Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

268 results about "Bulk crystal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

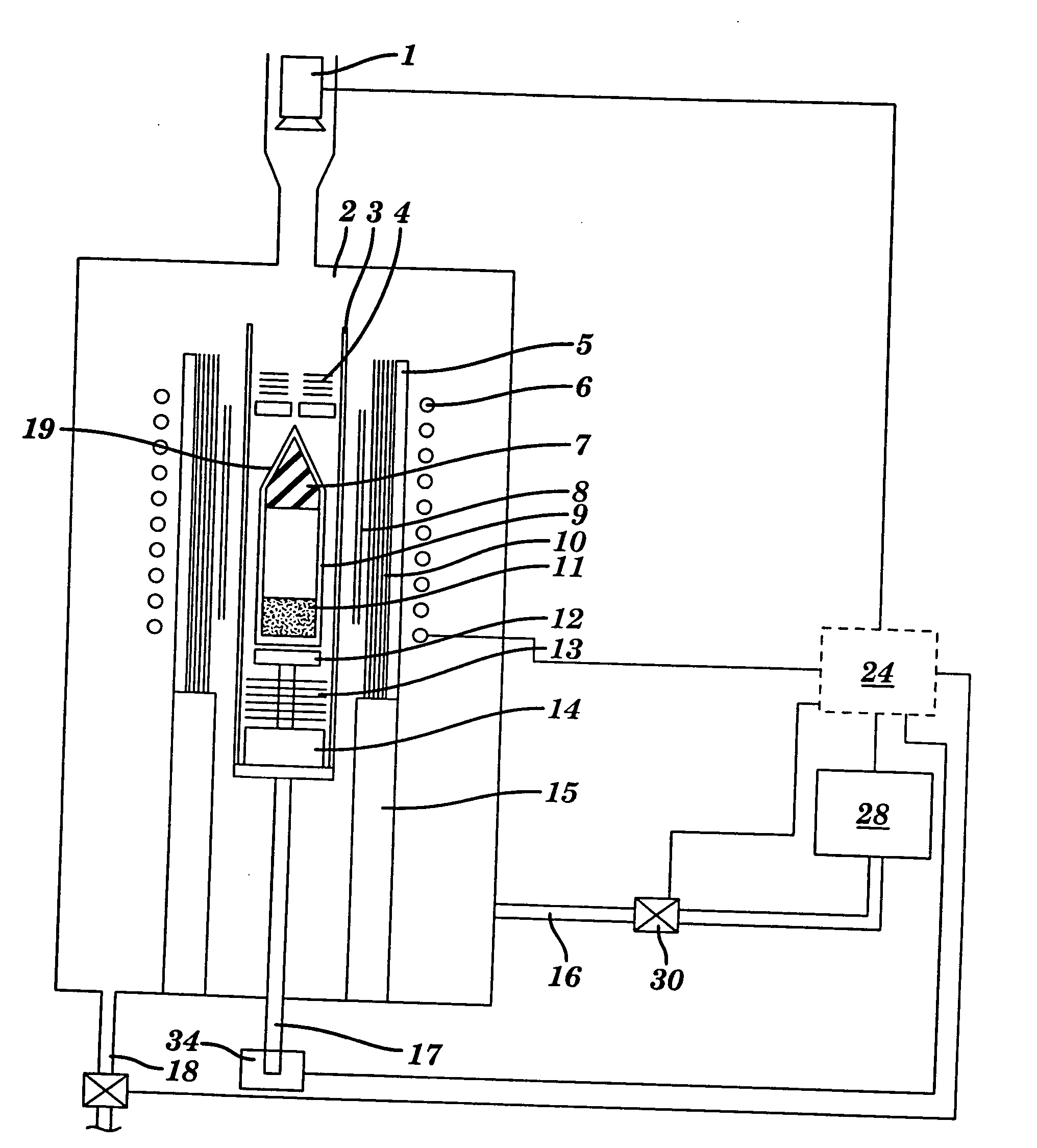

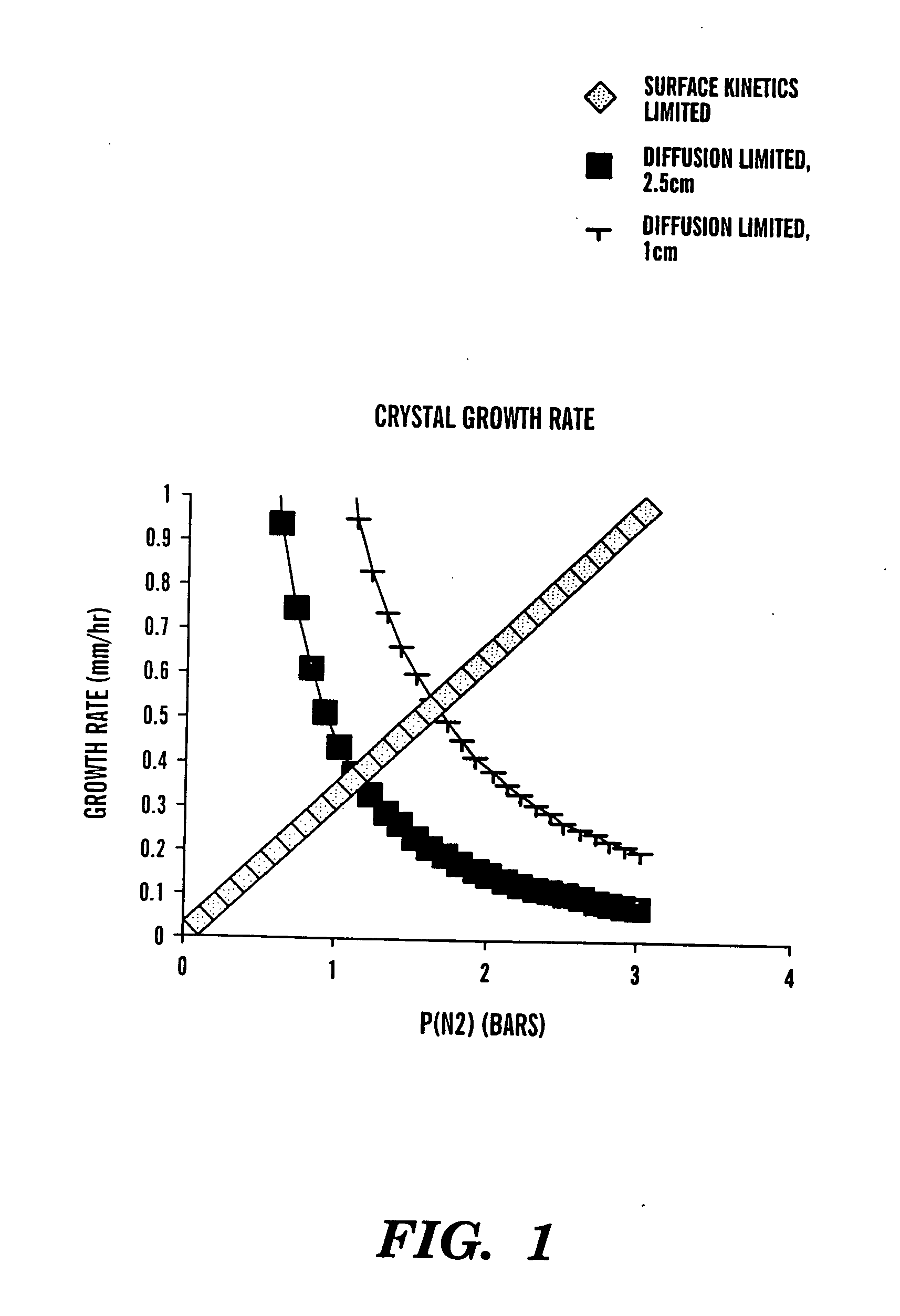

Method and apparatus for producing large, single-crystals of aluminum nitride

InactiveUS6770135B2After-treatment apparatusPolycrystalline material growthBulk crystalSource material

