Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12583 results about "Corrosion inhibitor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A corrosion inhibitor is a chemical compound that, when added to a liquid or gas, decreases the corrosion rate of a material, typically a metal or an alloy. The effectiveness of a corrosion inhibitor depends on fluid composition, quantity of water, and flow regime. A common mechanism for inhibiting corrosion involves formation of a coating, often a passivation layer, which prevents access of the corrosive substance to the metal. Permanent treatments such as chrome plating are not generally considered inhibitors, however. Instead corrosion inhibitors are additives to the fluids that surround the metal or related object.

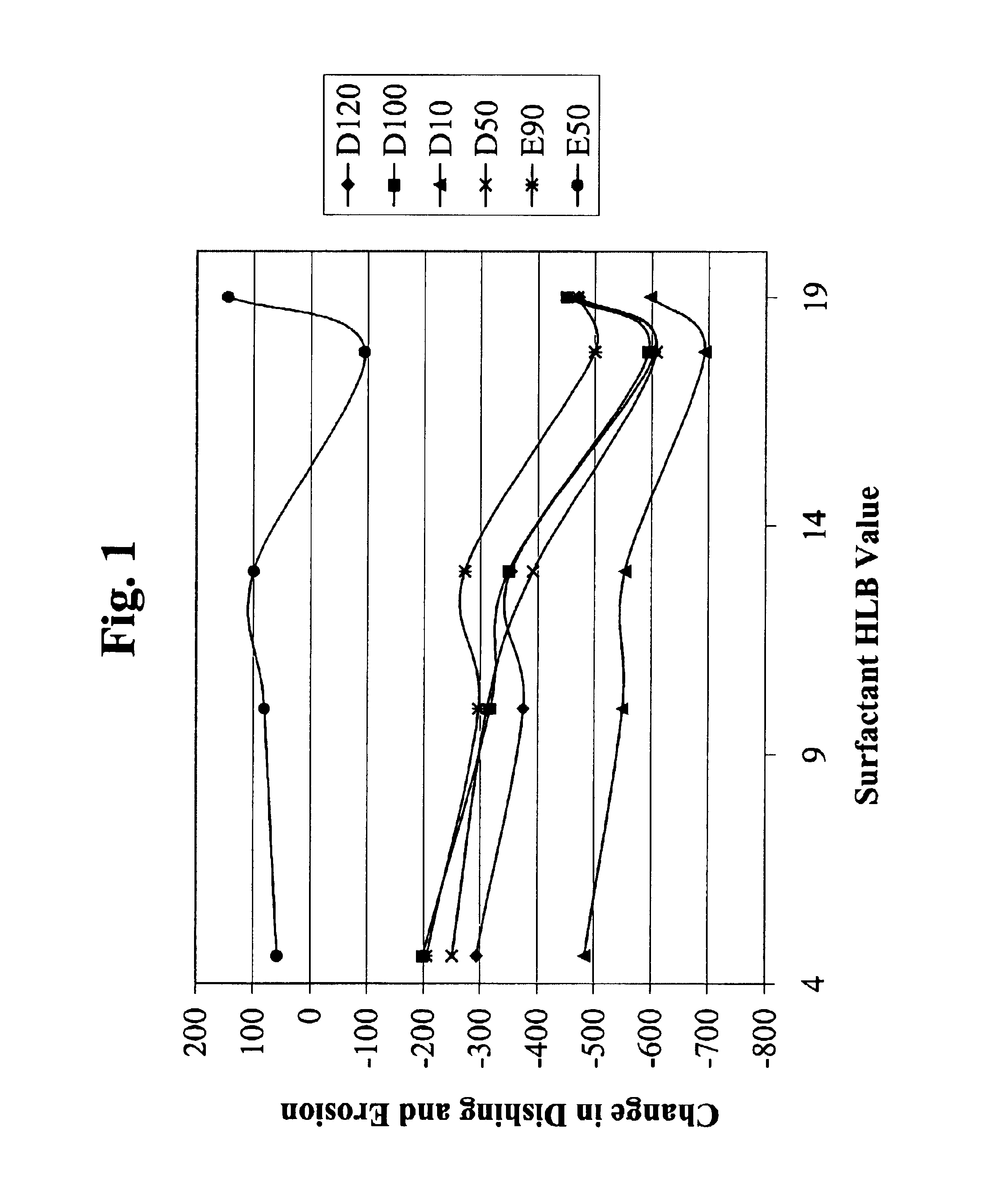

Slurry compositions for chemical mechanical polishing of copper and barrier films

InactiveUS20050090104A1High selectivityShorten the counting processSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesSlurryPolymer

Owner:INNOVATIUM TECH

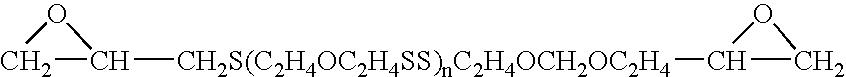

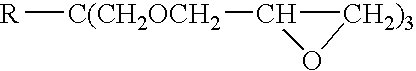

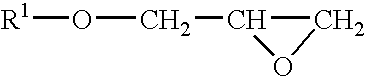

Epoxy coating

InactiveUS7037958B1Improve adhesionAvoid corrosionLiquid surface applicatorsAircraft carriersEpoxyGlass fiber

This invention concerns an epoxy coating for use as a non-skid surface for applications such as the deck of an aircraft carrier. The epoxy coating can be formulated from (a) an amine curing agent, (b) an epoxide-containing toughening agent such as a polysulfide and / or a polythioether, (c) an epoxy resin, (d) a rubber toughening agent, and (e) an optional fire retardant, a glass fiber thixotrope and impact toughening agent, an optional pigment, an optional corrosion inhibitor, an optional moisture penetration inhibitor, an optional ultraviolet light stabilizer, an optional abrasive aggregate, or a combination thereof.

Owner:TEXAS RES INT

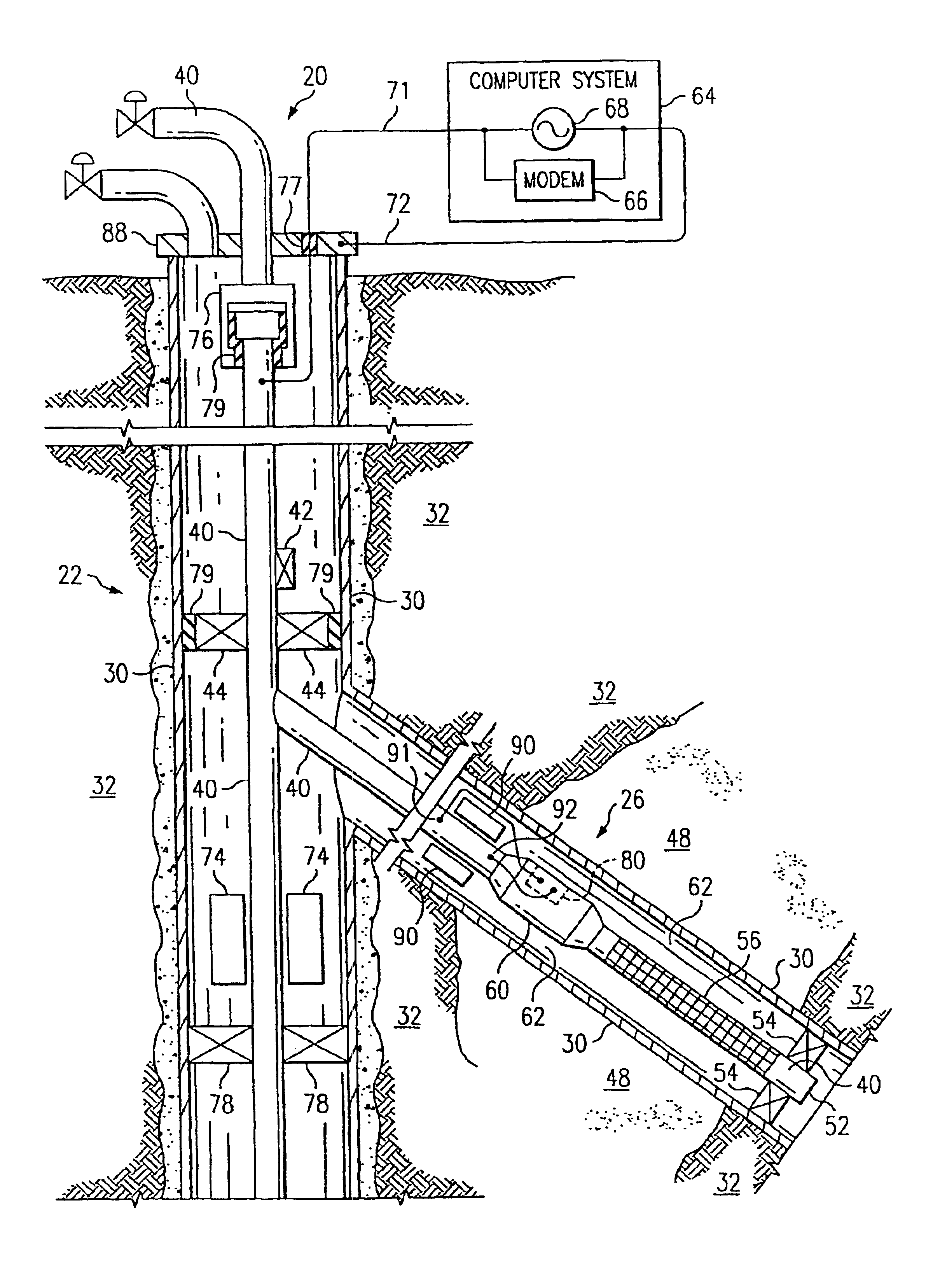

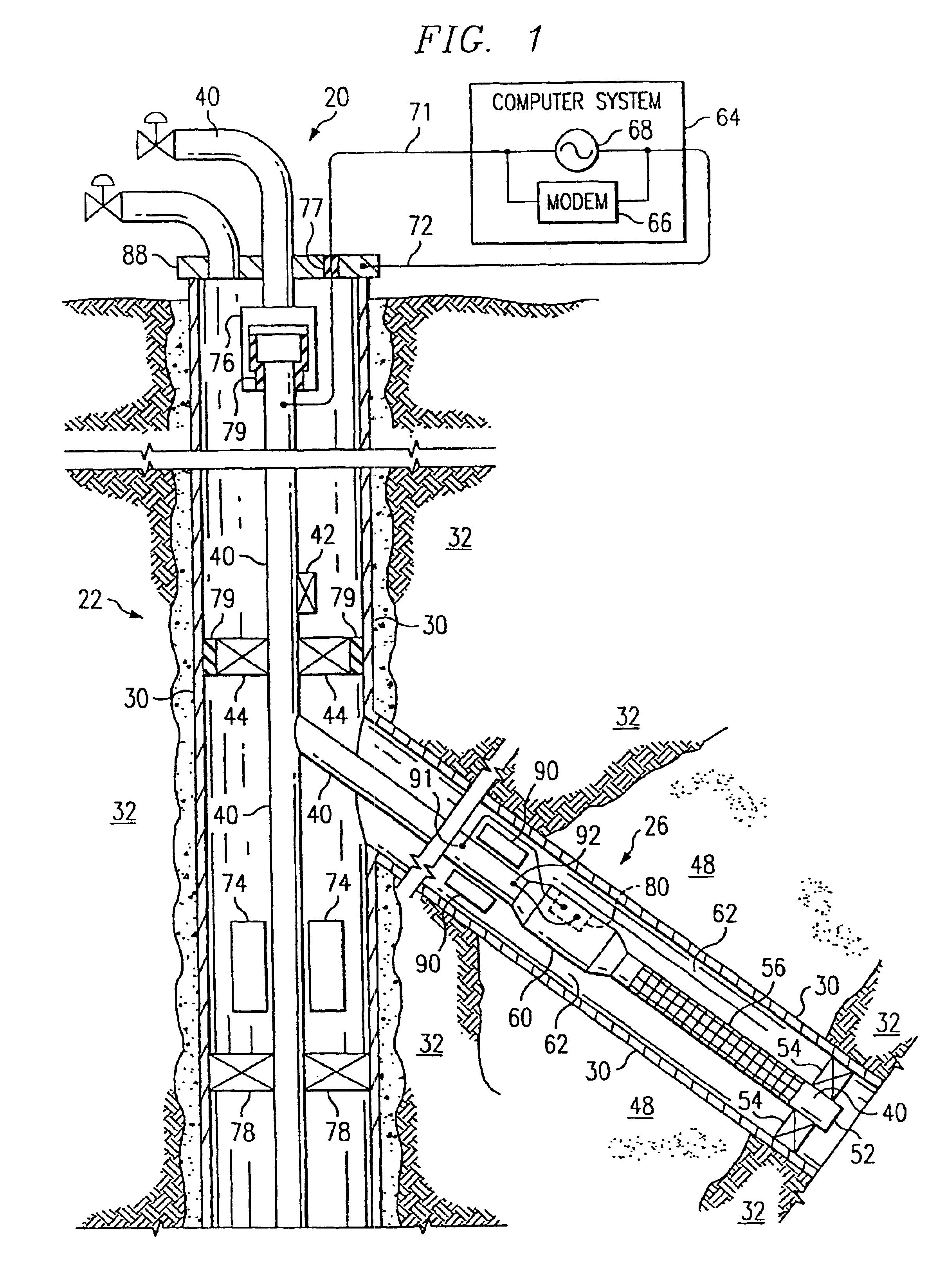

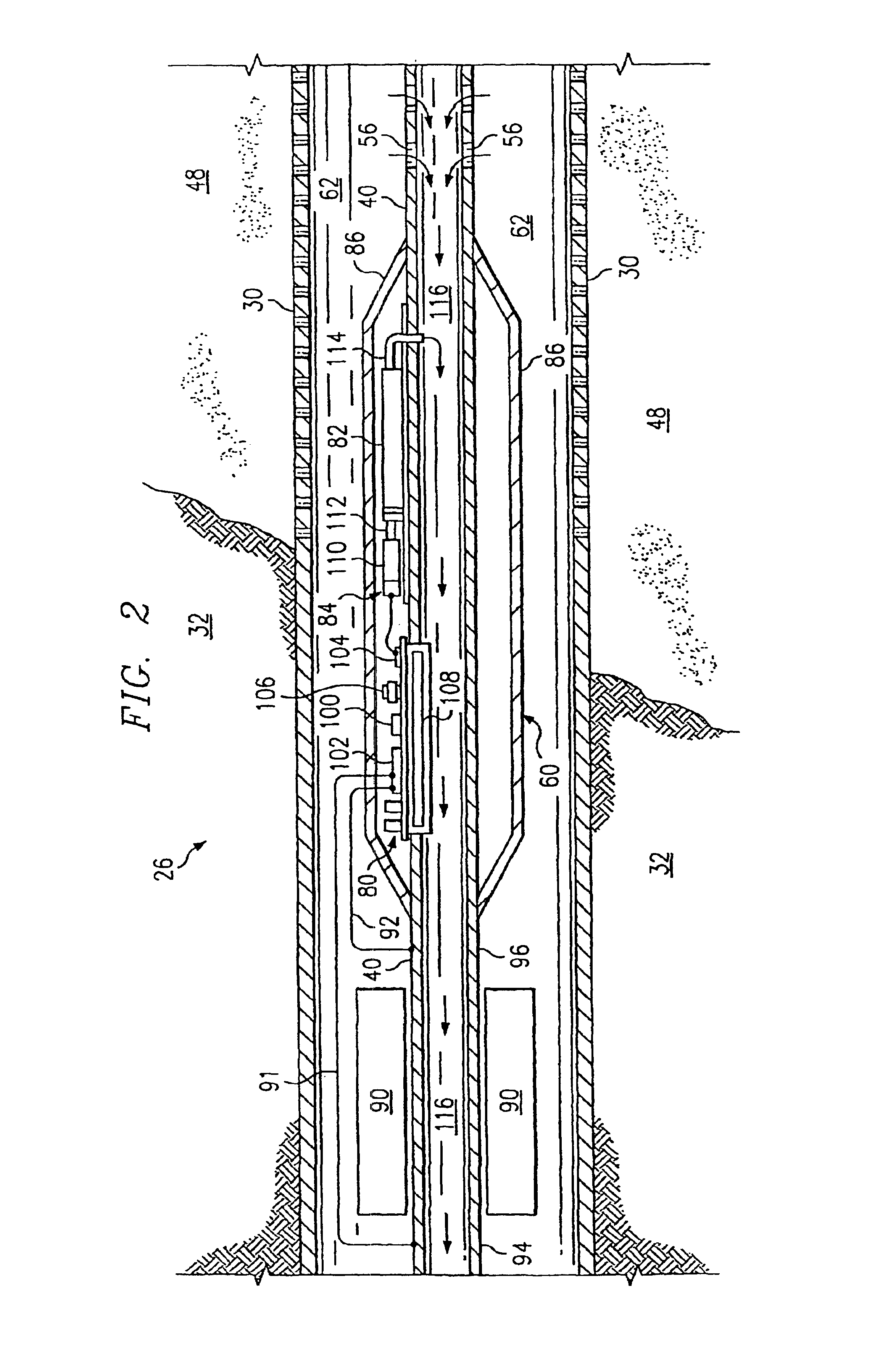

Controlled downhole chemical injection

InactiveUS6981553B2Improve efficiencyImprove flow characteristicsNear-field transmissionSurveyElectrical conductorPetroleum

