Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1190results about How to "Enhanced light absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

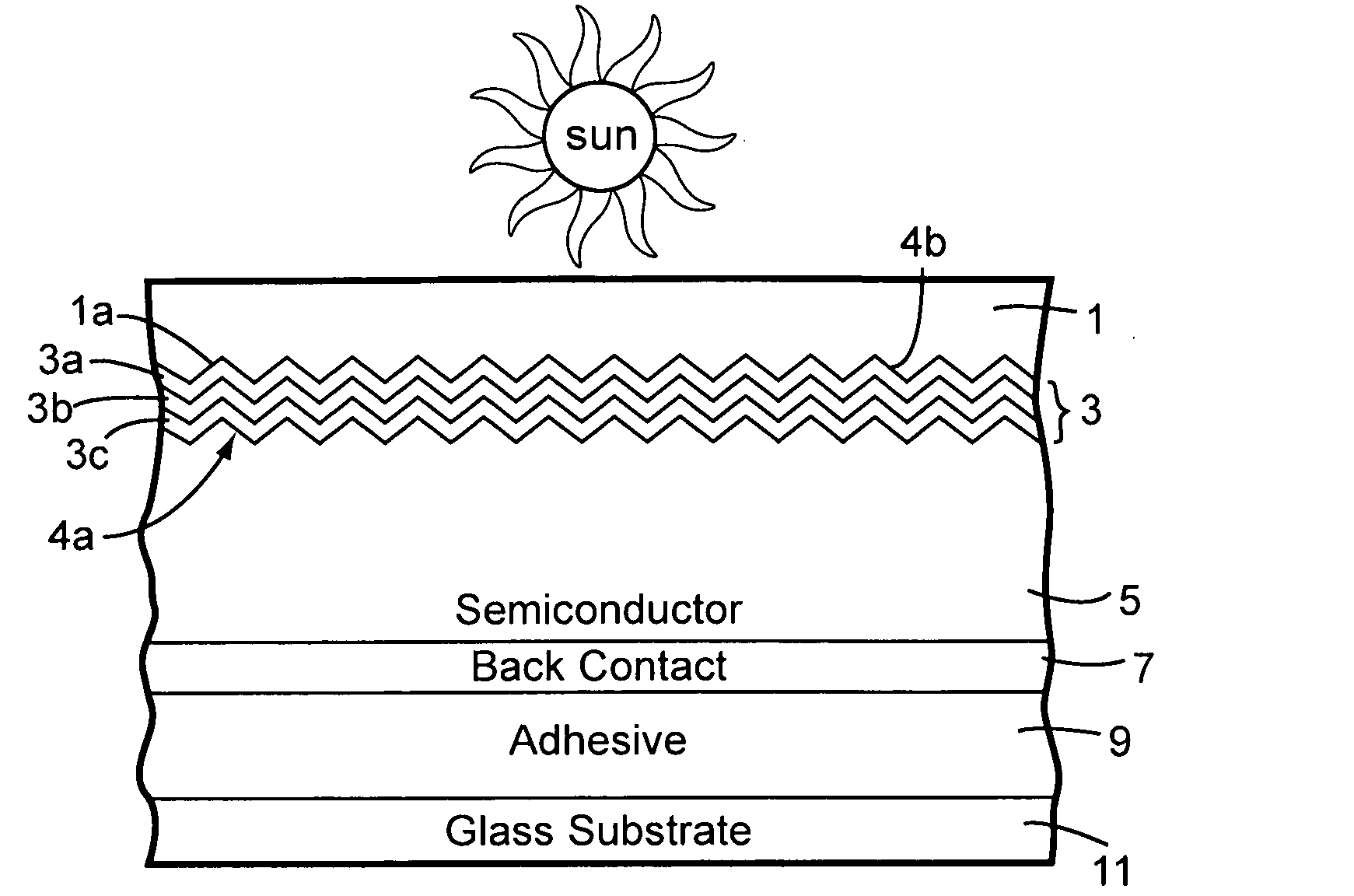

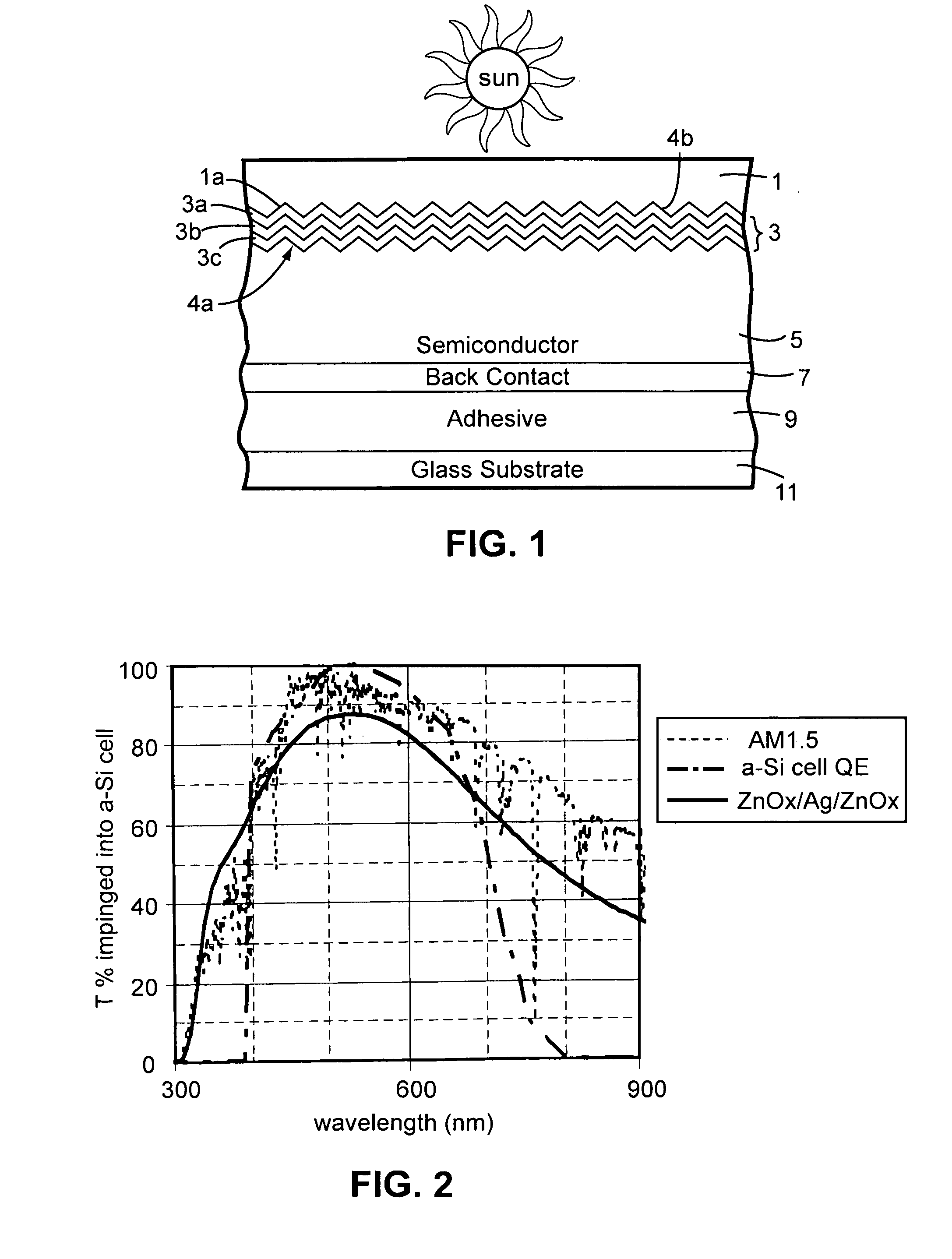

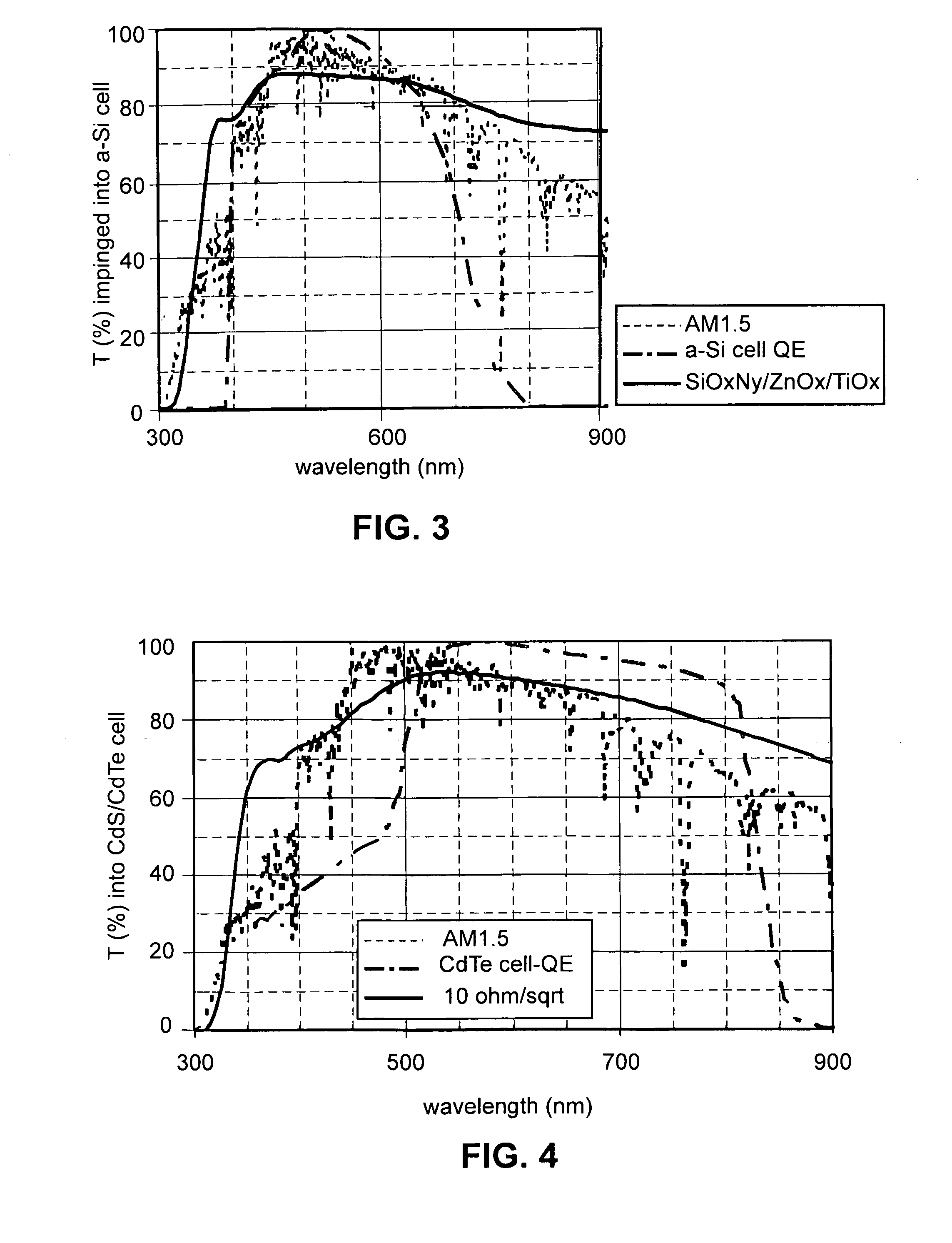

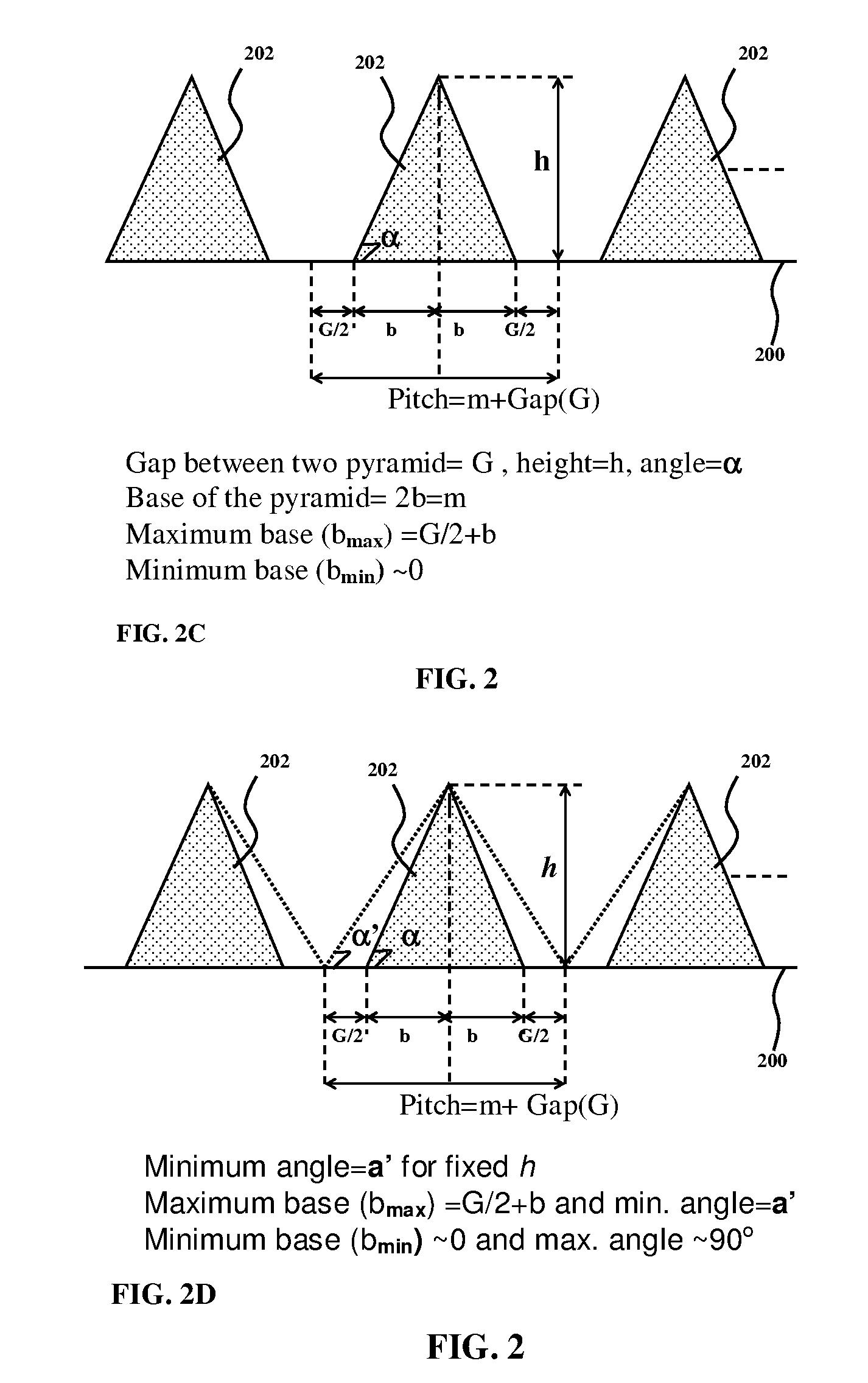

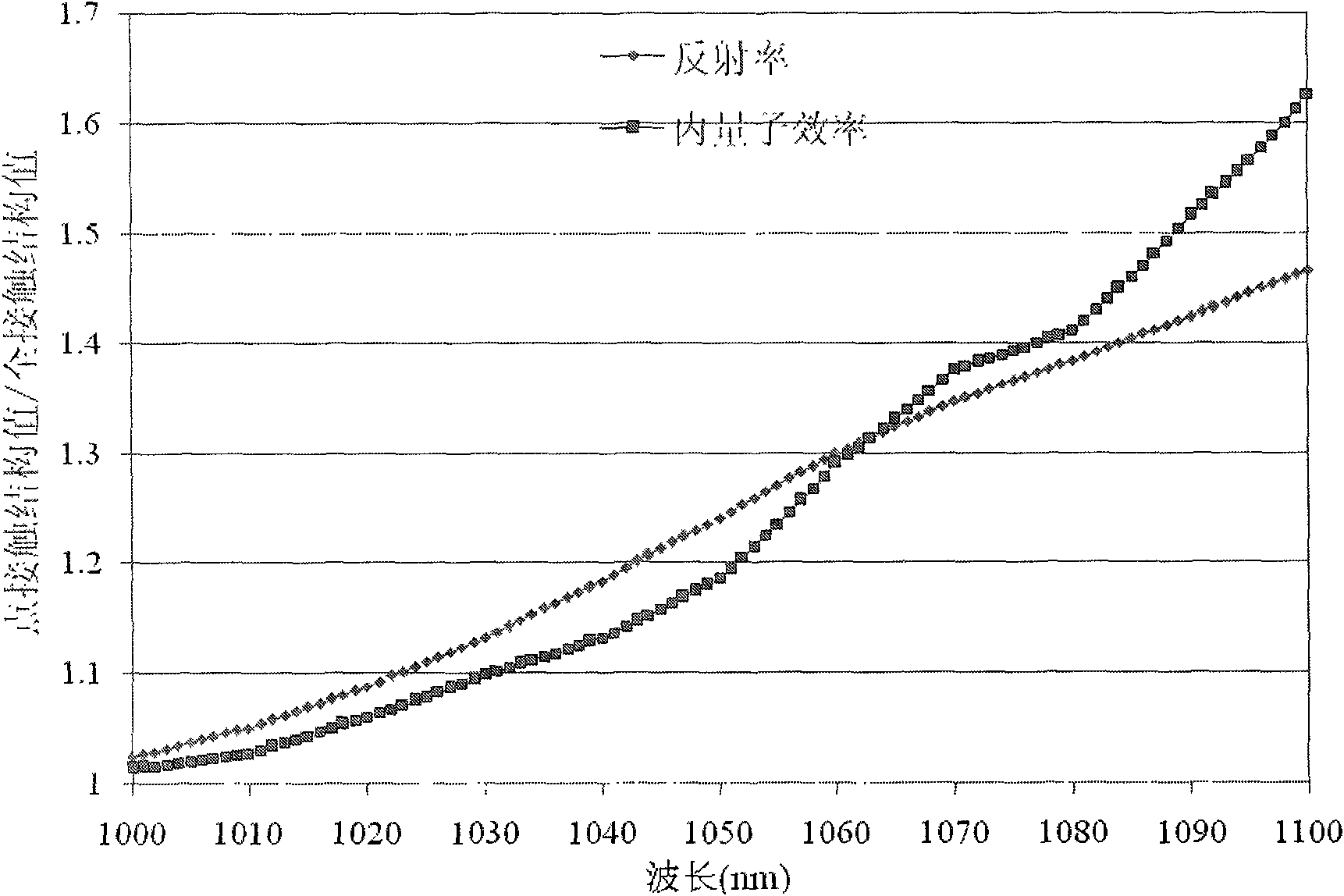

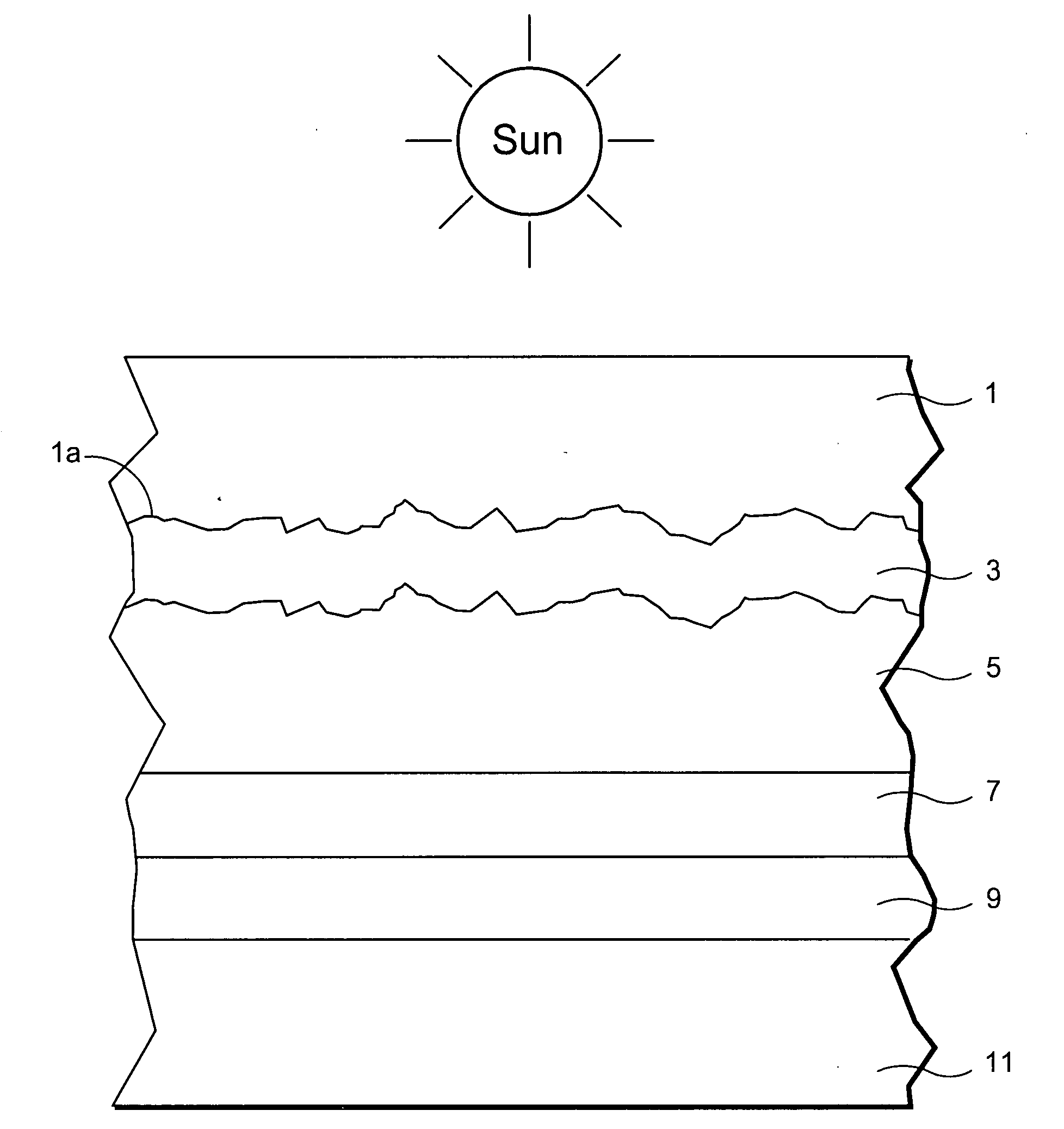

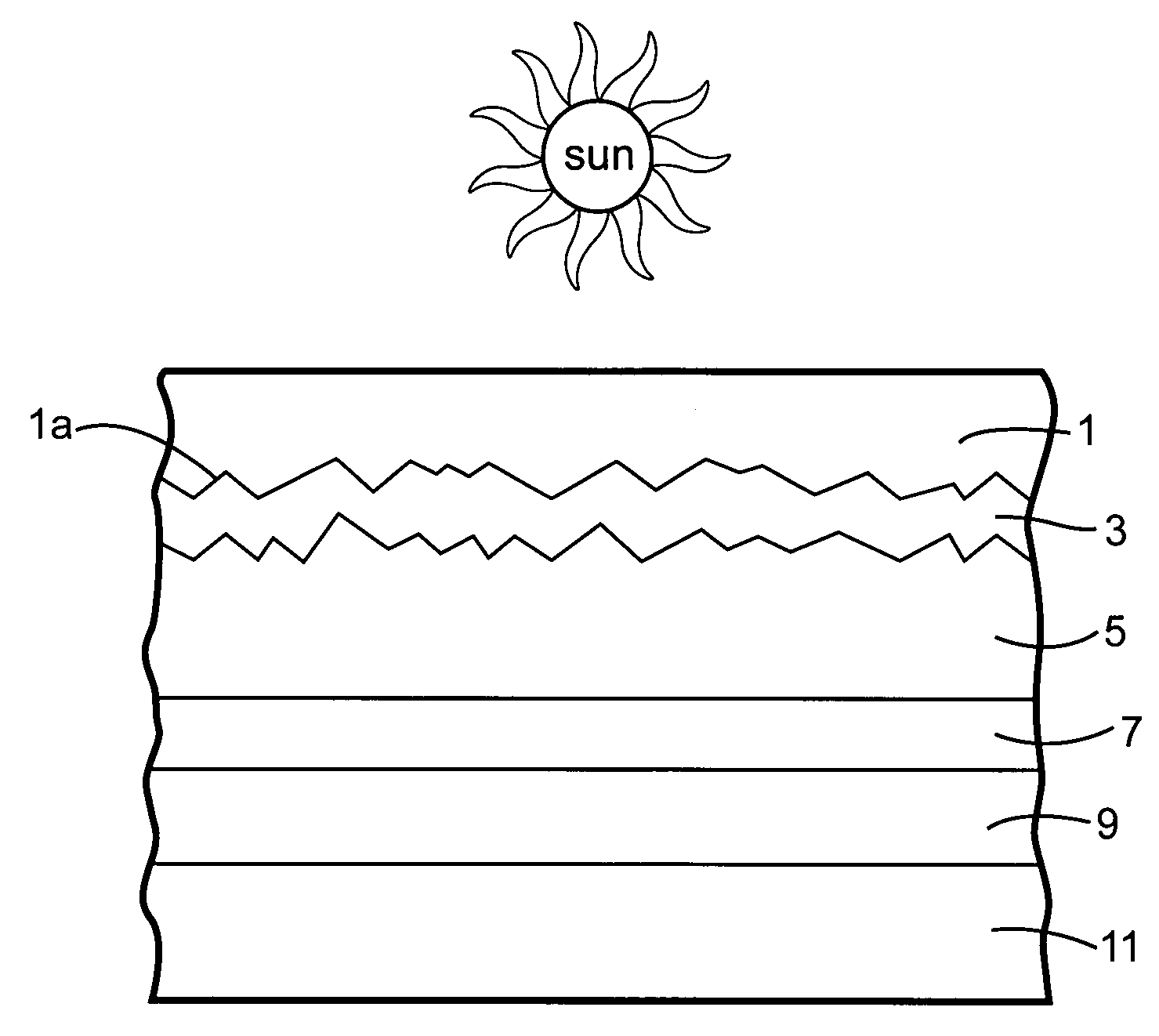

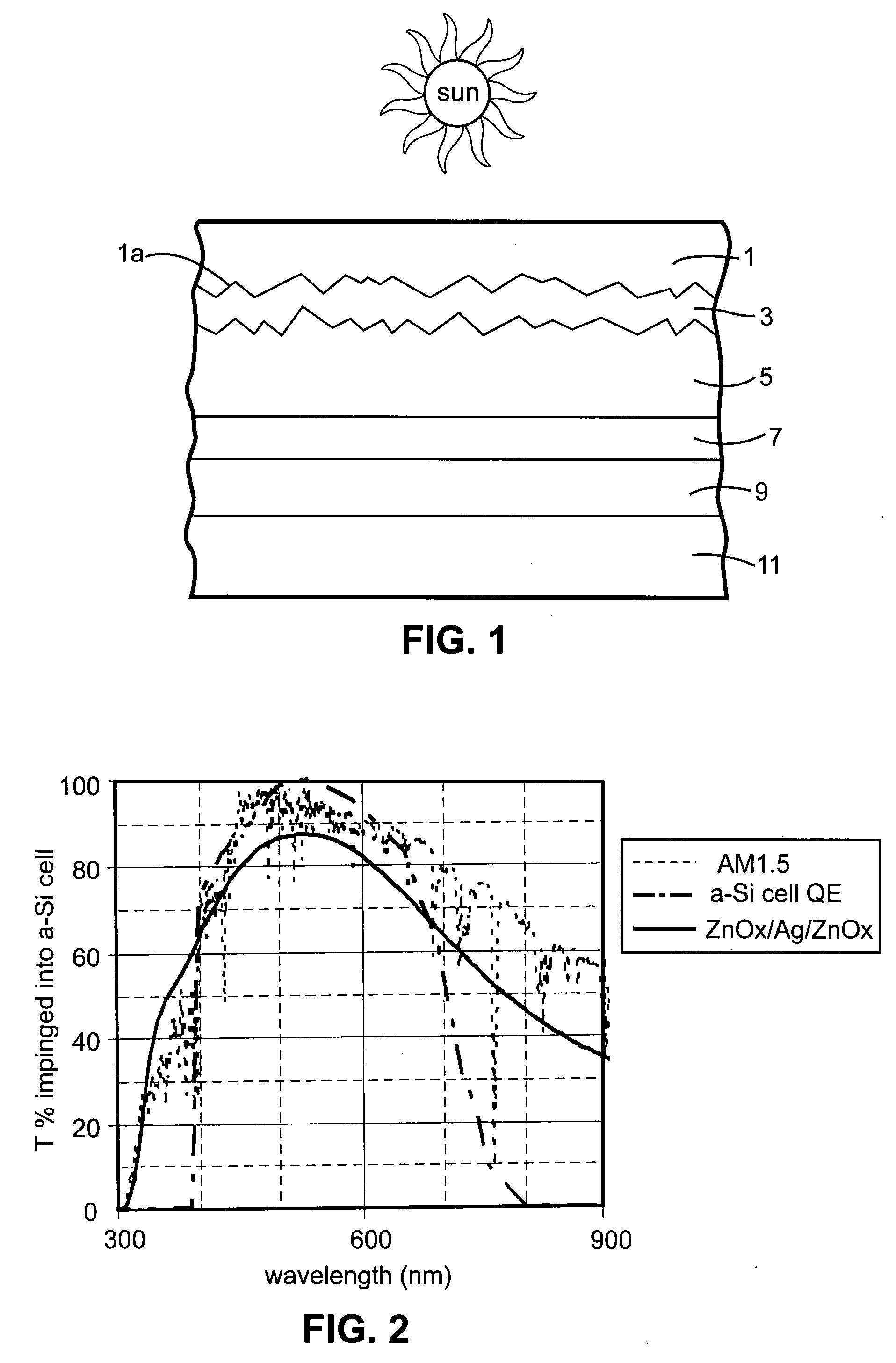

Front electrode including transparent conductive coating on patterned glass substrate for use in photovoltaic device and method of making same

InactiveUS20080178932A1Reduced visible light reflectionImprove conductivitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationPeak valuePeak area

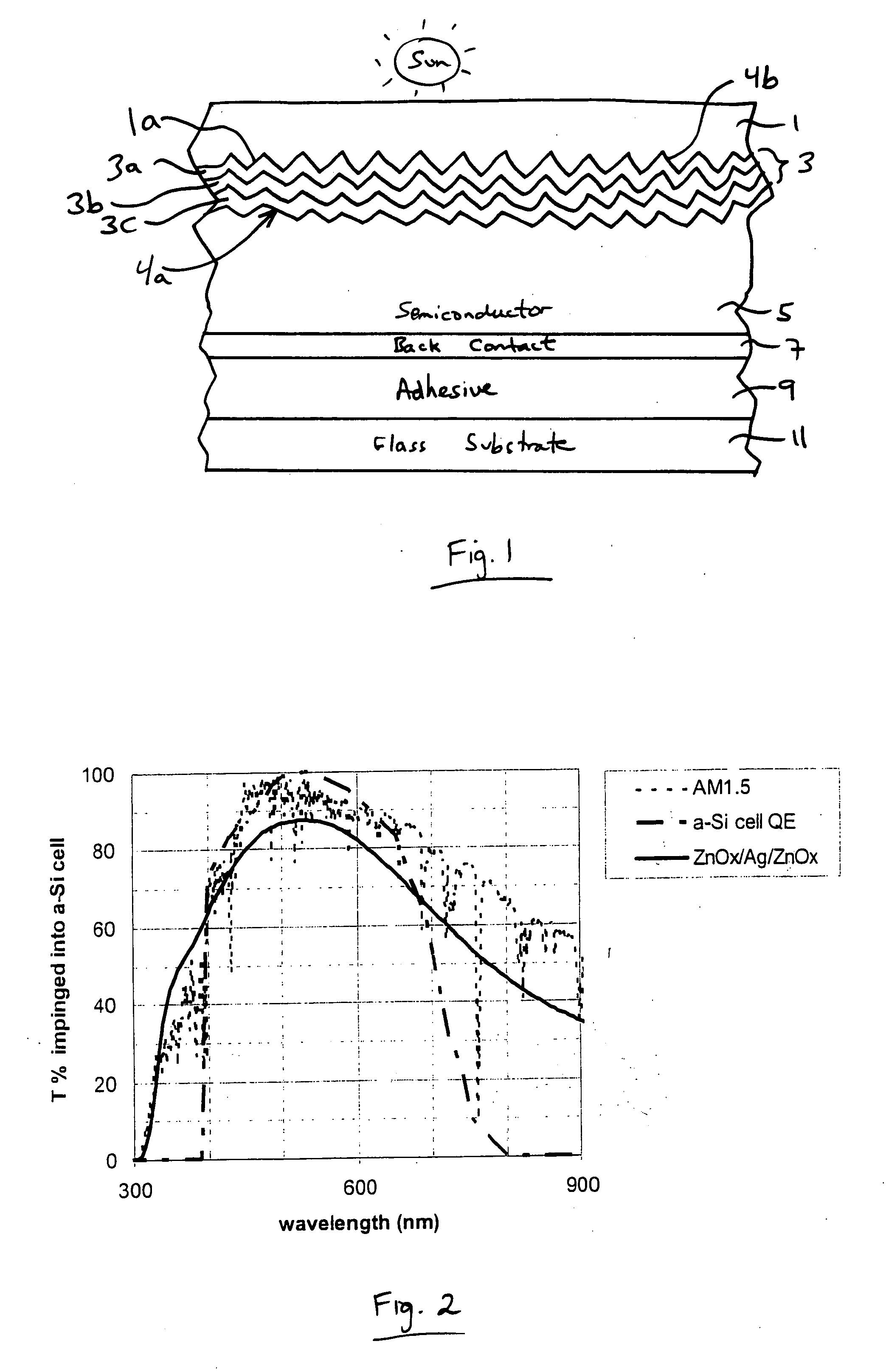

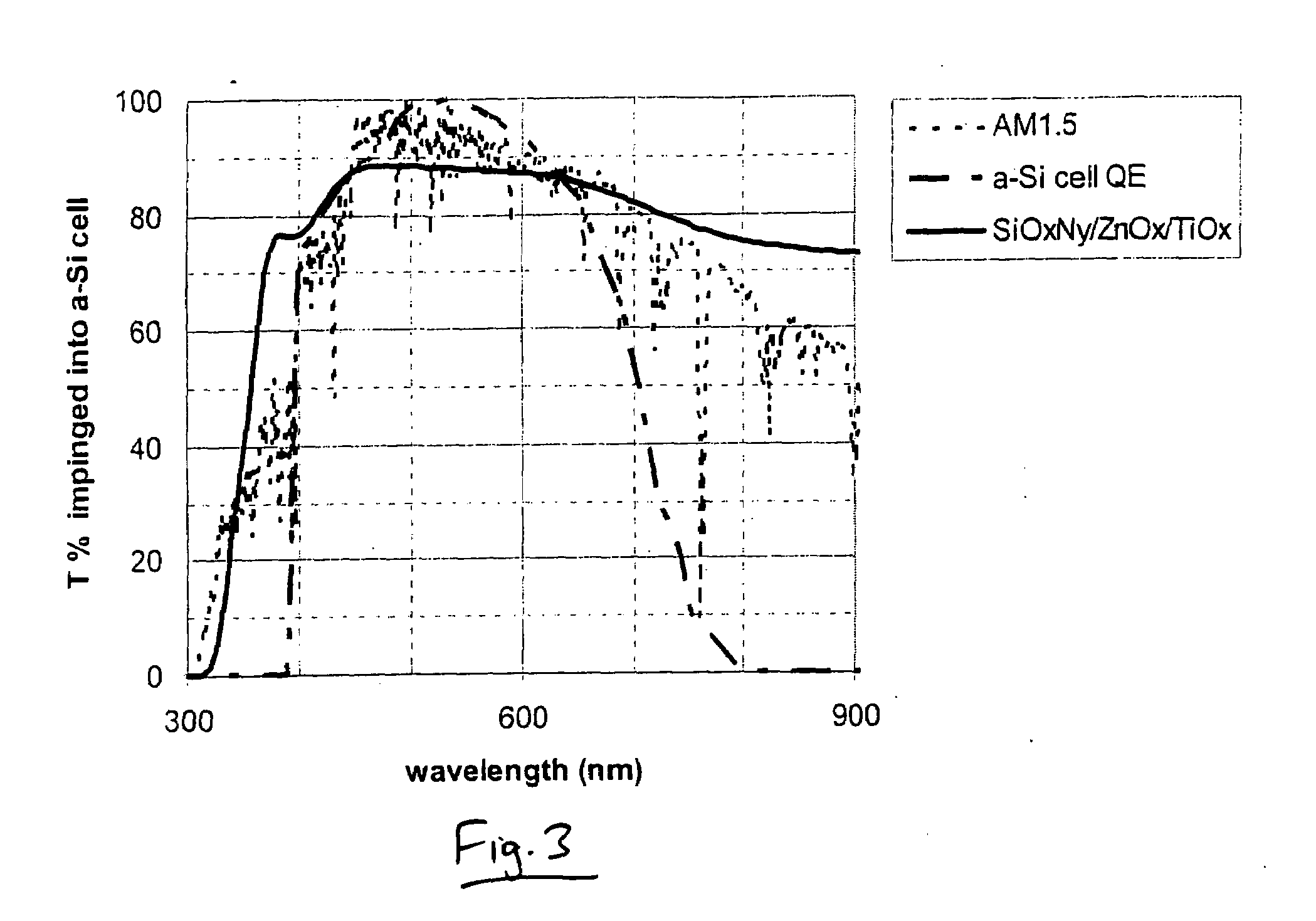

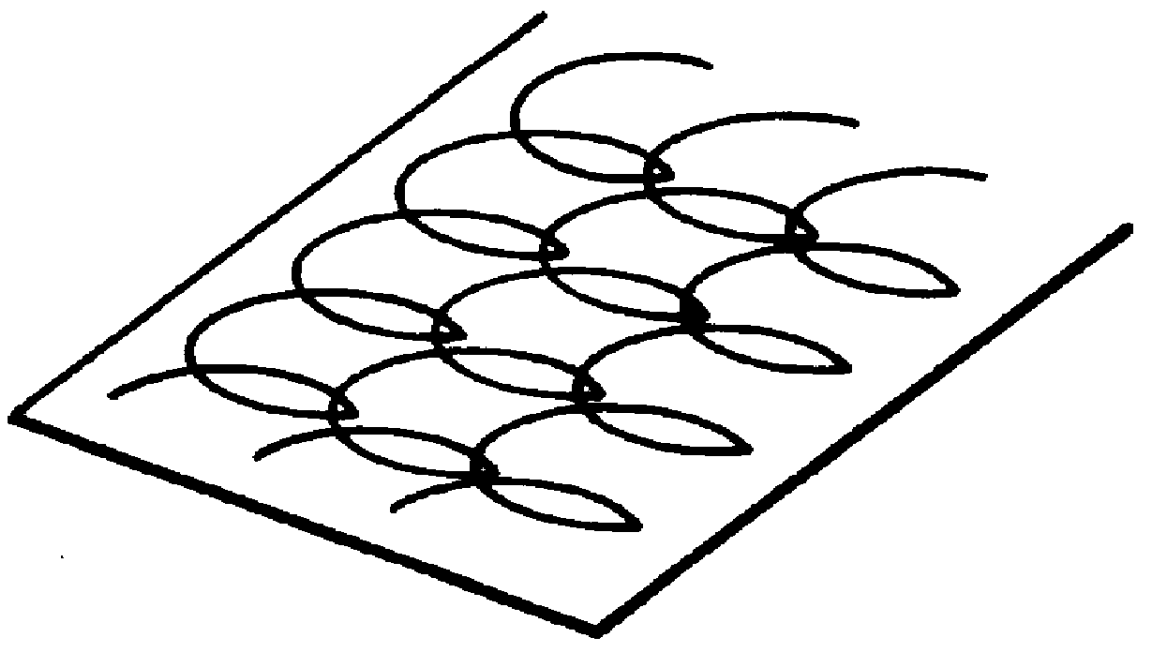

This invention relates to a photovoltaic device including an electrode such as a front electrode / contact. In certain example embodiments, the front electrode of the photovoltaic device includes a multi-layered transparent conductive coating which is sputter-deposited on a textured surface of a patterned glass substrate. In certain example embodiments, a maximum transmission area of the substantially transparent conductive front electrode is located under a peak area of a quantum efficiency (QE) and / or QEx (photon flux of solar radiation) curve of the photovoltaic device and a light source spectrum used to power the photovoltaic device. In certain example embodiments, the front electrode includes a transparent conductive layer of or including one or more of (i) titanium zinc oxide doped with aluminum and / or niobium, and / or (ii) titanium niobium oxide.

