Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

169 results about "Electron backscatter diffraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

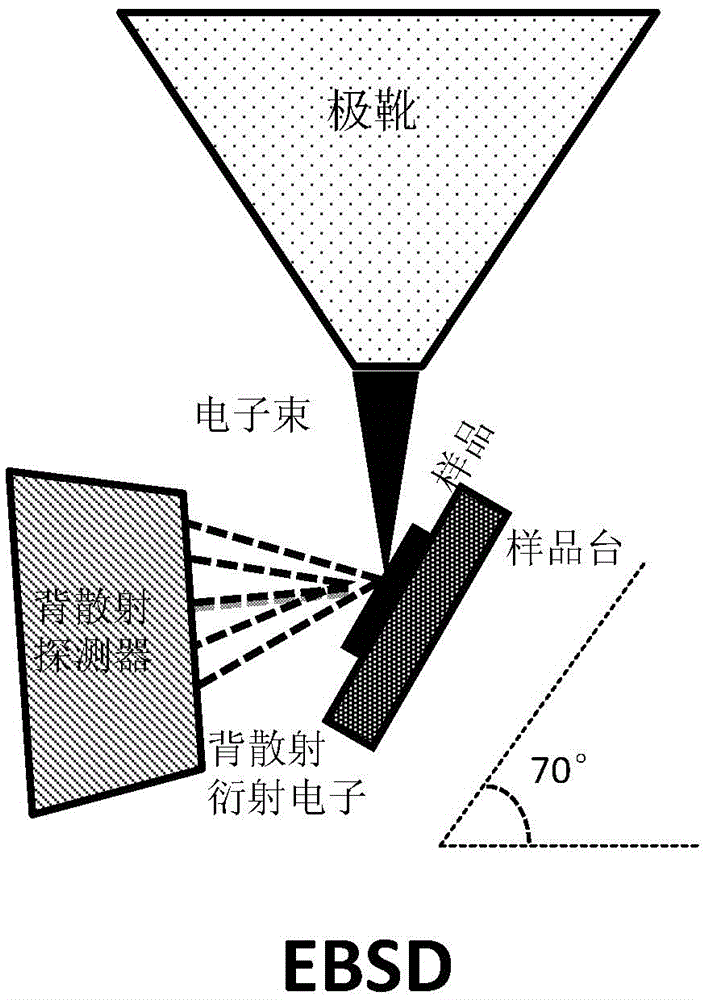

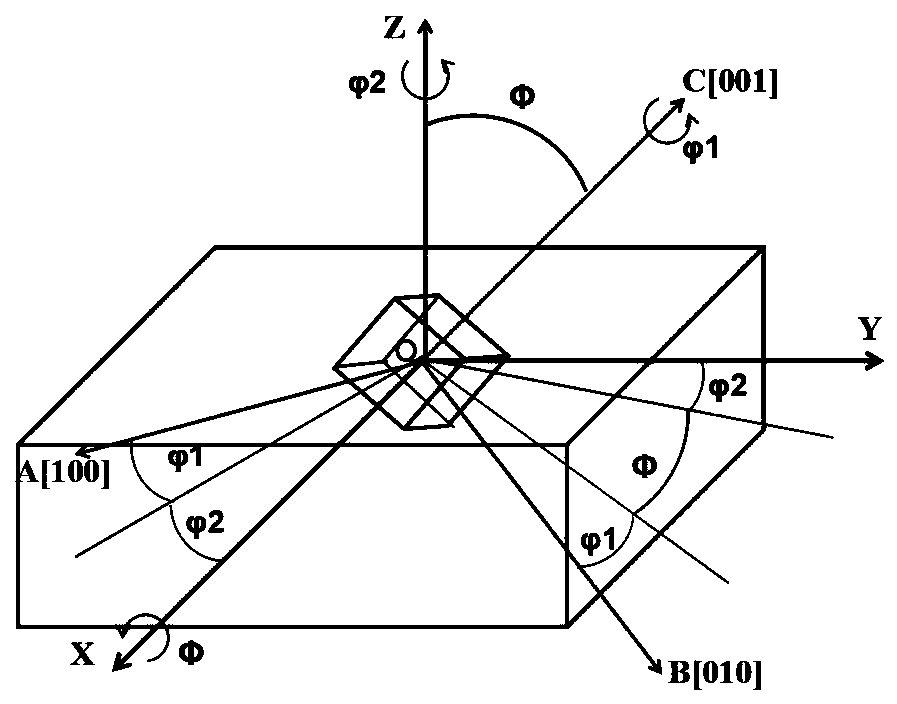

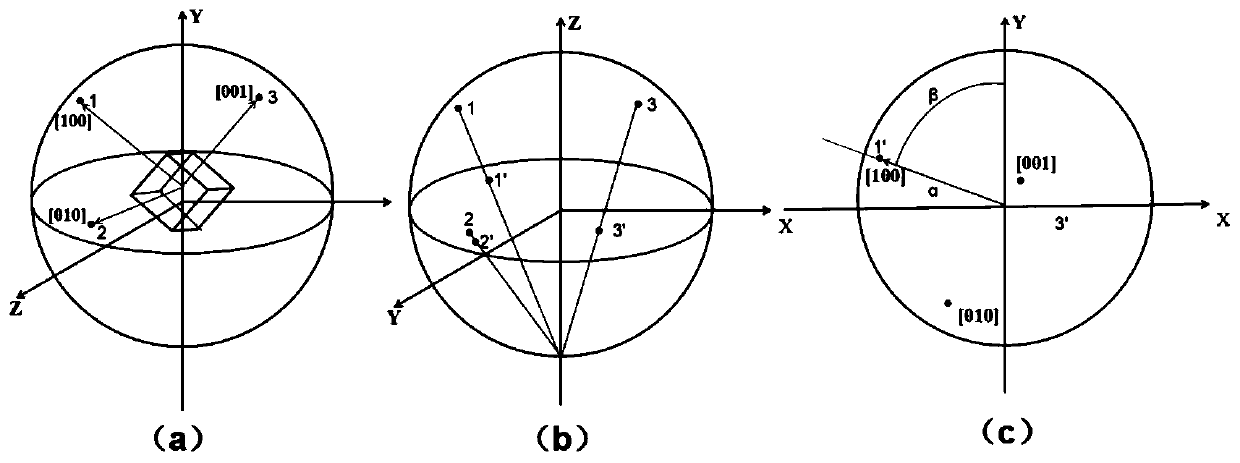

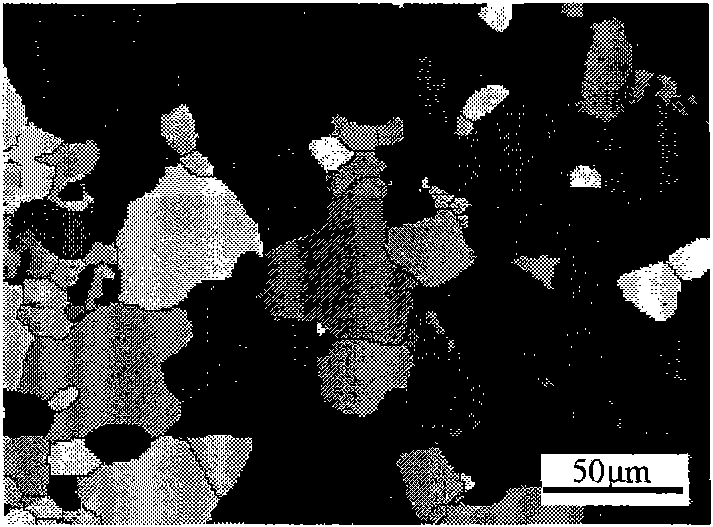

Electron backscatter diffraction (EBSD) is a scanning electron microscope–based microstructural-crystallographic characterization technique commonly used in the study of crystalline or polycrystalline materials. The technique can provide information about the structure, crystal orientation, phase, or strain in the material. Traditionally these types of studies have been carried out using X-ray diffraction (XRD), neutron diffraction and/or electron diffraction in a Transmission electron microscope.

Ai-based alloy sputtering target and process for producing the same

InactiveUS20080223718A1Increase deposition rateSuppress the sputtering defectsCellsSemiconductor/solid-state device detailsSputteringAlloy

