Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

23301 results about "Mineralogy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mineralogy is a subject of geology specializing in the scientific study of the chemistry, crystal structure, and physical (including optical) properties of minerals and mineralized artifacts. Specific studies within mineralogy include the processes of mineral origin and formation, classification of minerals, their geographical distribution, as well as their utilization.

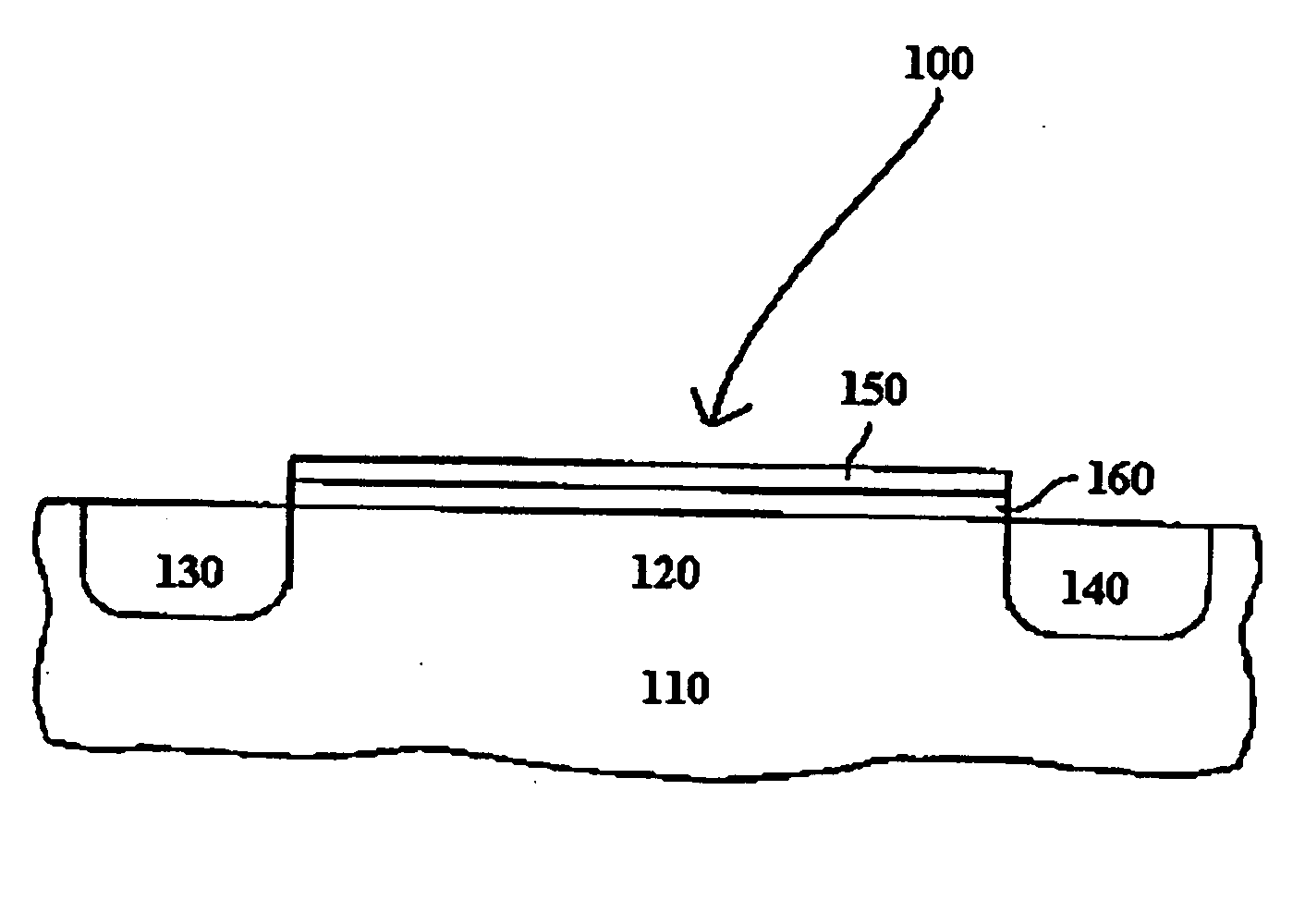

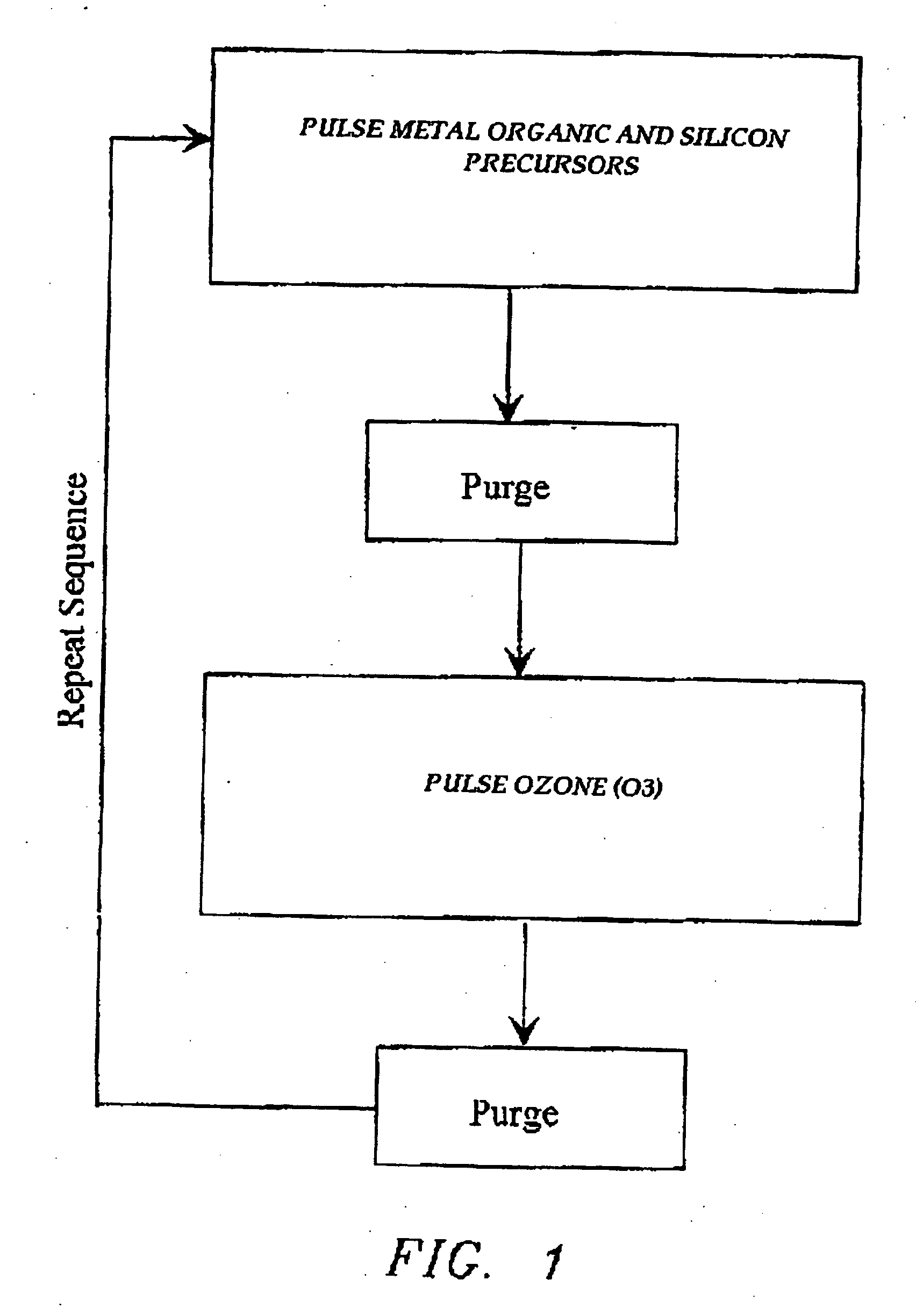

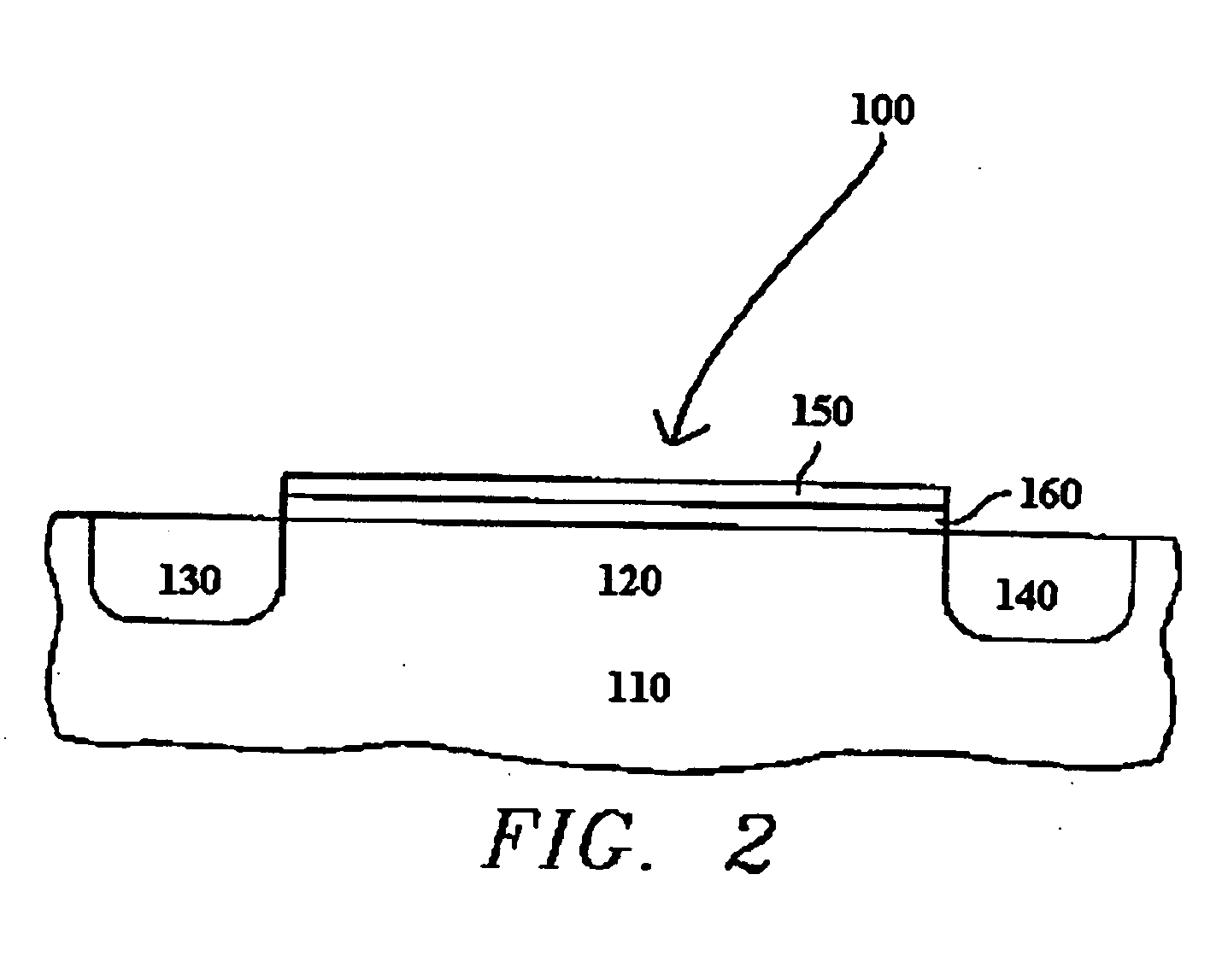

Atomic layer deposition of high k metal silicates

InactiveUS20060228888A1Reduce carbon pollutionReduce stepsSolid-state devicesSemiconductor/solid-state device manufacturingHafniumAtomic layer deposition

The present invention relates to the atomic layer deposition (“ALD”) of high k dielectric layers of metal silicates, including hafnium silicate. More particularly, the present invention relates to the ALD formation of metal silicates using metal organic precursors, silicon organic precursors and ozone. Preferably, the metal organic precursor is a metal alkyl amide and the silicon organic precursor is a silicon alkyl amide.

Owner:AVIZA TECHNOLOGY INC +1

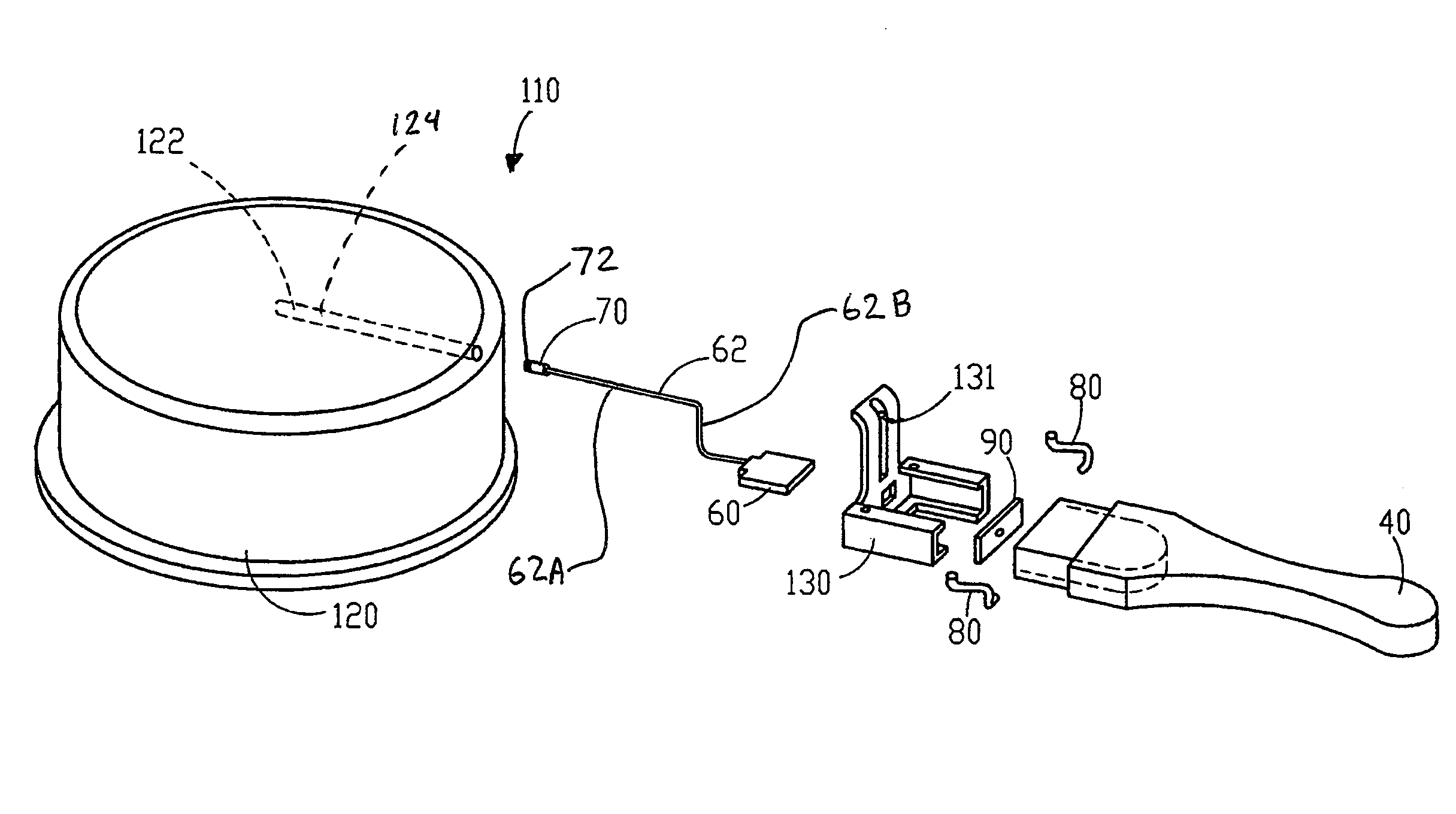

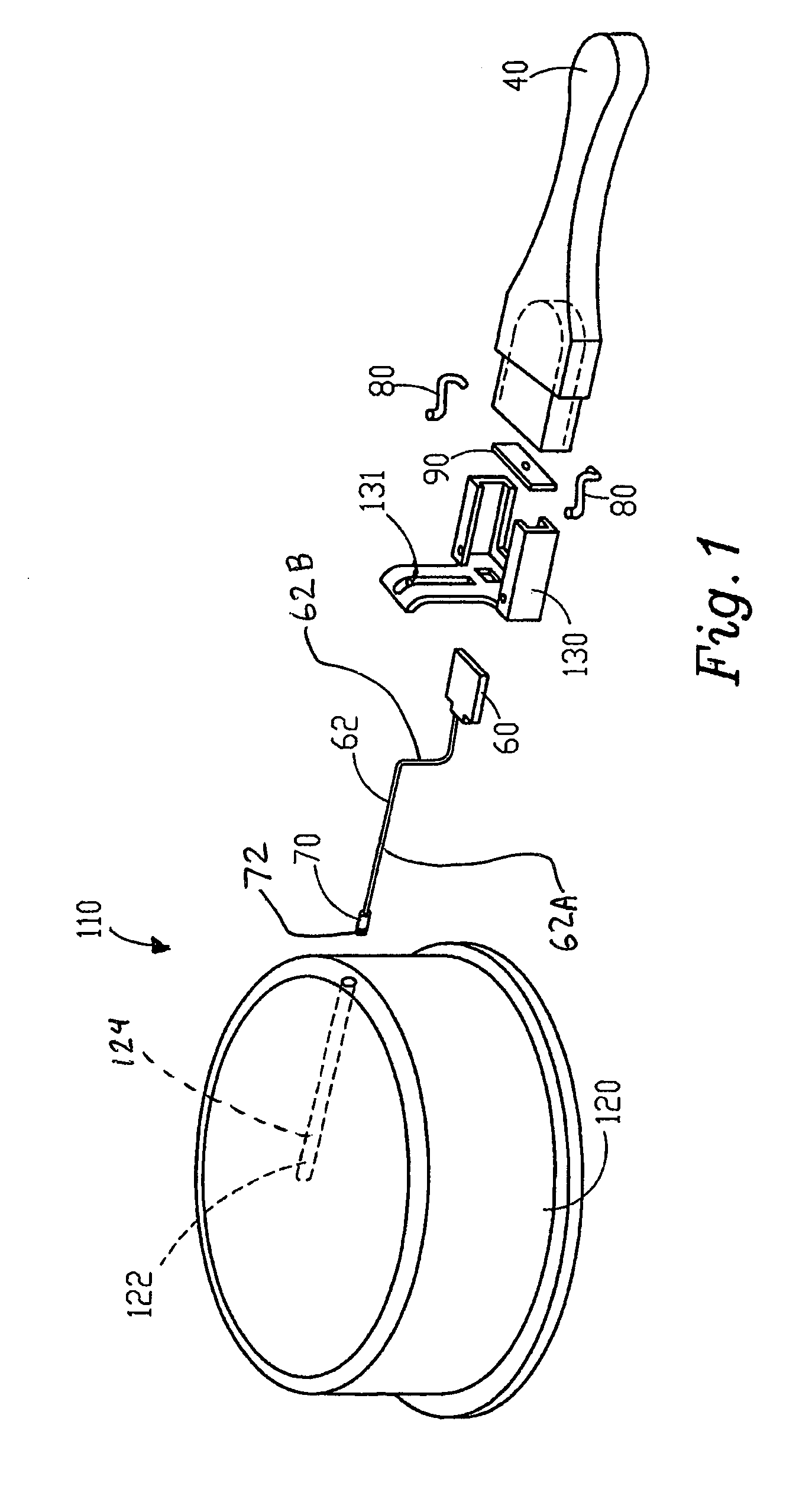

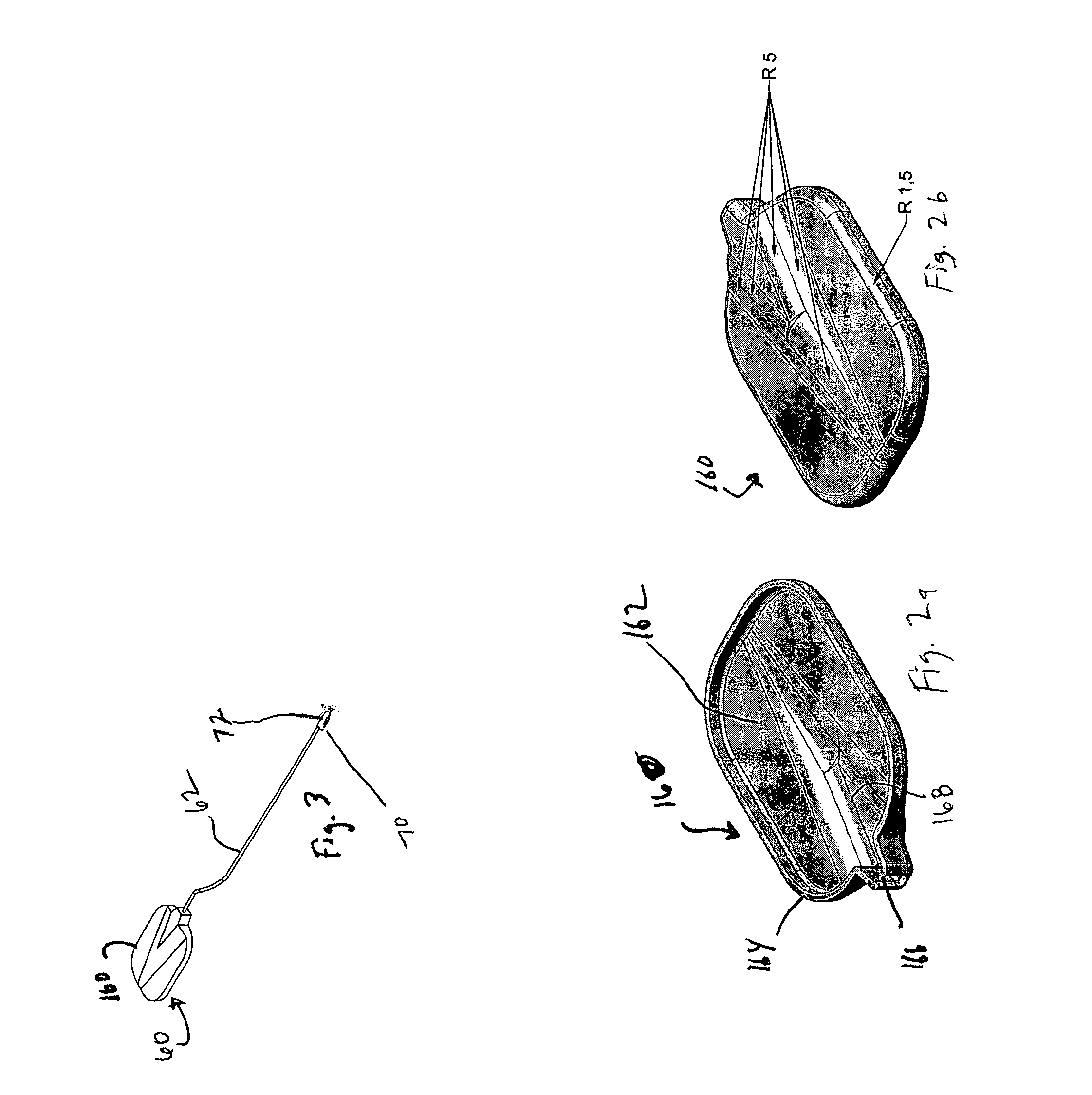

Tag assembly for radio frequency identification controlled heatable objects

ActiveUS7875836B2Improved operation/functionalityAdditional componentBoiling over preventionNear-field systems using receiversEngineeringRadio frequency

Components for use in a temperature controlled heatable object are provided in which a temperature sensor is connected to a transmitter such as a Radio Frequency Identification (RFID) tag. The RFID tag is encased in a protective overmolding and connected to the temperature sensor via a mineral insulated cable. An end cap containing a potting material (such as silicone or ceramic) is placed over the temperature sensor and laser welded to a sheathing of the mineral insulated cable. A potting material for use in a heatable object is also provided comprising a silicone-based material that is modified by adding bauxite to increase thermal conductivity.

