Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1220 results about "Softwood" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Softwood is wood from gymnosperm trees such as conifers, as well as Amborella. The term is opposed to hardwood, which is the wood from angiosperm trees.

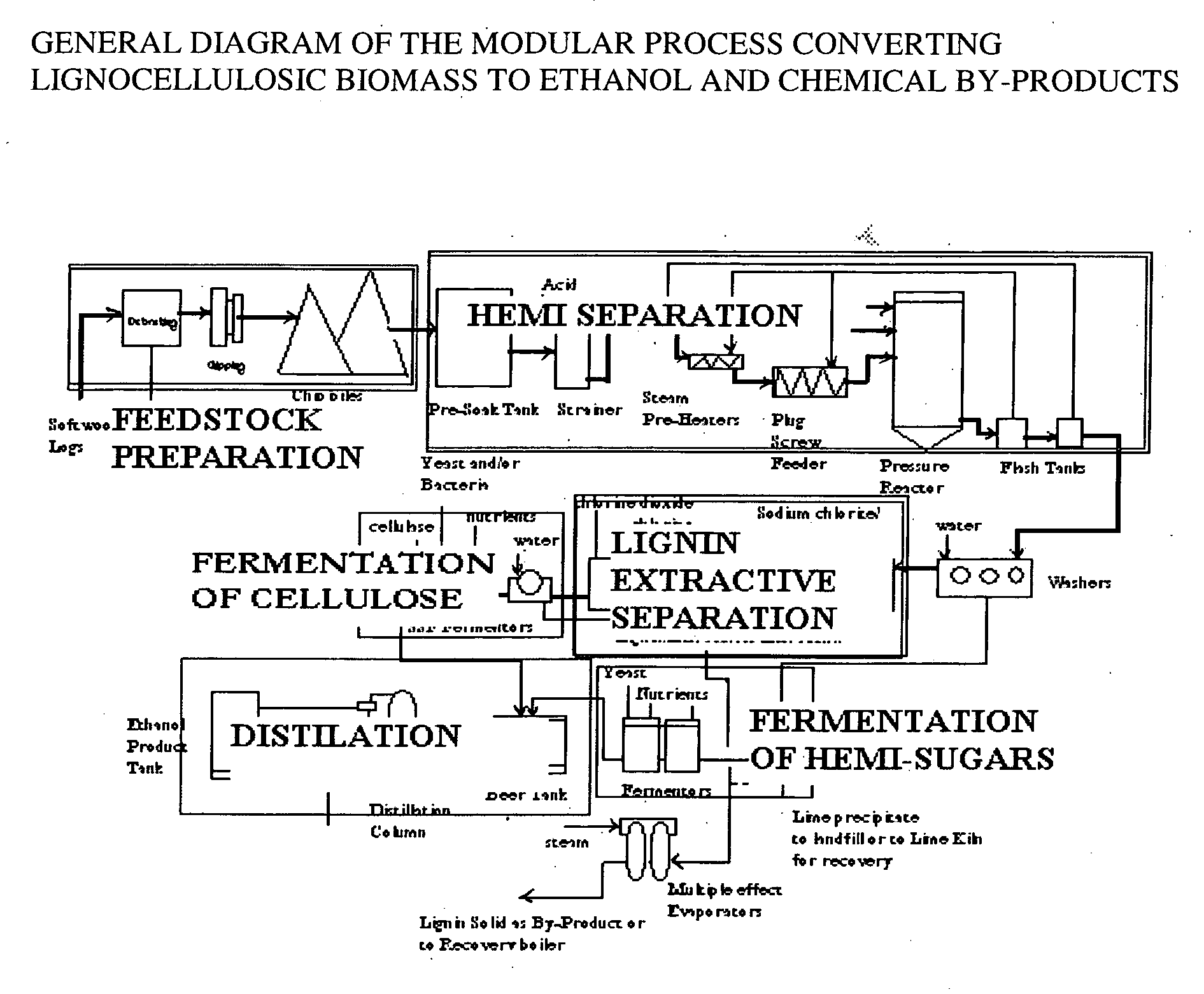

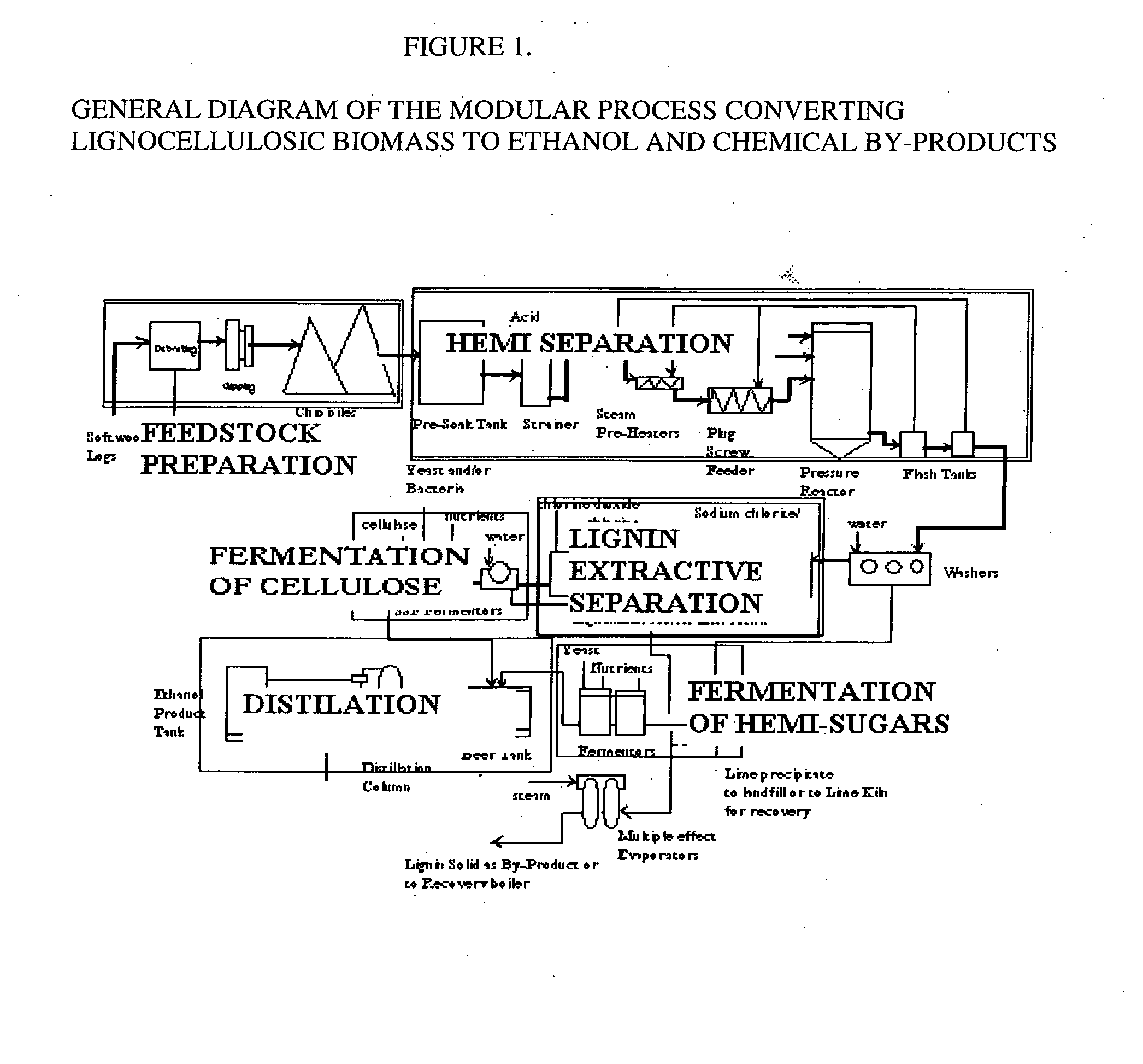

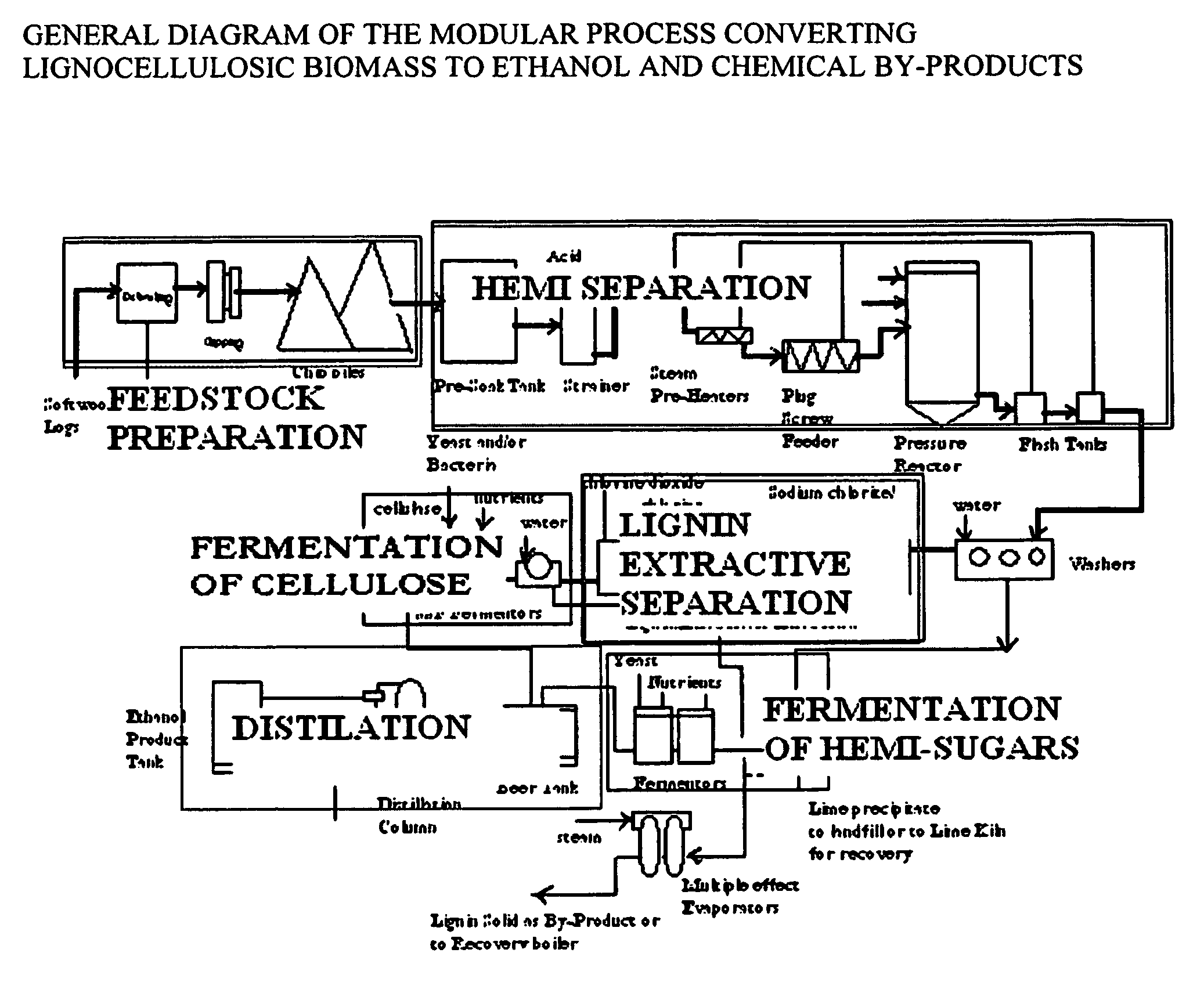

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS20080057555A1Robust and cost-effectiveImprove responseChemical industryBiofuelsChemical treatmentButanediol

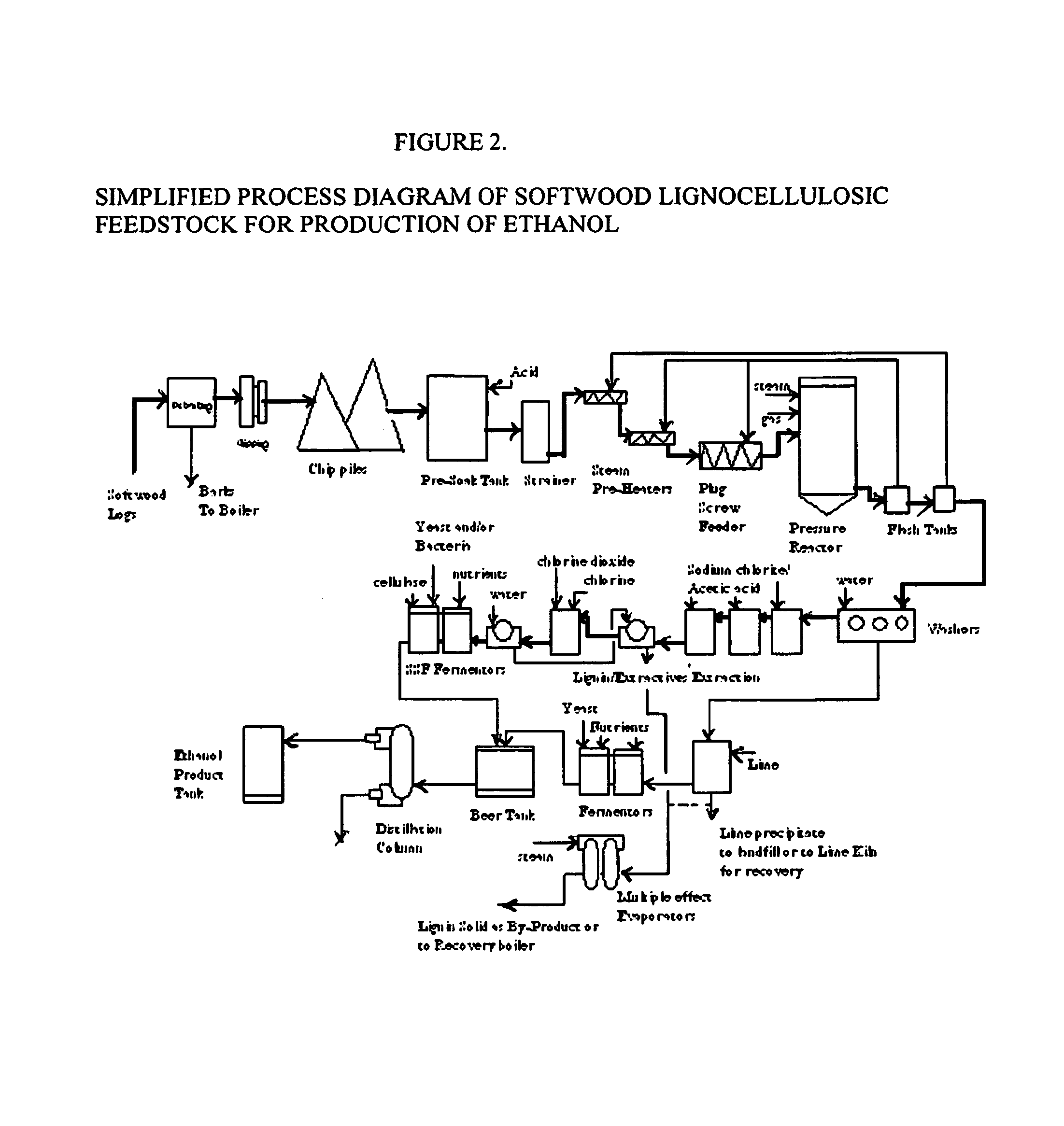

A continuous and modular process converts lignocellulosic materials for the production of ethanol principally and / or chemicals such as methanol, butanediol, propanediol, hydrocarbon fuel, etc. Renewable lignocellulosic biomass such as but not all inclusive hardwoods (gum, beech, oak, sweet gum, poplar, eucalyptus, etc.), soft woods (pines, firs, spruce, etc.), corn stovers, straws, grasses, recycled papers, waste products from pulp and paper mills, etc can be used as feedstock. The process is designed to be modular and the feed entry point can be selected to adapt to different biomass feedstock. Lignocellulosic biomass such as hardwood and softwood are subjected to chemical / pressure treatment stages using potent and selective chemicals such as sodium chlorite / acetic acid (anhydrous) and chlorine / chlorine dioxide to separate the main components—lignin, cellulose (glucose) and hemicelluloses (xylose, arabinose, galactose)—into three process streams. The separated carbohydrates are further subjected to washing, cleaning, neutralization, and / or mild hydrolysis and subsequently fermented to produce ethanol. Residual lignin and extractives remained with the cellulose are removed by chemical treatment steps to enhance the fermentations of cellulose. Pre-hydrolysate after neutralization to neutralize and remove toxic components such as acetic acid, furfural, phenolics, etc. containing (xylose, arabinose, galactose) and hexoses (glucose) can be either separately or together with the purified cellulosic fraction fermented to produce ethanol. Approximately 100 gallons of ethanol, suitable to be used as a fuel, can be produced from one dried ton of wood. Significant amount of lignin are separated as a by-product and can be converted to hydrocarbon fuel, surfactant, drilling aid, or can be incinerated for generation of power and steam.

