Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2228 results about "Pulverized fuel ash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

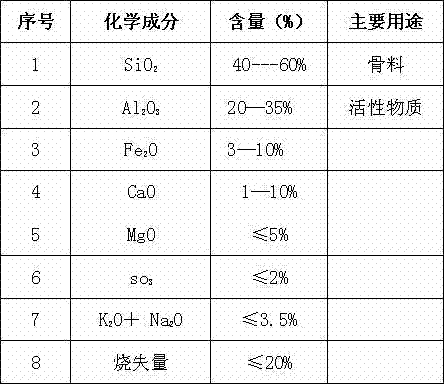

Pulverised Fuel Ash is a pozzolanic additive, extracted from spent fuel hoppers of coal fired boilers and ground to a fine powder. Pozzolans are materials that are not themselves cementitious, but contain constituents which react with lime at ordinary temperatures in the presence of water to form stable hydraulic compounds.

Enhanced mercury control in coal-fired power plants

InactiveUS6808692B2Easy to captureEliminate dischargeChloride preparationUsing liquid separation agentPulverized fuel ashElemental mercury

A method of treating a coal combustion flue gas, which includes injecting a molecular halogen or thermolabile molecular halogen precursor, such as calcium hypochlorite, able to decompose to form molecular halogen at flue gas temperature. The molecular halogen converts elemental mercury to mercuric halide, which is adsorbable by alkaline solids such as subbituminous or lignite coal ash, alkali fused bituminous coal ash, and dry flue gas desulphurization solids, capturable in whole or part by electrostatic precipitators (ESPs), baghouses (BHs), and fabric filters (FFs), with or without subsequent adsorption by a liquid such as a flue gas desulphurization scrubbing liquor.

Owner:HAZELMERE RES

Methods of operating a coal burning facility

ActiveUS20070168213A1Improve balanceIncrease valueSustainable waste treatmentSolid fuel pretreatmentHalogenSorbent

Methods involve adding sorbent components, such as calcium oxide, alumina, and silica, as well as optional halogens as part of environmental control. Use of the sorbents leads to significant reductions in sulfur and mercury emissions that otherwise would result from burning coal. Use of the sorbents leads to production of waste coal ash that, while higher in mercury, is nevertheless usable as a commercial product because the mercury in the ash is non-leaching and because the coal ash has a higher cementitious nature by virtue of the increased content of the sorbent components in the ash. Thus, the methods involve adding powders having qualities that lead to the production of a cementitious coal ash while at the same time reducing emissions from a coal burning facility.

Owner:NOX II LTD

Enhanced mercury control in coal-fired power plants

InactiveUS20030161771A1Enhanced capture of mercuryEliminating undesirable dischargeUsing liquid separation agentHalide preparation methodsPulverized fuel ashElemental mercury

A method of treating a coal combustion flue gas, which includes injecting a molecular halogen or thermolabile molecular halogen precursor able to decompose to form molecular halogen at flue gas temperature. The molecular halogen coverts elemental mercury to mercuric halide adsorbable by alkaline solids such as subbituminous or lignite coal ash, alkali fused bituminous coal ash capturable in whole or part by electrostatic precipitators (ESPs), baghouses (BHs), fabric filters (FFs), dry flue gas desulphurization solids, with or without subsequent adsorption by a liquid such as a flue gas desulphurization scrubbing liquor.

Owner:HAZELMERE RES

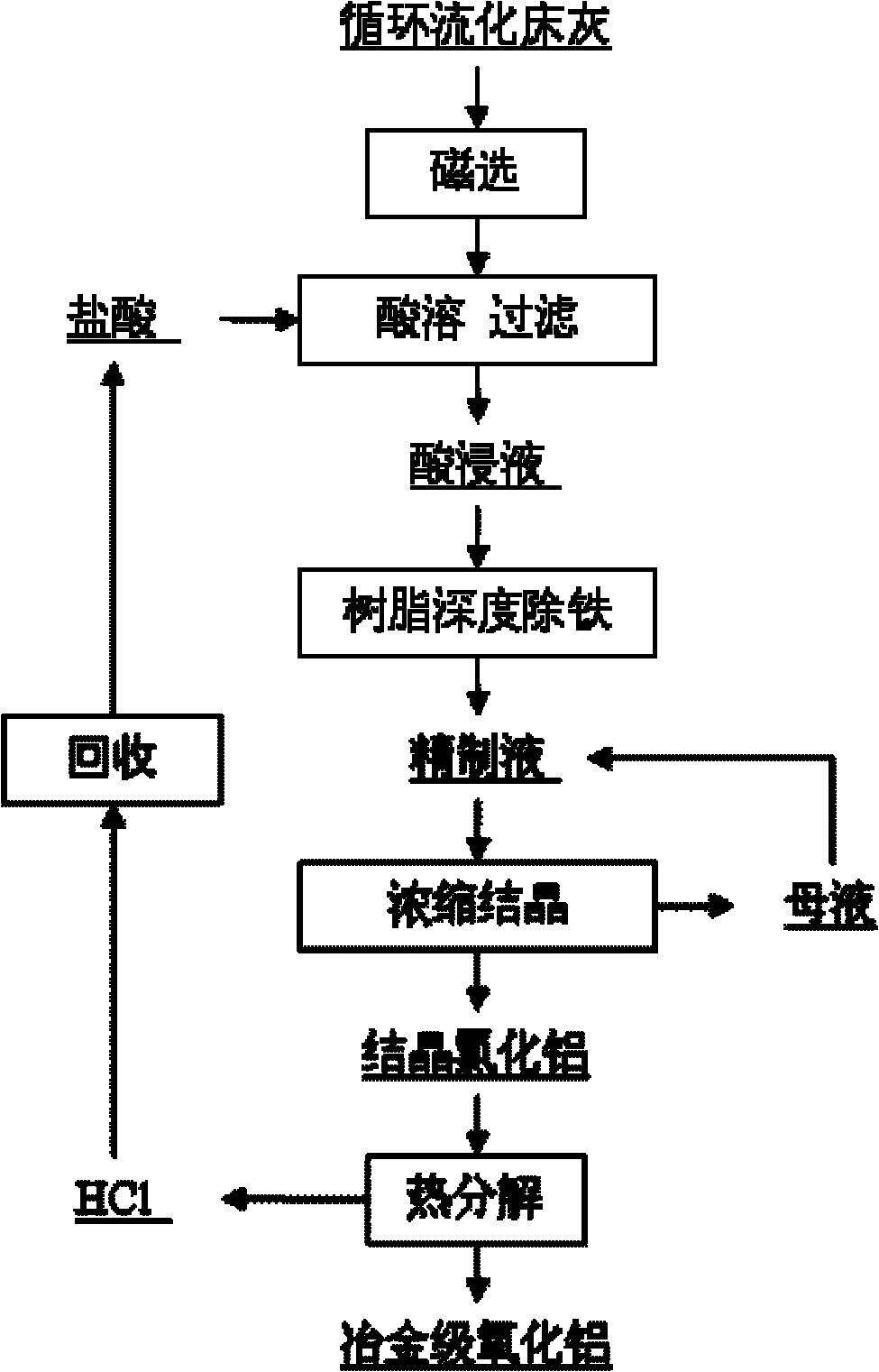

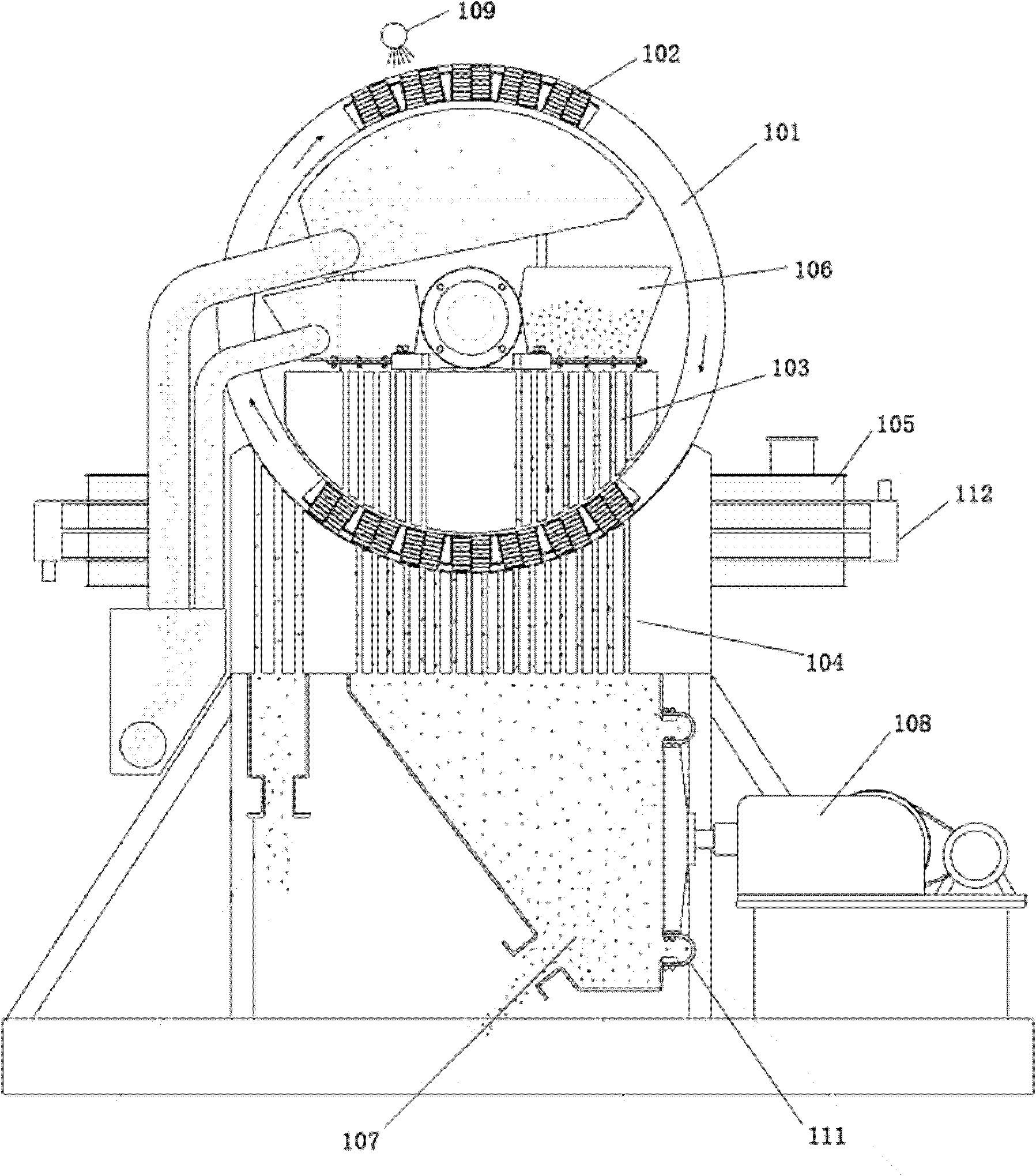

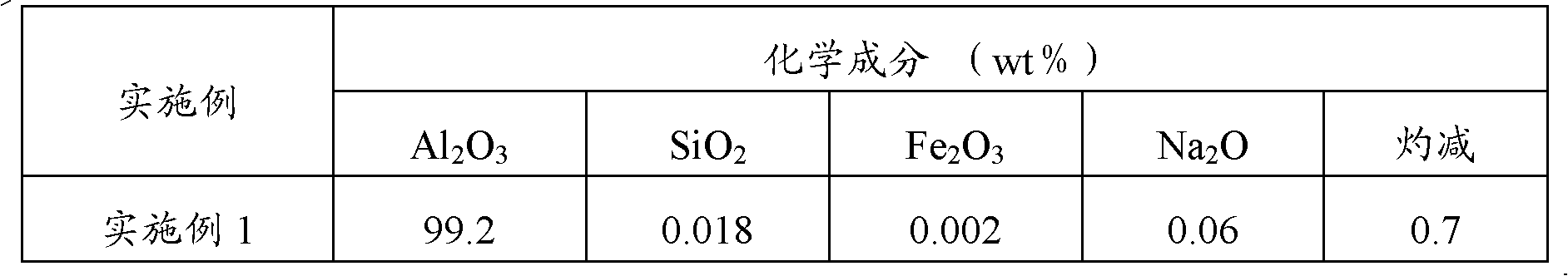

Method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash

ActiveCN102145905AHigh extraction rateReduce manufacturing costSolid waste disposalTransportation and packagingAluminium chloridePulverized fuel ash

The invention discloses a method for preparing metallurgy-level aluminum oxide by using fluidized bed pulverized fuel ash as a raw material. The method comprises the following steps of: a) grinding the pulverized fuel ash, and removing iron by a wet magnetic separation method; b) reacting the pulverized fuel ash subjected to magnetic separation with hydrochloric acid to obtain hydrochloric acid immersion liquid; c) allowing the hydrochloric acid immersion liquid to pass through a large pore type cation resin column for further iron removal to obtain refined aluminum chloride solution; d) concentrating the refined aluminum chloride solution, and crystallizing to obtain an aluminum chloride crystal; and e) calcining the aluminum chloride crystal and decomposing to obtain the metallurgy-level aluminum oxide. The method has a simple process and an easily-controlled production process, and is high in aluminum oxide extraction efficiency, low in production cost and stable in product quality.

