Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101 results about "Disc mill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A disc mill is a type of crusher that can be used to grind, cut, shear, shred, fiberize, pulverize, granulate, crack, rub, curl, fluff, twist, hull, blend, or refine. It works in a similar manner to the ancient Buhrstone mill in that the feedstock is fed between opposing discs or plates. The discs may be grooved, serrated, or spiked.

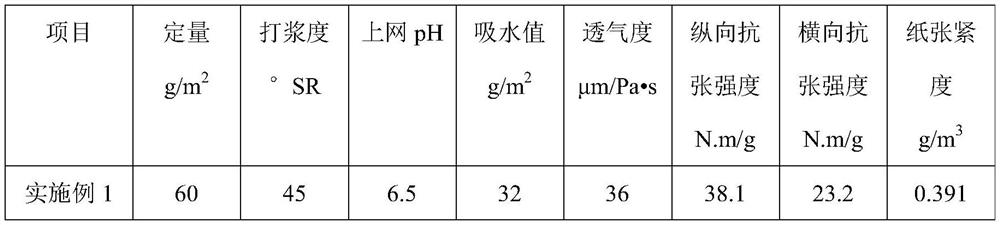

Method for preparing stainless steel lining paper

InactiveCN1936182AImprove performanceSolve the problem of only producing high-weight paperNatural cellulose pulp/paperFlexible coversFiberParaffin wax

The invention discloses a manufacturing method for a stainless steel lining paper that includes the following steps: adopting white wood pulp as raw material, and white sulfate softwood pulp: white hardwood pulp =70-80wt%: 30-20wt%; adopting short fiber shiny beating method, and 330 disc mill basalt stone lapping to take jordaning; using chemical auxiliary agent that adding 5-20wt% olefin emulsion, 0.5-1.0wt% positive ion starch, 0.5-1.0wt% AKD, 1.0-2.0wt% silicone emulsion, 0.3-0.5wt% CPAM, and 0.25-0.75wt% PAE. It has the advantages of high intension, laceration endurable, super smooth, clean and high temperature endurable. It could fit different manufacture technology requests of stainless steel.

