Method for preparing silicon nano-pillar array based on nanosphere etching technology

A technology of nanosphere etching and silicon nanopillars, which is applied in microstructure technology, technology for producing decorative surface effects, decorative arts, etc., can solve complex processes, difficulties in large-area preparation, and the need to improve the stability of nanostructures, etc. problem, to achieve the effect of simple production process, good verticality, and improved specific capacity and specific power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

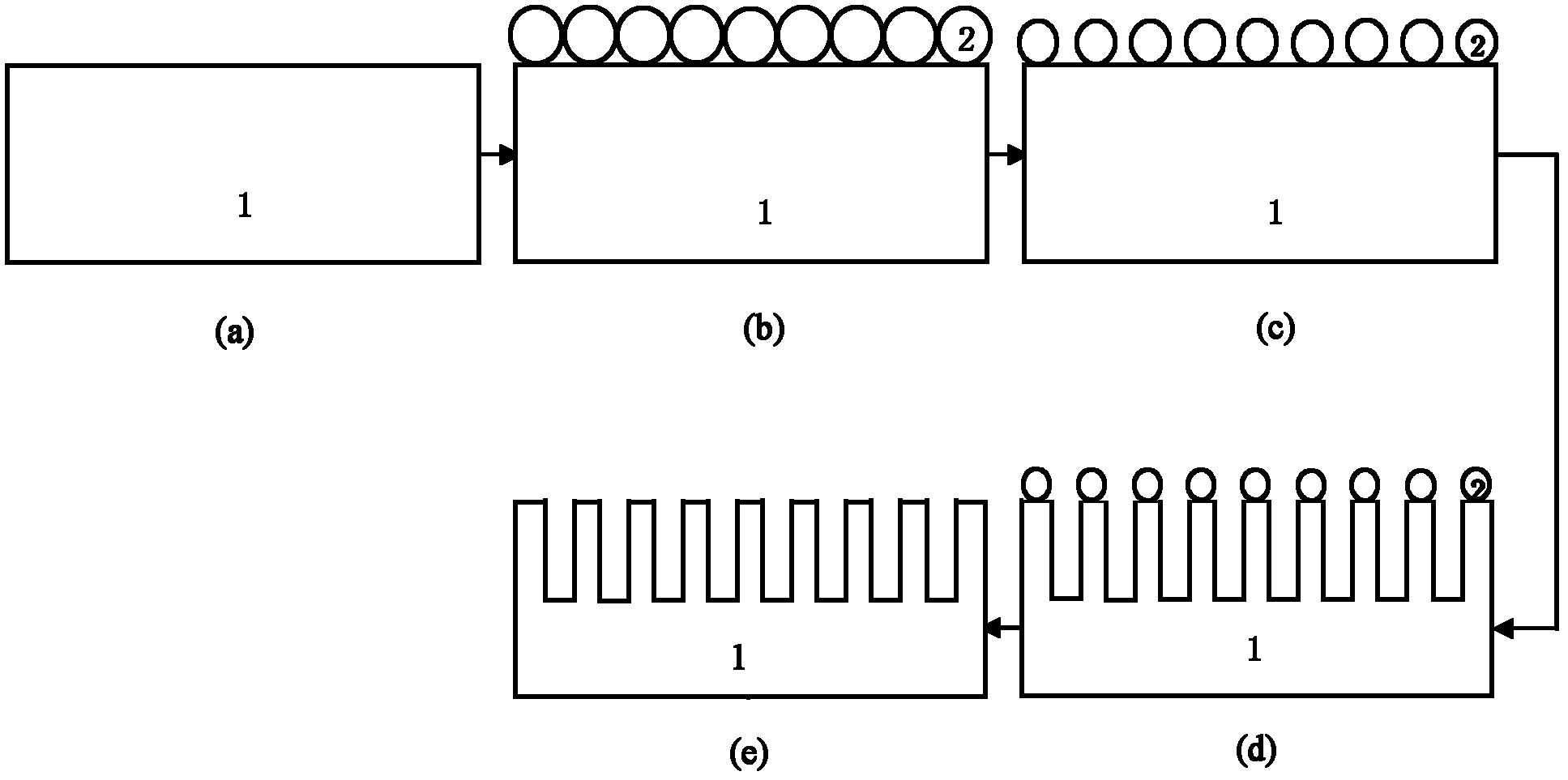

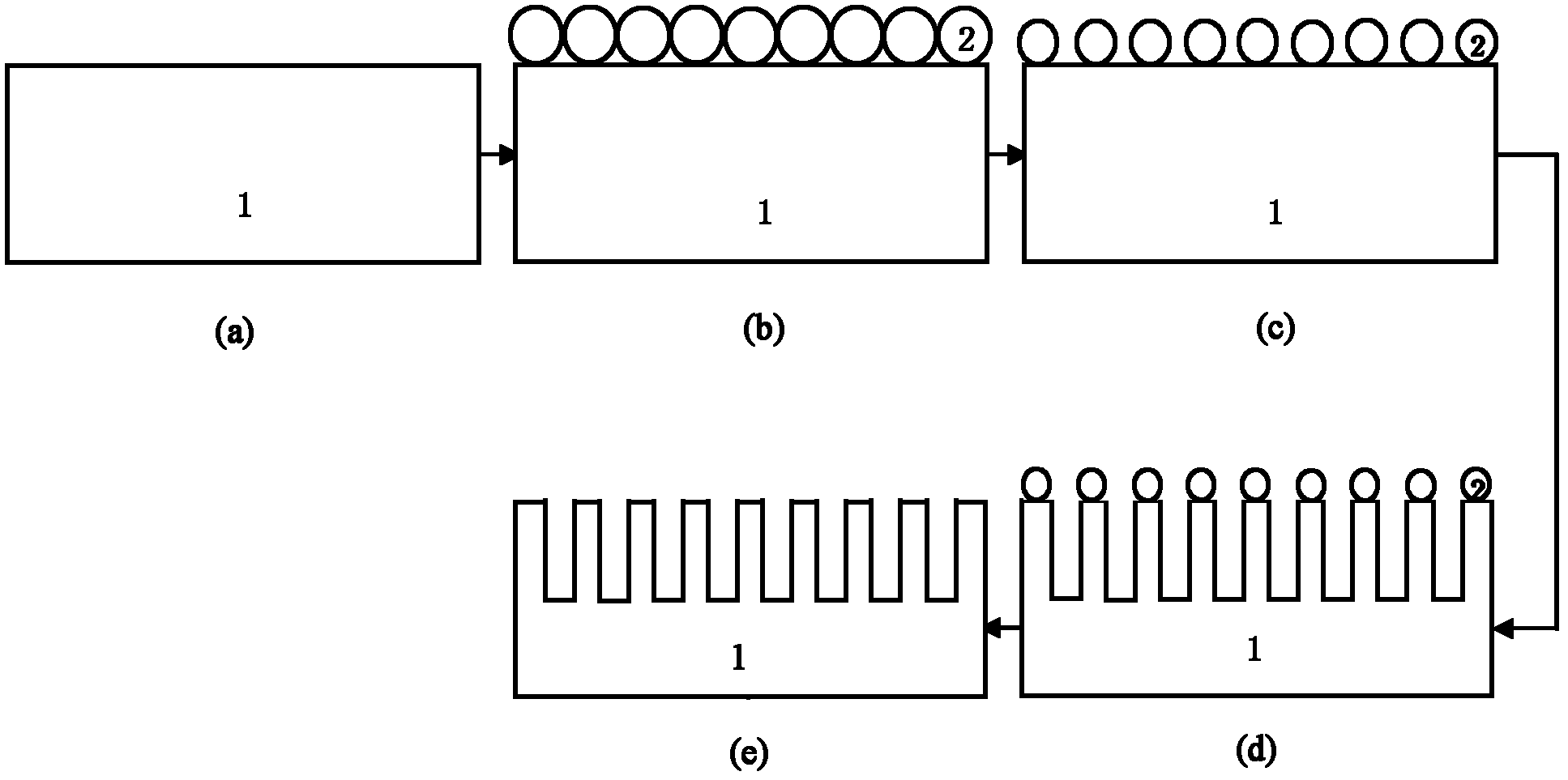

[0025] 1) First use standard cleaning on the silicon substrate, and then use the RIE system to activate the silicon wafer at a power of 60-80W for 3-10 minutes, which increases the hydrophilicity of the silicon wafer surface and is beneficial to obtain a large-area single-layer PS Nanospheres (Figure-1a).

