Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

121 results about "Kappa number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Kappa number is an indication of the residual lignin content or bleachability of wood pulp by a standardised analysis method.

Pulping processes

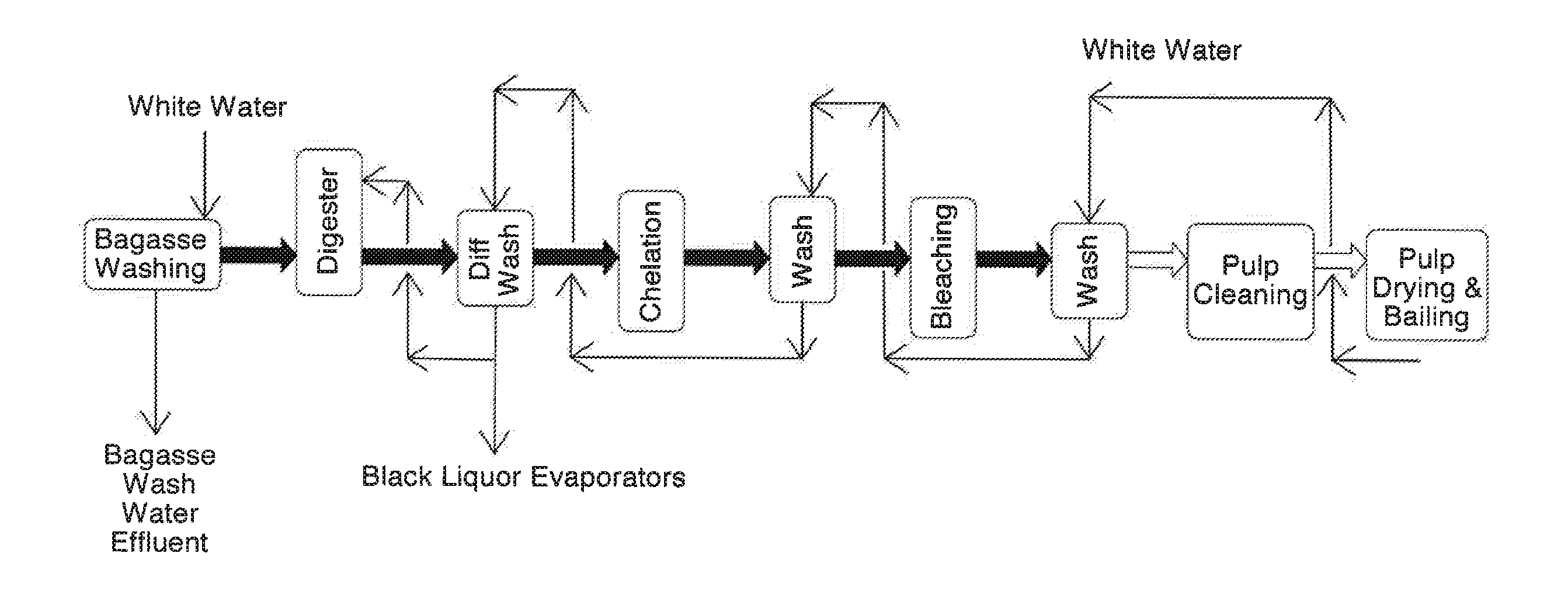

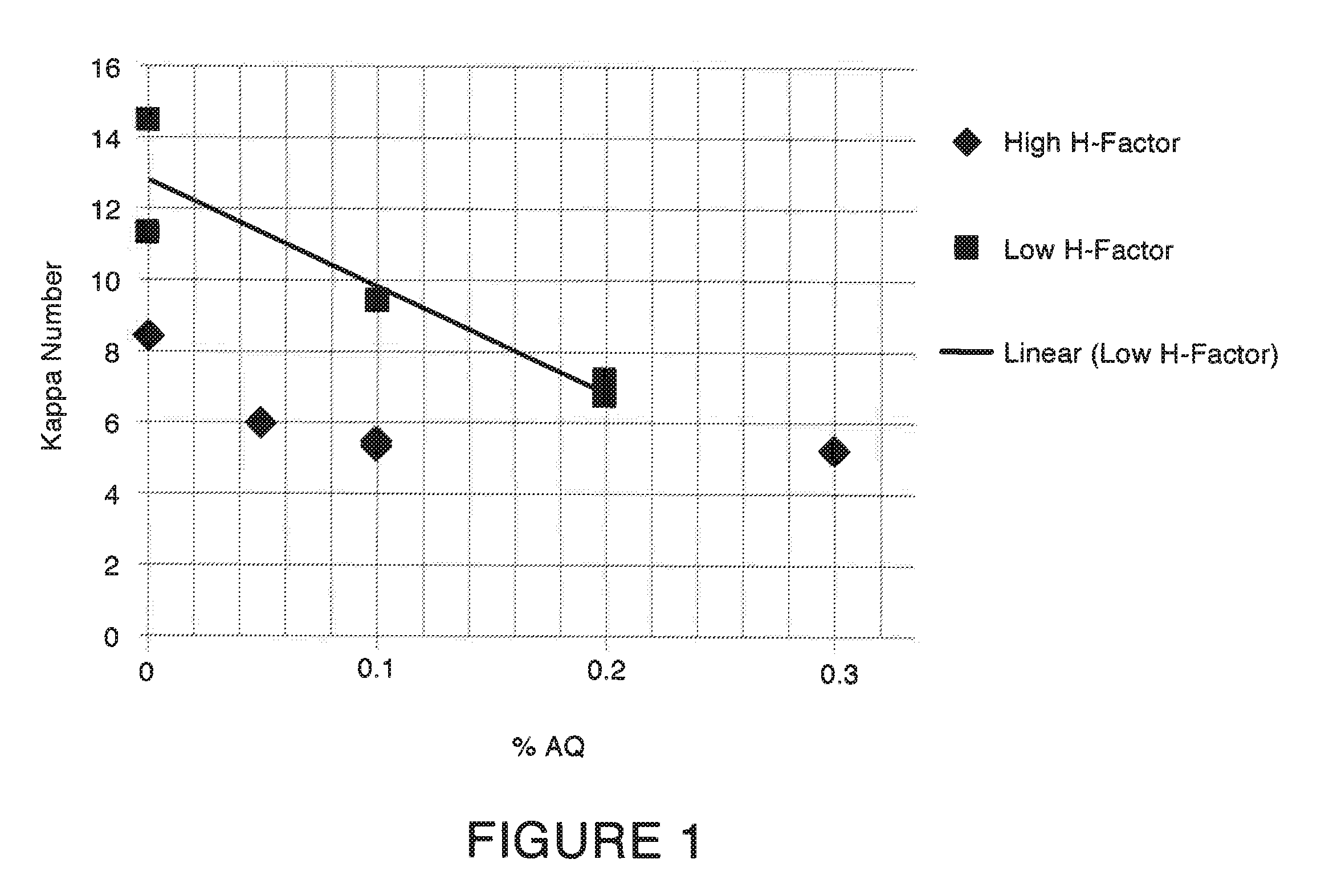

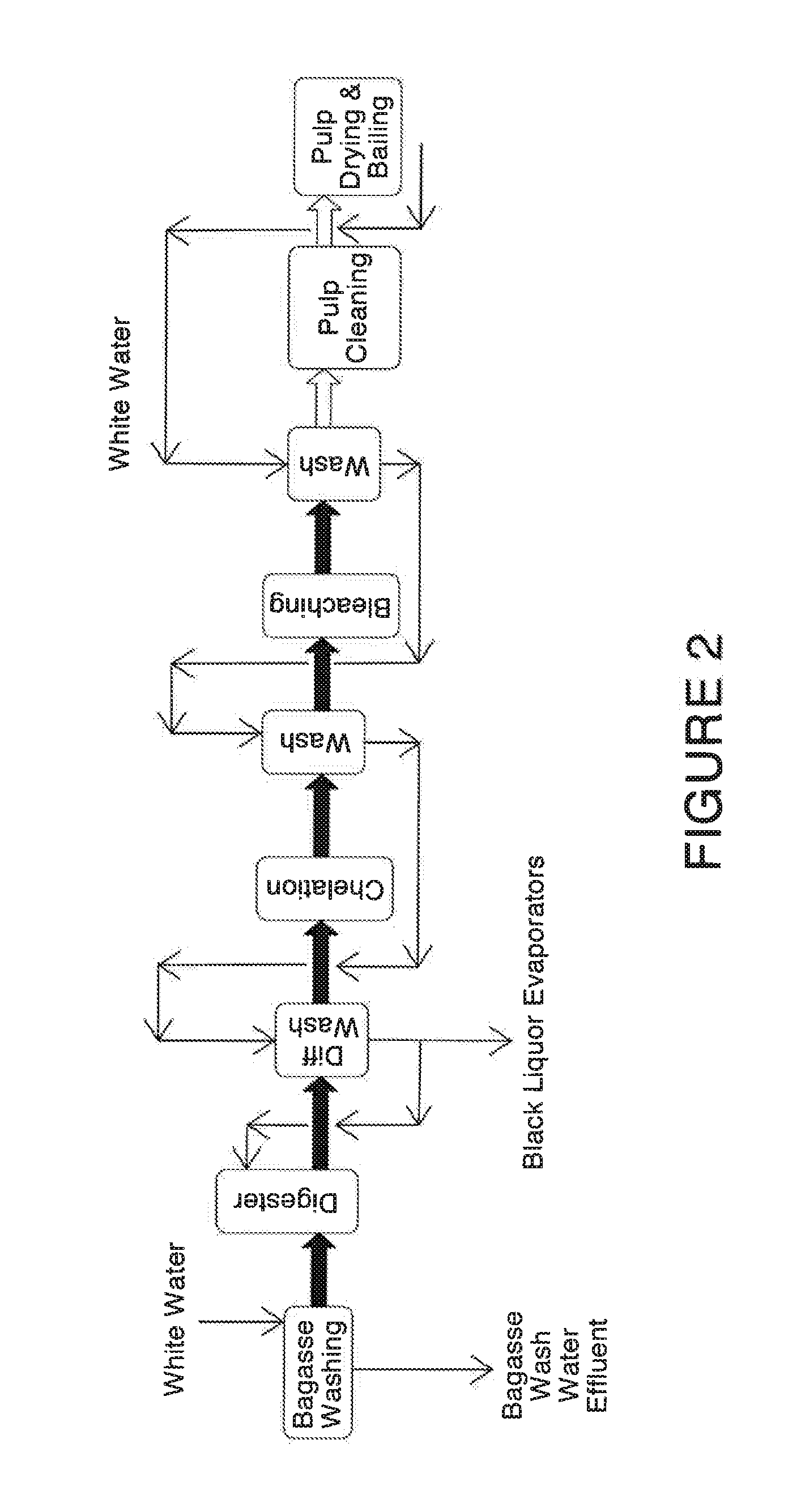

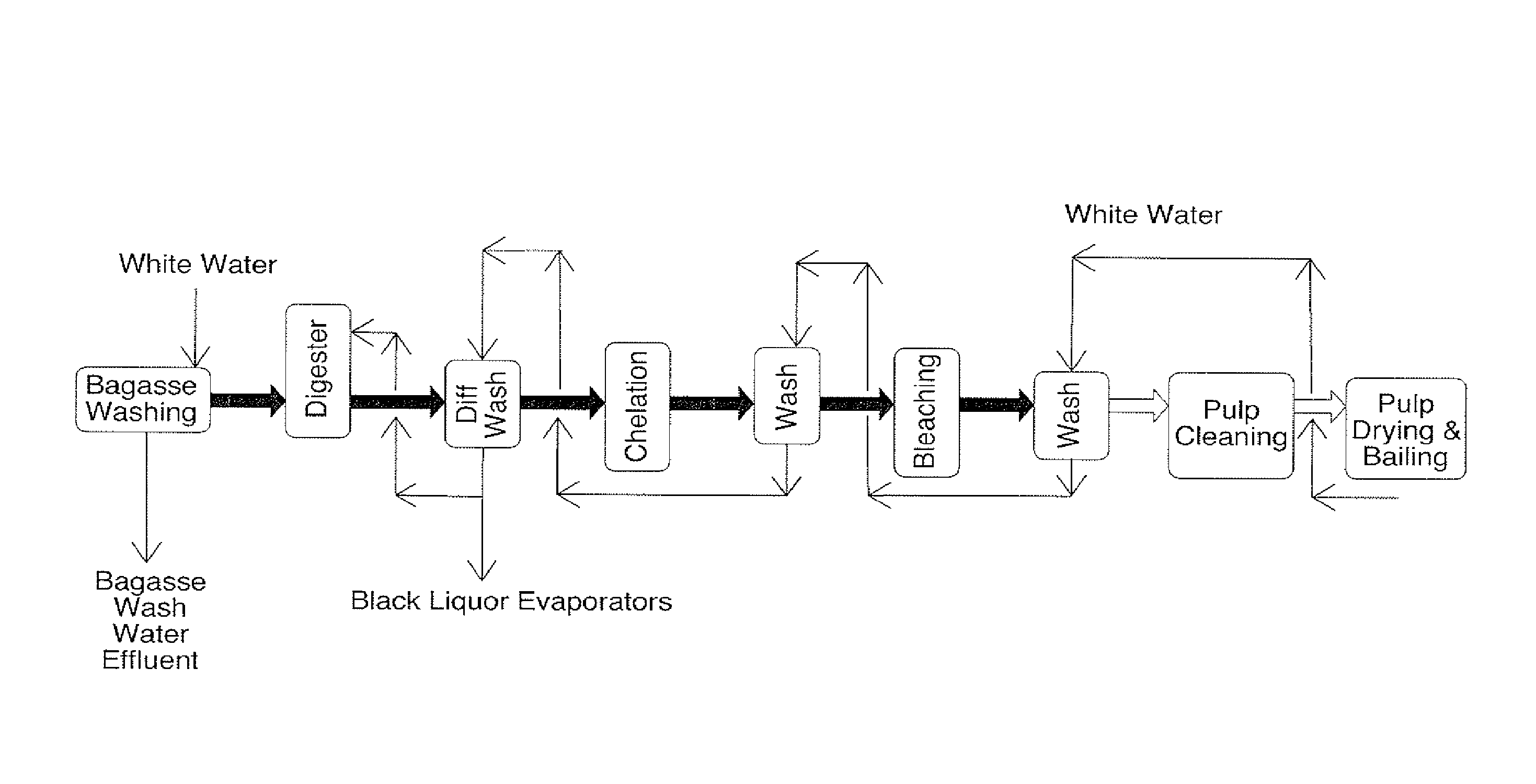

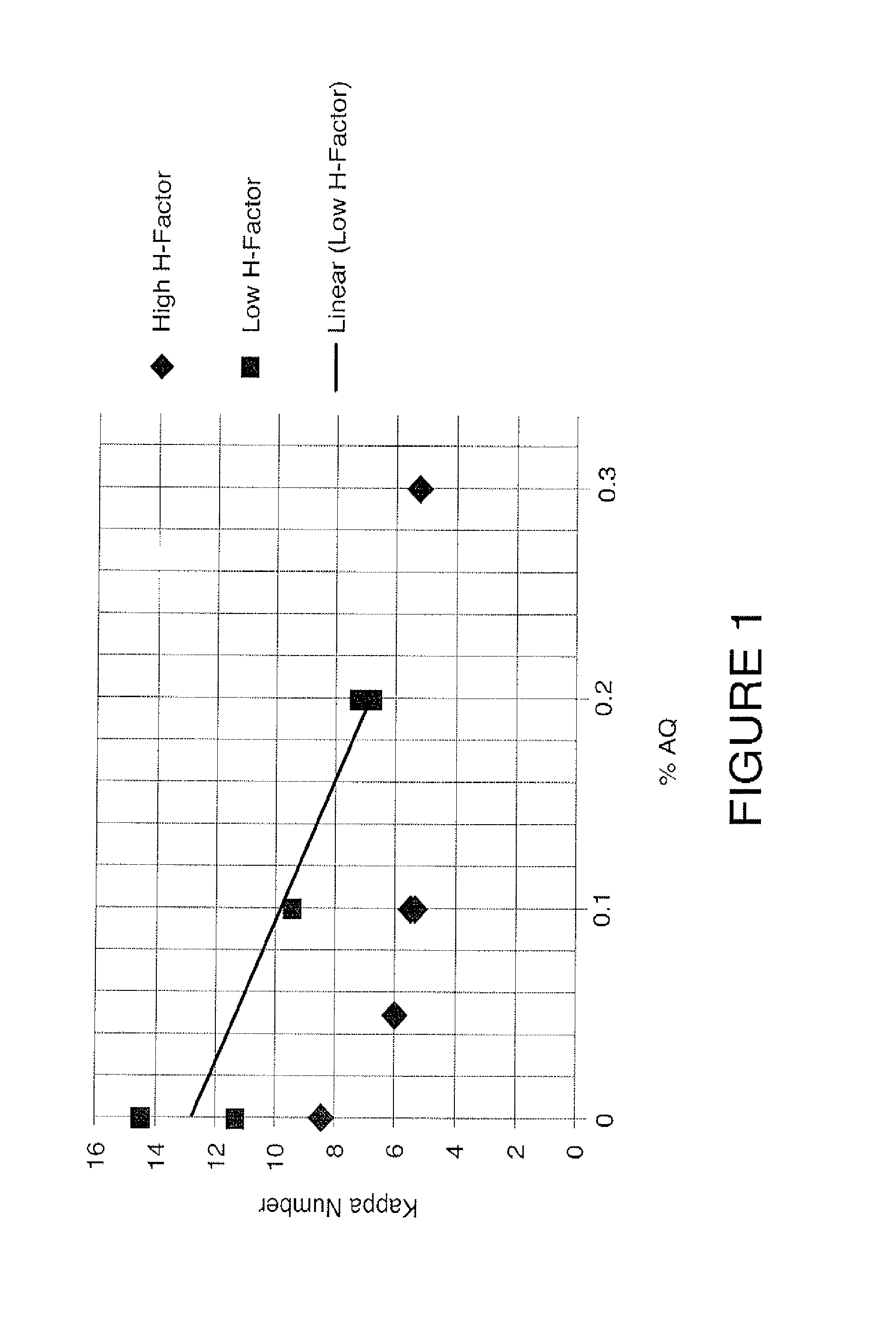

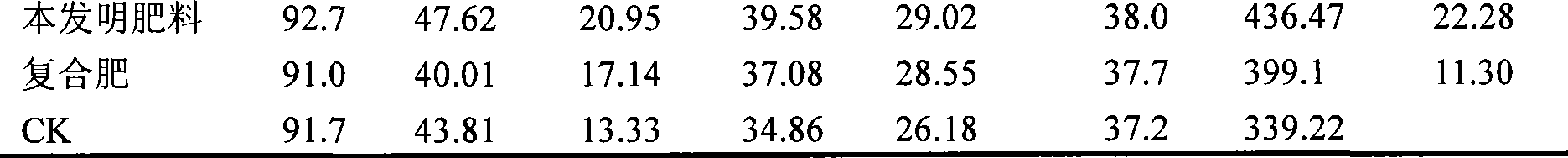

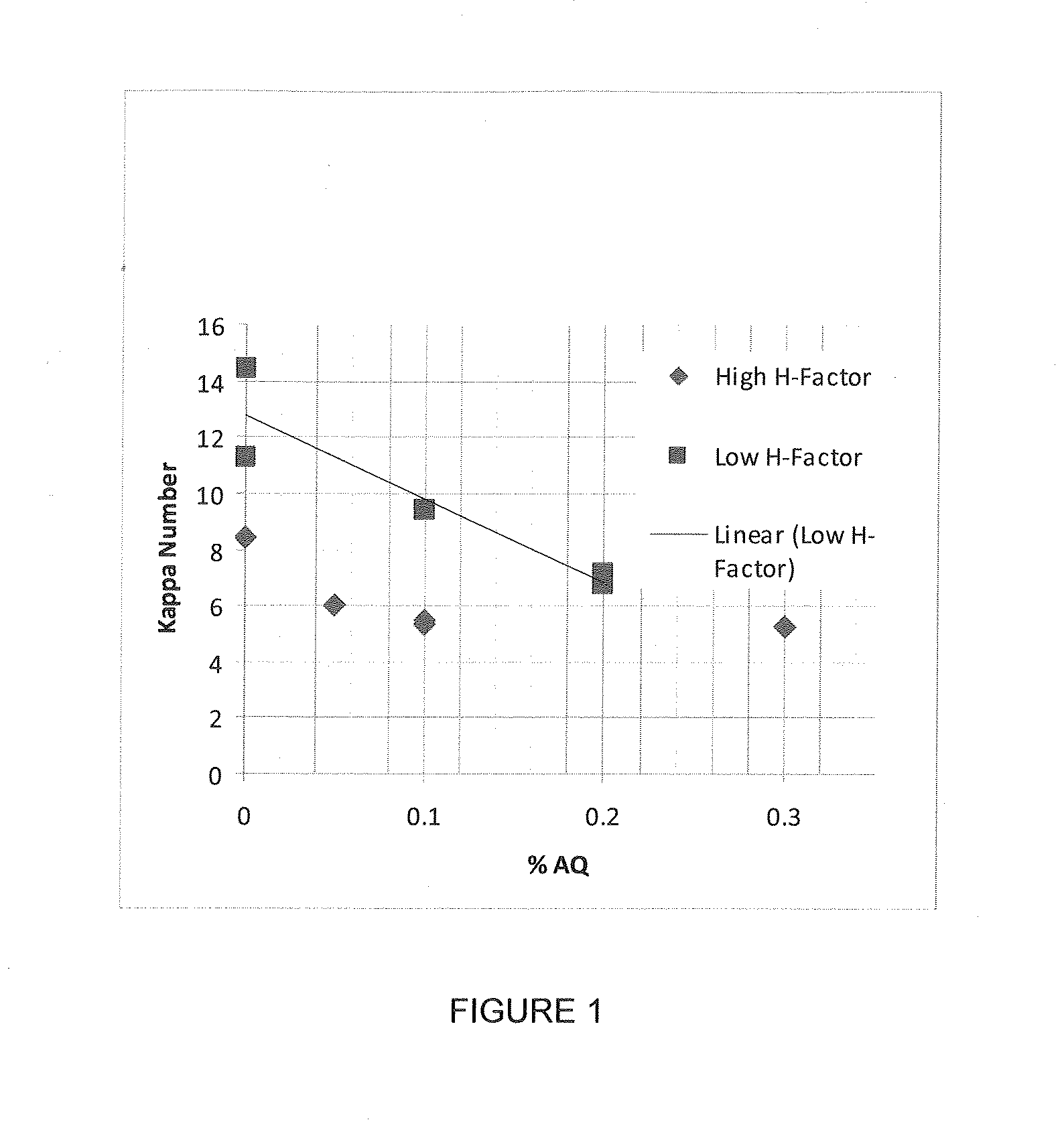

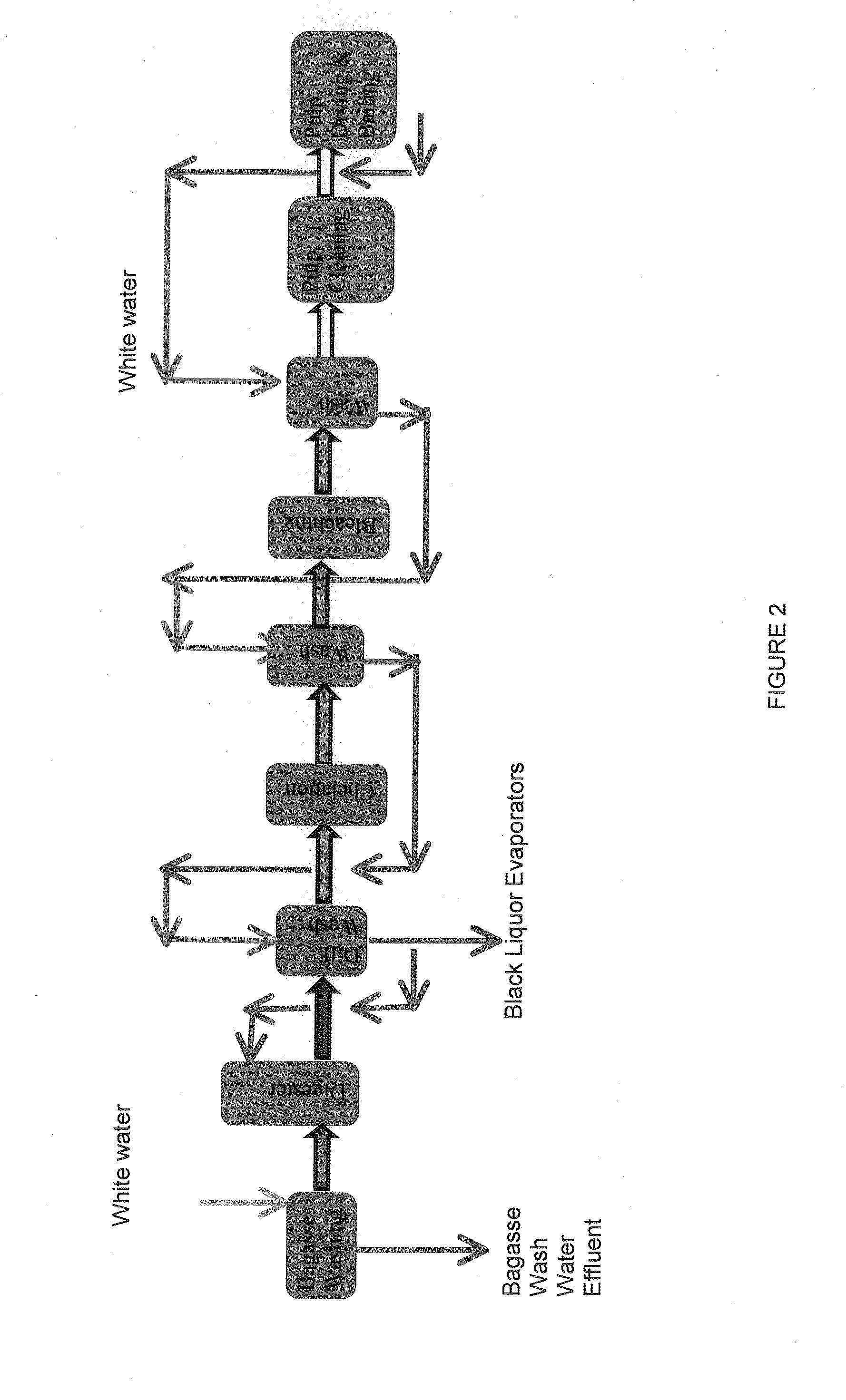

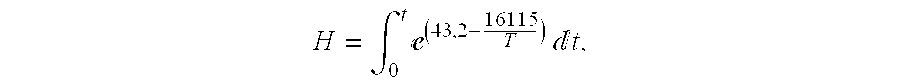

A pulping process comprises using a high concentration of anthraquinone (AQ). The pulping process is capable of providing a pulp having low Kappa number with unexpectedly high strength. The pulping process can use wood or non-wood fibers (e.g., bagasse and corn stover) to provide pulp having good papermaking quality. The method for pulping a fiber comprising cooking a first mixture comprising the fibers, water, an alkali, and a delignification selectivity enhancing chemical for a cooking time and at a cooking condition sufficient to form a first pulp having a desired Kappa number of about 15 or less, and strength parameters that are sufficient for papermaking, where the starting material prior to cooking has a Kappa number of 60 or greater.

Owner:CARGILL INC

Fiber blend having high yield and enhanced pulp performance and method for making same

InactiveUS20080308239A1Increase stiffnessHigh strengthFibreboardPulp properties modificationFiberKappa number

