Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1702results about How to "Accurate Calibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

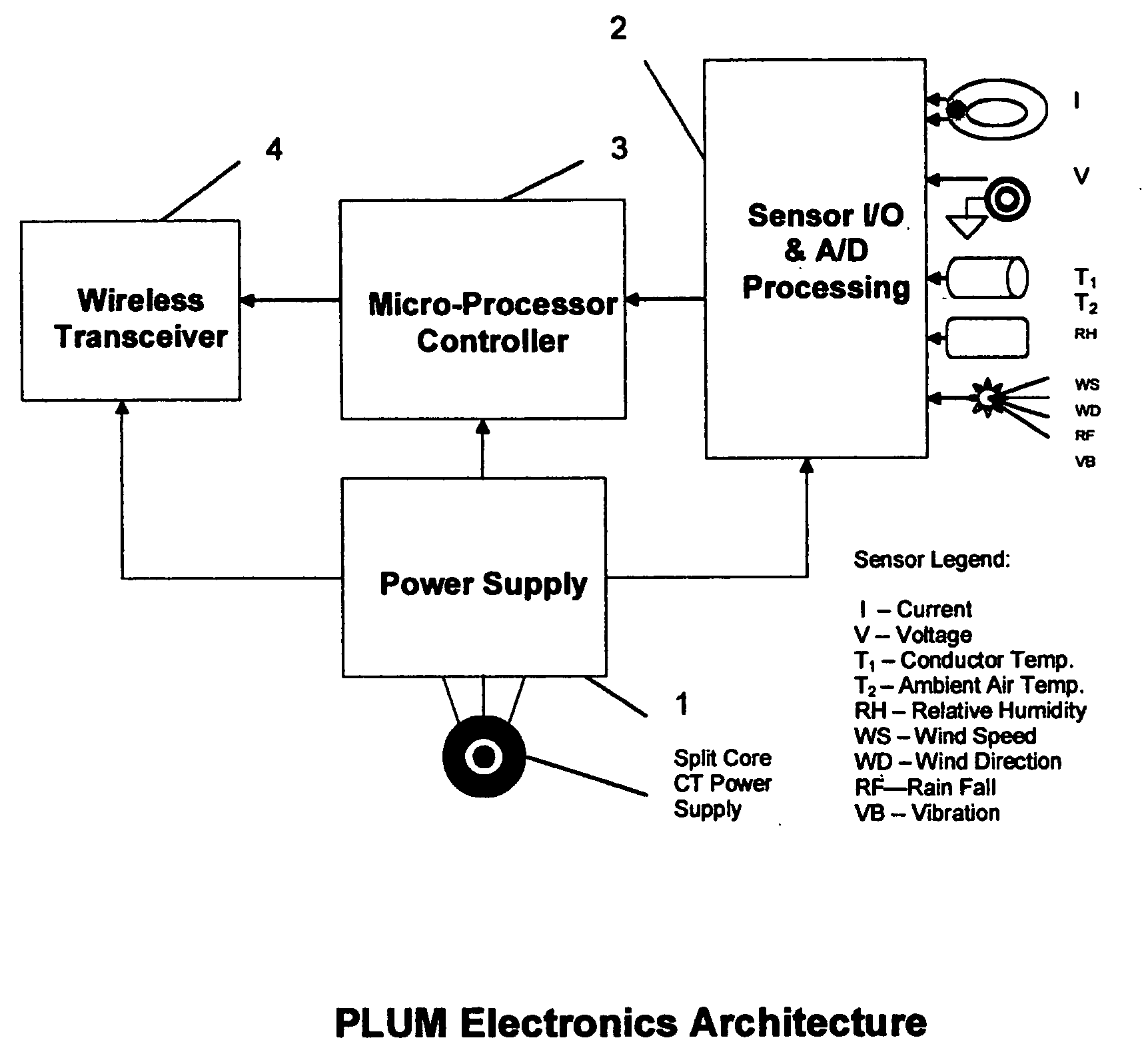

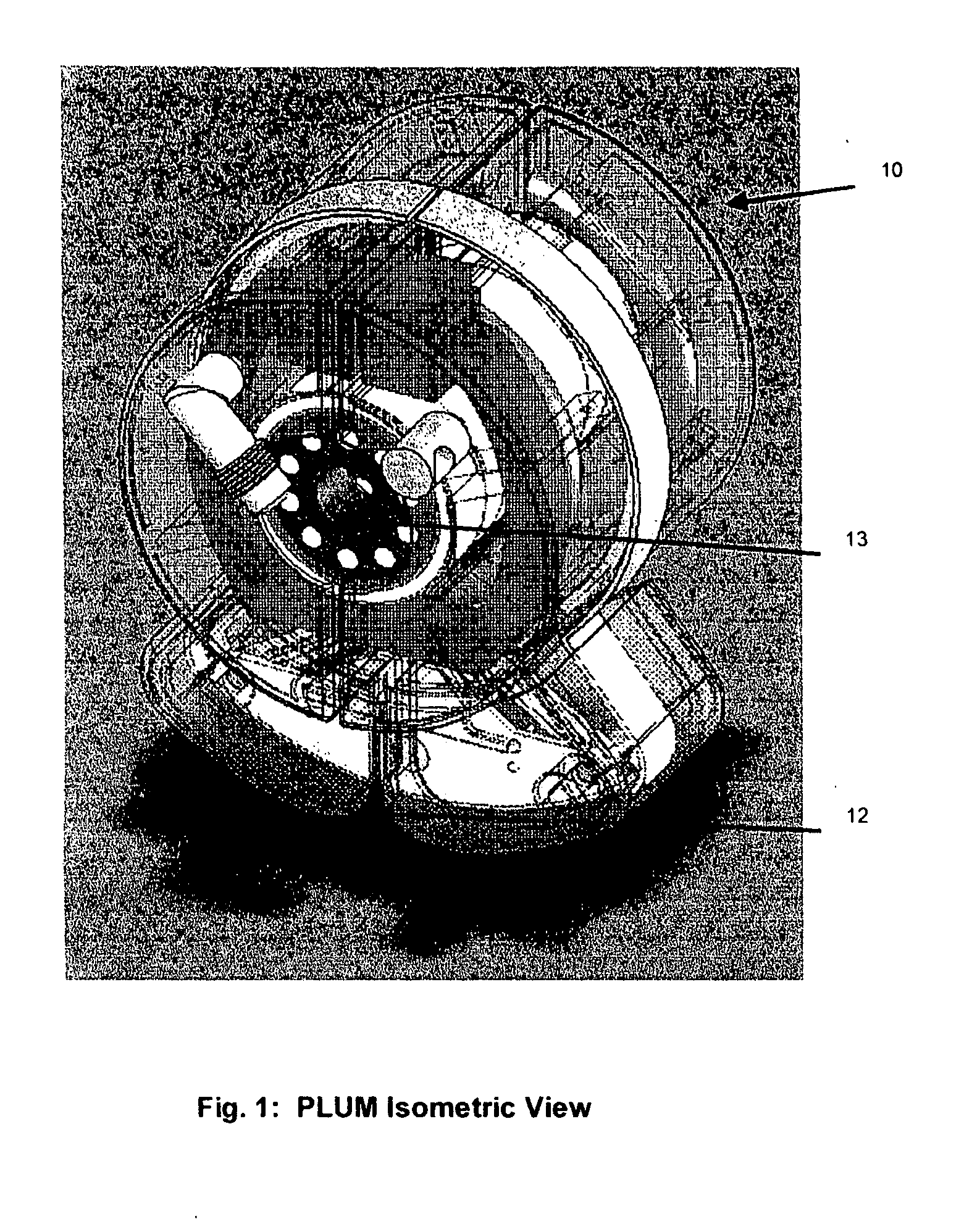

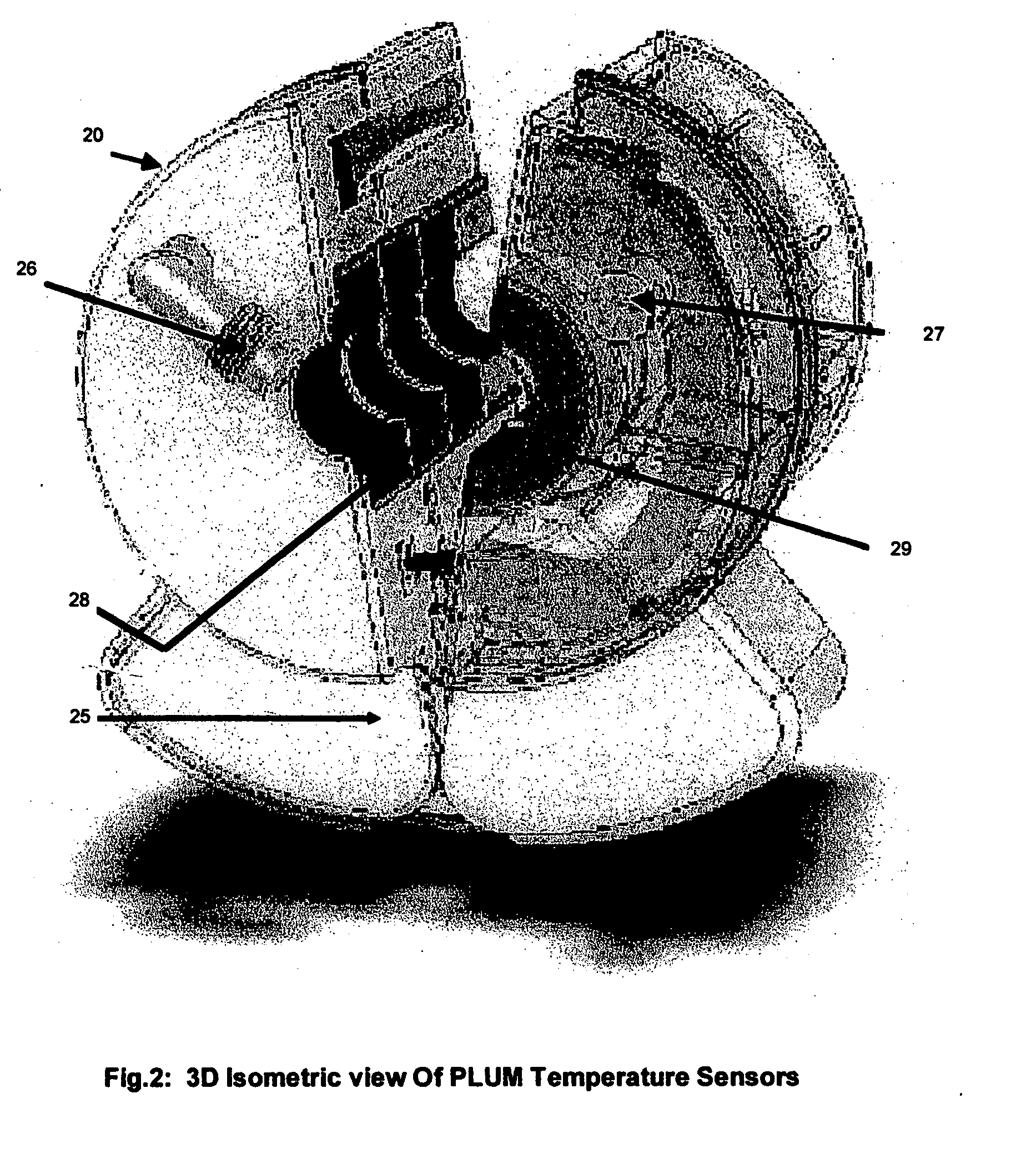

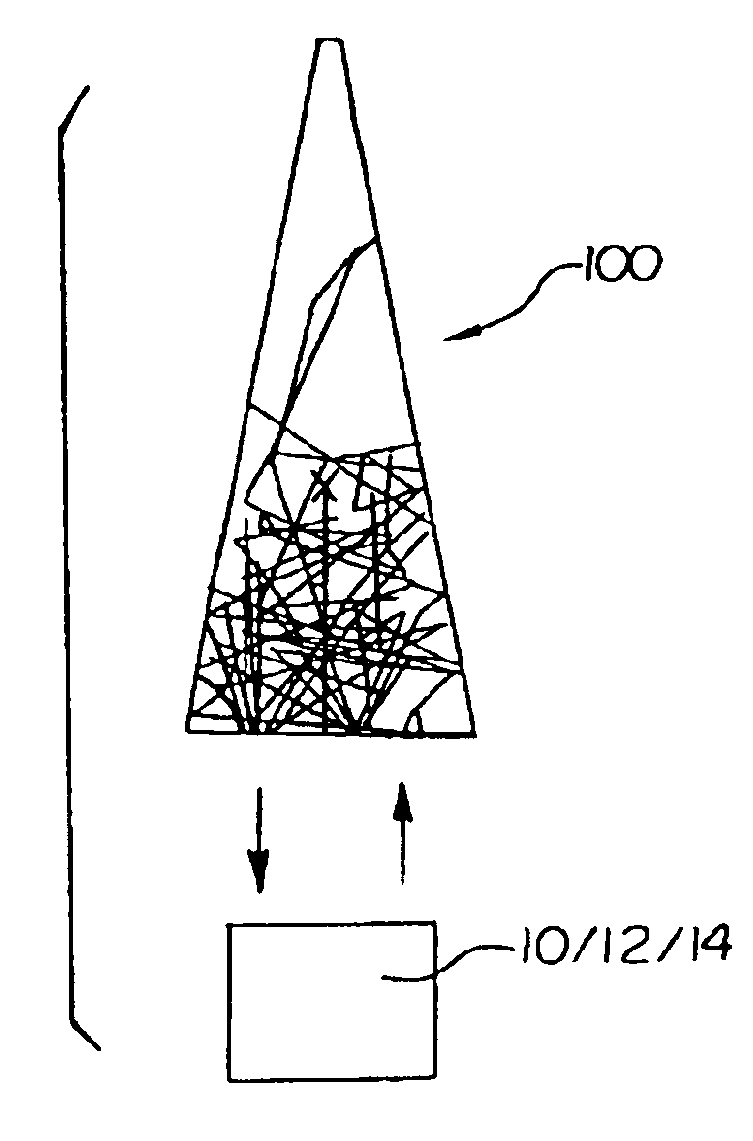

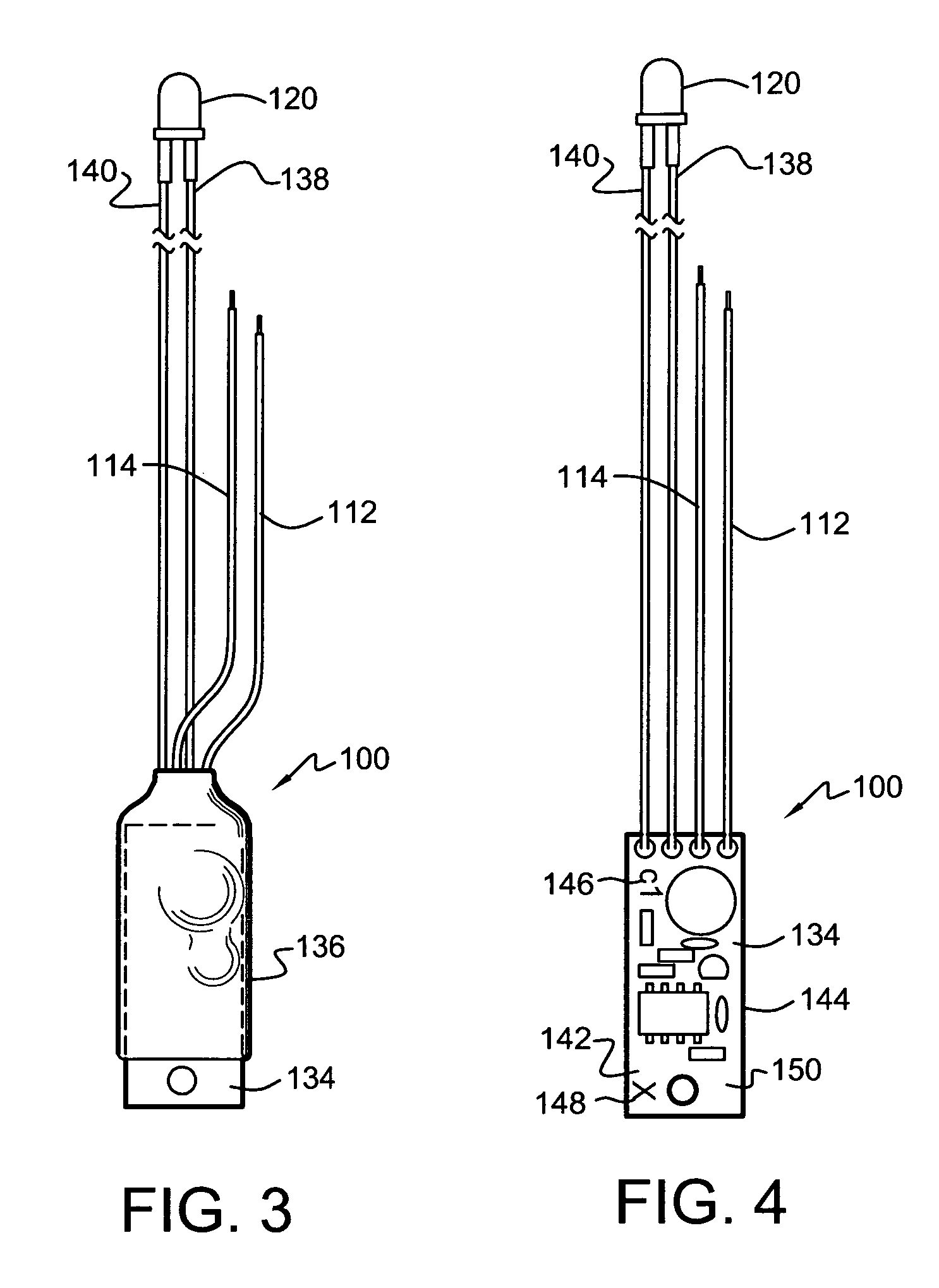

Power line universal monitor

InactiveUS20080077336A1Avoid susceptibilityAccurate CalibrationElectric signal transmission systemsBatteries circuit arrangementsSatelliteHigh impedance

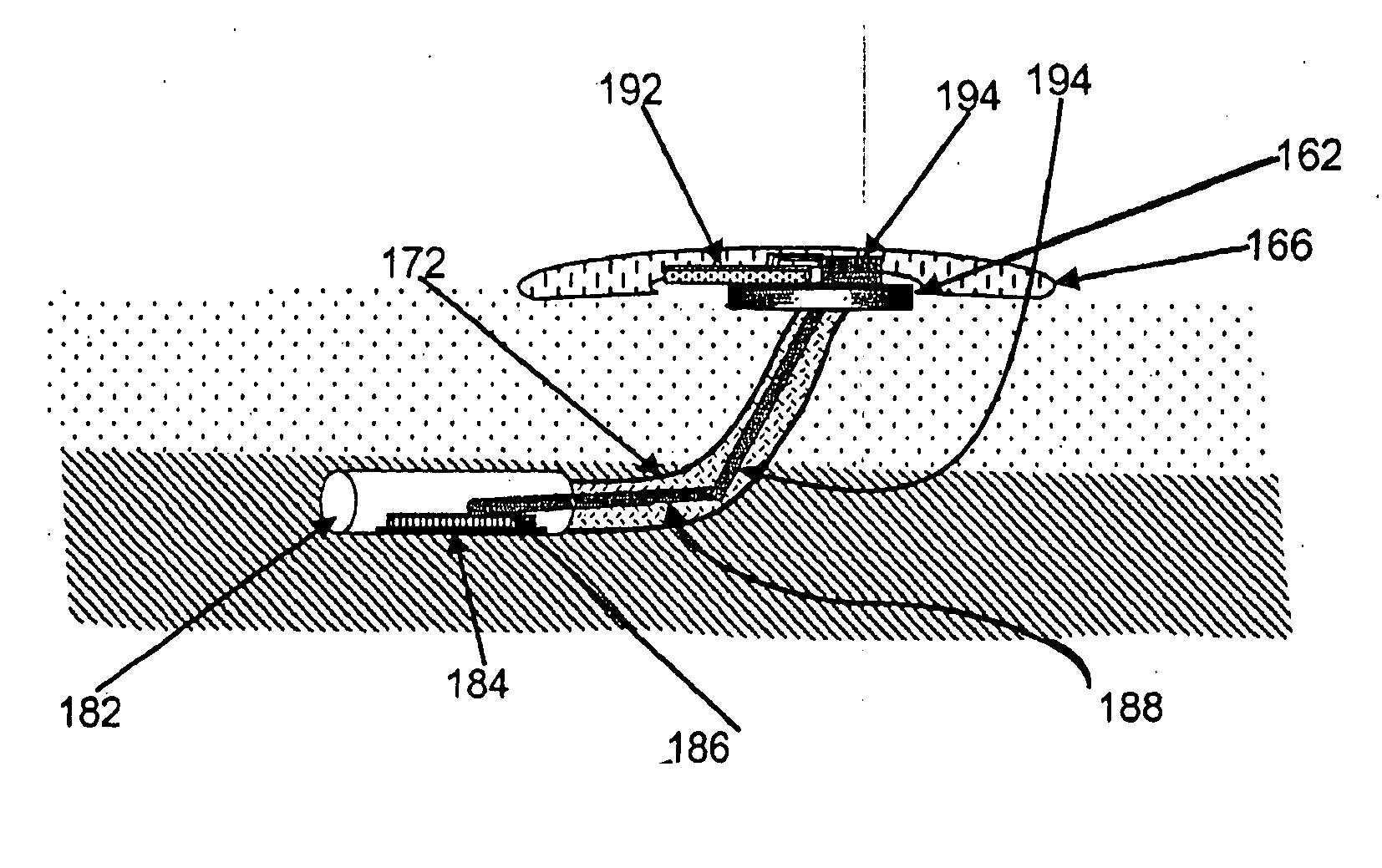

The invention is primarily directed to hot-stick mountable wireless High Voltage Power Line Universal Monitors (PLUM) upon energized electrical power conductors. The PLUM wireless sensors monitor parameters associated with normal, overload and emergency operation of the power line. The present invention provides 0.2% metering grade voltage measurement accuracy through unique e-field measurements, synchronized through UltraSatNet Global Positioning Satellite (GPS) accuracy timing pulses. The invention further improves accuracy using a unique calibration technique during initial installation of the PLUM sensor modules. A PLUM master controller receives time-synchronized data from multiple modules within a substation and across a state-wide power grid for accurate post-fault, sequence-of-events analysis, high impedance fault signature analysis, and environmental and earthquake monitoring.

Owner:FERNANDES ROOSEVELT

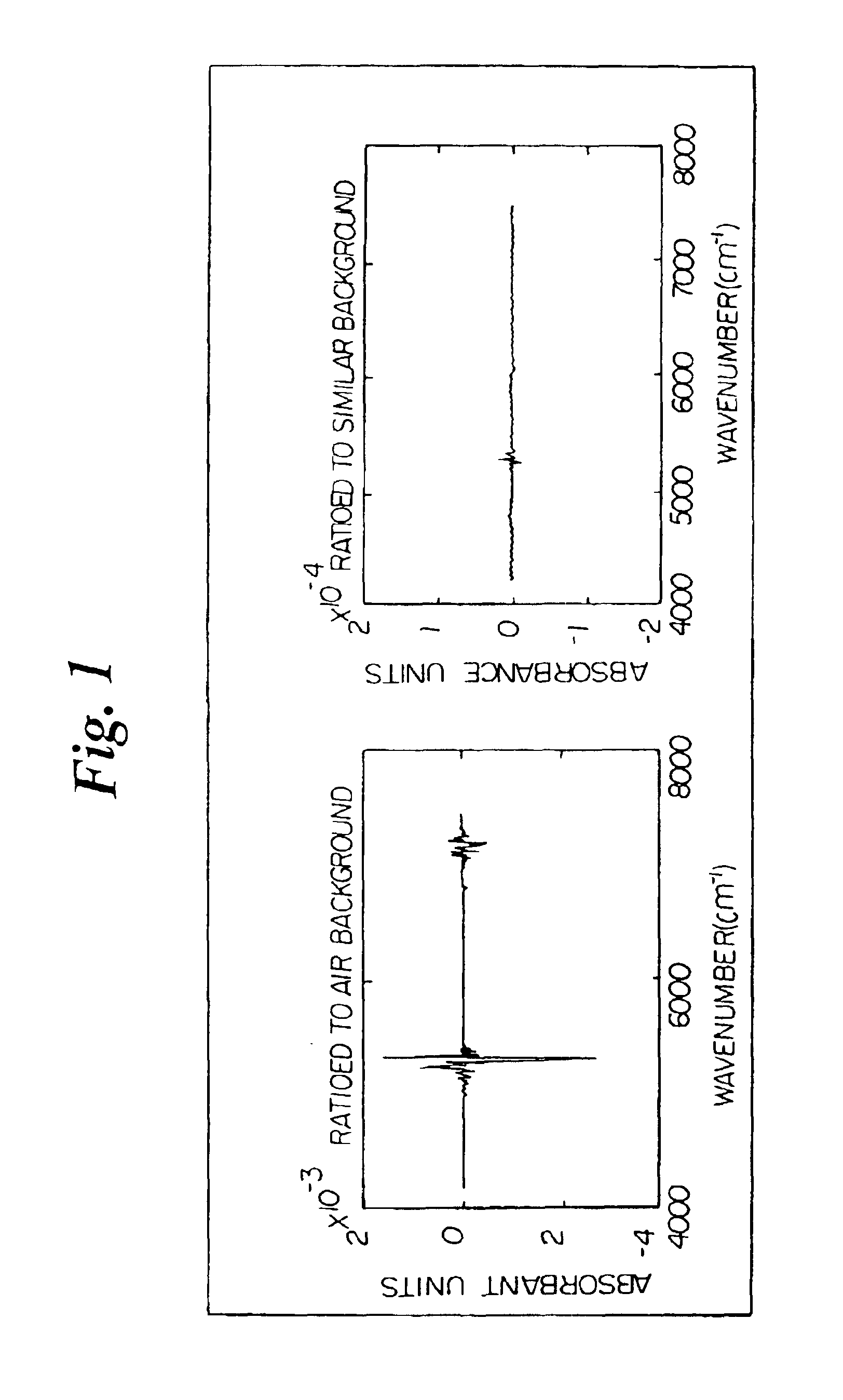

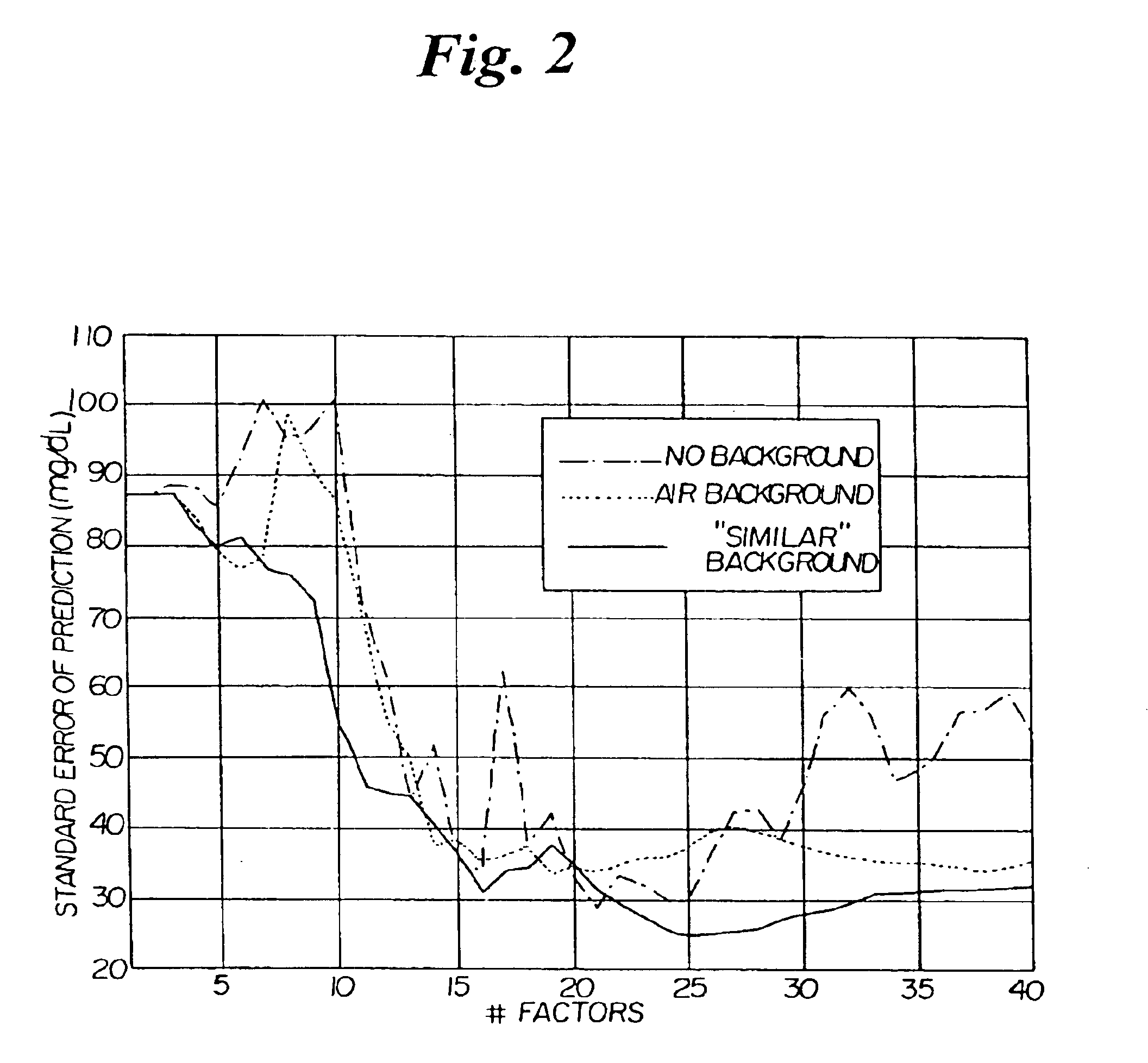

Optically similar reference samples and related methods for multivariate calibration models used in optical spectroscopy

InactiveUS6983176B2Easy to implementAccurately calibrateDiagnostics using spectroscopySensorsMultivariate calibrationSpectral signature

Systems and methods for establishing and / or maintaining the prediction capability over time of a multivariate calibration model designed for quantitative optical spectroscopic measurement of attributes or analytes in bodily tissues, bodily fluids or other biological samples, which are particularly useful when the spectral absorbance of the attribute or analyte is small relative to the background. The present invention provides an optically similar reference sample to capture the characteristics of instrument and environmental variation and to reduce the effect of such variation on the measurement capability of the model. The optically similar reference is preferably stable over time and is designed such that its optical properties are sufficiently matched to the sample of interest that instrument and environmental variations are captured in the same manner in both the test sample of interest and the optically similar reference sample. The optically similar reference sample may include one or more physical components which are spectroscopically measured in a manner which closely mimics the spectroscopic measurement of the test sample of interest. Spectral similarity may also be achieved by using alternative components with spectral characteristics similar to the components contained in the test sample of interest.