Owner:IMURA INT USA

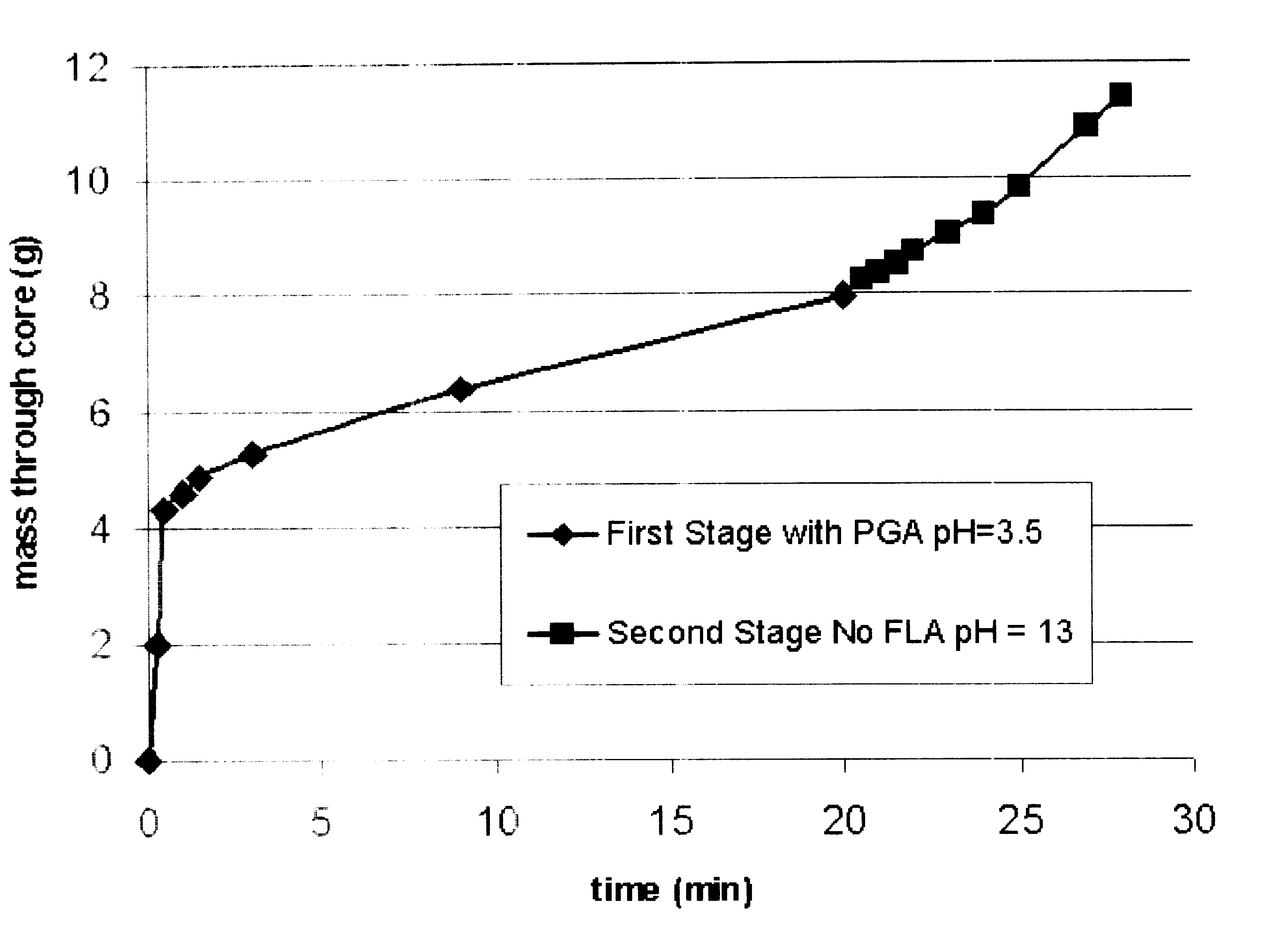

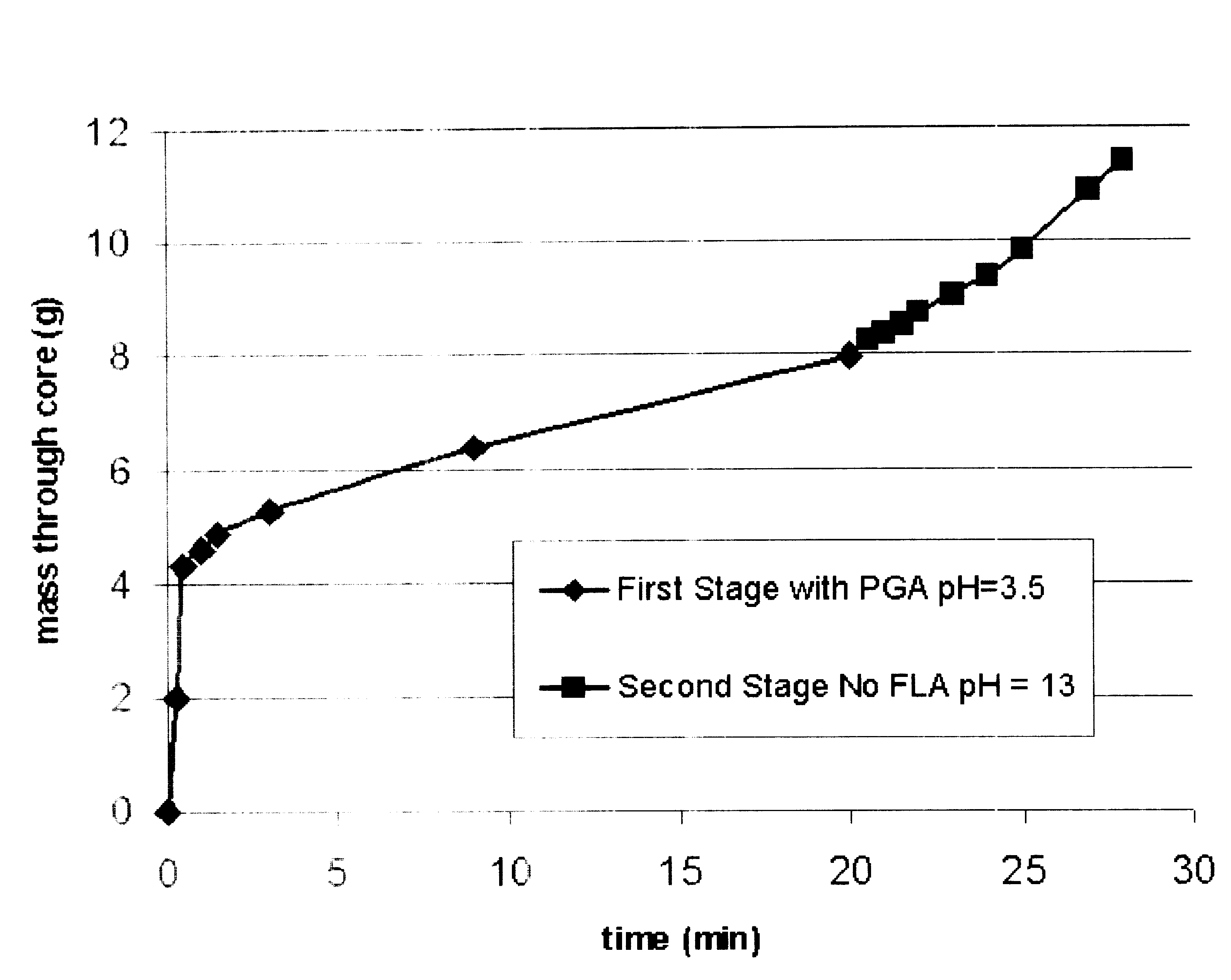

Dissolving Filter Cake

InactiveUS20040094300A1Needed propertyWider fractureCleaning apparatusFluid removalSolid baseCarrier fluid

Methods are presented to induce a screenout during a subterranean formation fracturing or combined fracturing and gravel packing treatment having a viscoelastic surfactant-based carrier fluid by laying down a filter cake at least a portion of which is a base-soluble material, injecting proppant slurry, and causing hydrolysis and dissolution of the solid base-soluble material by adding base so that leak-off increases, the concentration of proppant in the fracture increases, and the proppant screens out. A method of gravel packing with a viscoelastic surfactant-based carrier fluid by laying down a filter cake at least a portion of which is a base-soluble material, injecting gravel, and causing hydrolysis and dissolution of the solid base-soluble material by adding base. Methods of slowing or accelerating the hydrolysis and dissolution are given, and addition of bridging-promoting materials is included.

Owner:SCHLUMBERGER TECH CORP

Gravel attapulgite flower ceramsite

ActiveCN102503372BHigh strengthLower sintering temperatureCeramic materials productionCeramicwarePhysical chemistryMaterials science

The invention discloses gravel attapulgite flower ceramsite. The key point of the technical scheme is that the gravel attapulgite flower ceramsite consists of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, kieselguhr tailing powder and rice husk powder.t. The gravel attapulgite flower ceramsite is produced by the following steps of mixing the ingredients, pelleting, baking, cooling, smashing, sieving and packaging. The gravel attapulgite flower ceramsite is an irregularly-shaped granule, and has a rough and porous surface, light weight, high strength and high water absorption. The gravel attapulgite flower ceramsite can be soaked in water without being cracked and release nutrition required by flowers continuously and slowly. The gravel attapulgite flower ceramsite is produced by utilizing the sludge and tailings comprehensively, so that the utilization rate of resources is improved, waste materials are changed into wealth, and environment is protected. Besides, the gravel attapulgite flower ceramsite is suitable for planting the flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

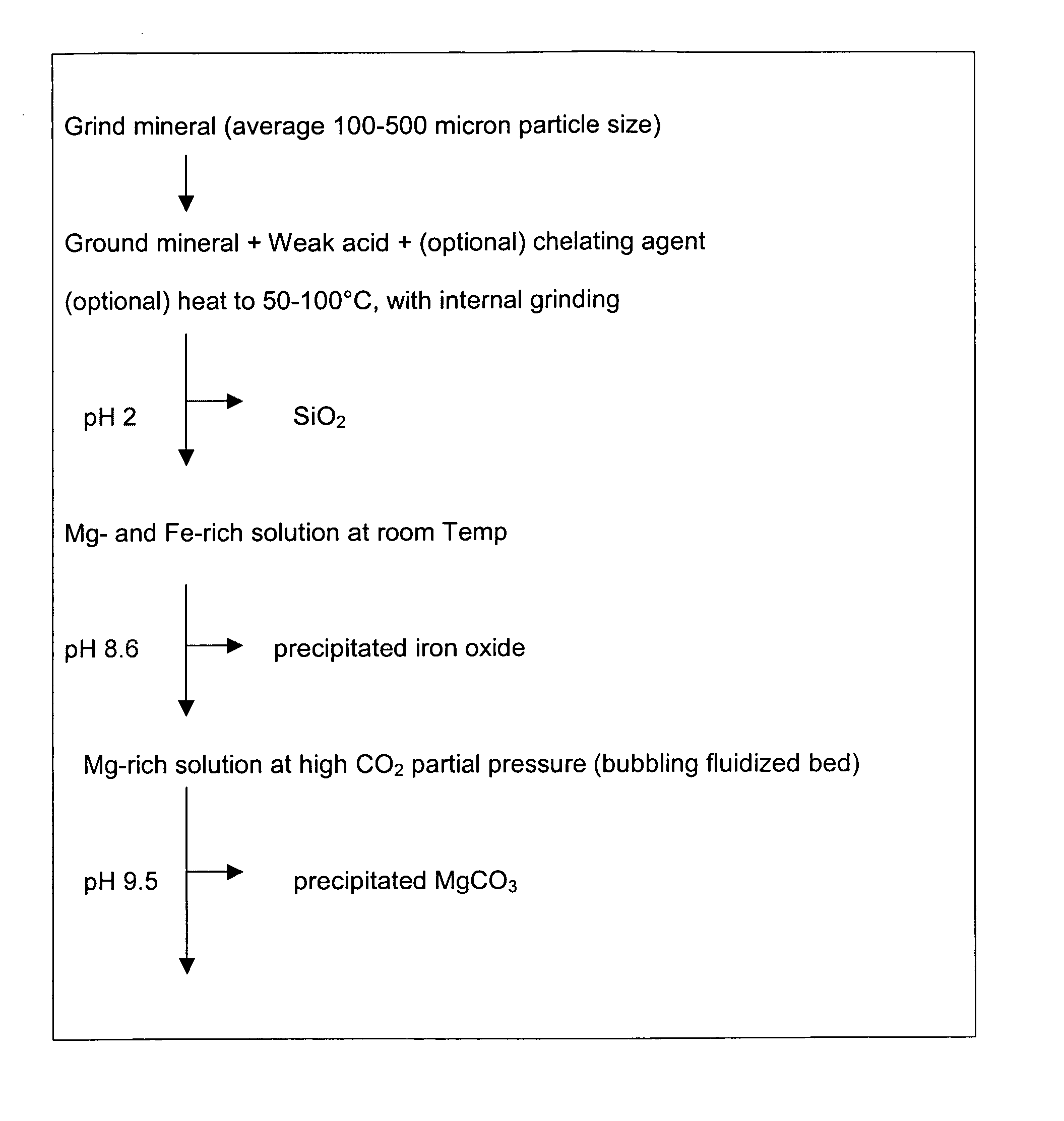

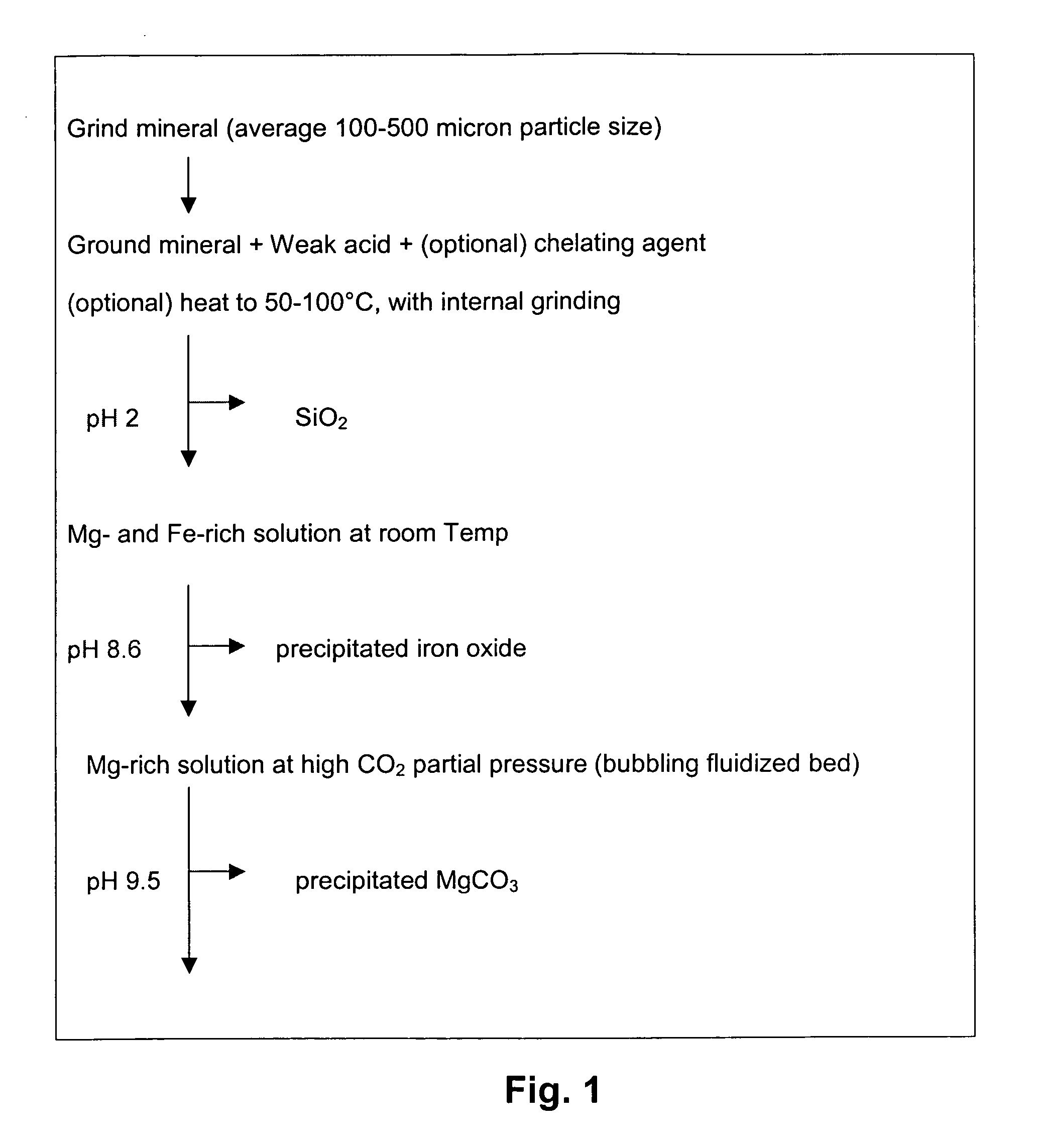

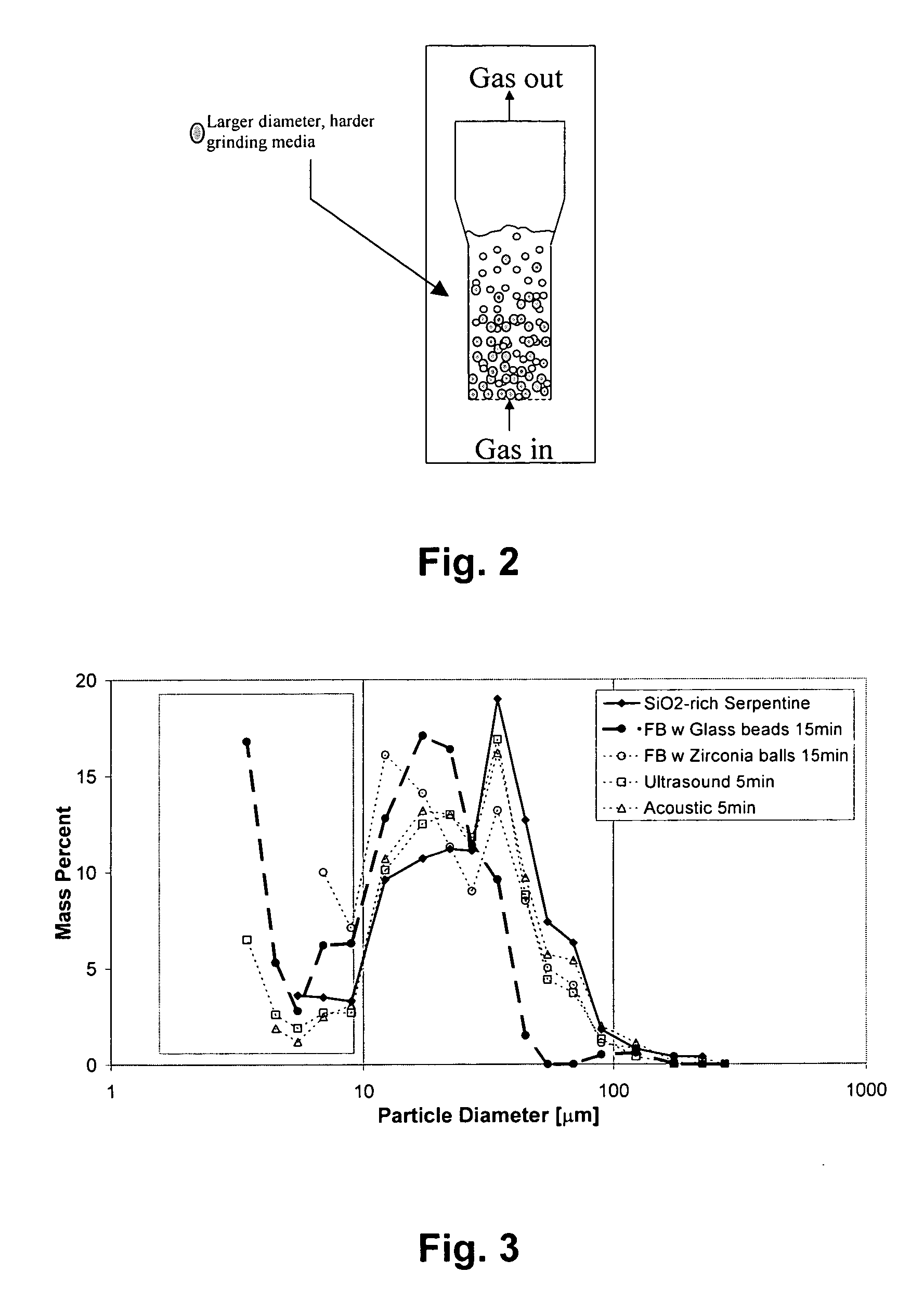

Carbon dioxide sequestration using alkaline earth metal-bearing minerals

ActiveUS20050180910A1High dissolution rateEfficient removalCalcium/strontium/barium carbonatesProductsParticulatesAlkaline earth metal

A method for mineral sequestration of pollutant gases resulting from the combustion of carbon-based fuels such as carbon and sulfur dioxides is provided and includes, providing a particulate magnesium-containing mineral and exposing the magnesium-containing mineral to a weak acid to dissolve magnesium from the mineral and form a magnesium-containing solution. The surface of the particulate magnesium-containing mineral is physically activated to expose and dissolve additional magnesium into the solution. Pollutant gases such as carbon dioxide are mixed with the magnesium-containing solution. When the pH of the magnesium-containing solution is increased, solid magnesium carbonate is formed.

