Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5326 results about "Spin coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

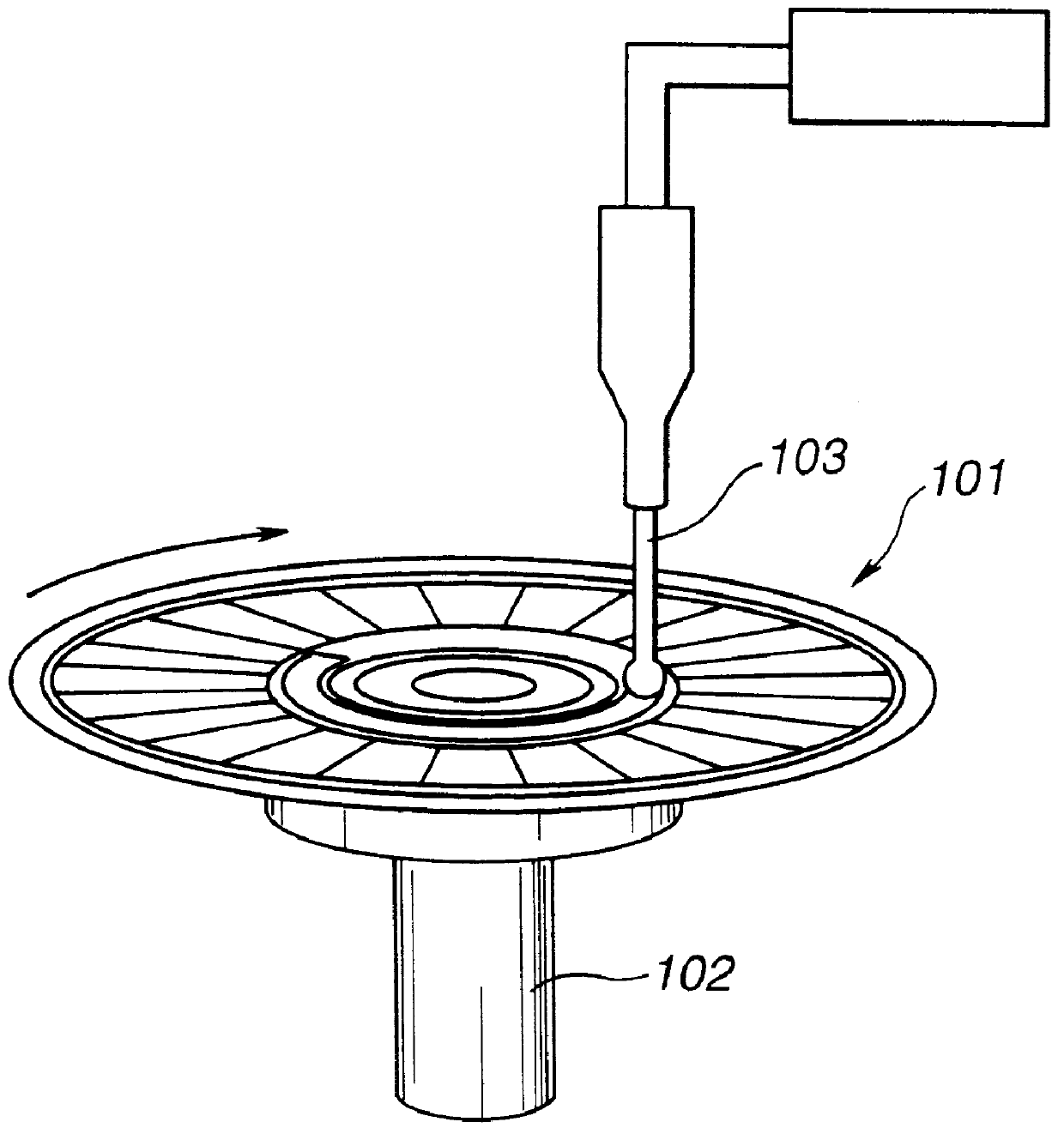

Spin coating is a procedure used to deposit uniform thin films onto flat substrates. Usually a small amount of coating material is applied on the center of the substrate, which is either spinning at low speed or not spinning at all. The substrate is then rotated at high speed in order to spread the coating material by centrifugal force. A machine used for spin coating is called a spin coater, or simply spinner.

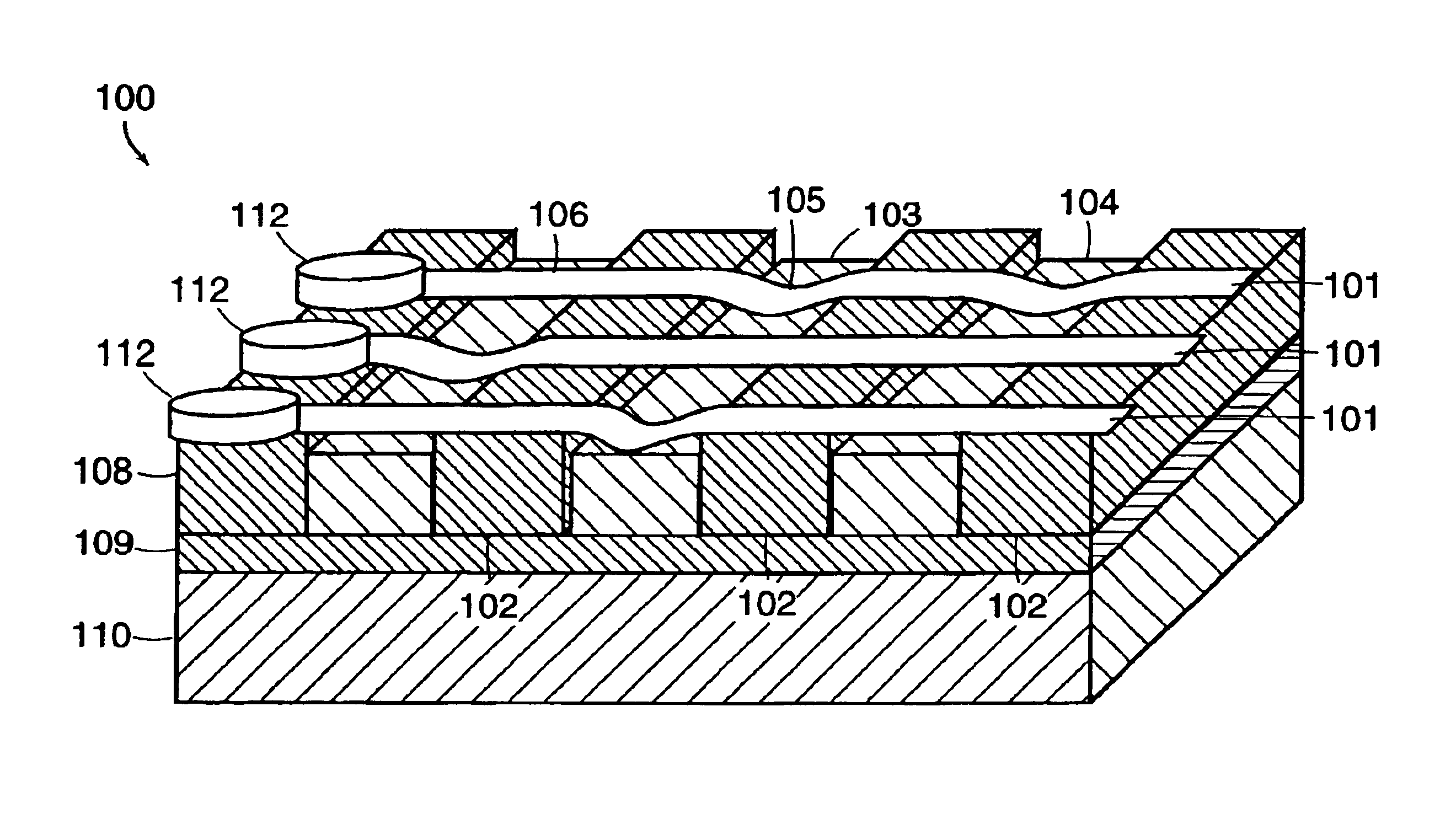

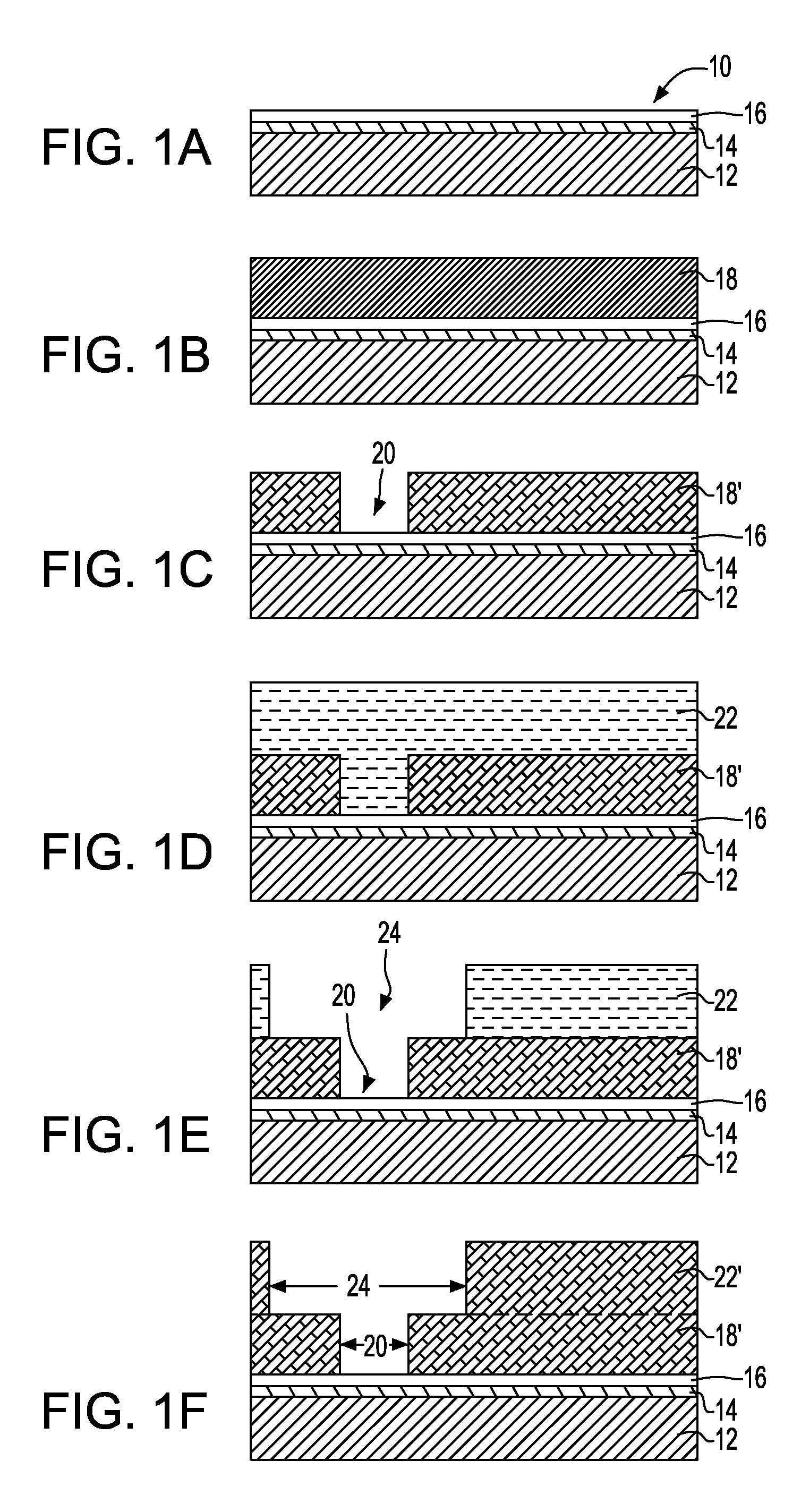

Methods of nanotubes films and articles

InactiveUS20050101112A1Discharge tube luminescnet screensNanoelectromechanical switchesGas phaseNanotube

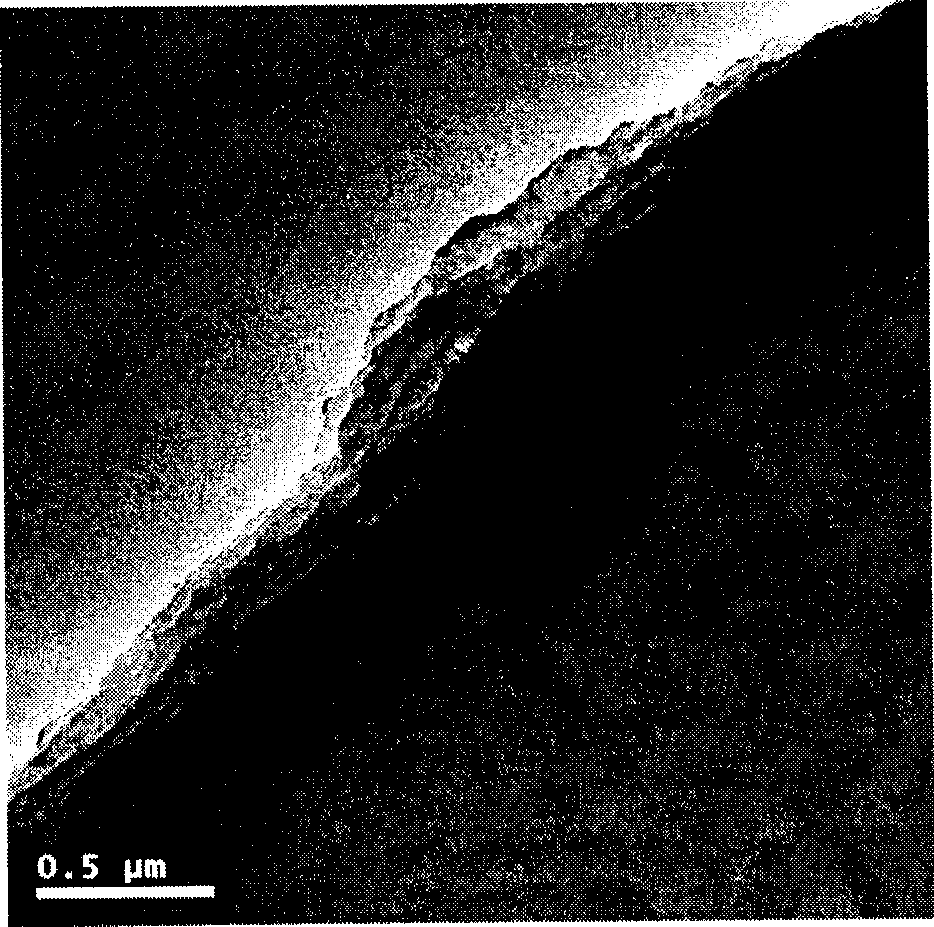

Nanotube films and articles and methods of making the same are disclosed. A conductive article includes an aggregate of nanotube segments in which the nanotube segments contact other nanotube segments to define a plurality of conductive pathways along the article. The nanotube segments may be single walled carbon nanotubes, or multi-walled carbon nanotubes. The various segments may have different lengths and may include segments having a length shorter than the length of the article. The articles so formed may be disposed on substrates, and may form an electrical network of nanotubes within the article itself. Conductive articles may be made on a substrate by forming a nanotube fabric on the substrate, and defining a pattern within the fabric in which the pattern corresponds to the conductive article. The nanotube fabric may be formed by growing the nanotube fabric on the substrate using a catalyst, for example, in which the catalyst is a gas phase catalyst, or in which the catalyst is a metallic gas phase catalyst. The nanotube fabric may be formed by depositing a solution of suspended nanotubes on the substrate. The deposited solution may be spun to create a spin-coating of the solution. The solution may be deposited by dipping the substrate into the solution. The nanotube fabric is formed by spraying an aerosol having nanotubes onto a surface of the substrate.

Owner:ZEON CORP

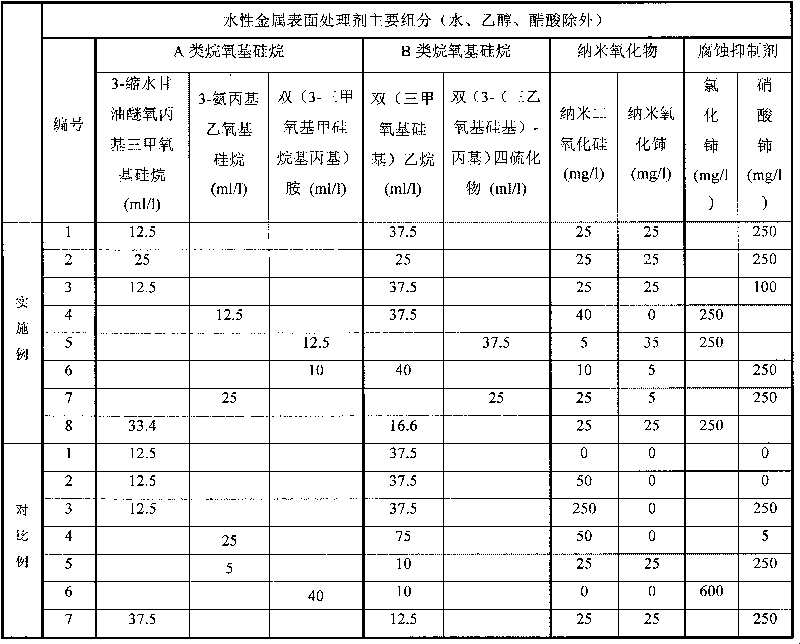

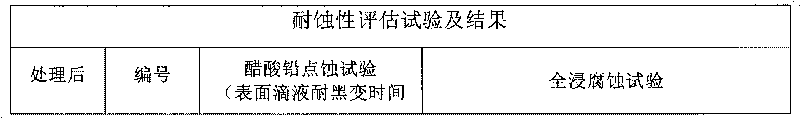

Environment-friendly nano water-based silane treatment agent capable of improving anti-corrosion performance of metal surface

ActiveCN101717930ASimple processApplicable industrial scaleMetallic material coating processesWater basedEpoxy

The invention discloses an environment-friendly nano water-based silane treatment agent capable of improving anti-corrosion performance of metal surface. The treatment agent is water-based silane solution which consists of at least one alkoxy silane containing epoxy or at least one alkoxy silane containing amino, at least one disilyl silane, nano-silicon dioxide, rare earth salt type corrosion inhibitor or rare earth salt type and rare earth nano oxide, water, or acetic acid and a small amount of ethanol. The metal material is coated by using the silane solution for impregnation, brushing, spraying or spin-coating, a siloxane layer is formed on the metal surface, then the long-acting corrosion resistance is formed by curing for 3 hours at the temperature of 100 DEG C, and a nano organic silane film which has close bonding force with a coating is formed. Nanoparticles can not only improve the corrosion resistance and enhance the mechanical strength of the silane film in a coating layer, but also realize the synergistic corrosion resistance with the corrosion inhibitor. The technology has the advantages of simple process, greenness, environmental protection and strong practicality.

