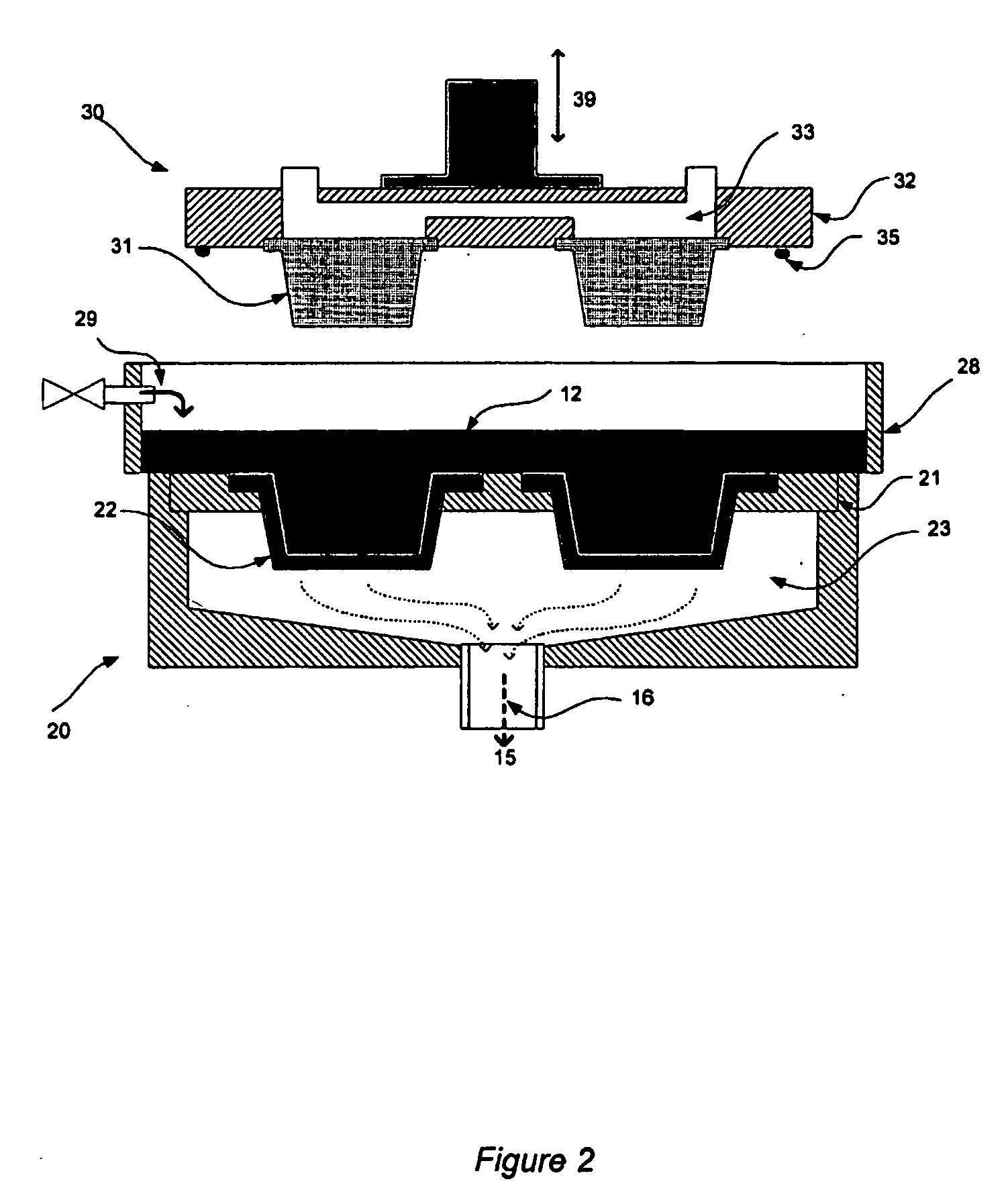

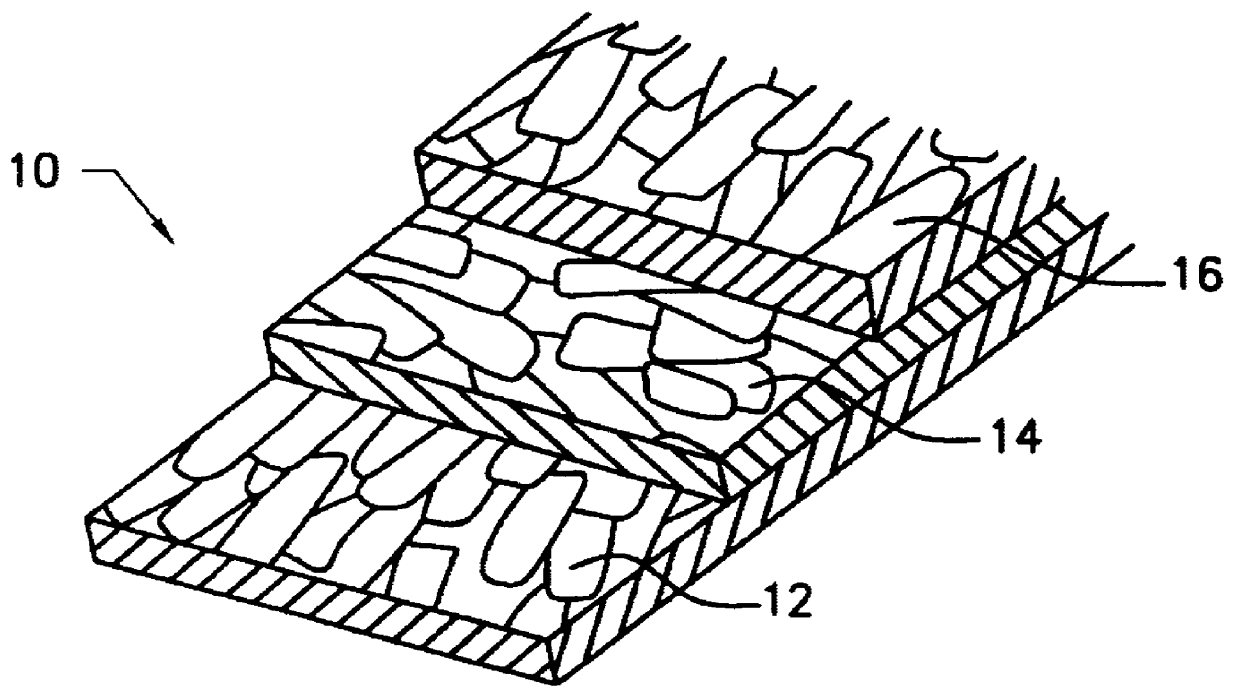

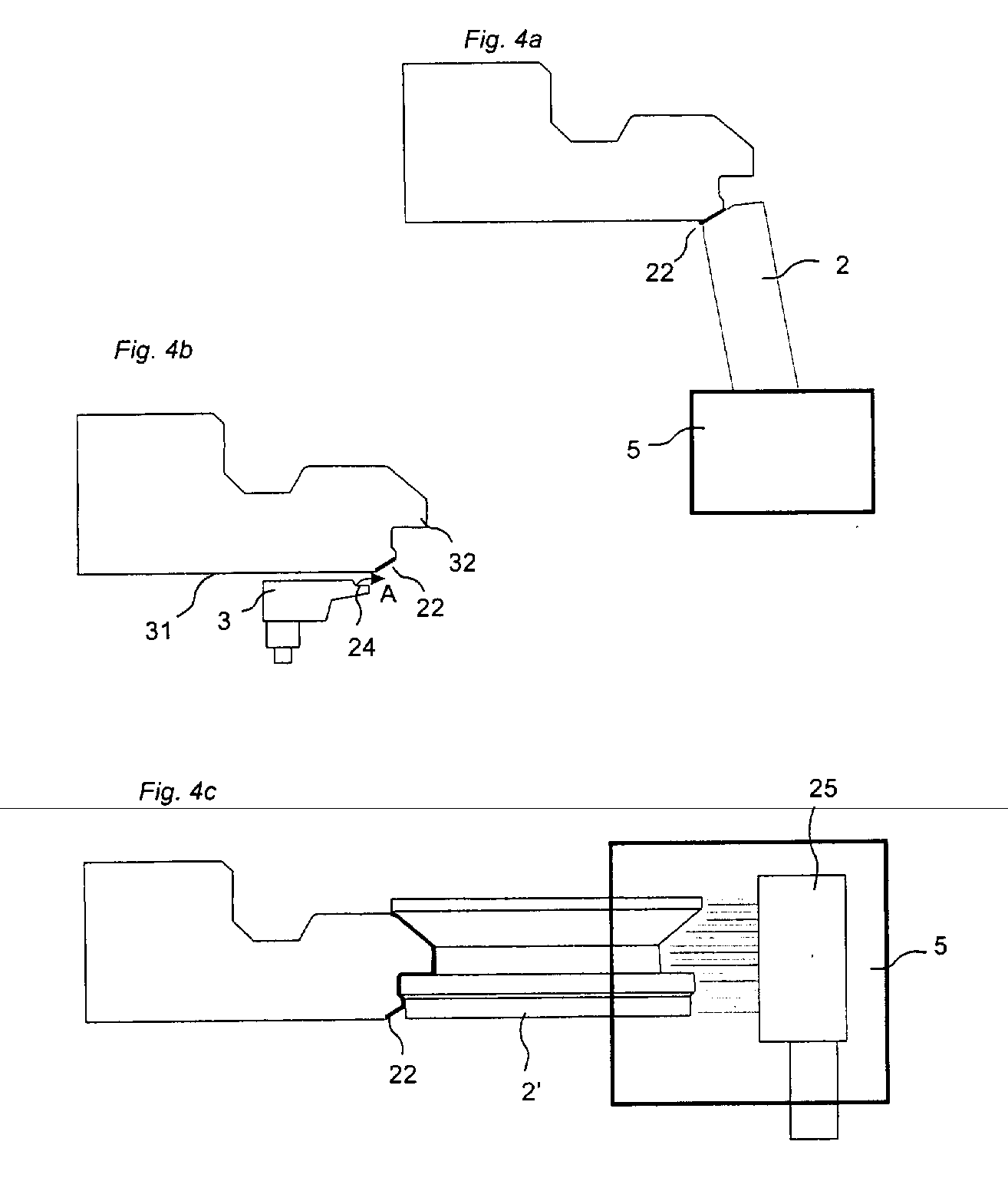

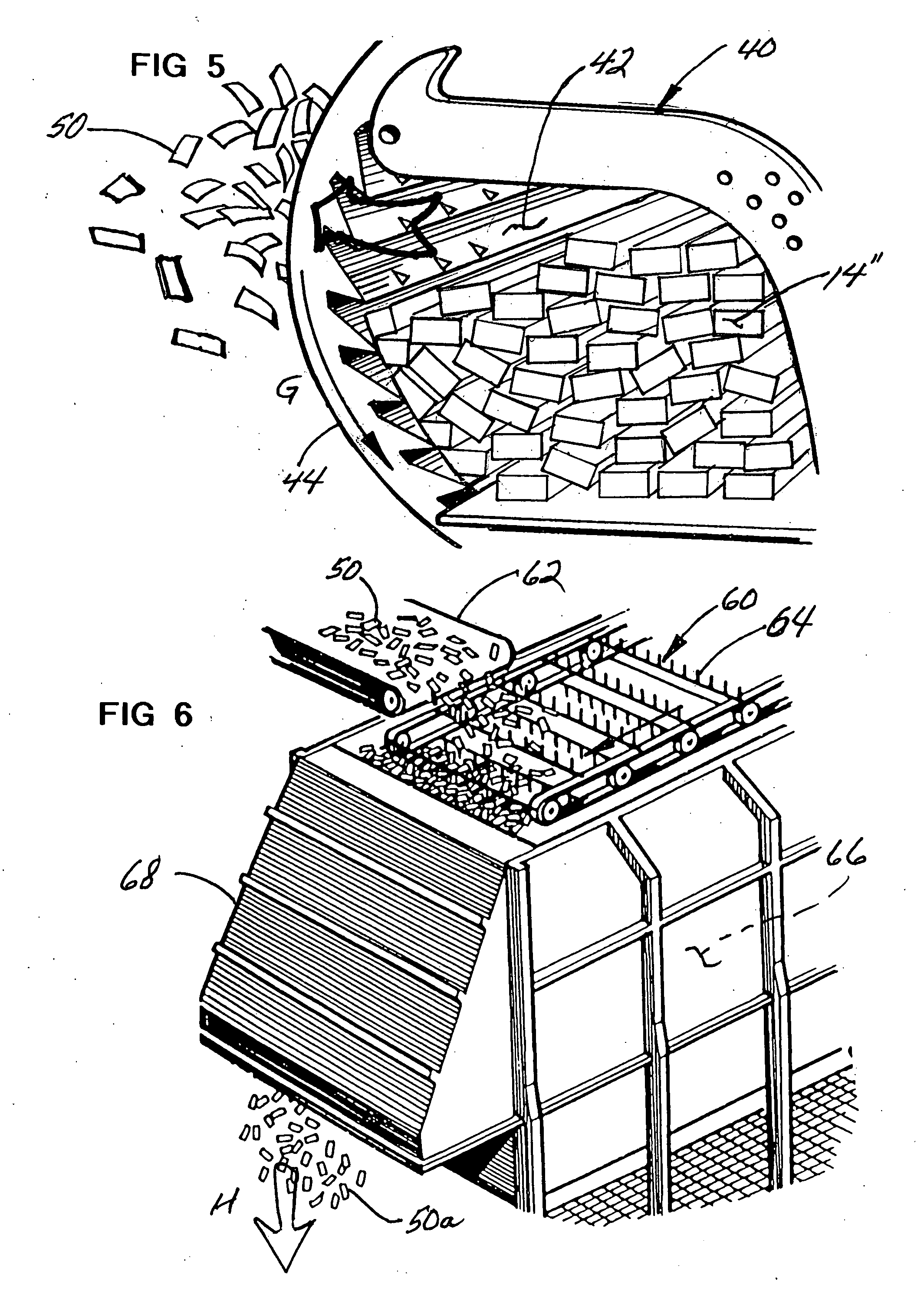

Molded fiber manufacturing

InactiveUS20050150624A1Reduce energy consumptionPrevent air infiltrationFibreboardWater-repelling agents additionFiberMolded pulp

Molded fiber products using agriculture residues are economical and environmentally beneficial. Molded fiber manufacturing is different from molded pulp. The present invention discloses a method of and an apparatus for the manufacturing of molded fiber shaped body (10) using low consistency fiber slurry (12) subject to vacuum-forming and thermo-curing. The use of porous material as mold inserts for both vacuum-forming (101) and thermo-curing (102) stations provides improved productivity and enables ease of mold release. The incorporation of self-cleaning techniques further ensures consistent performance of the manufacturing system.