Owner:THE OHIO STATES UNIV

Processes for incorporating inert gas in a cement composition containing spherical beads

ActiveUS20050098317A1High densityModifies its propertySolid waste managementFluid removalAl powderPhysical chemistry

The present invention provides a process for forming cement in a well bore. In this process, a cement composition is formed that comprises a cement and one or more beads mixed with the cement. The cement composition containing the beads is displaced into the well bore, and an inert gas phase is introduced to the cement composition to control a density of the cement composition. The inert gas phase can be introduced by adding a gas generating material to the cement composition and / or a porous material to the cement composition. In an embodiment, the gas generating material is a nitrogen generating material that may be activated by an oxidizing agent. In another embodiment, the gas generating material is a hydrogen generating material, e.g., an aluminum powder. The present invention further provides a cement composition comprising a cement, one or more beads combined with the cement, and an inert gas phase created by, e.g., a gas generating material and / or a porous material.

Owner:HALLIBURTON ENERGY SERVICES INC

Process for preparing batch materials for the manufacture of glass

The invention relates to a process for manufacturing compounds based on one or more silicates of alkali metals and / or of alkaline-earth metals, optionally in the form of mixed silicates that combine at least two of these elements, said process involving:(i) preferably a conversion reaction (1) in which halides of said alkali metals and / or of said rare earths and / or of said alkaline-earth metals are converted into the corresponding sulfates;(iii) a conversion reaction (2) in which said sulfates together with silica are converted into the corresponding silicates, the heat supply needed for this conversion being provided, at least in part, by a combustion reaction (3) using a submerged burner or a plurality of submerged burners.

Owner:SAINT-GOBAIN GLASS FRANCE

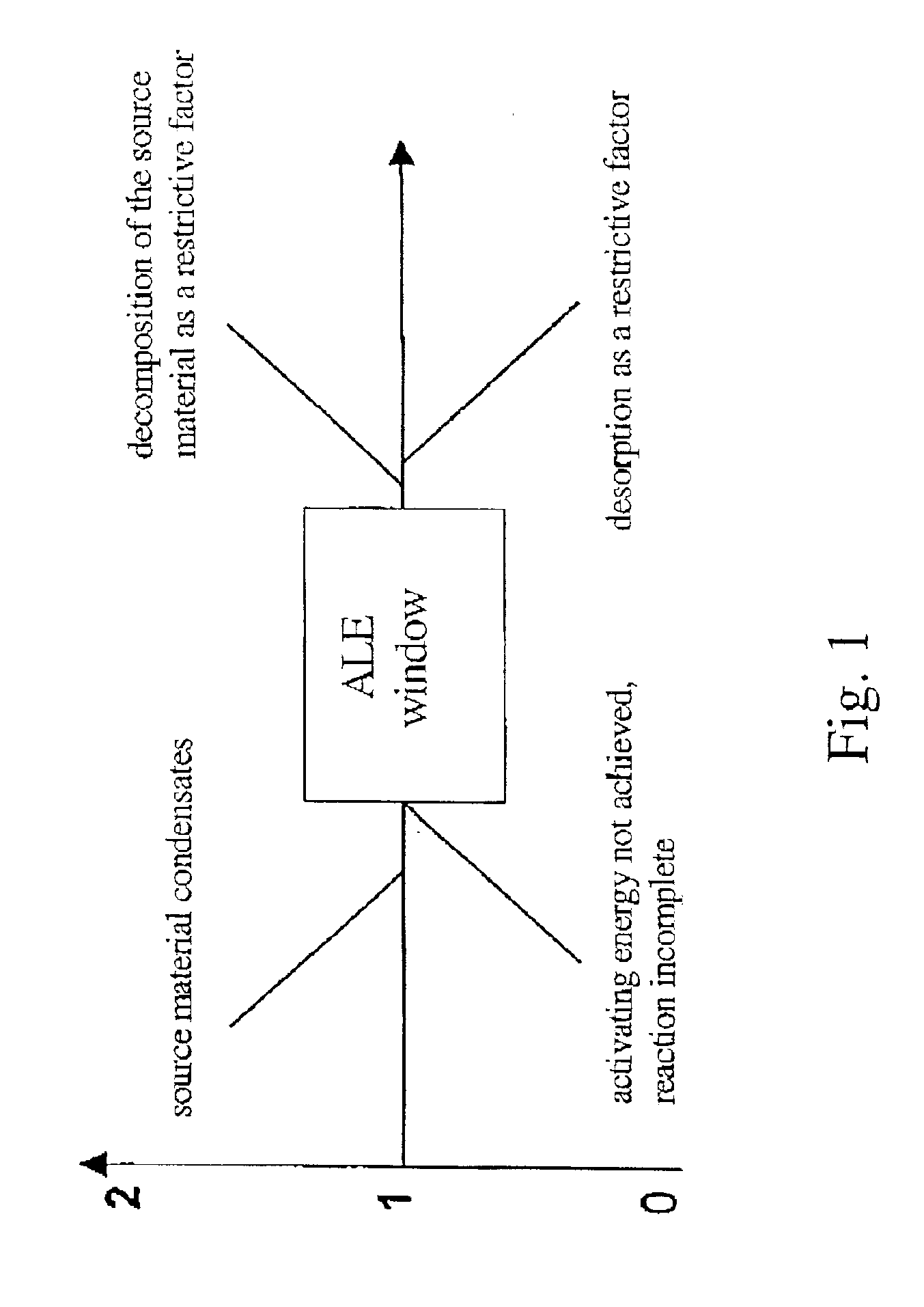

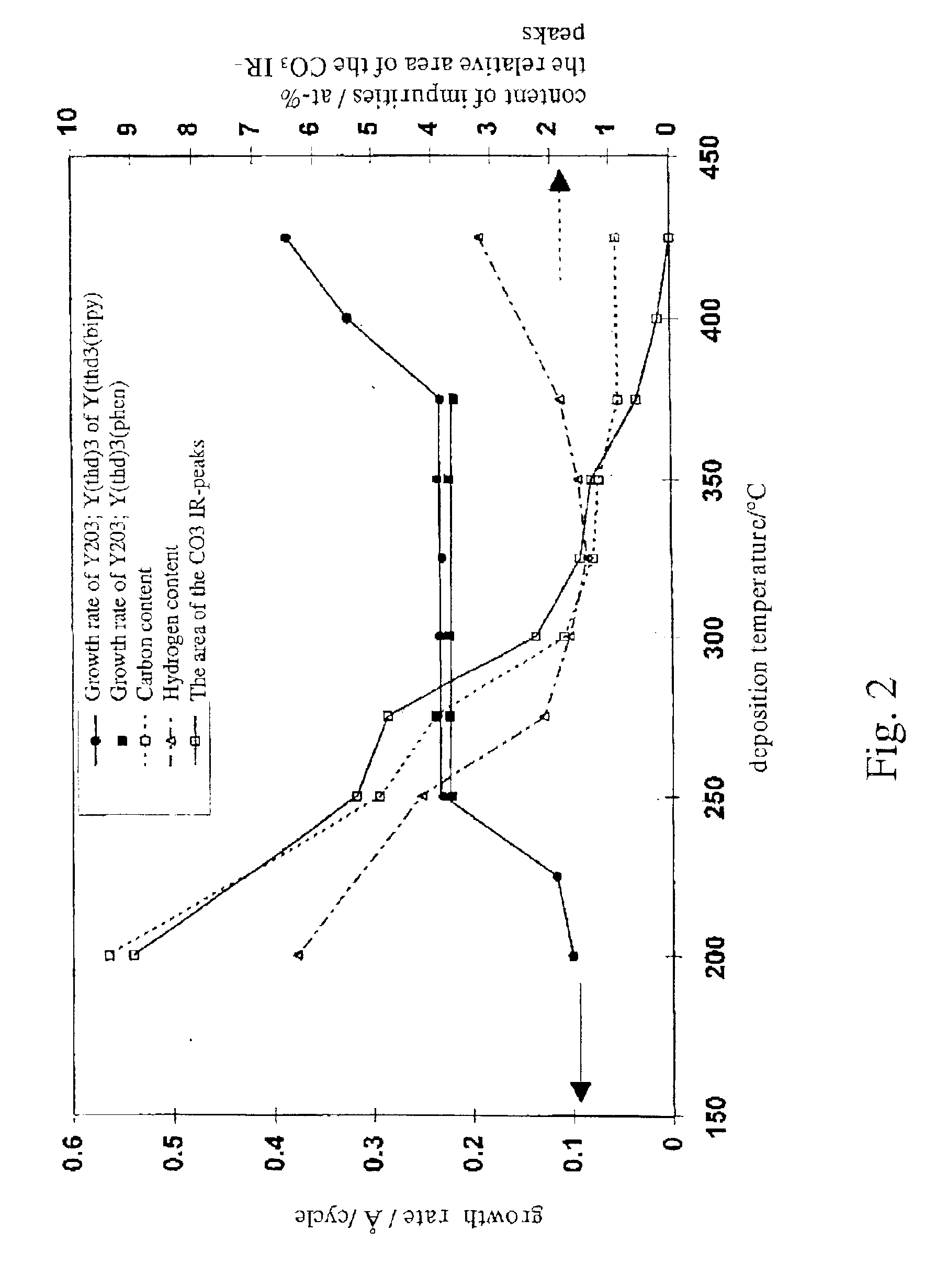

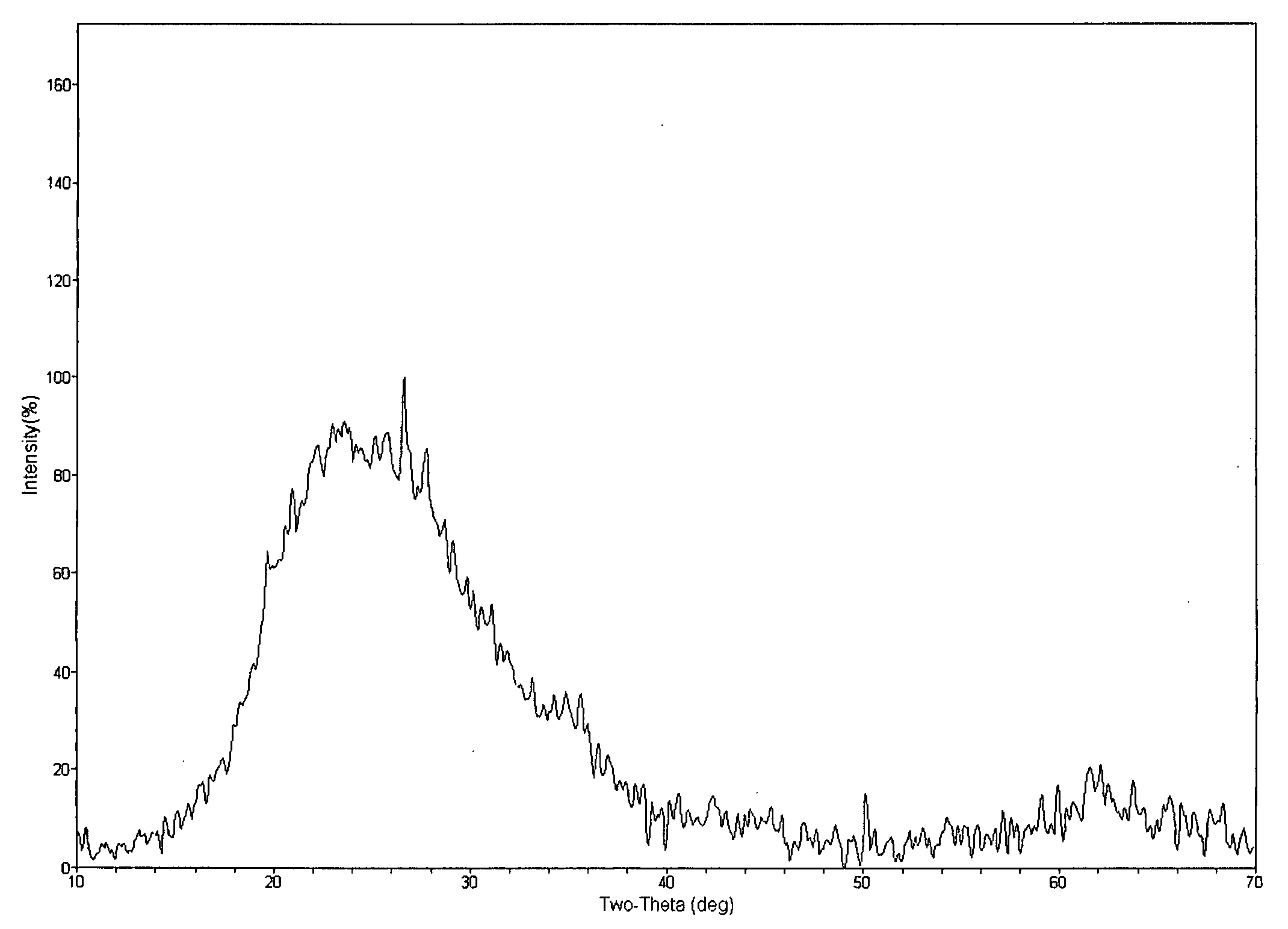

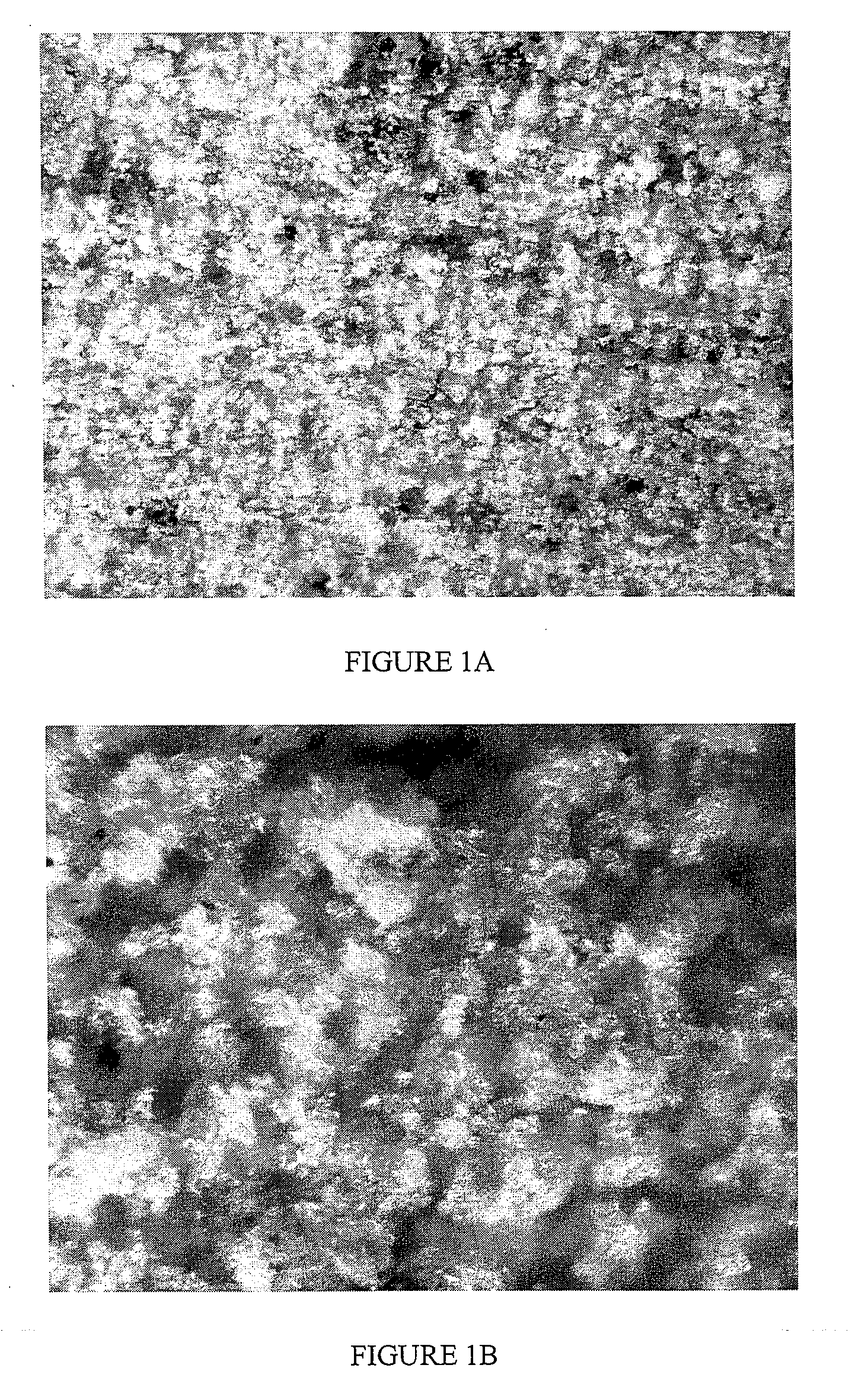

Method of depositing rare earth oxide thin films

InactiveUS6858546B2Increase probabilityIncrease ratingsPolycrystalline material growthSemiconductor/solid-state device manufacturingDeposition temperatureGadolinium

The present invention concerns a process for depositing rare earth oxide thin films, especially yttrium, lanthanum and gadolinium oxide thin films by an ALD process, according to which invention the source chemicals are cyclopentadienyl compounds of rare earth metals, especially those of yttrium, lanthanum and gadolinium. Suitable deposition temperatures for yttrium oxide are between 200 and 400° C. when the deposition pressure is between 1 and 50 mbar. Most suitable deposition temperatures for lanthanum oxide are between 160 and 165° C. when the deposition pressure is between 1 and 50 mbar.

Owner:ASM INTERNATIONAL

Pumice containing compositions for cementing a well

ActiveUS20090105099A1Reduce carbon dioxide emissionsReduce CO<subSolid waste managementFlushingWell cementingOil well

A cement composition comprises fine pumice particles, for use in cementing subterranean wells, and oil and gas wells in particular. The pumice containing cement blends feature enhanced compressive strength, and favourable compressive strength to Young's Modulus ratios. Lightweight cement blends containing pumice, and their use in cementing oil and gas wells are also described.

Owner:SANJEL ENERGY SERVICES INC

Removal of minerals from cellulosic biomass

InactiveUS7503981B2Reduce mineral contentEnhancing cellulosic saccharificationNon-fibrous pulp additionSpecial paperCellulosePre treatment

Disclosed is a method for removing minerals from a cellulosic biomass. For example, the biomass may be prewashed with an acid solution and rinsed with water to remove minerals prior to acid saccharification. The removal of minerals may reduce overall acid requirements, and decrease pretreatment costs.

Owner:TRUSTEES OF DARTMOUTH COLLEGE THE

Mullite-aluminum titanate body and method for making same

InactiveUS20060021308A1Low thermal expansionHigh thermal shock resistanceInternal combustion piston enginesDispersed particle filtrationYttriumBismuth preparation

This invention relates to a mullite-aluminum titanate body having a low coefficient of thermal expansion of less than 15×10−7 C−1, a high porosity of at least 38% by volume, a median pore diameter of at least 8 microns, and a narrow pore size distribution as characterized by the relation (d50-d10) / d50 being less than 0.50 corresponding to a high degree of interconnected porosity. The inventive ceramic body also contains at least 0.10% by weight metal oxide, the metal being either yttrium, calcium, bismuth, a lanthanide metal or combinations of thereof. The inventive ceramic body is particularly useful as a wall-flow filter for diesel exhaust. A method of fabrication is provided where the sintering temperature is between 1375°-1550° C.

