Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Resolve recovery rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting vanadium from vanadium-containing steel slag by using highly-alkaline sodium hydroxide medium

ActiveCN102094123AReduce productionEmission reductionProcess efficiency improvementSlagEconomic benefits

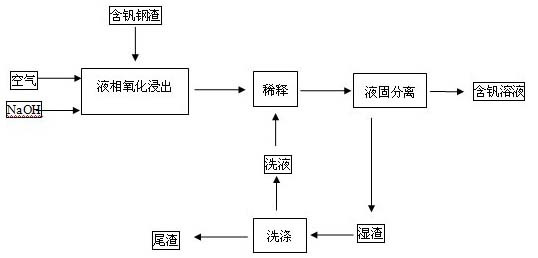

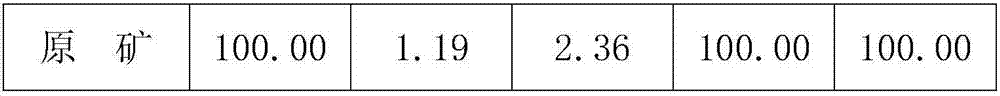

The invention relates to a method for extracting vanadium from vanadium-containing steel slag by using a highly-alkaline sodium hydroxide medium, belonging to the technical field of metallurgy. The technical scheme comprises the following steps: adding steel slag, water and NaOH into a reactor together, wherein the mass concentration of the NaOH solution is 65-90%; decomposing and leaching under atmospheric pressure, and diluting the obtained slurry with a diluter to obtain a slurry mixture; and separating the slurry mixture by filtering at constant temperature, and washing the slag with a washing solution to obtain tailings and a vanadium-containing water solution. The method provided by the invention can be implemented under atmospheric pressure at low temperature (greatly lower than the roasting temperature in the traditional pyrogenic process), and is easy to operate and safe; and the extraction rate of vanadium is greatly higher than that of the existing vanadium recovery technique based on the pyrogenic process and wet process, the one-time recovery rate of vanadium is 85-90%, and the total content of vanadium in the tailings is 0.3-0.6 wt%. The invention solves the problem that vanadium in the vanadium-containing steel slag can not be easily recovered, and has the advantages of high recovery rate of vanadium, low production cost, favorable economic benefit and environmental benefit, and the like.

Owner:承德承钢柱宇钒钛有限公司

Beneficiation method of micro-fine particle dissemination type lead-zinc sulphide ore containing marmatite and pyrrhotite

ActiveCN107252731ASolve efficiency problemsSolve the accuracy problemFlotationWet separationActivated carbonSeparation technology

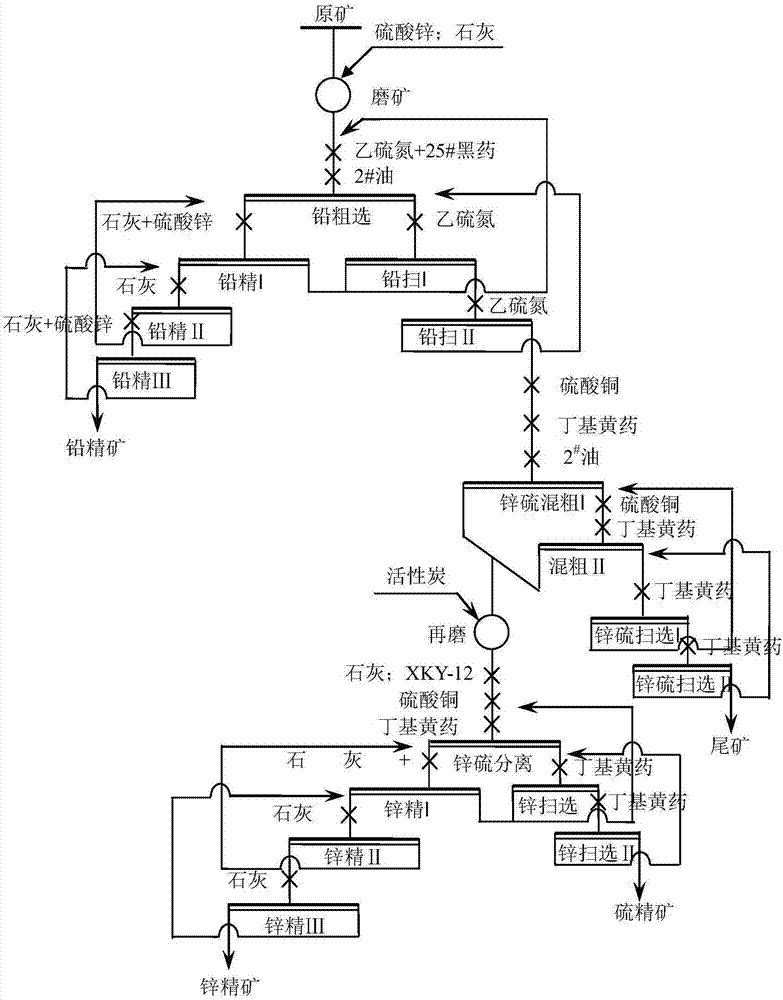

The invention discloses a beneficiation method of micro-fine particle dissemination type lead-zinc sulphide ore containing marmatite and pyrrhotite. For the complicated nature of micro-fine particle dissemination type lead-zinc sulphide ore containing marmatite and pyrrhotite, the zinc-sulphide two-stage bulk flotation-zinc-sulphide mixed rough concentrate regrinding and separation technology is adopted, easy-floating zinc-sulphide minerals are preferentially floated during zinc-sulphide mixed first-stage flotation, difficult-floating marmatite flotation is reinforced in the second stage, two-stage mixed rough concentrate is reground so as to promote sufficient monomer separation of zinc-sulphide intergrowth minerals, activated carbon is added in the regrinding process to enhance mineral surface reagent removal, during separation floatation, XKY-12 is added to form deep restraining of pyrrhotite, and efficient separation of marmatite and pyrrhotite is enhanced; according to the method, the good ore dressing recovery rate is ensured, and qualified and high-quality zinc concentrate is obtained; meanwhile, the efficient pyrrhotite inhibitor XKY-12 is adopted, and the problems that the marmatite and pyrrhotite separation efficiency is low and the separation precision is poor are solved.

Owner:WESTERN MINING CO LTD +3

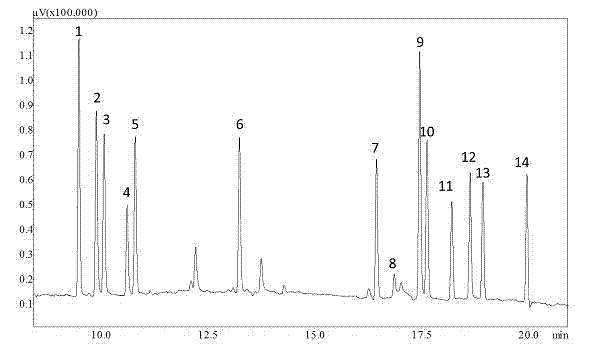

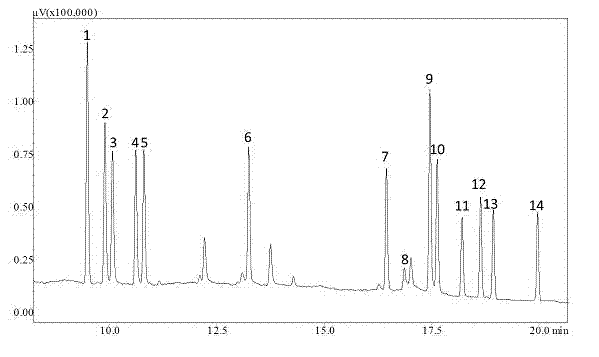

Sample pretreatment method for detection of organochlorine pesticide residue in food

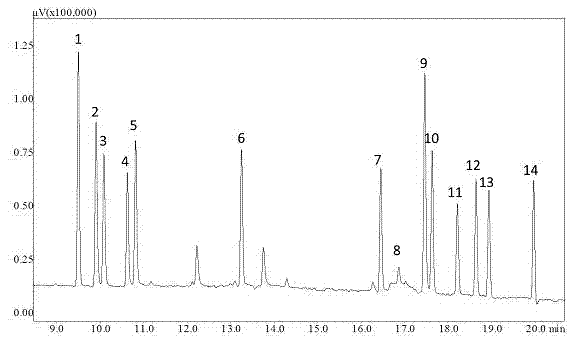

The invention discloses a sample pretreatment method for detection of organochlorine pesticide residue in food and is characterized by comprising the following steps: water is added to a food sample, sample solution is swirled, and then inorganic salt and hydrophilic organic solvent are added to the sample solution, the sample solution is swirled and shaken uniformly, the sample solution undergoes phase splitting after centrifugation at room temperature, the upper-phase liquid is purified through dispersion solid-phase extraction method, the extraction temperature is 20-30 DEG C, and finally the upper-phase liquid is detected by gas chromatography; and the mass percent of the inorganic salt accounts for 5%-35% of the total mass of the system, the mass percent of the hydrophilic organic solvent accounts for 10%-50% of the total mass of the system, and water is of the residual amount, and the total mass of the system is the mass sum of water contained in the sample, the added water, the inorganic salt and the hydrophilic organic solvent. According to the sample pretreatment method, a dual-water-phase system consisting of the hydrophilic organic solvent, the organic salt and water is utilized, the partition coefficient is increased by means of changing the types and concentrations of the organic solvent and the inorganic salt, and the organochlorine pesticide residue in the sample can be directly extracted at room temperature.

Owner:YANTAI UNIV

Smelting method for stably increasing content of boron in boron-containing steel

The invention relates to a smelting method for stably increasing the content of boron in boron-containing steel. The smelting method is characterized in that high-carbon ferromanganese, high-carbon ferrochromium and iron-core aluminum are subjected to the deoxidation alloying in the steel tapping process of a converter, and a whole-course bottom argon blowing and wash heat technology is adopted for reducing oxygen content and nitrogen content in the steel; after steel tapping is completed, molten steel is lifted to an argon station, and the molten steel is converted to an LF (Ladle Furnace) after ferroaluminium is added for adjusting the activity of oxygen in the steel to a required control range; and submerged arc operation, soft argon blowing control, a deep deoxidation technology and a titanium alloy technology are adopted for refining in the LF, then boron alloying is carried out, and later the long-time soft argon blowing is carried out, thus the recovery rate of boron in the steel reaches 82%-86%, the problems of low and instable recovery rate of boron are solved, the fluctuation quantity between the furnaces is less than 0.0005%, the ideal control level is achieved, the dependence of boron alloying on vacuum refining is eliminated, and the requirement of subsequent process for the quality of the boron-containing steel is ensured.

Owner:WUKUN STEEL

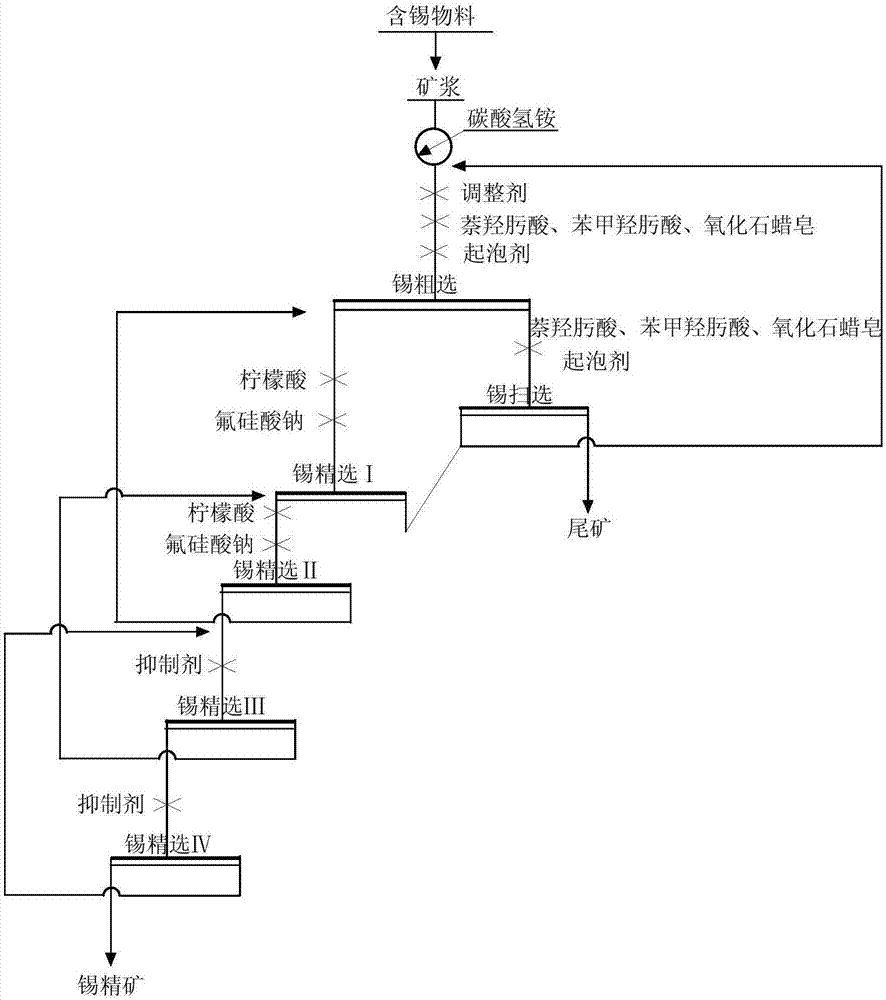

Micro-fine particle cassiterite flotation method

The invention relates to a micro-fine particle cassiterite flotation method. The micro-fine particle cassiterite flotation method comprises the steps that tin-containing materials are prepared into pulp, and ammonium bicarbonate is added in the pulp; then an adjusting agent, collecting agents and a foaming agent are added, wherein the collecting agents comprise naphthalene hydroximic acid, benzohydroxamic acid and oxidized paraffin wax soap; and the pulp is subjected to roughing, and then citric acid and sodium fluosilicate are added into tin rough concentrate for choiceness to obtain cassiterite concentrate. The problems that the micro-fine particle cassiterite flotation recovery rate is low, the concentrate grade is unsatisfactory, and the impurity content is high are solved, and the tin concentrate with the Sn content being larger than or equal to 35% and the recovery rate being larger than or equal to 90% can be obtained; and compared with the prior art, the thin concentrate recovery rate is increased by 15-20%, and the tin concentrate grade is improved by 10-15%. The low-carbon, environment-friendly, economical and efficient method for micro-fine particle cassiterite recovery through flotation is simple in technique, has the advantages that the material adaptability is high, using is safe and stable, the reagent dosage is few, and pollution is little, and has good application prospects.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

