Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8207 results about "Compression molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compression Moulding is a method of moulding in which the moulding material, generally preheated, is first placed in an open, heated mould cavity. The mould is closed with a top force or plug member, pressure is applied to force the material into contact with all mould areas, while heat and pressure are maintained until the moulding material has cured. The process employs thermosetting resins in a partially cured stage, either in the form of granules, putty-like masses, or preforms.

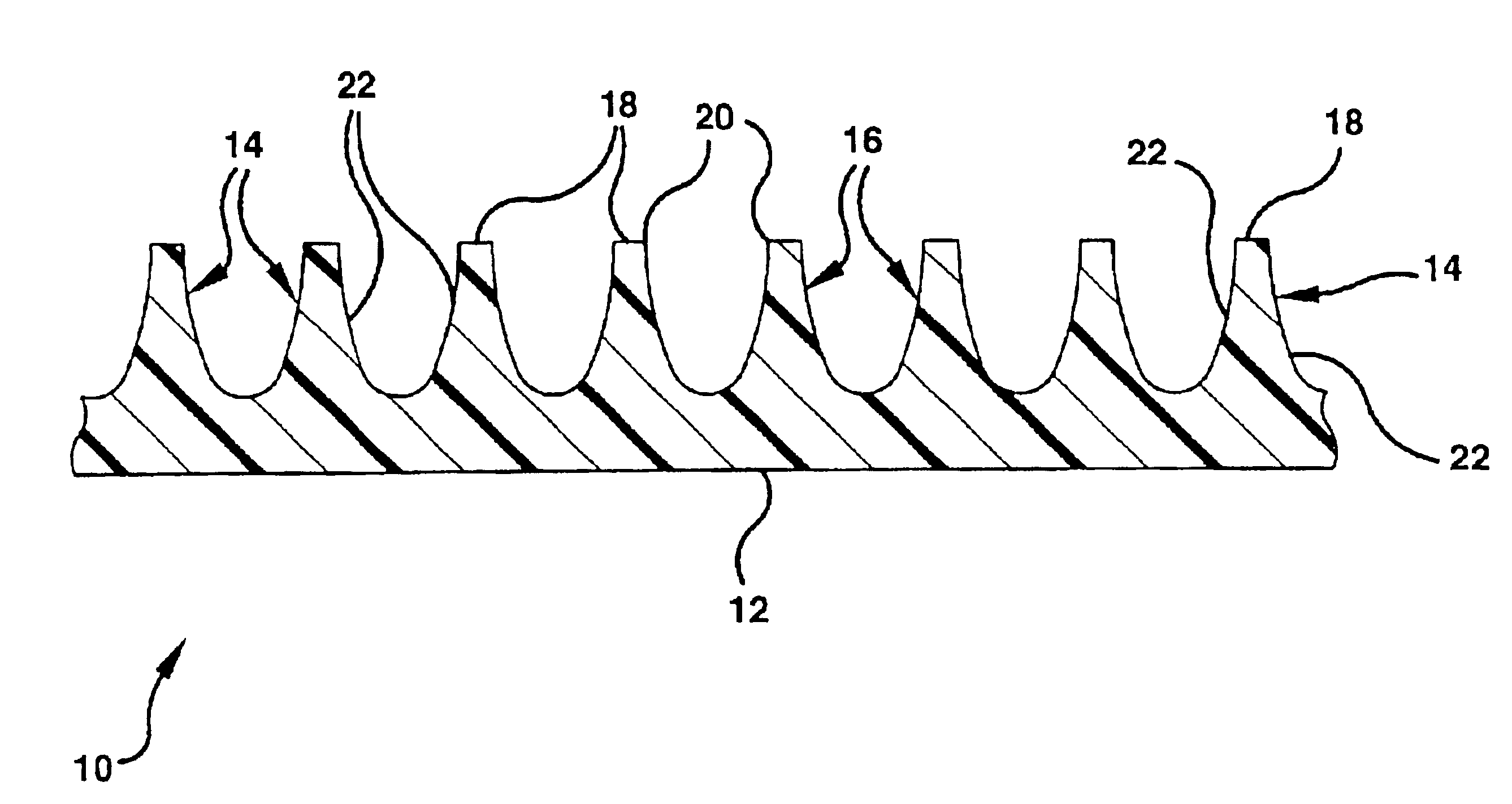

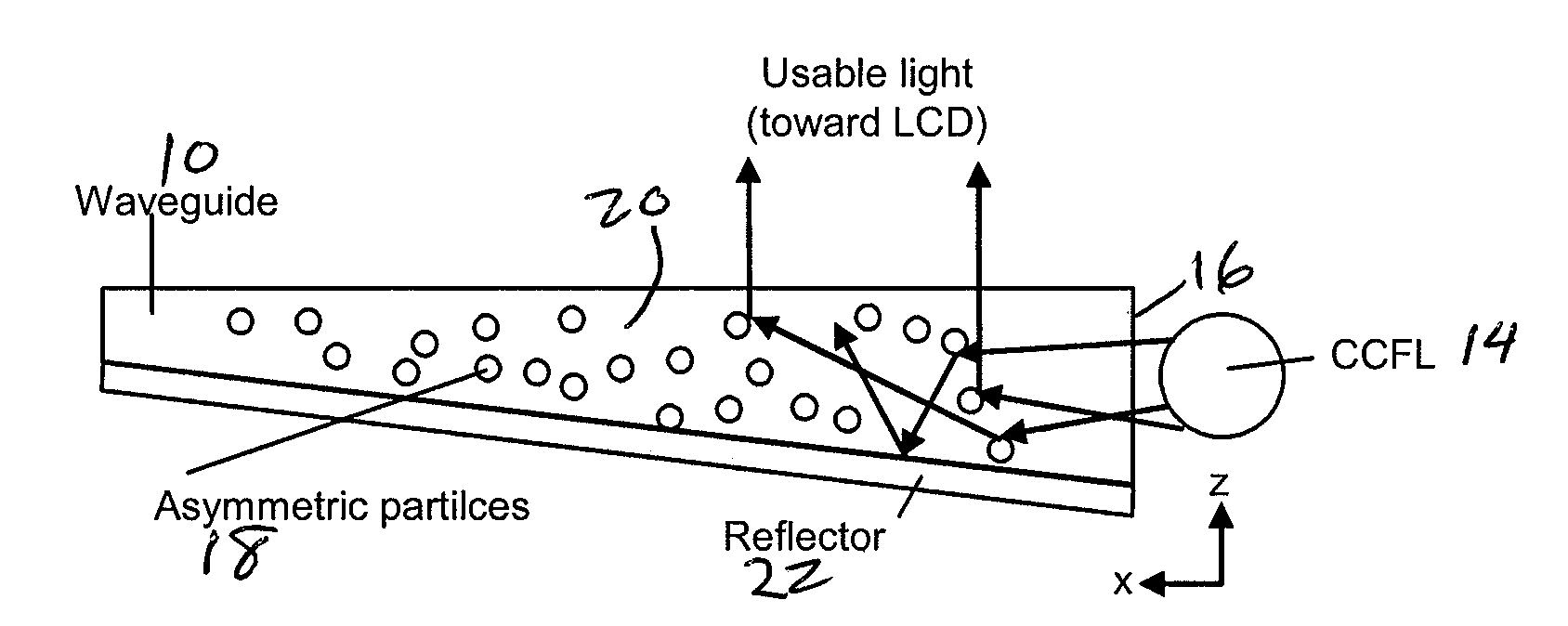

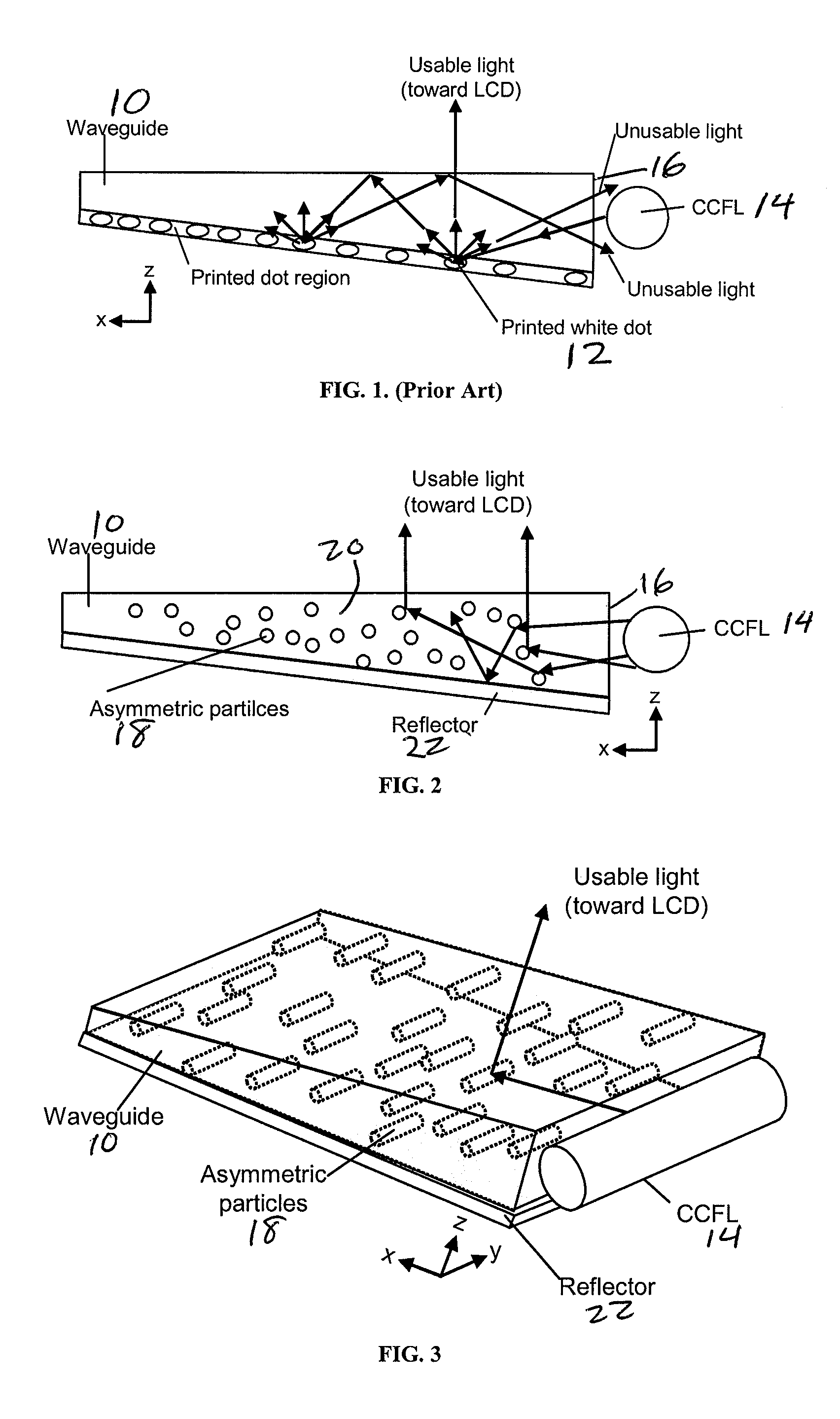

Enhanced LCD backlight

ActiveUS20060056166A1Improved backlight assemblyAvoid less flexibilityElectric discharge tubesDiffusing elementsCompression moldingEllipsoidal particle