Owner:樊运民

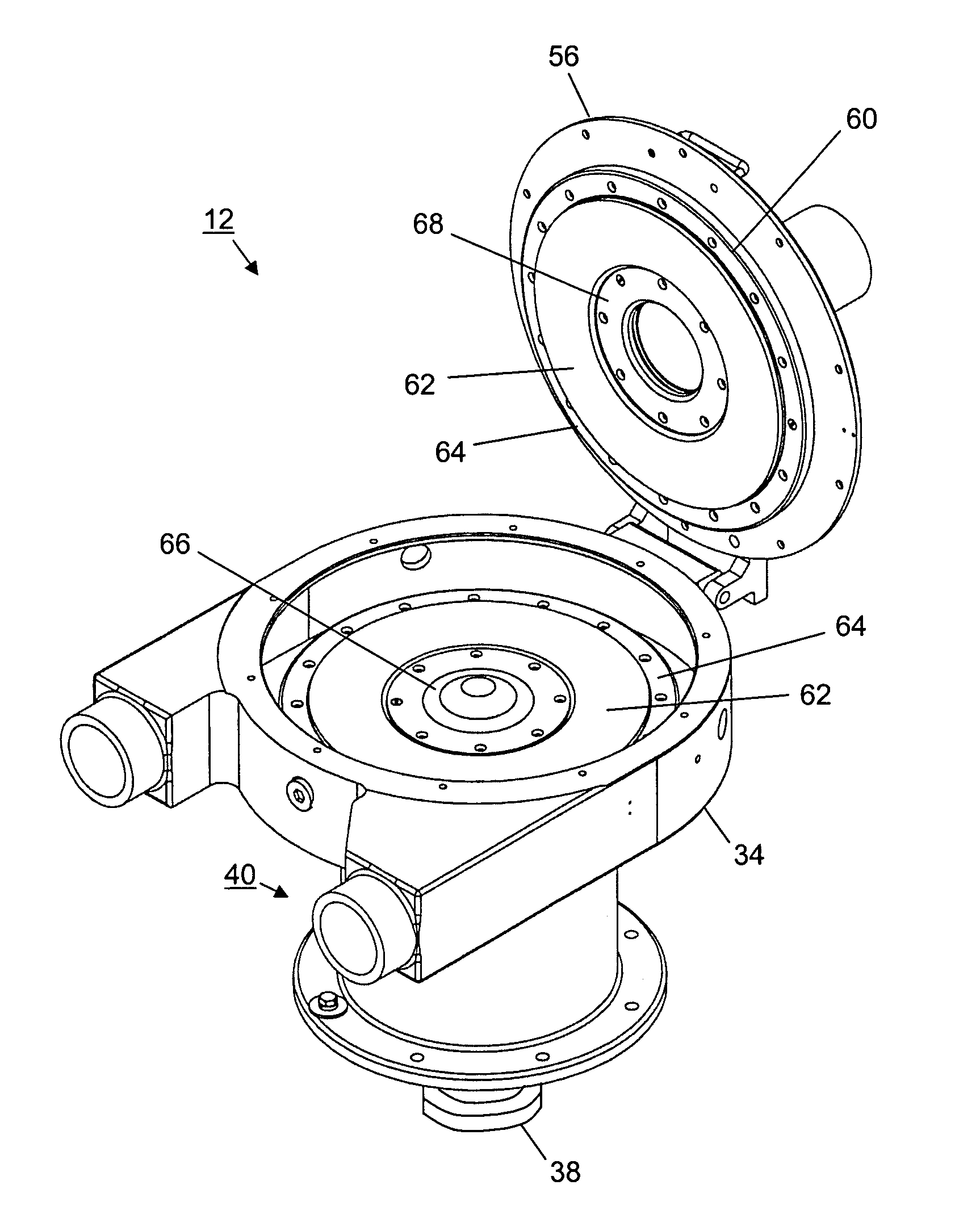

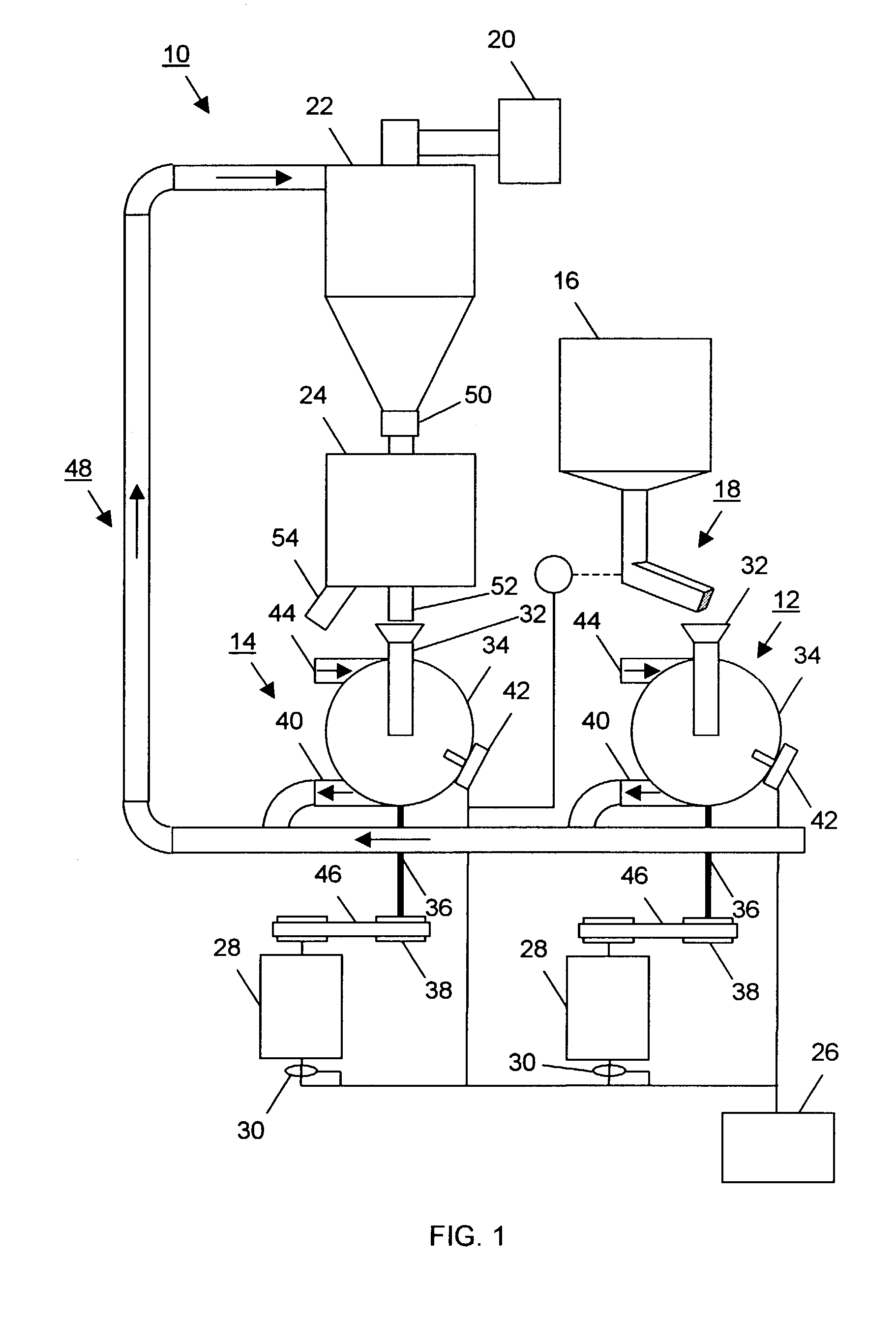

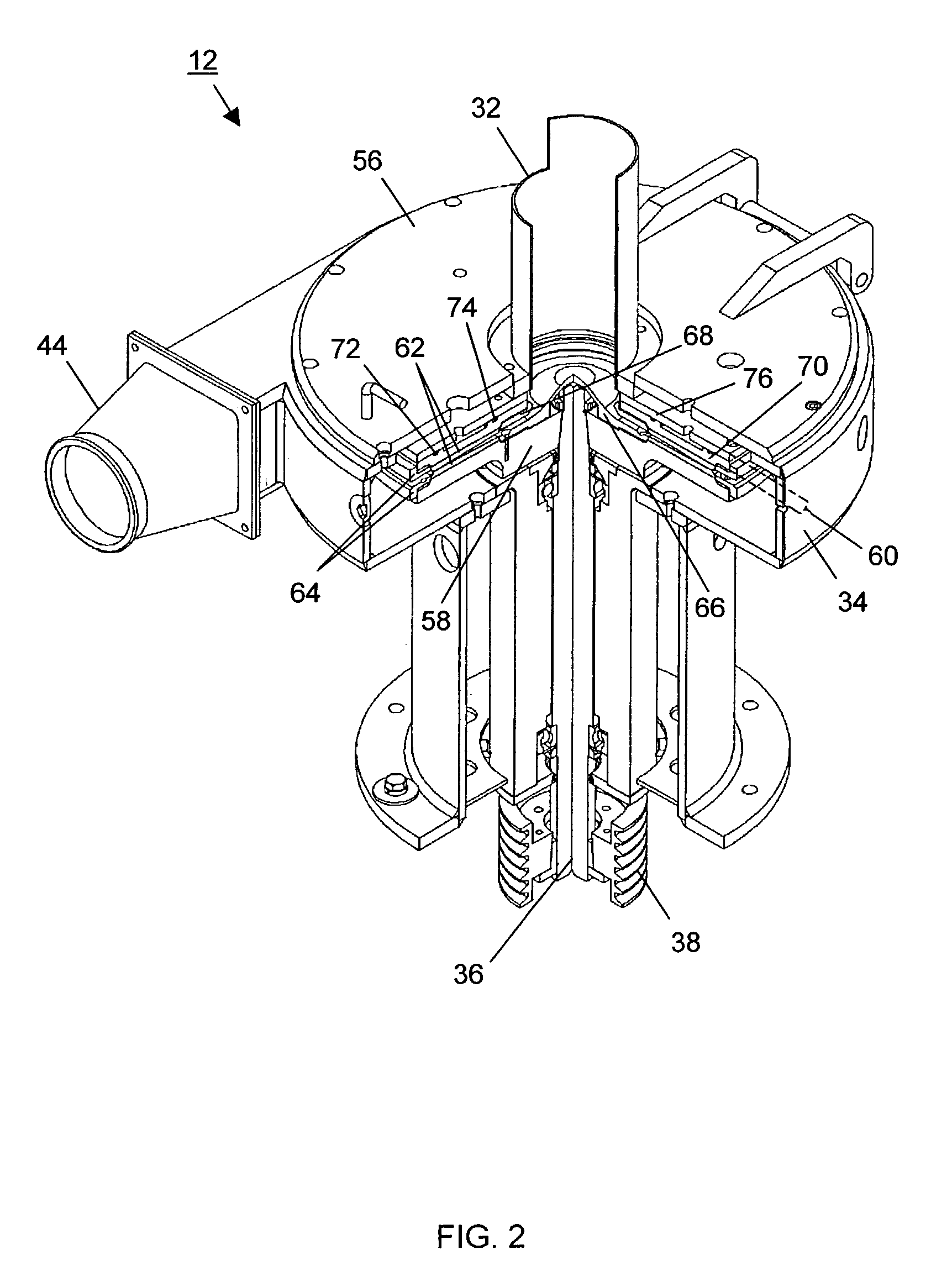

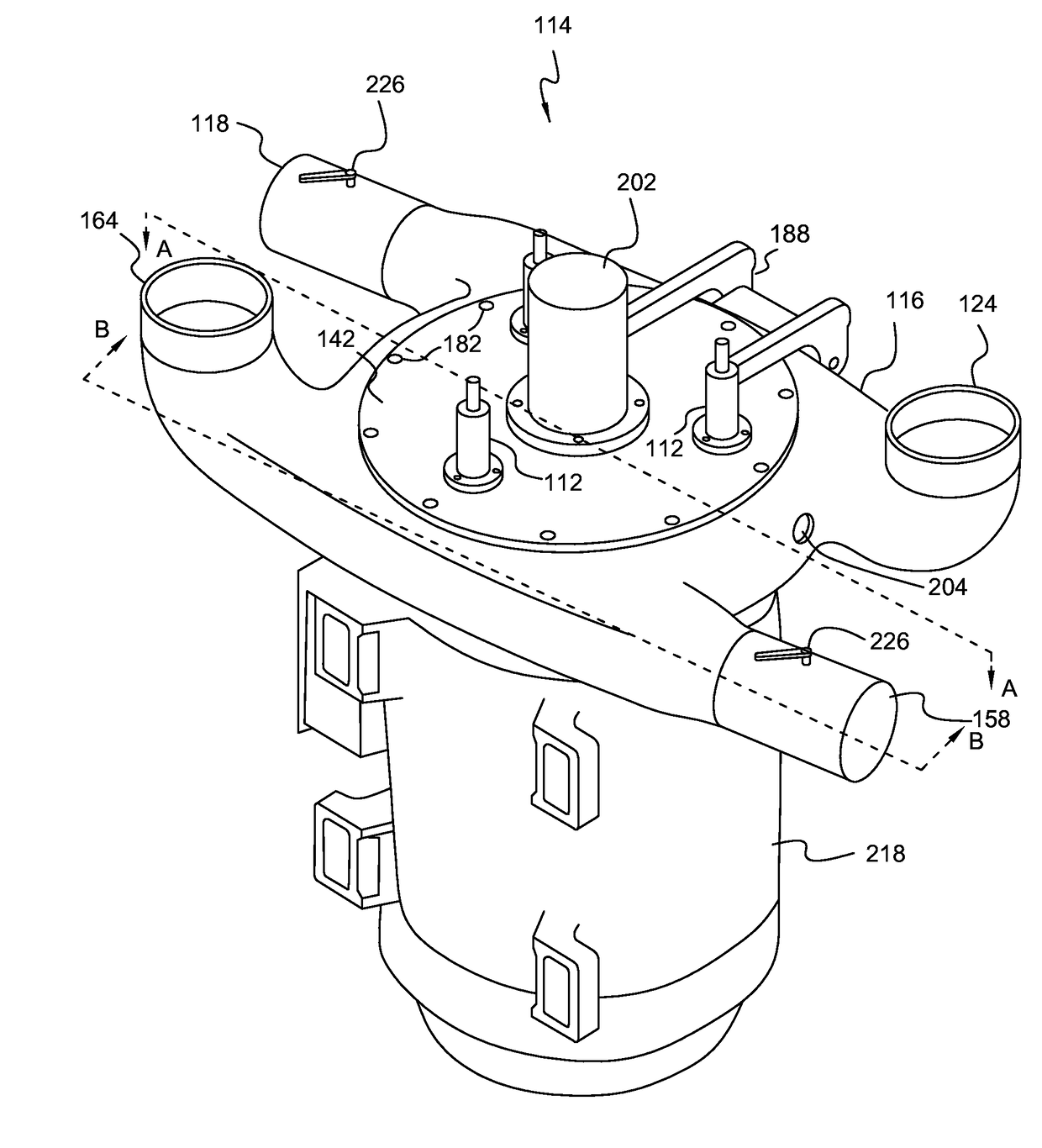

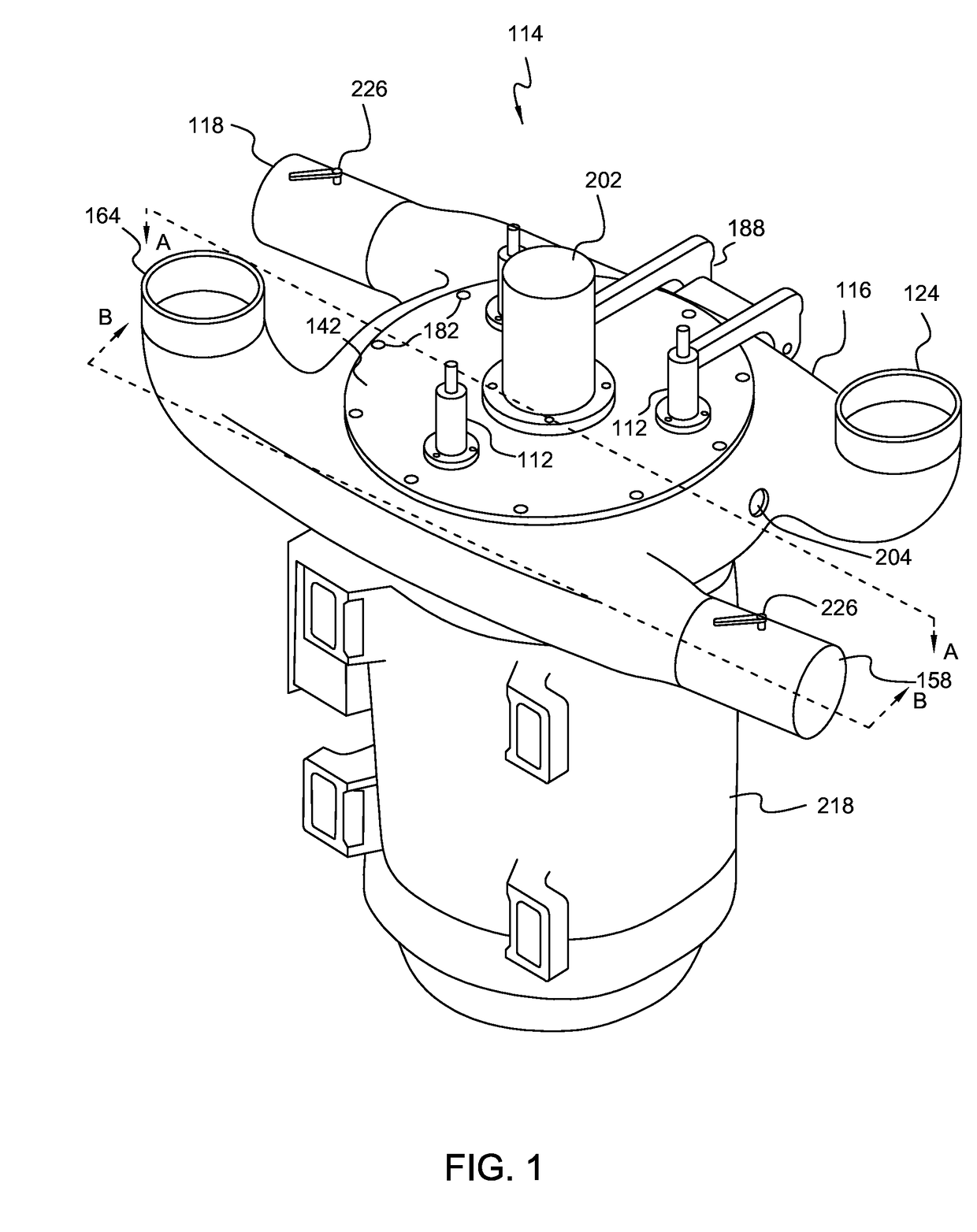

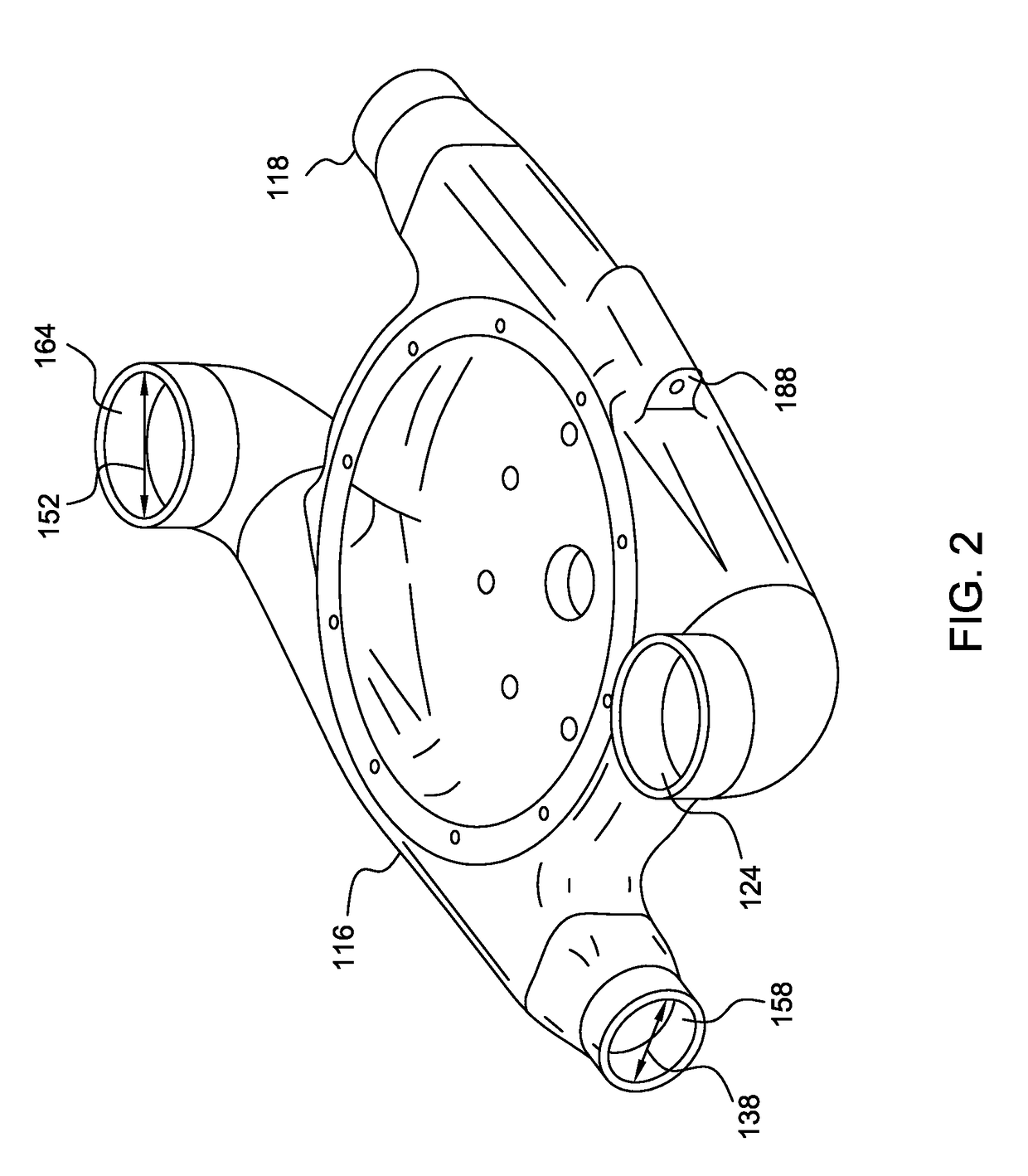

Disc mill assembly for a pulverizing apparatus

This invention relates to the art of methods and apparatuses for grinding various materials into smaller particles; particularly, to those known in the art as pulverizing systems and devices. This invention provides methods and apparatuses for an improved disc mill assembly that utilizes a tapered flywheel and water jacket in conjunction with planar grinding disk cutting devices to create a tapered grinding channel.

Owner:REDUCTION ENG

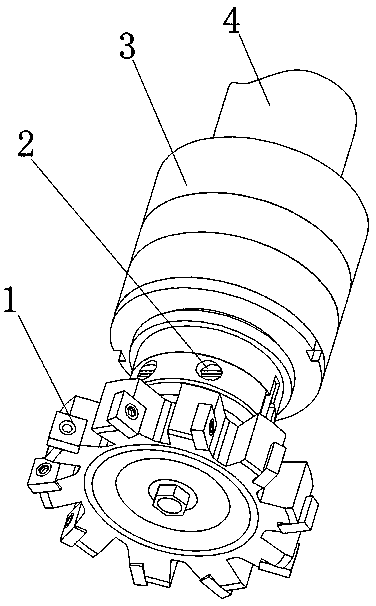

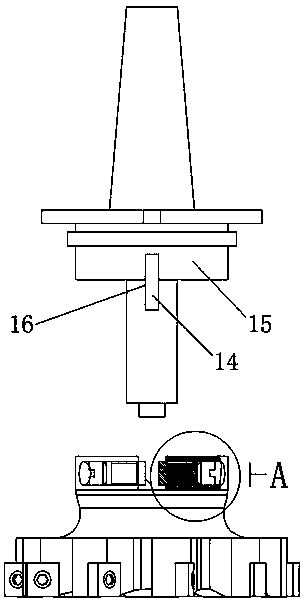

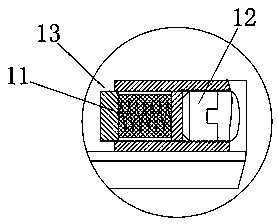

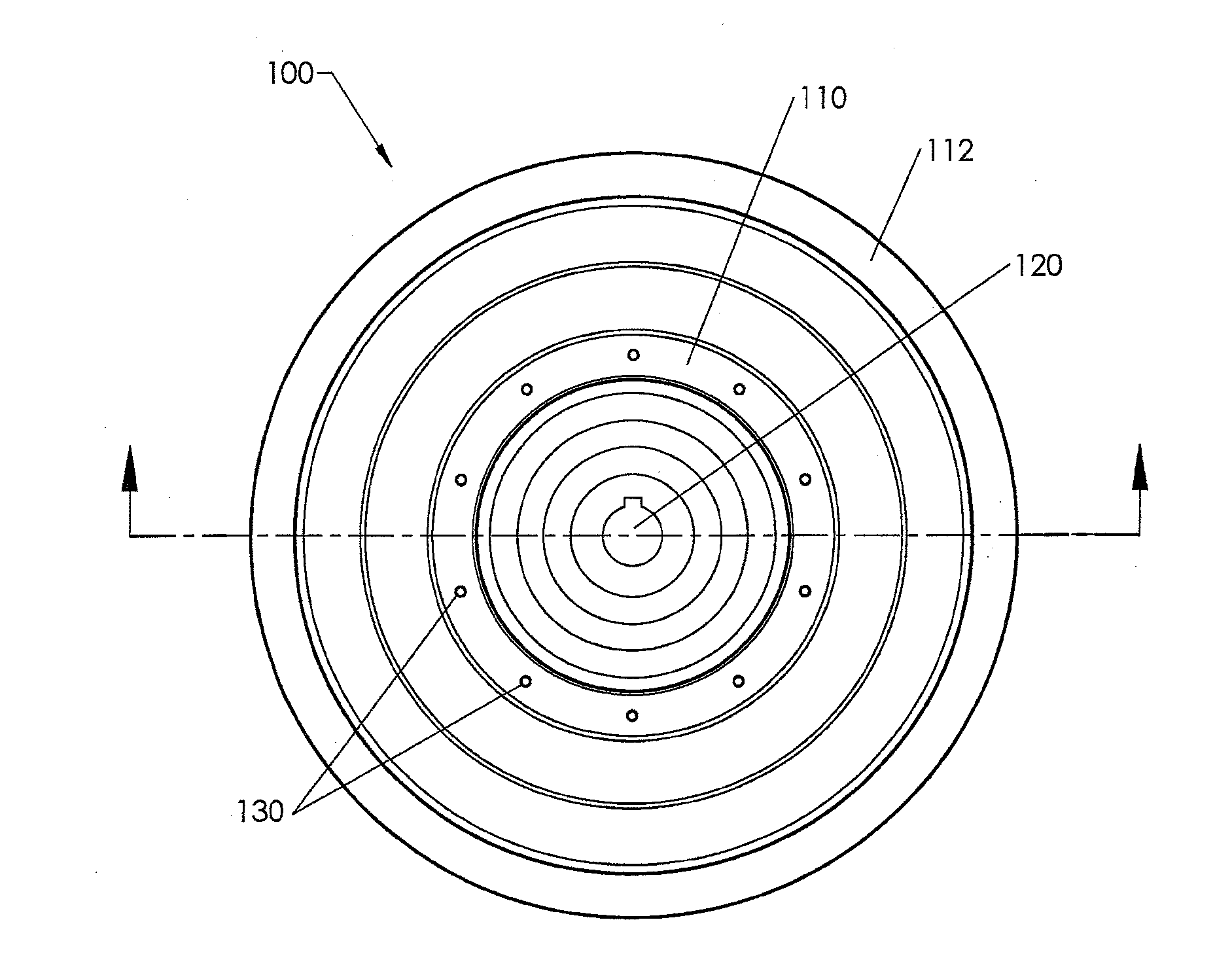

Milling device suitable for high-speed plane finish milling

InactiveCN104191005AAvoid shockImprove cutting stabilityMilling equipment detailsDisc millMilling cutter

The invention discloses a milling device suitable for high-speed plane finish milling. The milling device suitable for high-speed plane finish milling comprises a milling cutter plate, an adjustable vibration milling device and an online dynamic balance device, wherein the adjustable vibration milling device is mounted at the joint between a cutter handle and the milling cutter plate; the rear part of the online dynamic balance device is connected with a main shaft system of a milling machine; the front end of the online dynamic balance device is connected with the adjustable vibration milling device. By virtue of vibrators of the adjustable vibration milling device, feedback regulation is performed; an electric control hydraulic multi-way valve is used for controlling oil feeding amounts of different oil channels when the online dynamic balance device detects an unbalanced amount so as to achieve the dynamic balance during milling of a disc mill cuter, so that the purpose of high-speed and stable milling of the milling machine can be achieved; the stability during high-speed milling is ensured; the service life of a blade is prolonged.

Owner:HUNAN UNIV

Chemical mechanical pulping process for whole corn stalk

The invention relates to a chemical mechanical clean pulping process with whole corn stalk as a raw material. Firstly, the cut corn stalk is subjected to pre-extraction in hot water, after solid-liquid separation, the stalk is squeezed, ground and washed, the washed stalk is subjected to three-section high-concentration normal-pressure slurry grinding after being subjected to pre-impregnating treatment, and high-yield and high-strength chemical mechanical pulp is obtained, wherein the corn stalk is cut in a conventional hay cutter; extraction in hot water is chemical-free heating autocatalyticextraction under normal pressure; the extrusion and grinding process is performed in a double-screw extrusion and grinding machine; pre-impregnation is impregnation with sodium hydroxide under normalpressure; three-section high-concentration normal-pressure slurry grinding is performed in a high-concentration normal-pressure disc mill. The process has the benefits that compared with conventionalcorn stalk pulping processes, the process does not require physical separation of stalks and leaves of the corn stalk and is applicable to pulping of the whole corn stalk, part of non-fiber components are separated while fiber components in raw materials are almost completely reserved, a few chemicals are consumed in the pulping process, the obtained pulp is high in yield and good in strength, and high-pressure environment is avoided in the whole process. Produced waste liquids can be directly used as raw materials for other procedures.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

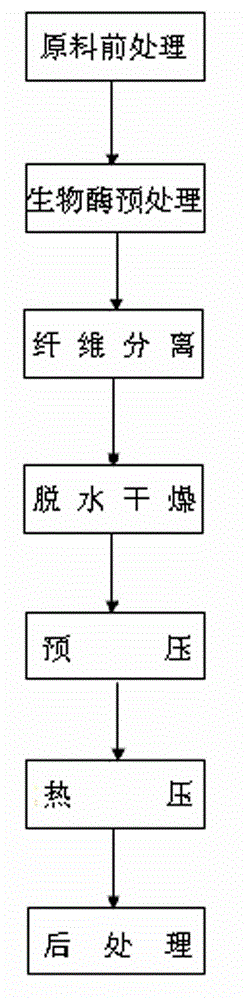

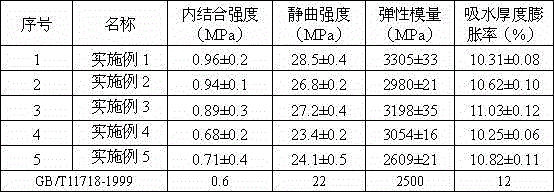

Low-energy-consumption method for preparing fiberboards by using bio-enzyme to separate fibers

InactiveCN103600405AReduce energy consumptionReduce manufacturing costWood working apparatusFlat articlesFiberDisc mill

The invention discloses a low-energy-consumption method for preparing fiberboards by using a bio-enzyme to separate fibers. The method includes making woody raw materials, crop straws or bamboo into wood chips or crushed aggregates, and utilizing the bio-enzyme for pretreatment under a certain condition; dissolving the bio-enzyme in water at the temperature of 20-60 DEG C, wherein concentration of the bio-enzyme is 0.05-50%, a proportion of the wood chips or the crushed aggregates and a bio-enzyme solution is 10-50%, and treatment time is 5-120min; utilizing a disc mill to further separate the wood chips, the crushed aggregates or bamboo chips into fibers to replace a mode that a hot-grinding method in a conventional fiberboard preparation process is utilized to separate fibers to prepare the fiberboards. A principle that the bio-enzyme can degrade pectin and lignin in a fiber intercellular layer is creatively utilized to separate the fibers, so that compared with the hot-grinding method, the method has the advantages of cleanliness, environment protection, low energy consumption and low cost. Reduction of energy consumption and production cost during producing of the fiberboards is facilitated, and the low-energy-consumption method has good social benefit and economic benefit.