Owner:CORNING INC

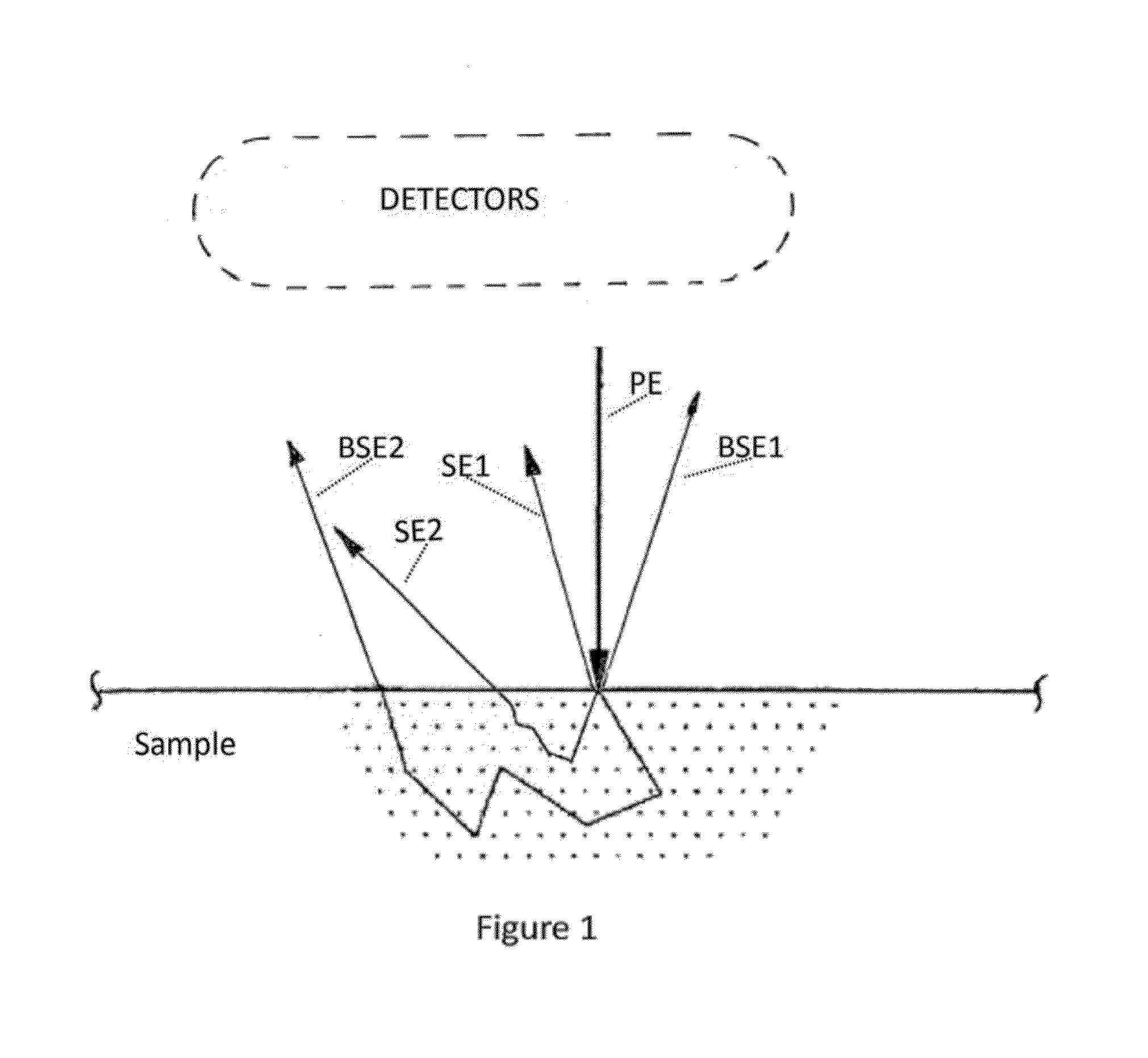

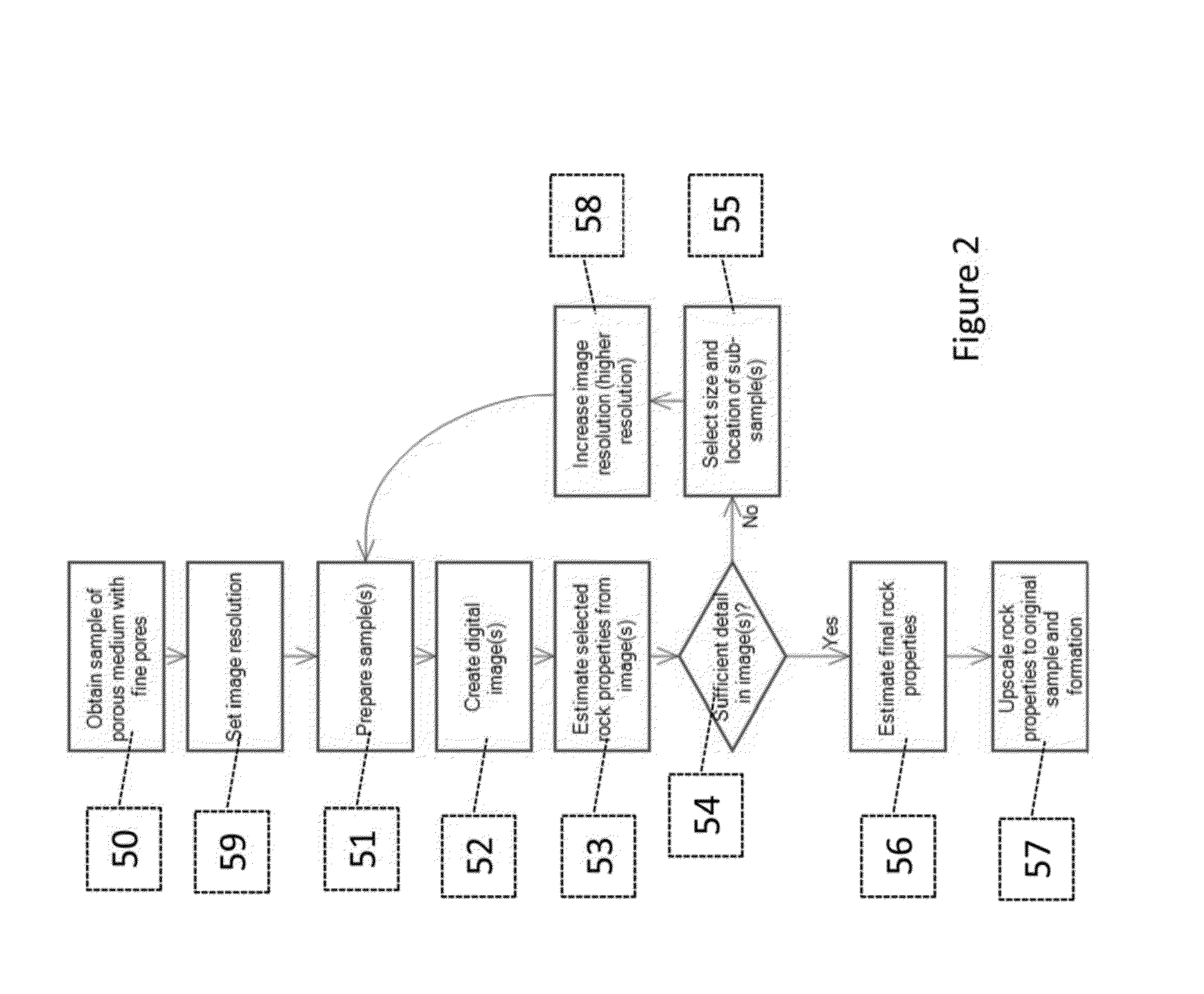

Method And System For Estimating Properties Of Porous Media Such As Fine Pore Or Tight Rocks

A method for estimating properties of porous media, such as fine pore or tight rocks, is provided. The method comprises digital image scanning of sequential sub-samples of porous media at progressively higher resolution to systematically identify sub-sections of interest within the original sample and then estimate properties of the porous media. The resulting properties of the porous media then can be optionally upscaled to further estimate the properties of larger volumes of the porous media such as rock facies or subterranean reservoirs. A system operable for conducting the method also is provided.

Owner:HALLIBURTON ENERGY SERVICES INC

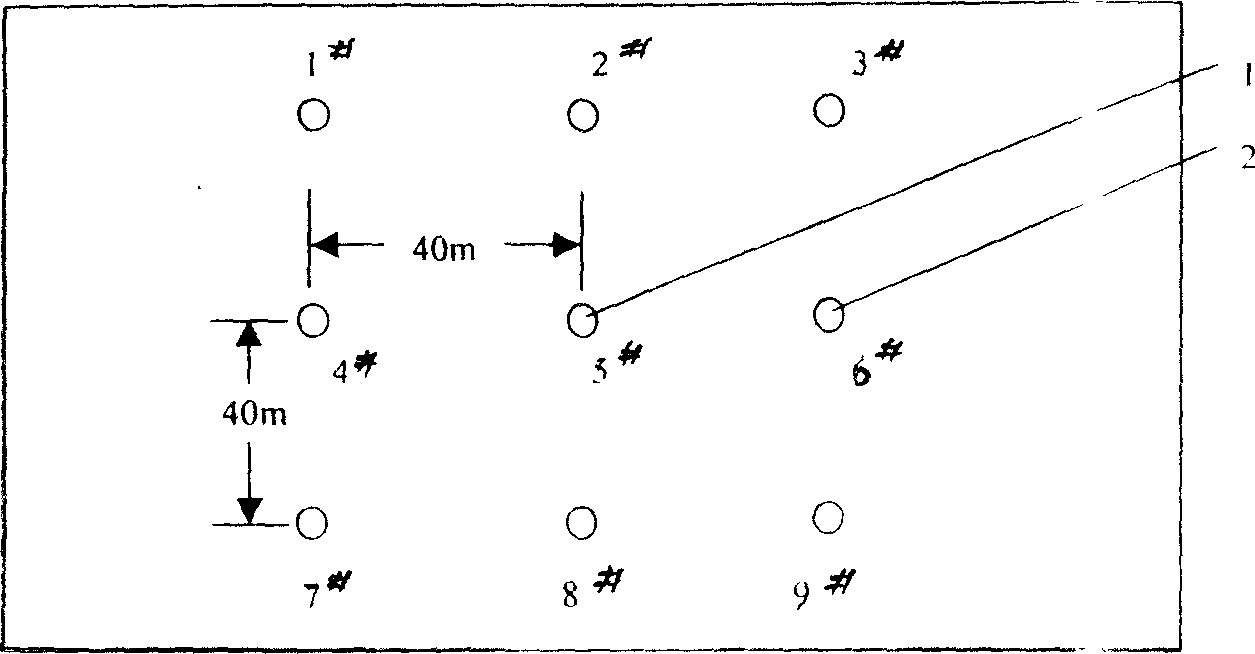

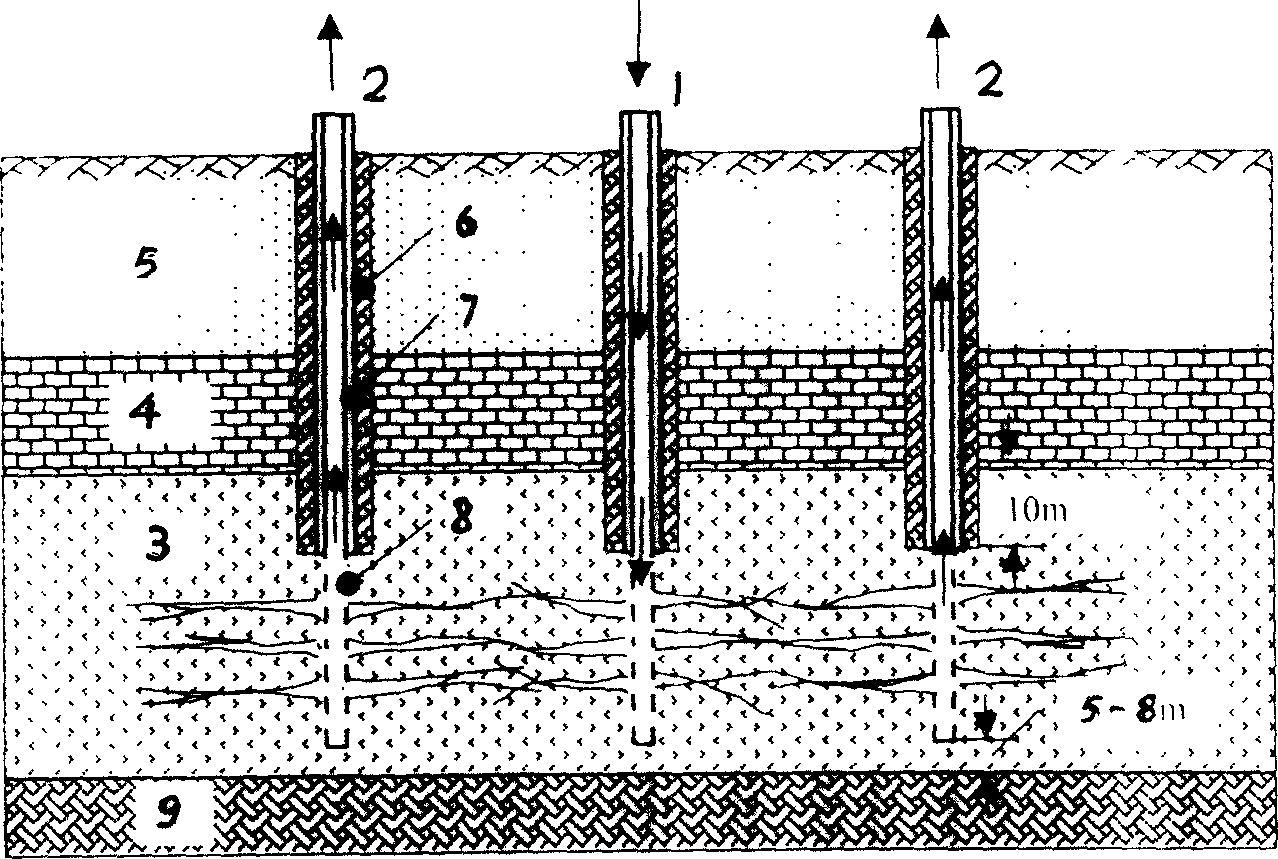

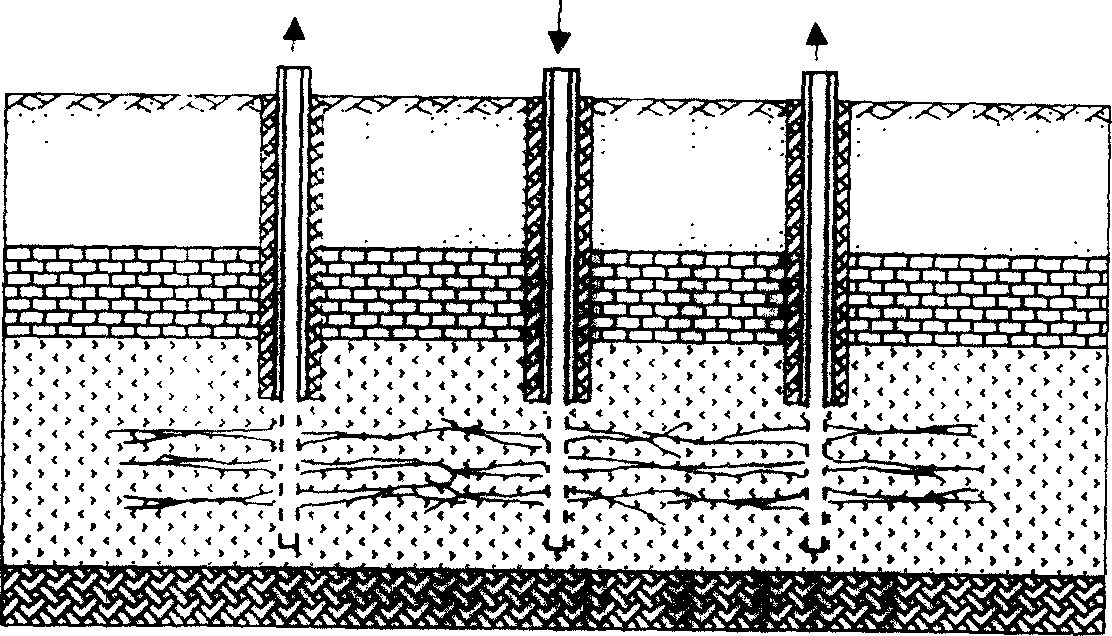

Method for extracting oil and gas by convection heating of oil shale

A kind of mining oil gas method of the convection heating up oil-shale, involves the underground solid state energy and the mineral mining method improvement. The existing technical mining method efficiency is low, the cost is high, the scale is small, the big area implements and lacks the market competition ability with difficulty. This invention through in the ground arrangement group well, and selects the compression fracture method causes the group well to be interlinked, then the gap takes turns to choose the note hot-well and work-well, hot-well pours into 400 deg.C - 700 deg.C steam along the note oil-shale the ore level, heats up the ore level causes cheese root thermal decomposition to form the oil gas, and carries after the low temperature steam or the water along the production separates to the ground, finally forms the oil gas product. In the separation process may simultaneously the pre- hot water, and uses the water-injection well withdraws with work-well the convection way dries up oil-shale and the ore level around shale region afterheat, thus realized the goal of this invention is fast, big scale, low cost from oil-shale ore level mining oil gas.