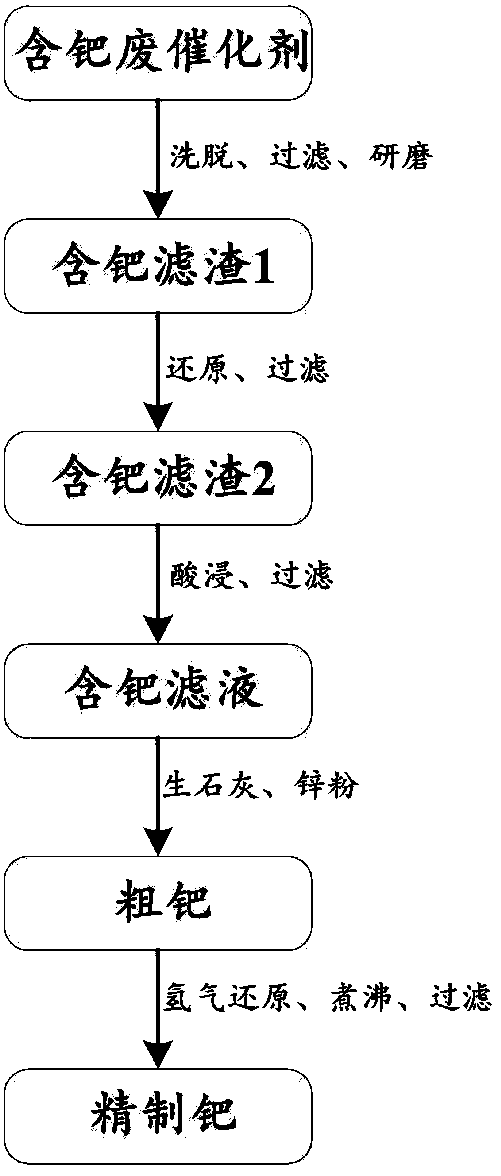

Method for recycling palladium from palladium-contained waste catalyst

ActiveCN108642300AHigh recovery rateSolve the problem of energy consumptionProcess efficiency improvementHigh energyPalladium oxide

The invention discloses a method for recycling palladium from a palladium-contained waste catalyst. The method comprises following steps that firstly, waste pre-treatment, wherein composite liquid isadopted for eluting the palladium-contained waste catalyst, filtering is carried out, and palladium-contained filter residue is obtained; secondly, palladium formation through palladium oxide reduction, wherein a reducing agent and the palladium-contained filter residue are used for having a reaction, the palladium oxide in the waste residue is reduced into elementary substance palladium; thirdly,acid soluble operation to obtain palladium ions, wherein organic acid haves a reaction with the elementary substance palladium, and an acid solution system existing in a palladium ion state is obtained; fourthly, replacement to obtain palladium, wherein a metal replacement method is adopted to carry out replacement on the palladium ions in the acid solution system, and sponge palladium is obtained; fifthly, palladium refining, wherein hydrogen is further used for reducing the metal palladium, and high-purity metal palladium is obtained. The organic composite liquid is used for eluting the palladium-contained waste catalyst, the problems of high energy consumption and environment pollution in the prior art are solved, the process flow is short, and the problems that in the current palladium recycling technology, energy consumption is high, and the recycling rate is low are solved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

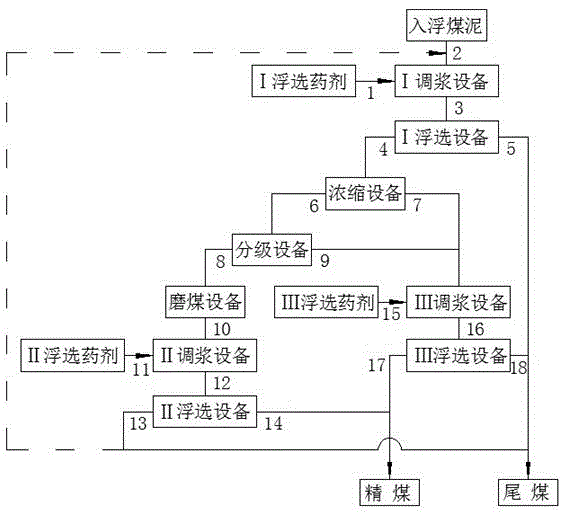

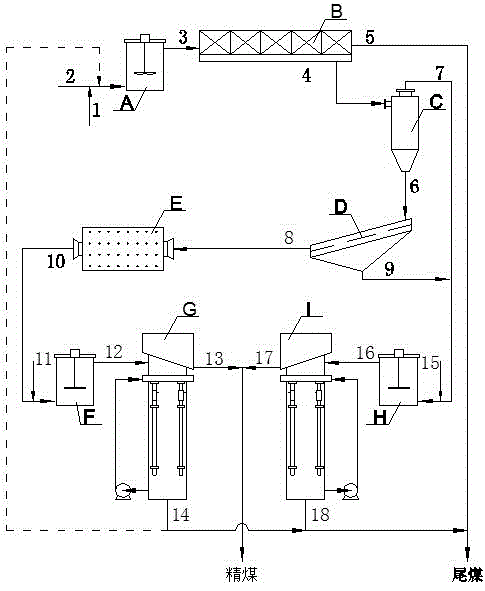

Flotation process for difficultly selected coal slime with high middle density substance content

The invention discloses a flotation process for difficultly selected coal slime with high middle density substance content. The flotation process consists of five parts, namely preparing input floating coal slime into slurry, performing rough selection on the coal slime subjected to slurry preparation, grading cleaned coal subjected to rough selection, grinding and performing rough selection again on the coarse cleaned coal subjected to rough selection after the coarse cleaned coal is graded and performing fine selection on the fine cleaned coal subjected to rough selection. Flotation equipment is adopted and matched with corresponding concentration grading equipment and coal grinding equipment, so that a process of performing rough selection by the flotation equipment, grading the cleaned coal subjected to rough selection, grinding the coarse cleaned coal subjected to rough selection and independently performing fine selection on the fine cleaned coal subjected to rough selection is formed. Most high-ash gangue minerals are removed from the input floating coal slime after primary rough selection, so that the adverse influence of the high-ash fine slit on the subsequent coal slime grinding process is reduced; and due to the separation of coal and gangue integrated bodies in the coarse cleaned coal subjected to rough selection and further flotation recycling of the coal slime subjected to separation, the contradiction between the quality and the recycling rate of a difficultly selected coal slime separation product is avoided. The flotation process is simple, small in investment, low in power consumption and low in running cost. Compared with the conventional separation process, the flotation process is high in separation efficiency, high in combustible recycling rate and remarkable in economical benefit.

Owner:CHINA UNIV OF MINING & TECH

Separation method for roughing slime through teetered bed separator (TBS) and concentrating coarse slime difficult to separate through slime dense medium cyclone

InactiveCN105080701ASolve the accuracy problemSolve the shortcomings of poor sorting effectFlotationWet separationCycloneWater velocity

The invention discloses a separation method for roughing slime through a teetered bed separator (TBS) and concentrating coarse slime difficult to separate through a slime dense medium cyclone. Slime of a slime water system is pumped to a hydraulic classification cyclone to be classified, and overflows into flotation equipment to be separated; and underflow enters the TBS, high-ash tailings and coarse clean coal with a high ash content are obtained at a high ascending water velocity under a high bed density, the coarse clean coal enters the slime dense medium cyclone to be concentrated, and finally clean coal and middling products are obtained. According to the method, the advantages of the TBS and the advantages of the slime dense medium cyclone are combined, the advantages are enhanced, and disadvantages are avoided; the coarse slime difficult to separate is roughed through the TBS to obtain the high-ash tailings and the coarse clean coal; by making use of the characteristic that the separation precision of the slime dense medium cyclone is high, the coarse clean coal is concentrated, and the high-quality clean coal meeting the requirements of a low ash content and a high recovery rate is obtained. Not only are the common problems of 'coarse coal running', 'ash carrying' and the like in coal preparation plants solved, but also the technological problems of high-precision separation of the high-ash coarse slime difficult to separate are solved.

Owner:CHINA UNIV OF MINING & TECH

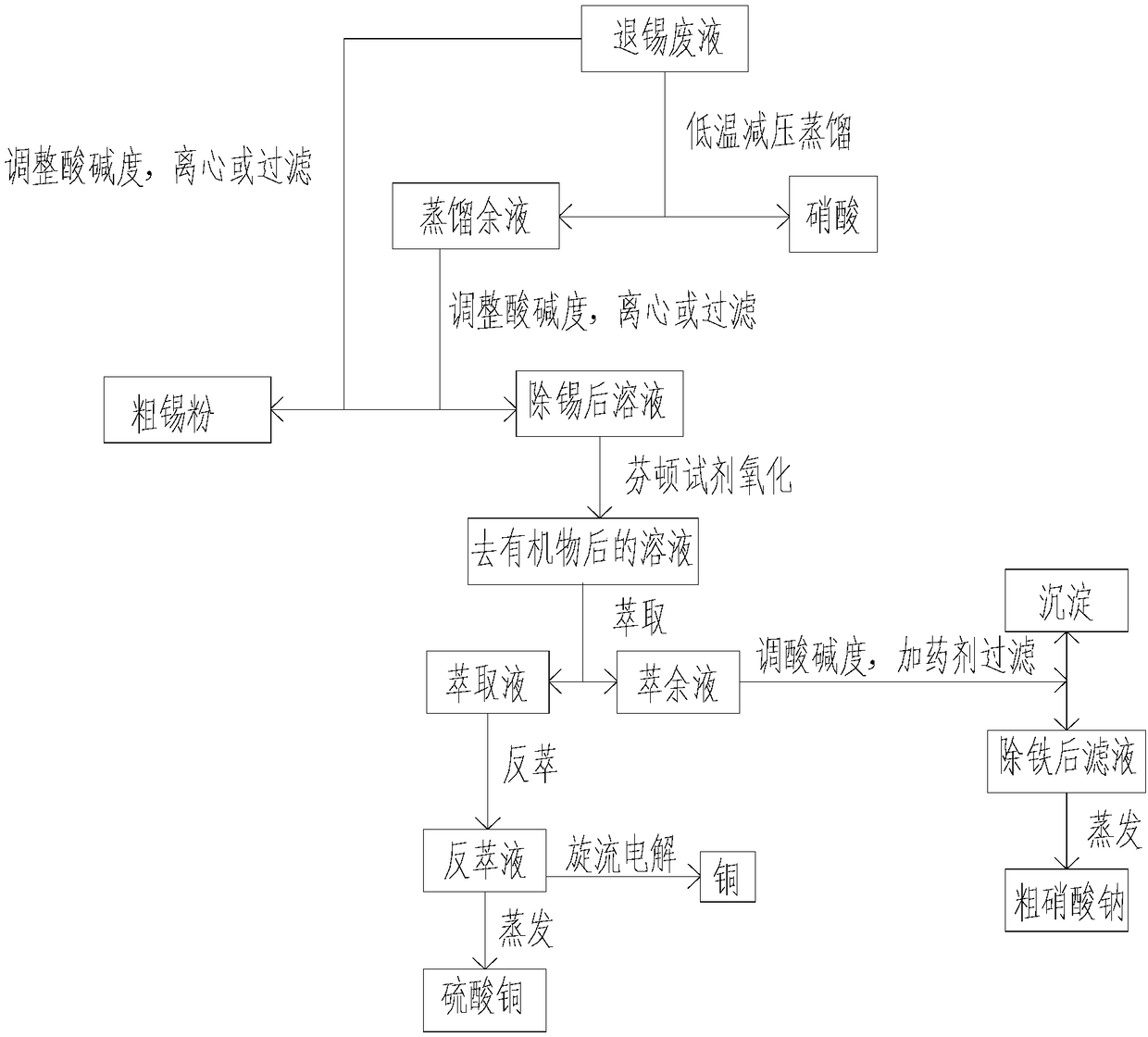

Comprehensive recovery method for tin-stripping waste liquid

ActiveCN108070720AResolve recovery rateAddress process complexityProcess efficiency improvementRecovery methodElectrolysis

The invention discloses a comprehensive recovery method for tin-stripping waste liquid. The method includes the following steps that (1) the tin-stripping waste liquid is subjected to reduced pressuredistillation so that nitric acid in the tin-stripping waste liquid can be recovered, a still residue is obtained, and tin powder is recovered from the still residue; or the pH value of the tin-stripping waste liquid is directly adjusted to recover the tin powder; (2) organic matter in a tin-removed solution is removed by means of oxidation with a Fenton reagent; (3) extraction is performed, and electrolysis or evaporation is conducted to extract copper; (4) iron and lead in the residue are removed; and (5) sodium nitrate is recovered through evaporation. Compared with the prior art, the method mainly solves the problems that the comprehensive recovery rate of the substances like tin and copper in the recovery process of the tin-stripping waste liquid is low, the technology is complicated,secondary pollution is serious, and all the components in the tin-stripping waste liquid cannot be fully recovered. By adoption of the method, various resources like the nitric acid, tin, copper andiron in the tin-stripping waste liquid can be effectively recovered step by step, the recovery rate is high, the technology is simple, secondary pollution is avoided, aero release in tin-stripping waste liquid treatment is realized, and the practical value and comprehensive benefits are good.