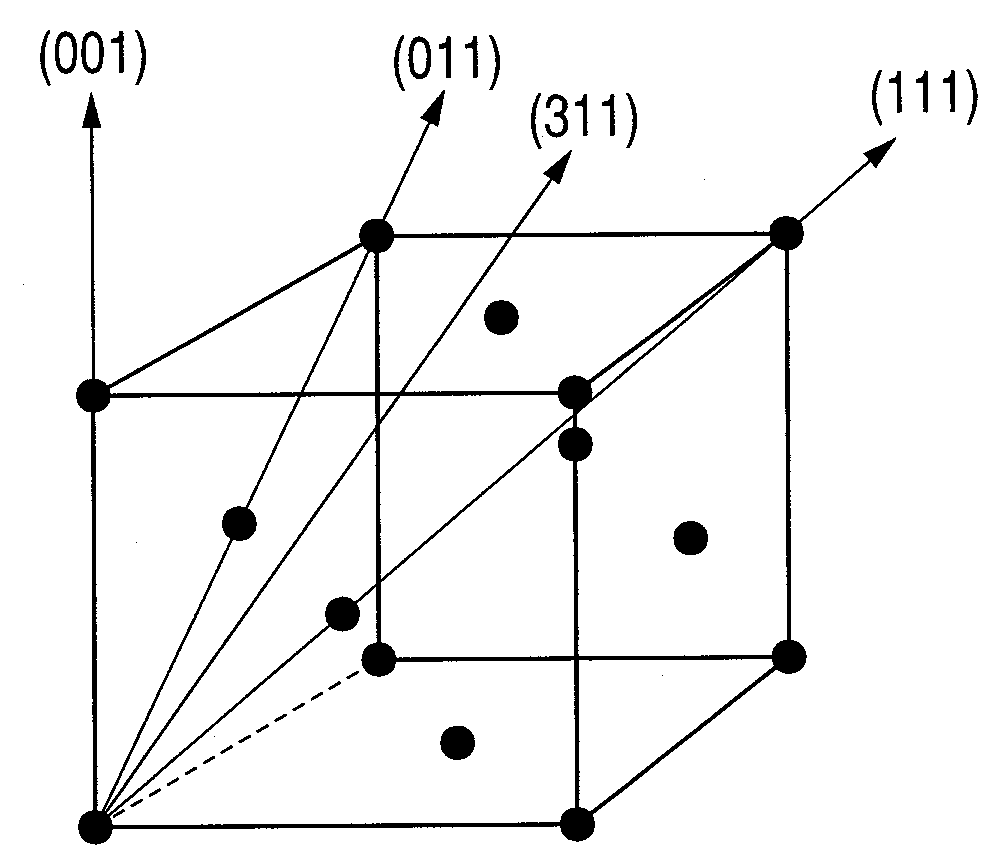

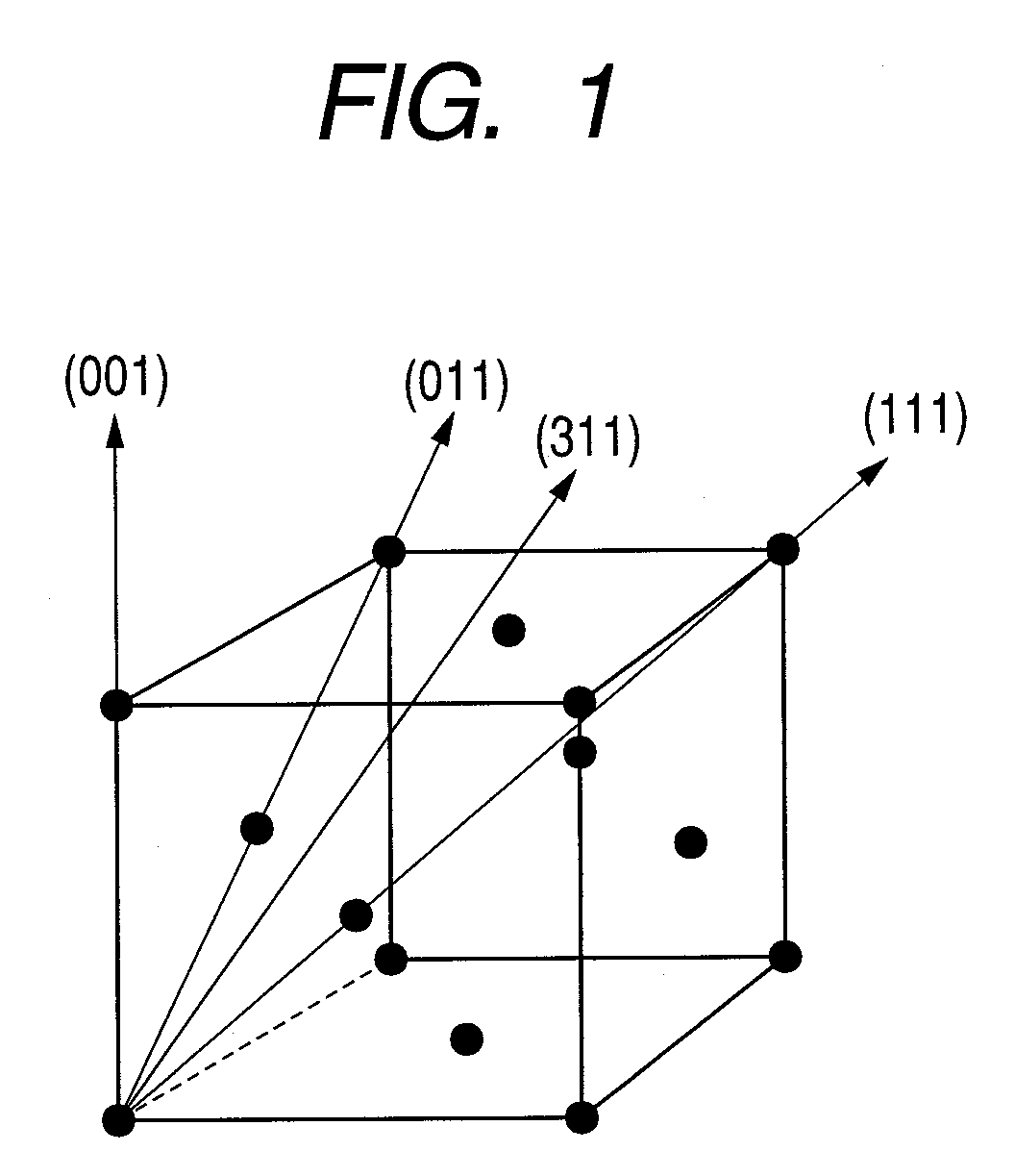

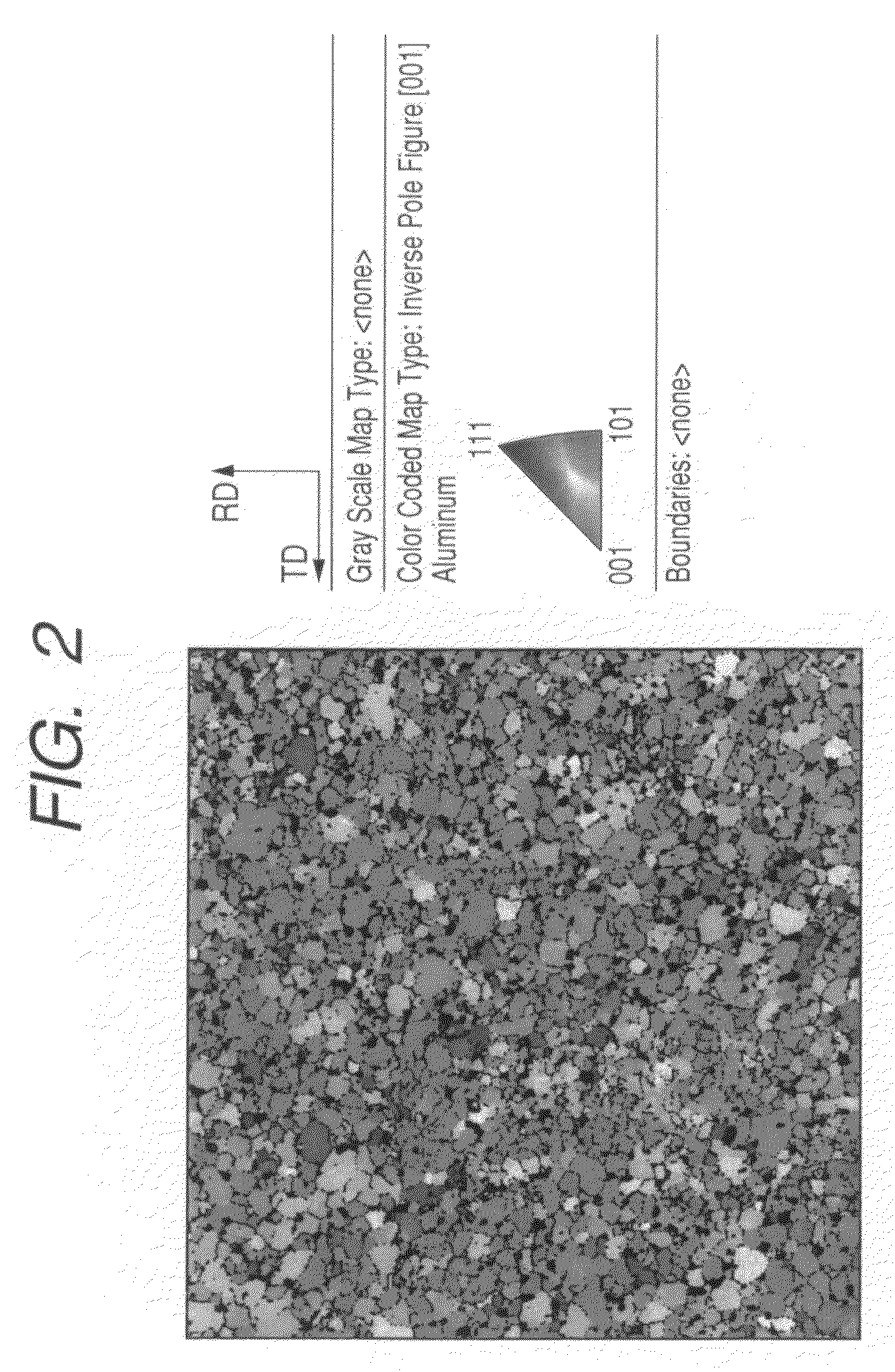

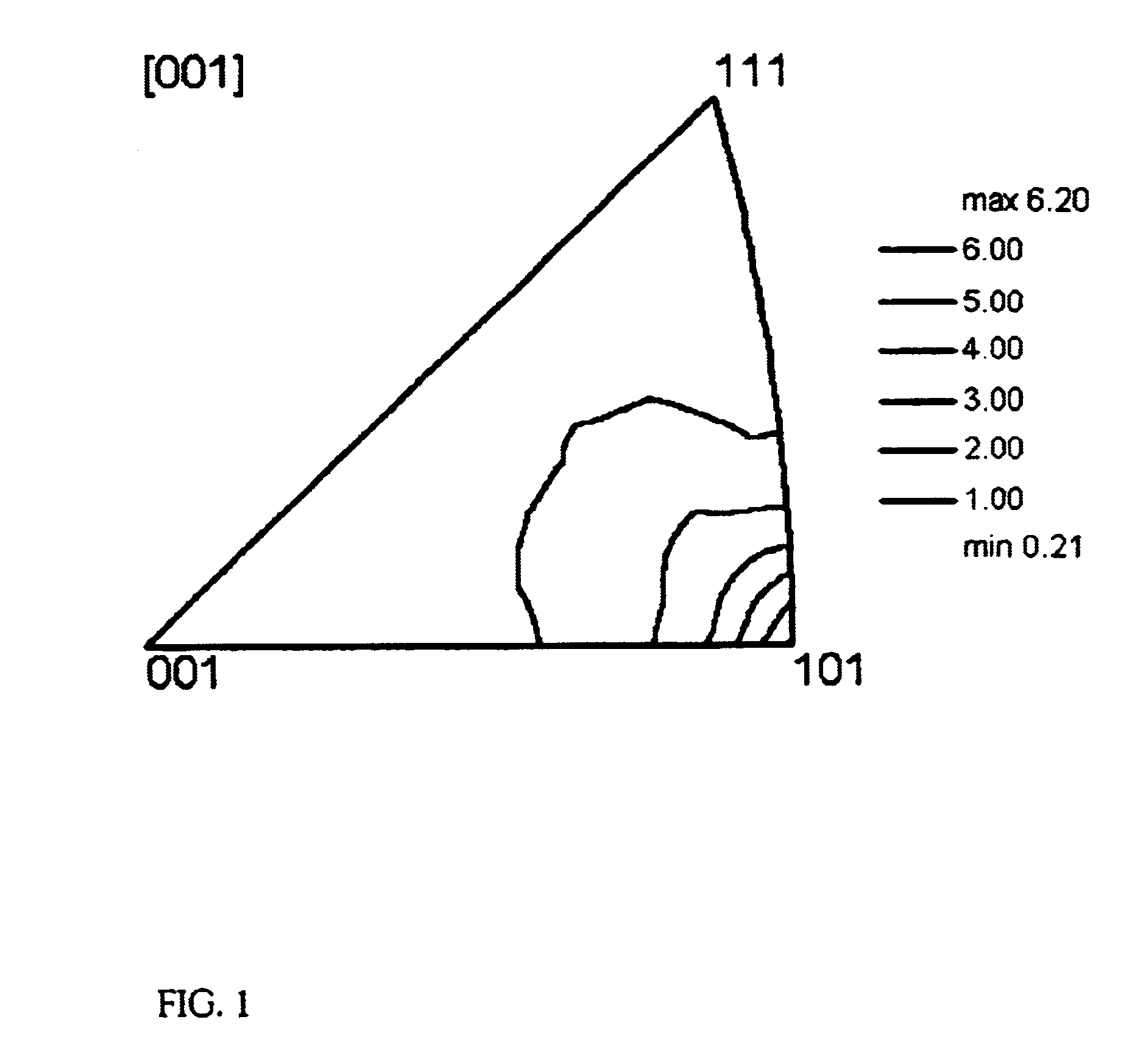

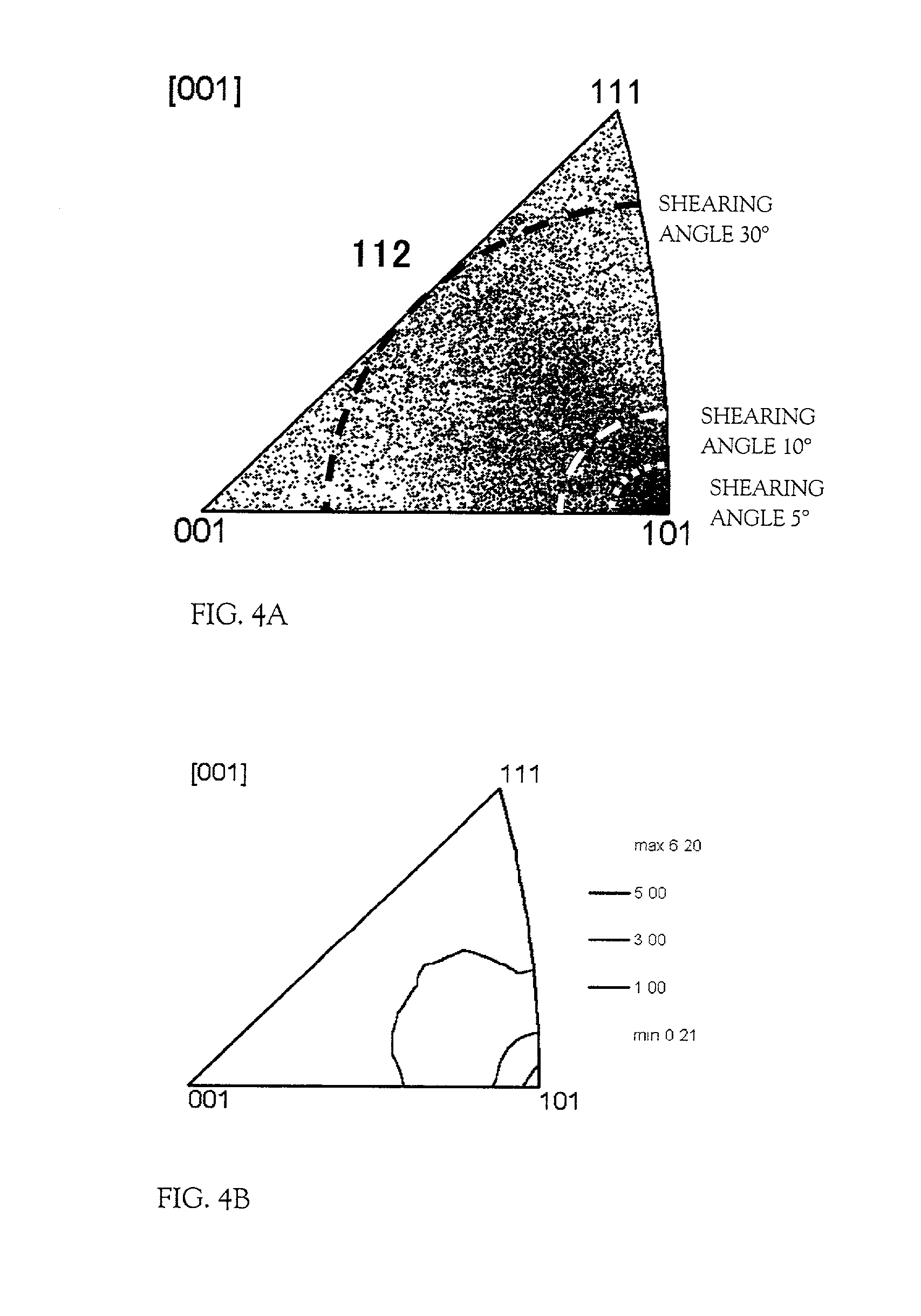

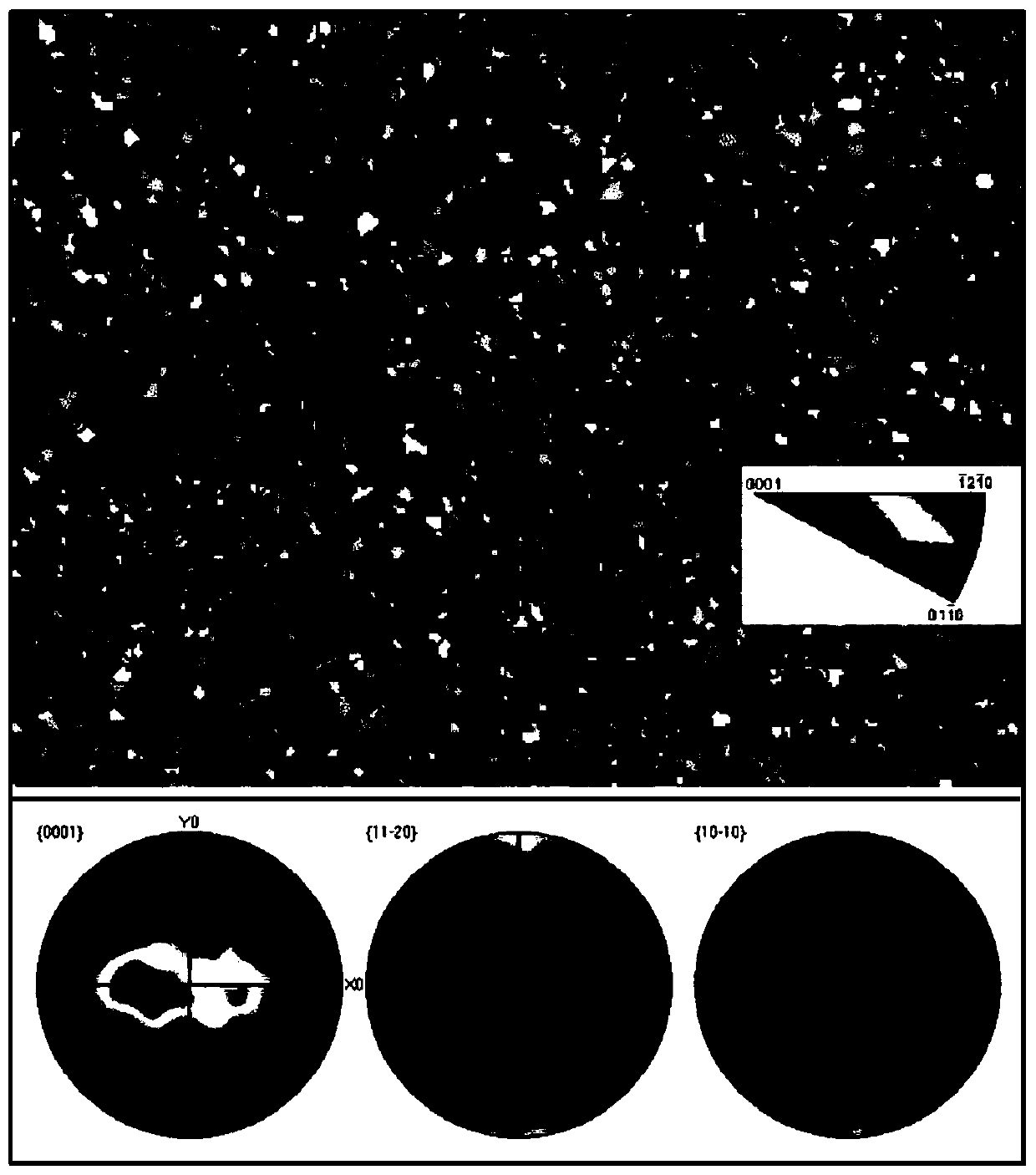

The present invention relates to an Al-based alloy sputtering target, comprising Ni in an amount of 0.05 to 10 atomic percent, wherein the Al-based alloy sputtering target satisfies: (1) that a ratio of a P value to a total area of a sputtering surface is 70% or more, wherein the P value indicates a total of area fractions of <001>±15°, <011>±15°, <111>±15° and <311>±15°; (2) that a ratio of the area fraction of <011>±15° to the P value is 30% or more; and (3) that a ratio of the area fraction of <111>±15° to the P value is 10% or less, when crystallographic orientations <001>, <011>, <111> and <311> in a normal line direction to a sputtering surface of the Al-based alloy sputtering target are observed in accordance with the electron backscatter diffraction pattern method.

Owner:KOBE STEEL LTD +1

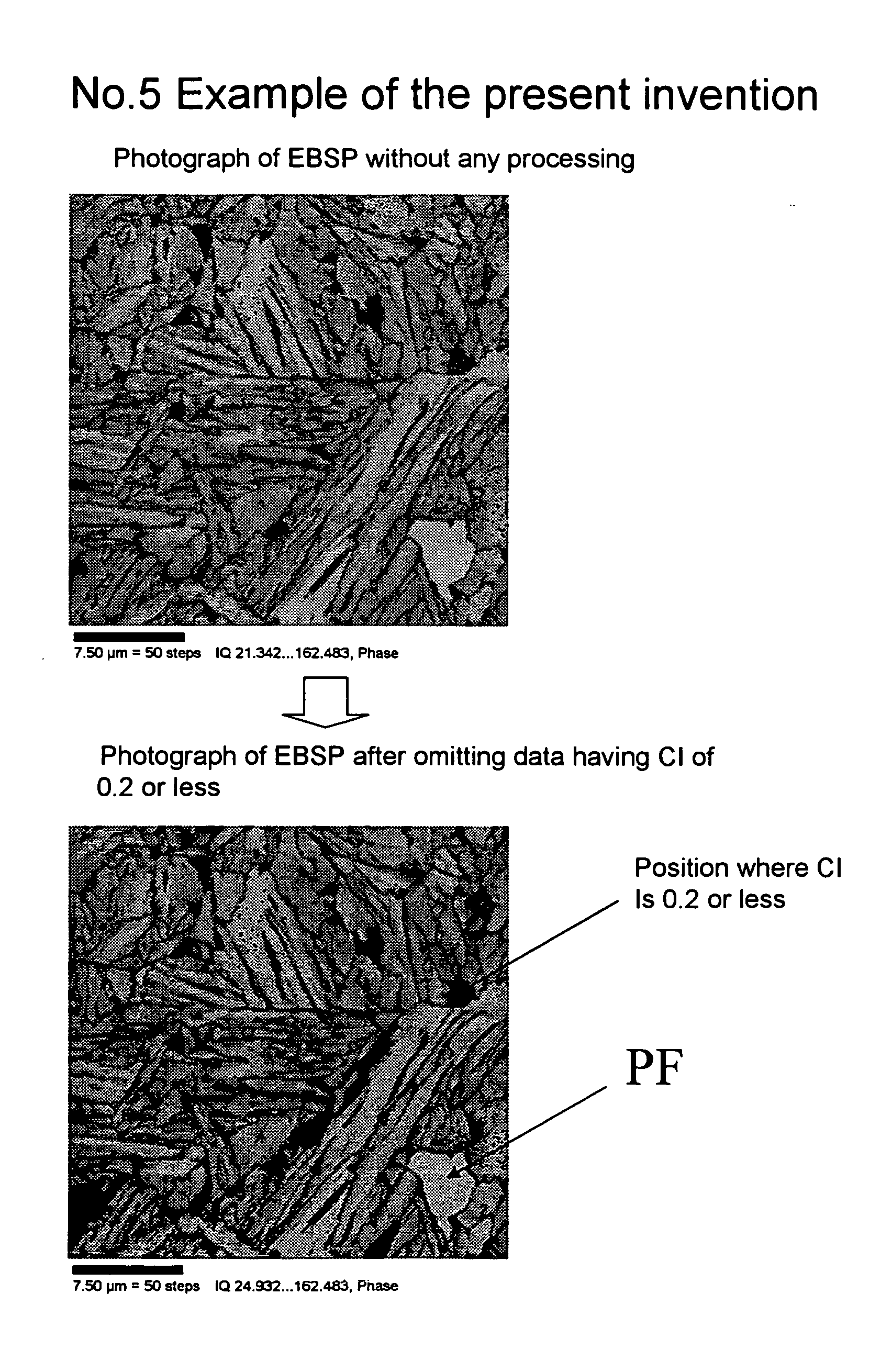

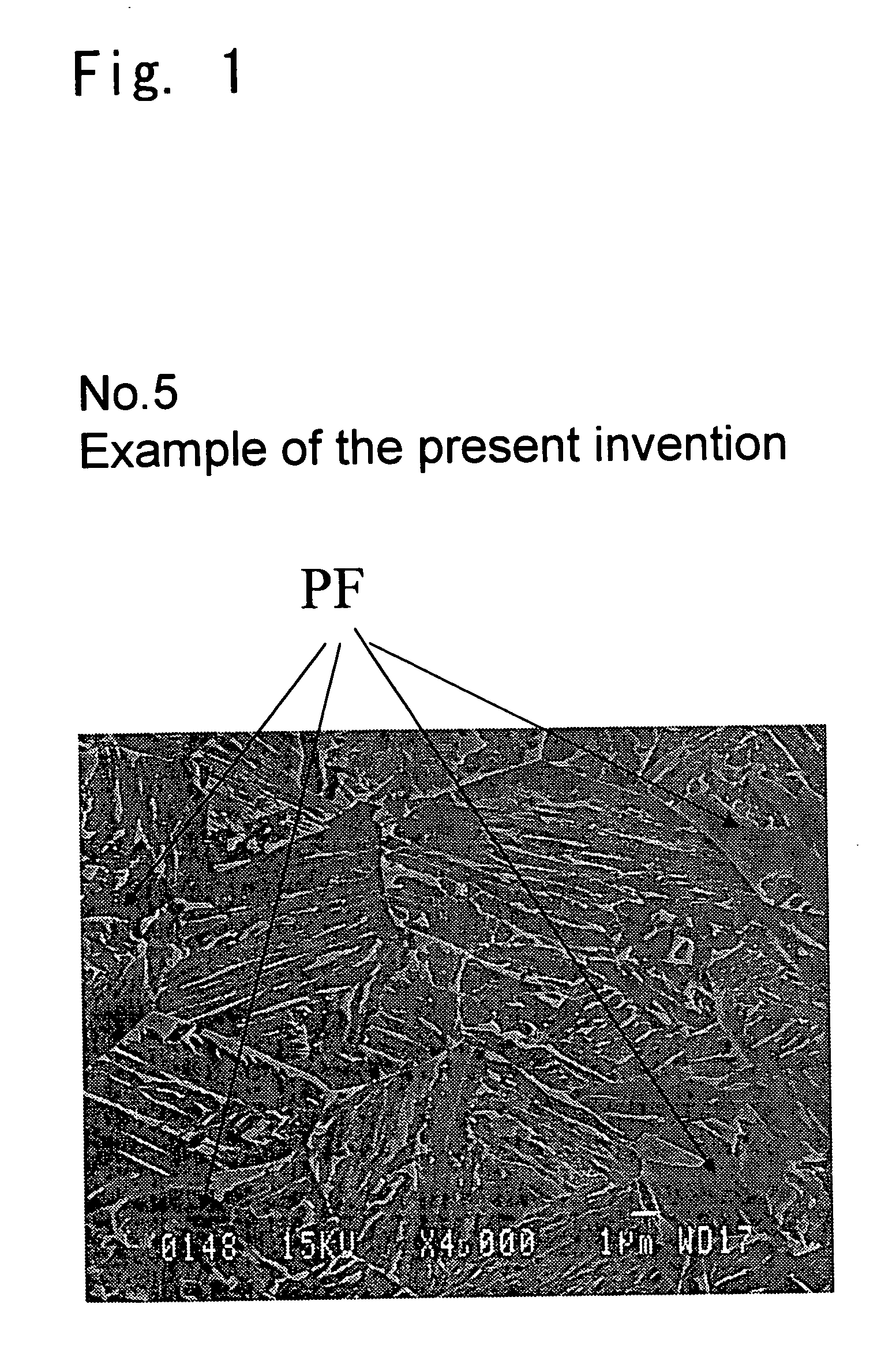

Ultra-high strength steel sheet having excellent hydrogen embrittlement resistance, and method for manufacturing the same

InactiveUS20050150580A1High strengthImprove hydrogen embrittlement resistanceManganeseUltimate tensile strength

