Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1920 results about "Chemical solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

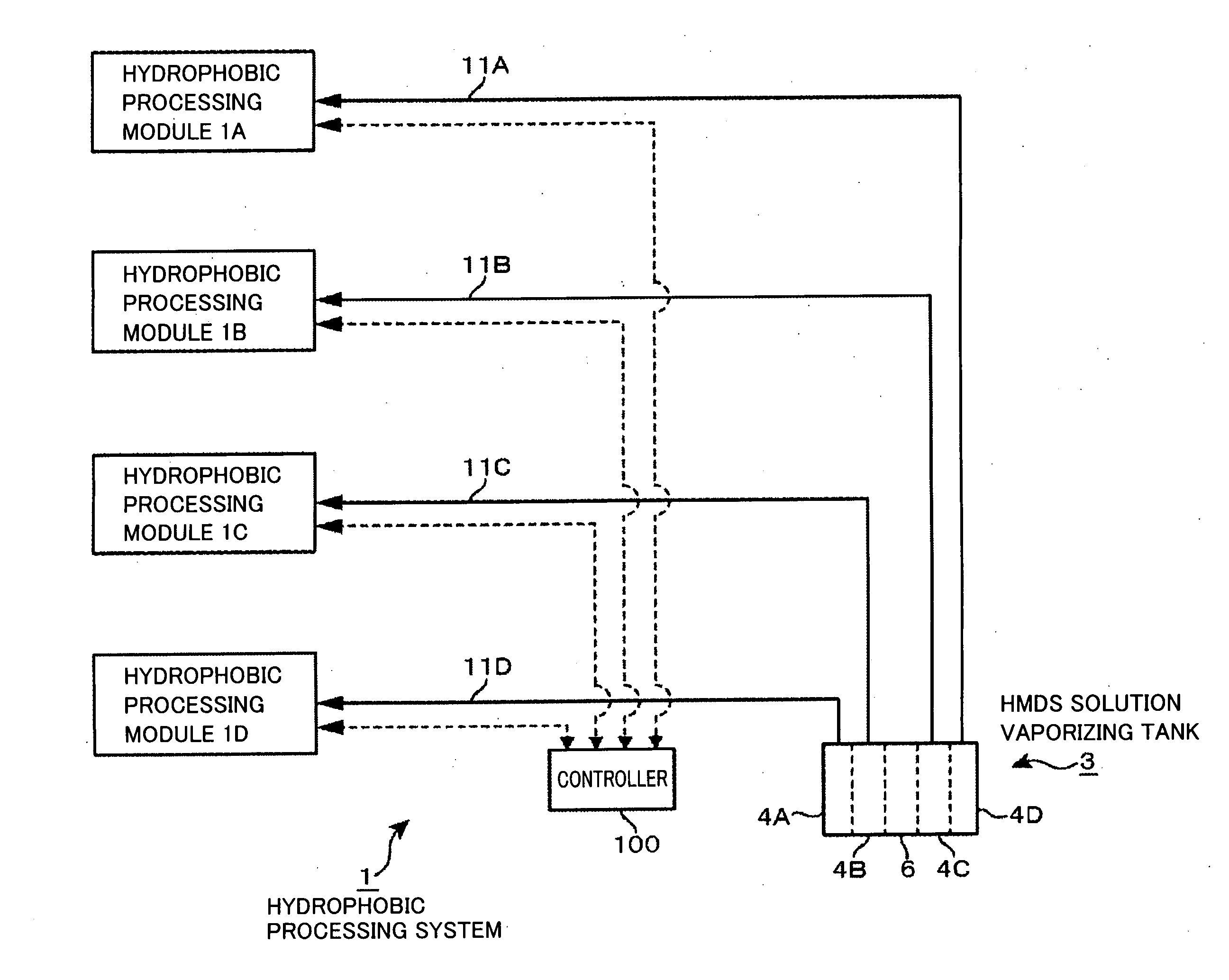

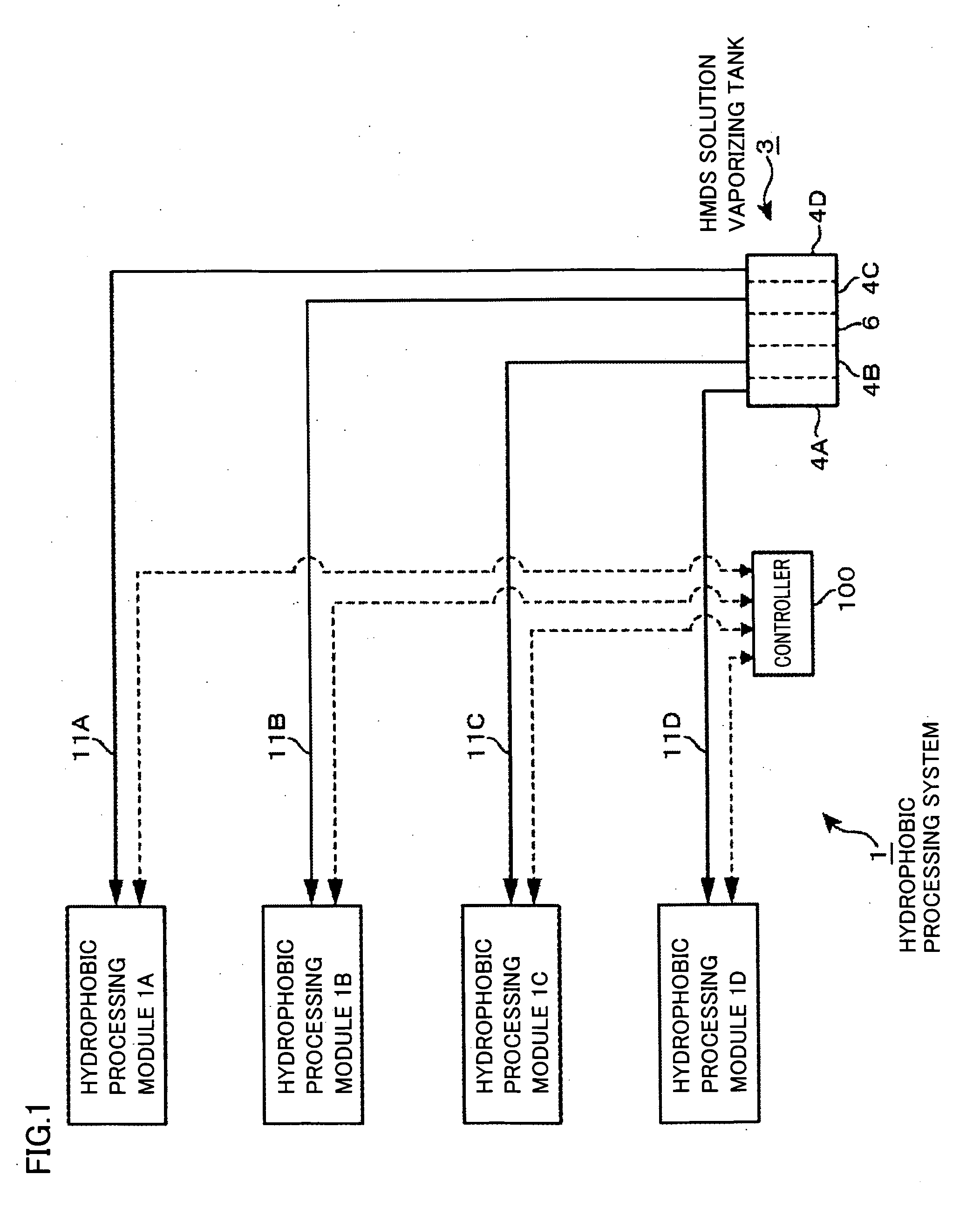

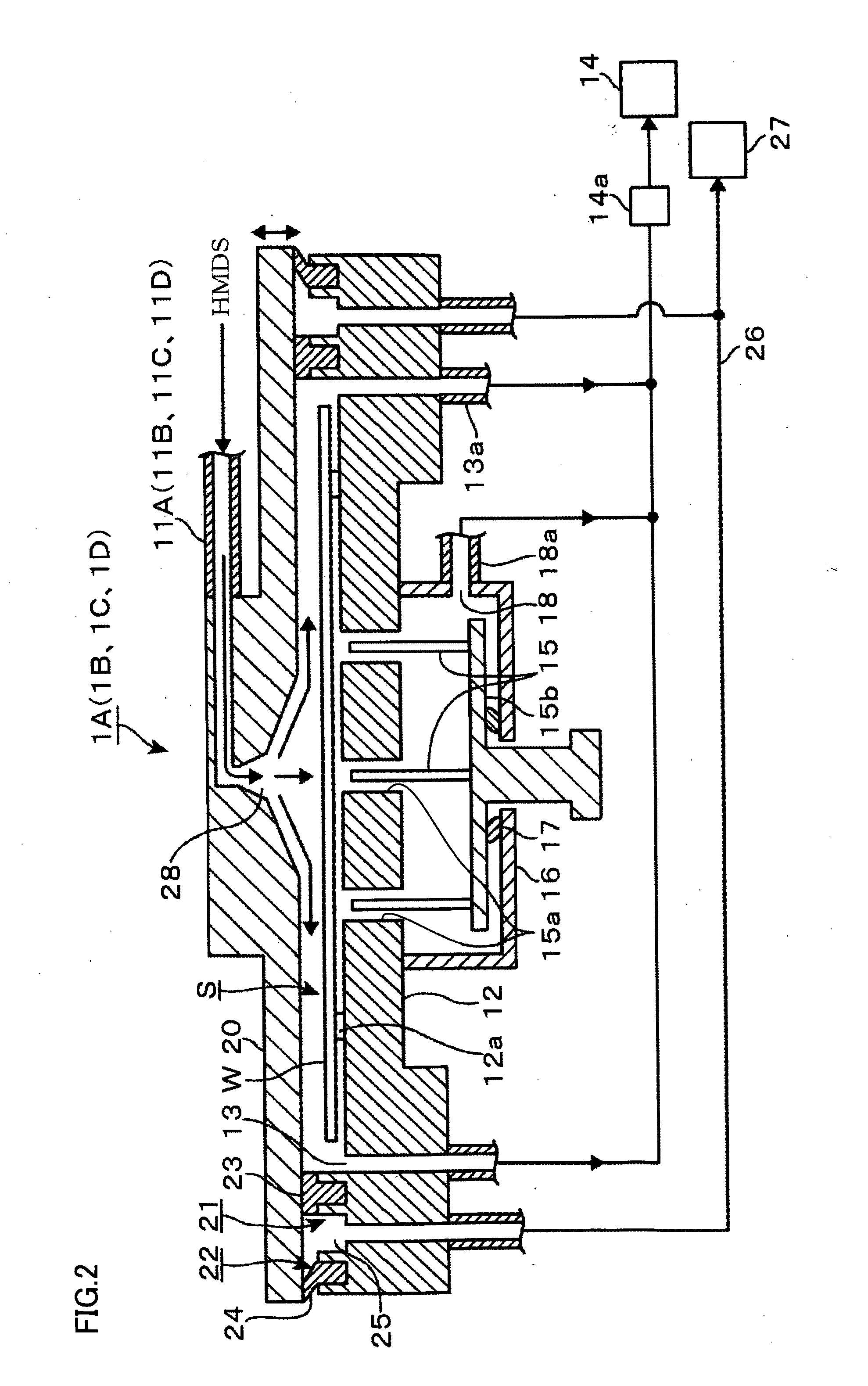

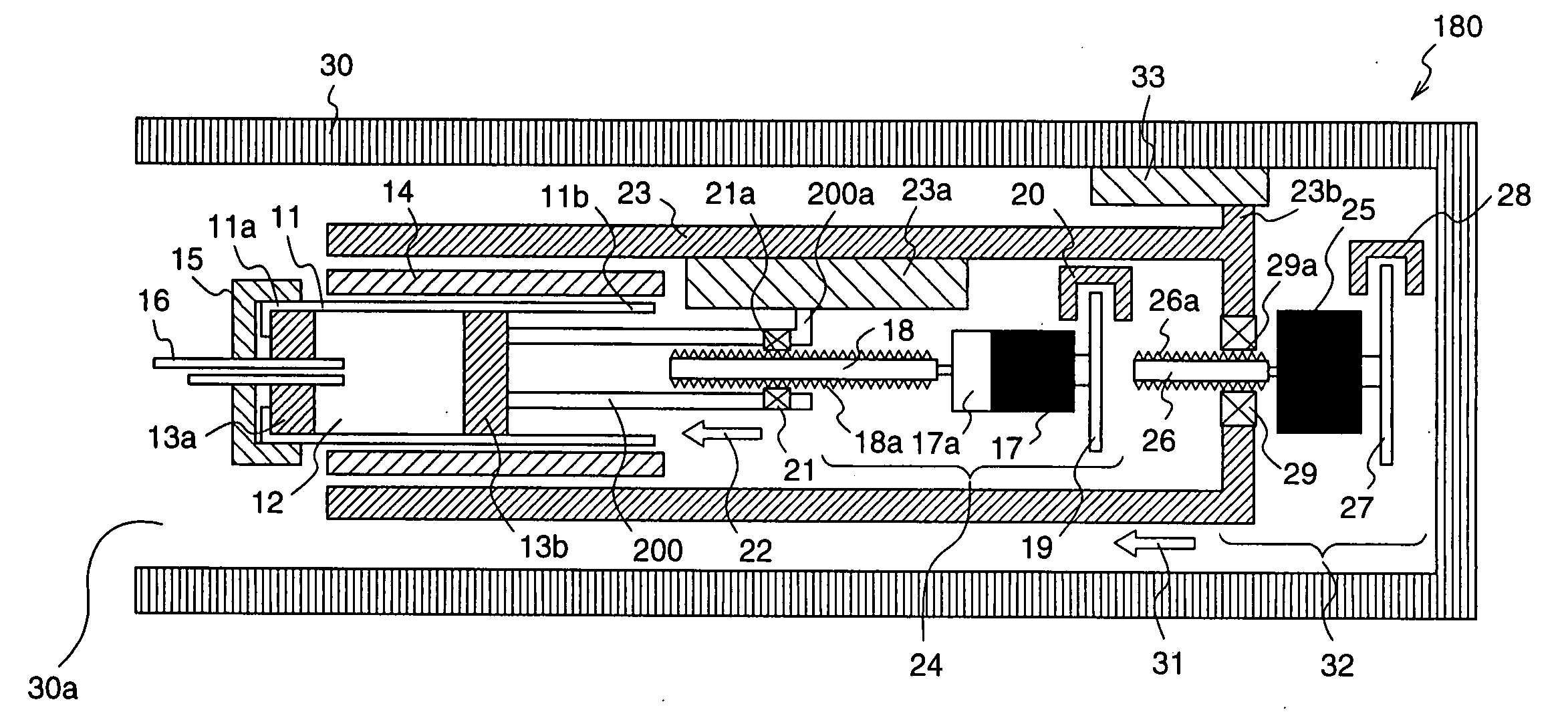

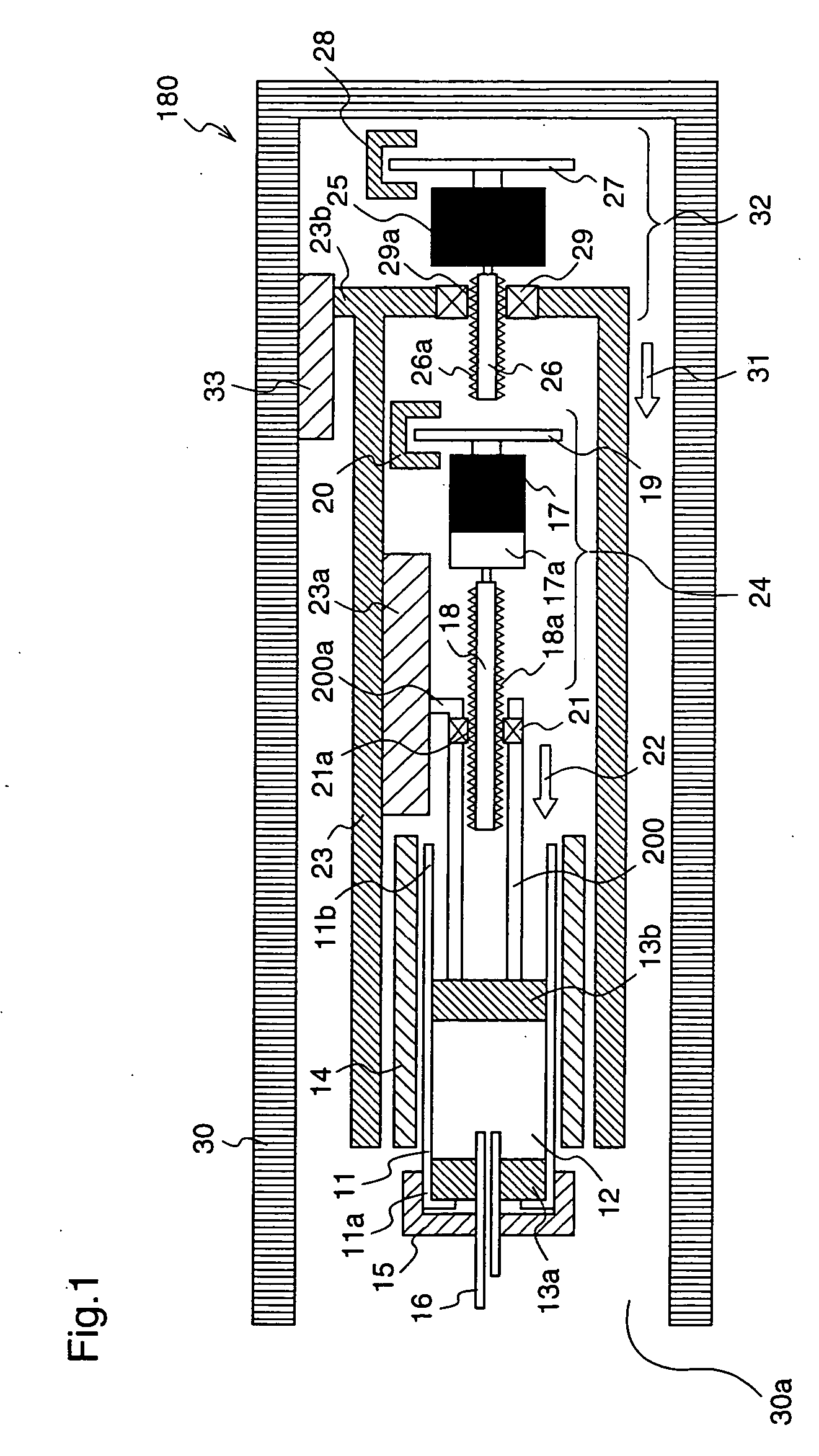

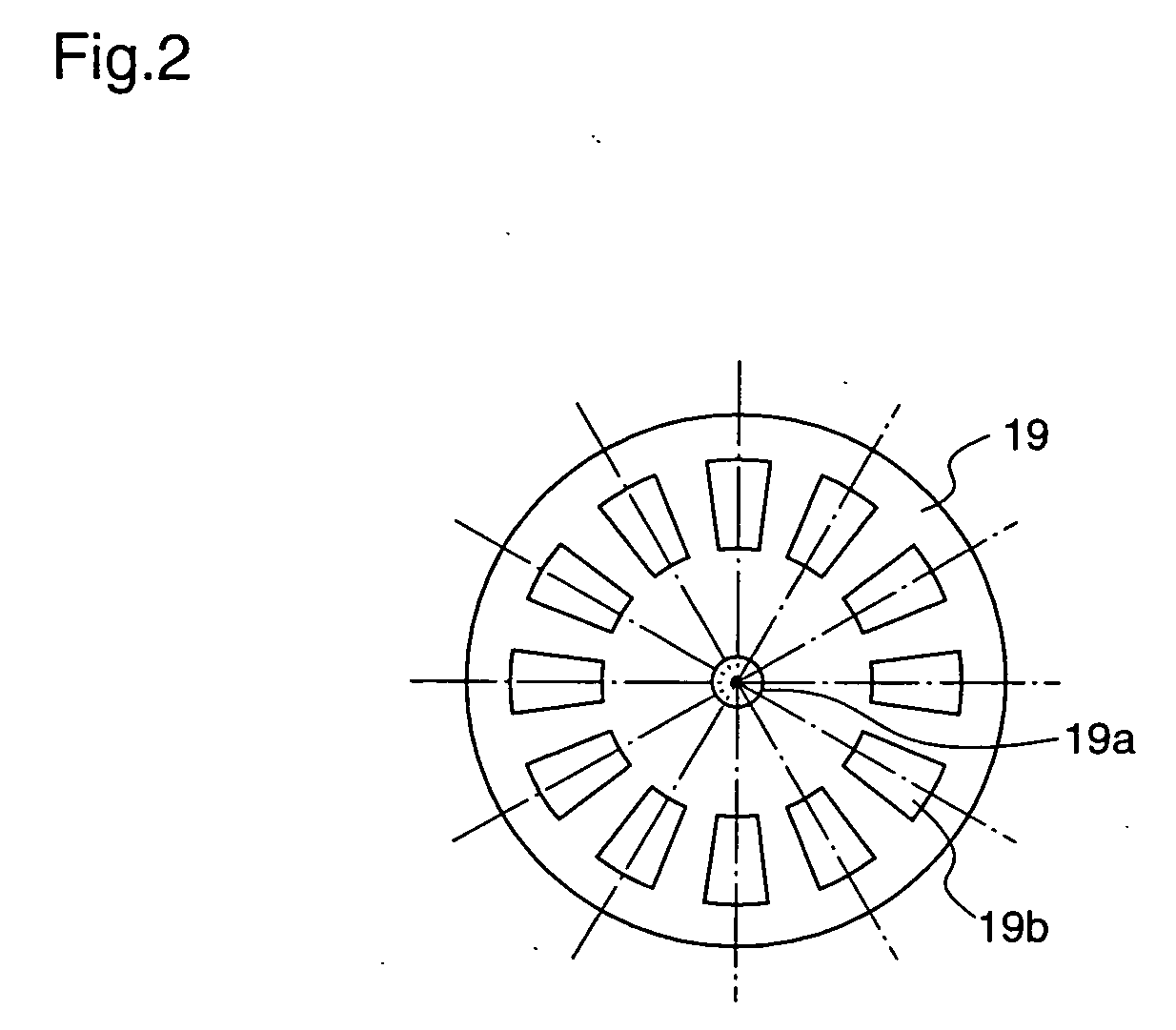

Chemical solution vaporizing tank and chemical solution treating system

ActiveUS20090020072A1Concentration differenceVariations in concentration of the chemical solutions can be suppressedLiquid surface applicatorsSemiconductor/solid-state device manufacturingChemical solutionProduct gas

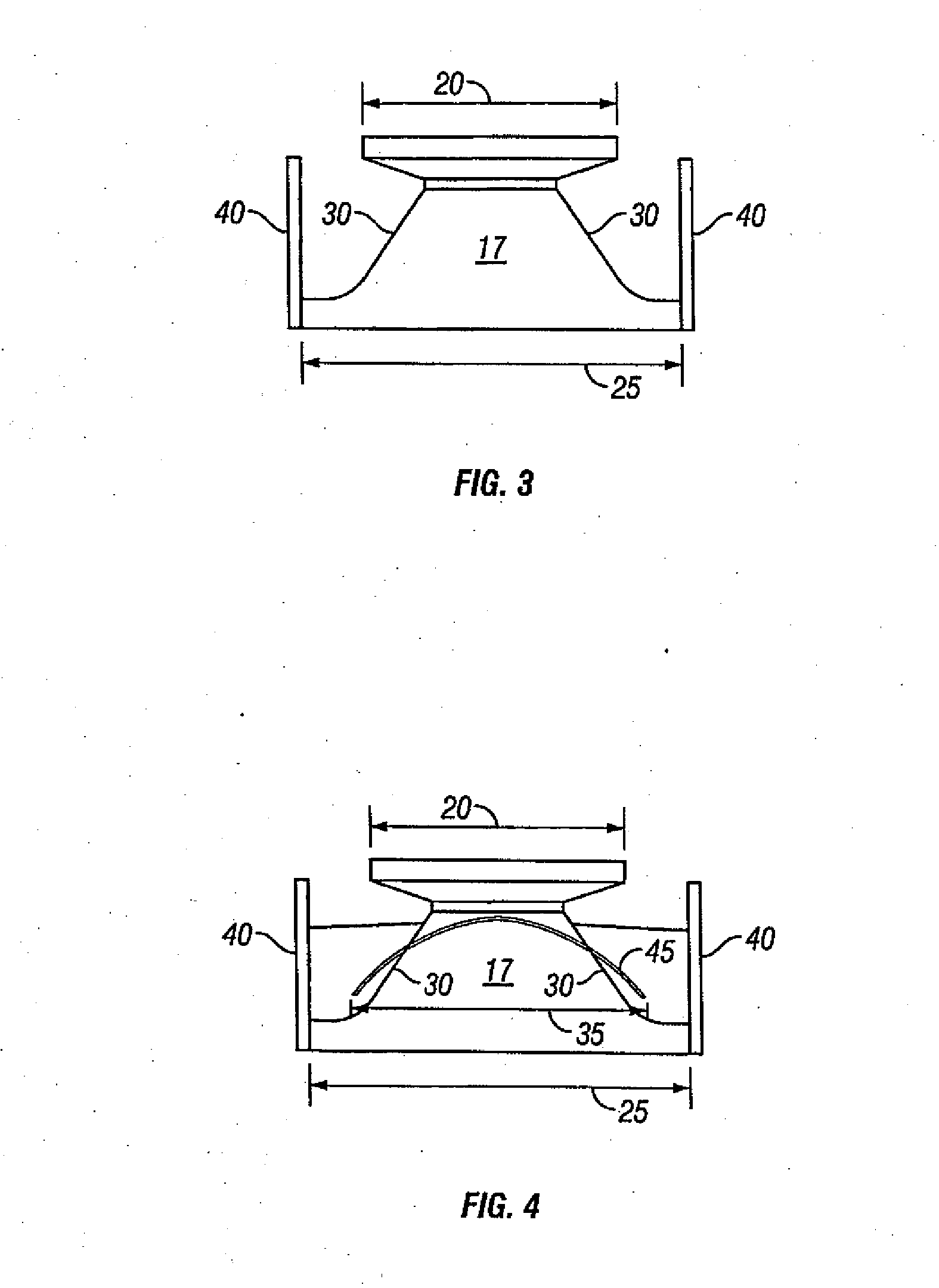

An object is to suppress differences in concentration between processing gases supplied to a plurality of works in a chemical solution vaporizing tank. The chemical solution vaporizing tank includes a tank body having a plurality of vaporizing chambers formed by laterally and airtightly partitioning an internal space of the tank body, a chemical solution passage located under a liquid level in each vaporizing chamber and formed at each partition member for passing the chemical solution between the vaporizing chambers, and a gas passage located above the liquid level in each vaporizing chamber and formed at the partition member to communicate the vaporizing chambers with each other for uniformizing pressures in the respective vaporizing chambers. A quantity of the channel layer in each vaporizing chamber is controlled by managing, e.g., the liquid level.

