Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

575results about How to "Improve flow characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

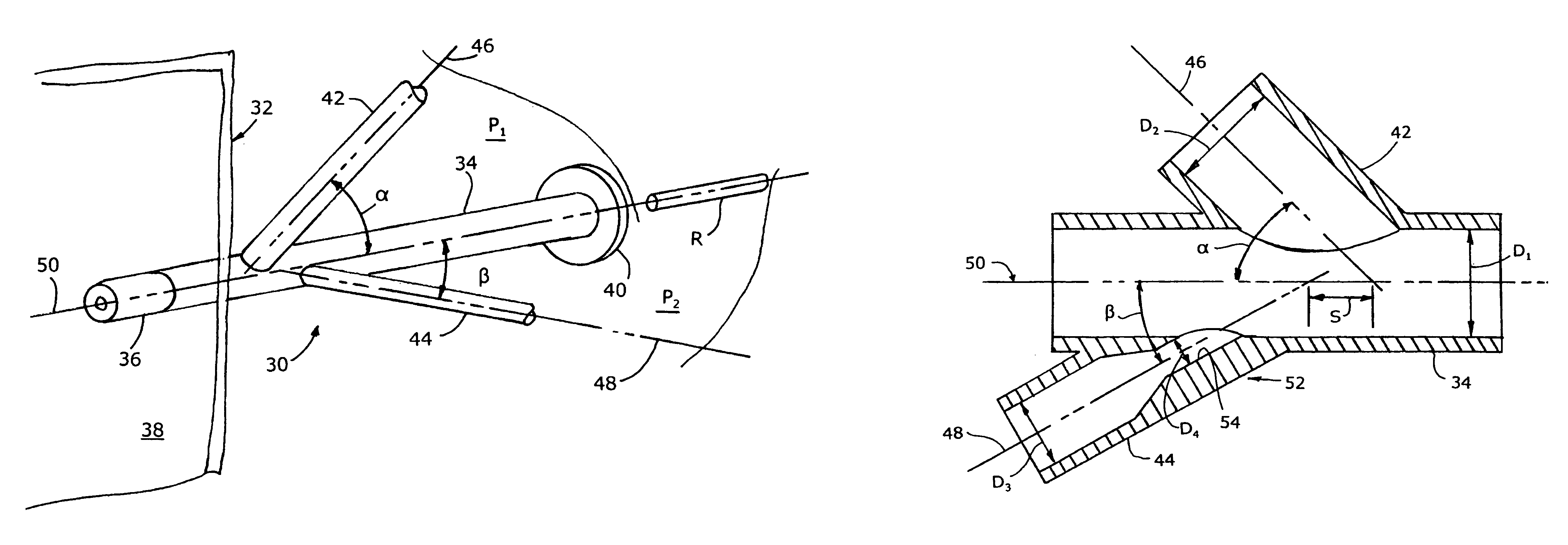

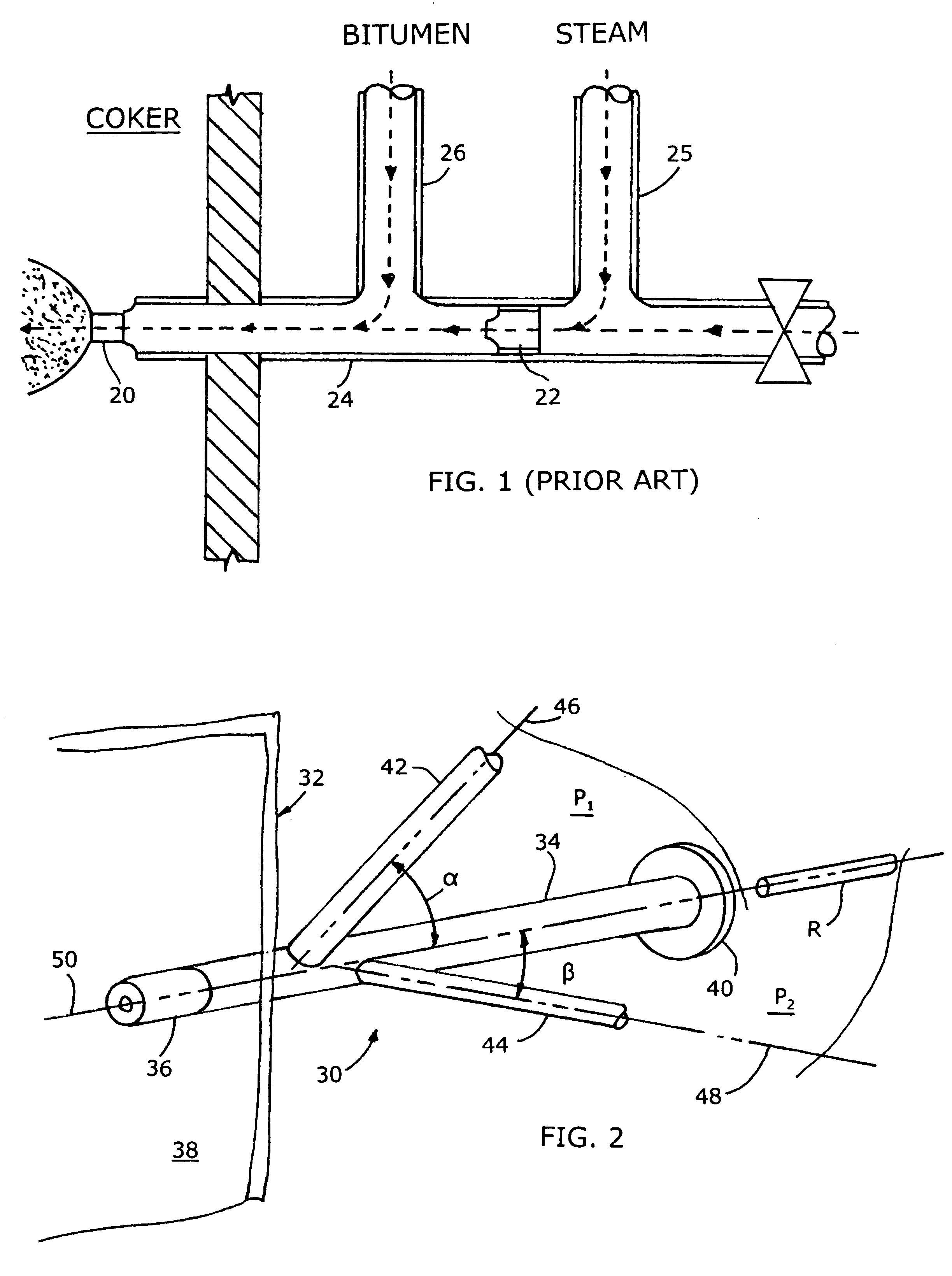

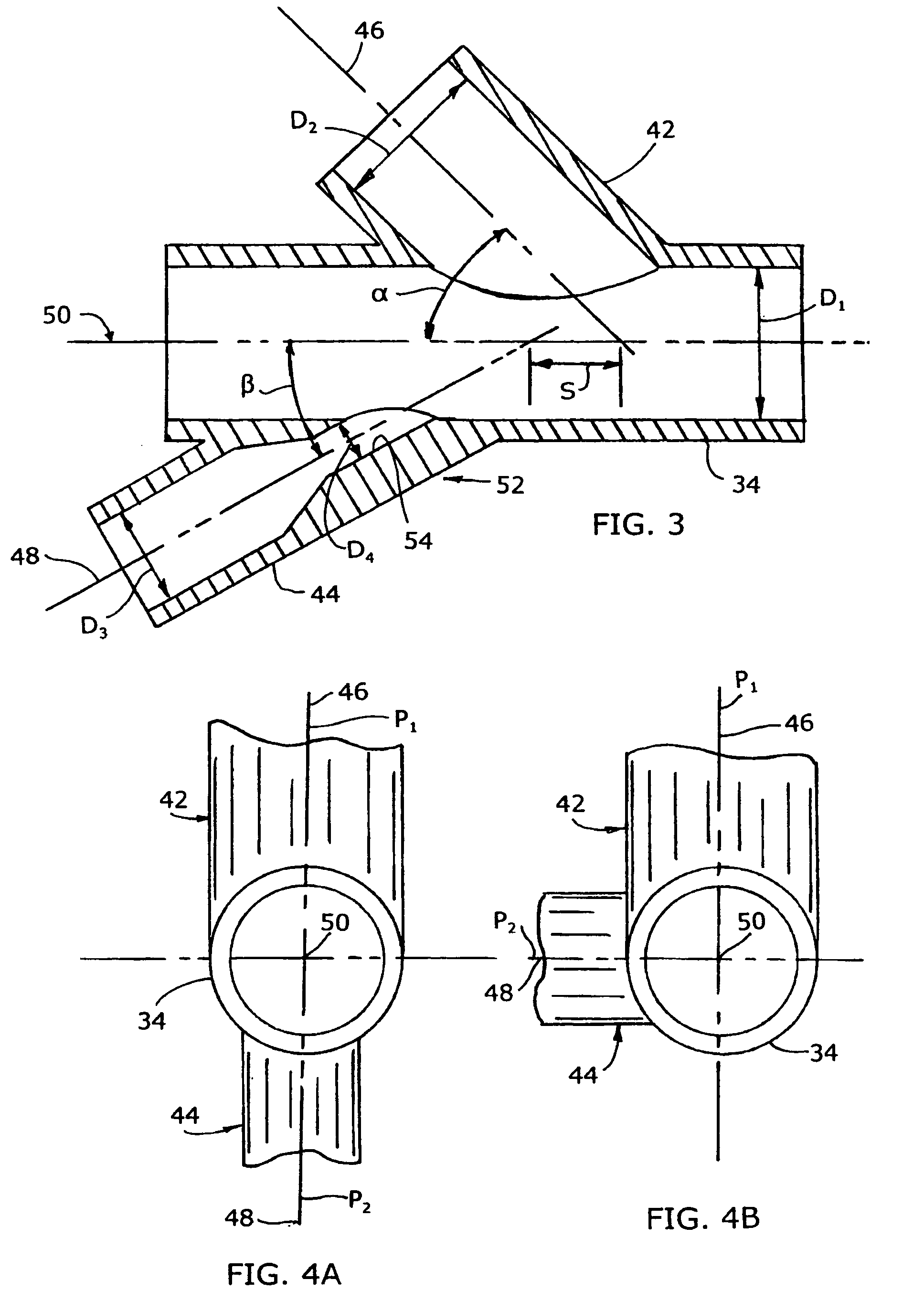

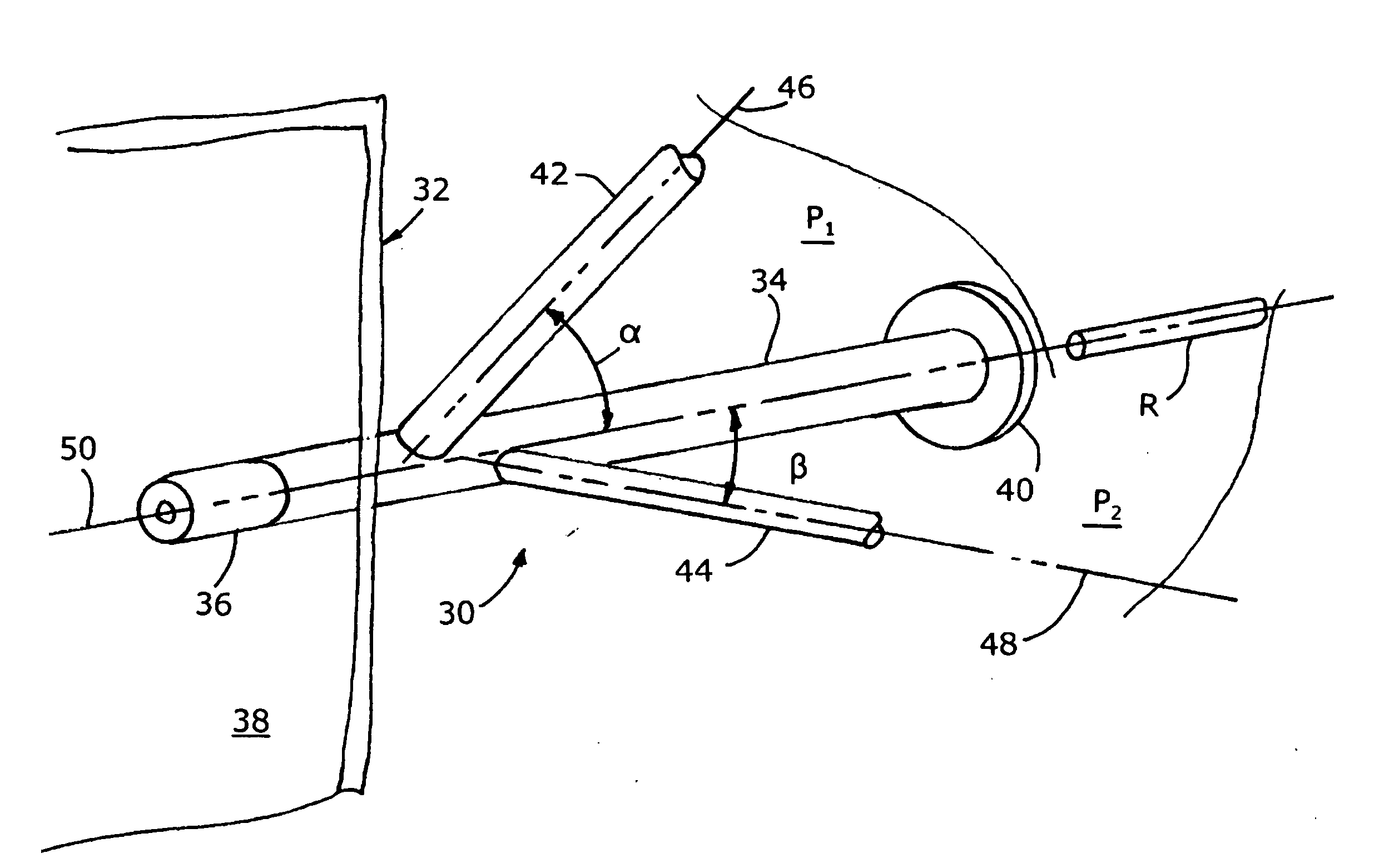

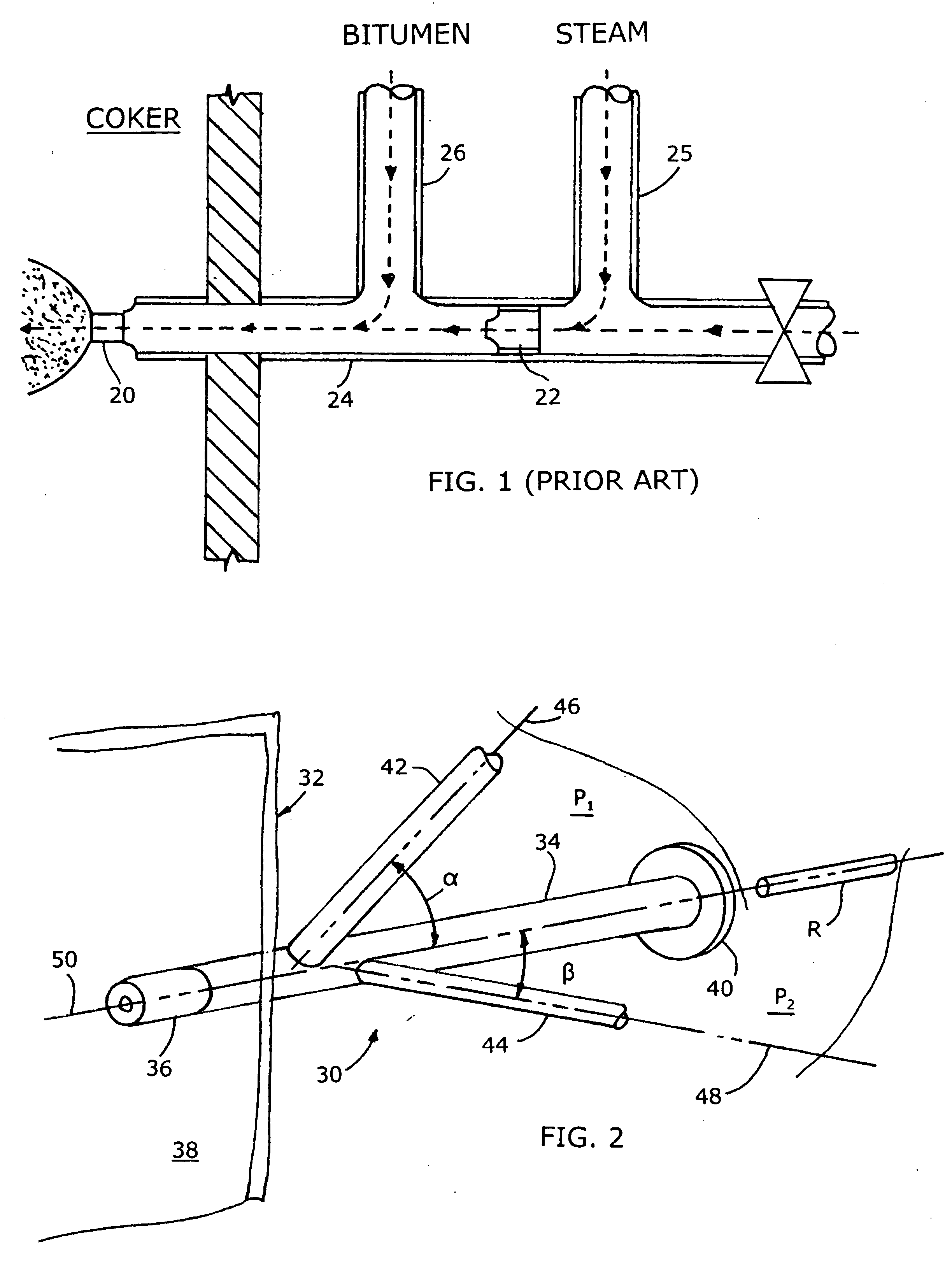

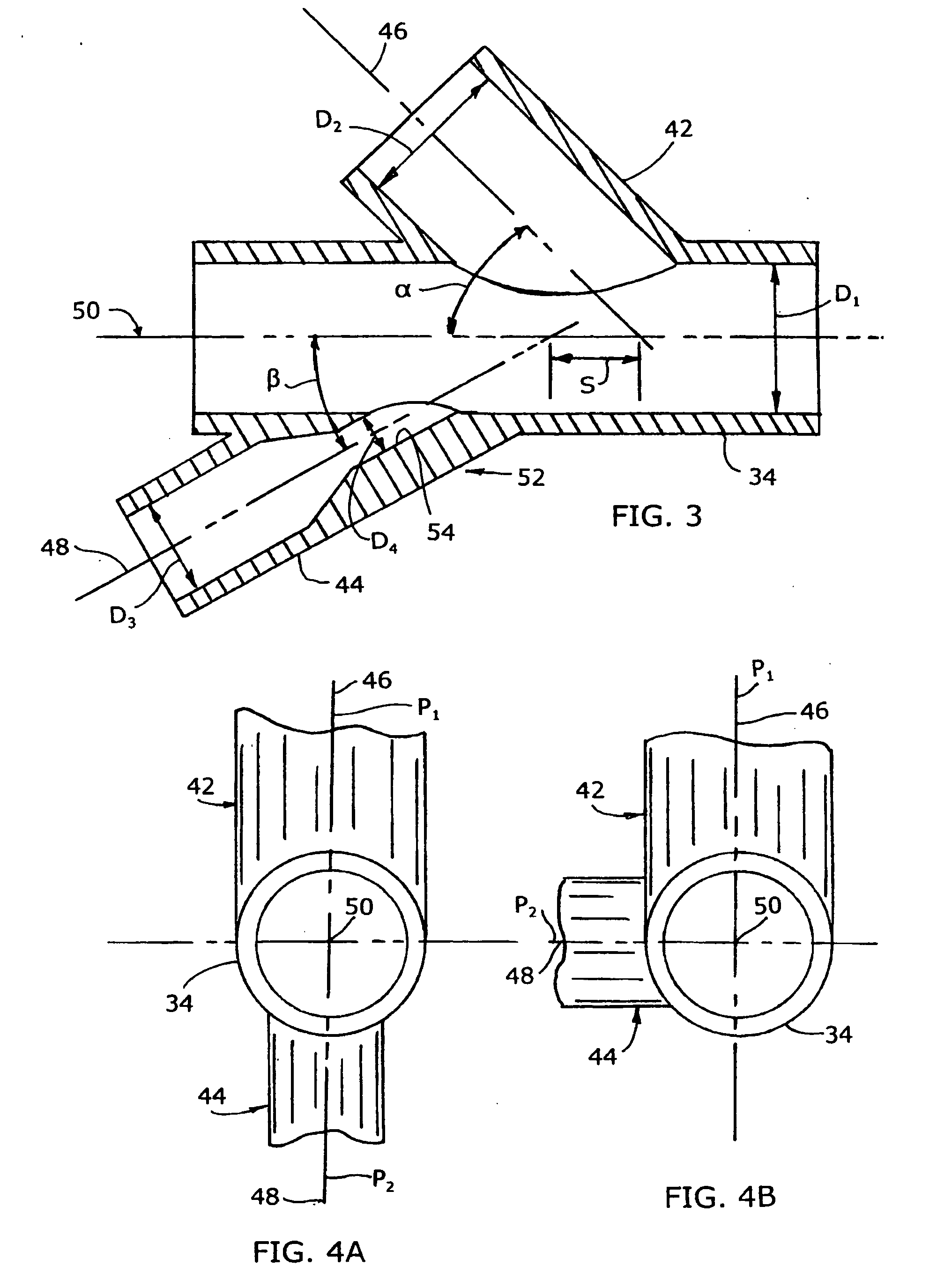

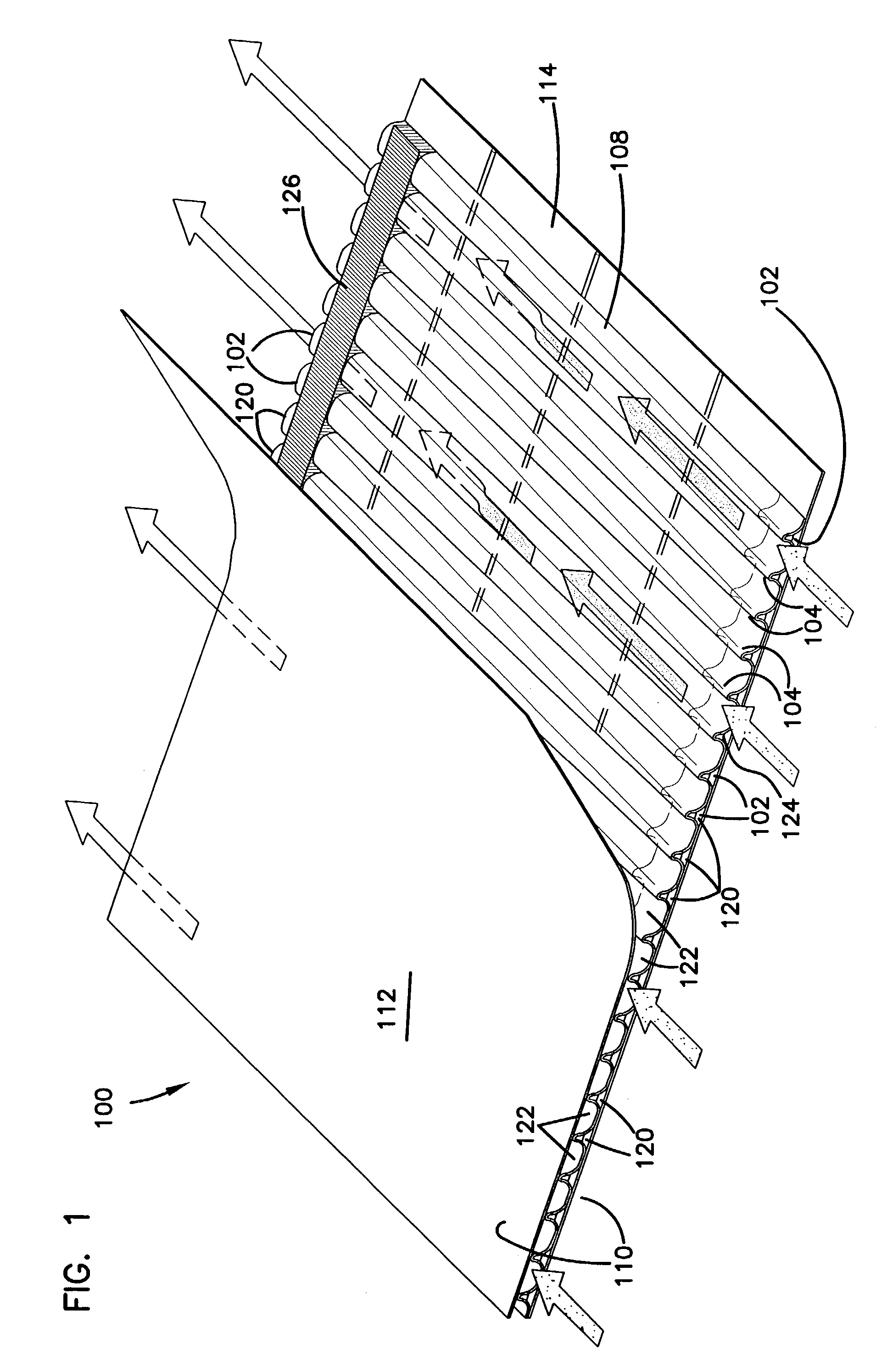

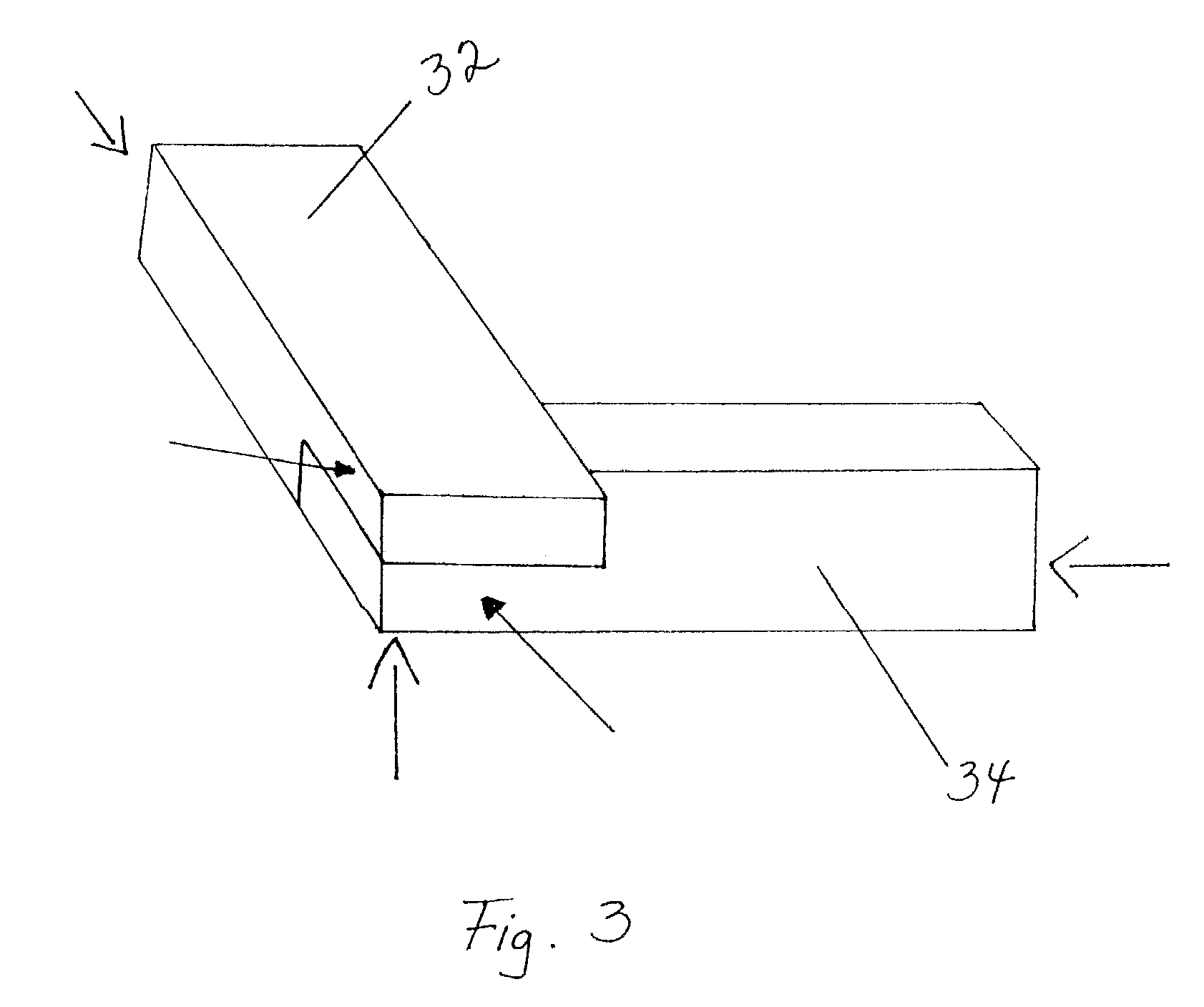

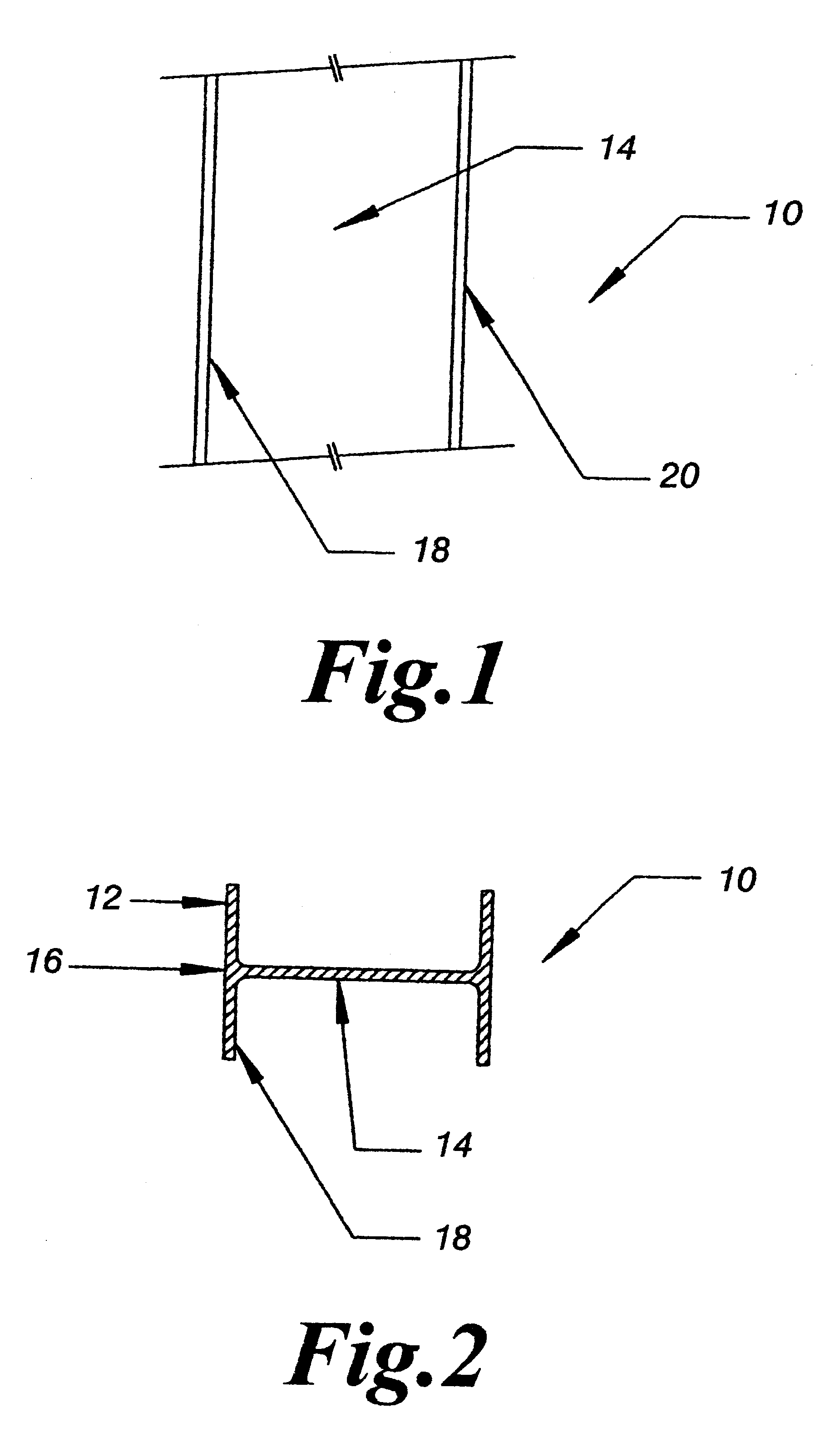

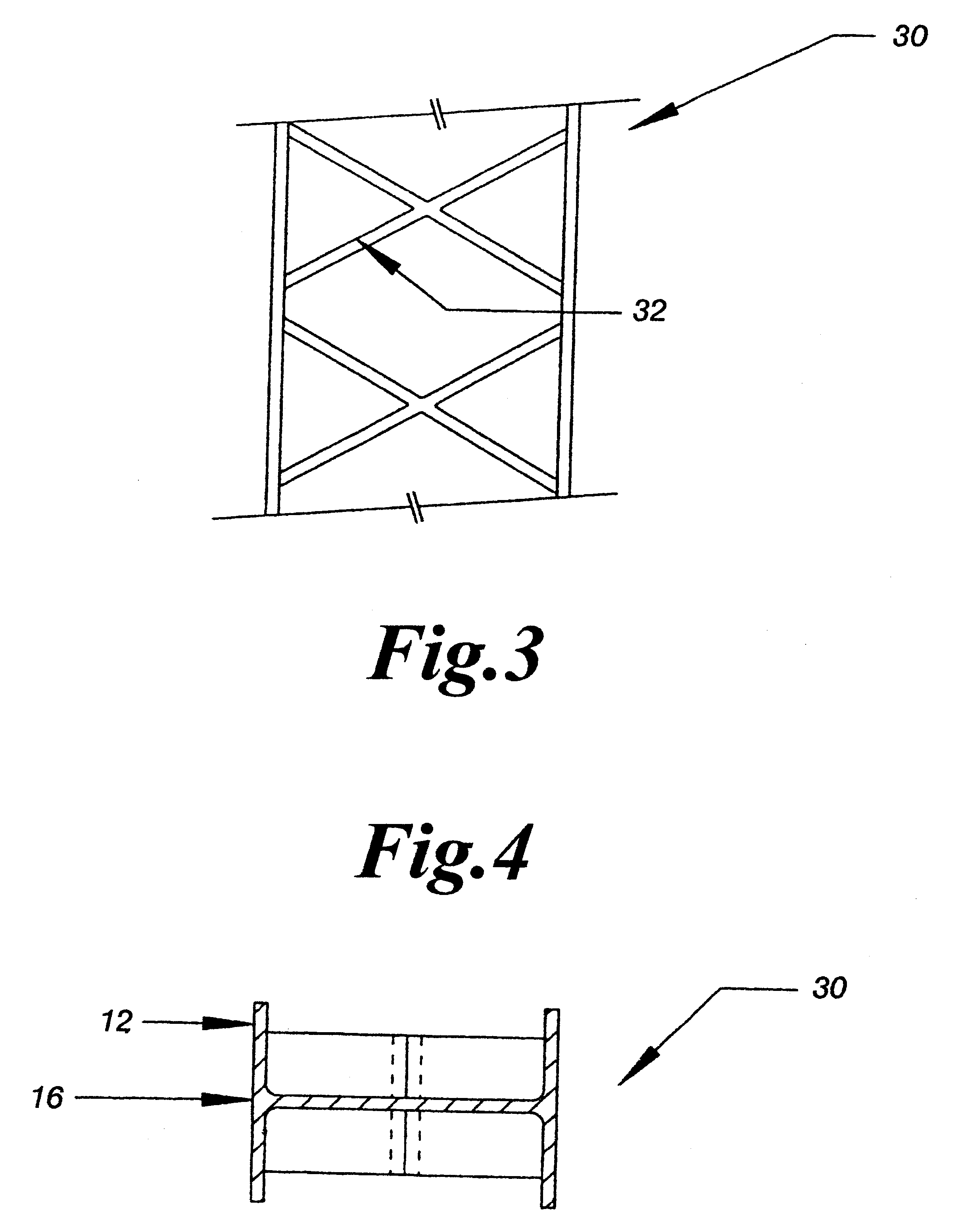

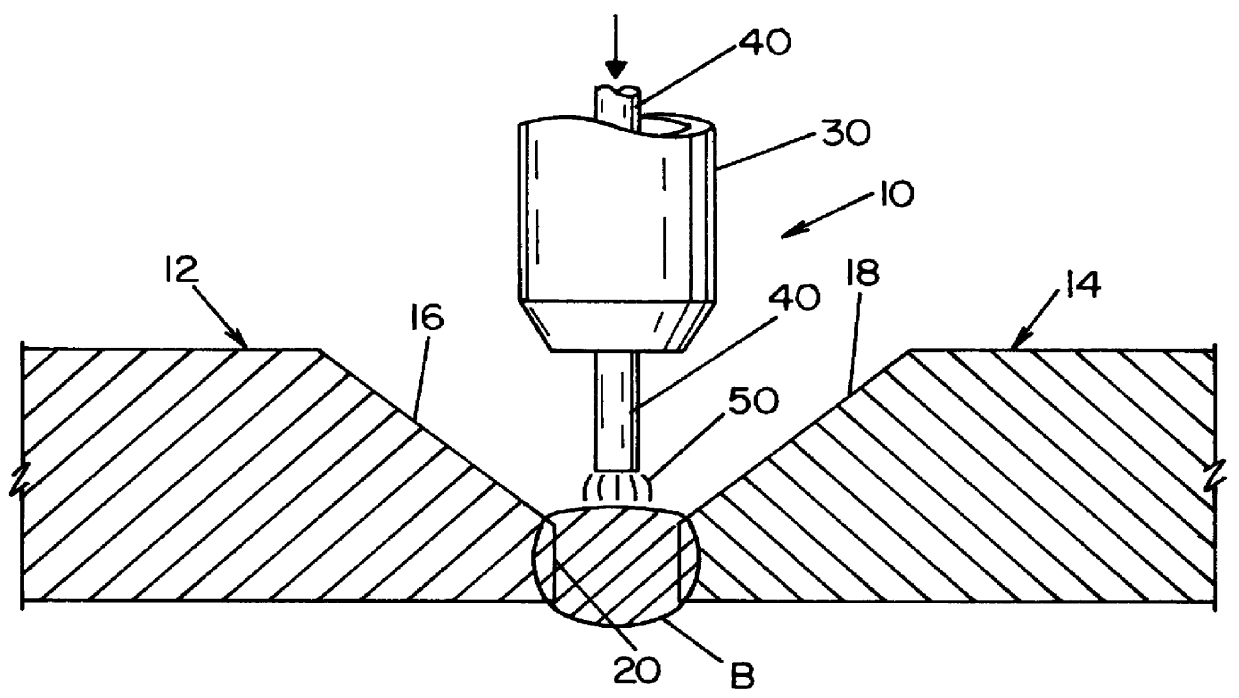

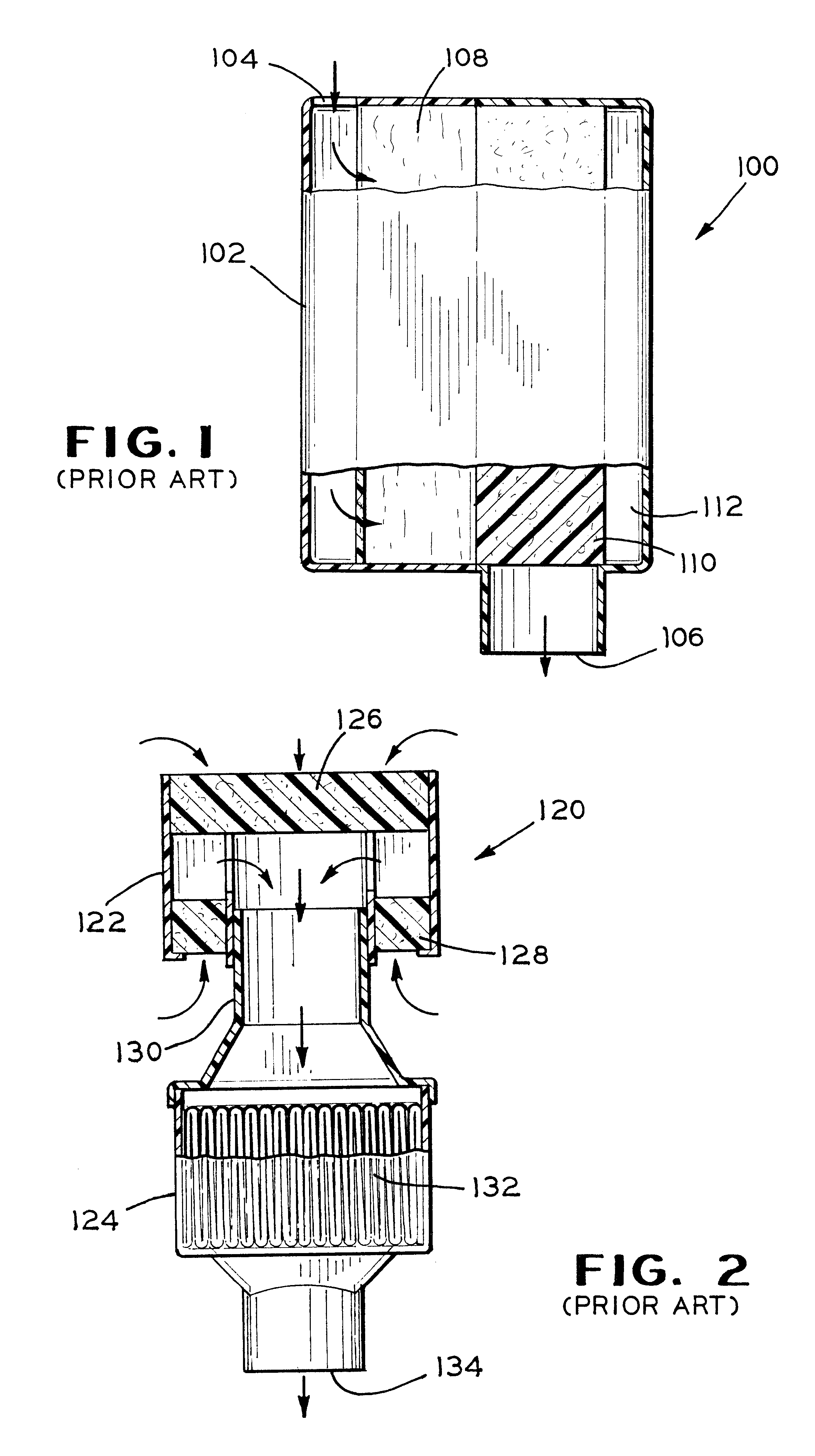

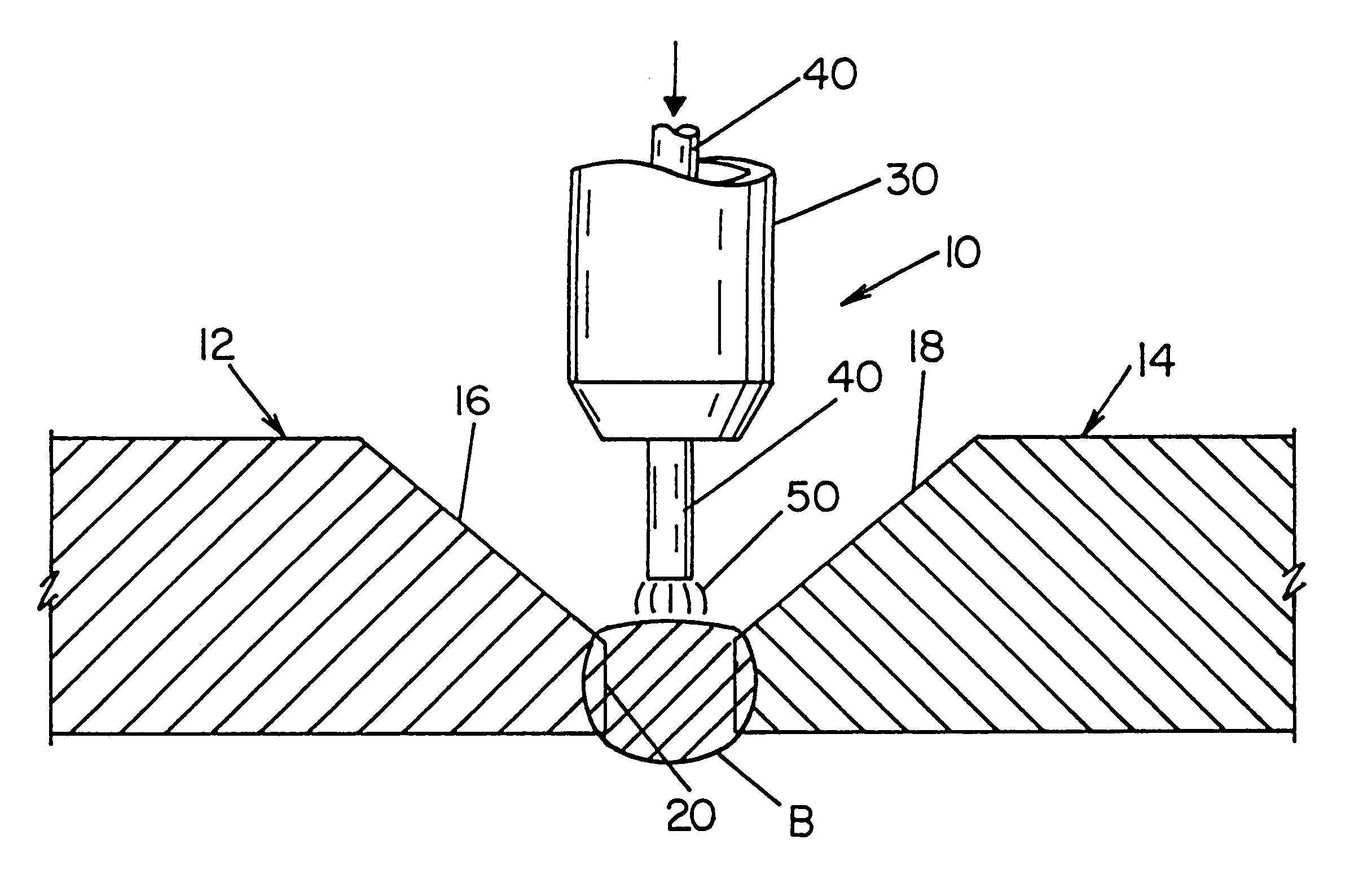

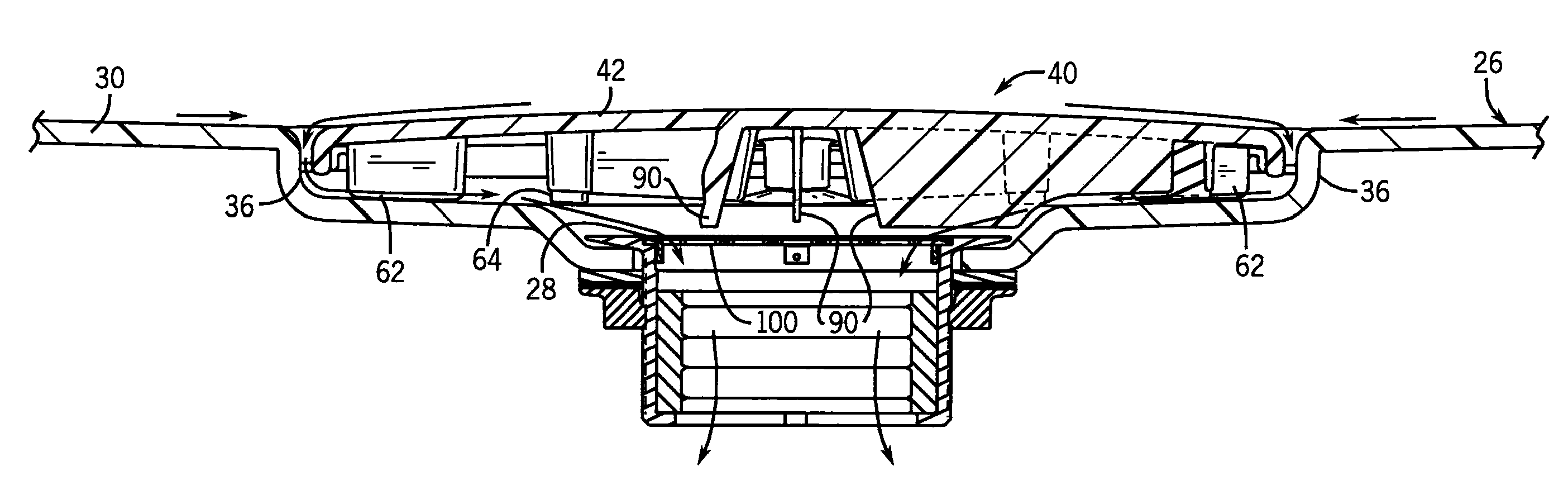

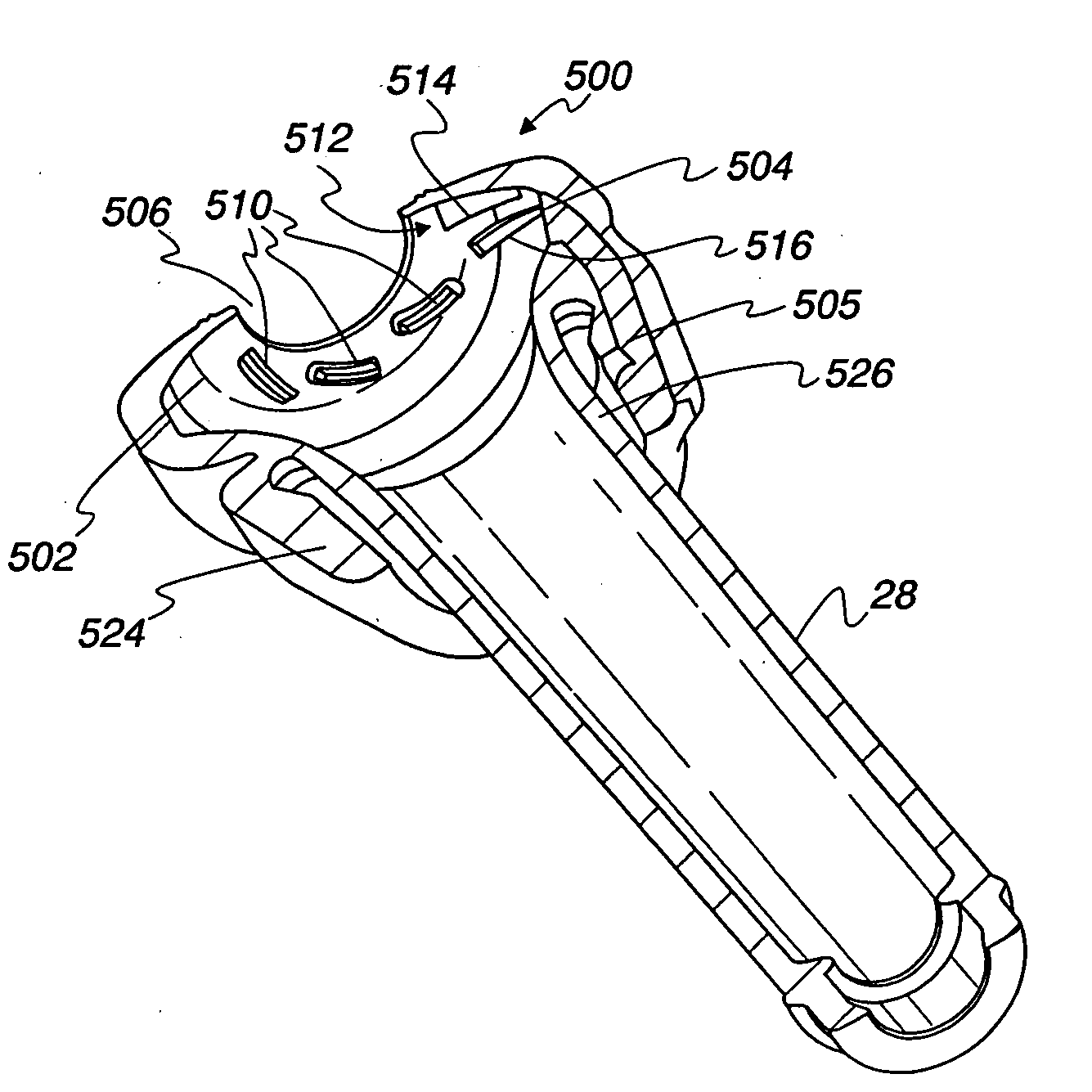

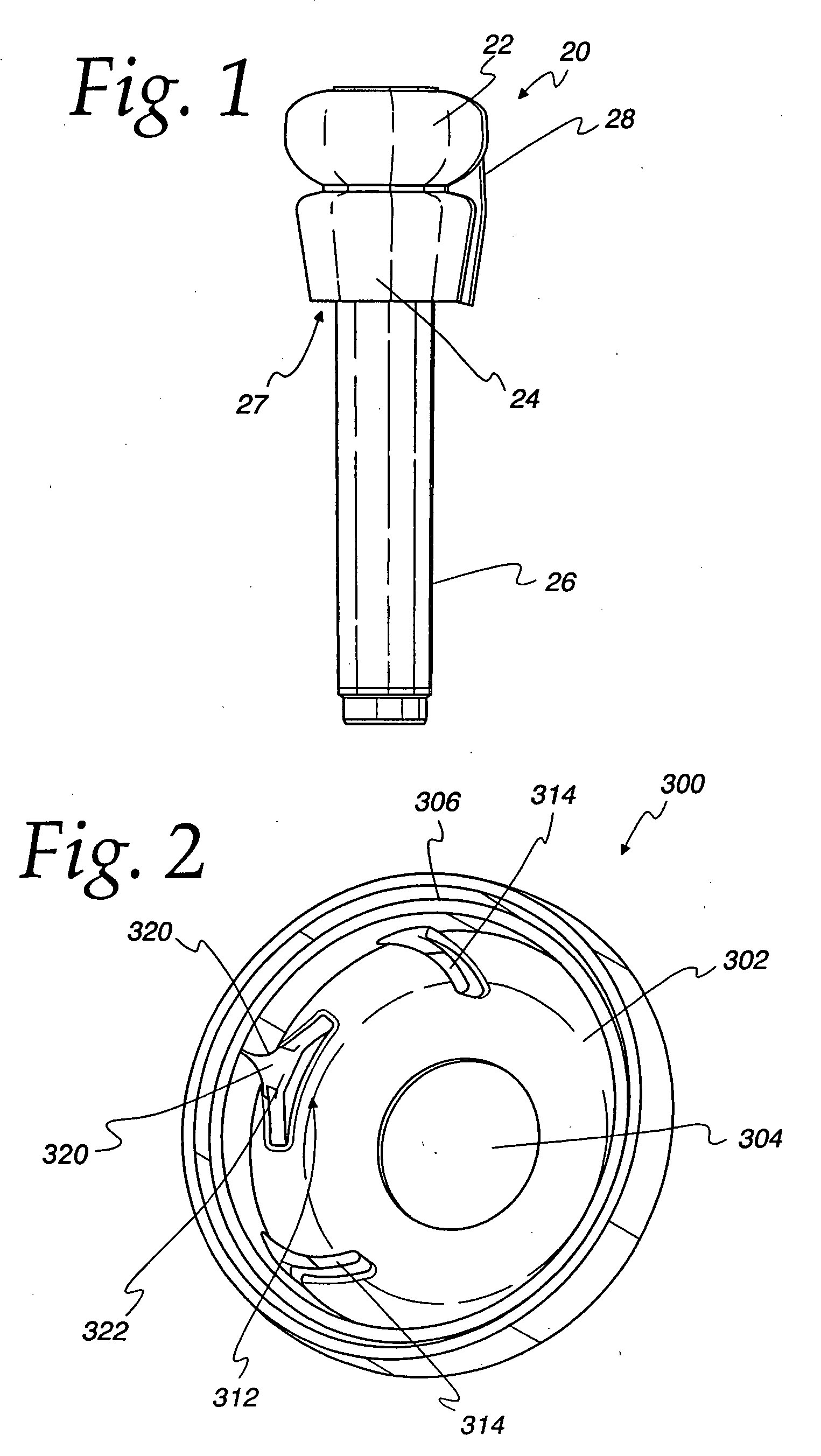

Mixing arrangement for atomizing nozzle in multi-phase flow

ActiveUS7140558B2Smooth transitionEasy to processCharging-discharging device combinationsFlow mixersAcute angleShortest distance

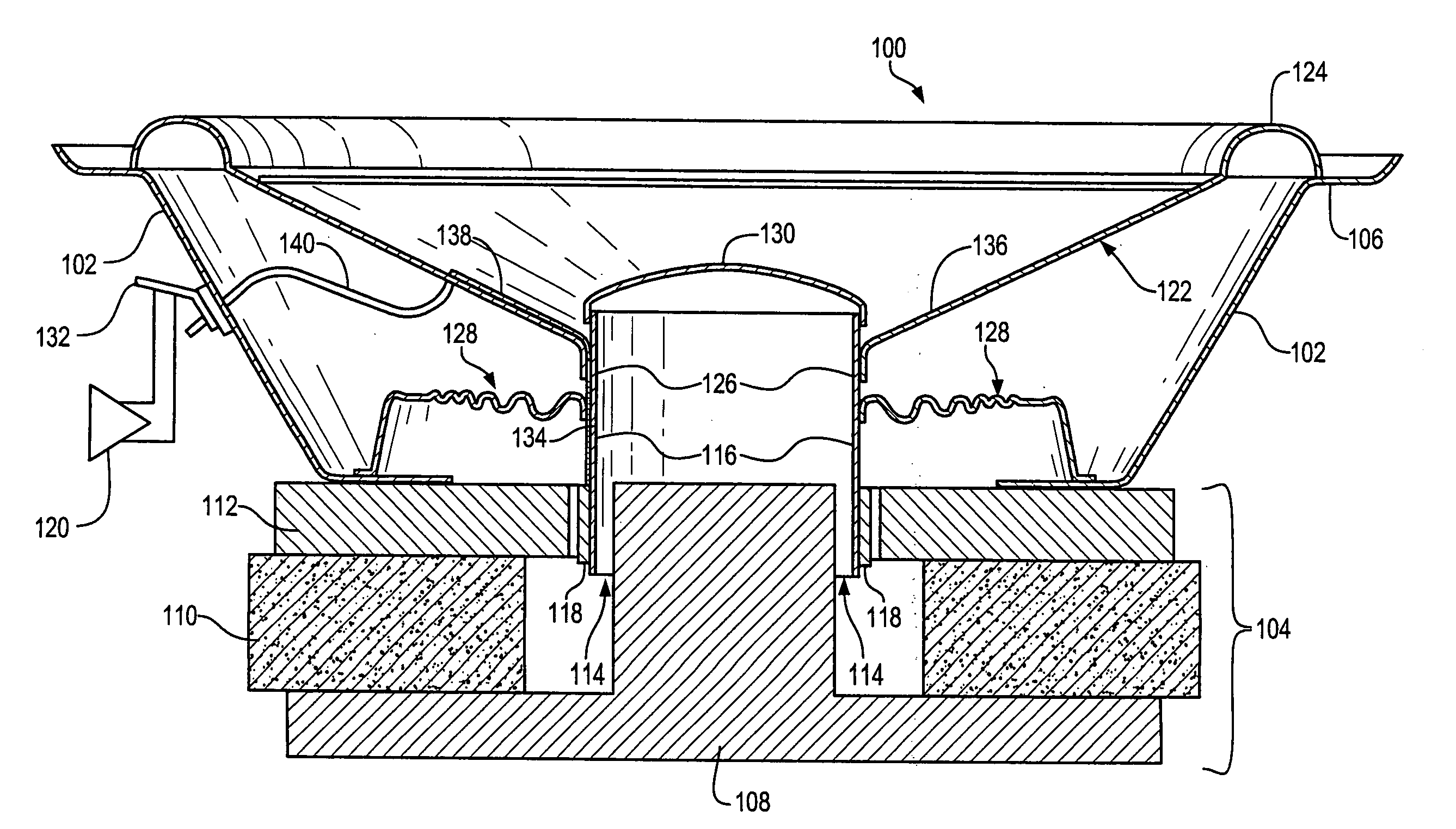

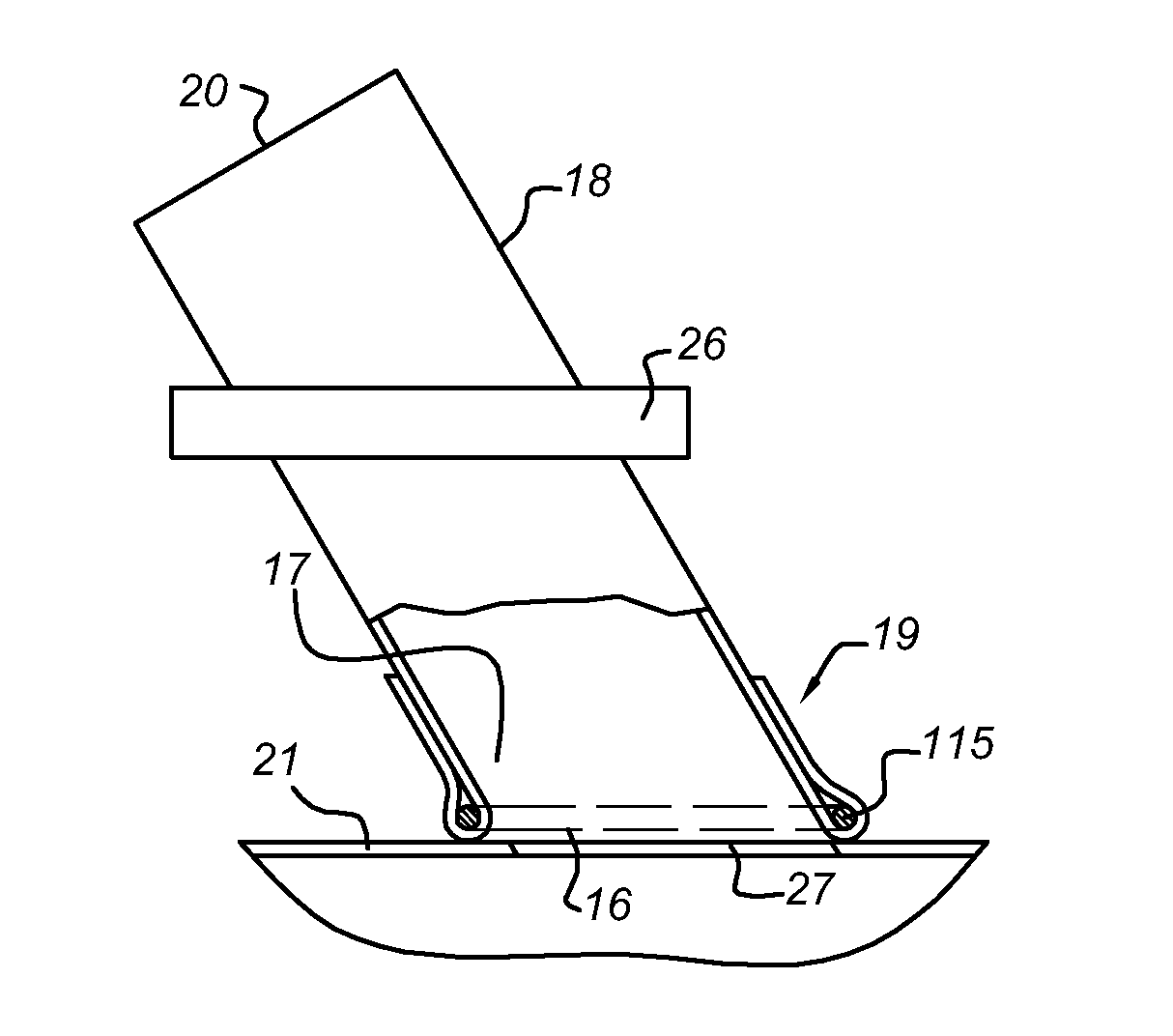

The invention relates to an improved mixing arrangement for, primarily, moving bitumen in steam from sources of such bitumen and steam to a reactor or coker for further processing of the bitumen into petroleum products. The invention provides a main conduit connected to an atomizing nozzle mounted in a wall of the reactor and first and second conduits