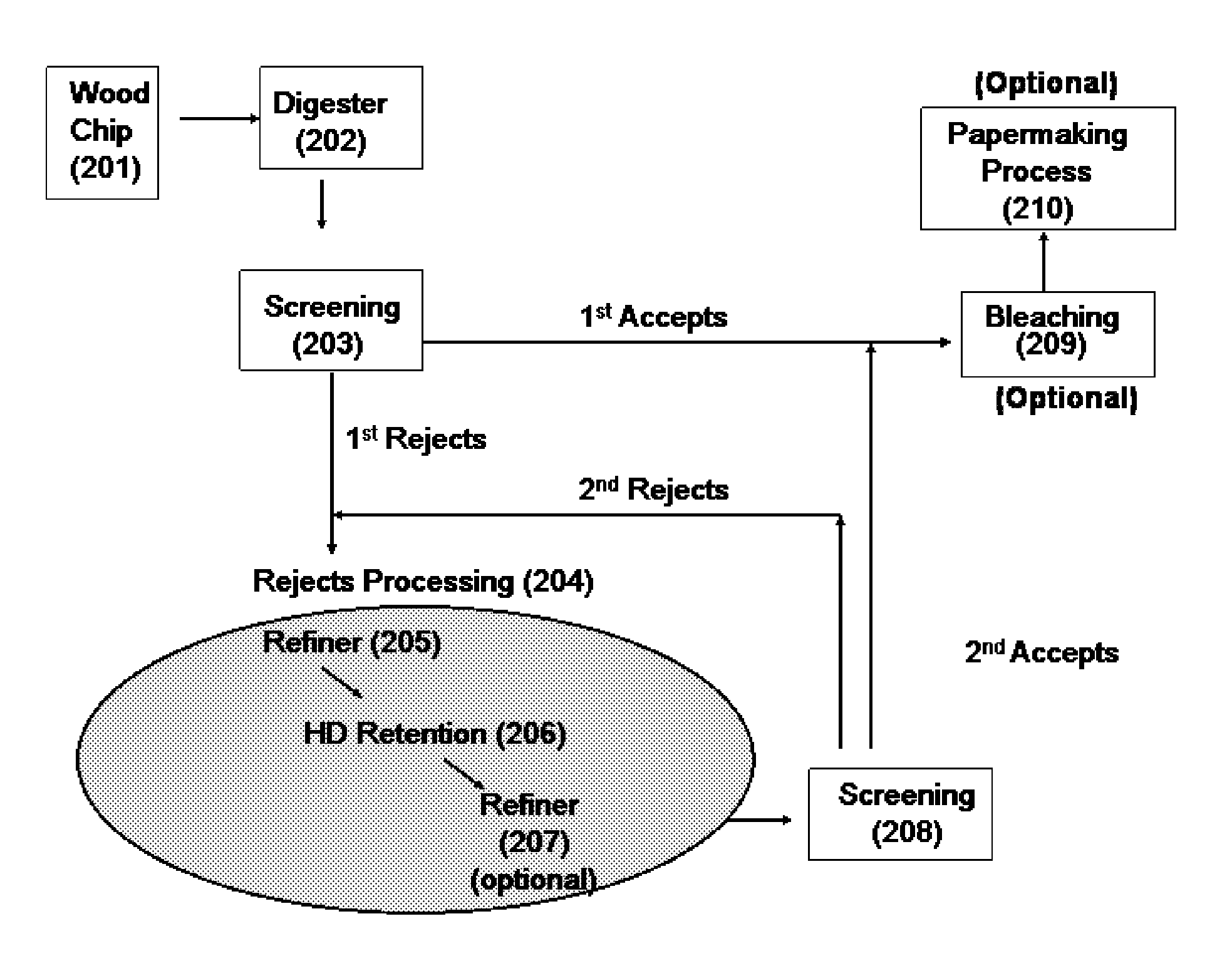

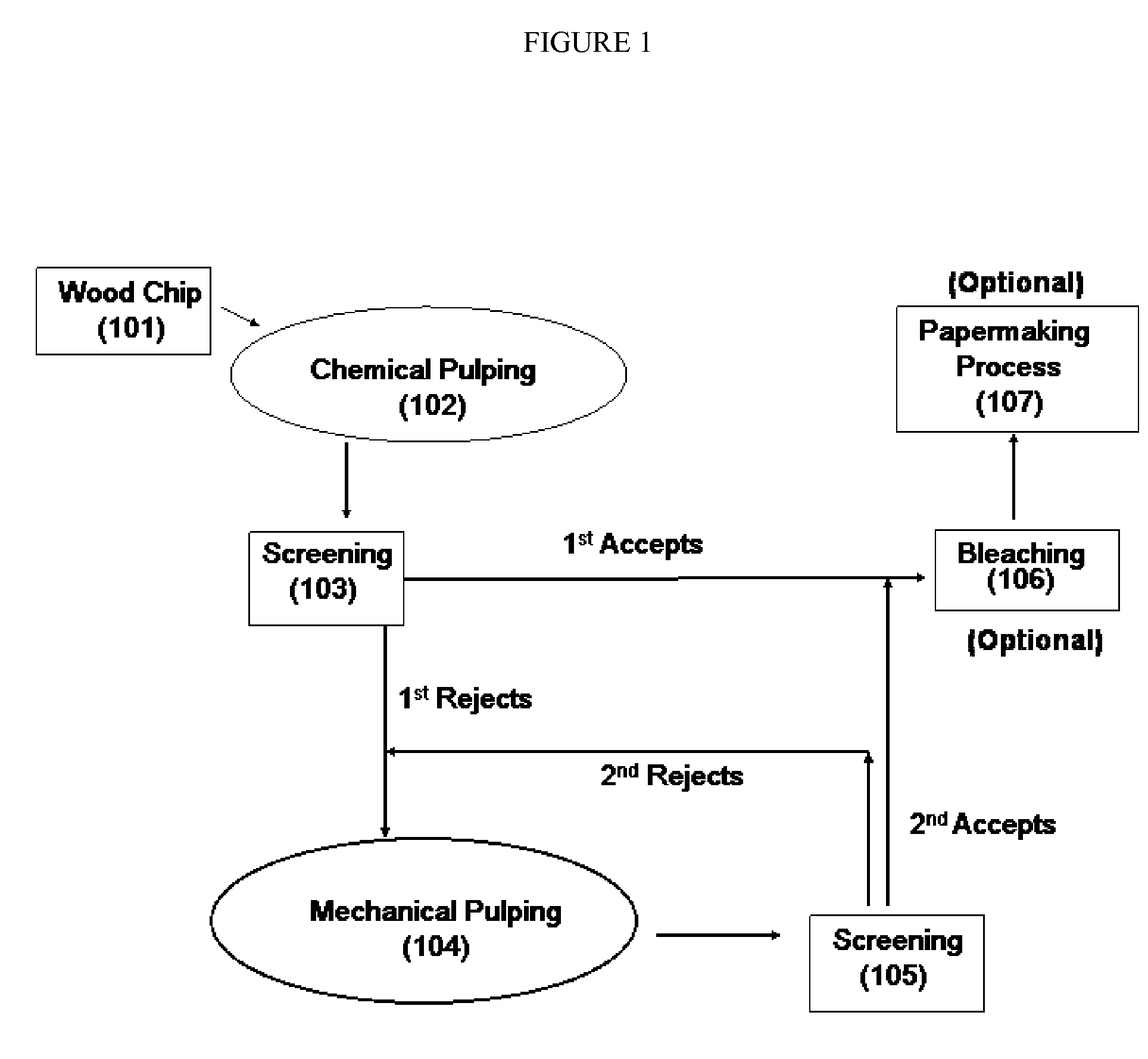

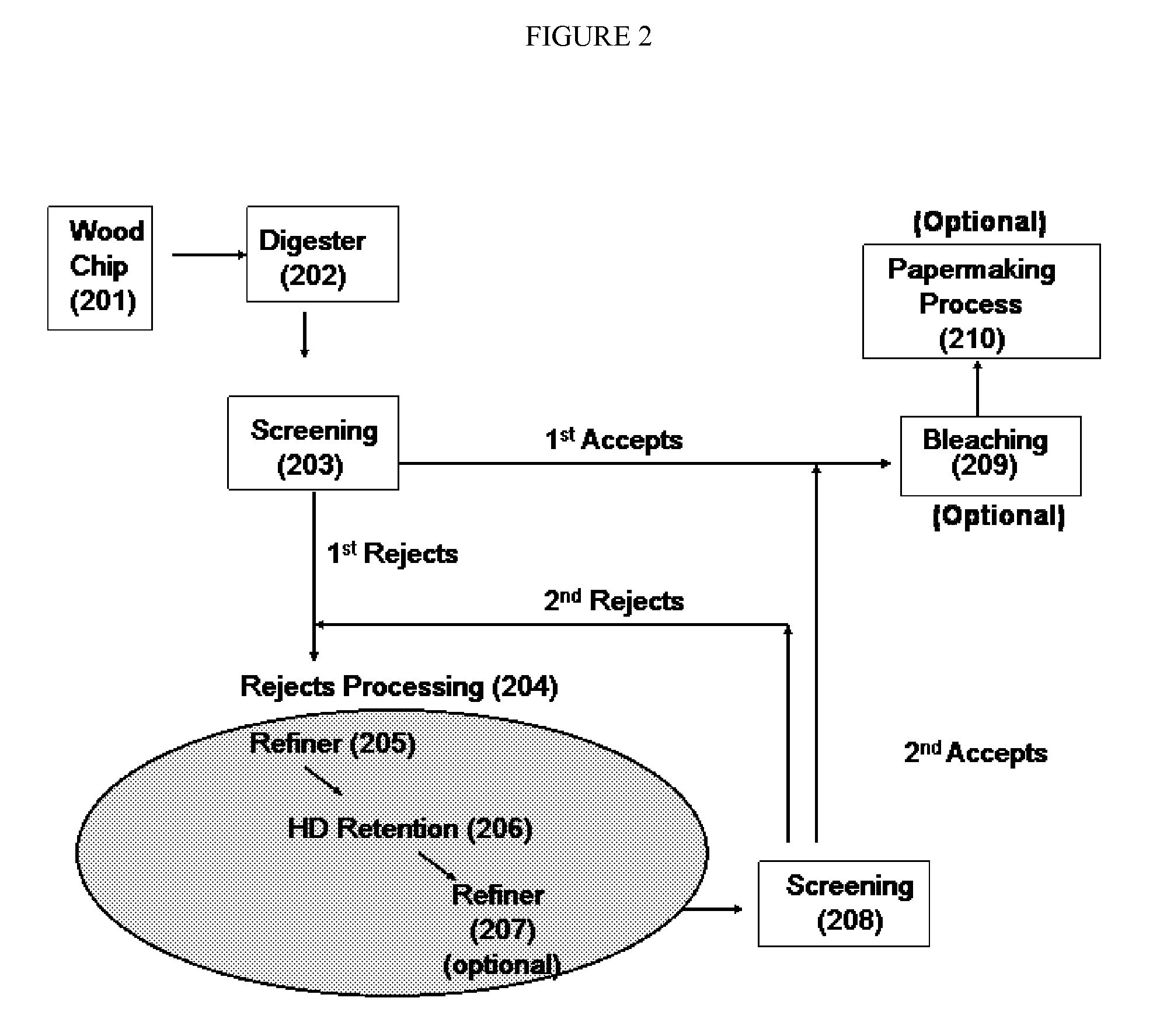

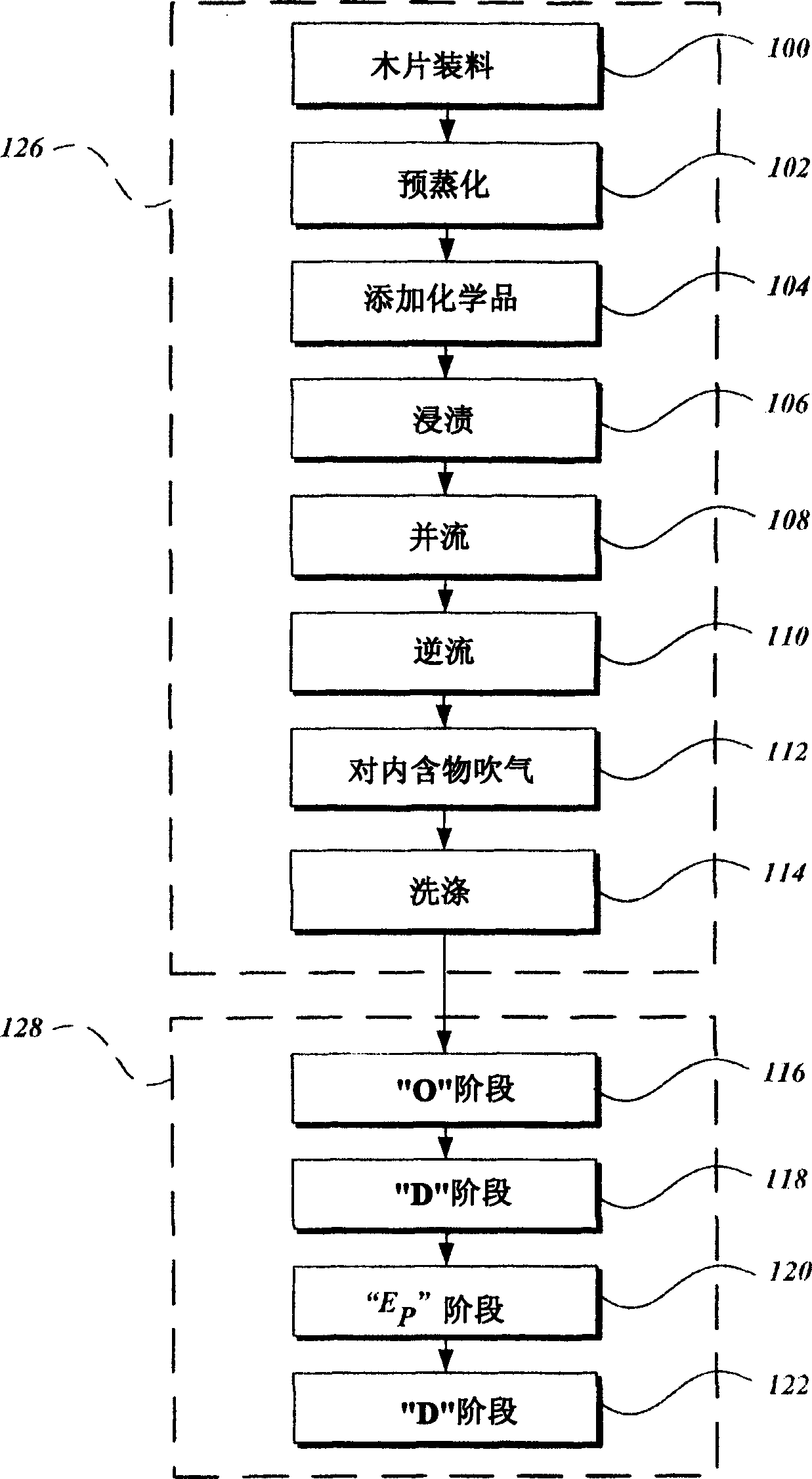

The present disclosure relates to producing paper or paperboard having improved stiffness and strength, compared to the conventional paperboard at the same basis weight. It also discloses a method of wood pulping having a significantly increased yield and providing fiber pulps with enhanced properties such as strength and stiffness. Wood chips are chemically pulped to a high kappa number, providing a rejects component and an accepts component. The rejects component is subjected to a substantially mechanical pulping process, optionally in a presence of bleaching agent, prior to blending back into the accepts component. The resulting fiber blend is washed, optionally bleached, and subjected to a papermaking process to provide paper or paperboard with enhanced strength and stiffness at low basis weight.

Owner:MEADWESTVACO CORP

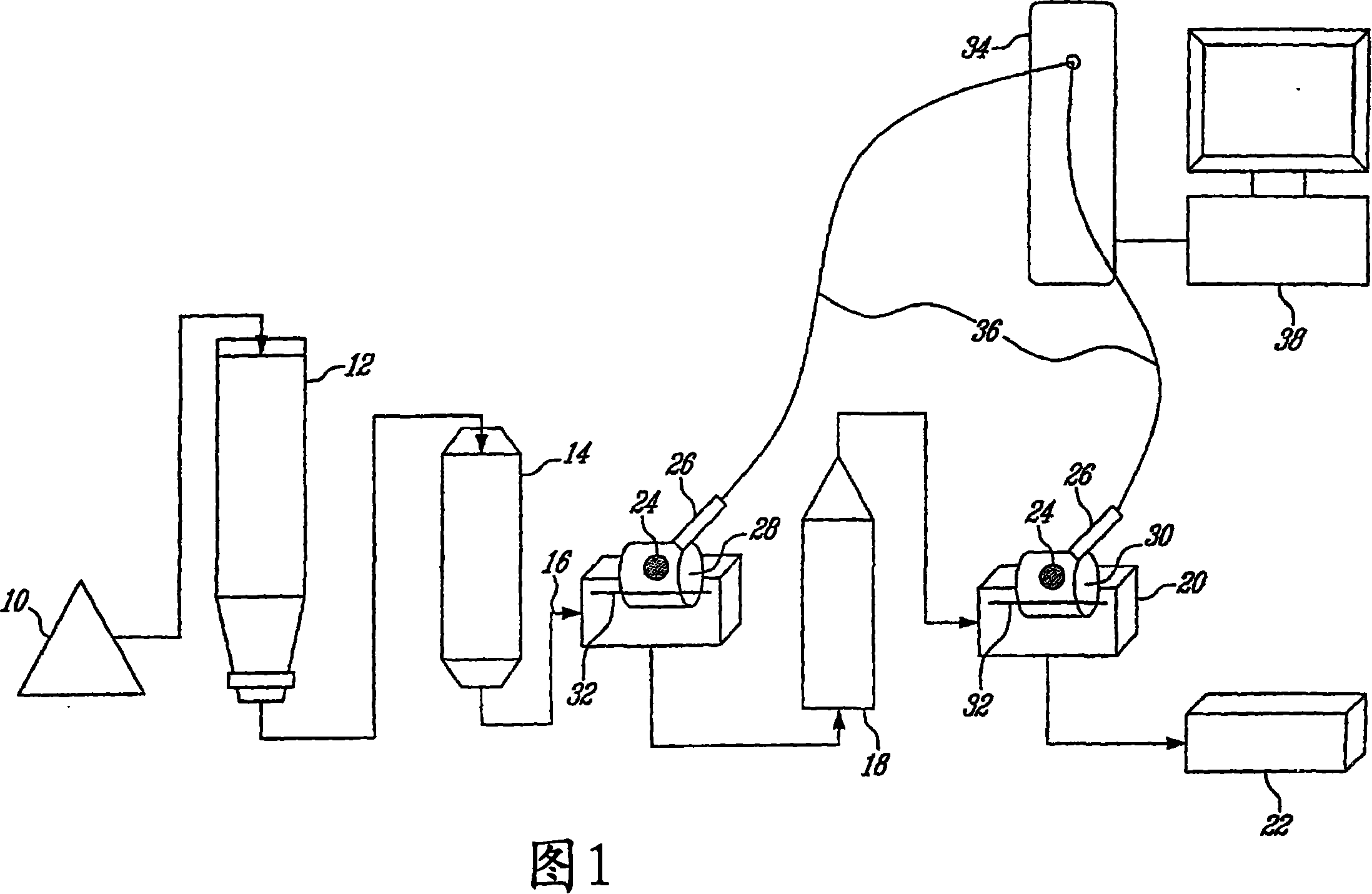

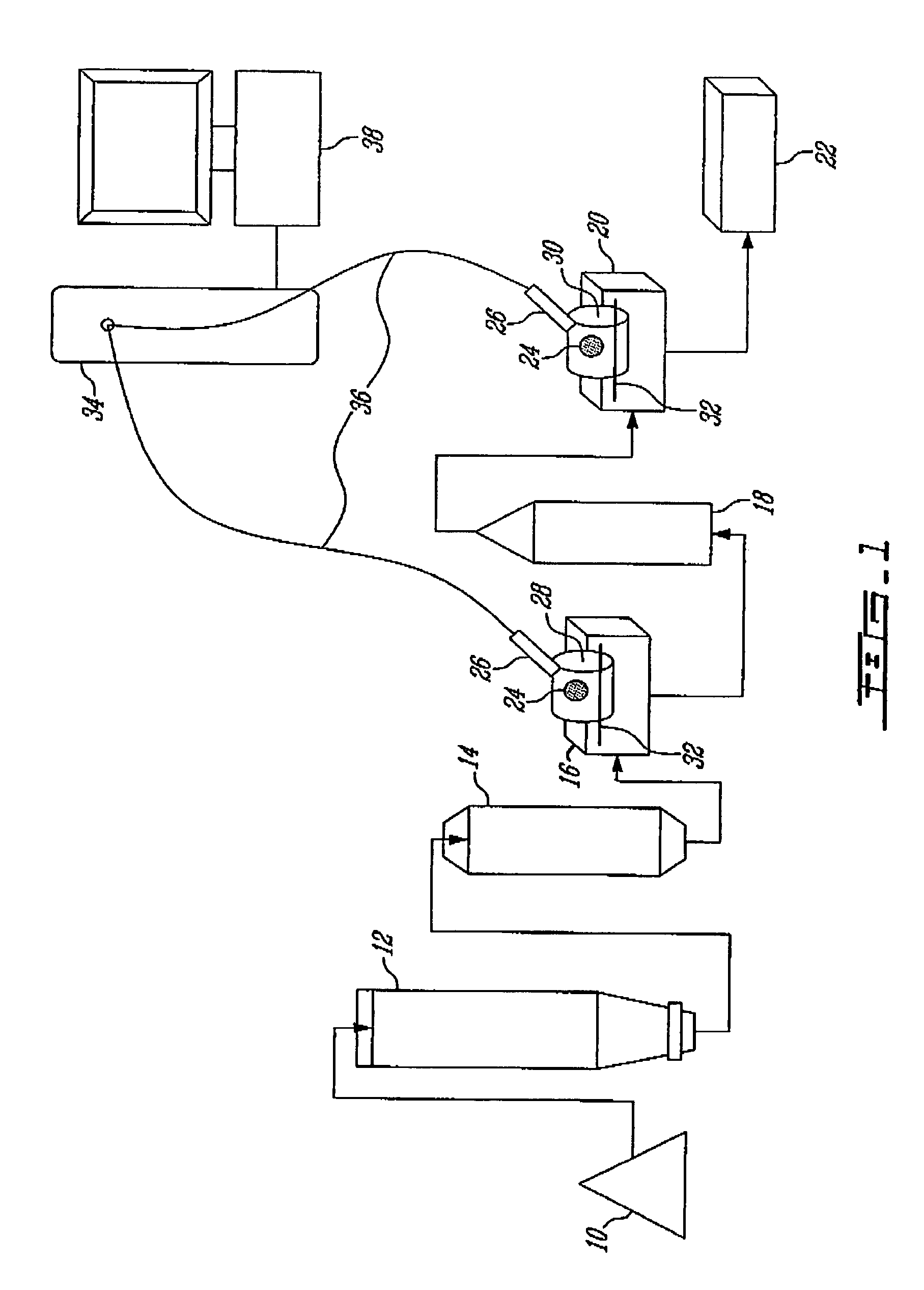

Method for determining chemical pulp Kappa number with visible-near infrared spectrometry

ActiveUS20060196622A1Overcomes shortcomingCellulosic pulp after-treatmentRadiation pyrometryContinuous measurementPresent method