Owner:GUARDIAN GLASS LLC

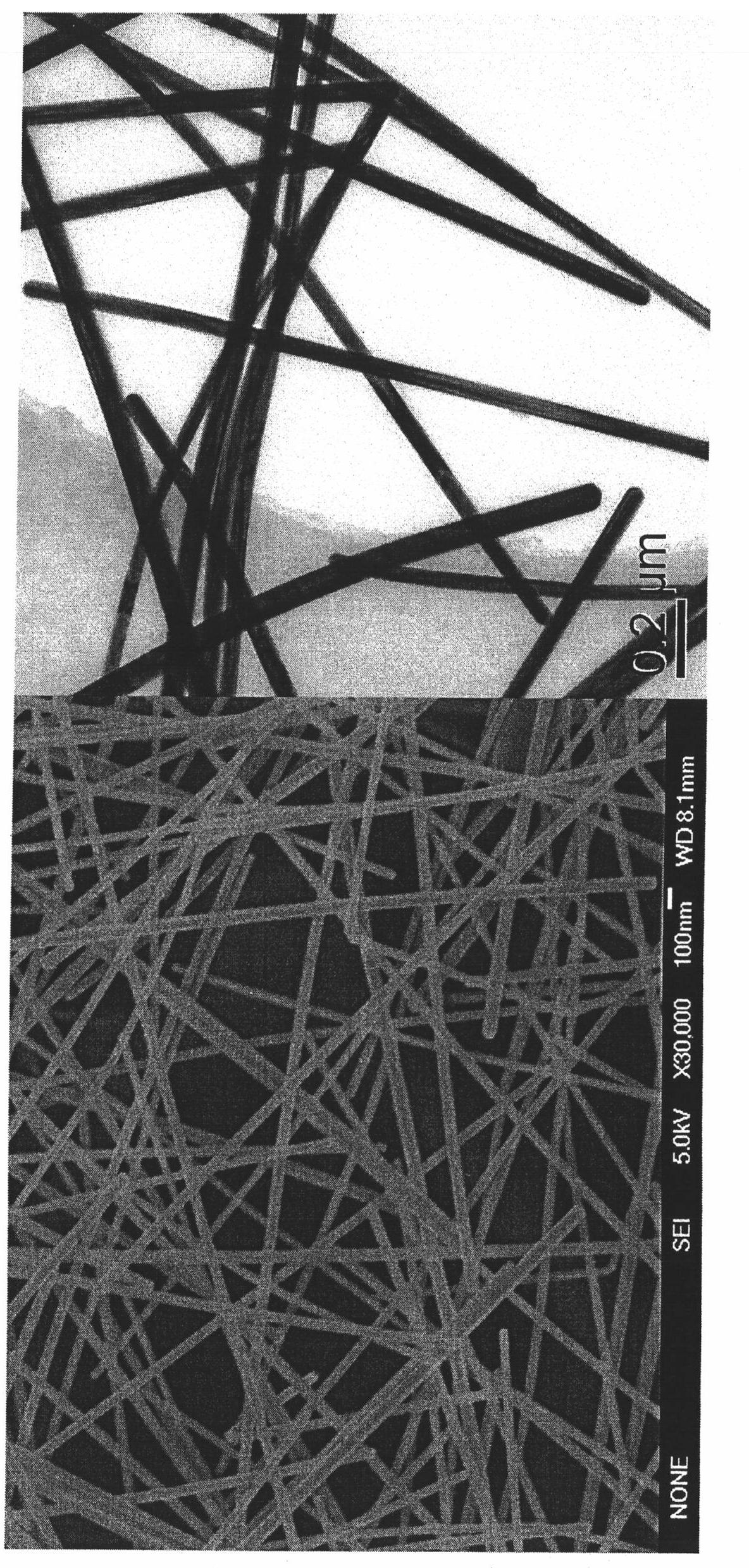

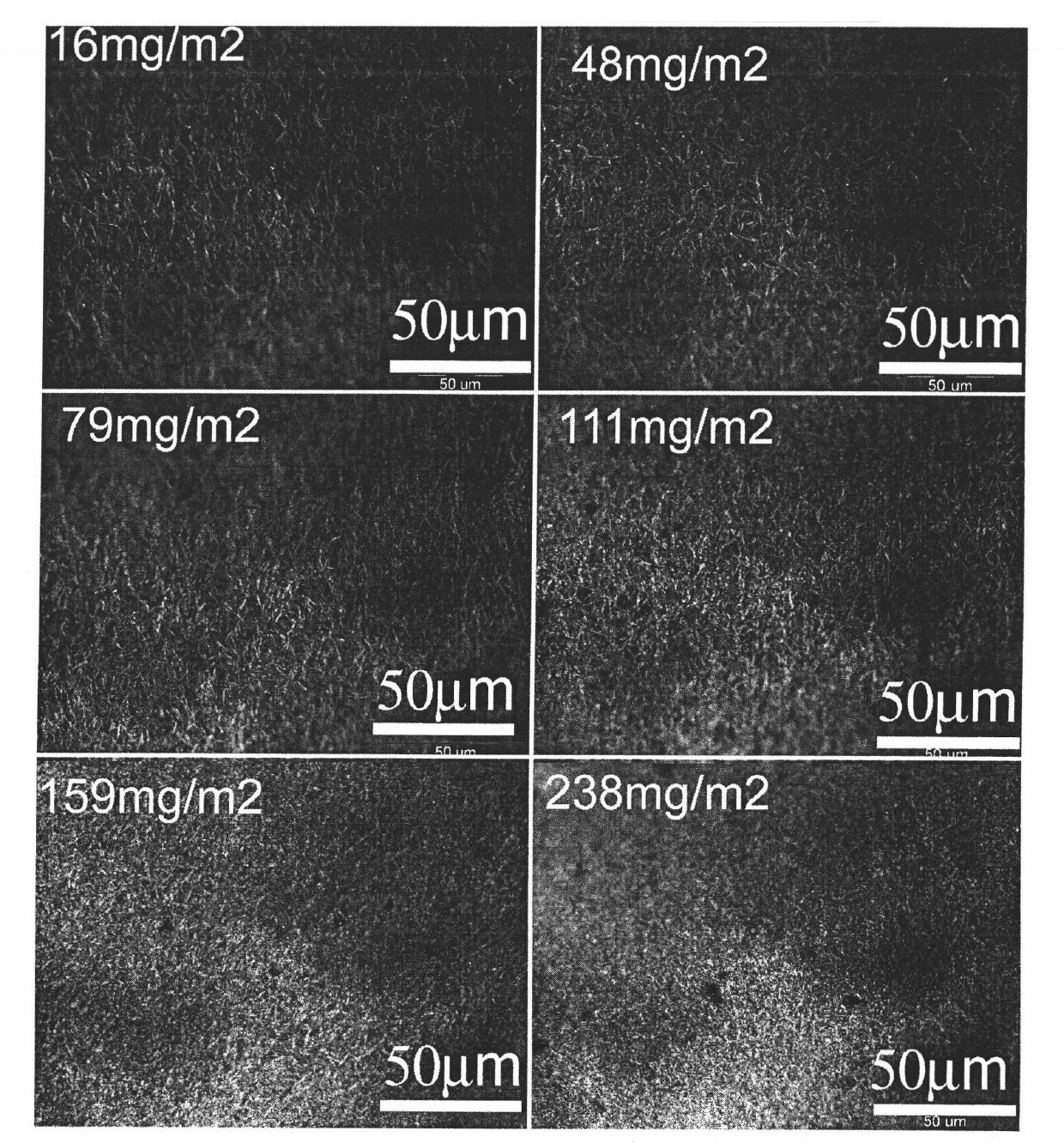

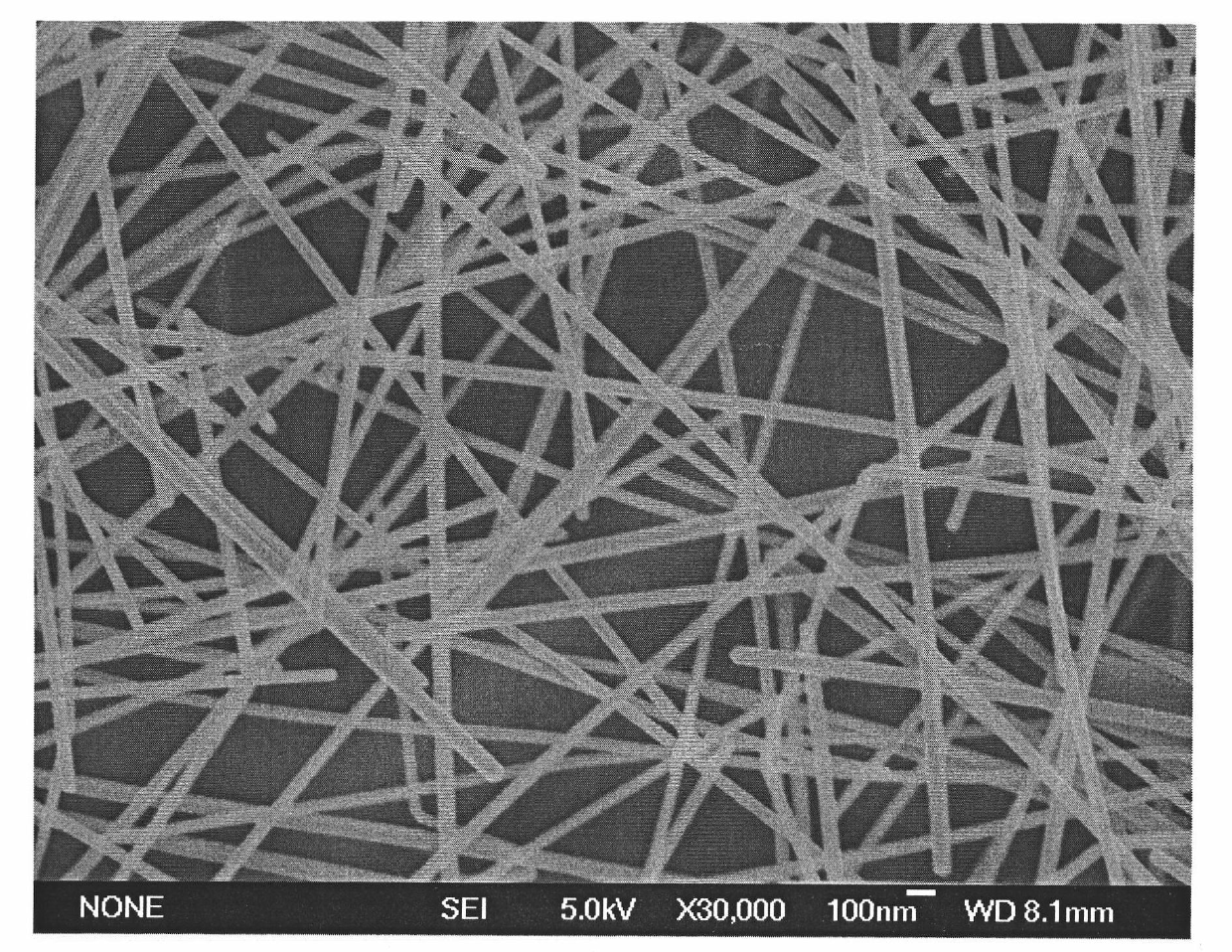

Silver nanowire-based transparent conductive thin film and preparation method thereof

InactiveCN102087886AReduce roughnessReduce transmittanceConductive layers on insulating-supportsIndividual molecule manipulationPolyvinyl alcoholPolymethyl methacrylate

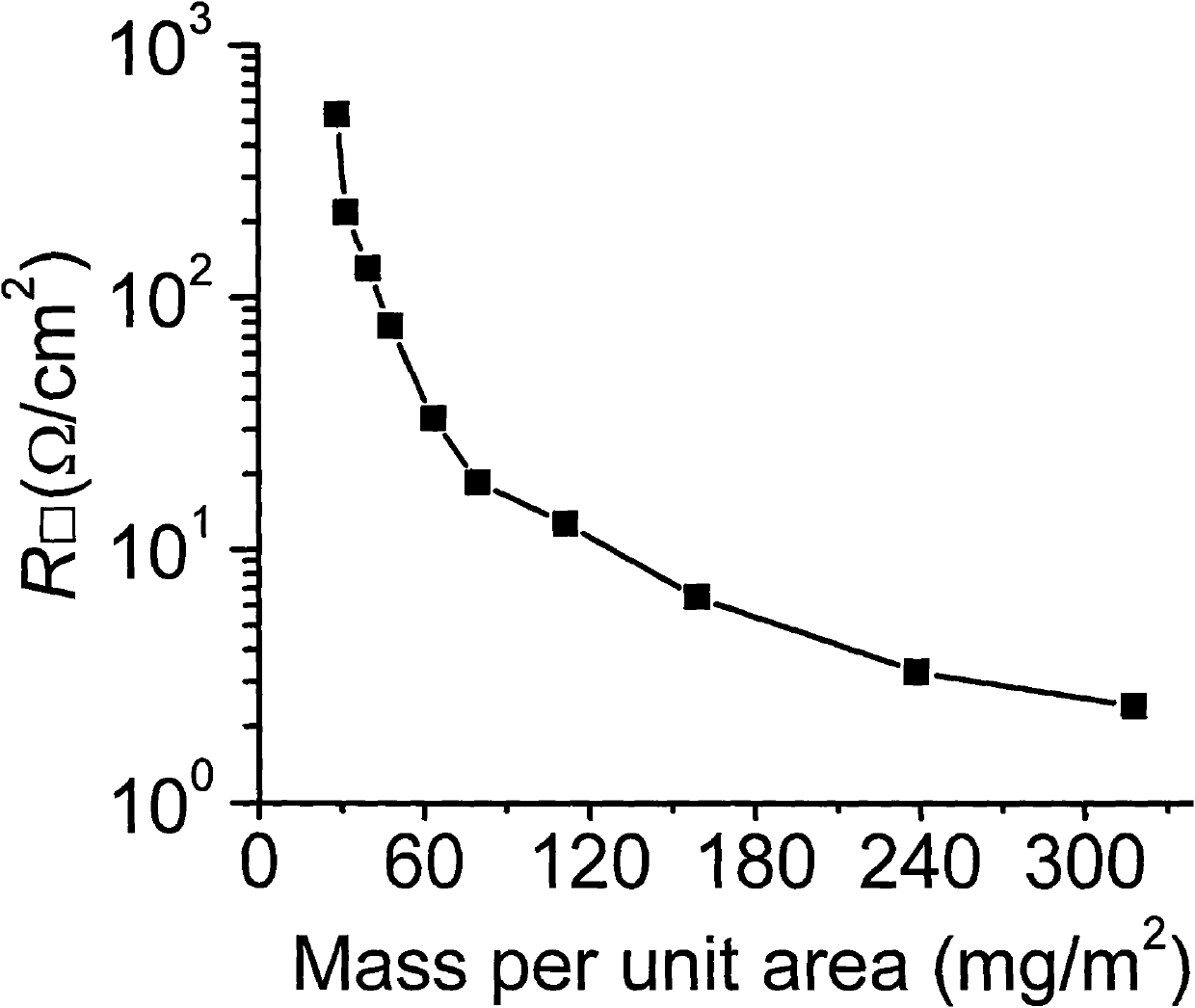

The invention provides a silver nanowire-based transparent conductive thin film and a preparation method thereof. The preparation method is characterized by comprising the following steps of: forming a uniform adhesive layer on a substrate by organic polymer fluid; and forming a silver nanowire conductive layer on the adhesive layer, wherein silver nanowires can be firmly adhered to the adhesive layer. Through the adhesive layer, the firmness and the reliability of the silver nanowire transparent conductive thin film are greatly improved, the problem of easiness of falling of the silver nanowires is solved, and the selection range of the substrate is expanded. If the adhesive layer is formed by polyvinyl alcohol on a polymethyl methacrylate (PMMA) substrate, the visible light transmittance reaches 84 percent when square resistance is 130.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

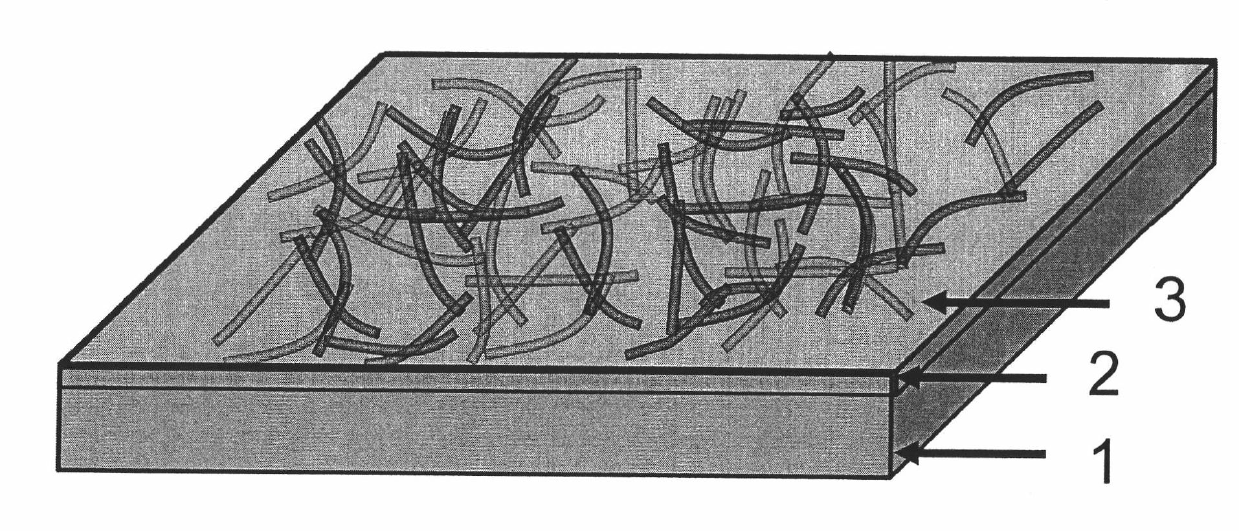

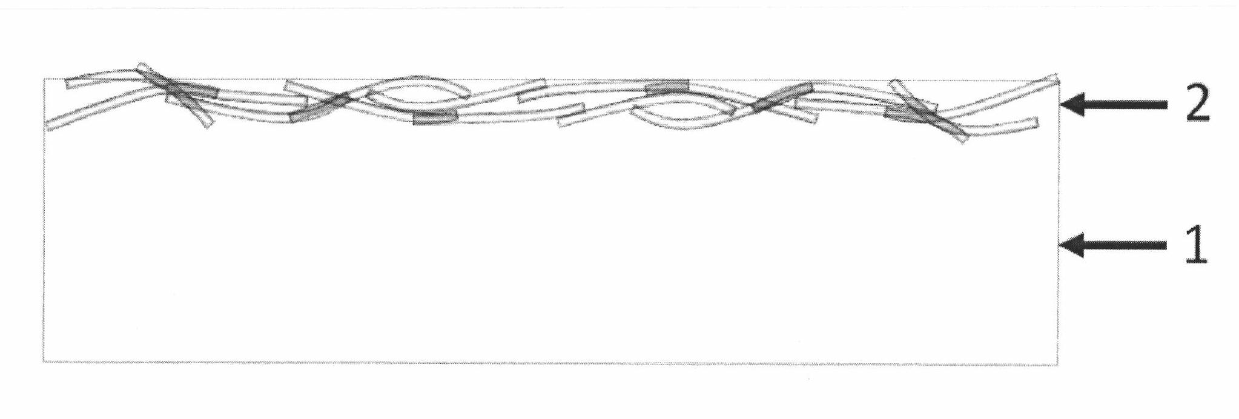

Flexible transparent conductive film based on organic polymers and silver nanowires and preparation method thereof

InactiveCN102087884AEnhanced light absorptionImprove conductivityConductive layers on insulating-supportsIndividual molecule manipulationElectrically conductiveNanometre

The invention provides a flexible transparent conductive film based on organic polymers and silver nanowires and a preparation method thereof. The flexible transparent conductive film based on organic polymers and silver nanowires is characterized in that a continuous conductive network formed by the silver nanowires is half-buried in the surface layer of the organic polymers, part of the surfaces of the silver nanowires is exposed on the surfaces of the organic polymers, and the conductive surface of the transparent conductive film is formed by the surfaces of the organic polymers and the surfaces of the silver nanowires. First, a conductive silver nanowire layer is prepared and uniformly distributed on a flat surface, and then a transparent organic polymer layer is distributed on the silver nanowire layer, thus the flexible transparent conductive film is formed. The flexible transparent conductive film has the advantages of high visible light transmittance, low square resistance, firm combination and flat surface.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

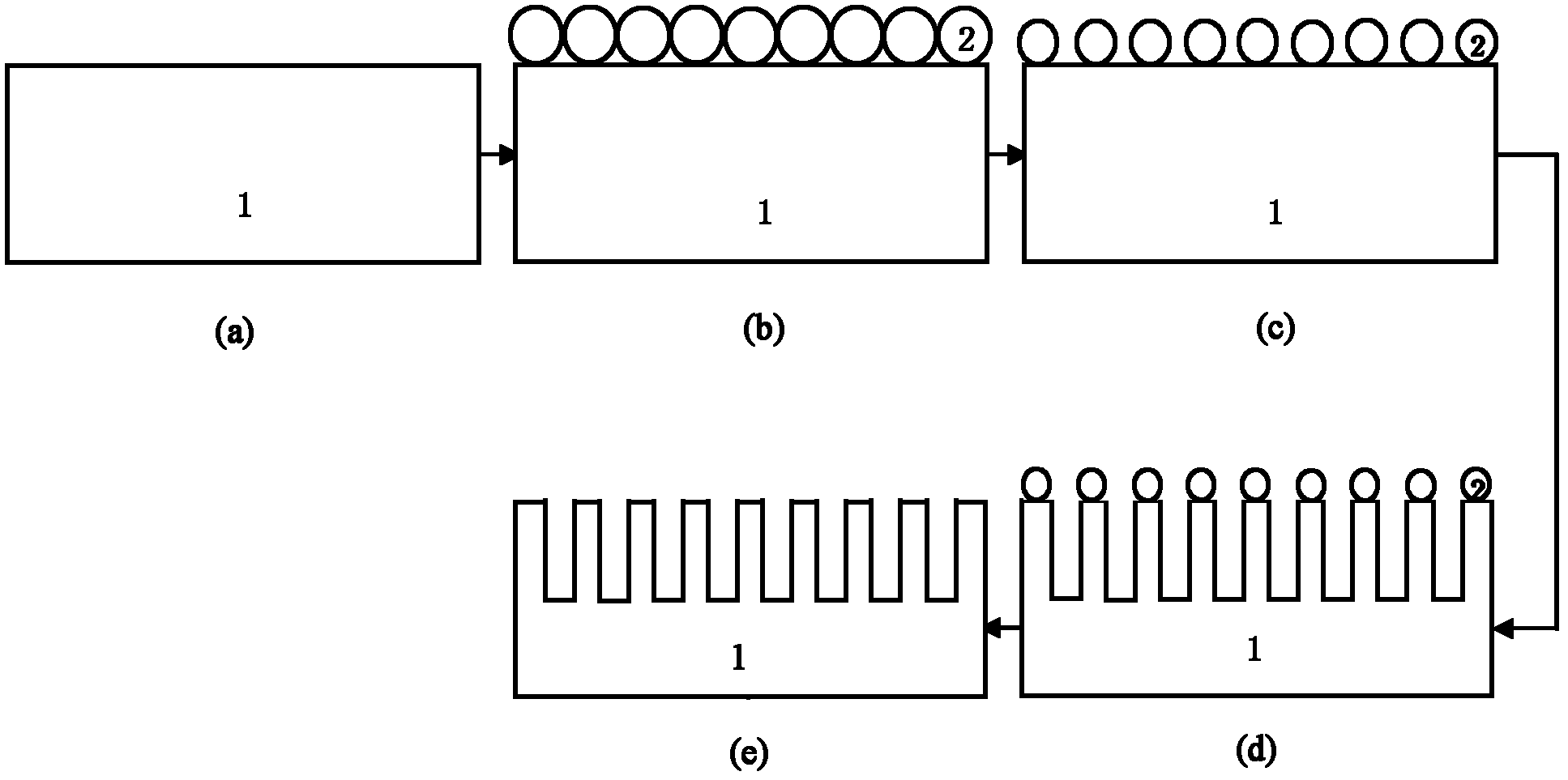

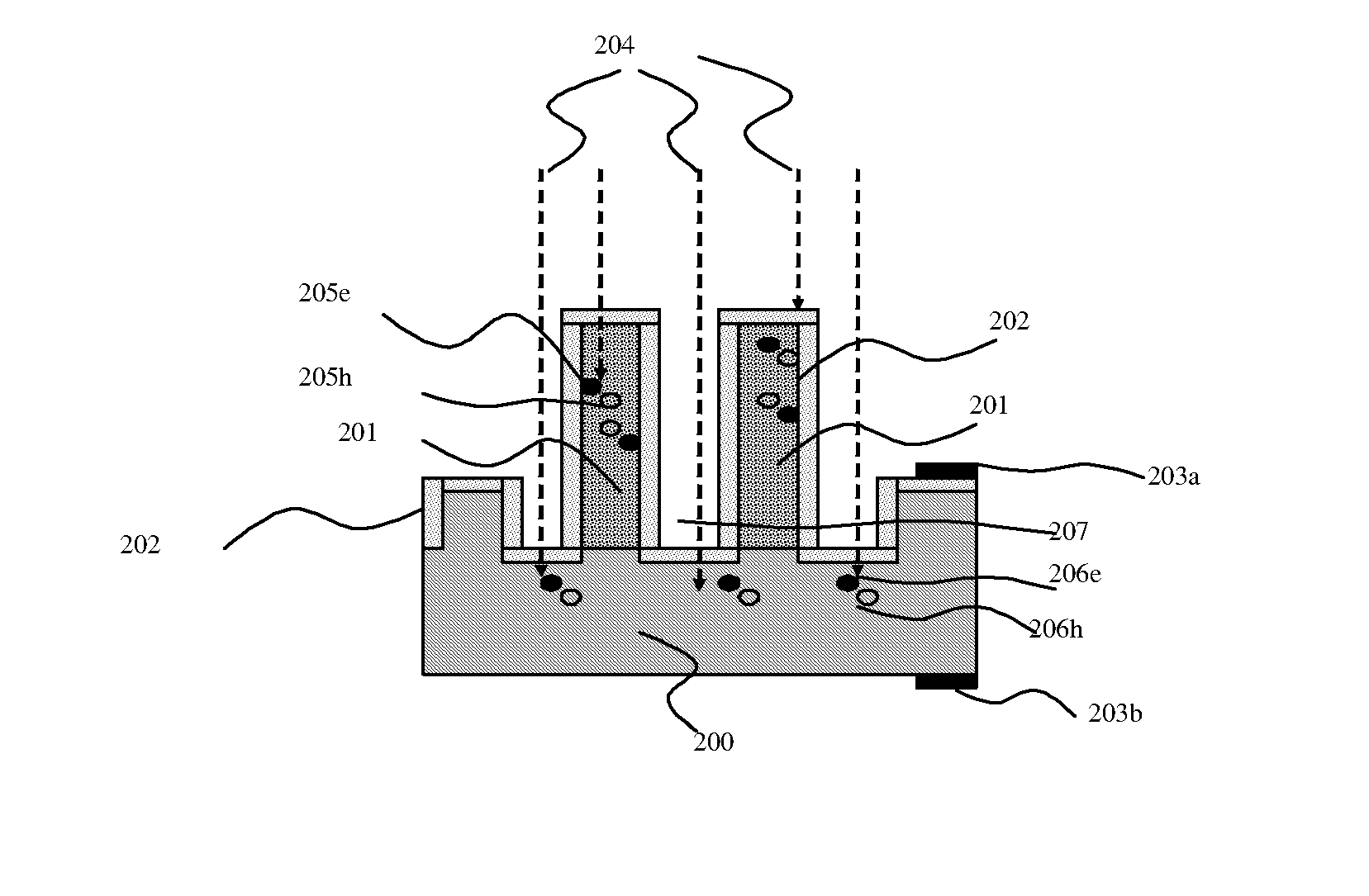

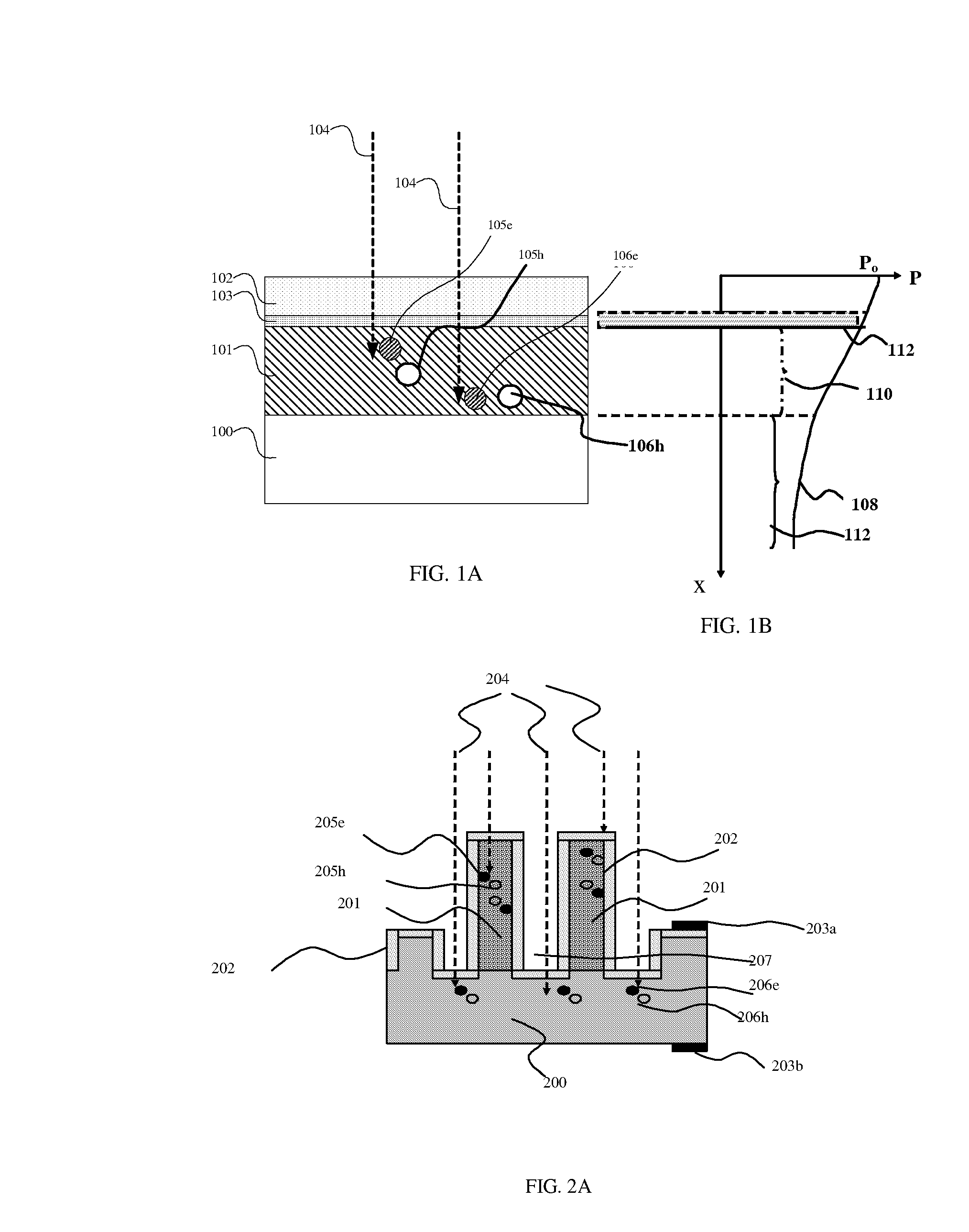

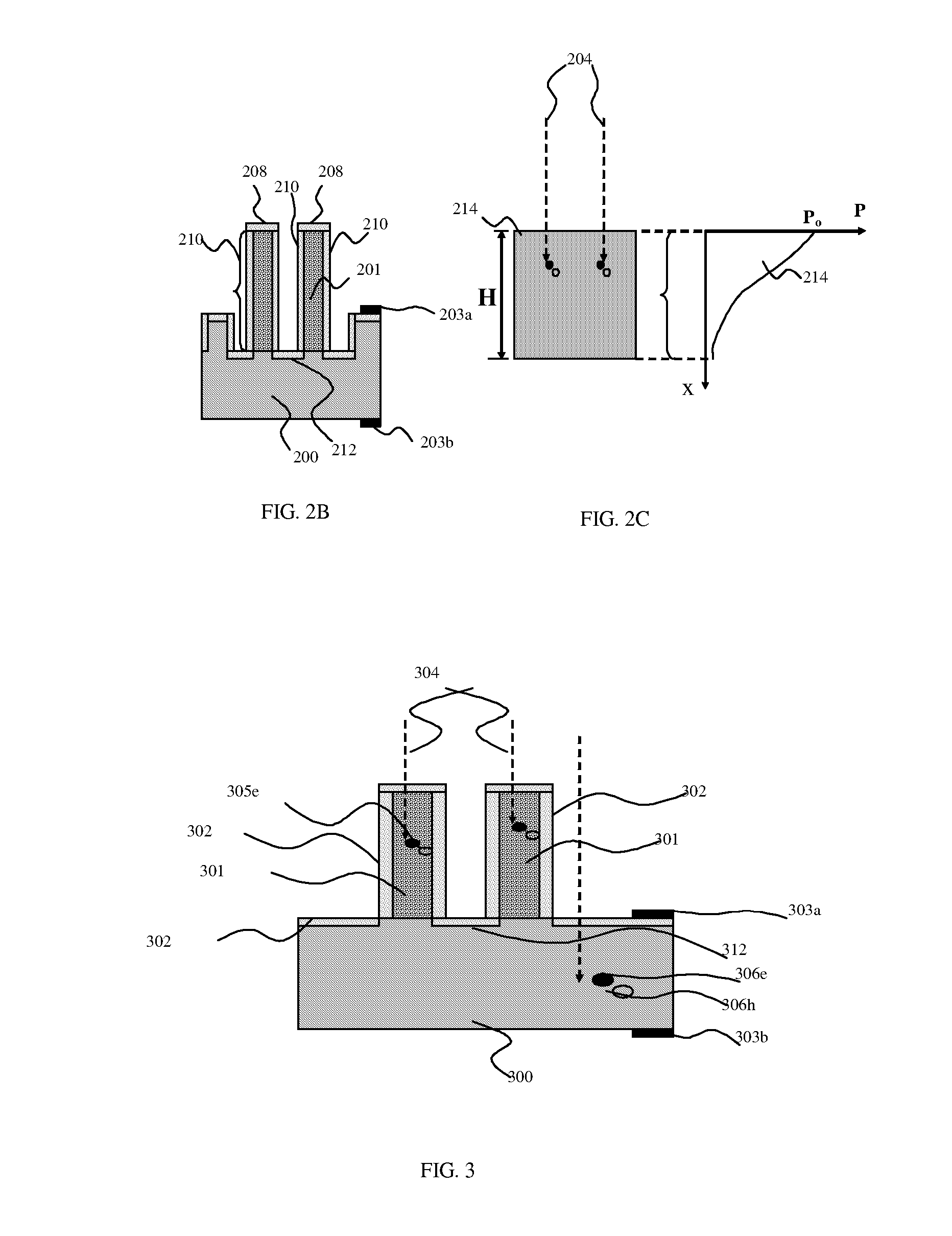

Amorphous-crystalline tandem nanostructured solar cells

InactiveUS20080110486A1Enhanced light absorptionBroad spectrumMaterial nanotechnologyPV power plantsEngineeringSolar cell

A photovoltaic device that includes a plurality of elongated nanostructures disposed on the surface of a substrate and a multilayered film deposited conformally over the elongated nanostructures forming a plurality of photoactive junctions. A method making such a photovoltaic device includes generating a plurality of elongated nanostructures on a substrate surface and conformally depositing a multilayered film forming a plurality of photoactive junctions. The plurality of photoactive junctions are designed to capture different wavelengths of light. A solar panel includes at least one photovoltaic device.