Owner:RIO GRANDE MEDICAL TECH

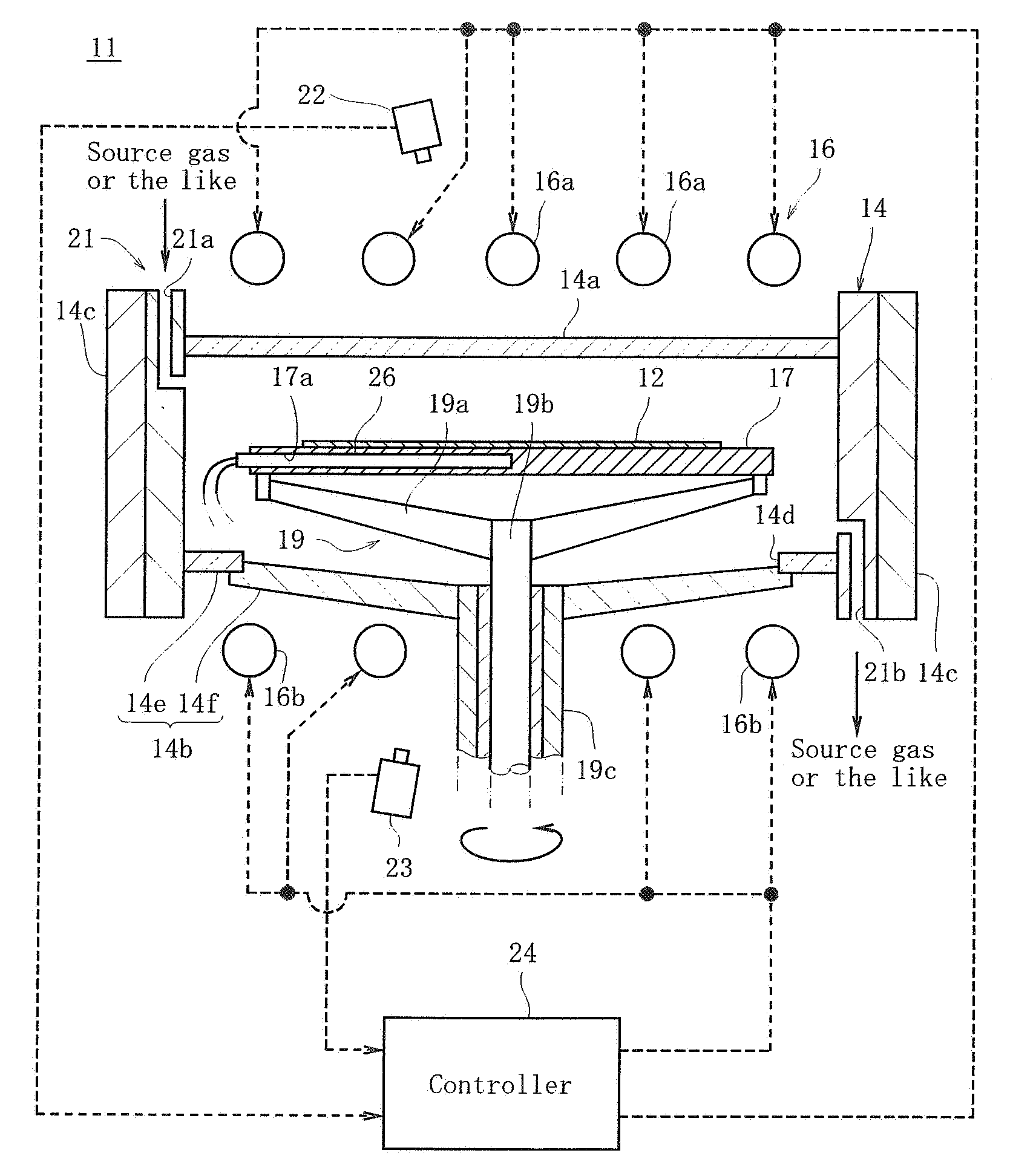

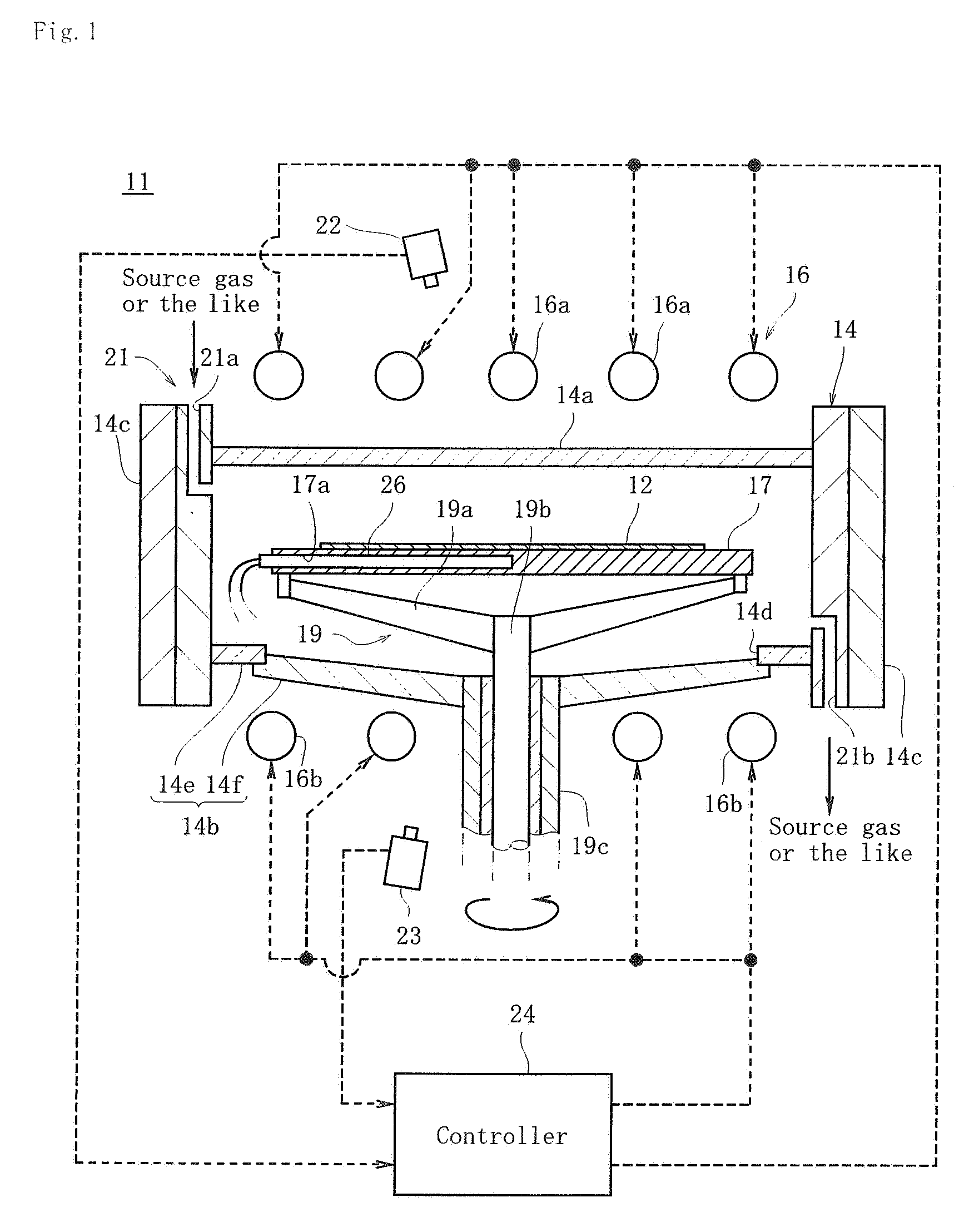

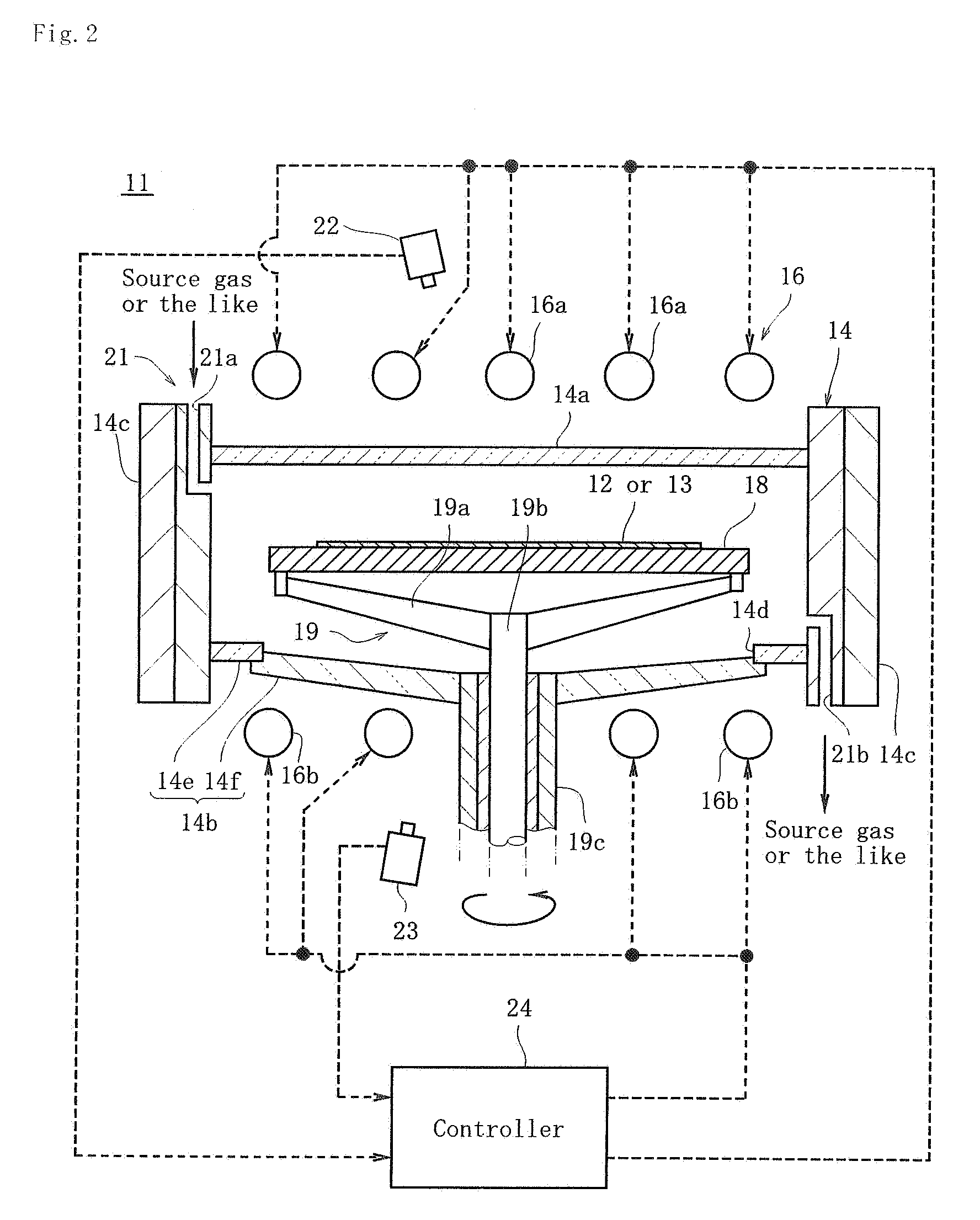

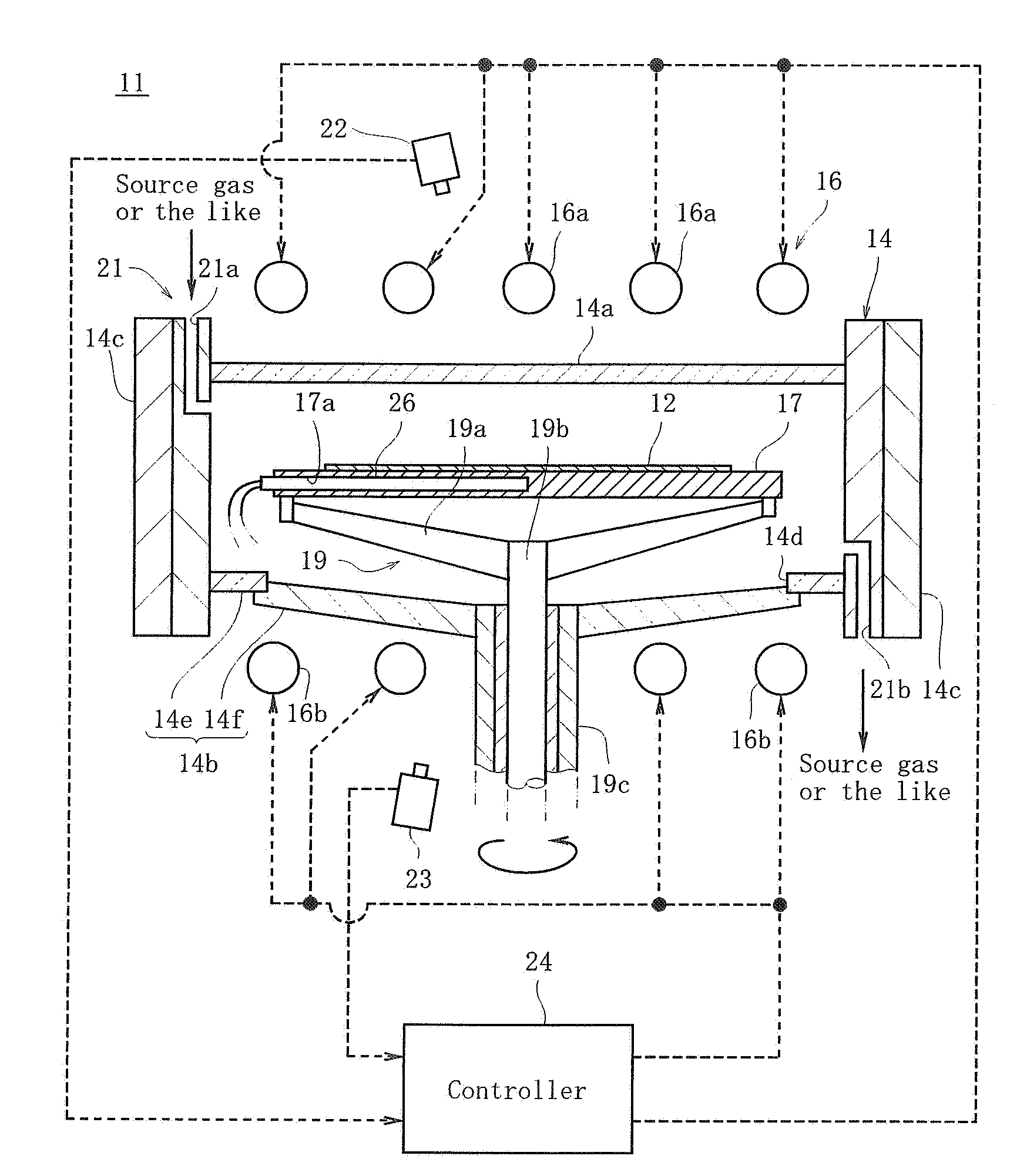

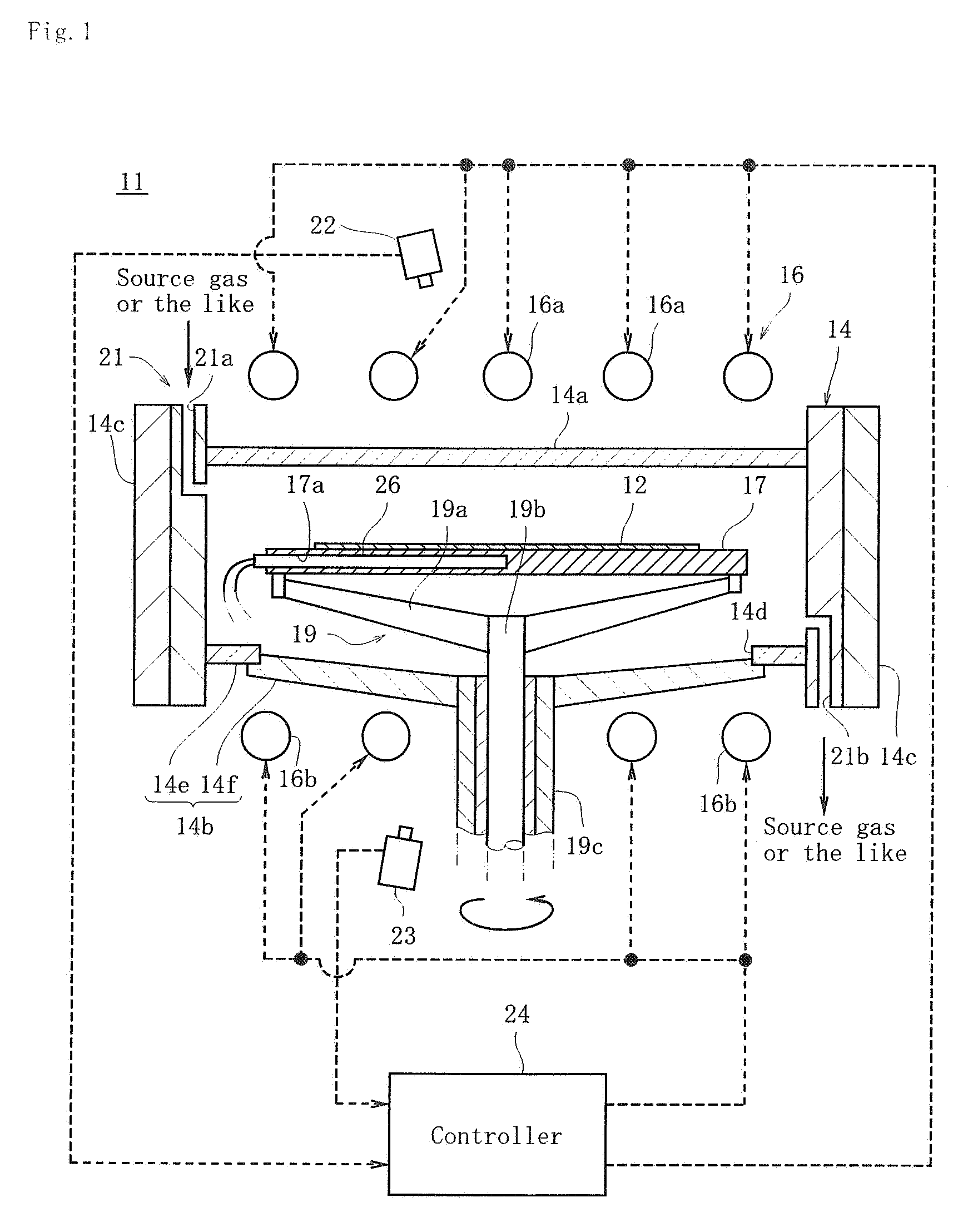

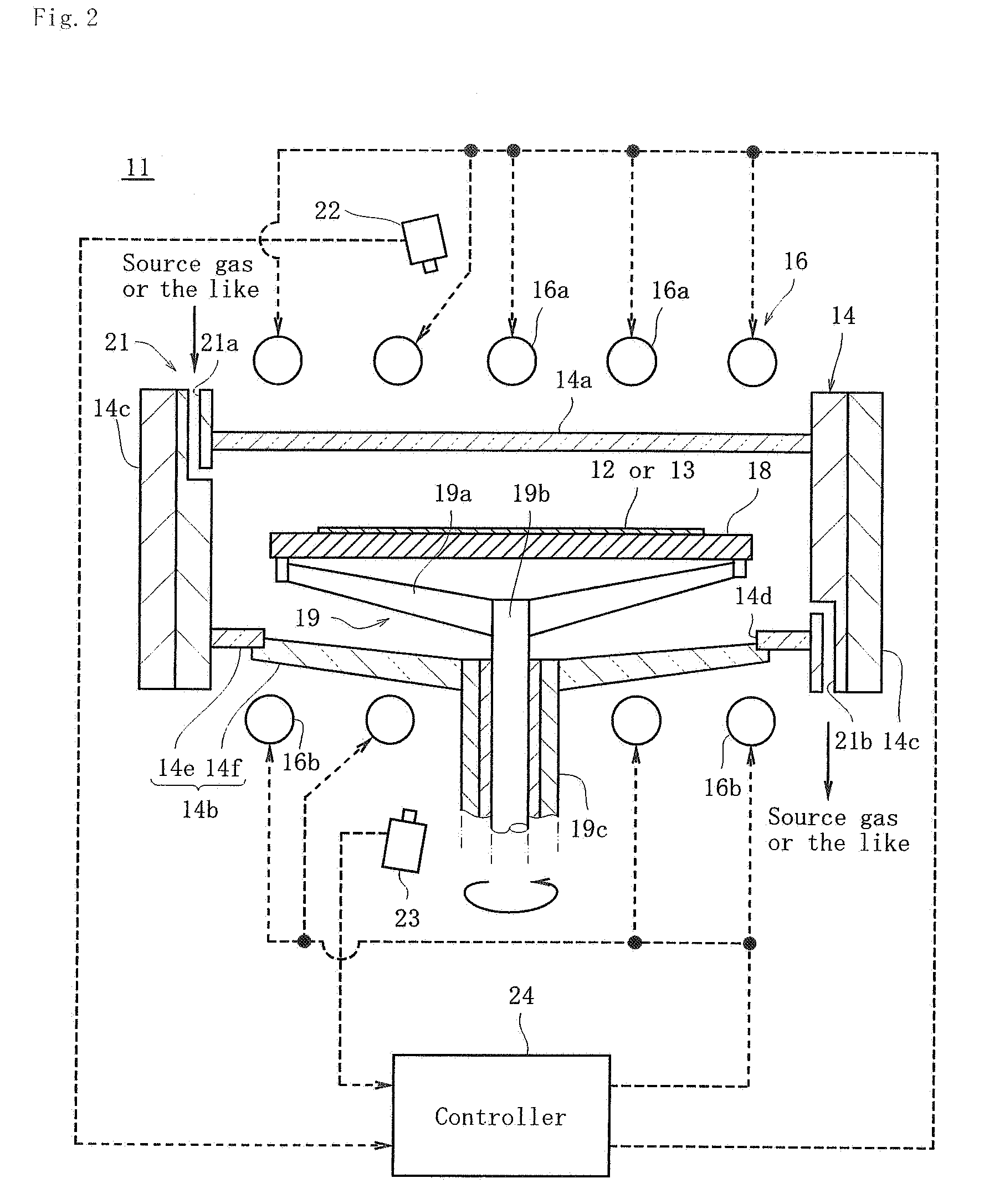

Temperature Control Method of Epitaxial Growth Apparatus

ActiveUS20070062439A1Quality improvementPrevent slippingPolycrystalline material growthThermometer testing/calibrationTemperature controlSusceptor

An object of the invention is to calibrate an upper pyrometer for indirectly measuring a substrate temperature at the time of epitaxial growth in a comparatively short time and with accuracy to thereby improve the quality of an epitaxial substrate. After calibrating an upper pyrometer by a thermocouple mounted to a temperature calibrating susceptor, a measured value of a lower pyrometer is adjusted to a calibrated value of the upper pyrometer. Then, a correlation line between substrate temperature indirectly measured by the upper pyrometer at the time of epitaxial growth onto a sample substrate and haze of a sample substrate measured immediately after epitaxial growth is set to indirectly measure a substrate temperature by the upper pyrometer at the time of epitaxial growth onto a mass-production substrate. Moreover, substrate temperature at the time of epitaxial growth onto the mass-production substrate is estimated by applying the haze of the mass-production substrate measured immediately after epitaxial growth to the correlation line and then a measured temperature of the upper pyrometer is adjusted to the estimated temperature.

Owner:SUMCO CORP

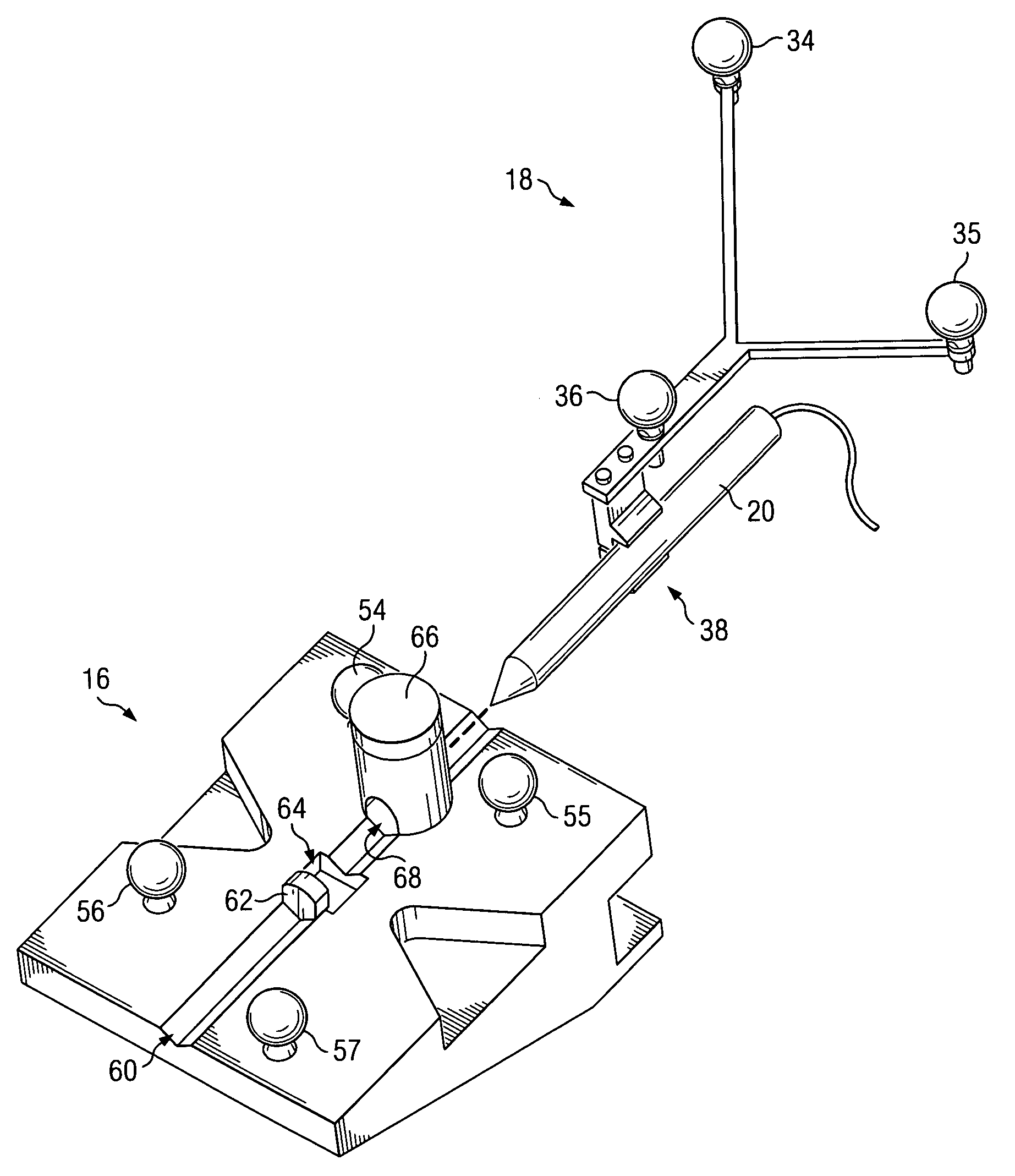

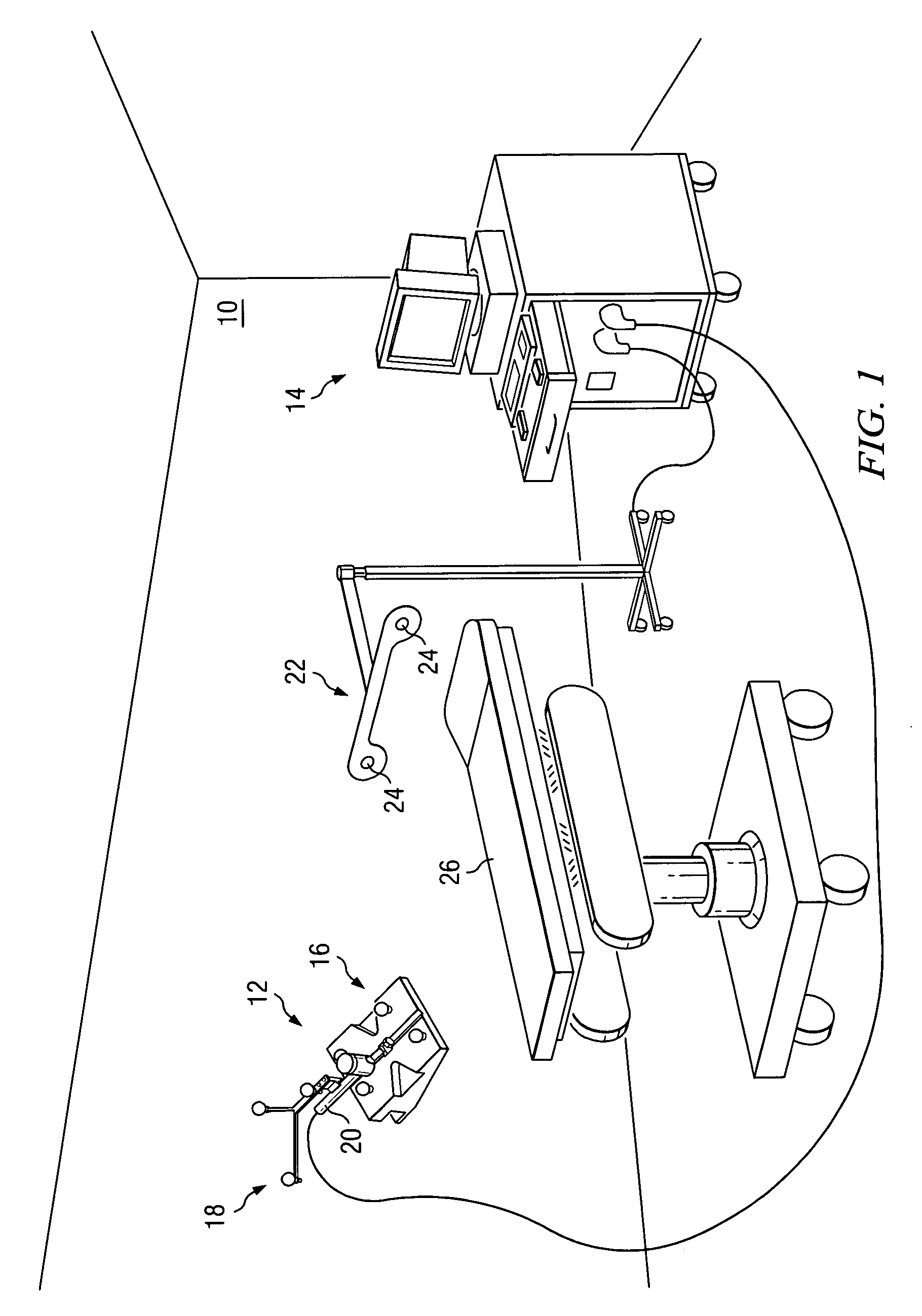

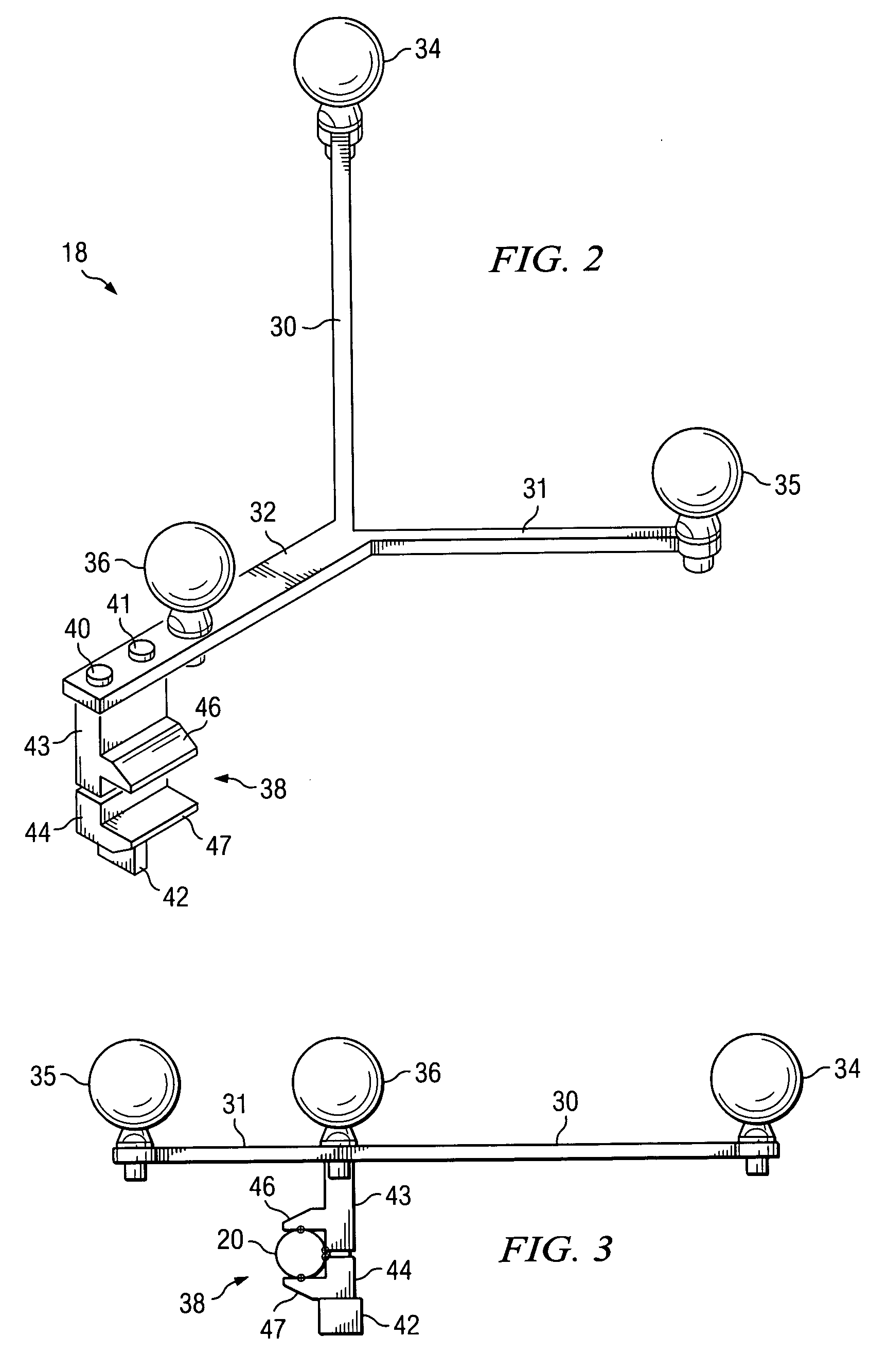

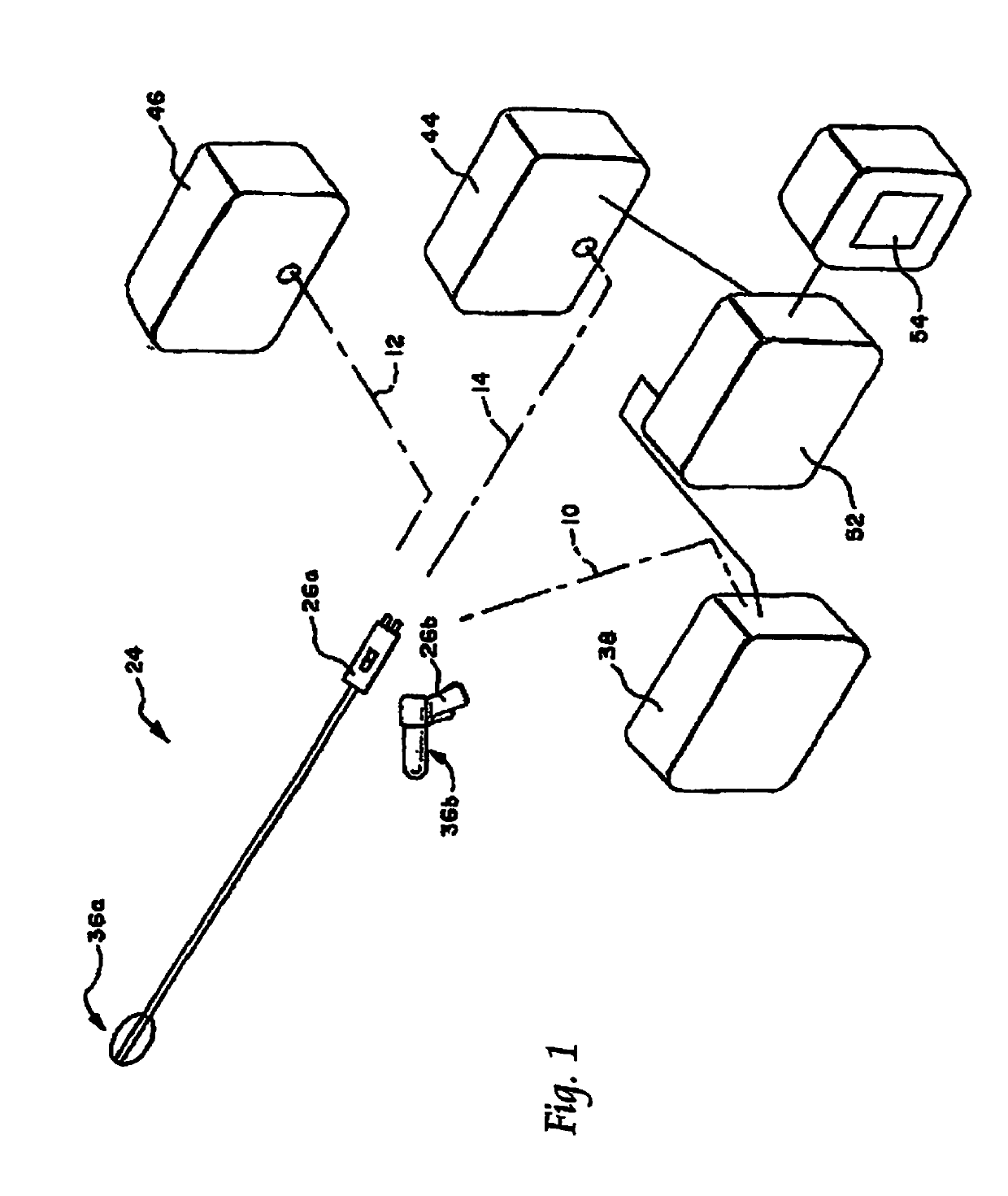

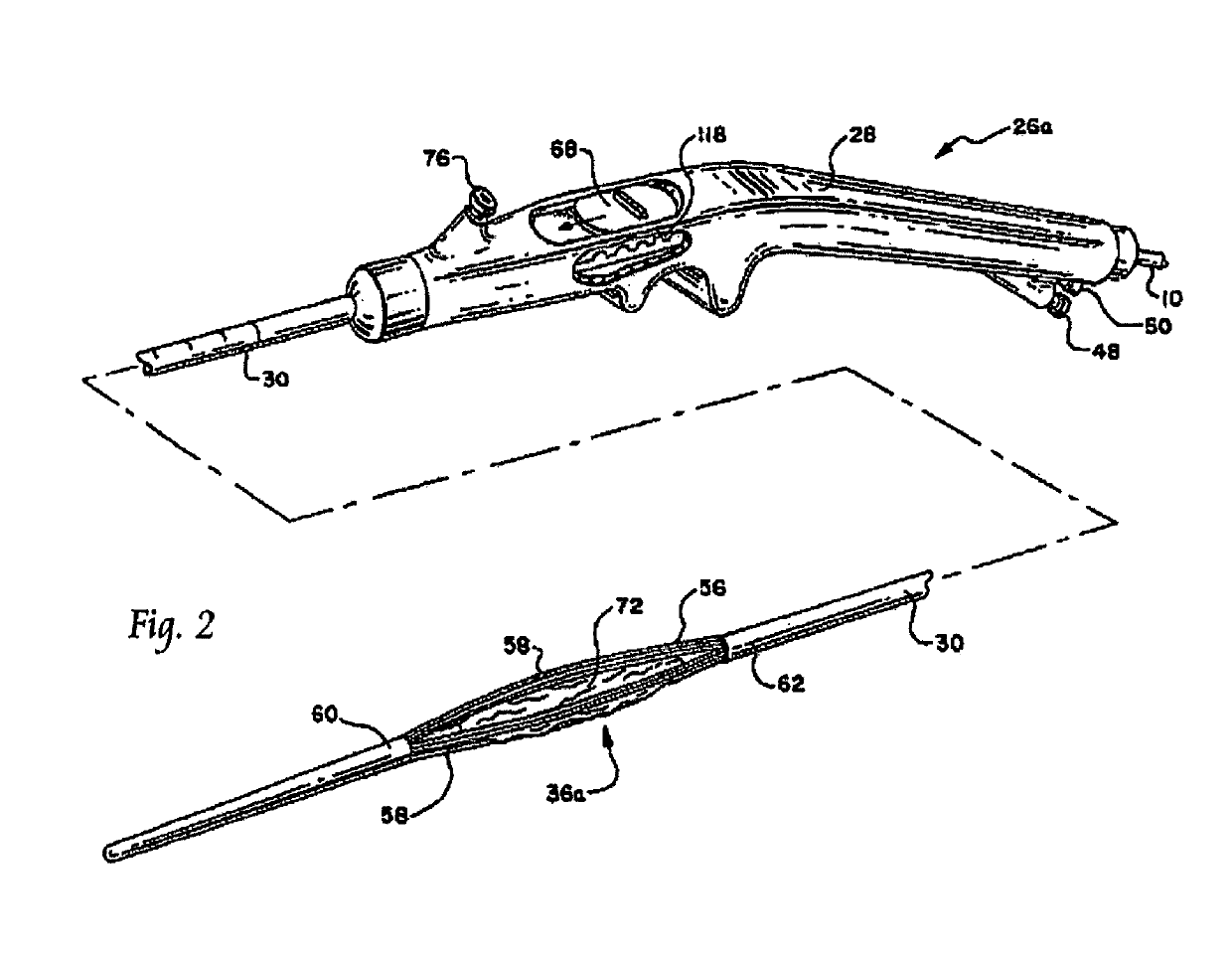

Tool calibrator and tracker system

InactiveUS7043961B2Accurately processSimplifyWave based measurement systemsDiagnosticsEngineeringMechanical engineering

Owner:MAKO SURGICAL CORP

Temperature control method of epitaxial growth apparatus

ActiveUS7833348B2Accurate CalibrationQuality improvementPolycrystalline material growthThermometer testing/calibrationTemperature controlSusceptor

An object of the invention is to calibrate an upper pyrometer for indirectly measuring a substrate temperature at the time of epitaxial growth in a comparatively short time and with accuracy to thereby improve the quality of an epitaxial substrate.After calibrating an upper pyrometer by a thermocouple mounted to a temperature calibrating susceptor, a measured value of a lower pyrometer is adjusted to a calibrated value of the upper pyrometer. Then, a correlation line between substrate temperature indirectly measured by the upper pyrometer at the time of epitaxial growth onto a sample substrate and haze of a sample substrate measured immediately after epitaxial growth is set to indirectly measure a substrate temperature by the upper pyrometer at the time of epitaxial growth onto a mass-production substrate. Moreover, substrate temperature at the time of epitaxial growth onto the mass-production substrate is estimated by applying the haze of the mass-production substrate measured immediately after epitaxial growth to the correlation line and then a measured temperature of the upper pyrometer is adjusted to the estimated temperature.