Owner:CHINA SHENHUA ENERGY CO LTD

Use of high carbon coal ash

InactiveUS6755905B2Avoid insufficient heatingReduce flowCharge manipulationHandling discharged materialSlagHigh carbon

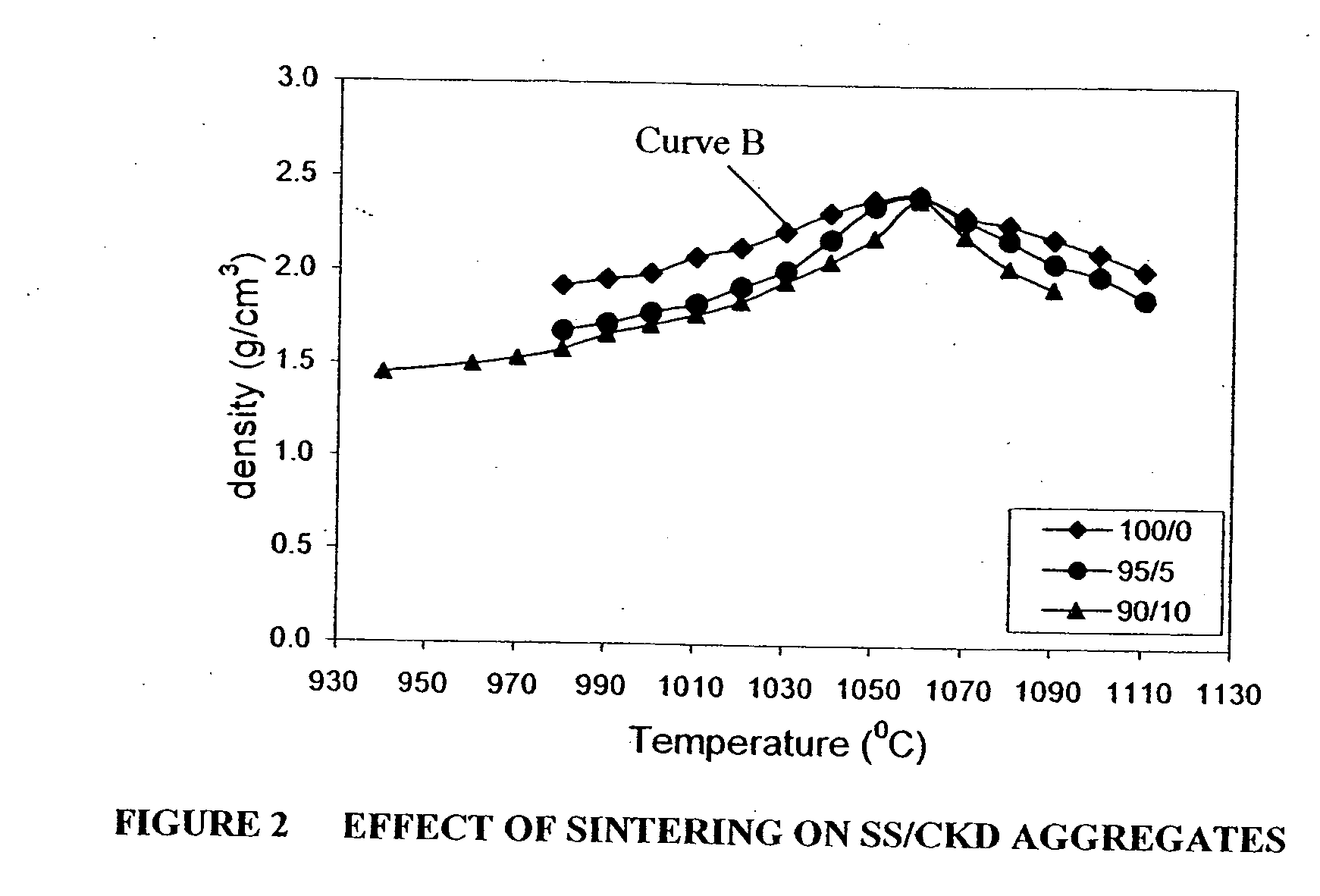

A synthetic slag is produced by a high temperature combustion reaction between coal ash having a high carbon content, and a source of lime such as cement kiln dust. The carbon content of the coal ash is oxidized by oxygen gas, which typically is derived from air or an air / oxygen combination in an exothermic reaction and the heat generated is exploited in the melting process. In this way the gaseous products will typically comprise nitrogen, unreacted oxygen and carbon dioxide, and heat energy can be readily recovered from the hot off gas products evolving during the combustion reaction. The synthetic slag may be pelletized and employed as lightweight mineral aggregate or milled to cement fineness to provide slag cement.

Owner:LAFARGE CANADA INC

Reducing mercury emissions from the burning of coal

ActiveUS7758827B2Reduce waste disposal costsReduce concrete costsSolid waste managementUsing liquid separation agentCombustionHalogen

Sorbent components containing calcium, alumina, silica, and halogen are used in combination during coal combustion to produce environmental benefits. Sorbents are added to the coal ahead of combustion and / or are added into the flame or downstream of the flame, preferably at minimum temperatures to assure complete formation of the refractory structures that result in various advantages of the methods. When used together, the components ● reduce emissions of mercury and sulfur; ● reduce emissions of elemental and oxidized mercury; ● increase the efficiency of the coal burning process through de-slagging of boiler tubes; ● increase the level of Hg, As, Pb, and / or Cl in the coal ash; ● decrease the levels of leachable heavy metals (such as Hg) in the ash, preferably to levels below the detectable limits; and ● make a highly cementitious ash product.

Owner:NOX II LTD

Rapid hardening hydraulic cement from subbituminous fly ash and products thereof

A rapid hardening hydraulic cement is provided that is made substantially exclusively from a subbituminous fly ash with no portland cement or other strengthening aid.

Owner:CEMEX

Coal slime flotation collector and preparation method thereof

The invention discloses a coal slime flotation collector and a preparation method thereof. The coal slime flotation collector comprises the following matters in percentage by weight: 20-50 percent of kerosene and / or light diesel oil, 1-5 percent of primary emulsion, 0.006-0.015 percent of auxiliary emulsion and the balance of water; wherein the primary emulsion is a mixture of polyoxyethylene sorbitan fatty acid ester and dehydrated sorbitol fatty acid ester, and the hydrophile-lipophile balance (HLB) value of the primary emulsion is within 12.8-14.3; the auxiliary emulsion is selected from the following (1) or (2), wherein the (1) is sodium dodecyl benzene sulfonate, and the (2) is a mixture obtained by mixing fatty alcohol polyoxyethylene ether sulfate and the sodium dodecyl benzene sulfonate according to the mass ratio of 1: 0.5-2. The coal slime flotation collector has good stability, simple preparation process and 40-60 percent of the oil-saving ratio on the premise of improving the float yield and the tail coal ash proportion. The collector is beneficial to saving the energy, reducing the emission and improving the economical benefit when being used for floating the coal slime.