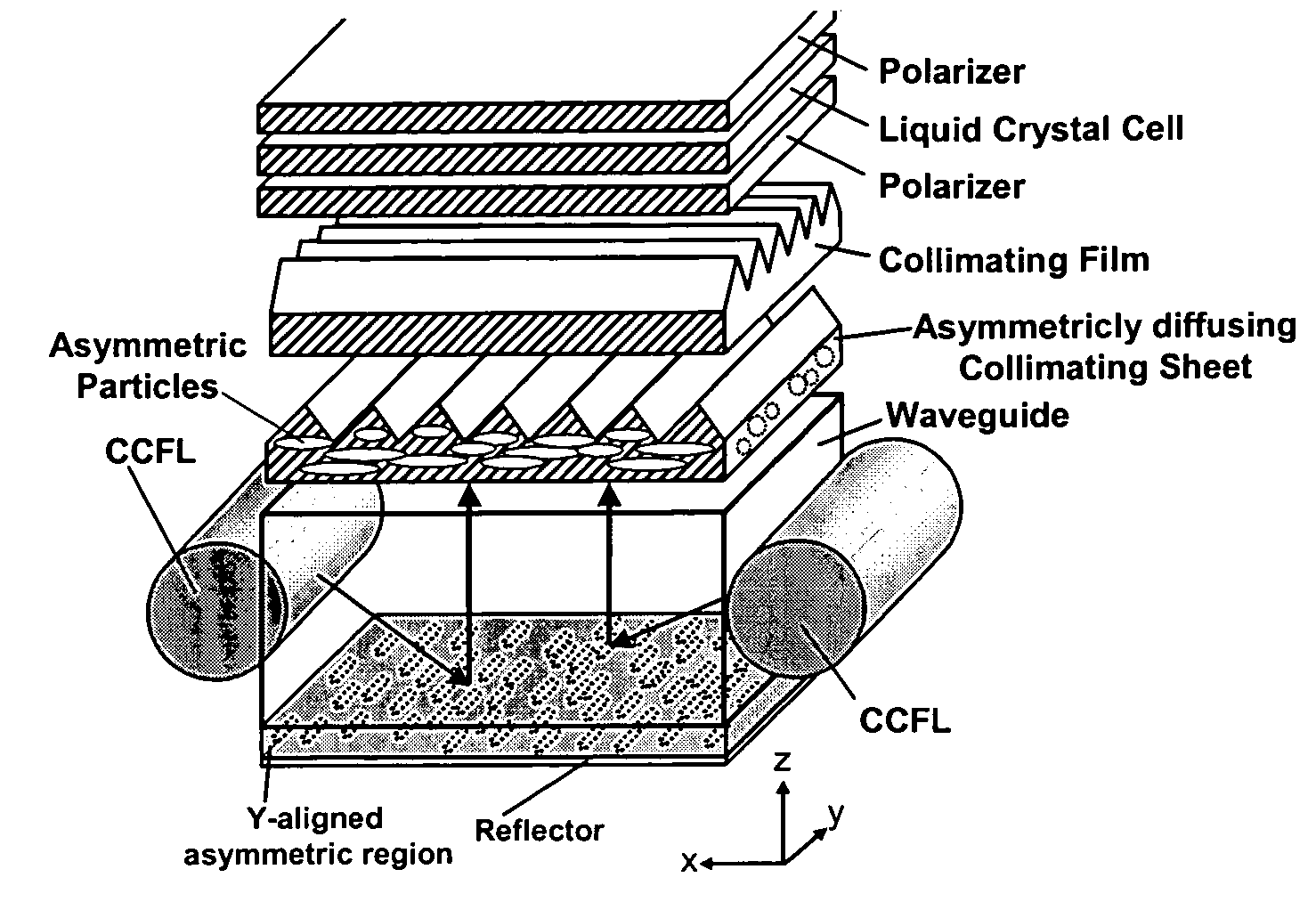

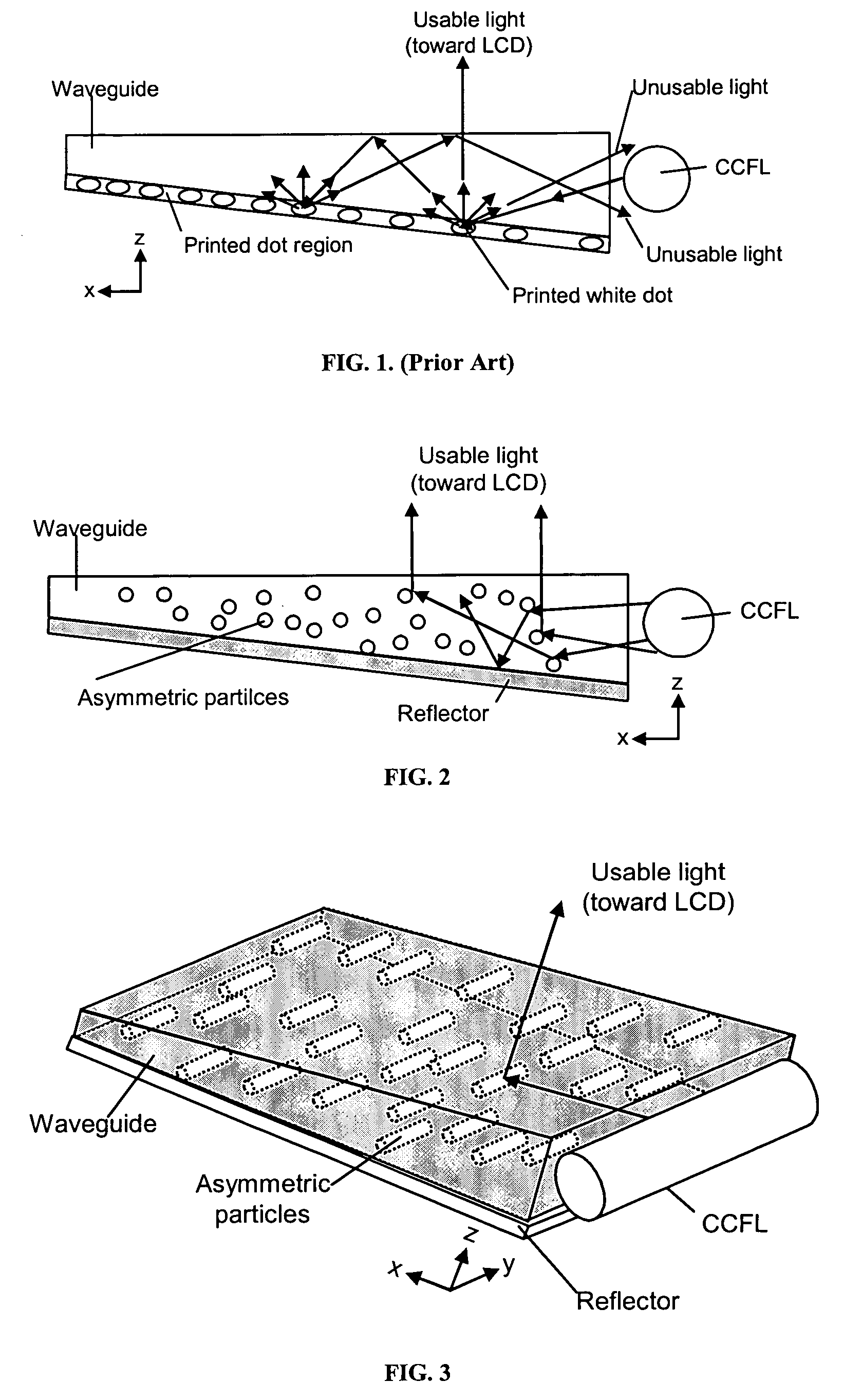

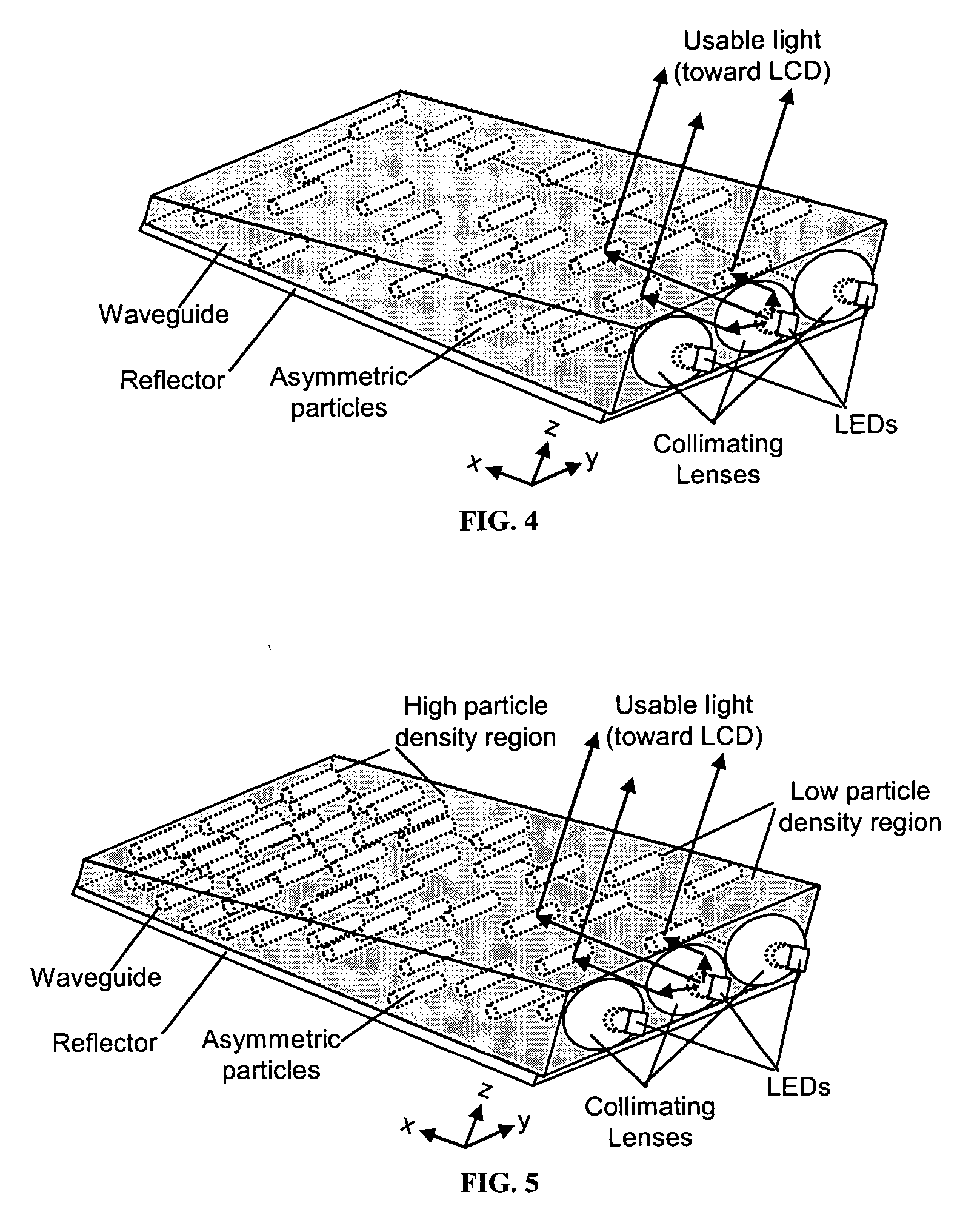

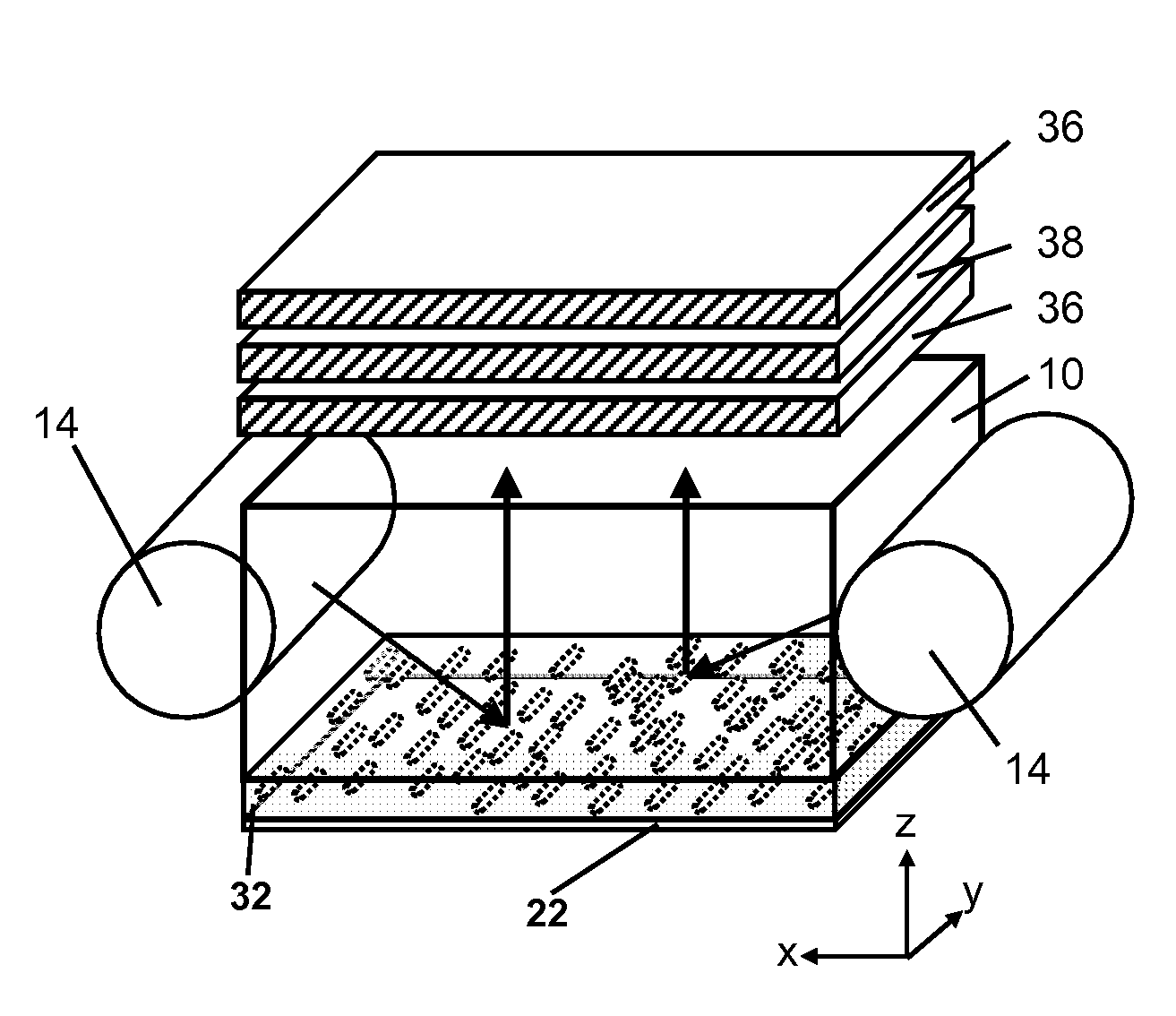

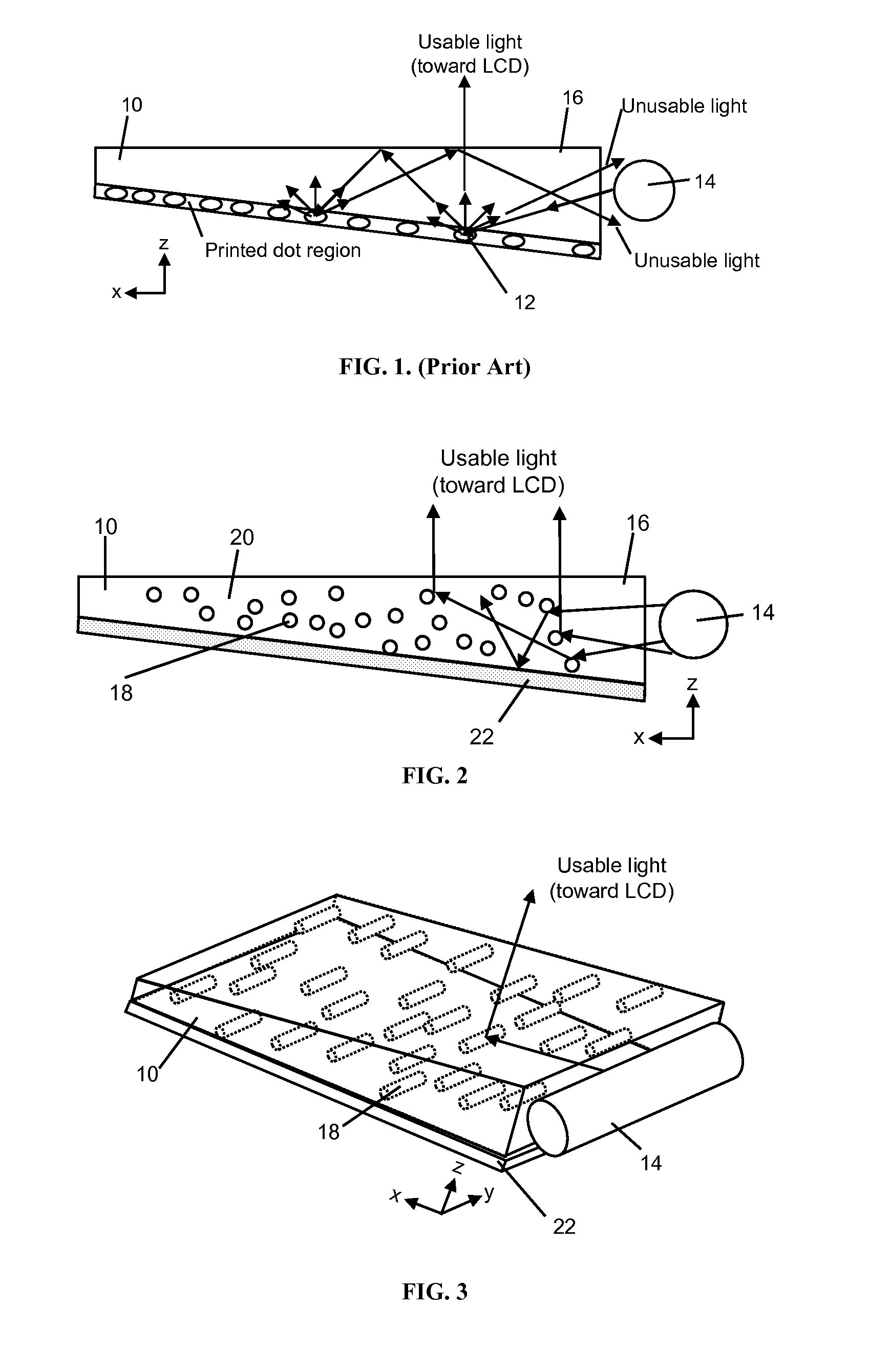

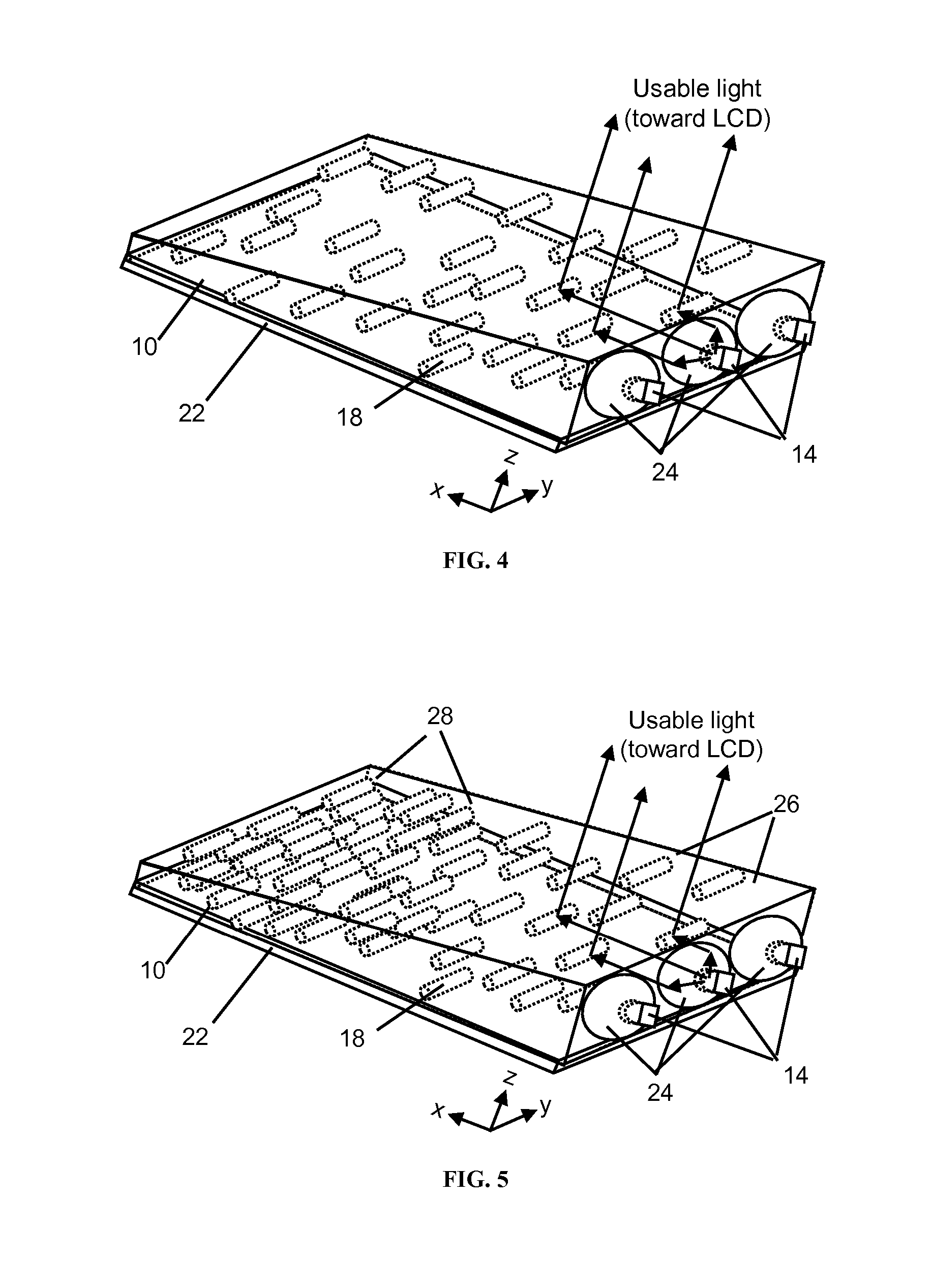

The present invention provides an improved light guide with inherently more flexibility for display system designers and higher optical efficiency. By using a light guide containing substantially aligned non-spherical particles, more efficient control of the light scattering can be achieved. One or more regions containing ellipsoidal particles may be used and the particle sizes may vary between 2 and 100 microns in the smaller dimension. The light scattering regions may be substantially orthogonal in their axis of alignment. Alternatively, one or more asymmetrically scattering films can be used in combination with a backlight light guide and a reflector to produce an efficient backlight system. The light guides may be manufactured by embossing, stamping, or compression molding a light guide in a suitable light guide material containing asymmetric particles substantially aligned in one direction. The light scattering light guide or non-scattering light guide may be used with one or more light sources, collimating films or symmetric or asymmetric scattering films to produce an efficient backlight that can be