Owner:SUMCO CORP

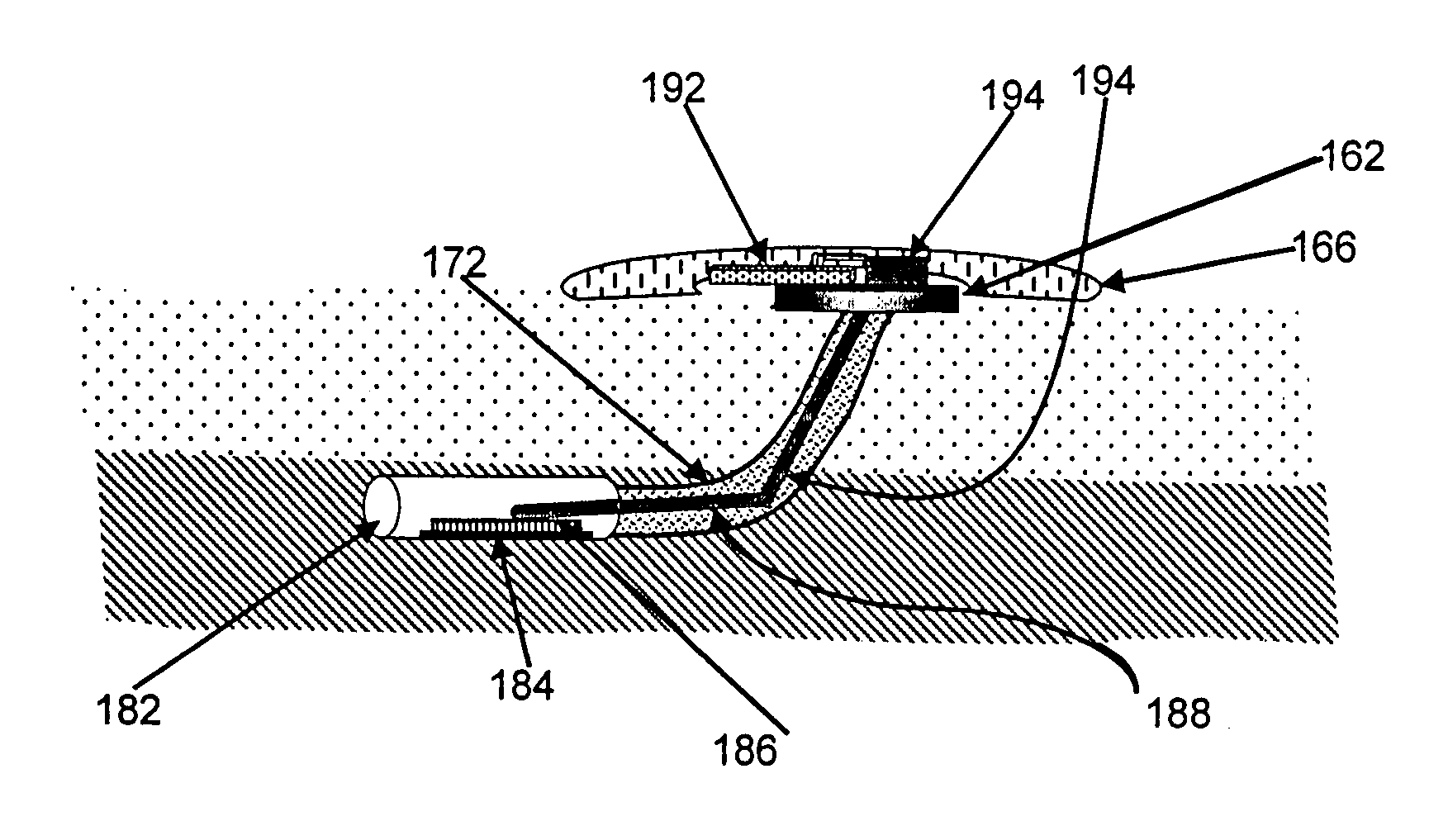

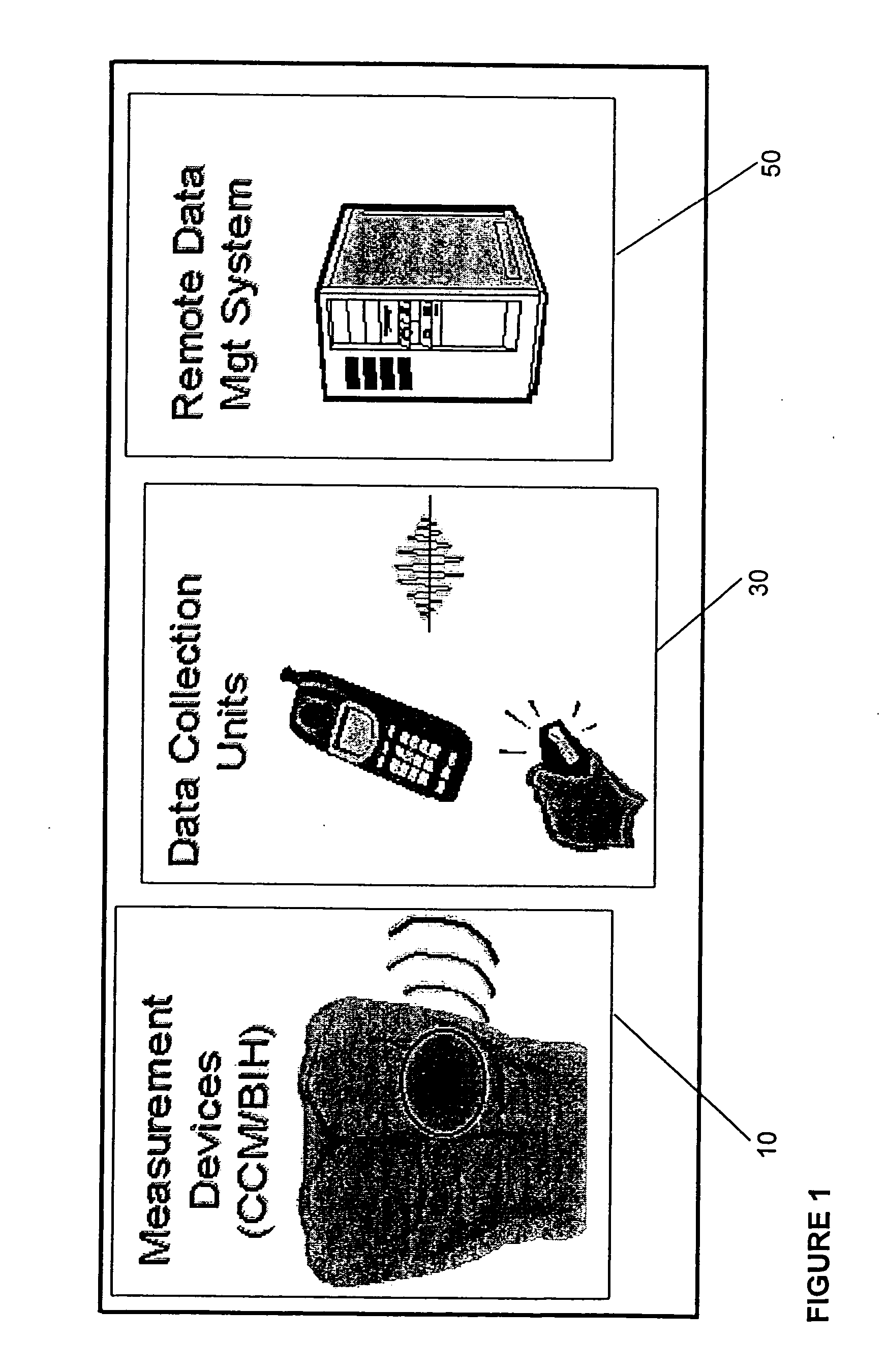

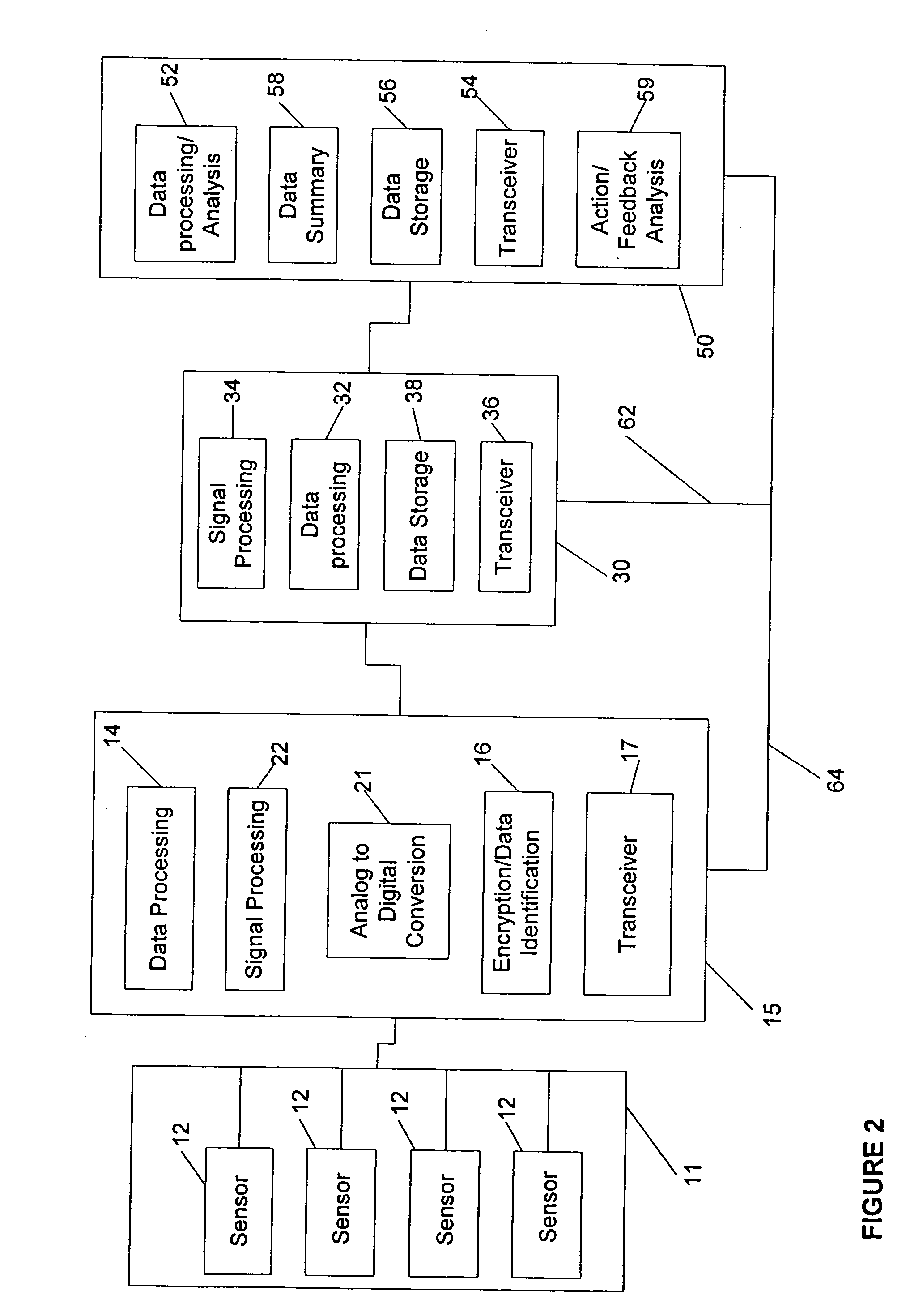

Gateway platform for biological monitoring and delivery of therapeutic compounds

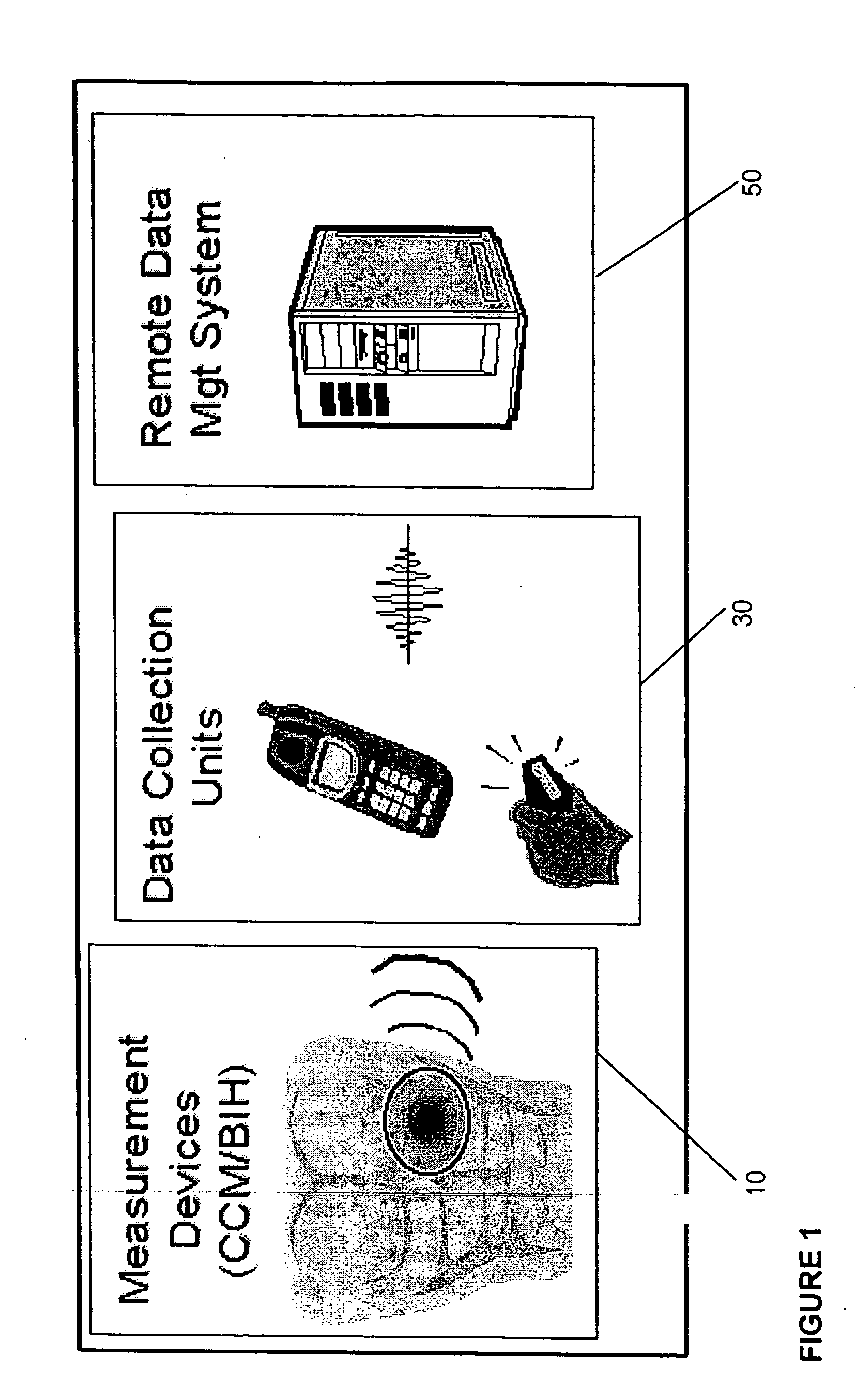

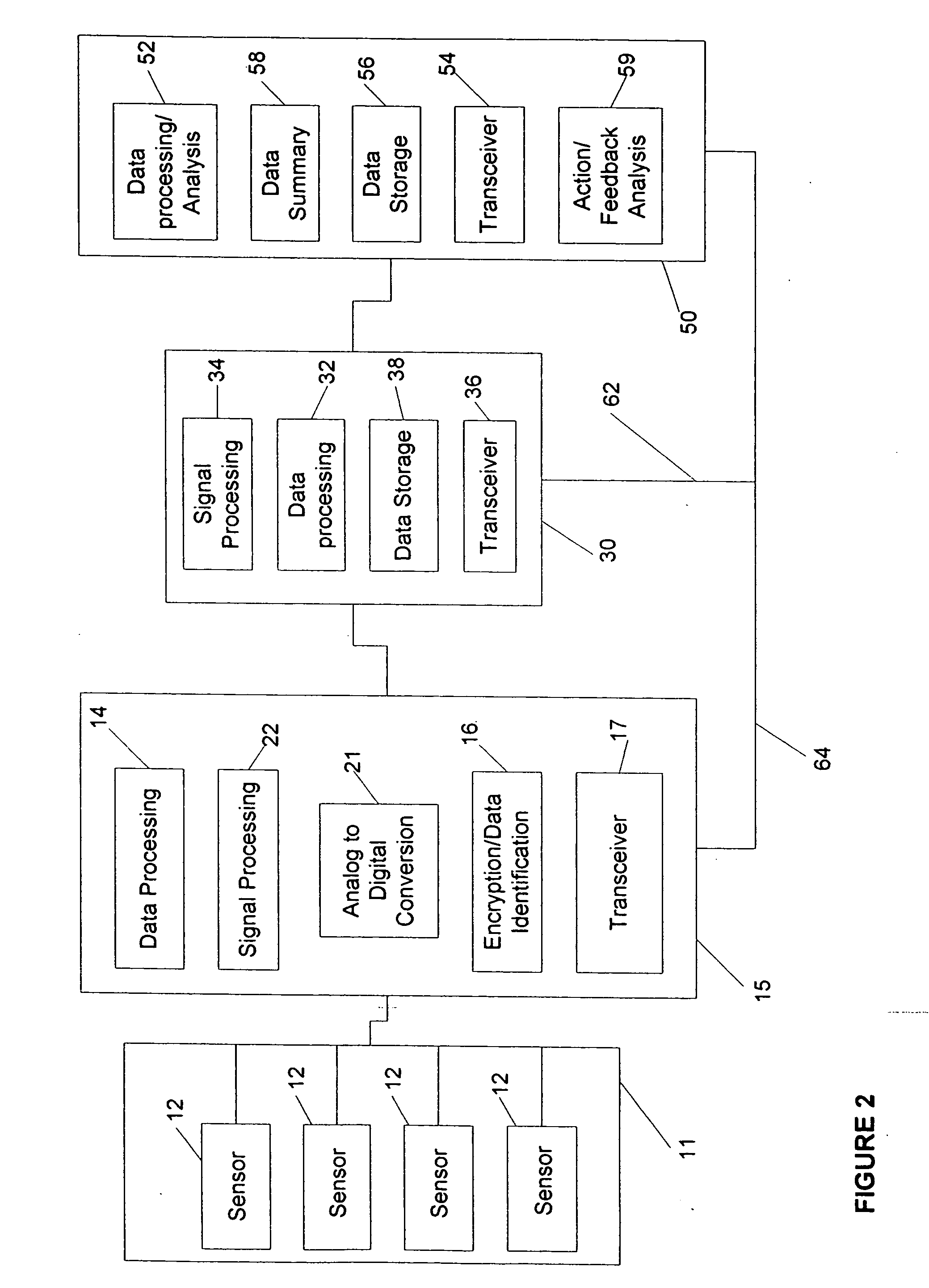

InactiveUS20070060800A1Decrease adhesion and encapsulationImprove data qualityBioelectric signal measurementDrug and medicationsBiomonitoringComputer science

The invention relates to methods and devices for remote or distributed continuous monitoring of physiologically relevant states. The invention provides for methods to automatically detect deviations or other states in physiological parameters and automatically alert a measured subject, user or other authorized party. The device provides for a universal platform for sensors, and further provides for the automatic compensation or distribution of devices or bioactive agents at appropriate levels and / or intervals in response to deviations or other states sensed in various physiological parameters.

Owner:PHILOMETRON

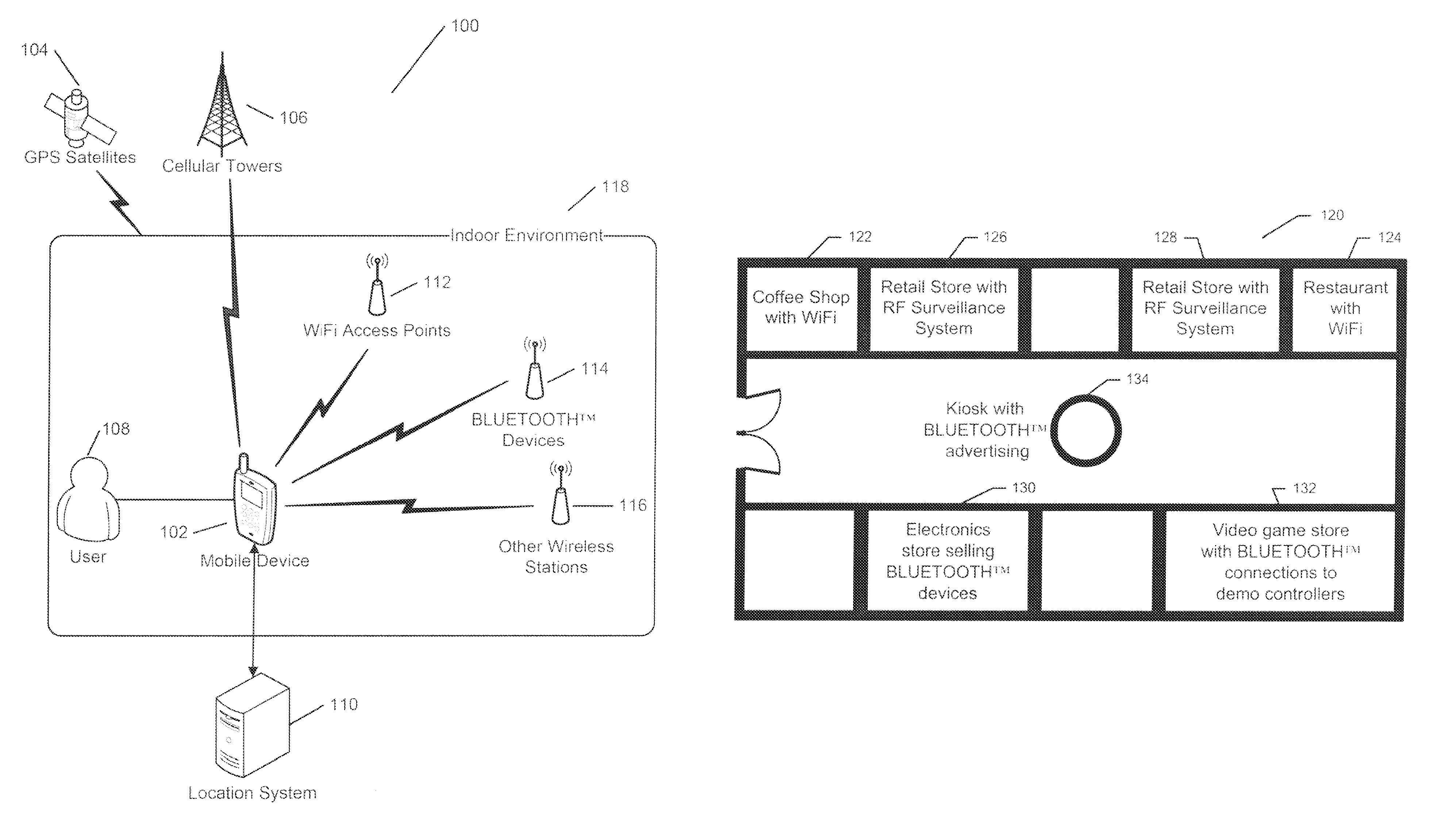

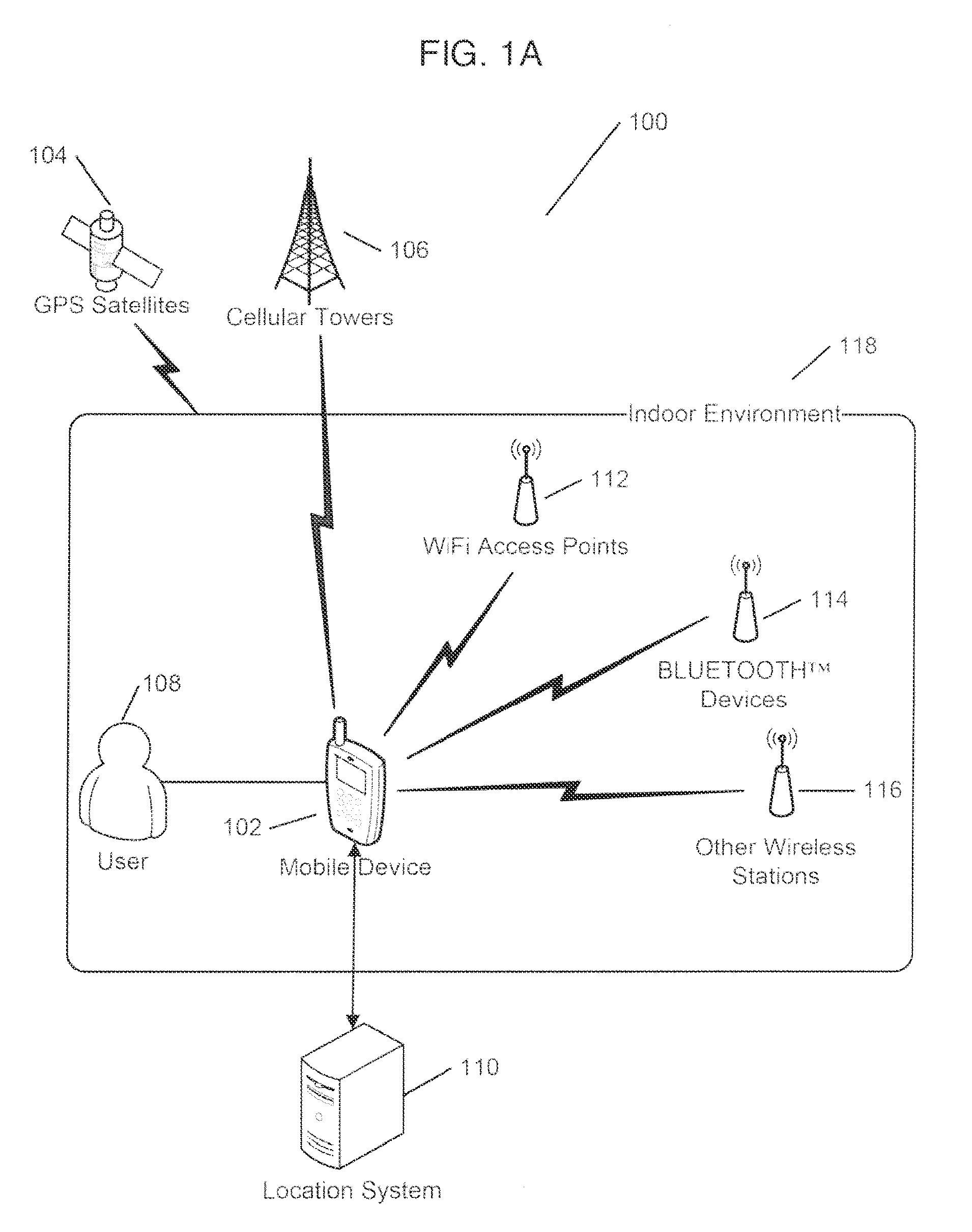

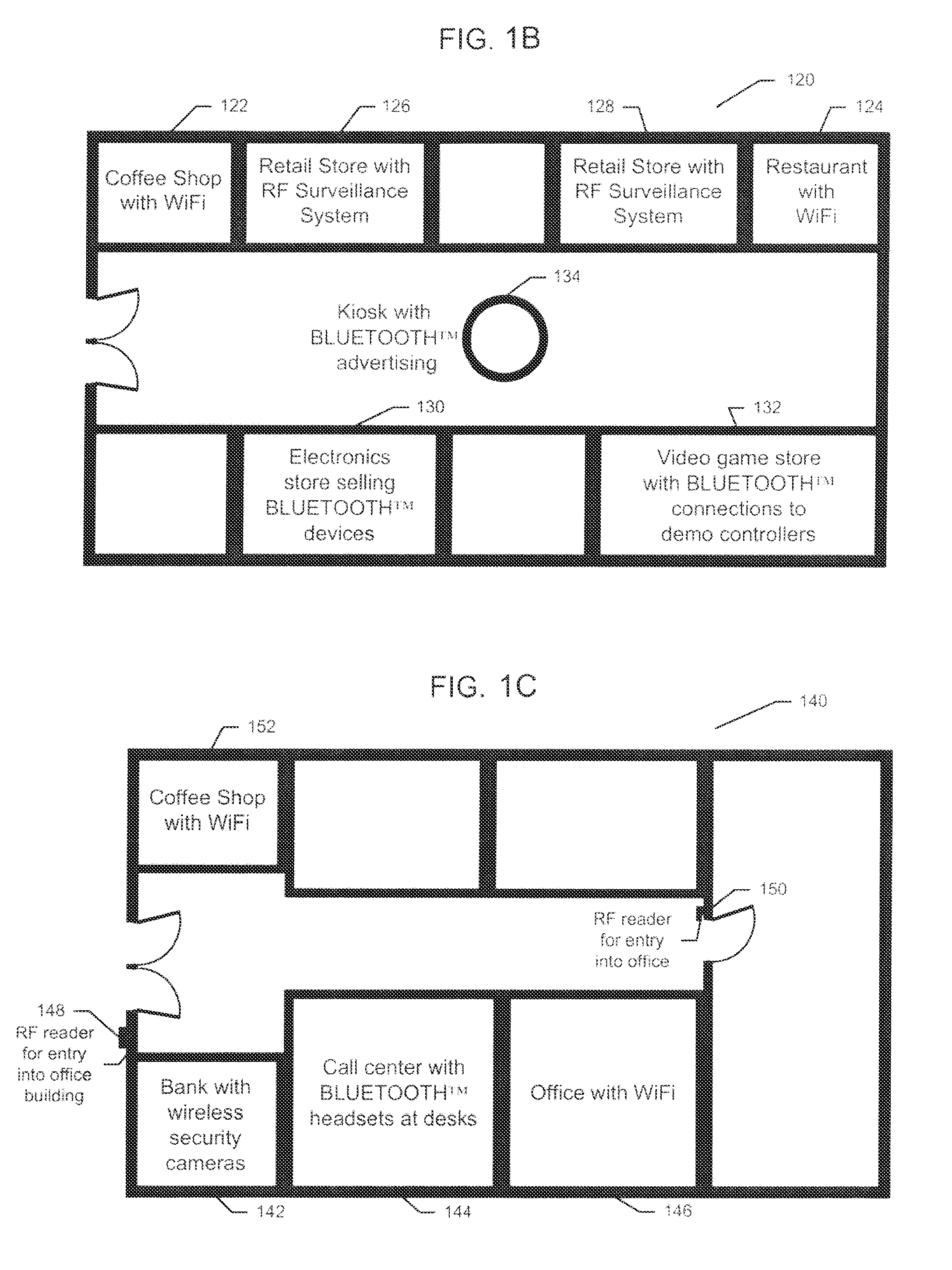

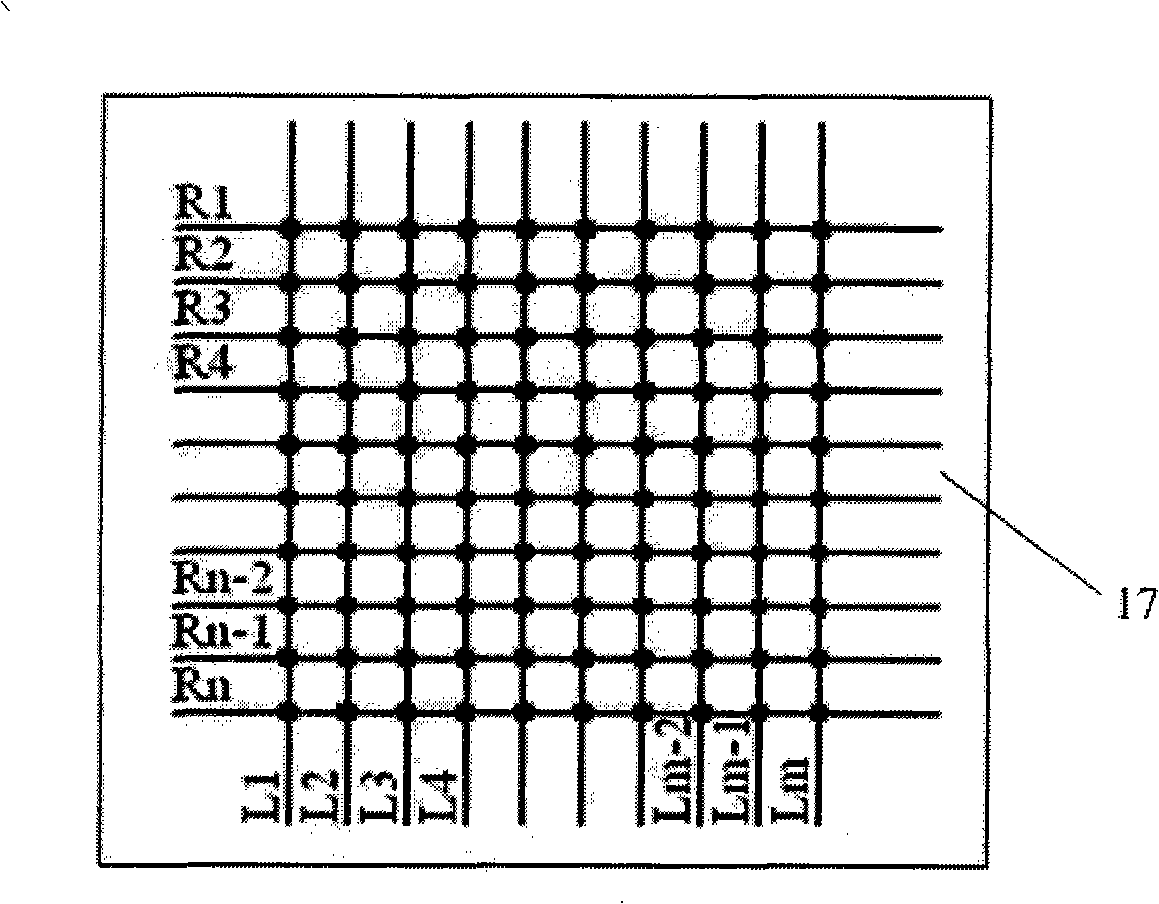

Systems and methods for calibration based indoor geolocation

ActiveUS9439041B2Improve accuracyAccurate CalibrationDirection finders using radio wavesParticular environment based servicesIndoor geolocationSystems analysis

In a system facilitating the calibration of a map-point grid for an indoor location determination, the grid includes several map points, each having a radio frequency (RF) data fingerprint being associated therewith. At least one of: (i) RF signal data from several RF sources, (ii) a user specified location indication, and (ii) tracking data from a sensor, the tracking data indicating a user's movement relative to a base map point, are received. The map-point grid is updated based on, at least in part, at least one of (i) adjusted RF data, the received RF data being adjusted using systematic analysis thereof, (ii) the tracking data, and (iii) the location indication. A user's location may be determined based on the fingerprints associated with the map-point grid, and sensor data.

Owner:LIGHTHOUSE SIGNAL SYST

Filtration monitoring and control system

InactiveUS6077435AUseful controlAccurate CalibrationDispersed particle filtrationUltrafiltrationFouling indexFiltration

PCT No. PCT / AU96 / 00144 Sec. 371 Date Jan. 12, 1998 Sec. 102(e) Date Jan. 12, 1998 PCT Filed Mar. 15, 1996 PCT Pub. No. WO96 / 28236 PCT Pub. Date Sep. 19, 1996A method and apparatus for determining the fouling effect of a feedstream on a filter having known characteristics disclosed. The method comprises passing the feedstream through a filter (5) having known characteristics; determining the change in resistance to flow of the feedstream across the filter, either continuously or over a number of time intervals and from this data, calculating a feed fouling index (FFI) representative of the fouling characteristics of the feedstream with respect to the filter. A method and apparatus for monitoring the operation of a filtration system is also disclosed the method comprising sampling system parameter values at selected locations within the filtration system at a predetermined sampling rate; generating a parameter profile characteristic from the sampled parameter values at predetermined intervals of time; and analysing the parameter profile characteristic to determine correct operation of the filtration system. A further method and apparatus of monitoring and controlling a filtering system based on backwash efficiency is also disclosed, the method comprising determining resistance values of filtering elements used in the filtering system at predetermined times during the backwash cycle of the system by monitoring a number of operating parameters of the system; calculating a backwash efficiency value representative of the efficiency of the backwash cycle of the filtering system using the resistance values determined; and controlling the operation of the filtering system in dependence on the value of the backwash efficiency calculated.

Owner:EVOQUA WATER TECH LLC

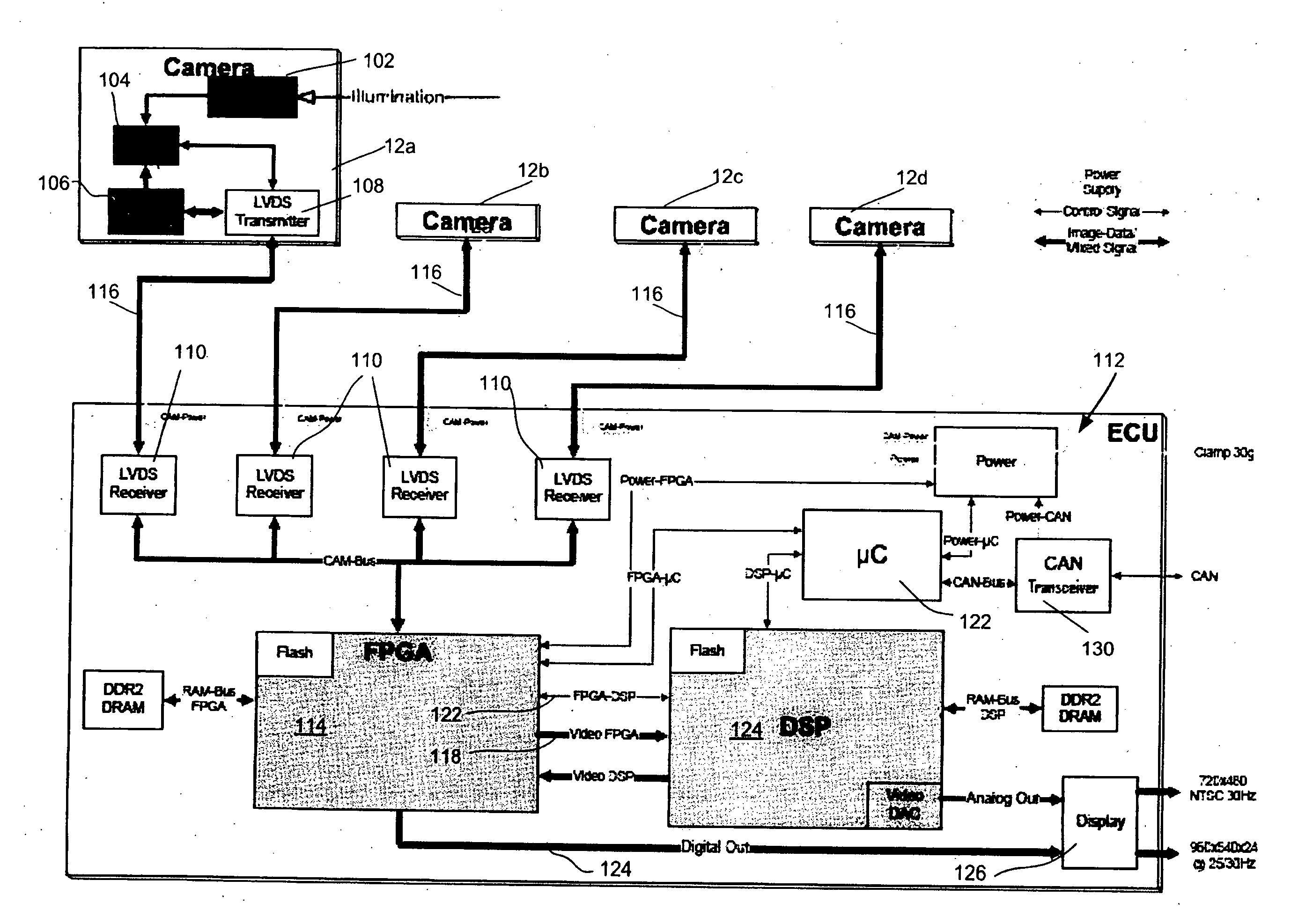

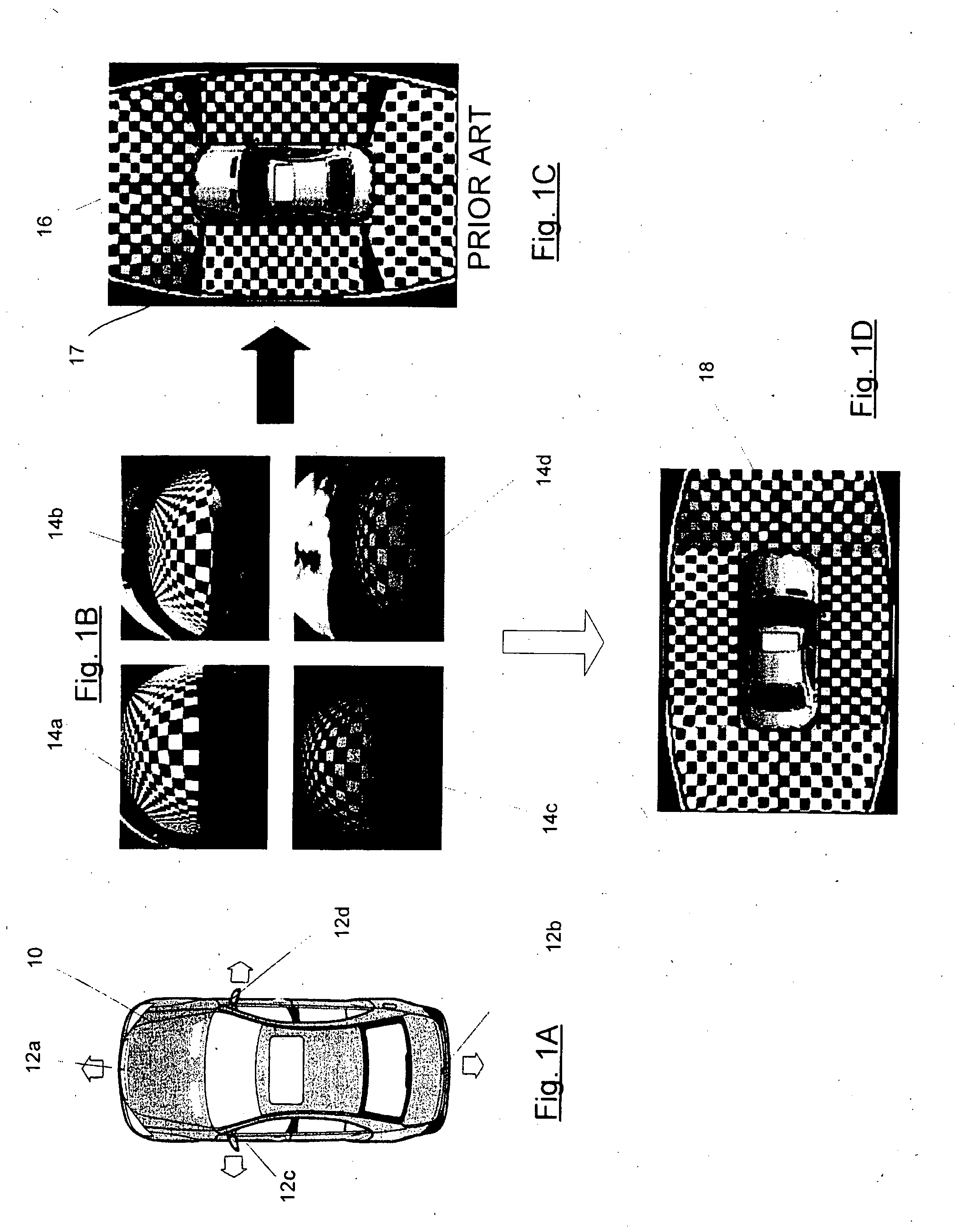

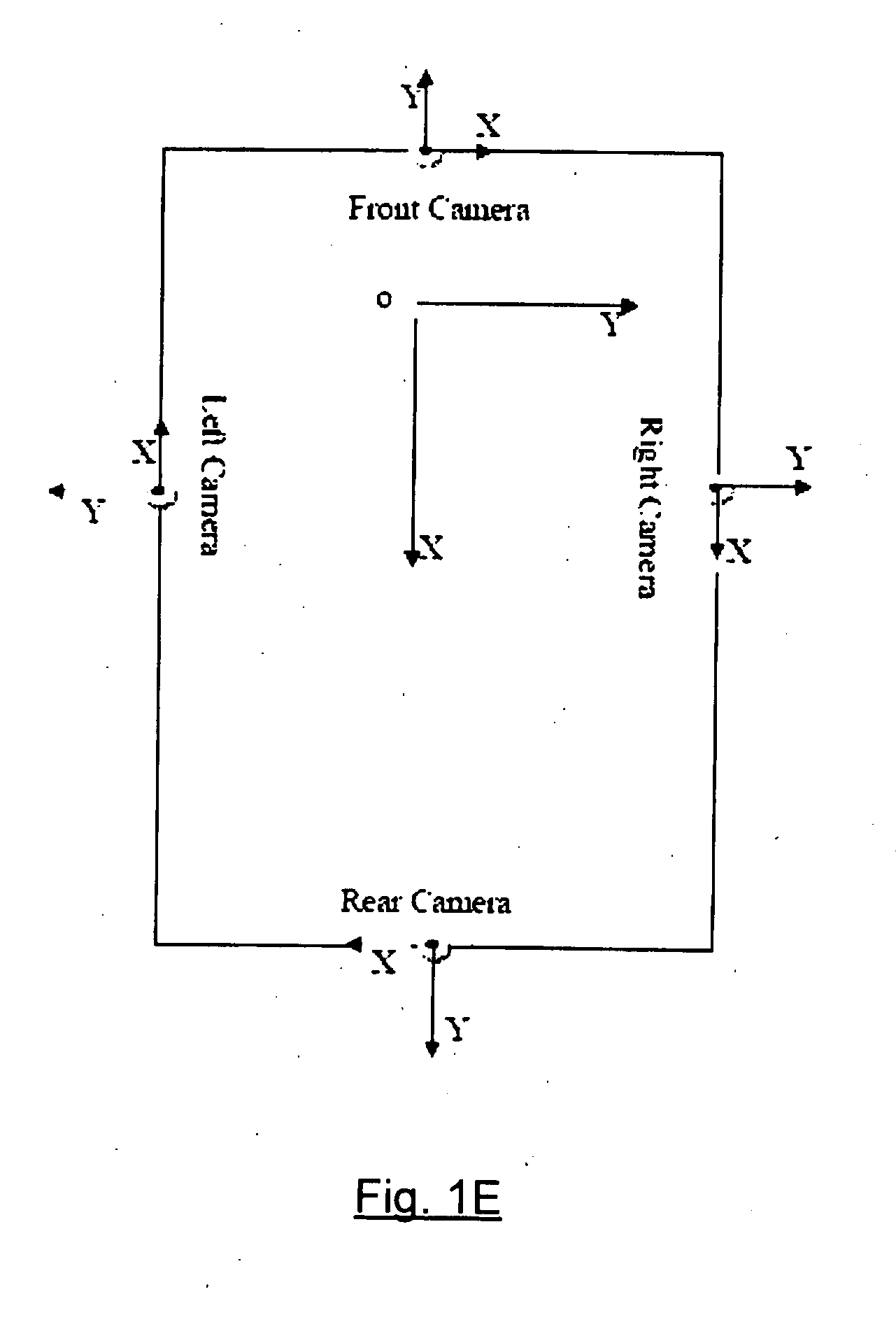

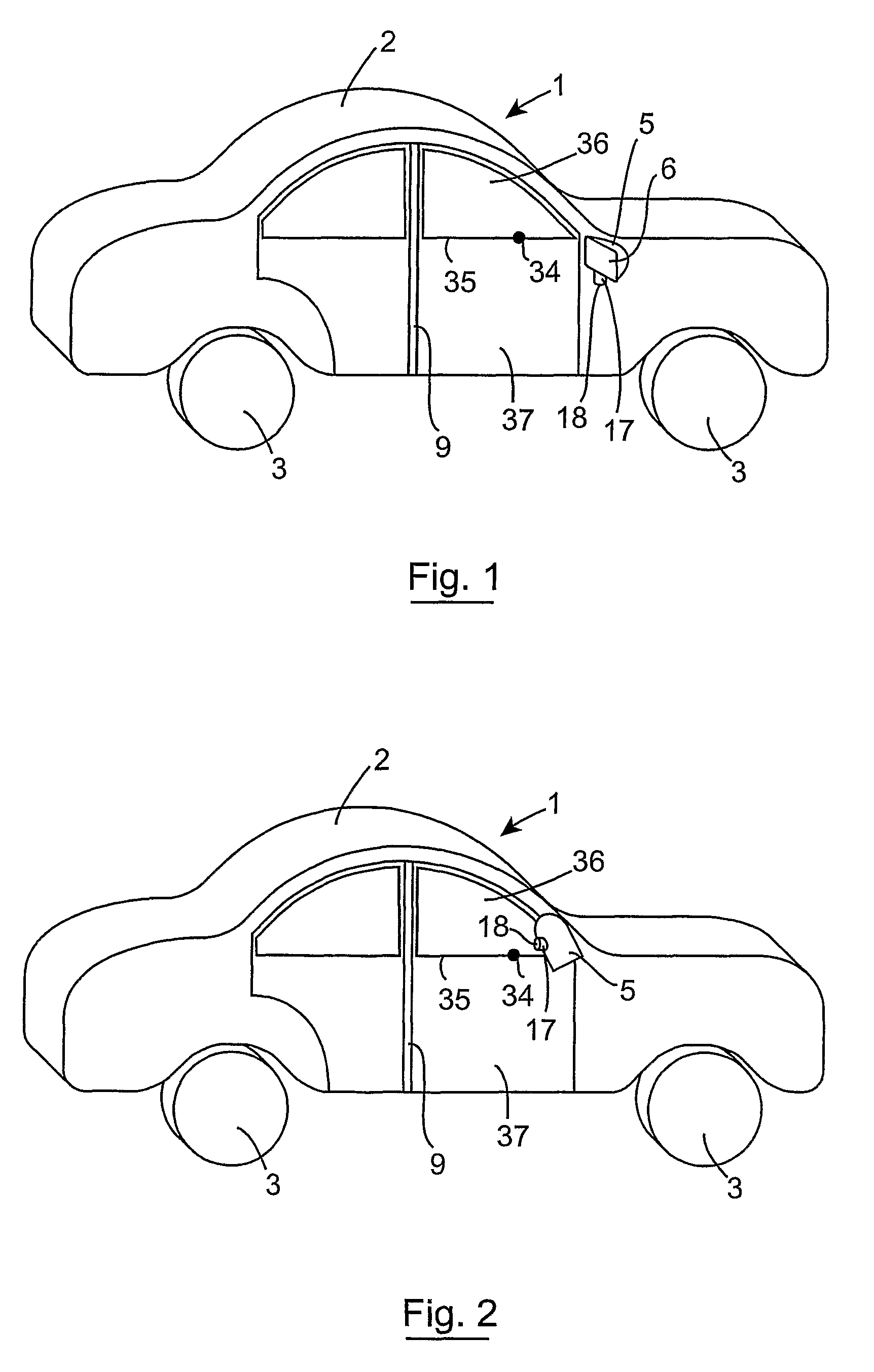

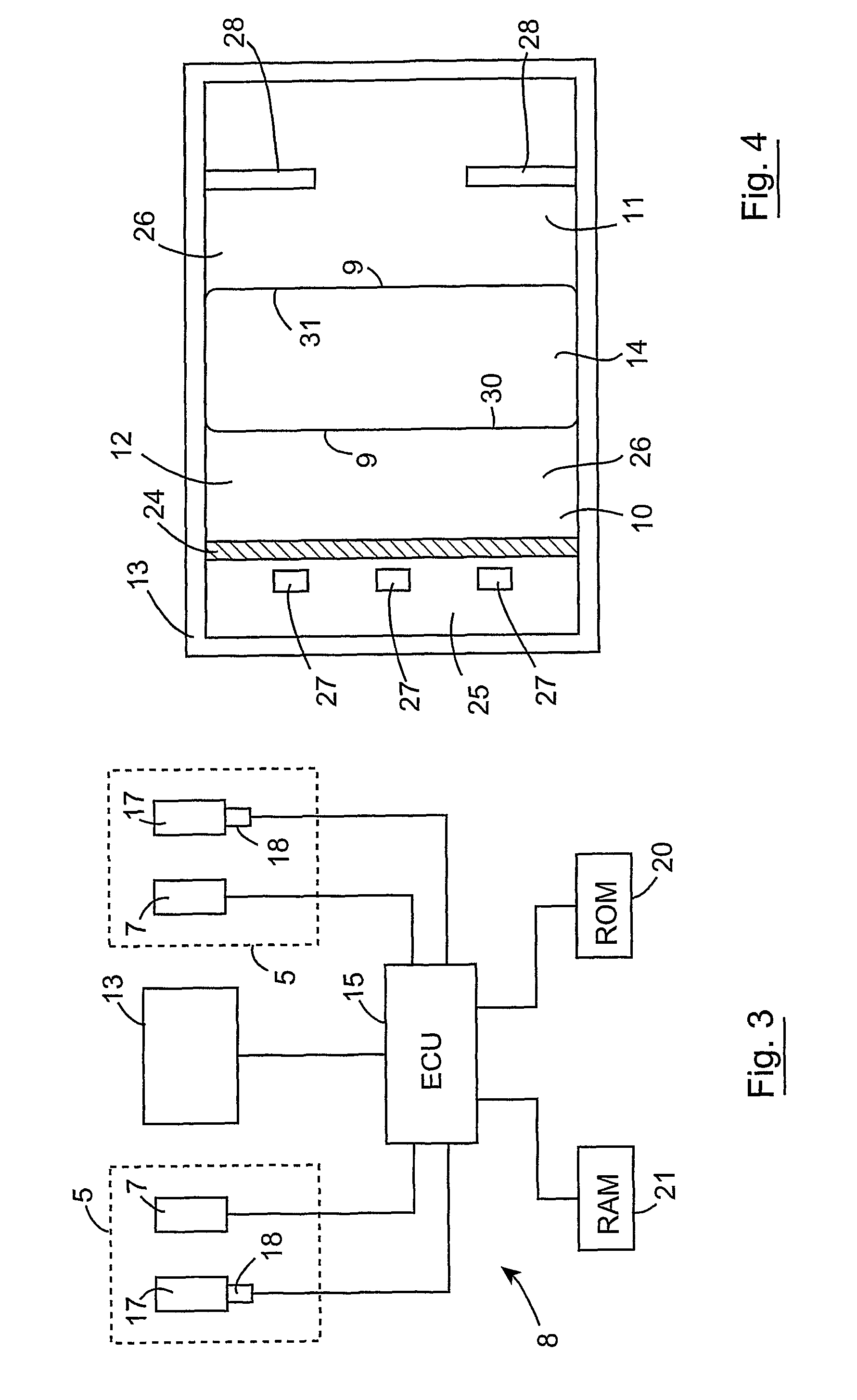

Method and system for dynamically calibrating vehicular cameras

A method of dynamically calibrating a given camera relative to a reference camera of a vehicle includes identifying an overlapping region in an image frame provided by the given camera and an image frame provided by the reference camera and selecting at least a portion of an object in the overlapped region of the reference image frame. Expected pixel positions of the selected object portion in the given image frame is determined based on the location of the selected object portion in the reference image frame, and pixel positions of the selected object portion are located as detected in the given image frame. An alignment of the given camera is determined based on a comparison of the pixel positions of the selected object portion in the given image frame to the expected pixel positions of the selected object portion in the given image frame.