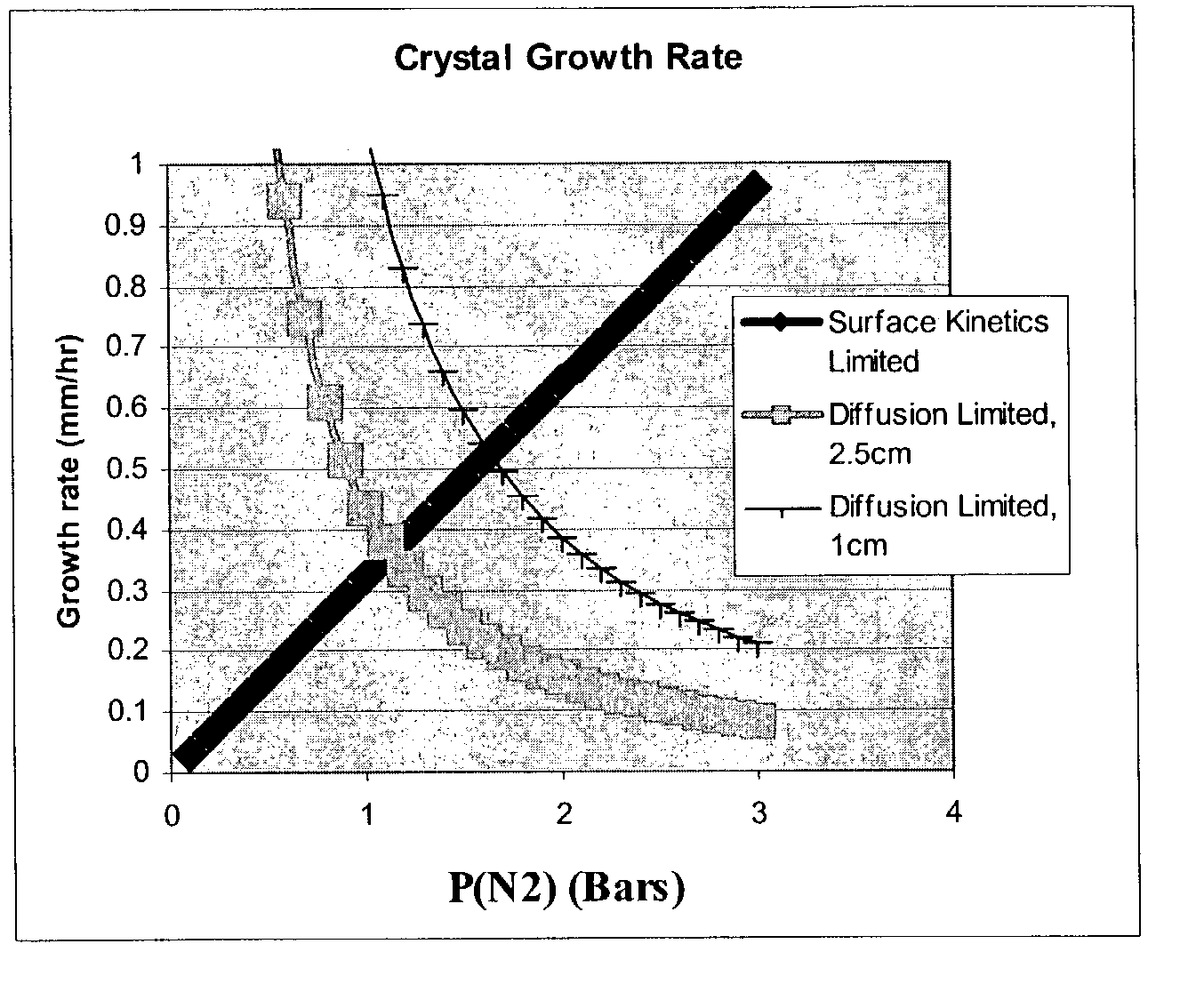

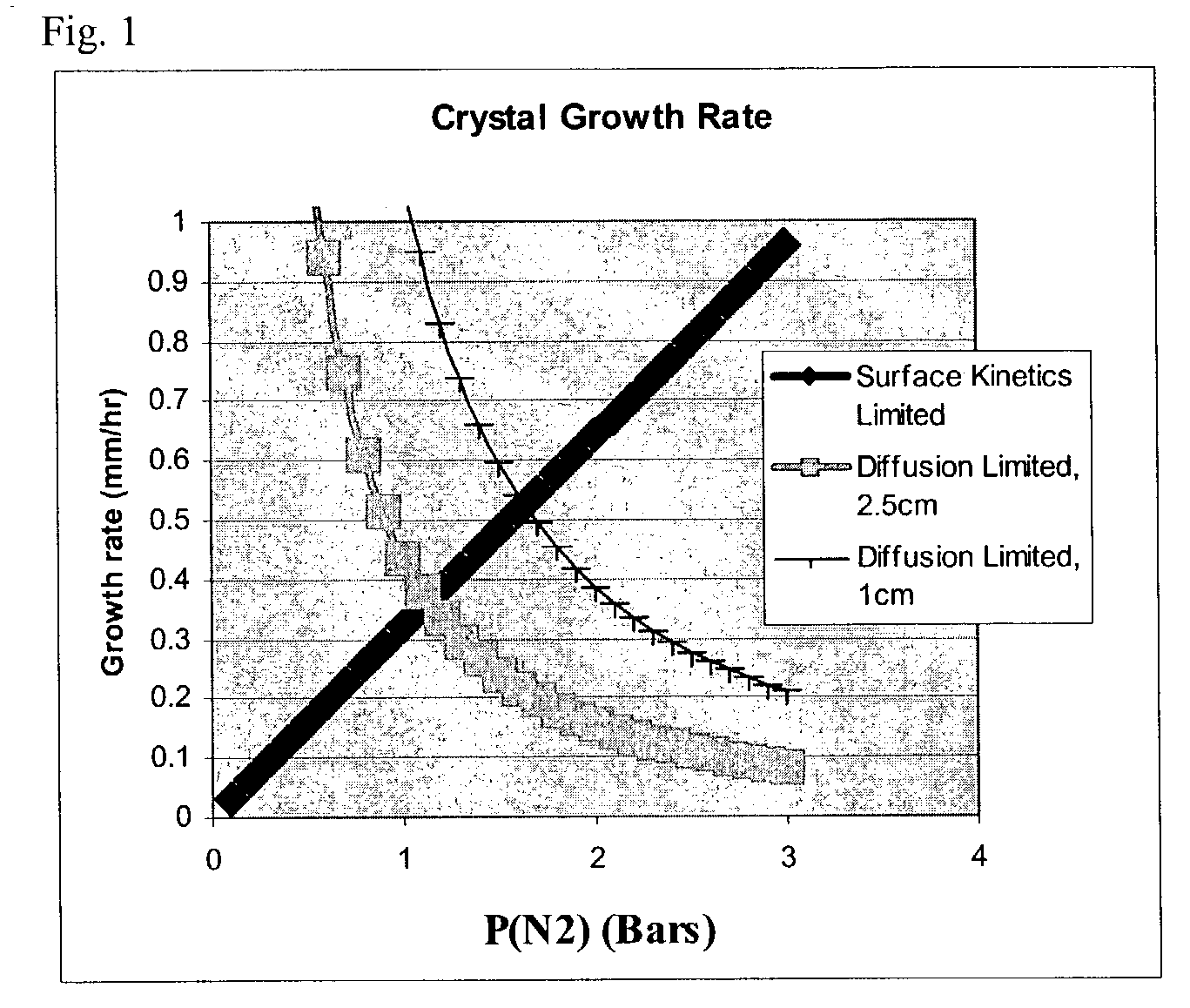

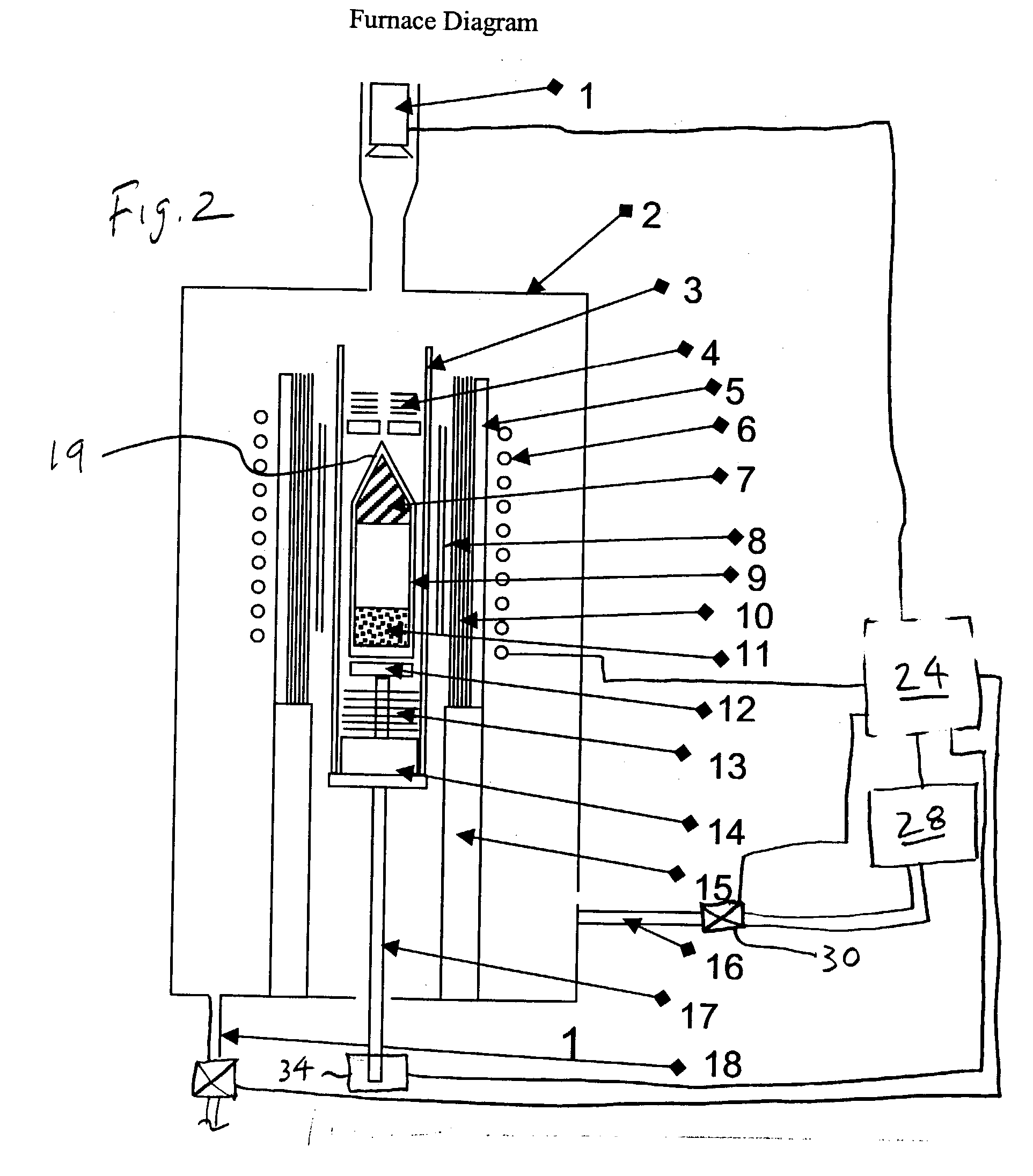

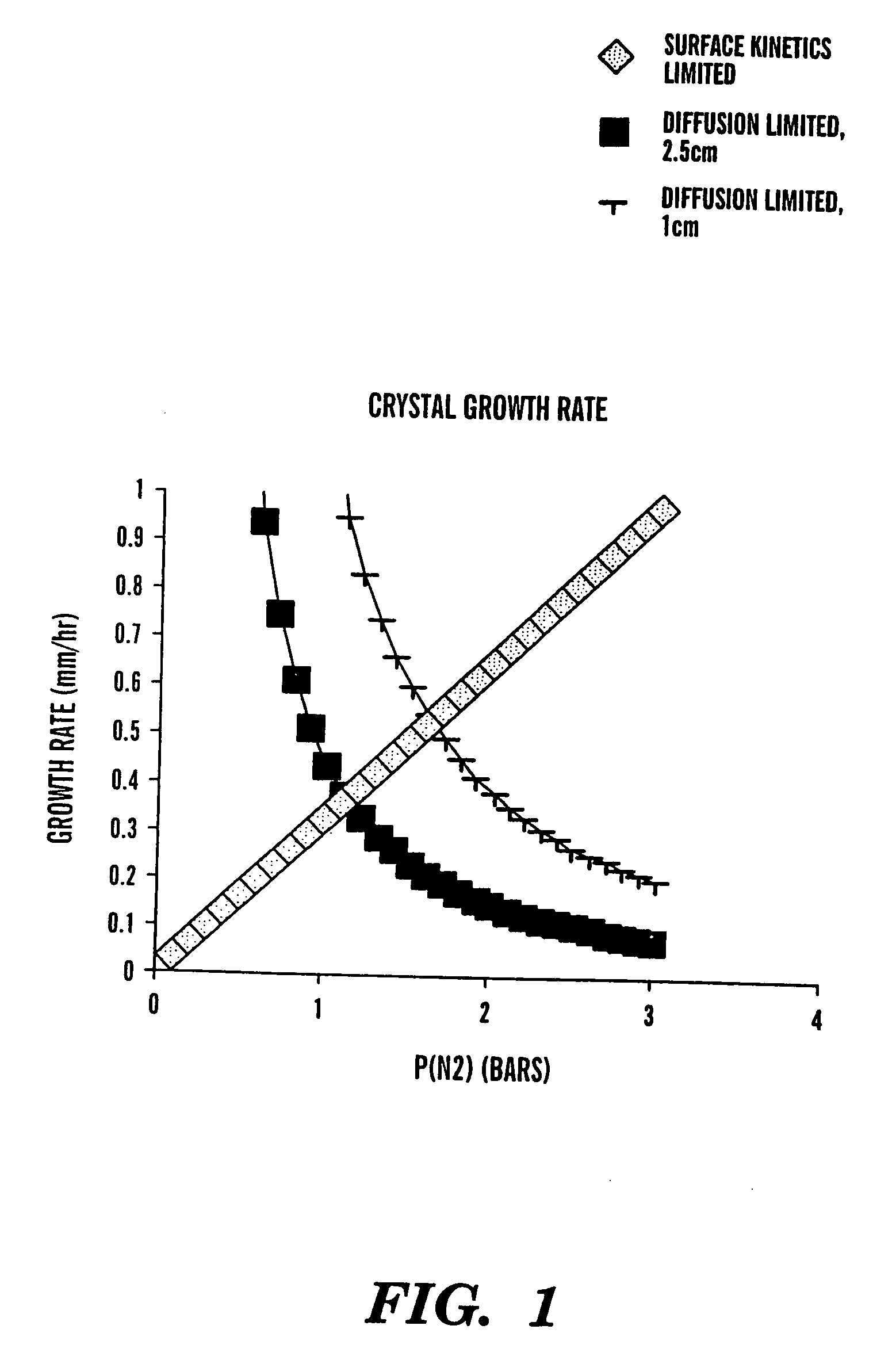

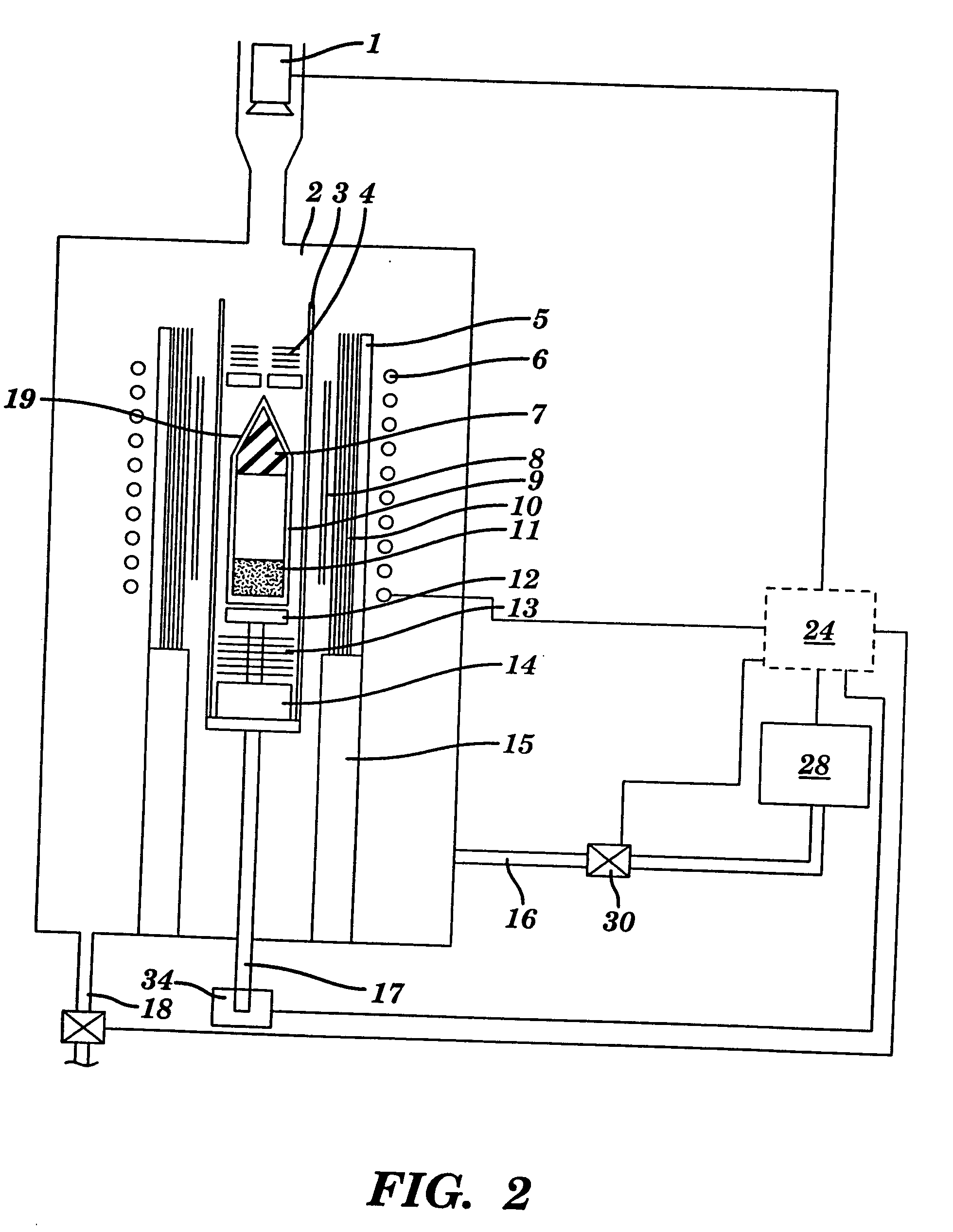

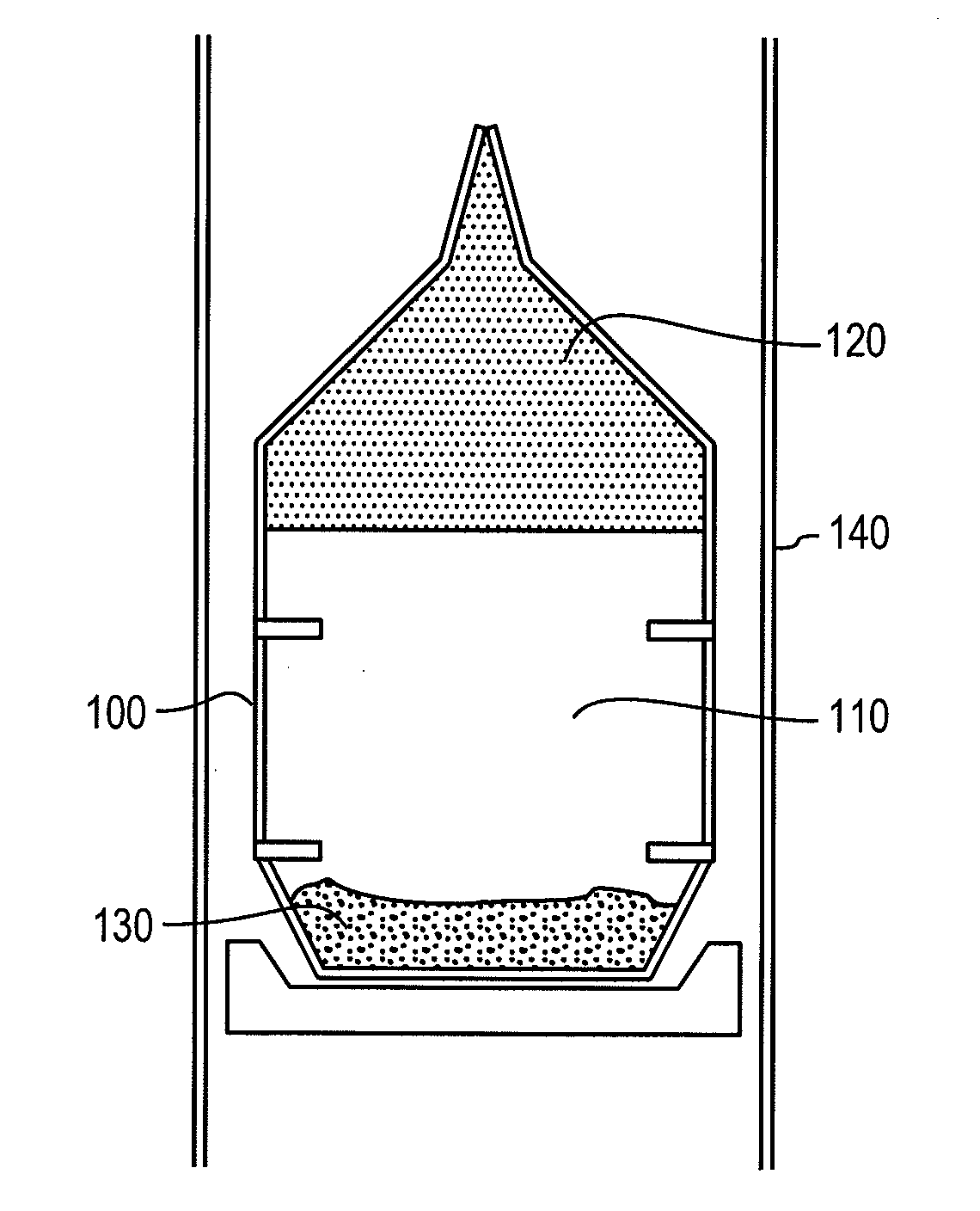

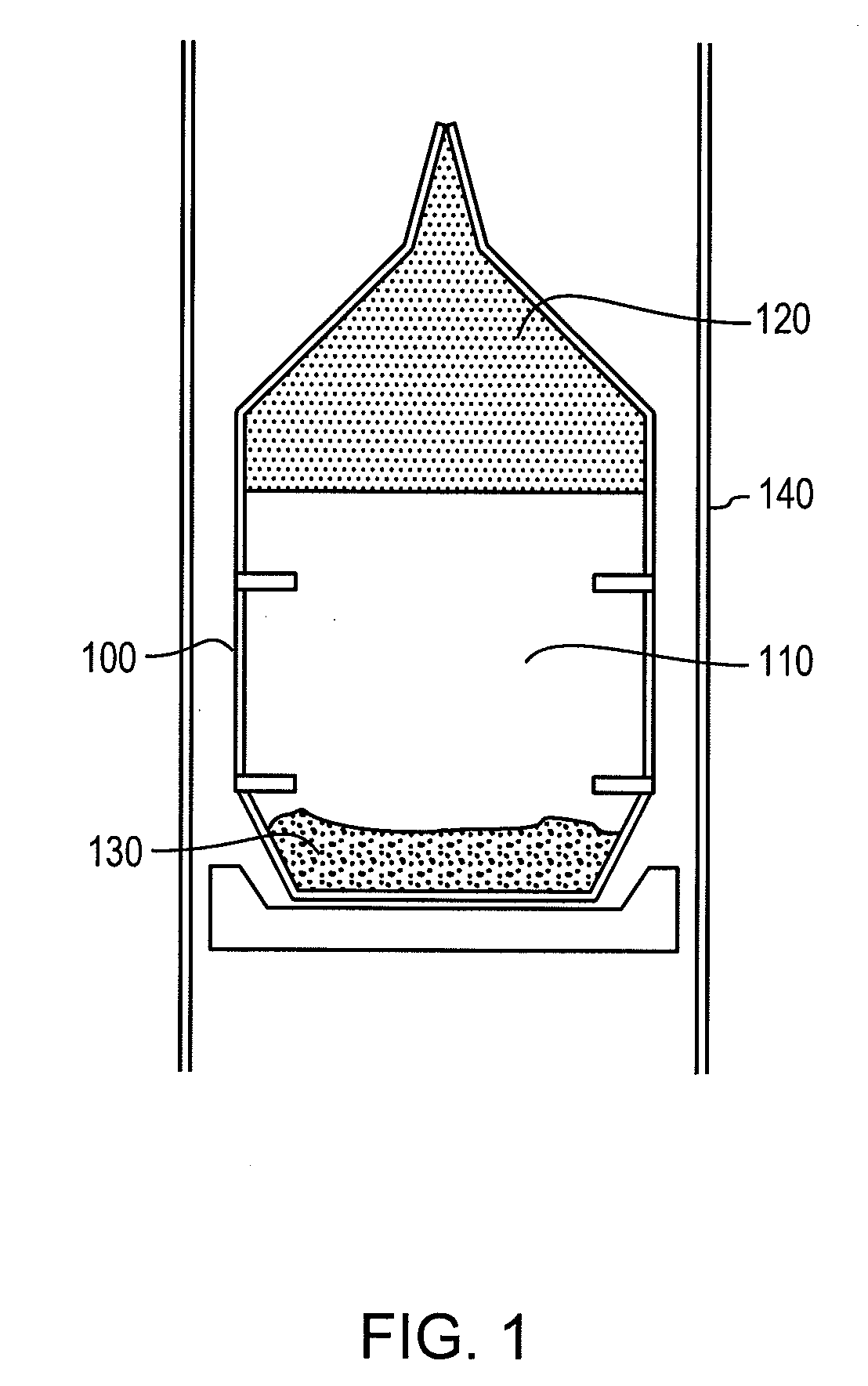

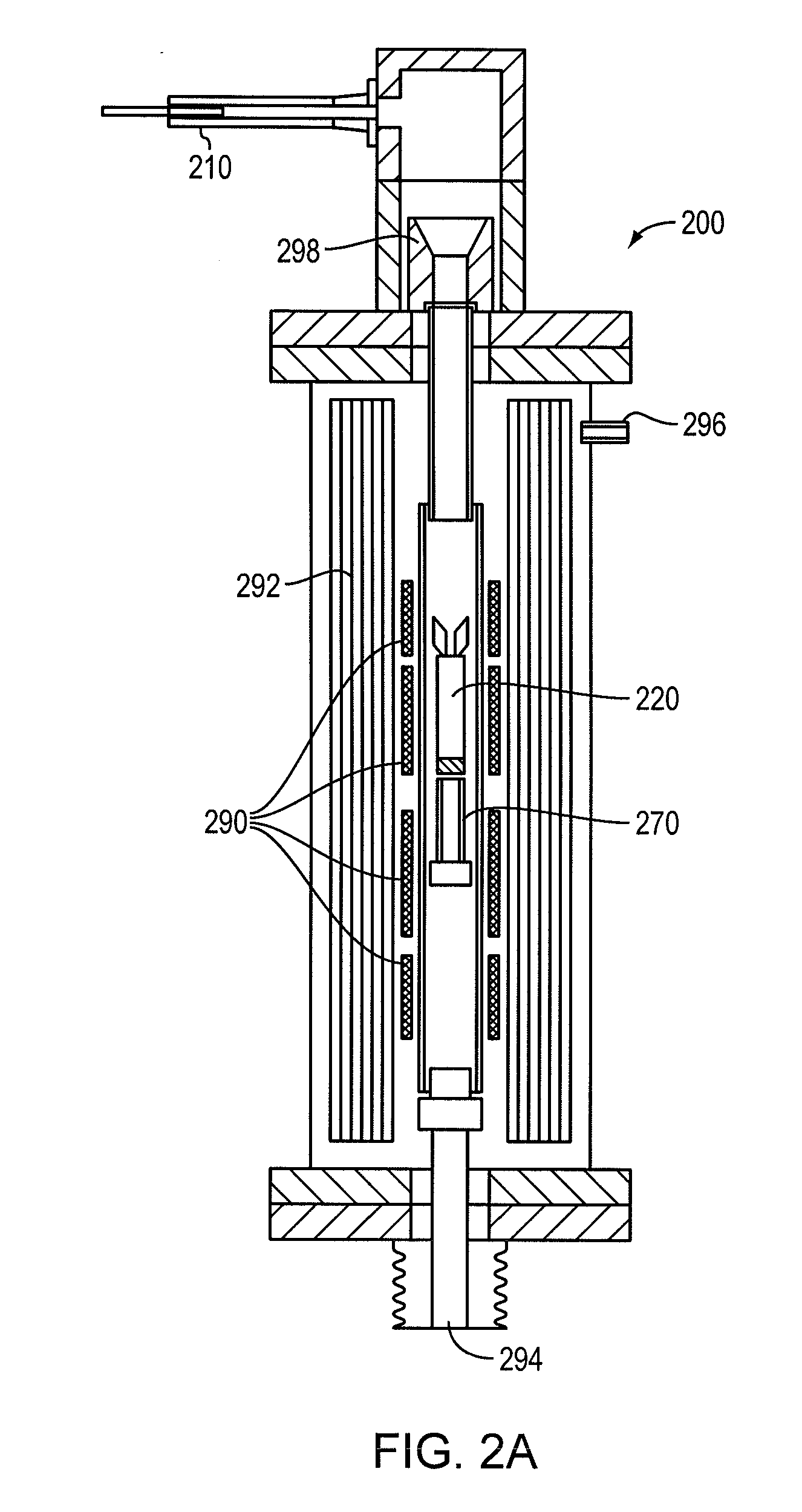

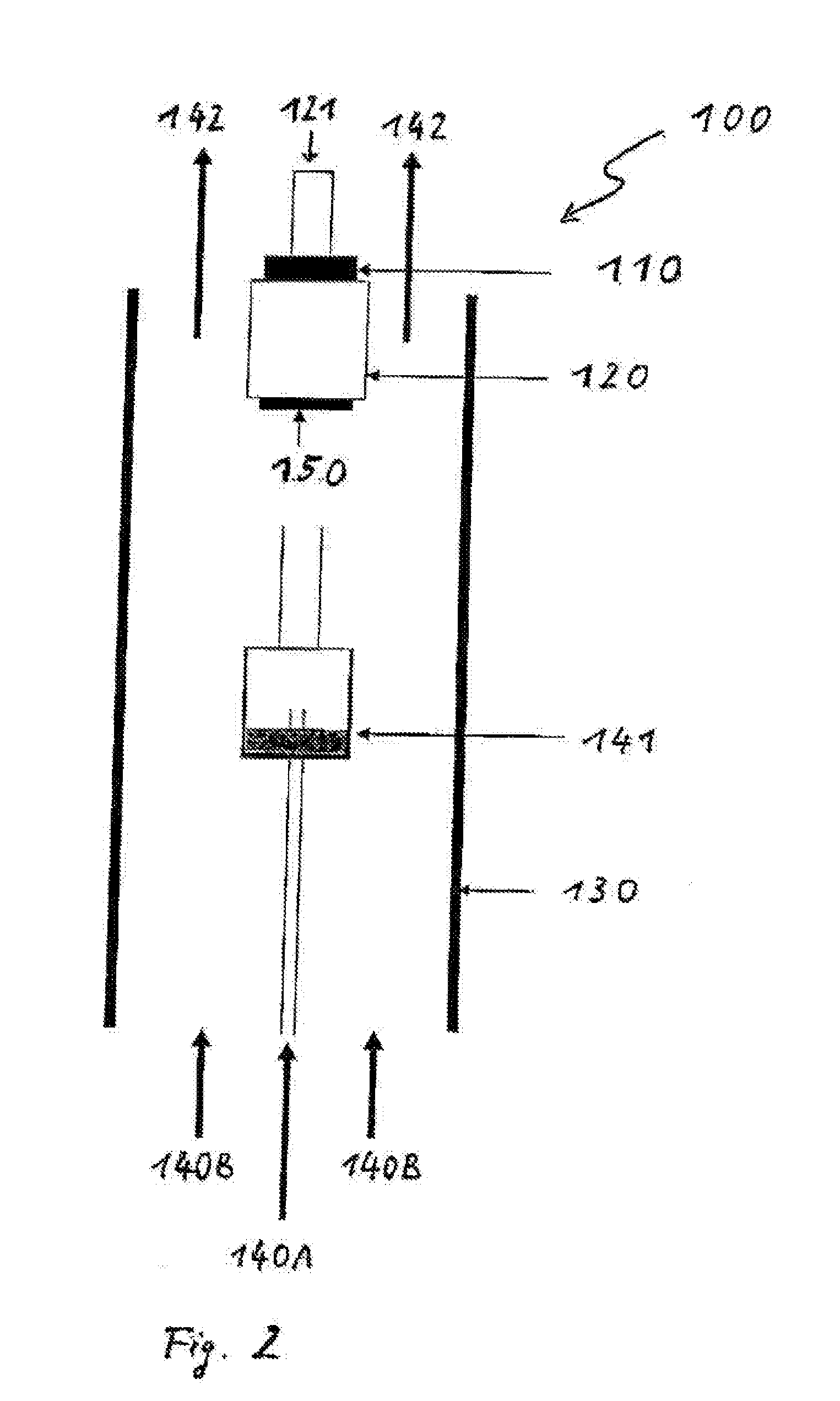

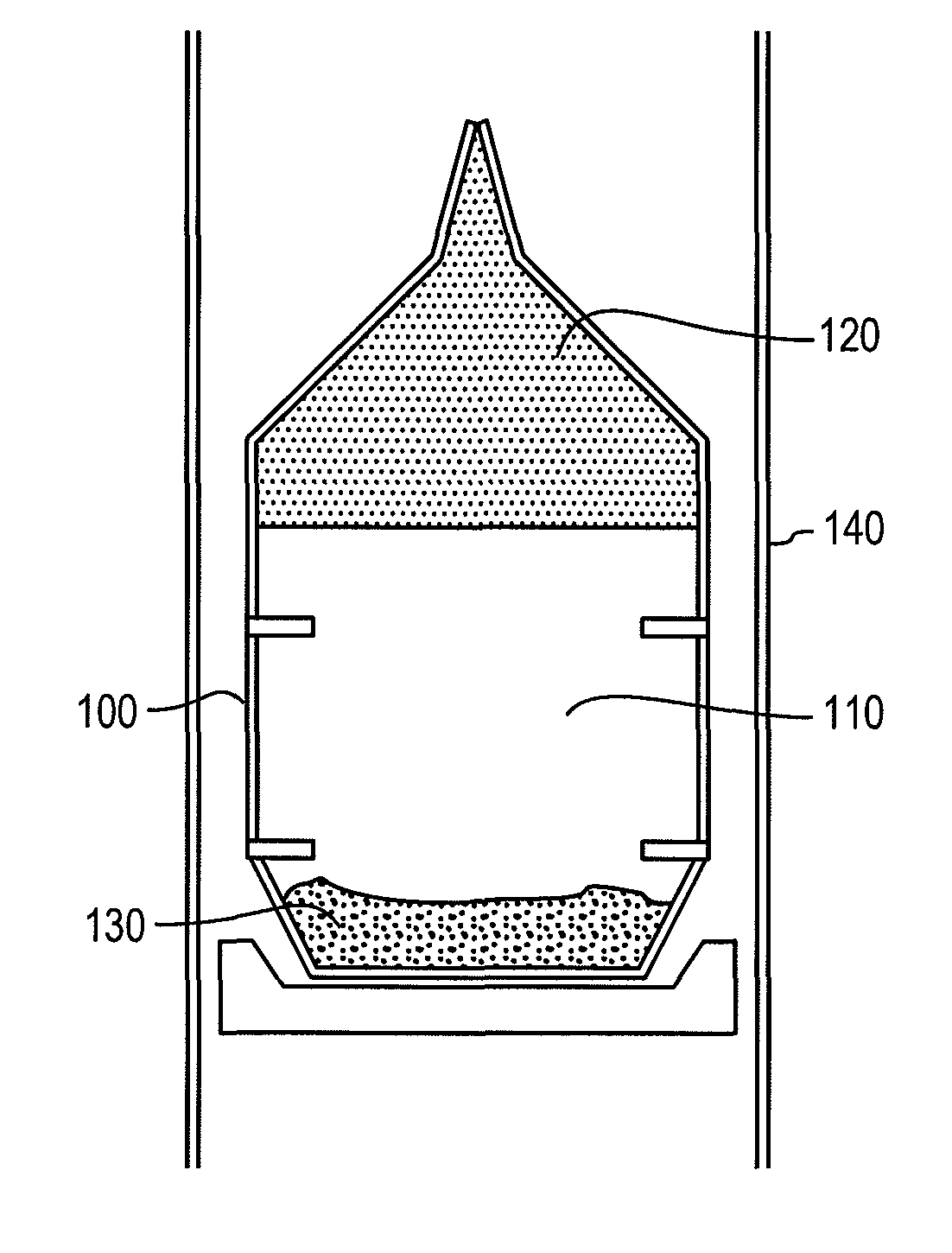

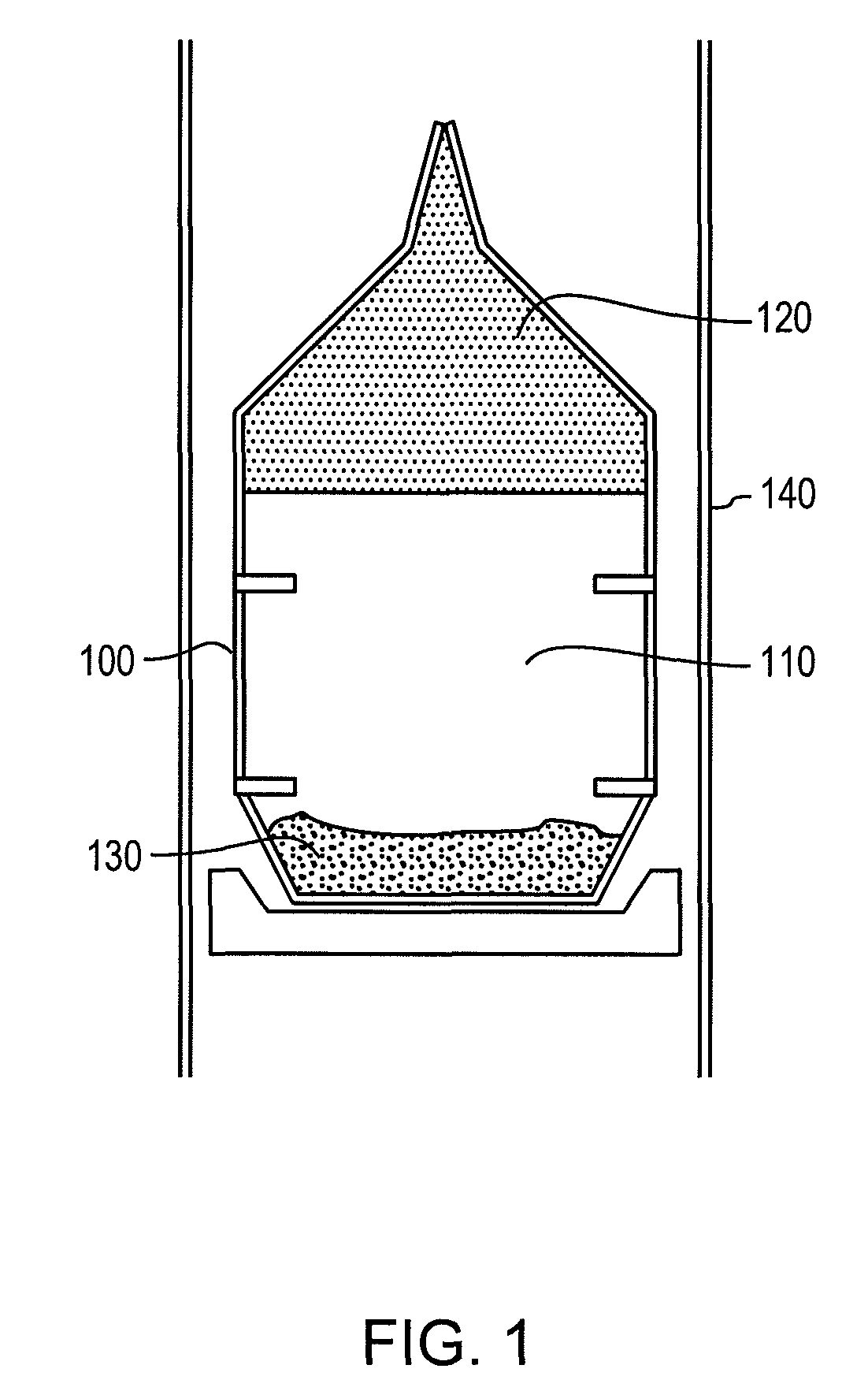

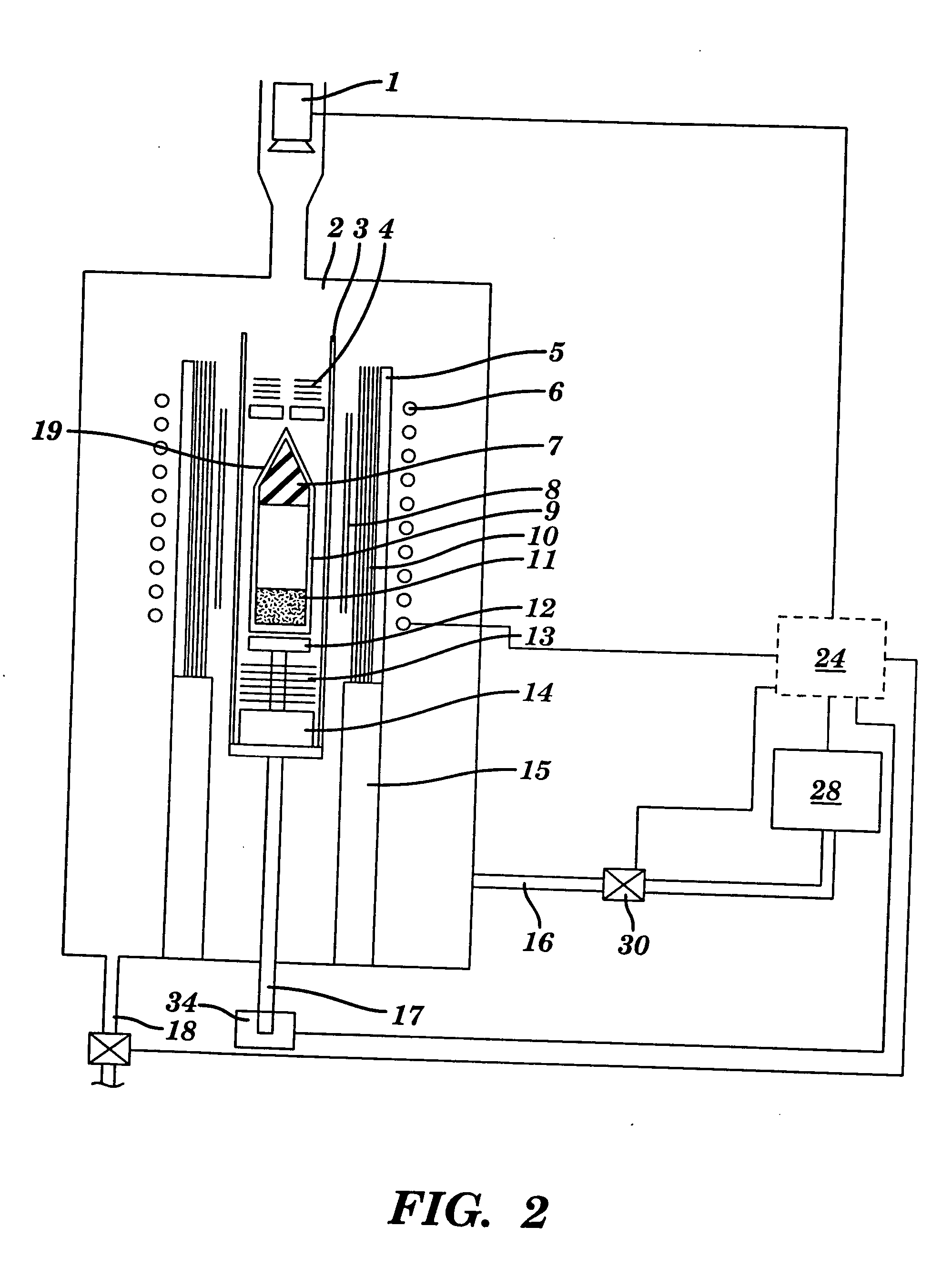

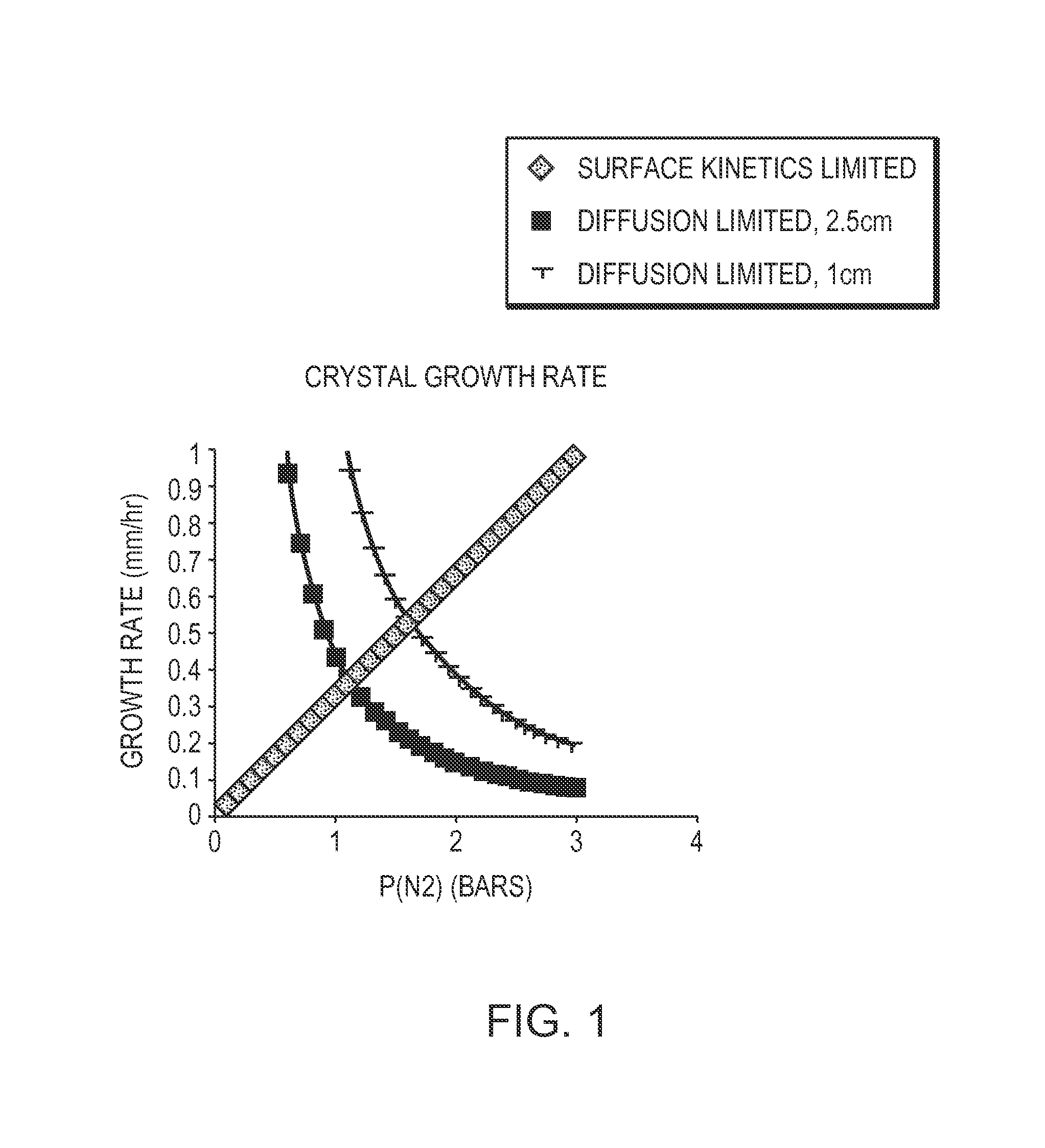

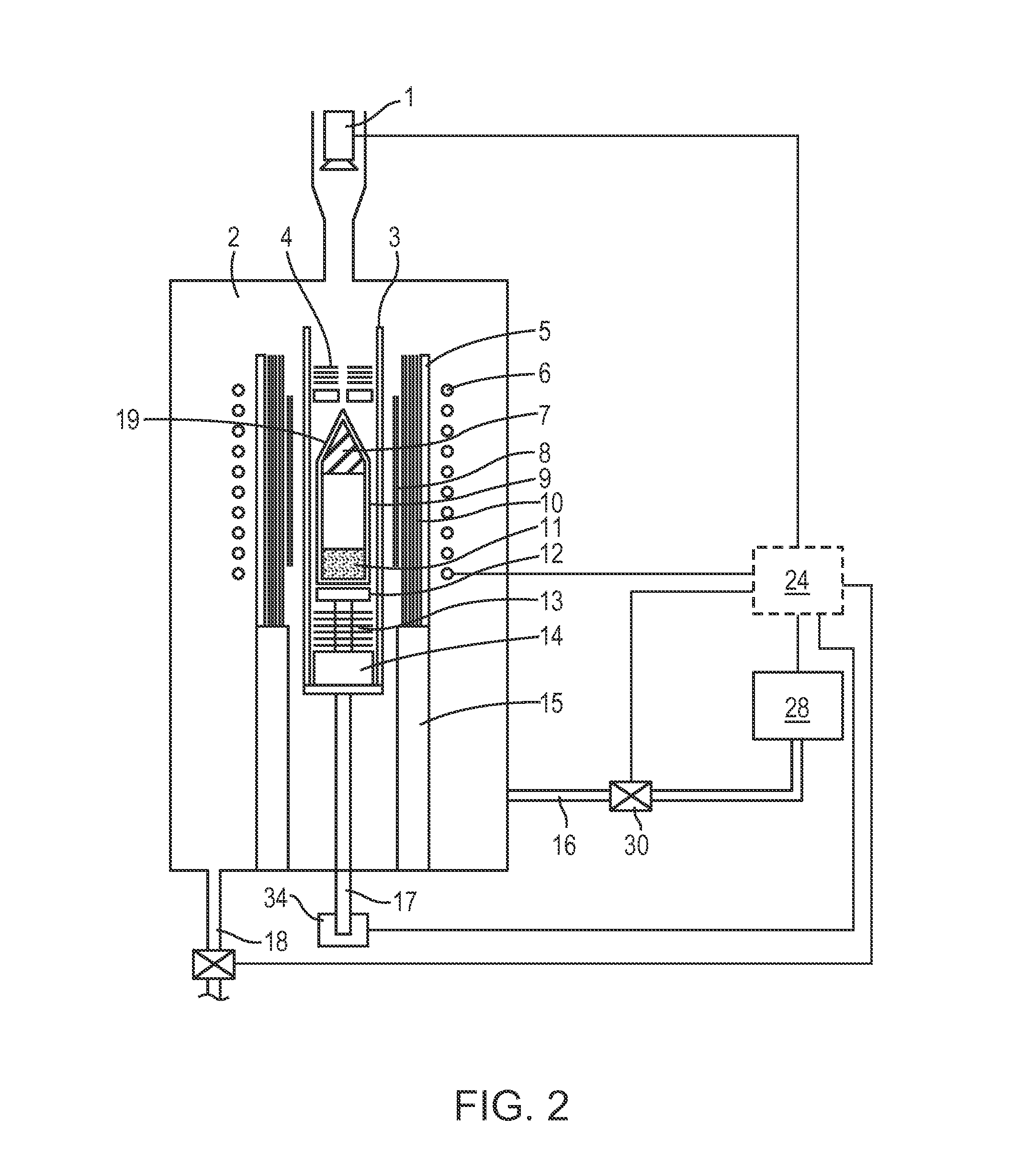

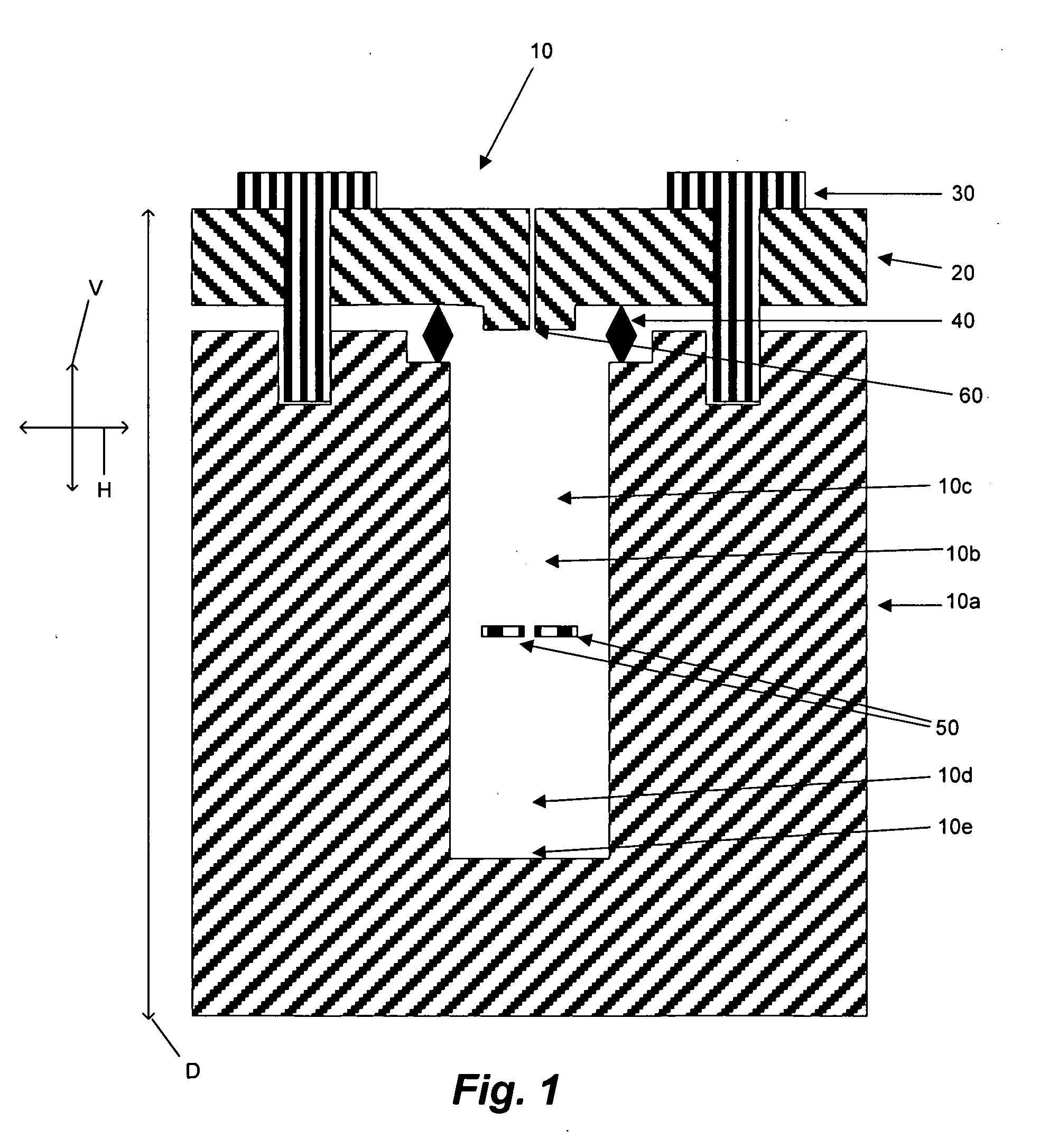

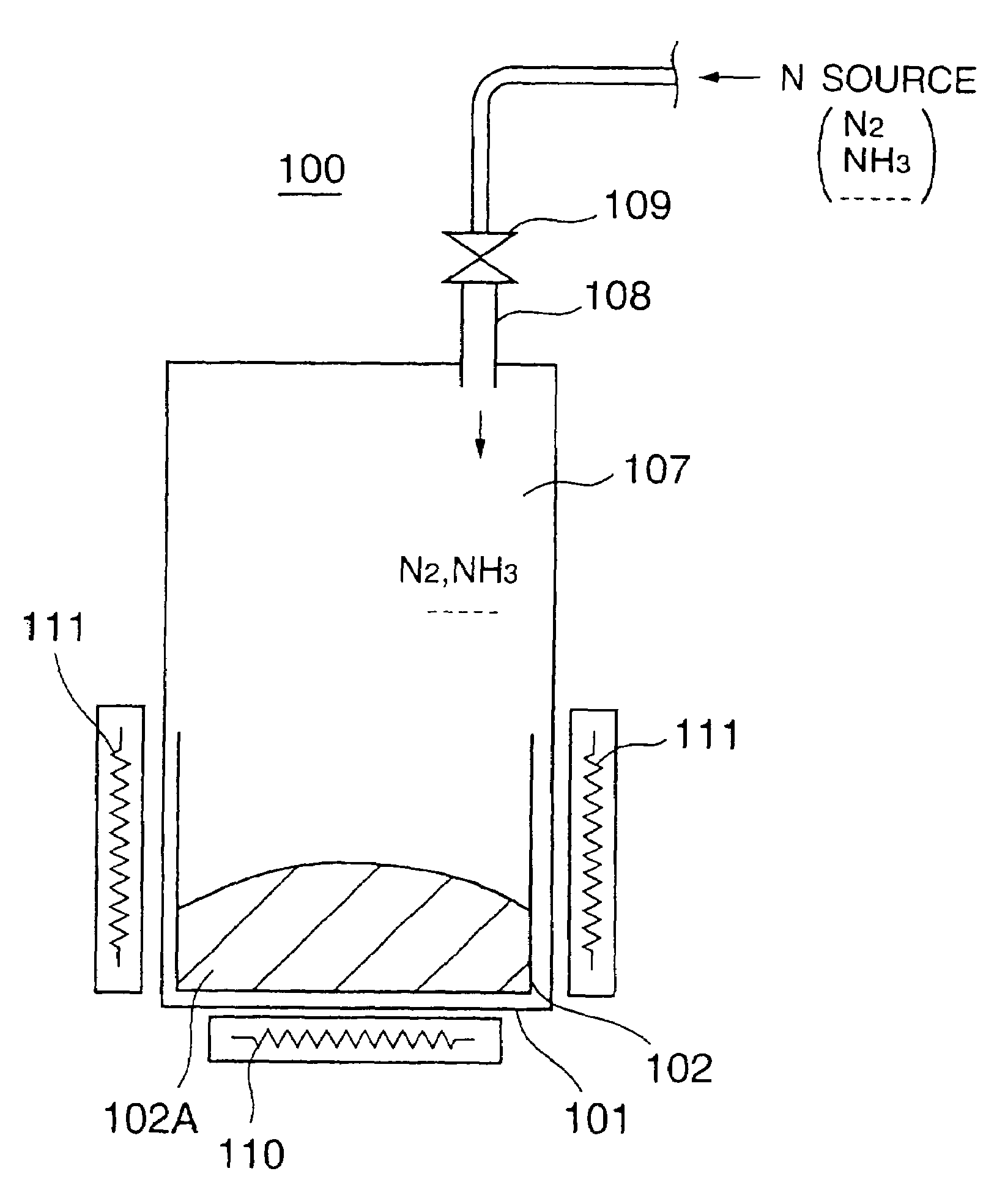

A method and apparatus for producing bulk single crystals of AlN includes a crystal growth enclosure with Al and N2 source material therein, capable of forming bulk crystals. The apparatus maintains the N2 partial pressure at greater than stoichiometric pressure relative to the Al within the crystal growth enclosure, while maintaining the total vapor pressure in the crystal growth enclosure at super-atmospheric pressure. At least one nucleation site is provided in the crystal growth enclosure, and provision is made for cooling the nucleation site relative to other locations in crystal growth enclosure. The Al and N2 vapor is then deposited to grow single crystalline AlN at the nucleation site.

Owner:CRYSTAL

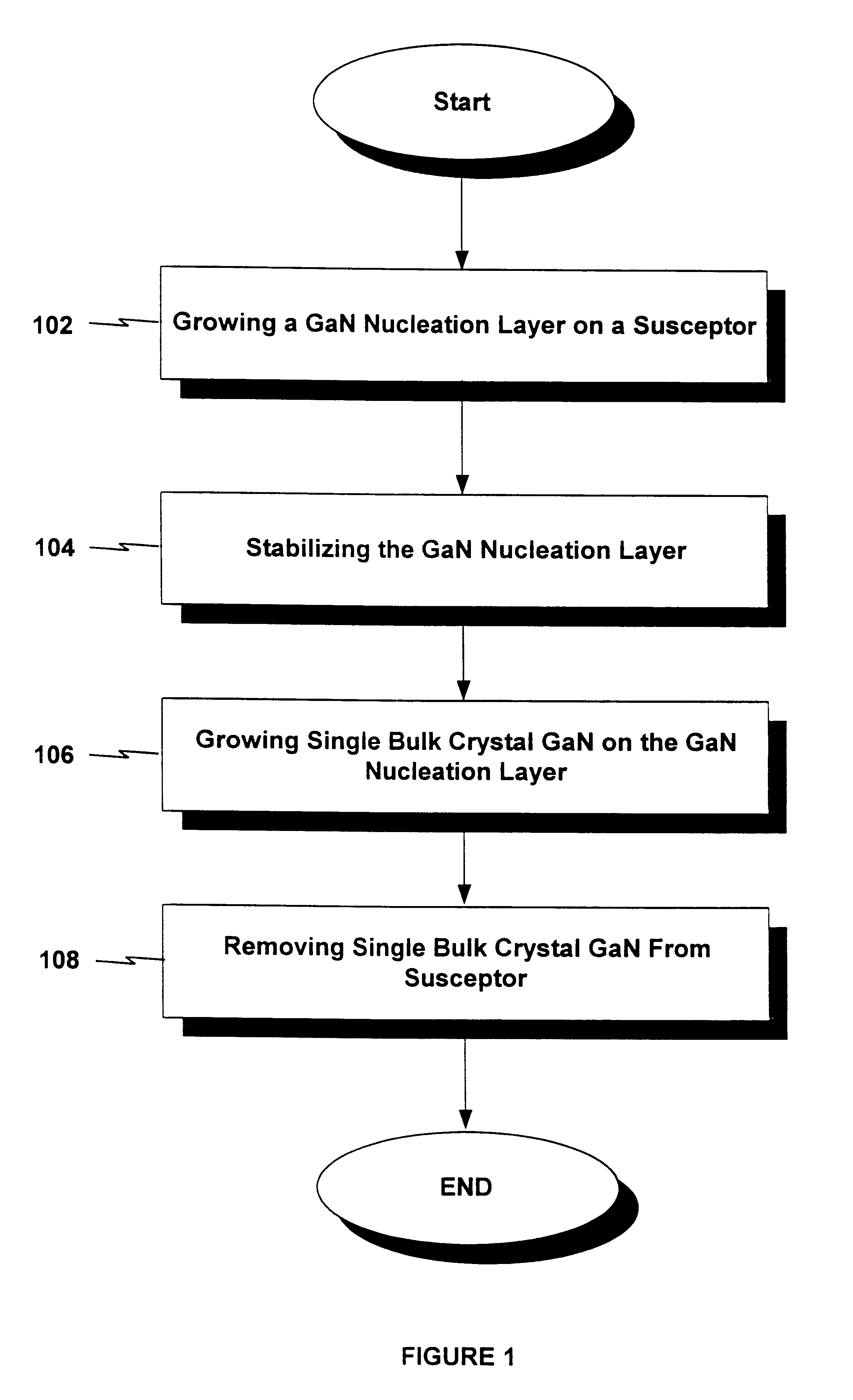

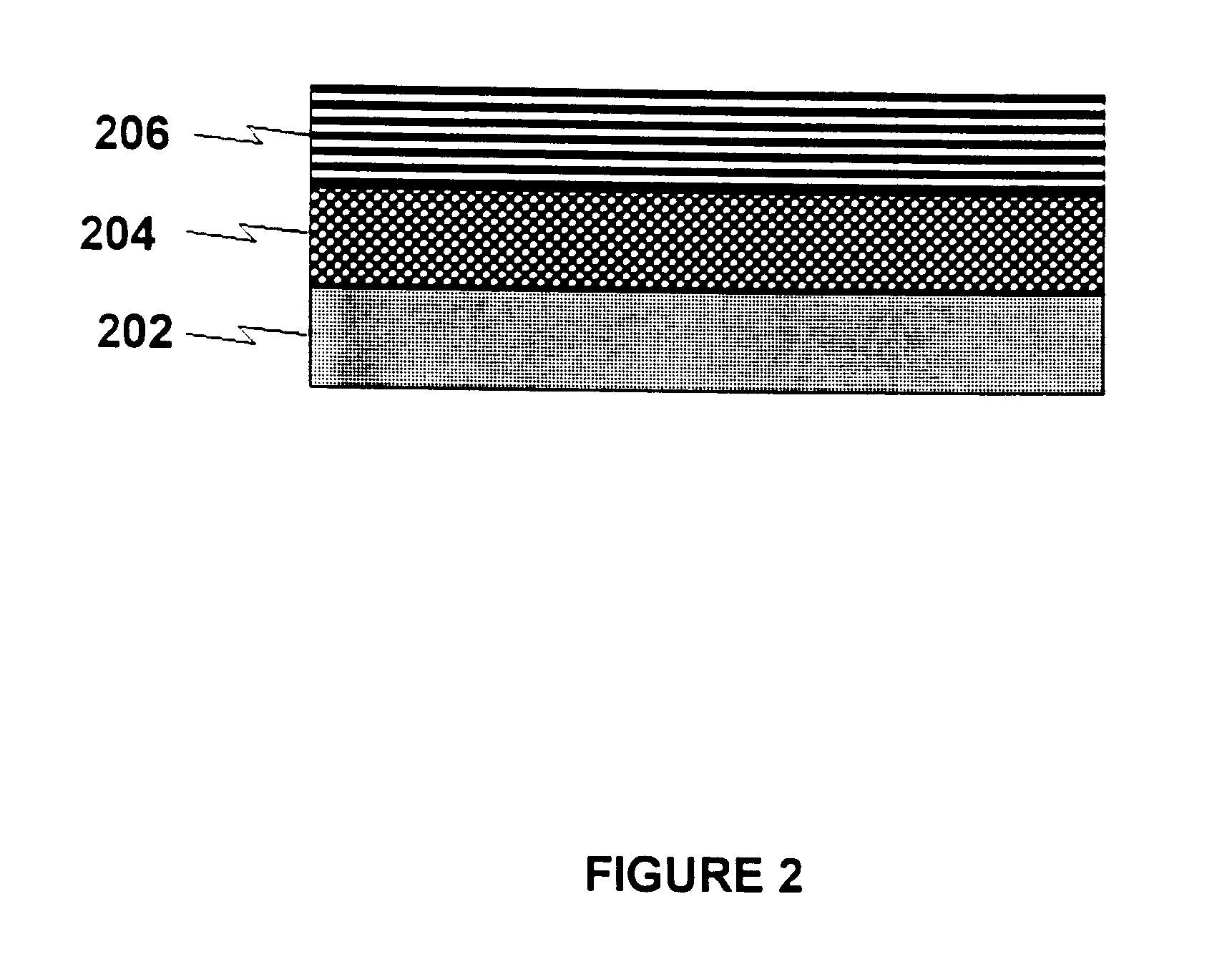

Method and apparatus for single crystal gallium nitride (GaN) bulk synthesis

InactiveUS6372041B1Polycrystalline material growthSemiconductor/solid-state device manufacturingBulk crystalGas phase