Owner:C3 PROTECTION +1

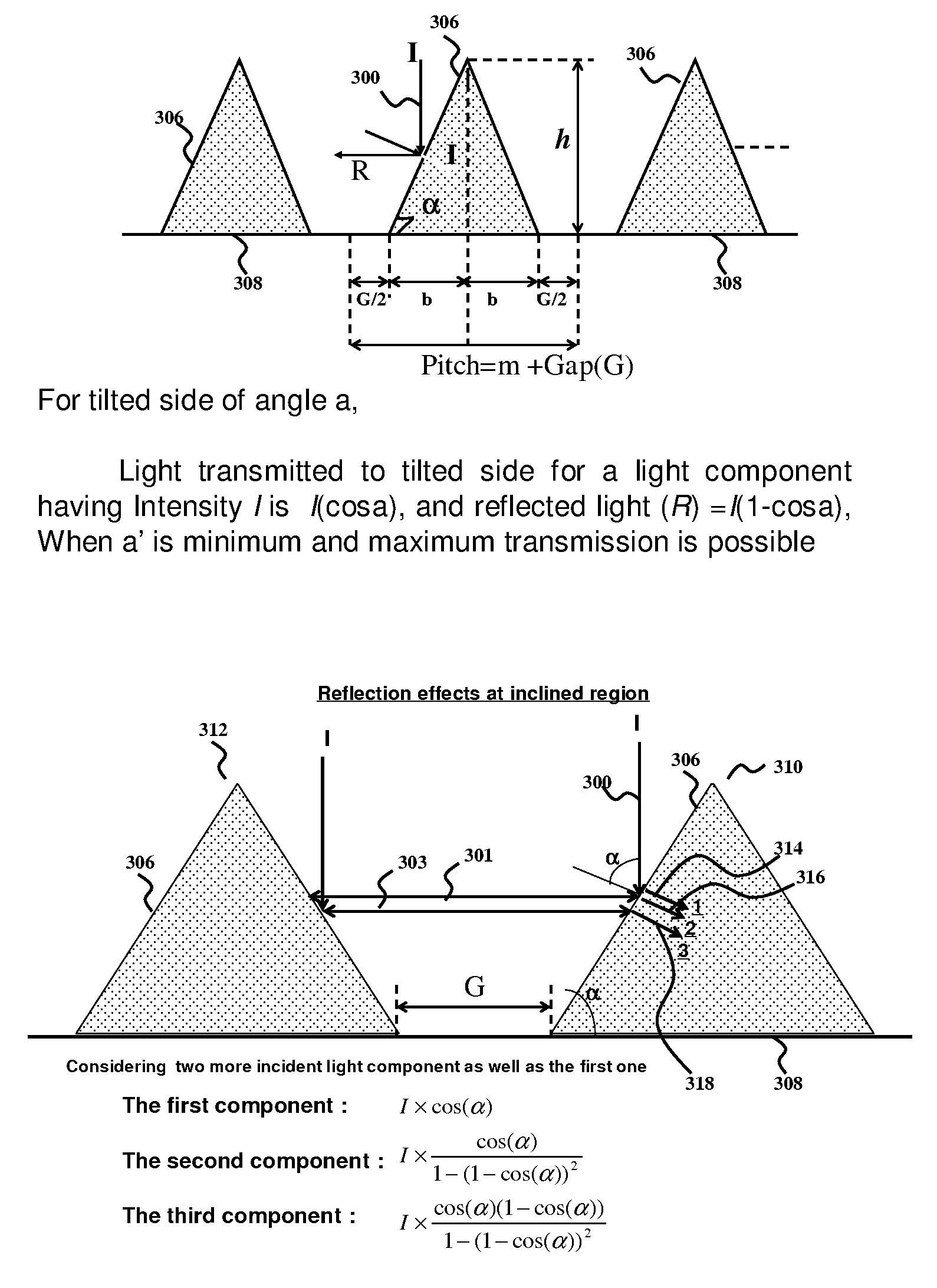

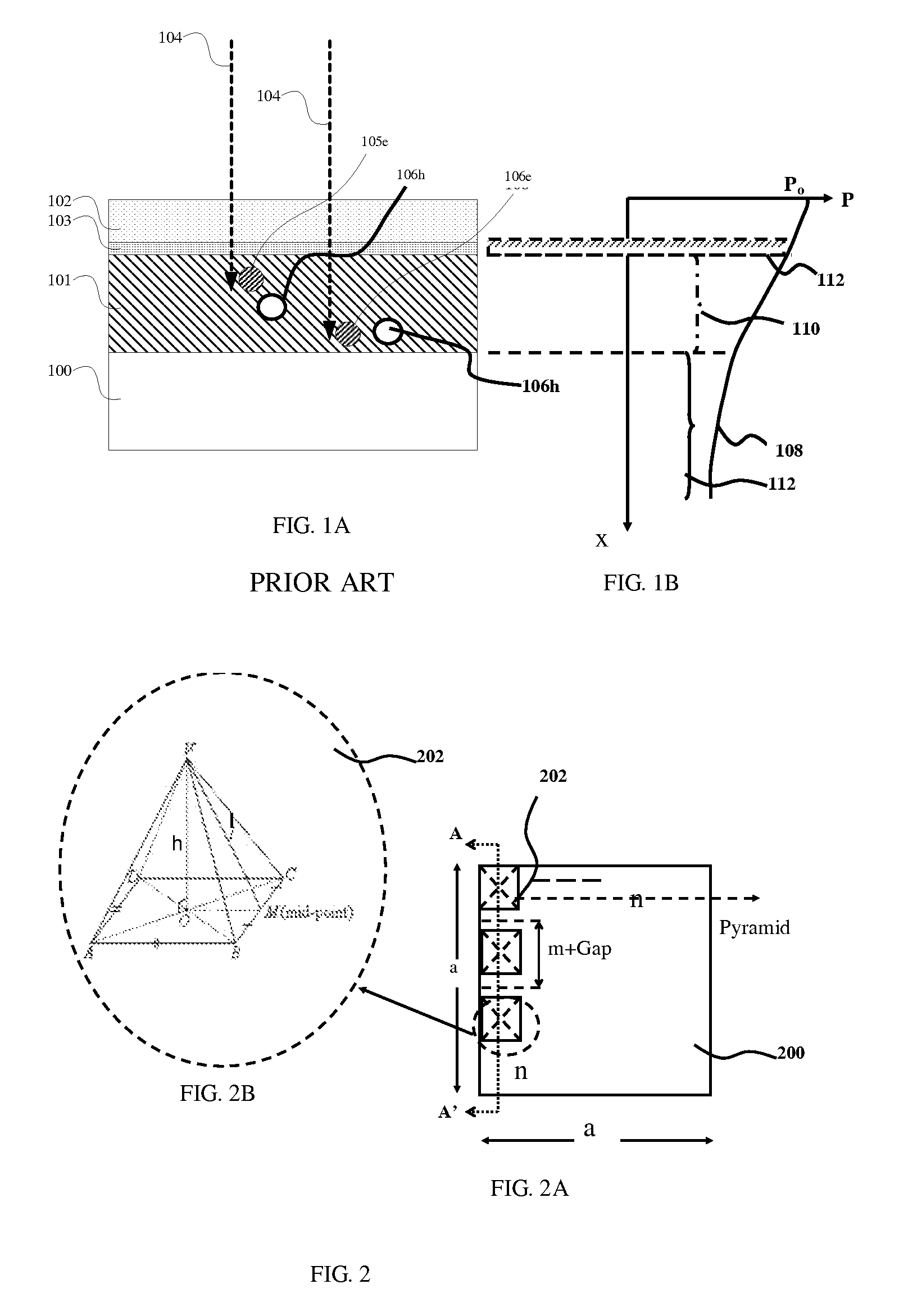

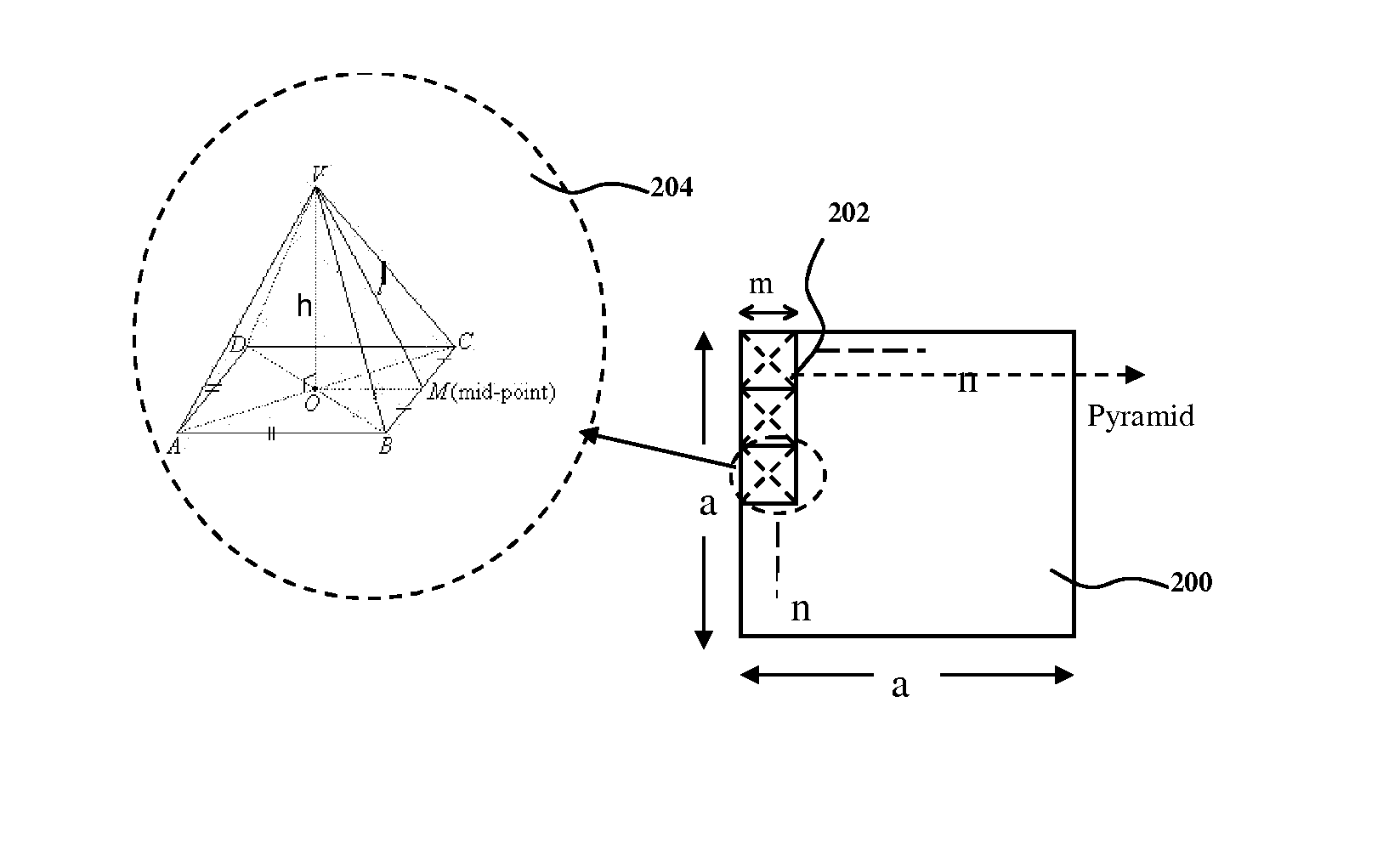

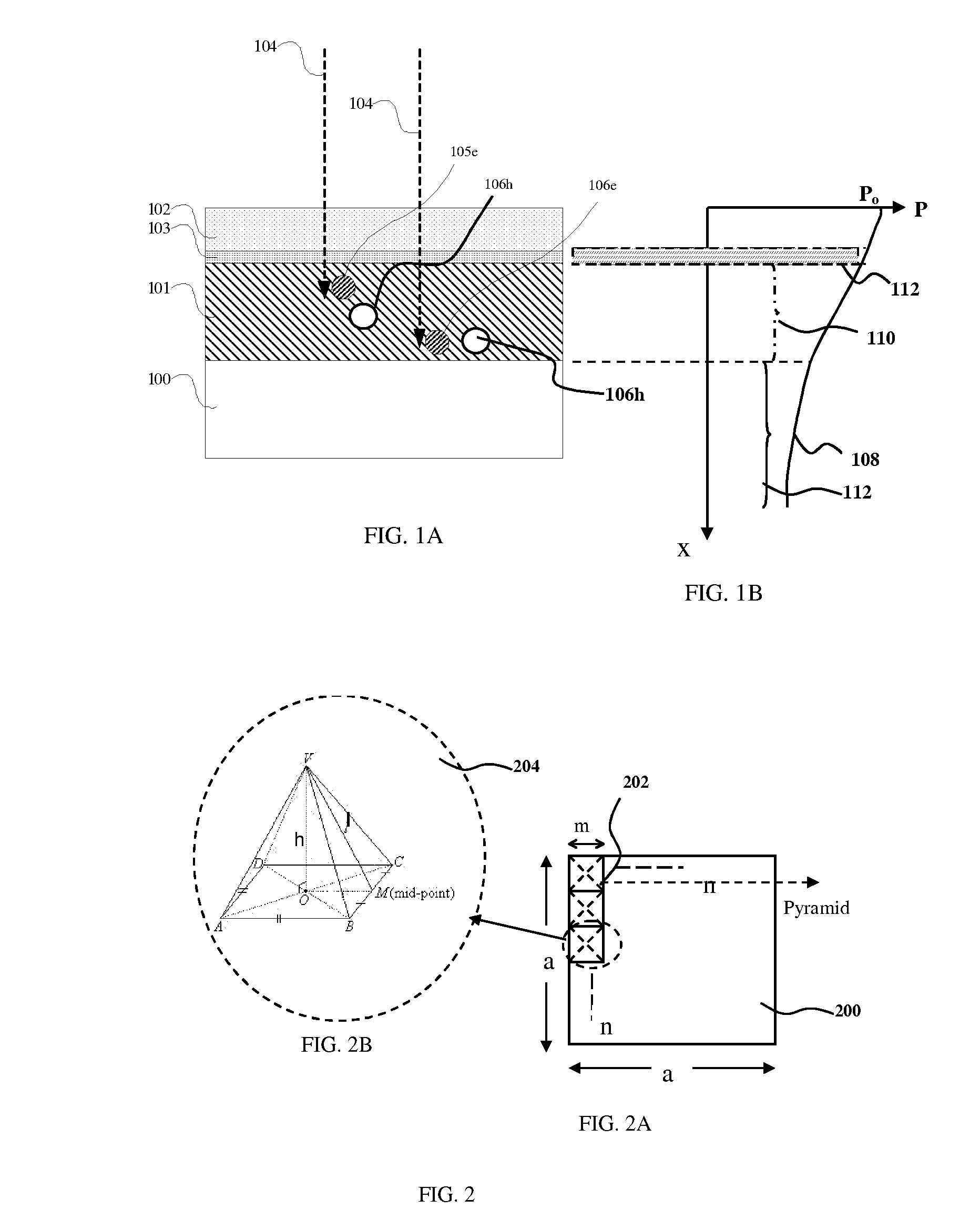

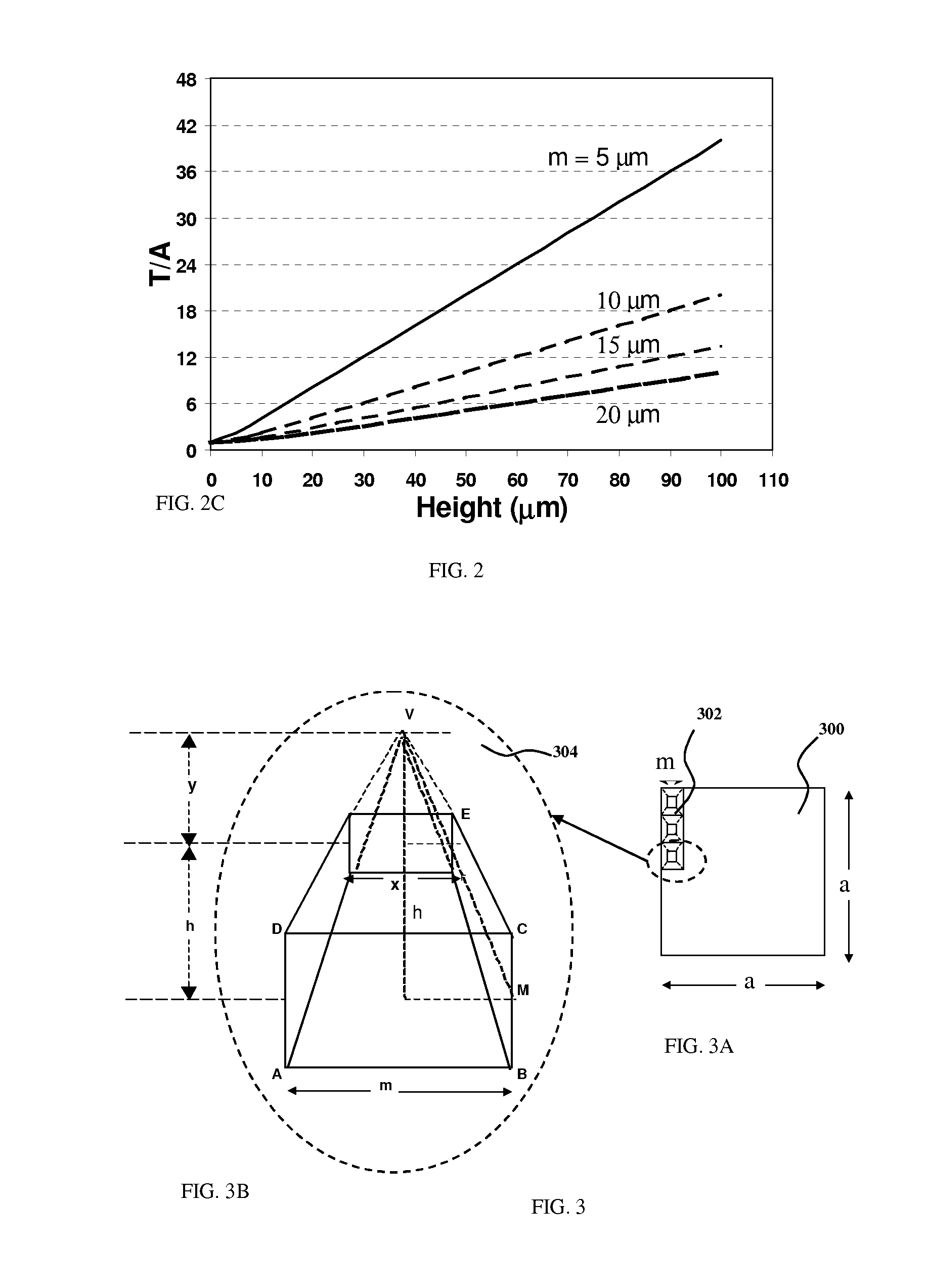

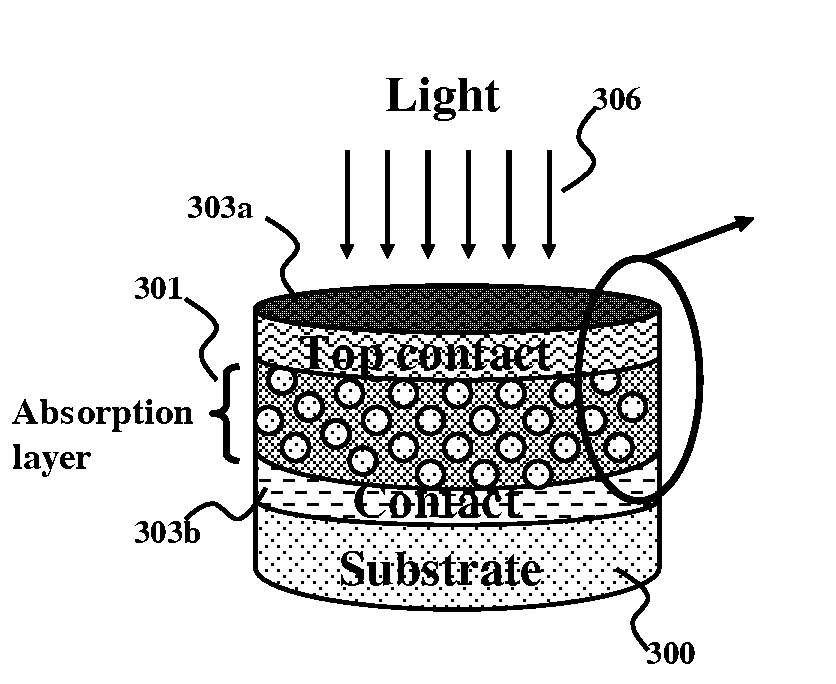

High efficiency photovoltaic cells with self concentrating effect

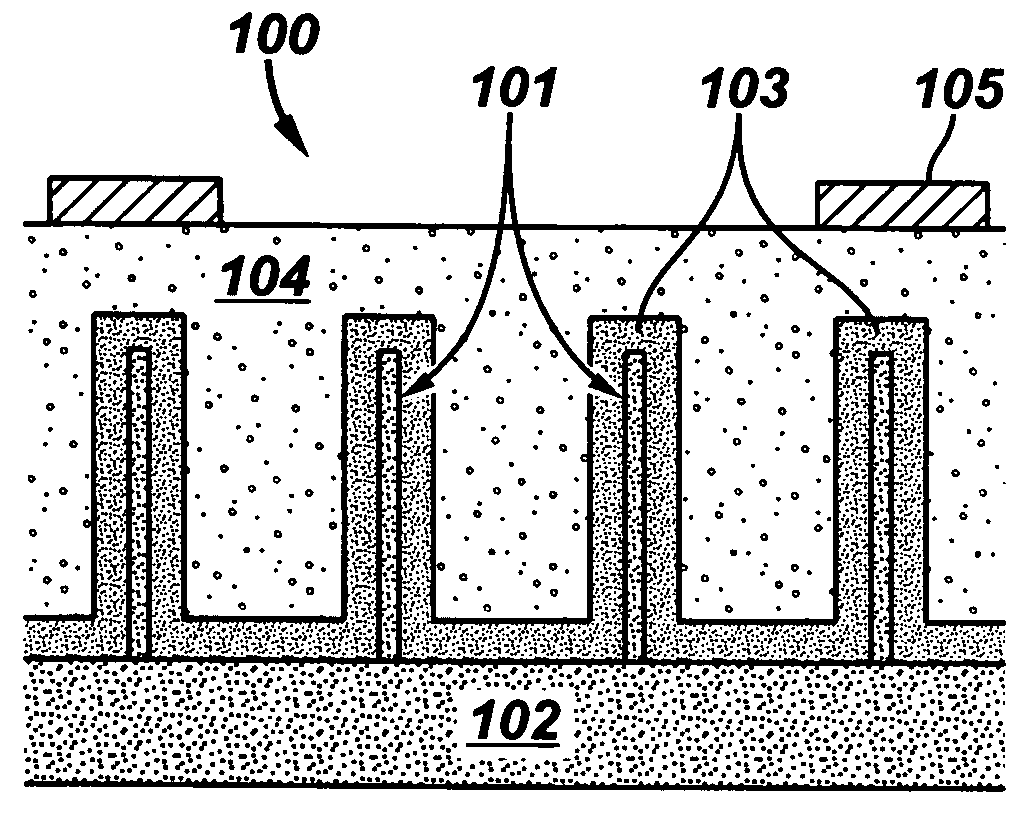

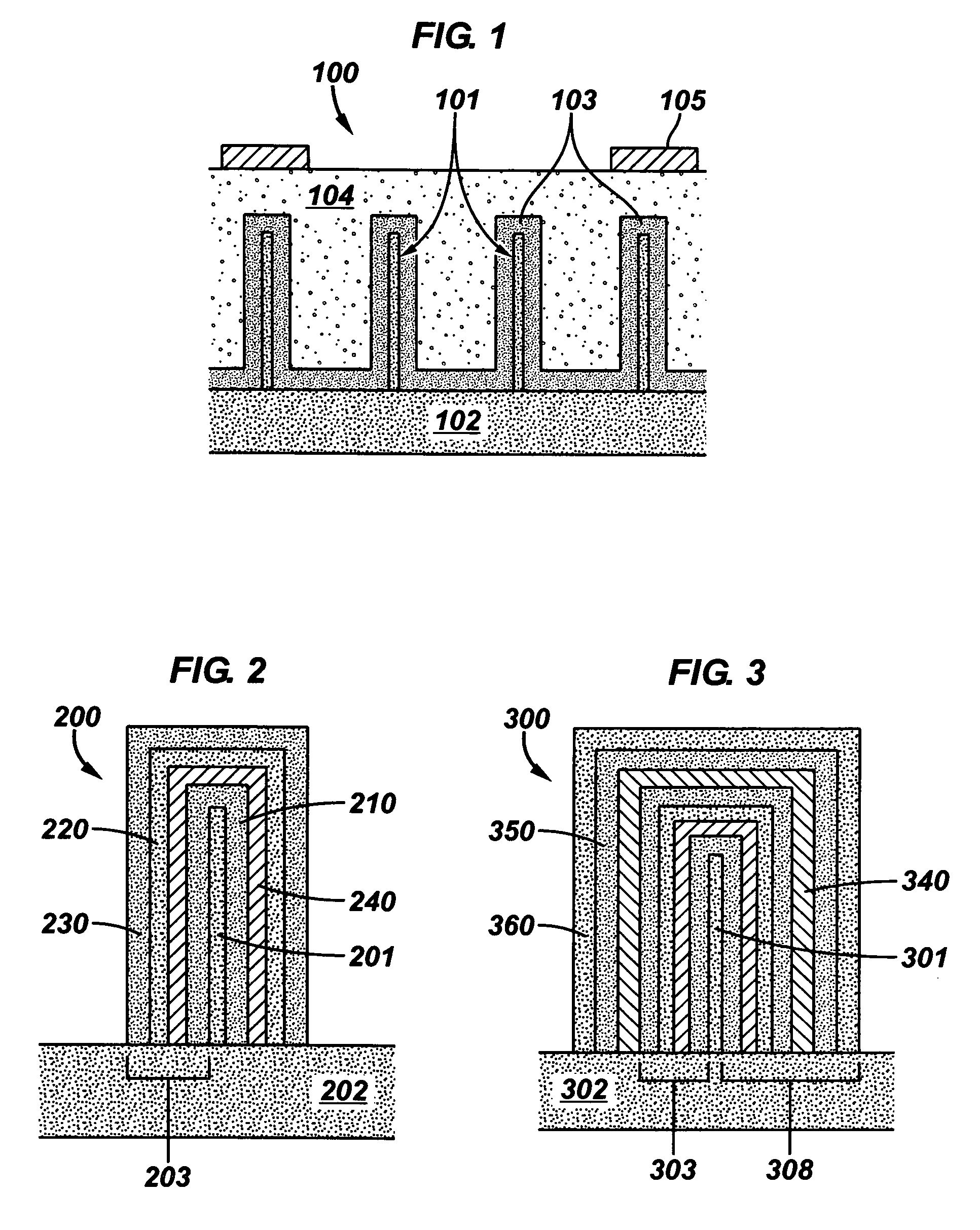

ActiveUS20080072958A1Low-cost manufacturing processEnhanced light absorptionPhotovoltaic energy generationSemiconductor devicesSolar cellNanostructure

Novel structures of photovoltaic cells (also called as solar cells) are provided. The Cells are based on the micro (or nano) structures which could not only increase the surface area but also have the capability of self concentrating the solar spectrum incident onto the cell. These photovoltaic cells have large power generation capability per unit physical area over the conventional cells. These cells will have enormous applications such as in space, in commercial, residential and industrial applications.

Owner:BANPIL PHOTONICS

Front electrode including transparent conductive coating on patterned glass substrate for use in photovoltaic device and method of making same

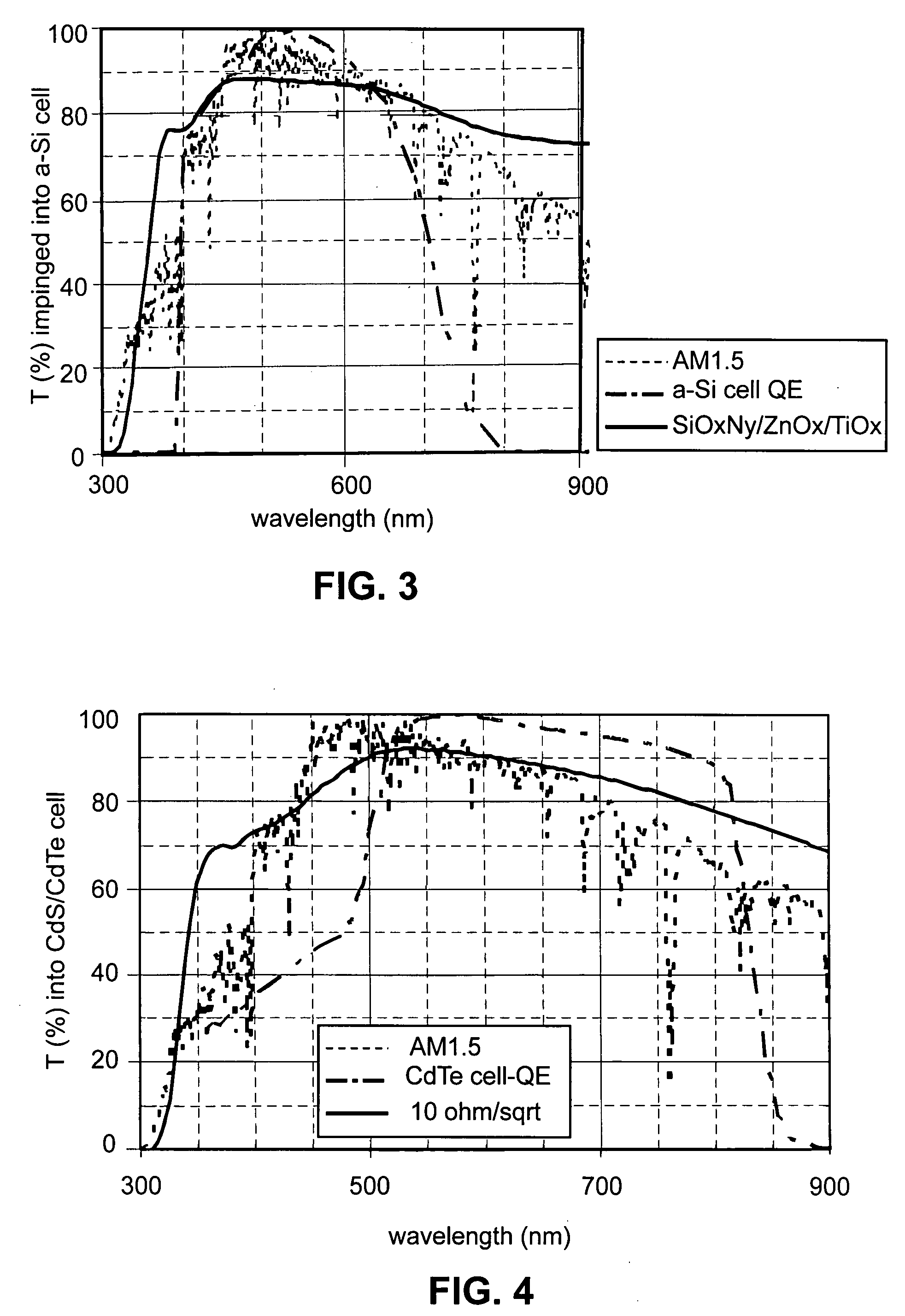

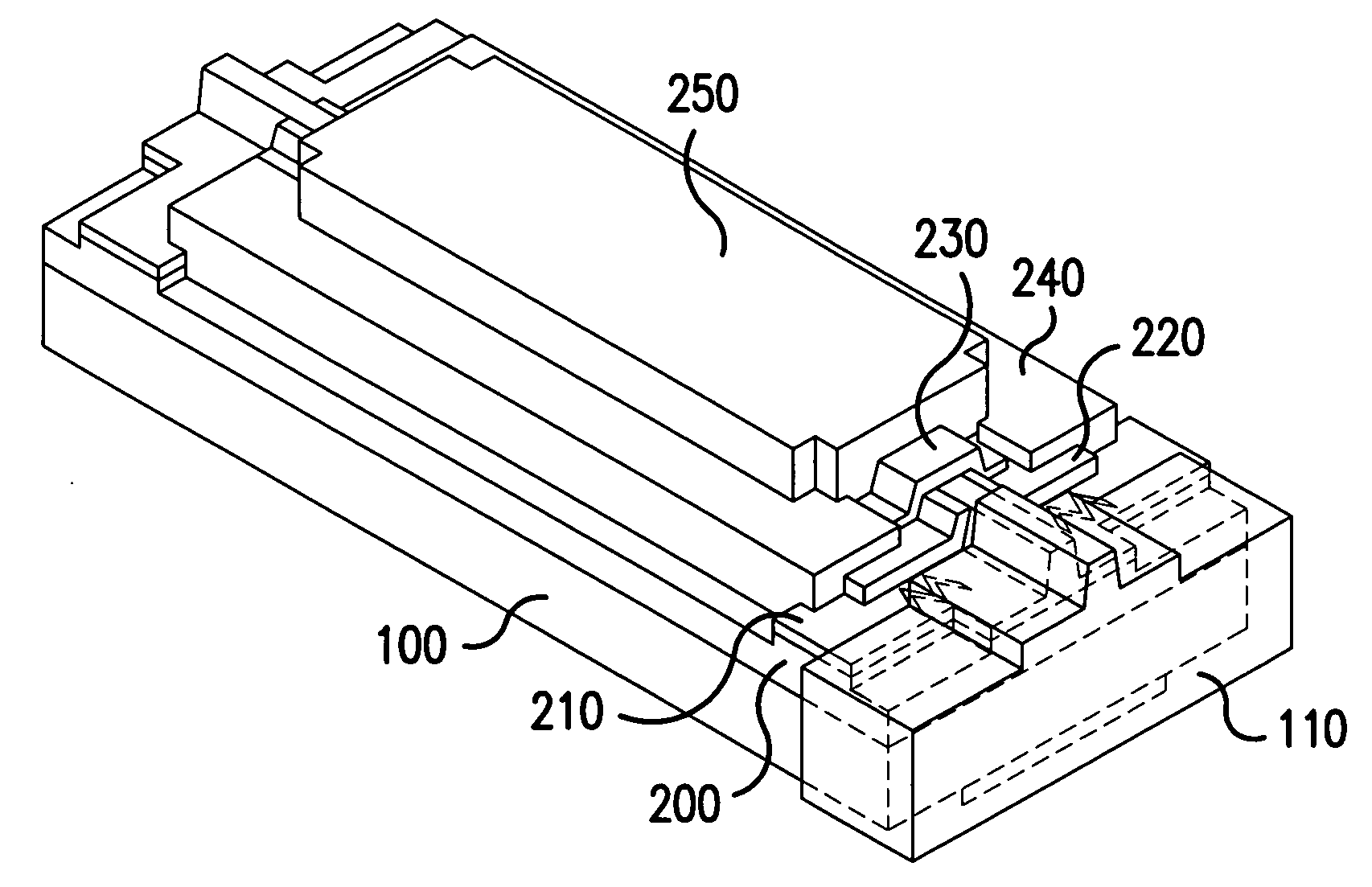

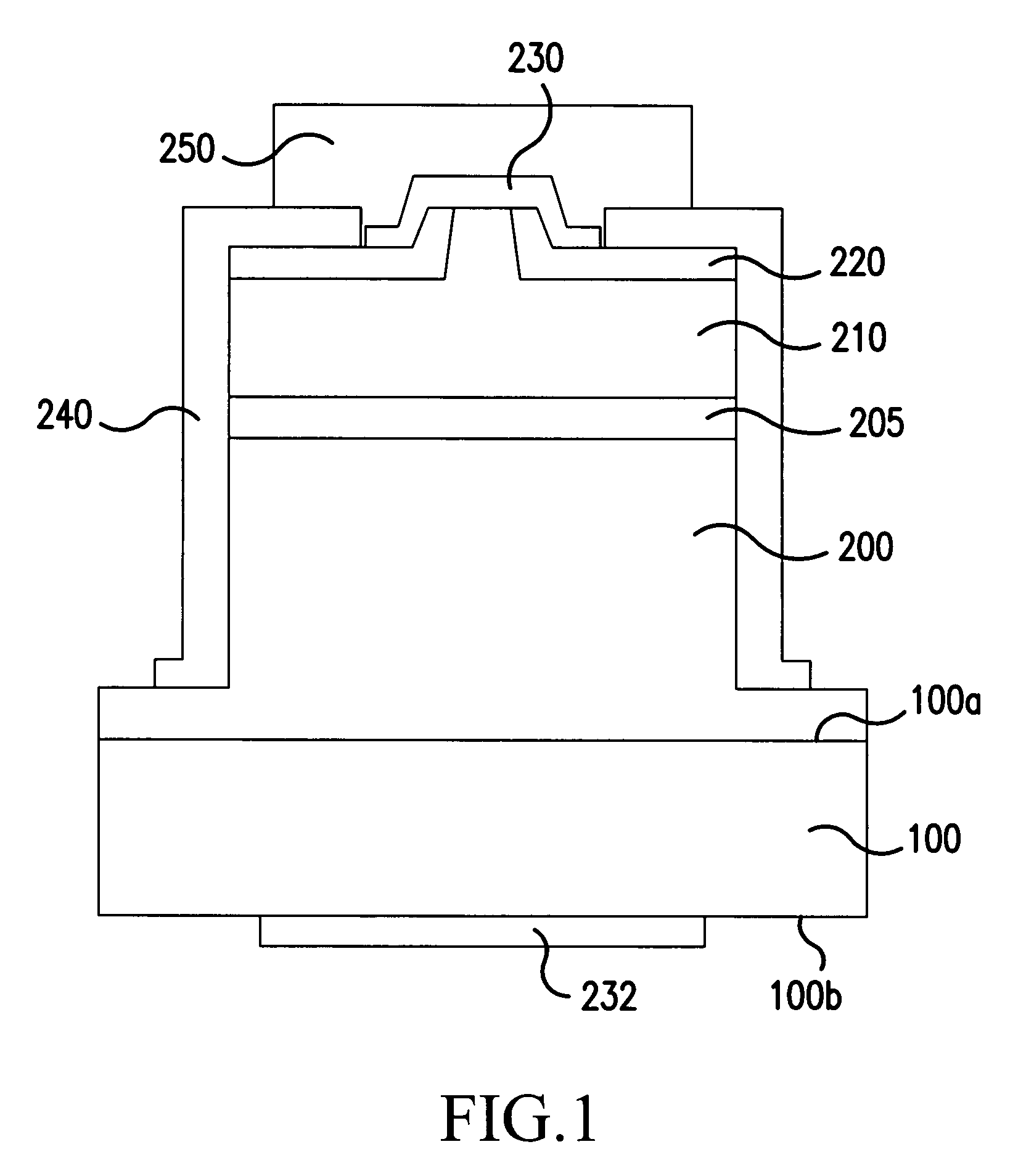

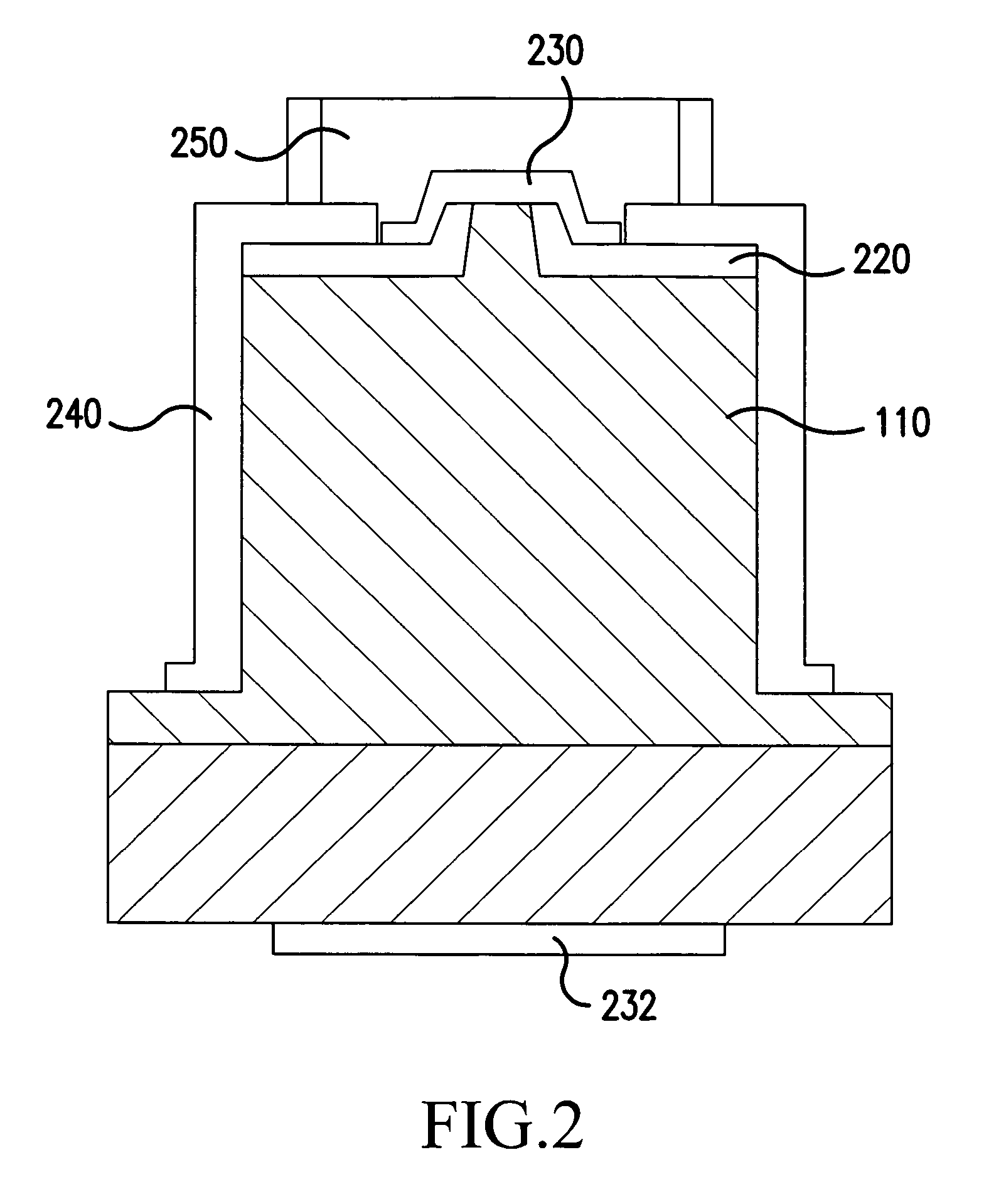

InactiveUS20080107799A1Reduced visible light reflectionImprove conductivityPV power plantsVacuum evaporation coatingQuantum efficiencyConductive coating

This invention relates to a photovoltaic device including an electrode such as a front electrode / contact. In certain example embodiments, the front electrode of the photovoltaic device includes a multi-layered transparent conductive coating which is sputter-deposited on a textured surface of a patterned glass substrate. In certain example embodiments, a maximum transmission area of the substantially transparent conductive front electrode is located under a peak area of a quantum efficiency (QE) curve of the photovoltaic device and a light source spectrum used to power the photovoltaic device.

