Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2690 results about "Waste paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

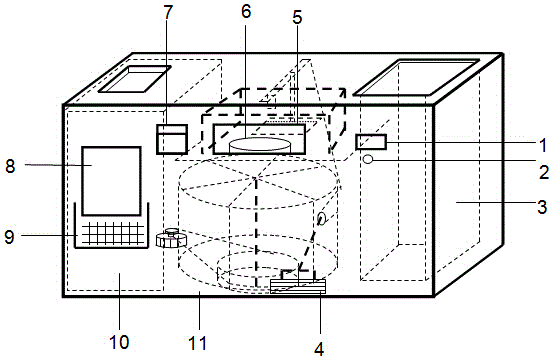

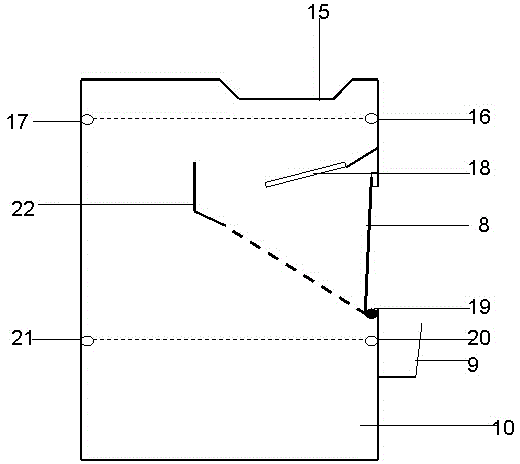

Apparatus for separating waste from cellulose fibres in paper recycling processes

InactiveUS20100133197A1Economically manufacturedEconomically usedLoose filtering material filtersFibrous raw materialsCyclic processWax

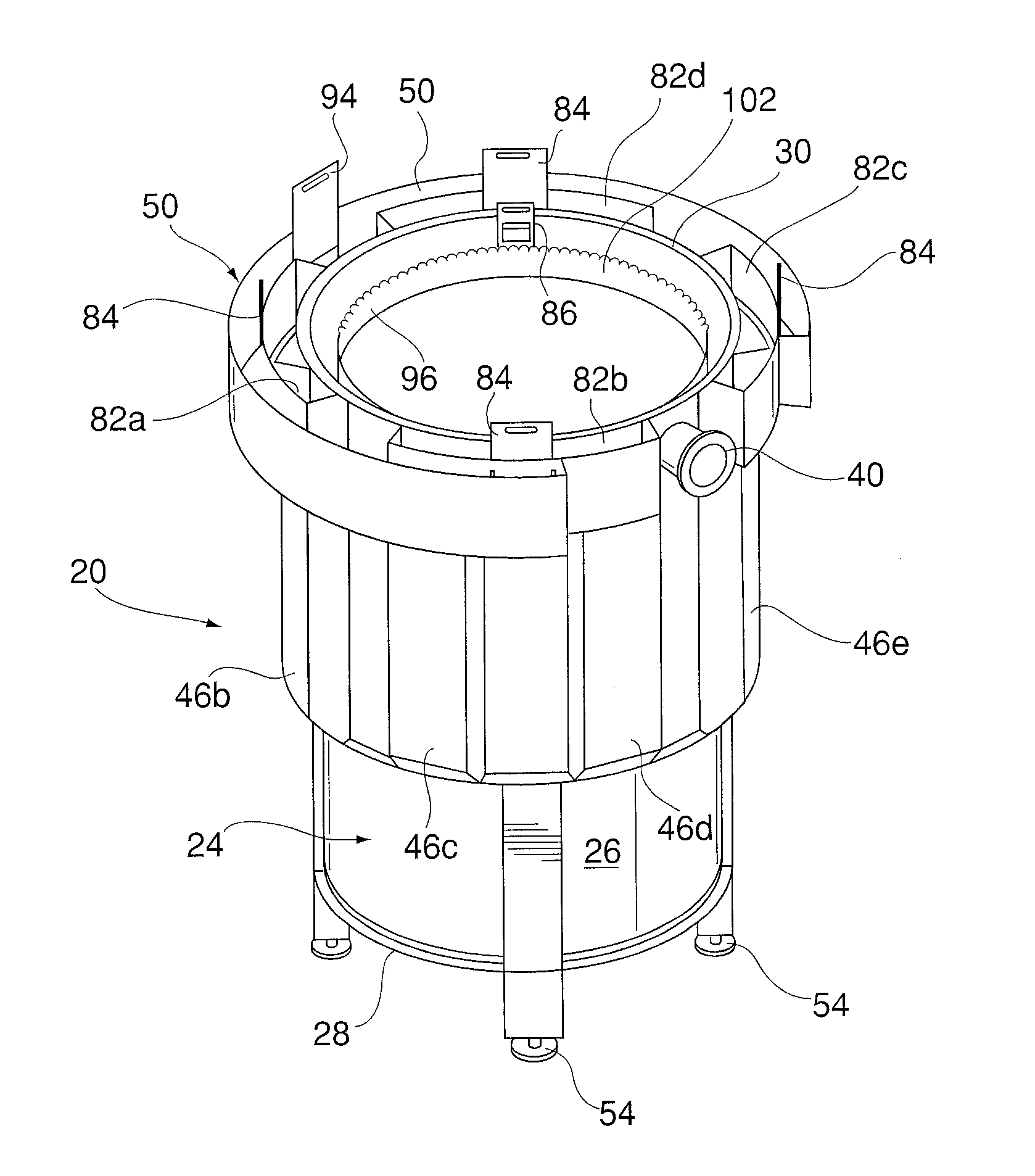

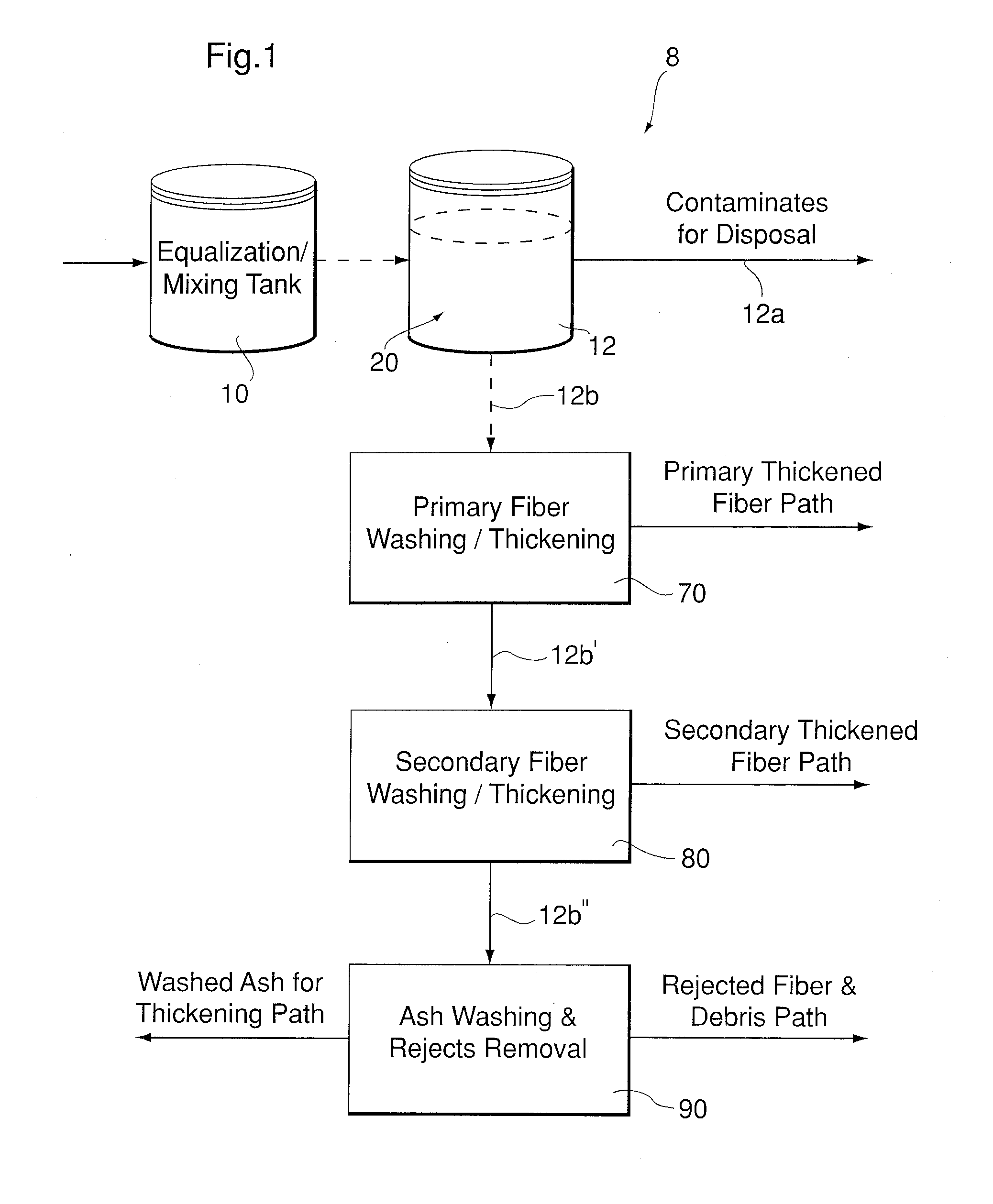

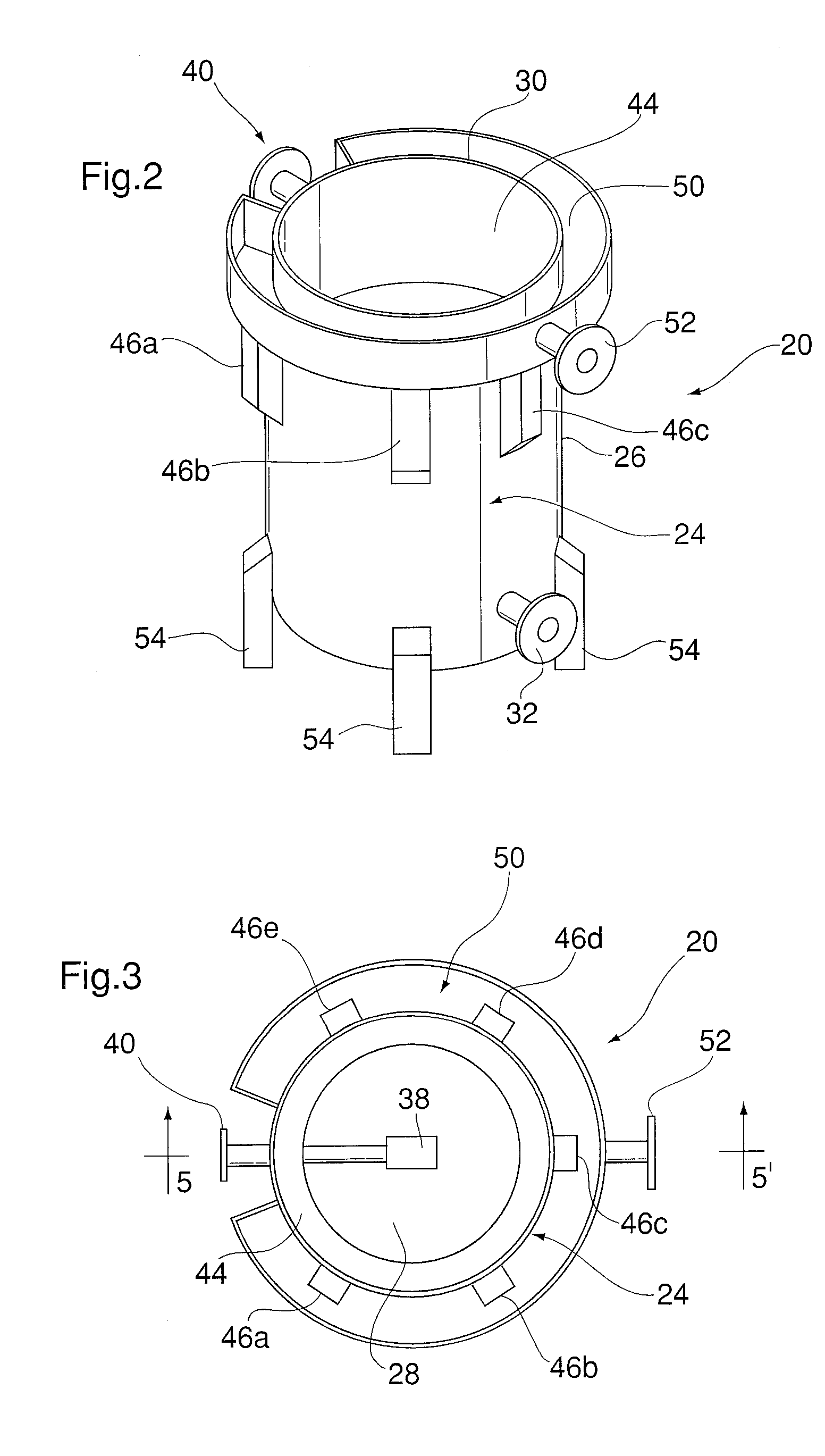

A contaminate separation apparatus for use in separating contaminant materials from cellulose and / or paper fibres in a paper recycling process includes a reservoir for receiving a waste paper slurry therein. The reservoir is provided with an inlet opening for the input of the slurry, one or more fibre discharge outlets or passages, and at least one waste outlet positioned vertically above the fibre discharge outlet opening. An agitator provided in a lower portion of the reservoir generates differential flow currents within the reservoir, to selectively divert plastics, waxes, adhesives and / or other sticky waste materials outwardly towards the waste outlet, while providing a flow of suspended paper and / or cellulose fibres to one or more of the fibre discharge outlets.

Owner:LANGNER HERBERT GUNTHER JOACHIM

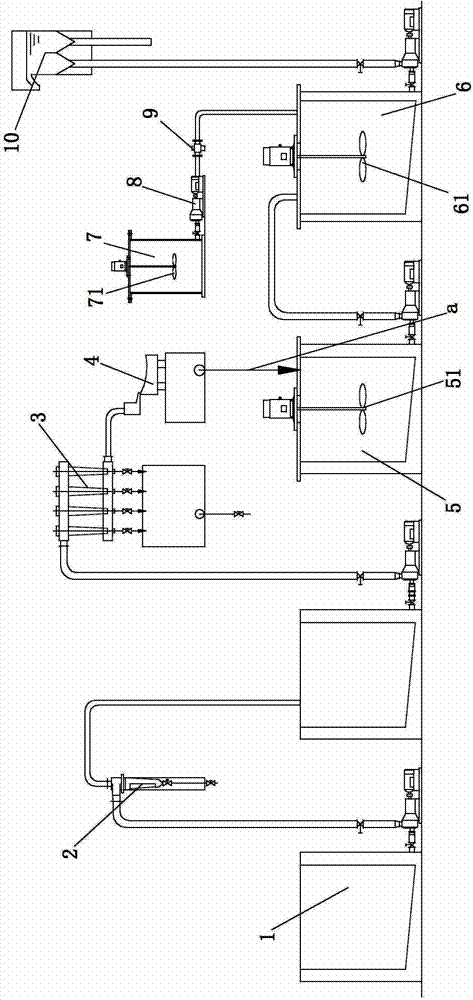

Separating method and system for waste paper and waste plastic mixture

InactiveCN1834340AReduce energy consumptionReduce loadGas current separationWashing/displacing pulp-treating liquorsFiberSingle stage

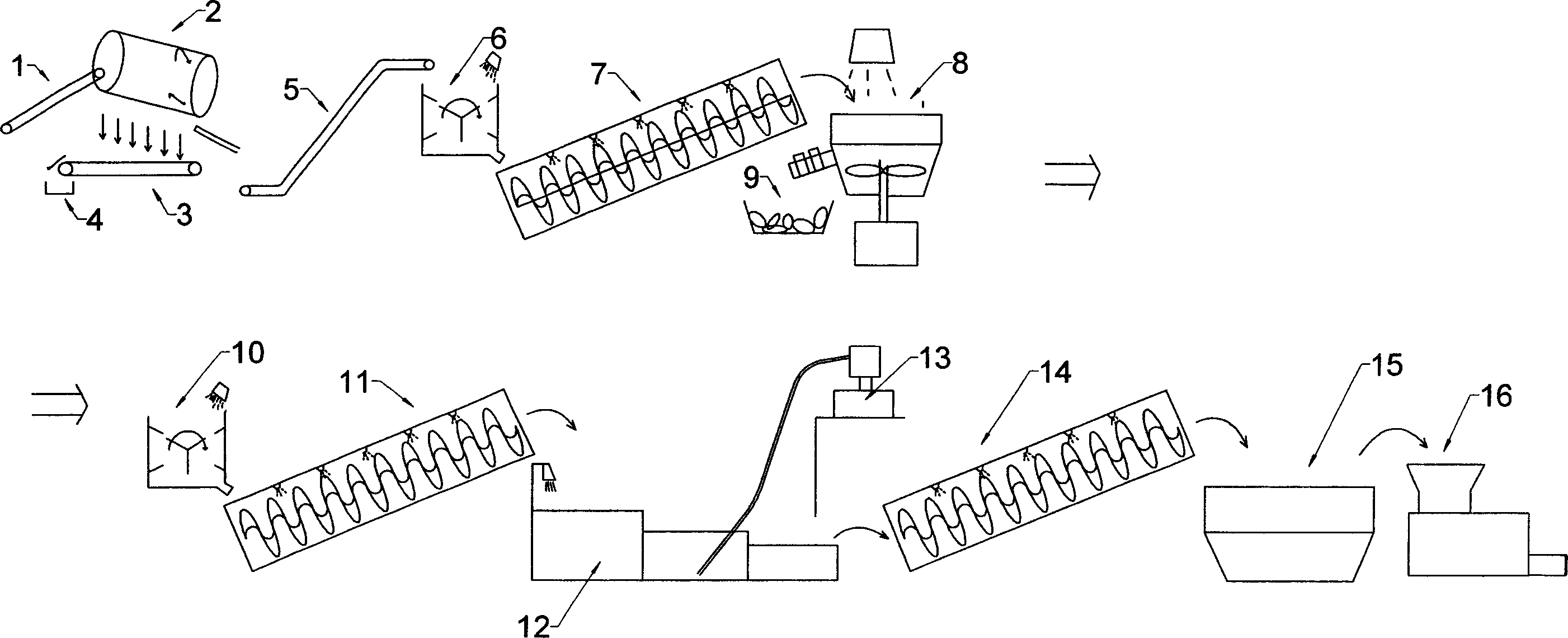

A method for separating out waste paper and waste plastic form their mixture including preliminary selecting, using magnetic separator to select out magnetic impurities, using hand to pick up large impurity block without plastic, using fan to blow impurities with different gravities into different grooves at different distance, using mechanical rubbing machine to separate paper fiber from plastic, using single stage floating tank to beat floating matters for releasing paper fiber off, storing floated out plastic and palletizing them for reutilization.

Owner:曾碚凯

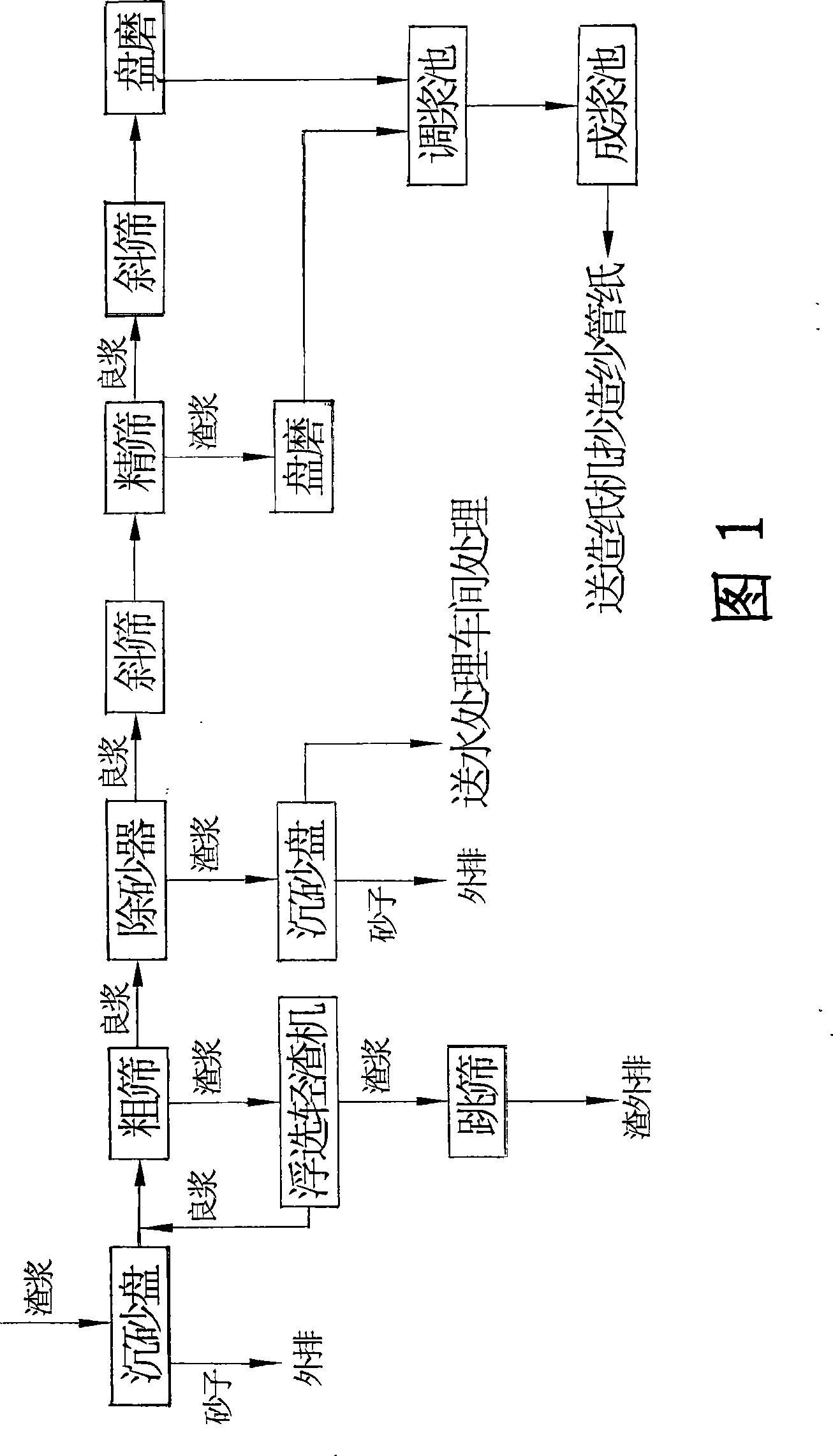

Method for producing recuperated yarn tube base paper by using waste slag and product thereof

ActiveCN101435171ASave resourcesAvoid churnWater-repelling agents additionPaper recyclingYarnProcess engineering

The invention relates to a manufacturing method which utilizes waste residue to produce regenerated yarn cop base paper and an obtained product thereof. The method comprises the following steps: the full stuff of processed waste slurry residue and the full stuff of processed waste paper are mixed according to proportion to carry out sand paper tube forming and then the regenerated yarn cop base paper is obtained. By adopting the method, waste paper resources can be saved, waste water treatment can be reduced, and the obtained regenerated yarn cop base paper has the advantages of low ration, good quality and the like.

Owner:JIAN GRP

Environment-friendly efficient filter filtering paper and preparation method thereof

ActiveCN102888784AImprove efficiencyImprove filtration efficiencyNon-fibrous pulp additionPaper/cardboardSolubilityGlycerol

The invention discloses an environment-friendly efficient filter filtering paper. The environment-friendly efficient filter filtering paper is prepared by the following raw materials in part by weight: 40-50 parts of softwood pulp, 30-40 parts of waste paper pulp, 20-30 parts of high-silica glass fiber, 2-5 parts of modified vermiculite, 1-3 parts of zeolite molecular sieve, 2-4 parts of nanometer calcium, 1-2 parts of modified pulverized fuel ash, 2-3 parts of water-solubility organic silicon resin emulsion, 1-2 parts of water-solubility polytetrafluoroethylene emulsion, 0.5-0.8 parts of ammonium polyphosphate, 3-4 parts of glycerol triacetate, 0.5-1 parts of diethanolamide, 0.5-1 parts of silane coupling agent KH560, 0.4-0.8 parts of sodium dodecyl sulfate, 0.5-1 parts of antioxidant DSTP, and 4-6 parts of polyethylenimine. The filtering paper prepared by the method provided by the invention has the advantages of being good in water permeability, large in filtering area, small in maximum diameter of hole, high in filtering precision, strong in bursting strength, high-temperature-resistant, good in water resistance and the like, can achieve the filtering efficiency by 99.98%, has stable performance index at atmospheric and high-temperature working conditions, as well as better temperature resistance and filtering effects.