A petroleum well having a well casing, a production tubing, a source of time-varying current, a downhole chemical injection device, and a downhole induction choke. The casing extends within a wellbore of the well. The tubing extends within the casing. The current source is located at the surface. The current source is electrically connected to, and adapted to output a time-varying current into, the tubing and / or the casing, which act as electrical conductors for providing downhole power and / or communications. The injection device having a communications and control module, a chemical container, and an electrically controllable chemical injector. The communications and control module is electrically connected to the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The induction choke is adapted to route part of the electrical current through the communications and control module by creating a voltage potential between one side of the induction choke and another side of the induction choke. The communications and control module is electrically connected across the voltage potential. Also, a method is provided for controllably injecting a chemical into the well downhole, which may be used to: improve lift efficiency with a foaming agent, prevent deposition of solids with a paraffin solvent, improve a flow characteristic of the flow stream with a surfactant, prevent corrosion with a corrosion inhibitor, and / or prevent scaling with scale preventers.

Owner:SHELL OIL CO

Micro-emulsion type metal cutting liquor composition

InactiveCN101240217AEasy to handleImprove the lubrication effectAdditivesBase-materialsMaterials scienceCutting fluid

Disclosed is a microemulsifying metal-cutting-fluid composition, comprising base oil or oily agent, mixed alcohol-amine, boric acid, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative, deionized water and the like. The invention has the advantages of excellent lubricity, cooling ability, cleaning ability and a long lifetime of metal cutting fluid, being suited to various metal processing technologies such as cutting, reaming, boring, grinding. Also, the wastewater is easy to treat.

Owner:益田润石(北京)化工有限公司

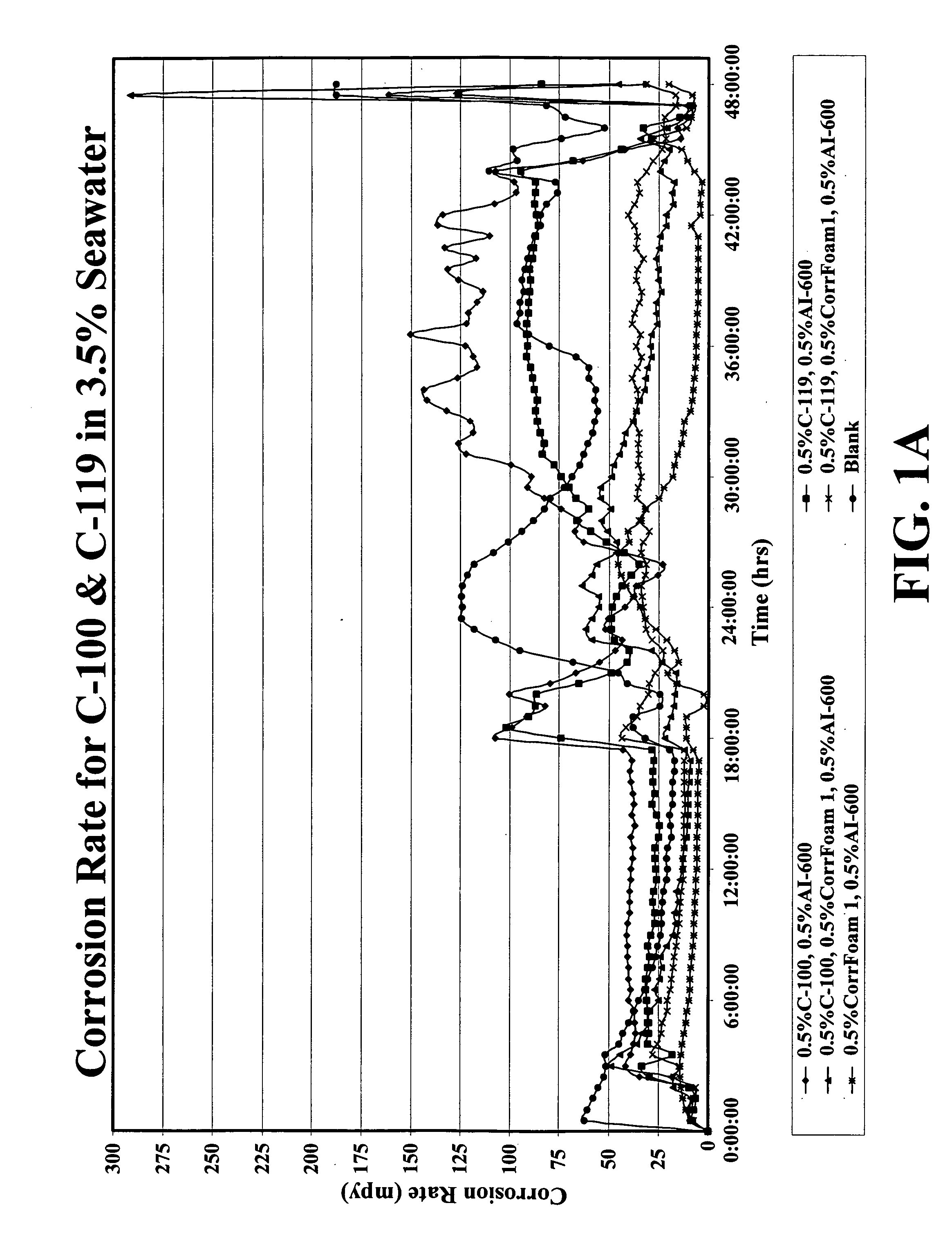

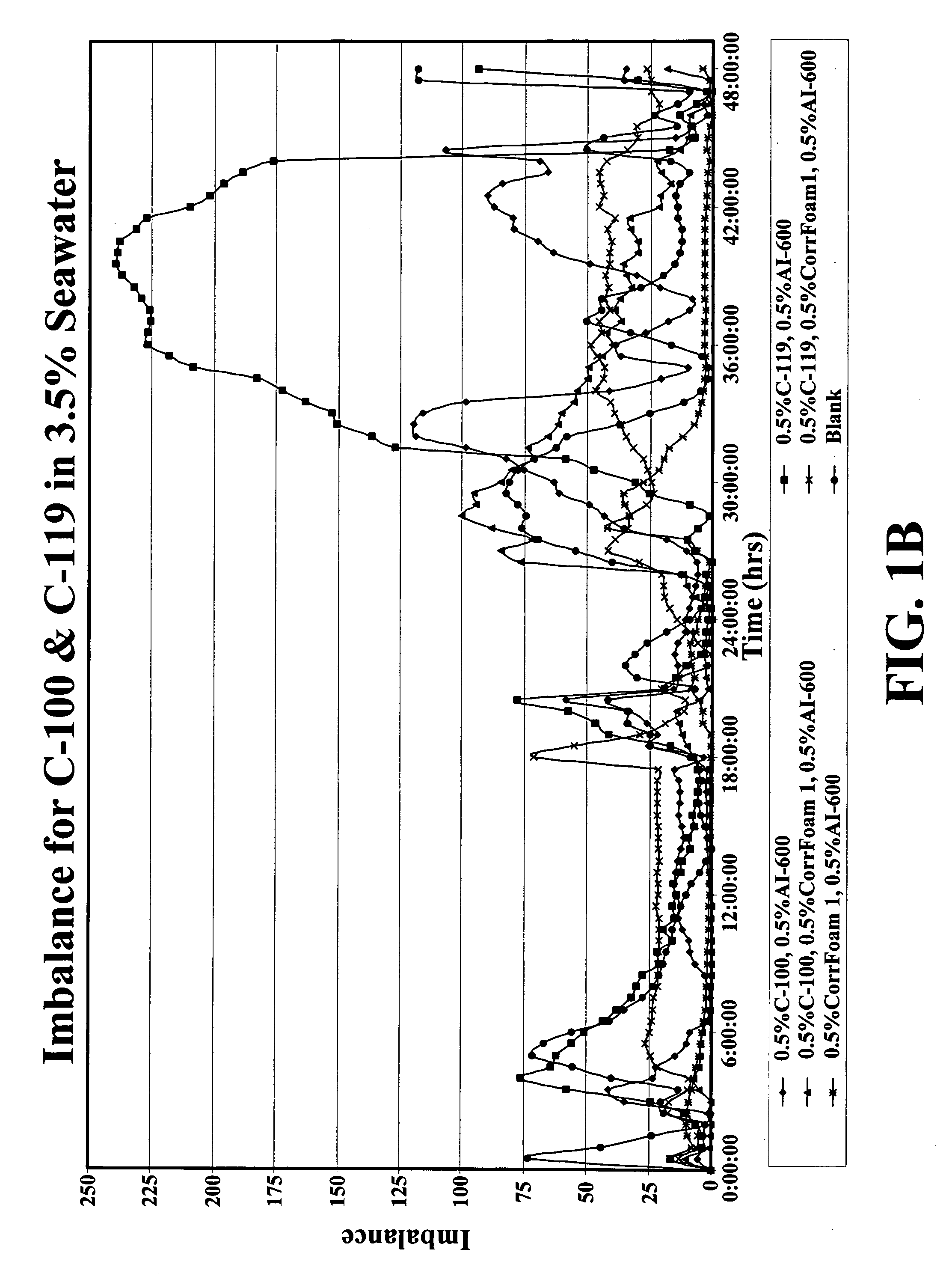

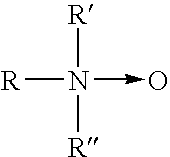

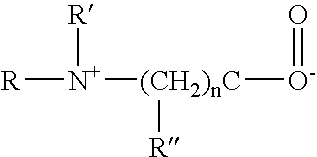

Corrosion inhibitor systems for low, moderate and high temperature fluids and methods for making and using same

A corrosion control system is disclosed including an anionic oxygen inhibitor, a cationic acid inhibitor or dispersant, and a noxious species inhibitor or scavenger for use in a fluid in contact with a metallic surface at low temperature, moderate temperature and especially at high temperature. A drilling fluid, a completion fluid, a production fluid and a geothermal fluid including an effective amount of the corrosion control system is also disclosed as well as methods for making and using same.