Owner:GUARDIAN GLASS LLC

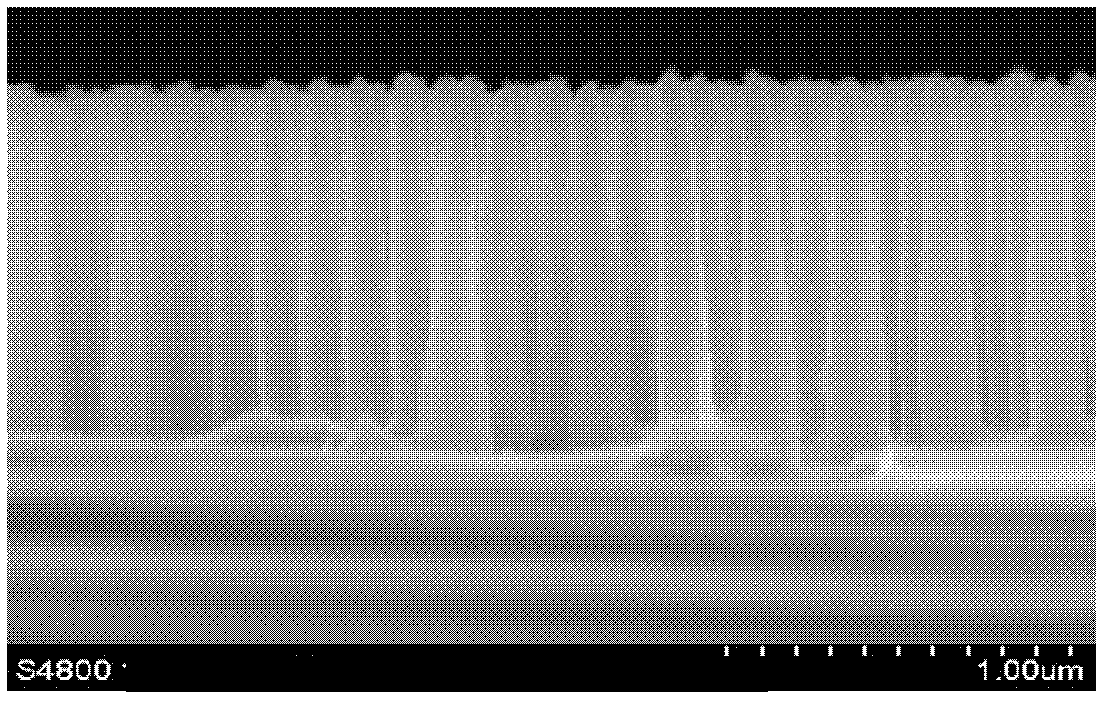

Process for forming zinc oxide film and processes for producing semiconductor device substrate and photo-electricity generating device using the film

InactiveUS6106689AHigh production yield and reliabilityEnhanced light absorptionElectrolytic inorganic material coatingFinal product manufactureElectricitySurface roughness

A process for forming a zinc oxide film including immersing an electroconductive substrate having a surface including a plurality of linear projections in an aqueous solution containing at least nitrate ions and zinc ions to form a zinc oxide film on the electroconductive substrate by a liquid-phase deposition. The plurality of linear projections may preferably provide an uneven surface which has a center-line average surface roughness Ra(X) of 15-300 nm when scanned in a direction parallel to the linear projections, a center line average surface roughness Ra(Y) of 20-600 nm when scanned in a direction perpendicular to the linear projections, and an Ra(X) / Ra(Y) ratio of at most 0.8. The thus formed zinc oxide film is provided with an uneven surface suitable for an optical-confinement layer of a photo-electricity generating device excellent in photoelectric performances.

Owner:CANON KK

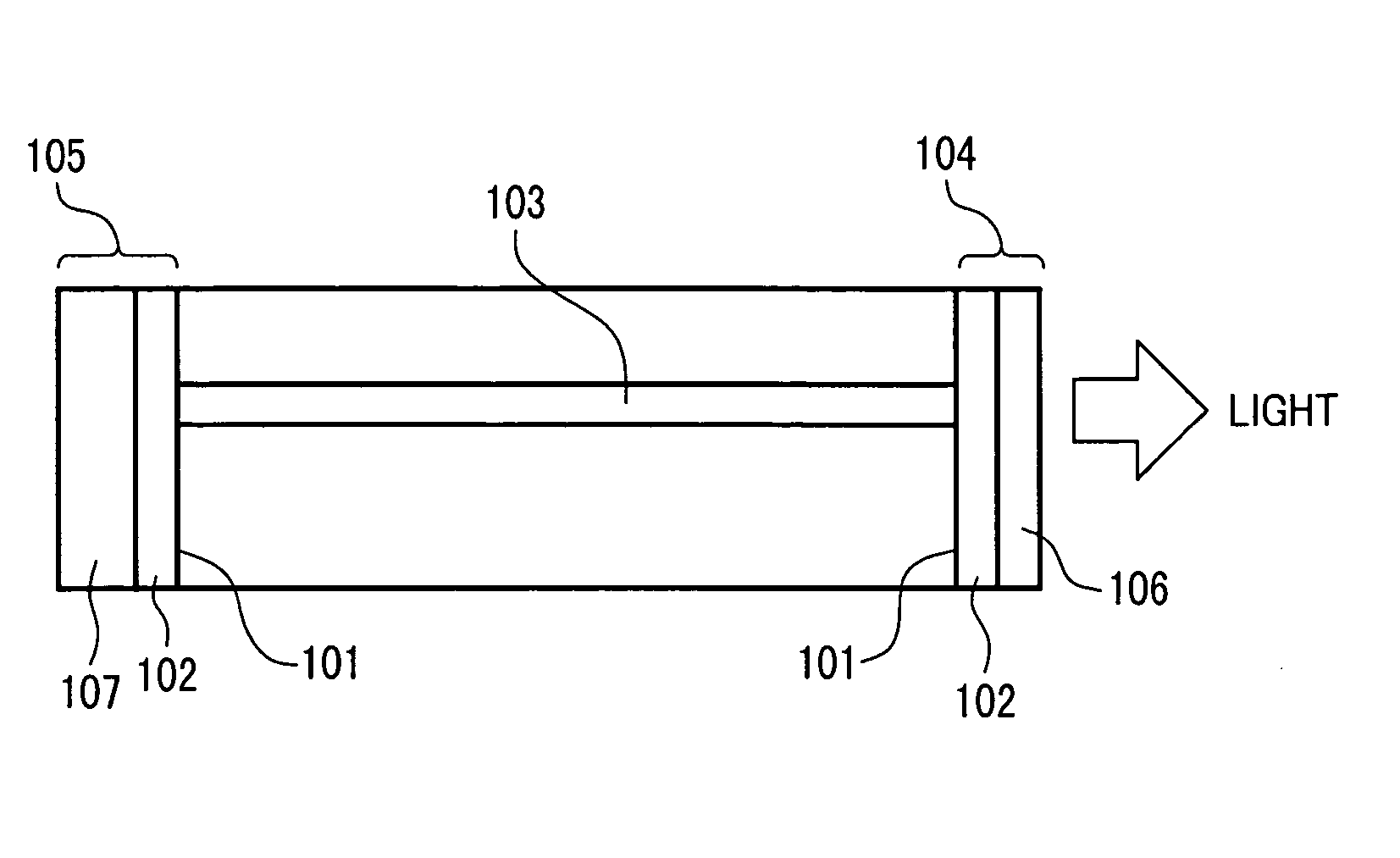

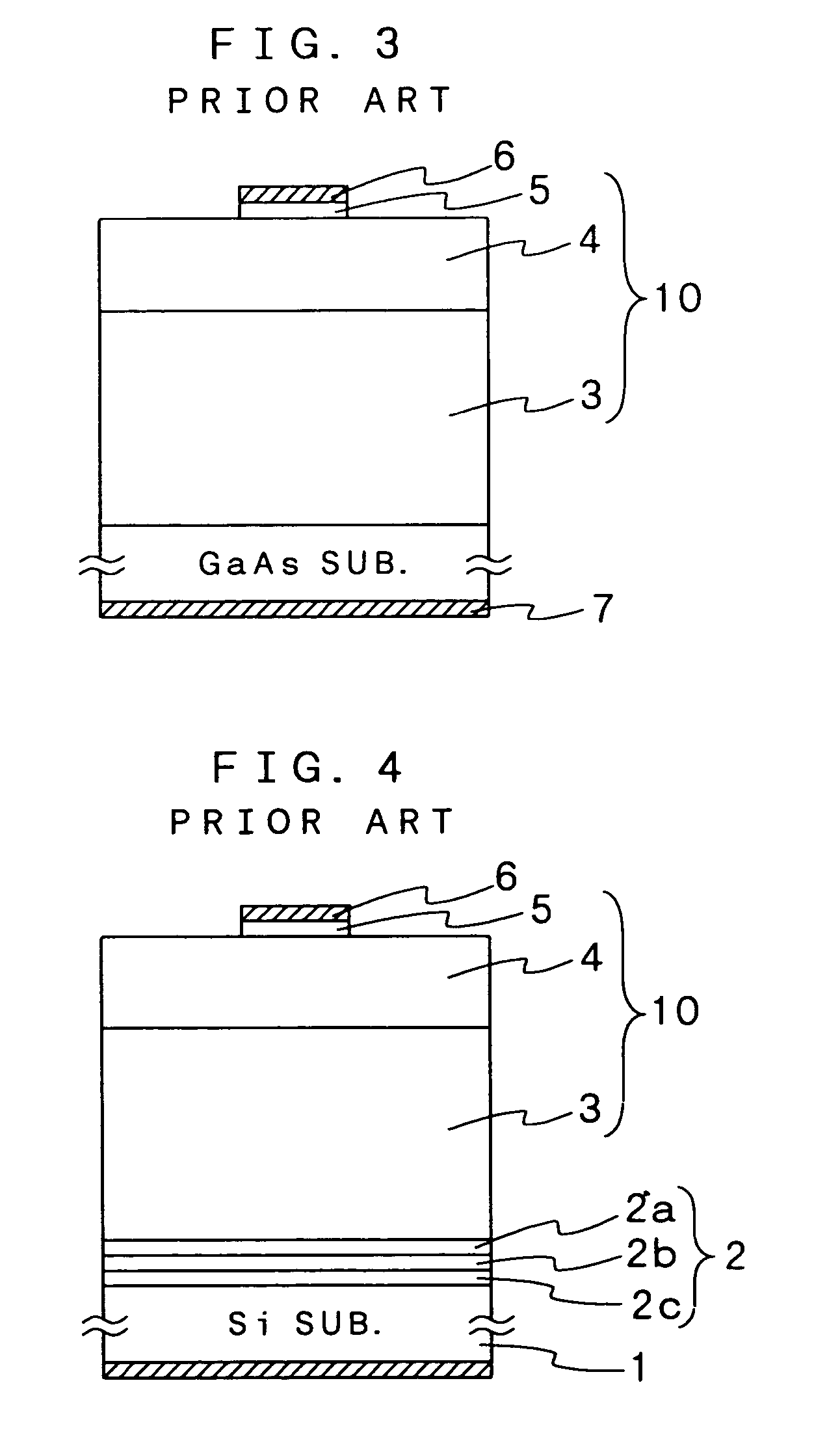

Laser diode and manufacturing method thereof

ActiveUS20050127383A1Lower resistanceLight increaseLaser detailsLaser optical resonator constructionPhysicsResonator

Laser diodes containing aluminum at high concentration in an active layer have been usually suffered from remarkable facet deterioration along with laser driving operation and it has been difficult for the laser diodes to attain high reliability. An aluminum oxide film lacking in oxygen is formed adjacent to the semiconductor on an optical resonator facet, by which facet deterioration can be minimized and, accordingly, the laser diode can be operated with no facet deterioration at high temperature for long time and a laser diode of high reliability can be manufactured at a reduced cost.

Owner:LUMENTUM JAPAN INC

High efficiency photovoltaic cells and manufacturing thereof

ActiveUS20070204902A1Low costElectric power generatedElectrolytic capacitorsFinal product manufactureMicrometerEngineering

Novel structures of photovoltaic cells (also treated as solar cells) are provided. The cells are based on nanometer or micrometer-scaled wires, tubes, and / or rods, which are made of electronic materials covering semiconductors, insulators, and may be metallic in structure. These photovoltaic cells have large power generation capability per unit physical area over the conventional cells. These cells will have enormous applications such as in space, commercial, residential and industrial applications.

Owner:BANPIL PHOTONICS

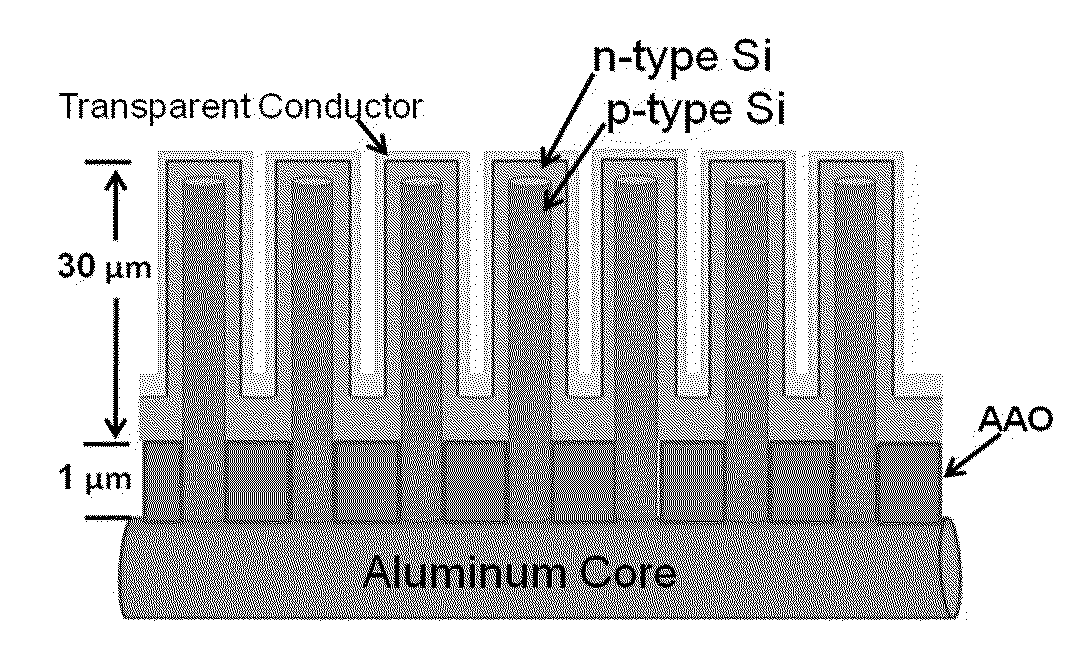

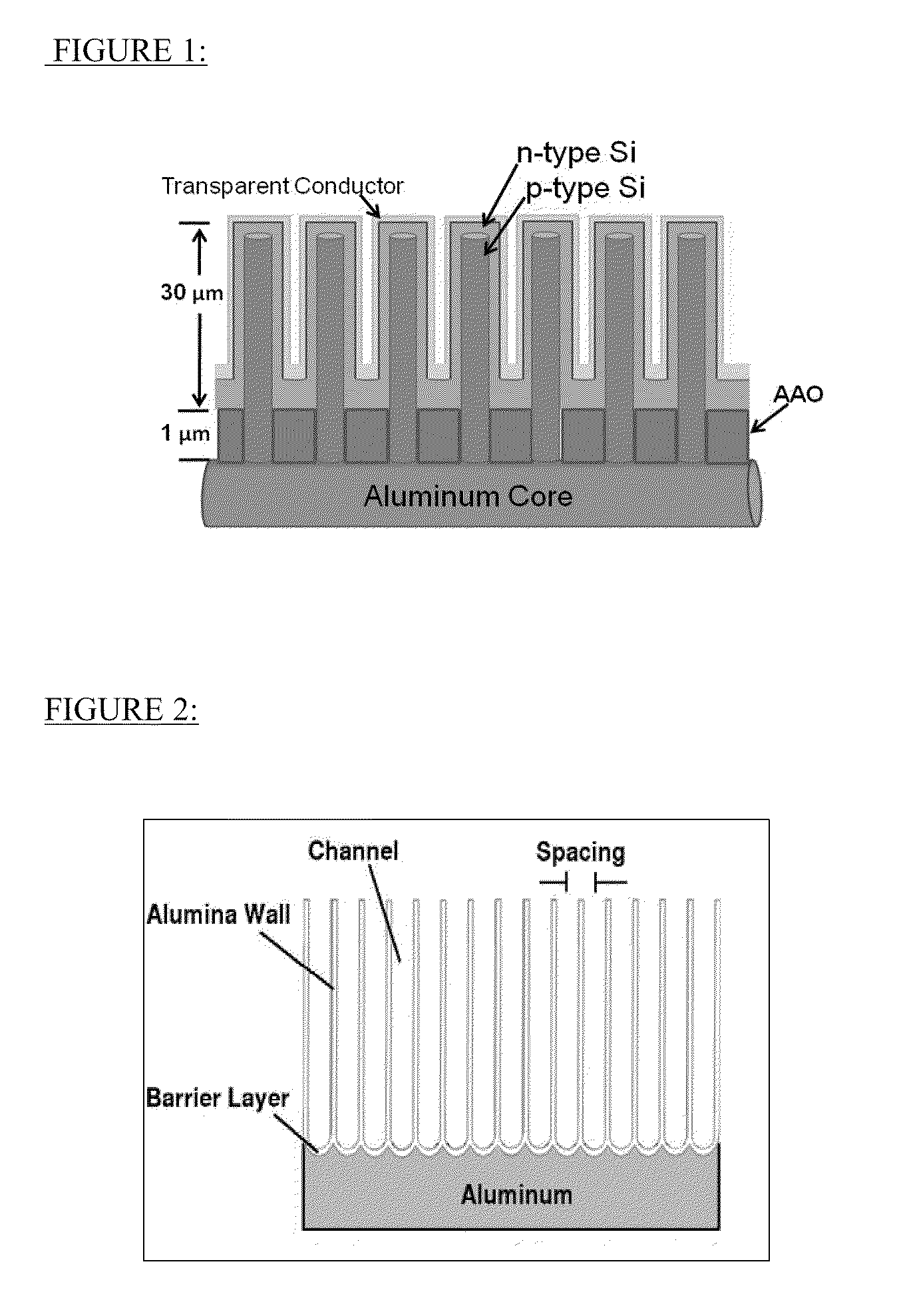

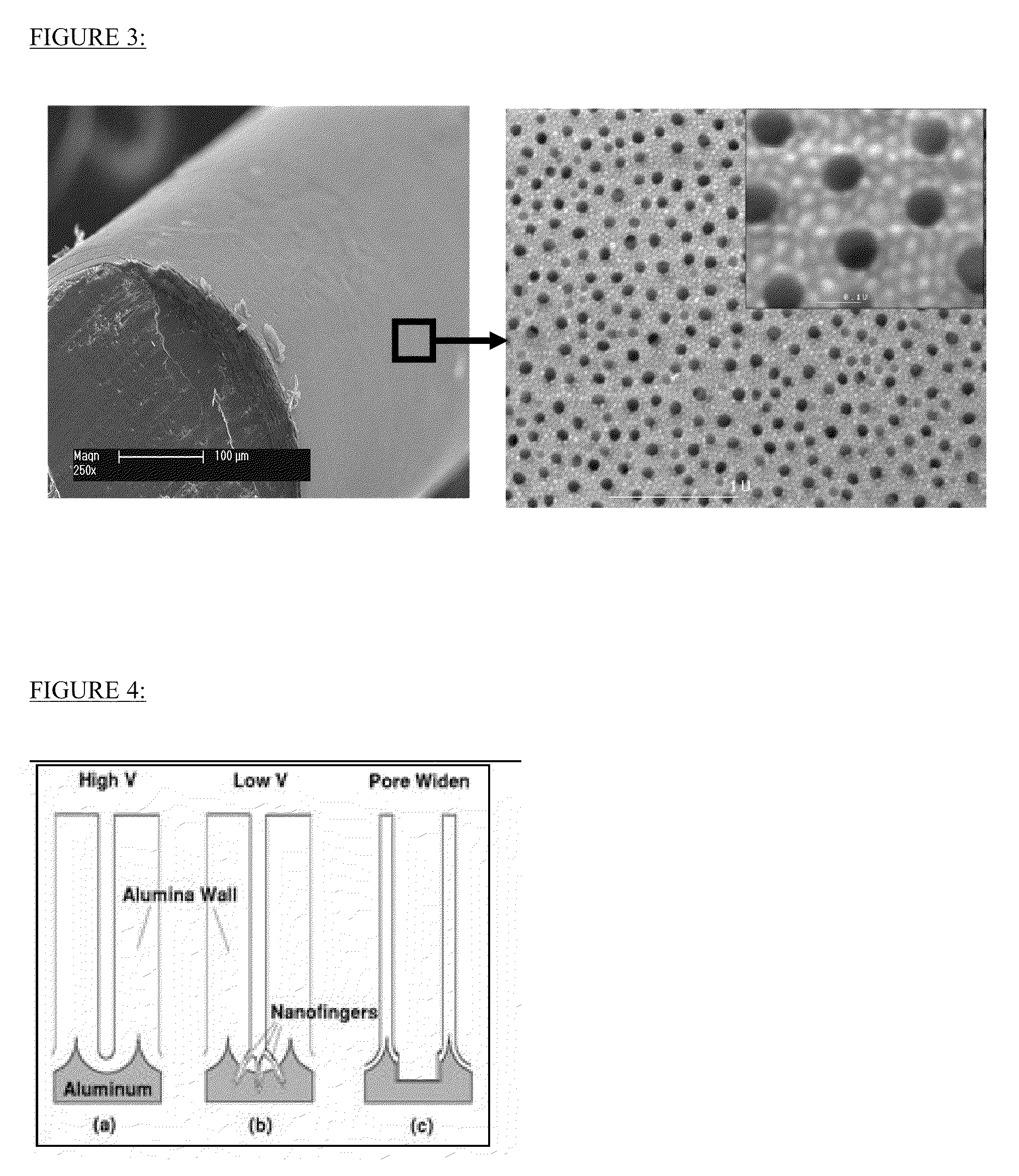

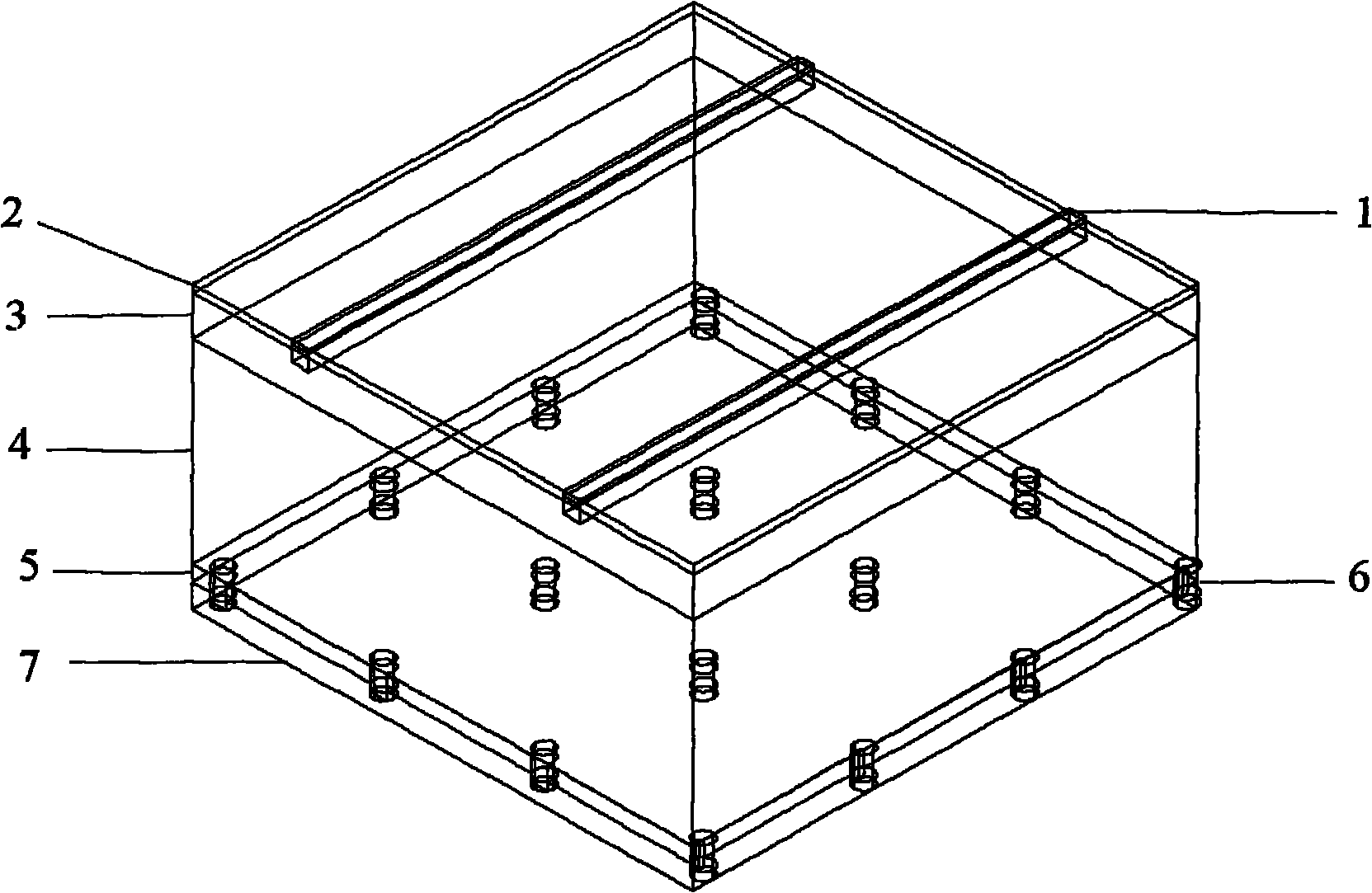

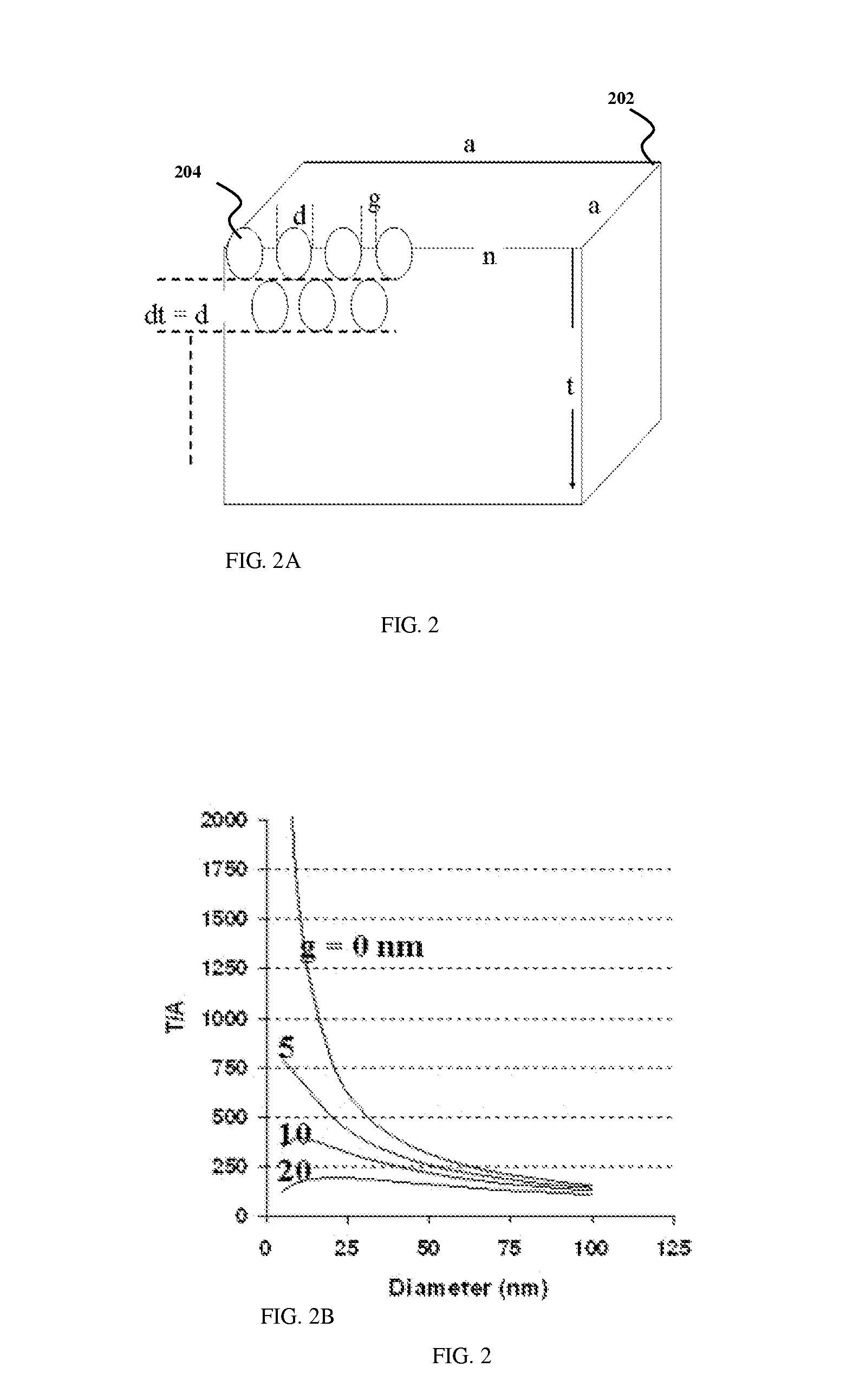

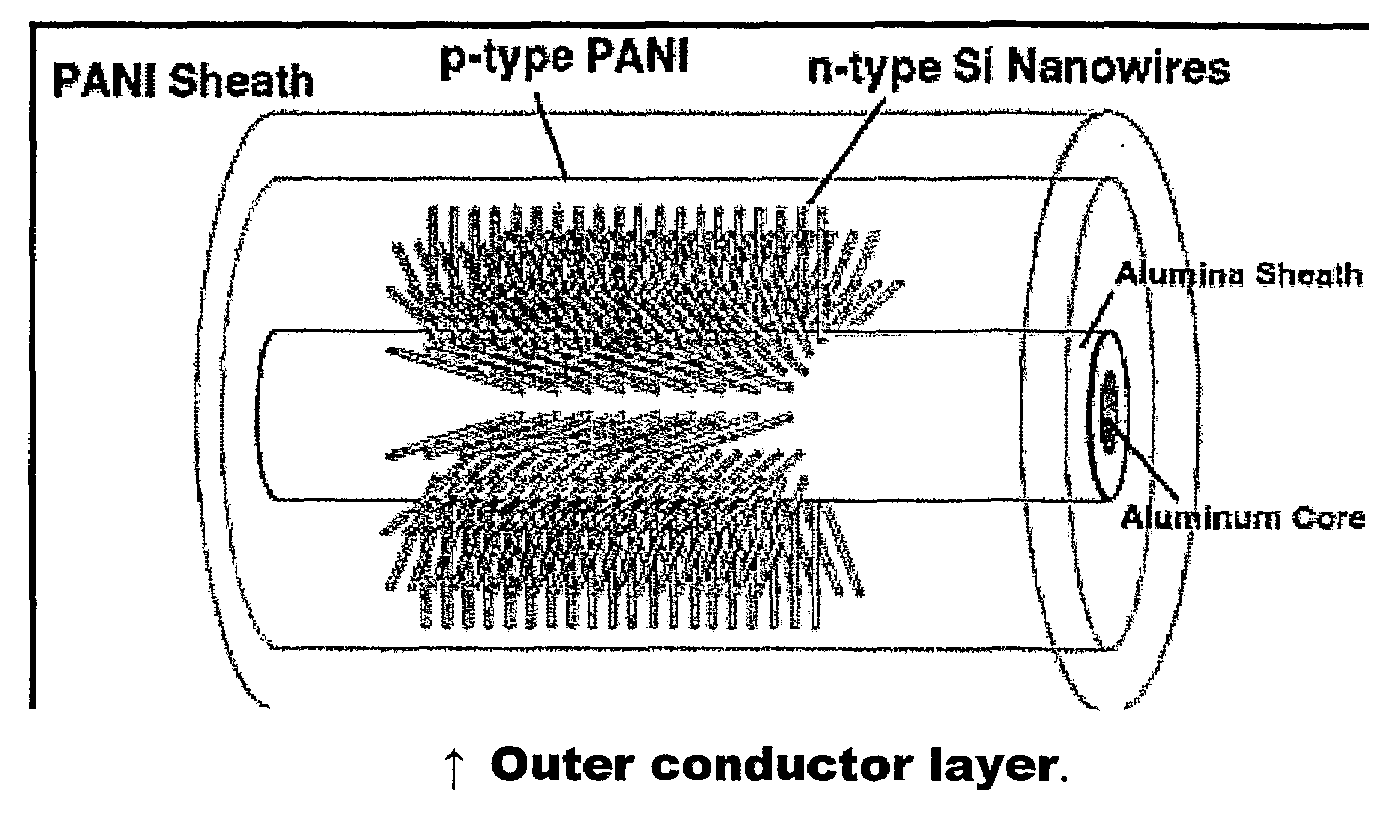

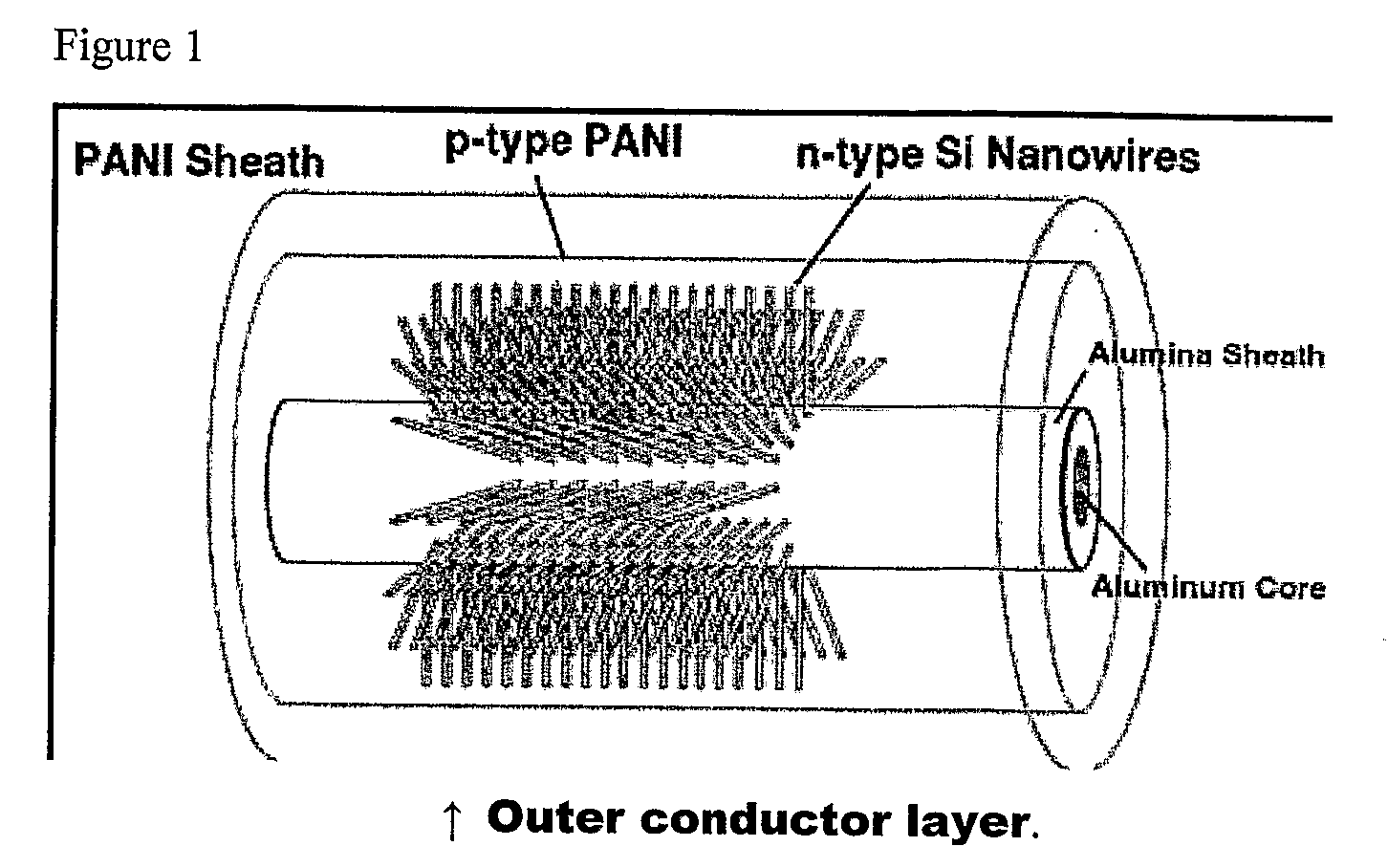

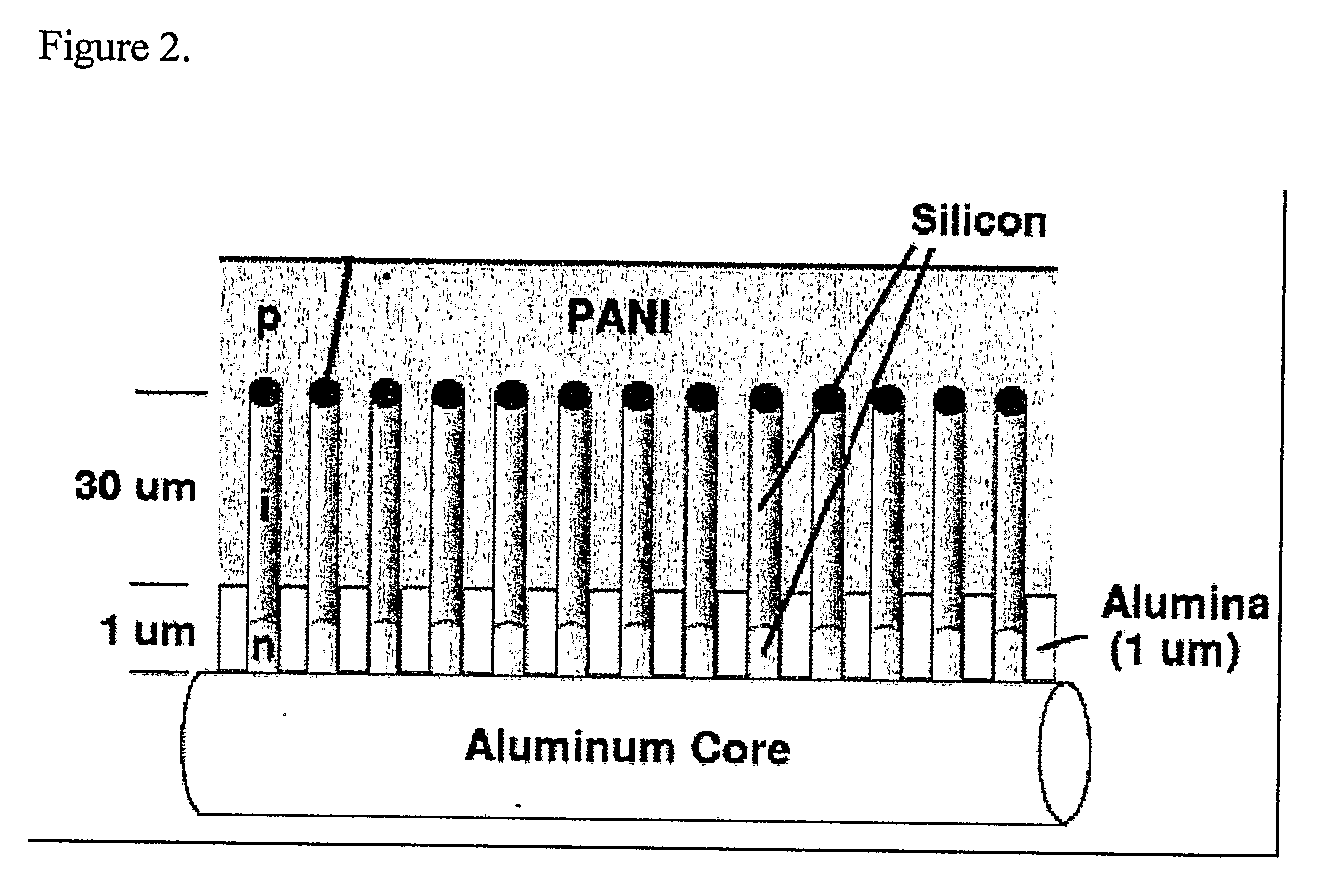

Semiconducting nanowire arrays for photovoltaic applications

InactiveUS20100193768A1Novel design attributeEasy to produceSolid-state devicesSemiconductor/solid-state device manufacturingDopantSilicon nanowires

This invention relates to the fabrication of nanowires for electrical and electronic applications. A method of growing silicon nanowires using an alumina template is disclosed whereby the aluminum forming the alumina is also used as the catalyst for growing the silicon nanowires in a VLS (CVD) process and as the semiconductor dopant. In addition, various techniques for masking off parts of the aluminum and alumina in order to maintain electrical isolation between device layers is disclosed.

