Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5744results about "Cement production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zeolite-containing drilling fluids

Methods and compositions for wellbore treating fluids, especially drilling fluids, that comprise zeolite and a carrier fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

Alkali activated supersulphated binder

The invention describes an activated supersulphated aluminosilicate binder containing aluminosilicates, calcium sulphate and an activator containing alkali metal salts, wherein the aluminosilicates are selected from the group consisting of blast furnace slag, clay, marl and industrial by-products such as fly ash with the proviso that the Al2O3 content is greater than 5% by weight, wherein blast furnace slag is present in an amount exceeding 35% by weight and clay, marl and / or fly ash is present in an amount exceeding 5% per weight and wherein cement kiln dust in an amount of from 3 to 10% by weight is added to the mixture as an activator and calcium sulphate is used in an amount exceeding 5% by weight.

Owner:HOLCIM

Geopolymer composition and application in oilfield industry

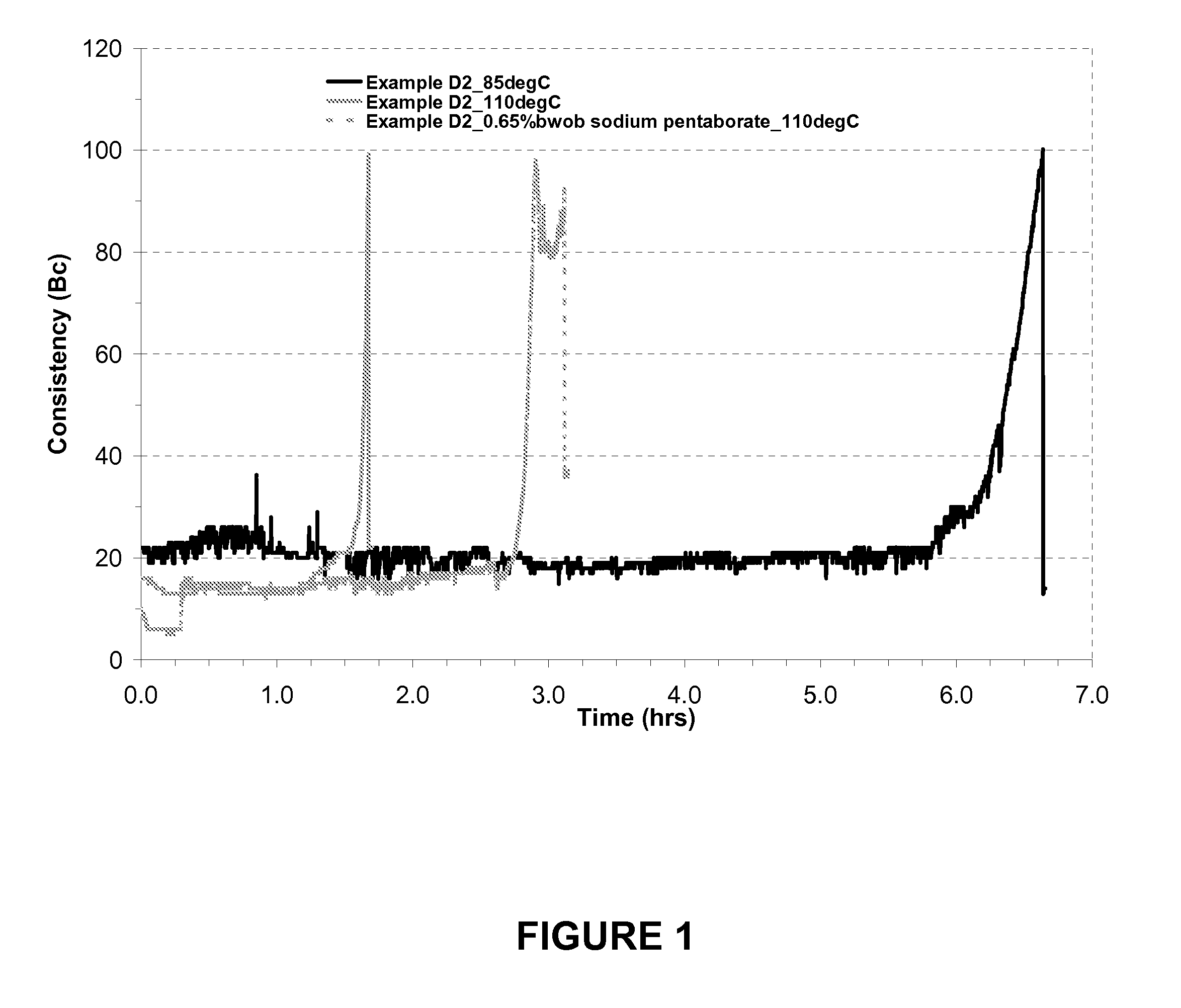

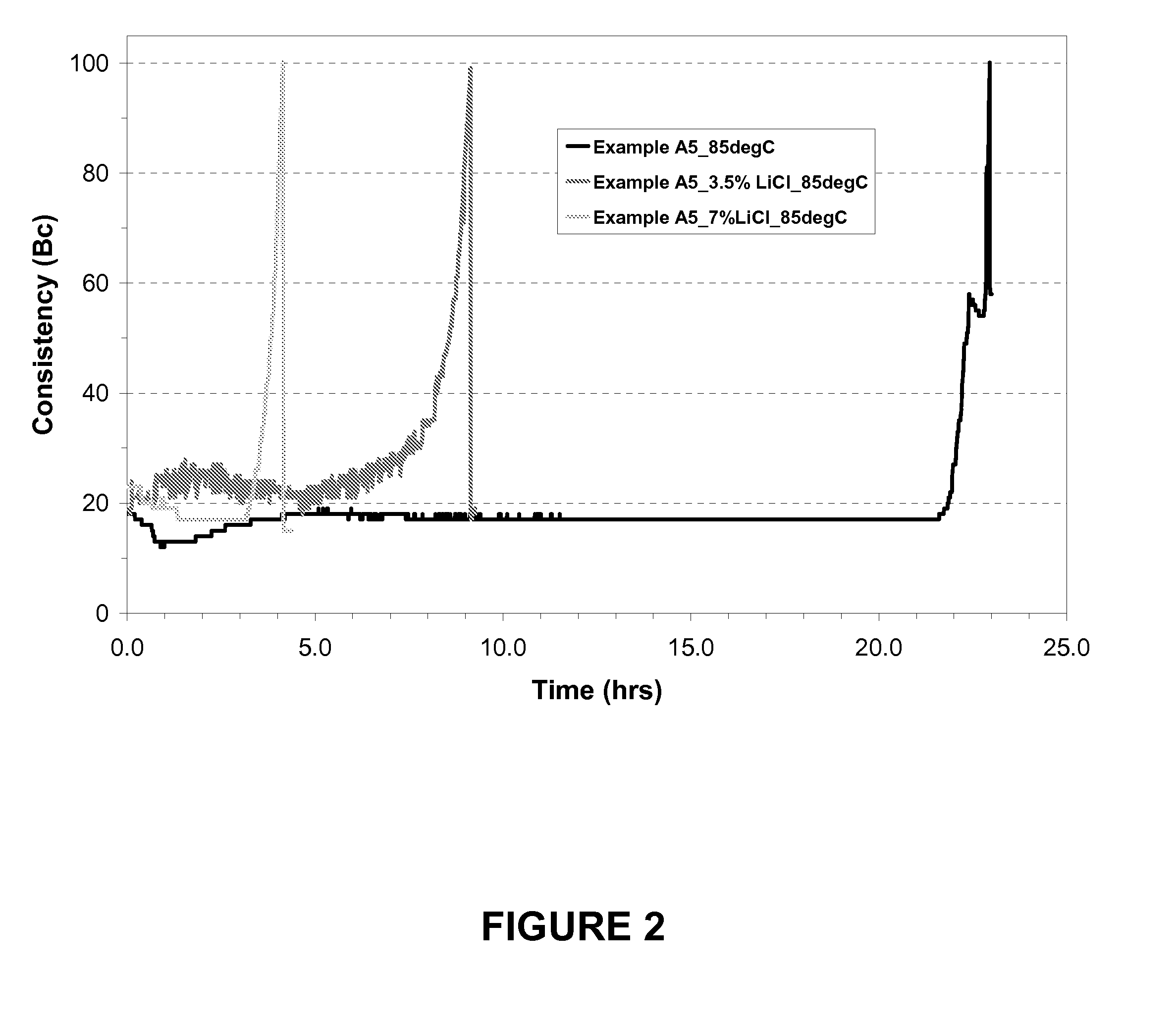

ActiveUS20080028994A1Enhanced pumpabilityImprove stabilitySolid waste managementAlkali metal silicate coatingsGeopolymerSlurry

The invention provides geopolymeric compositions, which have controllable thickening and setting times for a wide range of temperatures and a large range of geopolymer slurry densities. The geopolymer slurry compositions have good mixability and pumpability, whilst the set materials develop good compressive strength and permeability. The invention discloses a method for preparing geopolymer for oilfield cementing applications. The geopolymeric compositions according to the invention comprises a suspension comprising an aluminosilicate source, a metal silicate, an alkali activator, lightweight or heavyweight fillers and a carrier fluid wherein the suspension of said geopolymeric composition is pumped in a well and allowed to set.

Owner:SCHLUMBERGER TECH CORP

Activated aluminosilicate binder

An activated aluminosilicate binder containing aluminosilicates, calcium sulphate and an activator containing alkali metal salts is disclosed. The aluminosilicates are selected from a group consisting of blast furnace slag, clay, marl and industrial by-products, such as fly ash, and has an Al2O3 content greater than 5% by weight. Blast furnace slag is present in an amount less than 35% by weight, and cement kiln dust, in an amount of from 1 to 20% by weight, is added to the mixture as an activator.