Owner:WEATHERFORD TECH HLDG LLC

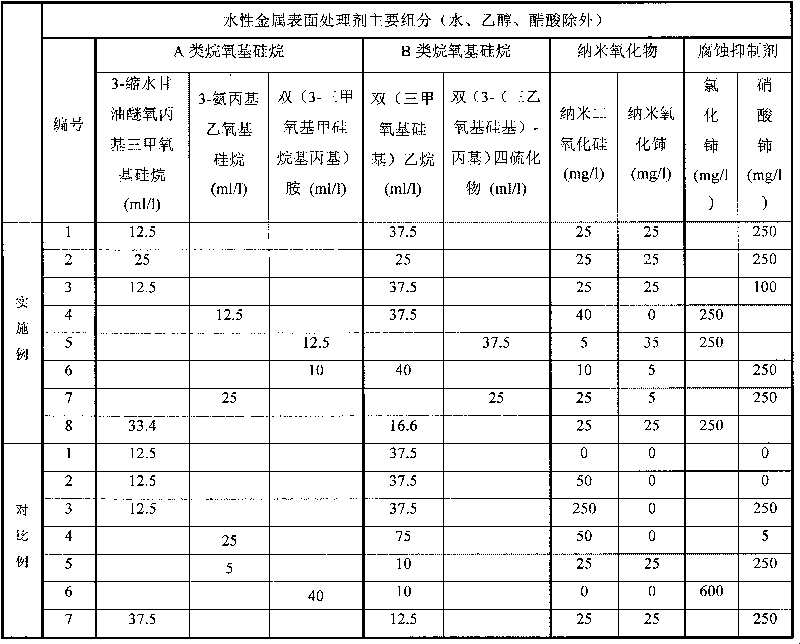

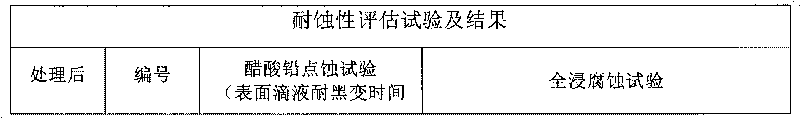

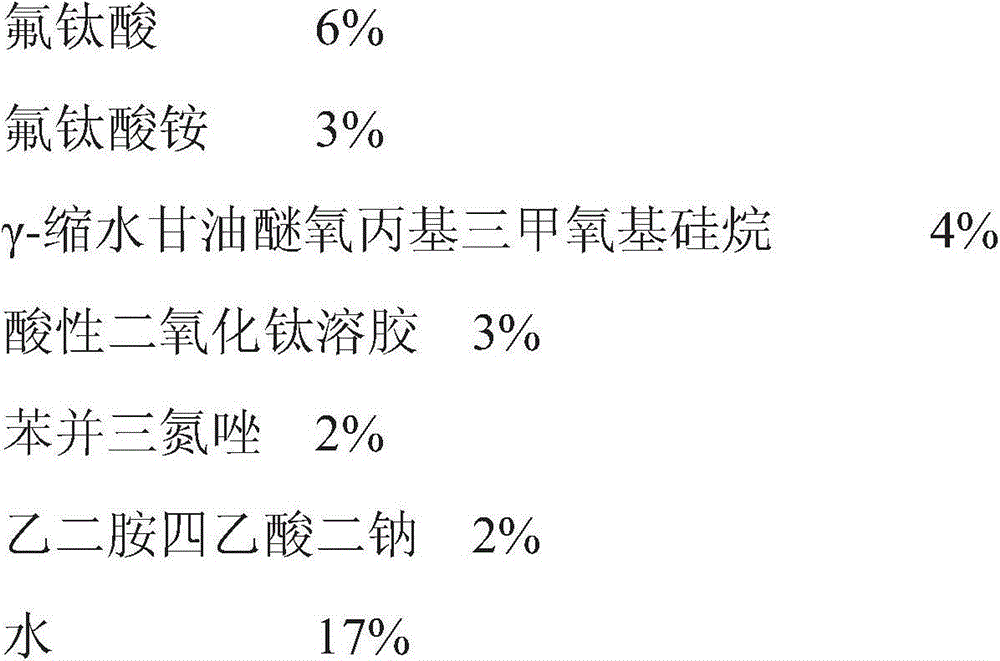

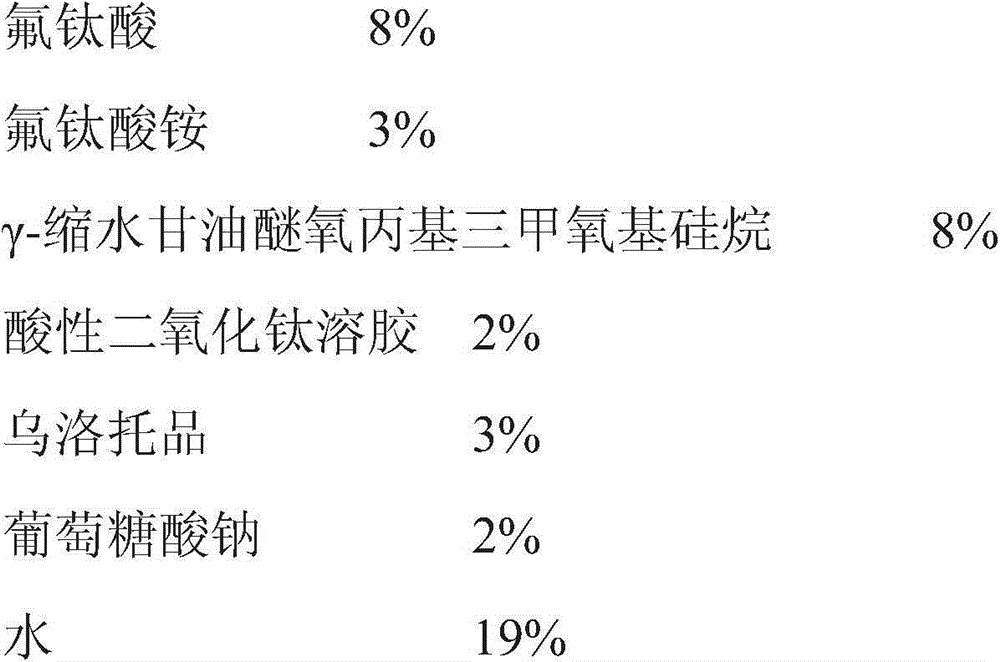

Environment-friendly nano water-based silane treatment agent capable of improving anti-corrosion performance of metal surface

ActiveCN101717930ASimple processApplicable industrial scaleMetallic material coating processesWater basedEpoxy

The invention discloses an environment-friendly nano water-based silane treatment agent capable of improving anti-corrosion performance of metal surface. The treatment agent is water-based silane solution which consists of at least one alkoxy silane containing epoxy or at least one alkoxy silane containing amino, at least one disilyl silane, nano-silicon dioxide, rare earth salt type corrosion inhibitor or rare earth salt type and rare earth nano oxide, water, or acetic acid and a small amount of ethanol. The metal material is coated by using the silane solution for impregnation, brushing, spraying or spin-coating, a siloxane layer is formed on the metal surface, then the long-acting corrosion resistance is formed by curing for 3 hours at the temperature of 100 DEG C, and a nano organic silane film which has close bonding force with a coating is formed. Nanoparticles can not only improve the corrosion resistance and enhance the mechanical strength of the silane film in a coating layer, but also realize the synergistic corrosion resistance with the corrosion inhibitor. The technology has the advantages of simple process, greenness, environmental protection and strong practicality.

Owner:HAISO TECH

Alkaline, post plasma etch/ash residue removers and photoresist stripping compositions containing metal-halide corrosion inhibitors

InactiveUS20070060490A1Avoiding consequenceAvoid expensesDetergent mixture composition preparationElectrostatic cleaningAlkaline earth metalMetal halides

The invention provides alkaline compositions useful in the microelectronics industry for stripping or cleaning semiconductor wafer substrates by removing photoresist residues and other unwanted contaminants. The compositions contain (a) one or more bases and (b) one or more metal corrosion inhibiting metal halides of the formula: WzMXy where M is a metal selected from the group Si, Ge, Sn, Pt, P, B, Au, Ir, Os, Cr, Ti, Zr, Rh, Ru, and Sb; X is a halide selected from F, Cl, Br and I; W is selected from H, to an alkali or alkaline earth metal, and a metal ion-free hydroxide base moiety; y is a numeral of from 4 to 6 depending on the metal halide; and z is a numeral of 1, 2 or 3.

Owner:AVANTOR PERFORMANCE MATERIALS INC

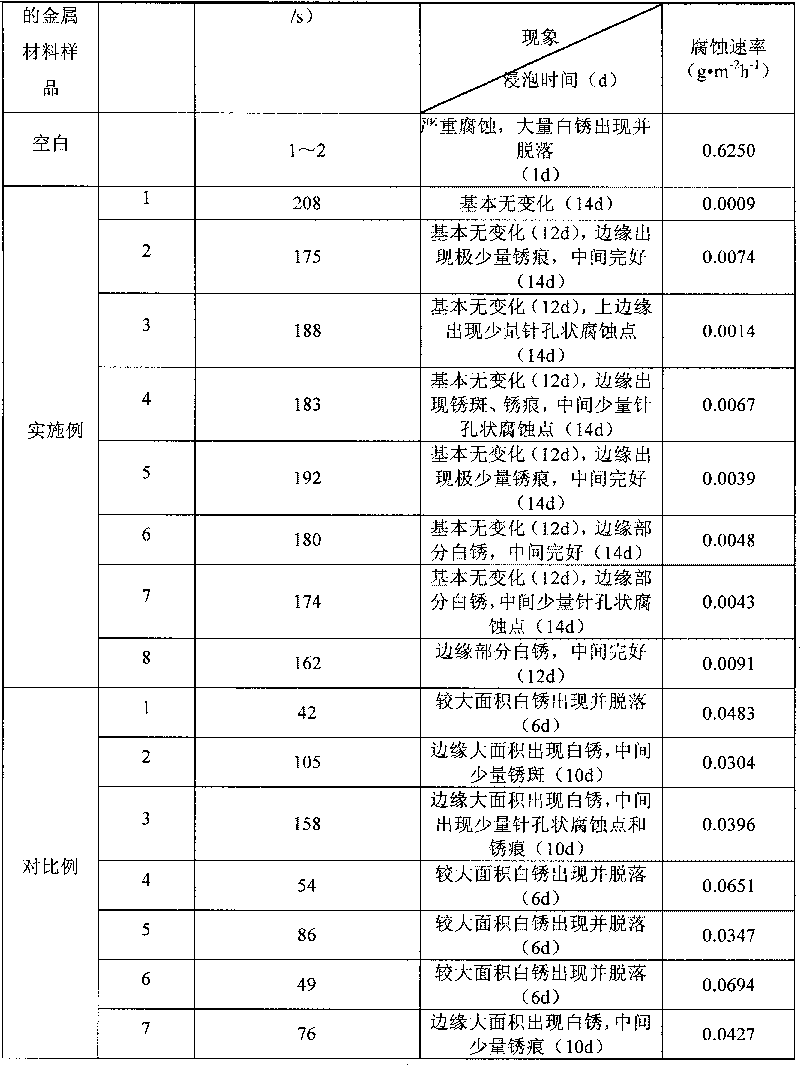

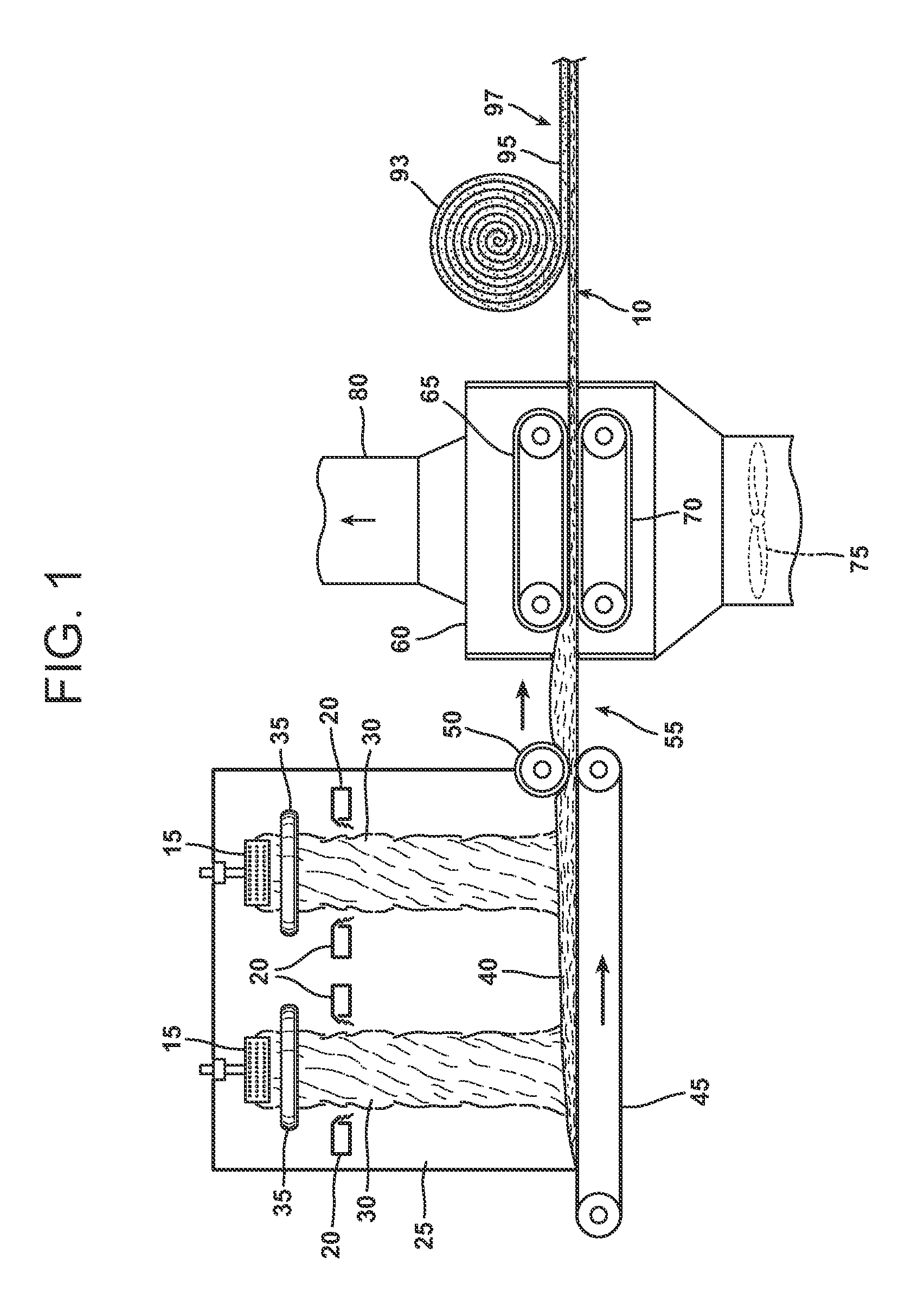

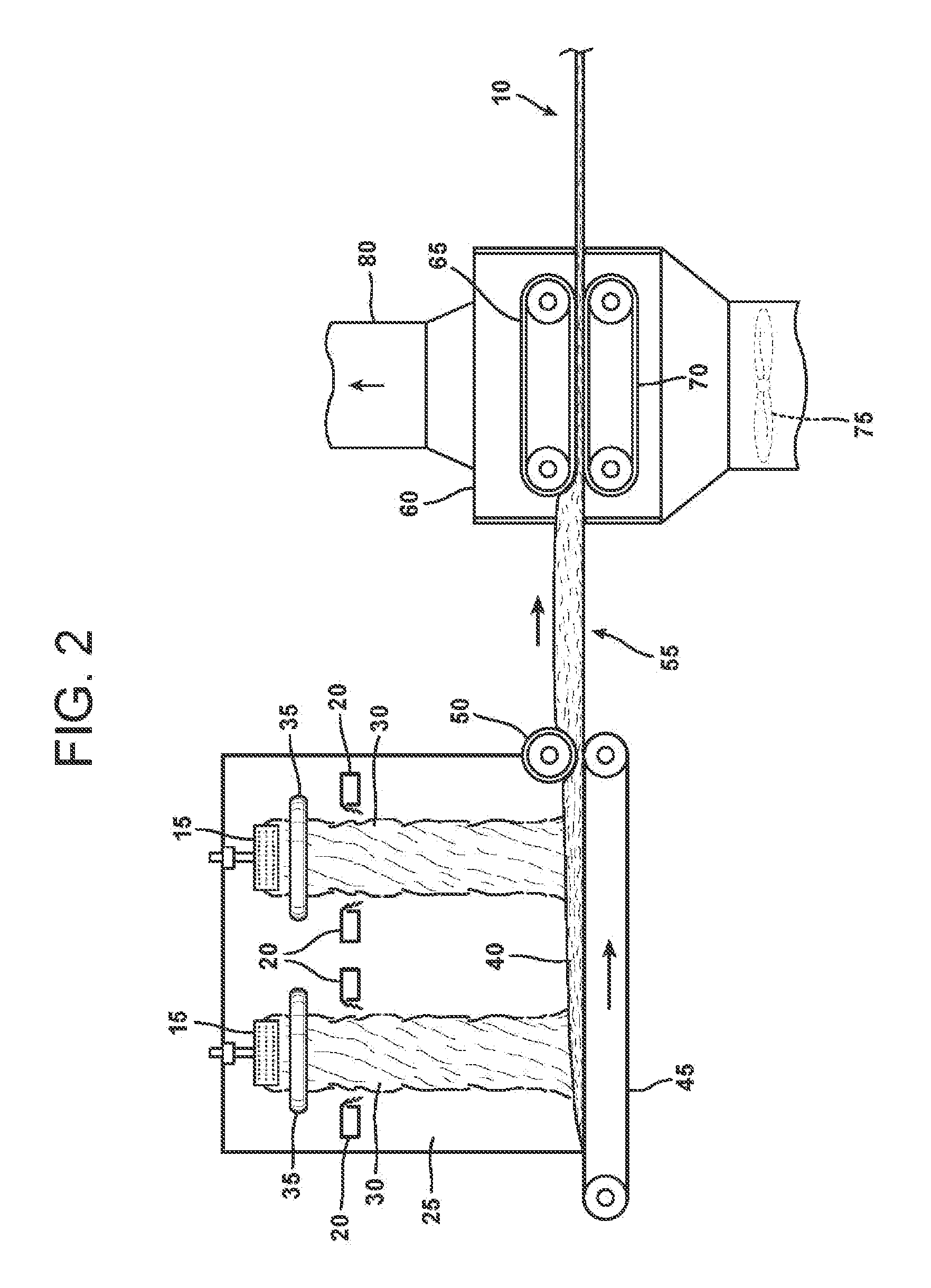

Bio-based binders for insulation and non-woven mats

ActiveUS20110086567A1Readily availableLow costStarch dervative coatingsStarch adhesivesFiberProcedure Agents

An aqueous binder composition is provided that includes a carbohydrate and a crosslinking agent. In exemplary embodiments, the carbohydrate-based binder composition may also include a catalyst, a coupling agent, a process aid, a crosslinking density enhancer, an extender, a moisture resistant agent, a dedusting oil, a colorant, a corrosion inhibitor, a surfactant, a pH adjuster, and combinations thereof. The carbohydrate may be natural in origin and derived from renewable resources. Additionally, the carbohydrate polymer may have a dextrose equivalent (DE) number from 2 to 20. In at least one exemplary embodiment, the carbohydrate is a water-soluble polysaccharide such as dextrin or maltodextrin and the crosslinking agent is citric acid. Advantageously, the carbohydrates have a low viscosity and cure at moderate temperatures. The environmentally friendly, formaldehyde-free binder may be used in the formation of insulation materials and non-woven chopped strand mats. A method of making fibrous insulation products is also provided.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Water soluble full-alloy metal grinding fluid

ActiveCN104017636ALubricity achievedImprove stabilityLubricant compositionOrganic EsterNonferrous metal

The invention discloses a water soluble full-alloy metal grinding fluid which belongs to the technical field of metal grinding fluids. The metal grinding fluid is prepared from the following components in percentage by weight: 5-40wt% of an antirust agent, 1-20wt% of a cleaning agent, 0.1-10wt% of a lubricating corrosion inhibitor, 1-20wt% of a penetrant, 1-20wt% of a solubilizer, 10-40wt% of a PH adjustor, 0.5-5wt% of a defoamer and the balance of water. Based on the total weight of the water soluble full-alloy metal grinding fluid, the pH value of the water soluble full-alloy metal grinding fluid is 7-11. The lubricating corrosion inhibitor is long chain nitrogen heterocyclic ring organic ester. The water soluble full-alloy metal grinding fluid has excellent lubricating, rust-preventing, cleaning and cooling performances and can be widely applied to grinding of ferrous metals and nonferrous metals.