Owner:TAIYUAN UNIV OF TECH

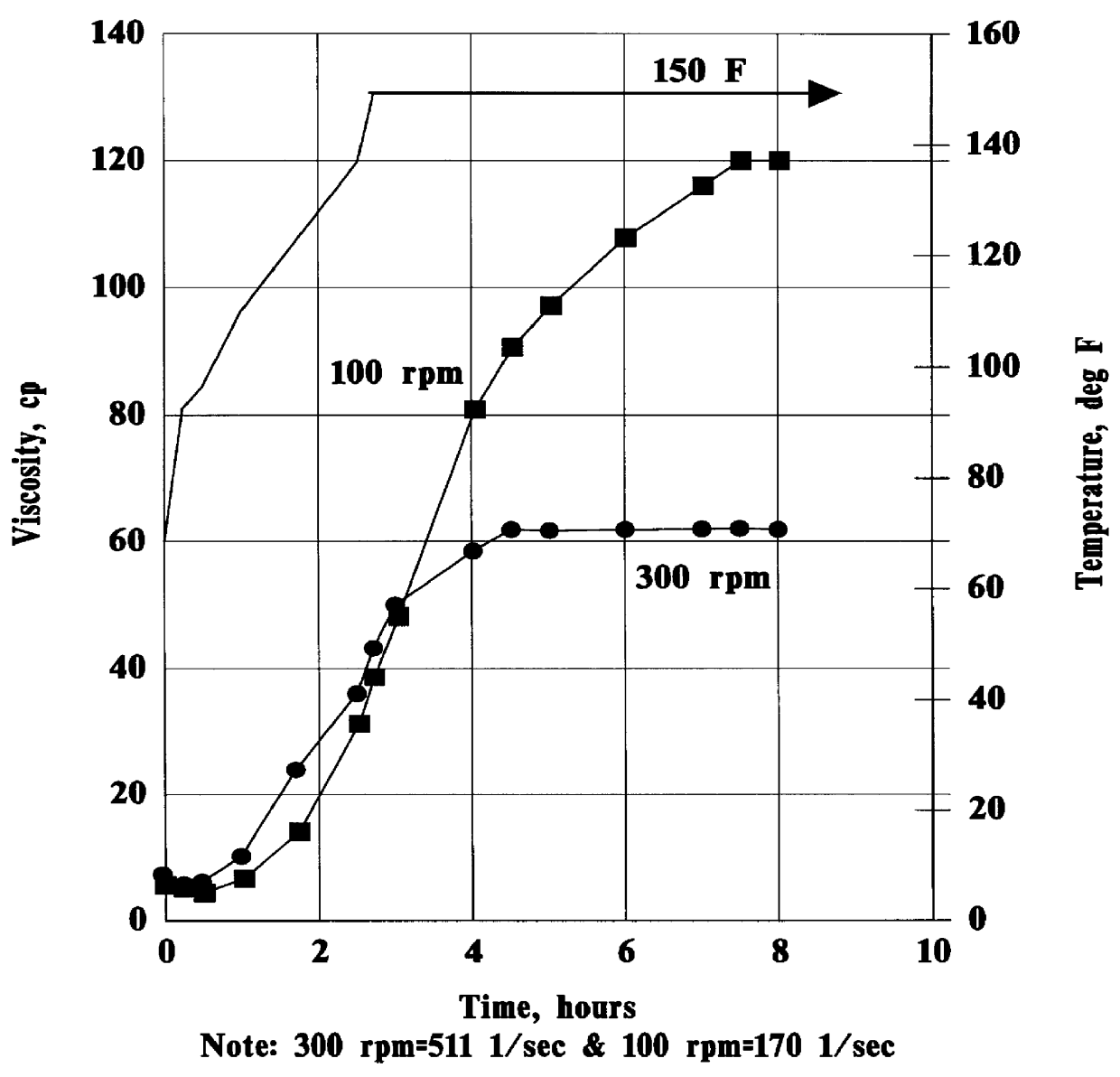

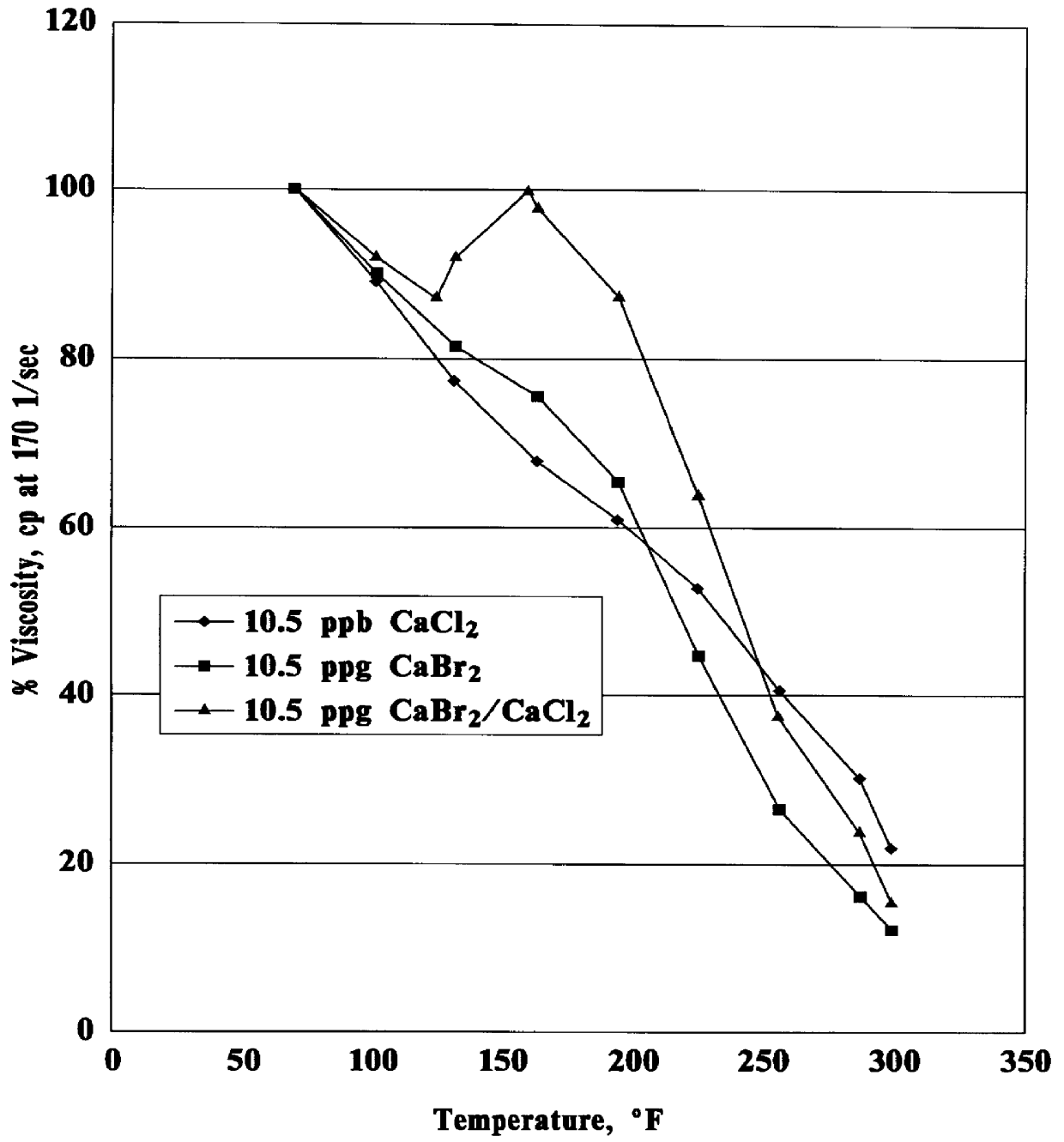

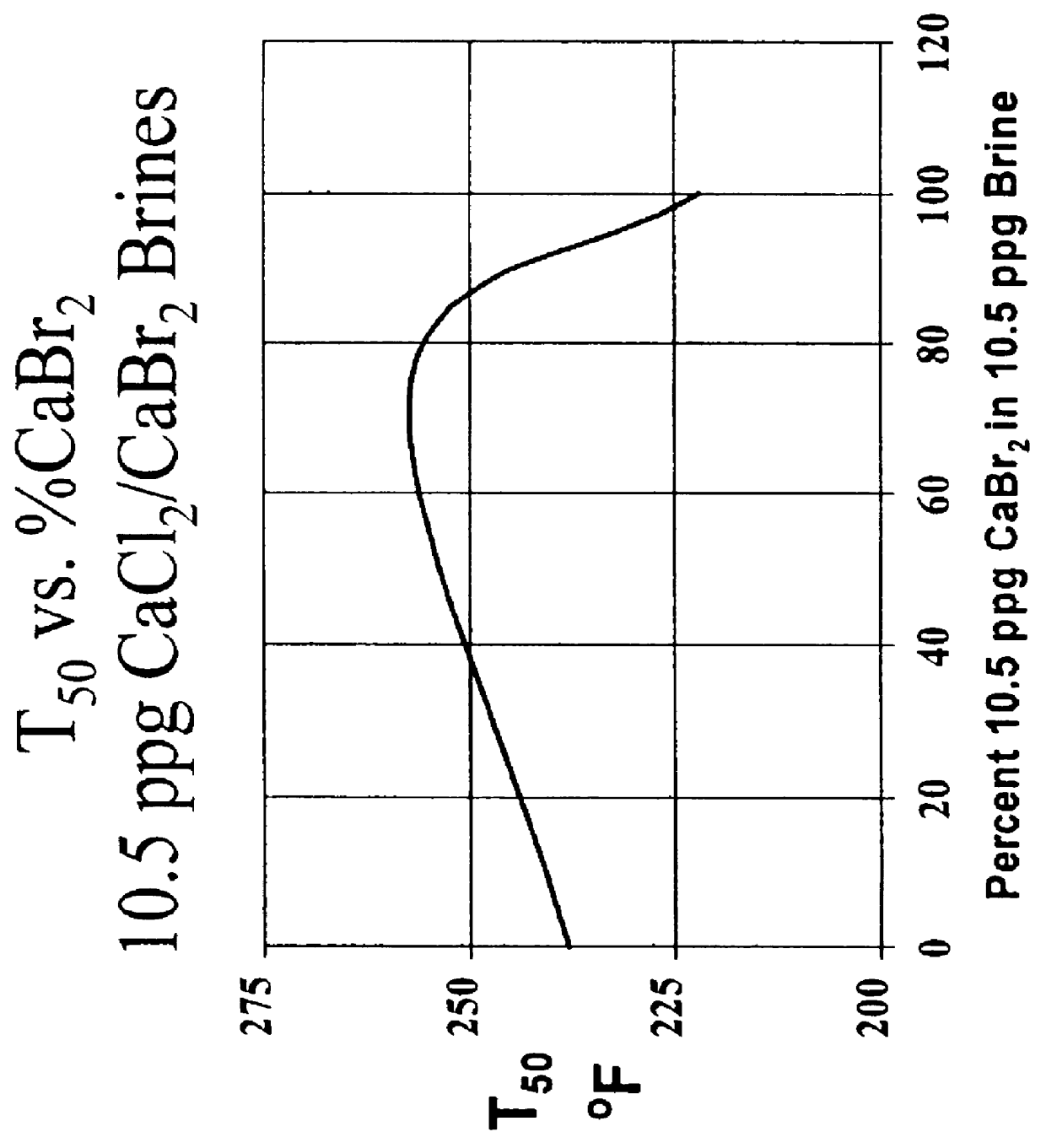

High density, viscosified, aqueous compositions having superior stability under stress conditions

Owner:BJ SERVICES CO

Calcium phosphate cement composition and a method for the preparation thereof

ActiveUS6929692B2Good water solubilityIncreased formationOther chemical processesBone implantChemical synthesisCalcium biphosphate

The invention describes a new calcium phosphate cement powder, whose composition can best be described over the Ca / P molar ratio range of 1.35 to 1.40, most preferably 1.39, and whose two components were prepared by wet chemical synthesis procedures. One component is chemically-synthesized, bi-phasic alpha-TCP (Ca3(PO4)2, 95 wt %)+HA (Ca10(PO4)6(OH)2, 5 wt %) powder, while the second component is again a chemically-synthesized, single-phase DCPD (CaHPO4·2H2O) powder. A setting solution (Na2HPO4·2H2O) is used to form a self-setting calcium phosphate cement from the powder mixture. This cement can be used as bone filler or bone substitute in applications, which require higher rates of resorption.

Owner:DR AHMET CUNEYT TAS

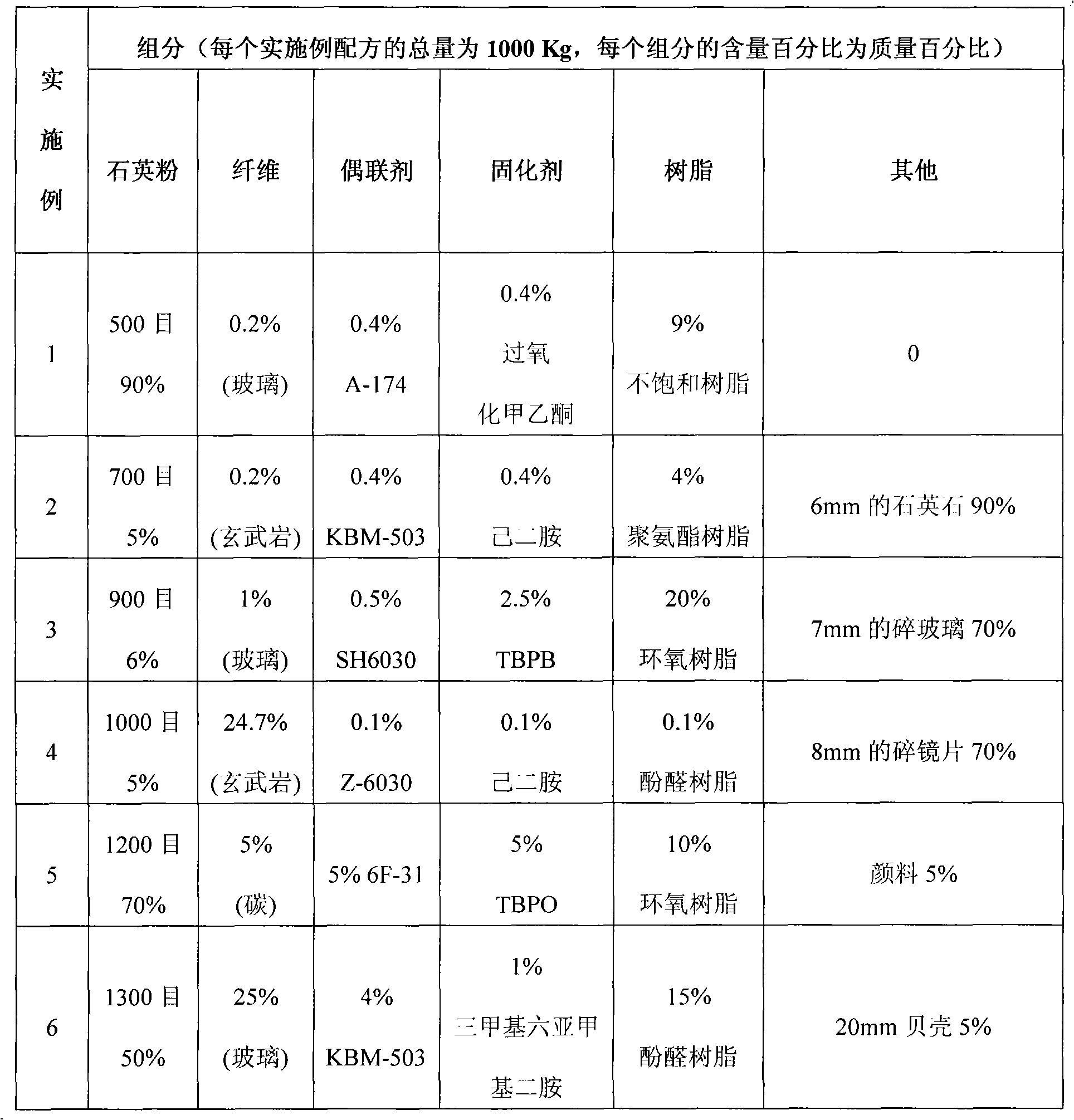

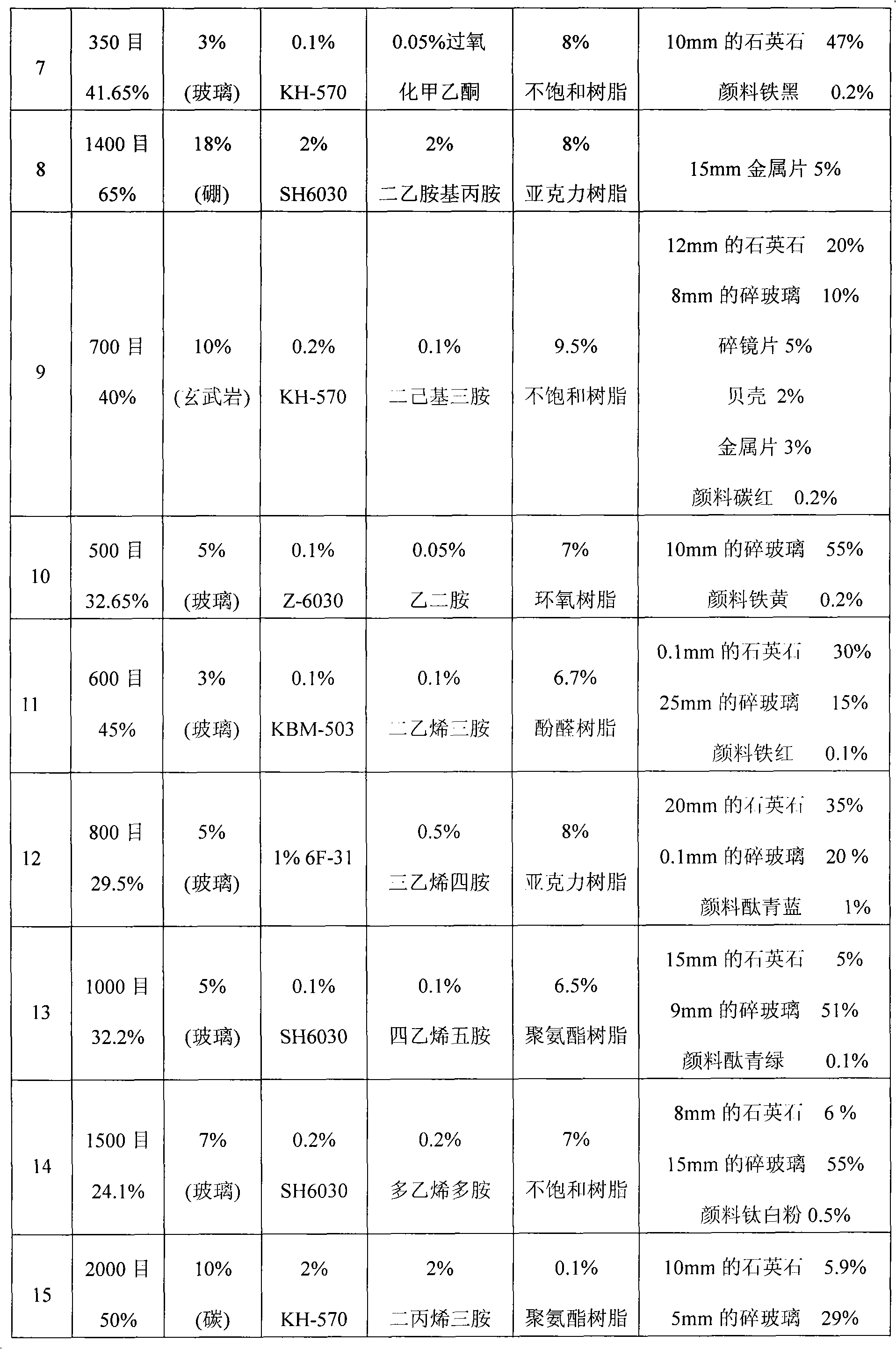

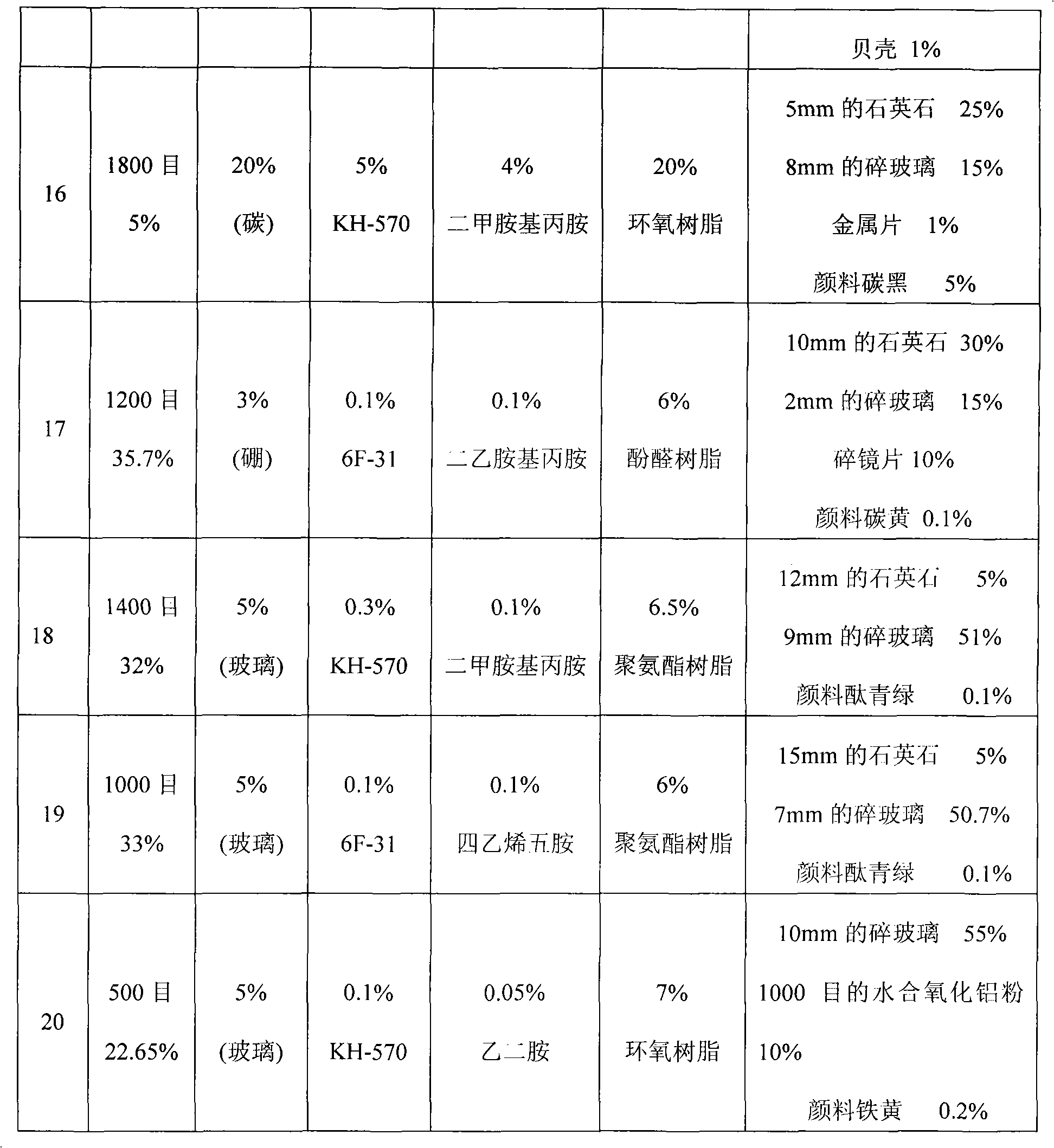

Artificial quartz in lump and fabrication technology thereof

The invention discloses a man-made quartz stone, which comprises 0 to 90 percent of quartz stone, 5 to 90 percent of silica flour, 1 to 25 percent of fiber, 0.1 to 20 percent of resin, 0.1 to 5 percent of a coupling agent, 0.1 to 5 percent of a curing agent, 0 to 70 percent of cullet, 0 to 70 percent of broken glass block, 0 to 5 percent of paint, 0 to 5 percent of shell, 0 to 5 percent of metal sheet by mass. The tear resistance, the compressive strength and the buckling strength of the man-made quartz stone are significantly improved compared with the prior man-made quartz stone. The invention further relates to a manufacturing process for a man-made quartz stone plate or block and vessel.

Owner:张璐 +1

Novel vaccine formulations

ActiveUS20060233831A1Improve stabilityStable and safe and easily administrableAntibacterial agentsBiocideAdjuvantNon ionic

The present invention relates to oil-in-water emulsions, their use as adjuvants, and pharmaceutical, immunologic, or vaccine compositions that may comprise the same. In one embodiment, the oil-in-water (O / W) emulsion may comprise an aqueous solution containing an immunogen, a mineral oil, a non-ionic lipophilic ethoxylated fatty alcohol and a non-ionic hydrophilic surfactant. In another embodiment, the oil-in-water (O / W) emulsion may comprise an aqueous solution containing an immunogen, a non-ionic lipophilic surfactant, a mineral oil and a non-ionic hydrophilic ethoxylated fatty alcohol. The present invention also encompasses a method of making a vaccine composition using the adjuvant of the instant invention, the vaccine composition so obtained and methods of use.

Owner:MERIAL INC

Storable water-microsphere suspensions for use in well cements and methods

Storable water-microsphere suspensions for use in well cements and methods of cementing well bores are provided. The storable water-microsphere suspensions are basically comprised of water, microspheres and an effective amount of a suspending agent selected from the group consisting of microfine or colloidal materials and gel forming polymers.

Owner:HALLIBURTON ENERGY SERVICES INC

Complex admixture and method of cement based materials production

The present invention relates to admixtures production and to a method of application of the admixtures in cement and concrete technology. The method allows production of high-strength and high durable cement based systems, as well as cement systems with specially designed properties or cheap high-volume mineral admixture cements.