Owner:SHANXI MEDICAL UNIV

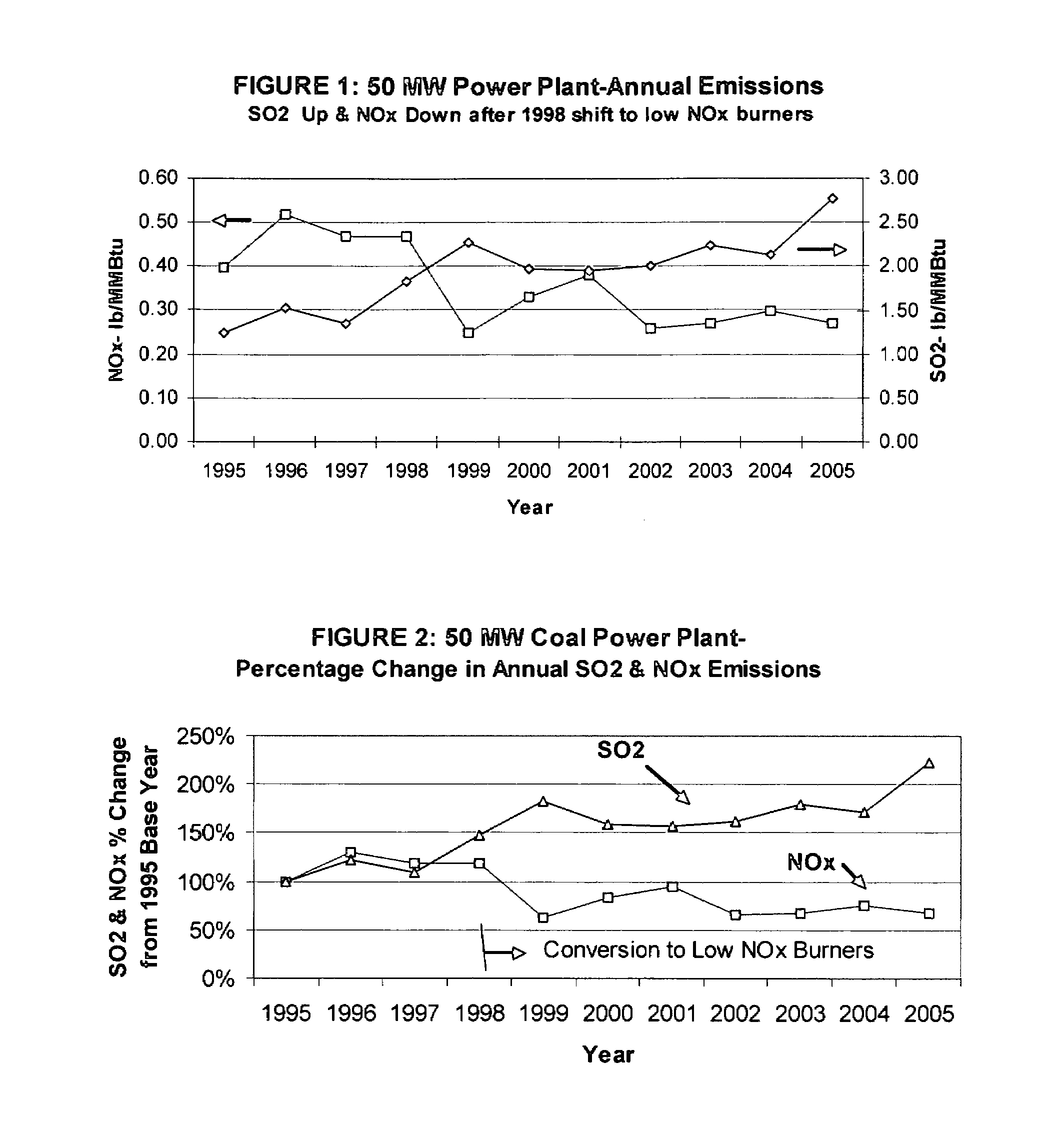

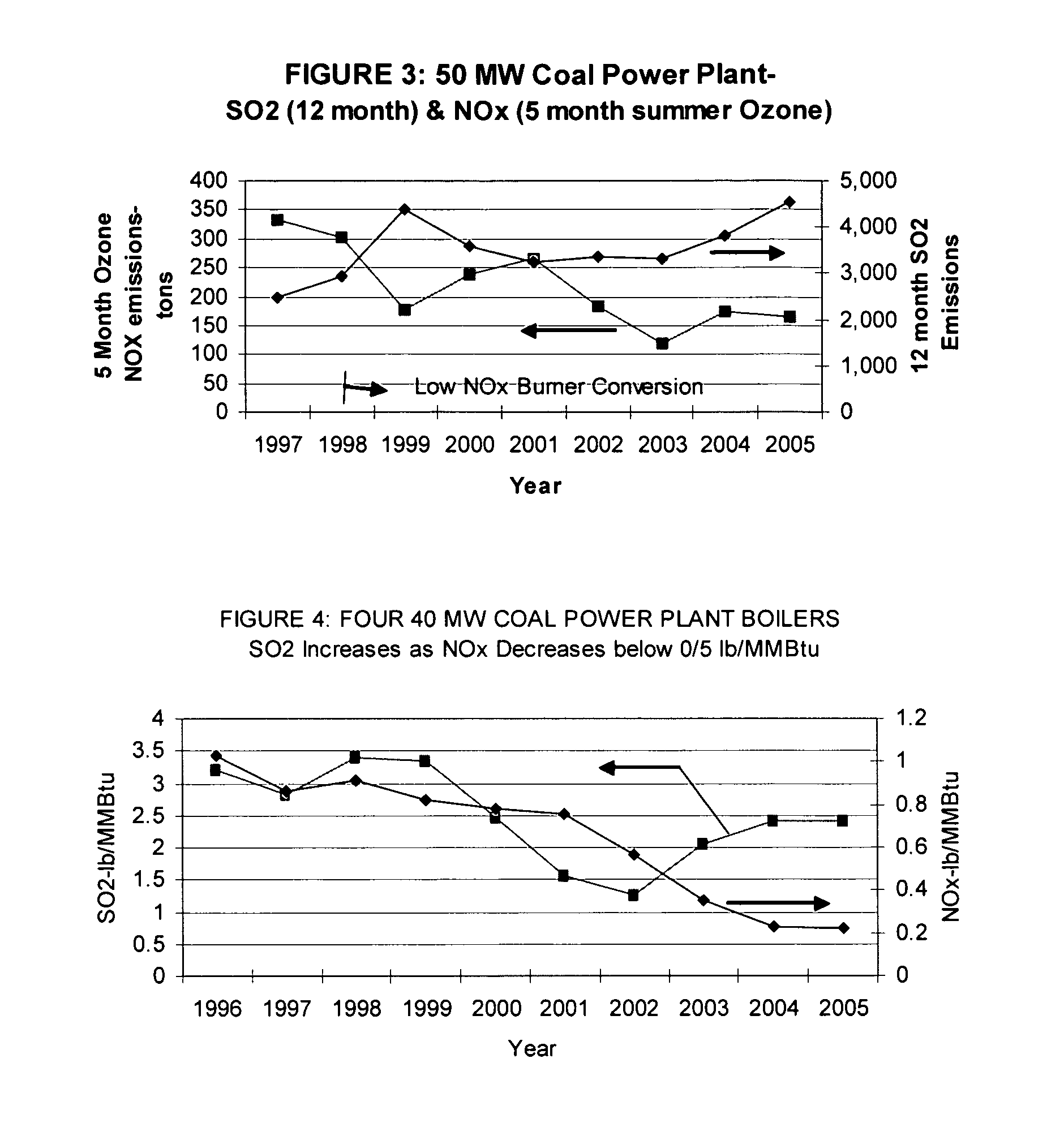

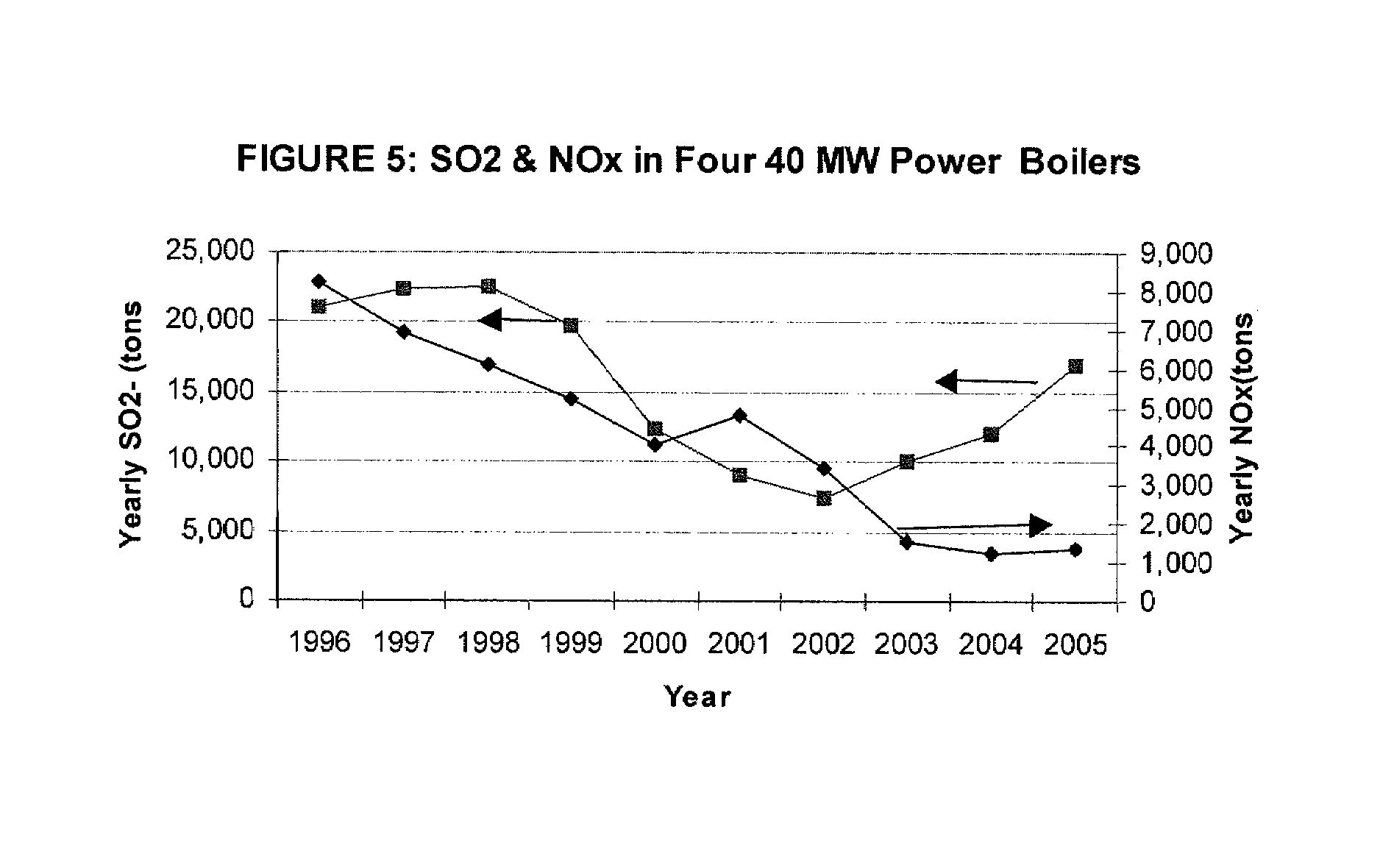

Technical and economic optimization of combustion, nitrogen oxides, sulfur dioxide, mercury, carbon dioxide, coal ash and slag and coal slurry use in coal fired furnaces/boilers

InactiveUS7553463B2Minimal equipment costLow costNitrogen compoundsUsing liquid separation agentParticulatesWater use

Methods by which new or used boilers or furnaces ranging from small industrial to the largest utility units that are designed for coal or oil or natural gas or shredded waste or shredded biomass firing can substantially improve their technical operation and sharply reduce their capital and operating costs by implementing component modifications and process steps that (a) minimize the adverse impacts of coal ash and slag on boiler surfaces and particulate emissions thereby also facilitating the use of oil or gas designed boilers for coal firing, (b) drastically reduce the loss of water used to transport coal in slurry form to power plants, (c) essentially eliminate the combined total nitrogen oxides (NOx), sulfur dioxide (SO2), mercury (Hg), trace metals, and carbon dioxide (CO2) emissions, (d) separate and permanently sequester carbon dioxide released during combustion and (e) improve the coal and solid fuel combustion efficiency.

Owner:ZAUDERER BERT

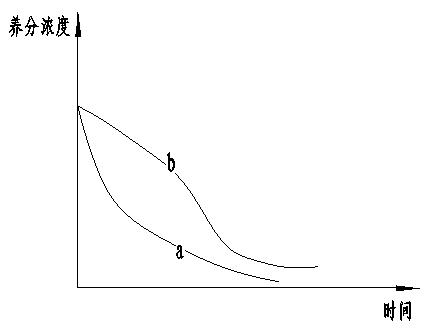

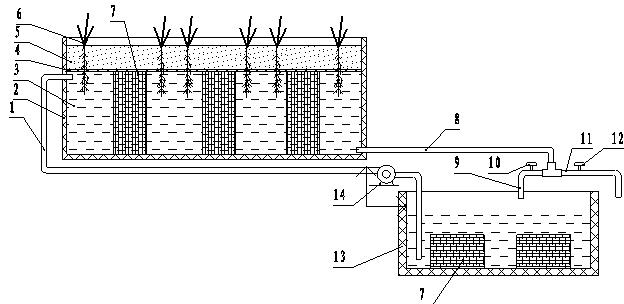

Small soilless culture method and device

ActiveCN102119651AIncrease the concentration of inputFewer deliveriesAgriculture gas emission reductionCultivating equipmentsSlagPeat

The invention relates to a small soilless culture method and device. A nutrient solution is contained in a culture disk or a nutrient solution storage pool; crops are planted into the nutrient solution; a soil copy material is added into the nutrient solution; the soil copy material comprises the following raw materials in parts by weight: 20-90 parts of organic matter and 2-80 parts of nonmetal mineral substance, wherein the organic matter is one or mixture of peat, fermented straw, fermented bagasse and fermented livestock and poultry manure; the nonmetal mineral substance is one or mixtureof coal ash, steel slag, zeolite, bentonite, opal, attapulgite mineral soil, pearlite, vermiculite, rectorite clay, sepiolite clay and kieselguhr; and the proportion of the nutrient solution to the soil copy material is (5-2):1. By adding the soil copy material into the nutrient solution, the nutrient charge concentration can be improved, the nutrient charge frequency is reduced, and the labor cost is reduced; meanwhile, when the concentration is reduced due to the absorption of the nutrients, the concentration reduction range is slower, and a deficiency symptom caused by lacking nutrients ofplants is lightened; in addition, trace elements needed by plants can be also supplemented.

Owner:杜友萍

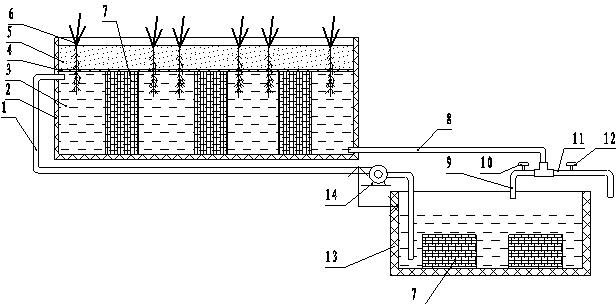

Insulating dry powder mortar

InactiveCN101525226ALoose bulk densityLow thermal conductivitySolid waste managementFiberCrack resistance

The invention discloses insulating dry powder mortar which is made from portland cement, pulverized fuel ash and / or slag powder, organic polymer emulsion powder, flame-retardant polystyrene foam particles, thermal insulating aggregate, composite fiber, water resisting agent and admixture. The insulating dry powder mortar has the advantages of light volume weight, low thermal conductivity, comprehensive utilization of waste material, environmental protection, resource saving, cracking resistance, ageing resistance, strong cohesive force, favorable workability and construction performance, convenient use, waterproofness, permeation resistance, high compression strength, convenient storage and transportation, no environmental pollution, and the like and can be widely used for preserving heat in the internal wall and the external wall of a building and other special engineering.

Owner:CHANGSHA YUANPENG CHEM TECH

Method for producing baking-free bricks by using phosphorous gypsum based cementitious material to solidify yellow phosphorous slags

InactiveCN101637936ASolve pollutionLow costSolid waste managementMixing operation control apparatusBrickSlag

Owner:KUNMING UNIV OF SCI & TECH

Thermal insulation building mortar and preparation process thereof

InactiveCN101759416AWith thermal insulationWith phase change energy storageCement mixing apparatusSodium BentoniteThermal insulation

The invention discloses a thermal insulation building mortar. The thermal insulation building mortar is prepared by the mixing portland cement, pulverized fuel ash, calcium bentonite, re-scattering glue powder, hypromellose, polyacrylamide powder, polypropylene fibre, wood fiber, permeating crystal waterproof agent, air entraining agent, vitrified micro-bead, sizing phase-change material and hollow glass bead. A preparation process thereof comprises the steps of: a) preparing the sizing phase-change material, b) preparing the permeating crystal waterproof agent and c) preparing the thermal insulation building mortar. The mortar of the invention is characterized by the functions of thermal insulation, phase-change energy storage, temperature control, water resistance and energy saving, the wide application scope and low cost. The mortar is widely applied in thermal insulation work inside or outside the buildings and has a broad prospect.

Owner:唐山市思远涂料有限公司

Sullage solidifying method

InactiveCN101220590AHigh strengthThe surrounding environment is beautified and tidyRoadwaysSolid waste managementSludgePrice ratio

A sludge solidification method is a method for carrying out solidification treatment to the sludge produced in water conservancy projects and civil engineering. The method is that: a. the liquid water content, the clay content and organic content of dredging sludge are tested. b. curing agent is prepared: the curing agent mainly contains cement and calcium oxide which play the function of solidification; wherein, the weight proportion is between 1 : 1 to 4 : 1; waste gypsum is used as water reducing agent which occupies 1 to 8 percent of the sum of cement and calcium oxide in proportion; mealy sand or pulverized fuel ash are used as concrete aggregate which occupies 3 to 5 percent of the sum of the cement and calcium oxide in proportion; c. the curing agent-mixing ratio which is usually controlled from 5 to 20 percent is determined; sampling respectively is carried out, setting time is tested and the unconfined compressive strength which maintains 7, 14 and 28 days is tested by sampling, and the curing agent-mixing ratio finally is determined according to optimal performance price ratio; d. the sludge is carried out curing and constructing in site; mechanical devices are used for stirring the curing agent and the sludge rapidly and evenly, thereby leading the solidification to be rapid and full.