Owner:TSINGHUA UNIV

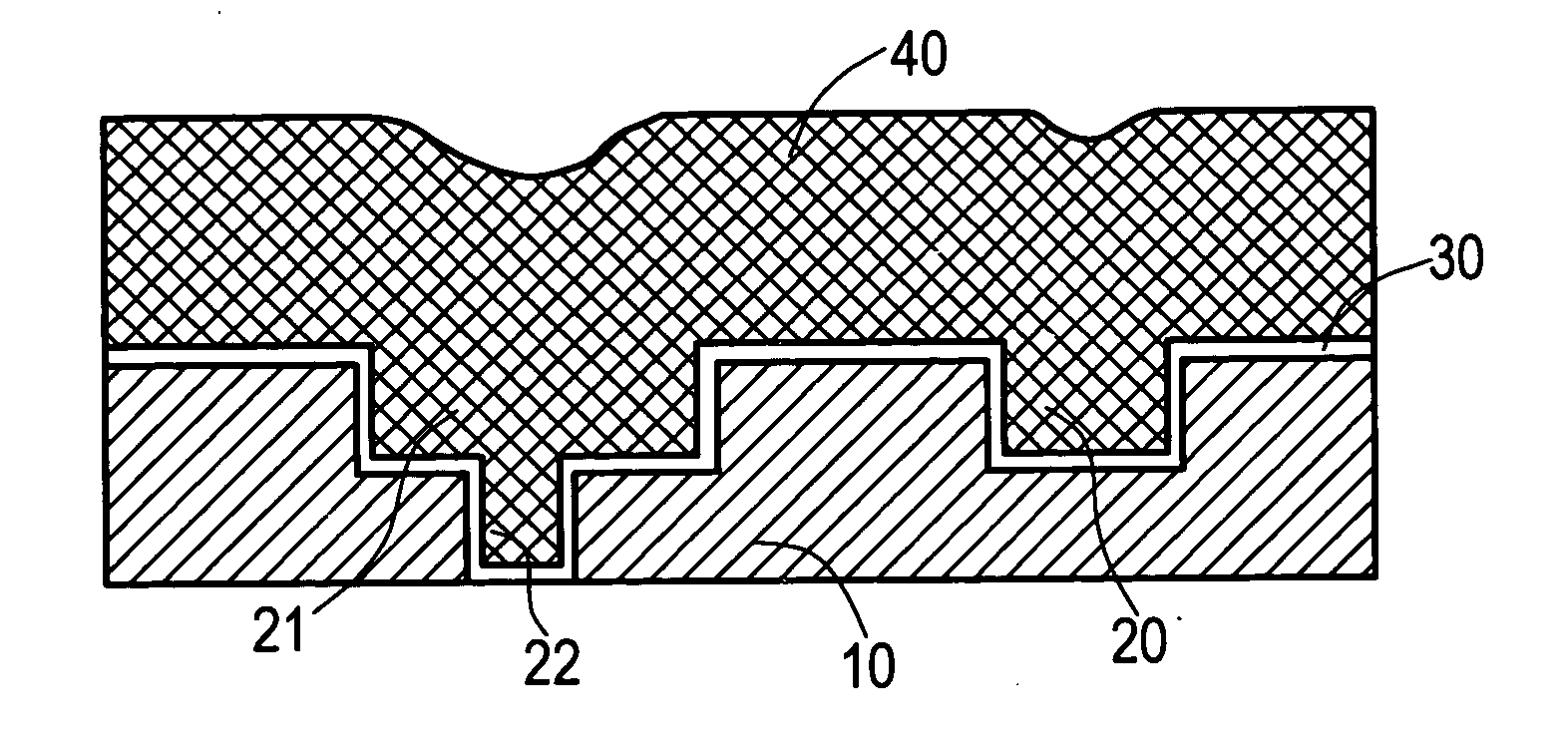

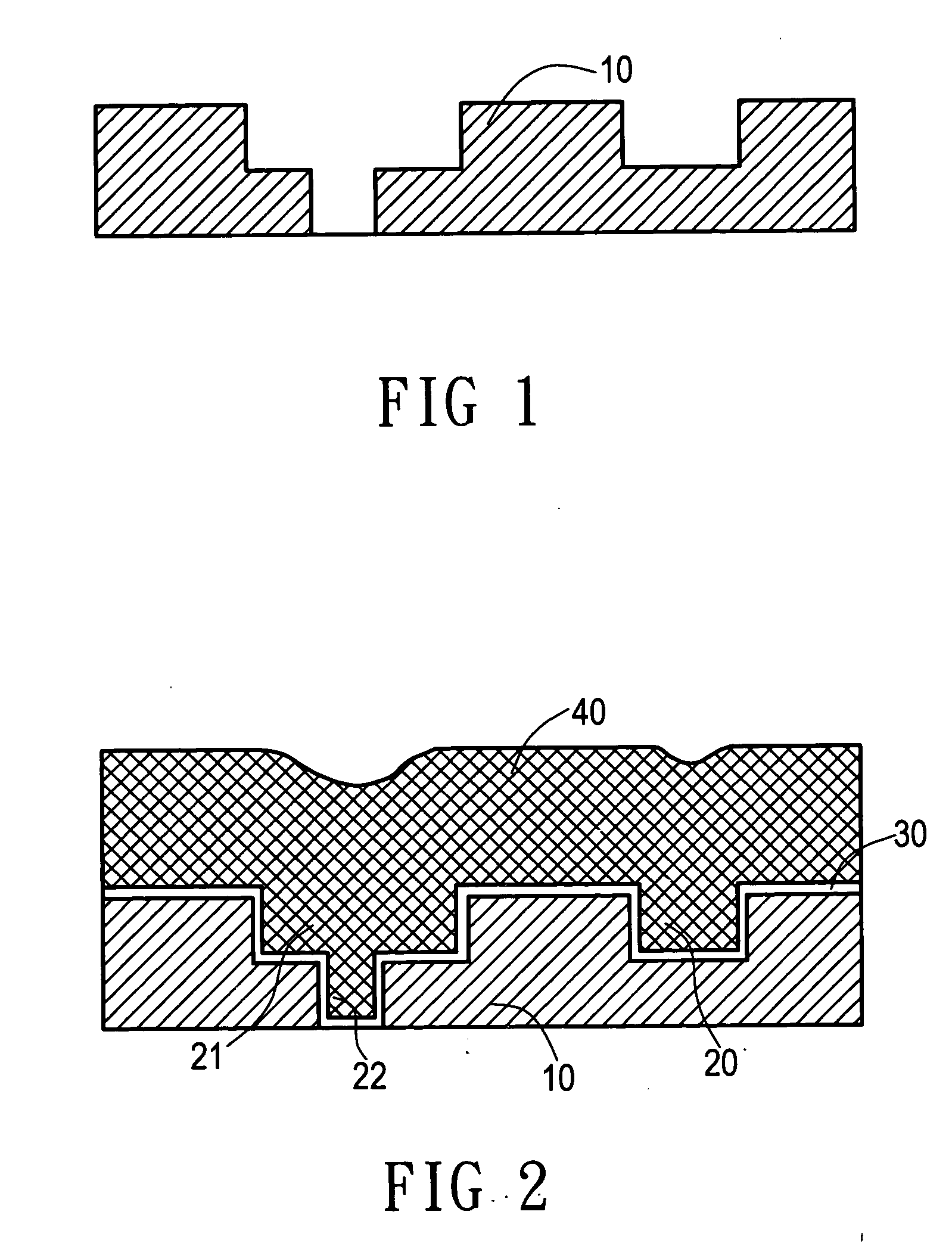

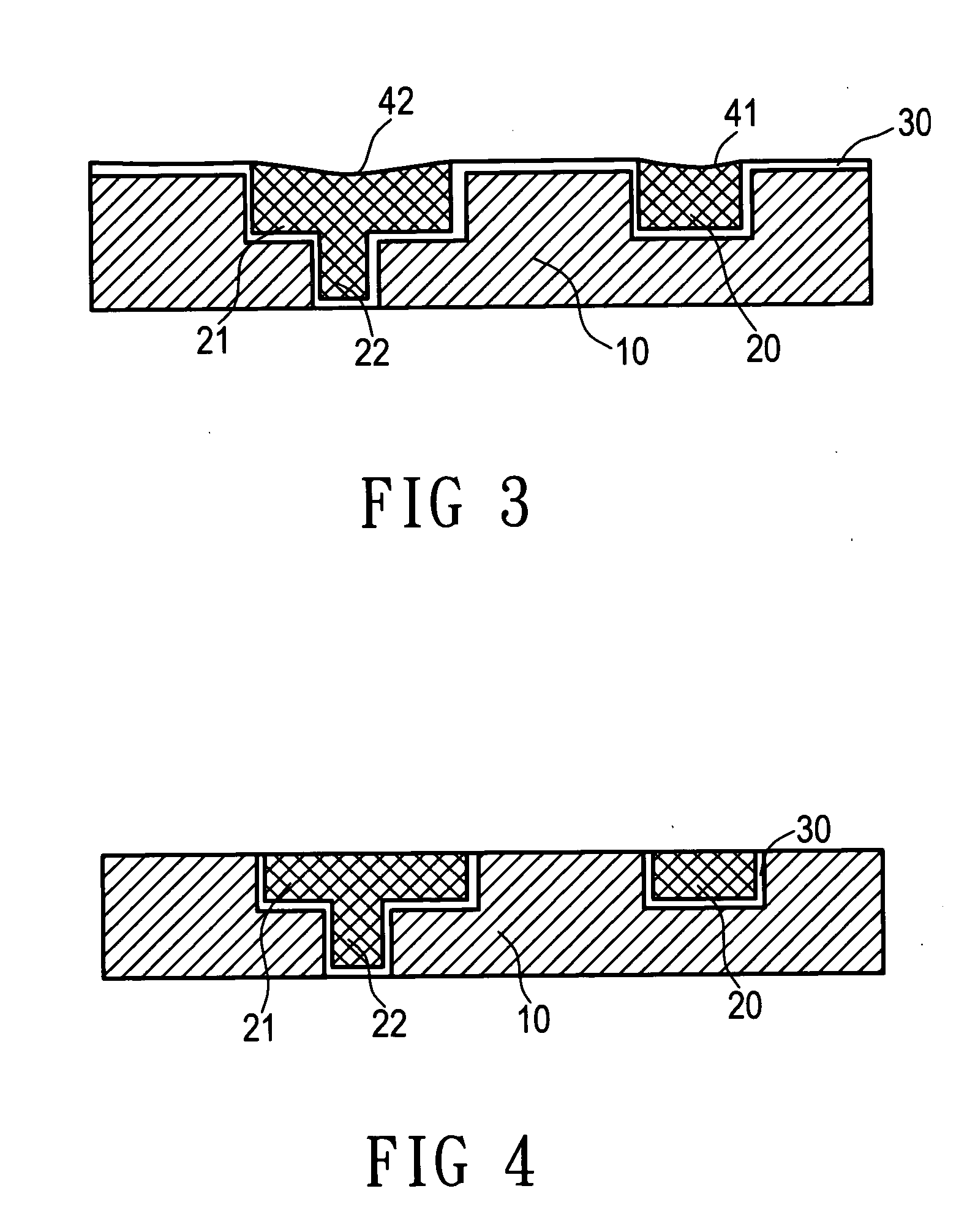

Latent coating for metal surface repair

InactiveUS6075072AEasy curingExtended service lifeLiquid surface applicatorsSynthetic resin layered productsCorrosion inhibitorMetal

A corrosion protective coating composition, applied over a metal surface, contains frangible microcapsules which rupture and release fluid upon impact or other stress likely to damage the coating. The fluid, from the microcapsules, contains a film forming component to cover the damaged area of the coating and a corrosion inhibitor for the metal surface.

Owner:3M INNOVATIVE PROPERTIES CO

Boron-free chlorine-free formaldehyde-free microemulsified cutting fluid and application thereof

The invention discloses a boron-free chlorine-free formaldehyde-free microemulsified cutting fluid and application thereof. The microemulsified cutting fluid is prepared from the following raw materials in percentage by mass: 30-60% of base oil, 1-5% of rust inhibitor, 0-5% of extreme pressure agent, 1.5-8% of bactericide, 3-15% of mixed base, 0-5% of coupling agent, 1-8% of anti-hard water agent, 1.2-5% of corrosion inhibitor, 5-20% of lubricant, 3-15% of anionic surfactant, 3-20% of emulsifier and the balance of water. The microemulsified cutting fluid disclosed by the invention has excellent lubricating properties, and can simultaneously satisfy multiple processing modes, including fraising, boring, tapping, threading, high-speed milling, hole drilling and the like. The microemulsified cutting fluid is especially suitable for processing electronic aluminum alloys. In addition, the microemulsified cutting fluid has the advantages of excellent defoaming property, excellent wettability, high raw liquor stability, high emulsifying stability, high biological stability, longer service life, lower consumption and lower cost.

Owner:GUANGZHOU MECHANICAL ENG RES INST

Compositions and method for removing coatings and preparation of surfaces for use in metal finishing, and manufacturing of electronic and microelectronic devices

InactiveUS20090120457A1Improve performanceLow costDetergent mixture composition preparationDetergent compounding agentsPhotoresistContamination

Improved cleaning compositions for removing particles, organic contamination, photoresist, post-ash residue, coatings, and other materials from metal and silicon surfaces including substrates present during the manufacture of integrated circuits, liquid crystal displays, and photovoltaic devices. The cleaning and surface preparation compositions comprise one or more water soluble strongly basic components, one or more water soluble organic amines, one or more water soluble oxidizing agents, balance water. Optional components can include corrosion inhibitors, surfactants and chelating agents.