for flowing bitumen and steam respectively into the main conduit. The first conduit is angled relative to the main conduit at an acute angle of about 45° and the second conduit is angled relative to the main conduit at an acute angle of about 30°. The second conduit is positioned upstream of the first conduit by a short distance of about 23 mm and may be angled radially relative to the first conduit by any angle, although a 90° angle is preferred. A flow accelerating nozzle is located in the second conduit adjacent the entrance therefrom into the main conduit The arrangement of the invention improves the flow characteristics of 2-phase material flowing to the atomizing nozzle, reducing pulsations in the main conduit and improving the resulting atomization of the bitumen in the reactor.

Owner:NAT RES COUNCIL OF CANADA +1

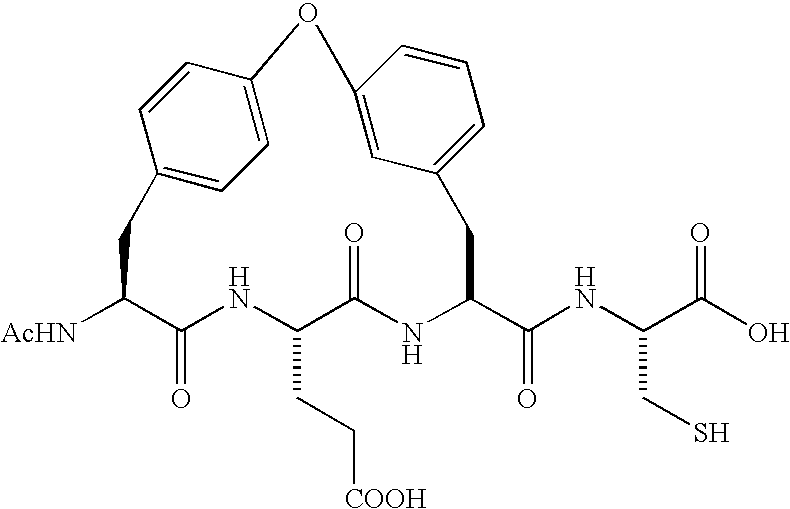

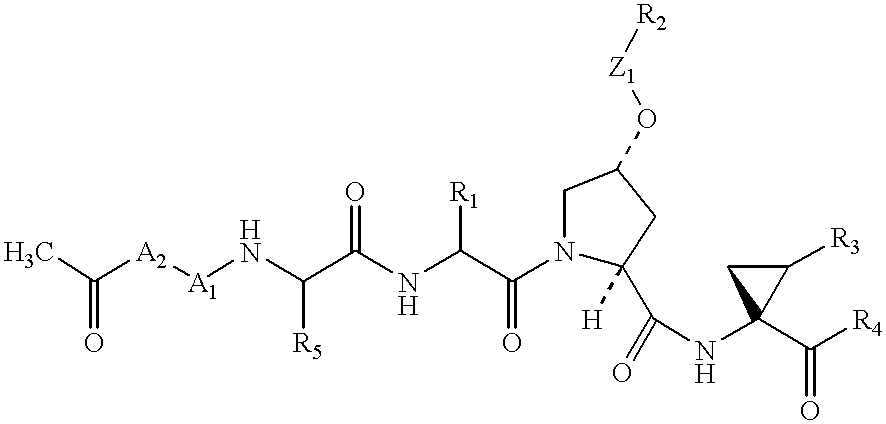

Imidazolidinones as NS3-serine protease inhibitors of hepatitis C virus

InactiveUS6838475B2Reduce frictionReduce wearBiocideOrganic active ingredientsSerine Protease InhibitorsHepacivirus

The present invention discloses novel imidazolidinones which have HCV protease inhibitory activity as well as methods for preparing such compounds. In another embodiment, the invention discloses pharmaceutical compositions comprising such imidazolidinones as well as methods of using them to treat disorders associated with the HCV protease.