Owner:SOUTHEAST UNIV

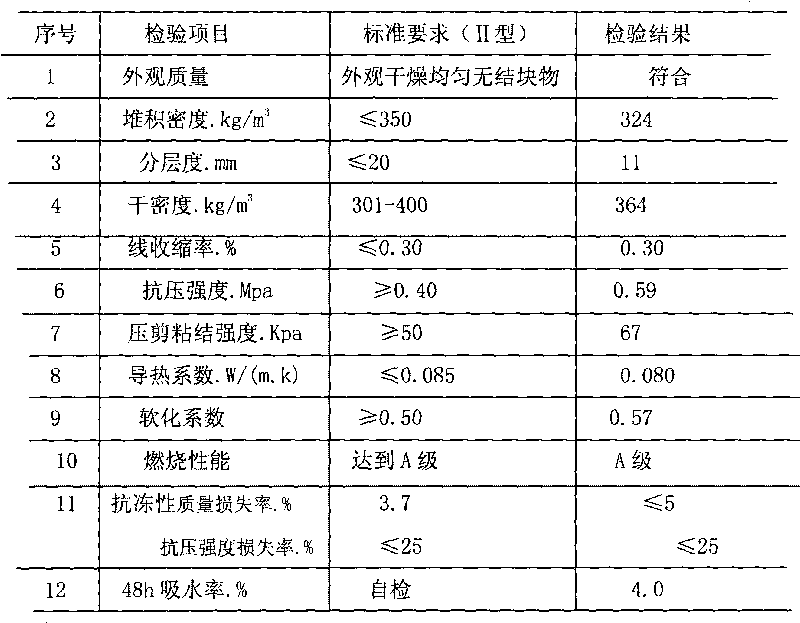

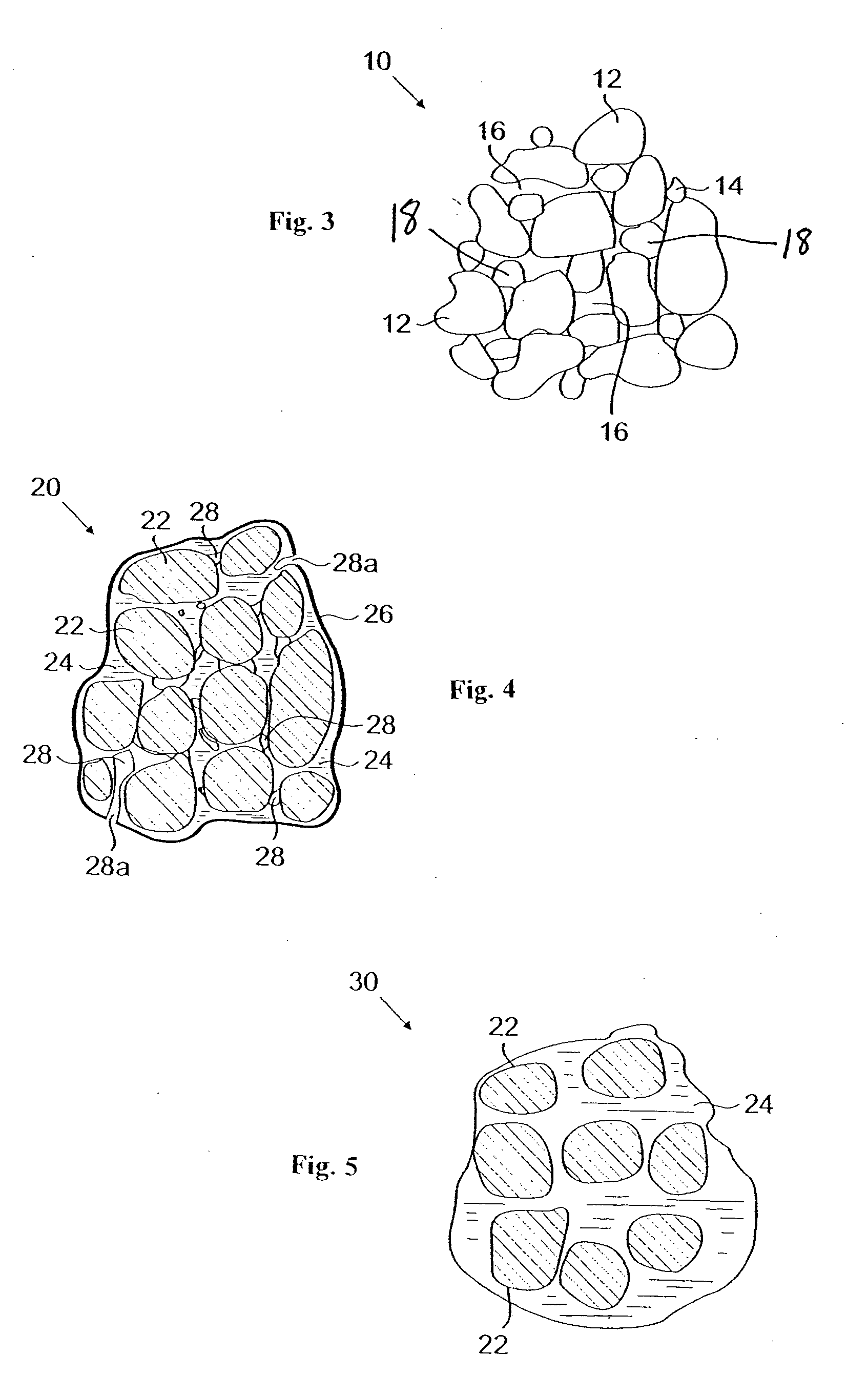

Synthetic aggregates comprising sewage sludge and other waste materials and methods for producing such aggregates

In one example of an embodiment of the invention, a method for producing an aggregate is disclosed comprising mixing sewage sludge from a waste water treatment facility with a non-coal combustion ash silicoaluminous waste material, agglomerating the mixture to form an agglomerate, and pyroprocessing the agglomerate to form an aggregate. The waste material may comprise municipal solid waste incinerator bottom ash, incinerator fly ash, incinerator filter dusts, cement kiln dusts, waste glass, blast furnace slag, kiln dusts, and / or granite sawing residues, for example. The method may further comprise milling the waste material prior to mixing. Preferably, the milling is wet milling. Pyroprocessing of the agglomerate may take place in a rotary kiln. The resulting aggregate may be a lightweight or a normal weight, sintered or vitrified aggregate. Aggregates and methods for making aggregates of high and low calcium silicoaluminous materials are also disclosed.

Owner:ALKEMY

Inorganic heat insulation load-bearing concrete

InactiveCN101628797AImprove insulation effectHigh strengthSolid waste managementCeramicwarePulverized fuel ashMix proportion

Owner:李珠 +1

Environment-friendly efficient filter filtering paper and preparation method thereof

ActiveCN102888784AImprove efficiencyImprove filtration efficiencyNon-fibrous pulp additionPaper/cardboardSolubilityGlycerol

The invention discloses an environment-friendly efficient filter filtering paper. The environment-friendly efficient filter filtering paper is prepared by the following raw materials in part by weight: 40-50 parts of softwood pulp, 30-40 parts of waste paper pulp, 20-30 parts of high-silica glass fiber, 2-5 parts of modified vermiculite, 1-3 parts of zeolite molecular sieve, 2-4 parts of nanometer calcium, 1-2 parts of modified pulverized fuel ash, 2-3 parts of water-solubility organic silicon resin emulsion, 1-2 parts of water-solubility polytetrafluoroethylene emulsion, 0.5-0.8 parts of ammonium polyphosphate, 3-4 parts of glycerol triacetate, 0.5-1 parts of diethanolamide, 0.5-1 parts of silane coupling agent KH560, 0.4-0.8 parts of sodium dodecyl sulfate, 0.5-1 parts of antioxidant DSTP, and 4-6 parts of polyethylenimine. The filtering paper prepared by the method provided by the invention has the advantages of being good in water permeability, large in filtering area, small in maximum diameter of hole, high in filtering precision, strong in bursting strength, high-temperature-resistant, good in water resistance and the like, can achieve the filtering efficiency by 99.98%, has stable performance index at atmospheric and high-temperature working conditions, as well as better temperature resistance and filtering effects.

Owner:ANHUI PHOENIX INT CO LTD

Method for preparing foamed ceramic insulation board by waste glass ceramic wafer

The invention discloses a method for preparing a foamed ceramic insulation board by a waste glass ceramic wafer, belonging to the field of preparation technology of the foamed ceramic insulation board. The method comprises the steps of: washing the waste glass ceramic wafer with clear water, drying and grinding by ball milling to obtain waste glass ceramic powder with the fineness less than or equal to 100mu m; mixing the waste glass ceramic powder, pulverized fuel ash, furnace slag, coal gangue, ceramic tailings, foaming agent and modifying agent according to the mass ratio of (30-40):(10-15):(5-7):(10-18):(25-35):(1.8-2.2):(1.1-1.5); putting the mixture into a ball grinding mill, carrying out wet grinding and evenly mixing to form mixed slurry; drying by a pressure type spray granulation dryer and putting the dried product into a foaming refractory mould coated with aluminum oxide; heating to 1120-1150 DEG C in a heating furnace; and finally, annealing, cooling and cutting to obtain the foamed ceramic insulation board. The method is low in production cost and simple in technology, and can be used for continuously preparing the porous foamed ceramic insulation board with large size; and the product is good in performances.

Owner:ANSHENG SCI & TECH DEP

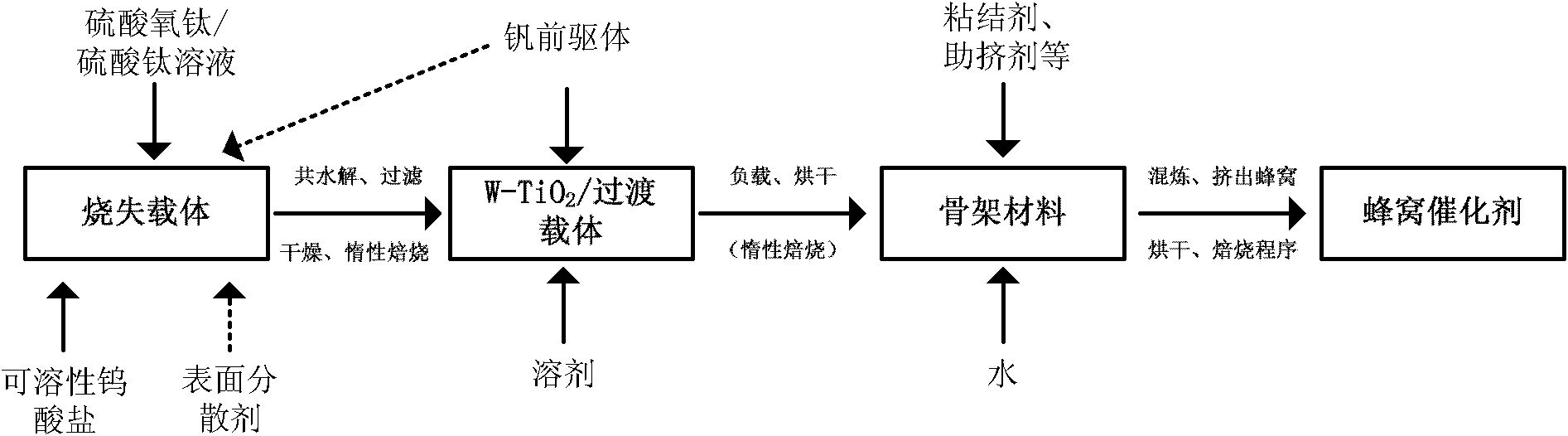

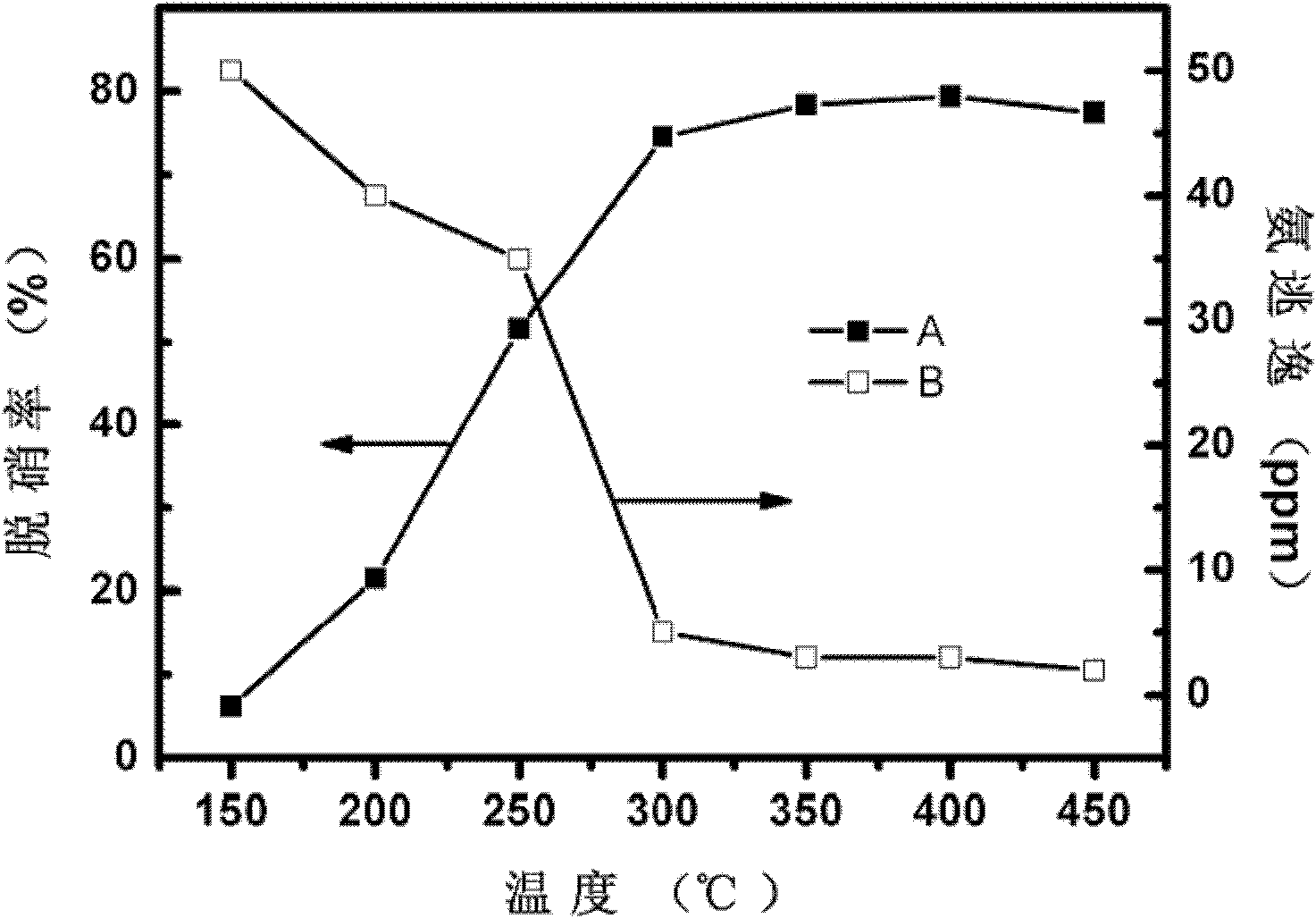

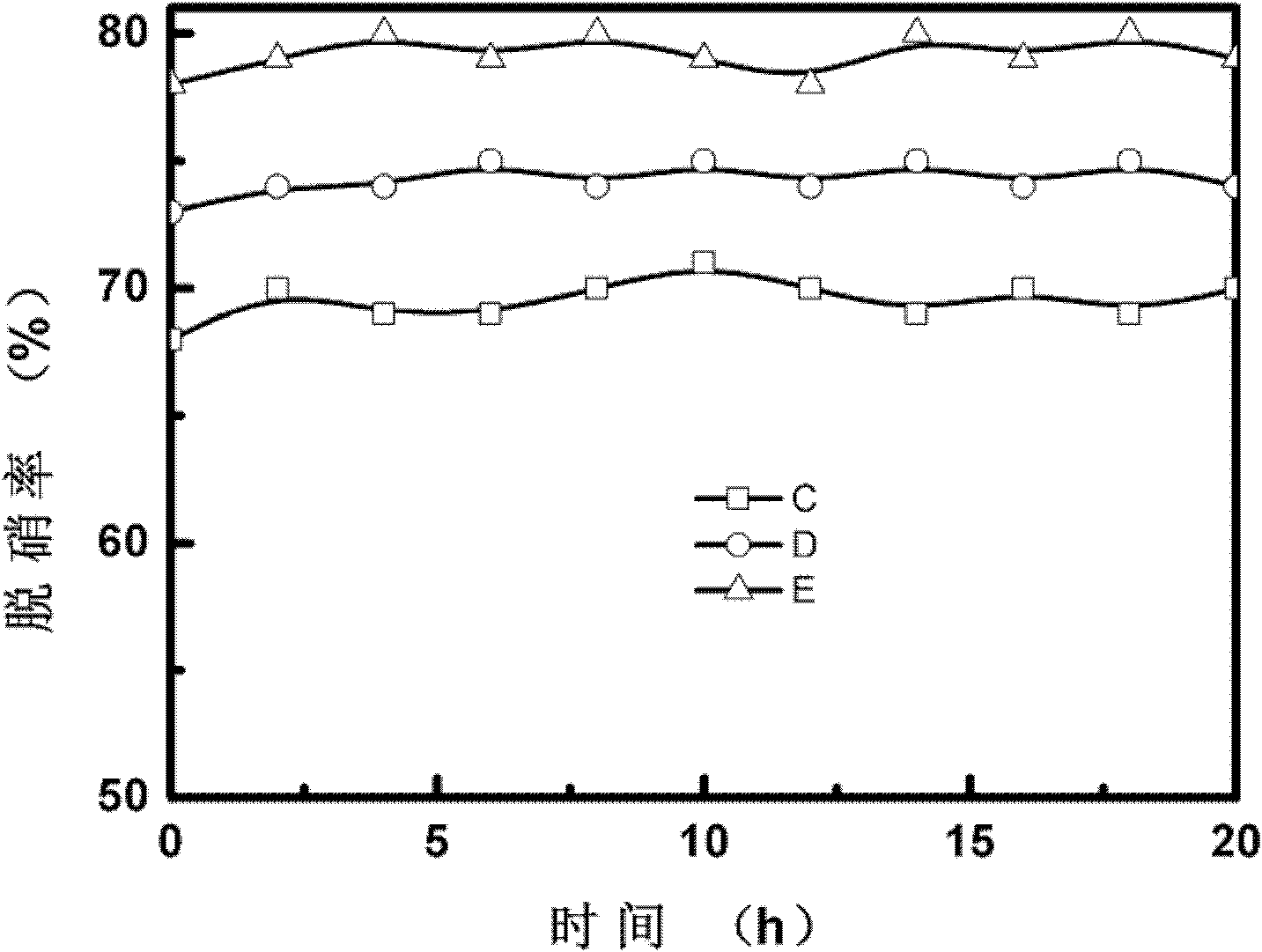

Surface deposition honeycomb flue gas denitration catalyst and preparation method thereof