Owner:TOKYO ELECTRON LTD

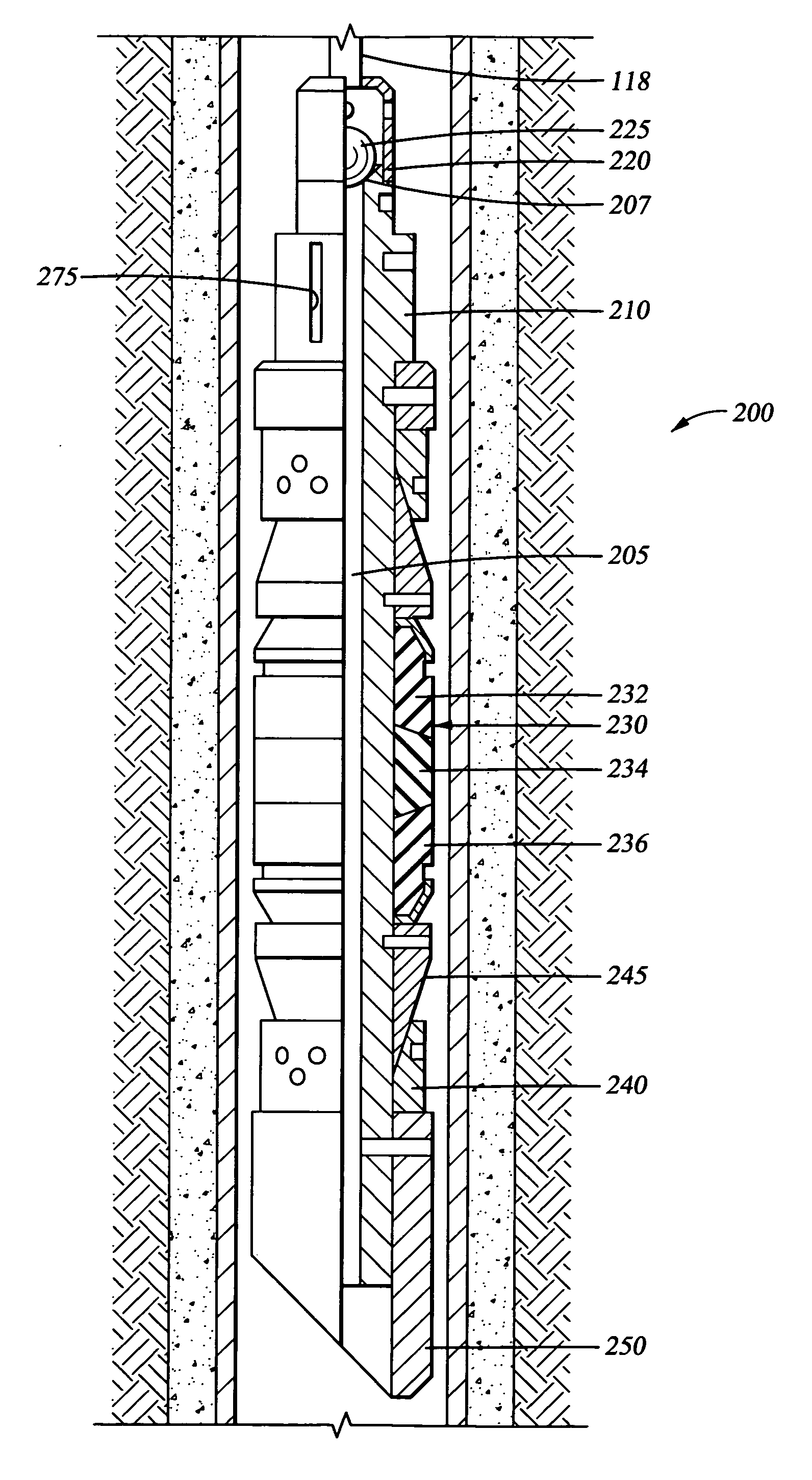

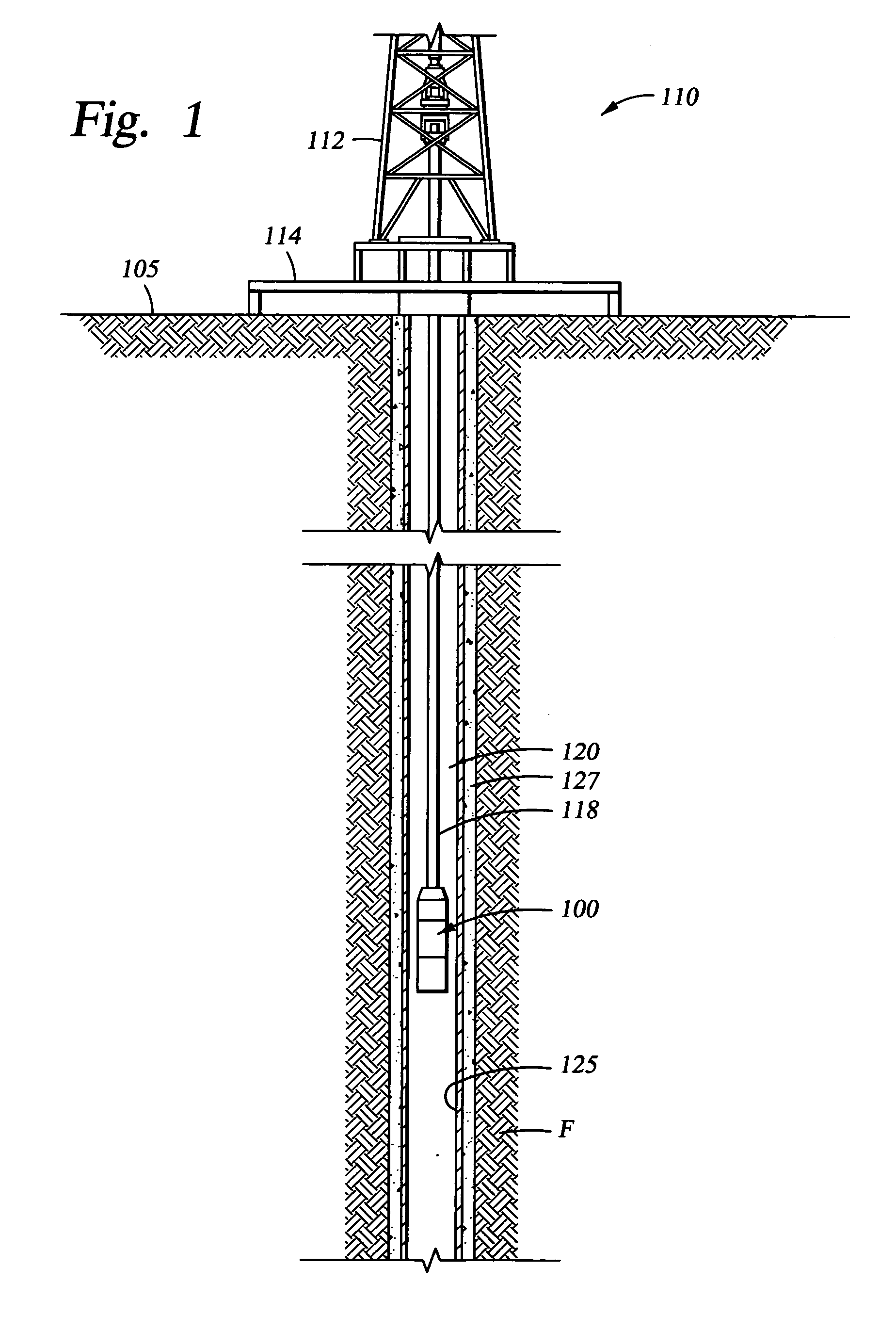

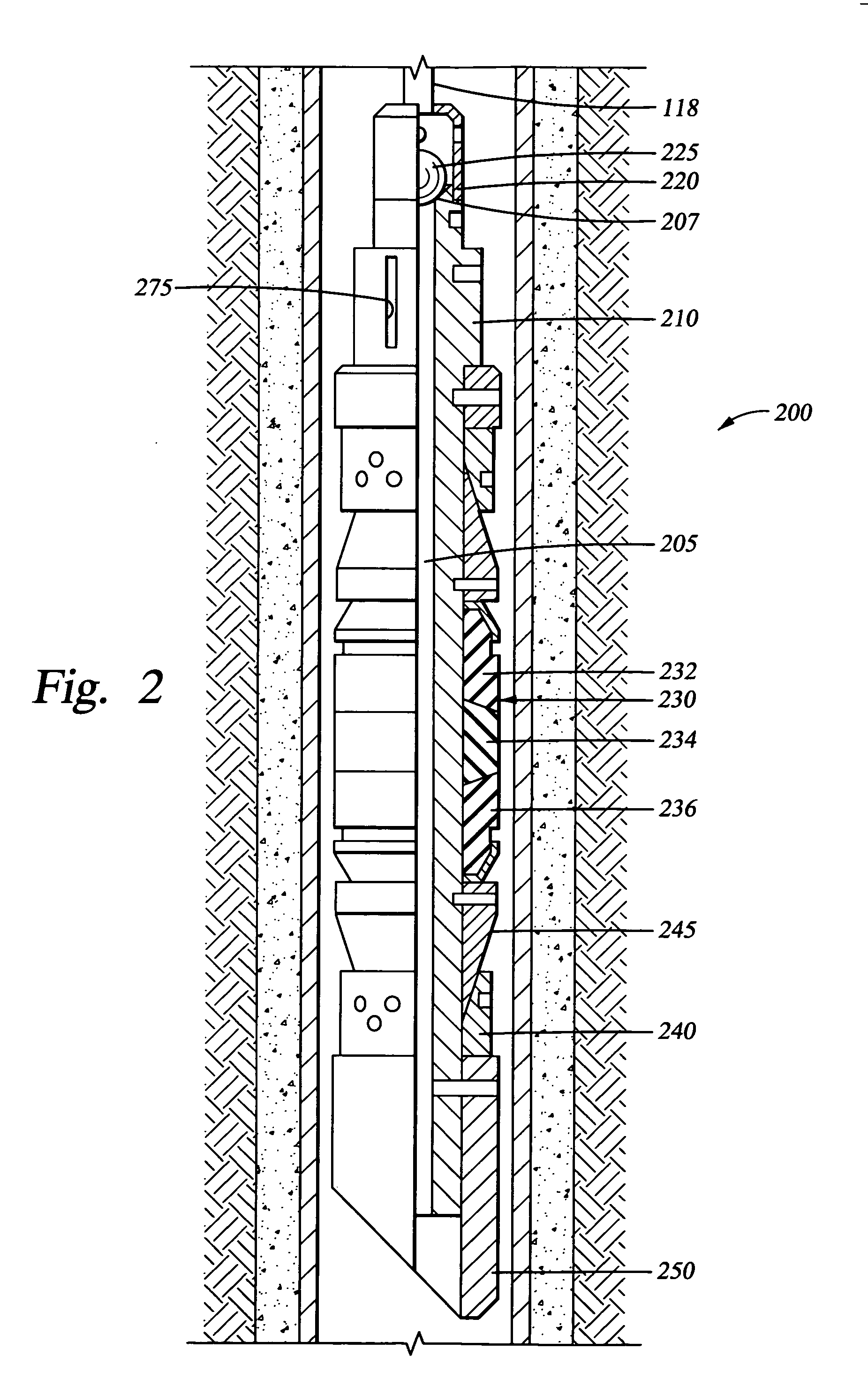

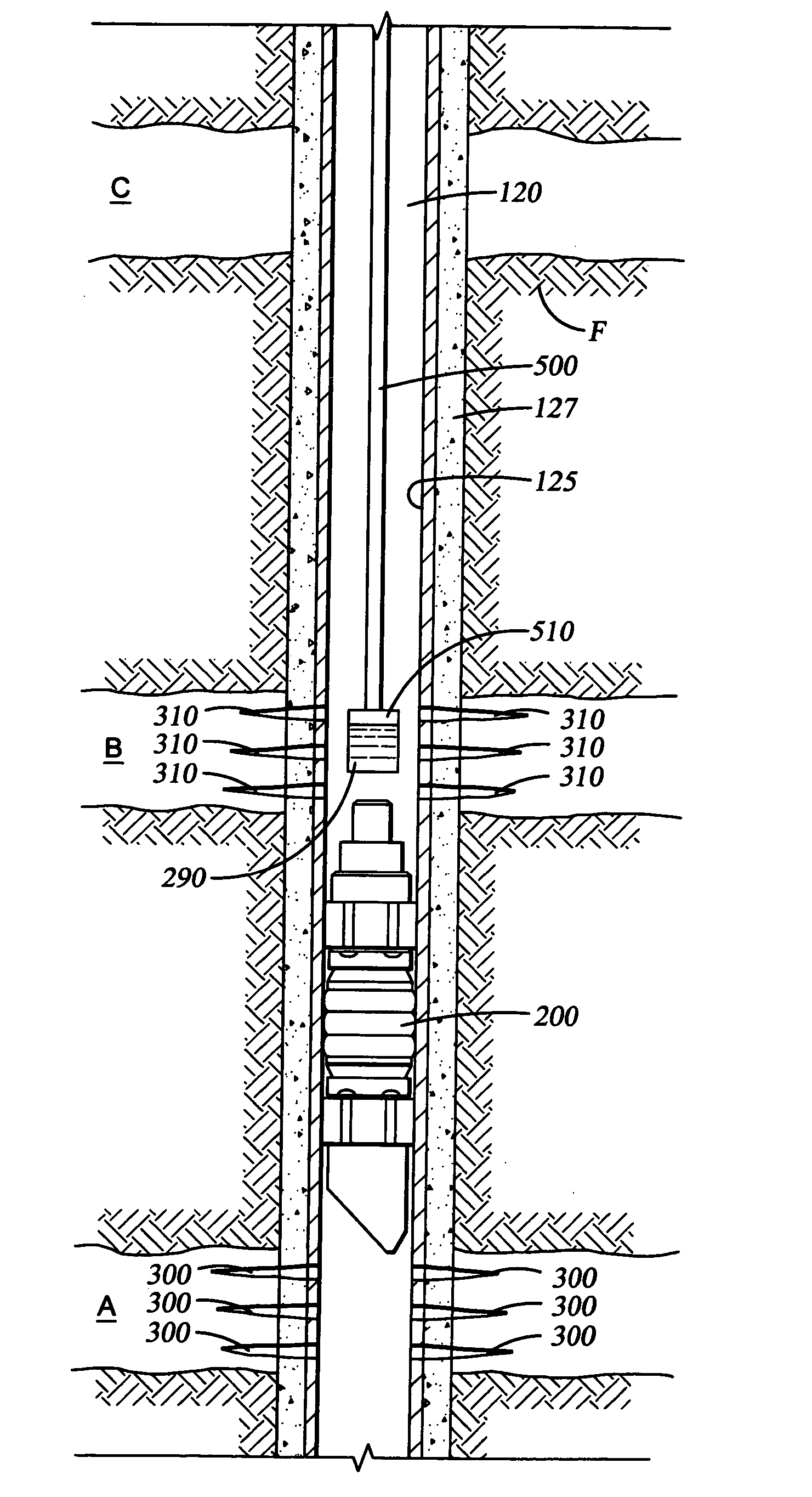

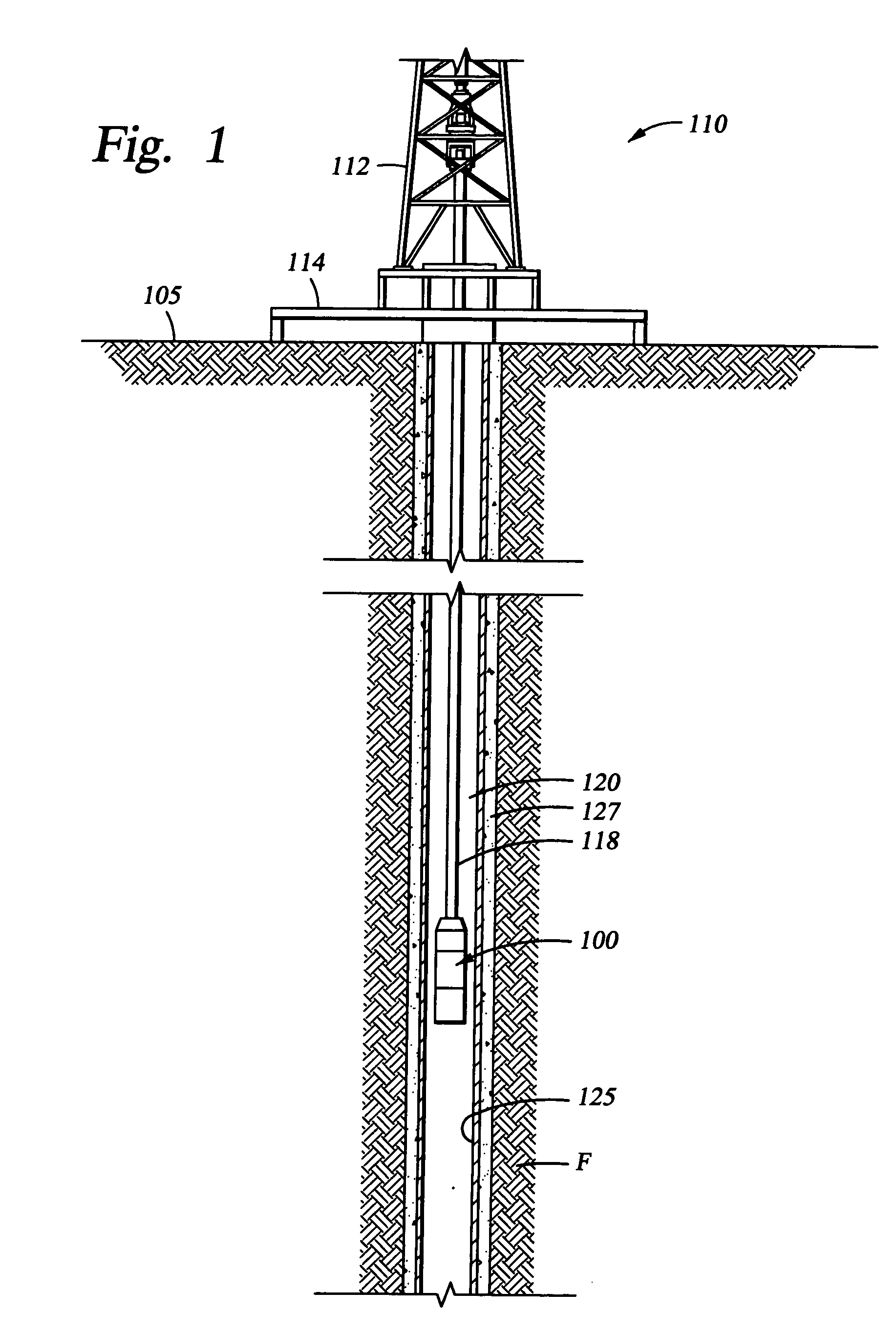

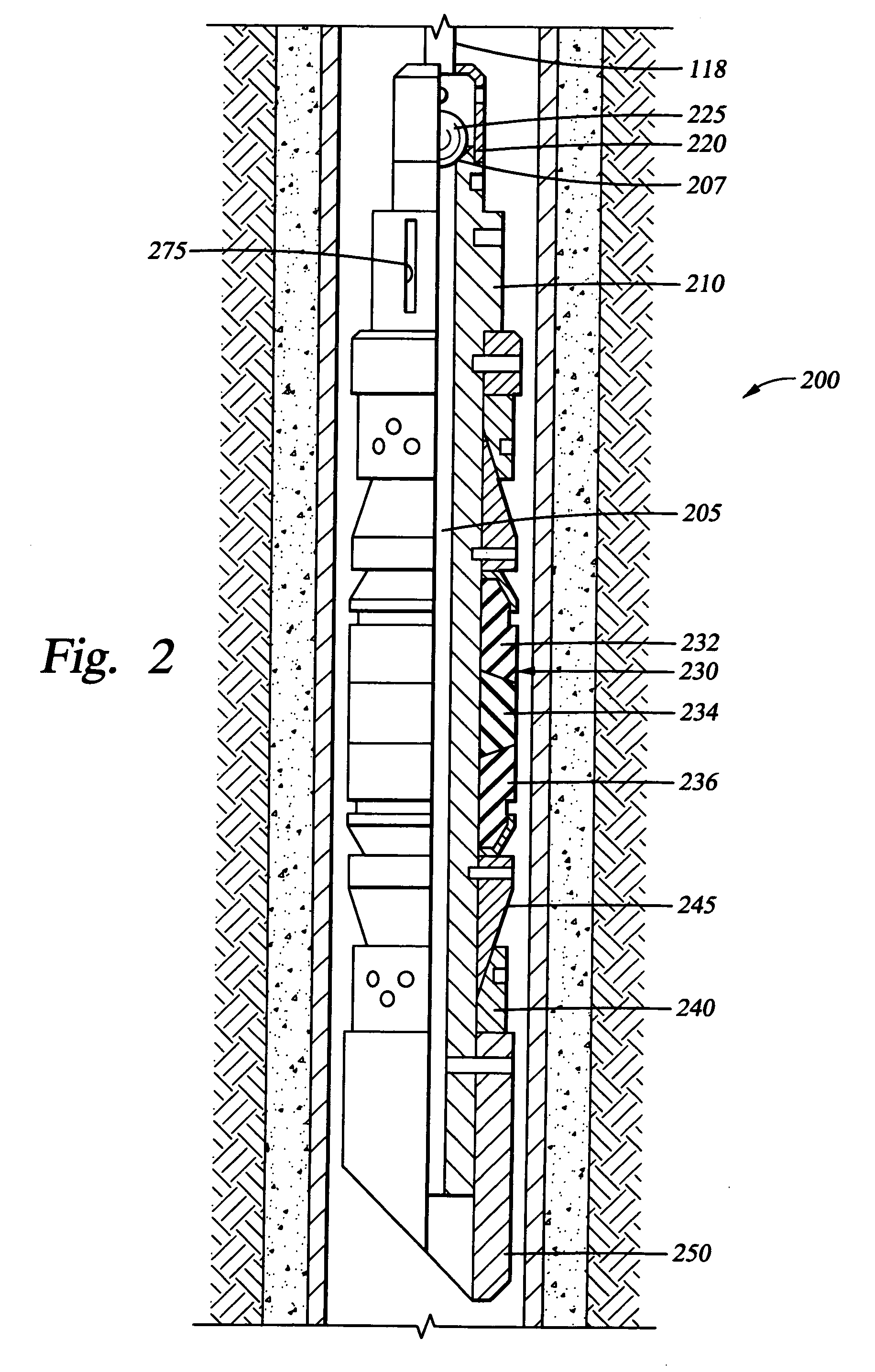

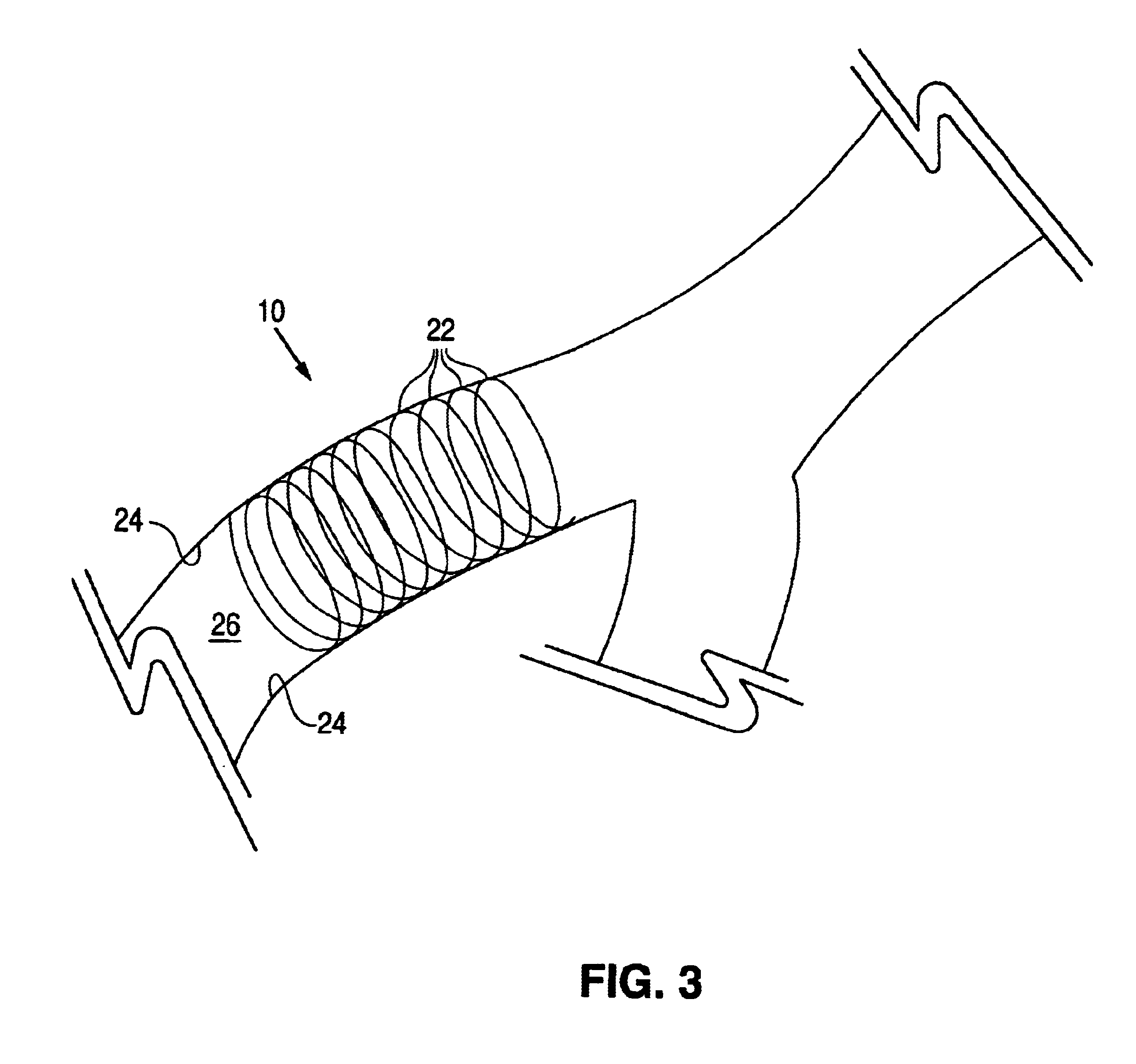

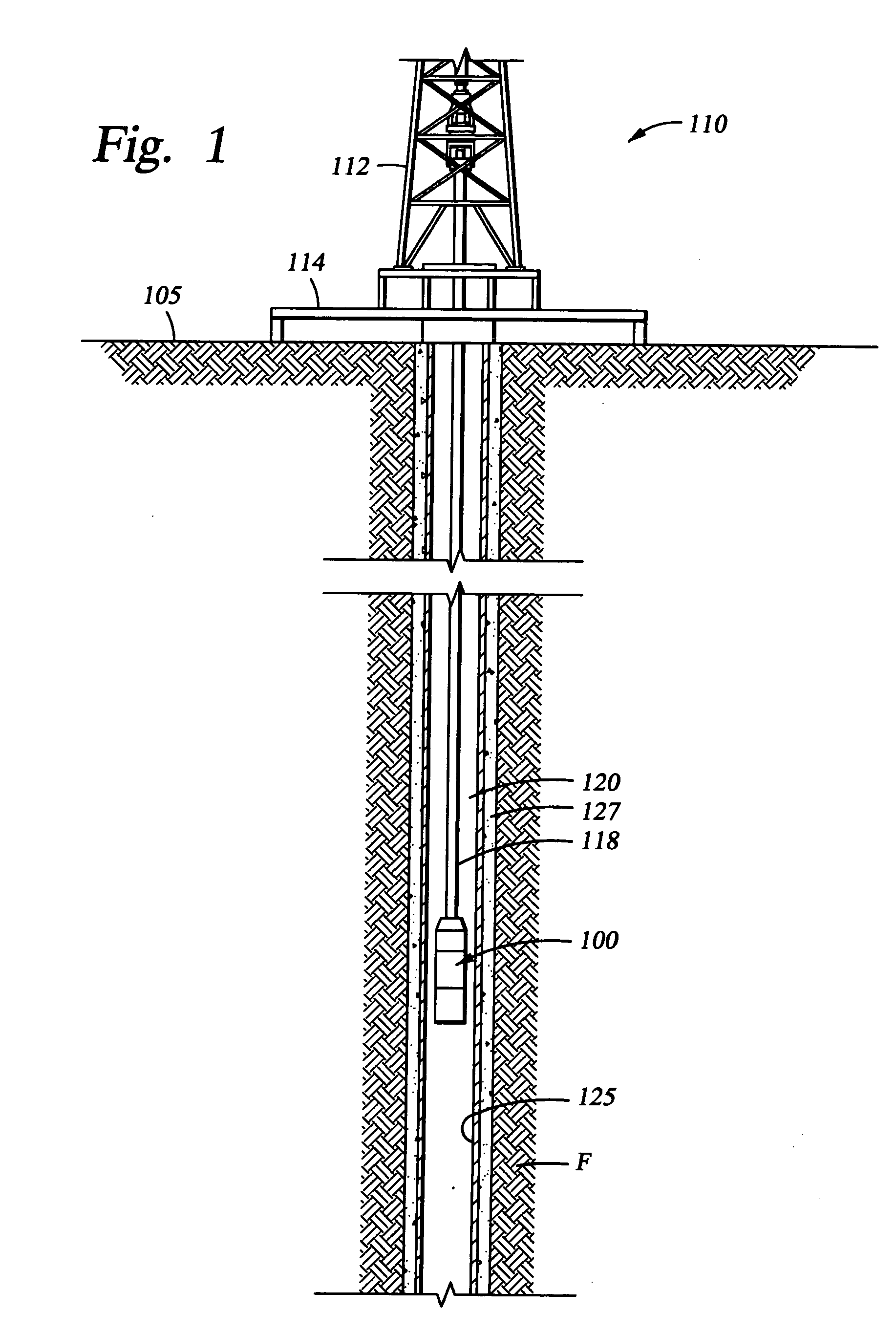

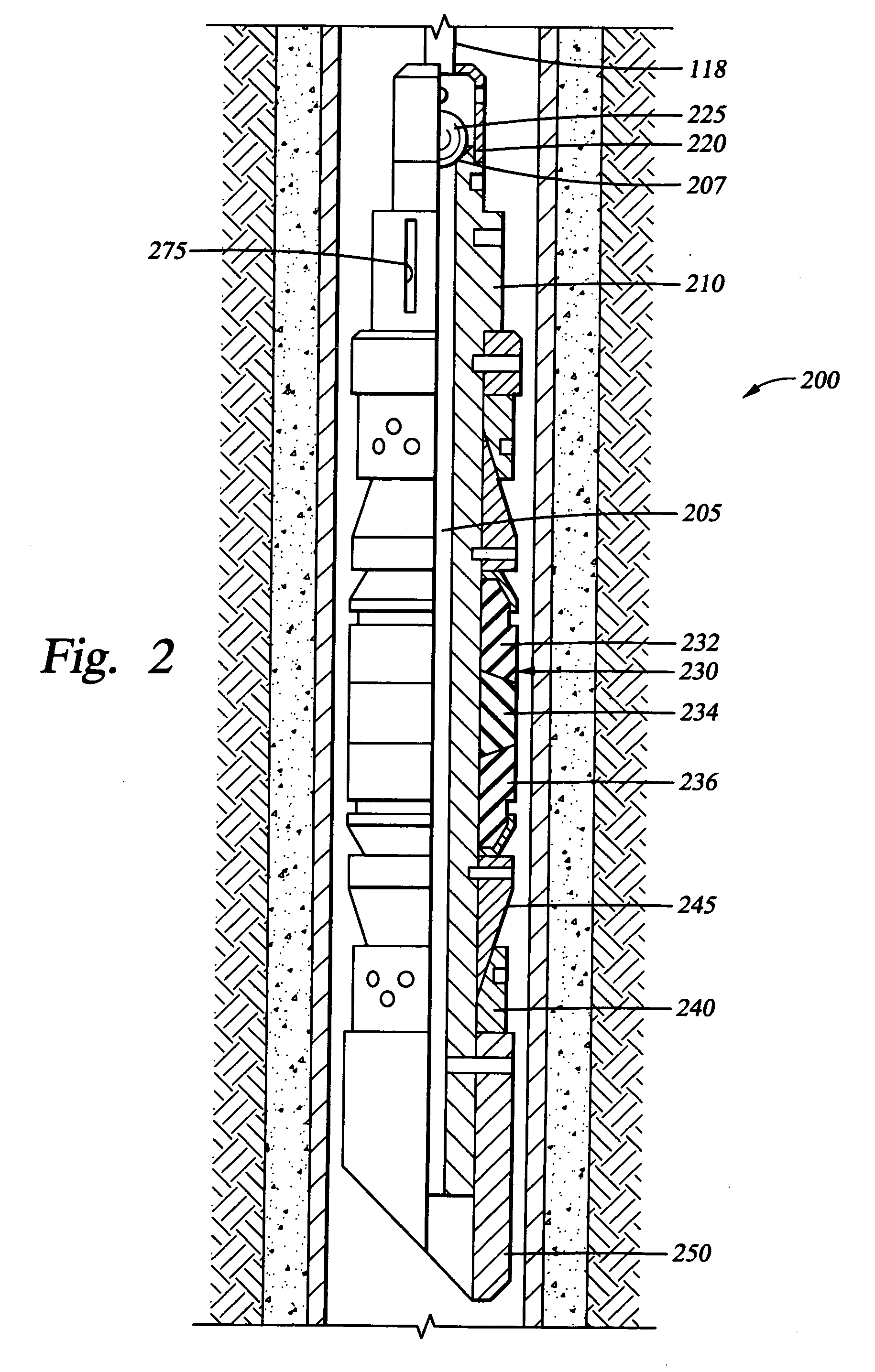

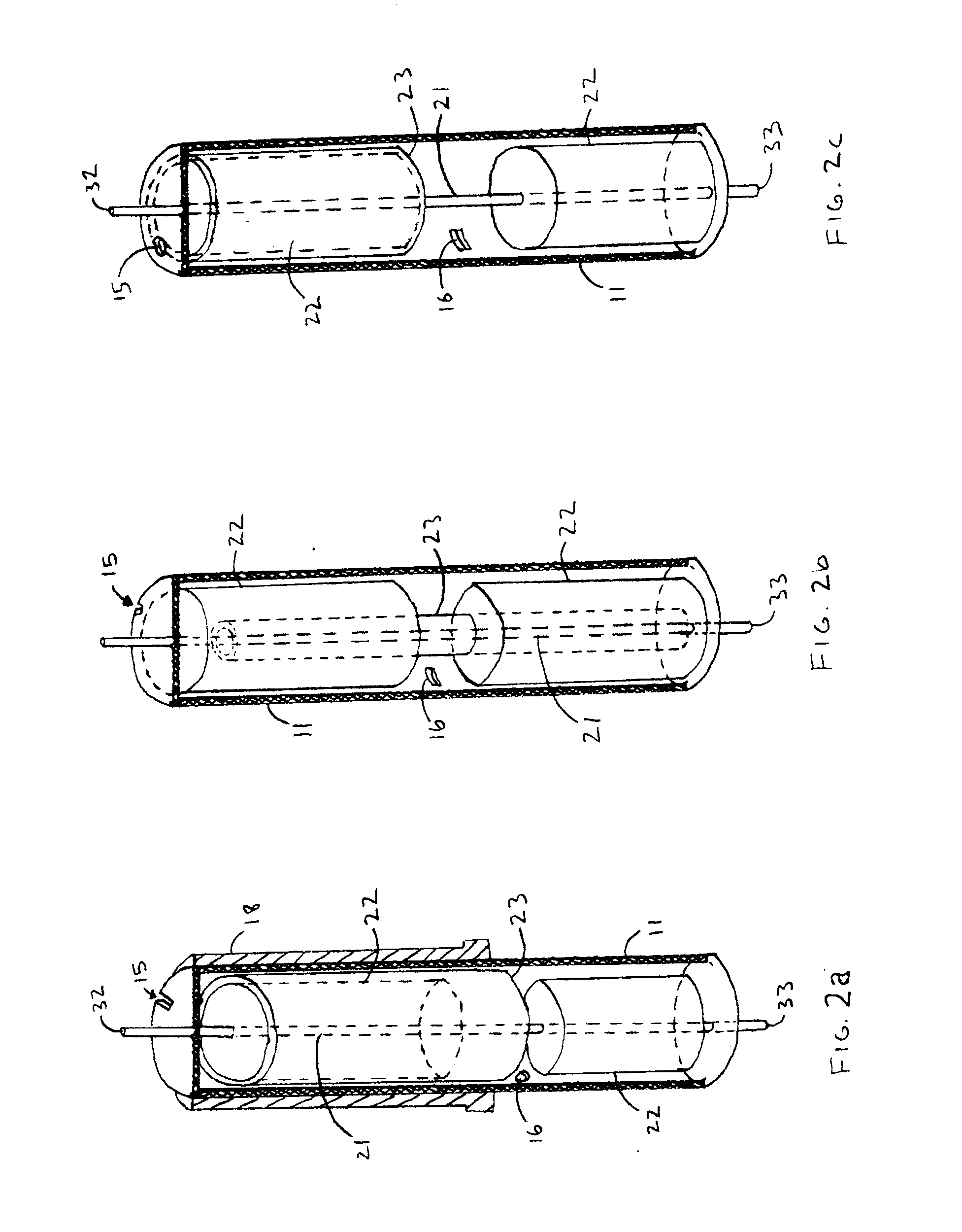

Biodegradable downhole tools

A disposable downhole tool or a component thereof comprises an effective amount of biodegradable material such that the tool or the component thereof desirably decomposes when exposed to a wellbore environment. In an embodiment, the biodegradable material comprises a degradable polymer. The biodegradable material may further comprise a hydrated organic or inorganic solid compound. The biodegradable material may also be selected to achieve a desired decomposition rate when the tool is exposed to the wellbore environment. In an embodiment, the disposable downhole tool further comprises an enclosure for storing a chemical solution that catalyzes decomposition. The tool may also comprise an activation mechanism for releasing the chemical solution from the enclosure. In various embodiments, the disposable downhole tool is a frac plug, a bridge plug, or a packer.

Owner:HALLIBURTON ENERGY SERVICES INC

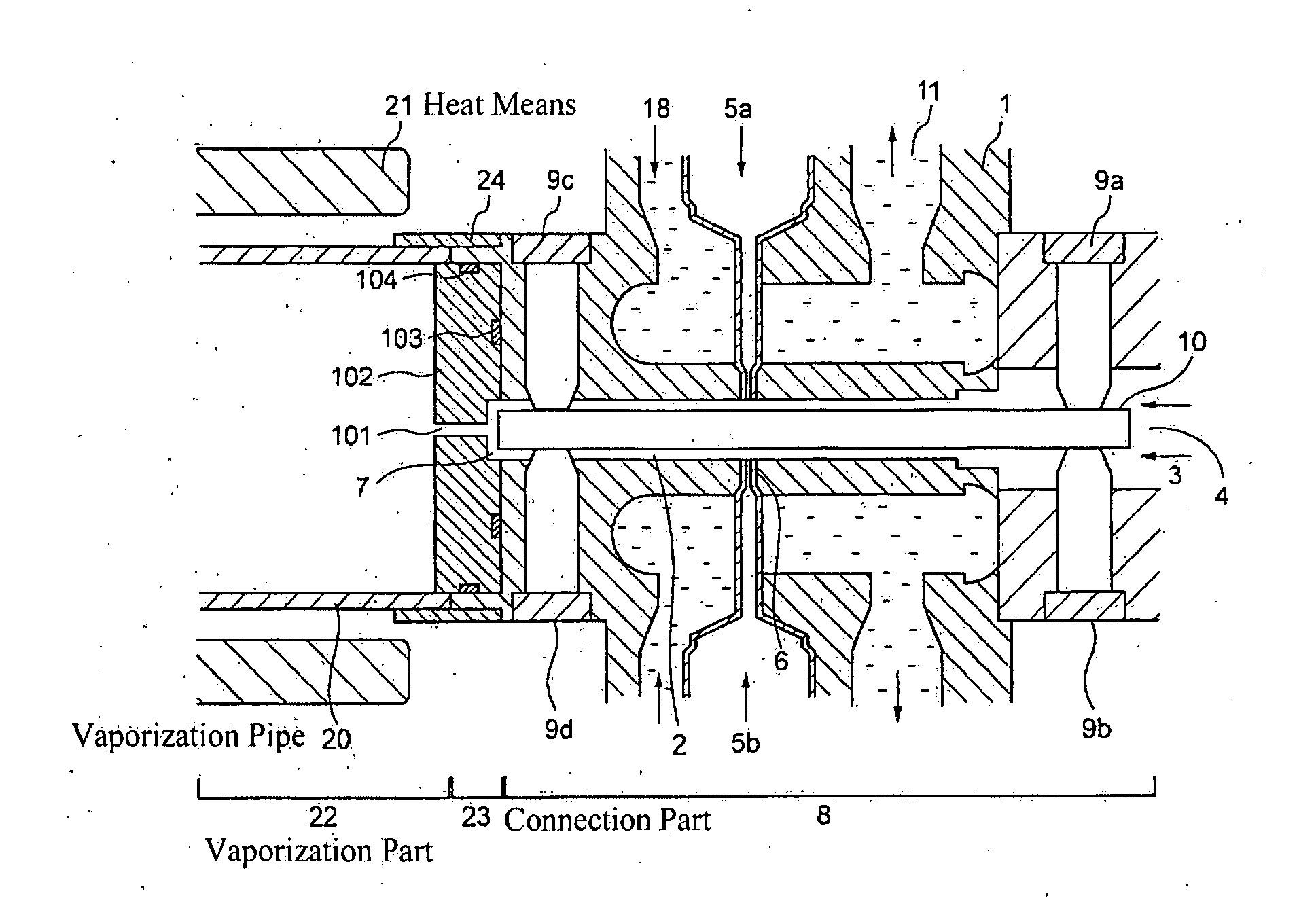

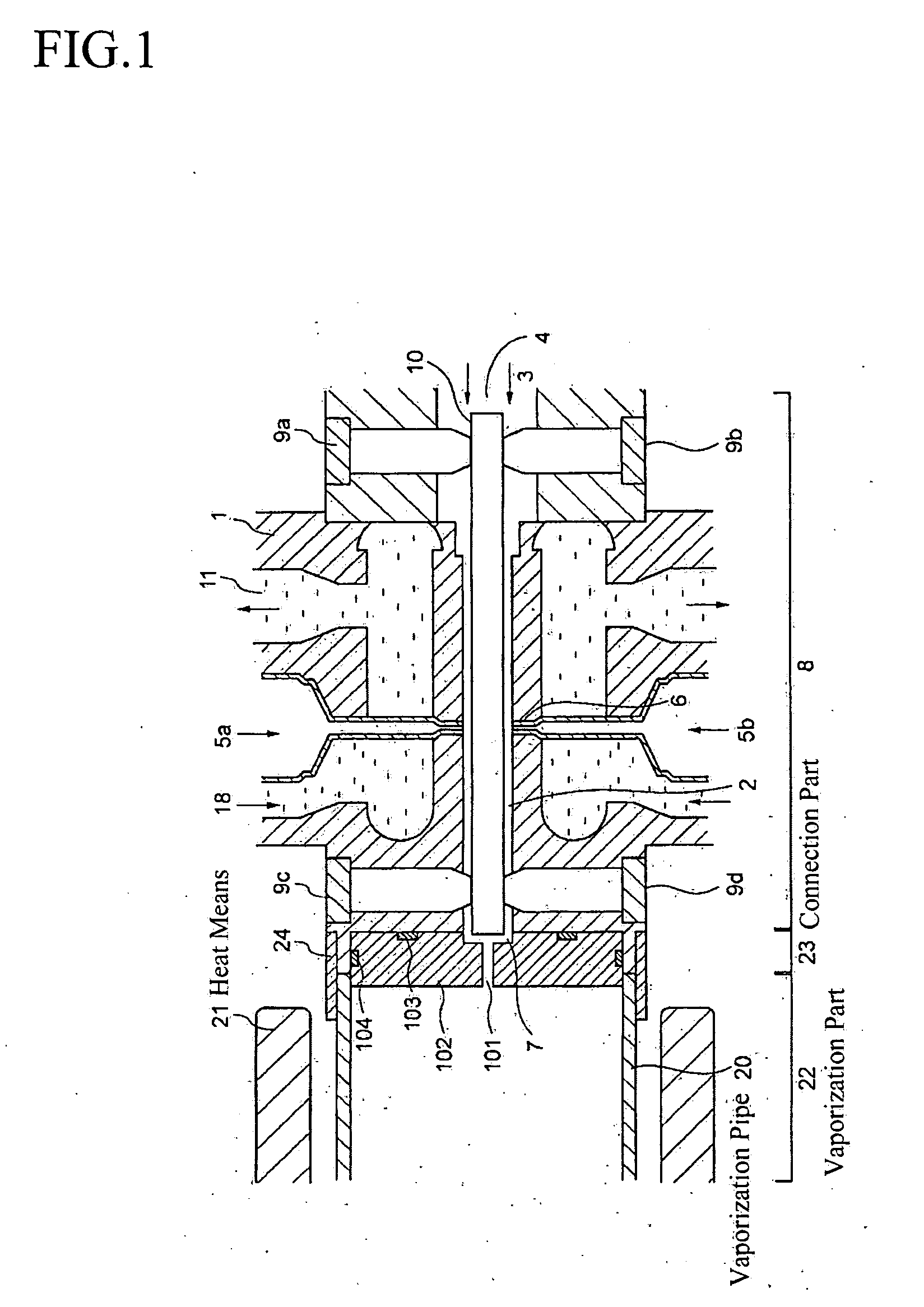

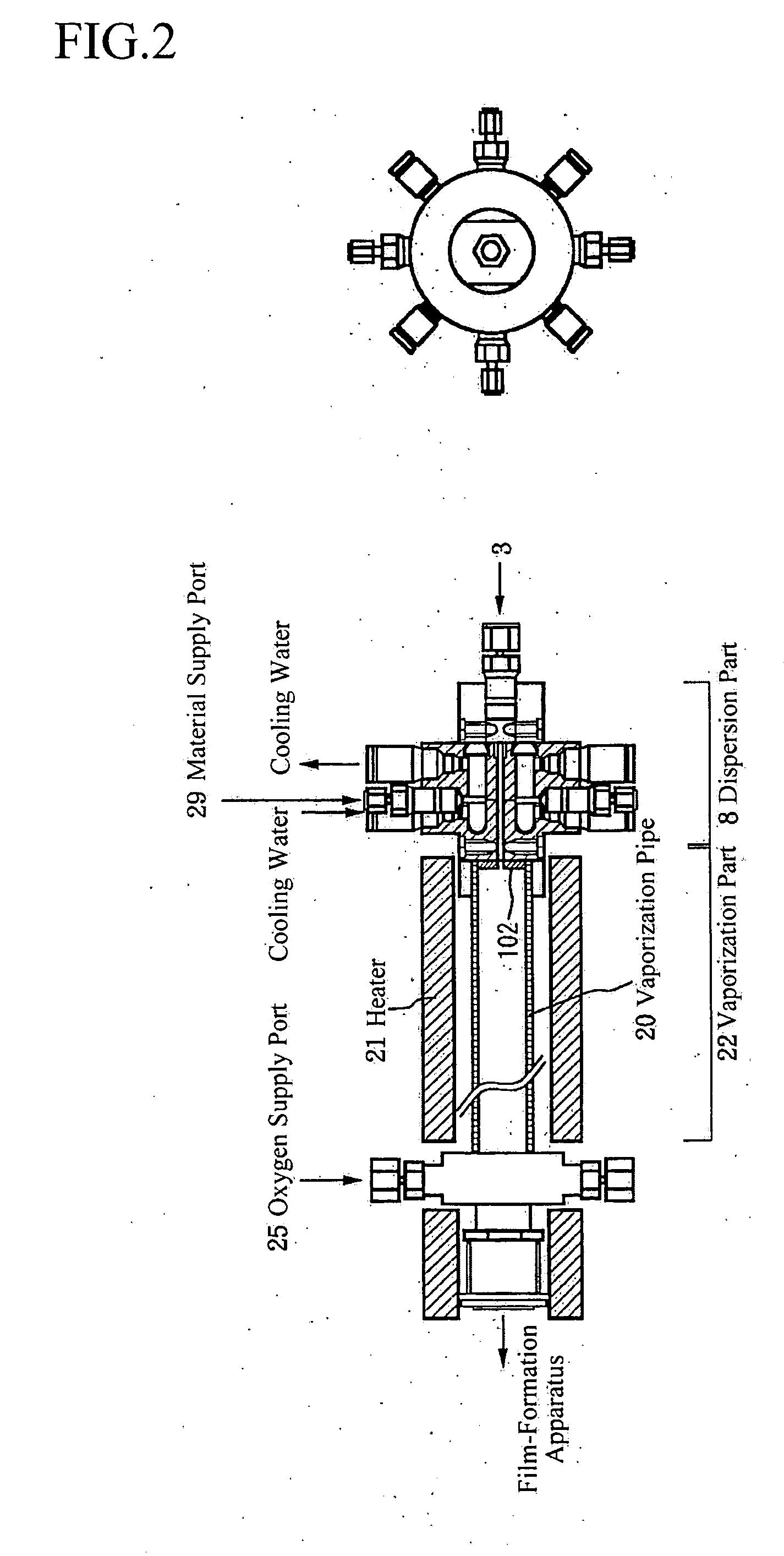

Vaporizer, film forming apparatus including the same, method of vaporization and method of forming film

InactiveUS20070166457A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical solutionEngineering

It is aimed at providing a vaporization apparatus and a vaporization method capable of keeping track of a progressive condition of clogging of the apparatus. It is also aimed at providing a vaporization apparatus and a vaporization method capable of eliminating clogging prior to occurrence of complete clogging, without disassembling the apparatus. It provides a vaporization apparatus for introducing a carrier gas from one end of a gas passage and for feeding, the carrier gas including a material solution, from the other end of the gas passage to a vaporization part to thereby vaporize the material solution, characterized in that a mass flow controller (MFC) is provided at the one end of the gas passage, and means for detecting a pressure within the gas passage is provided. The vaporization apparatus is characterized in that the same is provided with means for introducing a chemical solution capable of dissolving therein matters deposited or sticked to the inside of the gas passage, into the gas passage.