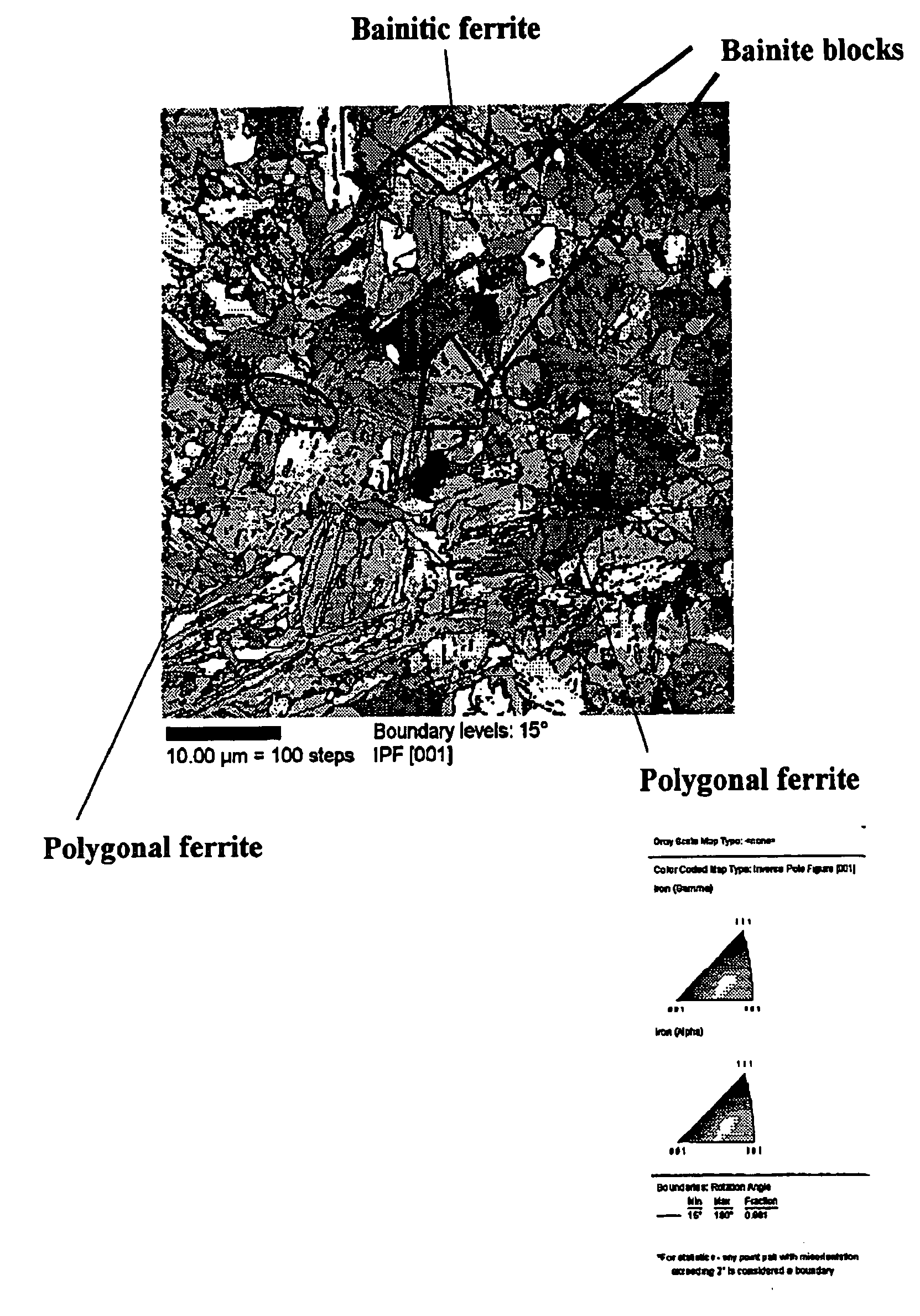

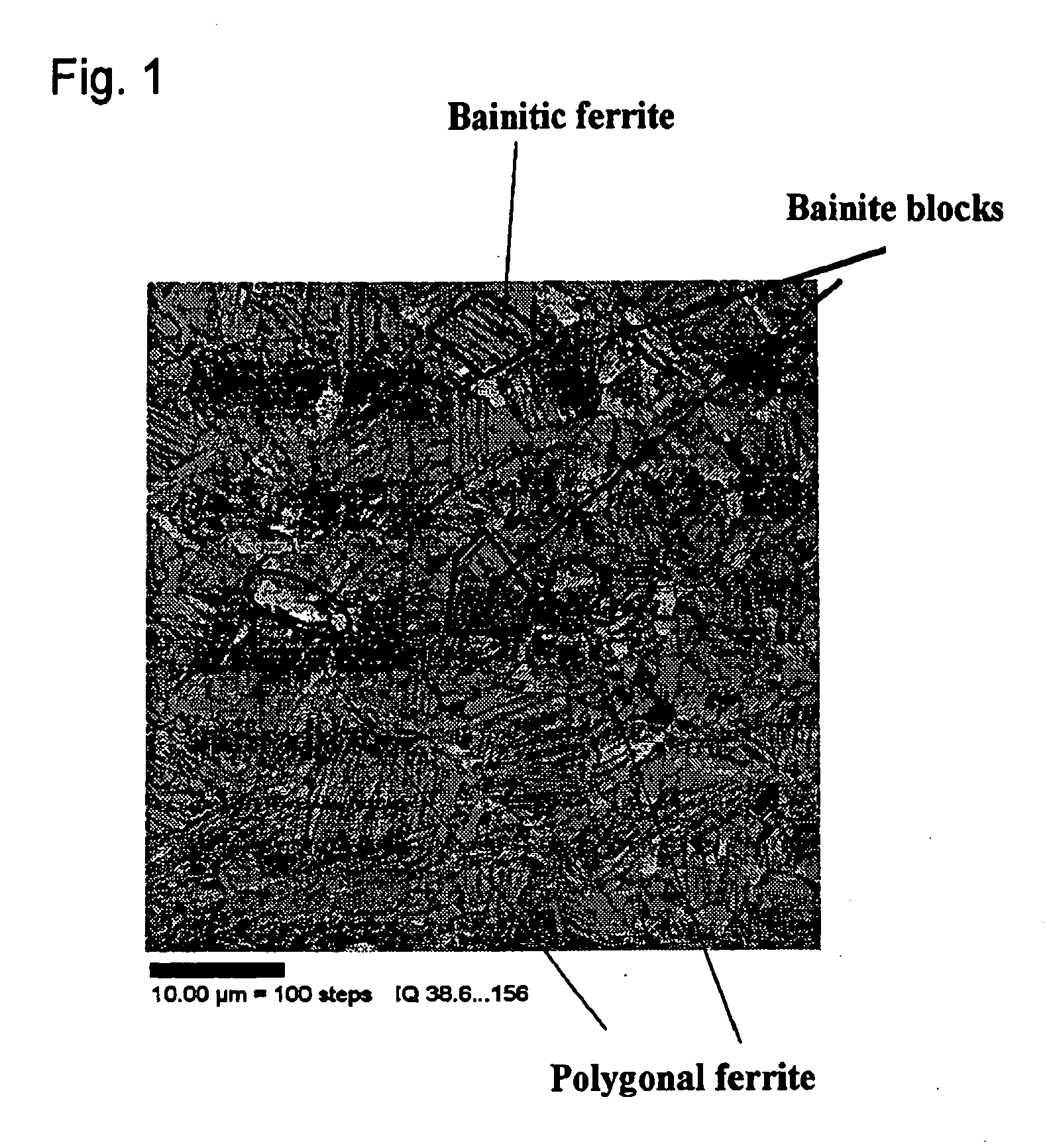

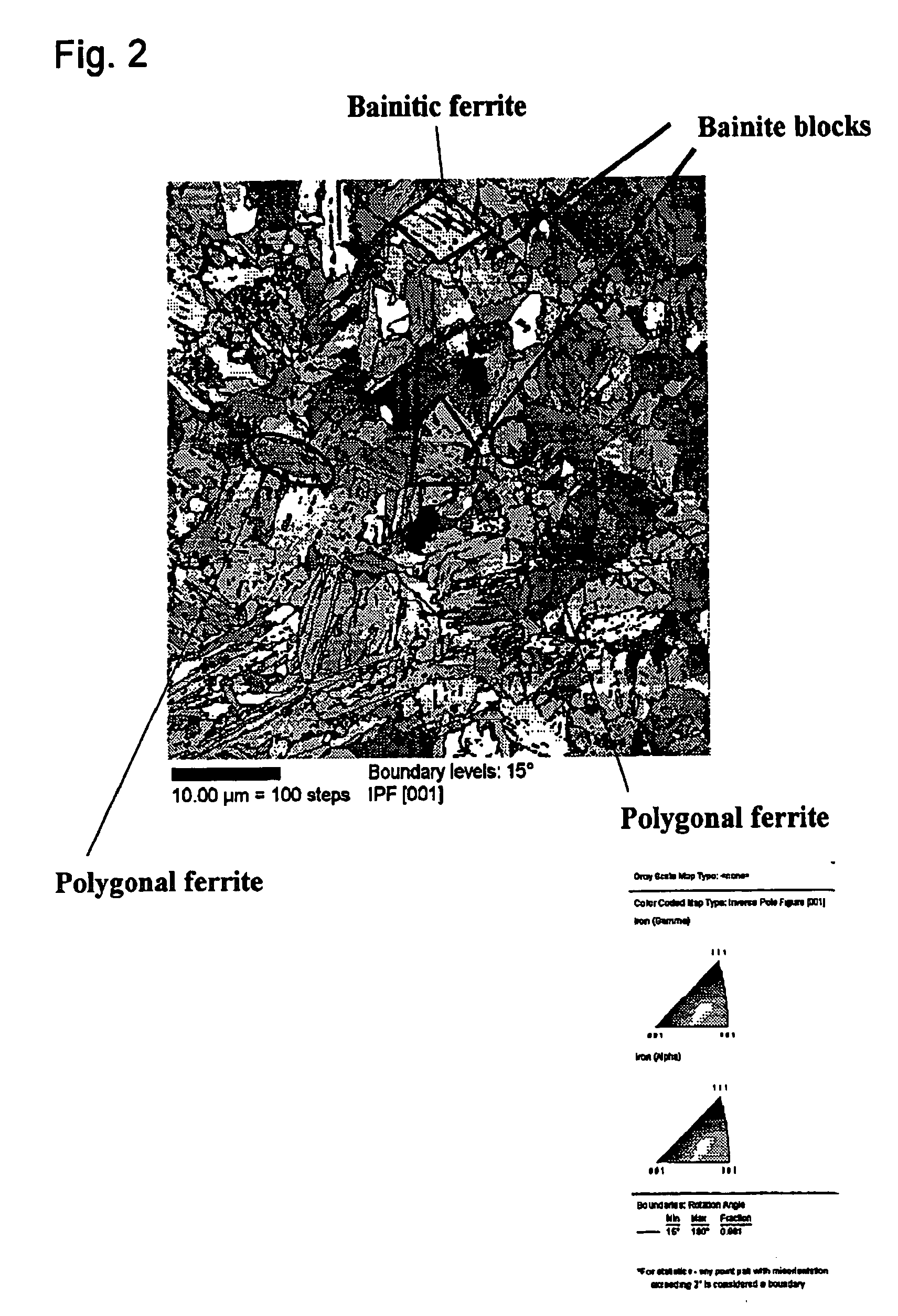

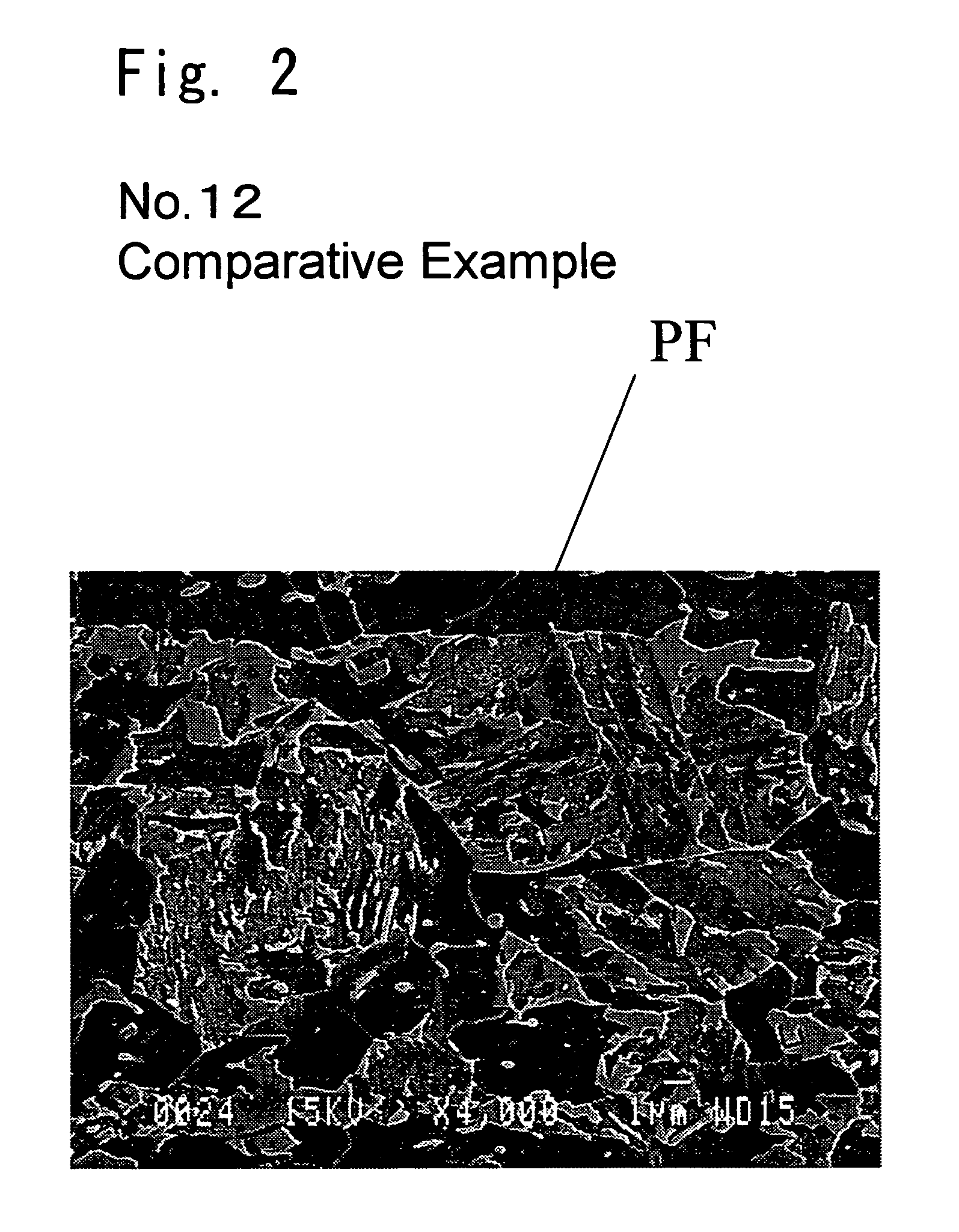

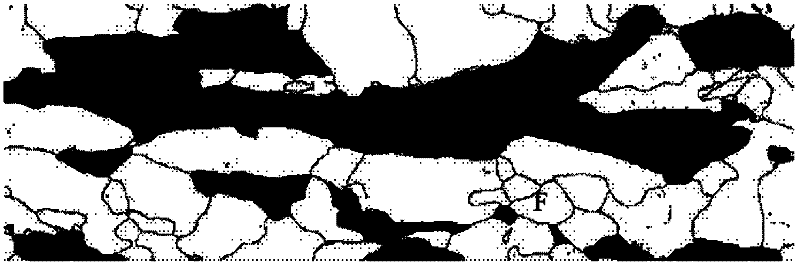

The present invention provides an ultra-high strength steel sheet having excellent hydrogen embrittlement resistance, which includes: 0.06 to 0.6% of C; 0.5 to 3% of Si+Al; 0.5 to 3% of Mn; 0.15% or lower of P; and 0.02% or lower of S in terms of mass percentage, and also includes 3% or higher of residual austenite structure, 30% or higher of bainitic ferrite structure, and preferably 50% or lower of polygonal ferrite in terms of an areal ratio to the entire structure, wherein a mean grain size of bainite blocks is smaller than 20 μm as determined by comparing observations of the same region of the bainitic ferrite structure by EBSP (electron back scatter diffraction pattern) and SEM.

Owner:KOBE STEEL LTD

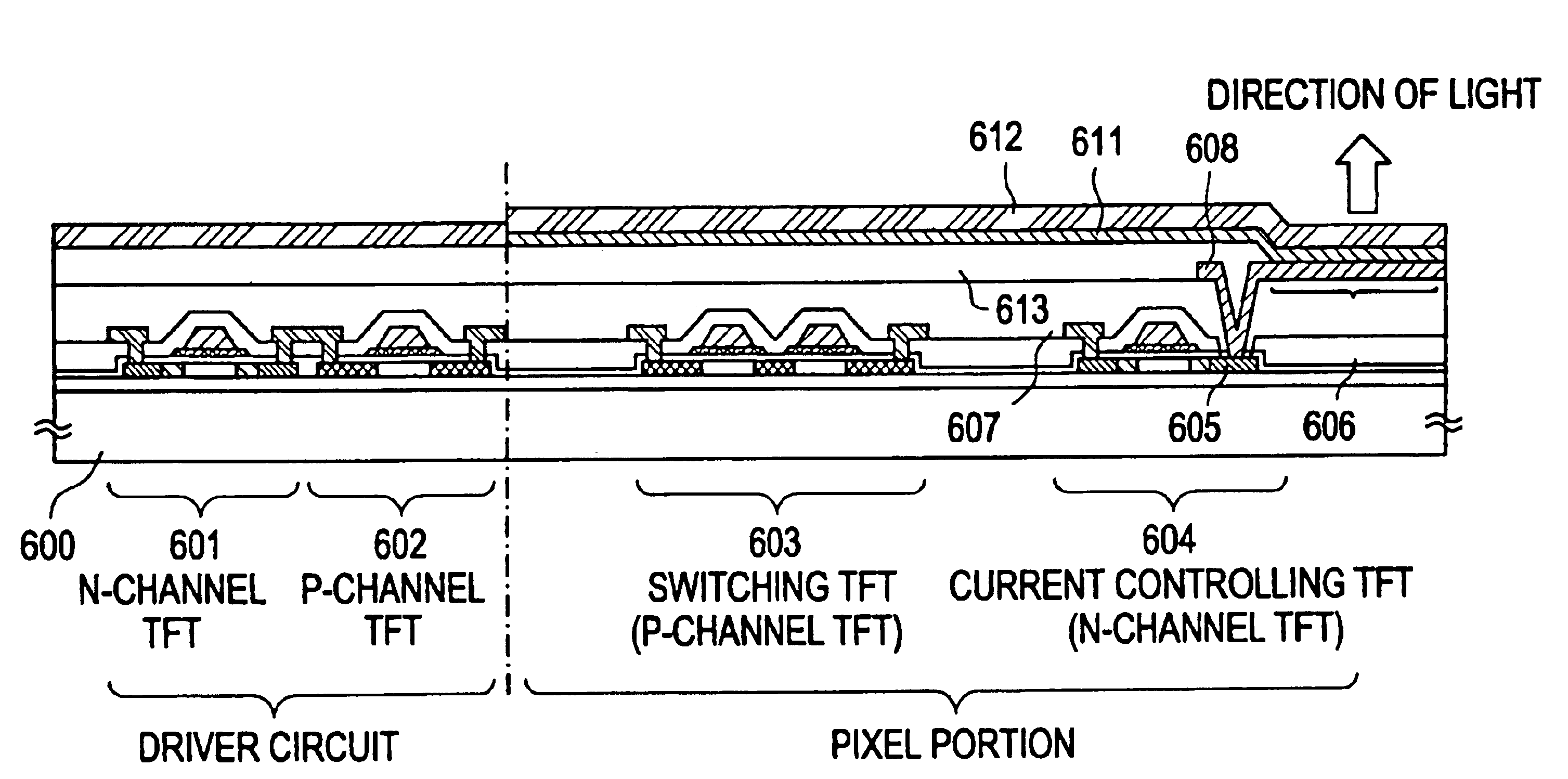

Thin film transistors and semiconductor device

InactiveUS6690068B2Increase critical radiusLow densityTransistorSemiconductor/solid-state device detailsLattice planeElectron