Owner:SCI CON TECH

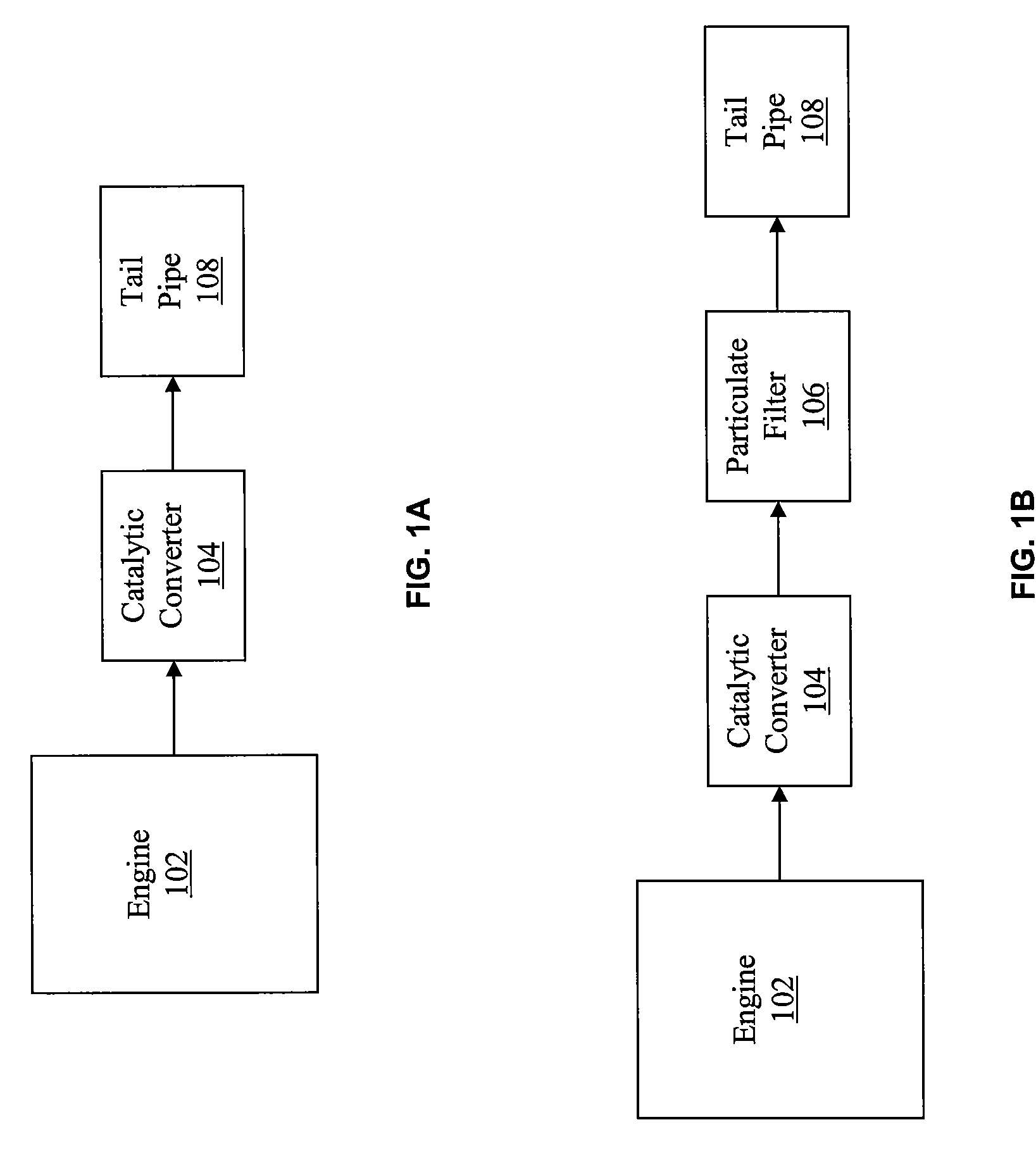

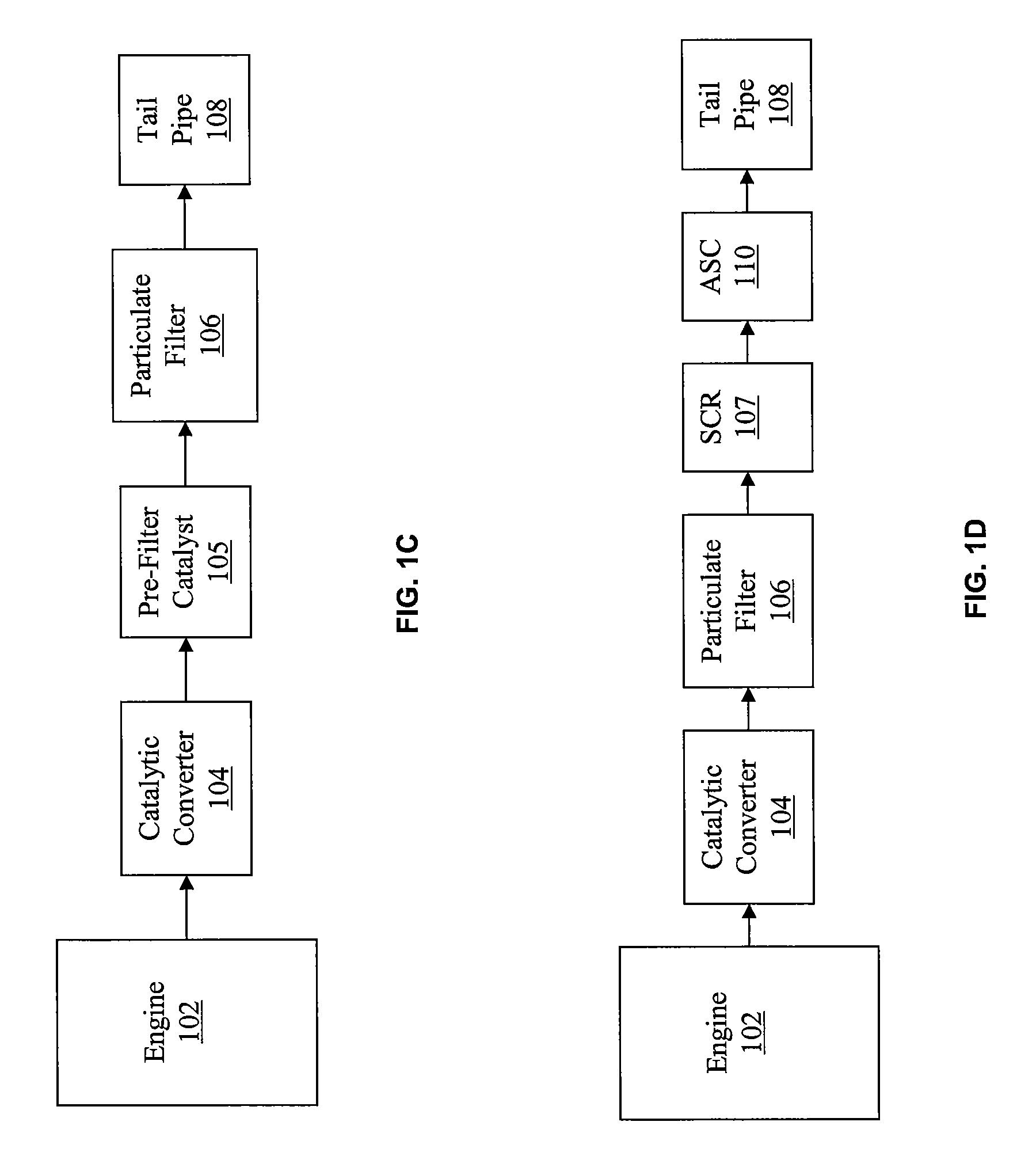

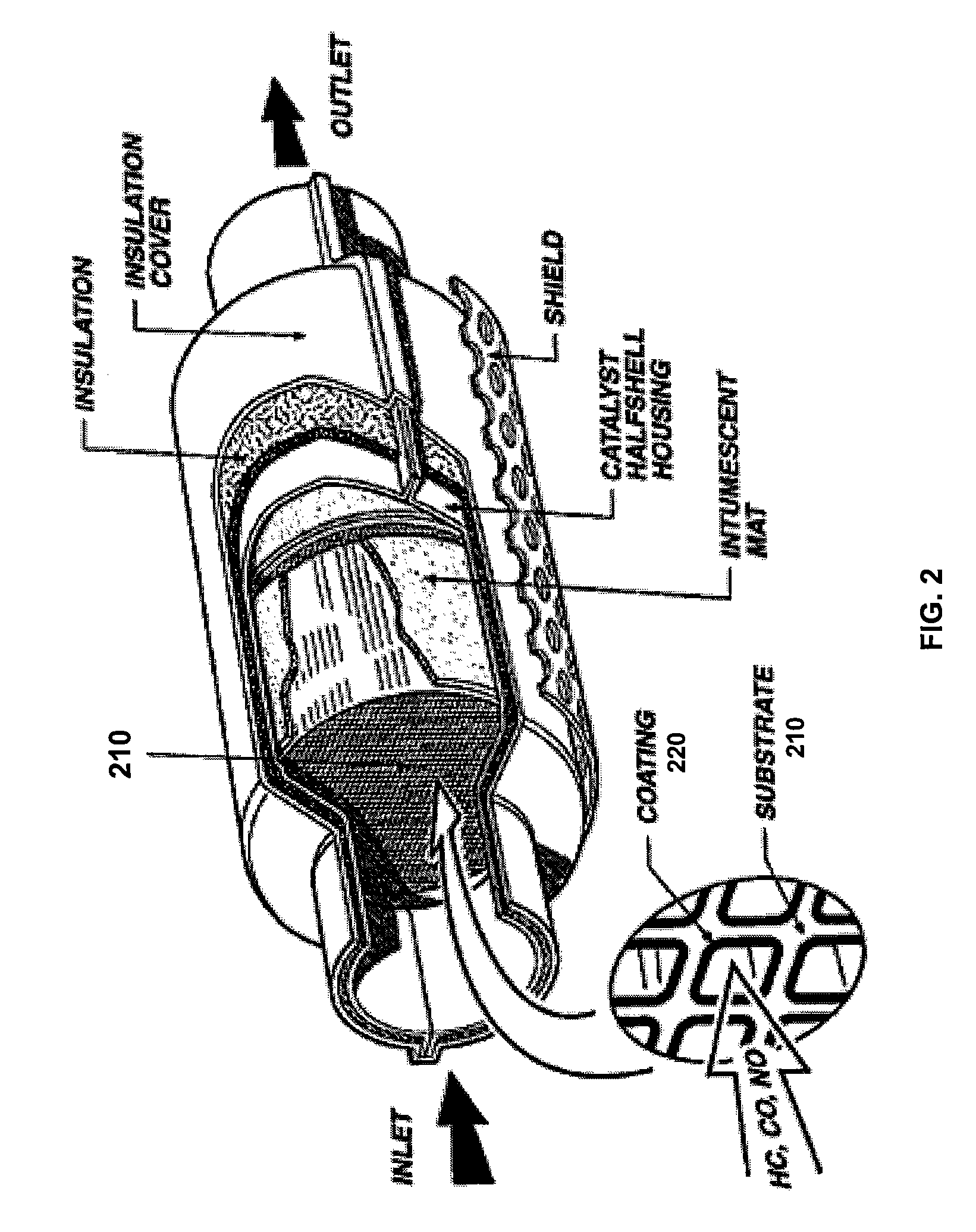

Engine exhaust catalysts containing zeolite and zeolite mixtures

A multi-layer emission control catalyst exhibits improved CO and HC reduction performance. The bottom layer includes a supported catalyst comprising platinum and palladium particles or palladium and gold particles. The middle layer includes zeolites. The top layer includes a supported catalyst comprising platinum and palladium particles. The use of zeolite mixture in the middle layer further improves CO and HC reduction performance in comparison with using zeolite of a single type. The use of a supported catalyst comprising palladium and gold particles in the bottom layer further improves CO and HC reduction performance in comparison with using a supported catalyst comprising platinum and palladium particles.

Owner:WGC HLDG LTD

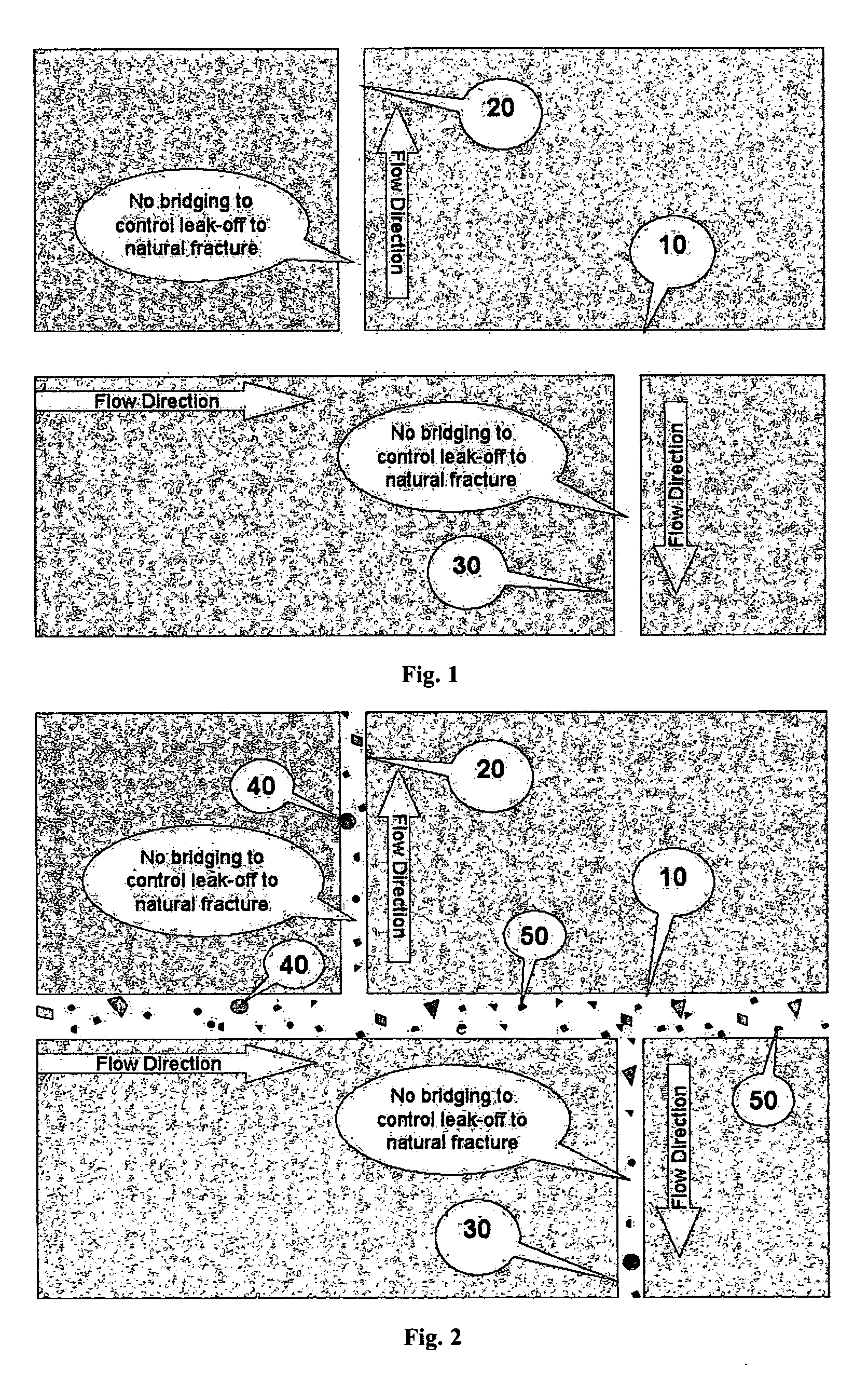

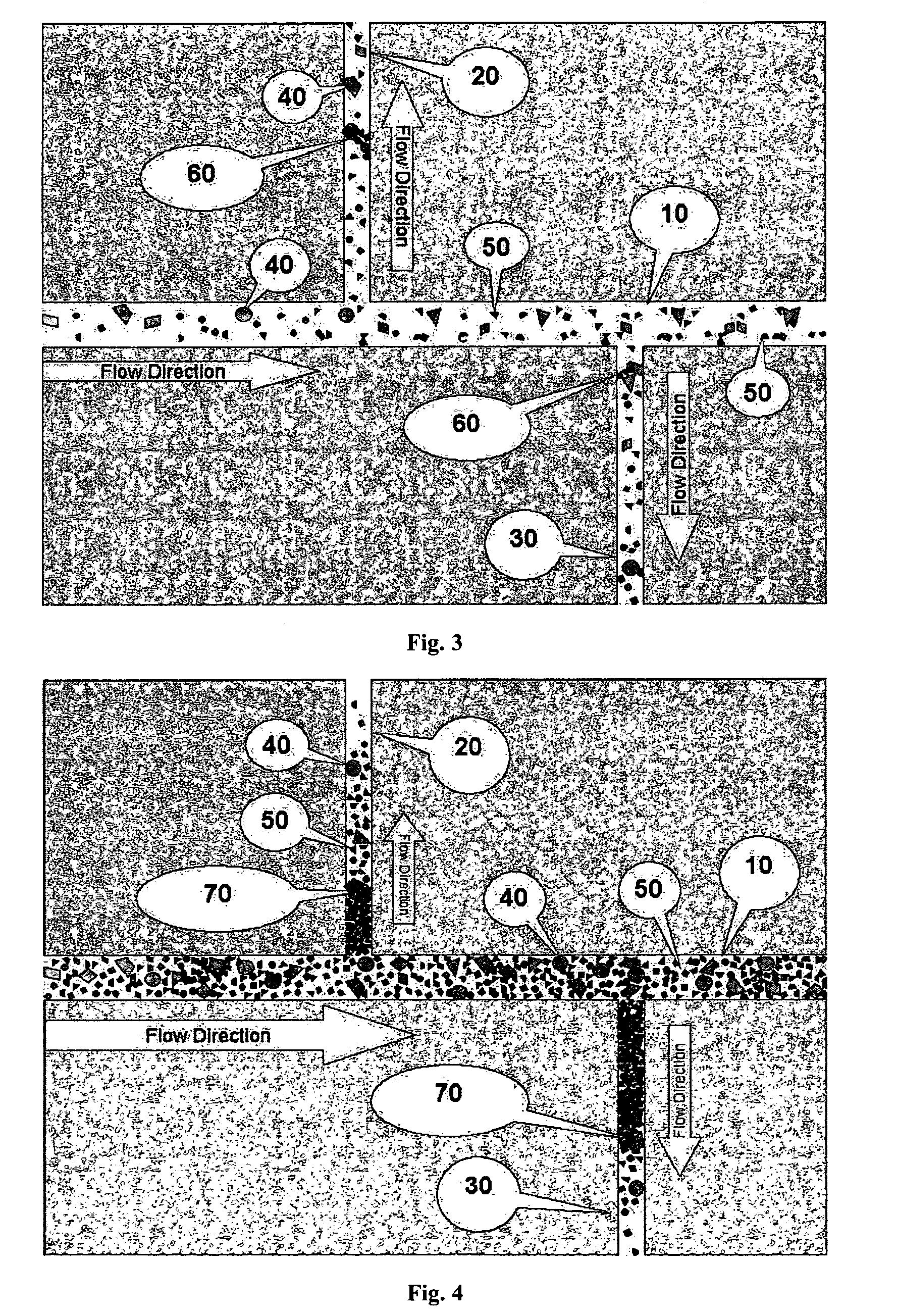

Method of enhancing hydraulic fracturing using ultra lightweight proppants

ActiveUS20060065398A1Improve productivityEnhances effective fracture lengthFluid removalCarbon-dioxide storageFracturing fluidHydraulic fracturing

A subterranean formation having natural fractures, which is to be subjected to hydraulic fracturing, is first pre-treated with an ultra lightweight (ULW) proppant having an average particle size between from about 12 / 20 to about 40 / 70. The small ULW proppant flows into the natural fractures and packs the fractures. The formation is then subjected to hydraulic fracturing. The pre-treatment serves to enhance the effective propped fracture length of the formation during the hydraulic fracturing by reducing the loss of fluid from the subsequently pumped fracturing fluid. The method is applicable to hydrocarbon bearing formations as well as non-hydrocarbon bearing formations and has particular applicability to coal beds.

Owner:BAKER HUGHES INC

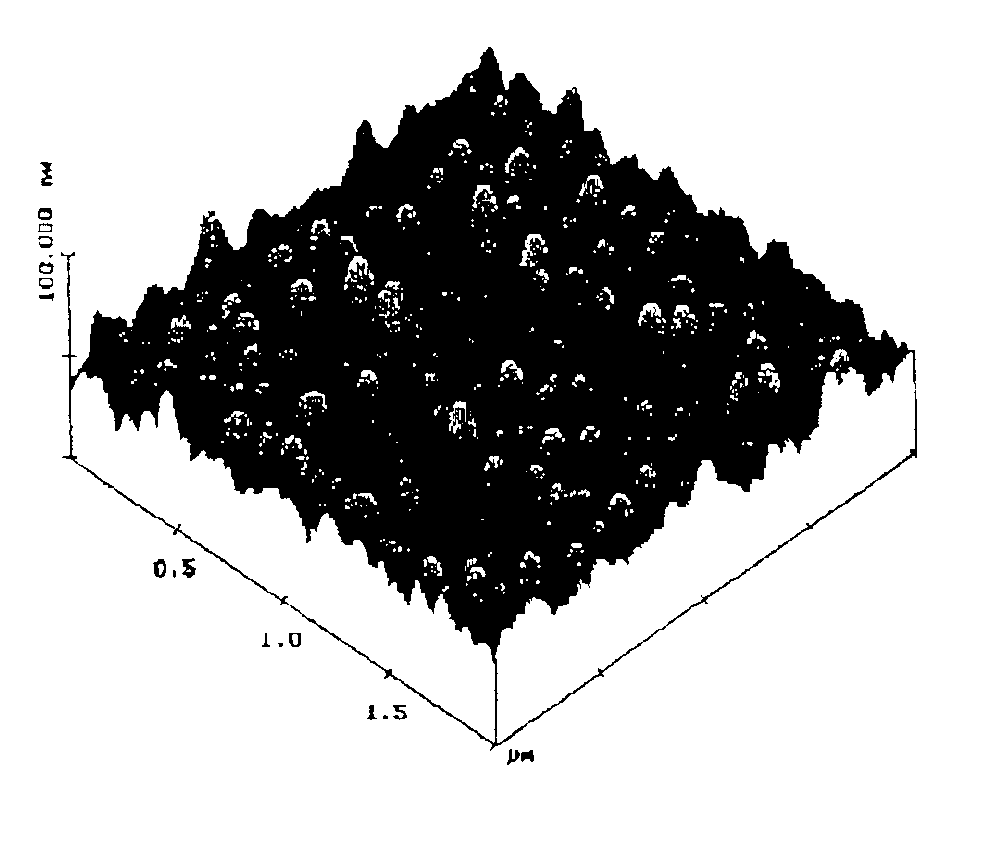

Porous body precursors, shaped porous bodies, processes for making them, and end-use products based upon the same

ActiveUS20110136659A1Low costShorten the timeOrganic chemistryMolecular sieve catalystsPore diameterProduct base

The present invention provides porous body precursors and shaped porous bodies. Also included are catalysts and other end-use products based upon the shaped porous bodies and thus the porous body precursors. Finally, processes for making these are provided. The porous body precursors, comprise one or more topography-enhancing additives, i.e., additives that are capable of at least marginally enhancing one or more of surface area, aspect ratio, pore volume, median pore diameter, surface morphology, etc. Downstream products need not necessarily comprise the topography-enhancing additives in order to exhibit the benefits of their inclusion in the porous body precursors.