Owner:ANHUI PHOENIX INT CO LTD

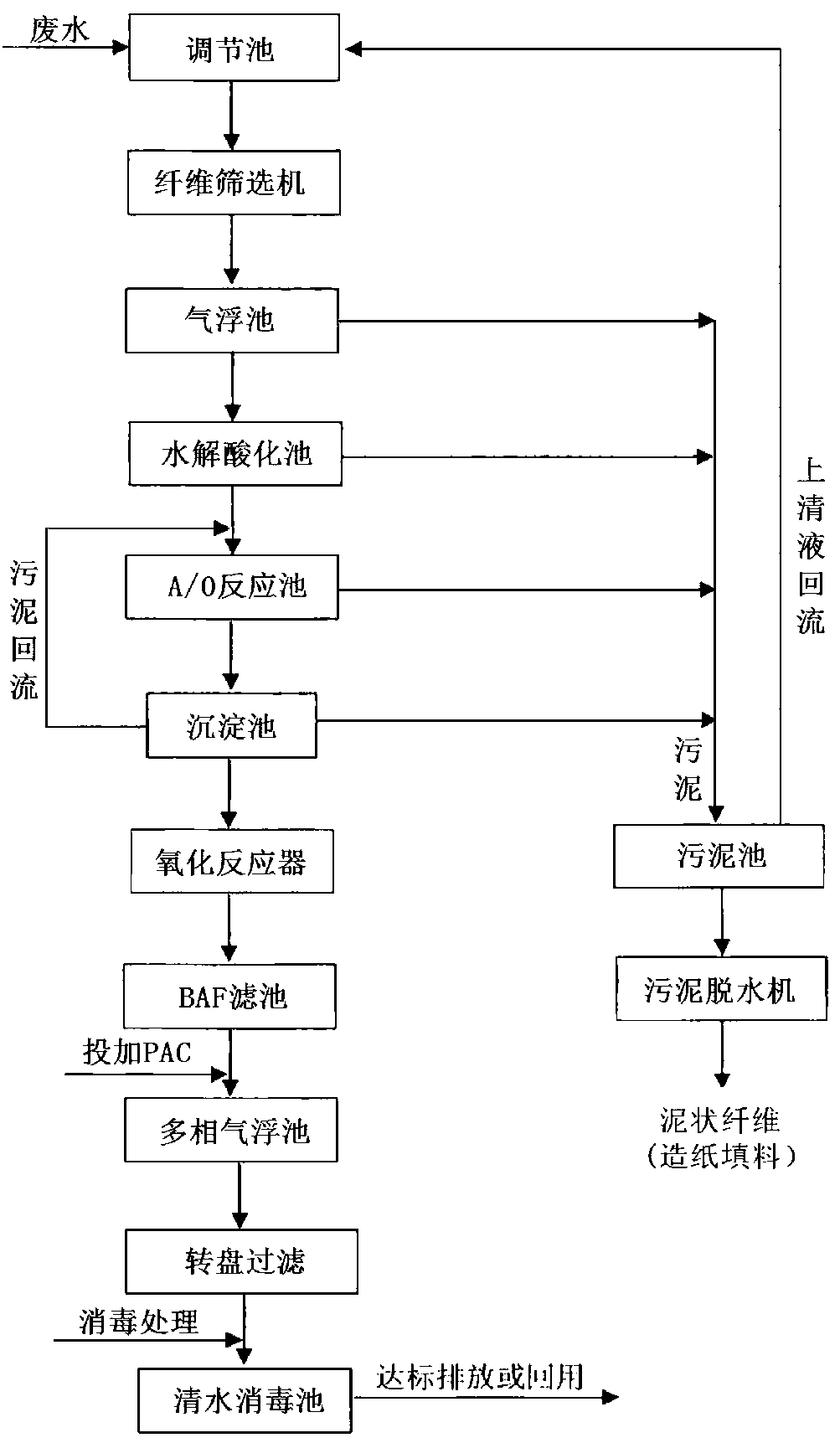

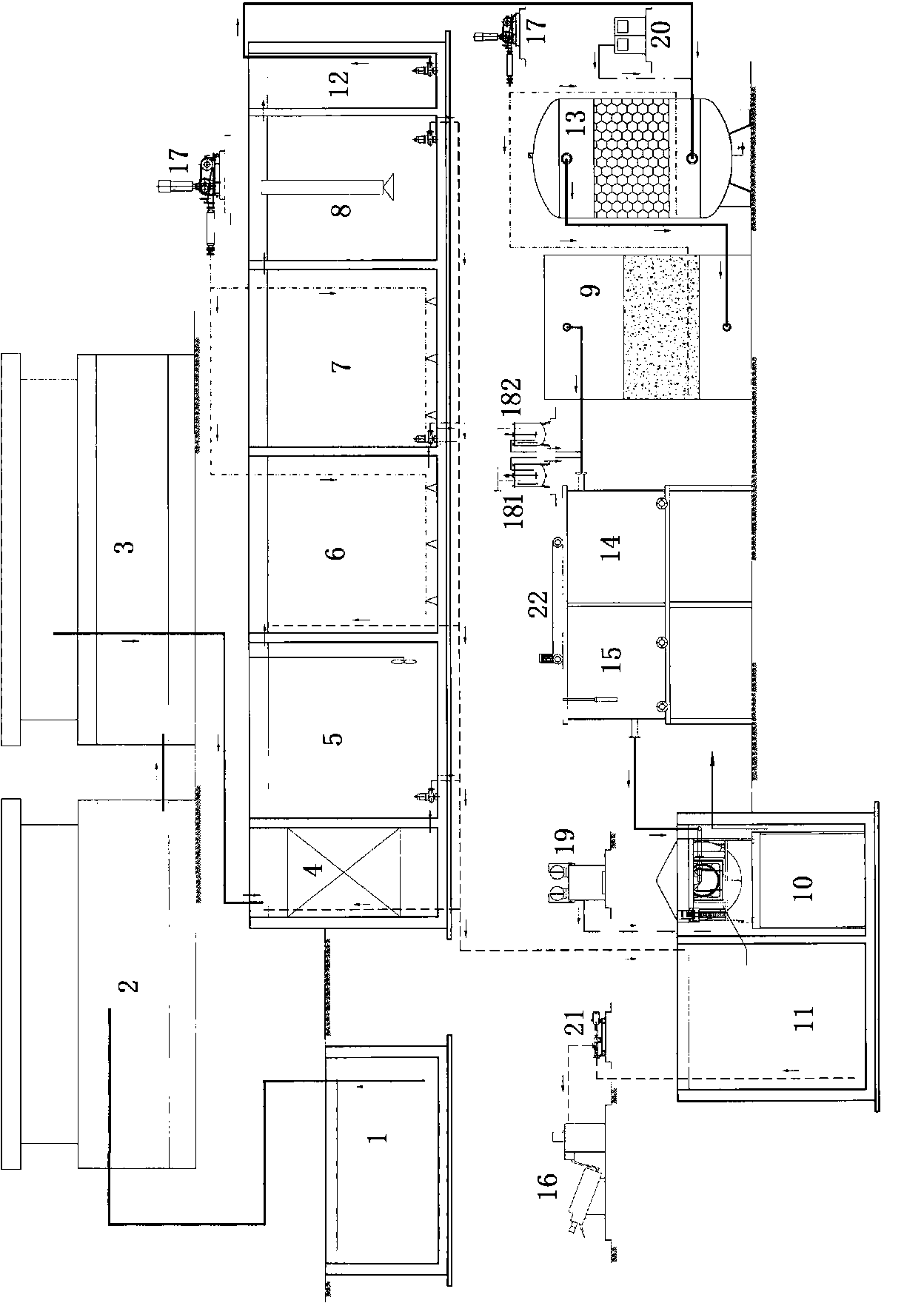

Water paper paper-making wastewater efficient treatment and comprehensive recycling method and device

ActiveCN103058467AEasy to handleEmission reductionMultistage water/sewage treatmentWaste water treatment from plant processingSludgeWastewater

The invention discloses a water paper paper-making wastewater efficient treatment and comprehensive recycling method and a device. The method comprises the steps of pre-treatment, a hydrolysis reaction, biochemical treatment, separated oxidization, aeration treatment and post-treatment; the device comprises an adjusting tank, a sieving device, an air floating tank, a hydrolysis and acidification tank, an anaerobic tank, an aerobic tank, a sedimentation tank, a clean water disinfection tank and a sludge tank; the adjusting tank, the sieving device, the air floating tank and the hydrolysis and acidification tank are connected in sequence through pipelines; the hydrolysis and acidification tank, the anaerobic tank and the sedimentation tank are communicated in sequence; the clean water disinfection tank is provided with a disinfection opening, a water discharging opening and a sludge discharging opening; and the disinfection opening is connected with a disinfection device; and the sludge discharging opening is connected with the sludge tank through a pipeline. According to the water paper paper-making wastewater efficient treatment and comprehensive recycling method and device, all the functional tanks are integrated and a comprehensive synergistic effect of each tank is expressed and the comprehensive treatment effect is improved. The valuable paper-making raw material resources are recycled, the emission amount is reduced and the output water can reach national A-grade emission standard.

Owner:富民宝地纸业有限公司

Intelligent identifying card automatic sorting collecting method

ActiveCN104443949AAvoid pollutionSolve the problem of sorting and recyclingGlass recyclingPlastic recyclingWaste productSmart card

The invention discloses an intelligent identifying card automatic sorting collecting method. Classifying recycling of waste paper, waste plastics, waste metal, waste glass, waste batteries and waste electronic products can be achieved, and intelligent point accumulation can be achieved. Meanwhile, recycling, sorting and automatic point accumulation of PET plastic bottles can be achieved. Classifying recycling of unrecyclable garbage such as kitchen garbage can be achieved. Various recycled waste products are converted into accumulated points suitable for daily consumption according to the number, the weight and the value, and the accumulated points are charged into an intelligent card automatically. According to the method, an intelligent identifying card sorting collecting device (11), a PET bottle recycling device (10), an unrecyclable garbage recycling box (3) and an intelligent card sensor (7) in which accumulated points can be recorded are included. The combination structure can carry out classifying recycling on garbage generated in daily life conveniently, practical value is given to household garbage and is converted into the accumulated points for consumption in daily life, garbage classifying is promoted, and people are encouraged to actively participate in the activities of garbage recycling.

Owner:CHANGCHUN UNIV OF TECH

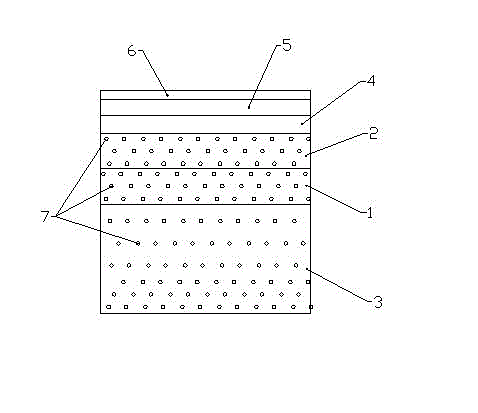

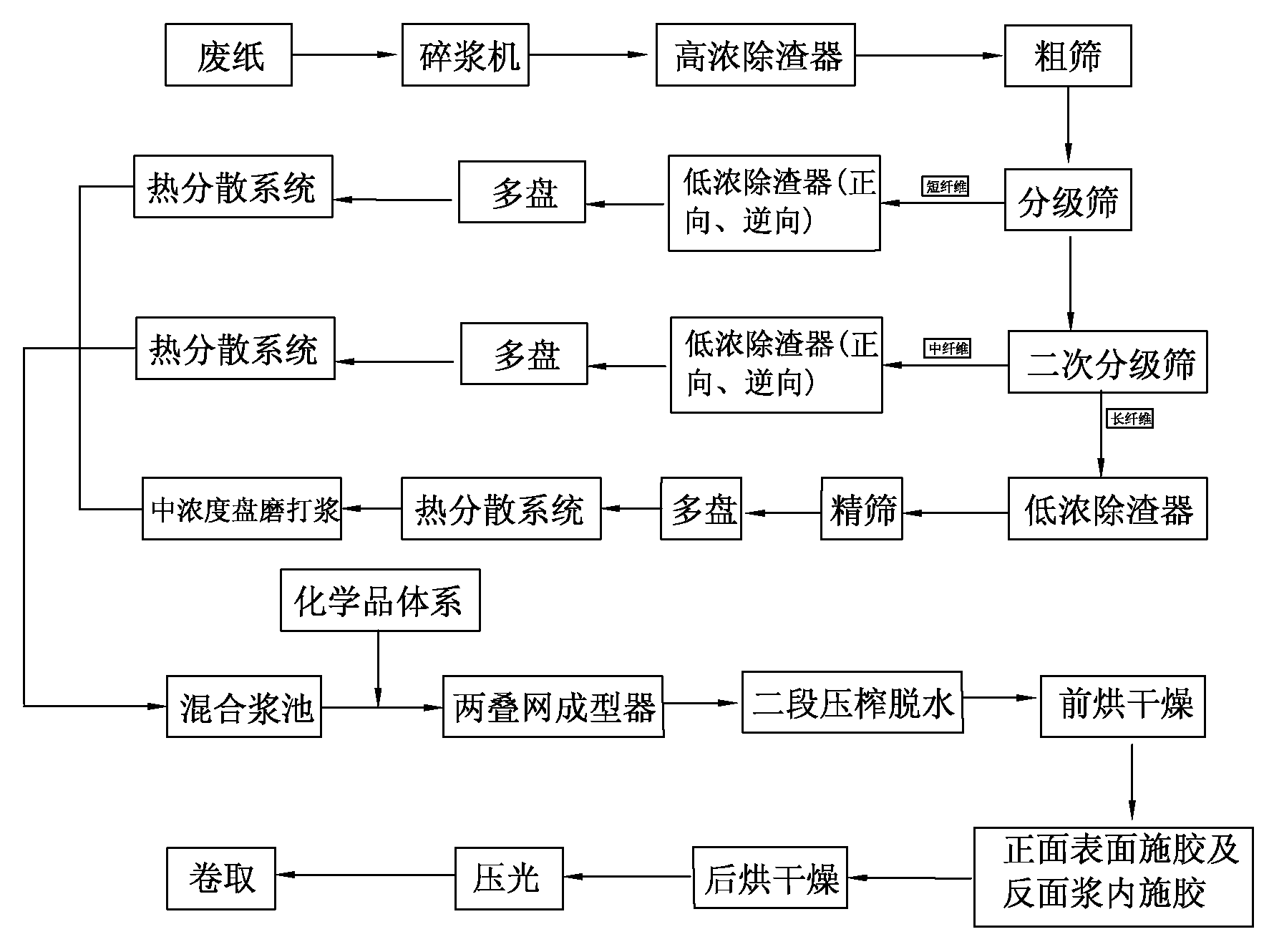

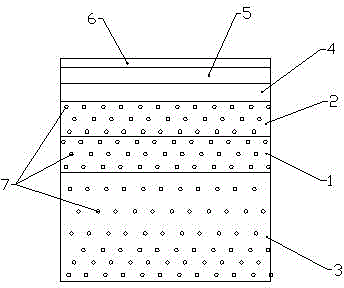

White-surface coated craft paper and production method thereof

ActiveCN102912689AIncrease varietyImprove qualityCoatings with pigmentsSpecial paperAfter treatmentRegenerating fibers

The invention discloses white-surface coated craft paper and a production method thereof. The white-surface coated craft paper comprises a core paper layer; the upper side of the core paper layer is a surface paper layer, and the lower side is a bottom paper layer; a coating layer is arranged on the upper surface of the surface paper layer; the bottom paper layer and the core paper layer of the white-surface coated craft paper are prepared by the steps of: dosing the waste paper, preparing waste paper pulp to obtain non-deinked waste paper pulp, and manufacturing paper through a paper layer to obtain a wet bottom paper layer and a wet core paper layer; the surface paper layer is prepared by the steps of: mixing the bleached hardwood pulp, bleached softwood pulp and bleached regenerated fiber pulp DIP at any proportion, and manufacturing paper through a paper layer to obtain a wet surface paper layer; and the wet bottom paper layer, the wet core paper layer and the wet surface paper layer are subjected to the steps of compounding with the coated body paper, preliminary drying, sizing, later drying, paper surface calendering, paper surface coating and after-treatment to obtain the white-surface coated craft paper. The available waste paper types are increased, and the fiber source is wider; and meanwhile, the quality of the waste paper pulp is effectively stabilized so as to guarantee the quality stability of the coated body paper and the white-surface craft paper and avoid easy layering, splitting and scaling.

Owner:山东晨鸣纸业集团股份有限公司 +1

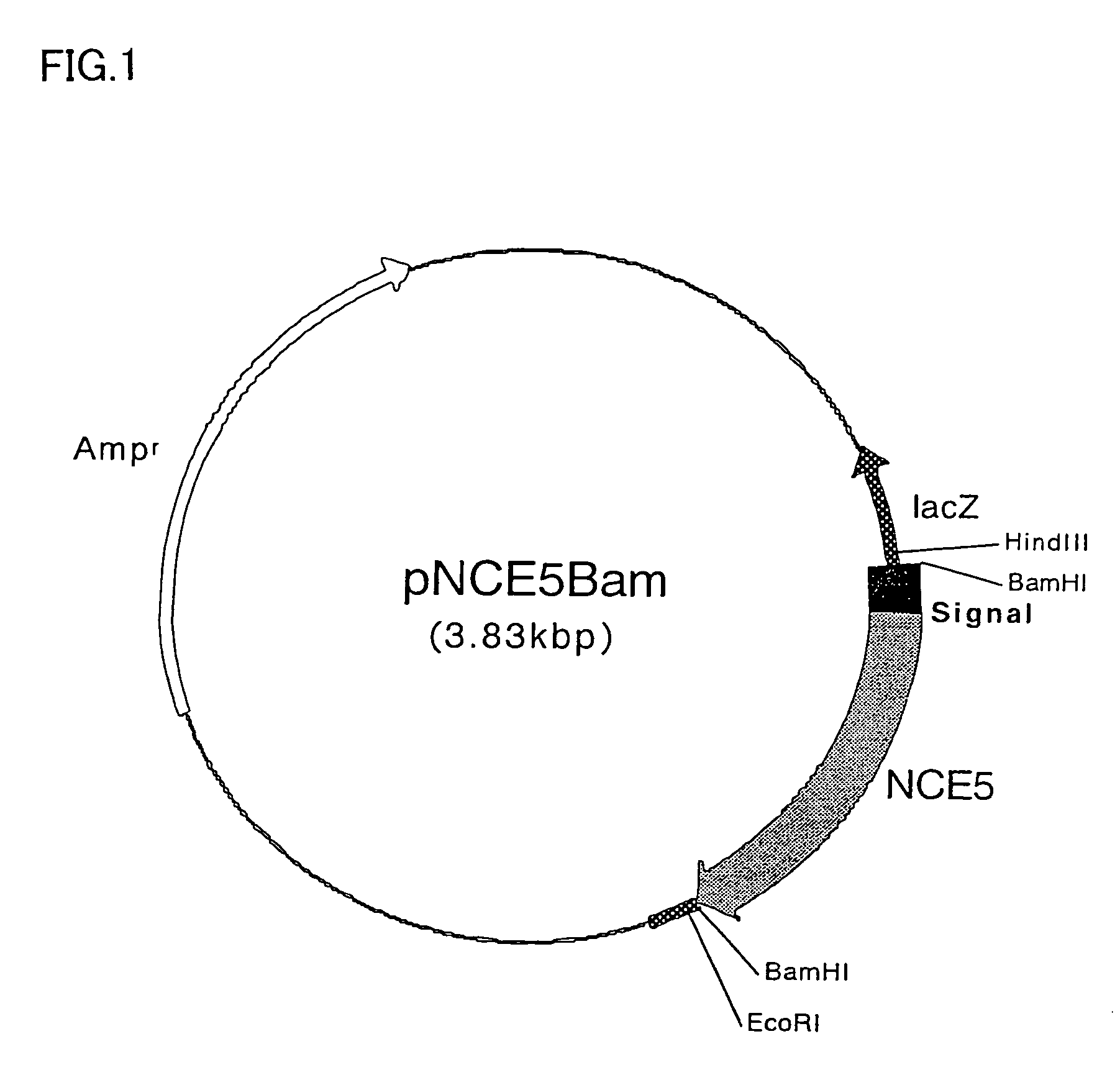

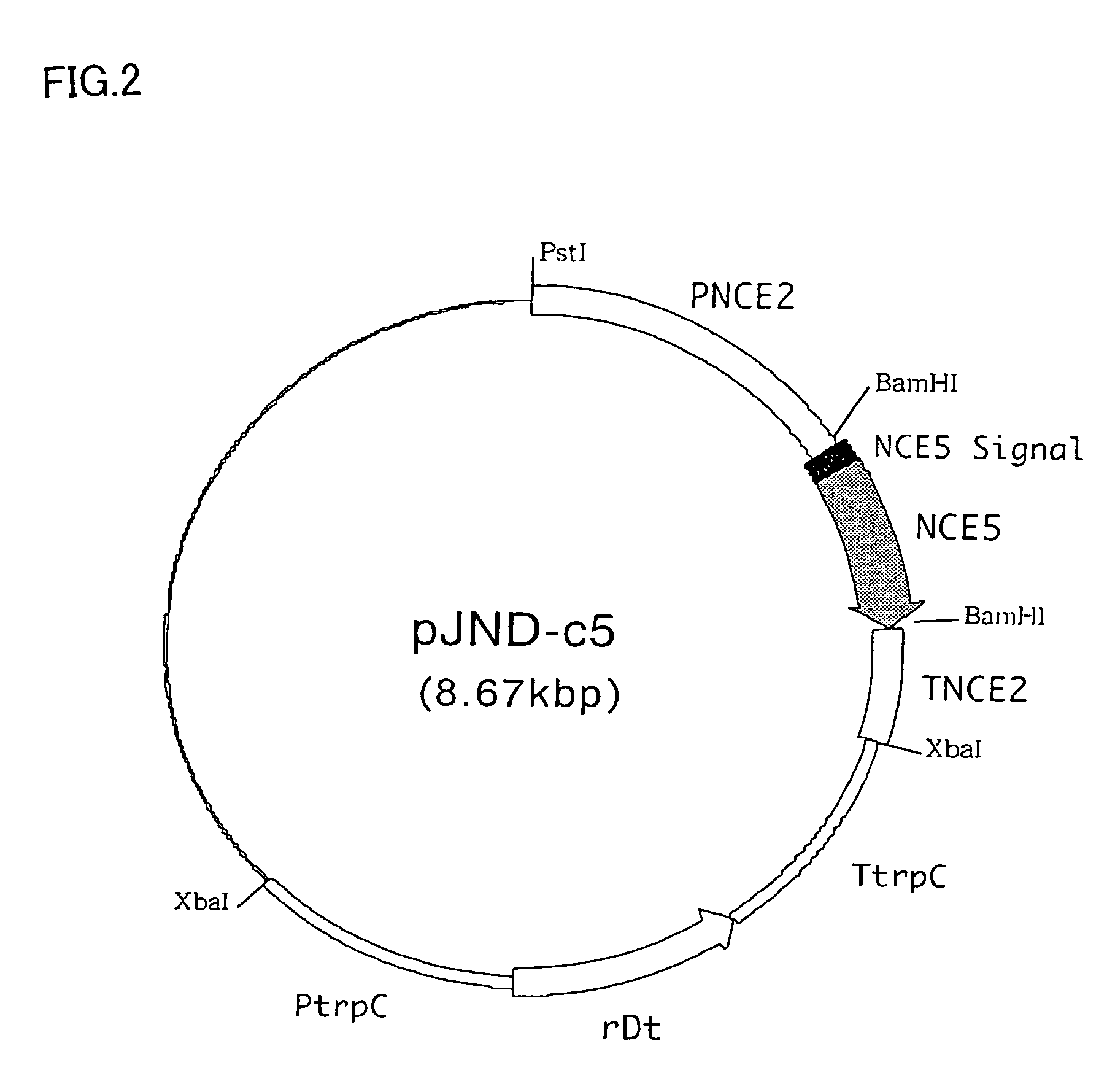

Endoglucanase enzyme NCE5 and cellulase preparations containing the same

InactiveUS7138263B2Efficient and inexpensive treatmentLow degreeFungiOrganic detergent compounding agentsBiotechnologyCellulase

There is provided an endoglucanase enzyme, which is useful for reducing fuzz of regenerated cellulose-containing fabrics, improving the touch and appearance, color clarification, localized variation in color, reducing stiffness and using it as components of a detergent, as well as deinking waste paper and improving freeness of paper pulp. A cDNA coding for the endoglucanase enzyme NCE5 was cloned and its DNA sequence and amino acid sequence derived from it were determined.