[0026] In step 1), the size of the silicon wafer may be less than or equal to 100 mm, and the thickness may be 300-500 μm; the cleaning process may be:

[0027] (1) Sonicate the acetone solution for 3 to 5 minutes, and the absolute ethanol for 3 to 5 minutes, repeat twice before and after, then rinse with hot and cold deionized water;

[0028] (2) Use HF solution (HF:H 2 O) Soak for 30s and rinse with deionized water for 15 minutes;

[0029] (3) Use lotion I (NH 4 OH: H 2 O 2 : H 2 O), first heat the deionized water to 85℃ and pour NH 4 OH and H 2 O 2 , Put the chip into the beaker, cook for 15 minutes, and rinse with deionized water 6 to 7 times;

[0030] (4) Use diluted HF solutio...

Embodiment 2

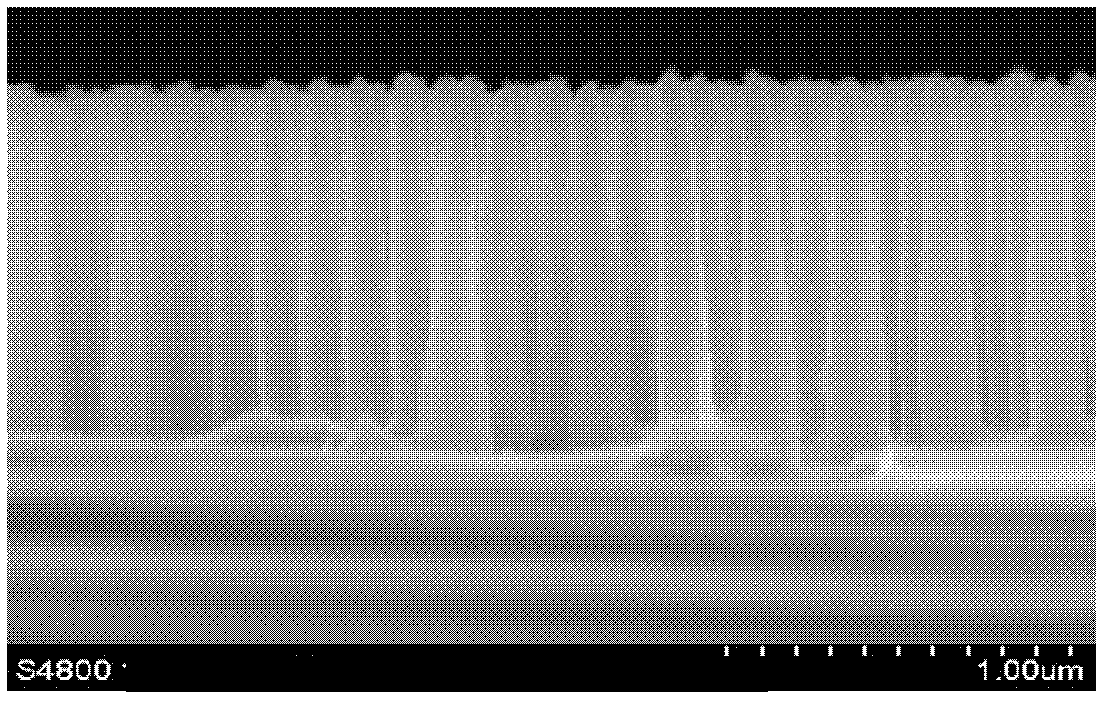

[0044] Firstly, the standard cleaned silicon wafer (size: 50mm) is activated for 5 minutes in an RIE system with a power of 80W, and then a single-layer PS nanosphere (diameter 330nm) is self-assembled. The rotation speed is controlled at 500rpm and the spin coating time is 30s. High speed 2500rpm, spin coating time 40s. Subsequently, the above-mentioned Si wafer with a single-layer PS nanosphere as a mask was placed in an RIE system with a power of 80W for etching for 30s. The next step is to put the above-mentioned processed sample into the ICP system for etching treatment, and the etching gas SF 6 Flow rate 50sccm / min, time 7s, sidewall shielding gas C 4 F 8 Flow rate is 100sccm / min, time is 5s. Cycle 40. The ion source power is 1000W, the substrate bias power is 20W, the reaction chamber pressure is 6mT, and the reaction chamber temperature is 20°C. Finally, the etched sample was soaked in tetrahydrofuran for 10 hours, and then ultrasonically cleaned with acetone and alco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com