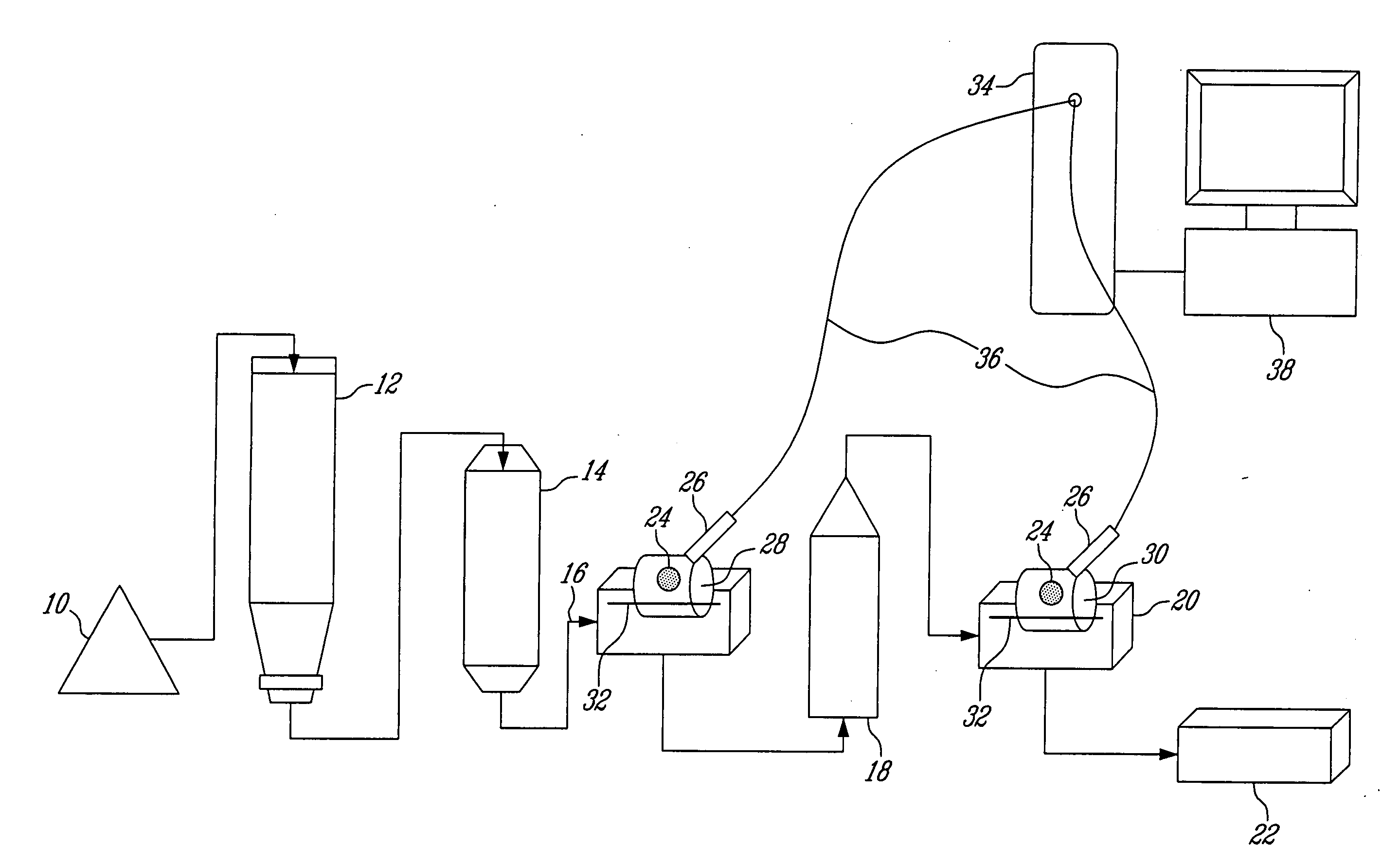

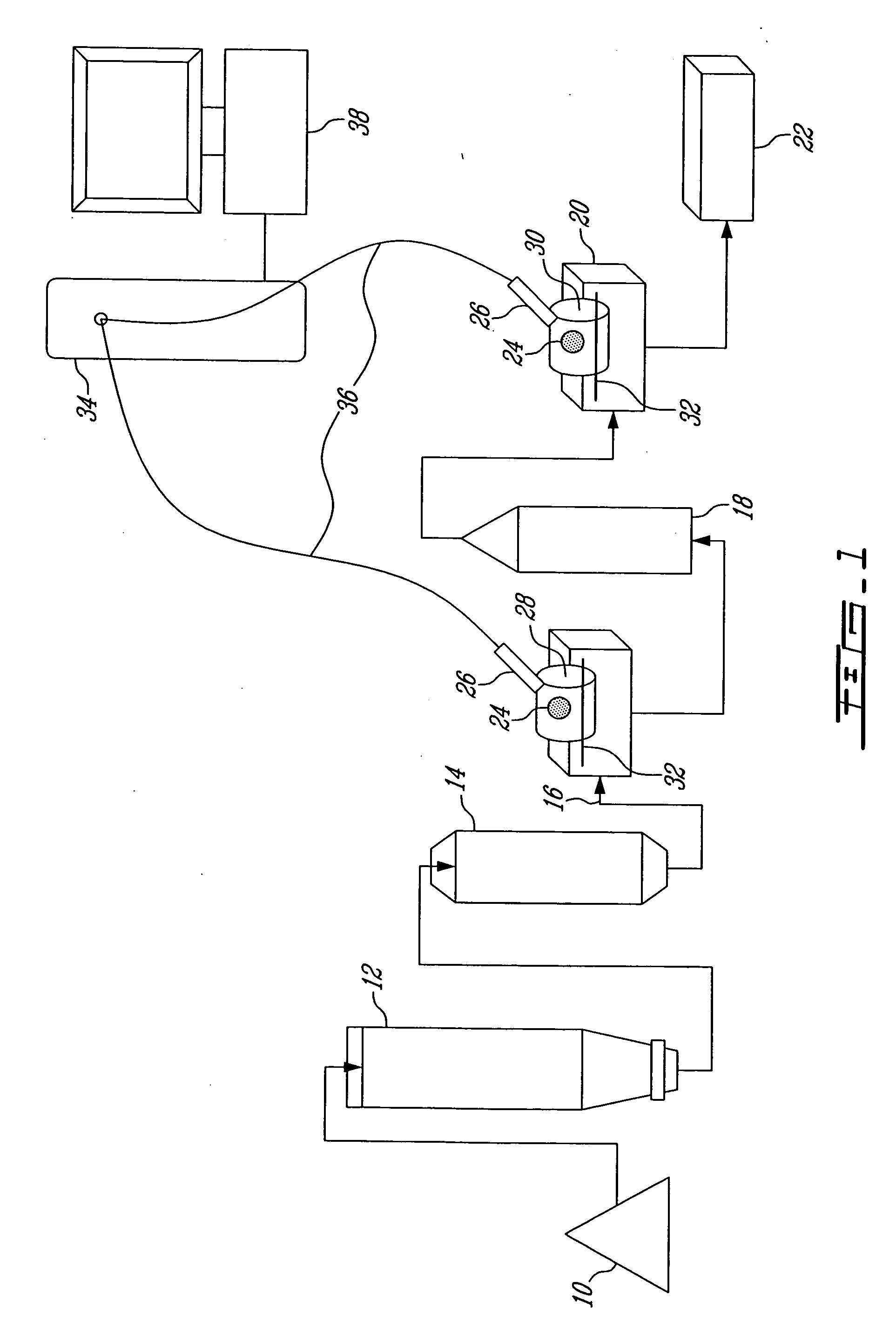

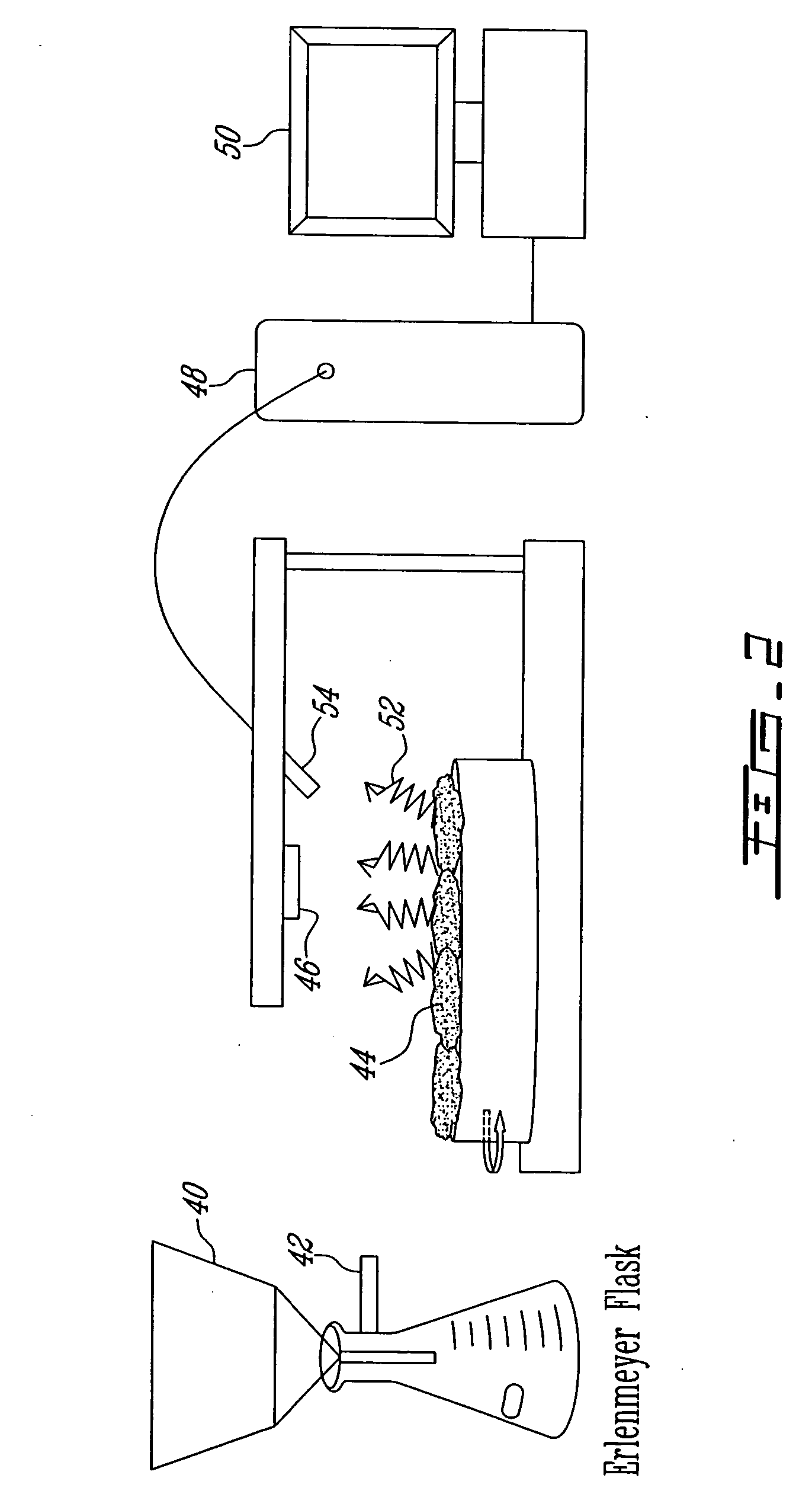

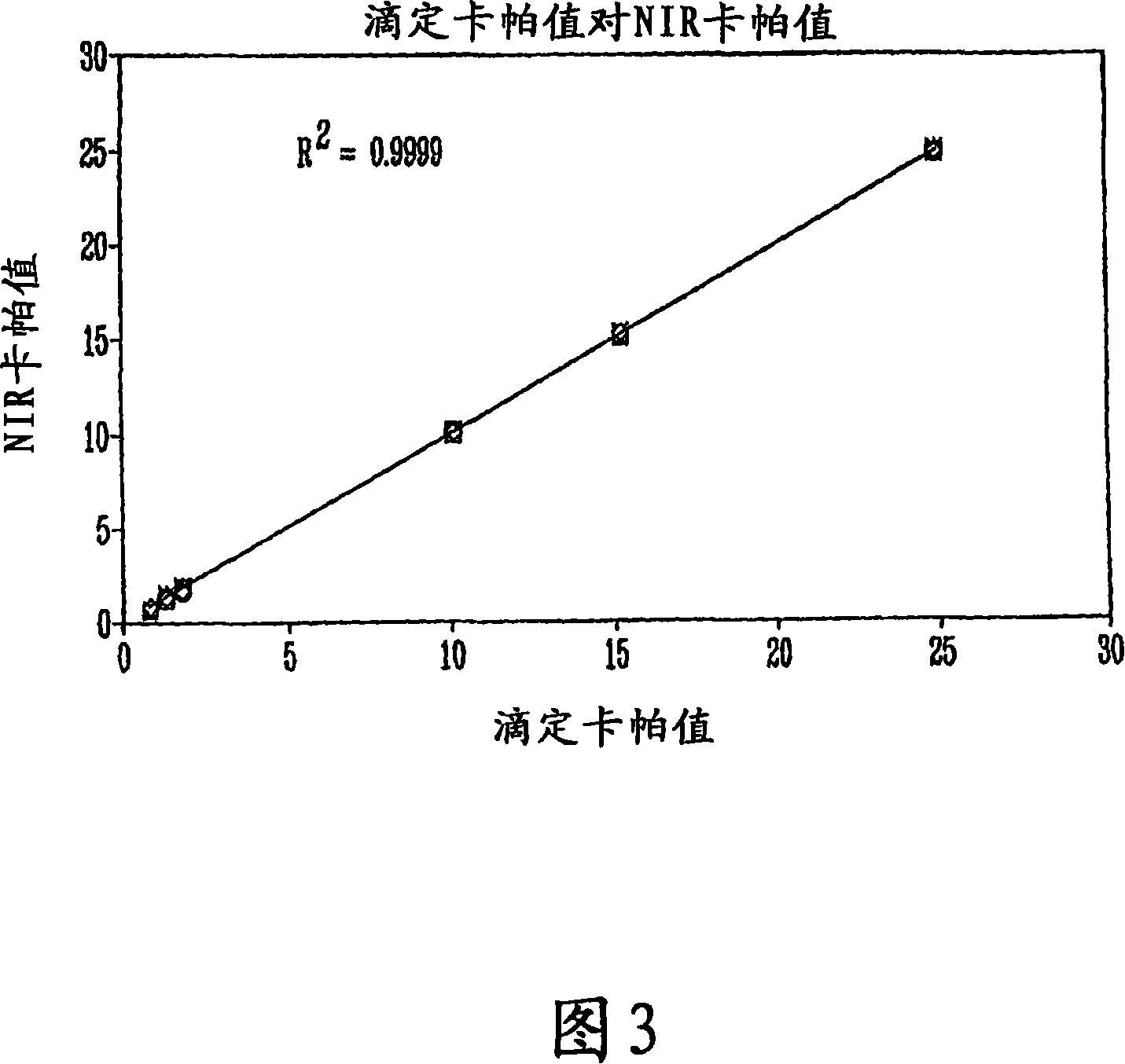

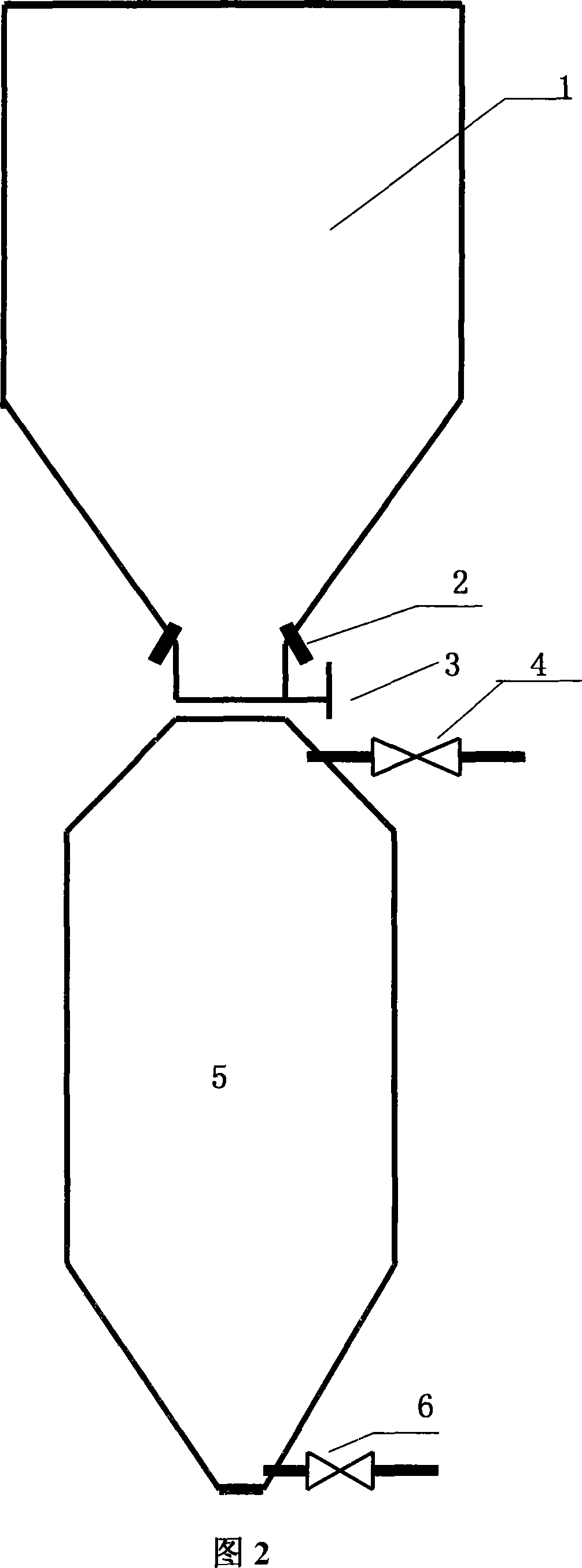

A method for the determination of cellulosic-fibre properties, such as, but not limited to, residual lignin content of chemical pulp, with the aid of a spectroscopic technique obtained over a range covering the visible and the near-infrared regions of the electromagnetic spectrum, comprising the steps of obtaining a sample from the process line, minimally removing some excess water, exposing the fibres in the sample to a large beam light source, optionally moving the sample at a constant speed, and acquiring the spectral data over a pre-determined length of time, and correlating the spectrum to a previously determined calibration so as to determine the Kappa number. Alternatively, as an arrangement for process control, along with other varying configurations, the instant invention includes the mounting of the excitation light source and fibre-optic probe along the various locations of the kraft cooking and bleaching process, such as 1) at the drum brownstock washers and 2) throughout the bleach plant deckers, located just before the doctored blade, the probe being connected to a fast scanning spectrometer, via fibre optic cables, with a computer sequencing spectral acquisition and correlating the spectrum against a predetermined calibration, and logging the results. The process configuration, with the use of the instant invention, overcomes all limitations of prior art, including sampling hardware and sample preparation, and provides true online Kappa number determinations of the order of seconds, as compared to current state of the art Kappa analyzers which require 10 to 15 minutes per analysis. The present method is capable of measuring residual lignin content of chemical pulps with varying consistency, accounts for species effects to provide species insensitivity and can provide analysis in less than 10 seconds. The method can provide true online continuous measurement of Kappa number for feedforward and feedback control of the bleaching, paper machine and kraft cooking processes.