Owner:DOW TECH INVESTMENTS

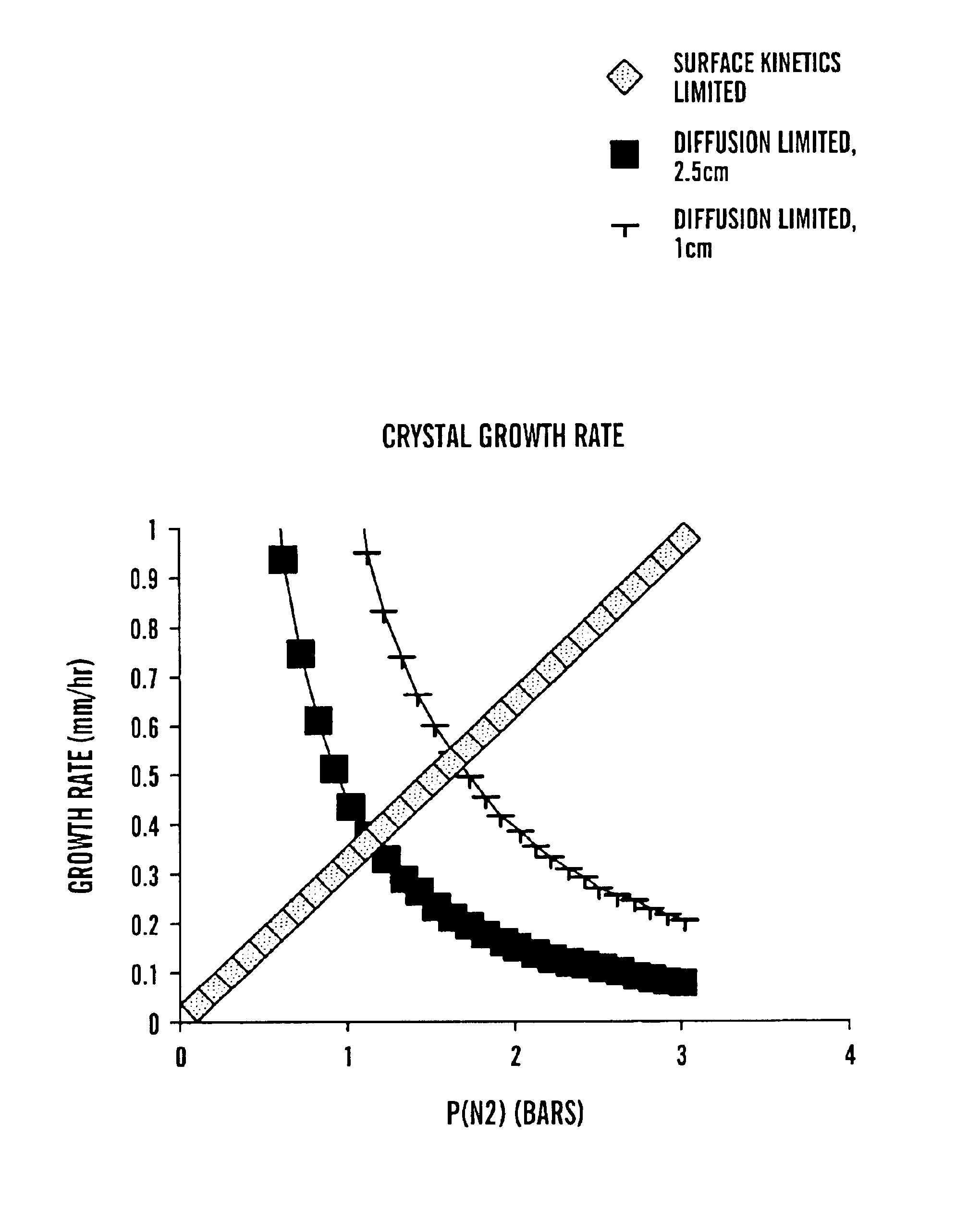

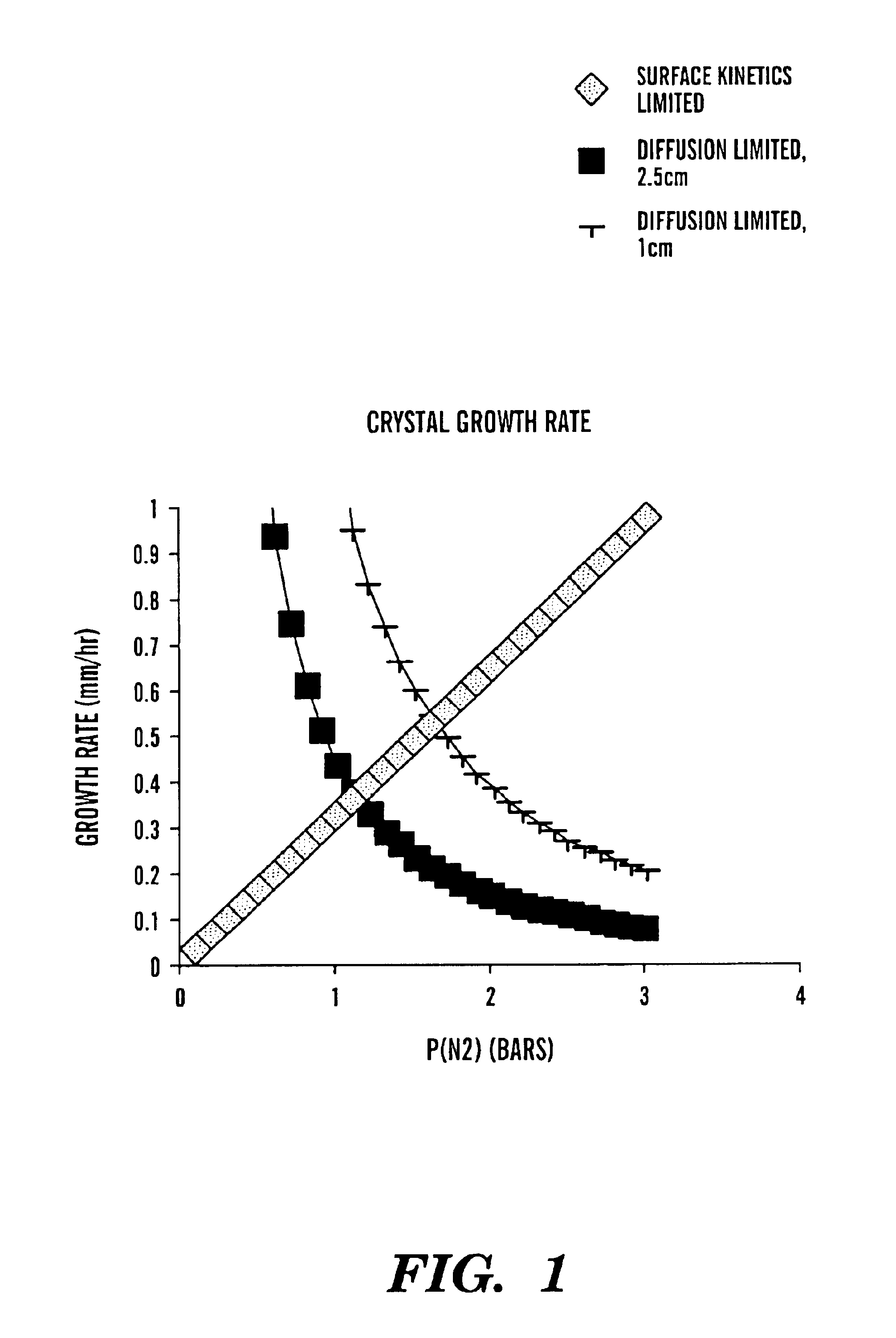

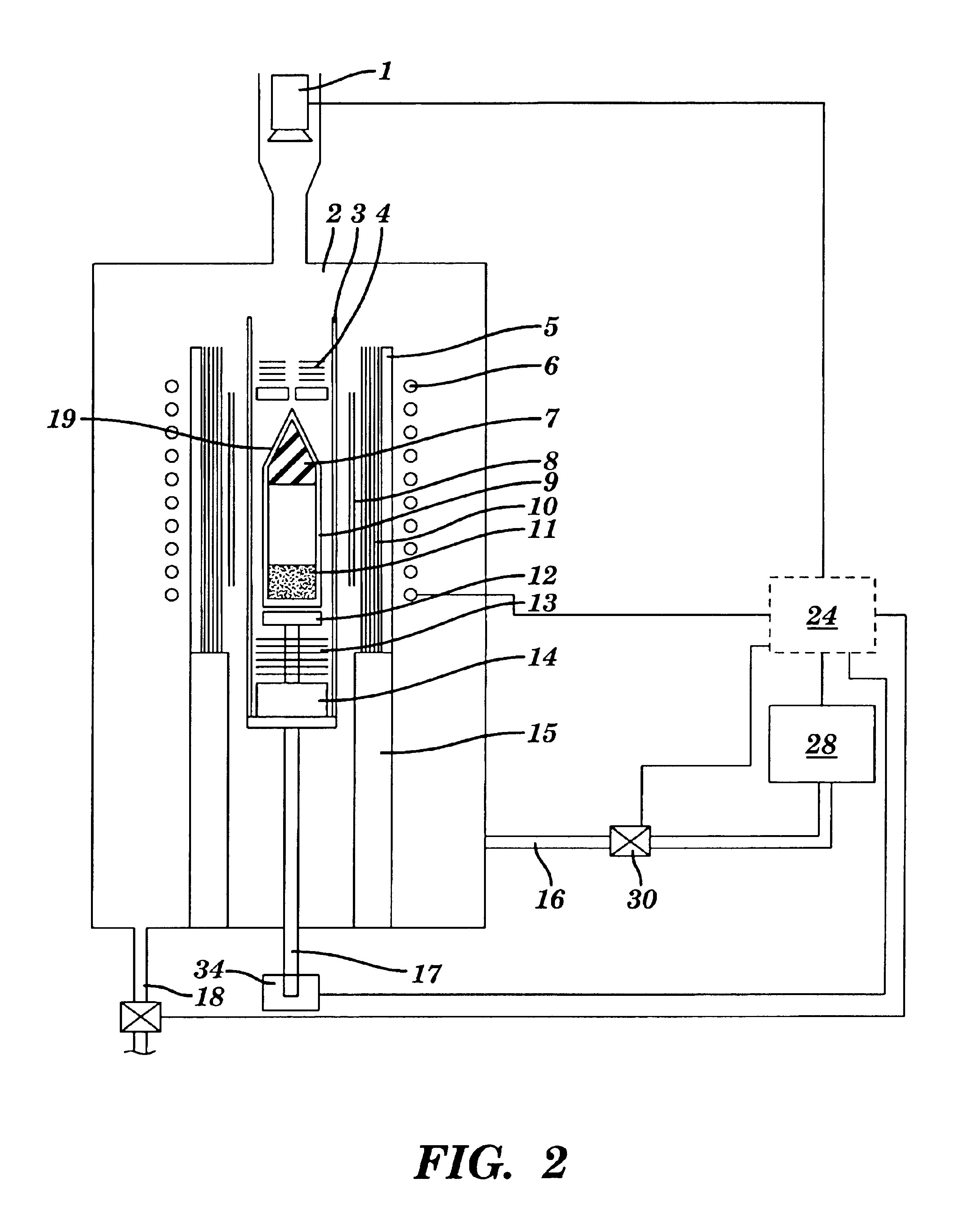

Method and apparatus for producing large, single-crystals of aluminum nitride

InactiveUS6770135B2After-treatment apparatusPolycrystalline material growthBulk crystalSource material

A method and apparatus for producing bulk single crystals of AlN includes a crystal growth enclosure with Al and N2 source material therein, capable of forming bulk crystals. The apparatus maintains the N2 partial pressure at greater than stoichiometric pressure relative to the Al within the crystal growth enclosure, while maintaining the total vapor pressure in the crystal growth enclosure at super-atmospheric pressure. At least one nucleation site is provided in the crystal growth enclosure, and provision is made for cooling the nucleation site relative to other locations in crystal growth enclosure. The Al and N2 vapor is then deposited to grow single crystalline AlN at the nucleation site.

Owner:CRYSTAL

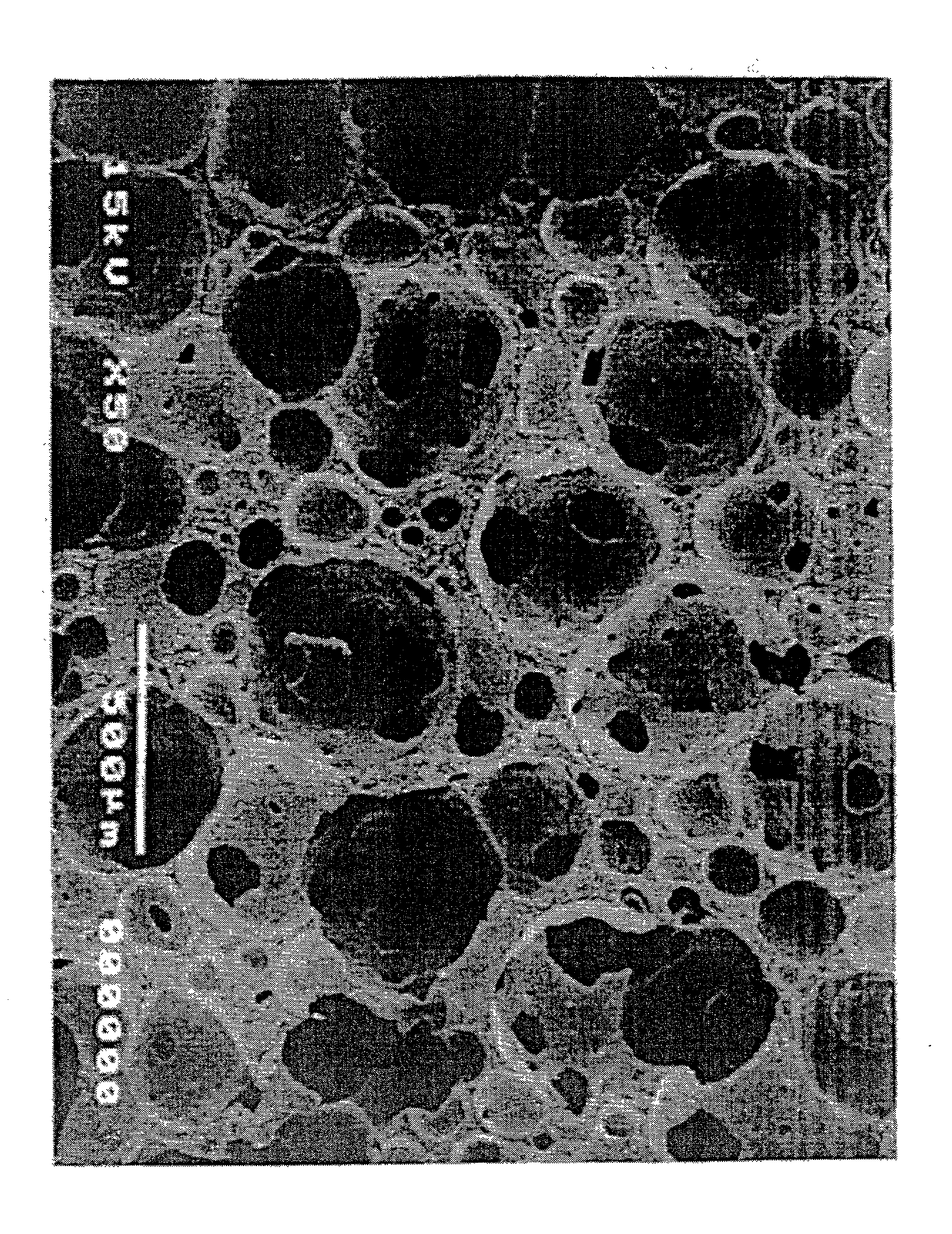

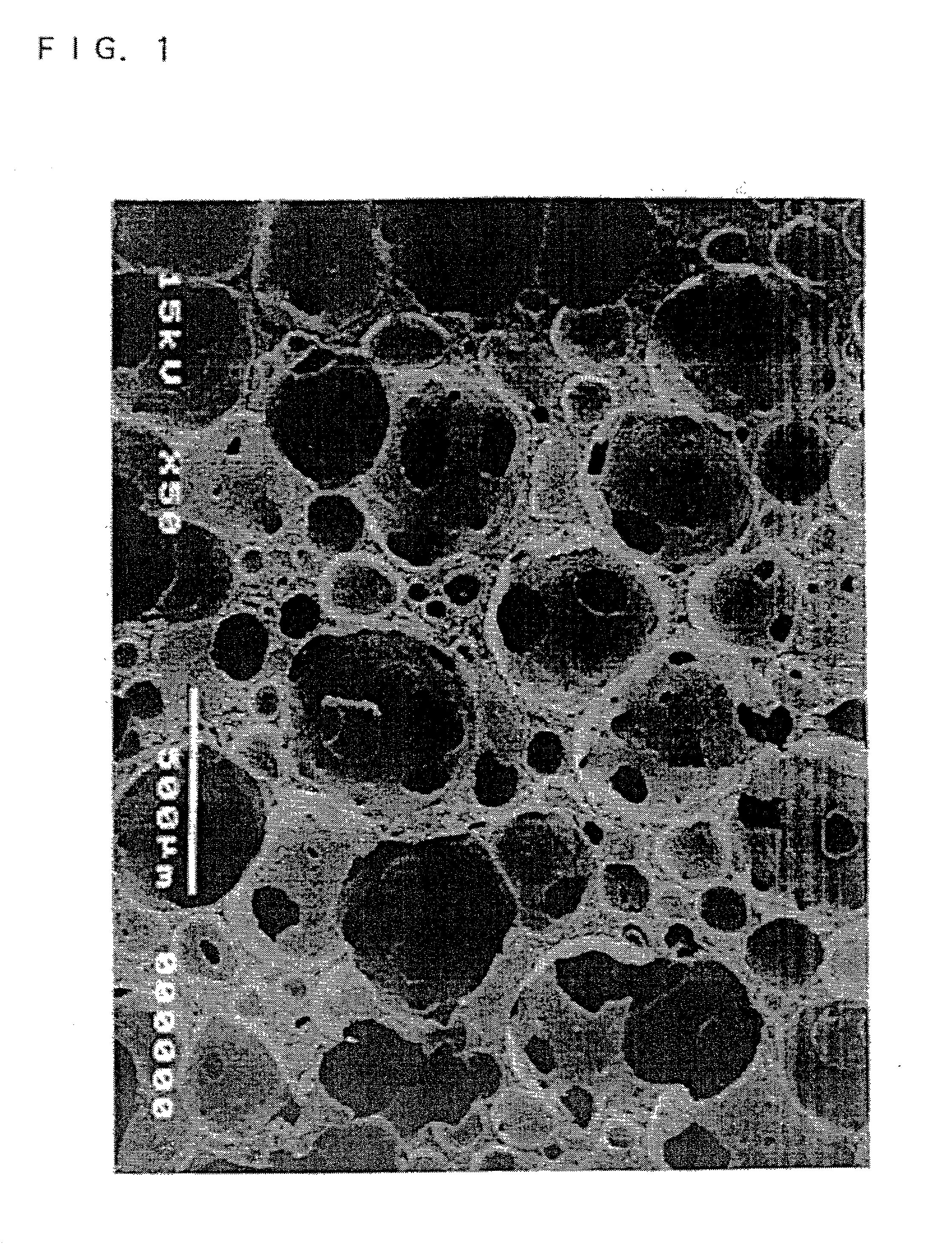

Biomaterial

InactiveUS20020022885A1Cell infiltration into an inner surface is very fastBone implantCalcium biphosphatePore diameter

A porous body is a calcium phosphates sintered body having a number of substantially globular pores 1. A porosity is not less than 55% and not more than 85%, and simultaneously, and a mean pore diameter is not less than 50 mum and not more than 800 mum. A pore 11 having a size larger than the mean pore diameter has at least three communicating pores 2 having a diameter of not less than 5 mum, on the average, and simultaneously, a pore having at least the three communicating pores 2 has at least one communicating pore 2 having a diameter of not less than 25 mum, on the average. The total opening area of the communicating pore 2 which is possessed by the pore 11 having a size larger than the mean pore diameter occupies the ratio of not more than 50% of the pore surface area. In a dry state, it is possible to wet the whole the porous body by dropping water and blood.

Owner:OCHI TAKAHIRO +2

Methods and compositions for stabilizing unconsolidated subterranean formations

The present invention provides methods of stabilizing subterranean formations and methods of reducing the production of particulates from subterranean formations, which are useful in conjunction with subterranean formations surrounding wellbores and fractures. The methods comprise the steps of applying to a subterranean formation a combination aqueous liquid and surfactant preflush solution, an integrated consolidation fluid and an afterflush fluid and then waiting a chosen period of time.