Owner:HAISO TECH

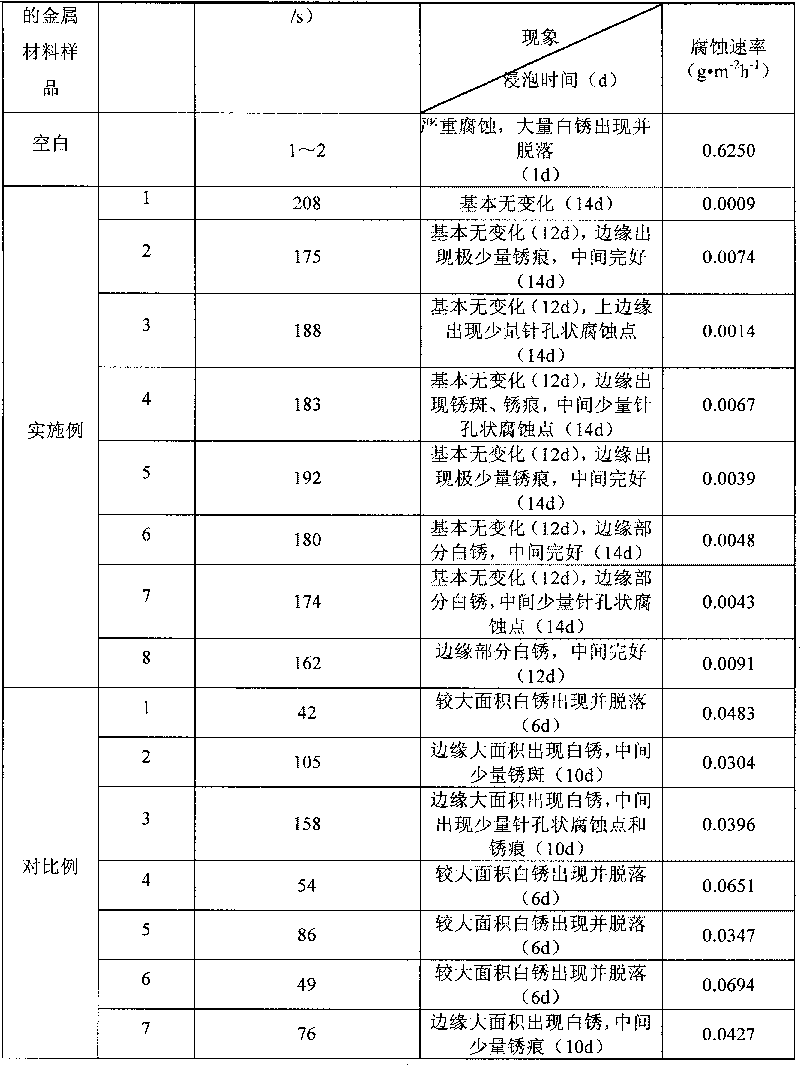

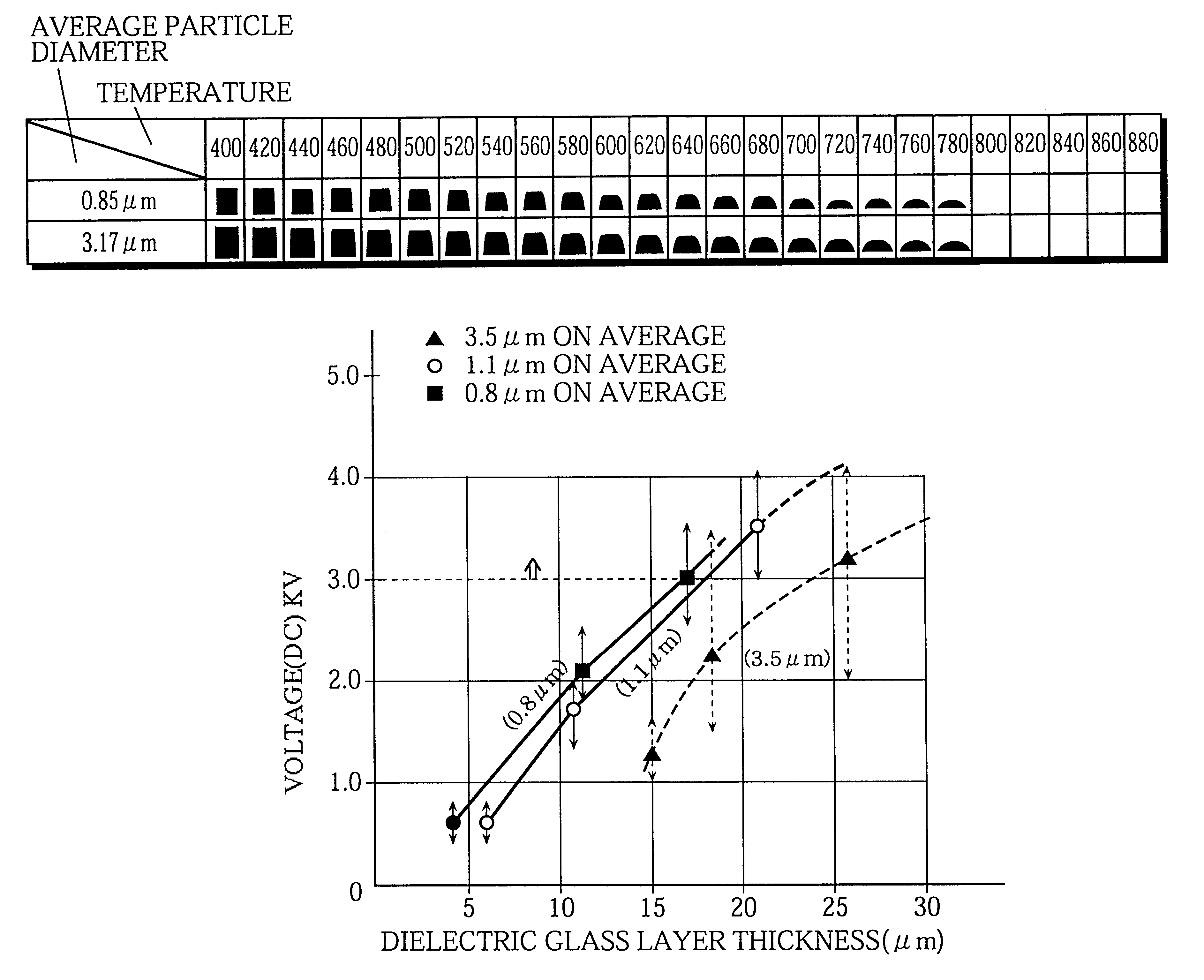

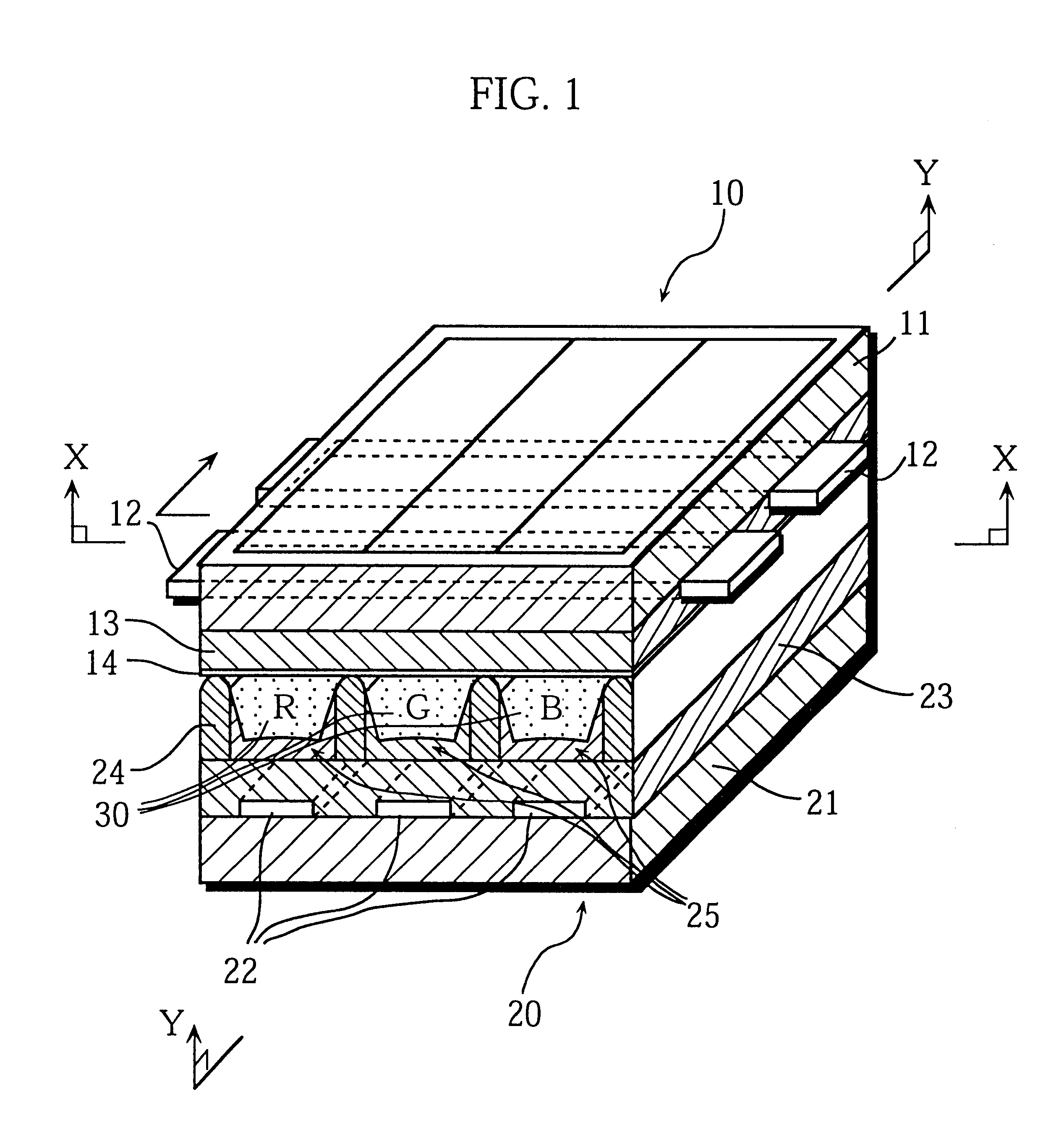

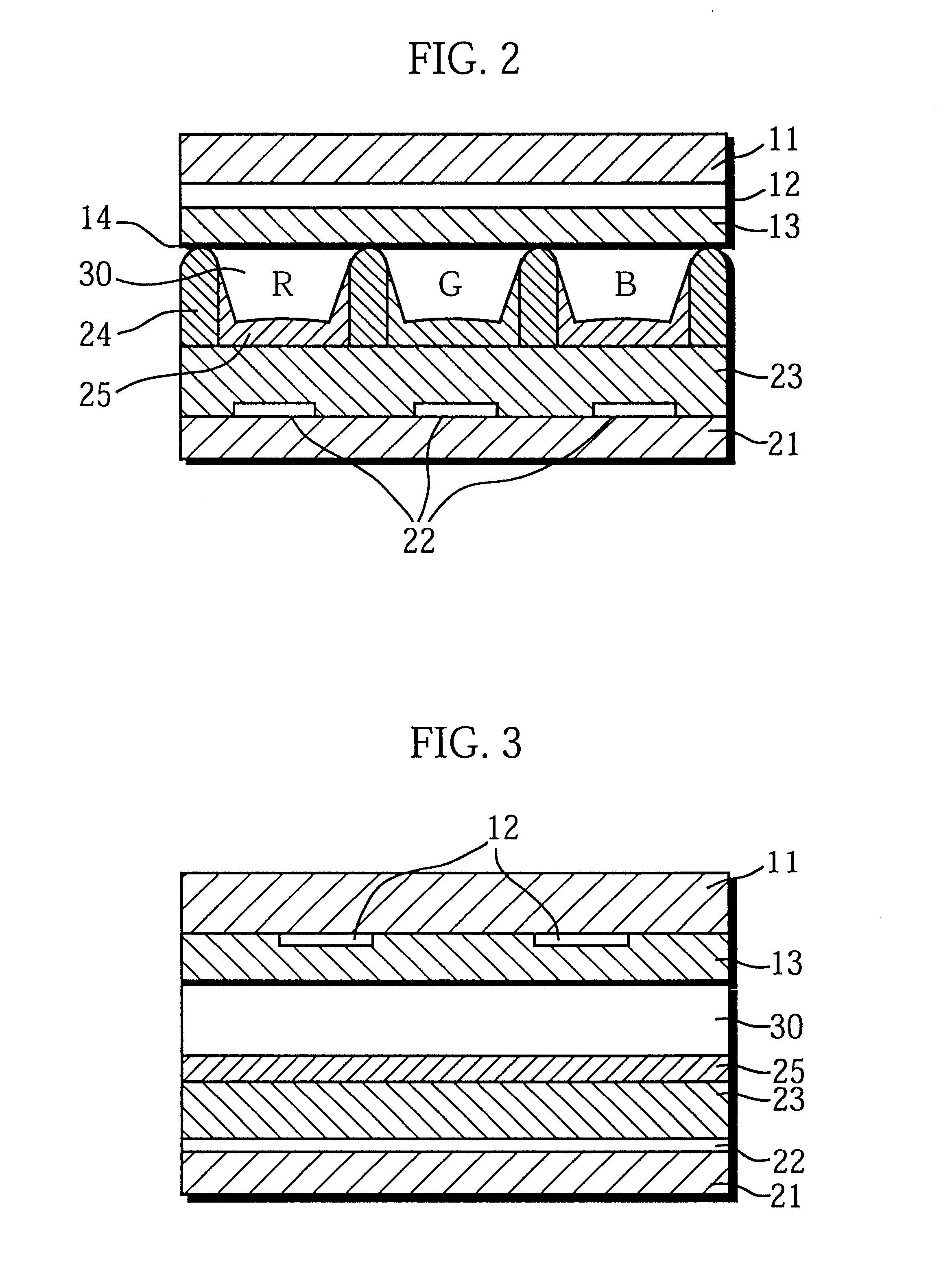

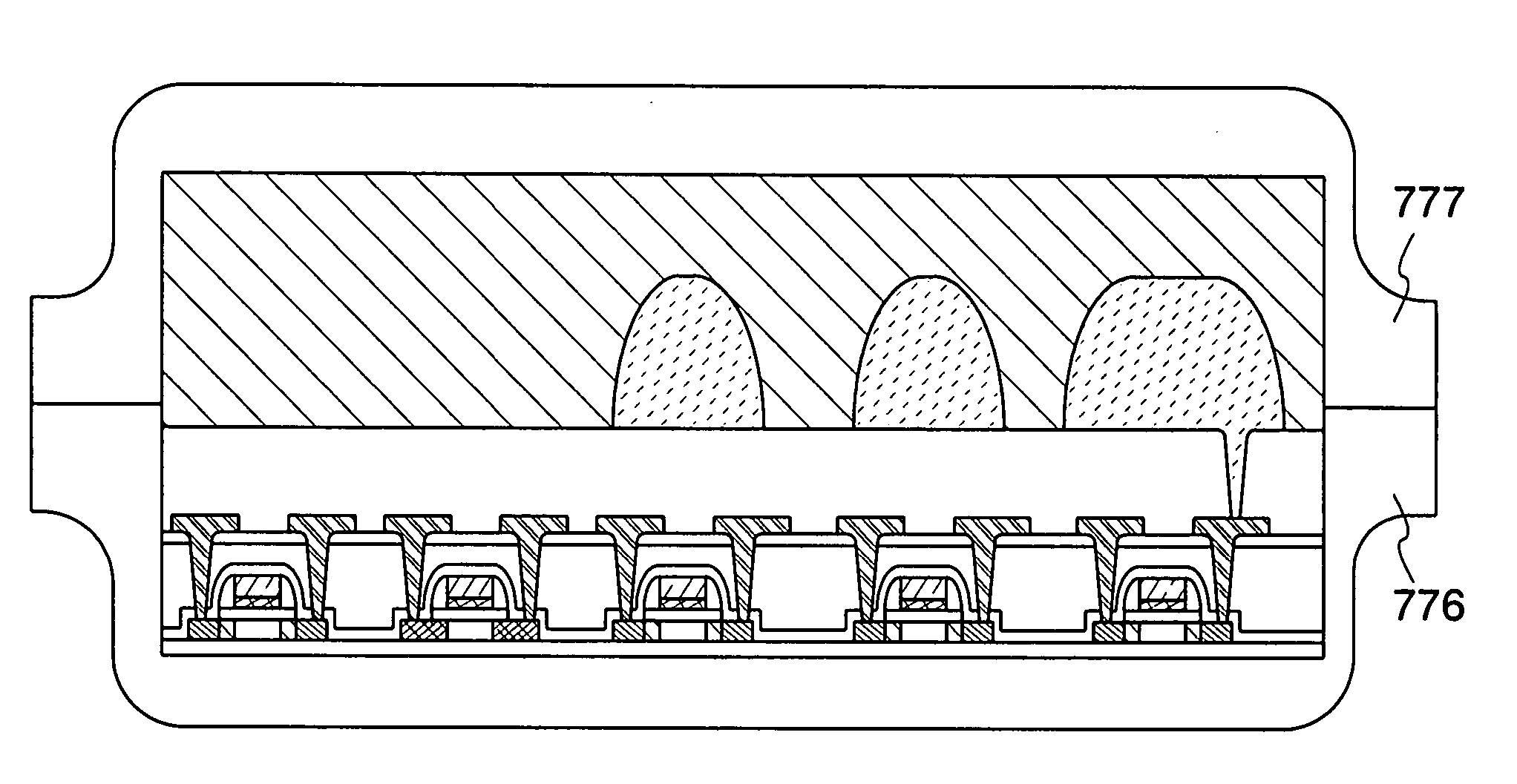

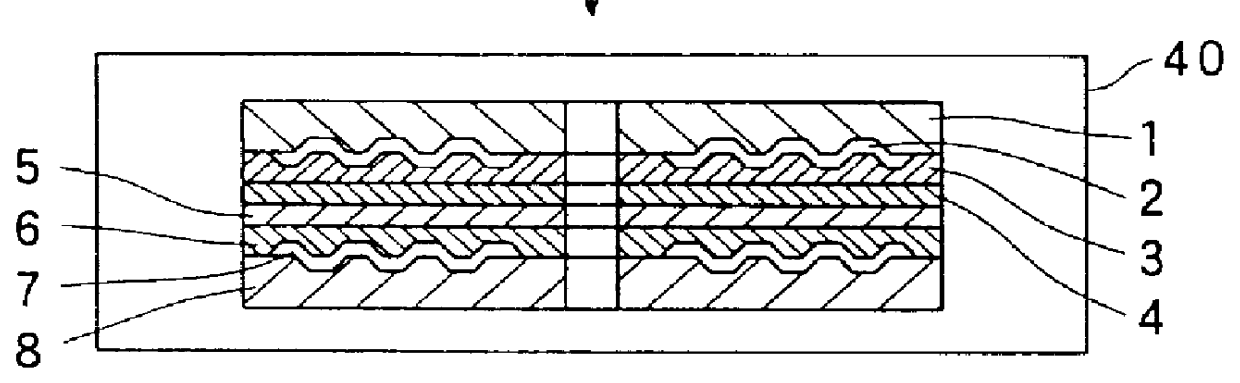

Manufacturing method of plasma display panel that includes adielectric glass layer having small particle sizes

InactiveUS6439943B1Alternating current plasma display panelsVessels or leading-in conductors manufactureScreen printingMetallurgy

The object of the present invention is to provide a high-intensity, reliable plasma display panel even when the cell structure is fine by resolving the problems such as a low visible light transmittance and low voltage endurance of a dielectric glass layer. The object is realized by forming the dielectric glass layer in the manner given below. A glass paste including a glass powder is applied on the front glass substrate or the back glass substrate, according to a screen printing method, a die coating method, a spray coating method, a spin coating method, or a blade coating method, on each of which electrodes have been formed, and the glass powder in the applied glass paste is fired. The average particle diameter of the glass powder is 0.1 to 1.5 mum and the maximum particle diameter is equal to or smaller than three times the average particle diameter.

Owner:PANASONIC CORP

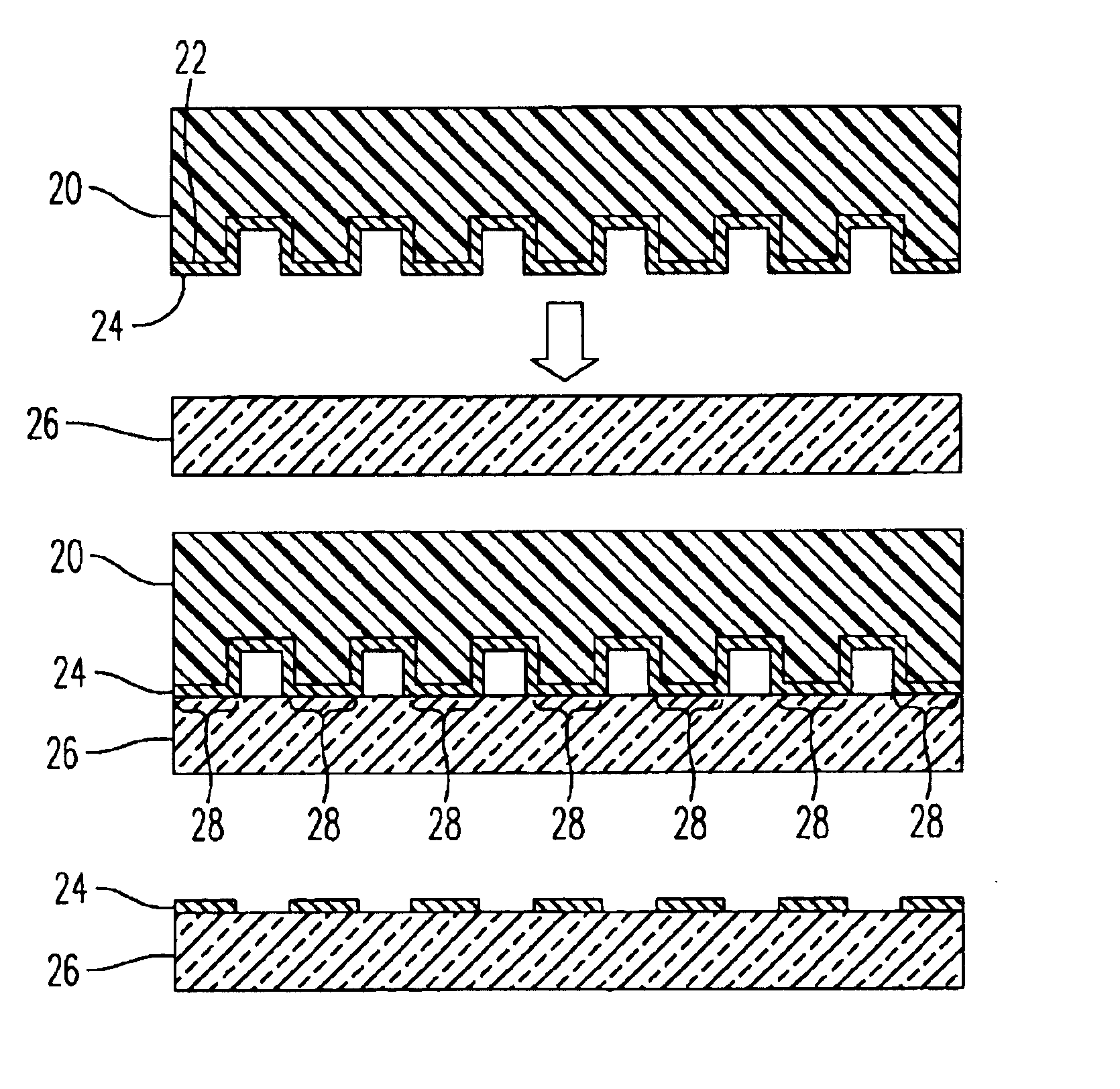

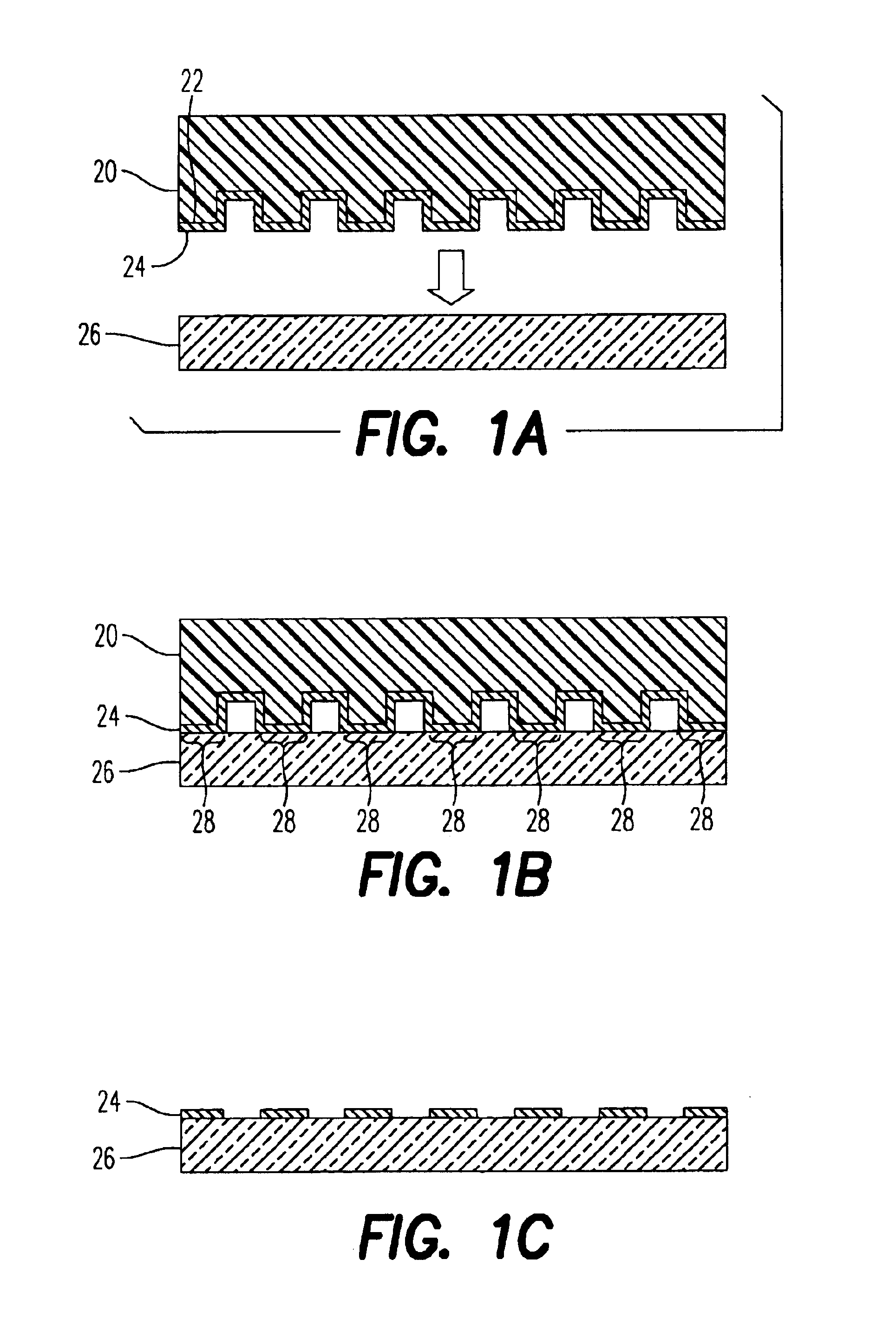

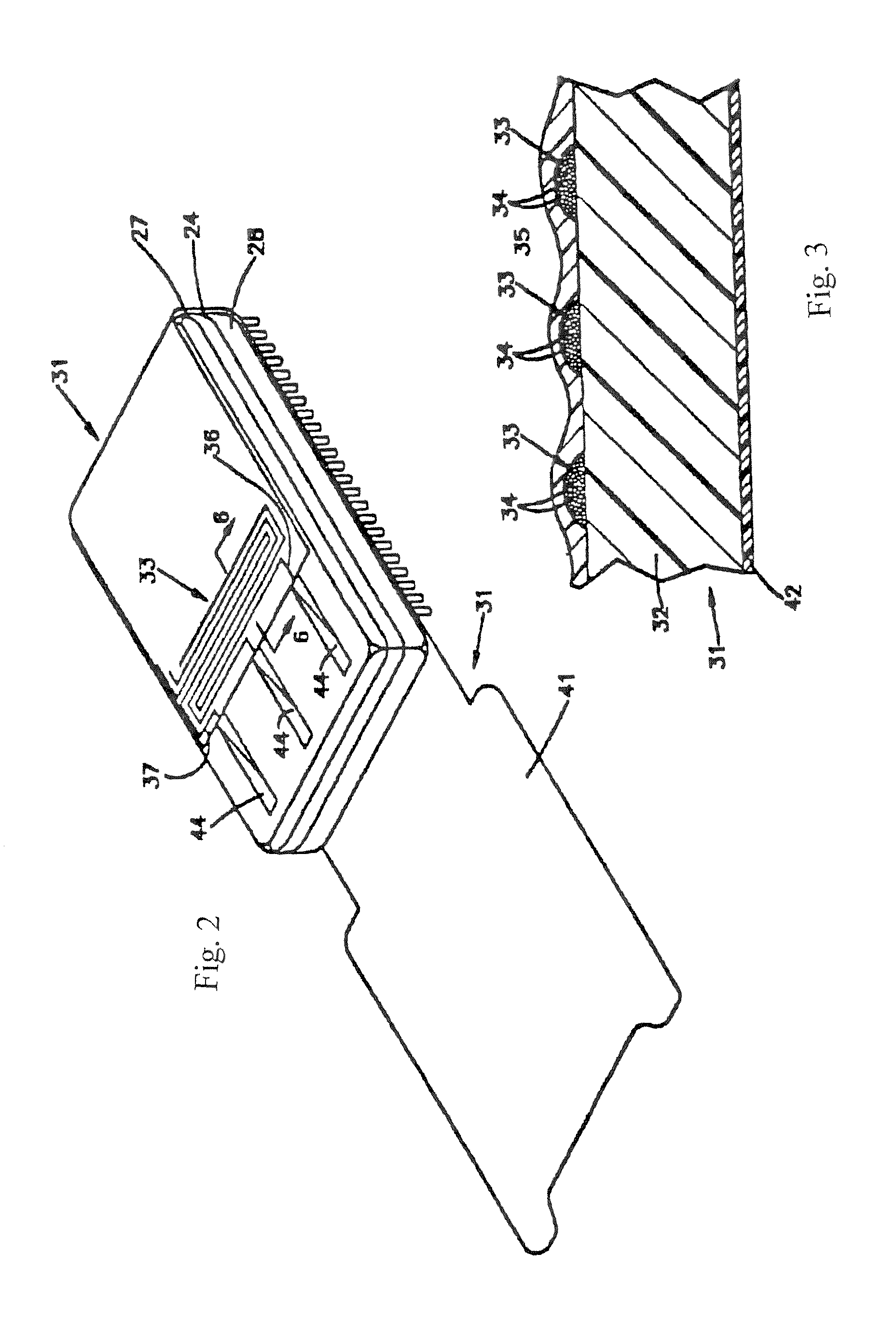

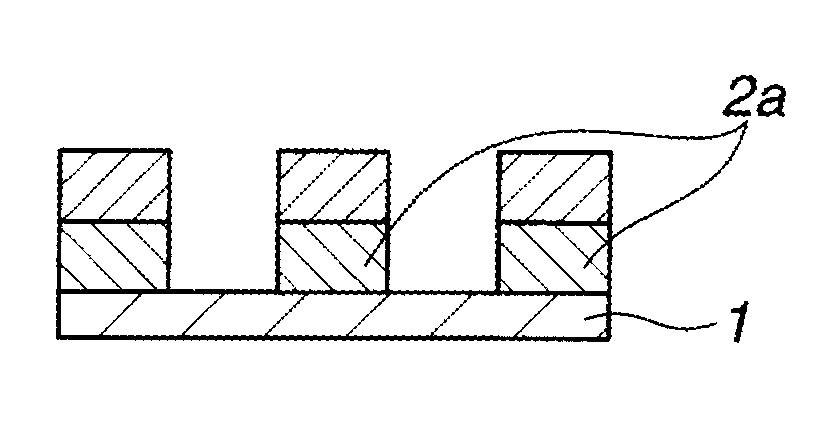

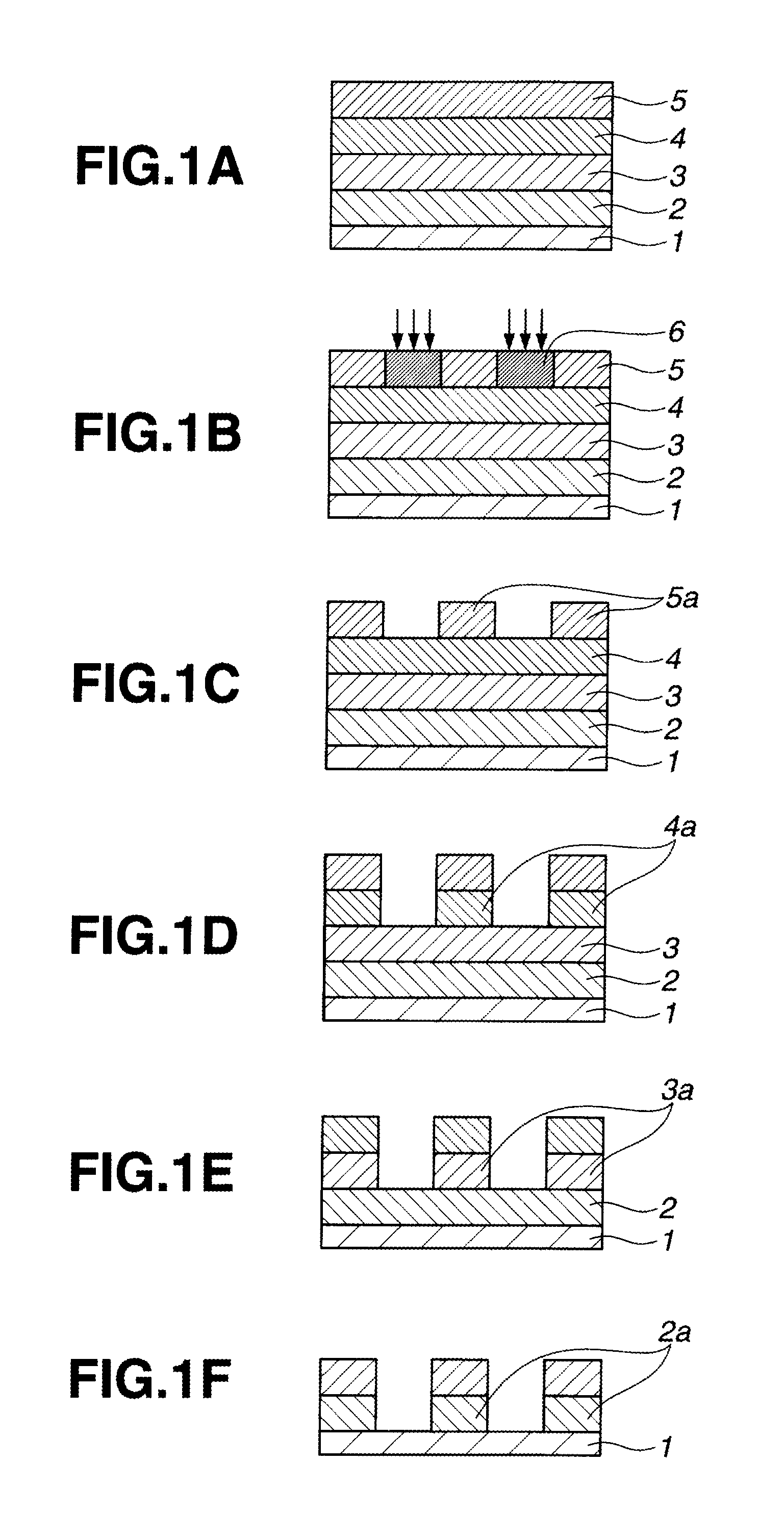

Patterning solution deposited thin films with self-assembled monolayers

InactiveUS6887332B1Low costMaterial nanotechnologyNanoinformaticsSelf-assembled monolayerDeposition process

The present invention provides a method of forming a patterned thin film on a surface of a substrate having thereon a patterned underlayer of a self-assembled monolayer. The method comprises depositing a thin film material on the self-assembled monolayer to produce a patterned thin film on the surface of the substrate. The present invention further provides processes for preparing the self-assembled monolayer. The present invention still further provides solution-based deposition processes, such as spin-coating and immersion-coating, to deposit a thin film material on the self-assembled monolayer to produce a patterned thin film on the surface of the substrate.

Owner:IBM CORP

Grapheme-organic material layered assembling film and preparation method thereof

InactiveCN101474897ALow priceLight in massLayered productsPretreated surfacesChemical industryElectromagnetic shielding

The invention relates to a graphene-organic material layered assembly film and a preparation method thereof. The preparation method comprises: using a graphene material and an organic material as raw materials, utilizing interaction of static electricity, hydrogen bonds, coordinate bonds or charge transfer and the like between the graphene and the organic material, and superposing films layer by layer through the film preparation methods such as spin coating, spraying, dipping, lifting and pulling and the like to prepare the film, wherein the thickness of each layer of the film can be controlled between 10 nanometers and 2 millimeters according to requirement. The layered assembly film and the preparation method have the characteristics that multilayer film materials with different functions are prepared by utilizing unique electric, magnetic, mechanical and chemical properties of the grapheme, and can be used as biomaterials, conductive materials, electromagnetic shielding and wave absorbing materials, photovoltaic materials, electrode materials, film filtering and separating materials, and the like to be applied to chemistry and chemical industry, biology and precision instruments, and manufacture of micro electrons, machinery and aviation and aerospace devices according to the selected different organic materials.

Owner:NANKAI UNIV

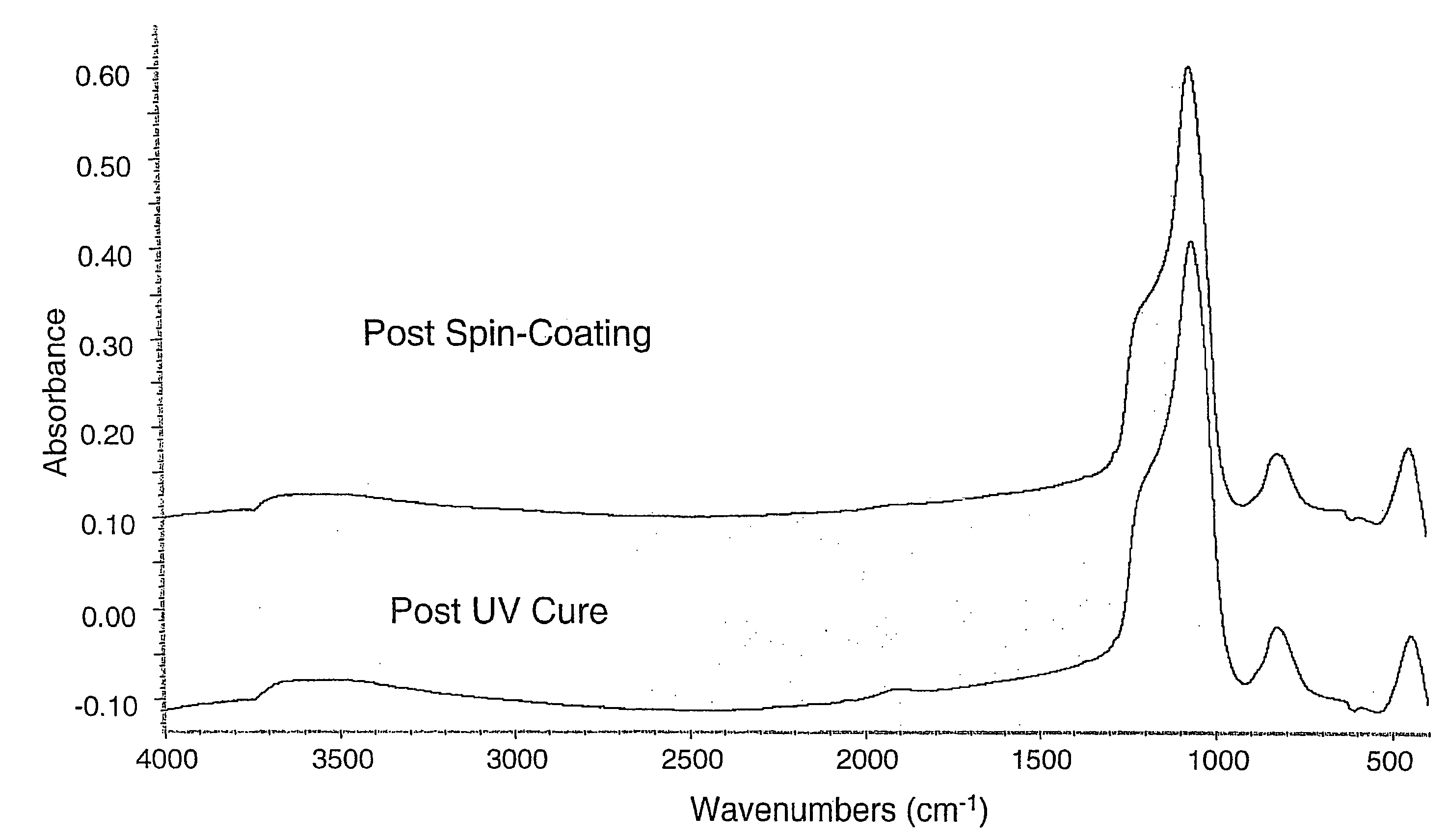

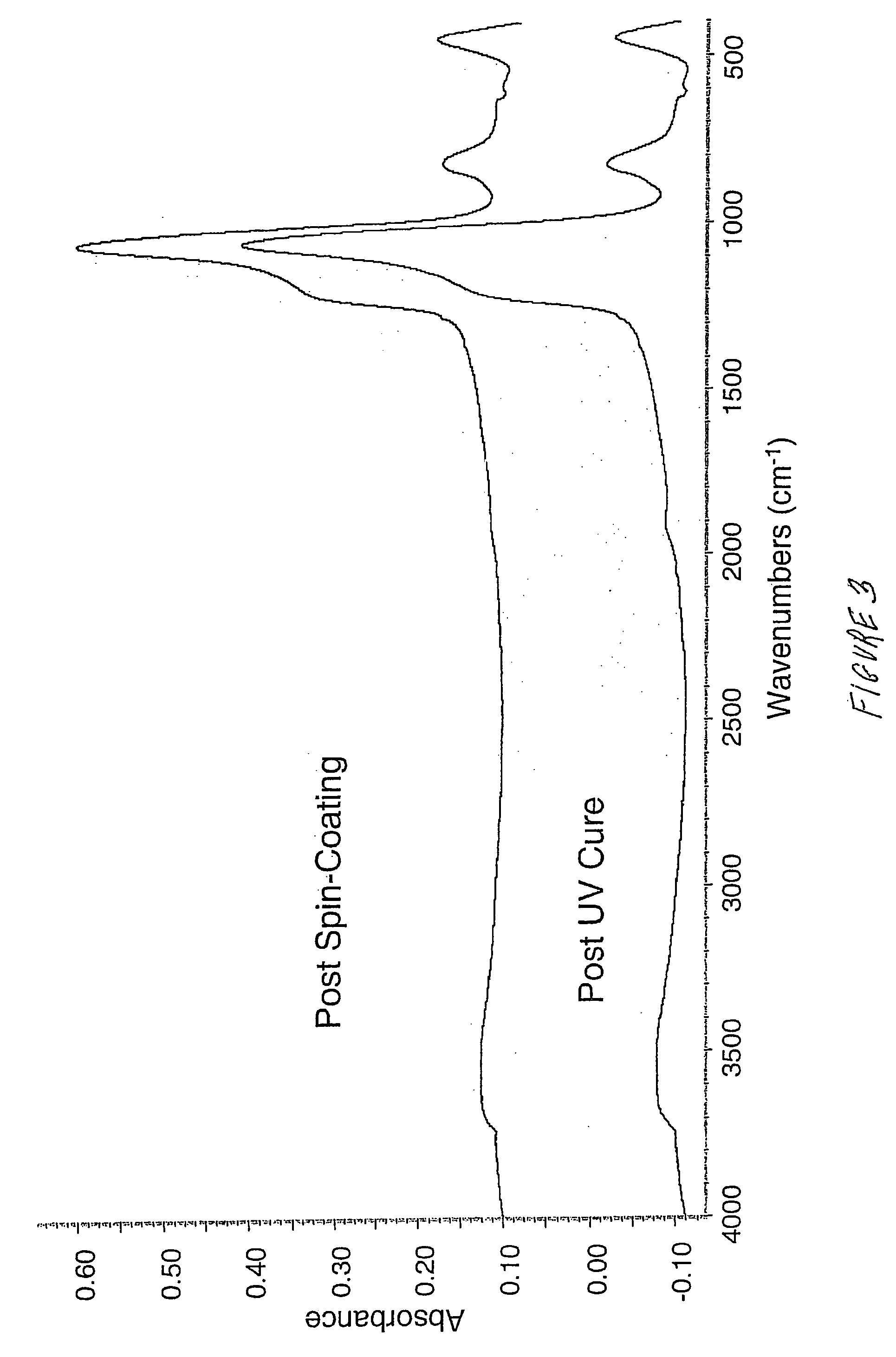

Ultraviolet curing process for spin-on dielectric materials used in pre-metal and/or shallow trench isolation applications

InactiveUS20050272220A1Reduce organic contentSemiconductor/solid-state device manufacturingUV curingUltraviolet radiation

A UV curing process for a dielectric material used in pre-metal and shallow trench isolation applications comprises coating a suitable dielectric material onto a substrate; and exposing the dielectric material to ultraviolet radiation in an amount effective to reduce an organic content and / or increase a density and. / or increase a wet etch resistance of the dielectric material. Optionally, the UV cured dielectric material may be exposed to multiple ultraviolet radiation patterns.