Owner:MEIJI SEIKA KAISHA LTD

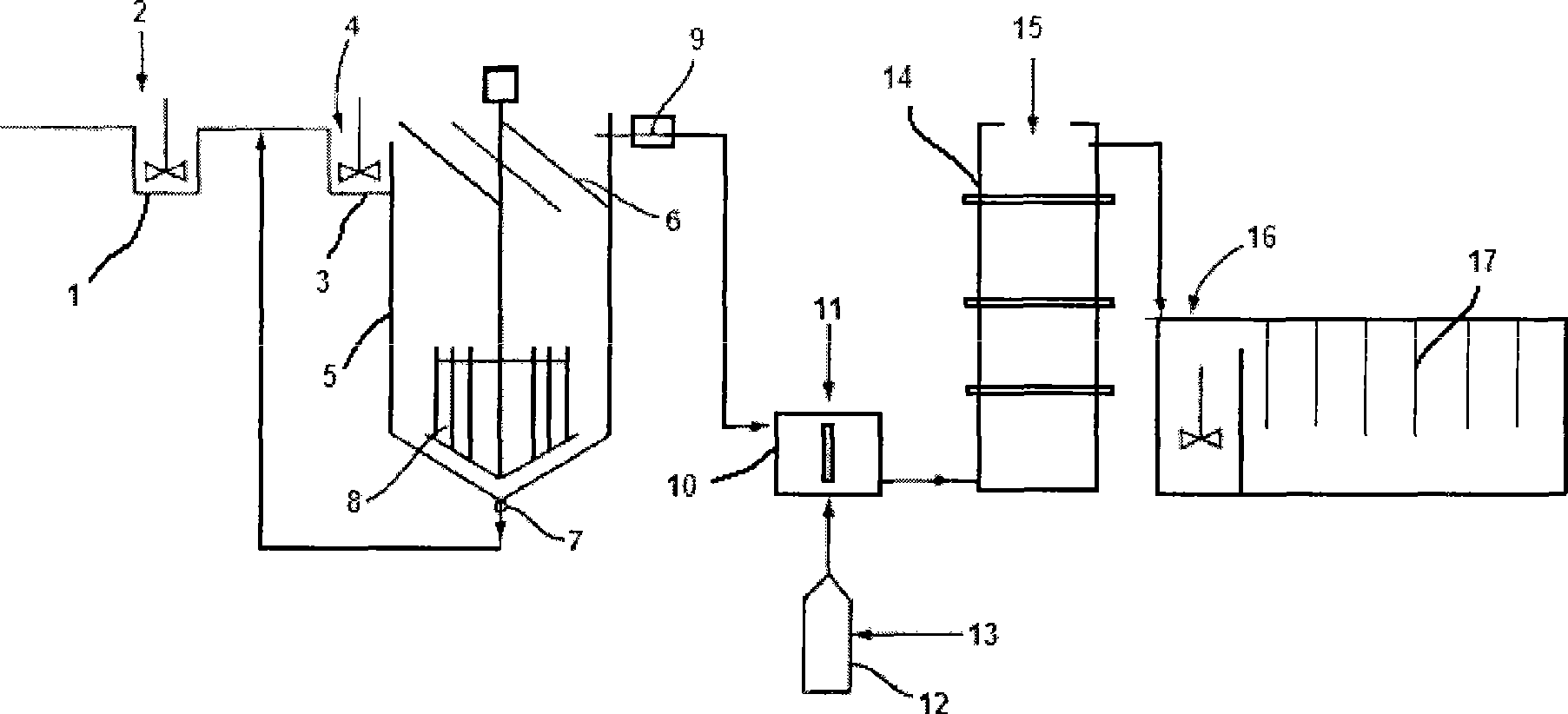

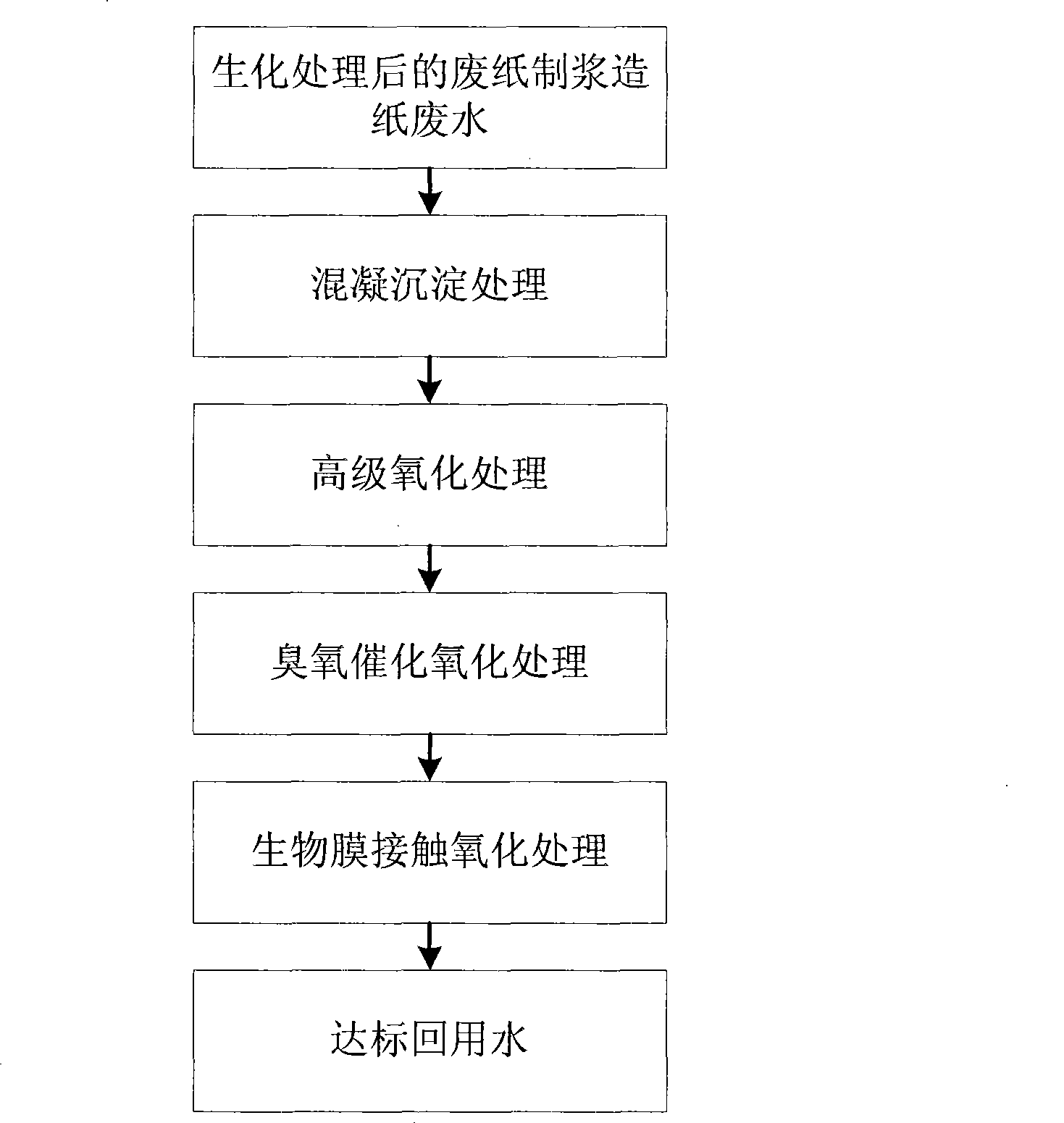

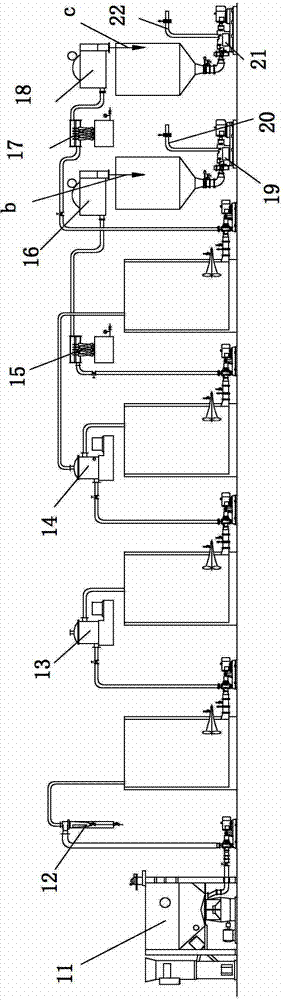

Advanced treatment method and processing system for wastepaper pulping and papermaking waste water

InactiveCN101372382AHigh degree of modernizationEasy to operateMultistage water/sewage treatmentWaste water treatment from plant processingTreatment resultsAfter treatment

The invention discloses a wastewater advanced treatment method of pulping and paper making from waste paper and a treatment system thereof. The system is a wastewater advanced treatment system formed in a way that a pre-coagulation tank, a coagulation reaction tank, a coagulation sedimentation tank, an advanced oxidation treatment device, a catalytic ozonation device and a biomembrane contact oxygenation device are connected in sequence. The system can realize the organic combination of the coagulation sedimentation treatment, the advanced oxidation treatment, catalytic ozonation treatment and biomembrane contact oxygenation treatment. The wastewater treatment of pulping and paper making from waste paper is carried out by the combination of physical, chemical and biological treatments, and can achieve better treatment result on the premise that low operation cost is guaranteed. After treatment, the effluent can not only meet the first class discharge standard, but also meet the requirements of industrial reused water.

Owner:SOUNDGRP CO LTD

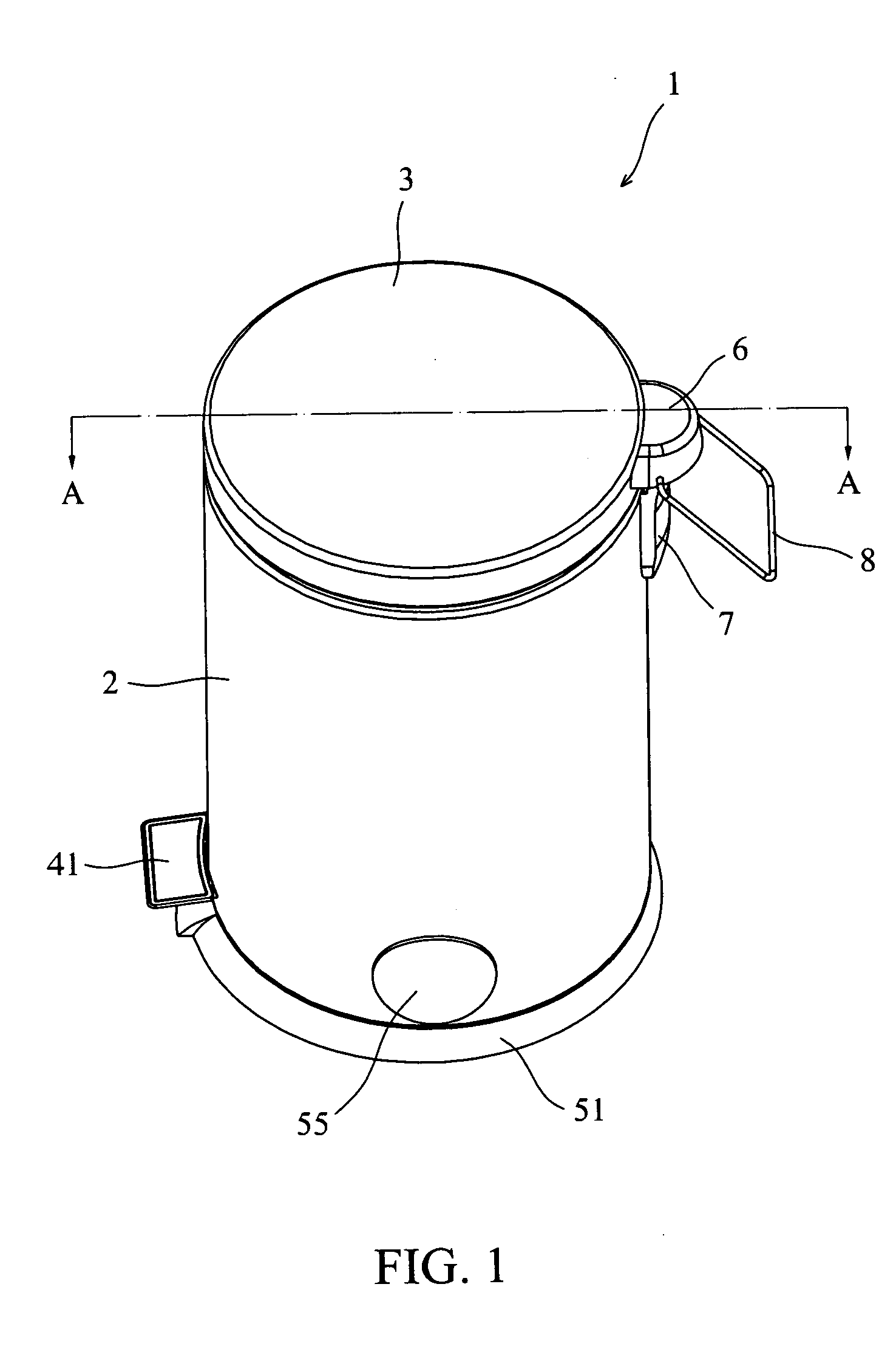

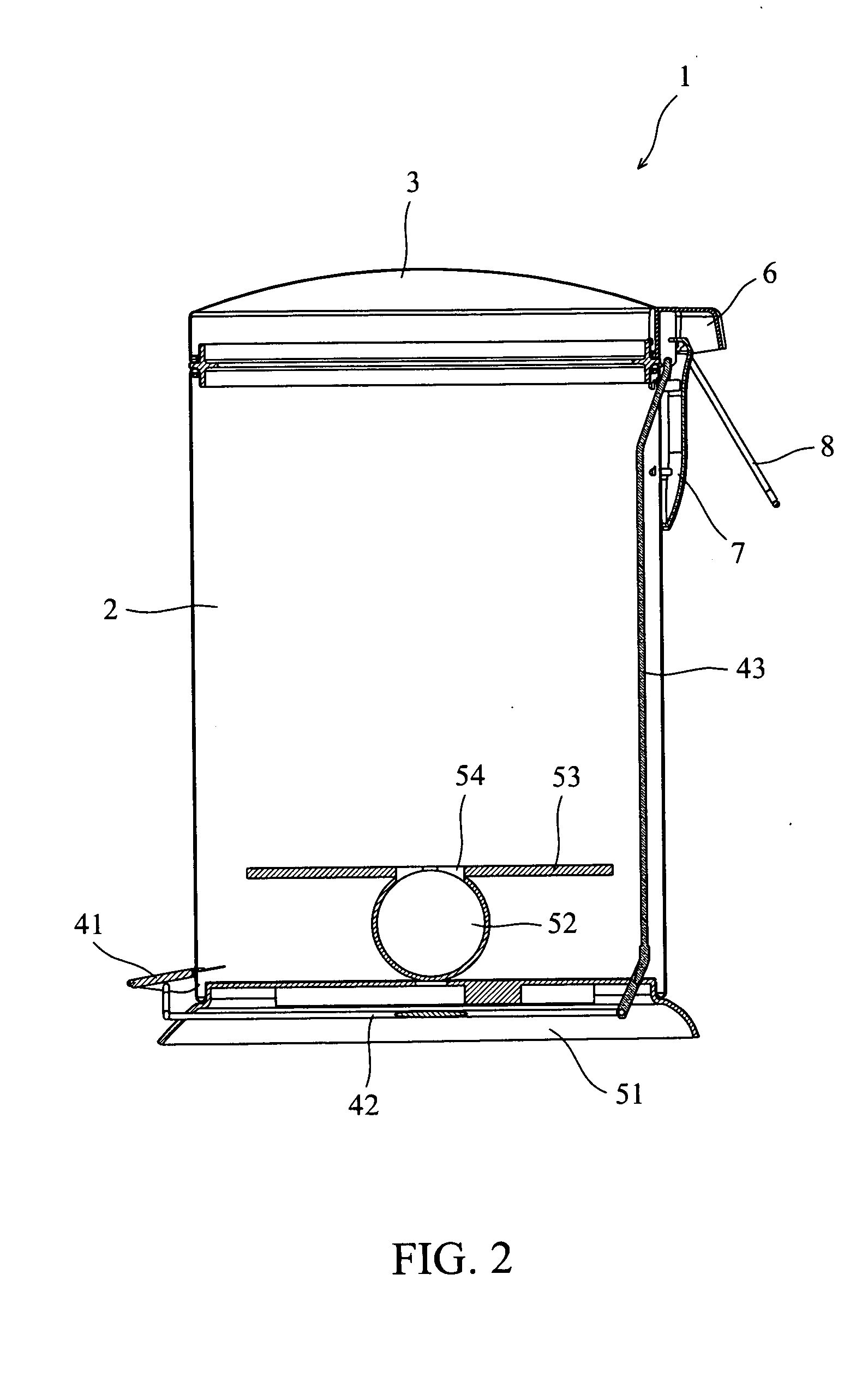

Waste paper basket

A waste paper basket comprises a body, a lid, a pedal unit, a basket base, a pivotal portion, a fixation portion and a handle. The pedal unit comprises a pedal and a linkage; the basket base comprises a base, a roller and a supporting base plate; the body is fastened on the basket base; the lid is sleeve jointed to the body; the linkage is connected to the pedal and the fixation portion; the handle is plugged into the pivotal portion, which is connected to the fixation portion and assembled on the external periphery of the junction of the lid and the body. A roller cap passes through a hole of the body and then is sleeve jointed to the roller. It is possible to place waste bags inside the roller of the waste paper basket in advance, so that when the waste bag on the supporting base plate is taken out for disposal, a new waste bag is drawn out from the roller along with the old waste bag.

Owner:TEST RITE INT

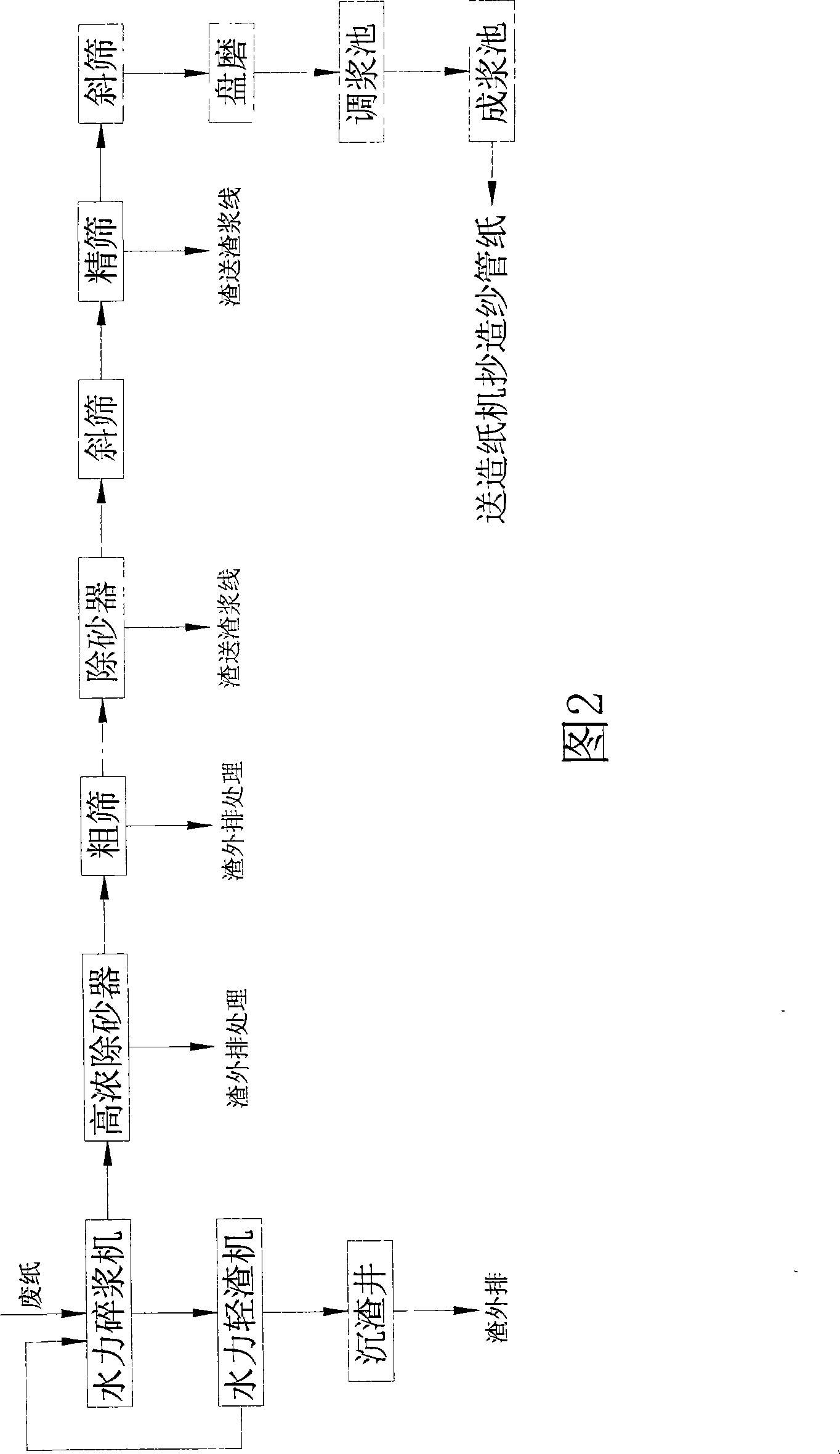

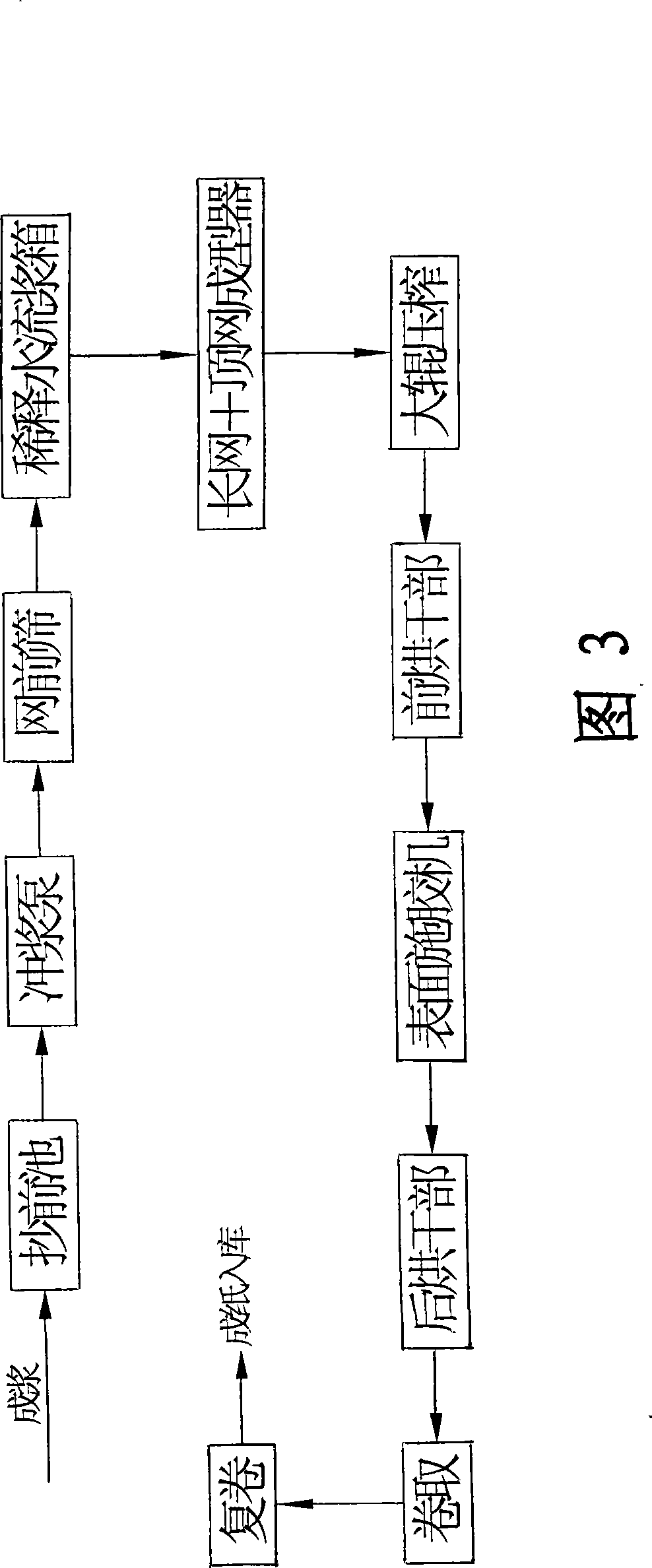

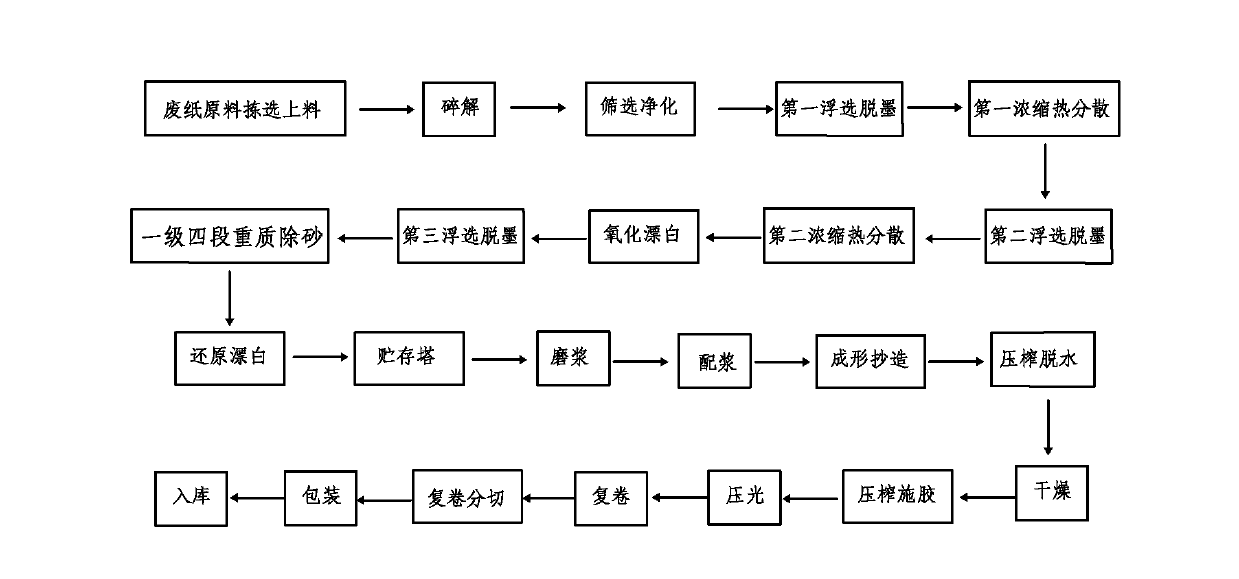

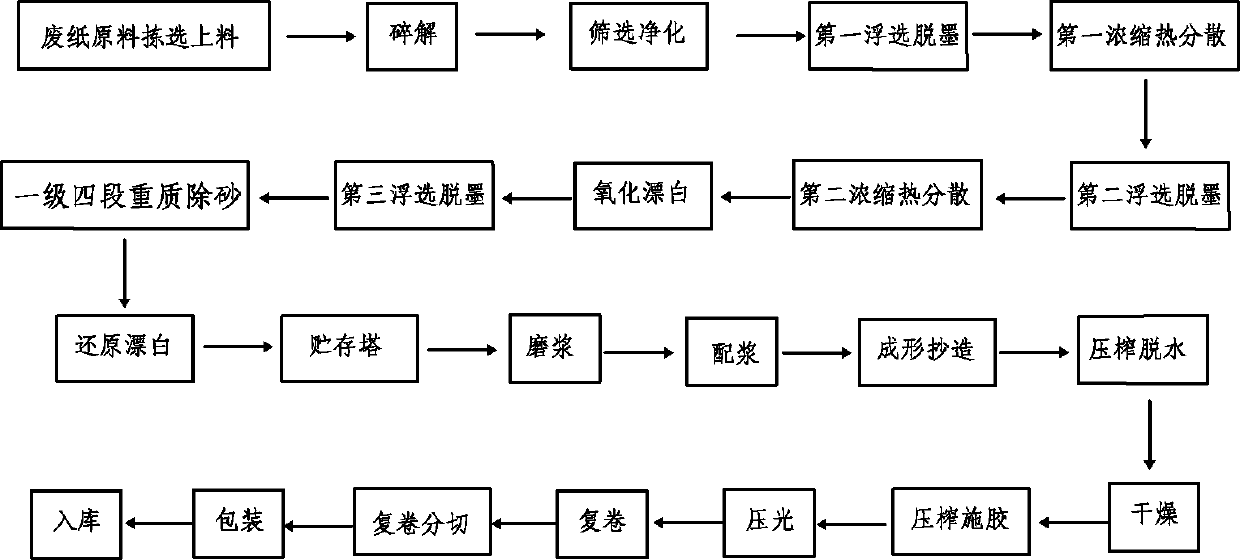

Process for preparing cultural paper by utilizing full-recovered pulp

InactiveCN102677532AQuality improvementImprove cleanlinessPaper recyclingLuminescent/fluorescent substance additionPapermakingSizing

