Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1867 results about "Molybdenum sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molybdenum disulfide is the inorganic compound with the formula MoS2. This black crystalline sulfide of molybdenum occurs as the mineral molybdenite. It is the principal ore from which molybdenum metal is extracted.

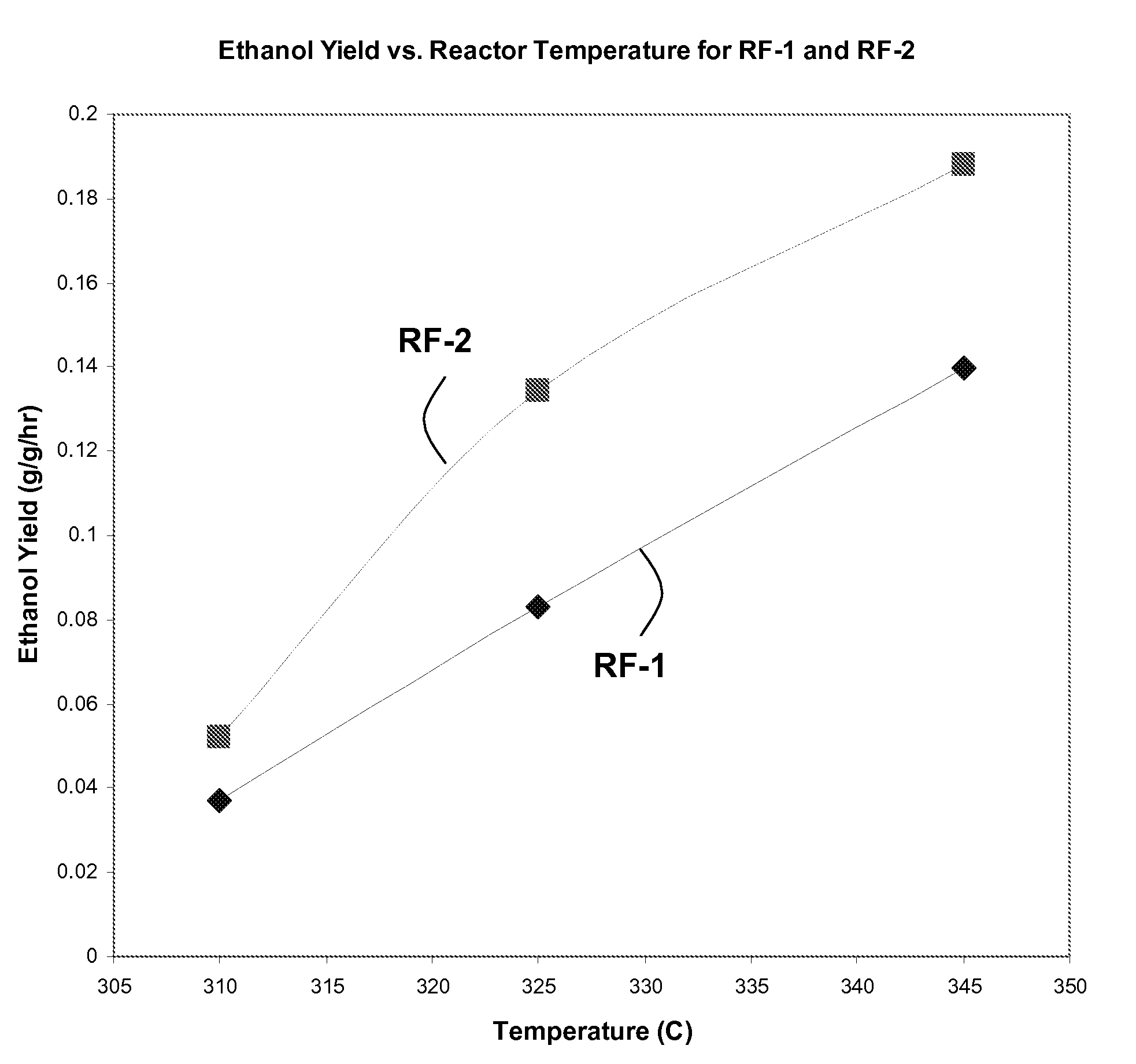