Owner:FPINNOVATIONS INC

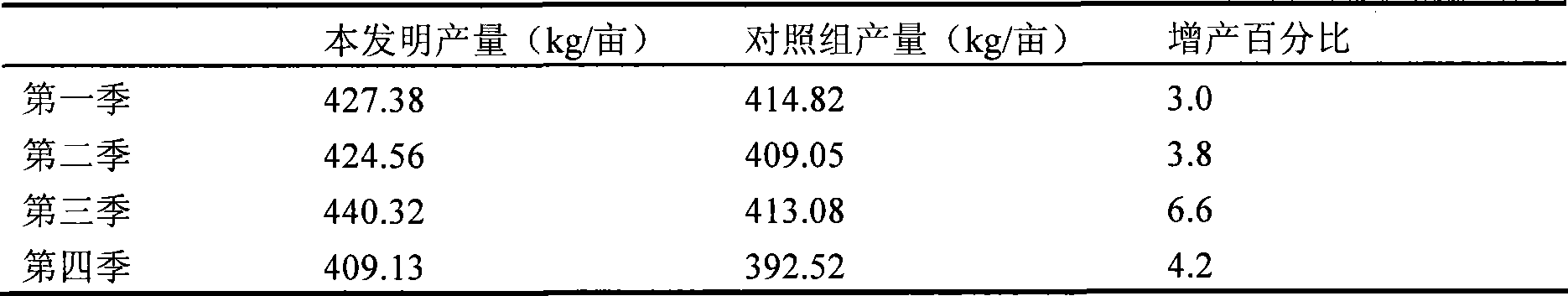

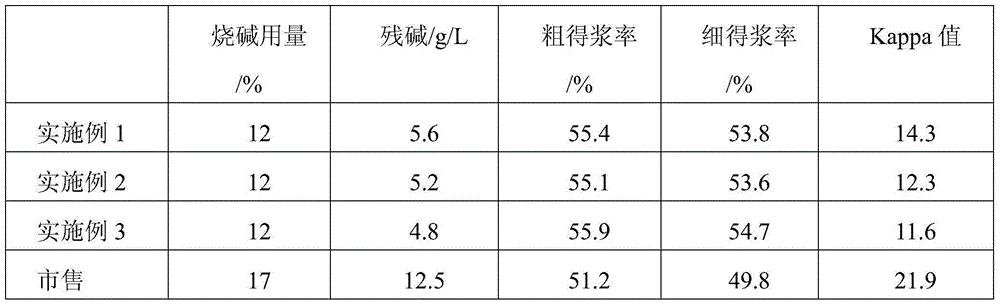

Prepared high hardness pulp using grass kind plant as raw material and preparation method thereof

ActiveCN101089290AReduce dosageReduce manufacturing costDigestersPulping with acid salts/anhydridesKappa numberHardness

The present invention discloses a method for preparing high-hardness pulp by using graminoid plant as raw material and its cooking process. The hardness of said high-hardness pulp is equal to Kappa number 24-50. The described cooking method includes the following steps: preparing graminoid plant raw material, soaking said raw material, feeding said raw material into a cooker, adding cooking liquor into said cooker, introducing steam to make heating operation to attain the requird pressure, then heat-insulating to the required time.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

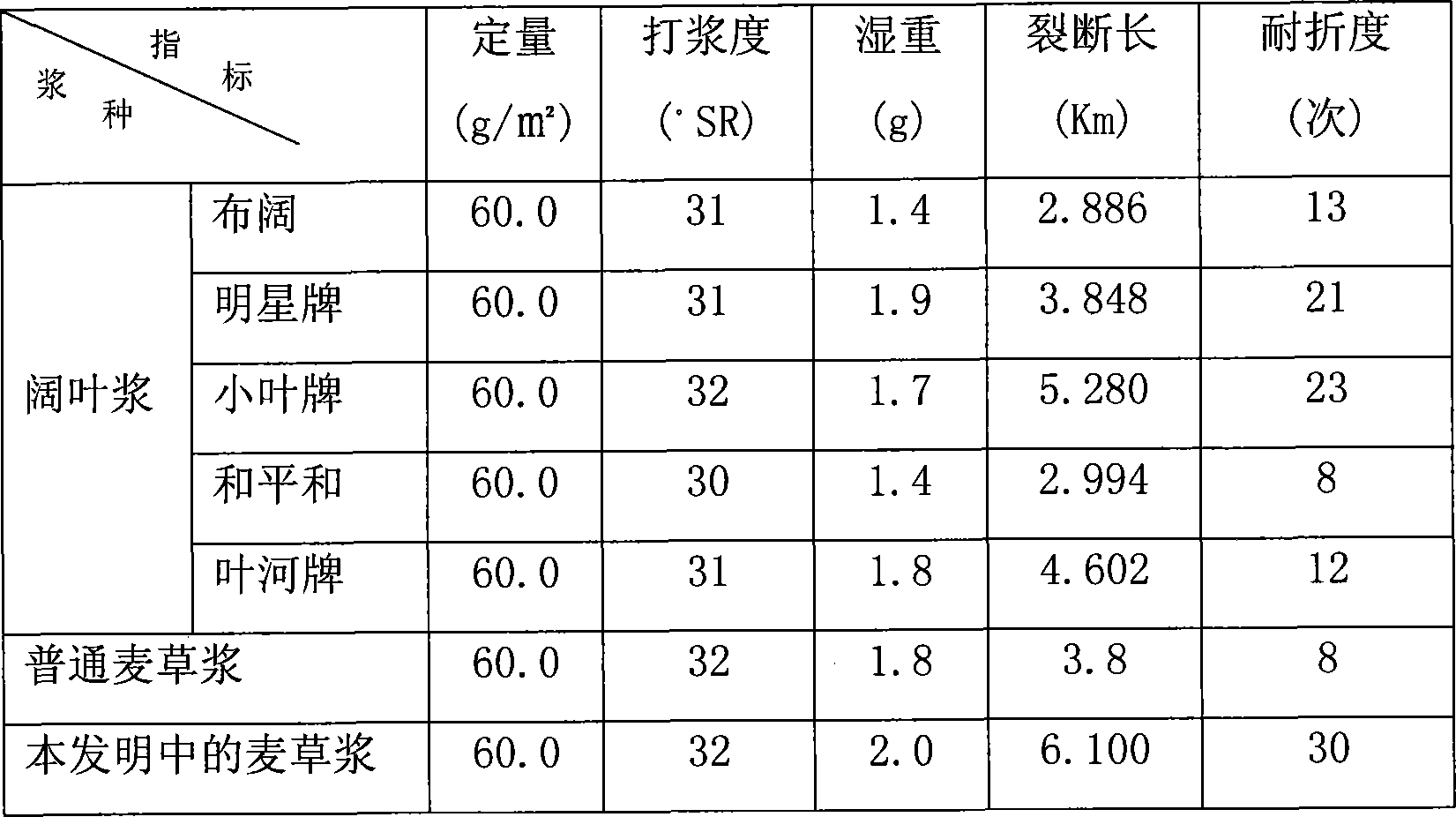

Prepared bleach chemical pulp using grass kind plant as raw material and preparation method thereof

ActiveCN101089291AReduce manufacturing costQuality improvementDigestersPulp de-wateringKappa numberFolding endurance

The present invention discloses a bleached chemical pulp prepared by using graminoid plant as raw material and its preparation method. Said invention is characterized by that it utilizes a high-hardness pulp which is obtained by using cooking process and whose permanganate number is 16-28 and equal to Kappa number 26-50 and makes said high-hardness pulp undergo the processes of pulp-washing and bleaching treatment so as to obtain the invented bleached chemical pulp whose breaking length is 4500-8000 m and folding endurance is 20-70 times.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Articles of manufacture made from pulp composition

InactiveUS20140205777A1Strength parameter sufficientSynthetic resin layered productsPulp bleachingFiberKappa number

One aspect of the invention relates to an article of manufacture made from a pulp composition comprising an ARF pulp. In one embodiment, the pulp composition made from agricultural renewable fibers (ARF) having low Kappa number with unexpected quality sufficient for papermaking (e.g., high strength parameters and high freeness). In another embodiment, the ARF pulp has ISO brightness of 60% or higher, and unexpected quality sufficient for papermaking (e.g. high strength.parameters and high freeness). In another embodiment, the ARF pulp is made from a pulping process comprising using a high concentration of anthraquinone (AQ).

Owner:CARGILL INC

Cooking method for pulp

InactiveUS20020088576A1Pulping with acid salts/anhydridesPulping with inorganic basesKappa numberCellulose

A lignocellulose material is cooked by means of an alkaline cooking liquor containing polysulfides in the presence of a quinone-hydroquinone compound, of which the oxidation-reduction potential in the form present during the cooking, which potential is a value calculated as a standard oxidation-reduction potential (Ea) with a hydrogen ion activity of 1, is within a range of from 0.12 to 0.25V to the standard hydrogen electrode potential. It is thereby possible to cook the lignocellulose material with a low Kappa number and in good yield and at the same time, to reduce the amount of the chemical solution used and to reduce the load on a recovery boiler.

Owner:KAWASAKI KASEI CHEMICALS LTD +1

Grass type un-bleaching pulp, preparation method and use thereof

ActiveCN101451322AProtection strengthLow priceCellulosic pulp after-treatmentDigestersCelluloseKappa number

The invention discloses grass unbleached pulp and a preparation method thereof. The fracture length of the unbleached pulp is between 3.48 and 7.2km, the folding resistance is between 15 and 70 times, the tearability is between 180 and 275 mN, the whiteness is 33 to 48 percent ISO, and the beating degree is between 33 and 38 DEG SR. The unbleached pulp can be taken as pulp of corrugated paper, napkin paper and packing paper. The preparation method comprises the steps of cooking, oxygen delignification and so on, and the unbleached pulp is obtained by obtaining high-hardness pulp the hardness of which has a potassium permanganate value of between 16 and 28 and is equivalent to a Kappa number of between 24 and 50 through the cooking, and then performing oxygen delignification treatment by introducing oxygen and adding sodium hydroxide, or being matched with a pulp squeezing step and / or a disintegration step before the oxygen delignification. The use of the method can not cause the unbleached pulp to be polluted by a bleaching agent, and the strength of the pulp is protected at the same time, thereby preventing cellulose in the pulp from being degraded due to the influence of bleaching.

Owner:SHANDONG TRALIN PAPER

Hardwood alkaline pulping processes and systems

InactiveUS20070240837A1Reduce rejectionReduce percentagePretreatment with alkaline reacting compoundsPretreatment with acid reacting compoundsKappa numberWaste product

Hardwood pulp rejects at a given Kappa number can be reduced by subjecting the hardwood pulp to specified cooking conditions at the end of cooking. In this regard, it has been discovered that s-lignin reacts faster than g-lignin and that there exists a higher proportion of g-lignin at the end of a hardwood cook as compared to the g-lignin present at the beginning of the cook. Thus, when cooking hardwoods, relatively harsher cooking conditions (e.g., higher cooking temperatures) at the end of the cooking have been discovered to decrease the g-lignin content which in turn decreases the percentage of pulp rejects at a given Kappa number. In preferred embodiments, methods and systems are provided for continuously producing chemical cellulose pulp from a slurry of comminuted hardwood material by subjecting the slurry of comminuted hardwood material to a first cooking stage under conditions sufficient to reduce syringyl lignin (s-lignin) content in the hardwood material as compared to guaiacyl lignin (g-lignin) content therein, and thereafter subjecting the slurry of comminuted hardwood material to a second cooking stage under conditions sufficient to reduce the g-lignin content remaining therein after the first cooking stage.

Owner:ANDRITZ INC

Pulp composition

One aspect of the invention relates to a pulp composition made from agricultural renewable fibers (ARF) having low Kappa number with unexpected quality sufficient for papermaking (e.g., high strength parameters and high freeness). Another aspect of the invention relates to an ARF pulp having ISO brightness of 60% or higher, and unexpected quality sufficient for papermaking (e.g. high strength parameters and high freeness). Another aspect of the invention relates to a pulp composition made from a pulping process comprising using a high concentration of anthraquinone (AQ). The pulping process can use wood or nonwood fibers (e.g., bagasse and corn stover) to provide pulp having good paper-making quality.

Owner:CARGILL INC

Method for determining chemical pulp kappa number with visible-near infrared spectrometry

A method for the determination of a cellulosic-fibre property, namely, residual lignin content or Kappa number of chemical pulp, with the aid of a spectroscopic technique obtained over a range covering the visible and the near-infrared regions of the electromagnetic spectrum, comprising exposing the wet fibres to a light source covering a range in the visible region of 350 nm to 750 nm and a range in the near-infrared of 1100 nm to 2400 nm, reflecting light from the wet fibres, establishing a spectrum, comparing the spectrum with a known spectrum of the property and evaluating the comparison; the method has particular utility in a pulp manufacture line; an apparatus is described for carrying out the method.

Owner:FPINNOVATIONS INC

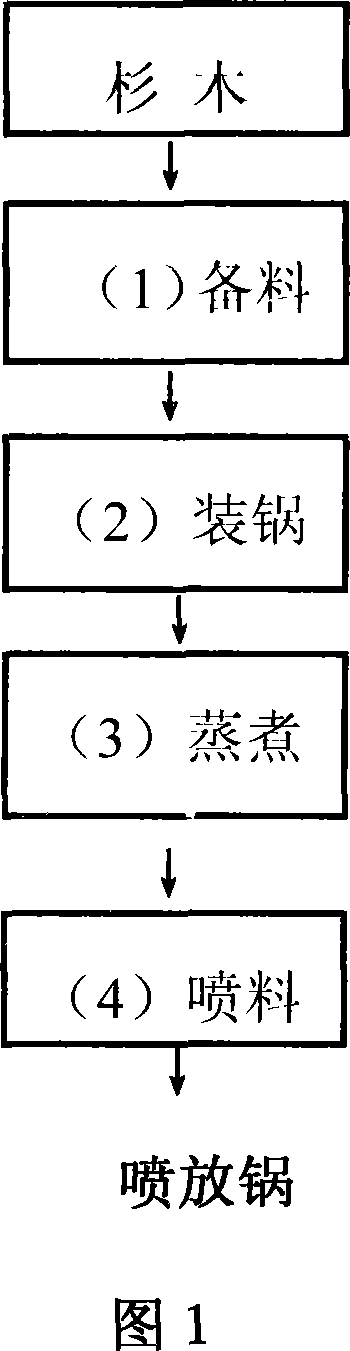

Method of producing fir chemical pulp

ActiveCN101058951AIncrease production capacitySolve the technical problem of pulp production reductionDigestersVeneer manufactureKappa numberLiquid ratio

A production method of fir wood chemical pulp uses fir as raw materials and sulphate process for boiling, the alkali amount 20-24% (measured on NaOH), the sulfide degree 10-23%, liquid ratio 1:2-1:3. 2, the total cooking time is 2 hours and 50 minutes to 3 hours and 10 minutes, Kappa number of prepared pulp is between 36 to 60, it is suitable for producing high-intensity wrapping paper in original color. The present invention shortens the boiling time and improves the availability ratio of boiler, solves the technical issues of pulp amount is lowered caused by fir small specific density, small pot capacity and bin door easy to be blocked up, it can prepare chemical pulp using the fir processing residual sideboard, resolve the issue of a large number of fir sideboard have to be wasted and has advantages of saving timber resources and reducing energy consumption.