Owner:NGUYEN XUAN NGHINH

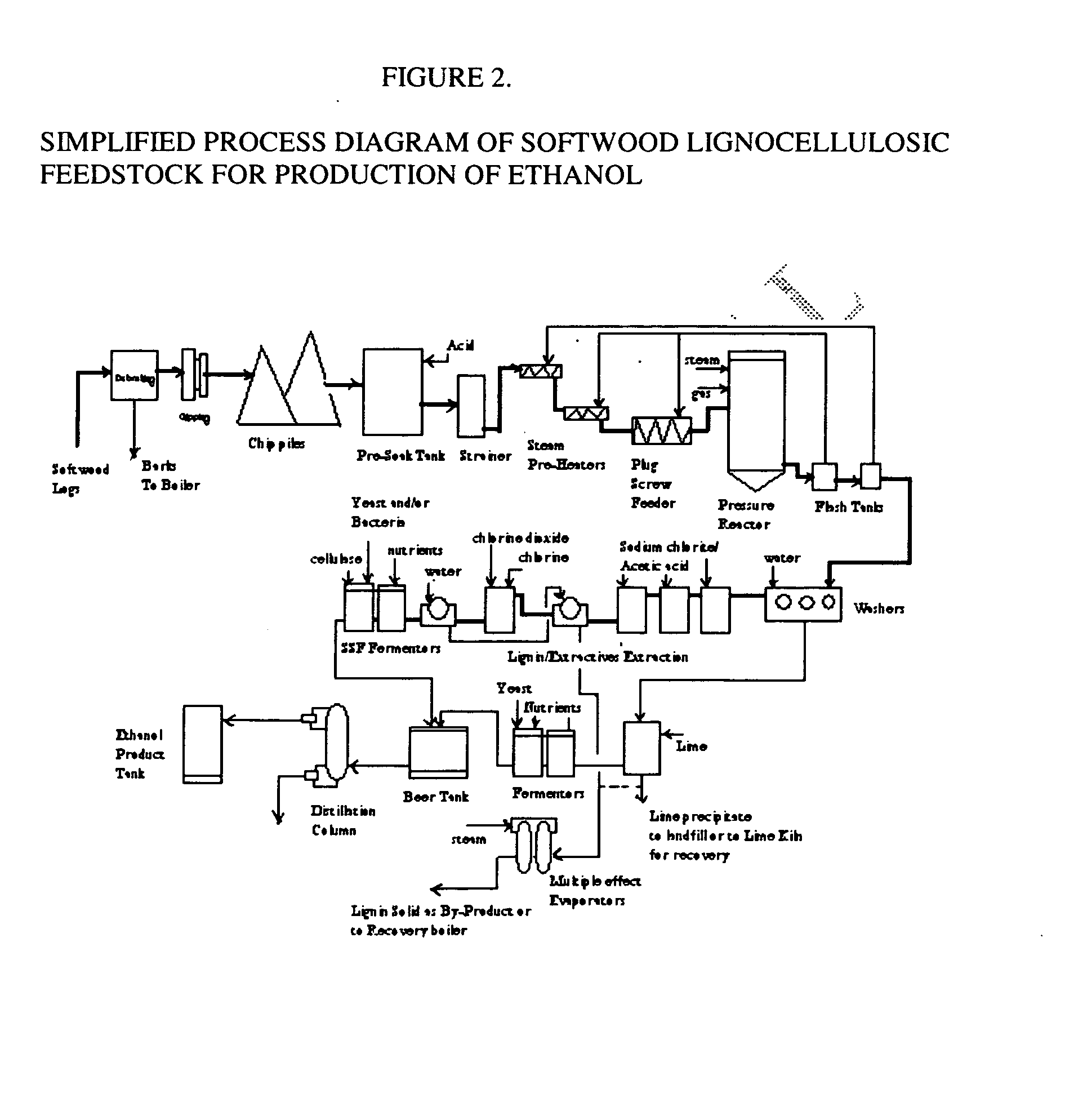

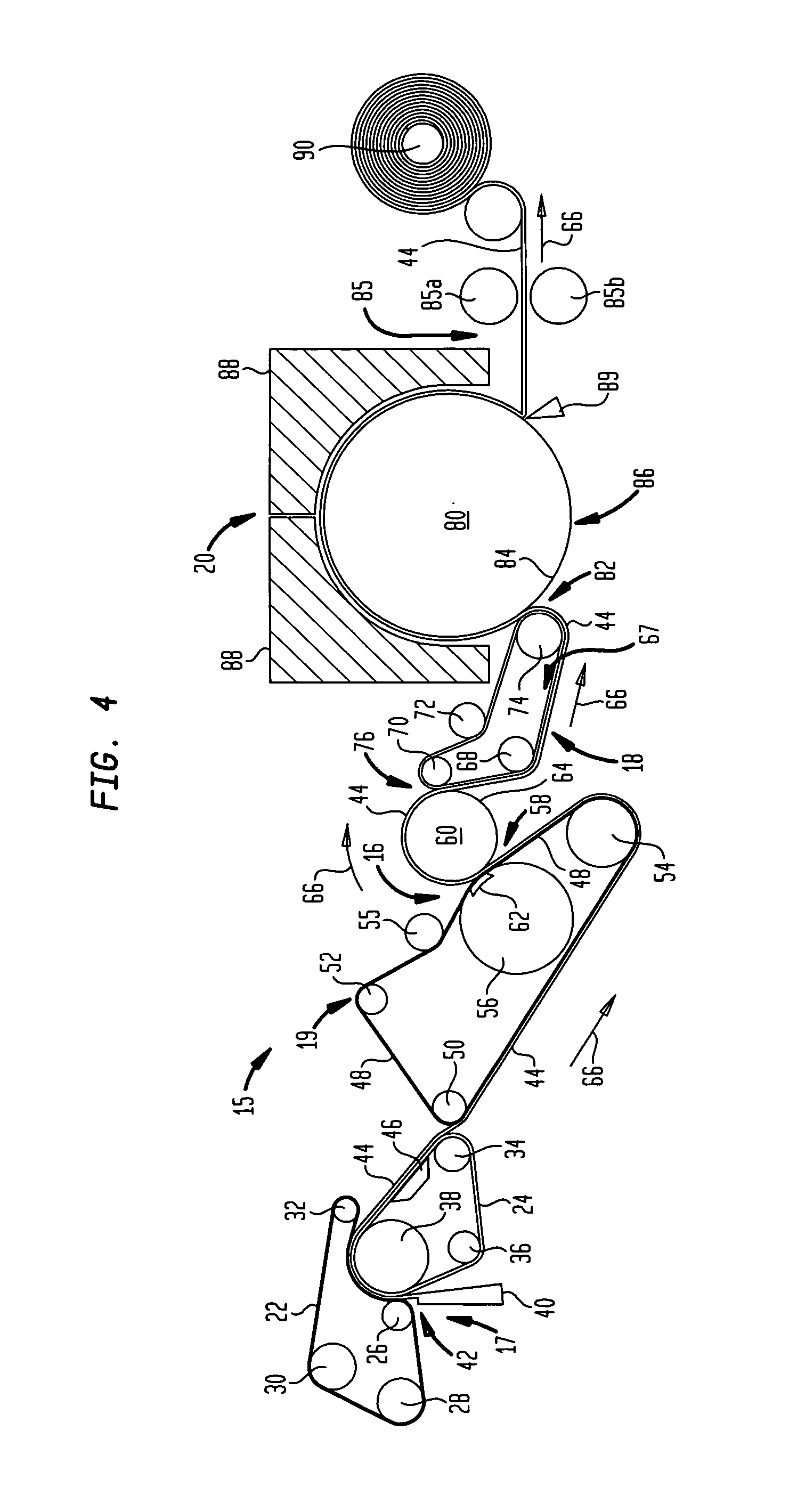

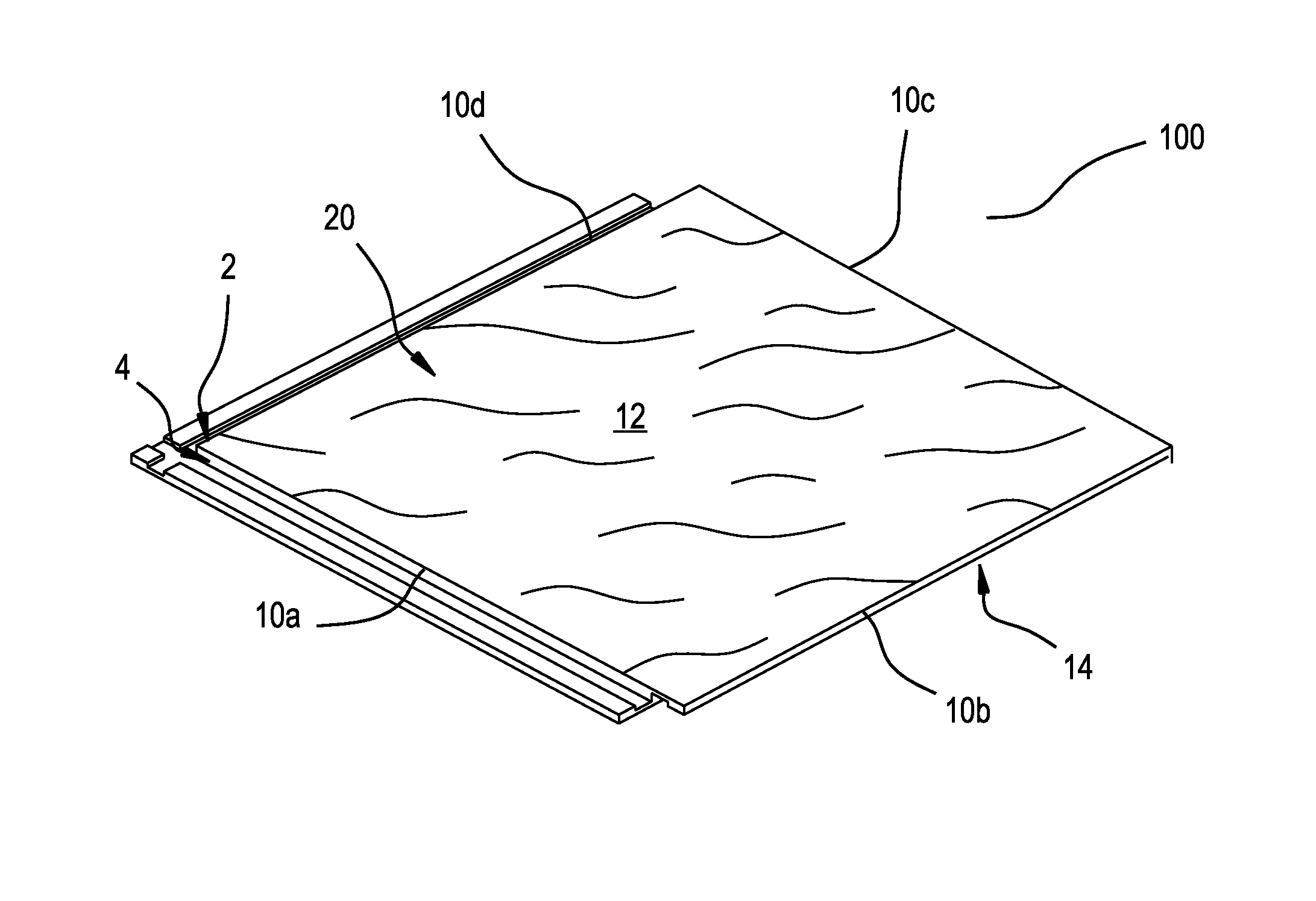

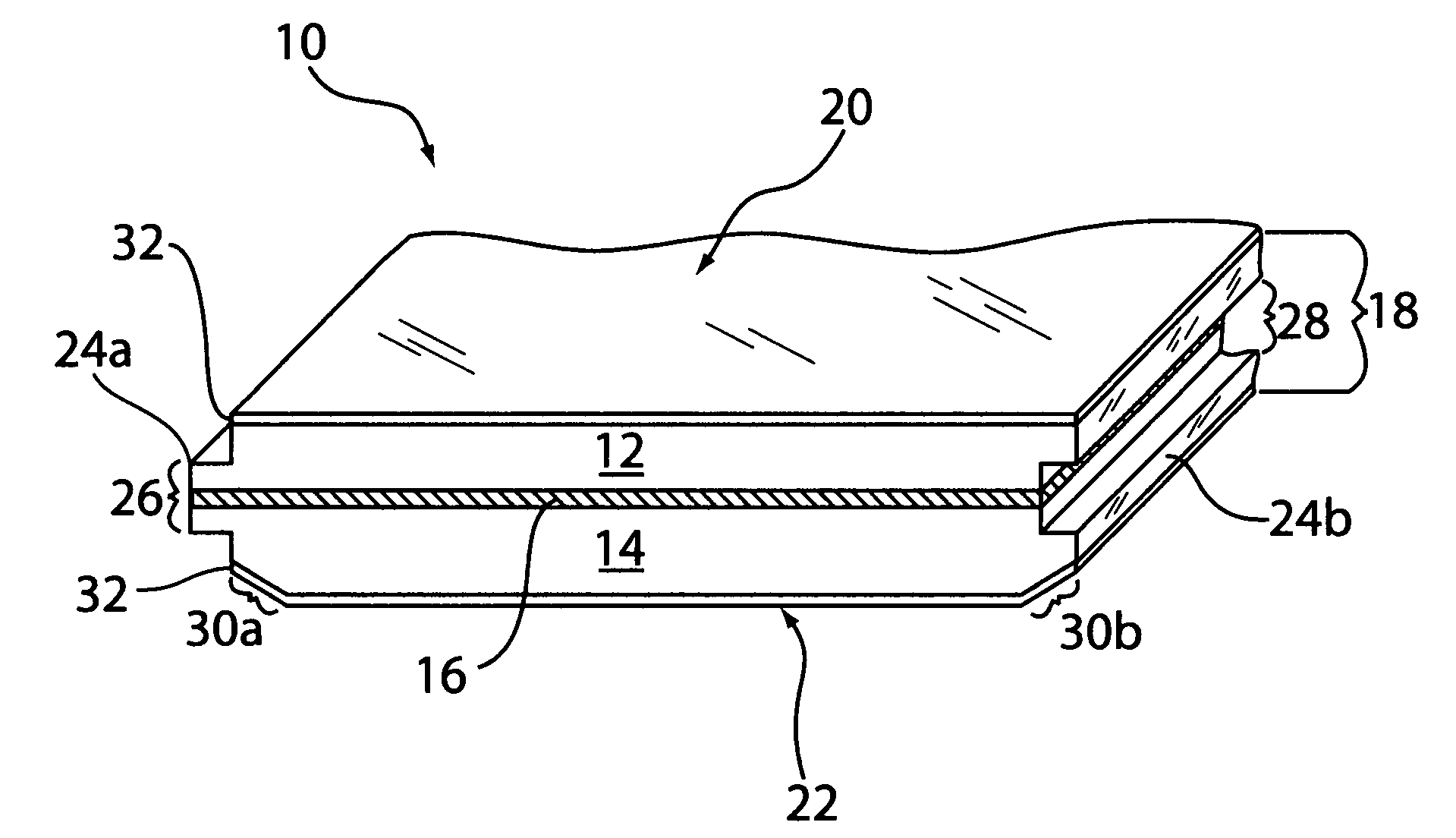

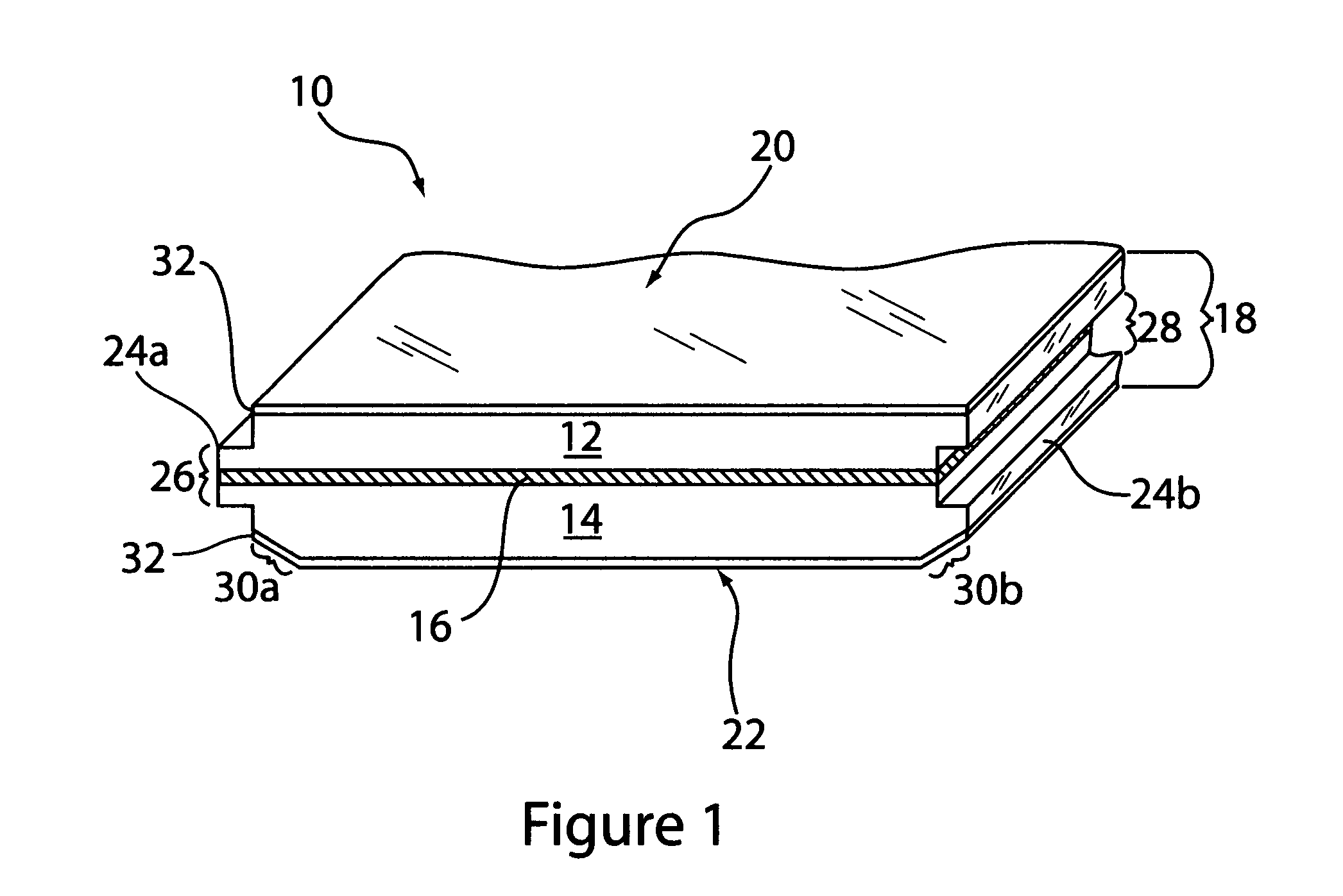

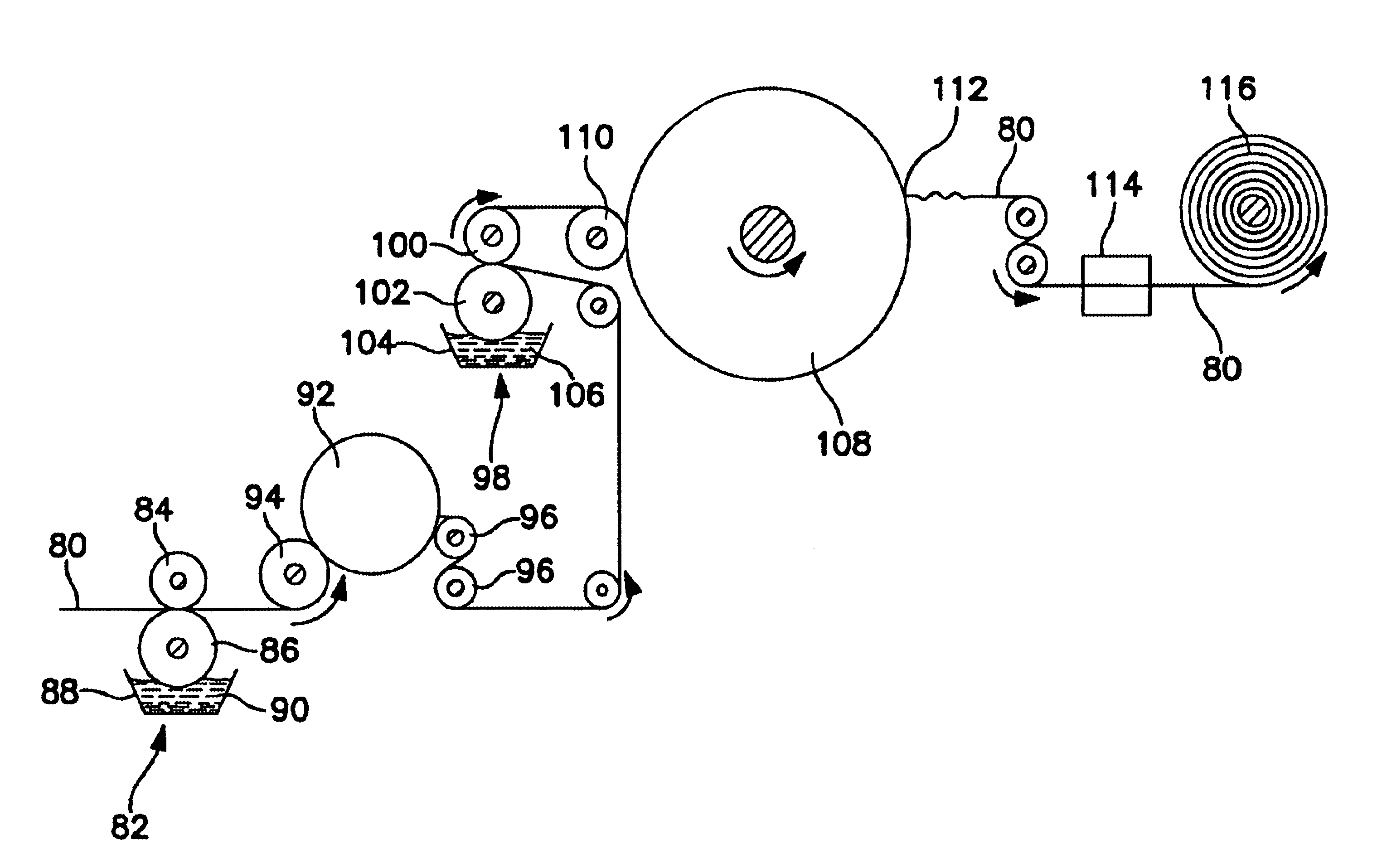

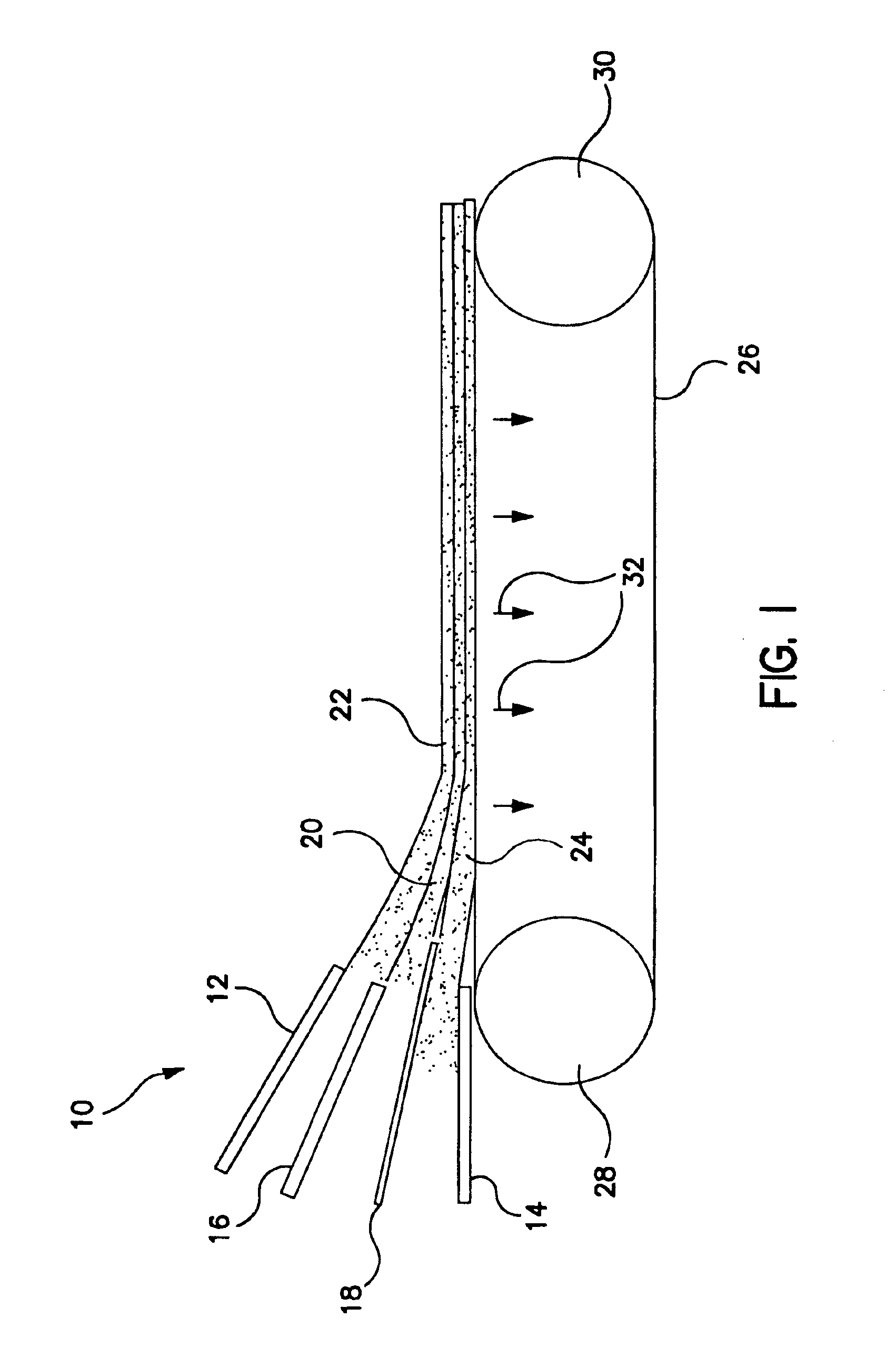

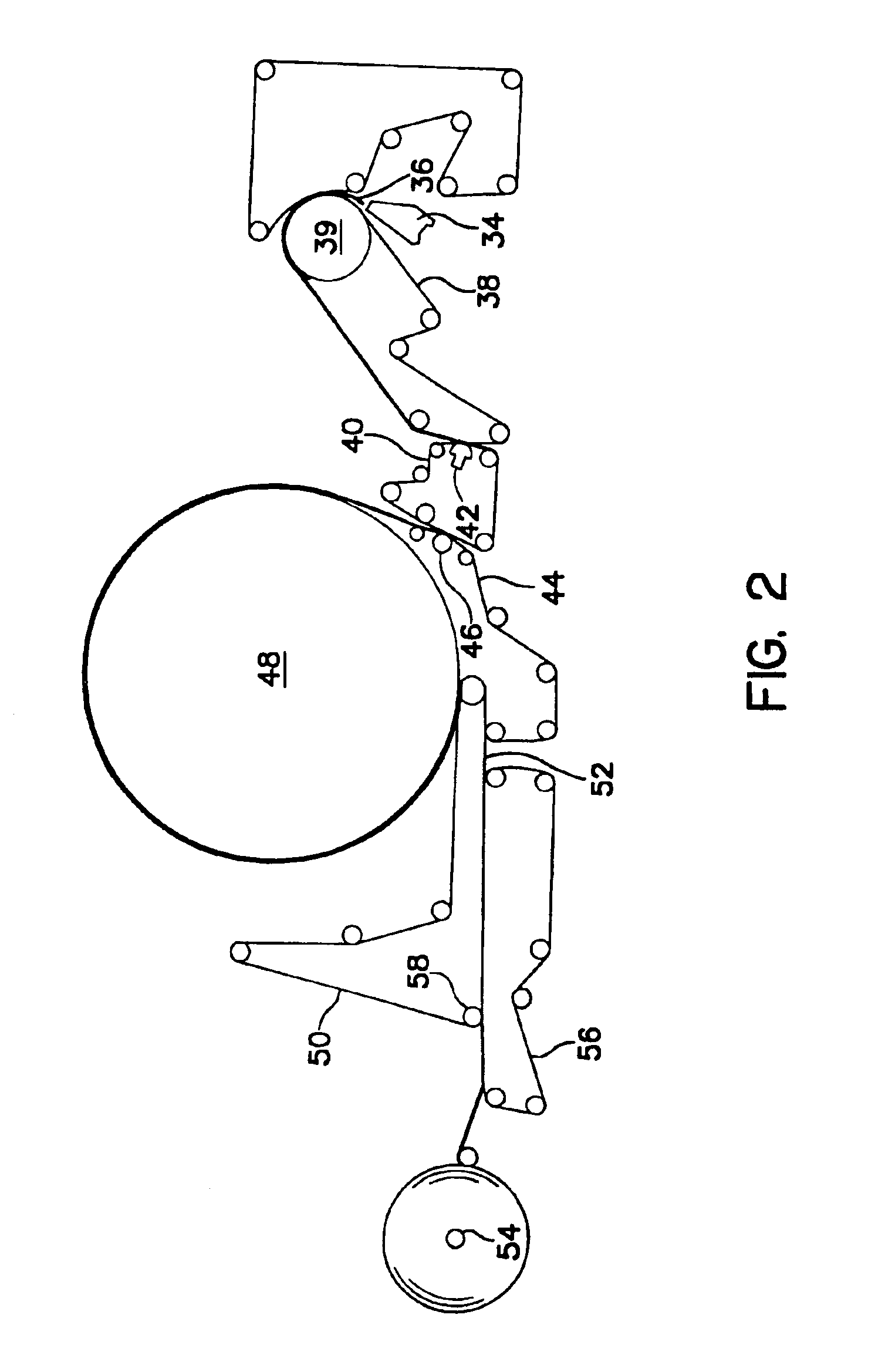

Wet-pressed tissue and towel products with elevated CD stretch and low tensile ratios made with a high solids fabric crepe process

ActiveUS20050241786A1The implementation process is simpleNatural cellulose pulp/paperMechanical working/deformationMedicineCellulose fiber