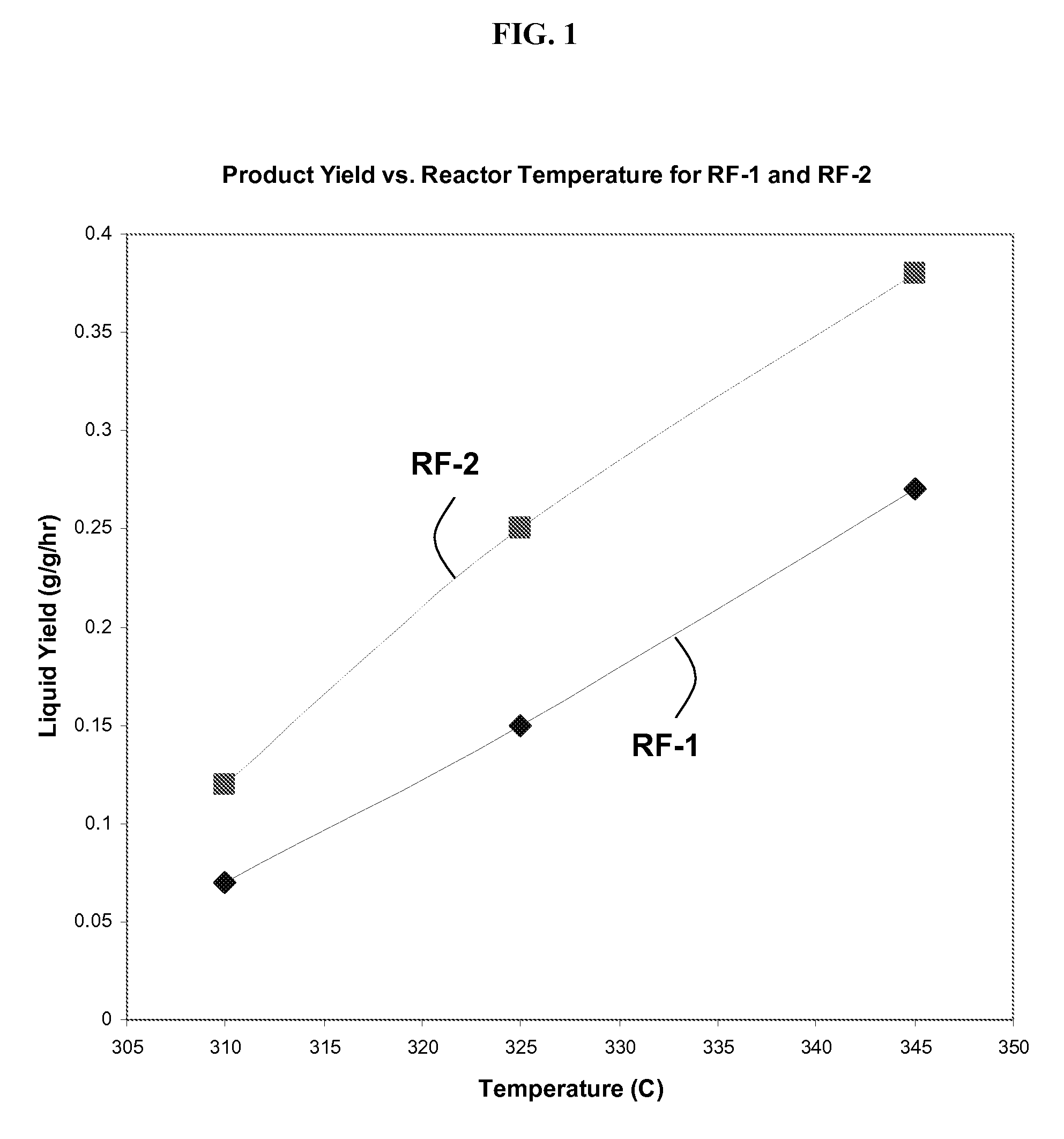

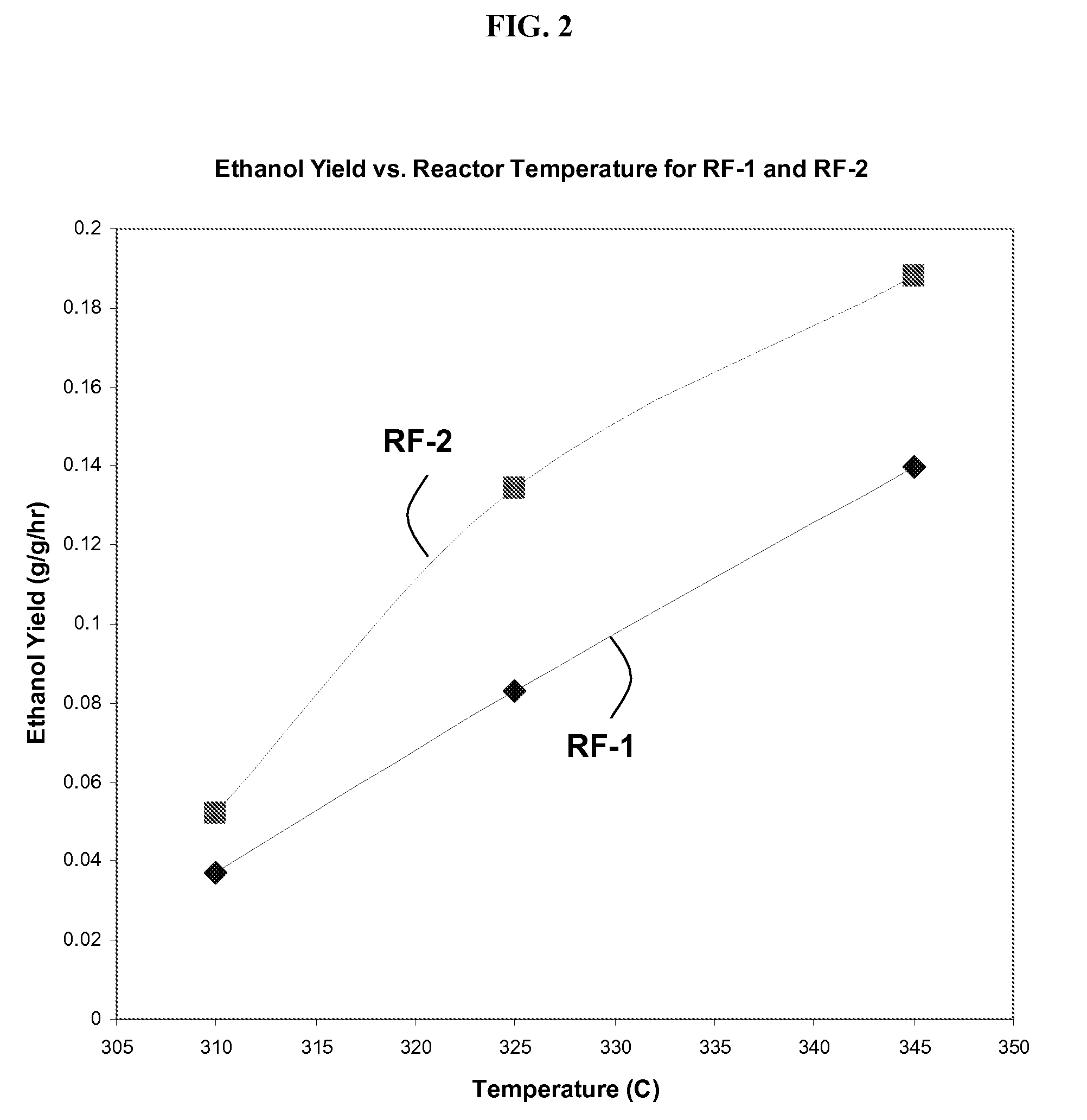

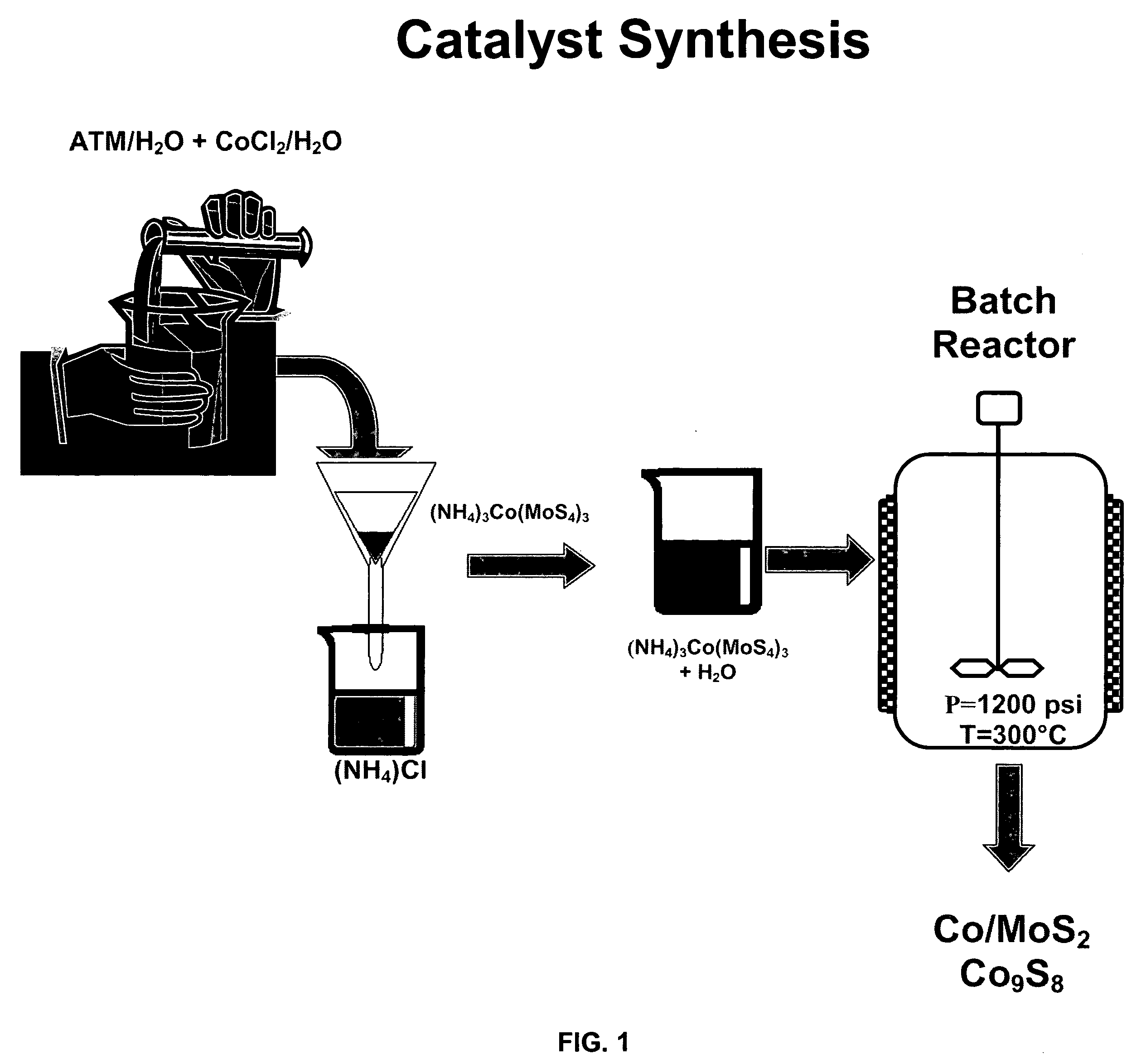

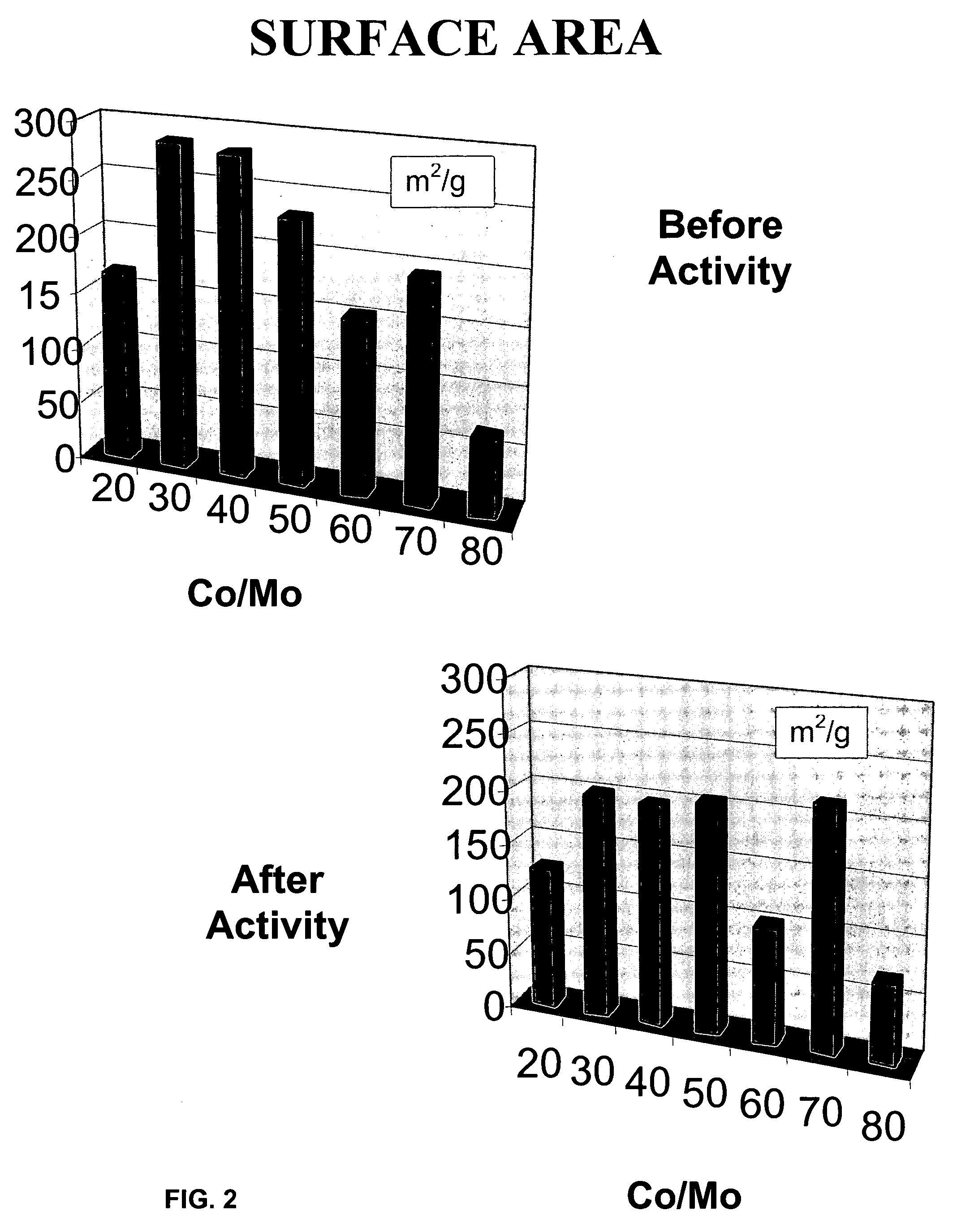

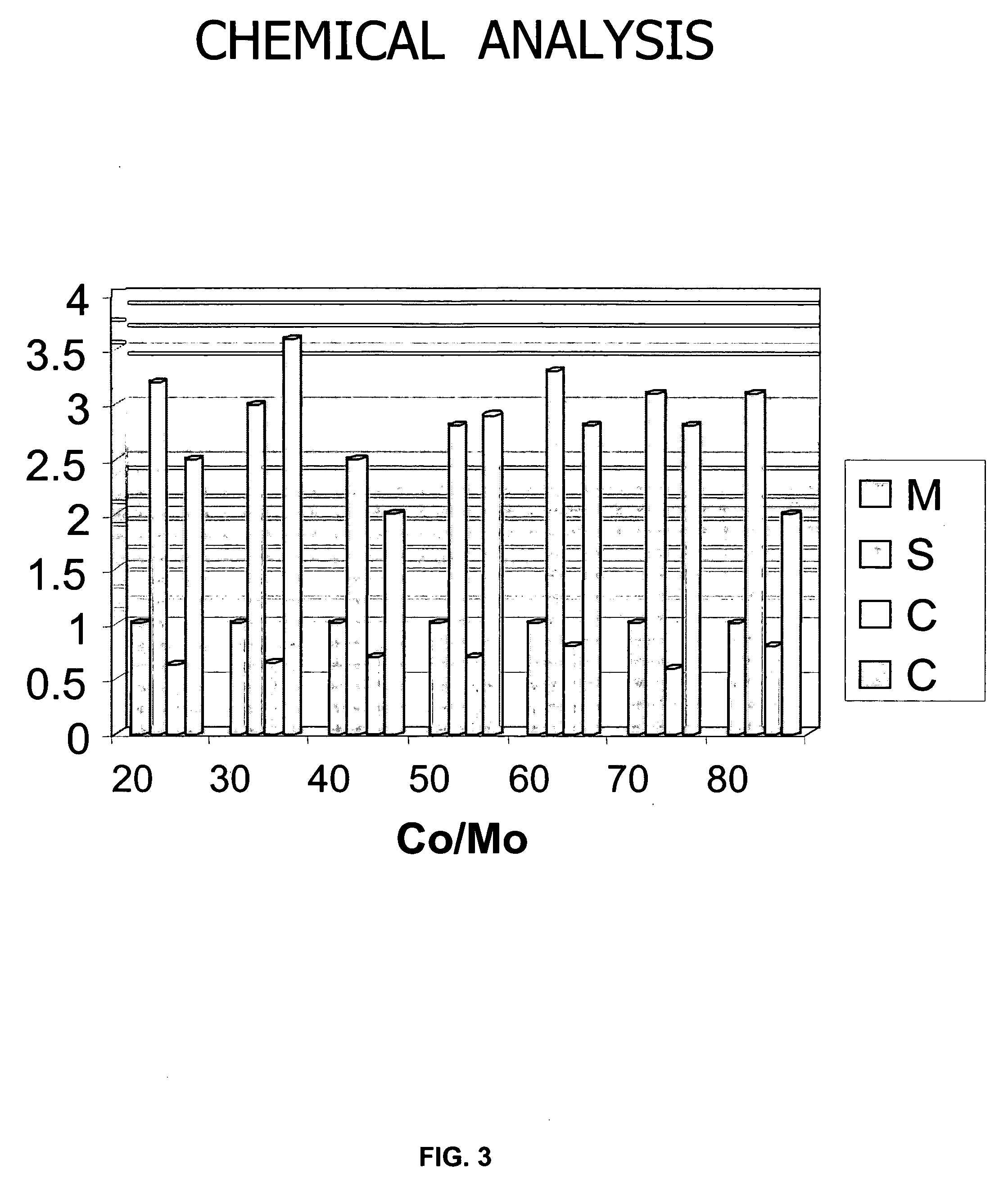

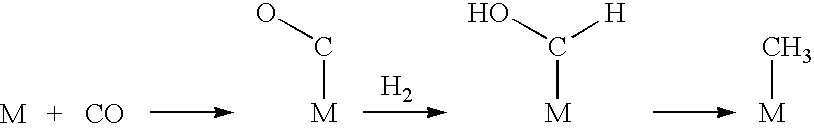

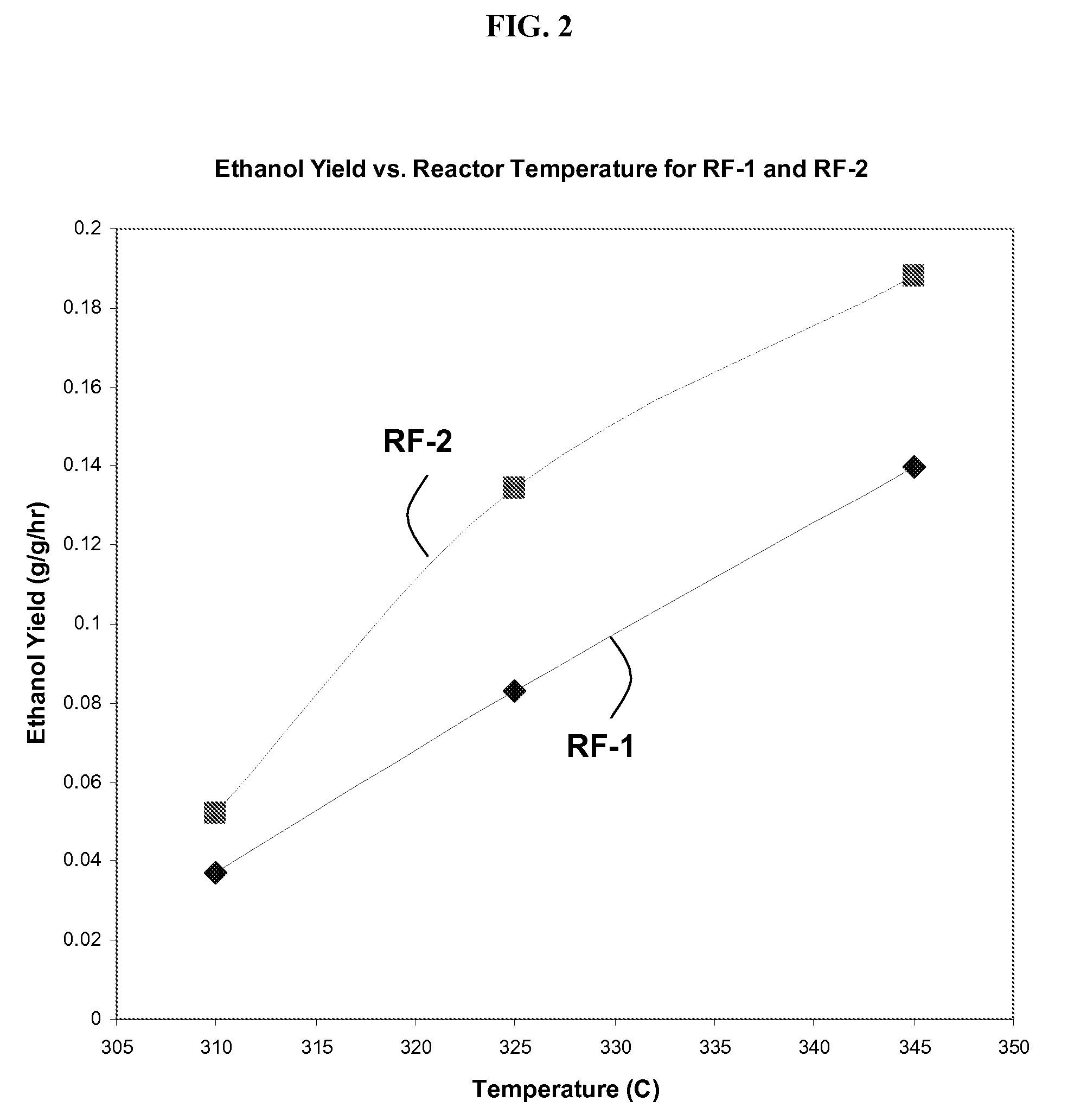

Cobalt-molybdenum sulfide catalyst materials and methods for ethanol production from syngas