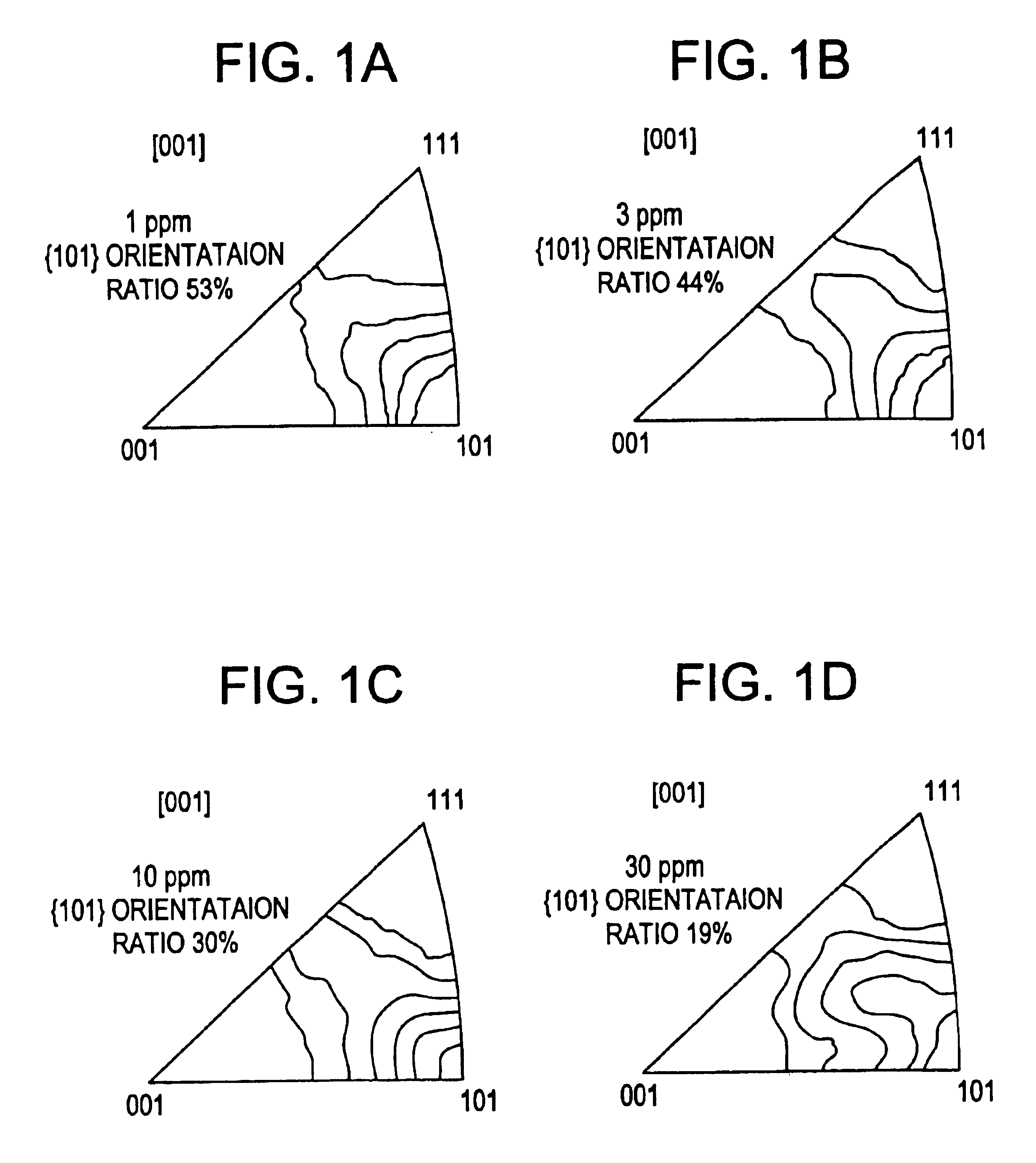

The TFT has a channel-forming region formed of a crystalline semiconductor film obtained by heat-treating and crystallizing an amorphous semiconductor film containing silicon as a main component and germanium in an amount of not smaller than 0.1 atomic % but not larger than 10 atomic % while adding a metal element thereto, wherein an orientation ratio of the lattice plane {101} is not smaller than 20% and the lattice plane {101} has an angle of not larger than 10 degrees with respect to the surface of the semiconductor film, and an orientation ratio of the lattice plane {001} is not larger than 3% and the lattice plane {001} has an angle of not larger than 10 degrees with respect to the surface of the semiconductor film, and an orientation ratio of the lattice plane {001} is not larger than 5% and the lattice plane {111} has an angle of not larger than 10 degrees with respect to the surface of the semiconductor film as detected by the electron backscatter diffraction pattern method.

Owner:SEMICON ENERGY LAB CO LTD

Thin film transistors and semiconductor device

InactiveUS20020008286A1Increase critical radiusLow densityTransistorSemiconductor/solid-state device detailsLattice planeElectron

The TFT has a channel-forming region formed of a crystalline semiconductor film obtained by heat-treating and crystallizing an amorphous semiconductor film containing silicon as a main component and germanium in an amount of not smaller than 0.1 atomic % but not larger than 10 atomic % while adding a metal element thereto, wherein not smaller than 20% of the lattice plane {101} has an angle of not larger than 10 degrees with respect to the surface of the semiconductor film, not larger than 3% of the lattice plane {001} has an angle of not larger than 10 degrees with respect to the surface of the semiconductor film, and not larger than 5% of the lattice plane {111} has an angle of not larger than 10 degrees with respect to the surface of the semiconductor film as detected by the electron backscatter diffraction pattern method.

Owner:SEMICON ENERGY LAB CO LTD

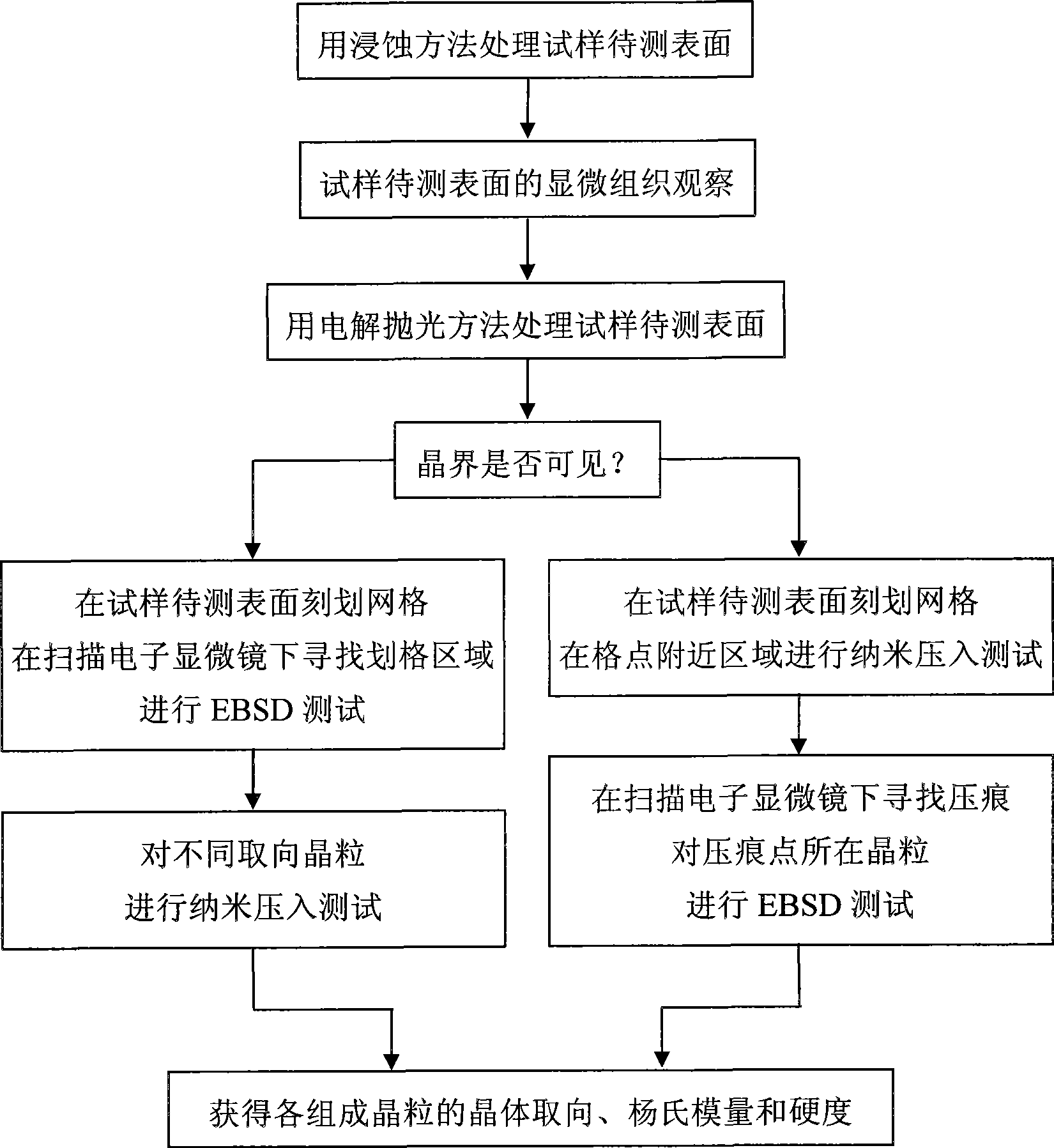

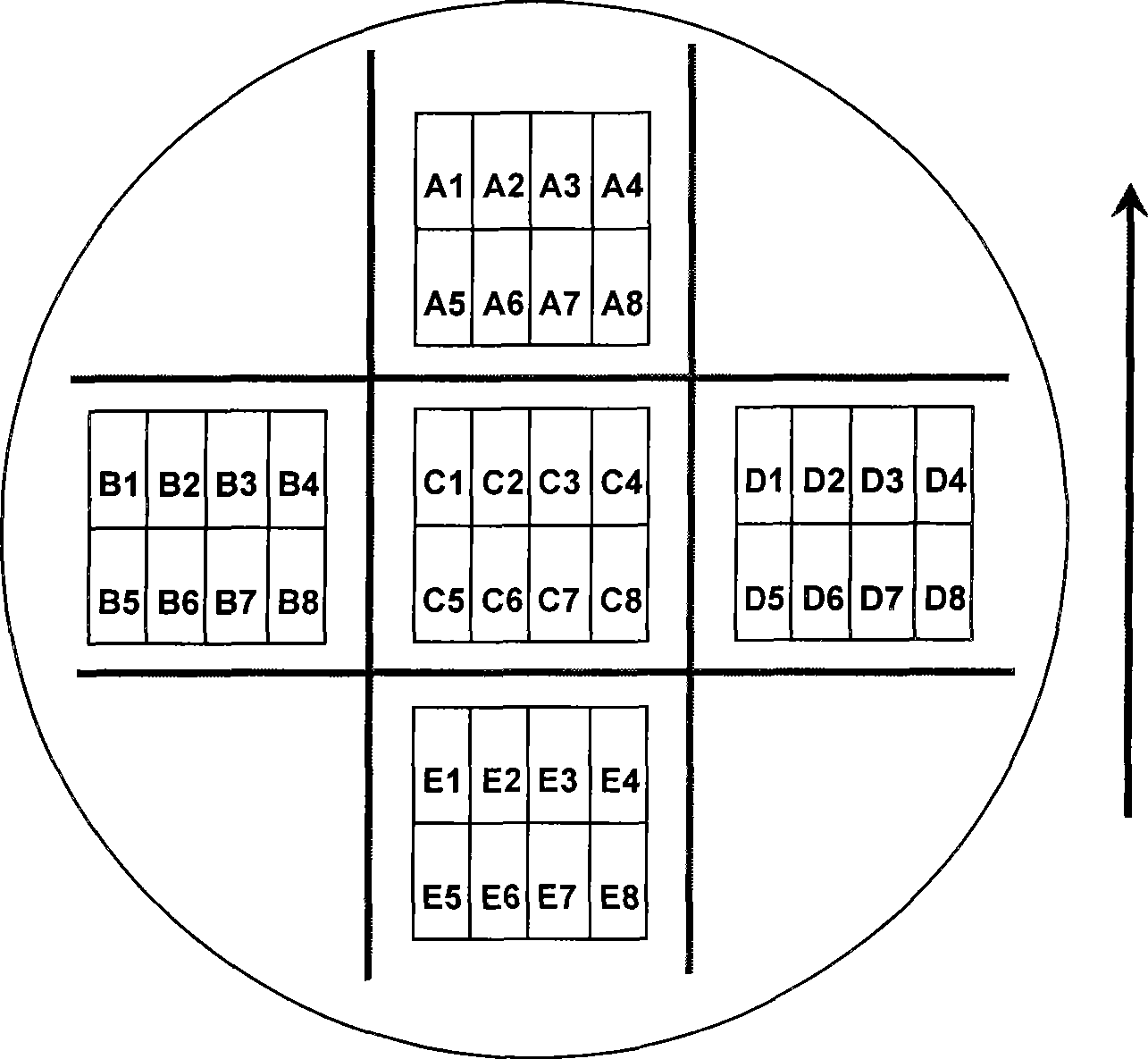

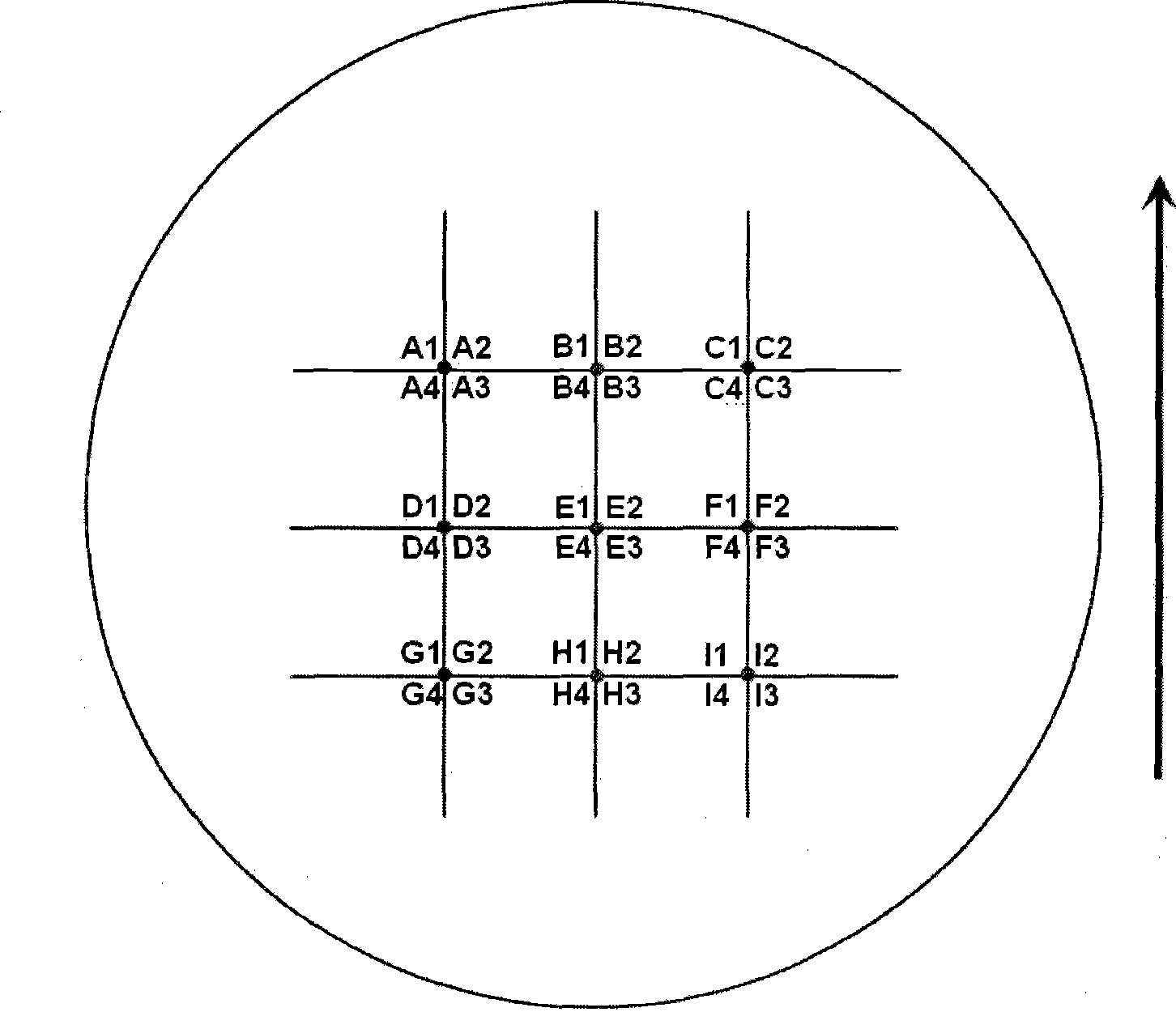

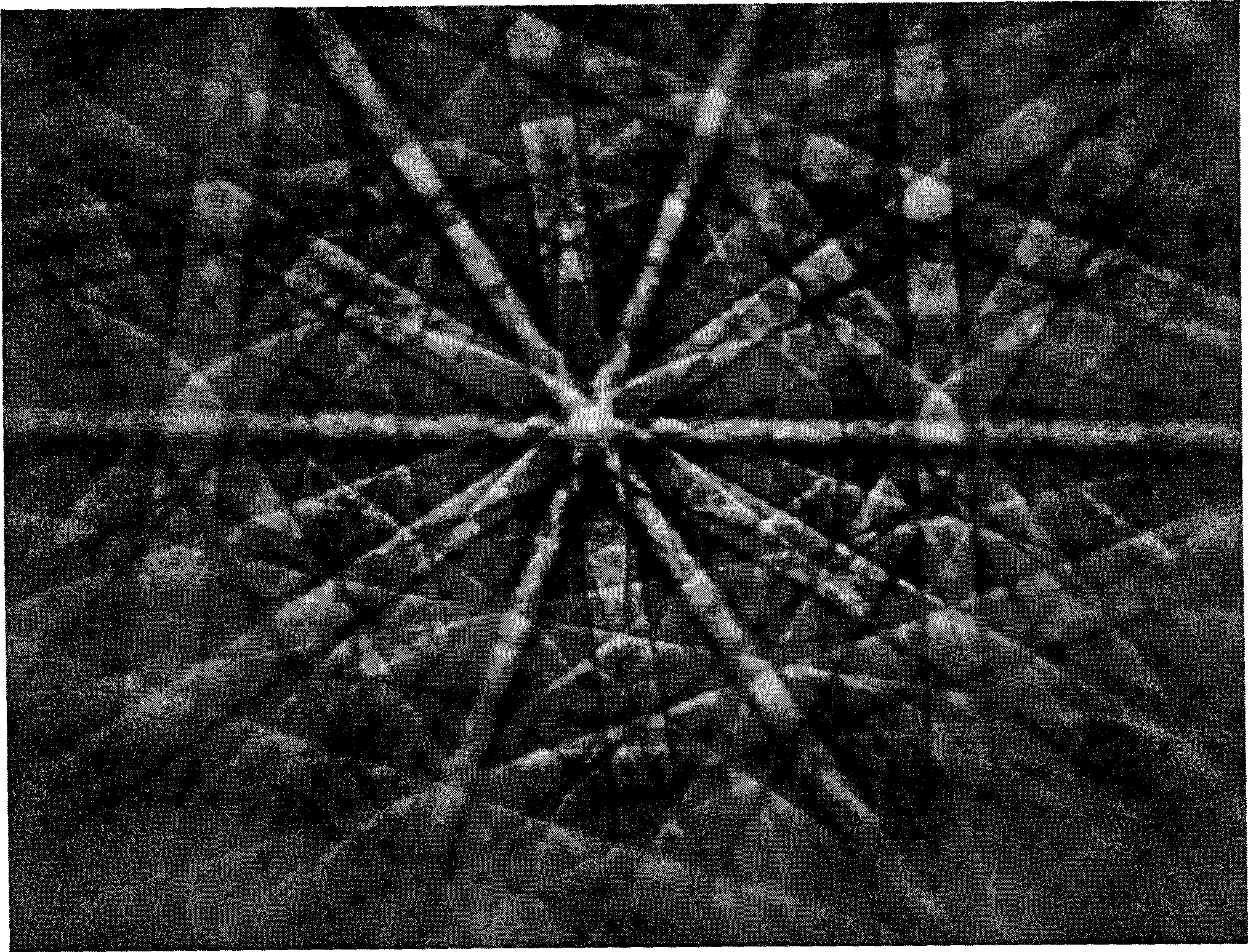

Crystal orientation and micromechanics performance measurement method of each composition crystal grain in polycrystal

ActiveCN101532970AEnsuring in situ characterizationSolve the mechanical propertiesMaterial analysis using wave/particle radiationMaterial analysis by optical meansCrystal orientationHardness

The invention discloses a crystal orientation and micromechanics performance measurement method of each composition crystal grain in polycrystal, which comprises the steps of: (1) processing the surface to be measured of a sample by using an etching method; (2) implementing microstructure observation on the surface to be measured; (3) processing the surface to be measured of the sample by using an electrolytic polishing method; (4) implementing observation on the surface to be measured of the sample and confirming whether the crystal boundary of the polycrystal sample is visible, (5) aiming at two situations that the crystal boundary is visible or invisible, scoring different grids on the surface to be measured of the sample; (6) for two samples respectively with visible crystal boundary and invisible crystal boundary, implementing nano-indentation and electron backscatter diffraction (EBSD) testing with different sequences; and (7) analyzing the effective data of measured crystal orientation, Young modulus and hardness of each crystal grain.