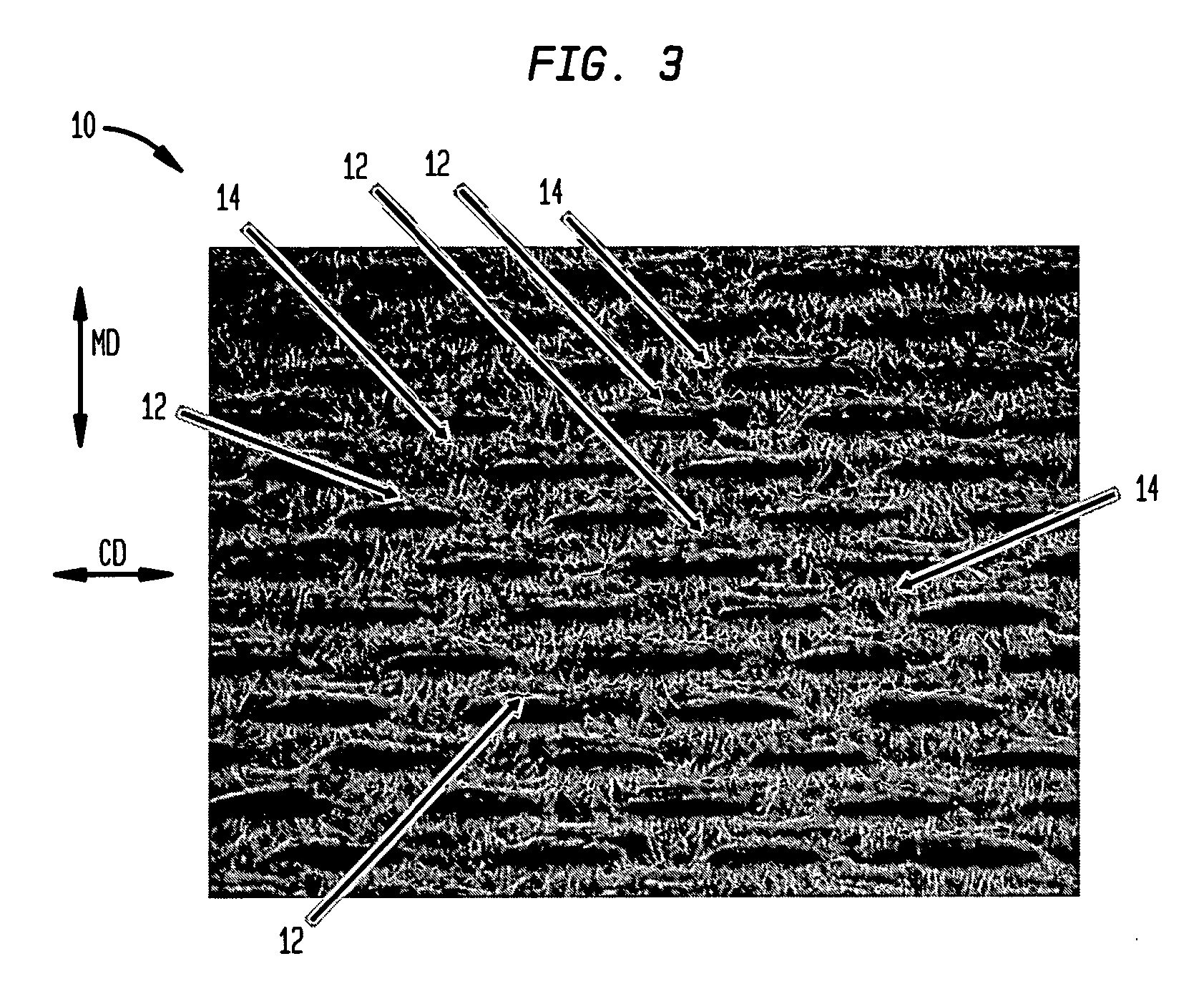

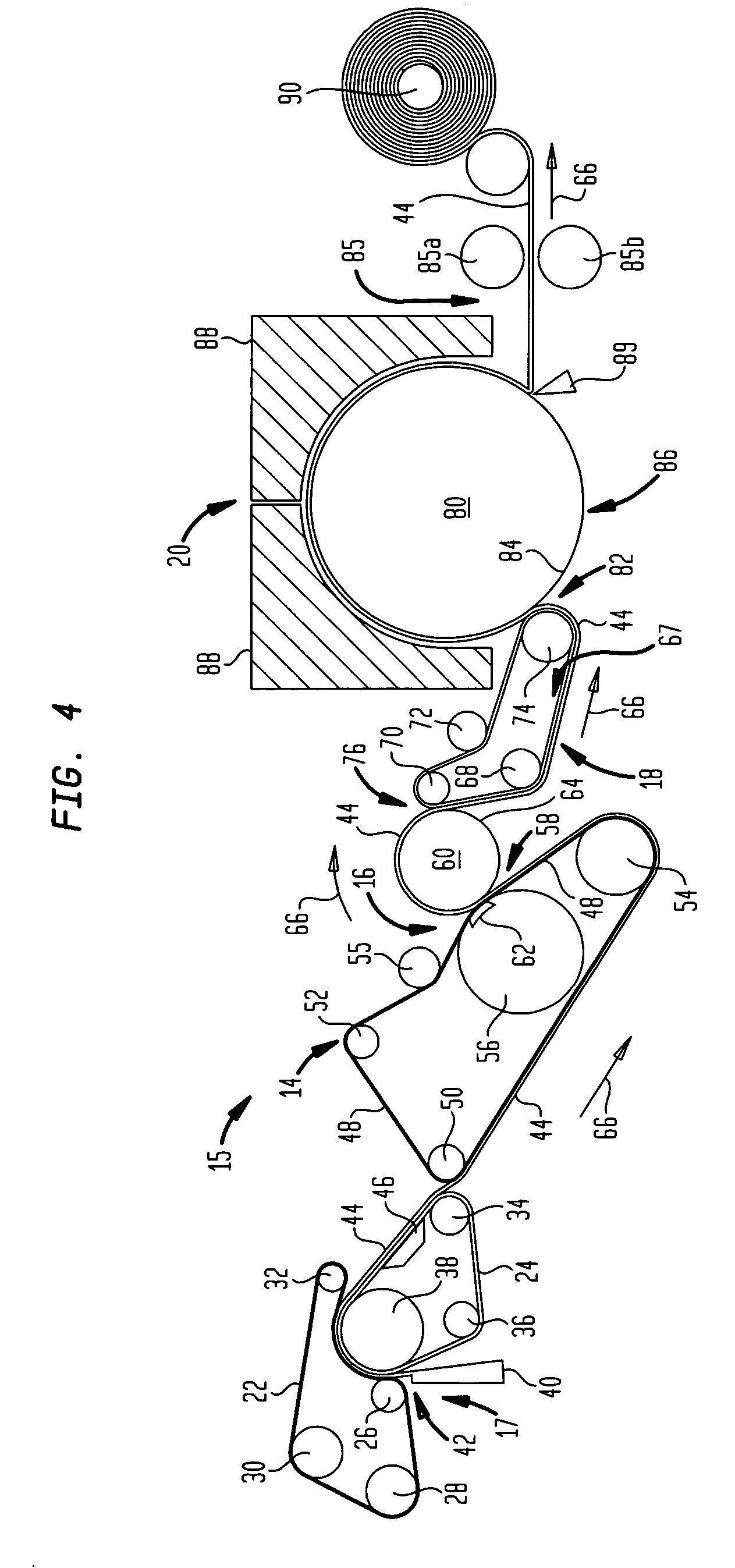

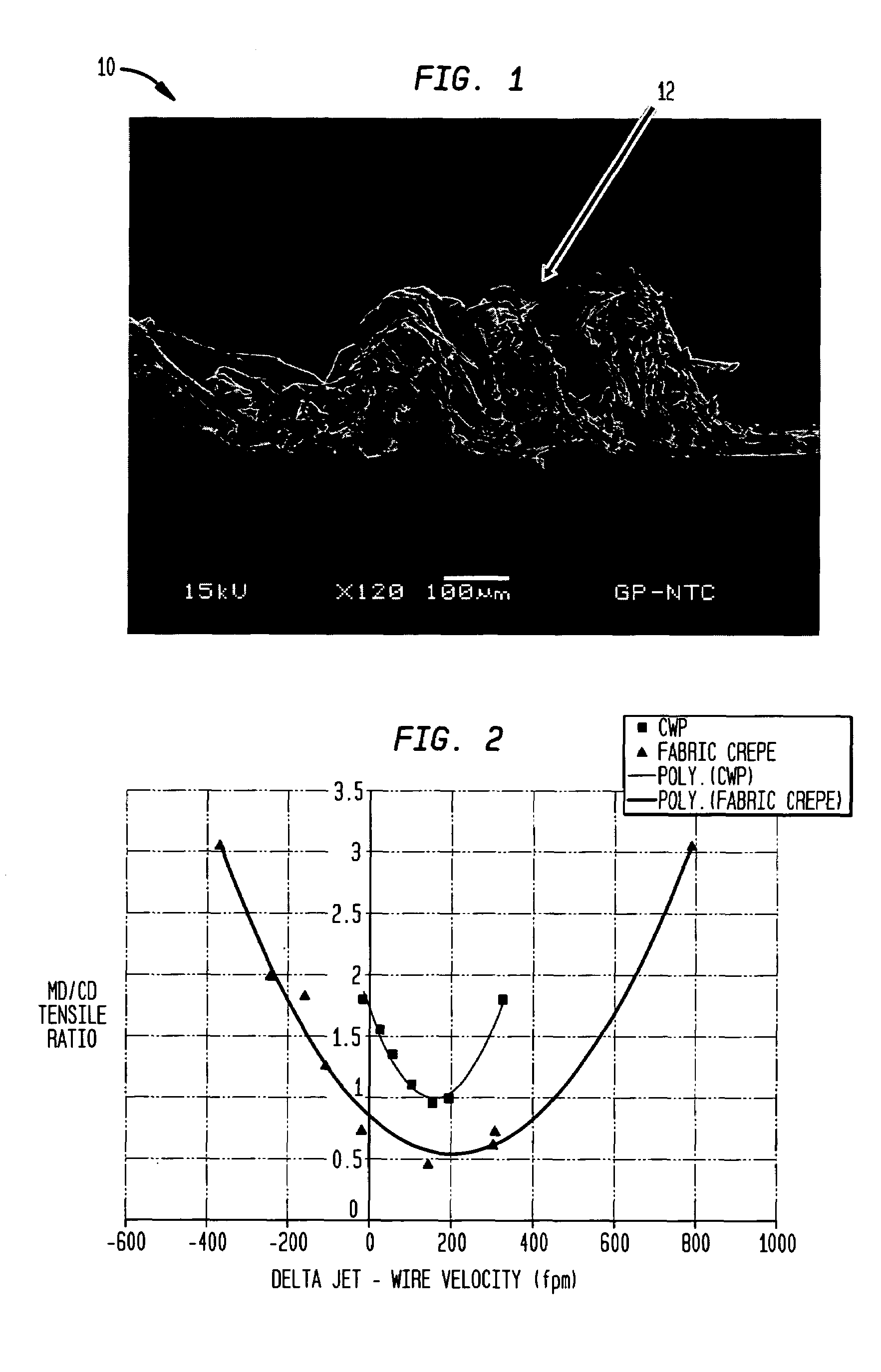

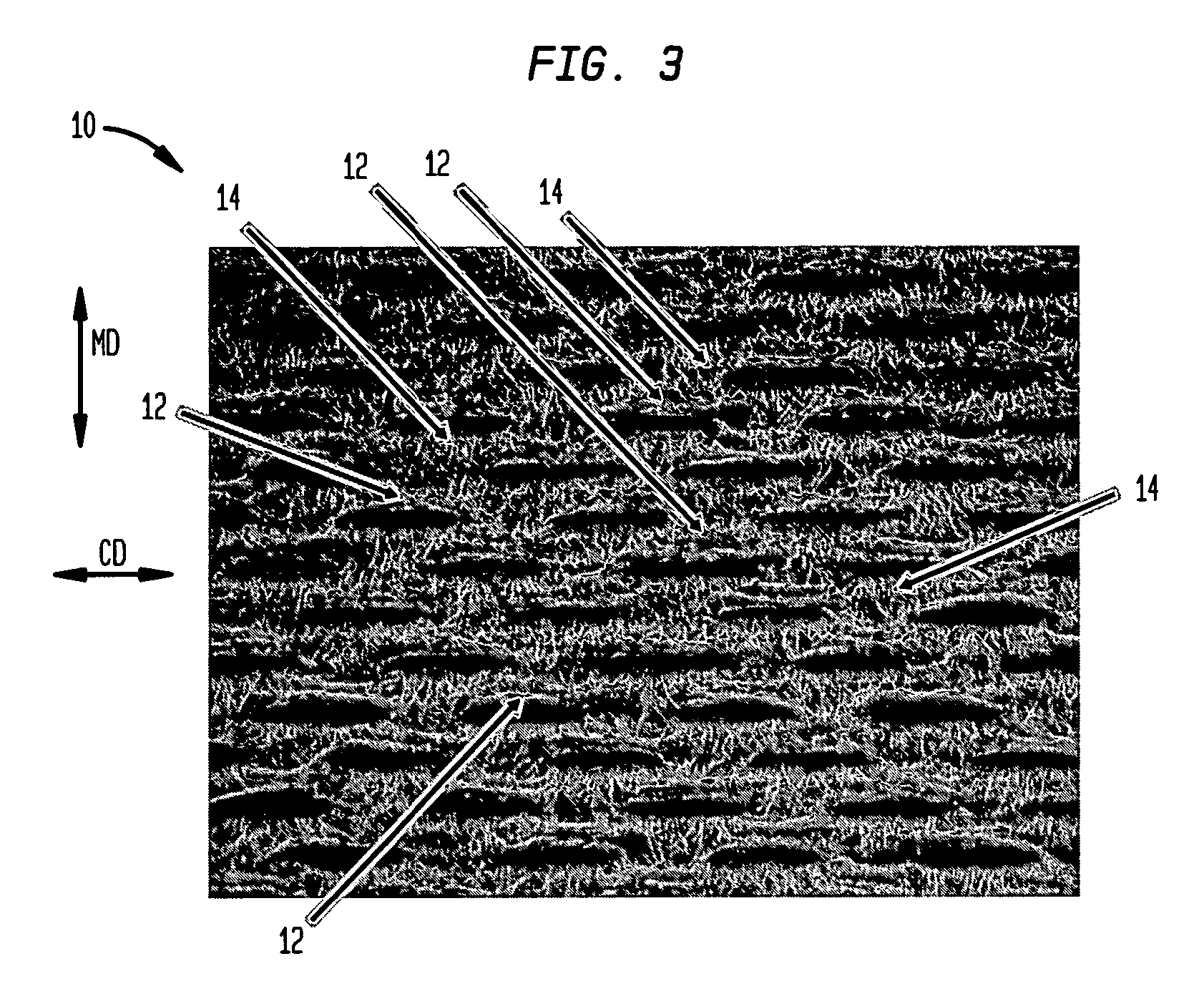

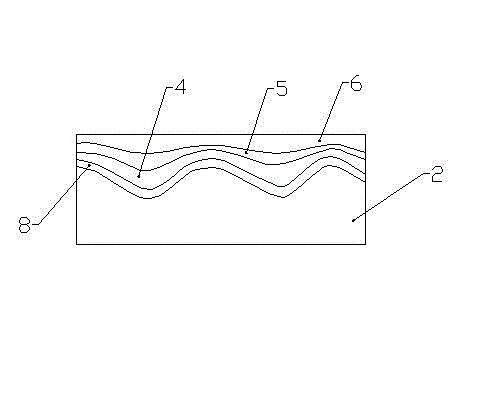

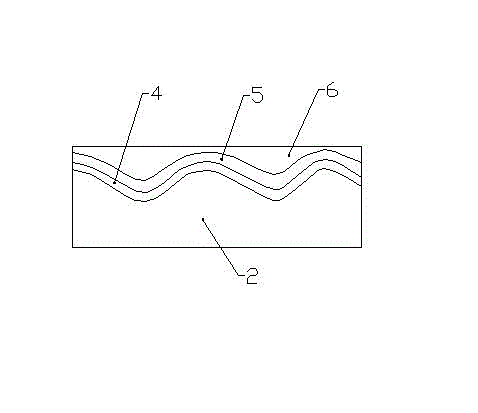

An absorbent sheet of cellulosic fibers includes a mixture of hardwood fibers and softwood fibers arranged in a reticulum having: (i) a plurality of pileated fiber enriched regions of relatively high local basis weight interconnected by way of (ii) a plurality of lower local basis weight linking regions whose fiber orientation is biased along the machine direction between pileated regions interconnected thereby, wherein the sheet exhibits a % CD stretch which is at least about 2.75 times the dry tensile ratio of the sheet. Tensile ratios of from about 0.4 to about 4 are readily achieved.

Owner:GPCP IP HLDG LLC

Wet-pressed tissue and towel products with elevated CD stretch and low tensile ratios made with a high solids fabric crepe process

An absorbent sheet of cellulosic fibers includes a mixture of hardwood fibers and softwood fibers arranged in a reticulum having: (i) a plurality of pileated fiber enriched regions of relatively high local basis weight interconnected by way of (ii) a plurality of lower local basis weight linking regions whose fiber orientation is biased along the machine direction between pileated regions interconnected thereby, wherein the sheet exhibits a % CD stretch which is at least about 2.75 times the dry tensile ratio of the sheet. Tensile ratios of from about 0.4 to about 4 are readily achieved.

Owner:GPCP IP HLDG LLC

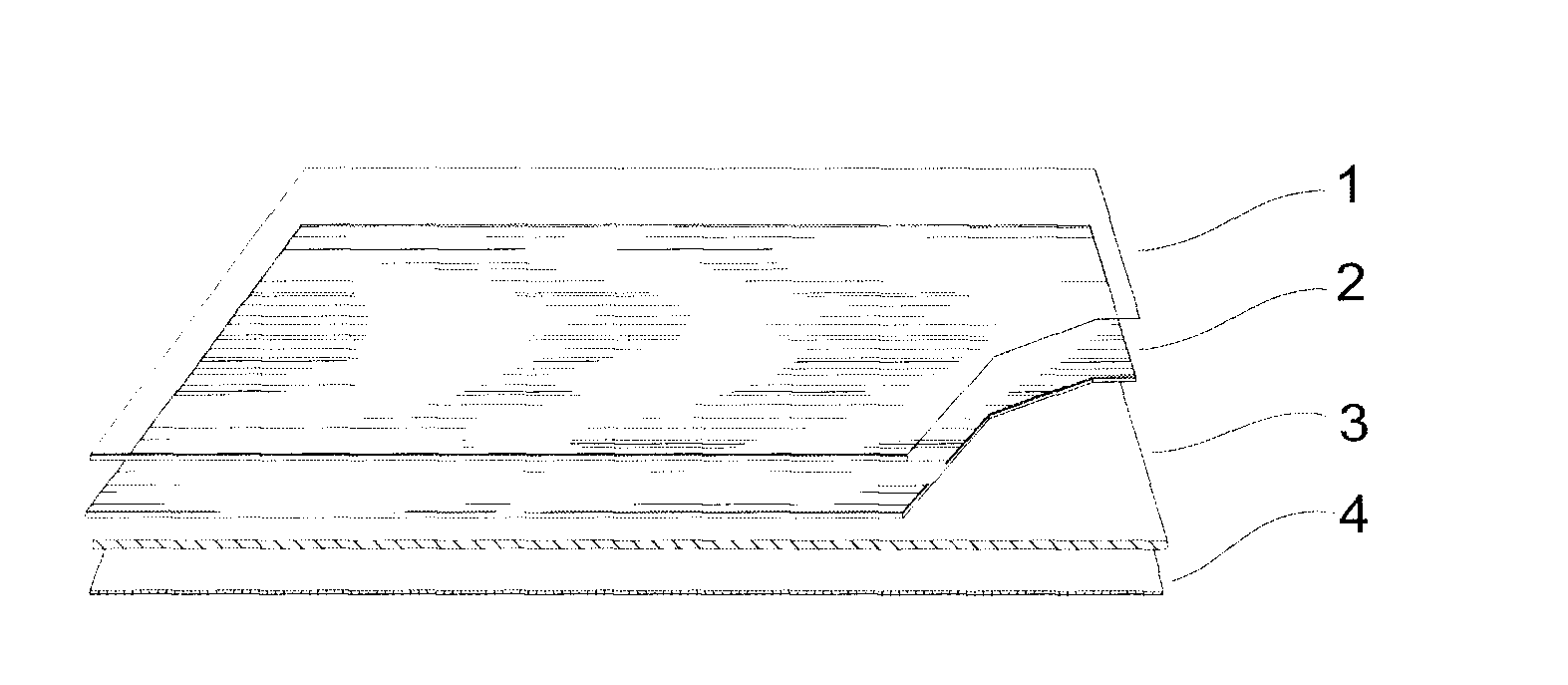

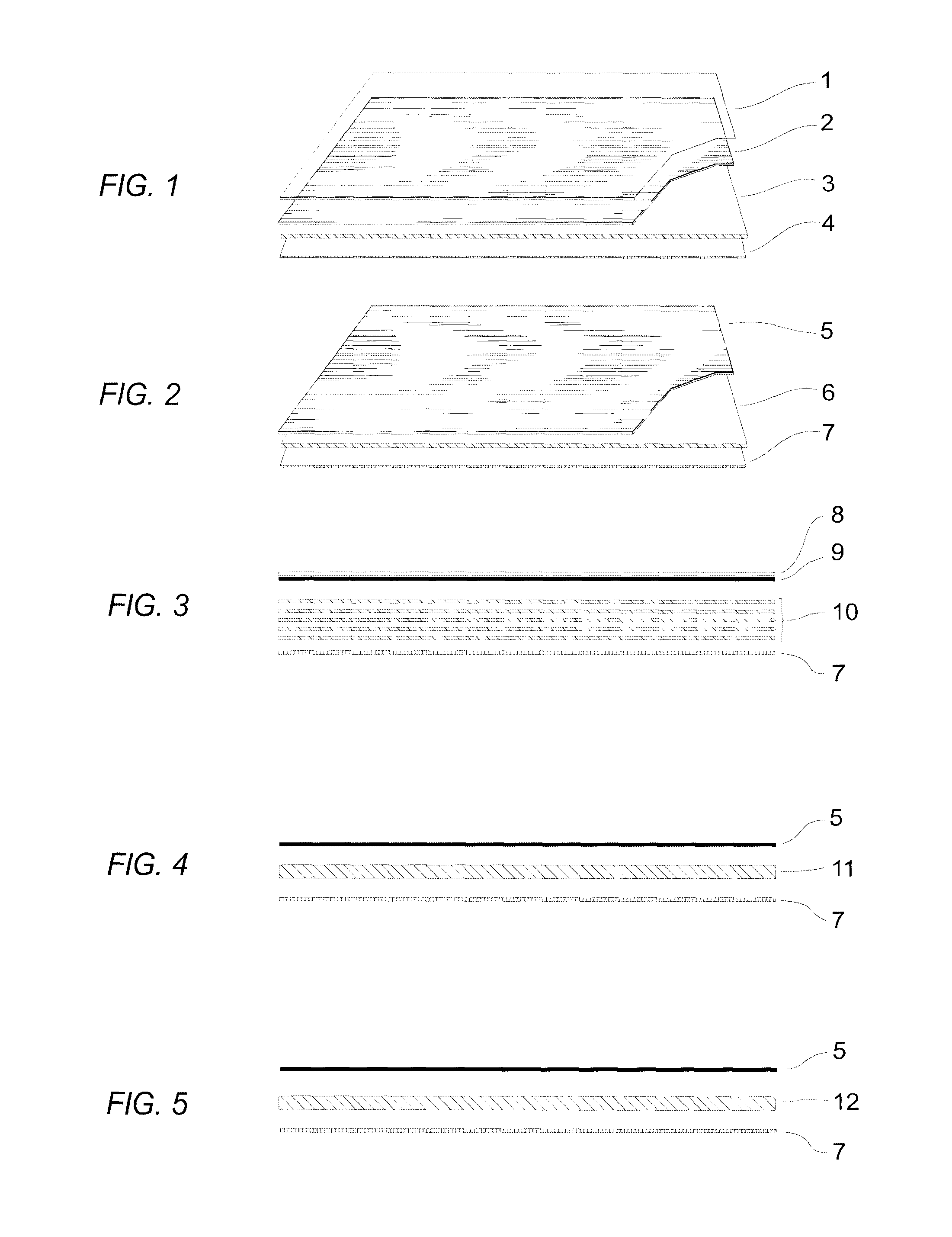

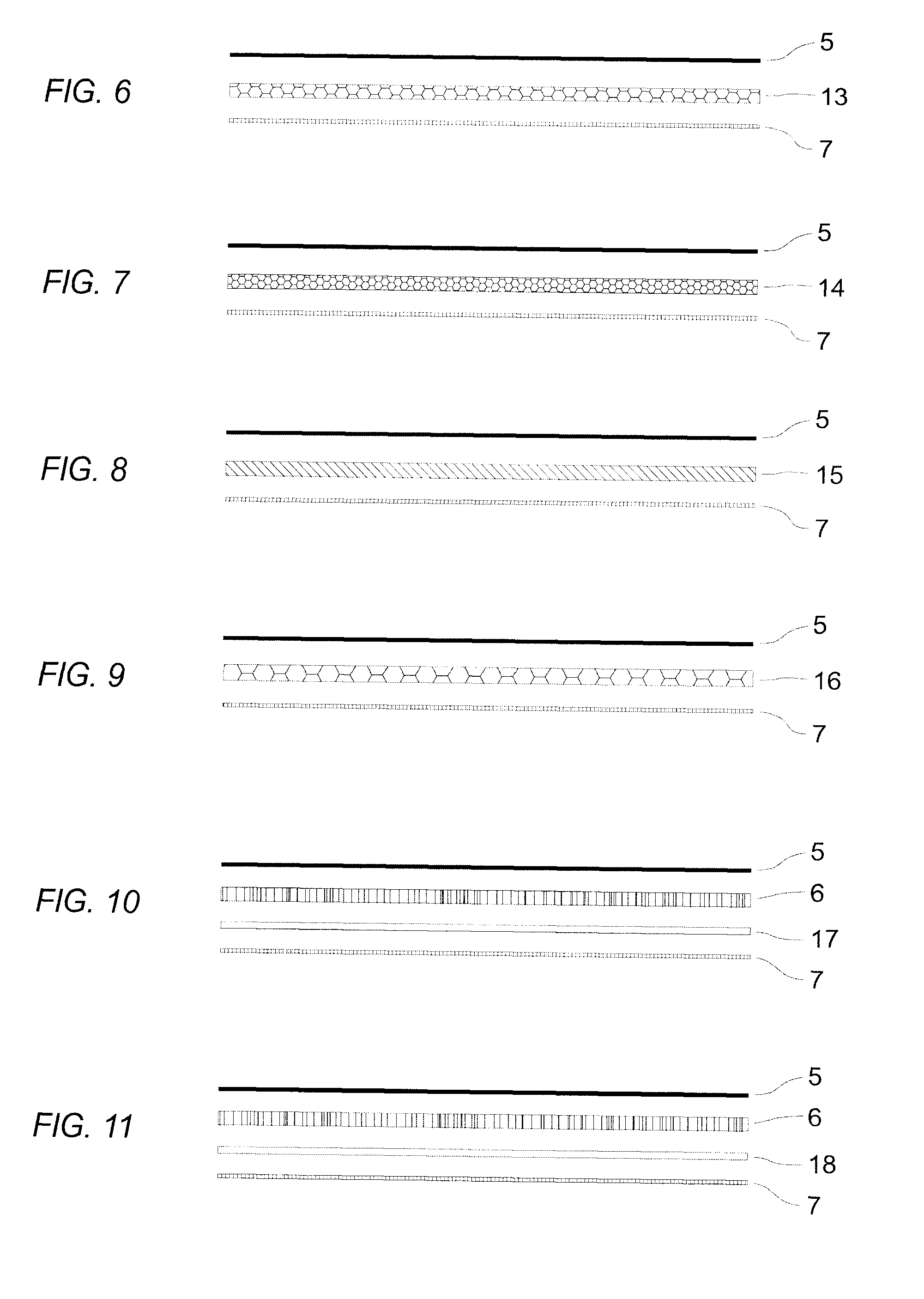

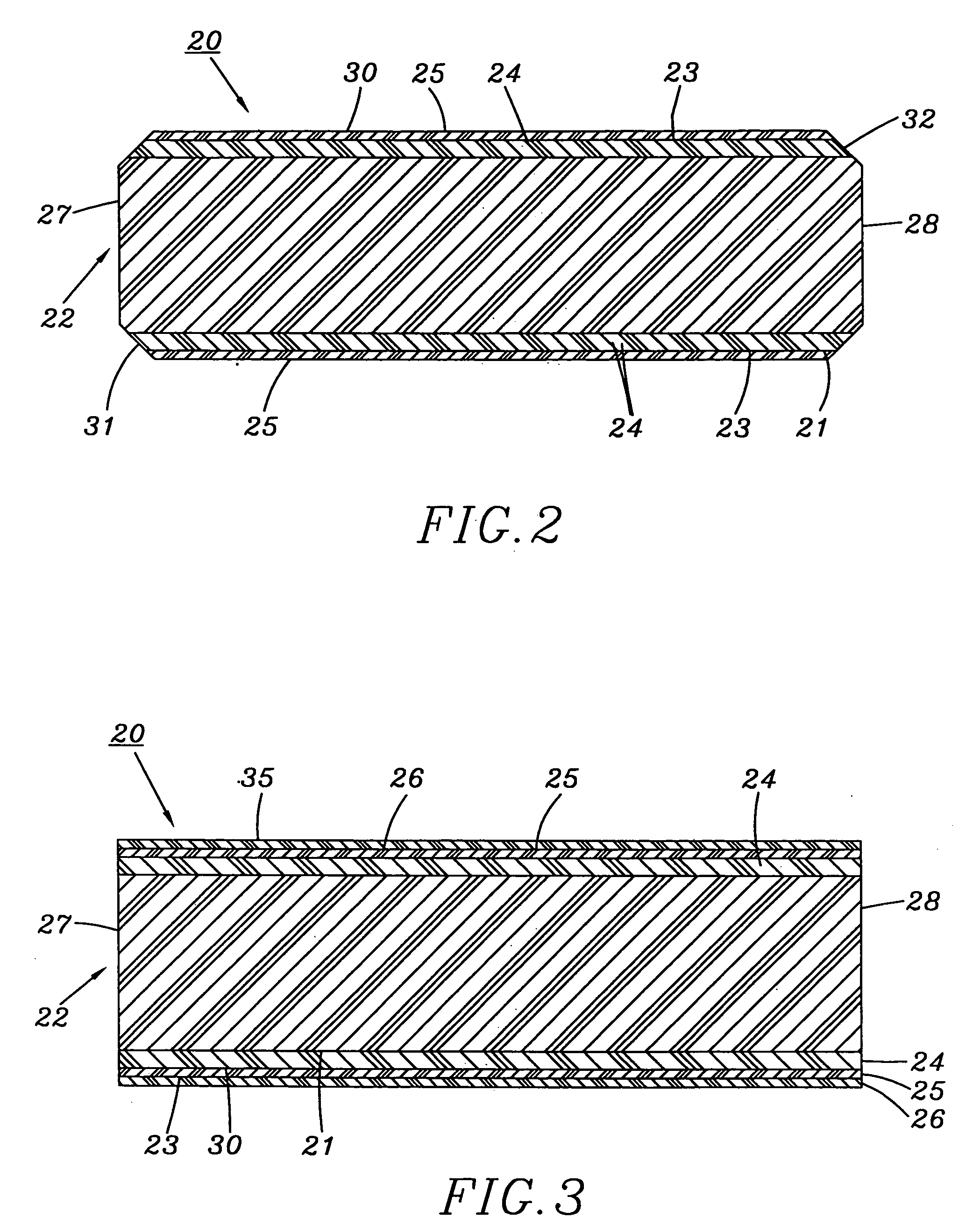

Resilient flooring compositions

InactiveUS20120276348A1Improve wear resistanceReduce the possibilityCovering/liningsSpecial ornamental structuresWood veneerNatural fiber

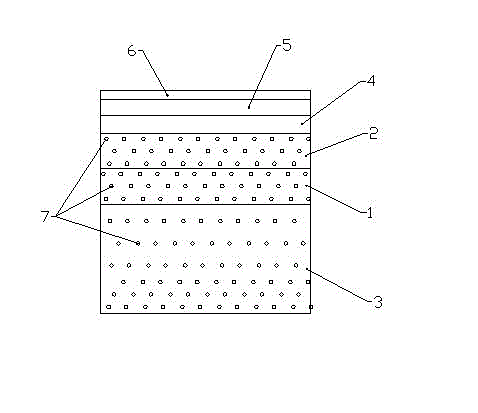

Resilient flooring materials made from impregnated papers or foils and core materials are provided. As well, the methods for producing such products are provided. In particular, panels, with a layered structure, created by forming an assembly which consists of laminating a heat-activated resin impregnated decorative layer with printed graphics or a wood veneer decorative layer, a core material made up of one or more heat-activated resin-impregnated papers or other materials including linoleum, natural or synthetic rubber, cork, flexible natural fiber composites or other core materials, and a heat-activated resin impregnated paper backing layer. The heat-activated resin also acts to waterproof each of the layers and abrasion particles may be incorporated to improve wear properties. The panels may also be formed into three-dimensional products.