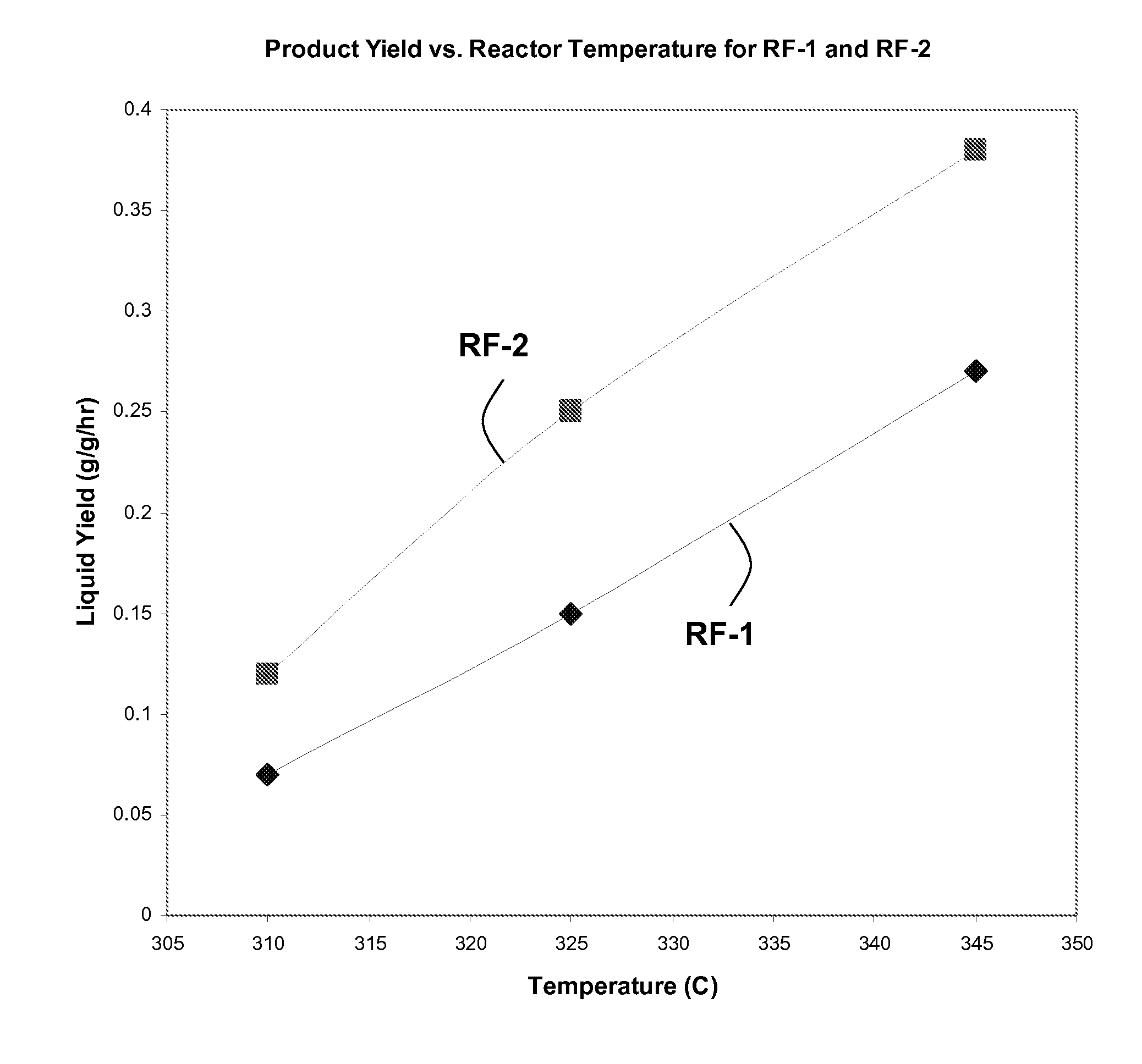

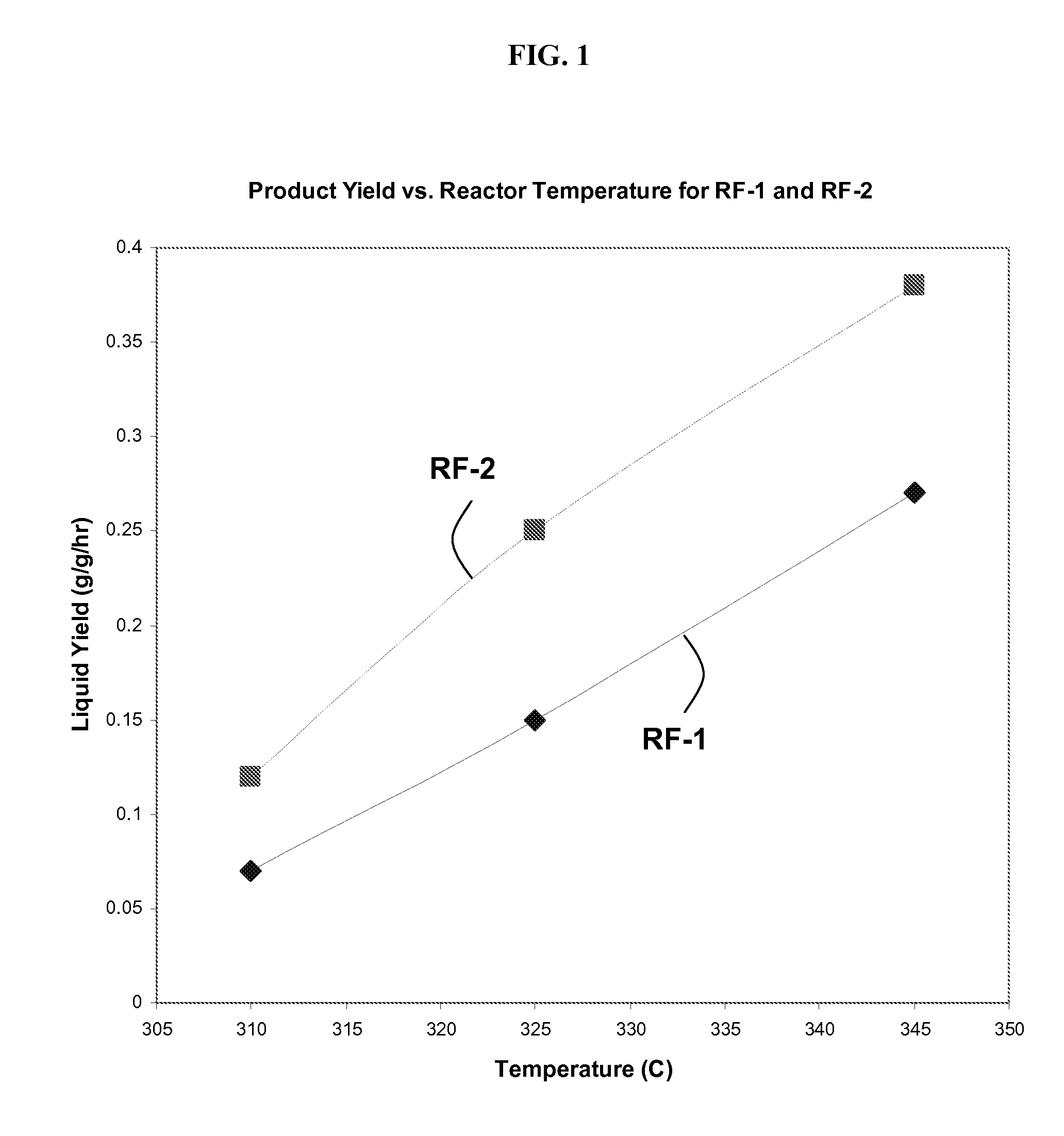

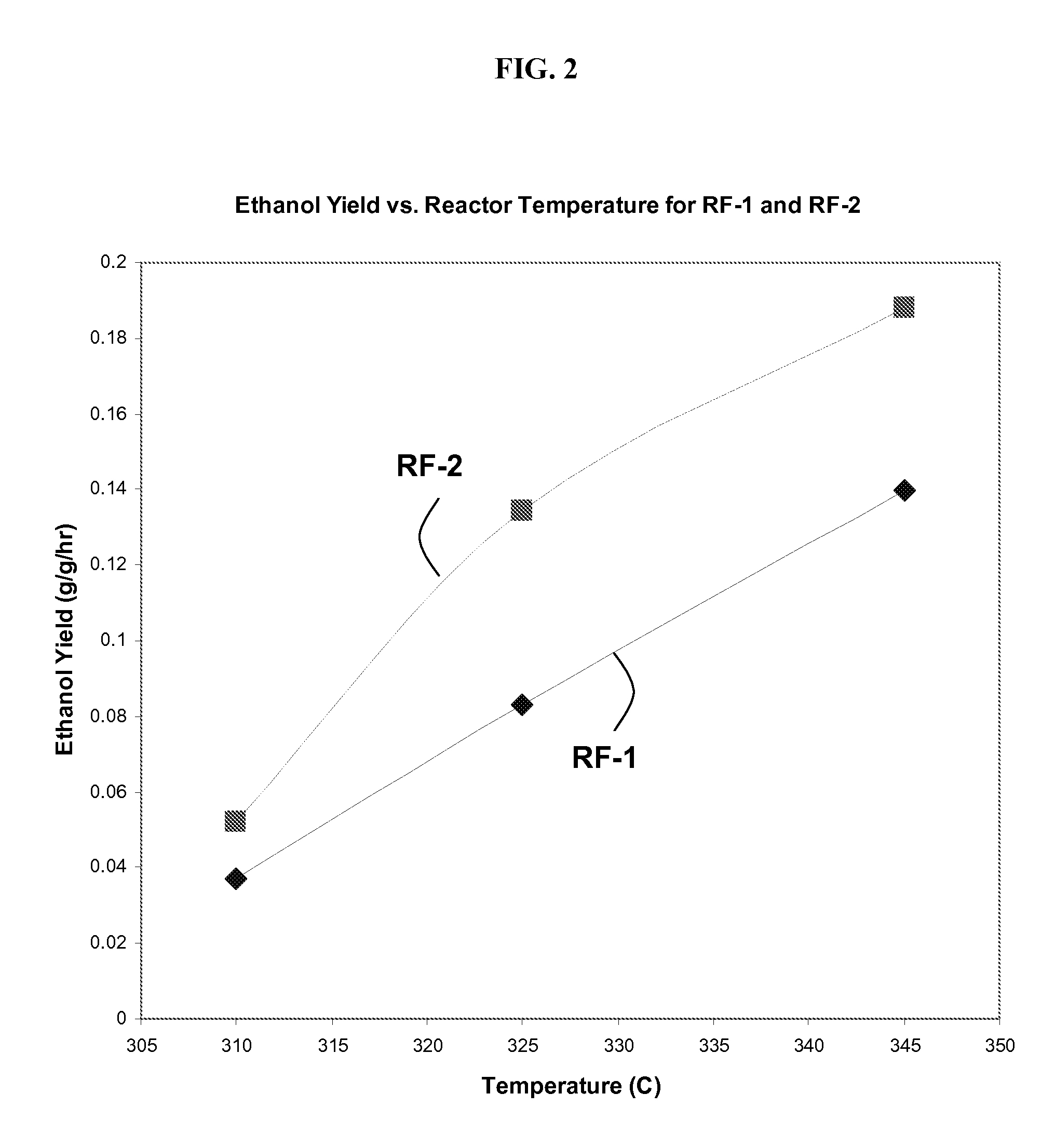

The present invention provides methods and compositions for the chemical conversion of syngas to alcohols. The invention includes catalyst compositions, methods of making the catalyst compositions, and methods of using the catalyst compositions. Certain embodiments teach compositions for catalyzing the conversion of syngas into products comprising at least one C1-C4 alcohol, such as ethanol. These compositions generally include cobalt, molybdenum, and sulfur. Preferred catalyst compositions for converting syngas into alcohols include cobalt associated with sulfide in certain preferred stoichiometries as described and taught herein.

Owner:ALBEMARLE CORP

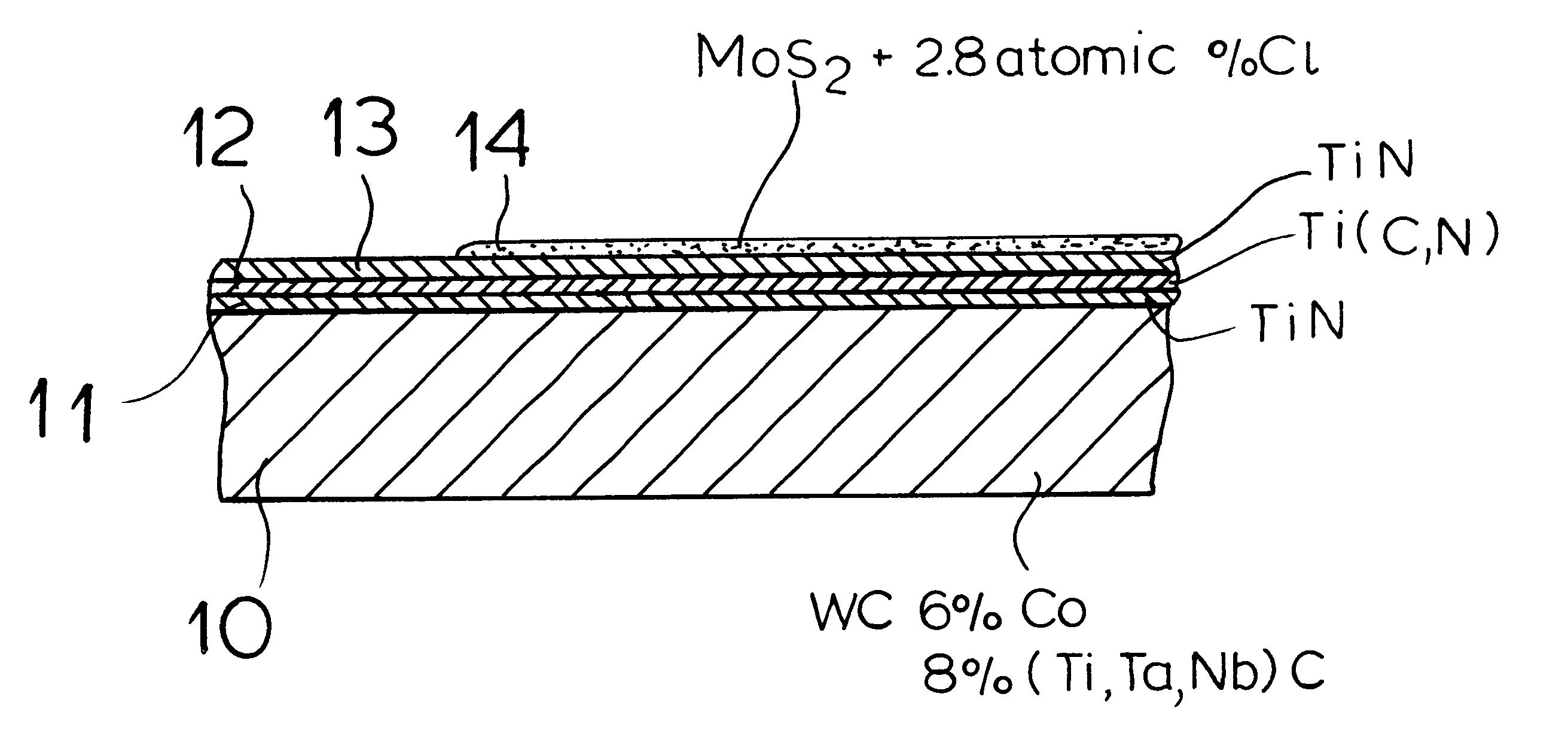

Tool with a molybdenum sulfide containing coating and method for its production

InactiveUS6528171B1Improve wear resistanceRecord information storageMagnetic recordingMetallic materialsMonolayer

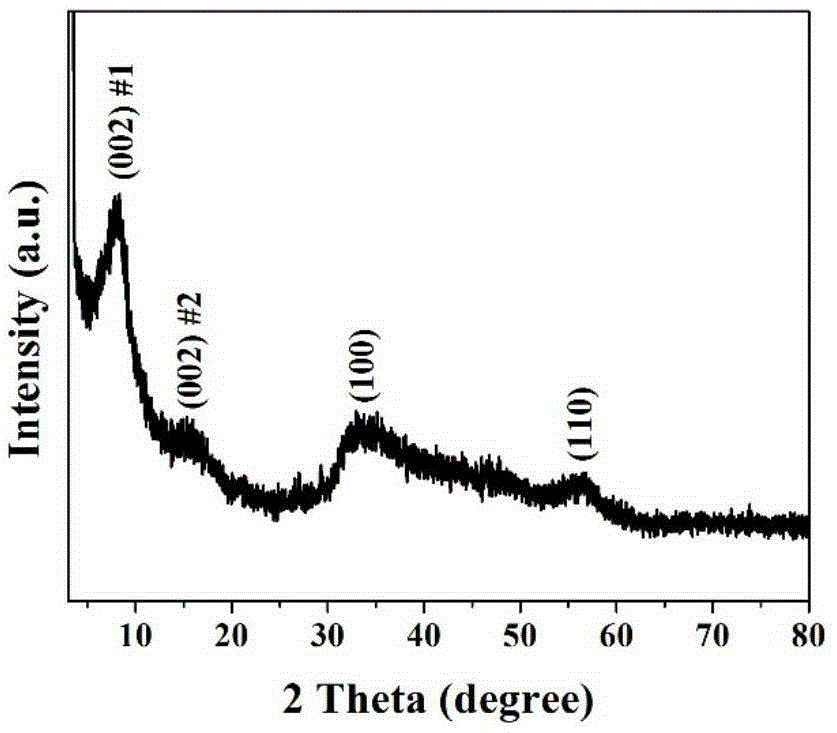

The invention relates to a tool, especially a cutting insert for cutting metallic materials, which consist of a hard metal, cermet ceramics or steel base, especially of a high speed steel base, and at least one layer deposited thereon. The single layer, or in the case of several layers the outer layer or the layer underneath the outer layer, contains molybdenum sulfide. The aim of the invention is to improve the resistance to wear of the friction-reducing, molybdenum sulfide containing layer even at high pressures. To this end, the molybdenum sulfide containing layer consists of an alternating sequence of two layer that are different from one another. The first layer contains 51 to 100% by weight of metallic molybdenum and the second layer contains 21 to 100% by weight of MoS2 which substantially consists of hexagonal crystals that are at least substantially oriented in a plane parallel to the tool surface.

Owner:WIDIA

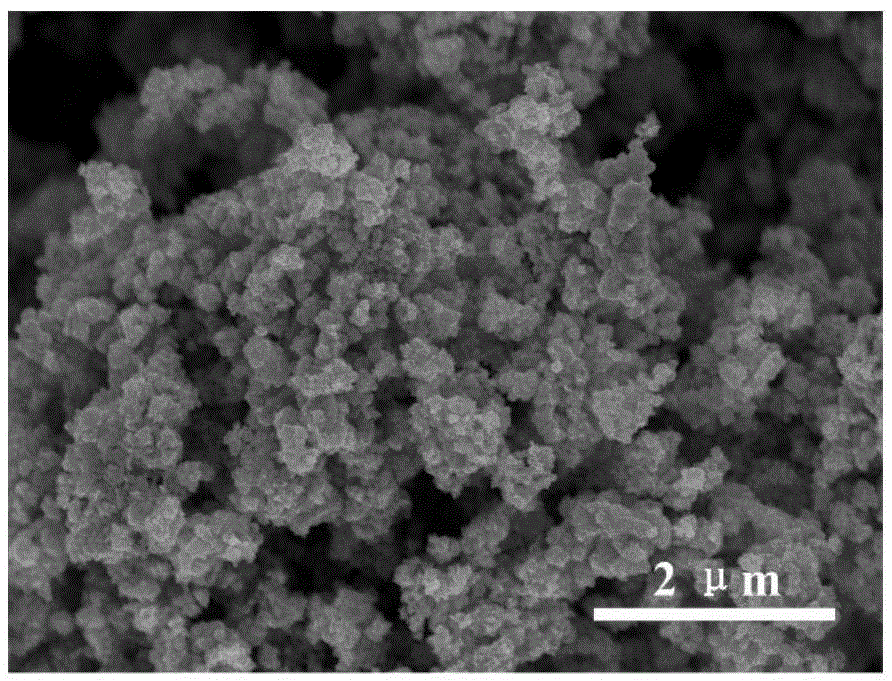

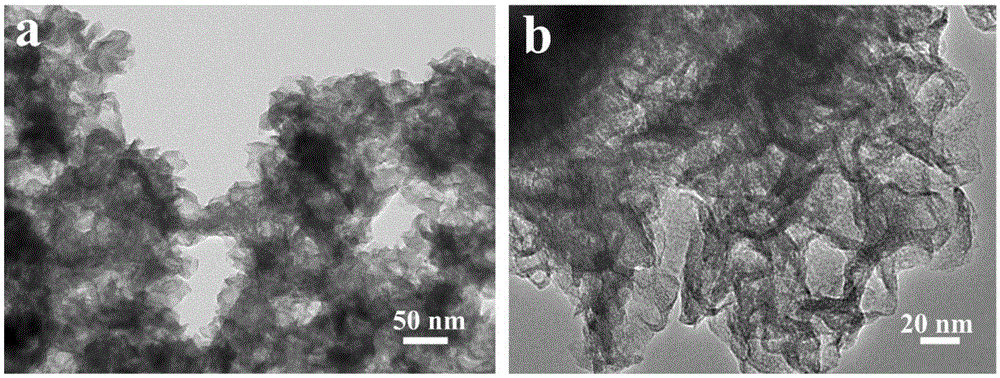

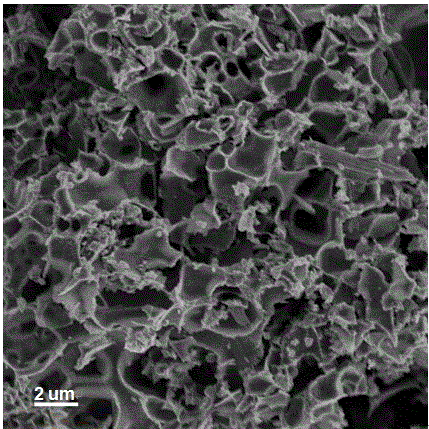

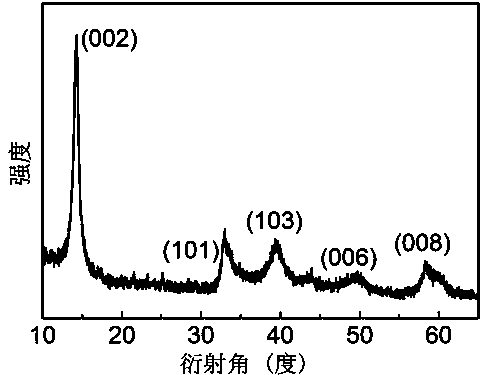

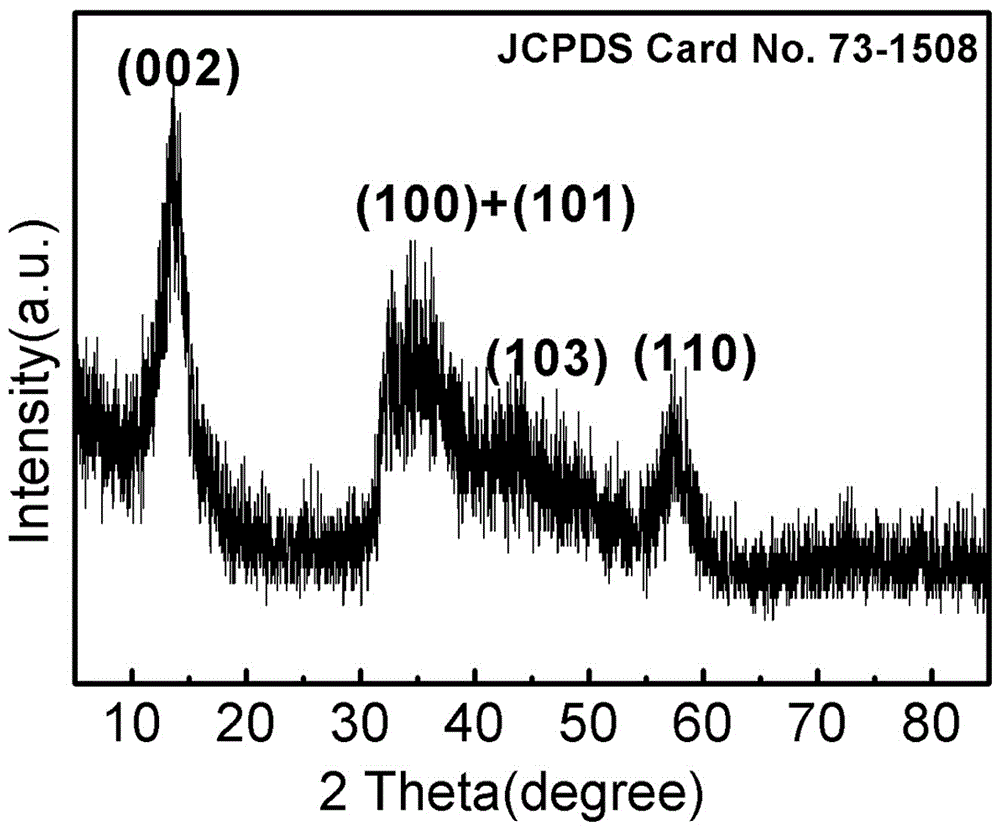

Cobalt-intercalated molybdenum sulfide secondary battery material and preparation method and application thereof