Owner:BAOSHAN IRON & STEEL CO LTD

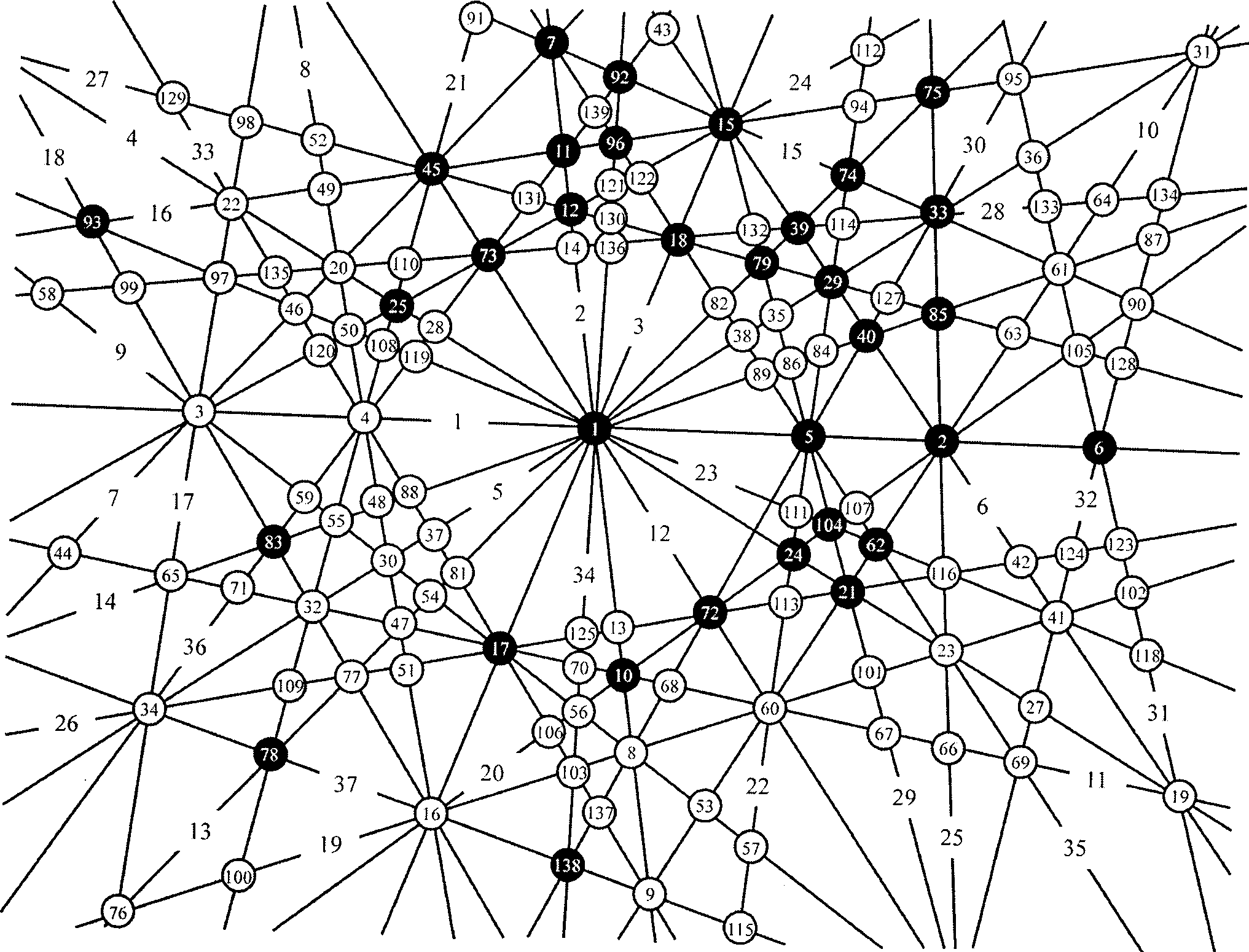

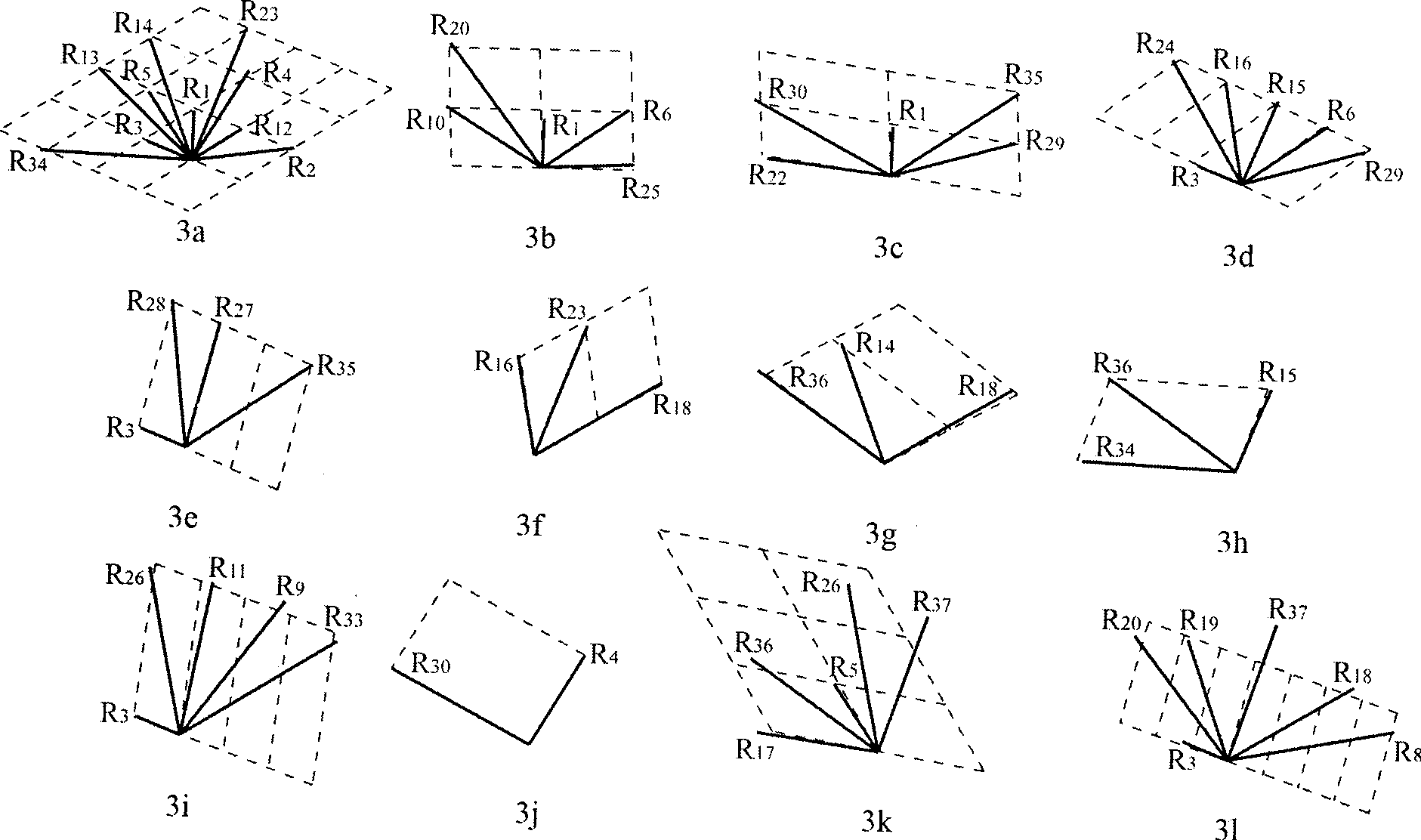

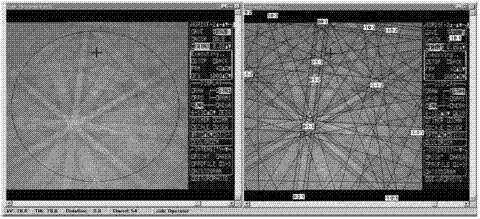

Method for determining unknown crystal Bravais lattice by electric back scattering diffraction

InactiveCN101413906ARealize analysisMaterial analysis using wave/particle radiationBravais latticeReal time analysis

The invention provides a method used for determining Bravais lattice of unknown crystal by electron backscatter diffraction. The invention is characterized in that the method comprises the steps as follows: 1) an electron backscatter diffraction spectrum is obtained and the crystal diffraction information in the diffraction spectrum is measured; 2) a two-dimensional reciprocal surface of the crystal is obtained; 3) a three-dimensional reciprocal primitive cell is reconstructed by the two-dimensional reciprocal surface; 4) the cell parameter of the three-dimensional reciprocal primitive cell s worked out according to the width of the Kikuchi band and the angle between the Kikuchi bands in the same Kikuchi electrode; 5) a reciprocal reduced cell of the crystal is solved; 6) the Bravais lattice of the crystal is determined in the reciprocal space; 7) the Bravais lattice of the crystal is determined. In the method, only a scanning electron microscope and an electron backscatter diffraction accessory are used to realize the analysis on unknown lattice of bulk crystals, and the exponential of the Kikuchi band and the Kikuchi electrode in the electron backscatter diffraction spectrum is marked at the same time. The method has no special requirement on the samples to be analyzed, is suitable for quickly analyzing bulk samples, and can be used for analyzing the microstructure morphologies and crystal structure in the buck samples.

Owner:SHANDONG UNIV OF TECH

High-strength cold rolled steel sheet having excellent formability, and plated steel sheet

InactiveUS20050247378A1Well-balanced elongationWell-balanced tensile strengthHigh intensityUltimate tensile strength

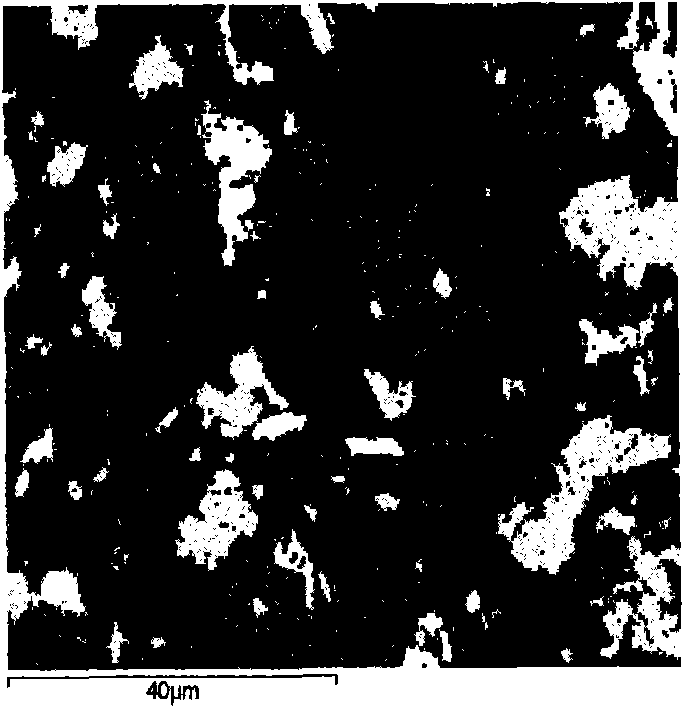

To provide a high-strength cold rolled steel sheet that has well-balanced tensile strength and elongation as well as well-balanced tensile strength and stretch-flangeability, and a plated steel sheet manufactured by plating the steel sheet. The high-strength cold rolled steel sheet contains: 0.10 to 0.28% of C, 1.0 to 2.0% of Si, 1.0 to 3.0% of Mn, and 0.03 to 0.10% of Nb in terms of % by mass, wherein the content of Al is controlled to 0.5 or less, the content of P is controlled to 0.15% or less, and the content of S is controlled to 0.02% or less, and wherein residual austenite accounts for 5 to 20%, bainitic ferrite accounts for 50% or more, and polygonal ferrite accounts for 30% or less (containing 0%), of the entire structure, and wherein a mean number of residual austenite blocks is 20 or more as determined when the random area (15 μm×15 μμm) is observed by EBSP (electron back scatter diffraction pattern).

Owner:KOBE STEEL LTD

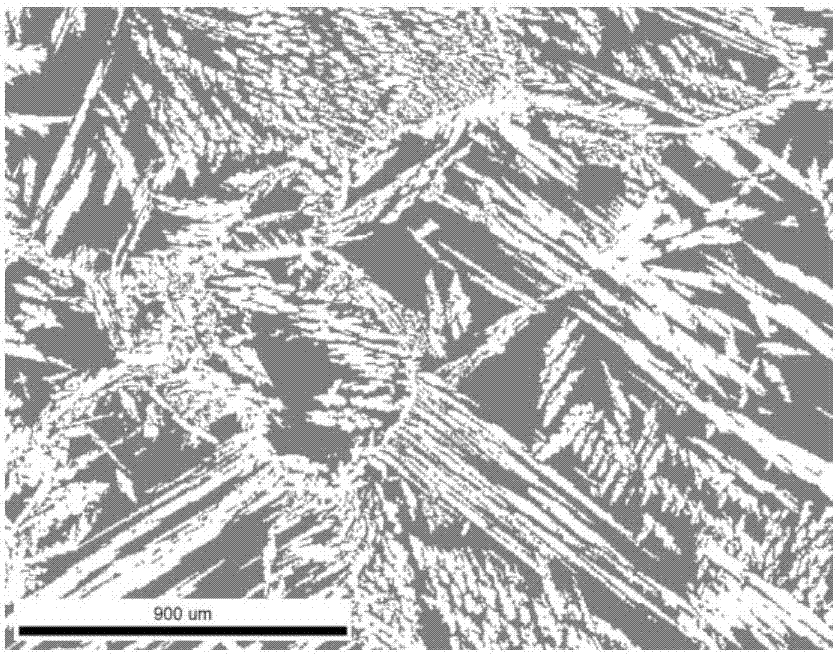

Quantitative measurement method for acicular ferrite of pipeline steel

InactiveCN101907585AAccurate measurementImprove correspondenceMaterial analysis using wave/particle radiationScanning probe techniquesScanning electron microscopeElectron microscope

The invention relates to a quantitative measurement method for acicular ferrite of pipeline steel, which utilizes an electron backscattered diffraction (EBSD) assembled on a scanning electron microscope (SEM) to carry out quantitative measurement on the acicular ferrite of the pipeline steel and comprises the following steps: grinding the cross section of a pipeline steel sample into a metallographical polished surface; etching the polished surface with natal, eliminating surface stress and showing an acicular texture; utilizing a conductive adhesive to fix the prepared sample on an EBSD sample stage; controlling the sample stage to rotate for 70 degrees by utilizing the SEM; vacuumizing an electron microscope sample chamber; when the vacuum degree reaches the electron microscope operating requirements, applying operational high pressure to acquiring an image, and finding a typical viewing field; stretching the probe of the EBSD into the sample chamber, and acquiring EBSD pattern data; and carrying out statistical treatment on the EBSD pattern data to obtain the effective crystallite dimension of the acicular ferrite texture. The invention is applied to the quantitative measurement of the acicular ferrite texture with unsharp boundaries in the pipeline steel.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Method for discriminating bainite in hot rolled TRIP steel and calculating three phase ratio of hot rolled TRIP steel

InactiveCN102353690AAccurate CalibrationEasy to calculateMaterial analysis using radiation diffractionMaterial analysis by measuring secondary emissionTRIP steelScanning electron microscope

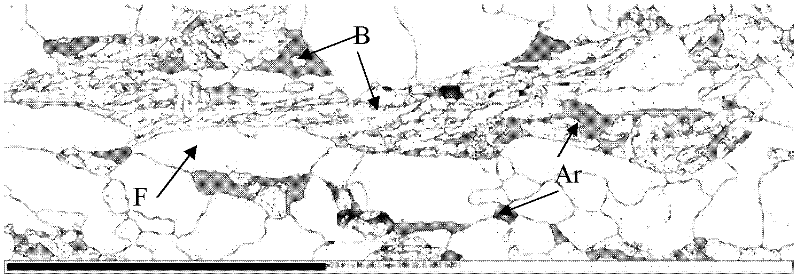

The invention relates to a method for discriminating bainite in a hot rolled TRIP steel and calculating a three phase ratio of the hot rolled TRIP steel. According to the method, an electron backscatter diffraction (EBSD) apparatus arranged on a scanning electron microscope is utilized to carry out quantitative measurement on FCC phase ( residual austenite) and BCC phase (ferrite+ bainite) of a hot rolled TRIP steel; processing is carried out on EBSD pattern data; a bainite structure is distinguished from the BCC phase by utilizing addition of a low angle grain boundary; Image Tool software is utilized to carry out statistics and calculation on three phase structure phase distinguishment graph of the hot rolled TRIP steel so as to obtain a content of a ferrite; and finally, a ration of the residual austenite to the ferrite to the bainite in the hot rolled TRIP steel is determined. Beneficial effects of the method is as follows: calibration on a phase structure can be carried out accurately and it is convenient to calculate all phase structures; and orientation information obtained by an EBSD technology can be utilized to carry out processing on various data according to own researches; therefore, researchers can accurately calibrate all phase structures in controlled rolling and controlled cooling steel with multi-phase structures without increased extra work.

Owner:UNIV OF SCI & TECH BEIJING

Dual-phase stainless steel crystalline grain structure display method

InactiveCN102721715AMaterial analysis using wave/particle radiationPreparing sample for investigationTest sampleCrystal orientation

The invention discloses a dual-phase stainless steel crystalline grain structure display method which comprises four working procedures of mechanical polishing, electrolytic polishing, scanning crystal orientation measurement with an electron back-scattering diffraction (EBSD) instrument and crystalline grain structure display. The method comprises the following steps of: processing a test piece; performing mechanical polishing and electrolytic polishing on the test piece; then performing surface scanning crystal orientation measurement on a selected region on the test sample; performing phase discrimination on ferrite phase and austenite phase; and finally performing computer data analysis on crystal orientation data acquired by EBSD, and displaying different orientations with different colors. According to the method, ferrite and austenite dual-phase crystalline grains can be clearly displayed.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

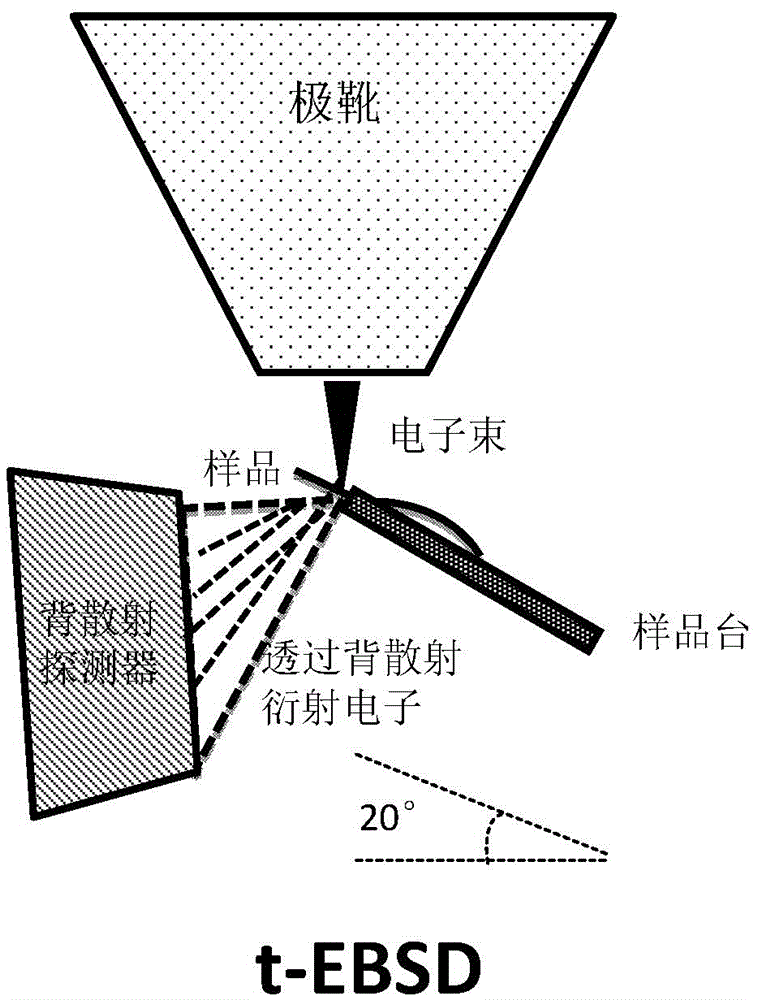

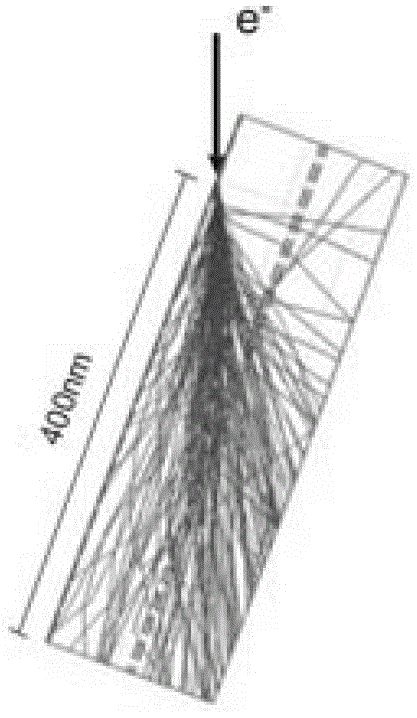

SEM transmission electron Kikuchi diffraction apparatus and analytical method

InactiveCN105651792AImprove spatial resolutionShorten working distanceNanoparticle analysisParticle size analysisCrystal twinningNanoscopic scale

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Convenient method for directionally cutting any crystal face of crystal

ActiveCN101733848AImprove accuracySimple and fast operationStone-like material working toolsCrystal systemCrystal orientation

The invention discloses a convenient method for directionally cutting any crystal face of crystal, belonging to the technical field of crystal material cutting processing. The method is implemented by cutting out a plane arbitrarily to be as the reference plane, then determining longitudinal, transverse and normal indexes of the reference plane by using electron backscattered diffraction (EBSD) technology, then calculating the needed included angle between the reference plane and any crystal face, and finally regulating the crystal cutting direction to obtain the crystal face satisfying requirements by once cutting processing. With the EBSD technology adopted, the EBSD instrument and the traditional crystal material cutting device are combined, thus the crystal of any crystal system can be cut out any crystal face in directional way, namely, the needed crystal face is a high index diffraction face or an extinction face, the invention is especially suitable to the crystal with unknown reference plane orientation and larger crystal orientation deviation, and the bearing accuracy is high, the operation is simple and convenient and the crystal consumption is reduced.