Owner:HOLCIM

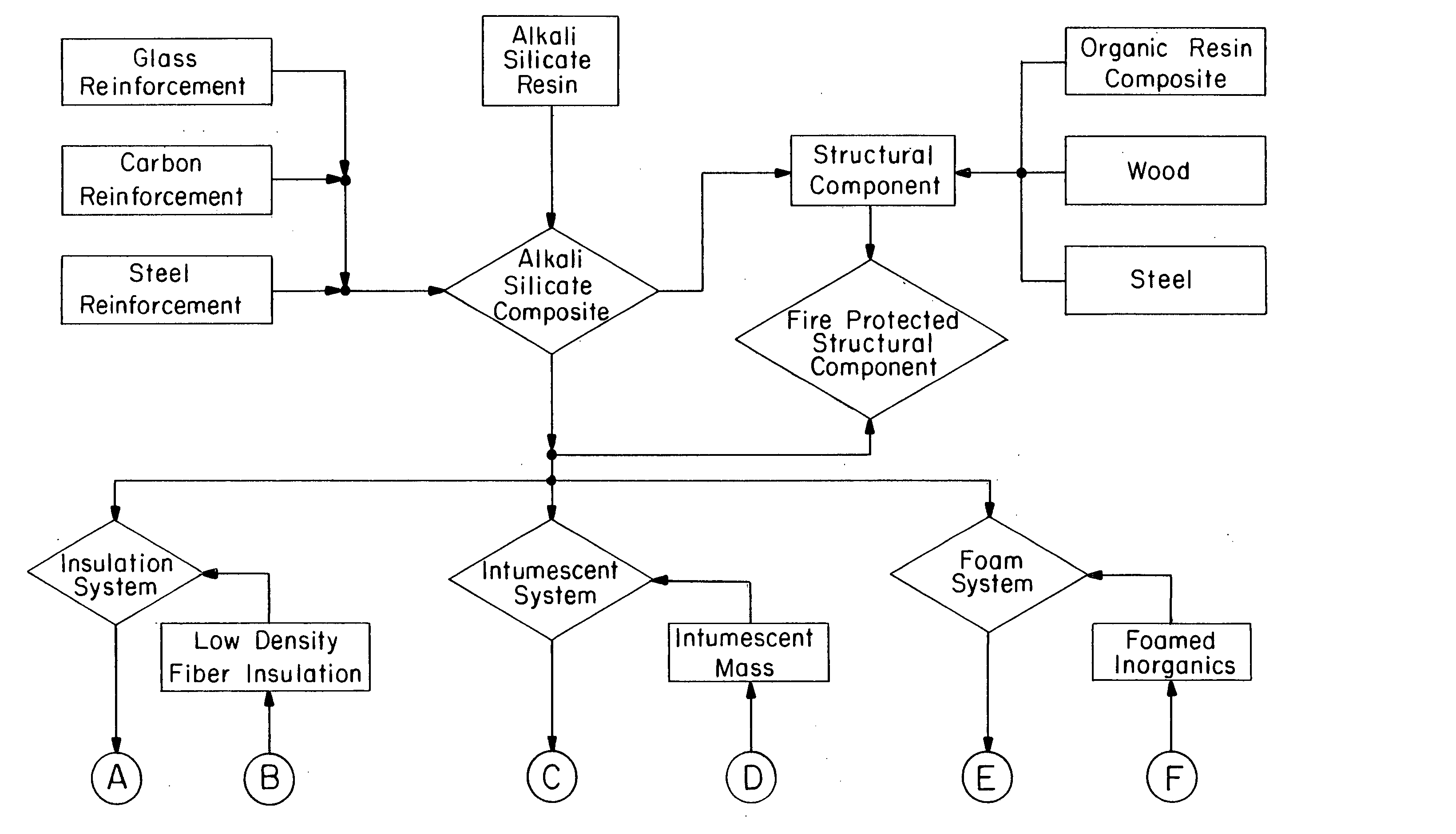

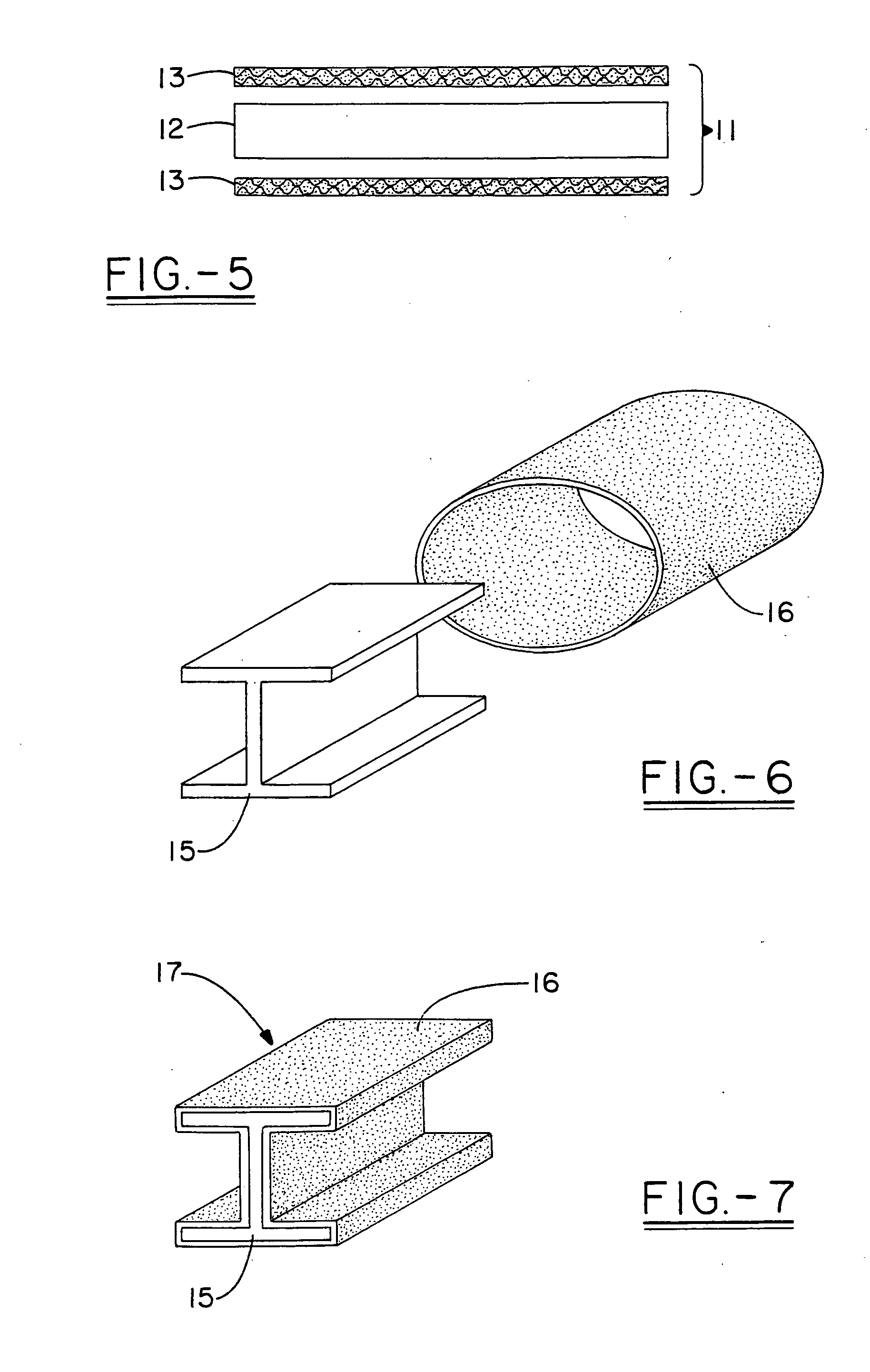

Multi-layer fire barrier systems

InactiveUS20050031843A1Good thermal and electrical insulating characteristicMaintain good propertiesWood working apparatusCement productionInsulation layerCombined use

A fire-barrier system comprises at least one alkali silicate resin composition layer and at least one layer of any of the following: an insulation layer, an intumescent layer, a foam layer, a corrugated layer, a reflective surface layer, and a reinforcing material layer. The fire-barrier system when utilize in association with a substrate such as wood, a polymer, etc. provides enhanced fire resistance performance, thermal barrier, an oxidation barrier, and the like.

Owner:THE BF GOODRICH CO

Reducing mercury emissions from the burning of coal

Processes and compositions are provided for decreasing emissions of mercury upon combustion of fuels such as coal. Various sorbent compositions are provided that contain components that reduce the level of mercury and / or sulfur emitted into the atmosphere upon burning of coal. In various embodiments, the sorbent compositions are added directly to the fuel before combustion; are added partially to the fuel before combustion and partially into the flue gas post combustion zone; or are added completely into the flue gas post combustion zone. In preferred embodiments, the sorbent compositions comprise a source of halogen and preferably a source of calcium. Among the halogens, iodine and bromine are preferred. In various embodiments, inorganic bromides make up a part of the sorbent compositions.

Owner:NOX II LTD

Zeolite-containing remedial compositions

Methods and compositions for wellbore treating fluids, especially remedial compositions such as pills, that include zeolite and at least one carrier fluid.

Owner:HALLIBURTON ENERGY SERVICES INC

Reducing mercury emissions from the burning of coal

Processes and compositions are provided for decreasing emissions of mercury upon combustion of fuels such as coal. Various sorbent compositions are provided that contain components that reduce the level of mercury and / or sulfur emitted into the atmosphere upon burning of coal. In various embodiments, the sorbent compositions are added directly to the fuel before combustion; are added partially to the fuel before combustion and partially into the flue gas post combustion zone; or are added completely into the flue gas post combustion zone. In preferred embodiments, the sorbent compositions comprise a source of halogen and preferably a source of calcium. Among the halogens, iodine and bromine are preferred. In various embodiments, inorganic bromides make up a part of the sorbent compositions.

Owner:NOX II LTD

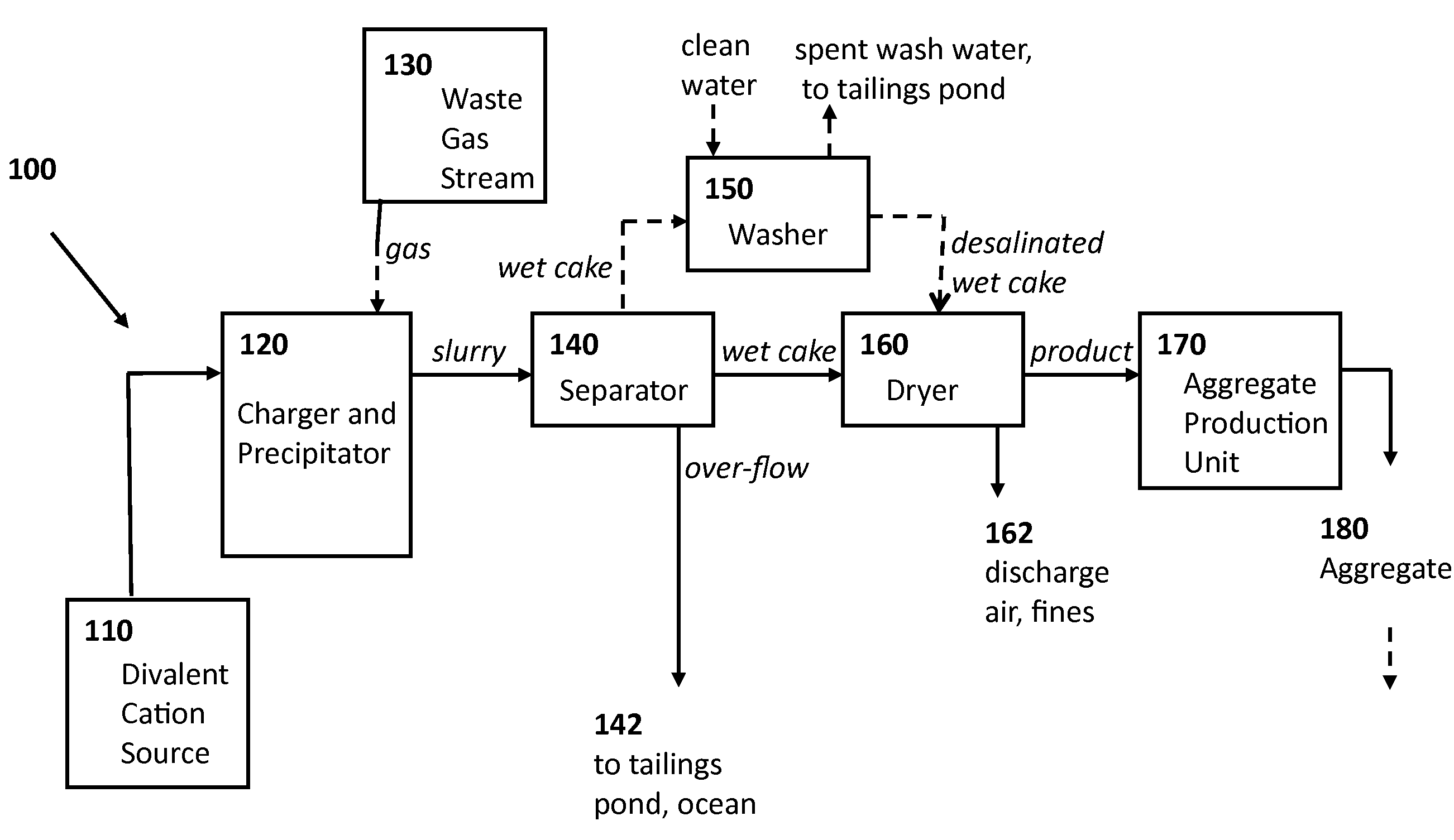

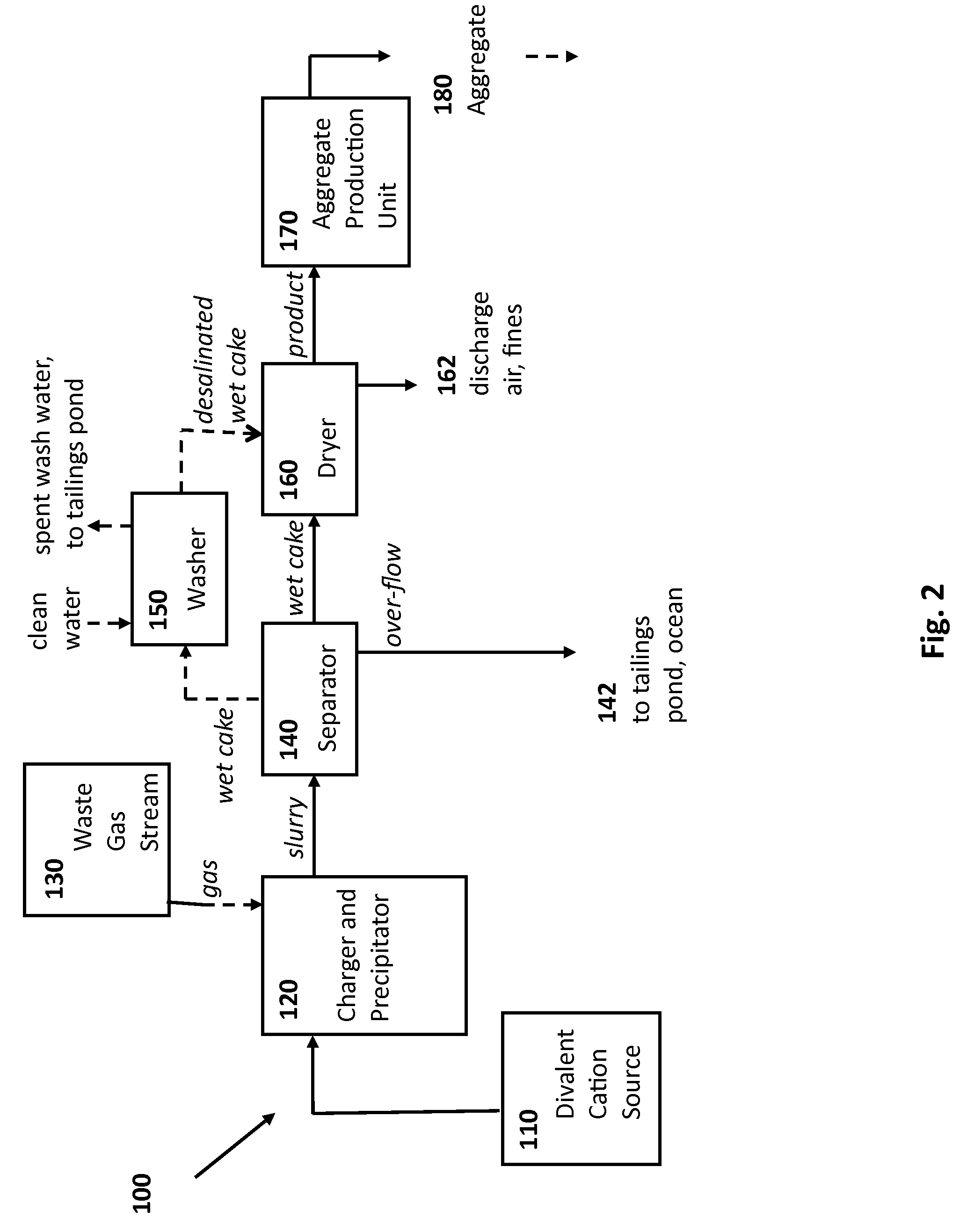

Rocks and aggregate, and methods of making and using the same

ActiveUS7753618B2Calcium/strontium/barium carbonatesUsing liquid separation agentCarbonateIndustrial waste

Compositions comprising synthetic rock, e.g., aggregate, and methods of producing and using them are provided. The rock, e.g., aggregate, contains CO2 and / or other components of an industrial waste stream. The CO2 may be in the form of divalent cation carbonates, e.g., magnesium and calcium carbonates. Aspects of the invention include contacting a CO2 containing gaseous stream with a water to dissolve CO2, and placing the water under precipitation conditions sufficient to produce a carbonate containing precipitate product, e.g., a divalent cation carbonate.