Owner:HOHAI UNIV

High-tellurium copper slag treatment method

ActiveCN107201448AHigh recovery rateAchieve the purpose of separationElectrolysis componentsProcess efficiency improvementBismuthMaterials science

The invention discloses a high-tellurium copper slag treatment method. The high-tellurium copper slag treatment method comprises the following steps of: (1) ball-milling; (2) acidifying; (3) low-acid leaching; (4) bismuth precipitating; (5) copper precipitating; (6) high-acid pickling; (7) gold, sliver and lead recycling; (8) solution replacing; (9) antimonium precipitating; (10) tellurium leaching; (11) purifying; (12) neutralizing and tellurium precipitating; and (13) electrolyzing and tellurium extracting. The method disclosed by the invention can be adopted to clean and efficiently treat copper slag, comprehensively recycles noble metals such as gold, silver, tellurium, antimonium, bismuth and copper, and radically solves the problems such as a lagged process, poor comprehensive utilization, a low metal recovery rate and severe environmental pollution of the conventional method.

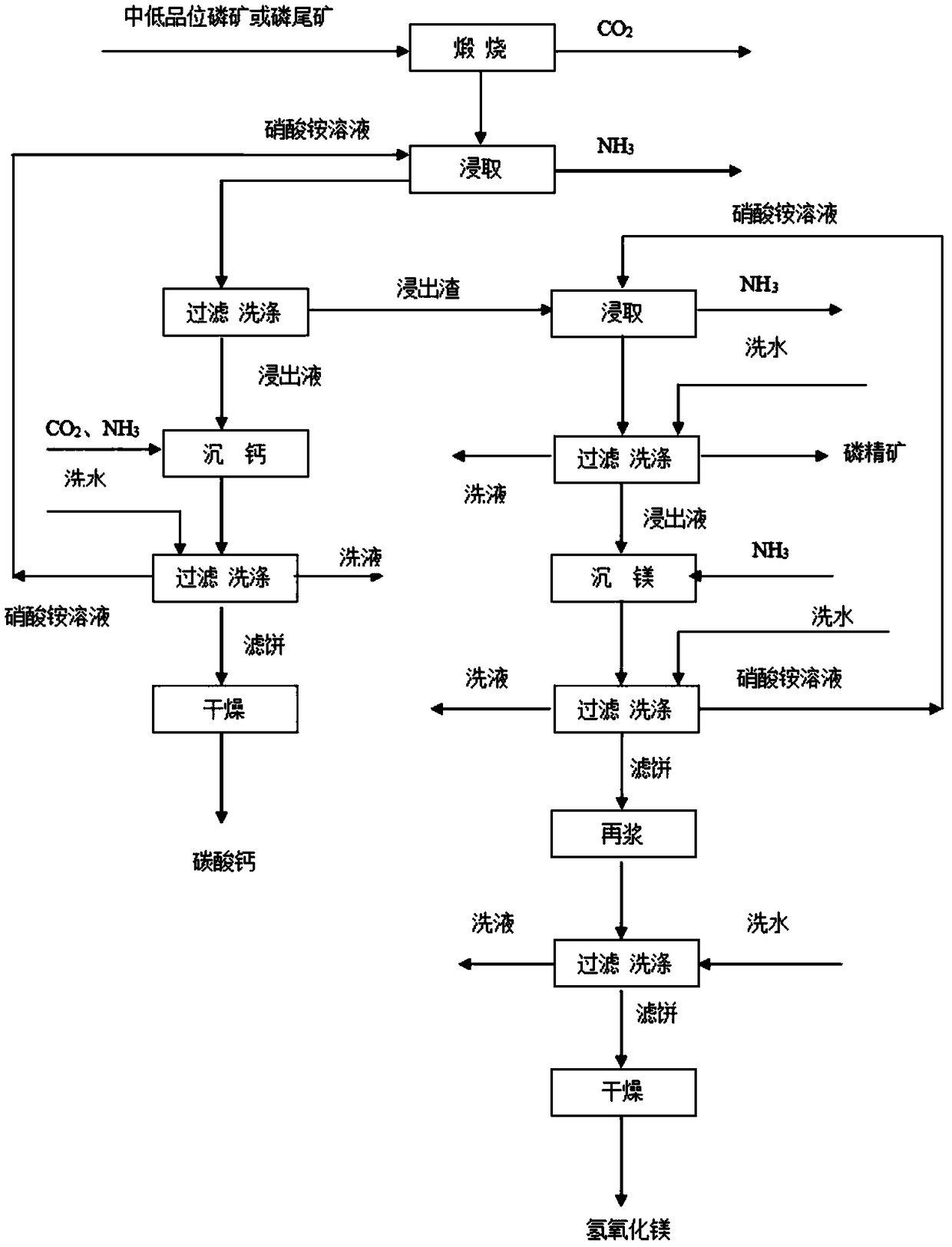

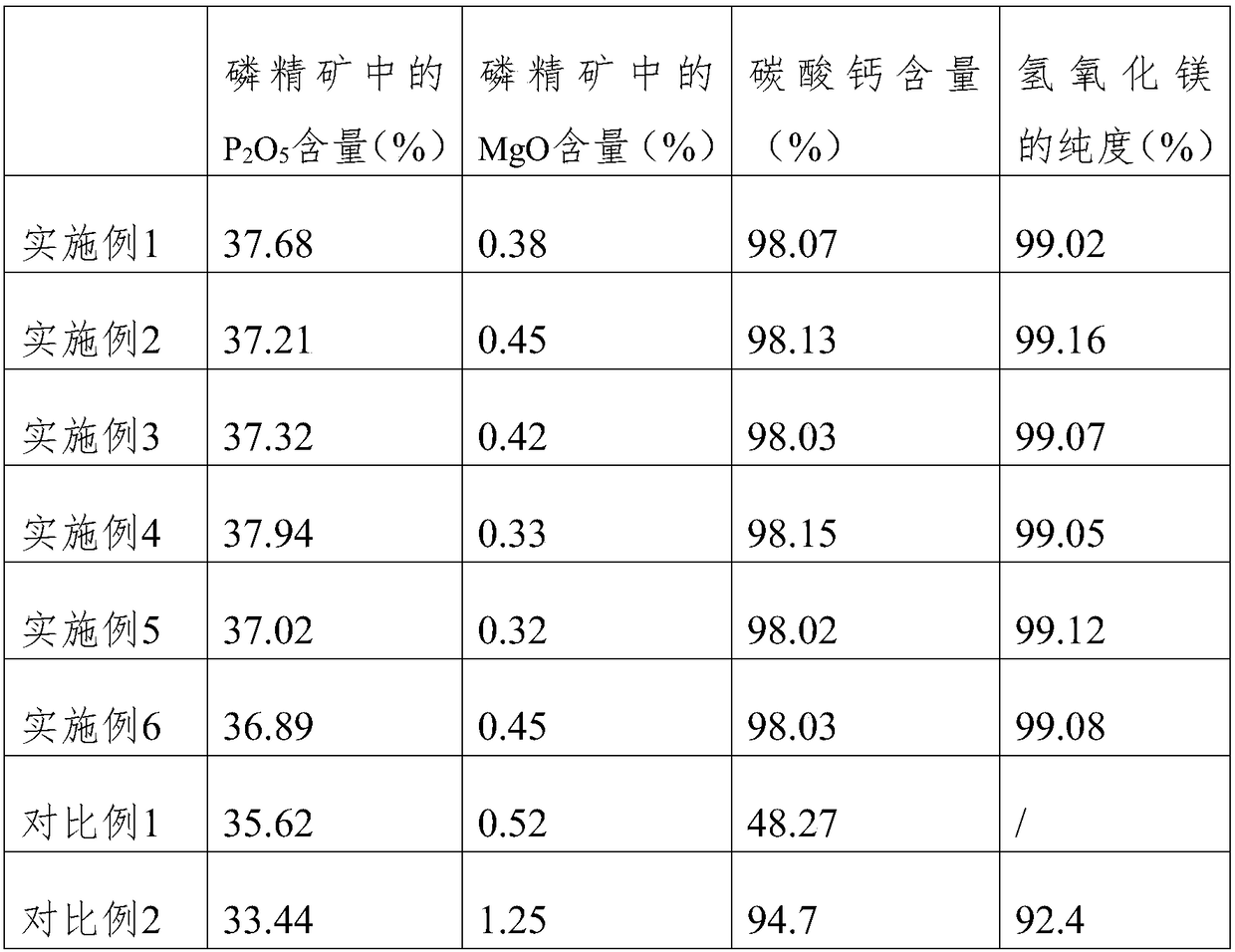

Technology for enriching phosphate concentrate and recycling calcium carbonate and magnesium hydroxide from middle-low grade phosphate rock or phosphate tailing simultaneously

ActiveCN109264686AGood separation effectSolve the low recovery rate of phosphorusCalcium/strontium/barium carbonatesRaw phosphate material treatmentMagnesium carbonate hydroxideChemistry

The invention relates to the technical field of inorganic chemical industry and specifically relates to a technology for enriching phosphate concentrate and recycling calcium carbonate and magnesium hydroxide from middle-low grade phosphate rock or phosphate tailing simultaneously. According to the technology disclosed by the invention, middle-low grade phosphate rock or phosphate tailing is utilized as a main raw material to enrich phosphate concentrate and recycle calcium carbonate and magnesium hydroxide simultaneously, so that the problems that an existing twice reverse-flotation phosphateconcentrate enriching technology for phosphate is low in phosphorus recovery rate and discharges a lot of tailing to bring environment-friendly risk. Phosphate or phosphate tailing is roasted at thetemperature of 700 to 1200 DEG C, so that calcite and dolomite are decomposed, and contained fluorapatite (Ca5F(PO4)3) is not decomposed; by means of twice ammonium nitrate leaching, phosphate concentrate, high-quality light calcium carbonate and high-purity magnesium hydroxide can be finally obtained; calcium and magnesium can be effectively recycled, and a good economic benefit is achieved; meanwhile, the method can prevent new tailing from generating, and the problems of a lot of land occupancy, environment pollution and the like caused by a lot of phosphate tailing accumulation are effectively solved.