Owner:GRENIDEA TECH PTE

Advanced polymer wood composite

InactiveUS20020106498A1High modulusHigh modulus of elasticityFibreboardWood working apparatusThermoplasticPolymer science

The invention relates to a composition comprising a polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer and wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm3. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprise, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of an elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

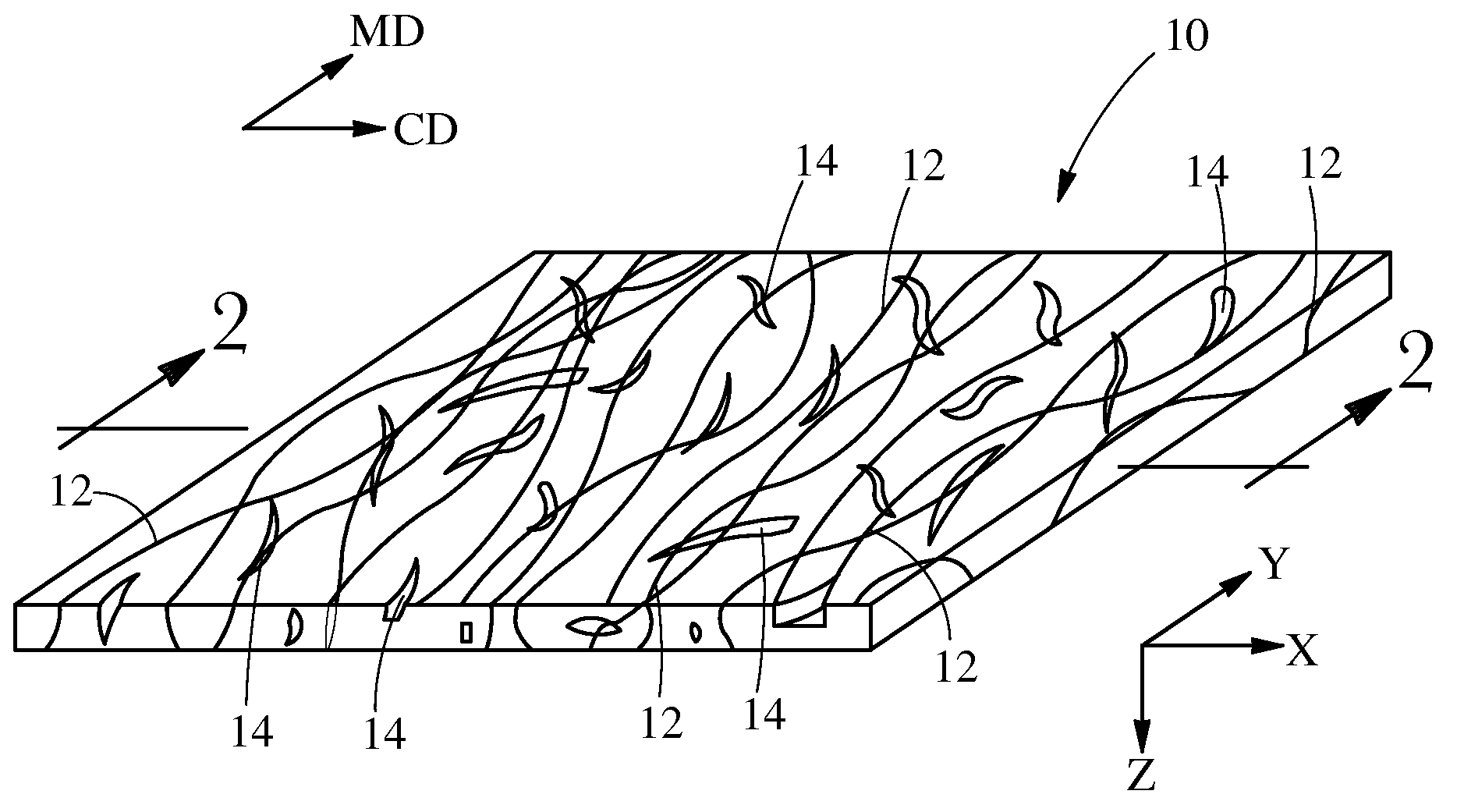

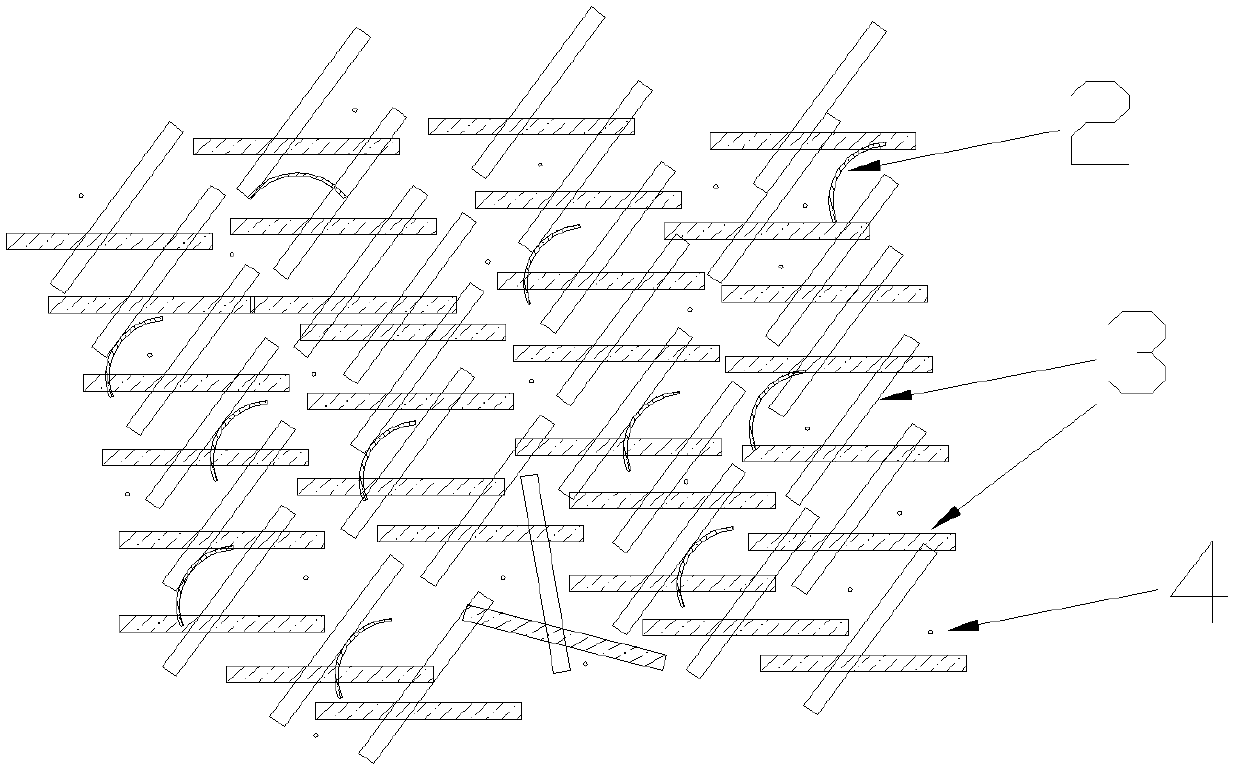

Surface treatment for wood materials including oriented strand board

Oriented strand board is post-fabrication treated with a polymeric coating which includes isocyanate constituents to produce a construction material which is smooth, has high gloss, and which is resistant to water, vapor, and chemical penetration. The isocyanate constituents are most preferably MDI or PMDI, and may be present in a coating composition alone or in combination with other binder materials such as PEEG or other polyols. Prior to application of the coating composition, the surface of the oriented strand board is pretreated using heat and pressure to compress and densify wood at the surface, and to smooth out minor surface irregularities. The coating composition is then applied to the wood surface, and is cured to form a polymeric coating which bonds to the wood material. The polymeric coating is preferably a polyurethane and functions to prevent water, vapor, and chemical penetration into the oriented strand board, thereby permitting its use as a construction material in a wide variety of applications it heretofore has not achieved commercial acceptance. In addition, the polymeric coating provides the oriented strand board with a smooth surface.

Owner:HUBER ENGINEERED WOODS

Cellulosic product

InactiveUS20110088860A1Reduce liquid penetrationGood heat sealing performanceFibreboardCosmetic preparationsMicrosphereCellulose fiber

The present invention relates to a process of producing a cellulosic product comprising (i) providing an aqueous suspension of cellulosic fibers, (ii) adding microfibrillar polysaccharide, (iii) adding thermoplastic microspheres, (iv) dewatering the suspension and forming a cellulosic product. The invention also relates to a process of producing a single layer cellulosic product comprising (i) providing an aqueous suspension of cellulosic fibers, (ii) adding microfibrillar polysaccharide derived from softwood and / or hardwood and optionally adding thermoplastic microspheres to the suspension, (iii) dewatering the suspension and forming a cellulosic product. The invention further relates to a cellulosic product obtainable from said processes. The invention also relates to a composition comprising microfibrillar polysaccharide and thermoplastic microspheres and the use thereof.

Owner:AKZO NOBEL NV

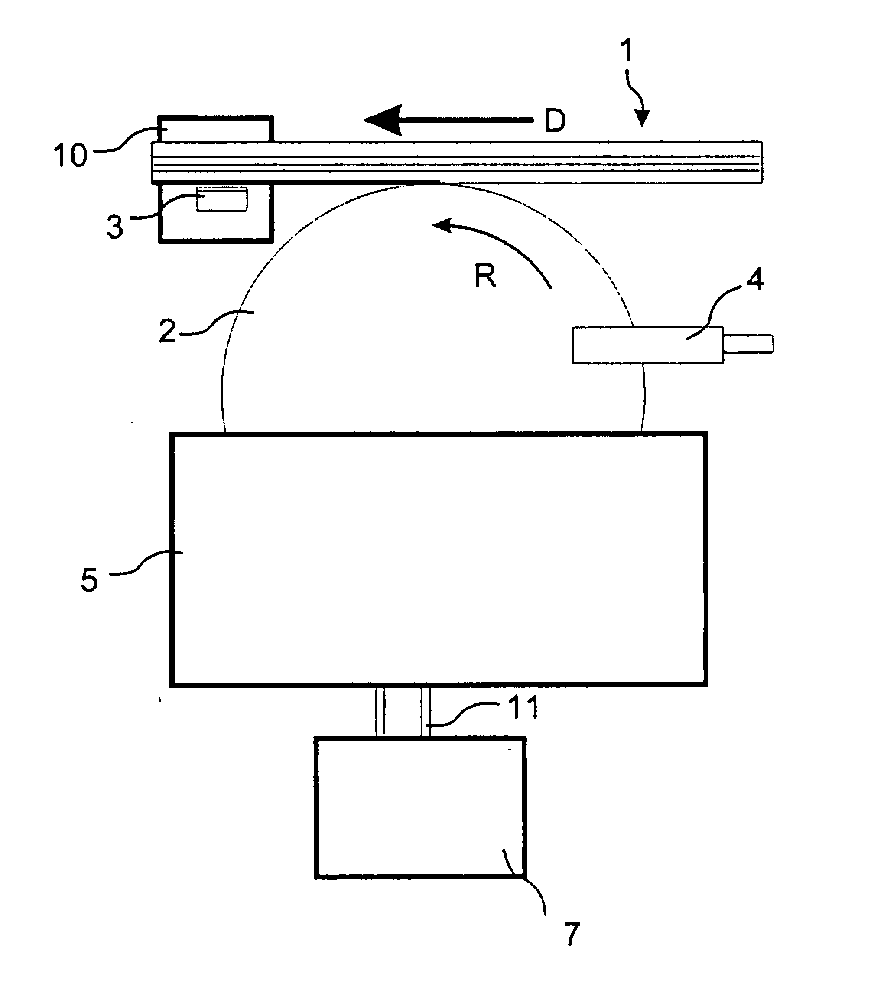

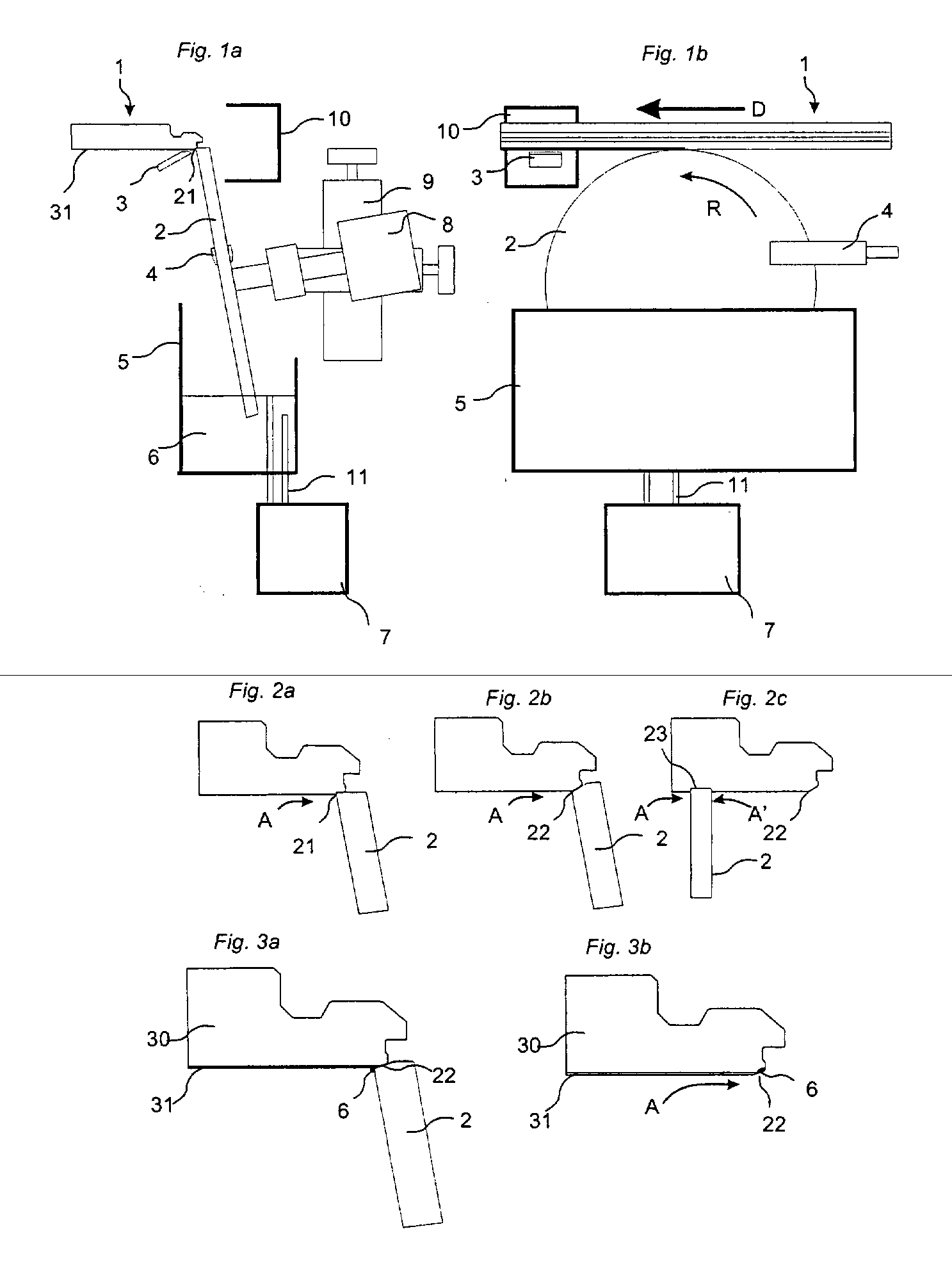

Appliance And Method For Surface Treatment Of A Board Shaped Material And Floorboard

ActiveUS20060073320A1Eliminates and reducesImprove accuracyFibreboardCovering/liningsMaterials scienceSurface coating

A device for coating surface portions of a board material with a liquid material. The device includes a wheel which transfers the coating material and compressed air which positions the coating material. A method for surface coating and a floorboard with a finished surface portion.

Owner:VÄLINGE INNOVATION AB

Fiber mat, preparation method and core material for vacuum thermal insulation plate

InactiveCN103306048ALow thermal conductivityHigh strengthFibreboardGlass/slag layered productsGlass fiberPunching

The invention discloses a fiber mat, comprising 50-100 (weight ratio accounting for the dried fiber mat and the same below) glass fiber and chopped strands, and one or more of 0.1-30 inorganic fibers, 0.1-30 natural fibers, 0.1-30 synthetic fibers, 0.1-30 manmade fibers and an anti-radiation material besides the glass fibers and the chopped strands. The fiber mat is prepared by a needle punching method, a spun lacing method, a thermal rolling method, a wet type paper-manufacturing acid process, a wet type paper-manufacturing thickener method, a wet type paper-manufacturing gel method and the like. According to the preparation method for the fiber mat disclosed by the invention, the conductive thermal coefficient of a vacuum thermal insulation plate made of the fiber mat achieves 25-65% under the premise of adopting the same production mode, and a more superexcellent thermal insulation effect is obtained.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