Owner:YAMOTO HISAYOSHI +5

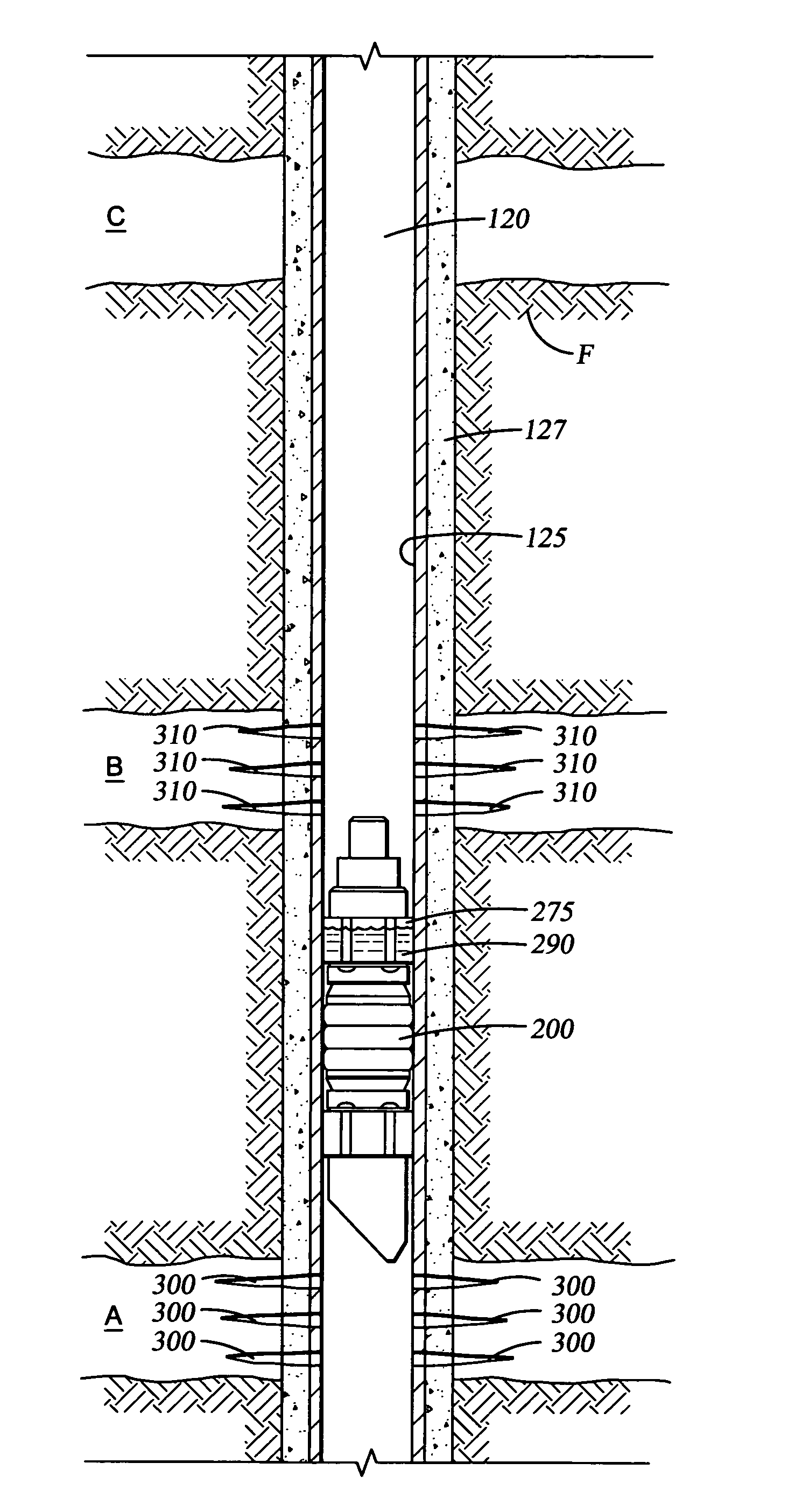

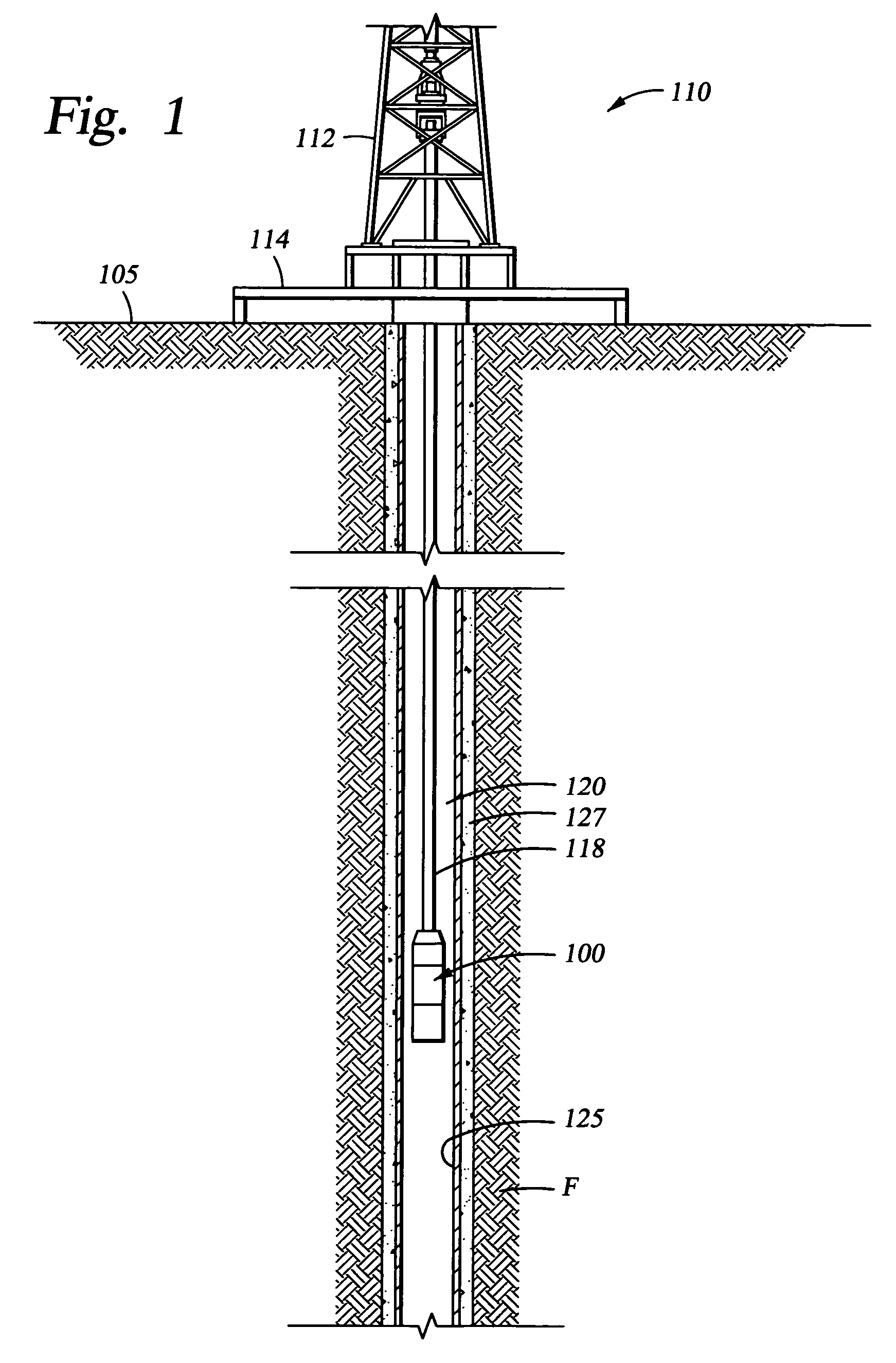

Biodegradable downhole tools

A disposable downhole tool or a component thereof comprises an effective amount of biodegradable material such that the tool or the component thereof desirably decomposes when exposed to a wellbore environment. In an embodiment, the biodegradable material comprises a degradable polymer. The biodegradable material may further comprise a hydrated organic or inorganic solid compound. The biodegradable material may also be selected to achieve a desired decomposition rate when the tool is exposed to the wellbore environment. In an embodiment, the disposable downhole tool further comprises an enclosure for storing a chemical solution that catalyzes decomposition. The tool may also comprise an activation mechanism for releasing the chemical solution from the enclosure. In various embodiments, the disposable downhole tool is a frac plug, a bridge plug, or a packer.

Owner:HALLIBURTON ENERGY SERVICES INC

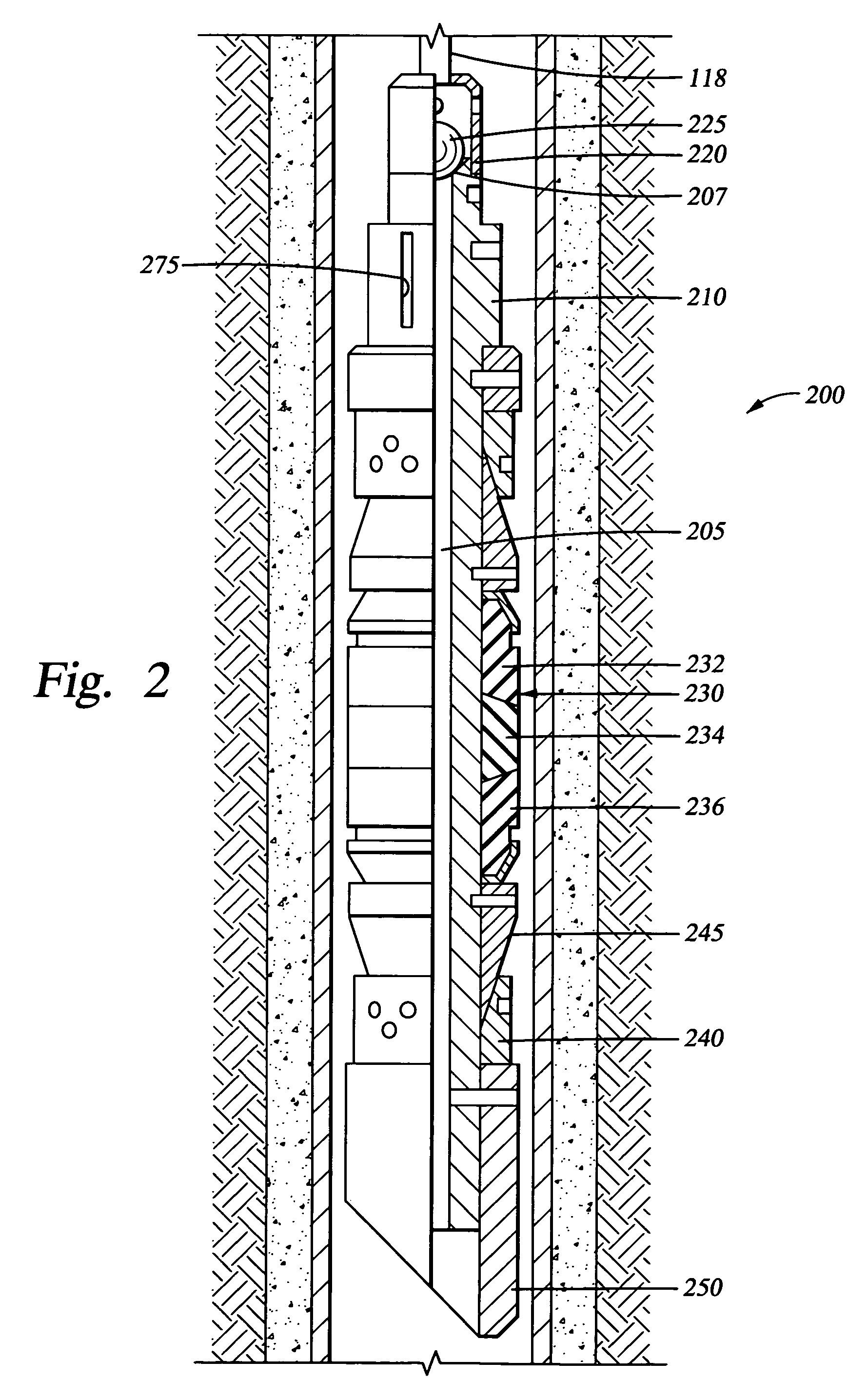

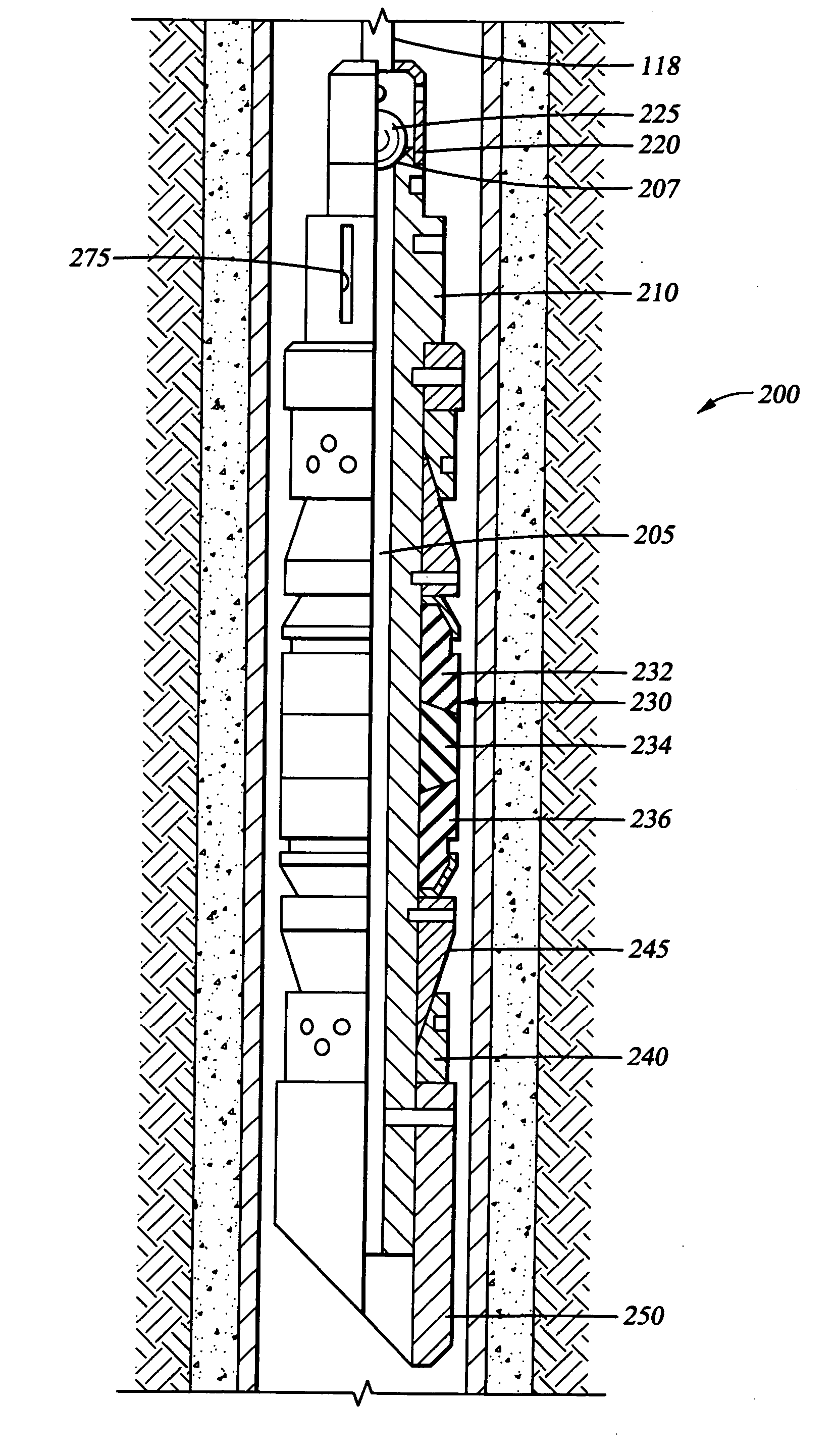

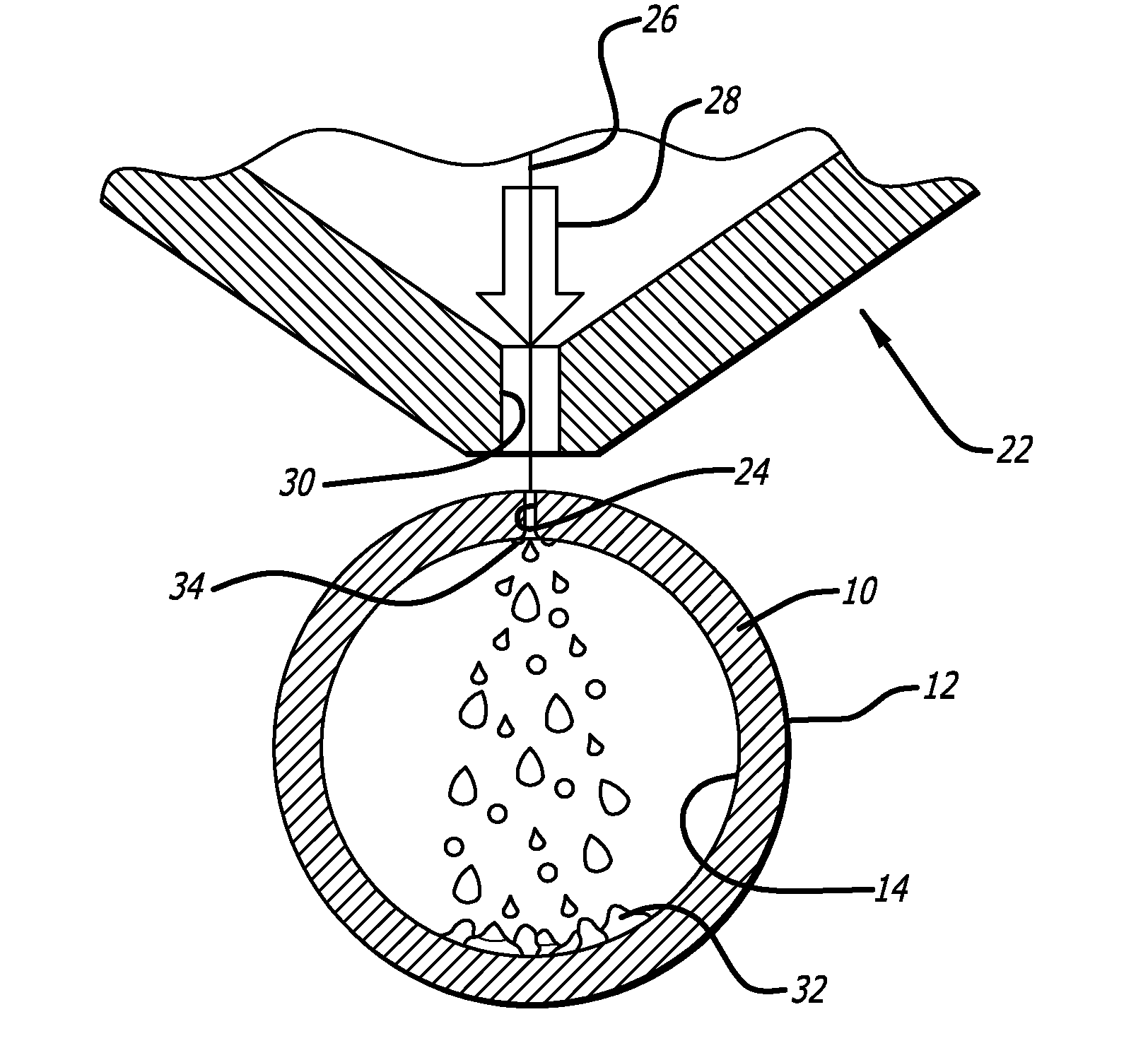

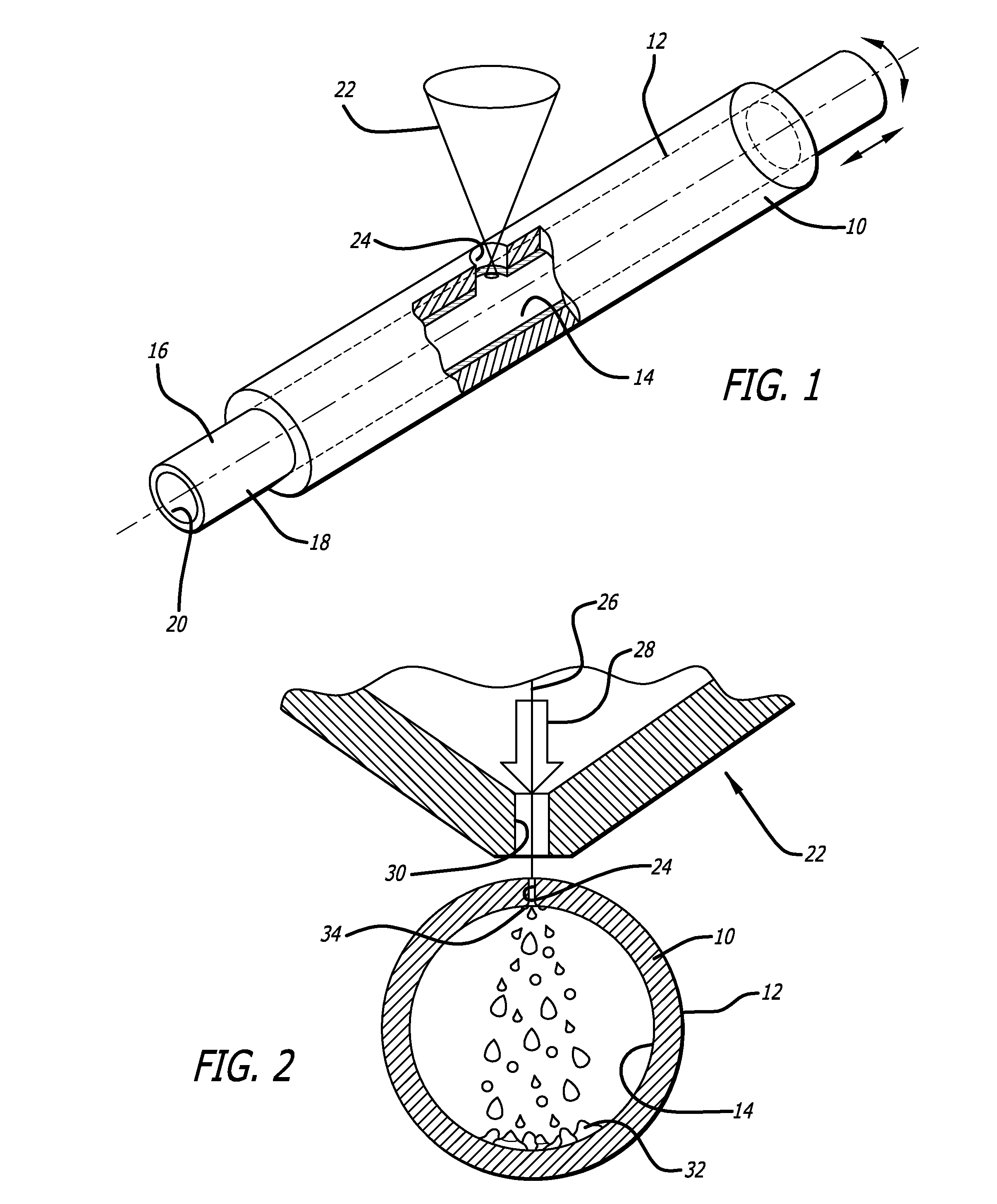

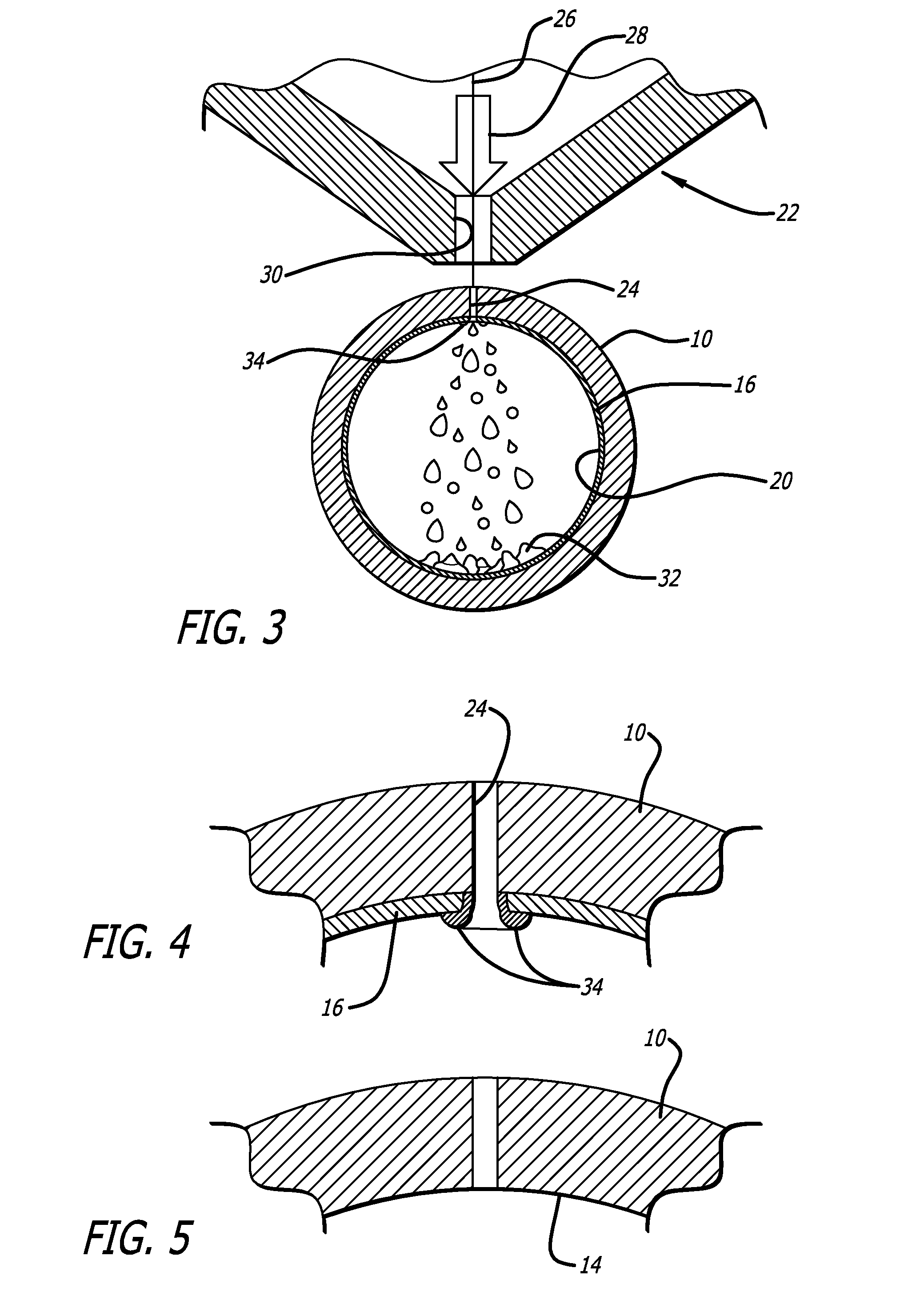

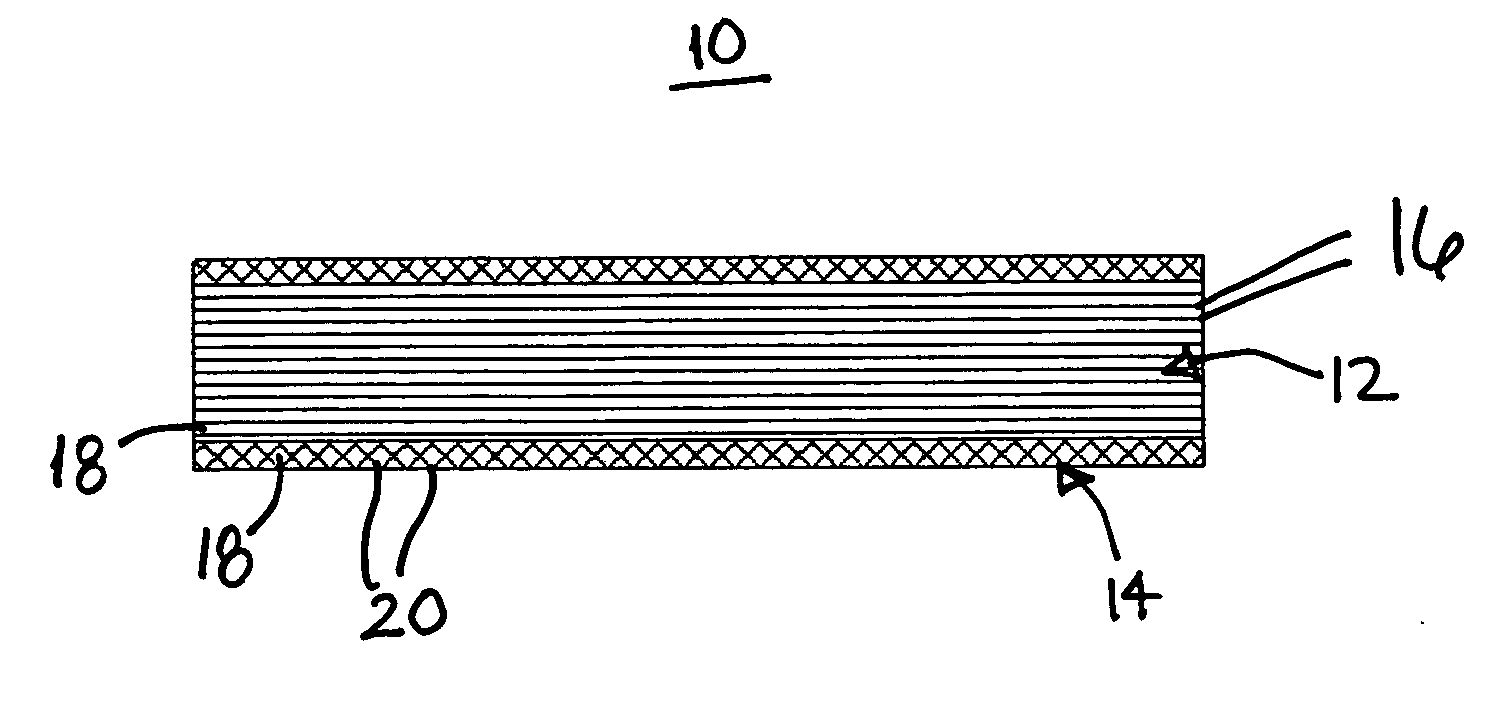

Dissolvable downhole tools

A disposable downhole tool comprises a material that dissolves when exposed to a chemical solution, an ultraviolet light, a nuclear source, or a combination thereof. In an embodiment, the material comprises an epoxy resin, a fiberglass, or a combination thereof. In another embodiment, the material comprises a fiberglass and a binding agent. The material may also be customized to achieve a desired dissolution rate of the tool. In an embodiment, the disposable downhole tool further comprises an enclosure for storing the chemical solution. The tool may also comprise an activation mechanism for releasing the chemical solution from the enclosure. In an embodiment, the disposable downhole tool is a frac plug. In another embodiment, the tool is a bridge plug. In yet another embodiment, the tool is a packer.

Owner:HALLIBURTON ENERGY SERVICES INC

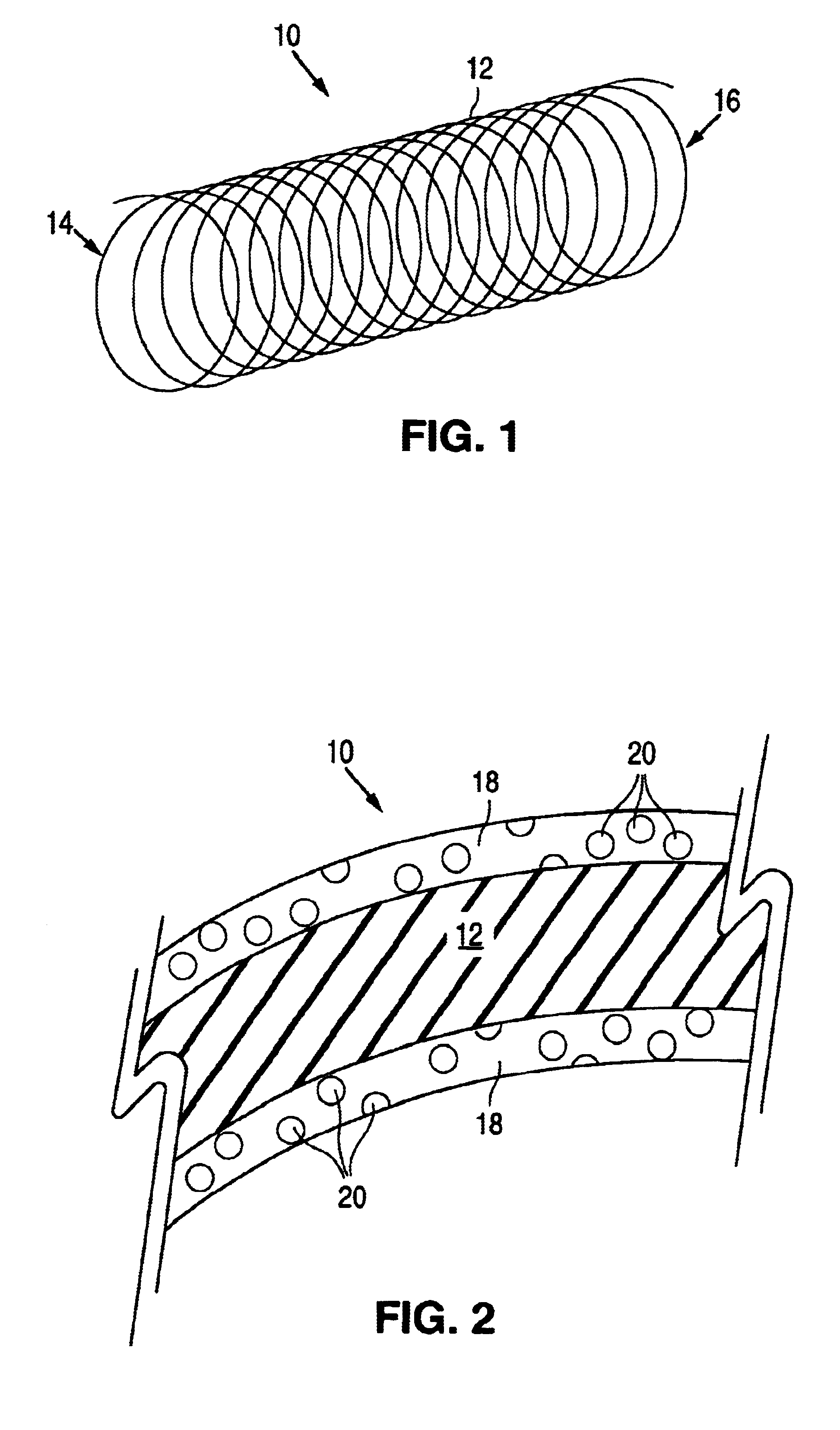

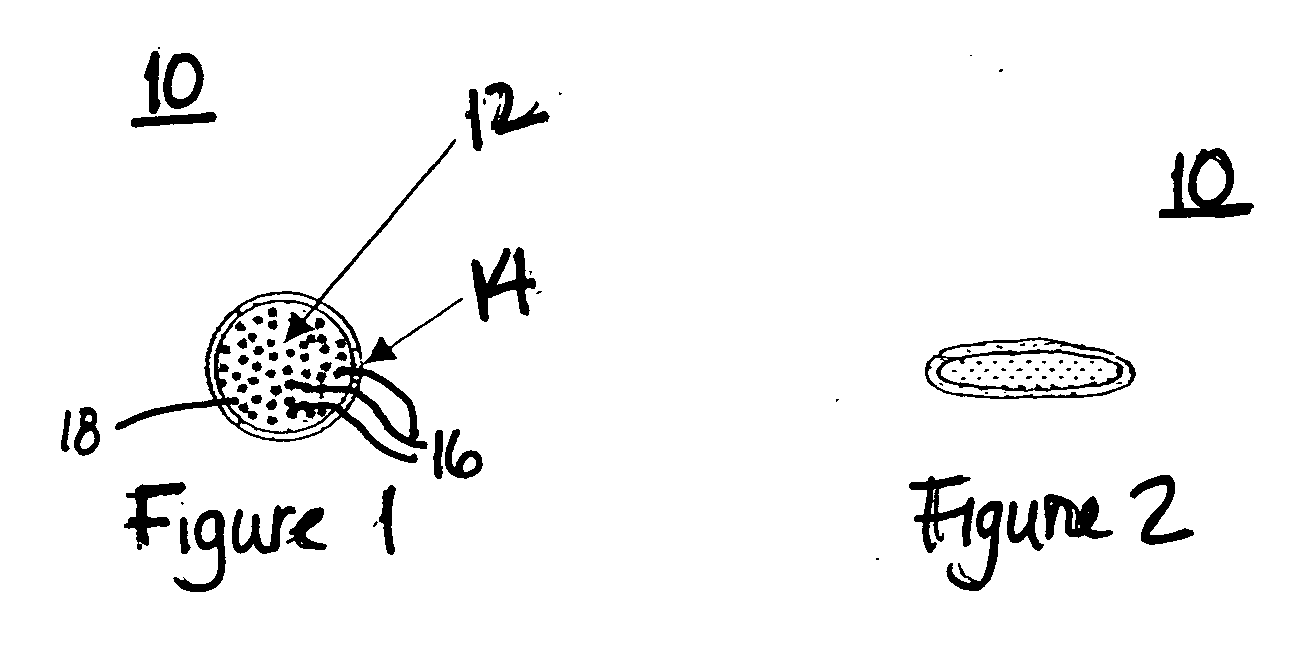

Microparticle coated medical device

A drug-loaded microparticle is applied to a medical device for subsequent application to biological tissues. A method of formulating a drug-loaded microparticle and applying it to the surface of a medical device, such as a stent, is disclosed. The drug-loaded microparticle is formulated by combining a drug with various chemical solutions. Specified sizes of the microparticles and amounts of drug(s) contained within the microparticles may be varied by altering the proportions of the chemicals / solutions. In addition to various drugs, therapeutic substances and radioactive isotopes may also be loaded into the microparticles. The drug-loaded microparticle are suspended in a polymer solution forming a polymer matrix. The polymer matrix may be applied to the entire surface or only selected portions of the medical device via dipping, spraying or combinations thereof.