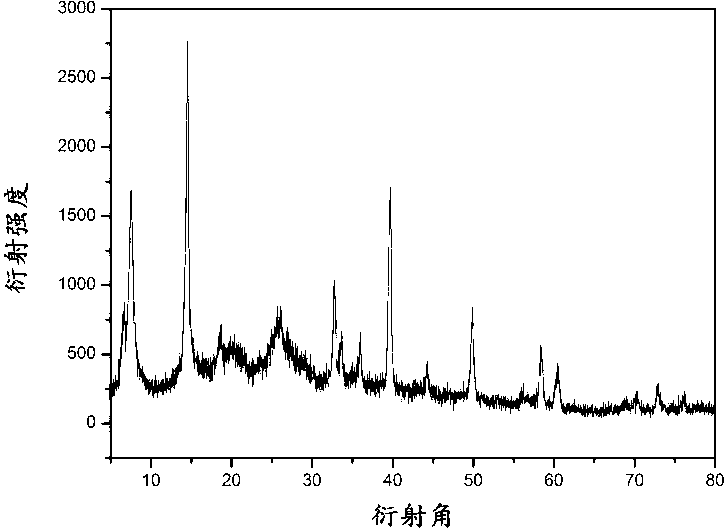

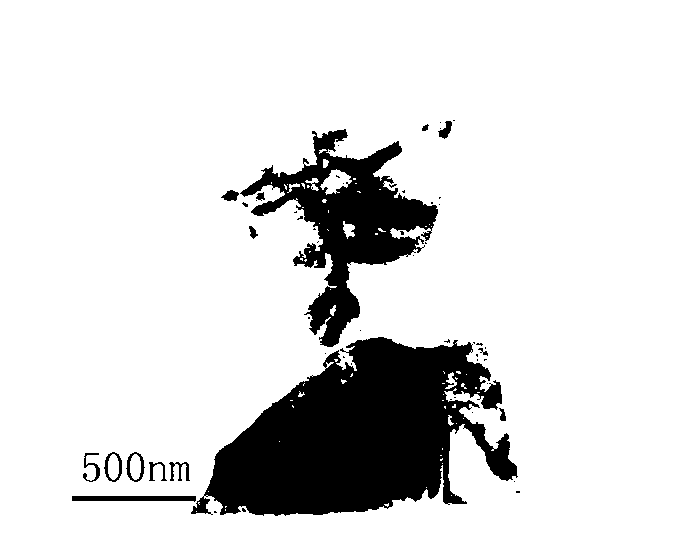

InactiveCN106611837AAvoid reunionAvoid stackingMaterial nanotechnologyHybrid capacitor electrodesLevel structureChemical solution

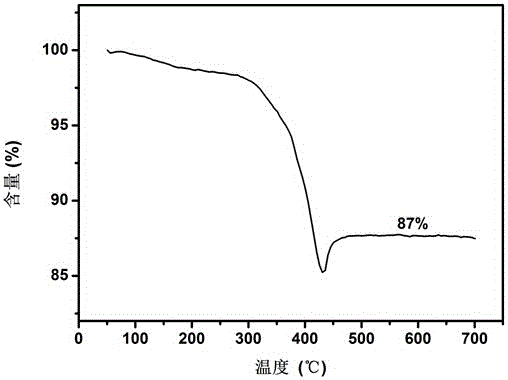

The invention relates to a cobalt-intercalated molybdenum sulfide secondary battery material and a preparation method and an application thereof. A three-dimensional cobalt-intercalated molybdenum sulfide multi-level structure is prepared by adopting a chemical solution method; firstly, a cobalt salt, a molybdenum salt and a sulfur source are dispersed into a solvent to prepare a reaction liquid; and then the prepared reaction liquid is subjected to solvent thermal treatment to obtain the three-dimensional cobalt-uniformly-intercalated molybdenum sulfide multi-level structure which is self-assembled by graphene-like ultra-thin nanosheets, wherein the size of the multi-level structure is about 100nm. The invention also discloses a preparation method for the multi-level structure. The secondary battery material prepared by the method is stable in nanomaterial performance, and long in cycle life when the secondary battery material is used as a negative electrode material of a lithium ion battery and an electrode material of a supercapacitor.

Owner:SHANGHAI JIAO TONG UNIV

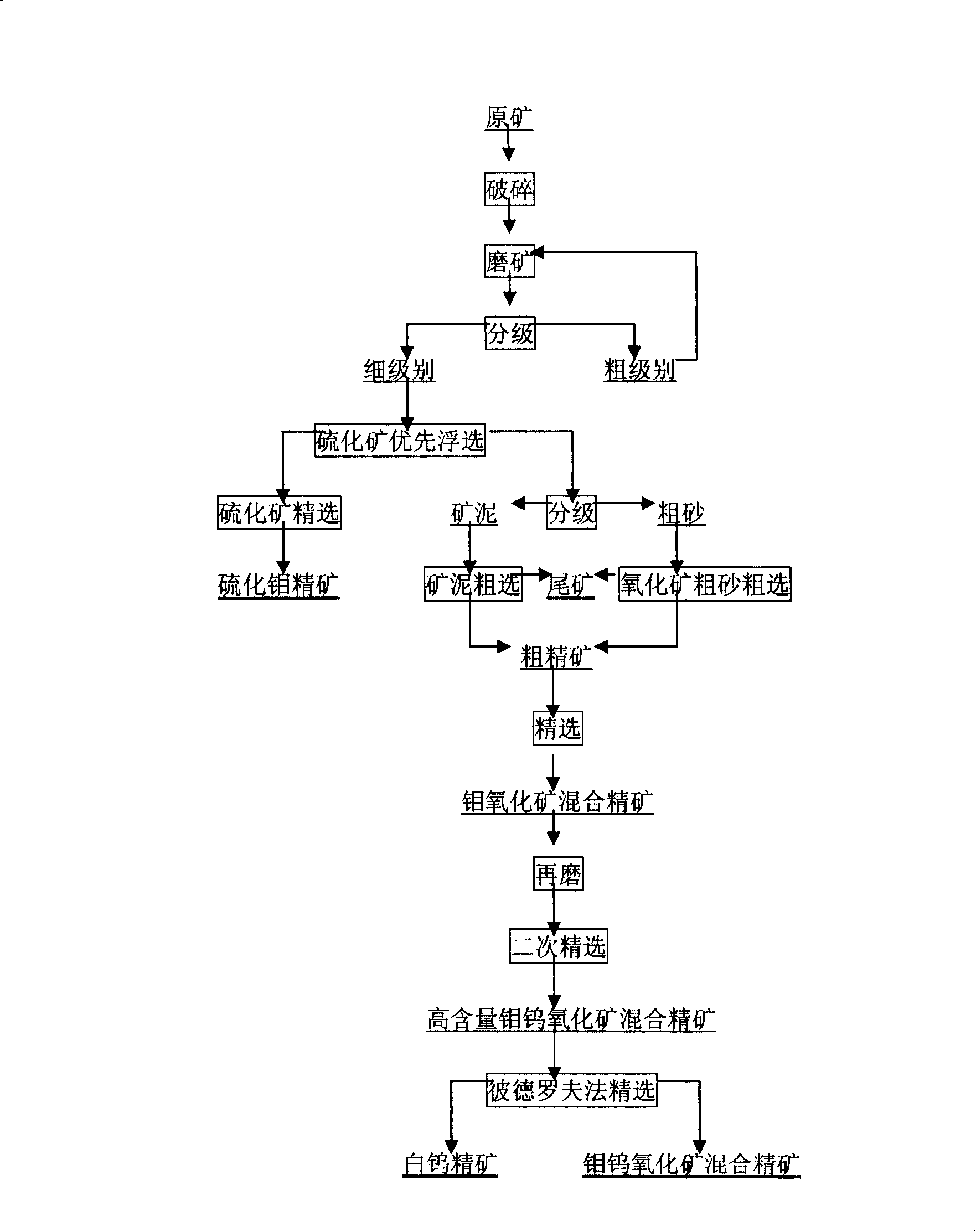

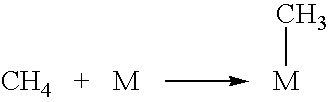

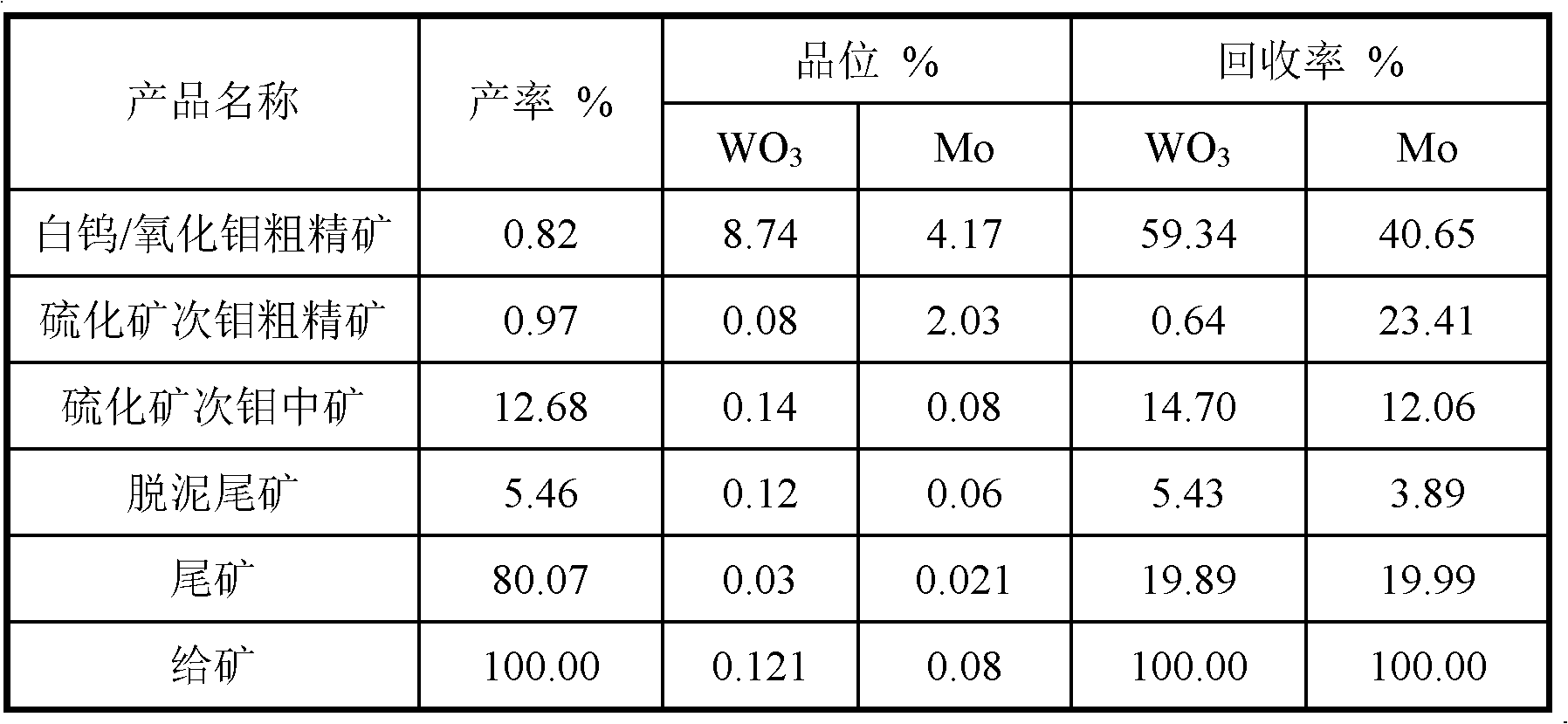

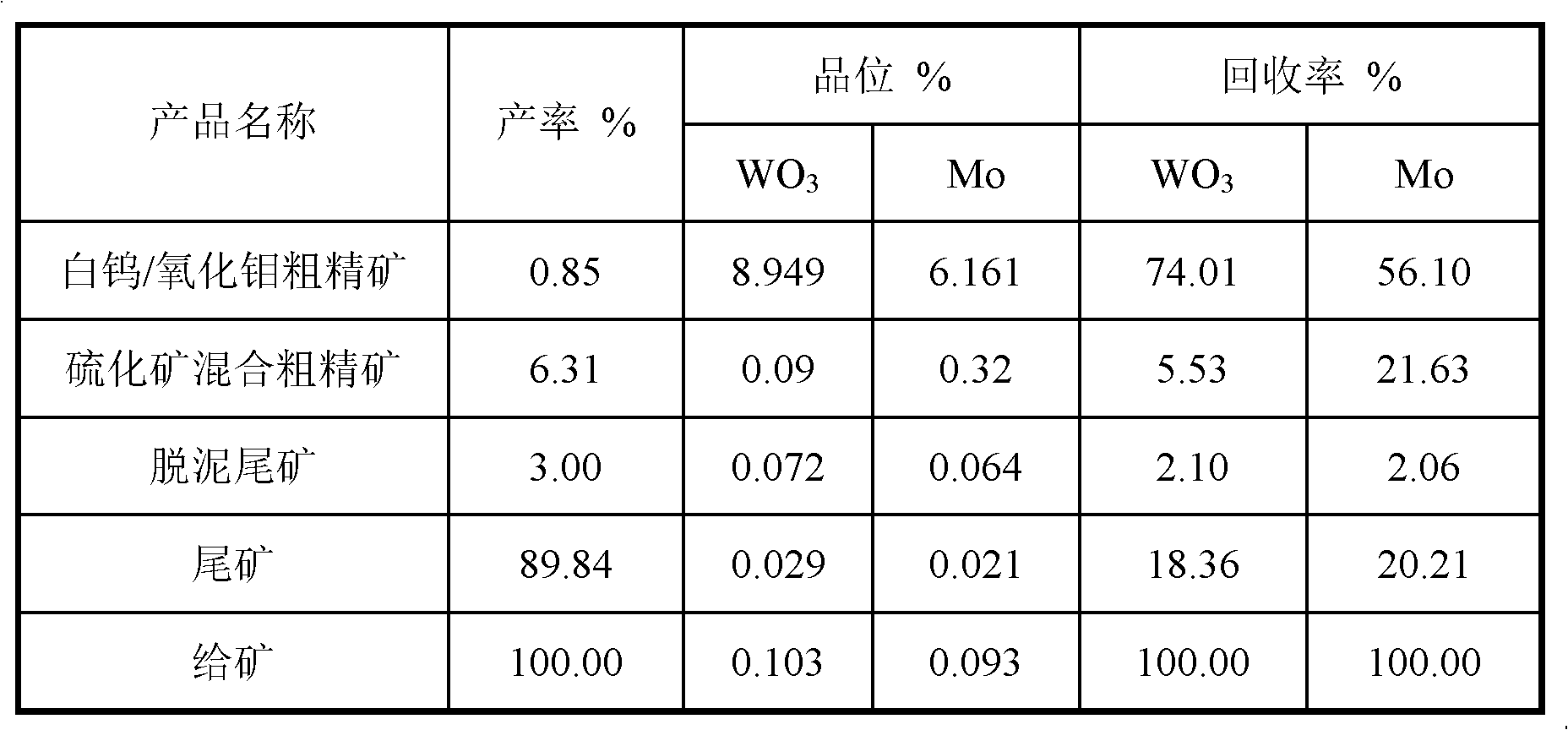

Processing technology for molybdenum and tungsten oxidized ore

InactiveCN101224441AHigh recovery rateResolve recovery rateSievingScreeningLaboratory testFatty acid

The invention discloses a beneficiation process of a molybdenum-tungsten oxide ore. The process of which is that: the liberation degree of ore crushing is higher than or equal to 70%; the flotation of molybdenum sulfide is preferred; the floatation tailing is classified and then a separation of slime and sand is carried out, wherein a slime and sand system takes alkali as the conditioning agent, sodium silicate as the depressant, and emulsified fatty acid as the collecting agent. The rough concentrate obtained from the separation of slime and sand is concentrated after being blended to obtain molybdenum-tungsten oxide ore collective concentrate. The collective concentrate is grounded again and added with the depressant, then a secondary concentrate can be gained through the concentration; the secondary concentrate is concentrated by means of Peter Roph method to obtain scheelite ore and oxidized molybdenum-tungsten beneficiation concentrate. The invention has the advantages that: 1. the invention discloses a beneficiation process flow for treating molybdenum-tungsten oxide ore; 2. the invention solves the difficulty of lowe technical specification of molybdenum - tungsten oxide ore beneficiation; 3. the invention completes laboratory tests and researches and fulfills industrialized implementation for the first time in China.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD +1

Molybdenum sulfide/carbide catalysts

InactiveUS7223713B2High activityImprove stabilityCell electrodesCatalyst activation/preparationMolybdateNitrogen

The present invention provides methods of synthesizing molybdenum disulfide (MoS2) and carbon-containing molybdenum disulfide (MoS2-xCx) catalysts that exhibit improved catalytic activity for hydrotreating reactions involving hydrodesulfurization, hydrodenitrogenation, and hydrogenation. The present invention also concerns the resulting catalysts. Furthermore, the invention concerns the promotion of these catalysts with Co, Ni, Fe, and / or Ru sulfides to create catalysts with greater activity, for hydrotreating reactions, than conventional catalysts such as cobalt molybdate on alumina support.

Owner:GABRIEL ALONSO +2

Tool with a molybdenum sulfide coating and method for producing the same

InactiveUS6521349B1Dense lattice structureHigh hardnessRecord information storageSolid state diffusion coatingGas phaseMetallic materials

The invention relates to a tool, especially a cutting insert for cutting metallic materials, consisting of a hard metal, cermet, ceramic or steel base body and at least one coating deposited thereon. This single coating or in the event that there are several layers, the outer layer or the layer below the outer layer, consists essentially of molybdenum sulphide. The invention also relates to a method for producing the molybdenum sulphide coating by chemical vapour deposition. According to the invention, the molybdenum sulphide coating contains a mixture of the sulphide phases MoS2 and Mo2S3 with an essentially random orientation (isotropic orientation) of the phase crystals. The coating is applied by means of a chemical vapour deposition procedure.