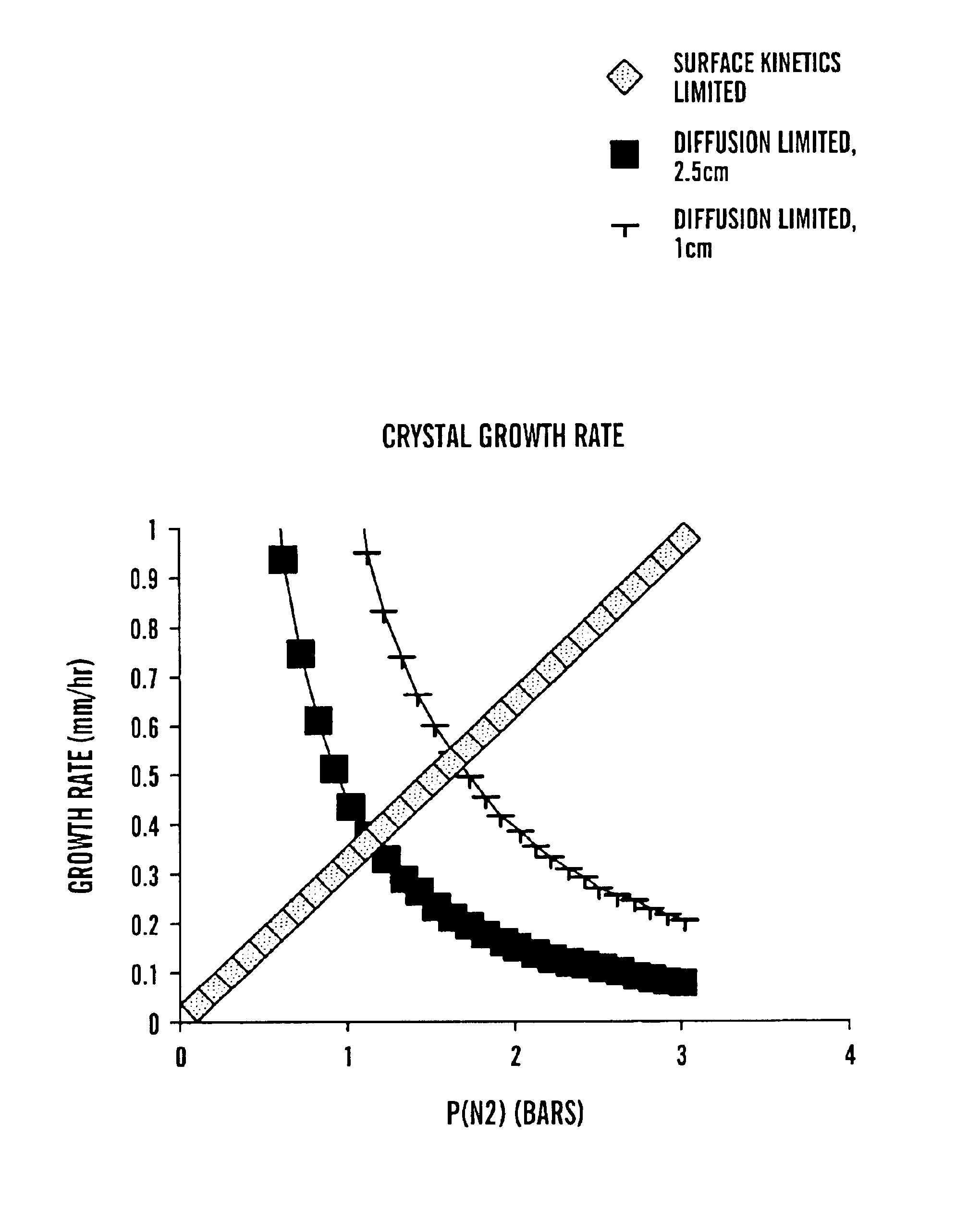

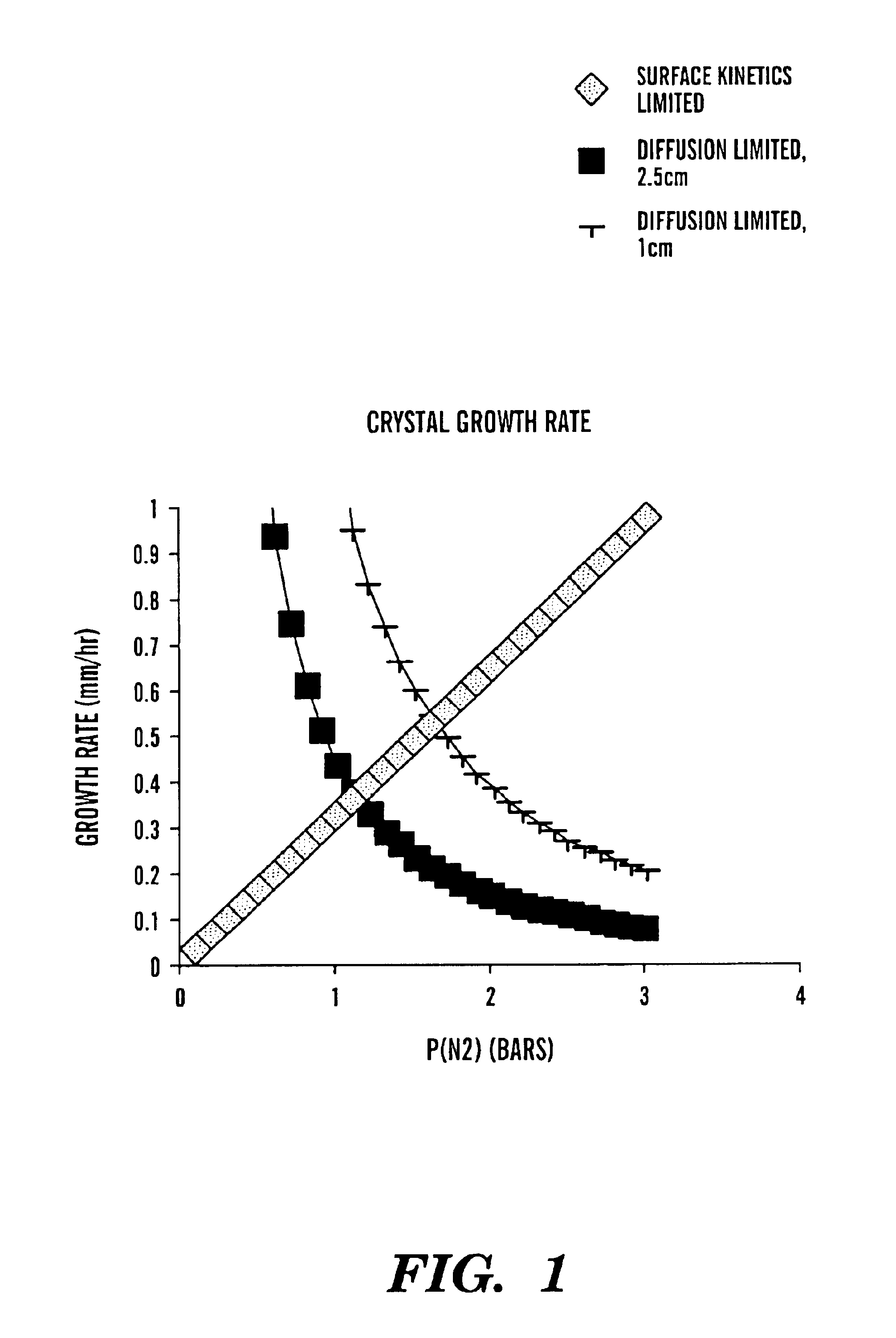

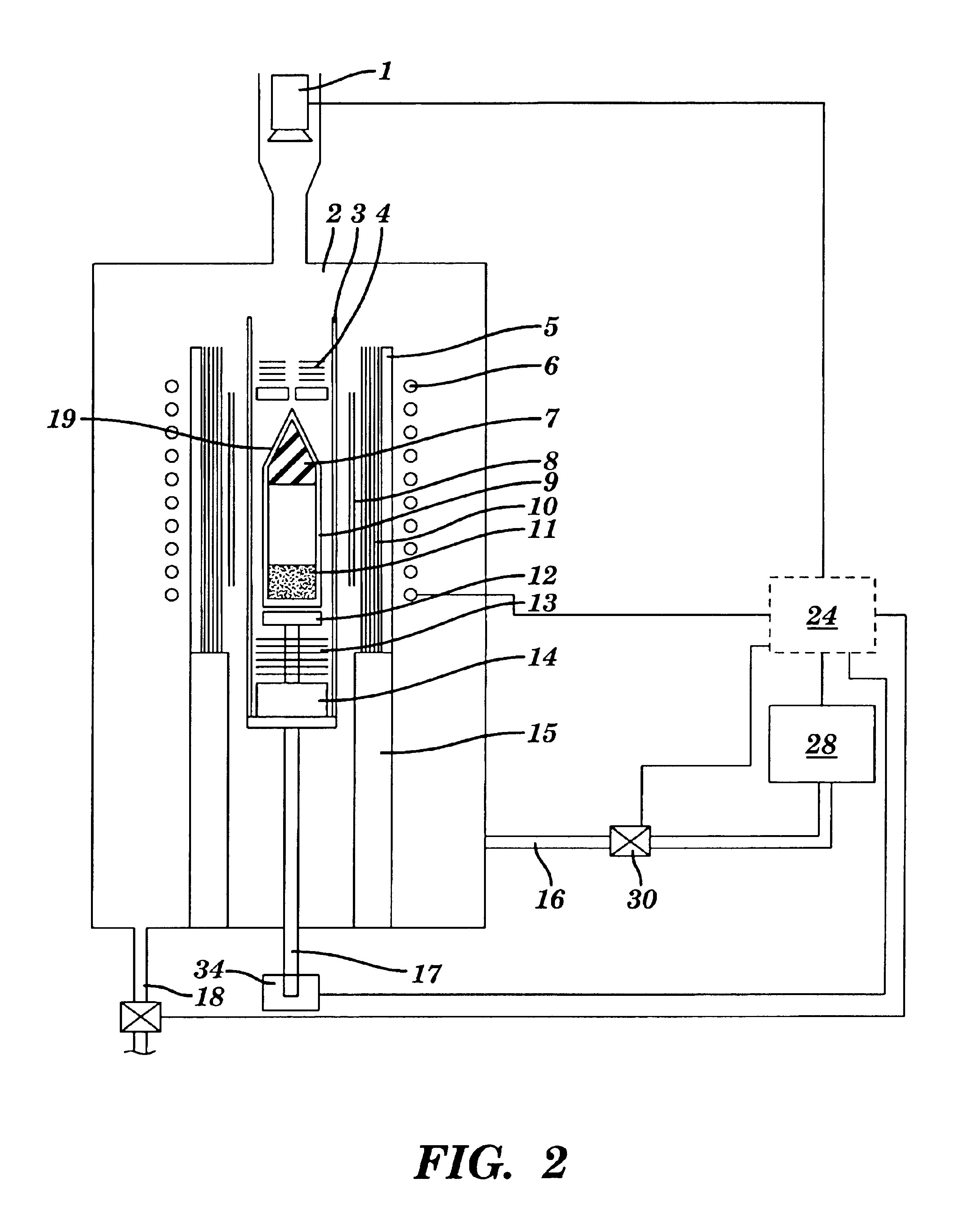

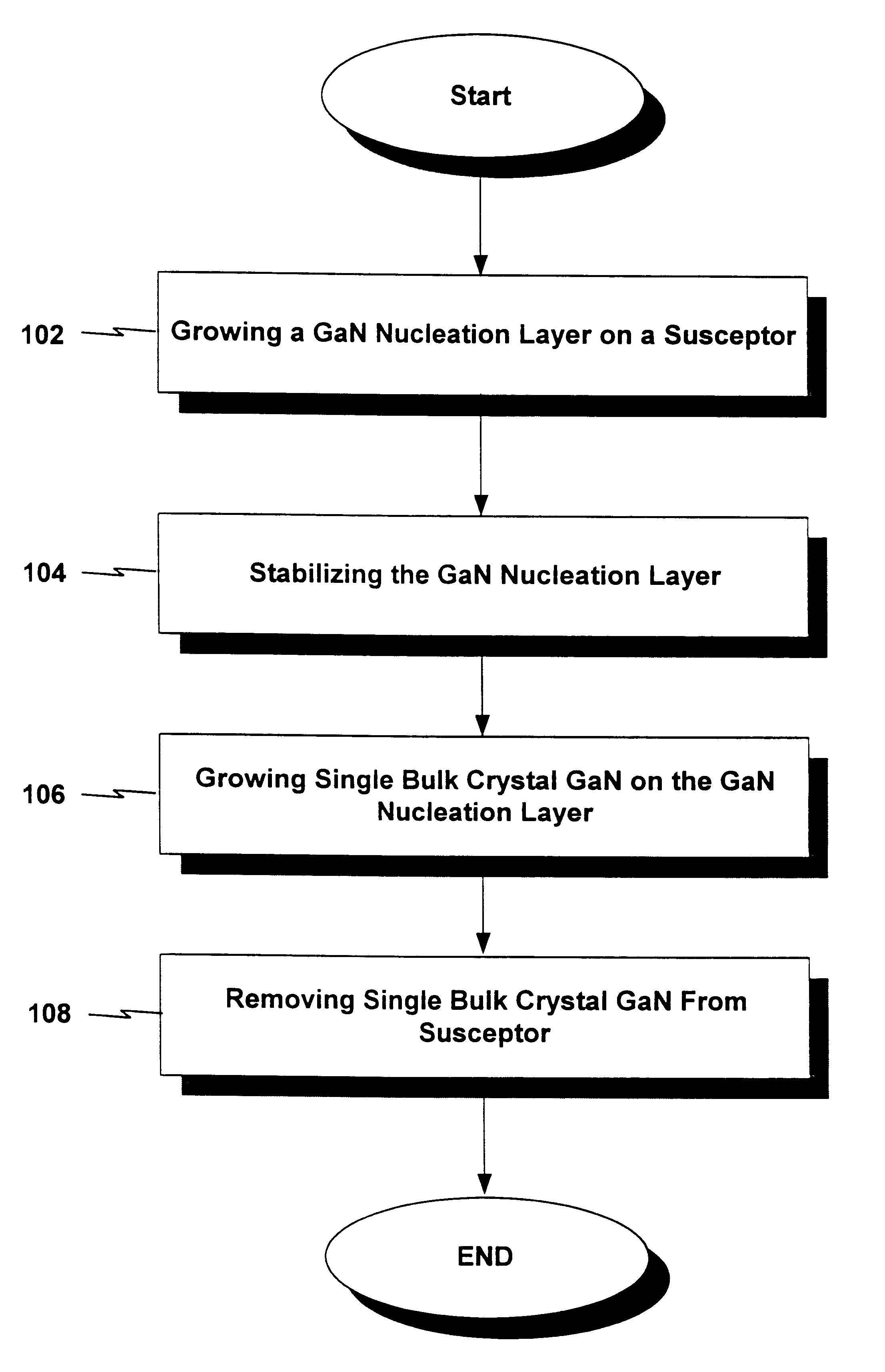

A method and apparatus for homoepitaxial growth of freestanding, single bulk crystal Gallium Nitride (GaN) are provided, wherein a step of nucleating GaN in a reactor results in a GaN nucleation layer having a thickness of a few monolayers. The nucleation layer is stabilized, and a single bulk crystal GaN is grown from gas phase reactants on the GaN nucleation layer. The reactor is formed from ultra low oxygen stainless steel.

Owner:DOW CORNING CORP

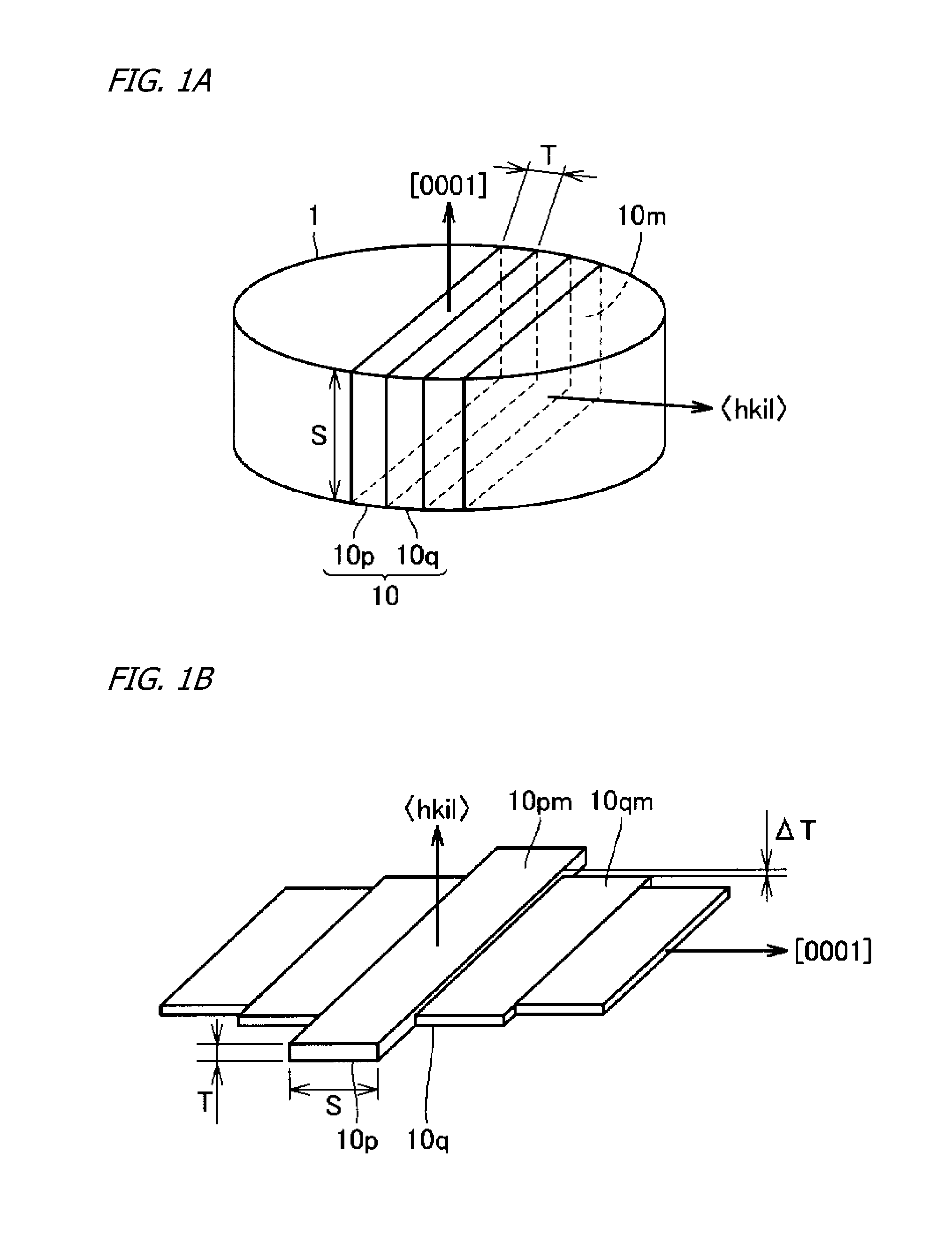

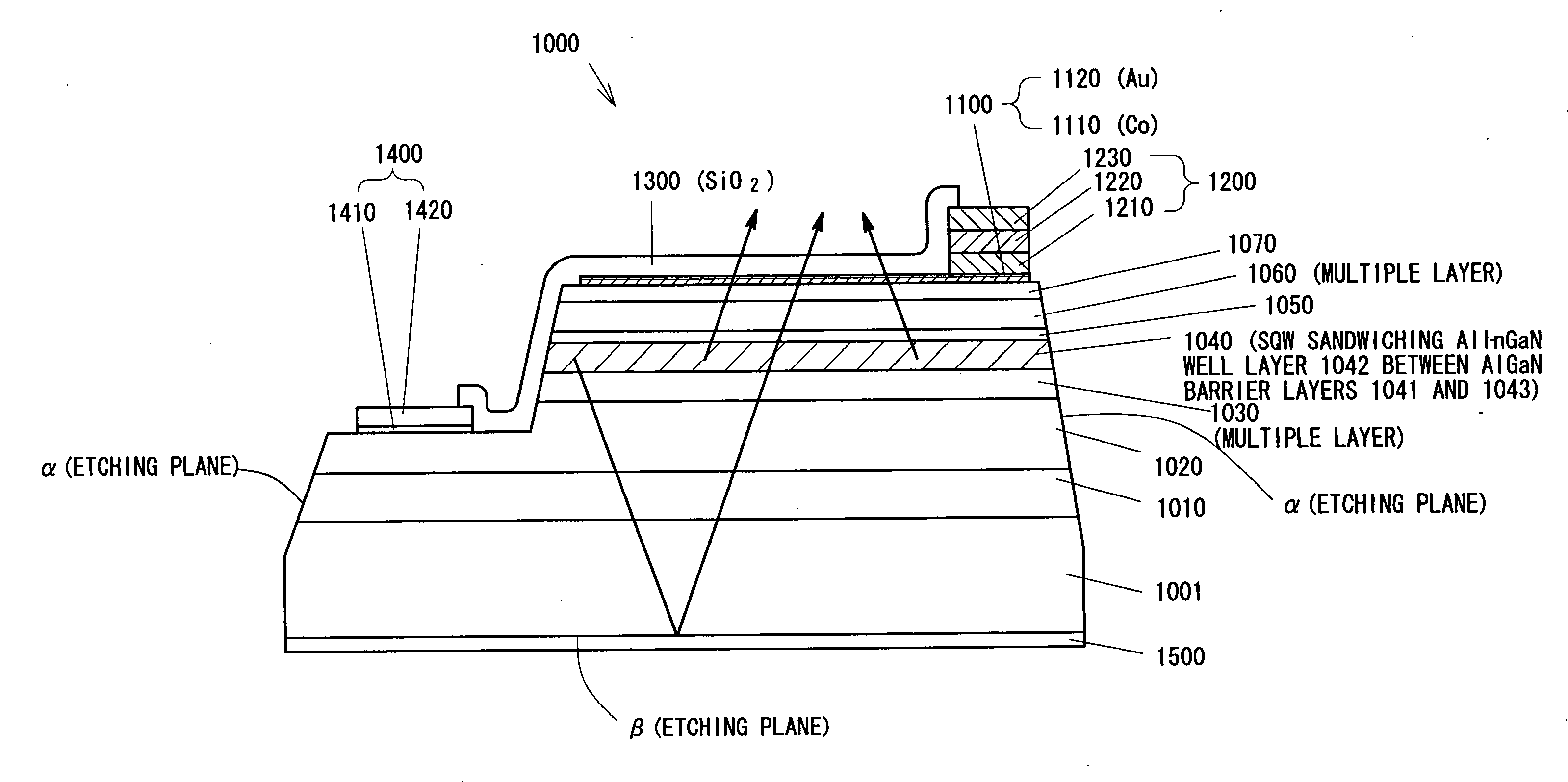

Method of Manufacturing III-Nitride Crystal, and Semiconductor Device Utilizing the Crystal

ActiveUS20090236694A1High crystallinityImprove efficiencyPolycrystalline material growthLiquid-phase epitaxial-layer growthBulk crystalPlane orientation