Owner:ABBOTT CARDIOVASCULAR

Dissolvable downhole tools

A disposable downhole tool comprises a material that dissolves when exposed to a chemical solution, an ultraviolet light, a nuclear source, or a combination thereof. In an embodiment, the material comprises an epoxy resin, a fiberglass, or a combination thereof. In another embodiment, the material comprises a fiberglass and a binding agent. The material may also be customized to achieve a desired dissolution rate of the tool. In an embodiment, the disposable downhole tool further comprises an enclosure for storing the chemical solution. The tool may also comprise an activation mechanism for releasing the chemical solution from the enclosure. In an embodiment, the disposable downhole tool is a frac plug. In another embodiment, the tool is a bridge plug. In yet another embodiment, the tool is a packer.

Owner:HALLIBURTON ENERGY SERVICES INC

Substrate processing apparatus

InactiveUS20070190746A1Easy thickness controlIncrease flexibilitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingChemical solutionSoi substrate

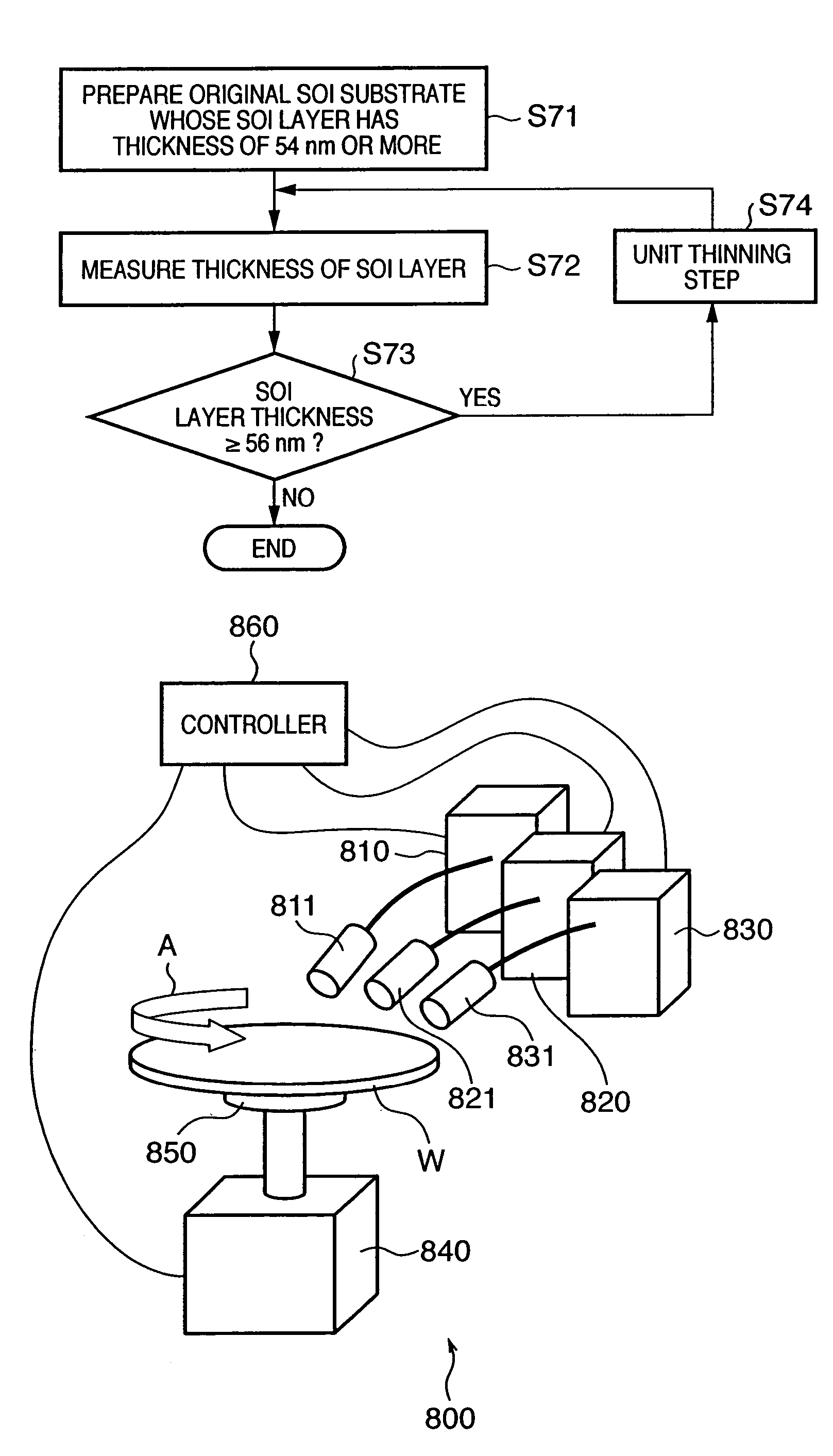

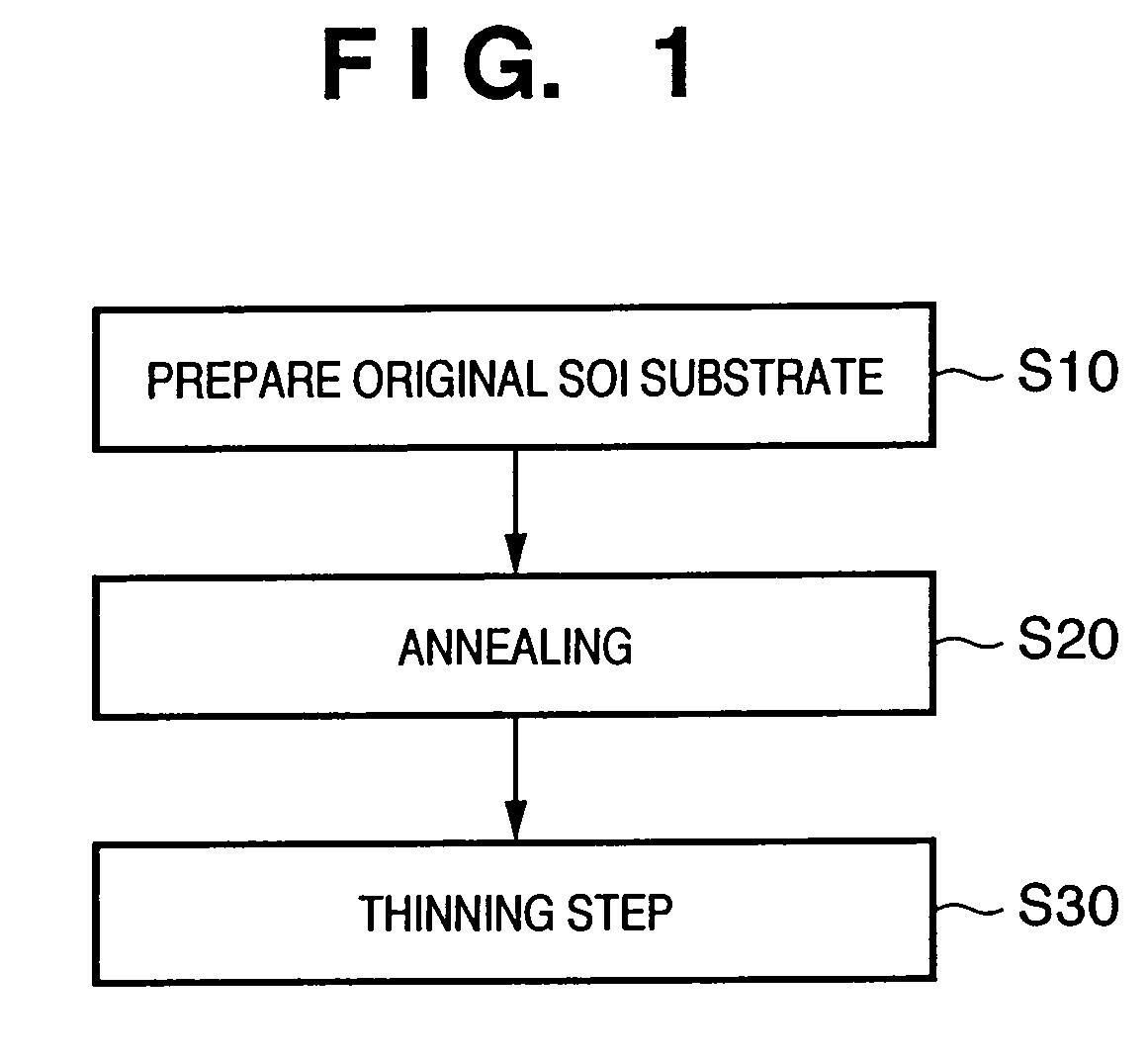

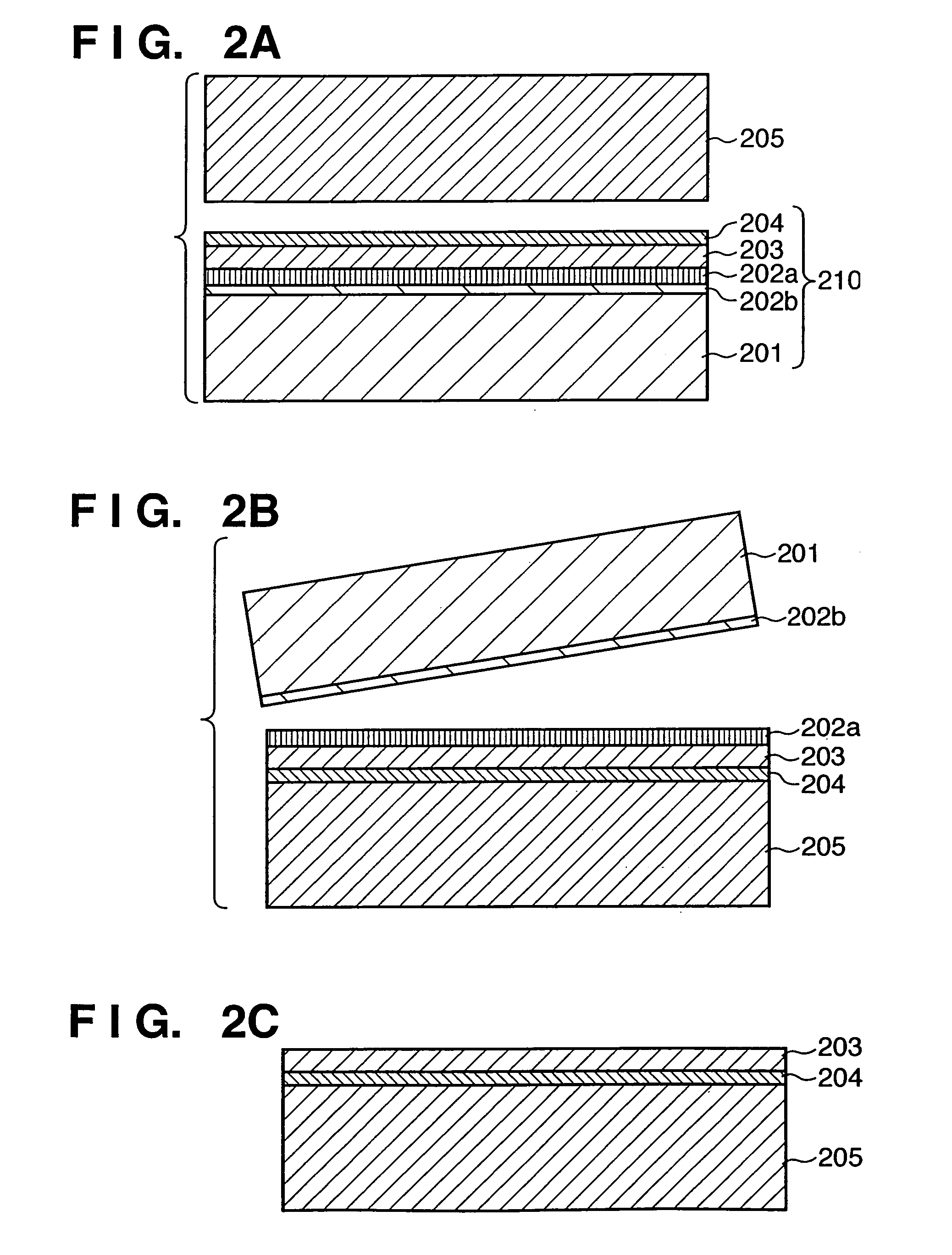

An SOI substrate which has a thick SOI layer is first prepared. Then, the SOI layer is thinned to a target film thickness using as a unit a predetermined thickness not more than that of one lattice. This thinning is performed by repeating a unit thinning step which includes an oxidation step of oxidizing the surface of the SOI layer by the predetermined thickness not more than that of one lattice and a removal step of selectively removing silicon oxide formed by the oxidation. The SOI layer of the SOI substrate is chemically etched by supplying a chemical solution to the SOI layer, and the film thickness of the etched SOI layer is measured. When the measured film thickness of the SOI layer has a predetermined value, a process of chemically etching the SOI layer ends.

Owner:CANON KK

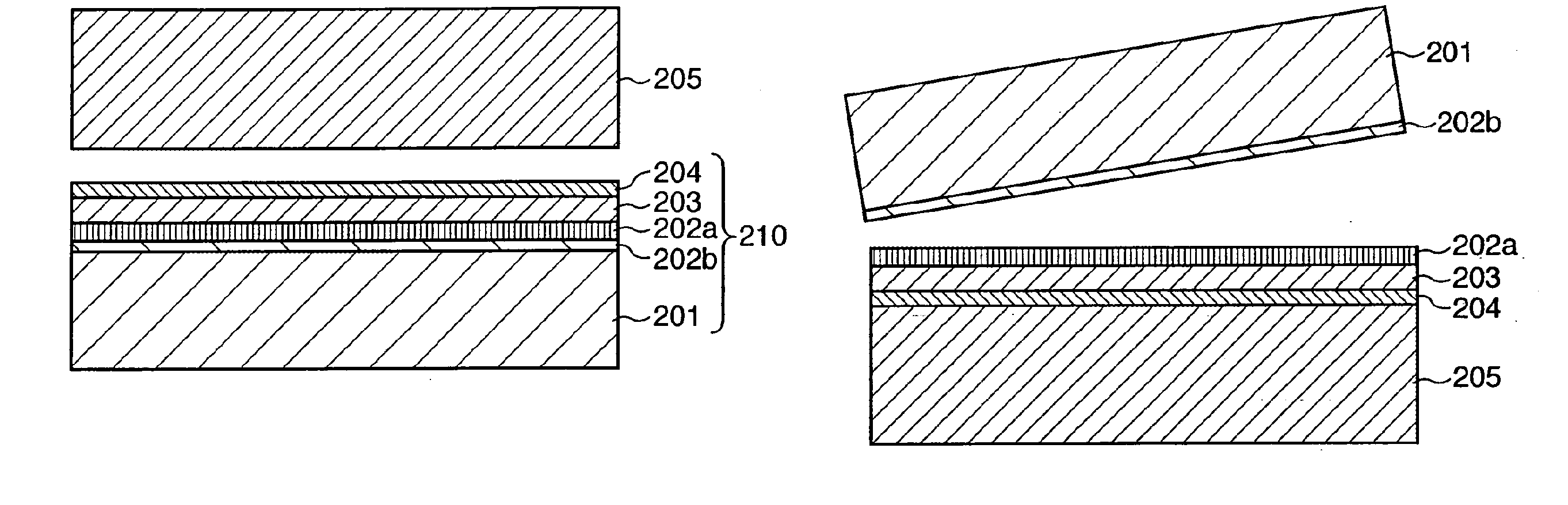

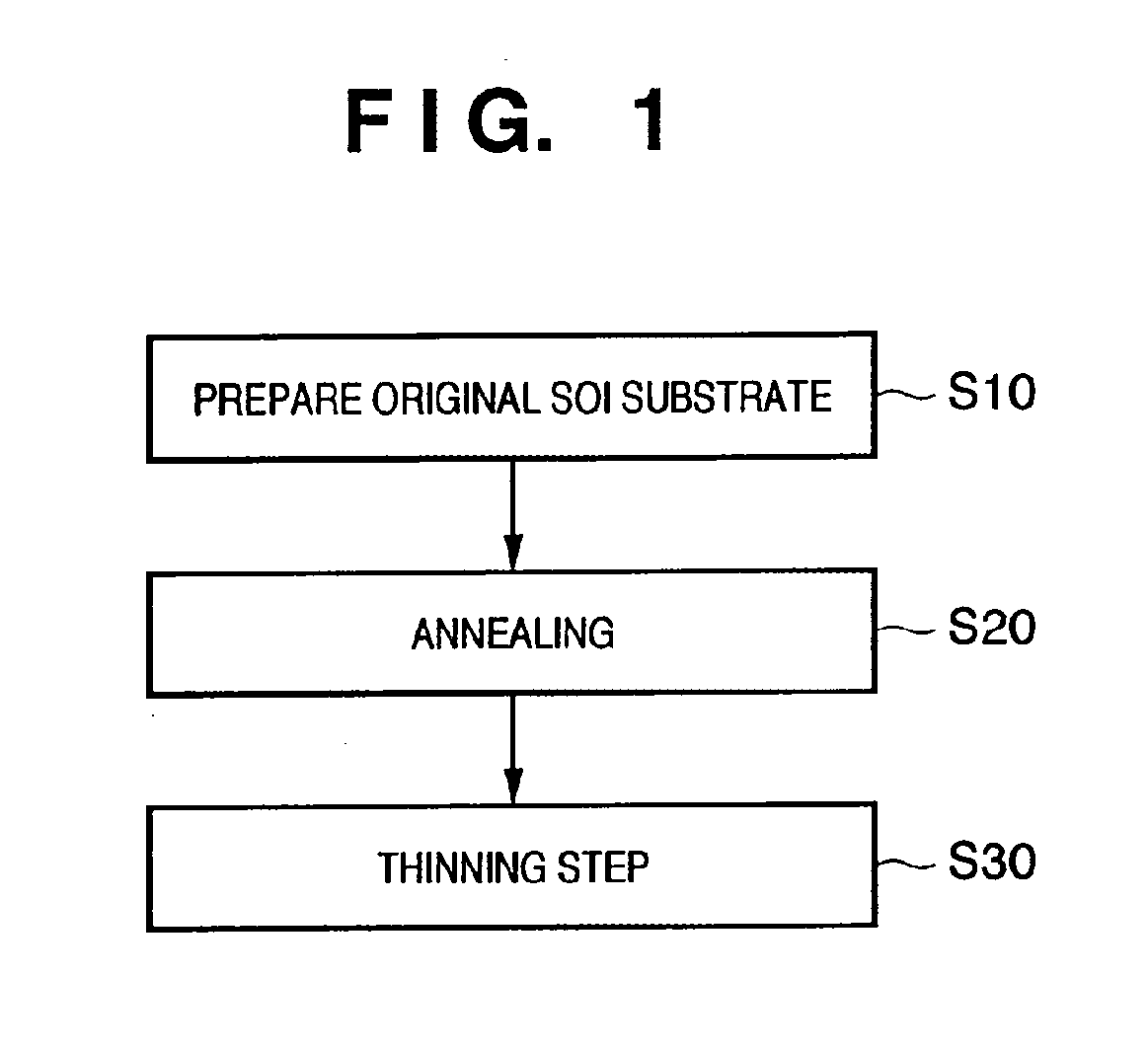

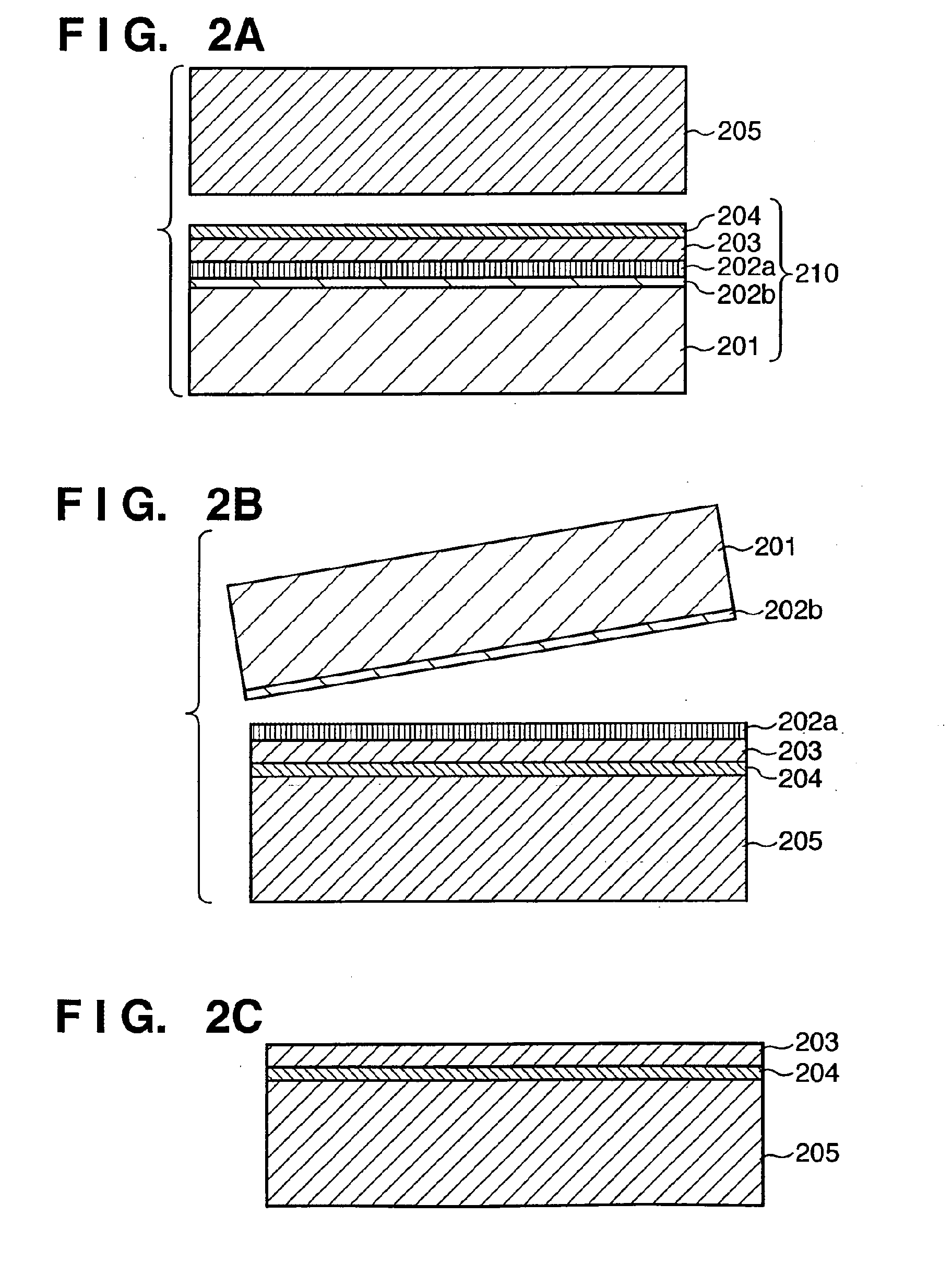

Substrate manufacturing method and substrate processing apparatus

InactiveUS7256104B2Easy thickness controlIncrease flexibilitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingChemical solutionSoi substrate

An SOI substrate which has a thick SOI layer is first prepared. Then, the SOI layer is thinned to a target film thickness using as a unit a predetermined thickness not more than that of one lattice. This thinning is performed by repeating a unit thinning step which includes an oxidation step of oxidizing the surface of the SOI layer by the predetermined thickness not more than that of one lattice and a removal step of selectively removing silicon oxide formed by the oxidation. The SOI layer of the SOI substrate is chemically etched by supplying a chemical solution to the SOI layer, and the film thickness of the etched SOI layer is measured. When the measured film thickness of the SOI layer has a predetermined value, a process of chemically etching the SOI layer ends.

Owner:CANON KK

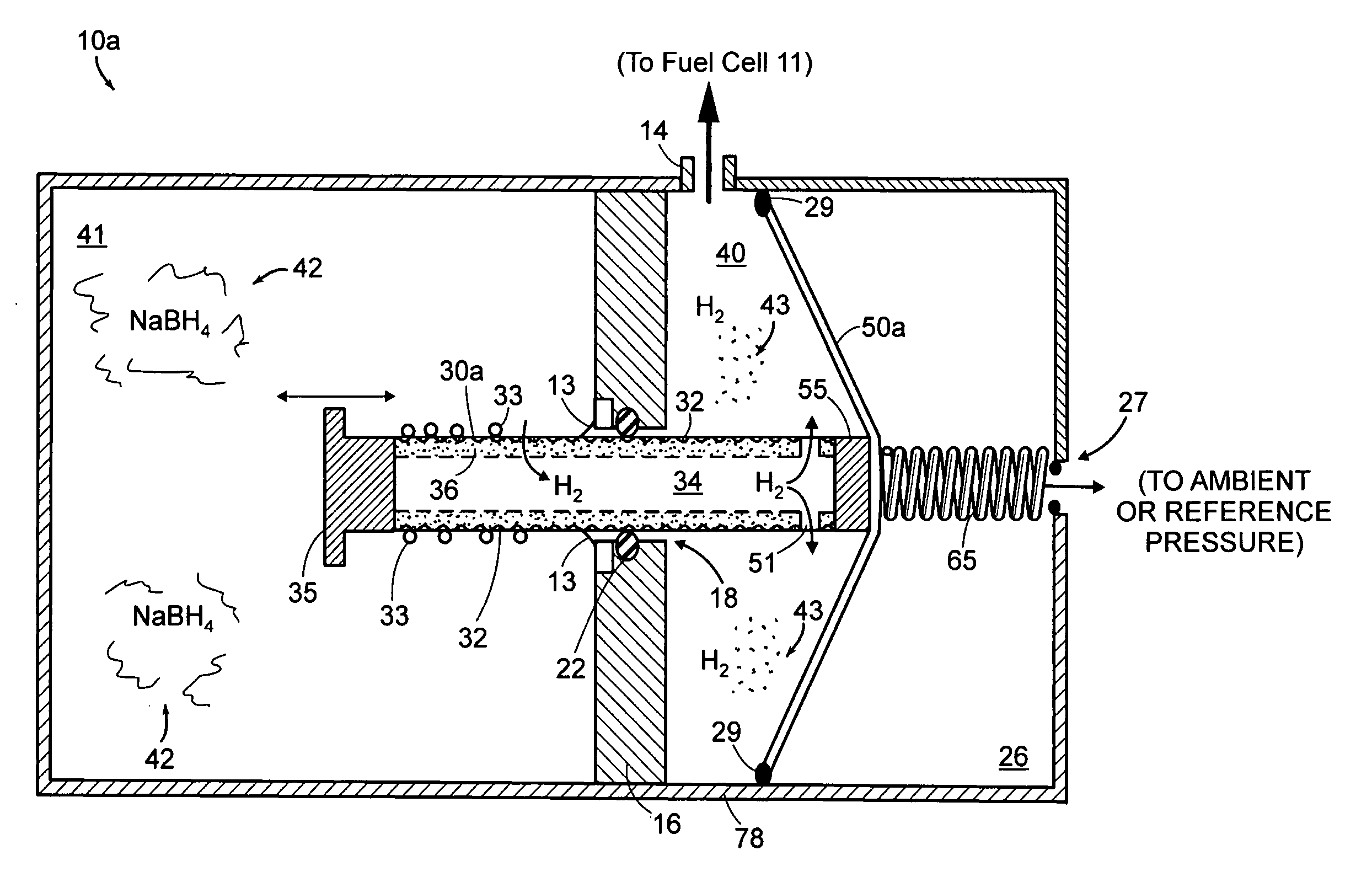

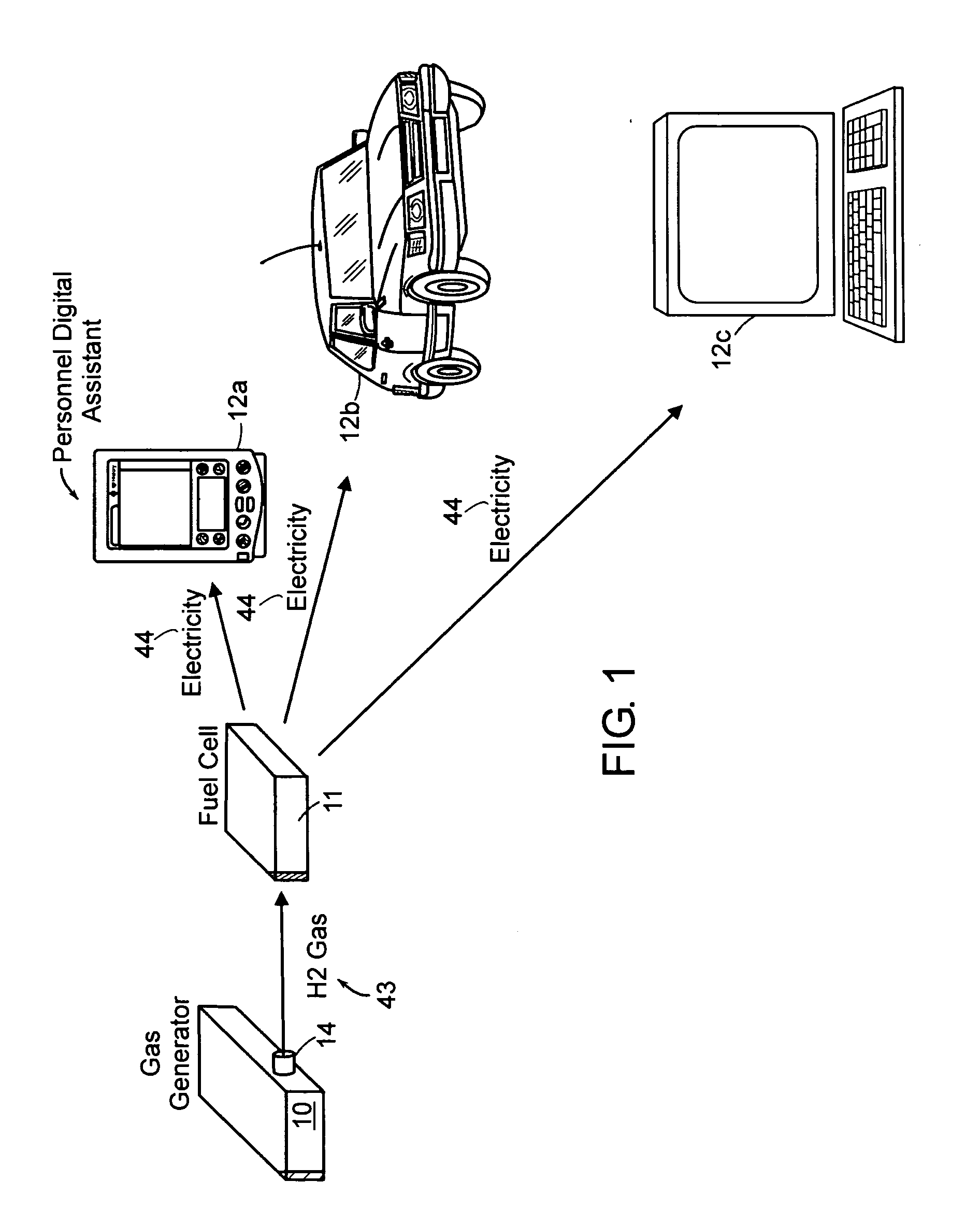

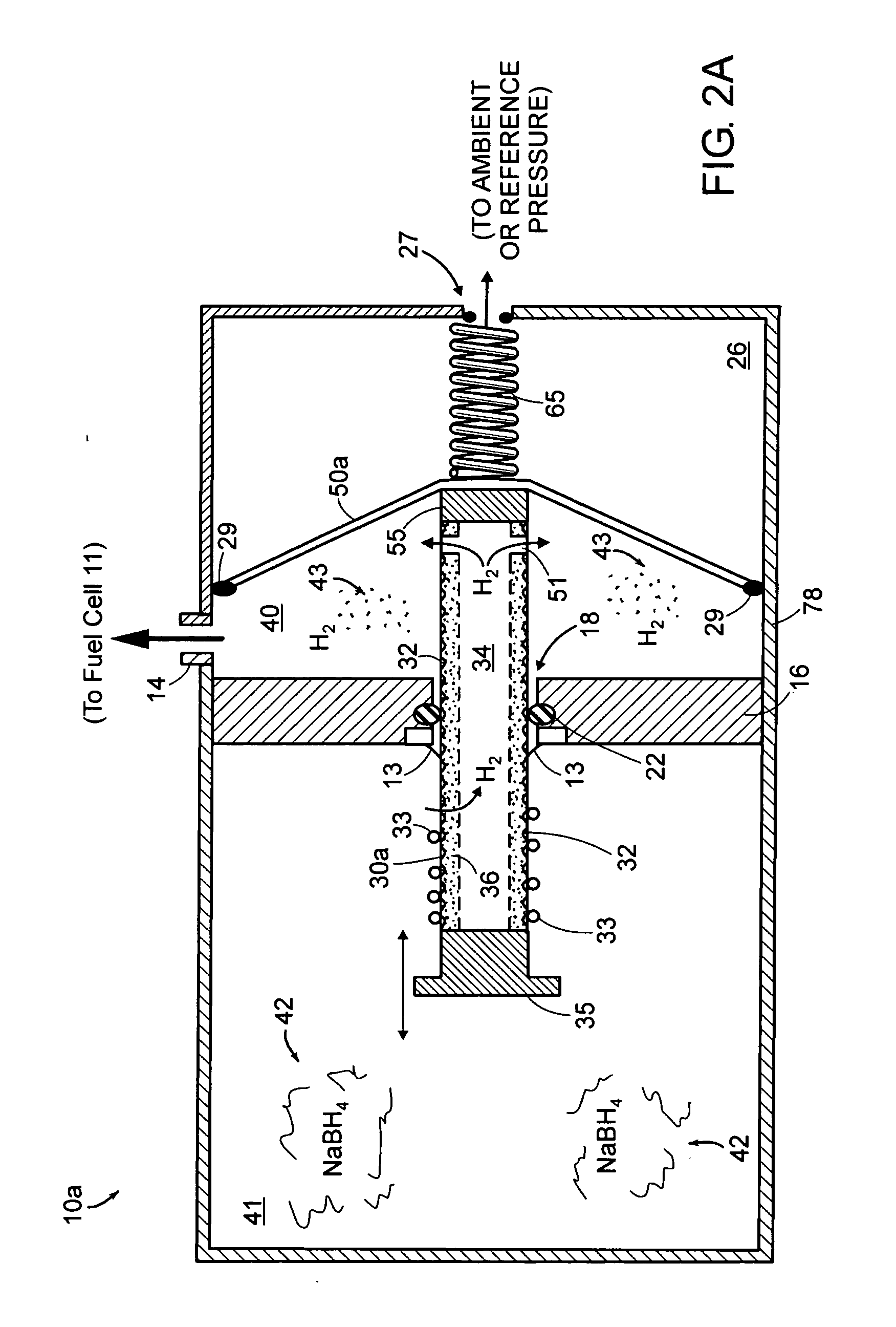

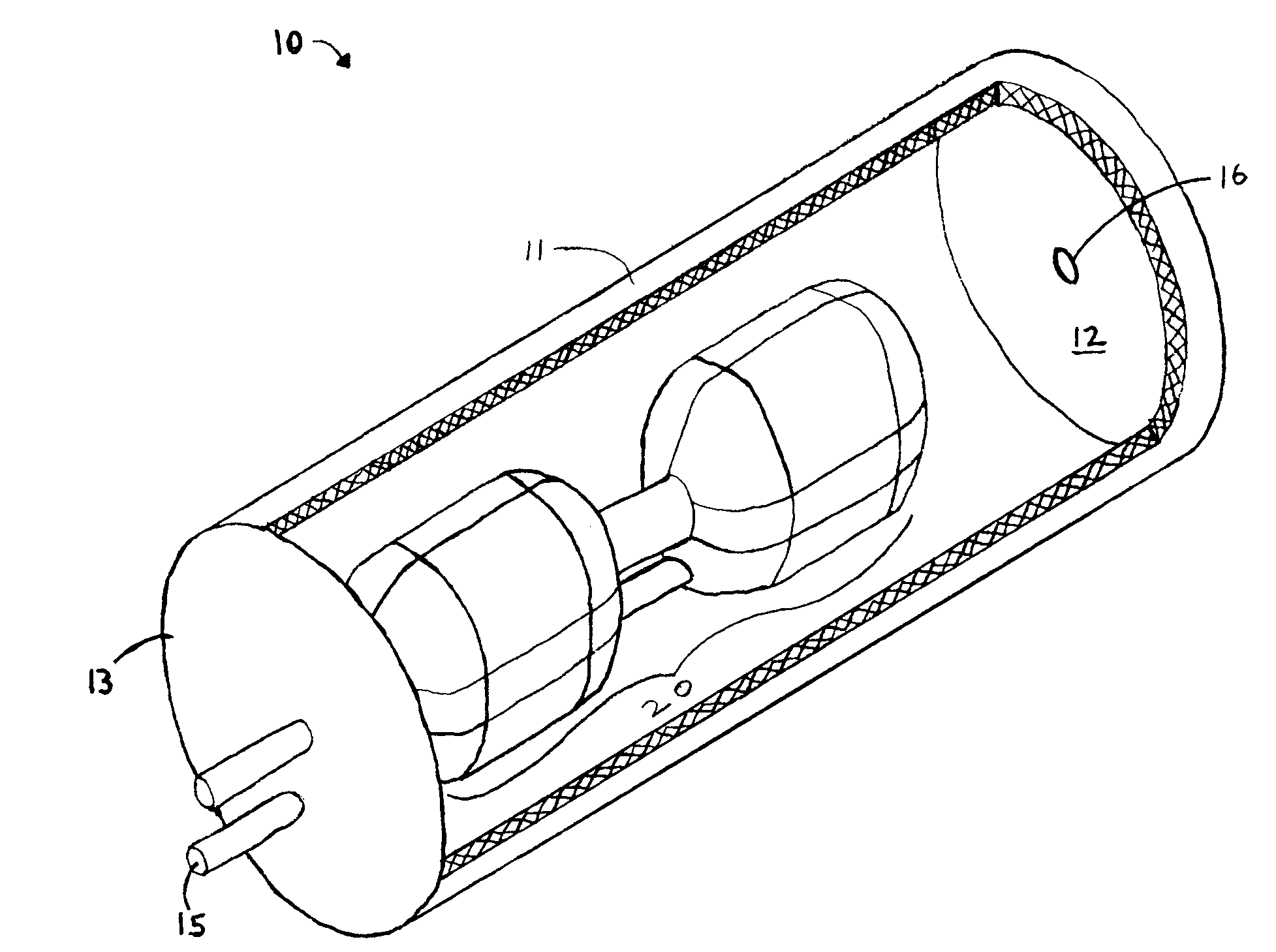

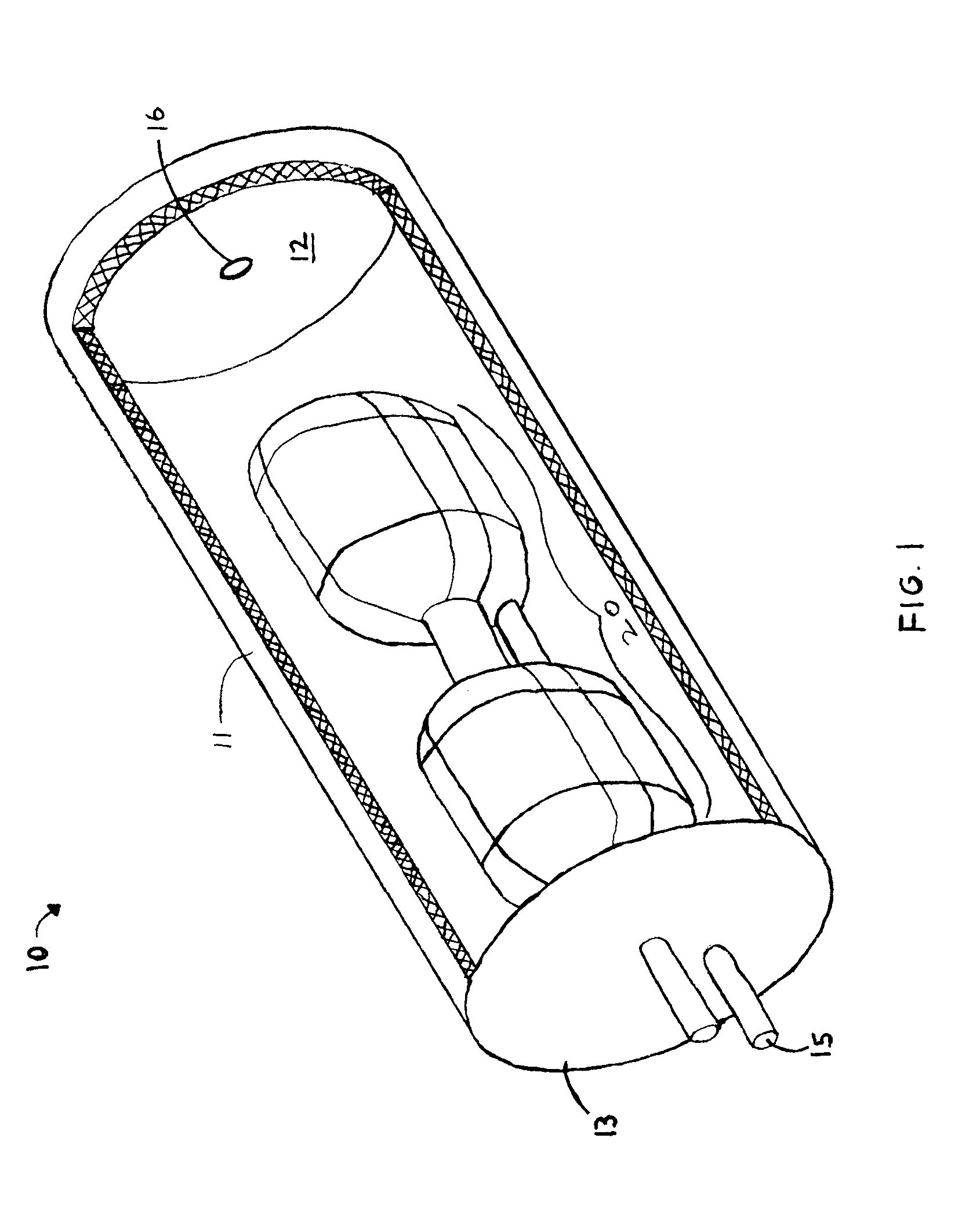

Self-regulating gas generator and method

ActiveUS20050158595A1Increase and decreases gas production rateExtend your lifeReactant parameters controlMultiple metal hydridesHydrogenFuel cells

A self-regulating gas generator that, in response to gas demand, supplies and automatically adjusts the amount of gas (e.g., hydrogen or oxygen) catalytically generated in a chemical supply chamber from an appropriate chemical supply, such as a chemical solution, gas dissolved in liquid, or mixture. The gas generator may employ a piston, rotating rod, or other element(s) to expose the chemical supply to the catalyst in controlled amounts. The gas generator may be used to provide gas for various gas consuming devices, such as a fuel cell, torch, or oxygen respiratory devices.