Owner:HALLIBURTON ENERGY SERVICES INC

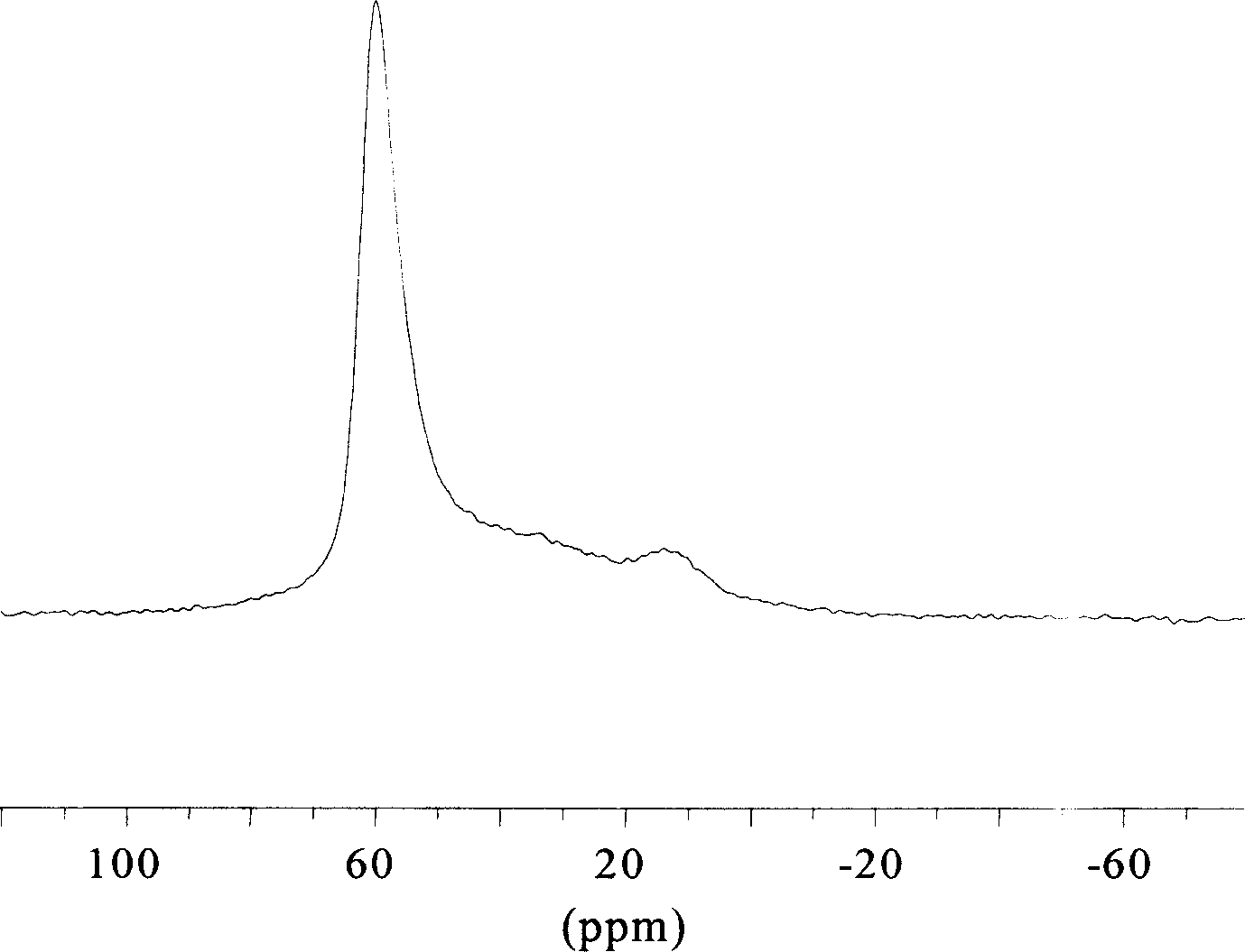

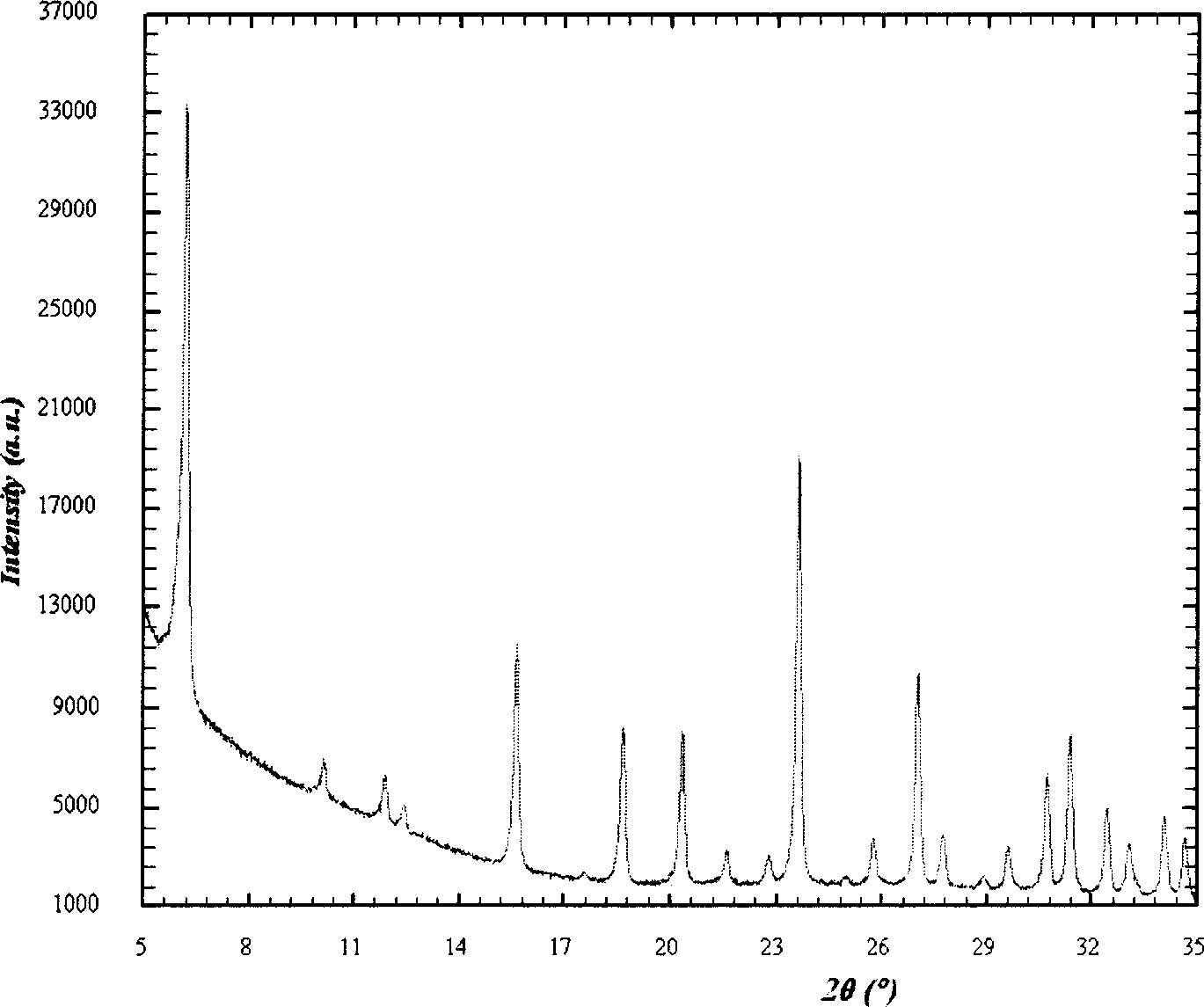

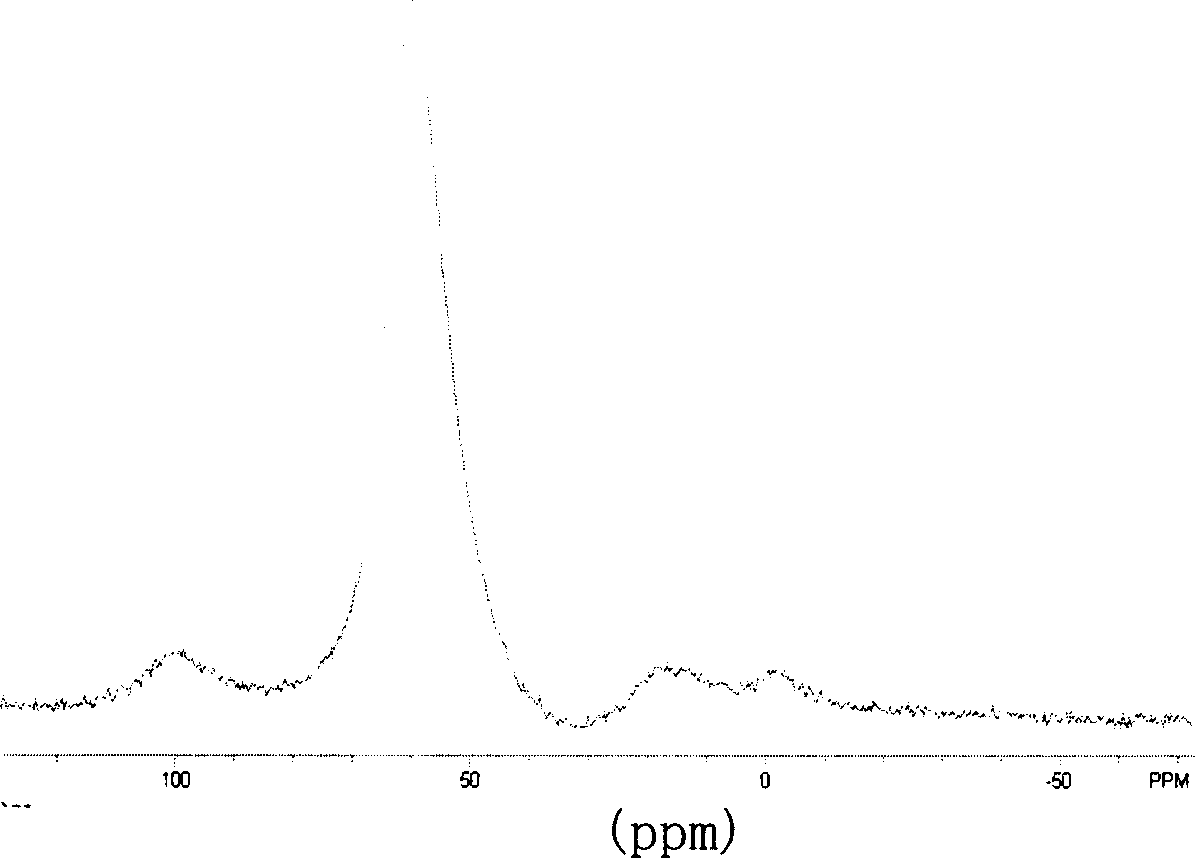

Rare earth Y molecular screen and process for preparing the same

This invention discloses a rare earth Y molecular sieve and preparation; wherein, the rare earth content is 12~22 w.t% considering the quantity of rare earth oxide in molecular sieve, all rare earth ion is in molecular sieve small cage; there is no peak at 0ppm in 27Al M AS NMR spectrogram. The step to obtain molecular sieve comprises: exchanging NaY molecular sieve liquid with ammonium salt or not, taking ion exchange with rare earth chloride by weight ratio of NaY dry basis:RECl3=1:0.17~0.35 at temperature 5~100Deg; pH=2.5~7.5, water: NaY=3~50; adjusting pH value to 8~11 with alkaline solution; mixing, filtering, cleaning, drying; baking for more than 0.1h with 0~100% vapor at temperature 200~950Deg; then, dealing with the molecular sieve according to weight ratio molecular sieve dry basis: ammonium salt :water=1:0~1:2~50 at temperature 60~100Deg; finally, cleaning, filtering, drying and obtaining the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Classified silica for improved cleaning and abrasion in dentifrices

InactiveUS20060140878A1Improve uniformityPrecision cleaningCosmetic preparationsSilicaToothpastePhysical chemistry

A method of making precipitated silica abrasive compositions having excellent cleaning performance and lower abrasiveness with post-reactor sizing of the abrasive particles being performed via air classification techniques is provided. By targeting a specific particle size range, it has been determined that higher pellicle film cleaning levels may be achieved without also increasing the dentin abrasion properties of the silica products themselves. As a result, dentifrices including such classified abrasive silica products, and exhibiting particularly desirable cleaning benefits, can be provided for improved tooth polishing, whitening, and the like, without deleteriously affecting the hard tooth surfaces. Also encompassed within this invention also are products of this selective process scheme and dentifrices containing such classified silica products.

Owner:J M HUBER CORP

Preparation of composite high-expansion cementing material by using industrial slag and preparation technique thereof

The invention relates to a preparation process of using industrial slag to prepare composite cementing materials with high expansibility. The cementing materials consist of four components. The first component includes three parts: one or a plurality of combinations of fly ashes, slag, etc., which contain aluminosilicate; one or a plurality of combinations of phosphogysum, fluorine gypsum, etc., which contain calcium sulfate; one or a plurality of combinations of carbide, alkaline residue, quick lime or slaked lime. The second component includes: one or a plurality of combinations of alkaline composition, such as the quick lime or slaked lime, the carbide slag, etc.. The third component includes one or a plurality of combinations of the phosphogypsum, fluorine gypsum, etc., which contain the calcium sulfate. The preparation method is: firstly, to evenly mix the raw materials of the first component which are grinded to be with the surface area of 200-500m<2> / kg through the steam curing of four hours to ten days at 50-100 DEG C and the calcining of 0.5-24h at the high temperature of 400-1000 DEG C to obtain the first component; secondly, to dry and grind the raw materials of the second and the third component to be with the surface area of 200-500m<2> / kg to obtain the second and the third component; thirdly, to evenly mix the first, the second and the third component.

Owner:BEIHANG UNIV

Quartz crystal device and method for sealing the same

ActiveUS20080231145A1High bonding strengthImprove reliabilityPiezoelectric/electrostriction/magnetostriction machinesImpedence networksOrganic solventHermetic seal

A quartz crystal device includes a crystal resonator element and a package including a plurality of components. The plurality of components are bonded using a metal paste sealing material containing a metallic particle having an average particle size from 0.1 to 1.0 μm, an organic solvent, and a resin material in proportions of from 88 to 93 percent by weight from 5 to 15 percent by weight, and from 0.01 to 4.0 percent by weight, respectively, to hermetically seal the crystal resonator element in the package.

Owner:SEIKO EPSON CORP

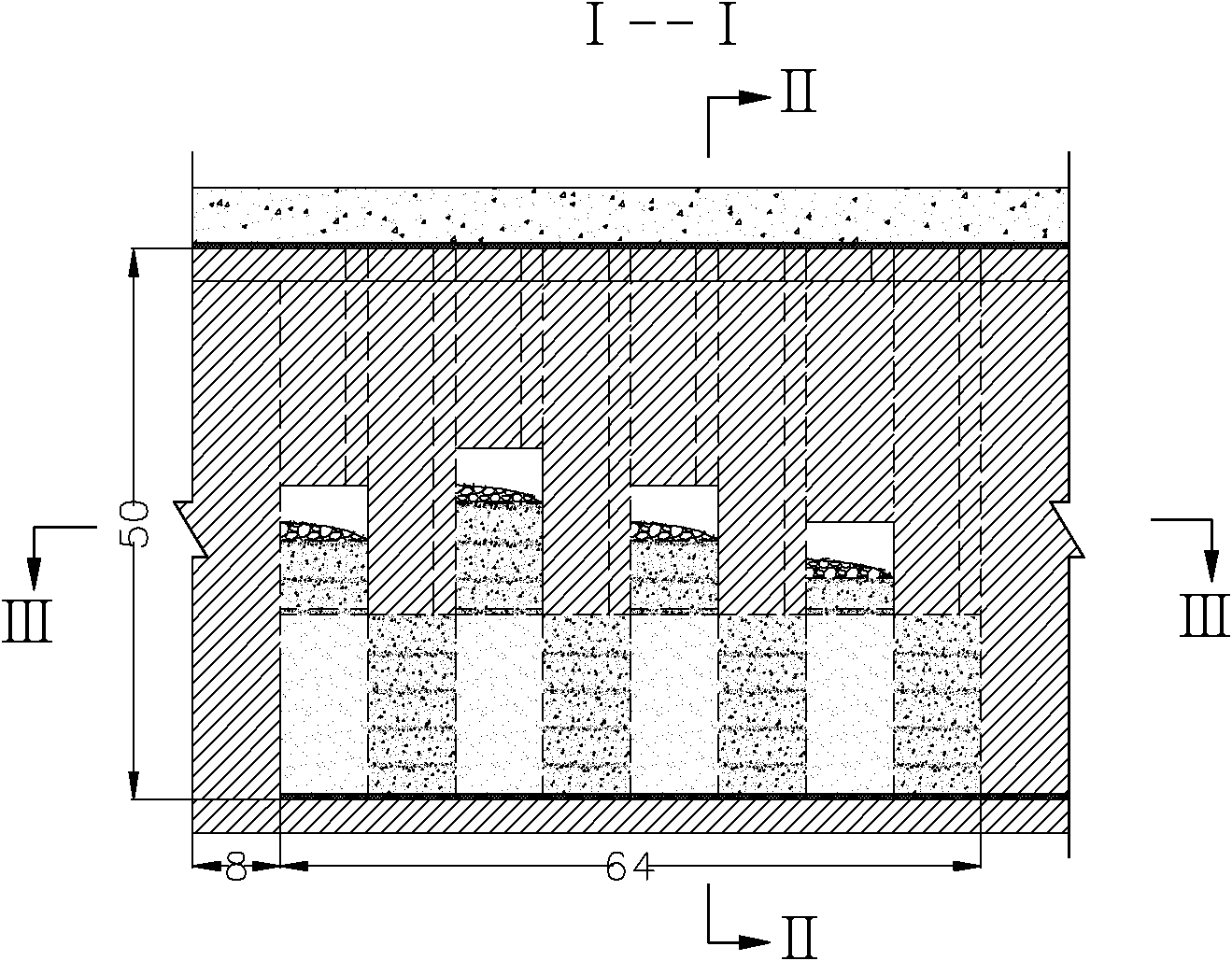

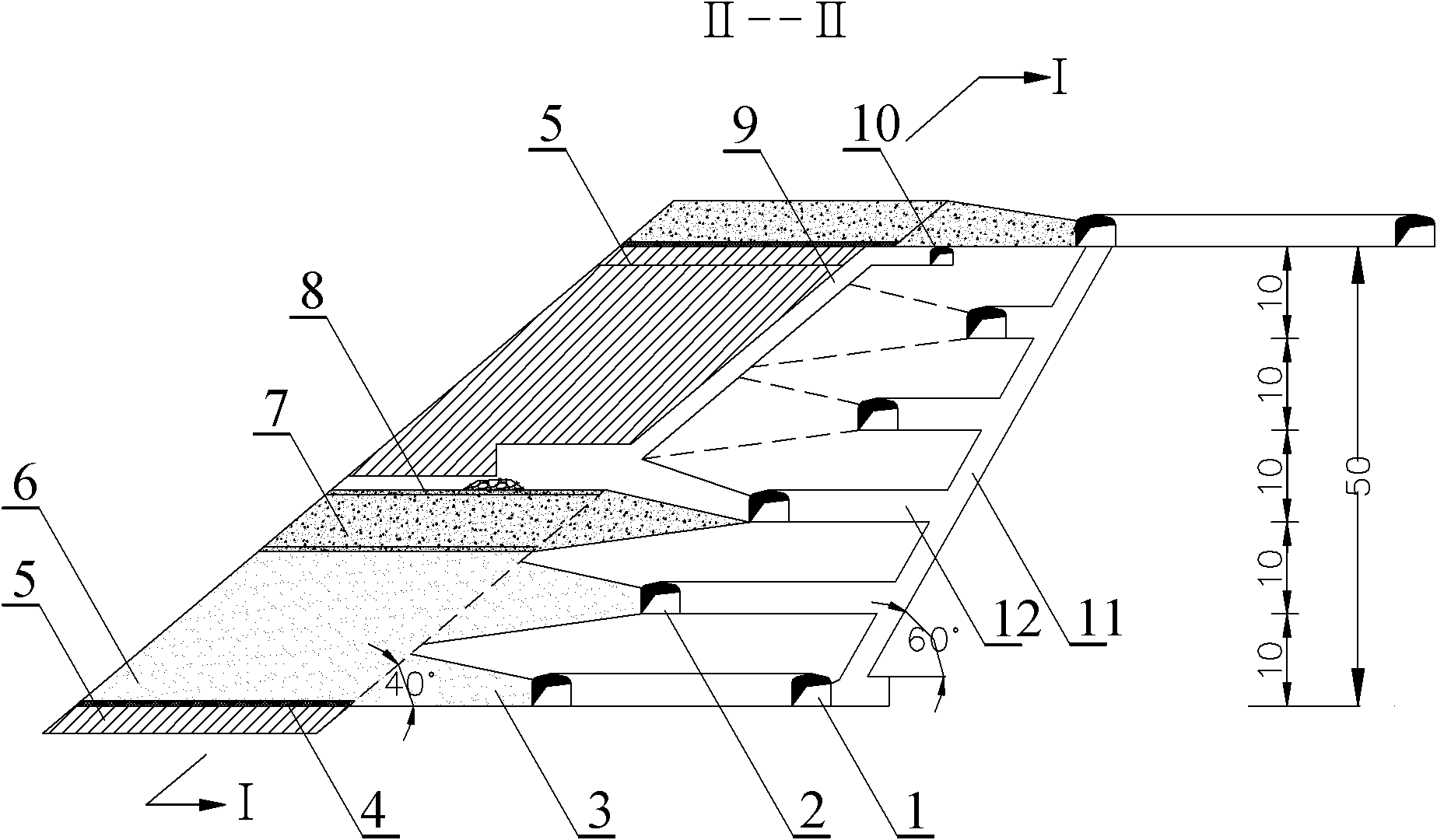

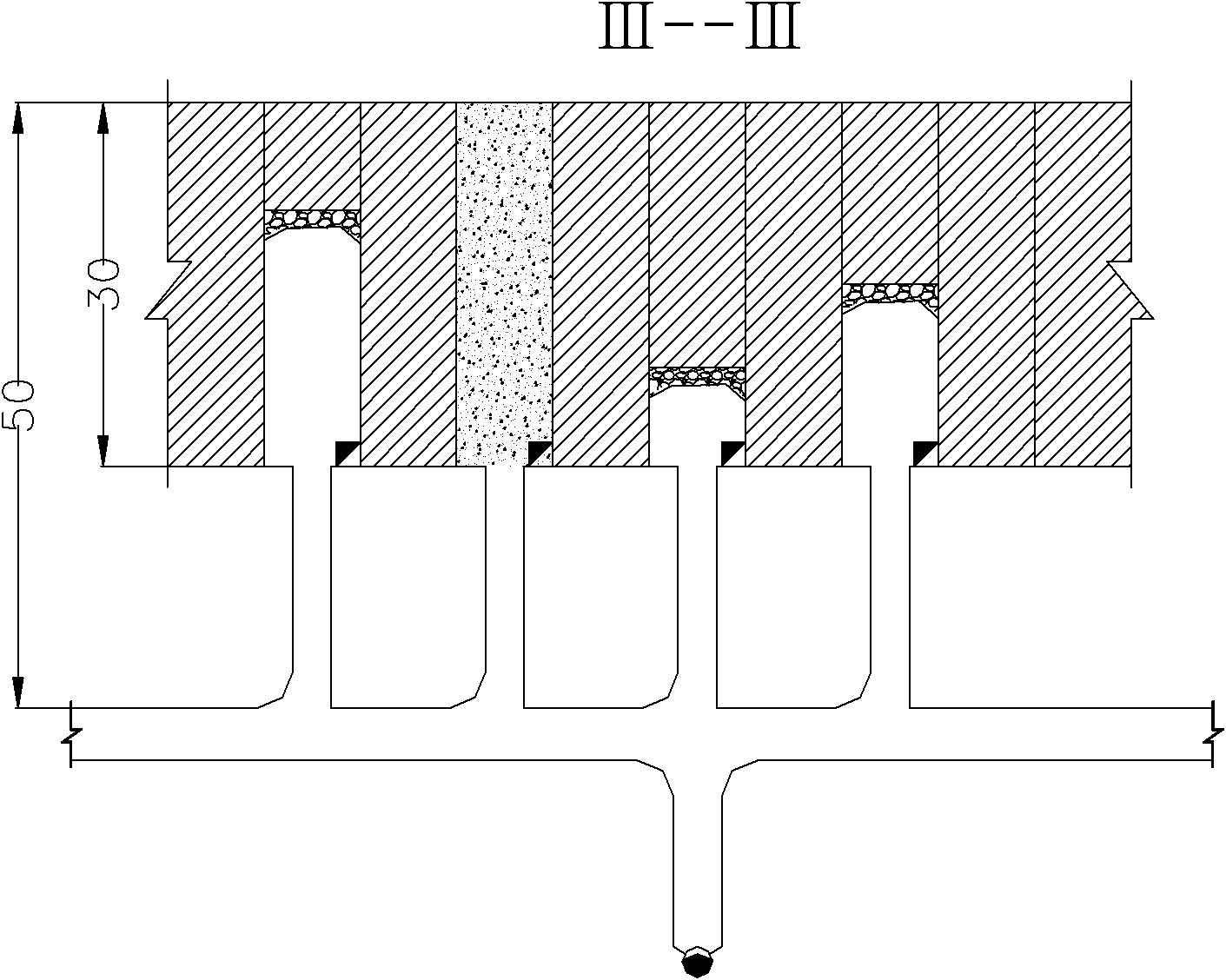

House pillar changeable panel upward demix filling mining method

InactiveCN101858217AReduced suspension heightImprove integrityUnderground miningSurface miningRoom and pillar miningMineralogy

The invention discloses a house pillar changeable panel upward demix filling mining method. An ore body is divided into an ore house and an ore pillar arranged at intervals along the strike direction; a plurality of house pillars form a panel; a rock trackless preparation system is adopted and comprises a ramp, a rock slice drift, a demix ventilation connection and a rock concentrated ore removal winze; the mechanical upward demix filling mining method is adopted for mining, which mines a slice and fills the slice until the position required by the lower slice blasting compensation is reached. The backstopping order of the house pillars in the panel is the ore house first and then the ore pillar; all ore houses are subjected to upward backstopping at the same time; after a backstopping unit of the ore house is finished, the roof-contacted filling is carried out, and the mining of the ore house is temporarily stopped and the mining of the ore pillar is started; after two backstopping units of the ore pillar are finished, the roof-contacted filling is carried out, and the mining of the ore house is resumed; the abovementioned steps are repeated until the backstopping of the ore block is completed. The invention has the remarkable characteristics of improving the backstopping safety, reducing the resource dilution rate, lowering the support cost, increasing the enterprise profit, and the like.

Owner:CENT SOUTH UNIV +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com