Owner:贵州盛源新材料股份有限公司

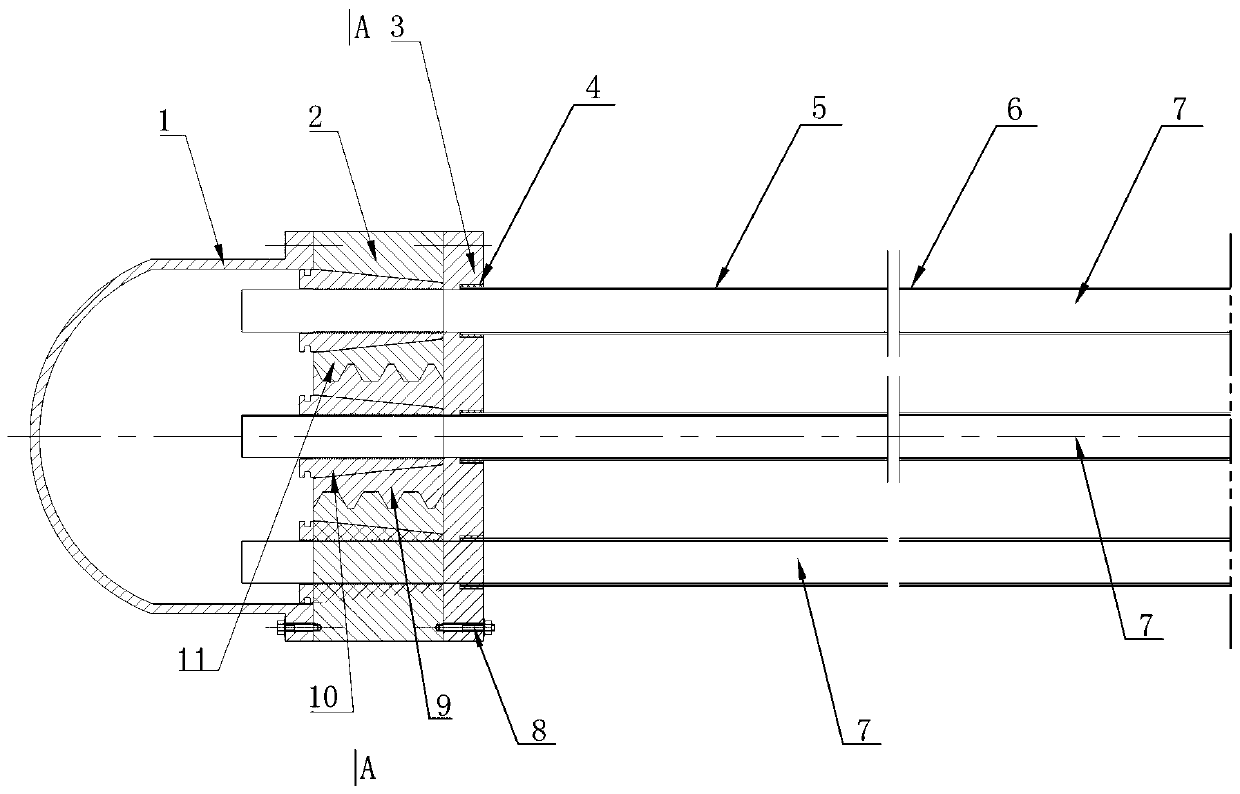

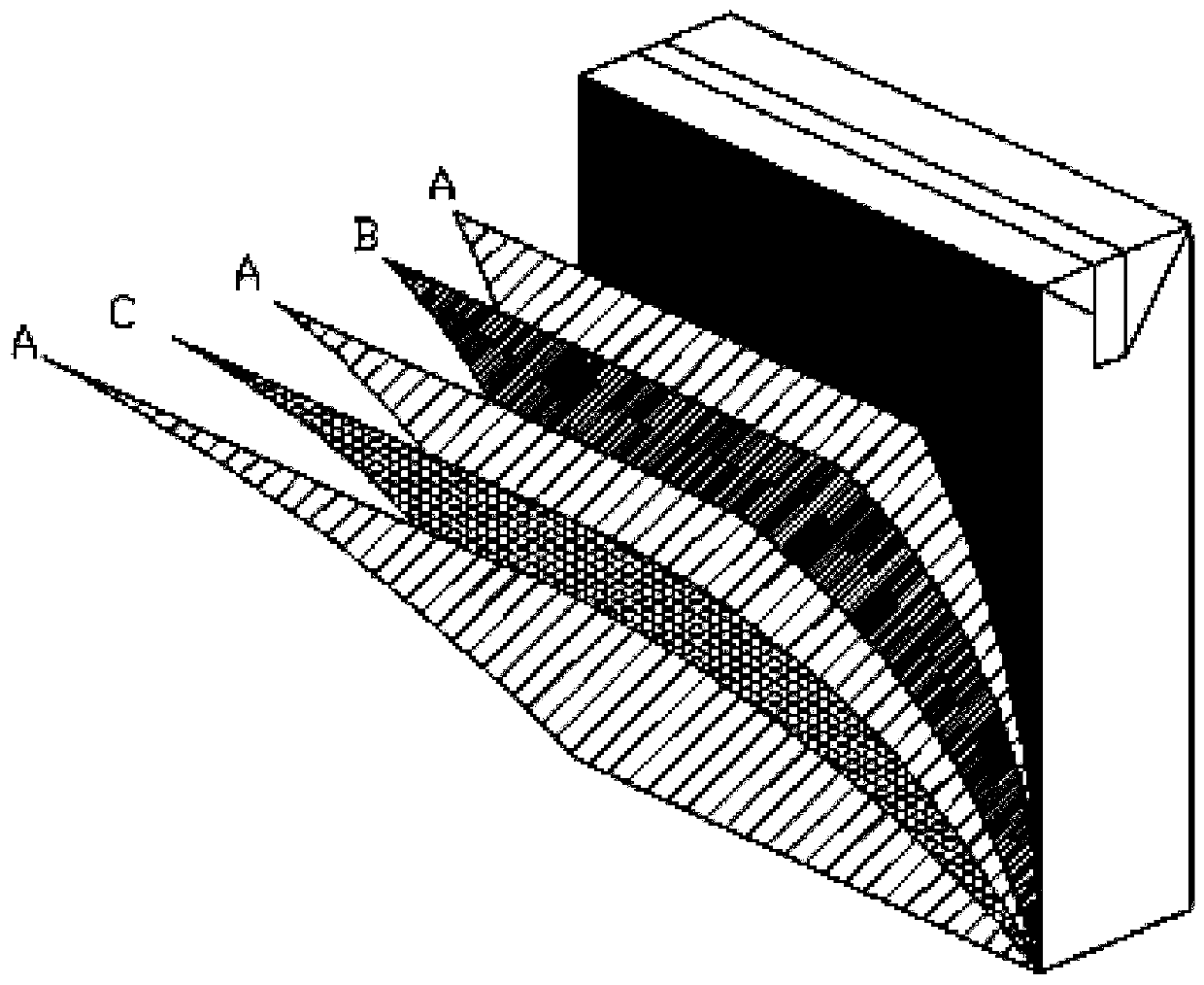

Detachable prestress anchor cable

The invention discloses a detachable prestress anchor cable. The detachable prestress anchor cable is characterized in that a bearing plate is provided with a center through hole and peripheral conical holes. The center through hole is connected with the adjacent peripheral conical holes through cavities, sliding blocks are arranged in the cavities, clamping sheets are sleeved with the peripheralconical holes, a screw pipe and a clamping sheet are arranged in the center through hole in a sleeved mode, one side of the sliding block is provided with a thread groove, the other side of the sliding block is provided with a circular arc groove, the sliding block is arranged in the cavity, the thread groove on one side is matched with screw pipe, the circular arc groove on the other side is matched with anchor cable clamping sheets, a steel strand in the center through hole is rotated to drive the screw pipe to rotate and retreat from the bearing plate to enter a sealing cap inner cavity, the vacated space enables the sliding blocks to be converged towards the center of the bearing plate, constraint of the anchor cable clamping sheets to the steel strand is released for unlocking, and the steel strand is pulled out for recycling. Compared with the prior art, the structure is simple, anchorage force is large, the problem that anchor cable steel strand wires are damaged after being stressed and low in recycling rate is effectively solved, and the engineering cost is further reduced.