Owner:YUEYANG FOREST & PAPER CO LTD

Pulp and black liquor prepared by grass type raw material, preparation method and use thereof

ActiveCN101451324AReduce dosageReduce degradationCellulosic pulp after-treatmentPulp liquor regenerationKappa numberFiber

The invention relates to unbleached pulp prepared by the ammonium sulfite cooking of a rice straw raw material and a preparation method thereof. The whiteness of the unbleached pulp is 35 to 48 percent ISO, the fracture length is between 5.0 and 7.5km, the tearability is between 200 and 275mN, and the folding times are between 30 and 100. The method comprises the steps of ammonium sulfite cookingand oxygen delignification, wherein the ammonium sulfite cooking is to cook the raw material into the pulp the harness of which has a potassium permanganate value of between 16 and 28 and is equivalent to a Kappa number of between 24 and 50. The unbleached pulp has higher strength, particularly has the fracture length and the folding times which exceed the level of hardwood pulp, can be used for manufacturing corrugated paper, lunch boxes, and packing paper which have quite high strength, or is applied to manufacturing other paper products more widely only by adding little wood pulp, greatly reduces the cost for products, and also ensures the strength of the products. The method can ensure that lignin is effectively removed and also try to reduce the degradation of fiber, thereby obtaining the unbleached pulp with good strength.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

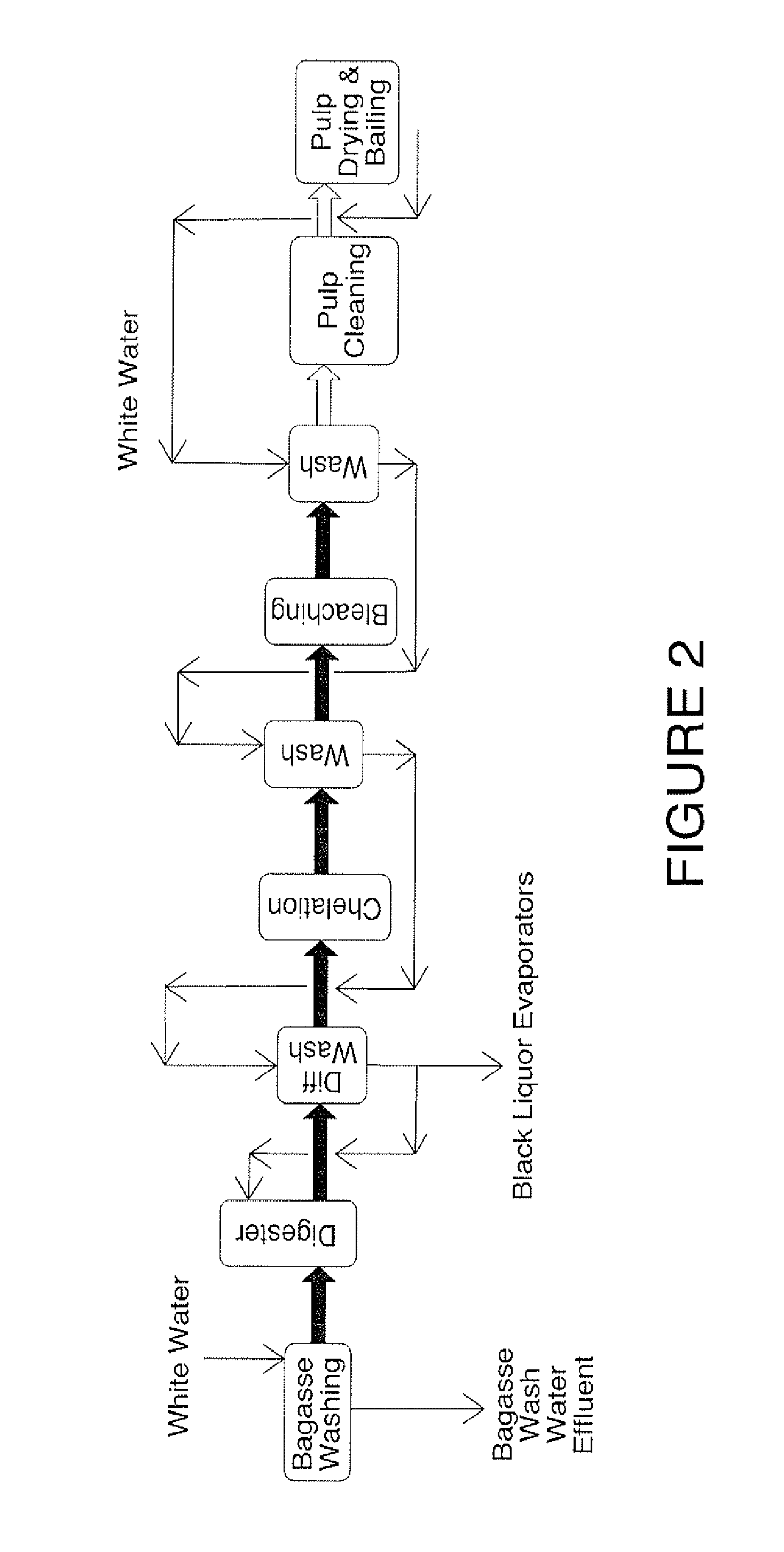

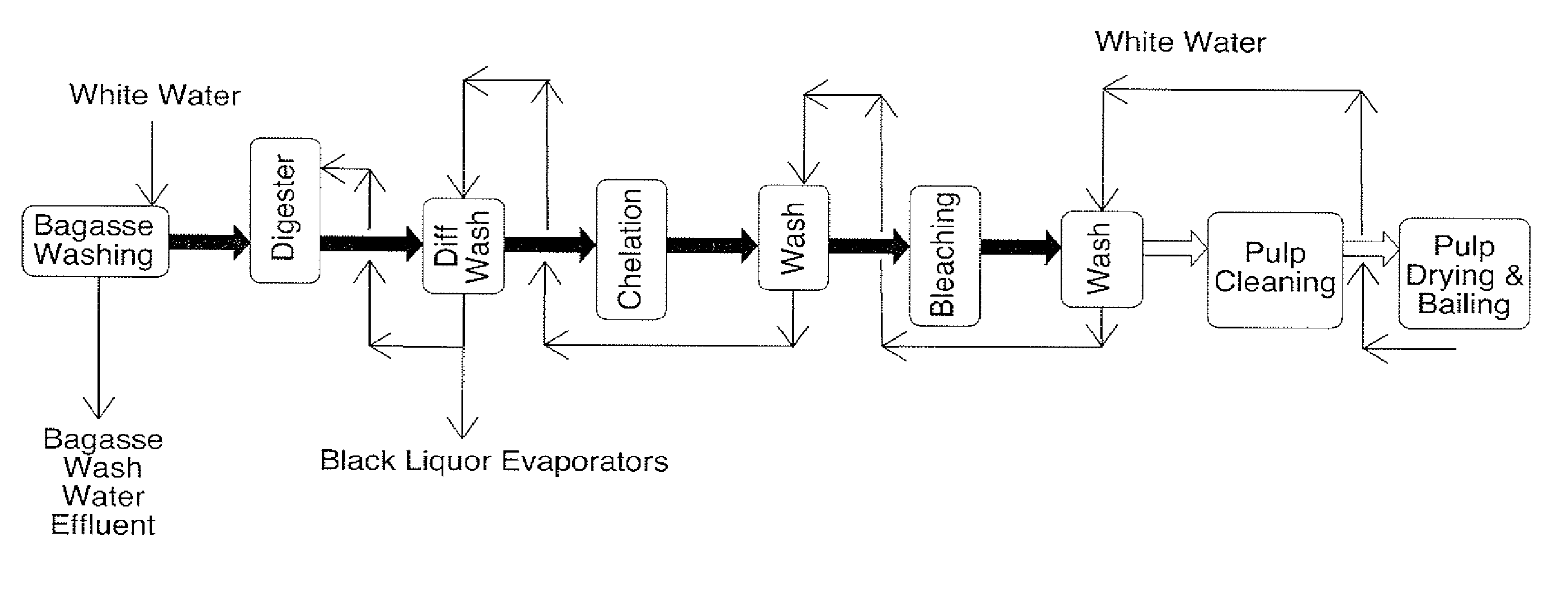

Pulp preparing method for increasing bagasse oxygen-alkali cooking effect

InactiveCN102587178AIncreased cooking fine pulp yieldHigh whitenessPulp bleachingRaw material pretreatmentKappa numberWater consumption

The invention discloses a pulp preparing method for increasing bagasse oxygen-alkali cooking effect, comprising the steps of replacing clear water with bleaching effluents of Eop section and P section of bagasse oxygen-alkali pulp, reusing in wet stockpiling process of bagasse, carrying out oxygen-alkali cooking on the bagasse, washing, selecting, screening and bleaching to finally obtain the pulp. Compared with the yield of pulp obtained through the oxygen-alkali cooking of the bagasse subjected to wet stockpiling and sprayed by using the clear water and the yield of pulp obtained through oxygen-alkali cooking of the bagasse not subjected to wet stockpiling, the pulp obtained by utilizing the method has the advantages that the yield is respectively increased by 1-3 percentage points and 2-6 percentage points and the whiteness of unbleached pulp is increased by 1-3% ISO and the viscosity is increased by 40-110mL / g under the circumstance that pulp kappa numbers are close; the pollution load of middle-stage effluents can be decreased by 20-40%; and the water consumption per ton of pulp is decreased by 5-18m<3>.

Owner:KUNMING UNIV OF SCI & TECH

Method for carrying out elemental chlorine free (ECF) multistage bleaching on masson pine kraft pulp by using glyoxal

The invention provides a method for carrying out elemental chlorine free (ECF) multistage bleaching on masson pine kraft pulp by using glyoxal. The method is characterized by firstly adopting chlorine dioxide to carry out delignification on the unbleached masson pine kraft pulp; then utilizing sodium hydroxide to carry out alkali extraction on the masson pine kraft pulp after delignification; then using chlorine dioxide to carry out delignification on the masson pine kraft pulp; and finally adopting hydrogen peroxide to bleach the masson pine kraft pulp to obtain the masson pine ECF pulp with high whiteness and excellent physical indexes. The method has the following beneficial effects: the whiteness of the prepared masson pine kraft pulp can reach 88.36% ISO, the Kappa number is 5.02 and the yield is about 90.28%; and the masson pine kraft pulp bleached by DEDP is used for manufacturing the handsheet and the tensile index is 40.08N.m / g, the tear index is 12.80mN.m<2> / g and the burst index is 3.45kPa.m<2> / g, thus showing that the finished paper has better physical strength.

Owner:SHAANXI UNIV OF SCI & TECH

Method of producing wet curtain paper

ActiveCN101033590AReinforcing agents additionChemical/chemomechanical pulpTemperature controlKappa number

A method to produce wet curtain paper which is made of masson pine, fir, broad-leaved wood sulfate pulp, matched paper-making wet strength agent and puffed agent. The mixture ratio of various slurries is 70-100% masson pine, 0-15% fir, 0-30% broad-leaved wood, 0.4-0.5% wet strength agent and 0-0.2% puffed agent. The conditions of producing technology are: slurry Kappa number: 42-58, degree of beating: 18-21 SR, upper gauze thickness: 0.3-0.5%, upper gauze pH: 6.5-8.5, pressure of press part: first pressure: 0.2-0.3MPa, second pressure: 0.1-0.4MPa and third pressure: 0.1- 0.4MPa. The invention aims at providing a method to produce wet curtain paper as key components of device for wet curtain temperature-control and damping-control.

Owner:YUEYANG FOREST & PAPER CO LTD

Pulping processes

A pulping process comprises using a high concentration of anthraquinone (AQ). The pulping process is capable of providing a pulp having low Kappa number with unexpectedly high strength. The pulping process can use wood or non-wood fibers (e.g., bagasse and corn stover) to provide pulp having good papermaking quality. The method for pulping a fiber comprising cooking a first mixture comprising the fibers, water, an alkali, and a delignification selectivity enhancing chemical for a cooking time and at a cooking condition sufficient to form a first pulp having a desired Kappa number of about 15 or less, and strength parameters that are sufficient for papermaking, where the starting material prior to cooking has a Kappa number of 60 or greater.

Owner:CARGILL INC

Method for using graphene/shell to prepare antibacterial paper

InactiveCN108130772AObvious advantage in delignification reactionObvious advantagesPulp properties modificationWater-repelling agents additionEscherichia coliFiber

The invention relates to a method for using graphene / shell to prepare antibacterial paper, and discloses a technology for preparing shell fiber. The technology comprises the steps of spiral squeezingprocessing, biological enzyme fermenting, papermaking, paper modifying and the like. The shell serves as raw materials for preparing fiber, then through the cooperation of ultrasonic waves and biological enzymes, the prepared fiber has high yield, high whiteness and a low kappa number, in the whole process, no harmful chemical products are introduced, and the hygiene of the fiber is ensured. Sincegraphene dispersion liquid is added in the pulping process, the obtained product has high electric conduction and bacterial resistance, and particularly has an effect of effectively inhibiting and killing staphylococcus aureus, escherichia coli and hemolytic streptococcus.

Owner:林荣铨

Base paper of sandpaper and production method thereof

ActiveCN102154899AEmission reductionReduce productionWater-repelling agents additionDigestersKappa numberFiber

The invention relates to a piece of base paper of sandpaper and a production method thereof. The method comprises the following steps: a fibre raw material is cooked to form paper pulp; and the fibre raw material comprises 70-80% of masson pine and the rest of eucalyptus, and the cooking kappa number is 38-48; and the paper pulp is prepared through pulping, desanding, mixing, finely screening by a pressurized screen, forming by loading a net, pressing, drying, calendering, winding, re-winding and packing. The longitudinal tensile index of the paper is no less than 80Nm / g, the transversal tensile index of the paper is no less than 45Nm / g, the folding strength of the paper is no less than 1,000 times, the horizontal shrinkage rate of the paper is no more than 3.5%, the tightness degree of the paper is no less than 0.78g / cm3, the smoothness of the paper is no less than 15s, the sizing degree of the paper is no more than 30g / m2, the longitudinal tensile strength of the paper is no less than 8.0kN, the horizontal tensile strength of the paper is no less than 3.0kN, the color of the paper is brown, the whiteness of the paper is 19%-26%, and the hue is as follows: L value of 65-75, a value of 3.5-7.5 and b value of 21-27.