Owner:SURFACE CHEM DISCOVERIES

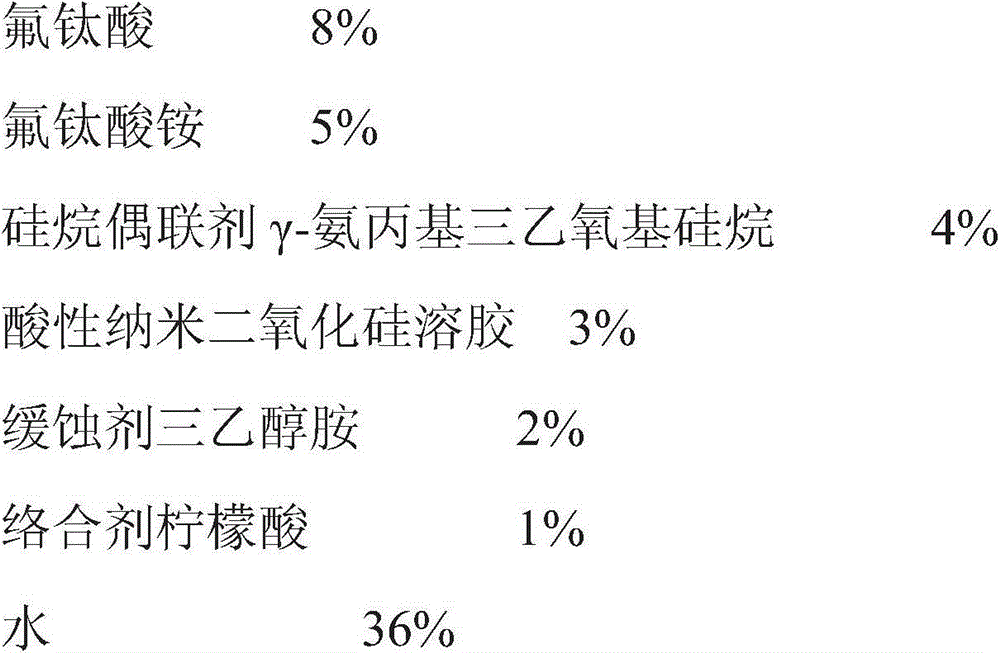

Corrosion-resistant magnesium aluminum alloy chromium-free passivation solution

InactiveCN104561970AHigh hardnessImprove stain resistanceMetallic material coating processesWater basedChromium free

The invention discloses a corrosion-resistant magnesium aluminum alloy chromium-free passivation solution, which comprises the following components: 10-40 parts of water-base resin, 1-10 parts of nanoparticle sol, 1-10 parts of fluoric-containing acid, 1-5 parts of fluoric acid-containing salt, 1-5 parts of a rare earth catalyst, 1-10 parts of a silane coupling agent, 1-5 parts of a corrosion inhibitor, 1-2 parts of a complexing agent and 40-70% of water. The corrosion-resistant magnesium aluminum alloy chromium-free passivation solution does not contain chromium and other toxic and harmful substances, meets the ROHS environmental protection law of the European Union, and meanwhile, can form an organic and inorganic composite passivation film and a thin film on the surface of a magnesium aluminum layer, and the formed composite passivation film has an excellent physical property and corrosion resistance, and has higher corrosion resistance and long salt fog time, so that the corrosion resistance of a magnesium aluminum alloy plate is better improved.

Owner:苏州禾川化学技术服务有限公司

Warewashing composition for use in automatic dishwashing machines, and method for using

ActiveUS20080274930A1Reduce corrosionReduce etchingInorganic/elemental detergent compounding agentsSpecific water treatment objectivesSolubilityAtmospheric pressure

A warewashing composition includes a cleaning agent having a detersive amount of a surfactant, an alkaline source in an amount effective to provide a use composition having a pH of at least about 8 when the use composition is measured at a solids concentration of about 0.5 wt %, and a corrosion inhibitor in an amount sufficient for reducing corrosion of glass when the warewashing composition is combined with water of dilution at a dilution ratio of at least about 20:1 water of dilution to detergent composition o form a use composition. The corrosion inhibitor includes a salt of calcium, magnesium, or a mixture of calcium and magnesium. The salt has a water solubility of less than about 0.5 wt % in water at about 20° C. and atmospheric pressure so that the salt precipitates to form a protective layer on a substrate in contact with the use composition.

Owner:ECOLAB USA INC

Hydrogen peroxide disinfectant with increased activity

InactiveUS6346279B1High activityReduced activityBiocideInorganic phosphorous active ingredientsDisinfectantPhosphoric acid

An acidic aqueous hydrogen peroxid solution is provided, with improved disinfectant activity. Concentrated solutions preferably contain up to about 8% and as-used concentrations contain about 0.5% peroxide. The solution also contains from 0.1 to 5.0% of at least one acid compound, e.g. phosphoric and / or a phosphonate with from 1 to 5 phosphonic acid groups, and from 0.02 to 5% of at least one anionic surfactant. The surfactant is selected from C8 to C16-alkyl aryl sulphonic acids, sulphonated C12 to C22 carboxylic acids, C8 to C22-alkyl diphenyl oxide sulphonic acids, naphthalene sulphonic acids, C8 to C22 alkyl sulphonic acids, and alkali metal and ammonium salts thereof, and alkali metal C8 to C18 alkyl sulphates, and mixtures thereof. Most preferably the solution has an emulsifier, e.g. a salt of an alkylated diphenyl oxide. The solution may also contain corrosion inhibitors and / or lower alcohols.

Owner:VIROX TECH

Dual layer tablet, method of making and use thereof

InactiveUS6863830B1Easy to optimizeComprehensive treatmentOrganic chemistryOther chemical processesPotassium persulfateLithium hypochlorite

A method for treating a recirculating water system which comprises introducing into said water system a multifunctional, multilayer tablet, wherein the multilayer tablet comprises a fast dissolving layer and a slow dissolving layer, wherein said fast dissolving layer releases a combination of active ingredients including a member selected from the group consisting of lithium hypochlorite, calcium hypochlorite, trichloroisocyanuric acid (TCCA), anhydrous sodium dichloroisocyanurate, sodium persulfate, potassium persulfate, potassium monopersulfate, sodium monopersulfate, and mixtures thereof, and at least one of a clarifier, chelating agent, sequesterant, algaestat, water softener, algaecide, corrosion inhibitor, scale inhibitor, flocculent, disintegrant, dispersant, colorant, dissolution control agent, fragrance, or surfactant and, wherein said slow dissolving layer includes a member selected from the group consisting of trichloroisocyanuric acid (TCCA), calcium hypochlorite, 1,3-dichloro-5,5-dimethylhydantoin (DCDMH), 1,3-dibromo-5,5-dimethylhydantoin (DBDMH), 1-bromo-3-chloro-5,5-dimethylhydantoin (BCDMH), 1,3-dichloro-5-ethyl-5-methylhydantoin (DCEMH), 1,3-dibromo-5-ethyl-5-methylhydantoin (DBEMH), 1-bromo-3-chloro-5-methyl-5-ethylhydantoin (BCEMH), and mixtures thereof, and at least one of a clarifier, chelating agent, sequesterant, algaestat, water softener, algaecide, corrosion inhibitor, scale inhibitor, flocculent, disintegrant, dispersant, colorant, dissolution control agent or surfactant.

Owner:BIO LAB

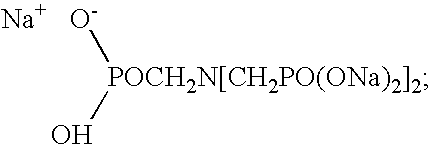

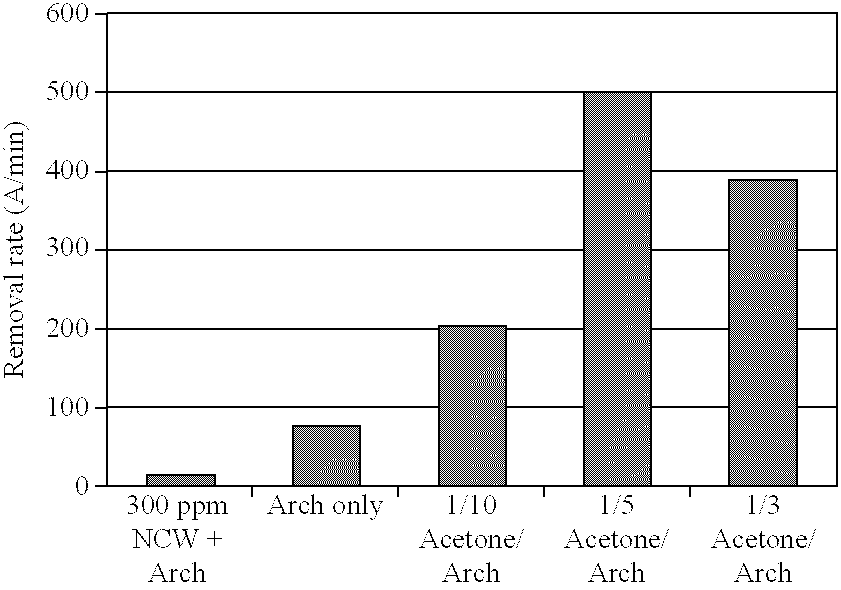

Additives to CMP slurry to polish dielectric films

A method and composition for planarizing a substrate. The composition includes one or more chelating agents, one or more oxidizers, one or more corrosion inhibitors, a polar solvent, and deionized water. The composition may further comprise one or more surfactants, one or more agents to adjust the pH and / or abrasive particles. The method comprises planarizing a substrate using a composition including a polar solvent.

Owner:APPLIED MATERIALS INC

High temperature foamer formulations for downhole injection

ActiveUS7122509B2Increase heightReduce pointsOrganic detergent compounding agentsAnionic surface-active compoundsFoaming agentDecomposition

Owner:WHITEBOX ADVISORS +1

Emulsification type metal cutting liquor composition

InactiveCN101240218AImprove the lubrication effectImprove cooling effectAdditivesBase-materialsPhenolCutting fluid

Disclosed is an emulsifying metal-cutting-fluid composition comprising base oil or oily agent, mixed alcohol-amine, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative and the like. The invention has a strong general usability, suitable for metal processing, particularly aluminum alloy metal processing with advantages of excellent lubricity, corrosion resistance, a low cost and being free of toxic or harmful substances such as nitrites and phenols, so as to keep the environment and operators away from harmfulness.