Owner:ILLUMINEX CORP

Method for preparing N-type crystalline silicon solar cell with aluminum-based local emitters on back side

InactiveCN101853897AAvoid damageAvoid Edge Leakage SituationsFinal product manufactureSemiconductor devicesP–n junctionMaterials science

The invention provides a method for preparing an N-type crystalline silicon solar cell with aluminum-based local emitters on the back side. The method comprises the following steps: firstly, selecting N-type silicon wafers to carry out the surface-textured etching process; further forming a front surface field through phosphorous diffusion; depositing a passivating film on the front surface after the phosphorosilicate glass is formed during the removal of diffused phosphorous; carrying out the back-side chemical polishing process on the silicon wafers to remove the N+ layer formed on the back side during the phosphorous diffusion; then, sequentially printing an aluminum layer or a silver-aluminum layer through the passivating film deposited on the back side, local holes or grooves on the back side and screens on the back side; then, printing silver paste on the front surface; and finally, carrying out the one-step sintering process to form a local P+ layer on the back side and allowing the P+ layer to coming into ohmic contact with the electrodes on the front and back surfaces. By using the N-type substrate, forming local aluminum-based P-N junctions on the back side and further using the back-side chemical polishing process to remove the edge junctions, the invention can substitute for the conventional stacking-type plasma etching process, simplify the technological procedures and further bring a series of performance improvement to cells.

Owner:JA YANGZHOU SOLAR PHOTOVOLTAIC ENG

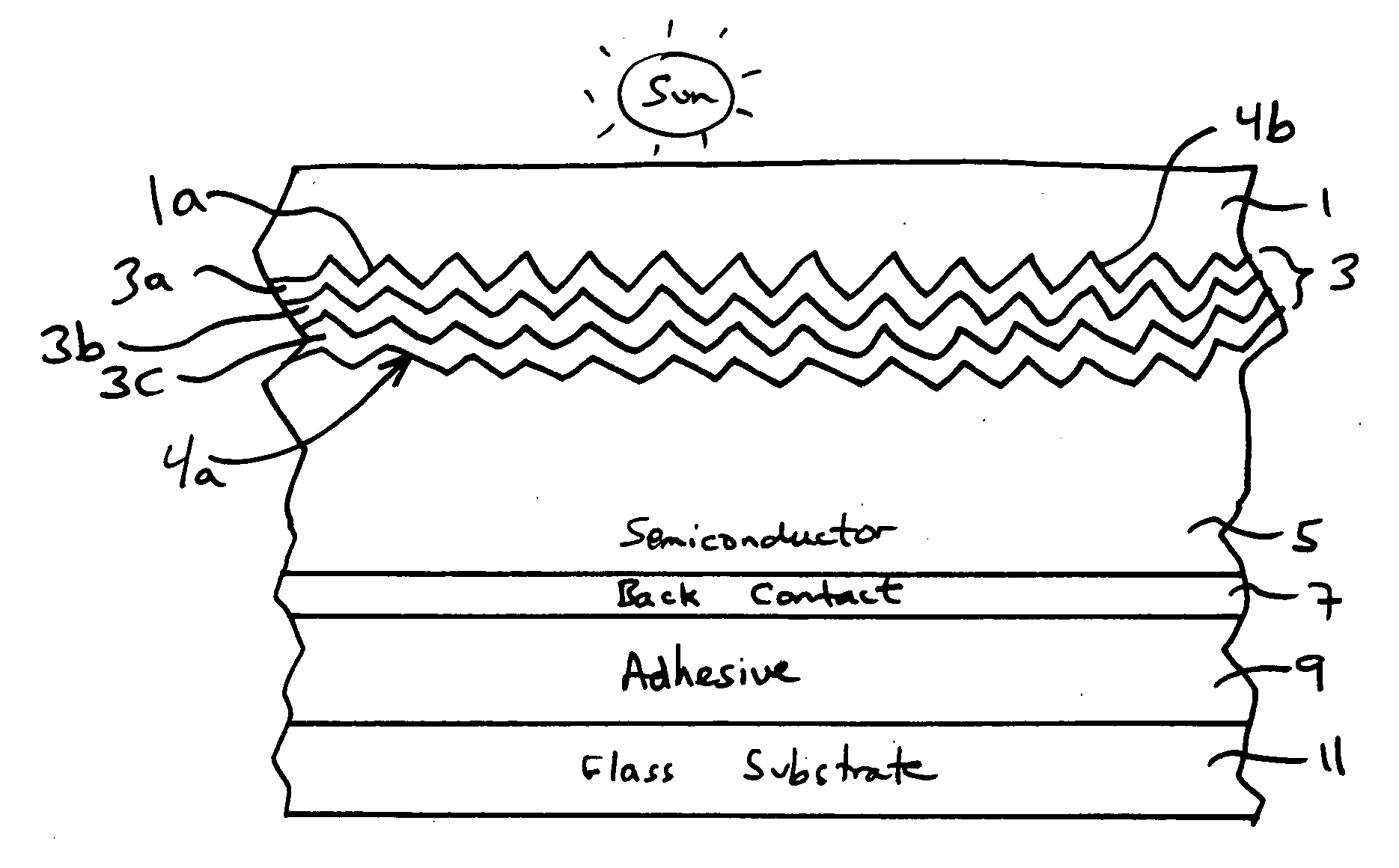

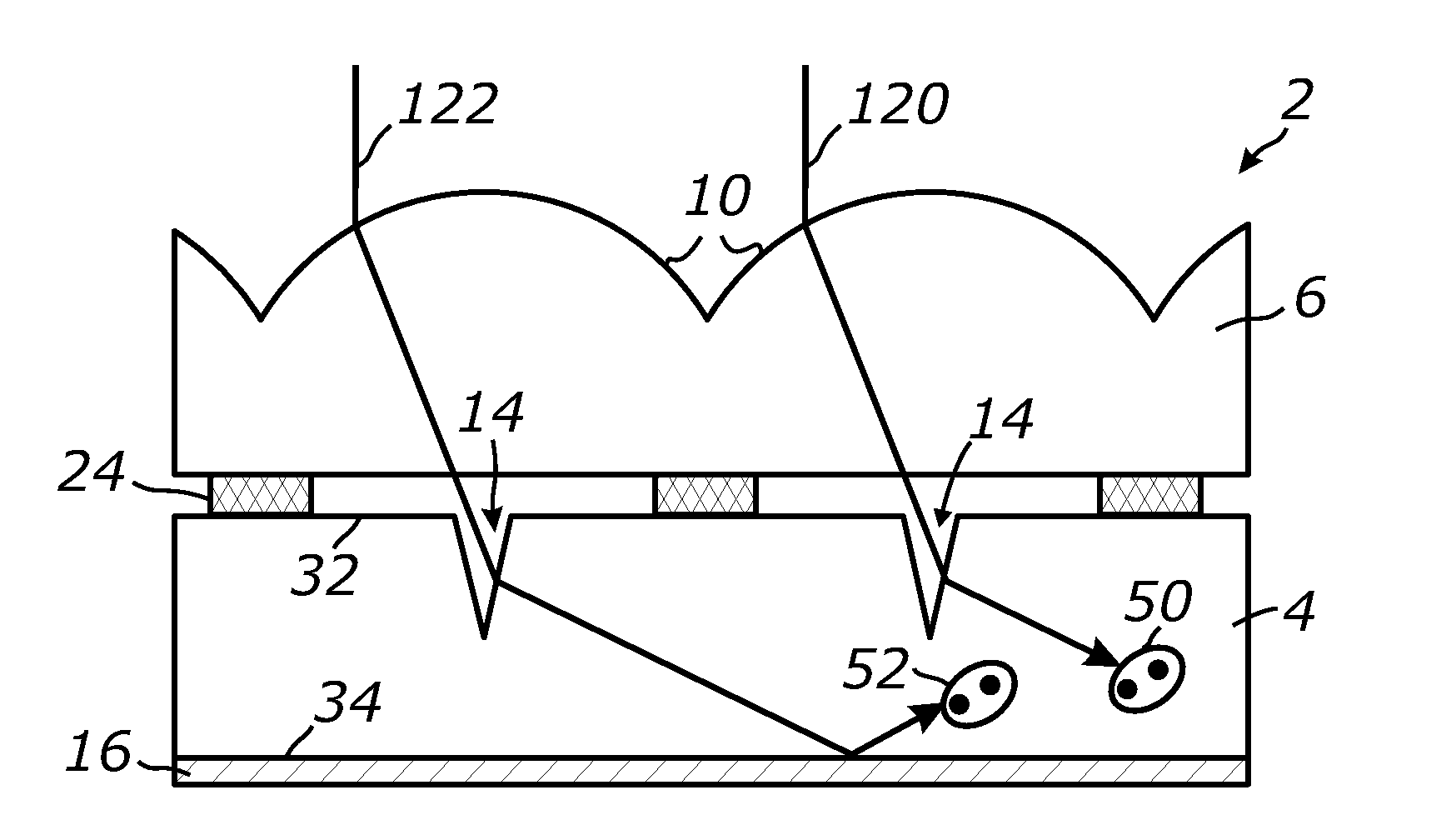

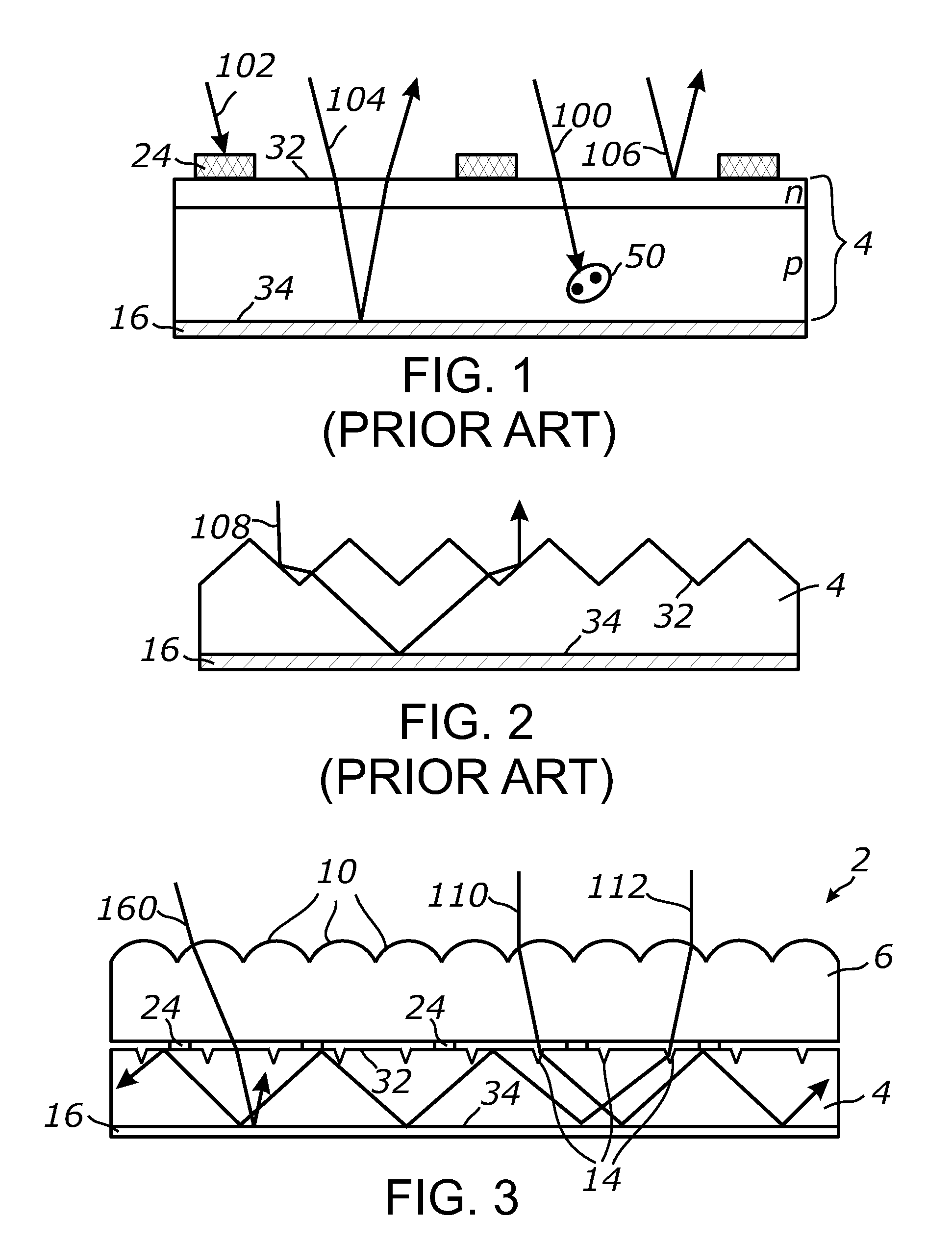

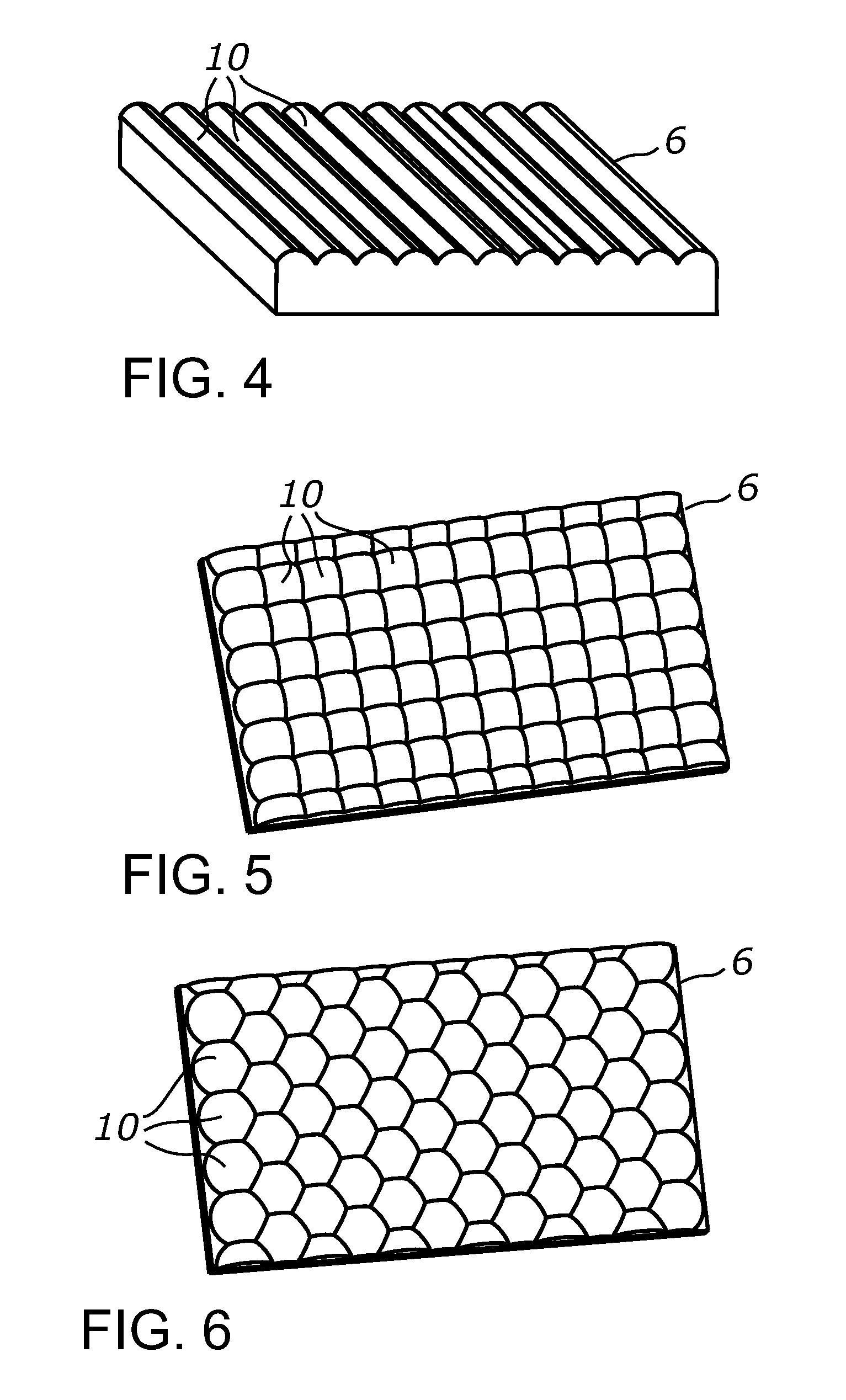

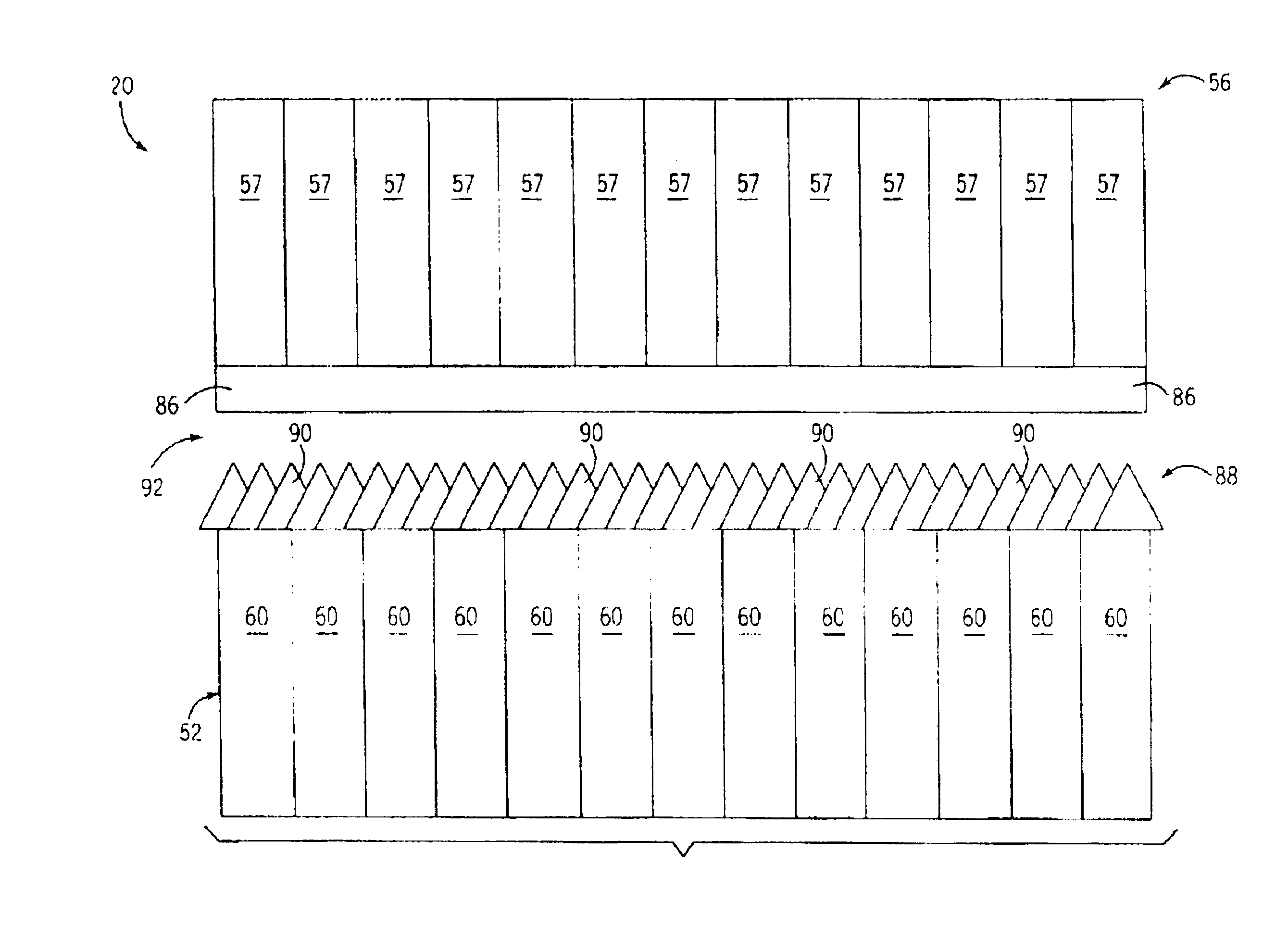

Light harvesting system employing microstructures for efficient light trapping

ActiveUS20120012741A1Enhanced light absorptionOptimizing light pathRadiation pyrometryBeam/ray focussing/reflecting arrangementsTotal internal reflectionTrapping

A light harvesting system employing a focusing array and a photoresponsive layer in which a plurality of microstructured areas is formed. Light received by the focusing array is injected transmissively into the photoresponsive layer through the microstructured areas. The injected light is retained in the photoresponsive layer by at least a total internal reflection and is propagated within the layer until it is substantially absorbed.

Owner:S V V TECH INNOVATIONS

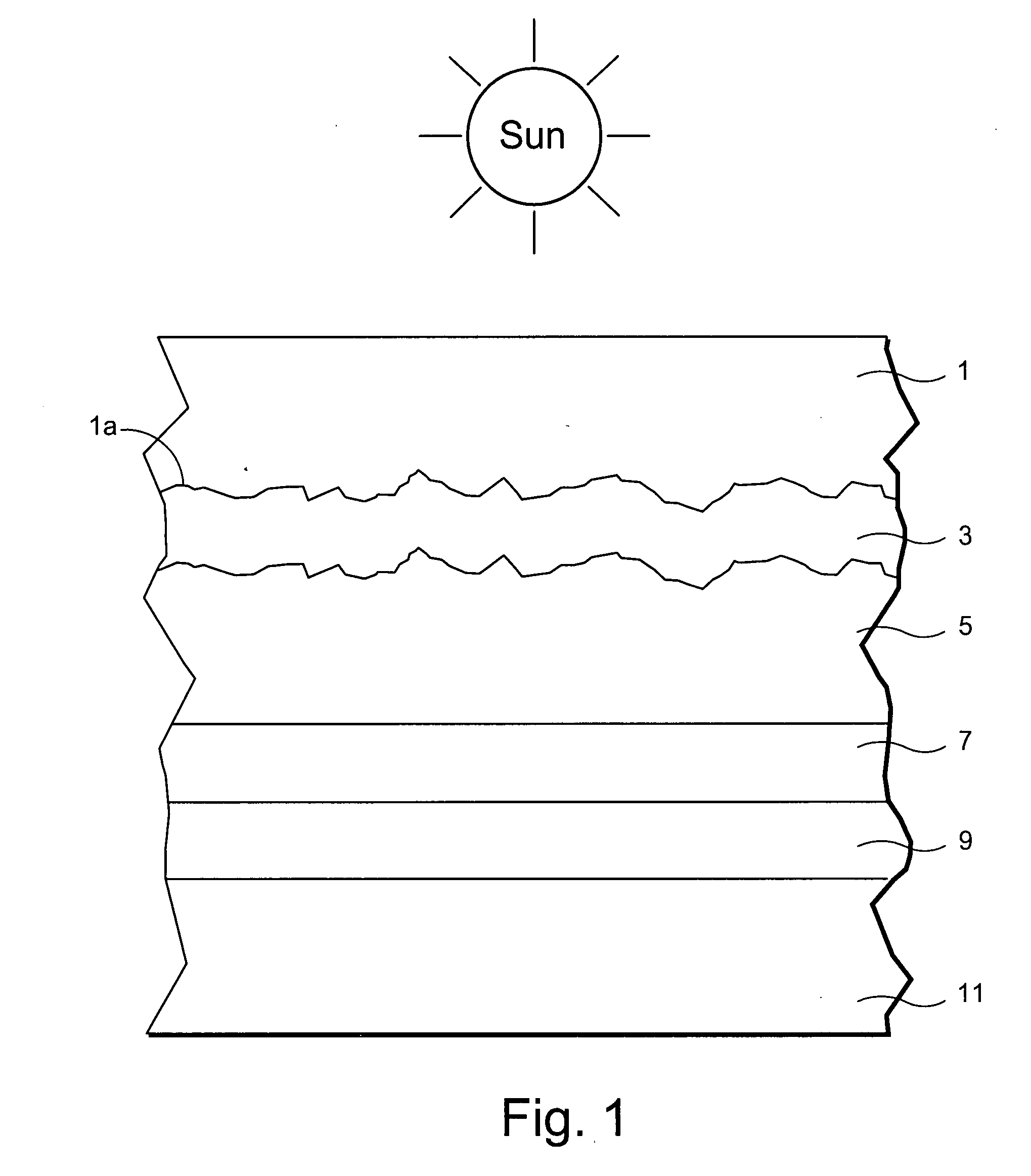

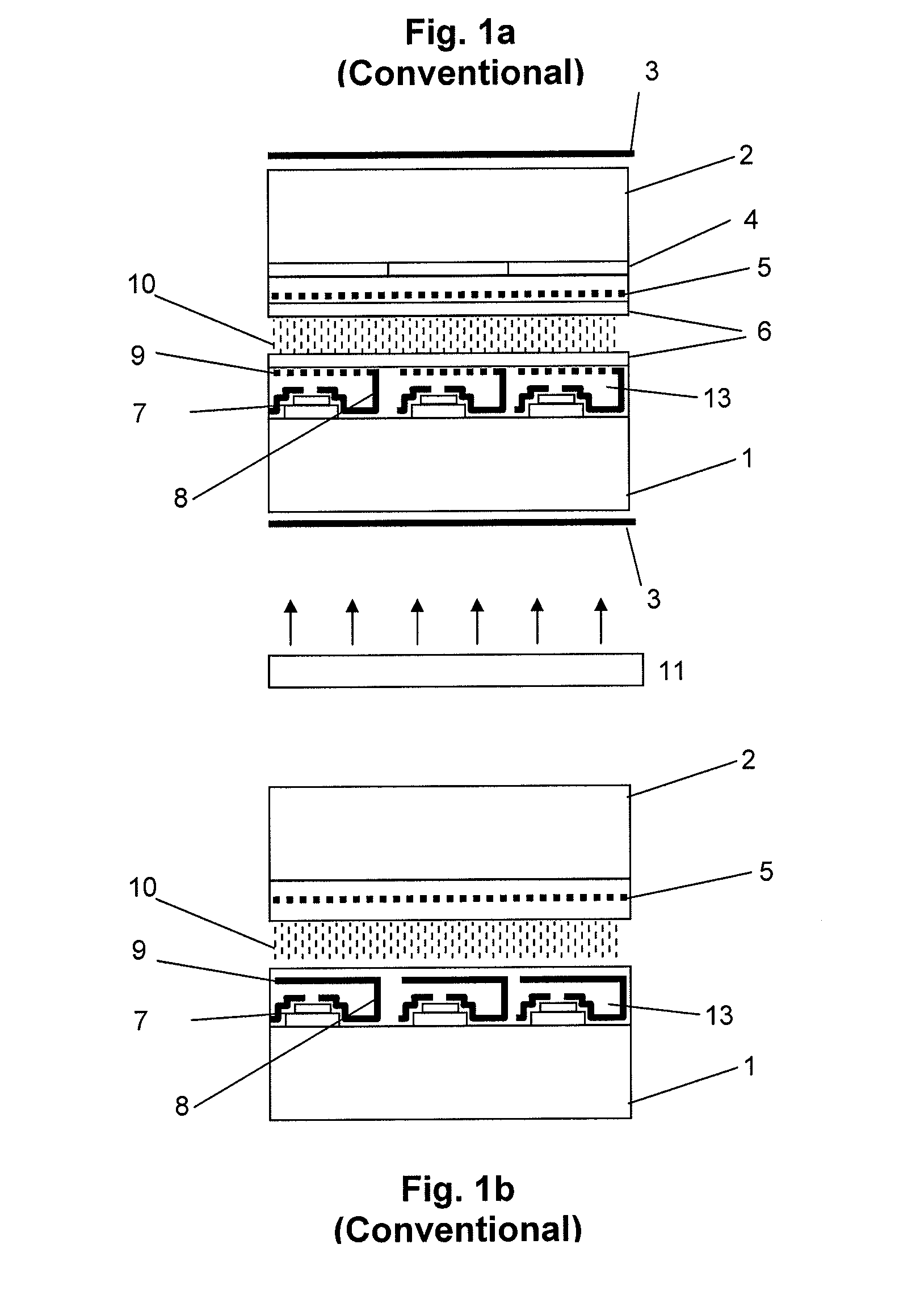

Front electrode including pyrolytic transparent conductive coating on textured glass substrate for use in photovoltaic device and method of making same

InactiveUS20080308146A1Low efficiencyImprove efficiencyOptical articlesPhotovoltaic energy generationConductive coatingSemiconductor

A photovoltaic device includes a front electrode on a textured front glass substrate. In certain example embodiments, the glass substrate is textured via roller(s) and / or etching to form a textured surface. Thereafter, a front electrode is formed on the textured surface of the glass substrate via pyrolysis. The front electrode may be of or include a transparent conductive oxide (TCO) such as tin oxide and / or fluorinated tin oxide in certain example embodiments. In certain example instances, this is advantageous in that efficiency of the photovoltaic device can be improved by increasing light absorption by the active semiconductor via both increasing light intensity passing through the front glass substrate and front electrode, and increasing the light path in the semiconductor photovoltaic conversion layer.

Owner:GUARDIAN GLASS LLC

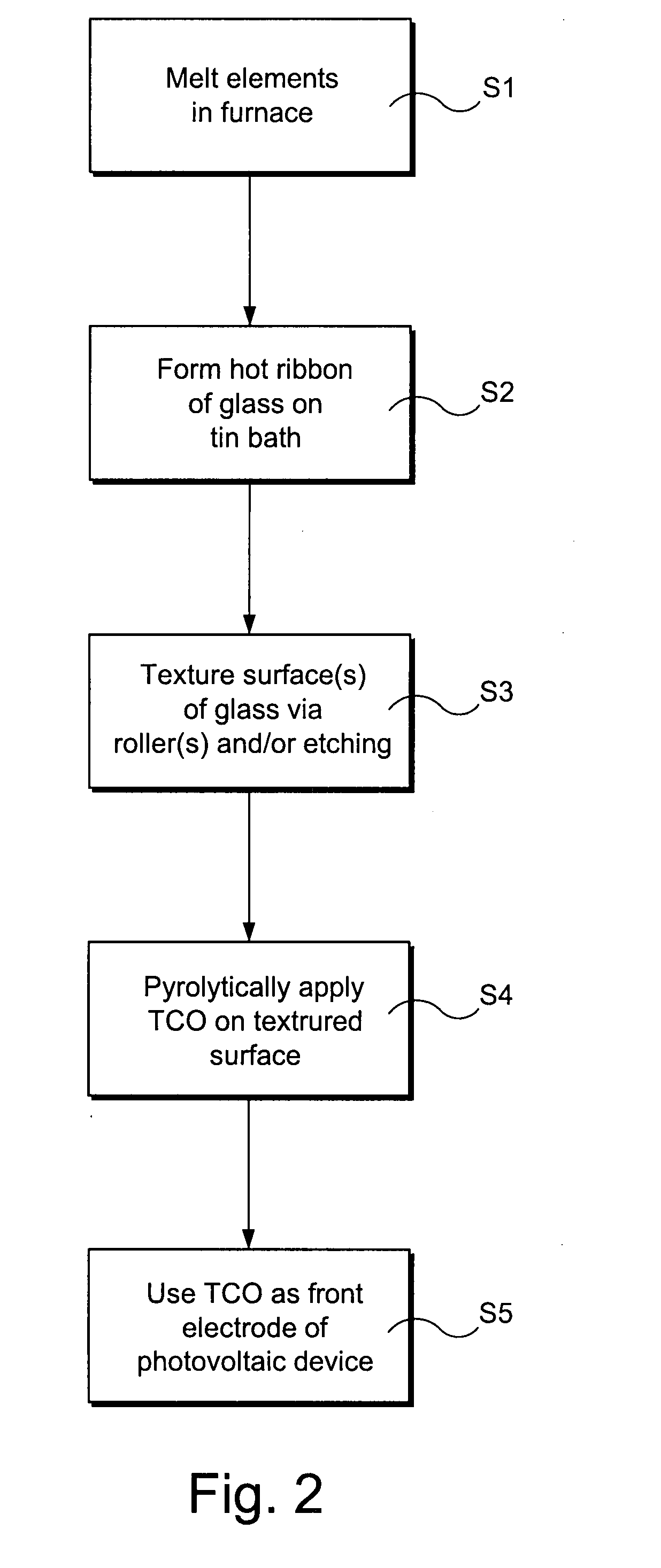

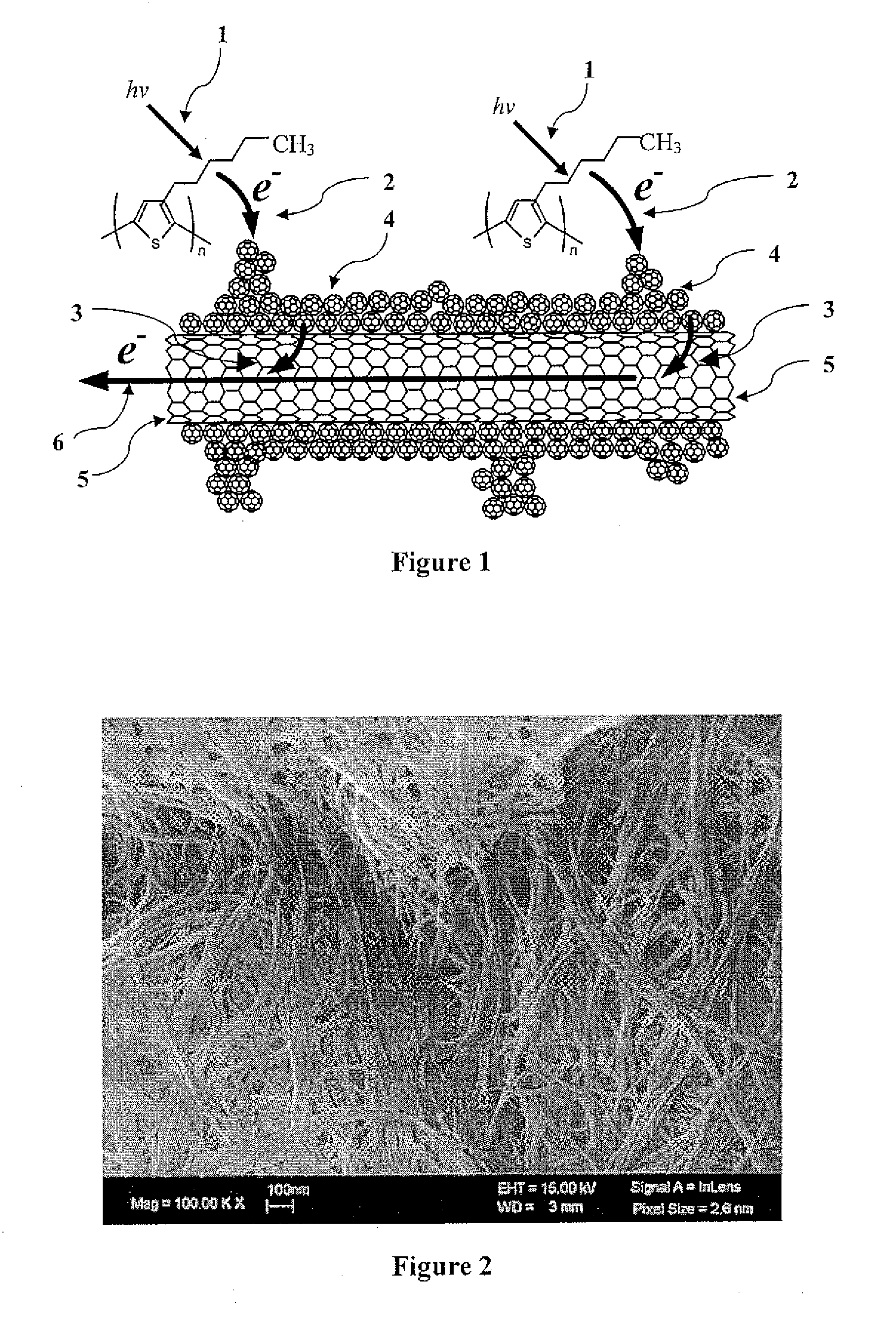

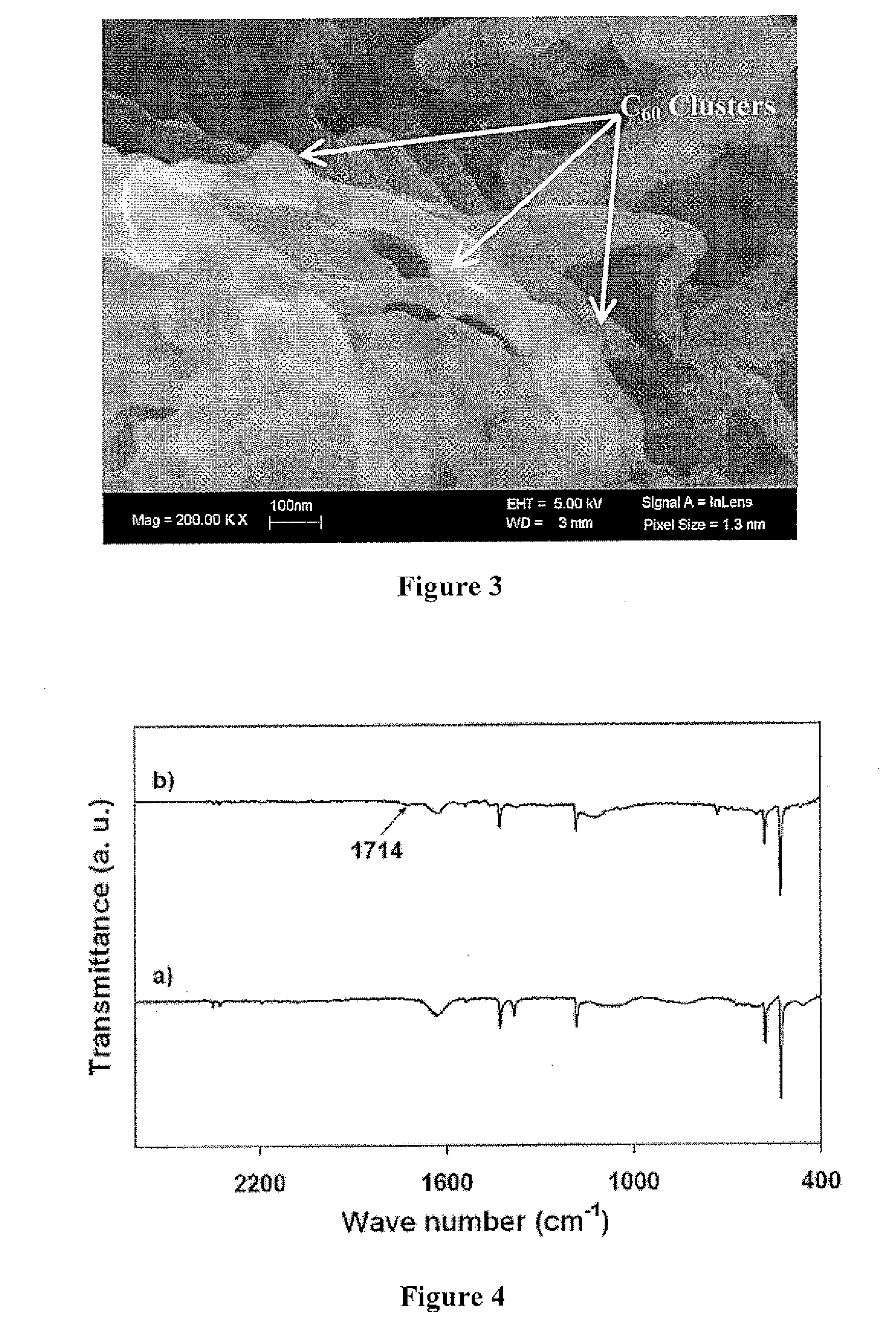

Carbon Nanotubes As Charge Carriers In Organic and Hybrid Solar Cells

InactiveUS20090205713A1Improve efficiencyImprove power conversion efficiencyFinal product manufactureNanoinformaticsHeterojunctionPhotoinduced charge separation