Owner:CLAUSI ROBERT N +1

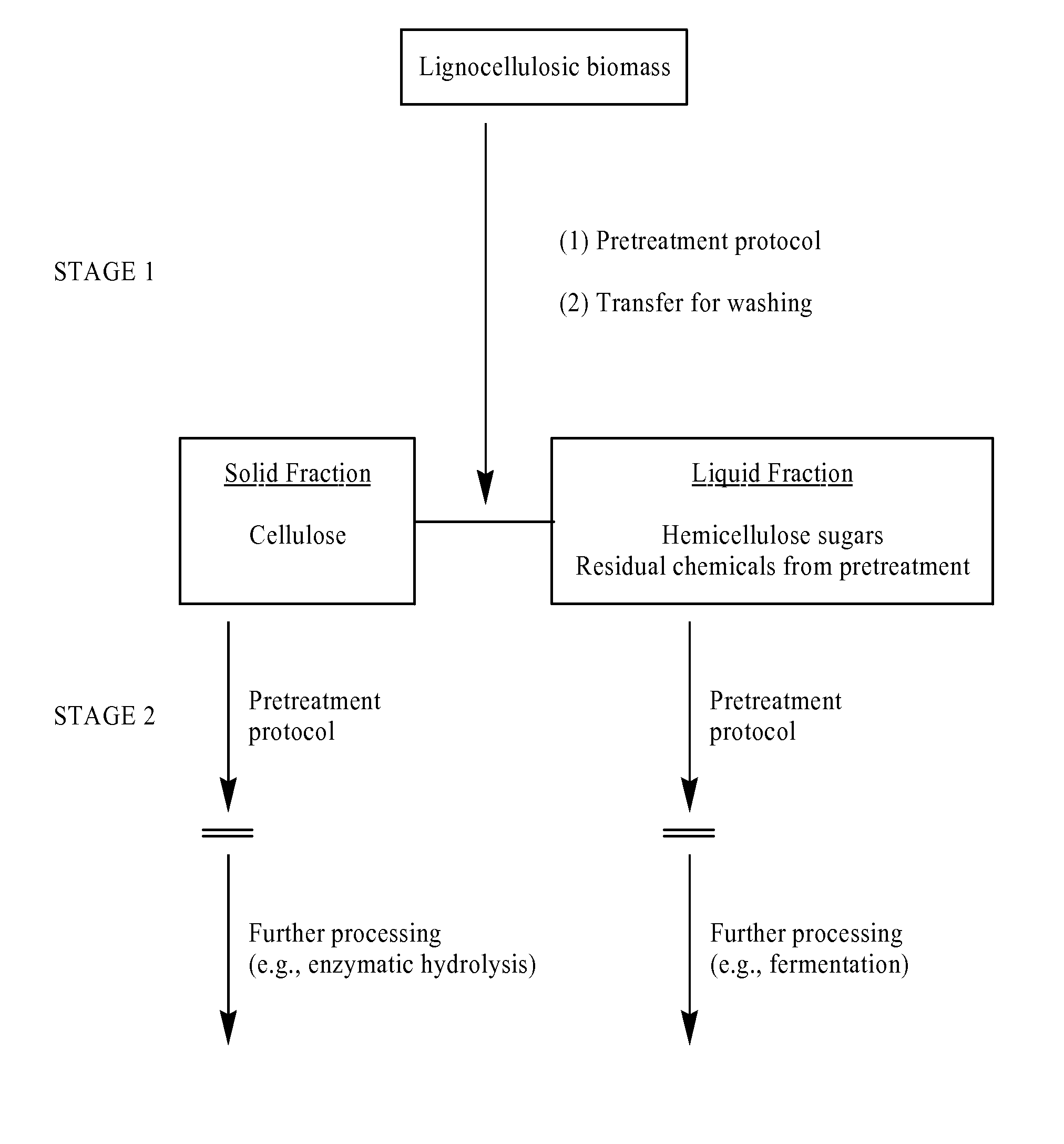

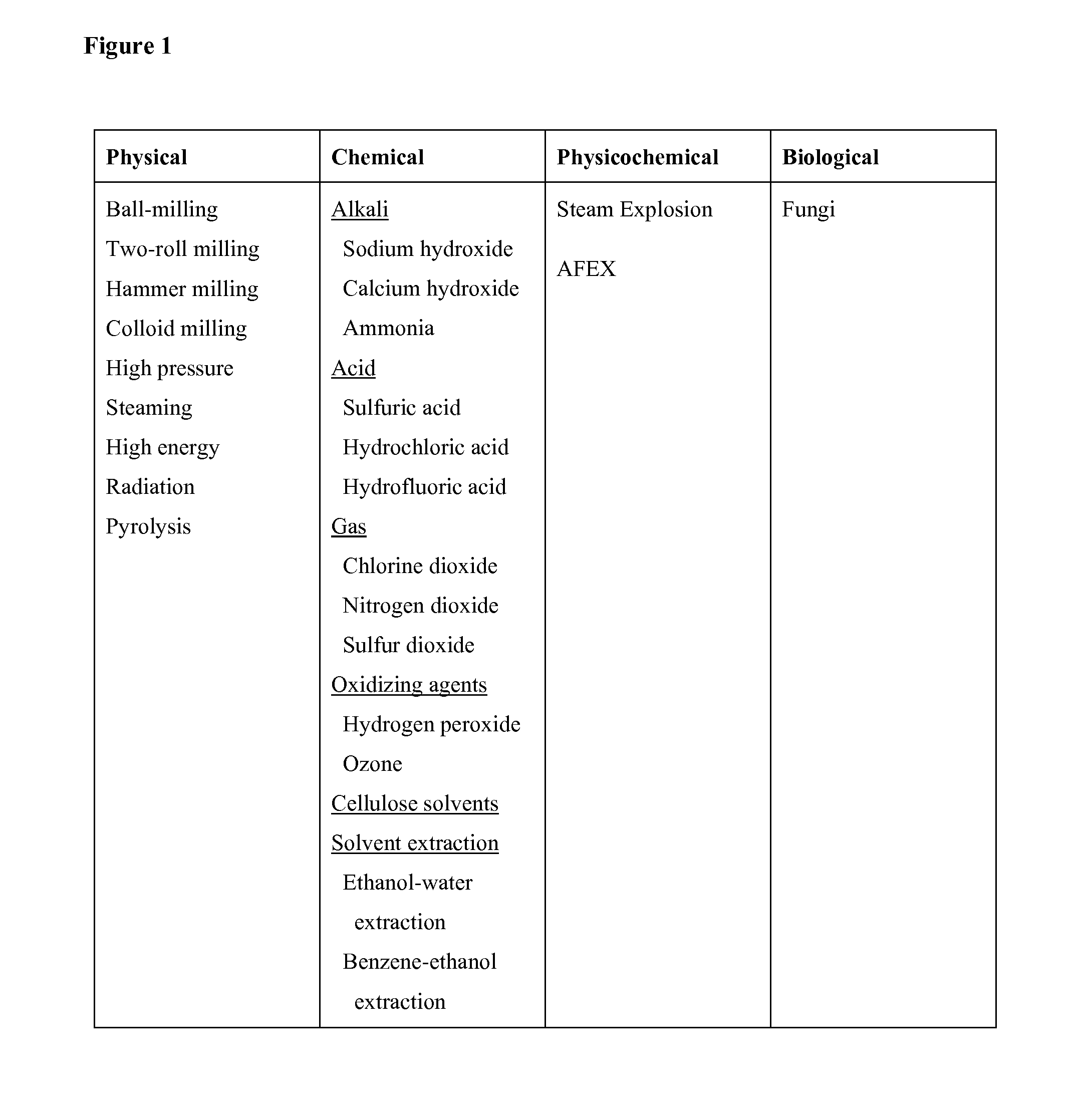

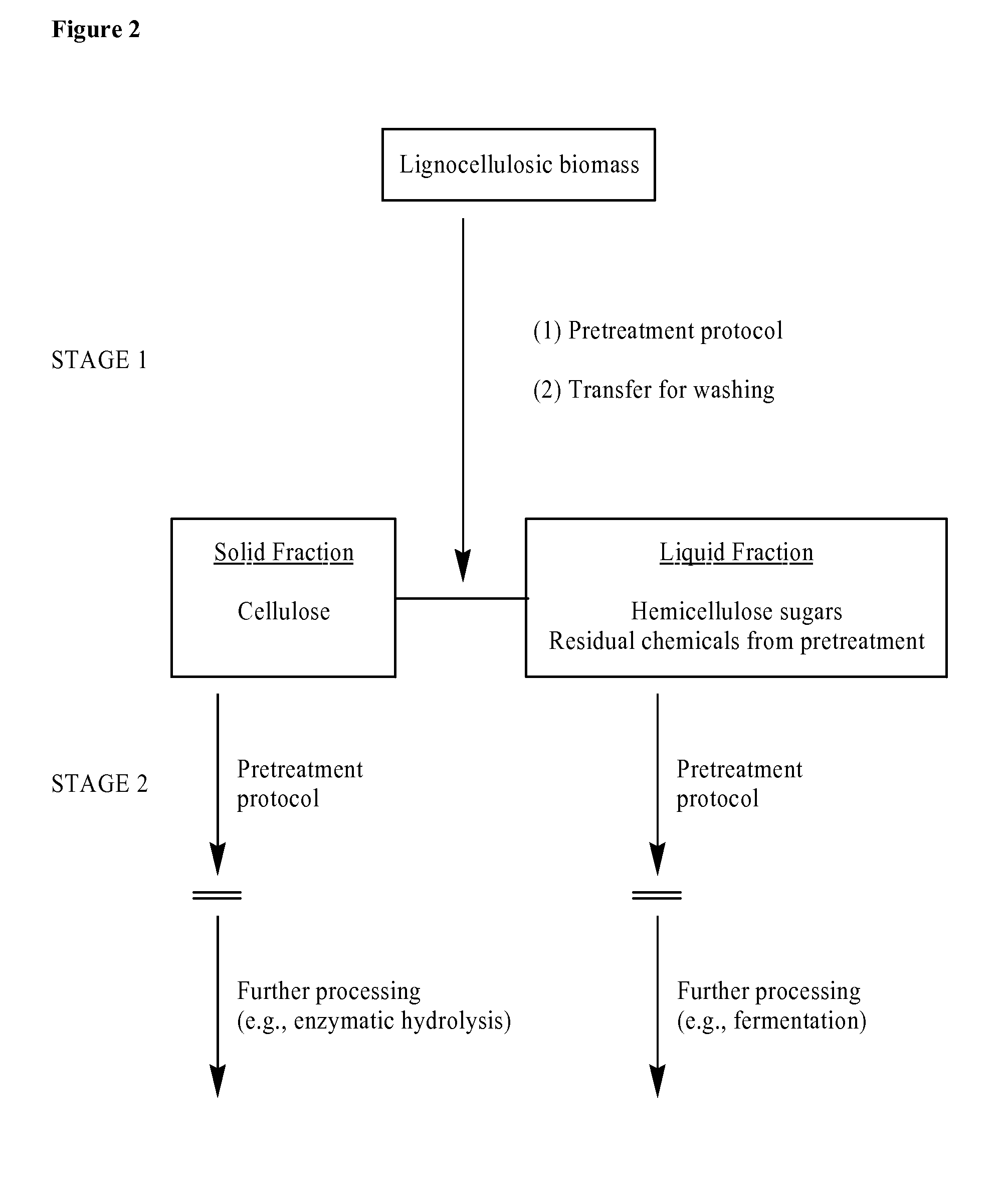

Two-stage method for pretreatment of lignocellulosic biomass

InactiveUS20100279361A1Reduce decreaseMaximize efficiencyOrganic compound preparationFood processingCelluloseFiber

One aspect of the invention relates to a process, comprising treating lignocellulosic biomass according to a first pretreatment protocol, thereby generating a first product mixture; separating the first product mixture into a first plurality of fractions; and treating at least one fraction of said first plurality of fractions according to a second pretreatment protocol, thereby generating a second product mixture. In one embodiment, the lignocellulosic biomass is selected from the group consisting of grass, switch grass, cord grass, rye grass, reed canary grass, miscanthus, sugar-processing residues, sugarcane bagasse, agricultural wastes, rice straw, rice hulls, barley straw, corn cobs, cereal straw, wheat straw, canola straw, oat straw, oat hulls, corn fiber, stover, soybean stover, corn stover, forestry wastes, recycled wood pulp protocol protocol fiber, paper sludge, sawdust, hardwood, softwood, and combinations thereof.

Owner:MASCOMA CORPORATION

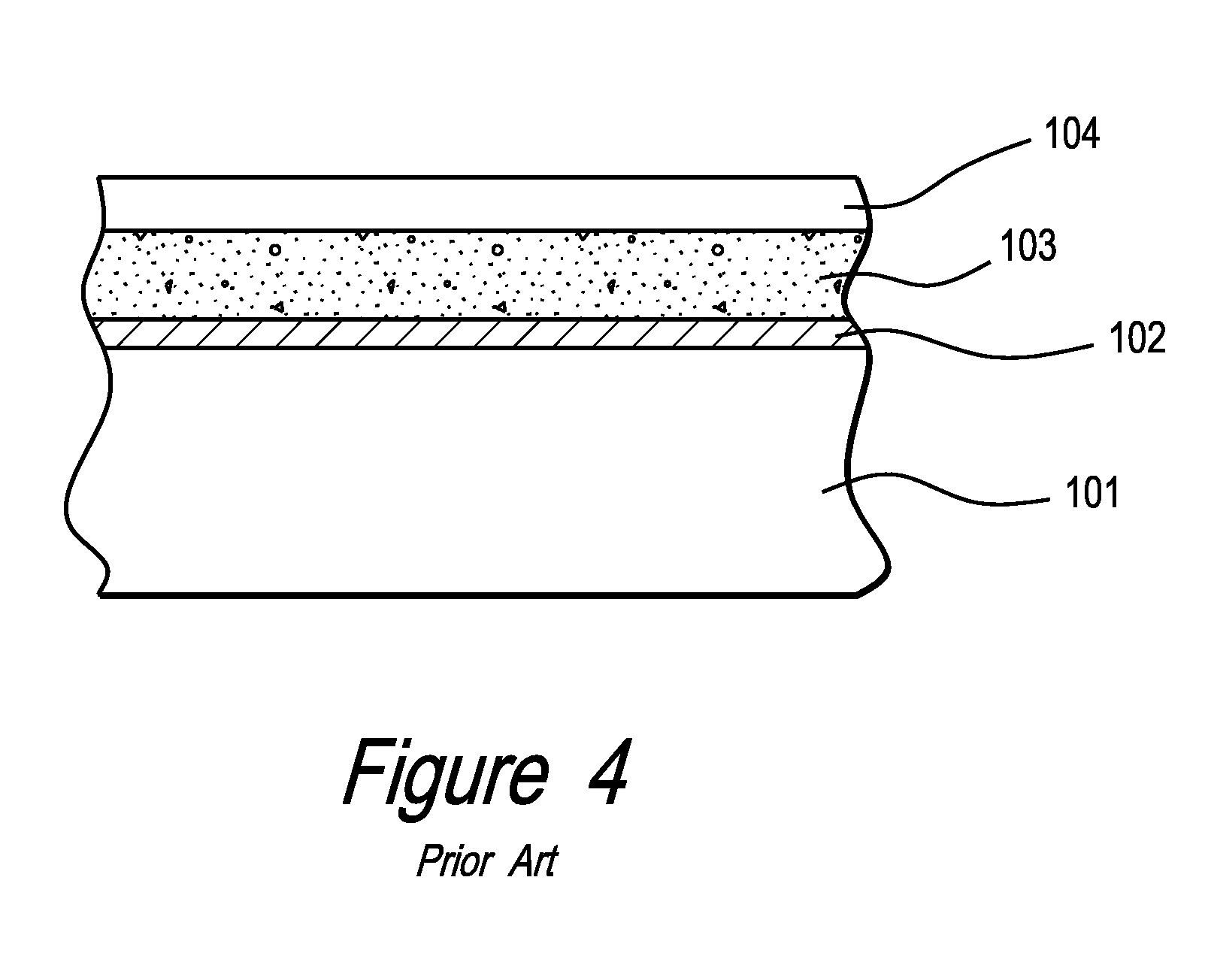

Floor Panel Containing A Polymer And Cork

ActiveUS20100319282A1Improve material performanceSlide fastenersBaby linensPolyvinyl chlorideEngineering

A vinyl floor panel for a flooring system prepared from a blend of a polymer and cork granules. The floor panel includes top and bottom surfaces with a first layer between both surfaces. A printed pattern is located on the top surface. The first layer is prepared from a blend of a polymer polyvinyl chloride and cork granules, where the cork granules are evenly distributed with the polyvinyl chloride throughout the length, width, and thickness of the first layer.