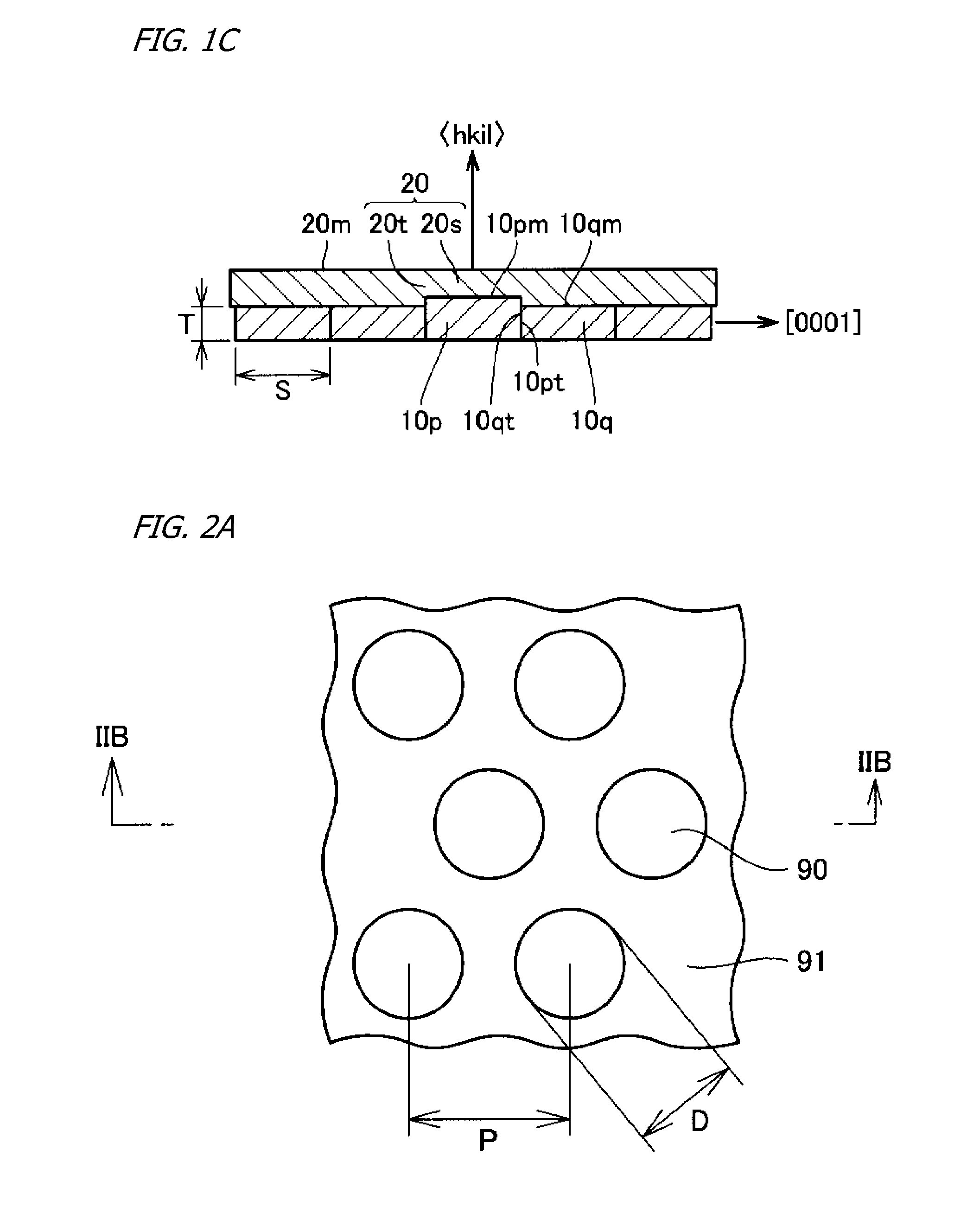

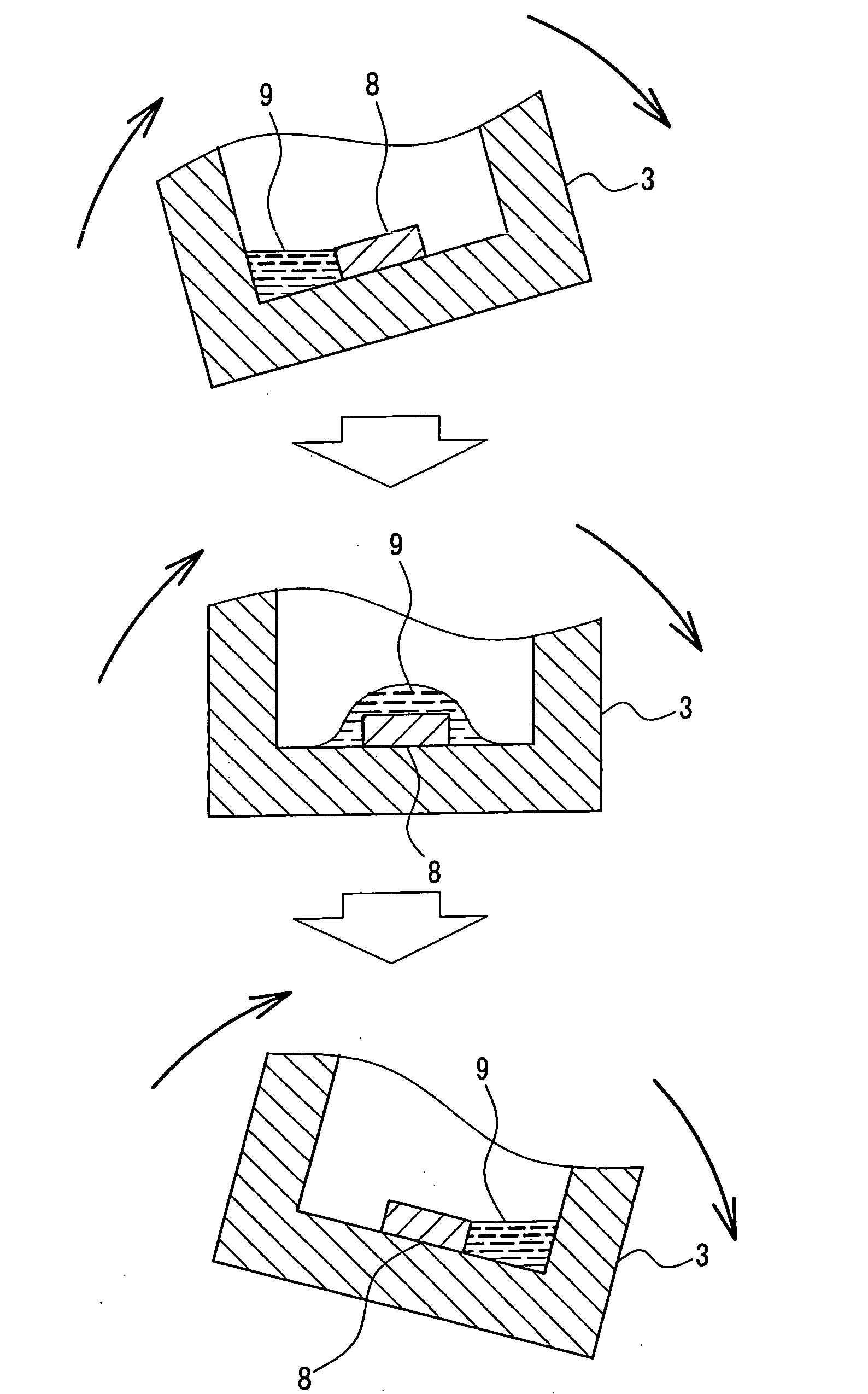

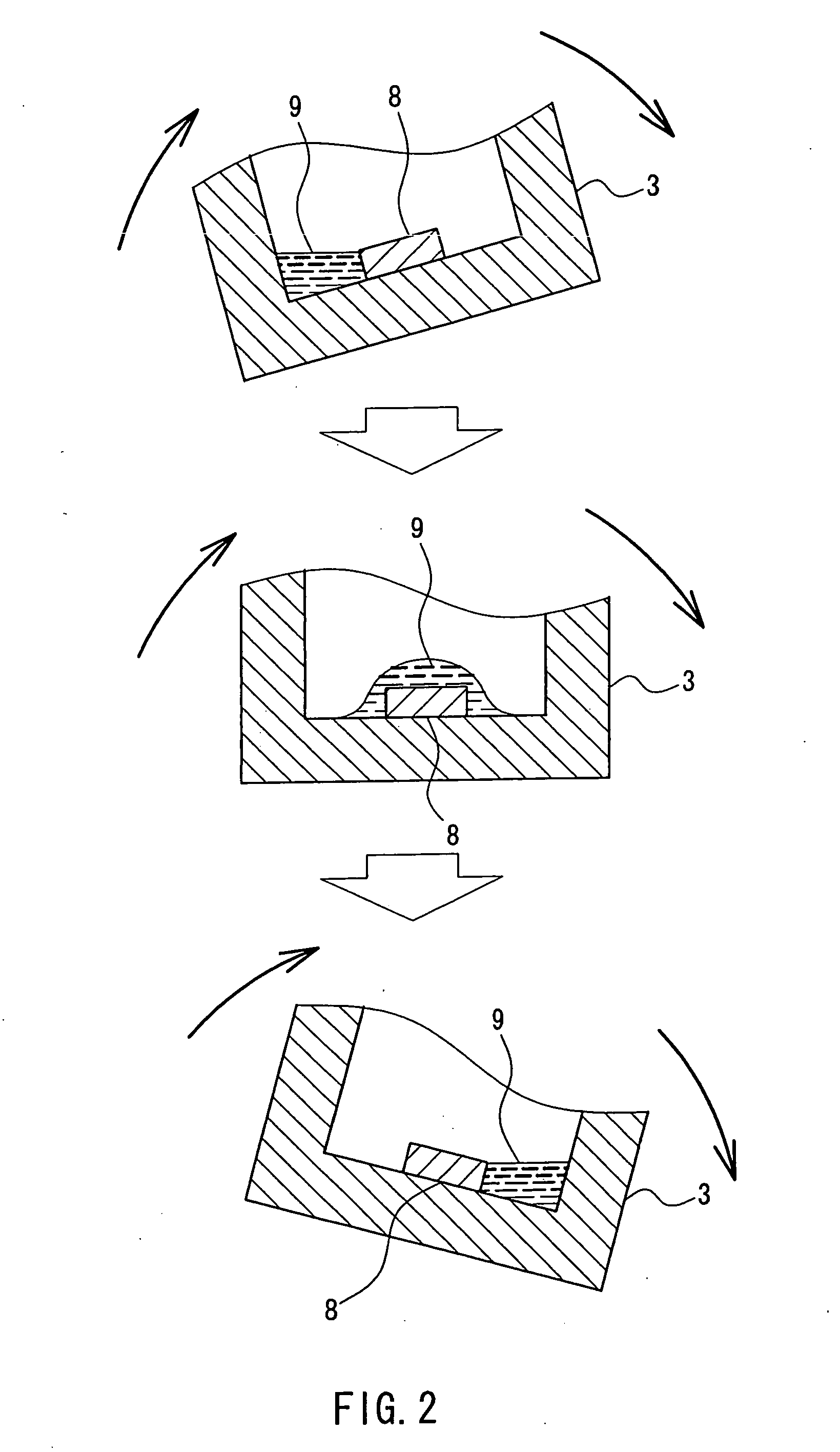

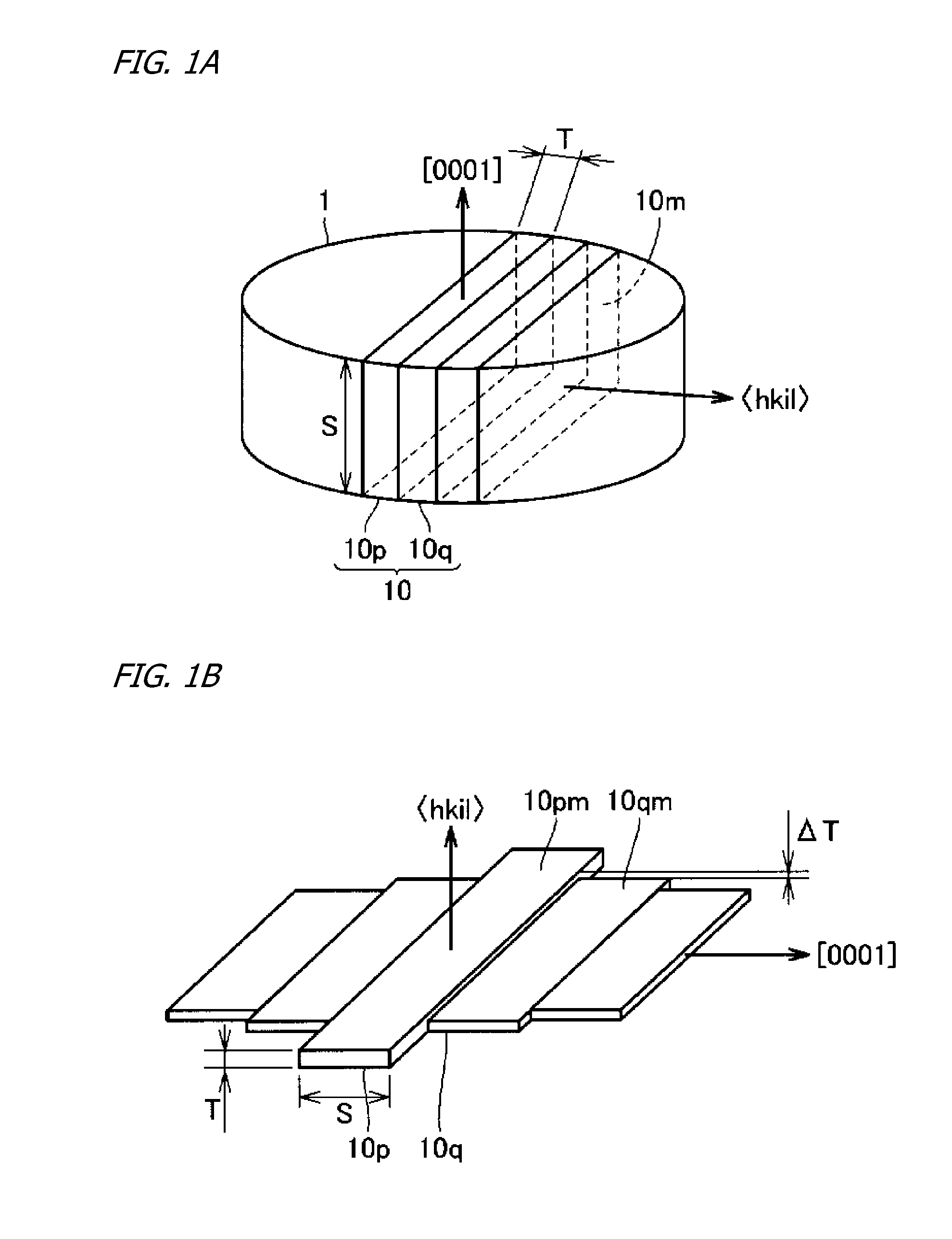

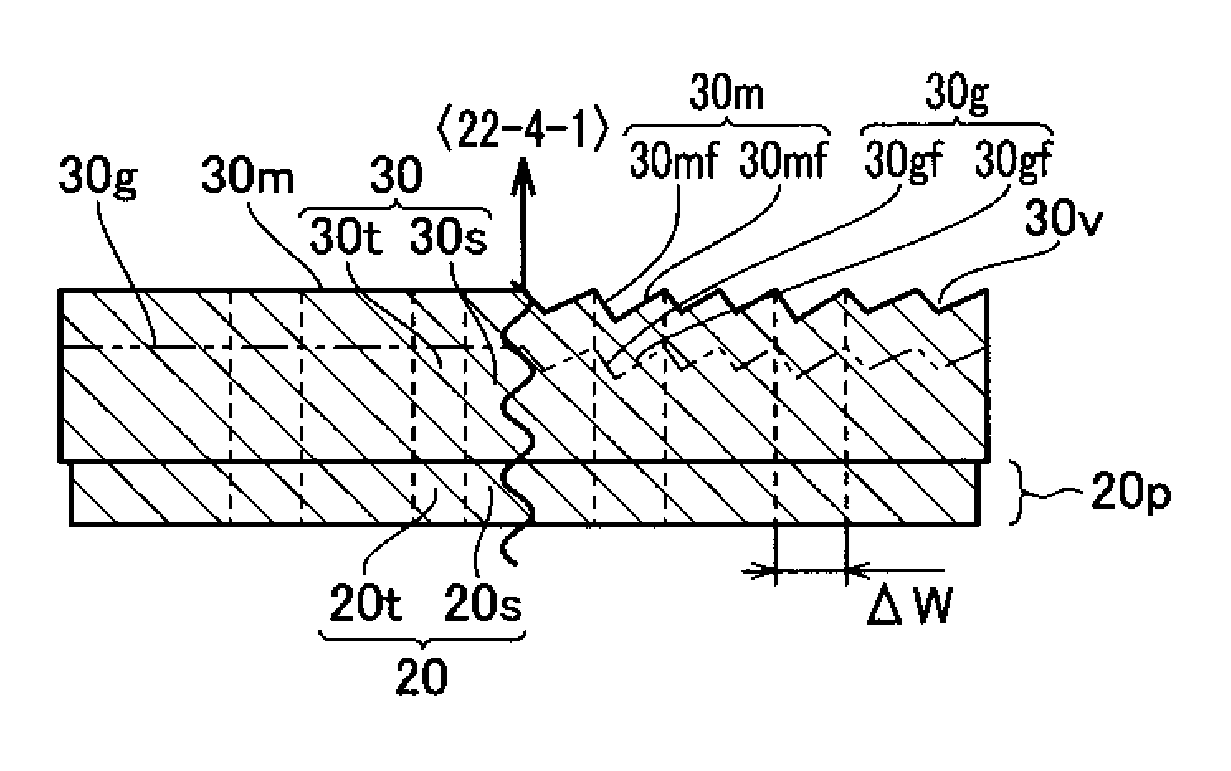

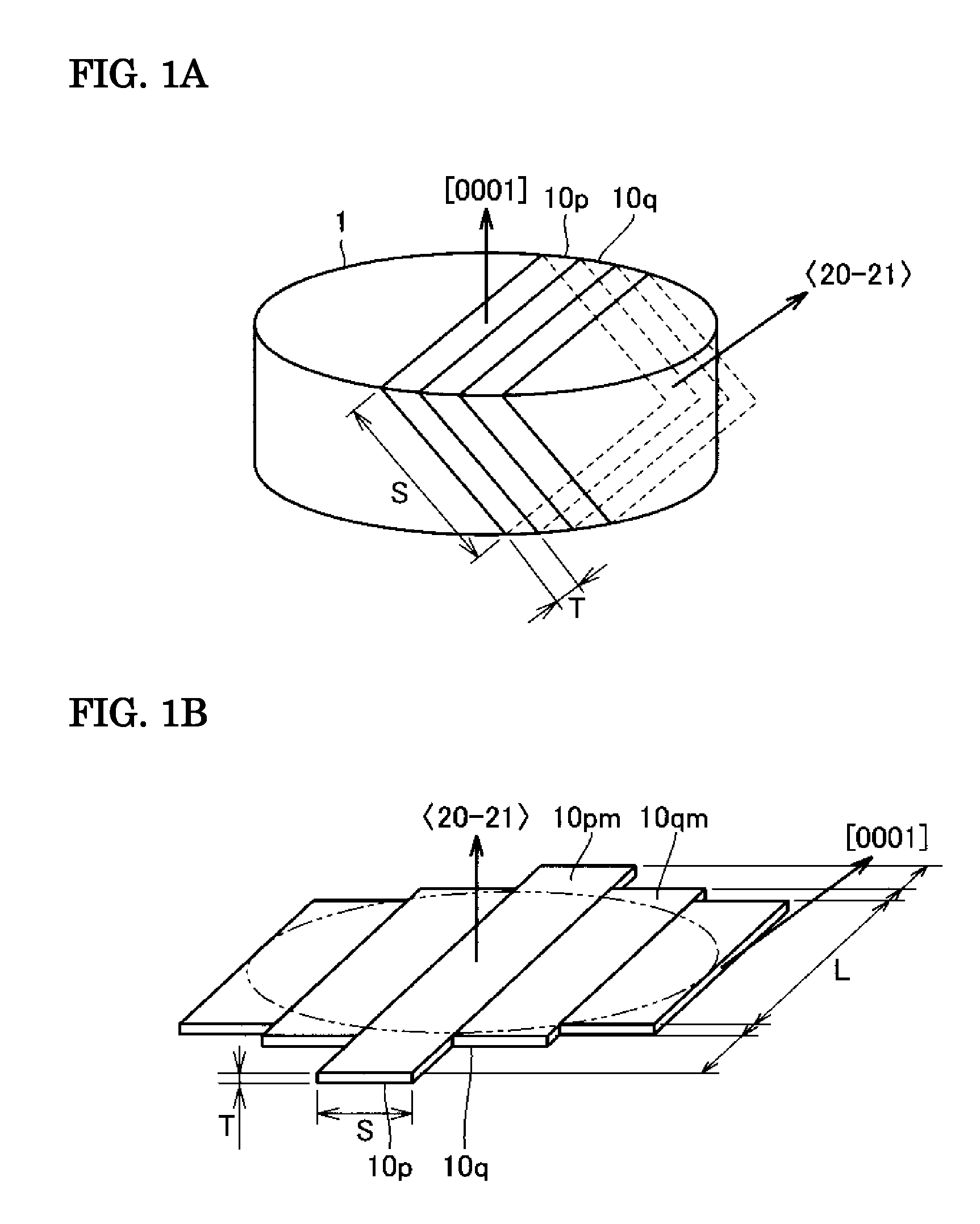

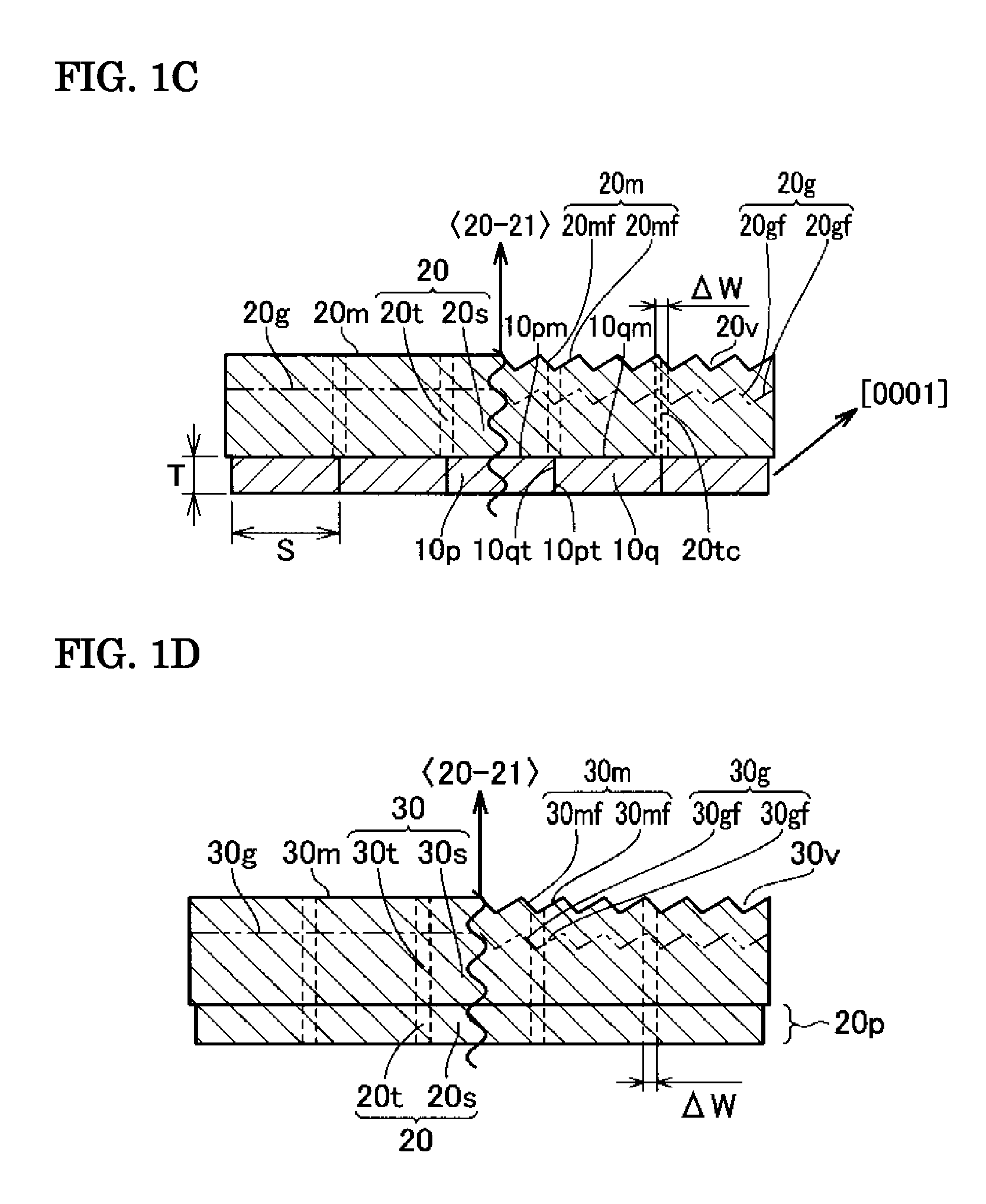

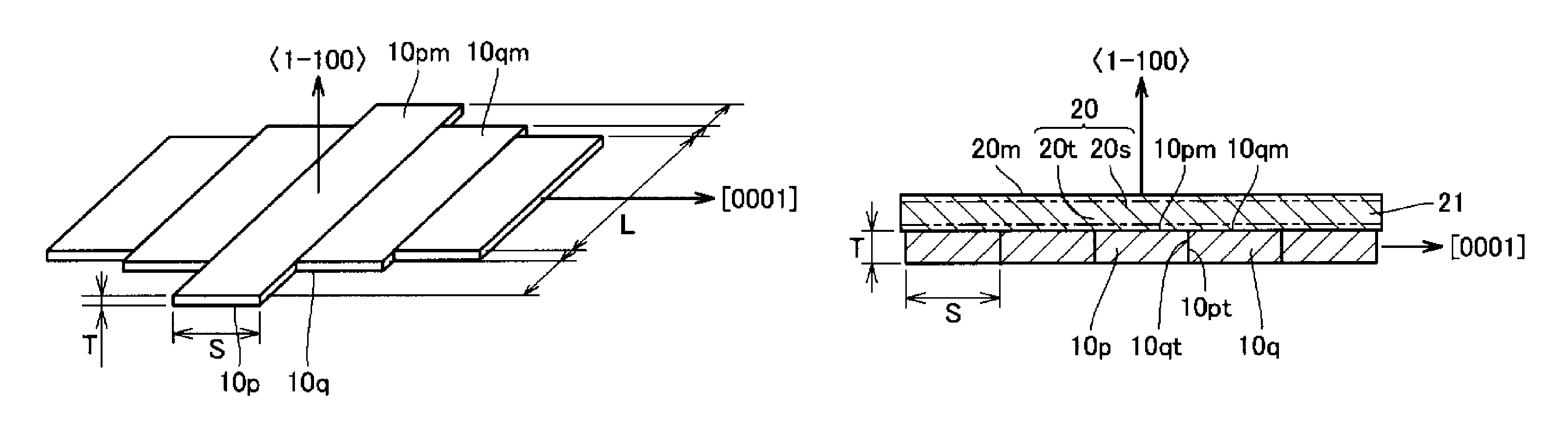

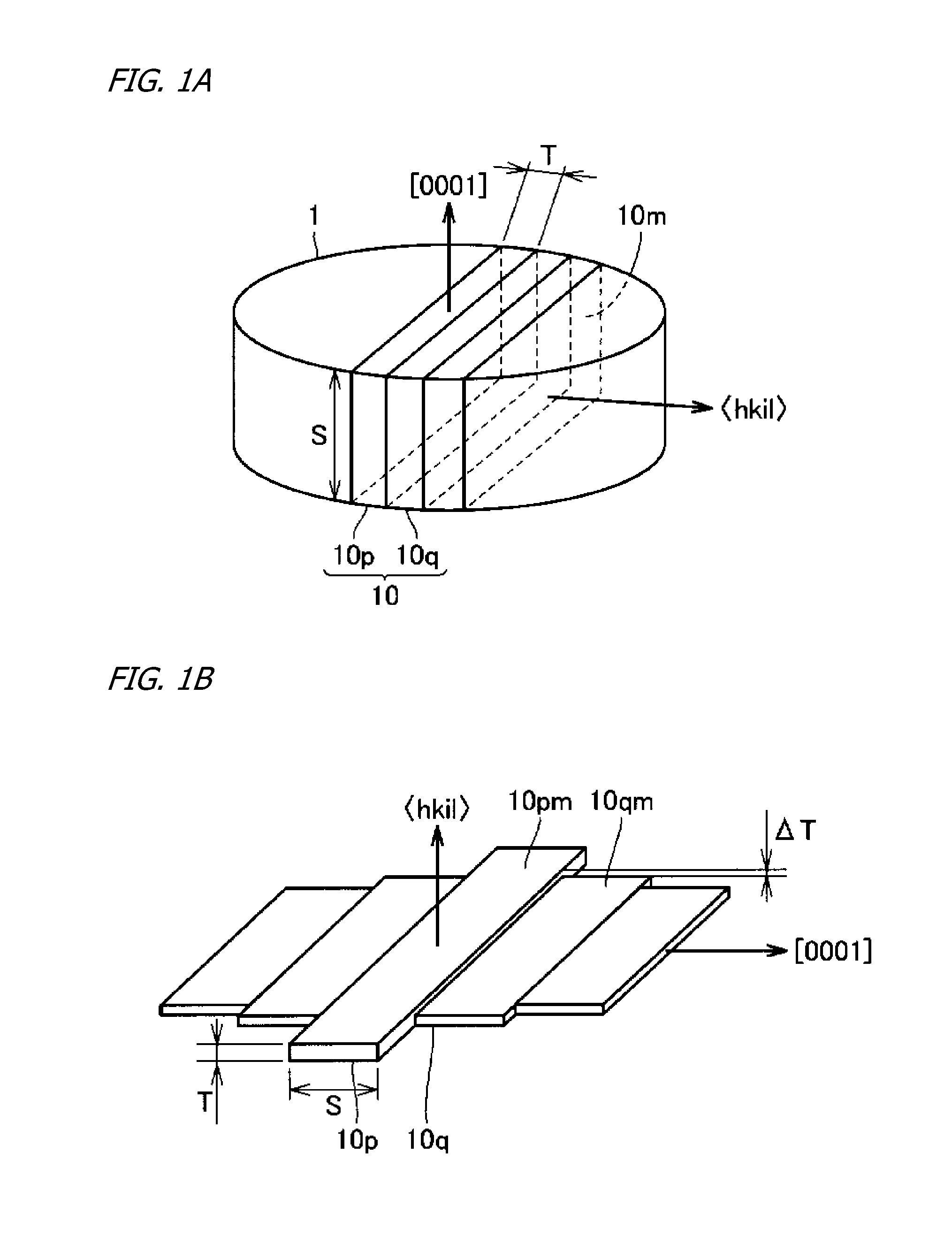

The present III-nitride crystal manufacturing method, a method of manufacturing a III-nitride crystal (20) having a major surface (20m) of plane orientation other than {0001}, designated by choice, includes: a step of slicing III-nitride bulk crystal (1) into a plurality of III-nitride crystal substrates (10p), (10q) having major surfaces (10pm), (10qm) of the designated plane orientation; a step of disposing the substrates (10p), (10q) adjoining each other sideways in such a way that the major surfaces (10pm), (10qm) of the substrates (10p), (10q) parallel each other and so that the [0001] directions in the substrates (10p), (10q) are oriented in the same way; and a step of growing III-nitride crystal (20) onto the major surfaces (10pm), (10qm) of the substrates (10p), (10q).

Owner:SUMITOMO ELECTRIC IND LTD

Method and apparatus for producing large, single-crystals of aluminum nitride

InactiveUS20030168003A1After-treatment apparatusPolycrystalline material growthBulk crystalSource material

A method and apparatus for producing bulk single crystals of AlN includes a crystal growth enclosure with Al and N2 source material therein, capable of forming bulk crystals. The apparatus maintains the N2 partial pressure at greater than stoichiometric pressure relative to the Al within the crystal growth enclosure, while maintaining the total vapor pressure in the crystal growth enclosure at super-atmospheric pressure. At least one nucleation site is provided in the crystal growth enclosure, and provision is made for cooling the nucleation site relative to other locations in crystal growth enclosure. The Al and N2 vapor is then deposited to grow single crystalline AlN at the nucleation site.

Owner:CRYSTAL

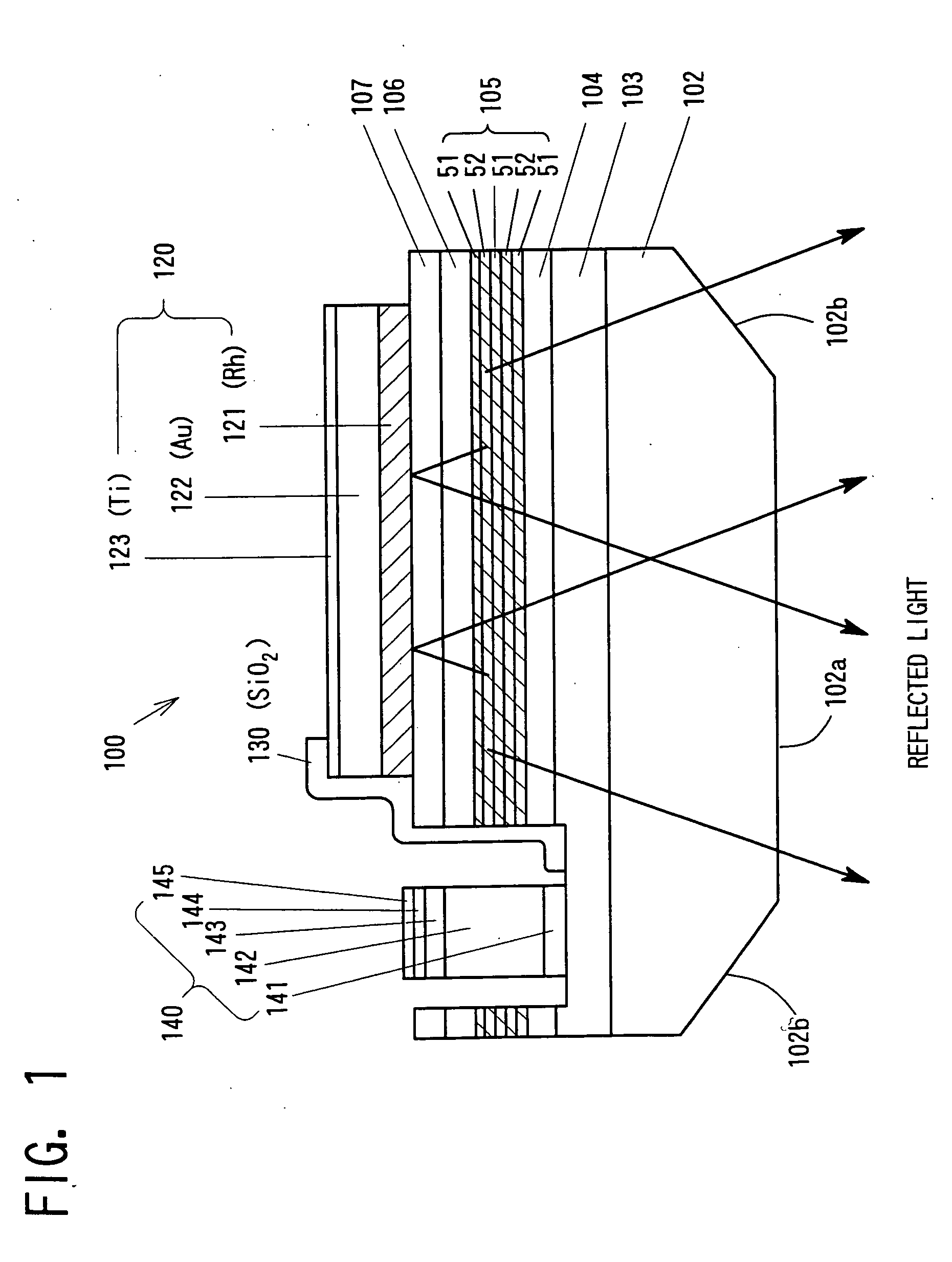

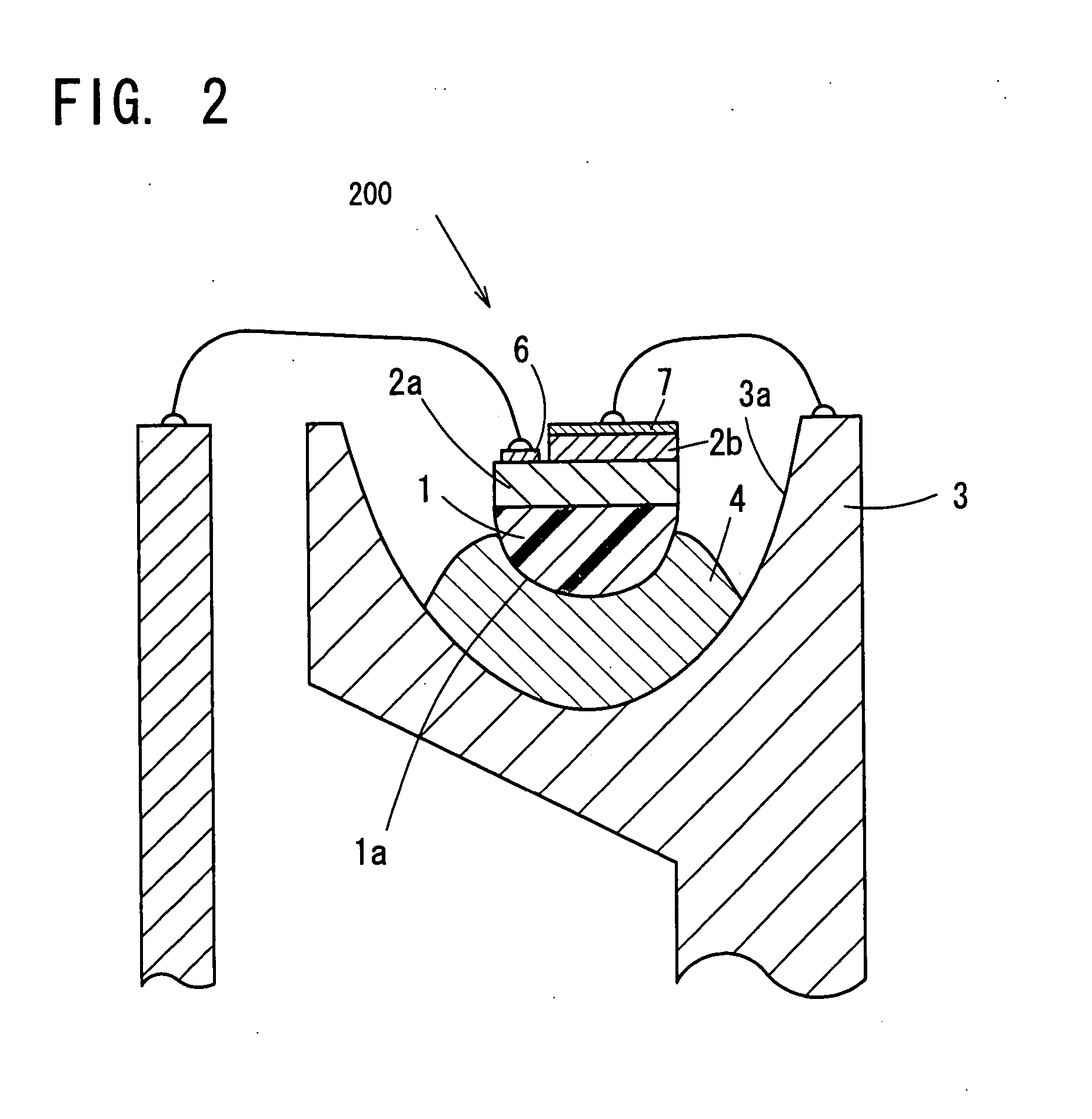

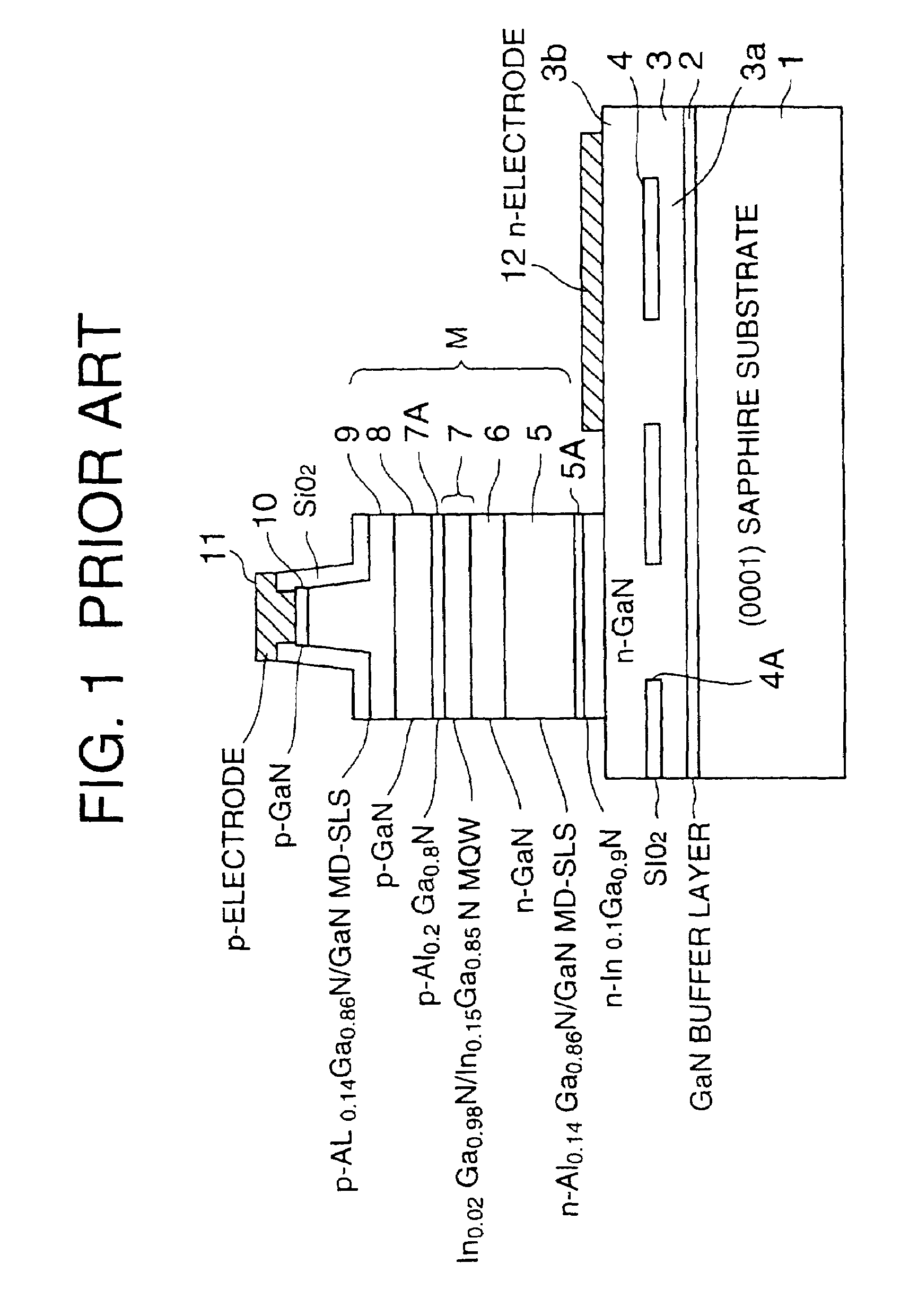

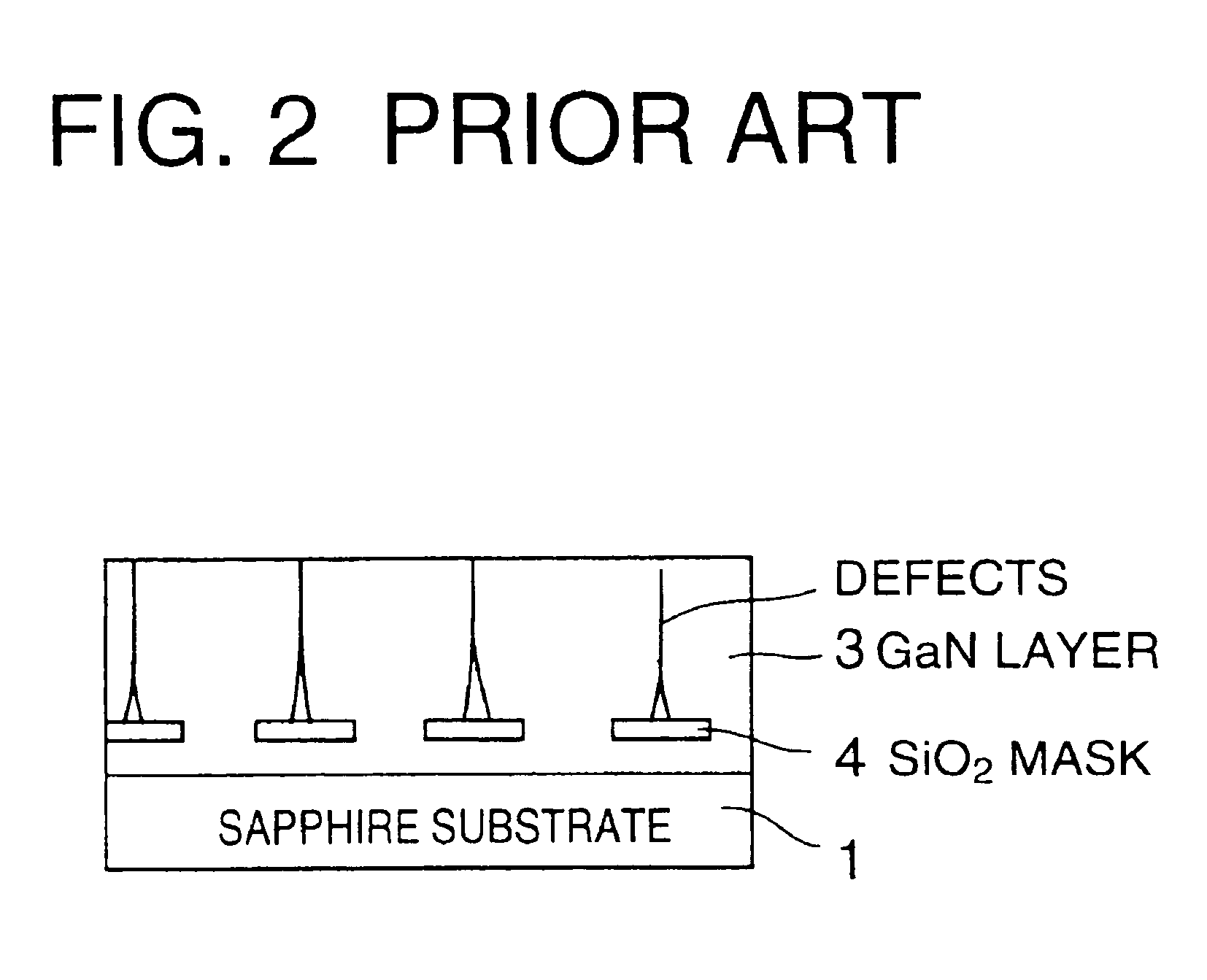

Light-emitting diode and process for producing the same

InactiveUS20060273324A1Efficient removalImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingBulk crystalUltraviolet lights

The back surface of a semiconductor crystal substrate 102 which has a thickness of about 150 μm and is made of undoped GaN bulk crystal consists of a polished plane 102a which is flattened through dry-etching and a grinded plane 102b which is formed in a taper shape and is flattened through dry-etching. On about 10 nm in thickness of GaN n-type clad layer (low carrier concentration layer) 104, about 2 nm in thickness of Al0.005In0.045Ga0.95N well layer 51 and about 18 nm in thickness of Al0.12Ga0.88N barrier layer 52 are deposited alternately as an active layer 105 which emits ultraviolet light and has MQW structure comprising 5 layers in total. Before forming a negative electrode (n-electrode c) on the polished plane of the semiconductor substrate a, the polished plane is dry-etched.

Owner:TOYODA GOSEI CO LTD

Method for Exfoliation of Hexagonal Boron Nitride

ActiveUS20110045223A1Simplify the chemical processEasy post-processingNitrogen compoundsLayered productsBulk crystalOrganic solvent

A new method is disclosed for the exfoliation of hexagonal boron nitride into mono- and few-layered nanosheets (or nanoplatelets, nanomesh, nanoribbons). The method does not necessarily require high temperature or vacuum, but uses commercially available h-BN powders (or those derived from these materials, bulk crystals) and only requires wet chemical processing. The method is facile, cost efficient, and scalable. The resultant exfoliated h-BN is dispersible in an organic solvent or water thus amenable for solution processing for unique microelectronic or composite applications.

Owner:NASA

Method and apparatus for producing large, single-crystals of aluminum nitride

InactiveUS20060005763A1Polycrystalline material growthSolid-state devicesBulk crystalSource material

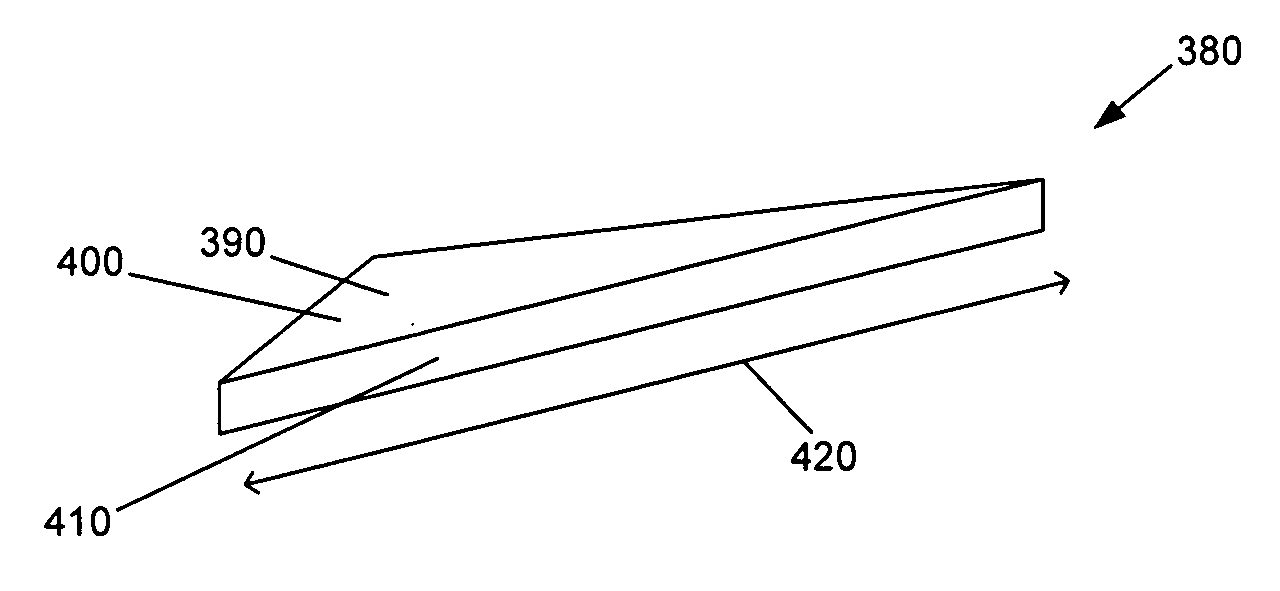

A method and apparatus for producing bulk single crystals of AlN having low dislocation densities of about 10,000 cm−2 or less includes a crystal growth enclosure with Al and N2 source material therein, capable of forming bulk crystals. The apparatus maintains the N2 partial pressure at greater than stoichiometric pressure relative to the Al within the crystal growth enclosure, while maintaining the total vapor pressure in the crystal growth enclosure at super-atmospheric pressure. At least one nucleation site is provided in the crystal growth enclosure, and provision is made for cooling the nucleation site relative to other locations in the crystal growth enclosure. The Al and N2 vapor is then deposited to grow single crystalline low dislocation density AlN at the nucleation site. High efficiency ultraviolet light emitting diodes and ultraviolet laser diodes are fabricated on low defect density AlN substrates, which are cut from the low dislocation density AlN crystals. Bulk crystals of ZnO may also be produced using the method.

Owner:CRYSTAL

Methods for controllable doping of aluminum nitride bulk crystals

ActiveUS20070243653A1Increase volumePolycrystalline material growthAfter-treatment detailsBulk crystalSingle crystal

Fabrication of doped and undoped stoichiometric polycrystalline AlN ceramics with high purity is accomplished by, for example, reacting Al pellets with nitrogen gas. Such polycrystalline AlN ceramics may be utilized in the fabrication of high purity AlN single crystals, which may be annealed to enhance a conductivity thereof.