Owner:SCHERING CORP

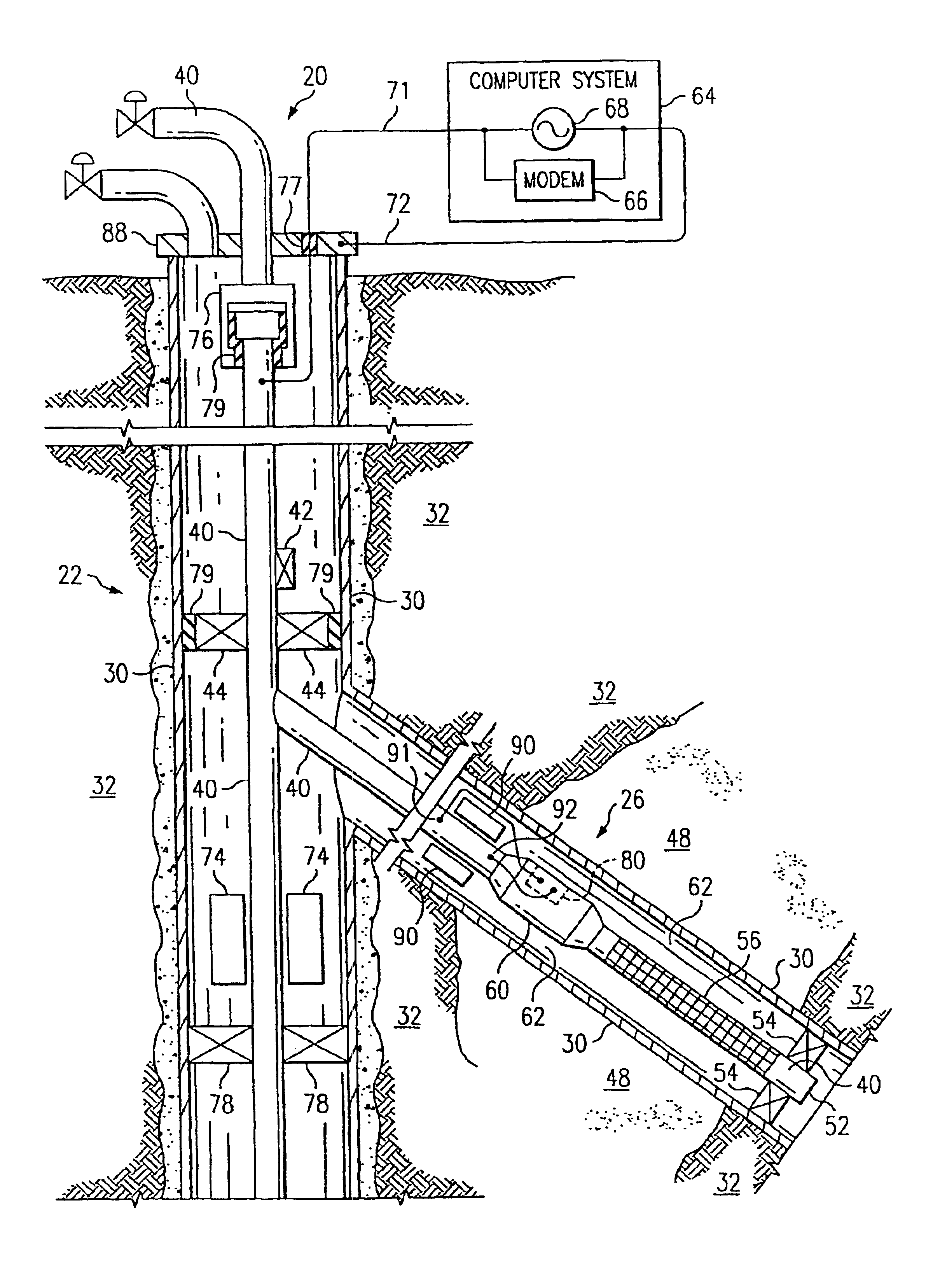

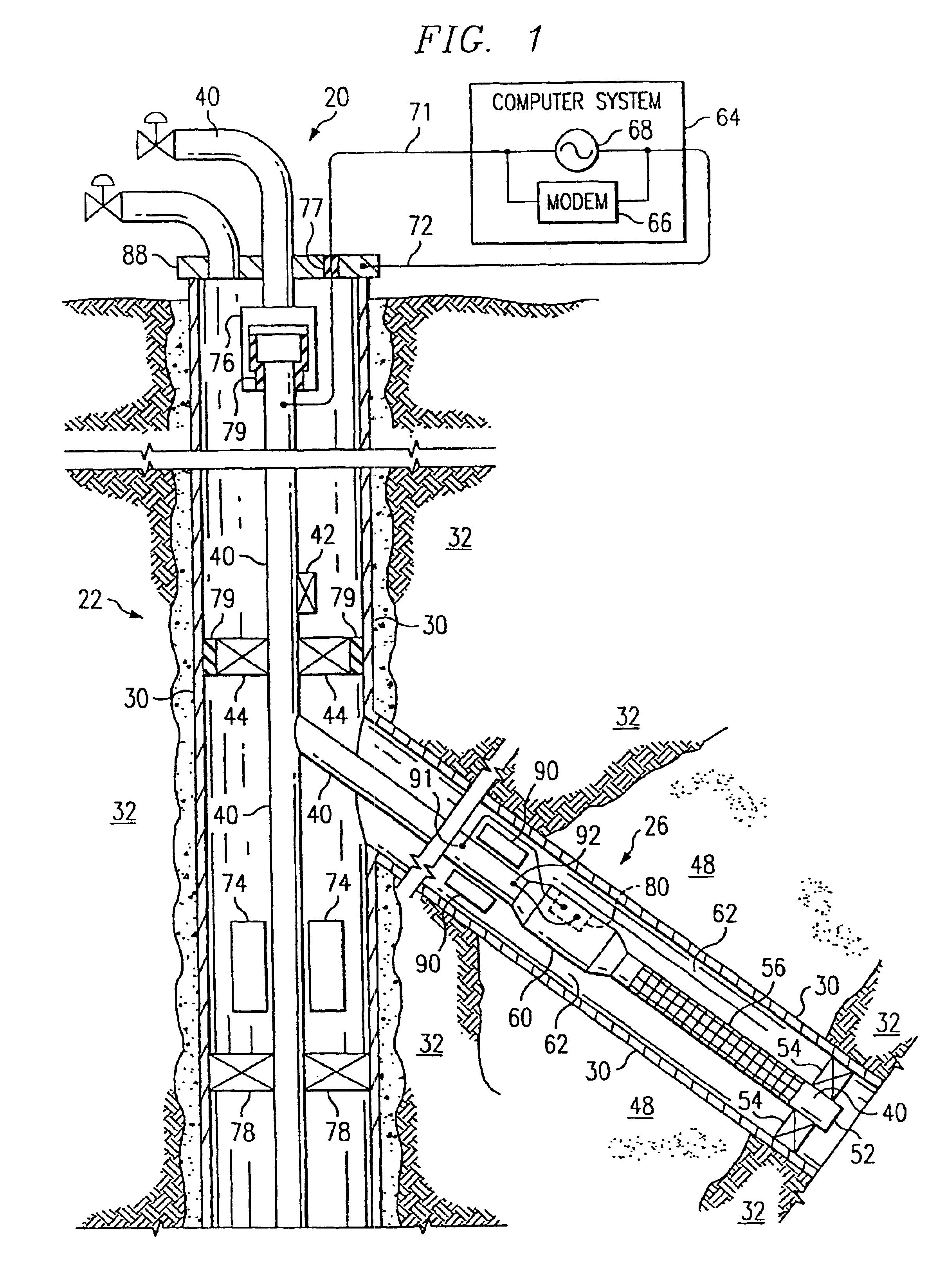

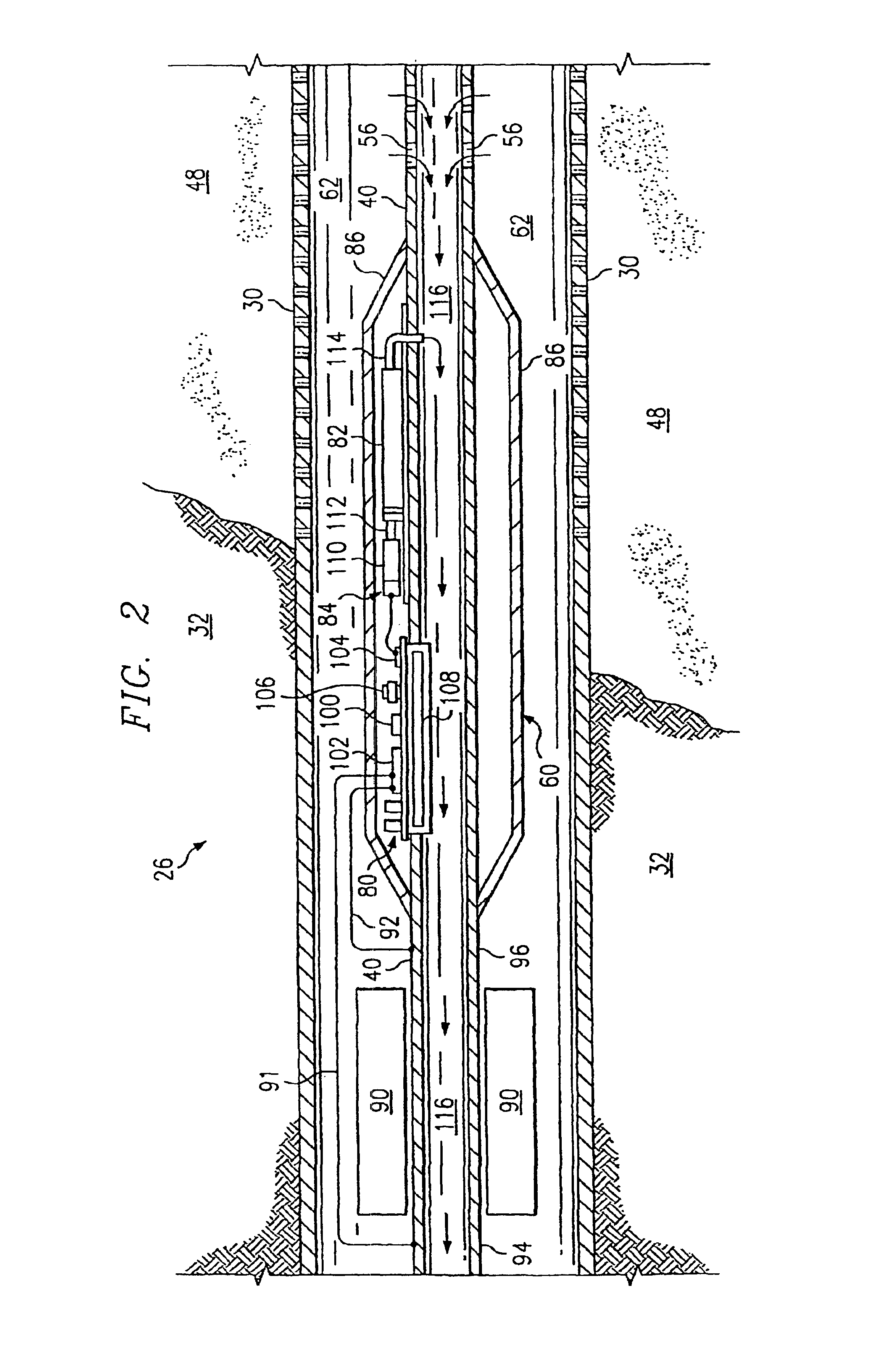

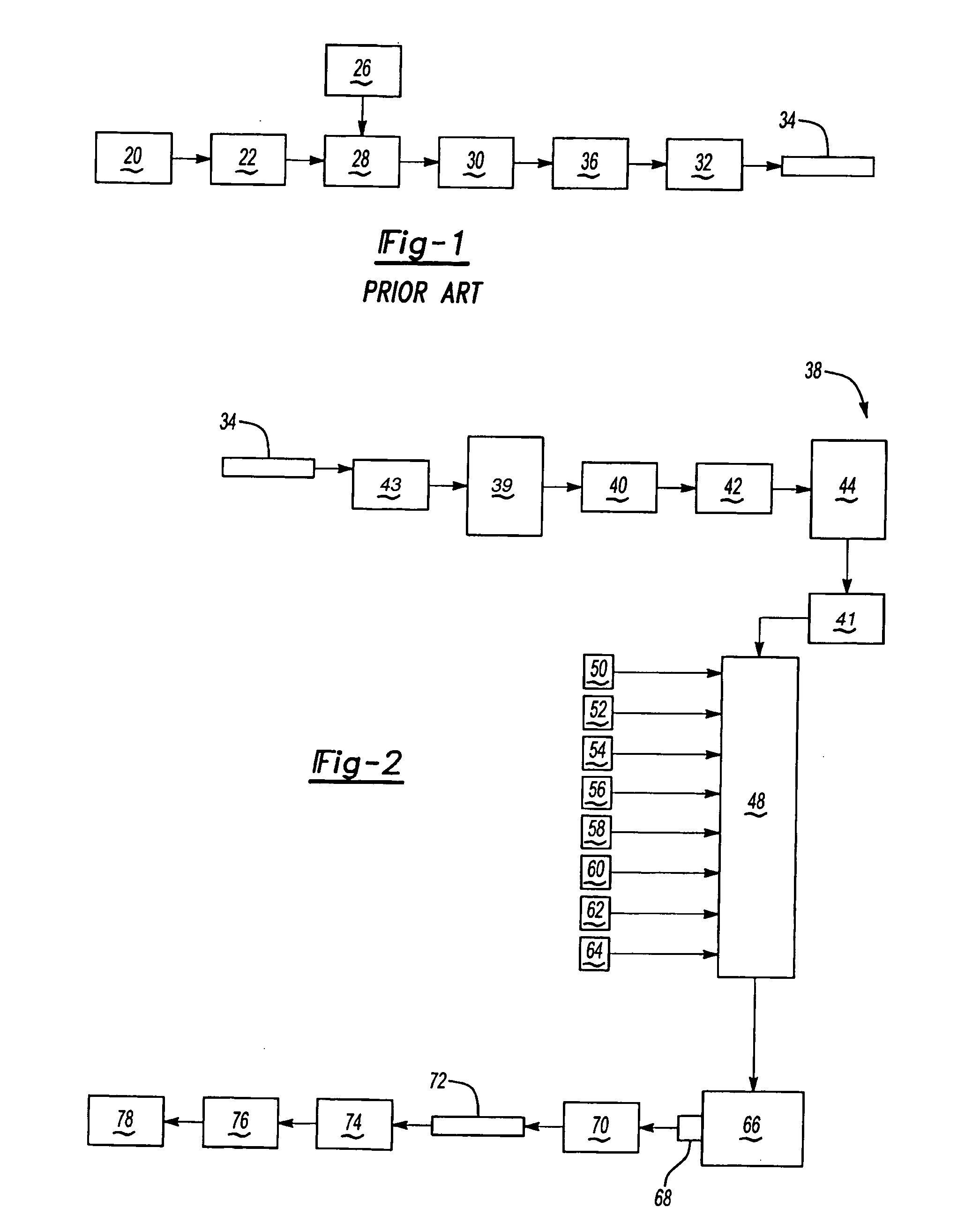

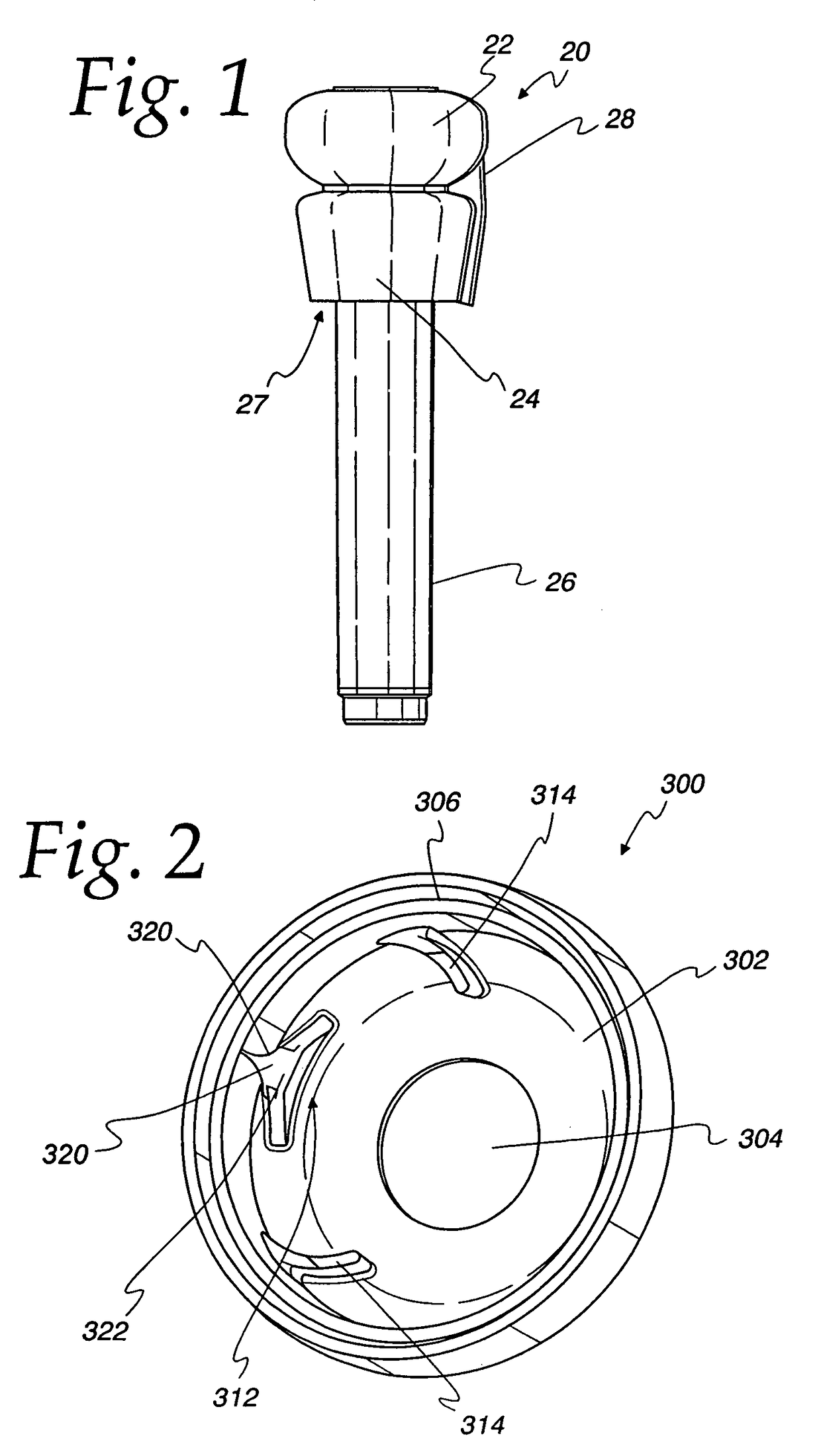

Controlled downhole chemical injection

InactiveUS6981553B2Improve efficiencyImprove flow characteristicsNear-field transmissionSurveyElectrical conductorPetroleum

A petroleum well having a well casing, a production tubing, a source of time-varying current, a downhole chemical injection device, and a downhole induction choke. The casing extends within a wellbore of the well. The tubing extends within the casing. The current source is located at the surface. The current source is electrically connected to, and adapted to output a time-varying current into, the tubing and / or the casing, which act as electrical conductors for providing downhole power and / or communications. The injection device having a communications and control module, a chemical container, and an electrically controllable chemical injector. The communications and control module is electrically connected to the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The chemical injector is electrically connected to the communications and control module, and is in fluid communication with the chemical container. The downhole induction choke is located about a portion of the tubing and / or the casing. The induction choke is adapted to route part of the electrical current through the communications and control module by creating a voltage potential between one side of the induction choke and another side of the induction choke. The communications and control module is electrically connected across the voltage potential. Also, a method is provided for controllably injecting a chemical into the well downhole, which may be used to: improve lift efficiency with a foaming agent, prevent deposition of solids with a paraffin solvent, improve a flow characteristic of the flow stream with a surfactant, prevent corrosion with a corrosion inhibitor, and / or prevent scaling with scale preventers.

Owner:SHELL OIL CO

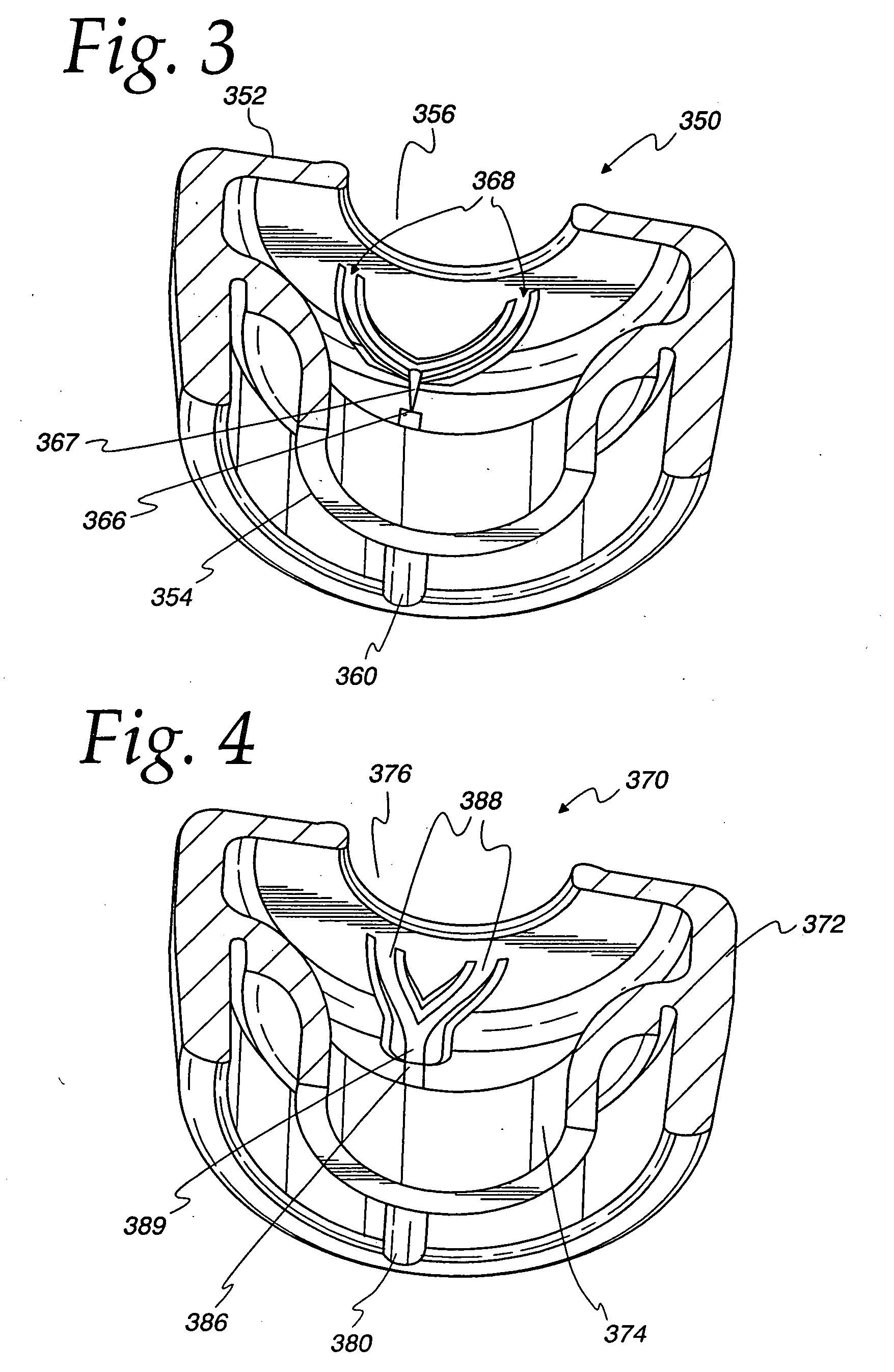

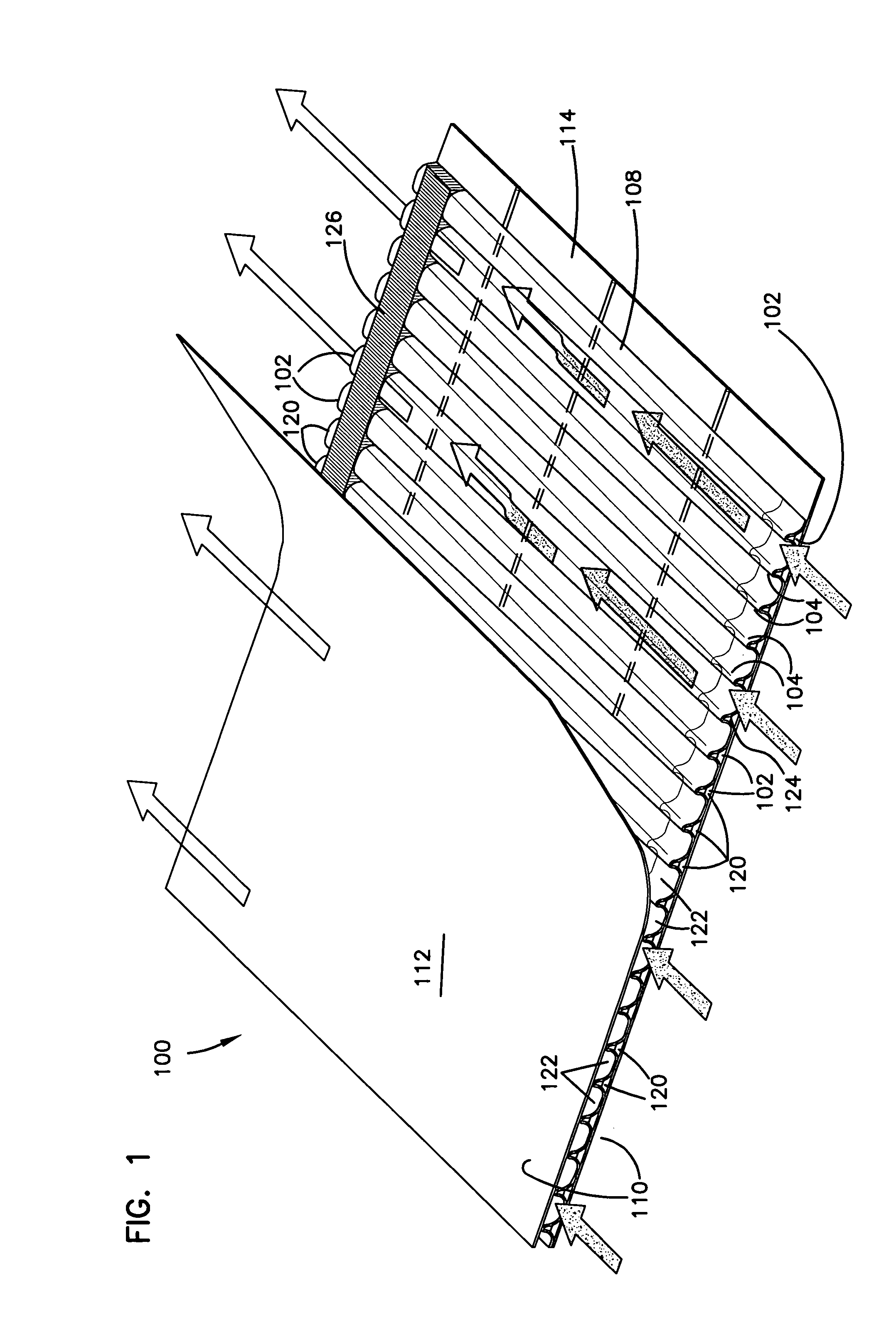

Mixing arrangement for atomizing nozzle in multi-phase flow

ActiveUS20050001062A1Smooth transitionEasy to processCharging-discharging device combinationsFlow mixersAcute angleShortest distance

The invention relates to an improved mixing arrangement for, primarily, moving bitumen in steam from sources of such bitumen and steam to a reactor or coker for further processing of the bitumen into petroleum products. The invention provides a main conduit connected to an atomizing nozzle mounted in a wall of the reactor and first and second conduits for flowing bitumen and steam respectively into the main conduit. The first conduit is angled relative to the main conduit at an acute angle of about 45° and the second conduit is angled relative to the main conduit at an acute angle of about 30°. The second conduit is positioned downstream of the first conduit by a short distance of about 23 mm and may be angled radially relative to the first conduit by any angle, although a 90° angle is preferred. A flow accelerating nozzle is located in the second conduit adjacent the entrance therefrom into the main conduit. The arrangement of the invention improves the flow characteristics of 2-phase material flowing to the atomizing nozzle, reducing pulsations in the main conduit and improving the resulting atomization of the bitumen in the reactor.

Owner:NAT RES COUNCIL OF CANADA +1

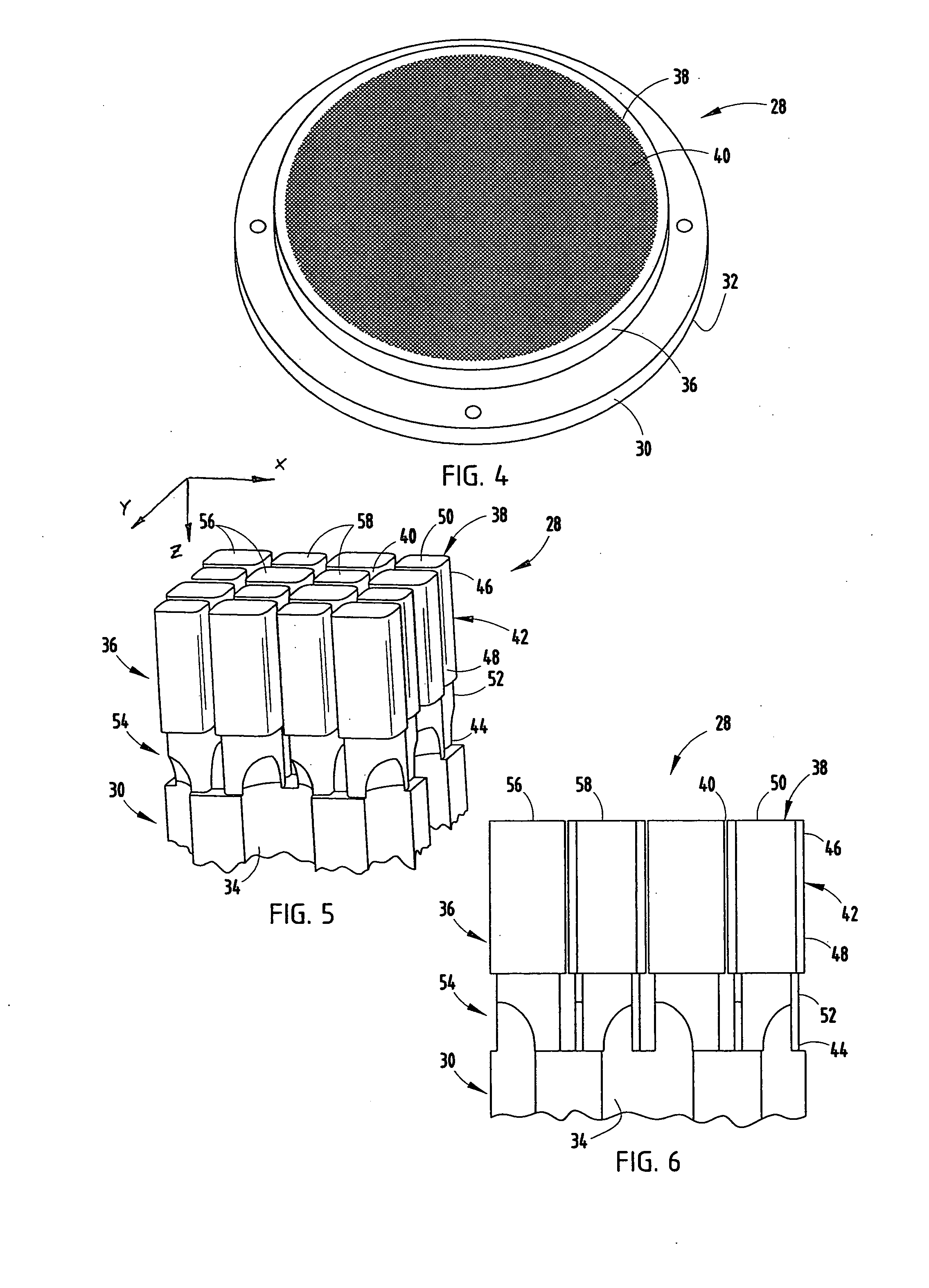

Loudspeaker plastic cone body

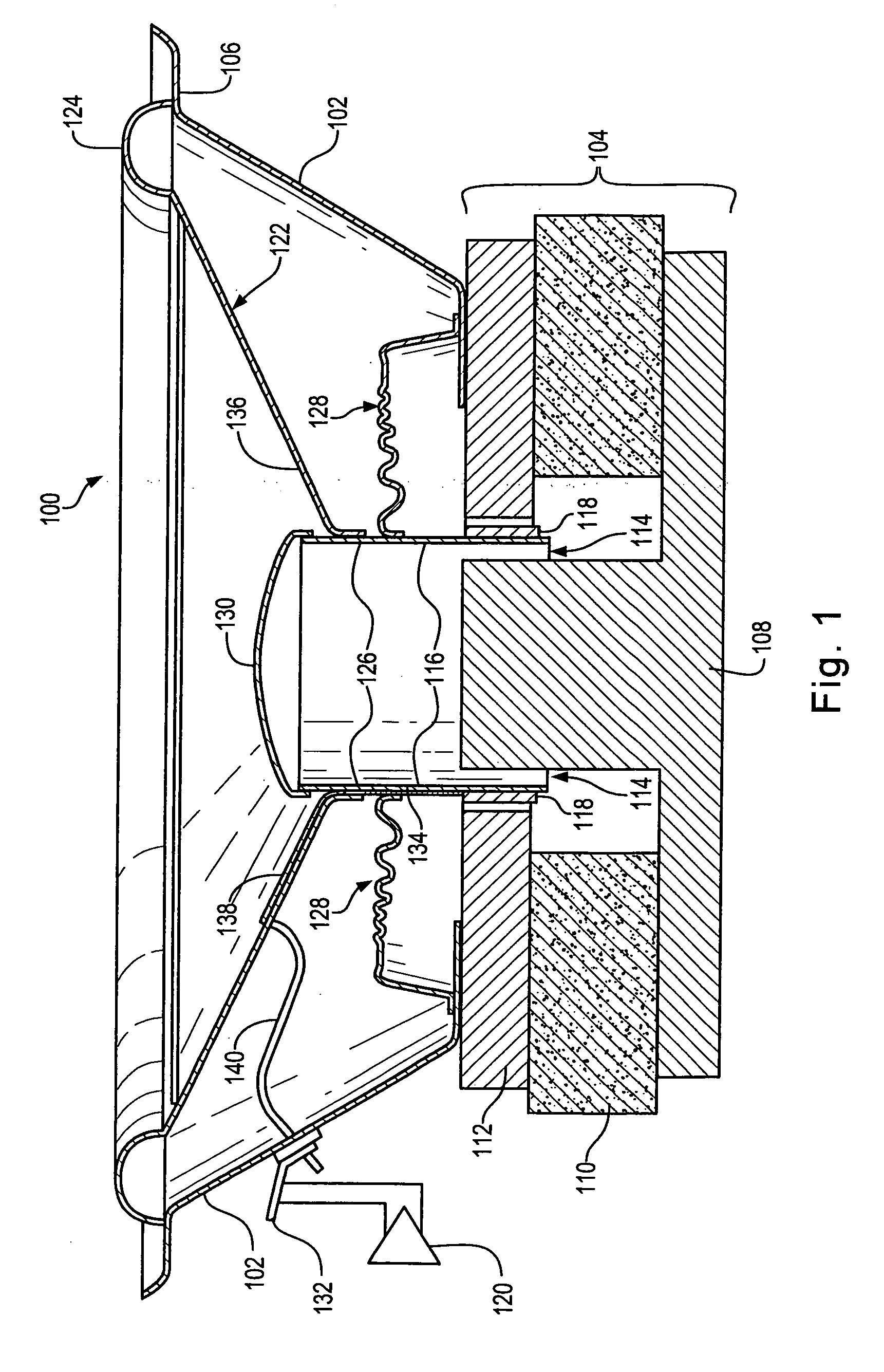

ActiveUS20060147081A1Easy to adjustImprove flow characteristicsFibre diaphragmsPolymeric diaphragmsFilling materialsEngineering

A loudspeaker cone body made of plastic includes a base carrier material and a filler material. The base carrier material is selected to optimize overall flow, weight and stiffness. The filler material may be a nanomaterial that provides for adjustment of process and acoustic related characteristics in the loudspeaker cone body that become relevant when the loudspeaker cone body is operated in a loudspeaker. Acoustic related characteristics that may be adjusted include a stiffness to weight ratio and an acoustic damping of the loudspeaker cone body. A predetermined weight percent of the filler material may be combined with the base carrier material to obtain repeatable desired acoustic related characteristics. The acoustic related characteristics may be adjusted by changing the predetermined weight percent of the filler material.