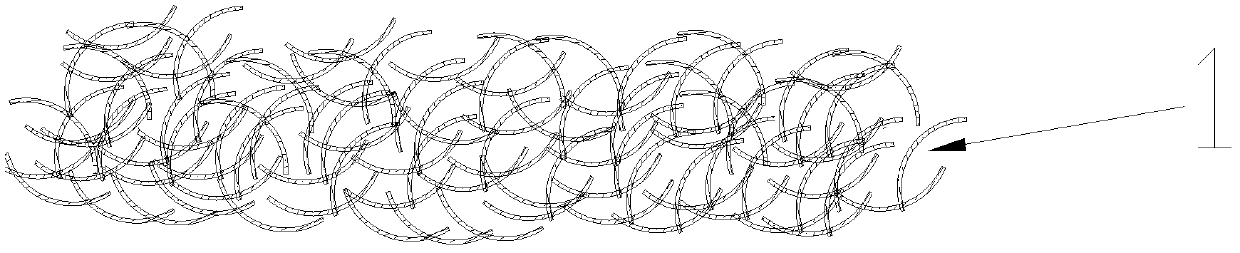

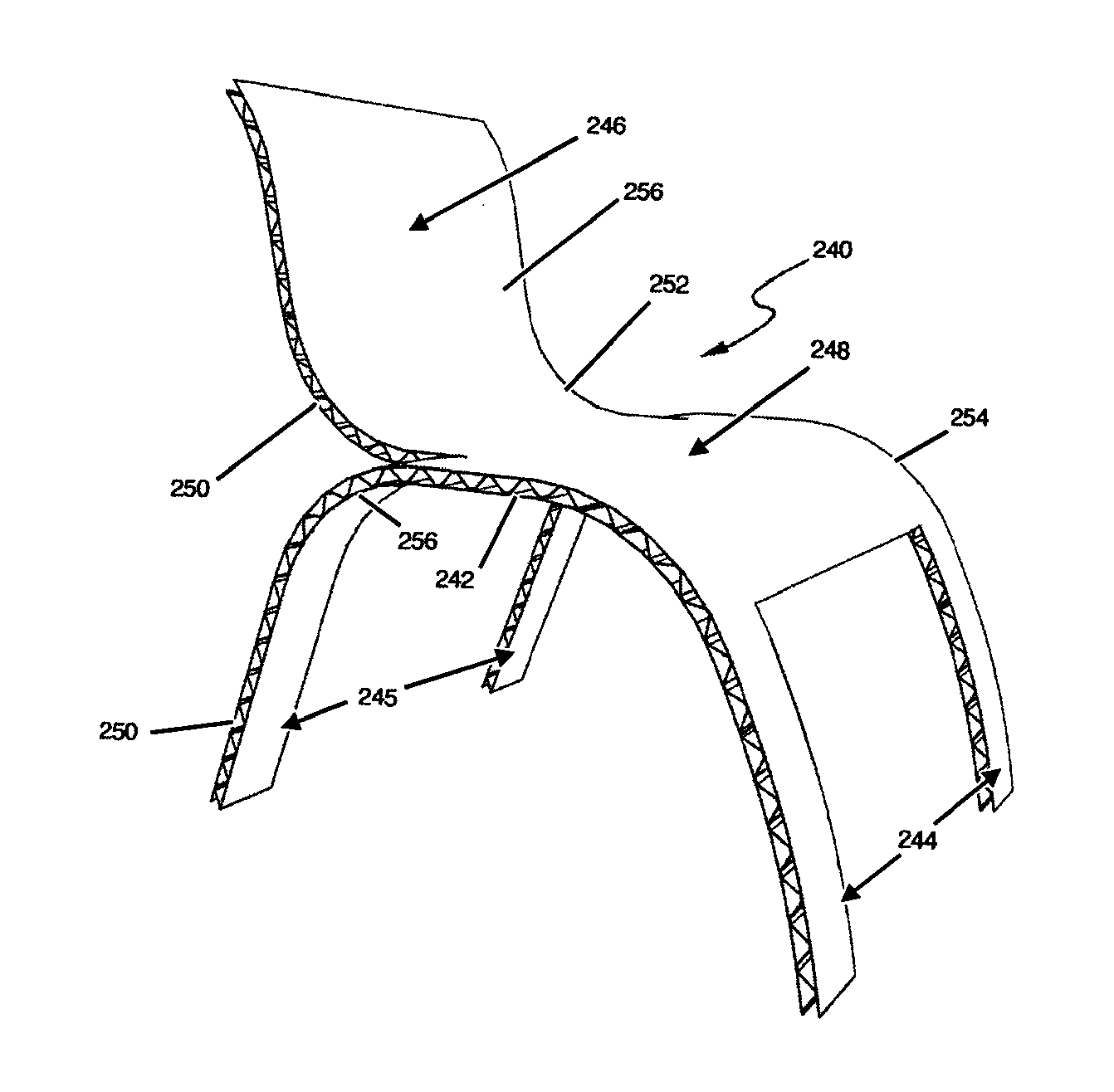

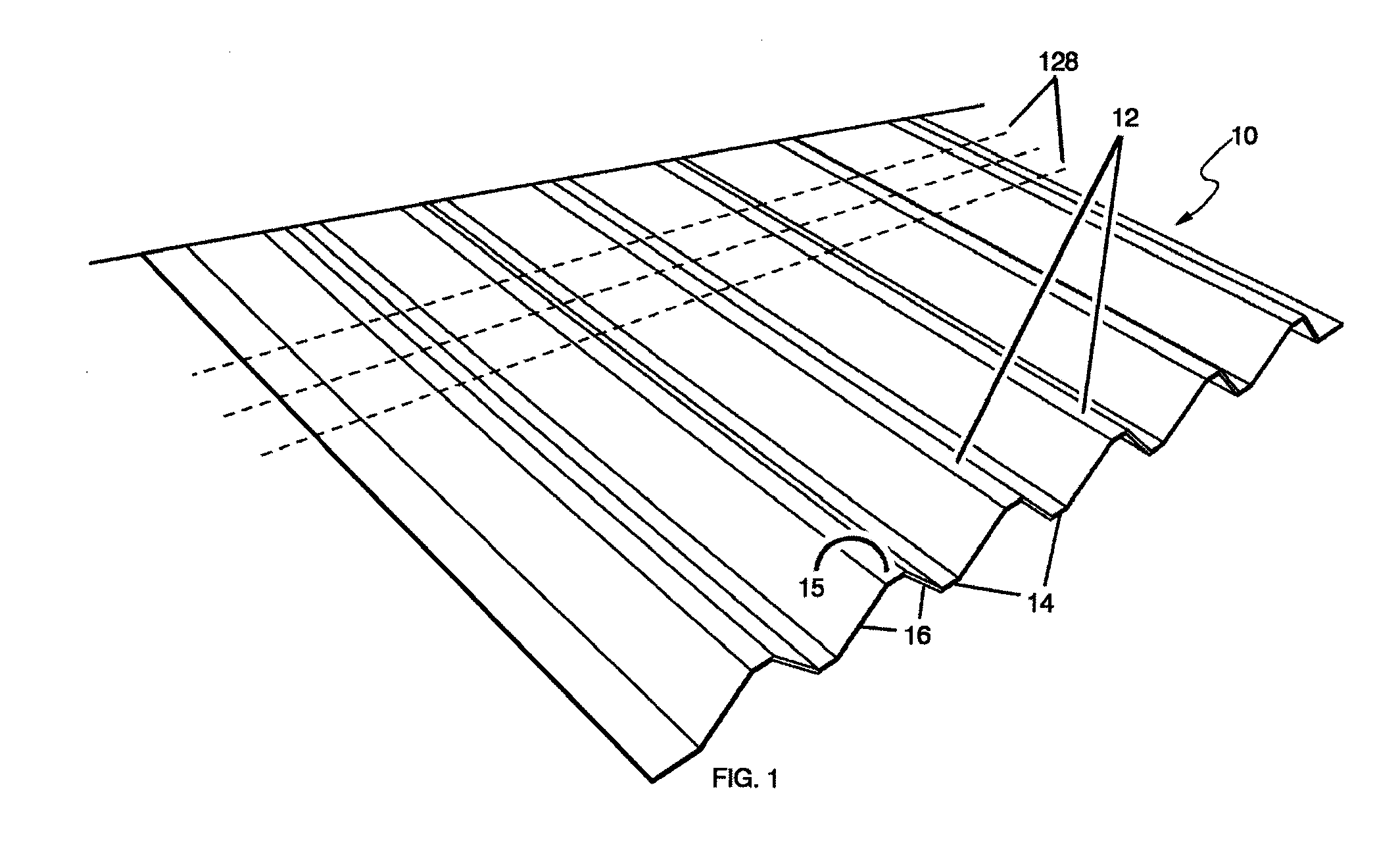

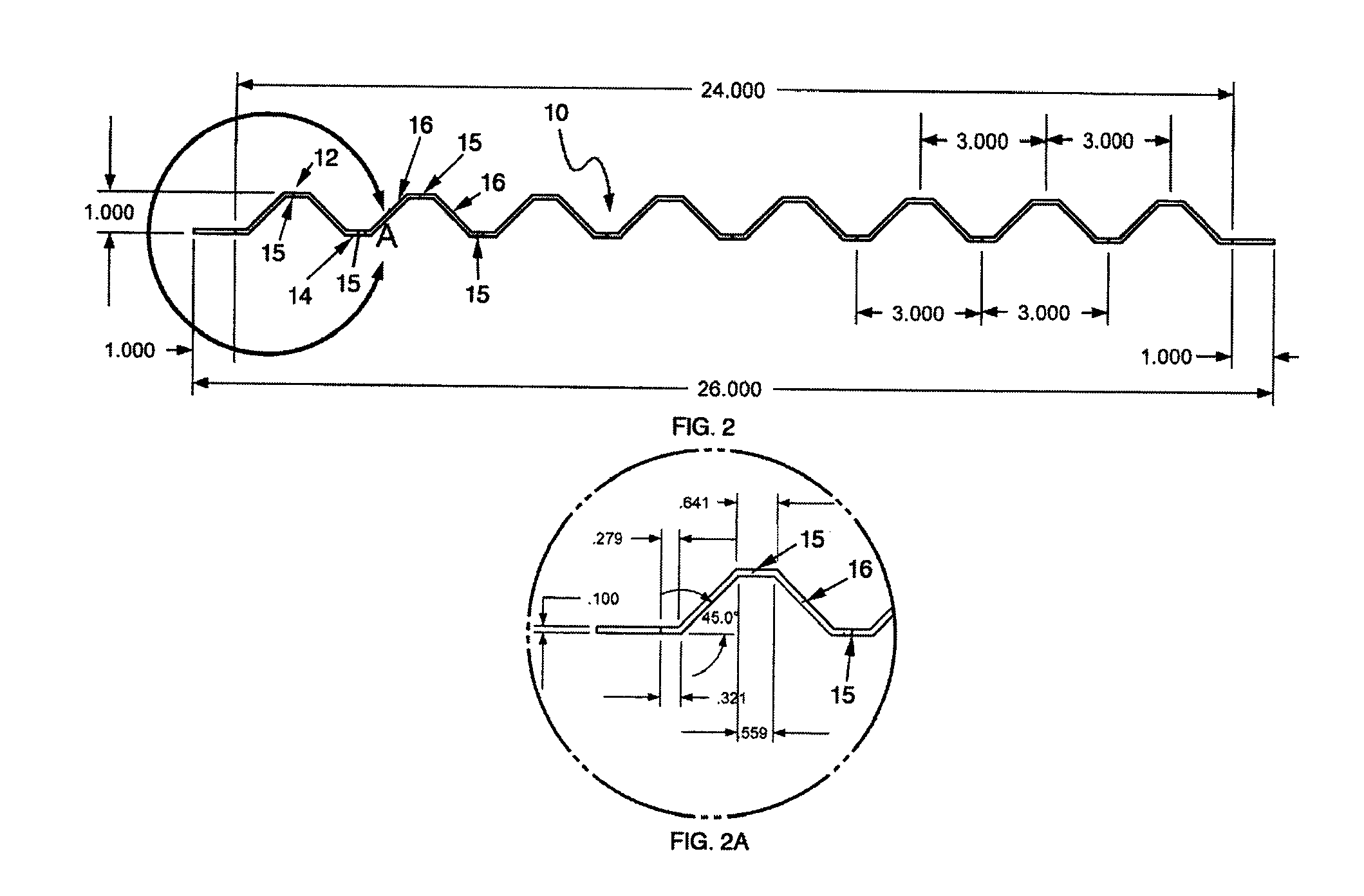

Engineered Molded Fiberboard Panels. Methods of Making the Panels, and Products Fabricated From the Panels

A honeycomb-shaped panel is formed from a plurality of generally sinusoidally shaped strips of molded fiberboard material each having spaced, oppositely directed flat peaks, the peaks of adjacent strips being secured together to form a plurality of hexagonally shaped cells extending perpendicular to the surfaces of the sheet. The strips may be cut from a single sheet of corrugated fiberboard sheet material and then secured together to form the honeycomb panel, or a plurality of such panels may be secured together face to face with their ribs aligned to form a stack, and selected cuts may be made through the secured, stacked panels to form a plurality of honeycomb panels of desired surface shape and height dimensions. The strips forming the cells are substantially rigid and resistant to collapse of the cells, and form a substantially rigid core when assembled between two flexible fiberboard skins, while the panel is bendable to adopt a desired panel curvature.