Owner:ENCITE LLC

Sealed Vaporization Cartridge and Vaporization Systems for Using

InactiveUS20090255534A1Low costRespiratorsOhmic-resistance heatingChemical solutionInhaled substance

A vaporization system for an inhalable substance includes a sealed cartridge. The sealed cartridge contains the chemical solution to be vaporized, a heating element which vaporizes the solution, and a wicking material for retaining the solution and bringing it into contact with the heating element through capillary action. The sealed cartridge may be disposable, having inexpensive elements so the cartridge can be replaced with little cost. Alternatively the sealed cartridge may be fully integrated with other components into a base unit, which may be disposable or may include a refill port which allows a user to refill the sealed cartridge with solution once the contained solution has been fully vaporized. A power source connects to the heating element and is activated by a switch that may be a breath detector. A disposable mouthpiece may be connected to the cartridge. The mouthpiece has an airway through which the vaporized solution is inhaled. The airway is restricted by a trap that prevents unvaporized droplets of the solution from passing through the airway into a user's mouth.

Owner:NJOY LLC

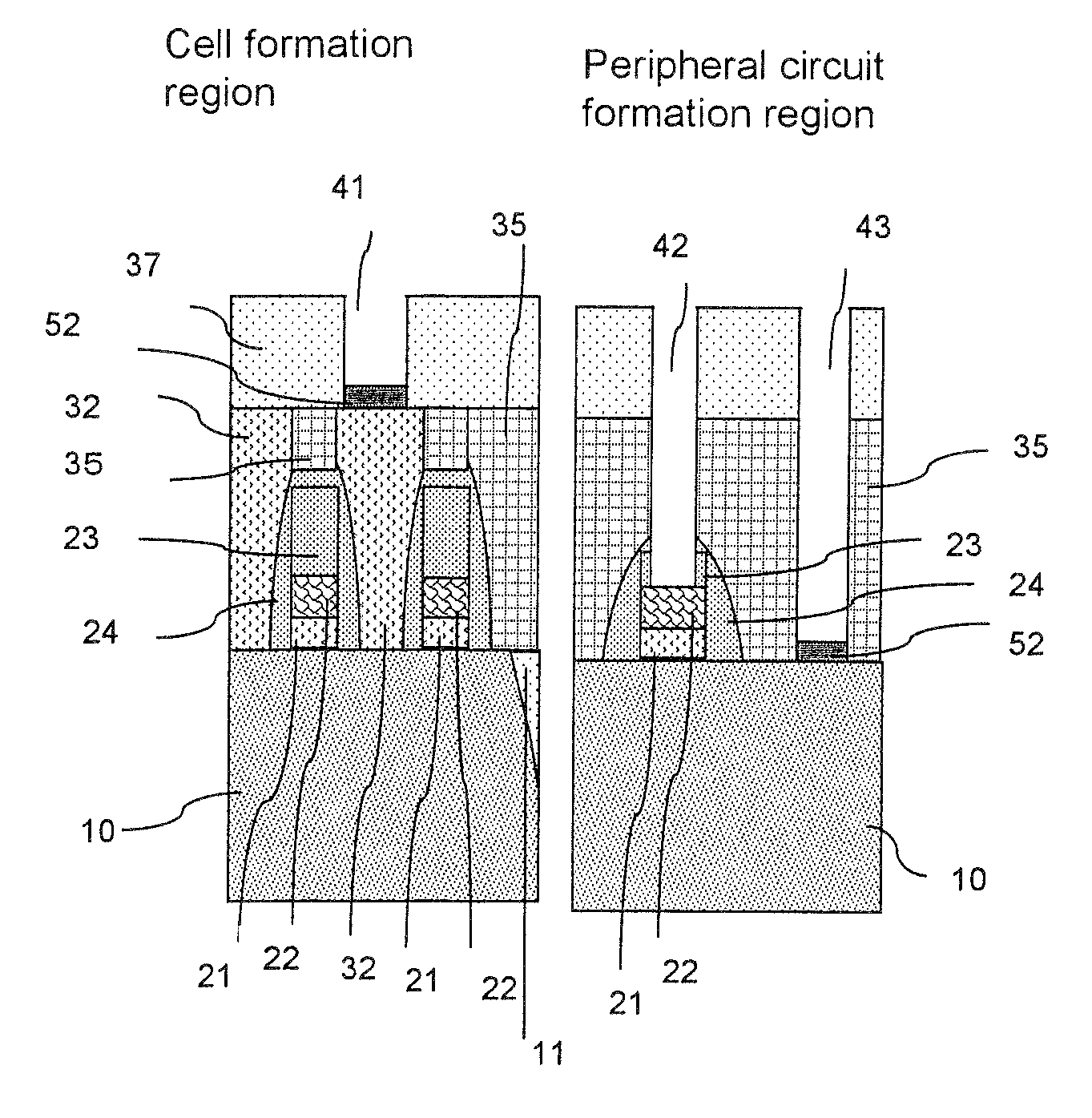

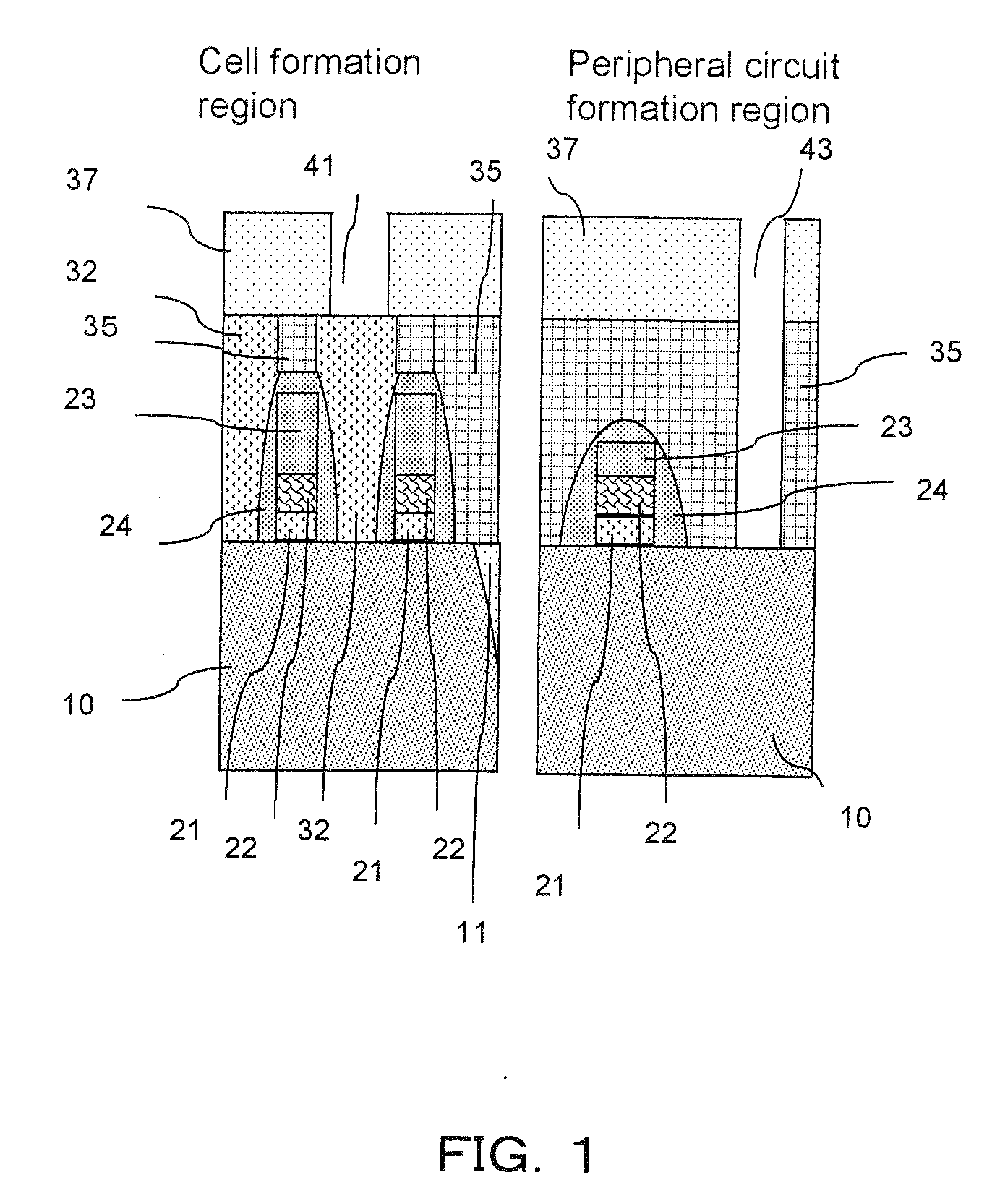

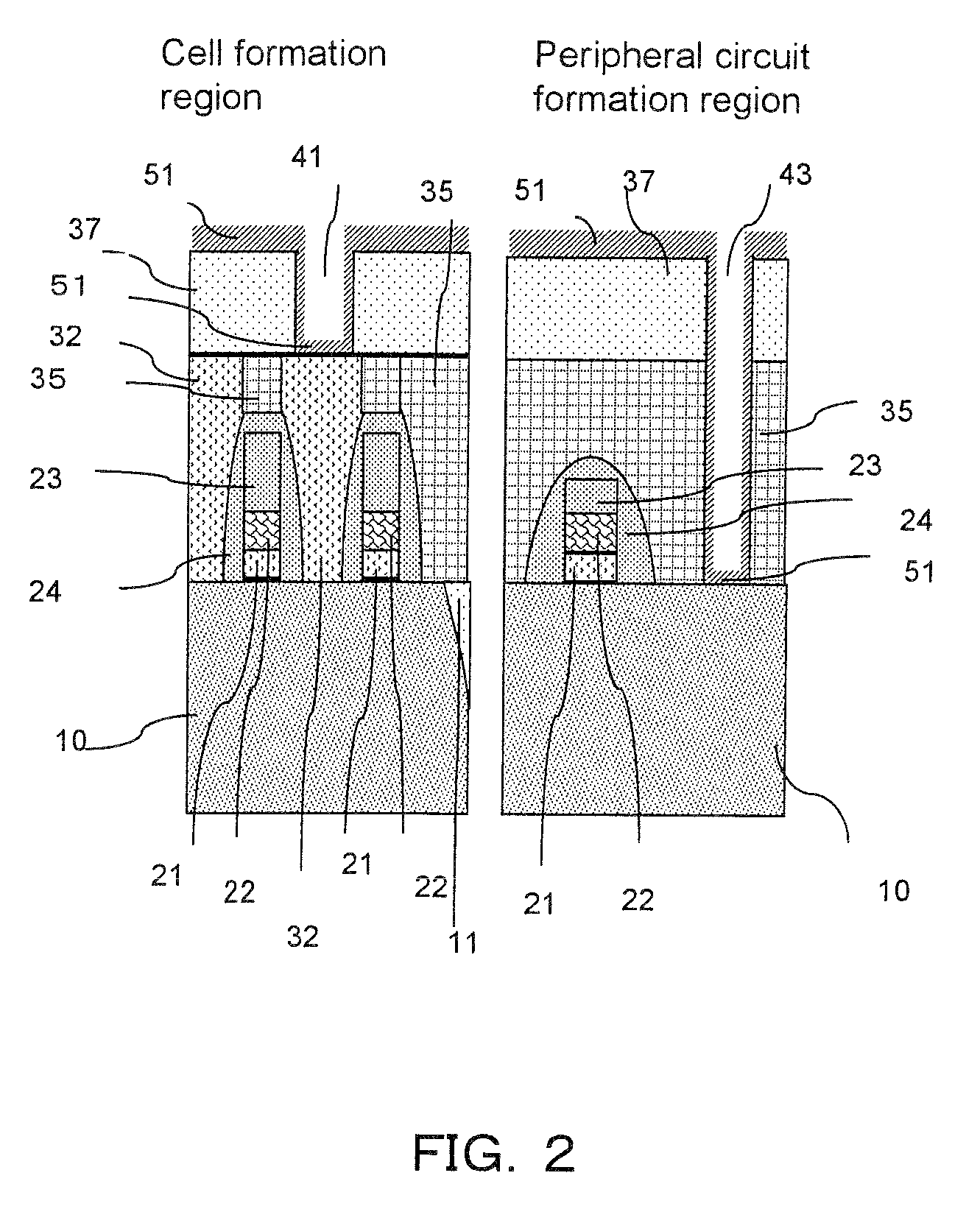

Manufacturing method of semiconductor device

ActiveUS20080081472A1Reduce processing stepsIncrease the number ofSemiconductor/solid-state device detailsSolid-state devicesChemical solutionDevice material

A first structure is formed, having a contact plug formed on the bottom of a first opening in an interlayer insulating film, a second opening formed through the interlayer insulating film to reach a semiconductor substrate, and a third opening formed through the interlayer insulating film to reach a polymetal gate electrode. A cobalt layer is deposited on the surface of the structure, and thermally treated to form a cobalt silicide layer on the surface of the contact plug and on the bottom face of the second opening. The structure is then treated to remove the cobalt, in the state in which the cobalt silicide layer is formed, with the use of a chemical solution capable of dissolving cobalt but not the polymetal.

Owner:HEFEI RELIANCE MEMORY LTD

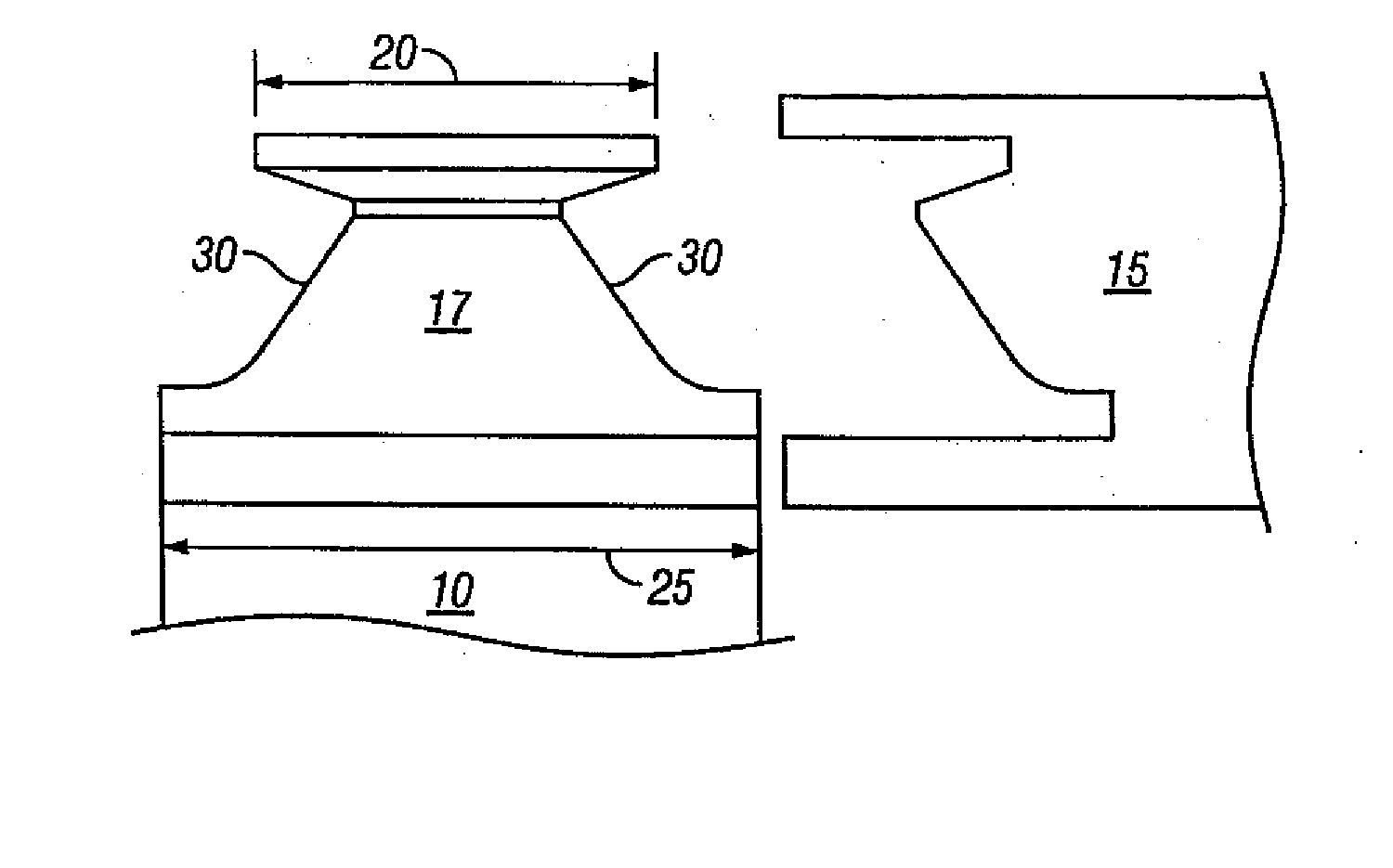

Hybrid contact lens system and method

InactiveUS20050018130A1Easy to createReduce penetrationOptical articlesEye diagnosticsChemical solutionPeripheral zone

A hybrid contact lens comprises a central zone comprising a substantially rigid, gas permeable material having a DK of at least 30, a relatively soft peripheral zone and an intermediate zone comprising a film or coating that is created around the central zone, and then cured. The film facilitates chemical bonding between the central zone and the peripheral zone, and also provides a protective barrier to prevent modification of the physical characteristics of the central zone. The film may be created by soaking the central zone in a chemical solution for a predetermined amount of soaking time.

Owner:SYNERGEYES

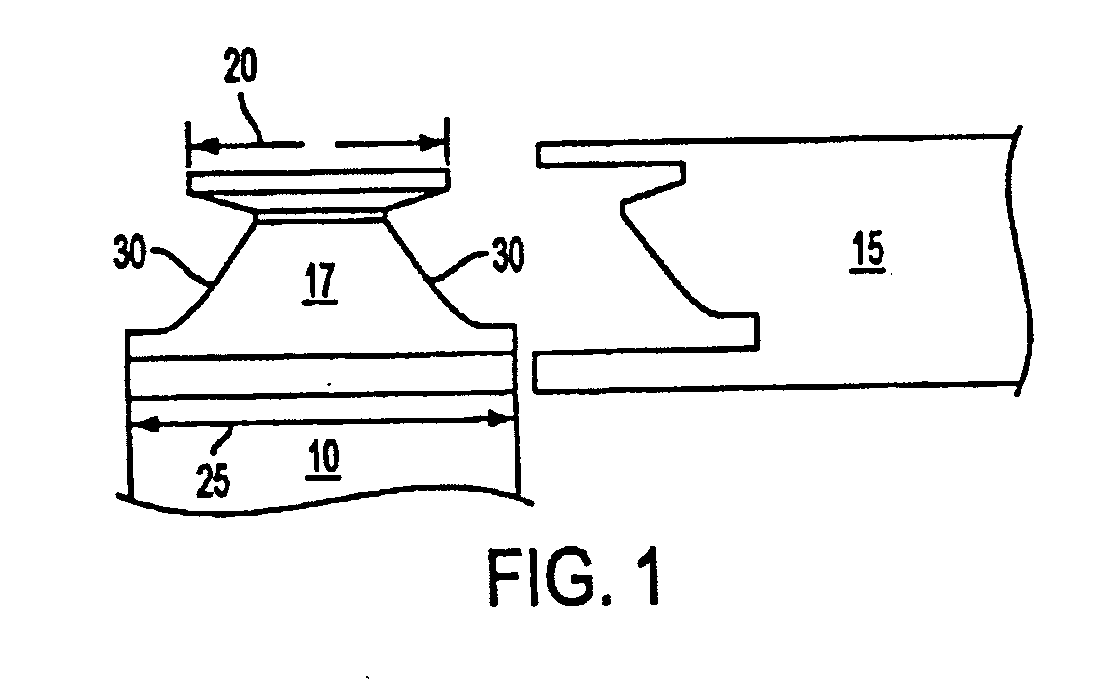

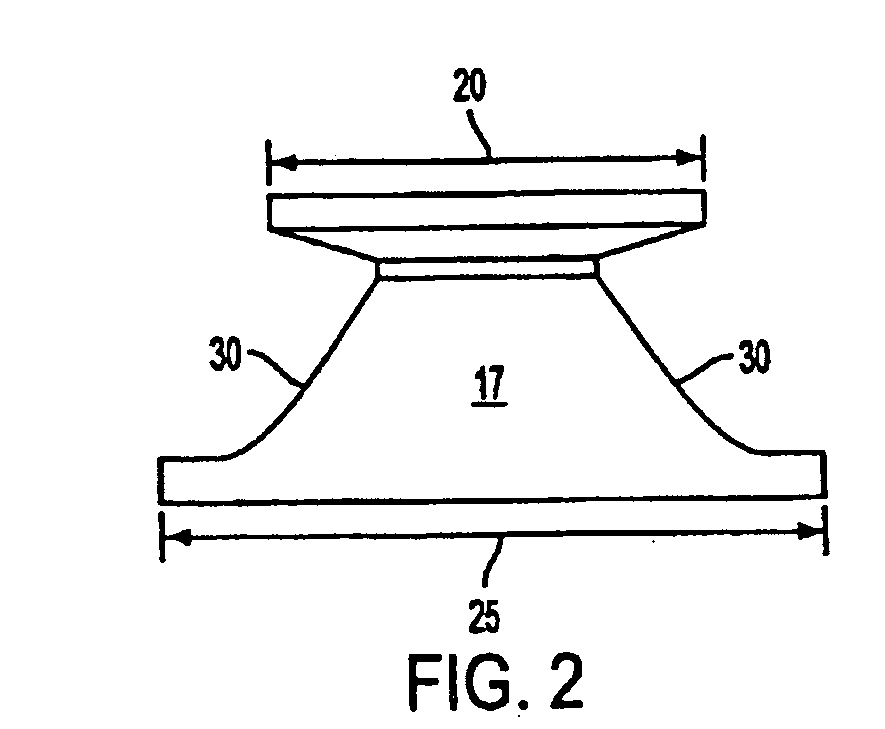

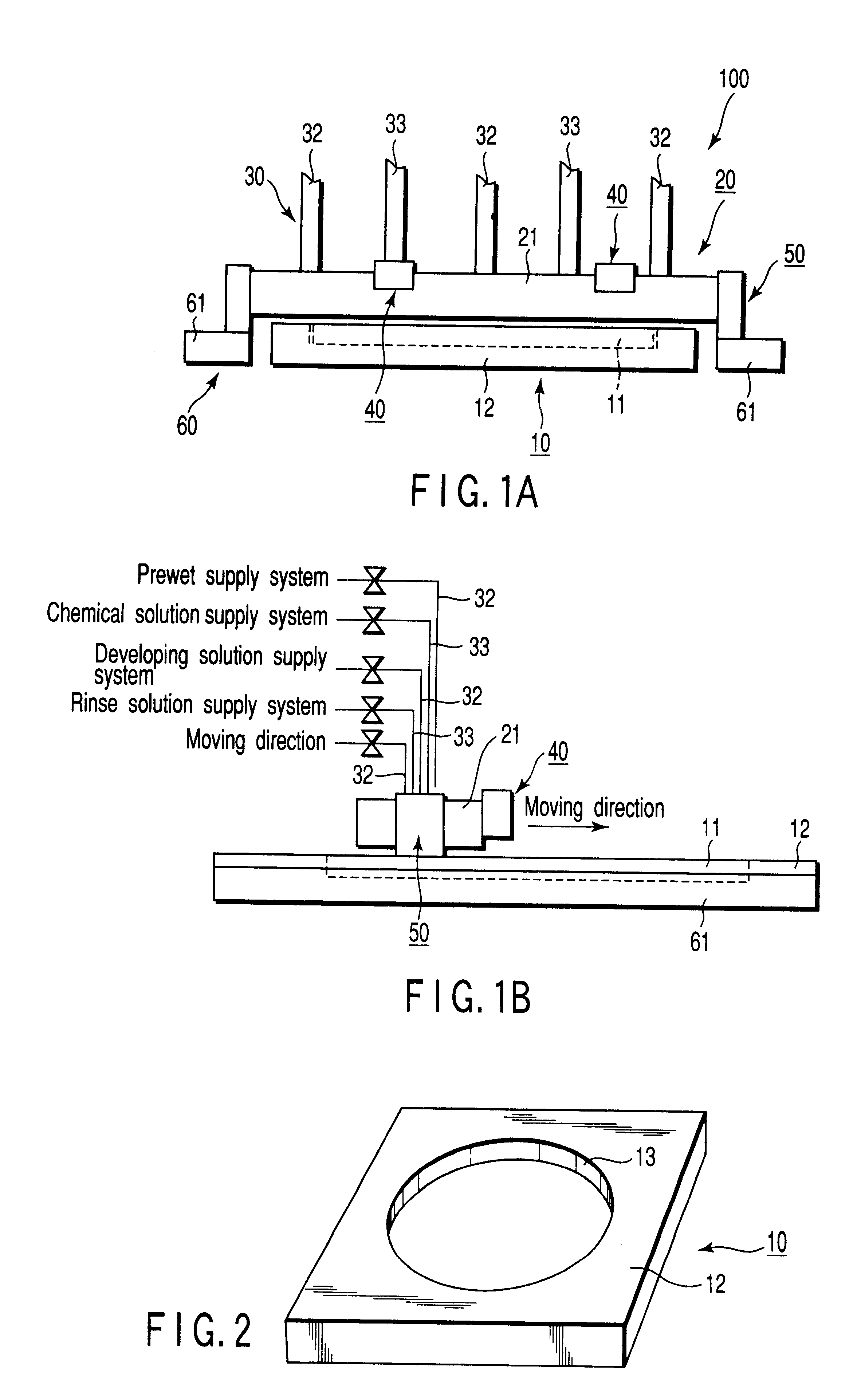

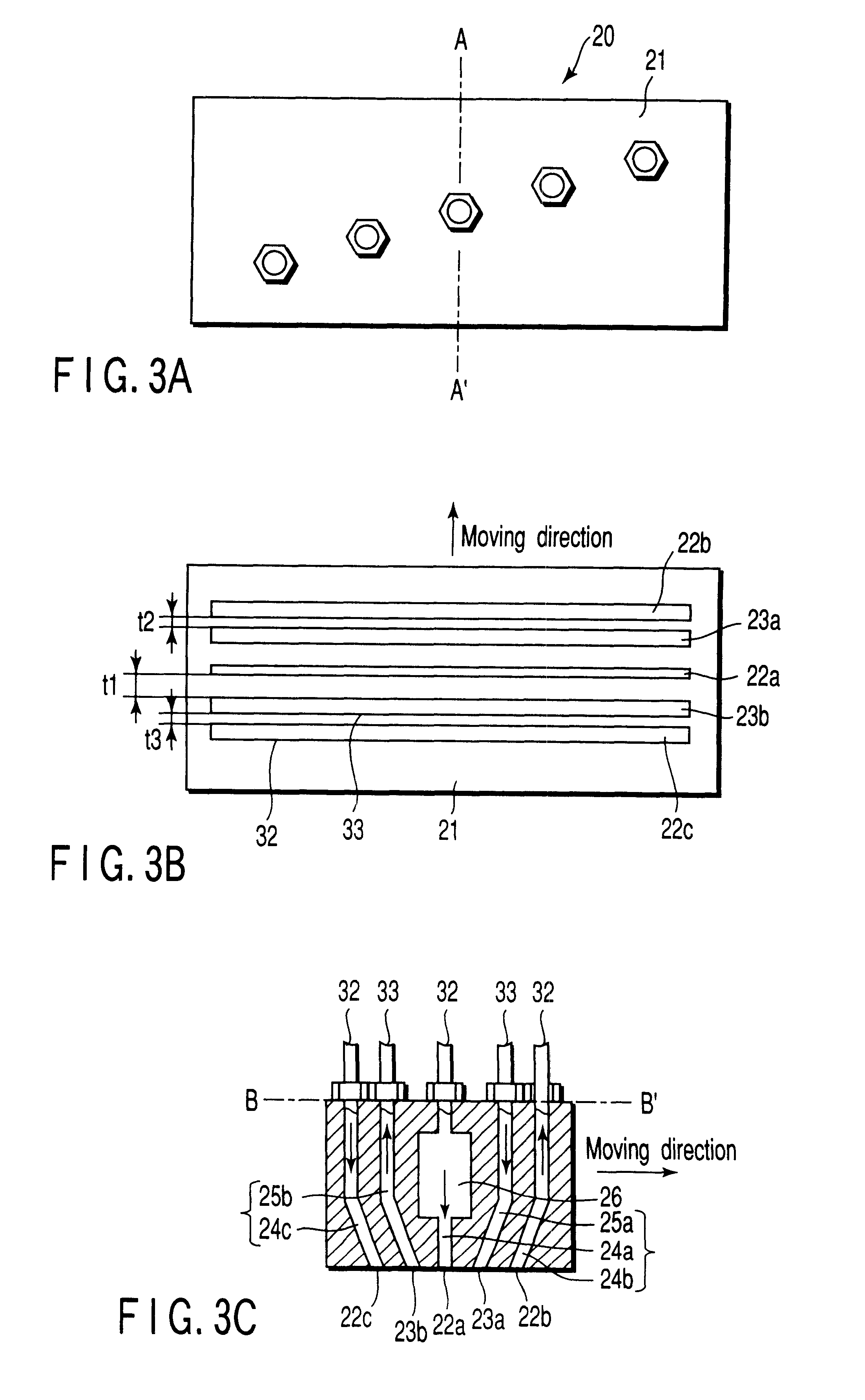

Substrate processing apparatus and processing method by use of the apparatus

InactiveUS6550990B2Liquid surface applicatorsReversal processingChemical solutionAnalytical chemistry

An apparatus for processing a substrate comprising a substrate holding mechanism for holding the substrate substantially horizontally, a chemical solution discharge / suction mechanism having a chemical solution discharge / suction portion which has a chemical solution outlet for discharging a chemical solution onto the substrate and chemical solution inlets for sucking up the chemical solution present on the substrate, and a chemical solution supply / suction system for supplying the chemical solution to the chemical solution discharge / suction mechanism simultaneously with sucking the chemical solution by the chemical solution supply / suction mechanism.