combined with a liquid crystal display or other transmissive display. By maintaining more control over the scattering, the efficiency of the recycling of light by using reflective polarizers can also be increased.

Owner:MASSACHUSETTS DEV FINANCE AGENCY

Polymer-bioceramic composite for orthopaedic applications and method of manufacture thereof

InactiveUS20040002770A1Promote ingrowthImprove toughnessBone implantJoint implantsCompression moldingPolymer science

Polymer-bioceramic structures are described for use in the repair of bone defects. The composites of the present disclosure are characterized by a polymer disposed in a porous bioceramic matrix. Processes for preparing the composites of the present invention by compression molding are described, including compression molding to induce orientation of the polymer is multiple directions. The composites of the present invention are also useful as drug delivery vehicles to facilitate the repair of bone defects.

Owner:DEPUY SYNTHES PROD INC

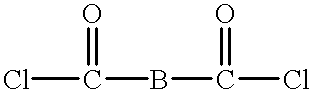

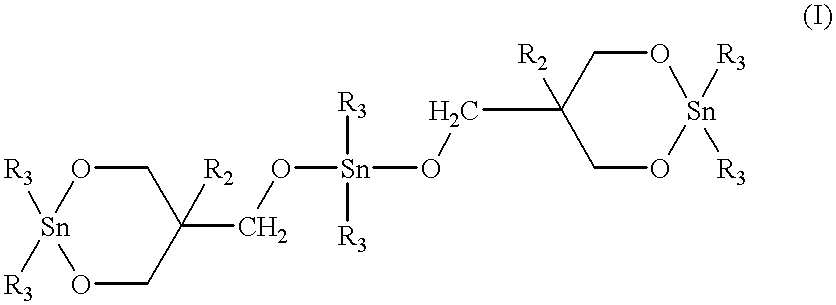

Blend material including macrocyclic polyester oligomers and processes for polymerizing the same

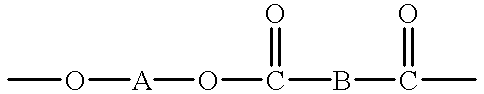

A blend of a macrocyclic polyester oligomer and a polymerization catalyst as a one component ready-to-use material with a long shelf life enables production of parts from macrocyclic polyester oligomers without the modification of existing equipment, thereby reducing time and cost of manufacture while expanding the application of macrocyclic polyester oligomers. In this blend material, the macrocyclic polyester oligomer remains intact in solid state at ambient conditions. Upon melting, the blend material initially forms low viscosity fluid, and then rapidly polymerizes to form high molecular weight polyesters which subsequently solidify to form crystalline polymers. In the case of certain macrocyclic polyester oligomers, for example, poly(1,4-butylene terephthalate), demolding can take place at the polymerization temperature, e.g., at about 180° C. to 200° C., because the resulting polyester polymer solidifies fairly rapidly at that temperature without cooling. In one aspect, the invention generally features a blend material that includes a macrocyclic polyester oligomer, a polymerization catalyst, and optionally, a filler. In another aspect, the invention generally features a process for preparing a blend material. In yet another aspect, the invention features processes such as rotational molding, resin film infusion, pultrusion, resin transfer molding, filament winding, making and using powder-coated or hot melt prepreg, compression molding, and roll wrapping, which use the blend material.