Owner:HARMAN INT IND INC

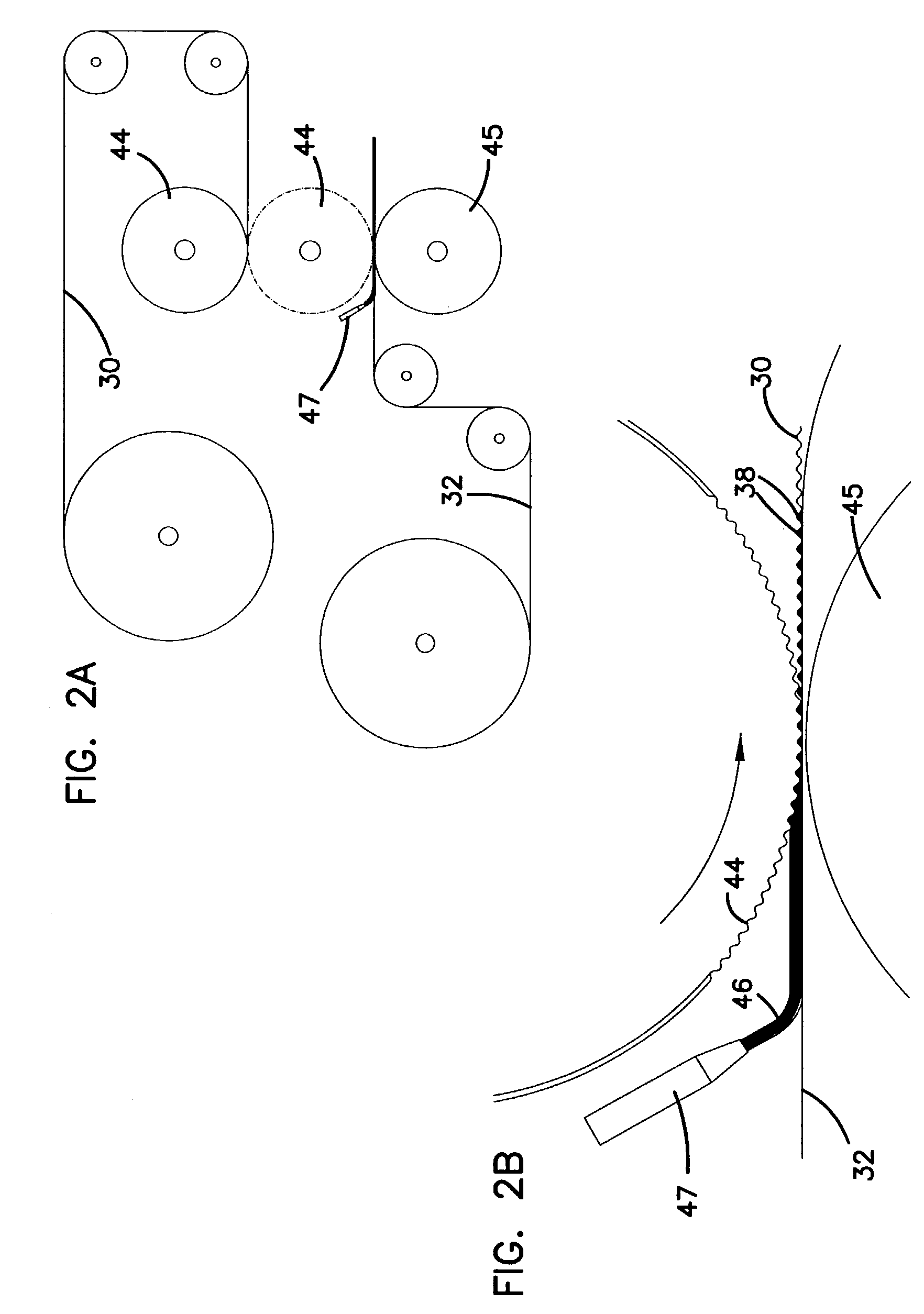

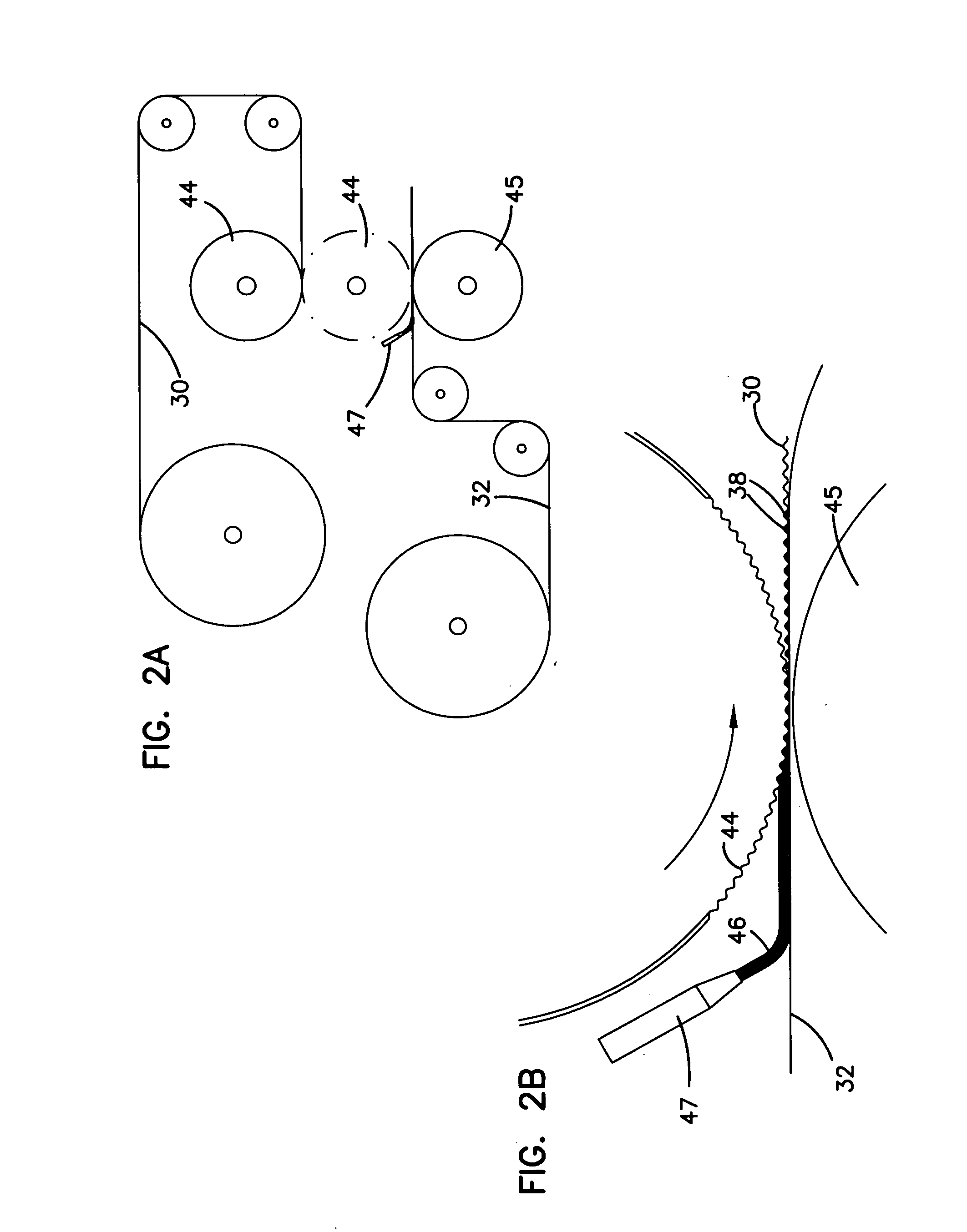

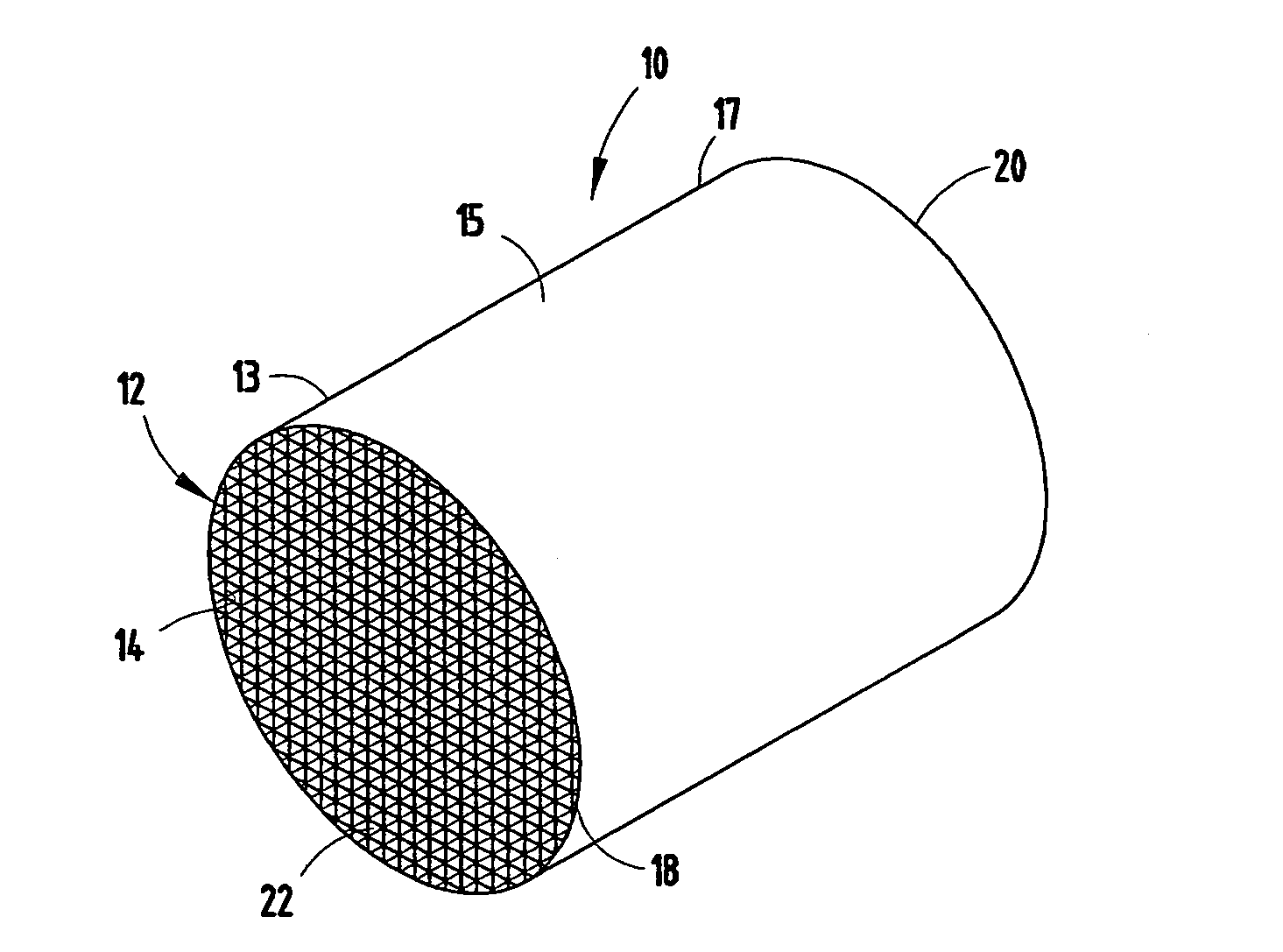

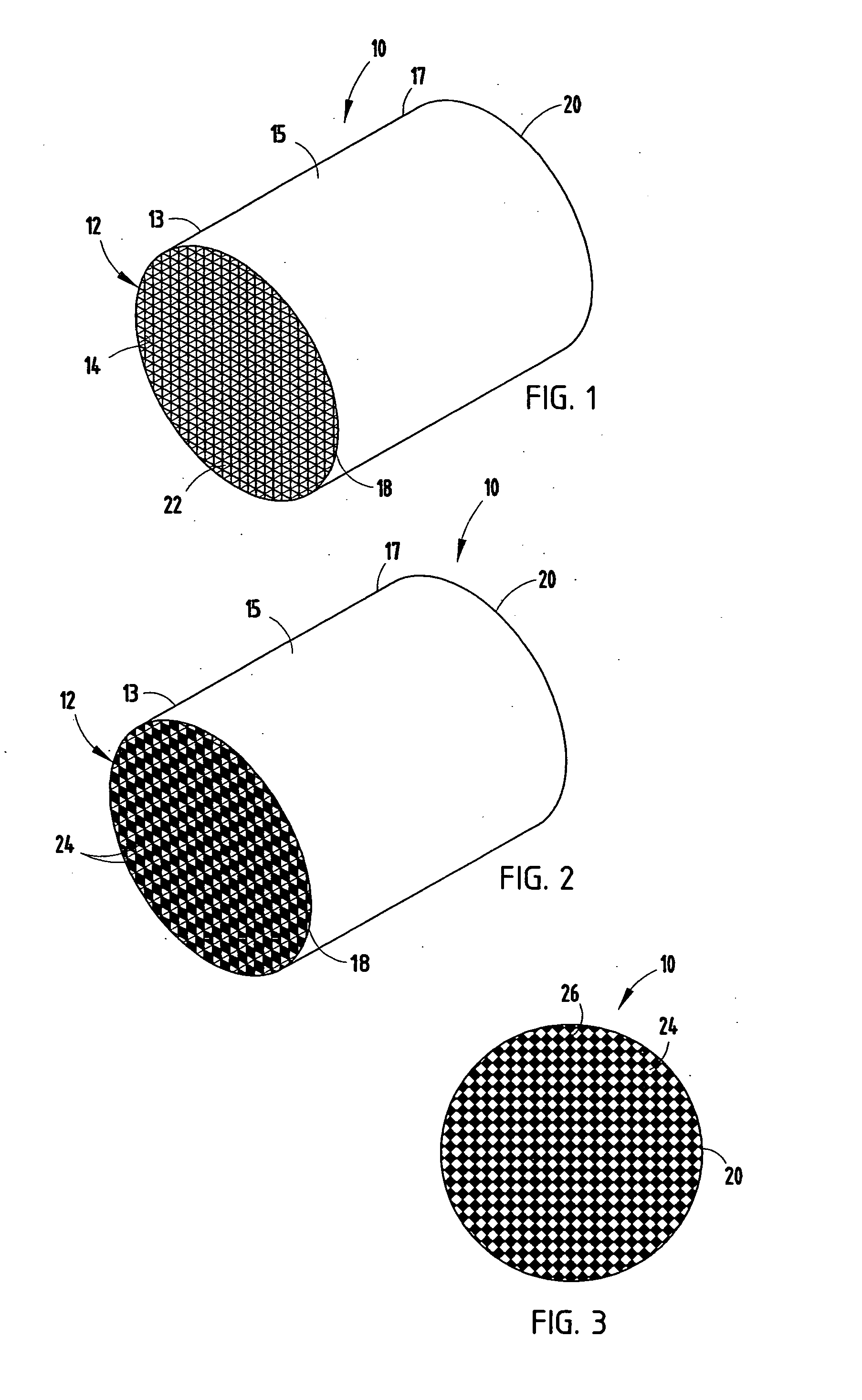

Method of making a fluted filter media for air filter

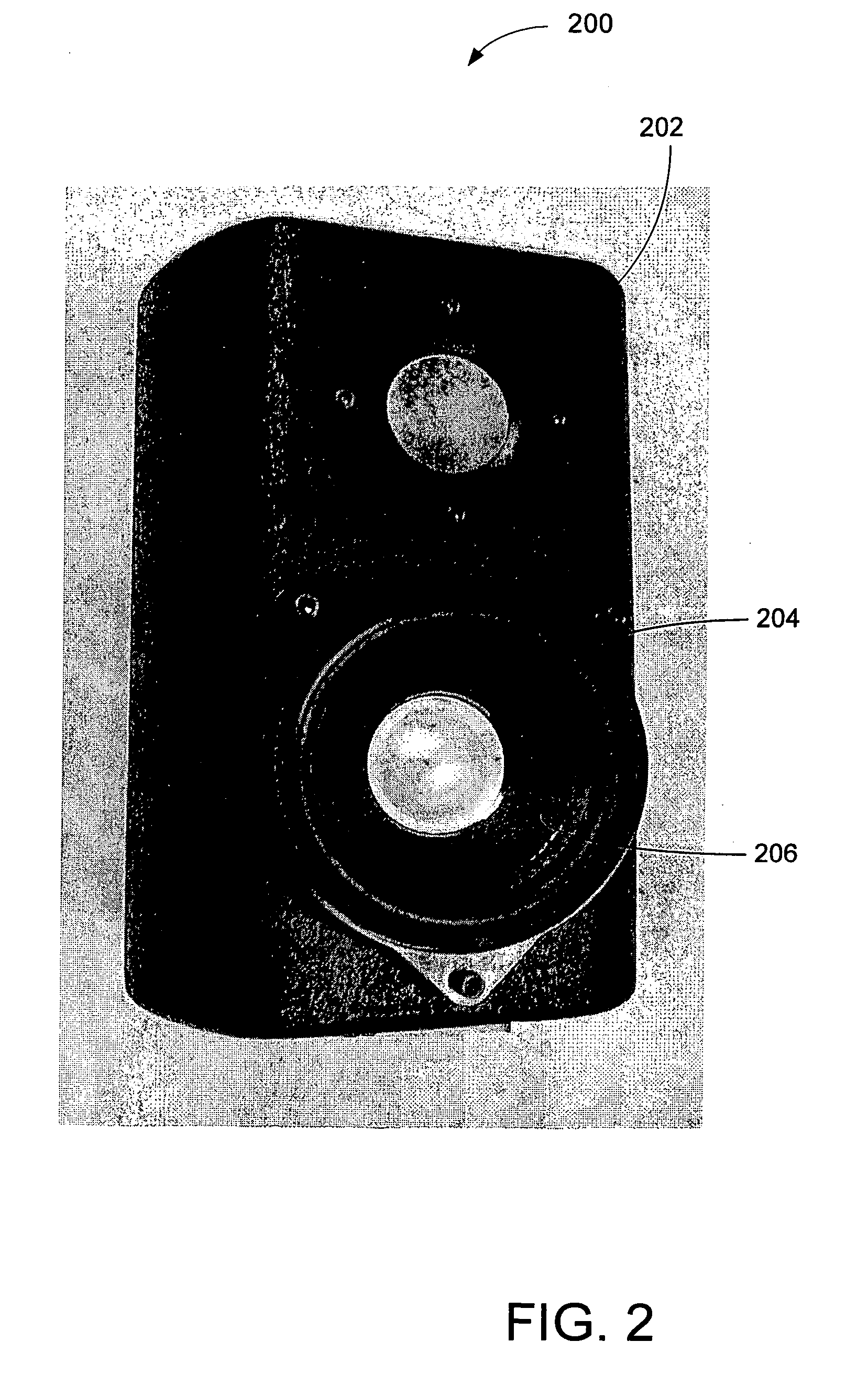

InactiveUS7329326B2Improve flow characteristicsReduce restrictionsMechanical working/deformationLamination ancillary operationsFluteAir filter

Fluted filter media includes filter material having a plurality of flutes formed therein having alternating ends of adjacent flutes closed to force fluid through filter material. A first embodiment of the filter media includes tapered flutes which have the open ends of the flutes larger in cross-section than the closed flutes, wherein the upstream open flutes converge toward the downstream end and the upstream closed end flutes diverge toward the downstream end. A second embodiment includes filter media which is asymmetric formed with dissimilar upstream and downstream flute cross-sections with larger flute openings to the upstream side of the filter. A third embodiment includes filter media with an upstream edge crushed to improve flow at the upstream edge. A fourth embodiment includes filter media with the upstream sealing material recessed from the upstream edge for reducing effects from blockages at the upstream edge of the filter.

Owner:DONALDSON CO INC

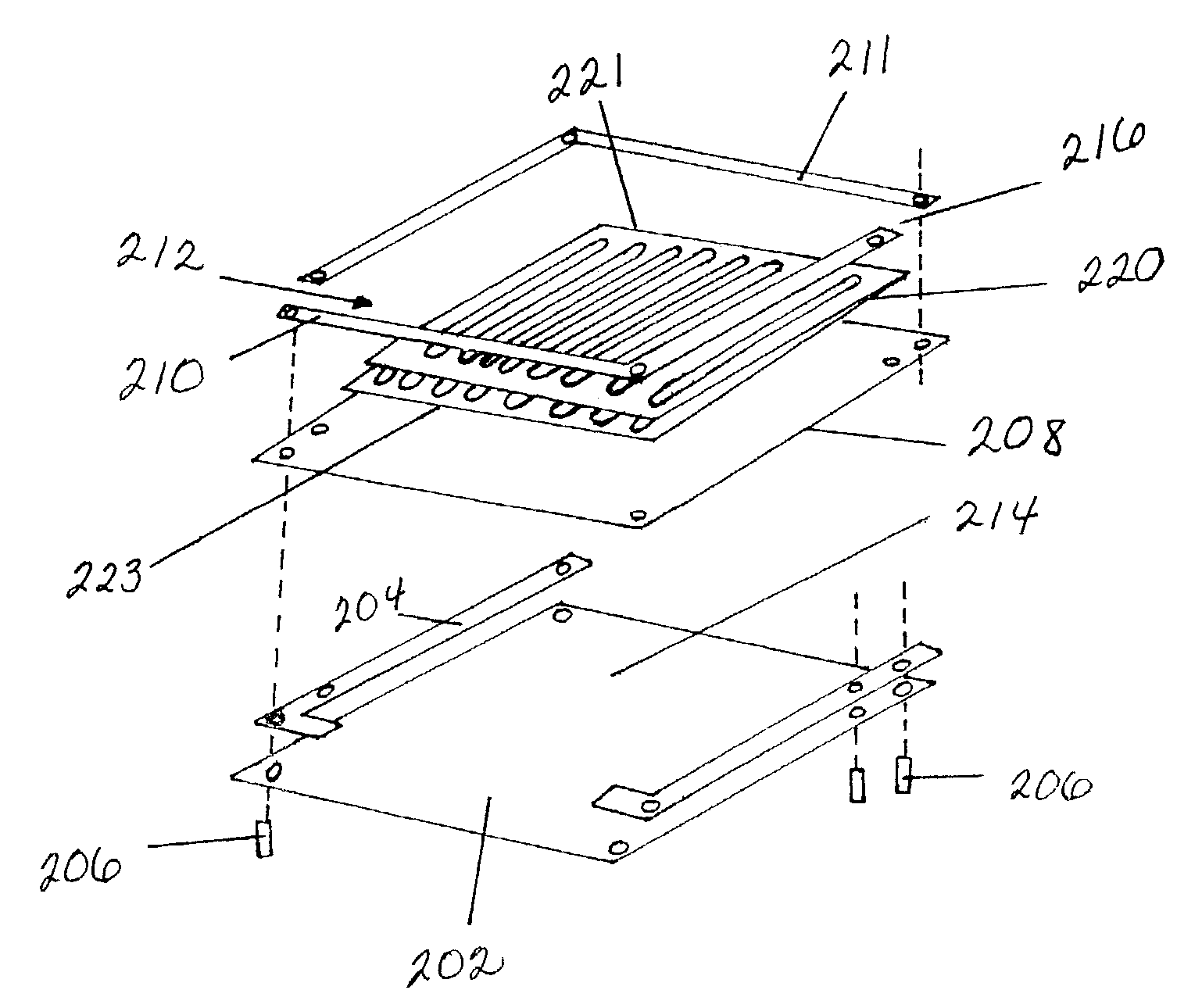

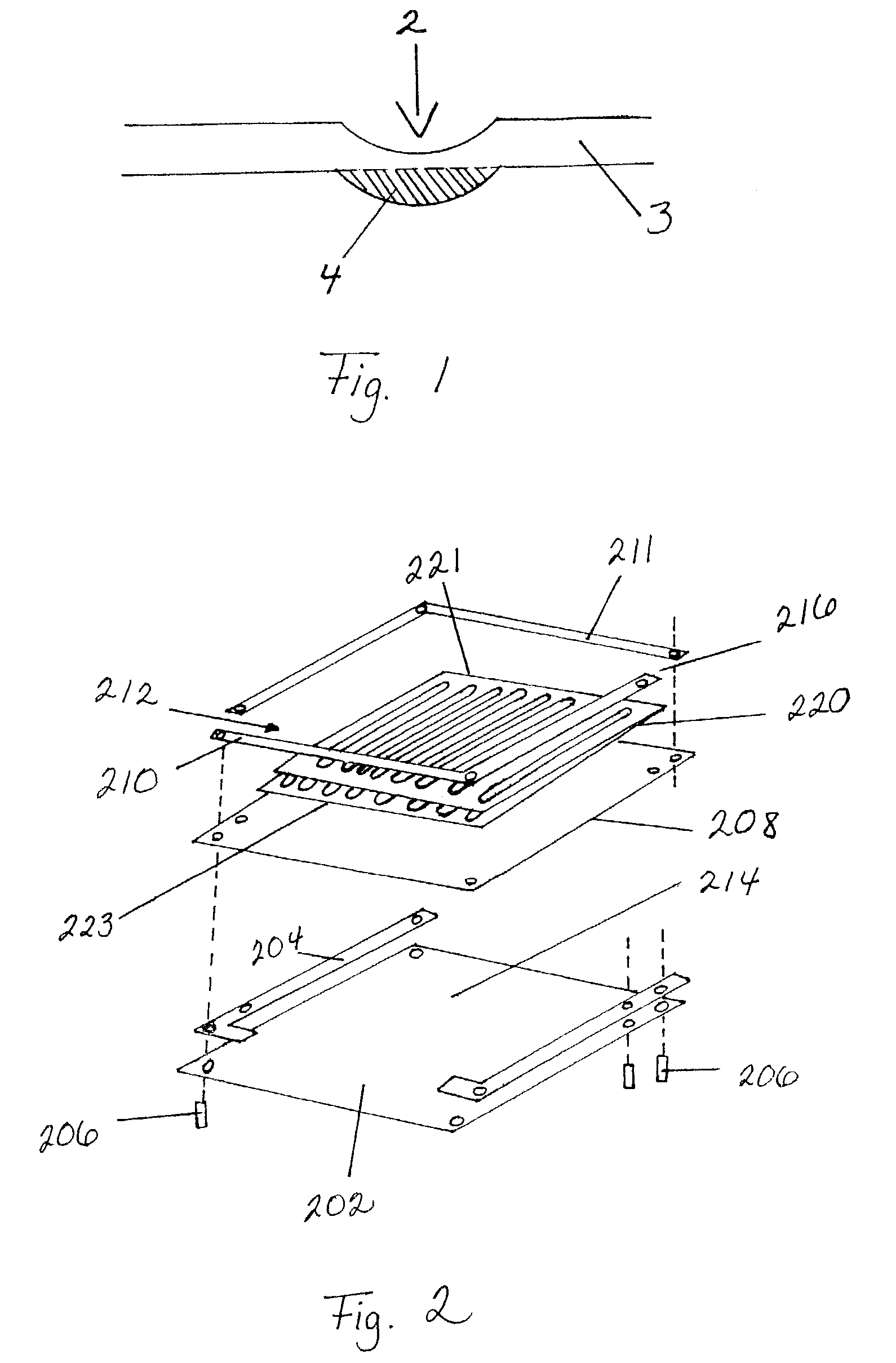

Microchannel apparatus, methods of making microchannel apparatus, and processes of conducting unit operations

InactiveUS6989134B2Low costReduce wasteFlow mixersTransportation and packagingUnit operationEngineering

Novel methods of making laminated, microchannel devices are described. Examples include: assembly from thin strips rather than sheets; and hot isostatic pressing (HIPing) to form devices with a hermetically sealed wall. Laminated microchannel articles having novel features are also described. The invention includes processes conducted using any of the articles described.

Owner:VELOCYS CORPORATION

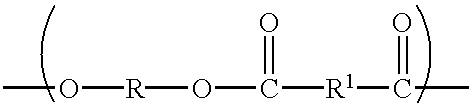

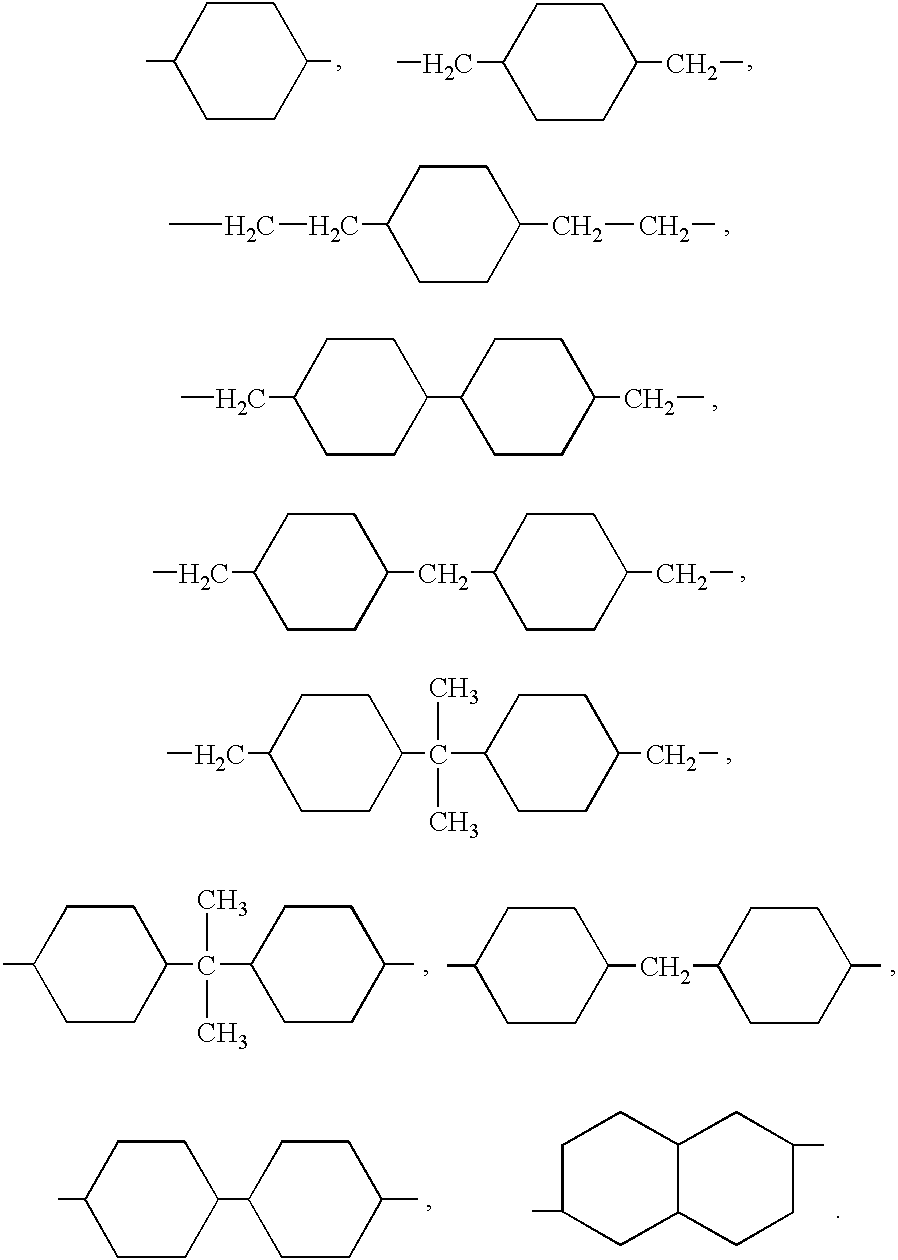

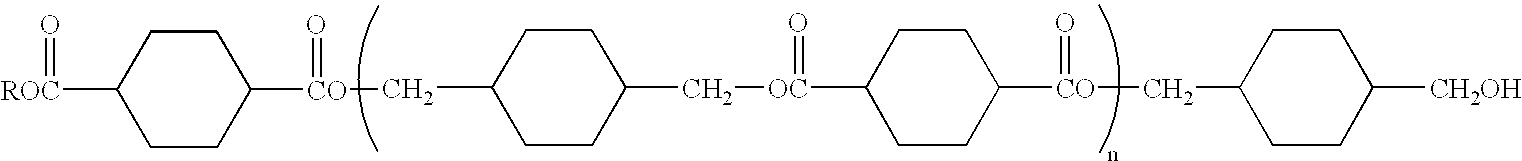

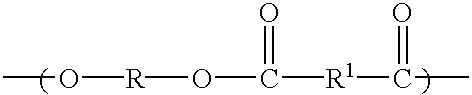

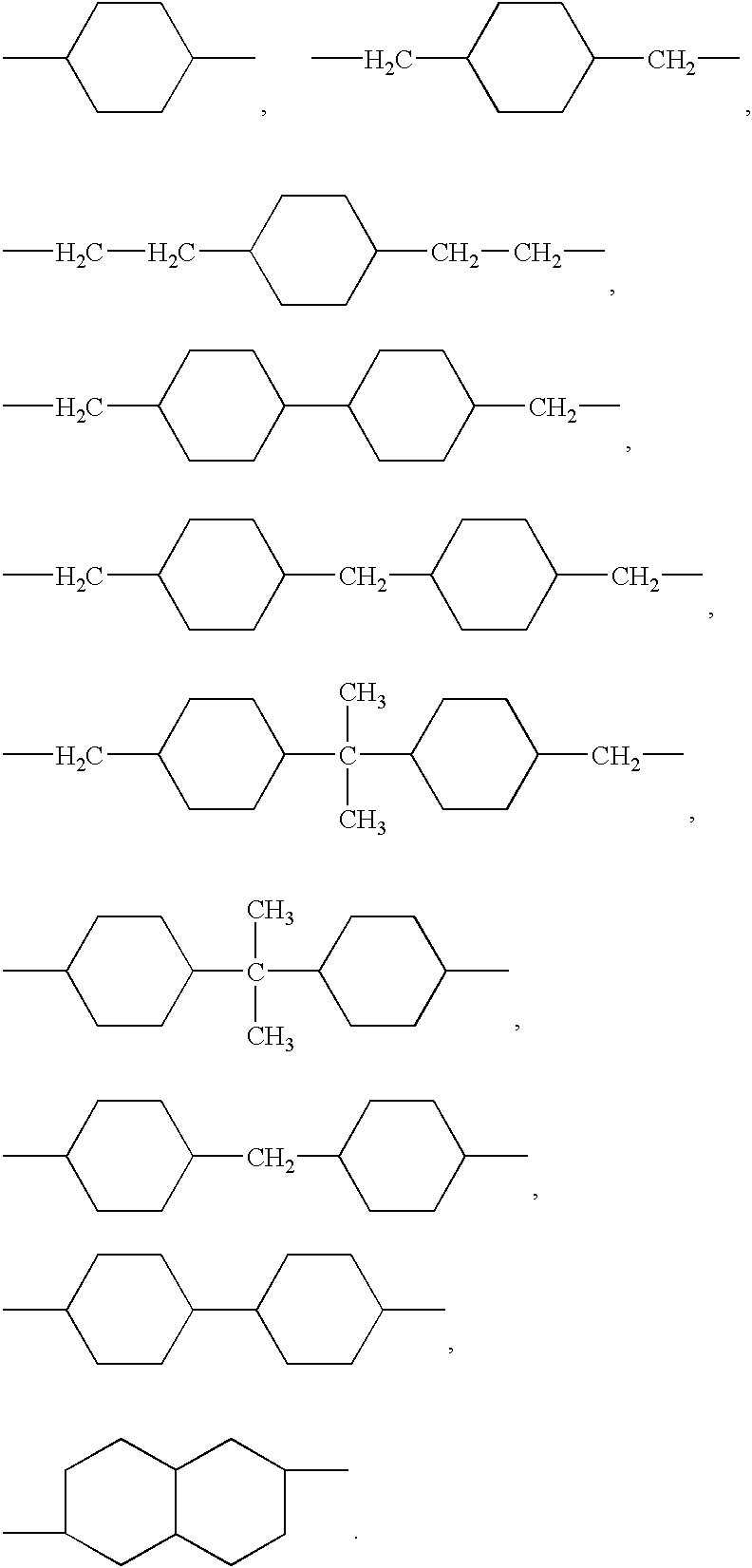

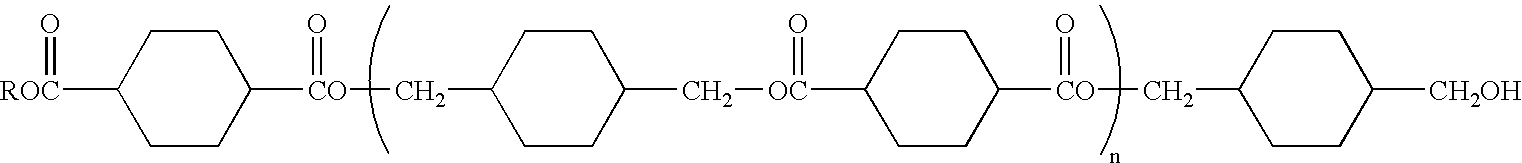

Insert molded article

InactiveUS6458913B1Prevent substrate deformationLow process temperatureSynthetic resin layered productsCeramic shaping apparatusPolymer substrateShell molding

A molded structure comprises a decorative film or substrate, and an adjacent injection molded polymeric base comprising a substantially transparent cycloaliphatic polyester resin which may have an opening for exposing the transparent polymeric base resin to the exterior of the molded article, and a process for making the molded structure is described.