Organic and organic / inorganic hybrid bulk heterojunction photovoltaic devices with improved efficiencies are disclosed. The organic photovoltaic device comprises a photoactive polymer:fullerene C60-carbon nanotube (polymer:C60-CNT) composite as a component of the active layer. Under light irradiation, photoinduced charge separation at the polymer:C60 interface is followed by electron transfer from C60 onto CNTs for efficient electron transport towards an electrode. The organic / inorganic hybrid photovoltaic device comprises quantum dots and carbon nanotubes. Power conversion efficiency enhancement methods of polymer-CNT based photovoltaics are also provided.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

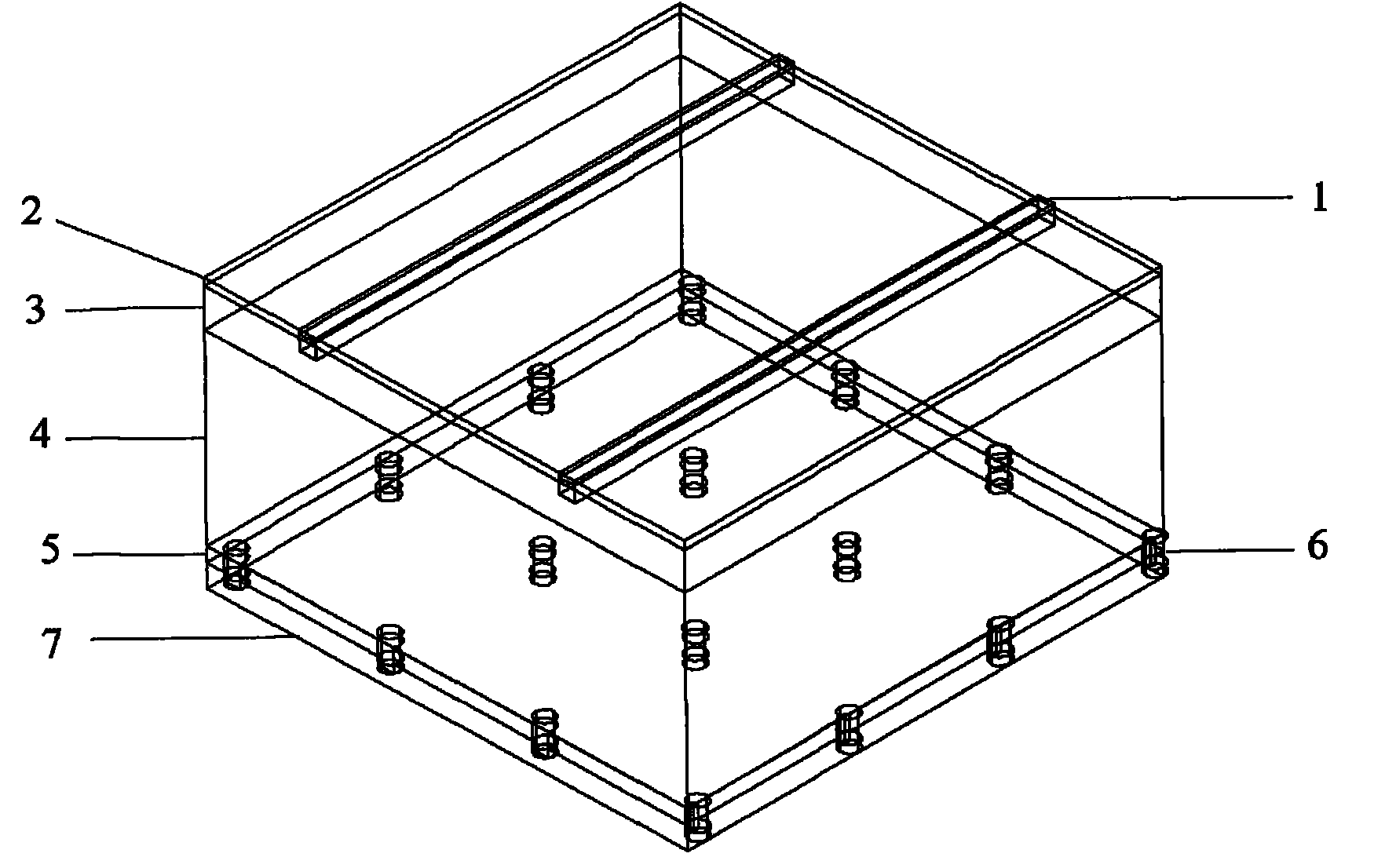

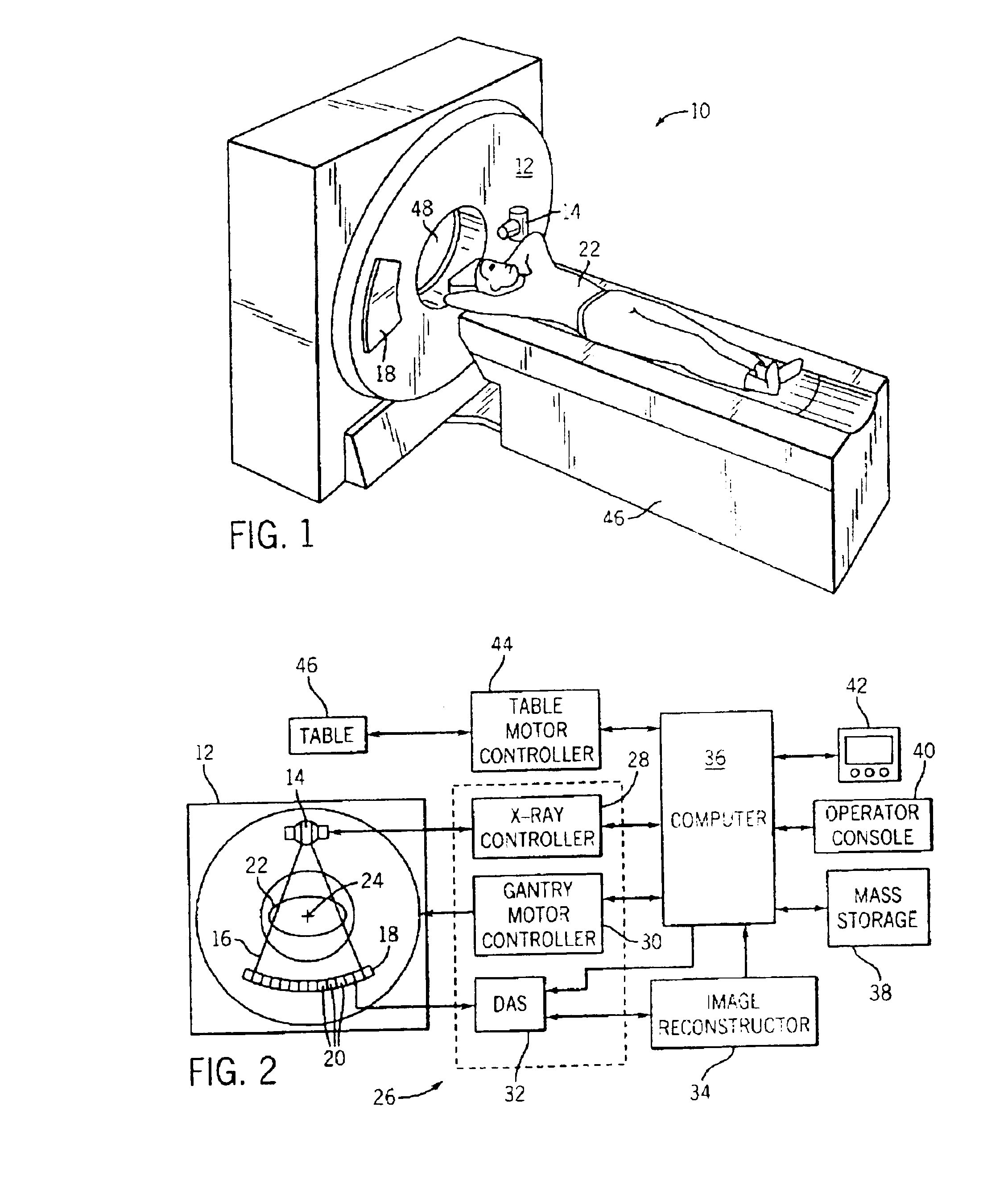

CT detector with integrated air gap

InactiveUS6907101B2Enhanced light absorptionImprove light collectionTelevision system detailsSolid-state devicesScintillatorPhotodiode

The present invention is directed to an improved CT detector scintillator to photodiode optical coupling. The CT detector utilizes a controlled air gap between the photodiode array and the scintillator array together with an anti-reflective layer on the scintillator array. To improve the absorption of light at the photodiode array, the photodiode array includes a textured light reception surface. By incorporating a textured layer with the photodiode array, the light collection efficiency of the photodiodes is improved. The textured layer may extend along an x- and / or z-axis and the texturing may be in different forms. For example, the textured layer may include a series of pyramidally-shaped protrusions.

Owner:GENERAL ELECTRIC CO

High efficiency photovoltaic cells

ActiveUS20070175507A1Low costReduce carrier recombinationPhotovoltaic energy generationSemiconductor devicesNanoparticleEngineering

Novel structures of photovoltaic cells (also called as solar cells) are provided. The cells are based on nanoparticles or nanometer-scaled wires, tubes, and / or rods, which are made of electronic materials covering semiconductors, insulators, and may be metallic in structure. These photovoltaic cells have large power generation capability per unit physical area over the conventional cells. These cells will have enormous applications such as in space, commercial, residential and industrial applications.

Owner:BANPIL PHOTONICS

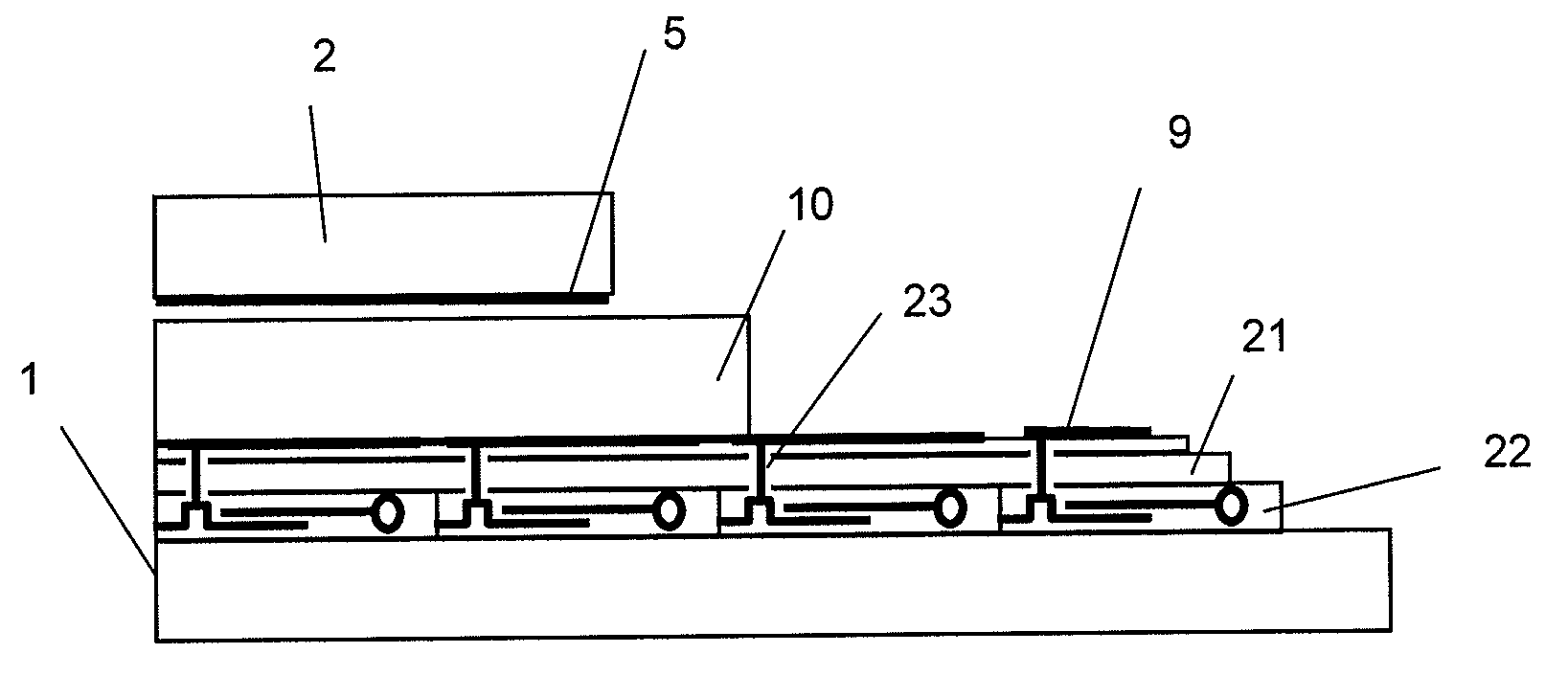

Integrated display and photovoltaic element

InactiveUS20110249219A1Increase display brightnessEfficient power generationVessels or leading-in conductors manufactureNon-linear opticsDisplay deviceEngineering

A display device includes a first layer having an optically active display portion, a second layer including a photovoltaic element, and a third layer including electronics operatively coupled to the first layer, wherein the electronics are configured to drive the optically active display portion. Further, the second layer is arranged between the first and third layers.

Owner:SHARP KK

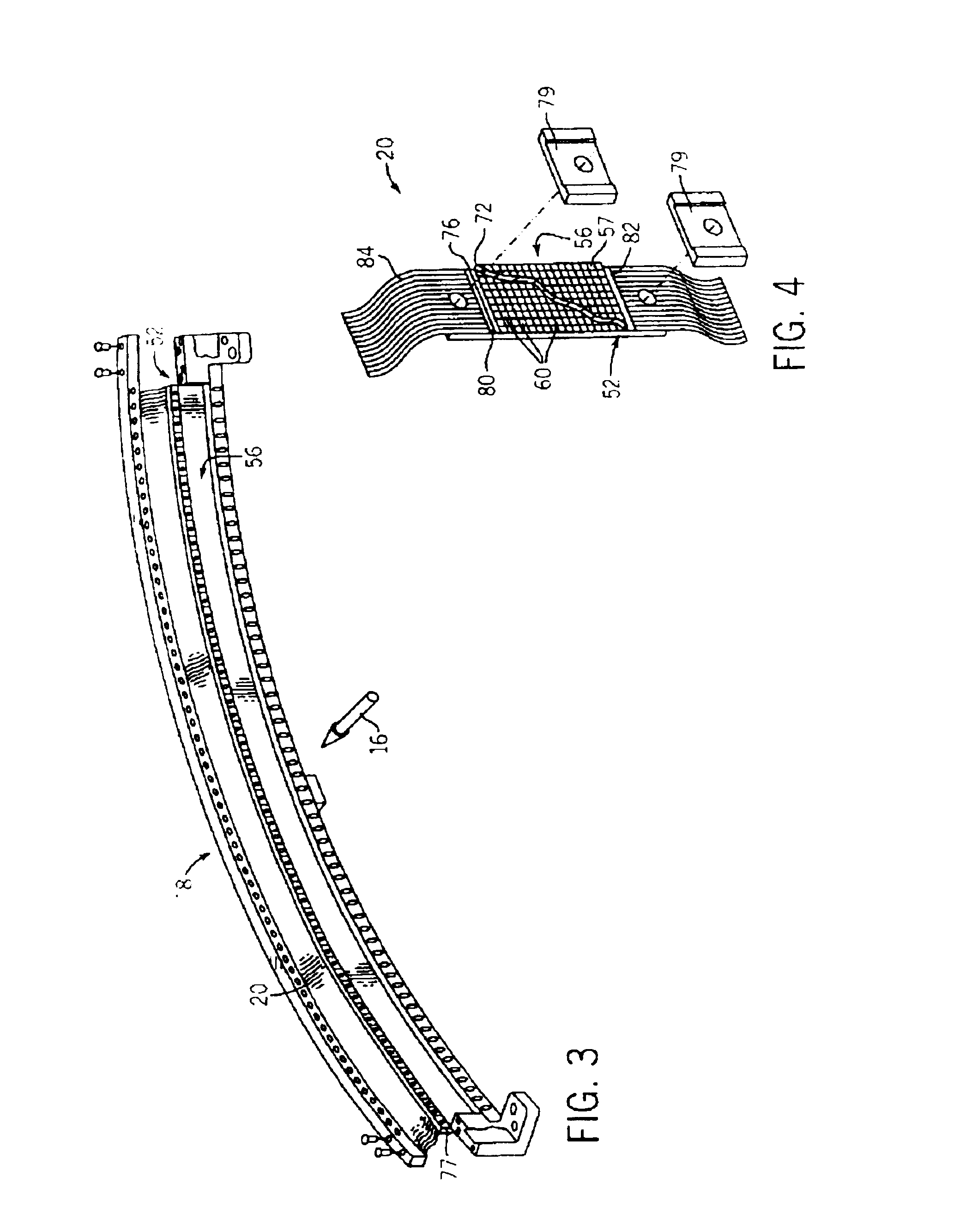

Photovoltaic wire

InactiveUS20090266411A1Efficient and economic use of materialEnhanced light absorptionSolid-state devicesPhotovoltaic energy generationPolymeric surfaceElectrical conductor

A photovoltaic wire is presented where the active layers coat a metallic wire, preferably aluminum. The active layers are an array of doped silicon nanowires electrically attached to the metallic wire that extend from the surface of the wire into a layer of semiconducting polymer, preferably polyaniline. The surface of the polymer is coated with a transparent conductor to complete the photovoltaic circuit.

Owner:ILLUMINEX CORP

Front electrode including transparent conductive coating on etched glass substrate for use in photovoltaic device and method of making same

InactiveUS20080308145A1Low efficiencyImprove efficiencyVacuum evaporation coatingSputtering coatingConductive coatingSputter deposition

Certain example embodiments of this invention relate to a front electrode provided on an etched / patterned front glass substrate for use in a photovoltaic device or the like. The glass is a low-iron soda-lime-silica based glass. Etching of the glass may include immersing the soda-lime-silica based glass in an acid inclusive solution such as hydrofluoric acid (e.g., HF in aqueous solution) and / or hydrofluoric acid with a buffer, in order to selectively dissolve some of the glass thereby producing at least one textured / patterned substantially transparent surface of the glass substrate. A front electrode (single or multi-layered) is then formed (e.g., via sputter-deposition) on the textured surface of the front glass substrate, and may be used in a photovoltaic device or the like.

Owner:GUARDIAN GLASS LLC

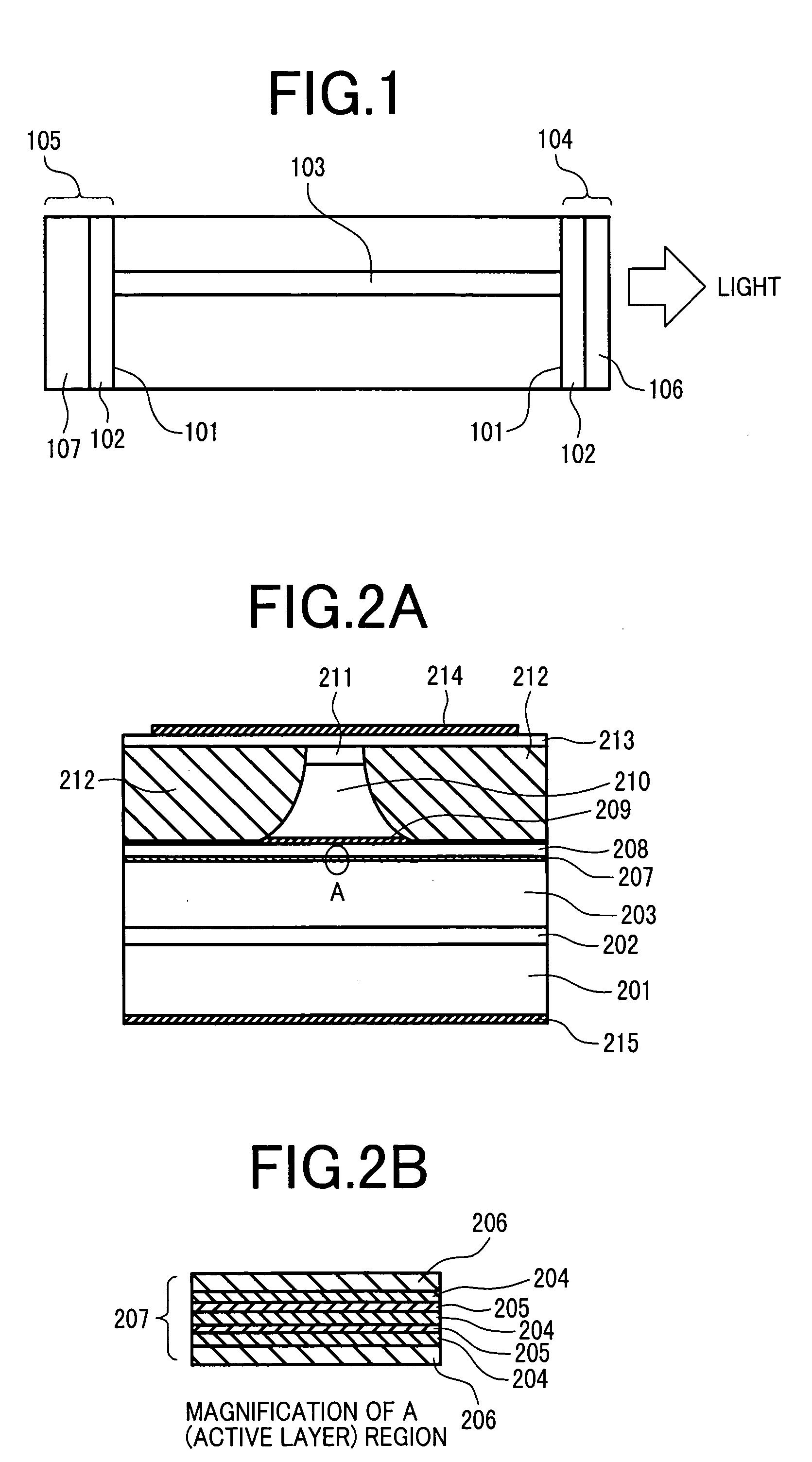

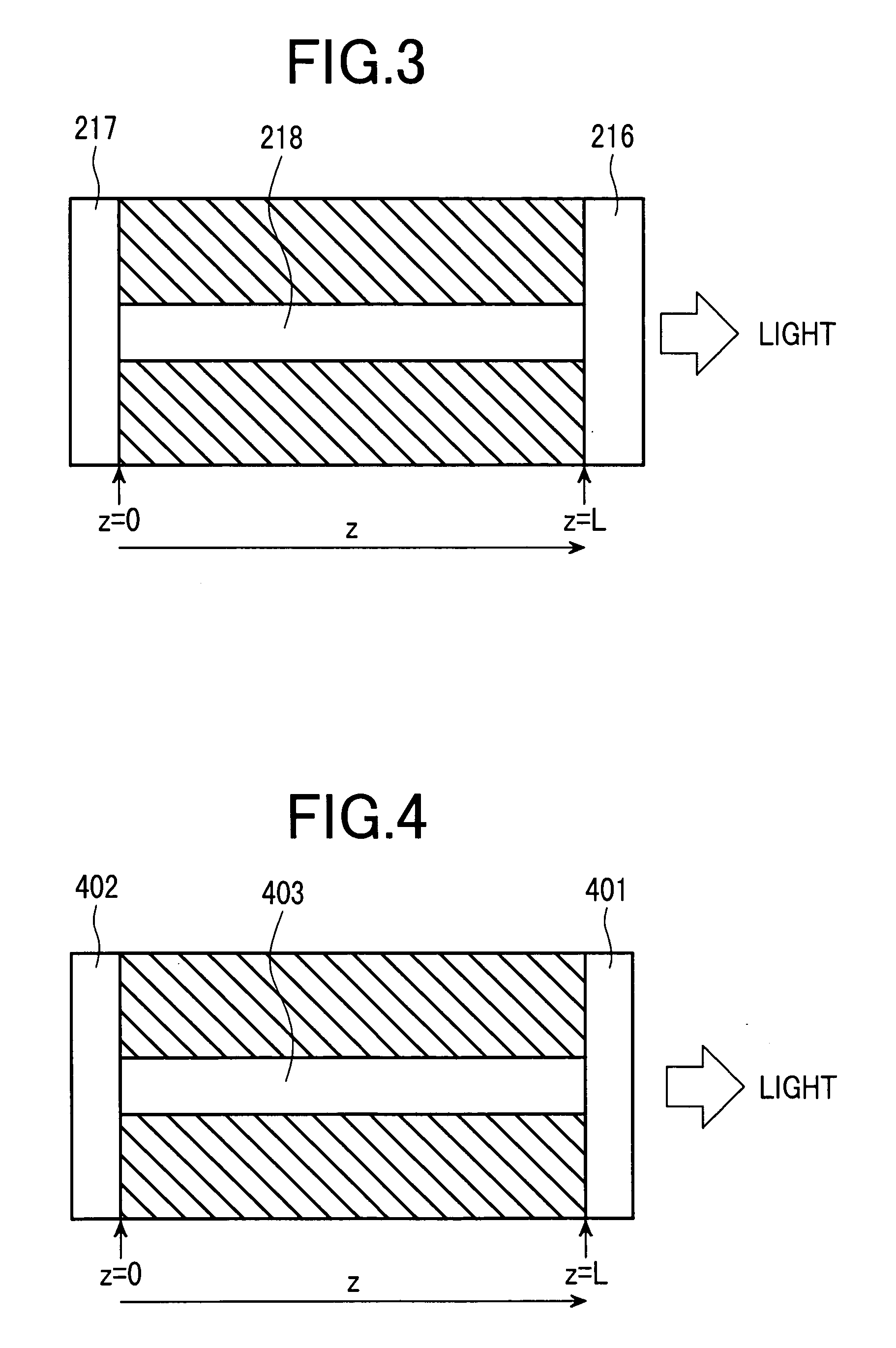

Semiconductor laser device

ActiveUS20070025231A1Avoid layeringImprove efficiencyLaser optical resonator constructionLaser active region structureTectorial membraneSingle crystal

A semiconductor laser device, which has a protective film at an end surface thereof, is adaptable to demands for higher outputs or shorter wavelengths. The semiconductor laser device according to the present invention includes a dielectric film on at least one end surface of an optical resonator, in which the dielectric film includes a first dielectric layer and a second dielectric layer comprised of the same elements and disposed in sequence from the end surface side of the semiconductor, the first dielectric layer including a layer made of a single crystal material and the second dielectric layer including a layer made of an amorphous material.

Owner:NICHIA CORP

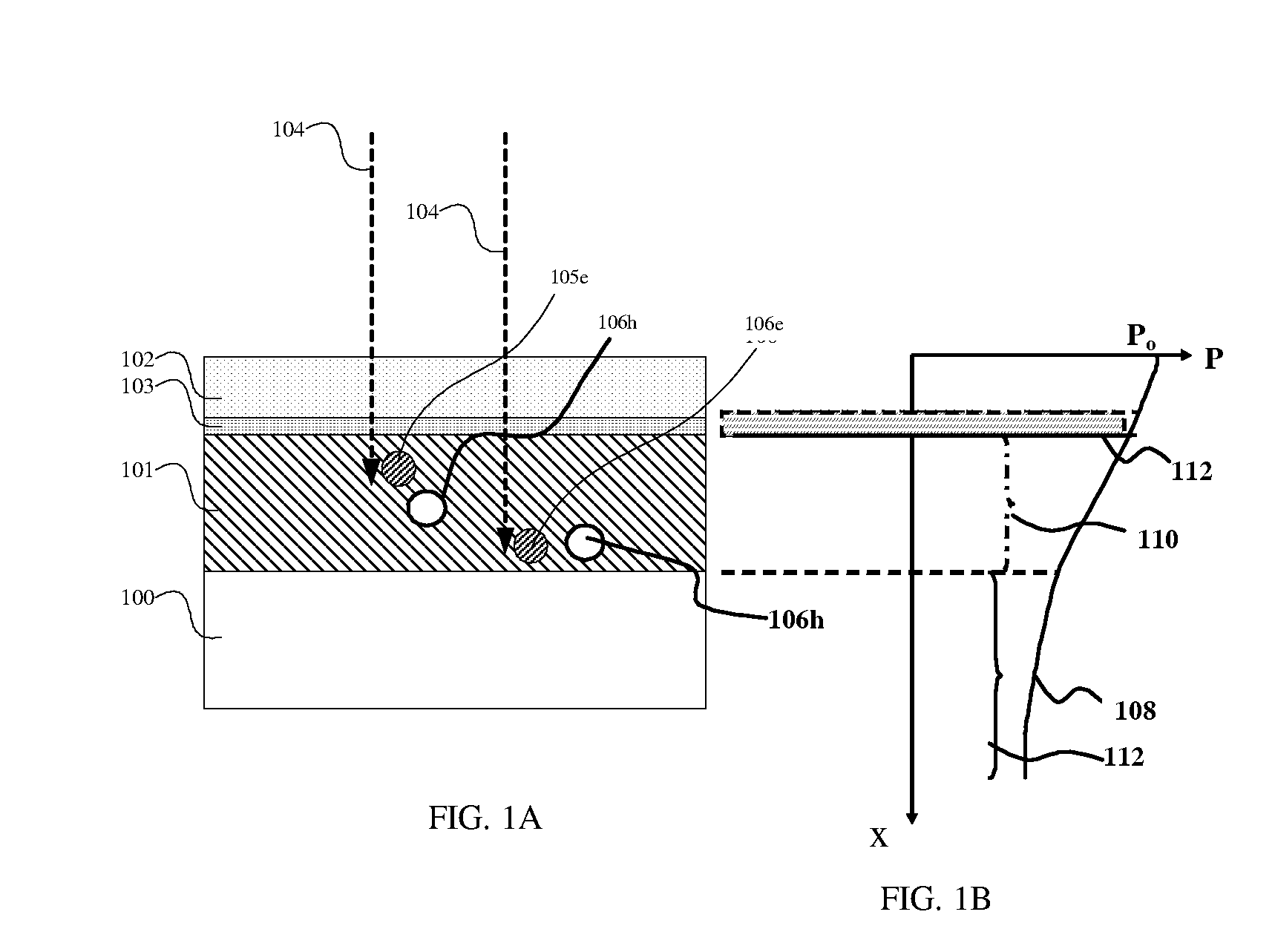

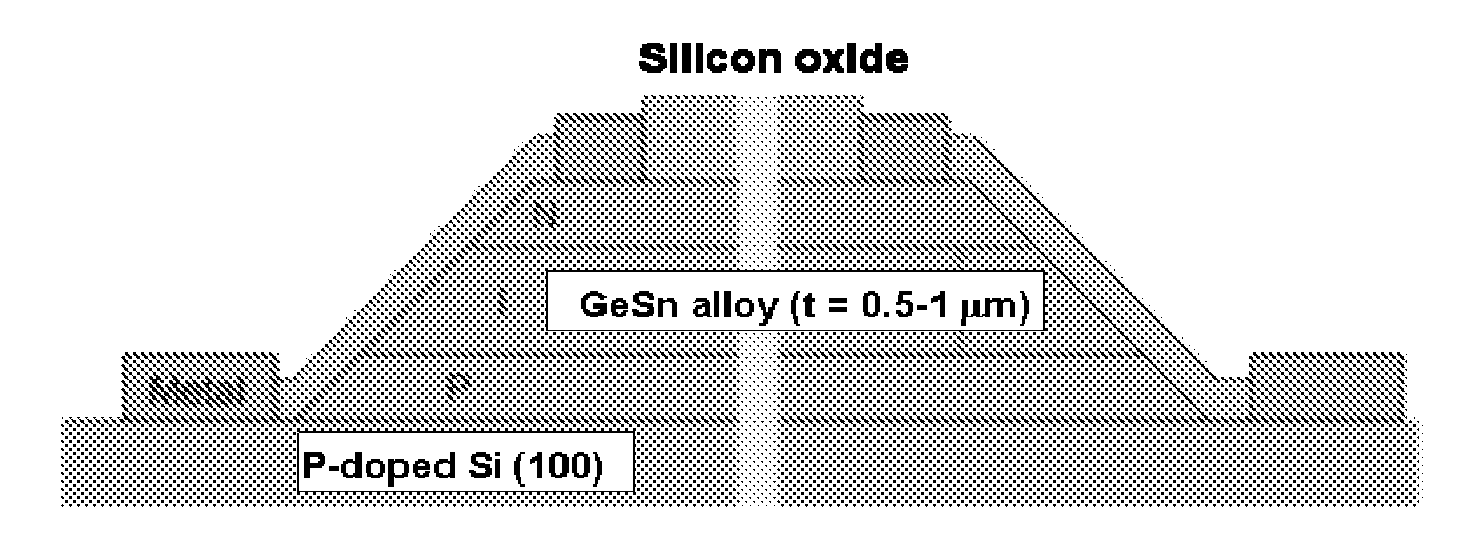

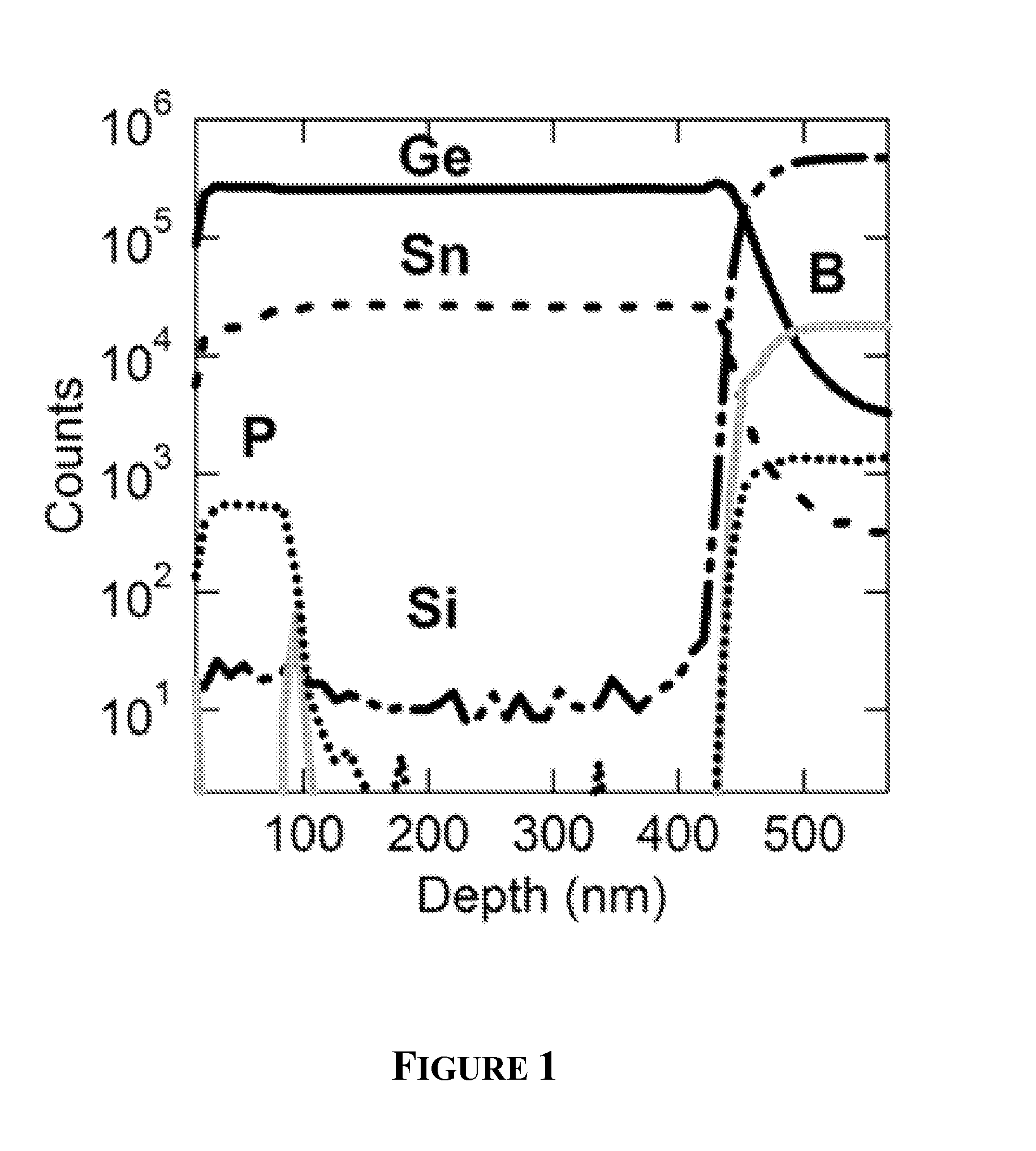

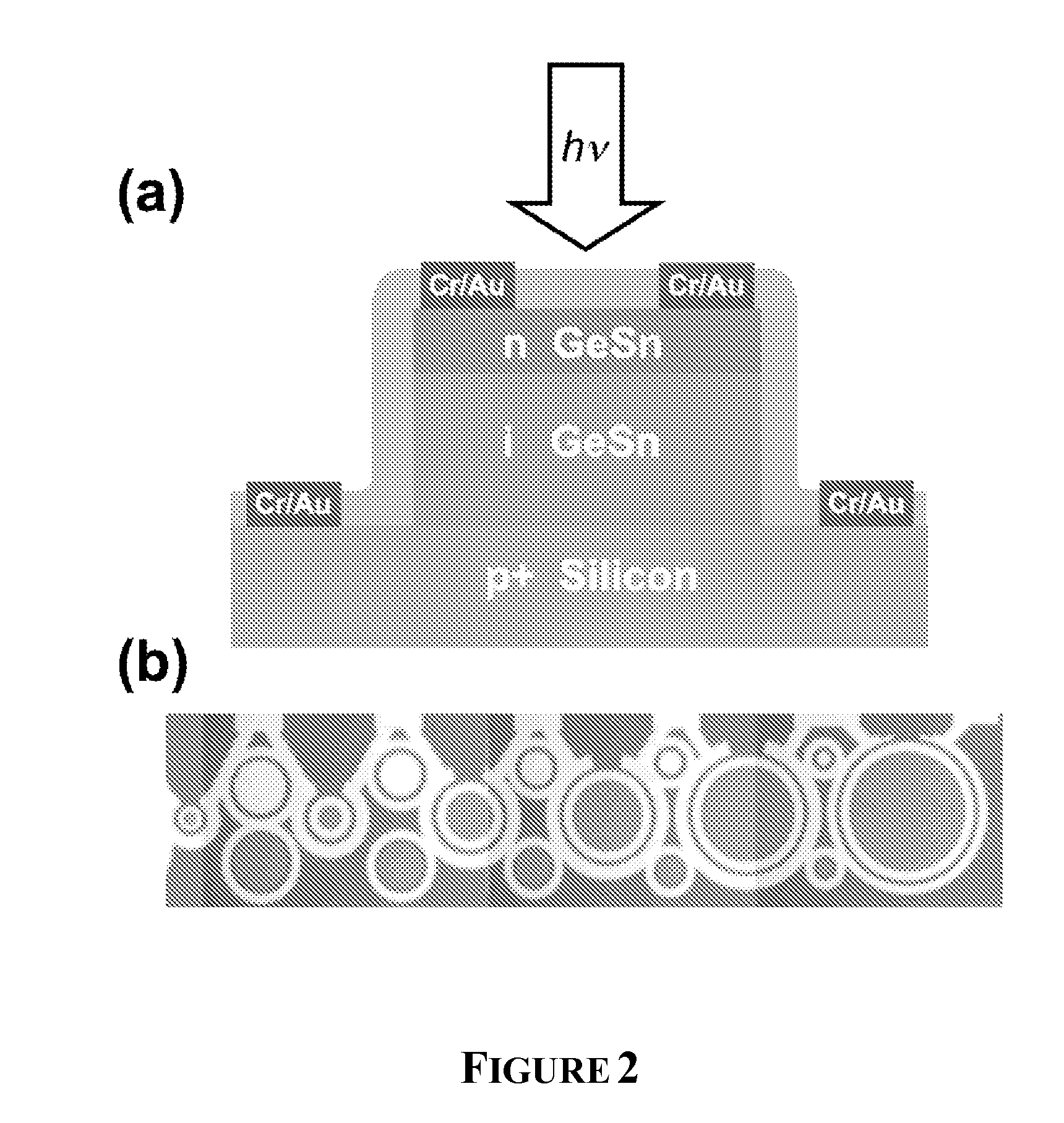

GeSn Infrared Photodetectors

InactiveUS20120025212A1Increase rangeEnhanced light absorptionSolid-state devicesSemiconductor/solid-state device manufacturingCMOSPhotovoltaic detectors

Photodiode devices with GeSn active layers can be integrated directly on p+ Si platforms under CMOS-compatible conditions. It has been found that even minor amounts of Sn incorporation (2%) dramatically expand the range of IR detection up to at least 1750 nm and substantially increases the absorption. The corresponding photoresponse can cover of all telecommunication bands using entirely group IV materials.