Owner:ARELAC INC

Process aid for preparing a flowable slurry

A process for preparing a flowable slurry comprising mixing 25-70 wt. % water; an alkaline material selected from the group consisting of chlorosilicon manufacturing byproducts, direct process residue gels, cement kiln dust, and mixtures thereof; and a process aid selected from the group consisting of sucrose, raffinose, lignin, methylglucopyranoside, lactose, fructose, sodium polyphosphate, trehalose and mixtures thereof to form a flowable slurry. This slurry is especially useful in the manufacture of cement.

Owner:DOW CORNING CORP

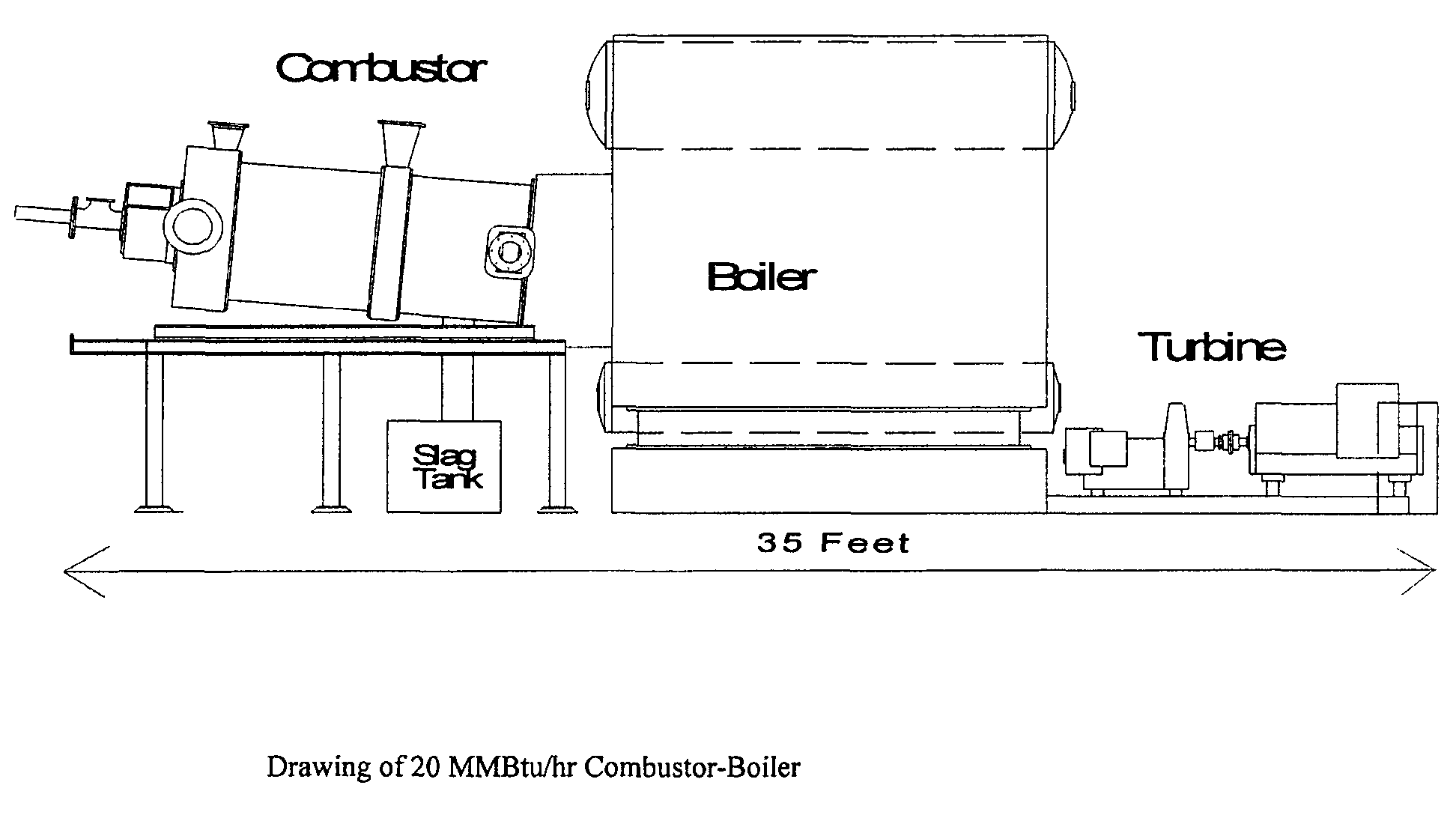

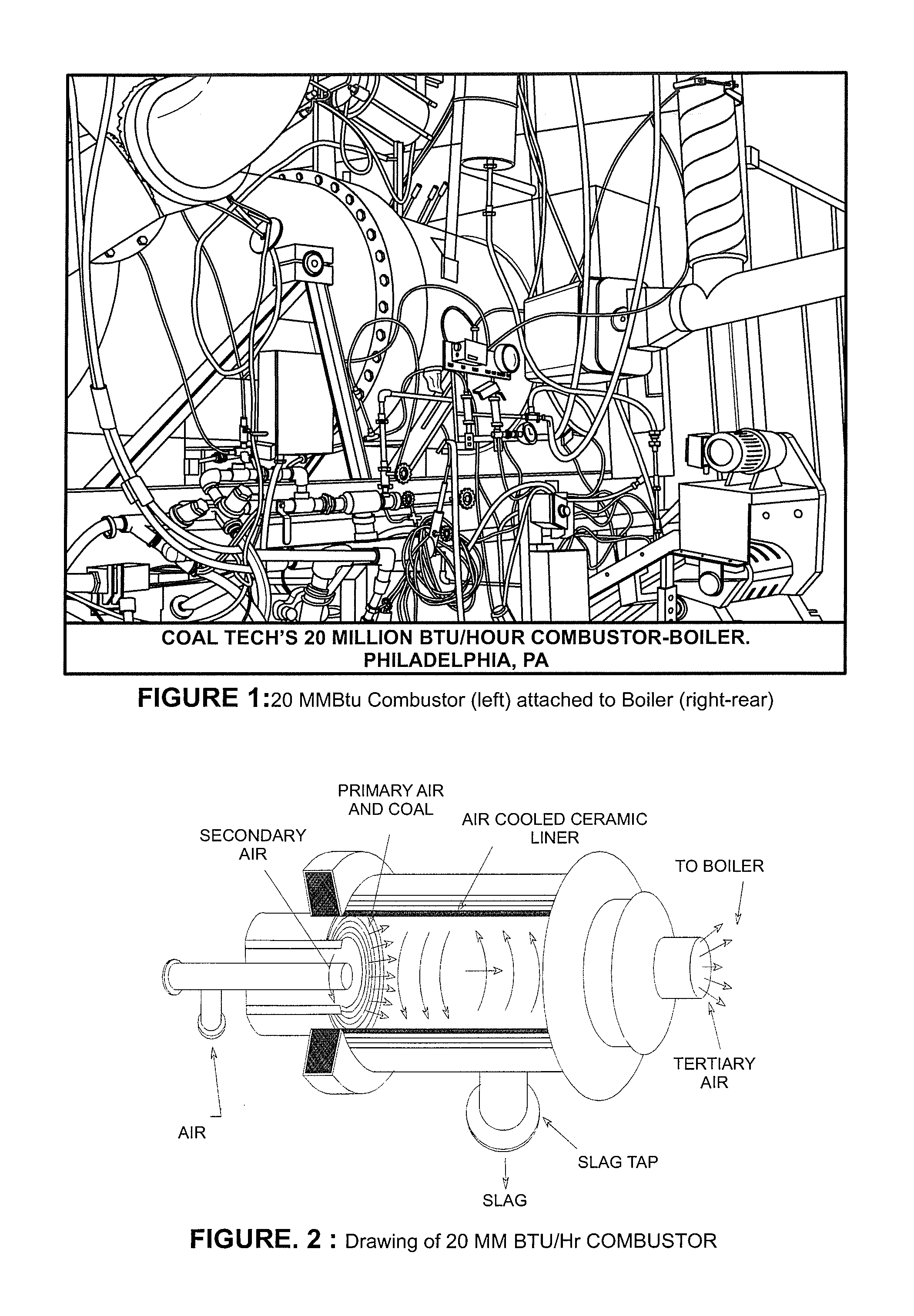

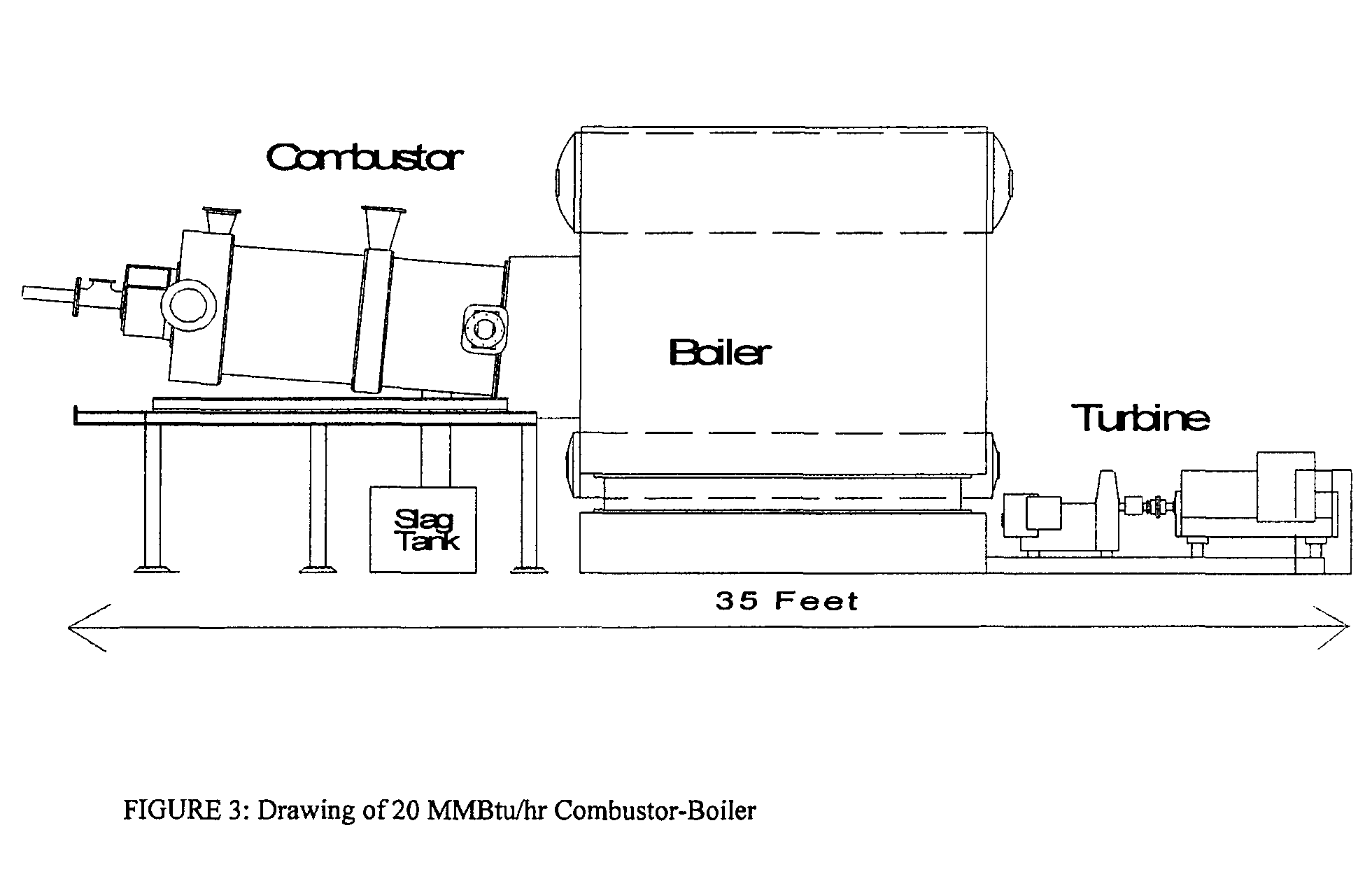

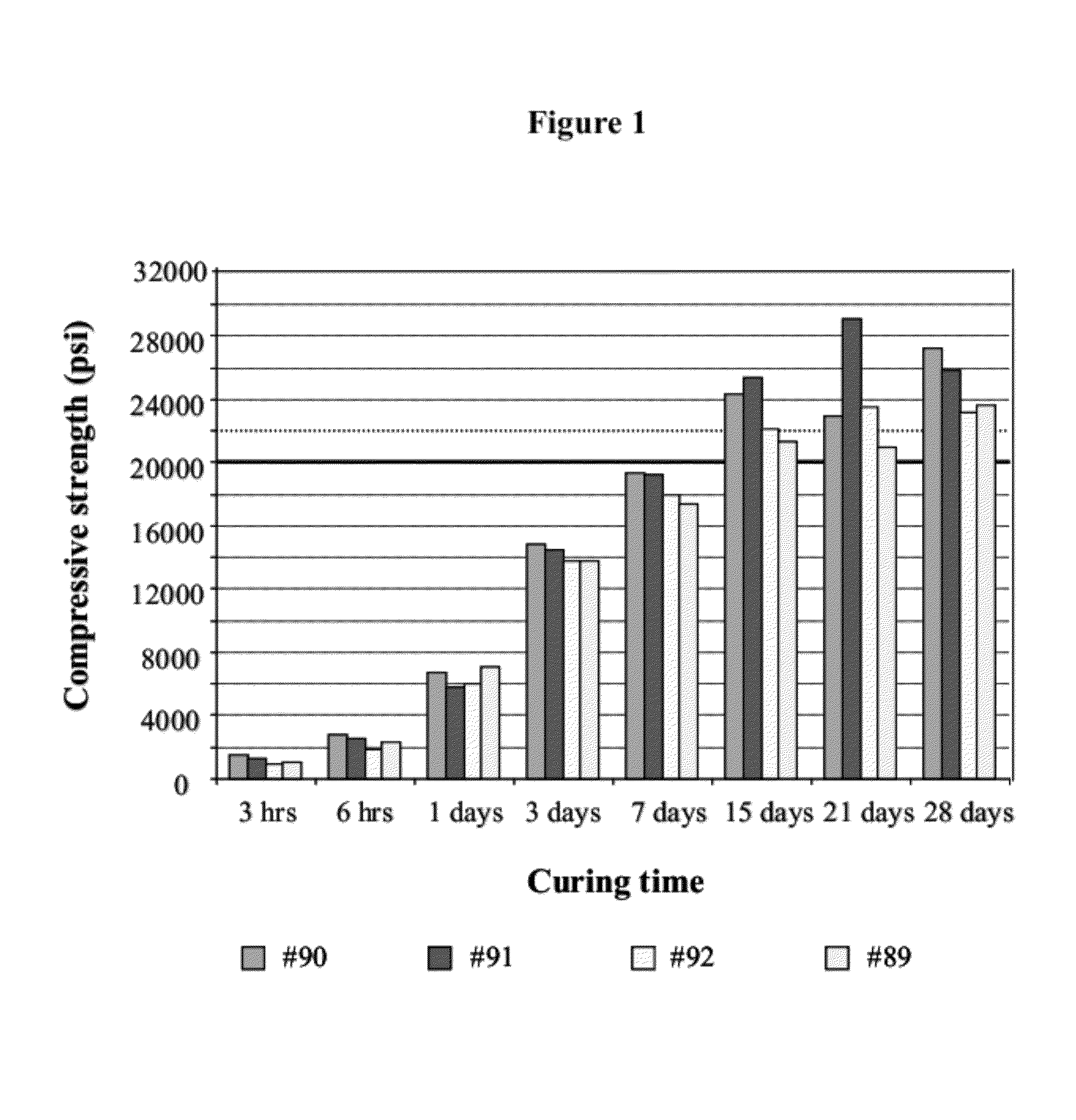

Slagging coal combustor for cementitious slag production, metal oxide reduction, shale gas and oil recovery, enviromental remediation, emission control and CO2 sequestration

InactiveUS8337613B2Reduce transportationMinimize disfiguringNitrogen compoundsSulfur compoundsCombustorEnvironmental remediation

Systems, methods and processes teach by specific examples how the cost of sequestering carbon dioxide (CO2) can be totally offset and turned into profits during coal powered electricity generation from revenue and co-benefits. The process is provided whereby fly ash-carbon mixtures, or de-volatilized coal char, or anthracite coal culm is co-fired in an air-cooled, slagging combustor with limestone or similar slag fluxing materials converts the ash into cementitious slag with properties similar to ground granulated blast furnace slag.

Owner:ZAUDERER BERT

Geopolymer composite for ultra high performance concrete

A geopolymer composite ultra high performance concrete (GUHPC), and methods of making the same, are provided herein, the GUHPC comprising: (a) a binder comprising one or more selected from the group consisting of reactive aluminosilicate and reactive alkali-earth aluminosilicate; (b) an alkali activator comprising an aqueous solution of metal hydroxide and metal silicate; and (c) one or more aggregate.

Owner:CATHOLIC UNIV OF AMERICA

Lightweight heat insulating material and method for making same

InactiveCN101182168ASimple preparation processImprove performanceSolid waste managementCement productionCoal gangueAluminium

The invention discloses a light isolated material and a preparation method thereof, including an aluminates polymer, the molar ratio of silicon (Si) and aluminum (Al) in which is more than or equal to one and less than or equal to three and which includes solid raw materials containing silicon and aluminum of 50-85 weight percent of fly ash, kaolin, coal gangue, coal slag, etc.; 14.5-48 percent of liquid alkaline activator; 0.5-2 percent of foaming agent. The liquid alkaline activator includes caustic solution and water glass, which are mixed and stirred with the solid raw materials and the foaming agent to produce a roof heat insulation plate, which is applied to both the direct pouring and the die molding prefabrication and can be used both for the heat insulation or the cold insulation of cold or heat equipment and for making large size building wallboards for heat insulation, deafening and fireproofing.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Preparation of composite high-expansion cementing material by using industrial slag and preparation technique thereof