Owner:河北九熙新材料科技有限公司

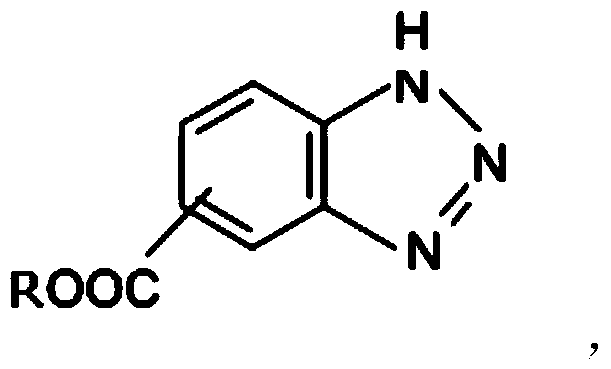

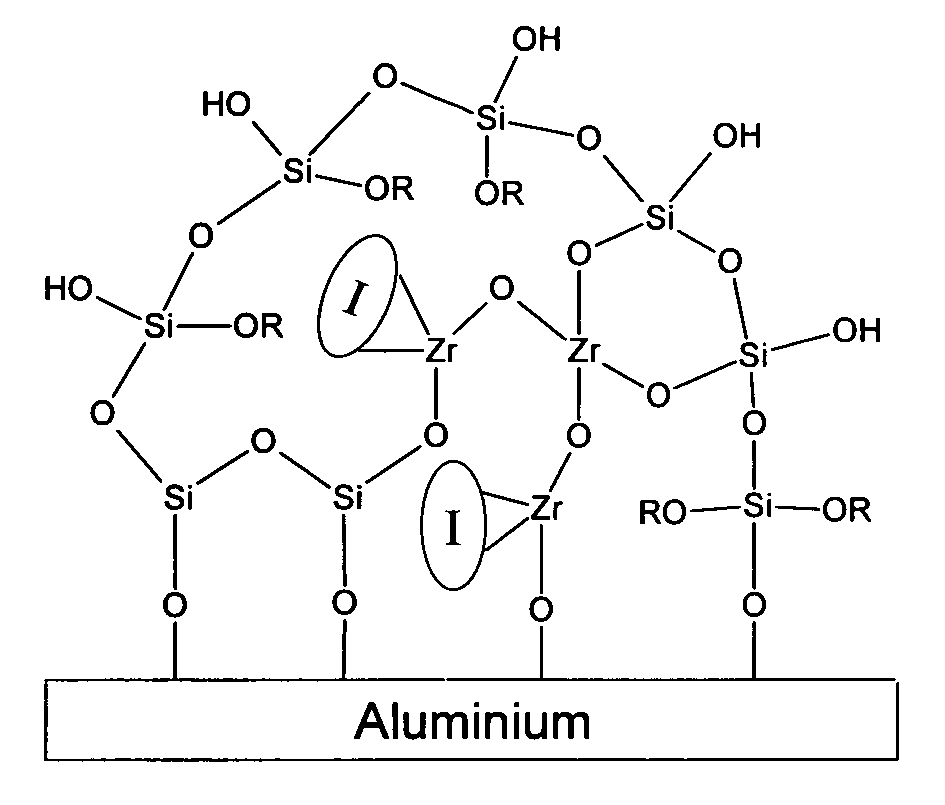

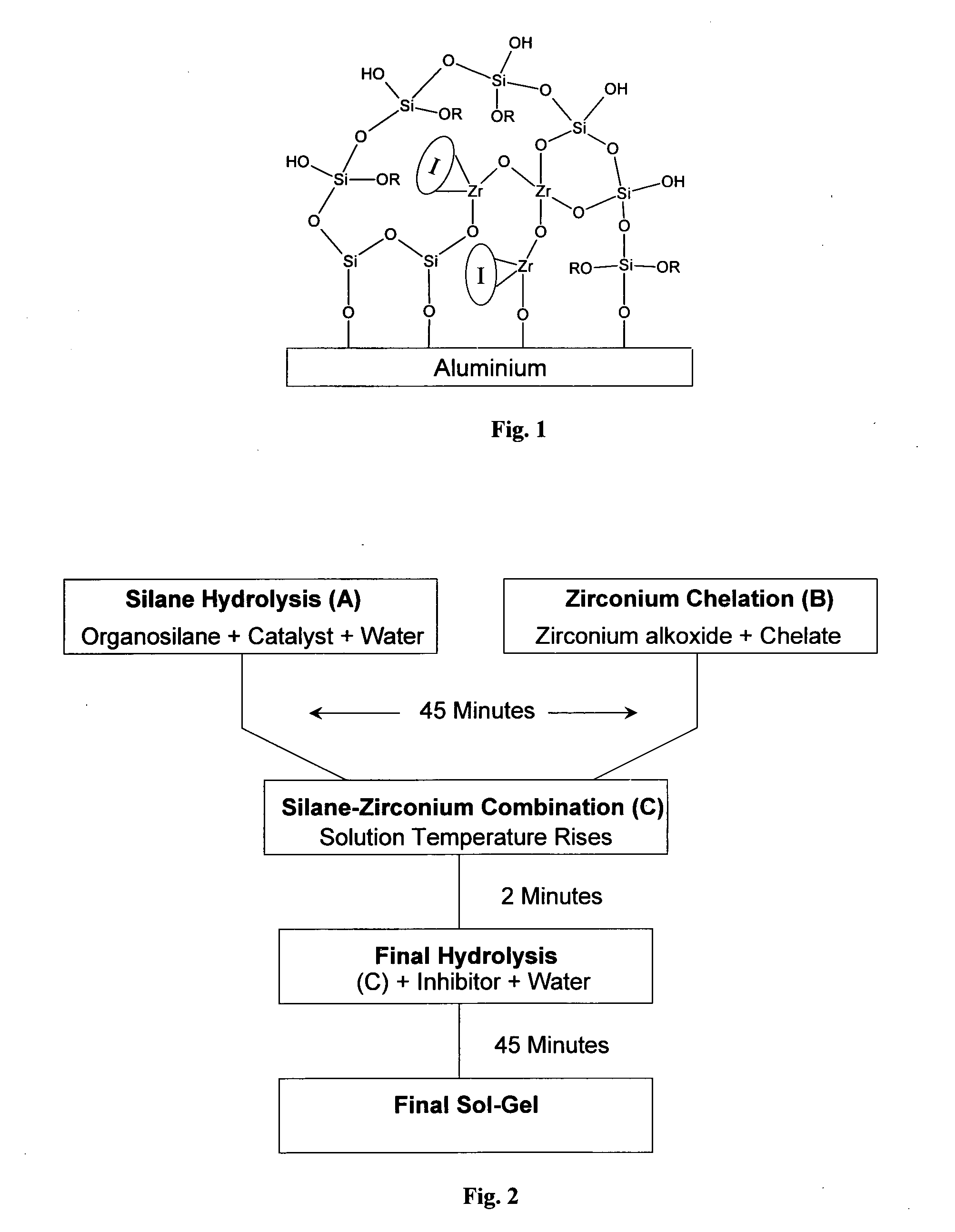

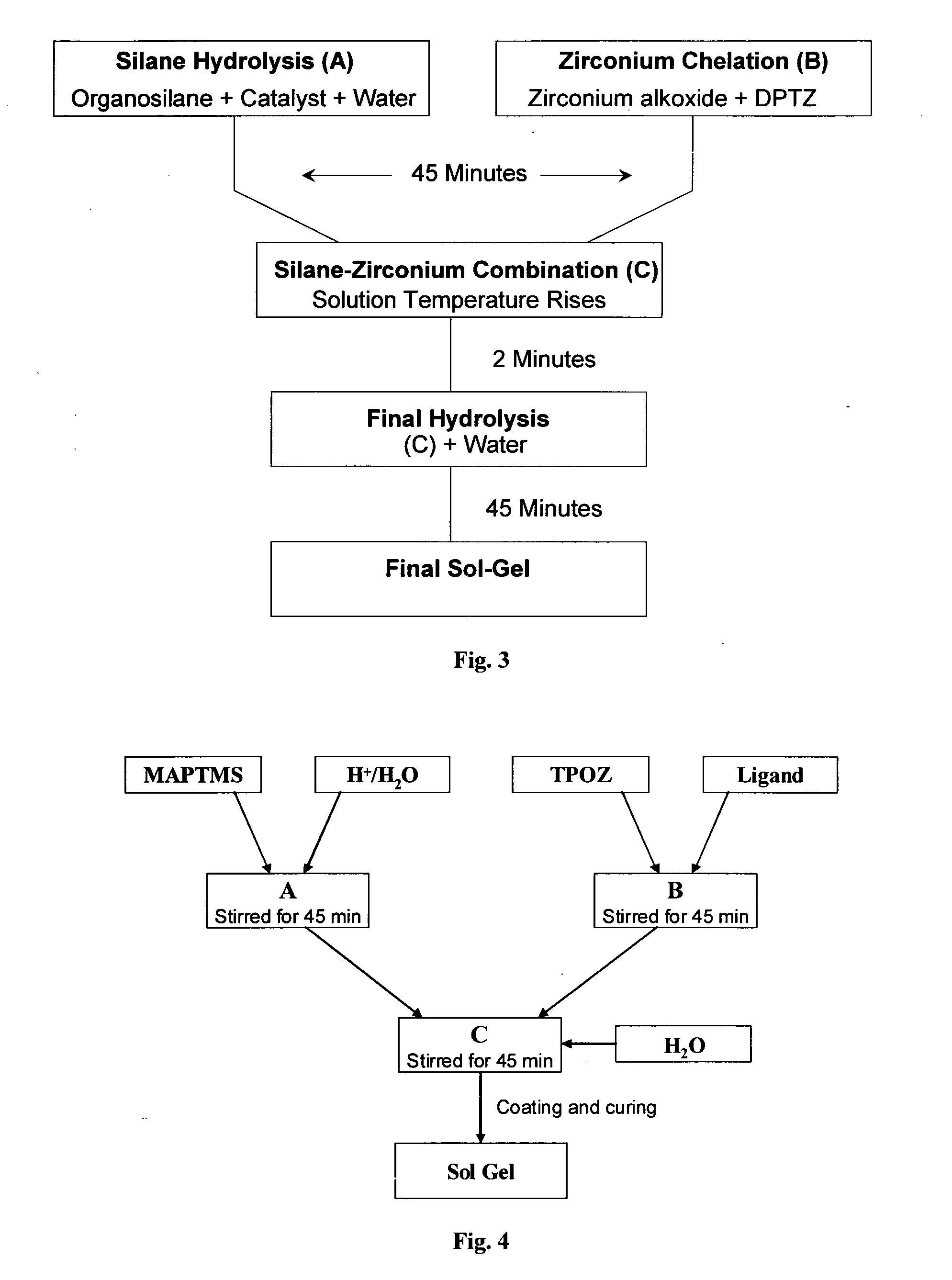

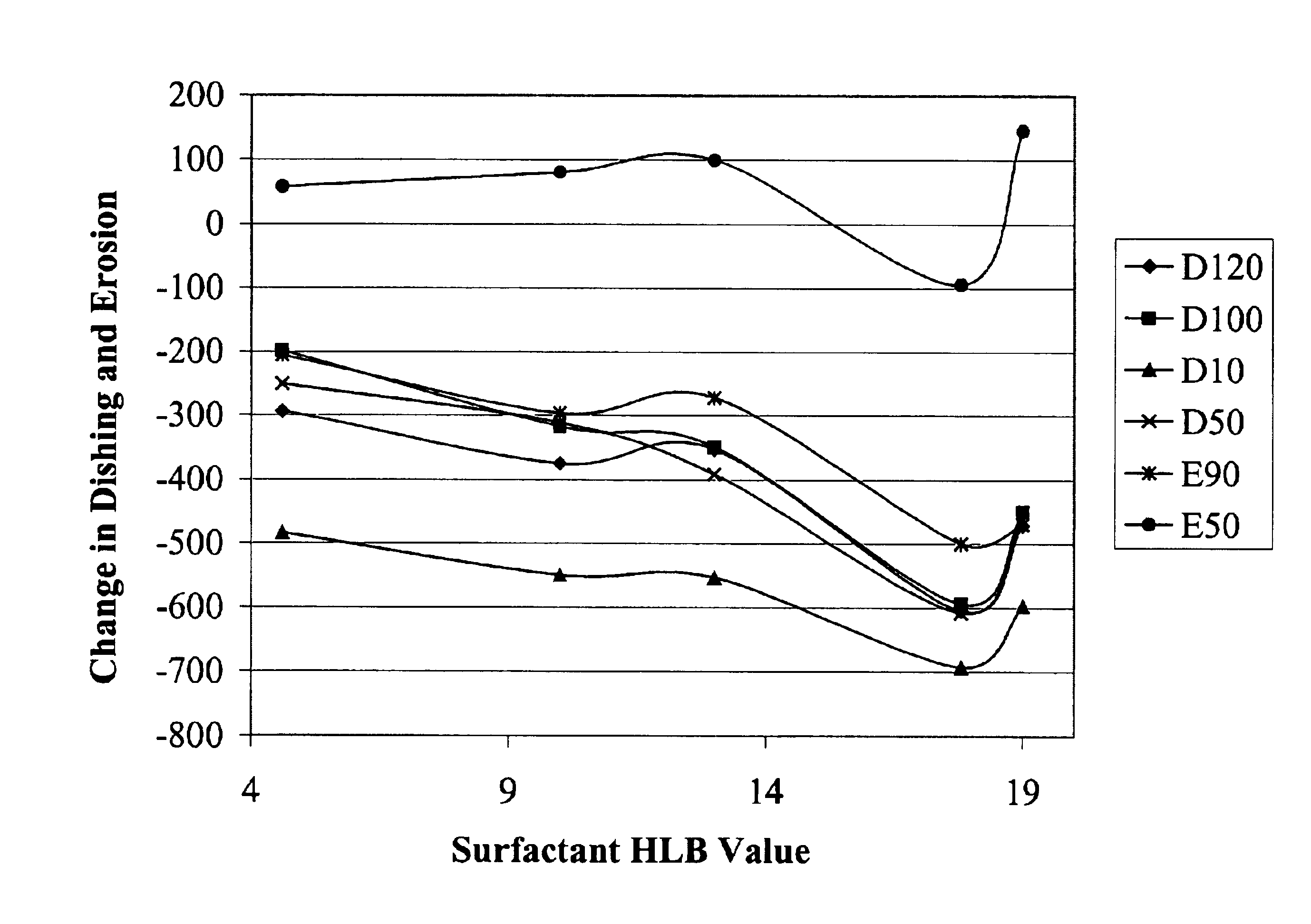

Organosilane Coating Compositions and Use Thereof

InactiveUS20100330380A1Increase flexibilityReduce presencePigmenting treatmentLayered productsSilanesSol gel coating

A sol-gel coating composition comprising a hydrolysed organosilane, an organometallic precursor and a corrosion inhibitor, wherein the corrosion inhibitor is a chelator for the organometallic precursor. The corrosion inhibitor and the organometallic precursor may form a nanoparticulate complex. The coating composition may comprise one or more additive selected from: an antimicrobial additive, a hardener, a water repelling additive, a dye, a scratch resistant additive and a flexibility enhancing additive. A process for preparing a sol gel coating composition is also described, the process comprising the steps of: hydrolysing an organosilane in the presence of a catalyst; chelating an organometallic precursor; mixing the hydrolysed silane and the chelated organometallic precursor; and hydrolysing the organosilane-organometallic precursor mixture.

Owner:DUBLIN CITY UNIVERSITY +1

Chromium-free passivation liquid for galvanized sheet and manufacture method thereof

InactiveCN101250699AImprove bindingImprove corrosion resistanceMetallic material coating processesChromium freeSealant

The invention in particular relates to passivation solution without chrome which is used for galvanized sheets and a method thereof. The technical scheme thereof comprises: firstly, dissolving inorganic salt corrosion inhibitor, then, adding the inorganic salt corrosion inhibitor into a stirred tank, adding dispersant, organic acid, sealant, silicone-acrylate emulsion and water while stirring, then, using inorganic acid or alkali to regulate the pH value to be 2.0-5.0, and then stirring for 1-2 hours under the condition that the temperature is 20-30 DEG C, the content of the components of each liter is: the inorganic salt corrosion inhibitor 10-55g, additive 4-10g, the organic acid 5-20g, the sealant 5-30g, the silicone-acrylate emulsion 150-300g, and the rest is the water. The method of the invention can additionally form a layer of organic resin separate layer on the basis of forming an inorganic metal compound precipitation film, additionally, since the silicon compound is added, not only the binding force between a passivation layer and zinc coating can be increased, but also the corrosion resistance, the scrubbing resistance and the wear resistance of the passivation layer can be increased, and the coating treatment after passivation can not be affected.

Owner:WUHAN UNIV OF SCI & TECH

Methods of simultaneously cleaning and disinfecting industrial water systems

InactiveUS6840251B2Reduce Microbial ContaminationReduce removalDetergent bleaching agentsWater/sewage treatment by neutralisationChlorine dioxideOnline and offline

On-Line and Off-Line methods of simultaneously cleaning and disinfecting an industrial water system are described and claimed. The methods involve the addition to the water of the industrial water system of a Compound selected from the group consisting of the alkali salts of chlorite and chlorate and mixtures thereof; and an acid, followed by allowing the water in the industrial water system to circulate for several hours. The reaction of the alkali salts of chlorite and chlorate and acid produces chlorine dioxide in-situ in the water of the industrial water system. The chlorine dioxide kills microorganisms and the acid acts to remove deposits upon the water-contact surfaces of the equipment. An alternative method involves the use of a chelating agent and a biocide. Other possible cleaning and disinfection reagents may be added as needed including corrosion inhibitors, chelating agents, biocides, surfactants and reducing agents. These cleaning and disinfecting methods work in a variety of industrial water systems including cooling water and boiler water systems.

Owner:ECOLAB USA INC

Non-phosphorus compound scale and corrosion inhibitor for treatment of circulating cooling water

ActiveCN1621362AEasy to useIncrease the concentration factorScale removal and water softeningPhosphateTungstate

The composite phosphate-free scale inhibiting corrosion inhibitor for treating circular cooling water consists of scale inhibitor and corrosion inhibitor. The scale inhibitor consists of one or several of PASP, PVA, oxidized starch, polyacrylic acid, acrylic acid / acrylate copolymer and acrylic acid / acrylate copolymer with sulfo radical. The corrosion inhibitor consists of one or several of sodium salt / potassium salt / ammonium salt of organic salt, sodium / potassium / ammonium borate, nitrous organic matter, soluble molybdenate, soluble tungstate, soluble nitrate, soluble nitrite and soluble zinc salt. The composite scale inhibiting corrosion inhibitor has excellent scale inhibiting and corrosion inhibiting performance, is environment friendly, and is especially the treatment of hard circulation water with high calcium and high alkali content.

Owner:BEIJING YANHUA XINGYE TECH DEV +1

Cleaning formulation for removing residues on surfaces

InactiveUS20080004197A1Surface-active detergent compositionsDetergent mixture composition preparationCarboxylic acidWater soluble

The present disclosure provides a non-corrosive cleaning composition that is useful for removing residues from a semiconductor substrate. The composition can comprise water, at least one hydrazinocarboxylic acid ester, at least one water soluble carboxylic acid, optionally, at least one fluoride-containing compound, and, optionally, at least one corrosion inhibitor not containing a carboxyl group. The present disclosure also provides a method of cleaning residues from a semiconductor substrate using the non-corrosive cleaning composition.