ActiveCN102319559AWide active temperature windowAchieving Directional Selective LoadingDispersed particle separationCatalyst activation/preparationEnvironmental resistanceSlag

The invention relates to the environmental protection field of flue gas treatment of gas-fired boilers, in particular to a surface deposition honeycomb flue gas denitration catalyst and a preparation method thereof. The catalyst comprises a honeycomb framework which takes clay, soot dust or slag as a substrate; TiO2 is taken as an active carrier; WO3 and V2O5 serving as active ingredients are loaded on the TiO2 active carrier, and are uniformly distributed in the honeycomb framework; and the catalyst comprises the following components in percentage by weight: 60-80 percent of clay, soot dust or slag, 13-33 percent of TiO2, 1-5 percent of WO3 and 0.1-2 percent of V2O5. By transferring an ignition lost transition carrier, highly dispersion of catalyst nanoparticles on a molding catalyst pore cannel and an outer surface is realized, and the utilization ratio and catalytic activity of the active ingredients are increased greatly.

Owner:CHINA KINGSUN MATERIAL TECH

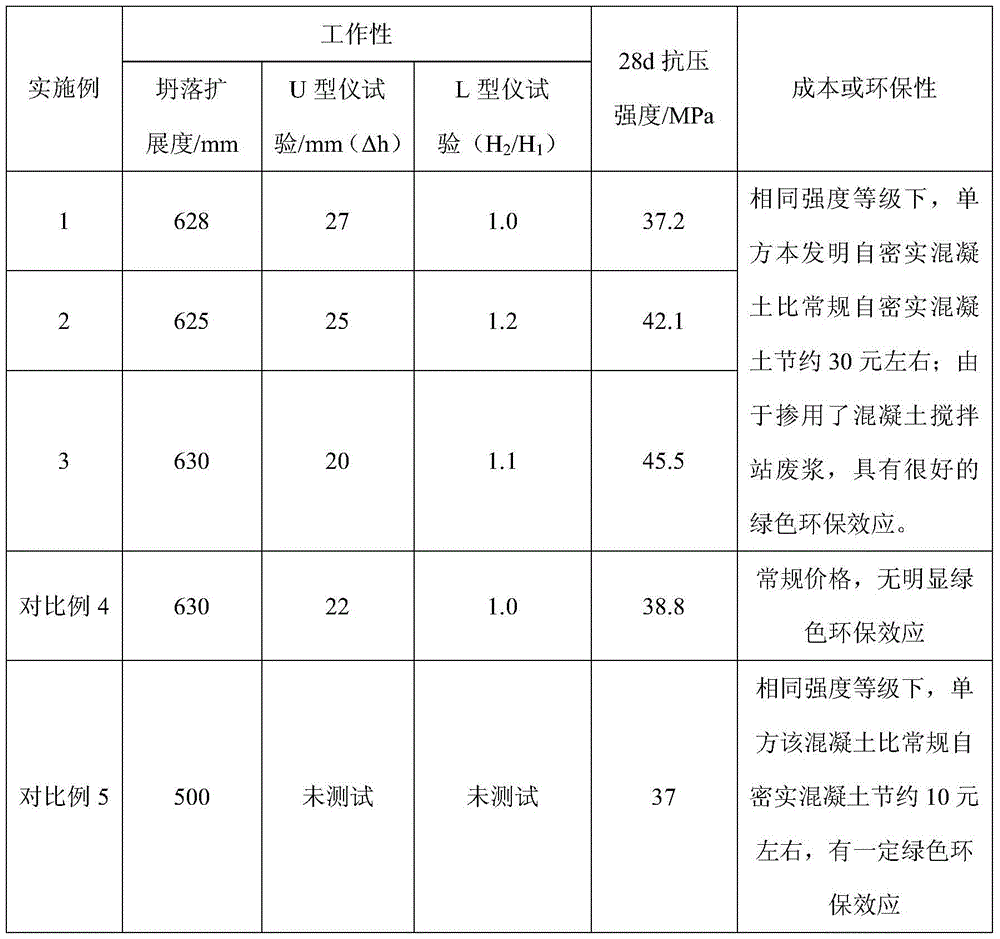

Self-compacting concrete prepared from concrete mixing station waste slurry

ActiveCN105776994AIncrease profitHigh value-added utilizationSolid waste managementWastewaterAdditional values

The invention discloses self-compacting concrete prepared from concrete mixing station waste slurry.The self-compacting concrete is prepared by mixing, by weight, 270-330 parts of cement, 135-165 parts of pulverized fuel ash, 90-110 parts of the concrete mixing station waste slurry, 770-840 parts of river sand, 875-940 parts of gravels, 4.5-5.5 parts of a water reducing agent and 100-150 parts of water, wherein the concrete mixing station waste slurry is formed by precipitating concrete mixing station wastewater, the water content of the concrete mixing station waste slurry is 45%-50%, and the concrete mixing station waste slurry is generated in 24 hours.Accordingly, the self-compacting concrete is prepared from the waste slurry obtained by precipitating the concrete mixing station wastewater, therefore, the dosage of the cementing material and the water is decreased, the cost of the self-compacting concrete is greatly reduced, harmless high-additional value utilization of the concrete mixing station waste slurry is achieved, the very good environmental protection effect is achieved, and a green sustainable development road is achieved.