The invention belongs to the technical field of a papermaking process and particularly relates to a process for preparing cultural paper by utilizing full-recovered pulp. The process for preparing the cultural paper by utilizing the full-recovered pulp comprises the following preparation steps of: a step A of sorting and loading waste paper raw materials; a step B of beating; a step C of screening and purifying; a step D of carrying out primary floatation deinking; a step E of carrying out primary concentration and heat dispersion; a step F of carrying out secondary floatation deinking; a step G of carrying out secondary concentration and heat dispersion; a step H of carrying out oxidation bleaching; a step I of carrying out reduction bleaching; a step J of storing in a tower; a step K of milling pulp; a step L of preparing the pulp; a step M of forming and manufacturing the paper with the pulp; a step N of squeezing and dehydrating; a step O of drying; a step P of squeezing and sizing; and a step Q of carrying out press polishing and then completing processing of a finished product by the working sections of reeling, rewinding, packaging and warehousing. According to the process disclosed by the invention, the high-quality cultural paper of which the appearance quality and the physical indexes all reach the domestic and overseas standards is produced by utilizing the low-price waste paper raw materials; the production cost is reduced; the production environment is clean and environmental-friendly; and the production efficiency is high.

Owner:DONGGUAN NINE DRAGONS PAPER IND

Process for treating waste paper pulping and papermaking waste water

InactiveCN103466884AAdaptableStrong impact resistanceMultistage water/sewage treatmentWaste water treatment from plant processingSludgeFiltration

The invention relates to a process for treating waste paper pulping and papermaking waste water. The process comprises the following steps of: removing large-particle suspended matters from waste paper pulping and papermaking waste water through a grille well arranged at a discharge outlet, then feeding the waste paper pulping and papermaking waste water in a water collection tank, and pumping into a filtration system of an inclined screen device through a waste water lift pump; regulating and homogenizing the quality and quantity of waste water in a regulating tank, pumping water from the regulating tank into a horizontal-flow flotation tank through the lift pump, feeding a coagulant for coagulating sedimentation; feeding outflowing water of the horizontal-flow flotation tank into a middle tank, pumping a part of outflowing water into a workshop for reuse through a backflow pump, and pumping the rest part of outflowing water into an anaerobic tank; enabling the outflowing water of the anaerobic tank to an aerobic tank, enabling the outflowing water of the aerobic tank to a secondary sedimentation tank; enabling a part of outflowing water sedimented to flow in a recycling water collection tank and then pumped into the workshop for recycling; and enabling the other part of outflowing water to flow in a terminal discharge tank to reach the emission standard; enabling a part of biochemical sludge discharged from the secondary sedimentation tank to flow back to the aerobic tank, and enabling the other part of sludge to flow in a sludge thickening tank to be thickened, discharging supernatant of the secondary sedimentation tank into the regulating tank, and enabling the thickened filtrate to flow back into the regulating tank.

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

Xylanases, Nucleic Acids Encoding Them and Methods For Making and Using Them

ActiveUS20110016545A1Low cost processingLow-cost and efficientImmobilised enzymesNon-fibrous pulp additionIncrease phCell wall

The invention relates to enzymes having xylanase, mannanase and / or glucanase activity, e.g., catalyzing hydrolysis of internal β-1,4-xylosidic linkages or endo-β-1,4-glucanase linkages; and / or degrading a linear polysaccharide beta-1,4-xylan into xylose. Thus, the invention provides methods and processes for breaking down hemicellulose, which is a major component of the cell wall of plants, including methods and processes for hydrolyzing hemicelluloses in any plant or wood or wood product, wood waste, paper pulp, paper product or paper waste or byproduct. In addition, methods of designing new xylanases, mannanases and / or glucanases and methods of use thereof are also provided. The xylanases, mannanases and / or glucanases have increased activity and stability at increased pH and temperature.

Owner:BP CORP NORTH AMERICA INC

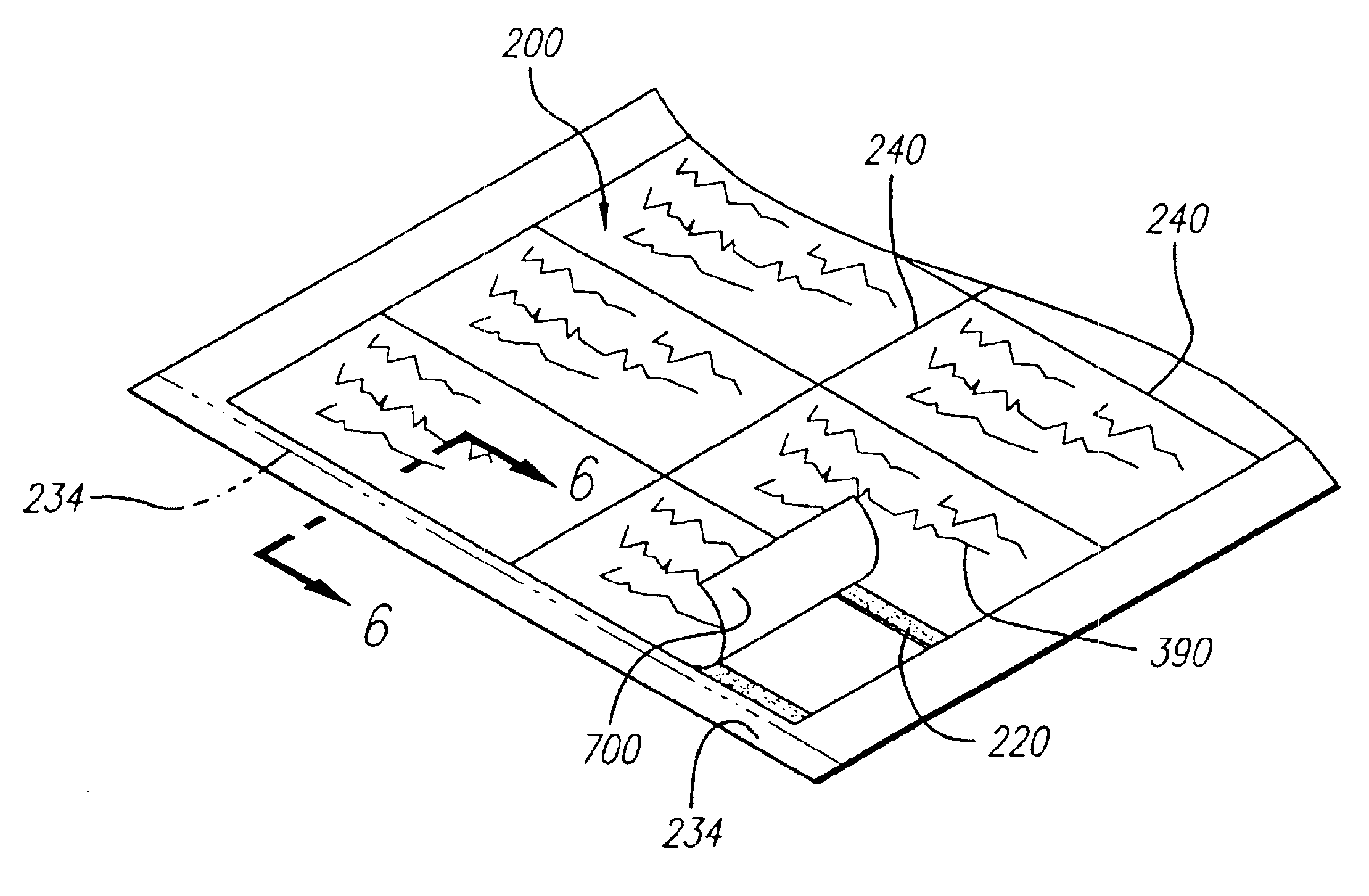

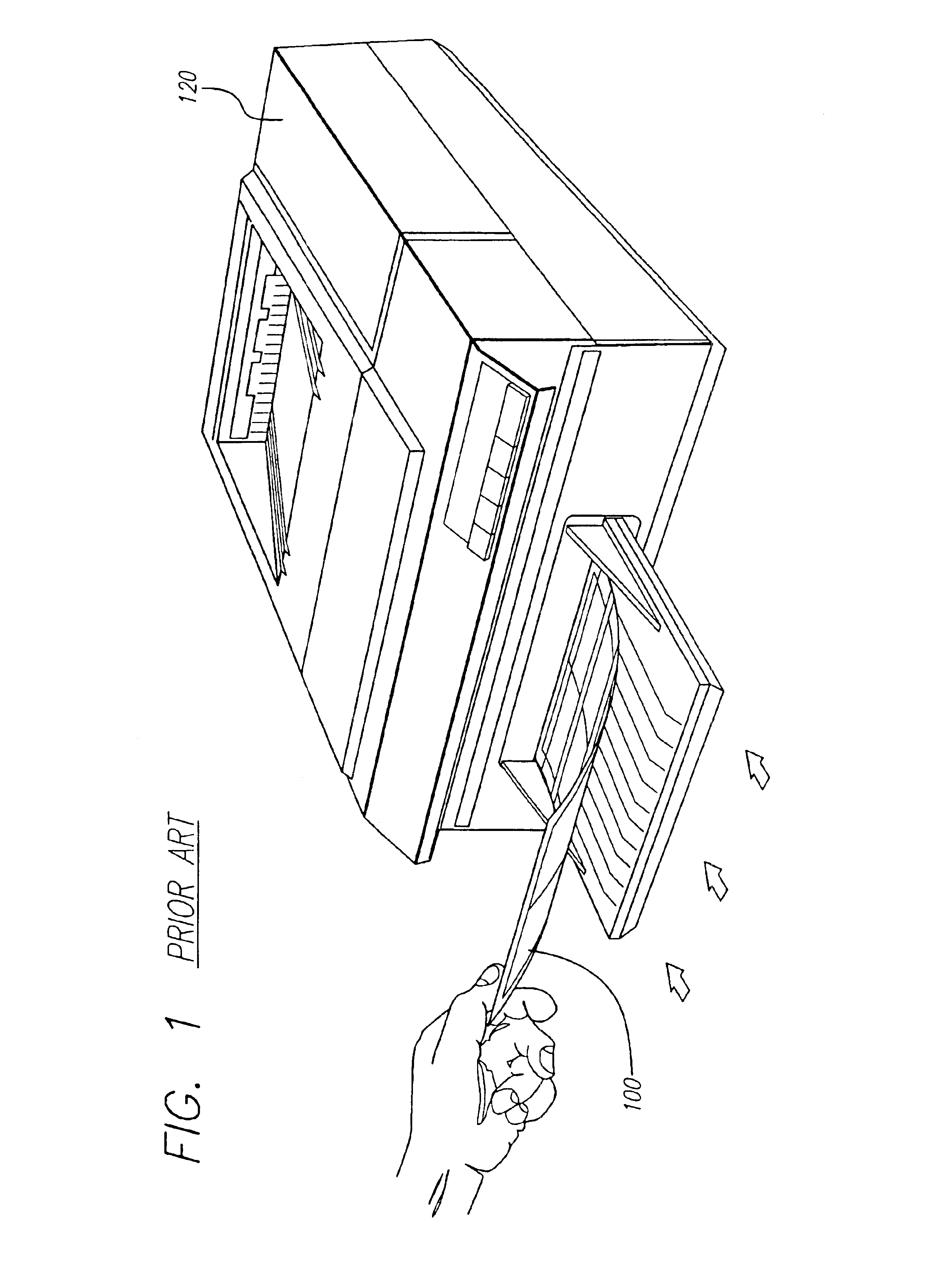

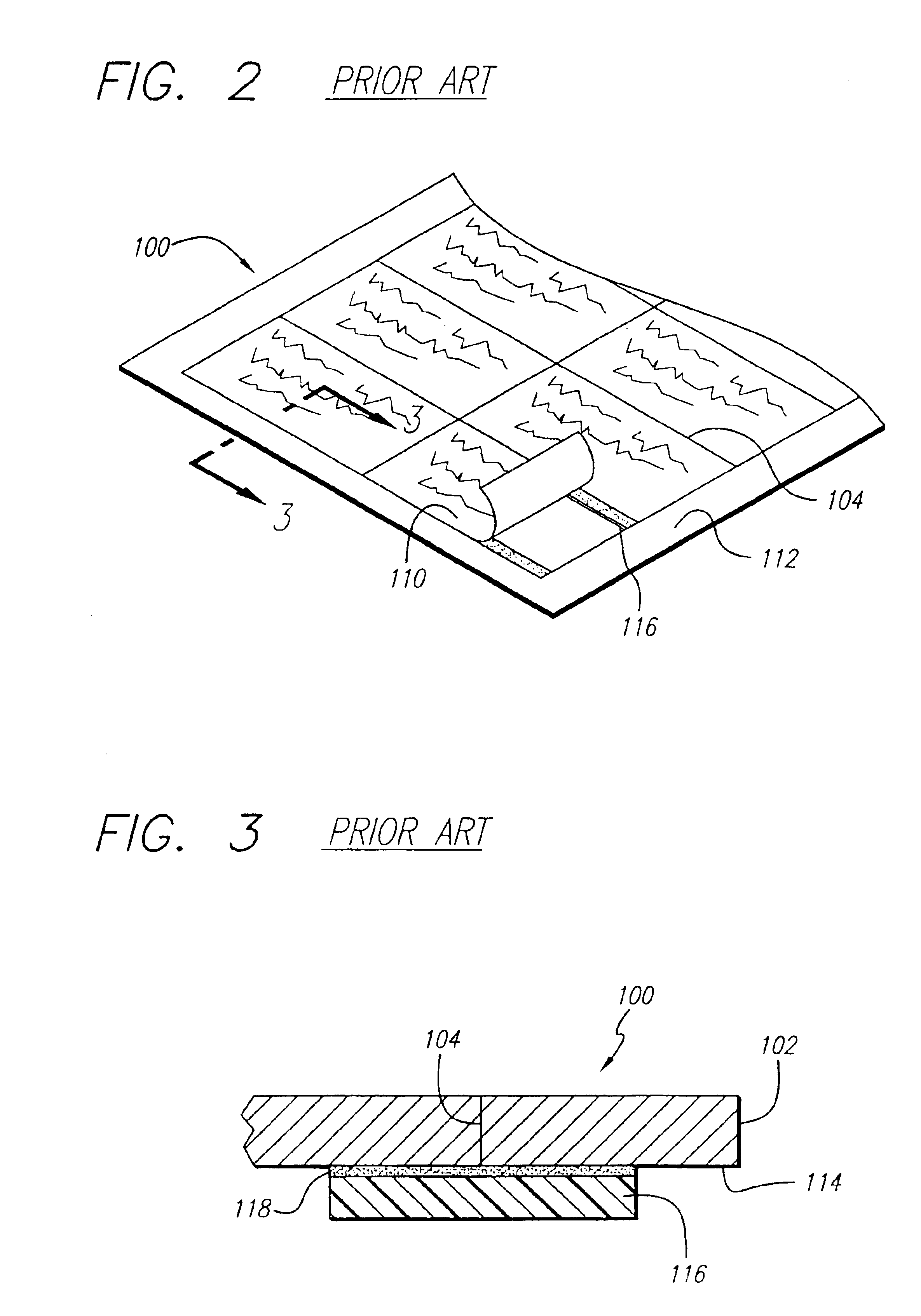

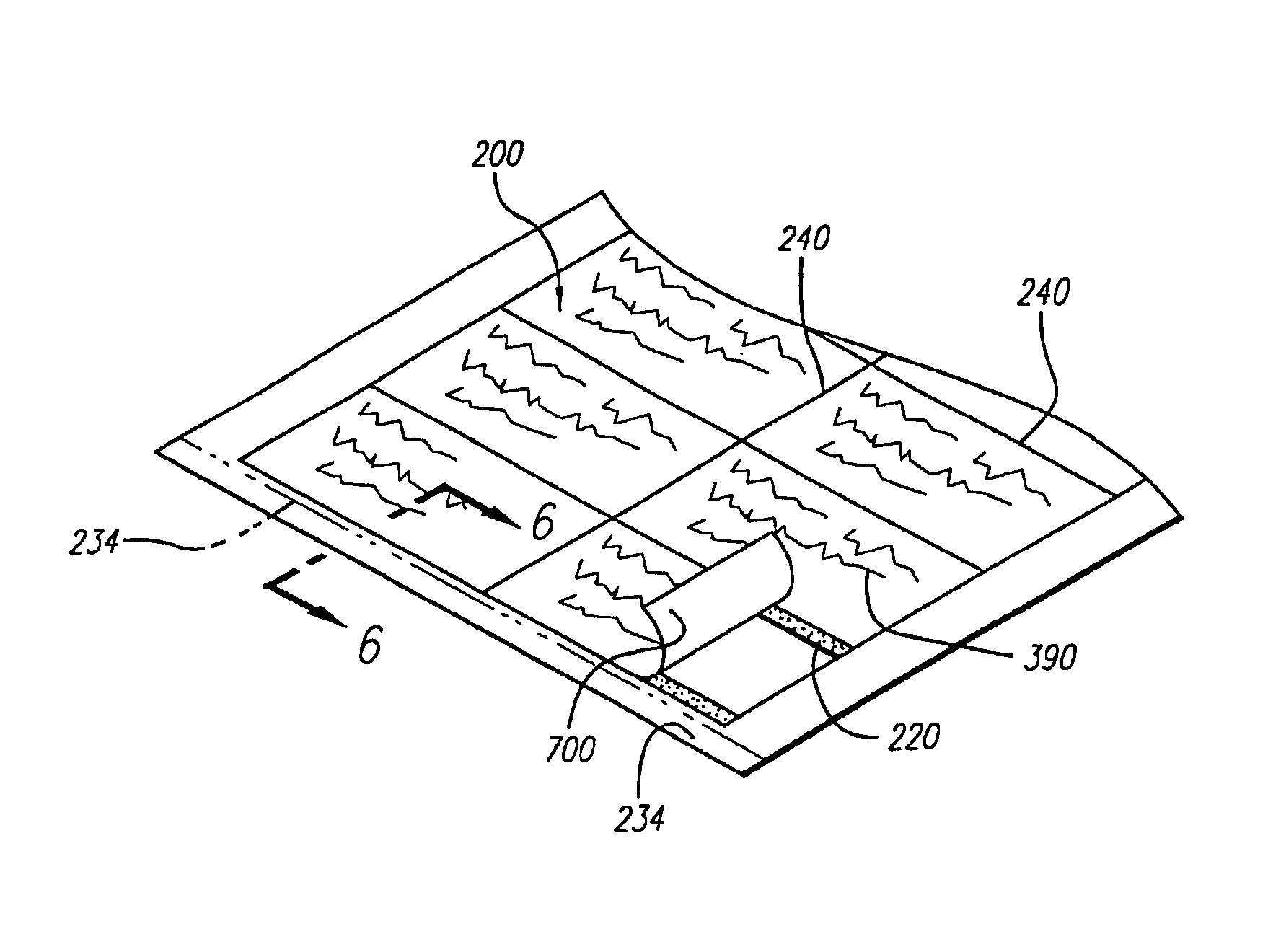

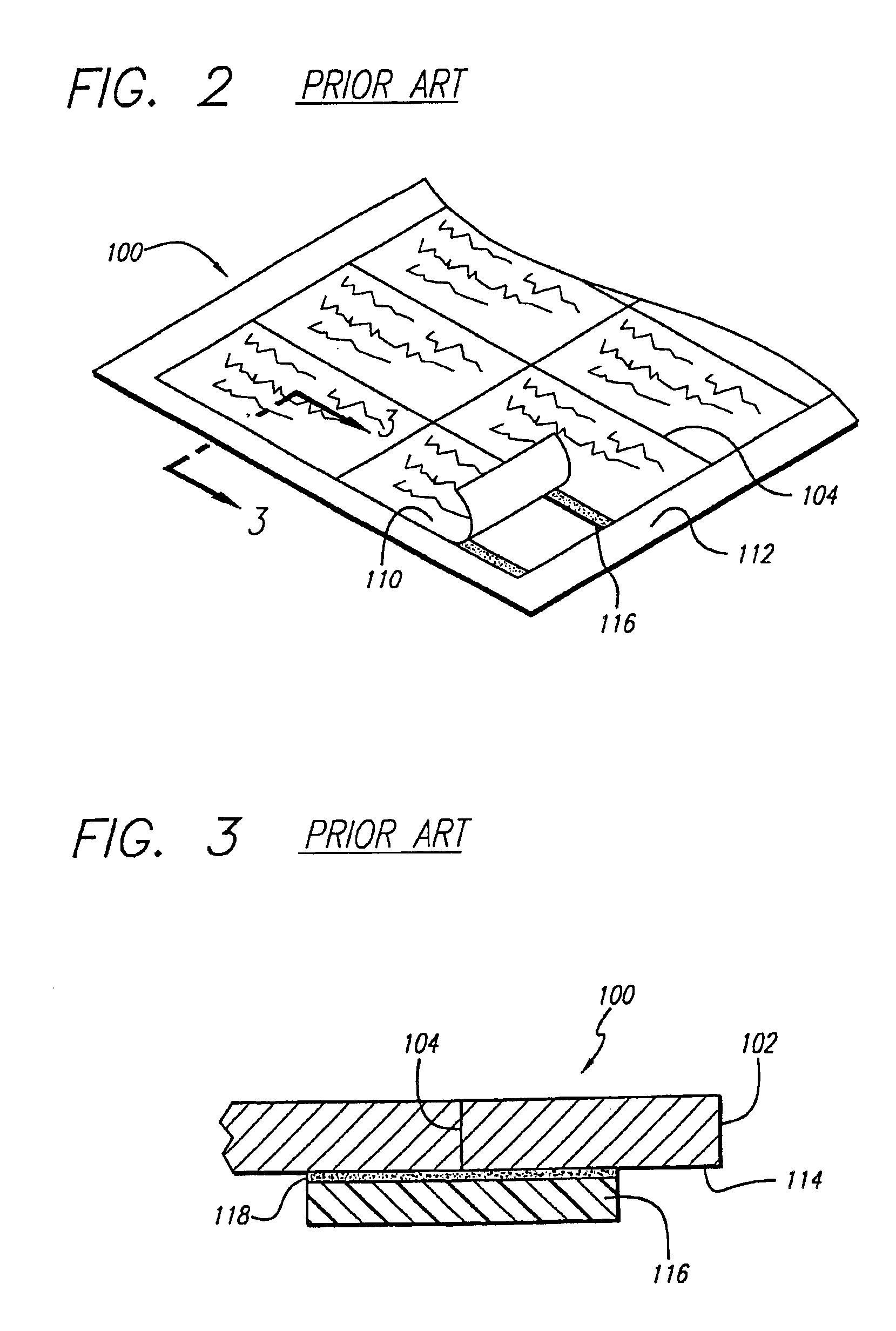

Method of forming printable media

InactiveUS6837955B1Less puckeringFeel moreOther printing matterLamination ancillary operationsCard stockBusiness card

Ultraremovable adhesive is applied to a paper sheet to form therewith a liner sheet and the liner sheet is laminated to a cardstock sheet to form a laminate cardstock. The cardstock sheet is then die cut therethrough, but not through the liner sheet, to form cardstock cut lines that define at least in part perimeters of business cards (or other printable media). The outer face of the liner sheet is then die cut therethrough, but not through the cardstock sheet, to form liner sheet strips on a back side of the cardstock sheet. Some of the strips define cover strips covering some of the cardstock cut lines, and others of the strips define waste strips. The waste strips are then matrix removed from the back of the cardstock sheet. The resulting business card sheet construction is then fed through a printer or copier by the user and the desired indicia printed on the front sides of the business cards, while the cover strips hold the cards together as a unit sheet construction. After this printing operation, the printed cards are easily peeled off of the cover strips, ready for use. By designing the sheet construction to form in the printed media with different sizes and shapes and by including optional scored fold lines, and / or additional flexibility cut lines or flexibility perforation lines, media aside from business cards, such as post cards and greeting cards, can be constructed and used pursuant to this invention.