Owner:SHANGHAI ZHIPING FOUNDATION ENG CO LTD

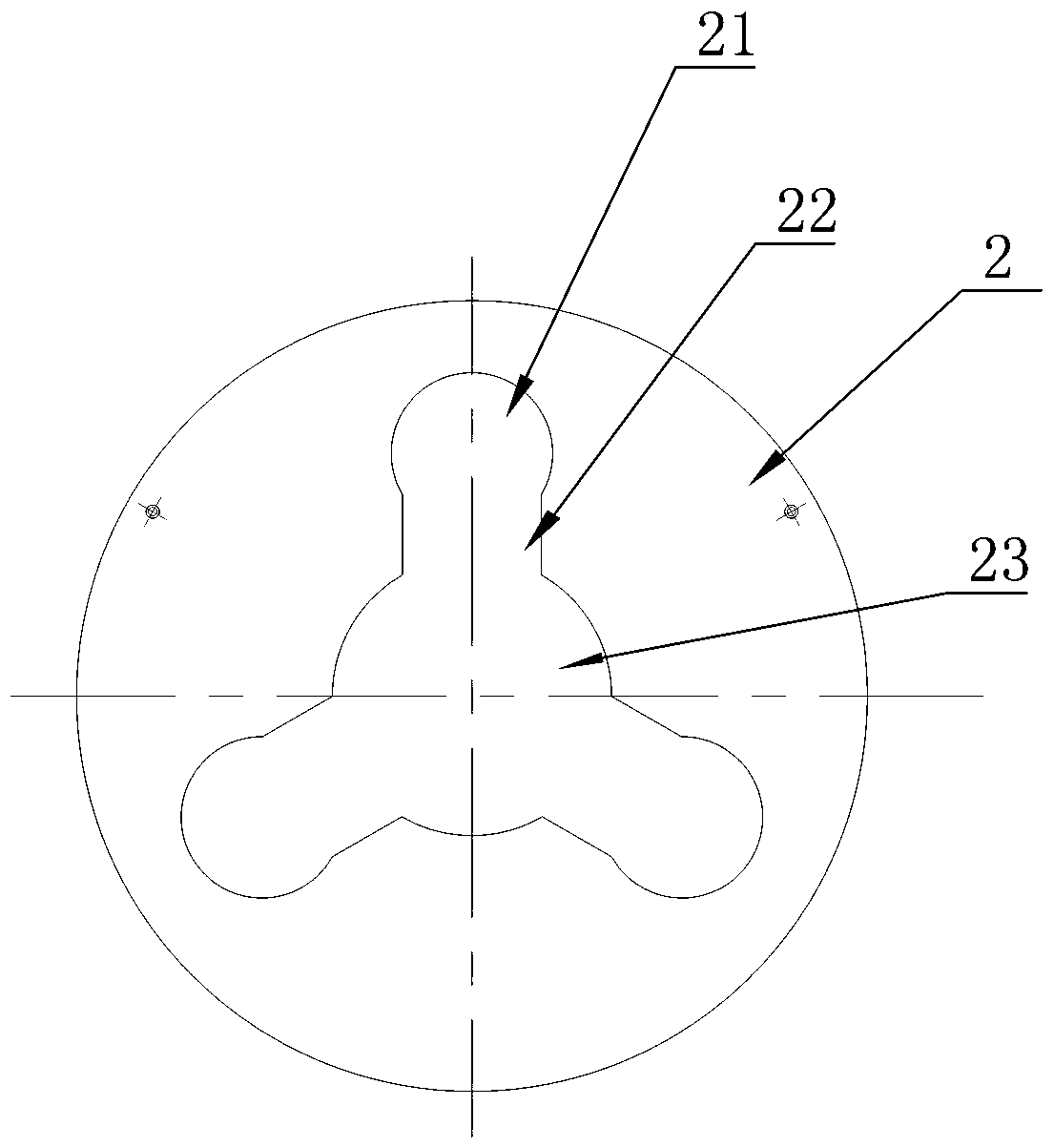

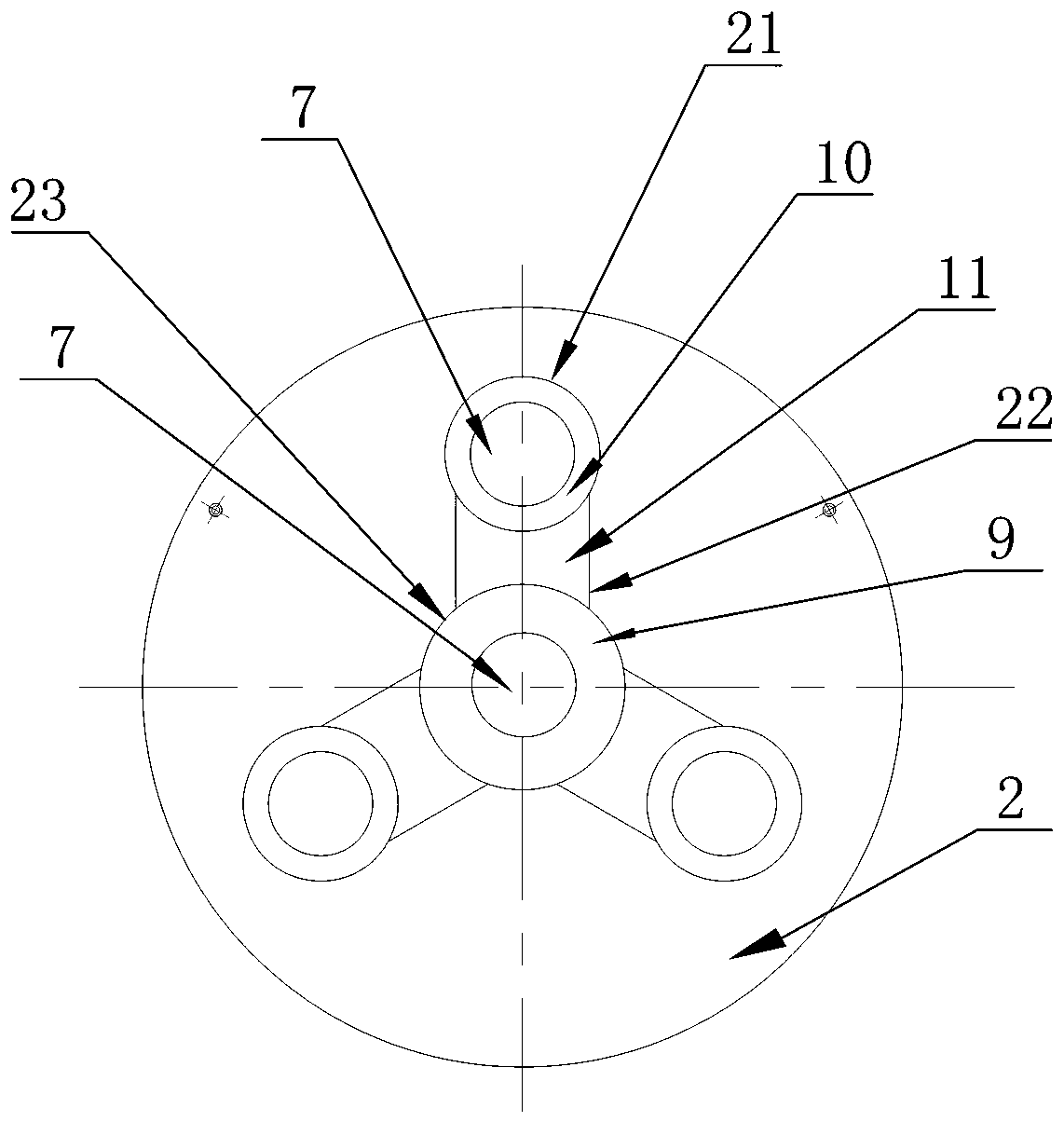

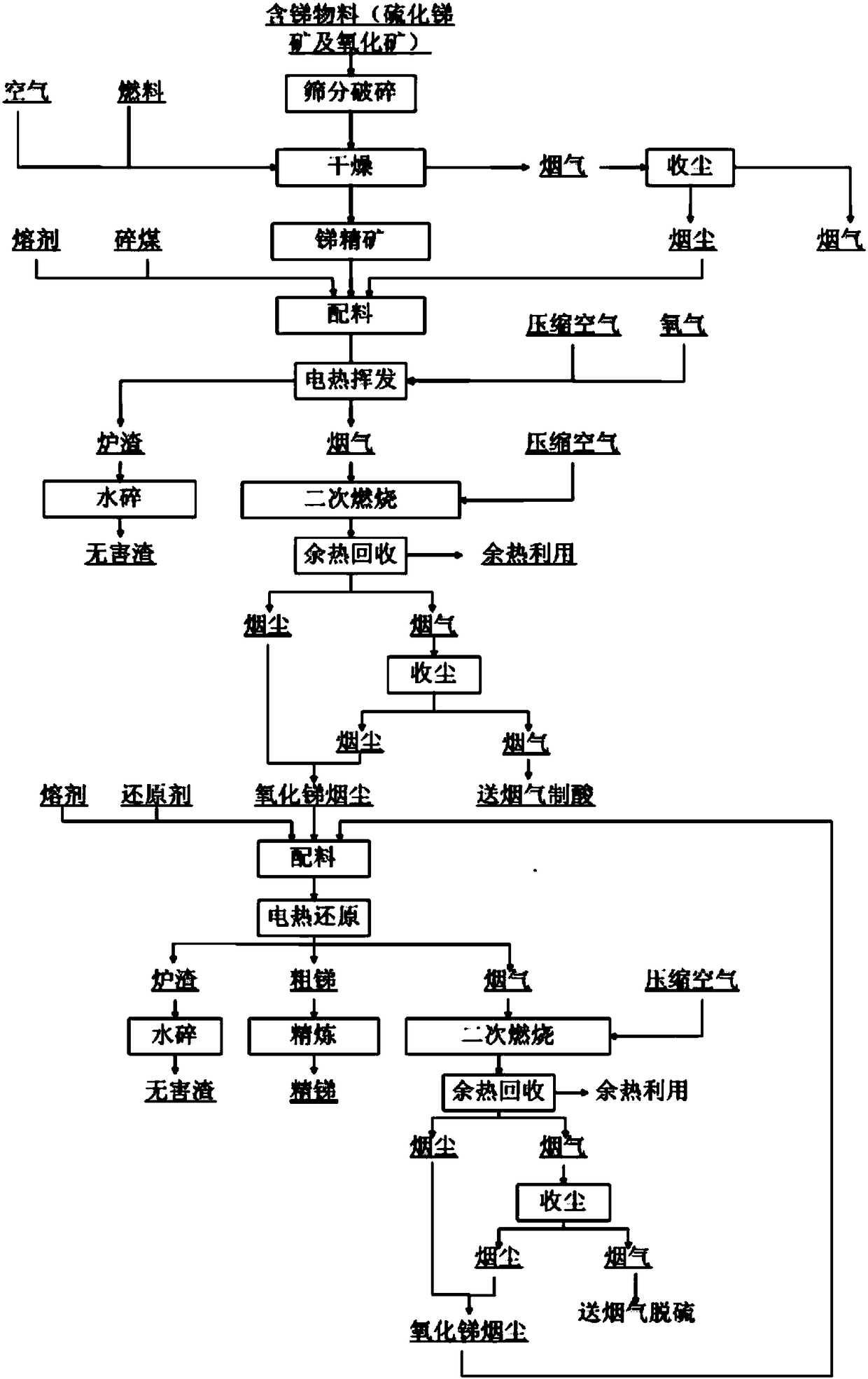

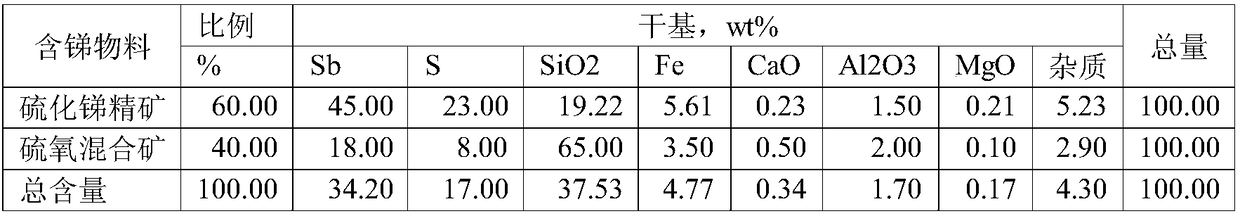

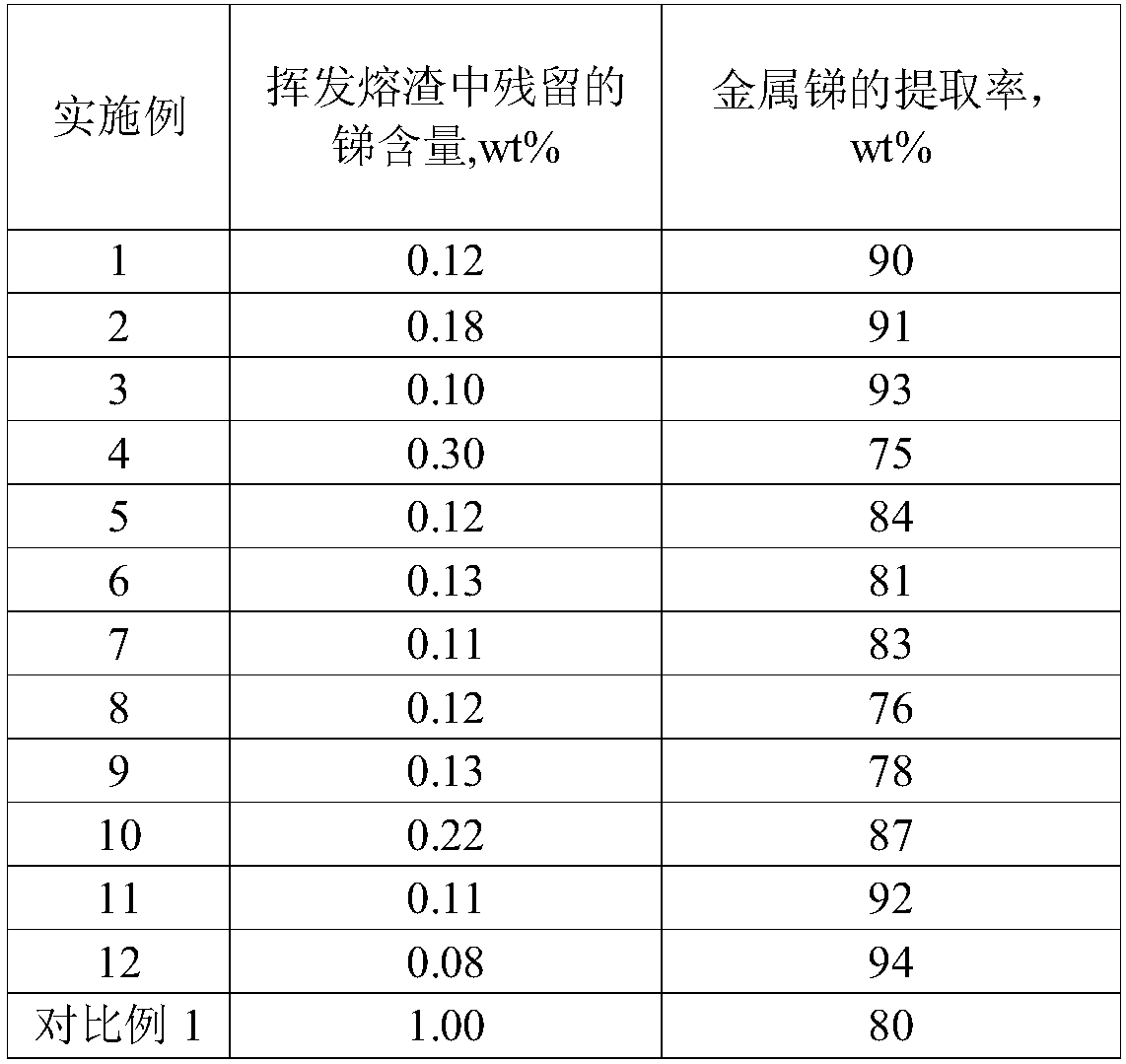

Method for extracting antimony metal

ActiveCN108456789AIncrease concentrationIncrease relative volatilityProcess efficiency improvementSulfideMaterials science

The invention provides a method for extracting an antimony metal. A device adopted by the method for extracting the antimony metal comprises an electrothermal volatilization device, a first dust collection device and an electrothermal reduction device which are connected in sequence. The method comprises the following steps: performing volatilization smelting on an antimony-containing material inthe electrothermal volatilization device so as to obtain an antimony-containing flue gas, wherein the antimony-containing material comprises antimony sulfide; collecting the antimony-containing flue gas from the first dust collection device so as to obtain antimony oxide dust; performing reduction smelting on the antimony oxide dust in the electrothermal reduction device, so as to obtain the antimony metal. The antimony-containing material is subjected to volatilization smelting through electric heating, and the whole volatilization smelting process needs no air blown combustion fuel, so thatthe flue gas quantity can be greatly reduced, and the concentration of SO2 in the flue gas can be increased. High electric heating efficiency can be achieved, not only is the amount of a fluxing agentreduced, but also residues can be reduced, and comprehensive benefits of environment protection, energy conservation, recycling rate increase, and the like, can be achieved. Due to electrothermal reduction, the heat efficiency can be greatly improved, the energy consumption can be reduced, the smelting intensity can be greatly improved, and the number of reduction devices can be greatly reduced.

Owner:CHINA ENFI ENGINEERING CORPORATION +1

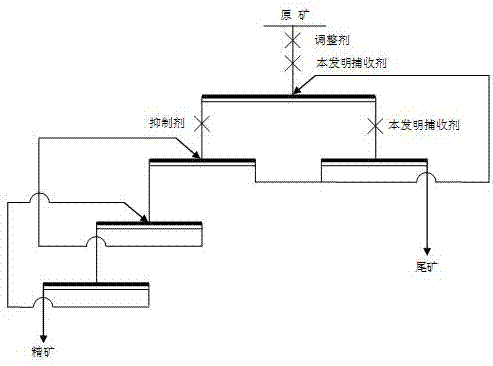

Preparation method of oxidized ore collecting agent and application thereof

The invention discloses a preparation method of an oxidized ore collecting agent and an application thereof. The oxidized ore collecting agent is prepared by mixing the following raw materials: 50-70% by mass of oleic acid, 20-30% by mass of sodium hydroxide, 20-30% by mass of water, 3-5% by mass of carboxymethylcellulose and 5-10% by mass of glycerol monostearate. The preparation method comprises the specific steps of: firstly, mixing oleic acid with sodium hydroxide; adding water to uniformly stir and heating the mixture to 50-60 DEG C; then adding carboxymethylcellulose to continuously stir till the mixture is emulsified to milk white paste; and further blending glycerol monostearate and uniformly stirring the mixture. The oxidized ore collecting agent disclosed by the invention can be applied to floating oxidized ores such as scheelite, lead-zinc oxide ores, rare earth ores and fluorite mine. Compared with other fatty acid collecting agents, the collecting agent shows relatively high selectivity on scheelite flotation. The WO3 grade and recovery rate of the floated tungsten concentrate are improved to a certain extent. The oxidized ore collecting agent disclosed by the invention has the characteristics of being simple to prepare, good in stability, good in dispersibility, high in selectivity and the like, and is suitable for being taken as a floating collecting agent for oxidized ores, in particular scheelite.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

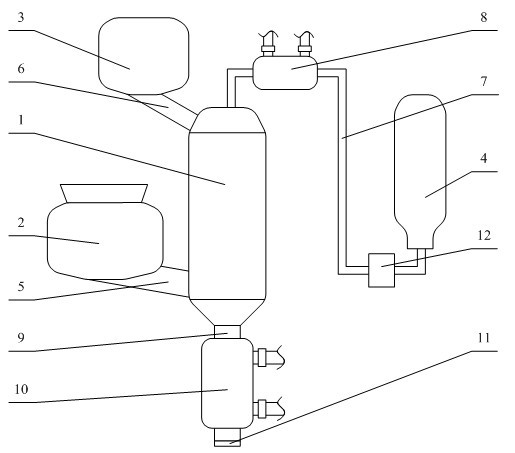

Apparatus and method for treating exhaust gas in the production of PVC gloves

ActiveCN105854478ATake advantage ofAchieve recyclingCombination devicesWaste water treatment from gaseous effluentsActivated carbonThermal energy

The invention discloses an apparatus and method for treating exhaust gas in the production of PVC gloves. The apparatus includes an adsorption canister, a layering tank and a distillation column, and further comprises a waste heat refrigeration device and an atomized condensate separator, which are connected by an exhaust pipe. The exhaust gas outlet of the atomized condensate separator is connected to the adsorption canister; a solvent mixed liquid outlet at the bottom outlet of atomized condensate splitter is connected to the layering tank; an atomized water inlet at the upper part of the atomized condensate separator is connected to the layering tank; the atomized condensate separator and the waste heat refrigeration device in circulation connection by a low temperature cold water pipe. After step by step condensation by the atomized condensate splitter, most of the solvent in the exhaust gas can be recovered, so as to reduce the load on the activated carbon adsorption canister adsorption system, reduce environmental pollution, achieve the recycling utilization of heat, atomized water, desorption water and solvent.

Owner:武汉旭日华环保科技股份有限公司

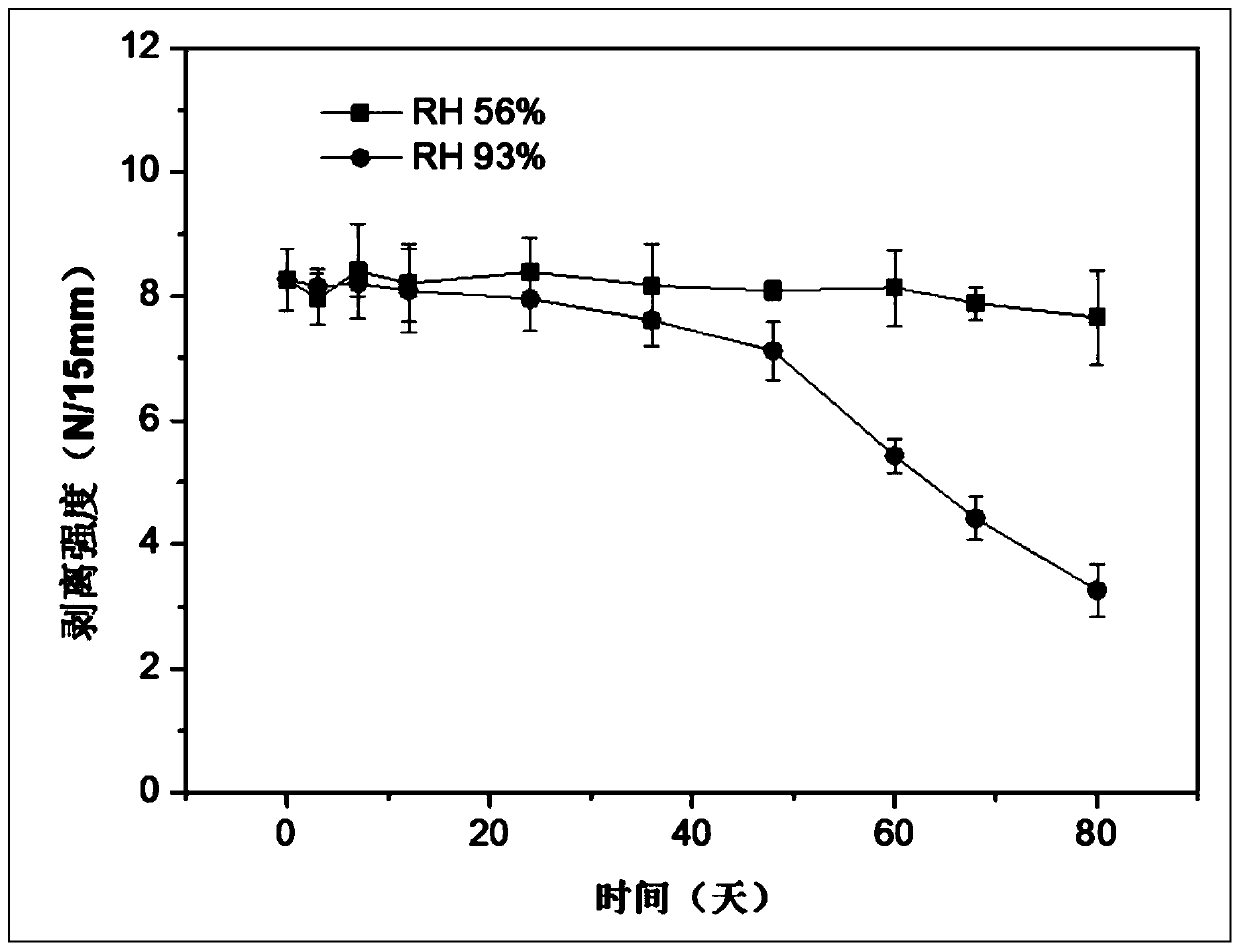

Composite film and preparation method thereof

InactiveCN111516317AGood mechanical propertiesGood low temperature heat sealabilitySynthetic resin layered productsFlat articlesPolyesterPolymer science

The invention discloses a composite film. The composite film has an A / B / A, A / B / A / C or A / B / A / C / A layer structure, the A layer is modified poly epsilon-caprolactone, the B layer is at least one of aluminum or paper, and the C layer is at least one of polyamide, polyester, polyolefin and enol copolymer. The composite film has good heat sealability, good tensile mechanical properties and high peel strength. The composite material comprises biodegradable modified poly epsilon-caprolactone (layer A) as a heat sealing layer, a sealing layer and an outer protective layer. After the use period of the composite flexible package material ends, the modified poly epsilon-caprolactone with excellent biodegradability can be degraded within a certain period of time, so that all layers forming the composite material are separated due to connection loss, the problem that the composite flexible package material is difficult to recycle is solved, and the ecological environment effect is reduced through adegradation, classification and recycling technology.