Owner:浙江华滋奔腾建材有限公司

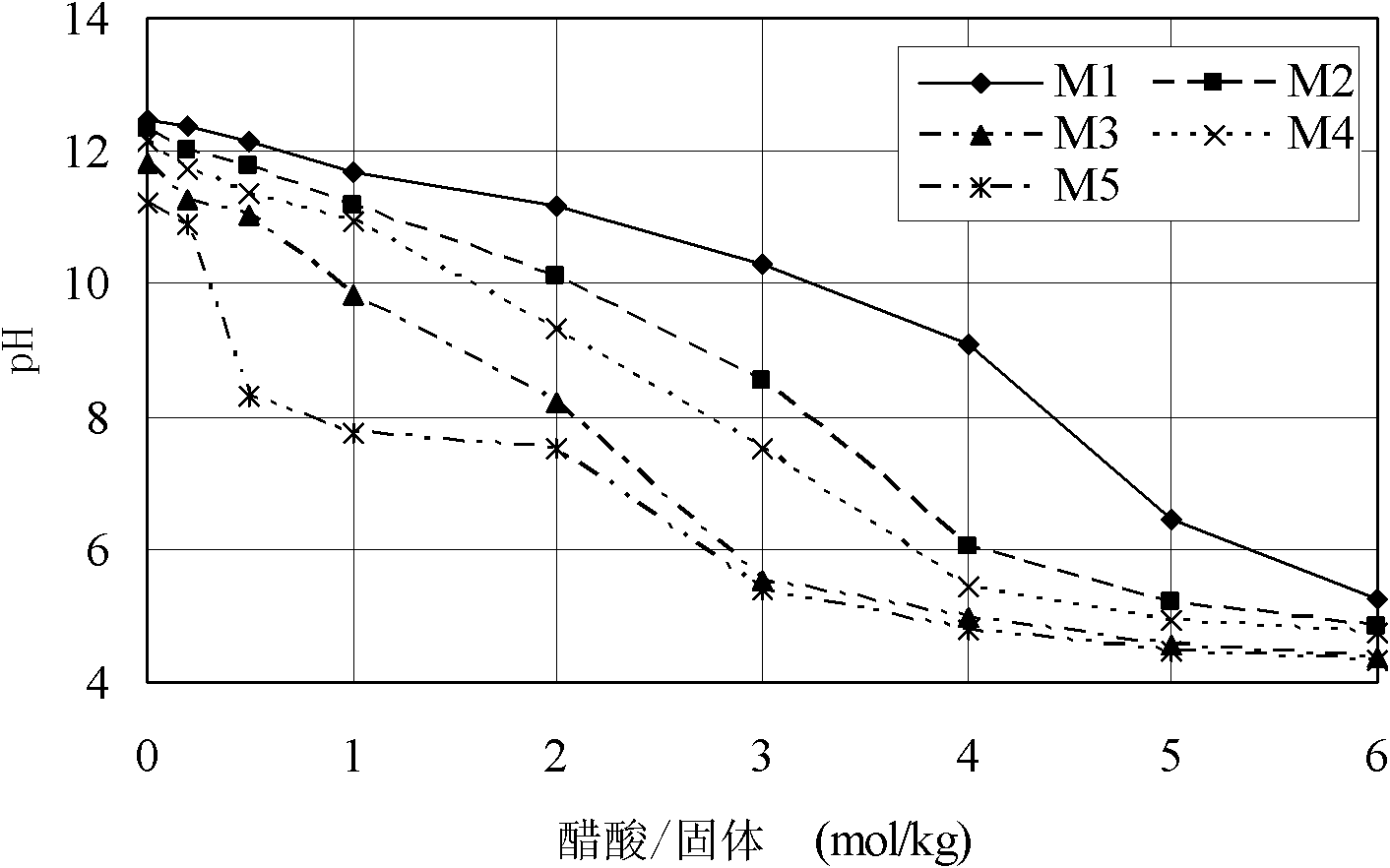

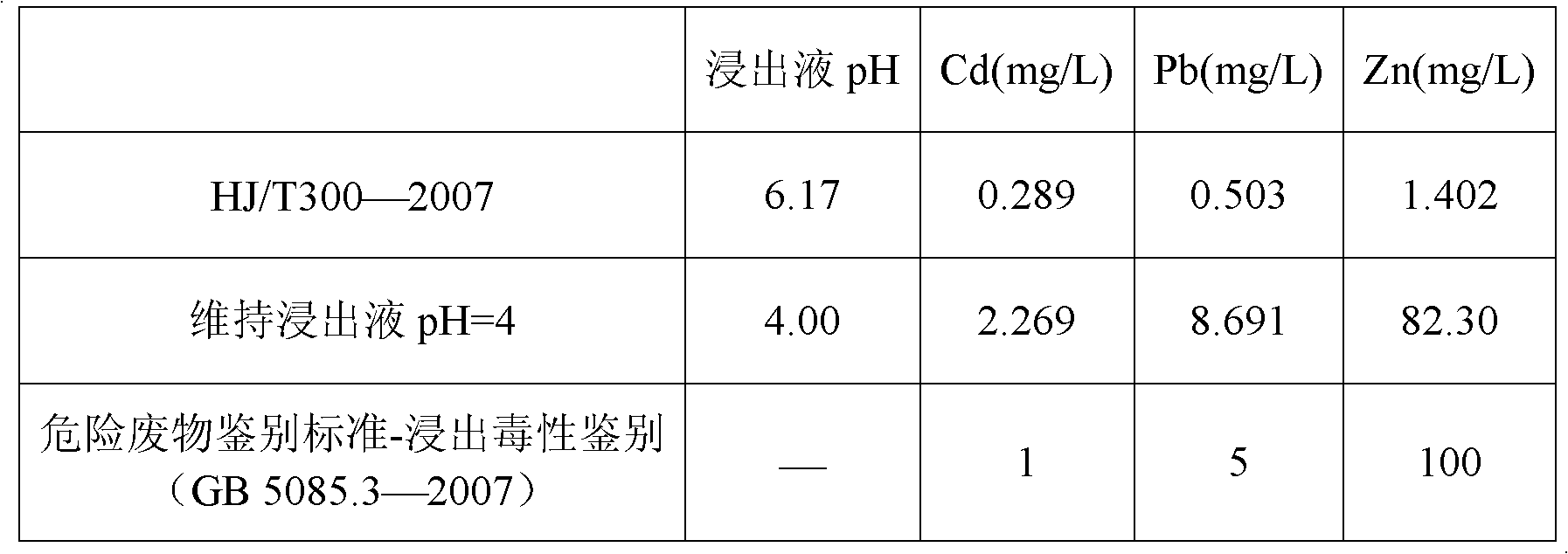

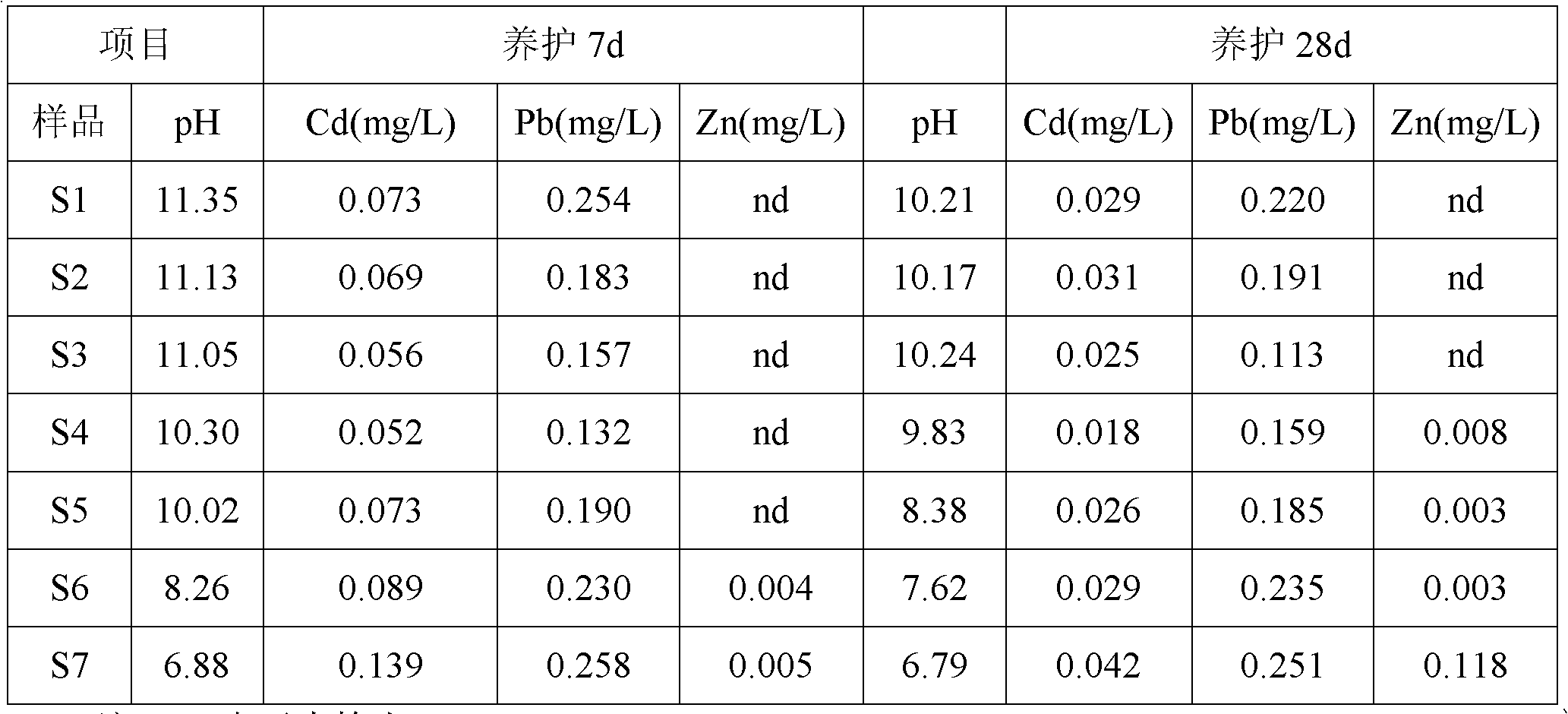

Heavy metal pollution bottle sediment curing agent and curing method thereof

InactiveCN101921090AReduce leaching concentrationWide variety of sourcesSludge treatmentSolid waste managementSludgeFirming agent

The invention relates to heavy metal sludge treated agent and a treating method thereof and in particular discloses a heavy metal pollution bottle sediment curing agent. The curing agent comprises cement and pulverized fuel ash, the mass ratio of the pulverized fuel ash to cement is 1:(0.5-11).The curing method of the curing agent comprises the following steps: directly adding the curing agent tothe heavy metal pollution bottle sediment with the use level of the curing agent being 0.4-1.5 times of the use level of the heavy metal pollution bottle sediment; maintaining the mixture after beingadded the curing agent for at least 3 days; and finally, completing the curing process.The curing agent and curing method of the invention not only has low processing cost but also ideal curing effect.

Owner:HUNAN UNIV

Rubber-cement grouting material applied to semi-flexible pavement

ActiveCN101700970ASmall mechanical propertiesImprove premature crack shrinkageSolid waste managementRoad surfacePulverized fuel ash

The invention relates to a rubber-cement grouting material applied to a semi-flexible pavement, belonging to waste recycling field in the environmental protection field and the application field of highway engineering. The rubber-cement grouting material applied to the semi-flexible pavement is characterized by being formed by mixing the components based on parts by weight: 100 parts of cement, 10-50 parts of pulverized fuel ash, 5-30 parts of expanding agent, 1-30 parts of rubber powder, 10-50 parts of sand, 0.1-5 parts of water reducing agent, 0.1-5 parts of early strength agent and 40-70 parts of water. The rubber-cement grouting material has high fluidity and anti-cracking property, lower contraction and higher early strength, and can meet the groutability and pavement performance of the semi-flexible pavement material.

Owner:WUHAN MUNICIPAL CONSTR GROUP

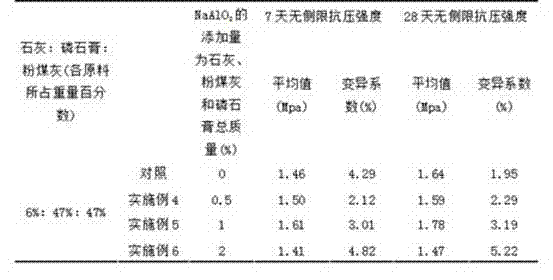

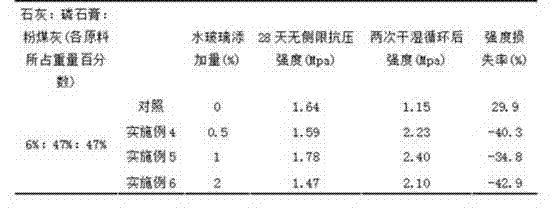

Roadbed filler for road and preparation method of roadbed filler

InactiveCN102690098AImprove early strengthImprove water stabilityRoadwaysPhosphogypsumPulverized fuel ash

The invention relates to a roadbed filler for a road and a preparation method of the roadbed filler. The roadbed filler for the road is characterized by being prepared from lime, pulverized fuel ash, phosphogypsum and stabilizer. The weight percentage of each material in the lime, the pulverized fuel ash and the phosphogypsum is 15% of lime, 30-50% of pulverized fuel ash and 35-60% of phosphogypsum; the sum of the weight percentages of the materials is 100%; the stabilizer is water glass or NaAlO2 (sodium metaaluminate); the adding amount of the water glass is 2-6% of total mass of the lime, the pulverized fuel ash and the phosphogypsum, and the adding amount of the NaAlO2 is 0.5-2% of total mass of the lime, the pulverized fuel ash and the phosphogypsum. Due to the roadbed filler for the road prepared by the method, not only can the early strength be improved, but also the problem of water stability can be solved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +2

Autoclaved aerated concrete brick prepared by utilizing pulverized fuel ash and preparation method thereof

InactiveCN103193447AStable compressive strength"Light weightSolid waste managementCeramicwareBrickAluminium powder

The invention provides an autoclaved aerated concrete brick prepared by utilizing pulverized fuel ash and a preparation method thereof. The brick is prepared from the following materials by weight percent: 65%-68% of pulverized fuel ash, 17%-23% of lime, 6%-10% of cement, 2%-4% of desulfurization gypsum, 1%-1.5% of water-soluble aluminum powder, 0.5% of fatty acid soap and 0.5% of gleditsia sinensis powder. The preparation method comprises steps of: adding water to pulverized fuel ash and desulfurization gypsum which are screened mechanically and grinding together to form slurry, wherein the fineness of the pulverized fuel ash has to reach the condition that the residual of a 0.08mm square hoe sieve is not more than 15%; carrying out stirring, pouring, cutting and thermal, static and suspension curing on the slurry together with the lime, the cement and the aluminum powder suspension liquid which are weighed according to a weight ratio of a formula; utilizing an autoclave with good sealing for heating with 180-200 DEG C saturated steam under proper pressure (1.0-1.2Mpa); and steam curing for 8-10 hours so as to produce the aerated concrete brick. The aerated concrete brick has the characteristics of light weight, high strength, good heat insulation performance, good fire resistance and sound absorption, labor saving and energy saving, waste recycling and the like; and the aerated concrete brick meets constructional engineering requirements and environment protection requirements, and the wastes of enterprises are reasonably used.

Owner:SHIYAN JINSHA WALL MATERIALS

Polyvinyl alcohol fiber reinforced cement-based material composition and preparation method and application thereof

InactiveCN101723620AImprove crack resistanceIncreased durabilitySolid waste managementClimate change adaptationFiberPolymer science

The invention relates to a polyvinyl alcohol fiber reinforced cement-based material composition, and a preparation method and application thereof, belonging to the technical field of building materials, wherein the polyvinyl alcohol fiber reinforced cement-based material composition is prepared by mixing polyvinyl alcohol fibers with a cement-based material. The polyvinyl alcohol fiber reinforced cement-based material composition is characterized in that: (1) the cement-based material is prepared from the following raw materials in parts by weight: 1000 parts of sand, 260 to 400 parts of cement, 300 to 350 parts of pulverized fuel ash, 25 to 30 parts of silicon ash, 0 to 120 parts of levigated quartz powder, 5 to 10 parts of high-efficiency water reducing agents and 300 to 350 parts of water; (2) the mixing quantity of the polyvinyl alcohol fibers is 0.75% to 1.5% of the total weight of a gelled material. The polyvinyl alcohol fiber reinforced cement-based material composition has the advantages of high crack resistance, high durability, easy acquirement of the raw materials, simple fabrication and low cost, can be extensively applied to the building materials, in particular to cement-based boards, building tiles, cement posts and the like.