Owner:CYCLICS CORP

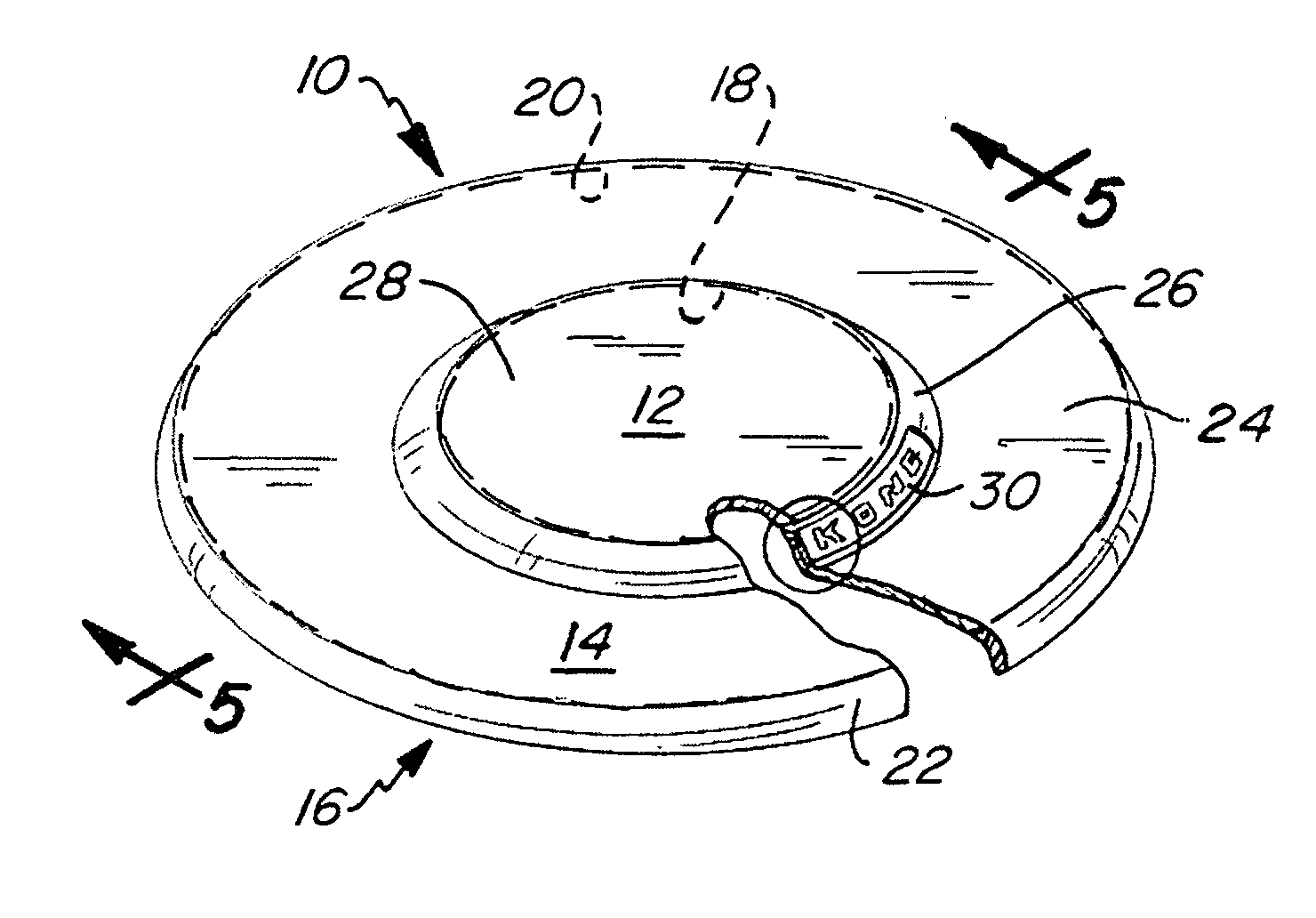

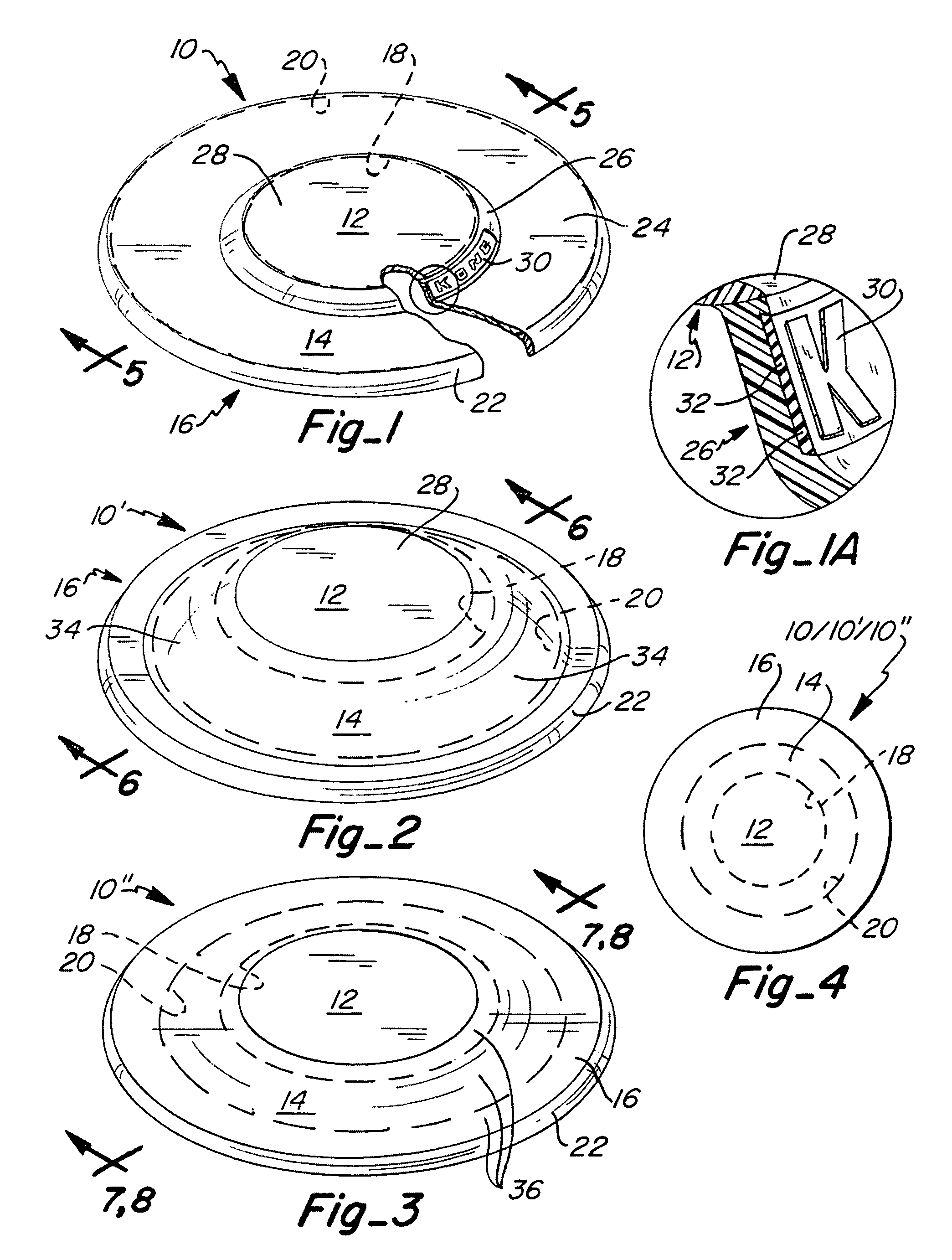

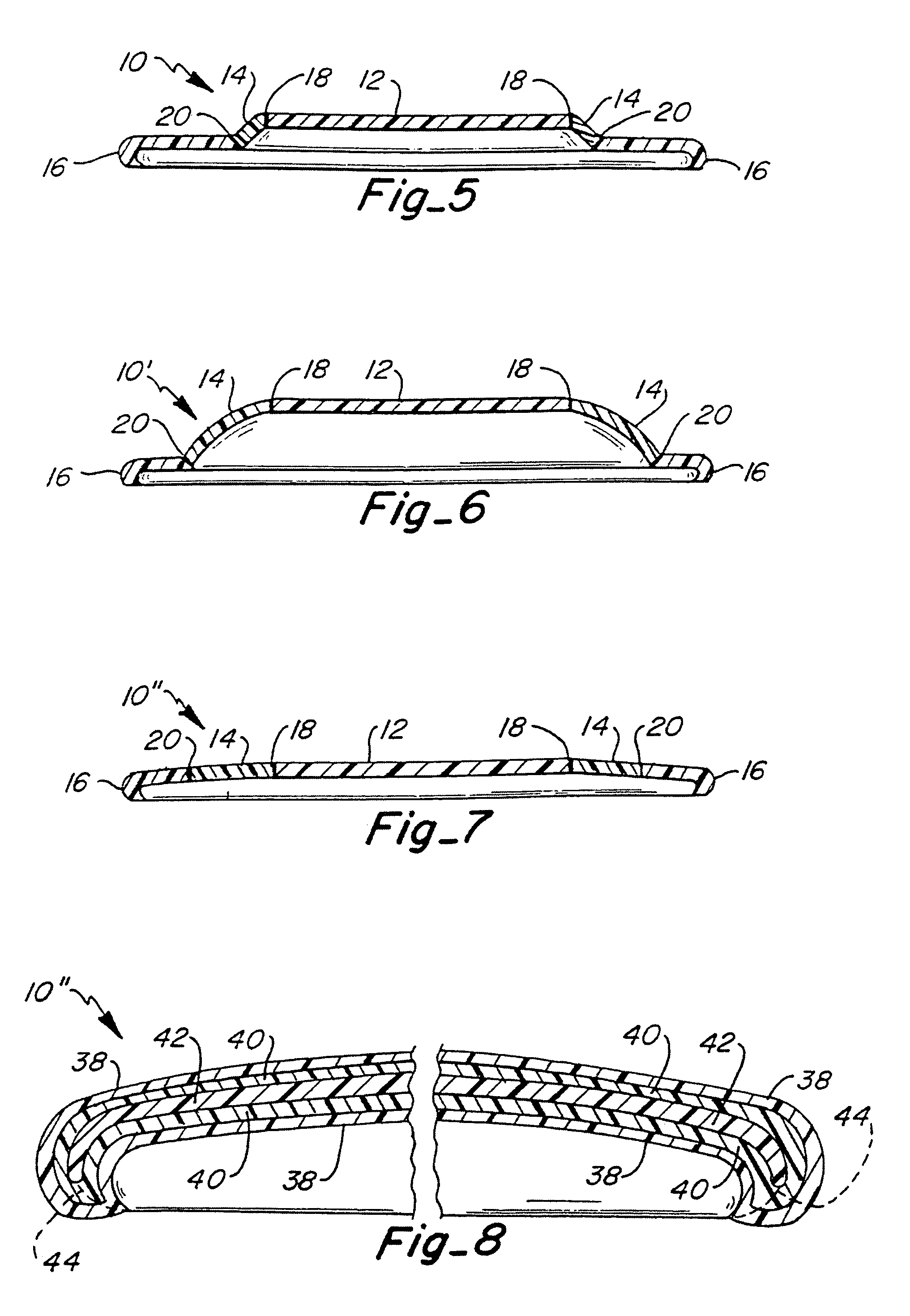

Vegetable-based dog chew

A chew toy having a substantial component of vegetable matter wherein such vegetable matter, in dried and powdered or granulation form, is melted as it is injection molded. The process provides a chew toy with a consistency and chewability preferred by most dogs that is not attainable by known prior art baking or compression molding techniques.