The invention relates to a preparation process of using industrial slag to prepare composite cementing materials with high expansibility. The cementing materials consist of four components. The first component includes three parts: one or a plurality of combinations of fly ashes, slag, etc., which contain aluminosilicate; one or a plurality of combinations of phosphogysum, fluorine gypsum, etc., which contain calcium sulfate; one or a plurality of combinations of carbide, alkaline residue, quick lime or slaked lime. The second component includes: one or a plurality of combinations of alkaline composition, such as the quick lime or slaked lime, the carbide slag, etc.. The third component includes one or a plurality of combinations of the phosphogypsum, fluorine gypsum, etc., which contain the calcium sulfate. The preparation method is: firstly, to evenly mix the raw materials of the first component which are grinded to be with the surface area of 200-500m<2> / kg through the steam curing of four hours to ten days at 50-100 DEG C and the calcining of 0.5-24h at the high temperature of 400-1000 DEG C to obtain the first component; secondly, to dry and grind the raw materials of the second and the third component to be with the surface area of 200-500m<2> / kg to obtain the second and the third component; thirdly, to evenly mix the first, the second and the third component.

Owner:BEIHANG UNIV

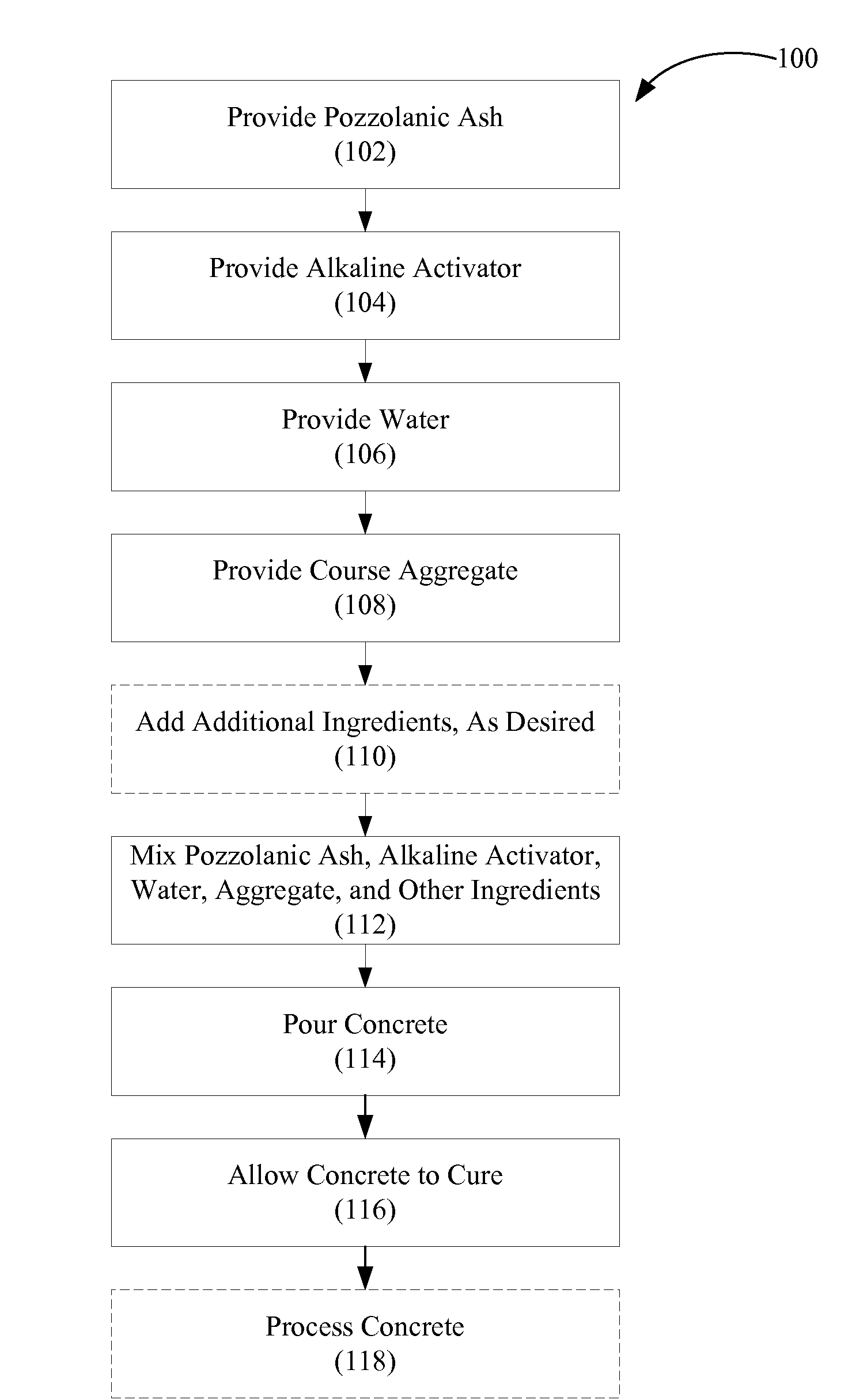

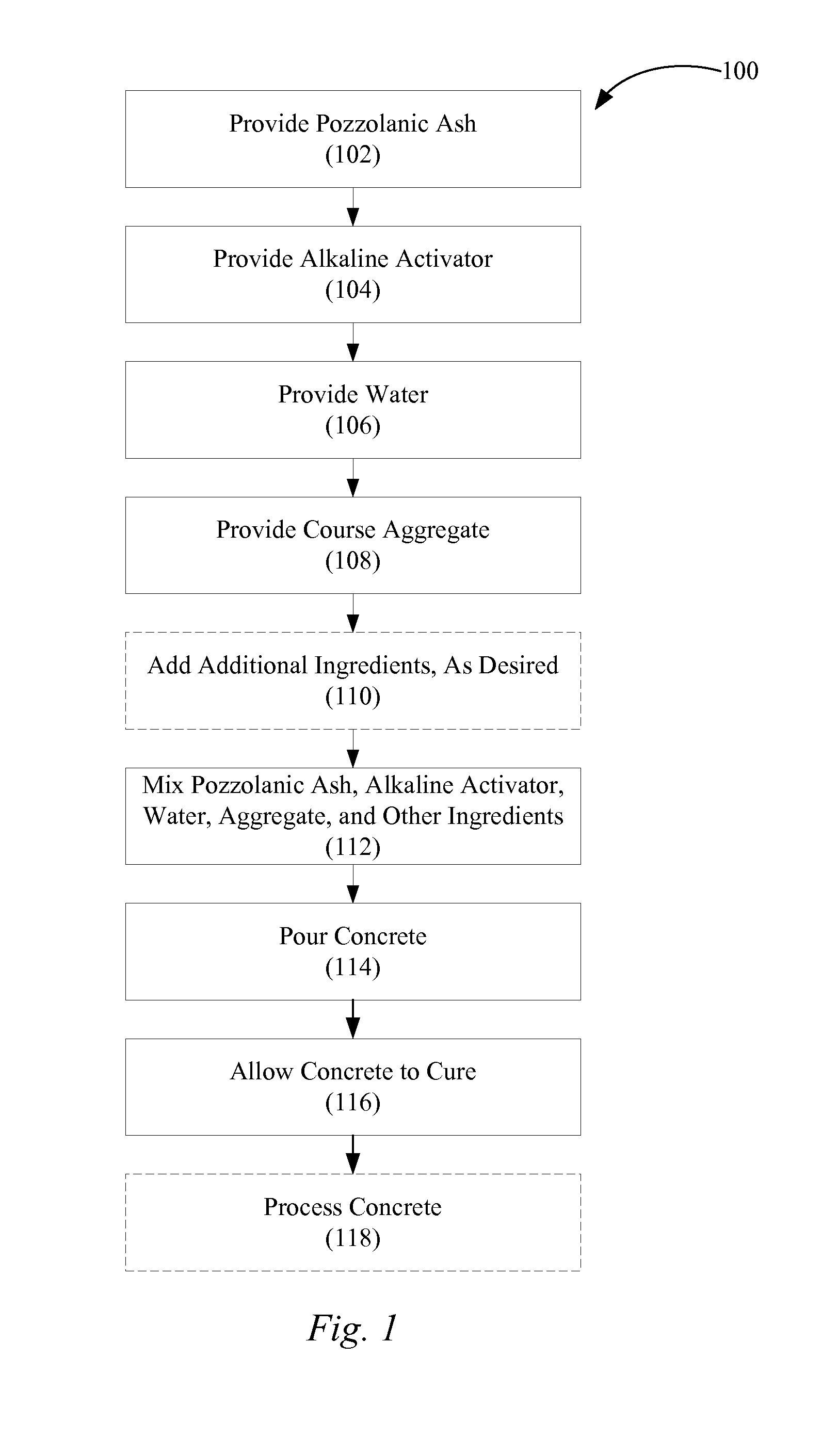

Previous concrete comprising a geopolymerized pozzolanic ash binder

ActiveUS20100058957A1Low costImprove performanceSolid waste managementCement productionAluminateCombustion

A process for making a pervious concrete comprising a geopolymerized pozzolanic ash. Generally, the process includes mixing a solid aggregate and a geopolymerized pozzolanic ash binder together to form a pervious concrete mixture. Some examples of suitable aggregates comprise recycled carpet, recycled cement, and aggregates of coal-combustion byproducts. The geopolymerized pozzolanic ash binder is made by combining a pozzolanic ash, such as fly ash, with a sufficient amount of an alkaline activator and water to initiate a geopolymerization reaction. The activator solution may contain an alkali metal hydroxide, carbonate, silicate, aluminate, or mixtures thereof. In some aspects, the final concrete forms a solid mass in the form of pavement or a pre-cast concrete shape. The solid mass of concrete may have a void content of between about 5% and about 35%.