Owner:FUJIFILM ELECTRONICS MATERIALS US

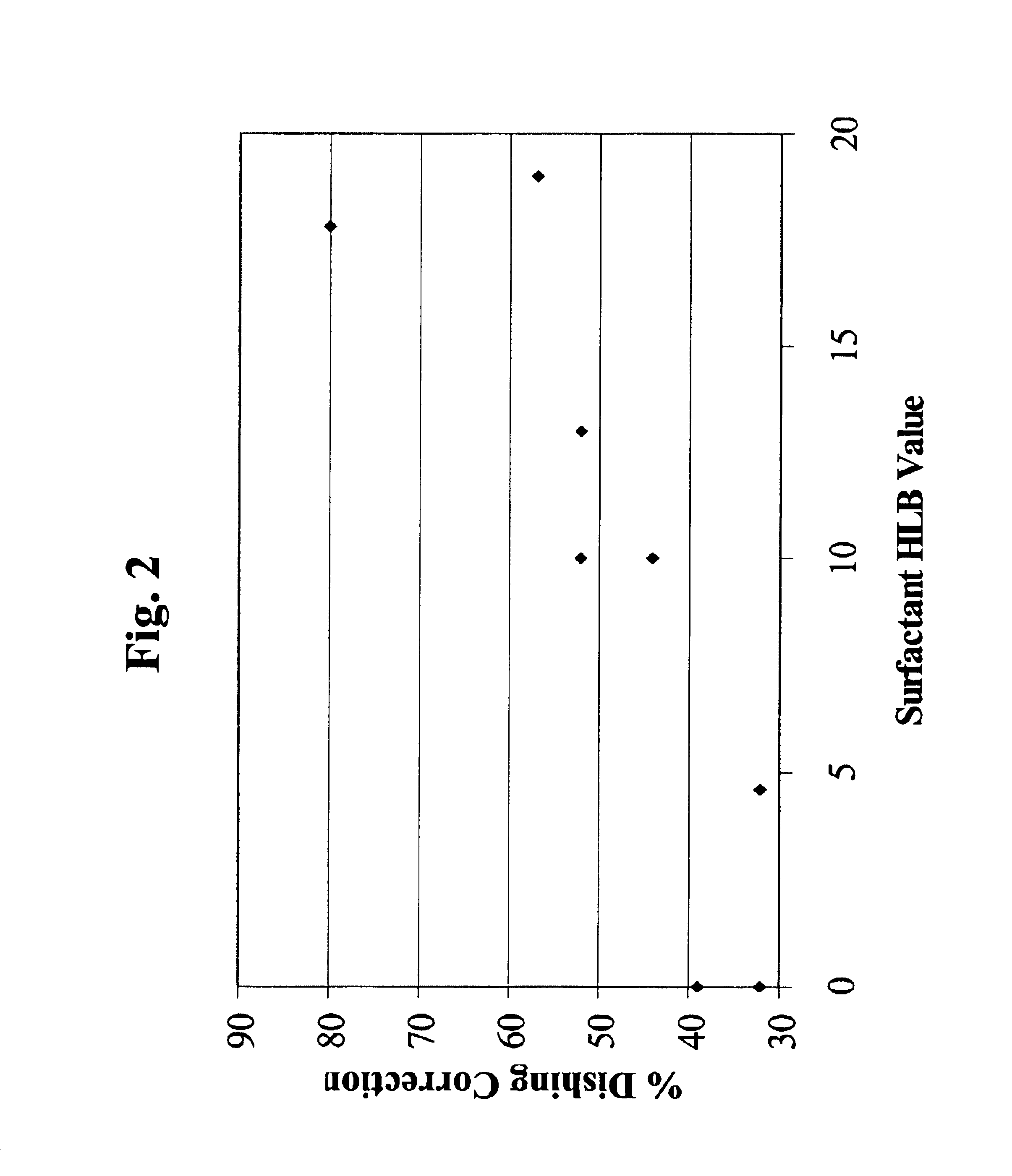

CMP method utilizing amphiphilic nonionic surfactants

InactiveUS6936543B2Other chemical processesSemiconductor/solid-state device manufacturingOrganic acidCopper

The invention provides methods of polishing a substrate comprising (i) contacting a substrate comprising at least one metal layer comprising copper with a chemical-mechanical polishing (CMP) system and (ii) abrading at least a portion of the metal layer comprising copper to polish the substrate. The CMP system comprises (a) an abrasive, (b) an amphiphilic nonionic surfactant, (c) a means for oxidizing the metal layer, (d) an organic acid, (e) a corrosion inhibitor, and (f) a liquid carrier. The invention further provides a two-step method of polishing a substrate comprising a first metal layer and a second, different metal layer. The first metal layer is polishing with a first CMP system comprising an abrasive and a liquid carrier, and the second metal layer is polished with a second CMP system comprising (a) an abrasive, (b) an amphiphilic nonionic surfactant, and (c) a liquid carrier.

Owner:CMC MATERIALS INC

Water-based cutting fluid used in slice machining of hard brittle crystal material and preparation method of water-based cutting fluid

InactiveCN102618374AGuaranteed lubrication effectGuaranteed anti-rust performanceAdditivesWater basedTool wear

The invention discloses a water-based cutting fluid used in slice machining of a hard brittle crystal material, comprising the following compositions: base oil, organic amine, organic acid, synthetic ester, emulsifier, rust and corrosion inhibitor, dispersion flocculation and hard-water resisting agent, antiseptic bactericide, antifoaming agent, coupling agent, adjuvant and a proper amount of water. Aiming at the machining techniques of inner circle slicing and outer circle slicing, the water-based cutting fluid has good generality, lubricity, strong antirust property and a long service life; when the cutting fluid is used, the machining situation can be observed easily, the cooling property is good, the cleaning and the permeability are strong, cuttings subside easily, and the machining problems of machining error, crack and the like caused by cutter blocking, abrasion and the like are solved; according to the invention, the problems that cuttings are easy to adhere and suspend, a cutter is seriously abraded, a machined product cracks easily, the accuracy is not high, the machining efficiency is low, the later period cleaning is complex and the like existing in the current slice machining of the hard brittle crystal material are solved, and further, a machine bed is protected, and the cost is reduced.

Owner:AMER TECH CO LTD

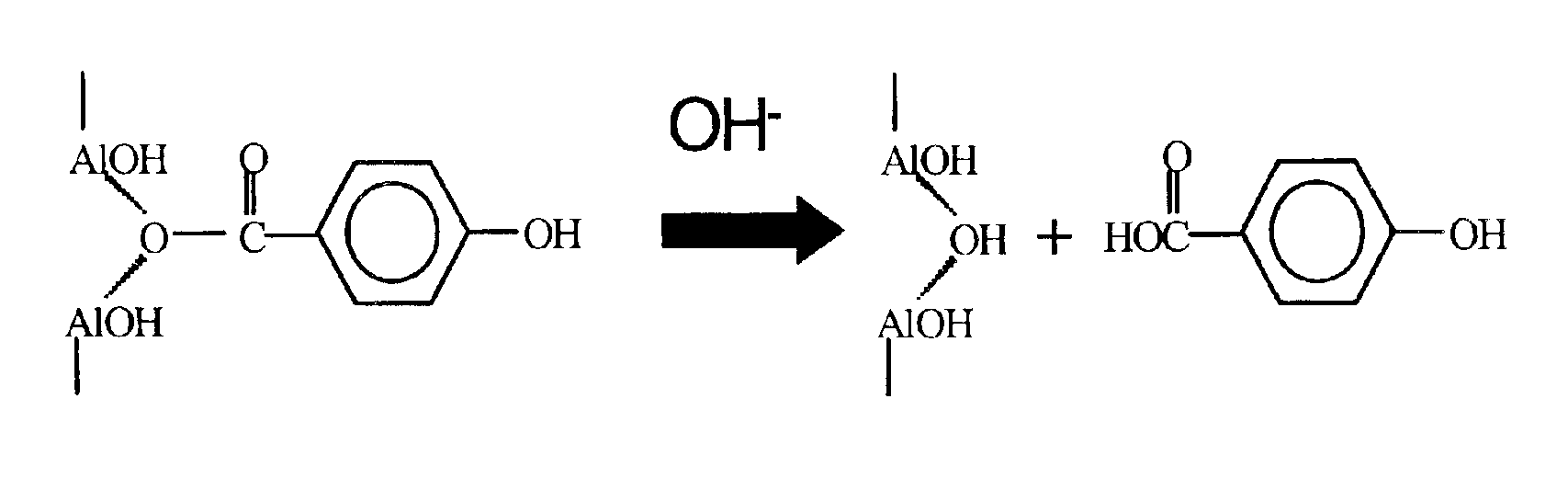

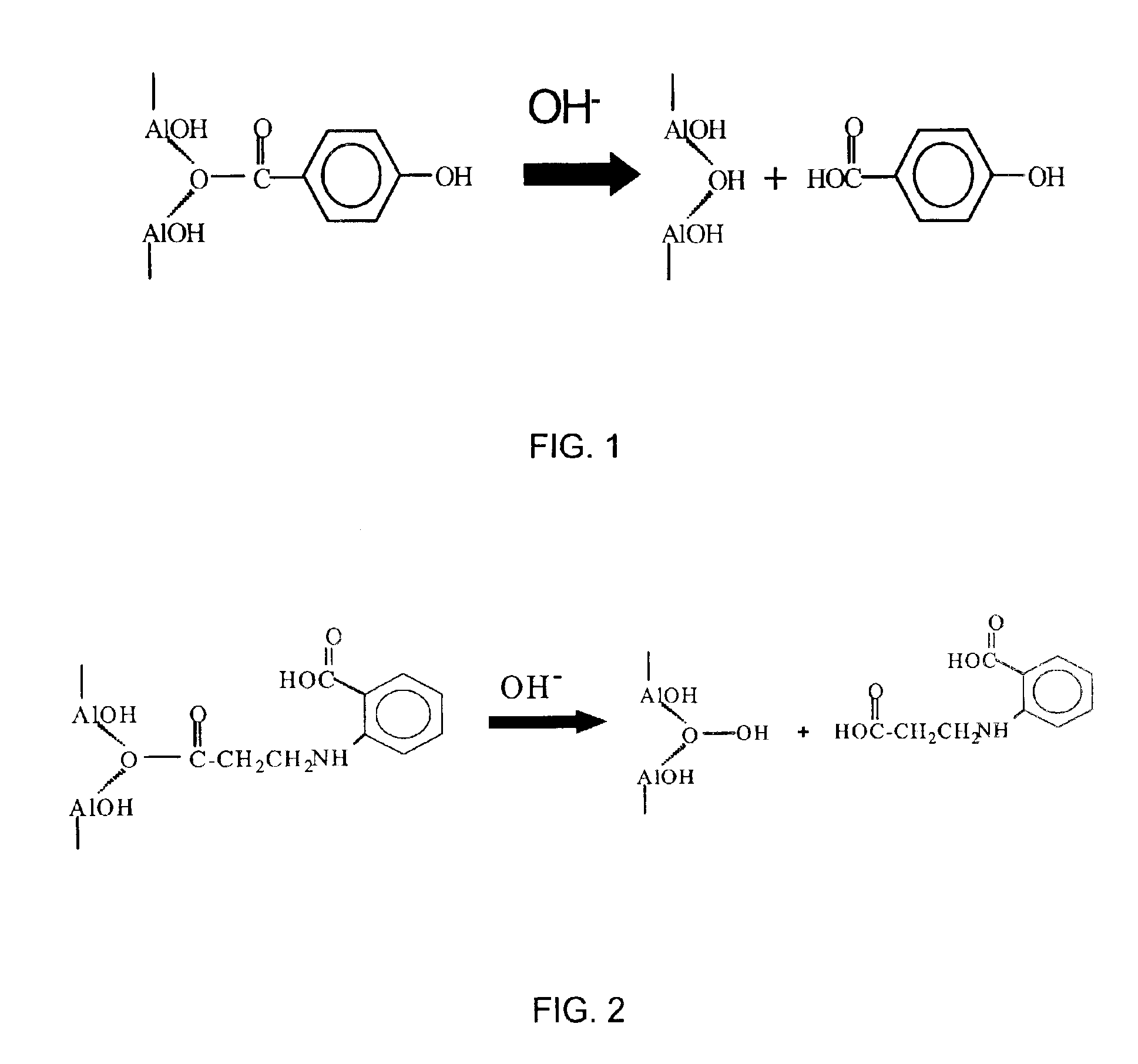

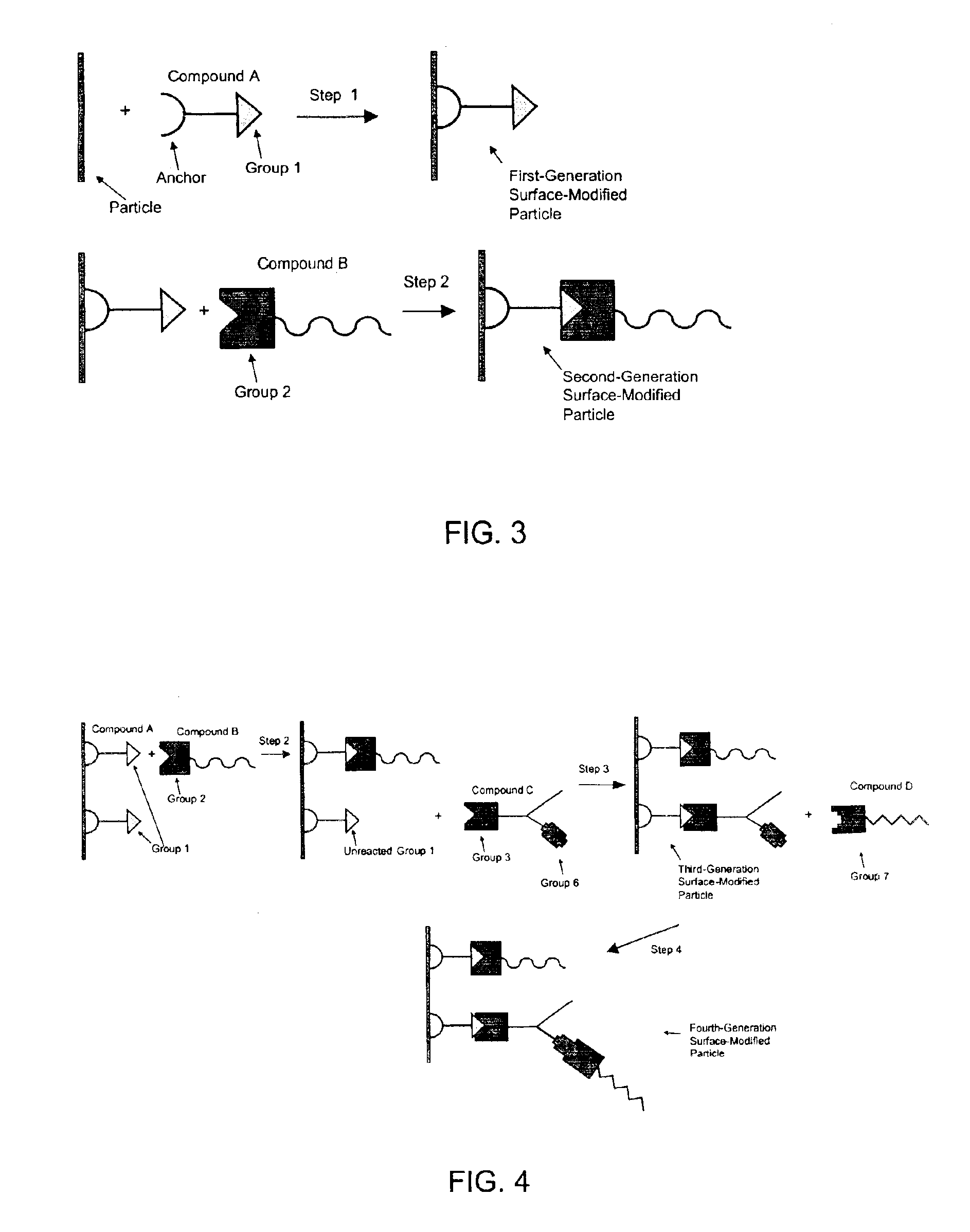

Releasable corrosion inhibitor compositions

InactiveUS6933046B1Without degrading physical property and performance of coatingReduce impactMaterial nanotechnologyPigmenting treatmentCarboxylic acidMetal

A new class of releasable corrosion inhibiting materials for protective coatings, methods of making the same, methods of using the same, and coatings containing the same are provided. The materials comprise one or more corrosion inhibitors that are chemically anchored to the surface of a particle having an aluminum oxyhydroxide surface through a carboxylate bond. The carboxylate / aluminum-oxyhydroxide-surface bond breaks under corrosion-causing conditions (for example the presence of high levels of hydroxide ions generated by the cathodic oxygen reduction reaction on metals such as iron and aluminum) thereby allowing the corrosion inhibitors to detach from the particle surface when corrosion is present.