Owner:MAGNA ELECTRONICS

Gateway platform for biological monitoring and delivery of therapeutic compounds

InactiveUS20060253005A1Decrease adhesion and encapsulationImprove data qualityBioelectric signal measurementDrug and medicationsBiomonitoringComputer science

Owner:PHILOMETRON

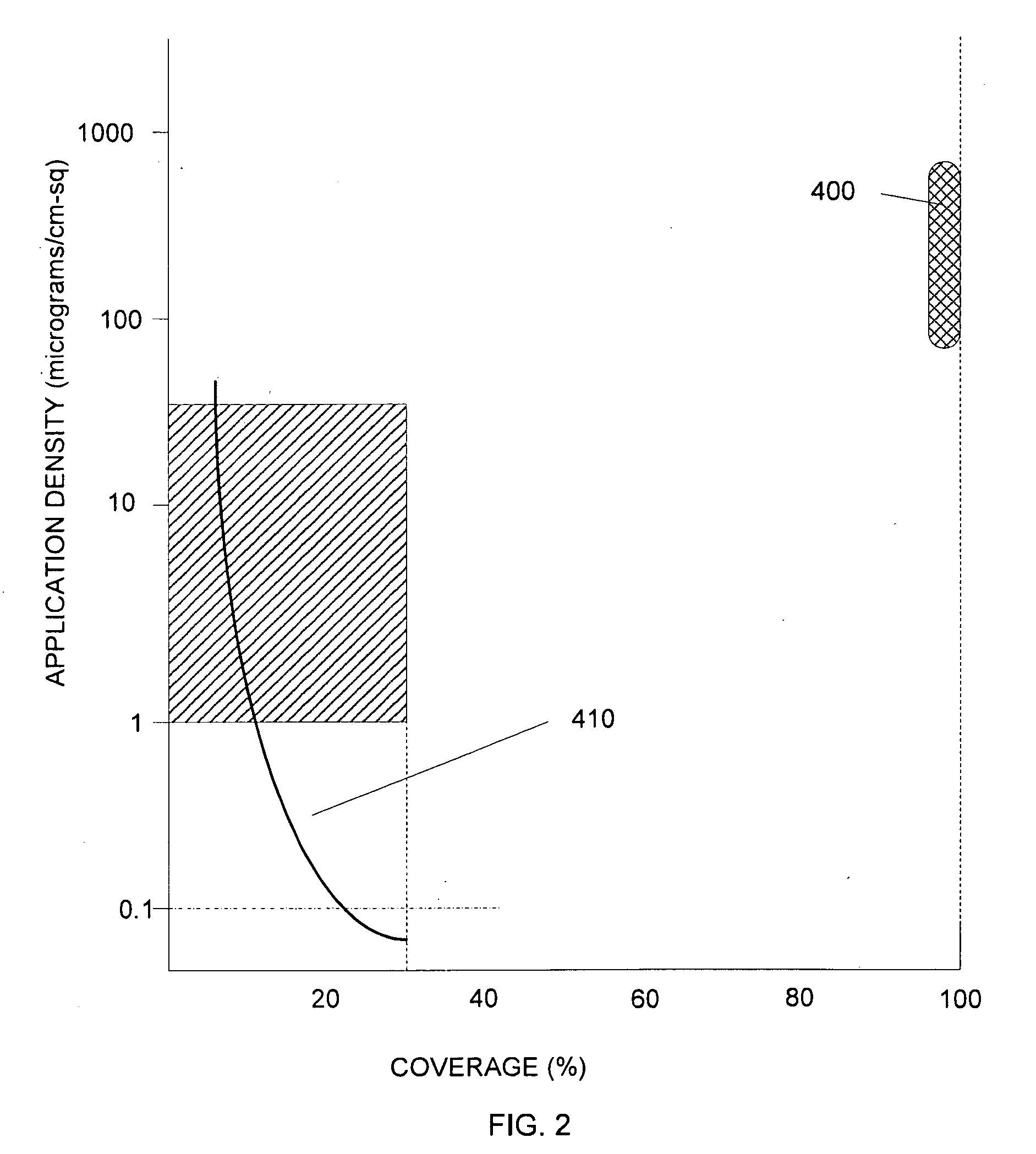

Apparatus and method for the precision application of cosmetics

ActiveUS20090025747A1Easy to moveArea coveredTypewritersPackaging toiletriesCamera imageVolumetric Mass Density

One or more reflectance modifying agent (RMA) such as a pigmented cosmetic agent is applied selectively and precisely with a controlled spray to human skin according to local skin reflectance or texture attributes. One embodiment uses digital control based on the analysis of a camera images. Another embodiment, utilizes a calibrated scanning device comprising a plurality of LEDs and photodiode sensors to correct reflectance readings to compensate for device distance and orientation relative to the skin. Ranges of desired RMA application parameters of high luminance RMA, selectively applied to middle spatial frequency features, at low opacity or application density are each be significantly different from conventional cosmetic practice. The ranges are complementary and the use of all three techniques in combination provides a surprisingly effective result which preserves natural beauty while applying a minimum amount of cosmetic agent.

Owner:TCMS TRANSPARENT BEAUTY LLC

Systems and methods for treating tissue with radiofrequency energy

ActiveUS10386990B2Reduce morbidityAccurate CalibrationPhysical therapies and activitiesDiagnosticsThermal treatmentRadio frequency

A system for controlling operation of a radiofrequency treatment device to apply radiofrequency energy to tissue to heat tissue to create lesions without ablating the tissue. The system includes a first treatment device having at least one electrode for applying radiofrequency energy to tissue, a controller including a connector to which a first treatment device is coupled for use, and a generator for applying radiofrequency energy to the electrodes. The controller controls application of energy so that the tissue is thermally treated to create lesions but preventing thermal treatment beyond a threshold which would ablate the tissue.

Owner:MEDERI RF LLC

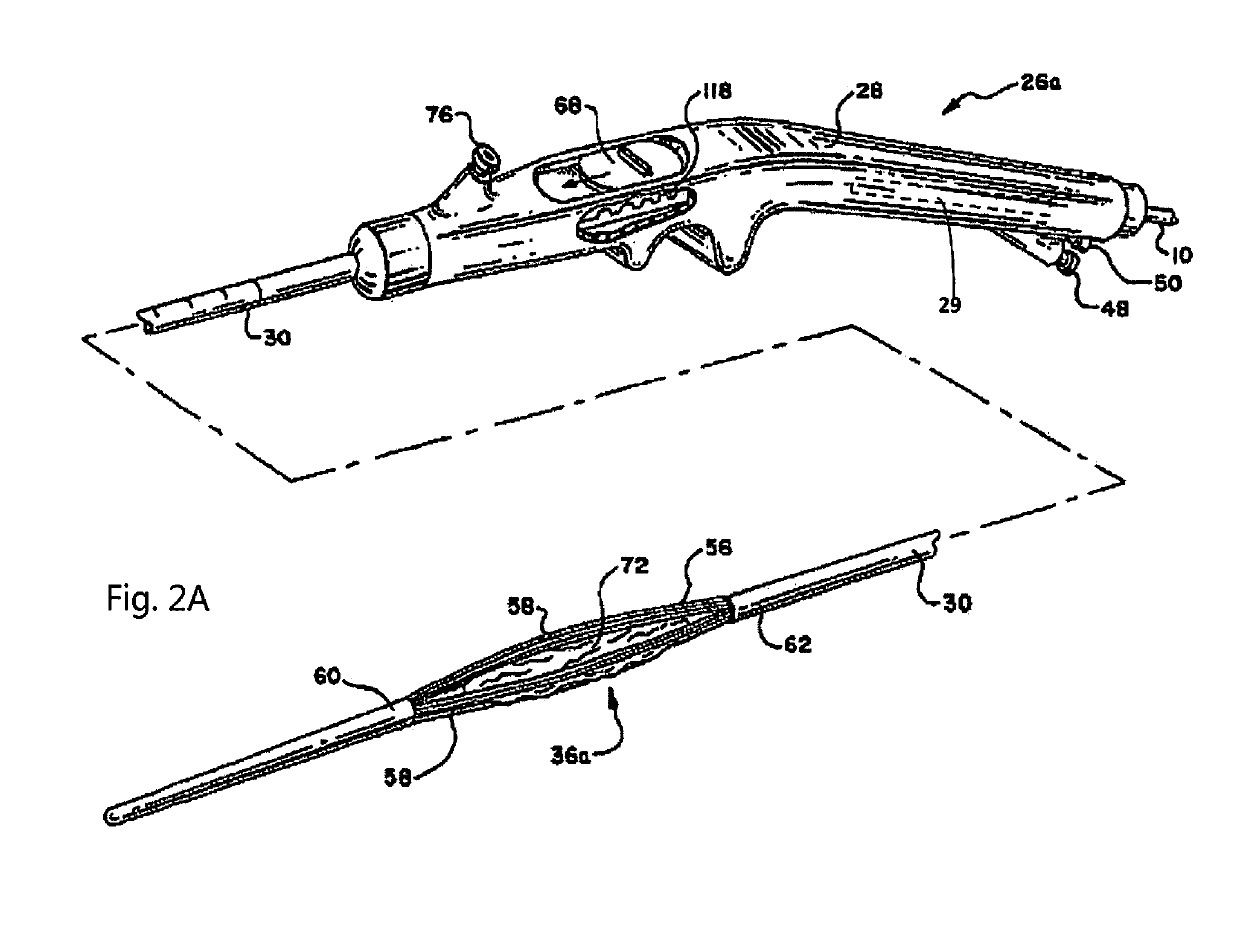

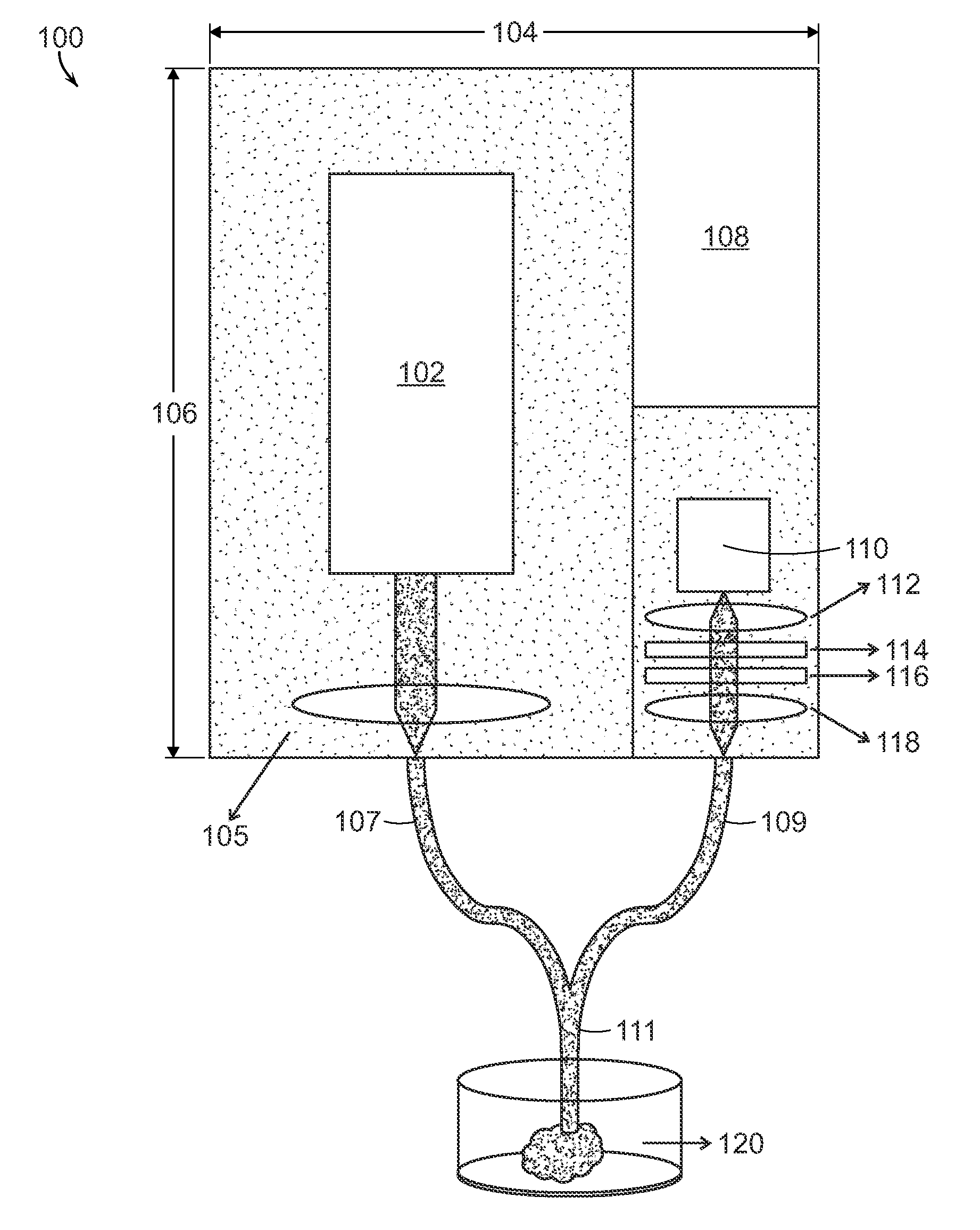

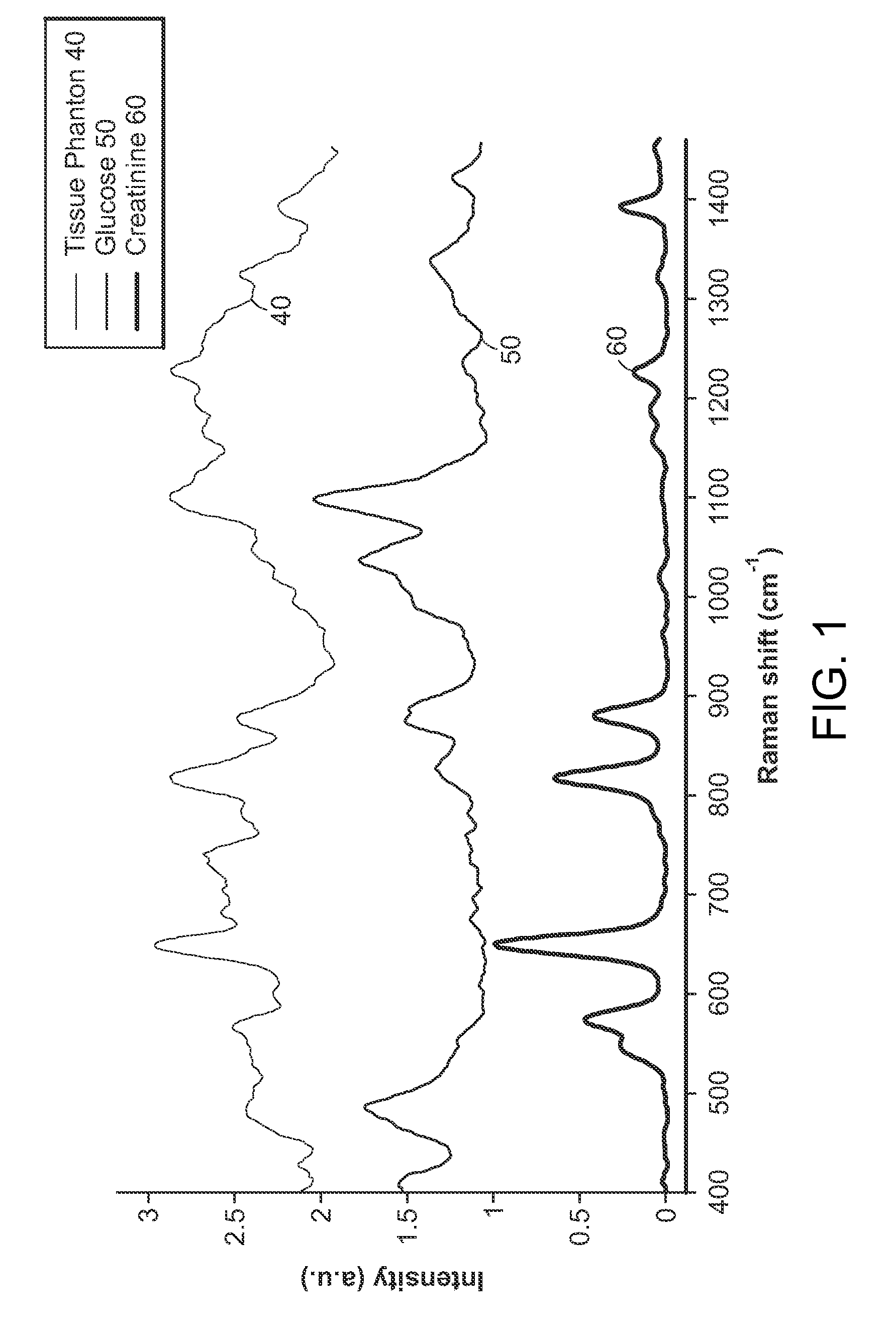

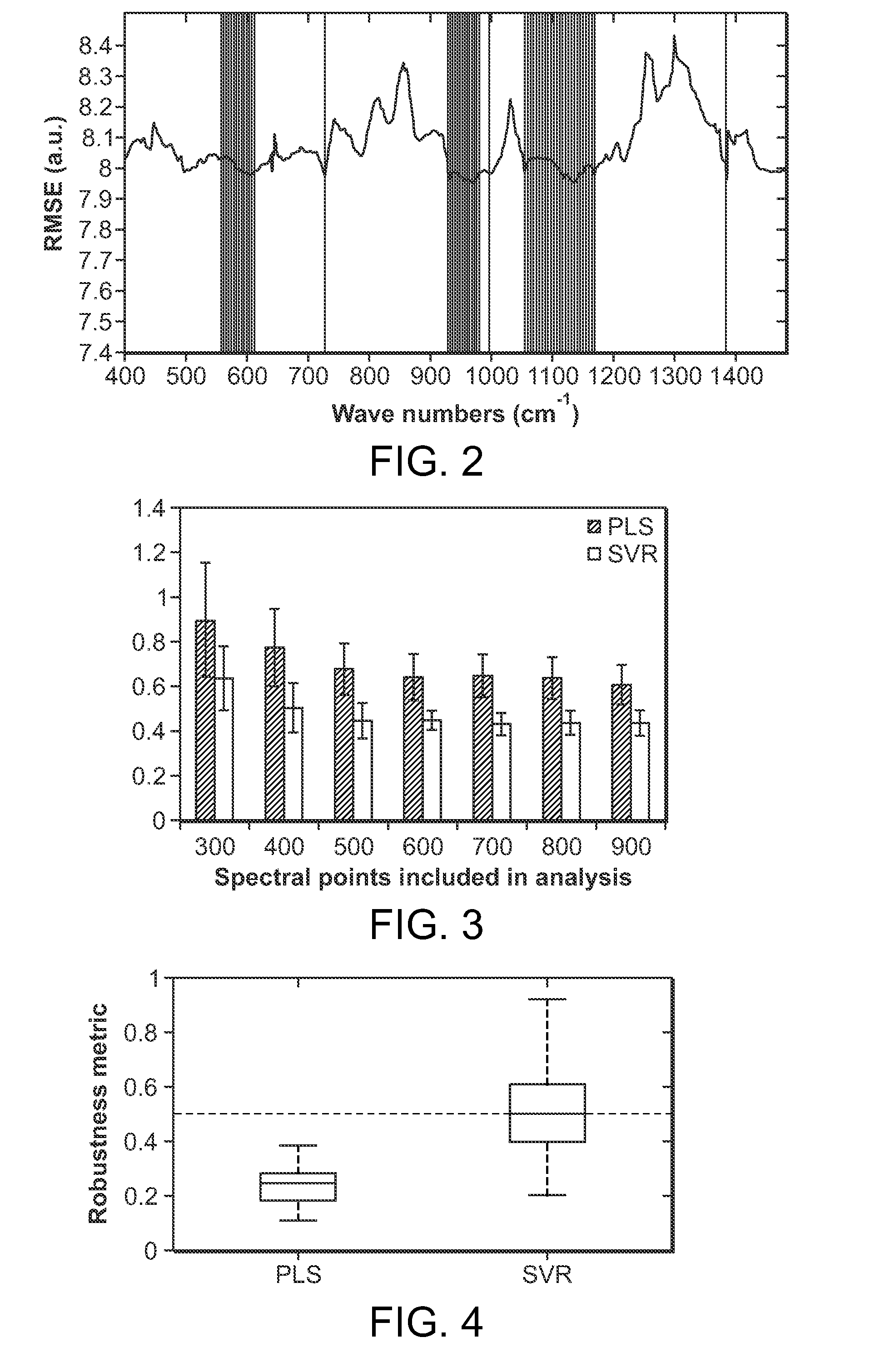

Portable raman diagnostic system

ActiveUS20120035442A1Small sizeReduce weightRaman scatteringDiagnostic recording/measuringSpectral bandsRaman Optical Activity Spectroscopy

The present invention further relates to the selection of the specific filter combinations, which can provide sufficient information for multivariate calibration to extract accurate analyte concentrations in complex biological systems. The present invention also describes wavelength interval selection methods that give rise to the miniaturized designs. Finally, this invention presents a plurality of wavelength selection methods and miniaturized spectroscopic apparatus designs and the necessary tools to map from one domain (wavelength selection) to the other (design parameters). Such selection of informative spectral bands has a broad scope in miniaturizing any clinical diagnostic instruments which employ Raman spectroscopy in particular and other spectroscopic techniques in general.

Owner:MASSACHUSETTS INST OF TECH

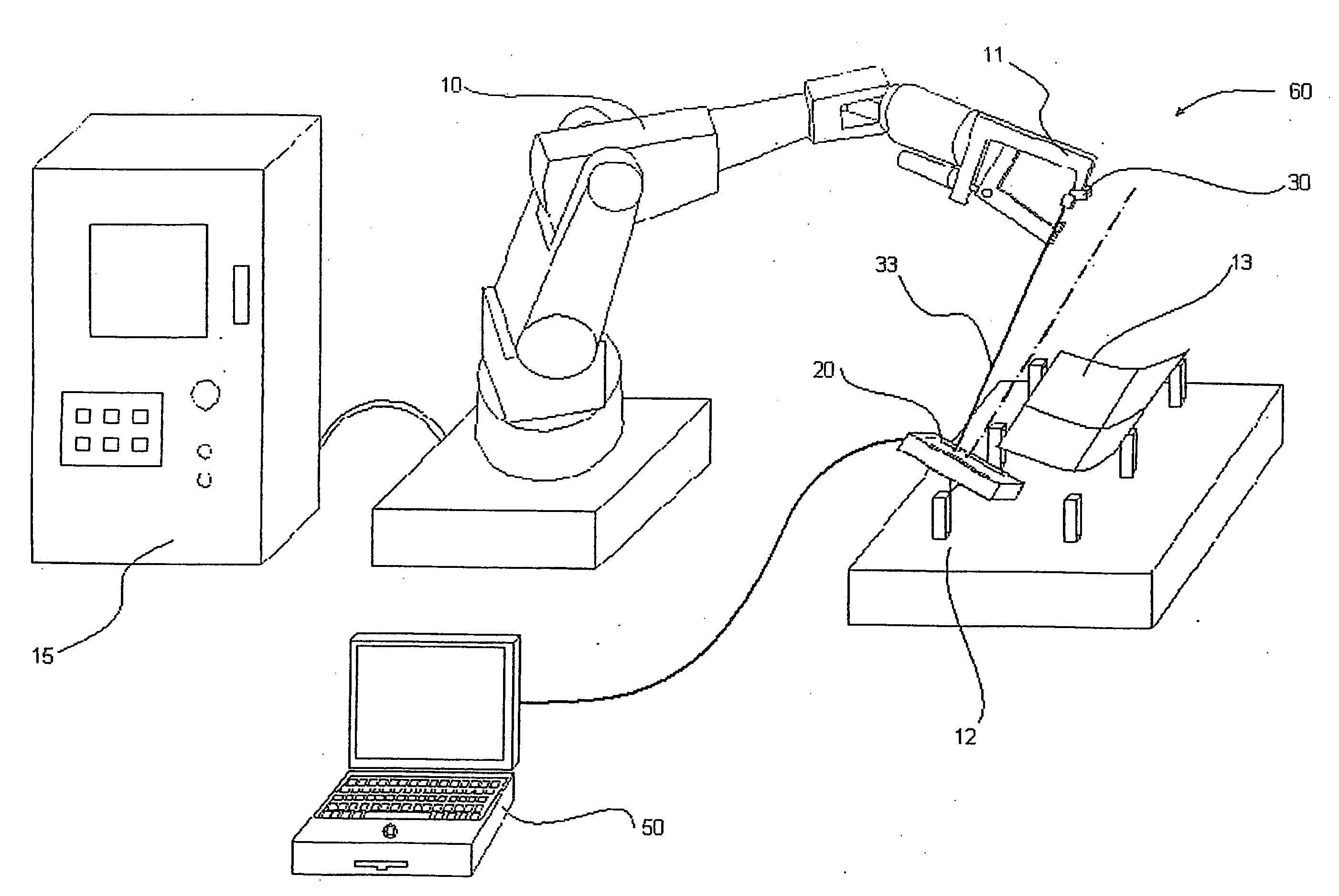

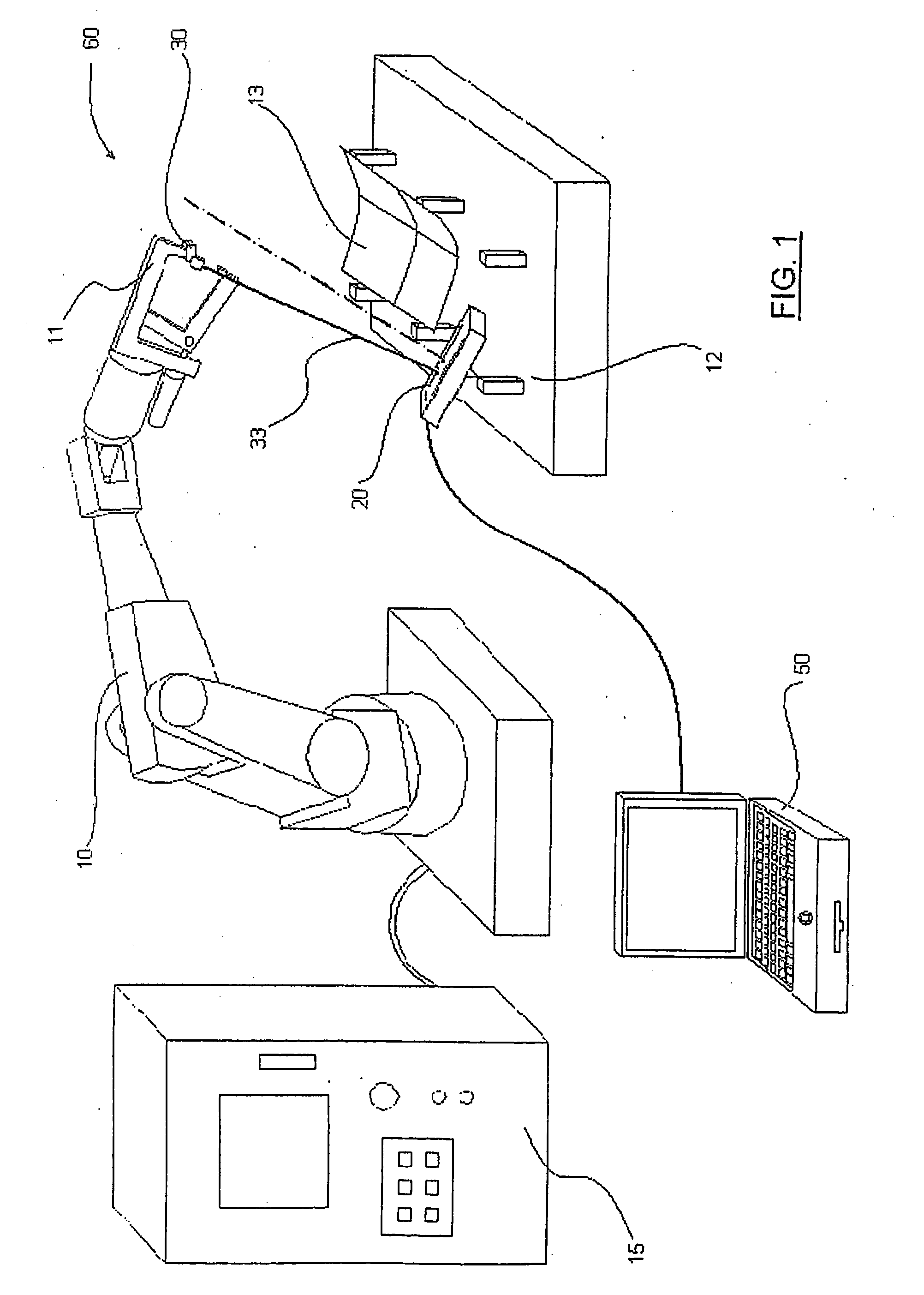

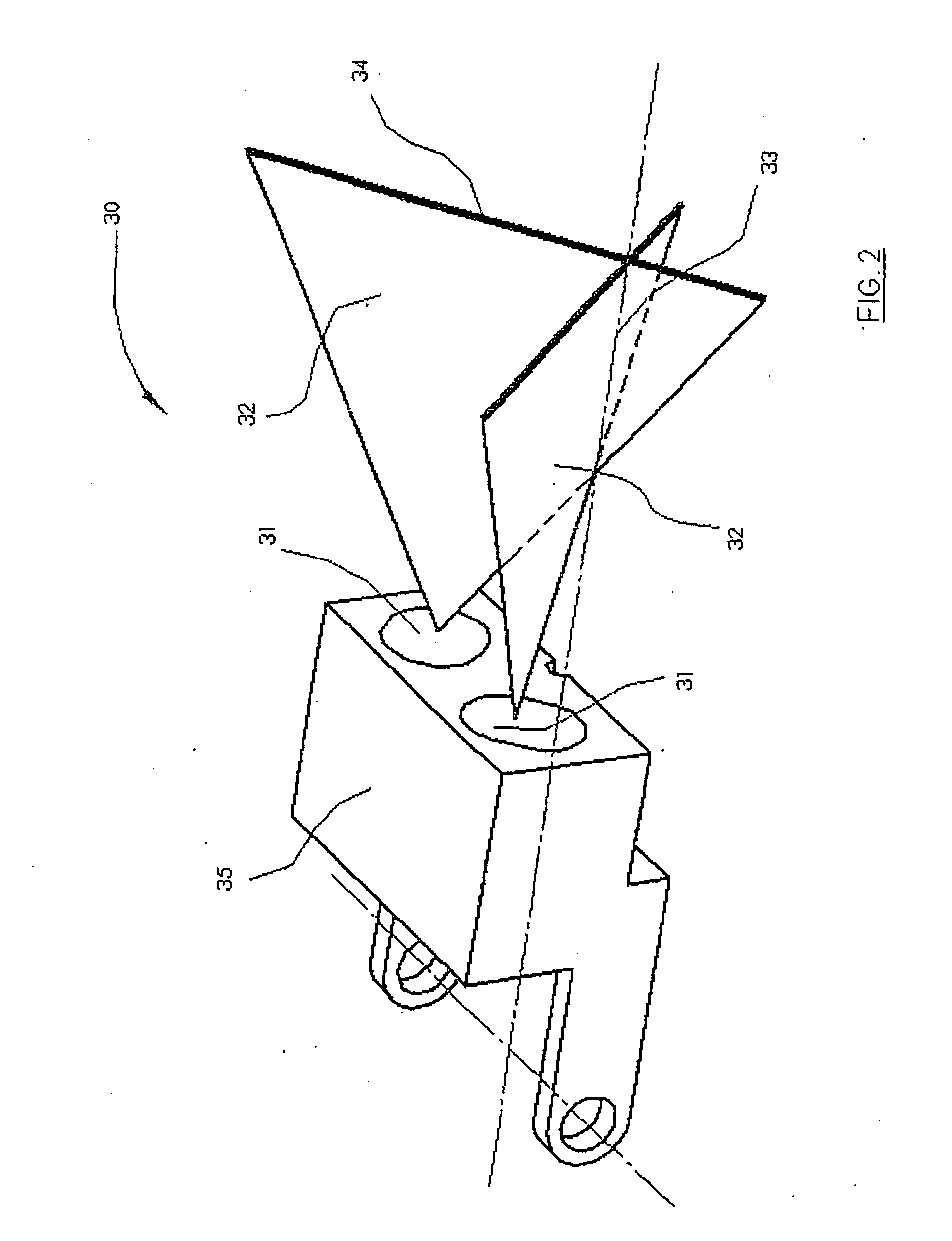

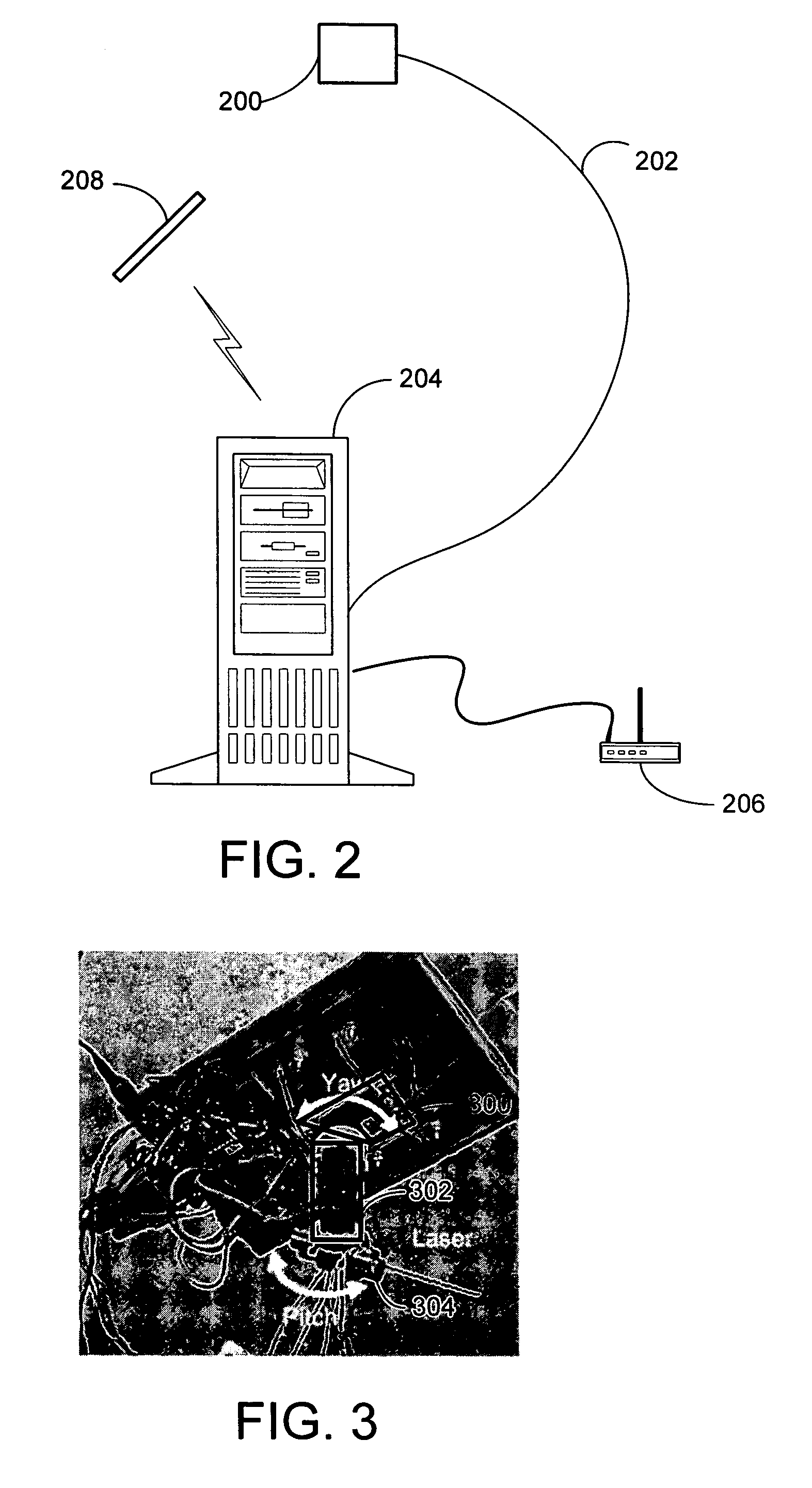

Robot-cell calibration

InactiveUS20090157226A1Easy to transportImplementation issueProgramme-controlled manipulatorComputer controlEngineeringLaser beams

A calibration system for a robot and its peripheral includes an emitter attached to the robot or its peripheral and emits a laser beam and a receiver also mounted to the robot or its peripheral at a point to permit calibration and for receiving the laser beam and to permit calculations to determine the dimension between the emitter and the receiver.