Owner:WIDIA

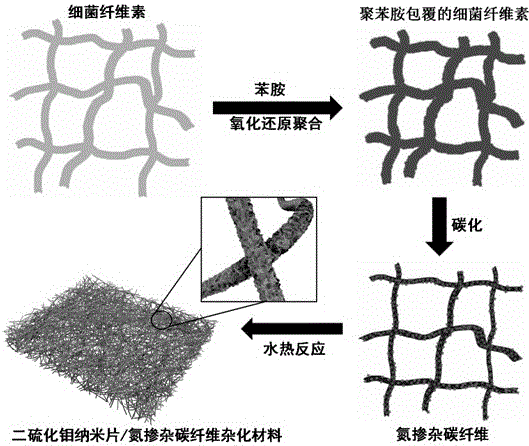

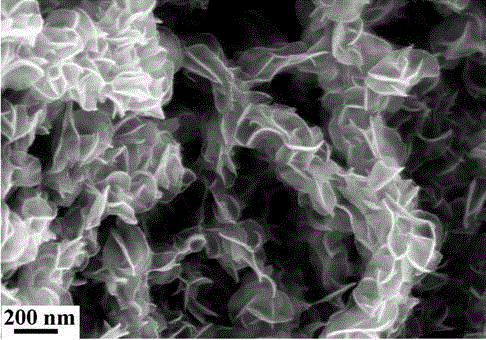

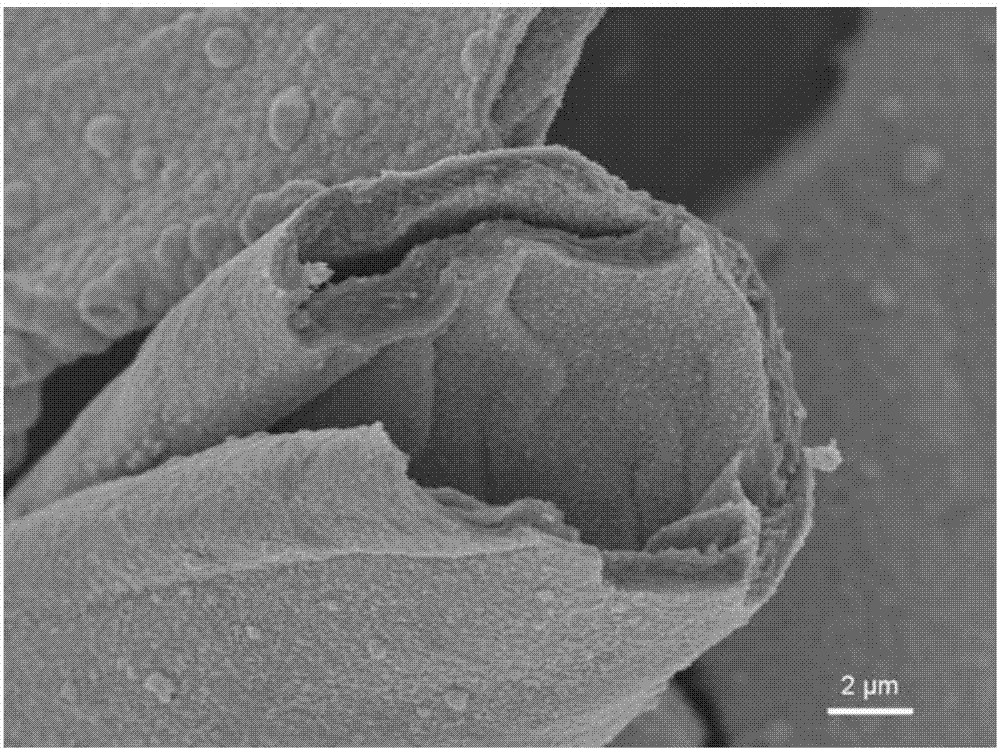

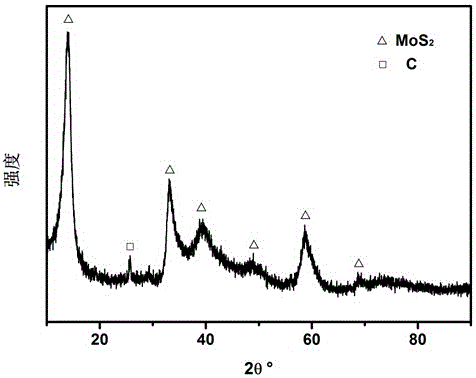

Molybdenum disulfide nanosheet/nitrogen-doped carbon fiber hybrid material and preparation method therefor

InactiveCN105056983AHigh electrical conductivityReduce reunionPhysical/chemical process catalystsElectrodesFiberCarbon fibers

The invention belongs to the technical field of carbon fiber materials, and particularly discloses a molybdenum disulfide nanosheet / nitrogen-doped carbon fiber hybrid material and a preparation method therefor. The molybdenum disulfide nanosheet / nitrogen-doped carbon fiber hybrid material is prepared by growing a molybdenum disulfide nanosheet on a nitrogen-doped carbon fiber with a three-dimensional network structure in situ by taking molybdenum salt and sulfosalt as precursors; A preparation process for the molybdenum disulfide nanosheet / nitrogen-doped carbon fiber hybrid material comprises: preparing the nitrogen-doped carbon fiber through in-situ oxidization-reduction reaction, freeze-drying and high-temperature carbonization; and growing the molybdenum disulfide nanosheet on the nitrogen-doped carbon fiber in situ through a one-step solvothermal method. According to the nitrogen-doped carbon fiber prepared by the preparation method, the wettability of the carbon fiber and a solvent is improved, and more active sites are provided for growth of inorganic particles; and moreover, the electrical conductivity of the carbon fiber is greatly improved, so that the migration rate for electrons in an electro-catalysis hydrogen-evolution process is increased. The molybdenum disulfide nanosheet / nitrogen-doped carbon fiber hybrid material prepared by the preparation method can be used as an ideal high-performance catalyst material and can be used for the electro-catalysis hydrogen-evolution field.

Owner:FUDAN UNIV

Preparation method of polyaniline and molybdenum disulfide intercalated composite material

The invention discloses a preparation method of a polyaniline and molybdenum disulfide intercalated composite material. The preparation method comprises the steps of preparing suspension of graphene molybdenum disulfide from molybdenum disulfide powder through a chemical intercalation process, adding an aniline monomer, an oxidizing agent and organic acid dopants, and implementing in-situ emulsion polymerization to prepare the polyaniline / molybdenum disulfide intercalated composite material. The preparation method is simple and convenient, controllable and environment-friendly; the material is in emulsion or solid powder, and can be formed by coating, deposition, or pressing powder thereof, and other methods; the material is uniform in texture, stable in performance, and excellent in both photoelectrical performance and thermal stability; and the composite material is applicable to the fields of photoelectronic devices such as a secondary battery, a super-capacitor, an electromagnetic shielding device, an antistatic device, a field effect transistor, a sensor, an organic electroluminescence device and the like.

Owner:HEFEI UNIV OF TECH

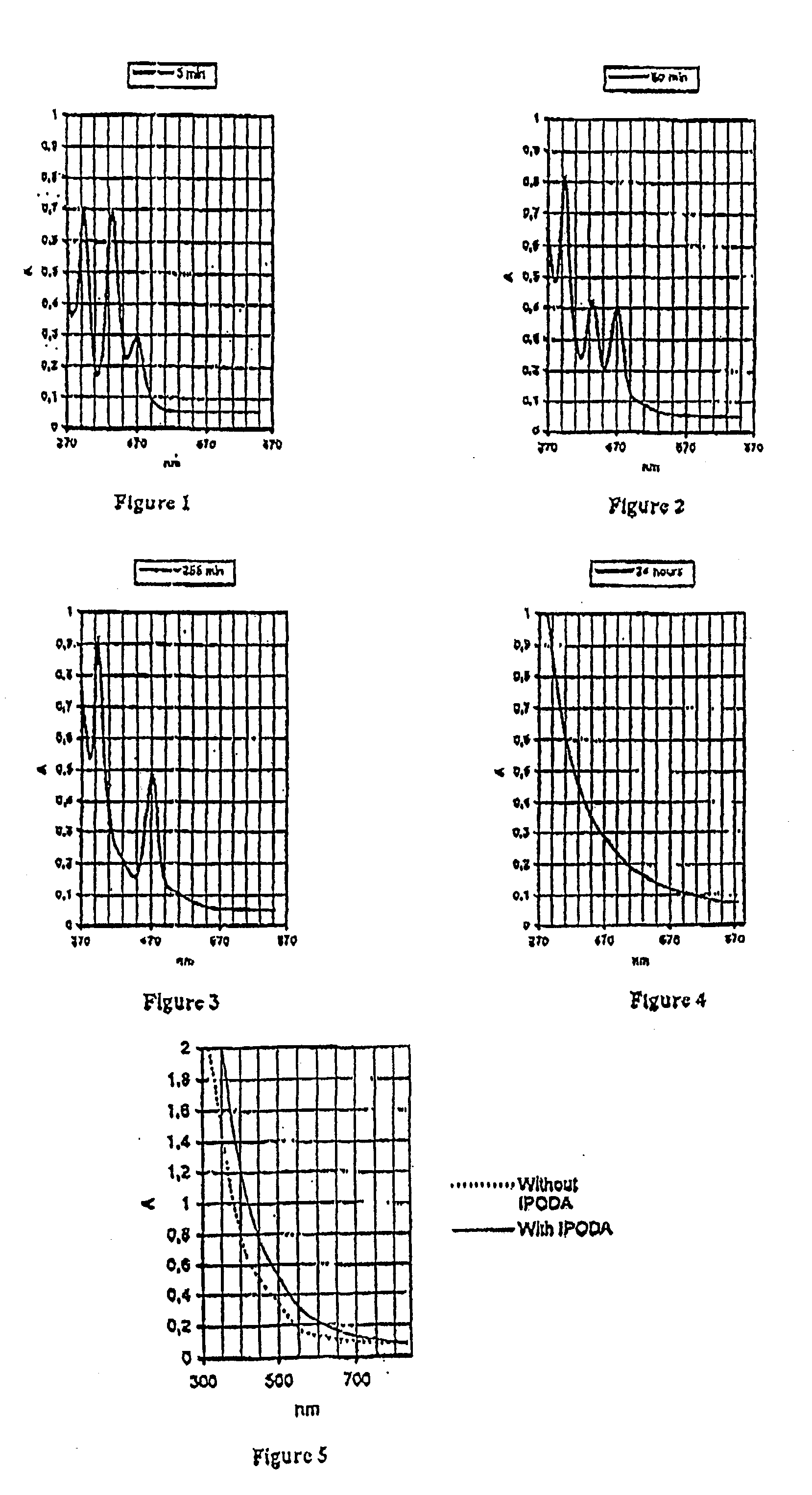

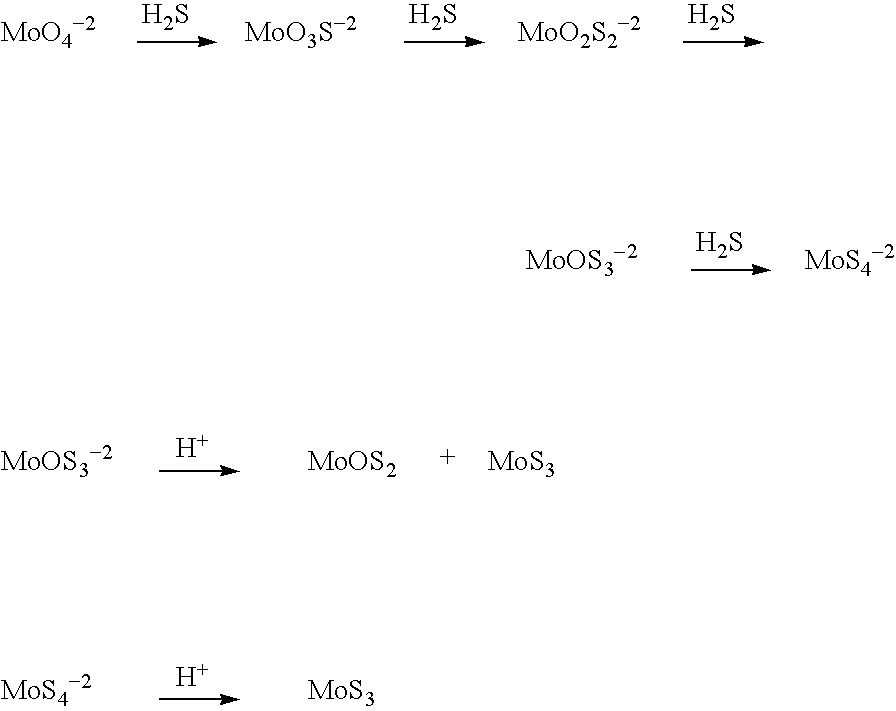

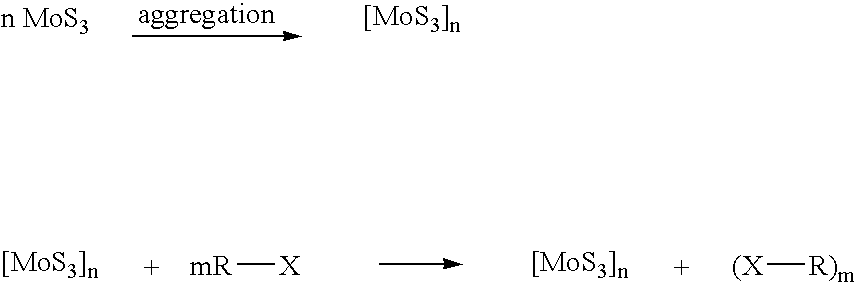

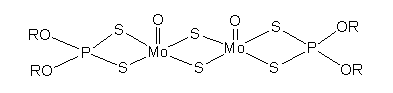

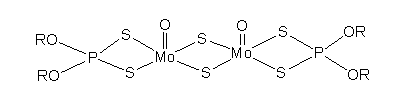

Nanosized particles of molybdenum sulfide and derivatives,method for its preparation and uses thereof as lubricant additive

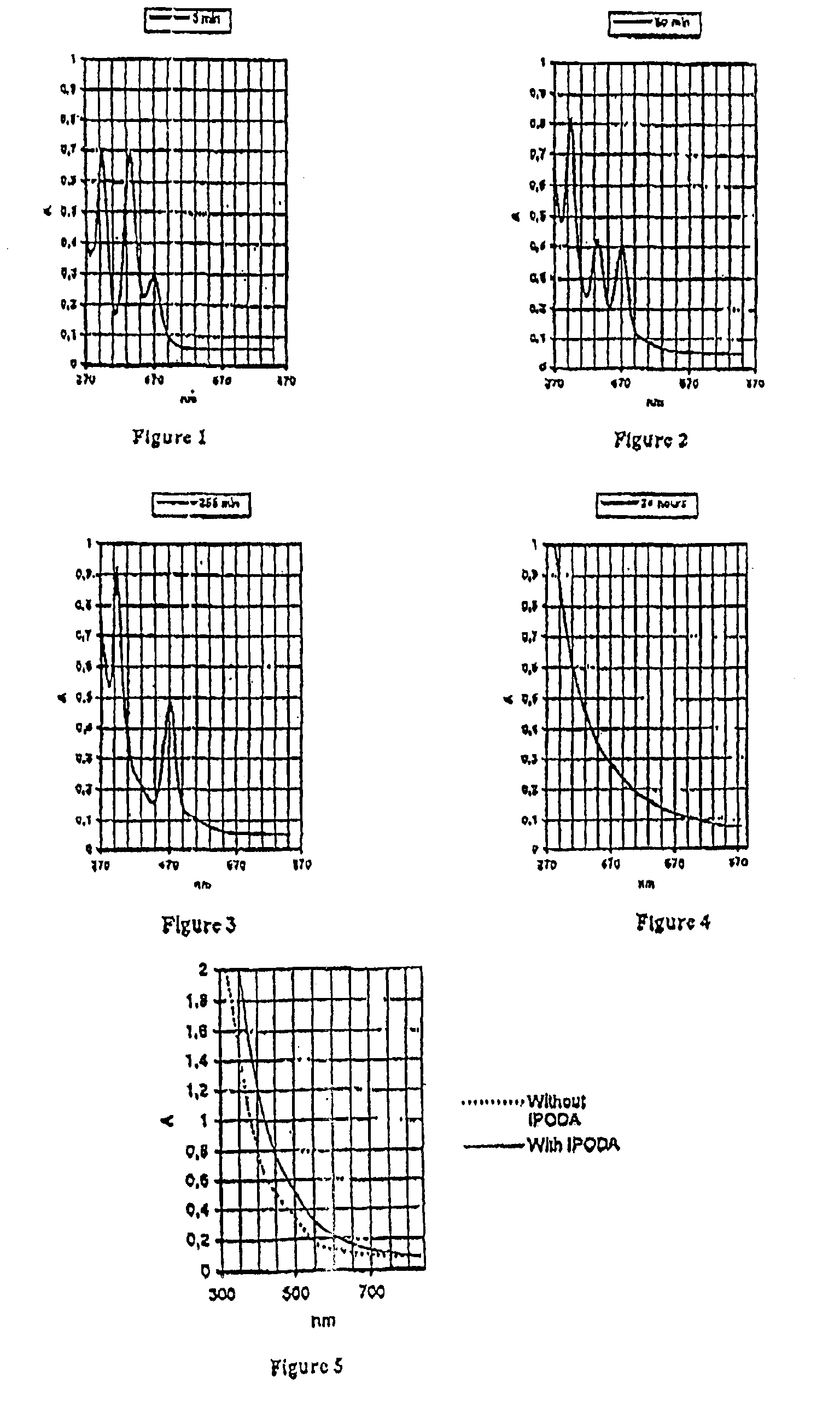

InactiveUS20050065044A1Prevent coagulationProvide solubilityGroup 1/11 element organic compoundsAdditivesMolybdenum compoundsSulfidation

A lubricant composition is disclosed that comprises: (a) a lubricant and (b) at least one molybdenum-containing compound in the form of surface-capped nanosized particles of the general formula: (Z)n(X—R)m wherein Z is an inorganic moiety comprising molybdenum and sulfur in the form of particles having dimensions in the range of from about 1 to about 100 nm; (X—R) is a surface-capping reagent wherein R is a C4 to C20 straight or branched-chain alkyl or alkylated cycloalkyl radical or radicals and X is a functional group capable of specific sorption and / or chemical interaction with molybdenum / sulfur moiety; n is the number of molecules of Z in the particles; m is an integer representing the amount of surface-capping reagents relative to a single particle; and the ratio of m to n is in the range of from about 1:1 to about 10:1.