Owner:ARIZONA STATE UNIVERSITY

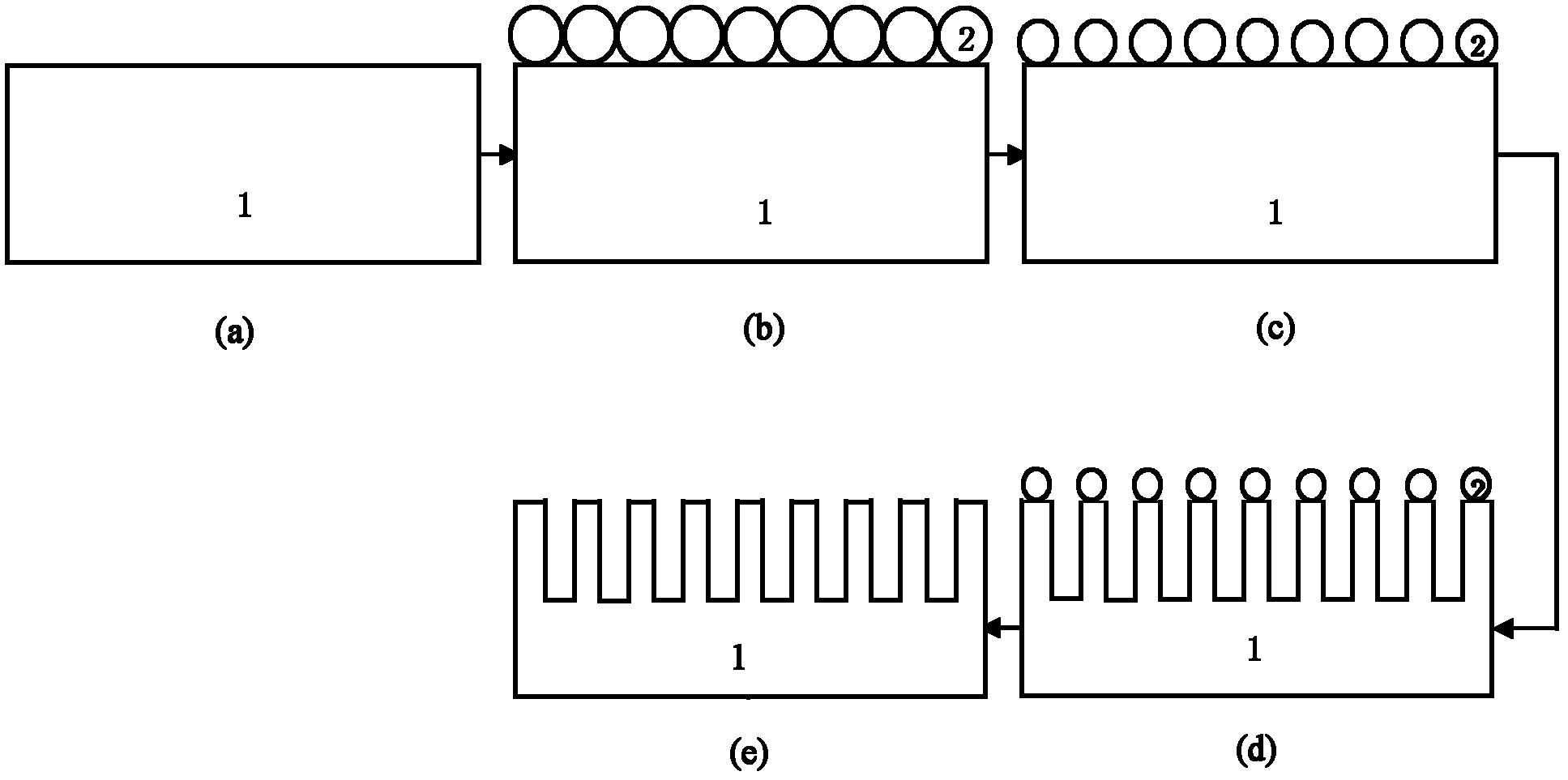

Method for preparing silicon nano-pillar array based on nanosphere etching technology

InactiveCN102633230AQuality improvementHigh feasibilityDecorative surface effectsChemical vapor deposition coatingNano structuringSelf assemble

A method for preparing a silicon nano-pillar array based on nanosphere etching technology relates to a Si nano-structure. The method comprises the following steps of: after cleaning a silicon slice, performing activation treatment on the silicon slice by means of a reactive ion etching system, thereby obtaining a silicon slice surface with hydrophilicity; self-assembling single-layer polystyrene nanospheres on a silicon substrate by a spin coating method; regulating and controlling the diameters of the single-layer polystyrene nanospheres by means of the reactive ion etching system, thereby obtaining the single-layer polystyrene nanospheres different in diameter; taking the single-layer polystyrene nanospheres as masks, performing etching by means of the masks and by inductively coupled plasma etching technology, and performing etching and sidewall protection by alternately using SF6 and C4F8; and removing the masks and by-products produced in the etching process by using an organic reagent, thus finally obtaining the silicon nano-pillar array.

Owner:XIAMEN UNIV

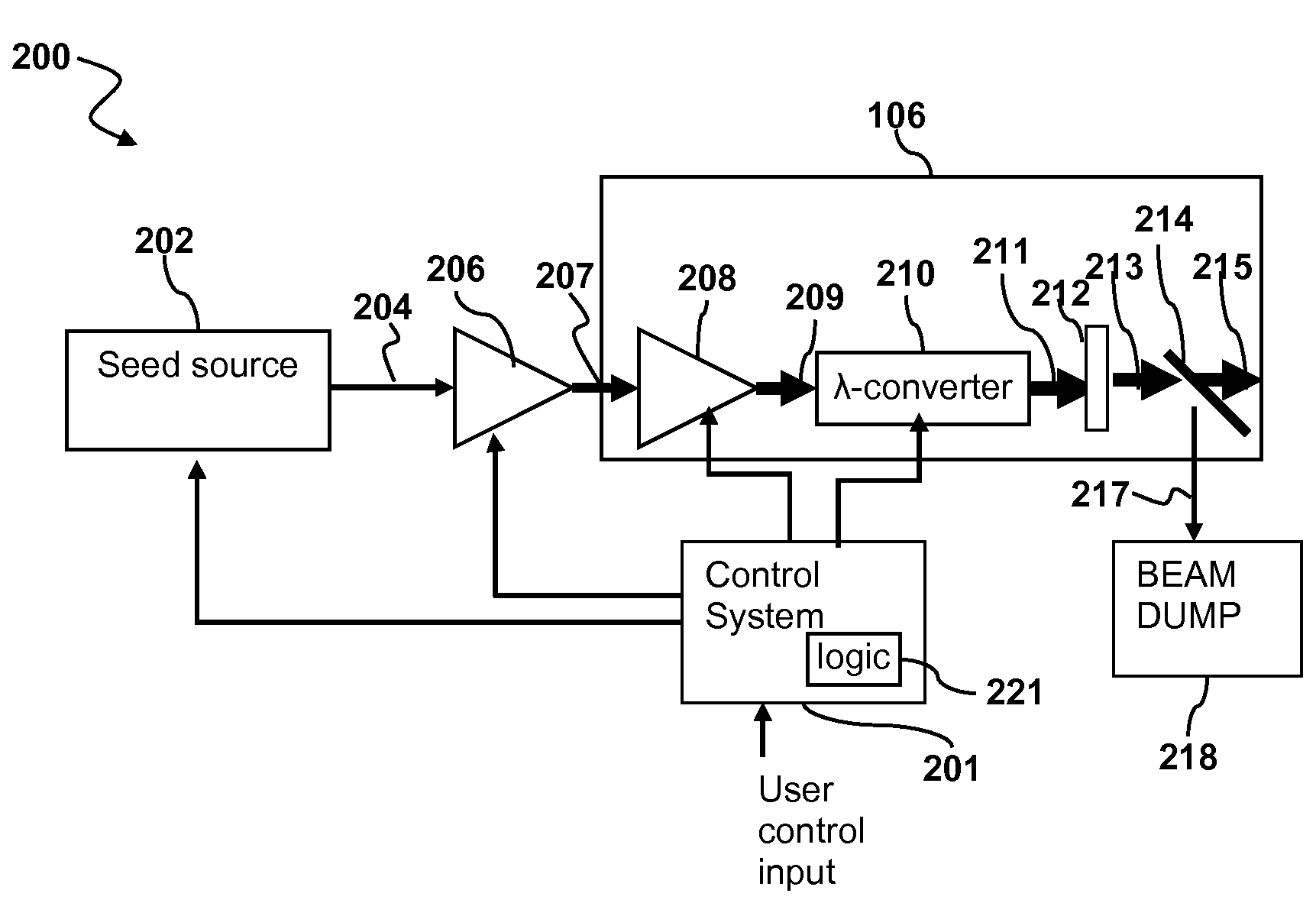

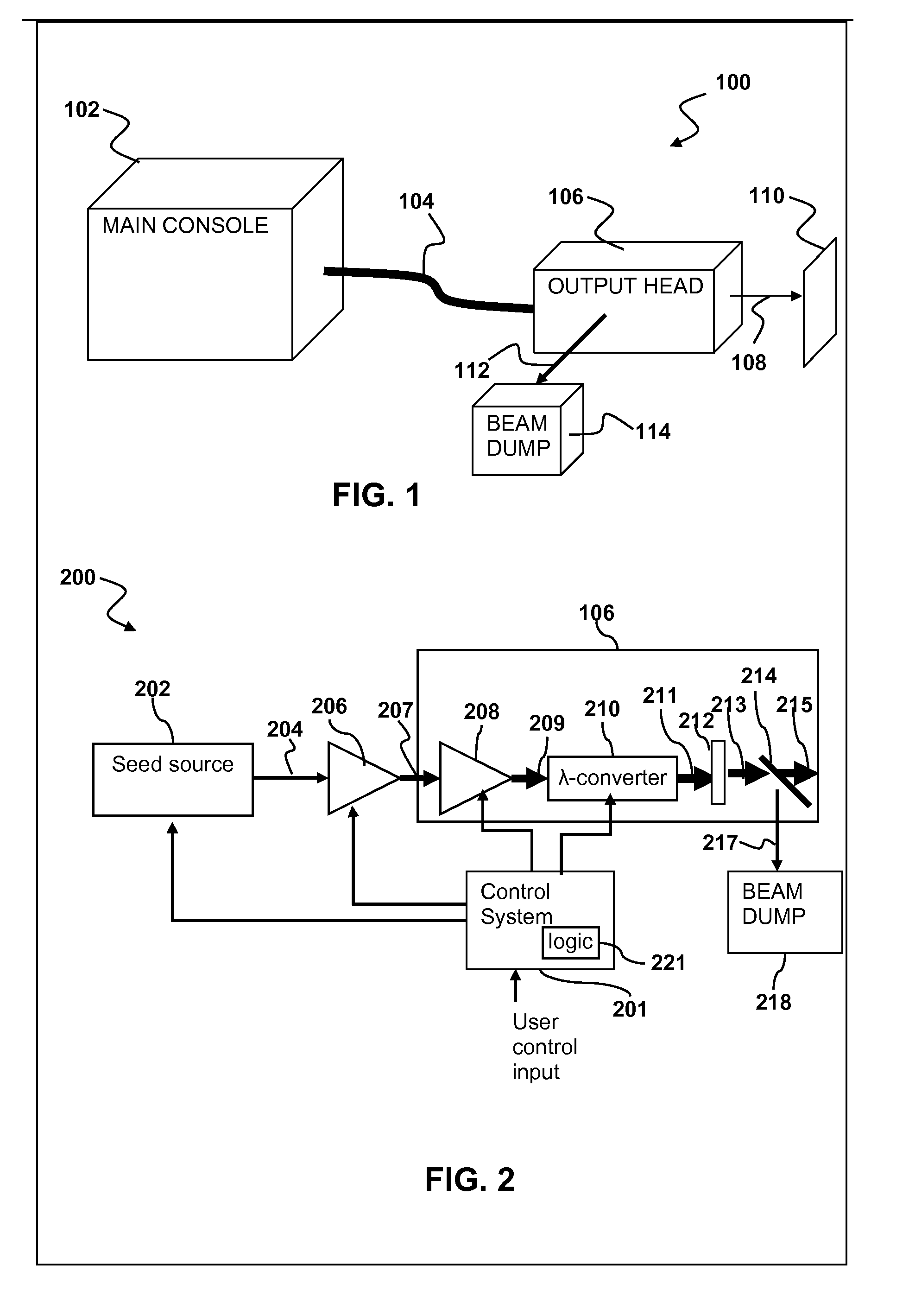

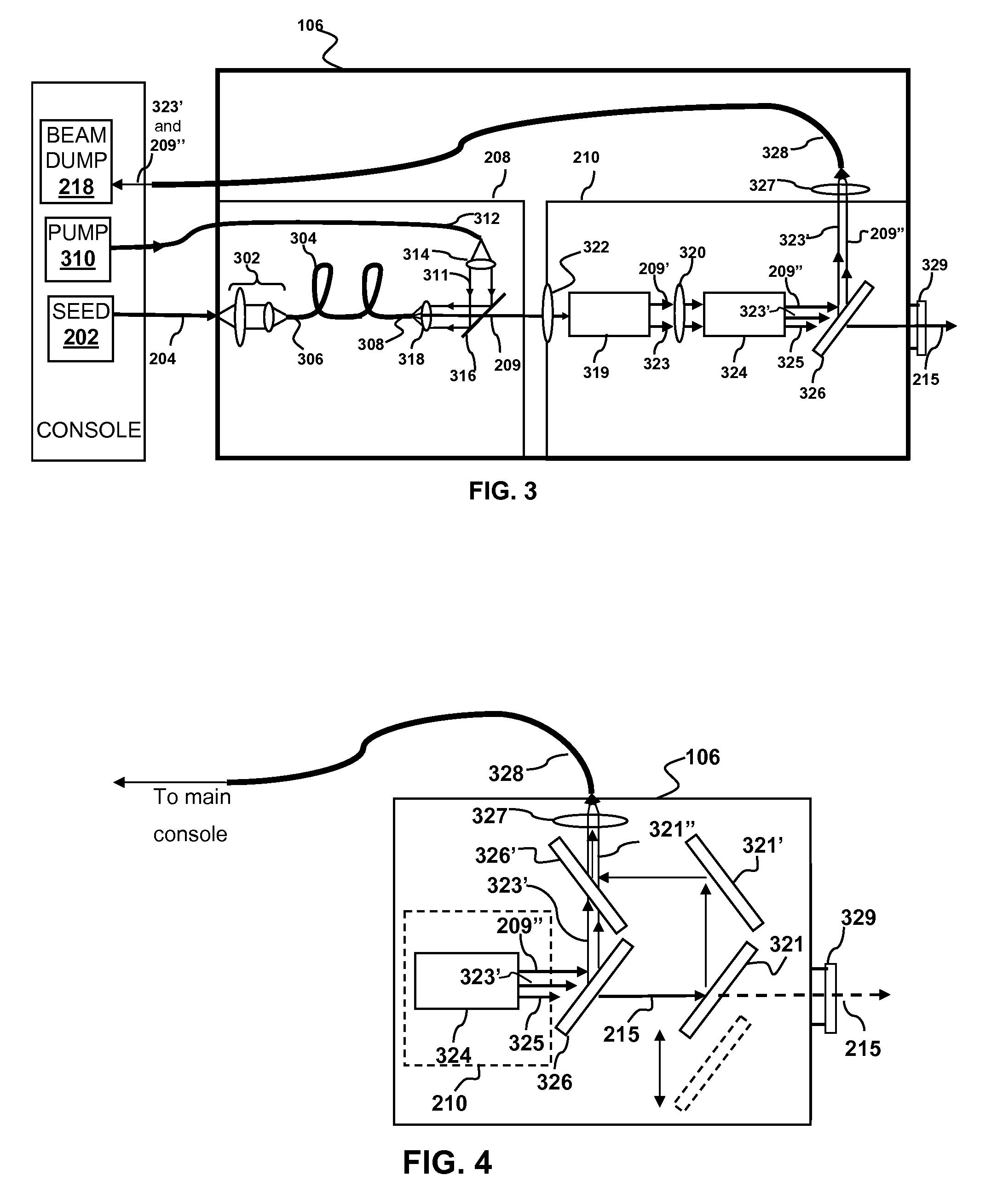

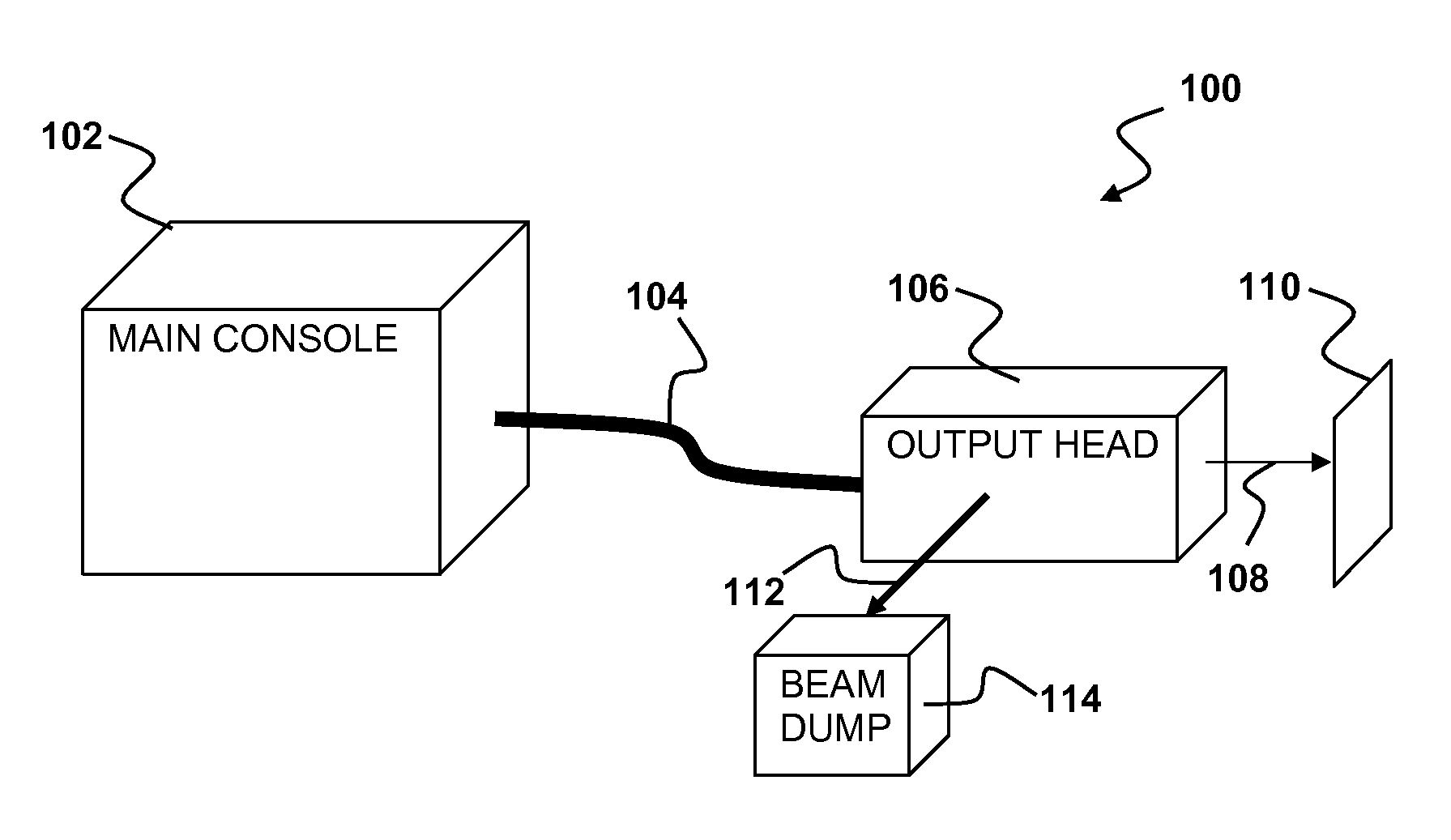

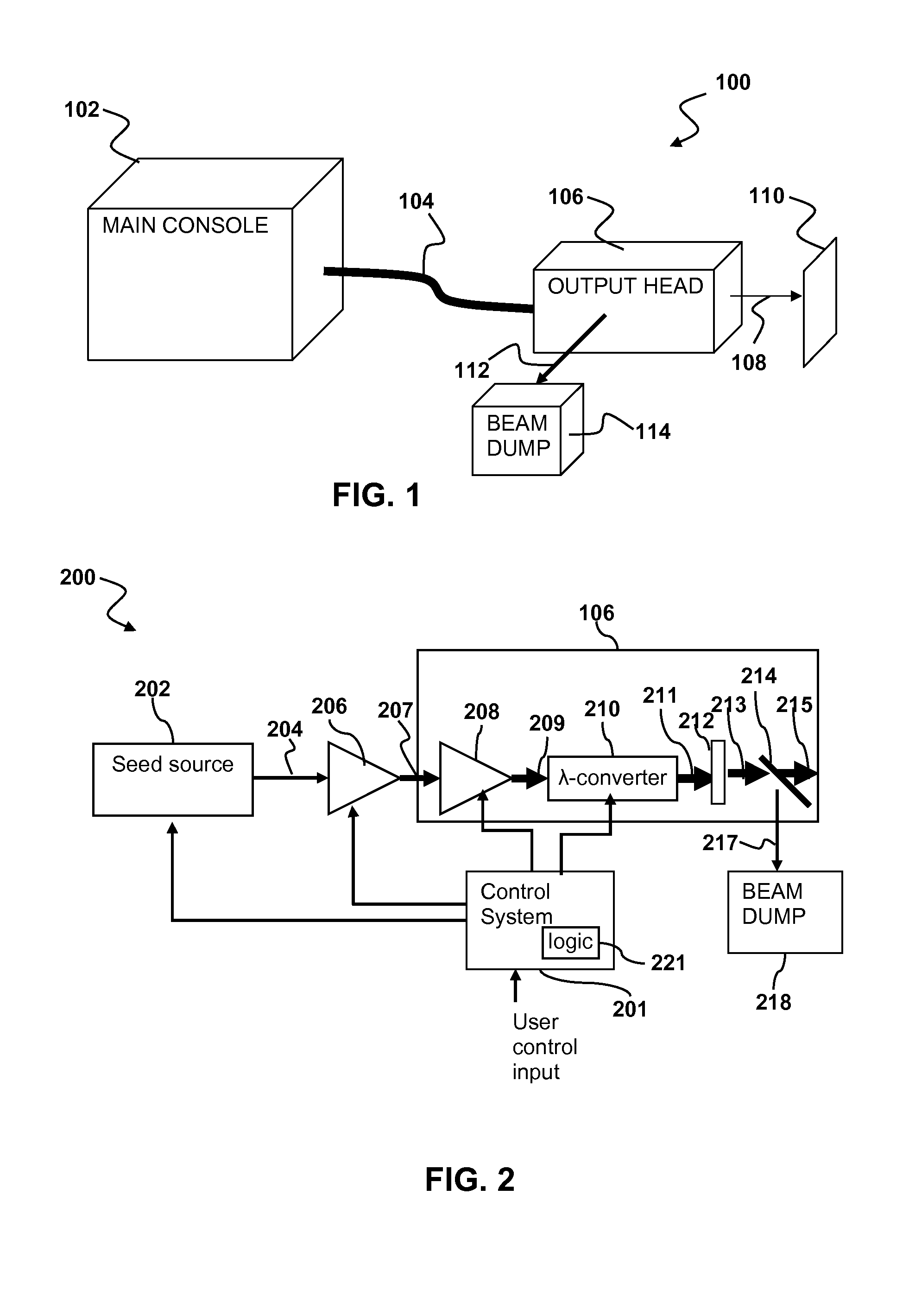

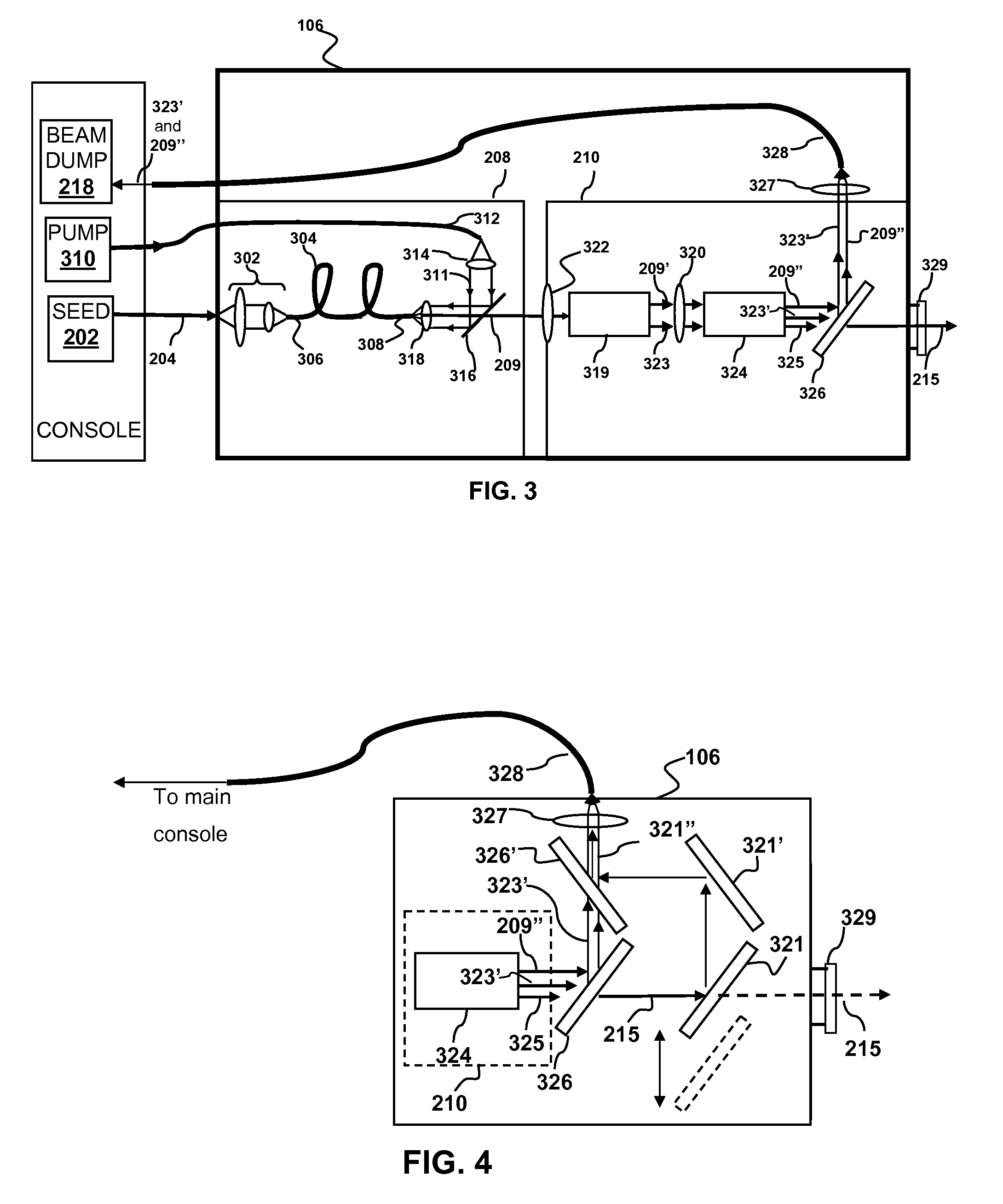

Reducing thermal load on optical head

ActiveUS20080056642A1Reduce heat loadAvoid damageCoupling light guidesOptical devices for laserEngineeringOptical fiber cable

Methods and apparatus for reducing a thermal load on an optical head are described. Waste light is captured at one or more locations in the optical head and directed to a location that is thermally isolated from the one or more locations in the optical head using or more optical fibers.

Owner:DISCO CORP

Photovoltaic cells based on NANO or micro-scale structures

ActiveUS20070204901A1Electric power generatedLarge power generation capabilitySolid-state devicesSemiconductor/solid-state device manufacturingScale structureEngineering

Novel structures of photovoltaic cells (also treated as solar cells) are provided. The cells are based on nanometer-scaled wires, tubes, and / or rods, which are made of electronic materials covering semiconductors, insulators or metallic in structure. These photovoltaic cells have large power generation capability per unit physical area over the conventional cells. These cells will have enormous applications in space, commercial, residential, and industrial applications.

Owner:BANPIL PHOTONICS

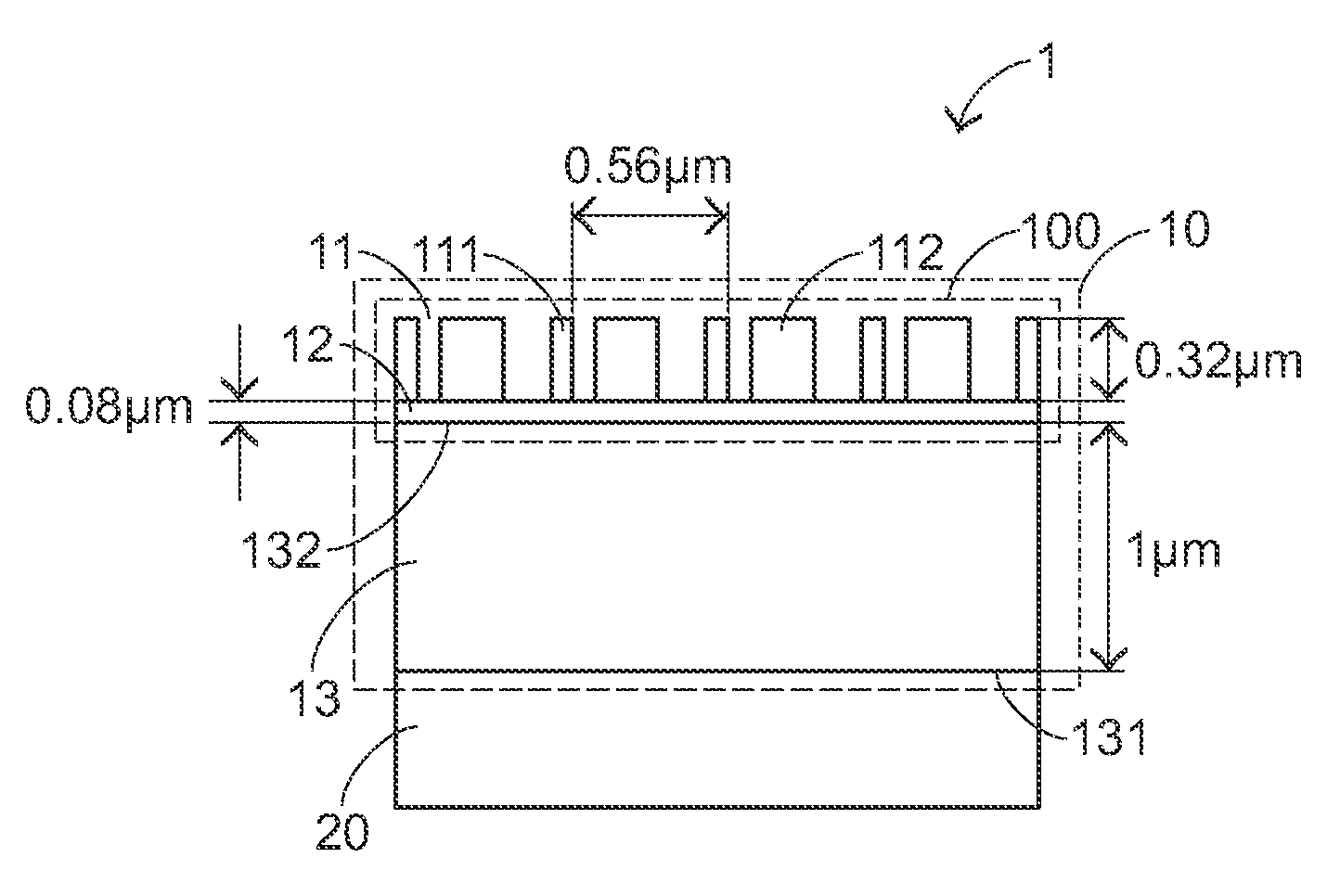

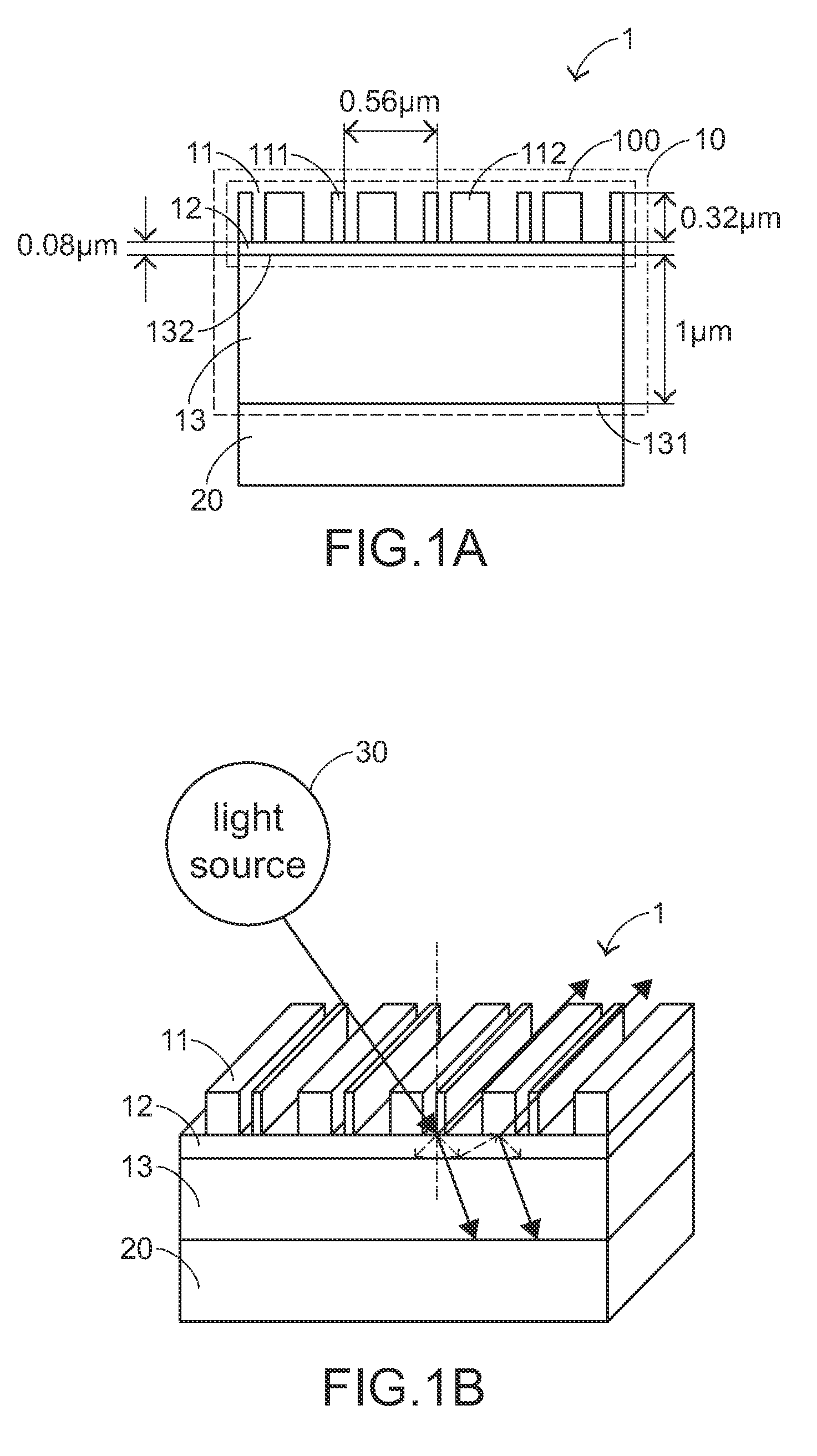

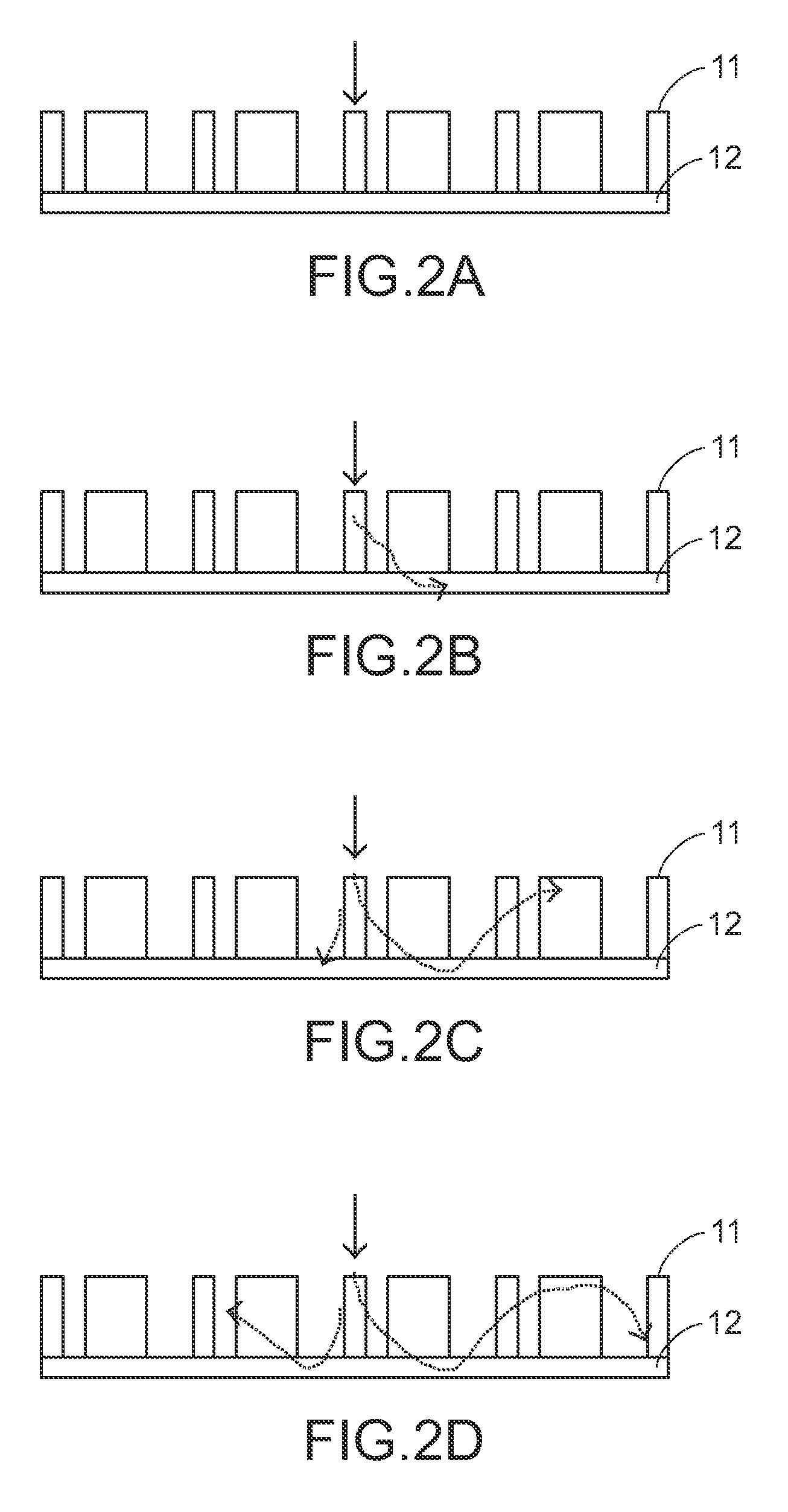

Guided mode resonance solar cell

InactiveUS20100126577A1Easy to trapOptical path lengthCoupling light guidesPhotovoltaic energy generationGratingLight pillar

A guided mode resonance solar cell includes a solar cell body and a guided mode resonance unit. The solar cell body is used for converting optical energy into electrical energy. The guided mode resonance unit is formed on the solar cell body, and includes a grating structure and a waveguide structure. The grating structure includes multiple sub-wavelength light pillars. When a light emitted from a light source is incident onto the grating structure, a resonant of the light occurs in the grating structure to facilitate trapping the light in the waveguide structure and elongating an optical path length.