Owner:DYNALOG

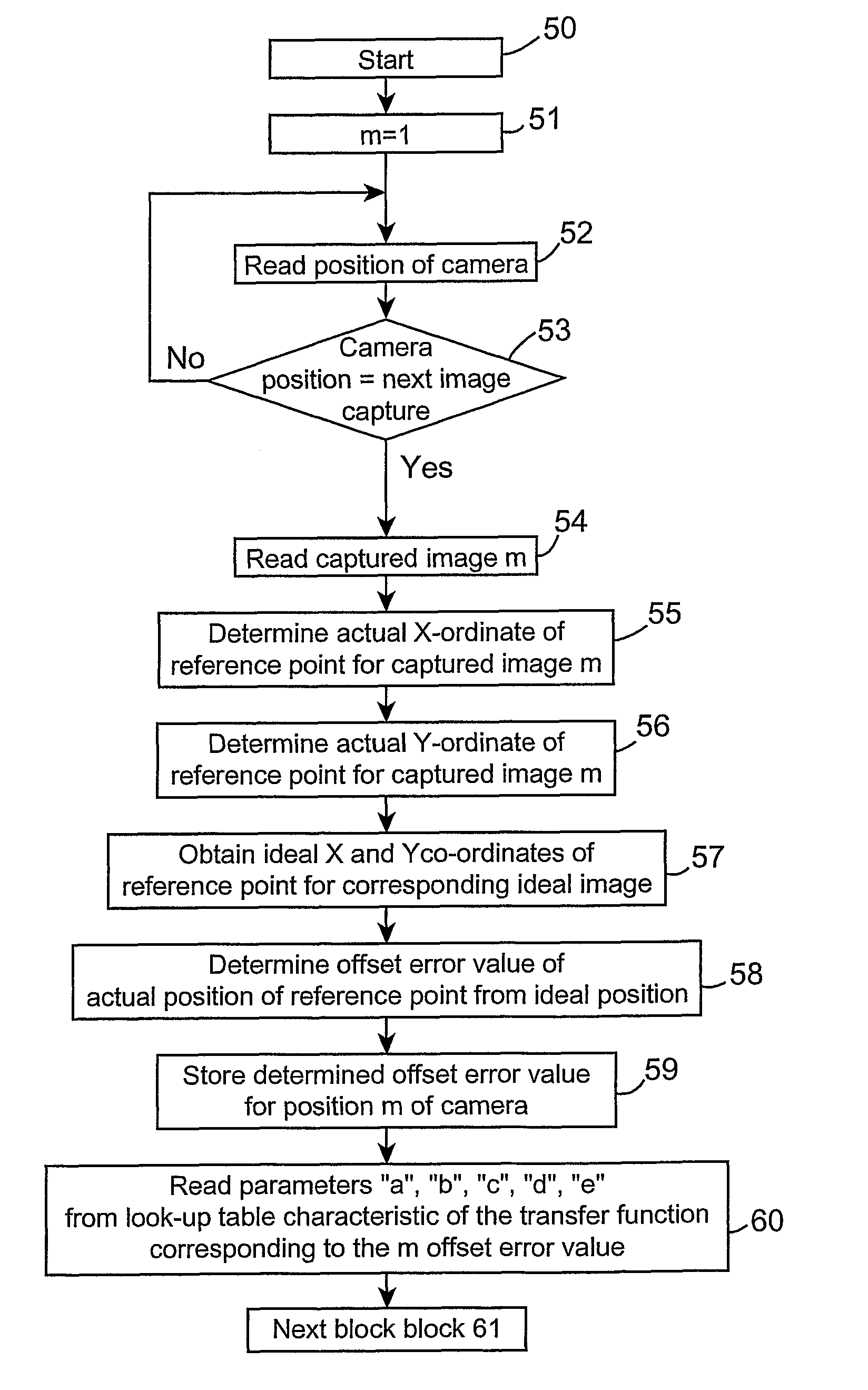

Method and apparatus for calibrating an image capturing device, and a method and apparatus for outputting image frames from sequentially captured image frames with compensation for image capture device offset

ActiveUS7949486B2Accurate CalibrationAutomatically calibratingTelevision system detailsImage enhancementRest positionIn vehicle

A camera (17) mounted on a rear view minor housing (5) of a vehicle (1), which captures a plan view image of the ground on one side of the vehicle for display on an in-vehicle visual display unit (13) is calibrated to correct for offset of the camera (17) from an ideal position. During calibration an image of a reference point (34) on the vehicle (1) is captured as the mirror housing (5) is swiveled from a rest position to an operative position. The offset of the actual position of the image of the reference point in the captured image from its ideal position is computed, and a look-up table is prepared, which indicates the position at which pixels of subsequently captured image frames should be located to produce image frames with offset correction.

Owner:CONNAUGHT ELECTRONICS

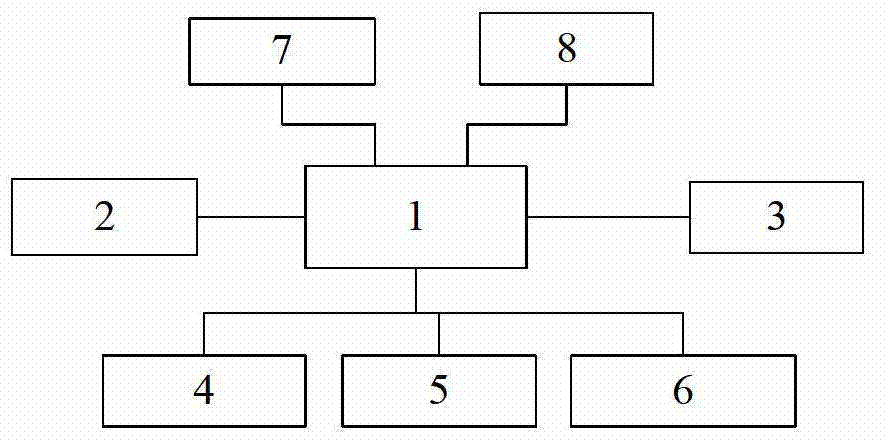

Pointing device and cursor for use in intelligent computing environments

InactiveUS7038661B2Improves upon XWand systemAccurate CalibrationCathode-ray tube indicatorsInput/output processes for data processingPointing deviceComputer science

A system and process for directing a laser beam within a space is presented. The system includes a pointing device which periodically outputs orientation data indicative of the direction it is pointing and a cursor device which projects a laser beam. The orientation data is used to compute the direction the pointing device is pointing in terms of yaw and pitch angles. The laser beam is directed to locations in the space relative to the amount of movement of the pointing device. In an absolute mode, the pointed device and the laser beam of the cursor device are pointed at the same location in the space, whereas in a relative mode, the pointing device does not point at the same location as the laser beam. The position of the laser can be used to select a variety of hardware devices known to be in a room for future control actions.

Owner:MICROSOFT TECH LICENSING LLC

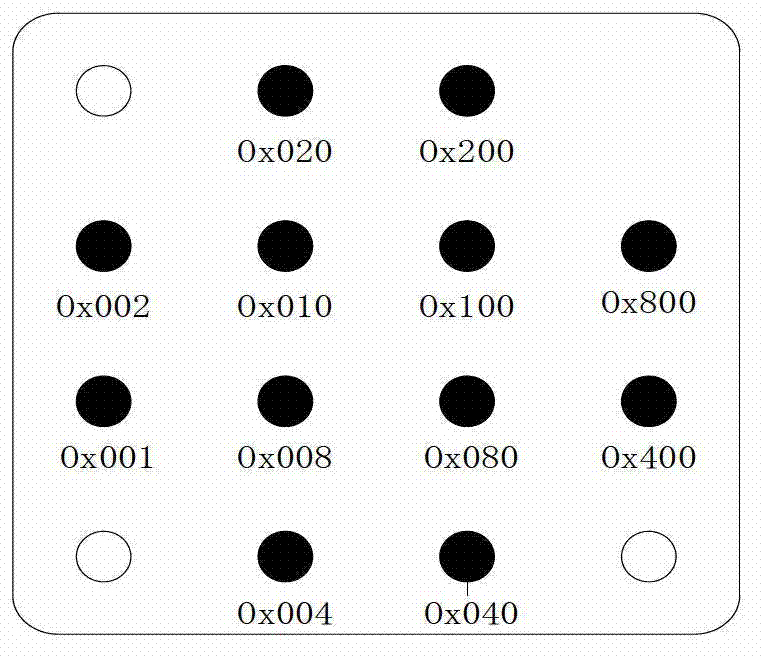

Quick and accurate locating system used for indoor mobile robot and working method thereof

The invention relates to a quick and accurate locating system used for an indoor mobile robot and a working method thereof. The quick and accurate locating system used for the indoor mobile robot comprises an alignment sensor and a plurality of reflected infrared ray passive tags, wherein the alignment sensor is arranged on the robot; the passive tags are installed on a working area ceiling; the alignment sensor comprises an image processing chip and is connected with a storage module, a COMS (complementary metal oxide semiconductor) camera, a data interface, a power supply and an infrared emission module; the infrared emission module comprises a plurality of infrared tubes, wherein the infrared tubes are arranged around the COMS camera and are divided into multiple groups; the passive tags are tags provided with a plurality of mark points; the mark points are divided into two classes, wherein the first class comprises direction points for determining the coordinate axis direction which is a unique determination direction, and the positions of only three of the four corners of the tags can be provided with the direction mark points; the second class comprises encoded points, i.e. residual mark points used for determining the ID (Identity) numbers of the tags; the mark points used for the direction are stuck with reflected infrared ray material; and the rest mark points used for encoding are stuck with the reflected infrared ray material according to the encoding requirement.

Owner:SHANDONG UNIV

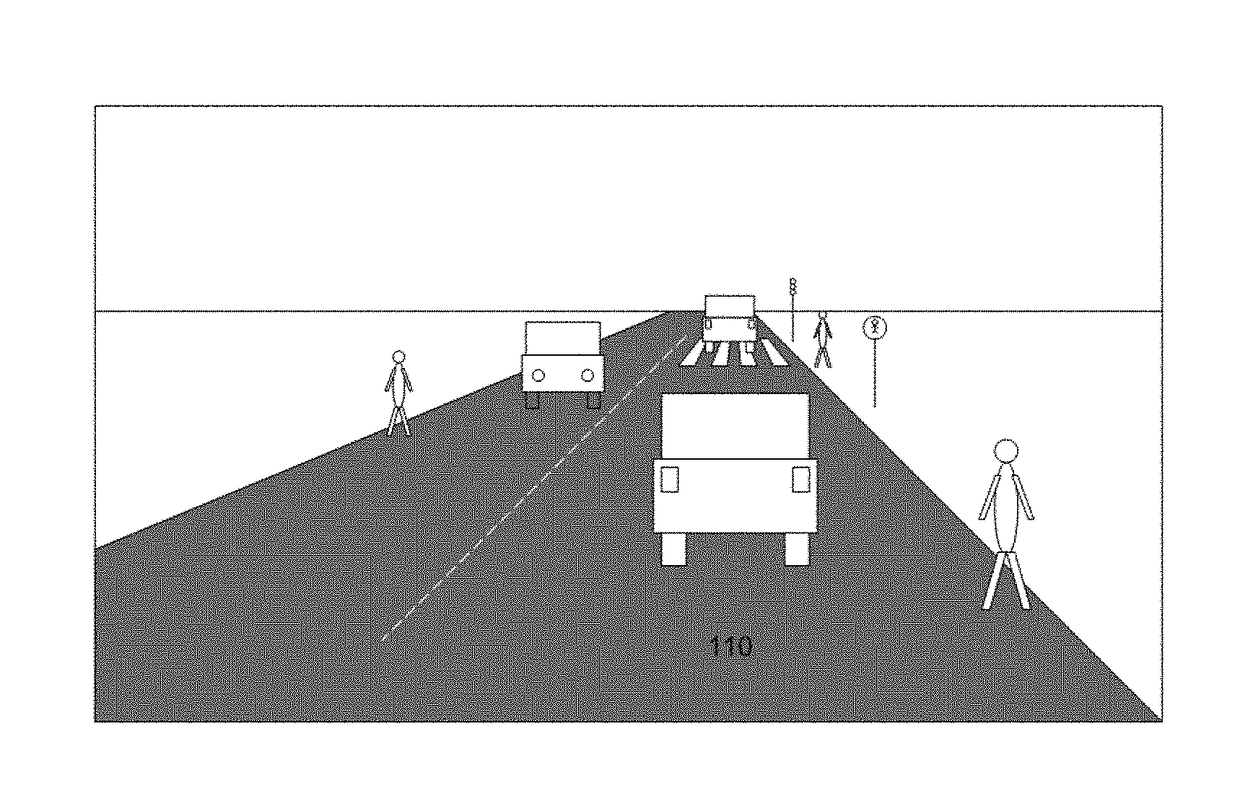

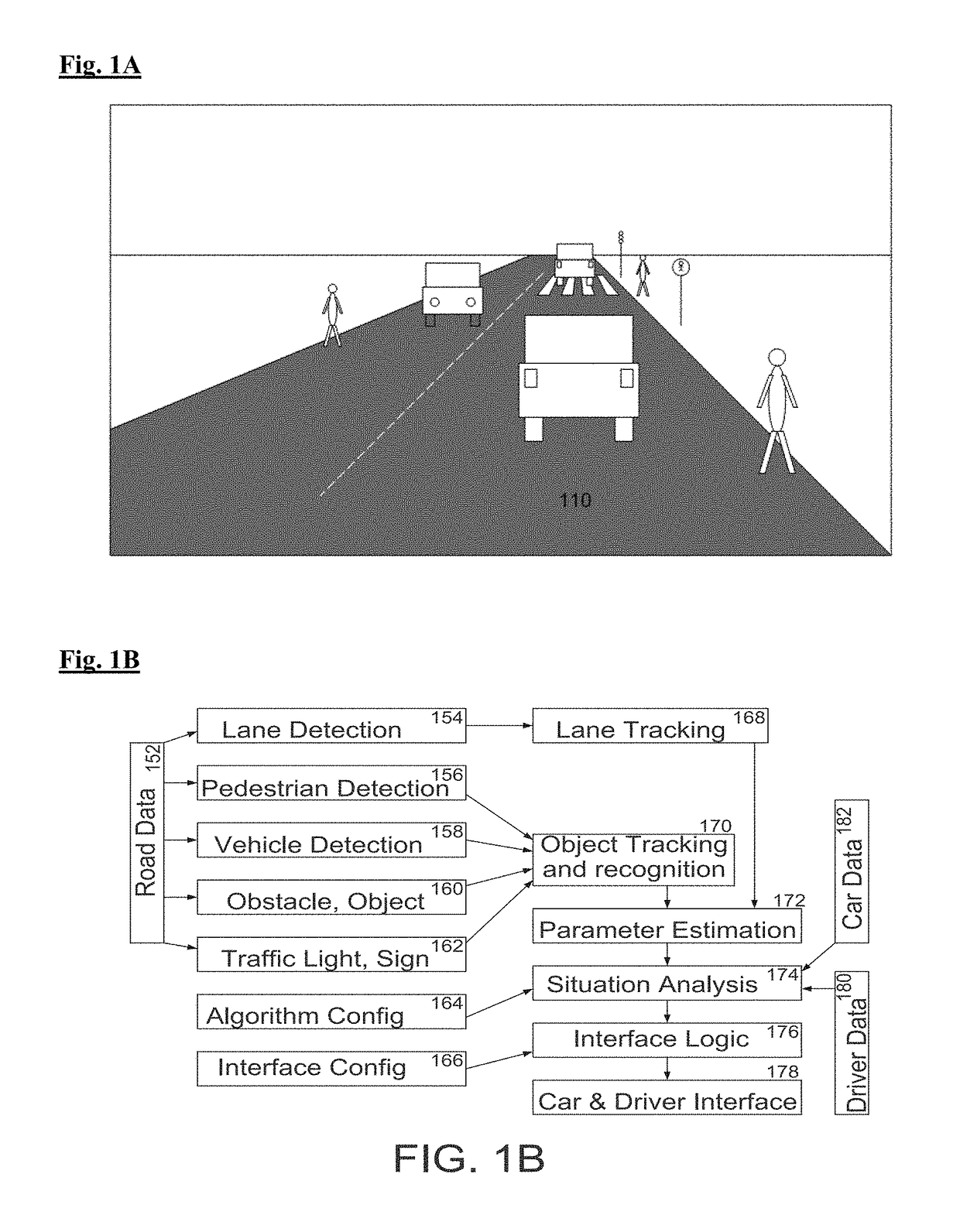

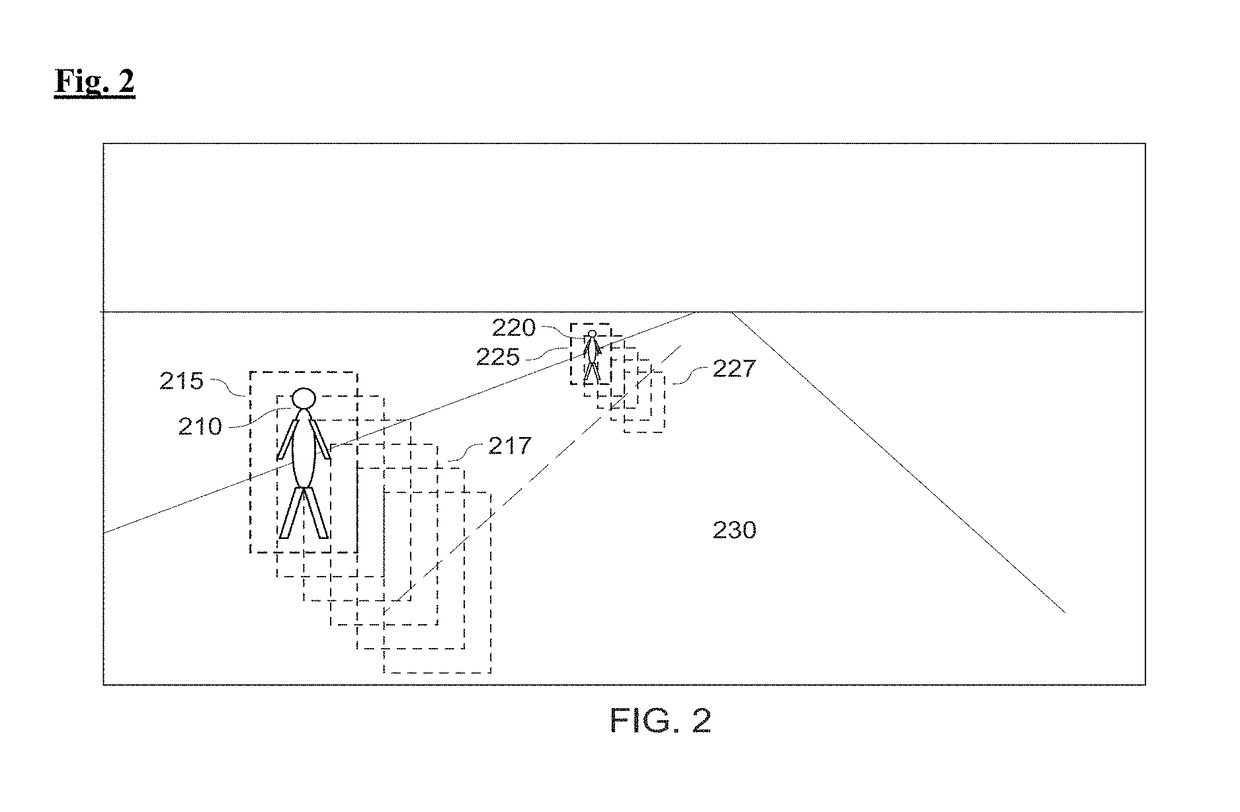

Computer Vision Based Driver Assistance Devices, Systems, Methods and Associated Computer Executable Code

InactiveUS20180012085A1Accurate CalibrationHigh resolutionInput/output for user-computer interactionImage enhancementDriver/operatorImaging processing

The present invention includes computer vision based driver assistance devices, systems, methods and associated computer executable code (hereinafter collectively referred to as: “ADAS”). According to some embodiments, an ADAS may include one or more fixed image / video sensors and one or more adjustable or otherwise movable image / video sensors, characterized by different dimensions of fields of view. According to some embodiments of the present invention, an ADAS may include improved image processing. According to some embodiments, an ADAS may also include one or more sensors adapted to monitor / sense an interior of the vehicle and / or the persons within. An ADAS may include one or more sensors adapted to detect parameters relating to the driver of the vehicle and processing circuitry adapted to assess mental conditions / alertness of the driver and directions of driver gaze. These may be used to modify ADAS operation / thresholds.

Owner:KAMI VISION INC

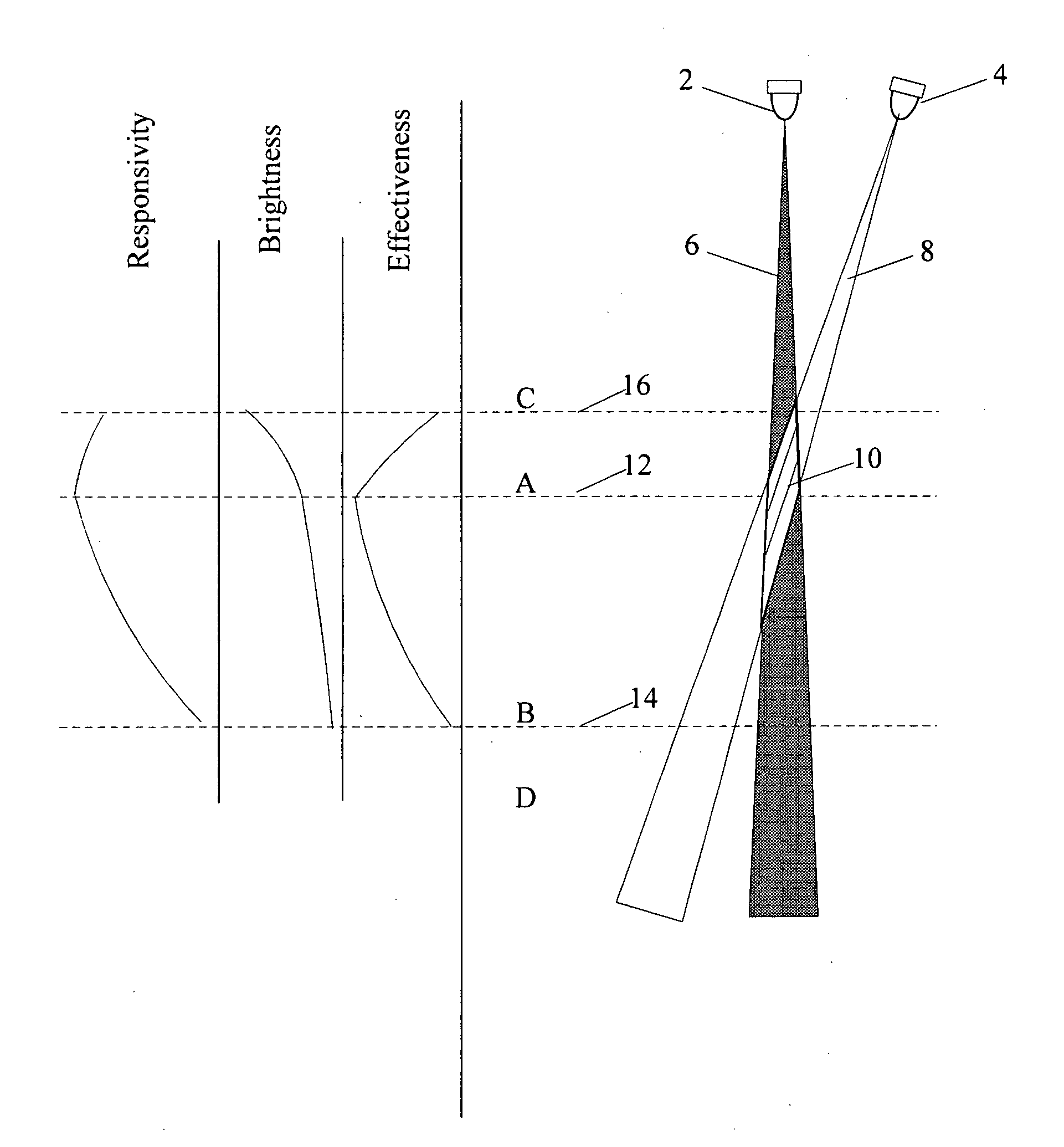

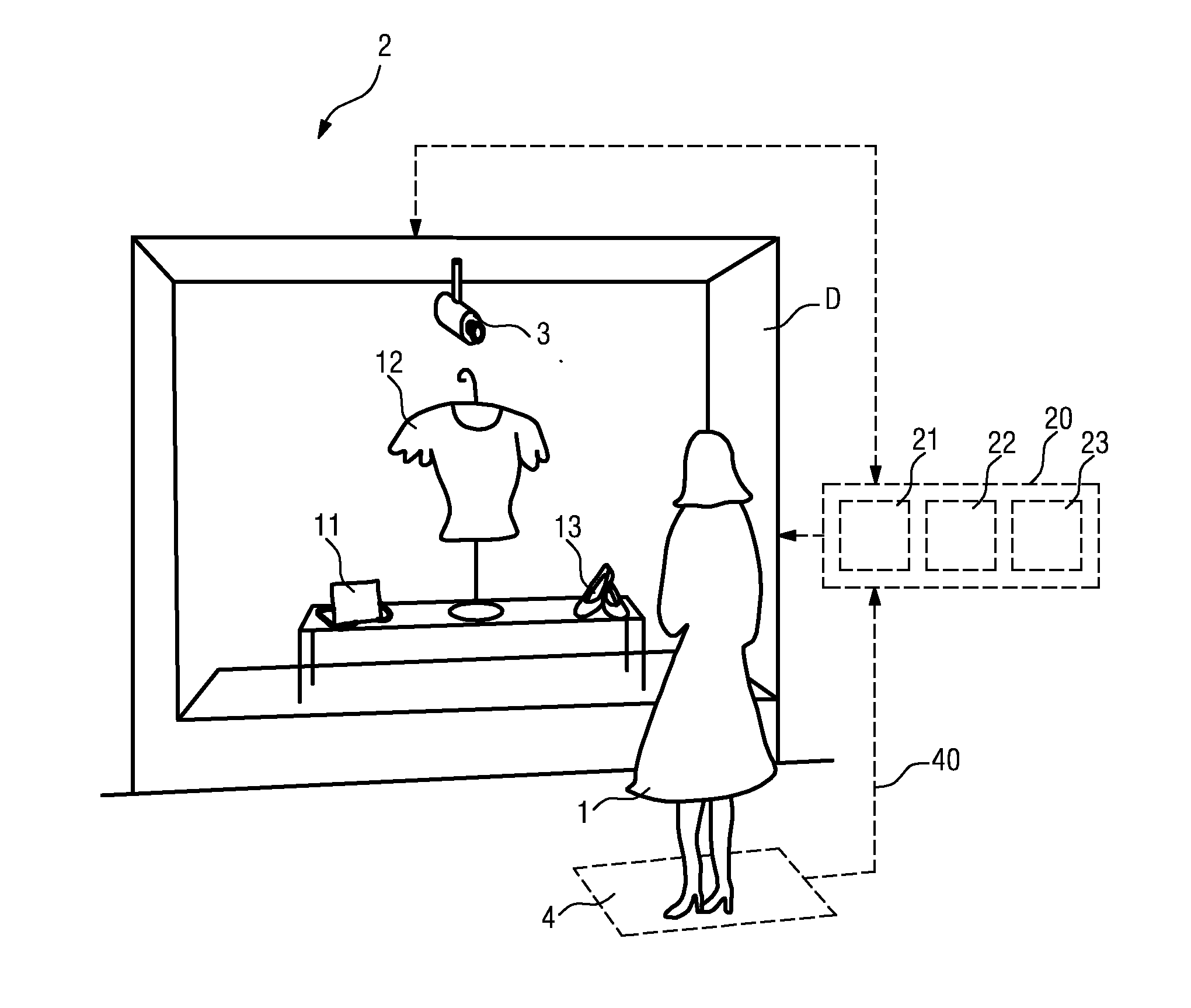

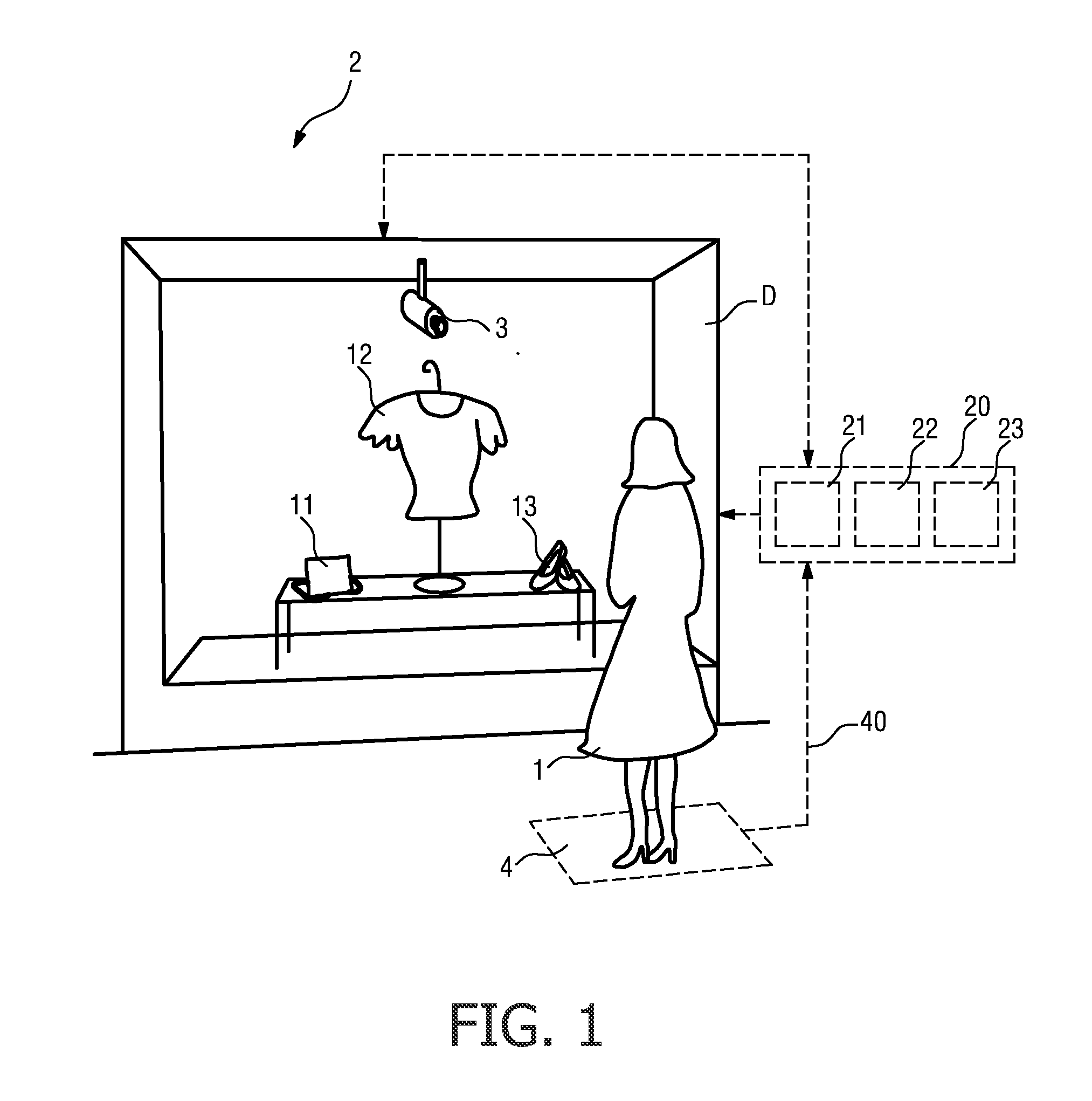

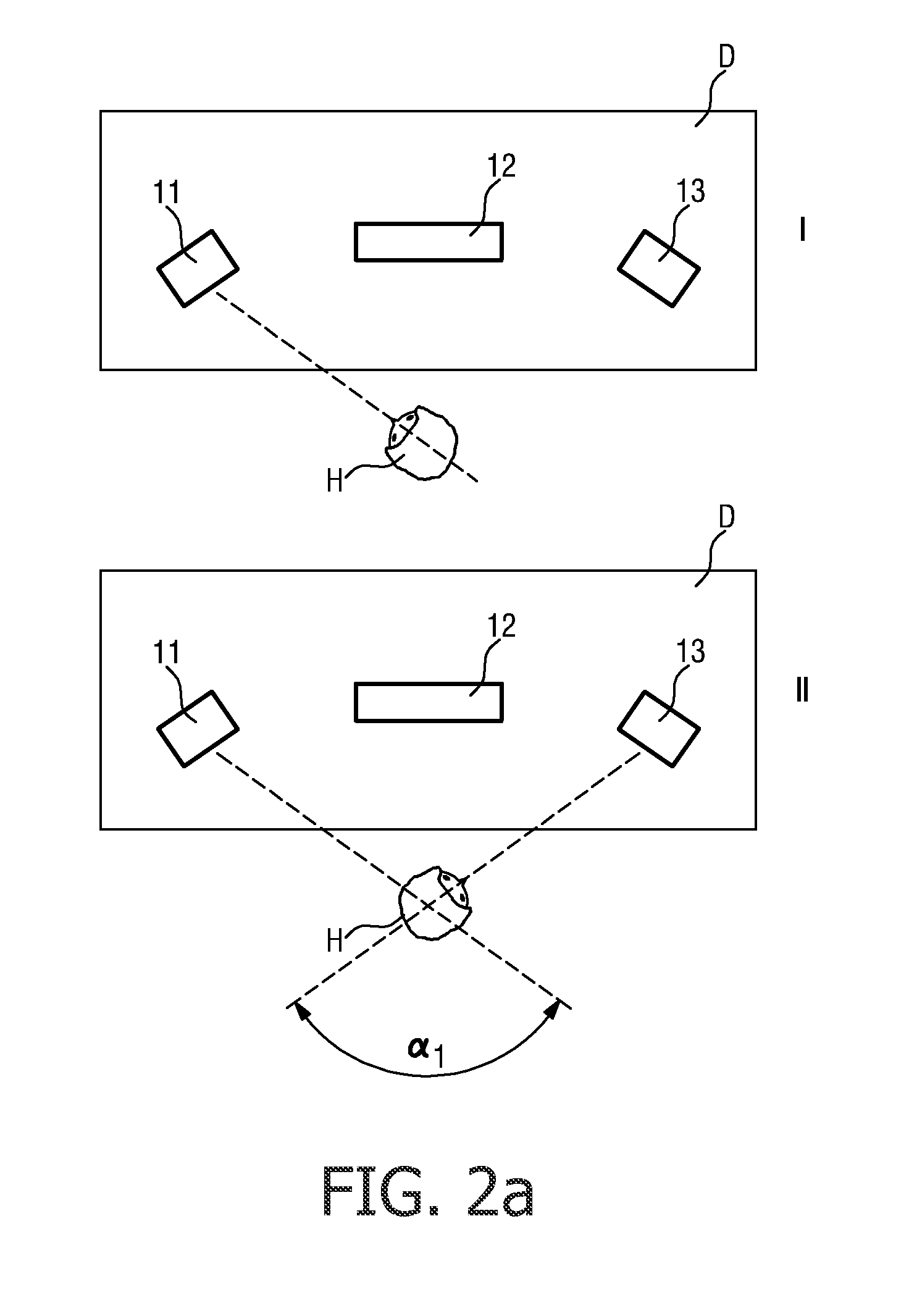

Method of and system for determining a head-motion/gaze relationship for a user, and an interactive display system

InactiveUS20110128223A1Accurate CalibrationComfortable appearanceCathode-ray tube indicatorsInput/output processes for data processingHead movementsOrientation measurement

The invention describes a method of determining a head-motion / gaze relationship for a user (1), which method comprises the steps of allocating at least one first target (T1) and at least one second target (T2) in a display area (D); attracting the user's gaze towards a first target (T1) and observing the user's head (H) to obtain a first head orientation measurement value (M1). The method further comprises the steps of subsequently attracting the user's gaze towards a second target (T2) and observing the user's head (H) to obtain a second head orientation measurement value (M2); and analysing the head orientation measurement values (M1, M2) to obtain a head-motion / gaze relationship (R) for that user (1). The invention further describes an interactive display system (2), and a method of performing a gaze-based interaction between a user (1) and an interactive display system (2).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