Owner:CCL LABEL INC

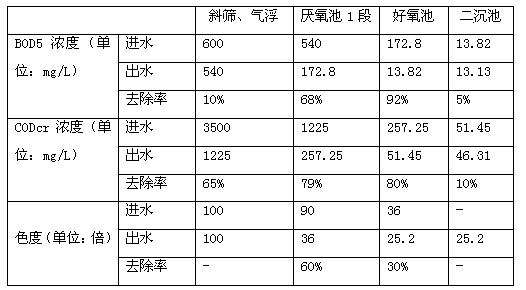

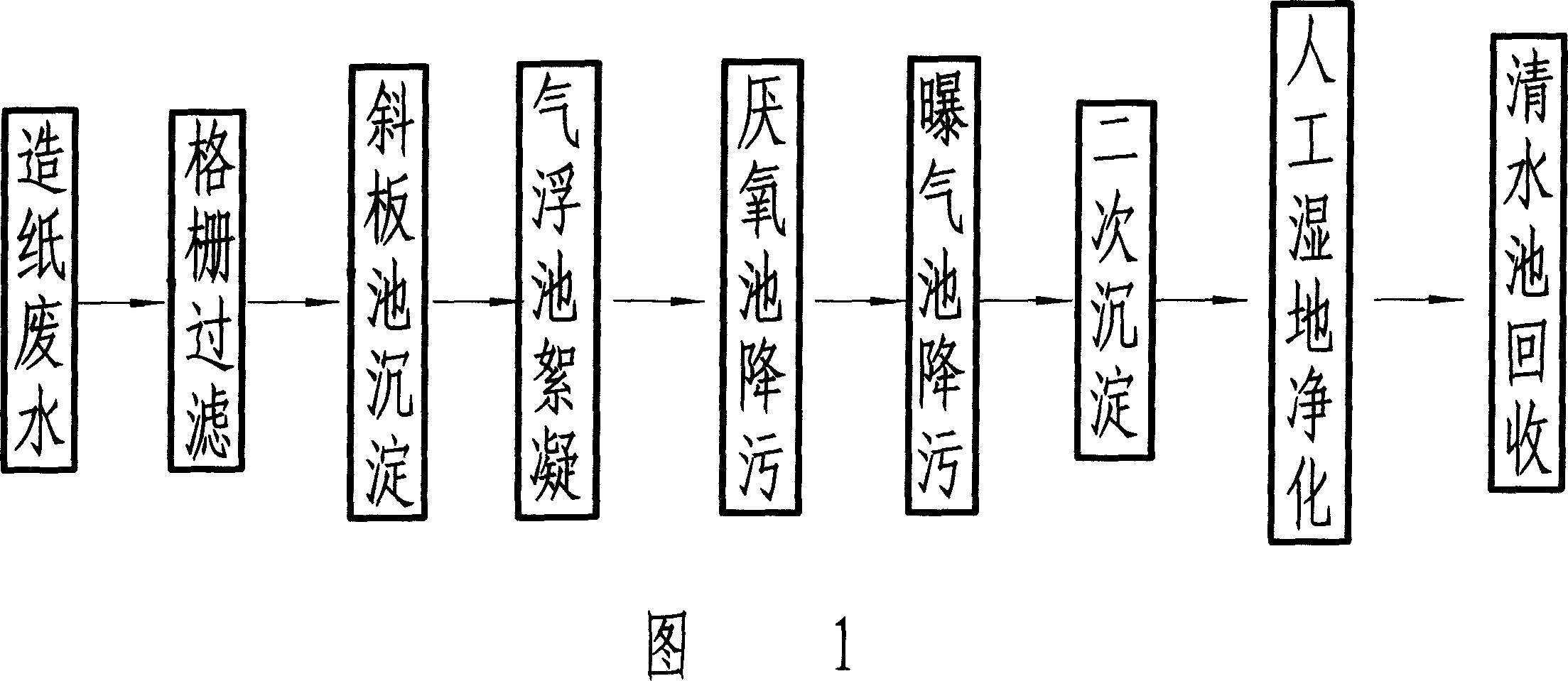

Method for processing paper-making waste water of regenerative paper

InactiveCN101077817AMeet the requirements of emission standardsSS reductionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentConstructed wetlandFiber

The process of treating effluent from making paper with waste paper belongs to the field of industrial effluent treating technology, and aims at lowering the harmful matter content in the effluent from making paper with waste paper to reach the exhaust standard. The process includes the first passing the effluent through grating to filter out fiber and suspended matter, the subsequent settling in a sloping plate settling tank to eliminate granular impurity, flocculating in an air floating tank with flocculant and fishing out the resultant suspended matter, anaerobic reaction in an anaerobic settling tank, treating with introduced air and active sludge in an aeration tank and eliminating suspended matter and colloidal matter, clarifying in a settling tank, and treating in artificial wetland to eliminate nitrogen and phosphate and obtain clear water. The process can reduce SS, BOD5 and CODcr of the effluent obviously and make the effluent reach draining standard.

Owner:云南恒昌造纸有限责任公司

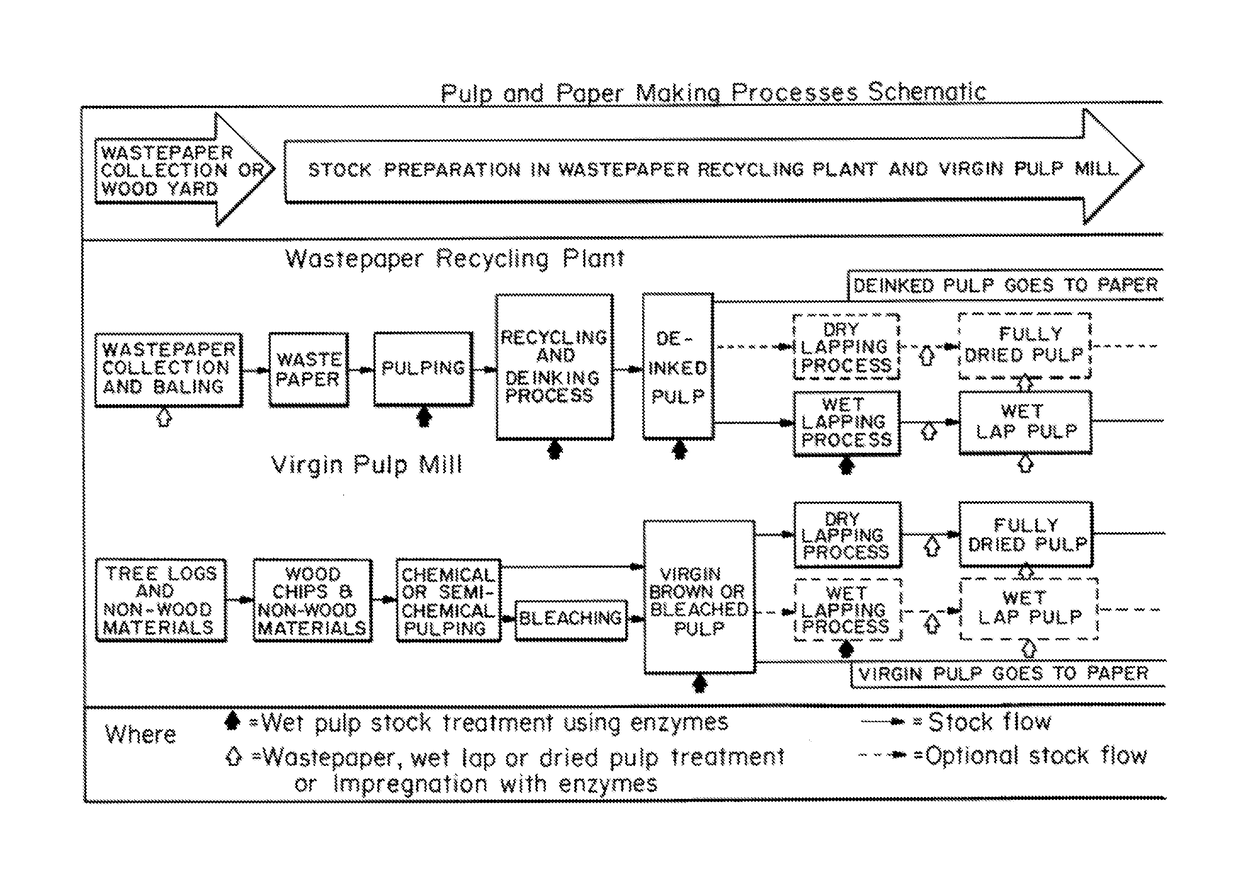

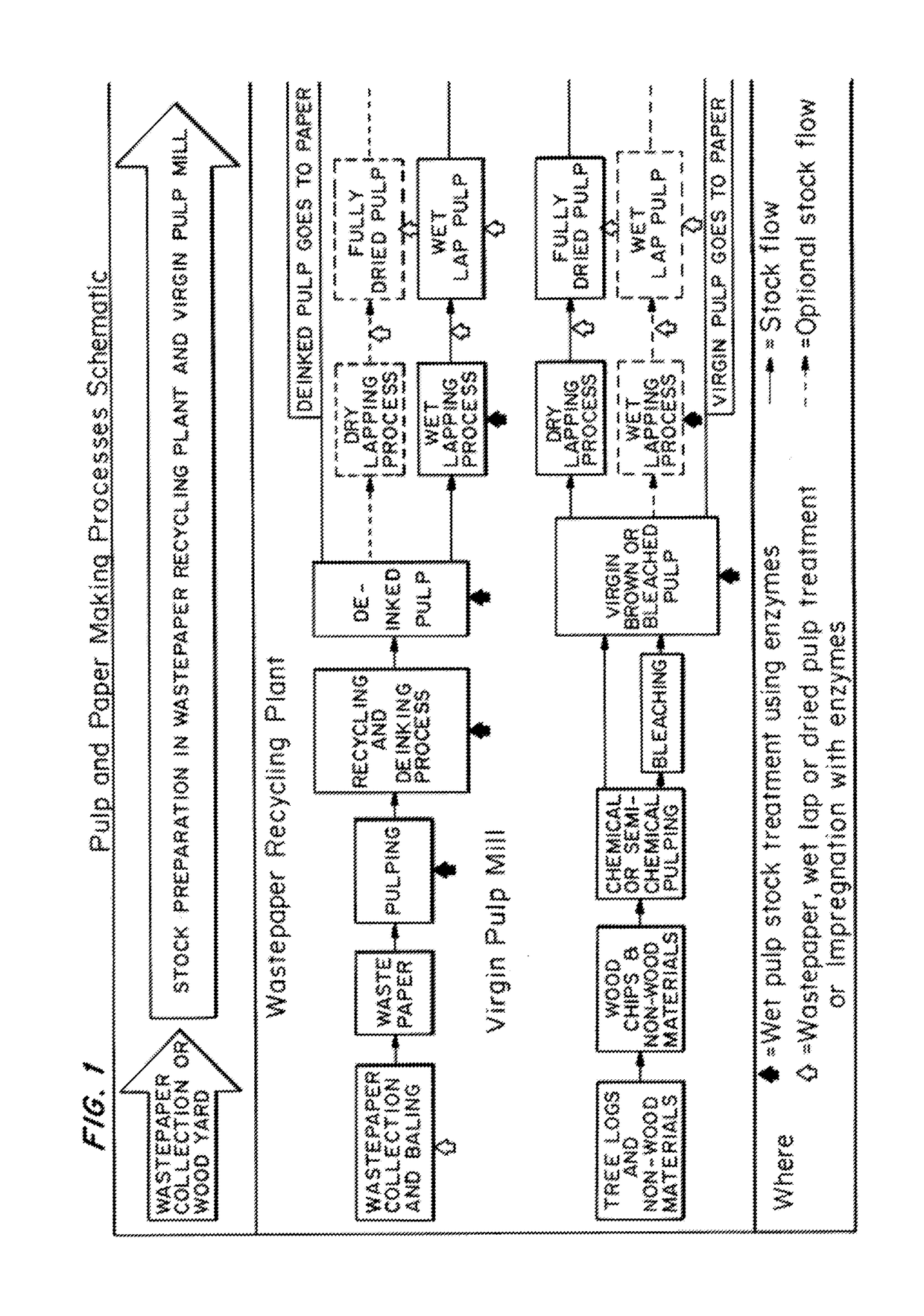

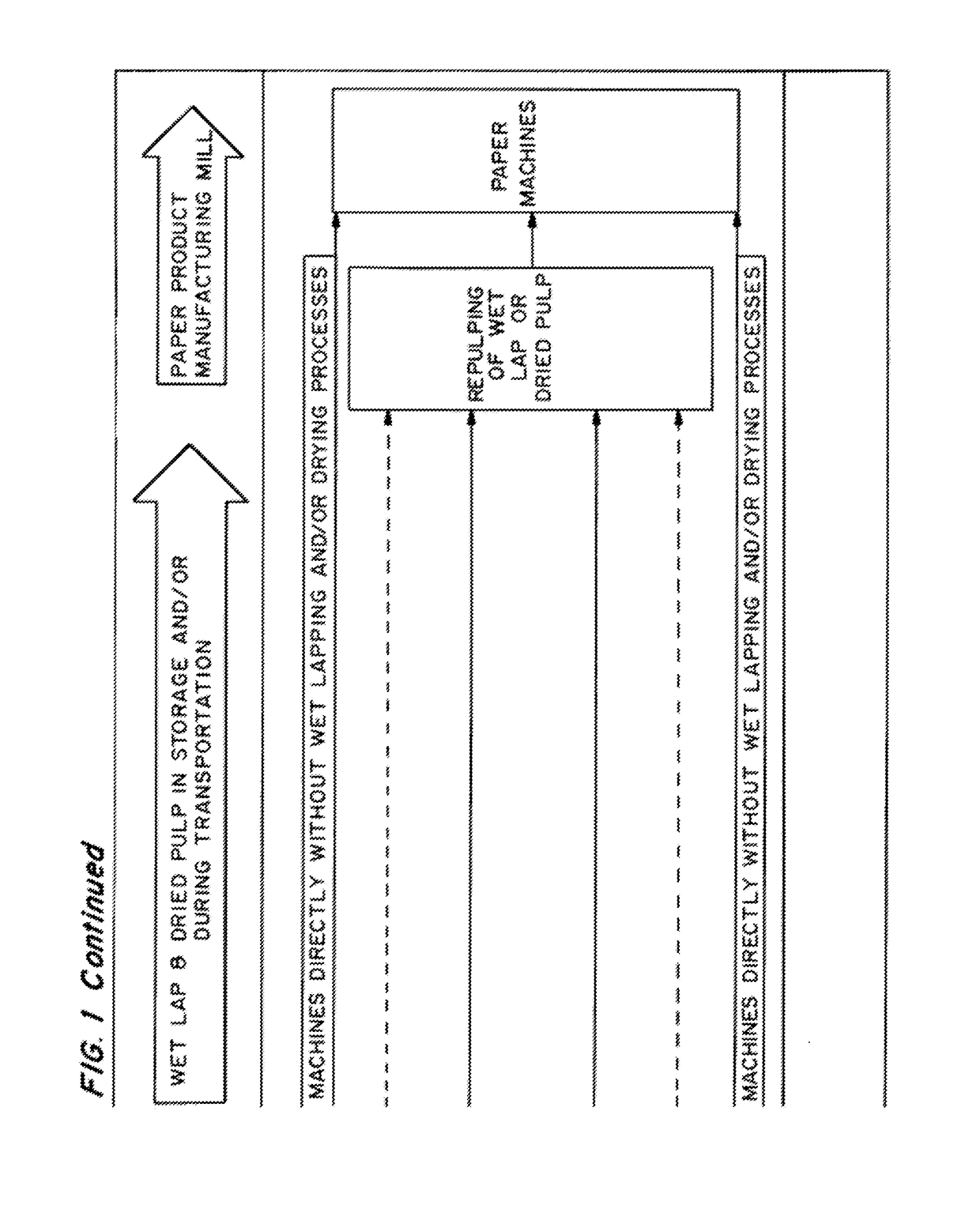

Enzymatic pre-treatment of market pulp to improve fiber drainage and physical properties

ActiveUS20170328006A1Increasing pulp drainage and strength propertyQuality improvementMicroorganism/enzyme additionPaper recyclingFiberPulp and paper industry

Owner:ENZYMATIC DEINKING TECH LLC

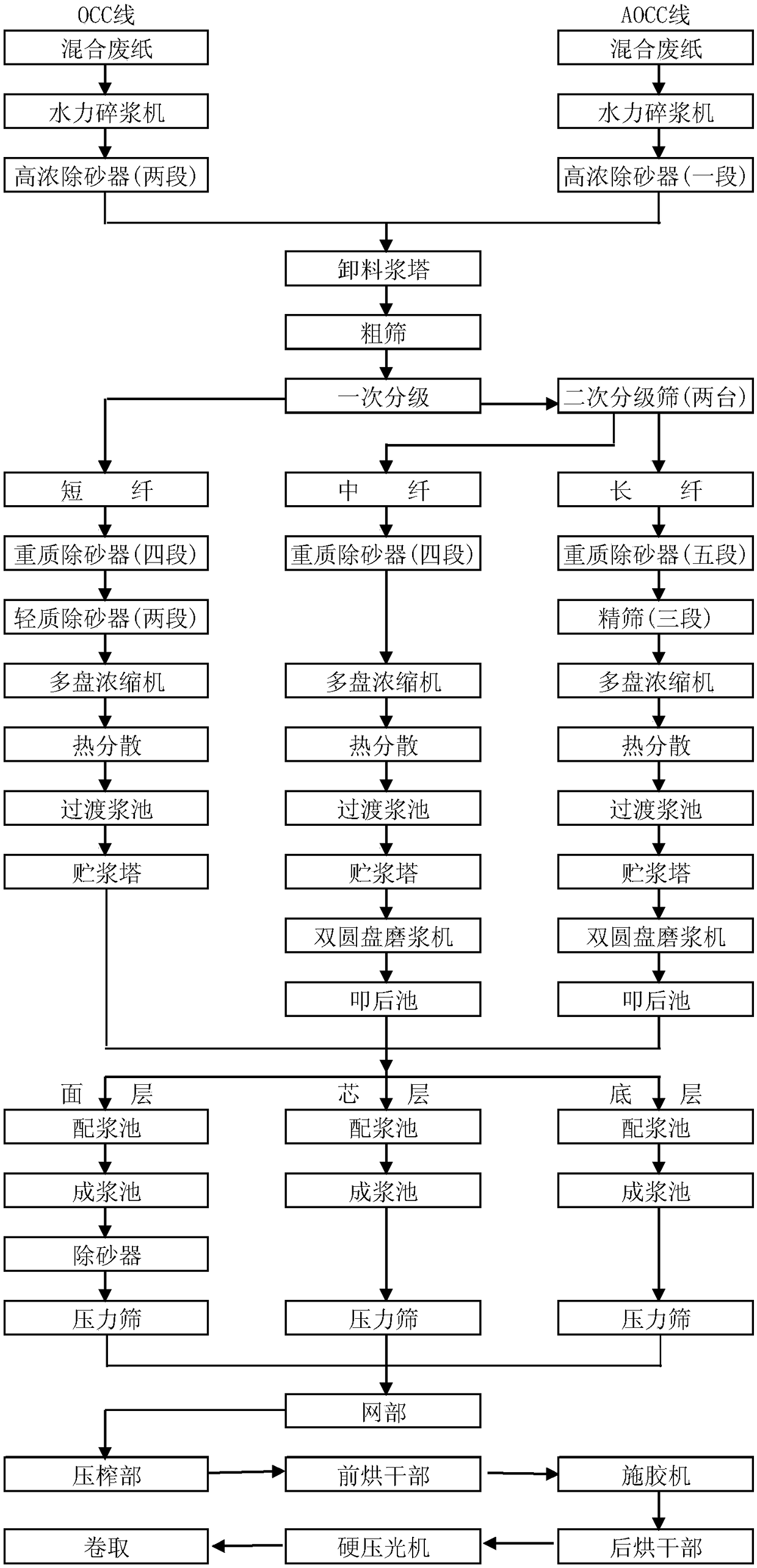

Preparation process of test-liner environment-friendly kraft cardboard paper

ActiveCN108252137AHigh burst resistanceReduce paper production costsDryer sectionPaper recyclingCardboardSlurry

The invention relates to a preparation process of test-liner environment-friendly kraft cardboard paper. The preparation process comprises the following steps: A, picking and selection of fine waste paper raw materials; B, crushing process; C, screening and purification; D, heat dispersion; E, treatment in a slurry storage tower; F, pulping process; G, treatment in a post-processing tank; H, treatment in a pulp distribution tank; I, treatment in a pulp forming tank; J, treatment by using a desander; K, treatment by using a pressure screen; L, treatment by using a net part; M, treatment by using a press part; N, treatment by using a front drying part; O, treatment by using a sizing machine; P, treatment by using a post-drying part; Q, treatment by using a hard calender; and R, reeling-up process. According to the preparation process provided by the invention, waste paper is recycled, and the obtained product with the same quality with test-liner environment-friendly kraft cardboard paper taking wood pulp as a raw material is produced, so that the cost is greatly reduced, the resources are saved, the effective circulation reuse of the renewable resources is guaranteed, and the damageto the environment is reduced. The preparation method has strong practicality and has strong promotion significance.

Owner:DONGGUAN JIANHUI PAPER CO LTD

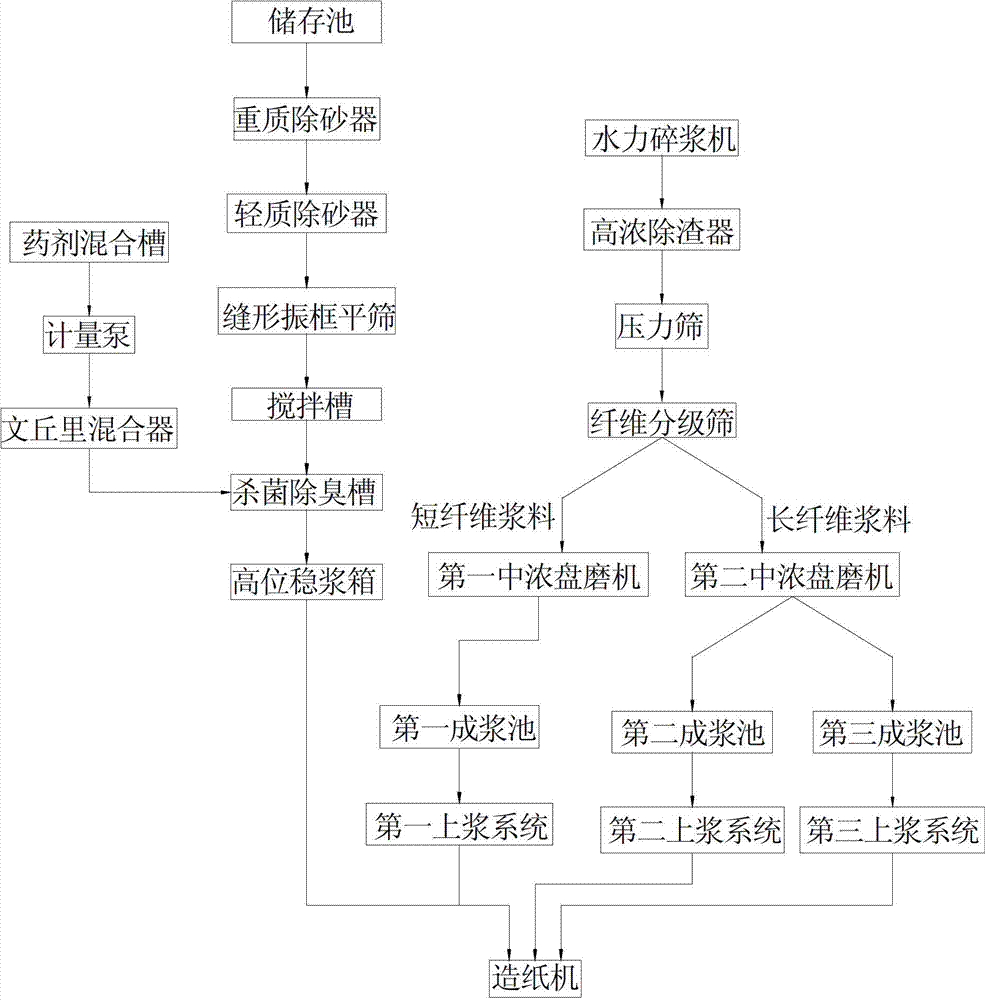

Device and method for producing cardboard paper by utilizing paper mill sludge and waste paper

InactiveCN103088695AReduce wasteReduce secondary pollutionPaper recyclingPaper/cardboardCardboardPulp and paper industry

The invention discloses a device and a method for producing cardboard paper by utilizing paper mill sludge and waste paper. According to the invention, impurity removal, sterilization, deodorization and the like are carried out on the paper mill sludge so that the paper mill sludge becomes paper pulp capable of being used for paper making, and then the paper pulp is combined with sizing agent prepared from the waste paper to produce the cardboard paper. According to the device and the method, the utilization value of the paper mill sludge is improved, and secondary pollution of paper making sludge to the environment is avoided; and simultaneously, the problem of timber resource shortage is solved, and the production cost of producing the cardboard paper is further reduced.