Owner:NOVALIS HLDG

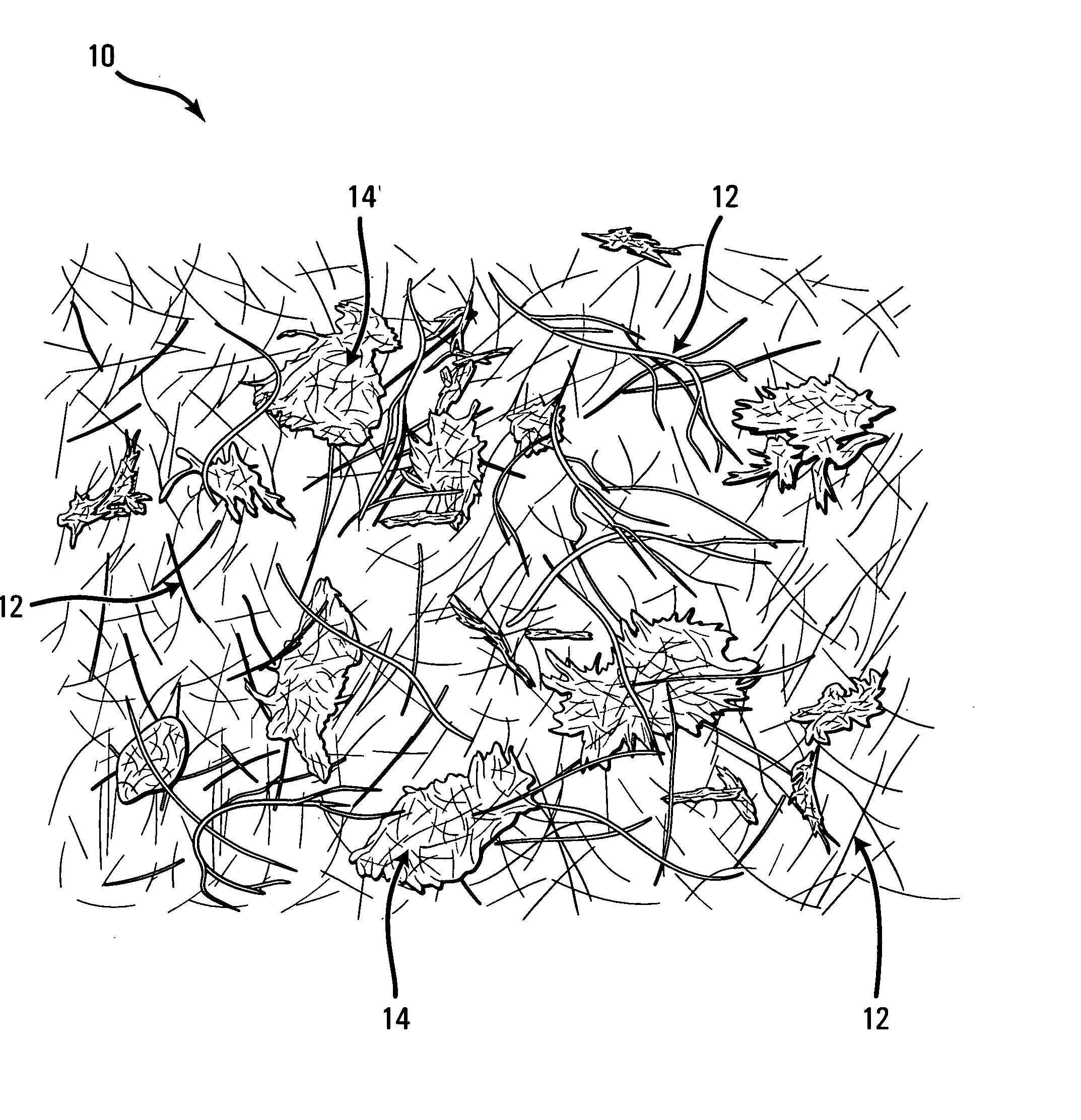

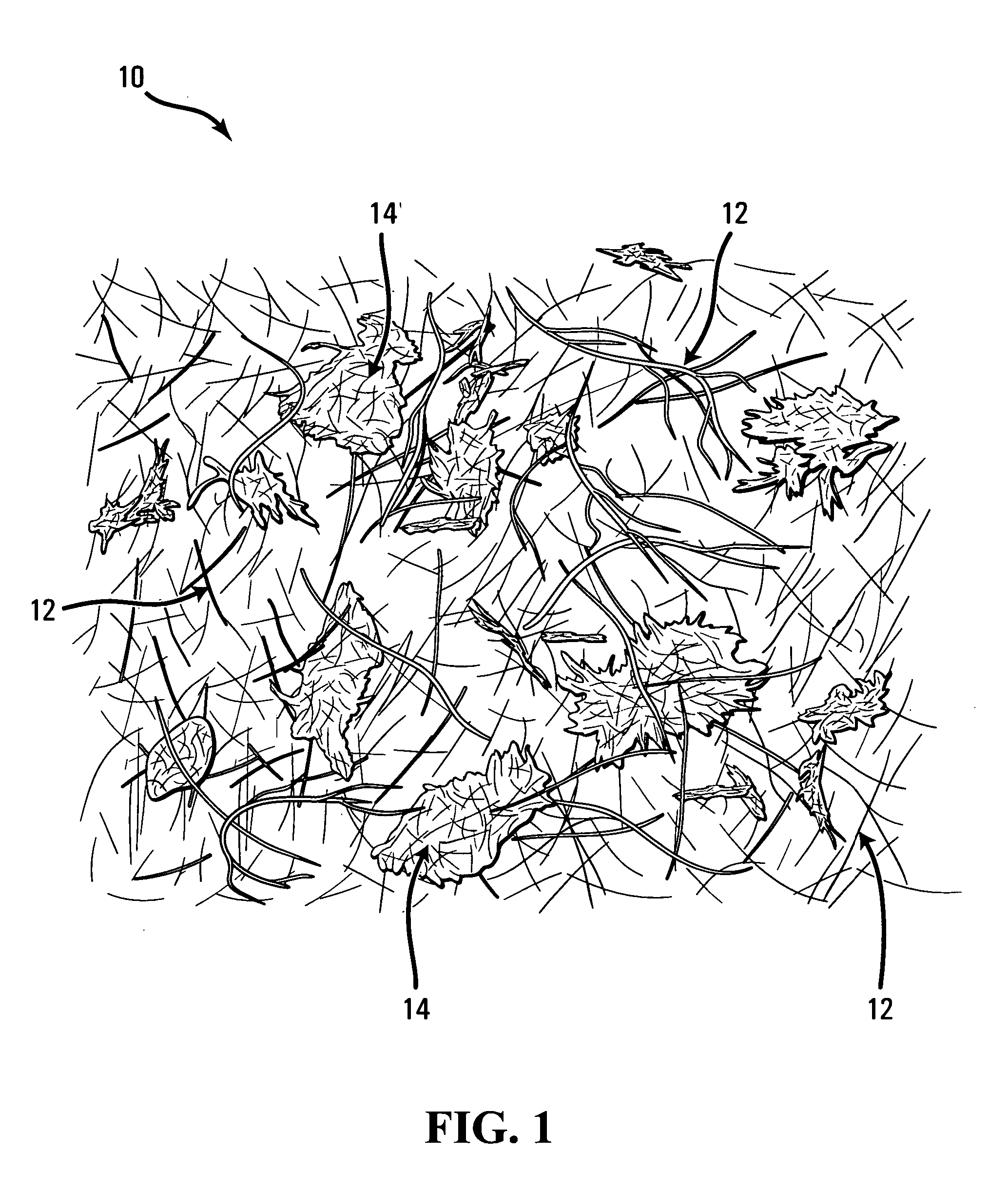

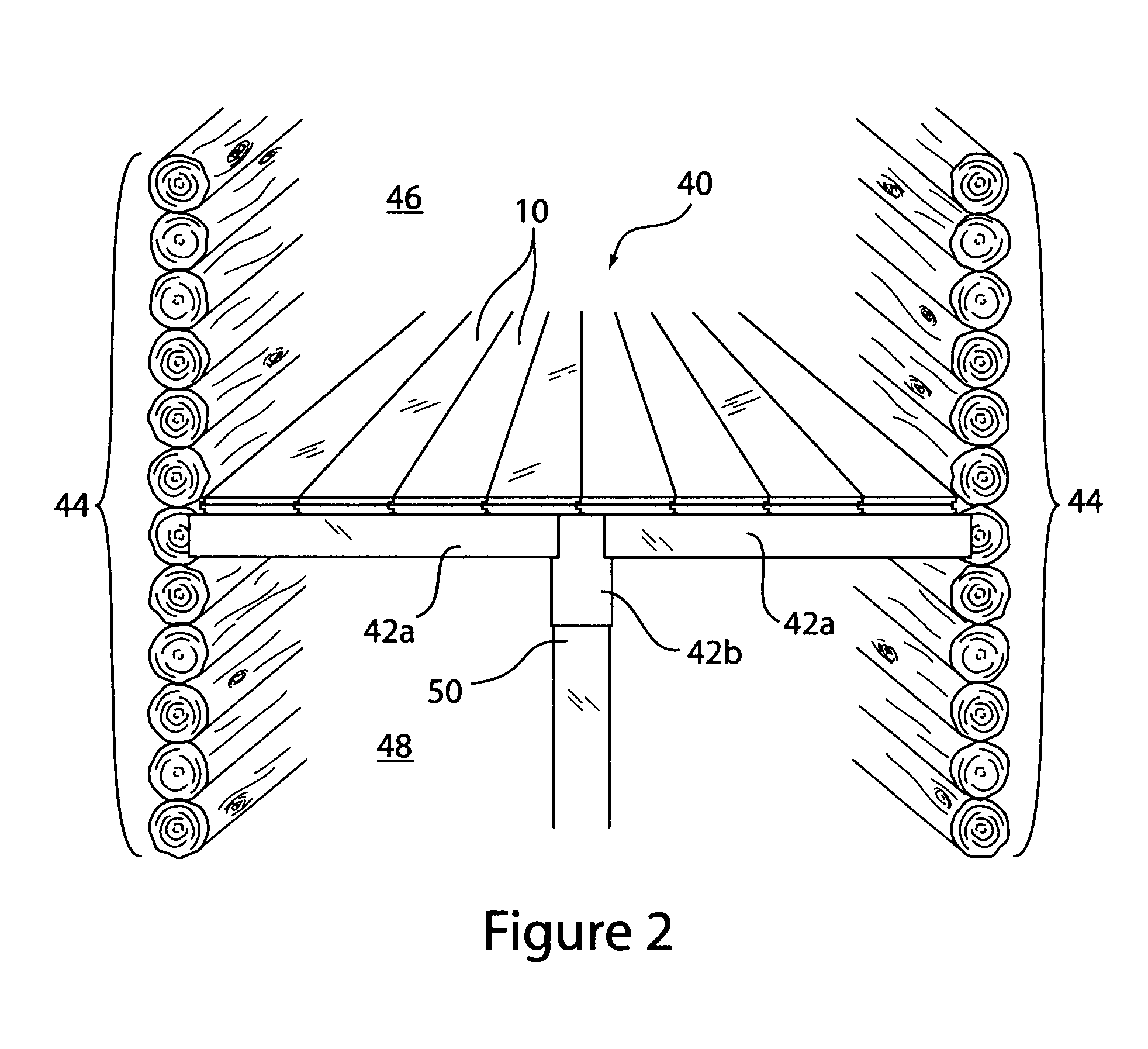

Blended mulch products for spray application to a surface

InactiveUS20070186463A1Increase coverageHigh load rateHorticulture methodsOrganic fertilisersCellulose fiberMaterials science

The invention provides in part a blended mulch product of at least two types of bio-degradable materials having different geometric shapes and physical properties. The first type of bio-degradable material may be a ligno-cellulosic fiber, such as a refined softwood ligno-cellulosic fiber, and the second type of bio-degradable material may be a wood-based flake, such as a processed wood residual.