Owner:SOUTHWEST FORESTRY UNIVERSITY

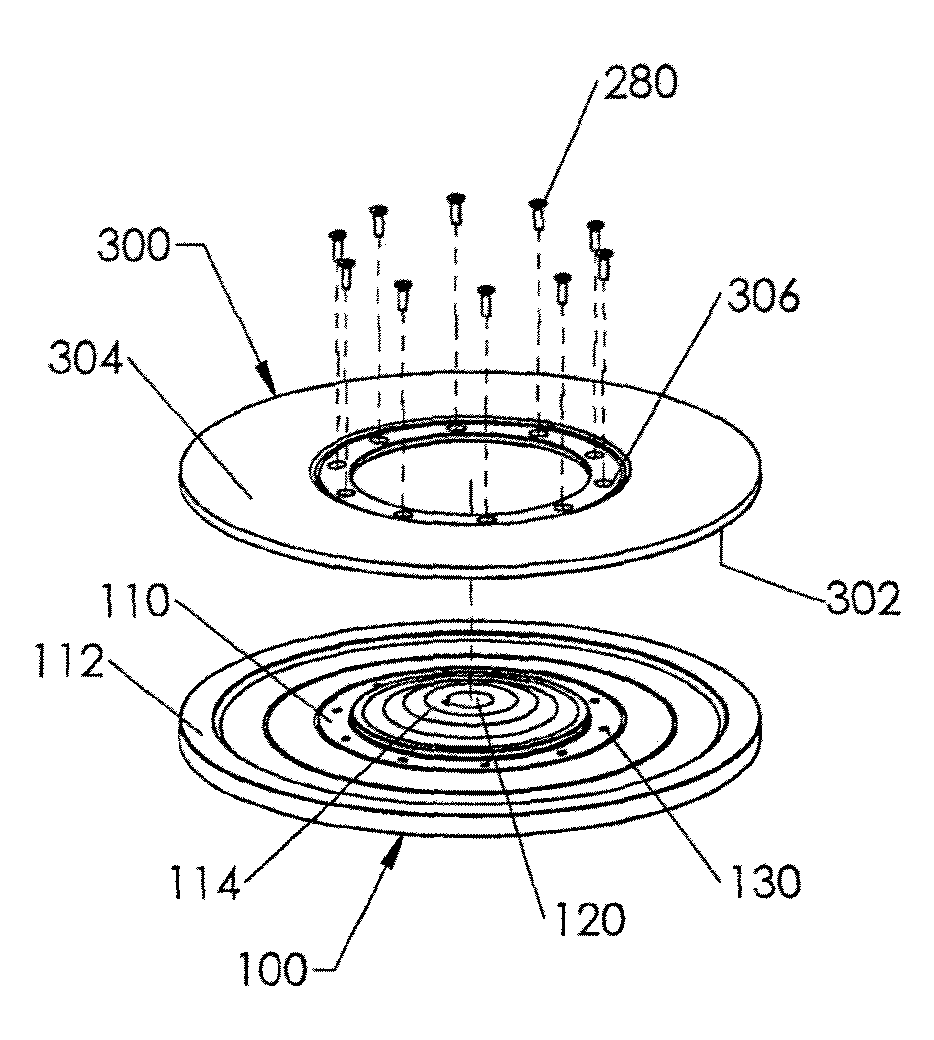

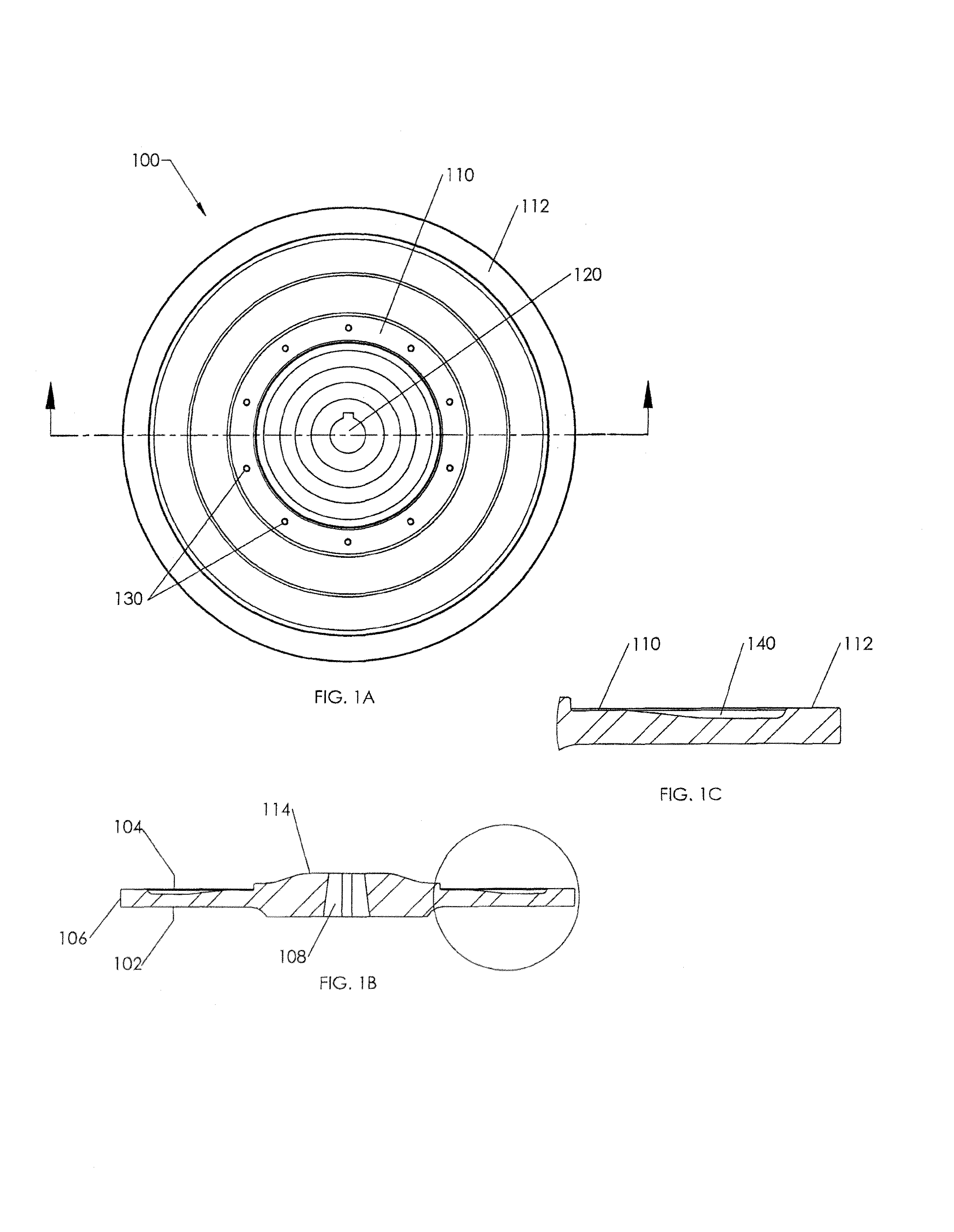

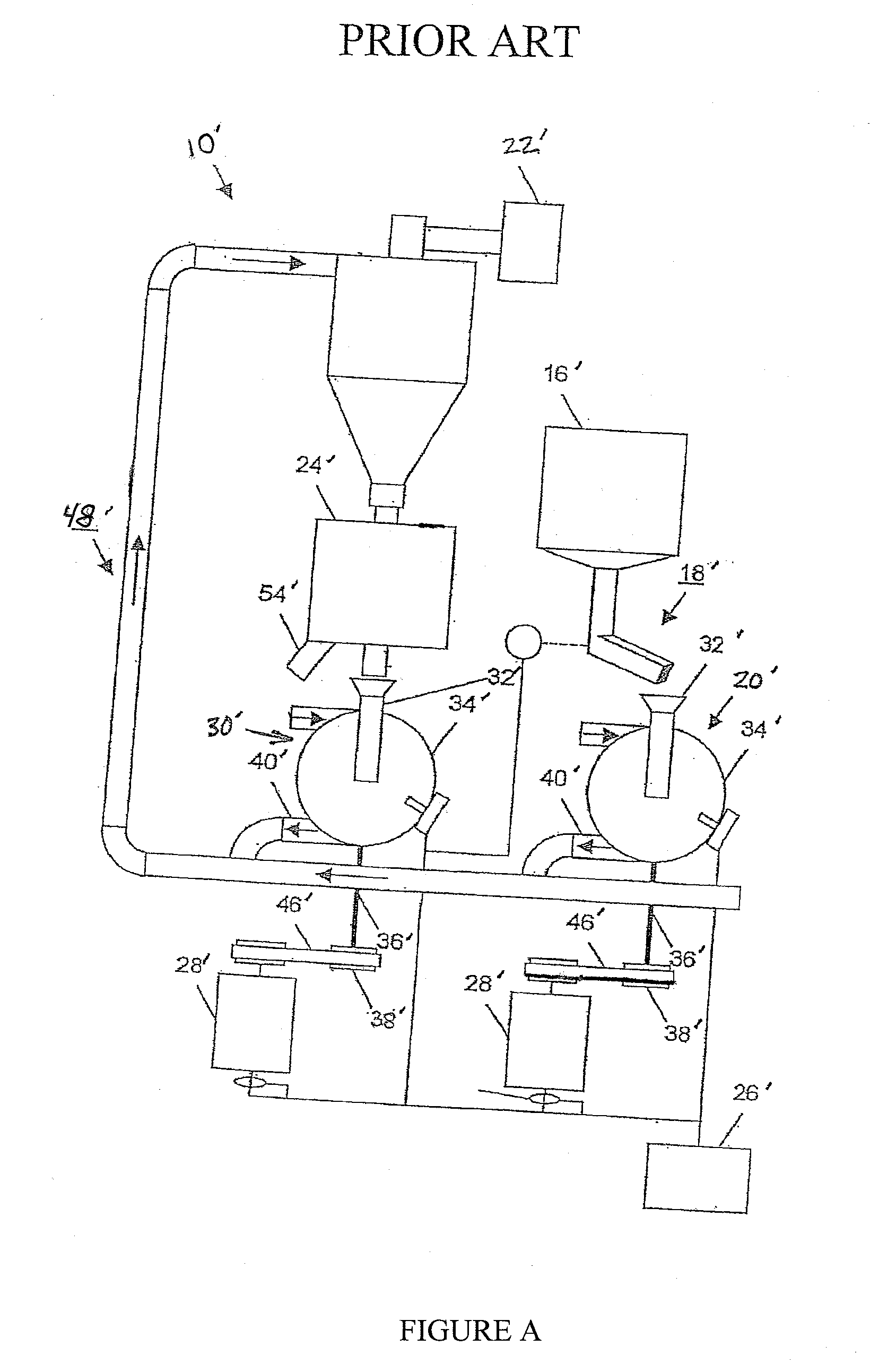

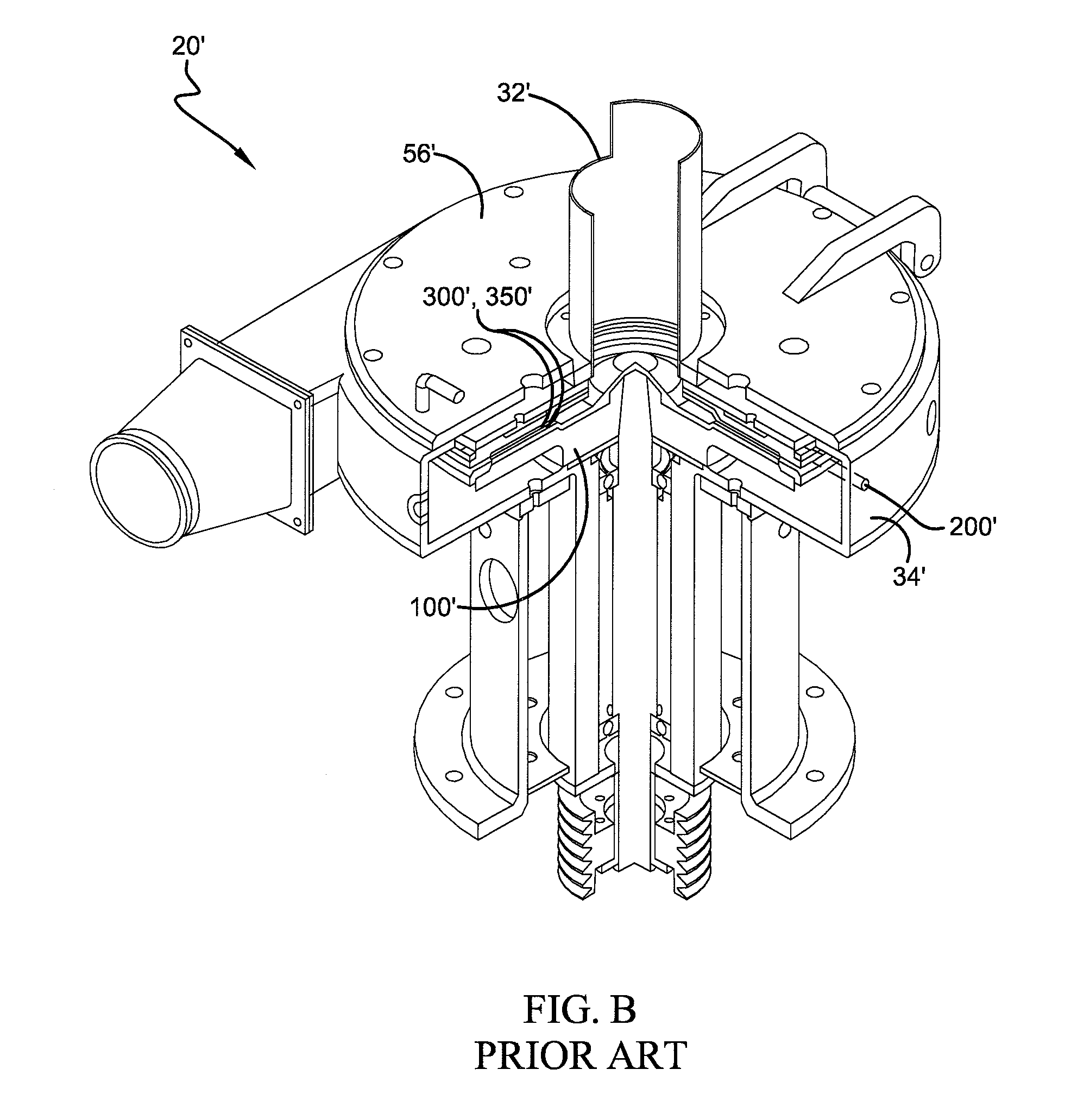

Disc mill assembly for a pulverizing apparatus

ActiveUS20110210193A1Light weightIncreased material throughputCocoaGrain treatmentsDisc millWater jacket

This invention relates to the art of methods and apparatuses for grinding various materials into smaller particles; particularly, to those known in the art as pulverizing systems and devices. This invention provides methods and apparatuses for an improved disc mill assembly that utilizes a tapered flywheel and water jacket in conjunction with planar grinding disk cutting devices to create a tapered grinding channel.

Owner:REDUCTION ENG

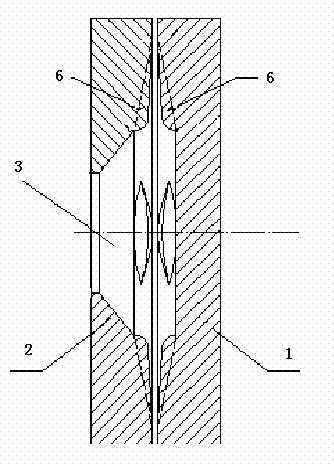

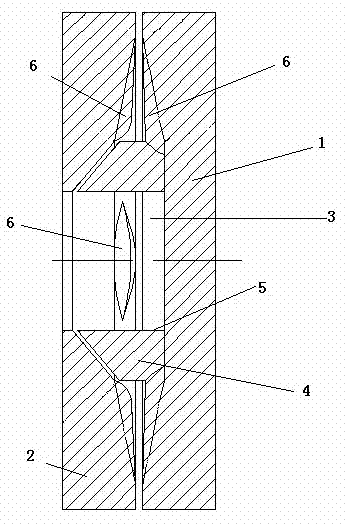

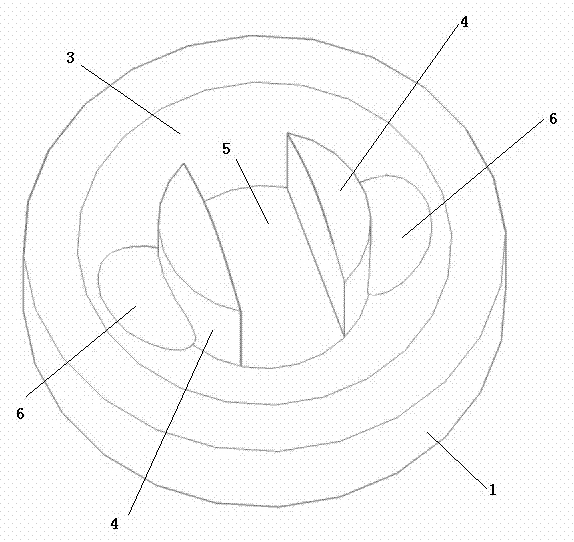

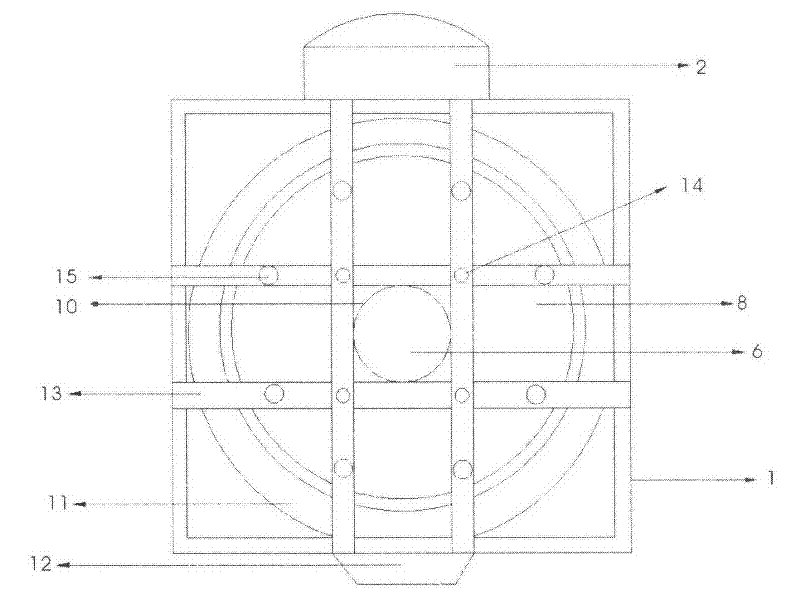

Disc mill

The invention discloses a disc mill which comprises a movable milling disc (1) and a fixed milling disc (2), two bosses (4) are arranged on a central plane of a processing material cavity (3) of the movable milling disc (1), a material throwing groove (5) is arranged between the two bosses (4), and protruding petals (6) are arranged on the outsides of the two bosses (4). The disc mill has the advantages of overcoming the defect that the movable milling disc of a horizontal type disc mill cannot drive all materials to be sufficiently smashed, lamination smashing along a circumferential normal direction in the processing material cavity of the milling disc is achieved, processed materials can be finely smashed, and a choice is provided for optimizing the disc mill.

Owner:贵阳探矿机械厂有限公司

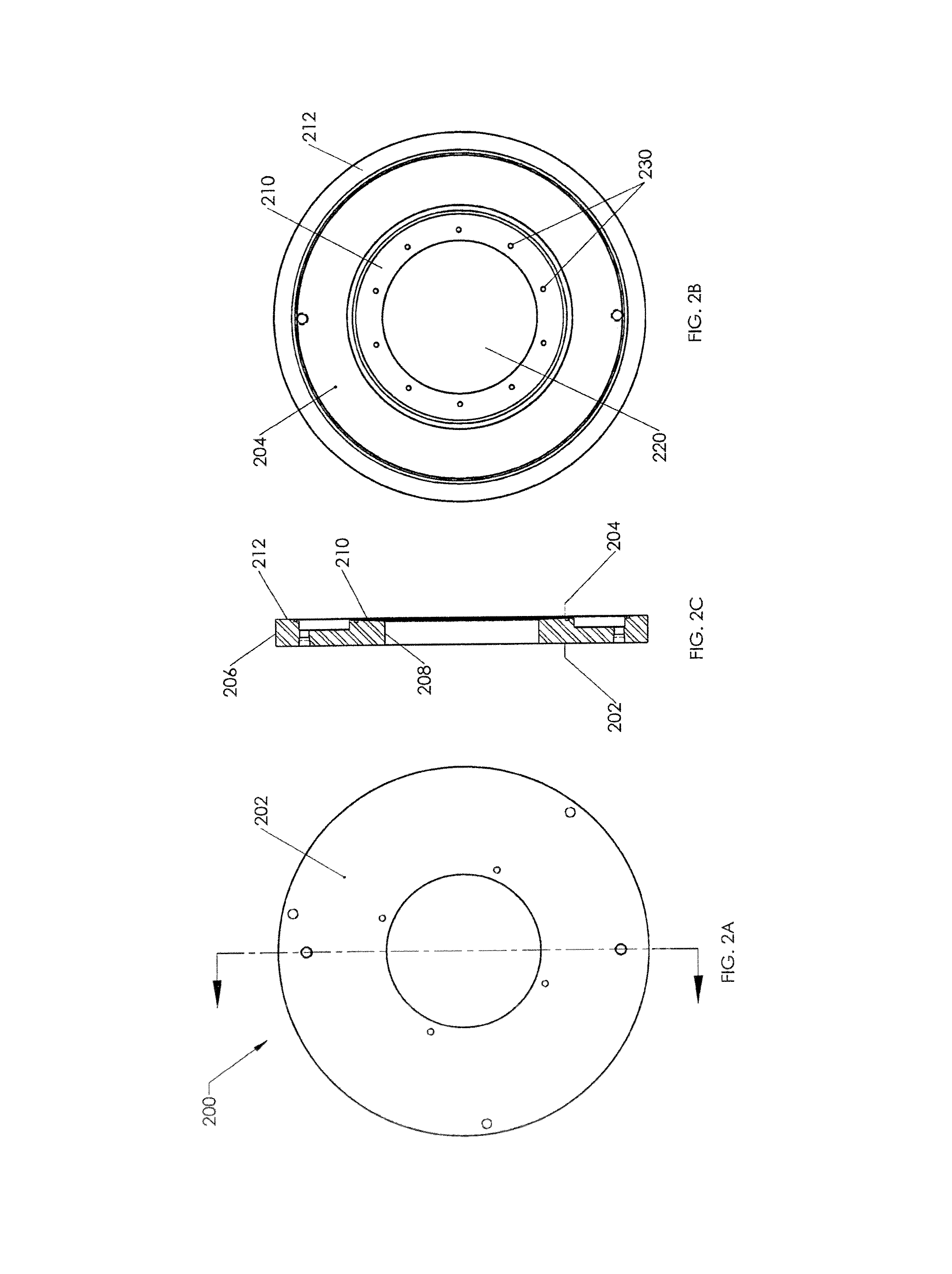

Disc mill assembly for pulverizing system

A disc mill assembly for a pulverizing system includes: a flywheel, a water jacket, two disc blades, and two ring clamps. In alternate embodiments, the disc mill assembly also includes: an air inlet to provide input air from an external air supply and an improved blade height adjustment mechanism. A disc blade is also provided. The disc blade is a single member with a central aperture that is the only through hole in the blade. Users may cost-effectively adopt a disposal versus sharpening policy for replacement of the disc blade. A method for controlling a temperature of material in a disc mill assembly having first and second disc blades is provided. The method includes: directing an adjustable input air stream, directing material to be ground, monitoring the temperature of the material, and controlling the air stream directing and / or the material directing in response to the temperature monitoring.