Owner:US SEC AGRI +1

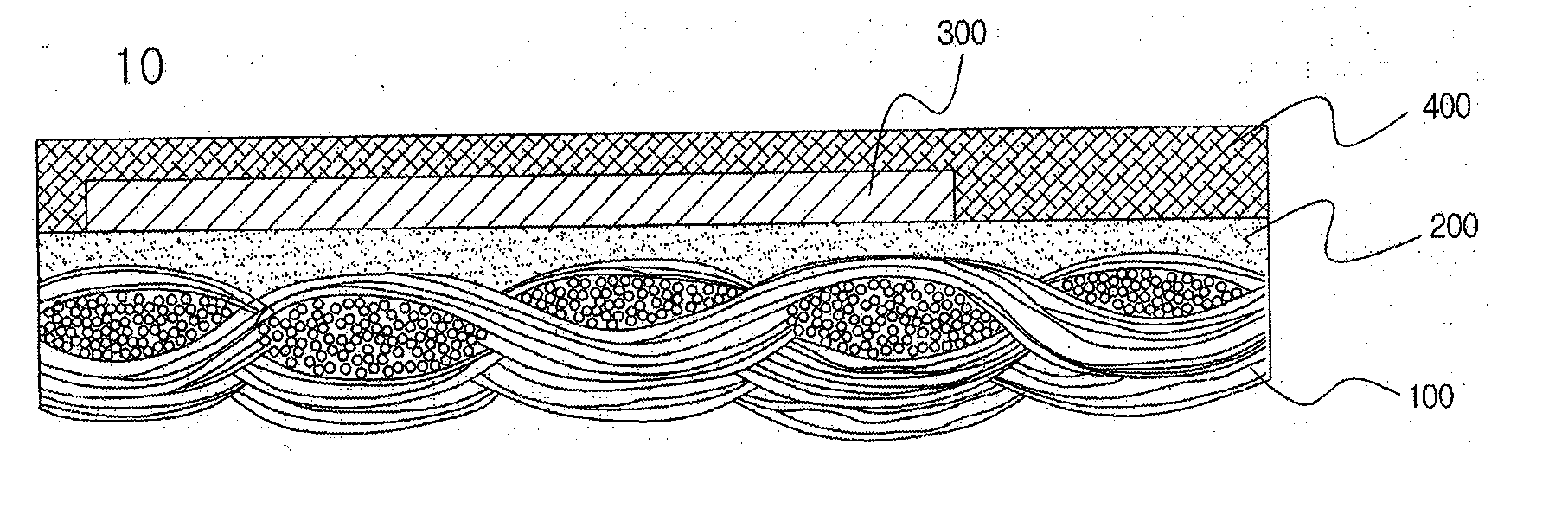

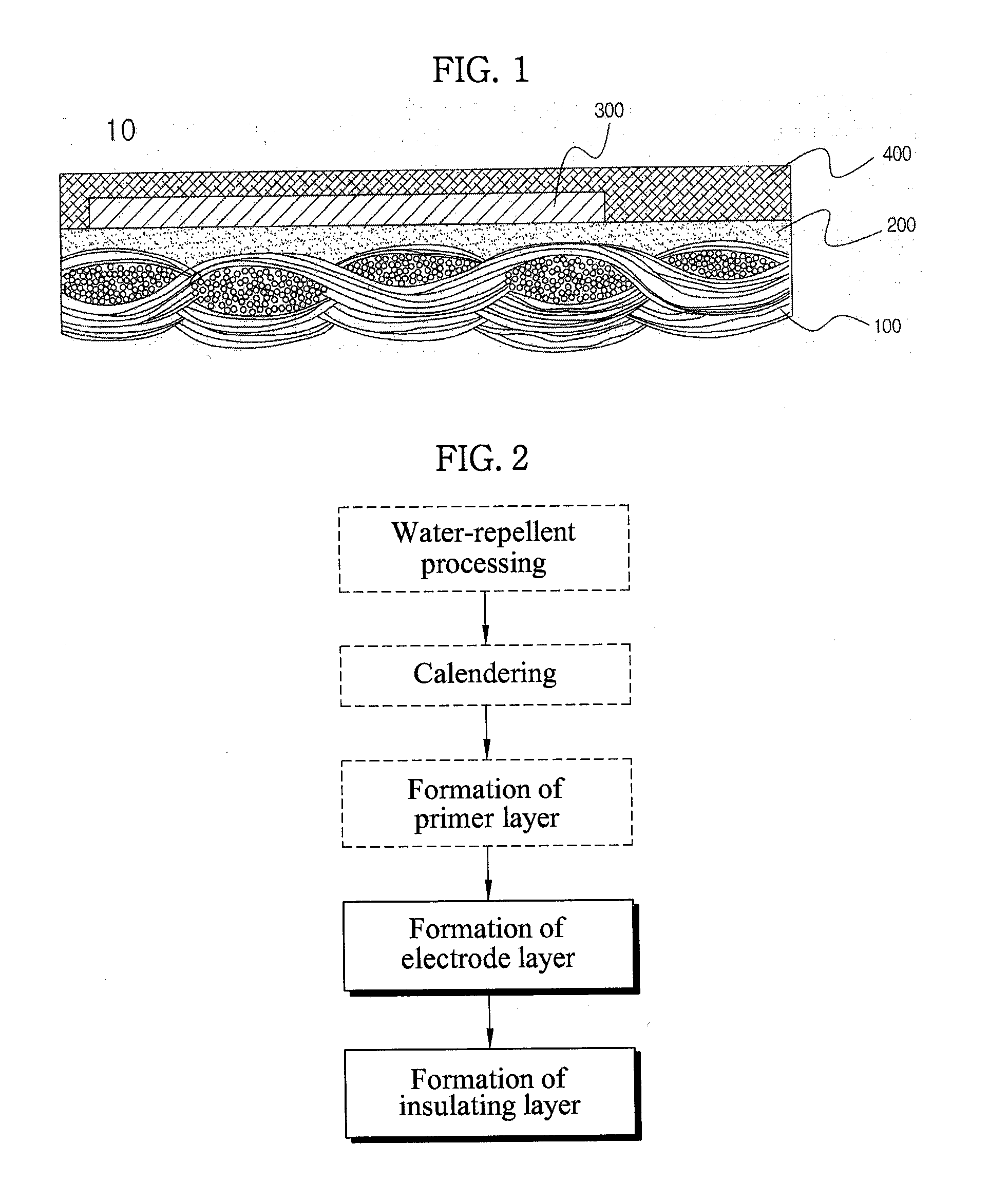

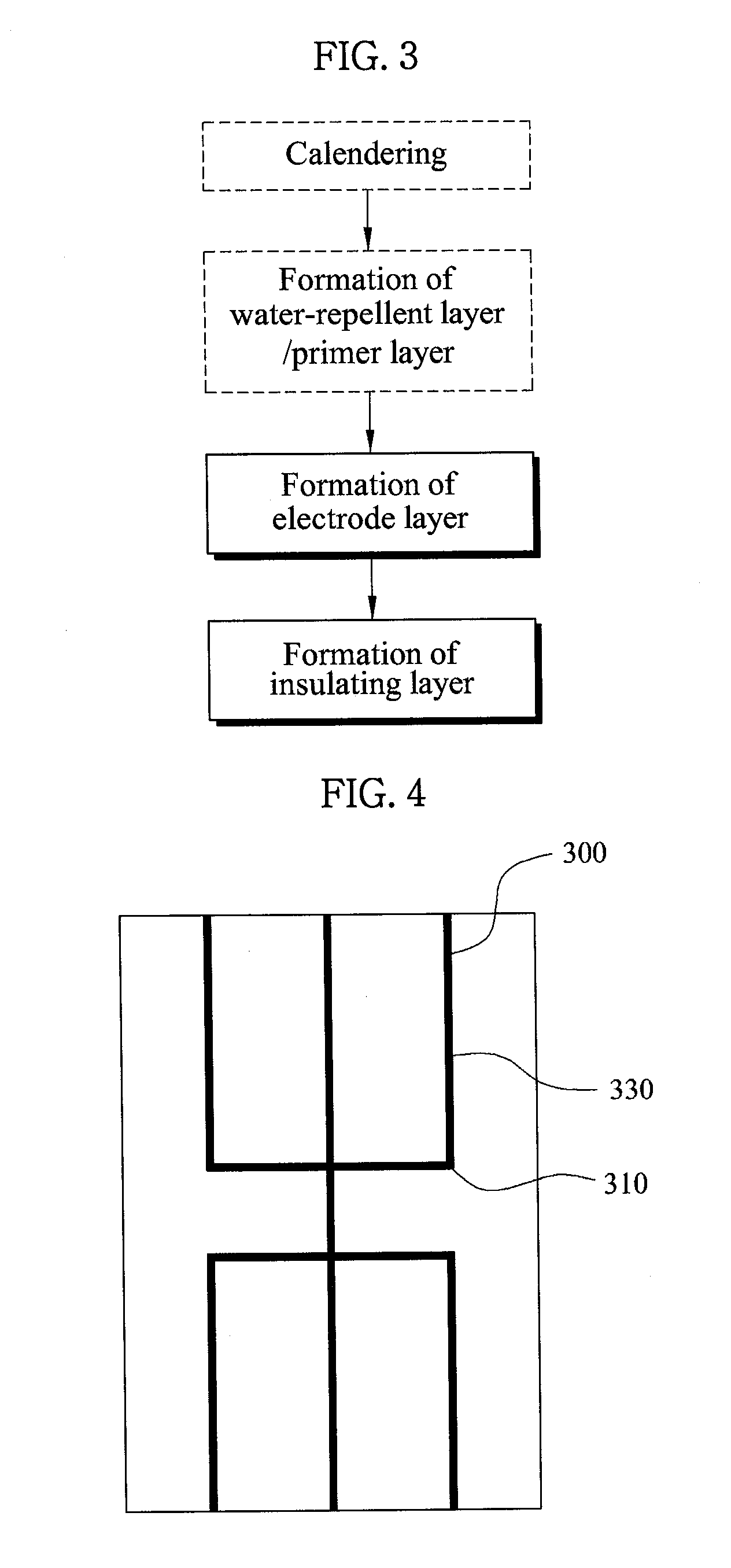

Flexible printed conductive fabric and method for fabricating the same

A conductive fabric is provided. The conductive fabric comprises a base layer composed of a synthetic, regenerated or natural fiber, a conductive layer formed on the base layer to be capable of being freely formed by a pre-designed electric pattern, and an insulating layer formed on the conductive layer to protect the conductive layer from damage.

Owner:KOLON GLOTECH INC

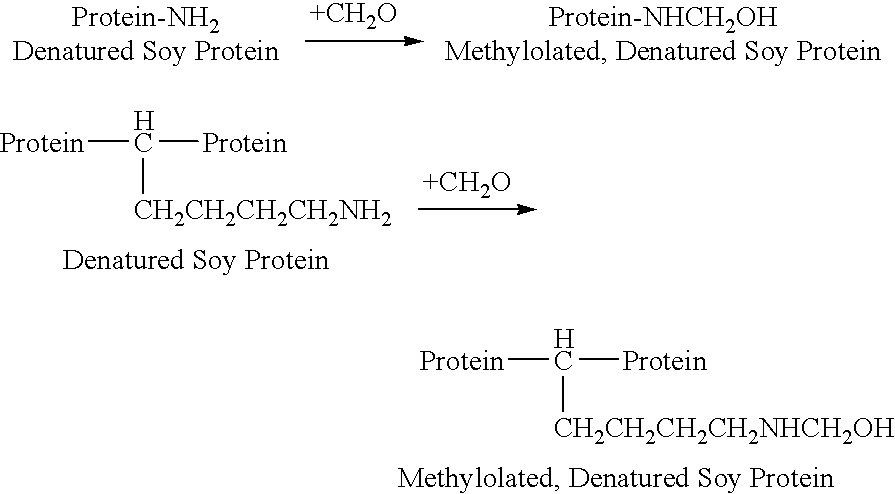

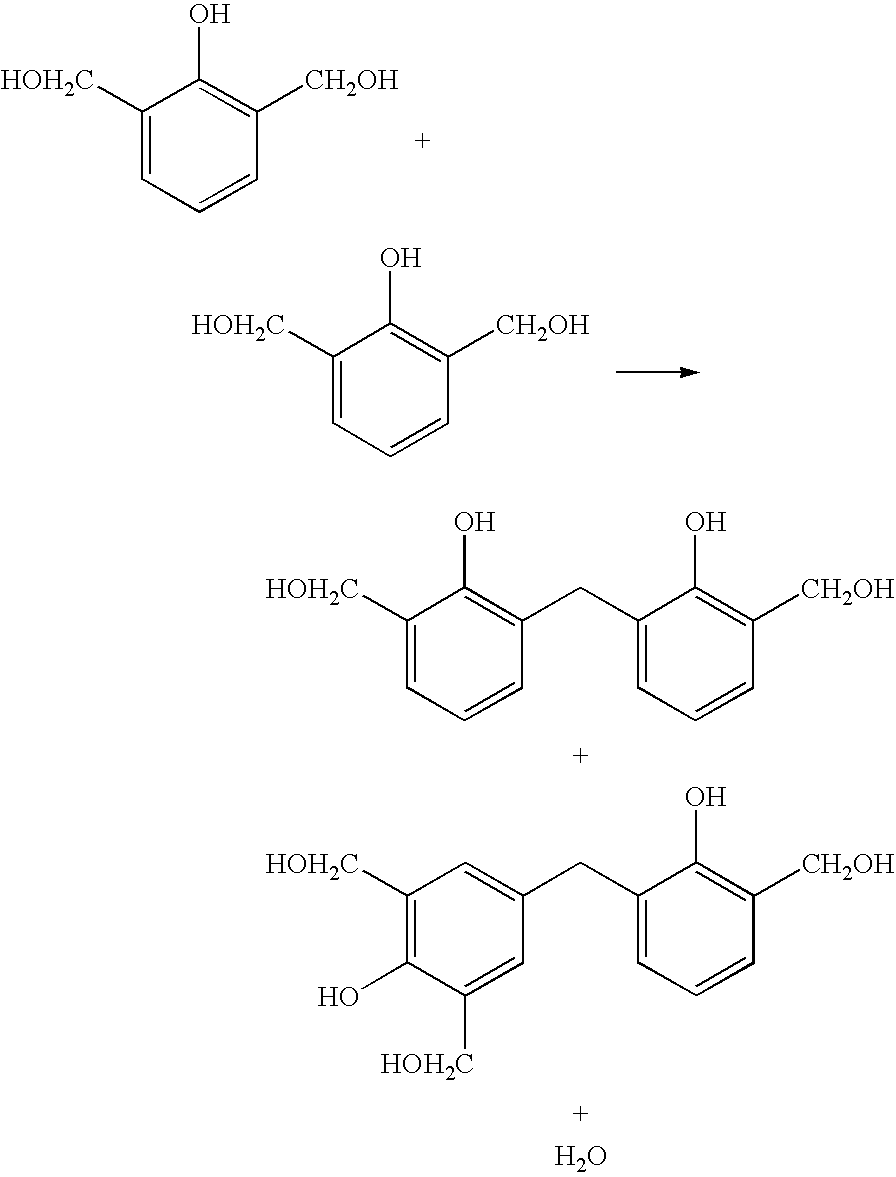

Water-resistant vegetable protein adhesive dispersion compositions

ActiveUS7345136B2Low costIncreased durabilityFibreboardPeptide preparation methodsAdhesiveWater resistant

Water-resistant, protein-based adhesive dispersion compositions and methods for preparing them are provided. The adhesive dispersions are prepared by copolymerizing a denatured vegetable protein, such as soy flour, that has been functionalized with methylol groups with one or more reactive comonomers, and preparing an acidic dispersion of the adhesive. The adhesive dispersions exhibit superior water resistance, and can be used to bond wood substrates, such as panels or laminate, or in the preparation of composite materials.