Owner:AXCELIS TECHNOLOGIES

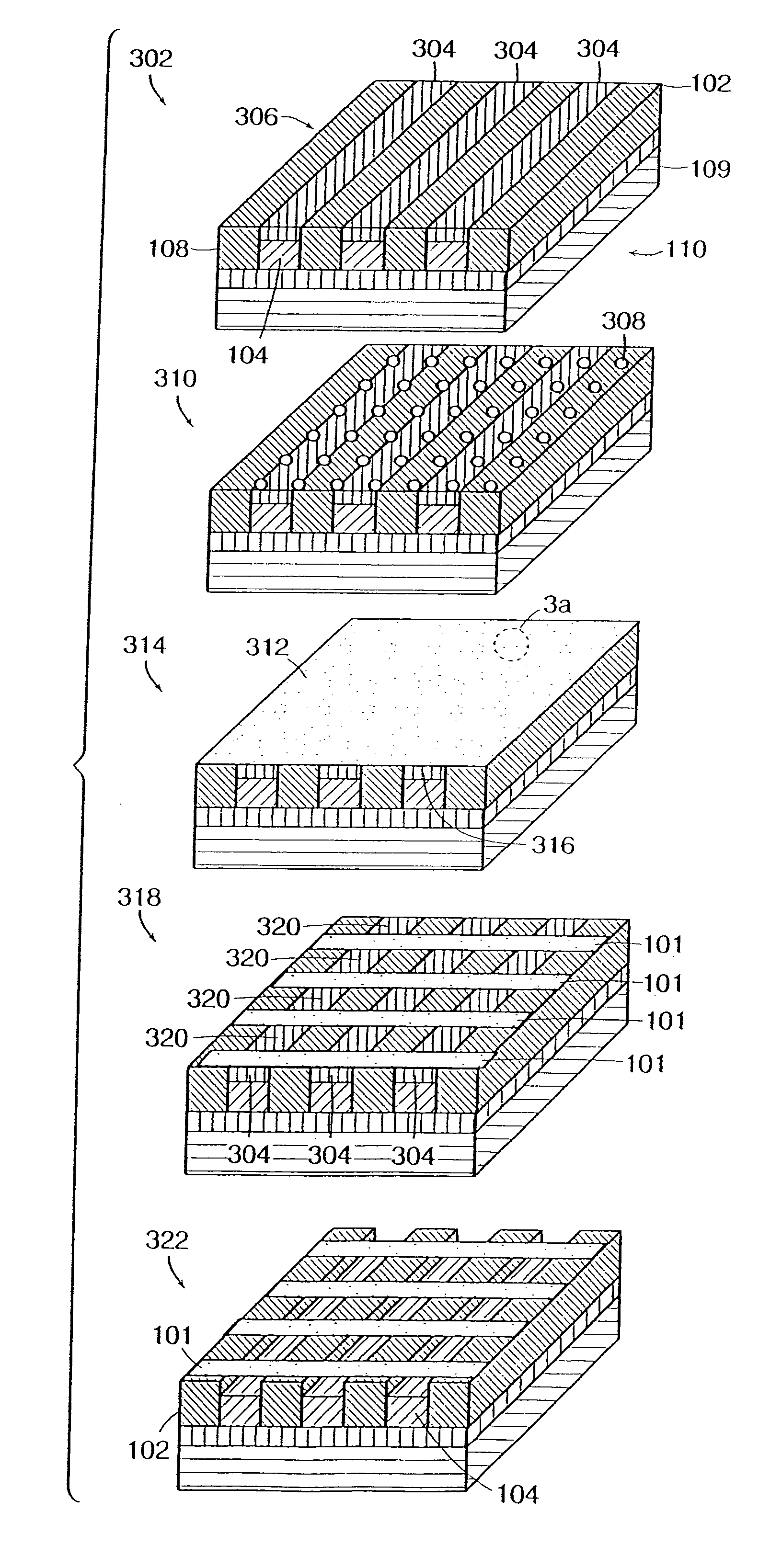

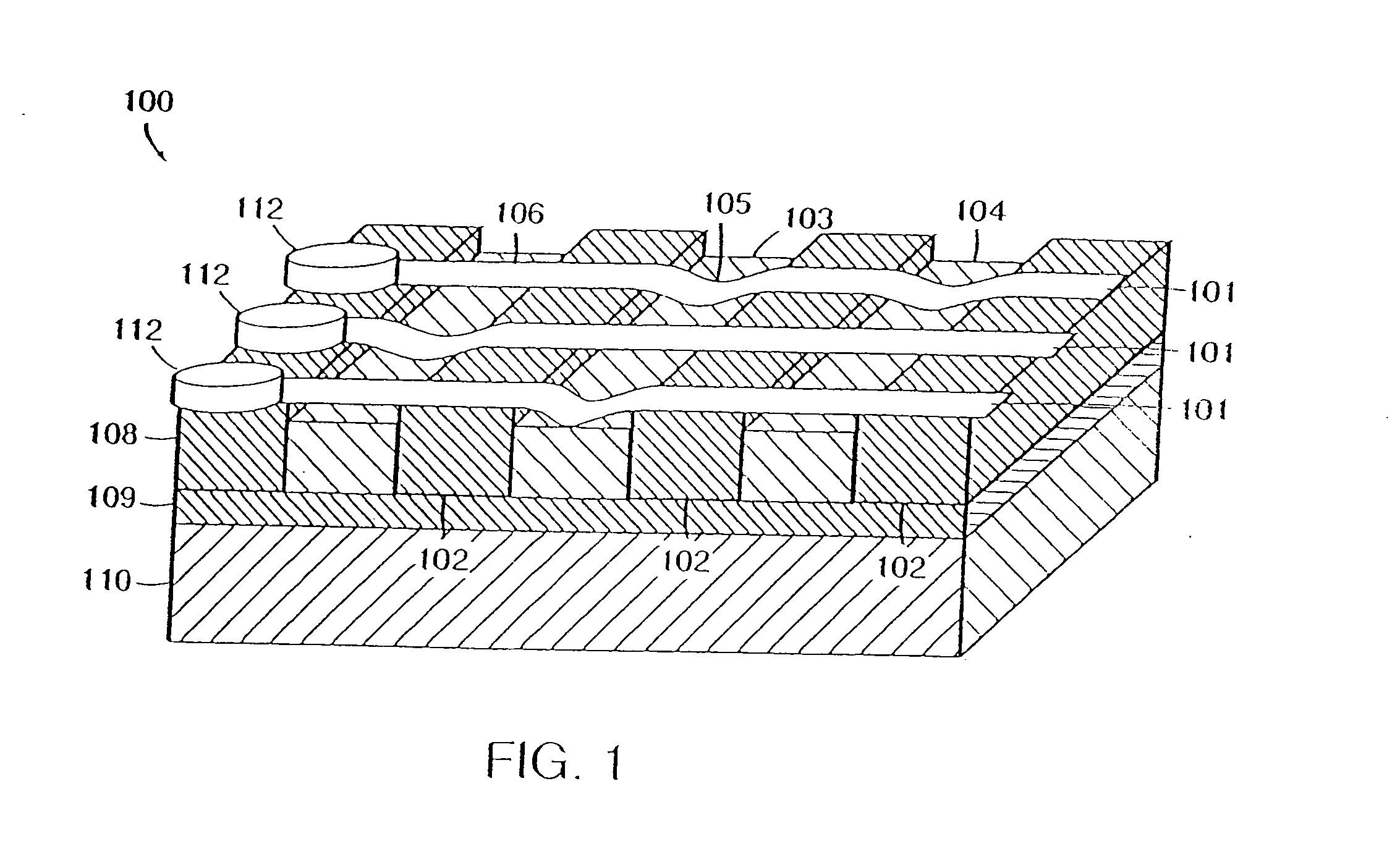

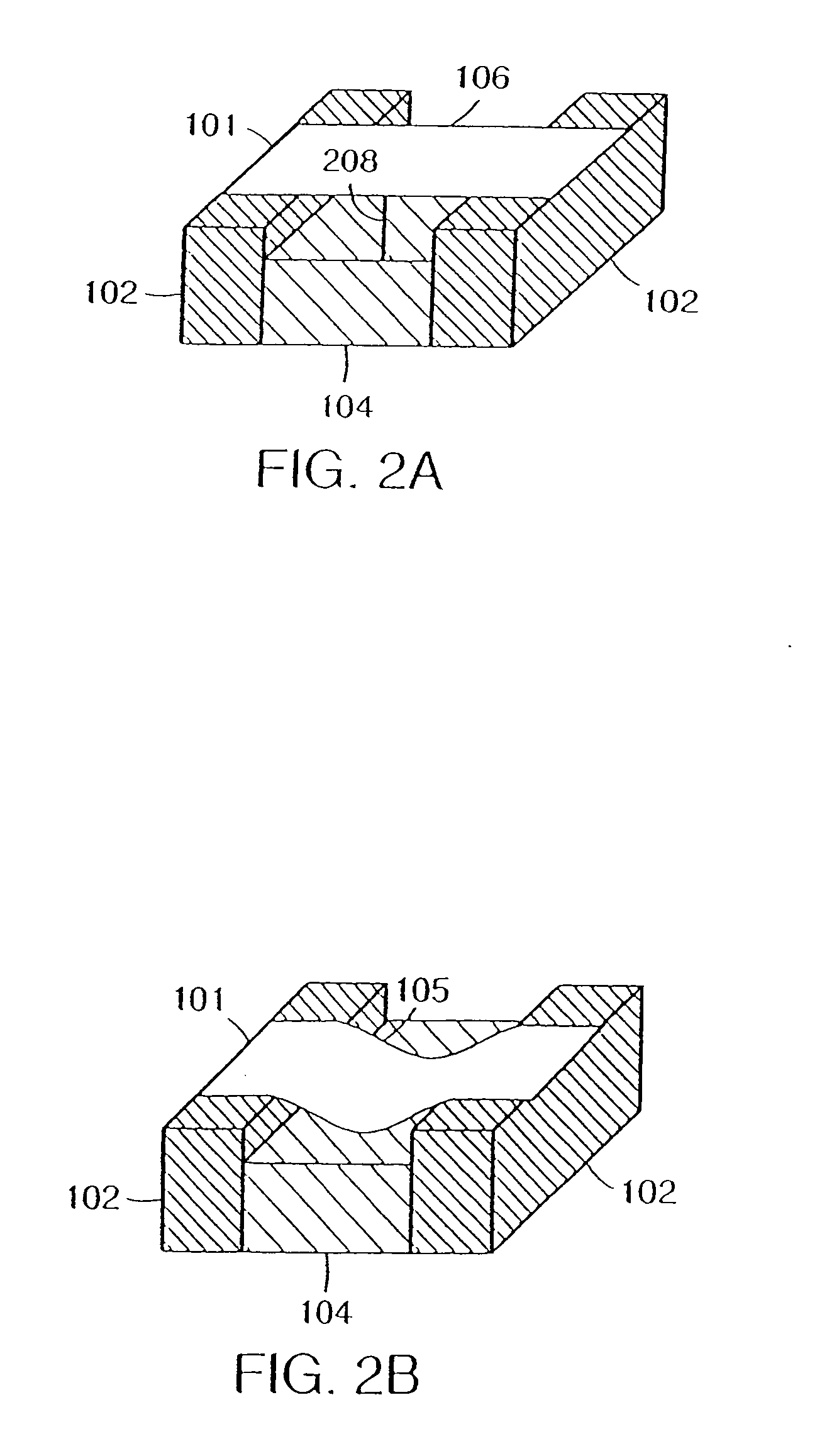

Nanotube films and articles

Nanotube films and articles and methods of making the same are disclosed. A conductive article includes an aggregate of nanotube segments in which the nanotube segments contact other nanotube segments to define a plurality of conductive pathways along the article. The nanotube segments may be single walled carbon nanotubes, or multi-walled carbon nanotubes. The various segments may have different lengths and may include segments having a length shorter than the length of the article. The articles so formed may be disposed on substrates, and may form an electrical network of nanotubes within the article itself. Conductive articles may be made on a substrate by forming a nanotube fabric on the substrate, and defining a pattern within the fabric in which the pattern corresponds to the conductive article. The nanotube fabric may be formed by growing the nanotube fabric on the substrate using a catalyst, for example, in which the catalyst is a gas phase catalyst, or in which the catalyst is a metallic gas phase catalyst. The nanotube fabric may be formed by depositing a solution of suspended nanotubes on the substrate. The deposited solution may be spun to create a spin-coating of the solution. The solution may be deposited by dipping the substrate into the solution. The nanotube fabric is formed by spraying an aerosol having nanotubes onto a surface of the substrate.

Owner:NANTERO

Manufacturing method for wiring

InactiveUS20050011752A1Improve throughputEfficient use ofElectric discharge tubesVacuum evaporation coatingResistEvaporation

In the case in which a film for a resist is formed by spin coating, there is a resist material to be wasted, and the process of edge cleaning is added as required. Further, when a thin film is formed on a substrate using a vacuum apparatus, a special apparatus or equipment to evacuate the inside of a chamber vacuum is necessary, which increases manufacturing cost. The invention is characterized by including: a step of forming conductive layers on a substrate having a dielectric surface in a selective manner with a CVD method, an evaporation method, or a sputtering method; a step of discharging a compound to form resist masks so as to come into contact with the conductive layer; a step of etching the conductive layers with plasma generating means using the resist masks under the atmospheric pressure or a pressure close to the atmospheric pressure; and a step of ashing the resist masks with the plasma generating means under the atmospheric pressure or a pressure close to the atmospheric pressure. With the above-mentioned characteristics, efficiency in use of a material is improved, and a reduction in manufacturing cost is realized.

Owner:SEMICON ENERGY LAB CO LTD

Conducting polymer composition, conductive film formed using the conducting polymer composition, and electronic device including the conductive film

InactiveUS20080020208A1Increase hole injectionEnhance transport capabilityNanostructure manufactureSynthetic resin layered productsOrganic solventAlcohol

Provided is a conducting polymer composition including a conducting polymer and an ionic conjugated polymer. The conducting polymer composition includes the ionic conjugated polymer having a conjugated structure, in addition to the conducting polymer, and thus, can enhance hole injection and transport capability. Furthermore, ionization potential and work function can be easily adjusted by chemically tuning the backbone of the ionic conjugated polymer. In addition, the conducting polymer composition can be dissolved in water, alcohol, or a polar organic solvent, thereby enabling a solution process and rendering spin-coating easier.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

Conductive carbon film based on graphene as well as preparation method and application

InactiveCN101474898AForm evenlySimple processMaterial nanotechnologyCarbon compoundsCarbon filmFilm base

The invention relates to a general conductive carbon film based on Graphene and a preparation method. The method for preparing the carbon film mainly comprises the following steps: (1) preparing water-soluble single-layer or multi-layer grapheme; (2) preparing organic soluble single-layer or multi-layer Graphene; (3) shaping the solution (or dispersion liquid) containing the Graphene in 1 or 2 by methods of spin coating, spraying, soaking or casting and the like to prepare a film based on the single-layer or multi-layer Graphene; and (4) chemically reducing or roasting the film obtained in 3 to prepare the carbon film based on the single-layer or multi-layer Graphene. The method can be used for preparing the carbon film on various matrixes such as steel, glass, ceramics, quartz, carbon materials, organic substances and the like.

Owner:NANKAI UNIV

Nanotube films and articles

InactiveUS20050058834A1Promote growthMaterial nanotechnologyNanostructure manufactureGas phaseNanometre

Nanotube films and articles and methods of making the same are disclosed. A conductive article includes an aggregate of nanotube segments in which the nanotube segments contact other nanotube segments to define a plurality of conductive pathways along the article. The nanotube segments may be single walled carbon nanotubes, or multi-walled carbon nanotubes. The various segments may have different lengths and may include segments having a length shorter than the length of the article. The articles so formed may be disposed on substrates, and may form an electrical network of nanotubes within the article itself. Conductive articles may be made on a substrate by forming a nanotube fabric on the substrate, and defining a pattern within the fabric in which the pattern corresponds to the conductive article. The nanotube fabric may be formed by growing the nanotube fabric on the substrate using a catalyst, for example, in which the catalyst is a gas phase catalyst, or in which the catalyst is a metallic gas phase catalyst. The nanotube fabric may be formed by depositing a solution of suspended nanotubes on the substrate. The deposited solution may be spun to create a spin-coating of the solution. The solution may be deposited by dipping the substrate into the solution. The nanotube fabric is formed by spraying an aerosol having nanotubes onto a surface of the substrate.