Owner:KING MACHINE & TOOL

Opposite netted disc mill

The invention aims to provide an opposite netted disc mill which has the advantages of energy saving, convenient arrangement, simple maintenance, stable performance, small occupied area and high output. The mill which comprises a frame, a motor and a speed reducer which are arranged at the bottom of the frame, and a stone inlet and a water inlet which are arranged above the frame is characterized in that: a stone salver which is arranged under millstones is connected with a stone outlet at one side of the central section of the frame, the coupling of the speed reducer is fixedly connected with the lower millstone, the upper millstone is connected with the frame through positioning pins, and springs are arranged surrounding the positioning pins; the upper millstone clings to the lower millstone, and netted mill courses are arranged on clinging surfaces; and the upper millstone is annular in shape, and the middle through hole is a stone channel. The motor is started to charge the stone from the stone inlet, and simultaneously water is charged from the water inlet; the stone enters a space between the upper millstone and the lower millstone through the middle through hole of the upper millstone, and the rotation of the lower millstone grinds the stone into stone flour; and the stone flour falls from a space between outer edges of the two millstones, and then is discharged from the discharge port through the inclined stone salver under the millstones.

Owner:莫虎林 +1

Disc mill and method for controlling action element action in beating process thereof

InactiveCN101413223AAvoid frictional collisionsGood production safetyPulp beating/refining methodsNumerical controlDisc millEngineering

The invention discloses a disc refiner and a control method for the actuation of executive elements during the beating of the disc refiner. The control method comprises the following steps: a pulp inlet pipeline or a pulp outlet pipe of the disc refiner is provided with a pressure sensor; and the actuation of the executive elements of the disc refiner is controlled according to the pulp flow pressure of the pulp inlet pipeline during the beating, thereby controlling the beating process of the disc refiner. The method adopted in the invention is to control the actuation of the executive elements during the beating of the disc refiner, and can effectively prevent the friction collision among the executive elements of the disc refiner caused by pulp interruption during beating, thereby protecting the disc refiner.

Owner:SOUTH CHINA UNIV OF TECH

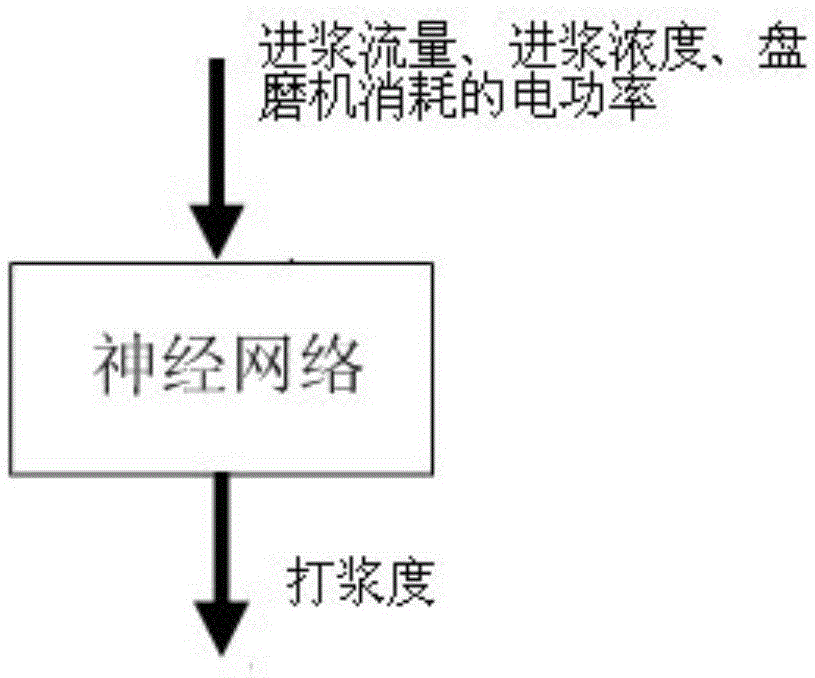

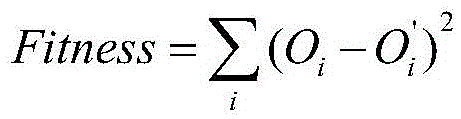

Disc mill control method

InactiveCN105568732AImplement soft sensingPulp beating/refining methodsSpecial data processing applicationsDisc millMomentum

The invention discloses a disc mill control method. The disc mill control method comprises the following steps: a neural network is established, and a BP neural network and an additional momentum learning rule are used to train the neural network according to existing historical monitoring data; the optimal input parameter of the neural network is solved with particle swarm optimization; through estimated and actually measured error data of the neural network, the additional momentum learning rule is used to update the trained neural network. The disc mill control method solves the problems that the beating degree of a pulp mill is mainly determined by manual assay and far lags behind a beating process and a disc mill cannot be controlled precisely and effectively, soft measurement of the beating degree is realized, and on-line detection signals are provided for real-time control of the disc mill.

Owner:ZHENJIANG COLLEGE

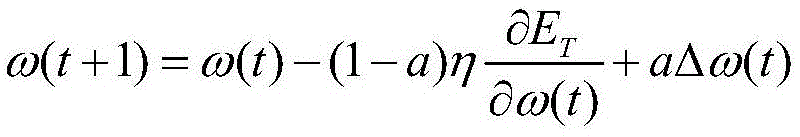

Method for producing lactic acid from bagasse

InactiveCN104694587ALarge amount of resourcesReduce lossesMicroorganism based processesFermentationCellulaseLACTIC ACID/UREA

The invention discloses a method for producing lactic acid from bagasse. The method comprises the following steps: grinding and filtering bagasse: adding water to the bagasse, carrying out wet grinding on the bagasse by virtue of a disc mill and sieving the bagasse; carryin gout green liquor-ethanol coupling pretreatment: carrying out a pretreatment course in a pressure-proof reaction kettle, adding the ground bagasse to the reactor and adding a green liquor, wherein heating temperature is 140-145 DEG C and reaction duration is 2-4h; filtering after the pretreatment so as to obtain solid residues; carrying out synchronous saccharification and fermentation: adding cellulase and lactobacillus strain to the solid residues obtained from pretreatment in a mode of taking the solid residues as a fermentation substrate, and reacting at 45 DEG C at pH value of 4.8-5.0 for 72-96h so as to produce the lactic acid. The method for producing the lactic acid from bagasse disclosed by the invention is high in conversion rate of hydrolyzing cellulase into cellulose and semi-cellulose; and the utilization rate of bagasse resource component is high and production cost is low.

Owner:BEIJING FORESTRY UNIVERSITY

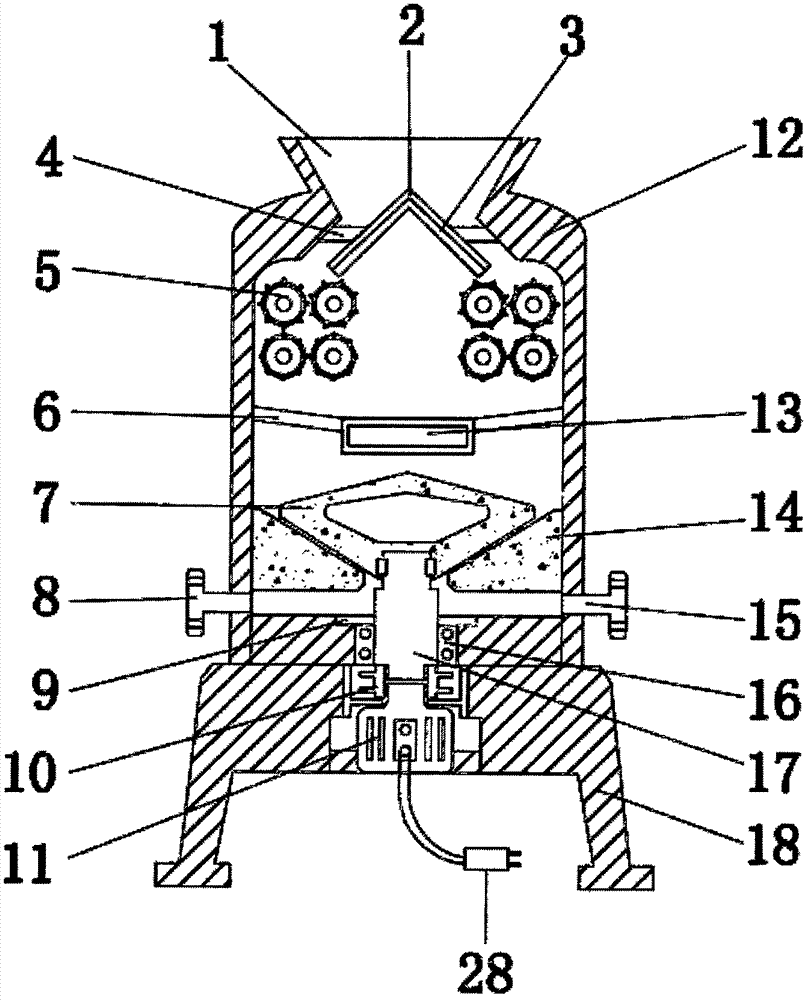

Highland barley kernel smashing machining device

The invention discloses a highland barley particle crushing and processing device, which comprises a base, a tank body is installed on the top of the base, a feeding hopper is arranged on the top of the tank body, and the left and right sides of the inner top of the tank body are equipped with A crushing roller, the outer wall of the crushing roller is provided with crushing teeth, the top of the rotating roller is equipped with a movable grinding disc, and the inner bottom of the tank body is equipped with a fixed grinding disc. The highland barley particle crushing and processing device, through the cooperation of the crushing roller, the movable crushing millstone and the fixed crushing millstone, drives the rotating roller to drive the crushing roller to rotate through the auxiliary rotating roller and the collar. The highland barley grains are crushed, and the rotating roller drives the movable grinding disc on the top to rotate, and the highland barley grains are further ground and pulverized through the grinding of the movable grinding disc and the fixed grinding disc. The pulverized highland barley powder is uniform in size and the crushing effect is ideal.

Owner:台州市金算子知识产权服务有限公司

Cotton stalk bleach pulp with disinfection function and method of manufacturing the same

InactiveCN101109162AHas the function of sterilization and disinfectionPulp bleachingChemical/chemomechanical pulpCelluloseFiber

The invention relates to a bleached cotton-stalk pulp with function of disinfection and sterilization and the preparing method for the pulp, which is to solve the problem associated with prior paper pulp that can't disinfect and sterilize, and is a bleached cotton-stalk pulp made from cotton-stalk natural-color pulp by bleaching with hydrogen peroxide. In the bleached cotton-stalk pulp, additionally some nanometer titanium whiting powder is added. The added volume of the nanometer titanium whiting powder is 0.05-3% of the dry weight of the bleached cotton-stalk pulp. The preparing method comprises in sequence the following procedures: 1) crushing; 2) separating into cellulose bundles by a rubbing and separating machine; 3) adding water onto the cellulose bundles in a moistening bin, heating up to 90-100 centigrade till the cellulose bundles soften; 4) rough grinding by a hi-concentration disc mill, extruding out lignin and black liquid by a pulp-extruding machine to get pulp in natural color; 5) adding water onto the natural-color pulp in a reaction bin, milling and bleaching the pulp by hydrogen peroxide decolorizer, extruding out white liquid by a pulp-extruding machine to get bleached cotton-stalk pulp; 6) neutralizing the extruded black and white liquid, defecating with oxidizing flocculator, the clean water from that will be guided into the moistening bin and the reaction bin for circulating. The invention has the functions of disinfection and sterilization, can be used for making sanitary napkins, napkin paper, hand towels and wall paper, etc. with disinfection function.