Owner:CRYSTAL

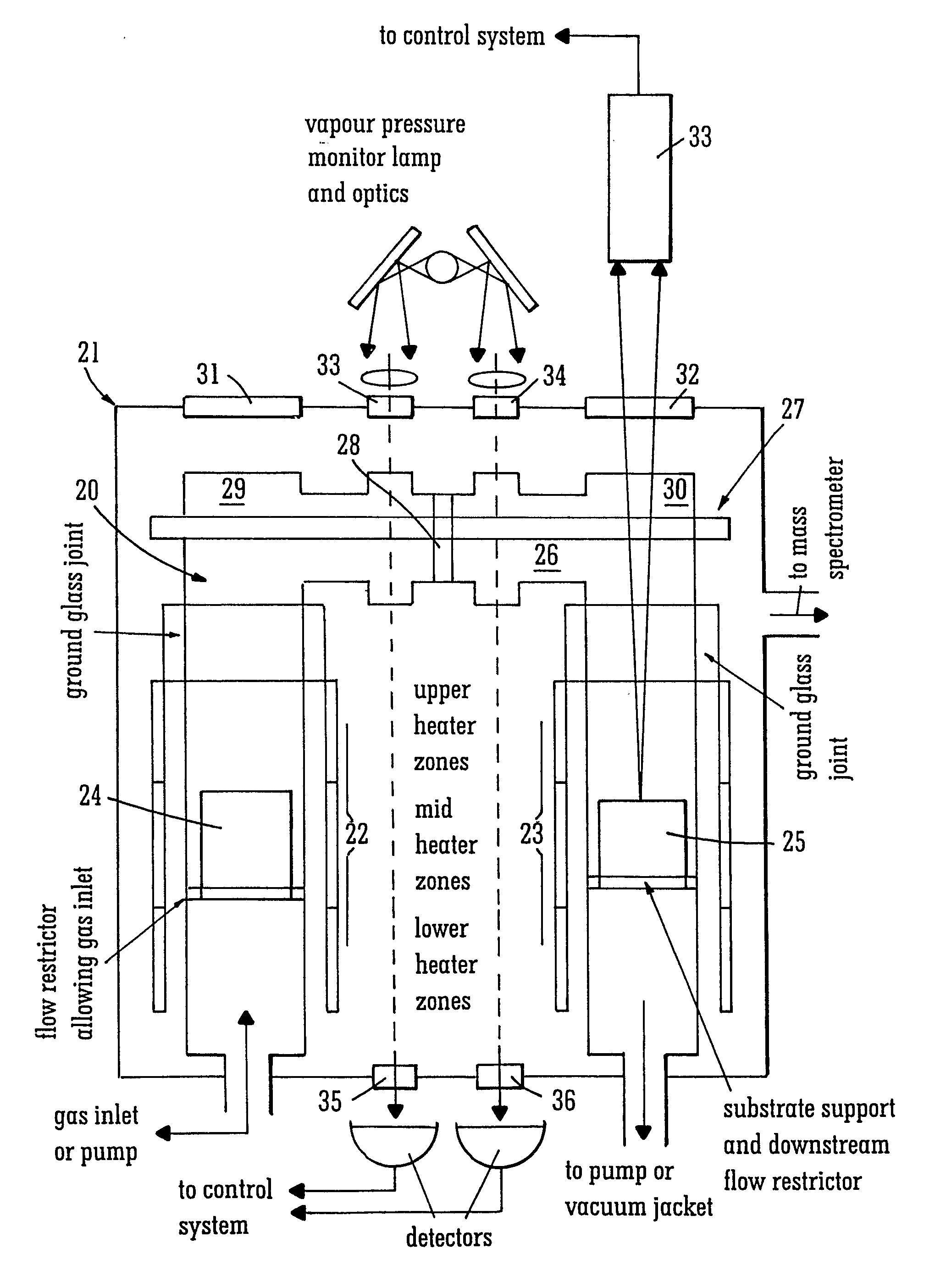

Process for producing a iii-n bulk crystal and a free-standing iii-n substrate, and iii-n bulk crystal and free-standing iii-n substrate

ActiveUS20070257334A1Improve crystal qualityEasy to producePolycrystalline material growthBy zone-melting liquidsBulk crystalSingle crystal substrate

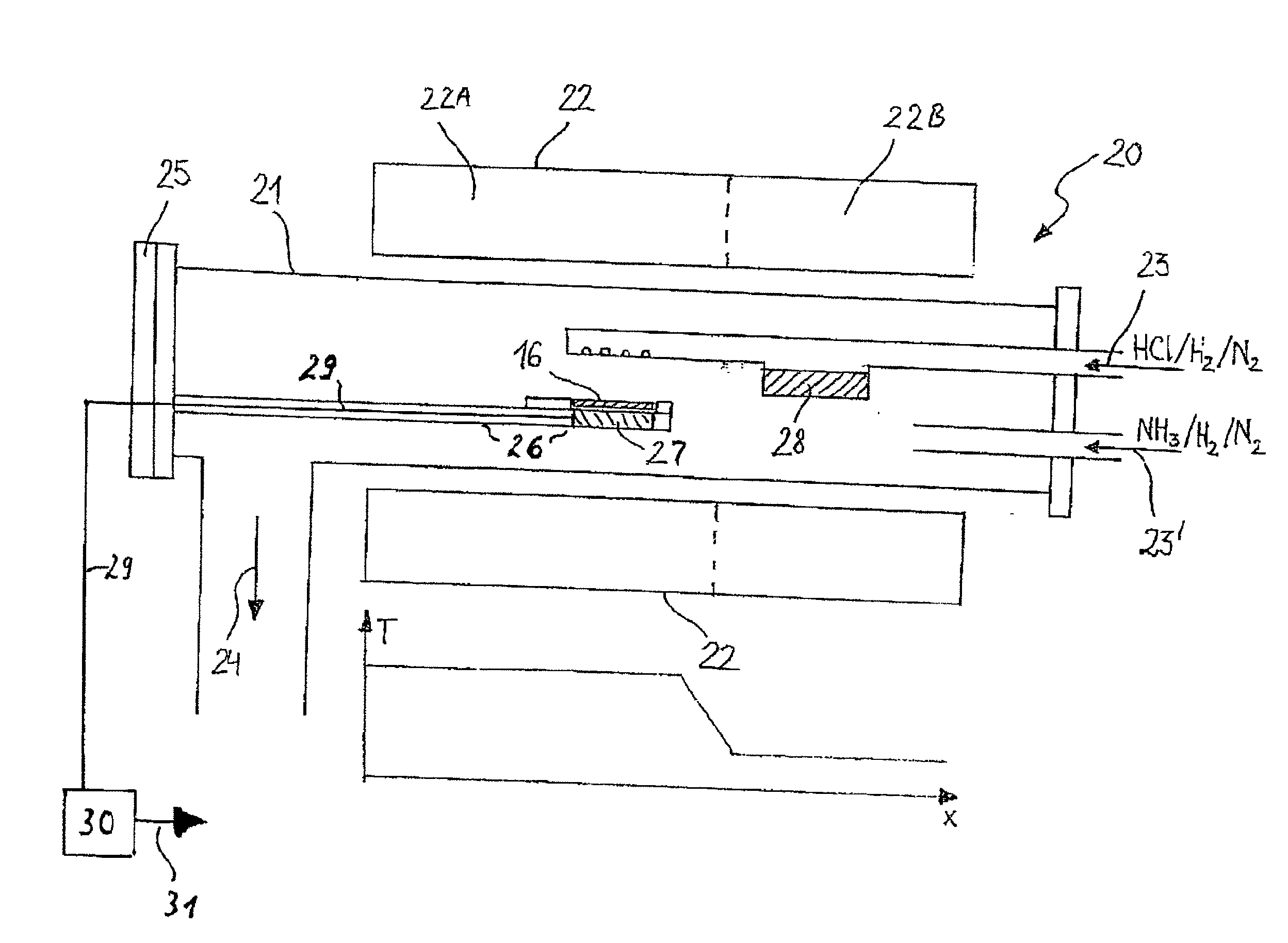

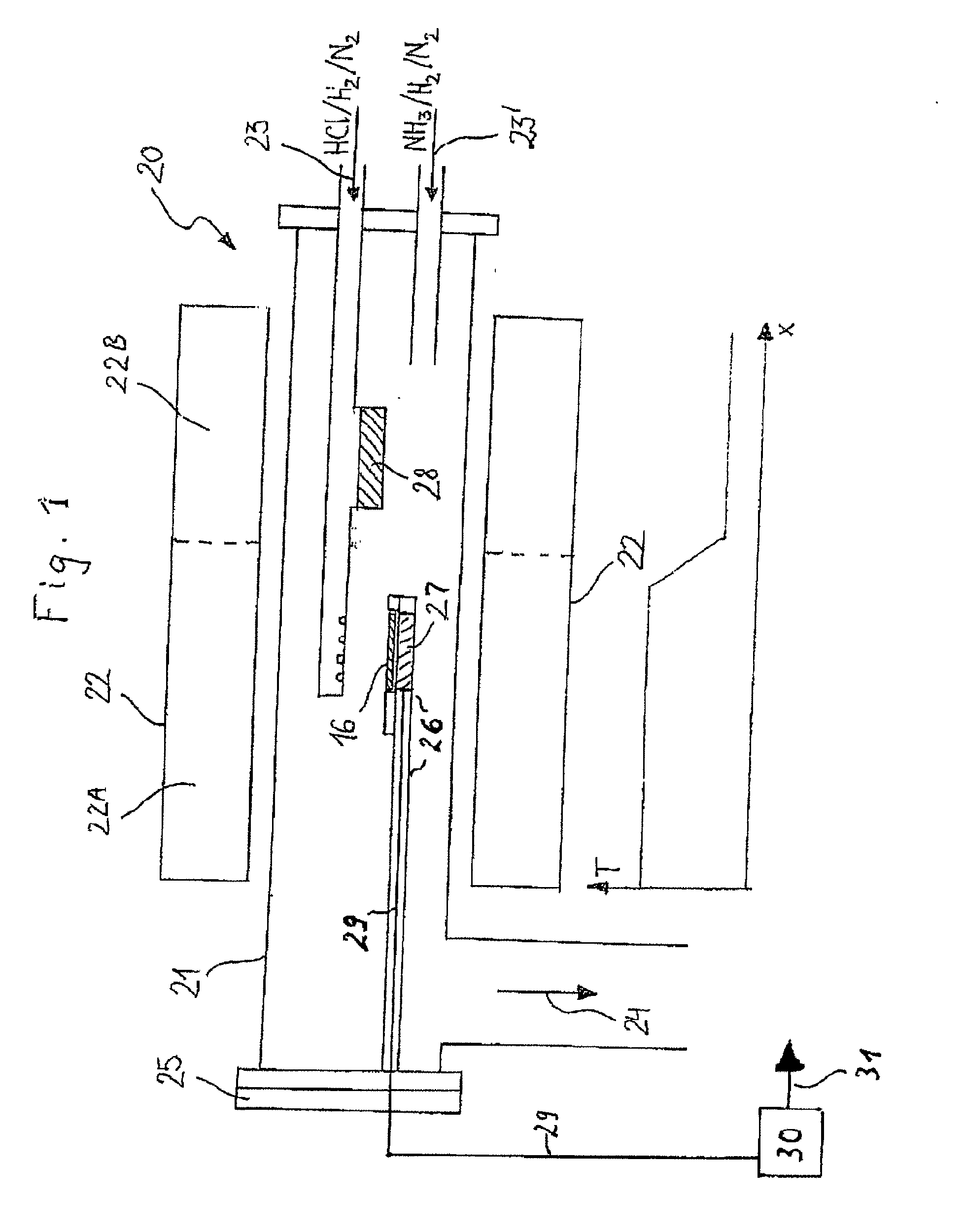

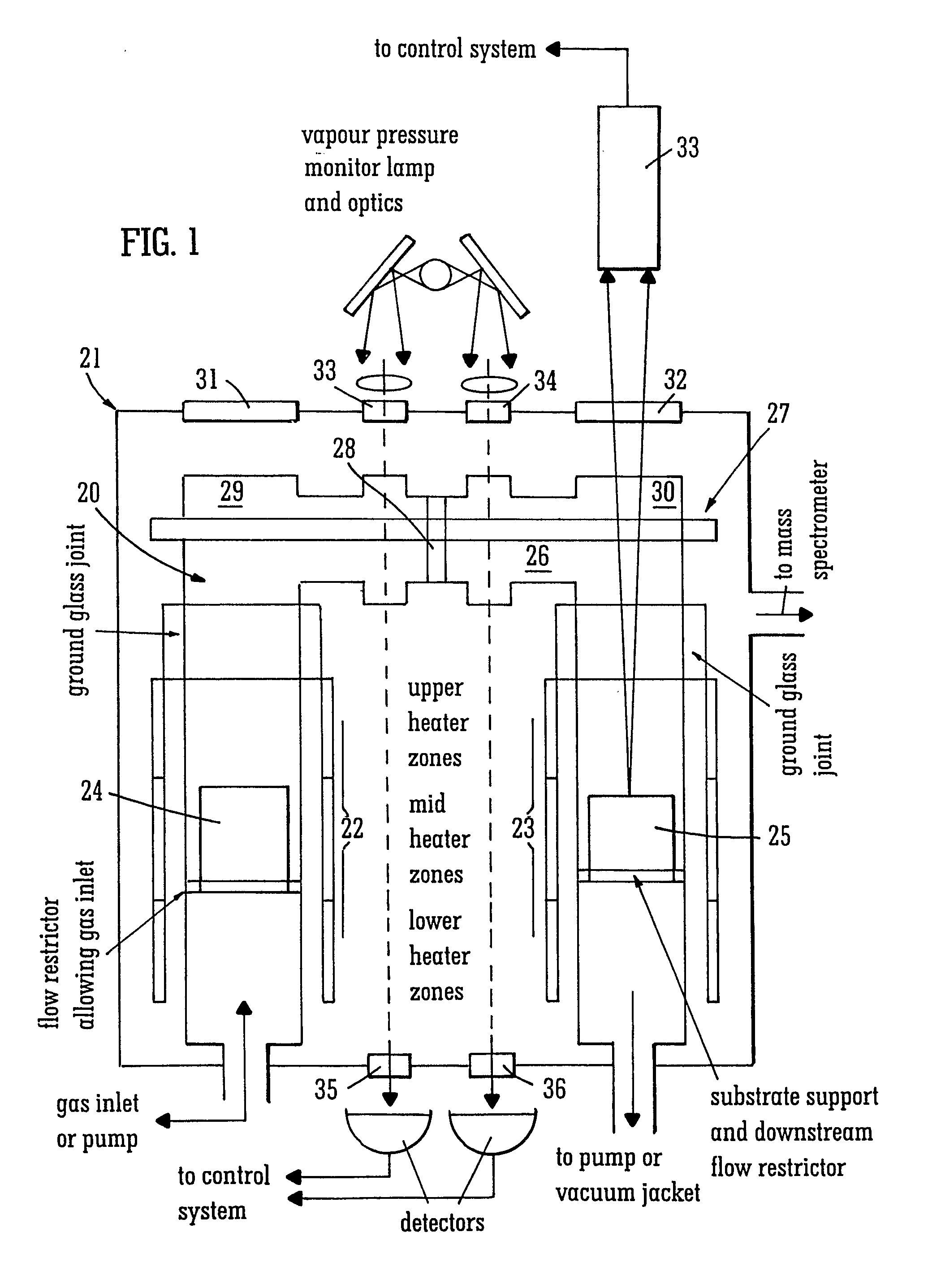

Embodiments of the invention relate to a process for producing a III-N bulk crystal, wherein III denotes at least one element selected from group III of the periodic system, selected from Al, Ga and In, wherein the III-N bulk crystal is grown by vapor phase epitaxy on a substrate, and wherein the growth rate is measured in real-time. By actively measuring and controlling the growth rate in situ, i.e. during the epitaxial growth, the actual growth rate can be maintained essentially constant. In this manner, III-N bulk crystals and individualized III-N single crystal substrates separated therefrom, which respectively have excellent crystal quality both in the growth direction and in the growth plane perpendicular thereto, can be obtained.

Owner:FREIBERGER COMPOUND MATERIALS

Methods for controllable doping of aluminum nitride bulk crystals

ActiveUS8012257B2Increase volumePolycrystalline material growthAfter-treatment detailsBulk crystalSingle crystal

Fabrication of doped and undoped stoichiometric polycrystalline AlN ceramics with high purity is accomplished by, for example, reacting Al pellets with nitrogen gas. Such polycrystalline AlN ceramics may be utilized in the fabrication of high purity AlN single crystals, which may be annealed to enhance a conductivity thereof.

Owner:CRYSTAL

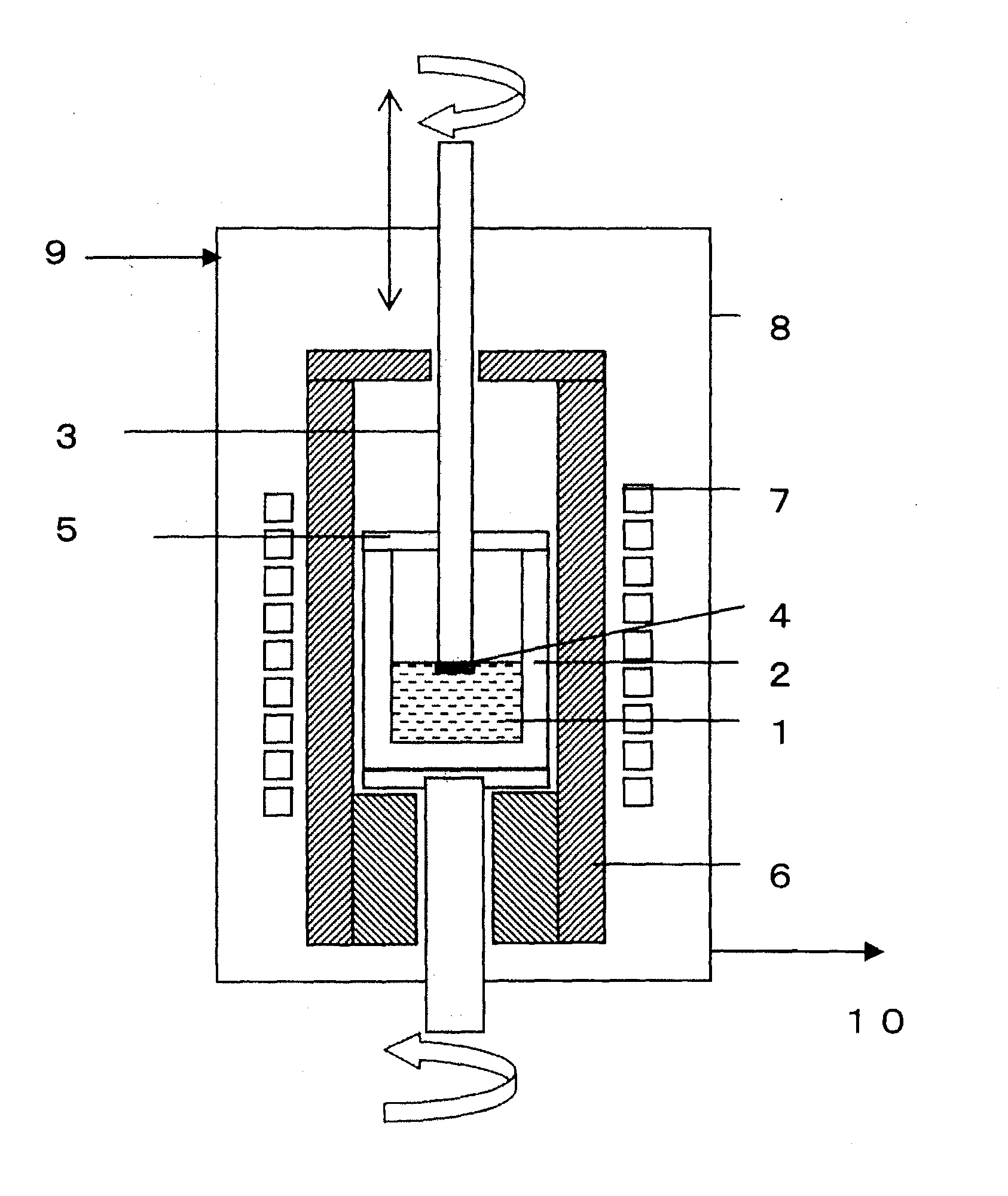

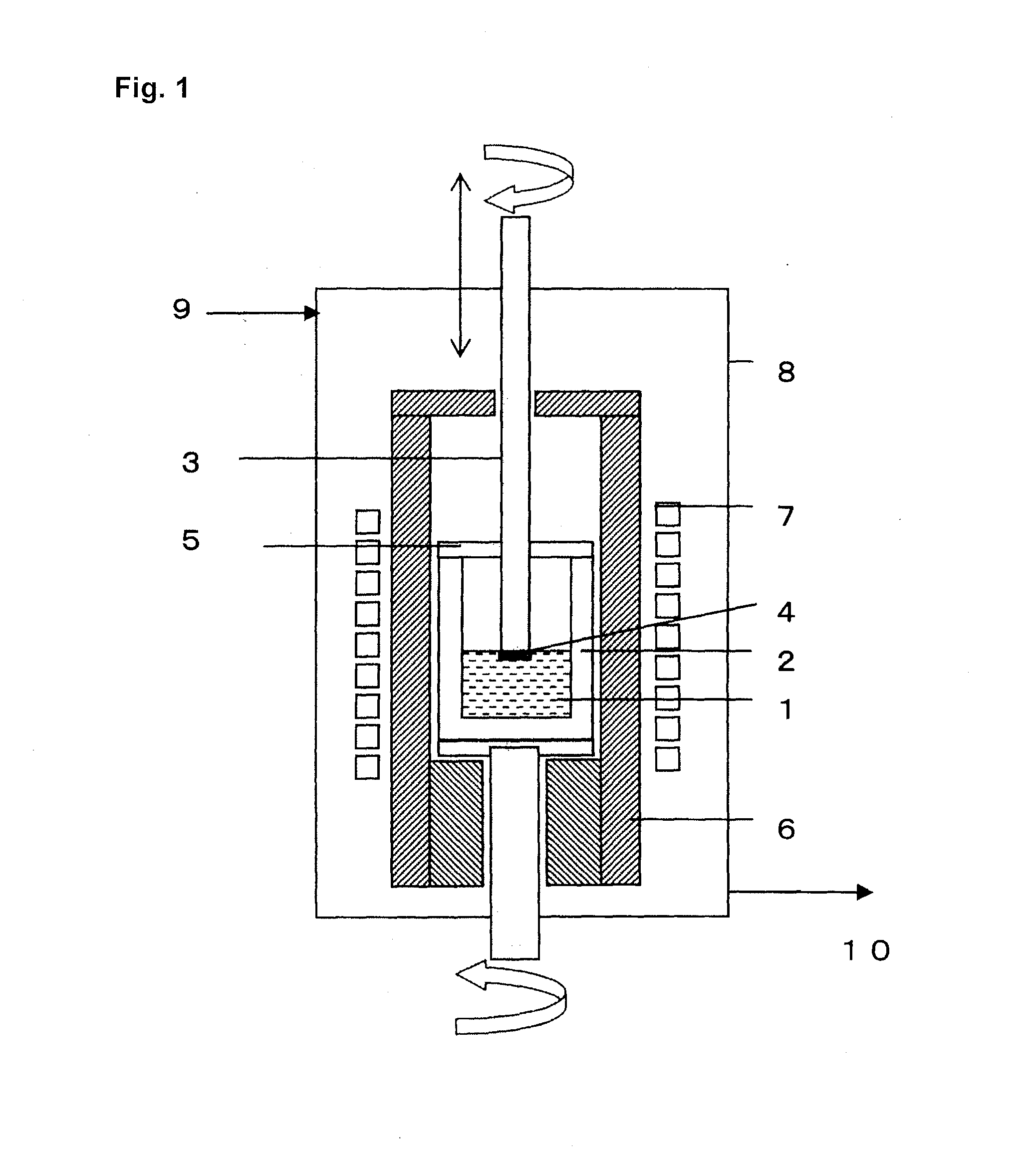

Method for producing group III nitride single crystal and apparatus used therefor

InactiveUS20060169197A1Reduce dislocation densityNon-uniform nitrogen distributionPolycrystalline material growthFrom normal temperature solutionsIndiumBulk crystal

A production method is provided in which Group-III-element nitride single crystals that have a lower dislocation density and a uniform thickness and are transparent, high quality, large, and bulk crystals can be produced with a high yield. The method for producing Group-III-element nitride single crystals includes: heating a reaction vessel containing at least one metal element selected from the group consisting of an alkali metal and an alkaline-earth metal and at least one Group III element selected from the group consisting of gallium (Ga), aluminum (Al), and indium (In) to prepare a flux of the metal element; and feeding nitrogen-containing gas into the reaction vessel and thereby allowing the Group III element and nitrogen to react with each other in the flux to grow Group-III-element nitride single crystals, wherein the single crystals are grown, with the flux being stirred by rocking the reaction vessel, for instance.

Owner:OSAKA UNIV

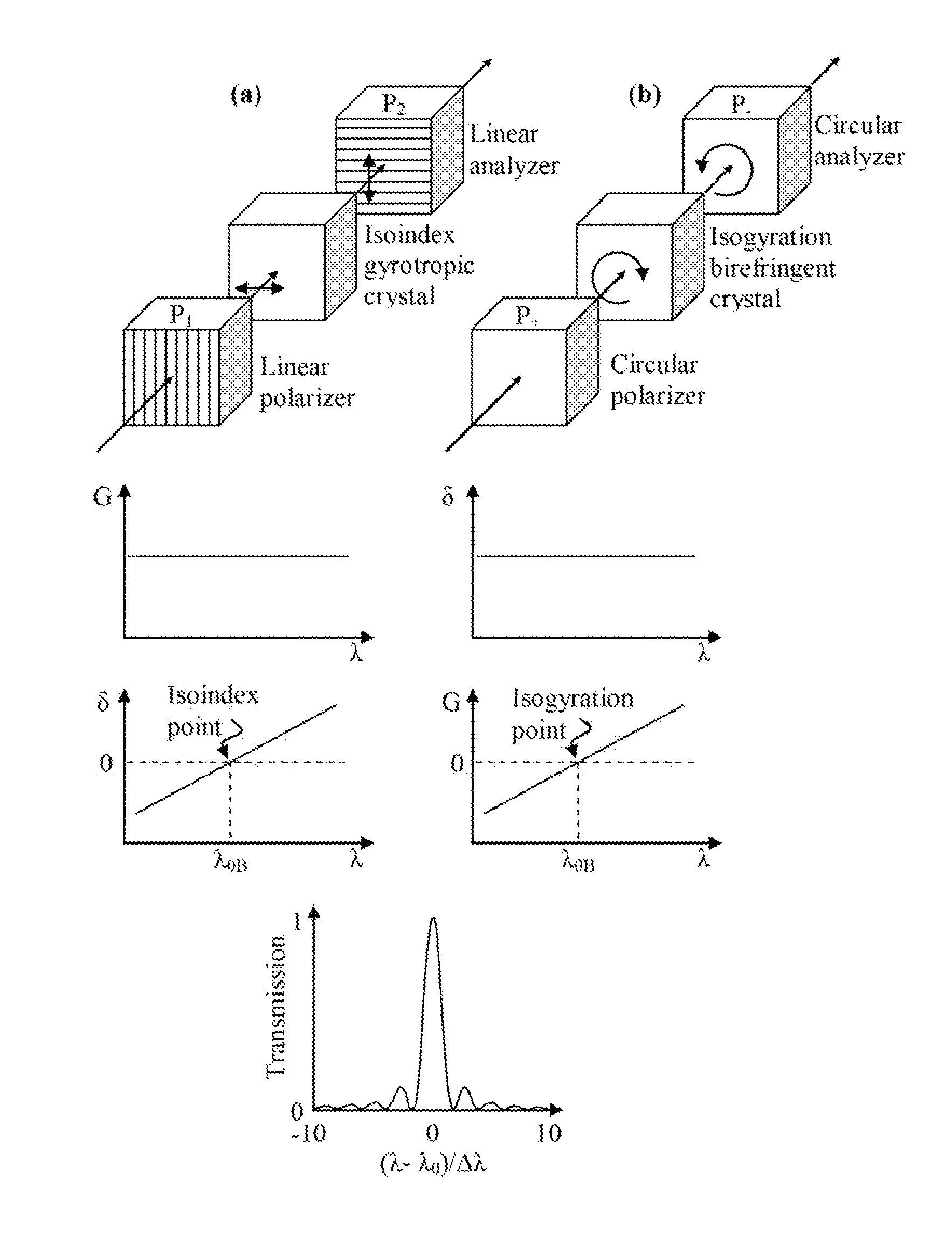

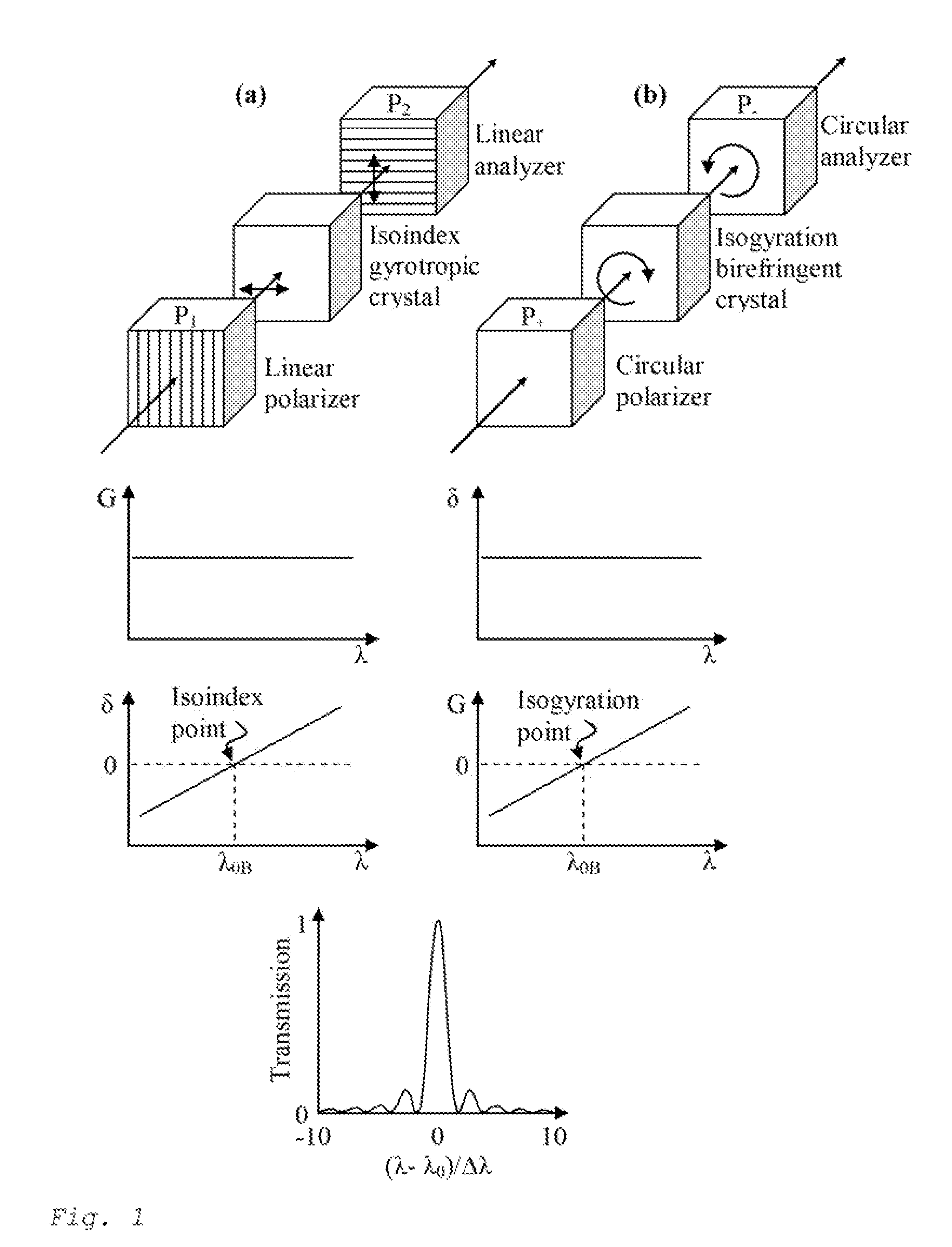

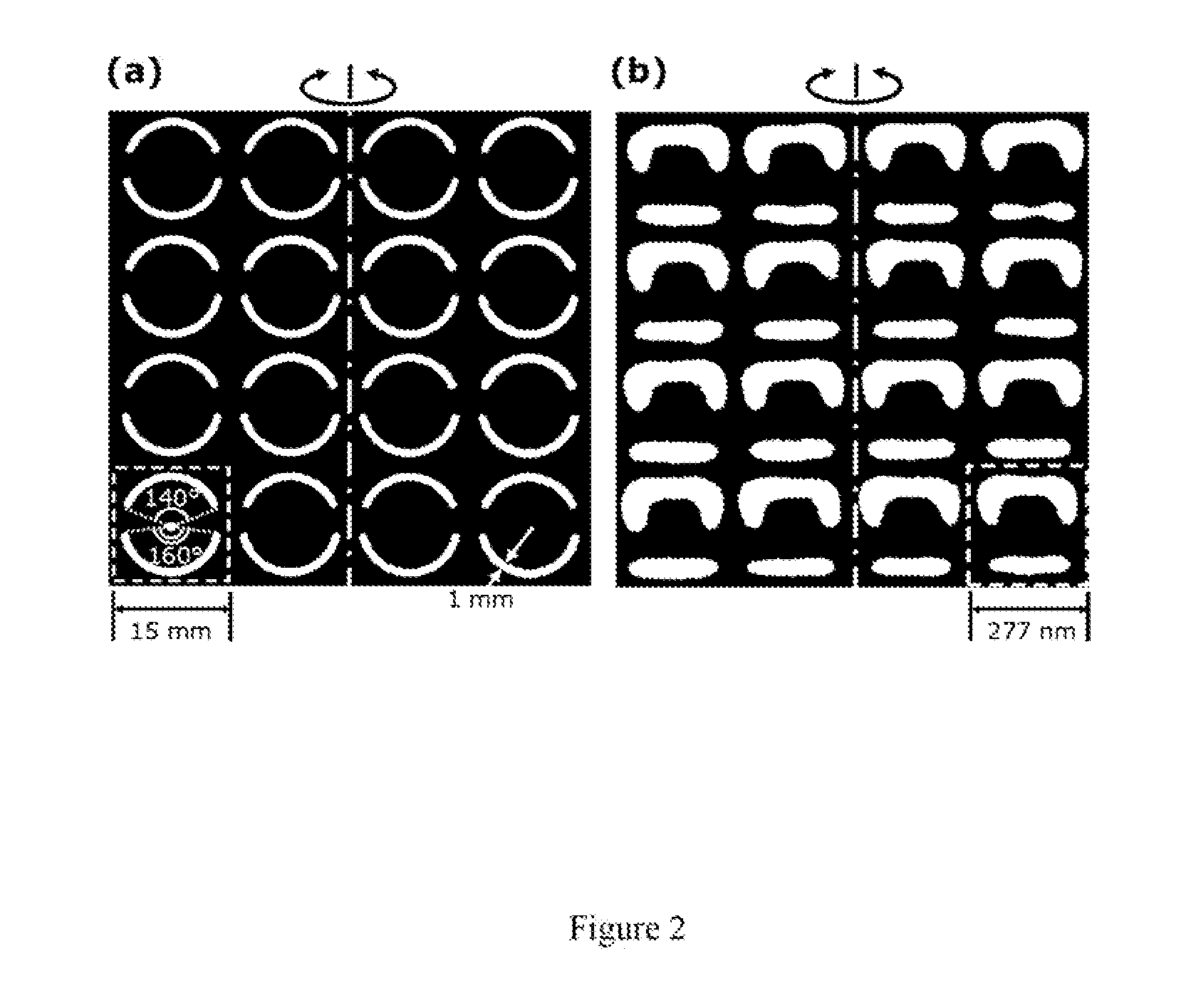

Spectral Filter

This invention relates to use of metamaterials for creating spectral selectors of electromagnetic radiation. Planar metamaterial films patterned on the sub-wavelength scale can be used in polarization filters instead of natural and synthesized bulk crystals. Characteristics and the quality factor of metamaterial filters is controlled by the geometry of the pattern. Various types of metamaterials and filter configurations are proposed.