Owner:睿泊(中国)环保科技有限公司

Method for preparing beryllium hydroxide by extracting from beryllium-containing ore

InactiveCN107641712AEfficient removalSimple production processProcess efficiency improvementBeryllium sulfateBeryllium hydroxide

The invention discloses a method for a method for preparing beryllium hydroxide by extracting from beryllium-containing ore. The method comprises the following steps: carrying out ball milling on rawore, adding quick lime and roasting; then pouring a mixture into water for freezing, and drying and breaking an obtained material to obtain a fine particle material; adding sulfate or aluminate into the obtained fine particle material, adding sulfuric acid and water, and curing to obtain a cured material; adding block rubber and water into the cured material, and leaching and filtering to obtain aberyllium sulfate solution, wherein the beryllium sulfate solution contains ferric sulfate impurity and aluminum sulfate impurity; adding ammonium sulfate into the beryllium sulfate solution for performing evaporation concentration; adding calcium carbonate, water and hydrogen peroxide and removing the ferric sulfate impurity; then filtering and introducing ammonia or ammonia water into the solution to obtain the beryllium hydroxide. The method disclosed by the invention has the characteristics of short flow process, simple production conditions, wide application range, high recovery rate, low production cost and the like; the difficult problem of extracting beryllium from low-grade raw ore is solved.

Owner:LONGZHOU WANHE TRADING CO LTD

Pyroxene peridotite type ilmenite depressing agent and preparation method thereof

InactiveCN103721853AResolve recovery rateSolve the technical problem of low concentrate gradeFlotationPhysical chemistryIlmenite

The invention belongs to the ilmenite flotation technology, and particularly relates to a pyroxene peridotite type ilmenite depressing agent and a preparation method of the pyroxene peridotite type ilmenite depressing agent. The preparation method of the pyroxene peridotite type ilmenite depressing agent comprises the step of carrying out oscillation, stir and curing on a mixed solution formed by sodium silicate, ferric nitrate and sulfuric acid to obtain the pyroxene peridotite type ilmenite depressing agent, wherein oscillation, stir and curing are carried out for 30-40min. The obtained pyroxene peridotite type ilmenite depressing agent comprises, by weight, 5-15 parts of the sodium silicate, 5-15 parts of the ferric nitrate and 1-10 parts of the sulfuric acid. The pyroxene peridotite type ilmenite depressing agent obtained through the preparation method has a good selective depressing effect on olivine and pyroxene, and has extremely important significance in obtaining of good technical indexes of titanium flotation of pyroxene peridotite type ilmenite.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

Nickel-containing industrial wastewater treatment device and process

InactiveCN107759006AProlong settling timeEasy to handleTreatment using aerobic processesWater contaminantsConstructed wetlandElectroless nickel

The invention discloses a device and a process for treating nickel-containing industrial wastewater. The device comprises a set of combined reactors, chemical nickel wastewater and electronickelling wastewater are respectively treated with a chemical precipitation method, the precipitation time is prolonged, and the natural precipitation and water discharge is realized. Ammonia nitrogen is treatedby an ammonia nitrogen blowing and lifting device, and finally, the COD (chemical oxygen demand) is efficiently treated in a classified manner with an anaerobic-aerobiotic-artificial wetland system combination method. The actual nickel-containing industrial wastewater is inflow water, nickel is removed and recovered in the form of a chemical precipitate by controlling the material addition amountand the reaction time, meanwhile, the COD and the ammonia nitrogen are efficiently removed with a physical-biological combination method, and finally, effluent reaches the national discharge standard. On the basis that the wastewater is effectively treated, the recovery of the nickel is improved, and the device and the process have the advantages of simple process method, low operating cost and the like.

Owner:HUNAN UNIV

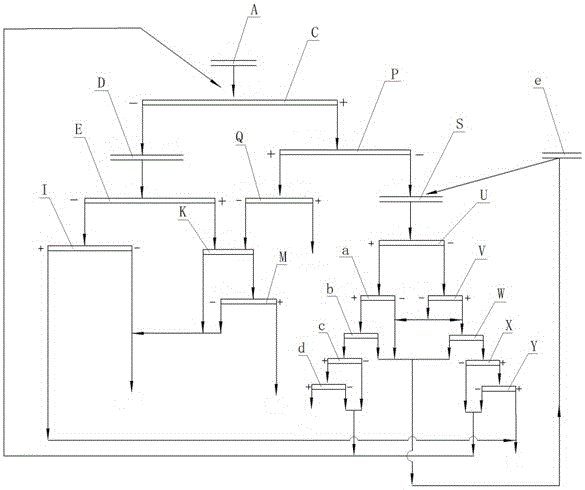

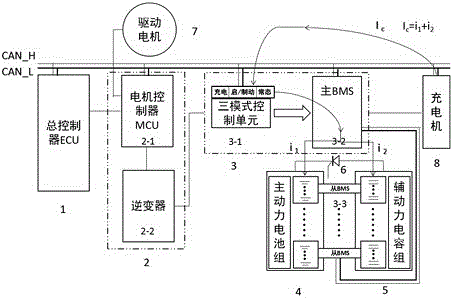

CAN communication based three-mode intelligent control method and application thereof in dual-power supply dynamic system

ActiveCN105871051ASolve the slow startSolve the problem of longevityBatteries circuit arrangementsPower network operation systems integrationMode controlNew energy

The invention relates to a CAN communication based three-mode intelligent control method, in particular to application of a CAN communication based three-mode intelligent control technology in a dual-power supply dynamic system composed of a lithium ion capacitor and all-solid-state lithium / lithium ion battery, and belongs to the field of application of new energy. The lithium ion capacitor is high in power density, ultrahigh in rate charging and discharging performance and relatively low in energy density, and the all-solid-state / lithium ion battery has excellent energy density. In the system, an all-solid-state lithium / lithium ion battery pack and a lithium ion capacitor pack form a dual-power energy source; with the CAN communication based three-mode intelligent control method, appropriate and intelligent control on stages such as charging, starting / braking and normal running is achieved, the energy impact brought by instant large current to the battery pack during frequent starting and braking of a power device is solved, high-efficiency braking energy is recycled, the service lifetime and the running time of the battery pack are prolonged, and the CAN communication based three-mode intelligent control method has favorable practical application value.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

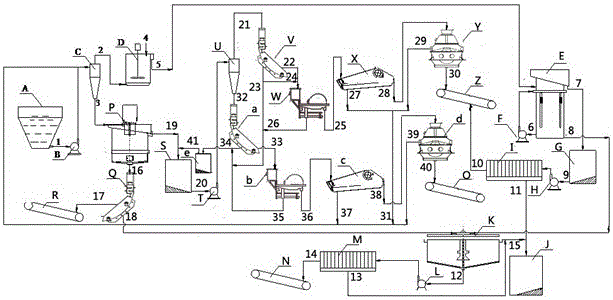

Smelting process for efficient and energy-saving regenerated lead

InactiveCN110551899AResolve recovery rateReduce lossesProcess efficiency improvementLead smeltingSmelting process

The invention discloses a smelting process for efficient and energy-saving regenerated lead. The smelting process for the efficient and energy-saving regenerated lead is characterized by comprising the following steps: step S1, preparation for a lead raw material for smelting; step S2, treatment for a lead paste; step S3, forming for the lead smelting raw material; step S4, smelting treatment; andstep S5, by-product aftertreatment. The invention further discloses the efficient and energy-saving regenerated lead prepared according to the smelting process for the efficient and energy-saving regenerated lead. The smelting process for the efficient and energy-saving regenerated lead is capable of efficiently, rapidly and safely smelting lead scraps and wastes into the regenerated lead, so that resource recycling is realized, waste is turned into wealth, and the problems of low metal recovery rate and high lead content of slag in an existing smelting process for regenerated lead, and environment pollution caused by the generation of lots of smoke containing lead, sulfur dioxide and acid mist, are solved; and the smelting process for the efficient and energy-saving regenerated lead hasthe advantages of being high in lead direct-recovery rate, comprehensive recovery rate and labor productivity, low in precious metal loss, and high in economic value, ecological value and social value.

Owner:骆驼集团(安徽)再生资源有限公司

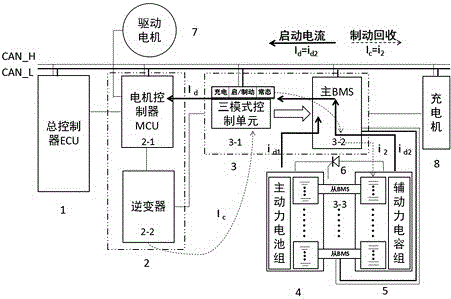

Method for depositing rare earth through oxalic acid

ActiveCN106119541AResolve recovery rateSolve the contradiction between oxalate consumptionProcess efficiency improvementChemistryMother liquor

The invention relates to a method for depositing rare earth through oxalic acid. The method comprises a rare earth dissolving material using process, a process for obtaining a rare earth chloride solution through extraction and reverse extraction and a rare earth depositing process. The rare earth depositing process comprises the steps that primary depositing with rare earth relatively excess is conducted on the rare earth chloride solution through an oxalic acid solution; one part of primary depositing mother liquor is directly recycled and used for the rare earth dissolving material process or the reverse extraction step; secondary depositing with oxalic acid relatively excess is conducted on the surplus primary depositing mother liquor through the oxalic acid solution; and secondary depositing mother liquor obtained in the second depositing process is totally recycled and used for depositing. By means of the method for depositing the rare earth through the oxalic acid, hydrochloric acid produced in the rare earth recycling process can be totally recycled, and the oxalic acid consumption amount can be equal to the stoichiometric ratio; the excess oxalic acid reagent consumption amount is substantially decreased, thus, the solutions in the whole recycling process can be recycled, and water for oxalic acid preparing is saved; and zero discharging of oxalic acid depositing mother liquor wastewater is achieved.

Owner:CHINA MINMETALS BEIJING RES INST OF RE

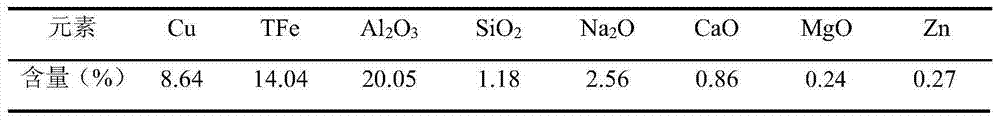

Method for using copper-containing sludge to produce copper concentrate

ActiveCN104726700AResolve separabilityImprove washing effectProcess efficiency improvementSludgeSlurry

The invention relates to a method for using copper-containing sludge to produce copper concentrate. The method includes: intermittently adding acid, controlling the pH of solution of the whole reaction process to be about 2.5, and reacting for about 100 minutes to obtain stirring acid leaching residue slurry; adding sodium sulfide solution into the stirring acid leaching residue slurry, and stirring for about 15 minutes to obtain vulcanized electroless plating copper residue slurry; adding about 12g of butyl xanthate serving as a collecting agent and about 13g of ammonium dibutyl dithiophosphate into each cubic meter of the vulcanized electroless plating copper residue slurry, stirring for 3 minutes, adding 2g of 2# oil serving as a foaming agent, continuing stirring for 2 minutes, and then roughing for 6 minutes to obtain rough copper concentrate and roughing tailing slurry; concentrating the rough copper concentrate for 5 minutes to obtain copper concentrate and middlings 1, adding 5g of butyl xanthate serving as the collecting agent and 5g of ammonium dibutyl dithiophosphate into each cubic meter of the roughing tailing slurry, stirring and scavenging to obtain middlings 2 and scavenging tailing slurry; adding lime milk to neutralize the scavenging tailing slurry, stirring for 50 minutes and controlling end point pH to be 8, and performing solid-liquid separation after reaction to obtain filtrate and filter cakes. The method is simple in production line and production process, low in total production cost, low in investment, fast to achieve desired results, low in energy consumption, high in copper recycling rate, and the like.