Owner:沂源县建设工程质量监督站

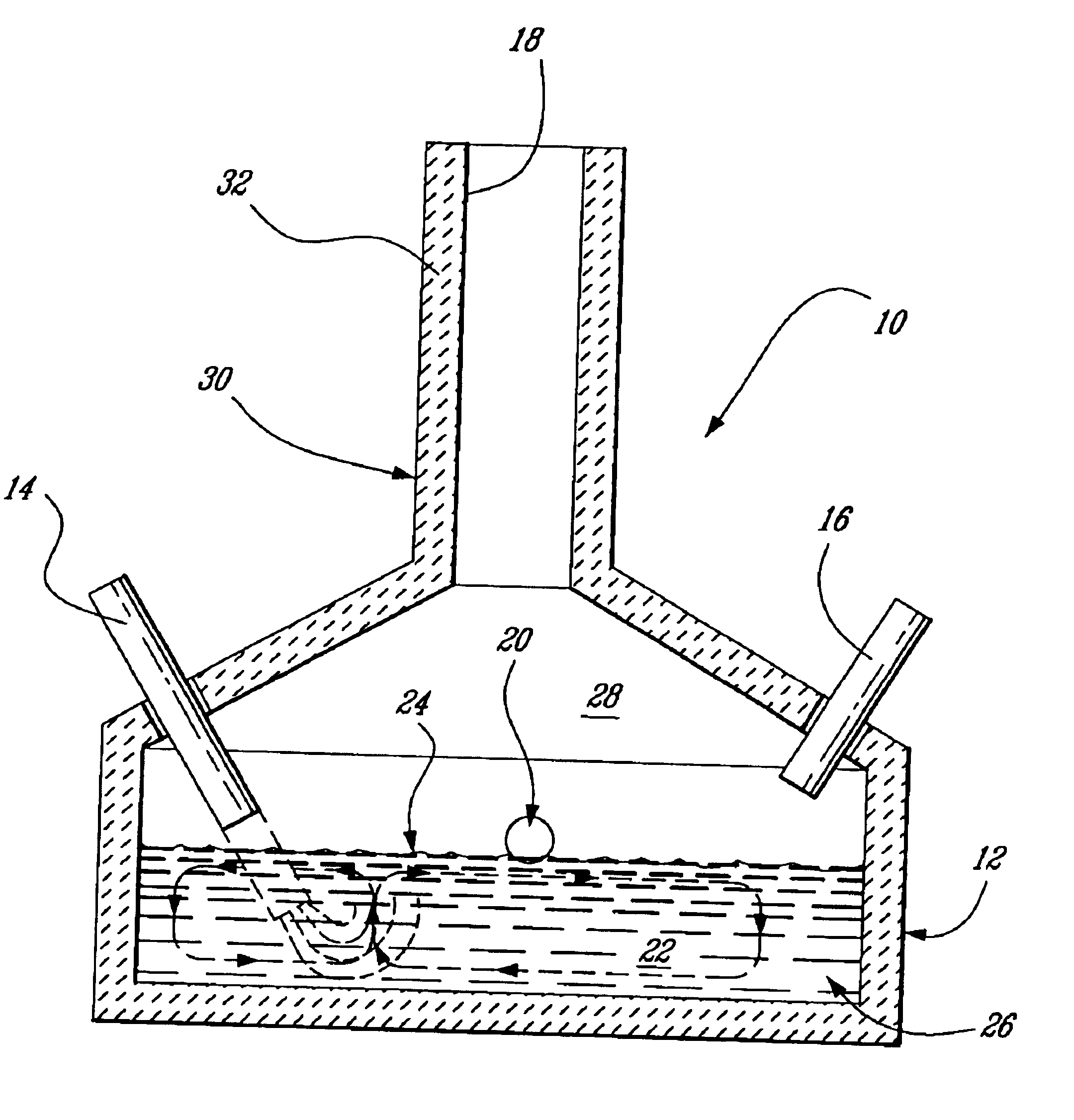

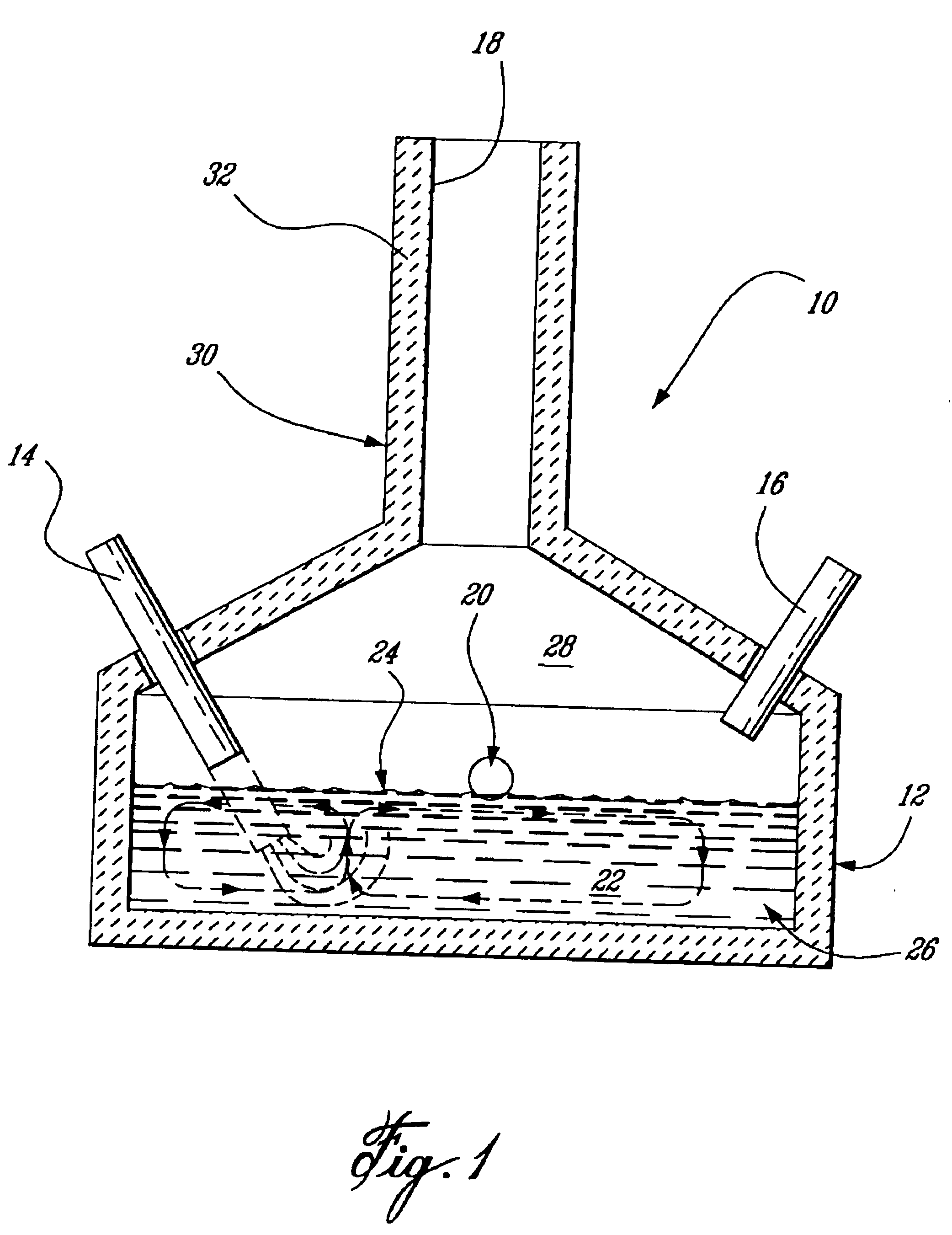

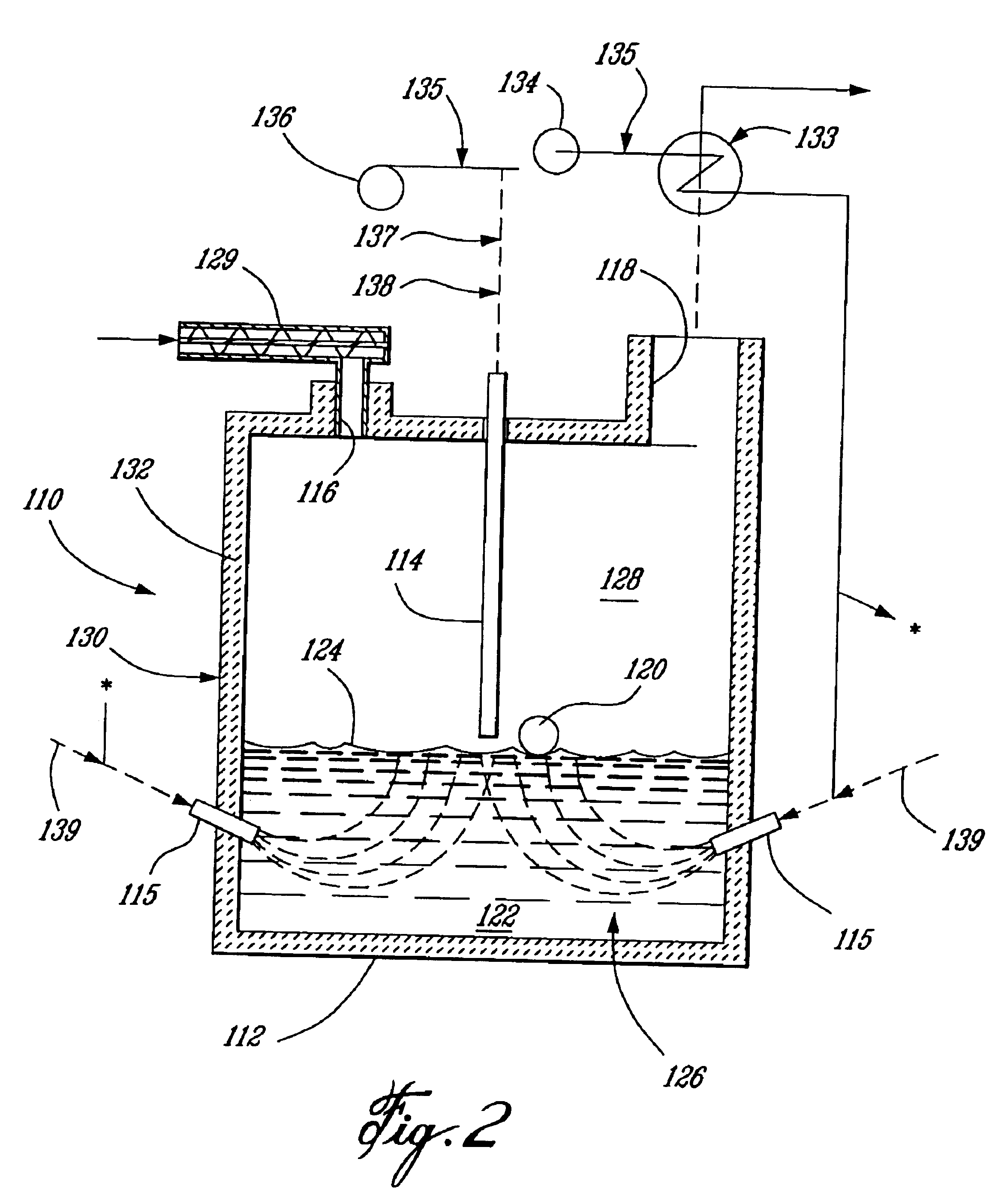

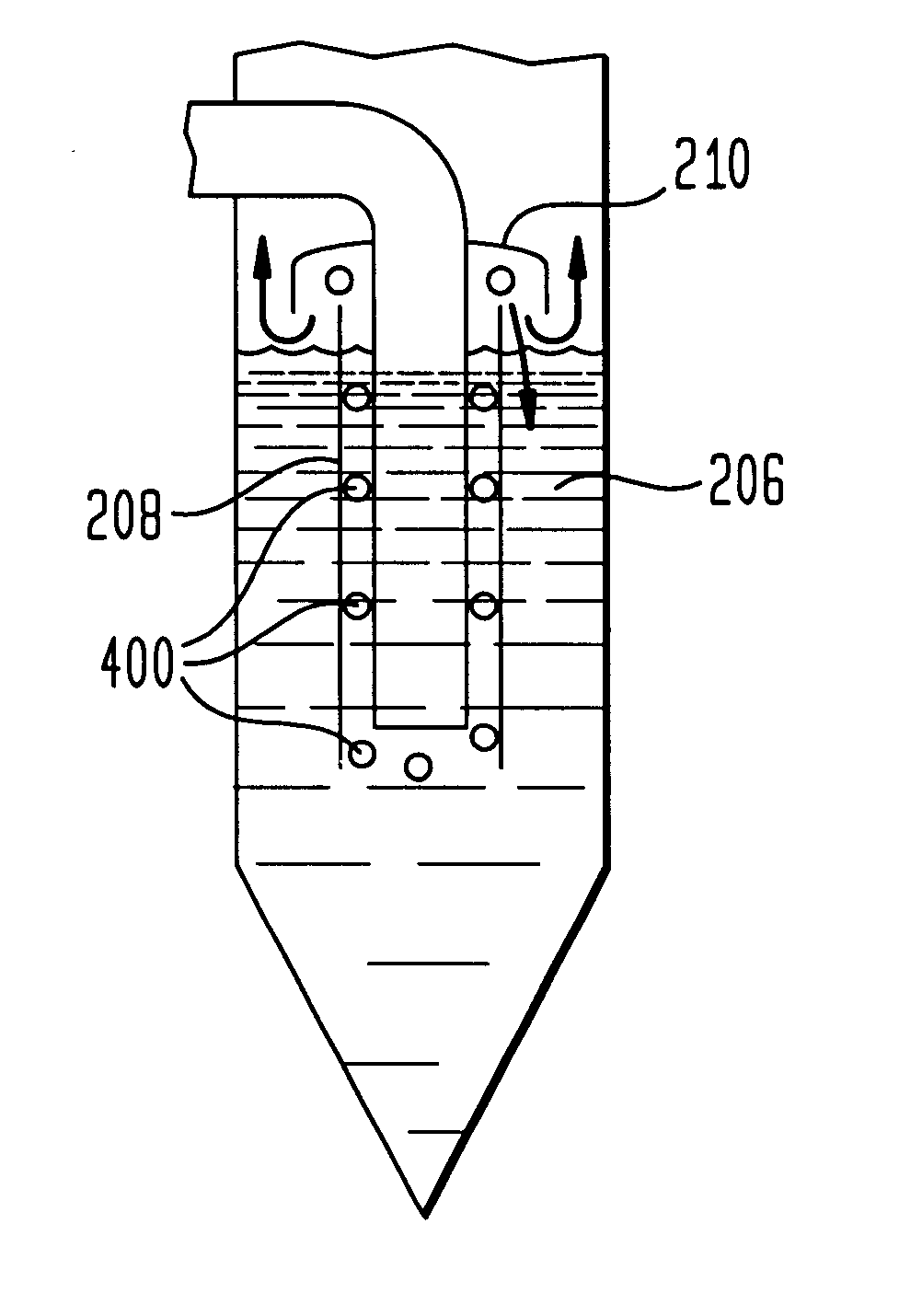

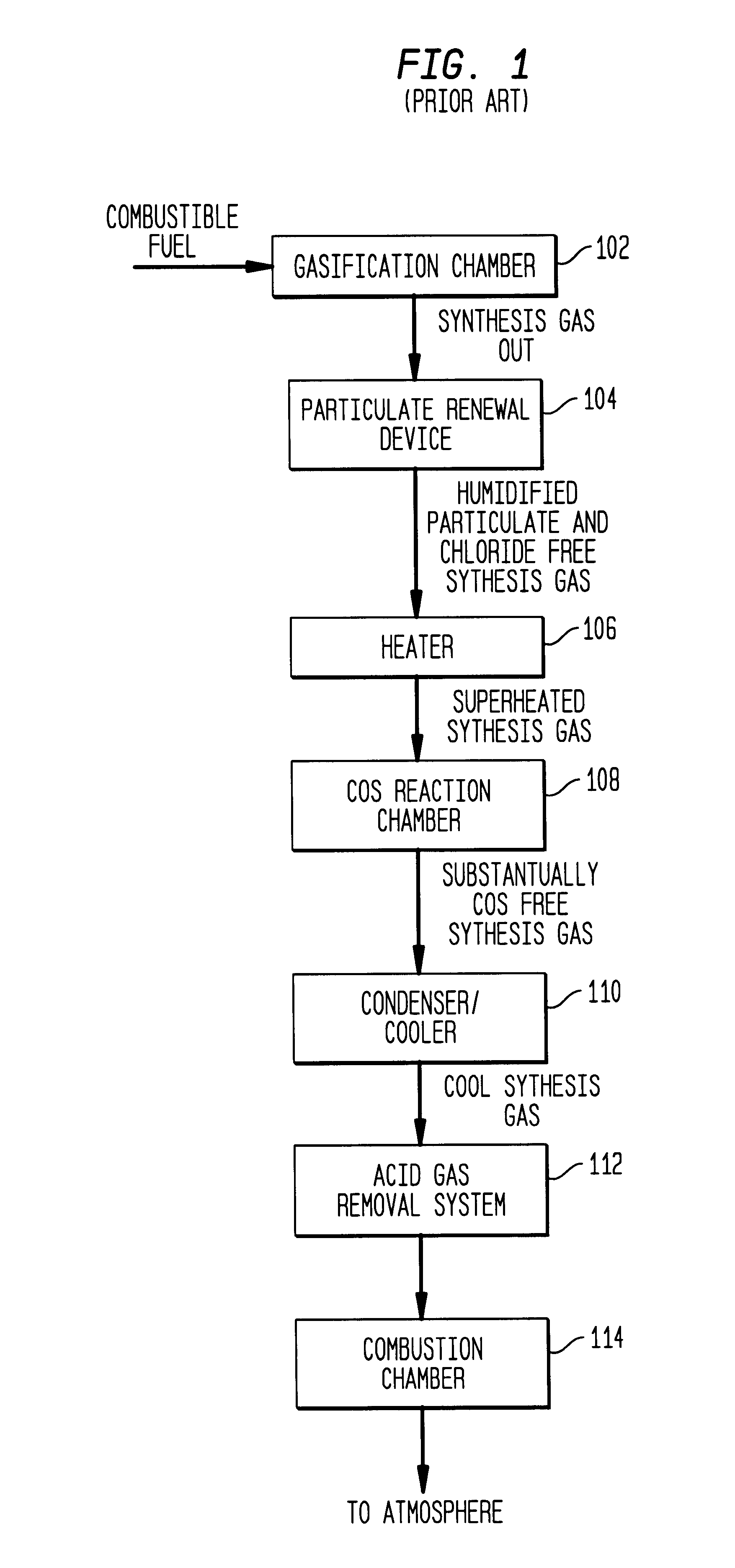

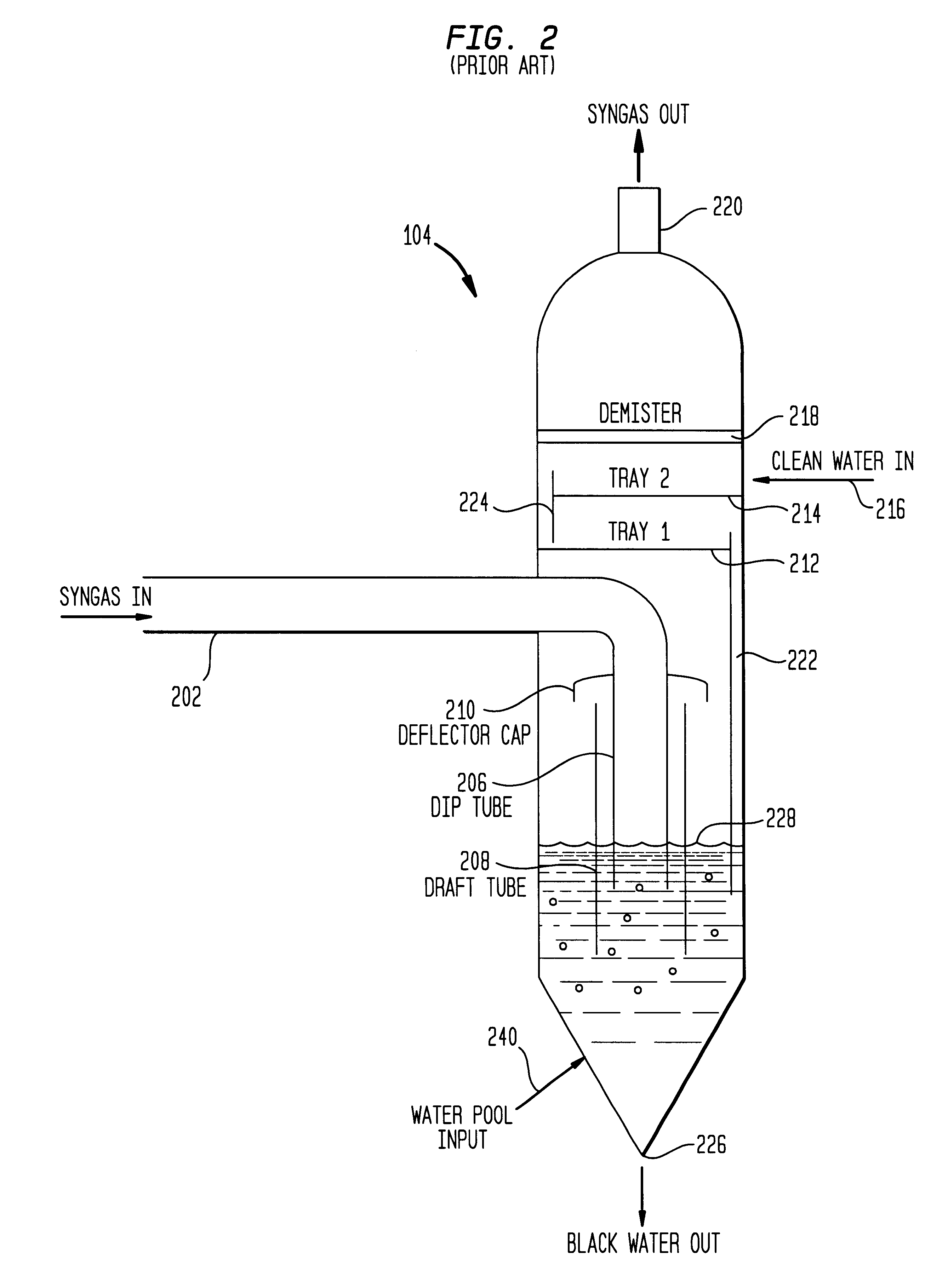

Method and apparatus for removing carbonyl sulfide from a gas stream via wet scrubbing

InactiveUS6322763B1Weaken energyLower Level RequirementsGas treatmentUsing liquid separation agentCarbonyl sulfideWater flow

Methods for removing carbonyl sulfide (COS) from a synthesis gas stream are disclosed. The method entails raising the water level of a wet scrubber so that hydrolysis of the COS may occur in the scrubber itself instead of a COS reduction chamber and no additional catalysts other than those naturally occurring in the production of the synthesis gas need be introduced into the scrubber. The water is raised, in one example, to a level such that water within an inner tube of the wet scrubber flows over an upper end of the inner tube. Raising the water level in the scrubber ensures intimate and vigorous interaction between the water, the COS, and the naturally occurring catalyst, and promotes the hydrolysis of the COS. In one example, the naturally occurring catalyst (e.g., alumina oxide) is present in the coal ash produced when coal is the fuel gasified that creates the synthesis gas stream.

Owner:MTI INSULATED PROD

Industrial waste slag-doped composite silicate cement and production method thereof

InactiveCN102101757ABlending amount increasedImprove early strengthCement productionMetallurgical slagAlloy

The invention discloses industrial waste slag-doped composite silicate cement and a production method thereof. The industrial waste slag-doped composite silicate cement comprises the following material components: 45-58 percent of silicate cement clinker, 3-5 percent of desulfurization gypsum, 1.5-4 percent of lime stone, 0.2-0.3 percent of cement grinding additive, 10-29 percent of granulated blast furnace slag, 2-10 percent of coal slag, 4-10 percent of pulverized fuel ash, 2-10 percent of ferroalloy slag, 2-10 percent of zinc metallurgical slag and 0.2-0.25 percent of waste slag grinding aid active excitant. The production method comprises the following steps of: taking and mixing the first four materials according to the proportion and grinding into 300-350m<2> / kg of powder; taking and mixing the rest six materials according to the proportion and grinding into 420-450m<2> / kg of superfine powder; and then combining the two kinds of powder, stirring and homogenizing. By adopting respective grinding of clinker and waste slag, the waste slag fineness reaches an optical value for stimulating the activity, the hydration progress and the cement clinker reach synchronization, and the doping amount and doping category of waste slag are also improved.

Owner:王明贵

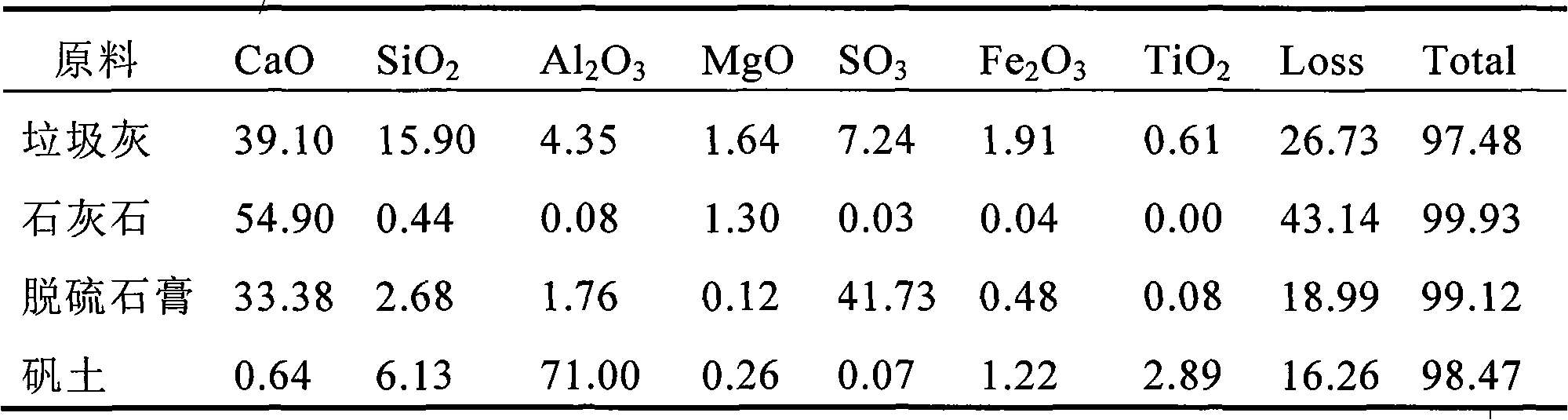

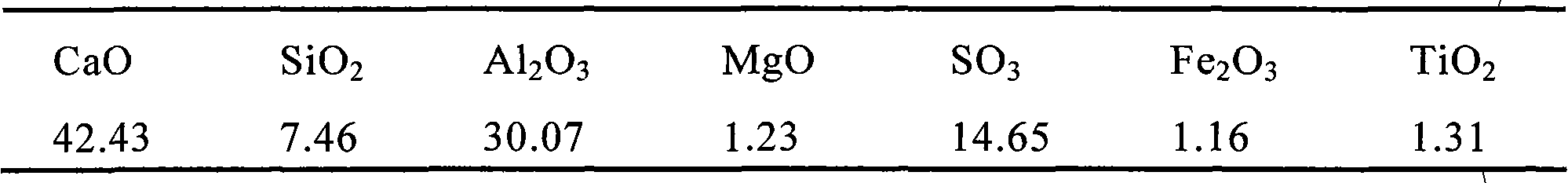

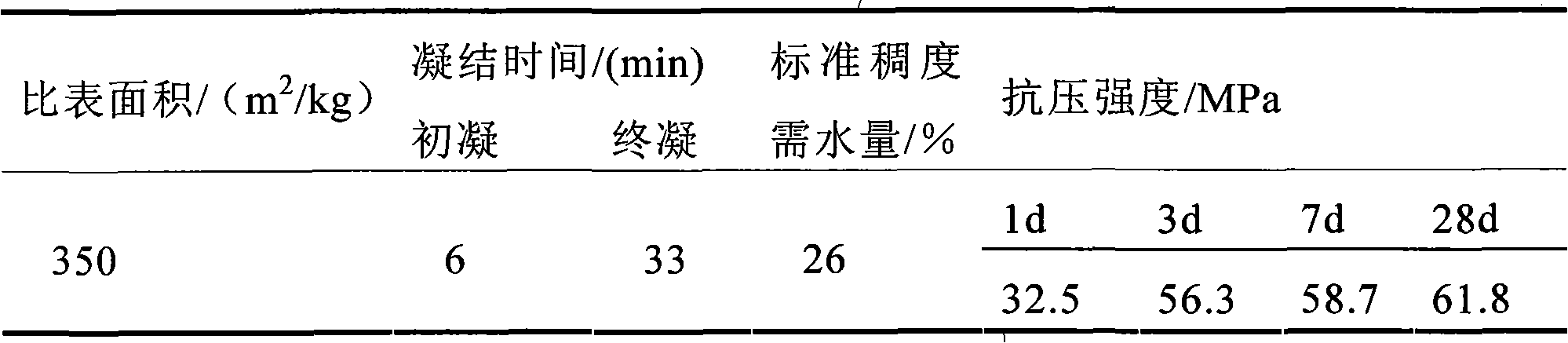

Method for preparing quick-hardened cement-based adhesive by utilizing refuse-incinerated fly ash

InactiveCN101921548ALighten the serious burdenReduce processing costsSolid waste managementInorganic adhesivesFiberAdhesive