Owner:UNIV OF SOUTHAMPTON

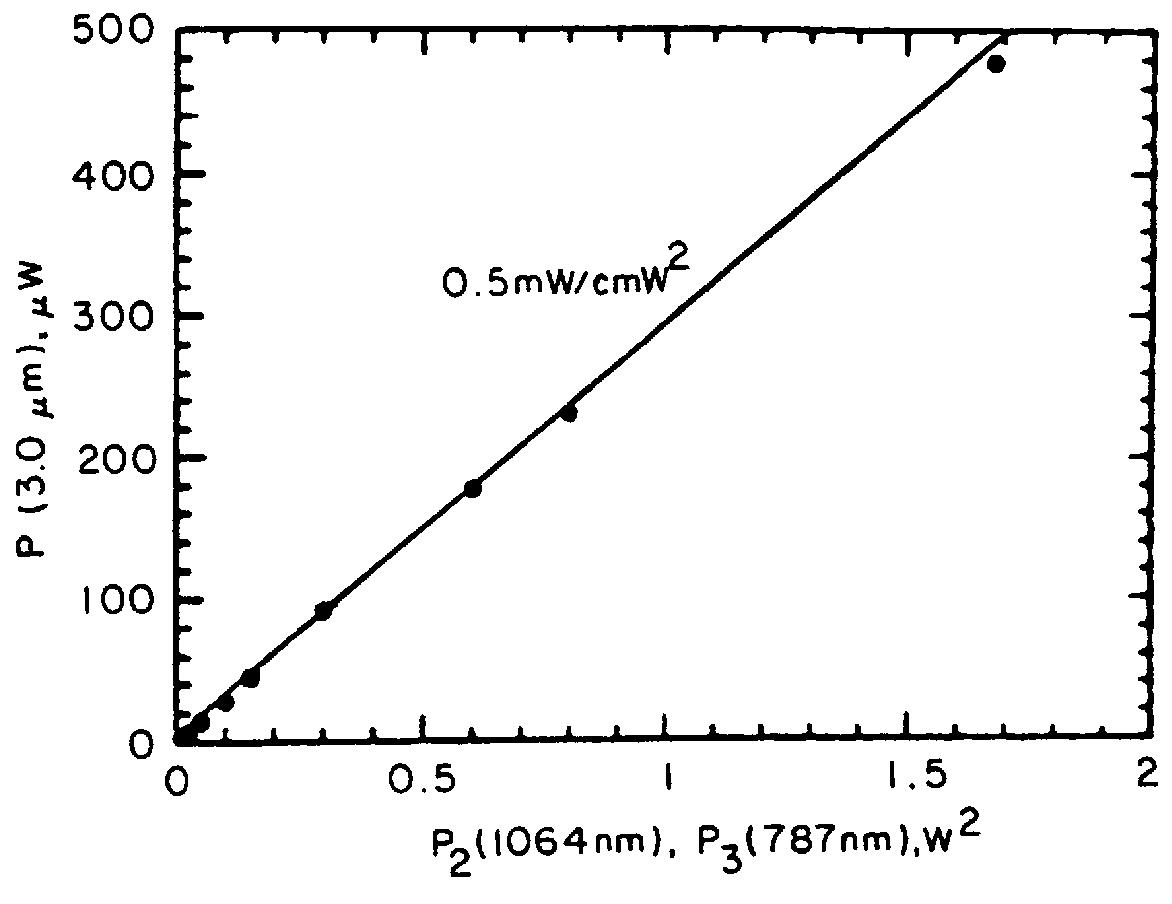

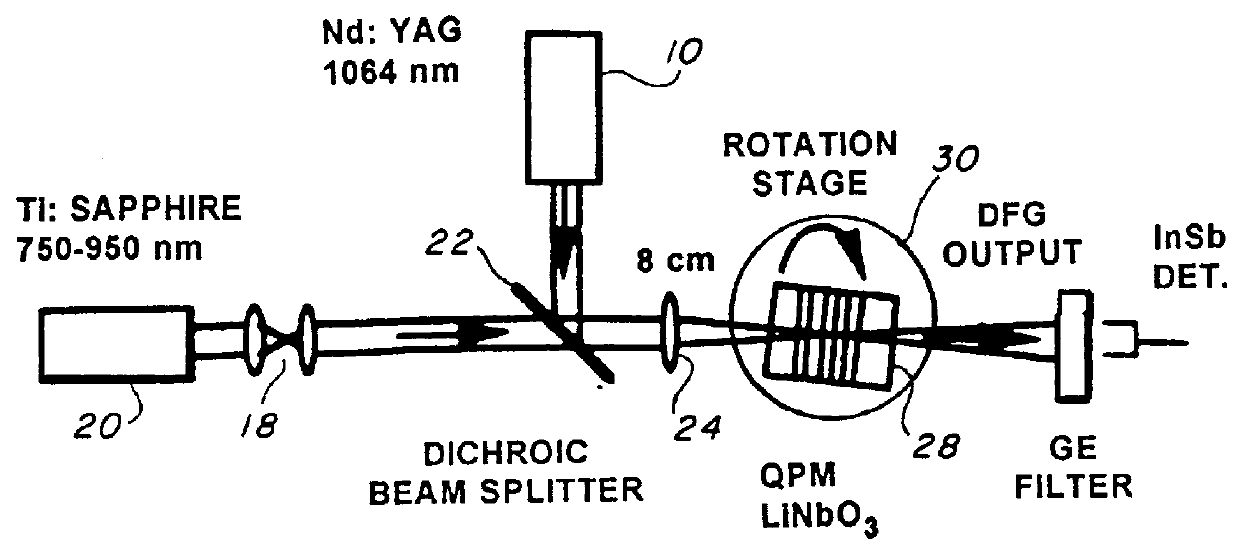

Compact continuous wave tunable infrared lasers and method therefor

A bulk, quasi-periodic phase-matched difference-frequency (DFG) process in field-poled LiNbO.sub.3 bulk crystal permits continuous tunability of the output radiation in the 3.0-4.1 .mu.m wavelength range through grating rotation. DFG in QPM-LiNbO.sub.3 crystal, carried out using a Nd:YAG laser and a high power semiconductor laser at the quasi-phased matching (QPM) degeneracy point, results in an ultra wide 0.5 .mu.m acceptance bandwidth, permitting crystal rotation-free wavelength tuning of 4.0-4.5 .mu.m, with 0.2 mW output power at 4.5 .mu.m.

Owner:BURNS WILLIAM K +2

Group-III Nitride Crystal Composite

ActiveUS20120315445A1Excel in light-emission efficiencyHigh crystallinityPolycrystalline material growthLiquid-phase epitaxial-layer growthBulk crystalNitride

III-nitride crystal composites are made up of especially processed crystal slices cut from III-nitride bulk crystal having, ordinarily, a {0001} major surface and disposed adjoining each other sideways, and of III-nitride crystal epitaxially on the bulk-crystal slices. The slices are arranged in such a way that their major surfaces parallel each other, but are not necessarily flush with each other, and so that the [0001] directions in the slices are oriented in the same way.

Owner:SUMITOMO ELECTRIC IND LTD

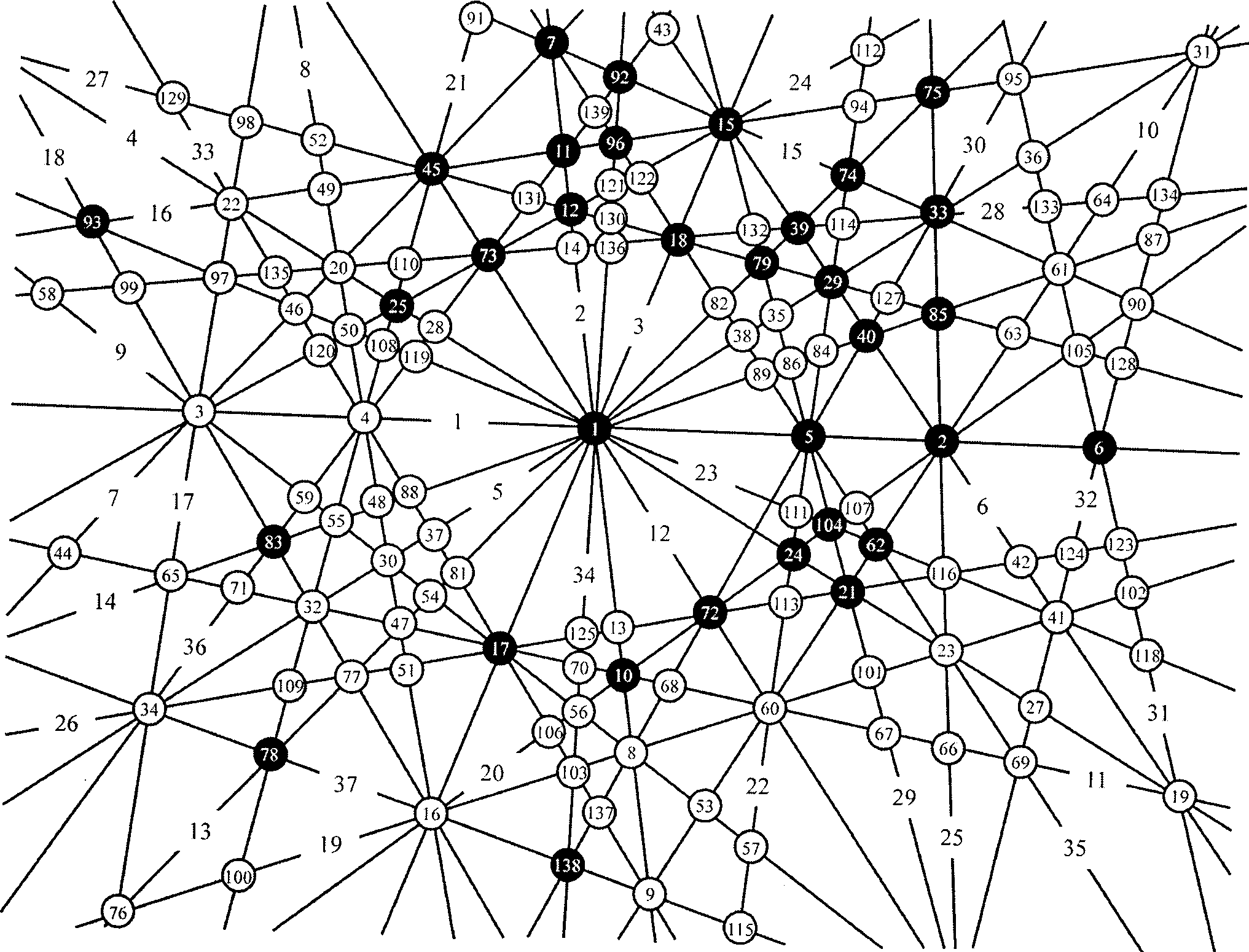

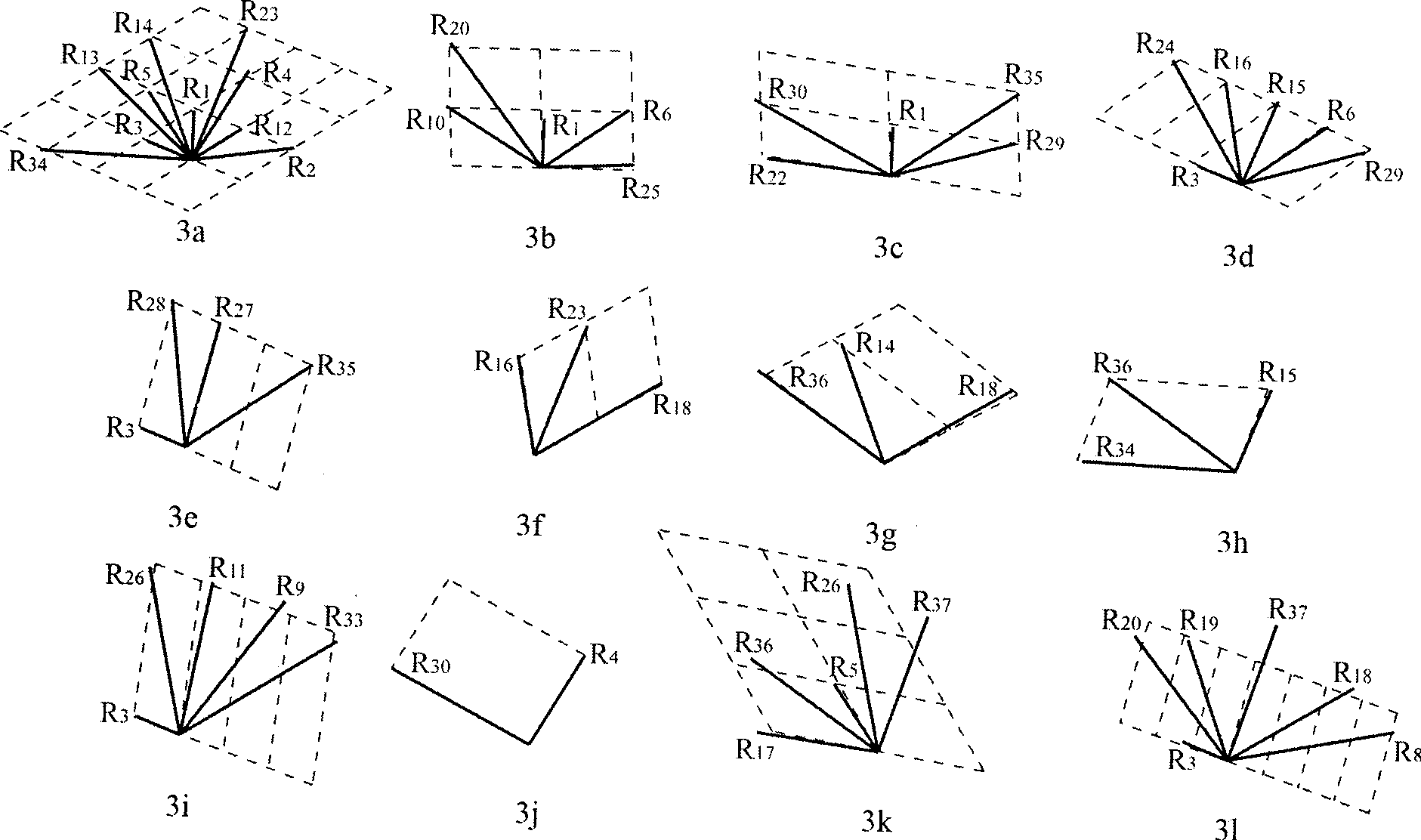

Method for determining unknown crystal Bravais lattice by electric back scattering diffraction

InactiveCN101413906ARealize analysisMaterial analysis using wave/particle radiationBravais latticeReal time analysis

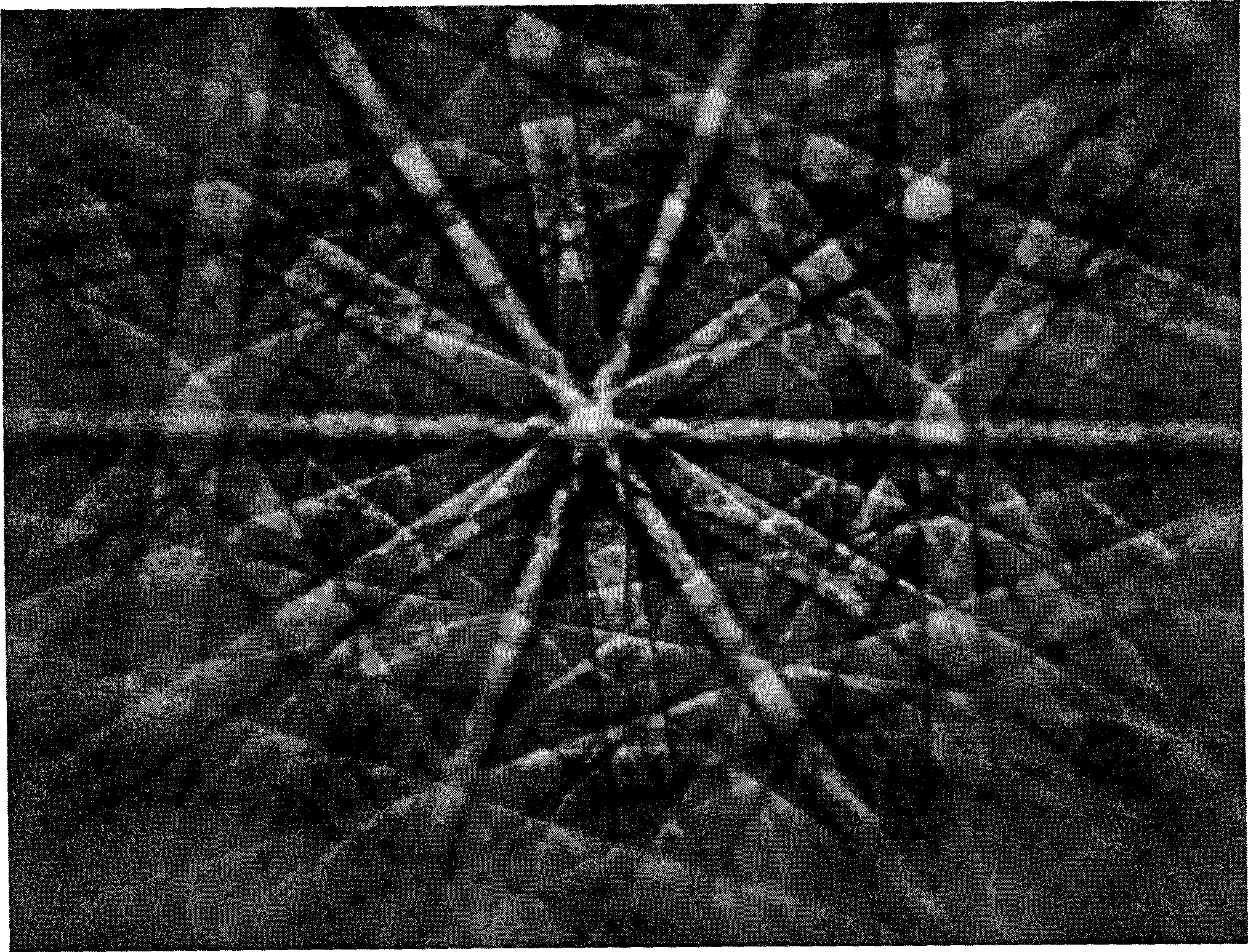

The invention provides a method used for determining Bravais lattice of unknown crystal by electron backscatter diffraction. The invention is characterized in that the method comprises the steps as follows: 1) an electron backscatter diffraction spectrum is obtained and the crystal diffraction information in the diffraction spectrum is measured; 2) a two-dimensional reciprocal surface of the crystal is obtained; 3) a three-dimensional reciprocal primitive cell is reconstructed by the two-dimensional reciprocal surface; 4) the cell parameter of the three-dimensional reciprocal primitive cell s worked out according to the width of the Kikuchi band and the angle between the Kikuchi bands in the same Kikuchi electrode; 5) a reciprocal reduced cell of the crystal is solved; 6) the Bravais lattice of the crystal is determined in the reciprocal space; 7) the Bravais lattice of the crystal is determined. In the method, only a scanning electron microscope and an electron backscatter diffraction accessory are used to realize the analysis on unknown lattice of bulk crystals, and the exponential of the Kikuchi band and the Kikuchi electrode in the electron backscatter diffraction spectrum is marked at the same time. The method has no special requirement on the samples to be analyzed, is suitable for quickly analyzing bulk samples, and can be used for analyzing the microstructure morphologies and crystal structure in the buck samples.

Owner:SHANDONG UNIV OF TECH

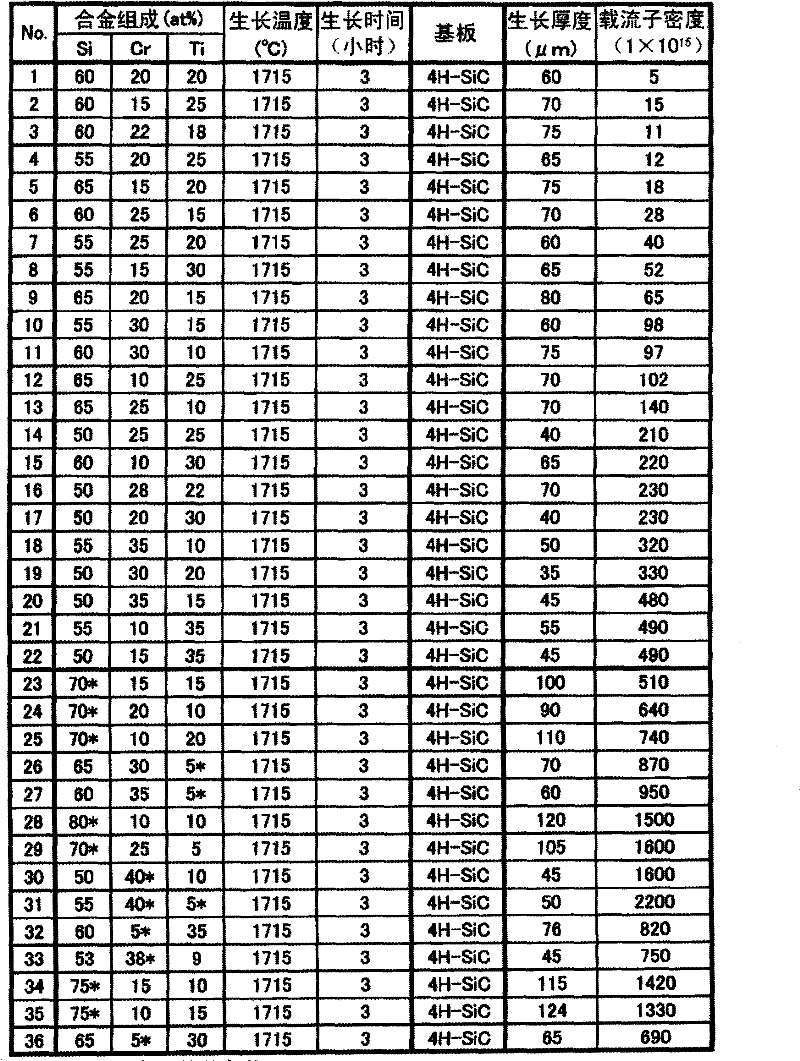

Method of manufacturing a silicon carbide single crystal

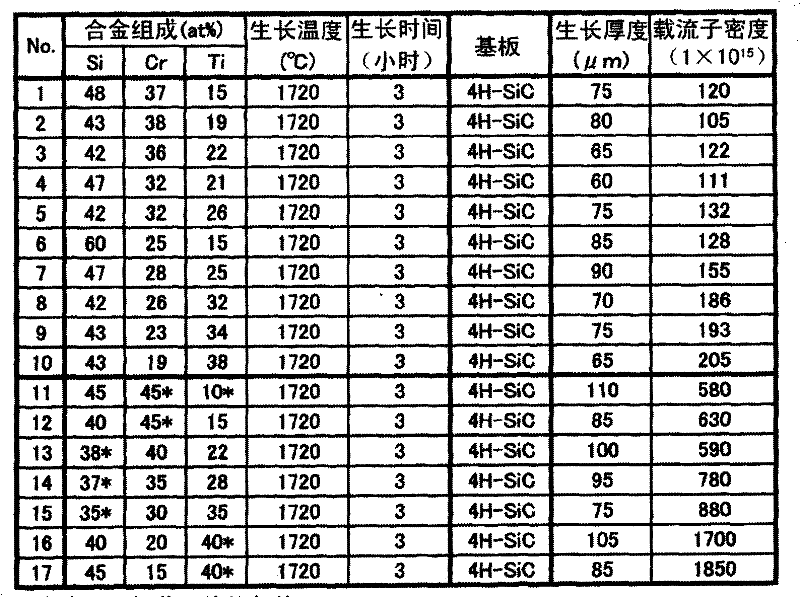

InactiveUS20110200833A1Efficient preparationReduce carrier densityPolycrystalline material growthLiquid-phase epitaxial-layer growthBulk crystalAlloy

A method capable of stably manufacturing a SiC single crystal in the form of a thin film or a bulk crystal having a low carrier density of at most 5×1017 / cm3 and preferably less than 1×1017 / cm3 and which is suitable for use in various devices by liquid phase growth using a SiC solution in which the solvent is a melt of a Si alloy employs a Si alloy having a composition which is expressed by SixCryTiz wherein x, y, and z (each in atomic percent) satisfy0.50<x<0.68, 0.08<y<0.35, and 0.08<z<0.35, or (1)0.40<x≦0.50, 0.15<y<0.40, and 0.15<z<0.35. (2)x, y, and z preferably satisfy 0.53<x<0.65, 0.1<y<0.3, and 0.1<z<0.3.

Owner:NIPPON STEEL & SUMITOMO METAL CORP

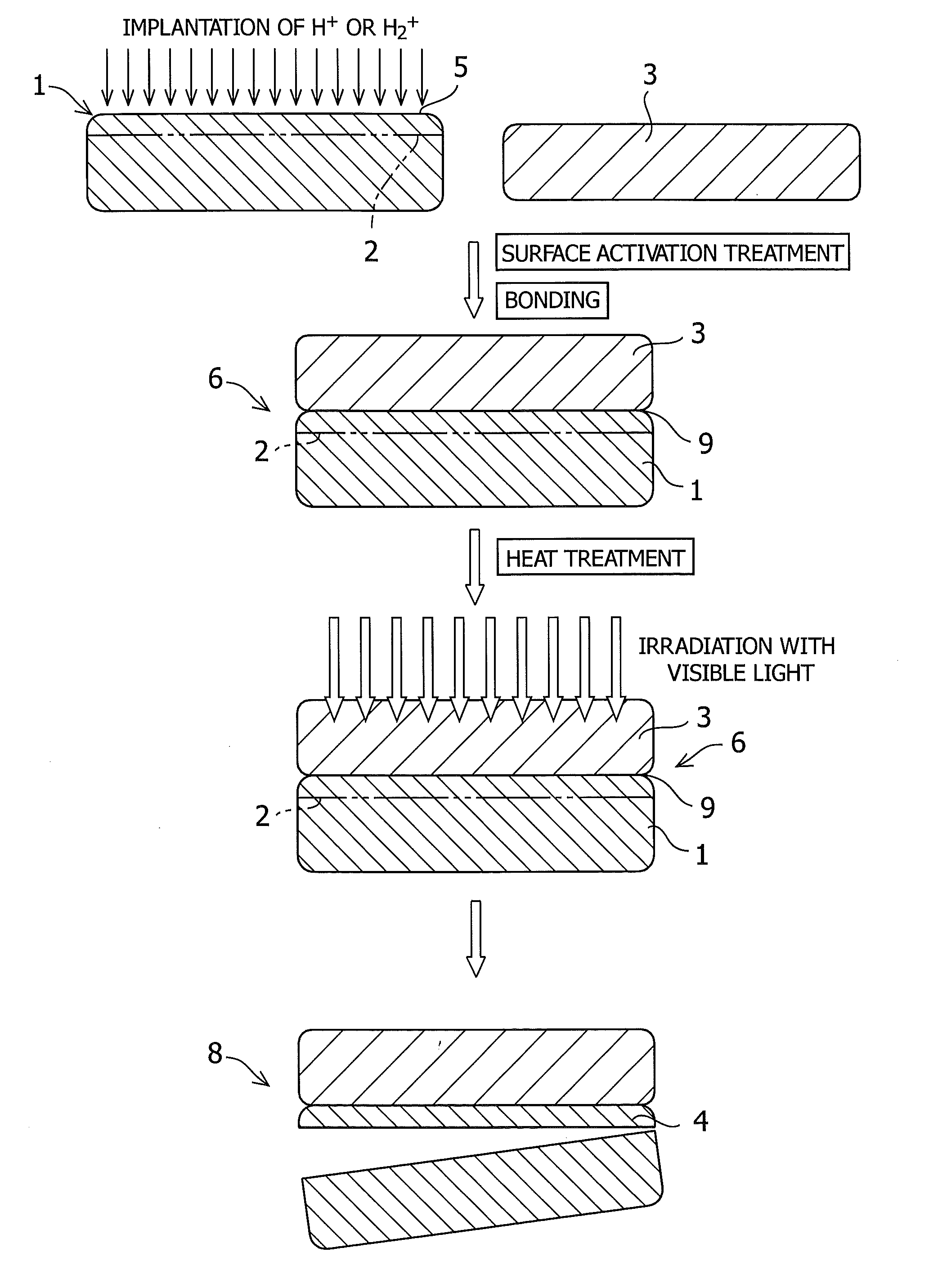

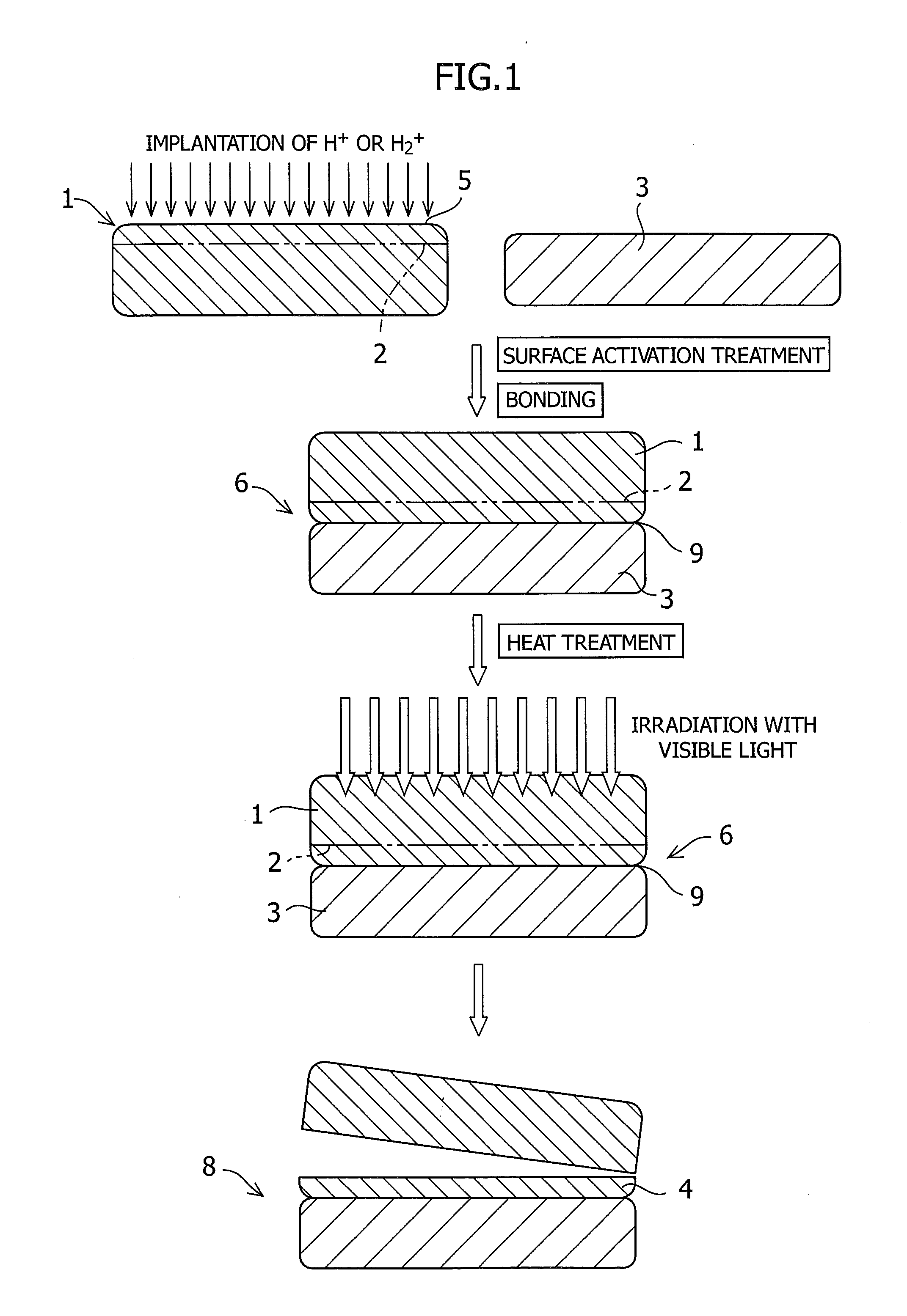

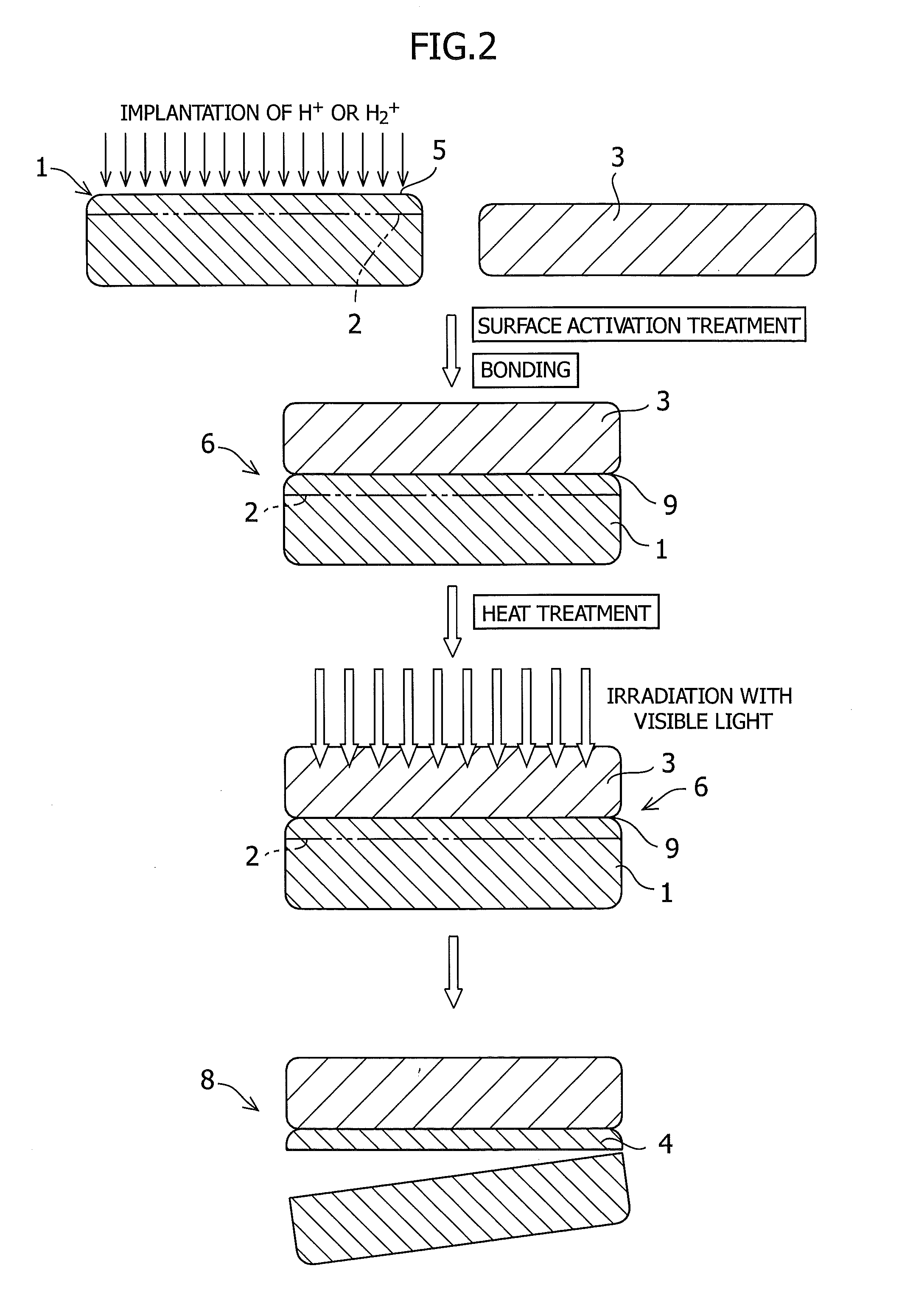

Method for manufacturing composite substrate comprising wide bandgap semiconductor layer

ActiveUS20110227068A1Prevent crack and chipLow costSemiconductor/solid-state device manufacturingSemiconductor devicesBulk crystalComposite substrate

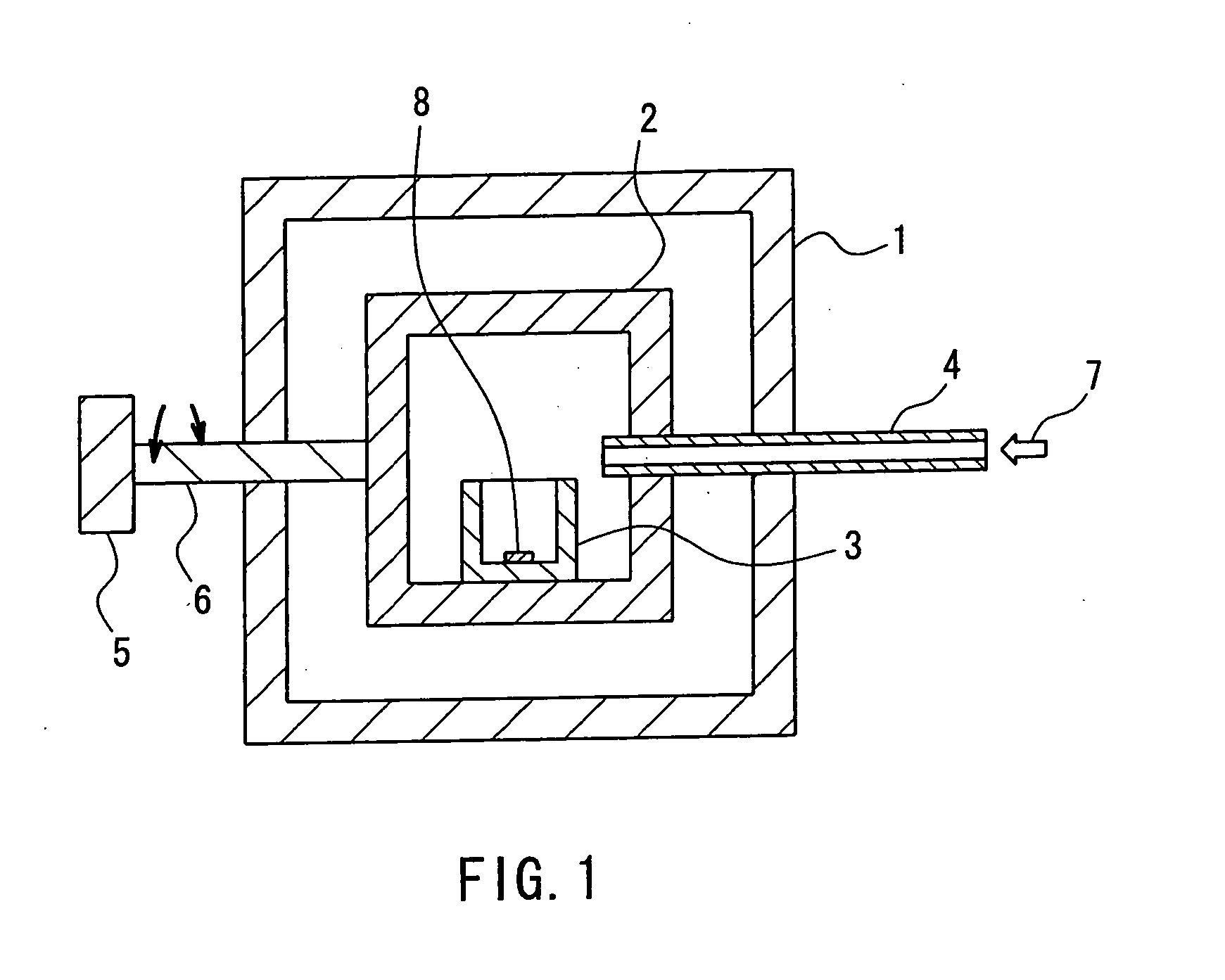

Provided is a method for manufacturing a low-cost bonded wafer (8) which allows bulk crystals of a wide bandgap semiconductor (1) to be transferred onto a handle substrate (3) as thinly as possible without breaking the substrate. More specifically, provided is a method for manufacturing a bonded wafer (8) by forming a wide bandgap semiconductor film (4) on a surface of a handle substrate (3), the method comprising a step of implanting ions from a surface (5) of a wide bandgap semiconductor substrate (1) having a bandgap of 2.8 eV or more to form an ion-implanted layer (2), a step of applying a surface activation treatment to at least one of the surface of the handle substrate (3) and the ion-implanted surface (5) of the wide bandgap semiconductor substrate (1), a step of bonding the surface (5) of the wide bandgap semiconductor substrate (1) and the surface of the handle substrate (3) to obtain bonded substrates (6), a step of applying a heat treatment to the bonded substrates (6) at a temperature of 150° C. or more and 400° C. less, and a step of subjecting the ion-implanted layer (2) of the wide bandgap semiconductor substrate (1) to irradiation of visible light from the semiconductor substrate (1) side of the bonded substrates (6) to embrittle an interface of the ion-implanted layer (2) and transfer the wide bandgap semiconductor film (4) onto the handle substrate (3).