Owner:YUEYANG FOREST & PAPER CO LTD

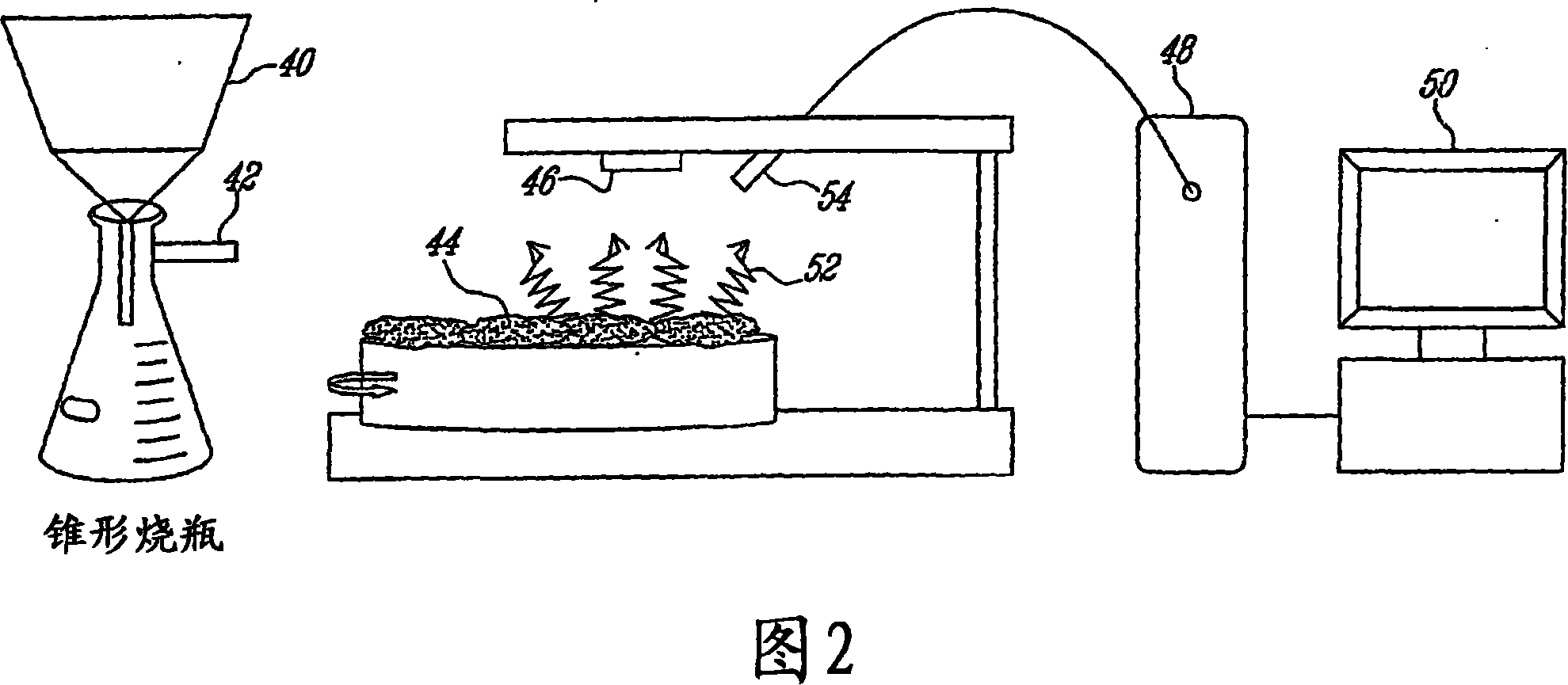

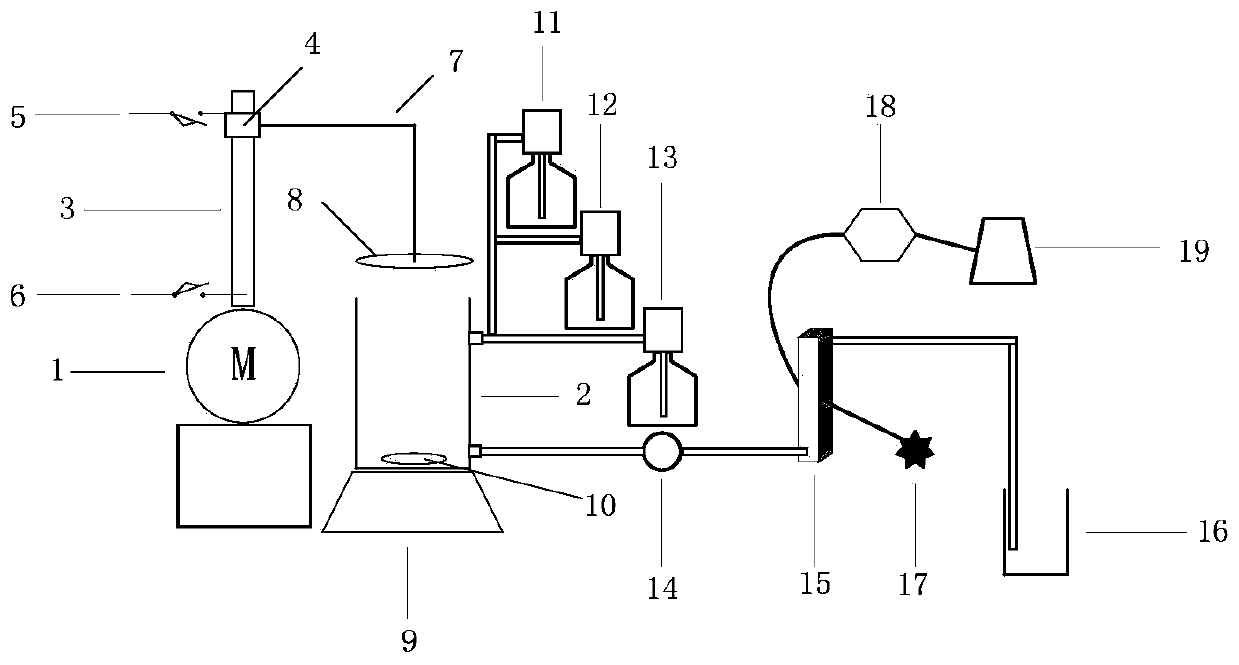

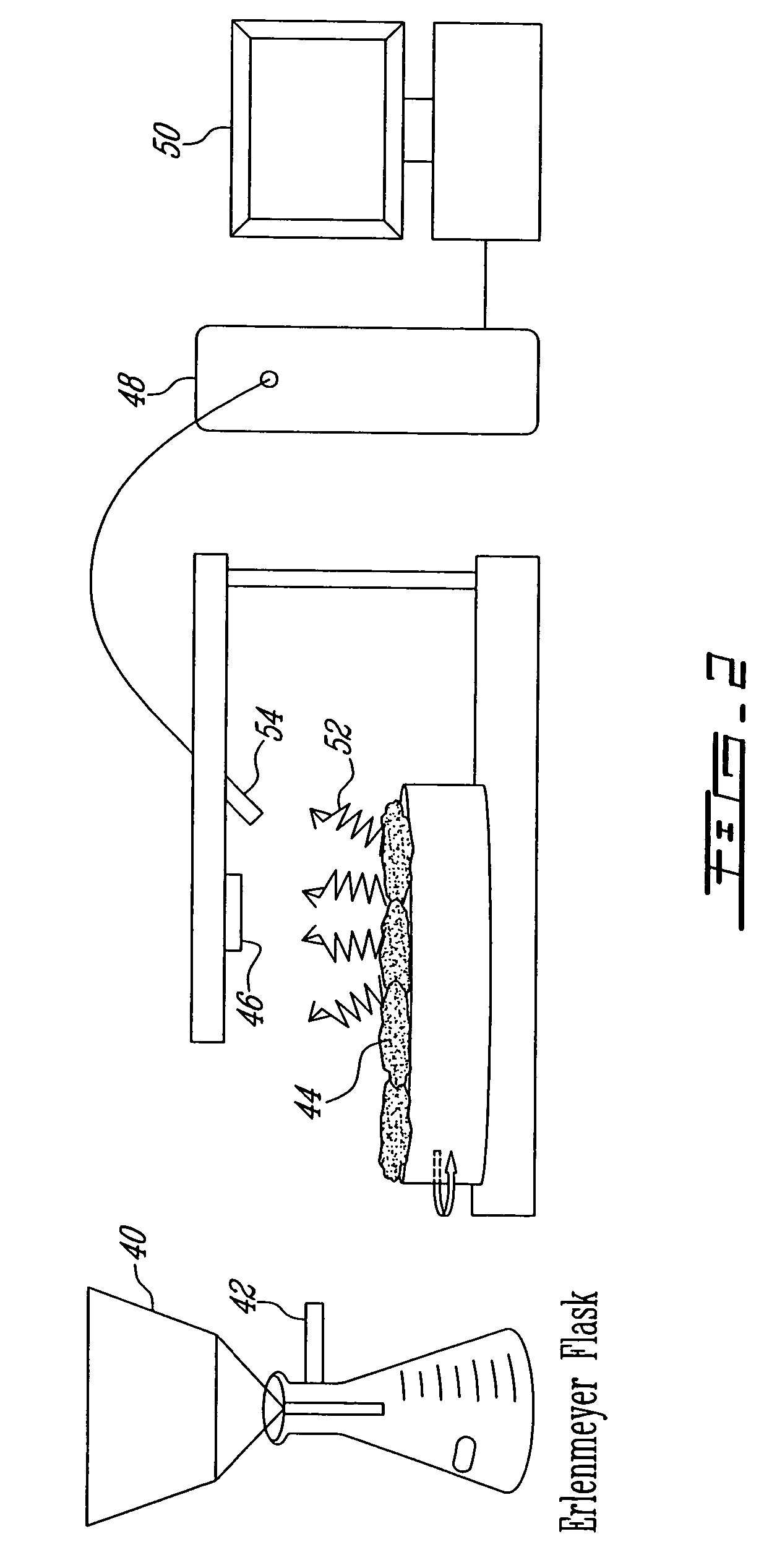

Rapid tester for paper pulp kappa number and control method of rapid tester

InactiveCN103630501AIncrease acidityHigh degree of intelligenceProgramme controlComputer controlData displayMicrocontroller

The invention discloses a rapid tester for a paper pulp kappa number and a control method of the rapid tester. The rapid tester comprises a reaction tank, three liquid adding units, a magnetic stirrer, a stepping motor, a sliding rail connected with the stepping motor, a slide block arranged on the sliding rail, an upper limiting switch, a lower limiting switch, a bracket fixedly connected with the slide block, a cuvette, a waste liquid tank, a peristaltic pump, a light source, a photovoltaic conversion device and a data displaying device, wherein the three liquid adding units are communicated with the reaction tank and are the same in structure; the magnetic stirrer is used for bearing the reaction tank; the peristaltic pump can be used for pumping liquid from the reaction tank to the waste liquid tank through the cuvette; light emitted by the light source passes through the cuvette and is received by the photovoltaic conversion device, and then the light is converted and conveyed into a single chip microcomputer; after the tester is electrified, self detection is carried out to ensure that the tester is at a normal initial state and simultaneously a power supply is driven to emit the light to pre-heat; before a sample to be detected is detected officially, blank deduction, base solution detection and standard sample detection operations need to be carried out firstly; after an experiment is finished, the device is washed.

Owner:SOUTH CHINA UNIV OF TECH

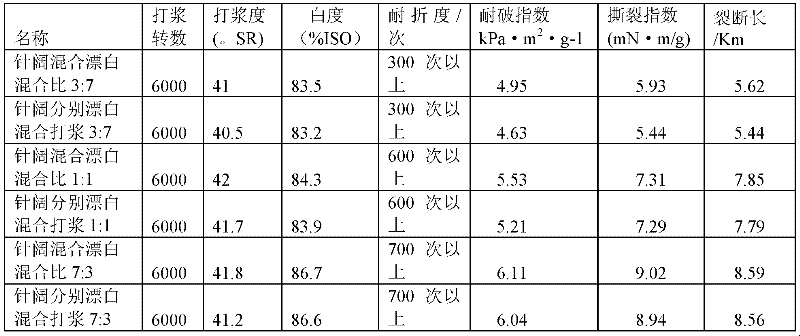

Process for bleaching needlebush and hardwood mixed chemical pulp stewed by using sodium hydroxide anthraquinone method

The invention relates to a process for bleaching needlebush and hardwood mixed chemical pulp stewed by using a sodium hydroxide anthraquinone method. The process comprises the steps of: mixing needlebush chemical pulp stewed by using the sodium hydroxide anthraquinone method with hardwood chemical pulp stewed by using the sodium hydroxide anthraquinone method in a mass ratio which ranges from 3:7to 7:3; and then performing high-whiteness bleaching by employing an ECF (elemental chlorine free) bleaching process having a bleaching working procedure of O1-O2-D0-OEP-D1-D2 or O1-O2-D0-OEP-D1. In the invention, the dosage of consumed chemicals in an entire process is equal to or a little lower than that of a process in which paper pulp is respectively stewed and respectively bleached. The two kinds of stewed crude pulp are similar in Kappa number, therefore other conditions of the bleaching process are milder, and the pulp provided by the invention is easier to bleach than the paper pulp with great hardness difference. Both the whiteness stability of the bleached paper pulp and various physical indexes such as burst index, fracture length, tearing index, folding strength and the like of made paper are better.

Owner:QILU UNIV OF TECH

Cooking auxiliary agent for papermaking and pulping

ActiveCN104099792AGood emulsifying effectImprove diffusivityCellulose material pulpingSodium acetateKappa number

The invention relates to a cooking auxiliary agent for papermaking and pulping, belongs to the field of papermaking, and aims to solve the problems that the existing cooking auxiliary agent is high in toxicity and severe in environmental pollution. The cooking auxiliary agent for papermaking and pulping comprises the following components in percentage by weight: 8-12% of primary alcobol ethoxylate, 10-20% of linear alkylbenzene sulfonates, 3-8% of alkyl sulfonate sodium acetate, 3-8% of alkyl phenyl polyoxyethylene ether, 2-5% of sodium nonylphenol polyoxyethylene ether sulfonate, 1-3% of methyl sulfone, 2-5% of carboxymethyl cellulose, 0.5-1.2% of oleamide, 0.1-0.5% of sodium pyrophosphate and the balance of deionized water. The cooking auxiliary agent is mainly applicable to the papermaking field, can reduce environmental pollution, improve the screened pulp yield and reduce Kappa number.

Owner:刘建国

Method for determining chemical pulp kappa number with visible-near infrared spectrometry

Owner:FPINNOVATIONS INC

Method for preparing high-yield ecru bamboo pulp through displacement cooking

InactiveCN107414989AImprove energy savingGood cooking uniformityWashing/displacing pulp-treating liquorsWood treatment detailsKappa numberHigh concentration

The invention discloses a method for preparing high-yield ecru bamboo pulp through displacement cooking. By means of improvement, the method comprises the following steps of material preparing, steam pretreating, cooking, shoving, high-concentration pulp grinding, low-concentration pulp grinding, washing and pulp beating. By means of the preparation method, the yield of the obtained pulp ranges from 70% to 90%, the kappa number is 80 or above, the whiteness ranges from 14% ISO to 24% ISO, and the b value ranges from 25% to 40%. According to the method, the displacement cooking technology is adopted, and by means of high-compression-ratio extruding and high-concentration pulp grinding, the preparation process has the beneficial effects that energy saving and environmentally friendliness are achieved, no emission is caused, and the production efficiency is high.

Owner:SICHUAN YONGFENG PAPER MAKING JOINT STOCK

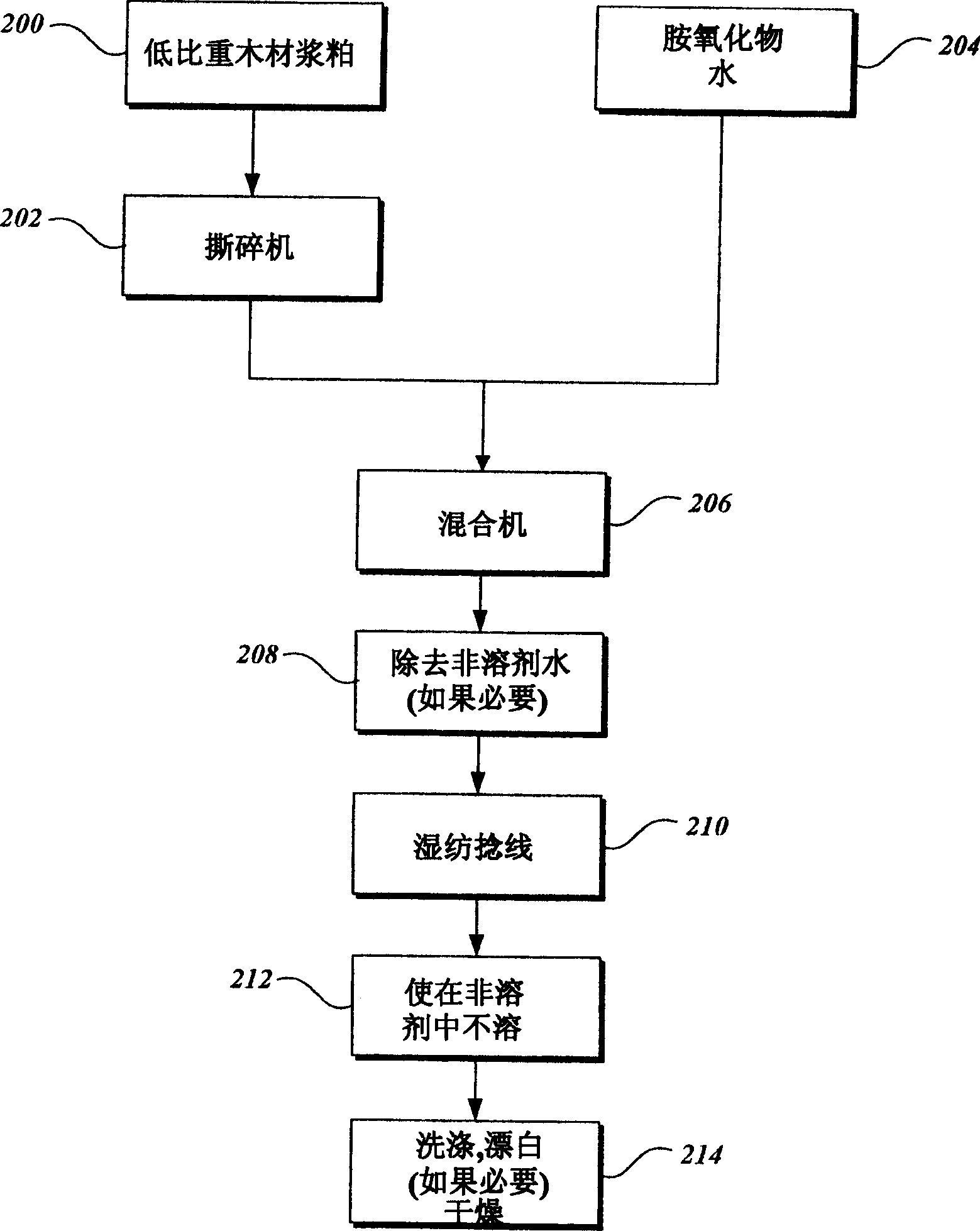

Use of thinnings and other low specific gravity wood for lyocell pulps method

ActiveCN1519424AReduce the temperatureDo not reduce the contentPulp properties modificationMonocomponent cellulose artificial filamentKappa numberBleach

The use of low specific gravity wood from thinning operations, for example, will produce a lower brownstock viscosity for a given kappa number target. A differential of 200-cP falling ball pulp viscosity has been detected from Kraft cooks of low and high specific gravity wood. Using low specific gravity wood can reduce the bleach stage temperature and the chemical dose needed in the bleach plant to produce lyocell pulp specifications. Low specific gravity wood also increases the ability to reduce pulp viscosity to very low levels without increasing the copper number of the pulp or the concentration of carbonyl in the pulp above acceptable levels.