Owner:TDA RES

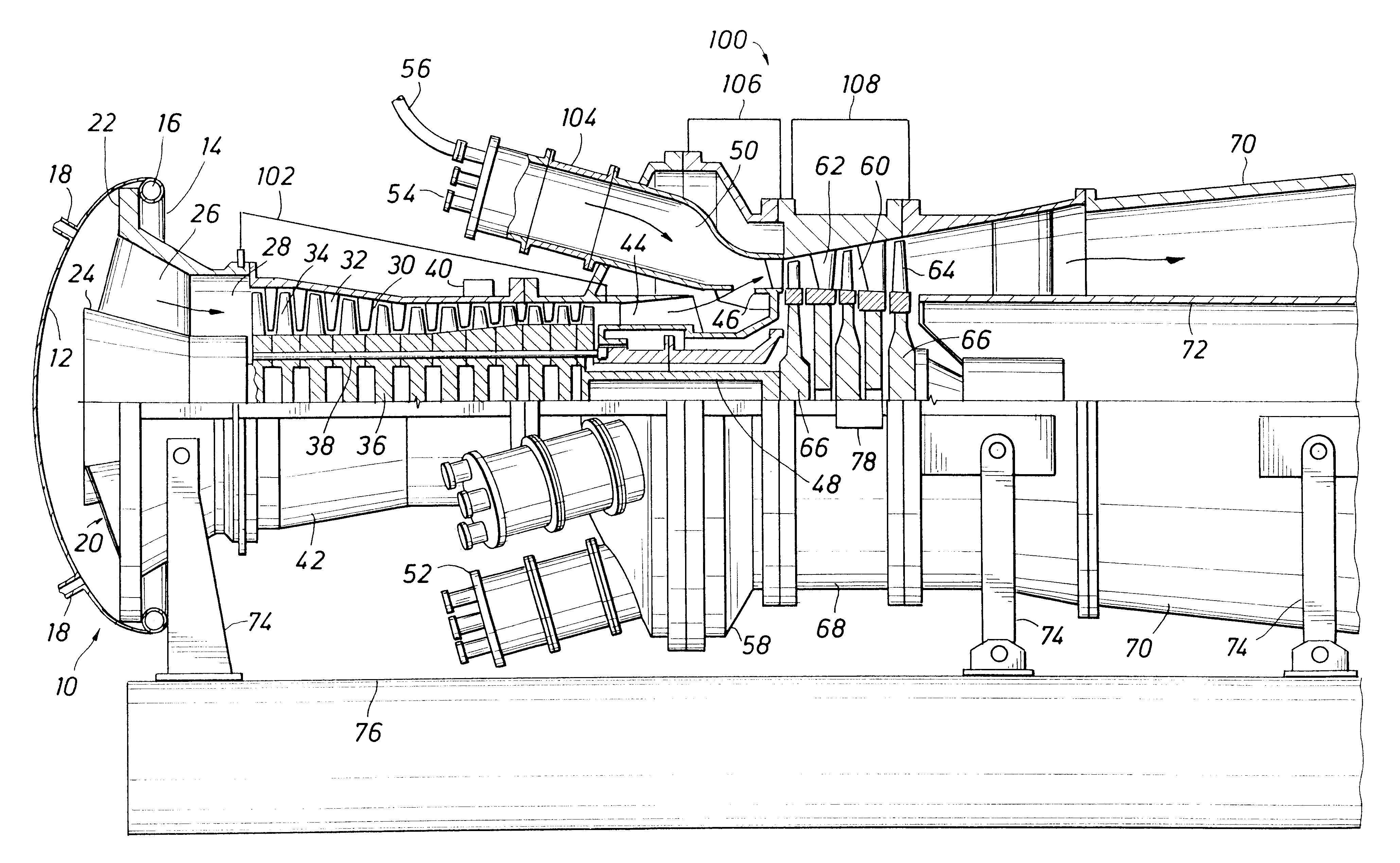

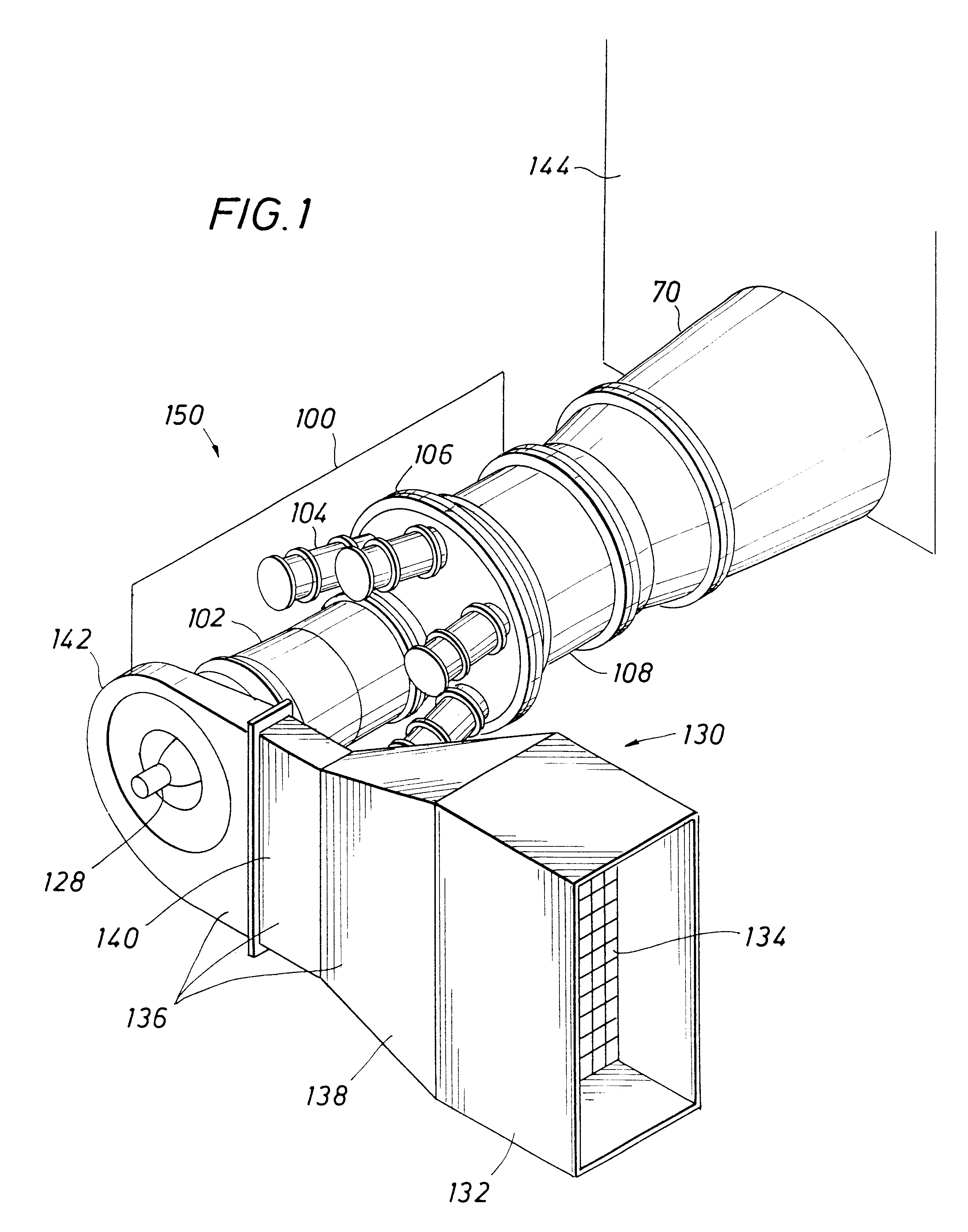

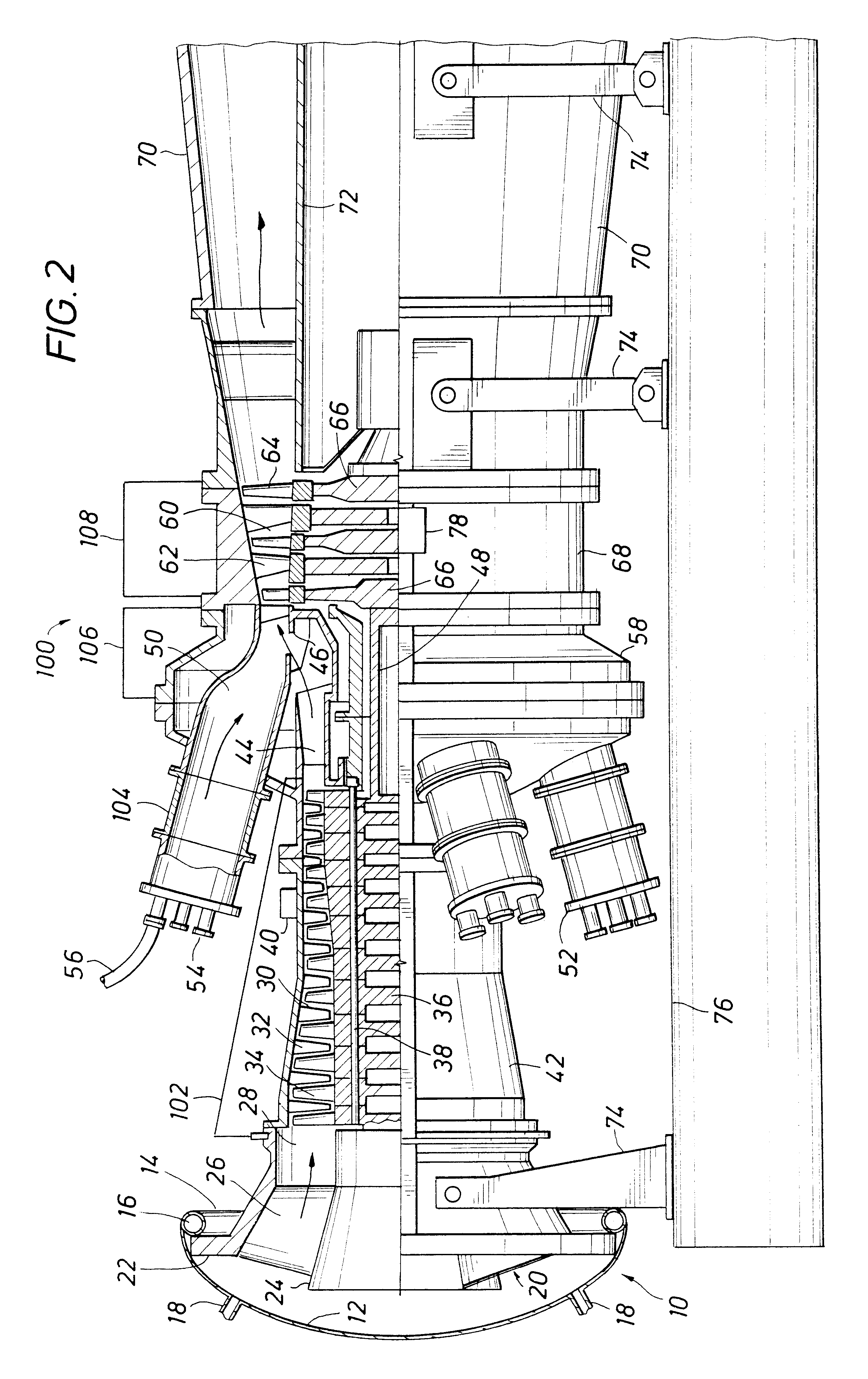

Manifold for use in cleaning combustion turbines

InactiveUS6491048B1Improve cleanlinessImprove effectivenessPump componentsElectrostatic cleaningParticulatesCombustion

The present invention is directed to a manifold for temporarily blocking the air intake of the compressor section of a combustion turbine to facilitate cleaning. A manifold suitable for providing a temporary seal about the air intake of the compressor section and through which a foamed cleaning solution can be pumped is disclosed. The manifold is conveniently provided as a flexible manifold body having an inflatable tubular member along the periphery thereof for sealing with the air intake and a plurality of hose connections through which a foamed cleaning solution can be delivered to the compressor section of the combustion turbine. Particulate films and contaminants adhering to the internal components of the compressor section of a turbine are readily removed by pumping a foamed cleaning solution such as a foamed, aqueous surfactant solution through the manifold and into the compressor section. Contaminants resulting from fuel combustion and deposited in the combustion and turbine sections are removed by pumping a second, foamed cleaning solution through those sections. The second solution typically comprises a foamed, aqueous acid solution optionally including a corrosion inhibitor. The compressor section must be isolated from such acid solutions, e.g. by pumping the foamed surfactant solution through the manifold and compressor section prior to and simultaneously with pumping the foamed acid solution through the combustion section.

Owner:GENERAL ELECTRIC CAPITAL AS AGENT

Novel vehicle alcohols environment-friendly fuel

The preparation of novel vehicle alcohols environment-friendly fuel aims to overcome a plurality of defects caused by replacing alcohols fuel with gasoline. The invention discloses the novel vehicle alcohols environment-friendly fuel which comprises the following components of 50-95 parts of main alcohols fuel, 3-30 parts of low-temperature ignition auxiliary material, 0.1-20 parts of burning value reinforcing agent, 0-15 parts of dispersant, 0-0.05 part of smoke abatement burning agent, 0-5 parts of ignition accelerating agent, 0-0.04 part of antioxidant, 0-0.3 part of emulsification dispersing agent, 0-0.08 part of metal anticorrosion inhibiter, 0-0.8 part of rubber plastic anti-dissolving additive, 0-8 parts of air-resistance regulating agent, 0-6 parts of fuel lubricating agent and 0-0.7 part of glyoxylic acid neutralizer. According to the novel vehicle alcohols environment-friendly fuel, low temperature ignitability is improved, dynamic performance is enhanced, burning is sufficient, discharging is environment-friendly and free form pollution, corrosivity of the alcohols fuel on metal can be controlled, swelling performance of the alcohols fuel on rubber can be controlled and the air resistance phenomenon can be effectively prevented.

Owner:罗浩南 +1

Formulations for removing cooper-containing post-etch residue from microelectronic devices

InactiveUS20090301996A1Decorative surface effectsNon-surface-active detergent compositionsMetal interconnectDiluent

A method and composition for removing copper-containing post-etch and / or post-ash residue from patterned microelectronic devices is described. The removal composition includes a diluent, a solvent and a copper corrosion inhibitor, wherein the diluent may be a dense fluid or a liquid solvent. The removal compositions effectively remove the copper-containing post-etch residue from the microelectronic device without damaging exposed low-k dielectric and metal interconnect materials.

Owner:ADVANCED TECH MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com