Owner:IMDETEK

Method for rapidly presenting specific crystal plane distribution characteristic of polycrystalline material

The invention provides a method for rapidly presenting a specific crystal plane distribution characteristic of a polycrystalline material. The method has high efficiency, cost is low and operation issimple. A plurality of specific crystal plane orientation characteristics in the polycrystalline material can be accurately presented. The method mainly comprises the following steps of EBSD sample preparation, sample surface information collection by using an electron backscattering diffraction analysis technology, data processing, specific crystal plane presentation and the like. The method canbe used for research of a grain size, distribution and an orientation relationship under the specific crystal plane characteristic, such as the research of an orientation genetic phenomenon of an alloy material in heat treatment and a hot working process. Secondly, the method can be used to explore the relationship between oxidation resistance and corrosion resistance performance of the material and the specific crystal plane distribution characteristic of the material surface. Besides, the method can be used to quantitatively study a combined effect of different crystal planes in the materialand a variety of specific crystal planes on the material performance so as to guide to make reasonable heat treatment and a processing technology in actual production, and fully exert or improve service performance of the material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Semiconductor device

InactiveUS6956235B2Improve directionIncreases critical radiusTransistorSolid-state devicesLattice planeImpurity

The orientation of a crystalline semiconductor film obtained by crystallizing an amorphous semiconductor film is improved and a TFT formed from this crystalline semiconductor film is provided. In a semiconductor device whose TFT is formed from a semiconductor layer mainly containing silicon, the semiconductor layer has a channel formation region and an impurity region doped with an impurity of one type of conductivity. 20% or more of the channel formation region is the {101} lattice plane that forms an angle of equal to or less than 10 degree with respect to the surface of the crystalline semiconductor film, the plane being detected by an electron backscatter diffraction pattern method, 3% or less of the channel formation region is the {001} lattice plane that forms an angle of equal to or less than 10 degree with respect to the surface of the crystalline semiconductor film, 5% or less of the channel formation region is the {111} lattice plane that forms an angle of equal to or less than 10 degree with respect to the surface of the crystalline semiconductor film.

Owner:SEMICON ENERGY LAB CO LTD

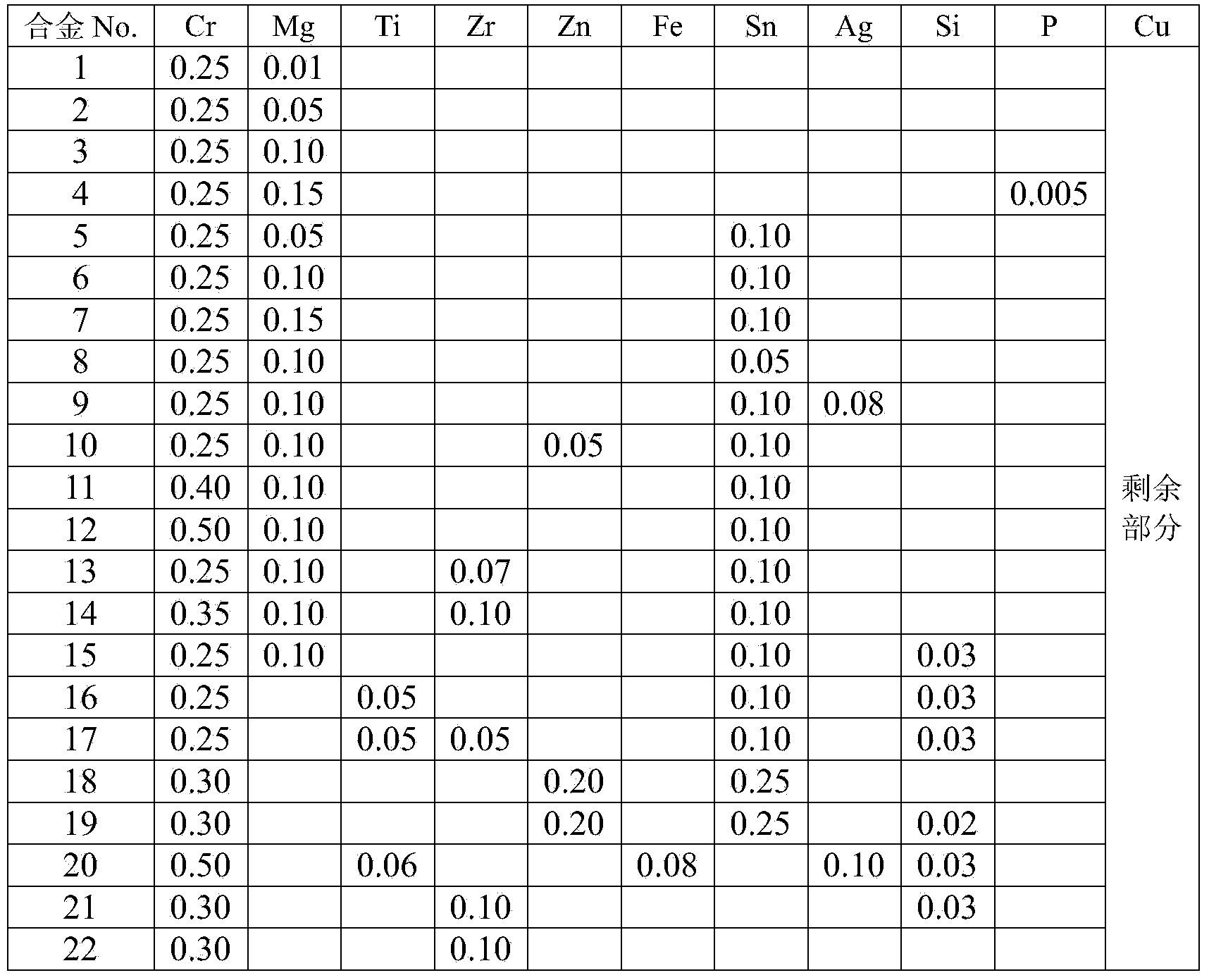

Copper alloy material and manufacturing method thereof

ActiveCN103534370AIncrease stressImprove featuresSingle bars/rods/wires/strips conductorsConductive materialCrystal orientationStress relaxation

Provided is a copper alloy material having excellent bendability, proof strength, conductivity, and stress relaxation resistance, and that is suitable for automotive components and the surrounding infrastructure, particularly in electric vehicles and hybrid electric vehicles, as well as for the lead frames, connectors, terminals, etc. of solar power generation systems and the like. The copper alloy material contains 0.1-0.8 mass% of Cr and 0.01-0.5 mass% in total of at least one type selected from the group consisting of additive element group 1 and additive element group 2, and the remainder comprises copper and inevitable impurities. In the crystal orientation analysis of a rolled surface carried out using electron backscatter diffraction measurement, the area proportion of crystal grains having an orientation that is offset at 15 DEG or less from the cube orientation {001}<100>; is 3% or above, and the proportion of S3 coincidence grain boundaries in the crystal grain boundaries is 20% or above.The additive element group 1 is 0.01-0.5 mass% in total of at least one type selected from the group consisting of Mg, Ti, and Zr; and additive element group 2 is 0.005-0.5 mass% in total of at least one type selected from the group consisting of Zn, Fe, Sn, Ag, Si, and P.

Owner:FURUKAWA ELECTRIC CO LTD

Method for detecting orientation of large-sized crystal grains

ActiveCN102103093ARapid Batch DetectionMaterial analysis using radiation diffractionMetallic materialsPolycrystalline material

The invention discloses a method for detecting orientation of large-sized crystal grains. The method mainly comprises the following steps of: establishing and storing a database; combining the colors of the crystal grains and crystallographic data by an electron backscatter diffraction pattern (EBSP) technology; establishing the correspondence between the colors and the crystallographic data; recording corrosion conditions of different metal materials and differently-oriented crystal grains; quickly retrieving the database to search a corrosion state after a large number of samples to be detected are obtained; corroding according to the same corrosion mode; and recording the colors of the crystal grains corresponding to the orientation, which accords with the conditions, of the database under the conditions of the same light source and the same viewing angle to finally realize quick and batch orientation detection of the crystal grains. In the method, the specific color of the differently-oriented crystal grains is obtained through observation under fixed conditions by quantitatively calculating the surface energy of the crystal grain orientation and proper corrosion time, and quick and batch orientation detection of a large-sized polycrystalline material is realized corresponding to the scanning of the database so as to determine the performance of the material.

Owner:ANGANG STEEL CO LTD

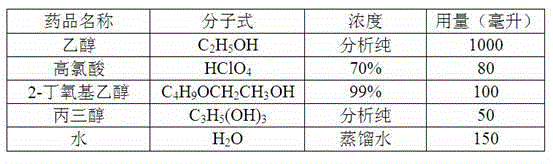

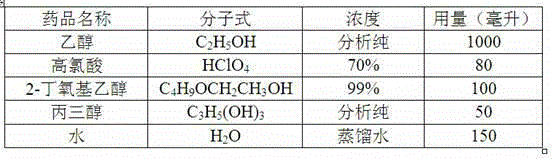

Preparation method of magnesium-alloy electron backscatter diffraction sample (EBSD) and special electrolyte thereof

InactiveCN102383176AImprove clarityLow costElectrolysis componentsPreparing sample for investigationElectrolysisAqueous alcohol

The invention relates to a preparation method of a magnesium-alloy electron backscatter diffraction sample (EBSD) and special electrolyte thereof, which belongs to the field of magnesium-alloy electrolysis process and is mainly applied in preparing high-quality EBSD samples. The method comprises the following steps of: (1) preparation of the electrolyte: putting perchloric acid and alcohol into a beaker according to the volume ratio of 1:9, and stirring till the minimum volume of the electrolyte can meet the condition that an electrolytic sample can be wholly immersed; (2) sample coating: covering the parts of the sample without need of electrolysis by using coating liquid, and avoiding from covering the connecting part of the sample and an anode; (3) electrolysis: pouring liquid nitrogen into the beaker containing the electrolyte, and when the temperature of the electrolyte is between -20 DEG C and -50 DEG C, carrying out electrolysis; and (4) sample cleaning. By adoption of the invention, the problems such as high cost and the like in the prior art can be solved, the electrolyte can replace the commercial electrolyte of magnesium alloy with expensive price, the qualified magnesium-alloy EBSD sample is prepared, the cost is low and the implementation is easy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