Owner:CROMPTON CORP

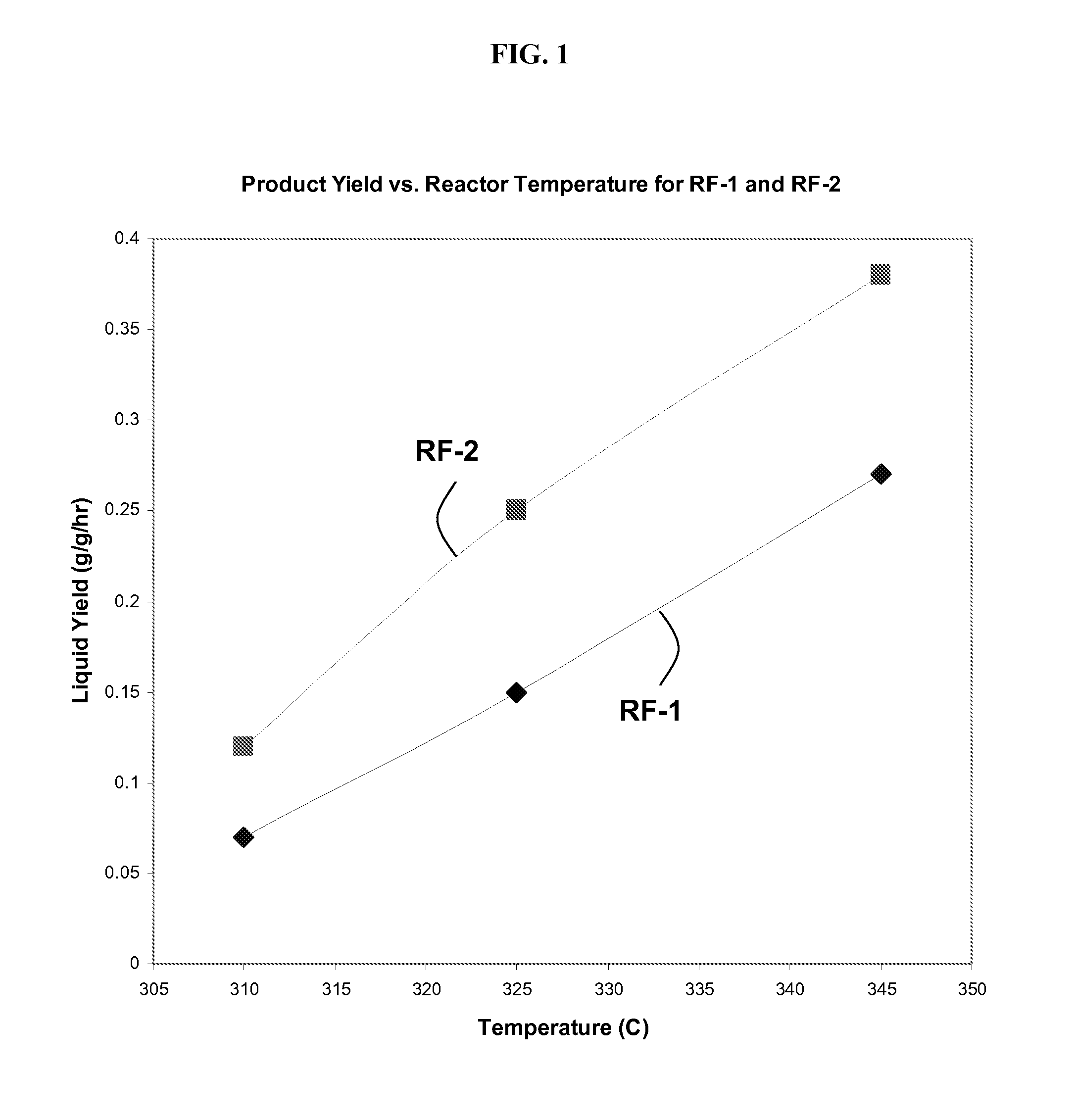

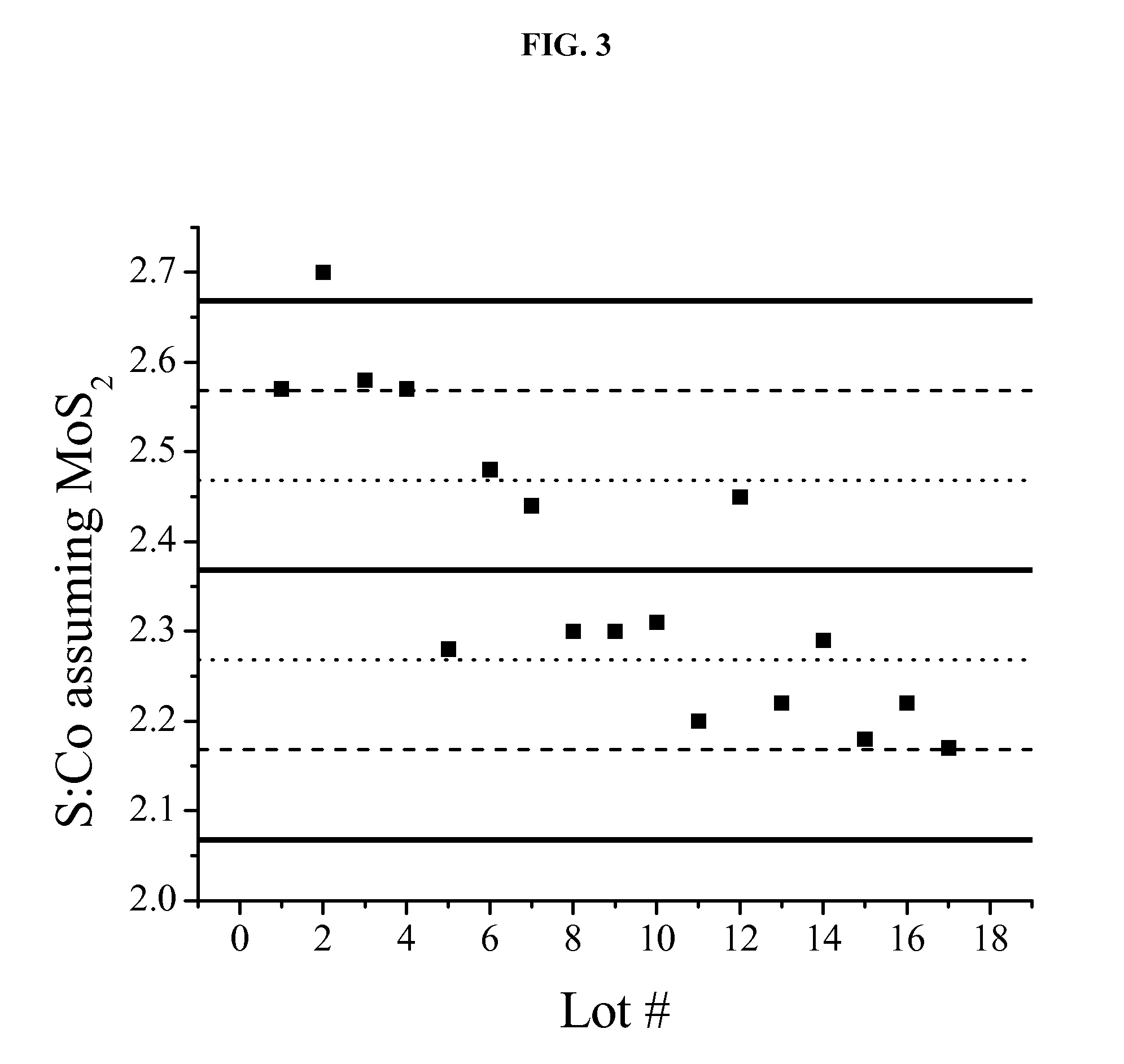

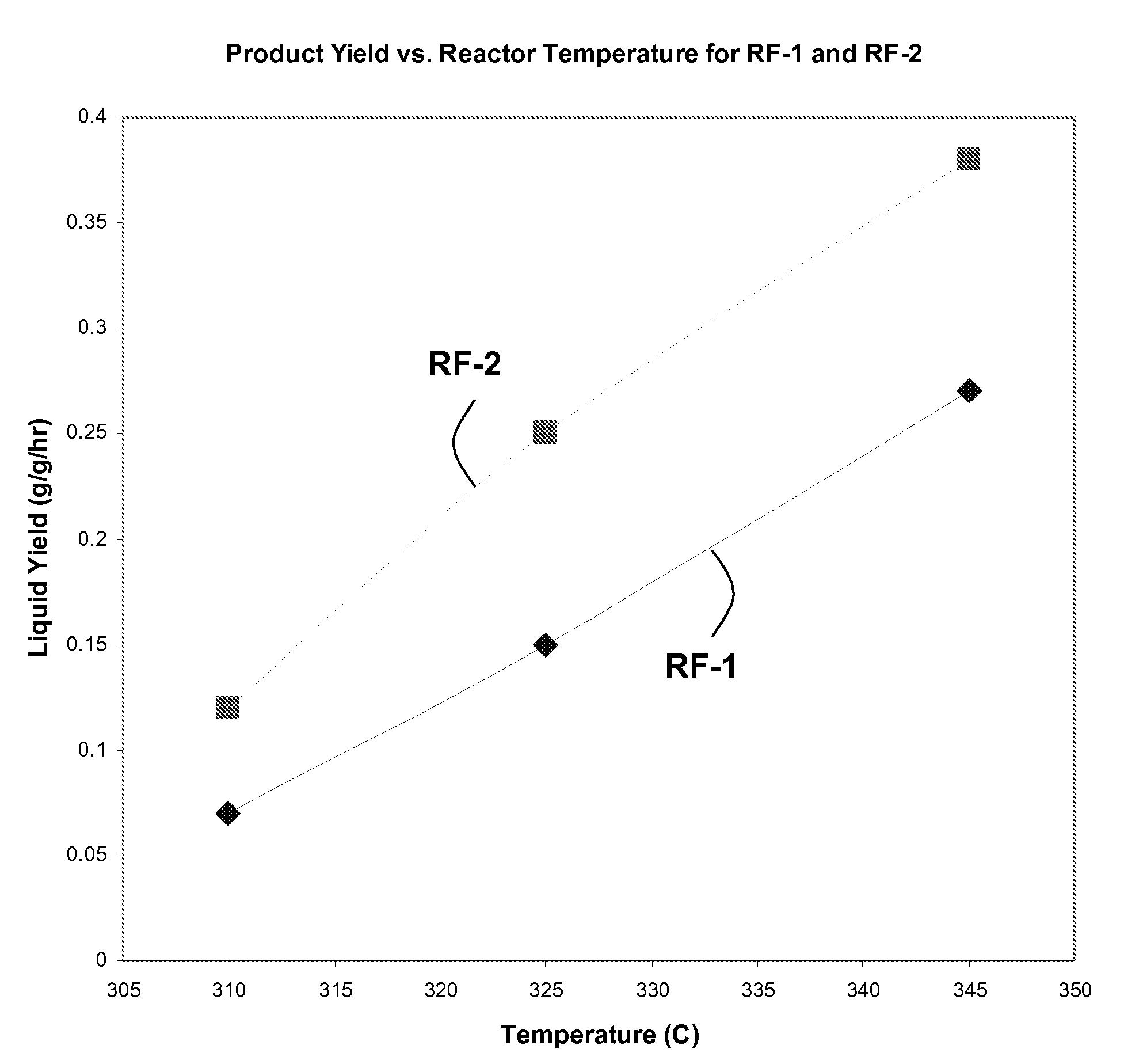

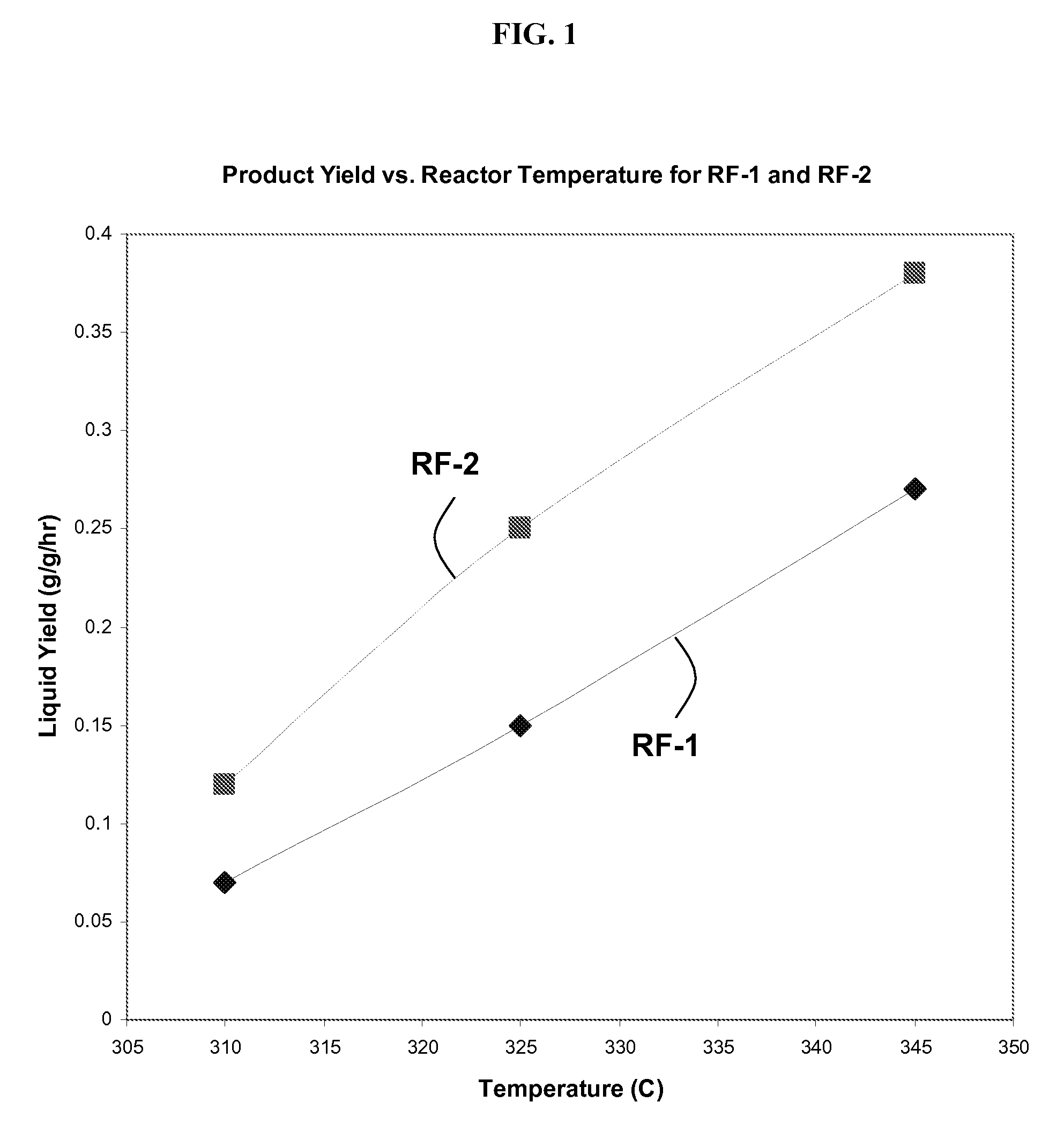

Cobalt-molybdenum sulfide catalyst materials and methods for stable alcohol production from syngas

The present invention provides methods and compositions for the chemical conversion of syngas to alcohols. The invention includes catalyst compositions, methods of making the catalysts, and methods of using the catalysts including techniques to maintain catalyst stability. Certain embodiments teach compositions for catalyzing the conversion of syngas into products comprising at least one C1-C4 alcohol, such as ethanol. These compositions generally include cobalt, molybdenum, and sulfur, and avoid metal carbides both initially and during reactor operation.

Owner:ALBEMARLE CORP

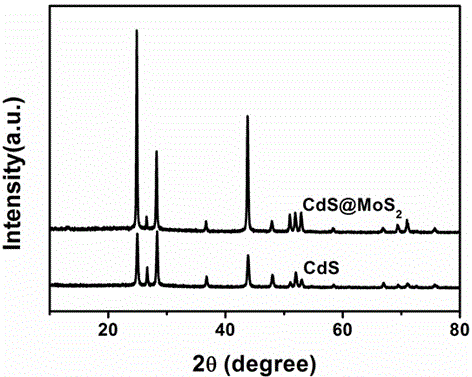

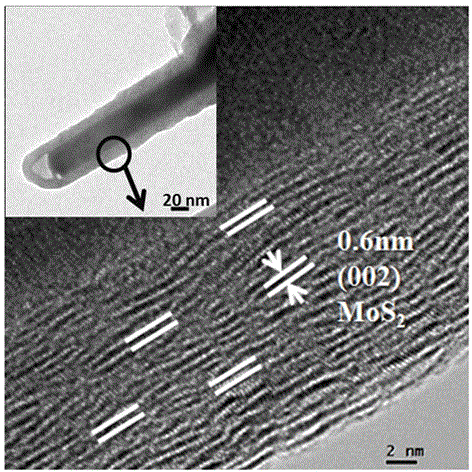

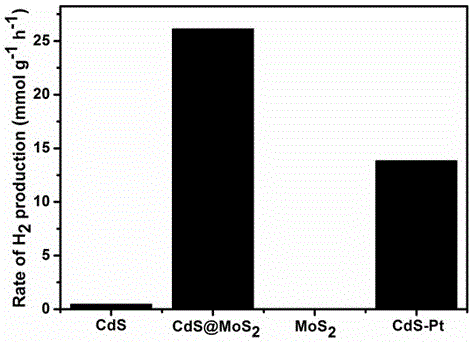

Composite photo-catalyst with molybdenum disulfide (MoS2) nanosheet/cadmium sulfide (CdS) nanowire core-shell structure

InactiveCN105688945AImprove photostabilityImprove photocatalytic activityPhysical/chemical process catalystsHydrogen productionNanowireCadmium sulphide

The invention discloses a composite photo-catalyst with a molybdenum disulfide (MoS2) nanosheet / cadmium sulfide (CdS) nanowire core-shell structure, and a preparation method of the composite photo-catalyst, belonging to the technical fields of material preparation and photo-catalysis. The composite photo-catalyst takes a one-dimensional CdS nanowire as a core and takes a two-dimensional MoS2 nanosheet as a shell, and is compounded by an electrostatic self-assembly method through a hydrothermal process. The raw materials of the composite photo-catalyst can be easily obtained, and the preparation method is simple in process and convenient to operate; the prepared composite material with the core-shell structure is better in stability, has excellent photocatalytic activity and can be used for catalyzing photolysis of water for preparing hydrogen; furthermore, the core-shell structure is capable of effectively preventing the sulfur loss of the CdS nanowire and slowing down photocorrosion, and has wide application prospect in the field of photo-catalysis.