Owner:TOSHIBA MEMORY CORP

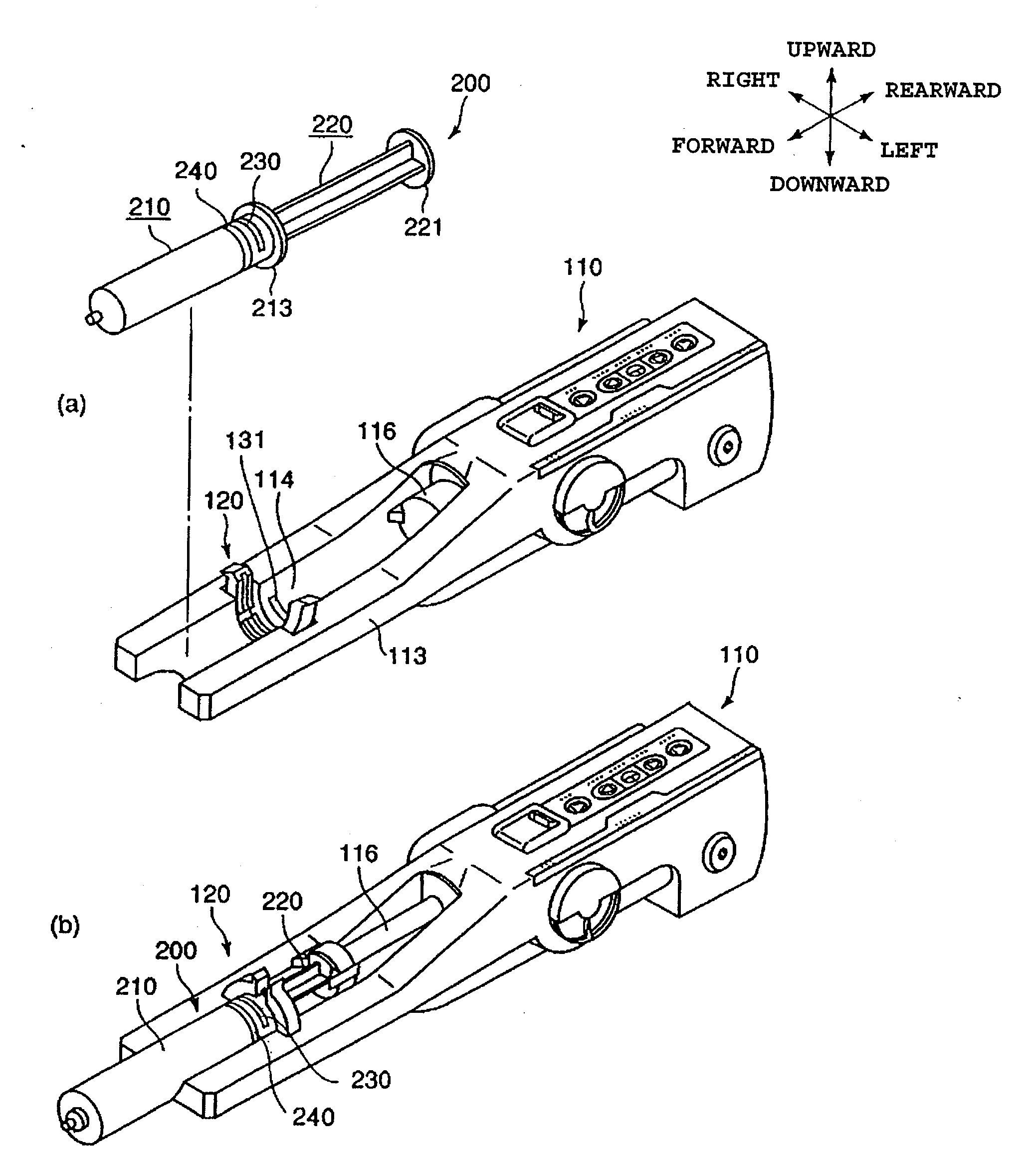

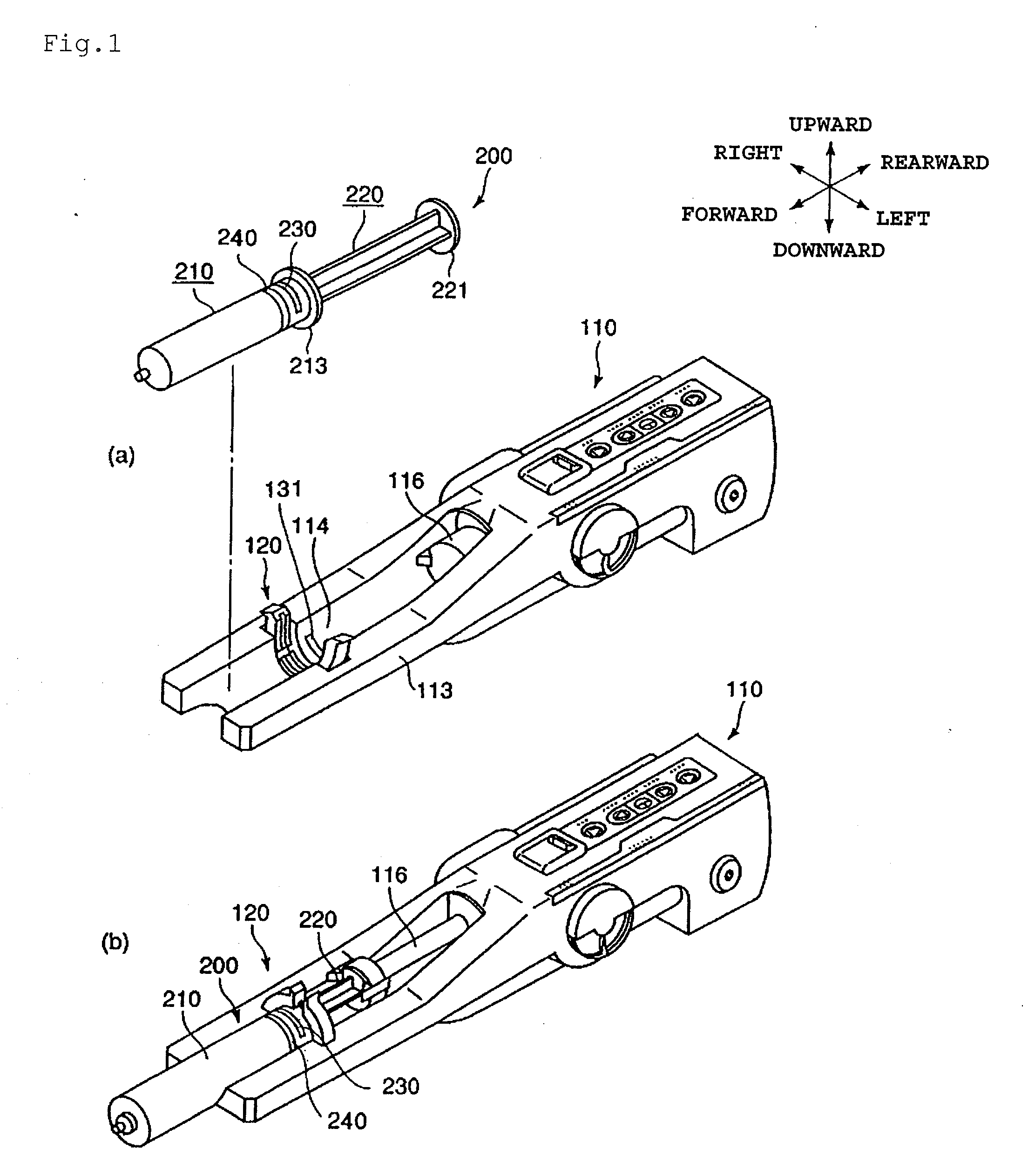

Chemical liquid infusion system

InactiveUS20090149744A1Improve communication performanceConvenient wireless communicationMedical devicesPressure infusionChemical solutionEngineering

A chemical solution injection system, wherein a RFID chip (230) is mounted on a chemical liquid syringe (200) in the state of being wrapped around the outer surface of the cylinder member (210) thereof. An amplification antenna (240) wrapped one turn around the outer surface of the cylinder member (210) is disposed at the front of the RFID chip (230) parallel with each other. Since the communication performance of the RFID chip is increased by the amplifying antenna, the RFID chip (230) of the chemical solution syringe (200) is allowed to satisfactorily communicate with the RFID reader (131) of injection head (110).

Owner:NEMOTO KYORINDO KK

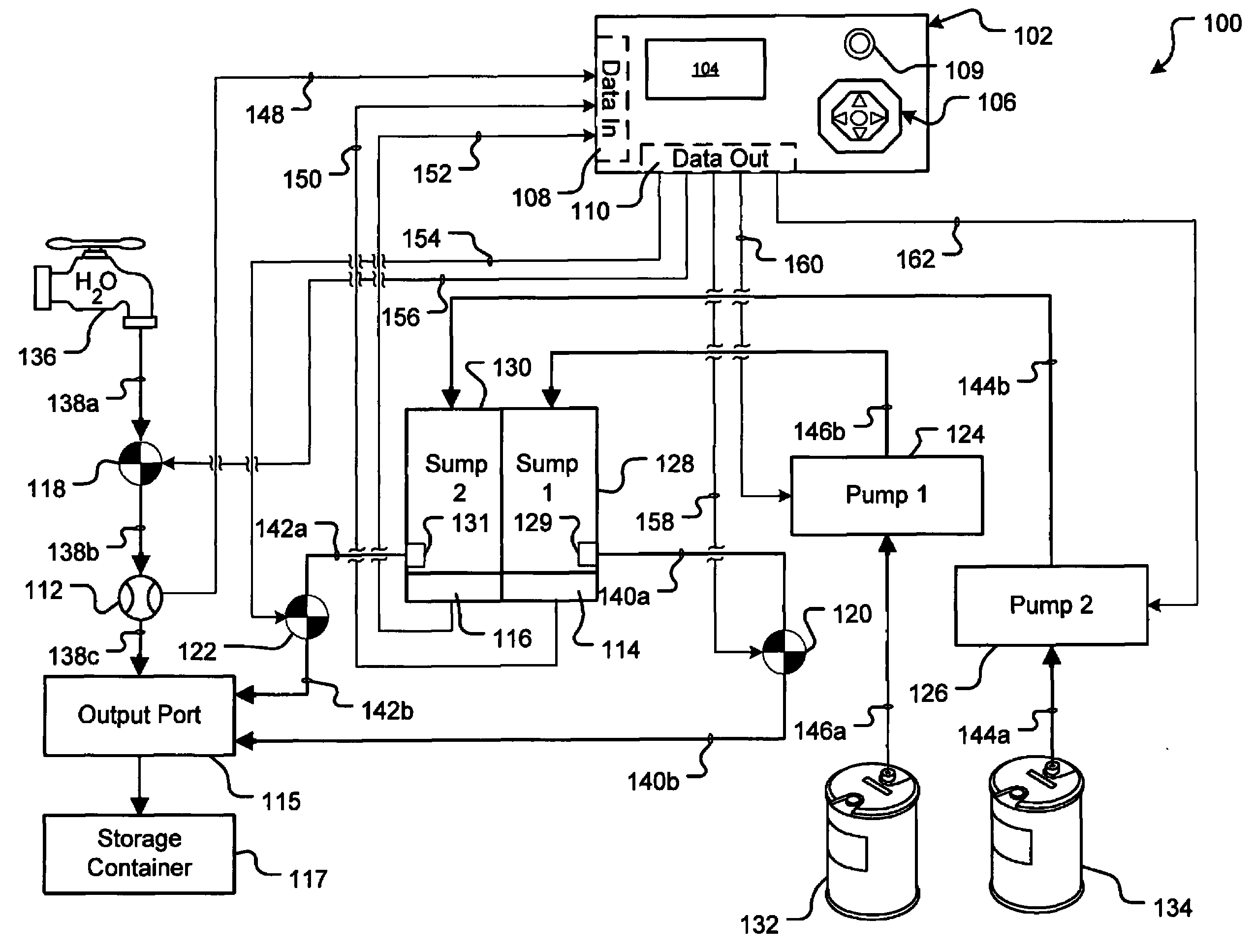

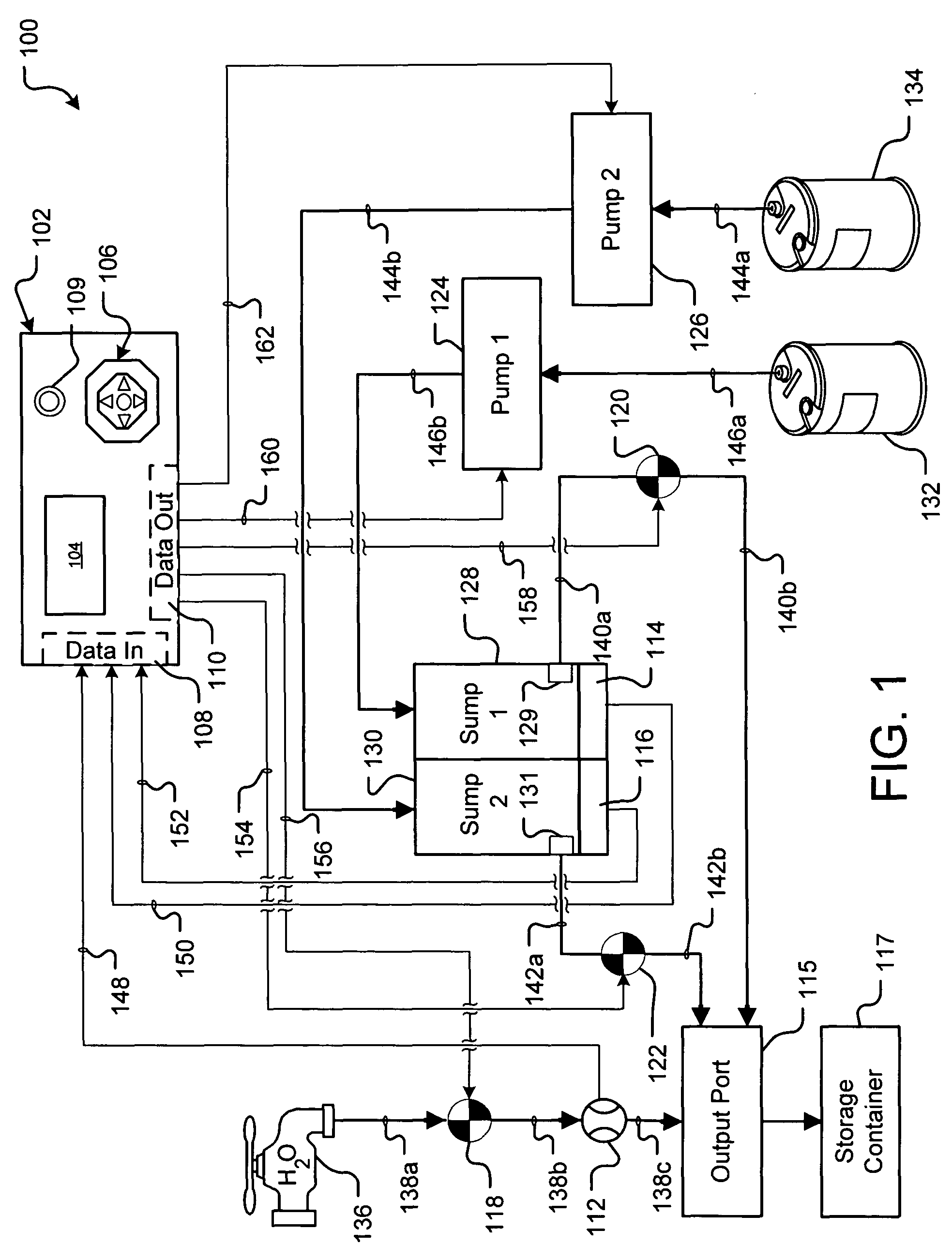

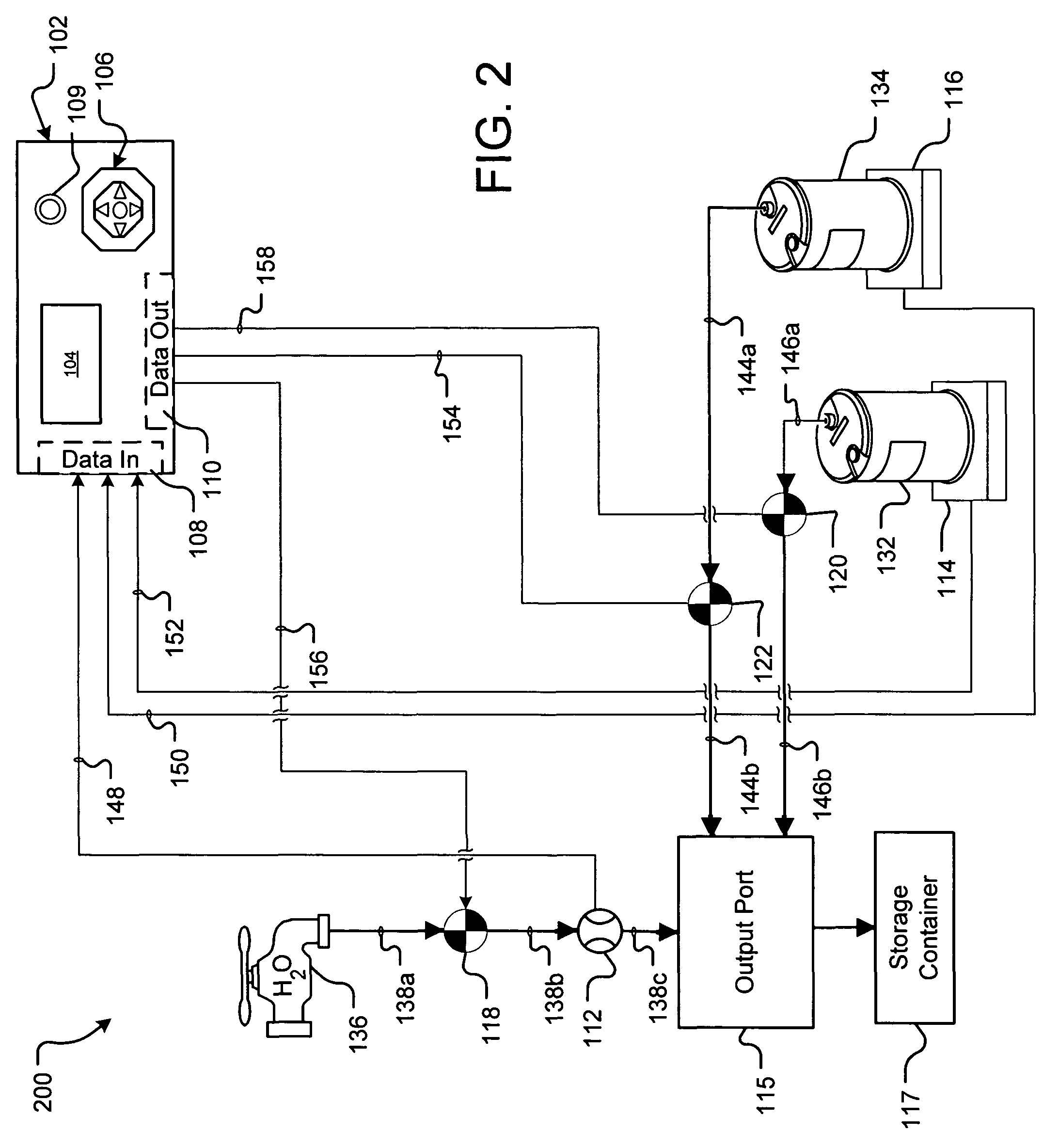

Formulating chemical solutions based on volumetric and weight based control measurements

A system and method for formulating a chemical solution using both volumetric and weight based measurements of components of the chemical solution is disclosed. The components of the chemical solution include water and at least one other component, which may take any form, such as, without limitation, liquid, solid, powder or gaseous form. Formulation of the chemical solution is administered by combining water with the one or more other components at an output port, from which this combination is dispensed to a solution storage tank. In response to a user's request to formulate a specified amount of the chemical solution, the volume of water provided to the output port is monitored by a flow meter and the weight of the other component(s) provided to the output port is monitored by one or more load cells. Based on such monitoring, appropriate amounts of water and the other component(s) are combined together to formulate the specified amount of the chemical solution in the solution storage tank.

Owner:ECOLAB USA INC

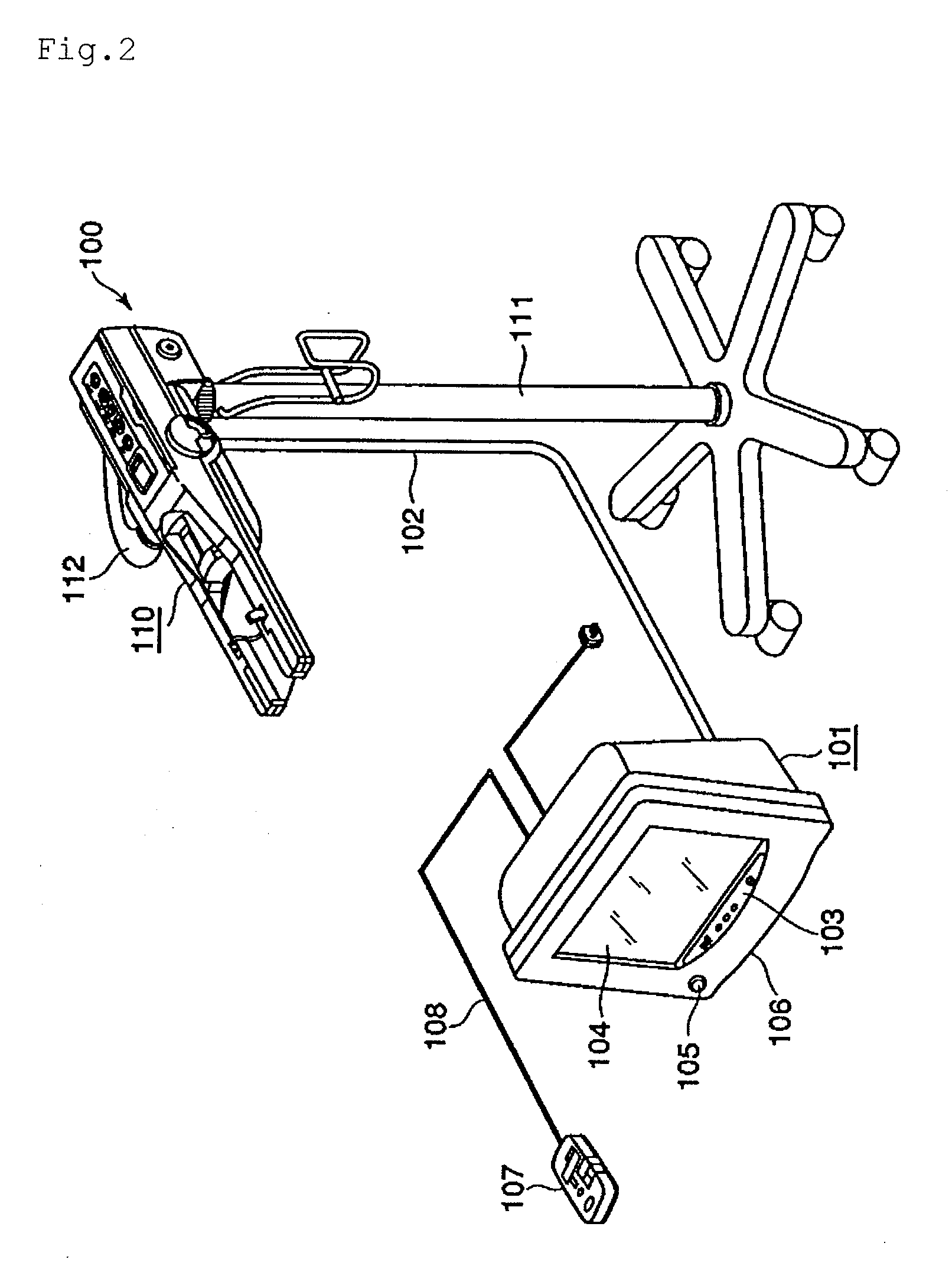

Injection device with puncture function, method for controlling injection device with puncture function, chemical solution administration device, and method for controlling chemical solution administration device

ActiveUS20070066938A1Easy to carryRealize miniaturizationAmpoule syringesElectrotherapyChemical solutionBiomedical engineering

An injection device with puncture function includes, in a single casing 30, a cylindrical cartridge 11 in which insulin 12 is enclosed, a cartridge holder 14 to which the cartridge 11 is inserted, a needle 16 inserted at a front end 11a of the cartridge 11, a reciprocation means 32 for reciprocating the cartridge 11 toward the needle 16, and an extrusion means 23 for extruding the insulin 12 from a rear end11b of the cartridge 11 toward the needle 16, and the motion speed and the motion amount of the reciprocation means 32 are made variable.

Owner:PHC HLDG CORP

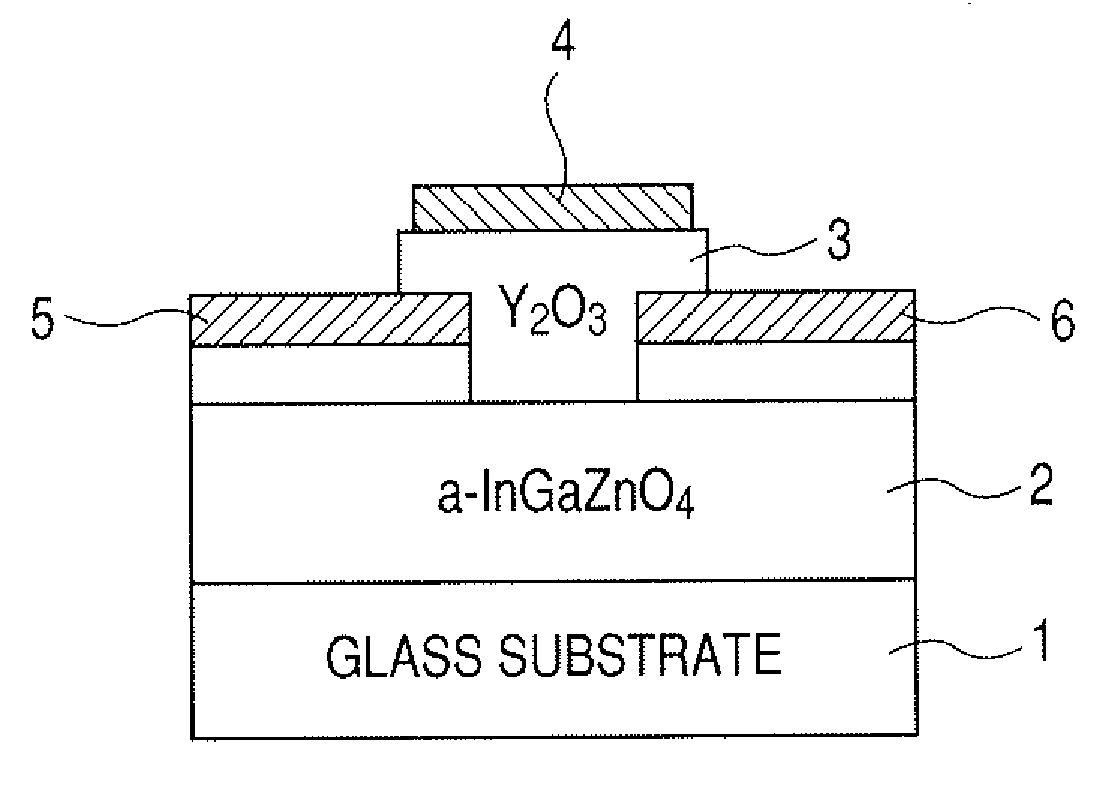

Field effect transistor manufacturing method

InactiveUS20100267198A1Semiconductor/solid-state device manufacturingSemiconductor devicesChemical solutionUltraviolet

Provided is a novel method for manufacturing a field effect transistor. Prior to forming an amorphous oxide layer on a substrate, ultraviolet rays are irradiated onto the substrate surface in an ozone atmosphere, plasma is irradiated onto the substrate surface, or the substrate surface is cleaned by a chemical solution containing hydrogen peroxide.

Owner:CANON KK +2

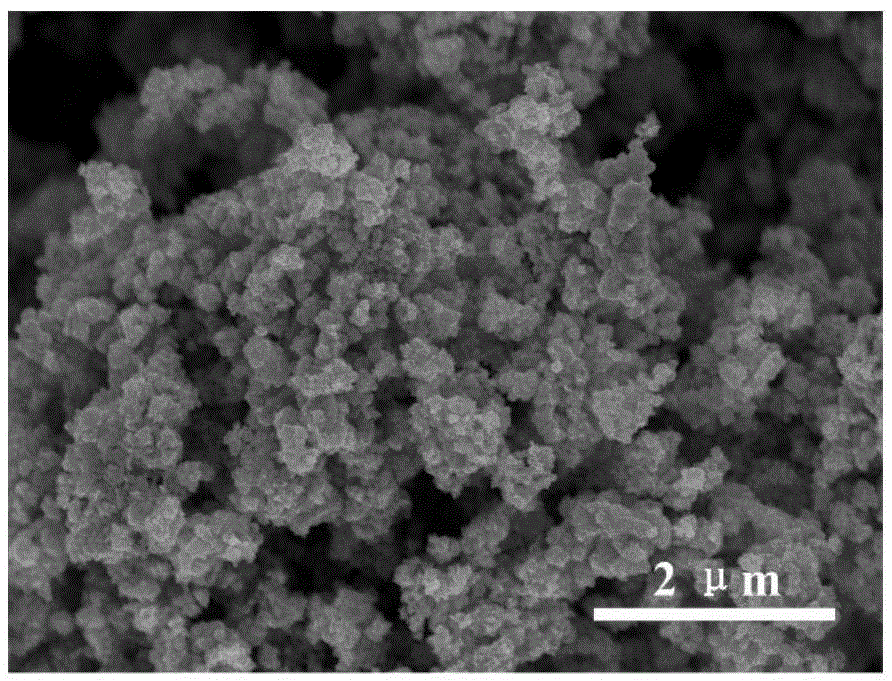

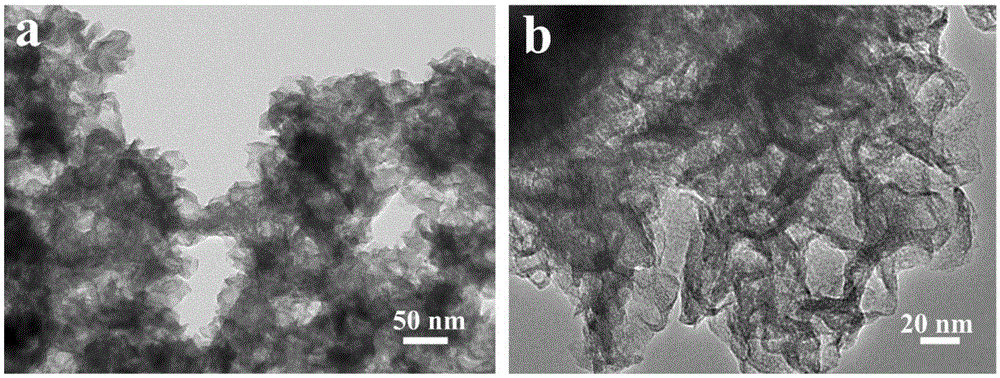

Cobalt-intercalated molybdenum sulfide secondary battery material and preparation method and application thereof

InactiveCN106611837AAvoid reunionAvoid stackingMaterial nanotechnologyHybrid capacitor electrodesLevel structureChemical solution

The invention relates to a cobalt-intercalated molybdenum sulfide secondary battery material and a preparation method and an application thereof. A three-dimensional cobalt-intercalated molybdenum sulfide multi-level structure is prepared by adopting a chemical solution method; firstly, a cobalt salt, a molybdenum salt and a sulfur source are dispersed into a solvent to prepare a reaction liquid; and then the prepared reaction liquid is subjected to solvent thermal treatment to obtain the three-dimensional cobalt-uniformly-intercalated molybdenum sulfide multi-level structure which is self-assembled by graphene-like ultra-thin nanosheets, wherein the size of the multi-level structure is about 100nm. The invention also discloses a preparation method for the multi-level structure. The secondary battery material prepared by the method is stable in nanomaterial performance, and long in cycle life when the secondary battery material is used as a negative electrode material of a lithium ion battery and an electrode material of a supercapacitor.

Owner:SHANGHAI JIAO TONG UNIV

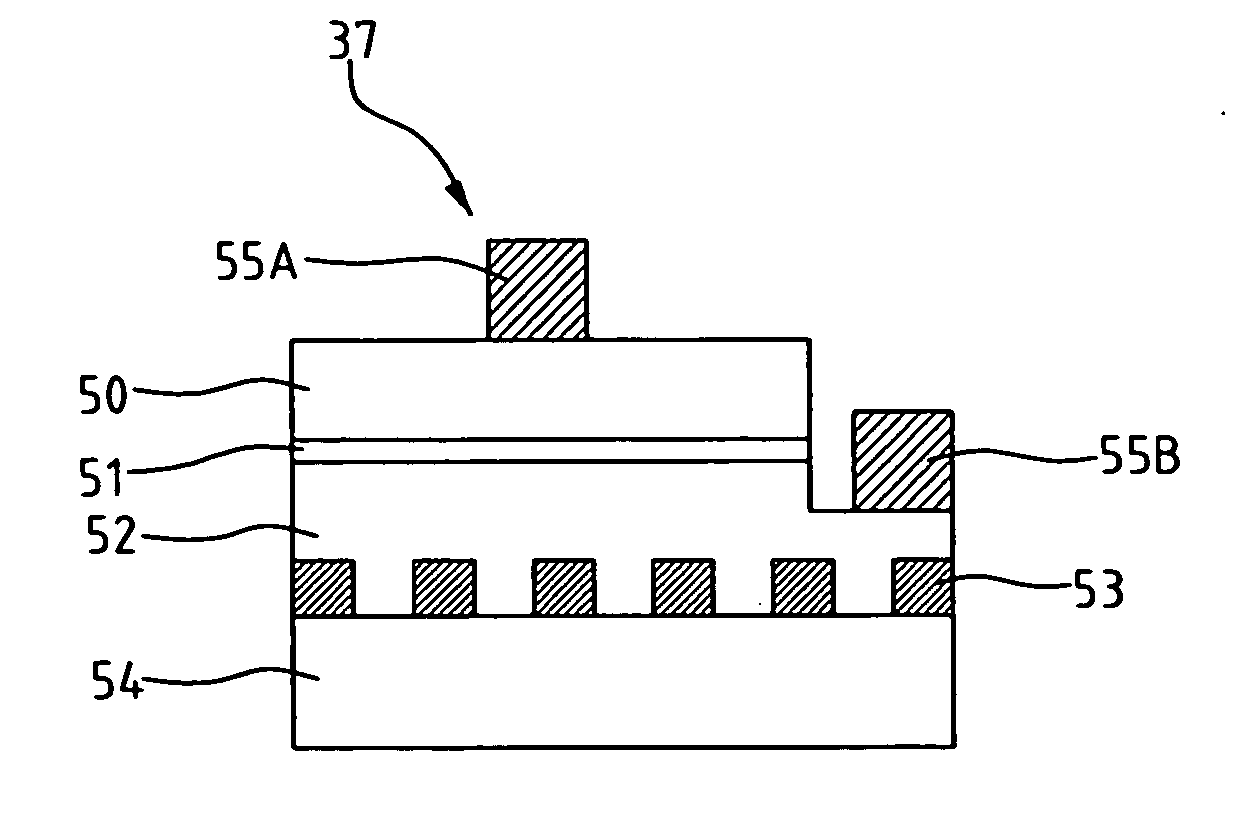

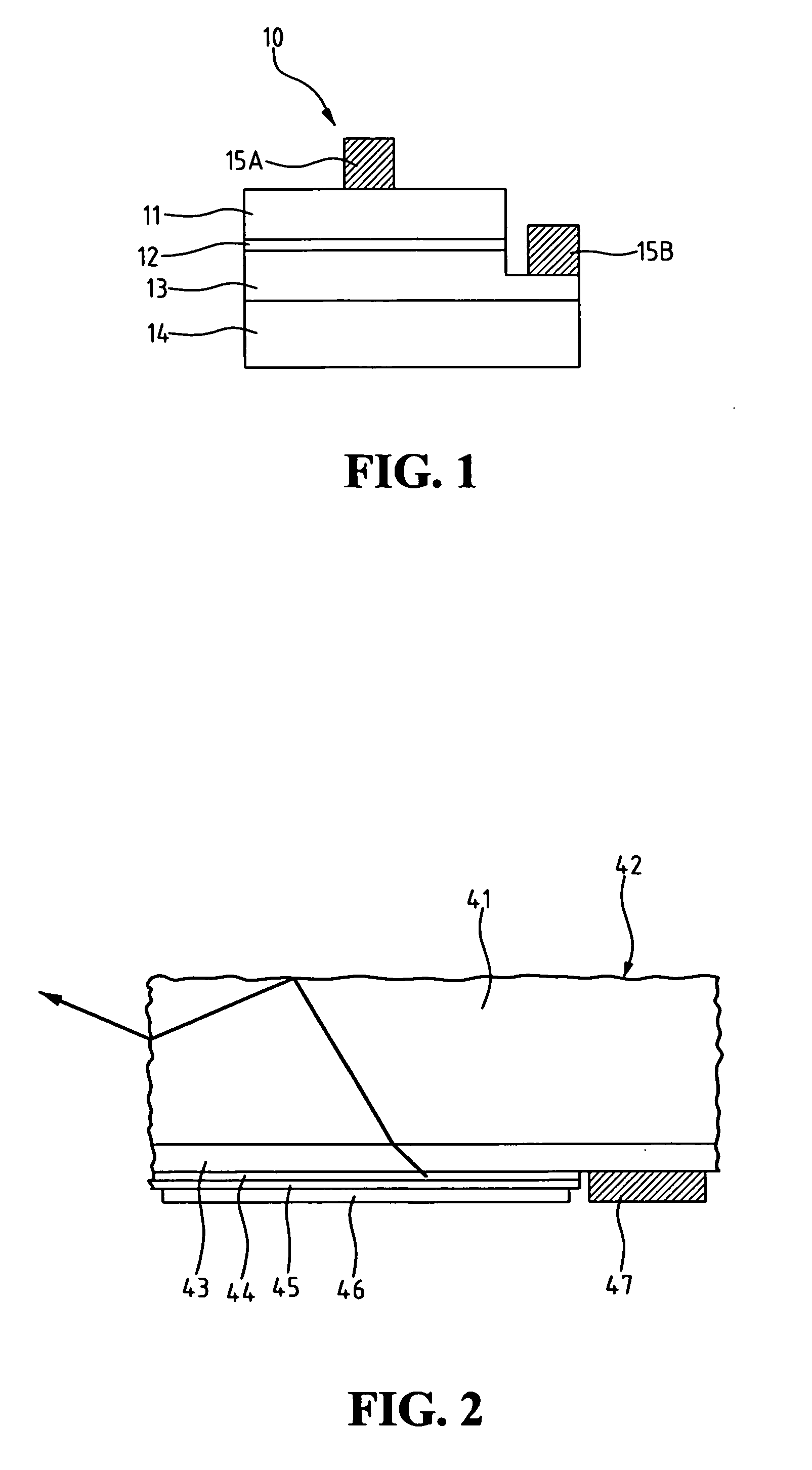

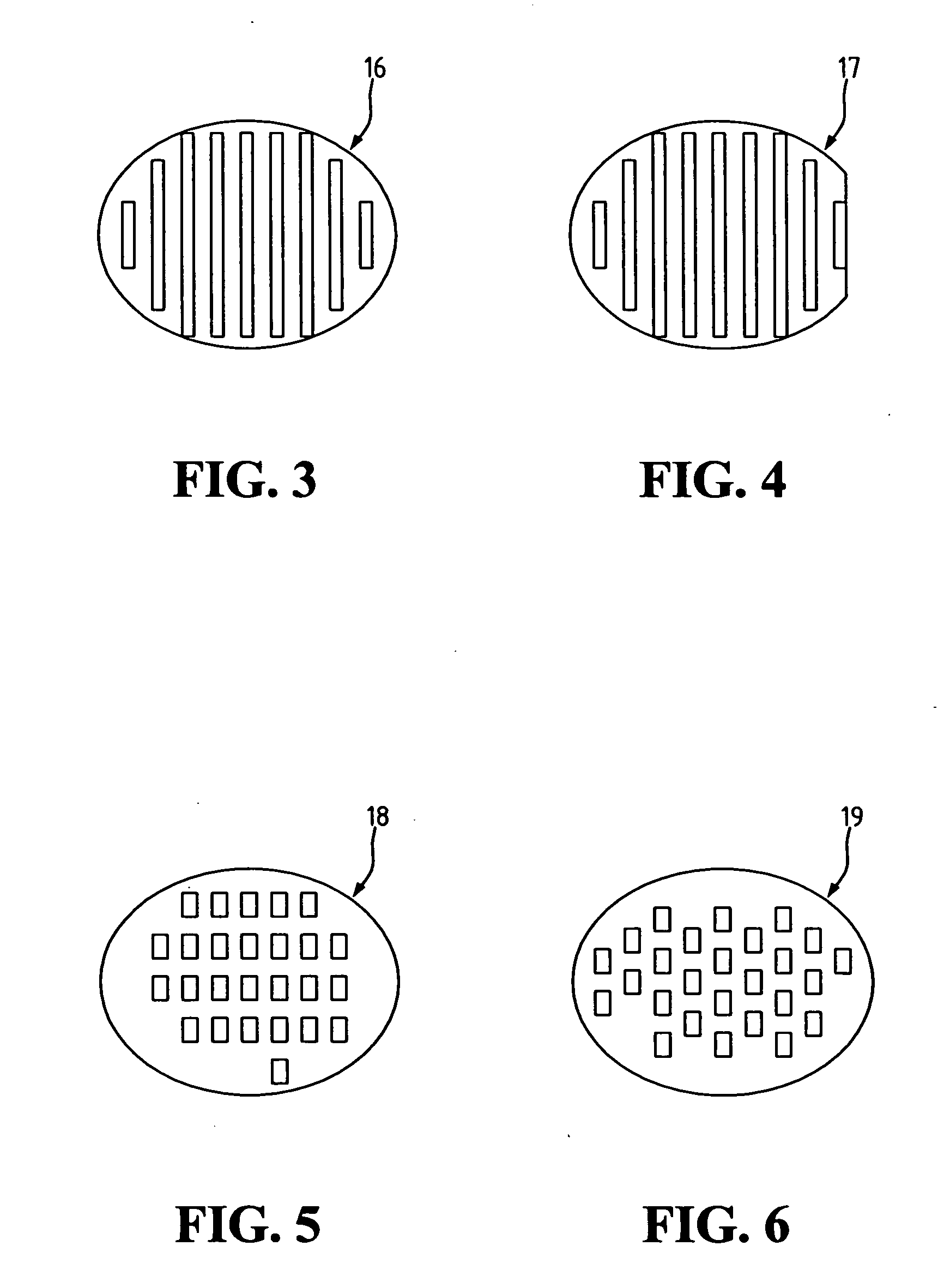

High performance nitride-based light-emitting diodes

InactiveUS20050145872A1Improve external quantum efficiencyReduce defectsSemiconductor devicesChemical solutionRefractive index

A nitride-based light-emitting diode is provided, including a substrate having a light extraction layer grown on the substrate, and a nitride semiconductor epitaxy layer grown on the light extraction layer. The external quantum efficiency is improved by changing the traveling path of the emitted light and by matching the refraction index between the light extraction layer and the substrate. Also, a high power nitride-based light-emitting diode having a sacrificial layer is disclosed. A sacrificial layer is used for growing a light-emitting structure, and a binding layer made of two or more metals or alloys is used to bind the grown light-emitting structure and a substrate with high thermoconductivity. The sacrificial layer is later entirely etched away with a chemical solution used in a chemical etching process, and the nitrogen epitaxy structure is placed on the substrate with high thermoconductivity so that the diode can operate at high electrical current to improve external quantum efficiency.