Owner:SABIC GLOBAL TECH BV

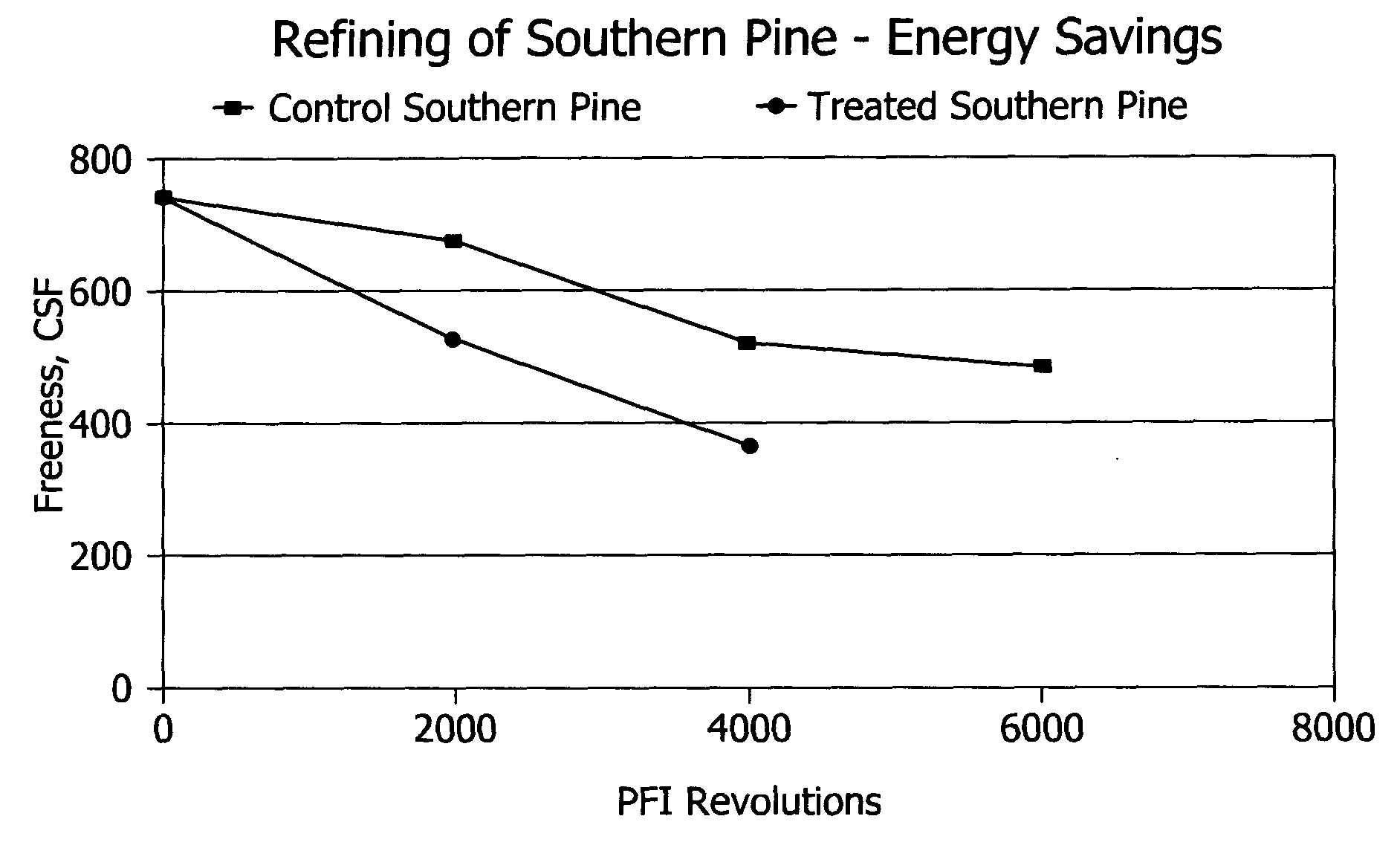

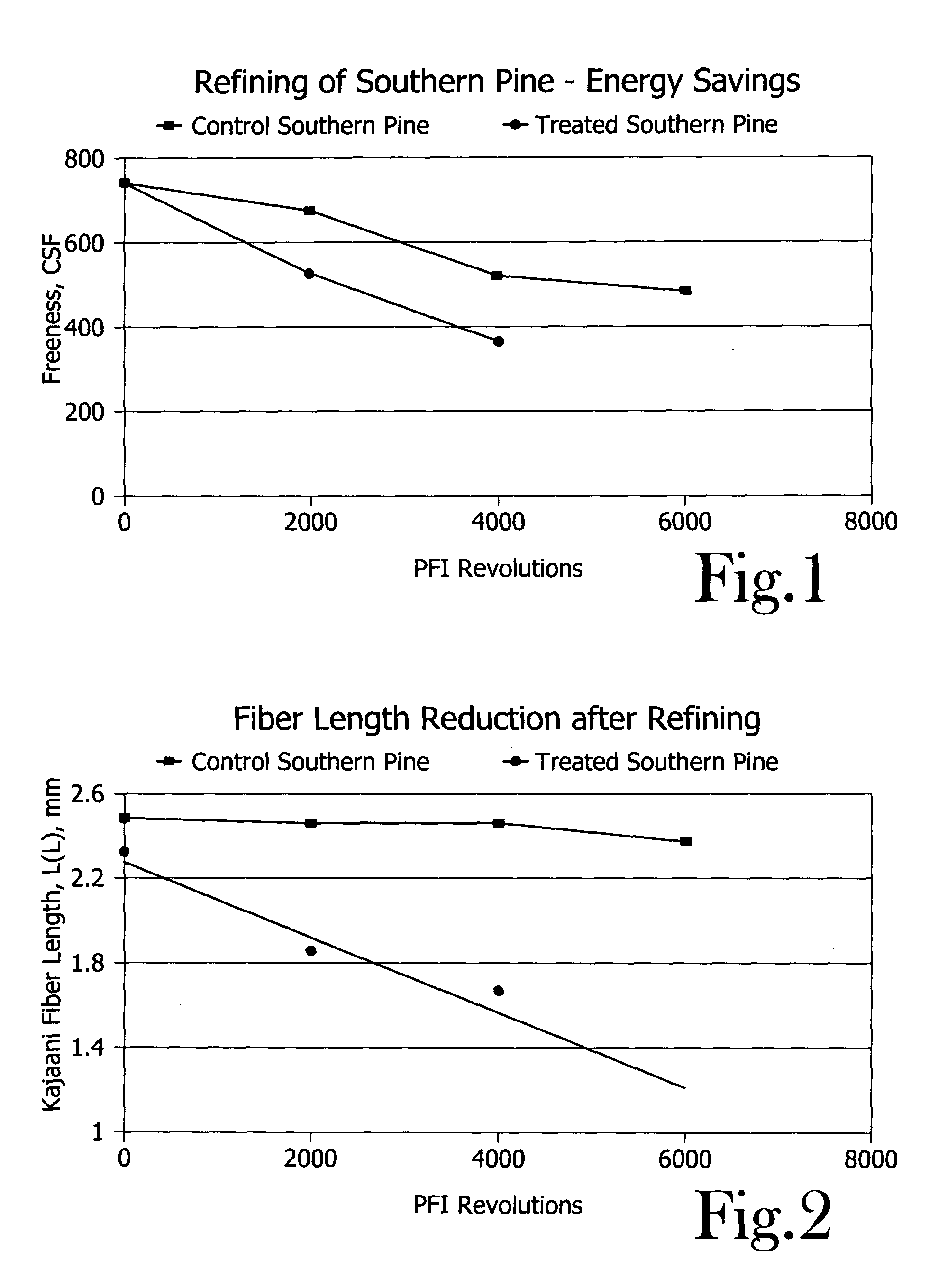

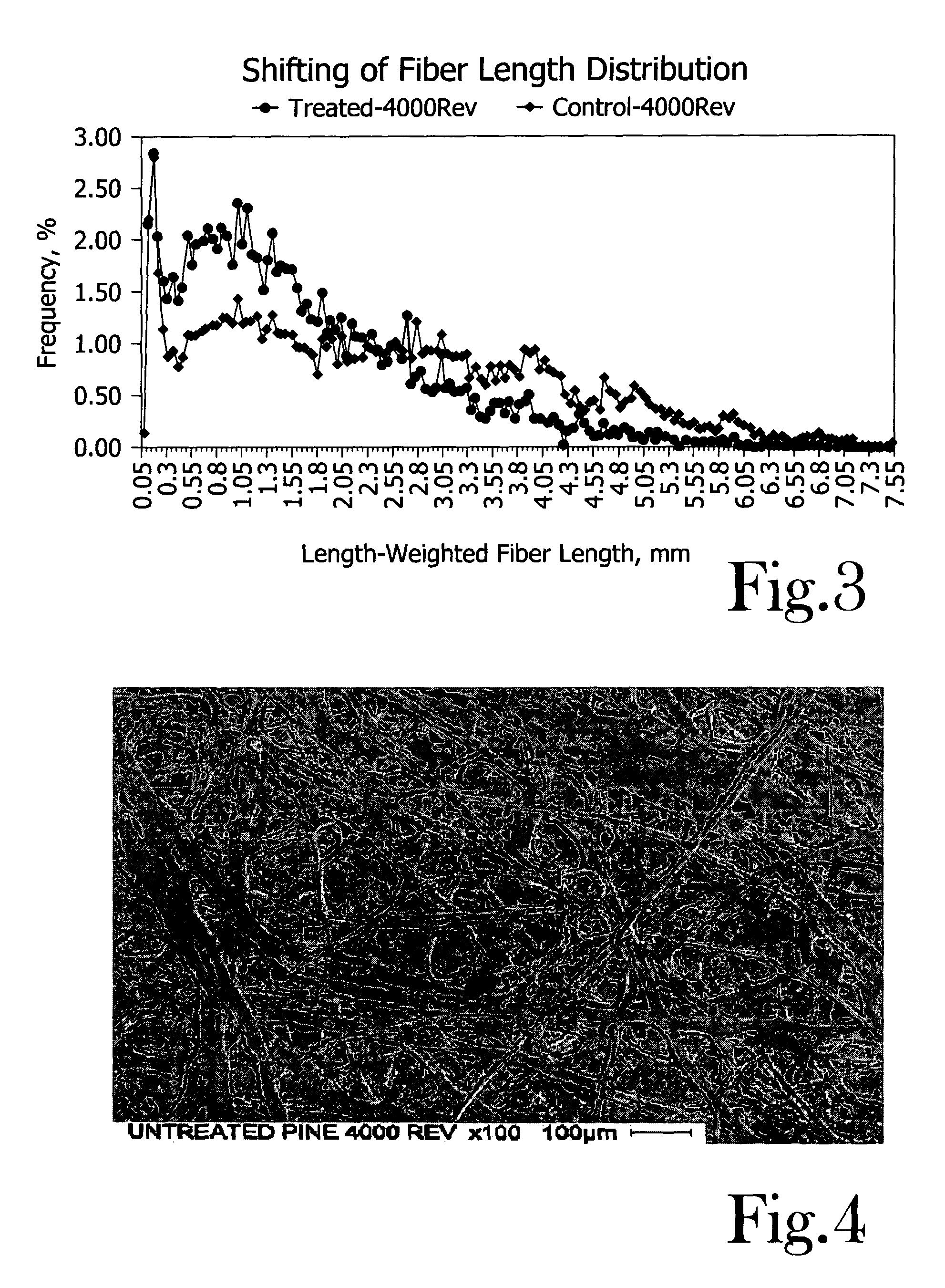

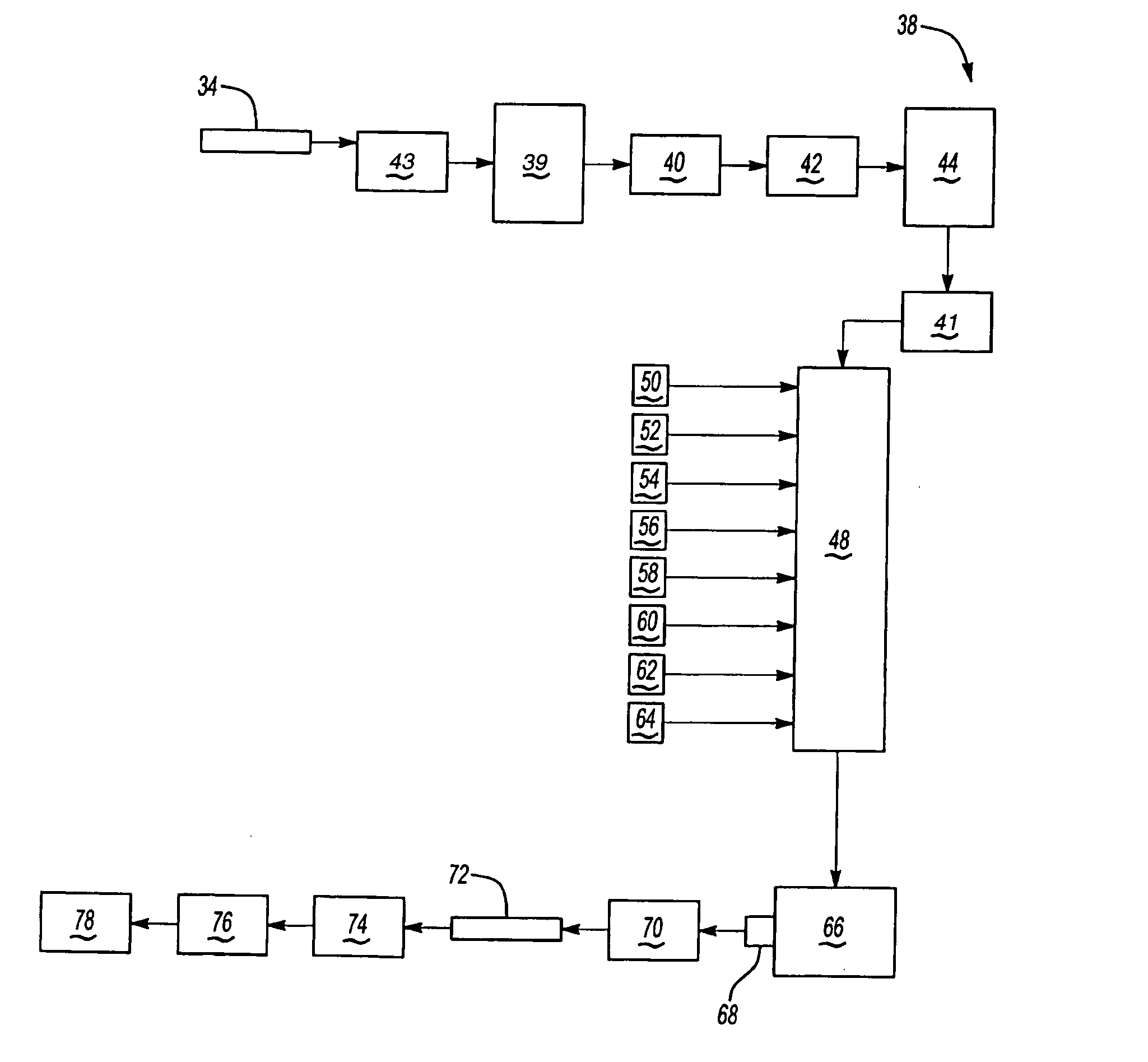

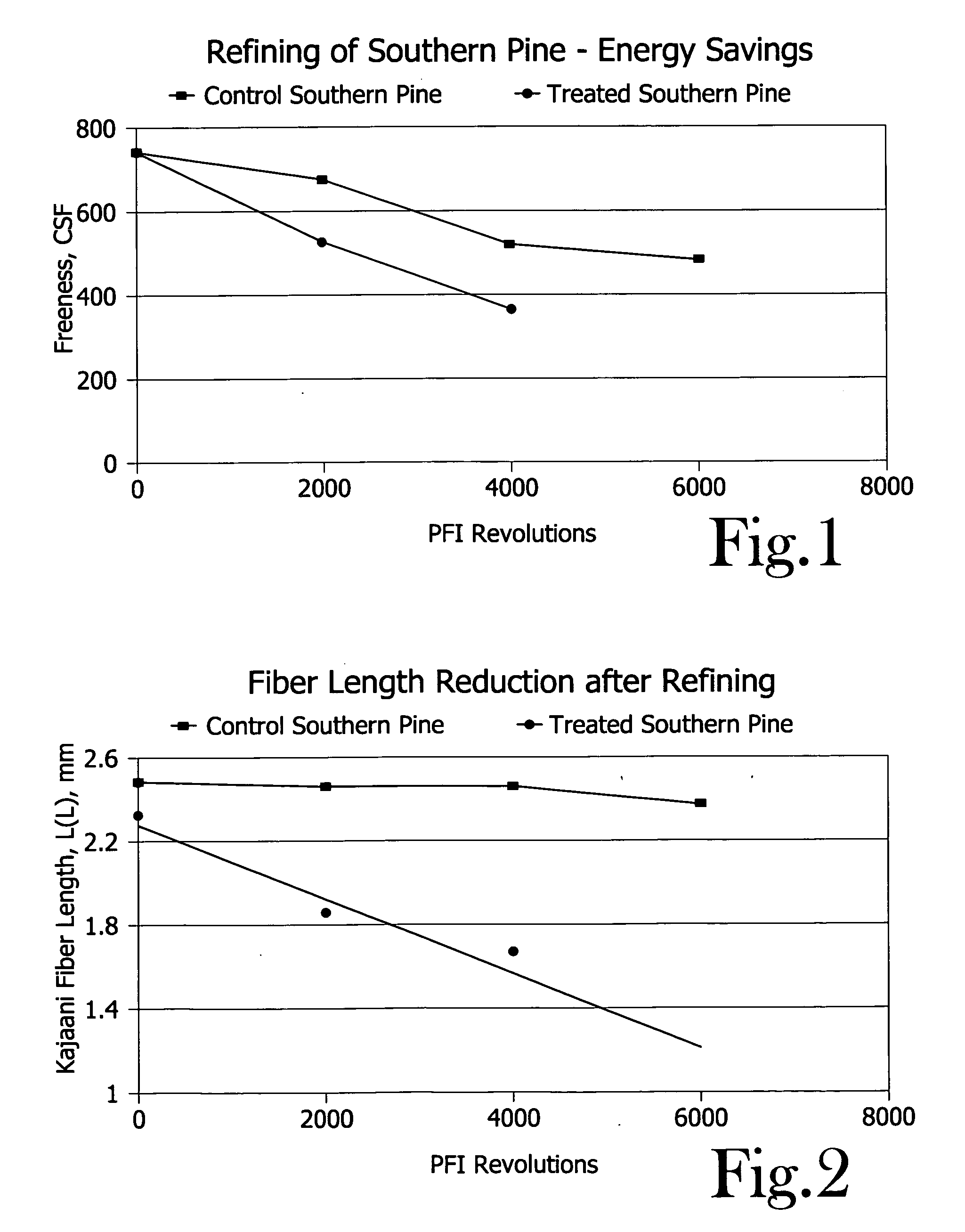

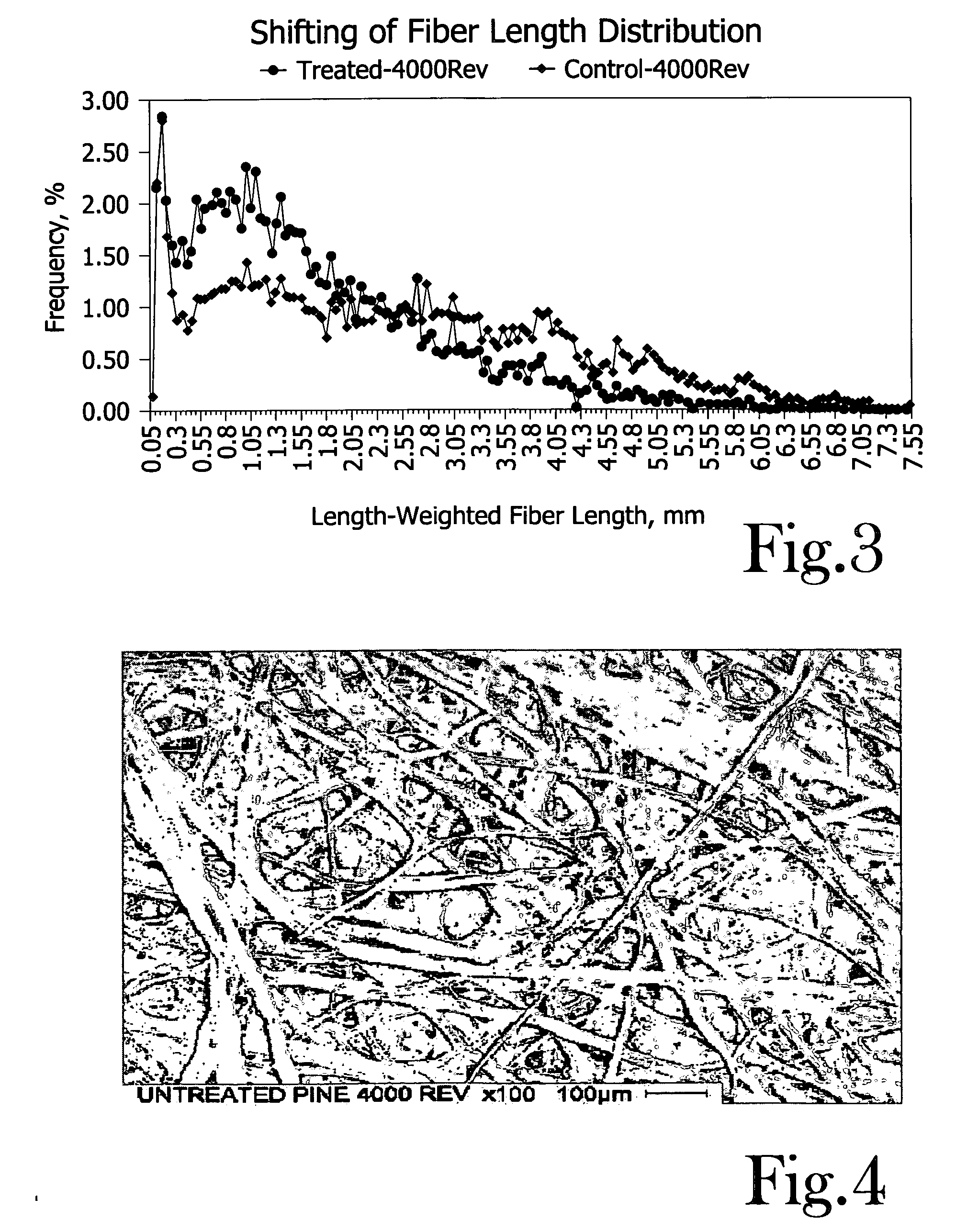

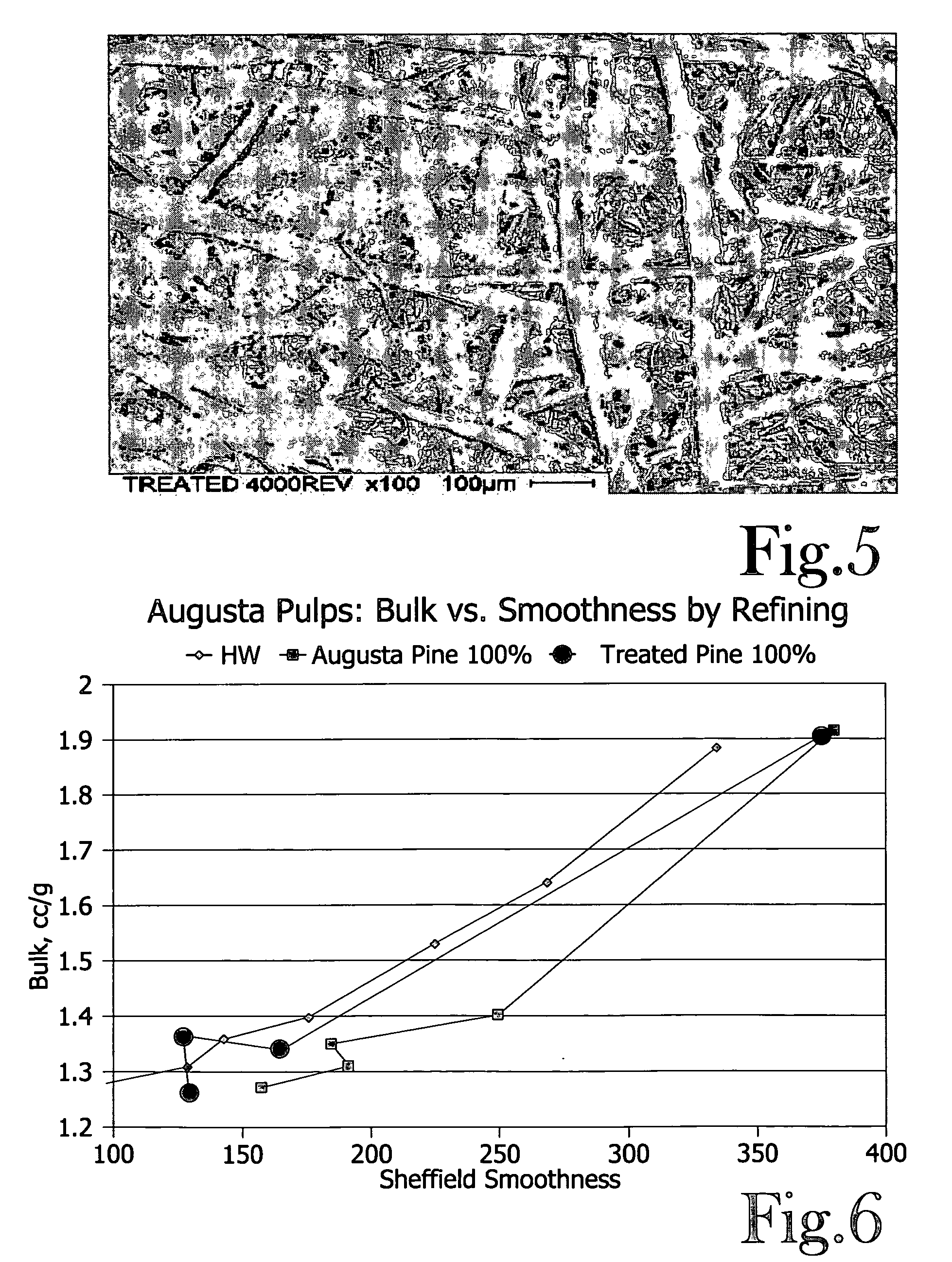

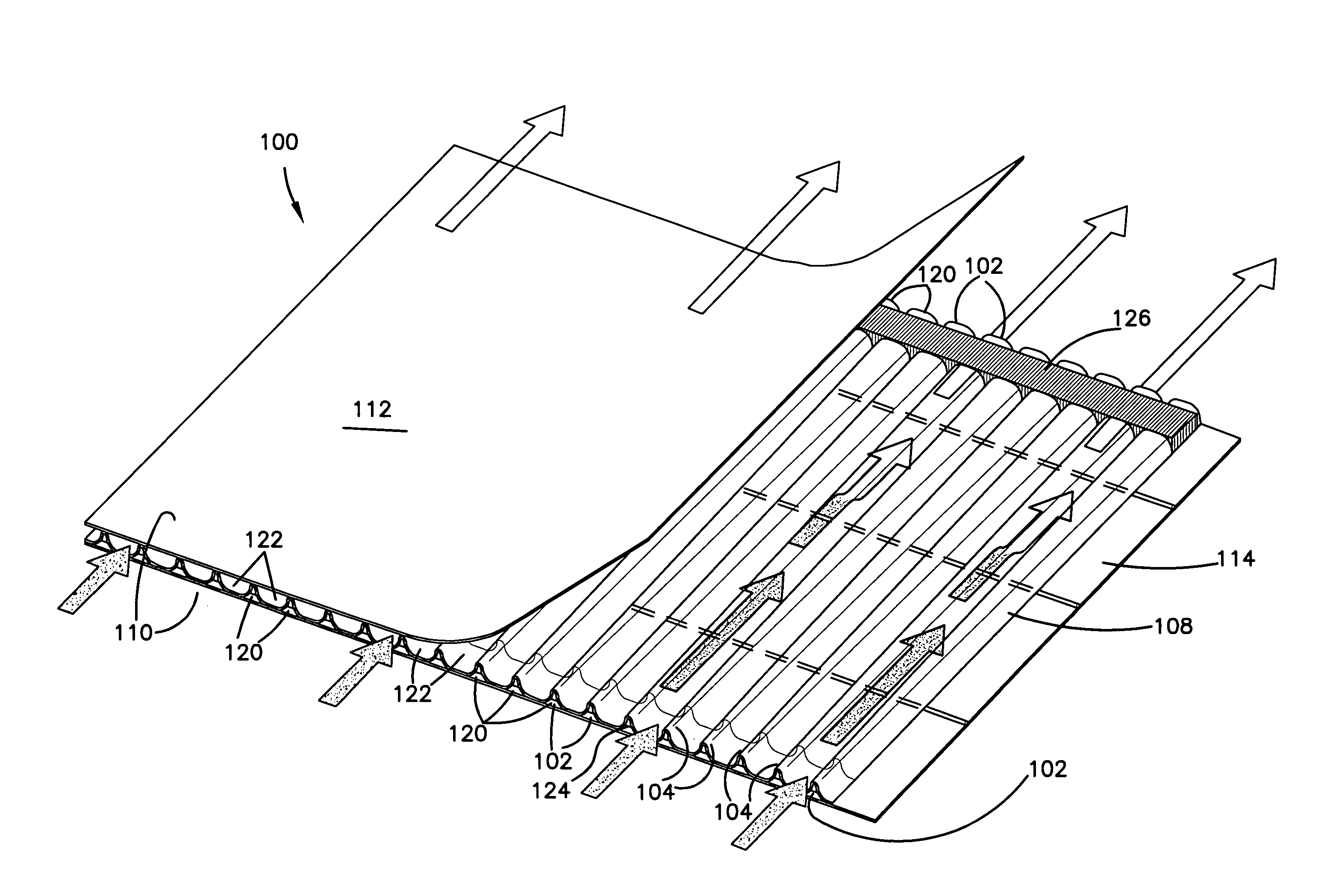

Chemical activation and refining of southern pine kraft fibers

InactiveUS20050061455A1Increase the pulp freenessEasy to drainPulp properties modificationPulp bleachingChemical treatmentCellulose fiber

A method for alteration of the morphology of cellulose fibers, particularly softwood fibers, by (a) subjecting the fibers to a metal ion-activated peroxide treatment carried out at a pH of between about 1 and about 9, preferably between 3 and 7, and (b) subjecting the treated fibers to a refining treatment thereby converts SW fibers to HW-like fibers in many respects. The metal ion-activated peroxide treatment has been noted to act on pulp cellulose and hemi-cellulose, causing oxidation and oxidative degradation of cellulose fibers. The chemical treatment of the pulp, taken alone, is not sufficient to attain the desired modification of the morphology of the fibers, however, subsequent refining or like mechanical treatment of the chemically-treated fibers to achieve a given degree of refinement of the fibers requires dramatically less refining energy to achieve a desired end point of refinement and to impart other desirable properties to the pulp. A pulp of modified SW fibers and a mixture of HW fibers and modified HW fibers are disclosed.