Owner:CERAMTEC

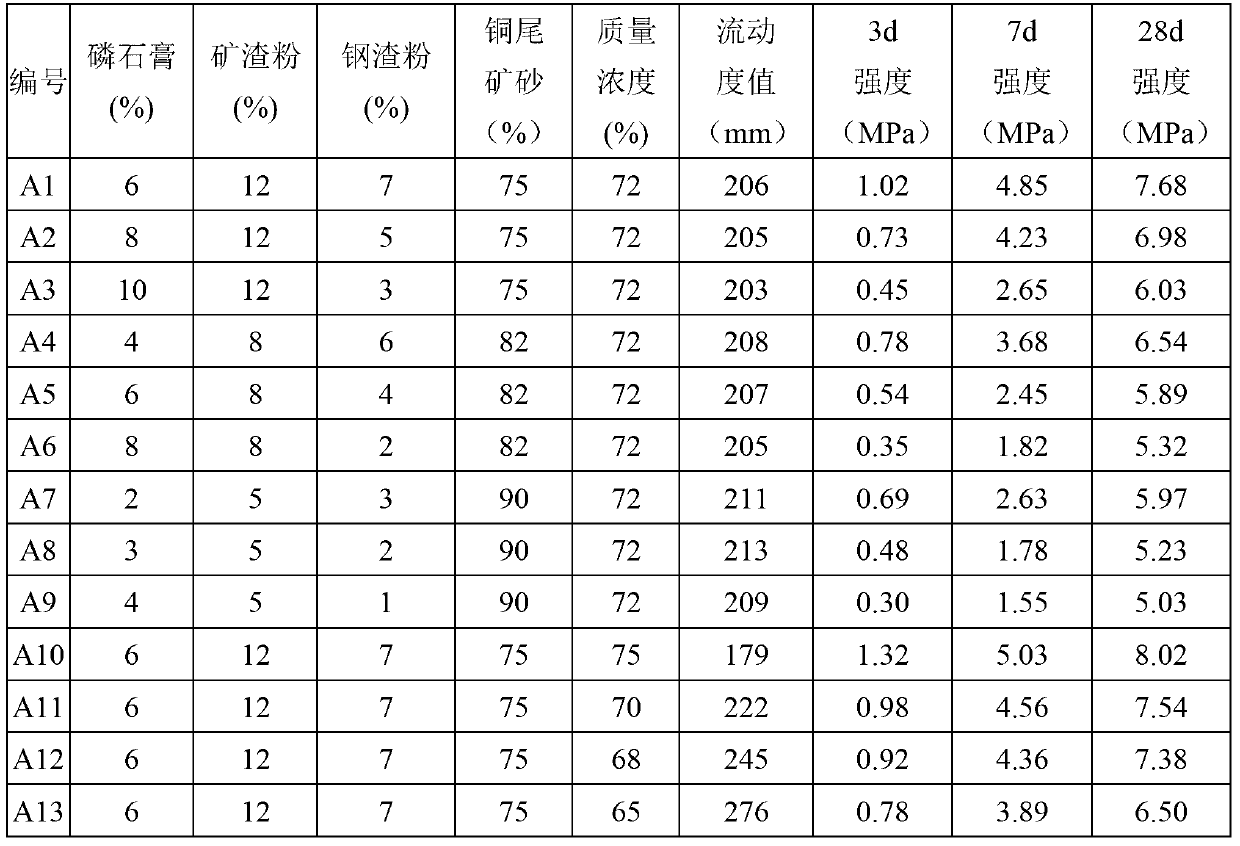

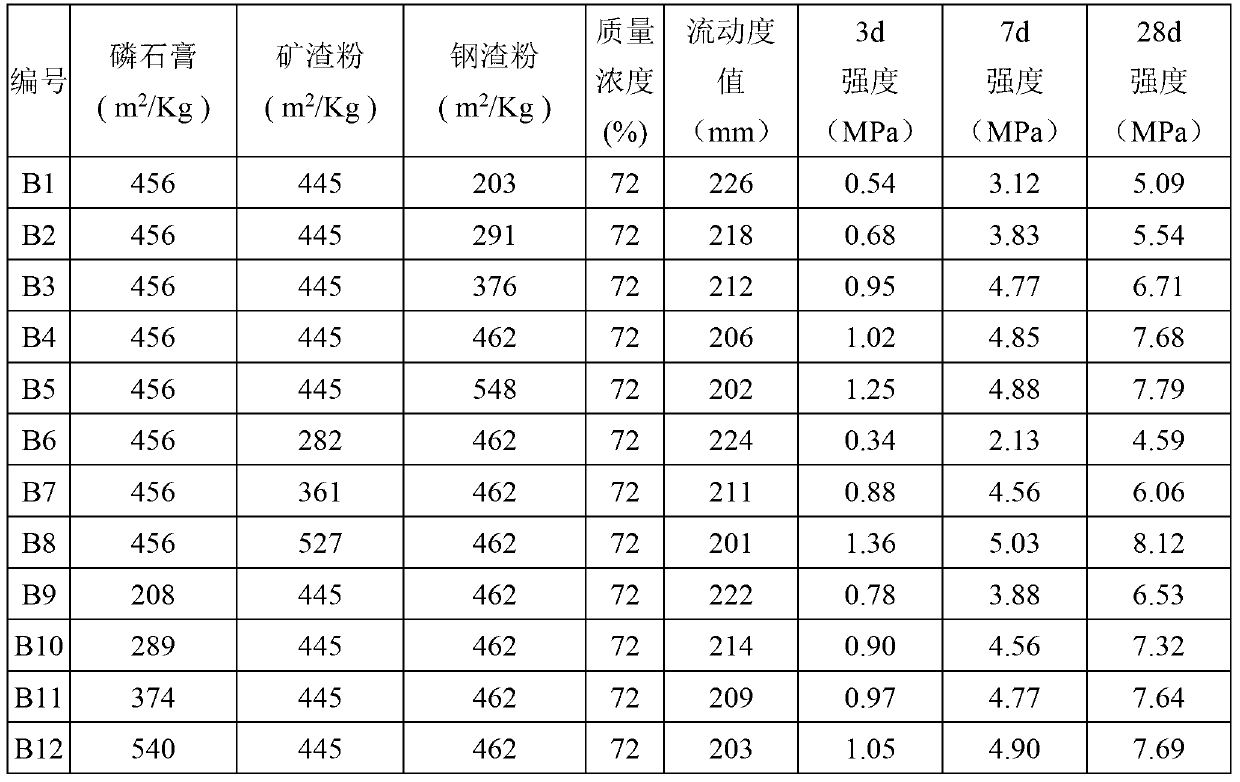

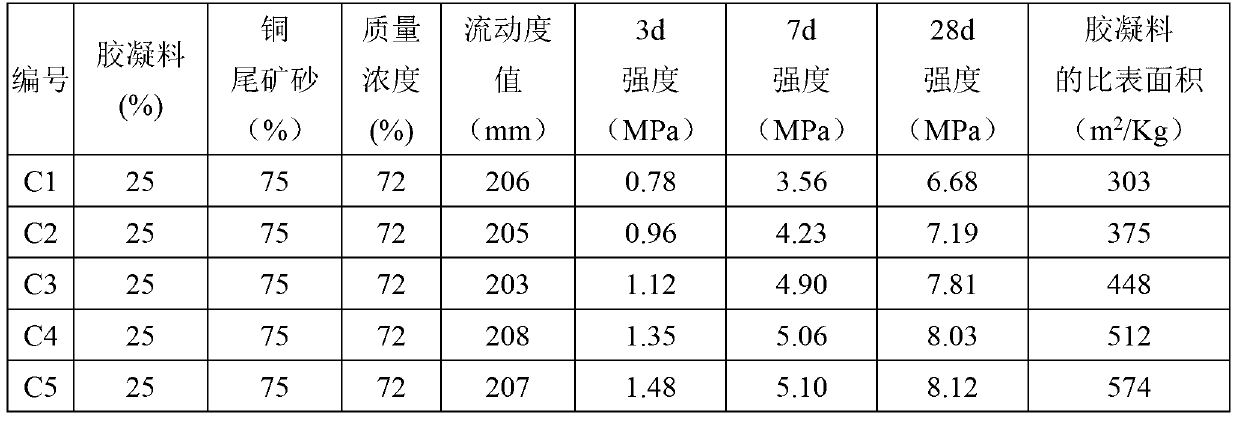

Mine filling cementing material slurry and preparation method thereof

The invention belongs to the technical field of mining engineering and building materials and particularly relates to a mine filling cementing material slurry and a preparation method thereof. The preparation method comprises the following steps of: with steel slag, mineral slag and industrial byproduct gypsum as cementing agents and tailing sand as a filling aggregate, adding water, mixing and stirring uniformly to prepare mine filling cementing material slurry, wherein a dry basis of raw materials comprises the following components in percentage by weight: 1-7% of steel slag, 5-12% of mineral slag, 2-10% of industrial byproduct gypsum and 75-90% of tailing sand, and the sum of the weight percentage of the dry basis of all the raw materials is 100%; adding water to regulate the mass concentration of the filling cementing material slurry to be between 65-75%. The mine filling cementing material slurry has the beneficial effects of higher strength, simple process, high flowability and suitablity for self-flowing filling; no cement or cement clinker or additives are added in the components of the filling cementing material slurry which is completely made of solid wastes, so that the utilization rate of the tailing sand is high, and the production cost is very low.