Owner:ZIJIN MINING GROUP

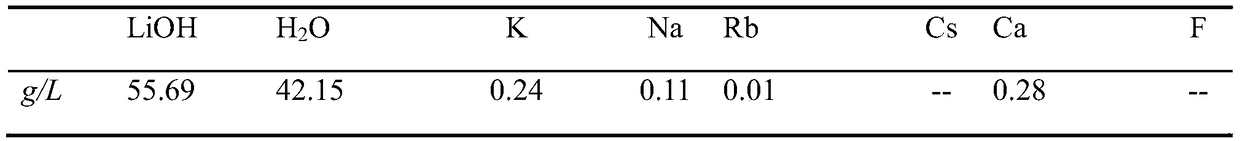

High temperature lepidolite hydrothermal treatment method for producing lithium hydroxide

ActiveCN108163874AHigh recovery rateLow recovery rateLithium oxides/hydroxidesEnvironmental resistanceLithium hydroxide

The invention discloses a high temperature lepidolite hydrothermal treatment method for producing lithium hydroxide. The method comprises following steps: step one, carrying out mechanical activation;step two, preparing raw materials; step three, carrying out preheating reactions; step four, performing hydrothermal reaction; step five, carrying out leaching and concentration; step six, removing salt: cooling concentrate at a temperature of 20 to 30 DEG C, and stirring the concentrate for 60 to 90 minutes to carry out crystallization to obtain a coarse product of lithium hydroxide. The methodhas the advantages of low energy consumption, cleanness, environmental friendliness, low cost, and high leaching efficiency, and is a novel method for fixing fluorine of lepidolite and leaching valuable metals. High temperature hydrothermal reactions are adopted to improve the burning performance of materials, and the problems that lepidolite is hard to melt at a high temperature and HF gas is generated during the melting process are solved. Moreover, the lithium conversion rate is largely improved at a proper temperature during a proper period, the technology is simpler, the material flux issmall during the production process, the recovery rate of lithium and alkali metals is high, and valuable metals are fully utilized.

Owner:江西云威新材料有限公司

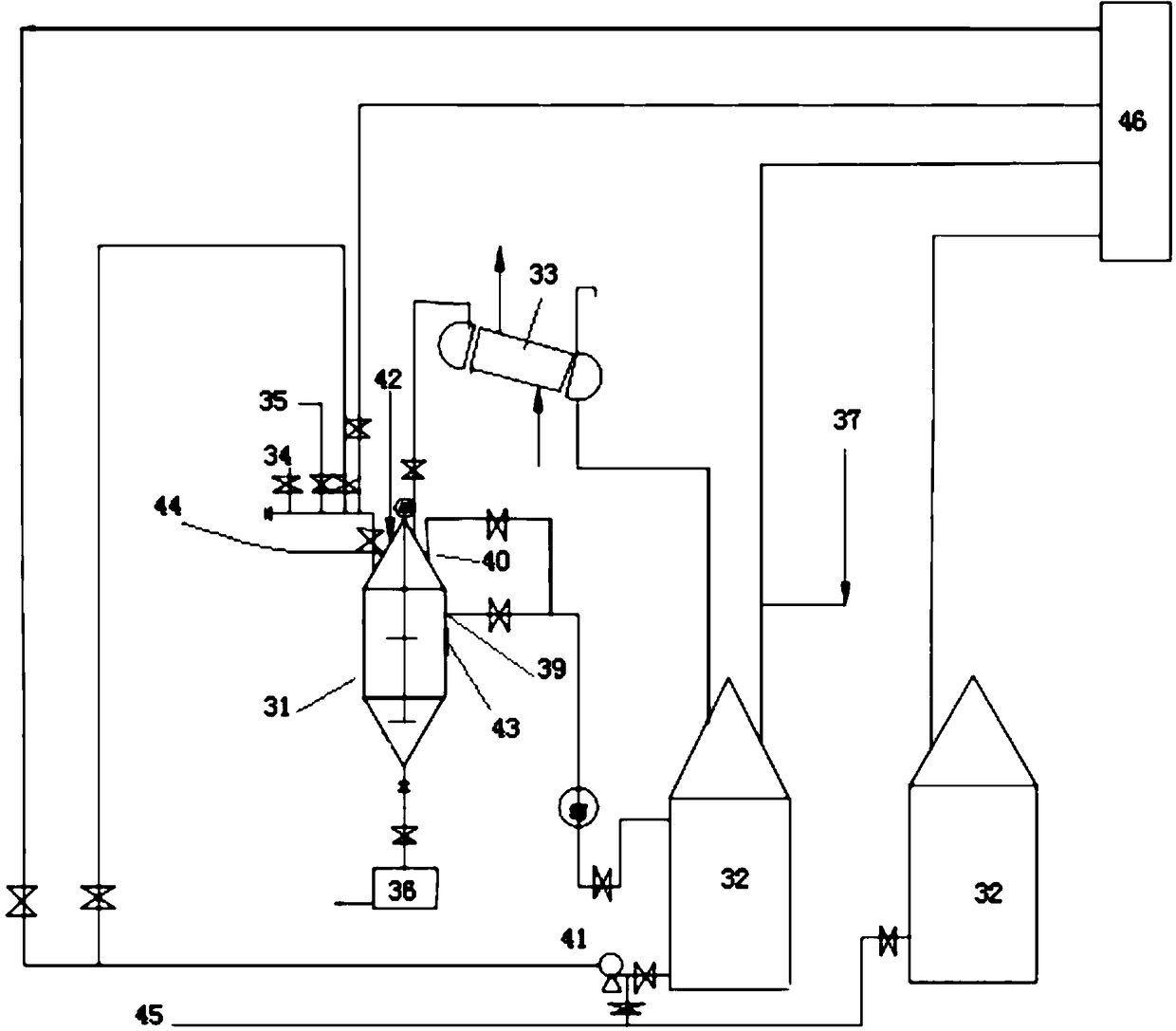

System and method for treating and recycling aged resin wastewater in production process of epoxy resin

PendingCN109110975ASolve stickyResolve recovery rateSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentEpoxySludge

The invention discloses a system and a method for treating and recycling aged resin wastewater in a production process of epoxy resin. The system comprises an aged resin precipitating and compressingdevice and a solvent extracting device, wherein the precipitating and compressing device comprises a precipitating tank, a centrifuging pump, a screw pump and a plate-and-frame filter press, wherein the inlet of the precipitating tank is connected with the outlet of the centrifuging pump; the inlet of the centrifuging pump is connected with a wastewater container; a flocculant filling pipeline isarranged on a centrifuging pump outlet pipeline and the flocculant filling pipeline is connected with a polyacrylamide solution container; a metering pump is arranged on the flocculant filling pipeline and the metering pump is connected with the precipitating tank; an overflow weir is arranged at the upper part of the precipitating tank; a clear water outflow pipe on the outer side of the overflowweir is connected with the precipitating tank; a discharging opening in the bottom of the precipitating tank is connected with a sludge tank through a discharging pipe; one side of the screw pump isconnected with the sludge tank through a pipeline; the other side of the screw pump is connected with the plate-and-frame filter press. According to the system and the method for treating and recycling the aged resin wastewater in the production process of epoxy resin, the aged resin wastewater is treated in the solvent extracting device by using a solvent extracting process; the problems that theaged resin treated by methylbenzene is viscous and the recycling rate of the epoxy resin is low are solved.

Owner:山东天茂新材料科技股份有限公司

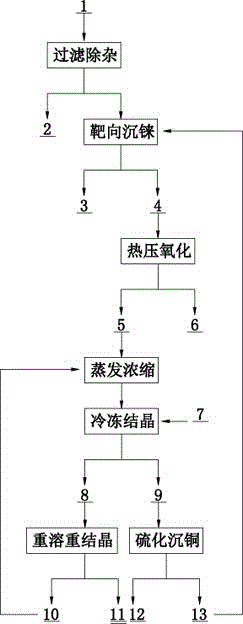

A method of comprehensively recovering rhenium and copper from copper smelting waste acid

ActiveCN105969985AIncrease sedimentation rateReduce dosageProcess efficiency improvementSlagPotassium

A method of comprehensively recovering rhenium and copper from copper smelting waste acid is disclosed. The method includes subjecting the copper smelting waste acid after being filtered to remove lead to targeted rhenium settling to obtain rhenium-rich slag, subjecting the rhenium-rich slag to hot-press oxidation leaching to obtain a rhenium-rich leachate, evaporating and concentrating to make the rhenium concentration 10-20 g / L, performing rhenium settling with KCl, and recrystallizing to obtain potassium perrhenate, and subjecting the liquid after rhenium settling to sulfuration copper settling. The objective of the method is to overcome complex processes, long treatment time, low recovery rates, and other disadvantages of processes recovering rhenium and copper from copper smelting waste acid through leaching at present, and to form a process which is low in investment, simple in operation, high in recovery rate, low in cost, low in pollution and convenient for industrial popularization and application, thus achieving high-value utilization of the rhenium resource in the copper smelting waste acid.

Owner:ZIJIN MINING GROUP

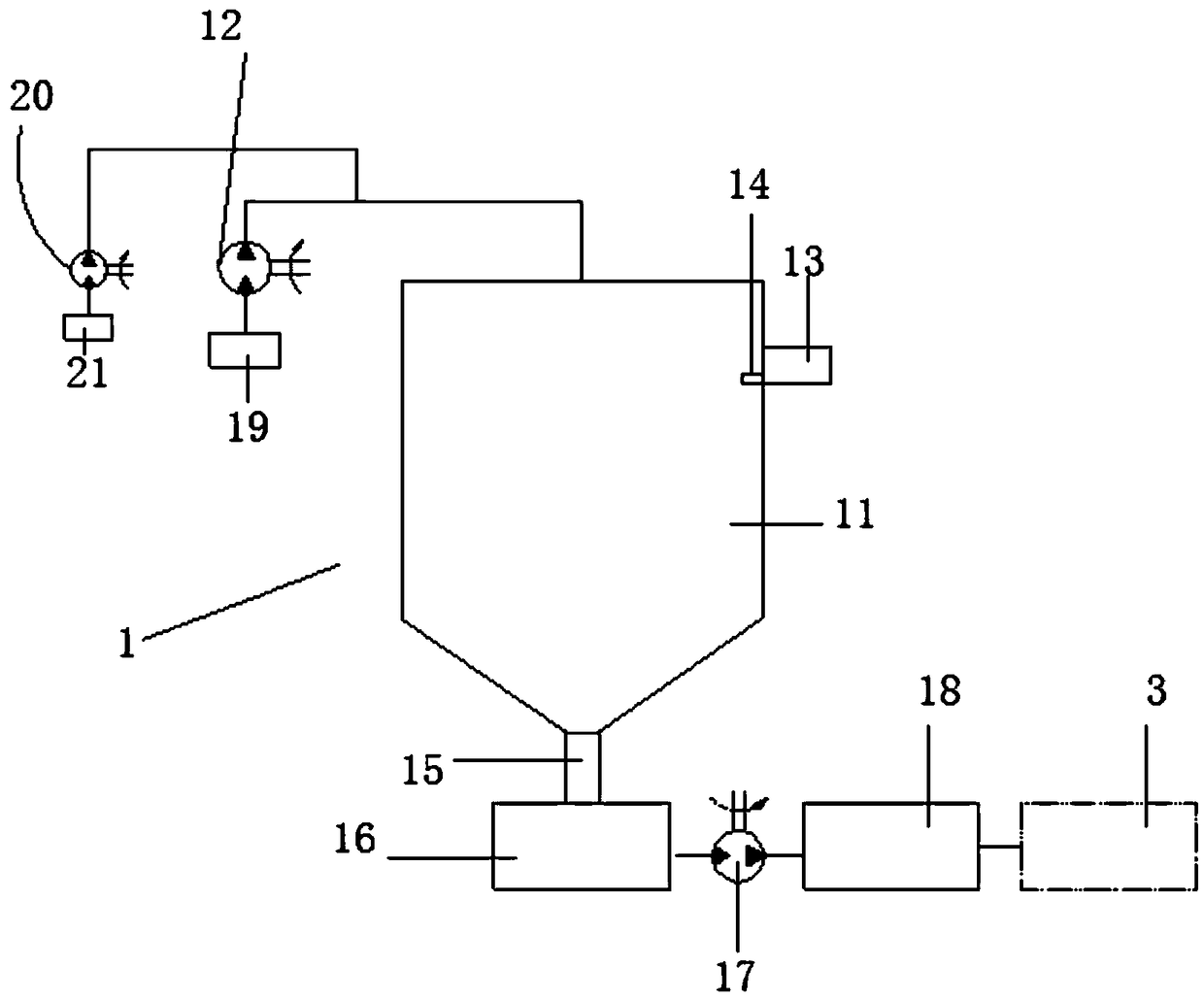

Method and device for recovering sensible heat of blast furnace slag

InactiveCN102050959AAvoid wastingSolve resource problemsChemical industryPlastic recyclingSlagProcess engineering

The invention provides a method for recovering sensible heat of blast furnace slag and a device for realizing the method. In the method for recovering sensible heat of blast furnace slag, sensible heat of blast furnace slag is recovered as chemical energy for pyrolytic reaction of a printed circuit board substrate, thereby avoiding wasting water resources; and thus, the invention has the advantage of high recovery rate of sensible heat of blast furnace slag, solves the problems of high consumption of water and low recovery rate of sensible heat in the existing water quenching treatment process for blast furnace slag, avoids the problem of secondary energy consumption in the pyrolytic treatment of the printed circuit board substrate, can be used for industrial treatment of printed circuit board substrate materials in electronic waste, and is beneficial to realizing energy saving and emission reduction. In addition, the obtained gas products and solid residues can be further utilized, and thus, the product utilization ratio is high. The device for recovering sensible heat of blast furnace slag comprises a pyrolyzing furnace, a dry-type granulating device, a powder container and a gas collection container. The device for recovering sensible heat of blast furnace slag has the advantage of simple structure, is easy to operate and is suitable for industrial application.

