Micro-fine particle cassiterite flotation method

A technology of fine-grained cassiterite, applied in flotation, solid separation, etc., can solve the problems of high impurity content, low flotation recovery rate of fine-grained cassiterite, unsatisfactory concentrate grade, etc., and achieve the effect of enhancing hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

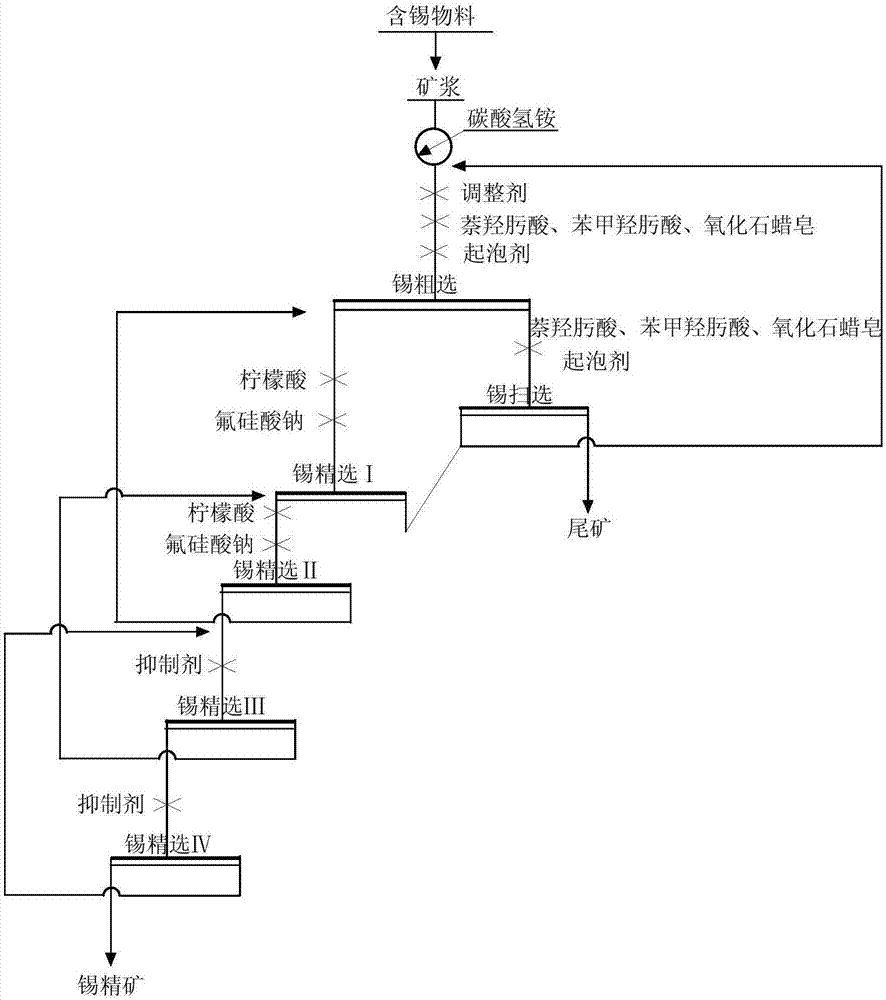

Image

Examples

Embodiment 1

[0048] The tin-containing material in this example is a gravity separation tailings in Bolivia, containing 0.46% tin. The gangue minerals in the tailings mainly include mica, quartz, tourmaline and kaolin, and the particle size of the minerals is less than 0.010 mm.

[0049] (1) The tin-containing material is directly prepared into an ore slurry with a solid phase concentration of 40wt%, and ammonium bicarbonate is added to the ore slurry. The amount of ammonium bicarbonate added is 330g / t of the tin-containing material, and stirred for 3min;

[0050] (2) Add regulator sodium carbonate and lead nitrate to the pulp after adding ammonium bicarbonate in step (1), the addition of sodium carbonate is 240g / t tin-containing material, the addition of lead nitrate is 300g / t tin-containing material , stirring for 6 minutes;

[0051] (3) add collector naphthalene hydroxamic acid, benzohydroxamic acid, oxidized paraffin wax soap in the ore pulp that step (2) obtains, and foaming agent met...

Embodiment 2

[0057] The tin-containing material in this embodiment is a gravity separation tailings in Peru, containing 0.53% tin. The gangue minerals in the tailings mainly include mica, calcite, quartz, and kaolin, and the particle size of the minerals is less than 0.010 mm.

[0058] (1) The tin-containing material is directly prepared into a slurry with a solid phase concentration of 40wt%, and ammonium bicarbonate is added to the slurry. The amount of ammonium bicarbonate added is 360g / t of the tin-containing material, and stirred for 3min;

[0059] (2) Add regulator sodium carbonate and lead nitrate to the pulp after adding ammonium bicarbonate in step (1), the addition of sodium carbonate is 230g / t tin-containing material, the addition of lead nitrate is 300g / t tin-containing material , stirring for 6 minutes;

[0060] (3) add collector naphthalene hydroxamic acid, benzohydroxamic acid, oxidized paraffin wax soap in the ore pulp that step (2) obtains, and foaming agent methyl isobuty...

Embodiment 3

[0065] The tin-containing material in this embodiment is a tin mine in Myanmar, containing 1.06% tin. The gangue minerals in this tin mine mainly include mica, quartz, and kaolin, and the cassiterite intercalation particle size is extremely fine.

[0066] (1) Grind the tin-containing material to a particle size of less than 0.019mm, then adjust it into a slurry with a solid phase concentration of 35wt%, add ammonium bicarbonate to the slurry, the amount of ammonium bicarbonate added is 380g / t of tin-containing material, and stir for 3 minutes;

[0067] (2) Add regulator sodium carbonate and lead nitrate to the pulp after adding ammonium bicarbonate in step (1), the addition of sodium carbonate is 260g / t tin-containing material, the addition of lead nitrate is 300g / t tin-containing material , stirring for 6 minutes;

[0068] (3) add collector naphthalene hydroxamic acid, benzohydroxamic acid, oxidized paraffin wax soap in the ore pulp that step (2) obtains, and foaming agent me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com