Owner:山东亿同多欧纸业投资有限公司

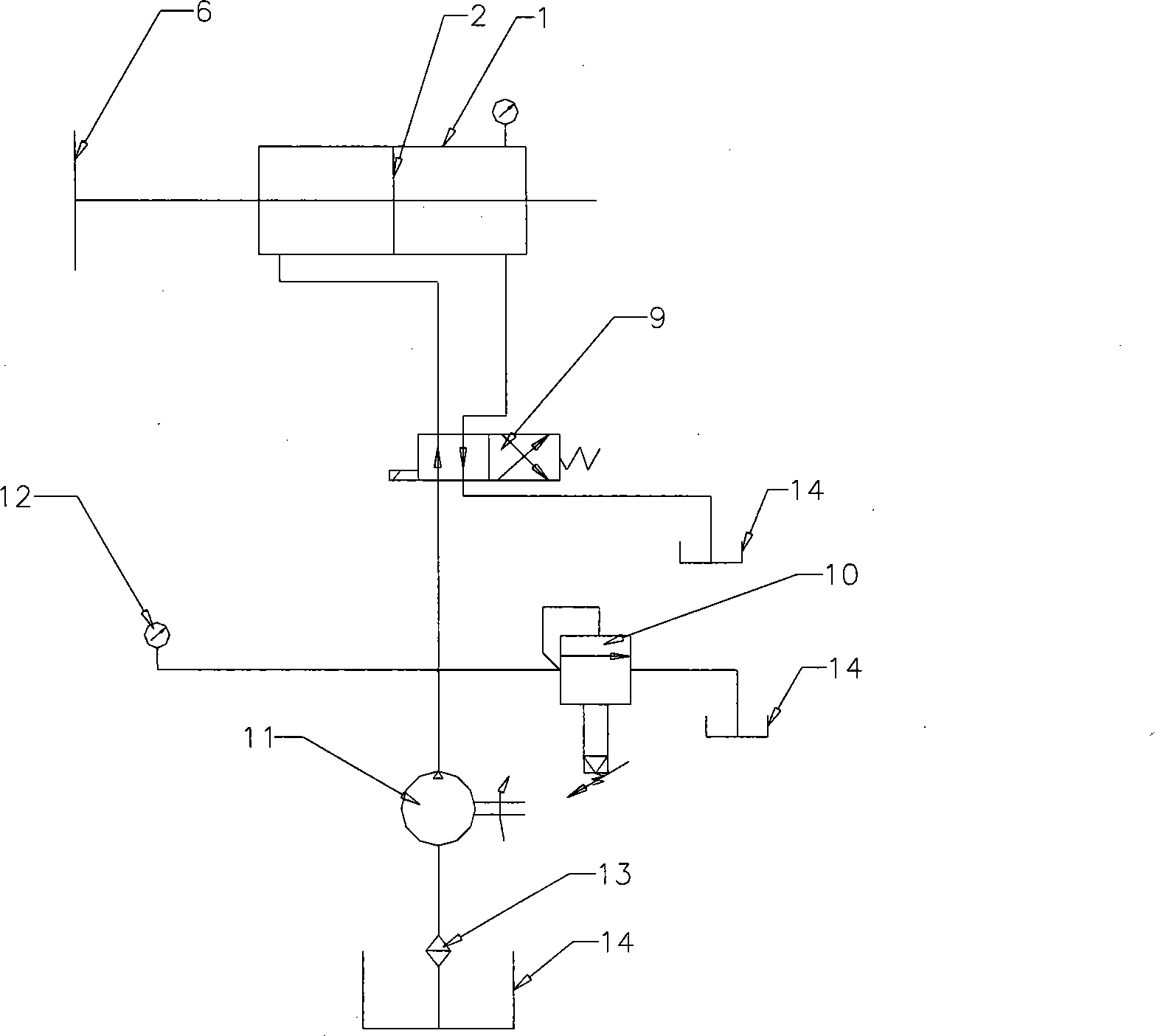

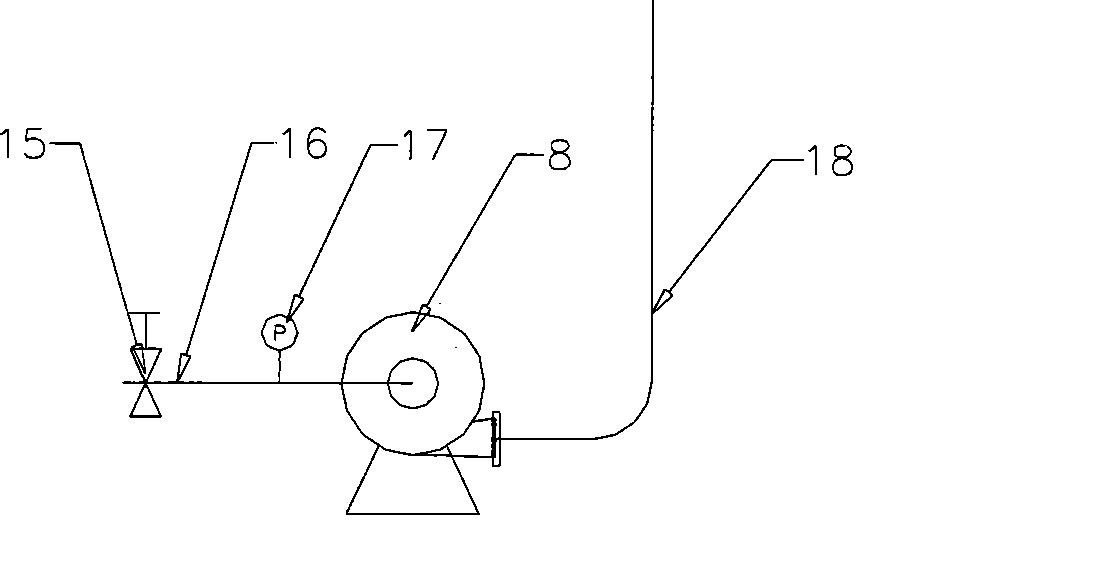

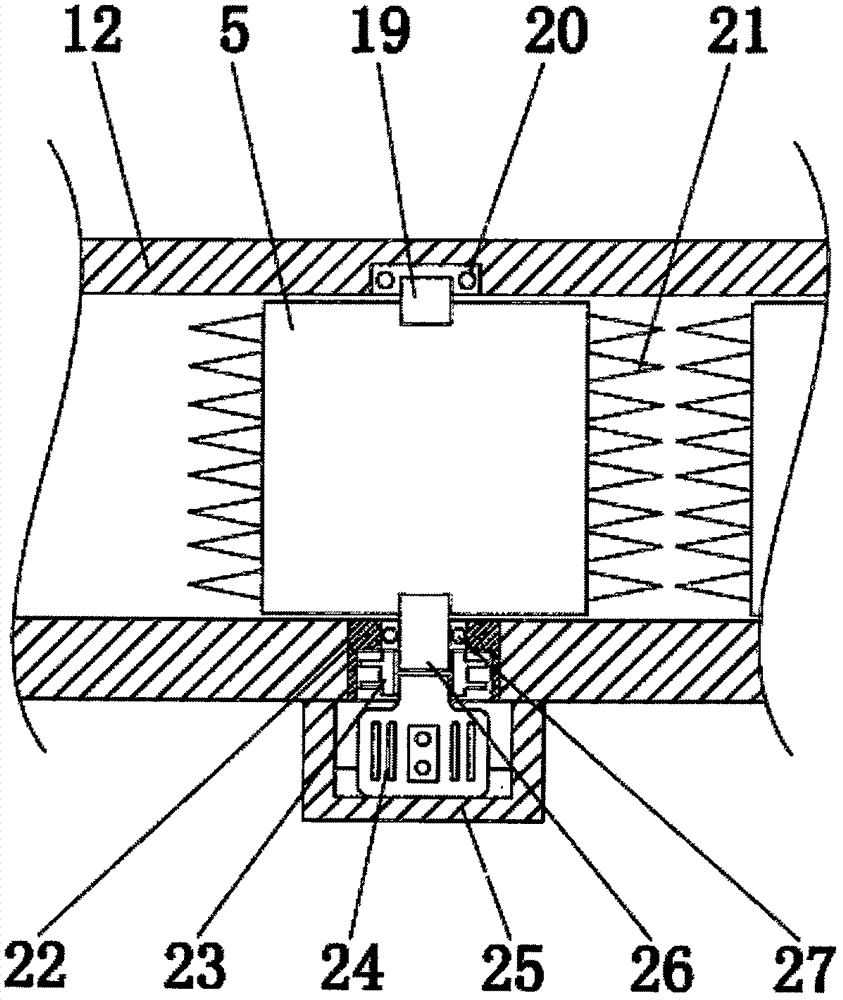

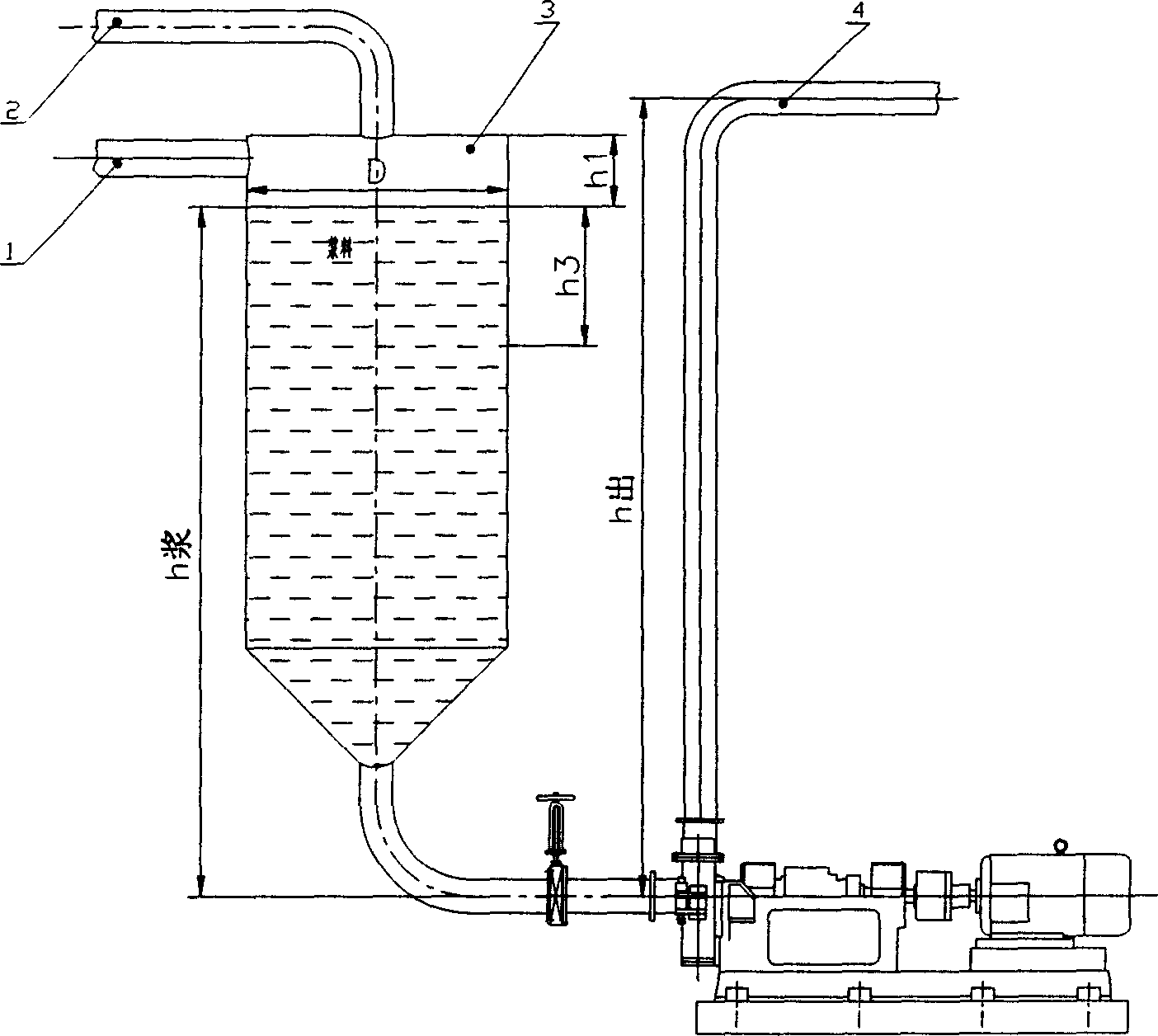

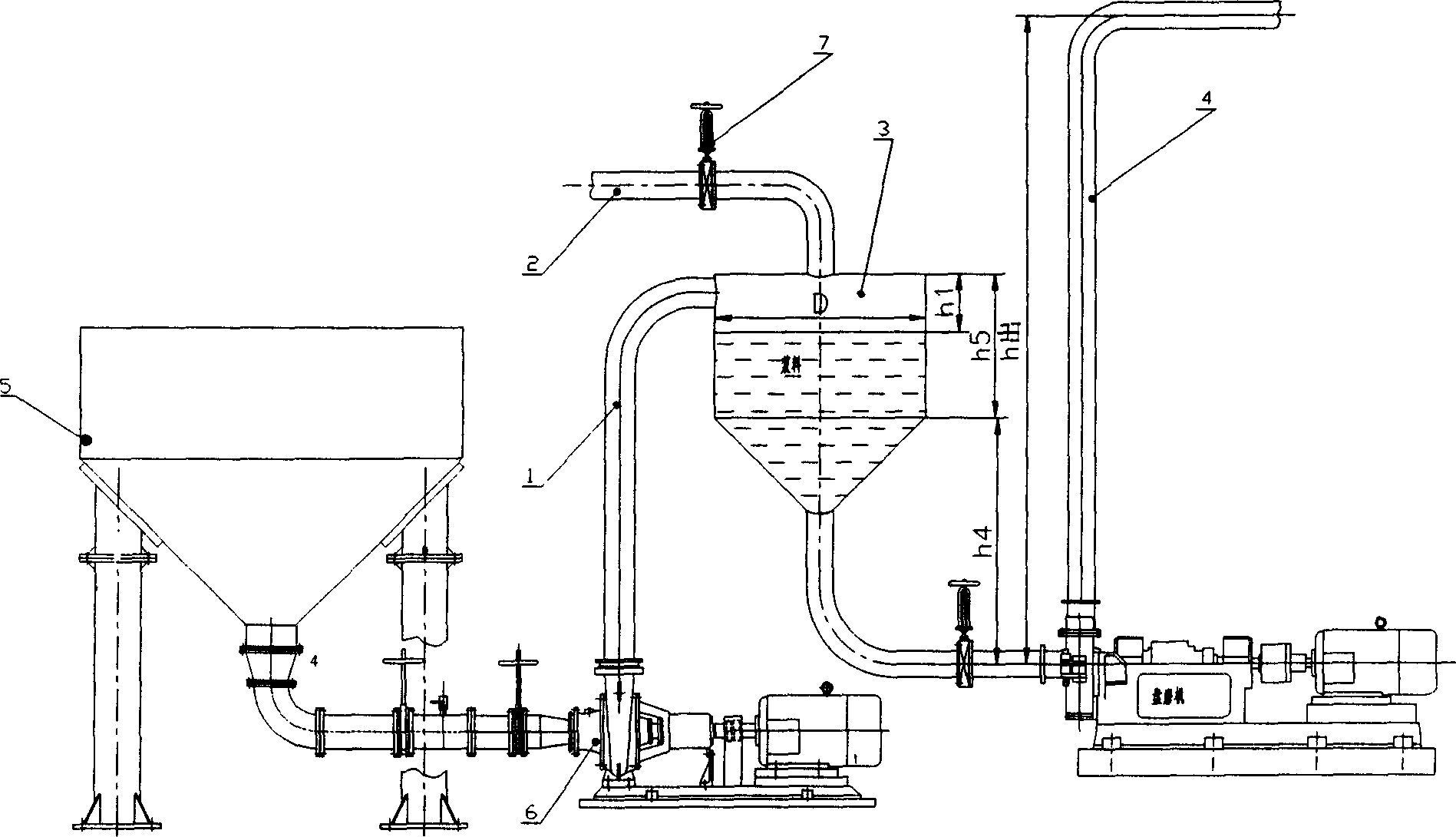

Pressure stabilizing method and its device for beating of disc mill

InactiveCN1616762ANo change in openingSimple structurePulp beating/refining methodsEngineeringAltitude control

The present invention provides a kind of beating pressure stabilizing device for disc refiner. The beating pressure stabilizing device set in front of the disc refiner is connected to the inlet of the disc refiner and is constituted by pulp inlet pipe, pressure stabilizing tower, overflow pipe, control valve, and pulp outlet pipe. The beating pressure stabilizing device has the pressure controlled via the height inside the pressure stabilizing tower or the opening of the overflow port. The present invention makes the disc refiner operate in relatively stable flow rate and pressure conditions to obtain stable beating quality and reduced power consumption. The present invention has production cost much lower than available dynamic control system.

Owner:SOUTH CHINA UNIV OF TECH

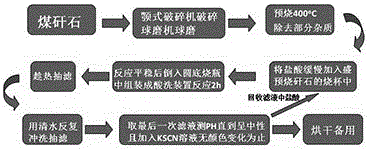

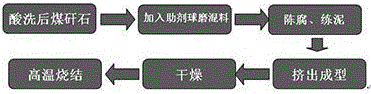

Method for preparing inorganic ceramic membrane separation device from coal gangue

InactiveCN106045488ARich preparation methodMembranesSemi-permeable membranesDisc millComposite ceramic

The invention discloses a method for preparing an inorganic ceramic membrane separation device from coal gangue. The process for removing impurities in the coal gangue through pickling comprises steps as follows: A, the coal gangue is mechanically crushed by a jaw crusher or a disc mill and subjected to ball milling by a ball mill; B, partial impurities are removed through pre-sintering at 400 DEG C; C, hydrochloric acid is slowly added to a beaker containing the pre-sintered coal gangue; D, the mixture is poured into a round-bottom flask after a reaction is stabilized and reacts for 2 h in an assembled pickling device; E, suction filtration is performed while the mixture is hot; F, repeated suction filtration is performed with clear water; G, a last-time filtrate is taken for measurement of PH until the filtrate is neutral and does not change color after an KSCN solution is added; H, the mixture is dried for use. The process for manufacturing a ceramic membrane comprises steps as follows: a, an aid is added to the pickled coal gangue for ball milling and mixing; b, decaying and pugging are performed; c, extrusion molding is performed; d, drying is performed; e, high-temperature sintering is performed. According to the method, component characteristics of the coal gangue are utilized, and a composite ceramic membrane tube with Al2O3 and SiO2 being the main components is developed and is used for high-temperature gas-solid separation in fields of industrial coal-fired boilers, metallurgy, building materials and the like.

Owner:GUIZHOU UNIV

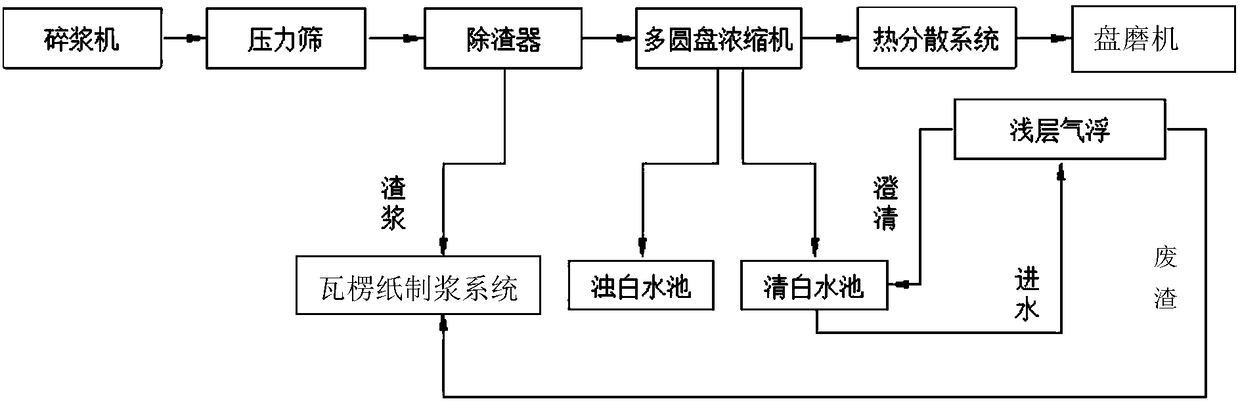

Cardboard paper pulping system

PendingCN108486937AIncrease production capacityTake advantage ofPulp beating methodsPaper recyclingCircular discCardboard

The invention relates to a cardboard paper pulping system. The cardboard paper pulping system comprises a craft paper pulping system and a corrugated paper pulping system and is characterized in thatcraft paper pulping system comprises a pulper, a pressure screen, a residue remover, a multi-disc concentrator, a heat dispersion system and a disc mill, the pulp outlet of the pulper is connected with the pulp inlet of the pressure screen, the pulp outlet of the pressure screen is connected with the pulp inlet of the residue remover, the pulp outlet of the residue remover is connected with the pulp inlet of the multi-disc concentrator, the pulp outlet of the multi-disc concentrator is connected with the pulp inlet of the heat dispersion system, the pulp outlet of the heat dispersion system isconnected with the pulp inlet of the disc mill, and the residual pulp outlet of the residue remover is connected with the corrugated paper pulping system. The cardboard paper pulping system has the advantages that by directly conveying residual pulp in the craft paper pulping system to the corrugated paper pulping system, the residual pulp discharged by the craft paper pulping system is fully utilized, and the pulping yield of the corrugated paper pulping system is increased.

Owner:NINE DRAGONS PAPER TAICANG LTD

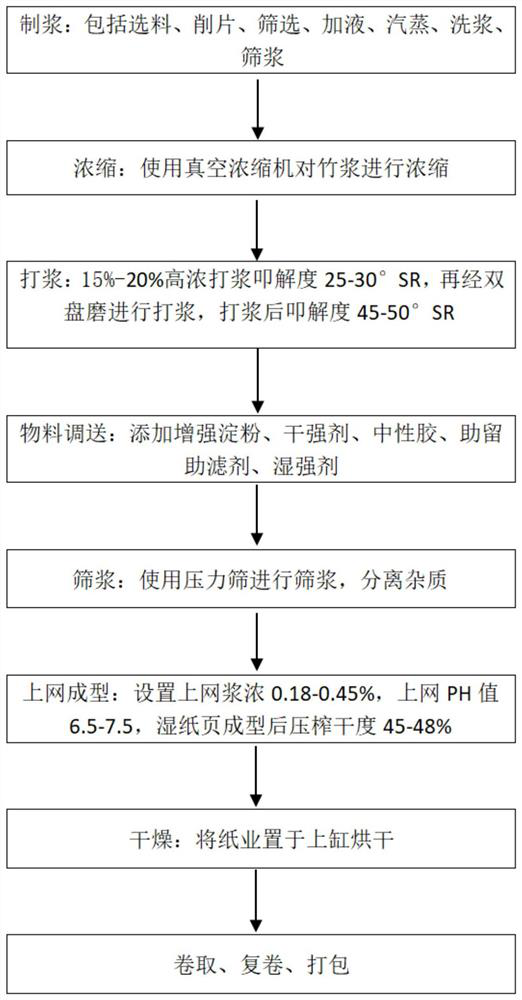

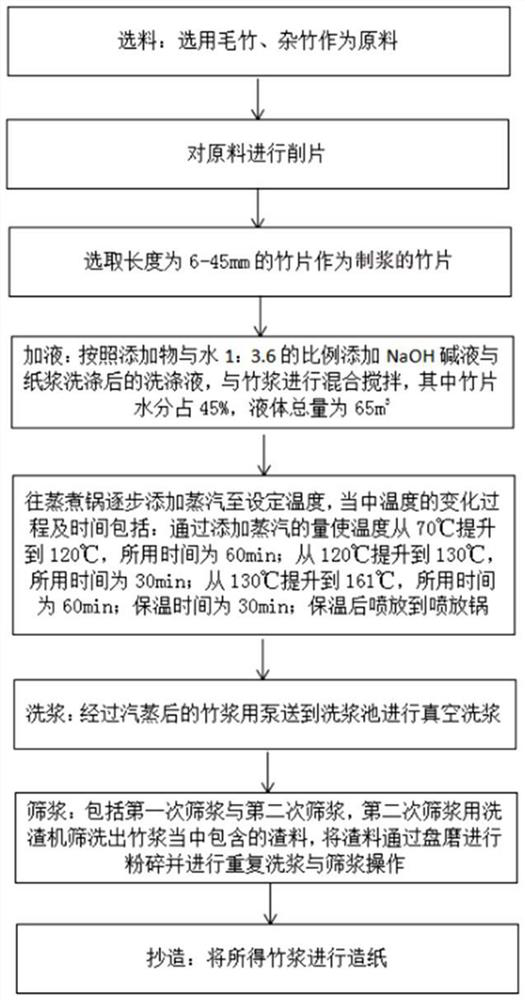

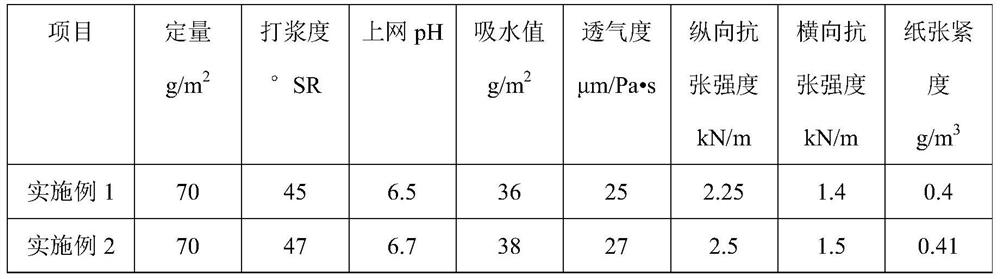

Method for producing degradable mulching film paper by utilizing bamboo pulp

PendingCN112442922ABroaden sources of raw materialsAlleviate tight supply situationSpecial paperWater-repelling agents additionFiberHigh concentration

The invention provides a method for producing degradable mulching film paper by using bamboo pulp. The method comprises the following steps of pulping, concentrating, high-concentration pulping, seasonings feeding, forming on a net, squeezing, drying, coiling, rewinding and packaging; pulping is carried out by using 100% of bamboo fiber pulp at high concentration of 15-20%, pulping is carried outby using a medium-concentration disc mill, and the net concentration is set to be 0.18-0.45% and the net pH value is set to be 6.5-7.5. After forming on a net, squeezing is performed through a four-roller three-pressing area until the dryness is 45%-48%; the obtained mulching film paper has the advantages that the quantification is 40-80g / m<2>, the paper dryness is 8%-9%, the air permeability is 15-60mu m / Pa.s, the longitudinal tensile strength is 1.2-3.2 kN / m, the transverse tensile strength is 0.8-2 kN / m, the water absorption value is 35-50g / m<2>, and the paper tightness is 0.4-0.5 g / m<3>. According to the invention, bamboo fibers are used as a raw material, so that the raw material source of the mulching film paper is expanded, the situation of tension supply of wood pulp is relieved, and the performance of the mulching film paper is improved to a certain extent.