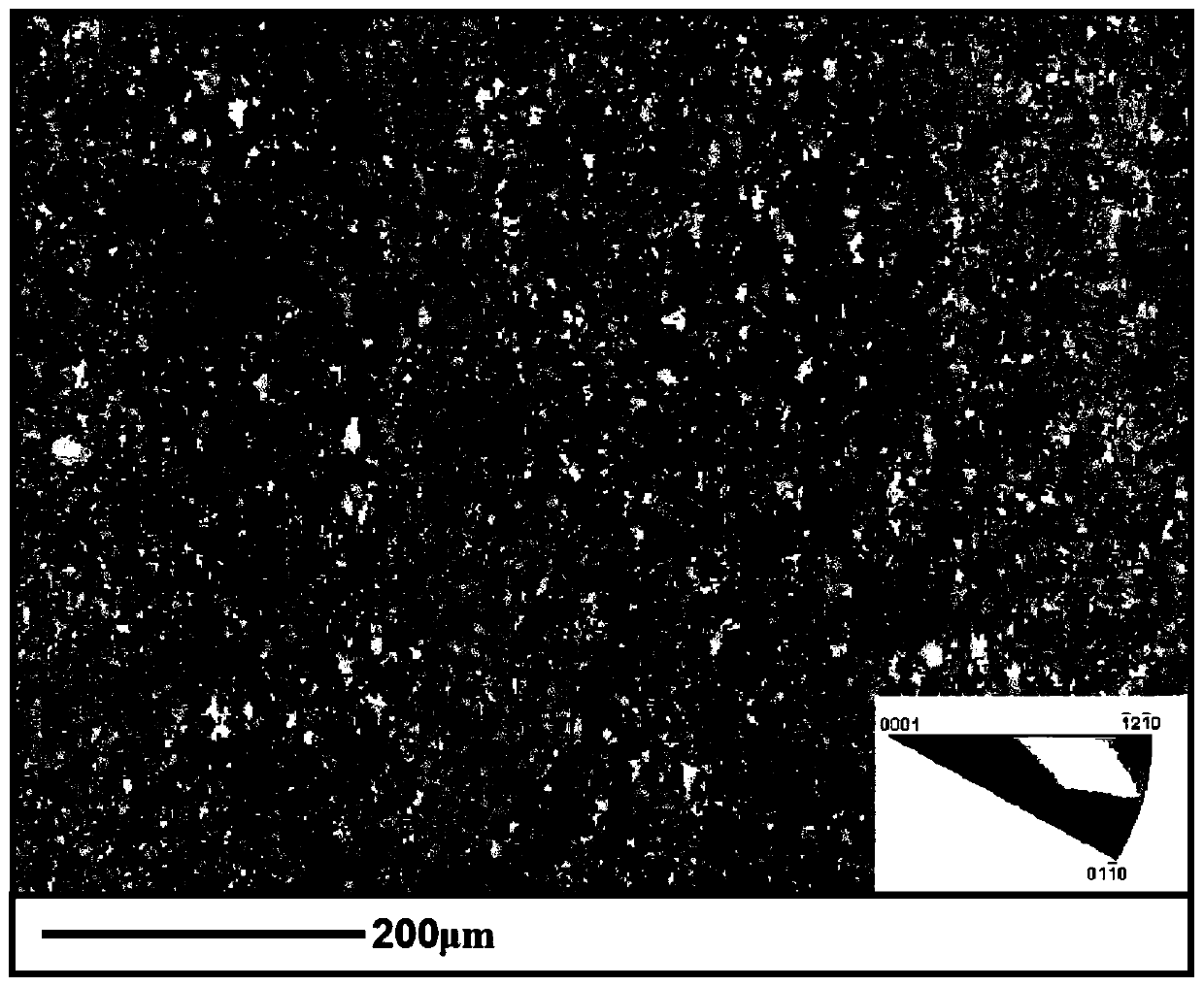

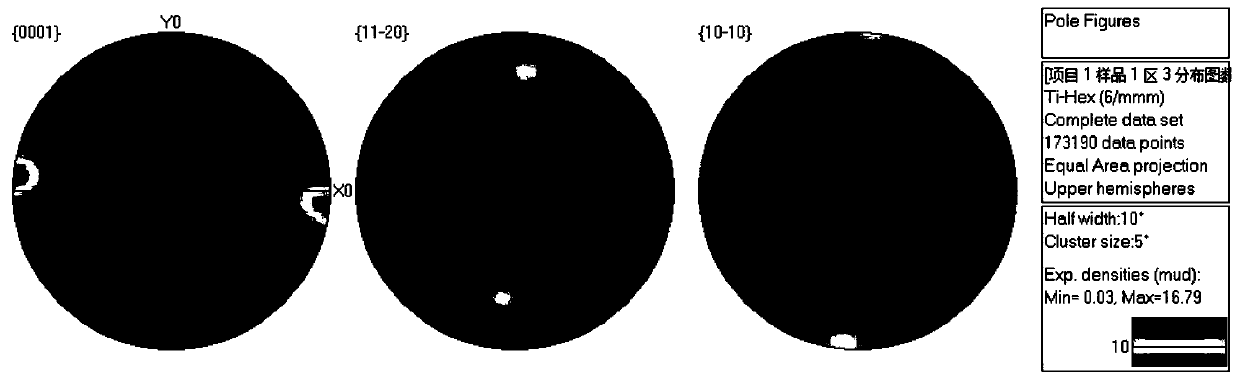

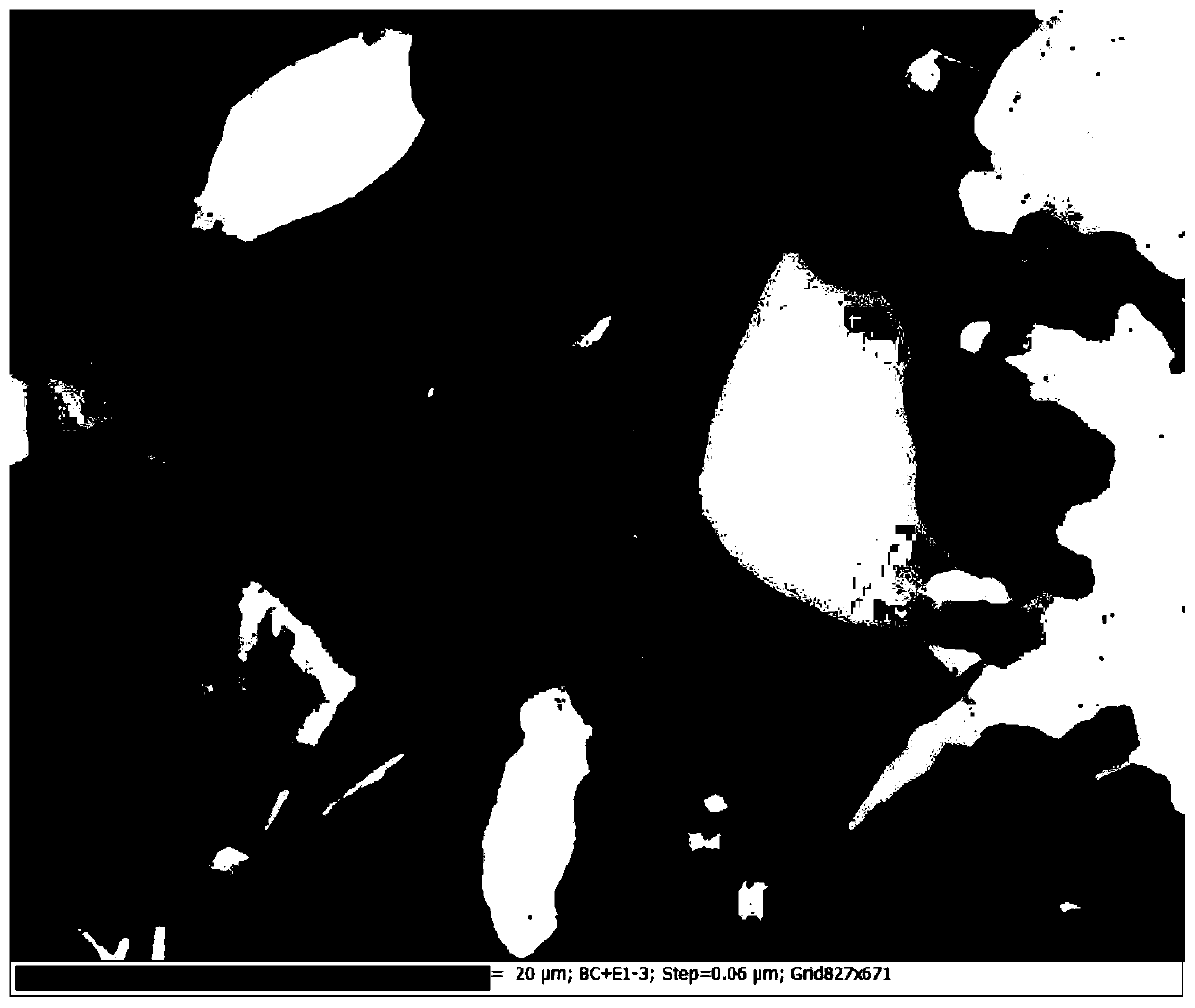

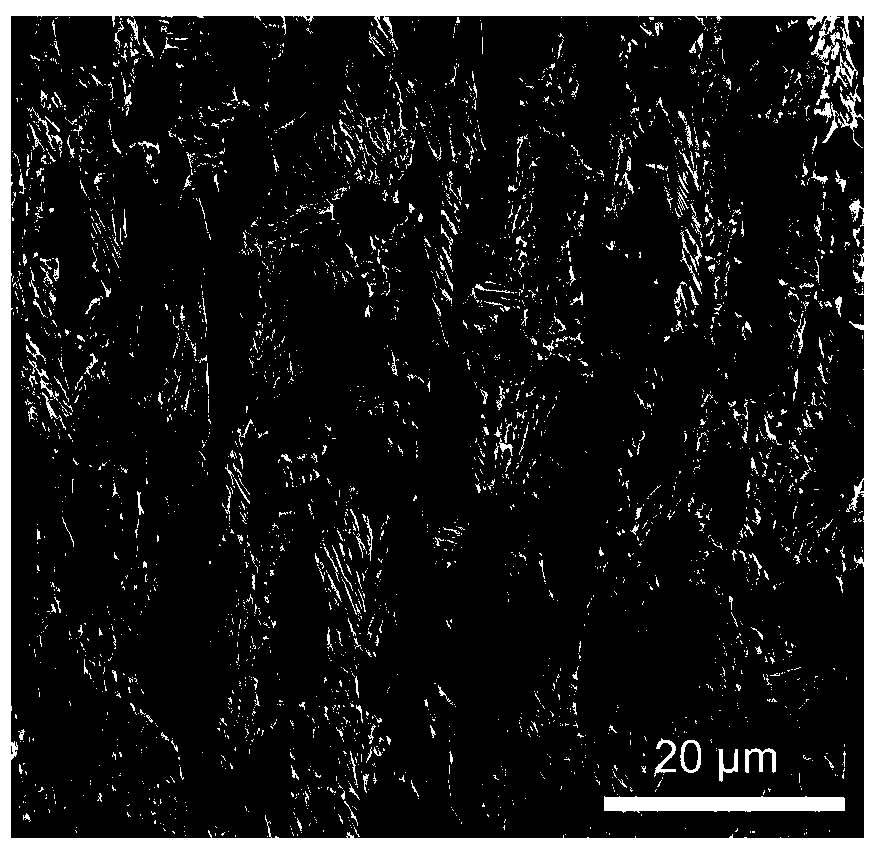

Method for preparation of double-phase zirconium alloy EBSD sample by electrolytic polishing

InactiveCN106556532AHigh surface finishExtensive sources of raw materialsPreparing sample for investigationMaterial analysis using radiation diffractionElectrolysisDouble phase

Owner:CHONGQING UNIV OF TECH

Semiconductor Device and Method of Manufacturing the Same

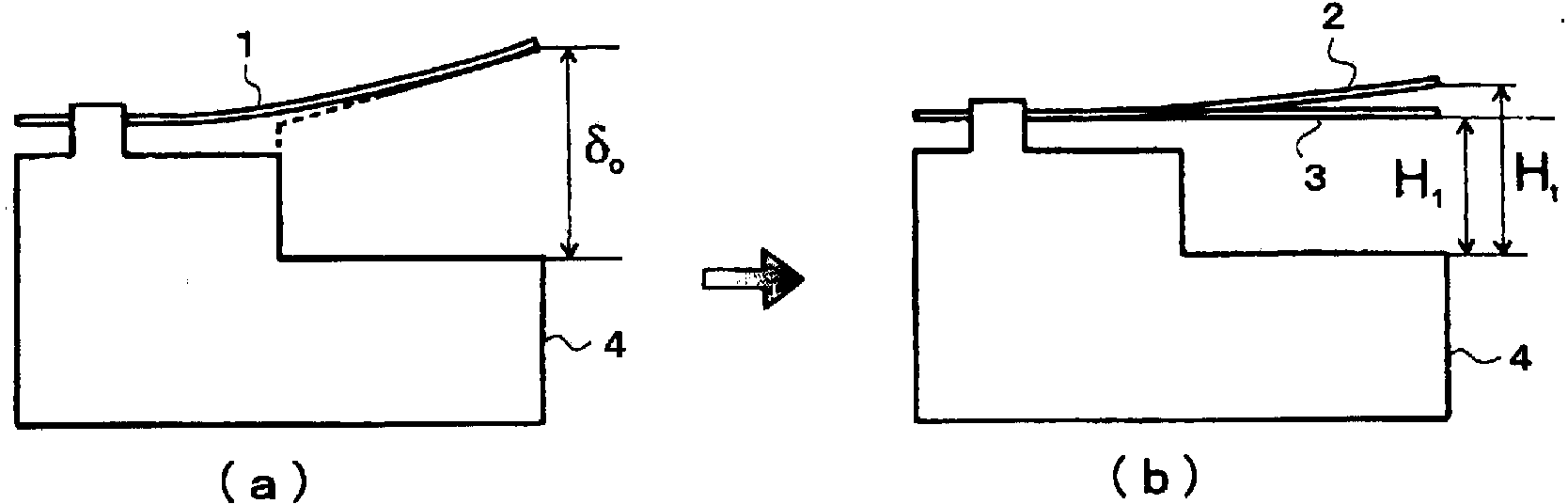

InactiveUS20060246638A1Raise the ratioIncrease critical radiusTransistorSolid-state devicesInfraredElectric discharge

The orientation ratio of a crystalline semiconductor film obtained by crystallizing an amorphous semiconductor film through heat treatment and irradiation of intense light such as laser light, ultraviolet rays, or infrared rays is enhanced, and a semiconductor device whose active region is formed from the crystalline semiconductor film and a method of manufacturing the semiconductor device are provided. In a semiconductor film containing silicon and germanium as its ingredient and having a crystal structure, the {101} plane reaches 30% or more of all the lattice planes detected by Electron backscatter diffraction. This semiconductor film is obtained by forming an amorphous semiconductor film containing silicon and germanium as its ingredient through plasma CVD in which hydride, fluoride, or chloride gas of a silicon atom is used, the repetition frequency is set to 10 kHz or less, and the duty ratio is set to 50% or less for intermittent electric discharge or pulsed electric discharge, and introducing an element for promoting crystallization of the amorphous semiconductor film to the surface thereof to crystallize the amorphous semiconductor film while utilizing the introduced element.

Owner:SEMICON ENERGY LAB CO LTD

Method of electron beam diffraction analysis

ActiveUS20150369760A1SpeedConvenient and accurateMaterial analysis using wave/particle radiationElectric discharge tubesData setAnalysis method

A method is provided for analysing electron backscatter diffraction data generated from a sample material. An image data set representative of an image of electron backscatter diffraction bands is obtained from the sample material. A set of estimated first diffraction parameters is then generated, these defining individual electron backscatter diffraction bands in the image data set. A candidate phase is then selected together with a respective orientation for the material, based upon the generated set of estimated parameters thereby identifying diffraction bands in the image data set. Second diffraction parameters of the identified diffraction bands are simulated for the candidate phase according to the respective orientation. These second diffraction parameters are then adjusted for the identified simulated bands so as to fit the simulated bands to the bands in the image data. A fitted orientation for the candidate phase is then calculated together with a corresponding fitting parameter defining the quality of fit.

Owner:OXFORD INSTR NANOTECH TOOLS

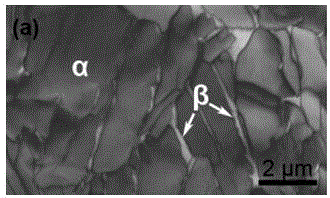

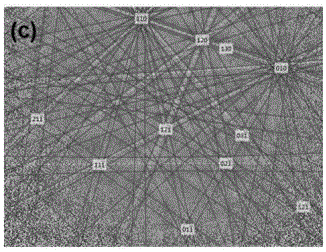

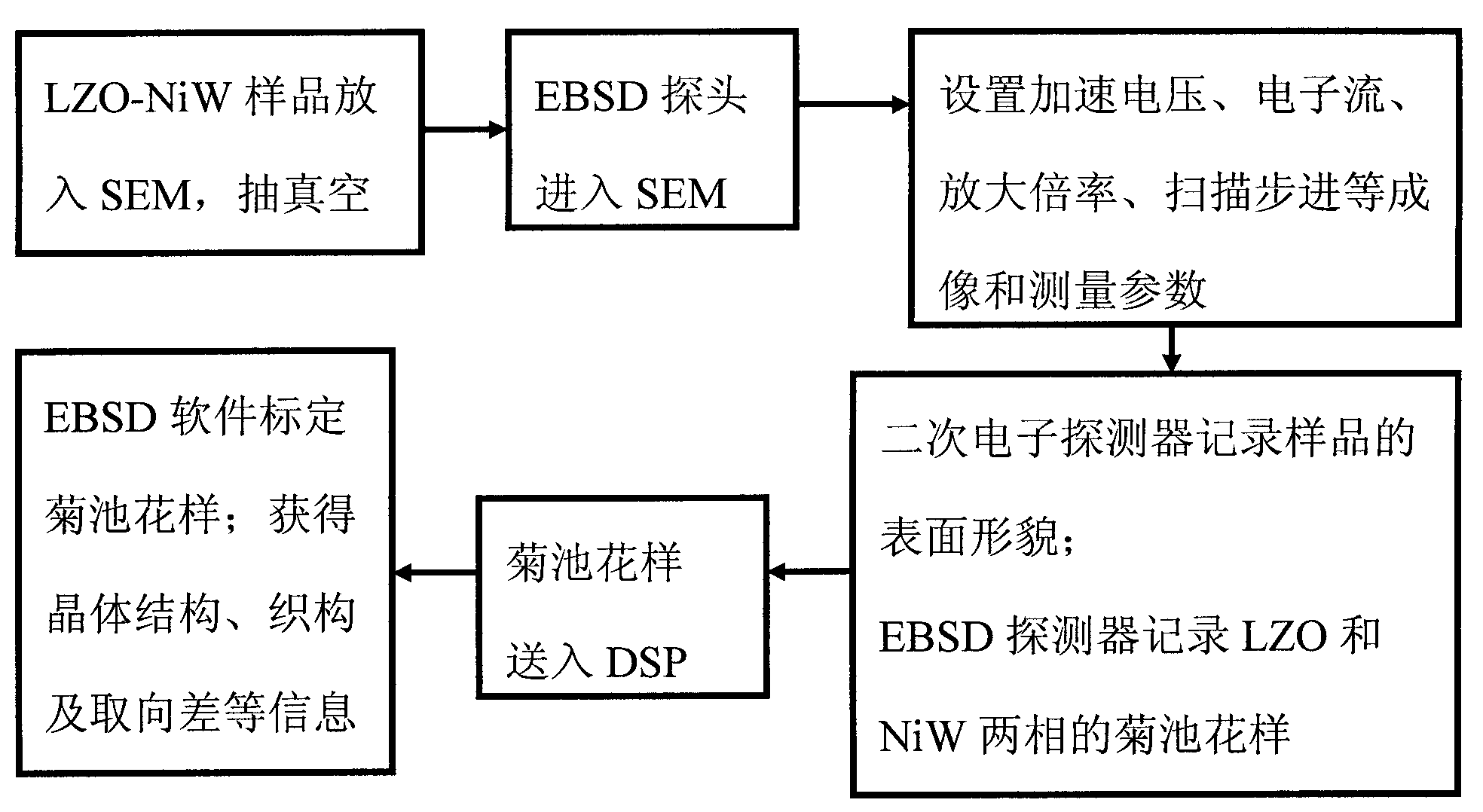

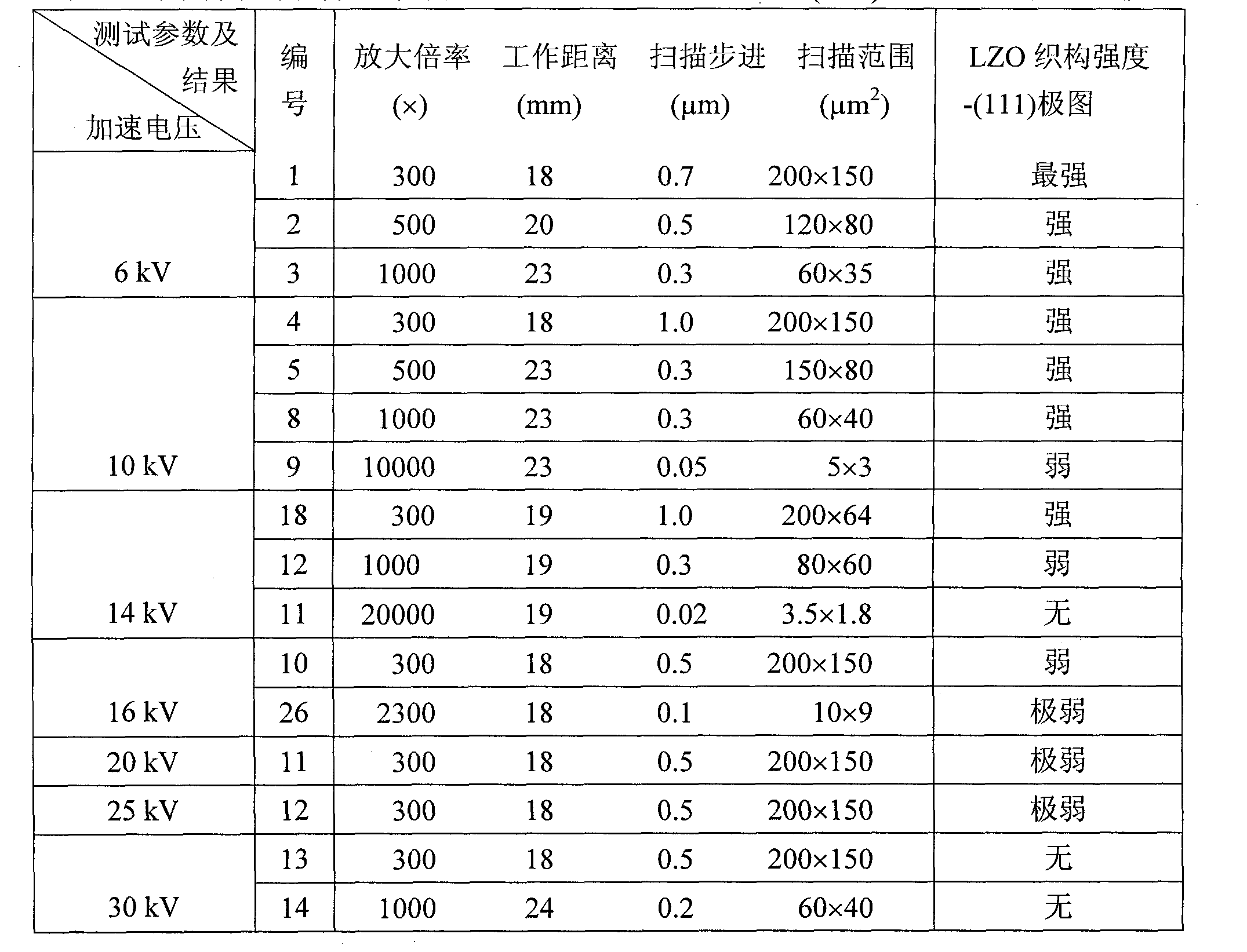

Electron backscattered diffraction (EBSD) test method of crystal orientation matching relationship of nanometer zirconic acid lanthanum epitaxial layer and Ni-W substrate

InactiveCN101813645AIncrease collection rateMaterial analysis using wave/particle radiationIn planeDouble phase

The invention discloses a test method of crystal orientation matching relationship of nanometer zirconic acid lanthanum epitaxial layer and Ni-W substrate, belonging to the technical field of superconducting thin film performance tests. The test method is characterized in that secondary electronic amplification factor is adjusted and stepping distance is scanned in a system of thermal field emission scanning electron microscope SEM-electron backscattered diffractometer (EBSD), so that 5nA incidence election current can realize that the zirconic acid lanthanum epitaxial layer and Ni-W substrate texture are simultaneously displayed in one polar diagram under the condition that the lowest accelerating voltage is 6kV; one Kikuchi pattern comprises a zirconic acid lanthanum epitaxial layer and Ni-W substrate double phases; on the basis, commercial EBSD analysis software is adopted to measure the crystal orientation matching relationship of the zirconic acid lanthanum epitaxial layer and the Ni-W substrate in the growth directions of in-plane and epitaxial (c-axis). The method is visual and simple, does not need to perform surface pretreatment on the zirconic acid lanthanum and is suitable for other epitaxial material systems.