Owner:INT PAPER CO

Method of manufacturing composite board

InactiveUS20060145384A1Improve flow characteristicsIncreased flexural modulusMouldsFrozen sweetsFiberThermoplastic

A composite board is made from waste medium density fiber (MDF) board or waste particle board that includes solid urea formaldehyde. The waste board is chopped and milled into particles having a size between 20 mesh and 150 mesh, creating a waste flour. After removing moisture from the waste flour, the dried waste flour is mixed with a thermoplastic to bind and encapsulate the waste flour. Internal lubricants are added to improve the flow characteristics of the blended material, and external lubricants are added to present sticking of the mixture to an extruder or mold. Mineral fillers are added to improve the flexural modules of the composite board, and a plasticizer can be added to improve the physical properties or mechanical characteristics of the mixture. An ultraviolet absorber, a biocide, and a pigment can also be added. The blended material is extruded or molded into a desired shape. When cooled, the thermoplastic hardens to form a solid composite board.

Owner:MASCO CABINETRY

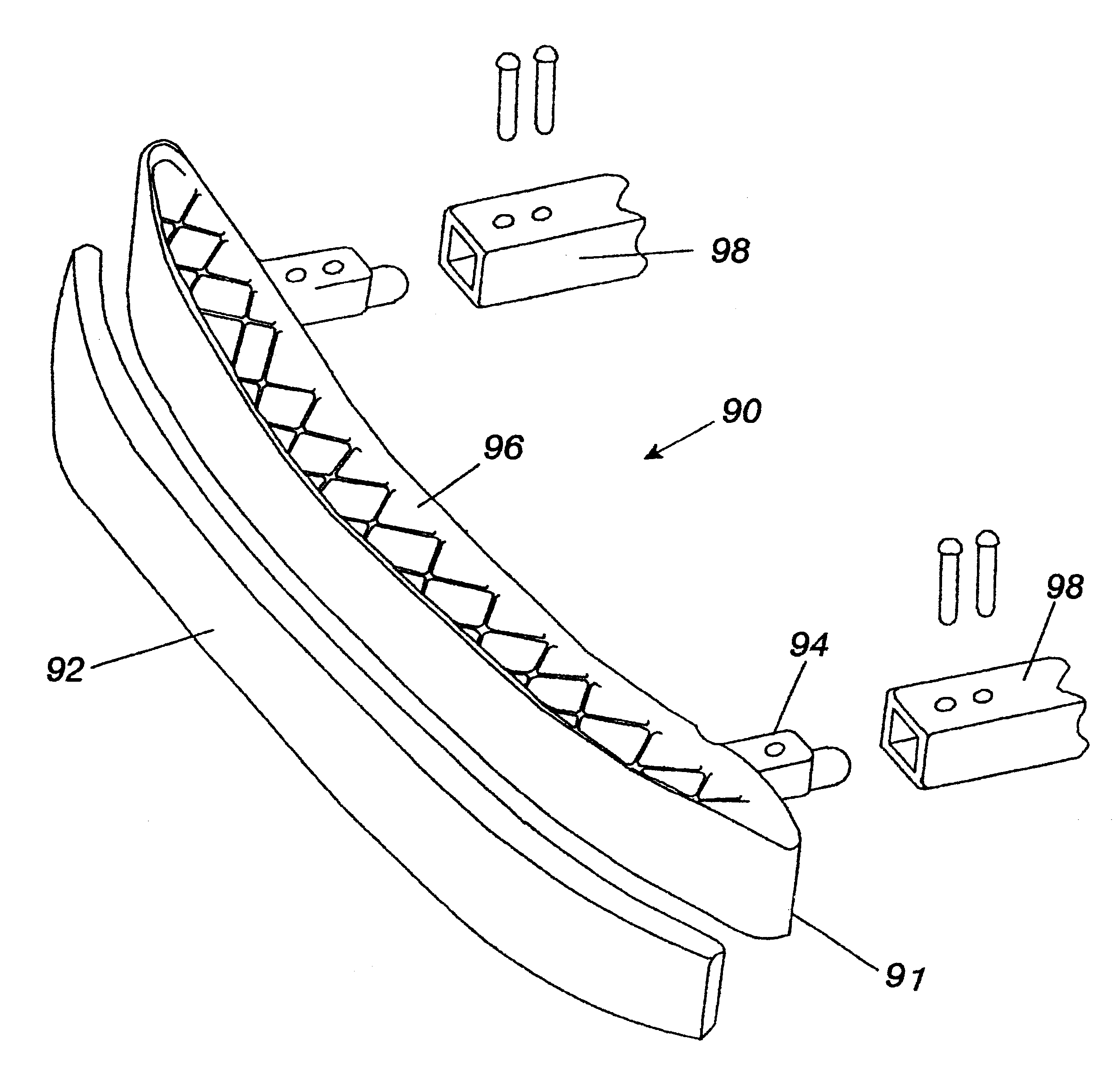

I-Section automotive bumper formed from mineral-filled glass mat thermoplastic (GMT) composite

InactiveUS6286879B1Improve flow characteristicsIncrease modulusBumpersCompression moldingShell molding

The invention is a fiber reinforced thermoplastic automotive bumper wherein the reduced fiber additions consist of a long, chopped glass mat with the addition of mineral fillers such as mica, talc or clay. The modified thermoplastic is used to produce I-section bumpers. The improved reinforced thermoplastic material has favorable flow characteristics which enable the material to substantially fill the deep ribs and mounting stay structures used in I-section bumpers during compression molding while improving the modulus or cross-face stiffness of the finished part. For the first time, improved flow characteristics during molding permit the material to flow evenly into small ribs, bosses and other features. The invention makes it possible to increase part integration, molding pencil braces, fascia supports, mounting holes and mounting stays. The front surface of the bumper may be covered with a conformal energy absorber made of plastic foarn. Moreover, the absorber serves to mount appearance fascia. The result is a cost-reduced, weight-reduced bumper with improved impact resistance.

Owner:AZDEL INC

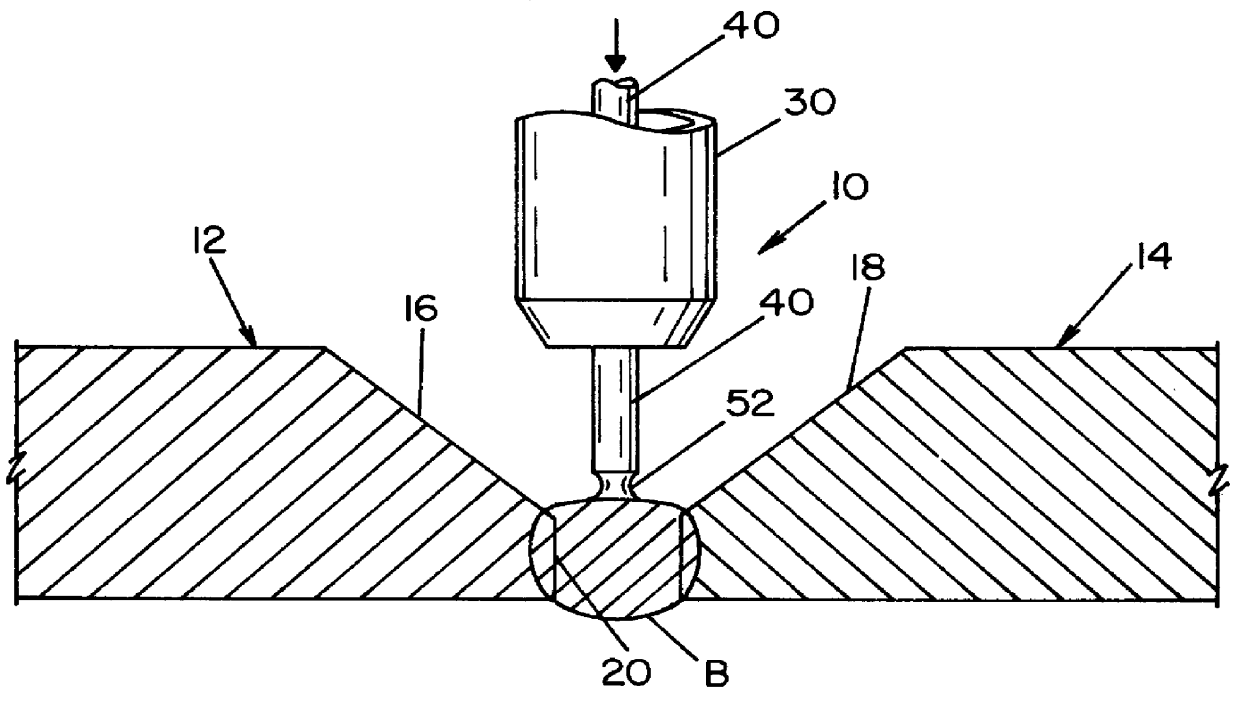

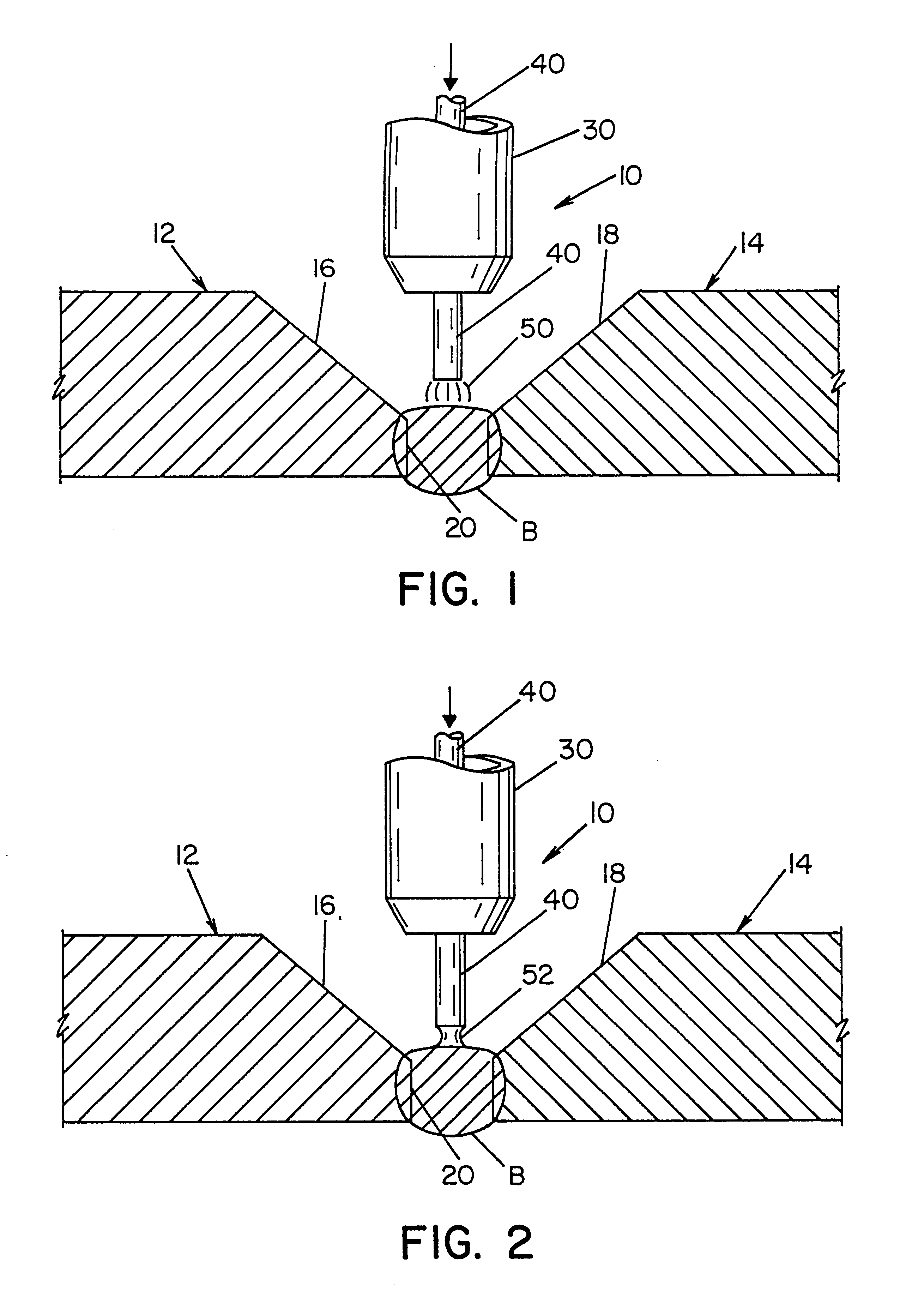

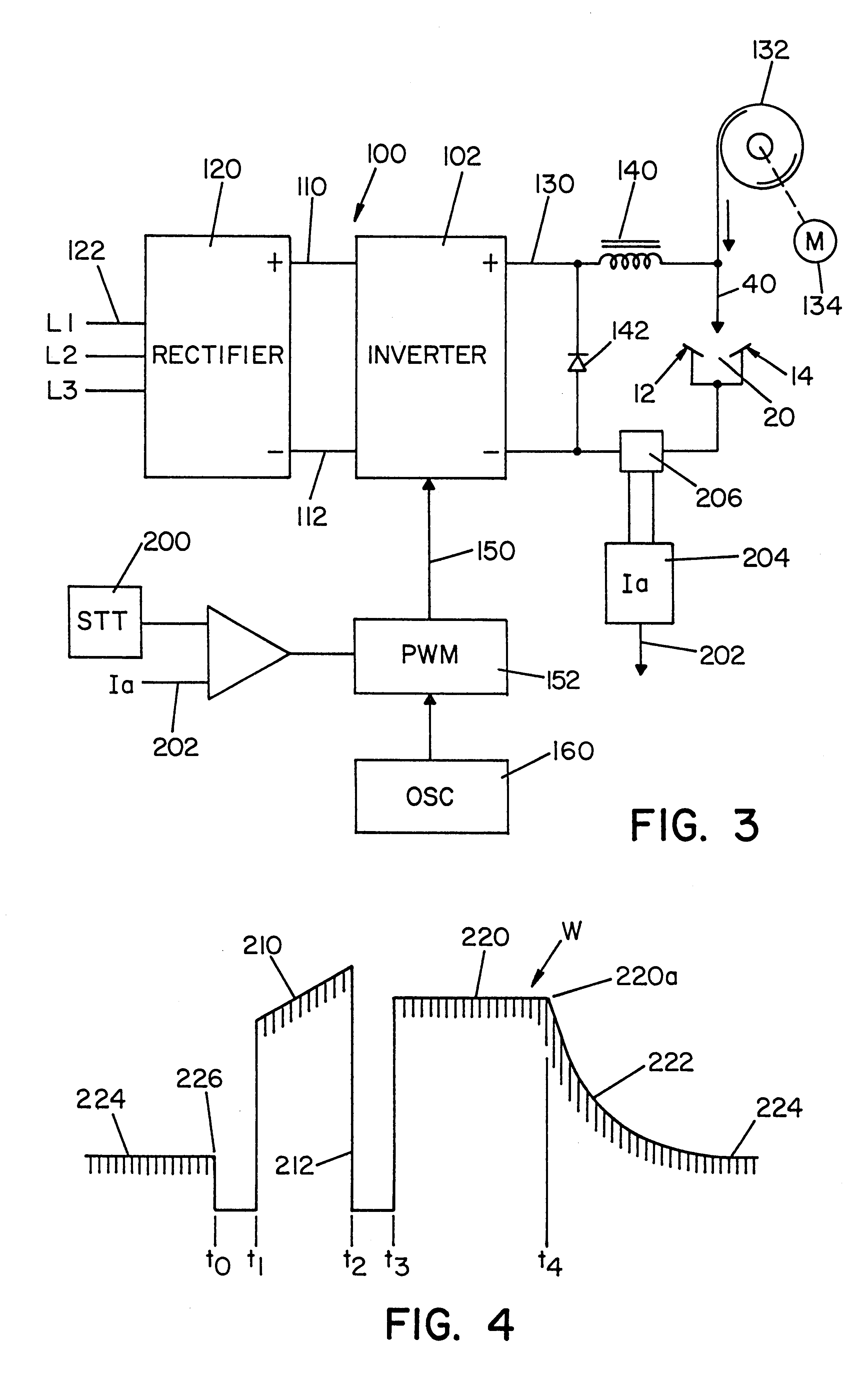

Method of pipe welding

InactiveUS6093906AGood lookingIncrease driving speedArc welding apparatusWelding/cutting media/materialsSulfurManganese

A method of welding the ends of two pipes at the open root between the spaced ends by an STT electric arc welder, which comprises: selecting a welding wire having 0.06-0.15% by weight carbon, 0.90-1.40% by weight manganese, and 0.45-0.75% by weight silicon, as well as phosphorous, copper, stainless steel alloys and sulfur; maintaining the sulfur at a given percentage level of the selected wire in the specific range of 0.015 to 0.035% by weight; and maintaining said phosphorous at a given percentage level of said selected wire in the specific range of less than about 0.015%.

Owner:LINCOLN GLOBAL INC

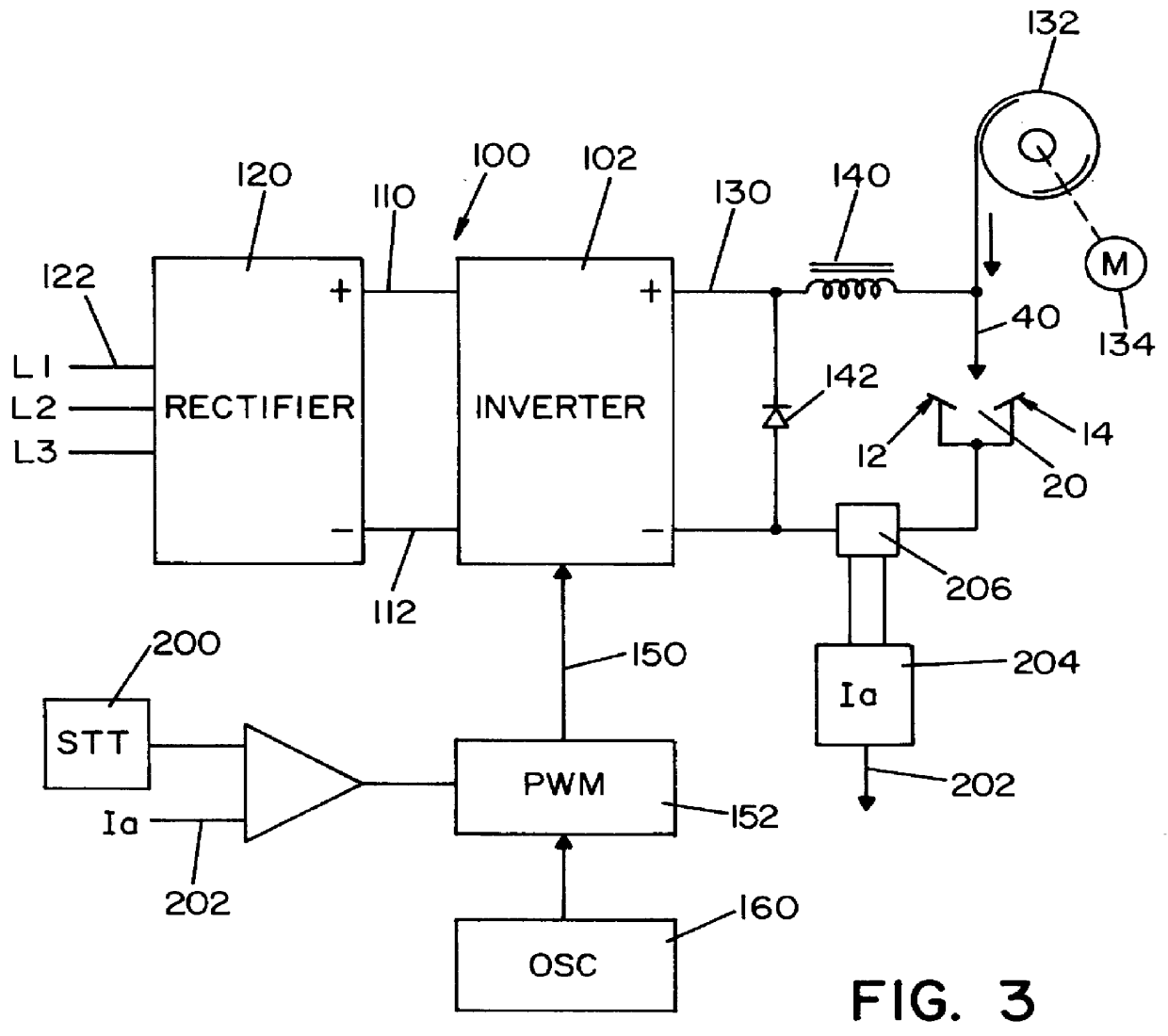

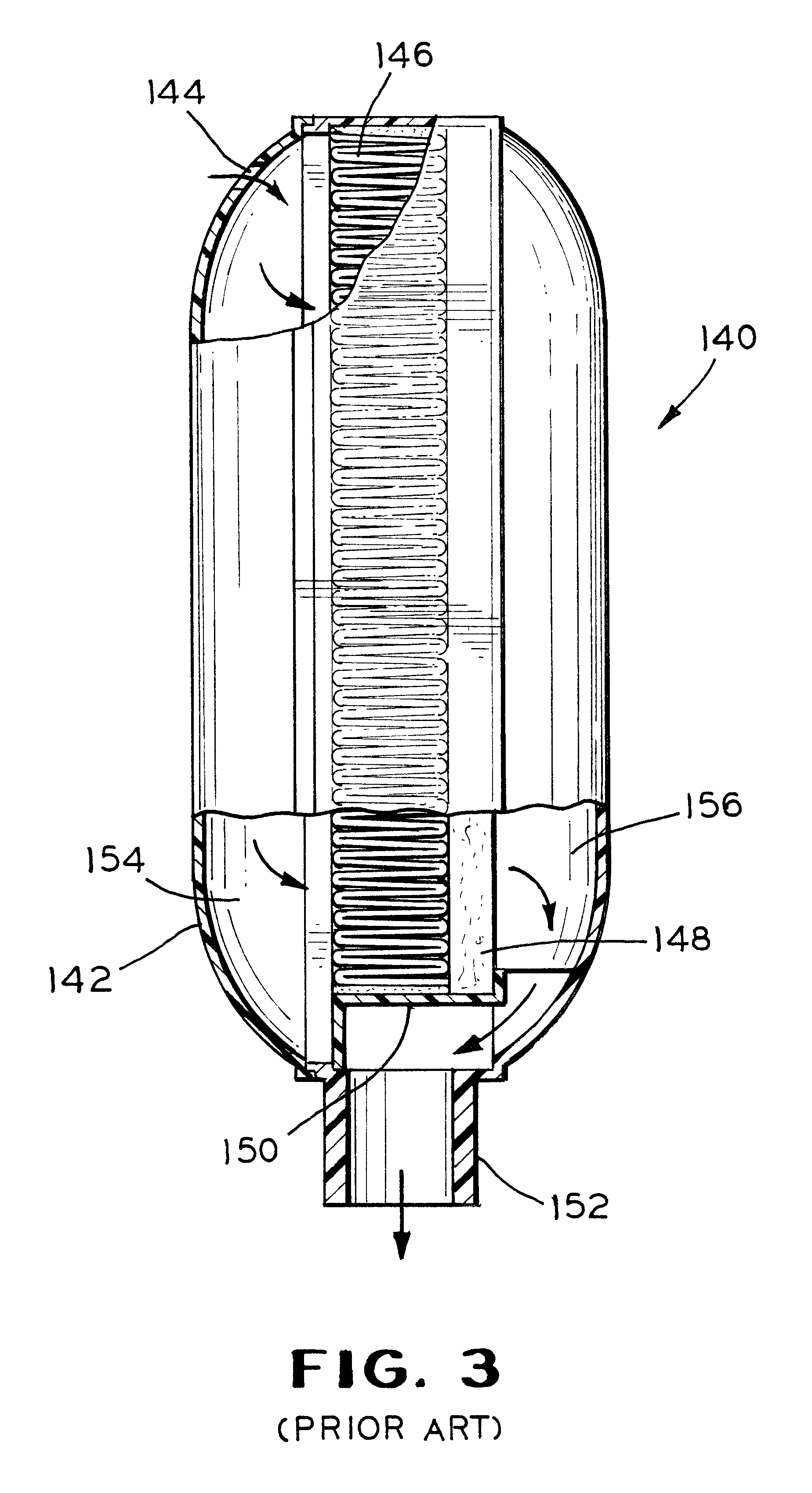

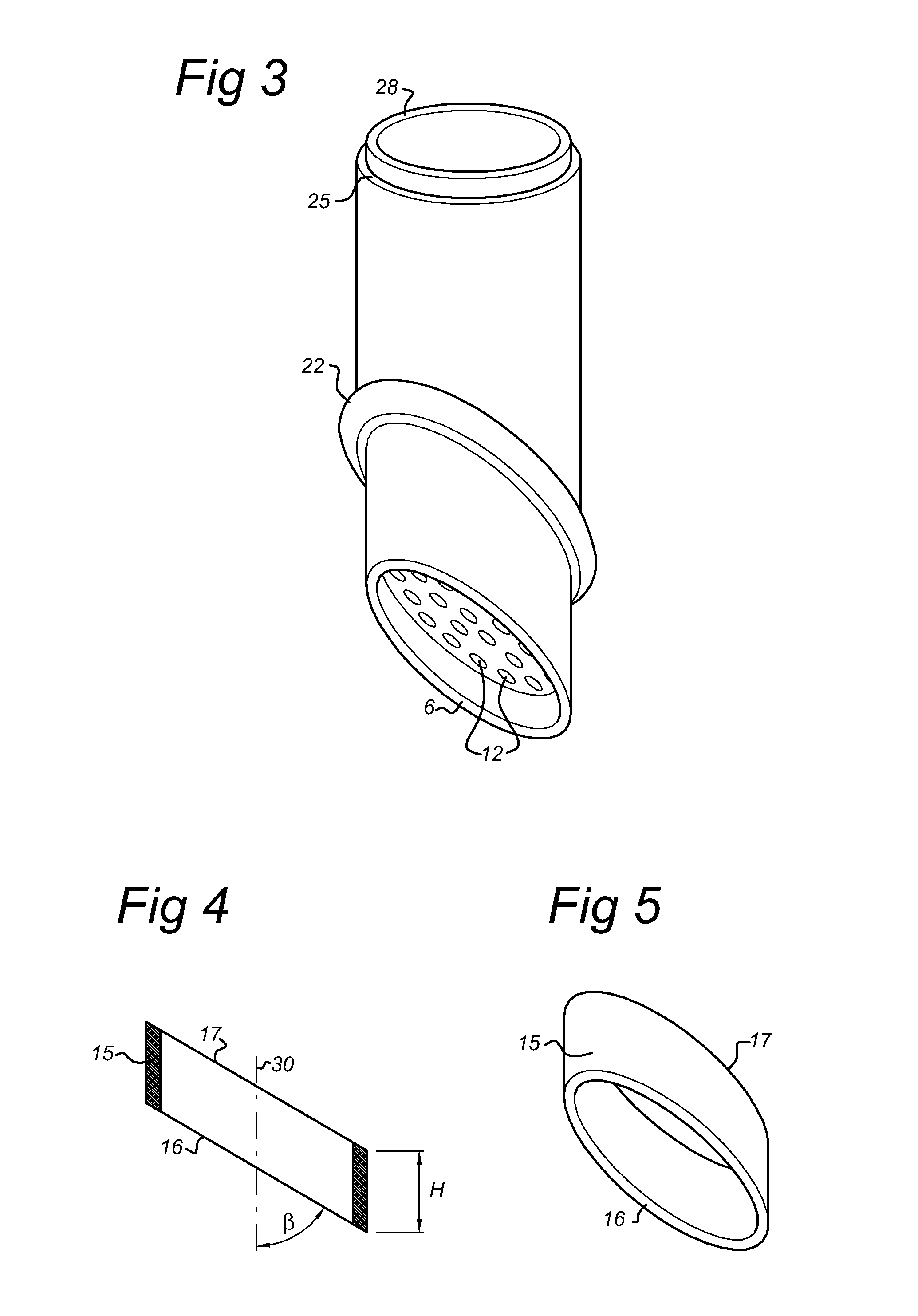

Inlet silencer/filter for an oxygen concentrator

InactiveUS6702880B2Stress minimizationReduce noiseCombination devicesAuxillary pretreatmentHEPAMuffler

An improved inlet silencer / filter for an oxygen concentrator includes a HEPA filter and an adjoining chamber for receiving air flow from the HEPA filter. The chamber is surrounded on one face by the HEPA filter, and by sound absorbing padding on at least 4 other faces. Air is forced from the HEPA filter, through the open chamber and then through the sound absorbing padding by a flow restrictor plate. Air flows from here through air channels and into an open chamber leading to an outlet from the air silencer / filter.

Owner:SHURFLO

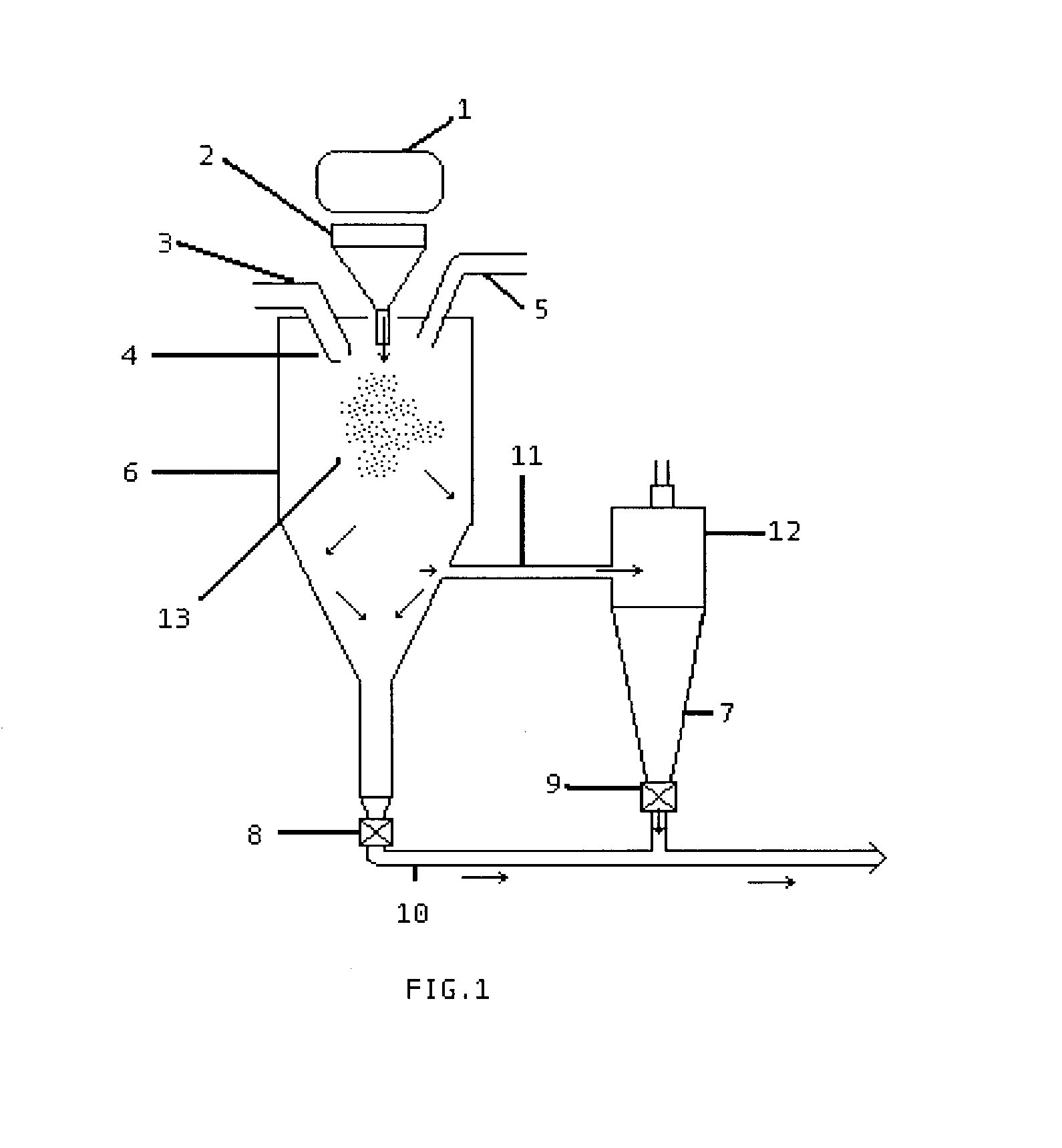

Process for preparing dry extracts

InactiveUS20030104076A1Reduce the amount requiredEasy to handleBiocideGranulation by liquid drop formationFood scienceSpray drying

Owner:J RETTENMAIER & SOEHNE GMBH CO KG ROSENBERG

Method of pipe welding

InactiveUS6204478B1Good lookingIncrease driving speedMeasurement of fluid loss/gain rateArc welding apparatusSulfurManganese

A method of welding the ends of two pipes at the open root between the spaced ends by an STT electric arc welder, which comprises: selecting a welding wire having 0.06-0.15% by weight carbon, 0.90-1.40% by weight manganese, and 0.45-0.75% by weight silicon, as well as phosphorous, copper, stainless steel alloys and sulfur; maintaining the sulfur at a given percentage level of the selected wire in the specific range of 0.015 to 0.035% by weight; and maintaining said phosphorous at a given percentage level of said selected wire in the specific range of less than about 0.015%.