Owner:US SEC AGRI +1

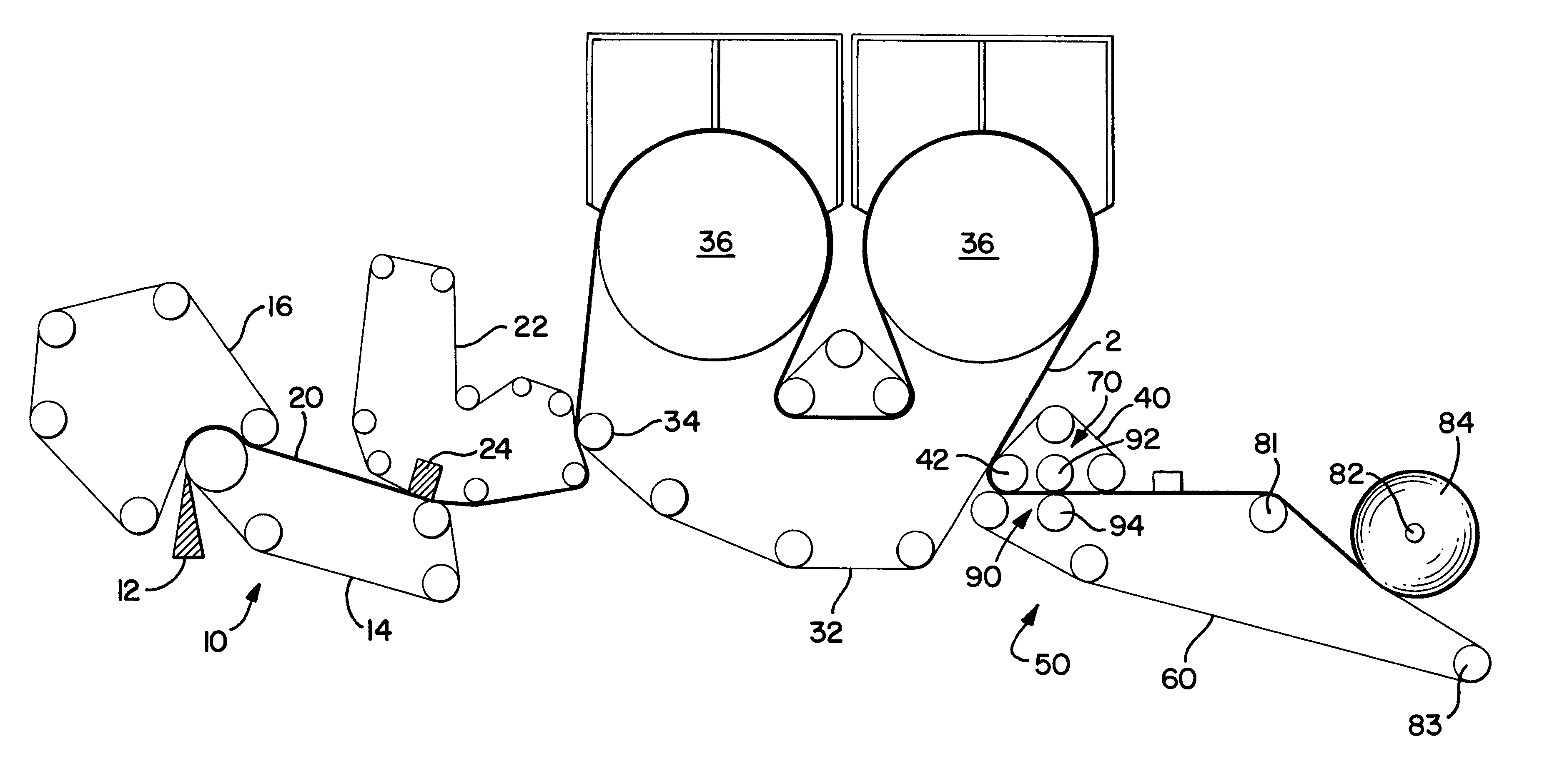

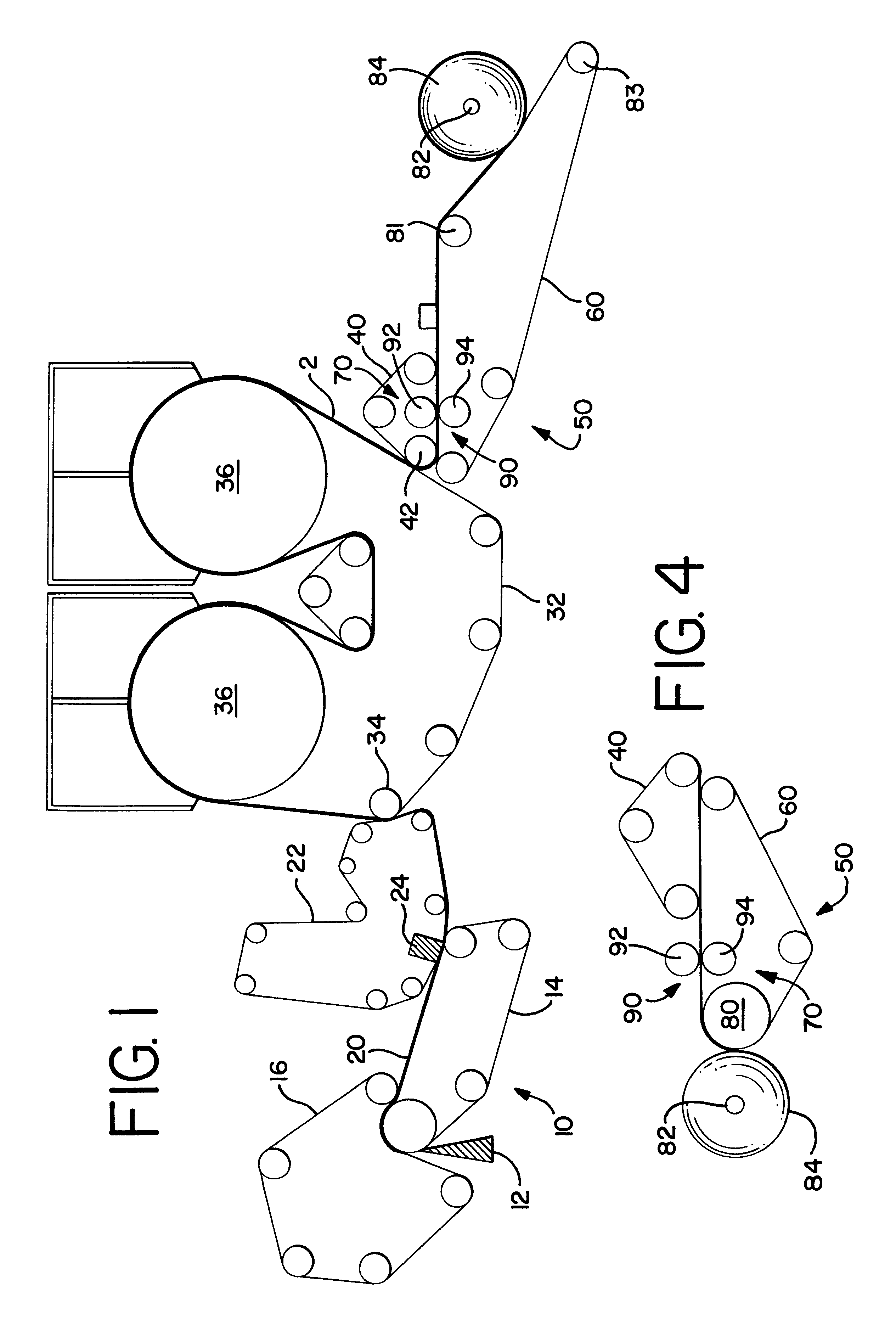

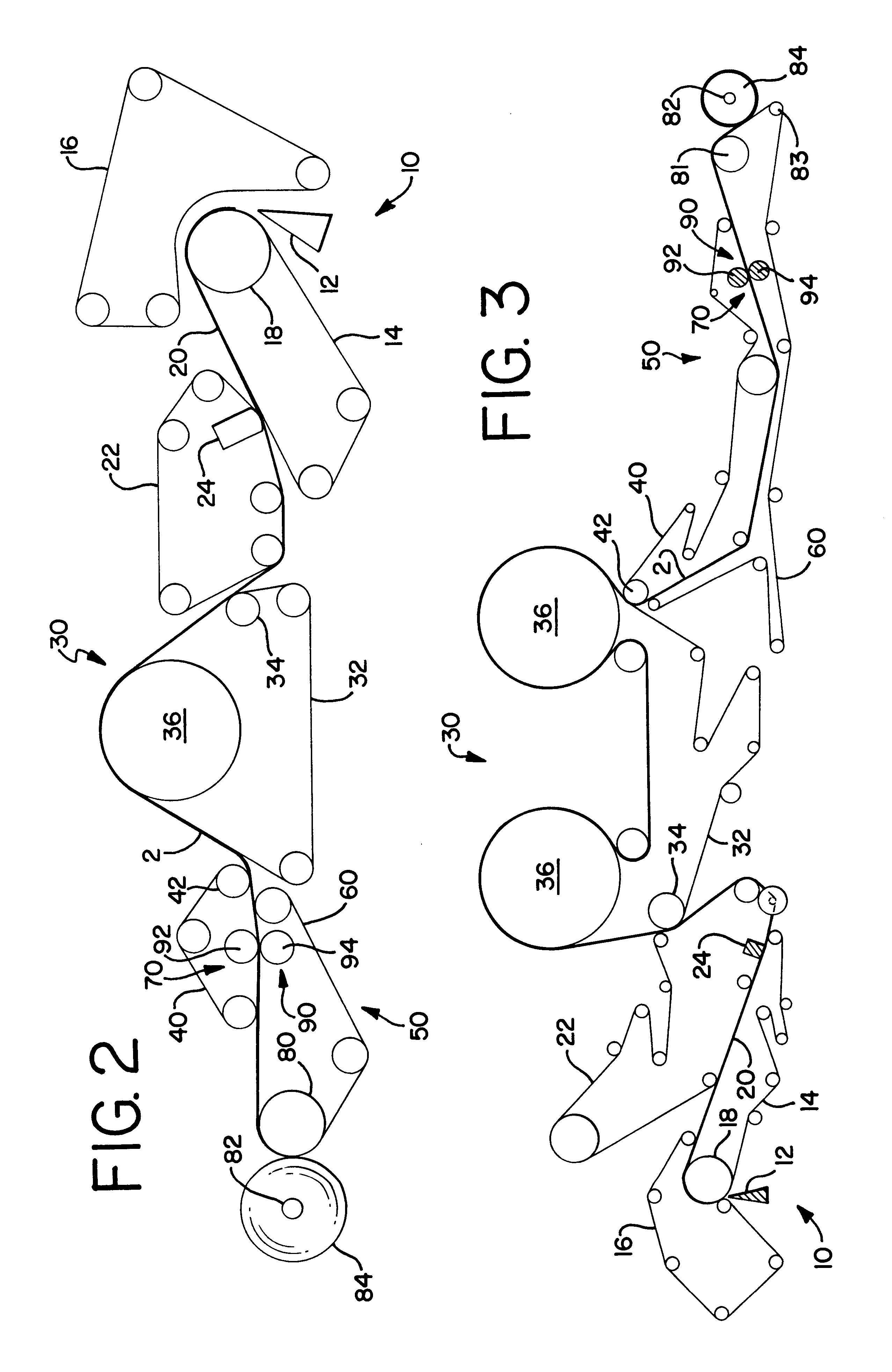

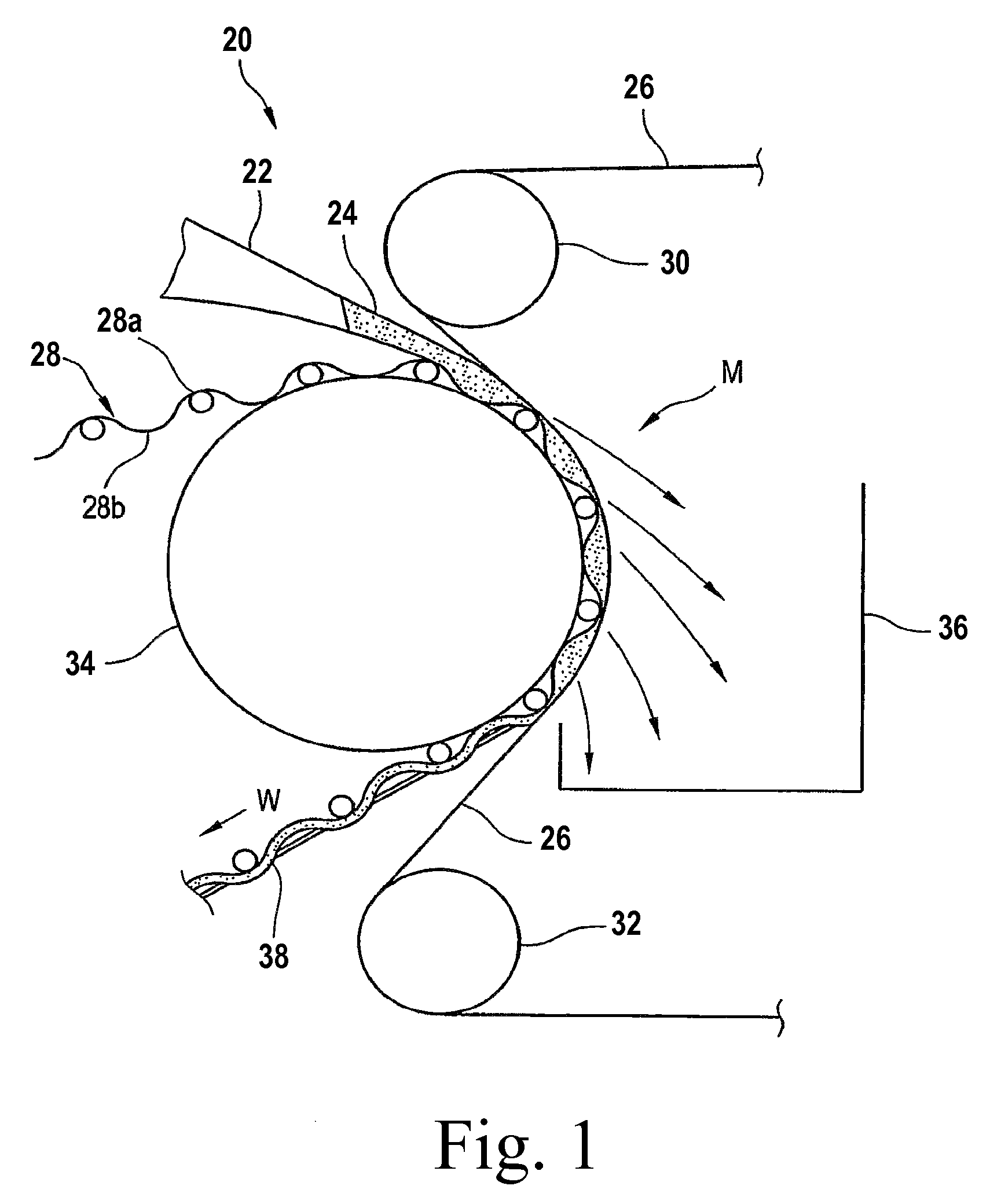

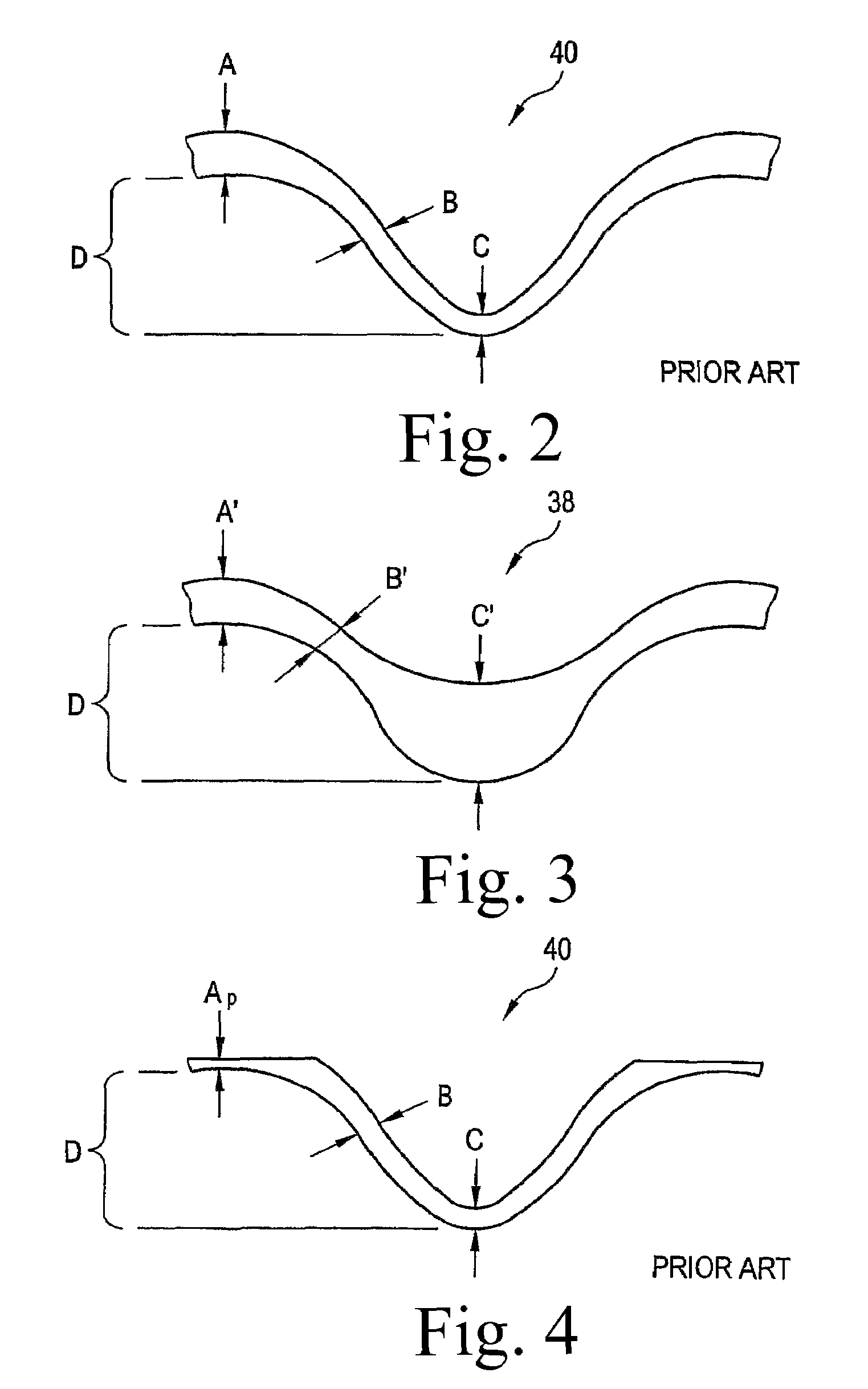

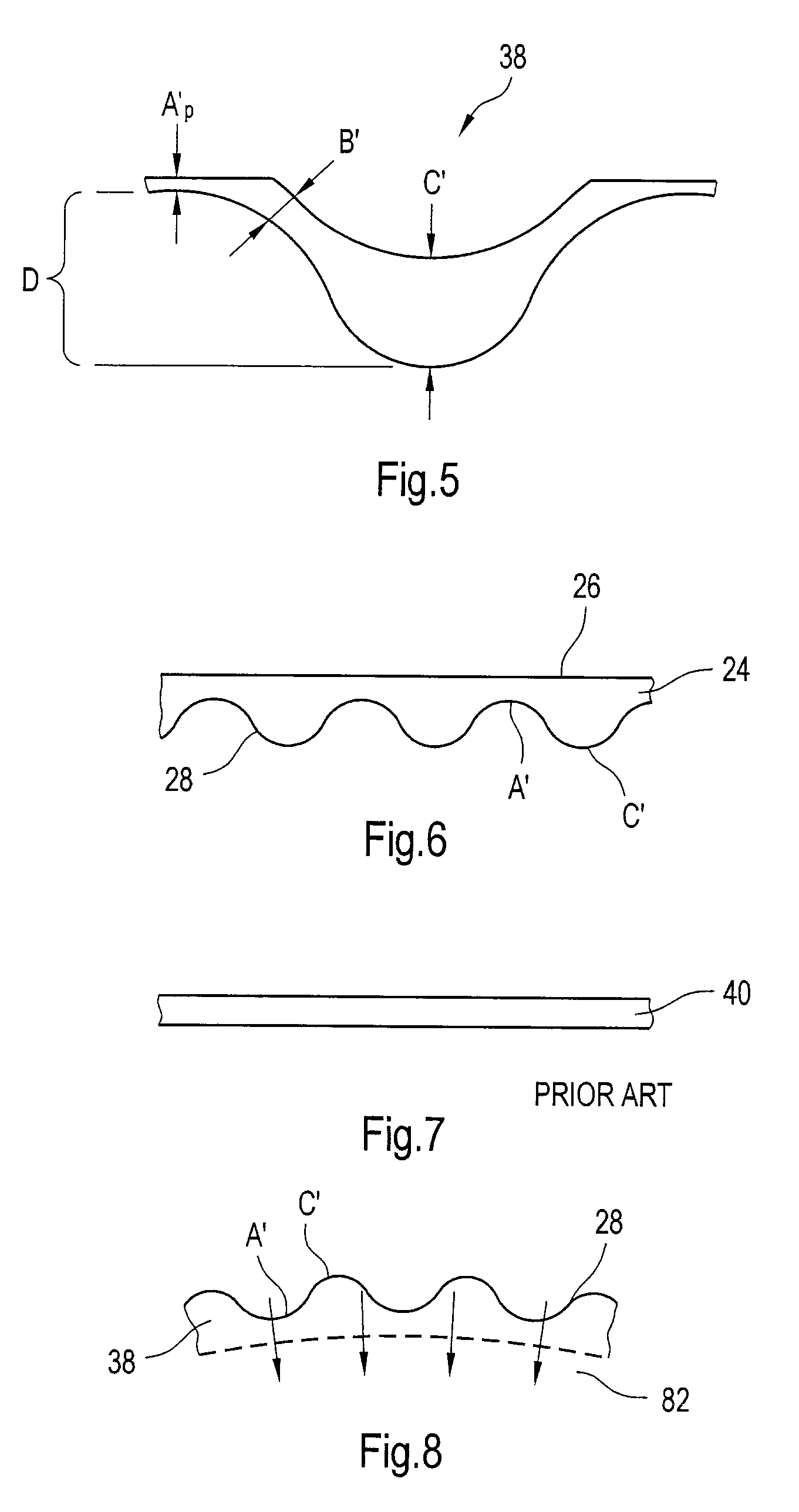

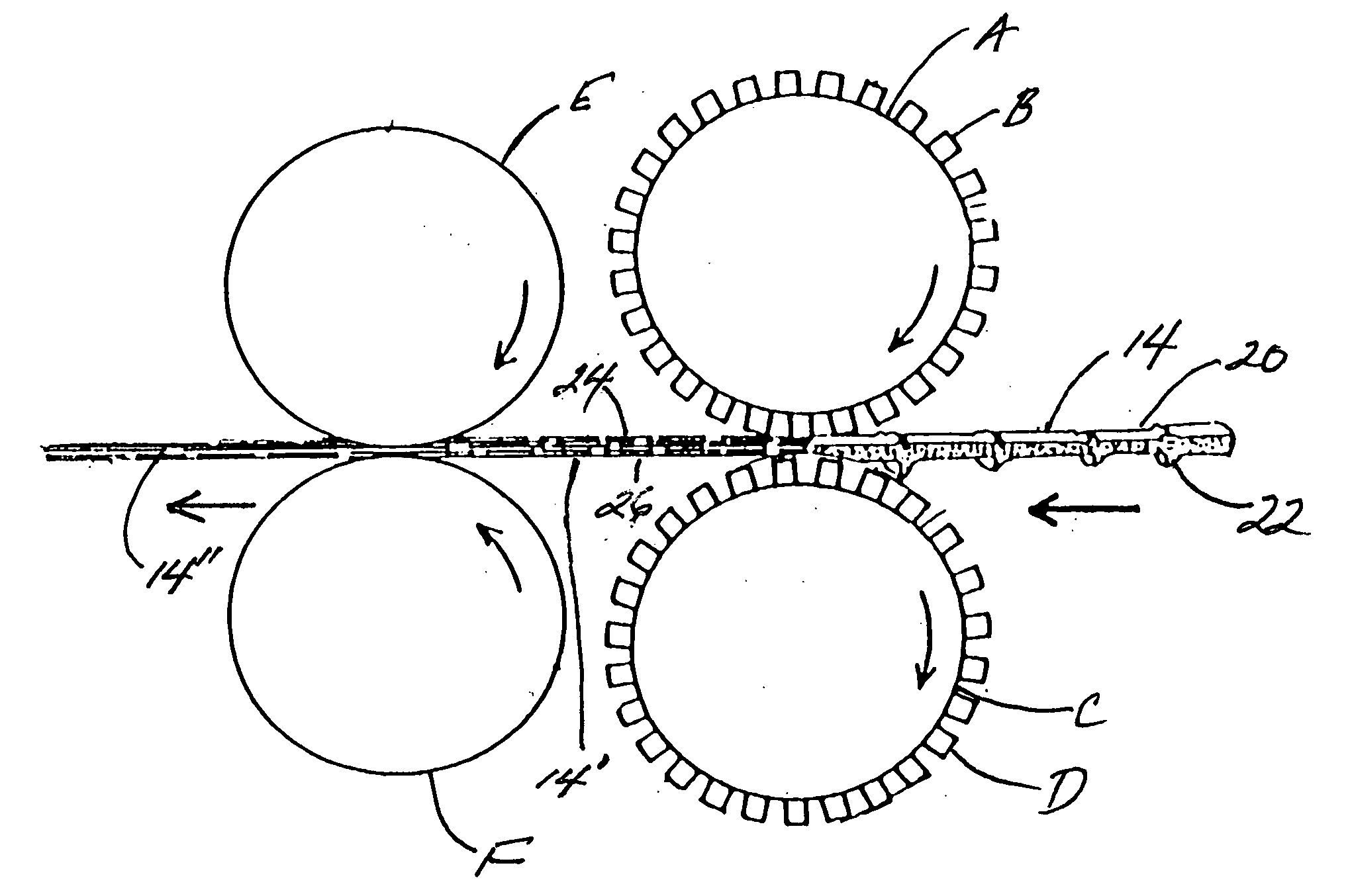

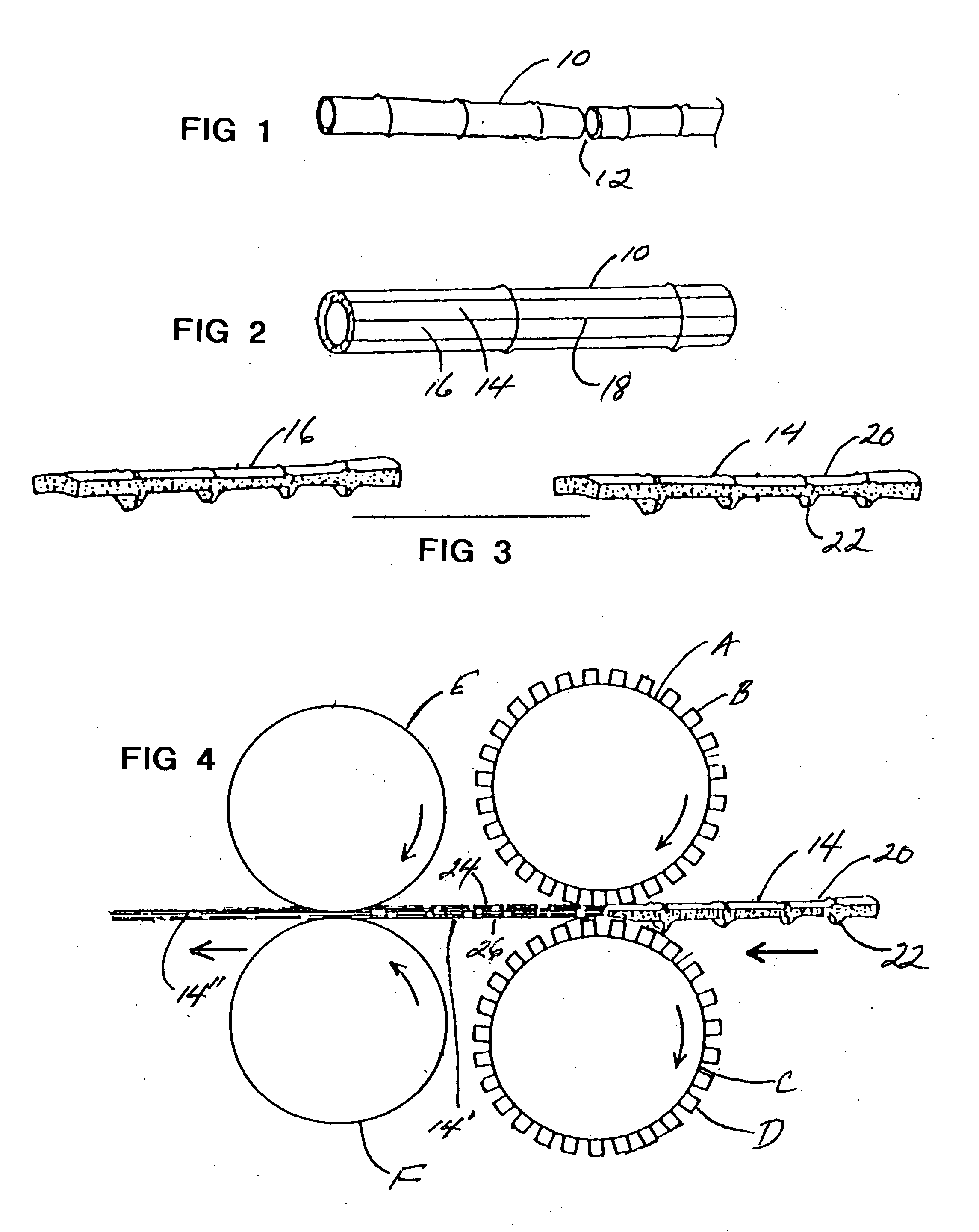

Method of calendering a sheet material web carried by a fabric

A method for calendering the sheet material web includes carrying the sheet material web on one or more carrier fabrics through the calender nip formed by the first and second calender rolls and applying a load to the carrier fabric, and sheet material carried thereby, so as to reduce the thickness of the sheet material web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Process for making a flowable and meterable densified fiber particle

InactiveUS7201825B2Speed up the flowEasy to transportFibreboardNon-fibrous pulp additionCellulose fiberDiscrete particle

Discrete particles of cellulosic material are flowable and meterable. They are easily dispersible in an aqueous or a dry medium. The particles comprise singulated cellulose fibers that have been densified. The particles have a density of at least 0.3 g / cc.

Owner:WEYERHAEUSER NR CO

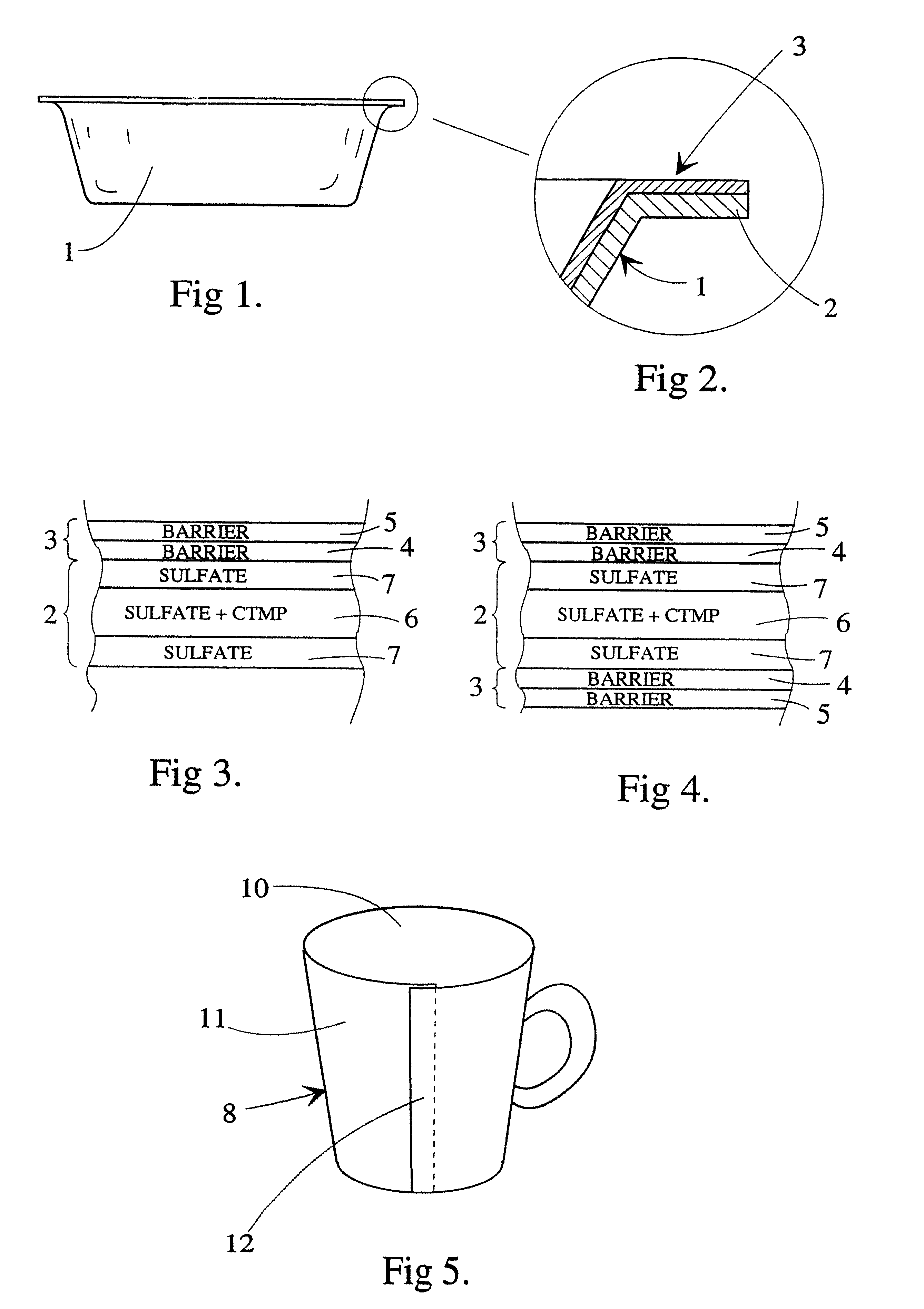

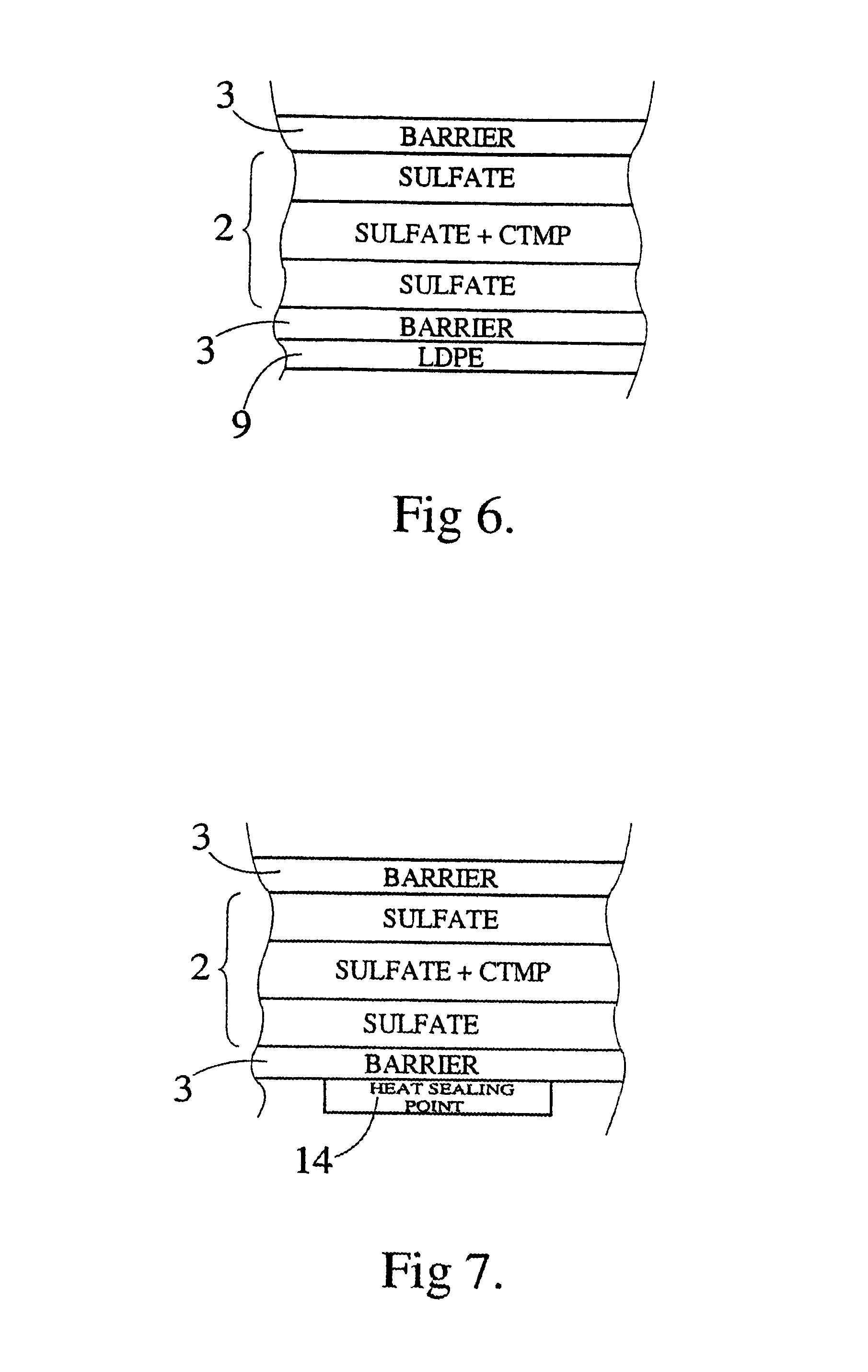

Coated board, a process for its manufacture, and containers and packaging formed therefrom

InactiveUS6531196B1Improve mechanical propertiesIncrease stiffnessFibreboardNon-fibrous pulp additionTalcProduct gas

The invention relates to coated board, a process for its manufacture, and containers and packaging formed therefrom. The board comprises at least one polymer-based coat preventing the transmission of liquids and gases, which coat is according to the invention made from a polymer dispersion to which talc particles are added so that talc will constitute 30-80% of the dry weight of the dried coat. The coating is applied onto the board during its manufacture as on-line coating. The board