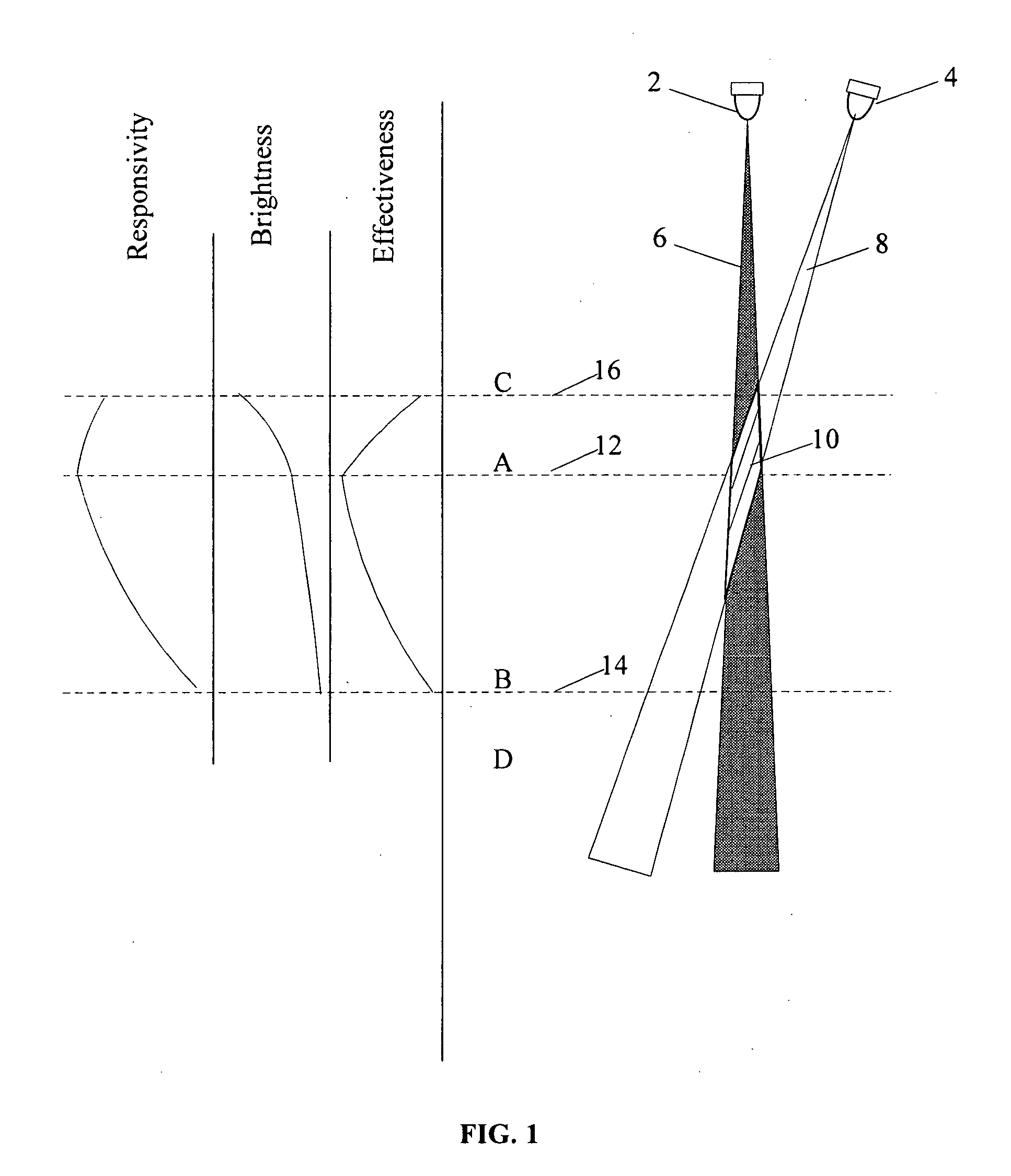

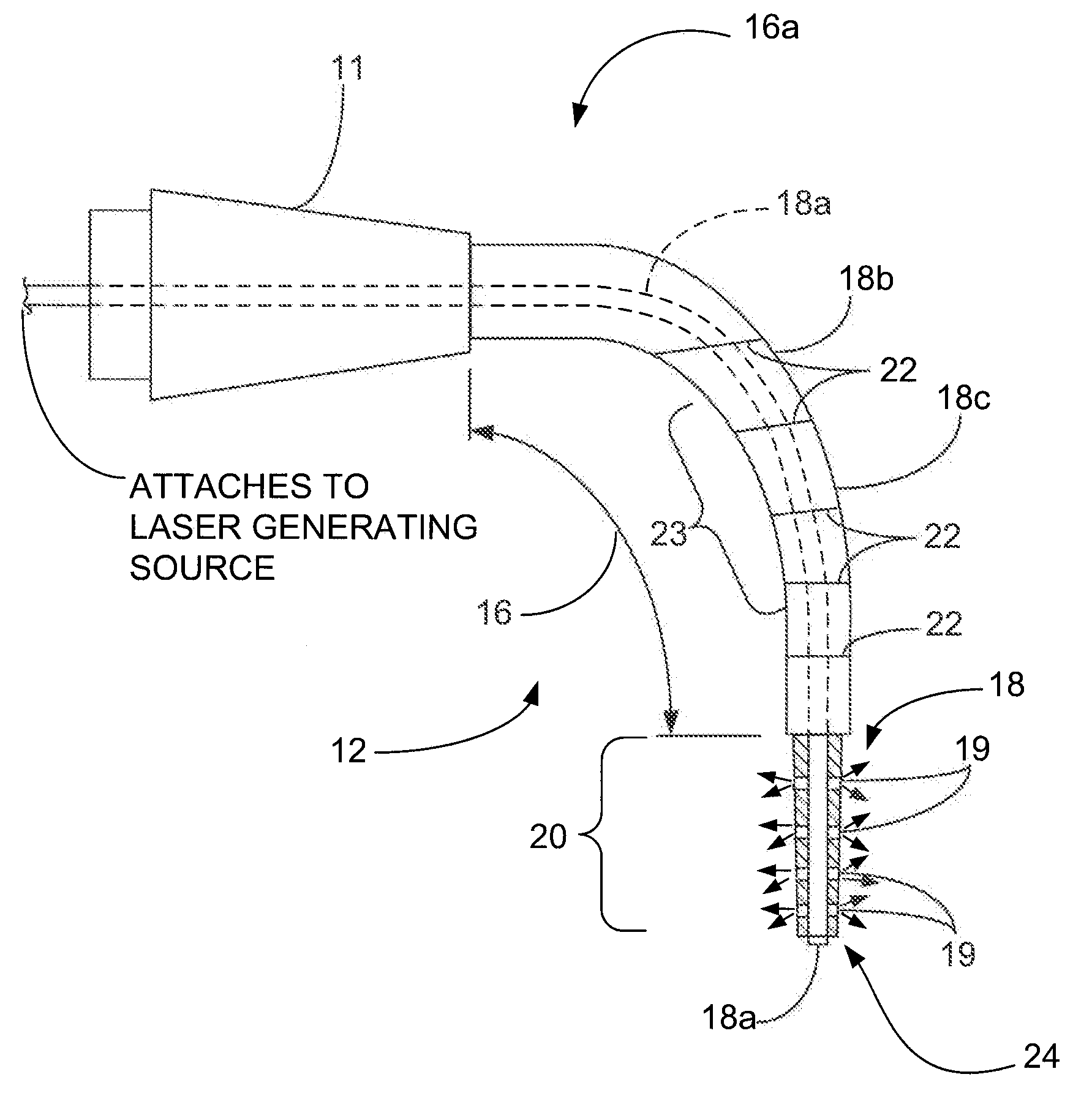

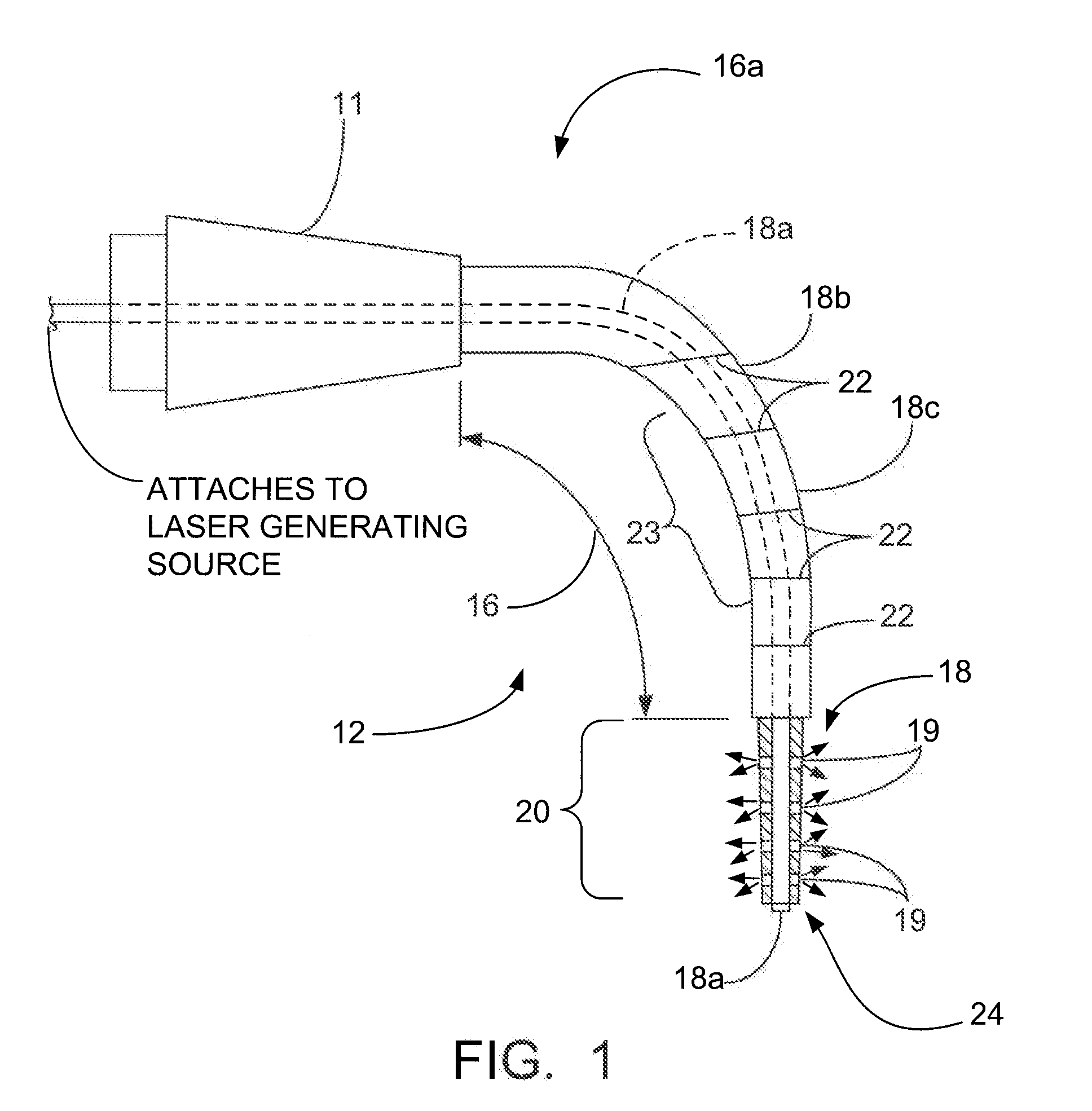

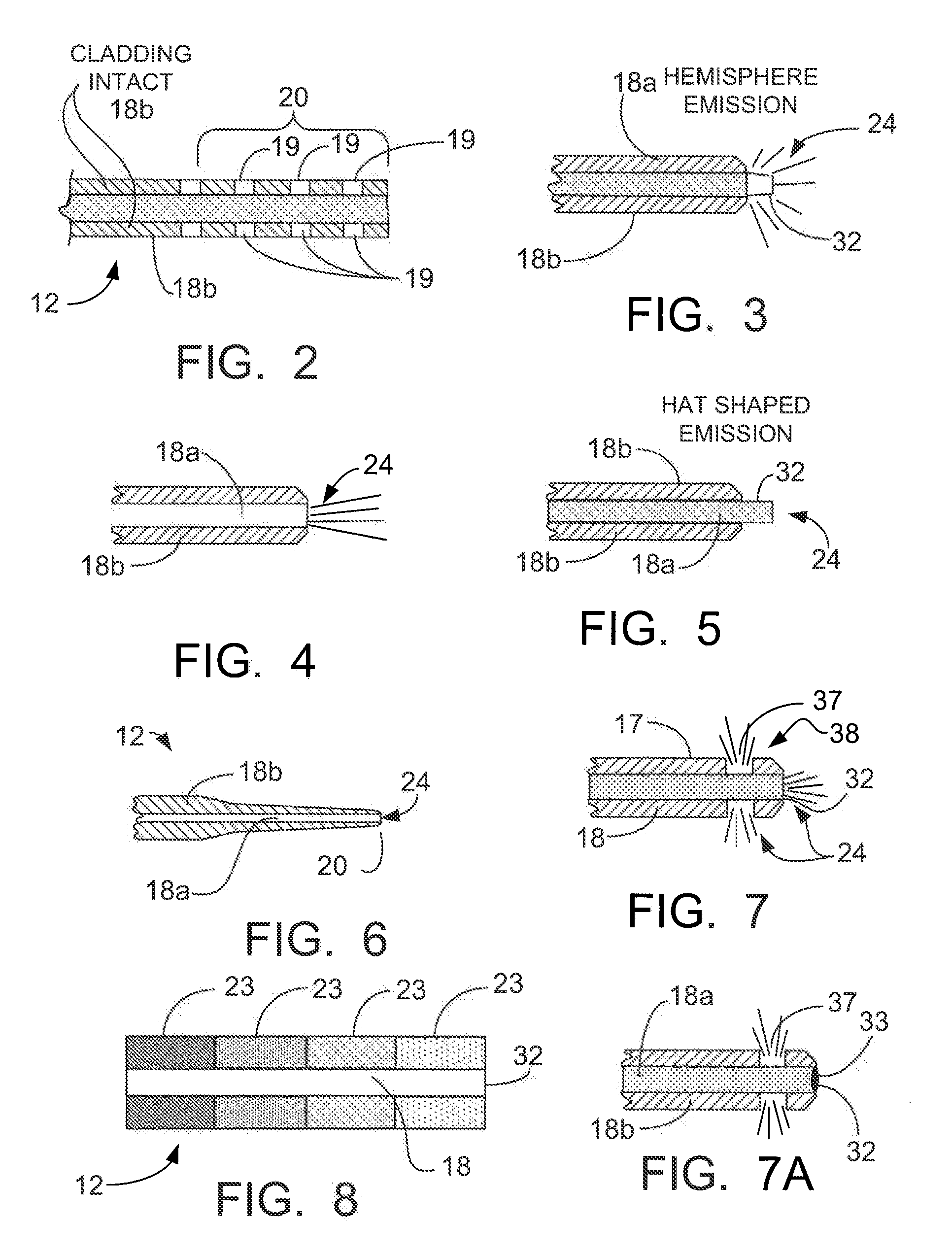

Method and Apparatus for Disinfecting or Sterilizing a Root Canal System Using Lasers Targeting Water

InactiveUS20090130622A1Sufficient deliveryEnhanced light absorptionSurgical instrument detailsDental toolsDiseaseEnergy absorption

Method and apparatus for disinfecting and / or sterilizing a root canal system by targeting the water content of disease and debris in the canals. The laser technique of employs a frequency of the wavelength emissions between about 930 to about 1065 nanometers with an optimum of 980 nm. This range of wavelengths targets the water content of tissue cells and pathogens as well as any residual organic debris in water within the root canal system after its preparation while being poorly absorbed by the surrounding dentin. The selection of the optimum wavelength produces significant effects generating and advancing treatment to the targeted aqueous environments. This is due to the rapid energy absorption by the water and the subsequent creation of gas bubbles, liberation of heat and subsequent propulsion of waves of heat and gas that impact along the canal walls and ramifications resulting in an enhanced bacterial kill and cleaning of the canal walls and ramifications. No dyes or other additives are necessary to enhance the effectiveness of the laser kill of bacteria, etc.

Owner:BOLLINGER JAMES EDWIN +2

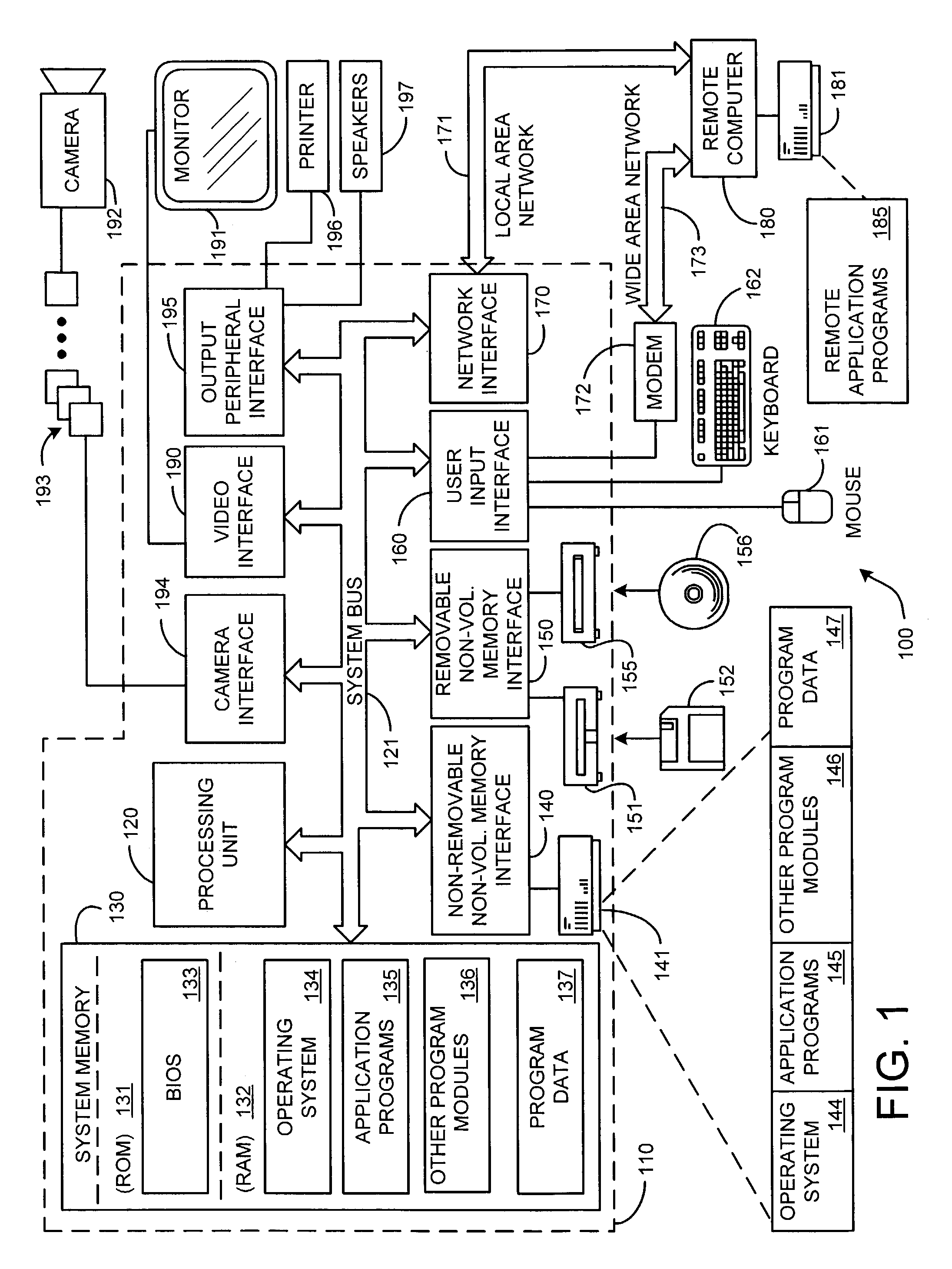

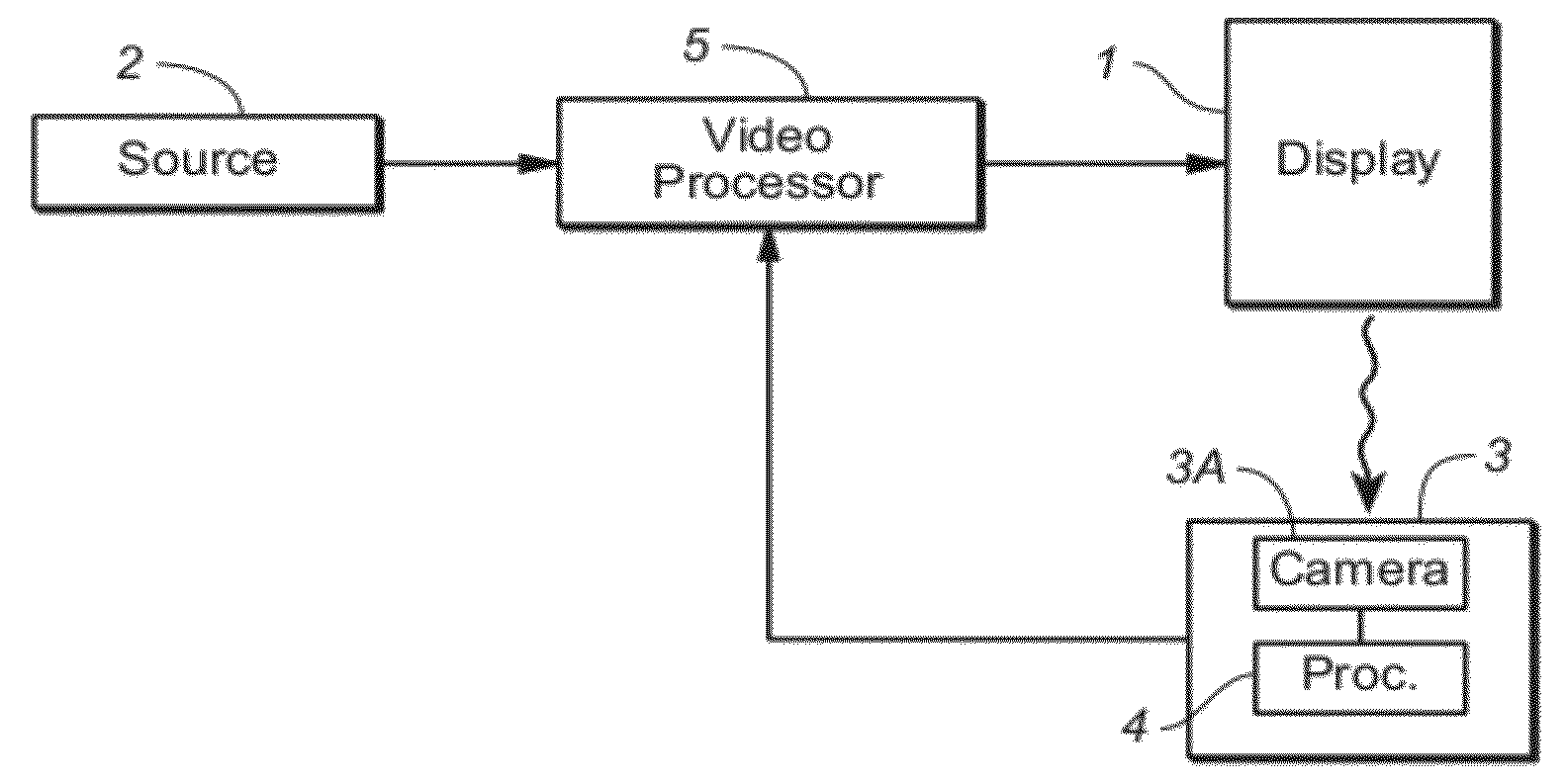

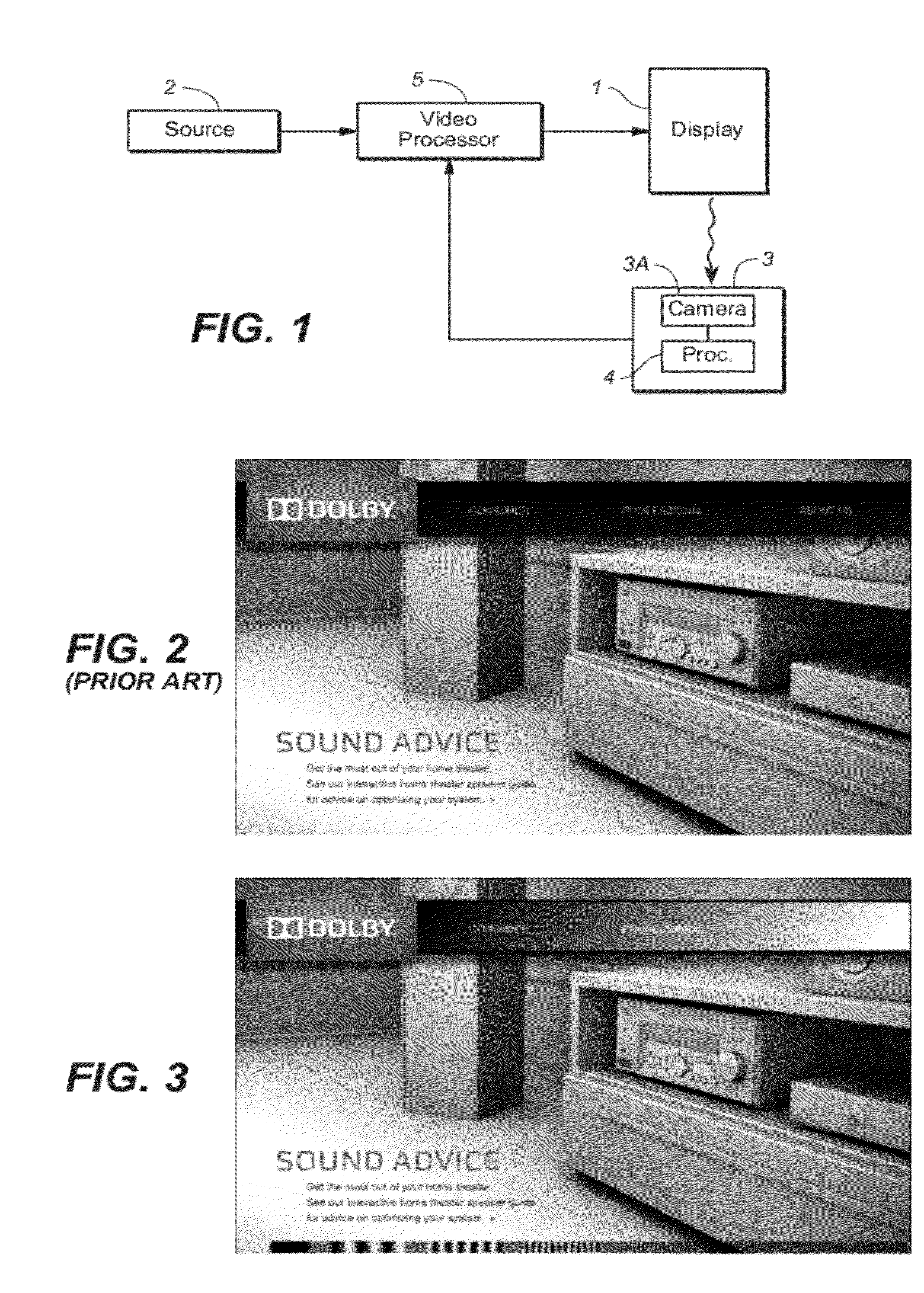

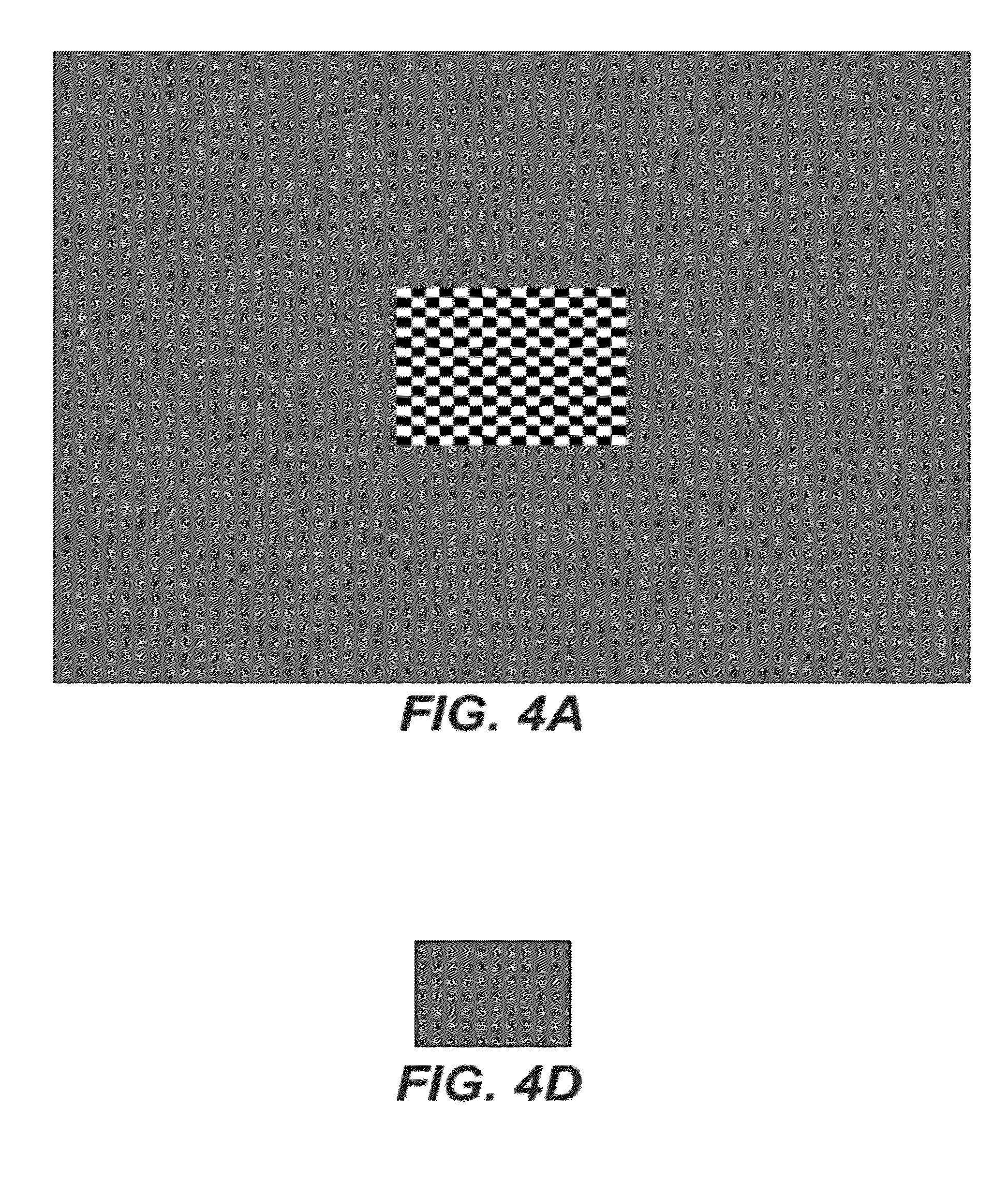

Method and System for Display Characterization or Calibration Using A Camera Device

ActiveUS20120127324A1Excessive removalAccurate representationStatic indicating devicesTelevision systemsMobile cameraComputer graphics (images)

In a class of embodiments, a method and system for characterizing a display device using a camera device (e.g., a consumer grade, mobile camera device) to sense light emitted by the display device during display of one or more test images, and to generate measurement data characterizing the display and / or calibration data useful for calibrating the display device. In some embodiments, the display device is adjusted or calibrated manually in response to such calibration data, for example by user actuation of display device controls in response to calibration data indicative of display setting recommendations. In some embodiments, the test image(s) are embedded in a video stream (e.g., overlaid on arbitrary video content). For example, test images including appropriate timing information and calibration sequences are embedded in a video stream for display by the display device. In some embodiments, the user is prompted to align the camera device (e.g., to position the camera device such that light emitted from a test image at least substantially fills the camera field of view).

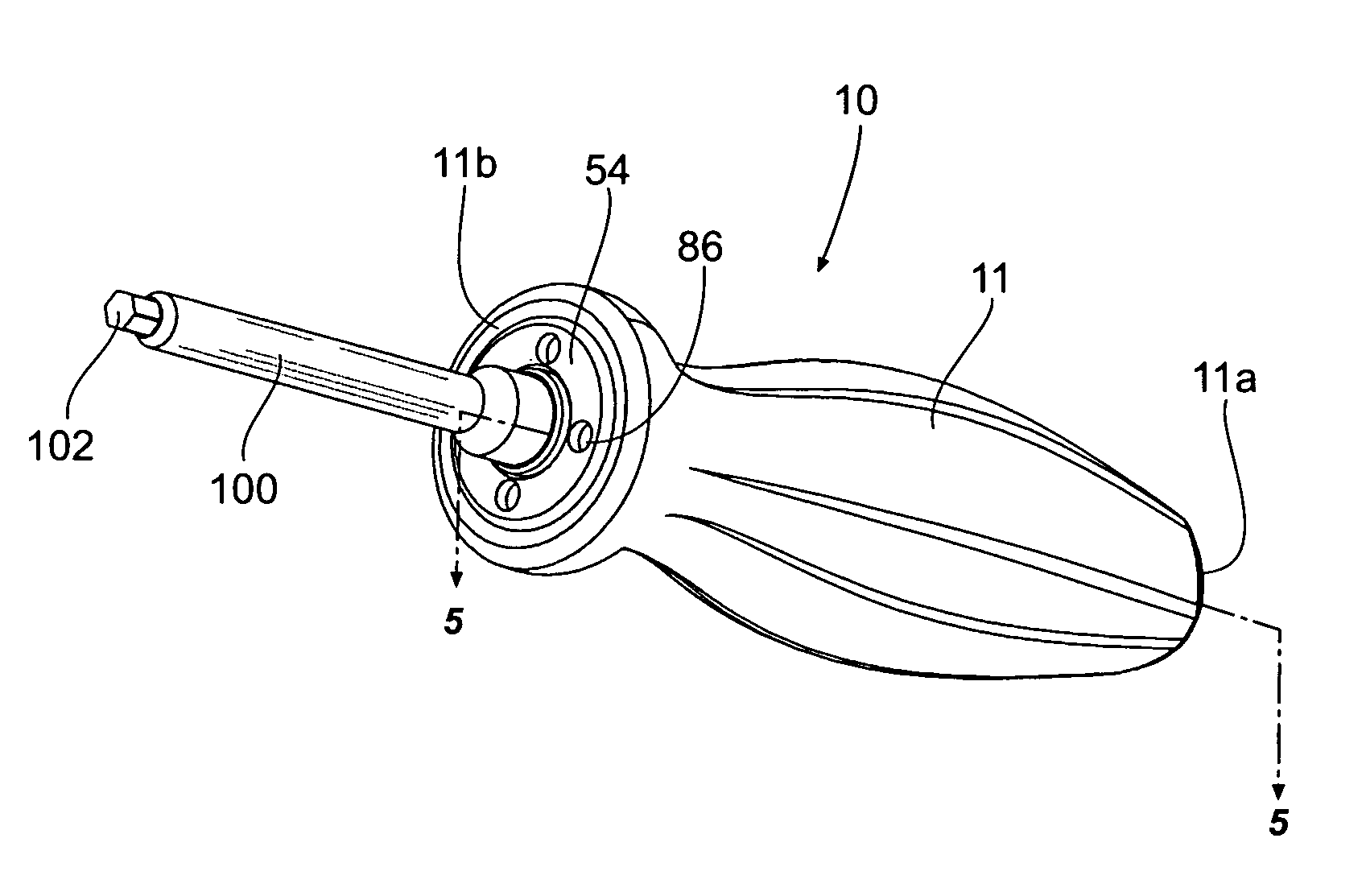

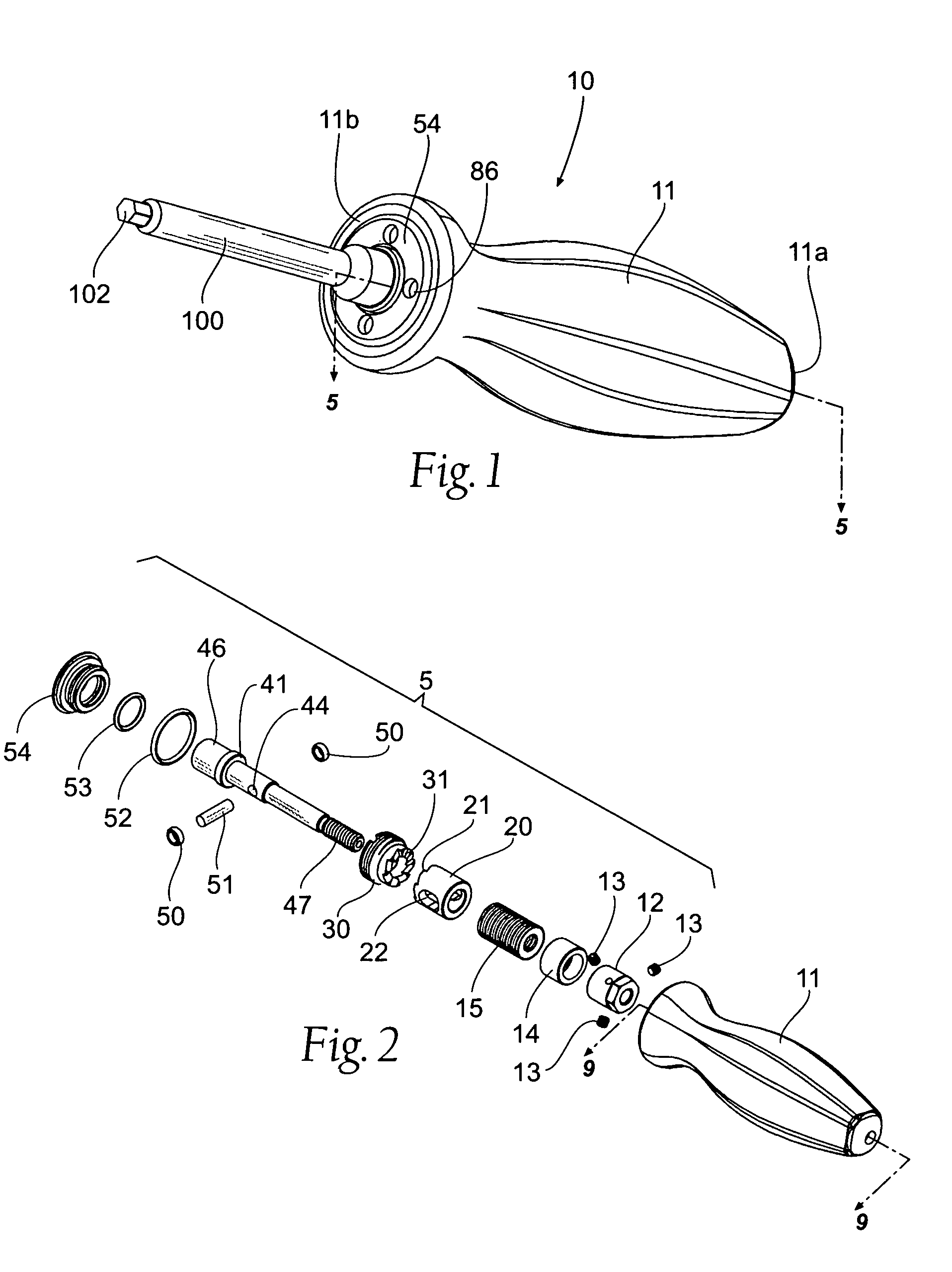

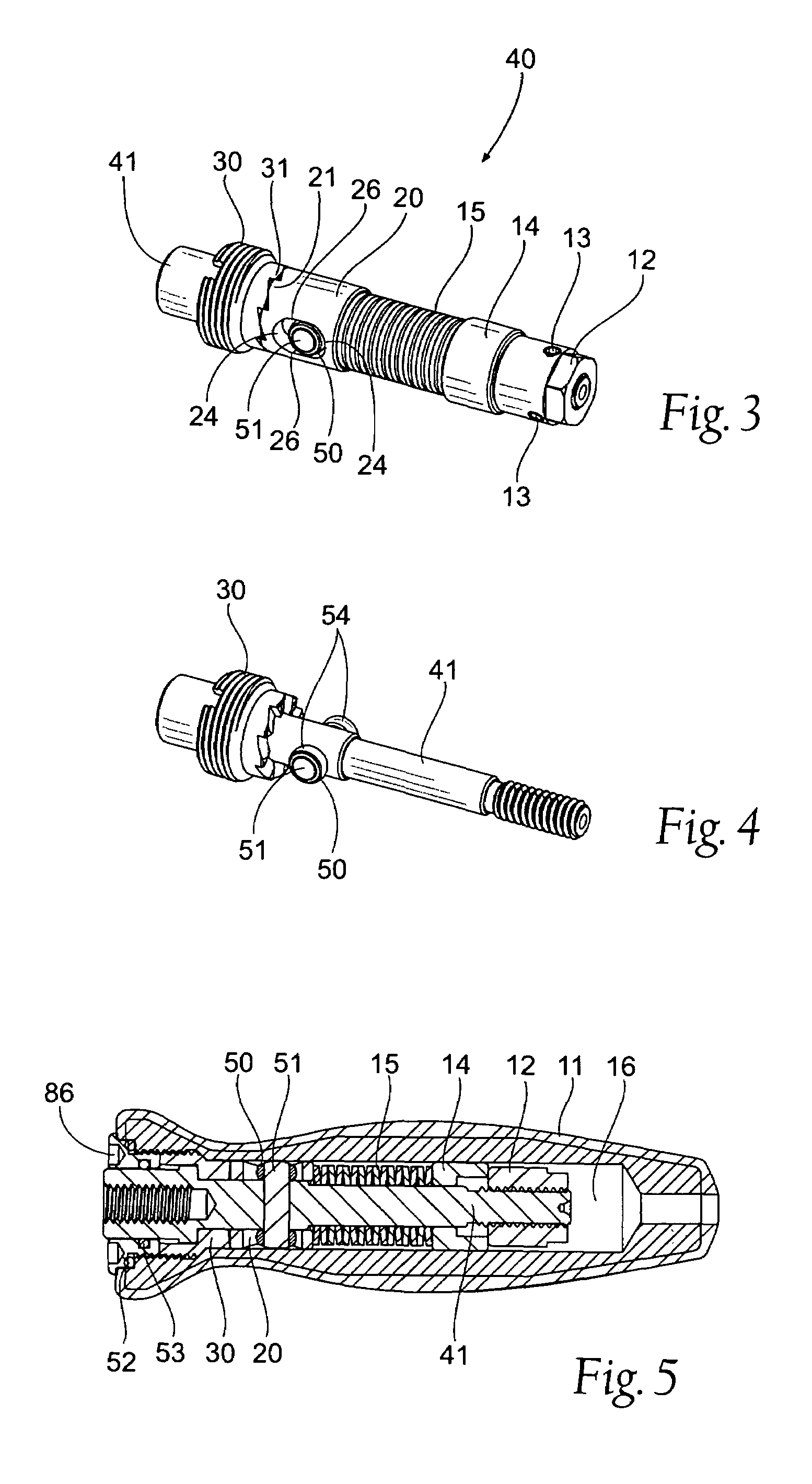

Torque limiting driver and assembly

ActiveUS7334509B1Accurate CalibrationEasy and efficientSpannersWrenchesEngineeringMechanical engineering

A method for assembling a torque-limiting driver, and the resulting drive. The method comprises the steps of providing a handle having a housing, drive assembly, and a testing assembly. The drive assembly is assembled, inserted into the testing assembly and calibrated. The drive assembly is then removed and inserted into the housing of the handle and secured to the handle.