Owner:SOUTH CHINA UNIV OF TECH

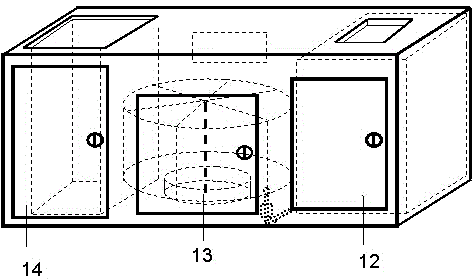

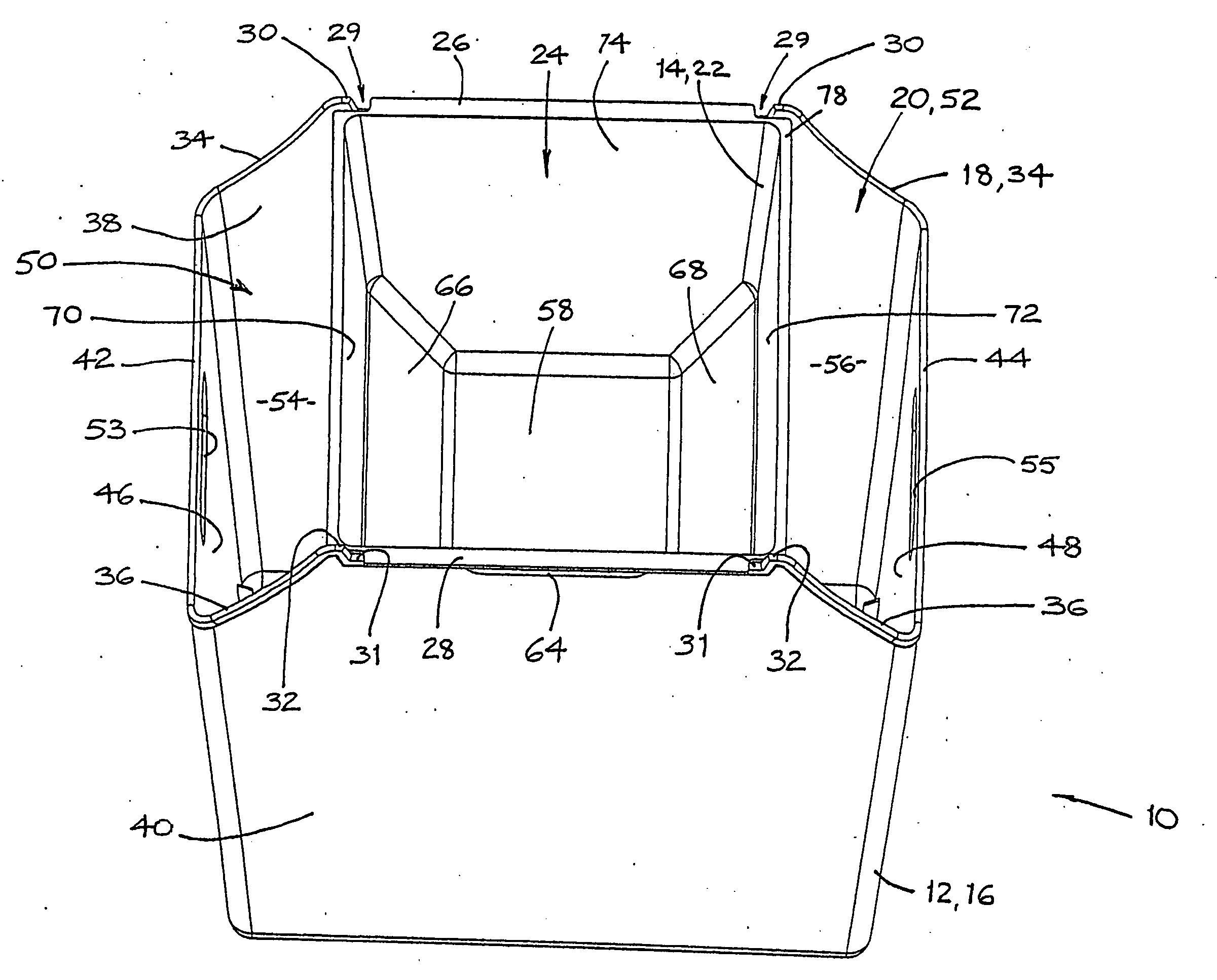

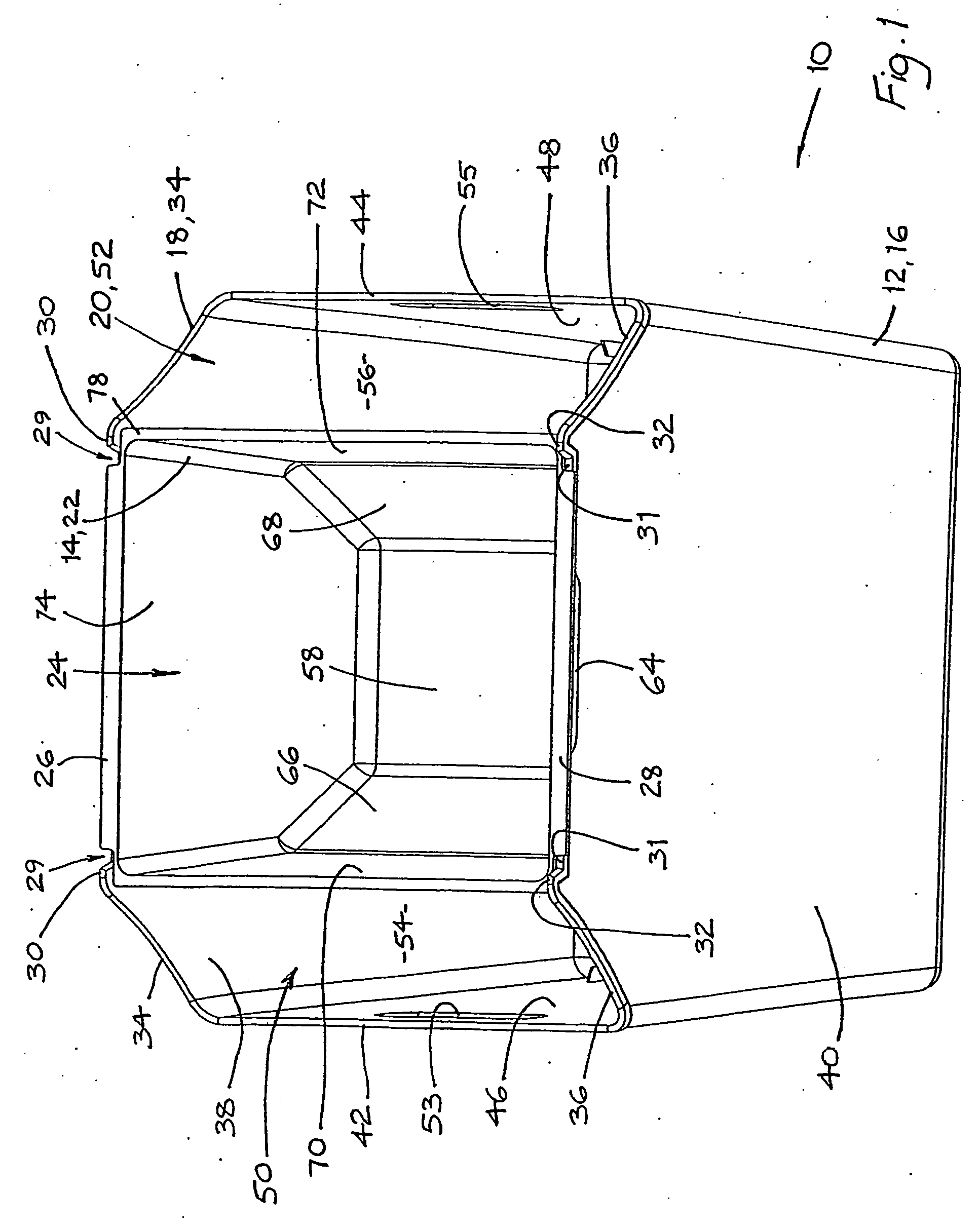

Waste recycling bin

A waste recycling bin (10) has a first compartment (12) adapted to receive recyclable waste paper, and at least a second compartment (14) adapted to receive non-recyclable waste. The first compartment (12) includes a main body (16) having a floor (60), side walls (38, 40, 46, 48) and a rim (18) which defines an opening (20) of the main body (16). The second compartment (14) includes a main body (22) having a floor (58), side walls (70, 72, 74, 76), a rim (78) which defines an opening (24) of the main body (22), and rim engaging flange portions (26, 28) for supporting the second compartment (14) against a portion (30, 32) of the rim (18) of the first compartment (12). The rim engaging flange portions (26, 28) so support the second compartment (14) against a portion (30, 32) of the rim 18 of the first compartment (12) that the main body (22) of the second compartment (14) descends into the opening (20) of the main body (16) of the first compartment (12) so as to form two openings (50, 52) to the first compartment (12) on opposed sides of the second compartment (14) for inserting waste paper therethrough. The portion (30, 32) of the rim (18) of the first compartment (12) is elevated from the remaining portion of the rim (18).

Owner:PAPER TO PAPER AUSTRALIA

Method of forming sheets of printable media

InactiveUS6890397B1Reduce the amount requiredEffectively fed into printerOther printing matterLamination ancillary operationsLow-density polyethyleneEngineering

A low density polyethylene film layer is extrusion coated on densified bleached kraft paper liner to form a film-coated liner sheet. A facestock sheet is adhered with a layer of hot melt adhesive to the film layer to form a laminate sheet web, which is rolled on a roll. The facestock sheet, the film layer and the adhesive layer together define a laminate feedstock. The roll is transported to and loaded on a press with the liner side up. One (or both) edge(s) of the web is (are) crushed with a calendering die to form thin lead-in edge(s). The web is die cut on the bottom face, up through the laminate facestock, but not through the paper liner, to form the perimeters of a grid of blank business cards or other printable media, with a waste paper frame of the laminate facestock encircling the grid. The web is then die cut from the top through the paper liner and to but not through the laminate facestock, to form liner strips covering the back face of the laminate facestock. According to one preferred embodiment of the invention, alternate ones of the strips are then pulled off of the laminate facestock web. A final production step is to sheet the web to form the desired sheet width (or length) of the laminated sheet construction. The individual laminated business card sheets can be stacked into the infeed tray of an ink jet printer for example, and the sheets individually and automatically fed lead-in edge first into the printer and a printing operation performed on each of the printable media, to form a sheet of printed media. The remaining strips on the back of the laminate facestock cover the lateral cut lines in the laminate facestock and thereby hold the facestock together as it is fed into and passed through the printer. The user then individually peels the printed media off of the strips and out from the waste paper frame. Thereby printed business cards (or other printed media), each with its entire perimeter defined by clean die cuts, are formed. Instead of calendering both edges of the web and thus the sheet, one end can be calendered and a strip of the laminate facestock can be stripped off of the liner sheet from the other end. The remaining thin liner sheet strip at the other end forms a thin infeed edge for feeding into a horizontal feed, ink jet printer.

Owner:CCL LABEL INC

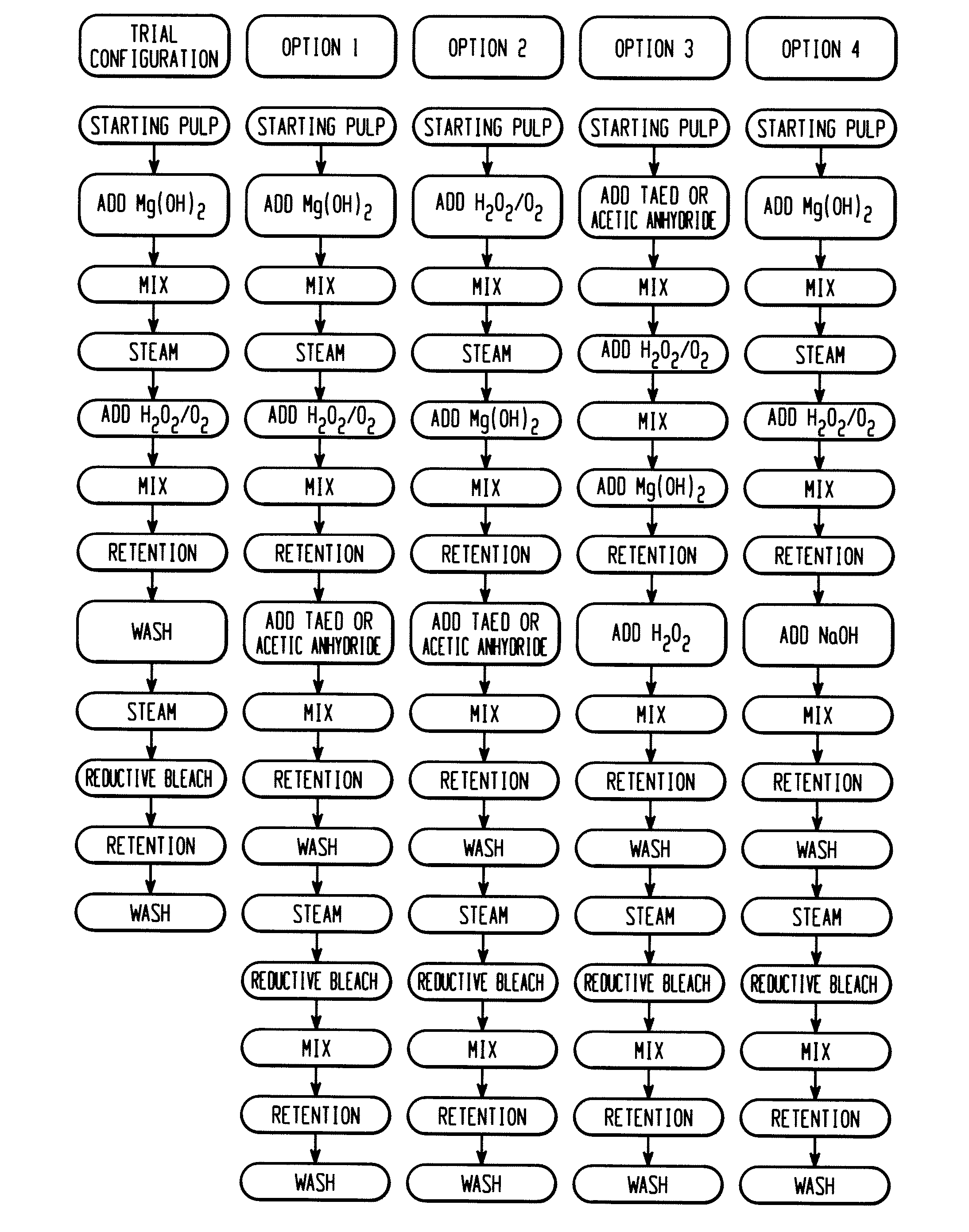

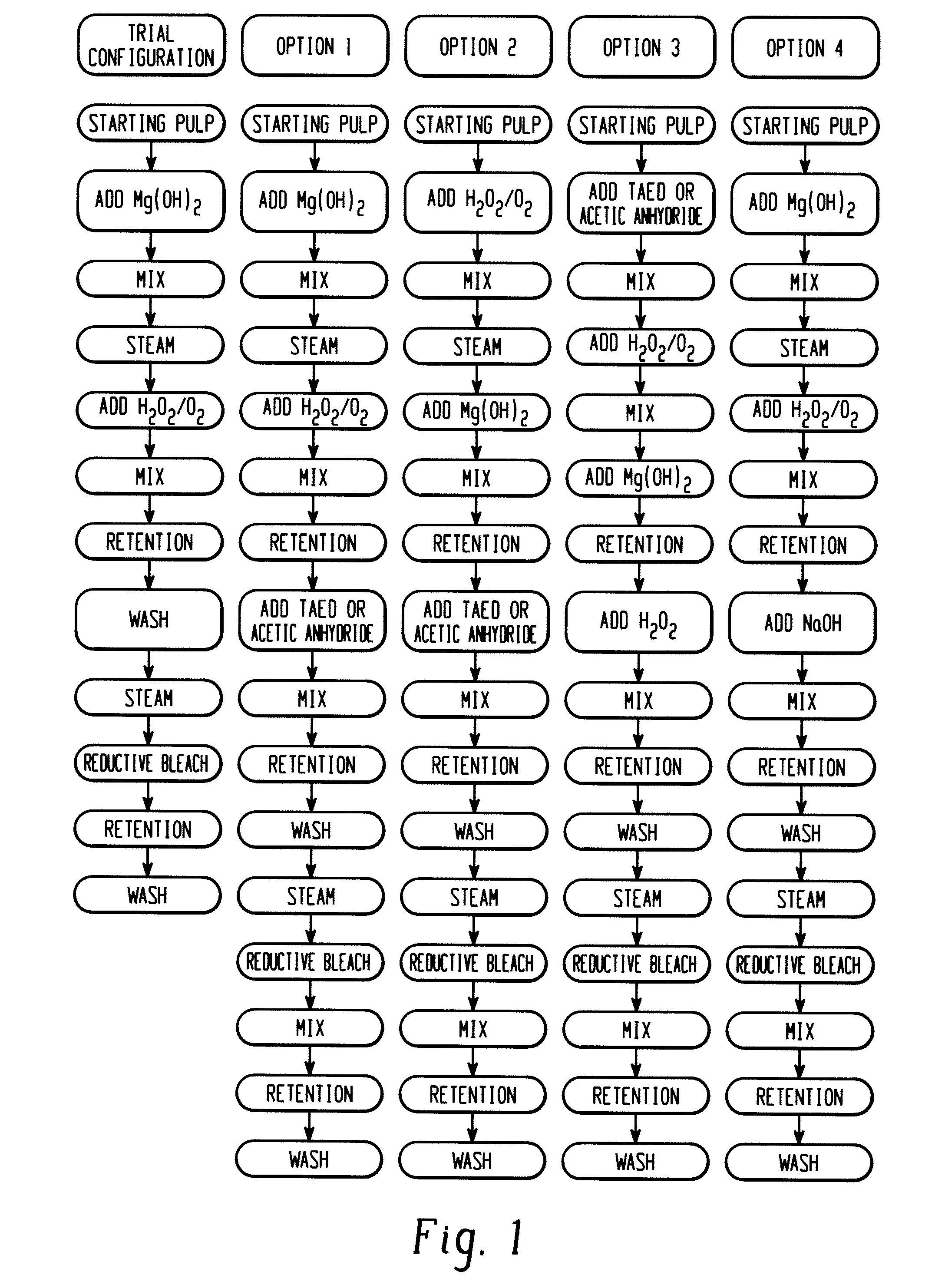

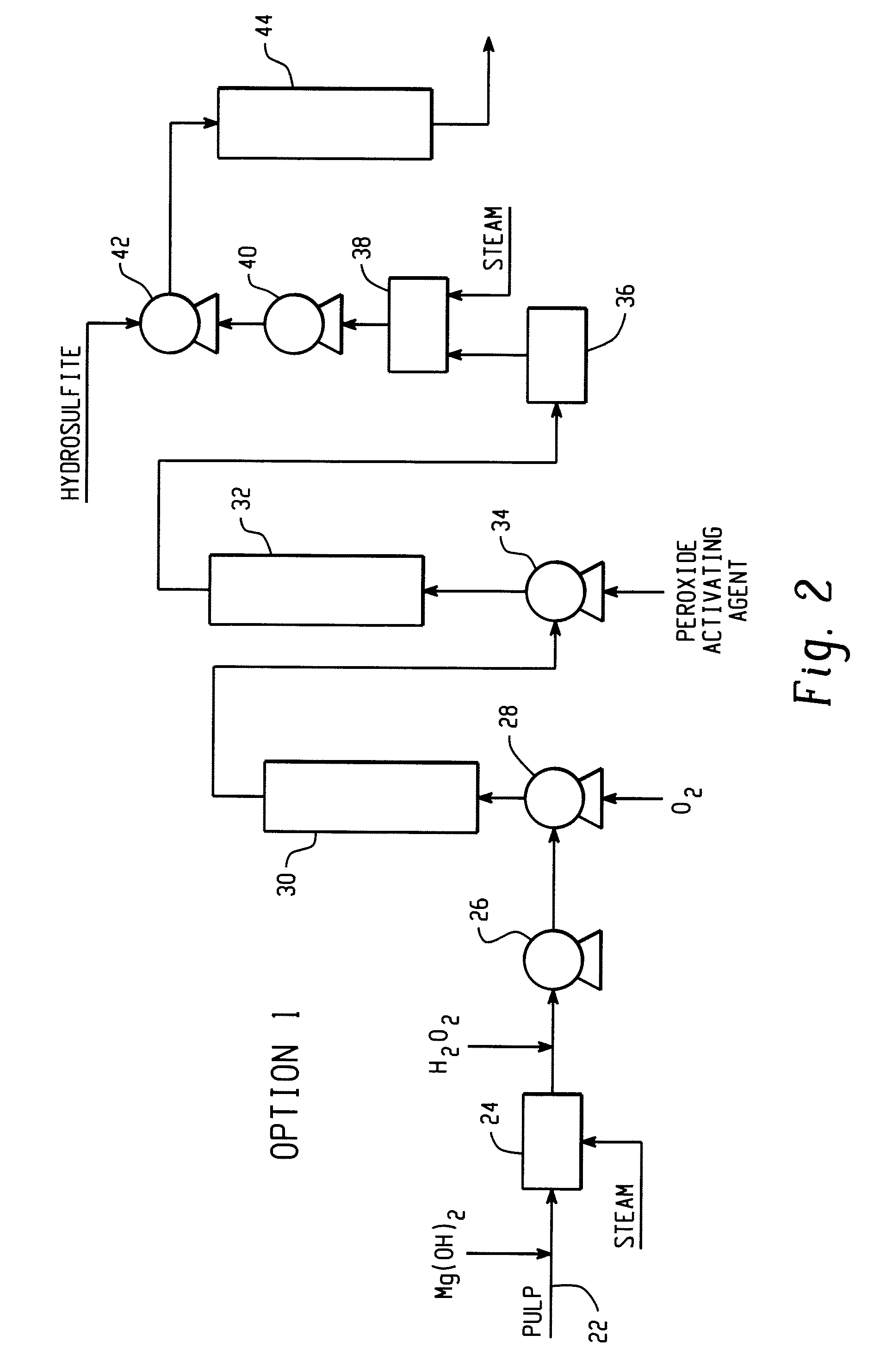

High Brightness Pulps From Lignin Rich Waste Papers

ActiveUS20120067532A1Avoid interferenceInhibition formationPaper recyclingPulp bleachingAcetic acidOxygen

This present invention relates to methods for preparing premium or near-premium brightness pulps for towel and tissue applications from fiber sources comprising substantial amounts of lignin-containing pulp and chemical pulp while controlling fines, scale and anionic trash. These methods use alkaline hydroxide in combination with peroxide and oxygen for initial bleaching stages followed by treatment with a peroxide activating agent to convert residual peroxide in the pulp into peracetic acid followed by a final reductive bleaching stage.