Owner:LINCOLN GLOBAL INC

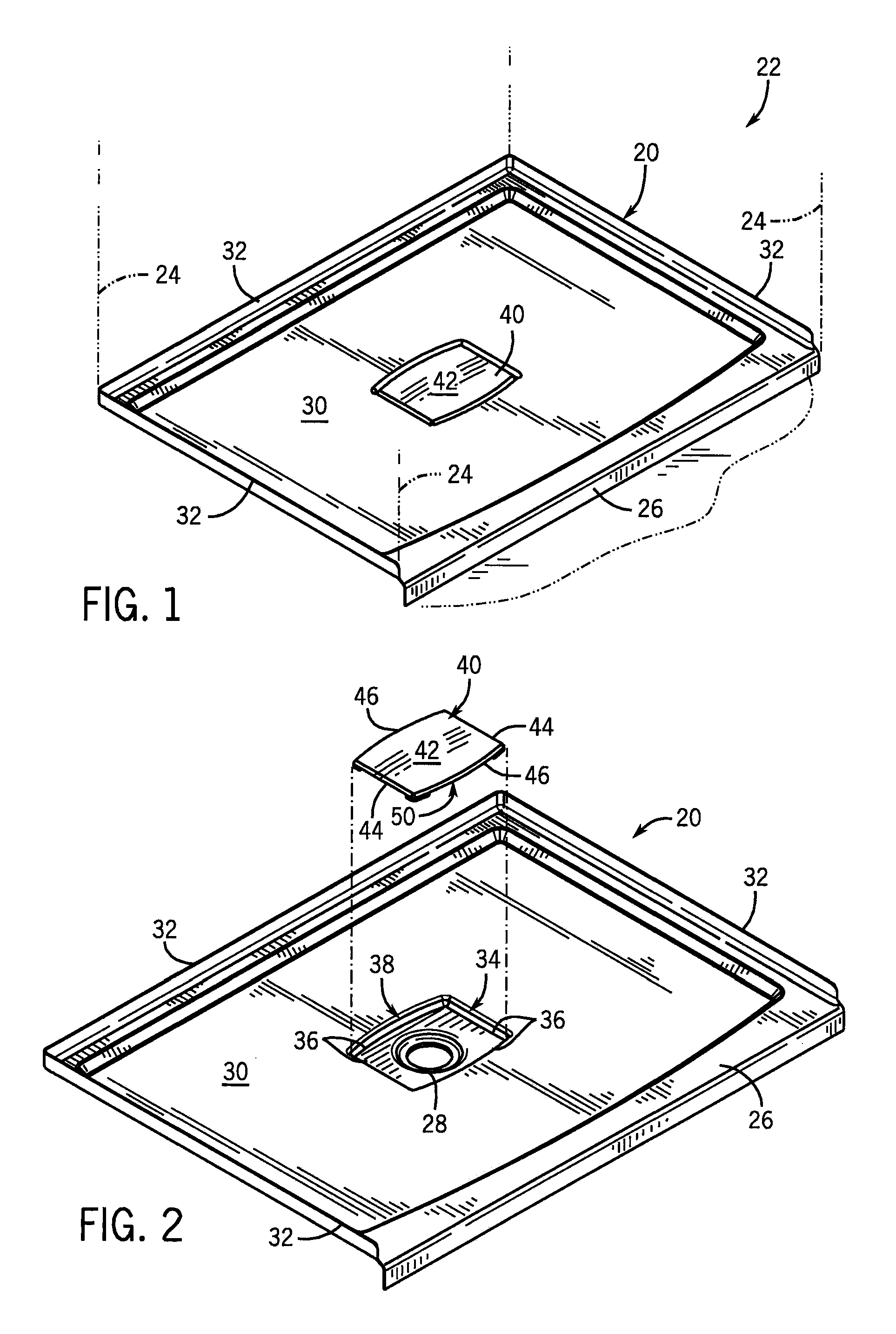

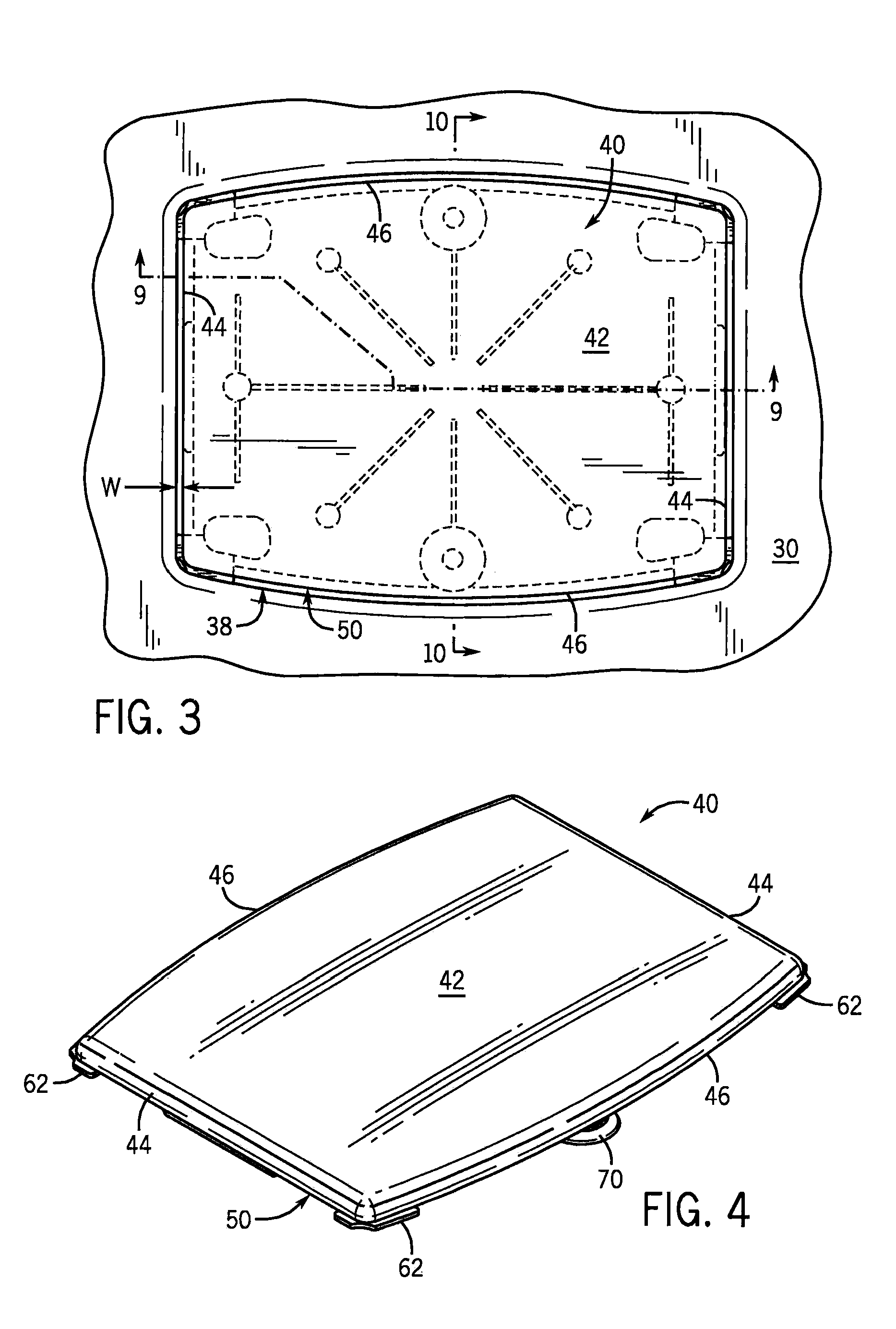

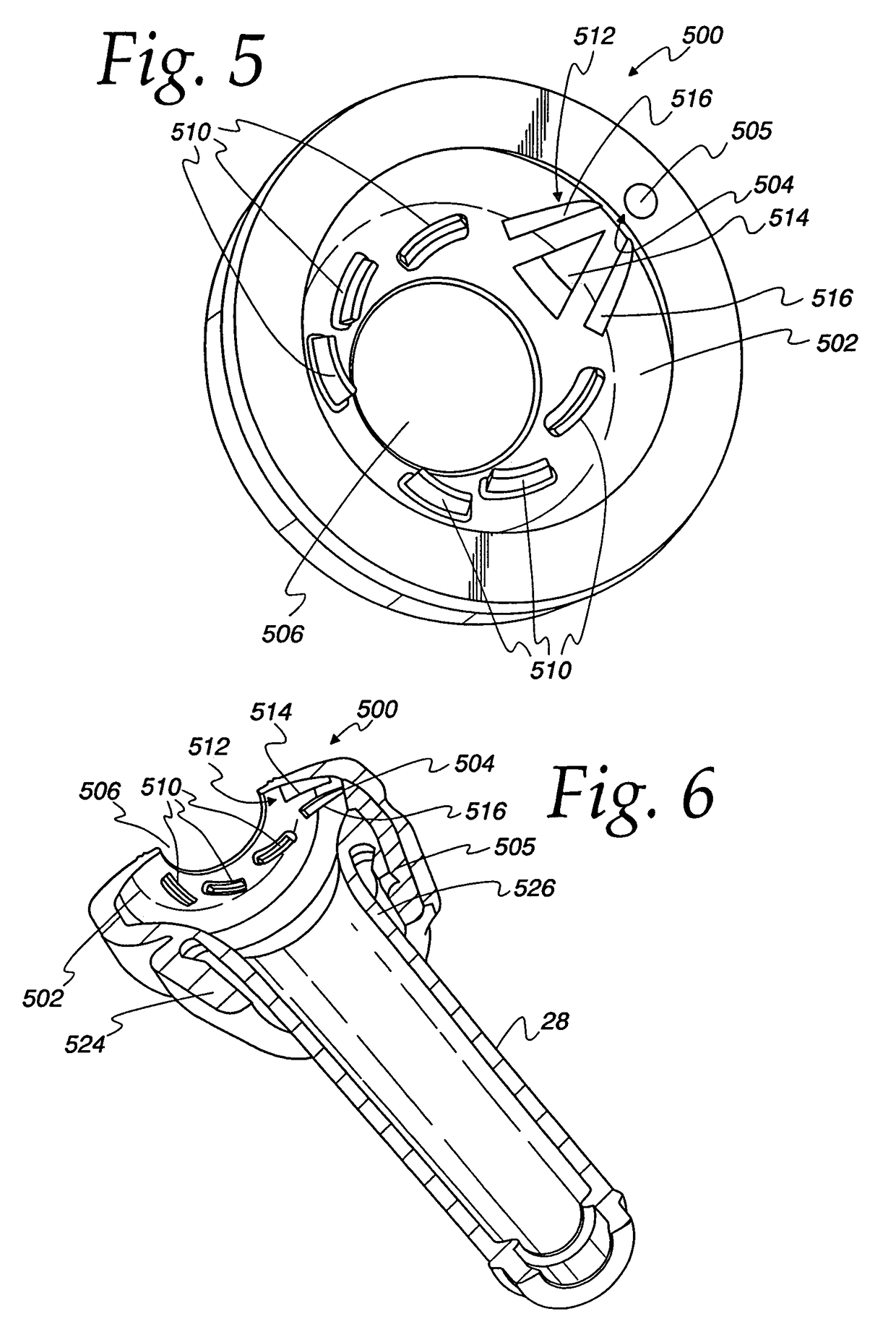

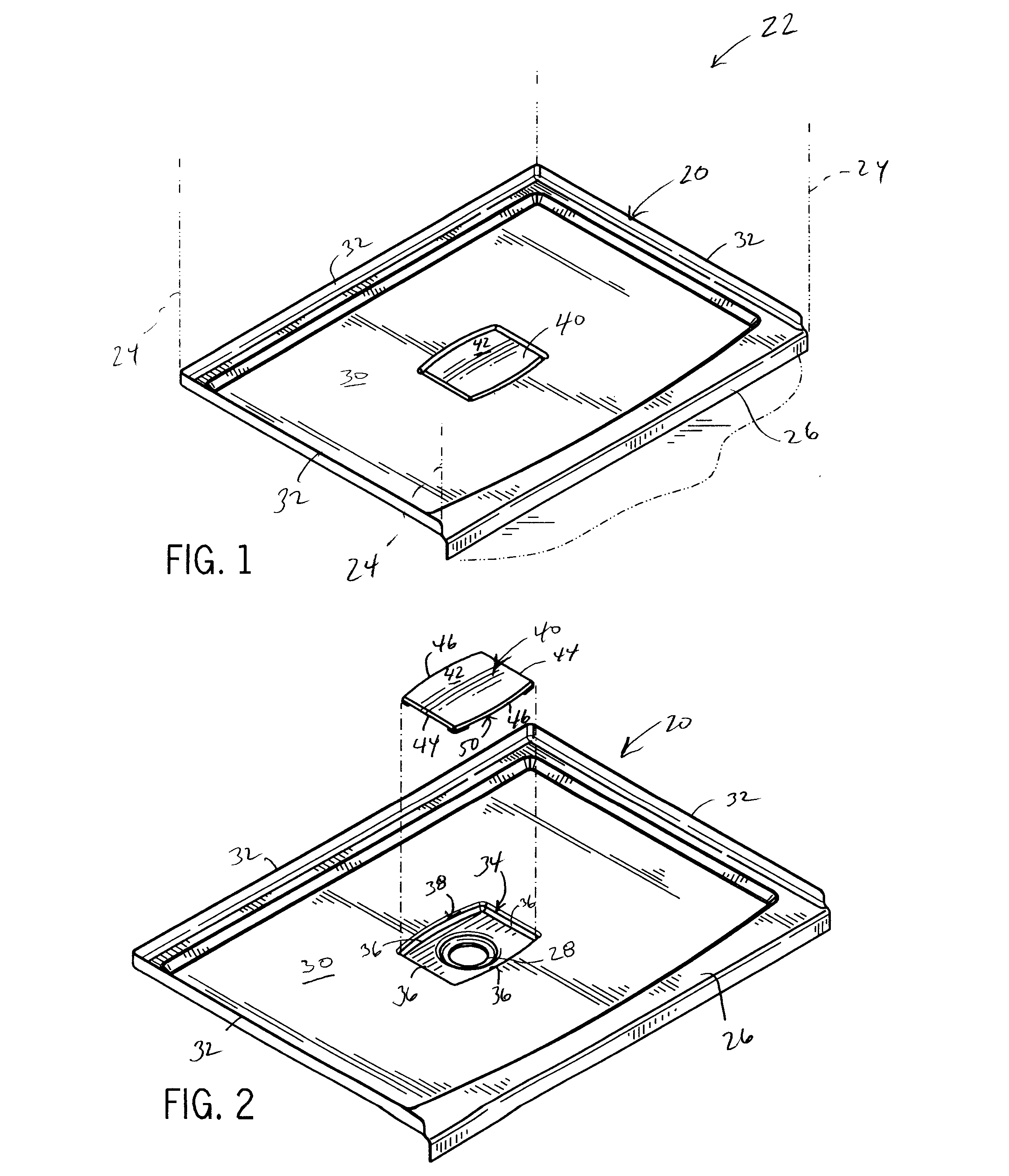

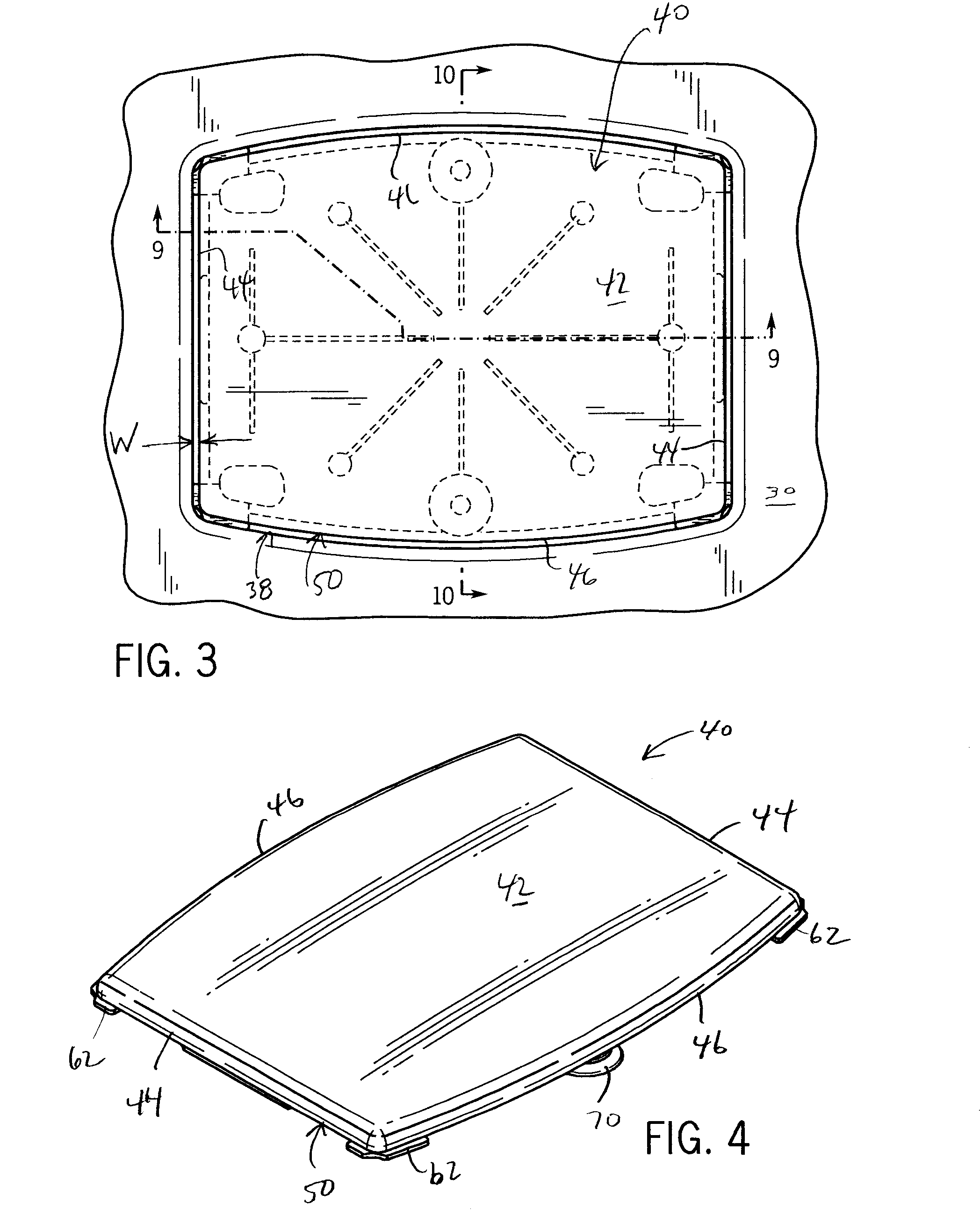

Shower base with flow enhancing covered drain

ActiveUS7739757B2Improve flow characteristicsIncrease flow rateSewerage structuresBathsEngineeringTube drain

A shower enclosure base has a flow enhancing flush-mounted drain cover that conceals the drain opening and provides a flat stepping surface. Drain flow is achieved through a narrow peripheral passage between the drain cover and the drain well in which it is seated. Despite the reduced flow area of passage, flow enhancing features of the drain cover serve to improve the flow rate through the drain. These features are radially converging ribs at the underside of the drain cover that interrupt the natural tendency for drain water to form a vortex as it passes into and through a circular drain opening. The drain cover can be removably secured to the base by suction cups that attach to the drain well.

Owner:KOHLER CO

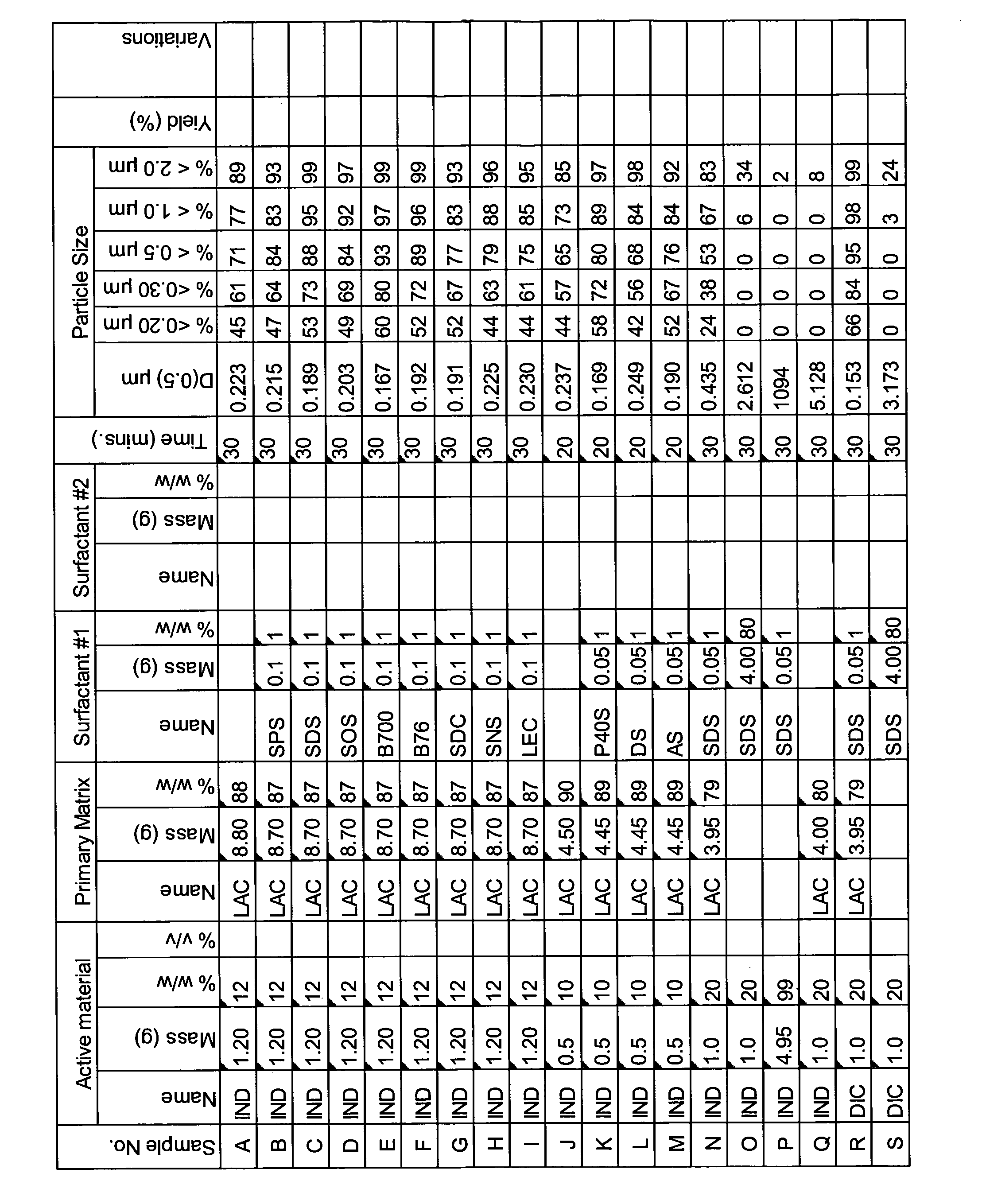

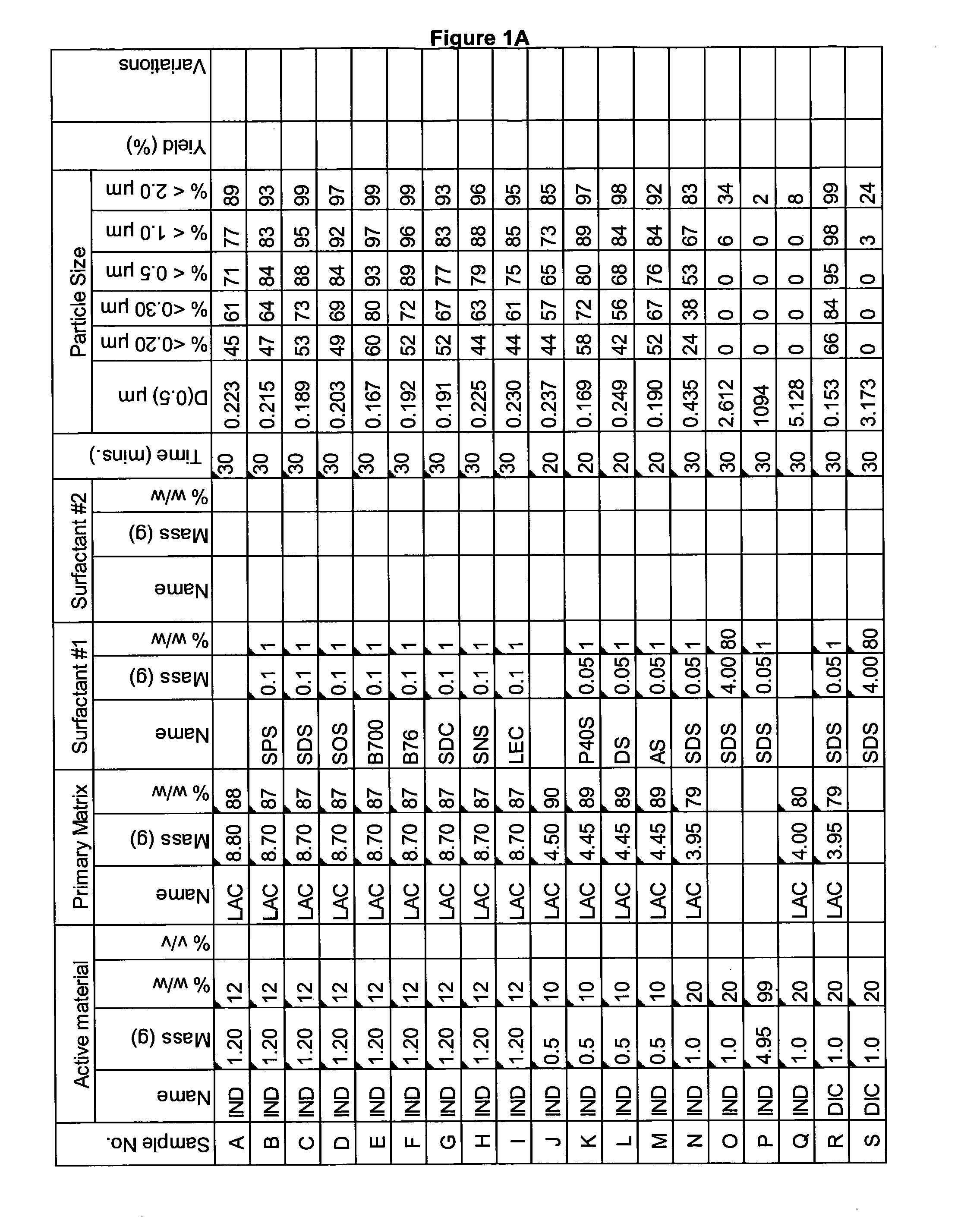

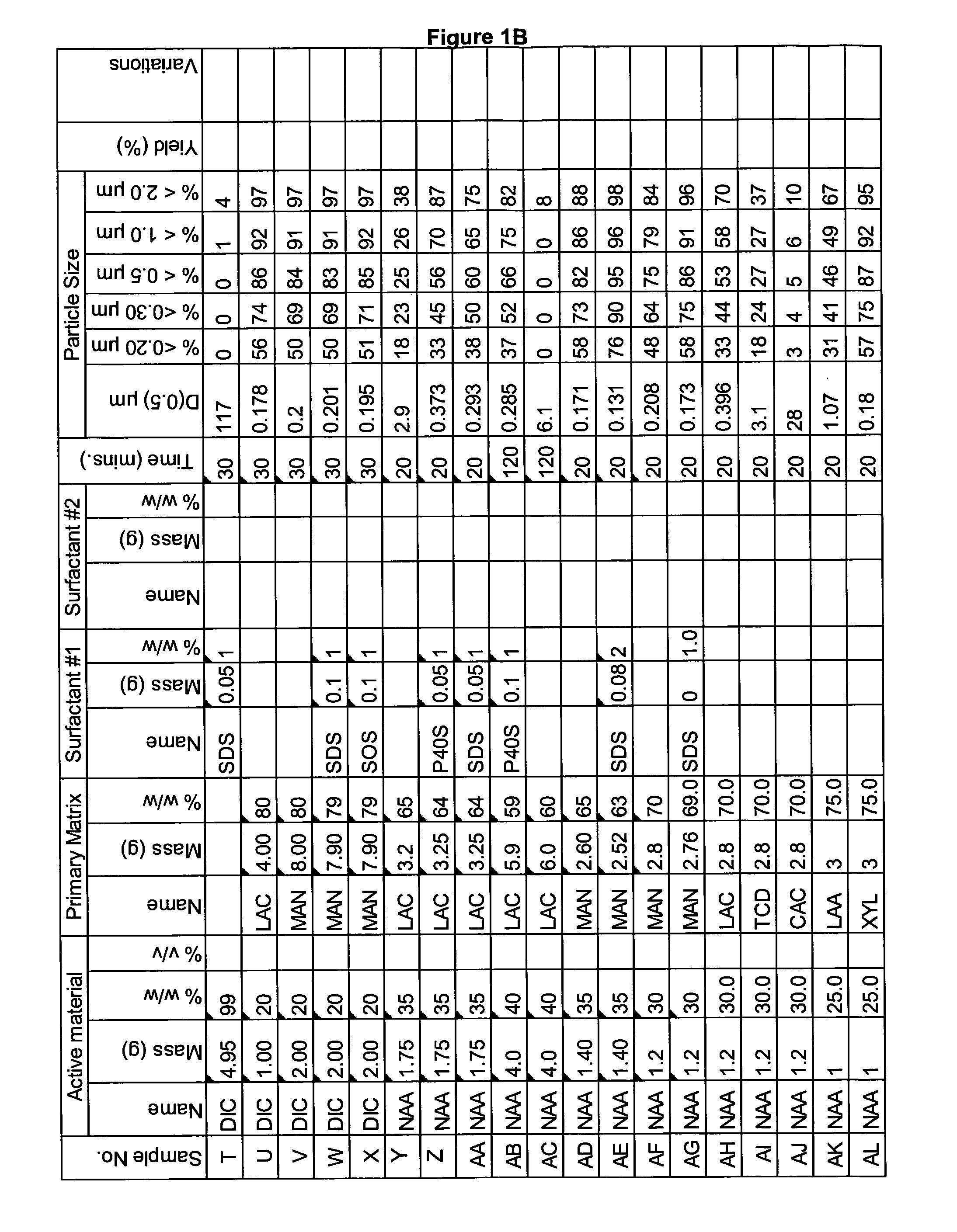

Method for the production of commercial nanoparticle and micro particle powders

InactiveUS20120160944A1Lower static chargeCohesiveness profileBiocidePowder deliveryParticulatesNanoparticle

The present invention relates to methods for producing nanoparticle and microparticle powders of a biologically active material which have improved powder handling properties making the powders suitable for commercial use using dry milling processes as well as compositions comprising such materials, medicaments produced using said biologically active materials in particulate form and / or compositions, and to methods of treatment of an animal, including man, using a therapeutically effective amount of said biologically active materials administered by way of said medicaments.

Owner:ICEUTICA PTY LTD

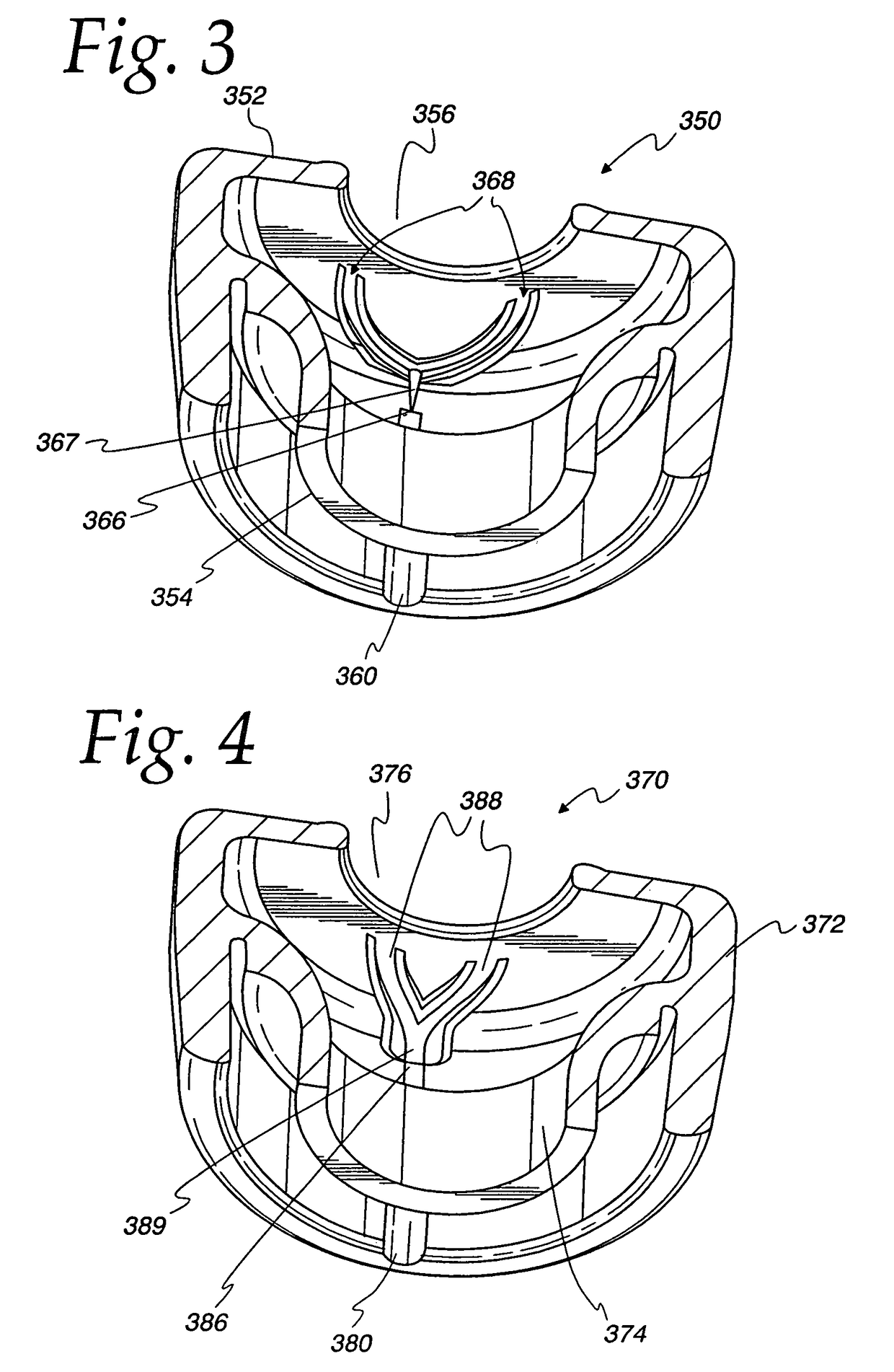

Milk tube dome with flow controller

ActiveUS20090320760A1Uniform deliveryReduce the amount requiredCathetersOther apparatusEngineeringFlow diverter

A milker unit liner dome having an inner surface and flow diverters joined to the inner surface to redirect teat dip from an inlet to provide more uniform coverage of dip on a teat. The liner dome can also include more than one flow diverter for redirecting teat dip flow.

Owner:GEA FARM TECH

Formed decorative film

InactiveUS20030030172A1Low process temperatureFaster cycle timeCoatingsShell moldingThree dimensional shape

In a method of molding, a decorative substantially transparent cycloaliphatic polyester resin substrate is formed into a three-dimensional shape, placed into a mold, and a resin is injection molded into the mold cavity space behind the formed substrate.