Owner:FORMOSA EPITAXY INCORPORATION

Preparation method of zinc oxide nano-rod film on fibre product

InactiveCN101012621ASmall granularityHigh purityFibre treatmentLiquid/gas/vapor textile treatmentFiberChemical solution

The invention relates to a manufacturing method for nanometer rod film of zinc oxide on fiber product, comprising (1) by sol-gel method ZnO nano-crystal grain is prepared and a great deal of ZnO seed crystal is deposited on the surface of fiber product, molar concentrations of zinc salt and alkaline agent are all 0.001M-0.75M; (2) by hydrothermal method or precipitation of chemical solution pool, nanometer rod film of zinc oxide grows on fiber product, molar concentrations of zinc salt solution and complexing agent solution are all 0.001M-0.05M; ZnO nanometer rod film with equal surface and good directivity is obtained. The manufacturing method is provided with simple method and low cost. It is suitable for industrial production.

Owner:DONGHUA UNIV

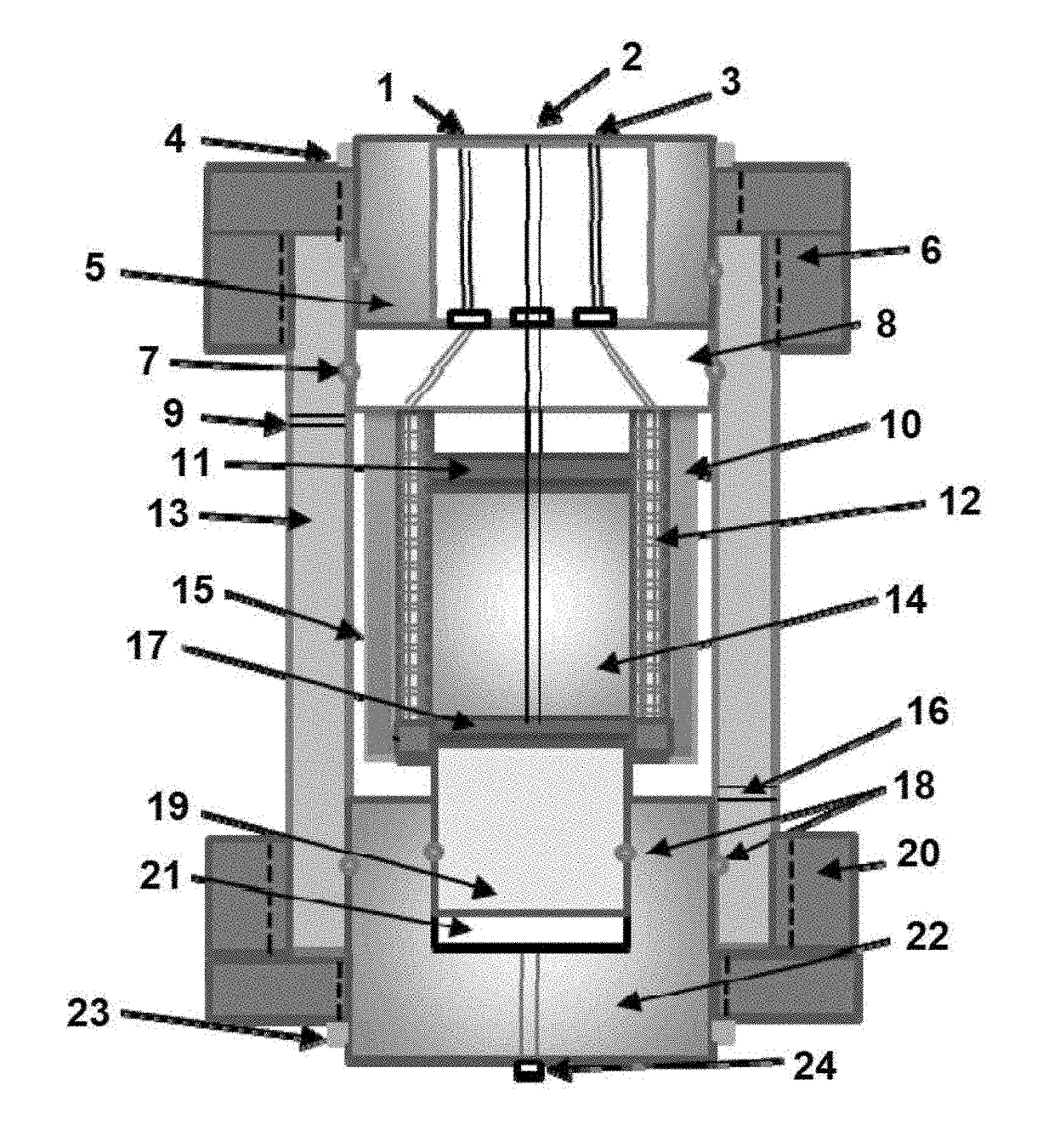

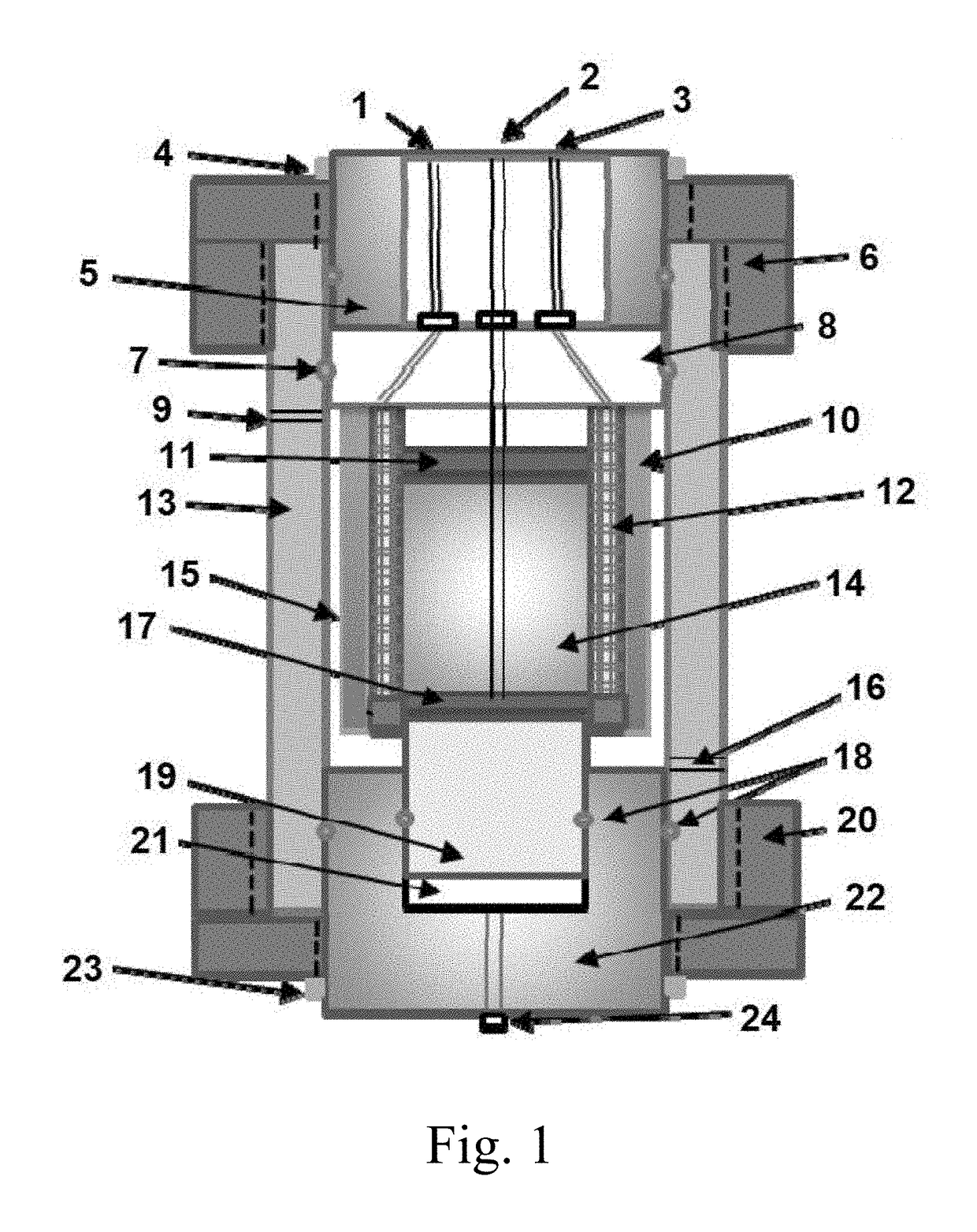

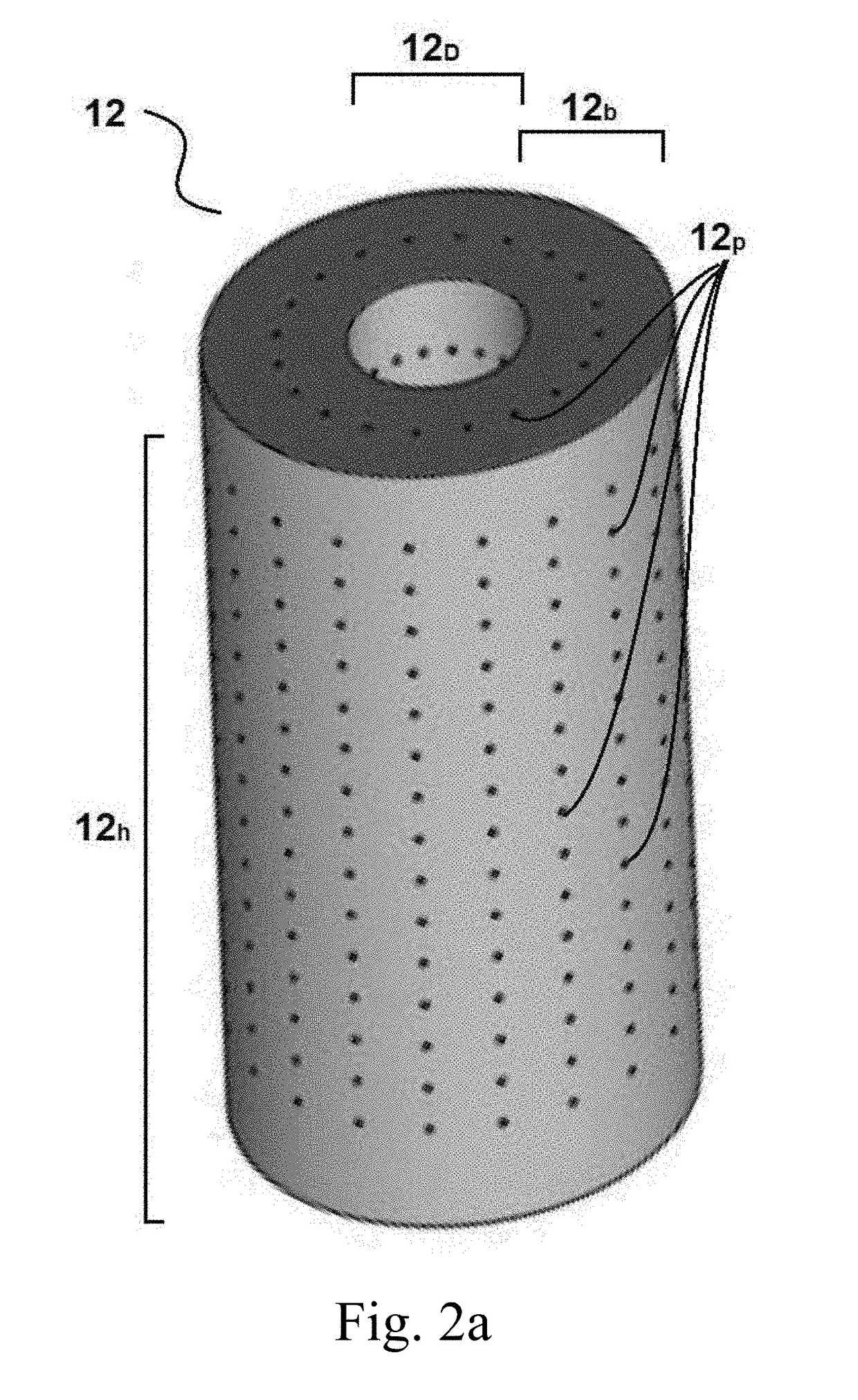

Radial core flooding apparatus and method for analysis of static and/or dynamic properties of reservoir rock

Apparatuses and methods suitable for (i) measuring lithological or petro-physical properties of reservoir core sample including shale rock; (ii) evaluating the degree of formation damage caused by foreign fluid into formation; (iii) conducting dynamic experiments, such as water flooding, chemical solution flooding, and supercritical CO2 injection to displacing oil tests; (iv) simulating physical radial flow experiments using reservoir core sample(s) at conditions of temperature up to 150° C. and pressure up to 6000 psi, are provided involving radial flow through the core sample(s) having at least partially hollow centers in an axial direction, up to annular axial cross-sections.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

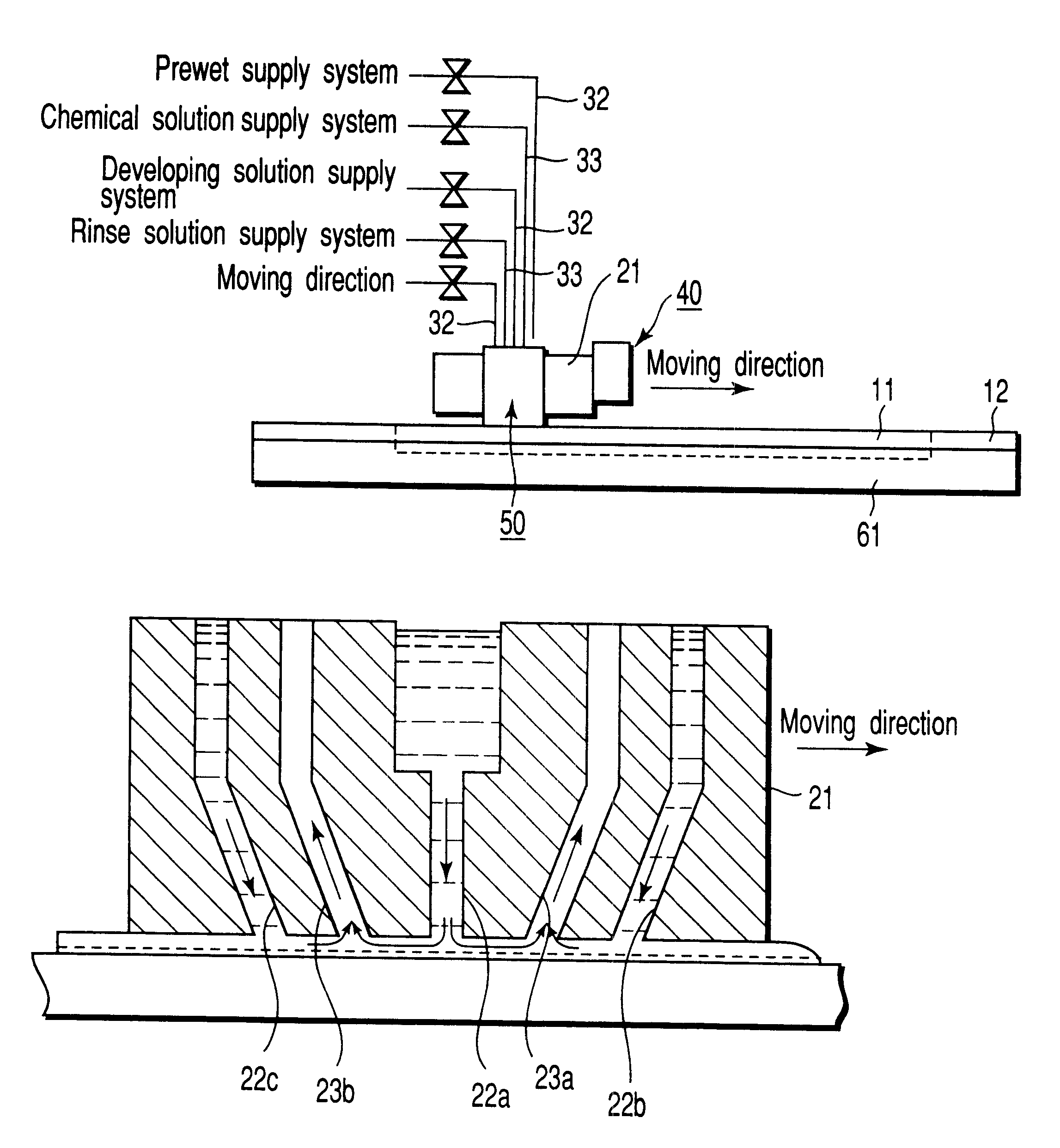

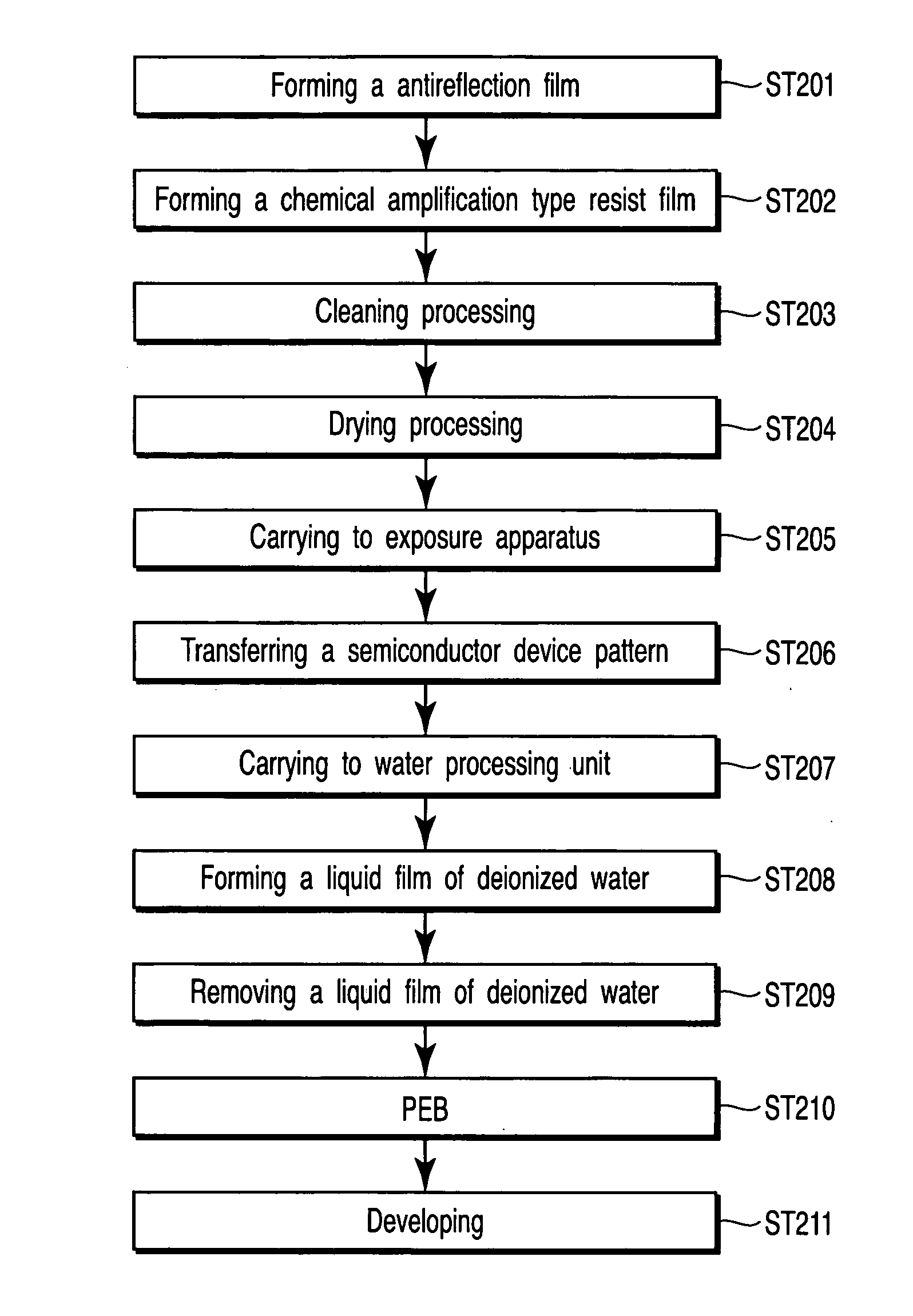

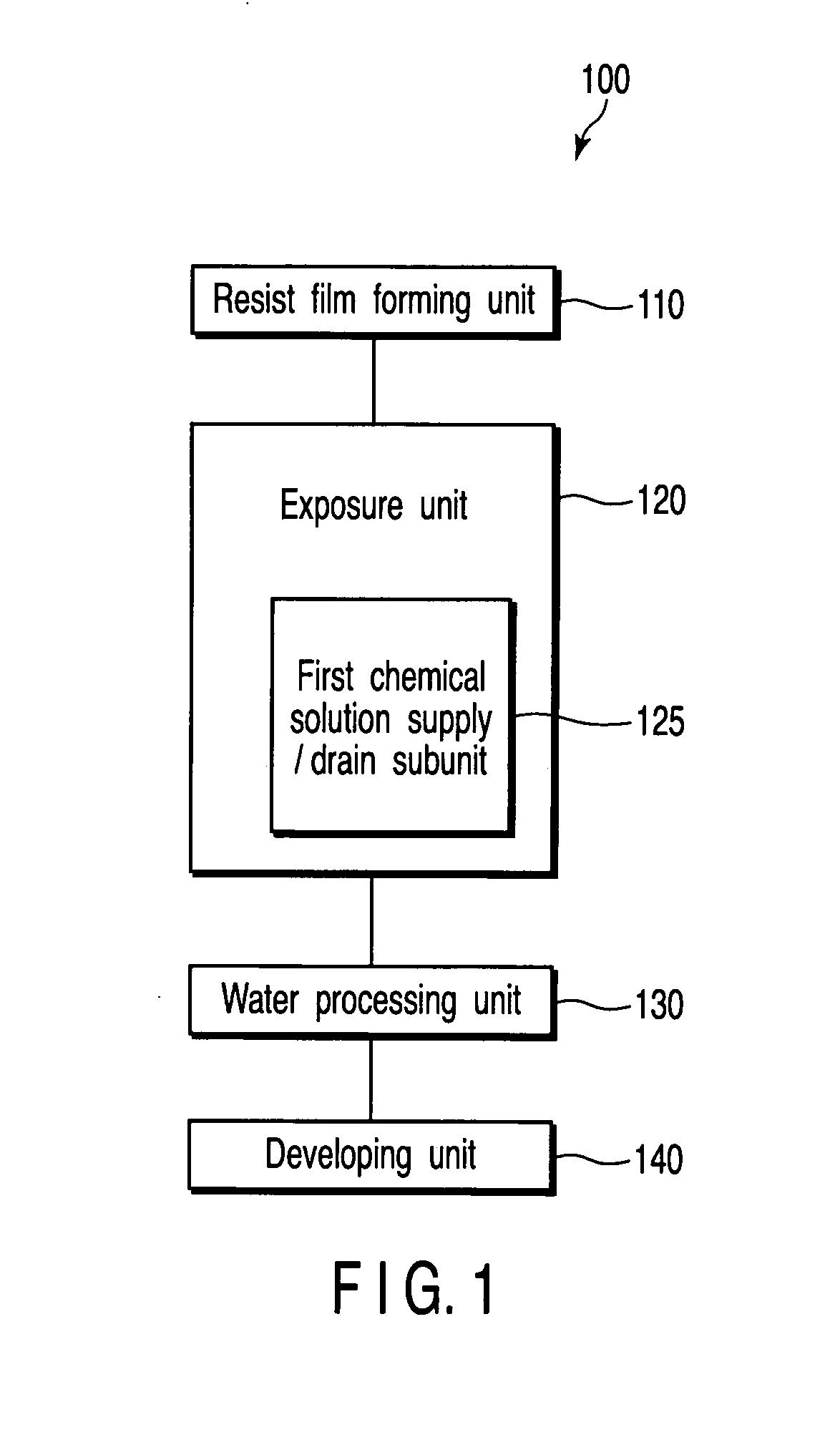

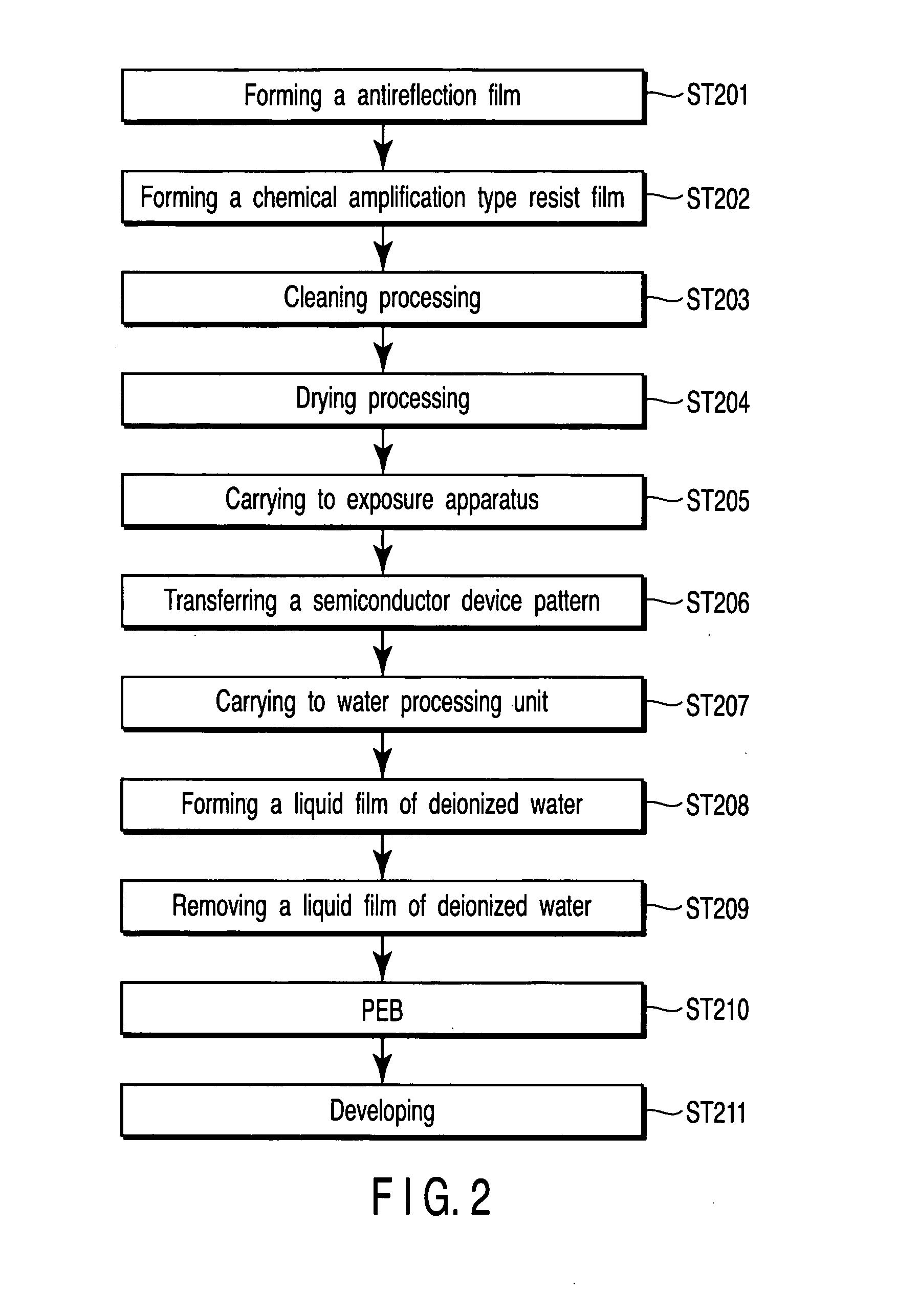

Resist pattern forming method, semiconductor apparatus using said method, and exposure apparatus thereof

ActiveUS20050221234A1Data processing applicationsSemiconductor/solid-state device manufacturingResistChemical solution

In immersion exposure, a resist pattern forming method suppressing resist pattern defects comprises mounting a substrate formed a resist film thereon and a reticle formed a pattern thereon onto an exposure apparatus, supplying a first chemical solution onto the resist film to selectively form a first liquid film in a local area on the resist film and draining the solution, the first liquid film having a flow and being formed between the resist film and a projection optical system, transferring the pattern of the reticle to the resist film through the first liquid film to form a latent image, supplying a second chemical solution onto the resist film to clean the resist film, heating the resist film, and developing the resist film to form a resist pattern from the resist film.

Owner:KIOXIA CORP

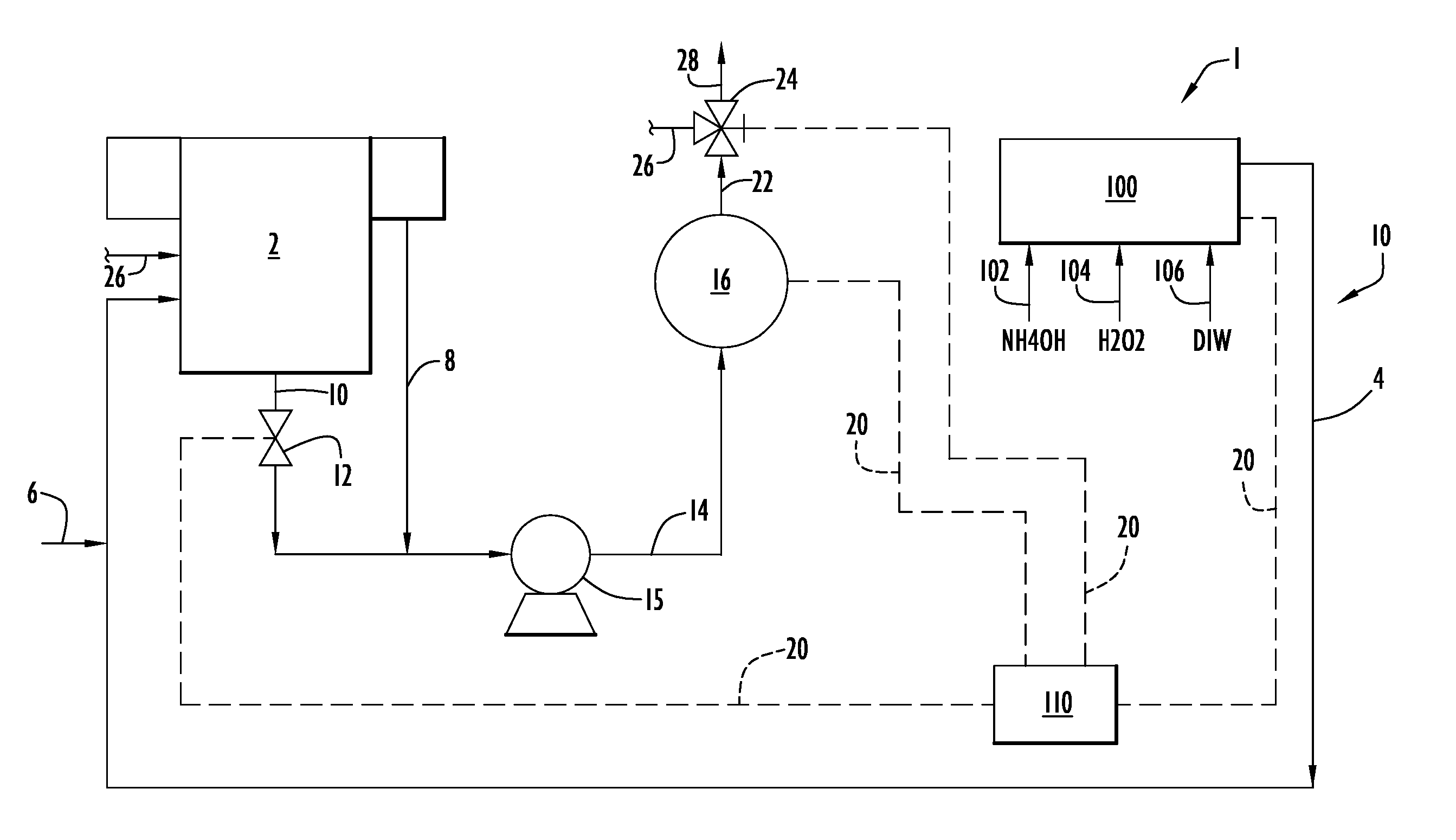

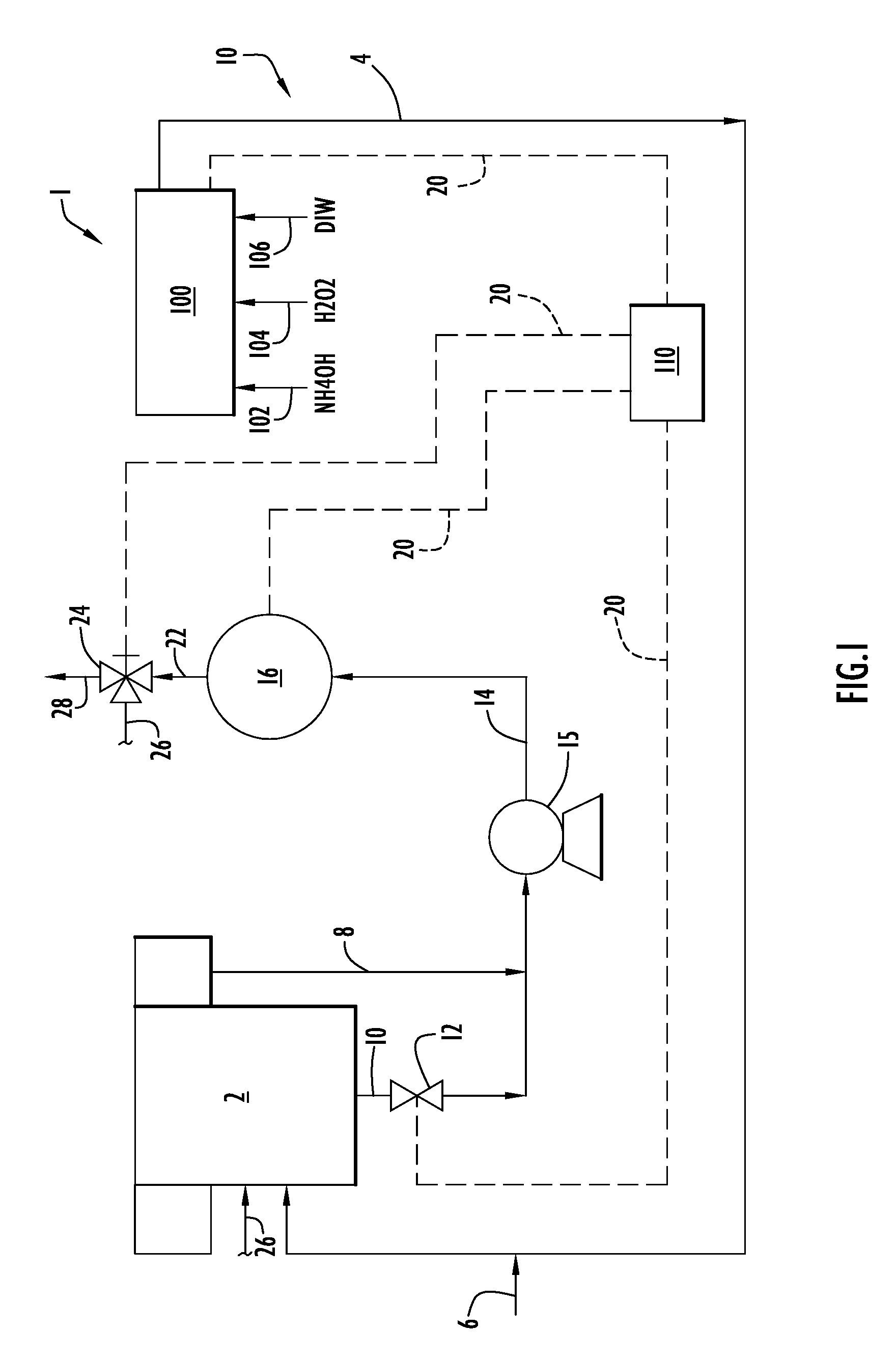

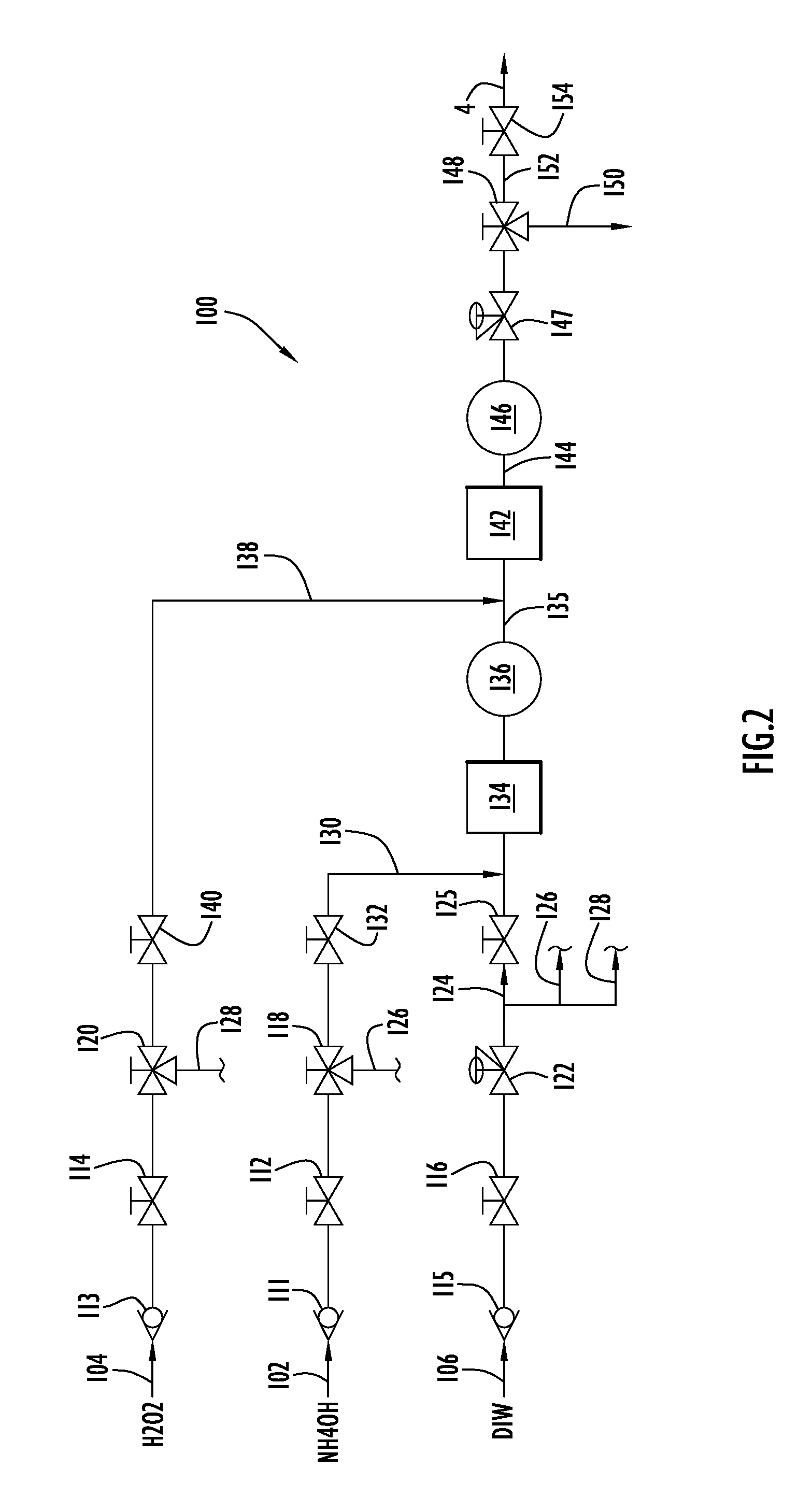

Point-of-use process control blender systems and corresponding methods

PendingUS20070070803A1Effective maintenanceControlling ratio of multiple fluid flowsTransportation and packagingChemical solutionChemical compound

A blender system is provided that maintains a chemical solution bath at desired concentrations. The blender system includes a blender unit configured to receive and blend at least two chemical compounds and deliver a solution including a mixture of compounds at selected concentrations to a tank that retains a selected volume of a chemical solution bath. The blender system further includes a controller configured to maintain at least one compound within a selected concentration range in the chemical solution bath. The controller controls at least one of operation of the blender unit to maintain the concentration of the compound within a selected concentration range within the solution delivered to the tank, and a change in flow rate of solution into and out of the tank when a concentration of the compound within the chemical solution bath falls outside of a target range.