Owner:江西中竹生物质科技有限公司

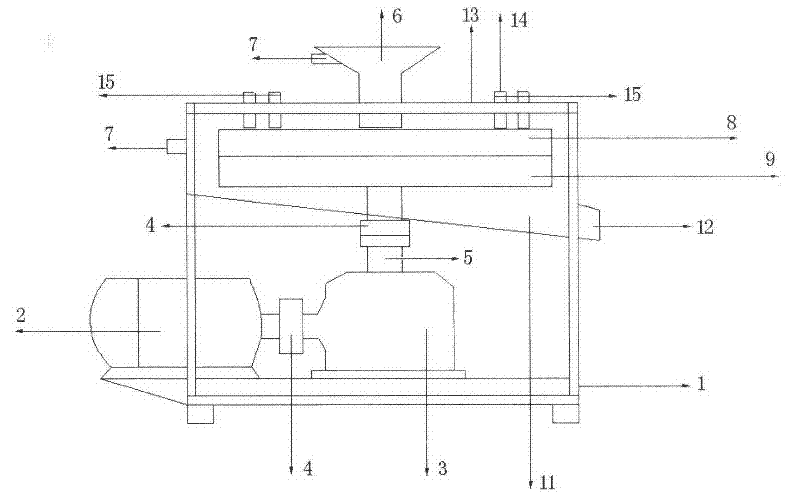

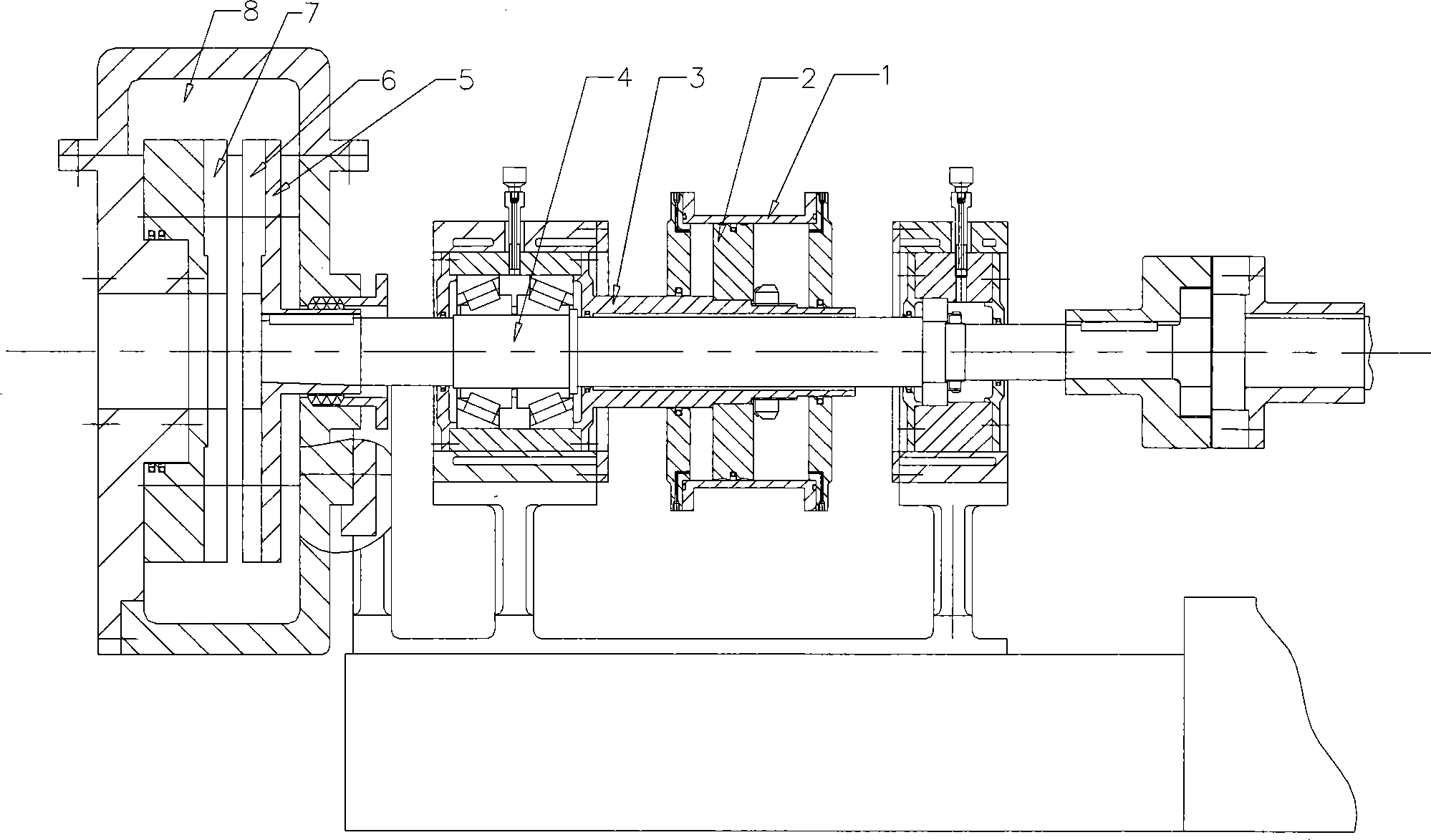

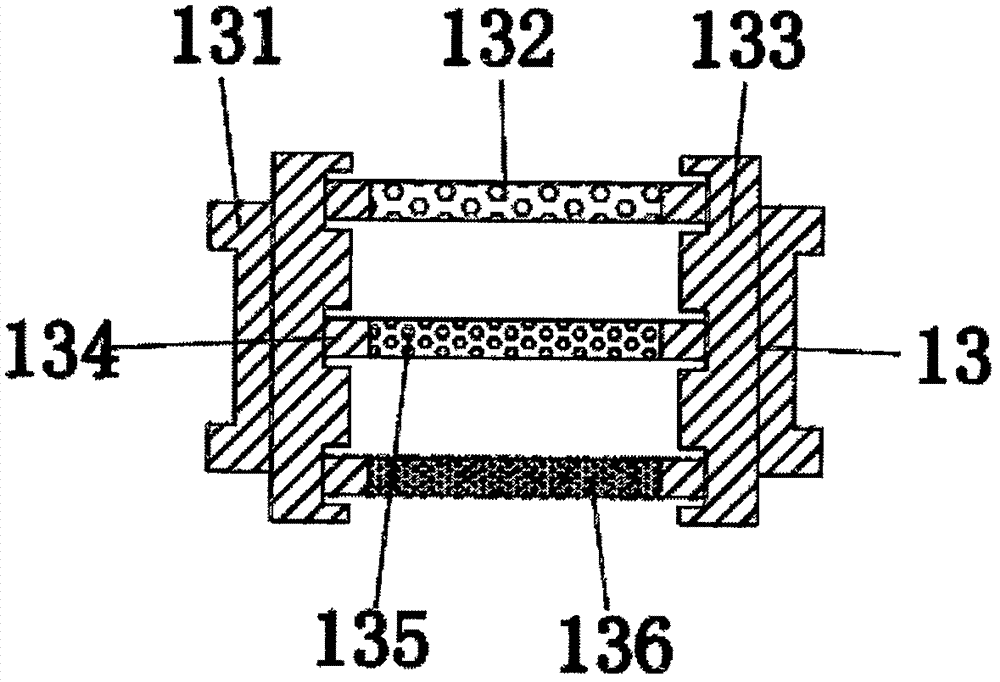

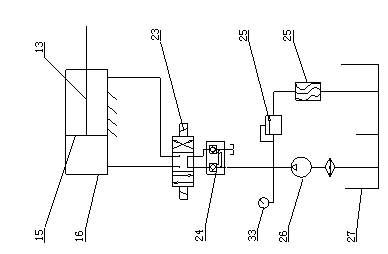

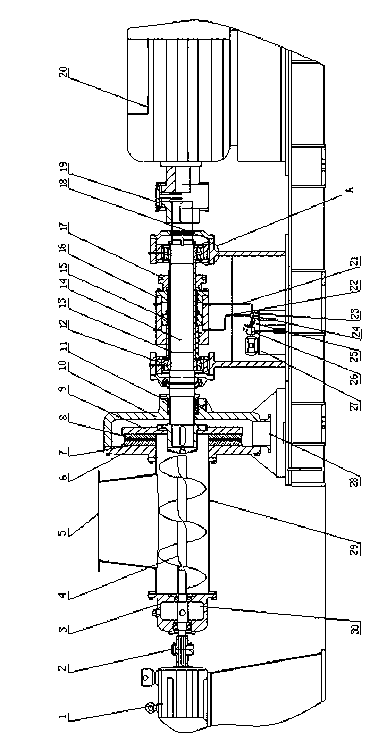

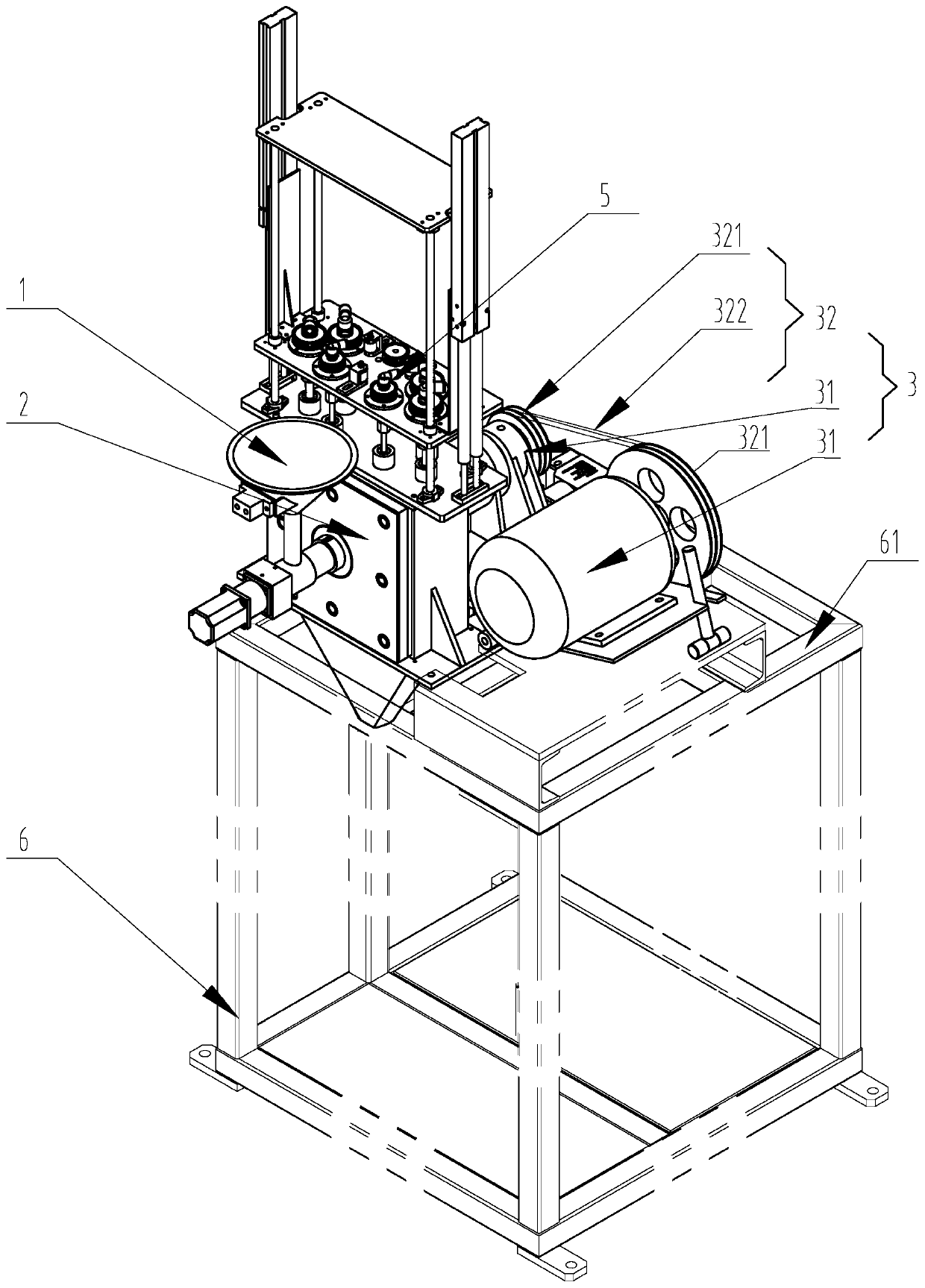

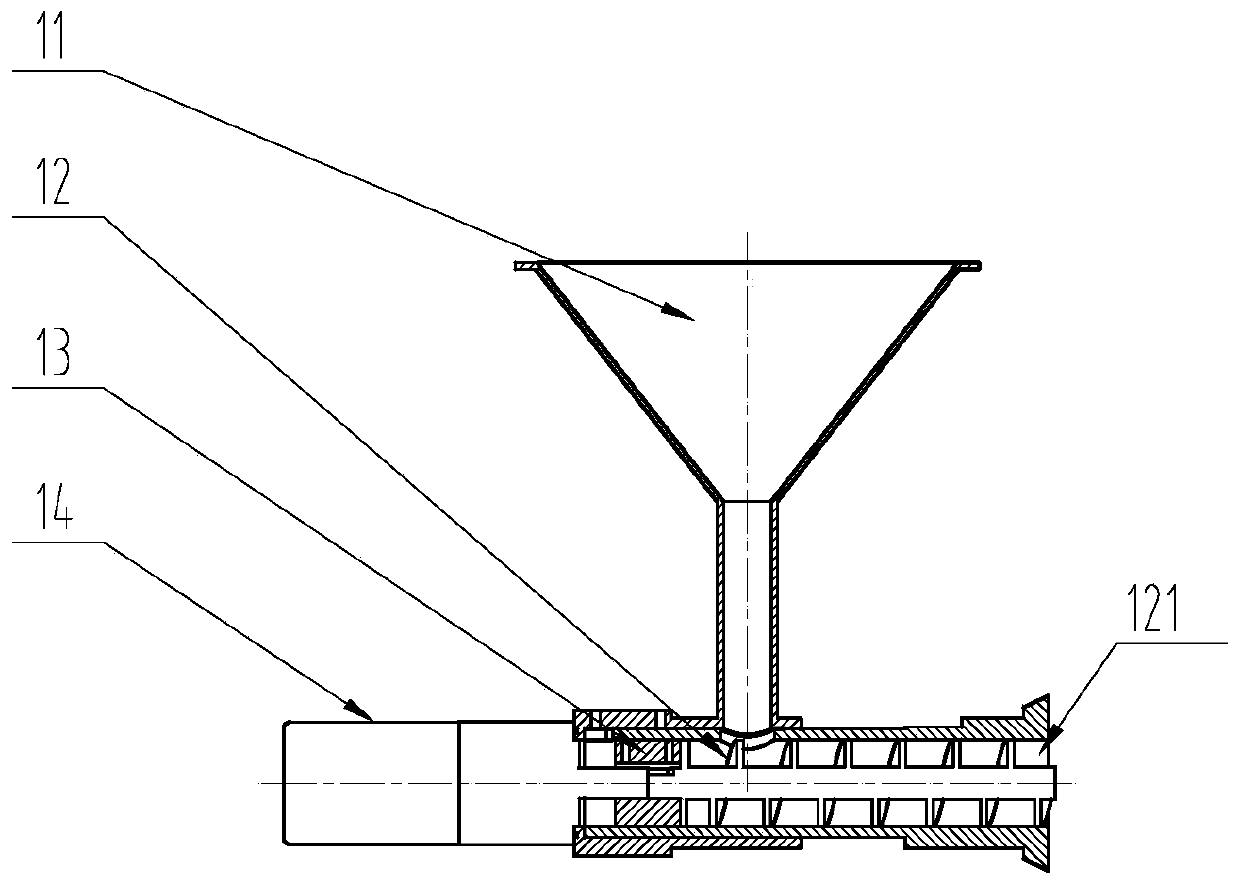

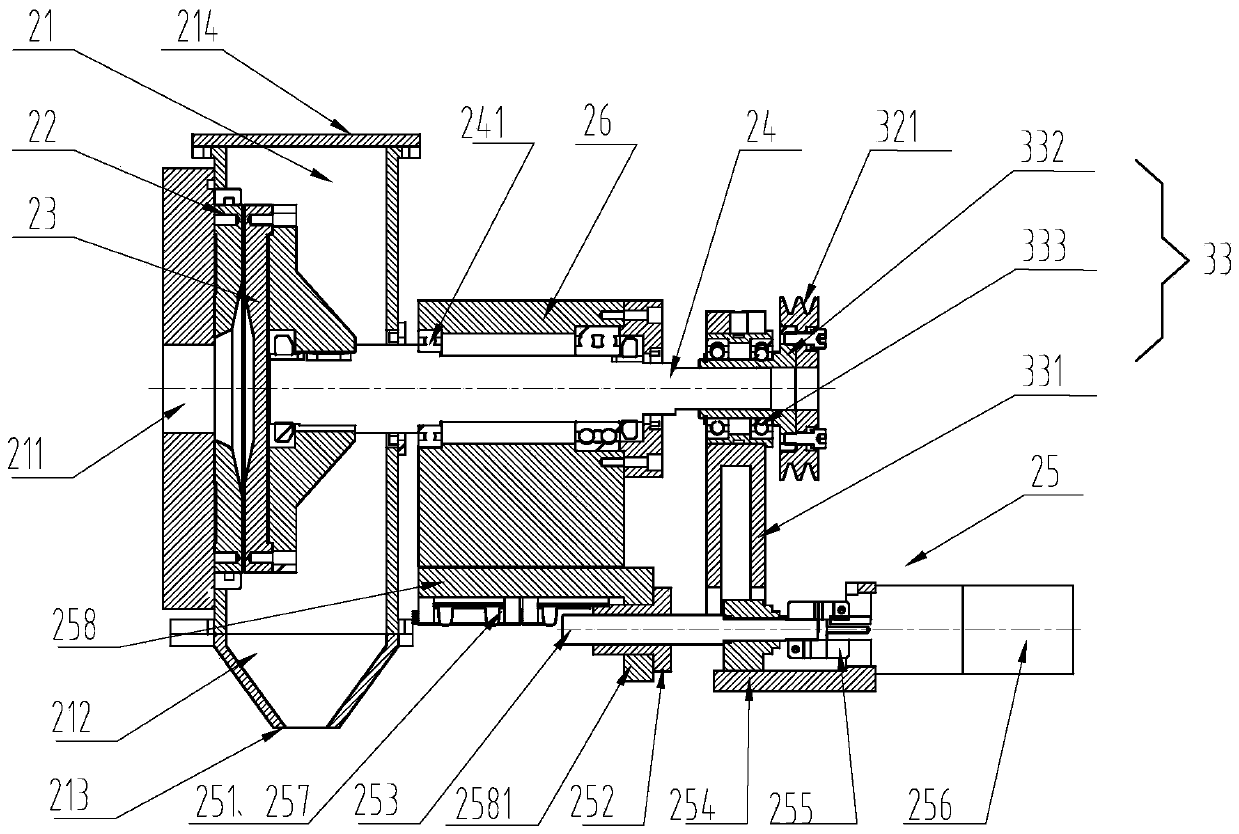

High-consistency hydraulic disc mill

InactiveCN103255667AEasy to adjustConvenient refining specific pressurePulp beating/refining methodsHydraulic cylinderDisc mill

A high-consistency hydraulic disc mill comprises a spiral feed unit, a hydraulic adjusting unit and a high-consistency disc mill body, wherein the rotating speed of a conveying screw is adjusted by a variable-frequency and variable-speed motor, and feed quantity of the high-consistency disc mill is matched with the defibrination output of the high-consistency disc mill. The hydraulic adjusting unit is composed of an oil tank, a hydraulic pump, a solenoid directional valve, a pressure regulating valve, a pressure retaining valve, a hydraulic cylinder, a piston, a thrust cylinder, a cooler, the pressure regulating valve and a pressure gauge, wherein the hydraulic cylinder is fixed on a bearing body suspended frame, the piston is fixed on the thrust cylinder, one end of the thrust cylinder is fixed on an front bearing cover, and a mechanical limiting fine tuning nut is arranged at the other end of the thrust cylinder. The high-consistency disc mill body is composed of a machine shell, a machine cover, a fixed disc, a rotating disc, the bearing body suspending frame, a bearing body, a shaft, a coupler and a motor, wherein the fixed disc is fixed on the machine cover and the rotating disc is fixed on the shaft. Due to the fact that the hydraulic regulating unit which is provided with a pressure retaining return circuit regulates the advancing and the retreating of a knife and defibrination specific pressure, producing of high-consistency milled defibrination with the fixed specific pressure is achieved, energy is saved, and defibrination efficiency is improved.