Owner:HOOGLAND GABRIE +3

Laser catheter for bypass surgery and assembly comprising said catheter

ActiveUS20100331793A1Obstruct passageAvoid leaningCatheterSurgical instrument detailsSlant angleLight beam

The invention is directed to a laser catheter (1) for bypass surgery, wherein the distal part (2) of the catheter (1) is provided with: a tubular arrangement (3) of optical fibres (4) having distal ends (5) defining a ring-shaped light emergence surface (6) for emitting a tubular bundle of light beams in the distal direction (D) of the catheter (1); and a stop surface (7) extending around the tubular arrangement (3) of optical fibres (4) and facing in the distal direction (D), the stop surface (7) being arranged at a distance (A) proximally from the light emergence surface (6). The light emergence surface (6) slants at a slanting angle (α) in the range of [20°, 60°] with respect to the longitudinal axis (8) of the catheter (1). The invention further relates to an assembly comprising such a catheter.

Owner:AMT MEDICAL

Chemical activation and refining of southern pine kraft fibers

InactiveUS20070119556A1Increase the pulp freenessEasy to drainPulp properties modificationPulp bleachingChemical treatmentCellulose fiber

A method for alteration of the morphology of cellulose fibers, particularly softwood fibers, by (a) subjecting the fibers to a metal ion-activated peroxide treatment carried out at a pH of between about 1 and about 9, preferably between 3 and 7, and (b) subjecting the treated fibers to a refining treatment thereby converts SW fibers to HW-like fibers in many respects. The metal ion-activated peroxide treatment has been noted to act on pulp cellulose and hemi-cellulose, causing oxidation and oxidative degradation of cellulose fibers. The chemical treatment of the pulp, taken alone, is not sufficient to attain the desired modification of the morphology of the fibers, however, subsequent refining or like mechanical treatment of the chemically-treated fibers to achieve a given degree of refinement of the fibers requires dramatically less refining energy to achieve a desired end point of refinement and to impart other desirable properties to the pulp. A pulp of modified SW fibers and a mixture of HW fibers and modified HW fibers are disclosed.

Owner:INT PAPER CO

Spherical rhenium powder

InactiveUS6551377B1Good flow characteristicsImprove flow characteristicsTransportation and packagingMetal-working apparatusPowder metallurgyTungsten

This invention relates to powders of substantially spherical particles that consist essentially of at least about 10% by weight rhenium optionally alloyed with up to about 90% by weight tungsten or up to about 60% by weight molybdenum. In one embodiment, the spherical particles have an average diameter of less than about 150 microns, and more preferably, an average diameter within the range of from about 10 to about 50 microns. The powders according to the invention exhibit good flow characteristics and can be used to fabricate components having complicated shapes and configurations using conventional powder metallurgy techniques.

Owner:RHENIUM ALLOYS

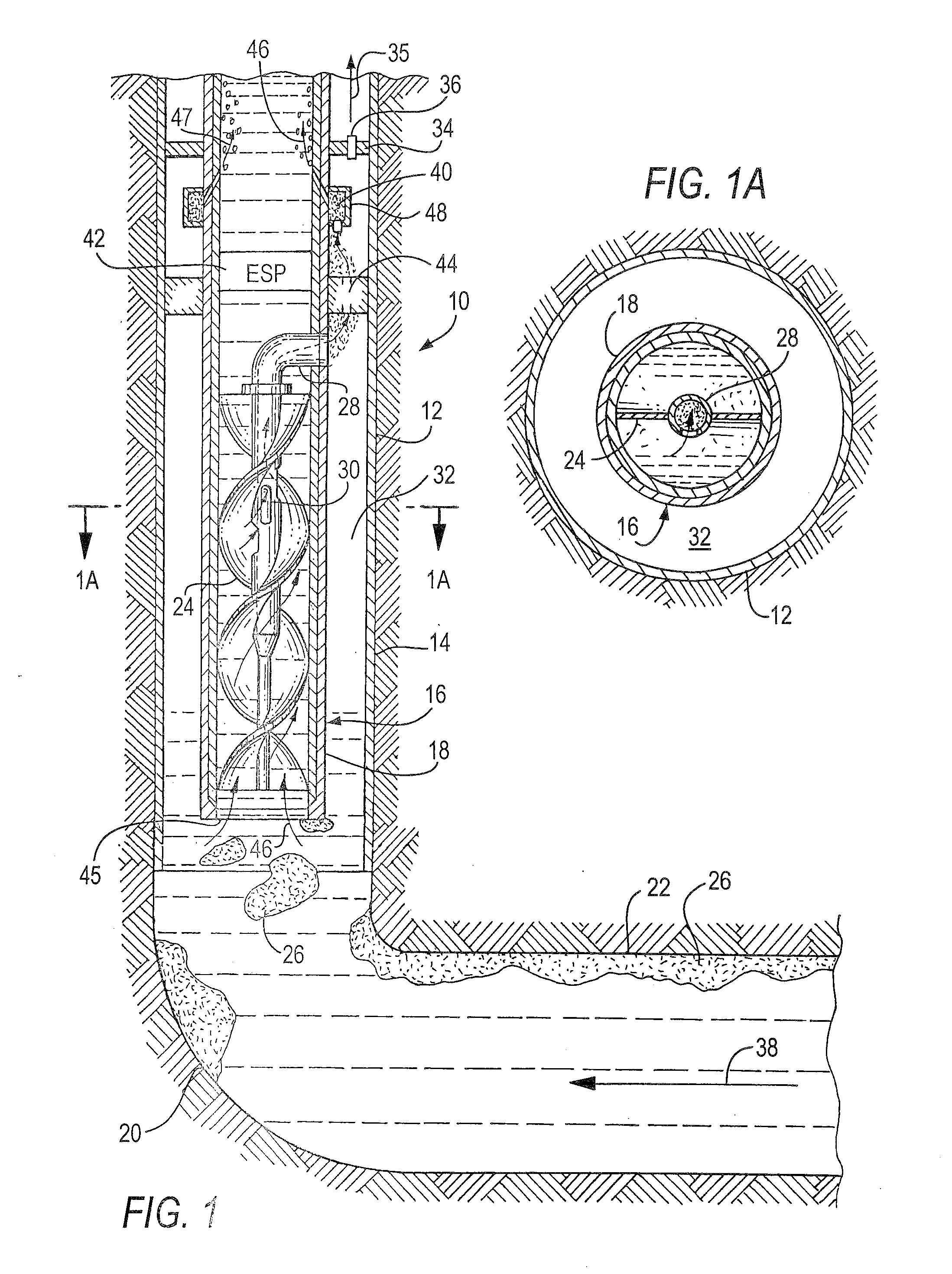

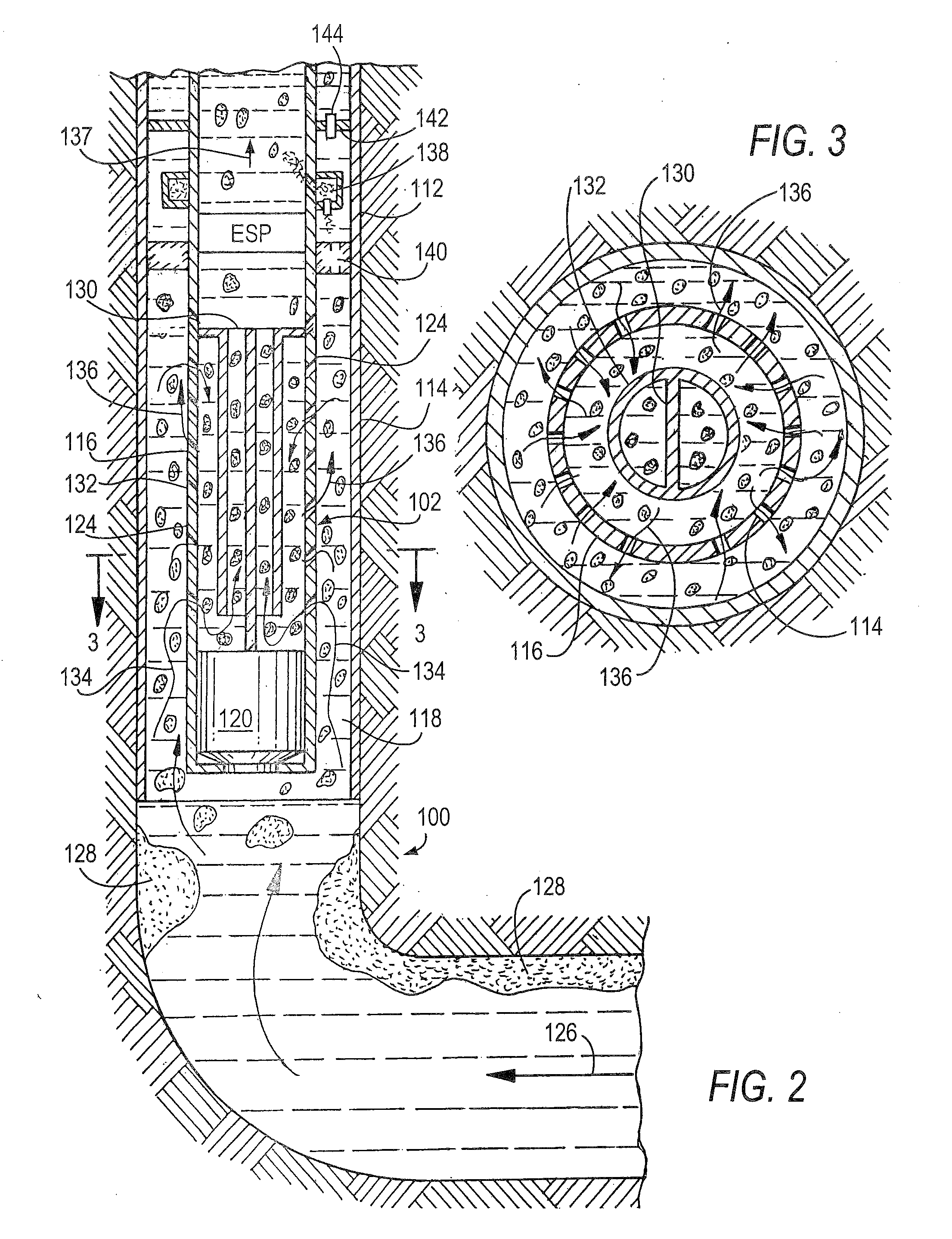

Fluid homogenizer system for gas segregated liquid hydrocarbon wells and method of homogenizing liquids produced by such wells

ActiveUS20150233228A1Improve flow characteristicsImproving homogeneity and flow characteristicLiquid degasificationFlow mixersLiquid productStream flow

A system and method for improving the flow characteristics of gaseous slug-laden liquid hydrocarbon wells, particularly from horizontal, of similar boreholes. The invention provides a system and method which essentially homogenizes the liquid and the gas, utilizing a unique flow tube arrangement and a sequence of steps by first breaking up and separating the slugged gas from the liquid at a first location, and then gathering it into holding location—i.e., an annulus section—where it is re-introduced in controlled amounts into the liquid downstream of the first location. The gas is re-introduced into the liquid flow in such pre-determined and controlled quantities as to promote better pressure and flow characteristics of the hydrocarbon liquid product. Various alternative gas / liquid separation devices are incorporated into the system of the invention, which devices may be located either in a vertical wellbore or a horizontal wellbore, depending upon the particular well characteristics. Optionally, an electric submersible pump may be incorporated where needed to assist the mixed production flow toward surface. A compressor may optionally be provided in the gaseous holding location, where needed. An apparatus for homogenizing production fluid from an oil well having one or more horizontal bores is also disclosed.

Owner:SAUDI ARABIAN OIL CO

Fluted filter media

InactiveUS20080216654A1Improve flow characteristicsReduce restrictionsDispersed particle filtrationPaper/cardboard wound articlesFluteFilter media

Fluted filter media includes filter material having a plurality of flutes formed therein having alternating ends of adjacent flutes closed to force fluid through filter material. A first embodiment of the filter media includes tapered flutes which have the open ends of the flutes larger in cross-section than the closed flutes, wherein the upstream open flutes converge toward the downstream end and the upstream closed end flutes diverge toward the downstream end. A second embodiment includes filter media which is asymmetric formed with dissimilar upstream and downstream flute cross-sections with larger flute openings to the upstream side of the filter. A third embodiment includes filter media with an upstream edge crushed to improve flow at the upstream edge. A fourth embodiment includes filter media with the upstream sealing material recessed from the upstream edge for reducing effects from blockages at the upstream edge of the filter.

Owner:DONALDSON CO INC

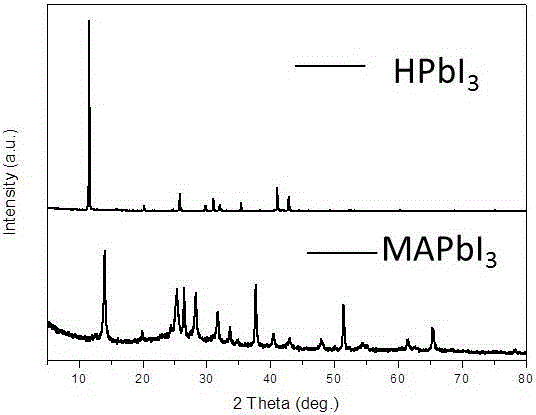

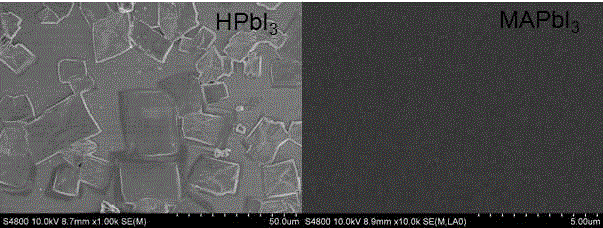

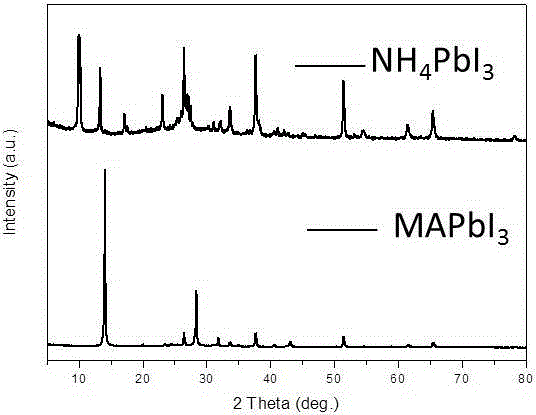

Novel method for preparing perovskite thin film

ActiveCN105336856AKeep the original shapeReduce defectsSolid-state devicesSemiconductor/solid-state device manufacturingLight sensingPerovskite solar cell

The invention relates to a novel method for preparing a perovskite thin film. The novel method comprises a step of carrying out organic amine processing on a prepared perovskite precursor thin film, thereby preparing the perovskite thin film. According to the invention, the preparation technology is simple; cost is low; surface roughness of the thin film is low; crystallinity is high; and the novel method is applicable for preparing a large number of highly-efficient perovskite solar cells, light emitting diodes, light sensing elements and laser devices.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

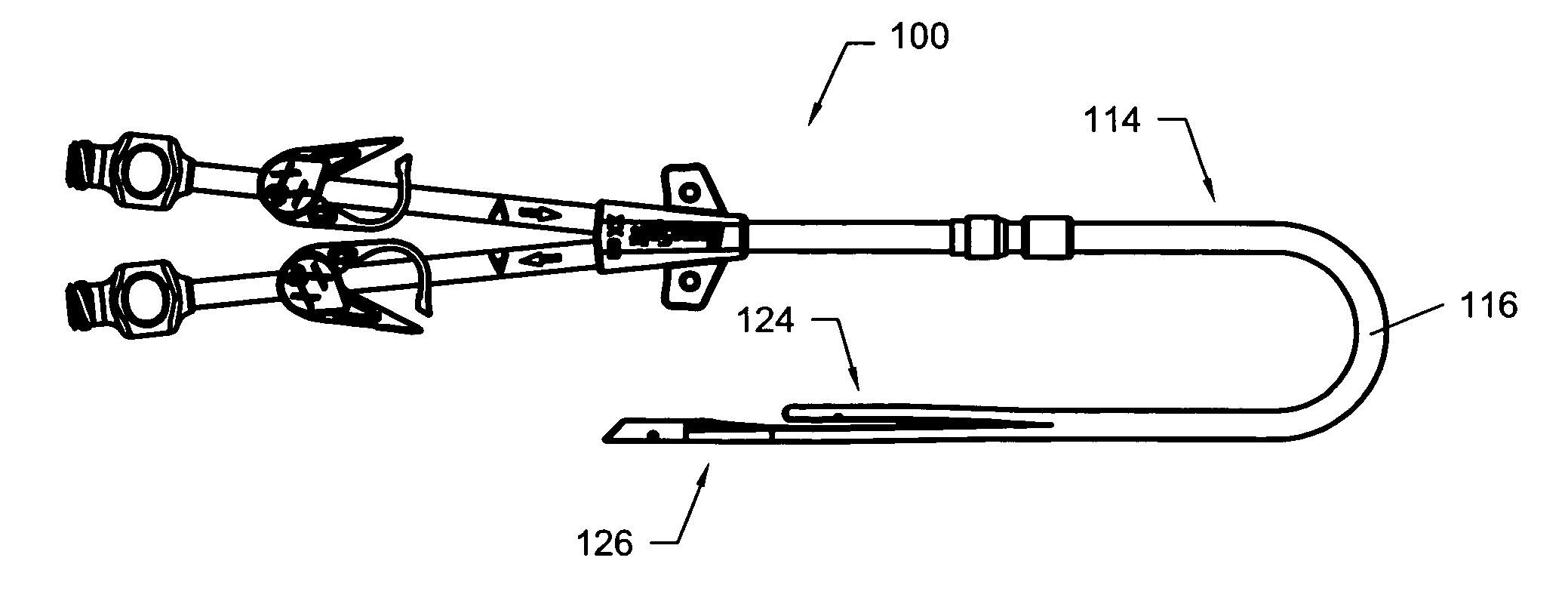

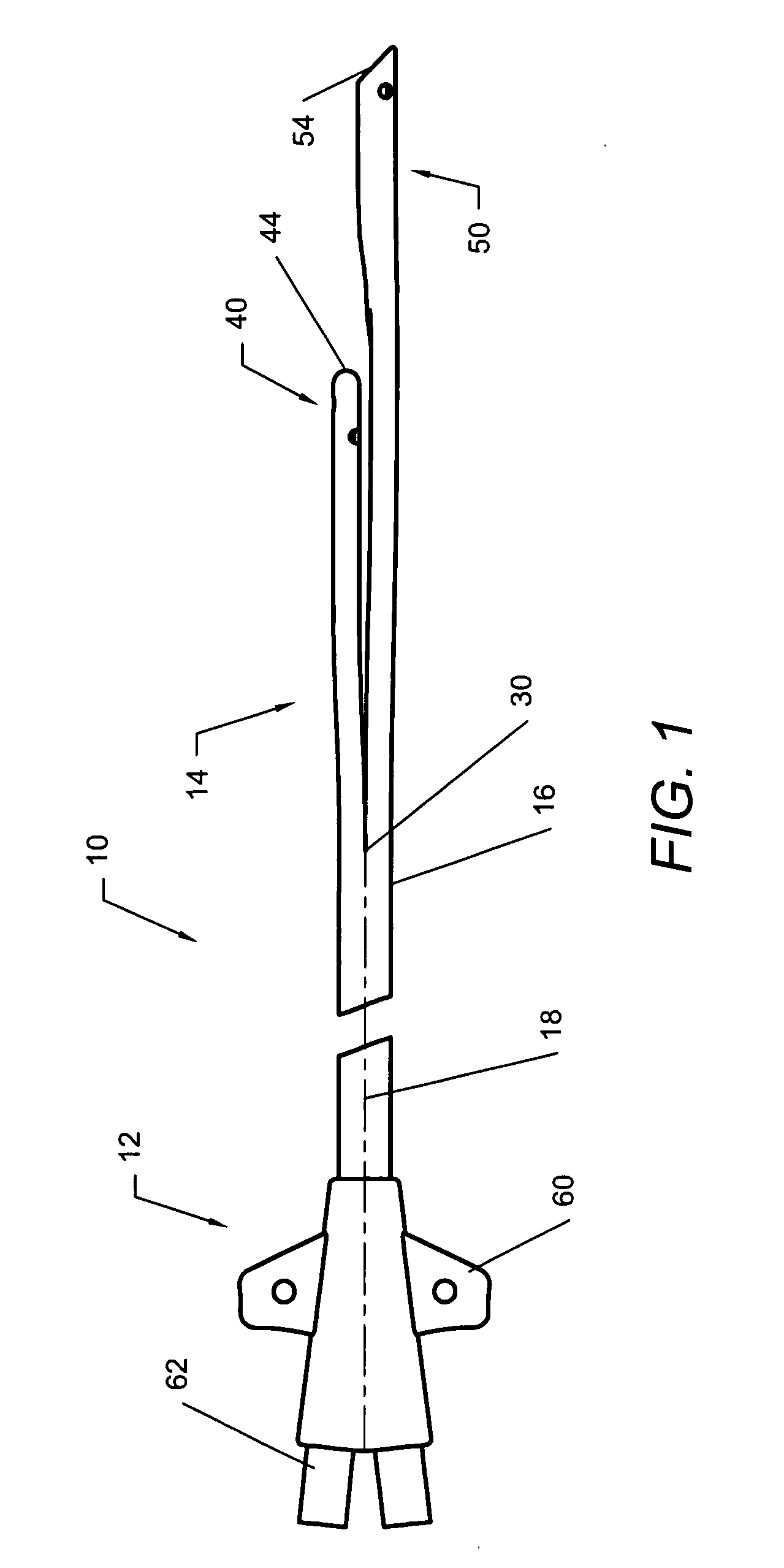

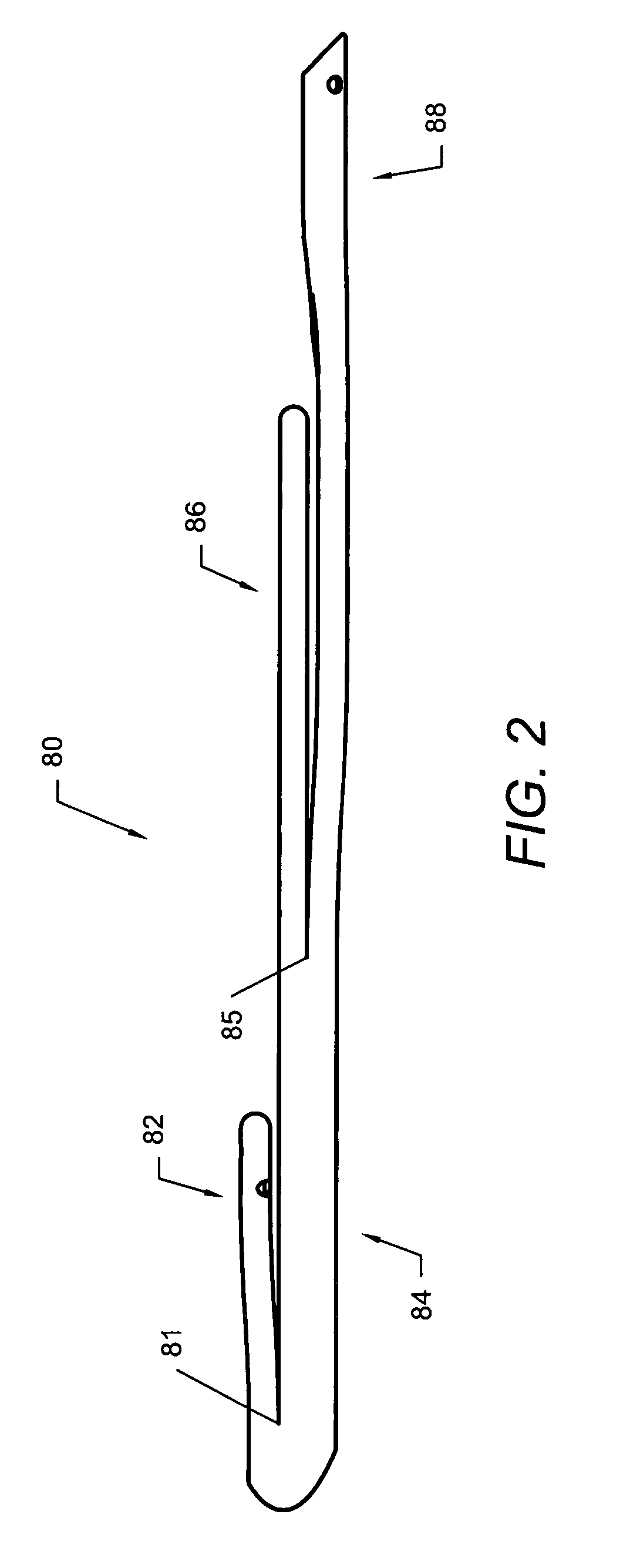

Multi-lumen catheter with separate distal tips

ActiveUS20080039774A1Improve flow characteristicsReduce deliveryMulti-lumen catheterOther blood circulation devicesCatheter device

A multi-lumen catheter including a generally cylindrical body enclosing a first and second lumen separated by a generally planar septum. A first and second tip section extend from a distal end of the body. The first and second tip section may each include a generally planar surface. The second tip section may include a first segment extending from the distal end of the catheter body to a transition segment and a second segment extending from the transition segment to a distal end of the second tip section.

Owner:CR BARD INC

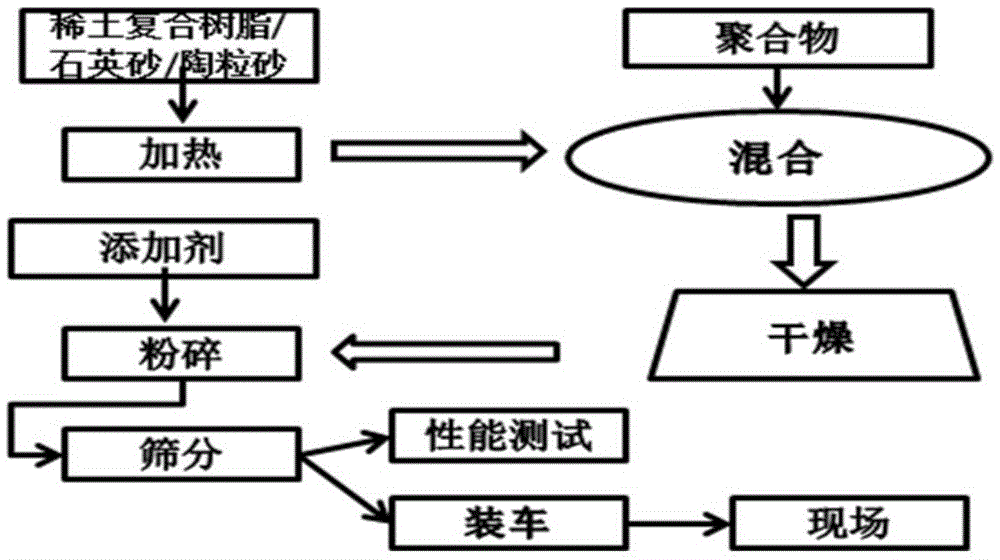

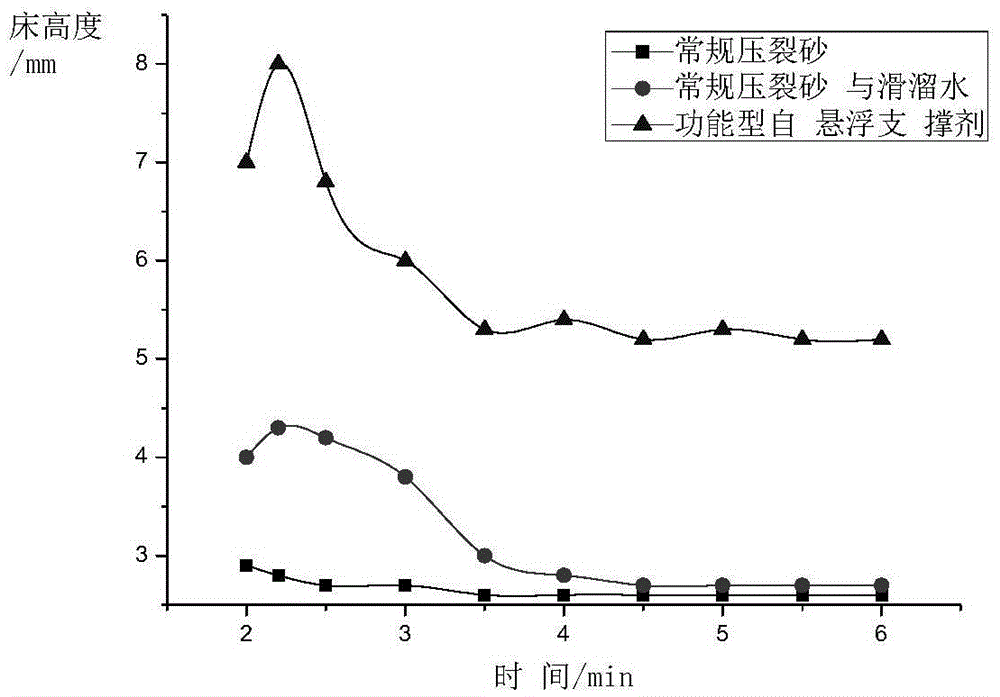

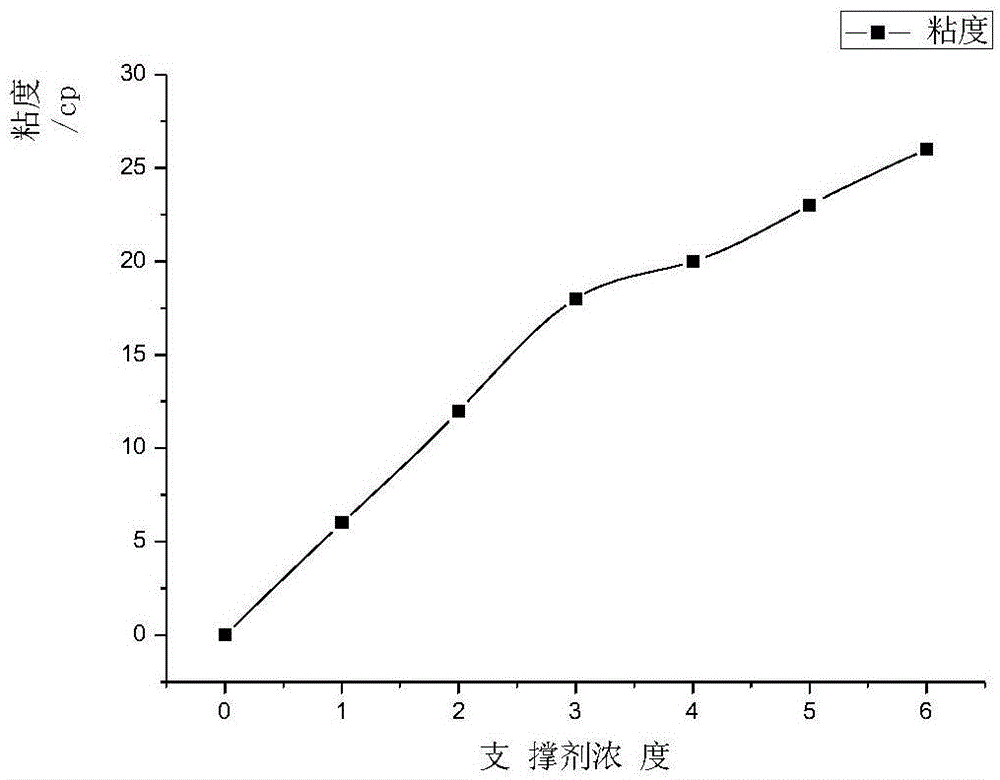

Water acid-sensitivity deformation magnetic tracer function self-suspension propping agent and preparation method thereof

InactiveCN105670600AReservoir damage is smallSave time and costFluid removalDrilling compositionMagnetic tracerSurface hydration

The invention belongs to the technical field of oil-gas field fracturing production-increase propping agent preparation, and relates to a water acid-sensitivity deformation magnetic tracer function self-suspension propping agent and a preparation method thereof. The propping agent comprises an aggregate and a surface hydration layer, wherein the aggregate is one of magnetic rare earth composite resin, quartz sand or ceramsite and like material; the surface hydration layer is composed of three layers, the innermost layer is a cationic macromolecule inner polymer layer or a modifier layer, the middle layer is an anionic macromolecule outer polymer layer, and the outer layer is anti-caking agent. The propping agent has the acid-sensitivity deformation self-suspension function of producing buoyant force while encountering water and breaking gel to precipitate while encountering the acid, and a tracer function of monitoring flow guiding position of the propping agent through electromagnetic imaging; in the process of exerting the fracturing engineering on shale, compact oil-gas or coal bed base and like argillaceous plasticity micronano hole reservoir, the fracturing liquid with the propping agent has excellent flow guiding characters of suspension sand-adding of non-floating to the roof and not sinking to the bottom; the permeation is improved, the hurt is avoided, the propping agent is efficient and capable of increasing production, the construction cost is lowered, and the application prospect is wide.

Owner:王展旭

Milk tube dome with flow controller

ActiveUS8117989B2Reduce the amount requiredUniform deliveryCathetersOther apparatusEngineeringFlow diverter

A milker unit liner dome having an inner surface and flow diverters joined to the inner surface to redirect teat dip from an inlet to provide more uniform coverage of dip on a teat. The liner dome can also include more than one flow diverter for redirecting teat dip flow.

Owner:GEA FARM TECH

Shower base with flow enhancing covered drain

ActiveUS20080148474A1Enhance flow characteristicIncrease flow rateSewerage structuresBathsEngineeringTube drain

A shower enclosure base has a flow enhancing flush-mounted drain cover that conceals the drain opening and provides a flat stepping surface. Drain flow is achieved through a narrow peripheral passage between the drain cover and the drain well in which it is seated. Despite the reduced flow area of passage, flow enhancing features of the drain cover serve to improve the flow rate through the drain. These features are radially converging ribs at the underside of the drain cover that interrupt the natural tendency for drain water to form a vortex as it passes into and through a circular drain opening. The drain cover can be removably secured to the base by suction cups that attach to the drain well.

Owner:KOHLER CO

Extrusion die manufacturing method

InactiveUS20080124423A1Improves Structural IntegrityImprove flow characteristicsConfectionerySweetmeatsHoneycombIrradiation

A method of forming an extrusion die comprises depositing at least one layer of a sinterable material, such as binder-free sinterable material, in a plane creating a layer of unsintered material, applying irradiation to the at least one layer of unsintered material along a pattern creating a layer of centered material, and forming the extrusion die as a single, integrally-formed piece by repeating the depositing and irradiating steps in a coordinate direction that is substantially orthogonal to the plane, wherein a new layer is superposed upon a previously sintered layer. The extrusion die formed via this method includes an inlet section having a die inlet face and a plurality of feed channels extending from the inlet face toward a honeycomb-forming section that is spaced from the inlet face and terminates in a die outlet face that includes an array of discharge channels formed from pins. Dies having at least two of the pins coupled to one another by a structural element other than at the pin root may be manufactured by the method.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com