Owner:重庆飞耀电炉有限公司

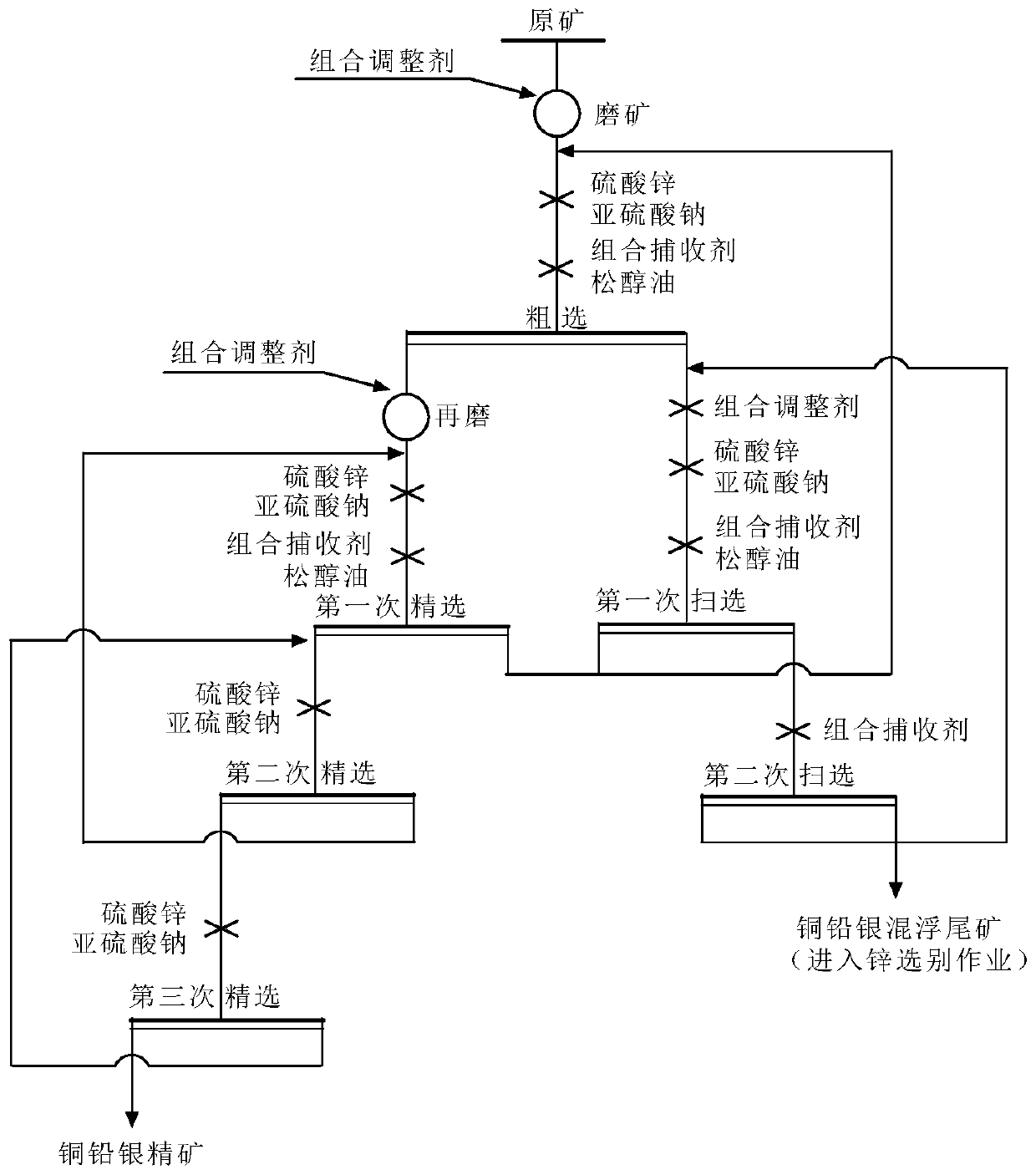

Combined collecting agent and beneficiation method for recovering copper, lead and silver from copper lead zinc and silver polymetallic ore

The invention discloses a combined collecting agent and a beneficiation method for recovering copper, lead and silver from copper lead zinc and silver polymetallic ore. The combined collecting agent is prepared by mixing dianilinodithiophosphoric acid, sodium carbonate and ethyl thio carbamate in a mass ratio of (3.0 to 5.0):(2.0 to 3.0):(1.0 to 2.0). The beneficiation method comprises the steps that a combined regulator is added into raw ore for grinding to prepare raw ore slurry; zinc sulfate, sodium sulfite, the combined collecting agent and terpineol oil are added into the raw ore slurry in turn for rough separation to obtain copper-lead mixed coarse concentrate; the copper-lead mixed coarse concentrate is subjected to thickening and dewatering, and then the combined regulator is addedfor grinding to prepare regrinding slurry; and the zinc sulfate, the sodium sulfite, the combined collecting agent and the terpineol oil are added into the regrinding slurry in turn, then fine separation is conducted, and thus copper-lead-silver mixed concentrate is obtained. According to the combined collecting agent and the beneficiation method for recovering the copper, the lead and the silverfrom the copper lead zinc and silver polymetallic ore, copper lead silver mineral in the high sulfur high arsenic copper lead zinc and silver polymetallic ore can be efficiently recovered.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Desalting and protein recovering method of salted egg white

InactiveCN103988972AEfficient desalinationLow viscosityProtein composition from eggsFood preparationAdditive ingredientWater resources

The invention provides a desalting and protein recovering method of salted egg white. The method for performing white comprises the following steps: filtering industrialized salted egg white, performing settling desalting by a flocculating agent, adding water for diluting settled salt, and filtering by a ceramic membrane so as to realize concentration desalting and the protein extraction recovery on the industrial salted egg. Compared with the prior art, the method is high in desalting rate and protein recovery rate, recovered protein has the advantages that the quality is stable, protein nutrients are not destroyed and the like, the whole treatment process is simple in step and easy to popularize and apply, the pollutant emission is reduced, and the method is free of environment and water resource pollution and has a wide application prospect.

Owner:FUJIAN INST OF MICROBIOLOGY

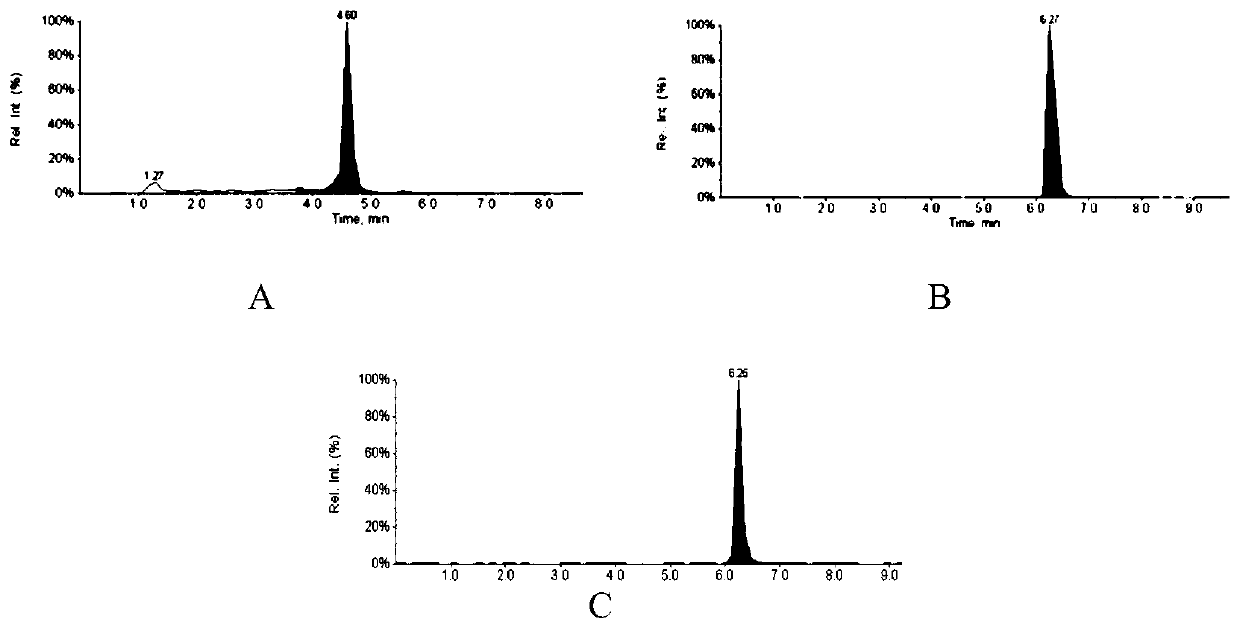

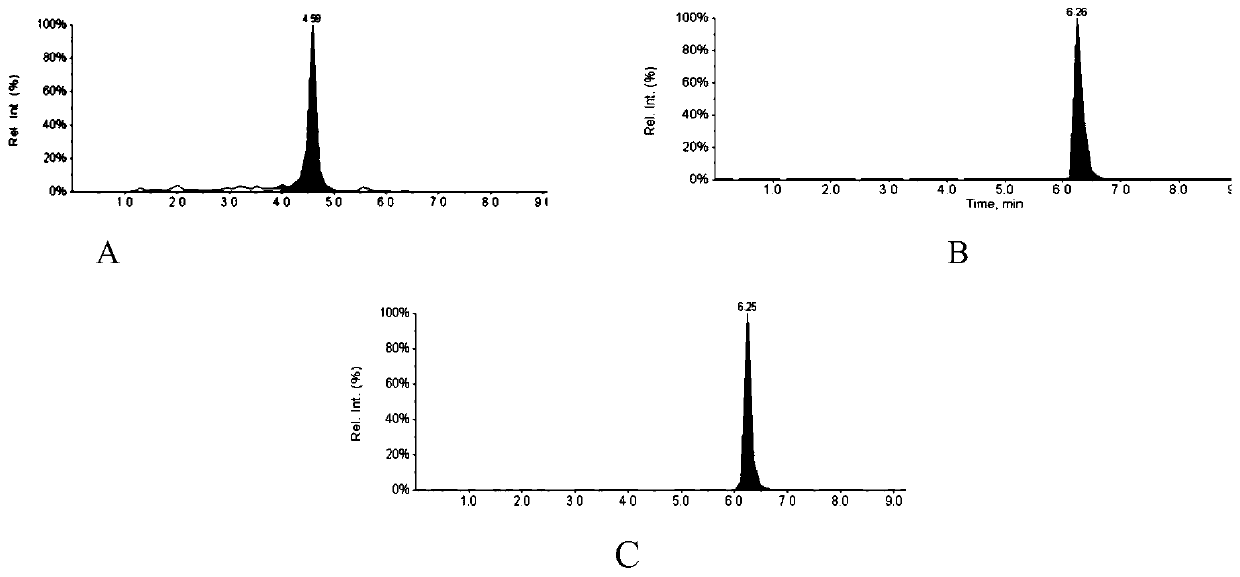

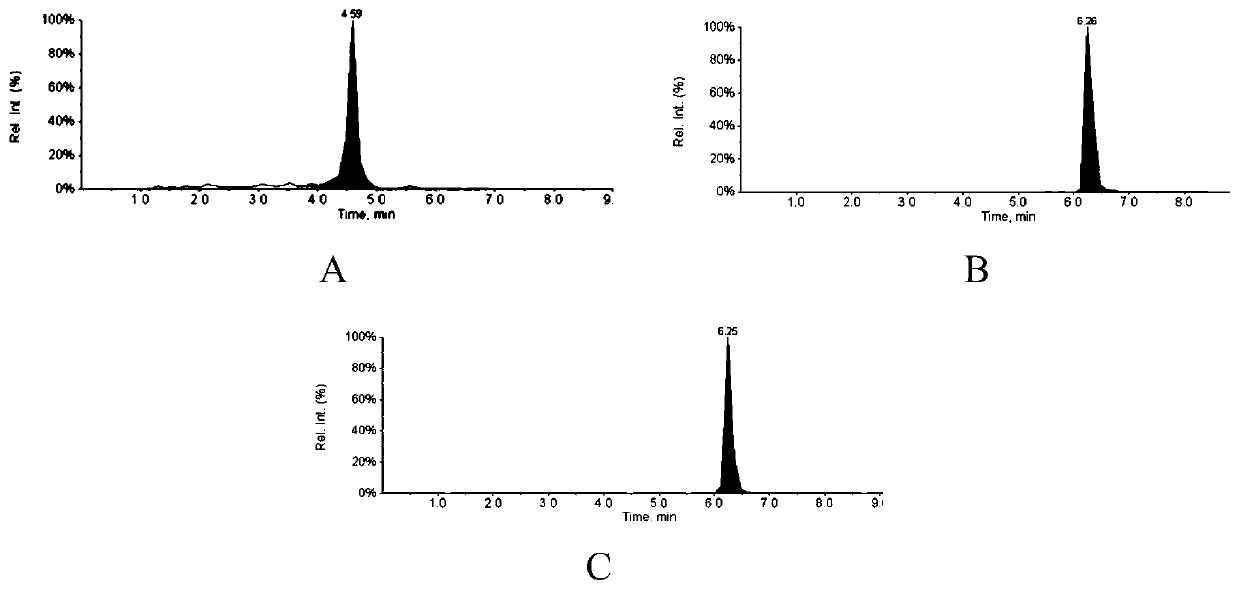

Method for detecting residues of amantadine, rimantadine and memantine in animal derived food

The disclosure provides a method for detecting residues of amantadine, rimantadine and memantine in an animal derived food. The method comprises the steps of: (1) taking a sample to add into recombinant solution of trichloroacetic acid and acetonitrile to carry out vortex oscillation, carrying out centrifugation after ultrasonic treatment, transferring supernatant A for additional storage, addingthe recombinant solution of the trichloroacetic acid and the acetonitrile into remaining residues to carry out vortex oscillation, carrying out centrifugation after ultrasonic treatment, taking out supernatant B to merge with the supernatant A, and then blow-drying to obtain sample extraction solution residues; (2) carrying out complex solution vertex oscillation on the extraction solution residues, adding C18, PAS and neutral alumina, carrying out centrifugation after ultrasonic treatment, and filtering supernatant through a filter membrane so as to obtain a to-be-detected sample; and (3) detecting content of the amantadine, the rimantadine and the memantine in the to-be-detected sample by utilizing an ultra-high performance liquid chromatography tandom mass spectrometer. According to themethod, the difficult problems of more interference and low recovery rate when the amantadine, the rimantadine and the memantine are simultaneously detected are effectively solved; cost is saved; andworking efficiency is improved.

Owner:FOSHAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com