Owner:NANTERO

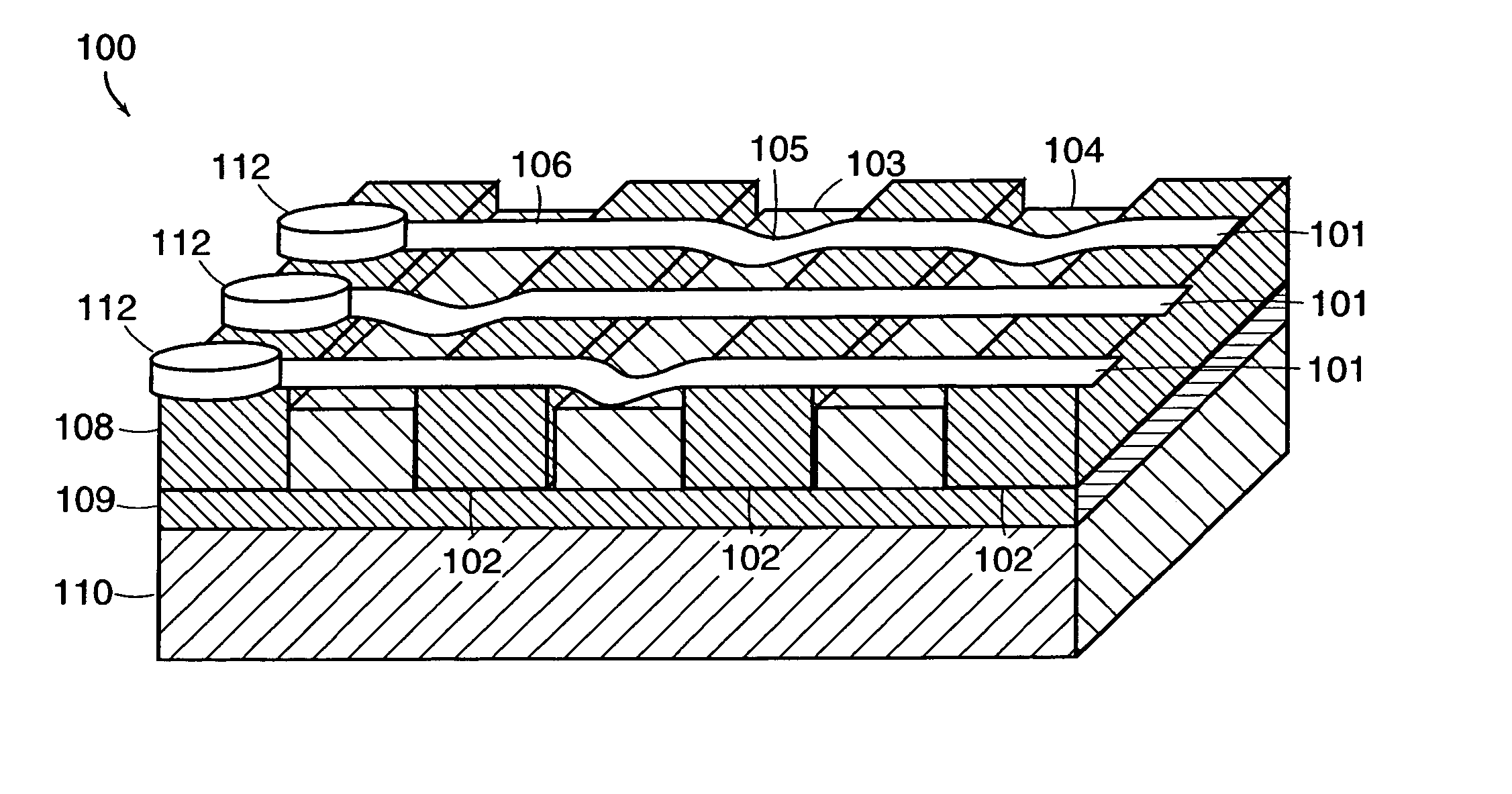

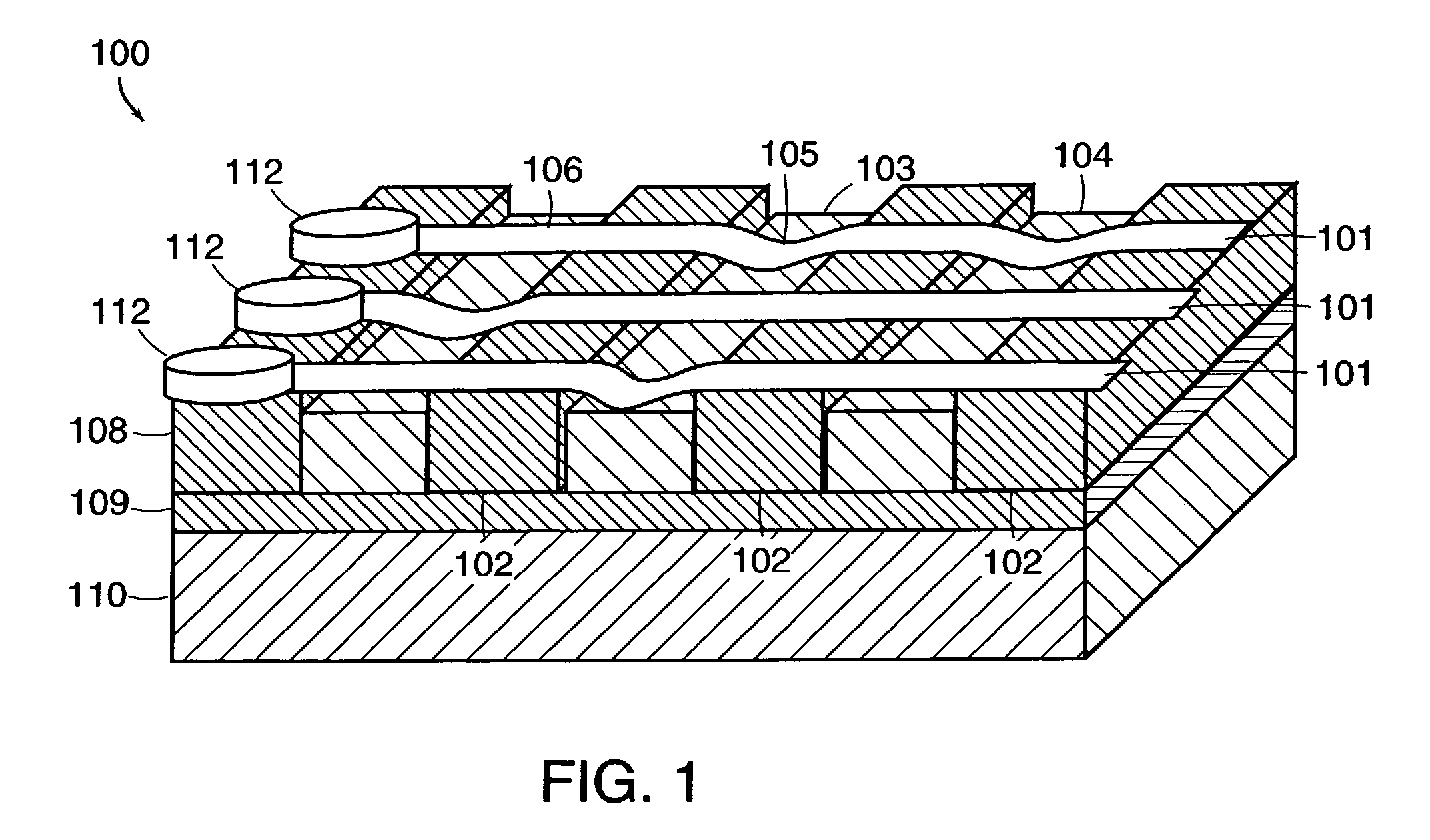

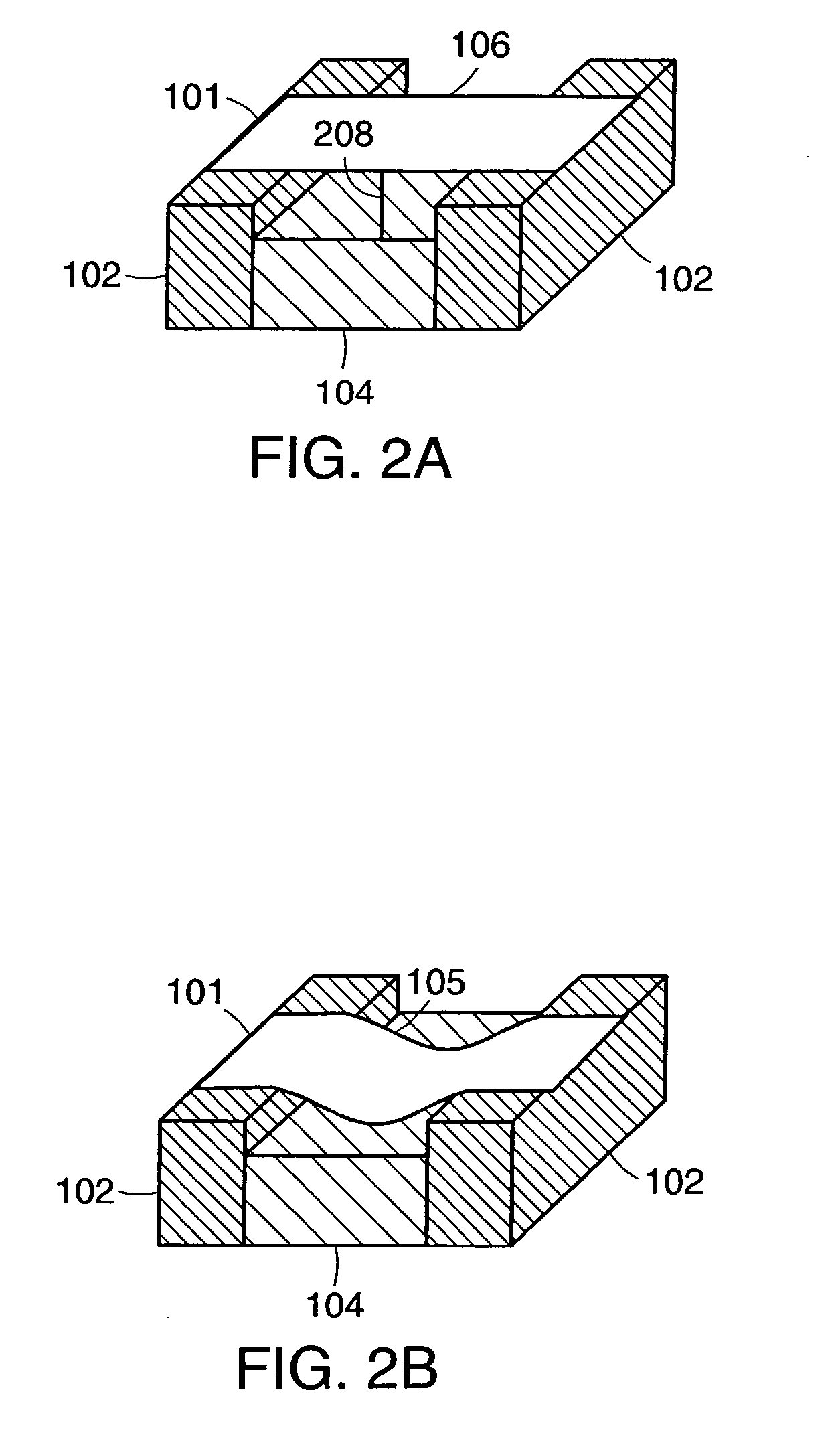

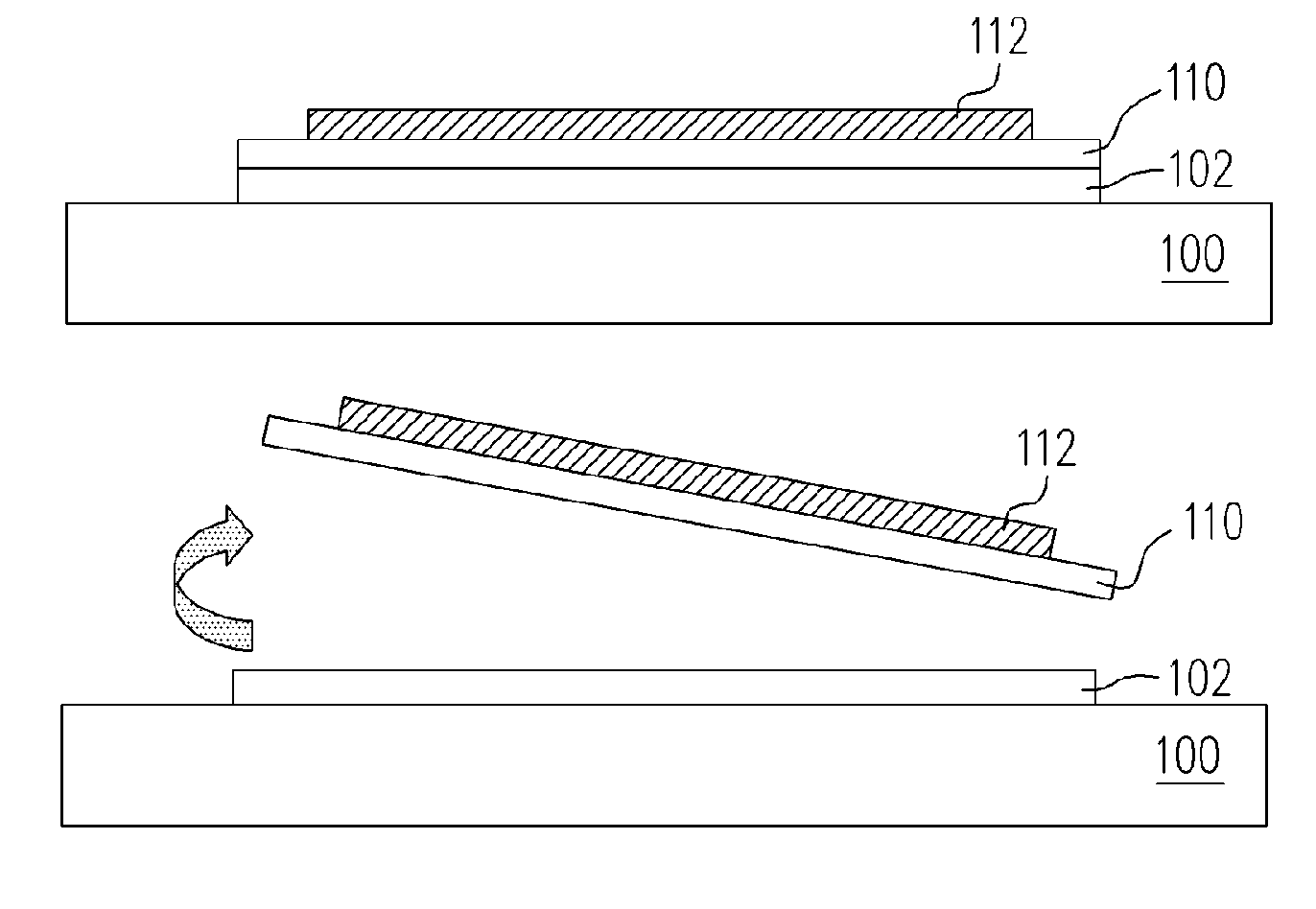

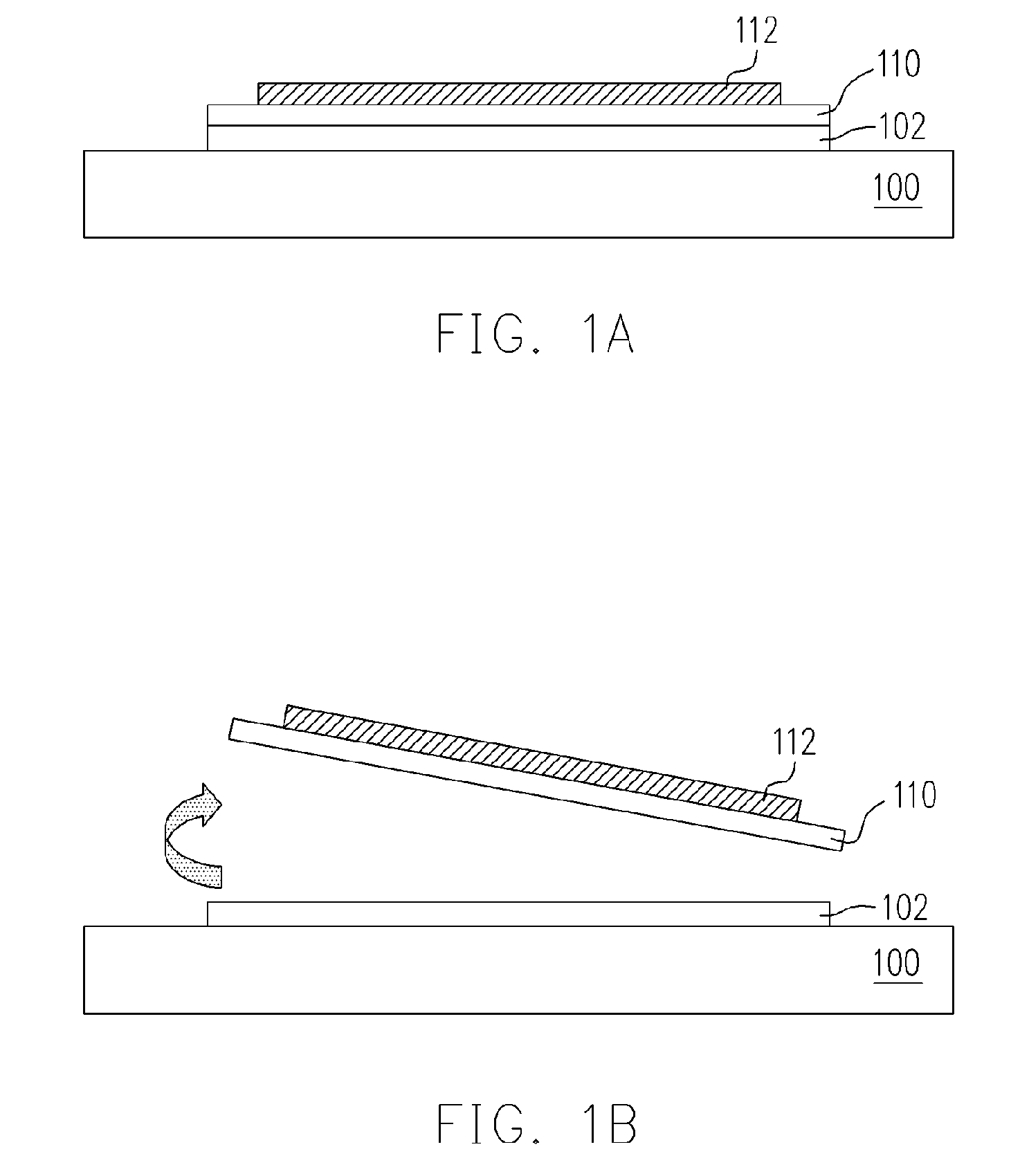

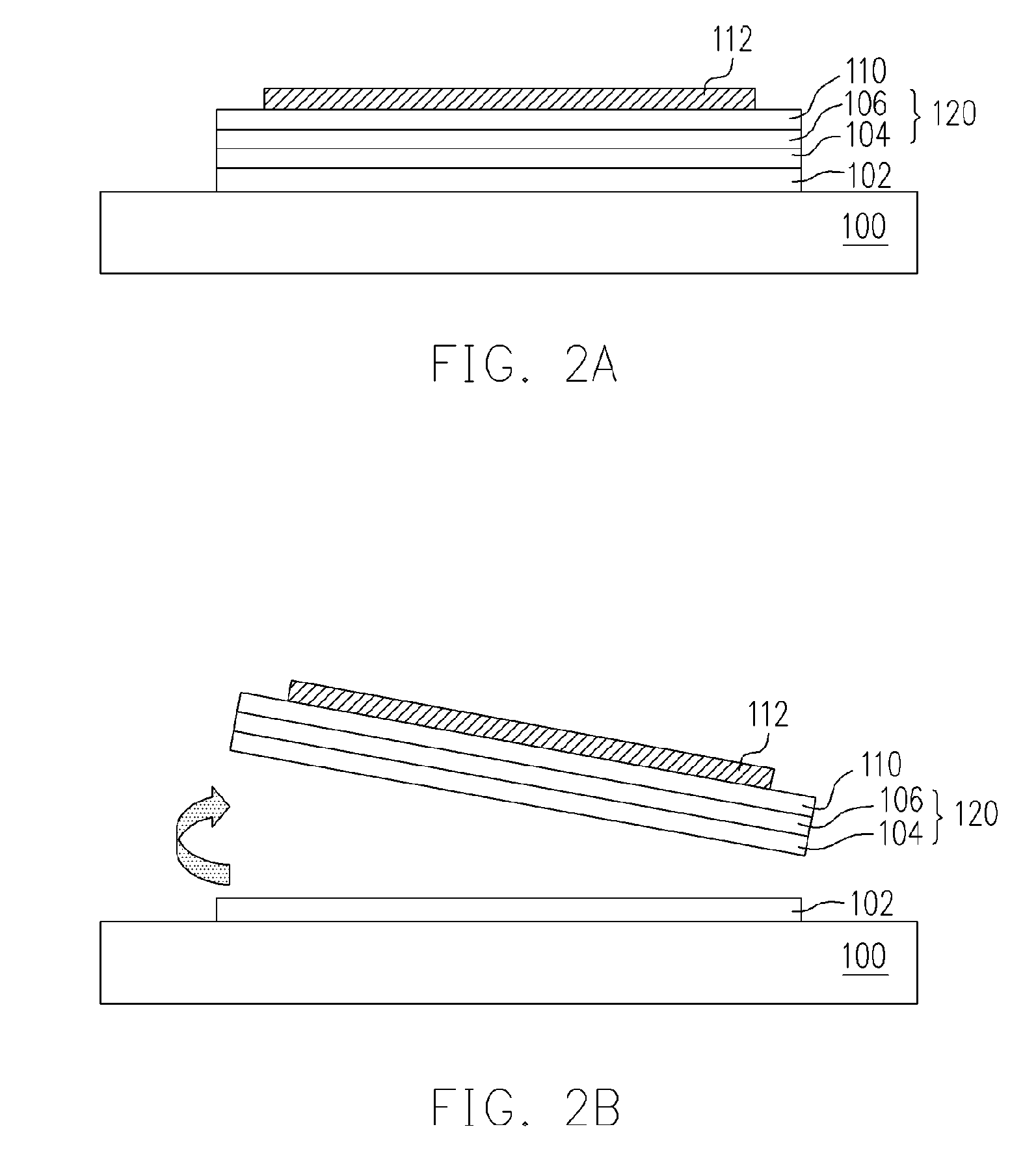

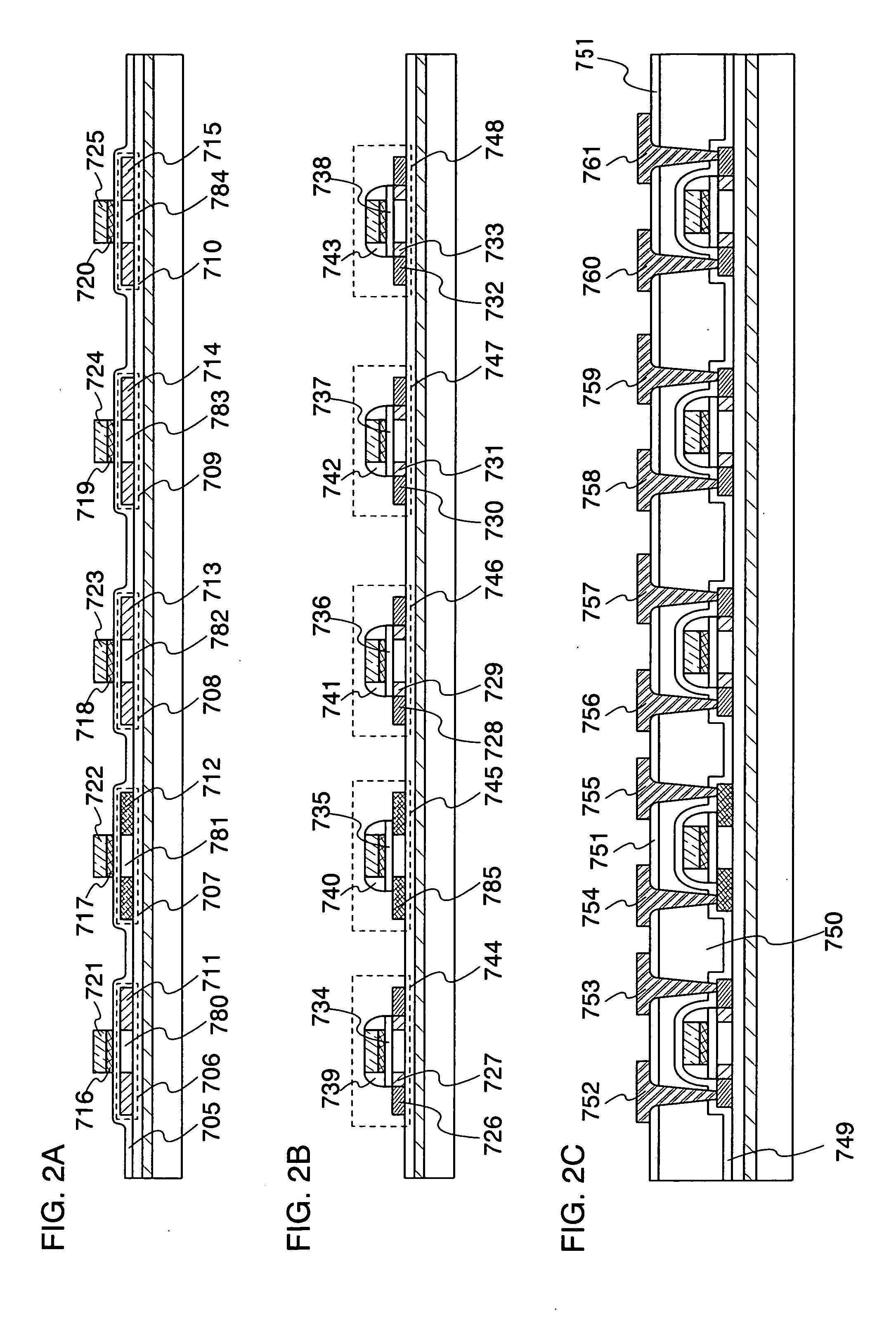

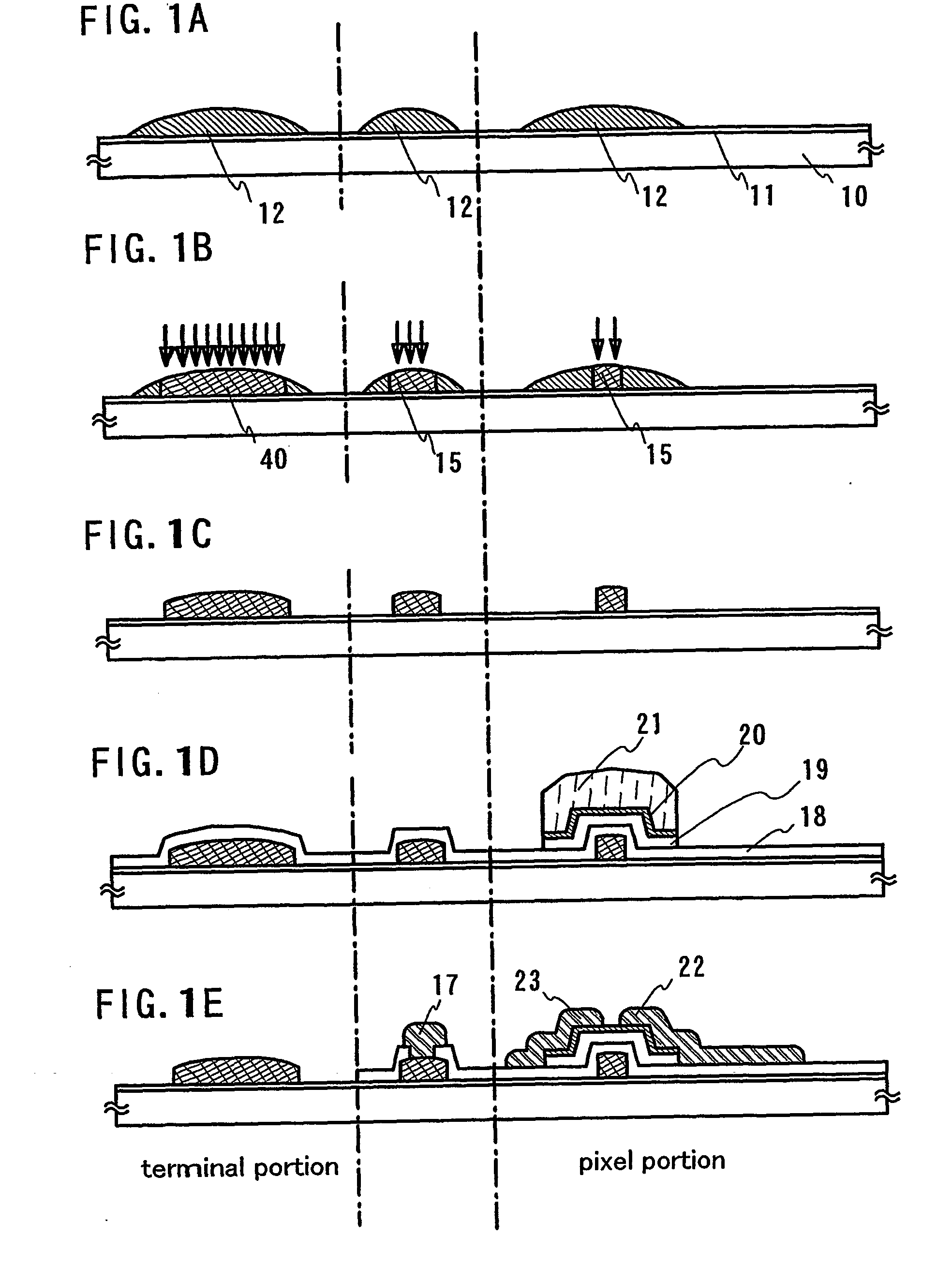

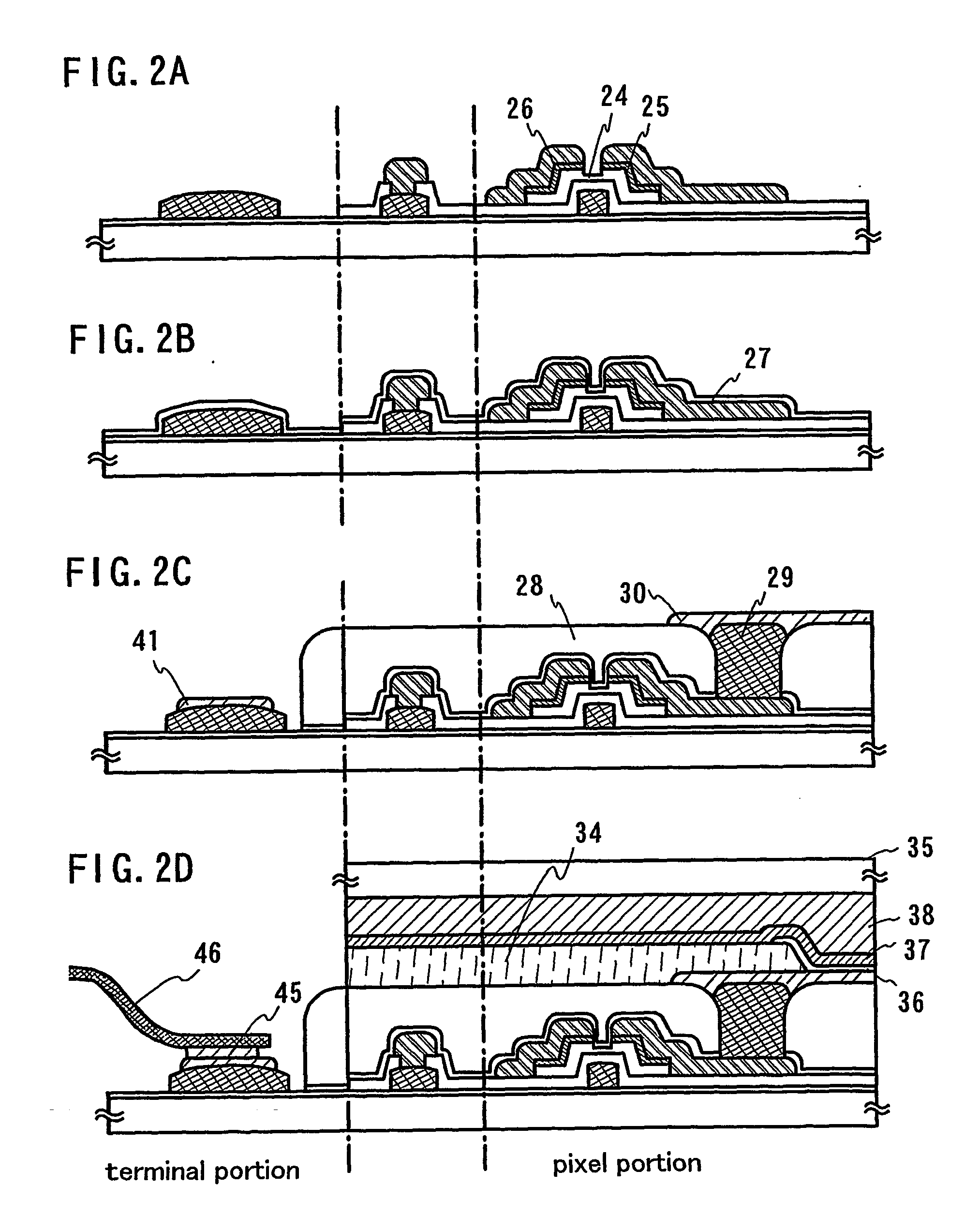

Flexible pixel array substrate and method for fabricating the same

ActiveUS20070059854A1Easy to separateHigh bonding strengthSolid-state devicesSemiconductor/solid-state device manufacturingPolymer sciencePolymer thin films

The present invention provides a method for fabricating a flexible pixel array substrate as follows. First, a release layer is formed on a rigid substrate. Next, on the release layer, a polymer film is formed, the adhesive strength between the rigid substrate and the release layer being higher than that between the release layer and the polymer film. The polymer film is formed by spin coating a polymer monomer and performing a curing process to form a polymer layer. Afterwards, a pixel array is formed on the polymer film. The polymer film with the pixel array formed thereon is separated from the rigid substrate.

Owner:HANNSTAR DISPLAY CORPORATION

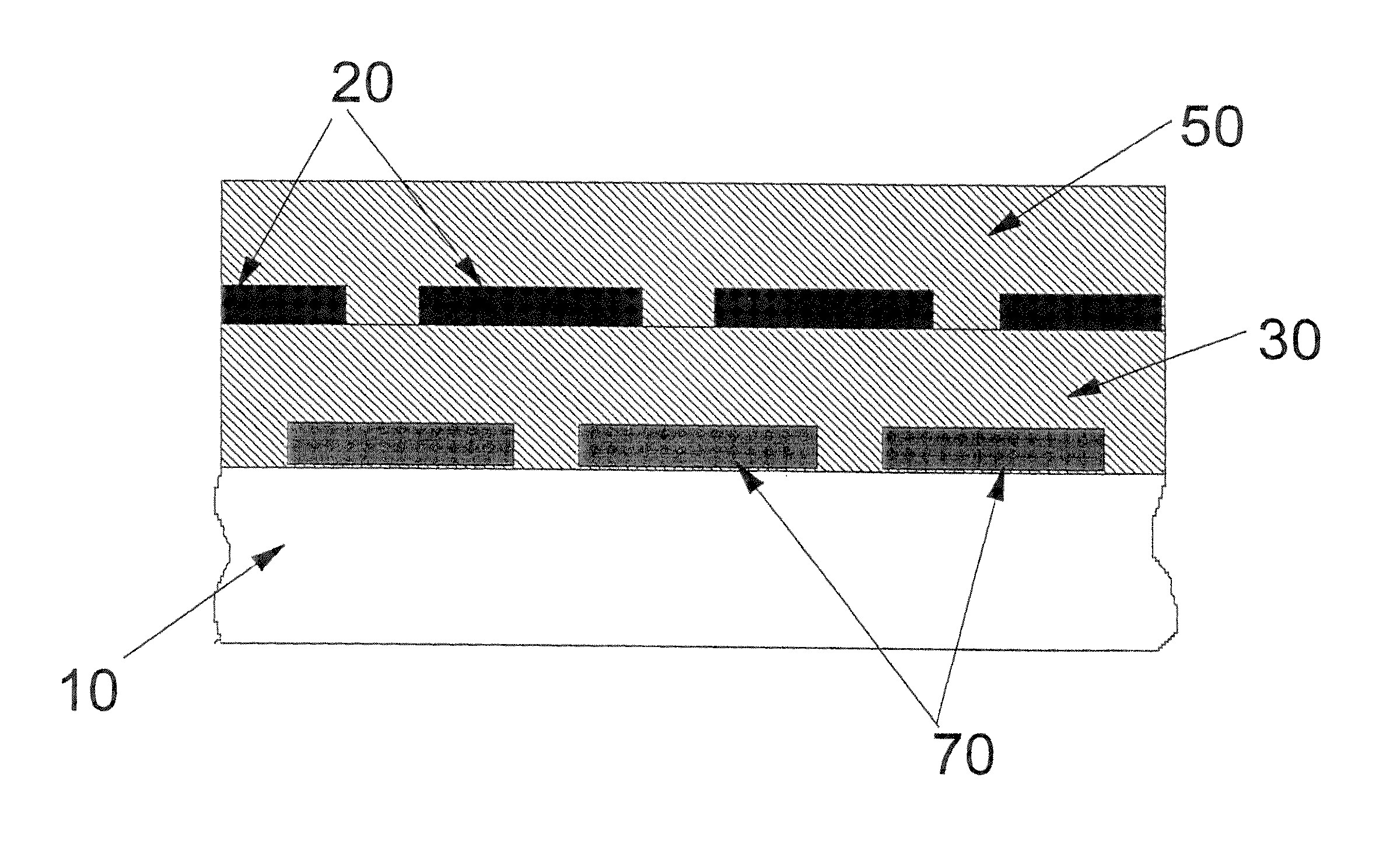

Data protection by detection of intrusion into electronic assemblies

InactiveUS7901977B1Improve adhesionImprove thermal stabilityPig casting plantsPrinted electric component incorporationResistFilling materials

Electronic assemblies, especially one containing volatile memory, used a flexible membrane with conducting lines which acts as an intrusion sensor against chemical and mechanical attacks. The lines are fabricated from inherently conducting polymers which are solution processed and directly patterned. The material was applied to a flexible polymer film by spin coating and patterned by application of a resist, followed by exposure / development of the resist and transferring the image into the polyaniline by reactive ion etching techniques. The conducting lines have high conductivity, tranparency properties which made them difficult to detect and possess excellent adhesion to the substrate film, as well as to the potting material which enclosed the structure. They also offered lightweight advantages over conventionally filled materials. These materials can also be used in conjunction with conventional conductor materials to further enhance protection against intrusion by sophisticated mechanical means.

Owner:IBM CORP

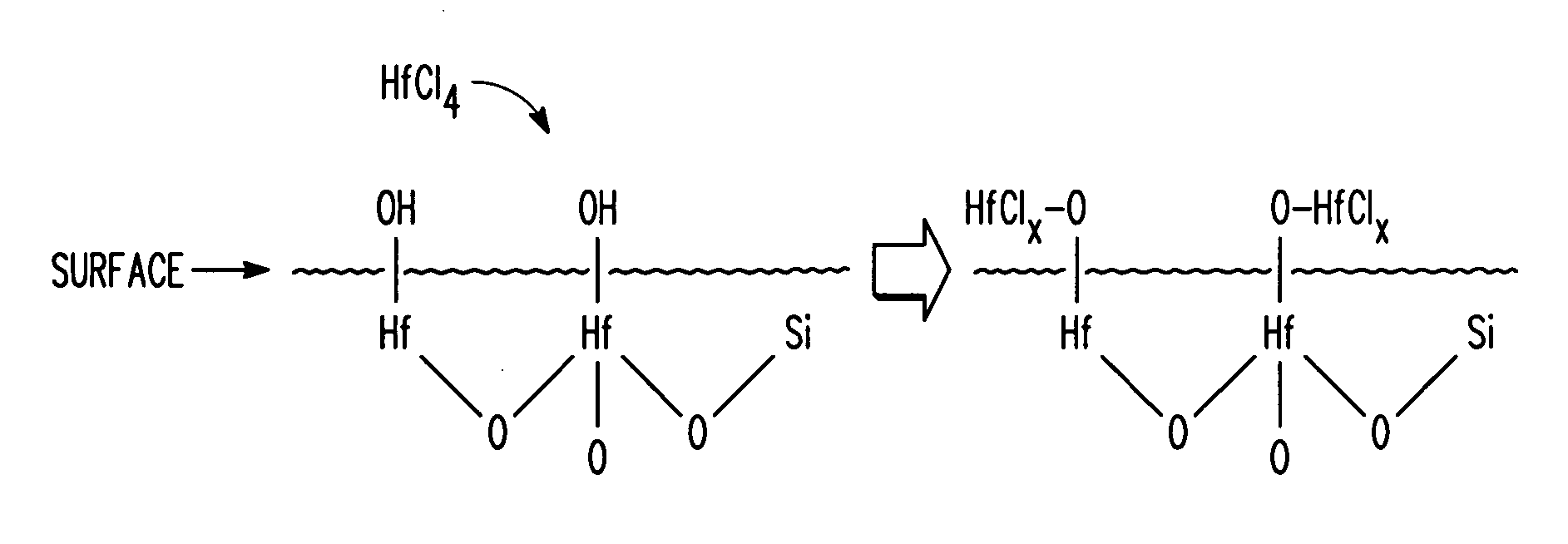

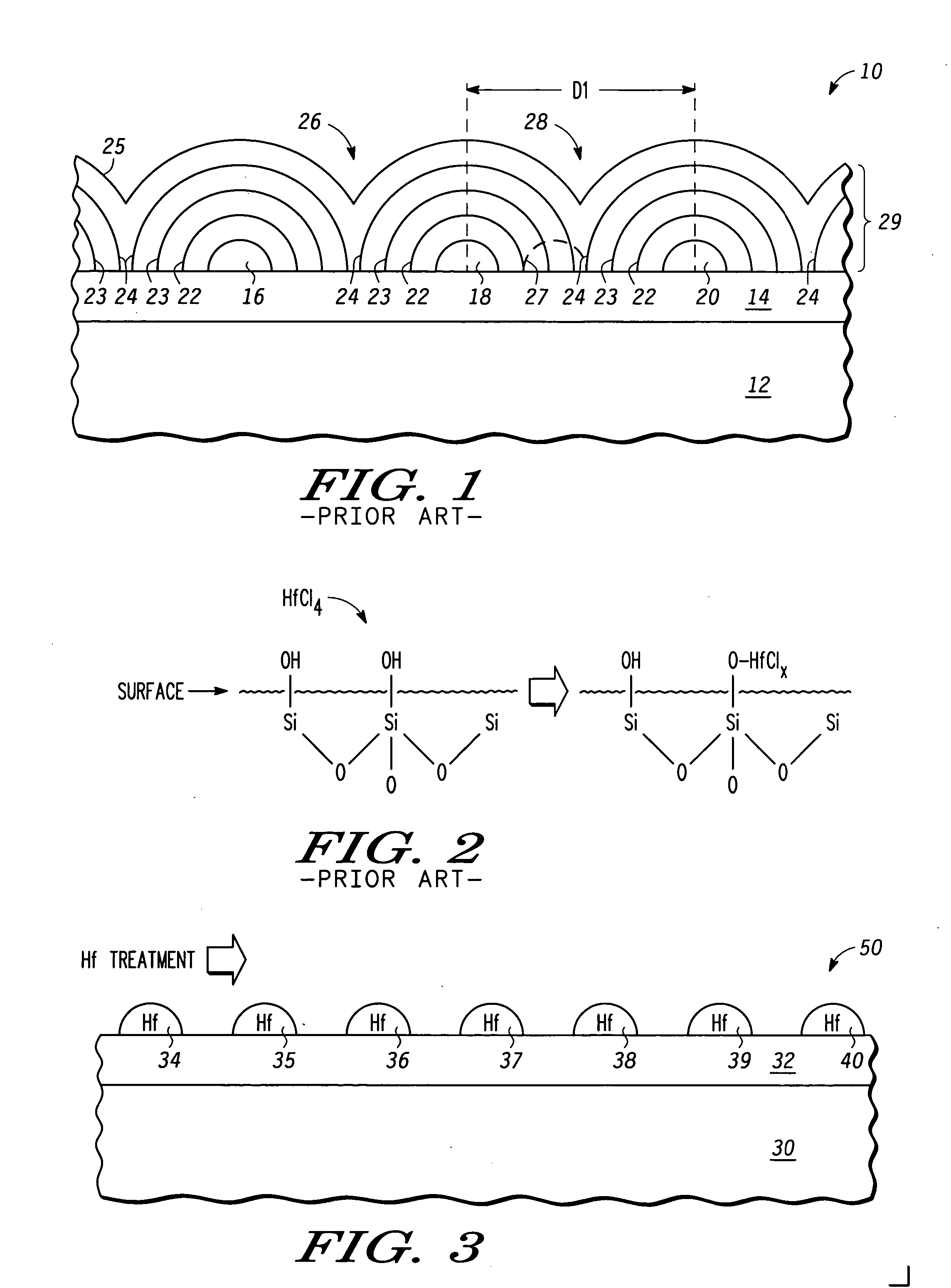

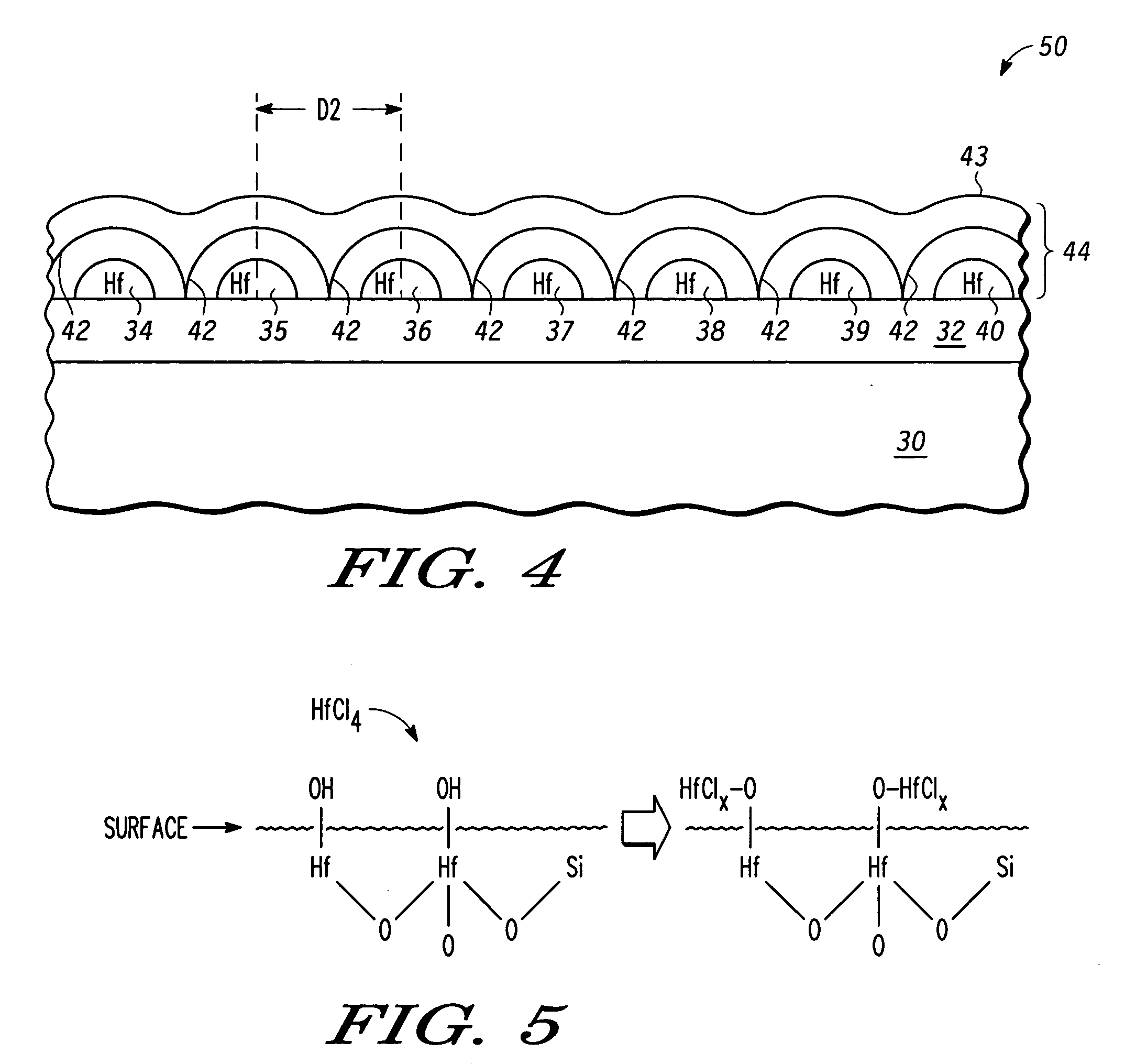

Method for treating a semiconductor surface to form a metal-containing layer

ActiveUS20050277294A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingRare earthHafnium

A method for treating a semiconductor surface to form a metal-containing layer includes providing a semiconductor substrate having an exposed surface. The exposed surface of the semiconductor substrate is treated by forming one or more metals overlying the semiconductor substrate but not completely covering the exposed surface of the semiconductor substrate. The one or more metals enhance nucleation for subsequent material growth. A metal-containing layer is formed on the exposed surface of the semiconductor substrate that has been treated. The treatment of the exposed surface of the semiconductor substrate assists the metal-containing layer to coalesce. In one embodiment, treatment of the exposed surface to enhance nucleation may be performed by spin-coating, atomic layer deposition (ALD), physical layer deposition (PVD), electroplating, or electroless plating. The one or more metals used to treat the exposed surface may include any rare earth or transition metal, such as, for example, hafnium, lanthanum, etc.