Owner:BRADSHAW MEDICAL

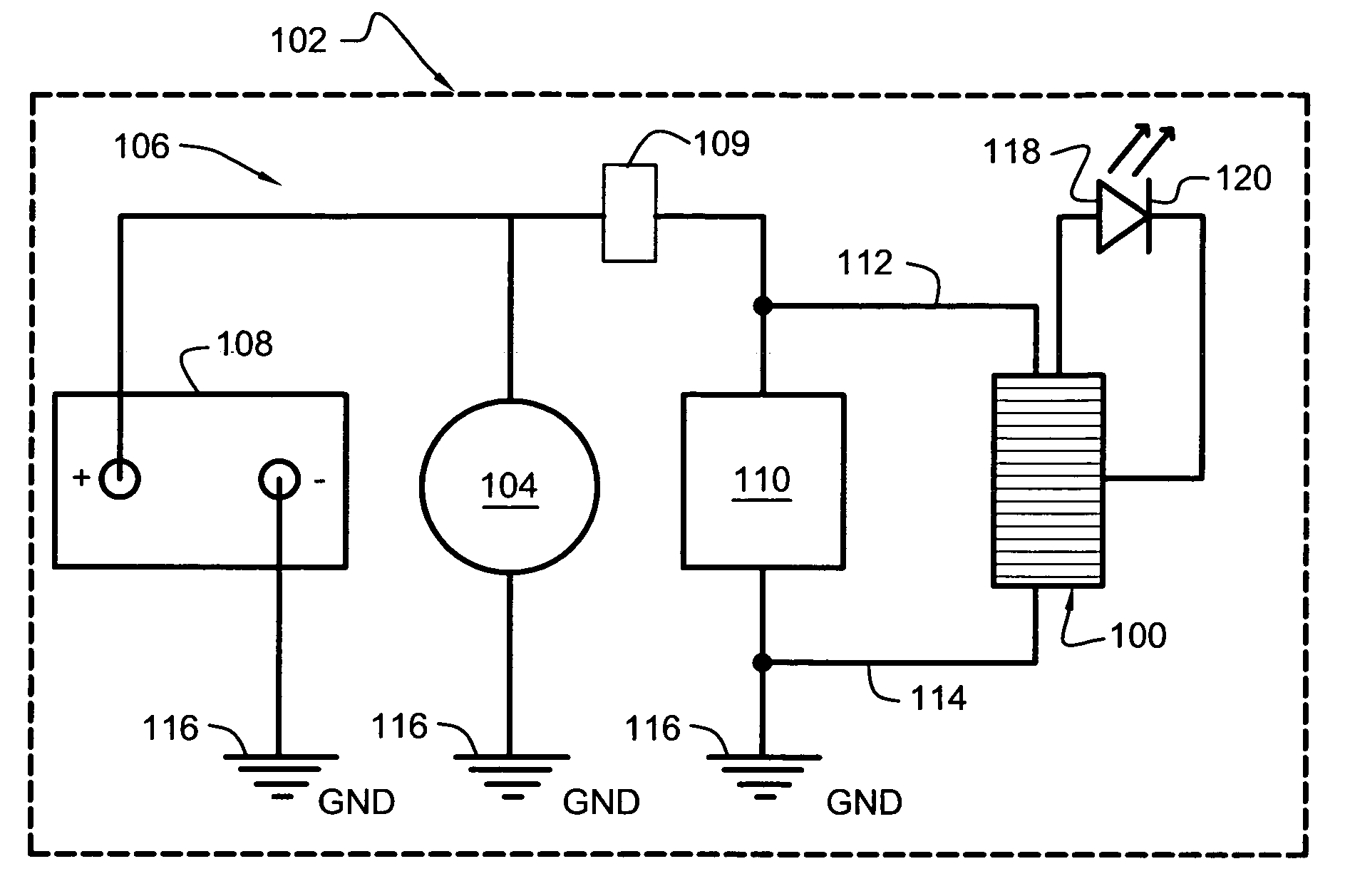

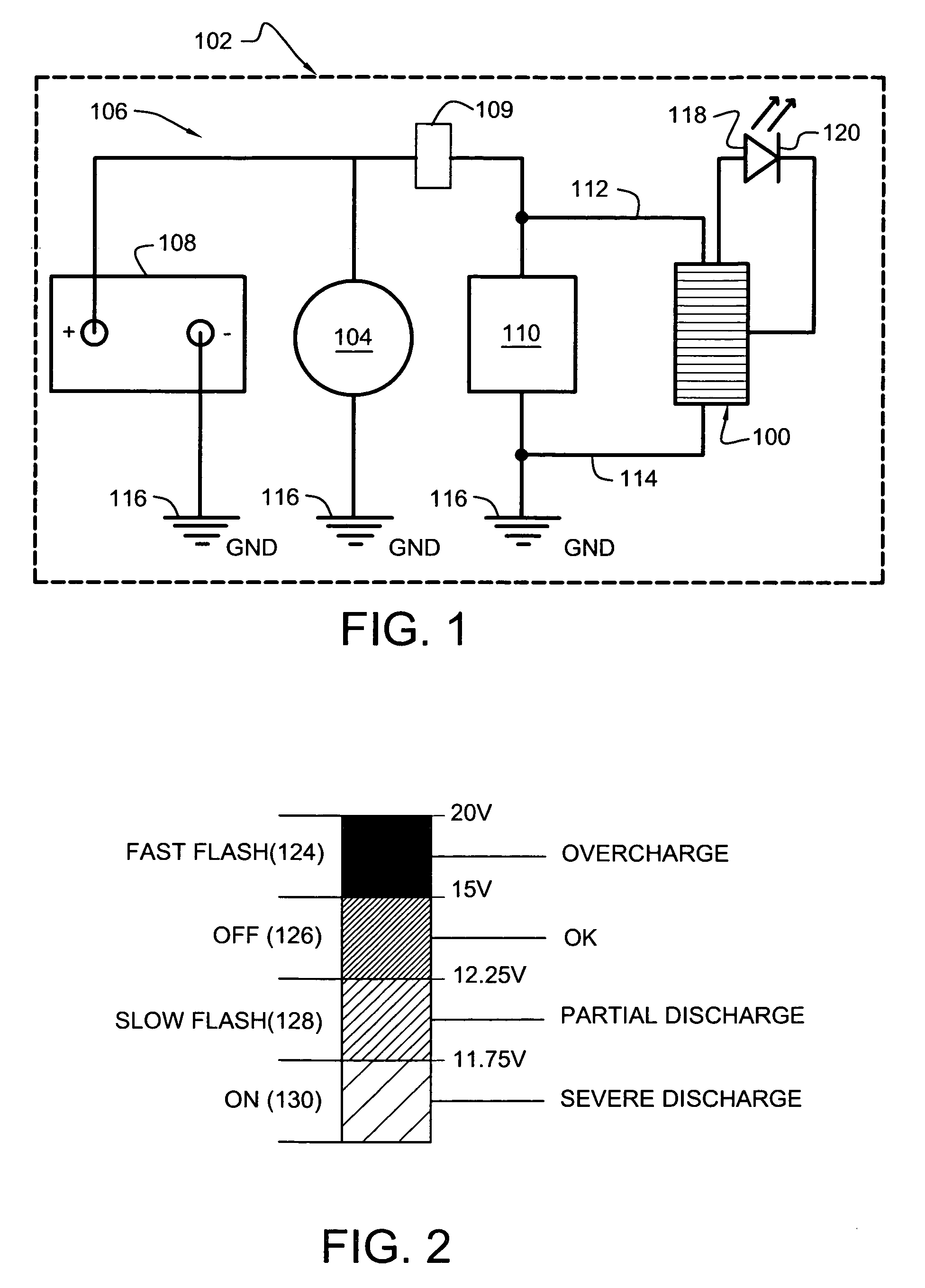

Charging monitoring systems

InactiveUS7039534B1Improve accuracyImprove monitoring accuracyCircuit monitoring/indicationCurrent/voltage measurementElectronic systemsElectrical battery

An electronic system for the continuous monitoring of voltage charge within the electrical system of a motor vehicle having an electrical generation source and a secondary electrochemical cell or battery. The system comprises a programmable in-vehicle monitor having a flashing LED indicator that alerts the vehicle operator of the condition of the electrical system. An example of the invention comprises a plug-in housing for use in a vehicle accessory-power-socket. Additionally, a method of market distribution is disclosed.

Owner:RYNO RONALD A +1

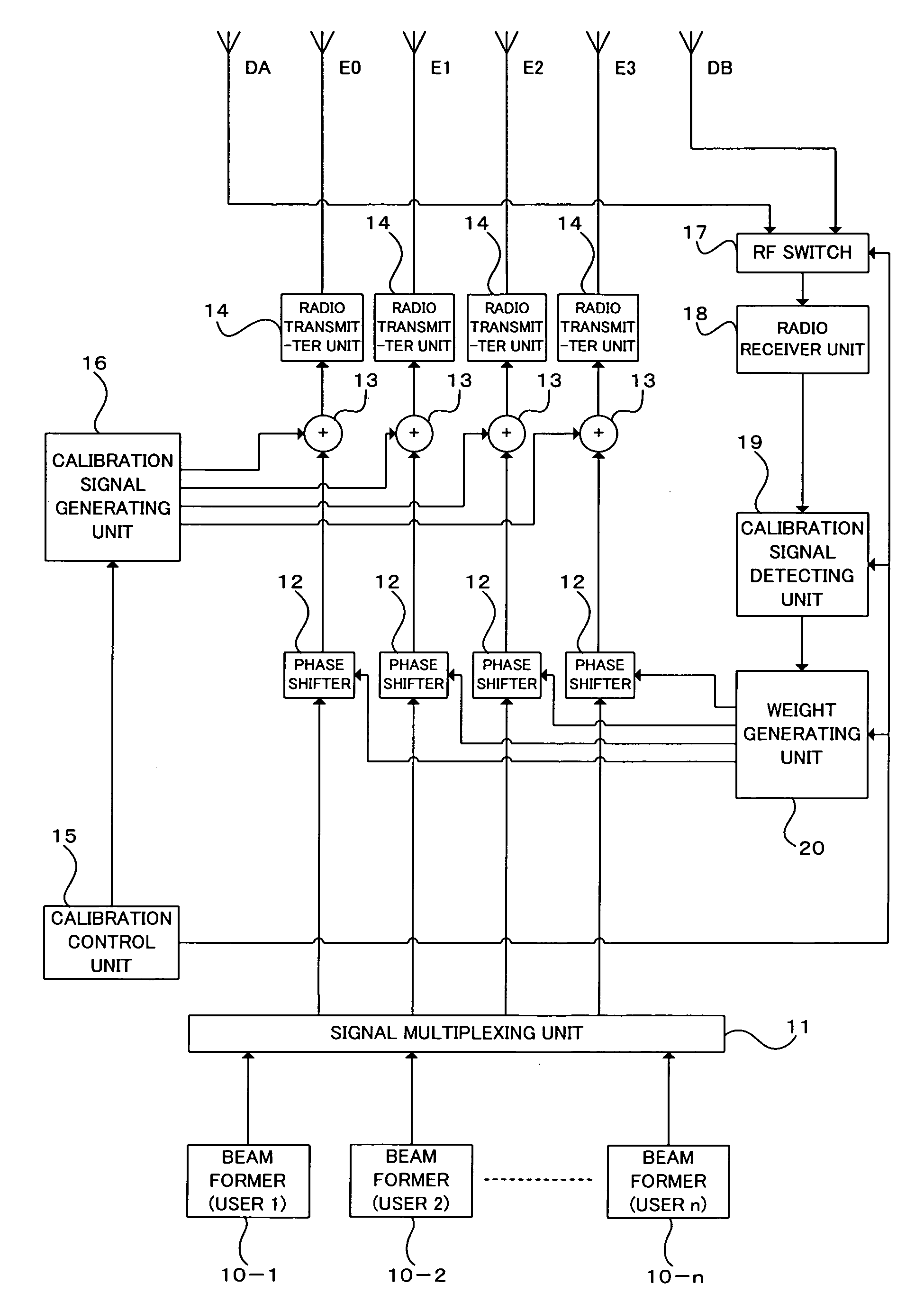

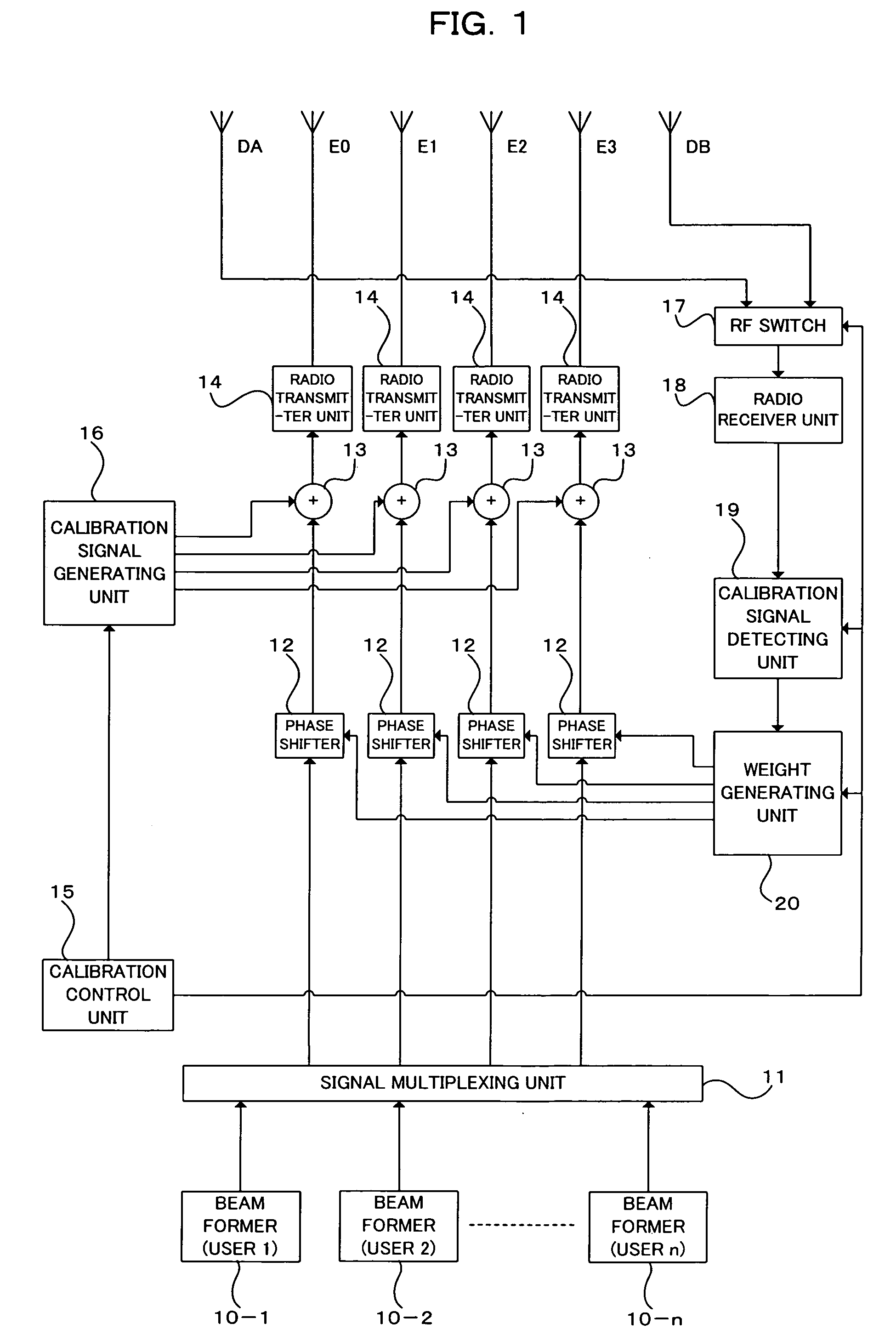

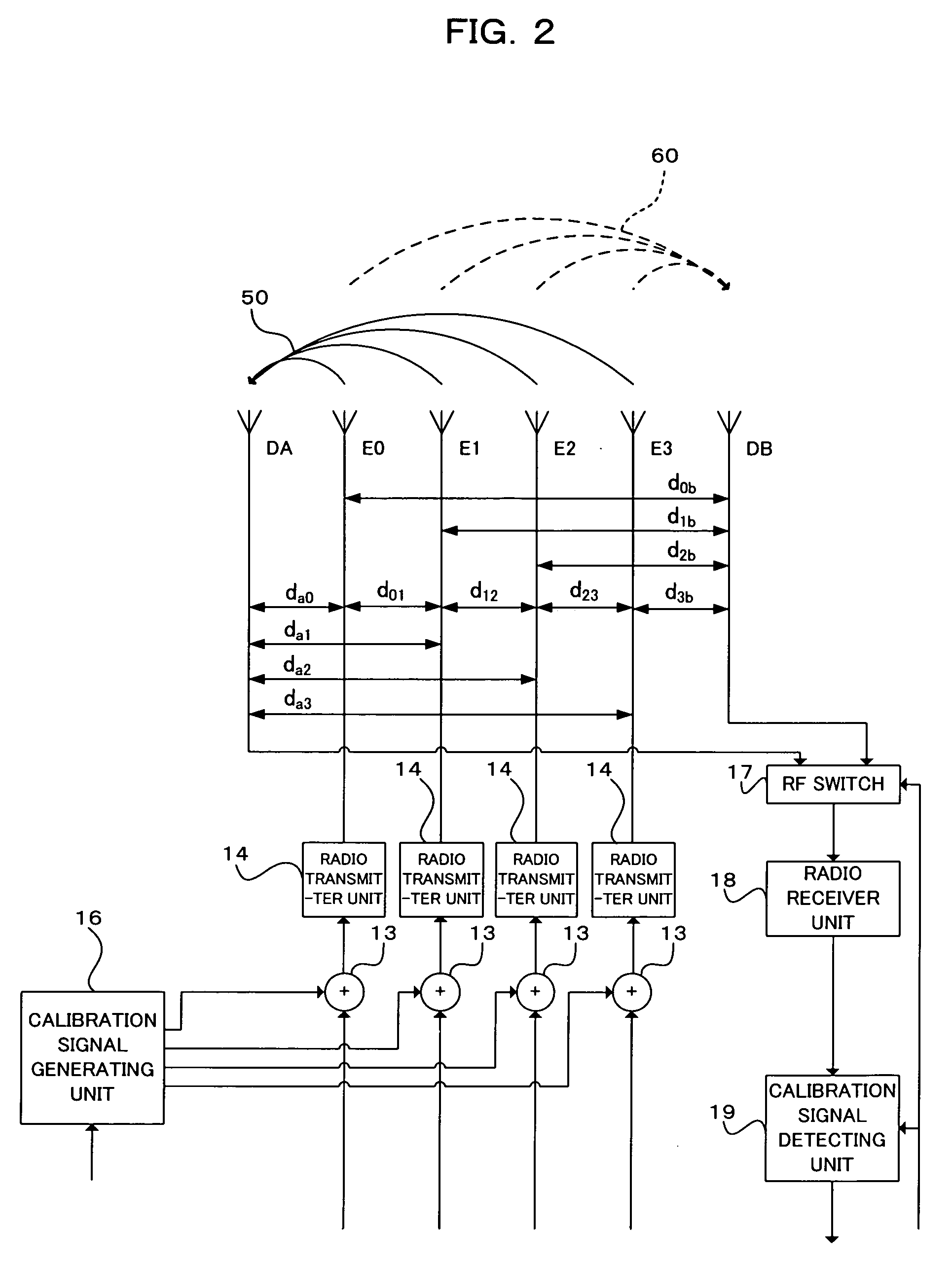

Array antenna calibration apparatus and method

InactiveUS7545321B2Accurate CalibrationReduce yieldWave based measurement systemsAntennasPhase differenceEngineering

The apparatus comprises a calibration signal supply means, which supplies calibration signals to a plurality of antenna elements that are to be subjected to calibration; a calibration signal extracting means, which extracts the calibration signals from signals received by the antenna elements placed, one on each side of the plurality of antenna elements that are to be subjected to calibration, and a calibration control means and which individually controls the phases of signals to be transmitted from the plurality of antenna elements that are to be subjected to calibration, based on the phase differences among the calibration signals extracted by the calibration signal extracting means. This will realize accurate calibration of an array antenna, irrespective of antenna element interval deviation.

Owner:FUJITSU LTD

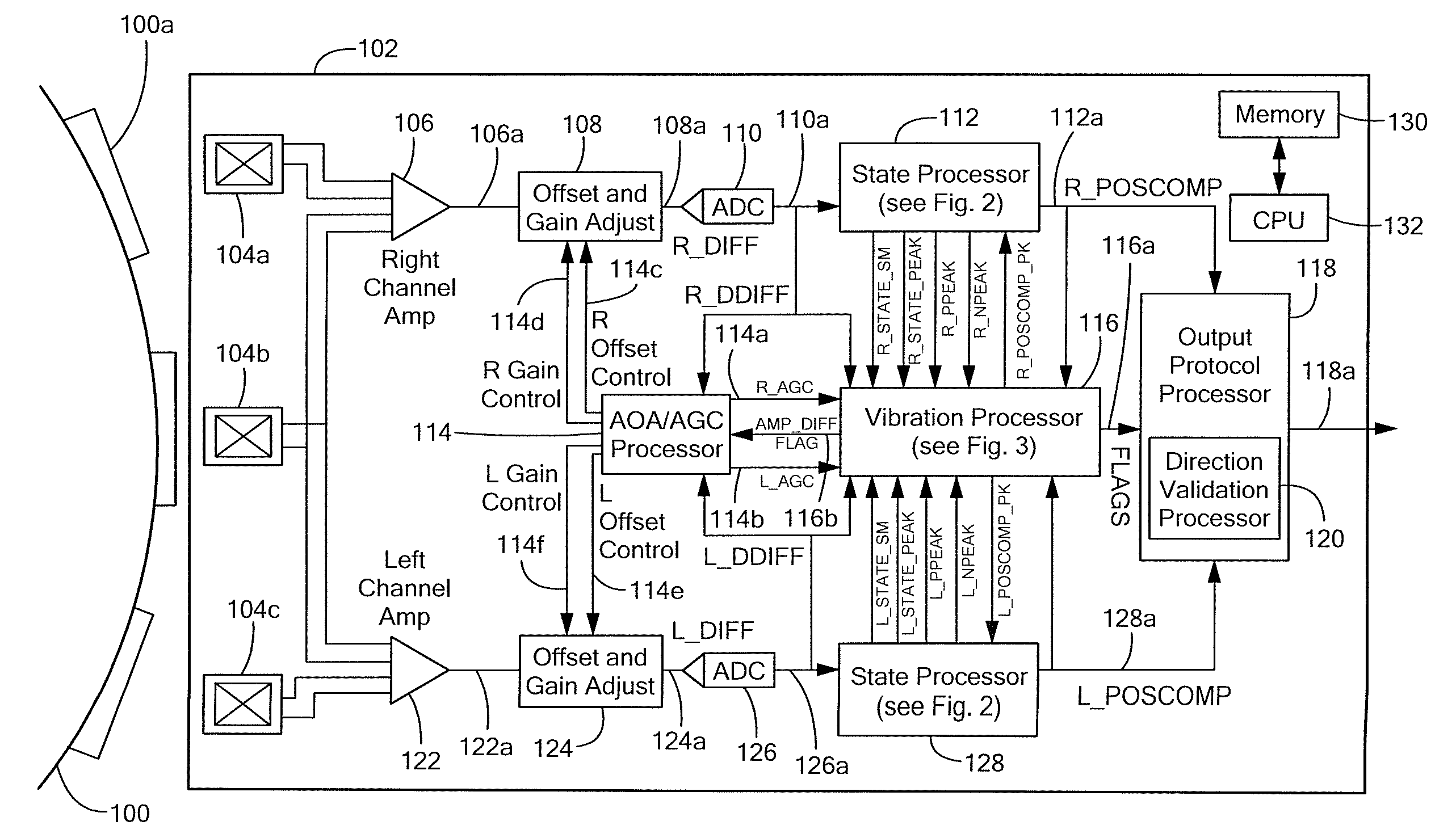

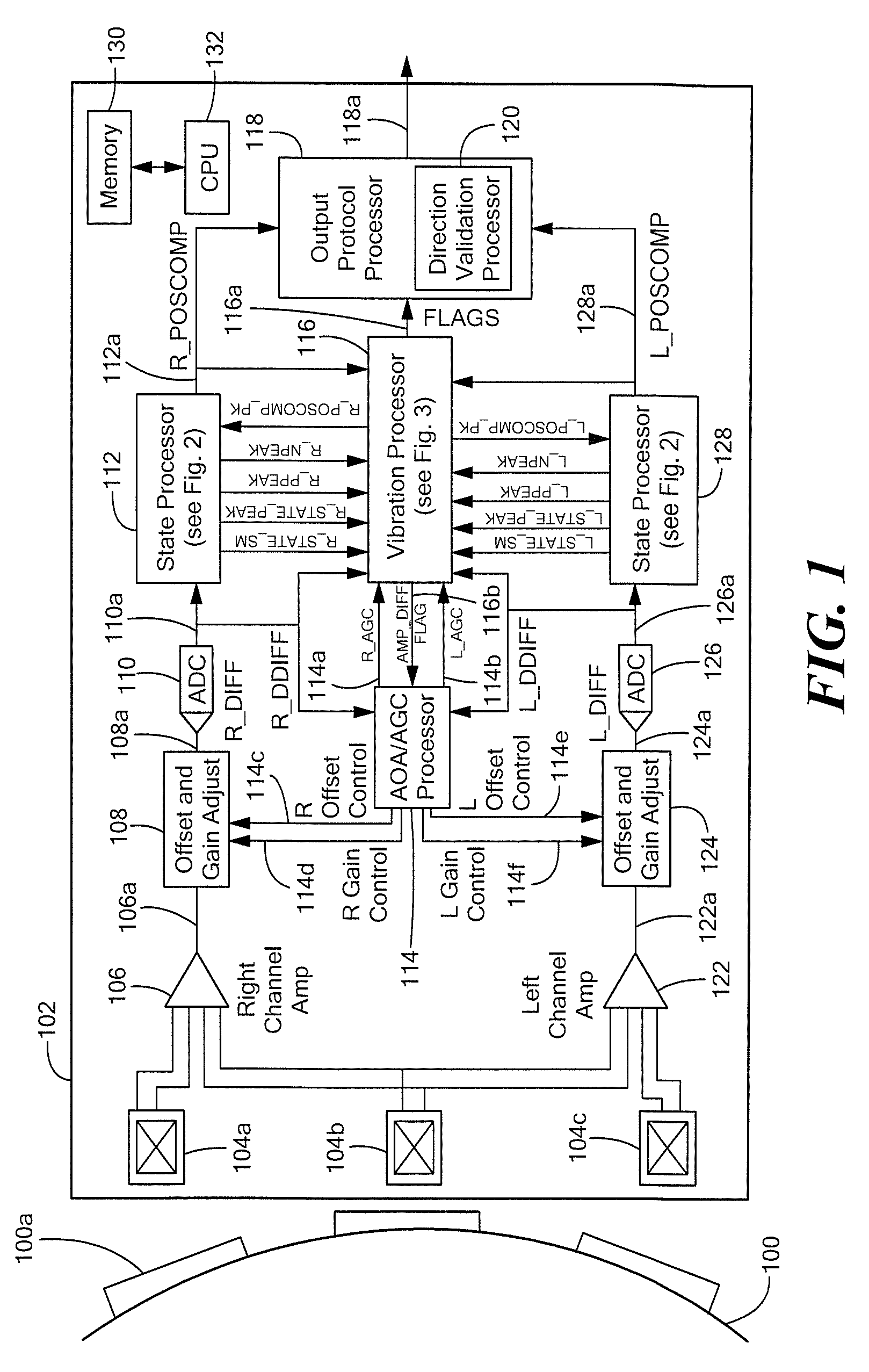

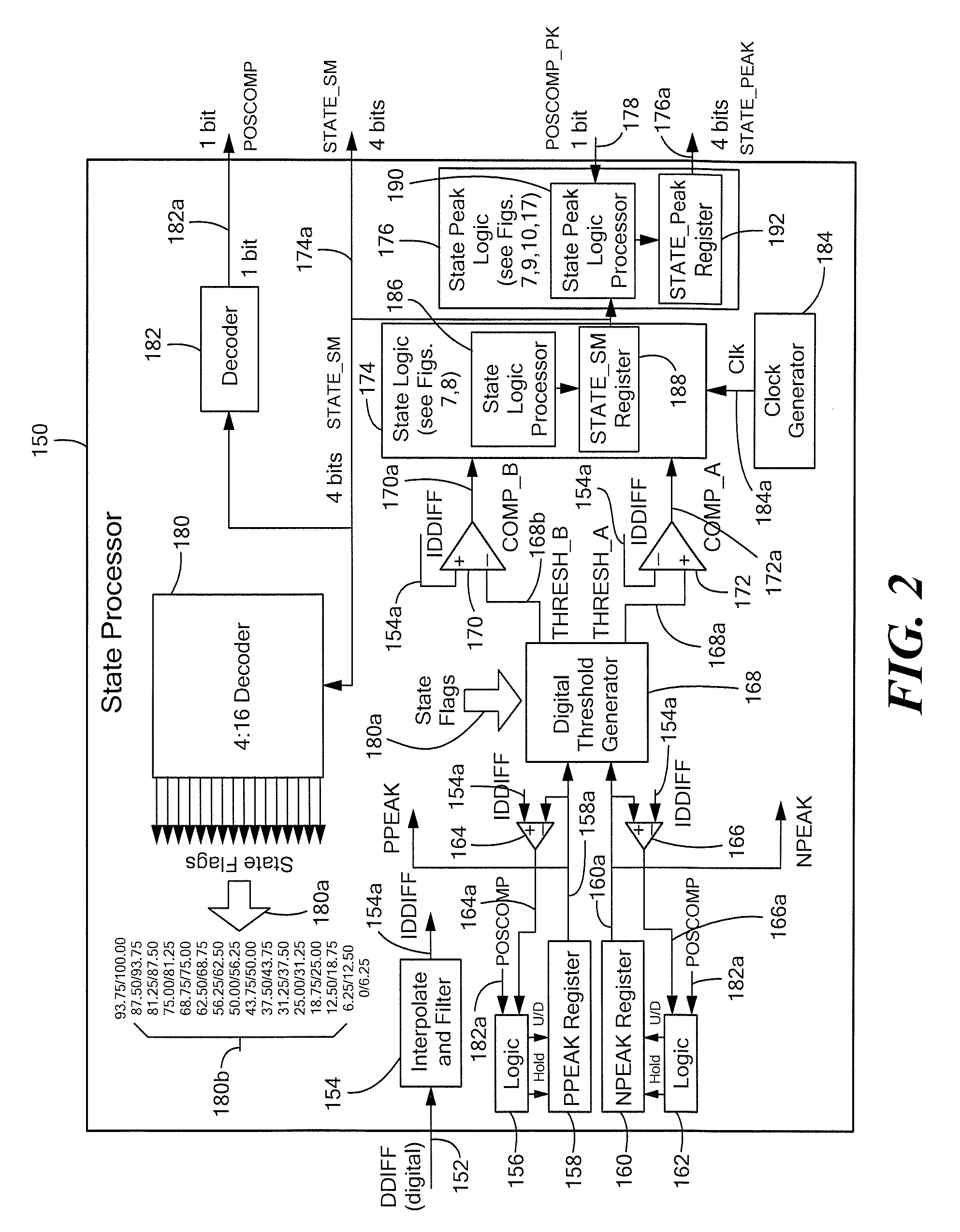

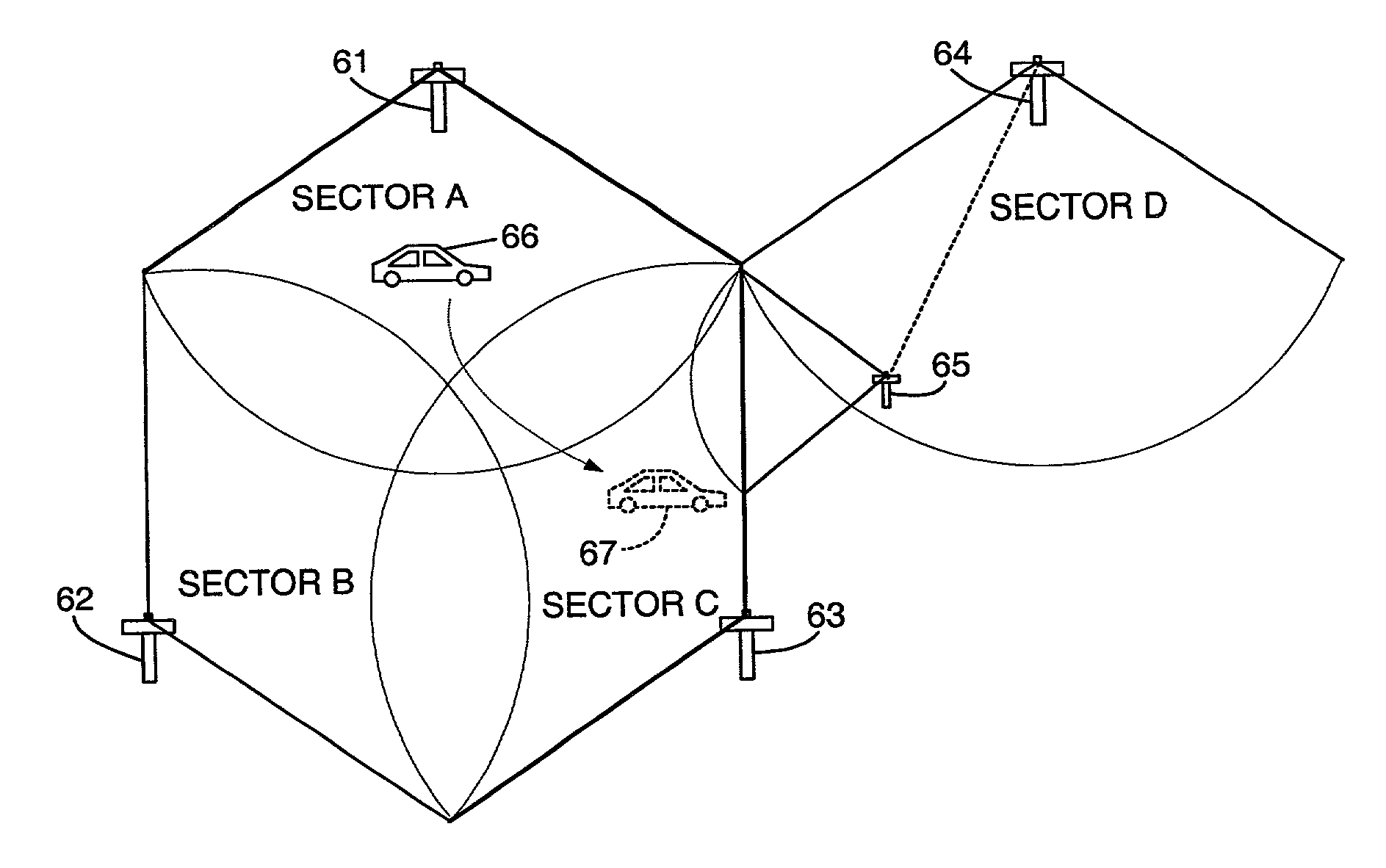

Motion Sensor, Method, and Computer-Readable Storage Medium Providing a Motion Sensor That Can Rapidly Calibrate Gains

ActiveUS20110298448A1Accurate gain calibrationRapid gain calibrationUsing electrical meansLinear/angular speed measurementEngineeringMotion sensors

Owner:ALLEGRO MICROSYSTEMS INC

Automation of maintenance and improvement of location service parameters in a data base of a wireless mobile communication system

InactiveUS7383049B2Improve accuracyAccurate CalibrationSpecial service for subscribersPosition fixationField testsMobile station

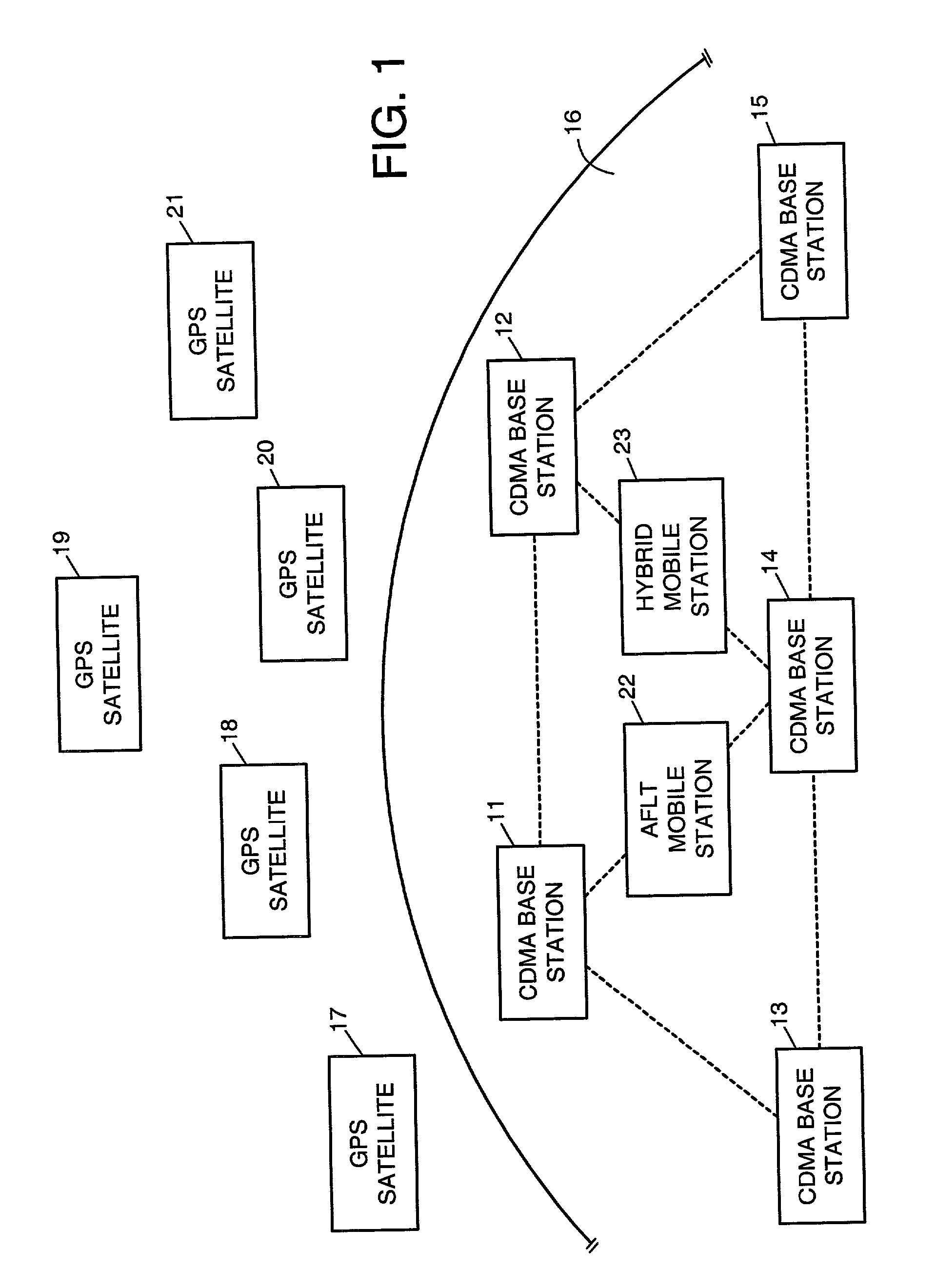

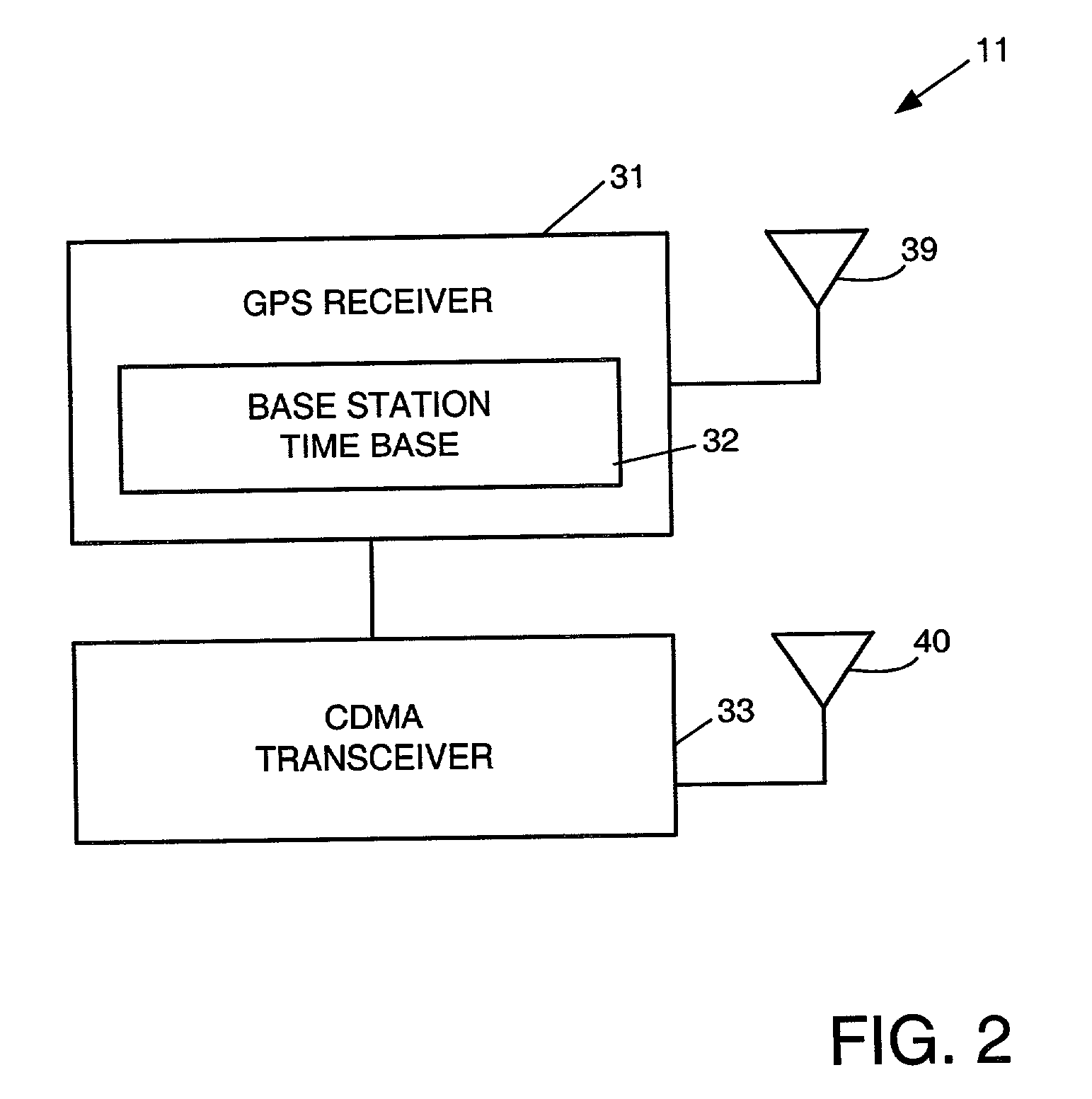

In a wireless telecommunication network, hybrid (GPS and AFLT) mobile stations provide redundant position information, which is used for time base calibration and / or correction of position measurements. Every mobile station (i.e., handset or cellular phone) can be used as a test instrument, and data from regular wireless phone calls can be supplemented by data from drive-around field test units. The time base and / or position offsets are stored in a base station almanac data base along with other information used for obtaining the most reliable position fixes under a variety of conditions. An automatic system is provided for creating, updating, and maintaining the base station almanac data base. The automatic system not only characterizes the performance of the wireless network but also characterizes the performance of the position determination system. The automatic system provides performance feedback to system operators and customers.