Owner:FUZHOU UNIV

Chromium-free self-lubricating passivation solution and preparation method thereof

InactiveCN103290401AReduce coefficient of frictionImprove the lubrication effectMetallic material coating processesSilanesFirming agent

The invention discloses a chromium-free self-lubricating passivation solution and a preparation method thereof. The chromium-free self-lubricating passivation solution is formed by compounding the following compositions in percentage by weight: 8%-12% of water-borne epoxy resin, 0.5%-1% of curing agent, 10%-15% of silane coupling agent, 0.5%-1% of inorganic component, 2%-4% of solid lubricant, 1%-2% of friction modifier, 0.5%-1% of anti-wear agent, 0.5%-1% of anti-sinking agent, and 60%-75% of diluting agent. The inorganic component is one or a combination of Ce(NO3)3 and sodium molybdate, the solid lubricant is one or a combination of two or more of polytetrafluoroethylene, polyethylene wax, polyethylene, molybdenum disulfide and graphite, the friction modifier is self-synthesized molybdenum dialkyldithiophosphate, the anti-wear agent is one or a combination of nanosilicon dioxide and nano aluminum oxide, the anti-sinking agent is attapulgite, and the diluting agent is a mixture of water and ethanol. A plate product coated with passivation solution has the advantages of being pollution-free, low-friction, anti-oxidized, anti-wear and extreme pressure-resistant, corrosion-resistant, finger-resistant, having good mechanical performance and the like, and the passivation solution can be directly coated on the surfaces of a zinc-plated plate and parts of certain mechanical equipment for use.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

Cutting tool and method of making same

InactiveUS6284366B1Improve wear resistanceImprove adhesionPigmenting treatmentOther chemical processesChlorineCoating

A tool having a substrate and at least as a sole layer or the outermost layer, a coating of the molybdenum sulfide containing 0.5 to 6 atomic % chlorine.

Owner:WIDIA

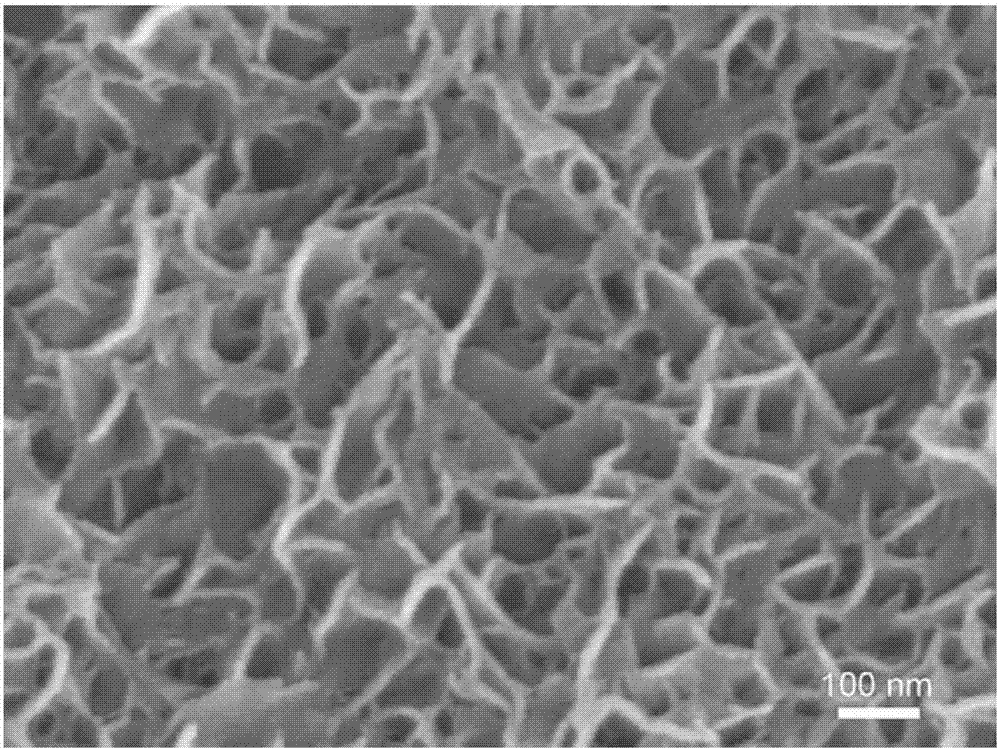

Three-dimensional porous quasi-graphene loaded molybdenum disulfide composite and preparation method thereof

The invention discloses a three-dimensional porous quasi-graphene loaded molybdenum disulfide composite and a preparation method thereof. The composite is prepared by uniformly loading large-area ultrathin molybdenum disulfide nanosheets onto the surface of three-dimensional porous quasi-graphene network. The preparation method comprises the following steps: with NaCl as a dispersant and template, fully dissolving and mixing NaCl, a molybdenum source and a sulfur source and carrying out freeze drying and porphyrization so as to obtain a mixture; putting the mixture in a tubular furnace and carrying out calcining under the protection of argon so as to obtain a calcined product A; and washing the calcined product A and drying the washed calcined product A so as to obtain the three-dimensional porous quasi-graphene loaded molybdenum disulfide composite. The invention has the following advantages: preparation process is safe and harmless, operation is simple, and yield is high; and the prepared three-dimensional porous quasi-graphene loaded molybdenum disulfide composite has good reversible capacity, cycle stability and rate capability as a cathode material of a lithium ion battery.

Owner:TIANJIN UNIV

MOS2 (molybdenum disulfide) and TiO2 (titanium dioxide) nanocomposites and production method thereof

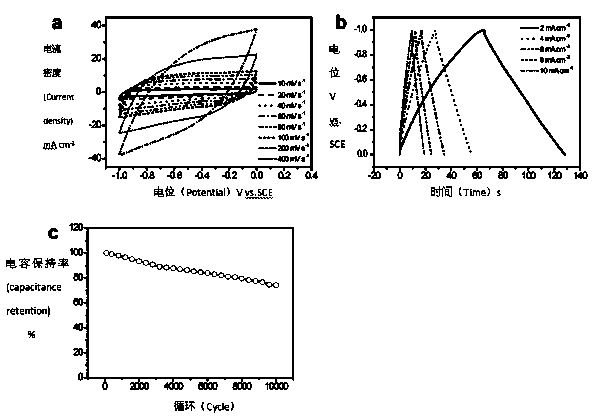

ActiveCN103426648AIncrease capacitanceIncrease the active siteHybrid capacitor electrodesNanocompositeMolybdenum disulfide

The invention relates to the energy storage field and discloses MOS2 (molybdenum disulfide) and TiO2 (titanium dioxide) nanocomposites and a production method thereof. The MOS2 and TiO2 nanocomposites are composite materials of nano molybdenum disulfide and titanium dioxide, namely the MOS2 and TiO2. The MOS2 and TiO2 nanocomposites are obtained through the two-step hydrothermal method which comprises, to be specific, growing titanium dioxide nanorods on a seed layer through the auxiliary hydrothermal method and coating a layer of molybdenum disulfide on the outer layer of the titanium dioxide nanorods through the direct hydrothermal method. According to the obtained MOS2 and TiO2 nanocomposites through production, the energy can be effectively stored and a good method is provided for the existing energy storage problem due to the high specific surface area of the titanium dioxide one-dimensional nanorods and the excellent super capacitance performance of the molybdenum disulfide. According to the production method, the energy consumption is low, the condition is simple, the large-scale production is easy and the like.

Owner:SUN YAT SEN UNIV

Nanosized particles of molybdenum sulfide and derivatives, method for its preparation and uses thereof as lubricant additive

InactiveUS6878676B1Prevent coagulationProvide solubility and stabilityGroup 1/11 element organic compoundsAdditivesNano sizeSulfur

A lubricant composition is disclosed that comprises: (a) a lubricant and (b) at least one molybdenum-containing compound in the form of surface-capped nanosized particles of the general formula: (Z)n(X—R)m wherein Z is an inorganic moiety comprising molybdenum and sulfur in the form of particles having dimensions in the range of from about 1 to about 100 nm; (X—R) is a surface-capping reagent wherein R is a C4 to C20 straight or branched-chain alkyl or alkylated cycloalkyl radical or radicals and X is a functional group capable of specific sorption and / or chemical interaction with molybdenum / sulfur moiety; n is the number of molecules of Z in the particles; m is an integer representing the amount of surface-capping reagents relative to a single particle; and the ratio of m to n is in the range of from about 1:1 to about 10:1.

Owner:CROMPTON CORP

Preparation method of graphite phase carbon nitride/molybdenum sulfide composite material

The invention discloses a preparation method of a graphite phase carbon nitride / molybdenum sulfide composite material. The preparation method comprises the following steps of mixing MoS2 and a nitrogen source uniformly, and adding a grinding agent for grinding for 30-60min until the materials are fully mixed uniformly to obtain a mixture, wherein the ratio of addition amount of MoS2 to the nitrogen source to the grinding agent is 1mmol:(3-7)mmol:(1-3)ml; (2) under the protection of N2, heating the mixture in the step (1) to 500-600 DEG C to roast for 3-5h to obtain a g-C3N4 / MoS2 composite material. Hydrogen cyanamide, dicyandiamide, tripolycyanamide or urea is taken as the nitrogen source. By using the method disclosed by the invention, the graphite phase carbon nitride / molybdenum sulfide composite material can be prepared by using a one-step method, so that the preparation process is simplified; and no chemical reagent is added, so that the production cost is reduced.

Owner:QINGDAO UNIV

Liquid fuel production process from cellulosic biomass and coal

InactiveUS20100186291A1Reduce ash fusion temperatureHighly effectiveBiofuelsHydroxy compound preparationAlkaneCellulose

A liquid fuel production process from Cellulosic biomass and coal comprises providing a mixture of Cellulosic biomass and coal, subjecting the mixture to gasification to obtain synthesis gas and converting the synthesis gas to a liquid fuel under the presence of catalyst. The catalyst includes molybdenum sulfide, alkali metal compound and a component activating the C—H bond in alkanes product, wherein the alkali metal compound is selected from the group of salts of Li, Na, K, Rb and Cs, the component activating the C—H bond in alkanes product is selected from Mo, V, Os, Re, Ir, Pt, Pd, Co, Rh, Ni and their mixture. Additionally, co-gasification of Cellulosic biomass and coal can reduce the ash fusion temperature of coal.

Owner:CHINA FUEL HUAIBEI BIOENERGY TECH DEV

Mineral processing method for recycling scheelite/molybdenum oxide ores from molybdenum sulfide flotation tailings

The invention discloses a mineral processing method for recycling scheelite / molybdenum oxide ores from molybdenum sulfide flotation tailings. The mineral processing method comprises the following steps of: taking the molybdenum sulfide flotation tailings as raw materials and further levigating the raw materials; carrying out reselection and / or flotation and desliming on ore pulp which is levigated according to demands; adding a regulator, an auxiliary inhibitor, an inhibitor and a modified aliphatic acid collecting agent into the flotation tailing pulp; and recycling the scheelite / molybdenum oxide ores at room temperature so as to obtain scheelite / molybdenum oxide ore concentrates after roughing, scavenging and concentrating. The mineral processing method disclosed by the invention has the advantages of simple process flow, low production cost, resource saving, high product level and high recovery.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL

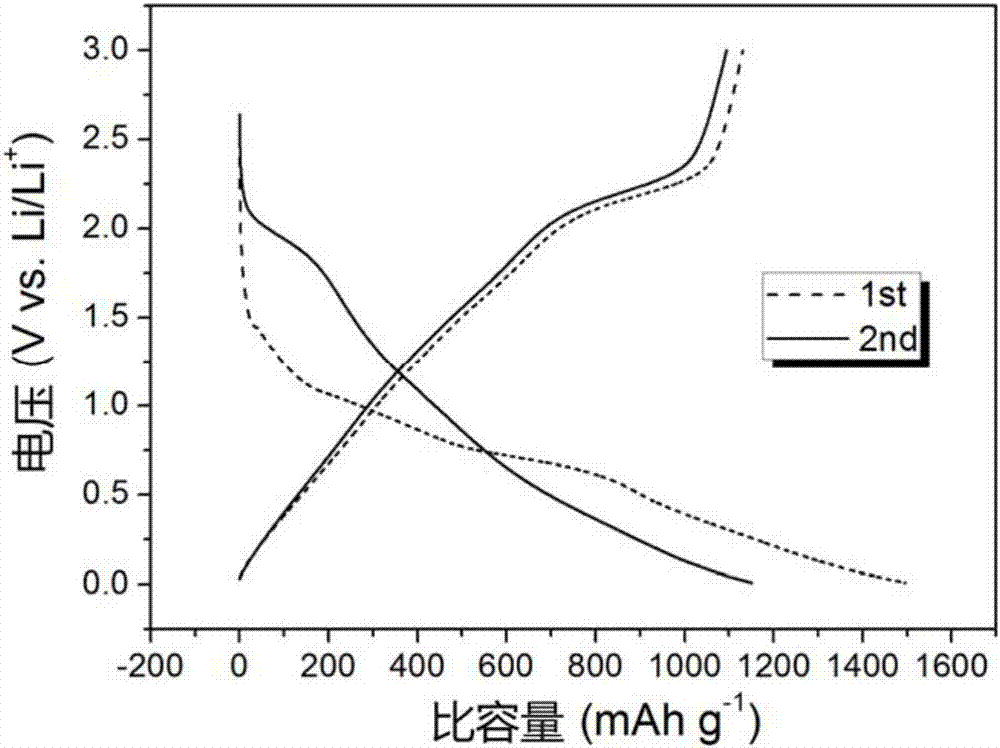

Molybdenum sulfide/carbon composite material and preparation method and application thereof

InactiveCN106910884AReduce manufacturing costImprove electrochemical performanceNegative electrodesSecondary cellsCarbon compositesElectrochemistry

The invention relates to a molybdenum sulfide / carbon composite material and a preparation method and application thereof. A mixed solution including a molybdenum source, a sulfur source and an organic carbon source is mixed with a cotton carbon source, then the obtained mixture is subjected to a hydrothermal reaction, solid is subjected to thermal treatment after solid-liquid separation, and the molybdenum sulfide / carbon composite material is obtained. In the preparation process, waste cotton materials are directly used as the carbon source and formworks or cotton materials are mainly used as the carbon source and the formworks, so that the material is environmentally friendly, a template agent is not needed, and the production cost is greatly reduced. The obtained molybdenum sulfide / carbon composite material has special appearance and structure, and has excellent electrochemical properties when used as a lithium ion battery negative pole material, and the first charge and discharge reversible specific capacity is 800-1400 mAh / g. The material is simple in process, mild in condition, suitable for industrial production and wide in application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

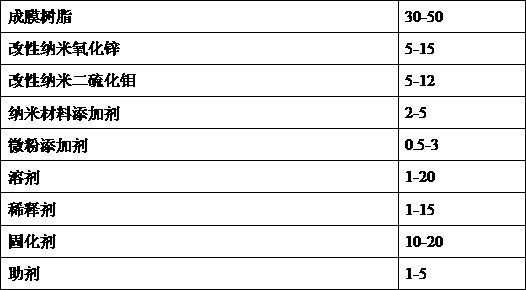

Temperature-resistant and wear-resistant nano composite functional coating

ActiveCN103232795AMeet needsGood synergyPolyurea/polyurethane coatingsEpoxy resin coatingsNano zinc oxideMolybdenum disulfide

The invention relates to a nano composite functional coating, a preparation method thereof and a use thereof. The coating comprises film-forming resins, modified nano zinc oxide, modified nano molybdenum disulfide, a nano material additive, a micro powder additive, a solvent, a diluent, a curing agent and auxiliaries in a certain mass ratio. The novel nano composite functional coating shows excellent high temperature resistance and abrasion resistance, and especially meets the environment requirement for high-temperature work; besides, the wear rate of the material is reduced and the service life of the material is prolonged; and therefore, the nano composite functional coating has wide industrial application prospect.

Owner:北京希柯节能环保科技有限公司

Molybdenum disulfide-carbon three-dimensional porous network composite and preparation method thereof

The invention discloses a molybdenum disulfide-carbon three-dimensional porous network composite and a preparation method thereof. The composite is prepared by compounding molybdenum disulfide nanosheets and carbon. The preparation method comprises the following steps: with NaCl as a dispersant and template, fully dissolving and mixing NaCl, a molybdenum source and a sulfur source and carrying out freeze drying and porphyrization so as to obtain a mixture; putting the mixture in a tubular furnace and carrying out calcining under the protection of argon so as to obtain a calcined product A; and washing the calcined product A and drying the washed calcined product A so as to obtain the molybdenum disulfide-carbon three-dimensional porous network composite. The invention has the following advantages: preparation process is safe and harmless, operation is simple, and yield is high; and the prepared molybdenum disulfide-carbon three-dimensional porous network composite has good reversible capacity and cycle stability as a cathode material of a lithium ion battery.