Owner:NXP USA INC +1

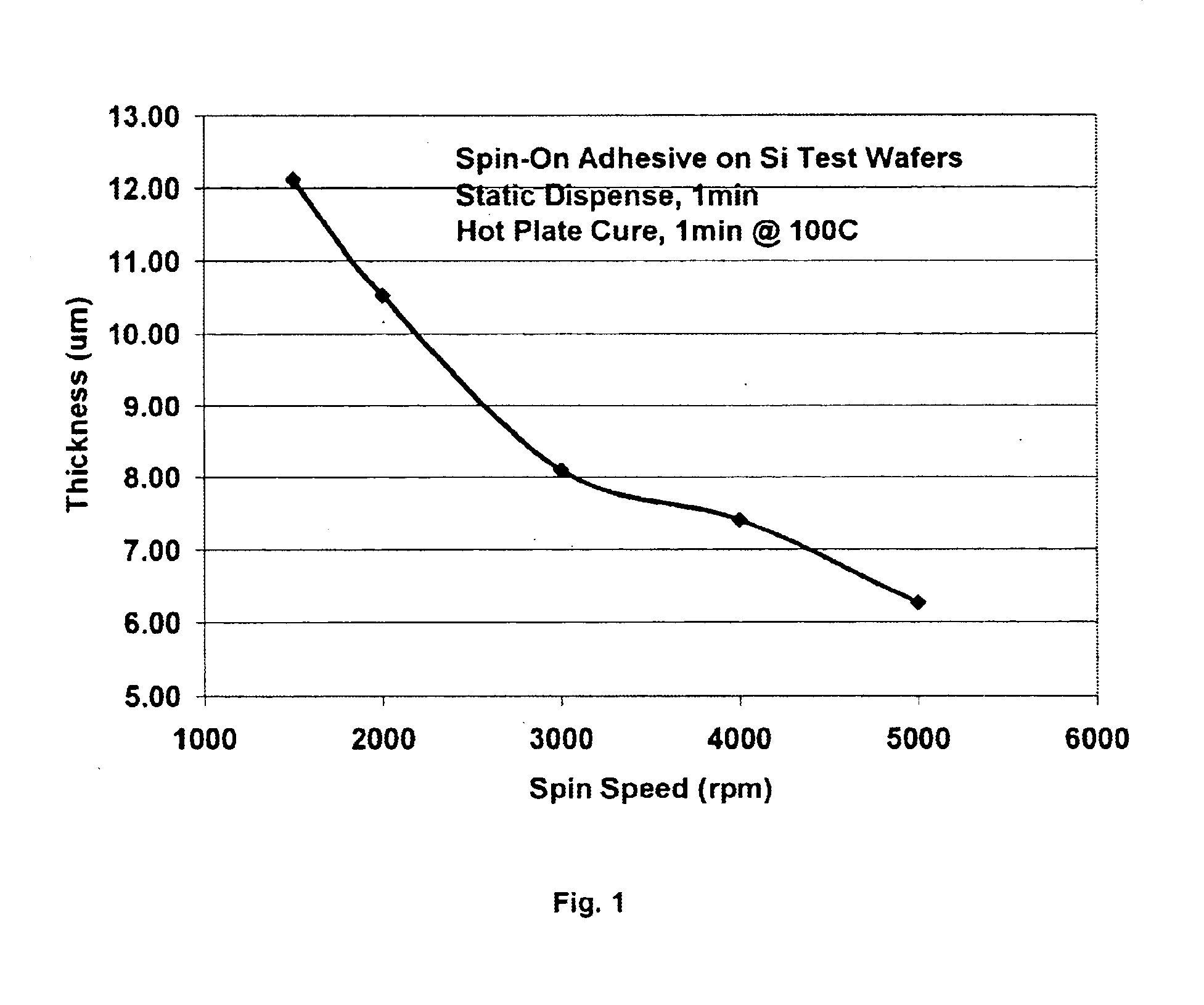

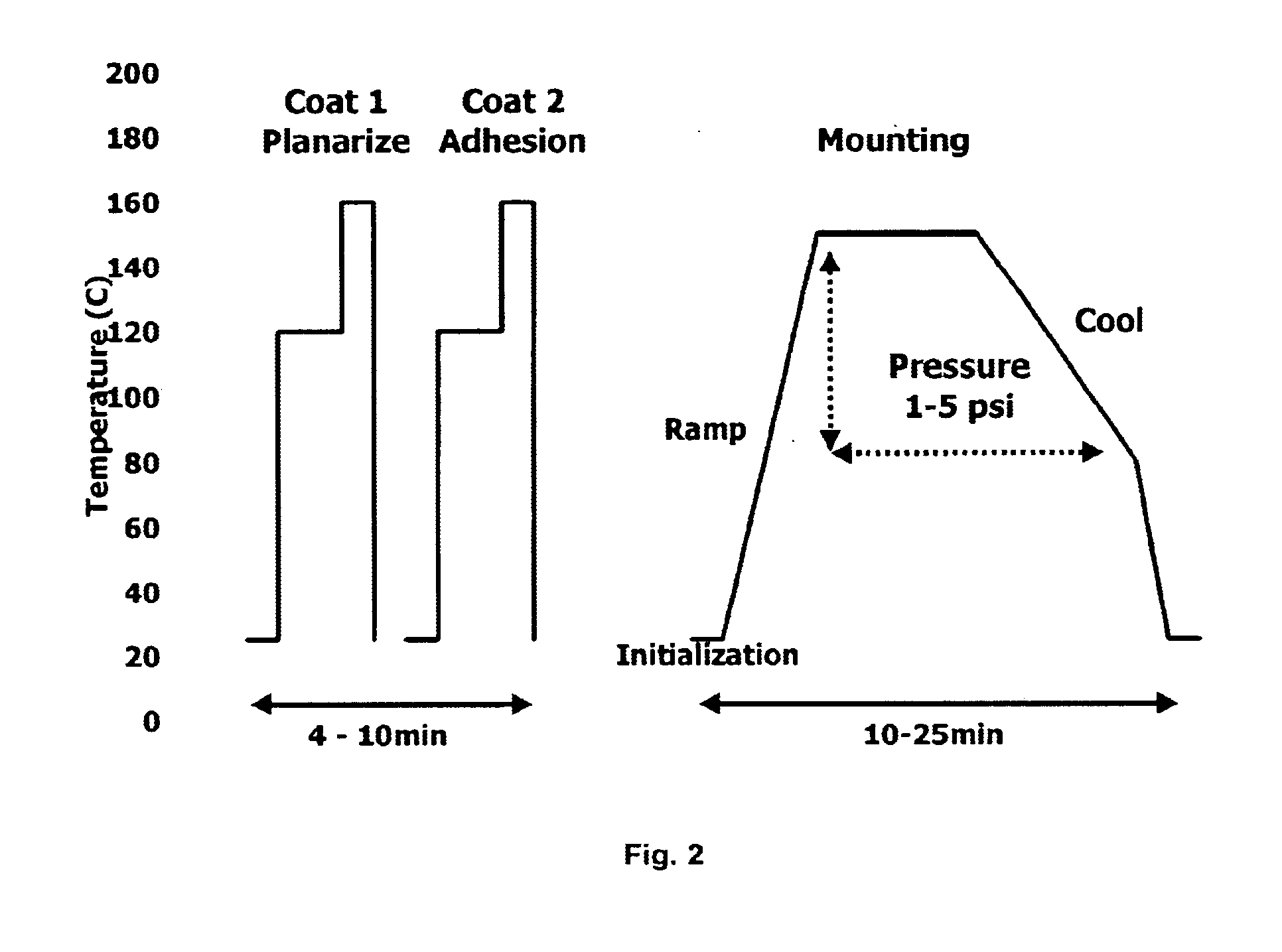

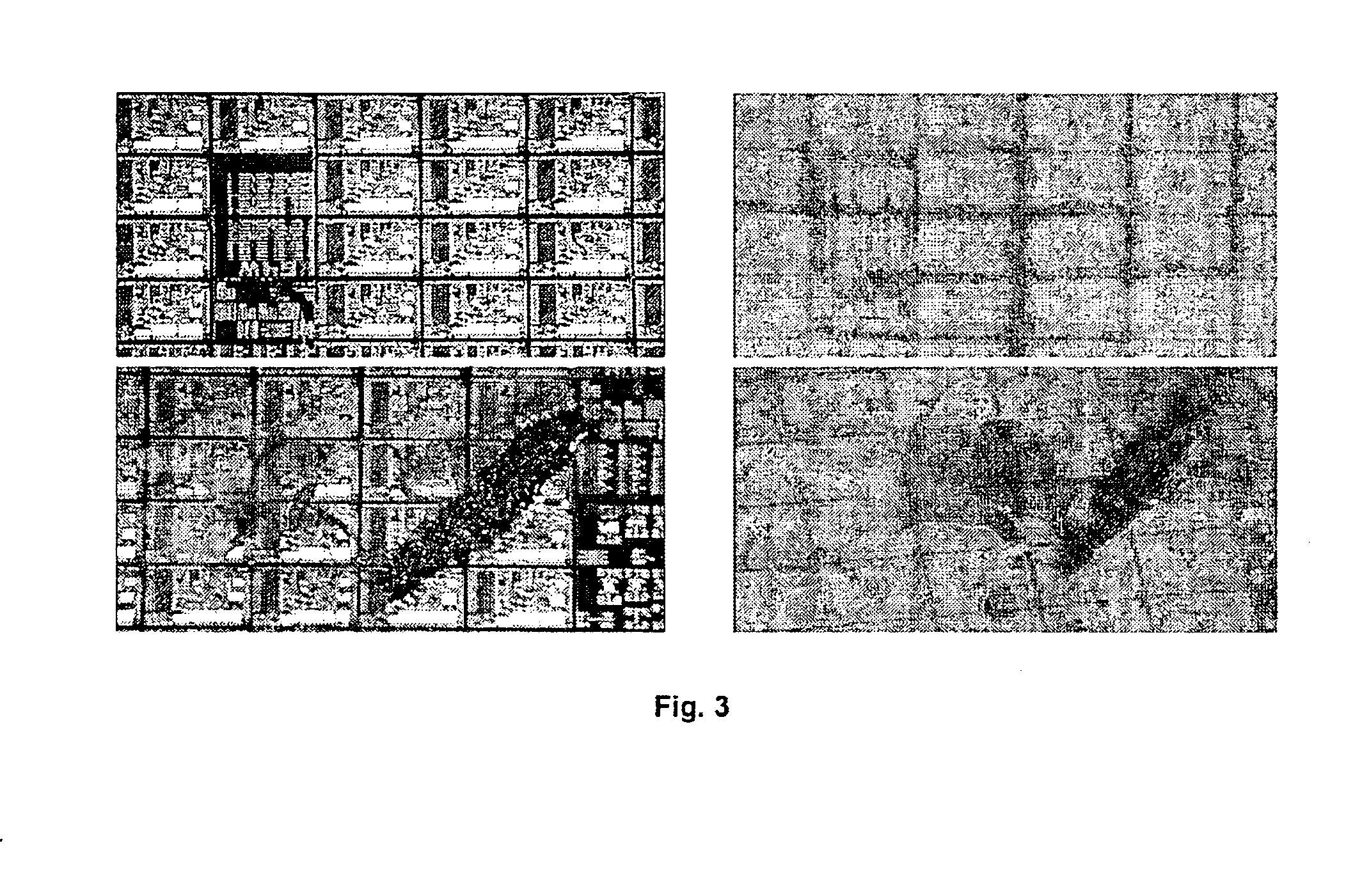

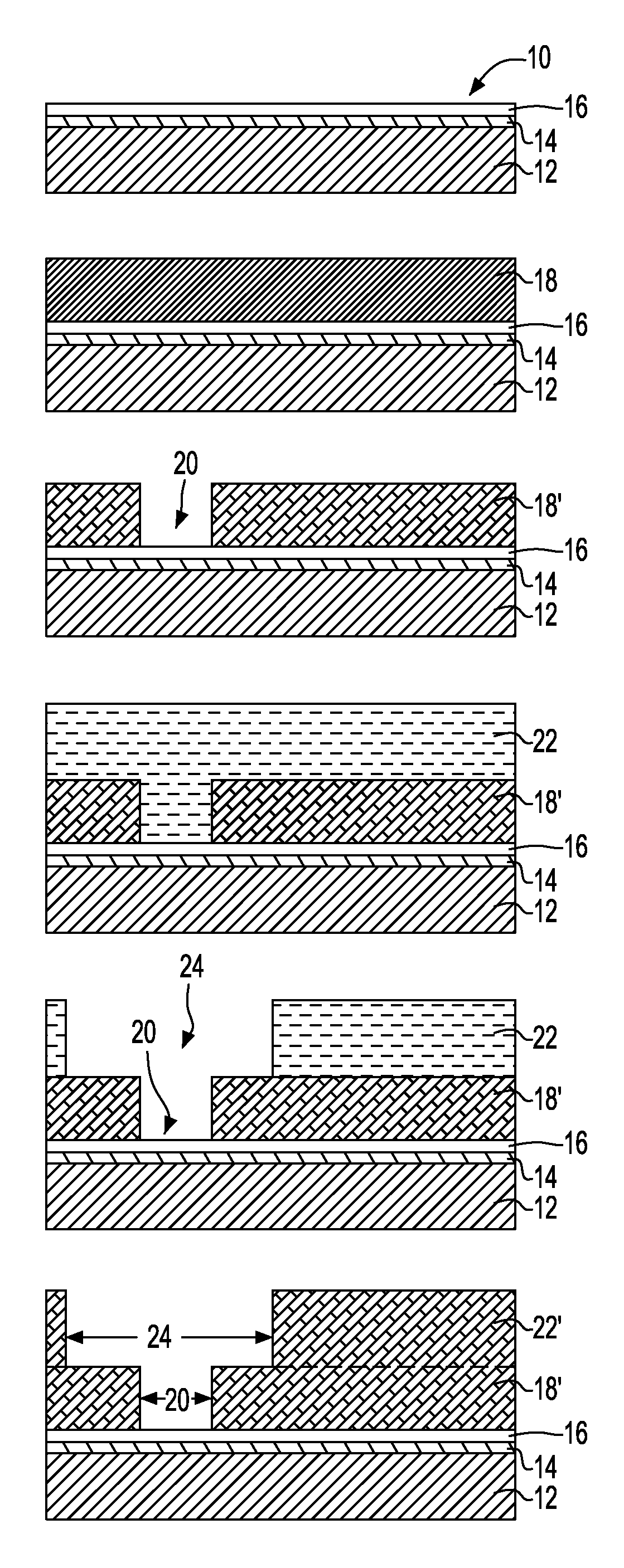

Spin-on adhesive for temporary wafer coating and mounting to support wafer thinning and backside processing

InactiveUS6869894B2Semiconductor/solid-state device testing/measurementSynthetic resin layered productsAdhesiveFluorescence

A liquid form adhesive system is provided for spin-coating on wafers and mounting to rigid carrier substrates to support thinning and backside processing. The liquid adhesive comprises about 30-35% of a rosin, between 5-10% of a thermoplastic urethane, a nonionic surfactant present between 1-3%, and a trace of an ultraviolet fluorescing dye. The entire system is dissolved in 50-65%, by weight, of a dual solvent mixture composed of dimethylacetamide and propylene glycol monomethyl ether. When the mixture is made to a specific viscosity, filtered, applied by a spin-coating method to the wafer frontside surface, and cured, the result is a uniform and smooth surface of defined thickness. When the coated wafer is mounted to a rigid substrate, it may be mechanically thinned to thicknesses down to and beyond 25 um, depending upon the wafer composition, diameter, and process. Once thinned, the adhesive is safe for backside processing and is dissolved away at completion to provide a thinned wafer that is clean and ready for final dicing or chipping operations.

Owner:GENERAL CHEM CORP +1

Spin-on antireflective coating for integration of patternable dielectric materials and interconnect structures

InactiveUS20090081418A1Reduce complexityReduce the number of layersPhotosensitive materialsDecorative surface effectsPhotoresistChromophore

The present invention provides a method of fabricating an interconnect structure in which a patternable low-k material replaces the need for utilizing a separate photoresist and a dielectric material. Specifically, this invention relates to a simplified method of fabricating single-damascene and dual-damascene low-k interconnect structures with at least one patternable low-k dielectric and at least one inorganic antireflective coating. In general terms, a method is provided that includes providing at least one patternable low-k material on a surface of an inorganic antireflective coating that is located atop a substrate. The inorganic ARC is liquid deposited and comprises a polymer that has at least one monomer unit comprising the formula M-R1 wherein M is at least one of Si, Ge, B, Sn, Fe, Ta, Ti, Ni, Hf and La and R1 is a chromophore. At least one interconnect pattern is formed within the at least one patternable low-k material and thereafter the at least one patternable low-k material is cured. The inventive method can be used to form dual-damascene interconnect structures as well as single-damascene interconnect structures.

Owner:GLOBALFOUNDRIES US INC

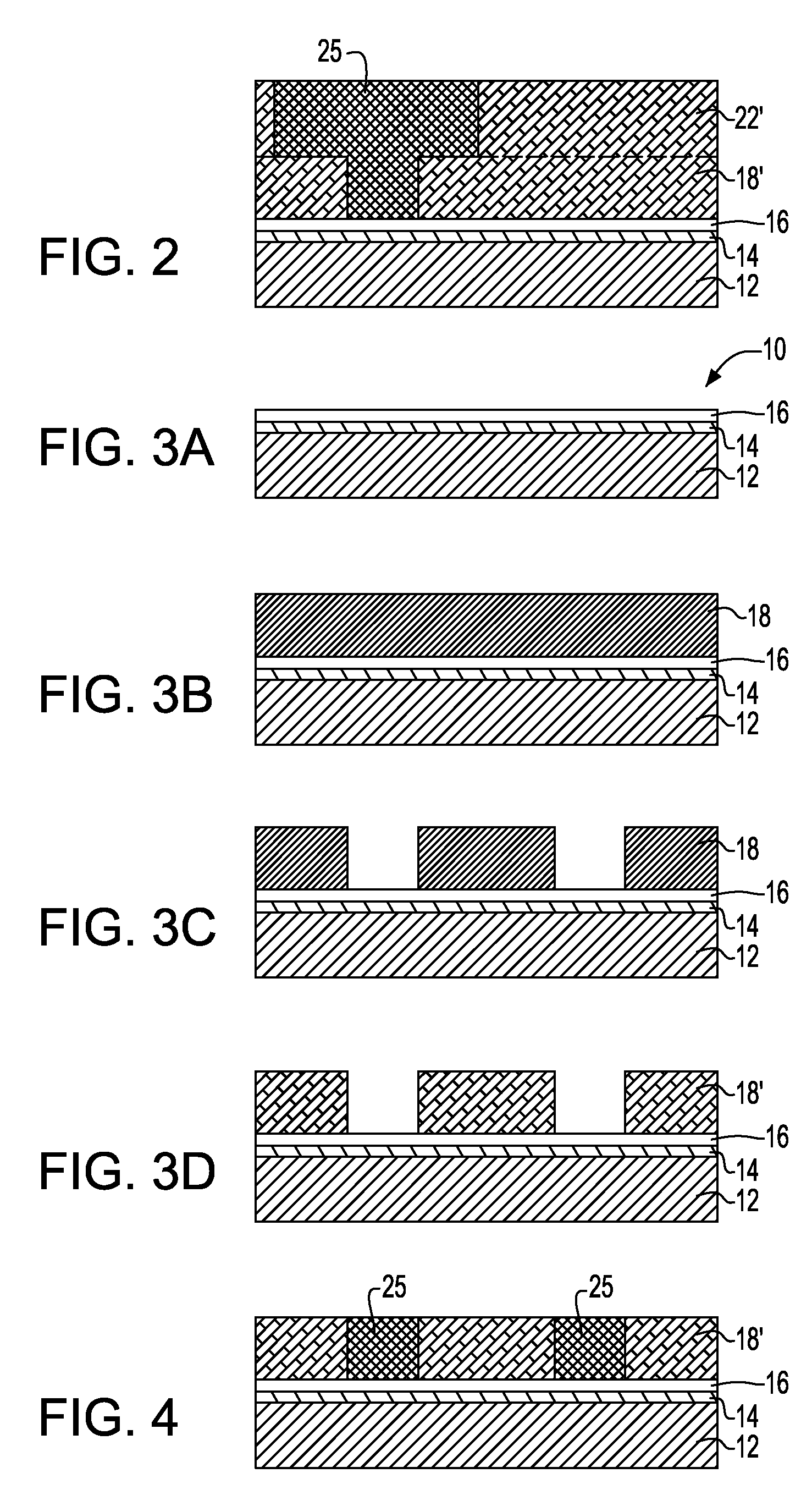

Film made from graphene-carbon nanotube composite material and preparation method of film

InactiveCN103725263AHave flexibilityGood flexibilityHeat-exchange elementsCooling/ventilation/heating modificationsComposite filmLiquid-crystal display

The invention discloses a film made from a graphene-carbon nanotube composite material and a preparation method of film. The preparation method comprises the following steps: mixing graphene and carbon nanotubes sufficiently and evenly via stirring and ultrasonic dispersion, reacting the graphene with the carbon nanotubes sufficiently via hydrothermal or solvothermal conditions, removing solvents after finishing the reaction to obtain the graphene-carbon nanotube composite materials which are preformed and tangled in a network structure, forming the film on the surfaces of various base materials via coating, spraying, spin-coating and filtering the obtained graphene-carbon nanotube composite materials to obtain the composite film made from the graphene-carbon nanotube composite materials and the base materials, and removing the base materials to obtain the film made from the graphene-carbon nanotube composite materials. According to the method, graphene-carbon nanotube composition is realized simply and effectively and dispersed in the solvents stably, and the two obtained films can be applied in the aspects of heat conduction and heat radiation systems of high calorific value electronic devices, LED (light-emitting diode) lamps and liquid crystal display products.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