Owner:SHIN ETSU CHEM IND CO LTD

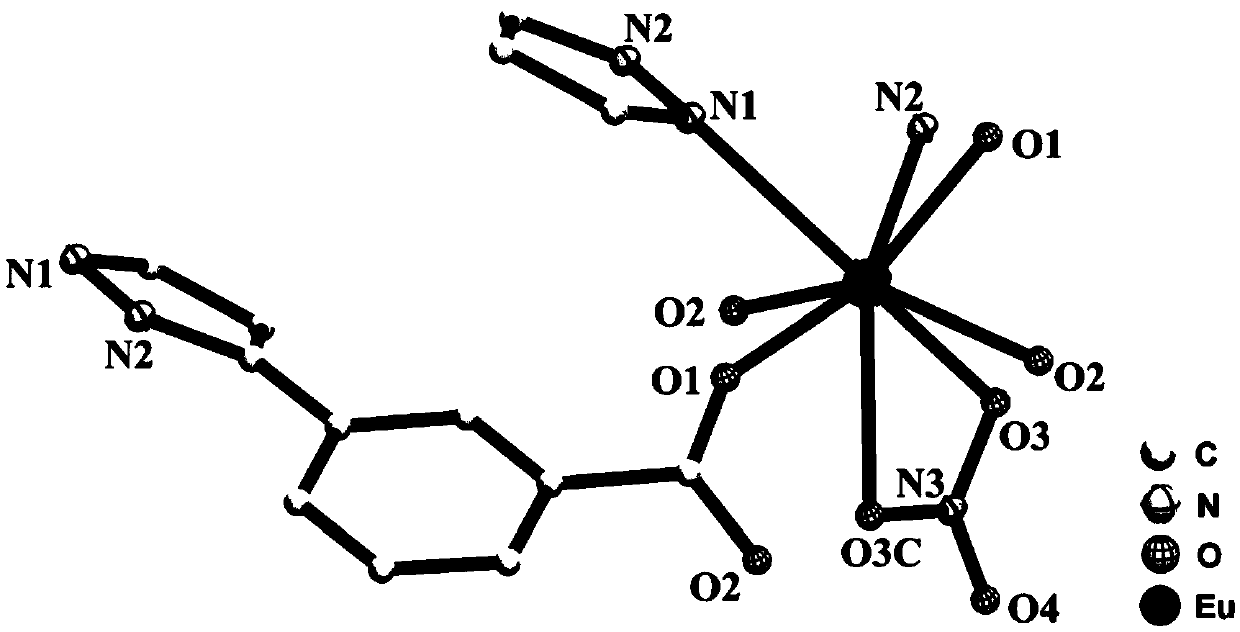

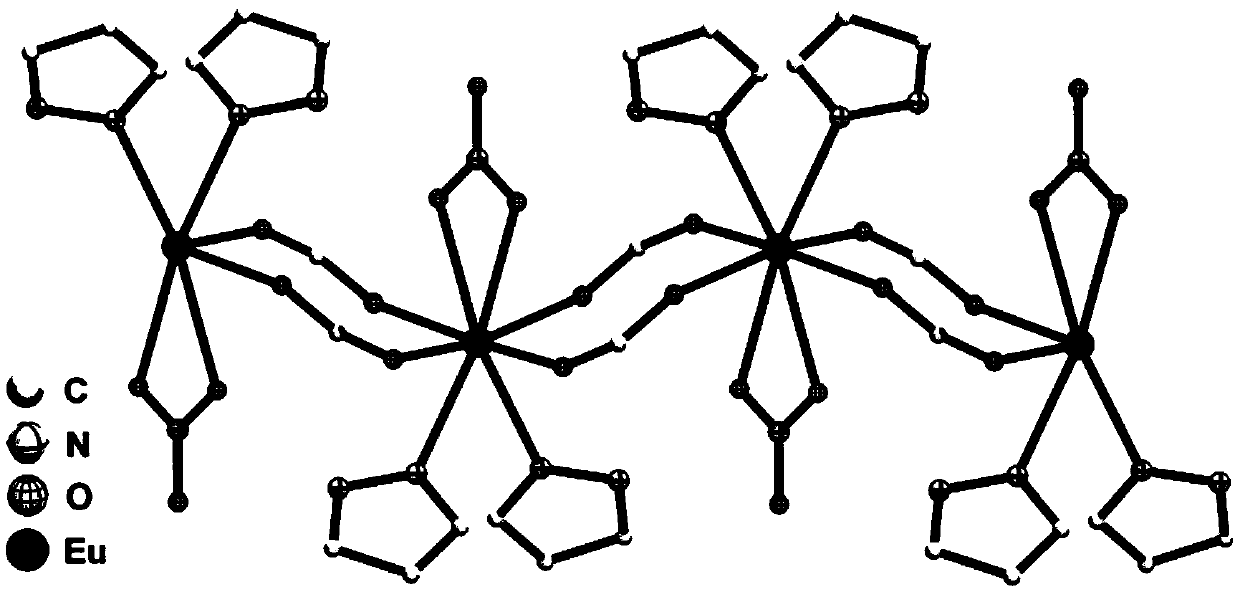

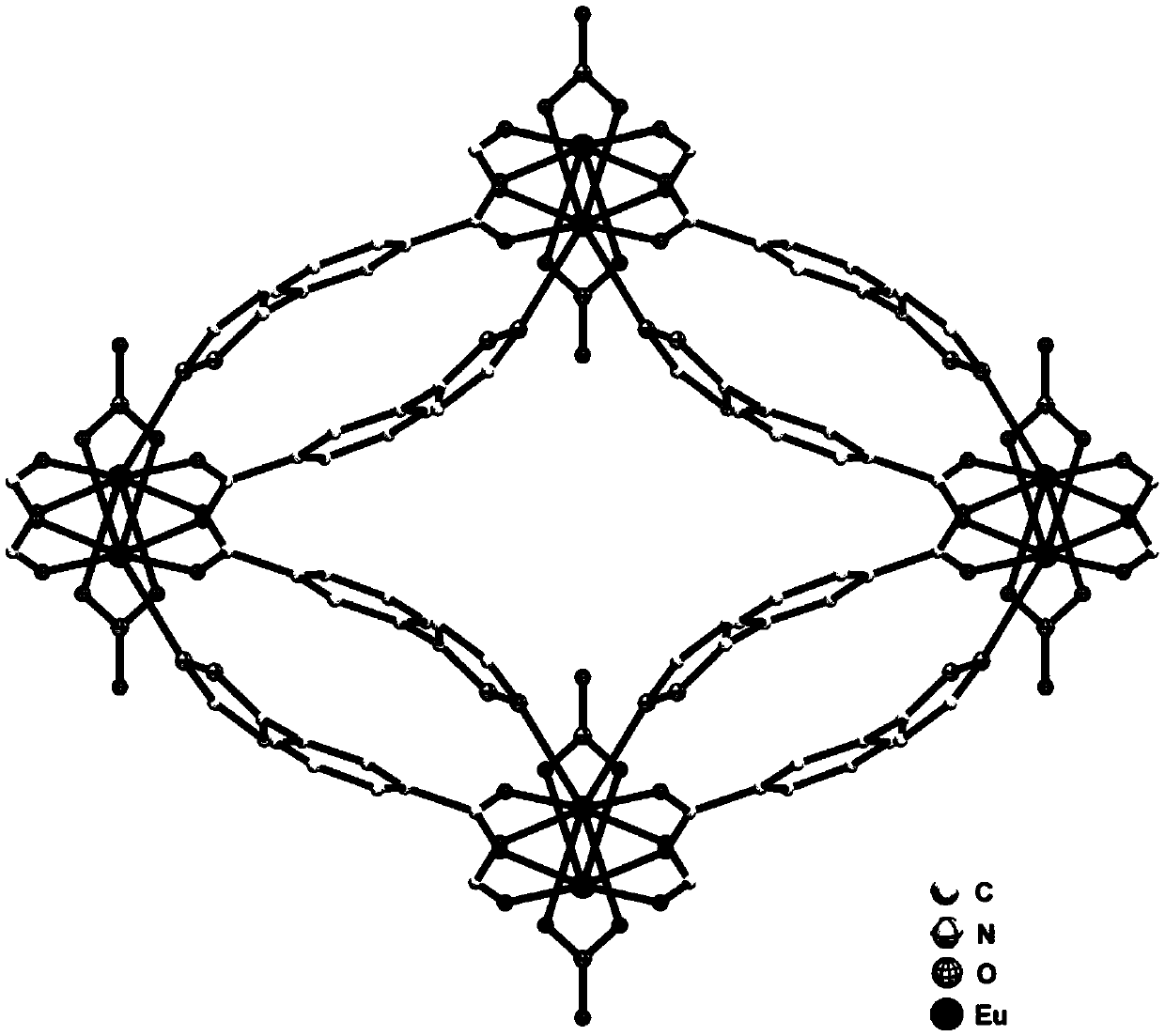

Europium metal-organic framework compound with fluorescent recognition function and preparation method and application

InactiveCN105503915AWith fluorescence recognition functionSimple preparation processGroup 3/13 organic compounds without C-metal linkagesFluorescence/phosphorescenceBenzoic acidBulk crystal

The invention relates to a europium metal-organic framework compound with a fluorescent recognition function and a preparation method and application. The chemical formula of the europium metal-organic framework compound with the fluorescent recognition function is [Eu(Hpzbc)2(NO3)].H2O. The preparation method of the europium metal-organic framework compound with the fluorescent recognition function comprises the steps that 1, europium nitrate hexahydrate and 3-(1H-3-pyrazolyl) benzoic acid are added to acetonitrile to be stirred to be uniform, and a mixed solution is obtained; 2, the mixed solution is put into a reaction kettle, the reaction kettle is sealed and heated for a reaction, and an intermediate product is obtained; 3, the temperature in the reaction kettle is decreased to room temperature through cooling, a colorless bulk crystal is obtained, and the colorless bulk crystal is the europium metal-organic framework compound with the fluorescent recognition function. The europium metal-organic framework compound with the fluorescent recognition function is used for detecting Fe<3+> ions and Cr2O7<2-> ions.

Owner:NORTHWEST UNIV(CN)

Method and apparatus for producing large, single-crystals of aluminum nitride

InactiveUS20080006200A1Polycrystalline material growthSolid-state devicesBulk crystalSource material

A method and apparatus for producing bulk single crystals of AlN having low dislocation densities of about 10,000 cm−2 or less includes a crystal growth enclosure with Al and N2 source material therein, capable of forming bulk crystals. The apparatus maintains the N2 partial pressure at greater than stoichiometric pressure relative to the Al within the crystal growth enclosure, while maintaining the total vapor pressure in the crystal growth enclosure at super-atmospheric pressure. At least one nucleation site is provided in the crystal growth enclosure, and provision is made for cooling the nucleation site relative to other locations in the crystal growth enclosure. The Al and N2 vapor is then deposited to grow single crystalline low dislocation density AlN at the nucleation site. High efficiency ultraviolet light emitting diodes and ultraviolet laser diodes are fabricated on low defect density AlN substrates, which are cut from the low dislocation density AlN crystals. Bulk crystals of ZnO may also be produced using the method.

Owner:CRYSTAL

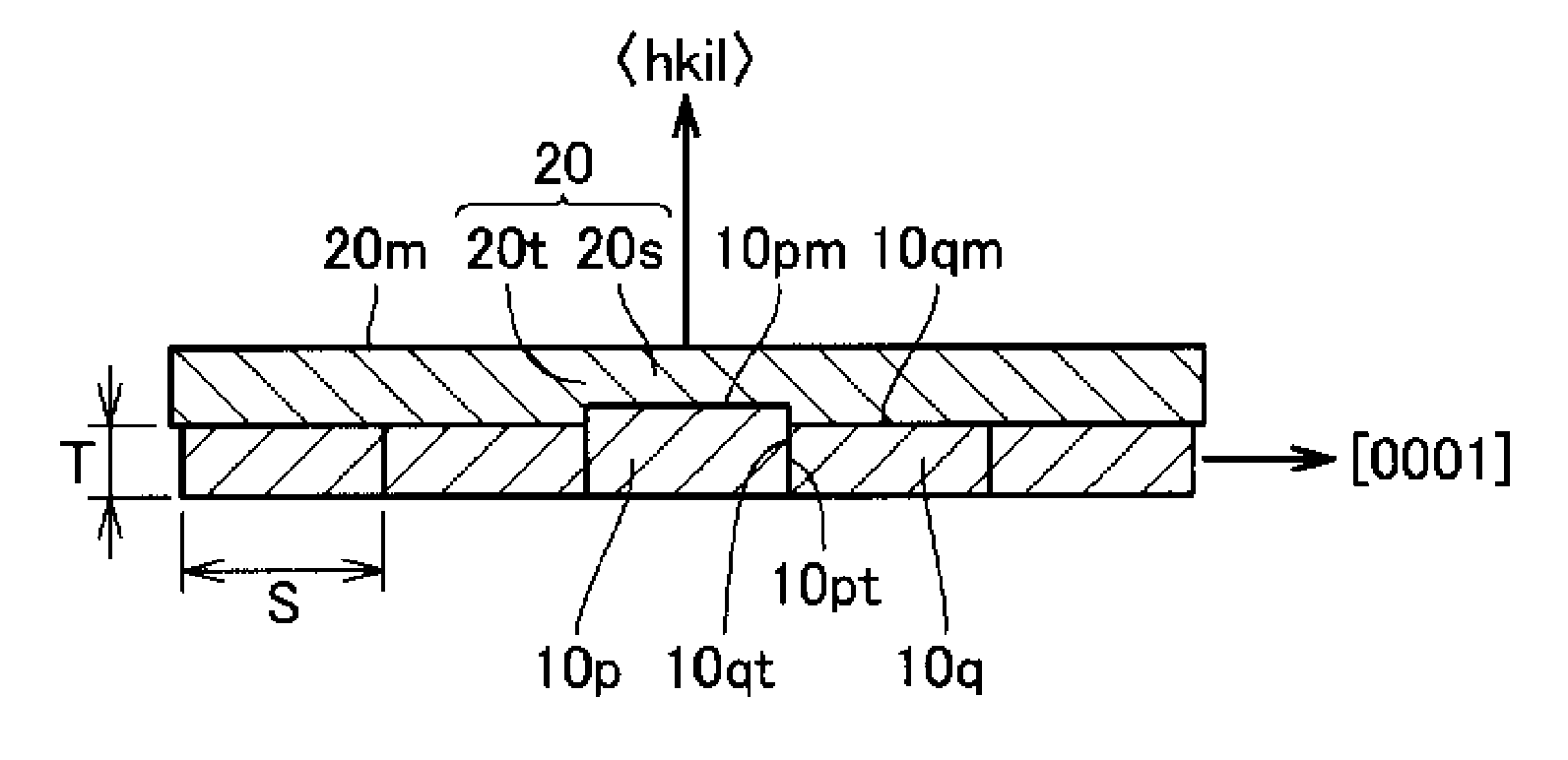

Group III Nitride Crystal and Method for Producing the Same

ActiveUS20120329245A1High crystal growth rateHigh ratePolycrystalline material growthAfter-treatment detailsBulk crystalPlane orientation

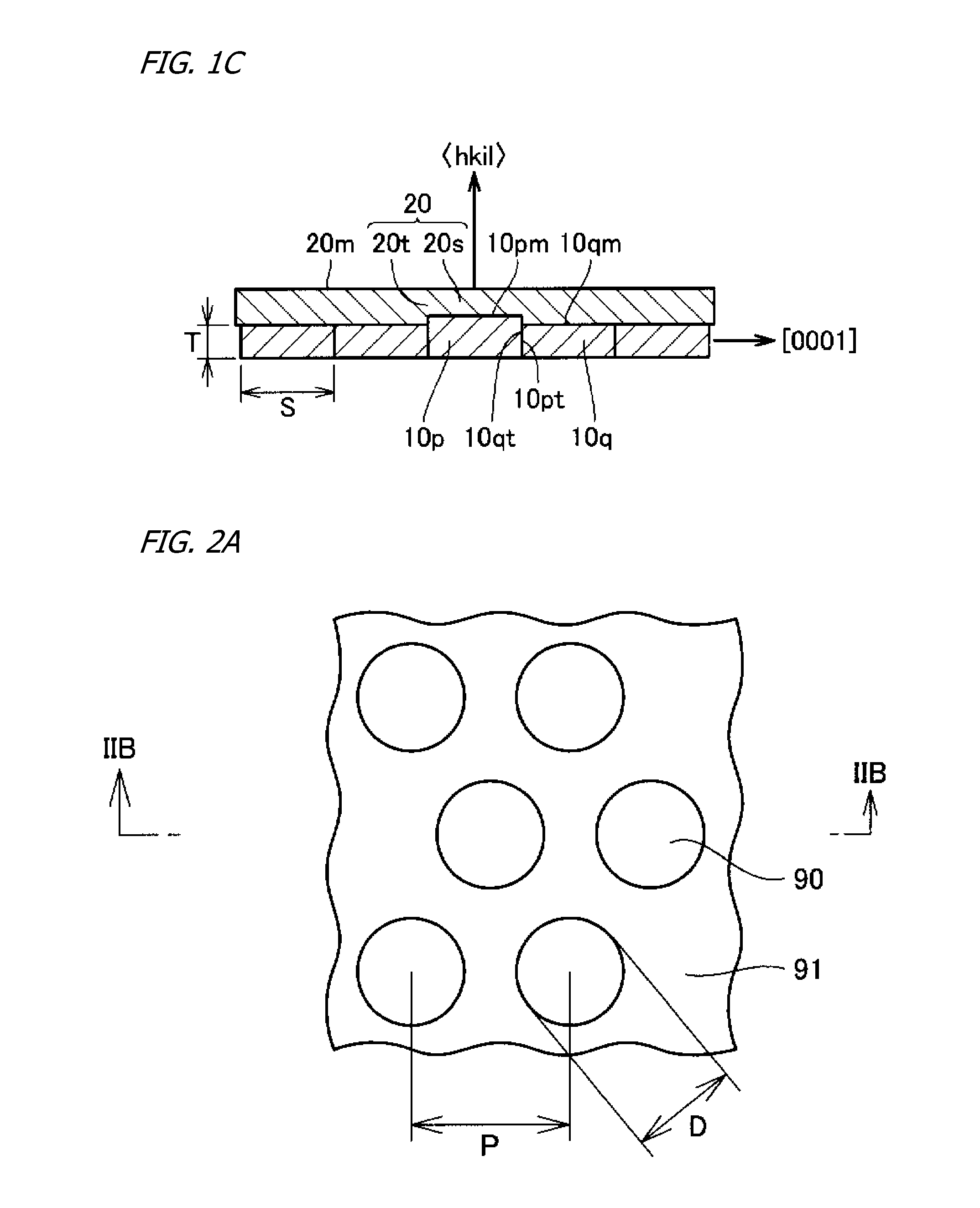

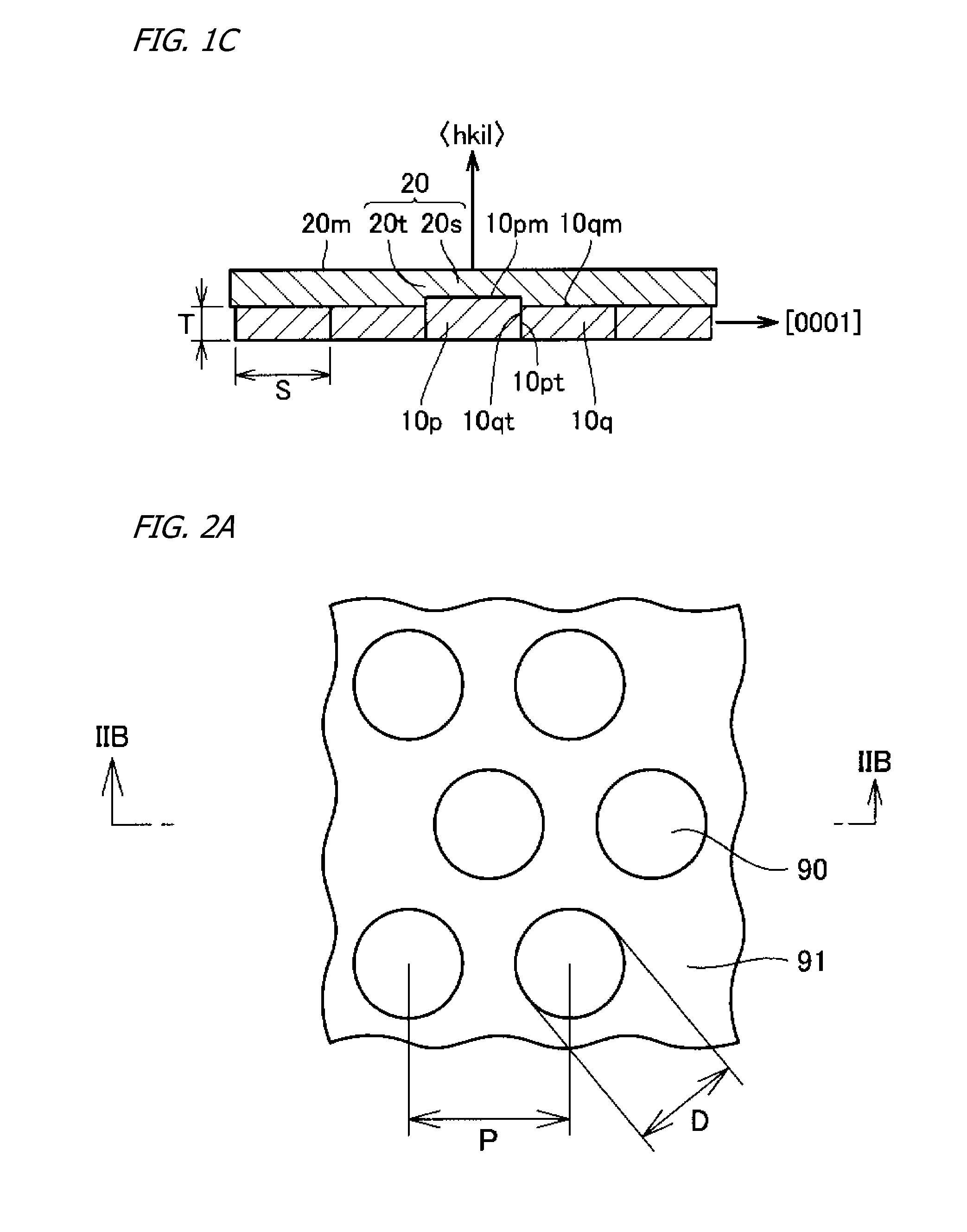

A method for producing a group III nitride crystal in the present invention includes the steps of cutting a plurality of group III nitride crystal substrates 10p and 10q having a main plane from a group III nitride bulk crystal 1, the main planes 10pm and 10qm having a plane orientation with an off-angle of five degrees or less with respect to a crystal-geometrically equivalent plane orientation selected from the group consisting of {20-21}, {20-2-1}, {22-41}, and {22-4-1}, transversely arranging the substrates 10p and 10q adjacent to each other such that the main planes 10pm and 10qm of the substrates 10p and 10q are parallel to each other and each [0001] direction of the substrates 10p and 10q coincides with each other, and growing a group III nitride crystal 20 on the main planes 10pm and 10qm of the substrates 10p and 10q.

Owner:SUMITOMO ELECTRIC IND LTD

Method for exfoliation of hexagonal boron nitride

ActiveUS8303922B2Simple processEasy to processNitrogen compoundsLayered productsBulk crystalOrganic solvent

A new method is disclosed for the exfoliation of hexagonal boron nitride into mono- and few-layered nanosheets (or nanoplatelets, nanomesh, nanoribbons). The method does not necessarily require high temperature or vacuum, but uses commercially available h-BN powders (or those derived from these materials, bulk crystals) and only requires wet chemical processing. The method is facile, cost efficient, and scalable. The resultant exfoliated h-BN is dispersible in an organic solvent or water thus amenable for solution processing for unique microelectronic or composite applications.

Owner:NASA

Method and apparatus for producing large, single-crystals of aluminum nitride

ActiveUS8545629B2Easy to manufactureReduce dislocationPolycrystalline material growthSolid-state devicesBulk crystalSingle crystal

Owner:CRYSTAL

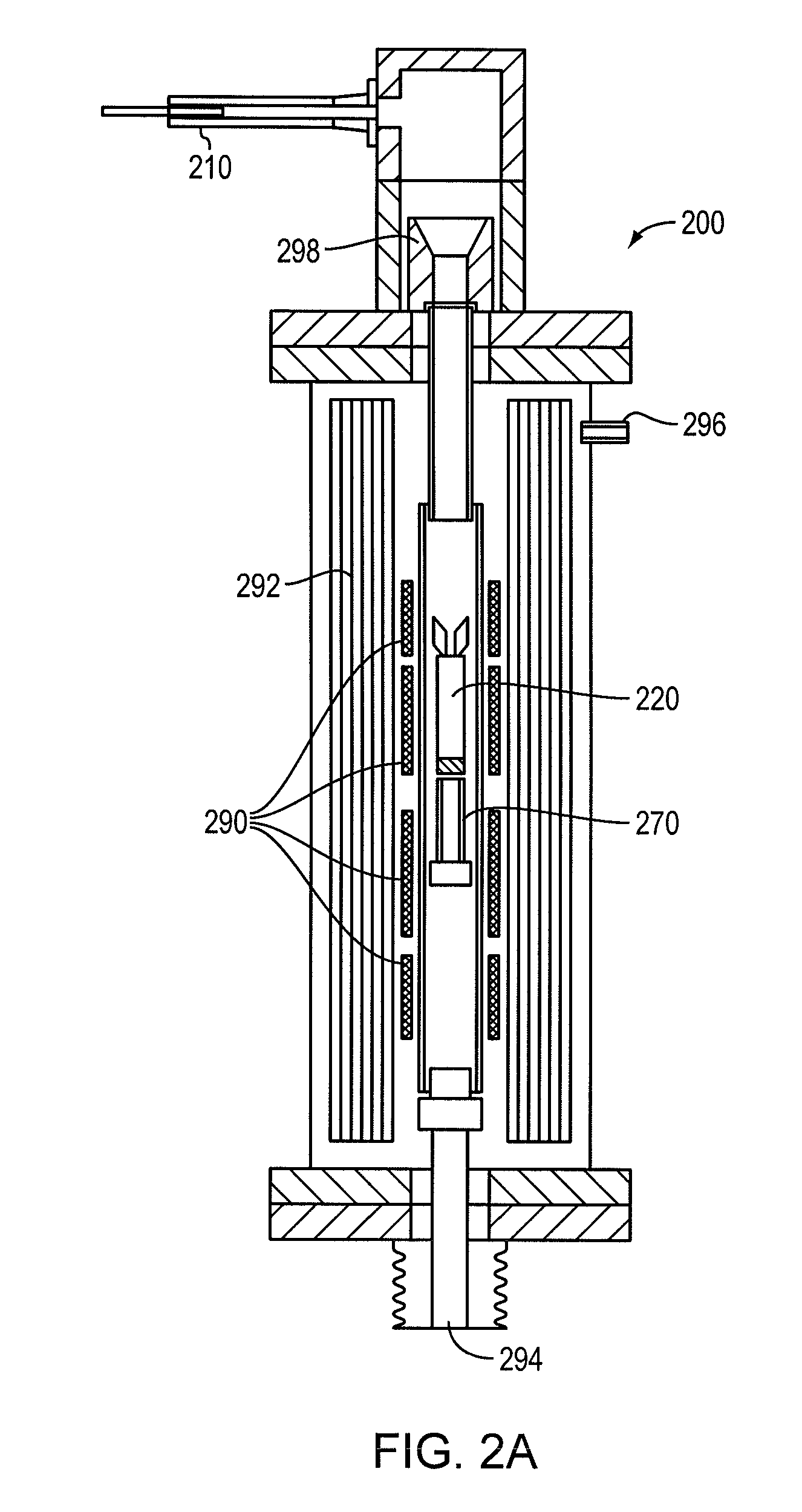

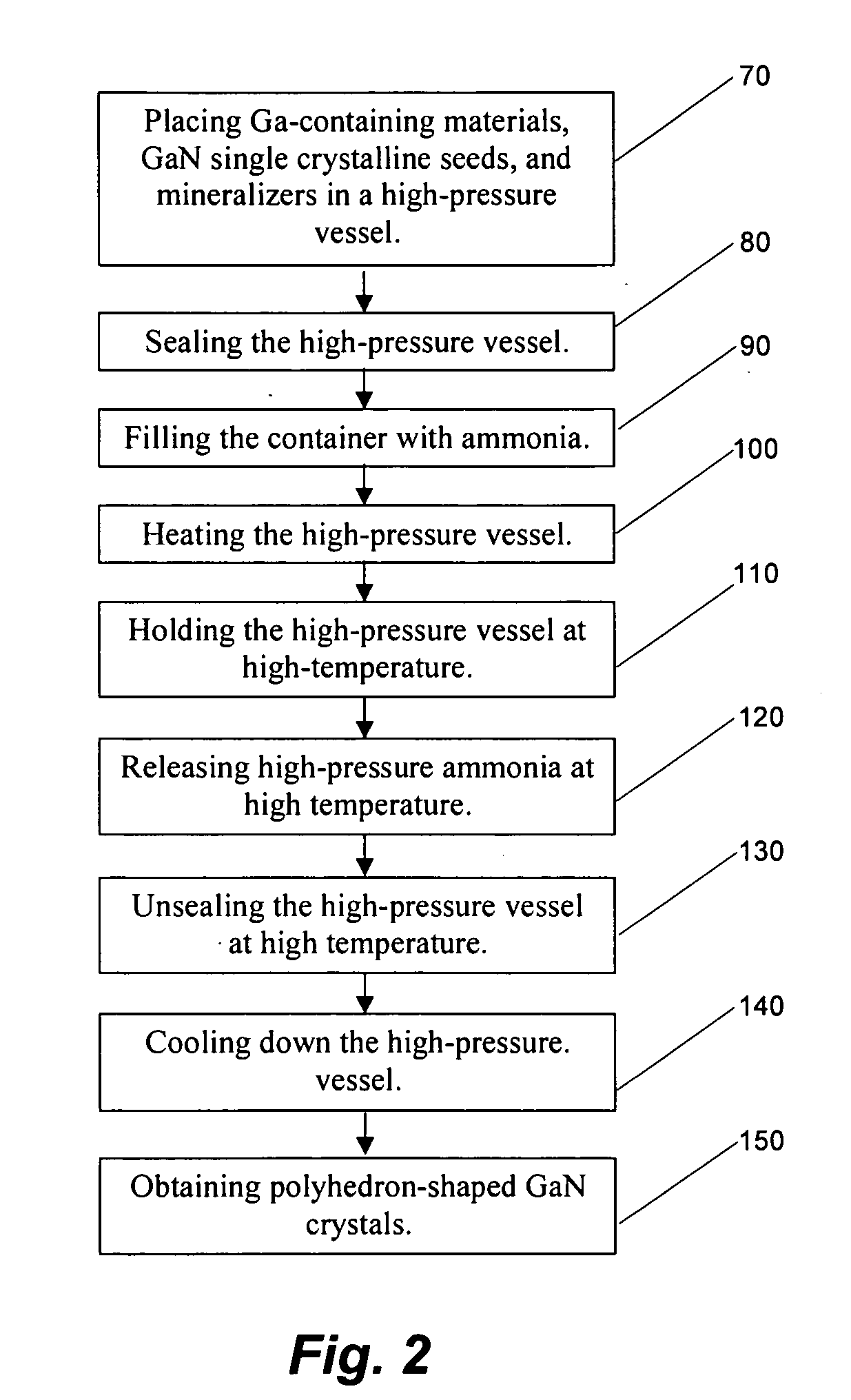

Gallium nitride bulk crystals and their growth method

ActiveUS20090072352A1Polycrystalline material growthFrom normal temperature solutionsBulk crystalElectrical polarity

A gallium nitride crystal with a polyhedron shape having exposed {10-10} m-planes and an exposed (000-1) N-polar c-plane, wherein a surface area of the exposed (000-1) N-polar c-plane is more than 10 mm2 and a total surface area of the exposed {10-10} m-planes is larger than half of the surface area of (000-1) N-polar c-plane. The GaN bulk crystals were grown by an ammonothermal method with a higher temperature and temperature difference than is used conventionally, and using an autoclave having a high-pressure vessel with an upper region and a lower region. The temperature of the lower region of the high-pressure vessel is at or above 550° C., the temperature of the upper region of the high-pressure vessel is set at or above 500° C., and the temperature difference between the lower and upper regions is maintained at or above 30° C. GaN seed crystals having a longest dimension along the c-axis and exposed large area m-planes are used.