Owner:NAT CENT UNIV

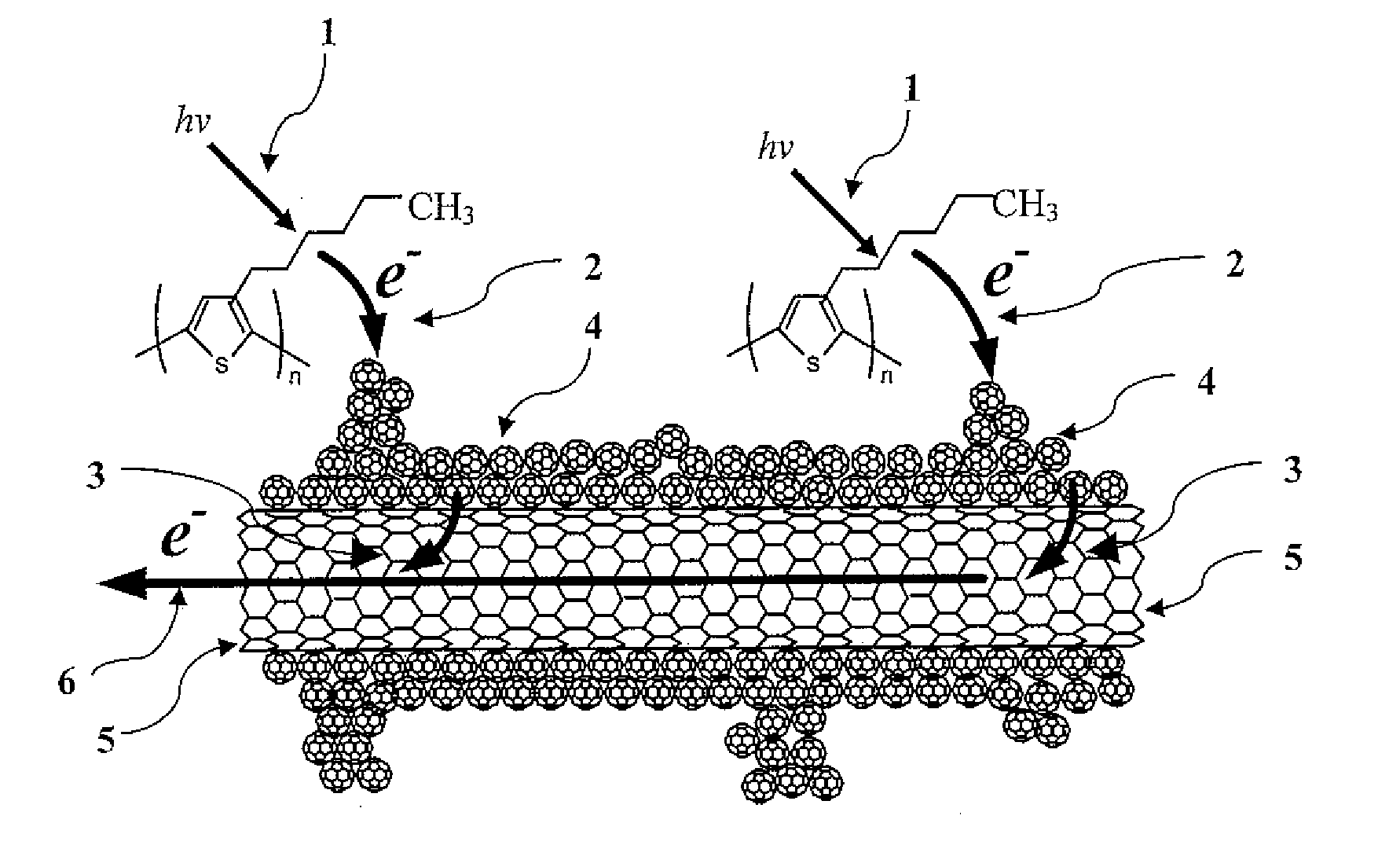

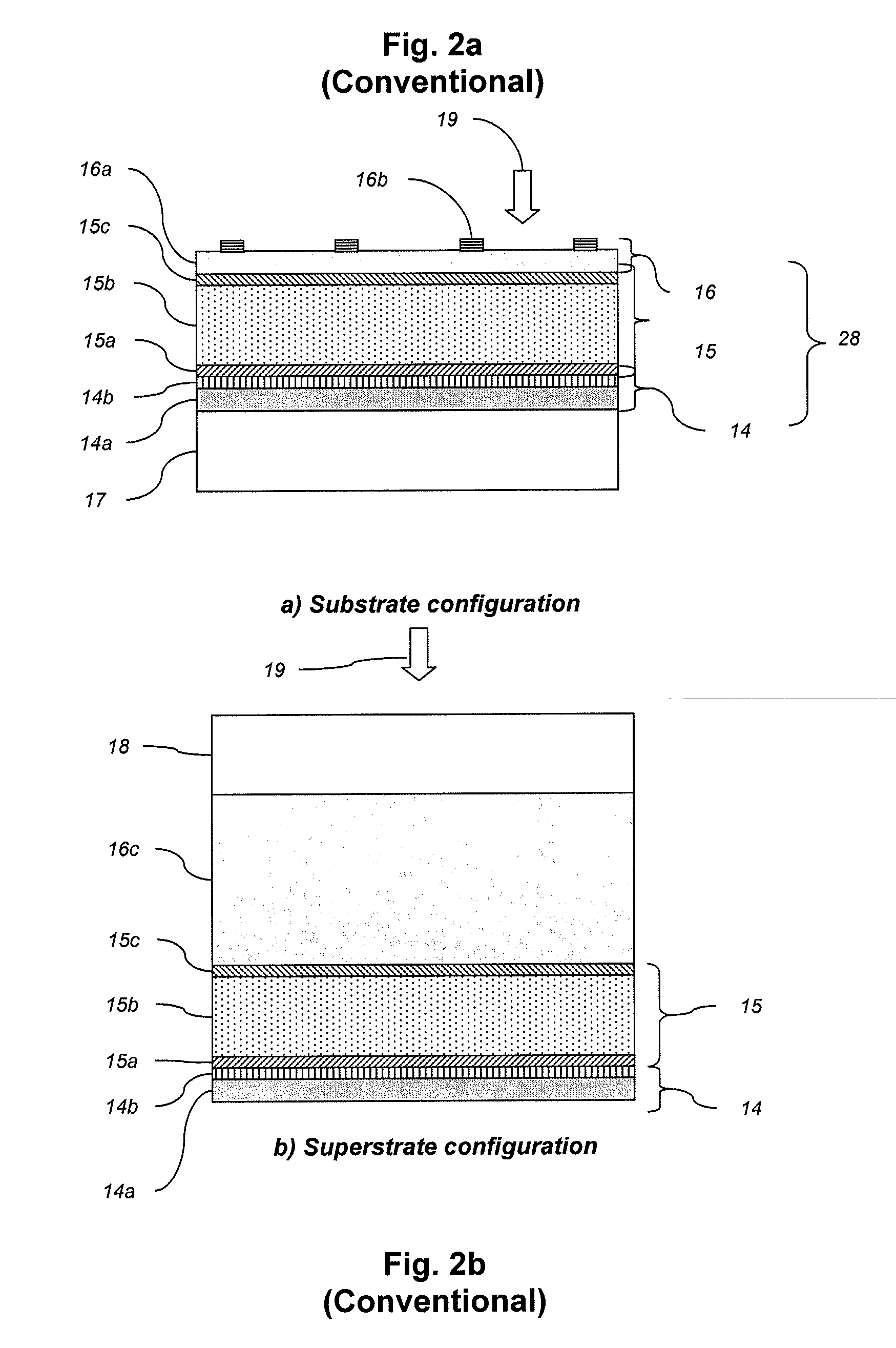

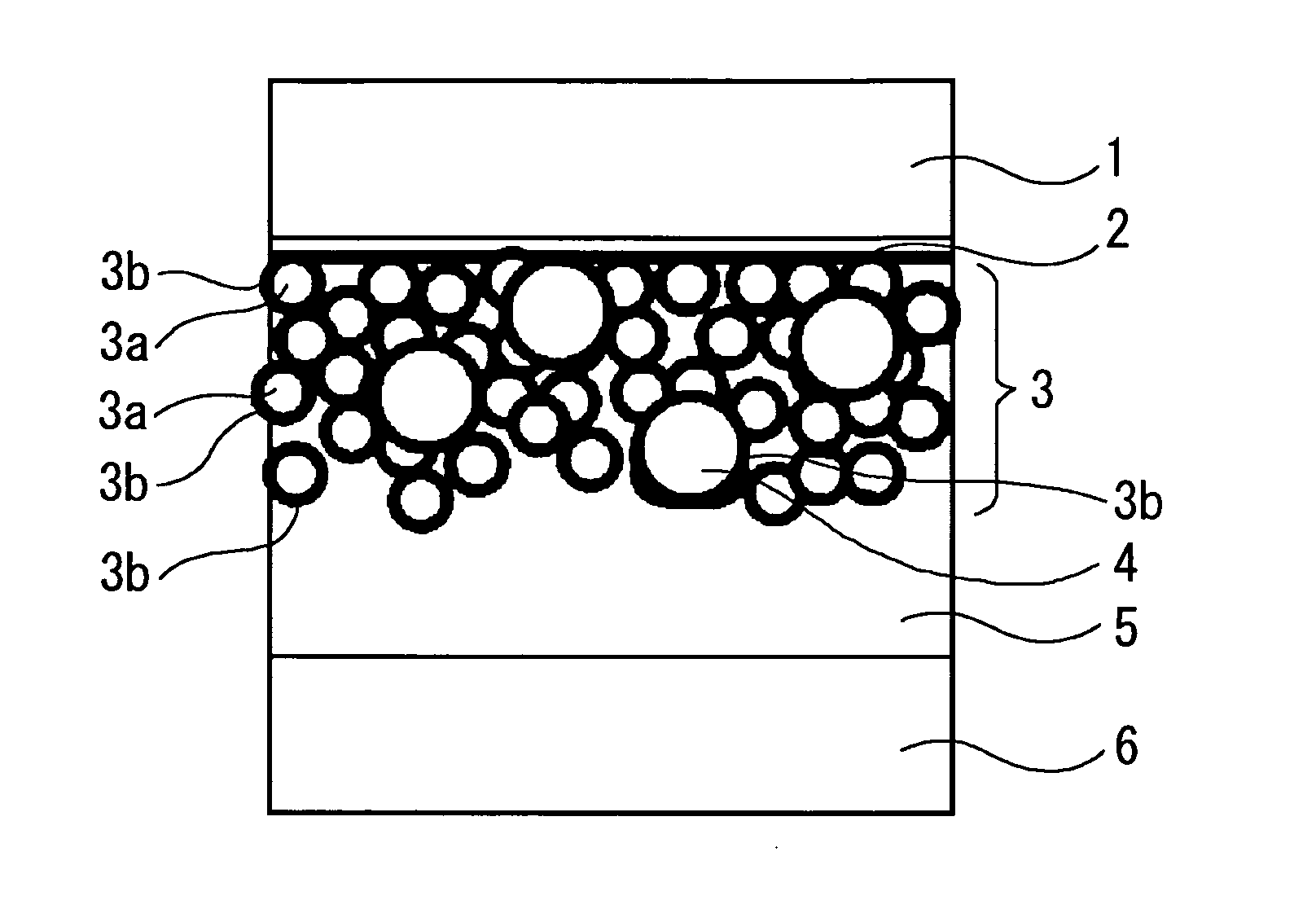

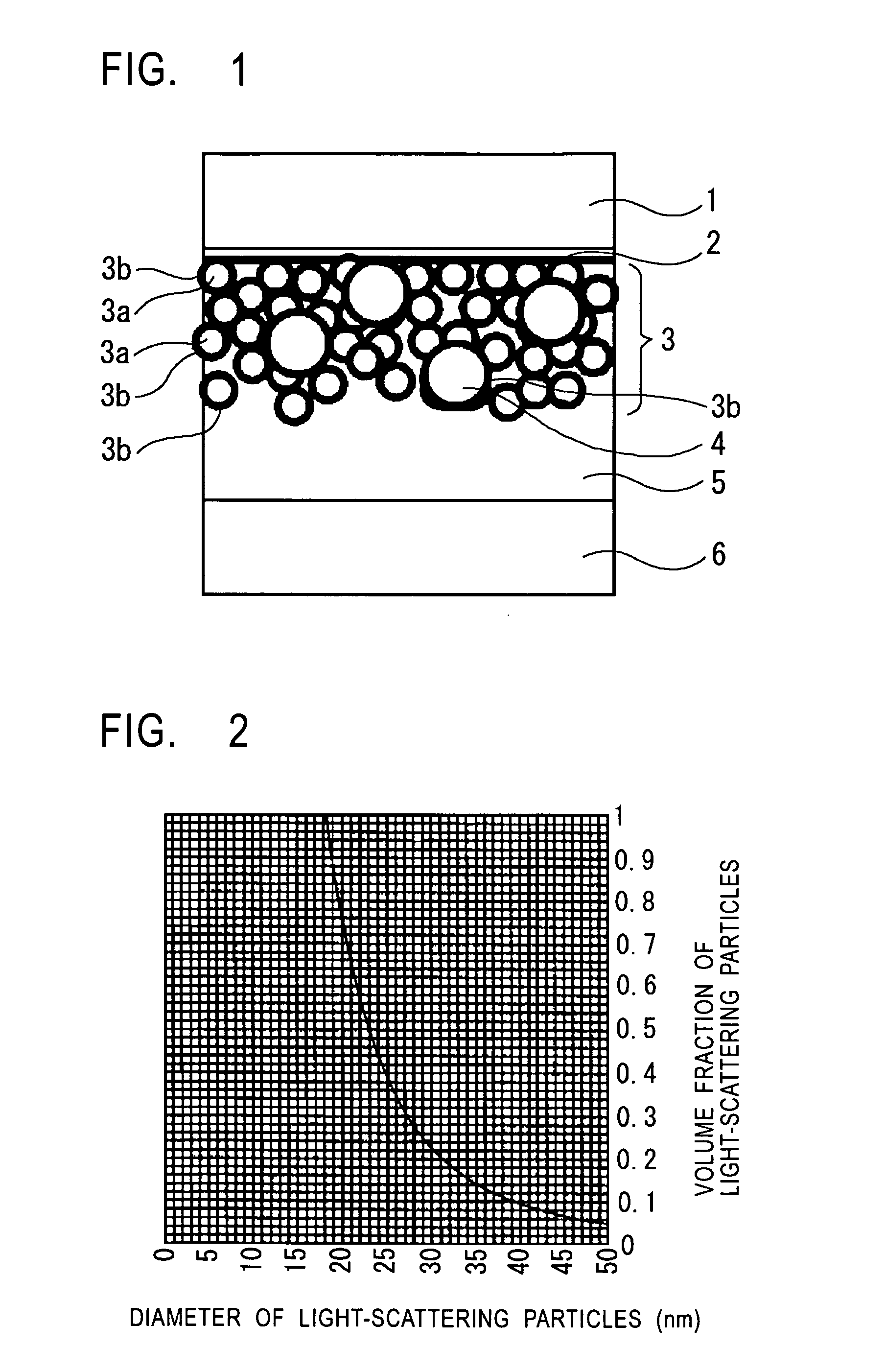

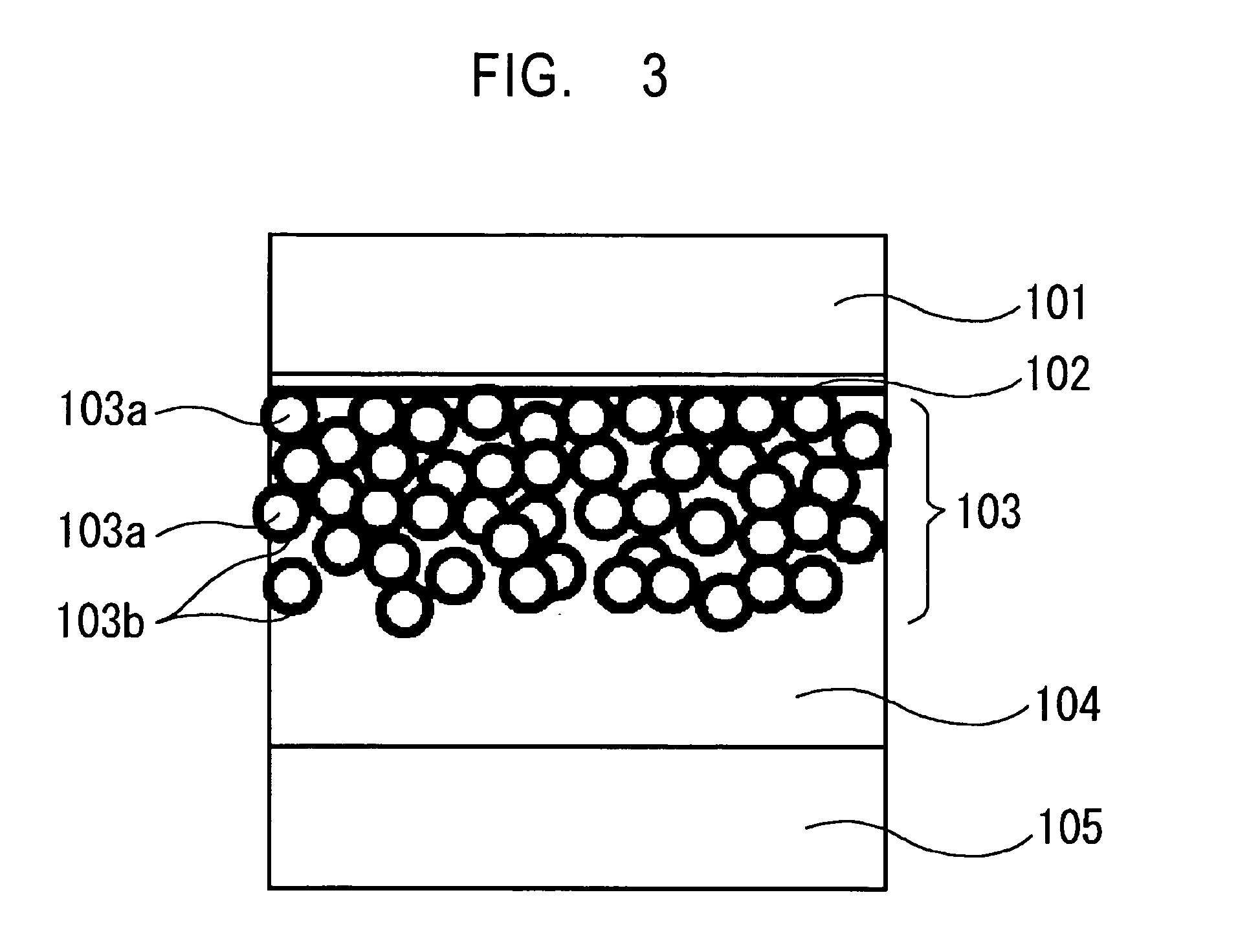

Dye-sensitized solar cell

InactiveUS20060048812A1Increase the optical path lengthPromote absorptionLight-sensitive devicesSolid-state devicesOptoelectronicsLight scattering

A dye-sensitized solar cell with high conversion efficiency is provided. The dye-sensitized solar cell according to the present invention has, between an electrode (2) formed on a surface of a transparent substrate (1) and a counter electrode (6), a light-absorbing layer (3) containing light-absorbing particles carrying dye and an electrolyte layer (5), characterized in that the light-absorbing layer (3) containing light-scattering particles (4) different in size from the light-absorbing particles. In such a dye-sensitized solar cell according to the present invention, the energy of light, which passes through a light-absorbing layer in a conventional cell structure, can be strongly absorbed by the dye in the light-absorbing layer of the present invention. This will increase the conversion efficiency and output current of the dye-sensitized solar cell.

Owner:SONY CORP

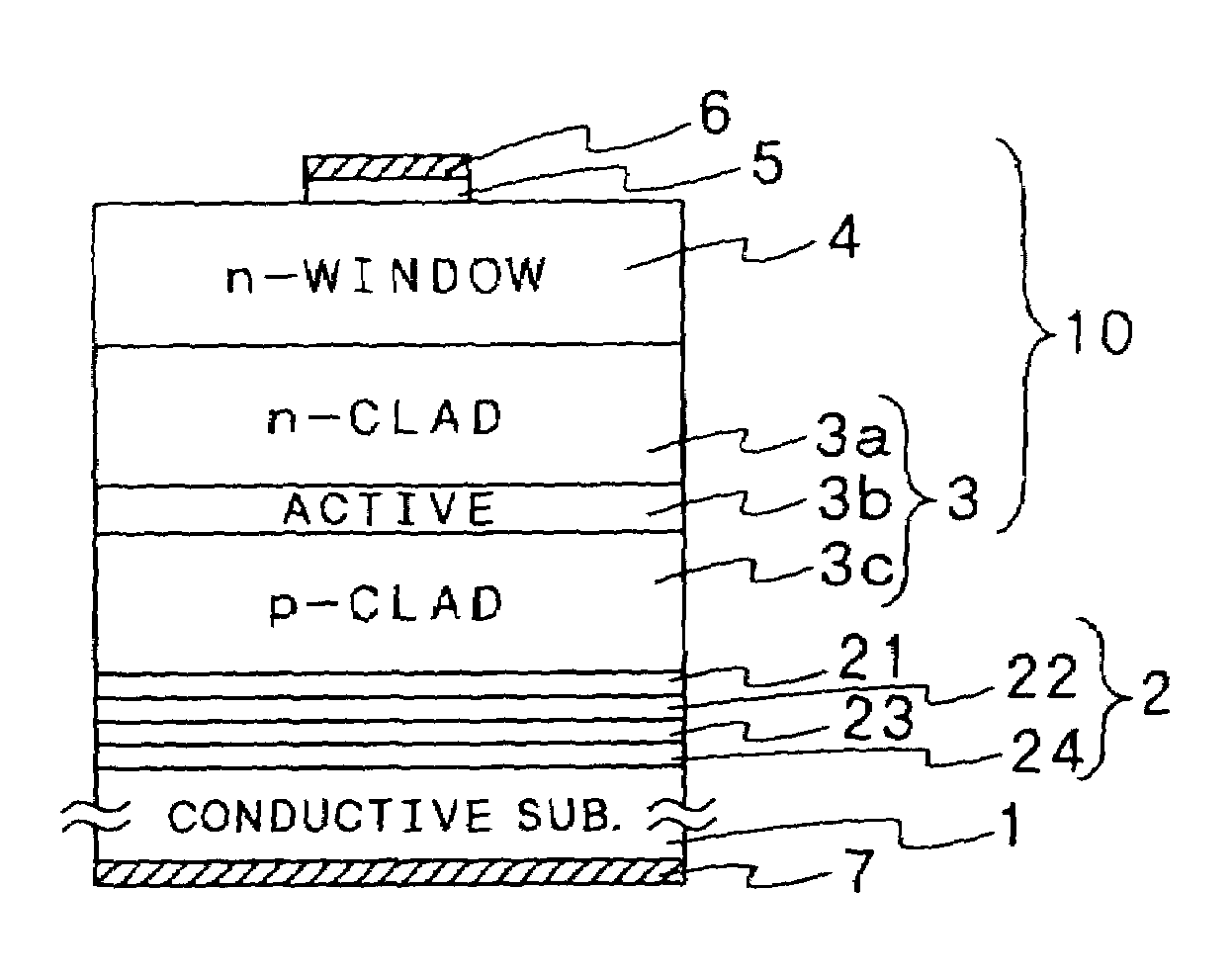

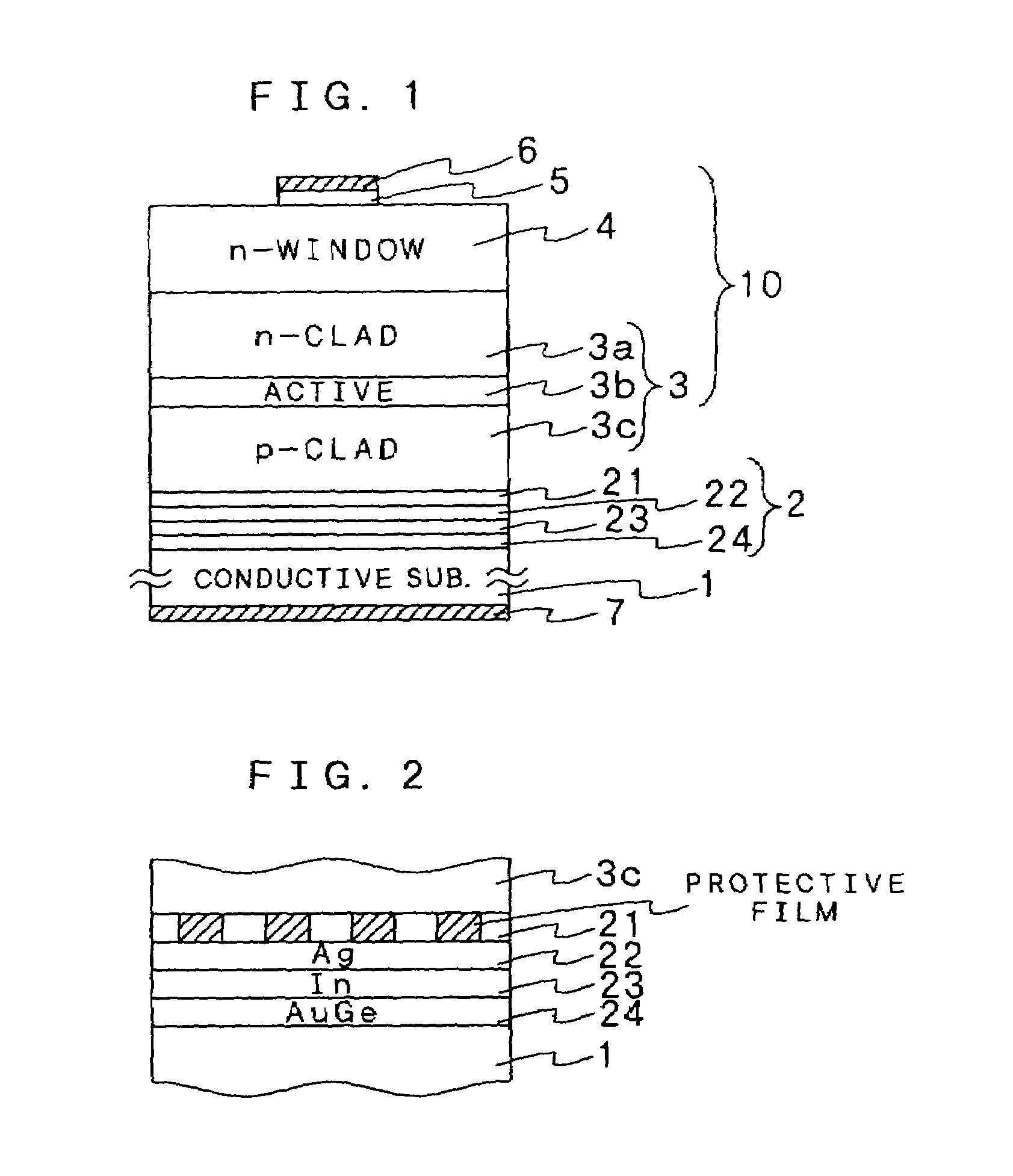

Semiconductor light emitting device

InactiveUS7019323B2Increase brightnessEnhanced light absorptionSolid-state devicesSemiconductor/solid-state device manufacturingOhmic contactLight emitting device

A semiconductor light emitting device is formed by adhering a semiconductor layered portion having a light emitting layer forming portion to a conductive substrate via a metal layer. The metal layer has at least a first metal layer for ohmic contact with the semiconductor layered portion, a second metal layer made of Ag, and a third metal layer made of a metal which allows adhesion to the conductive substrate at a low temperature. As a result, the rate of reflection of light from the metal layer increases due to the presence of Ag in the metal layer. Further, the metal in the metal layer is prohibited from diffusing into the semiconductor layer, so that the semiconductor layer does not absorb light. And therefore the brightness of the semiconductor light emitting device can further be increased.

Owner:ROHM CO LTD

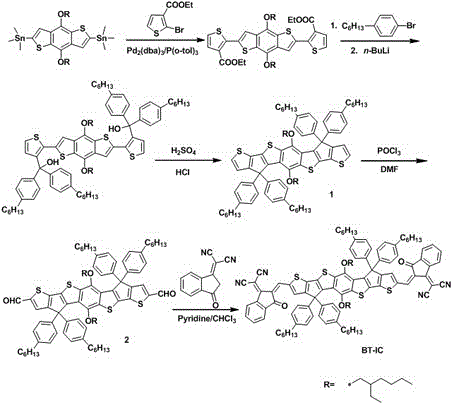

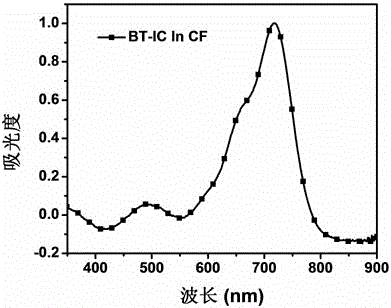

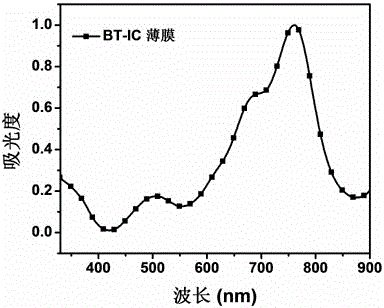

Non-fullerene solar energy cell acceptor material based on multiple condensed rings, preparation method and application thereof

ActiveCN106467547AIncrease the effective conjugate lengthReduced recombination energyOrganic chemistrySolid-state devicesChemical structureElectron mobility

The invention provides a non-fullerene solar energy cell acceptor material based on multiple condensed rings, a preparation method and an application thereof. A chemical structural formula of the acceptor material is shown in a specification, wherein X is selected from one of the following groups: Y is selected from one of the following groups: A is an acceptor unit having a pi-conjugated structure, and is respectively selected from the following groups. According to the non-fullerene solar energy cell acceptor material, the effective conjugation length is increased, at the same time, recombination performance is reduced, charge mobility is increased, good visible light near infrared area luminous absorption is guaranteed, electron mobility of the material is obviously increased, and the photoelectric conversion efficiency of an organic solar energy cell is greatly increased.

Owner:SUZHOU JOYSUN ADVANCED MATERIALS CO LTD

Reducing thermal load on optical head

ActiveUS7469081B2Raise transfer toEnhanced light absorptionRadiation pyrometrySpectrum investigationEngineeringOptical fiber cable

Methods and apparatus for reducing a thermal load on an optical head are described. Waste light is captured at one or more locations in the optical head and directed to a location that is thermally isolated from the one or more locations in the optical head using or more optical fibers.

Owner:DISCO CORP

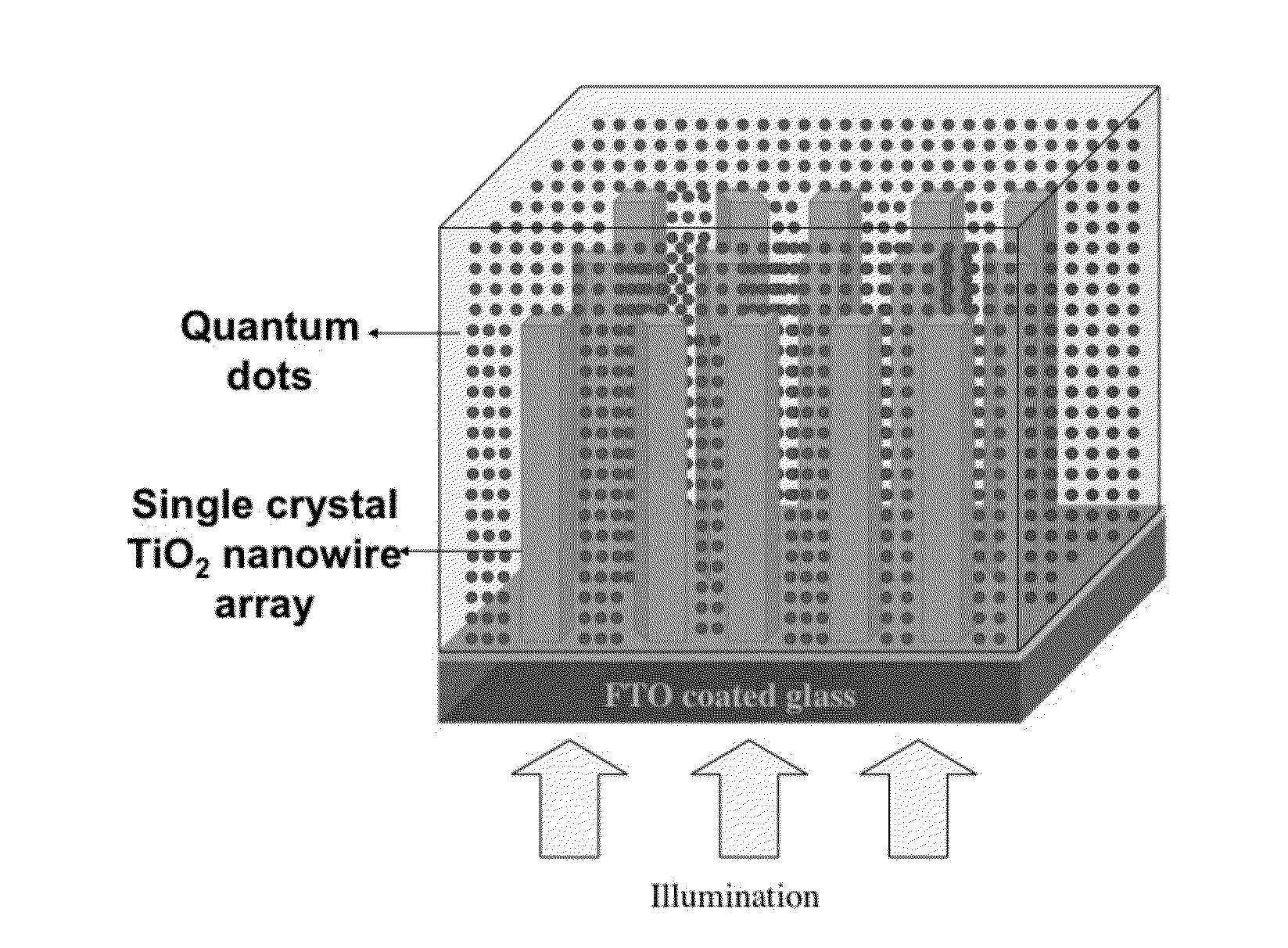

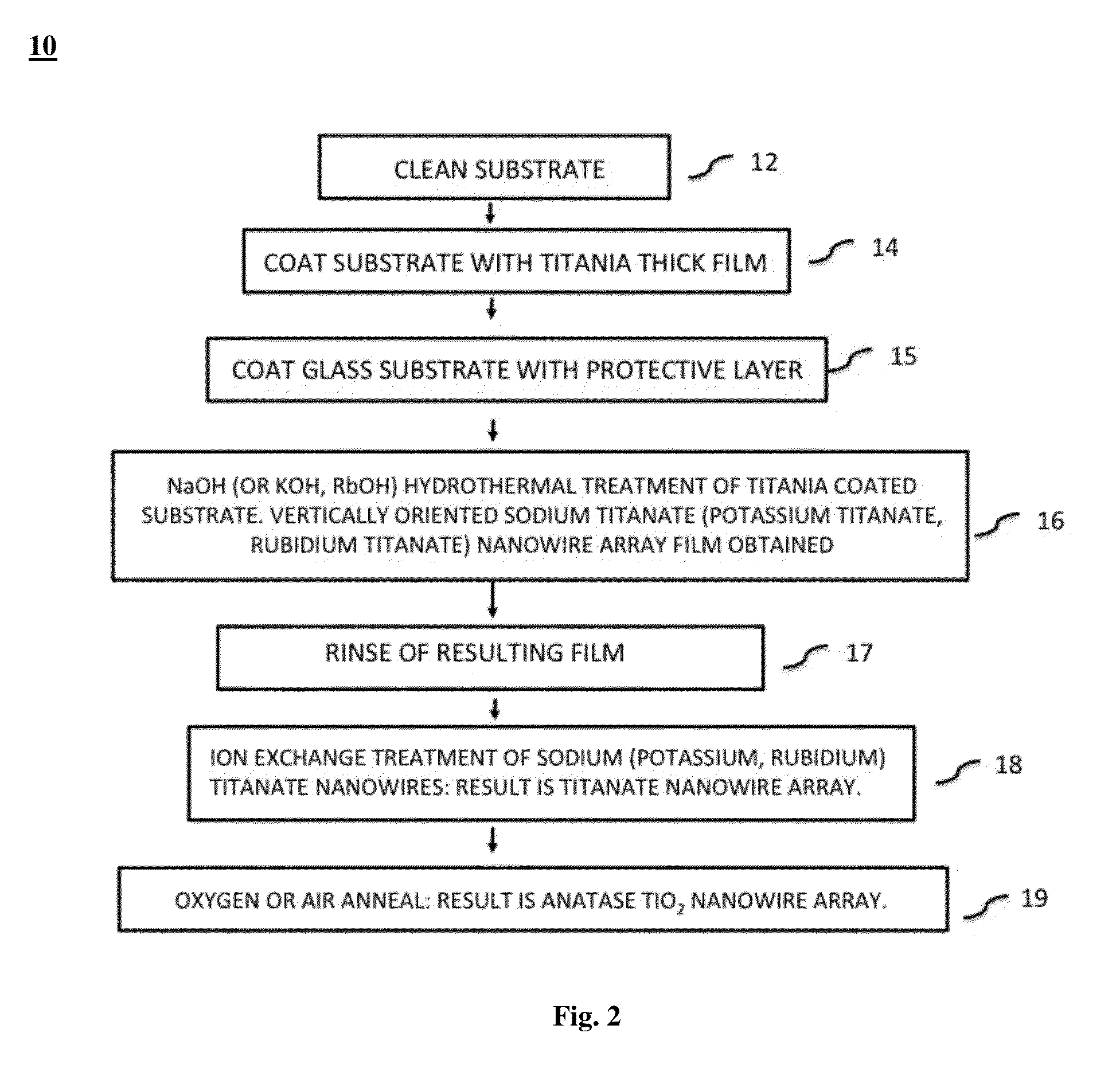

Methods to fabricate vertically oriented anatase nanowire arrays on transparent conductive substrates and applications thereof

ActiveUS20130048947A1Enhanced light absorptionImprove overall utilizationPolycrystalline material growthFrom normal temperature solutionsNanowire arrayElectrically conductive

The present invention relates to growth of vertically-oriented crystalline nanowire arrays upon a transparent conductive or other substrate for use in 3rd generation photovoltaic and other applications. A method of growing crystalline anatase nanowires includes the steps of: deposition of titania onto a substrate; conversion of the titania into titanate nanowires; and, treatment of the titanate nanowires to produce crystalline anatase nanowires.

Owner:COMSTOCK IP HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com