Owner:PROFILE PRODS LLC

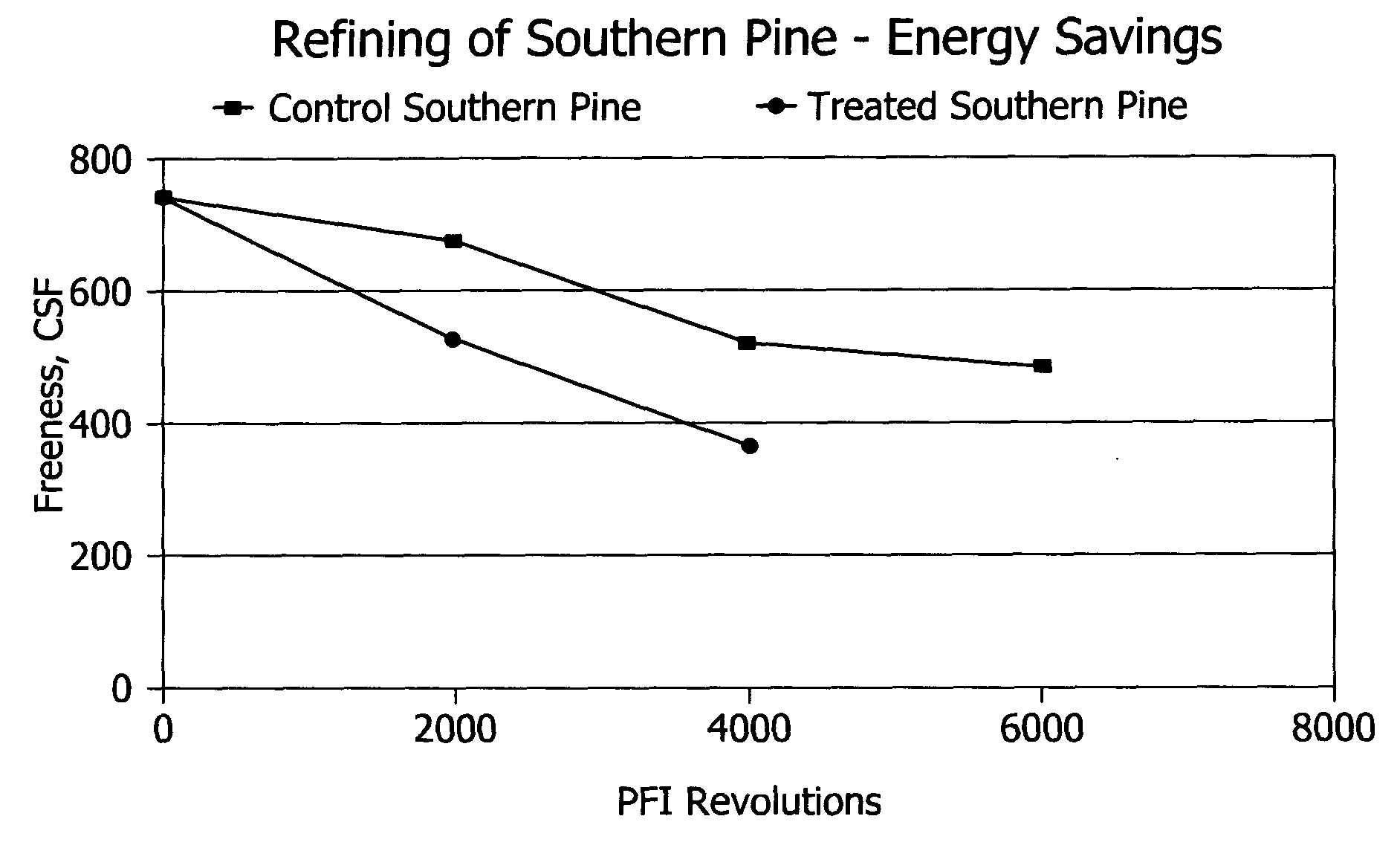

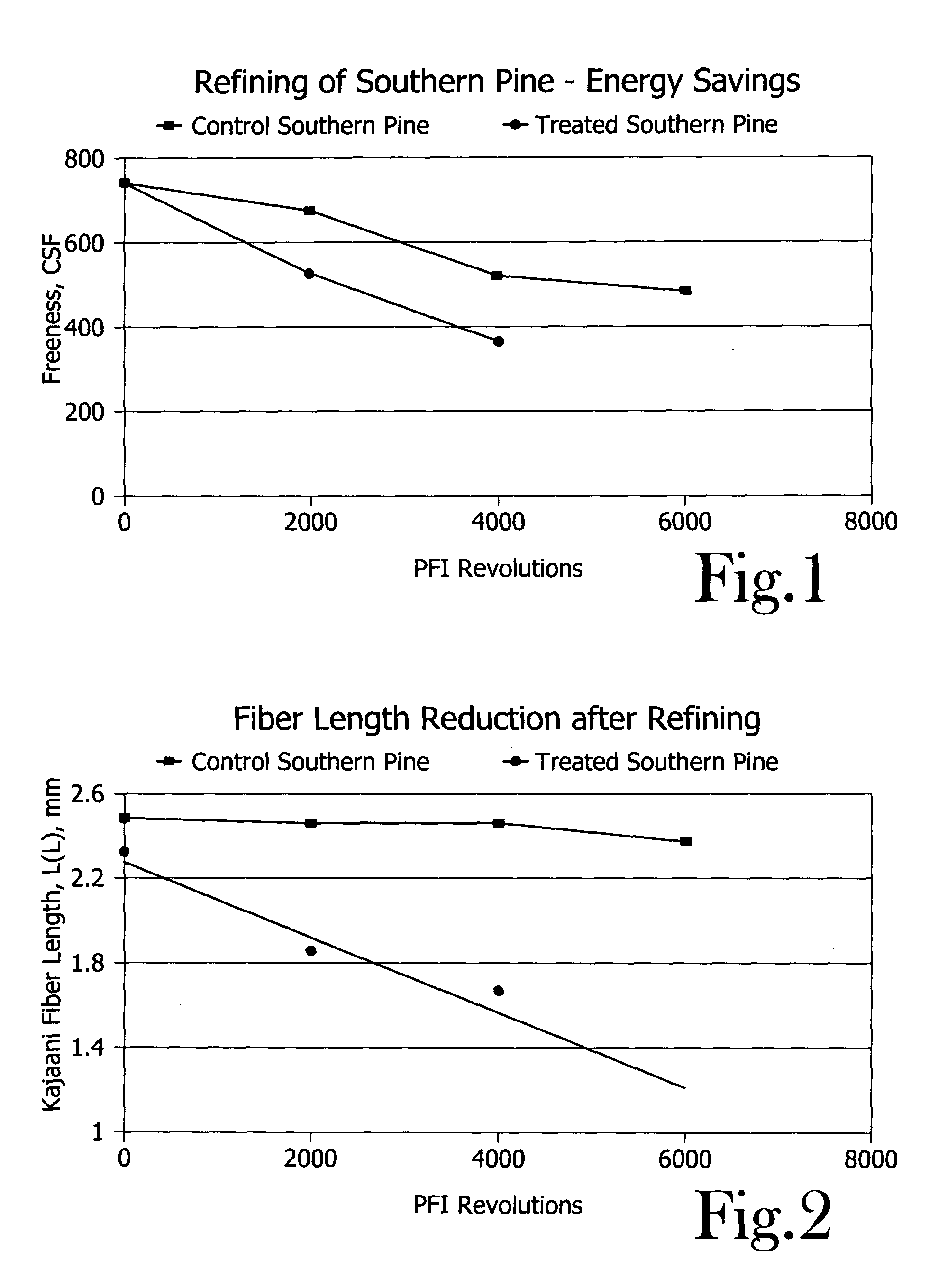

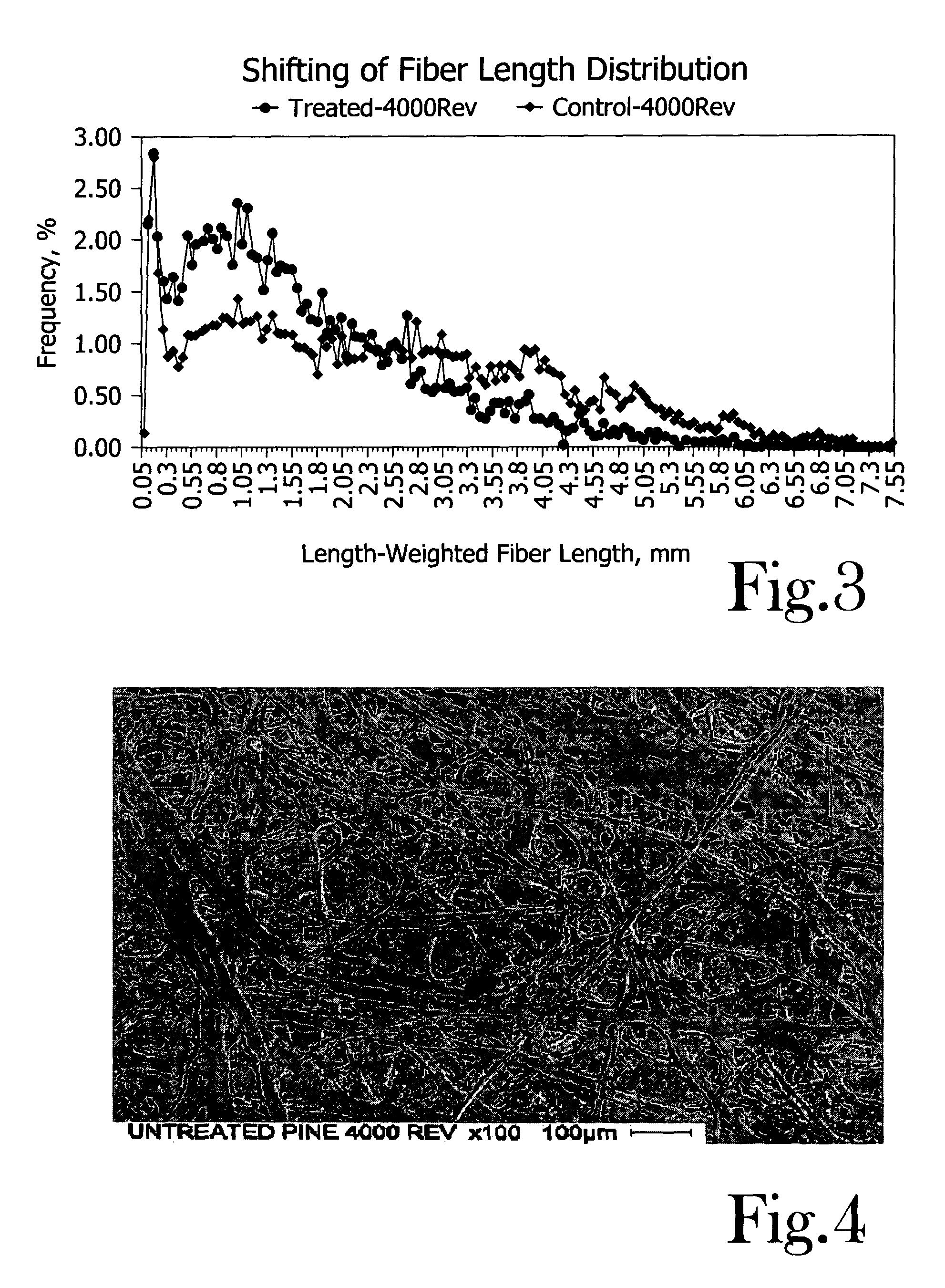

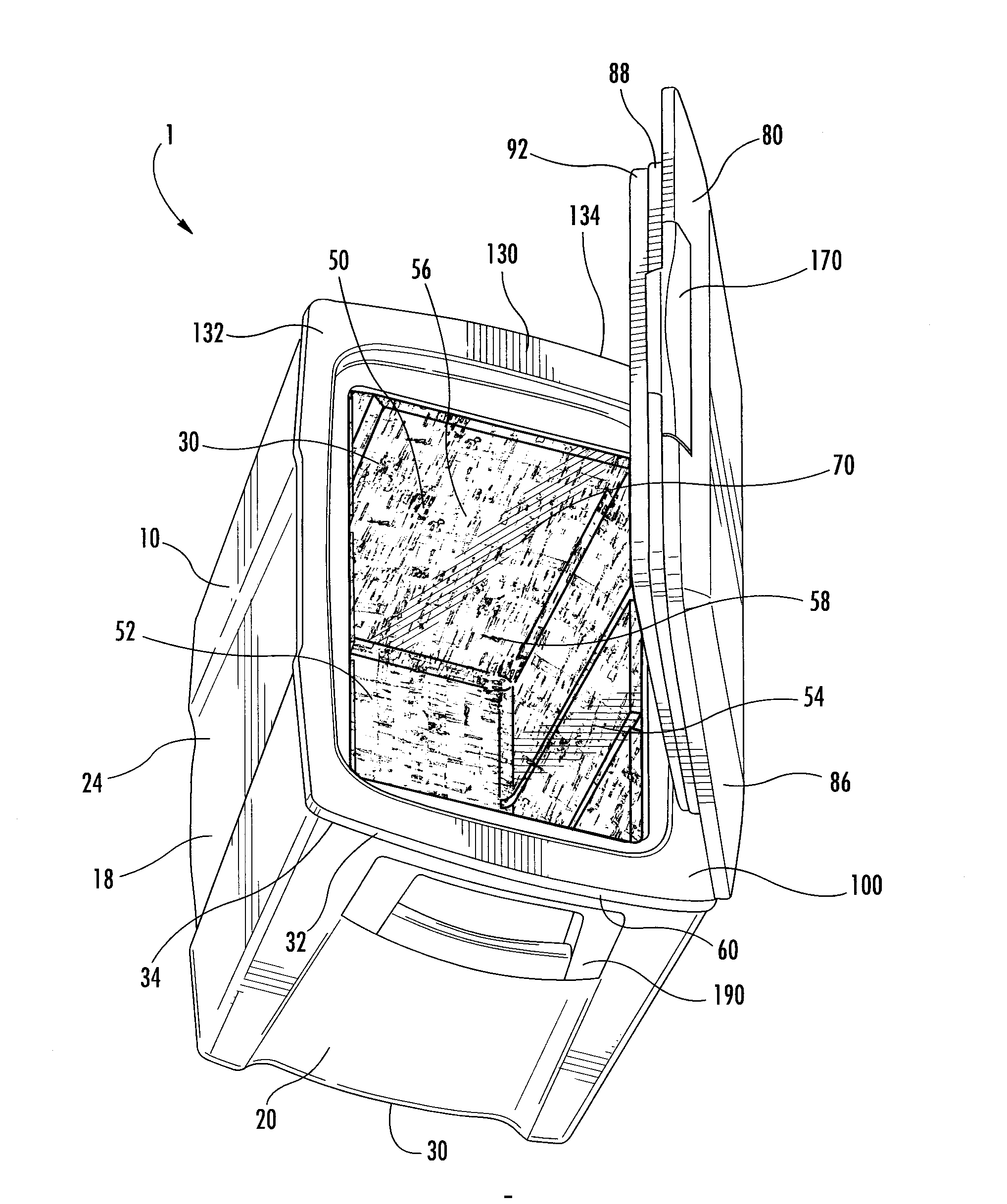

Chemical activation and refining of southern pine kraft fibers

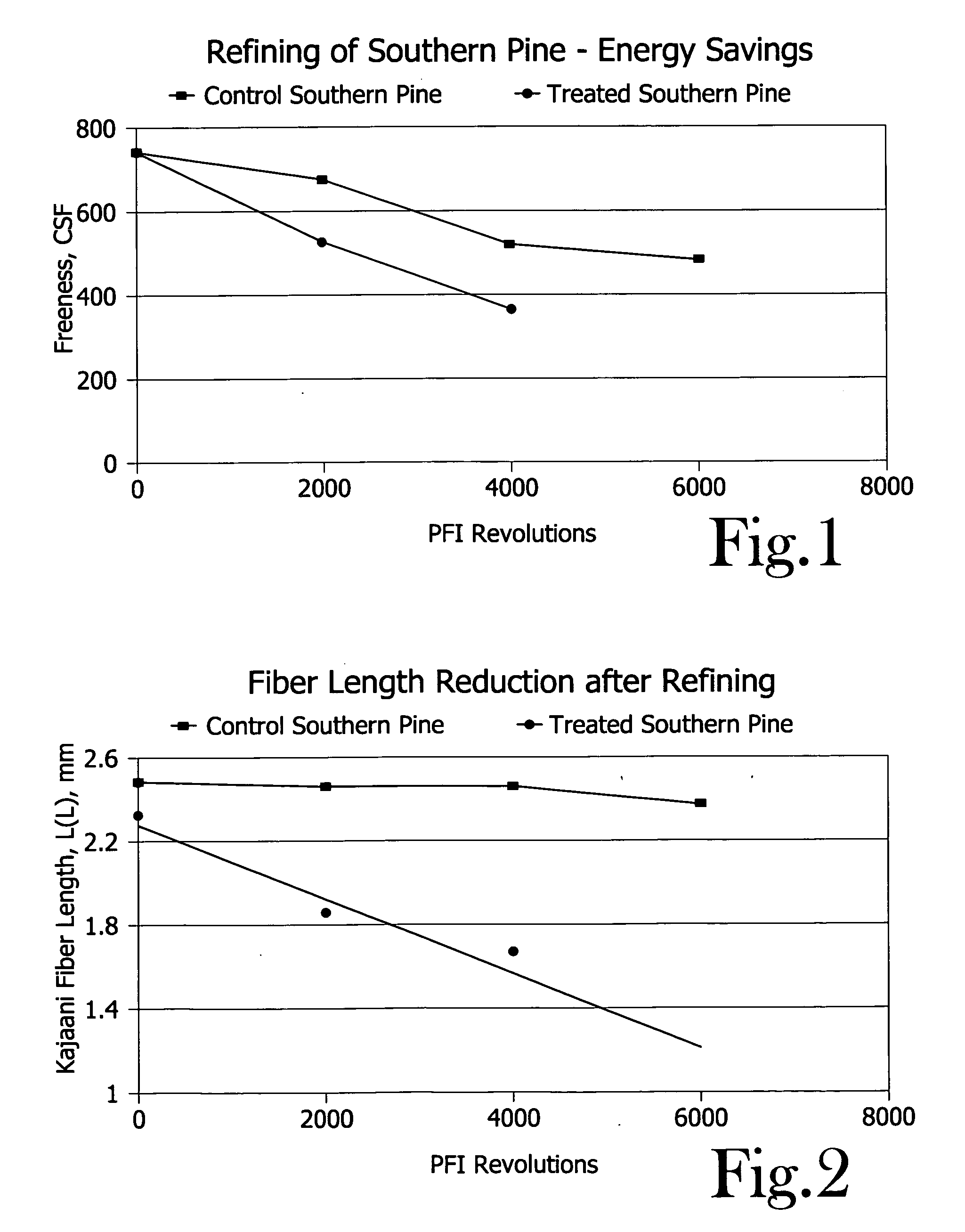

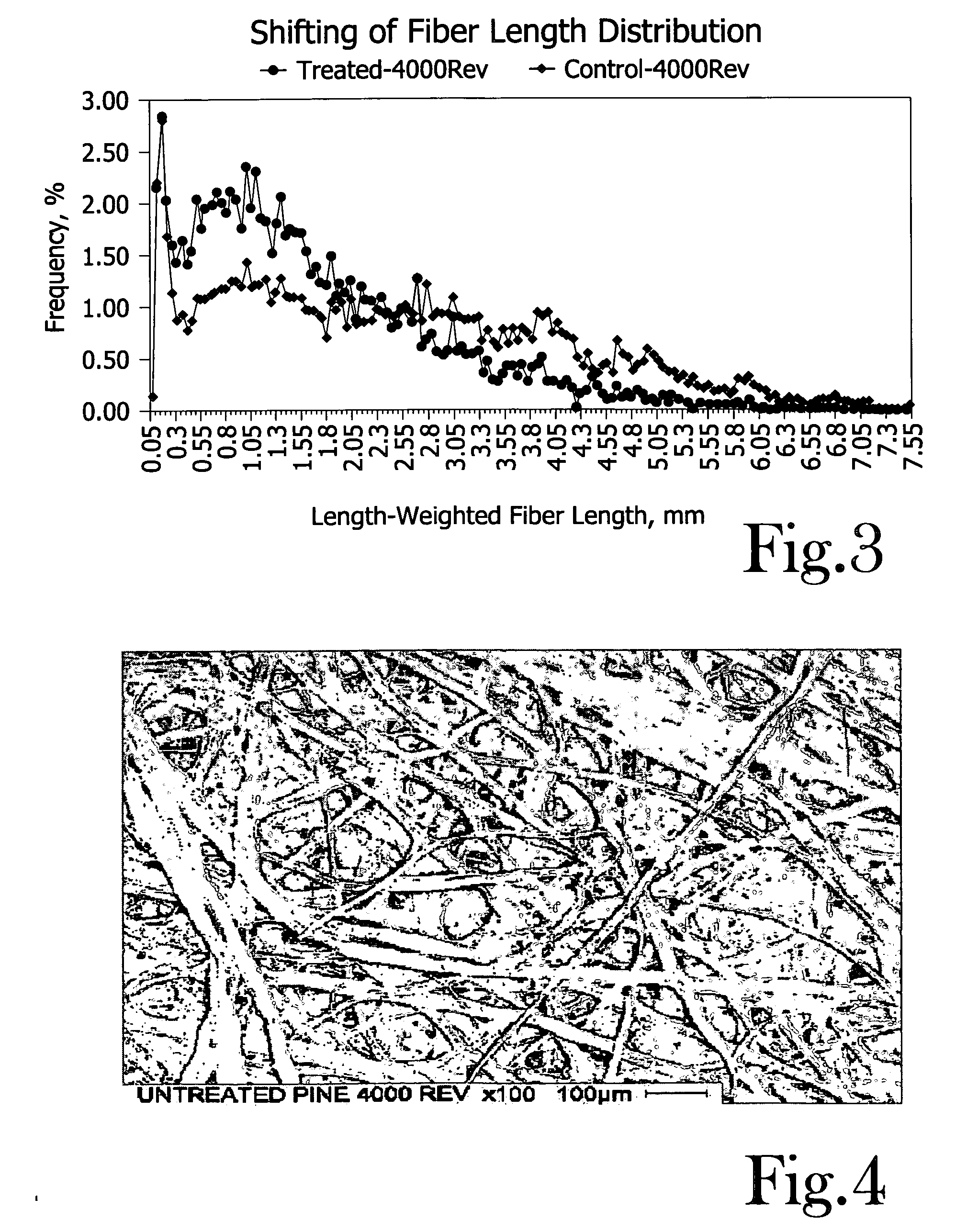

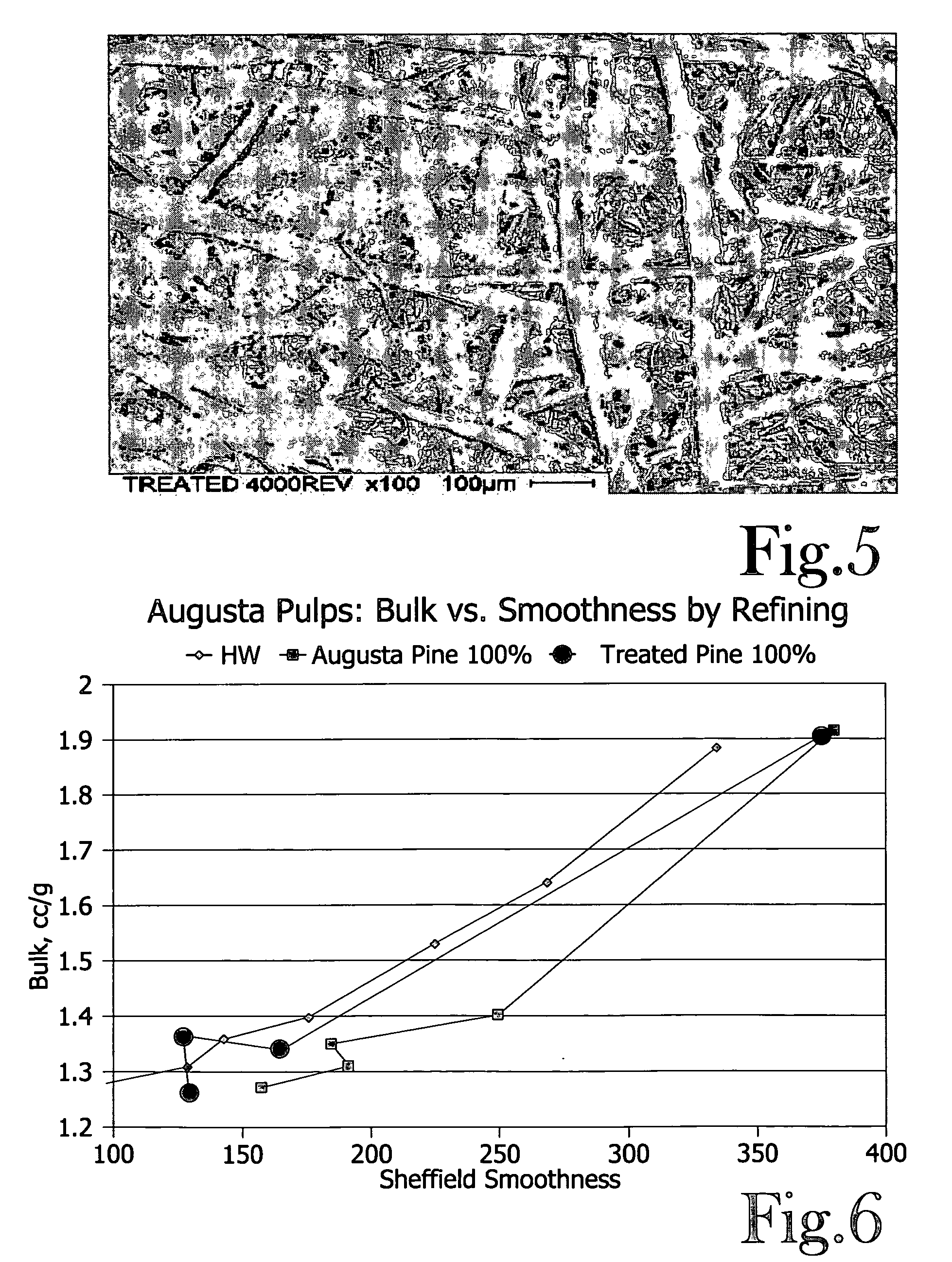

InactiveUS20050061455A1Increase the pulp freenessEasy to drainPulp properties modificationPulp bleachingChemical treatmentCellulose fiber

A method for alteration of the morphology of cellulose fibers, particularly softwood fibers, by (a) subjecting the fibers to a metal ion-activated peroxide treatment carried out at a pH of between about 1 and about 9, preferably between 3 and 7, and (b) subjecting the treated fibers to a refining treatment thereby converts SW fibers to HW-like fibers in many respects. The metal ion-activated peroxide treatment has been noted to act on pulp cellulose and hemi-cellulose, causing oxidation and oxidative degradation of cellulose fibers. The chemical treatment of the pulp, taken alone, is not sufficient to attain the desired modification of the morphology of the fibers, however, subsequent refining or like mechanical treatment of the chemically-treated fibers to achieve a given degree of refinement of the fibers requires dramatically less refining energy to achieve a desired end point of refinement and to impart other desirable properties to the pulp. A pulp of modified SW fibers and a mixture of HW fibers and modified HW fibers are disclosed.

Owner:INT PAPER CO

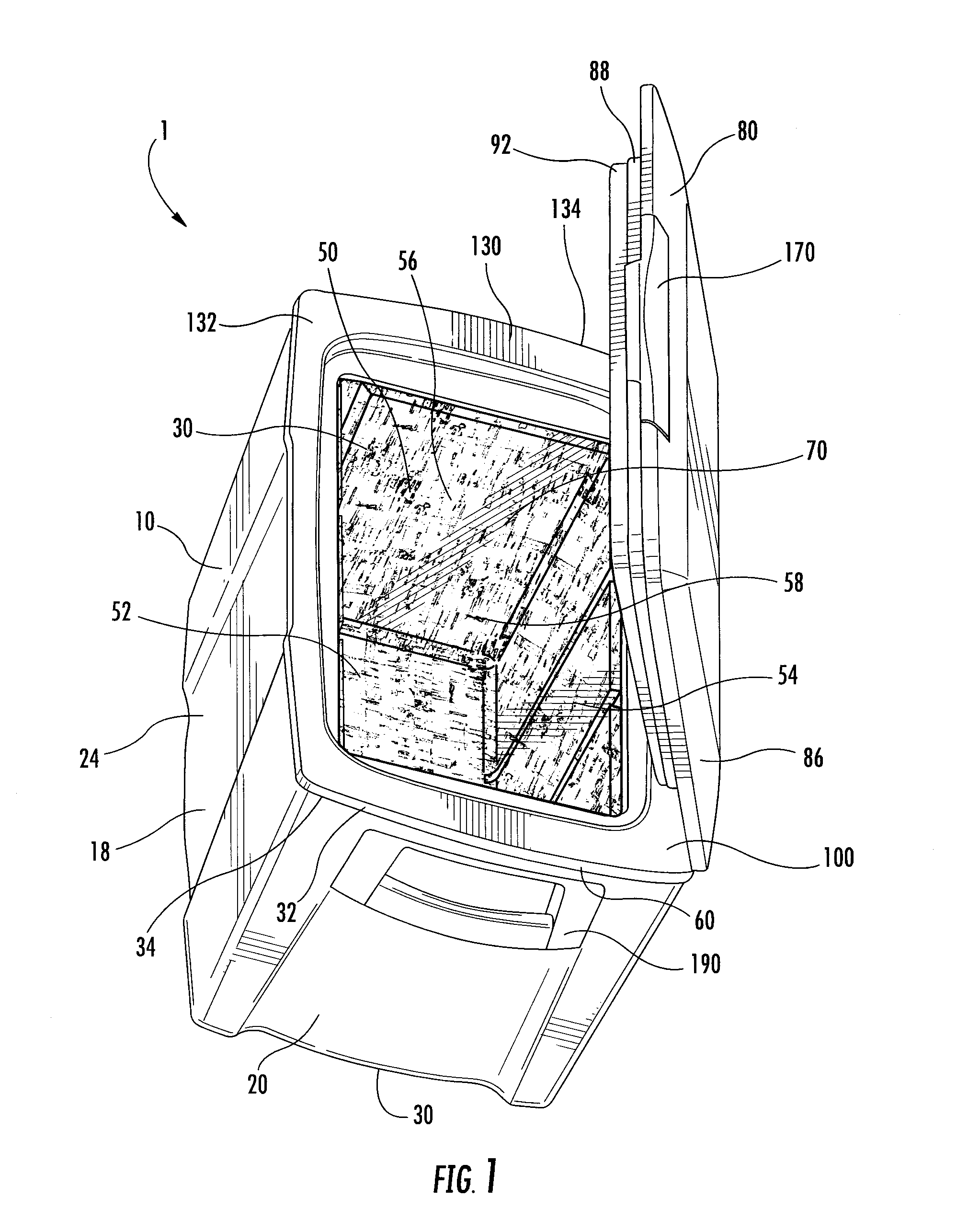

Transportable Transparent Cork-Insulated Cooler

InactiveUS20160023837A1Easy to slideAvoid pollutionDomestic cooling apparatusLighting and heating apparatusEngineeringSkid plate

A cork-insulated cooler having reversible skid plates and a transparent inner basin is described. The cooler is comprised of an outer basin having an open top, a plurality of cork panels lining the outer basin, a transparent inner basin having an open top which is constructed and arranged to hold and maintain the plurality of cork panels against the outer basin, a lid hingedly connected to the inner and outer basin such that the inner basin and lid cooperate to define a compartment, and at least one pair of reversible skid plates removably fastened to the bottom surface of the outer basin. The reversible skid plates include a skid side for easy sliding of the cooler and a non-skid side to keep the cooler in place.

Owner:SOVARO COOLERS

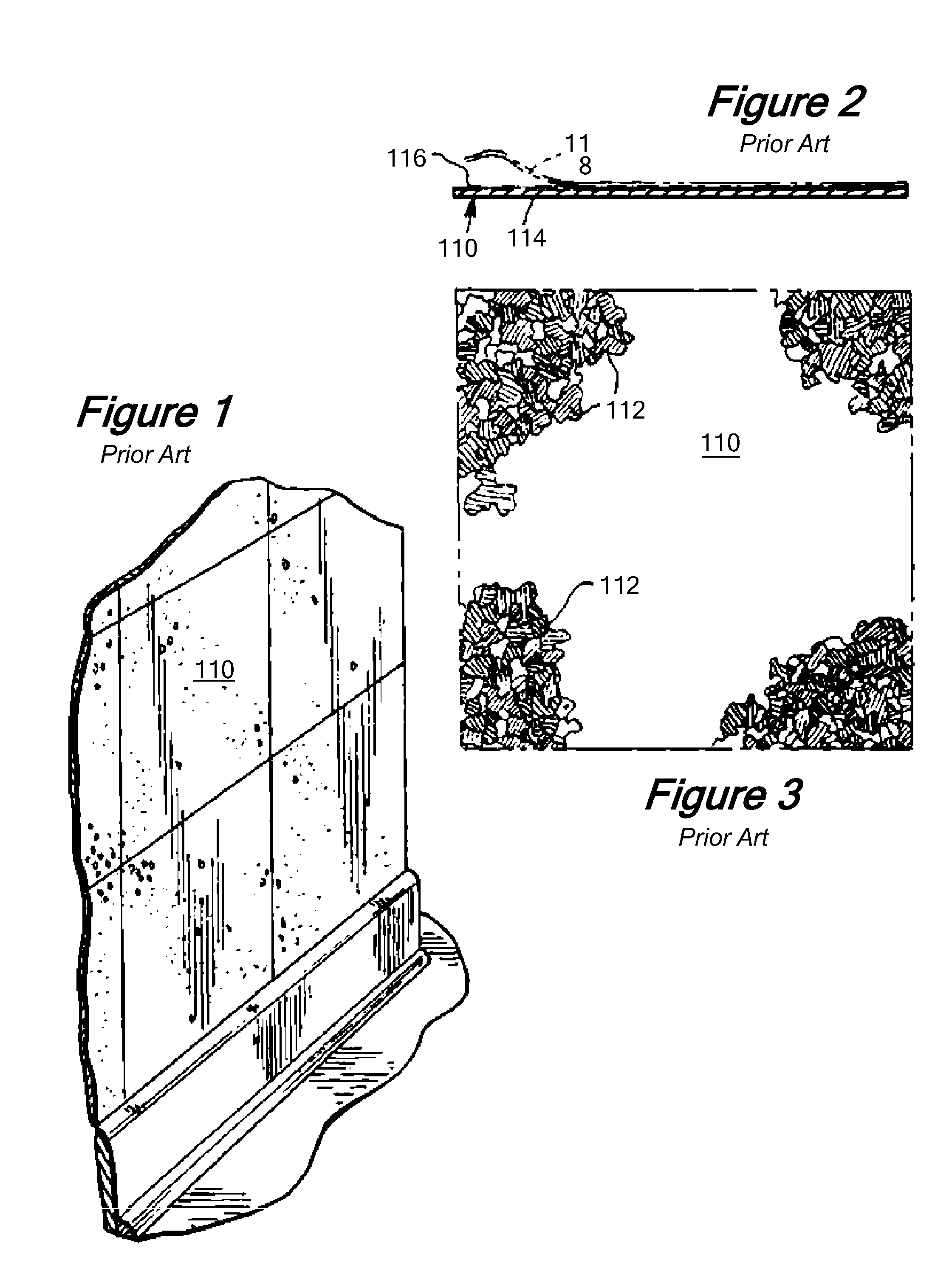

Plywood laminate having improved dimensional stability and resistance to warping and delamination

A plywood laminate having dimensional stability and resistance to warping and delamination is formed from a plurality of higher quality plies and a plurality of lower quality plies. The higher quality plies may be of hardwood and the lower quality plies may be of softwood or lower quality hardwoods, or the higher quality plies may have a veneer grade of better than ANSI / HPVA HP-1-2000 veneer grade C and the lower quality plies may have a veneer grade of no greater than ANSI / HPVA HP-1-2000 veneer grade C. The exposed plies are of the higher quality. In most embodiments, at least two adjacent interior plies are of the lower quality. In those embodiments having a tongue and groove or click-lock edge configuration, the tongue comprises portions of at least two plies and at least one of the plies is a higher quality ply.

Owner:AHF LLC

Cellulosic product

InactiveUS20110088860A1Reduce liquid penetrationGood heat sealing performanceFibreboardCosmetic preparationsMicrosphereCellulose fiber

The present invention relates to a process of producing a cellulosic product comprising (i) providing an aqueous suspension of cellulosic fibers, (ii) adding microfibrillar polysaccharide, (iii) adding thermoplastic microspheres, (iv) dewatering the suspension and forming a cellulosic product. The invention also relates to a process of producing a single layer cellulosic product comprising (i) providing an aqueous suspension of cellulosic fibers, (ii) adding microfibrillar polysaccharide derived from softwood and / or hardwood and optionally adding thermoplastic microspheres to the suspension, (iii) dewatering the suspension and forming a cellulosic product. The invention further relates to a cellulosic product obtainable from said processes. The invention also relates to a composition comprising microfibrillar polysaccharide and thermoplastic microspheres and the use thereof.

Owner:AKZO NOBEL NV

Integrated process for separation of lignocellulosic components to fermentable sugars for production of ethanol and chemicals

InactiveUS7666637B2Robust and cost-effectiveImproving biological reactivity of celluloseChemical industryBiofuelsChemical treatmentHydrolysate

The invented process separates main components in lignocellulosic biomass, specifically hardwoods, softwoods into lignin and fractions of high purity sugars which are used for ethanol production. The invented process comprises of treatment stages at high temperature and high pressure with hydrochloric acid or sulfuric acid. Residual lignin and extractives in the cellulosic solid fraction are selectively removed by chemical treatments of sodium chlorite, anhydrous acetic acid, chlorine and chlorine dioxide to enhance the purity and biological conversion of cellulose to ethanol. The pre-hydrolysate generated from the acid treatment stage, containing xylose, arabinose, galactose, glucose and the purified cellulosic fraction are enzymatically hydrolyzed and fermented to produce ethanol. Significant amount of lignin from the process is recovered as a by-product.

Owner:NGUYEN XUAN NGHINH

Chemical activation and refining of southern pine kraft fibers

InactiveUS20070119556A1Increase the pulp freenessEasy to drainPulp properties modificationPulp bleachingChemical treatmentCellulose fiber

A method for alteration of the morphology of cellulose fibers, particularly softwood fibers, by (a) subjecting the fibers to a metal ion-activated peroxide treatment carried out at a pH of between about 1 and about 9, preferably between 3 and 7, and (b) subjecting the treated fibers to a refining treatment thereby converts SW fibers to HW-like fibers in many respects. The metal ion-activated peroxide treatment has been noted to act on pulp cellulose and hemi-cellulose, causing oxidation and oxidative degradation of cellulose fibers. The chemical treatment of the pulp, taken alone, is not sufficient to attain the desired modification of the morphology of the fibers, however, subsequent refining or like mechanical treatment of the chemically-treated fibers to achieve a given degree of refinement of the fibers requires dramatically less refining energy to achieve a desired end point of refinement and to impart other desirable properties to the pulp. A pulp of modified SW fibers and a mixture of HW fibers and modified HW fibers are disclosed.