Owner:BEIJING UNIV OF TECH

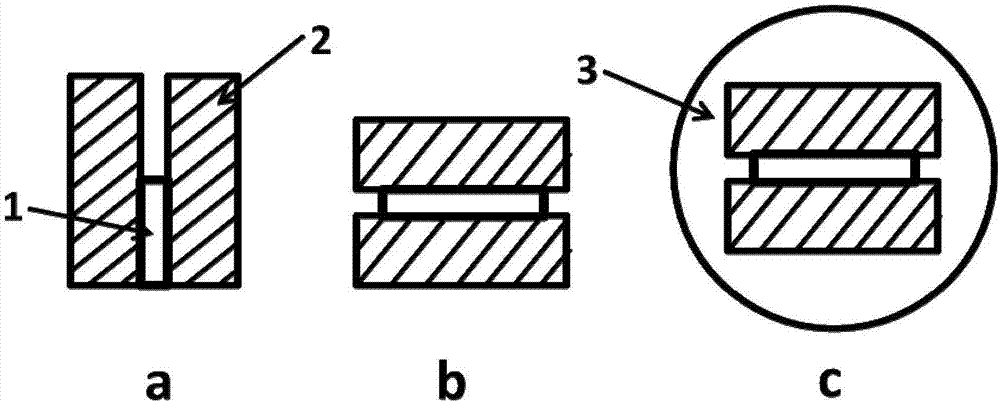

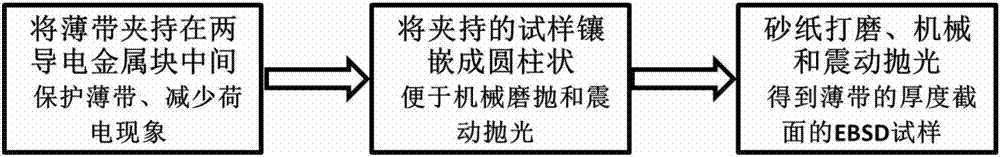

Preparation method of electron backscatter diffraction sample with alloy strip thickness section

InactiveCN107063797AImprove conductivityImprove surface qualityPreparing sample for investigationThin metalSurface stress

The invention discloses a preparation method of an electron backscatter diffraction sample with an alloy strip thickness section. The preparation method comprises the following steps: clamping an extremely-thin metal strip obtained by quenching and melt-spinning between two rectangular conductive metal blocks with hardness being approximate to the hardness of a strip alloy in order to fix the two rectangular conductive metal blocks and the thin strip together; vertically placing an alloy thin strip which is already parallel to the conductive metal blocks in a hot mounting press with a thickness section facing downwards horizontally; then, mounting a sample in conductive mounting powder by a hot mounting method, performing coarse grinding on metallographic abrasive paper, and integrally mounting into a cylinder with a certain diameter and a certain height by the hot mounting method; and then, removing a surface stress layer by performing mechanical grinding polishing and vibration polishing to prepare the electron backscatter diffraction sample which has superior surface quality and is provided with a thin strip with a thickness section of dozens of micrometers. The prepared sample has the characteristics of high conductive performance and high calibration rate in electron backscatter diffraction.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

High-strength steel sheet having excellent processability and low-temperature toughness, and method for producing same

InactiveCN105579605AHigh elongationEasy to processHot-dipping/immersion processesFurnace typesChemical compositionHigh intensity

A high-strength steel sheet according to the present invention satisfies a predetermined chemical composition, wherein the metal structure of the steel sheet is composed of a polygonal ferrite, a bainite formed in a high temperature range, a bainite formed in a low temperature range and a retained austenite each having a predetermined area ratio, and the distribution of specific crystal grains as determined by an electron backscatter diffraction method employing an average IQ value for each of the crystal grains satisfies formulae (1) and (2) shown below. According to the present invention, it becomes possible to provide a high-strength steel sheet that can exhibit excellent processability and low-temperature toughness even at tensile strength of 590 MPa or more. (1) (IQave-IQmin) / (IQmax-IQmin) >= 0.40; (2) [sigma]IQ / (IQmax-IQmin) <= 0.25

Owner:KOBE STEEL LTD

Analysis and detection method of two-phase proportion in as-cast structure of duplex stainless steel

InactiveCN107976459AClear boundariesEasy to identifyPreparing sample for investigationMaterial analysis by measuring secondary emissionElectrolysisAlcohol

The invention relates to an analysis and detection method of a two-phase proportion in an as-cast structure of a duplex stainless steel, and belongs to the field of the analysis of metal materials. The analysis and detection method is particularly applied to the accurate measurement of contents of ferrite and austenite phases in the as-cast structure of the duplex stainless steel. According to theanalysis and detection method, the electrolytic polishing is carried out for 20s to 30s in a perchloric acid alcohol solution with a volume fraction of 10 to 20 percent to remove a stress layer, wherein a voltage is 10V to 20V and an electric current is 1A to 2A. The two-phase distribution of a well prepared to-be-detected-and-analyzed product is determined according to a special kikuchi patternof each phase, which is possessed by an EBSD (Electron Backscattered Diffraction) analysis system; the determination is not limited to artificial corrosion dyeing, which is difficultly mastered, any more; the difficult differentiation resulted as a contrast between the phases is not obvious enough, which is caused due to a difference of a corrosion effect, is avoided; the quantitative analysis iscarried out on the content of each phase, and the accuracy is higher.

Owner:UNIV OF SCI & TECH BEIJING

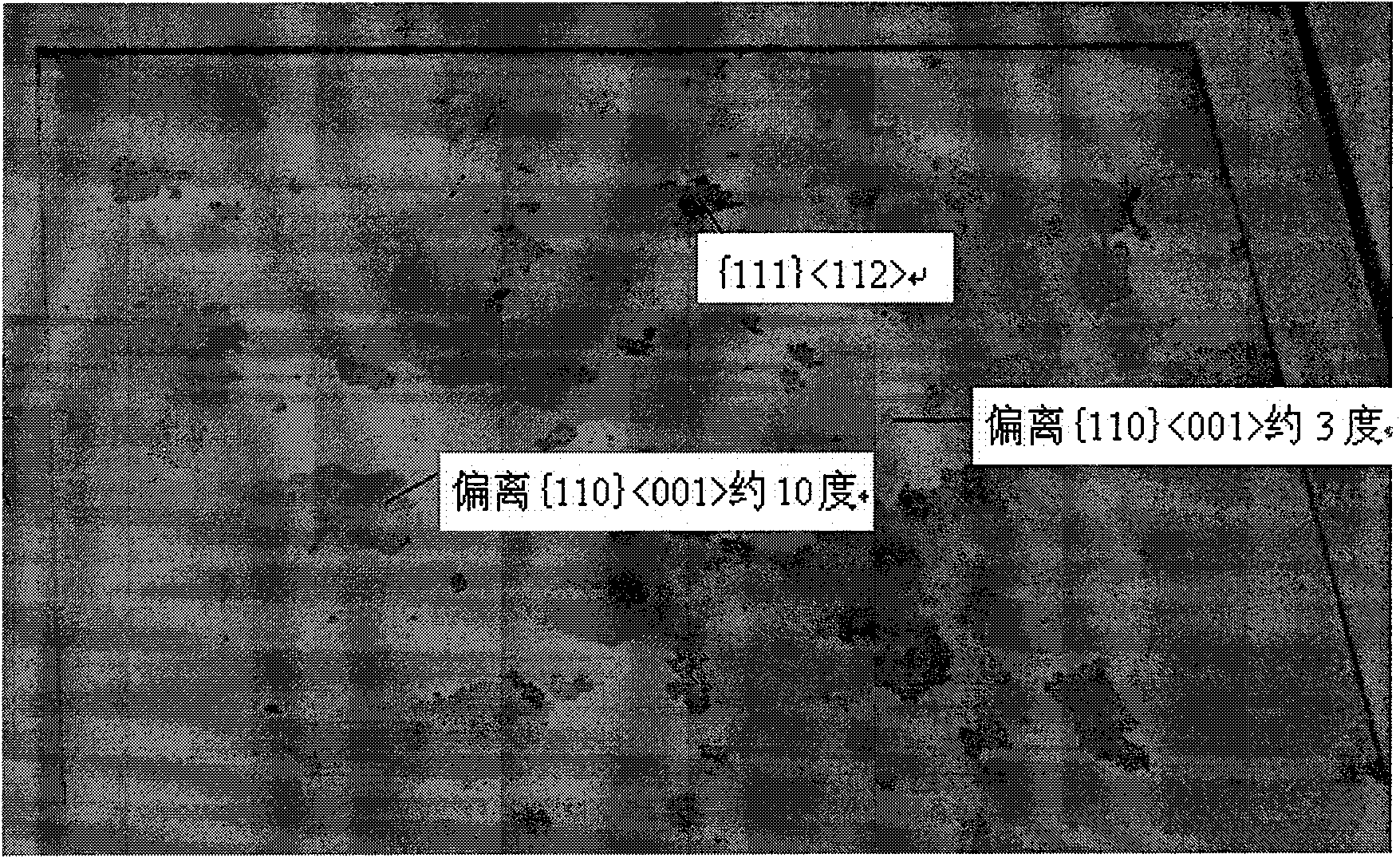

Analysis method for measuring large-grained silicon steel texture

InactiveCN104155323AMaterial analysis using wave/particle radiationImage analysisAnalysis methodSilicon

The invention discloses an analysis method for measuring a large-grained silicon steel texture. The analysis method comprises the following steps: I, preparing a to-be-tested electron backscatter diffraction sample from a silicon steel plate; II, cutting a to-be-tested area of the to-be-tested electron backscatter diffraction sample, and distinguishing each crystalline grain in the to-be-tested area according to a crystal boundary; III, calculating the area Am of each crystalline grain and the total area A of the total to-be-tested areas of the sample; IV, carrying out no-texturing treatment, and calculating a ratio A0 of each crystalline grain in the to-be-tested area; V, testing an orientation (hkl) of each crystalline grain in an electron backscatter diffraction way and acquiring an absolute value; VI, dividing Am by A and then by A0 to obtain a relative pole density P(hkl); and VII, marking the relative pole density P(HKL) on a position on a corresponding crystal face in an inverse pole figure. The analysis method has the characteristic that a correct corresponding relationship between a test result and the performance of a material can be established and can be widely applied to the field of the testing of large-grained materials.

Owner:武汉钢铁有限公司

Method for rapidly preparing Ni-based superalloy electron backscatter diffraction sample

InactiveCN102809500ASimple sample preparationSimple methodPreparing sample for investigationWire cuttingSuperalloy

The invention discloses a method for rapidly preparing a Ni-based superalloy electron backscatter diffraction (EBSD) sample. The method is characterized in that the electrolytic polishing is not required; and the sample is rapidly prepared by a chemical etching method. The method comprises the following steps of: cutting the sample by a wire cutting machine, pre-grinding the sample by using abrasive paper for metallograph, performing mechanical polishing, and etching the sample by using a chemical etchant. Kikuchi patterns of the Ni-based superalloy EBSD sample prepared by the method are clear. By the method, the disadvantages that a commonly used method for preparing an EBSD sample is complicated in electrolytic polishing sample preparation and has an unstable effect are overcome.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Copper alloy sheet material and method of producing the same

InactiveUS20120267013A1High mechanical strengthConductive materialMetal/alloy conductorsCrystal orientationArea ratio

A copper alloy sheet material, having an R value of 1 or greater, which is defined by:R=([BR]+[RDW]+[W]) / ([C]+[S]+[B])wherein [BR], [RDW], [W], [C], [S], and [B] represent an area ratio of crystal texture orientation component of BR orientation {3 6 2}<8 5 3>, RD-rotated-cube orientation {0 1 2}<1 0 0>, cube orientation {1 0 0}<0 0 1>, copper orientation {1 2 1}<1 1 1>, S-orientation {2 3 1}<3 4 6>, and brass orientation {1 1 0}<1 1 2>, respectively, in crystal orientation analysis in an EBSD (electron back scatter diffraction) analysis, and having a proof stress of 500 MPa or greater, and an electrical conductivity of 30%IACS or higher; and a production method of the same.

Owner:FURUKAWA ELECTRIC CO LTD

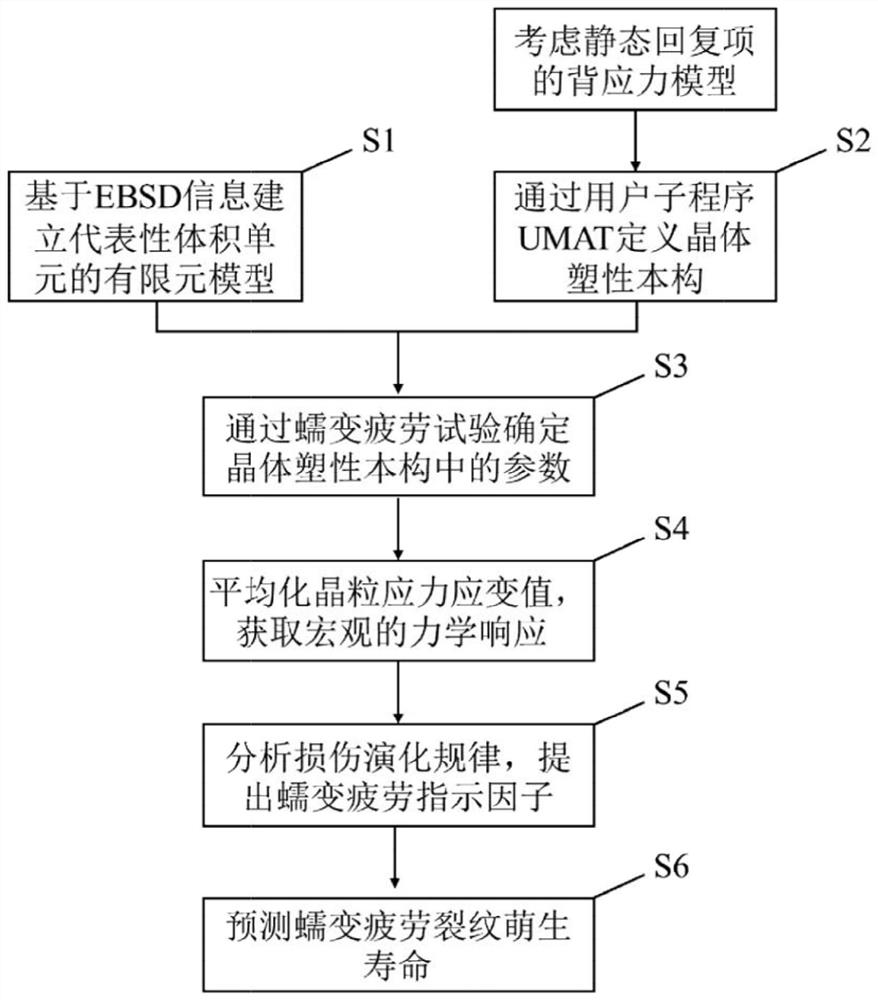

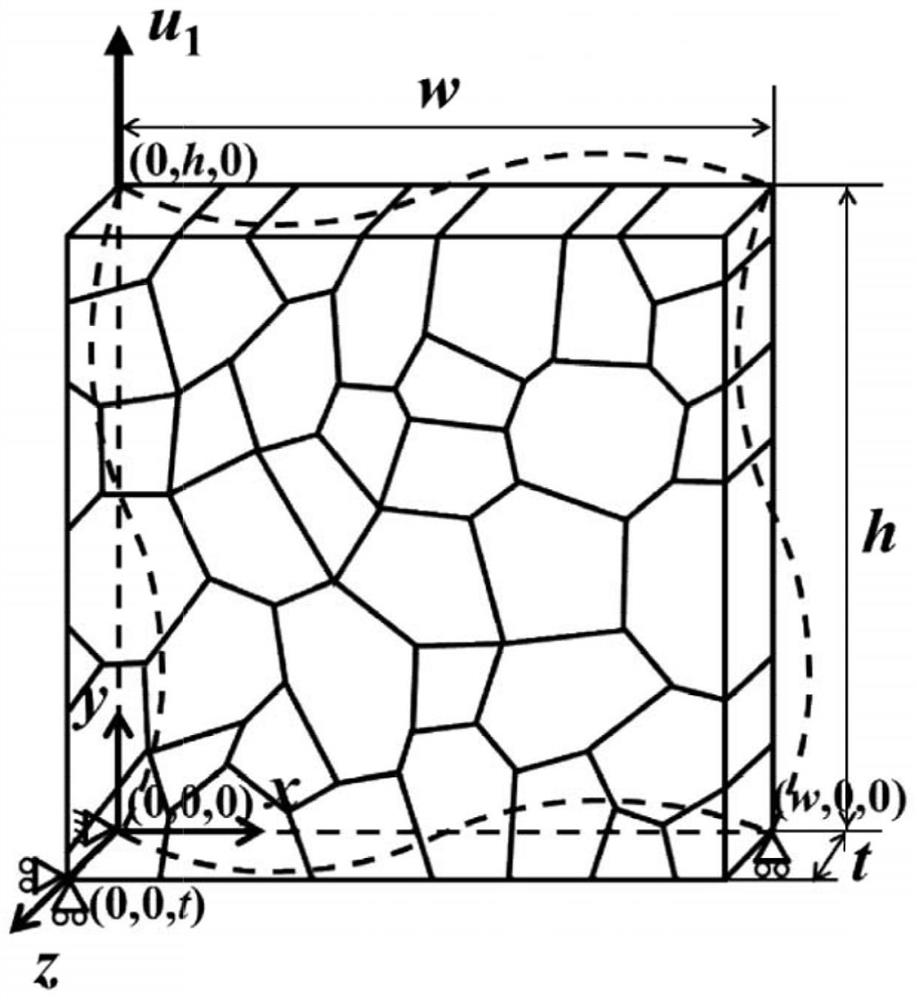

Creep fatigue life prediction method based on crystal plasticity

PendingCN112364535APredicted germination positionDesign optimisation/simulationConstraint-based CADCrystal plasticityCloud atlas

The invention provides a creep fatigue life prediction method based on a crystal plasticity theory. The method comprises the following steps: establishing a representative unit model of ABAQUS based on an electron back scattering diffraction technology; correcting the back stress model and writing the back stress model into a subprogram UMAT to obtain a creep fatigue hysteresis loop; fitting a creep fatigue hysteresis loop through a test parameter method to obtain material parameters; calculating a stress-strain value of each integral point and averaging the stress-strain values to obtain a creep fatigue hysteresis loop and a post-processing cloud atlas; extracting maximum plastic slippage and energy dissipation from the creep fatigue hysteresis loop and the post-processing cloud atlas, analyzing the change rule of the maximum plastic slippage and energy dissipation along with circulation cycles, and providing creep and fatigue indication factors; and predicting the creep fatigue crackinitiation life according to the indication factor. According to the creep fatigue life prediction method, plastic slippage and energy dissipation are used as fatigue and creep indication factors, the creep fatigue damage evolution rule can be better reflected, the crack initiation position can be accurately predicted, and the method has the advantages of being visual, high in applicability and high in accuracy.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing metal material EBSD (electron backscatter diffraction) sample on basis of ultra-low temperature weak current control

InactiveCN109900727AConsistent electropolishing parametersNo debugging requiredMaterial analysis using wave/particle radiationEconomic benefitsAlloy

The present invention provides a general electrolytic polishing method for preparing a metal material EBSD (electron backscatter diffraction) sample. The invention aims to improve the quality, efficiency and stability of the preparation of alloy EBSD samples. According to the method, an electrolytic sample is pre-treated at an earlier stage; an electrolytic polishing liquid containing only perchloric acid and absolute ethyl alcohol is prepared; and with a stainless steel sheet adopted as a cathode, the sample requiring electrolytic polishing adopted as an anode, and electrolytic polishing is performed under low temperature and weak current. The method has the advantages of simple equipment, high practicability and simple operation, high test repeatability, good sample preparation effect, great economic benefits and high popularization value. With the method adopted, the debugging of electrolytic polishing parameters is not required in a preparation process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for quantitatively evaluating each phase structure in hot rolling TRIP (transformation-induced plasticity) steel

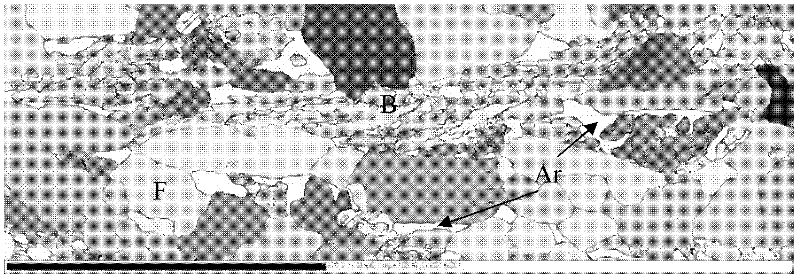

ActiveCN103454294AQuantitative results are accurateIncrease reflectionMaterial analysis using wave/particle radiationTRIP steelScanning electron microscope

The invention relates to a method for quantitatively evaluating each phase structure in hot rolling TRIP (transformation-induced plasticity) steel. The method comprises the following steps: quantitatively measuring an FCC phase (retained austenite) and a BCC phase (ferrite, bainite and martensite) of the hot rolling TRIP steel by using an electronic backscattered diffraction device arranged on a scanning electron microscope; firstly recognizing the retained austenite according to a distinct difference of the FCC phase and the BCC phase in structure, and then quantitatively distinguishing the three phases by using a gray value difference in a kikuchi band contrast BC (Band Contrast) image in EBSD (electron backscattered diffraction) processing software according to the difference of the three similar structure phases of the ferrite, the bainite and the martensite in kikuchi pattern quality, so as to achieve multi-phase separation and quantitative analysis of the hot rolling TRIP steel. The method is accurate and reliable, and can be applied to the technical field of measurement of tissues in the steel.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com