Owner:WUHAN UNIV OF TECH

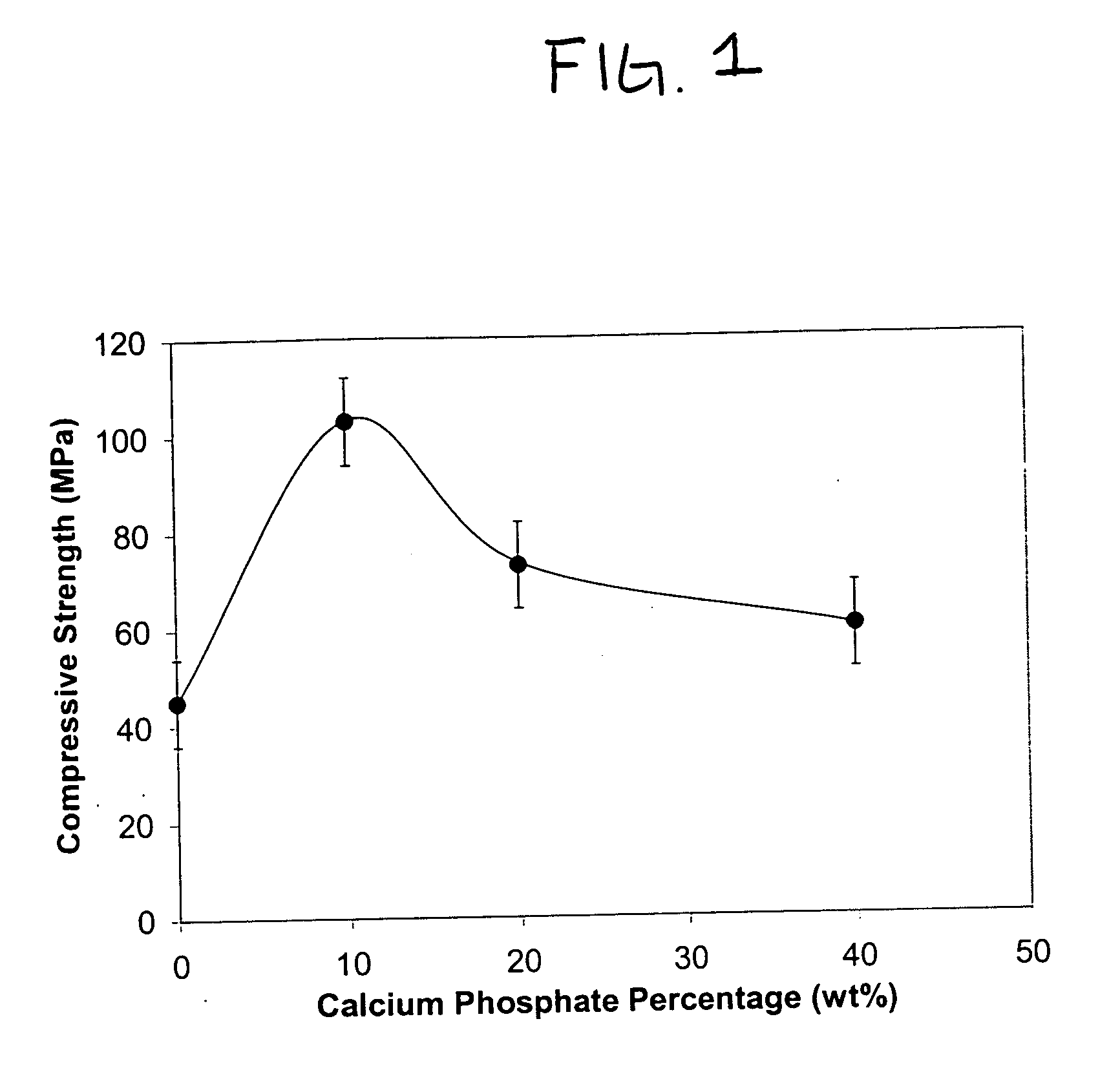

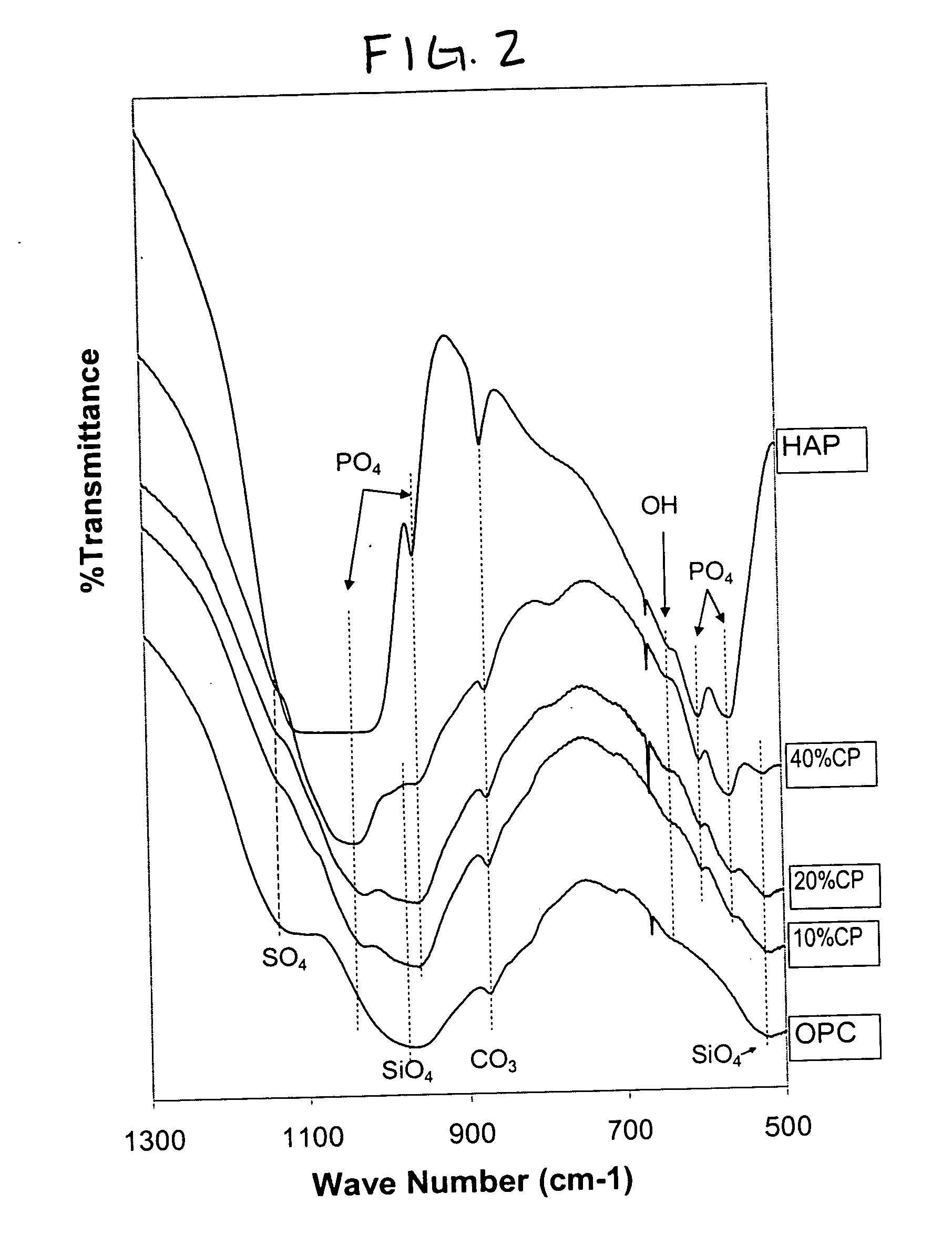

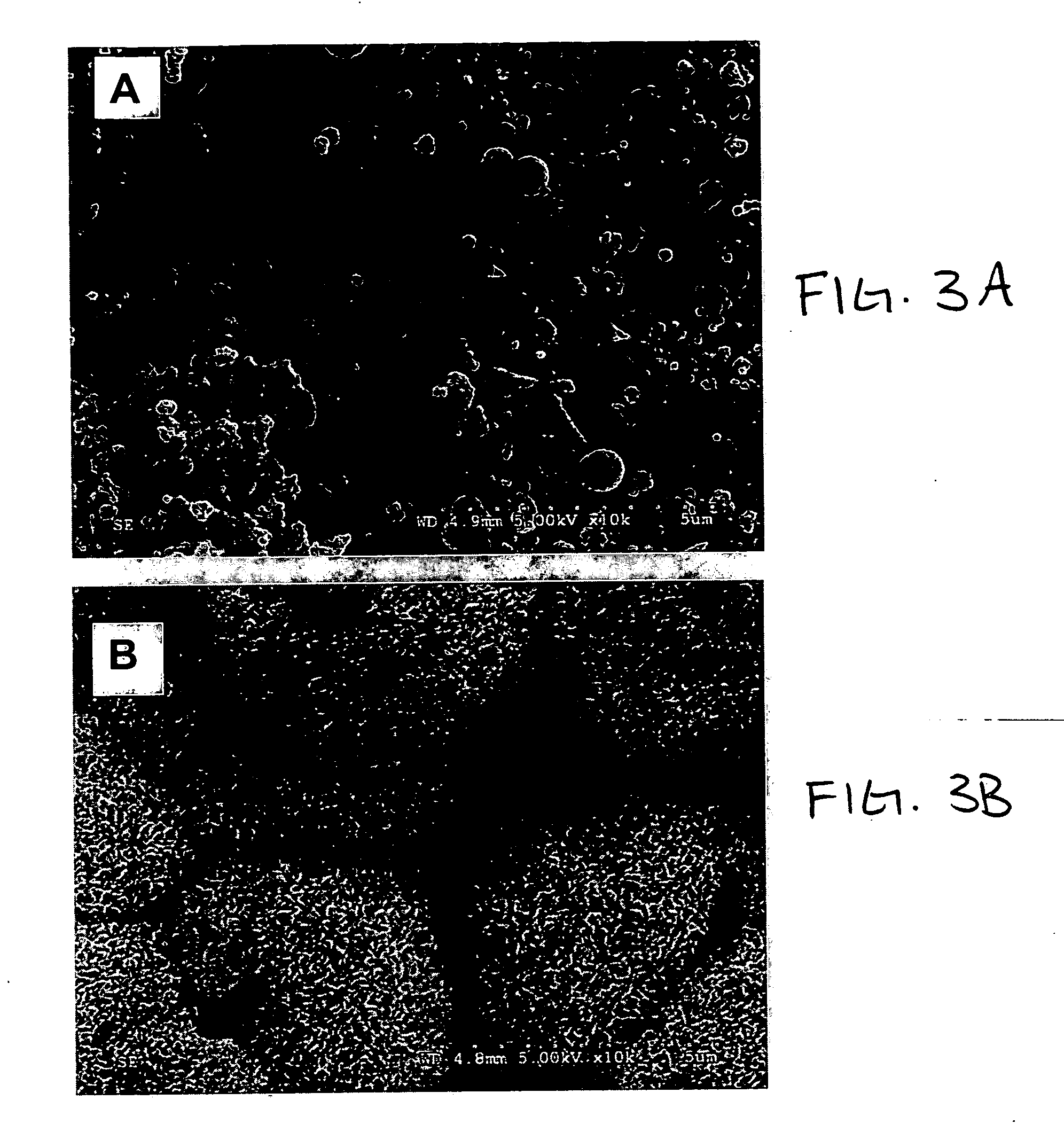

High strength biological cement composition and using the same

ActiveUS20070098811A1High mechanical strengthImprove biological activityBiocideSurgical adhesivesCalcium silicateApatite

A hydraulic cement for biomedical applications. The cement sets in-situ, hardening when exposed to water to produce nano-dispersed composite of calcium-silicate-hydrate gel mixed with hydroxyapatite. In comparison with prior cements, the composition provides high biocompatibility, high bioactivity and high biomechanical strength, due to the composite structure of the calcium silicate hydrate reinforced with co-precipitated particles of hydroxyapatite. Biocompatibility is also increased due to an absence of aluminum and magnesium in the composition. The cement is suitable for variety of applications, including dental implants, bone fixation, and bone repair.

Owner:INNOVATIVE BIOCERAMIX

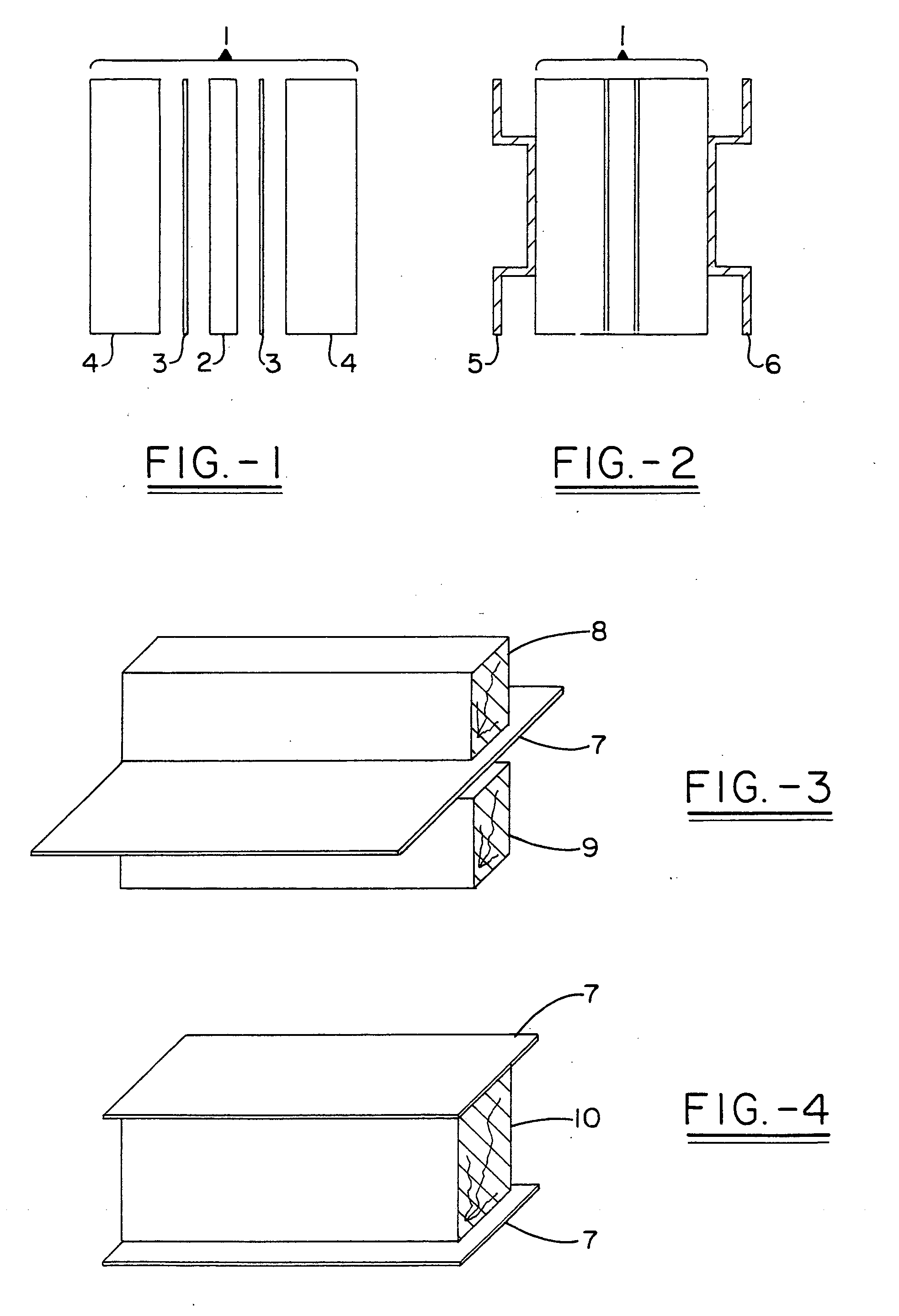

Inorganic matrix composition and composites incorporating the matrix composition

InactiveUS6969422B2Good physical and mechanical propertiesIncrease loadAlkali metal silicate coatingsCement productionSlurryOragene

A modified alkali silicate composition for forming an inorganic network matrix. The modified alkali silicate matrix is made by reacting an alkali silicate (or its precursors such as an alkali hydroxide, a SiO2 source and water), an acidic inorganic composition, such as a reactive glass, water and optional fillers, additives and processing aids. An inorganic matrix composite can be prepared by applying a slurry of the modified aqueous alkali silicate composition to a reinforcing medium and applying the temperature and pressure necessary to consolidate the desired form. The composite can be shaped by compression molding as well as other known fabrication methods. A notable aspect of the invention is that, although composite and neat resin components prepared from the invention can exhibit excellent dimensional stability to 1000° C. and higher, they can be prepared at the lower temperatures and pressures typical to organic polymer processing.