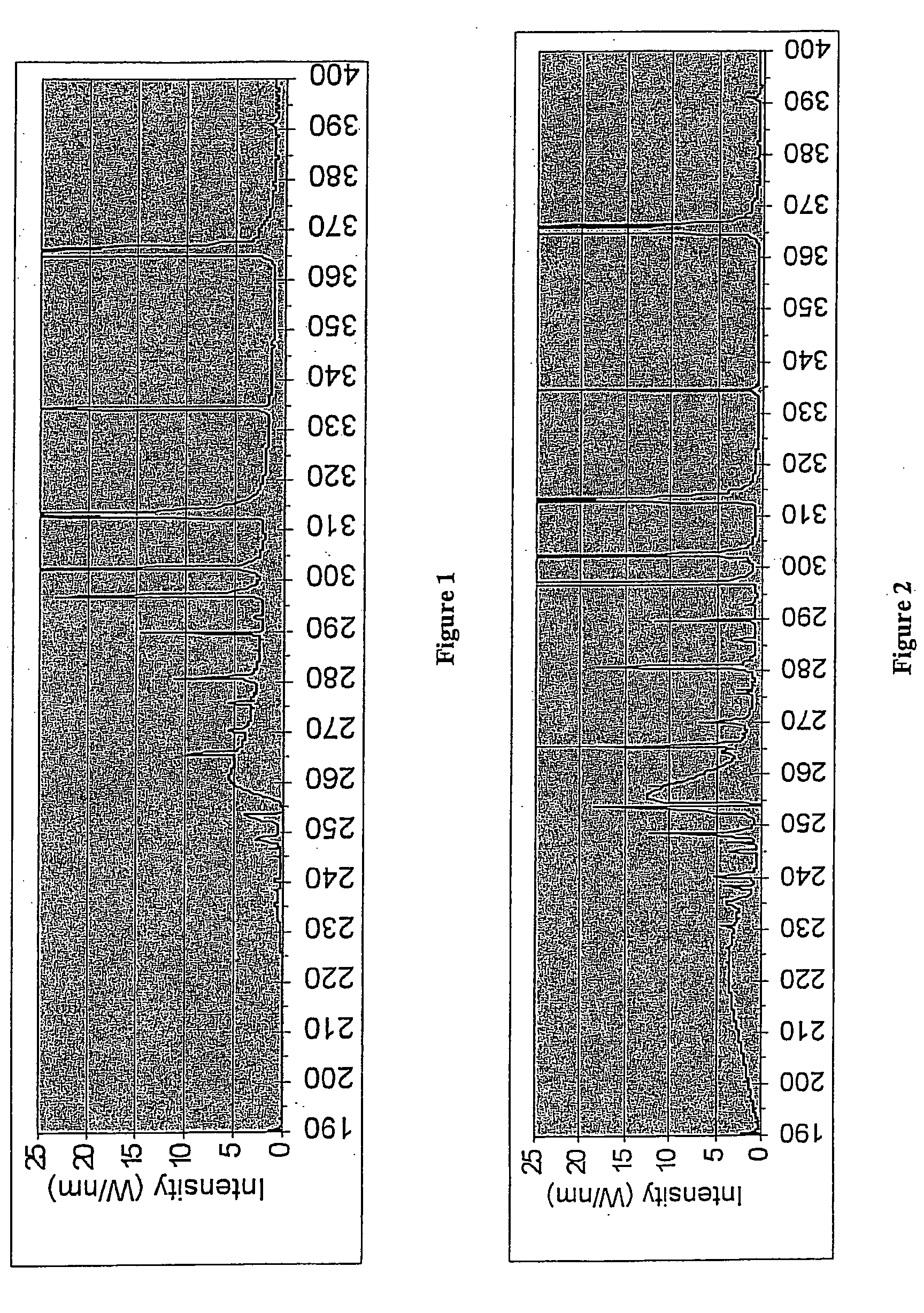

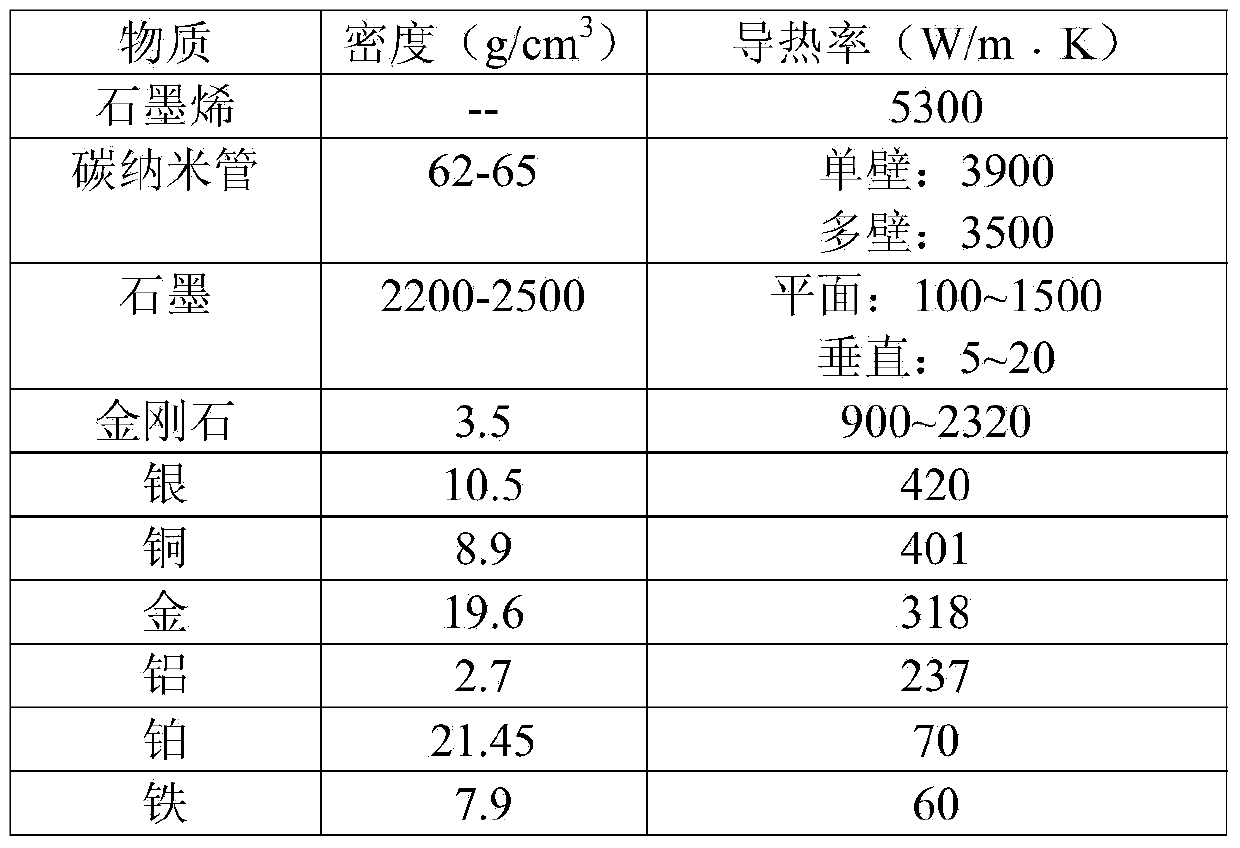

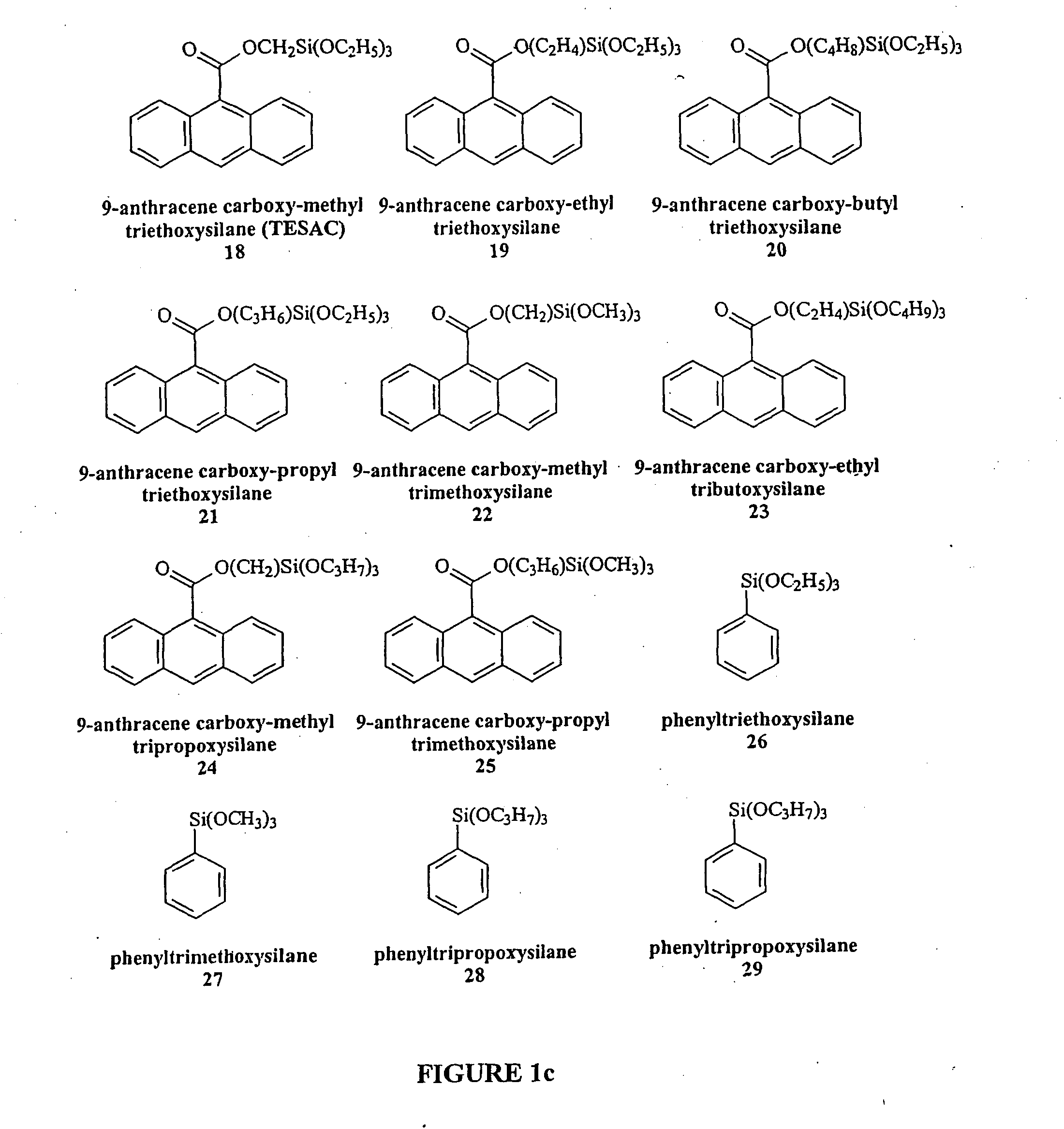

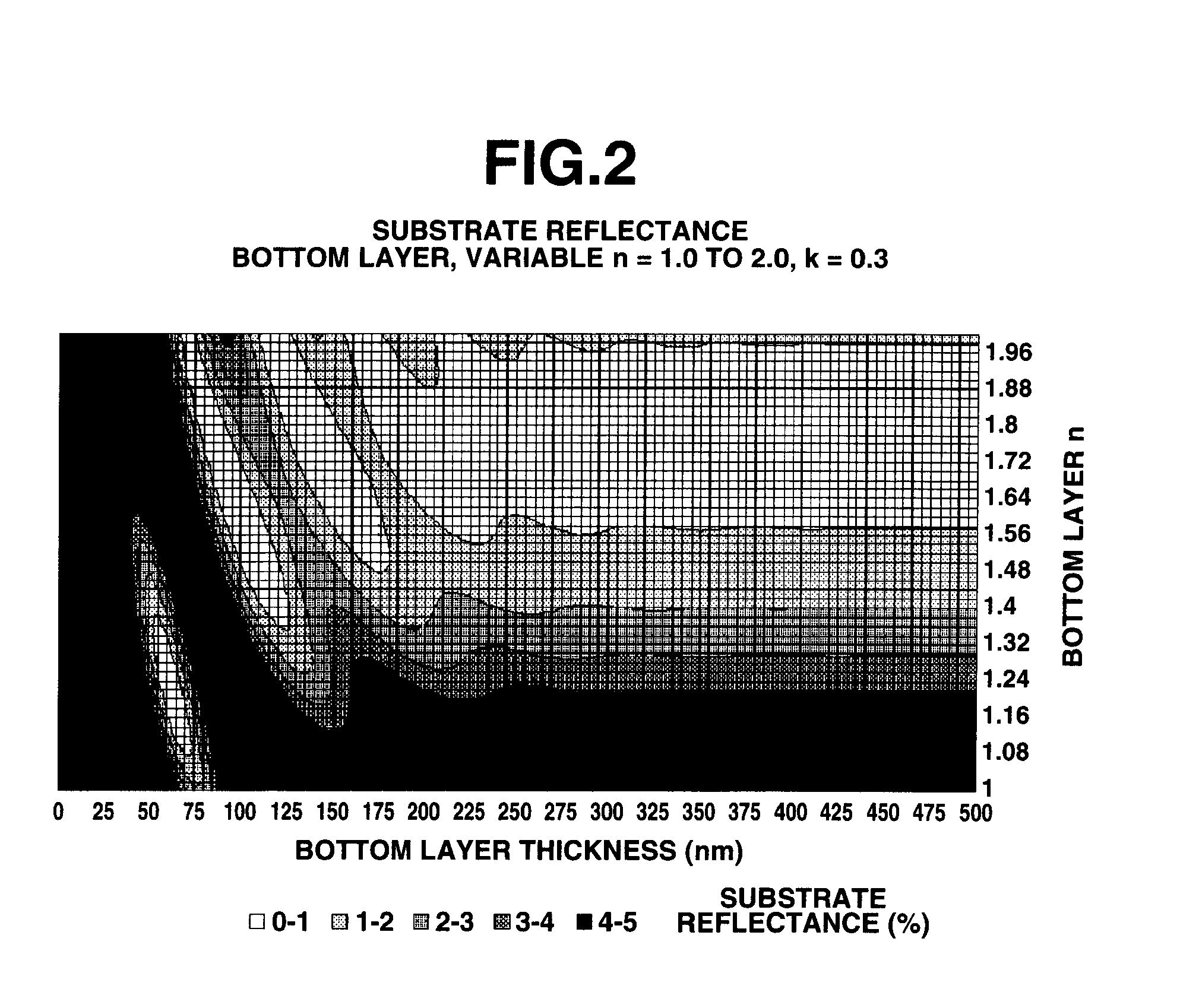

Spin-on anti-reflective coatings for photolithography

Anti-reflective coating materials for ultraviolet photolithography include at least one absorbing compounds and at least one pH tuning agent that are incorporated into spin-on materials. Suitable absorbing compounds are those that absorb around wavelengths such as 365 nm, 248 nm, 193 nm and 157 nm that may be used in photolithography. Suitable pH tuning agents not only adjust the pH of the final spin-on composition, but also influence the chemical performance and characteristics, mechanical performance and structural makeup of the final spin-on composition that is part of the layered material, electronic component or semiconductor component, such that the final spin-on composition is more compatible with the resist material that is coupled to it. More specifically, the pH tuning agent strong influences the polymeric characteristics, the structural makeup and the spatial orientation that results in increasing the surface properties of the anti-reflective coating for optimal resist performance. In other words, a pH tuning agent that merely adjusts the pH of the spin-on material without influencing the mechanical properties and structural makeup of the spin-on composition or the coupled resist material is not contemplated herein. A method of making absorbing and pH tuned spin-on materials includes combining at least one organic absorbing compound and at least one pH tuning agent with at least one silane reactant during synthesis of the spin-on materials and compositions.

Owner:HONEYWELL INT INC

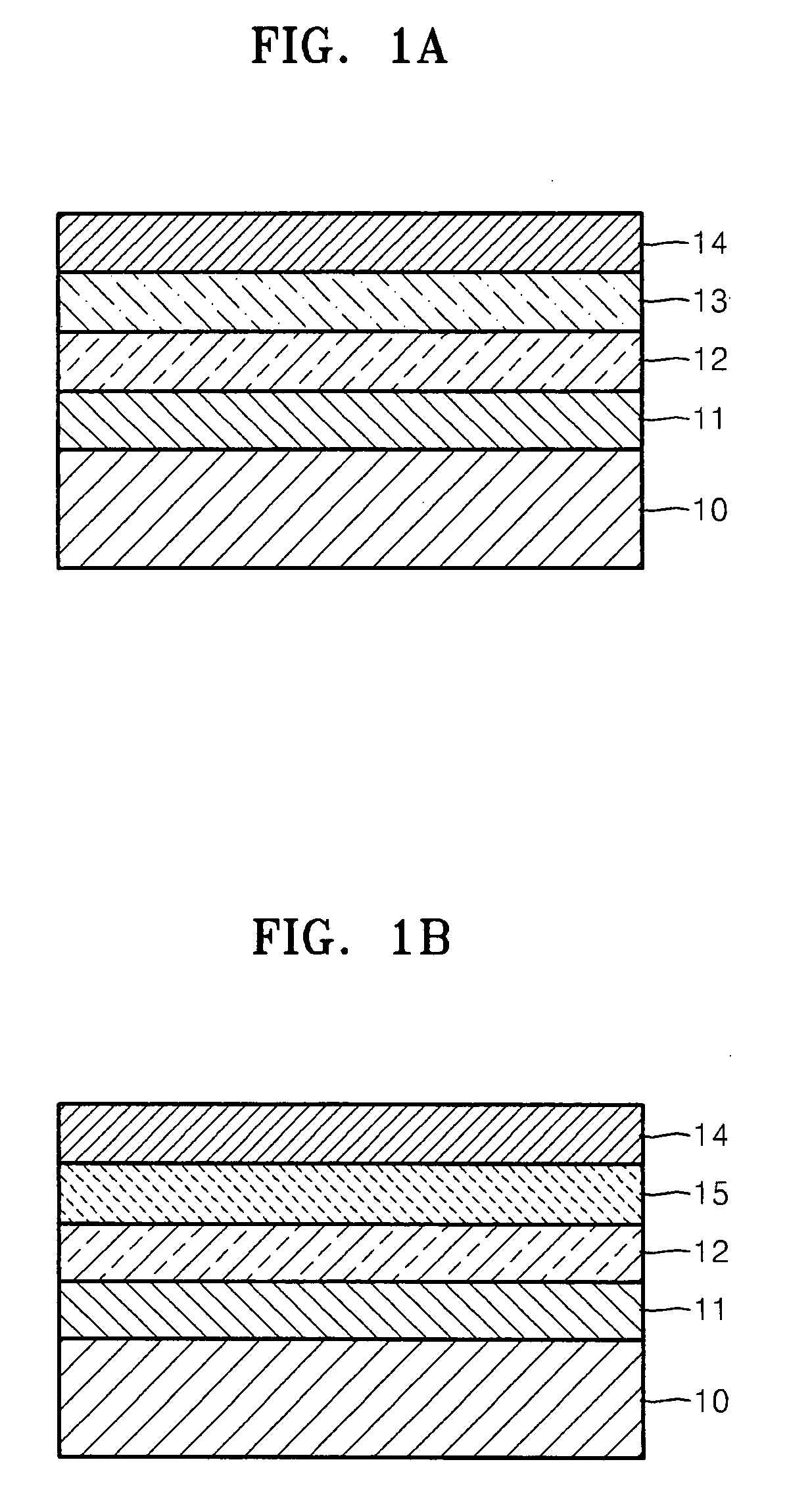

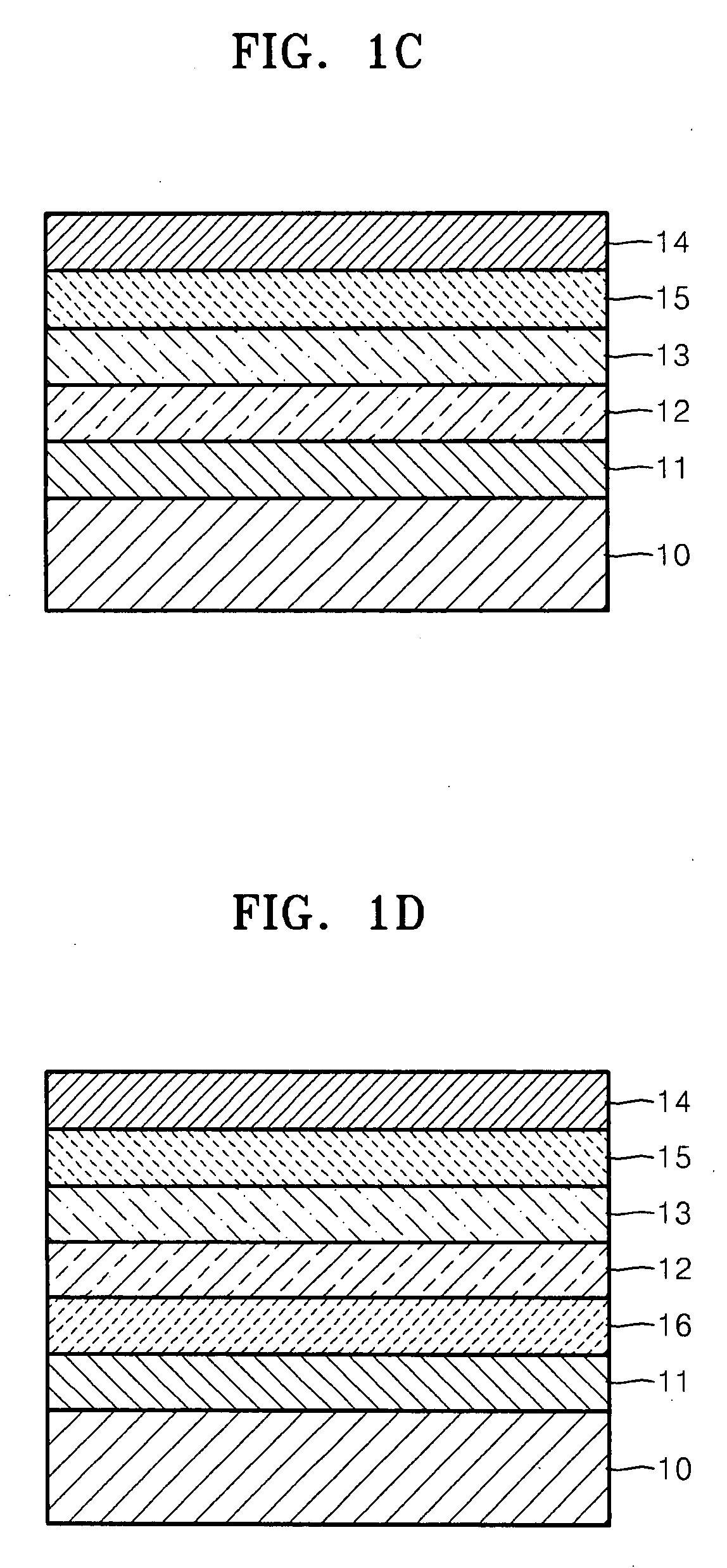

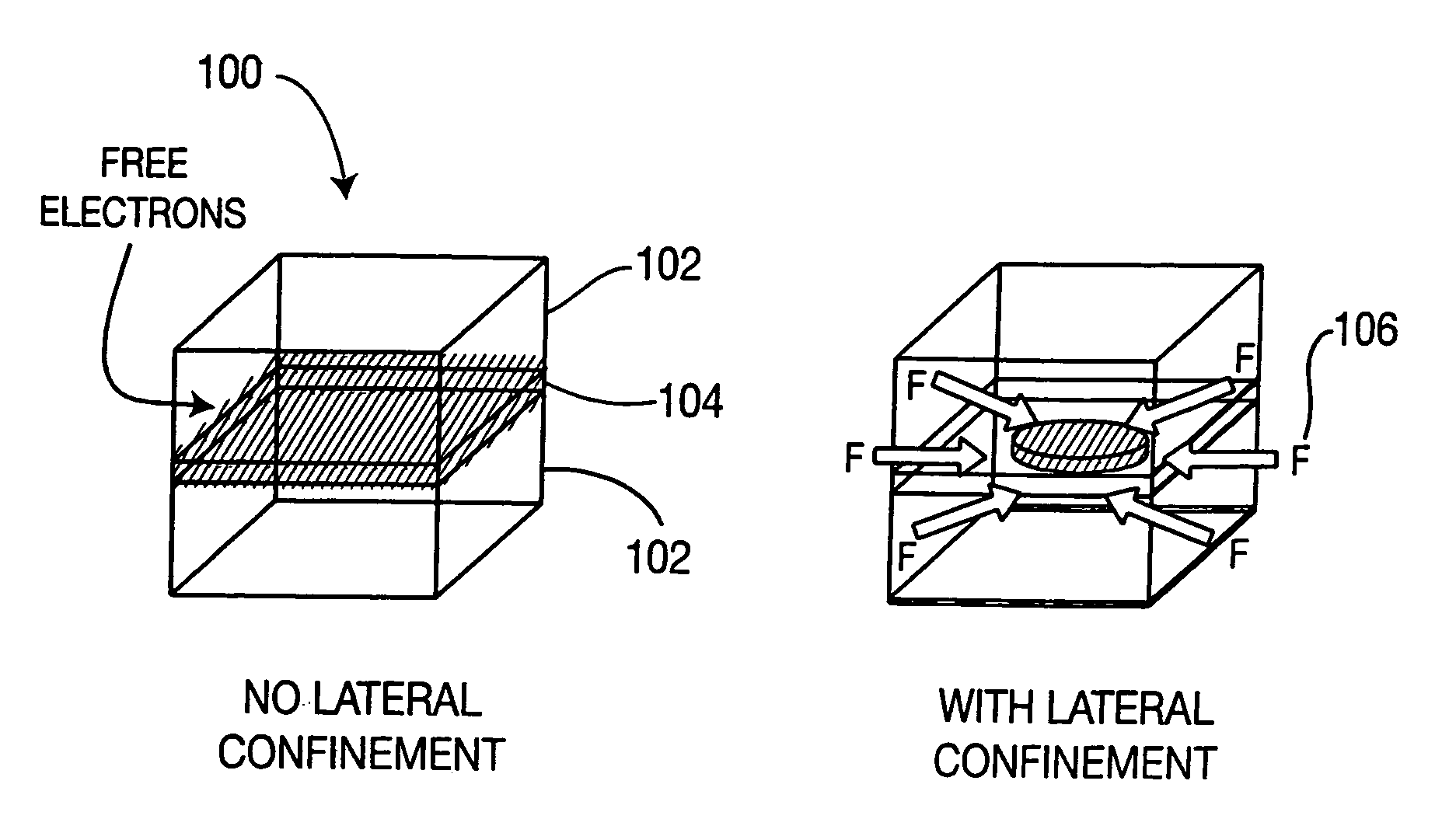

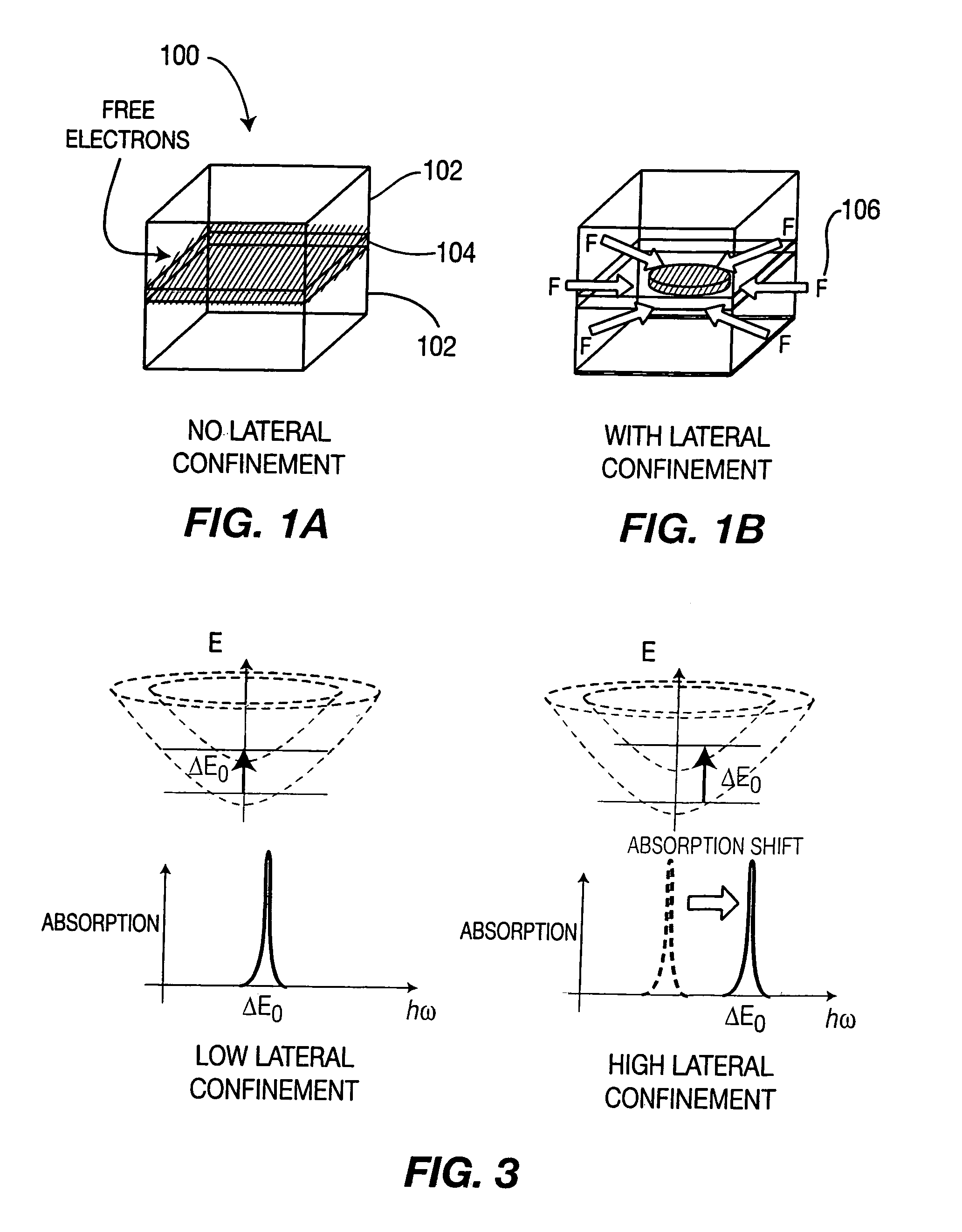

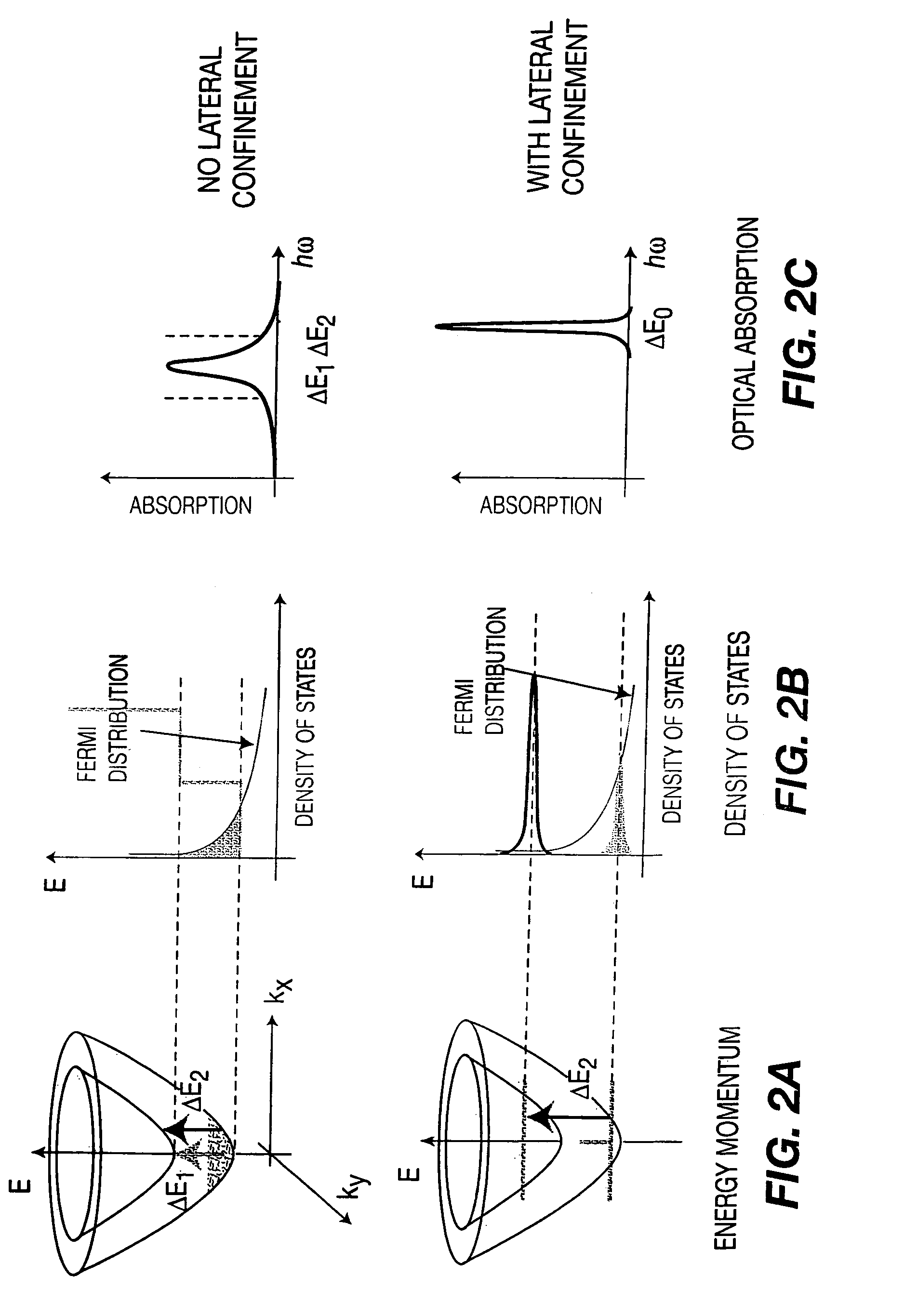

Electrically tunable quantum dots and methods for making and using same

InactiveUS7026641B2Inhibition formationNanoinformaticsSemiconductor/solid-state device manufacturingQuantum wellQuantum dot

A method of fabricating a tunable quantum dot apparatus, comprising: forming multi-quantum wells sandwiched substantially between at least two barrier layers; spin coating a non-continuous mask onto at least one of said barrier layers; forming a gate material onto the mask, wherein the non-continuity of the mask substantially prevents formation of a continuous gate material layer; lifting off at least a portion of the gate material; self isolating the gate material; and, forming a top contact onto at least a portion of said barrier layers

Method for backside surface passivation of solar cells and solar cells with such passivation

InactiveUS20050022863A1Easy to manufactureSimple and cheap to manufacturePV power plantsFinal product manufactureSemiconductor materialsAlloy

The present invention provides a method for dielectric passivating the surface of a solar cell by accumulation of negative fixed charges of a first type at the interface between semiconductor material and a passivating material. According to the invention the passivating material comprises an oxide system, for example a binary oxide system, comprising Al2O3 and at least one metal oxide or metalloid oxide which enhances the tetrahedral structure of Al2O3, for example, an (Al2O3)x(TiO2)1-x alloy. In this way it is possible to combine the desirable properties from at least two different oxides, while eliminating the undesirable properties of each individual material. The oxide system can be deposited onto the semiconductor surface by means of a sol-gel method, comprising the steps of formation of the metal oxide and / or metalloid oxide sol and the aluminum solution and then carefully mixing these together under stirring and ultrasonic treatment. Thin films of the oxide system can then be deposited onto the semiconductor surface by means of spin coating followed by a temperature treatment.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

Graphene/silicon carbide Schottky junction based photovoltaic cell and preparation method thereof

ActiveCN101771092AGood light transmissionImprove conductivityPhotovoltaic energy generationSemiconductor devicesGold filmTitanium

The invention provides a graphene / silicon carbide Schottky junction based photovoltaic cell and a preparation method thereof. The method comprises the following steps: placing a TiPdAg back electrode, an n-type monocrystalline silicon piece n-Si, an annular SiO2 layer and an annular gold film from bottom to top in a laminating mode, and forming stepped holes by an inner hole of the gold film, a through hole in the middle of the SiO2 layer and the upper surface of the n-type monocrystalline silicon piece n-Si; tiling the graphene or organic suspension of the graphene on the surface of the stepped holes by methods of directly transferring, spin coating, spraying, dipping and filtering, and leading the dried graphene film to be closely combined with the n-Si on a substrate electrode; and taking a lead wire extracted from one end of the graphene film as an anode of the photovoltaic cell, and taking a lead wire extracted from one end of the TiPdAg back electrode as a cathode of the photovoltaic cell. The photovoltaic cell reduces the utilization ratio of silicon, has simple assembly process and low cost, and is applicable to scale application.

Owner:TSINGHUA UNIV

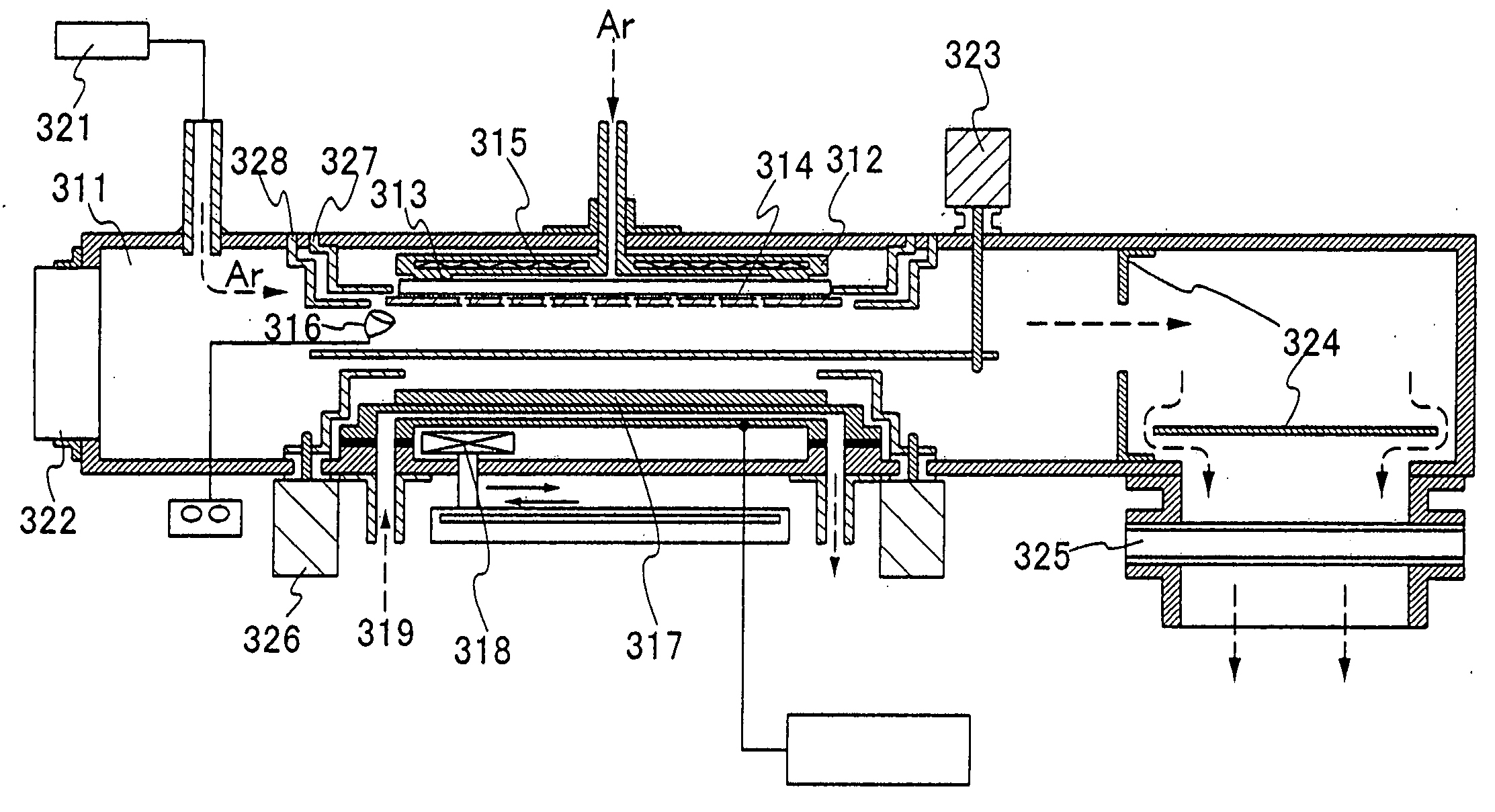

Method for manufacturing antenna and method for manufacturing semiconductor device

InactiveUS20060270175A1Improve communication distanceHigh expectationSemiconductor/solid-state device detailsSolid-state devicesScreen printingElectrical resistance and conductance

The present invention provides an antenna with low resistance and a semiconductor device having an antenna whose communication distance is improved. A fluid containing conductive particles is applied over an object. After curing the fluid containing the conductive particles, the fluid is irradiated with a laser to form an antenna. As a method for applying the fluid containing the conductive particles, screen printing, spin coating, dipping, or a droplet discharging method is used. Further, a solid laser having a wavelength of 1 nm or more and 380 nm or less is used as the laser.

Owner:SEMICON ENERGY LAB CO LTD

Naphthalene derivative, resist bottom layer material, and patterning process

ActiveUS20120064725A1Excellent etch resistanceMinimizing outgassingOrganic chemistryOrganic compound preparationBenzeneResist

A naphthalene derivative having formula (1) is provided wherein An and Art denote a benzene or naphthalene ring, and n is such a natural number as to provide a weight average molecular weight of up to 100,000. A material comprising the naphthalene derivative or a polymer comprising the naphthalene derivative is spin coated to form a resist bottom layer having improved properties. A pattern forming process in which a resist bottom layer formed by spin coating is combined with an inorganic hard mask formed by CVD is available.

