Environment-friendly nano water-based silane treatment agent capable of improving anti-corrosion performance of metal surface

A kind of metal surface treatment and environmental protection technology, applied in the direction of metal material coating process, etc., can solve the problems of short life of silane film and limited anti-corrosion ability, and achieve the goal of improving anti-corrosion performance, prolonging service life and enhancing adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

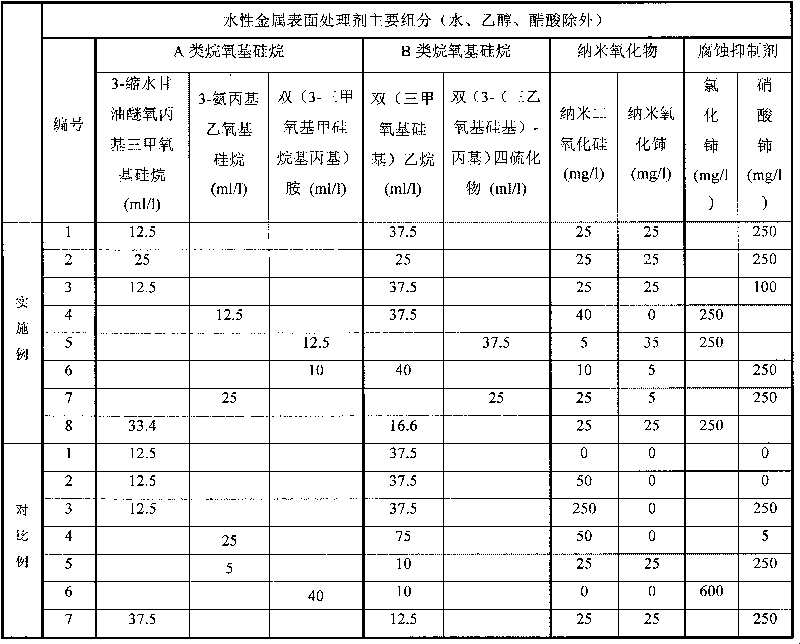

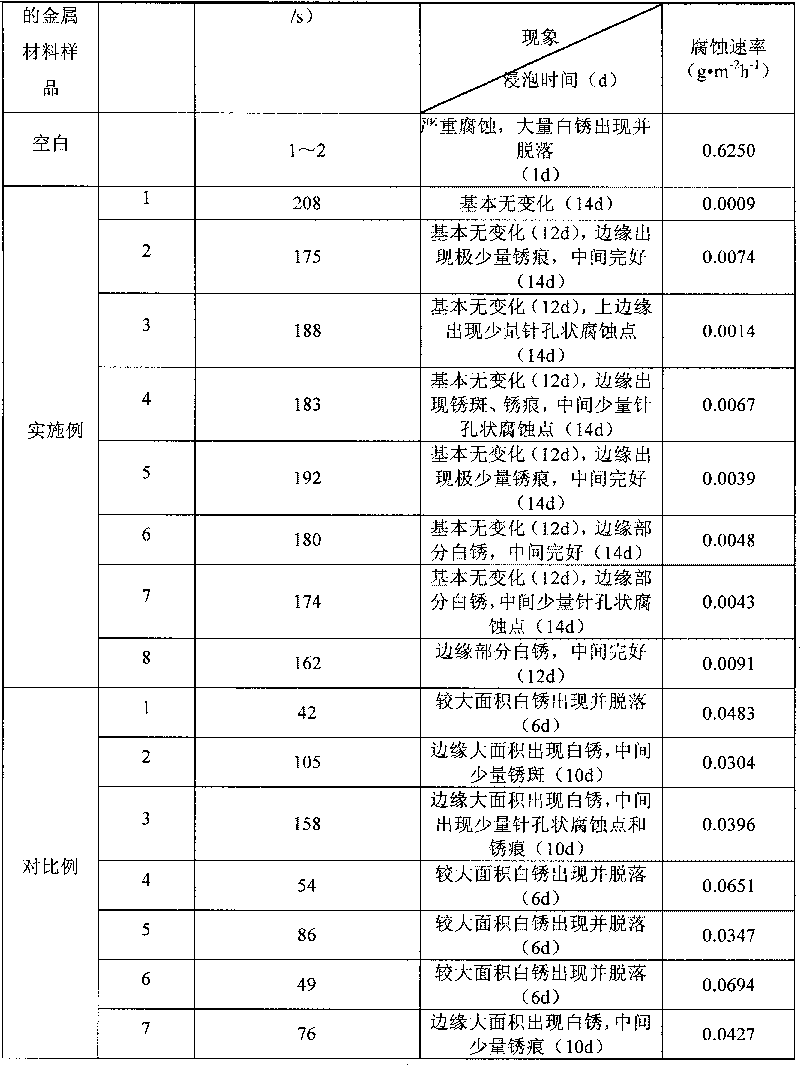

Embodiment 1

[0027]The preferred preparation method of environment-friendly metal surface treatment agent of the present invention comprises the following steps:

[0028] 1. Slowly add 37.5ml of 1,2-bis(trimethoxysilyl)ethane to 560ml of deionized water dissolved with a small amount of glacial acetic acid, stir vigorously during the addition, and control the amount of glacial acetic acid at a pH of 5-6 Between is appropriate. After adding BTMSE, add 40ml ethanol to the mixed solution;

[0029] 2. After the solution becomes completely clear and transparent, add 12.5ml of 3-glycidyl etheroxypropyltrimethoxysilane and stir thoroughly;

[0030] 3. Add 25 mg of water-dispersible silica to the mixed solution, stir vigorously for 5 minutes, and then put it in an ultrasonic cleaner for 15 minutes;

[0031] 4. Dissolve 250mg of cerium nitrate in 400ml of deionized water, and then add 25mg of nano-cerium oxide to it;

[0032] 5. Place the solution of step 4 above in an ultrasonic cleaner for 15 m...

Embodiment 2-3

[0035] According to the composition composition of the surface treatment agent in Example 1, without changing the type of composition, change the content of some composition components as shown in Table 1, the preparation steps of the treatment agent and the characterization of the metal material sample after treatment and the embodiment 1 is the same.

Embodiment 4

[0037] Type A alkoxysilane is 3-aminopropylethoxysilane, no cerium oxide is added, and cerium chloride is used as a corrosion inhibitor. The composition of other treatment agents remains unchanged. The specific content of each composition is shown in Table 1. . The preparation steps of the treatment agent and the characterization of the treated metal material sample are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com