Owner:GPCP IP HLDG LLC

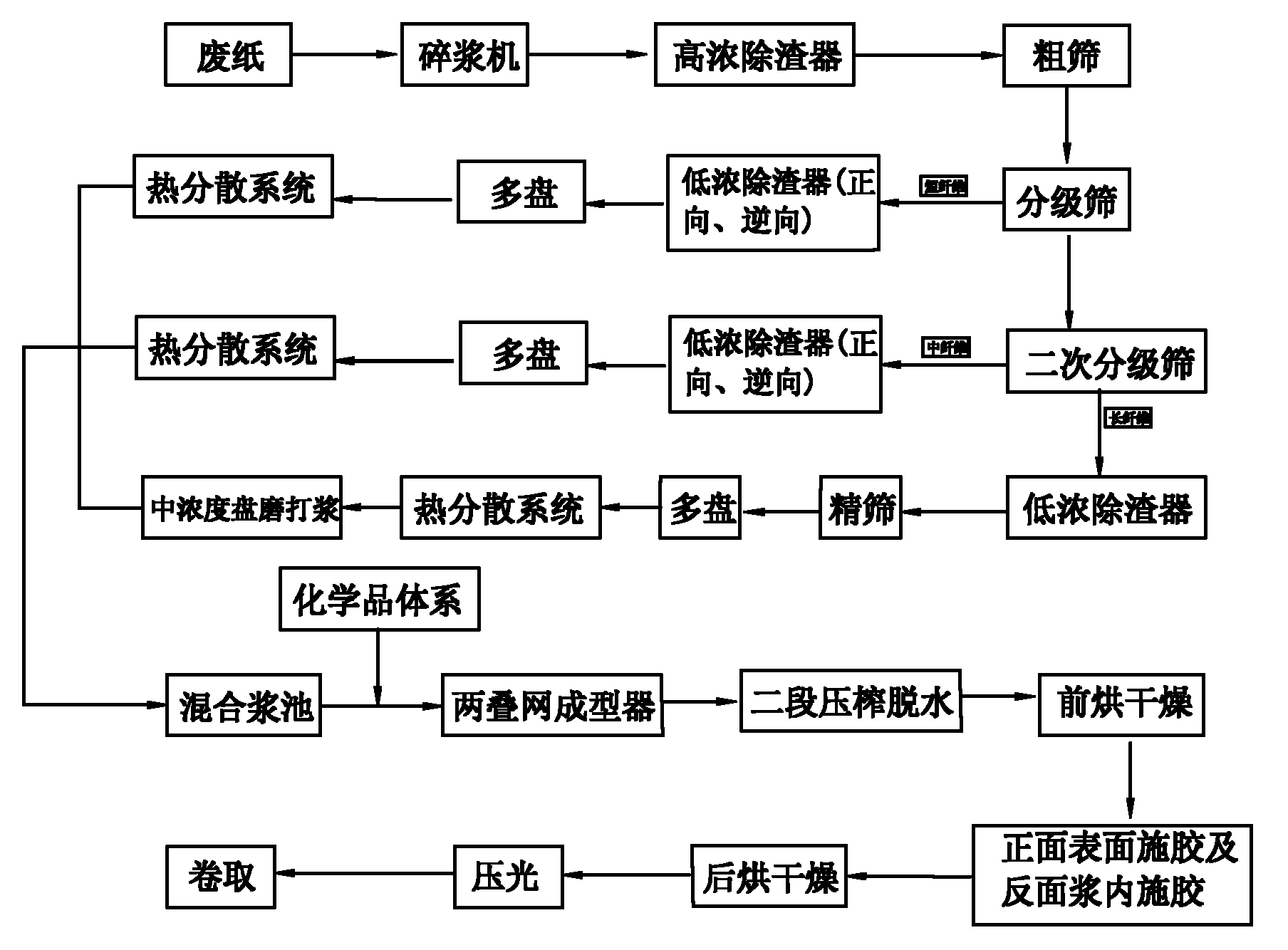

Production method of kraft cardboard with ultra low gram weight

ActiveCN102493261AHigh strengthReduce dosagePaper recyclingSecondary cellulose fibresCardboardViscose

The invention relates to the technical field of papermaking methods, especially to a production method of a kraft cardboard with an ultra low gram weight. The method comprises the following technological steps of: conducting batching; adding water for disintegrating so as to obtain a slurry; carrying out combined purification treatment to the slurry; performing moderate concentration beating; adding a chemical system into the combined slurry; papermaking; molding filtration water for papermaking; implementing two-stage squeezing dewatering; conducting primary baking for drying; carrying out sizing; performing further baking for drying; implementing calendering; and conducting coiling. The invention effectively solves the problems of low grade, poor strength, high pollution load of discharged sewage, large gram weight, incomplete treatment to viscose materials and hot melt materials in waste paper, large process investment and other problems in existing kraft cardboards. The production method of a kraft cardboard with an ultra low gram weight in the invention makes use of a combined technology of pulping and papermaking, and fully utilizes secondary fibers to prepare a kraft cardboard with an ultra low gram weight through papermaking, so that the fiber consumption is reduced. And the prepared kraft cardboard has high strength and a gram weight of 90g / m<2>. The method provided in the invention has high vehicle operation speed, reduces production cost and energy consumption, decreases pollutant discharge, and enhances economic benefits.

Owner:DONGGUAN NINE DRAGONS PAPER IND

Preparation of waste paper-reinforced regenerative high-density polyethylene composite material

InactiveCN101302312AImprove the level of comprehensive utilizationHigh strengthFiberPollutant emissions

The invention provides a waste paper reinforced recycled high density polyethylene composite material, which is characterized by comprising the following raw materials by mass percentage: 5 to 15 percent of waste paper, 85 to 95 percent of recycled high density polyethylene, 0 to 4 percent of coupling agent and 0 to 10 percent of compatilizer. The waste paper is mixed with the recycled HDPE, the coupling agent and the compatilizer after fiber dispersion, and the mixture is sent into an open dual-roller mixing device for mixing and homogenizing, pressed by a section mold, and then cooled, demoulded and made into the waste paper reinforced recycled high density polyethylene composite material. The waste paper reinforced recycled high density polyethylene composite material not only can fully utilize the waste paper and waste plastics and change the waste into the valuable but also can greatly improve the comprehensive utilization level of waste resources and save a large number of resources, and simultaneously can reduce the environmental pollution caused by mismanagement of waste material resources. Moreover, the waste paper reinforced recycled high density polyethylene composite material has the advantages of simple technique, short flow, low investment, no pollutant emission, energy conservation and low consumption, low cost of the raw materials, good texture and high strength of the composite material obtained, and no harmful gas emission, and is a waste utilization project which is favorable for the country, the people and the enterprises.

Owner:KUNMING UNIV OF SCI & TECH

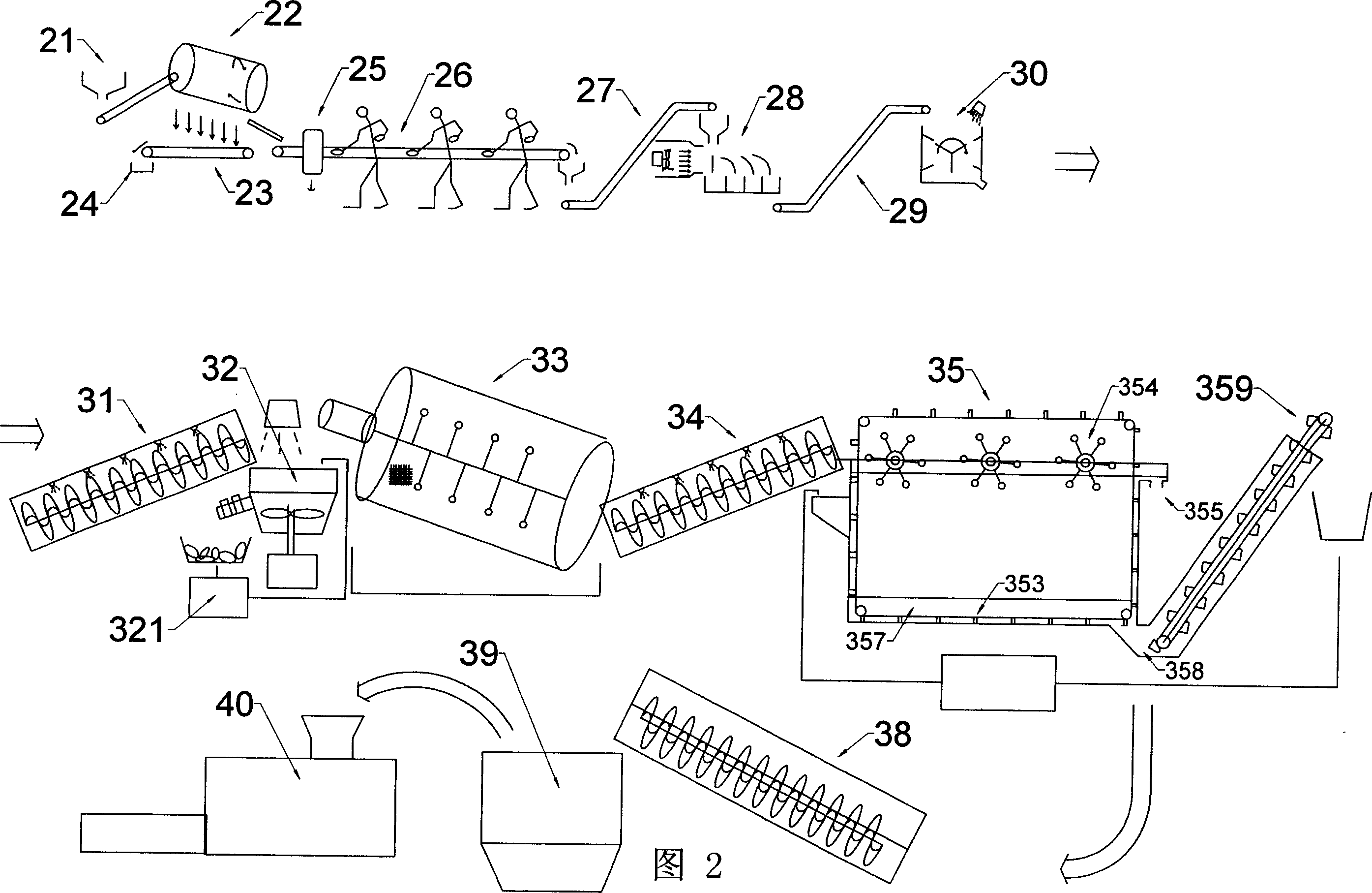

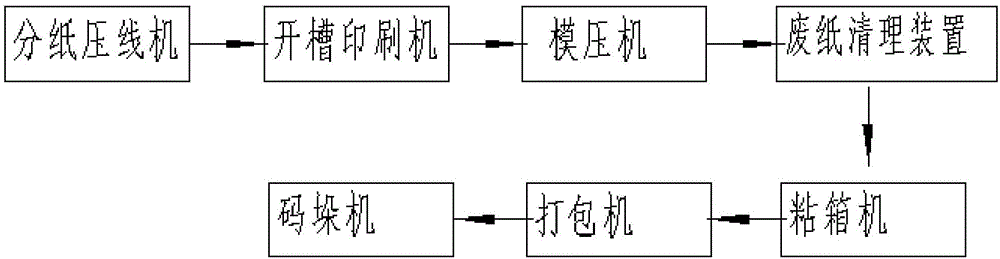

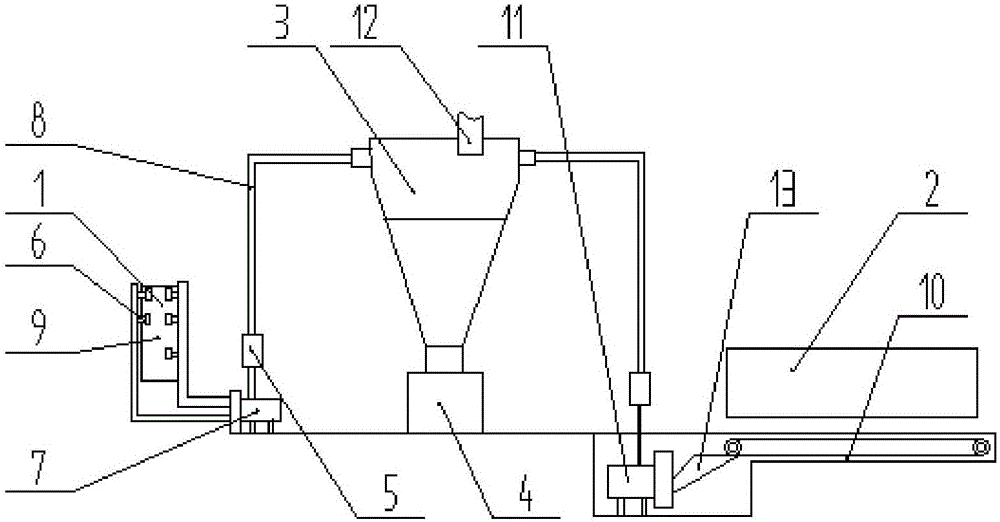

Corrugated carton production process and automatic production line thereof

InactiveCN106363953AIncrease productivityImprove qualityBox making operationsPaper-makingProduction lineStack machine

The invention relates to the technical field of printing and packaging, in particular to a corrugated carton production process and an automatic production line thereof. The corrugated carton production process includes the steps of paper splitting and line pressing, picture and text printing, mold pressing, connecting, bundling and stacking. The automatic production line comprises a paper splitting and line pressing machine, a slotting printing machine, a molding press, a waste paper removing device, a carton bonding machine, a packaging machine and a stacking machine, wherein the paper splitting and line pressing machine, the slotting printing machine, the molding press, the waste paper removing device, the carton bonding machine, the packaging machine and the stacking machine are sequentially connected through a conveying mechanism. The slotting printing machine is provided with an ultraviolet drying device, and a controller of the automatic production line is used for controlling communication and speed synchronization among all the single devices. According to the corrugated carton production process and the automatic production line thereof, the structure is reasonable, automatic production is achieved, production efficiency for existing corrugated cartons is improved, and the production cost is lowered.

Owner:玉溪万利包装材料有限公司

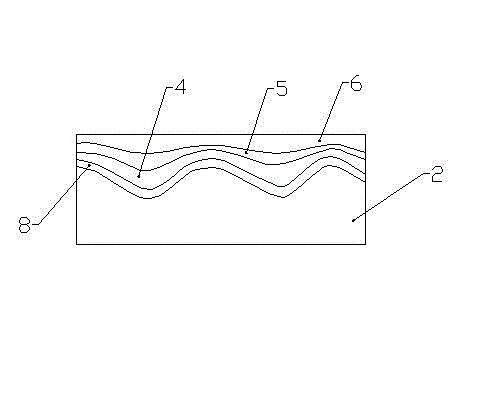

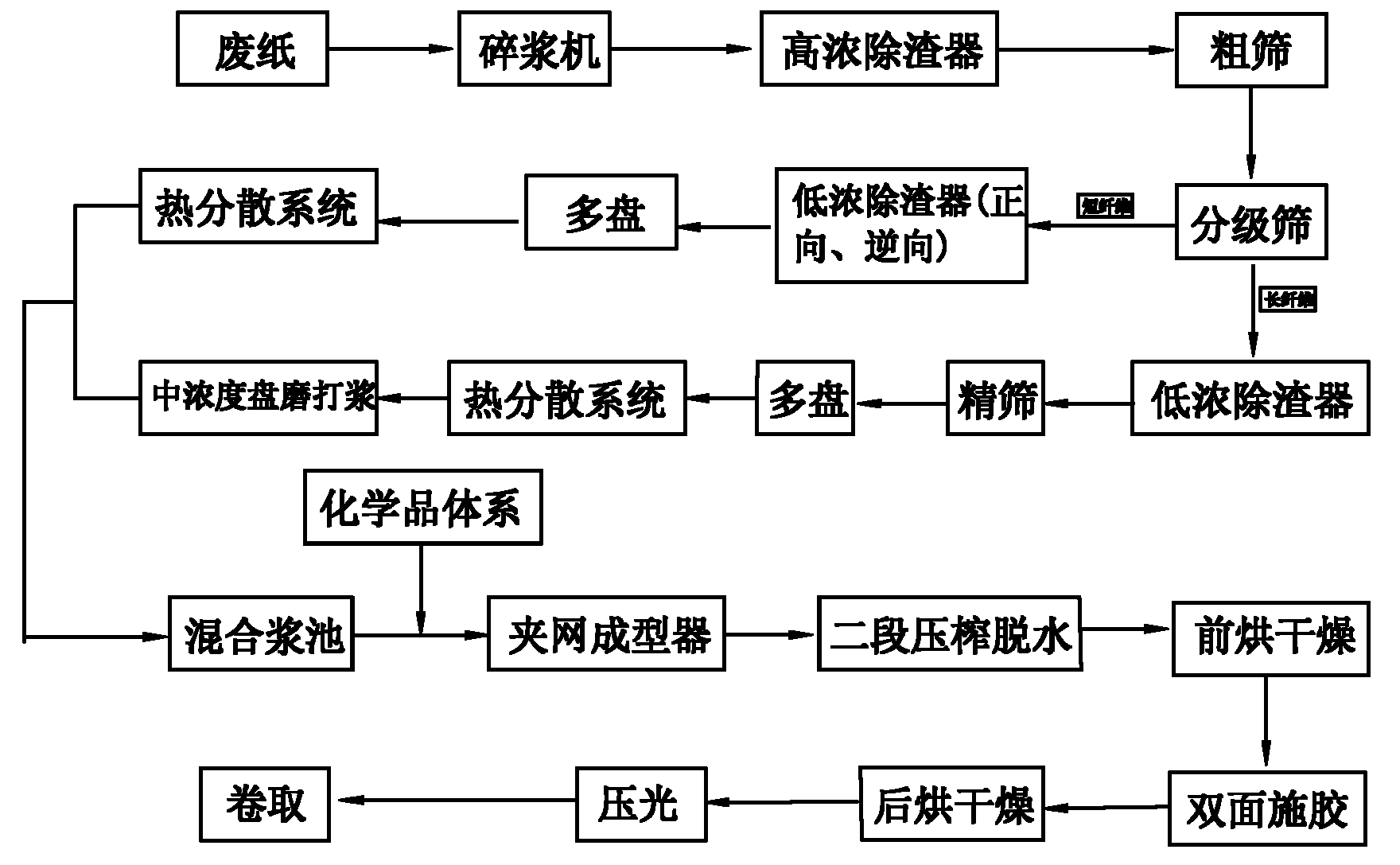

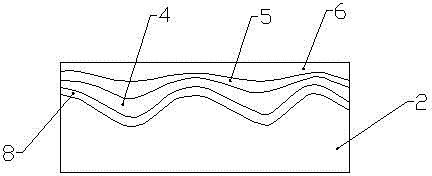

Coated craft paper and production method thereof

ActiveCN102912691AIncrease varietyImprove qualityCoatings with pigmentsSpecial paperAfter treatmentPulp and paper industry

The invention discloses coated craft paper and a production method thereof. The coated craft paper comprises a core paper layer; the upper side of the core paper layer is a surface paper layer, and the lower side is a bottom paper layer; a coating layer is arranged on the upper surface of the surface paper layer; the bottom paper layer and the core paper layer are prepared by the steps of: dosing the waste paper, preparing waste paper pulp to obtain non-deinked waste paper pulp, and manufacturing paper through a paper layer to obtain a wet bottom paper layer and a wet core paper layer; the surface paper layer is prepared by the steps of: manufacturing paper through a paper layer by taking the UKP pulp, the non-deinked waste paper pulp or the mixture of the UKP pulp and the non-deinked waste paper pulp as the pulp to obtain a wet surface paper layer; and the wet bottom paper layer, the wet core paper layer and the wet surface paper layer are subjected to the steps of compounding with the coated body paper, preliminary drying, sizing, later drying, paper surface calendering, paper surface coating and after-treatment to obtain the coated craft paper. The available waste paper types are increased, and the fiber source is wider; and meanwhile, the quality of the waste paper pulp is effectively stabilized so as to guarantee the quality stability of the coated body paper and the white-surface craft paper and avoid easy layering, splitting and scaling.