may be, for example, a multi-layer board (2) which has a middle layer (6) containing CTMP or other similar mechanical pulp, on its both sides outer layers (7) formed from sulfate pulp, against these on both sides of the board (2) talc-containing polymeric barrier layers (3), and on one side of the board a heat sealing layer (9) introduced onto the barrier layer (3).

Owner:STORA ENSO OYJ +1

Container flooring material and method of manufacture

A board suitable for use as container flooring uses bamboo and fast-growth low-density wood. Thin layers of high-density bamboo composites are used to overlay on surfaces of a core layer which can be the composite of wood veneer and wood strand-based composite, or wood veneer and bamboo stripe sheet composite. This invention combines the benefits of bamboo and wood materials to produce a bamboo-wood composite board having sufficient mechanical and physical strength and durability for use as container flooring.

Owner:ALBERTA INNOVATES TECH FUTURES

Acoustic ceiling tiles made with paper processing waste

ActiveUS20090173464A1Promote absorptionReduce the amount of solutionFibreboardNatural cellulose pulp/paperCellulose fiberSlurry

A composition and process suitable for making acoustic tiles are disclosed. Certain embodiments of the composition comprise: perlite; inorganic material selected from the group consisting of calcium sulfate, calcium carbonate, clay and mixtures thereof; a binder selected from the group consisting of starch, a combination of starch and cellulosic fibers, latex, kraft paper gel and mixtures thereof; optionally mineral wool; optionally gypsum; and cellulosic fiber, wherein at least a portion of the cellulosic fiber and at least a portion of the inorganic material are pulp and paper processing waste comprising cellulosic fiber, clay and calcium carbonate. Certain embodiments of the process comprise: forming an aqueous slurry; continuously flowing slurry onto a moving foraminous wire to form a cake; dewatering the cake to form a base mat; and drying the base mat.