Owner:TIANJIN UNIV

Cobalt-molybdenum sulfide catalyst materials and methods for stable alcohol production from syngas

ActiveUS20100210741A1Inhibition formationReduce conversionChemical analysis using catalysisOrganic compound preparationSyngasSulfur

The present invention provides methods and compositions for the chemical conversion of syngas to alcohols. The invention includes catalyst compositions, methods of making the catalysts, and methods of using the catalysts including techniques to maintain catalyst stability. Certain embodiments teach compositions for catalyzing the conversion of syngas into products comprising at least one C1-C4 alcohol, such as ethanol. These compositions generally include cobalt, molybdenum, and sulfur, and avoid metal carbides both initially and during reactor operation.

Owner:ALBEMARLE CORP

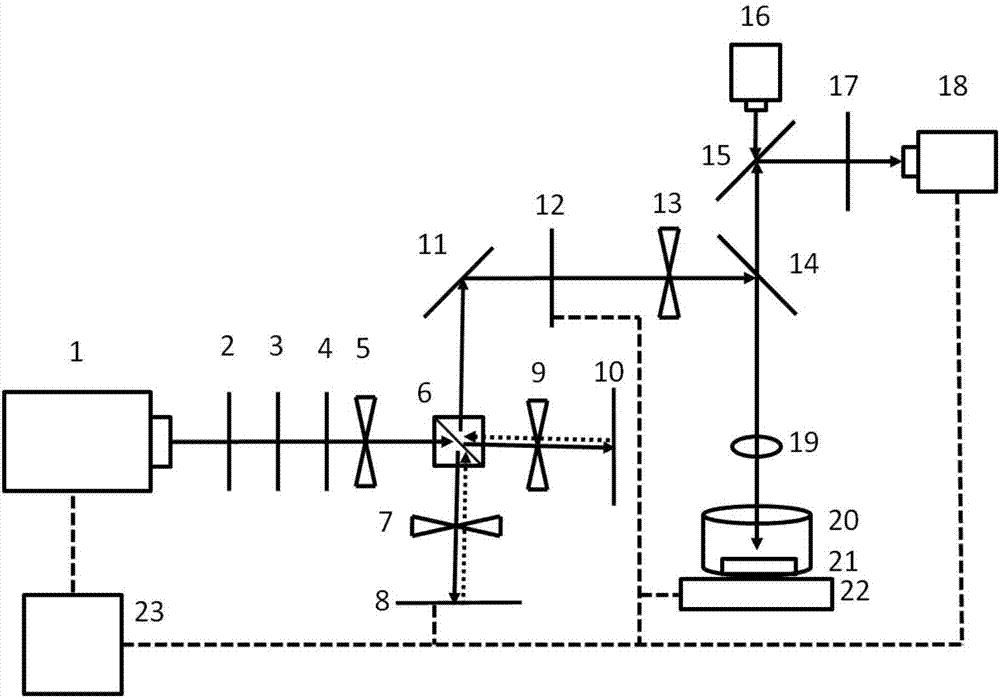

Method for preparing monolayer molybdenum disulfide quantum dots based on electronic dynamic regulation and control

ActiveCN106905966AHigh yieldPromote absorptionCatalyst activation/preparationNanotechnologyPhotoablationLaser scanning

The invention relates to a method for preparing monolayer molybdenum disulfide quantum dots based on electronic dynamic regulation and control, in particular to a method for obtaining the monolayer molybdenum disulfide quantum dots with uniform particle sizes by obtaining molybdenum disulfide suspension and then centrifugally separating and belongs to the field of femtosecond laser application. The method disclosed by the invention comprises the following steps: aiming at the characteristics of a molybdenum disulfide material, carrying out pulse shaping on traditional femtosecond laser monopulse by using a Michelson interferometer to form a pulse sequence; adjusting energy of the pulse sequence, delay among sub pulses, laser scanning speed and scanning intervals; ablating blocky molybdenum disulfide in water and further regulating and controlling local transient electronic dynamics in the interaction process of laser and the material to form multistage photoablation monolayer molybdenum, and obtaining the monolayer molybdenum disulfide quantum dots with the uniform particle sizes; carrying out laser-induced water dissociation to enhance light absorption and improve the yield of the molybdenum disulfide quantum dots. The method disclosed by the invention has the advantages of no need of special chemical environment or chemical reagent, greenness, no pollution, and simple and flexible operation.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Heavy oil hydrogenation protection catalyst, preparation and applications thereof

ActiveCN102989491AGood heavy oil protection performanceThe operation process is simple and convenientPhysical/chemical process catalystsRefining to eliminate hetero atomsDispersityPore distribution

The present invention relates to a heavy oil hydrogenation protection catalyst, preparation and applications thereof. According to the catalyst, Al2O3 or SiO2-containing Al2O3 is adopted as a carrier; a carrier pore volume is 0.98-1.15 ml / g; a specific surface area is 340-380 m<2> / g; pore distribution is as the follow: the amount of the pore volume of pores with a pore diameter of less than 5 nm is 10-15% of the amount of the total pore volume, the amount of the pore volume of pores with a pore diameter of 5-15 nm is 50-55% of the amount of the total pore volume, and the amount of the pore volume of pores with a pore diameter of more than 15 nm is 25-40% of the amount of the total pore volume; the catalyst is loaded with nickel-molybdenum-sulfur, nickel-tungsten-sulfur, molybdenum sulfide, tungsten sulfide, cobalt-molybdenum-sulfur, cobalt-tungsten-sulfur, nickel-cobalt-molybdenum-sulfur, nickel-cobalt-tungsten-sulfur or cobalt-molybdenum-nickel-tungsten, and the loaded material is combined with Ni2P to form the composite catalyst. The catalyst has characteristics of suitable pore size, high metal melting ability, small active ingredient scale, good dispersity and high catalyst activity, and is suitable for heavy oil and heavy oil protection catalysts.

Owner:PETROCHINA CO LTD

Cobalt-molybdenum sulfide catalyst materials and methods for ethanol production from syngas

The present invention provides methods and compositions for the chemical conversion of syngas to alcohols. The invention includes catalyst compositions, methods of making the catalyst compositions, and methods of using the catalyst compositions. Certain embodiments teach compositions for catalyzing the conversion of syngas into products comprising at least one C1-C4 alcohol, such as ethanol. These compositions generally include cobalt, molybdenum, and sulfur. Preferred catalyst compositions for converting syngas into alcohols include cobalt associated with sulfide in certain preferred stoichiometries as described and taught herein.

Owner:ALBEMARLE CORP

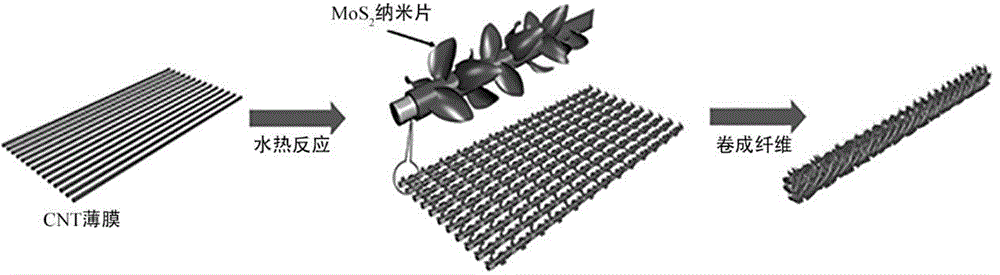

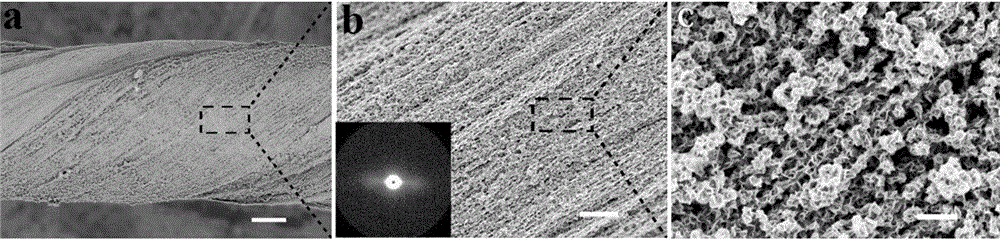

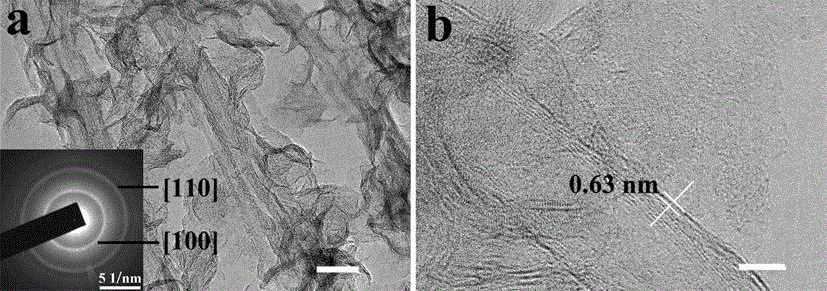

Aligned carbon nano tube/molybdenum disulfide composite fiber and preparation method and application thereof

InactiveCN105047927AImprove conductivityImprove electrochemical performanceHybrid capacitor electrodesCell electrodesFiberSpinning

The invention belongs to the technical field of an energy storage device, in particular relates to an aligned carbon nano tube / molybdenum disulfide composite fiber and a preparation method and application thereof. The preparation method comprises the following steps of: firstly, obtaining an aligned carbon nano tube thin film from a spinnable carbon nano tube (CNT) array by dry spinning; and secondly, immersing the CNT thin film in a precursor liquid in which (NH4)2MoS4 is taken as a precursor and polyvinyl pyrrolidone is taken as a surfactant for hydrothermal reaction to obtain a CNT / MoS2 composite thin film, and winding the thin film into the composite fiber. The aligned CNT / molybdenum disulfide composite fiber has excellent mechanical performance and electrochemical performance; a flexible fibrous supercapacitor and a lithium ion battery which are prepared from the composite fiber both show higher specific capacity than those of the traditional planar / fibrous device; and meanwhile, the two fibrous energy storage devices have favorable flexibility and stitchability, can be easily woven into fabrics, and show good application prospects in next-generation wearable and portable devices.

Owner:FUDAN UNIV

Preparation method of rare earth modified carbon fiber/ polypropylene composite material

InactiveCN1807496ASolve the problem of poor interface binding forceImprove mechanical propertiesAcetic acidPolypropylene composites

This invention is related to the method for making a rare-earth modification carbon fibre / polypropylene composite material. Firstly we use rare-earth modifier to do surface-modifying treatment to carbon fibre, then we compound the treated rare-earth modifier and polypropylene, add some molybdenum disulfide, blend mechanically, control the mass percent of carbon fibre to 10-20% of mixed powder, then we fill the mixed powder into non-corrodible steel mold to extrusion forming, sinter under high-temperature to produce rare-earth modification carbon fibre / polypropylene composite material. The components of rare-earth modifier contain rare earth compounds, ethanol, dimethylenedinitrilotetraacetic acid, ammonium chloride, nitric acid and carbamide. The process of this method is simple, low cost, no pollution to environment, the produced composite material has good mechanics and frictional behaviour.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of layered molybdenum sulfide nanosheet molecular separating membrane

InactiveCN103585896ALow costIncrease productionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisMaterials preparationFiltration

The invention discloses a preparation method of a layered molybdenum sulfide nanosheet molecule separating membrane. According to the preparation method, n-butyllithium is taken as an intercalation modular and enters a molybdenum sulfide crystal lattice after long-time stirring; water is added for decomposing n-butyllithium, so that the interlayer distances of a molybdenum sulfide sheet are enlarged; molybdenum sulfide is dispersed into monoatomic layer materials through ultrasonic treatment; redundant impurities are removed through dialysis, and a purified and clean molybdenum sulfide water solution is obtained; the obtained molybdenum sulfide water solution is treated with a vacuum filtration method, and the layered molybdenum sulfide nanosheet molecule separating membrane is obtained; and the thickness of the membrane is adjusted by adjusting the volume of the used molybdenum sulfide water solution. A molecule-selective separation membrane is obtained with a method of stacking the monoatomic layer materials to form the membrane; and the material preparation method is simple, the cost is low, and the obtained membrane has size selective separation performance on different molecules.

Owner:ZHEJIANG UNIV

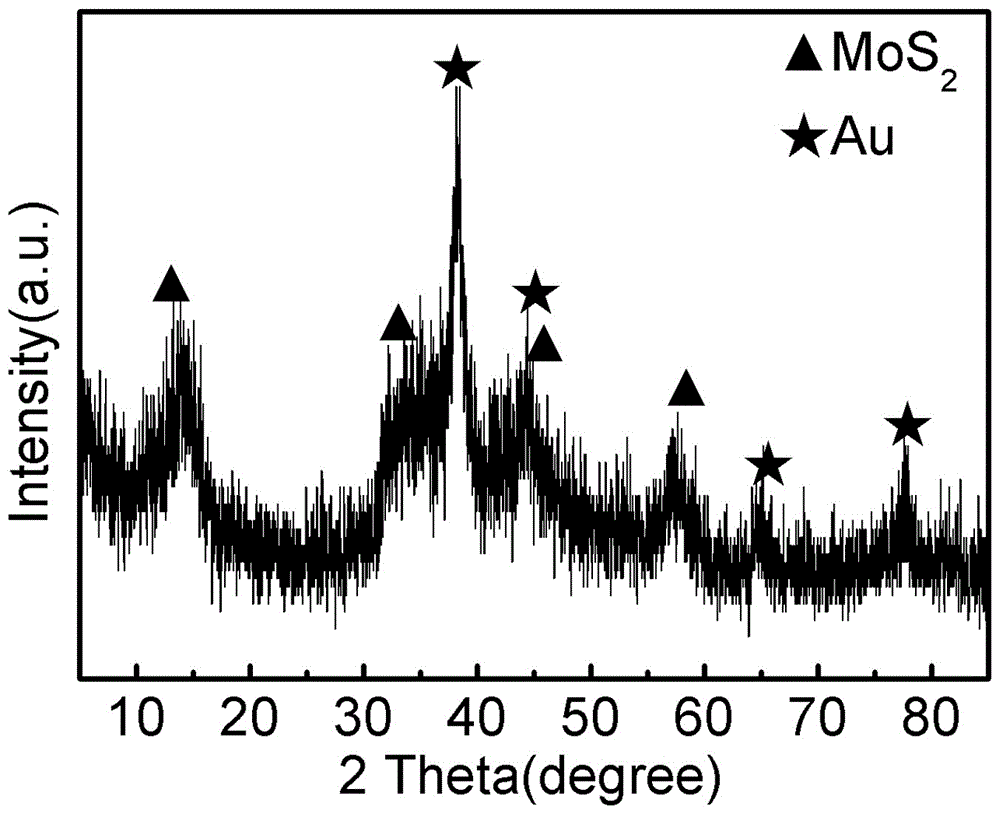

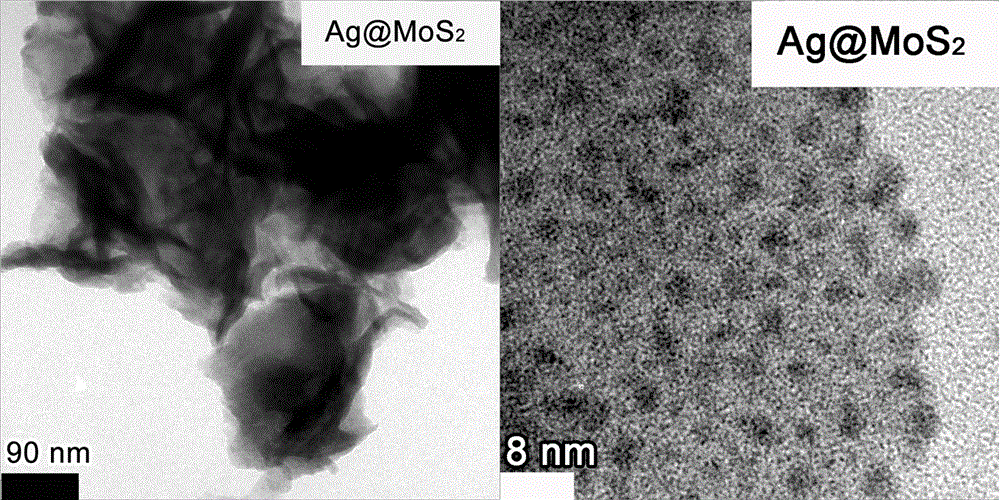

Supported two-dimensional layered molybdenum sulfide composite material and preparation method and application thereof

InactiveCN105664976AAvoid reunionHigh catalytic efficiencyPhysical/chemical process catalystsOrganic compound preparationChemical compoundNitrophenol

The invention belongs to a supported two-dimensional layered molybdenum sulfide composite material and discloses a noble metal (Ag, Au)-supported composite nano-catalytic material and its application in catalytic reduction of p-nitrophenol. The two-step synthetic technology is adopted in the invention. Firstly, molybdenum sulfide nanosheet with a porous ultrathin structure is synthesized by a hydrothermal method; then, by an ultraviolet reduction technology, noble metal nanoparticles are supported onto the surface of the two-dimensional layered compound molybdenum sulfide with a sandwich structure, and agglomeration phenomenon during the noble metal preparation process can be effectively avoided by the combination of nano confinement growth effects; and finally, noble metal nanoparticles with uniform size distribution are obtained. According to the supported catalyst system, the metal catalytic active center and a carrier together form a catalyst due to localized surface plasma resonance effect of noble metal active ingredients and synergistic effect between noble metal active ingredients and the carrier.

Owner:CHINA THREE GORGES UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com