Owner:山东晨鸣纸业集团股份有限公司 +1

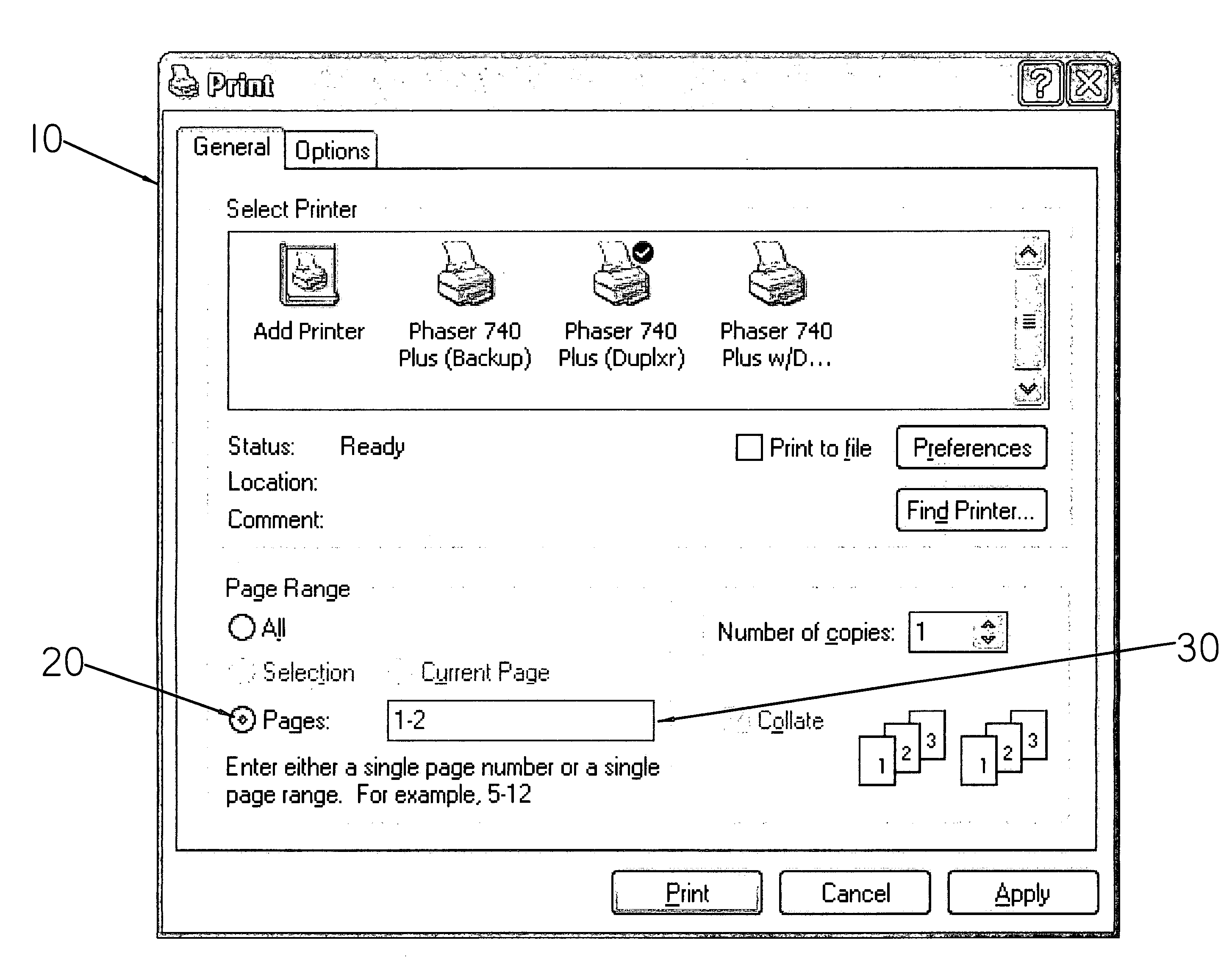

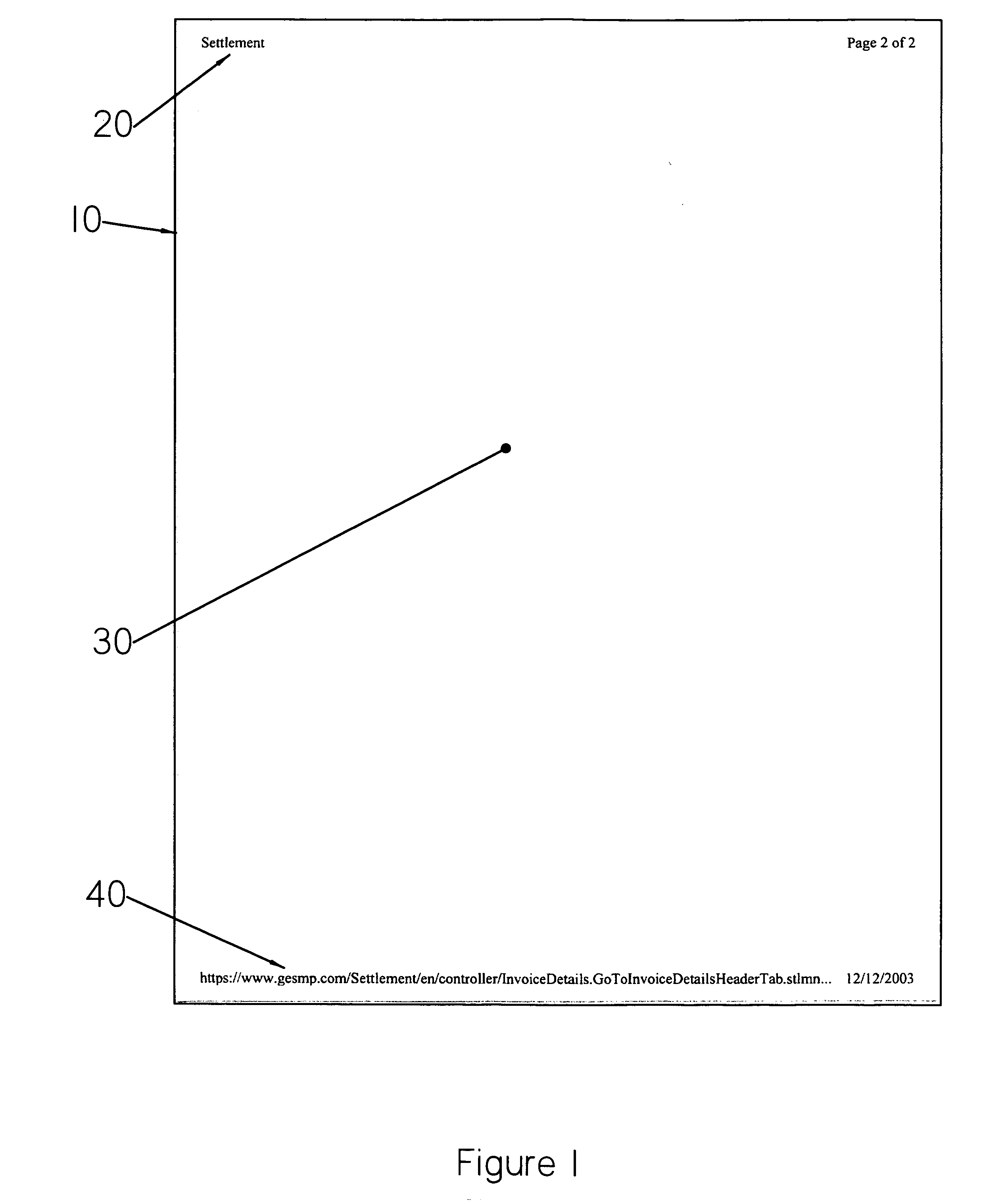

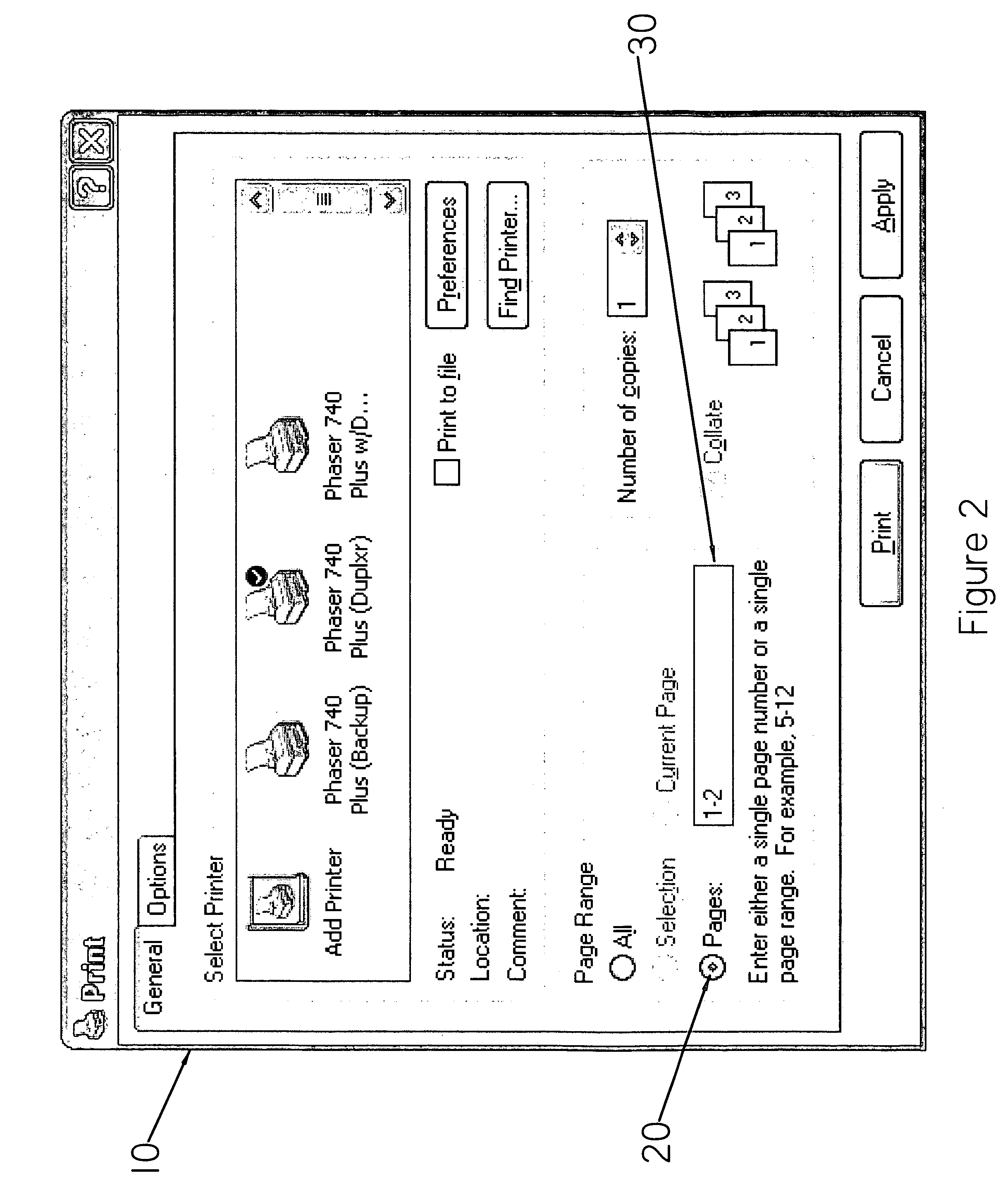

Method of limiting amount of waste paper generated from printed documents

This invention details a method of providing a method of limiting the amount of waste paper created when printing documents. One of the main problems encountered by today's business environments is the generation of tons of waste paper. With the current trend in maintaining a “recycle minded” mentality, it would seem obvious that in preference to recycling used paper, what is needed is a process that limits a amount a waste paper in the first place.

Owner:CONNECTICUT ANALYTICAL

Processing method for regenerative semi-chemical corrugated paper

InactiveCN1525004AImprove bindingReduce dosageReinforcing agents additionSecondary cellulose fibresHigh concentrationFiber

The invention is a regenerated corrugated raw paper manufacturing method, its main technical flows: mix import waste paper with internal waste paper, pulp by pulping engine, desand by high concentration desander, screen by fiber separator, desand by high concentration desander, screen by low concentration pressure sieve, desand by low concentration desander, condense by condenser, mill and pulp by medium concentration hydraulic disc, screen by pressure sieve, make by paper machine and spray papermaking chemical assistant when molding and cut by winder. The added quantity of import waste paper is 40-55% of total weight of the mixed waste paper. It changes traditional low concentration pulping technique. The technique is designed reasonably, and can effectively heighten the physical strength of the regenerated corrugated raw paper, reduce the raw material cost and be applied to medium-scale production.

Owner:ZHEJIANG BLUESTAR HLDG GRP

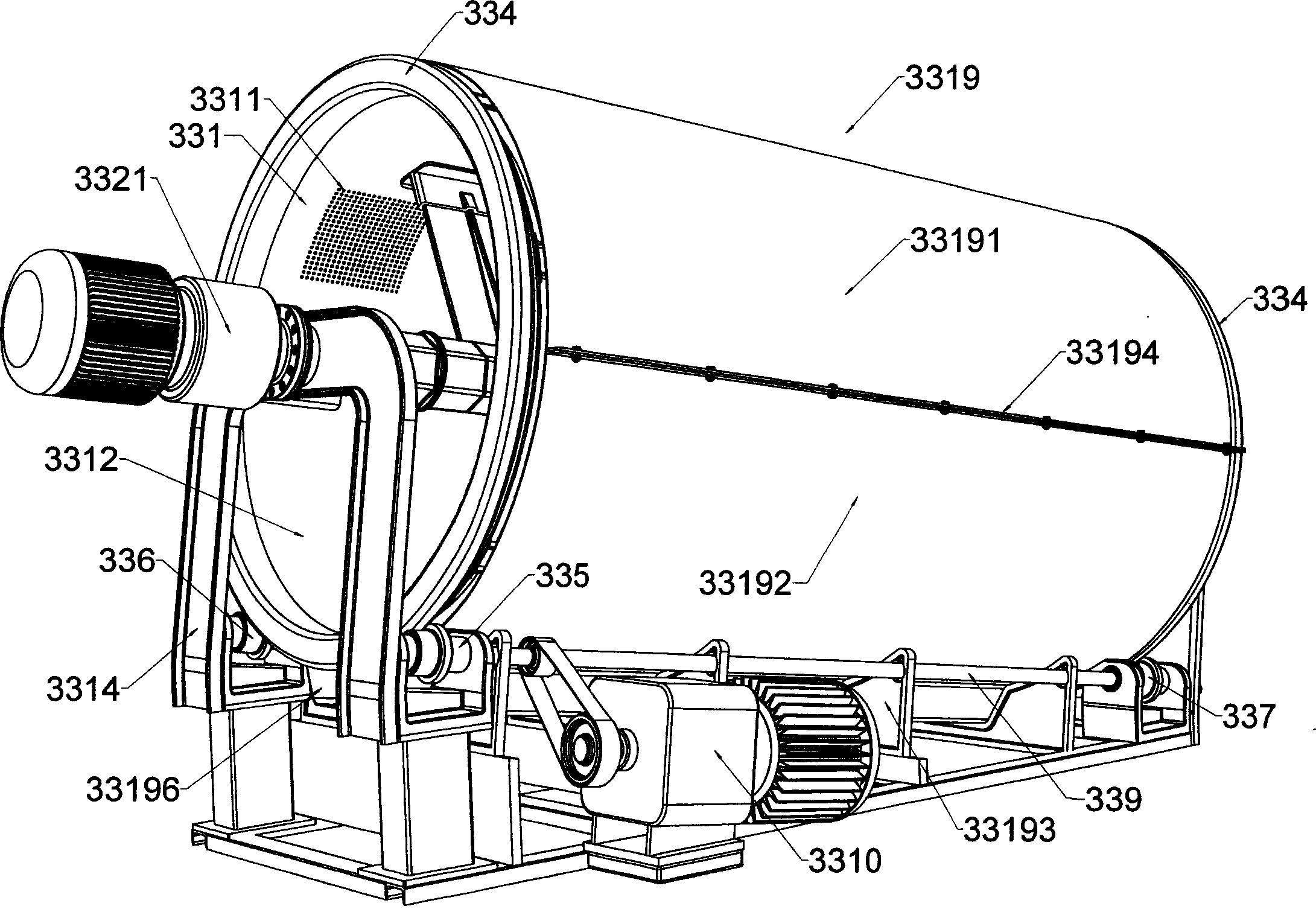

Pulping process of waste paper deinking pulp for furnishing high-grade printing paper

InactiveCN103061183AFull recoveryFull reusePaper recyclingPulp bleachingHigh concentrationPulp and paper industry

The invention relates to the technical field of pulping and papermaking, and particularly relates to a pulping process of waste paper deinking pulp for furnishing high-grade printing paper. The pulping process comprises the following procedures of: repulping, high-concentration desanding, coarse screening, middle-concentration desanding, fine screening, floatation, concentration, heat dispersion, decoloration, backwater and gooey treatment, wherein the repulping procedure comprises the following steps of: placing waste paper and water into a high-concentration hydrapulper; adding 0.1%-1.8% by weight of deinking agents, 0.1%-0.8% by weight of compound biological enzymes and 0.1%-2.0% by weight of surface active agents relative to the bone dry weight of waste paper into the high-concentration hydrapulper; controlling the repulping concentration at 10-20%, the temperature at 50-60 DEG C and the repulping time at 10-30 minutes, and keeping the temperature for 0-20 minutes to obtain broken deinking pulp. The waste paper deinking pulp prepared through the pulping process disclosed by the invention has the advantages of high whiteness, high gooey removal ratio, high dust removal ratio and high ERIC (Entire Combined Ink Content) removal ratio and meets the requirement of the high-grade printing paper.

Owner:福建省晋江优兰发纸业有限公司

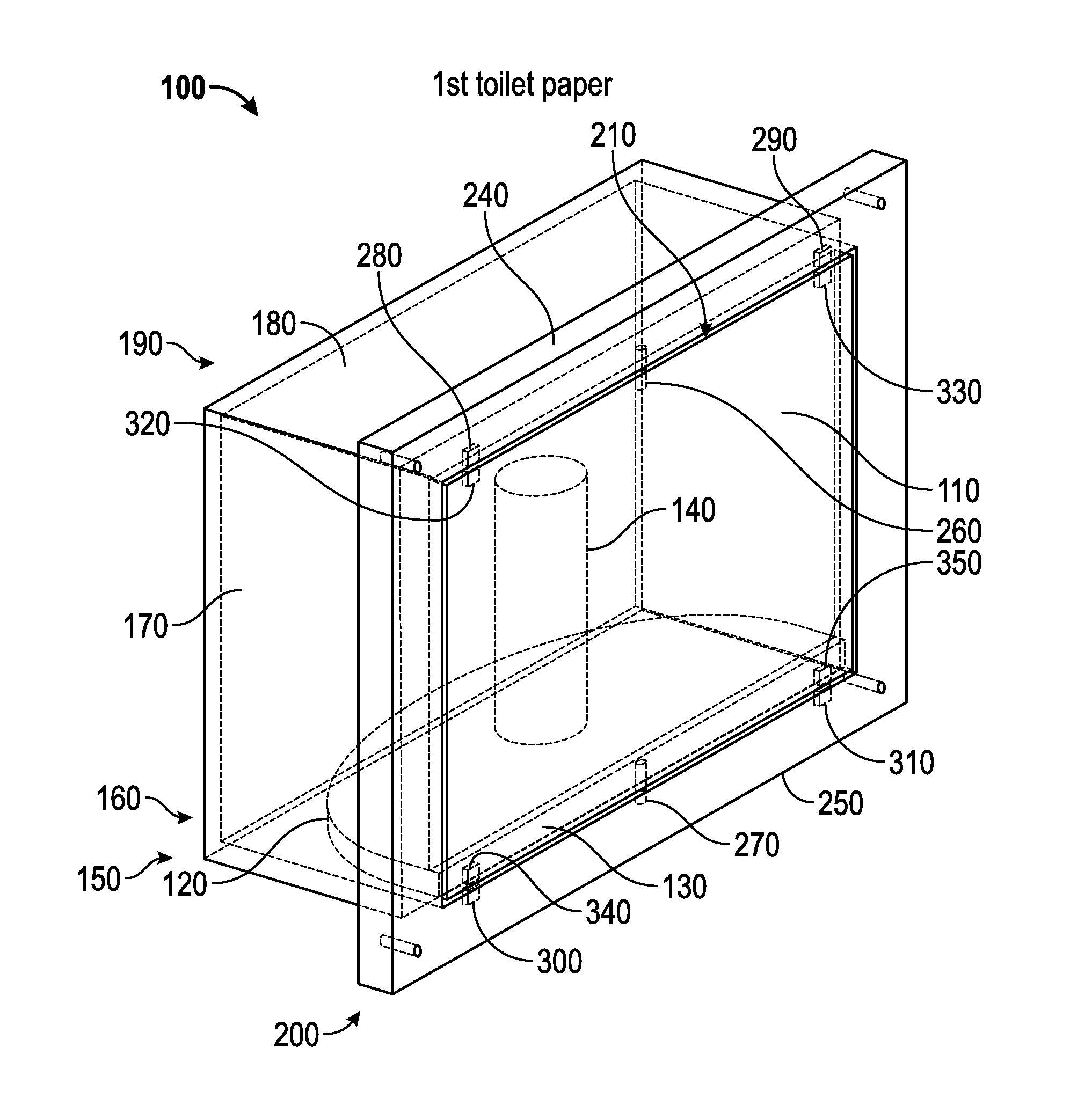

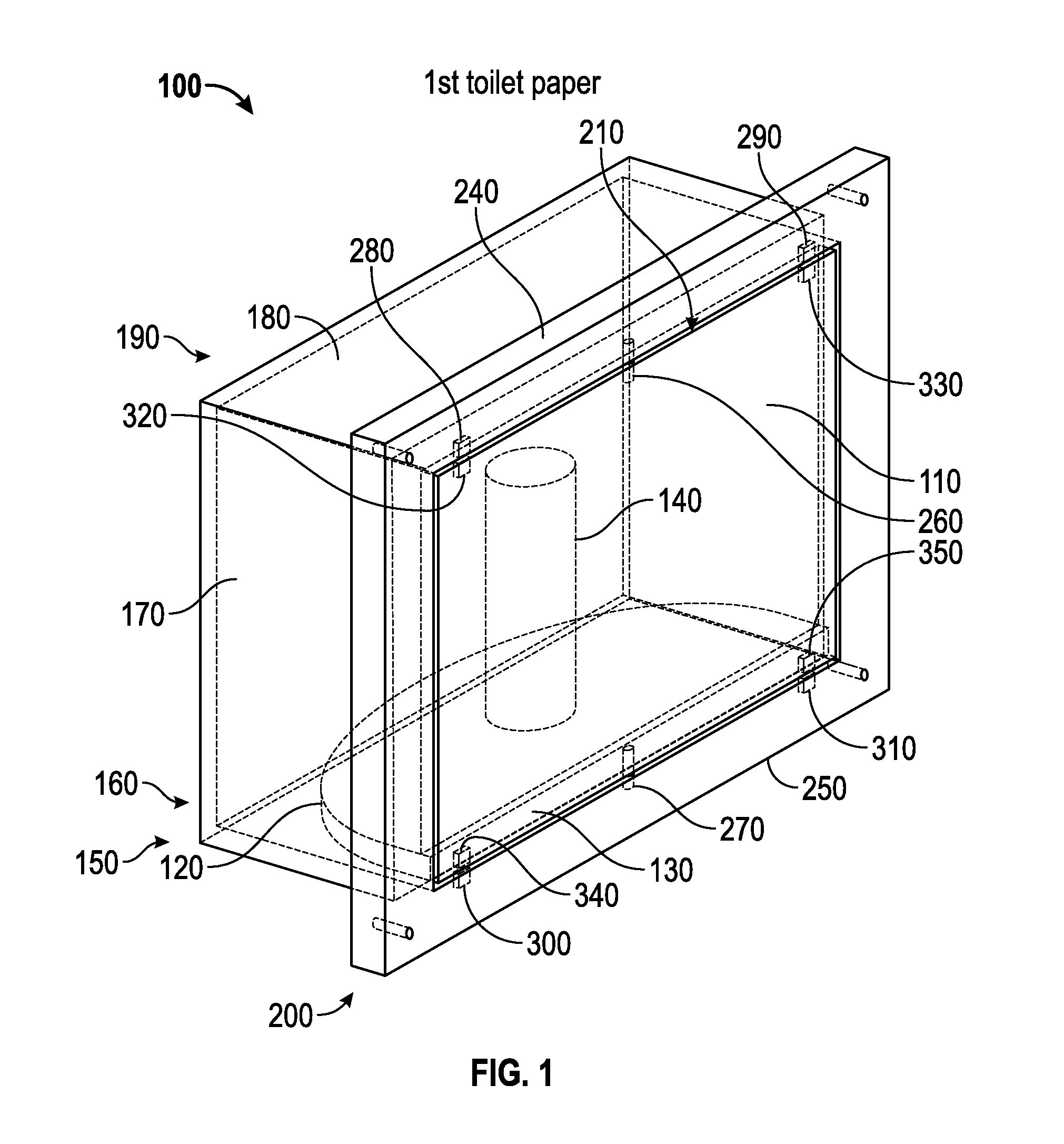

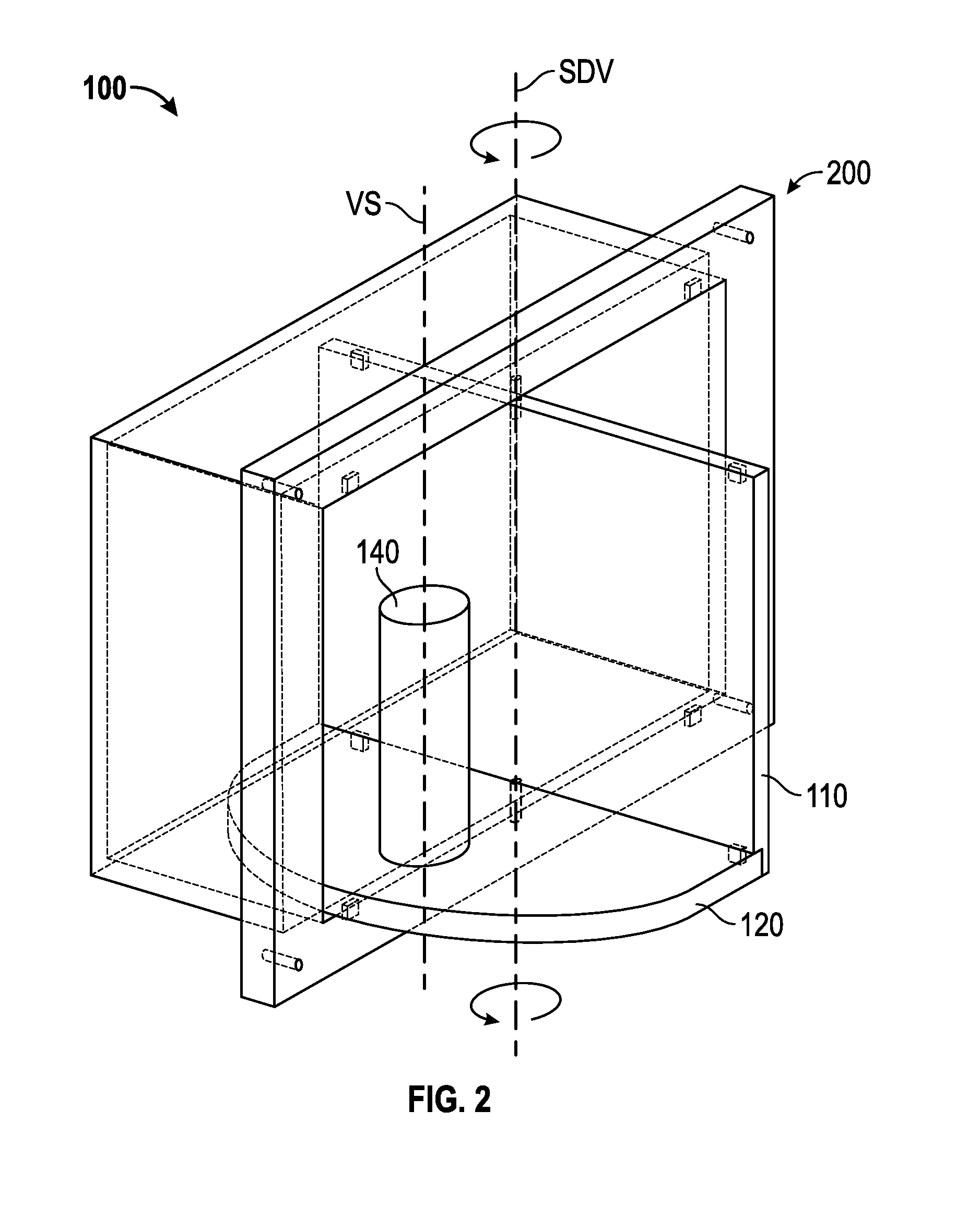

Concealable Toilet Paper Spindle and Method of Use

A concealable waste paper holder for dispensing waste paper from a waste paper roll includes a frame mountable to a wall; a door rotatably mounted to the frame about a door rotational axis between an open position where the waste paper roll is accessible and a closed position where the door is substantially parallel with the wall and conceals the waste paper roll; a spindle for rotationally receiving the waste paper roll about a spindle axis and dispensing the waste paper from the waste paper roll there when the door is is the open position, the spindle carried by the door for rotation with the door, and wherein the spindle axis and the door rotational axis are parallel.

Owner:CLARKIN CHAD

Light hollow ceramsite and production method thereof

ActiveCN102936127AHigh mechanical strengthThe protective effect is obviousCeramic materials productionClaywaresPolymer scienceSludge

The invention provides a light hollow ceramsite and a production method thereof and belongs to the technical field of artificial lightweight aggregate processing. The light hollow ceramsite is made of a ceramic forming material and a template material, wherein the ceramic forming material is composed of waste paper papermaking dry sludge, fly ash and clay, and the template material is composed of polyphenyl foam particles. The obtained light hollow ceramsite is spherical or similar to a sphere in appearance, a middle cavity is spherical or similar to a sphere, and the middle cavity is separated from the outside through a ceramic structure with wall thickness to be 0.5-2.5mm. According to the light hollow ceramsite, barrel pressure strength is 33MPa, stacking bulk weight is 300-500kg / m<3> and particle size is 5-20mm, and therefore the light hollow ceramsite can be used for preparing high performance light aggregate concrete or suspended bio-film ceramic filter materials used for sewage treatment.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com