Owner:INT PAPER CO

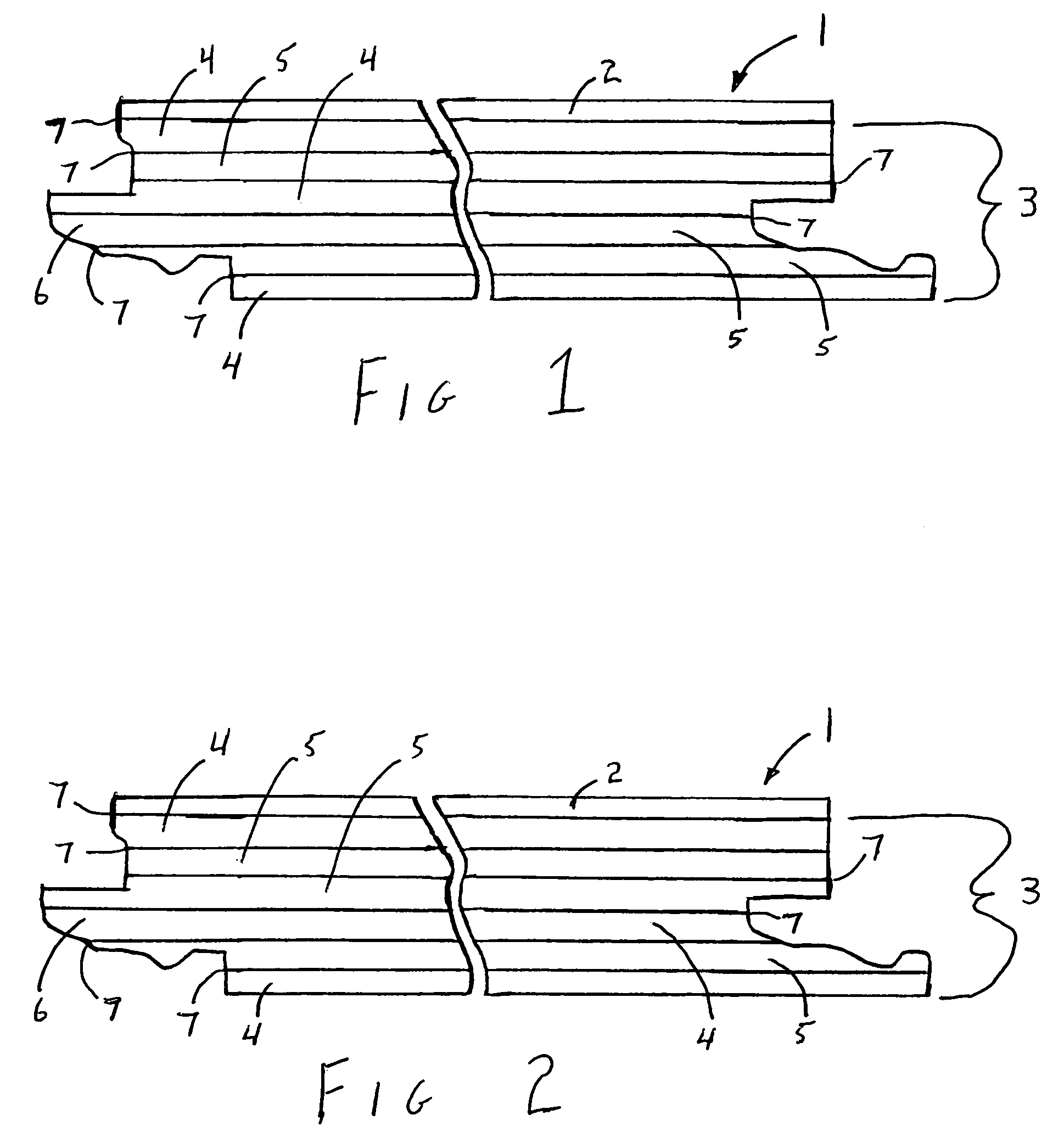

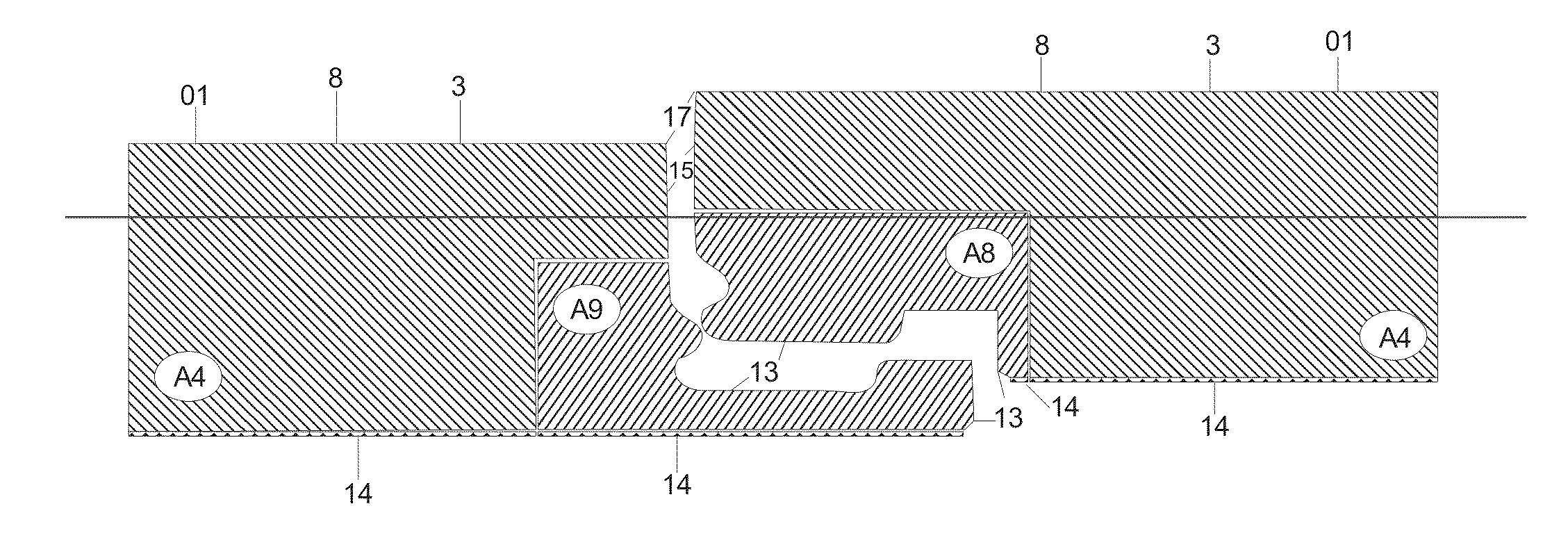

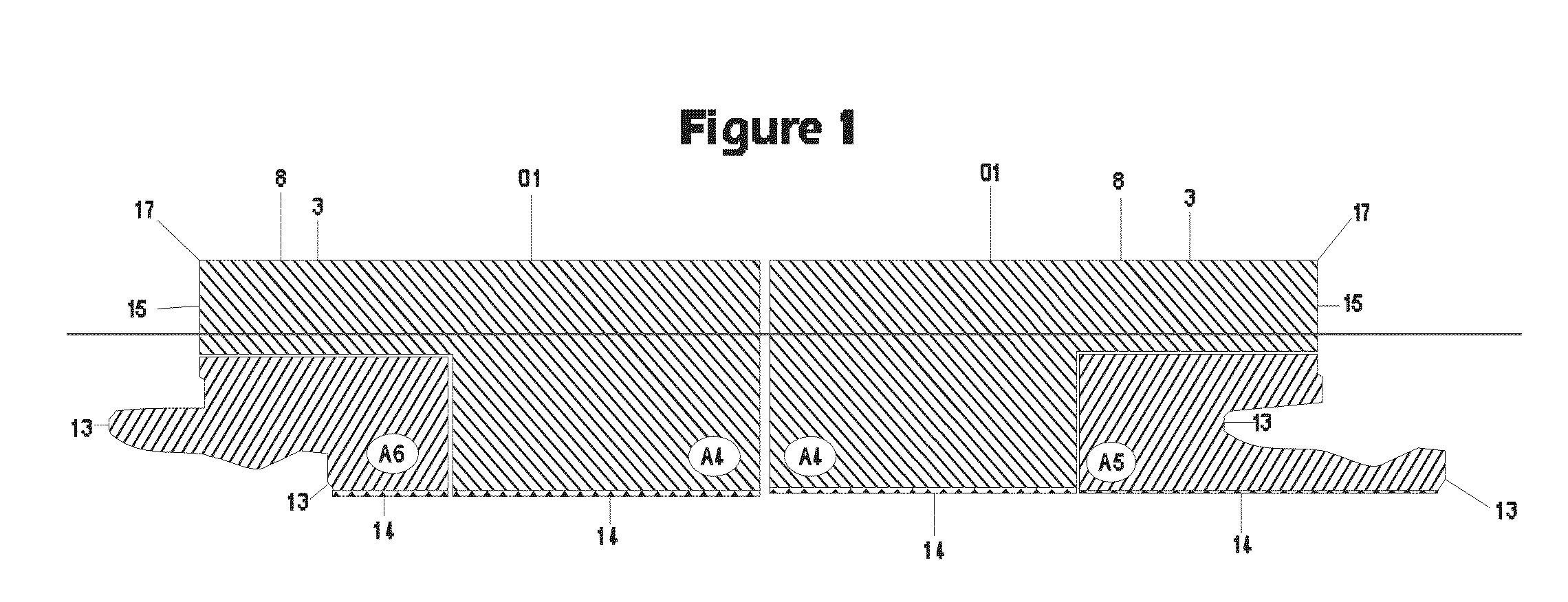

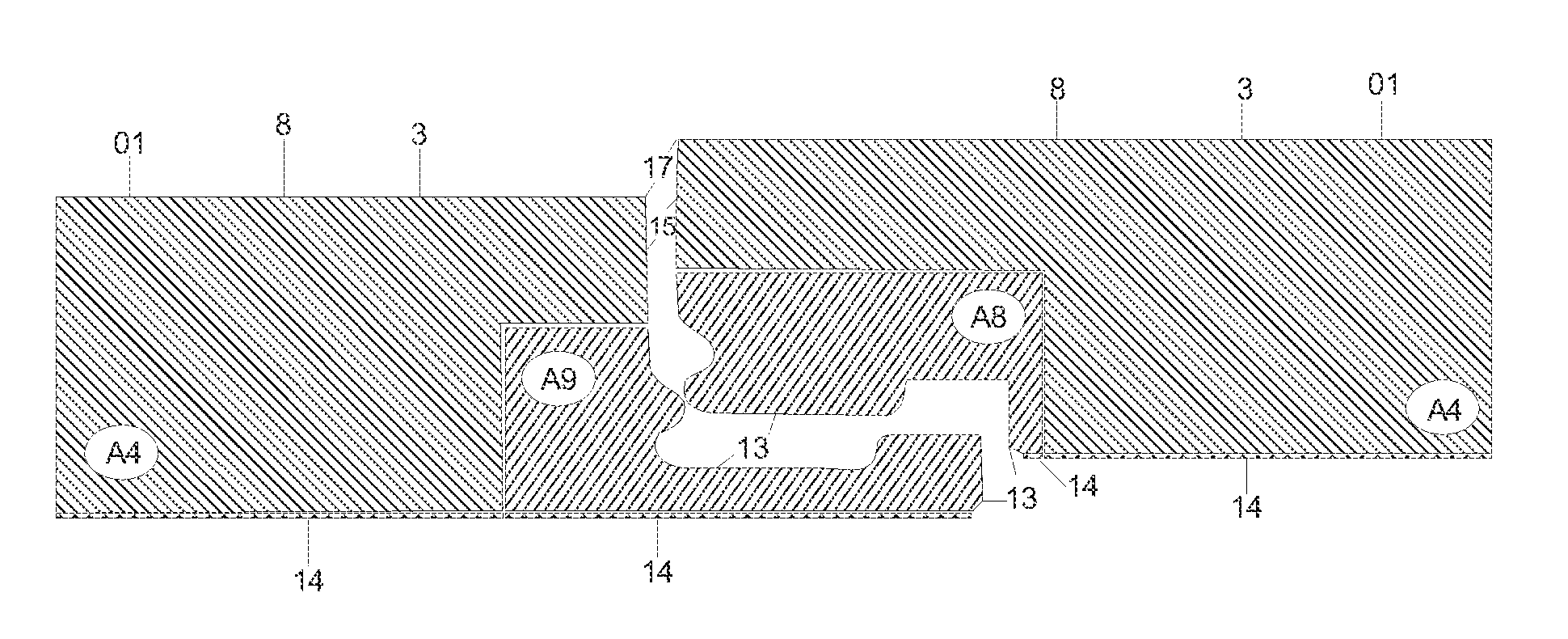

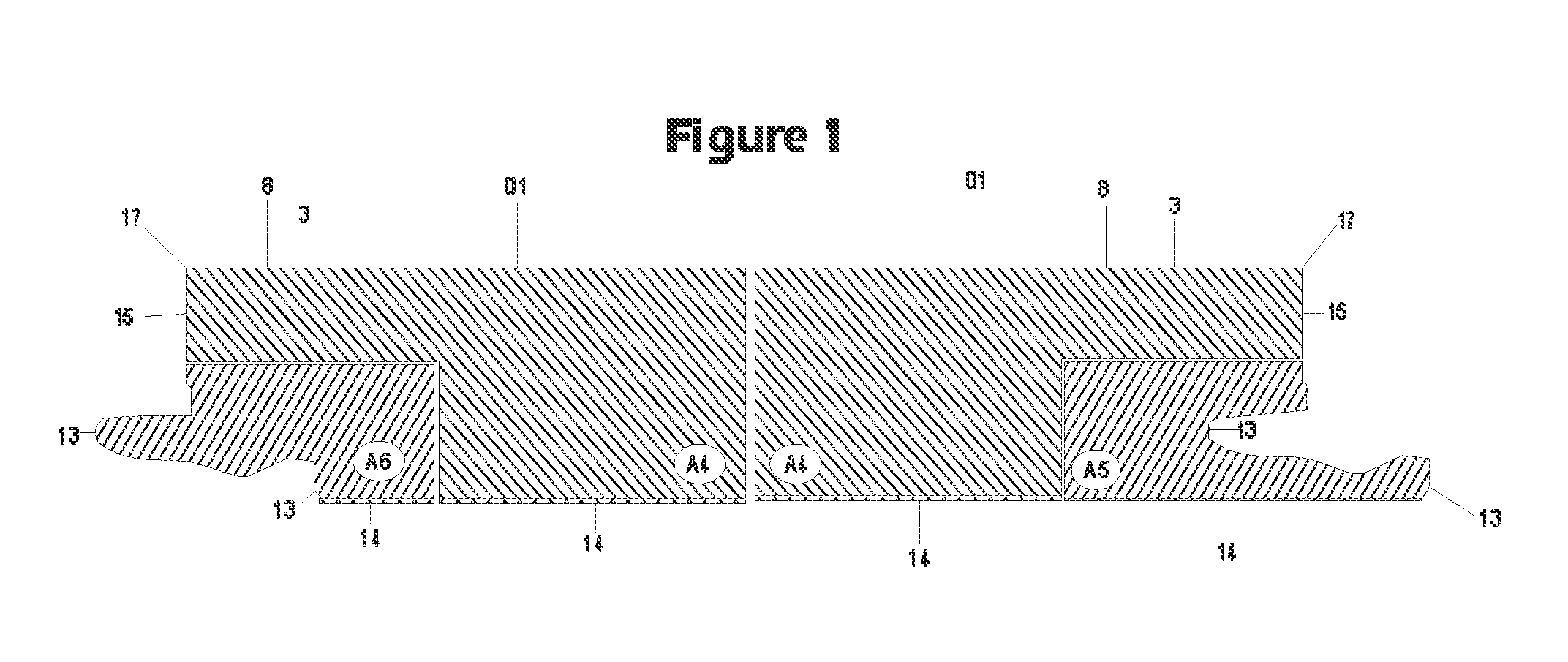

Stone Click Floor Coverings

ActiveUS20130042558A1Precise alignmentSimple preparation processConstruction materialFloorsCouplingAdhesive

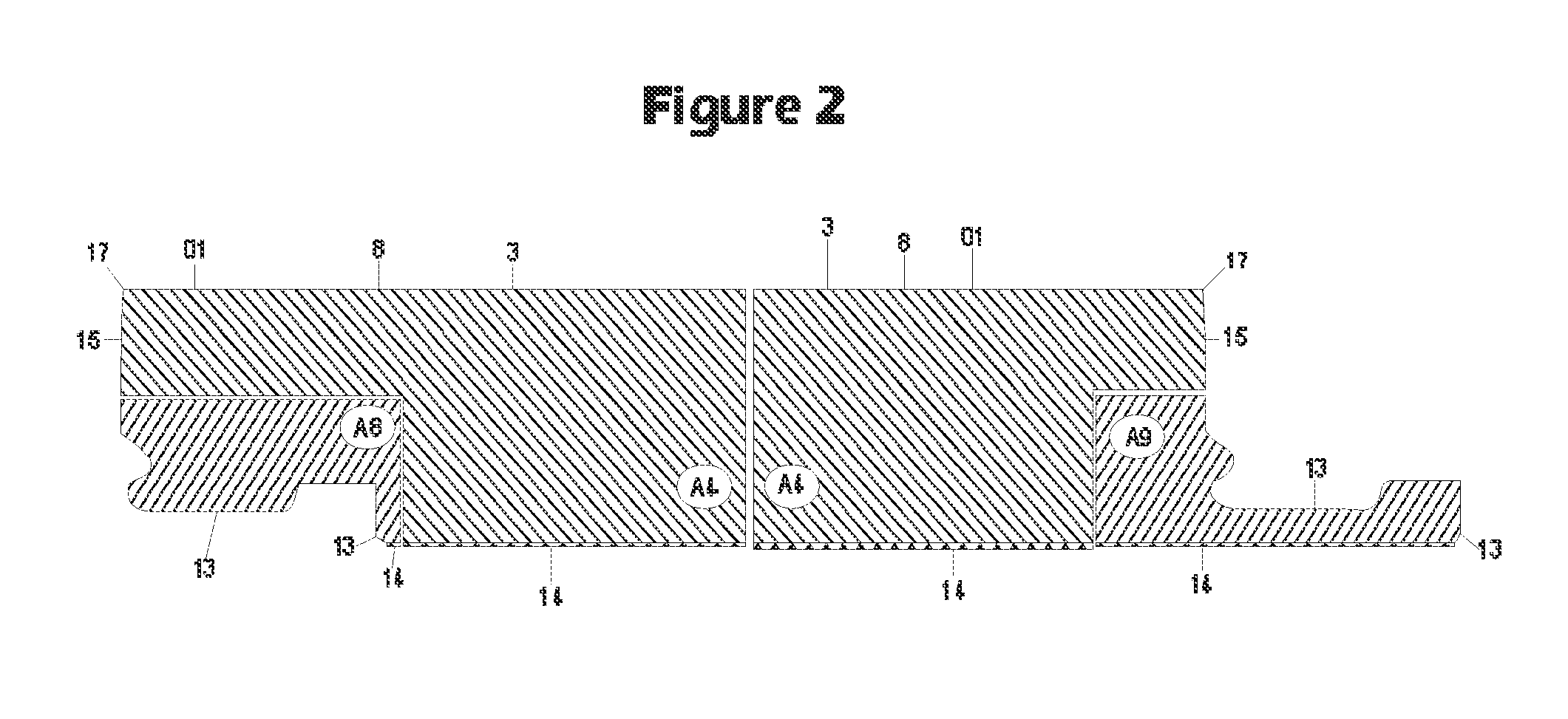

Floor covering (01) material, consisting of Natural Stones, i.e. Marble, Granite, Limestone, Onyx, Travertine and Sandstone, in format of tile slabs, in which the thickness is between 4 mm and 35 mm, in which at the two opposite edges or sides are jointed together and interlocked by mechanical locking means, by connecting or inserting (A6 to A5) and connecting or pressing downward (A8 to A9) using Polyvinyl Chloride (PVC) couplings, connecting in the form of a tongue and a groove which will prevent shifting of two interlocked tiles and or slabs into the opposed direction of each section tile or slab, with an integrated backing layer consisting of cork and / or syntactic foam material, The invention relates to a natural stone core tile slab, allowing for an installation without the use of cement, adhesives or grout, provided with such a mechanical locking system jointed to the core (A4) according to the invention.

Owner:CORDEIRO EURICO JANUARIO

Groutless Tile System

InactiveUS20130212971A1Comfortable feetAcoustical and thermal advantageCovering/liningsFiberAdhesive

Floor, ceiling and wall covering (01) material, consisting of natural stones, i.e. marble, granite, limestone, onyx, travertine and sandstone, cement based tiles, softwood and hardwood, wood fiber HDF, MDF, agglomerated cork, rubber, and composite tile materials, such as stone, quartz or vinyl composition tiles, in format of tile slabs. Which the thickness is between 4 mm and 35 mm in which at the two opposite edges or sides are jointed together and interlocked by mechanical locking means, by connecting or inserting, (A6 to A5) and connecting or pressing downward (A8 to A9) using polyvinyl chloride (PVC) couplings, connecting in the form of a tongue and a groove which will prevent shifting of two interlocked tiles and or slabs into the opposed direction of each section tile or slab, with an integrated backing layer consisting of cork syntactic foam material, The invention relates to a natural stone core tile slab, allowing for an installation without the use of cement, adhesives or grout, provided with such a mechanical locking system jointed to the core (A4) according to the invention.

Owner:CORDEIRO EURICO JANUARIO

Environment-friendly efficient filter filtering paper and preparation method thereof

ActiveCN102888784AImprove efficiencyImprove filtration efficiencyNon-fibrous pulp additionPaper/cardboardSolubilityGlycerol

The invention discloses an environment-friendly efficient filter filtering paper. The environment-friendly efficient filter filtering paper is prepared by the following raw materials in part by weight: 40-50 parts of softwood pulp, 30-40 parts of waste paper pulp, 20-30 parts of high-silica glass fiber, 2-5 parts of modified vermiculite, 1-3 parts of zeolite molecular sieve, 2-4 parts of nanometer calcium, 1-2 parts of modified pulverized fuel ash, 2-3 parts of water-solubility organic silicon resin emulsion, 1-2 parts of water-solubility polytetrafluoroethylene emulsion, 0.5-0.8 parts of ammonium polyphosphate, 3-4 parts of glycerol triacetate, 0.5-1 parts of diethanolamide, 0.5-1 parts of silane coupling agent KH560, 0.4-0.8 parts of sodium dodecyl sulfate, 0.5-1 parts of antioxidant DSTP, and 4-6 parts of polyethylenimine. The filtering paper prepared by the method provided by the invention has the advantages of being good in water permeability, large in filtering area, small in maximum diameter of hole, high in filtering precision, strong in bursting strength, high-temperature-resistant, good in water resistance and the like, can achieve the filtering efficiency by 99.98%, has stable performance index at atmospheric and high-temperature working conditions, as well as better temperature resistance and filtering effects.

Owner:ANHUI PHOENIX INT CO LTD

White-surface coated craft paper and production method thereof

ActiveCN102912689AIncrease varietyImprove qualityCoatings with pigmentsSpecial paperAfter treatmentRegenerating fibers

The invention discloses white-surface coated craft paper and a production method thereof. The white-surface coated craft paper comprises a core paper layer; the upper side of the core paper layer is a surface paper layer, and the lower side is a bottom paper layer; a coating layer is arranged on the upper surface of the surface paper layer; the bottom paper layer and the core paper layer of the white-surface coated craft paper are prepared by the steps of: dosing the waste paper, preparing waste paper pulp to obtain non-deinked waste paper pulp, and manufacturing paper through a paper layer to obtain a wet bottom paper layer and a wet core paper layer; the surface paper layer is prepared by the steps of: mixing the bleached hardwood pulp, bleached softwood pulp and bleached regenerated fiber pulp DIP at any proportion, and manufacturing paper through a paper layer to obtain a wet surface paper layer; and the wet bottom paper layer, the wet core paper layer and the wet surface paper layer are subjected to the steps of compounding with the coated body paper, preliminary drying, sizing, later drying, paper surface calendering, paper surface coating and after-treatment to obtain the white-surface coated craft paper. The available waste paper types are increased, and the fiber source is wider; and meanwhile, the quality of the waste paper pulp is effectively stabilized so as to guarantee the quality stability of the coated body paper and the white-surface craft paper and avoid easy layering, splitting and scaling.

Owner:山东晨鸣纸业集团股份有限公司 +1

Traditional Chinese medicine health-care tipping paper and production method thereof

InactiveCN103741553AImprove toughnessImprove water resistanceSpecial paperNon-macromolecular organic additionSodium sulfatePaper sheet

Traditional Chinese medicine health-care tipping paper is prepared from the following raw materials in parts by weight: 90-100 parts of softwood pulp, 40-50 parts of hardwood pulp, 2-3 parts of methyltriethoxysilane, 1-2 parts of sodium lignosulfonate, 1-2 parts of aerosol-OT, 2-3 parts of ?, 1-2 parts of sodium tripolyphosphate, 4-7 parts of bentonite, 1-2 parts of ascorbic acid, 1-2 parts of chitosan, 4-6 parts of kaolin powder, 1-2 parts of bamboo charcoal powder, 2-3 parts of carboxymethyl starch, 1-2 parts of sodium persulfate, 1-2 parts of soybean oil, 1-2 parts of green tea powder, 1-2 parts of pseudo-ginseng powder, 1-2 parts of gynostemma pentaphyllum powder and 1-2 parts of castanea mollissima leaf powder. The technological effects comprise that by adding traditional Chinese medicine health-care compositions such as pseudo-ginseng, gynostemma pentaphyllum and the like, the health-care performance is increased; also when a smoker keeps a cigarette holder in mouth, harm of smoking is reduced; and also, by adding ester materials and through cross-linking polymerization, the toughness and the flexibility of the tipping paper are increased, also the tipping paper is improved in water resistance and wet resistance and reduced in water absorbing property, and a paper sheet has good lip sticking resistance.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

Cationization modification method for nano-crystalline cellulose and preparation method of high-strength cigarette paper

ActiveCN102180979ALess investmentHigh strengthReinforcing agents additionPaper/cardboardFiberReaction temperature

The invention belongs to the field of production of special paper, and in particular relates to a cationization modification method of nano-crystalline cellulose and a method for preparing high-strength cigarette paper from the modified nano-crystalline cellulose. Specific to the characteristic of high specific surface area of nano-crystalline cellulose, KOH and a method for adding an etherification reaction accelerant are adopted, the reaction temperature is lowered below 50 DEG C, cationization modification is performed on the nano-crystalline cellulose, and the modified nano-crystalline cellulose has the characteristics of retention and enhancement, so that the modified nano-crystalline cellulose has a wider application prospect; in the method for preparing cigarette paper, softwood pulp is not used, and higher natural air permeability and higher bonding strength of a product are ensured under the condition of reducing broadleaf wood fiber devillicate and fibrillation, so that energy consumption in the production process of paper, in particular in the pulping process, is remarkably lowered, equipment investment of a paper mill is reduced, high-strength cigarette paper is manufactured, the page quality is improved, higher strength and air permeability of the product are achieved, and the requirements on energy conservation and emission reduction are met.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

A kind of food packaging paper and production method thereof

The invention discloses a food wrapping paper and a production method thereof. Poplar chemical mechanical pulp, bleached kraft softwood pulp and bleached kraft hardwood pulp are used as fiber raw materials. Sizing, desanding and degassing, sizing, fine sieving, wire dehydration forming, pressing, pre-drying, surface sizing, post-drying, calendering, coiling, and packaging to form food packaging paper. The present invention uses the surface sizing treatment method to process the product, and adds a starch surface sizing agent to the surface sizing to improve water resistance and adds a small amount of sizing agent alkyl ketene dimer to the surface sizing glue, which can Improve the retention rate, save costs, and make products more cost-effective.

Owner:YUEYANG FOREST & PAPER CO LTD

Softwood-ceiling / hardwood-floor structure comprised of a single set of bonded boards

A structure comprising a softwood-ceiling / hardwood-floor formed of a single set of adjacent boards. Each of the boards including a hardwood layer bonded to a softwood layer, the board having a first edge and a second edge, the first edge having a tongue, the second edge having a groove, the first edge having a first chamfer on the softwood layer, the second edge having a second chamfer on the softwood layer. All boards securely attached to carrying beams that span the walls between two levels within a building.

Owner:STANHOPE THOMAS SPENCER

Seedling cultivating method for cutting hard woods of acer palmatum

The invention discloses a seedling cultivating method for cutting hard woods of acer palmatum. The method comprises the following steps: (1) selecting an appropriate cutting time; (2) preparing a cutting substrate; (3) preparing rooting agent; (4) cutting slips processing and cutting; and (4) managing and transplanting after cutting. The seedling cultivating method for cutting the hard woods of the acer palmatum, disclosed by the invention, has the characteristics as follows: the cutting survival rate reaches more than 80%; compared with the cost of acer palmatum softwood cuttage, the cost of hard wood cuttage is reduced by 30-50%; the cost of hard wood cuttage is only about 20% of the cost of a tissue culturing method; and compared with a seedling cultivating period of the acer palmatum graftage, the seedling cultivating period of the hard wood cuttage is reduced by 2-3 years. The method disclosed by the invention has the advantages of simplicity, convenience and easiness in operation, low cost, simple technical requirements, easiness for promotion and application as well as important application and promotion values in acer palmatum seedling breeding production.

Owner:JIANGSU ACAD OF FORESTRY

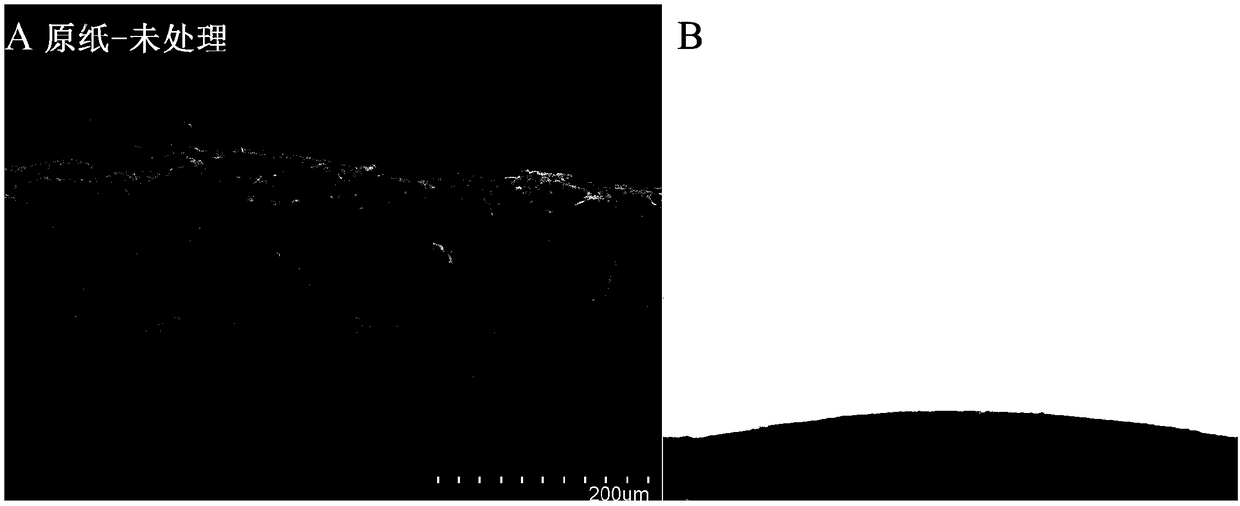

Preparation method of hydrophobic oilproof paper

ActiveCN108625219AImprove adhesionImprove water resistancePaper coatingPaper/cardboardPapermakingSoftwood

The invention relates to the field of papermaking and discloses a preparation method of hydrophobic oilproof paper. The preparation method includes: 1), making body paper: soaking bleached softwood chemical pulp, and pulping; mixing the bleached softwood chemical pulp, carboxymethyl cellulose, bacterial cellulose and dissolving pulp, making handsheet, and drying to obtain the body paper; 2), dissolving a natural polyhydroxy high molecular material in water, stirring, heating, holding temperature until a system is transparent, stirring, cooling to room temperature to obtain coating liquid, andcoating; 3), drying the body paper after being precoated, using an acyl chloride solution to treat the surface of the body paper, and drying to obtain a finished product. The problem that paper is porous is solved by means of coating the surface of the paper with the polyhydroxy high molecular material which is natural and easy to degrade, and an acyl chloride compound not containing fluorine is used to replace fluorine-containing polymer to endow the paper with hydrophobicity and oilproofness, so that environment friendliness is realized. In addition, paper prepared by the method has good strength performance and printability.