Owner:URQUHART KARL J

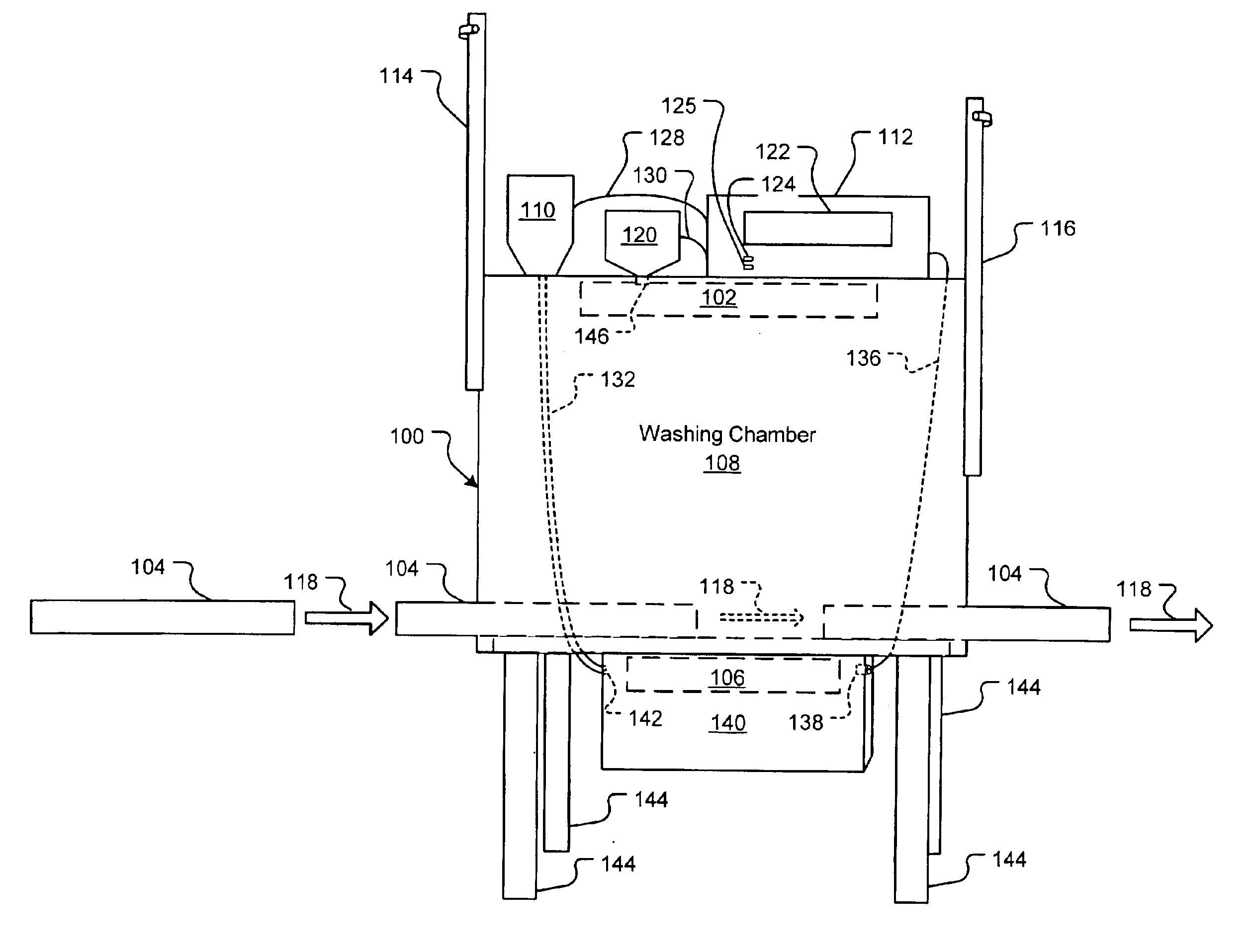

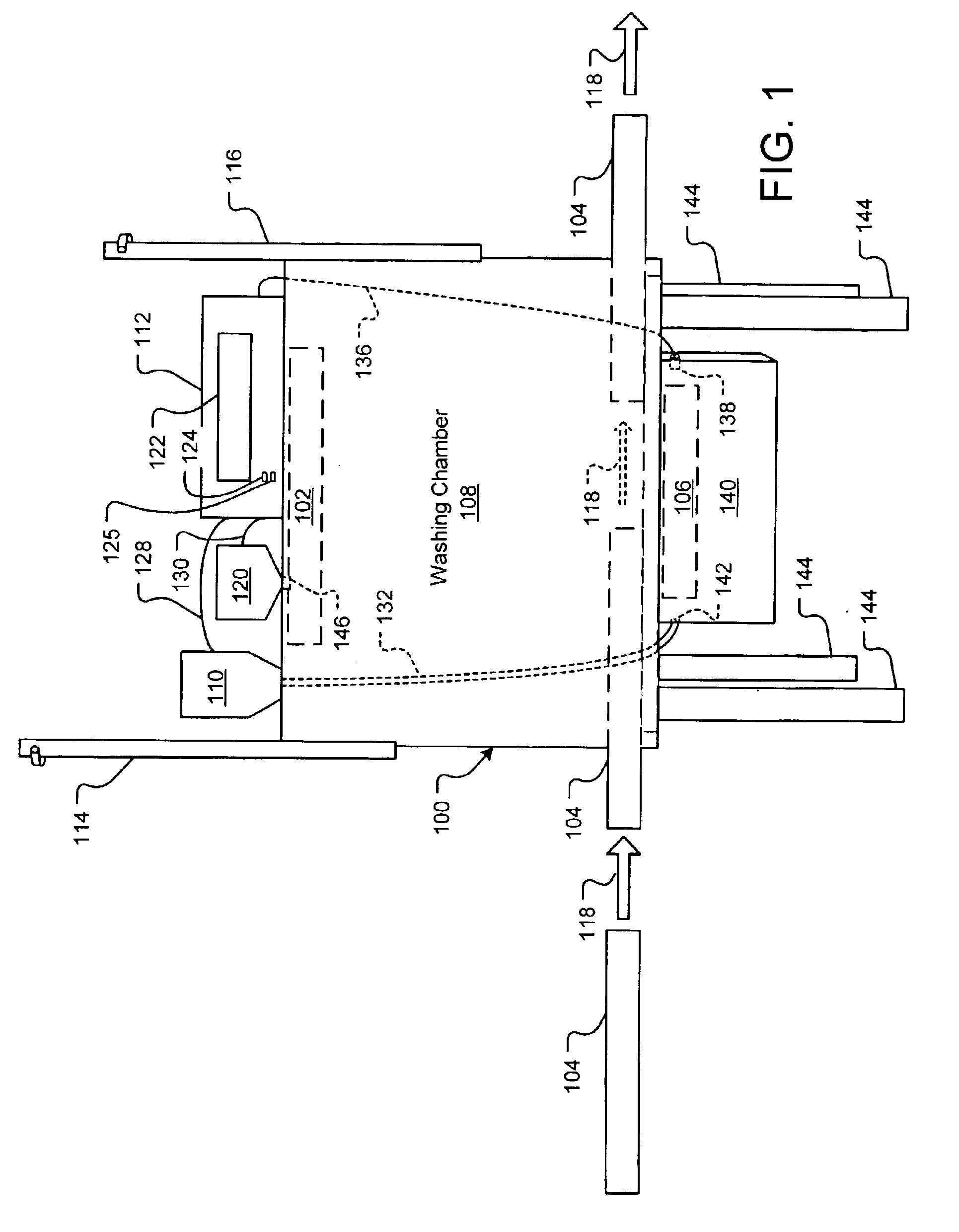

Controlling chemical dispense operations based on conductivity offset

ActiveUS6892143B2Washing controlling processesTableware washing/rinsing machine detailsChemical solutionCompound (substance)

A system and method is disclosed for controlling chemical dispense operations based on a conductivity offset determined for a chemical solution. The chemical dispense operations are performed by or in conjunction with operation of a utility device, such as a warewashing machine. The chemical solution is formed in a solution tank device by combining water with at least one component chemical product. The conductivity offset, which is the conductivity of the water, is used to normalize the conductivity estimated for the chemical solution relative to the component chemical product in the solution. During various points in time during operation of the utility device, the normalized conductivity is compared to a conductivity setpoint, and if the normalized conductivity falls below the conductivity setpoint, a specified volume of the component chemical product is supplied to the solution tank.

Owner:ECOLAB USA INC

Method for laser cutting tubing using inert gas and a disposable mask

InactiveUS20080296274A1Eliminate needAvoid crackingMetal working apparatusLaser beam welding apparatusChemical solutionBiomedical engineering

A method for making a device includes providing a tubular member which will be formed into the device, masking at least a portion of the inner surface of the tubular member with a removable sacrificial material, selectively removing a portion of the tubular member and sacrificial material using a laser device, and mechanically removing the sacrificial material from the inner surface of the tubular member. The method may also include applying a chemical solution to the tubular member and sacrificial material which primarily attacks the either the tubular member or sacrificial material.

Owner:ABBOTT CARDIOVASCULAR

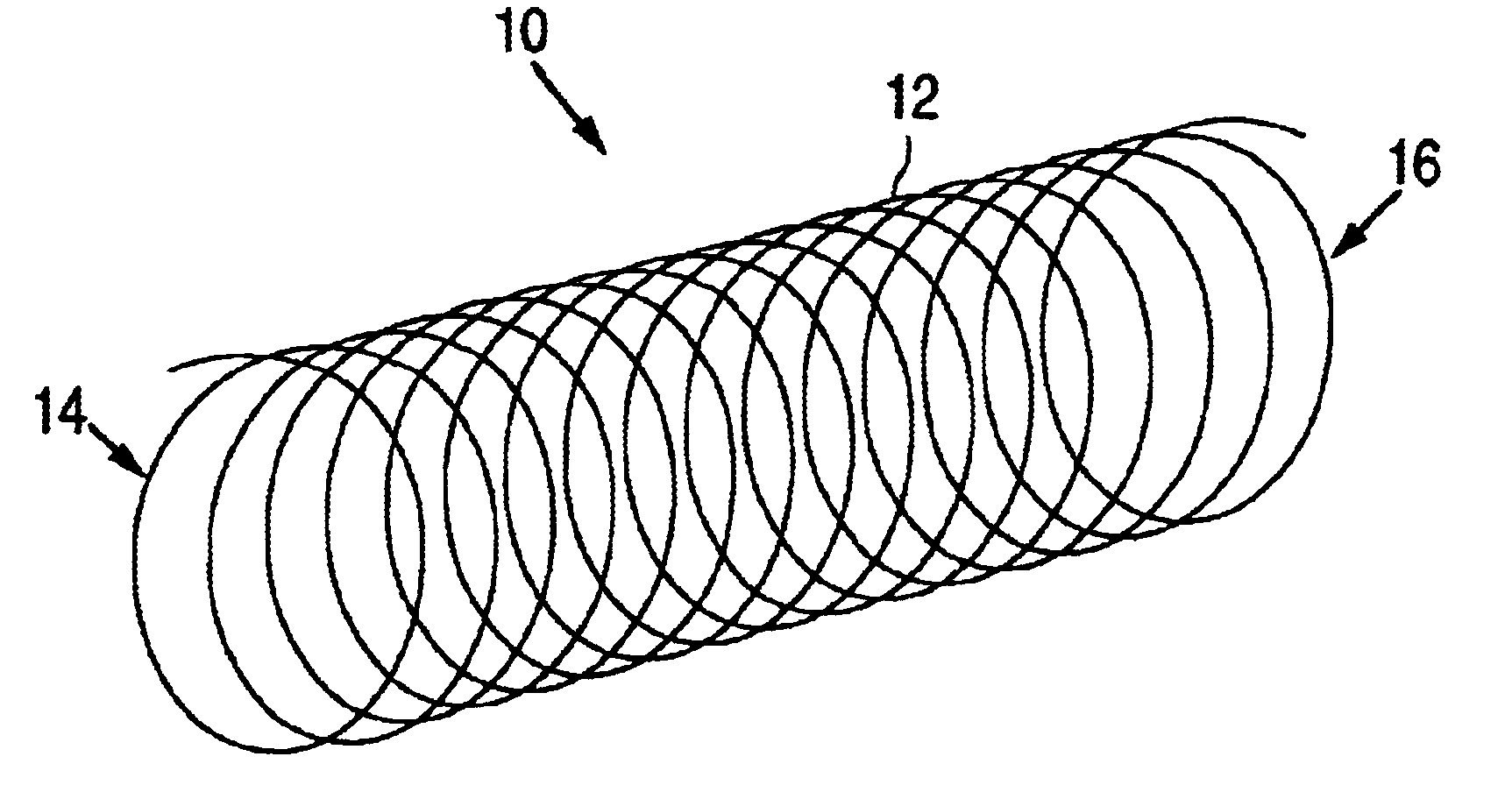

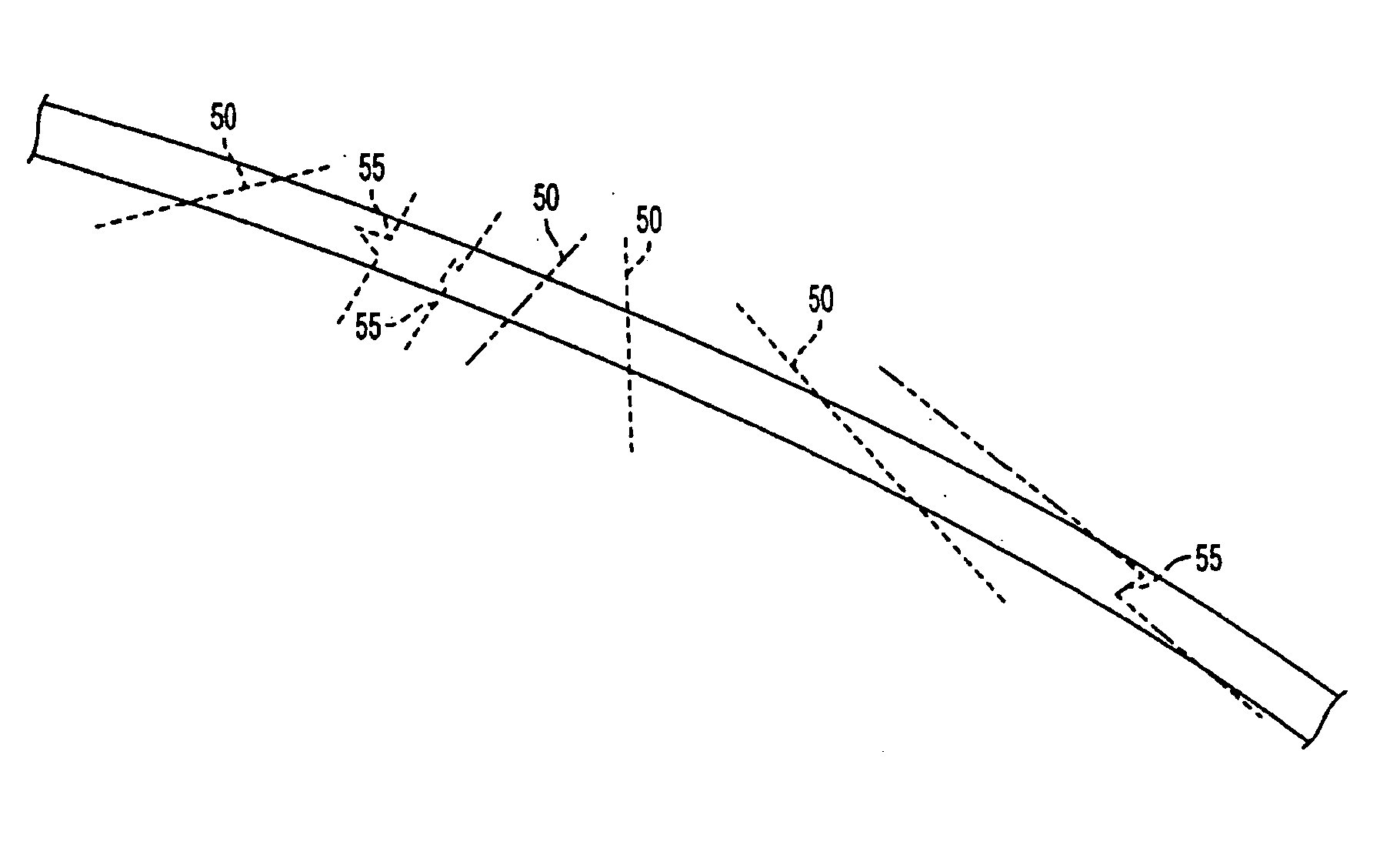

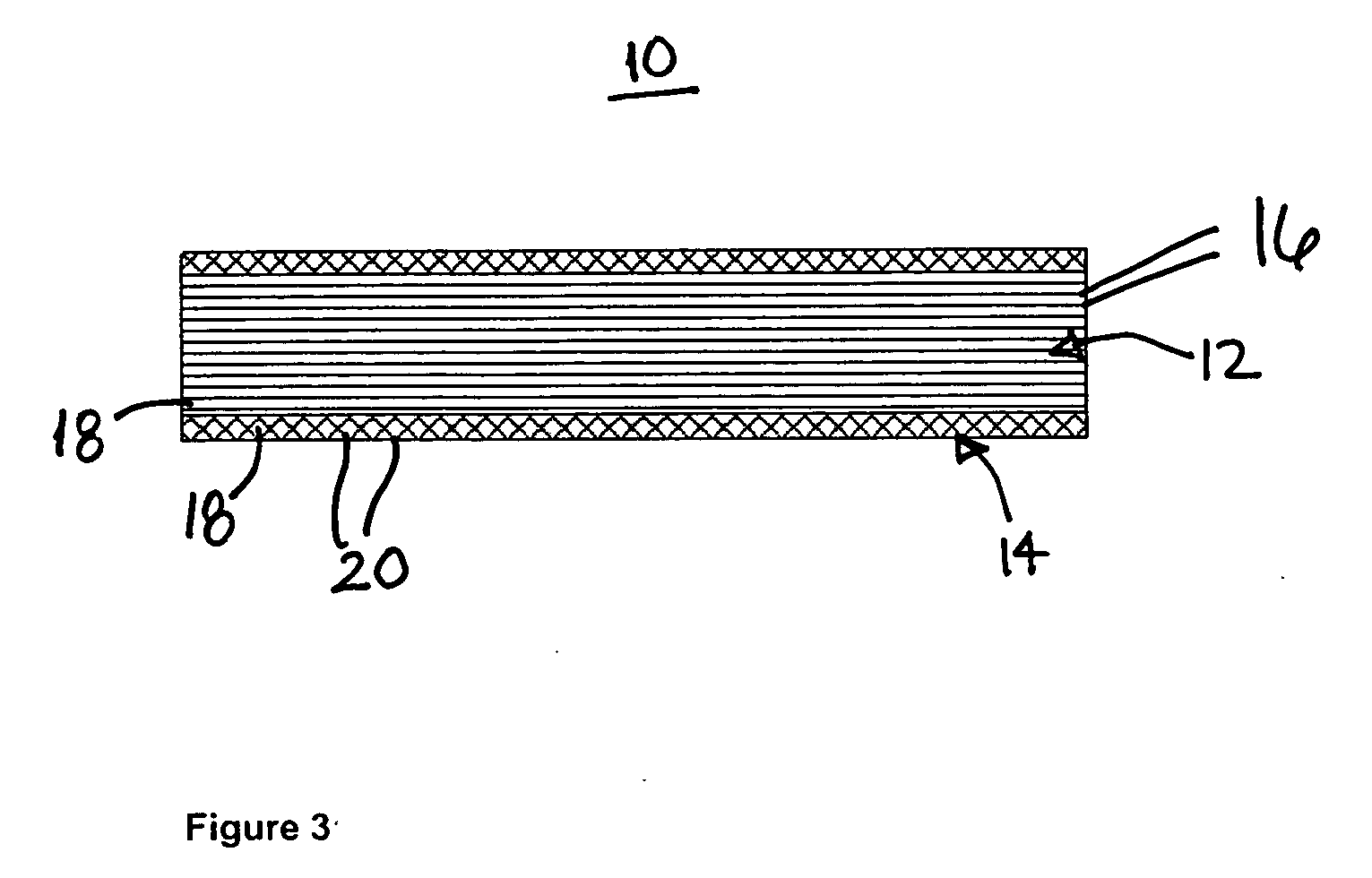

Fiber-reinforced composites for dental materials

A formable fiber-reinforced composite having an inner core of fiber-reinforced composite surrounded by a sheath of fiber-reinforced composite material. The inner core of fiber-reinforced composite has a plurality of longitudinally extending fibers disposed in a resin matrix material and formed in the shape of a rod and the outer sheath has woven or braided fibers impregnated with a resin matrix material in the form of a sleeve. In a method of manufacturing the formable fiber-reinforced composite material herein a rod is provided or fabricated of longitudinally extending fibers disposed in a resin matrix material. The resin matrix material is cured to provide a solid rod. A sheath of woven fibers is placed around the rod. The rod with the sheath thereon is treated to remove the resin matrix material. Treatment may be in the form of heat or chemical solution. If a chemical solvent is used, the fibers may be additionally heated. The resulting rod and sheath comprise longitudinally extending fibers enveloped by a sheath. Thereafter, the rod and sheath are impregnated with a resin matrix material. The resin is left uncured or partially cured to provide a formable fiber-reinforced composite material. The formable material may be furthered flattened to provide flattened strips of material or may be left in the shape of circular rods of material.

Owner:PENTRON CLINICAL TECH

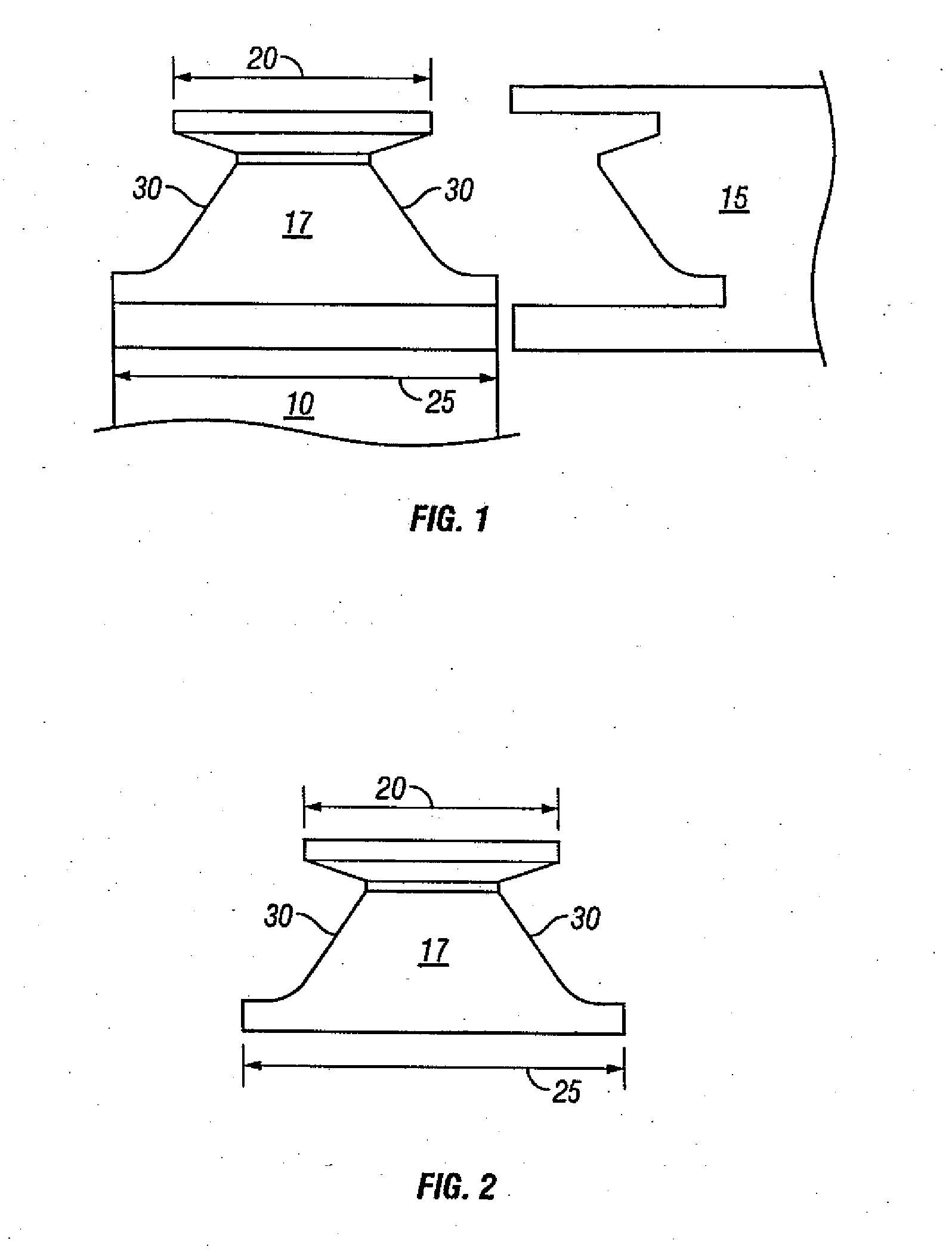

Hybrid contact lens system and method

InactiveUS20070013869A1Easy to createReduce penetrationOptical articlesEye diagnosticsChemical solutionPeripheral zone

A hybrid contact lens comprises a central zone comprising a substantially rigid, gas permeable material having a DK of at least 30, a relatively soft peripheral zone and an intermediate zone comprising a film or coating that is created around the central zone, and then cured. The film facilitates chemical bonding between the central zone and the peripheral zone, and also provides a protective barrier to prevent modification of the physical characteristics of the central zone. The film may be created by soaking the central zone in a chemical solution for a predetermined amount of soaking time.

Owner:DAHI ALI +4

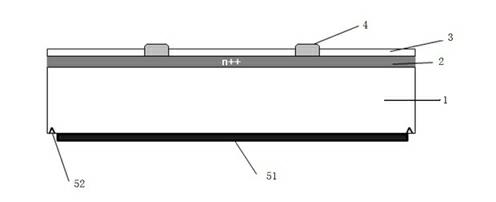

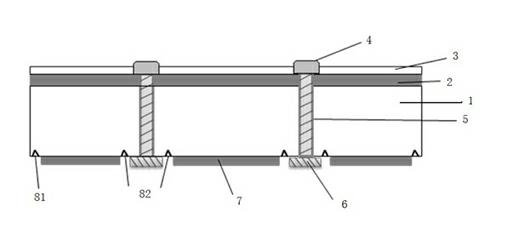

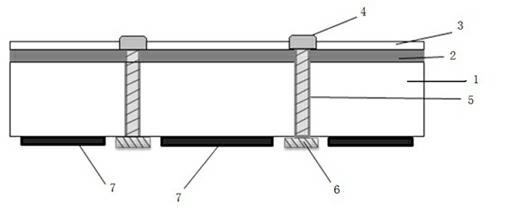

Preparation method of MWT (Metal Wrap Through) solar cell

ActiveCN102208486AImprove efficiencyBusbarPhotovoltaic energy generationSemiconductor devicesPhotovoltaic industryChemical solution

The invention discloses a preparation method of an MWT (Metal Wrap Through) solar cell, comprising the following steps of: (1) carrying out phosphorous diffusion by using a p-type crystal silicon substrate; (2) etching one surface of the crystal silicon substrate by using a chemical solution to remove a phosphorous diffused layer so as to form a polished surface; (3) depositing a passivated antireflective film on the other surface of the crystal silicon substrate to form a light receiving surface; (4) forming a conductive through hole on the crystal silicon substrate by using laser lights; (5) filling a conductive silver paste into the conductive through hole by using a wire mesh on the polished surface so as to form an emitter contact electrode; (6) printing an aluminum paste on the polished surface by using a wire mesh so as to form a base contact electrode; (7) printing a silver contact grid line on the light receiving surface and connecting the silver contact grid line with the conductive through hole; and (8) forming the ohmic contact between a metal and the silicon substrate through sintering so as to finish the solar cell making process. The preparation method of the MWT (Metal Wrap Through) solar cell, disclosed by the invention, has the advantages of simple process flow and easiness in operation, is completely compatible with a solar cell production line widely applied in the current photovoltaic industry and is suitable for mass production.

Owner:JA SOLAR TECH YANGZHOU

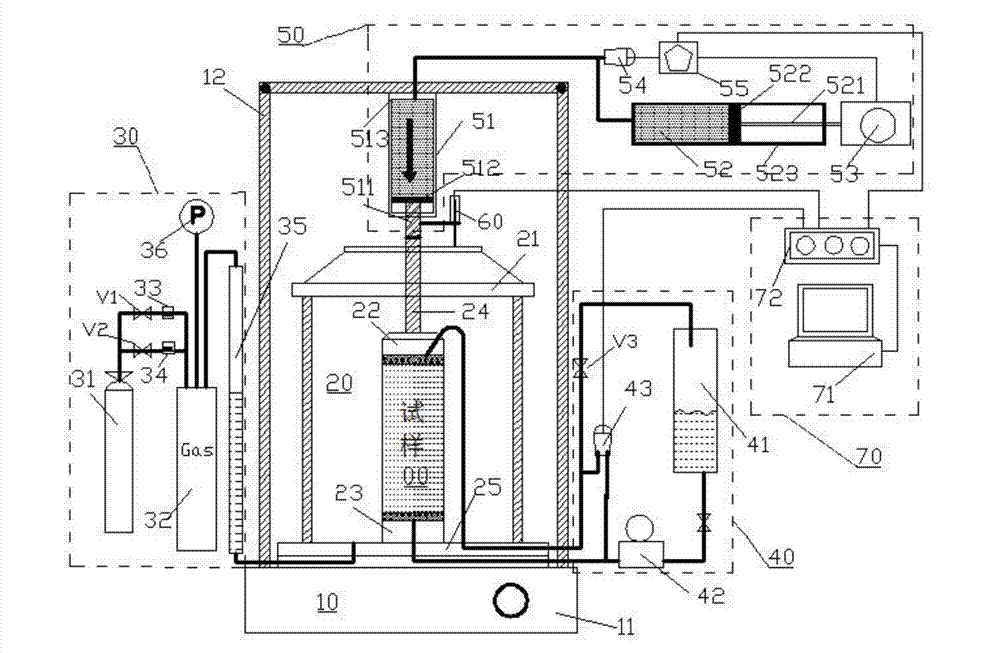

Triaxial test apparatus of soil under water-soil chemical action and method thereof

InactiveCN103091173ASolve the problem of accurate measurementPromote in-depth developmentMaterial strength using tensile/compressive forcesChemical solutionTriaxial shear test

The invention discloses a triaxial test apparatus of soil under water-soil chemical action and a method thereof, and relates to a testing technique of soil under a special environment. The device comprises a device frame (10), a triaxial pressure chamber (20), a confining pressure exerting and deformation test device (30), a solution cyclic displacement device (40), a stress / strain control loading device (50), a displacement sensor (60) and a data collecting and processing device (70). The uniformity of ingredients and concentration of internal pore water solution of a specimen is ensured by solution circulation; the change rules of soil deformation and strength caused by chemical solution transfusion under constant stress can be simulated and researched; the confining pressure exerting principle is improved; accurate measurement of body deformation is achieved; and the conversion of strain control and stress control can be achieved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

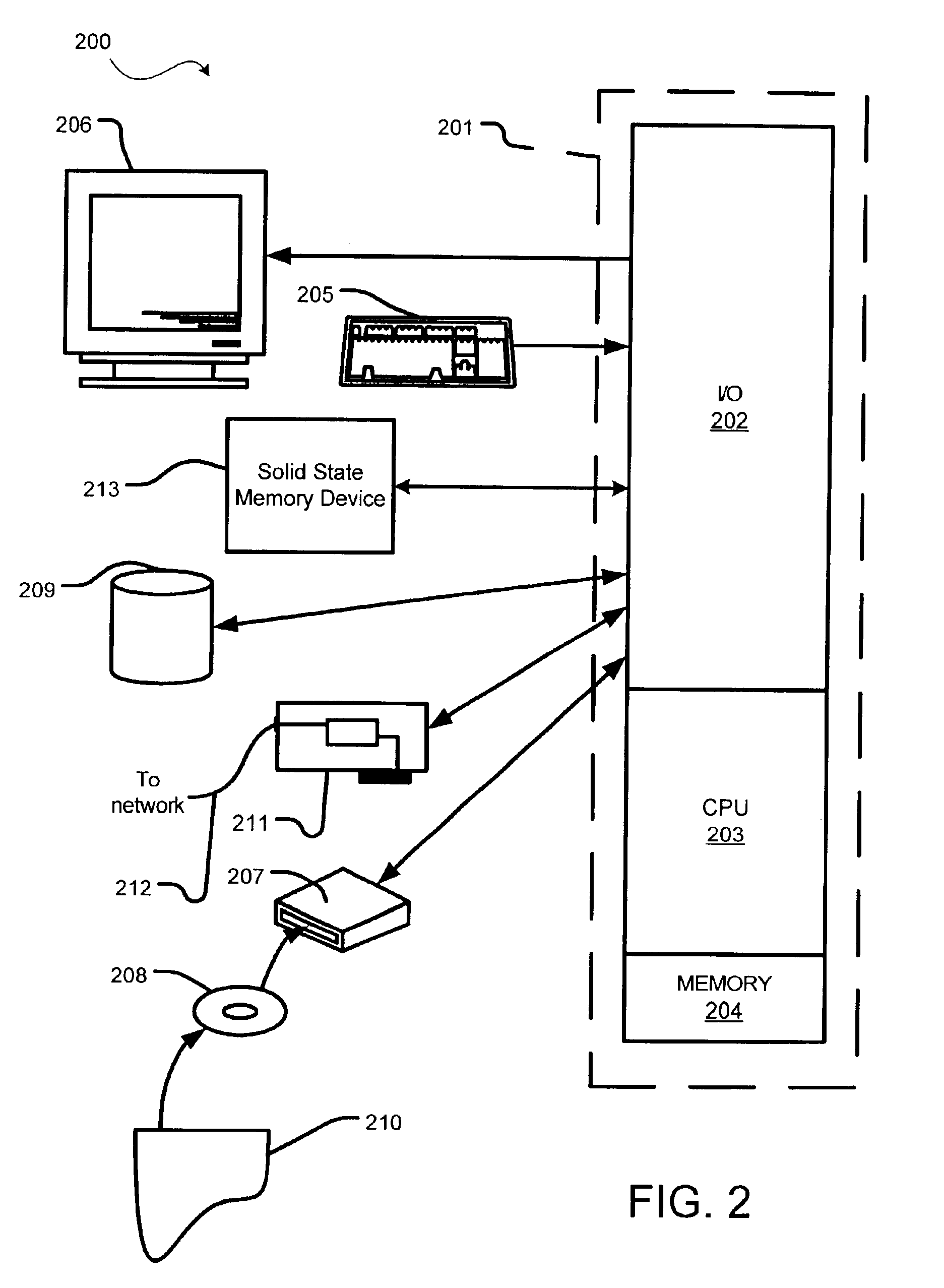

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com