The invention relates to a method for preparing a quick-hardened cement-based adhesive by utilizing refuse-incinerated fly ash, comprising the following steps of: (1) calcination of sulphoaluminate cement: raising the temperature of a sulphoaluminate cement raw material to 1,200-1,250 DEG C in the temperature rise speed of 20-30 DEG C / min, then preserving the temperature for 1-2h to form a sulphoaluminate cement clinker, and mixing the sulphoaluminate cement clinker with anhydrous gypsum to obtain the sulphoaluminate cement; and (2) preparation of the quick-hardened cement-based adhesive: blending the sulphoaluminate cement, quartz sand, pulverized fuel ash, hydroxypropyl methyl cellulose, re-dispersible rubber powder and fibers to obtain the quick-hardened cement-based adhesive. Comparedwith the prior art, the method can ensure the performance of the product and also can reduce serious environmental burden and processing cost which are caused by not utilizing the fly ash, desulfurized gypsum and the like.

Owner:TONGJI UNIV

Inorganic heat-preservation sand pulp with desulfurated gypsum as main gelled materials

InactiveCN101767971AImprove workabilityGood construction performanceSolid waste managementFiberInorganic Chemical

The invention belongs to the technical field of building materials and particularly relates to inorganic heat-preservation sand pulp with desulfurated gypsum as main gelled materials. The inorganic heat-preservation sand pulp is composed of the desulfurated gypsum, slag powder, pulverized fuel ash, Beta-semi-hydrated gypsum, lime, latex powder, vinol fibers, cellulose ether and an air entraining type high-efficiency water reducing agent. The invention not only can solve the high-efficiency recycling problem of the desulfurated gypsum (an industrial solid waste), but also can effectively avoid the problems that the hydration of the desulfurated gypsum is slow and the water resisting property of the traditional gypsum-based inorganic heat-preservation sand pulp is poor. Therefore, the invention is suitable for wall body heat-preservation engineering construction of various buildings and can meet certain requirement for the intensity.

Owner:TONGJI UNIV

Contaminated soil passivator and preparation method and application thereof

ActiveCN104560046ALow costNo secondary pollutionContaminated soil reclamationOrganic fertilisersMolecular sieveClay minerals

The invention relates to a contaminated soil passivator and a preparation method and application thereof. The passivator is formed by mixing the following raw materials in percentage by weight: 30-60 percent of a natural clay mineral material, 30-60 percent of industrial harmless wastes and 10-20 percent of a cation-exchanger, wherein the cation-exchanger refers to an X-type molecular sieve or a molecular sieve with the particle size of more than 4A. Compared with the prior art, the passivator disclosed by the invention is completely prepared from the natural clay mineral material and a mineral-like material, the cost is low, secondary pollution is avoided, the environment friendliness idea is completely achieved, the pulverized fuel ash and other industrial wastes are introduced, the problems such as waste storage and treatment are solved, and the passivator has good passivation effect and high long-term stability on the contaminated soil, particularly heavy metal contaminated soil, and is suitable for large-scale popularization and application.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com