Owner:杭州市化工研究院有限公司 +1

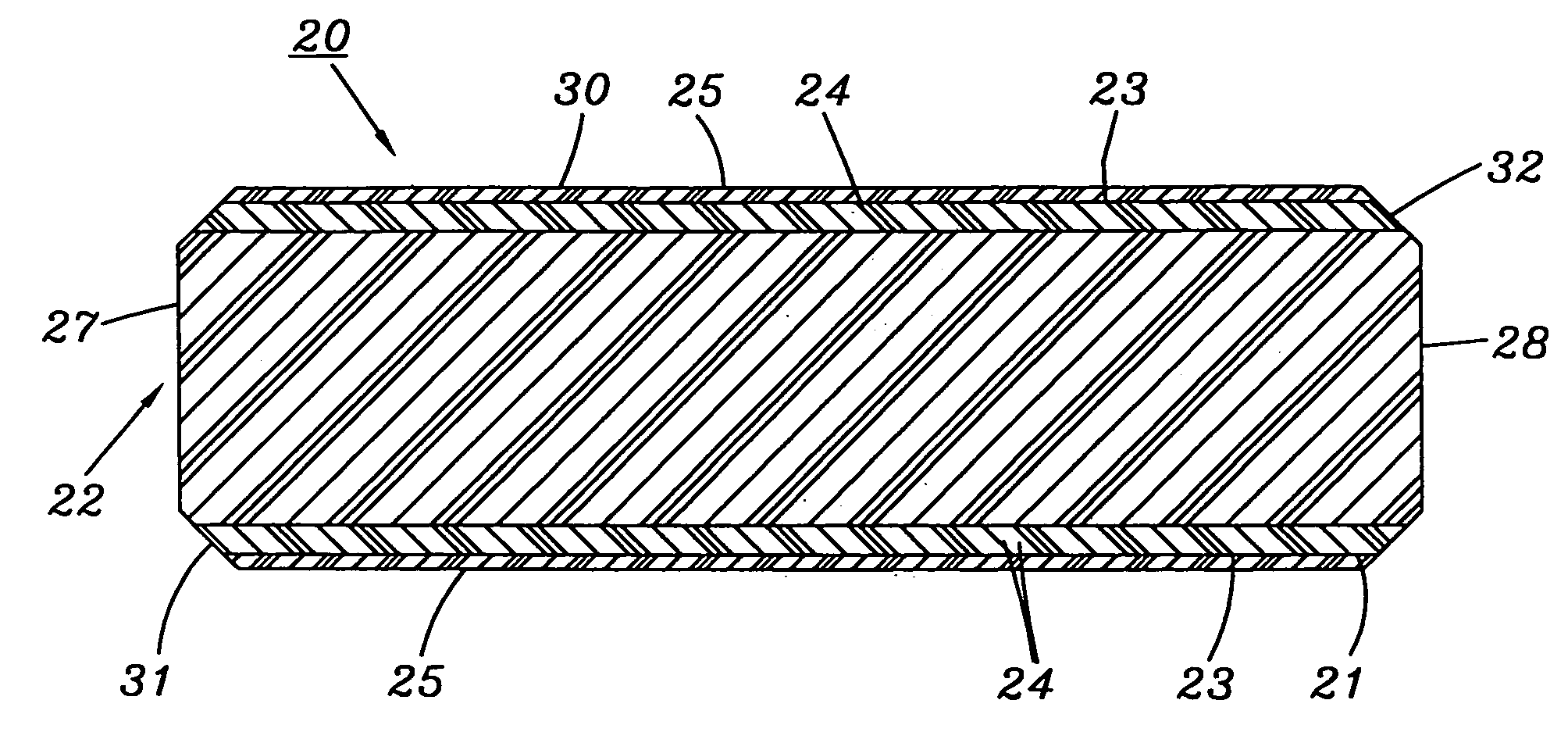

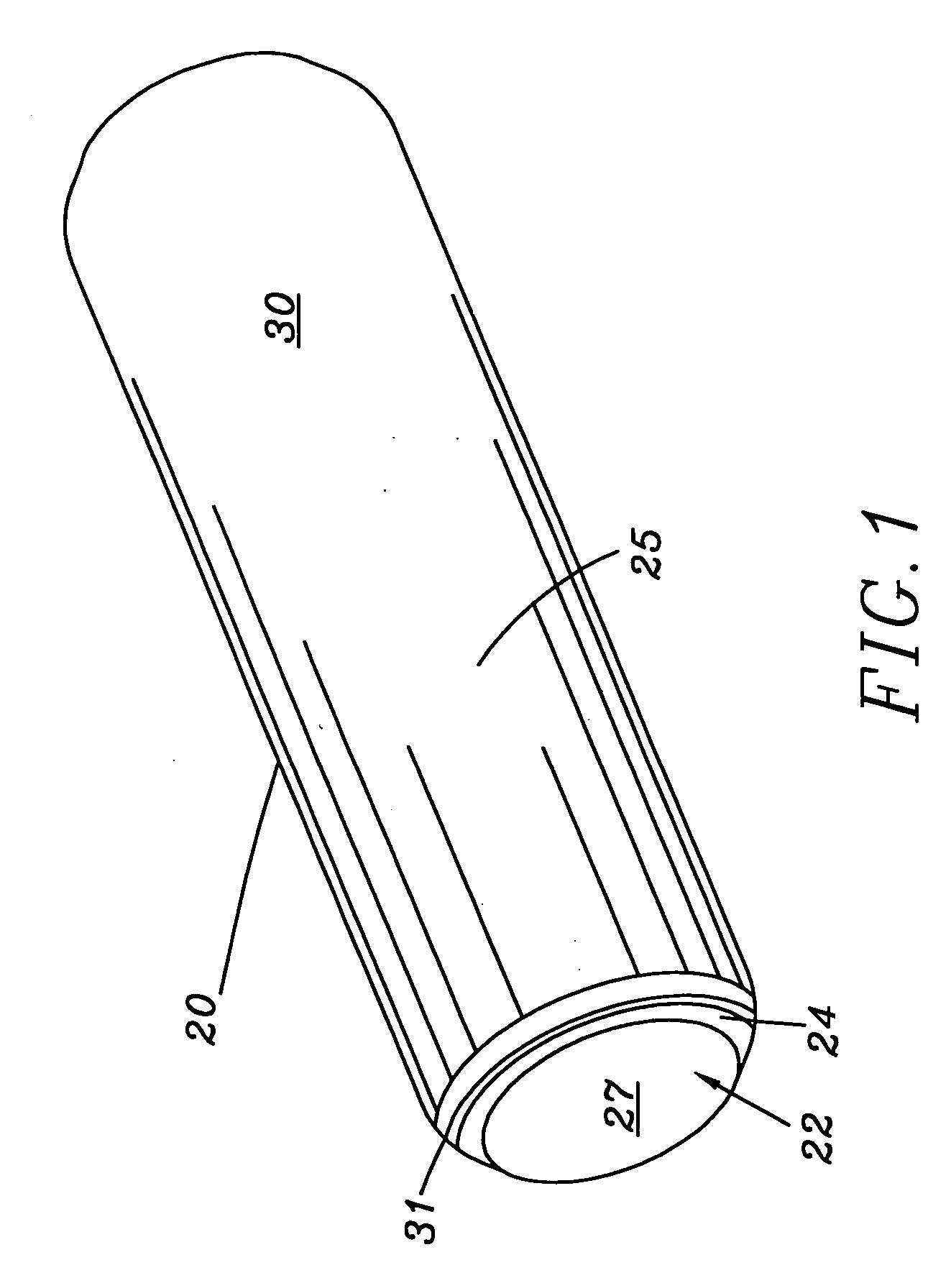

Synthetic closure

InactiveUS20060006132A1Prevent seepagePrevent leakageClosure using stoppersRemovable lids/coversPlastic materialsWine bottle

By achieving an extruded, foamed core formed from plastic material peripherally surrounded and integrally bonded with a plurality of cooperating synthetic, plastic, extruded, outer layers, a unique, multi-component, multi-layer synthetic closure is provided which may be employed as a bottle closure or stopper for any desired product, whether the product is a liquid, a viscous material, or a solid distributed in a bottle or container and dispensed through the open portal of the container neck. The present invention achieves a mass producible, resilient, synthetic bottle closure which is employable for any desired bottle, including wine. By employing the present invention, a multi-component or multi-layer synthetic closure is attained which possesses physical properties substantially equal to or better than the physical properties found in cork material, which has caused such cork material to be the principal closure material for wine bottles.

Owner:BANK OF AMERICA N A

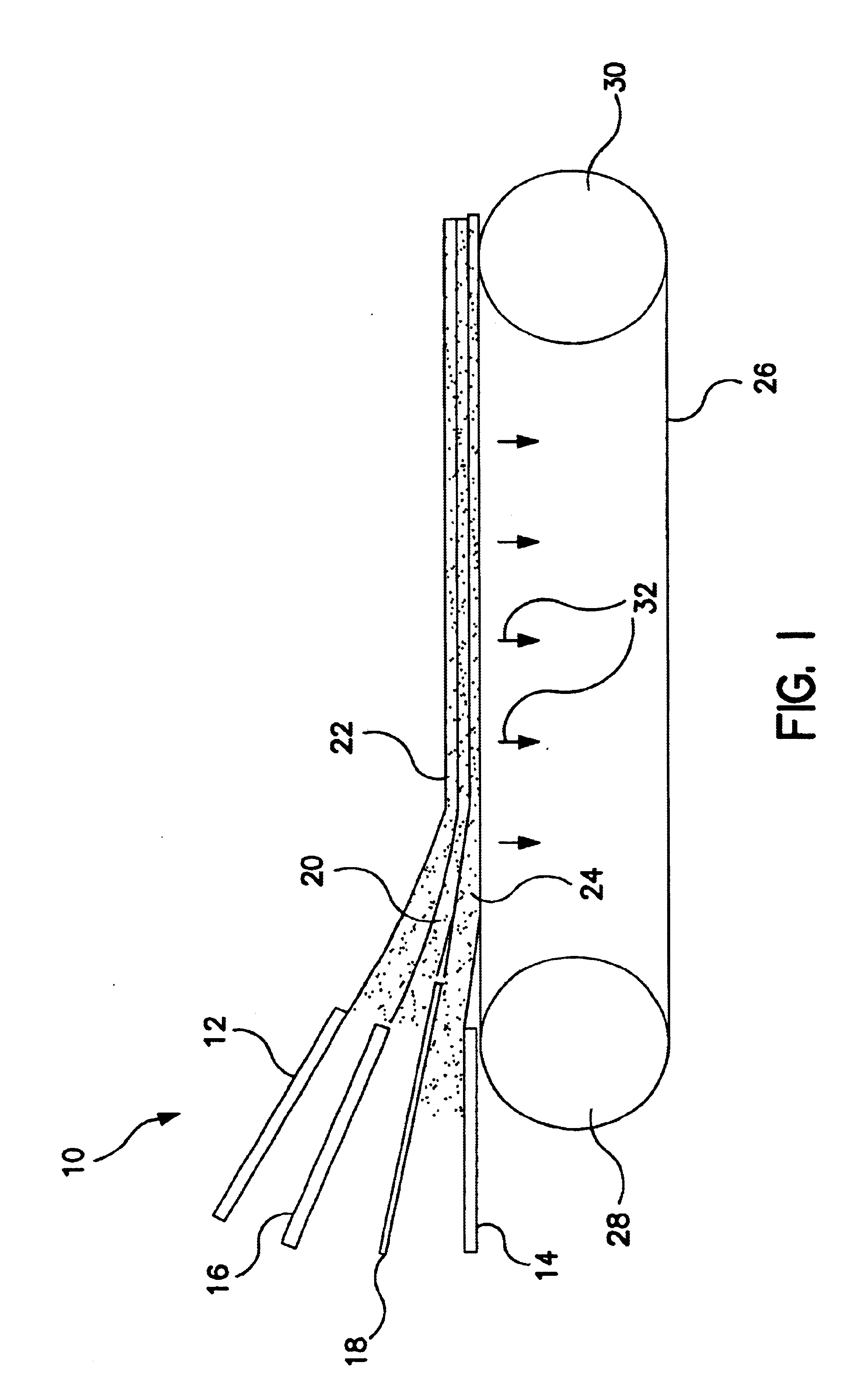

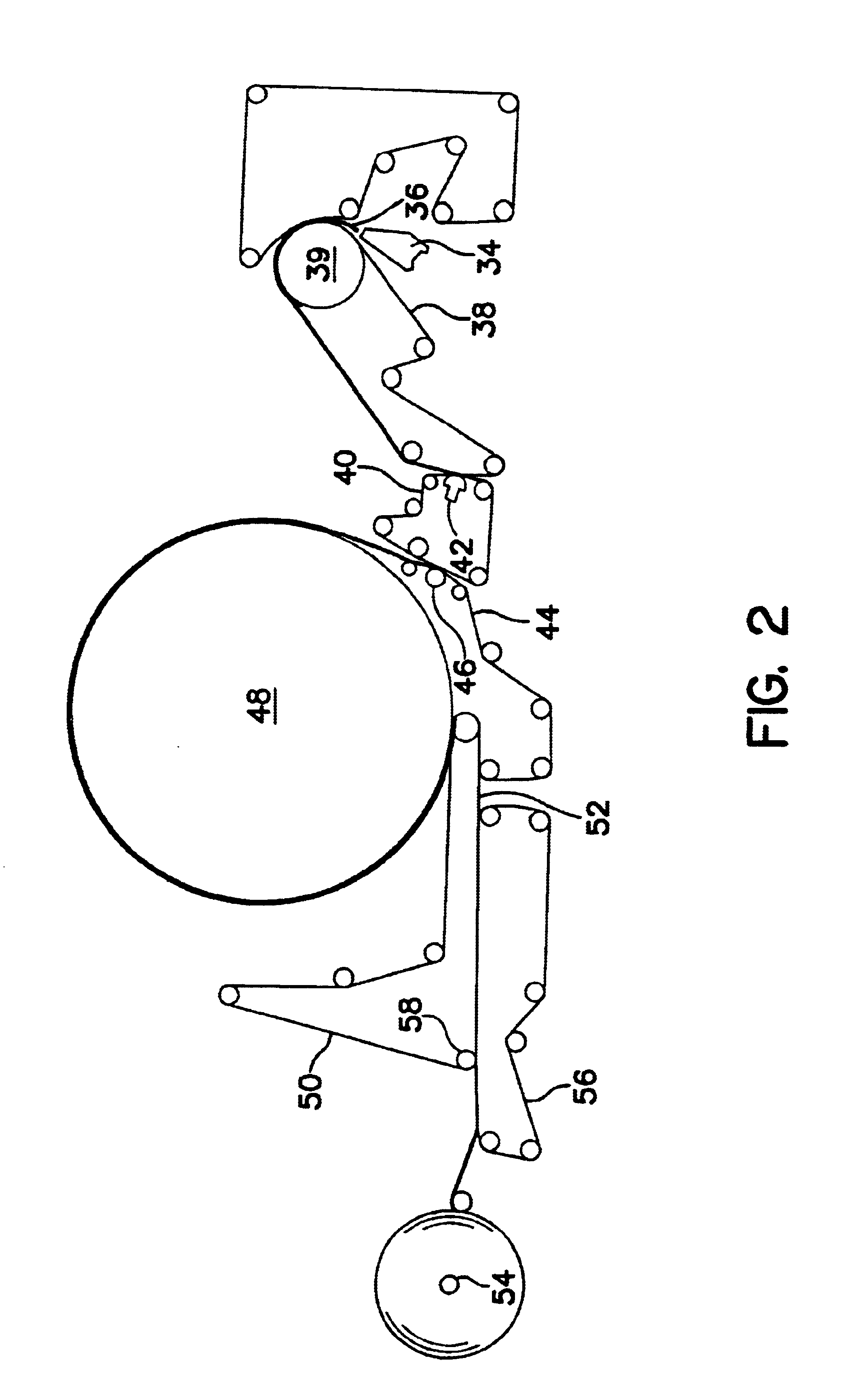

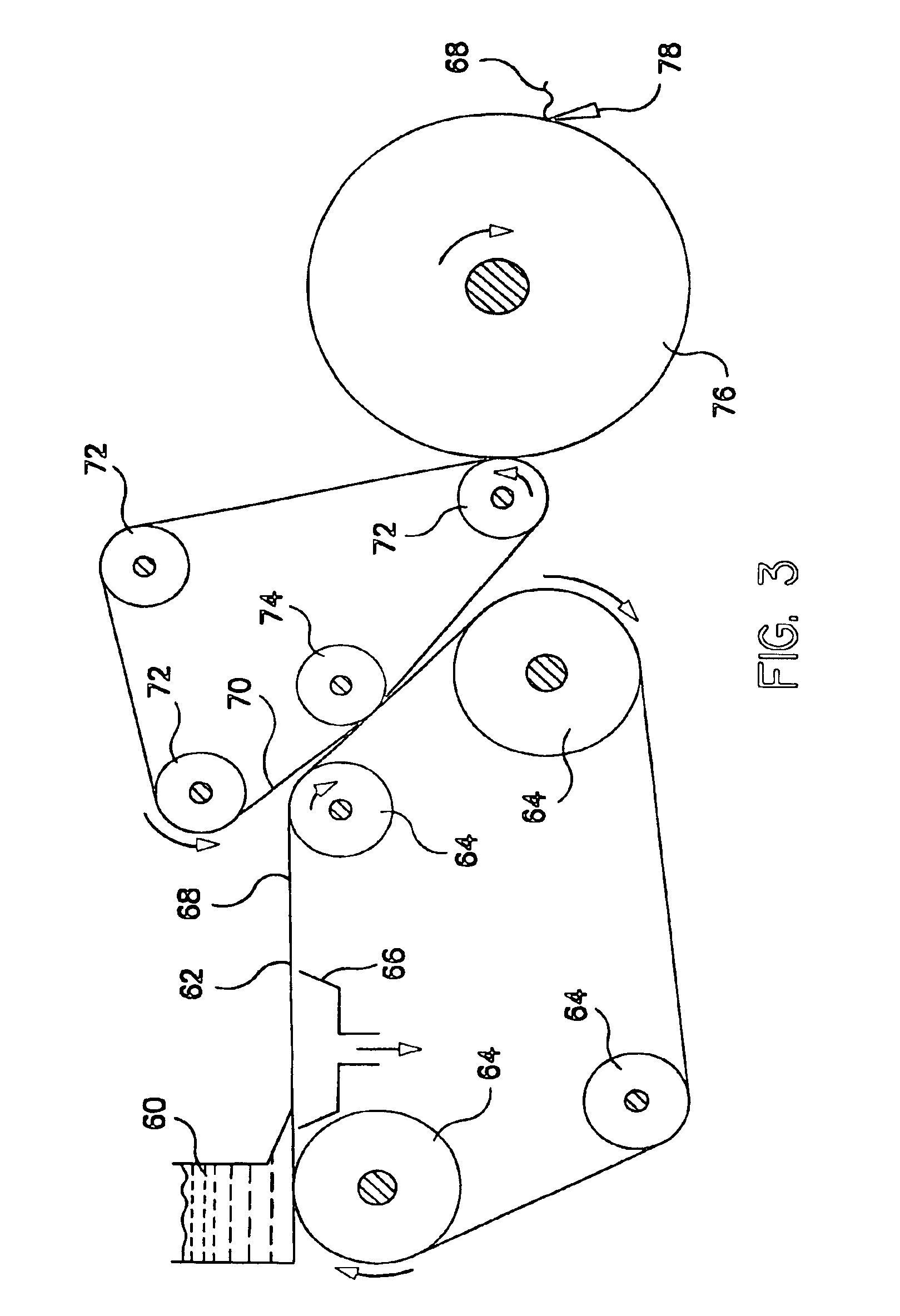

Wiping products made according to a low temperature delamination process

InactiveUS6846383B2Short durationReduce the temperatureNon-fibrous pulp additionNatural cellulose pulp/paperFiberAdhesive

The present invention is generally directed to paper products having great softness and strength. The paper products are formed from a paper web that can be made according to various methods. In one embodiment, the paper web is an uncreped through-air dried web. The web can contain softwood fibers in combination with high-yield fibers. For example, the high-yield fibers can be contained in the middle layer of a stratified fiber furnish. In accordance with the present invention, a first bonding material is applied to a first side of the web and a second bonding material is applied to a second side of the paper web. The bonding materials are applied according to preselected patterns. At least one side of the paper web is creped after one of the bonding materials is applied. The bonding material applied to the creped side of the web can be an adhesive selected that allows the web to be creped at relatively low temperatures.

Owner:ASHLAND OIL INC +1

Softwood cutting propagation method for liquidambar styraciflua

InactiveCN103222390AImprove reproductive efficiencySimple technical operationHorticultureShootAgricultural engineering

The invention discloses a softwood cutting propagation method for liquidambar styraciflua. The softwood cutting propagation method comprises the following steps of (1) cutting time; (2) preparing a rooting agent; (3) preparing a cutting medium; (4) implementing cutting shoot treatment and cutting; and (5) implementing after-cutting management and transplanting. The softwood cutting propagation method for the liquidambar styraciflua can achieve a cutting rooting rate greater than 83.5%. The method is simple and convenient to implement, and has the advantages that cost is low, operation is simple and easily implemented, popularization and application are easy, and the like; and the method has important application and popularization values on liquidambar styraciflua seedling production.

Owner:JIANGSU ACAD OF FORESTRY +1

Paper-making grade softwood pulp plate modifying production technique

ActiveCN101158125AMeet production requirementsReduce pollutionPretreatment with alkaline reacting compoundsFats/resins/pitch/waxes removal in pulpTO-18Cooking methods

The invention provides a denaturizing production technique of paper making needle wood pulp plate, which solves the problems of uneven dipping, slow hemicelluloses stripping, difficult accumulation descending, uneven cooking, single cooking method, single bleaching method and violent conditions existing in denaturizing production technique of wood pulp in the prior art. The invention comprises the following steps: wood pulp plate paging, alkali soaking, pressing, untwining and dispersion, cooking, washing, impurity removal, bleaching, a secondary washing and pulping; wherein, the wood pulp plate paging, alkali soaking, pressing, untwining and dispersion are to send papers into a alkali dipping barrel with concentration of 6 percent to 18 percent after the paper making bleaching wood pulp plates are separated by a paging device. When the wood pulp plates are changed into pulp with concentration of 3 percent to 6 percent, the pulp with concentration of 3 percent to 6 percent is sent to a squeezer to be squeezed and to untwine and disperse fiber. By adopting the invention, the quality of the dissolved viscose fiber wood pulp can be better and more stable; furthermore, the invention provides wider selection range of raw material.

Owner:YIBIN GRACE GROUP CO LTD

Method for bleaching mechanical pulp

InactiveUS20020144796A1Pulp bleachingPulping with inorganic basesAlkaline earth metalBiological activation

A method for bleaching unbleached softwood or hardwood pulps using hydrogen peroxide without added alkali for activation is described. The aqueous hydrogen peroxide solution contains an alkaline earth metal carbonate, preferably magnesium carbonate and can be used at elevated temperatures. Bleached hardwood or softwood mechanical pulps with high brightness, low yellowness (b*) and reduced reversion properties are produced.

Owner:WEST FRASER MILLS

Method for producing paper towel

InactiveCN102912676AReduce intensityHigh strengthWater-repelling agents additionReinforcing agents additionFiberPaper towel

The invention relates to a manufacturing method of a crepe paper product. A method for producing a paper towel comprises the following steps of: selecting 70-80 % of bleached softwood pulp and 20-30 % of straw pulp as raw materials; pulping the pulp by using a pulper, after beating the pulp by using a disc mill and adding auxiliary materials of an expanding agent, a softening agent and a wet strength agent to the pulp, molding, dehydrating and squeezing the pulp by using a Harper fourdrinier system; creping a wet paper sheet in a creping cylinder when the dryness of the wet paper sheet is 30-45 %, wherein an angle between a creping knife and the tangential line of a cylinder surface is 20-30 degrees, the cutting edge angle of a scraping knife sticking to the cylinder surface is 60-85 degrees, and the speed ratio of the creping cylinder and a heating cylinder is 1.15-1.18:1; and then drying the wet paper sheet by using the heating cylinder; and winding, rewinding and slicing the paper sheet so as to obtain a finished product. The method for producing the paper towel, provided by the invention, has the advantages as follows: through fiber variety and proportion selection and through the adoption of a wet creping process, the paper towel are produced; and the produced the paper towel has the advantages of tensile strength and proper air permeability; and the strength, wet strength, hydrophobicity, air permeability, flexibility and the like of the paper towel all reach higher standards; therefore, high quality and low cost are achieved.

Owner:QUANZHOU HUAXIANG PAPER IND

Multi-ply wiping products made according to a low temperature delamination process

InactiveUS6918993B2Short durationReduce the temperatureNon-fibrous pulp additionNatural cellulose pulp/paperFiberAdhesive

The present invention is generally directed to paper products having great softness and strength. The paper products are formed from one or more paper webs that can be made according to various methods. In one embodiment, the paper web is an uncreped through-air dried web. The web can contain softwood fibers in combination with high-yield fibers. For example, the high-yield fibers can be contained in the middle layer of a stratified fiber furnish. In accordance with the present invention, a first bonding material is applied to a first side of the web and optionally a second bonding material is applied to a second side of the paper web. The bonding materials are applied according to preselected patterns. At least one side of the paper web is creped after one of the bonding materials is applied. The bonding material applied to the creped side of the web can be an adhesive selected that allows the web to be creped at relatively low temperatures.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com