Owner:QUALCOMM INC

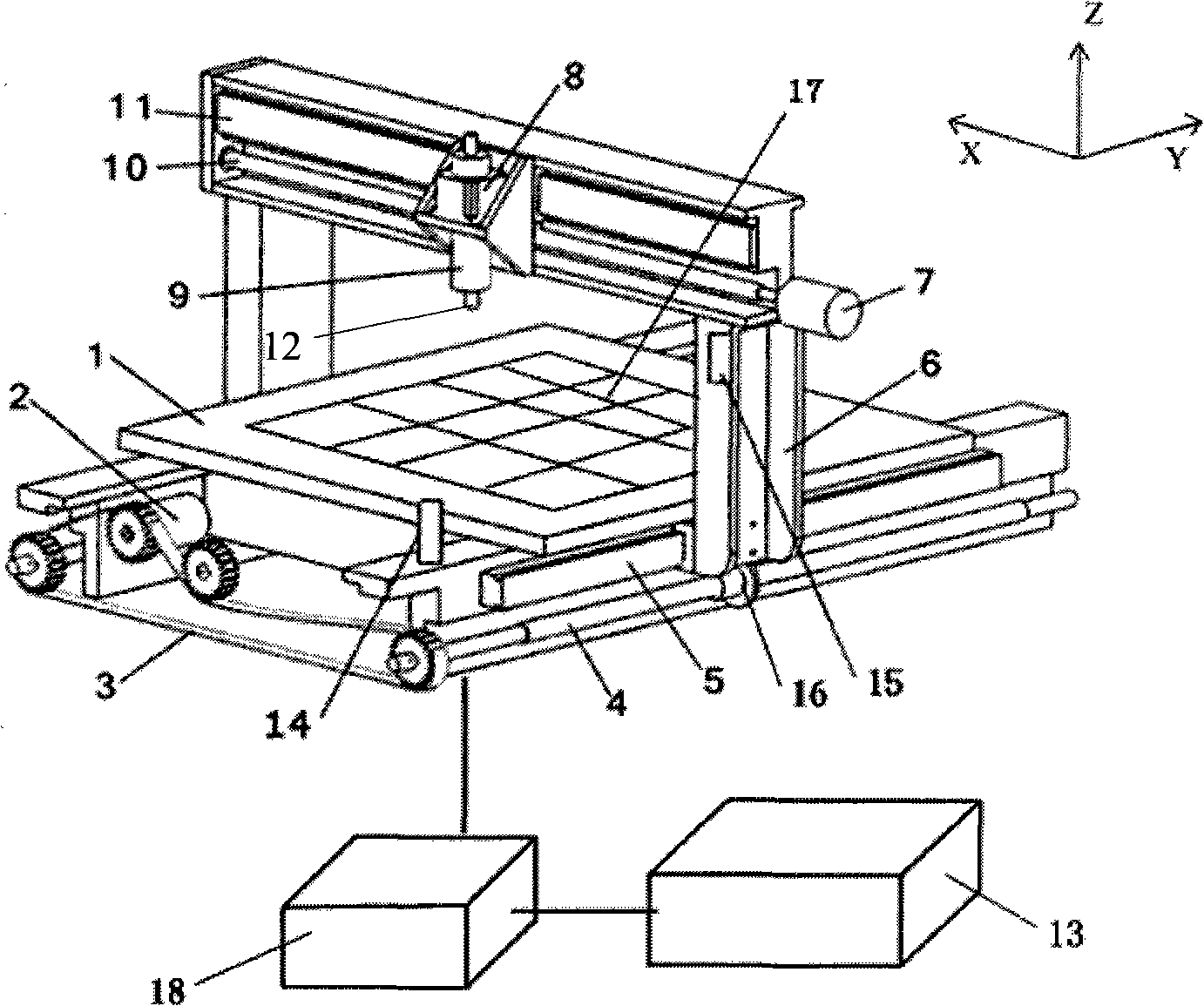

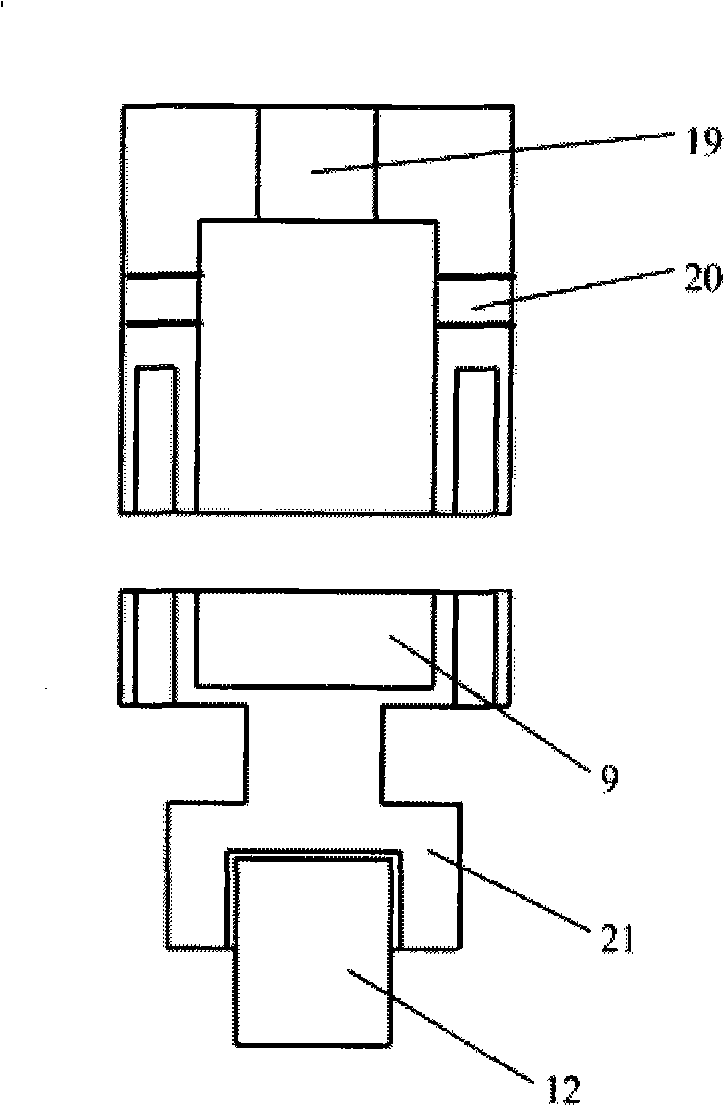

Mechanics sensor array calibrating apparatus and working method thereof

ActiveCN101281073APrecision mechanical designQuick start and stopForce/torque/work measurement apparatus calibration/testingSensor arrayElectricity

The present invention discloses a mechanical sensor array calibration device and the working method thereof. The device comprises locating transmission part and control part which is electrically connected with the locating transmission part; wherein, the locating transmission part comprises calibrated working platform and pressure head testing part; the pressure head testing part is connected with a force sensor through an extension head of a Z-directional linear stepper motor. Using the working method of the device adopts three stepper motors as the driving source; two stepper motors drive the coordinate motion of the slides on the guide rail to finish the location of coordinate point on the working platform; an extension of a linear stepper motor drives the pressure head to exert force on the tested sensor; when the force exerted by the pressure head achieves the set pressure valve, the singlechip collects the output of the tested sensor and the force sensor and the position coordinate of the tested sensor. The present invention is able to execute the choose and configuration of the calibrating mode and process according to the specific sensor array and the specific calibrating demand so as to enlarge the using range of the device.

Owner:ANHUI ZHONGKE BENYUAN INFORMATION TECH CO LTD

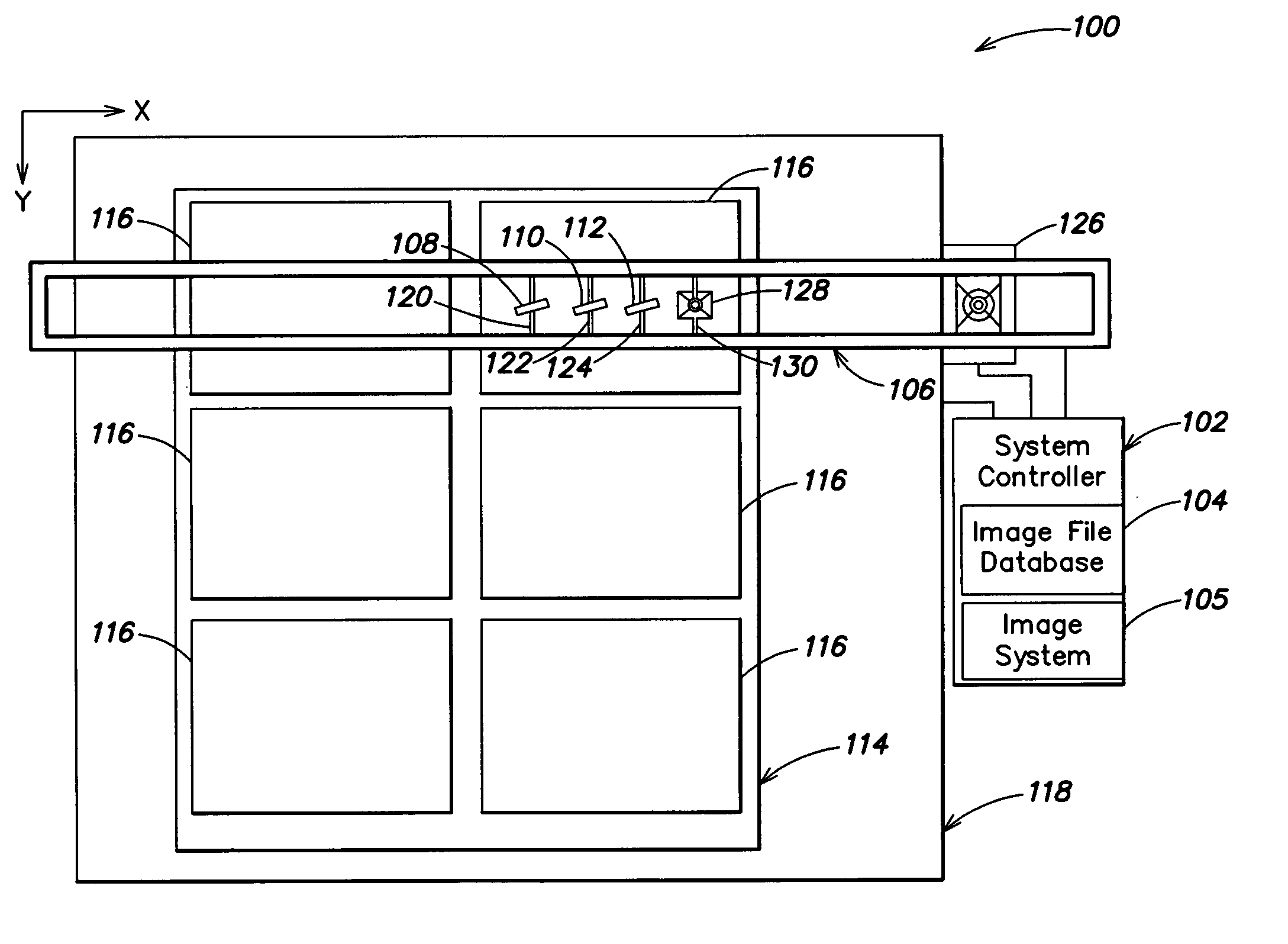

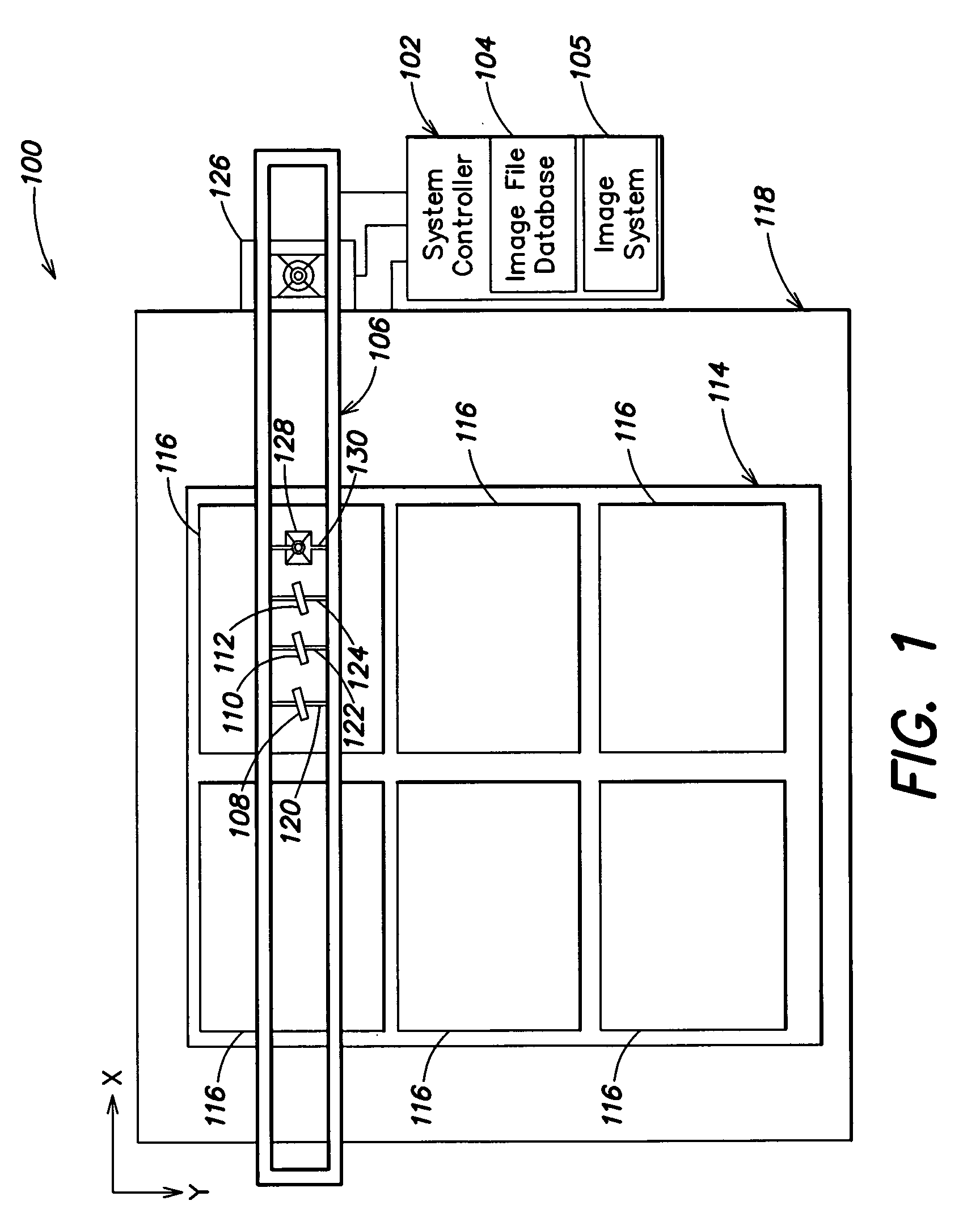

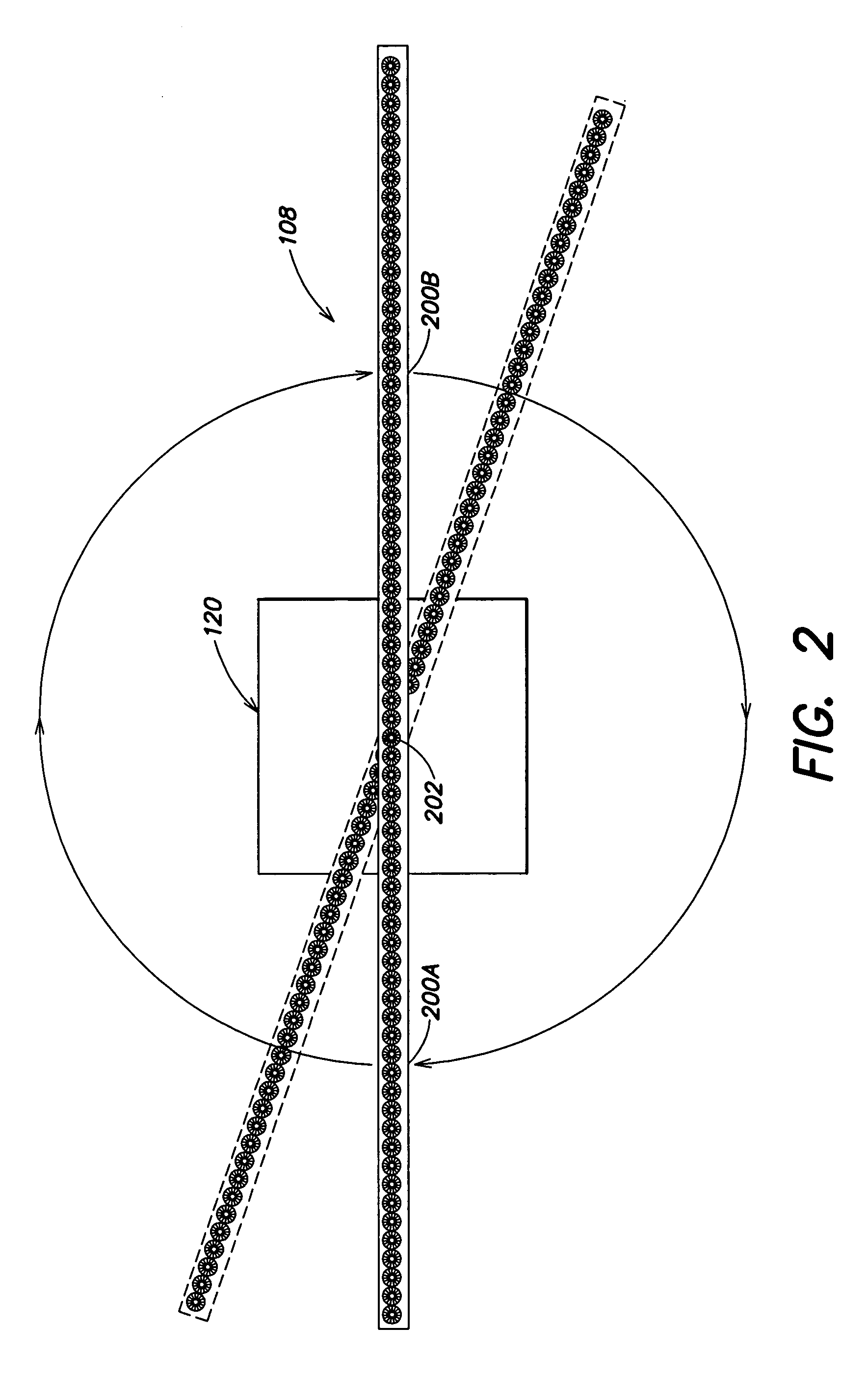

Methods and apparatus for aligning print heads

InactiveUS20060092199A1Accurate CalibrationMovable spraying apparatusTypewritersImage systemIndustrial engineering

In a first aspect, a system is provided. The system includes (1) a stage adapted to move a substrate relative to print heads during printing; (2) at least one print head suspended from a support above the stage and adapted to be moveable in a plane above the stage; (3) a controller operable to rotate the print head about a center of the print head; and (4) an imaging system adapted to capture an image of the print head and to determine a center point of the print head based upon images of the print head captured as the print head is rotated. Numerous other aspects are provided.

Owner:APPLIED MATERIALS INC

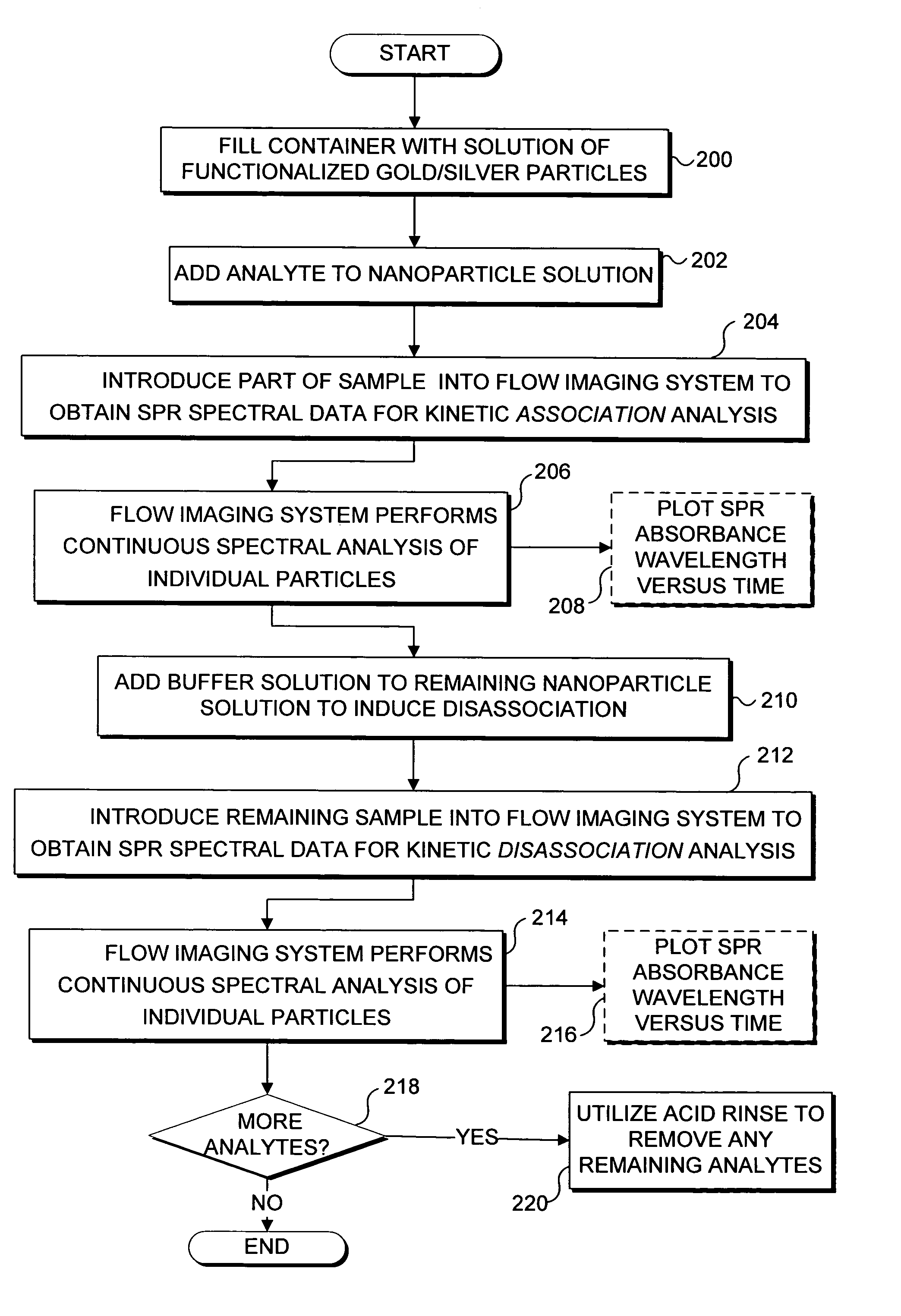

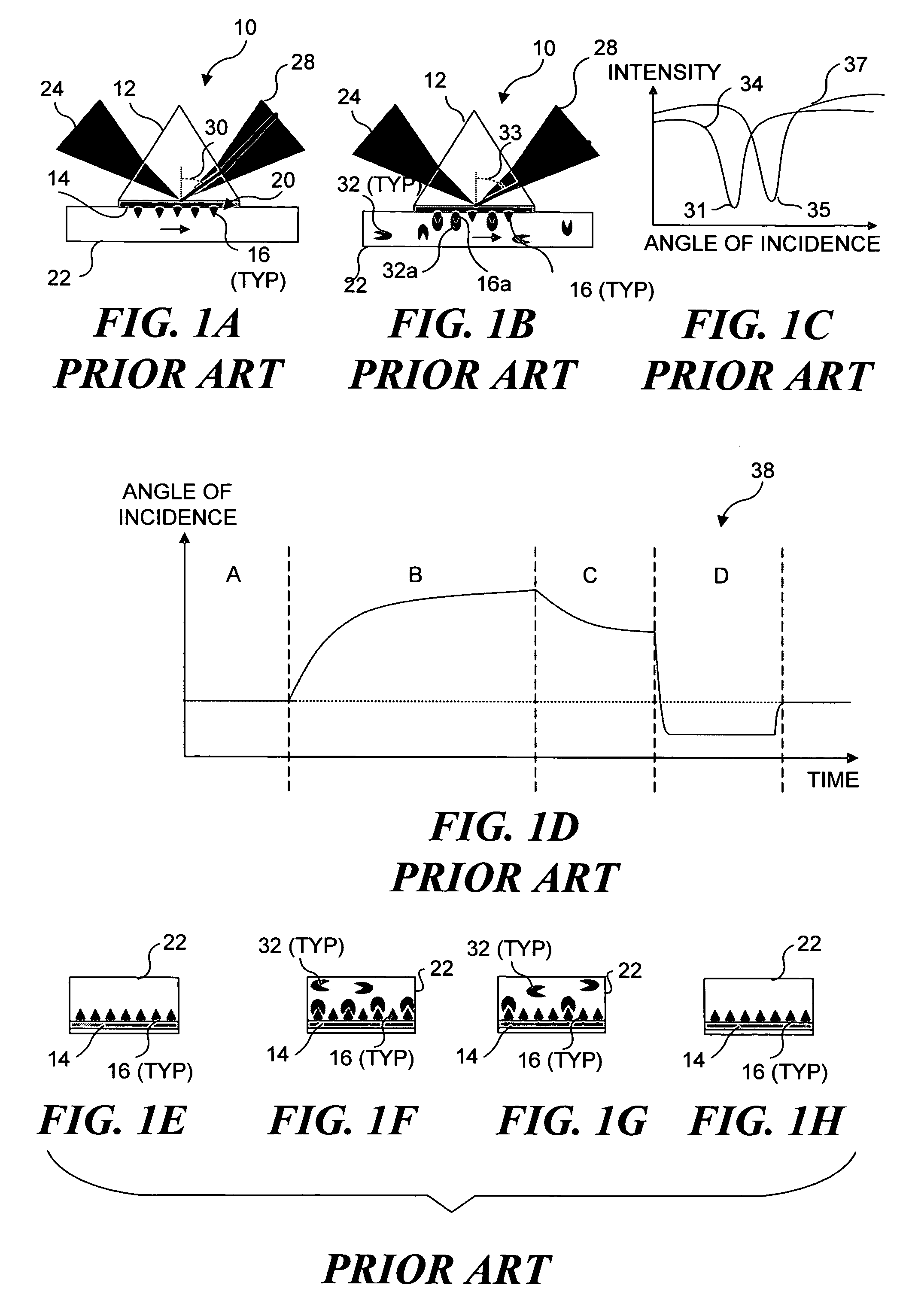

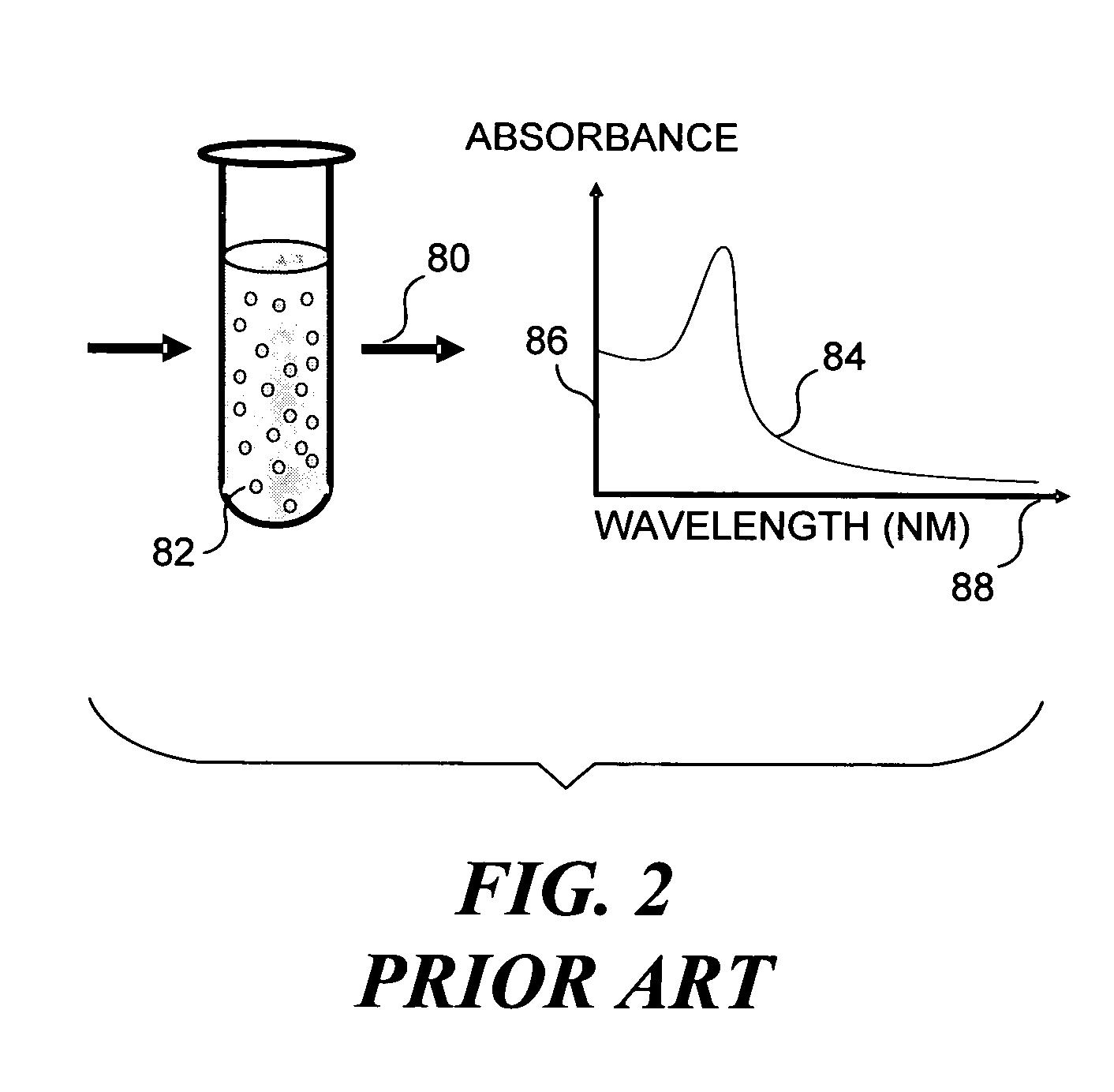

Imaging platform for nanoparticle detection applied to SPR biomolecular interaction analysis

InactiveUS7057732B2Increase curve 's linearityAccurate CalibrationSpectrum investigationInvestigating moving fluids/granular solidsSurface plasmonic resonanceAnalyte molecule

A flow imaging system is used to implement surface plasmon resonance (SPR) detection to study bio-molecular interactions. The flow imaging system is used to capture SPR absorption spectra of large numbers of objects, where each object includes both a metal film capable of exhibiting SPR, and detecting molecules. Analyte molecules are added to a solution of such objects, and the result is introduced into the flow imaging system which collects full SPR spectral data from individual objects. The objects can be nanoparticles or larger particles that support metal island films. The SPR spectral data can be used to determine specificity, kinetics, affinity, and concentration with respect to the interactions between the detecting molecules and the analyte molecules.

Owner:CYTEK BIOSCI

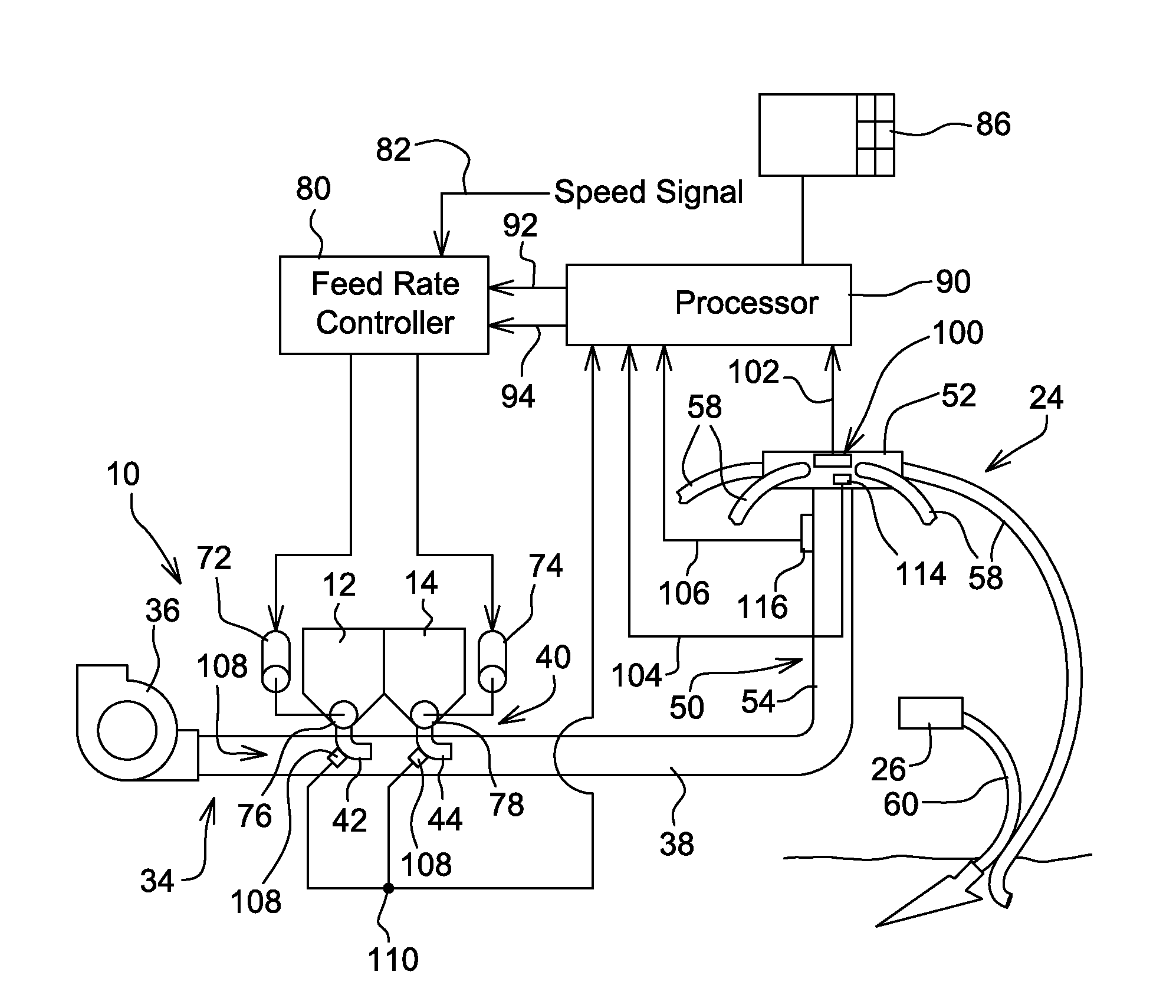

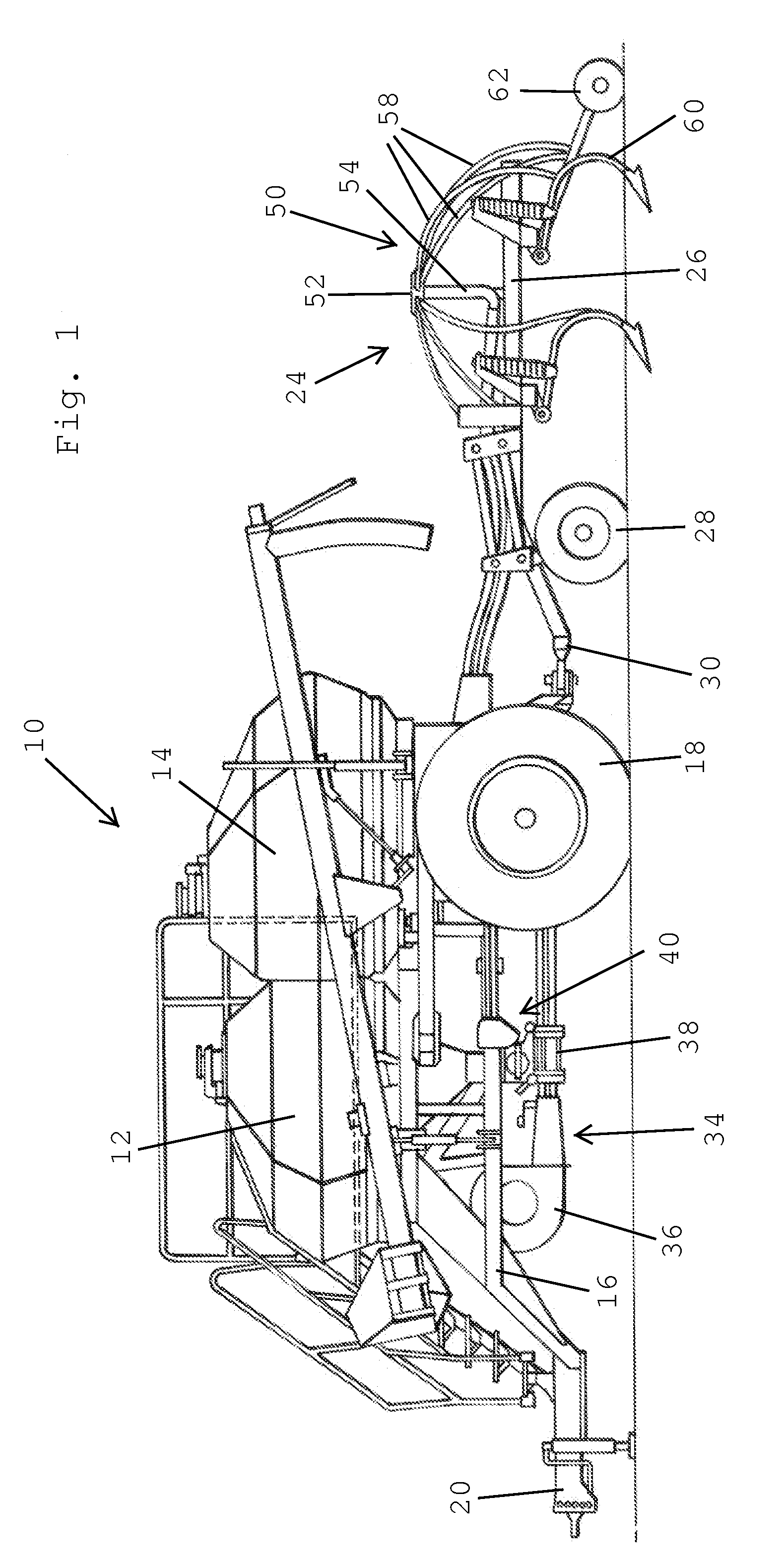

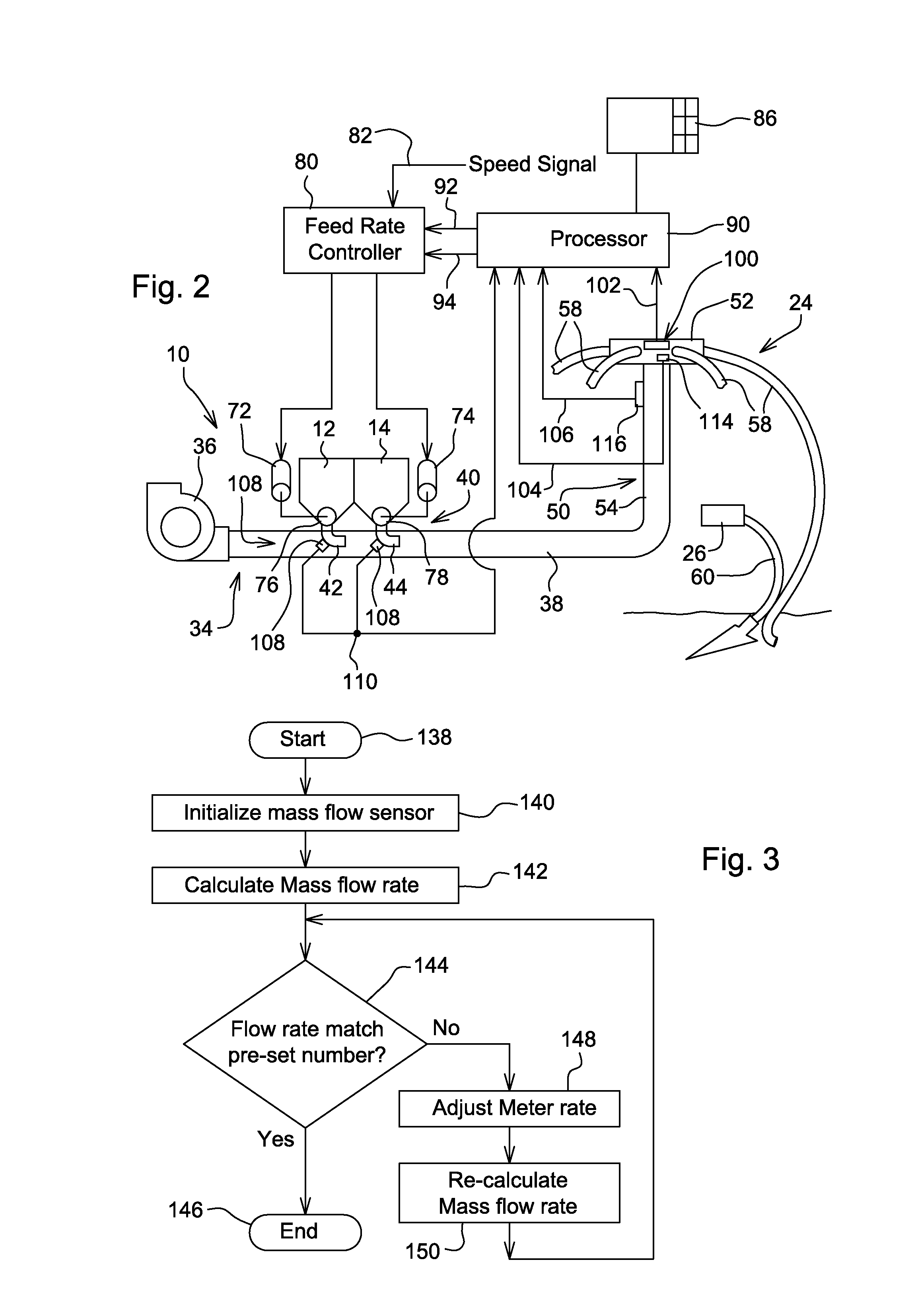

Particulate flow sensing for an agricultural implement

ActiveUS8504310B2Reduce delaysMore accurate seeding and fertilizing ratesFlow propertiesSowingAir velocityEngineering

Owner:DEERE & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com