Owner:SOUTH CHINA UNIV OF TECH

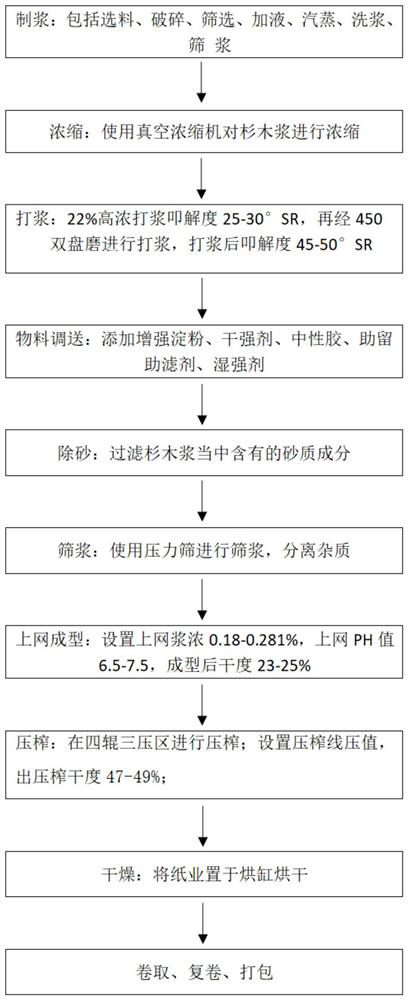

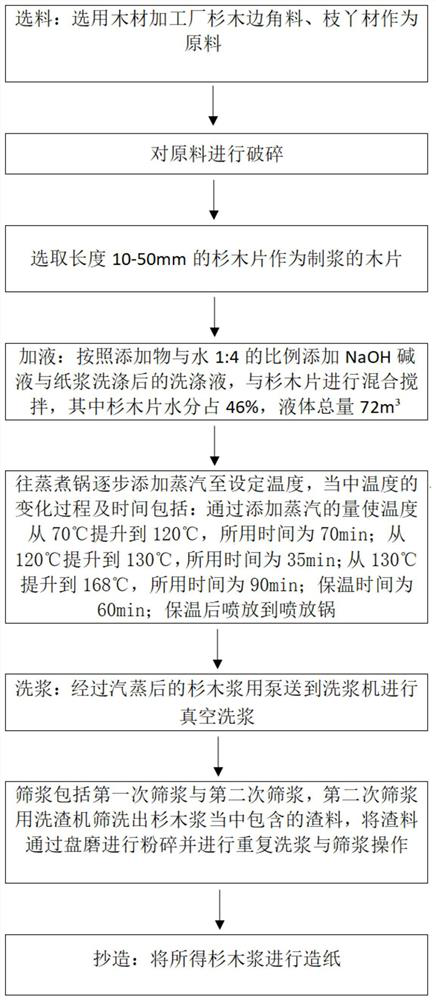

Method for producing degradable mulching film paper by utilizing fir leftover materials and branch material pulp

PendingCN112458780ABroaden sources of raw materialsAlleviate tight supply situationNatural cellulose pulp/paperPulp beating methodsFiberHigh concentration

The invention provides a method for producing degradable mulching film paper by utilizing fir leftover materials and branch material pulp. The method comprises the following steps of: pulping, concentrating, pulping at high concentration, feeding seasonings, removing sand, forming on a net, squeezing, drying, coiling, rewinding and packaging, wherein 100% fir fiber pulp is pulped at high concentration of 22%, and then pulped by a medium-concentration disc mill, the net concentration is set to be 0.18-0.3%, the the net pH value is 6.5-7.5, after forming on a net, squeezing is performed througha four-roller three-pressing area until the dryness is 47-49%, the paper quantity of the obtained mulching film paper is 50-60 g / m<2>, the paper dryness is 8-9%, the air permeability is 30-45 [mu]m / Pa.s, the longitudinal tensile index is 38-42 N.m / g, the transverse tensile index is 22-28 N.m / g, the water absorption value is 30-45 g / m<2>, and the paper tightness is 0.38-0.43 g / m<3>. According to the invention, fir leftover materials and branch material fibers are used as raw materials, so that the raw material source of the mulching film paper is expanded, the situation of tension supply of rawwood is relieved, and the performance of the mulching film paper is improved to a certain extent.

Owner:江西中竹生物质科技有限公司

Disc pulverizing mill

A method and system for of cooling a disc mill having a rotating disc blade is disclosed. A disc mill may have a first and second material outlet positioned generally along tangents to the rotating disc blade. Air may be drawn through the first and second material outlets. A disc mill may include first and second air inlets positioned generally along tangents to the rotating disc blade. The first and second inlets may direct air streams to cool a first and second portion of the rotating disc blade and pulverized material.

Owner:HUMMEL JAMES

Treatment method for improving performance of producing methane through anaerobic fermentation of straw and application thereof

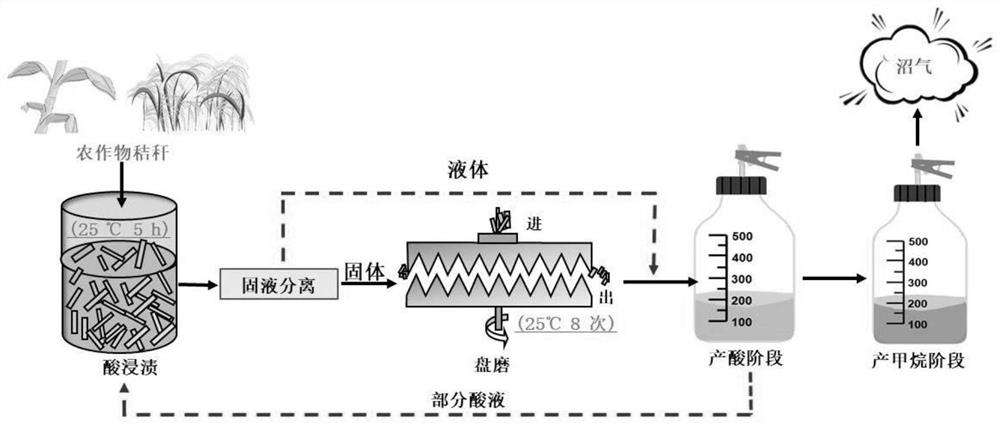

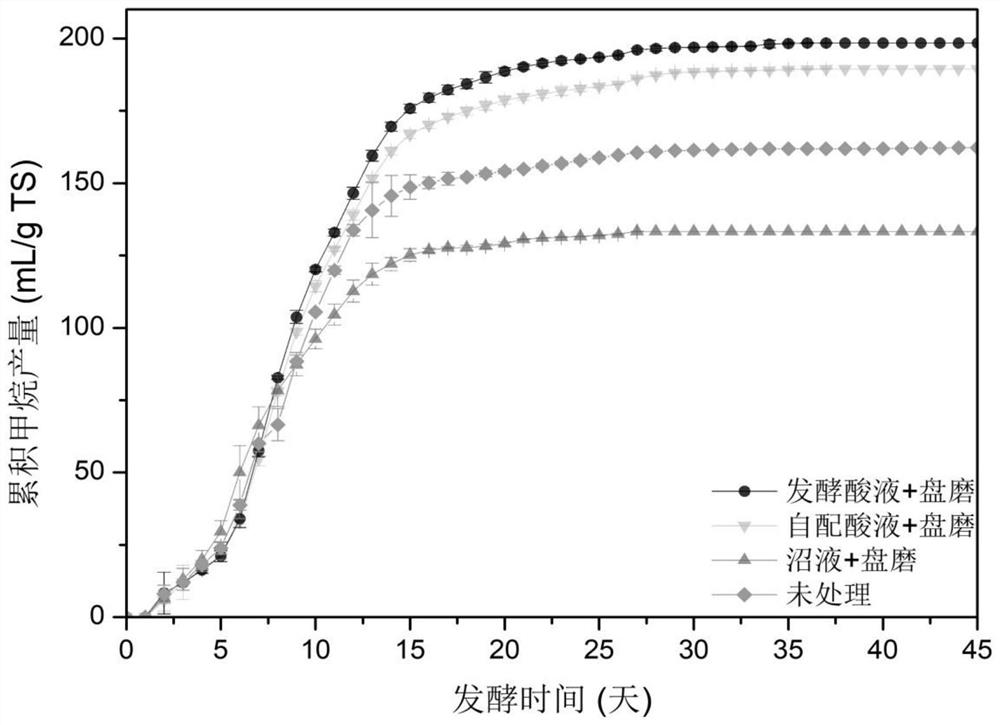

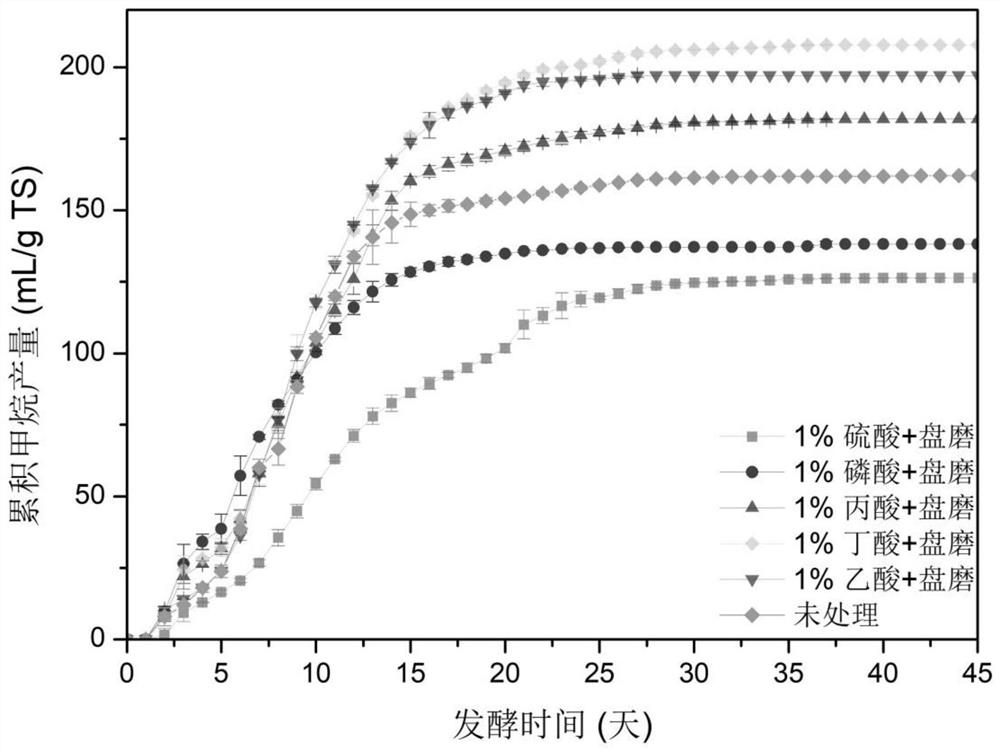

PendingCN112725383AIncrease productionImprove preprocessing effectWaste based fuelFermentationDisc millPretreatment method

The invention belongs to the technical field of preparation of biogas through anaerobic fermentation and conversion of organic solid waste, and particularly relates to a treatment method for improving the performance of producing methane through anaerobic fermentation of straw and application thereof. Aiming at the problems that crop straws are difficult to degrade in the anaerobic fermentation process and the pretreatment cost is high, the invention provides an environment-friendly, simple, convenient and efficient forestry and agricultural residue pretreatment method. According to the method, acid liquor generated in the crop straw anaerobic fermentation acidification process is used for replacing traditional acid chemical reagents, raw materials are dippedand swelled, then a mechanical disc mill with low energy consumption is combined to pretreat the biomass raw materials, the complex structure of lignocellulose biomass can be effectively damaged, the cellulose crystallinity is reduced, the porosity of the raw materials is improved, and the gas production efficiency of the biomass is improved. According to the method, an anaerobic fermentation process and a biomass pretreatment process are combined, a new way is provided for efficient conversion of biomass resources to prepare the biogas, and the method has important significance for development of biogas engineering.

Owner:CHINA AGRI UNIV

Production method of black facial mask paper

InactiveCN110552235AContinuous and efficient productionNatural black appearanceDryer sectionReinforcing agents additionDisc millPolyamide

The invention discloses a production method of black facial mask paper. The preparation method comprises the steps: S100, pulping: mixing softwood pulp fibers with nanoscale carbon black to form softwood pulp fiber-carbon black mixed pulp, respectively and continuously pulping the softwood pulp fiber-carbon black mixed pulp and hardwood pulp fibers by adopting a double-disc mill, and mixing the pulped softwood pulp fiber-carbon black mixed pulp and the pulped hardwood pulp fibers to prepare mixed pulp; S200, papermaking: diluting the mixed pulp, respectively adding calcium carbonate, a guar gum reinforcing agent and a guar gum retention aid through a short circulation system to form paper pulp, forming the paper pulp at a net part, and dehydrating the paper pulp at a squeezing part to obtain a wet paper sheet; and S300, drying: carrying out drying treatment on the wet paper sheet through a pre-drying drying cylinder to obtain a semi-dry paper sheet, coating a wet strength agent polyamide polyamine-epichlorohydrin resin PAE on a sizing part of the semi-dry paper sheet to obtain finished paper, carrying out drying treatment on the finished paper through a post-drying drying cylinder,and rolling to obtain the black facial mask paper. According to the production method of the black facial mask paper, the produced black facial mask paper has natural black appearance and is integrally uniform and breathable, wood pulp fibers and nanoscale carbon black are organically combined in the product, the facial mask paper is endowed with unique black appearance, and meanwhile, the oil stain adsorption, permeation and water replenishing capacities of a finally processed facial mask are enhanced.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

Disc mill capable of automatically cleaning

The invention provides a disc mill capable of automatically cleaning. The disc mill comprises a grinding mechanism, wherein the grinding mechanism comprises a grinding cavity, a static grinding disc with a central hole and a movable grinding disc arranged at an interval relative to the static grinding disc are arranged in the grinding cavity, the movable grinding disc is connected with a power mechanism through a rotating shaft so as to be capable of rotating, the rotating shaft is mounted on a rotating shaft supporting seat through a bearing, the disc mill further comprises a cleaning mechanism, the cleaning mechanism comprises a movable plate arranged above a top plate of the grinding cavity, a lifting device is connected with the movable plate, a plurality of air pipes are arranged on the movable plate, the lower ends of the air pipes penetrate into the grinding cavity, and spray holes are formed in the lower ends of the air pipes correspondingly. The disc mill solves the problem ofpollution due to the fact that in the prior art, a grinding cavity needs to be opened for pulverizer cleaning, and has the advantages of being reasonable and ingenious in structure and environmentally friendly.

Owner:JIANGXI GUANGMING INTELLIGENT TECH CO LTD

Floor heating structural module and preparation method thereof

InactiveCN107288310AReduce labor intensityEasy to installCovering/liningsFlooringEcological environmentDisc mill

The invention relates to a preparation method of a floor heating structural module. The preparation method comprises the following steps that firstly, preheating is conducted , specifically, plant straw is cut into small sections, the small sections are untwined hydraulically, dipped into alkali and washed, thus rough materials are obtained, then the rough materials are fed into a disc mill to be milled and separated, and plant fiber base materials are obtained; secondly, drying is conducted, specifically, the plant fiber base materials in the first step are taken, dispersed after water is added, evenly stirred after a cationic starch reinforcing agent is added and then added into a mould to be dehydrated; and thirdly, forming is conducted, specifically, the mould is pre-pressed and then subjected to drying-forming, and thus the floor heating structural module is obtained. Straw waste is used for replacing mixed powder coal-ash cement mortar, polystyrene foam plastic and phenolic foam plastic, so that on one hand, a new approach of resource utilization of the crop straw waste can be provided, and on the other hand, consumption of natural resources can be greatly reduced, and pollution to the ecological environment can be greatly lowered.