Owner:THE BF GOODRICH CO

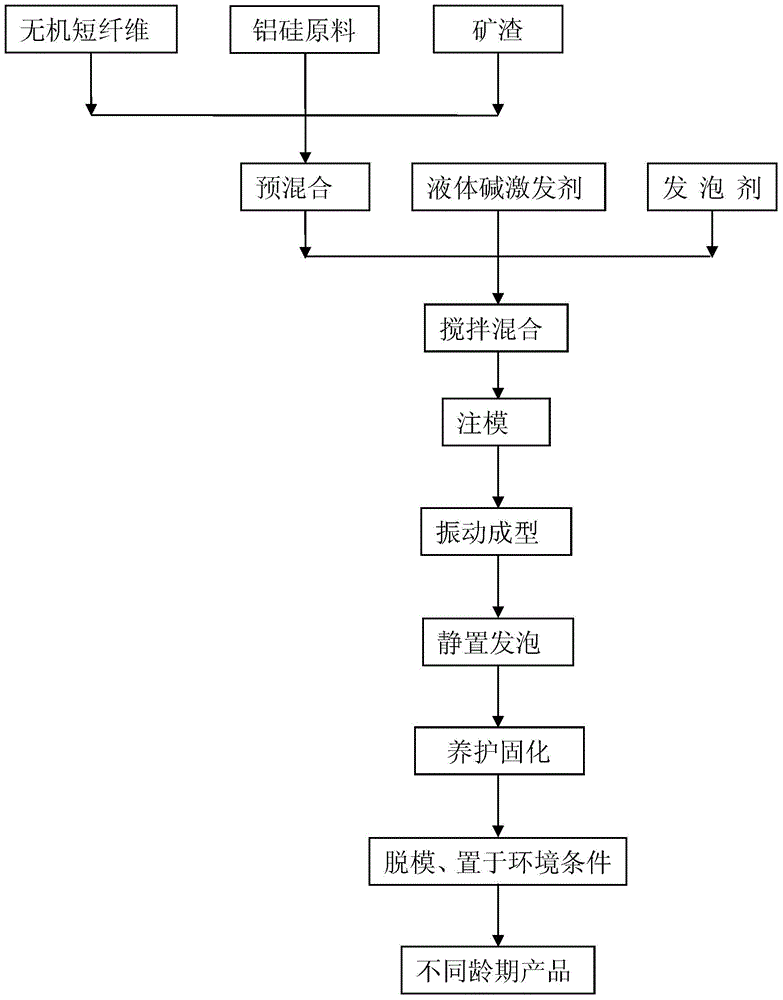

Fibre reinforced coal ash based geopolymer foam material and preparation method thereof

InactiveCN103601524ARealize high value utilizationReduce pollutionCement productionCeramicwarePolymer scienceSlag

The invention discloses a fibre reinforced coal ash based geopolymer foam material and a preparation method thereof. The fibre reinforced coal ash based geopolymer foam material disclosed by the invention comprises the following components in percentage by weight: 50-70% of aluminium silicon raw material, 5-15% of slag, 3-8% of inorganic fibre, 15-30% of liquid alkaline exciting agent, 0.2-2% of foaming agent, and 2.5-3.5% of foam stabilizer. The preparation method disclosed by the invention comprises the step of also adding the foam stabilizer while adding the foaming agent by adopting the liquid alkaline exciting agent by taking the inorganic fibre as the reinforcing agent, the slag as the Ca adjusting agent and other solid raw materials (such as coal ash, metakaolin and silica fume) as powder for providing aluminium silicon. The light foam material prepared by the invention has the characteristics of being high in intensity, small in size change rate, low in water absorption and the like in the event of having same volume weight and heat conductivity of the similar materials, and is applied to various applications.

Owner:TIANJIN UNIV

Cement composition

A cement composition of an environmental impact reducing type, used in the field of civil engineering and construction, which provides initial strength-development equal to that of ordinary Portland cement and which can reduce the clinker calcination amount, is provided. A cement composition containing Portland cement having a 3CaO.SiO2 content of at least 60% and a slowly cooled blast furnace slag powder, wherein the content of the slowly cooled blast furnace slag powder is from 10 to 50 parts per 100 parts of the cement composition.

Owner:DENKA CO LTD

High-performance base mortar

InactiveCN101696100AEasy to commoditizePrevent peelingSolid waste managementCement productionFiberDesign thinking

The invention aims at providing a low-cost multipurpose base mortar which comprises the following ingredients in proportions: 15-50 percent of cement, 50-85 percent of sand, 1-20 percent of inorganic composite material, 0.05-10 percent of organic composite material and 0.1-5 percent of fibrous material. The invention generates a super-composition effect by utilizing a multi-compositing design thinking and adding a plurality of inorganic and organic functional materials and enables that the mortar performance is greatly prompted, different types of prepared mortars satisfy the rigorous requirement for the mortar performance from various corresponding novel materials, the cost is not increased remarkably, and factory-produced dry-mixed mortar can be used in engineering construction actually.

Owner:北京艺高世纪科技股份有限公司

Method for producing silicon dioxide and alumina by using fly ash

This invention discloses a method for extracting SiO2 and Al2O3 from fly ashes. The method comprises: activating fly ashes, leaching with more than 40 wt. % NaOH solution so that Si is stripped out in the form of sodium cilicate, introducing CO2 to prepare SiO2, adding CaO or CaCO3 into the leaching residue, calcining to obtain a clinker, preparing Al2O3 by Bayer method, and preparing cement from the waste residue. The method extracts Si at first, thus increasing the Al / Si ratio in the leaching residue. Treated leaching residue can be directly subjected to Bayer method to extract Al2O3, which largely simplify Al2O3 extraction process and increase Al2O3 utility. The method has such advantages as simple process, low investment, and high product added value.

Owner:PINGSHUO INDAL

Inorganic matrix compositions and composites incorporating the matrix composition

InactiveUS20050022698A1Maintain good propertiesExcellent thermalAlkali metal silicate coatingsCement productionCompression moldingInorganic composition

A modified alkali silicate composition for forming an inorganic network matrix. The modified alkali silicate matrix is made by reacting an alkali silicate (or its precursors such as an alkali hydroxide, a SiO2 source and water), an acidic inorganic composition, such as a reactive glass, water and optional fillers, additives and processing aids. An inorganic matrix composite can be prepared by applying a slurry of the modified aqueous alkali silicate composition to a reinforcing medium and applying the temperature and pressure necessary to consolidate the desired form. The composite can be shaped by compression molding as well as other known fabrication methods. A notable aspect of the invention is that, although composite and neat resin components prepared from the invention can exhibit excellent dimensional stability to 1000° C. and higher, they can be prepared at the lower temperatures and pressures typical to organic polymer processing.

Owner:THE BF GOODRICH CO

Acid and high temperature resistant cement composites

InactiveUS20140047999A1Increase resistanceReduce resistanceSolid waste managementCement productionHigh resistanceSilicon dioxide

Process for production of acid and high temperature resistant cement composites, where the matrix is alkali activated F fly ash alone, F Fly ash combined with ground slag or ground slag alone. F-fly ash produces lower quality alkali activated cement systems. On the other hand the lack of calcium oxide results in very high resistance to medium and highly concentrated inorganic or organic acids. The high strength and low permeability of pure F-fly ash cement systems is achieved by using in the composition un-densified silica fume, the amorphous silicone dioxide obtained as by products in production of ferro-silicones. Precipitated nano-particle silica made from soluble silicates and nano-particle silica fume produced by burning silicon tetra chloride in the hydrogen stream.

Owner:RAZL IVAN

Nano-additive agent modified high-strength wall self-thermal insulation material and preparing method thereof

InactiveCN101318796ANo need for high temperature calcinationReduce heat transferSolid waste managementCement productionPolymer scienceBrick

The invention discloses a nano additive modified high strength wall self heat preservation brick and a preparation method thereof. The method comprises the following steps: according to mass portion, 1 to 20 portions of bonding agent, 0.1 to 5 portions of admixture and 0.5 to 5 portions of nano additive are evenly mixed and added with admixtures, the weight of which is 0.001 to 0.1 times against the weight of the mixture, and evenly mixed again; and the mixture obtained is added with water and shaped. For the wall self heat preservation brick prepared by the method of the invention, the pressive strength is between 5 and 14MPa, the coefficient of thermal conductivity is between 0.1 and 0.2w / m.k, so that the brick is a highly efficient energy saving building material with superior performance.

Owner:浙江中联建设集团有限公司 +2

Geopolymer gel material for rush repairs and rush constructions

ActiveCN101628791AGood mechanical propertiesEasy constructionSolid waste managementCement productionSlagMetakaolin

The invention provides a geopolymer gel material for rush repairs and rush constructions, which is prepared by adding water to 13-17 percent by weight of exciting agent and 82-87 percent by weight of slag containing aluminosilicate. The slag comprises one or the combination of more of blast furnace slag, steel slag, coal ash and coal gangue, and the exciting agent comprises the following components in percentage by weight: 35-75 percent of SiO2, 0-55 percent of Na2O, 0-65 percent of K2O, 0-1 percent of CaO and 0-1 percent of SO3. The geopolymer gel material which has the characteristic of quick setting and hardening is prepared by using the industrial waste slag as a main raw material and matching the exciting agent, and the geopolymer gel material has excellent mechanical property and controllable setting time and can replace gel materials such as fast setting and hardening cement, and the like in the processes of rush repairs and rush constructions. The industrial solid wastes such as the blast furnace slag, the steel slag, the coal ash, the coal gangue, and the like containing the aluminosilicate series are used as main raw materials, metakaolin is not added and the raw materials do not need to be calcined, thus the invention has low energy consumption, less pollution, simple process, low cost, environmental protection and energy saving.

Owner:深圳市航天新材科技有限公司

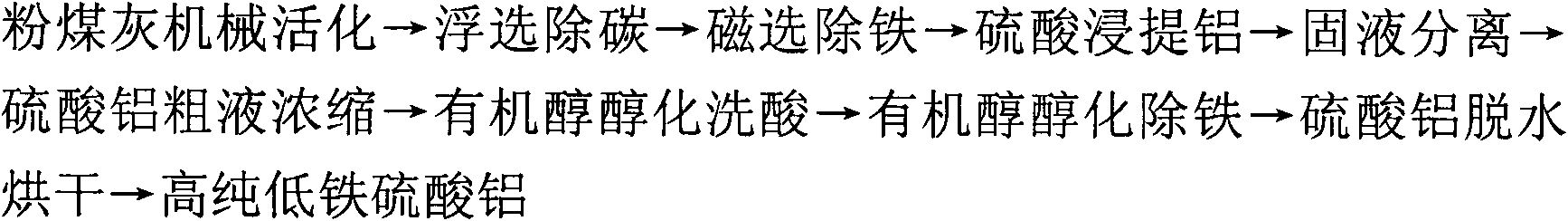

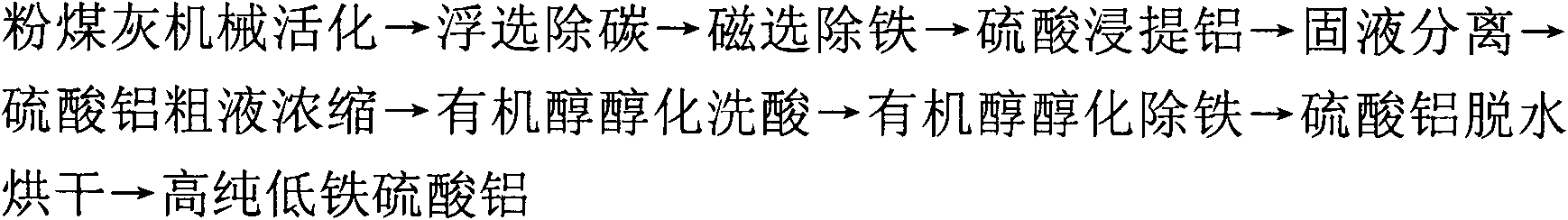

Technological method for producing high-purity low-iron aluminum sulfate by using coal ash and comprehensively utilizing coal ash

InactiveCN102101689AEasy industrial iron removalLow costPigmenting treatmentSolid waste disposalBiological activationCoal

The invention discloses a technological method for producing high-purity low-iron aluminum sulfate by using coal ash and comprehensively utilizing the coal ash, comprising the following steps of: carrying out mechanical activation, flotation decarburization, magnetic separation for deferrization, aluminum extraction with sulfuric acid, solid-liquid separation, concentration of aluminum sulfate crude liquor, organic alcohol alcoholization for acid rinse, organic alcohol alcoholization for deferrization and aluminum sulfate dewatering and drying on the coal ash to obtain the high-purity low-iron aluminum sulfate with low Fe content. The invention solves the problems on impurity removal and purification of the aluminum sulfate in the recycling process of the coal ash, simplifies the process flow, reduces the energy consumption, solves the technical problem of overlarge accumulation of secondary residue quantity, achieves high extraction ratio of aluminum contained in the coal ash, and realizes the recycling of organic alcohol and sulfuric acid and the comprehensive utilization of side products including unburnt black, magnetic iron powder, iron-containing aluminum sulfate crystals, high-silicon-dust active mineral blending materials or novel silicon-magnesium cement, and the like. The technological method has the advantages of simple process, short flow, easiness for control of a production process, high aluminum extraction ratio, low impurity content of products and stable quality.

Owner:内蒙古昶泰资源循环再生利用科技开发有限责任公司 +2

Geopolymeric concrete based on recycled aggregate and preparation method of geopolymeric concrete

InactiveCN103601424AReduce consumptionImprove thermal stabilitySolid waste managementCement productionAdhesiveRoad surface

The invention relates to geopolymeric concrete based on recycled aggregate, and a preparation method of the geopolymeric concrete. The concrete is prepared by taking construction waste as aggregate and inorganic geopolymer as an adhesive through an alkali activation process. The recycled aggregate geopolymeric concrete prepared by using the method has the characteristics that the concrete can be rapidly dried, the compressive strength, particularly the early-stage compressive strength is high, the volume shrinkage in the coagulation process is extremely low, the coefficient of volume expansion is approximate to 0, and acid-base corrosion resistance is good. Due to the adoption of the method, the defects that the conventional concrete is low in early-stage strength and the coagulation time is long are overcome; a method for rapidly repairing concrete pavement is provided, and problems of recycling and reusing construction waste aggregate and environment problems caused by the construction waste aggregate are solved.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