Owner:USG INTERIORS INC

High strength material using cellulose micro-fibril

InactiveUS20050067730A1Reduce amountHigh strengthFibreboardCellulosic pulp after-treatmentFiberPolymer science

The present invention relates to a high strength material and a high strength molded article comprising 65 to 100 wt. % of cellulose microfibrils; and products comprising these. The material, which is lightweight and has a very high strength, can be used for various purposes and can be produced by recycling wastepaper, used cloth and the like. Furthermore, by appropriately selecting the type and / or amount of binder, the material comprising microfibrils as a main component can be decomposed by microbes or the like after being dumped as waste, and is thus friendly to the global environment.

Owner:KYOTO UNIV

Structured forming fabric

InactiveUS7585395B2Increase surface areaImprove machine performanceFibreboardNon-fibrous pulp additionPulp and paper industryWeft yarn

A fabric for use by a papermaking machine, the fabric including a plurality of weft yarns, a plurality of warp yarns, and a woven fabric resulting from a repeating pattern of the weft yarns and warp yarns. Each of the weft yarn in the repeating pattern having a sequence of starting at a starting point then sequentially going over three adjacent warp yarns, under one warp yarn, over one warp yarn, under three warp yarns, over one warp yarn and under one warp yarn, the sequence then repeating.

Owner:VOITH PATENT GMBH

Method of making a thick and smooth embossed tissue

A paper tissue such as a facial tissue or a disposable handkerchief and a method for making a tissue paper product from a tissue paper web. The method comprises the steps of passing the tissue paper web through an embossing nip formed between a first and a second embossing roll, wherein at least one of the embossing rolls comprises at least 30 embossing elements per square centimeter; and passing the tissue paper web through a calendering nip formed between a first and a second calendering roll, wherein the first and the second calendering roll are in contact with the tissue paper web over a contact length measured parallel to the direction of the axis of the first calendering roll exert a pressure onto the paper web of at least 50 N per centimeter of the contact length.

Owner:THE PROCTER & GAMBLE COMPANY

Micronized organic preservative formulations

A wood preservative composition comprising micronized particles of organic biocide is provided. The composition comprises a dispersion comprising particles in the range of 0.001 to 25 microns. Also provided is a method for the application of the preservative composition to wood. In addition, wood products which have been treated with the preservative composition are also provided.

Owner:OSMOSE +1

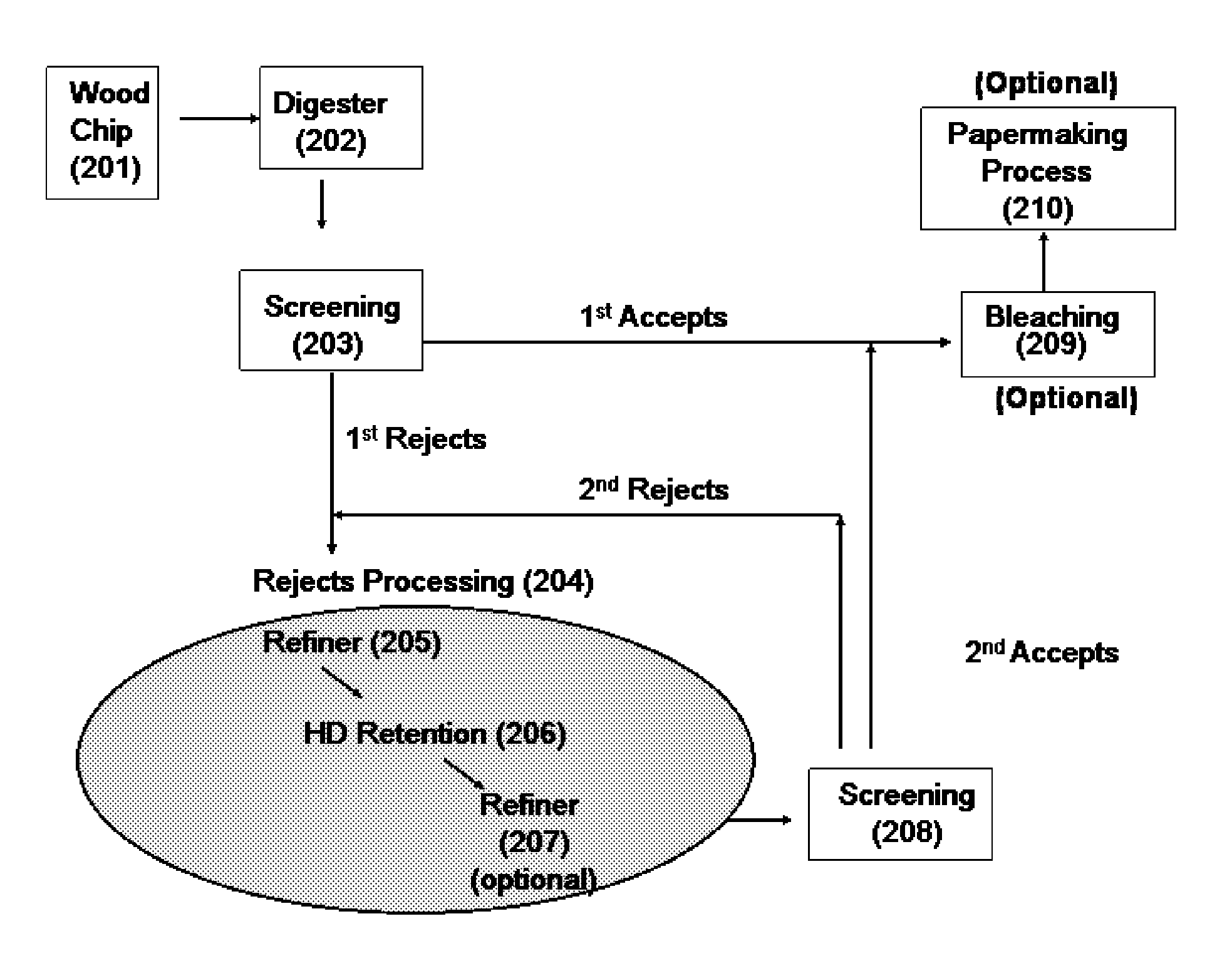

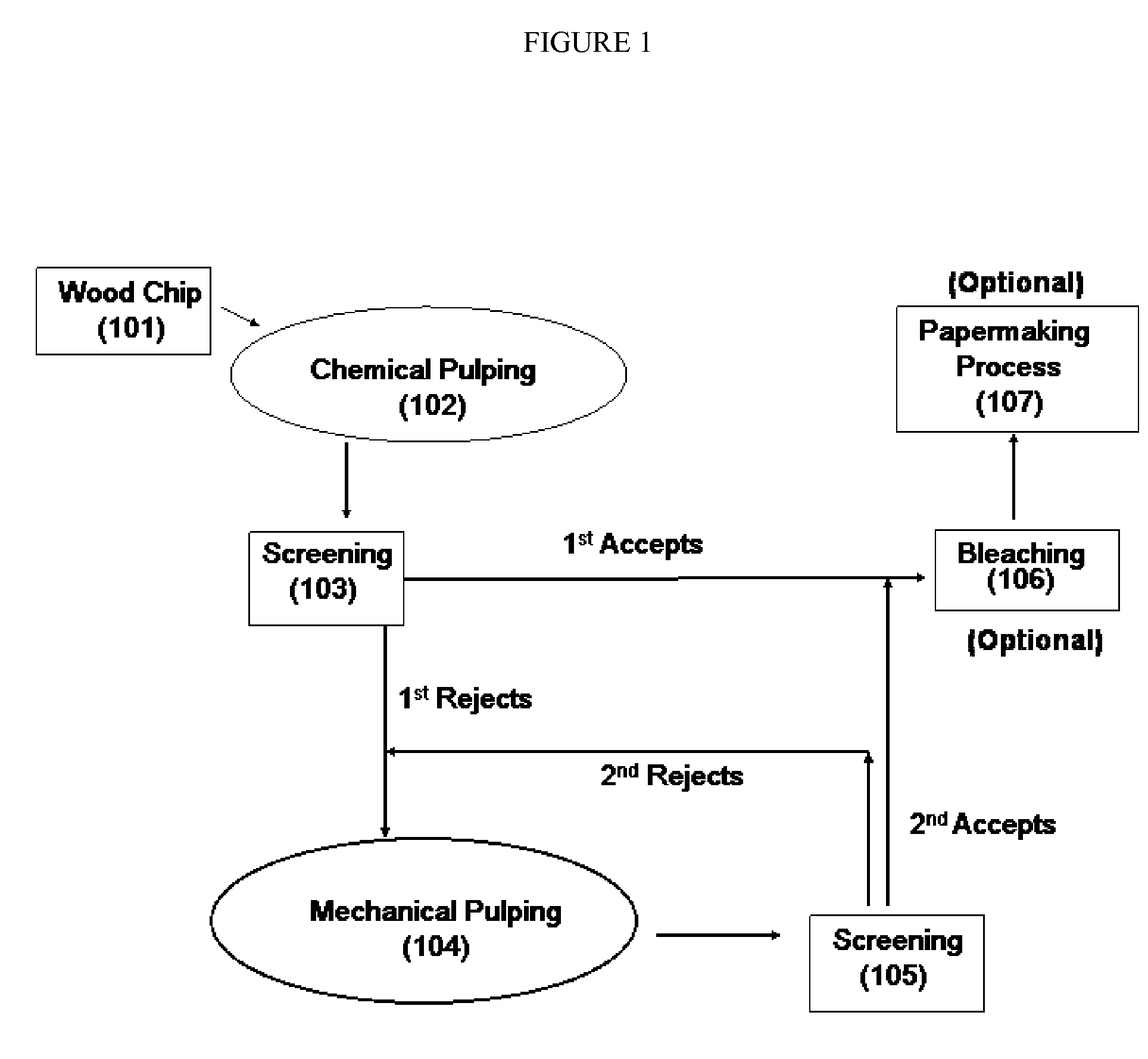

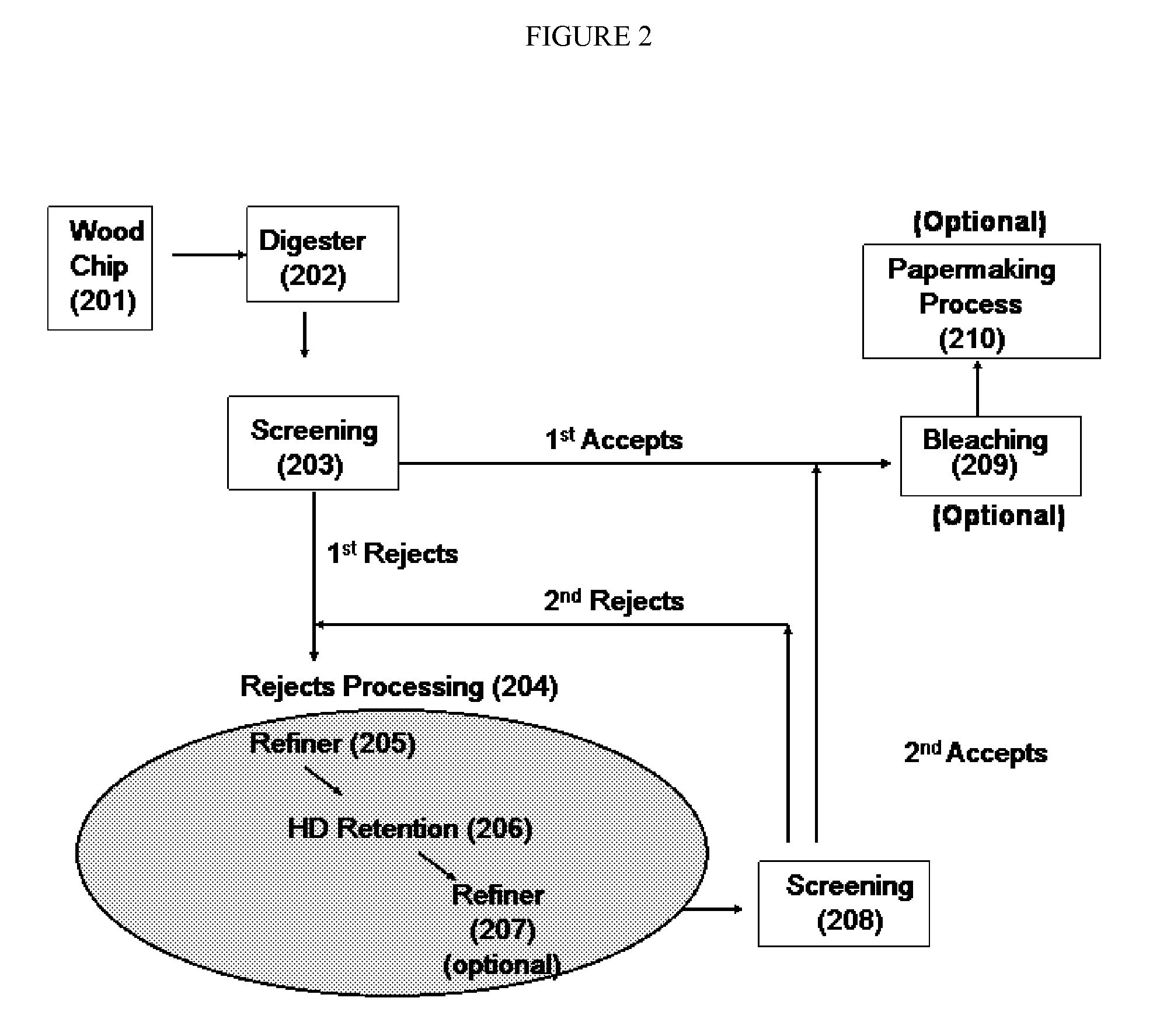

Fiber blend having high yield and enhanced pulp performance and method for making same

InactiveUS20080308239A1Increase stiffnessHigh strengthFibreboardPulp properties modificationFiberKappa number

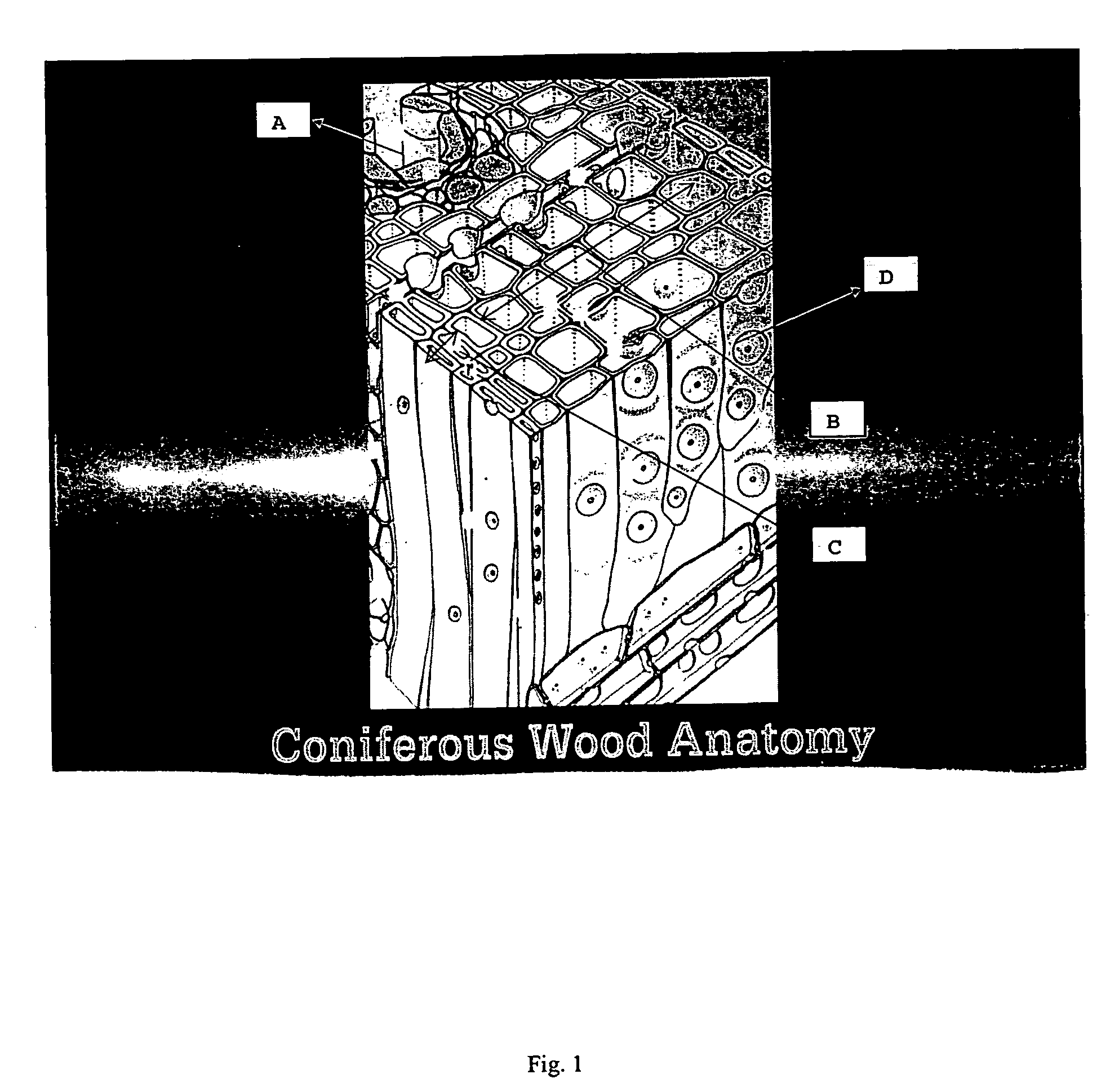

The present disclosure relates to producing paper or paperboard having improved stiffness and strength, compared to the conventional paperboard at the same basis weight. It also discloses a method of wood pulping having a significantly increased yield and providing fiber pulps with enhanced properties such as strength and stiffness. Wood chips are chemically pulped to a high kappa number, providing a rejects component and an accepts component. The rejects component is subjected to a substantially mechanical pulping process, optionally in a presence of bleaching agent, prior to blending back into the accepts component. The resulting fiber blend is washed, optionally bleached, and subjected to a papermaking process to provide paper or paperboard with enhanced strength and stiffness at low basis weight.