Owner:NORTHEAST FORESTRY UNIVERSITY

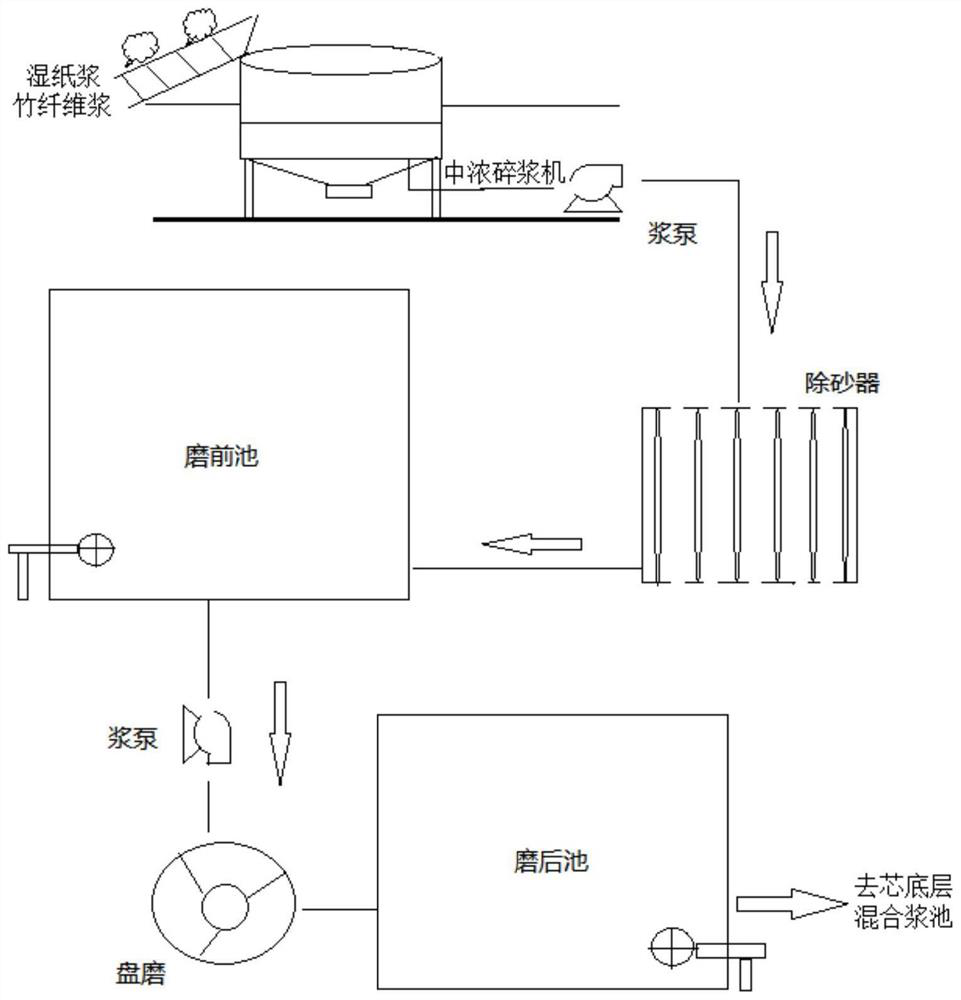

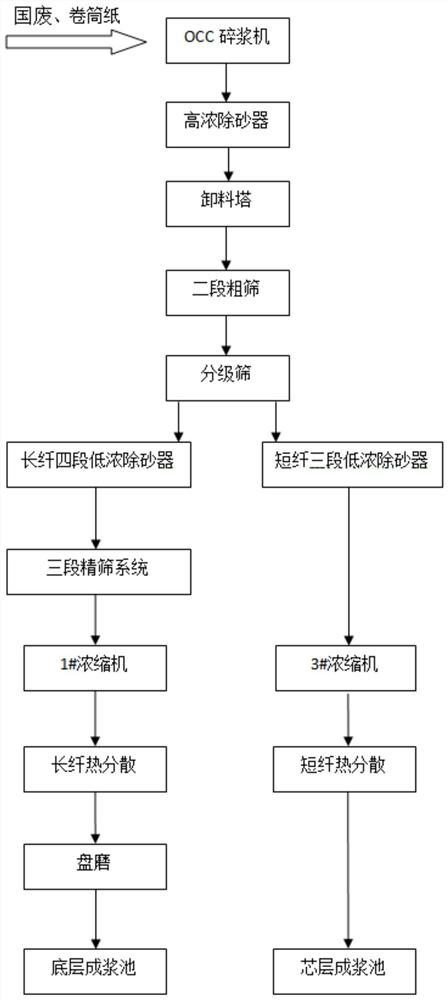

Production process of high-strength environment-friendly liner cardboard paper

PendingCN114293392ASolve limited problemsLow costPaper recyclingPulp beating/refining methodsCardboardFiber

The invention belongs to the technical field of cardboard paper, and provides a production process of high-strength environment-friendly liner cardboard paper, which comprises the following steps: taking domestic bamboo fiber pulp, imported wet paper pulp, imported roll paper and national waste as raw materials according to a specific ratio; the wet paper pulp and the bamboo fiber pulp are mixed and pulped through a medium-concentration pulper, a sand remover, a pre-grinding pool, a disc mill and a post-grinding pool in sequence, and first mixed pulp is obtained; in the OCC pulping line, the cut roll paper and national waste are treated through an OCC pulper, a high-concentration sand remover, a discharging tower, a two-section coarse screen and a classifying screen in sequence to obtain long fibers and short fibers, and then the long fibers and the short fibers are subjected to aftertreatment to obtain long fiber pulp and short fiber pulp; and mixing the long fiber pulp, the short fiber pulp and the first mixed pulp, and performing papermaking to obtain the liner cardboard paper. According to the production process, national waste is mainly used, quantitative roll paper, wet paper pulp and bamboo fiber pulp are matched, and the production process is optimized, so that the cost is reduced, the production efficiency is improved, the quality of finished paper can be improved, and the problem that external waste import is limited is solved.

Owner:东莞理文造纸厂有限公司

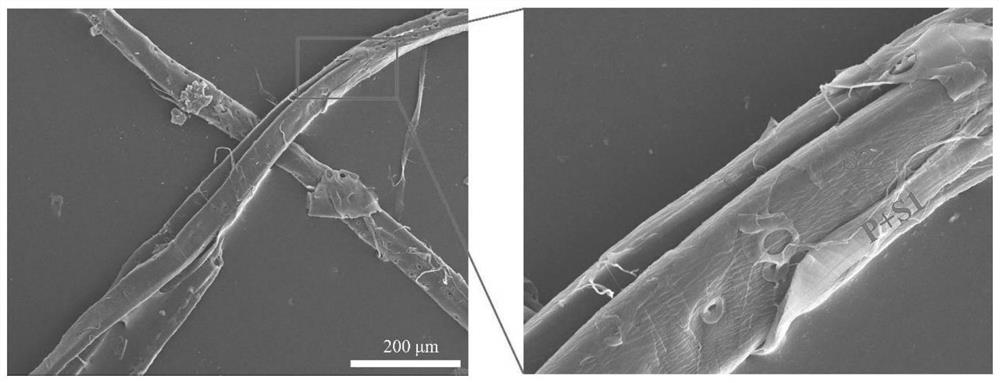

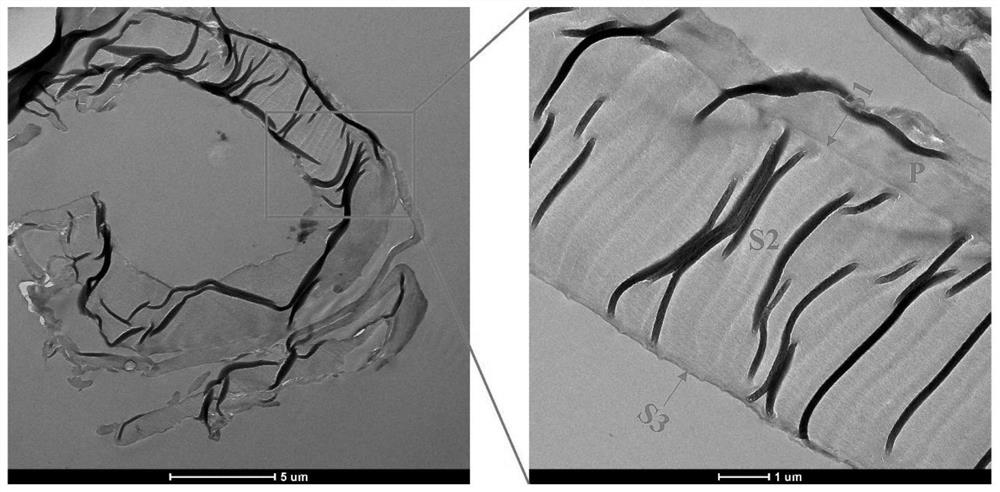

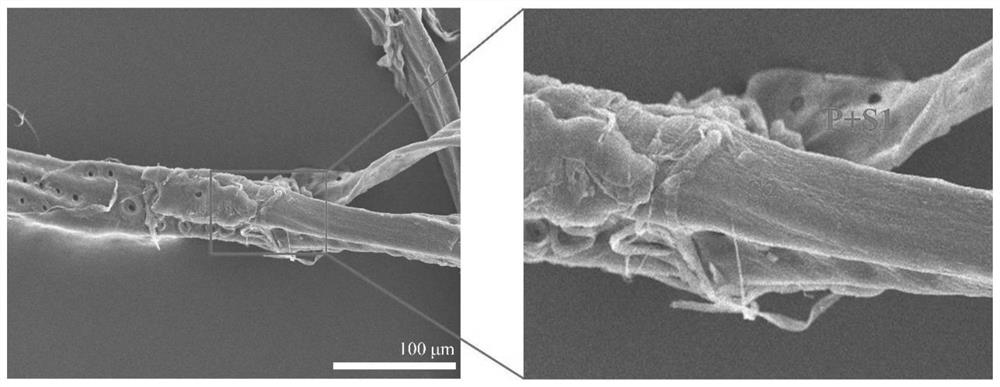

Method for dissociating plant fiber secondary wall S2 layer

PendingCN112941947AReserve space structureImprove accessibilityPulp beating/refining methodsCellulose material pulpingDisc millPlant fibre

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Book and cultural paper pulping method

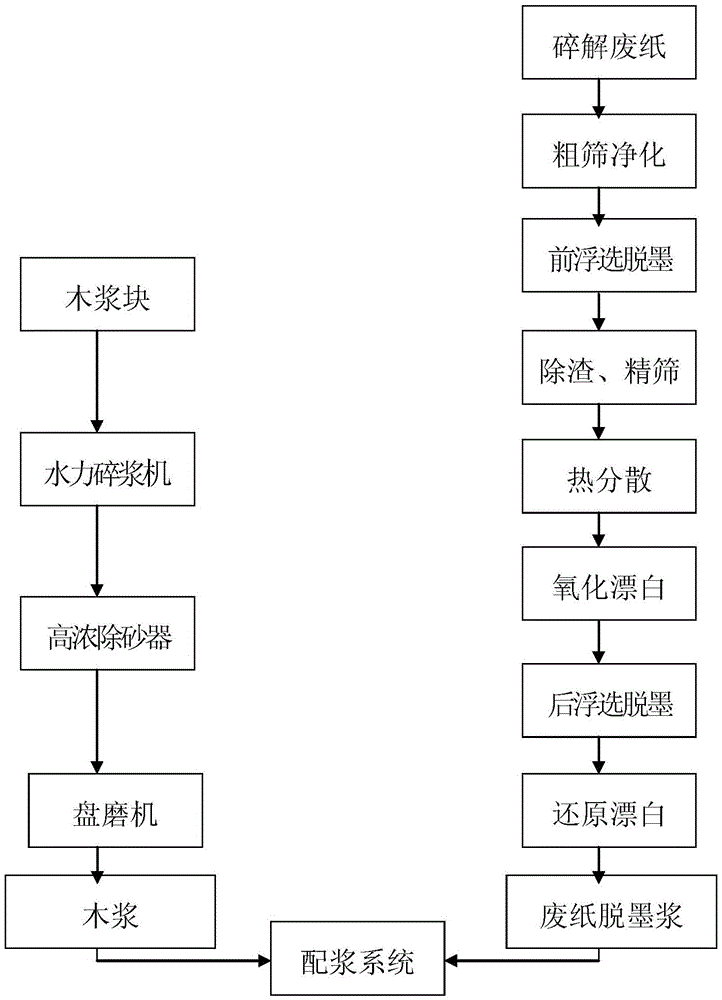

InactiveCN105648829ATake advantage ofMake full use of waste paper resourcesPulp bleachingSecondary cellulose fibresHigh concentrationDisc mill

The invention discloses a book and cultural paper pulping method which comprises a pulping step and a pulp mixing step. The book and cultural paper pulping method specifically comprises the following steps: (1) pulping: (a) preparing waste paper deinking pulp, namely pulping waste paper, coarsely screening for removing impurities, carrying out flotation deinking for removing ink particles, and entering a heat dispersion system after passing through a heavy impurity deslagging system and a primary multi-stage fine screening system, so that the sizes of large ink, dust and adhesives are reduced and the concentration reaches 28-32%; enabling the heat-dispersed pulp to enter a bleaching tower for oxidation bleaching; entering a rear flotation deinking system after bleaching, and separating the ink particles in the pulp; carrying out reductive bleaching to remove colored substances in the pulp until the concentration reaches 10%; mixing the pulp in a pulp storage tower; (b) preparing wood pulp, namely pulping a wood pulp block through a hydrapulper until the concentration is 4%-5%, enabling the pulp to enter an unloading pulp pool until the concentration reaches 3.5%, processing the pulp through a high-concentration grit catcher, processing the pulp through a disc mill and then entering the slurry pool for mixing; and (2) mixing pulp, namely mixing the pulp from the waste paper deinking pulp and the wood pulp at a ratio of 70%-80% to 20%-30% (v / v), and fully mixing until the concentration reaches 3.5%.

Owner:GUANGDONG HUATAI PAPER IND

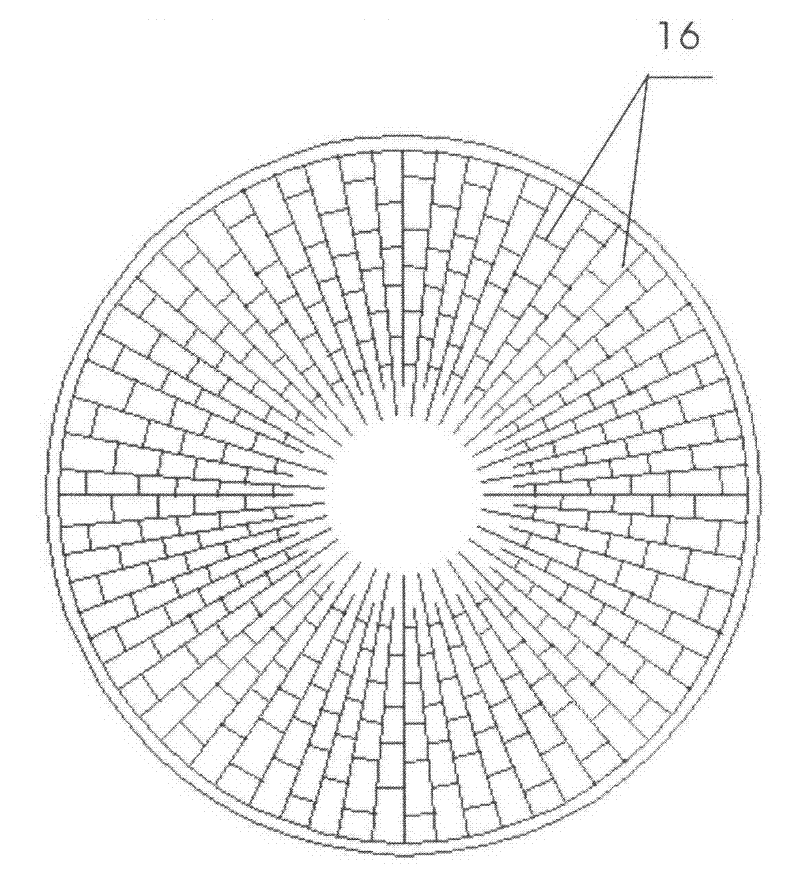

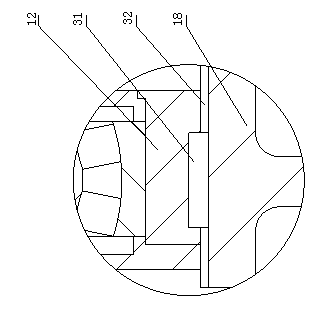

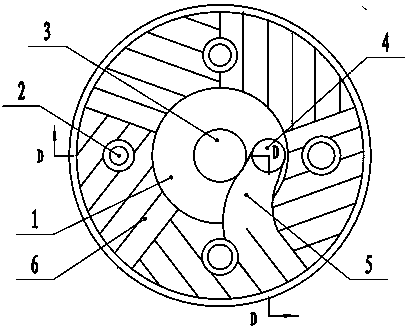

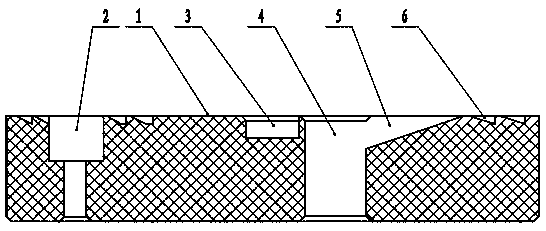

Spiral tooth feeding millstone of natural hard stone

The invention provides a spiral tooth feeding grinding disc for natural hard stone, which can effectively refine pulp and powder and dissipate heat, improve the quality of pulp and powder, and can be used as a replacement for easily worn grinding discs of a pulping and pulverizing machine. It consists of 1, It is a plane inner disk, 2, locking hole, 3, bearing hole, 4, feed hole, 5, feed groove, 6, helical helical tooth of spiral form. A bearing hole 3 is drilled in the center of the plane inner disc 1, the locking hole 2 is drilled on the grinding disc for locking and fixing, the bearing hole 3 is drilled on the center of the plane inner disc, the feed hole 4 is drilled on the plane inner disc 1, and the feed groove 5 chain feeding hole 4 opens out the chute, and the spiral helical tooth 6 divides the grinding disc into five equal parts, and takes the radius line as the baseline along the feeding groove 5 to form the grinding surface of the grinding disc, and the grinding surface of the grinding disc is discharged from the other half The grinding discs cooperate to start the power, and the food enters from the feeding hole 3 and starts to refine and grind through the feeding groove 5. The helical helical teeth 6 not only refine the pulp and grind finely, but also play the role of ventilation and heat dissipation.

Owner:王德仲

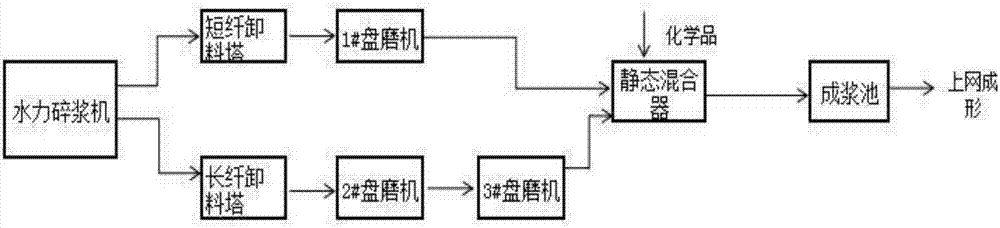

Novel household paper pulp preparing device and technology

PendingCN107503214AReduce energy consumptionWell mixedPulp beating/refining methodsFiberPulp and paper industry

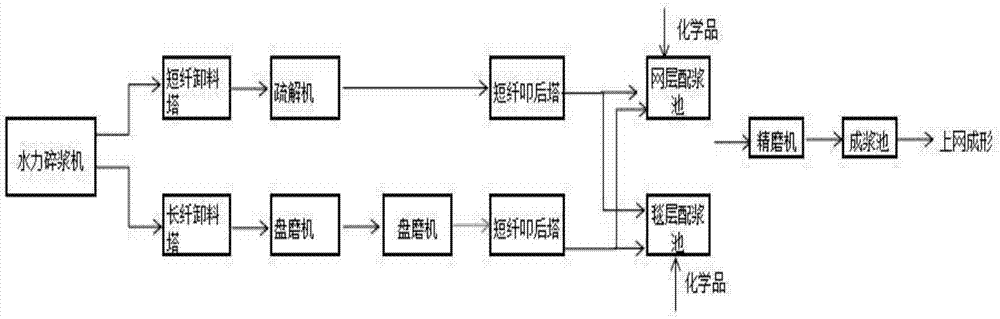

The invention discloses a novel household paper pulp preparing device and a novel household paper pulp preparing technology. Compared with the conventional pulp preparing device, the novel household paper pulp preparing device has the advantage as follows: staple fiber is treated through disc mills instead of a defibering machine; compared with the conventional technology, the novel household paper pulp preparing technology has the advantages as follows: in the whole process, one defibering machine, two beating towers, two pulp preparing tanks and corresponding four pulp pumps are reduced; a static mixer is used, and except for a mixed pulp, chemicals added from the tops of the conventional pulp preparing tanks are mixed more uniformly, so that the retention rate of the chemicals can be increased. The novel household paper pulp preparing device is simple in structure, reduces use of equipment, shortens the whole pulp preparing process, lowers the energy consumption, reduces the equipment, reduces use of workshops, and can adjust the technical system more quickly. By the novel household paper pulp preparing technology, an unnecessary temporary pulp storage point is omitted, the temporary storage time is shortened, a pulp preparing system is shortened, and repeated pumping and stirring of the pulp are reduced so as to achieve the purpose of lowering the energy consumption; meanwhile, the fixed investment can also be reduced.

Owner:SHANDONG HENGAN PAPER IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com