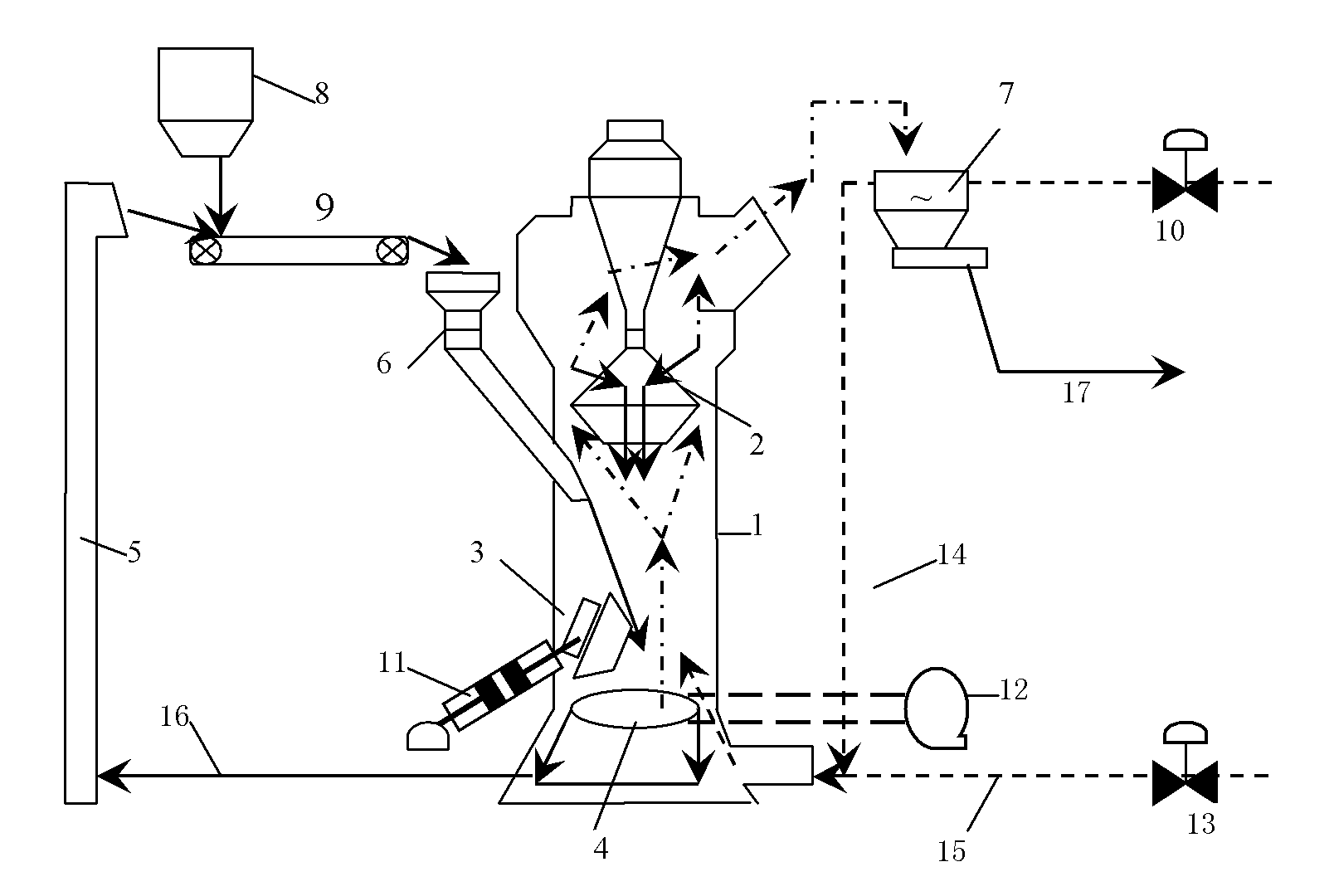

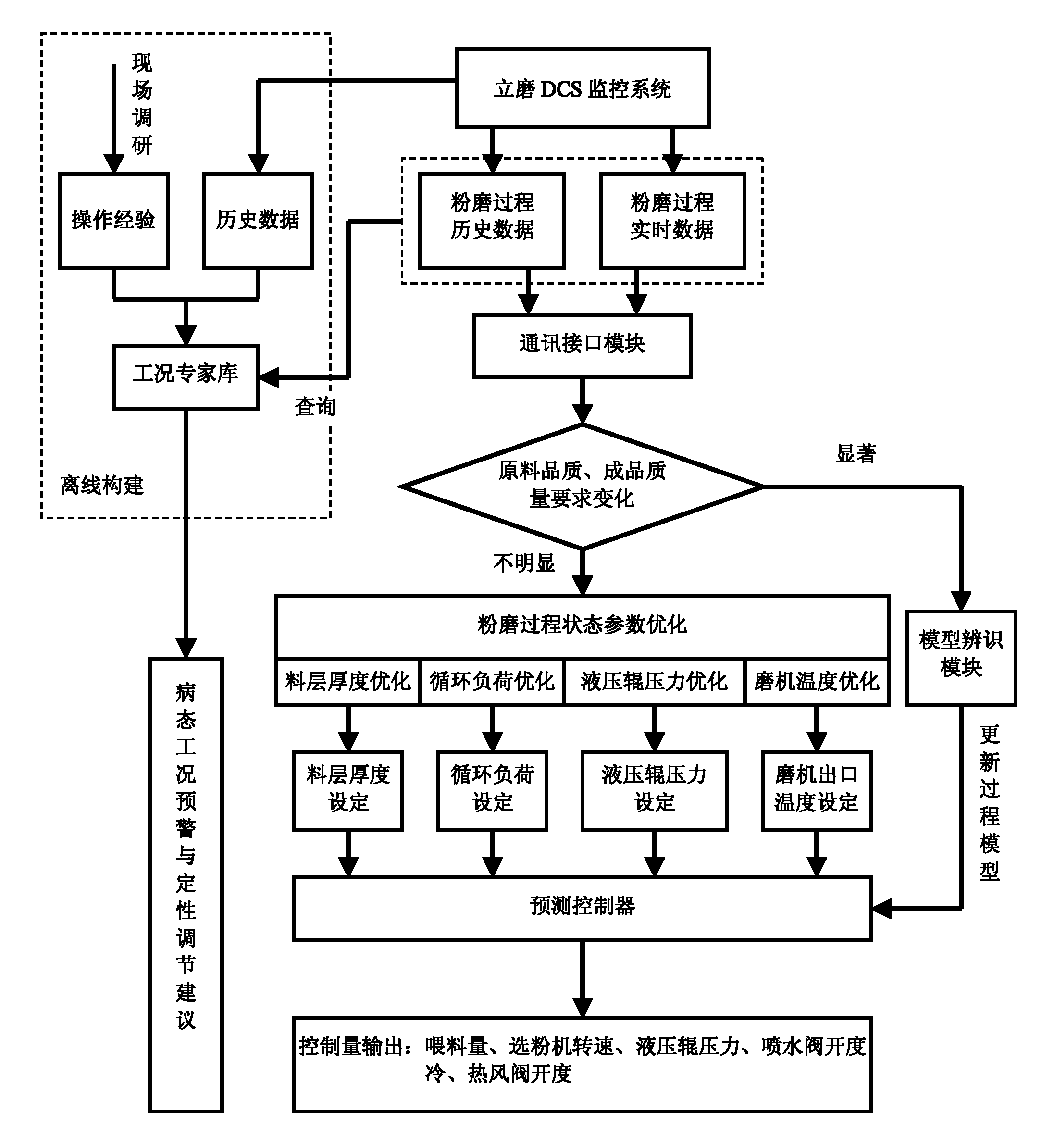

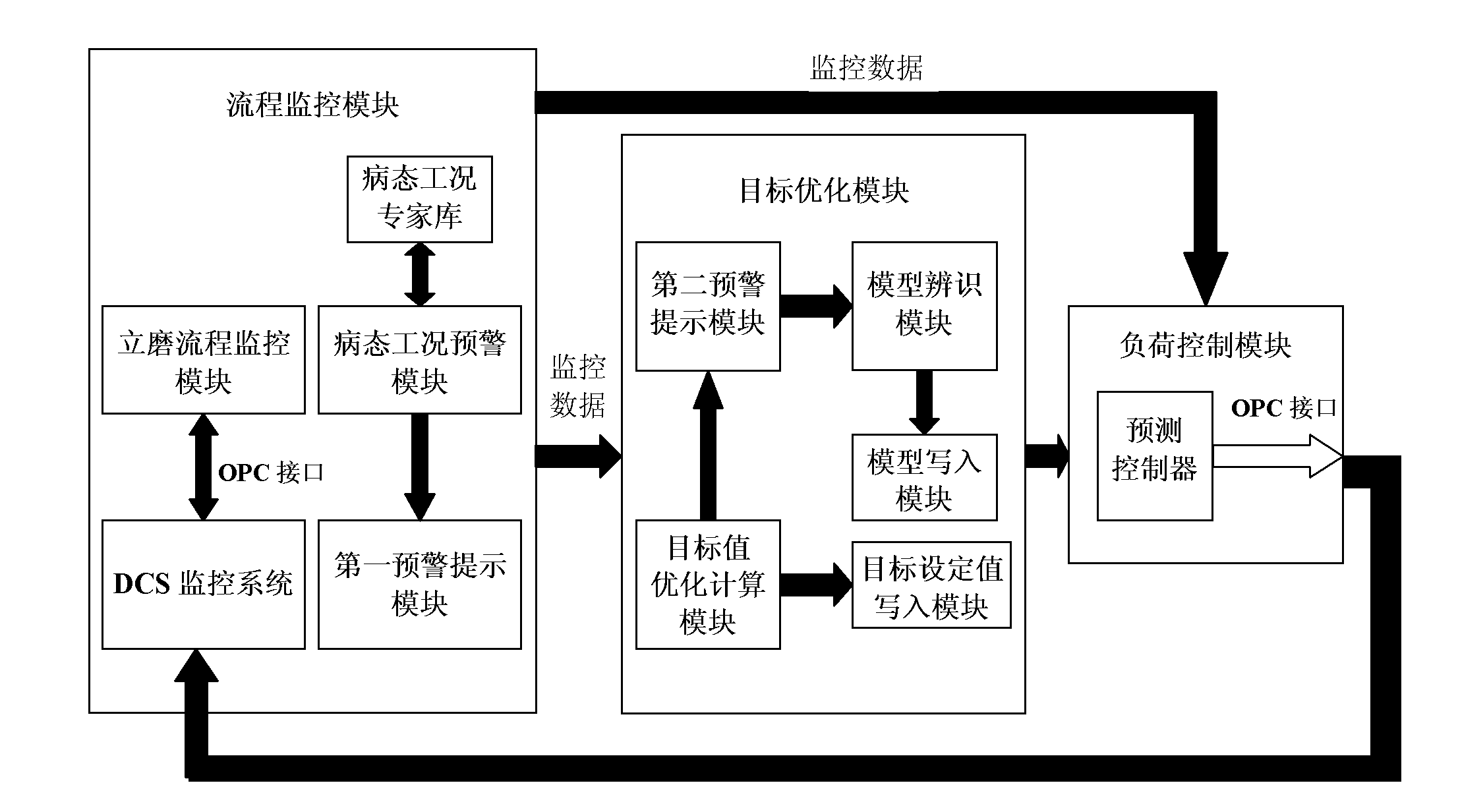

Advanced control method and system for vertical mill based on model identification and predictive control

InactiveCN102151605AIncrease the level of automationQuality improvementCement grindingCement productionMathematical modelOptimal control

The invention relates to raw material grinding in the field of cement process industries, and aims to provide an advanced control method and system for a vertical mill based on model identification and predictive control. The method comprises the following steps of: acquiring real-time data from a distributed control system (DCS) monitoring system; analyzing a variation trend of the operation and technology parameters, and then invoking a pathological working condition expert database for performing trend matching; if a pathological working condition appears, issuing early warning display and giving qualitative adjustment suggestion remind; giving an optimal target set value according to the basic operation condition of the vertical mill and the variation situation of the product quality requirement, and writing into a predictive controller; setting an optimal controlled quantity output according to the optimal target set value, and outputting to the DCS monitoring system to control a field actuator to take action. By adopting the invention, the qualitative adjustment suggestion can be precisely given; a mathematical model of the grinding process of the vertical mill is established and updated in real time; the steady-state error of the control system is reduced; and the grinding process of the vertical mill is instructed, so that the mill can operate stably for long term at a maximum efficiency point, and stable margin is maintained.

Owner:ZHEJIANG UNIV

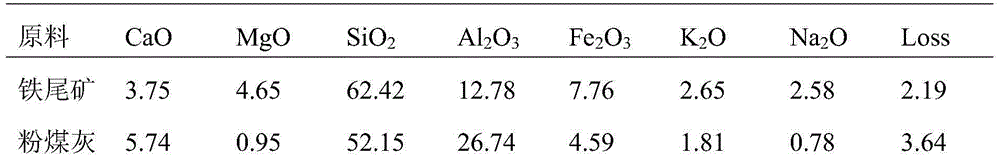

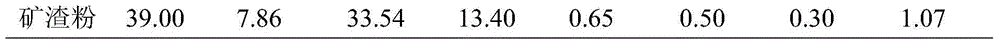

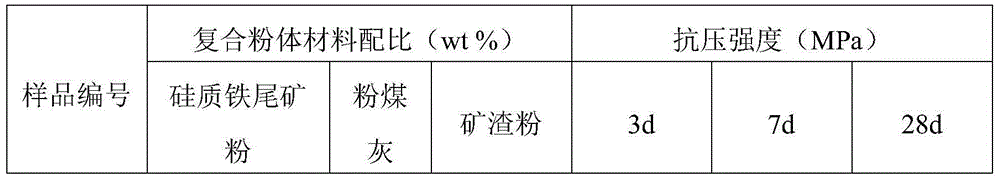

Alkali-activated cementing material and preparation method thereof

InactiveCN104446045ABroaden the way of resource utilizationIncrease consumptionCement productionLiquid waterAlkali activated

The invention relates to an alkali-activated cementing material prepared from siliceous iron tailings and a preparation method of the alkali-activated cementing material. The preparation method comprises the following steps: 1) proportionally and evenly mixing siliceous iron tailing powder, coal ash and slag powder together to obtain iron tailing powder-coal ash-slag powder compound powder; 2) mixing liquid water glass with water to obtain an alkali activating agent solution; 3) adding the alkali activating agent solution to the compound powder and stirring evenly to obtain an alkali-activated cementing material paste; 4) injecting the alkali-activated cementing material paste into a die for vibrating molding and maintaining under a normal temperature condition until knockout, thereby obtaining an alkali-activated cementing material net paste test piece; and 5) performing steam curing on the alkali-activated cementing material net paste test piece. The alkali-activated cementing material has the beneficial effects that the alkali-activated cementing material hardened paste has excellent mechanical properties, the 3d compressive strength of the optimal proportion of the hardened paste is greater than 60MPa and the 28d compressive strength of the hardened paste is greater than 80MPa.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com