Owner:SHIN ETSU CHEM IND CO LTD

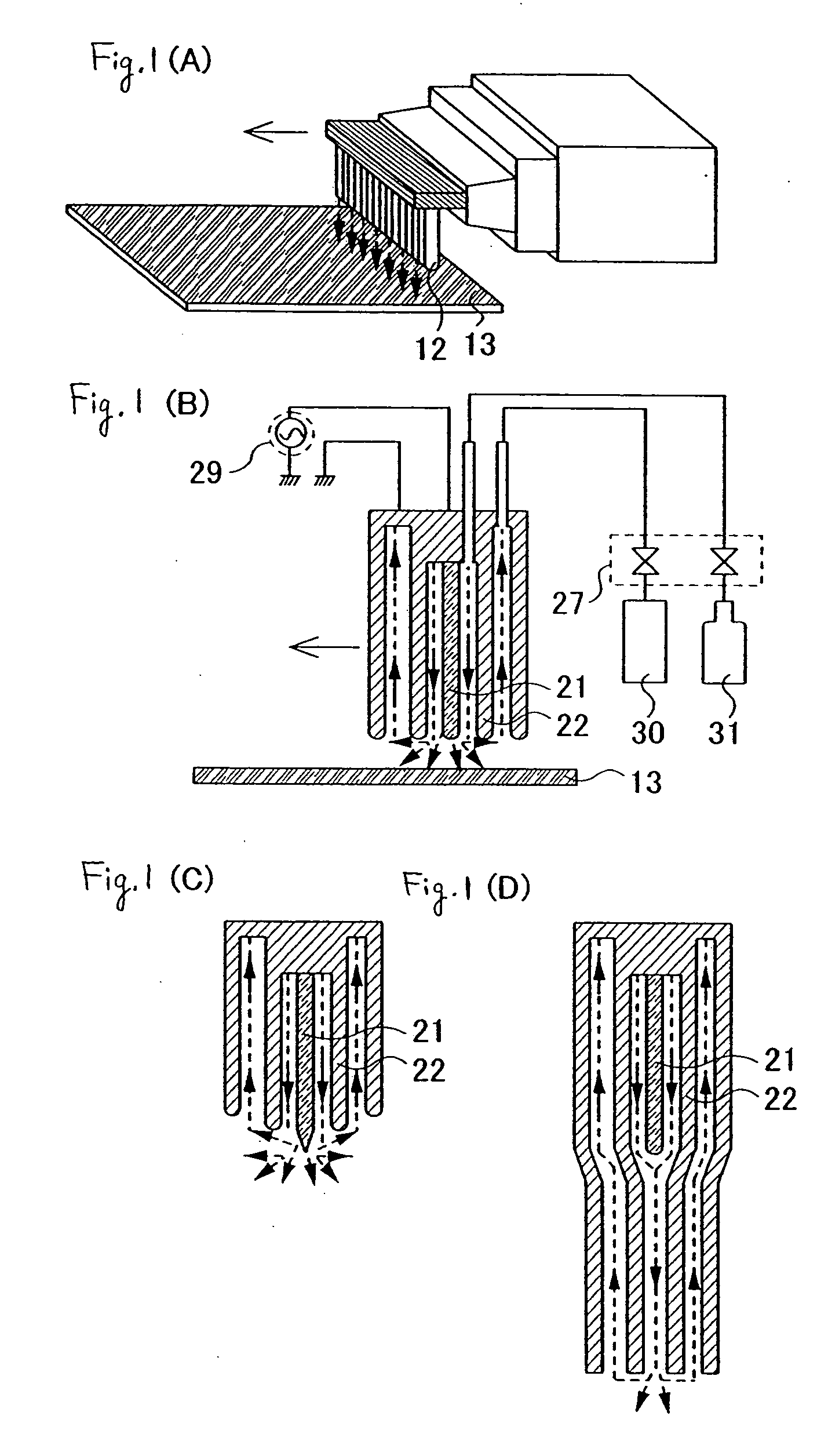

Liquid application apparatus, liquid application method, inkjet recording apparatus and inkjet recording method

InactiveUS20090165937A1Improve image qualityAvoid performance degradationInking apparatusDecorative surface effectsKnife bladesSpin coating

Owner:FUJIFILM CORP

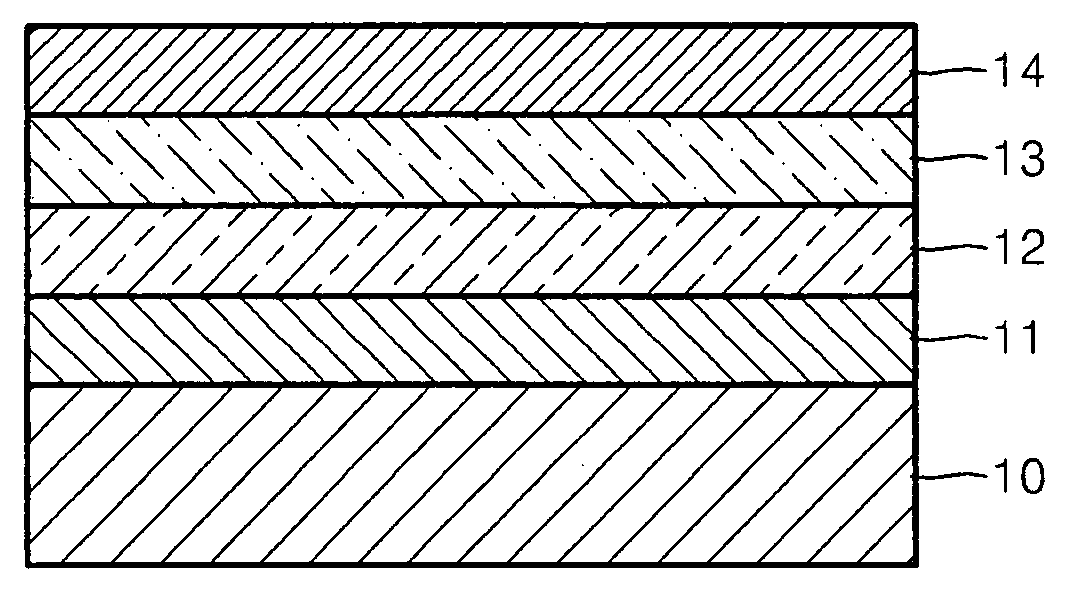

Electric appliance, semiconductor device, and method for manufacturing the same

InactiveUS20070093002A1Reduce drastically costReduce material usageTransistorElectroluminescent light sourcesDevice materialConductive materials

In the present circumstances, a film formation method of using spin coating in a manufacturing process is heavily used. As increasing the substrate size in future, the film formation method of using spin coating becomes at a disadvantage in mass production since a mechanism for rotating a large substrate becomes large, and there is many loss of material solution or waste liquid. According to the present invention, in a manufacturing process of a semiconductor device, a microscopic wiring pattern can be realized by delivering selectively photosensitive conductive material solution by droplet discharging, exposing selectively to laser light or the like, and developing. The present invention can reduce drastically costs since a patterning process can be shortened and an amount of material in a process of forming a conductive pattern can be reduced. Accordingly, the present invention can be applied to manufacture a large substrate.

Owner:SEMICON ENERGY LAB CO LTD

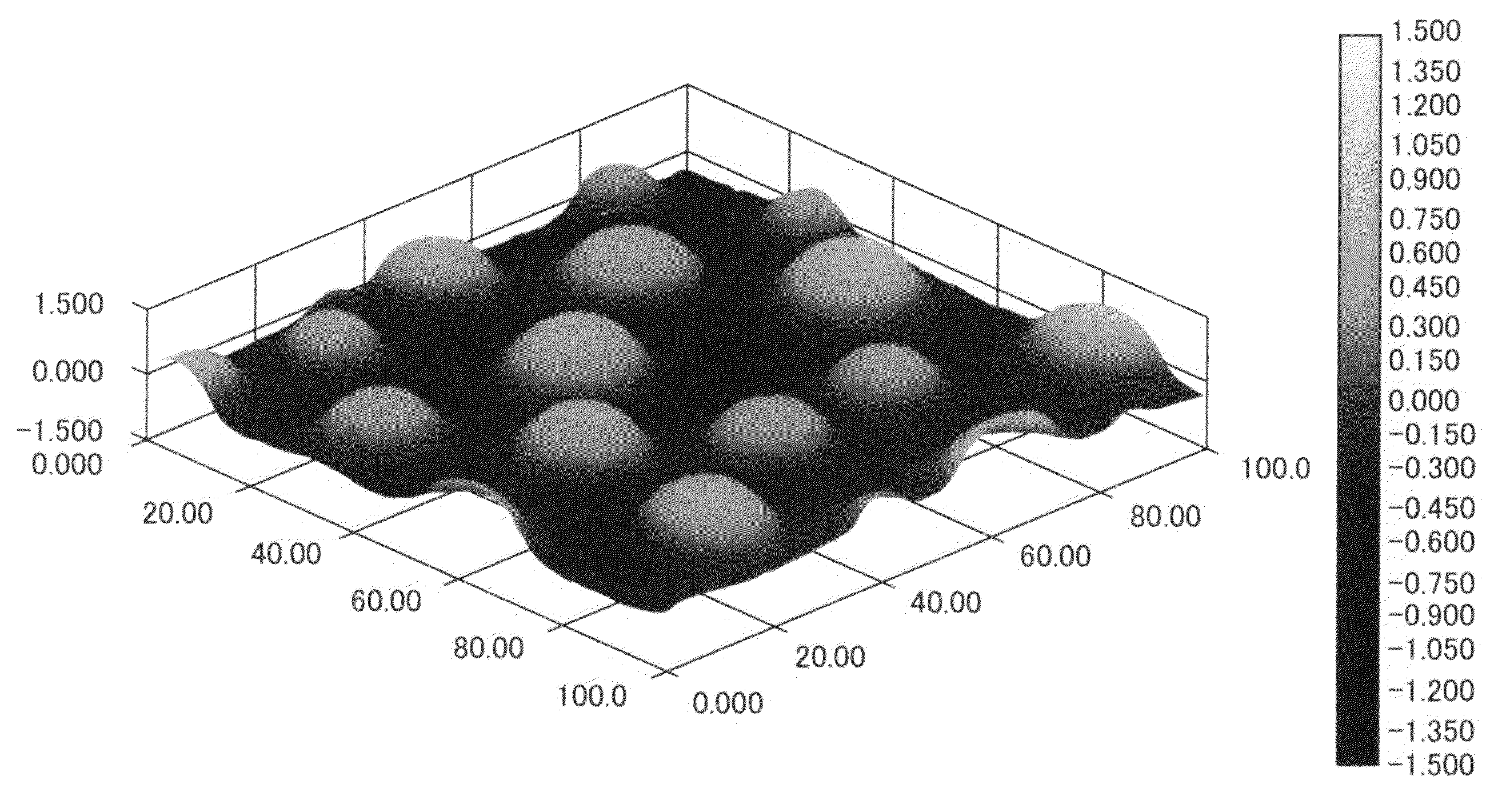

Anti-glare glass substrate

InactiveUS20070195419A1Improve visibilityWrite fluentlyLiquid crystal compositionsCoatingsArylPolymer science

An anti-glare glass substrate used for liquid crystal display devices is disclosed, which comprises a glass substrate; and a coating covering one side of said substrate, the coating having, on its surface, projection bodies which have round bottom surfaces and have an average bottom surface area ranging from 80 to 400 μm2, the projection bodies being randomly arranged on said coating at a density of 5 or more projection bodies per an area equivalent to one pixel of the liquid crystal display device, and the coating having a surface roughness from 0.1 to 0.4 μm. The anti-glare glass substrate can be prepared by the steps of (1) preparing a coating liquid by blending a silica sol (A) consisting of an oligomer whose crosslinks are formed from [SiO4 / 2] as crosslinking units and whose number average molecular weight ranges from 300 to 1000 (polystyrene conversion) and a silica sol (B) consisting of an oligomer in which silicon oxides having bonds between aryl groups and silicon atoms are formed as crosslinking units and whose number average molecular weight ranges from 500 to 1000 (polystyrene conversion); and (2) applying the resulting coating liquid onto the surface of a glass substrate according to the spin coating technique.

Owner:CENT GLASS CO LTD

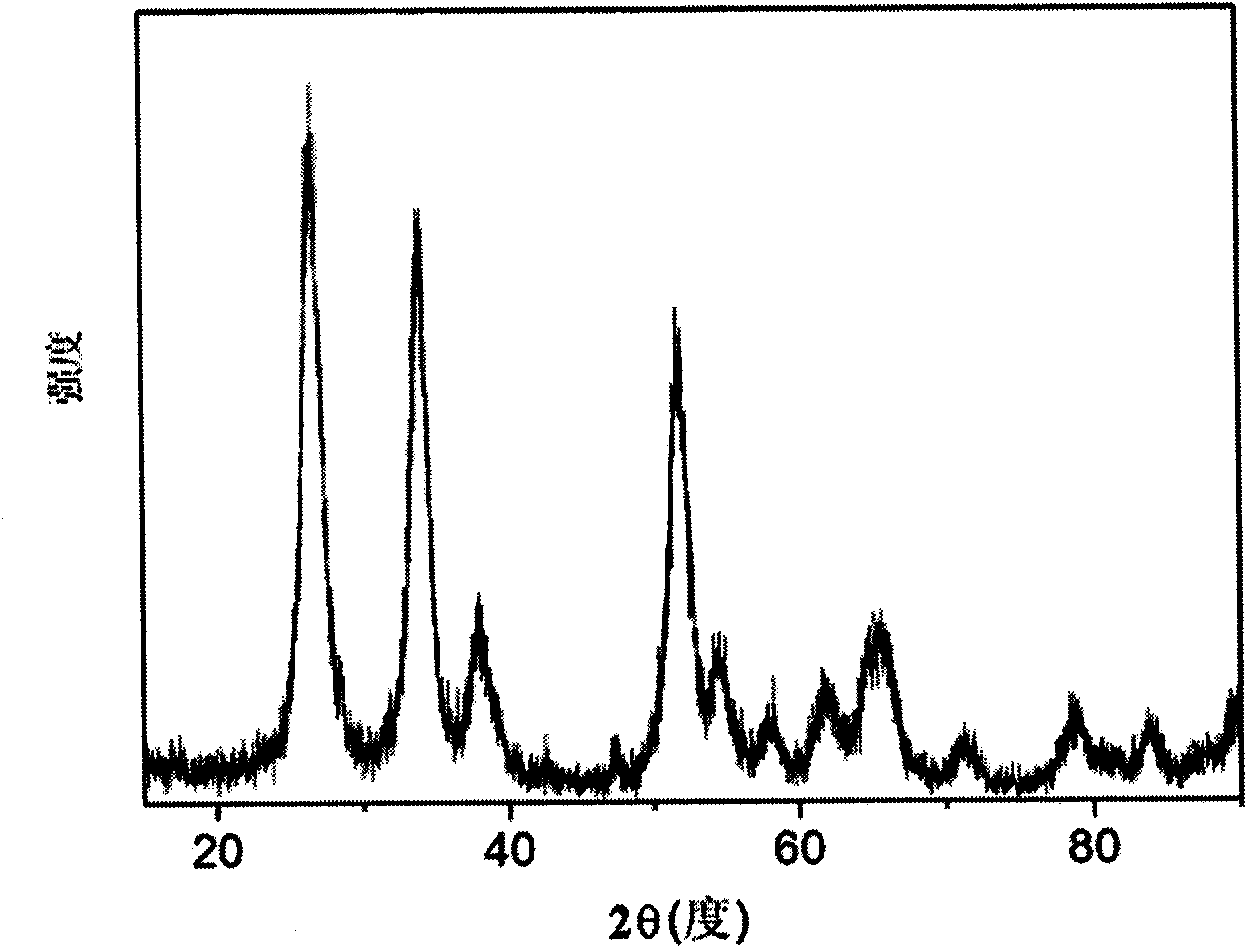

Method for preparing nano-doped tin oxide sol

ActiveCN101580270AGood dispersionImprove stabilityConductive layers on insulating-supportsMaterial resistanceLow emissivityGas detector

The invention relates to a method for preparing nano-doped tin oxide sol, belonging to the technical field of semiconductor nano film preparation process. The method provided by the invention mainly uses a sol-gel method to prepare nano-doped SnO2 sol on compatible reaction condition via hydrothermal processing. In the method, tin salt is taken as main raw material, villaumite and antimony salt or two parts of antimony or two parts of villaumite in appropriate content are added as doping agent to obtain doped SnO2 sol. High temperature calcination is unnecessary in the synthesized process, and nano-doped SnO2 sol can be obtained with even grains and fine dispersivity. Spray finishing, spin coating, and dipping and drawing method can be carried out on the obtained sol to prepare nano-doped SnO2 film. The film can be applied into various fields, such as low emissivity glass, display equipment, gas sensor, transparency electrode of solar battery and the like.

