Book and cultural paper pulping method

A technology for cultural paper and pulping, applied in pulp bleaching, cellulose pulp post-processing, papermaking, etc., can solve the problems of waste water, waste residue pollution, damage to forest resources, harmful to eyesight, etc., and achieve environmental protection of waste residue discharge and protection of forest resources. , the use of comfortable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1 Book culture paper pulping method

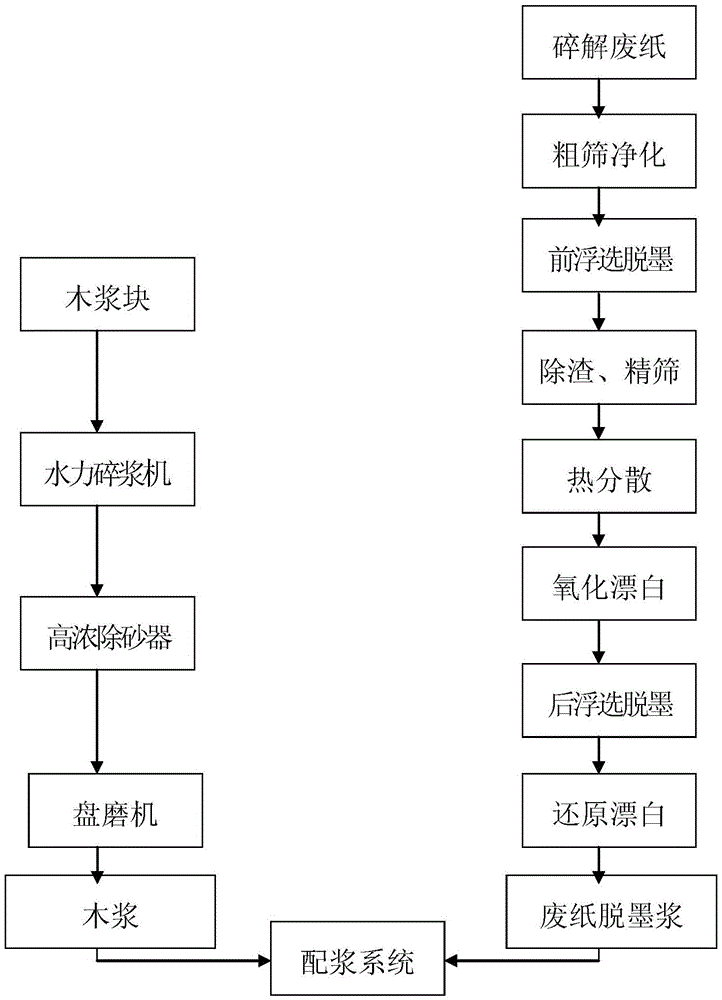

[0019] refer to figure 1 A pulping method for cultural paper for books and periodicals, comprising pulping and pulping, specifically comprising the following steps:

[0020] 1. Pulping:

[0021] 1.1 Preparation of waste paper deinking pulp: the waste paper is shredded to a concentration of 15% by a drum pulper, and the slurry enters a coarse screen purification system to remove some coarse heavy impurities and light impurities, and is pumped to discharge pulp after coarse screening Tower; the slurry from the unloading slurry tower enters the front flotation deinking system. After the ink particles are removed, it goes through the heavy impurity slag remover system and the first-stage multi-stage fine sieve system for slag removal and fine sieve, and then enters the thermal Dispersion system to make the size of large ink, dust and stickies smaller, and the concentration reaches 30%; the slurry after thermal dispersion en...

Embodiment 2

[0026] A pulping method for cultural paper for books and periodicals, including pulping and pulping, specifically includes the following steps:

[0027] (1) Pulping:

[0028] (a) Preparation of waste paper deinking pulp: shredding waste paper, coarse sieving to remove impurities, deinking by flotation, removing ink particles, and entering the heat dispersion system after passing through the heavy impurity slag removal system and the first-stage multi-stage fine screening system , to make the size of large ink, dust and stickies smaller, and the concentration reaches 32%; the slurry after thermal dispersion enters the hydrogen peroxide bleaching tower for bleaching, and the concentration reaches 30%; after bleaching, it enters the post-flotation deinking system, Separation of ink ions in the slurry; then use 0.25% of the weight of the slurry in sodium borohydride liquid reduction bleaching to remove the colored substances in the slurry, the concentration reaches 10%, and then g...

Embodiment 3

[0032] A pulping method for cultural paper for books and periodicals, including pulping and pulping, specifically includes the following steps:

[0033] (1) Pulping:

[0034] (a) Preparation of waste paper deinking pulp: shredding waste paper, coarse sieving to remove impurities, deinking by flotation, removing ink particles, and entering the heat dispersion system after passing through the heavy impurity slag removal system and the first-stage multi-stage fine screening system , to make the size of large ink, dust and stickies smaller, and the concentration reaches 28%; the slurry after thermal dispersion enters the hydrogen peroxide bleaching tower for bleaching, and the concentration reaches 30%; after bleaching, it enters the post-flotation deinking system, Separation of ink ions in the slurry; then use 0.25% of the weight of the slurry in sodium borohydride liquid reduction bleaching to remove the colored substances in the slurry, the concentration reaches 10%, and then g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com