Owner:WEYERHAEUSER CO

Oxidized white liquor in an oxygen delignification process

InactiveUS6691358B1Convenience to workIncrease productionCellulosic pulp after-treatmentPulp liquors combustionKappa numberWhite liquor

The invention refers to a method for an integrated treatment of cellulose pulp. The method includes the steps: providing said cellulose pulp (1), providing a determined quantity of white liquor (2) including alkali and sulphur components, providing an oxygen-containing gas, oxidizing (5) the sulphur components of the white liquor by the supply of a part of said gas in such a way that at least a part of the sulphur is present in the form of sulphate, transporting the cellulose pulp having a certain kappa number to at least one mixing device (4), and supplying the oxidized white liquor from the oxidizing step to the cellulose pulp, supplying a part of said gas to the cellulose pulp in said mixing device, mixing the cellulose pulp with the oxidized white liquor and said gas in said mixing device, and transporting the cellulose pulp from said mixing device to a delignification reactor (6) for oxygen delignification of said cellulose pulp, wherein the kappa number is reduced.

Owner:AGA AB

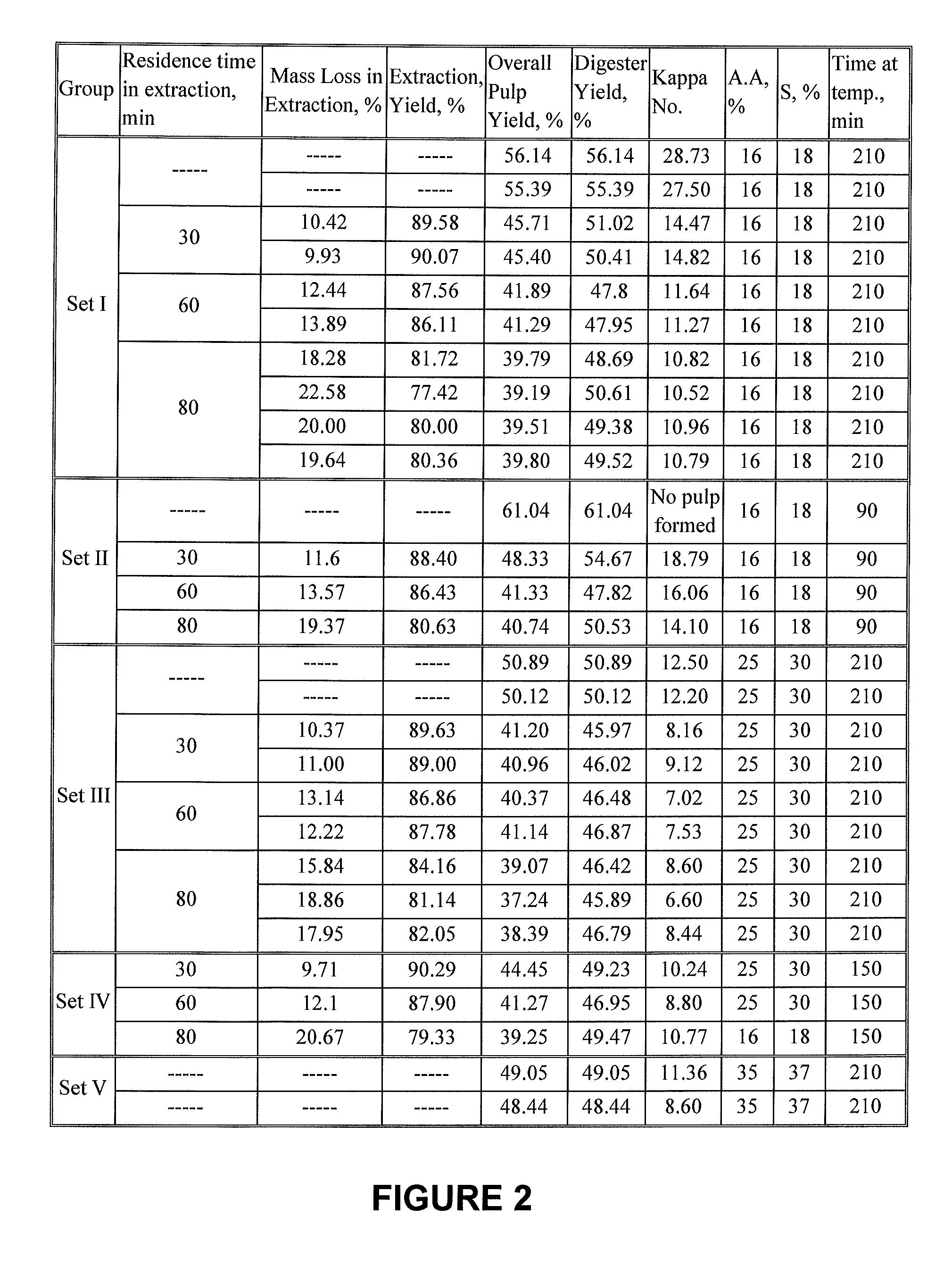

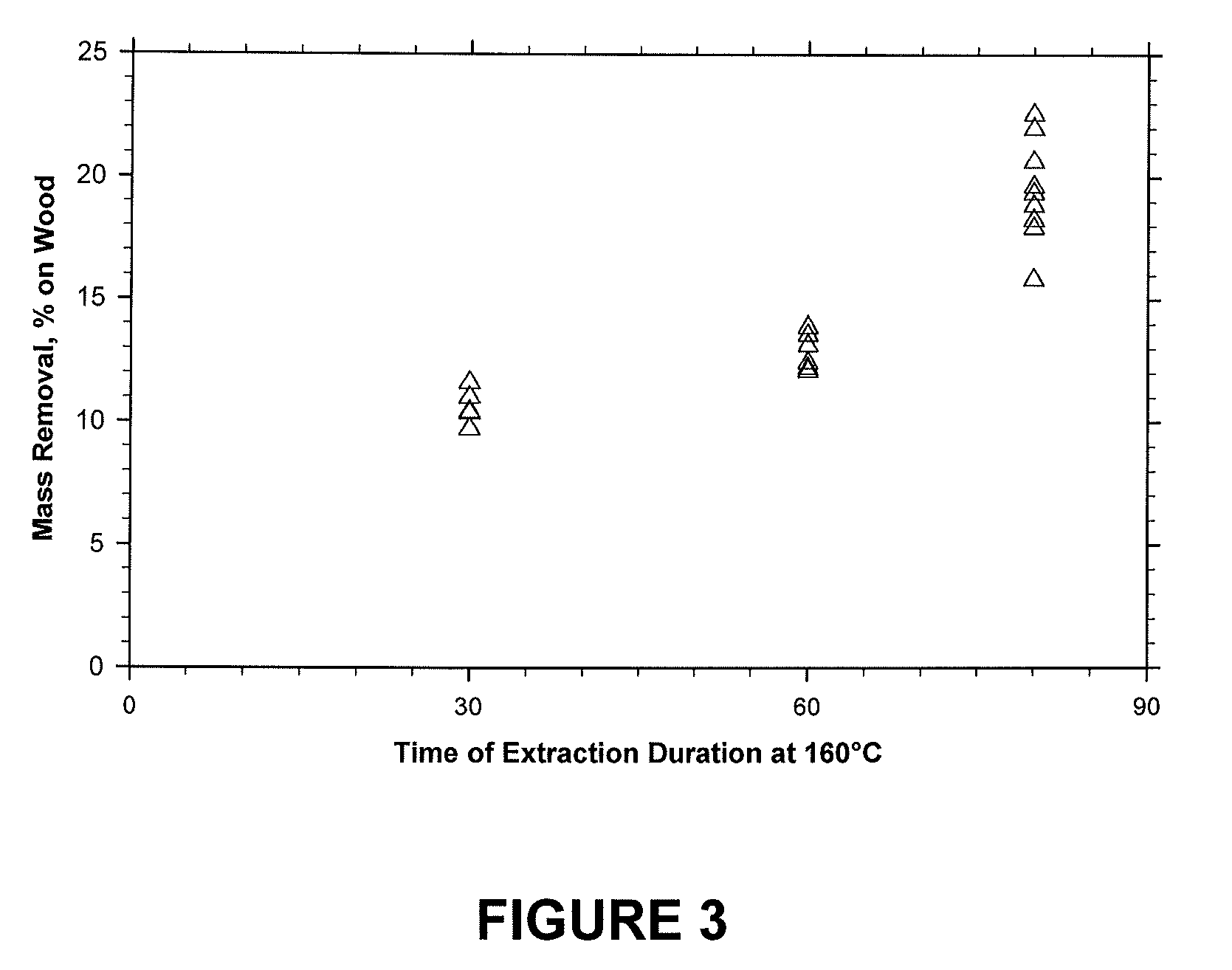

Kraft-Pulping of Hot Water Extracted Woodchips

InactiveUS20110073264A1Reduce weightIncrease in sizePretreatment with water/steamPulping with inorganic basesKappa numberWhitening Agents

The method of the present invention is directed towards a method to increase the pulp yield of a lignocellulosic material, or increasing pulp bulk and / or pulp viscosity. This method comprises the following steps; preparing a lignocellulosic material, contacting the lignocellulosic material in a vessel with hot water or steam for a predetermined time, producing acetic acid from the reaction of the hot water or steam and the lignocellulosic material, lowering the pH to less than about 4, removing lignocellulosic material extracts including a large percentage of hemicellulose, acetic acid and metal ions, exposing contacted lignocellulosic material to pulping chemicals in a pulping reactor, forming a contacted lignocellulosic material pulp with a kappa number below about 19 after about 90 minutes of contact with the pulping chemicals, exposing the contacted lignocellulosic material pulp to whitening agents, and producing a whitened hot water contacted lignocellulosic material pulp.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

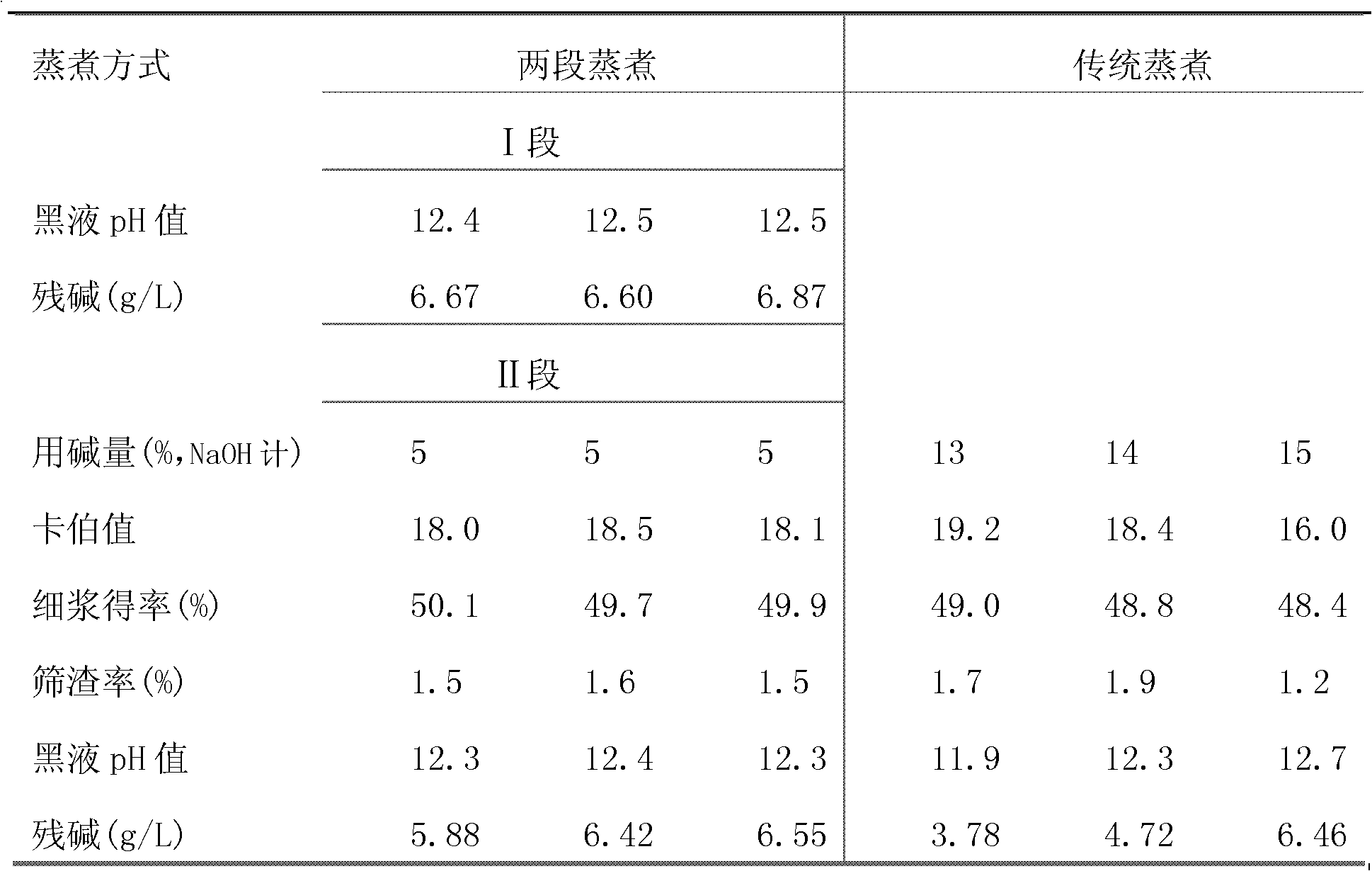

Method for cooking grass raw materials at two stages with soda anthraquinone by adding black liquor

InactiveCN102154873AUniform and stable yieldHigh yieldPulp bleachingPulping with inorganic basesKappa numberBlack liquor

The invention discloses a method for cooking grass raw materials at two stages with soda anthraquinone by adding black liquor. According to the characteristic of quick delignifying of the grass raw materials by adopting alkaline cooking, low temperature and normal pressure are adopted in a first stage, and black liquor is added for cooking at the two stages. A cooking result indicates that the Kappa number of paper pulp, the yield of screened pulp, the residual alkali in the black liquor and the like are uniform and stable, and stable operation can be realized. Compared with the conventional soda anthraquinone cooking method, the two-stage cooking method disclosed by the invention has the advantages: operation can be performed under low temperature condition, and the alkali amount is reduced, the yield of screened pulp is increased and the residue sieving rate is low under the condition that the Kappa number is basically the same. Moreover, O-DQ-P and O-Q-P-P bleaching are performed on pulp obtained by using the two-stage cooking method and the conventional soda anthraquinone cooking method, and the physical property of the pulp is detected. A result indicates that the whiteness and the viscosity of bleach pulp obtained by the two-stage cooking are higher than those of bleach pulp obtained by the conventional cooking, and the bleach pulp has better bleachability and higher mechanical intensity, and can be used for making writing paper, offset printing book paper and the like.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Thinning wood and other low specific wood used for leiser pomace

InactiveCN1517490AReduce the temperatureDo not reduce the contentPulp properties modificationMonocomponent cellulose artificial filamentKappa numberBleach

The use of low specific gravity wood from thinning operations, for example, will produce a lower brownstock viscosity for a given kappa number target. A differential of 200-cP falling ball pulp viscosity has been detected from Kraft cooks of low and high specific gravity wood. Using low specific gravity wood can reduce the bleach stage temperature and the chemical dose needed in the bleach plant to produce lyocell pulp specifications. Low specific gravity wood also increases the ability to reduce pulp viscosity to very low levels without increasing the copper number of the pulp or the concentration of carbonyl in the pulp above acceptable levels.

Owner:WEYERHAEUSER CO

Method for preparing paper pulp with raw biomass material and co-producing biochar

ActiveCN103031764AReduce dosageSimple process routePulp bleachingCarbon preparation/purificationKappa numberPapermaking

The invention relates to a preparation method of paper pulp, in particular to a method for preparing the paper pulp with a raw biomass material by utilizing organic acid. The method comprises the step of preparing the paper pulp by cooking the raw biomass material with formic acid and acetic acid mixed organic acid under the catalysis of hydrogen peroxide. According to the method for preparing the paper pulp, the productivity of the paper pulp is high; the cooking time is short; a bleaching technology is simple; and as hydrogen peroxide is added in a pulping process, lignin is removed to the greatest extent, a carbohydrate is prevented from being damaged, only simple chlorine-free bleaching is required in the subsequent bleaching technology, and the high-whiteness pulp can be obtained. The obtained paper pulp is good in drainability and property; the kappa number is low; biochar can be prepared with black liquor generated in a paper pulp production process; the effects of pollutants discharged in a papermaking process on an environment are reduced; and an economic benefit and an environmental benefit of an enterprise are improved.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com