Owner:SHANGHAI UNIV

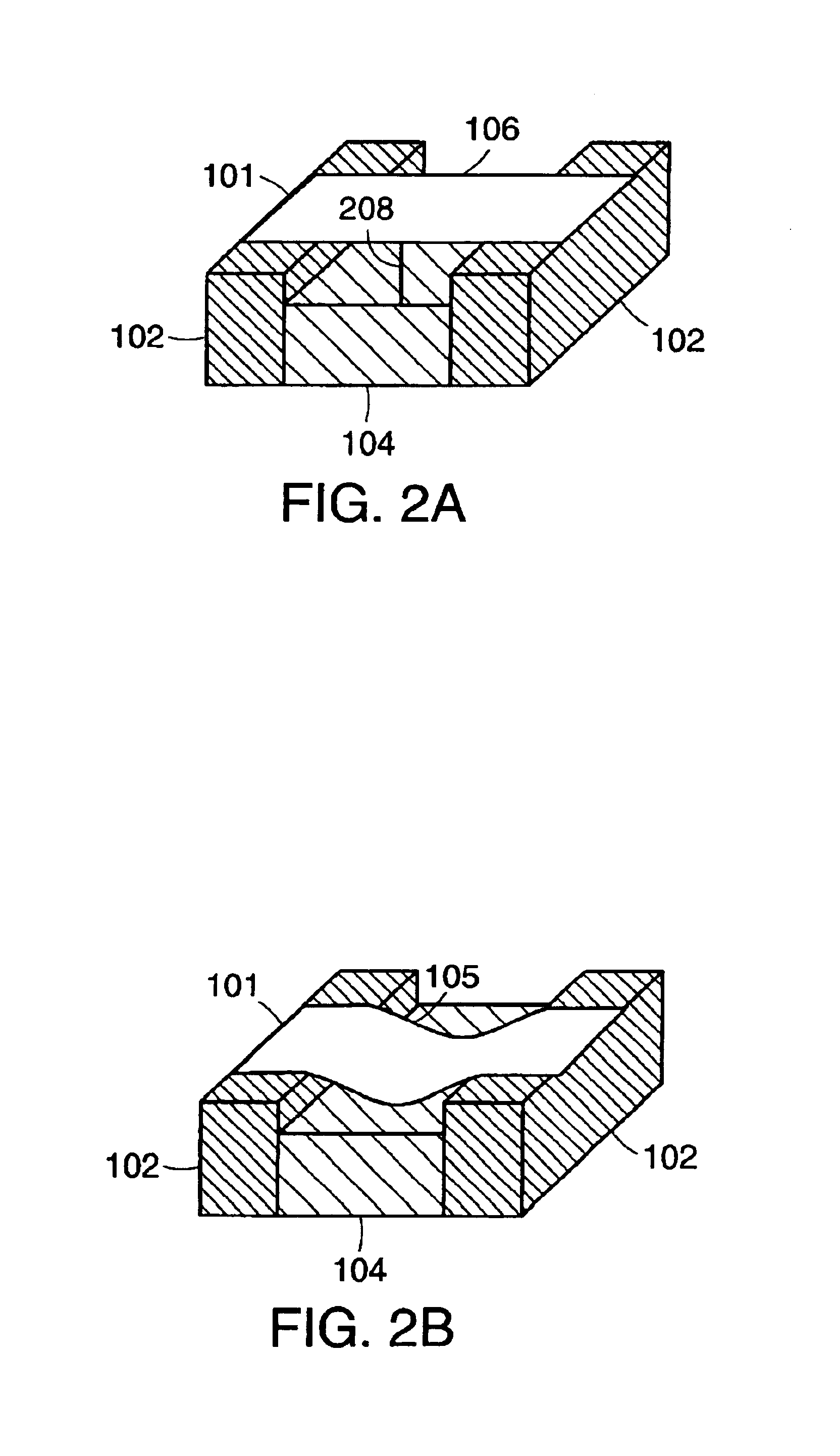

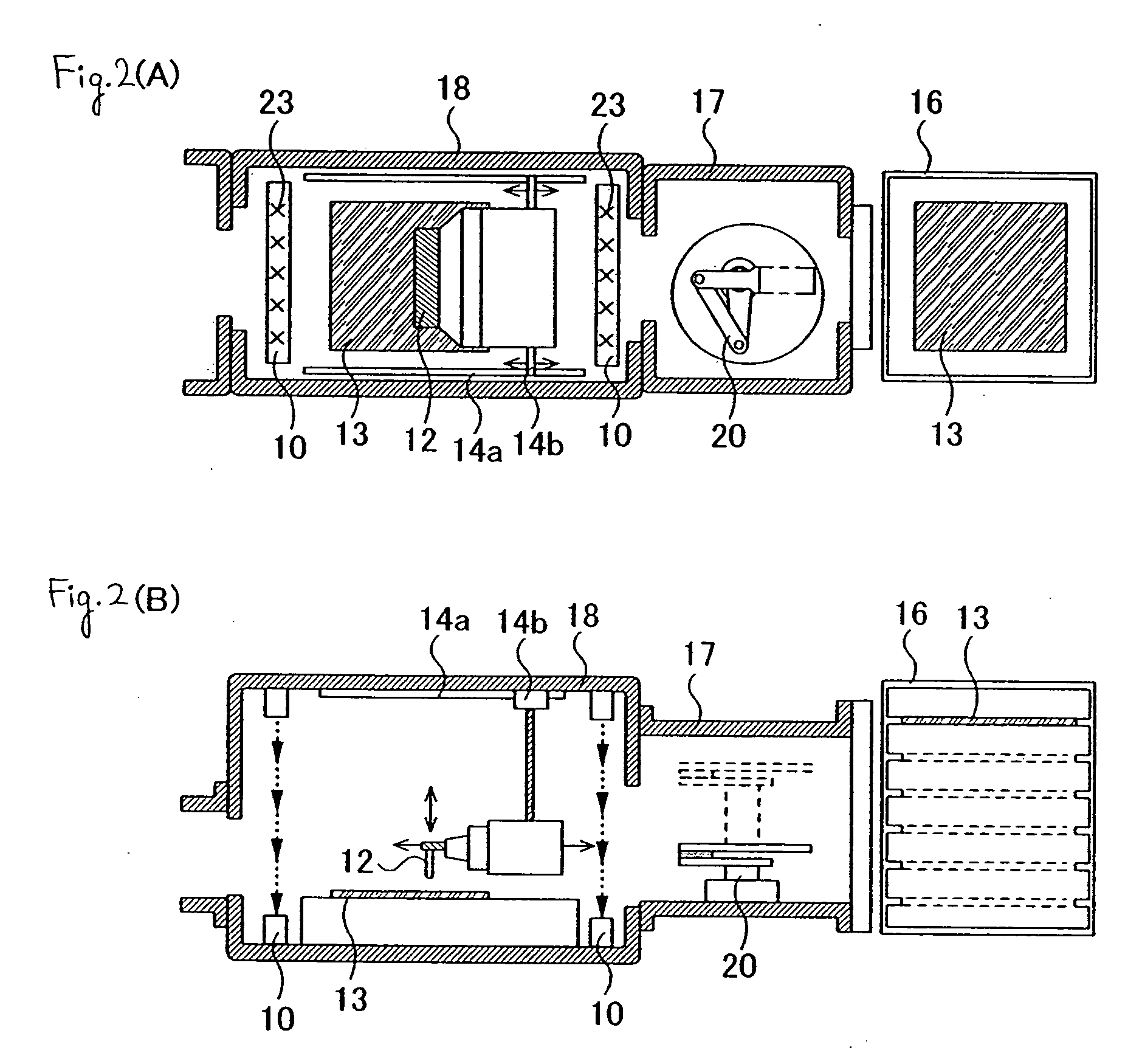

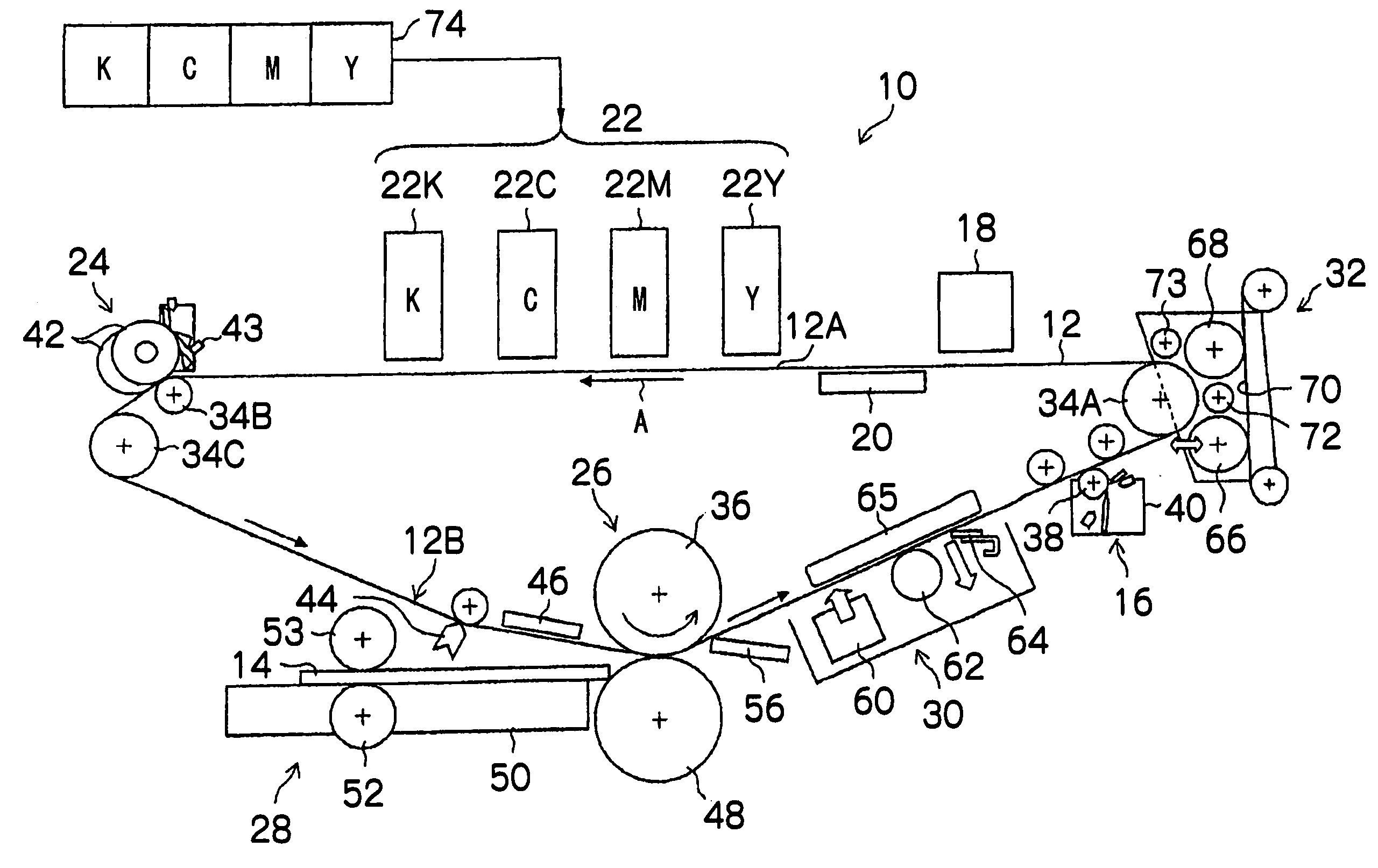

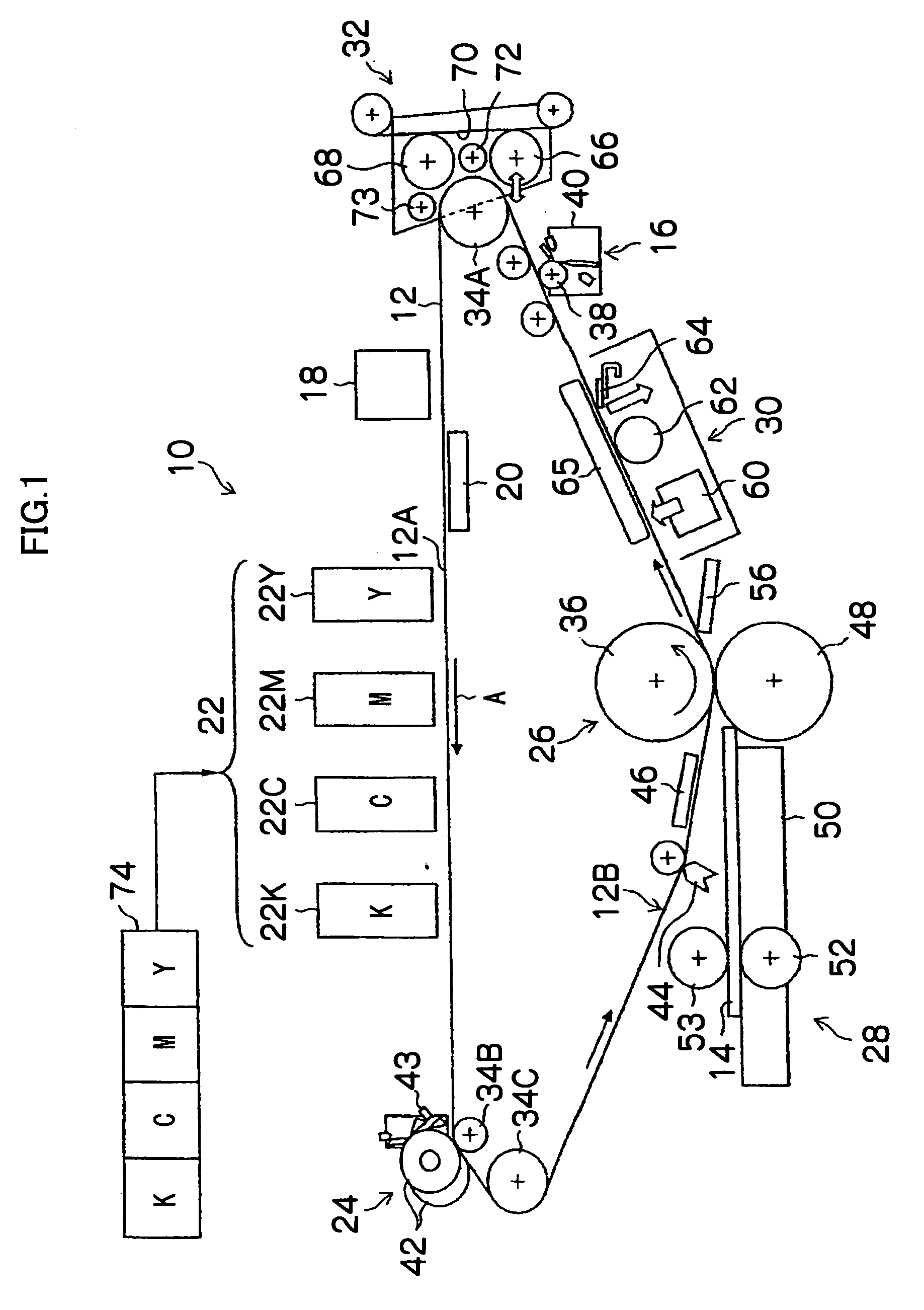

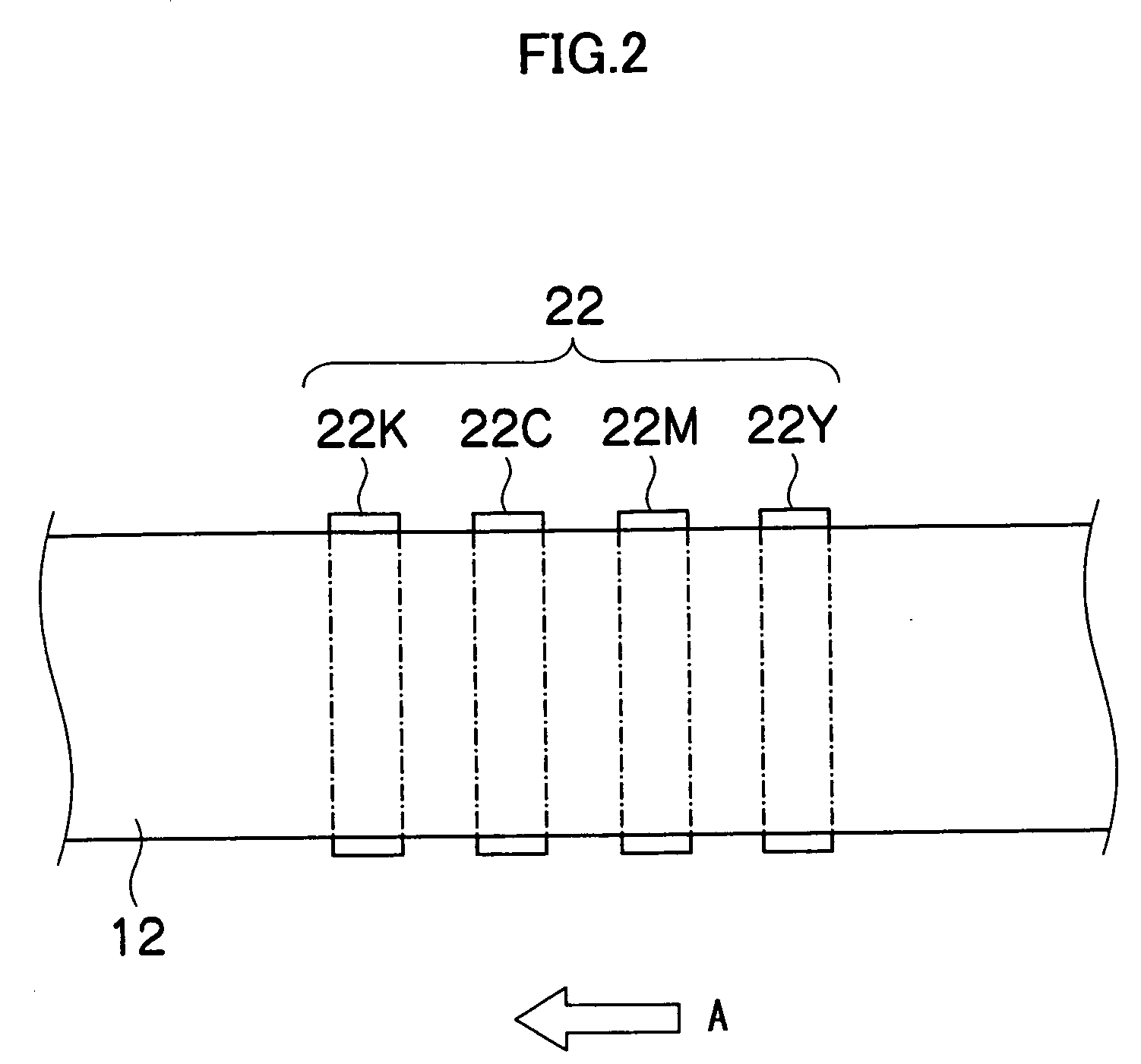

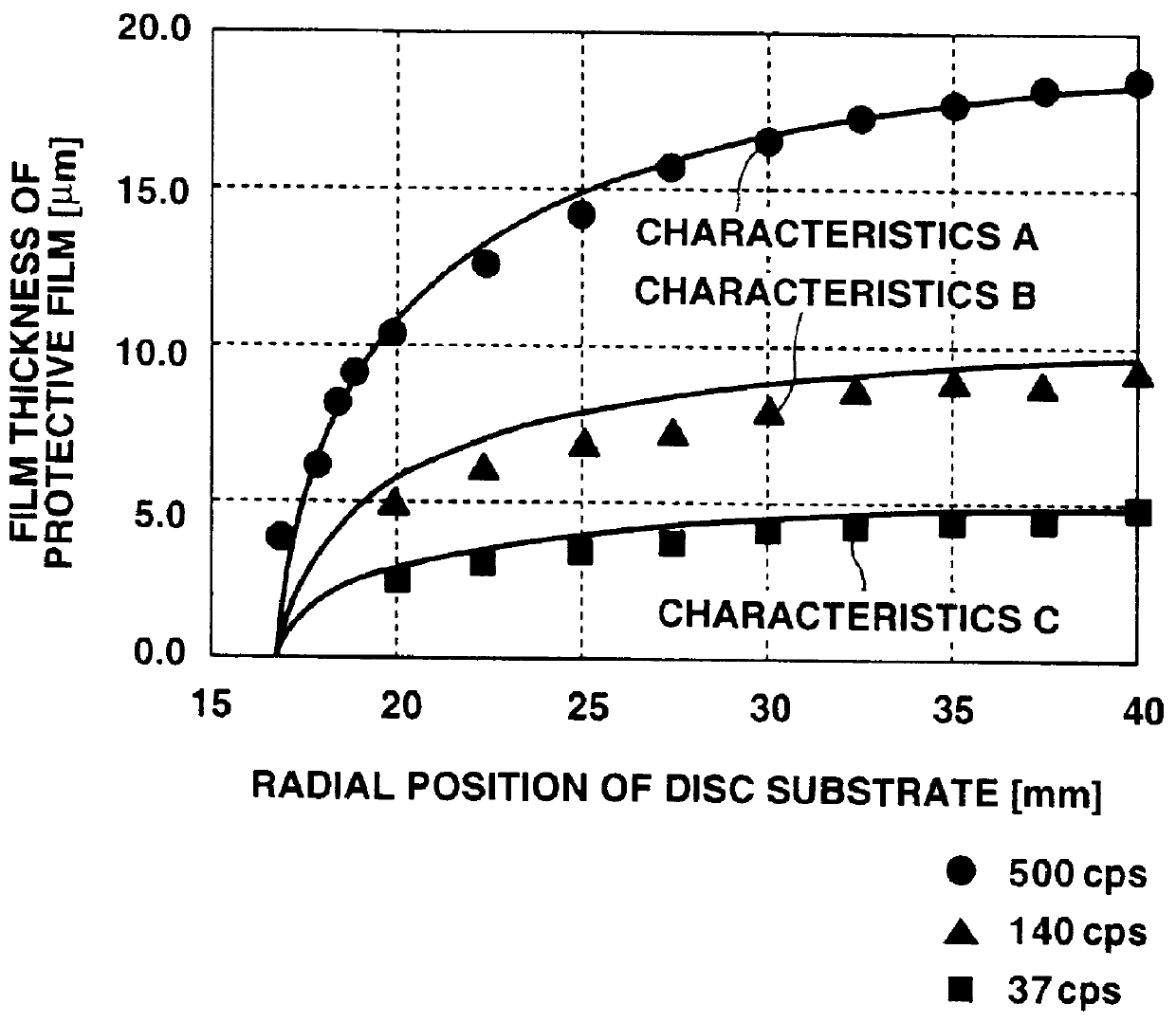

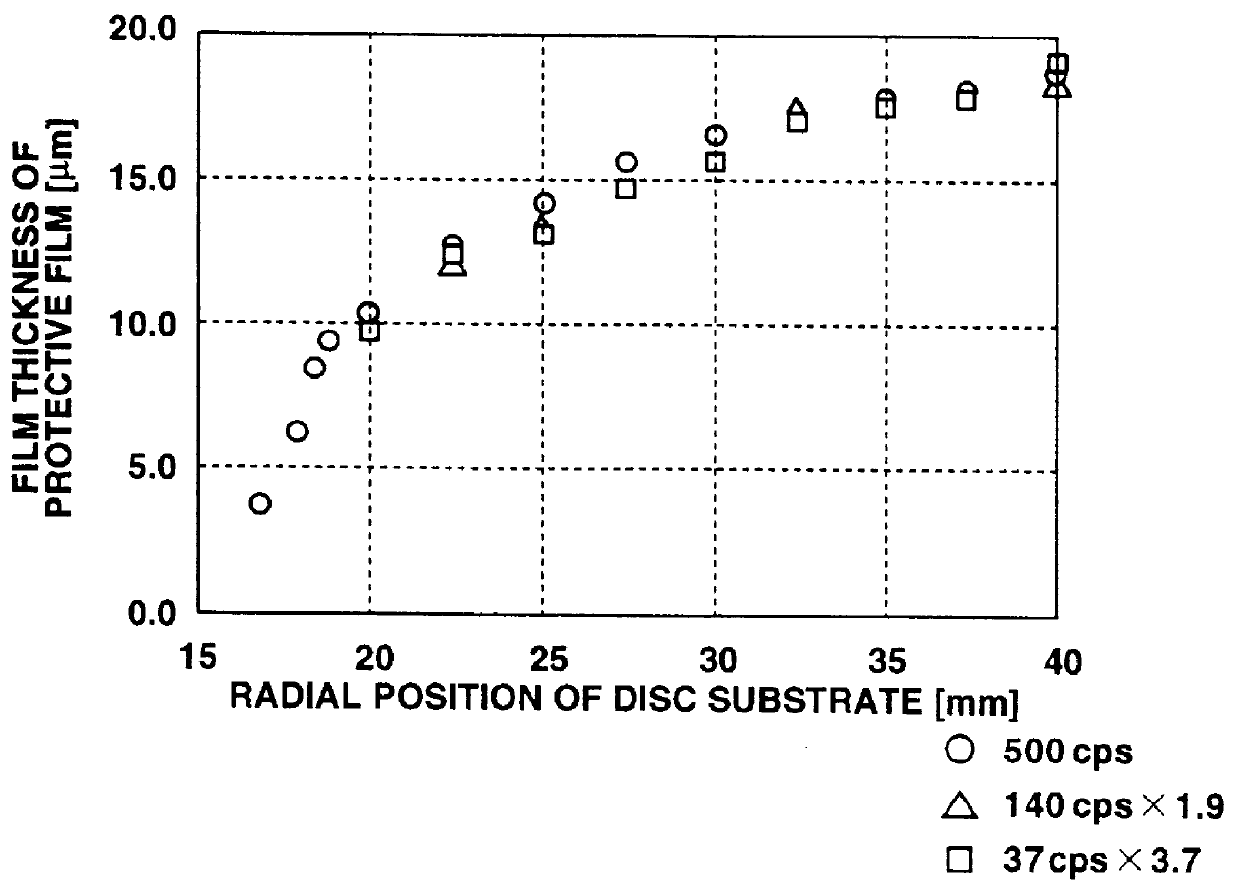

Method and apparatus for manufacturing disc-shaped recording medium

InactiveUS6077349ALarge diameterSuppress mutationRecord carriersSpraying apparatusCircular discEngineering

When applying a coating film by a spin coating method on a disc-shaped recording medium, the film thickness difference between the inner rim and the outer rim of the disc has to be suppressed. To this end, a coating liquid is supplied to a center portion of the disc-shaped recording medium and a rotary disc, as a center shaft of a rotary disc is inserted into a recess formed in a turntable on which the disc-shaped recording medium is set and the disc-shaped recording medium and a rotary disc are run in rotation. The coating liquid is spread under the centrifugal force caused by rotation for forming a coating film on the disc-shaped recording medium.

Owner:SONY CORP

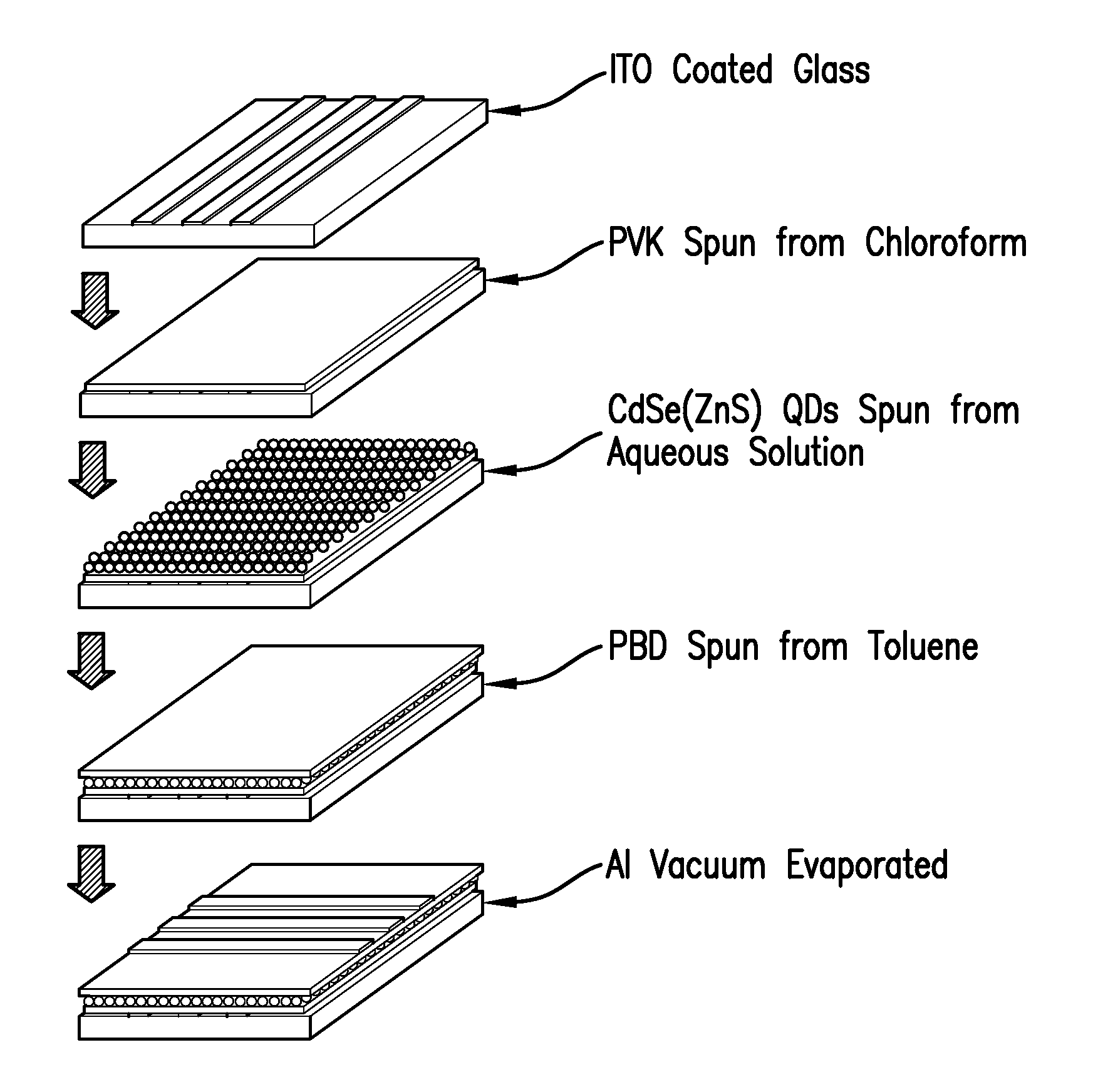

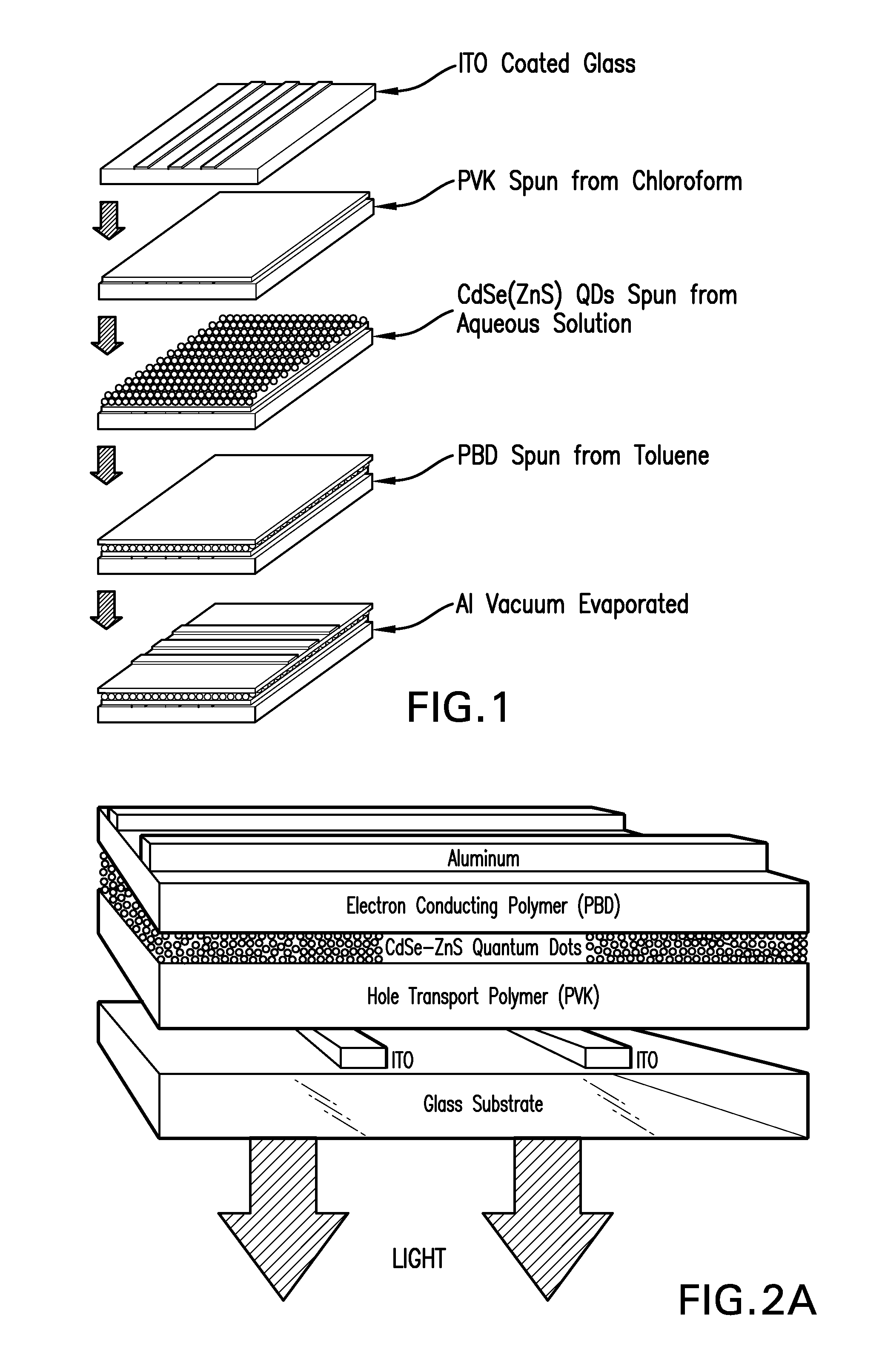

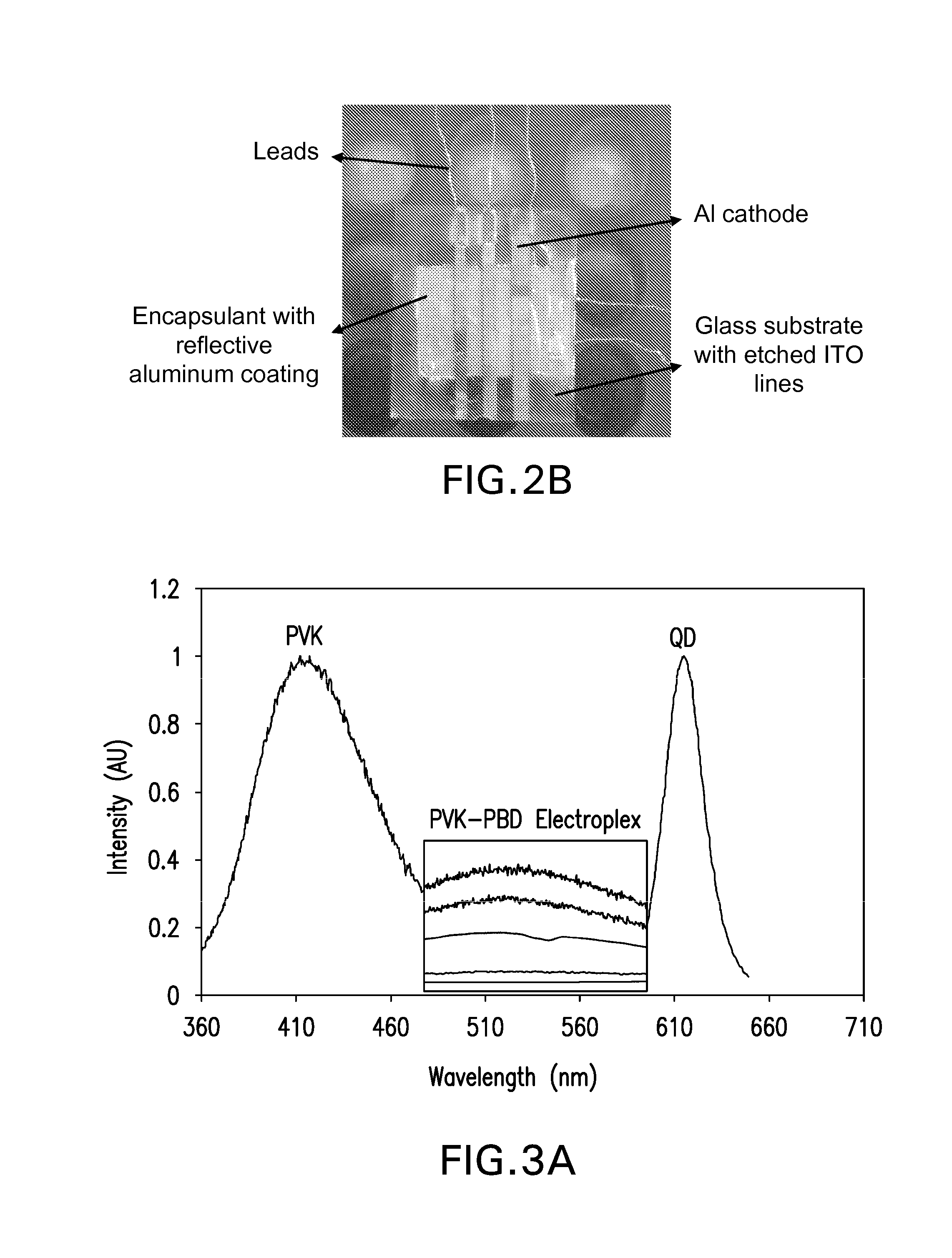

Multilayer polymer-quantum dot light emitting diodes and methods of making and using thereof

InactiveUS7132787B2Material nanotechnologyDischarge tube luminescnet screensQuantum dotLight-emitting diode

Owner:RGT UNIV OF CALIFORNIA

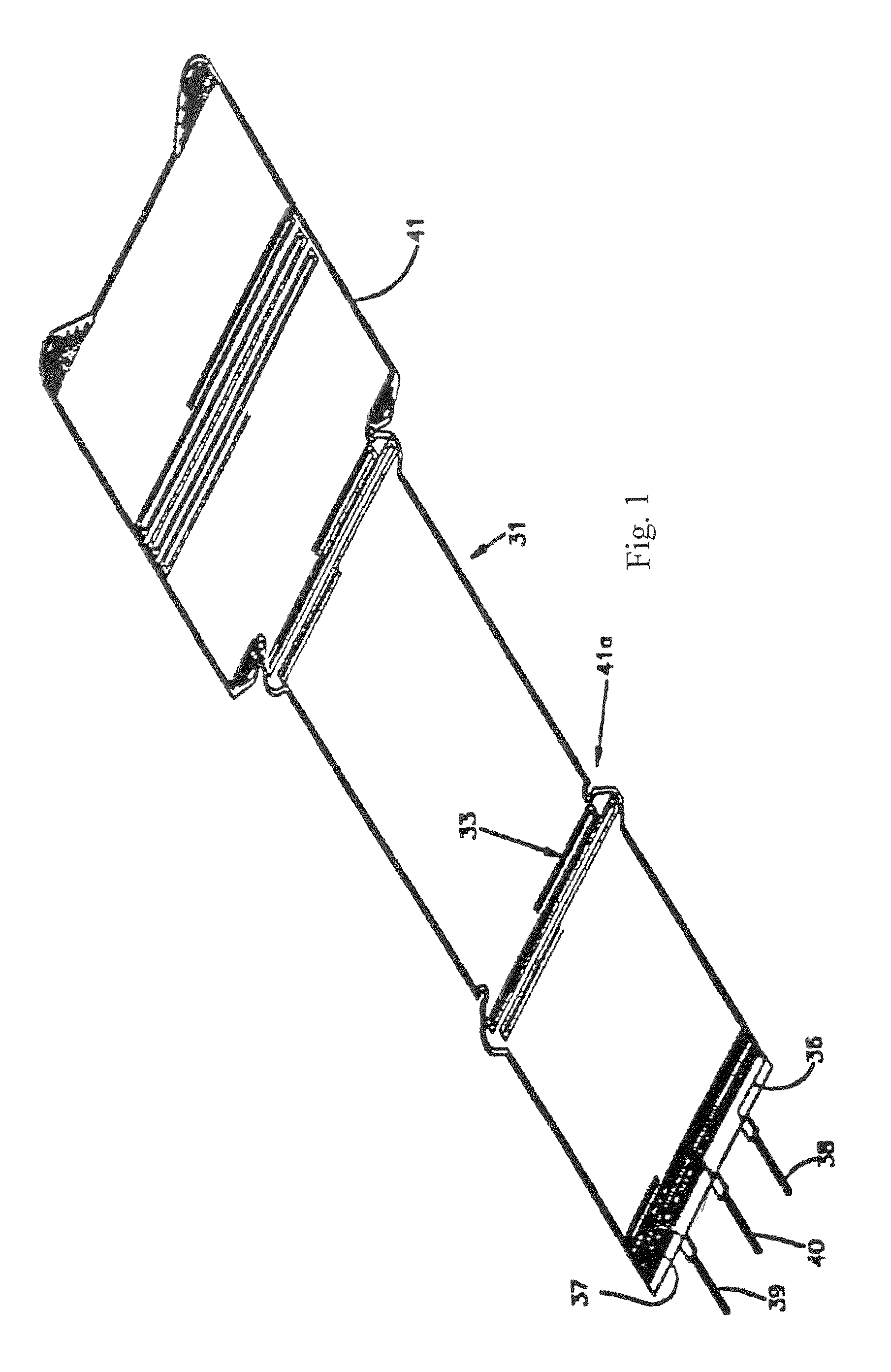

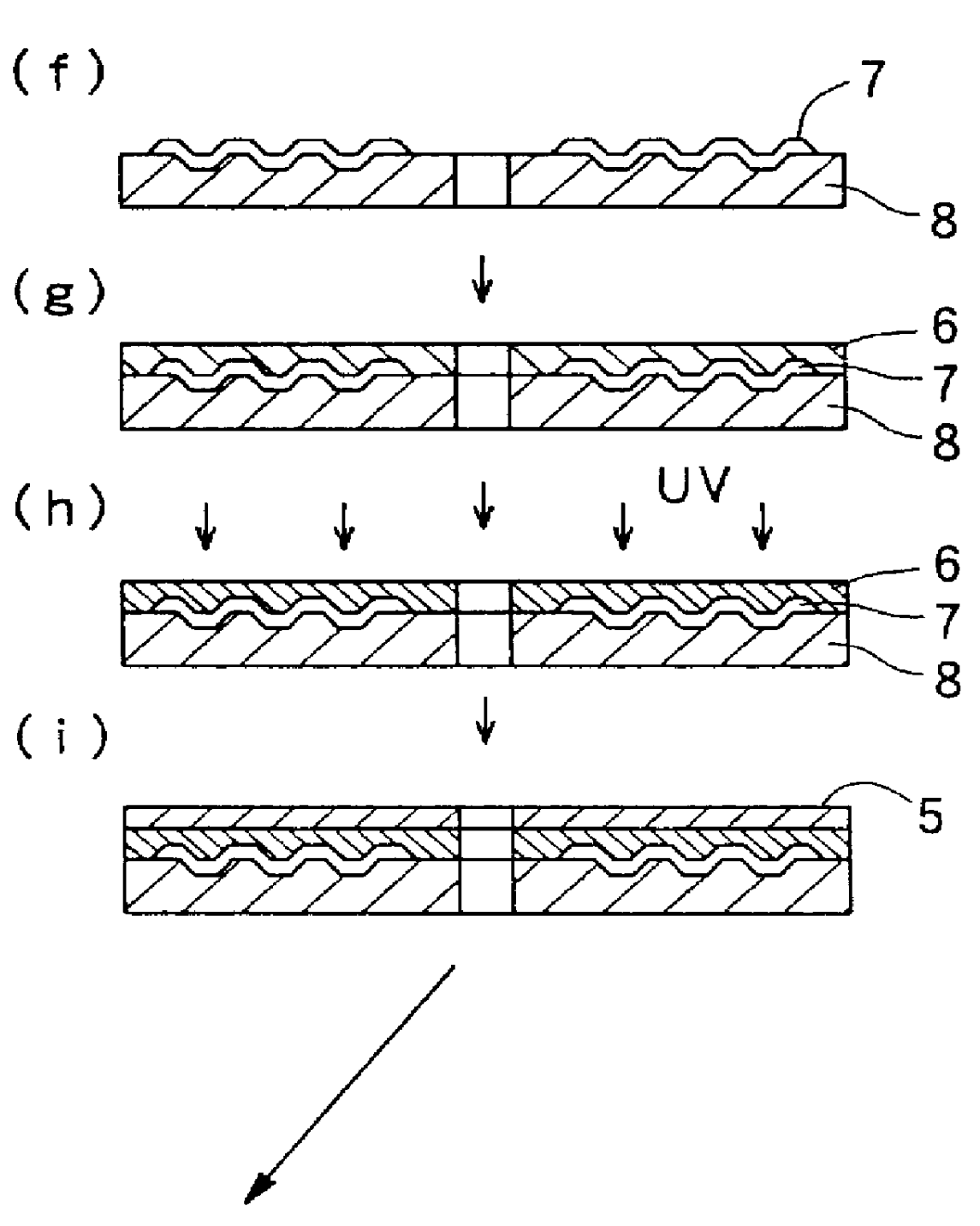

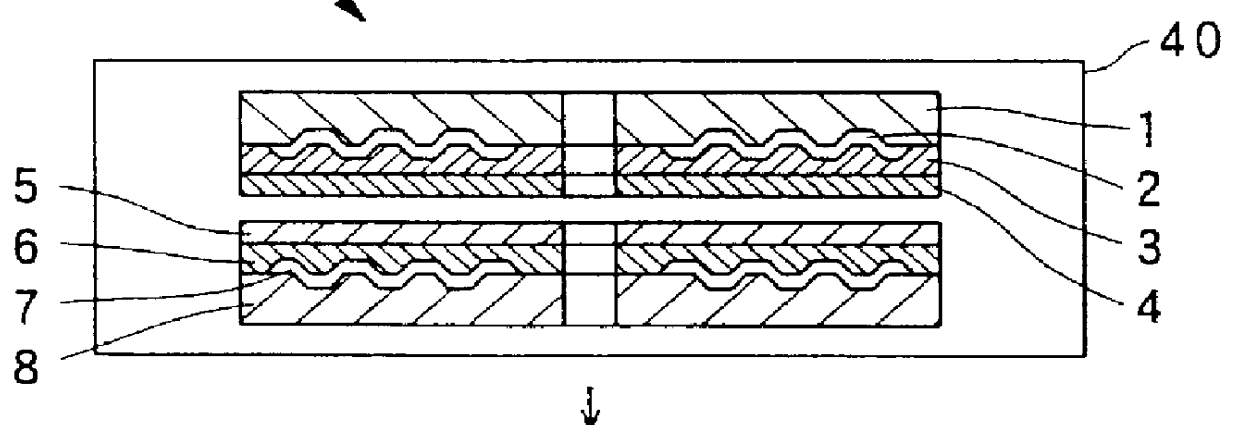

Method of producing optical disc of bonded type

InactiveUS6136133AUniform and constant thicknessEfficiently obtainedRecord carriersLamination ancillary operationsUltravioletPartial reflection

A method of producing an optical disc of bonded type includes the processes of: (A) forming a first reflection film, which is half transparent for partially reflecting and partially transmitting an incident light, on a first information record surface of a first transparent substrate; (B) forming a second reflection film, which has a reflective index higher than that of the first reflection film, on a second information record surface of a second transparent substrate; (C) dripping a liquid resin of ultraviolet hardening type onto one of the first and second reflection films by a spin coating method to form a first resin layer in a non-hardened condition; (D) dripping a liquid resin of ultraviolet hardening type onto the other of the first and second reflection films by a spin coating method; (E) emitting ultraviolet onto the liquid resin dripped by the process (D) to form a second resin layer of ultraviolet hardening type in a hardened condition; (F) provisionally bonding the first and second transparent substrates together in a pressure reduced environment; and (G) hardening the first resin layer by emitting ultraviolet from a side of the first transparent substrate.

Owner:PIONEER CORP +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com