Owner:MEADWESTVACO CORP

Plasterboard composition, preparation of this composition and manufacture of plasterboards

A plasterboard composition includes from 55 to 92% of hydratable calcium sulphate; from 0.1 to 5% of mineral and / or refractory fibres; from 3 to 25% of a mineral additive; from 1 to 5% of unexpanded vermiculite; and from 3 to 15% of hydrated alumina.

Owner:LAFARGE PALTRES SA

Process for producing a low density acoustical panel with improved sound absorption

A process useful for producing low density high mineral wool based acoustical panels with improved acoustical absorption properties using a water felting process is disclosed. The process includes forming a dilute slurry mixture including water, mineral wool, a thermoplastic binder and / or starch; and distributing the dilute slurry on a porous carrier to have the slurry dewatered to a base mat by gravity drainage to remove water by gravity. A vacuum is adjusted to gradually apply vacuum to the gravity dewatered base mat to further dewater the base mat without subjecting the mat to static pressure that would compress the base mat. The base mat is dried to form an acoustical ceiling product that has a low density and excellent acoustical absorption properties.

Owner:USG INTERIORS INC

Bamboo beam and process

Bamboo building material and process of manufacture therefor. The material includes a plurality of layers each formed of bamboo segments which have been dried and glue coated. The segments are substantially free of outer nodes and husk and inner membrane material prior to application of glue. The longitudinal axes of the segments in each layer are generally parallel to one another, each layer having segments oriented generally orthogonally with respect to the next adjacent layers thereto. The layers of segments being compressed and bonded together until the glue cures into a single integral structure.

Owner:BAMBOO STRUCTURAL PROD LLC

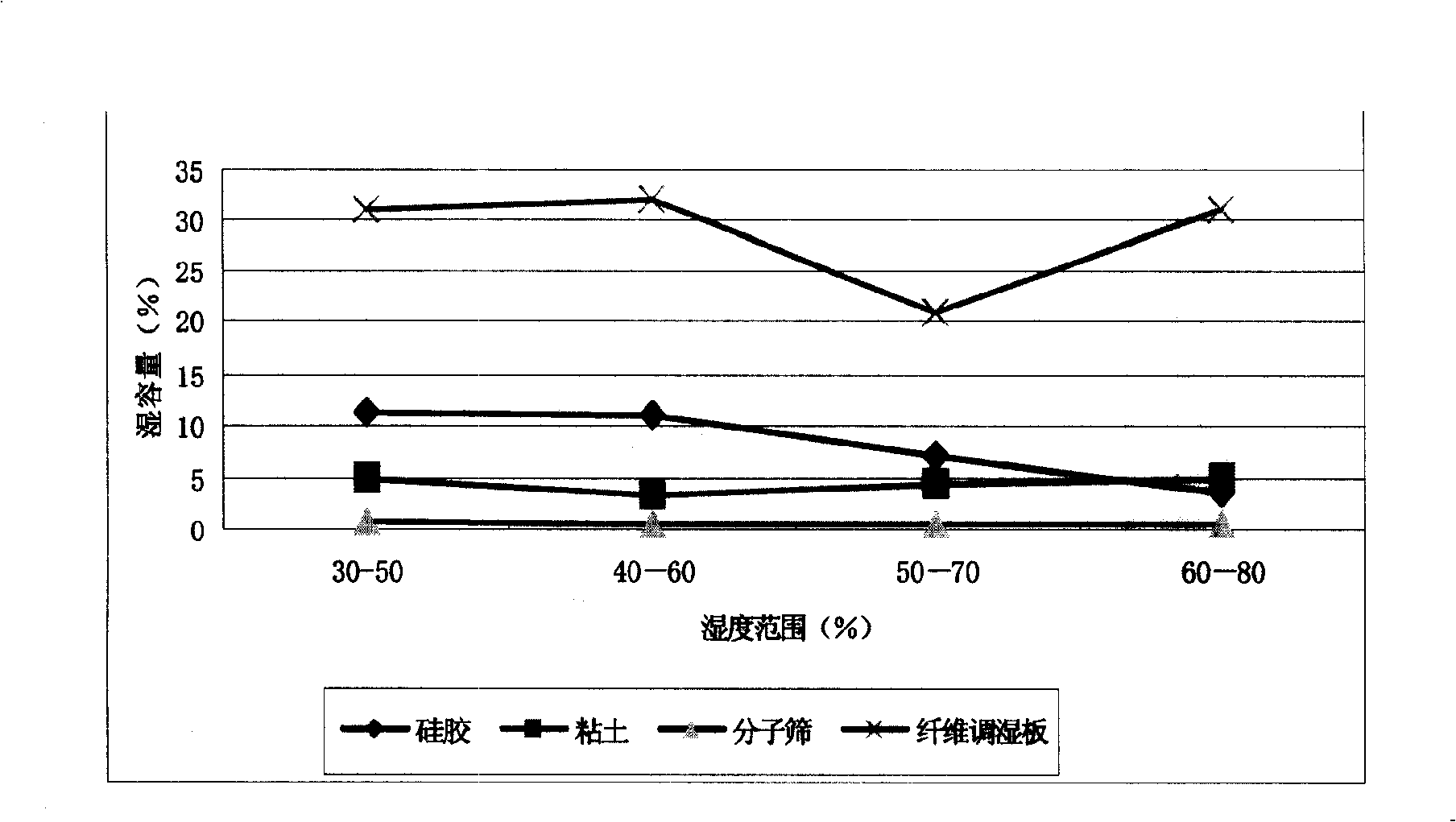

Fibre conditioning plate

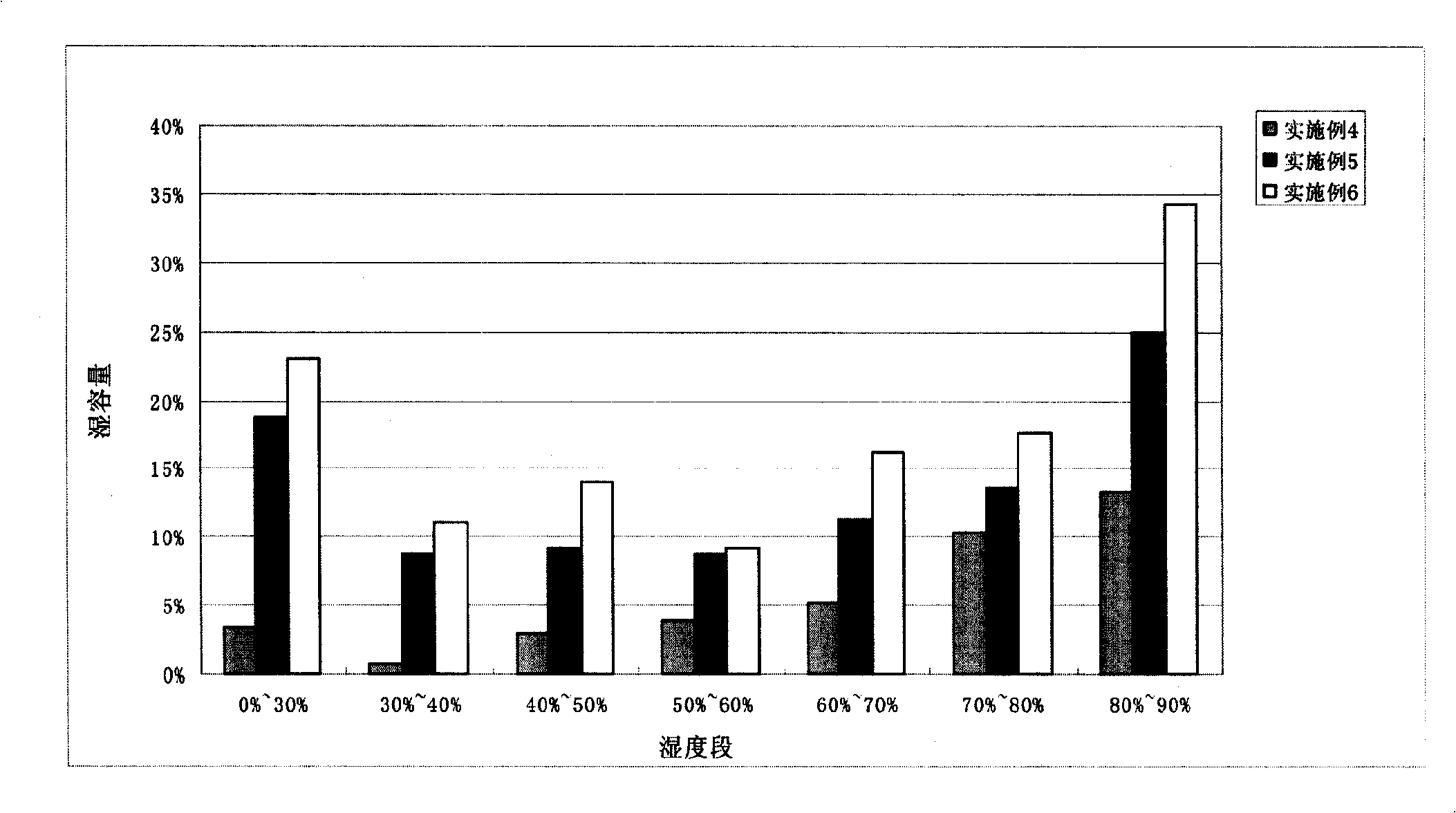

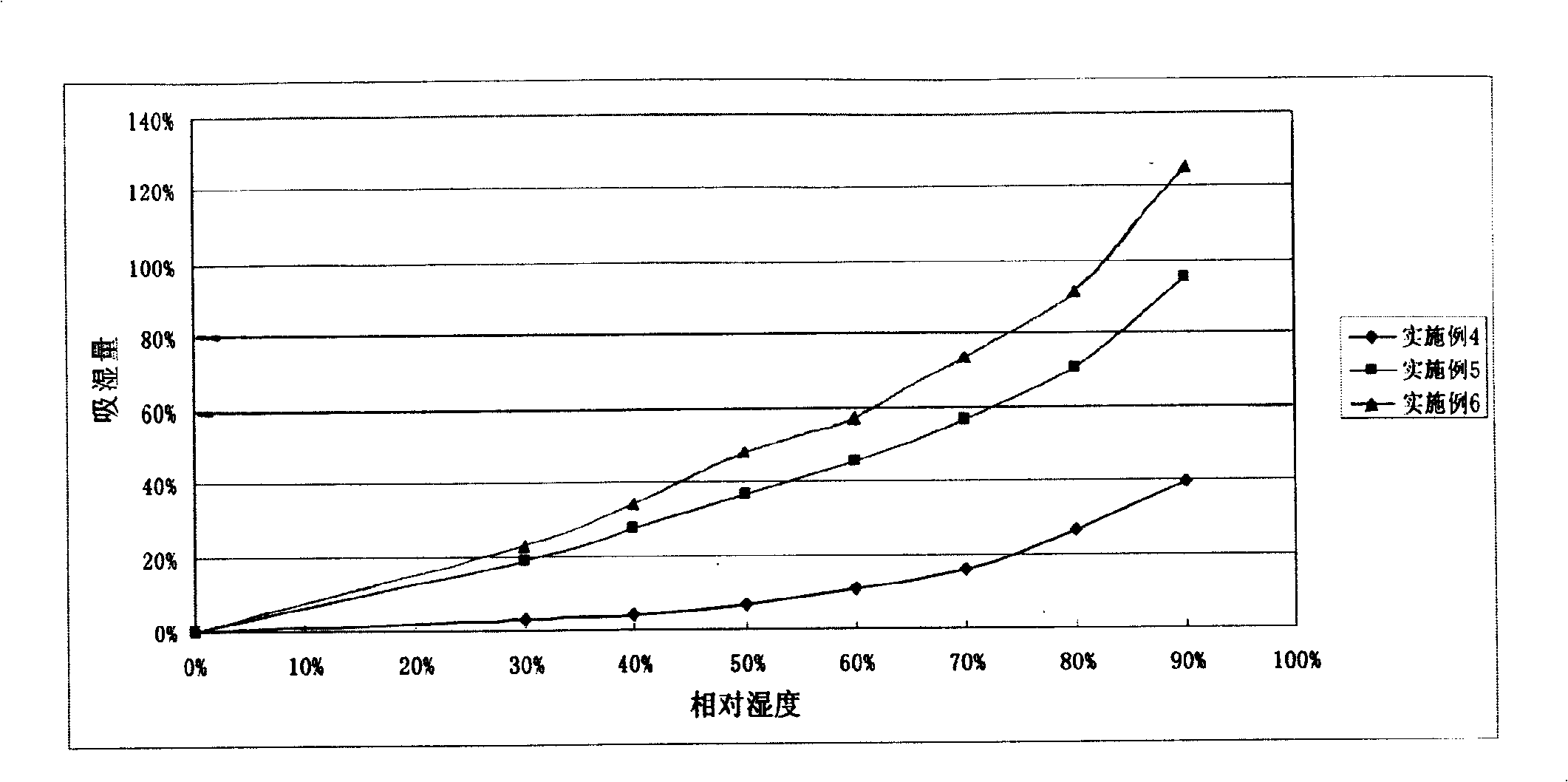

InactiveCN101343850AFully adsorbedConstant humidityFibreboardInorganic fibres/flakesSilica gelMoisture

The invention provides a fiber humidity adjusting board. The fiber humidity adjusting board is obtained by soaking a composite board in a humidity adjusting liquid, and the composite board is composed of a fiber material treated by carboxylation and porous inorganic particles dispersed in the fiber material, wherein the mass of the inorganic particles accounts for 5 to 30 percent of the solid content of the fiber, and the inorganic particles adopt one or the combination of silica gel, clay, concavo-convex rods, diatomaceous earth, activated carbon, wood charcoal and bamboo charcoal. The invention has the advantages that the fiber humidity adjusting board is a precise humidity adjusting product, when the ambient humidity changes, response can be rapidly made, and through moisture absorbing and releasing, the ambient humidity can be balanced, so as to maintain the humidity in the environment to be constant and ensure that the phenomena of wetting, mould damage or drying and cracking of the stored articles can not occur within the adjusting environment. A strap-shaped fiber humidity adjusting board is adopted, which can be cut arbitrarily; the humidity adjustment can be performed in function, and the moisture holding amount can reach and surpass the equivalent international humidity adjusting products. The fiber humidity adjusting board adopts non-toxic, harmless and recoverable raw material, and the fiber humidity adjusting board is a new-generation green and environment-friendly product.

Owner:SHANGHAI HENGYUAN MACROMOLECULAR MATERIALS CO LTD +1

Mold resistant acoustical panel

ActiveUS7056582B2Retaining its effectivenessIncrease concentrationFibreboardSolid waste managementSodium PyrithioneSlurry

A composition for a slurry for manufacture of acoustical panels includes one or more fillers, one or more binders, water and zinc pyrithione. At least of the fillers and / or binders includes microbial nutrients in an amount of at least 1% based on the dry weight of the acoustical panel. In another embodiment of the invention, acoustical panels include a core having a plurality of opposing surfaces and being at least ⅛ inches thick. The core comprises the dried product of a slurry of fillers, binders and water. Zinc pyrithione is present in at least one of the core and a coating applied to at least one of the surfaces of the core.

Owner:USG INTERIORS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com