Owner:JAPAN SCI & TECH CORP

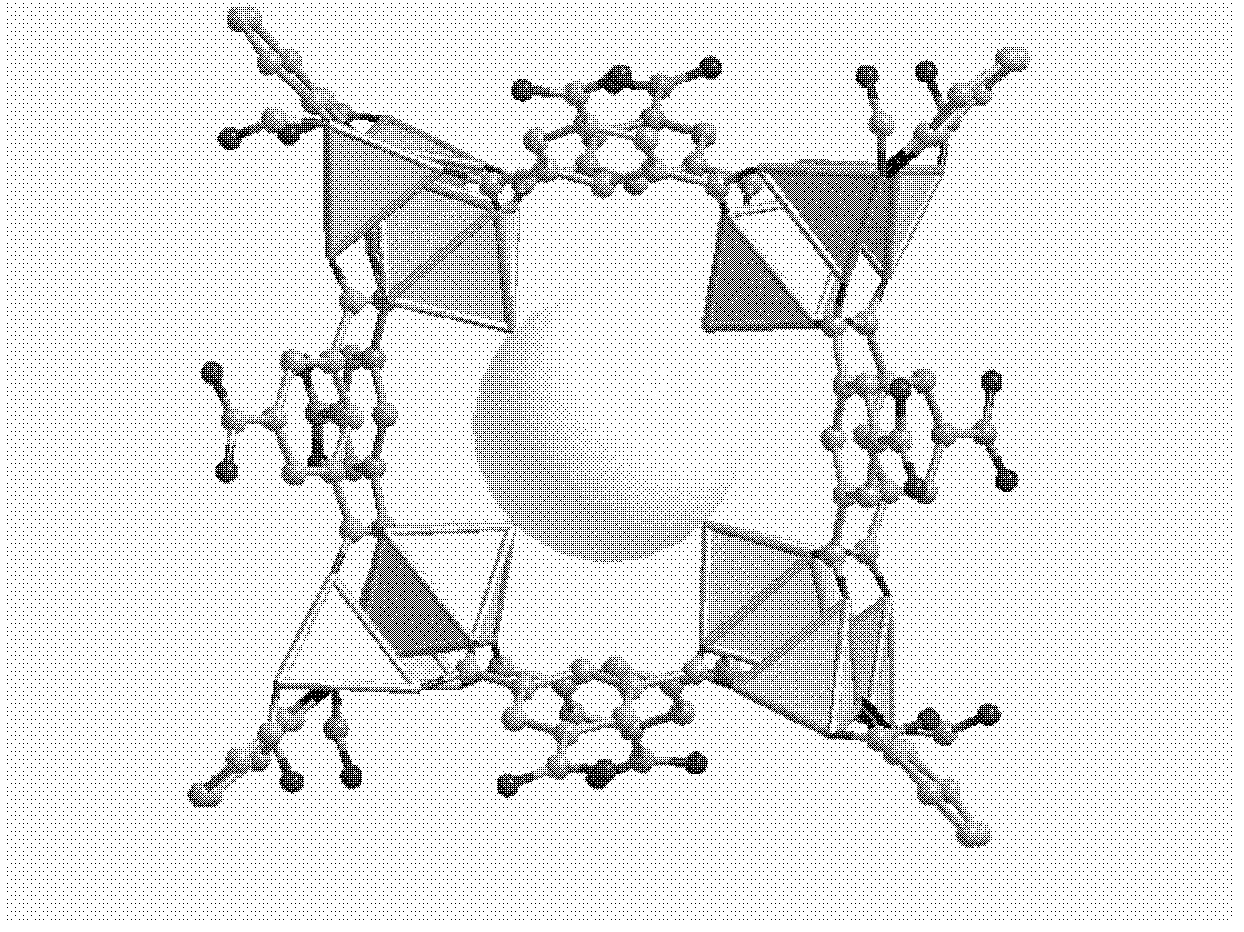

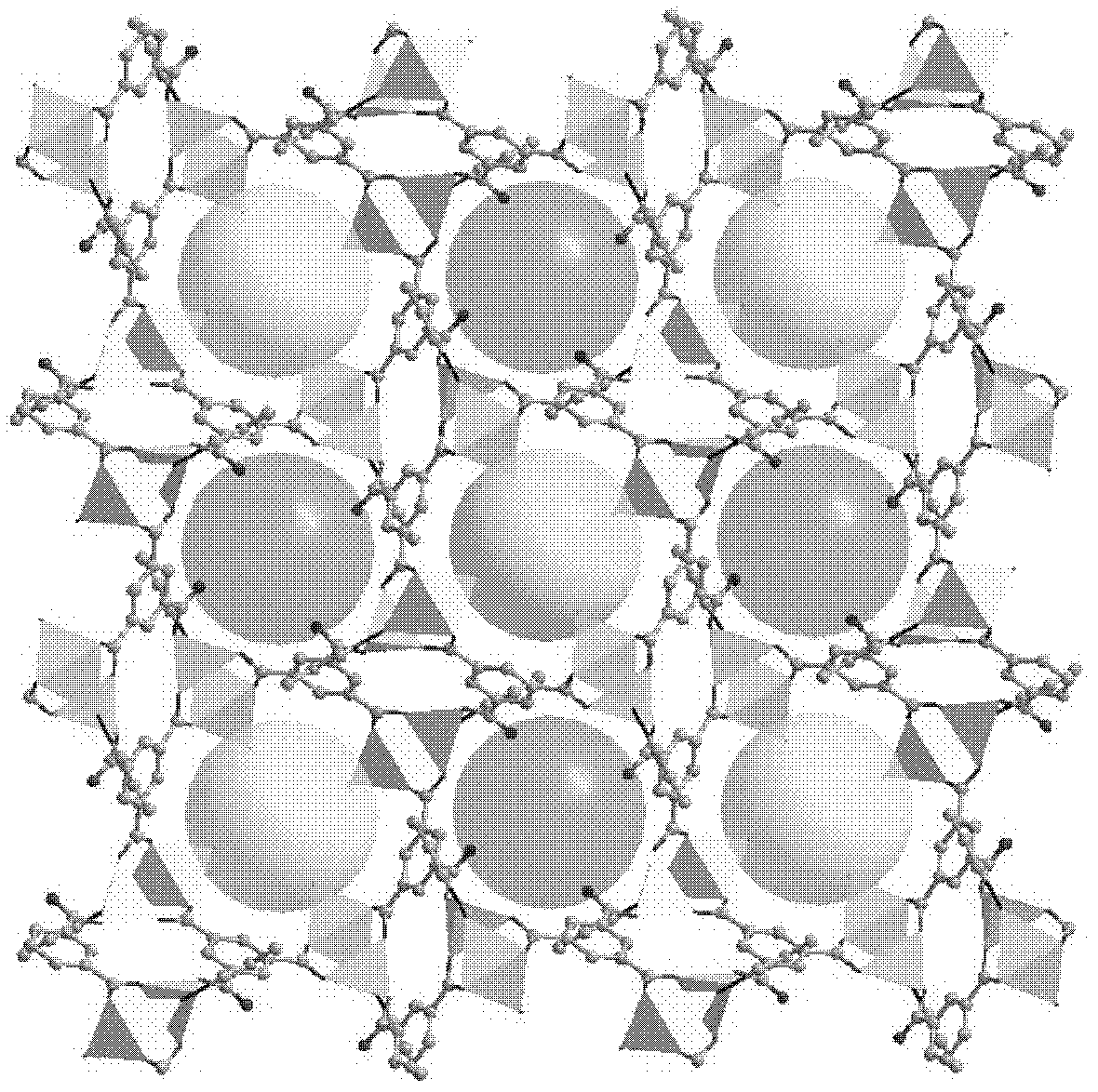

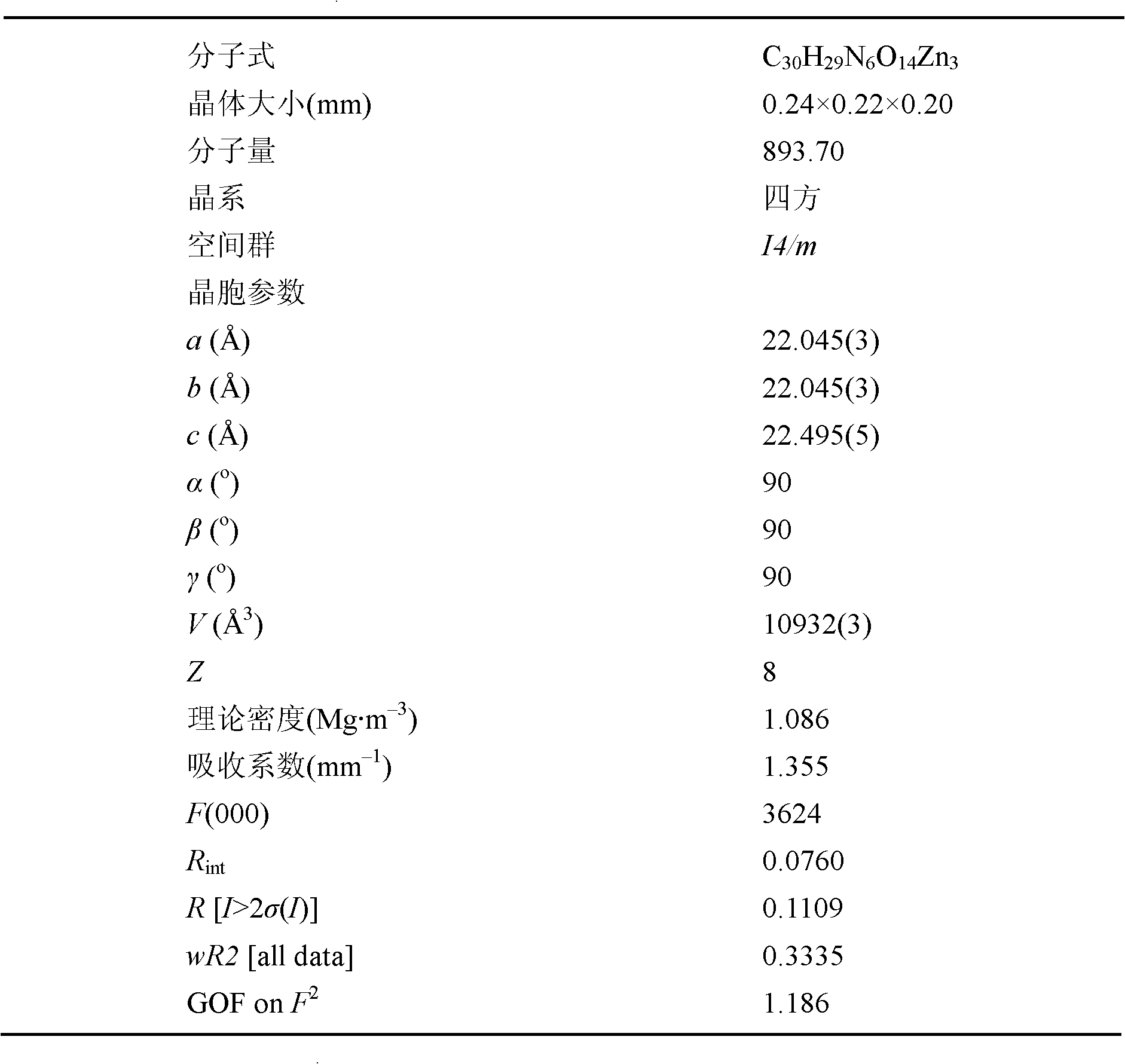

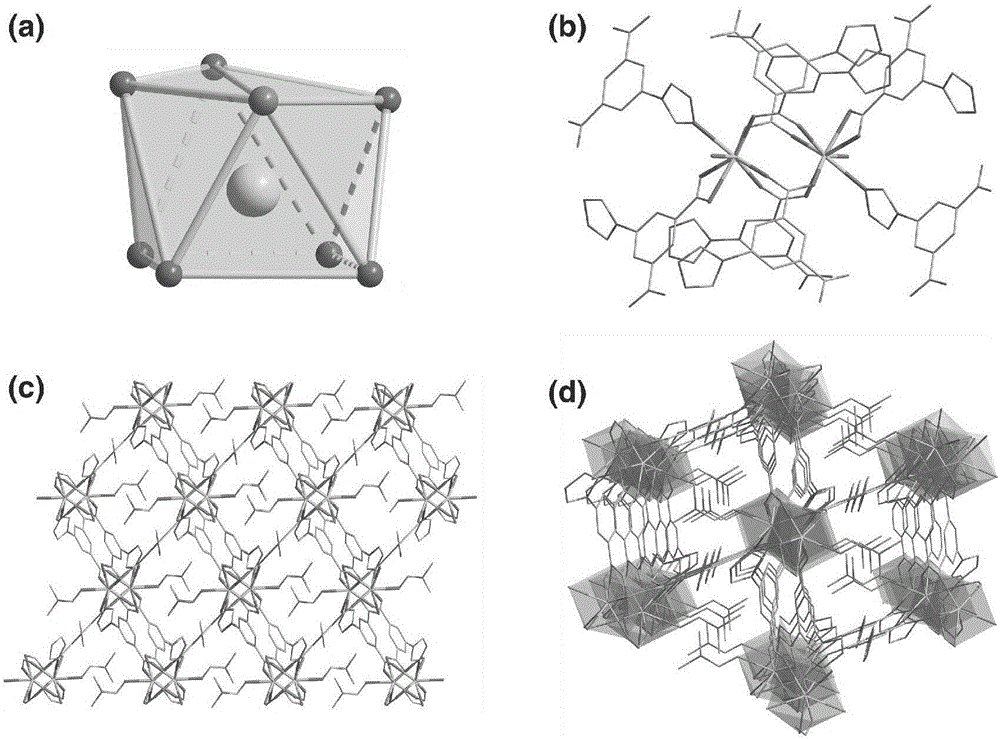

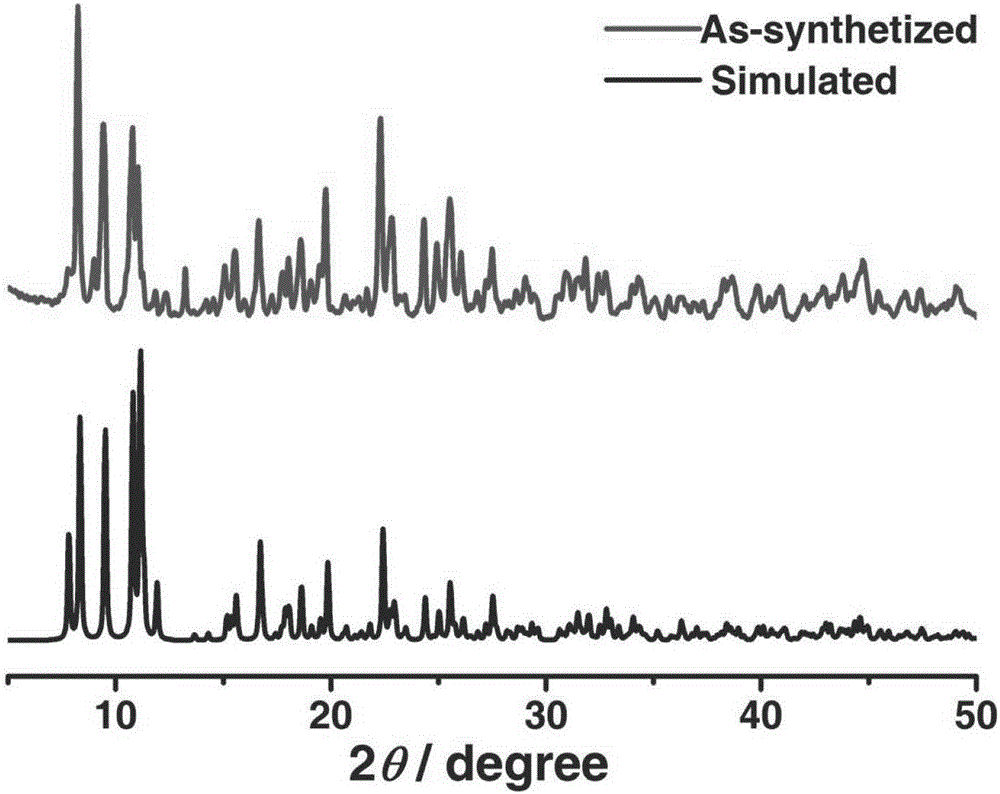

Zinc-cluster porous luminescent complex, and preparation method and application thereof

InactiveCN102491988AHigh purityHigh yieldFluorescence/phosphorescenceLuminescent compositionsN dimethylformamideBulk crystal

The invention provides a zinc-cluster porous luminescent complex. The chemical formula is [NH2(CH3)2][Zn3(BTC)2(BTA)].2DMF; the complex has a porous three-dimensional network structure; and one-dimensional channels are formed in c-axis directions of crystals, and dimethyl formamide molecules are filled in the channels. The preparation method comprises the following steps of: mixing trimesic acid, 1H-benzotriazole, zinc nitrate and N,N-dimethylformamide, performing crystallization reaction, naturally cooling to room temperature, and filtering a solution to obtain colorless transparent bulk crystals, namely single crystals of the complex. The invention has the advantages that: the preparation method is simple is process and easy to implement; the obtained crystals are high in purity, yield and reproducibility; the complex can produce fluorescence, has a fluorescence enhancement or quenching effect on copper and barium metal ions, can be used as a fluorescent material for preparing fluorescent probes, and is used for detecting metal ions in environments or foods; and the detection method is simple and higher in selectivity, and has a broad application prospect.

Owner:NANKAI UNIV

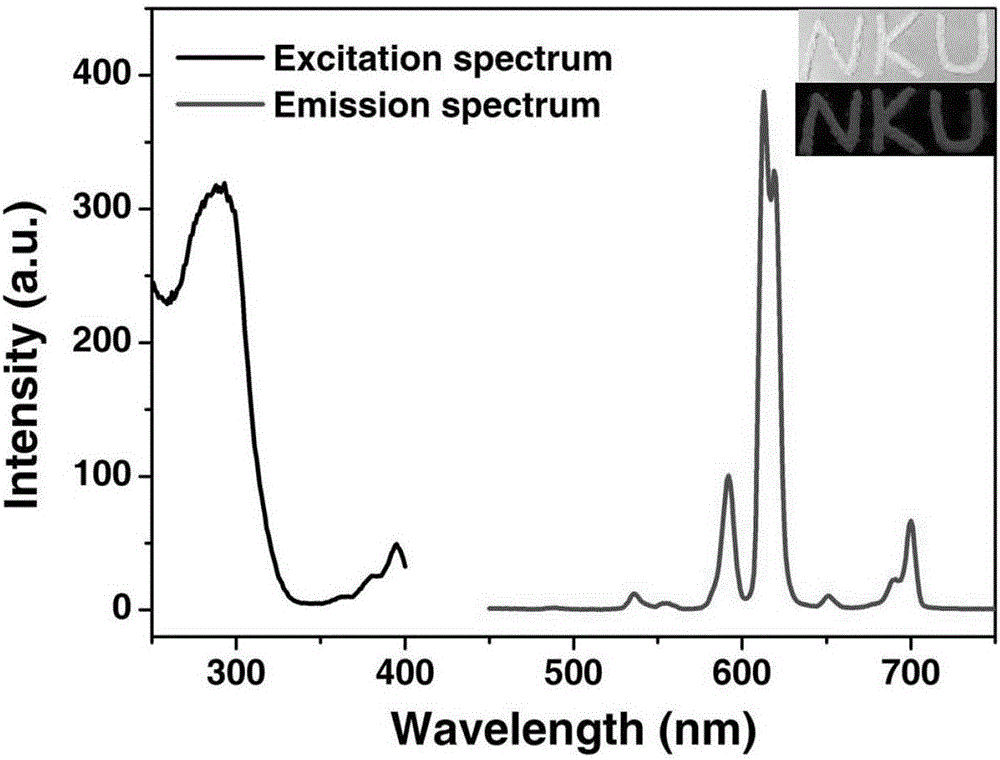

Europium rare earth metal-organic frame material and preparation method and application thereof

InactiveCN106674534ASimple preparation processMild reaction conditionsFluorescence/phosphorescenceLuminescent compositionsBulk crystalChlorobenzene

The invention relates to a europium rare earth metal-organic frame material and a preparation method and application thereof. The chemical formula of the product is {[Eu2(L)3(DMF)2]}n. The preparation method comprises the following steps: adding 5-(4-hydroxy-1,2,4-triazolyl)-4-benzene-1,3-dicarboxylic acid and europium chloride hexahydrate into a mixed solution of methanol and DMF, and stirring uniformly to obtain a mixed solution; then charging the mixed solution into a polytetrafluoroethylene lined hydrothermal synthesis high-pressure reaction kettle, cooling and filtering after reaction to obtain colorless bulk crystals; and then repetitively washing the colorless bulk crystals with the mixed solution of methanol and DMF to obtain the metal organic frame material. The europium rare earth metal-organic frame material has the advantages of simple preparation process, mild reaction conditions, high yield and low cost; and at room temperature, chlorobenzene, 1,2-dichlorobenzene, 1,2,4-trichlorobenzene, 1,2,3,4-tetrachlorobenzene, 1,2,4,5-tetrachlorobenzene, pentachlorobenzene and hexachlorobenzene have different degrees of fluorescence quenching responses on the material, and the material has good application prospects in environmental monitoring.

Owner:NANKAI UNIV

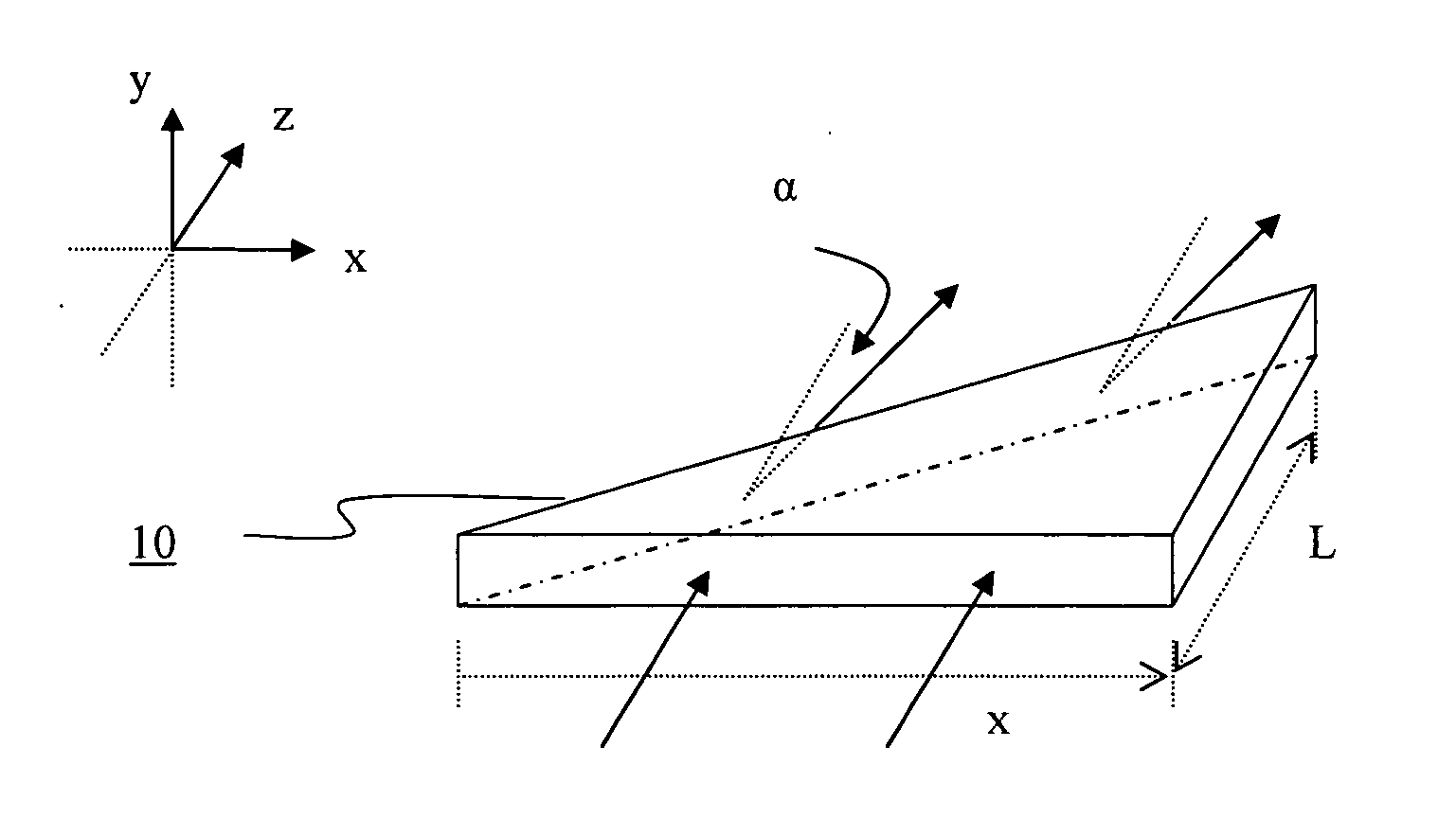

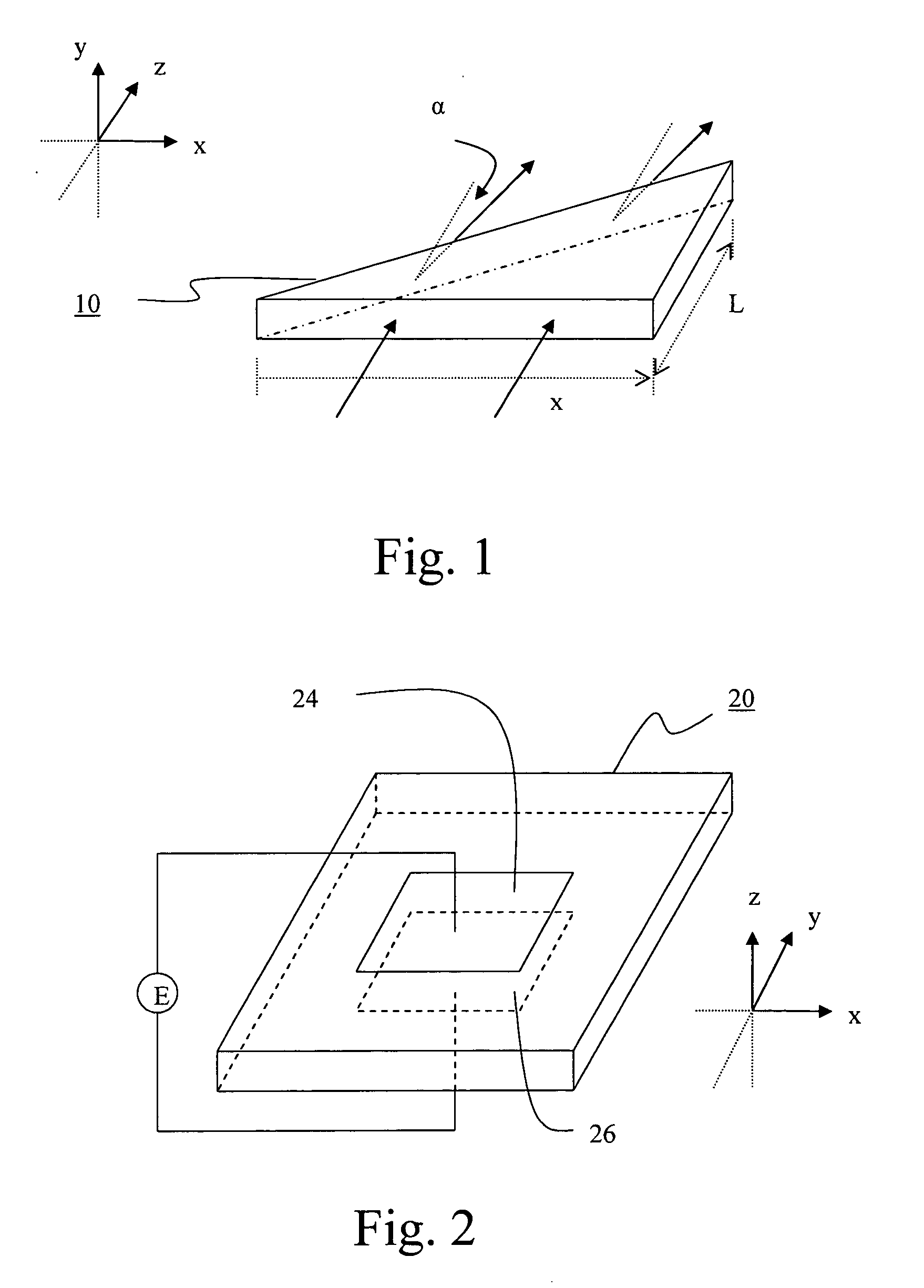

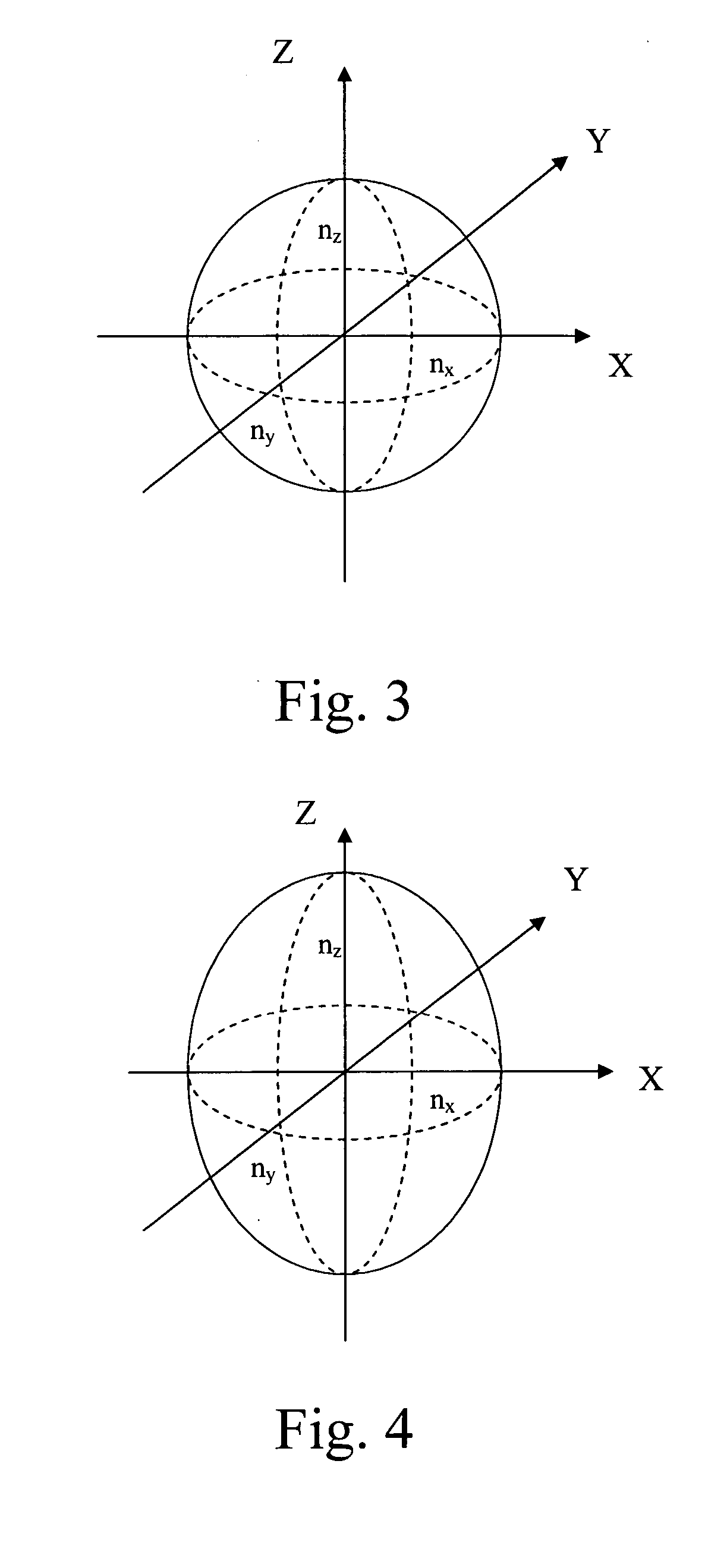

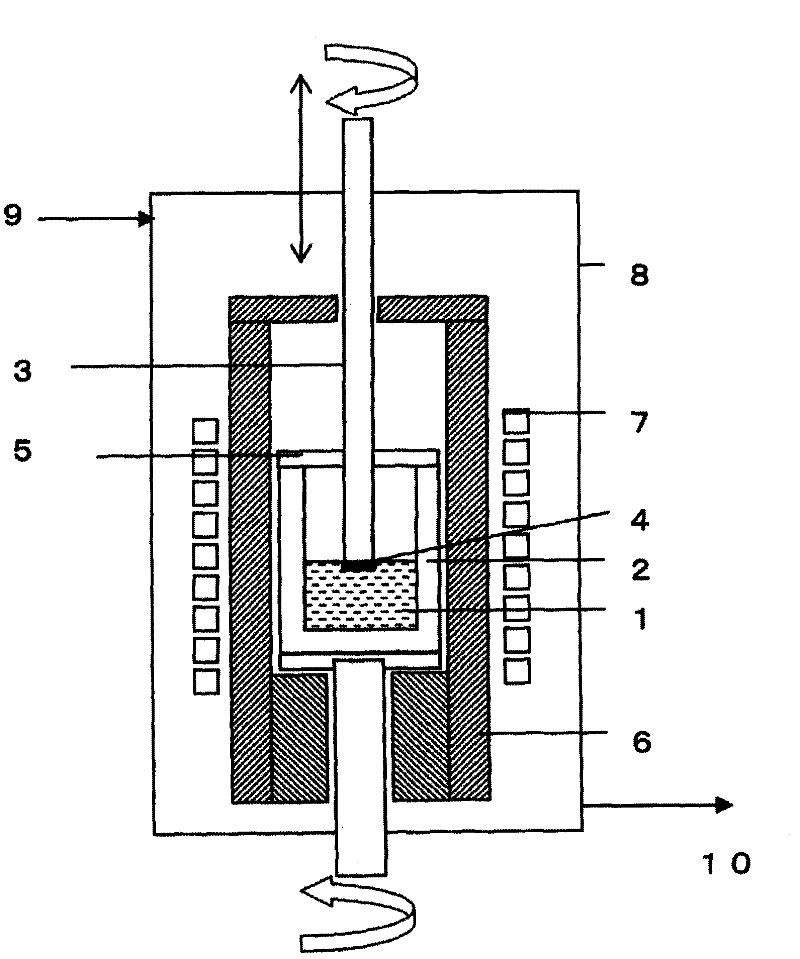

Electronically modulated prism

An electronically modulated prism, having a bulk crystal, a plurality of electrode pads formed on a top surface of the bulk crystal, and a common electrode formed on a bottom surface of the bulk crystal. The bulk crystal is optically isotropic with zero electric field applied thereto and optically anisotropic when subjected to a non-zero electric field. More specifically, the bulk crystal between each of the electrode pads and the common electrode has an index of fraction altered proportionally to the electric field applied thereto, such that an incident beam propagate through the crystal is modulated with an accumulated phase shift.

Owner:NORTHROP GRUMMAN SYST CORP

Manufacturing method for silicon carbide monocrystals

InactiveCN102203330AStable and effective growthInhibit coloringPolycrystalline material growthLiquid-phase epitaxial-layer growthBulk crystalAlloy

Disclosed is a method that can stably manufacture thin films or bulk crystals of SiC monocrystals that are suitable for use in various devices and have low carrier densities of 5 1017 / cm3 or less, and preferably less than 1 1017 / cm3, with liquid phase growth technology using a SiC solution that uses a molten Si alloy as the solvent. As the Si alloy, the method uses an alloy having a composition represented by SixCryTiz wherein x, y and z (each is atom%) satisfy (1) 0.50 < x < 0.68, 0.08 < y < 0.35 and 0.08 < z < 0.35 or (2) 0.40 < x = 0.50, 0.15 < y < 0.40 and 0.15 < z < 0.35. x, y and z preferably satisfy 0.53 < x < 0.65, 0.1 < y < 0.3 and 0.1 < z < 0.3.

Owner:NIPPON STEEL CORP

Method of manufacturing III-nitride crystal, and semiconductor device utilizing the crystal

ActiveUS8258051B2High crystallinityImprove efficiencyPolycrystalline material growthLiquid-phase epitaxial-layer growthBulk crystalEngineering

The present III-nitride crystal manufacturing method, a method of manufacturing a III-nitride crystal (20) having a major surface (20m) of plane orientation other than {0001}, designated by choice, includes: a step of slicing III-nitride bulk crystal (1) into a plurality of III-nitride crystal substrates (10p), (10q) having major surfaces (10pm), (10qm) of the designated plane orientation; a step of disposing the substrates (10p), (10q) adjoining each other sideways in such a way that the major surfaces (10pm), (10qm) of the substrates (10p), (10q) parallel each other and so that the [0001] directions in the substrates (10p), (10q) are oriented in the same way; and a step of growing III-nitride crystal (20) onto the major surfaces (10pm), (10qm) of the substrates (10p), (10q).

Owner:SUMITOMO ELECTRIC IND LTD

Production of a GaN bulk crystal substrate and a semiconductor device formed on a GaN bulk crystal substrate

InactiveUS7250640B2Solve the power is smallPolycrystalline material growthFrom normal temperature solutionsBulk crystalSingle crystal

A method of making a bulk crystal substrate of a GaN single crystal includes the steps of forming a molten flux of an alkali metal in a reaction vessel and causing a growth of a GaN single crystal from the molten flux, wherein the growth is continued while replenishing a compound containing N from a source outside the reaction vessel.

Owner:SUMITOMO CHEM CO LTD +1

Semiconductor device and method of manufacture thereof

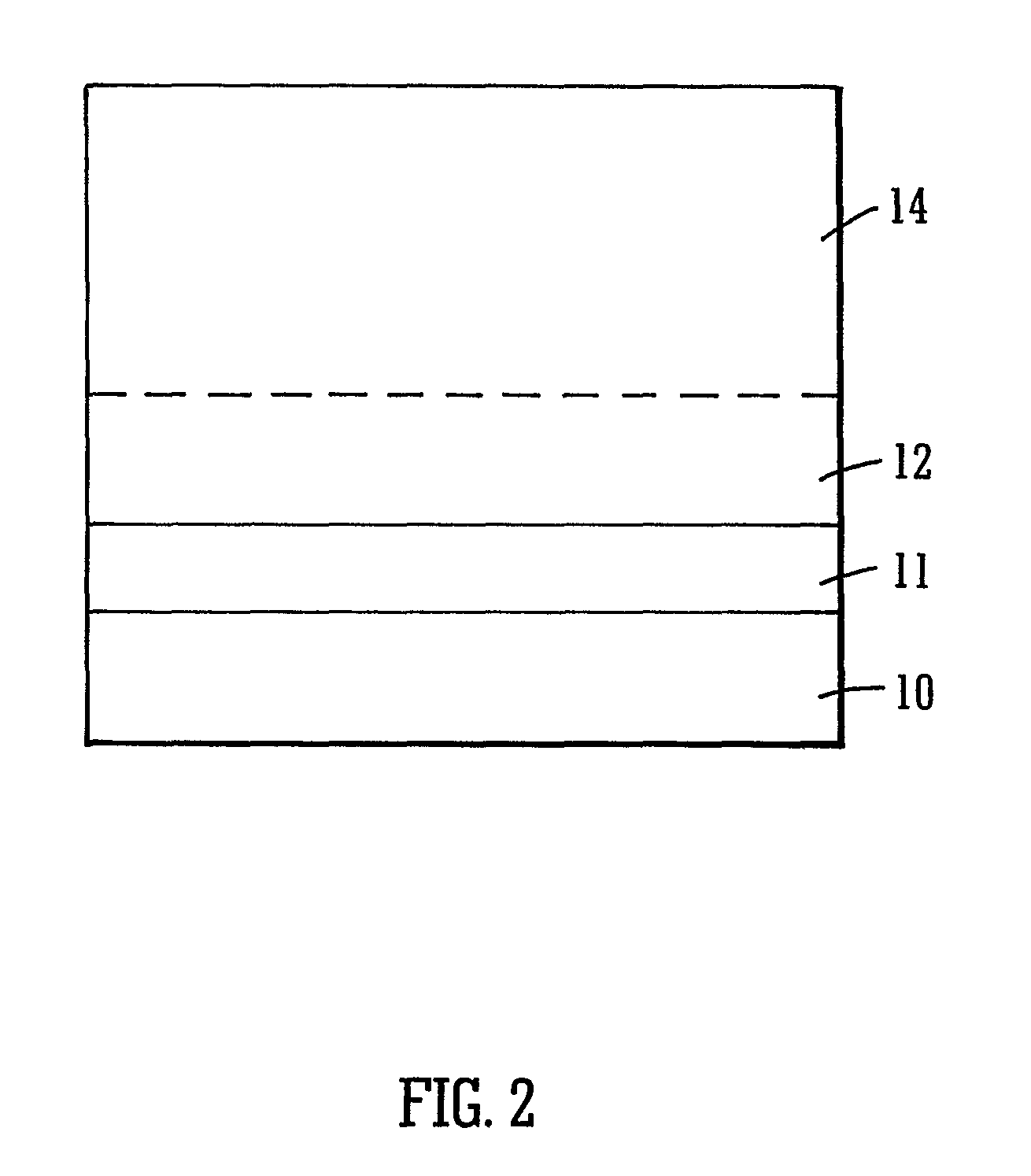

InactiveUS20090053453A1Improve consistencyMaterial becomes quickVacuum evaporation coatingSemiconductor/solid-state device manufacturingBulk crystalDevice material

A structure including a substrate, an intermediate layer provided and formed directly onto the substrate, a transition region, and a group II-VI bulk crystal material provided and formed as an extension of the transition region. The transition region acts to change the structure from the underlying substrate to that of the bulk crystal. In a method of manufacture, a similar technique can be used for growing the transition region and the bulk crystal layer.

Owner:KROMEK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com