Owner:T F H PUBLICATIONS

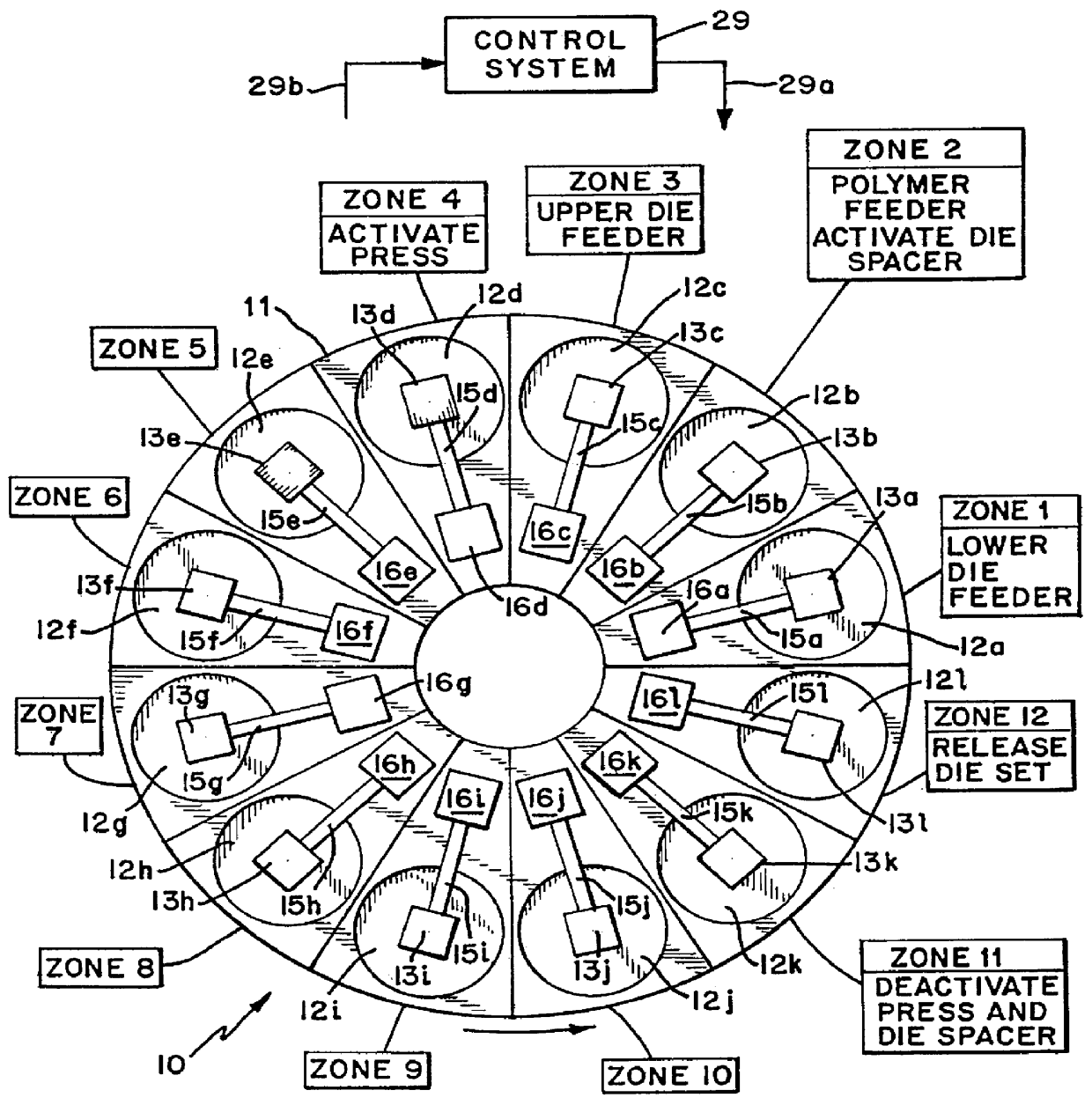

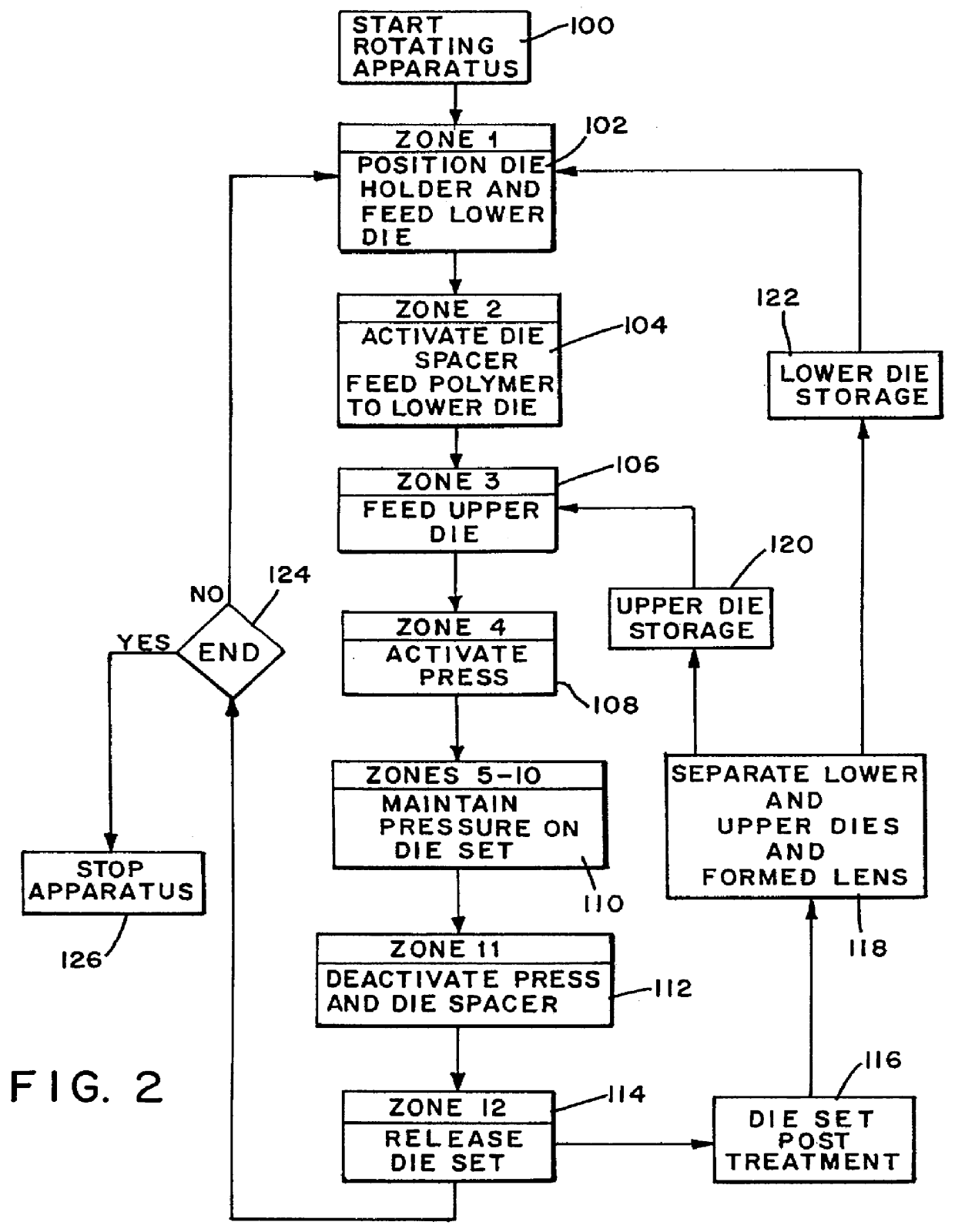

Continuous extrusion-compression molding process for making optical articles

InactiveUS6042754AEasy to processLong lastingRecord carriersConfectioneryCompression moldingShell molding

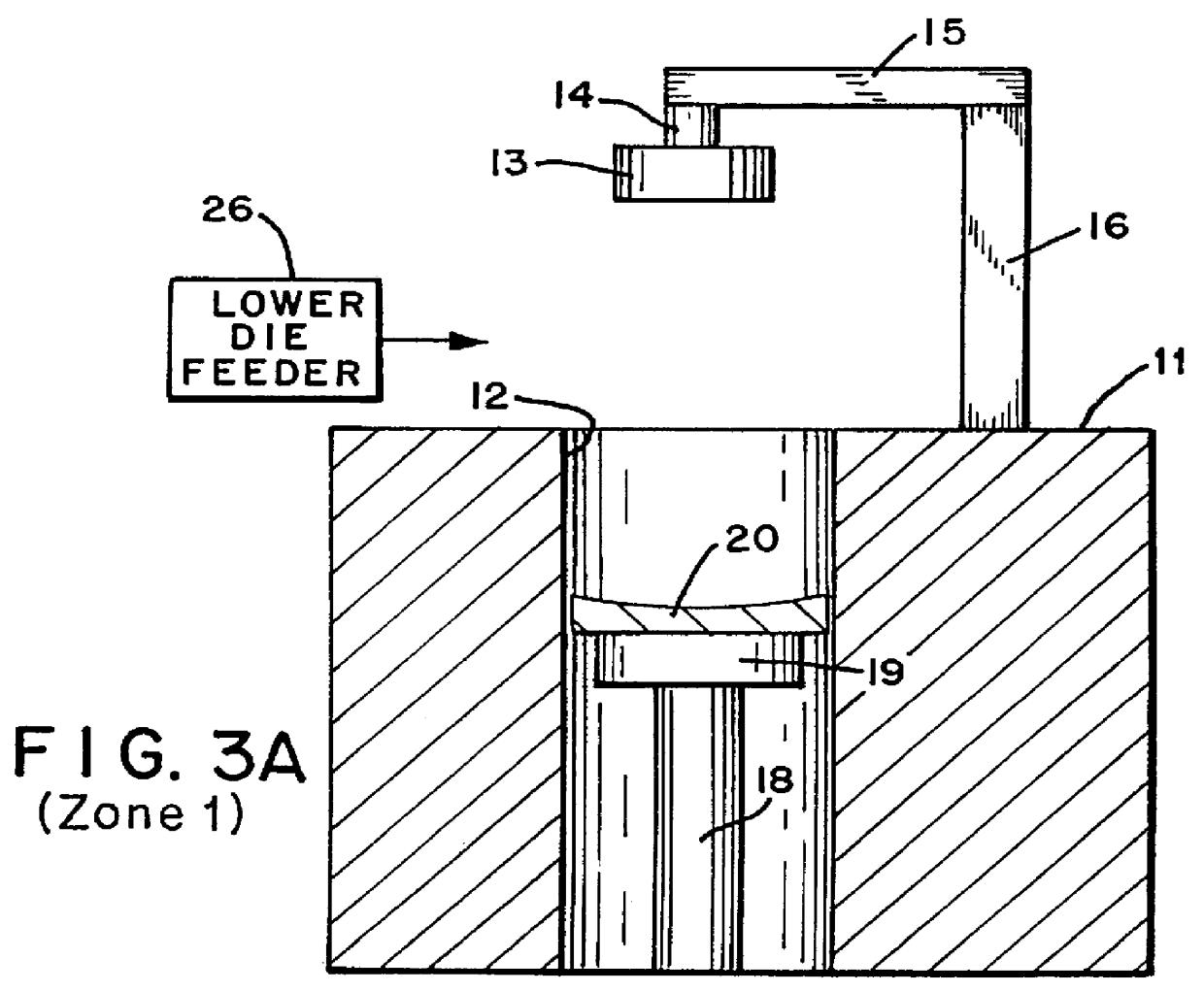

The present invention relates to making optical articles such as opthalmic lenses by molding and, in particular, to using a continuous extrusion-compression molding method to make plastic lenses whereby a polymer melt is fed from an extruder or melting apparatus to a first die of a plurality of rotating or conveyed sequentially processed compression die sets comprising a first die and a second die. The die sets are positioned on die supports on a rotating turntable or conveying system, the lenses formed by compressing the die sets with pressing means associated with each die support, the lenses separated from the dies and the dies recycled to die loading and the melt feed step of the process and the process repeated until the desired number of lenses or other optical articles such as compact disk substrates are produced.

Owner:FOREVER VISION

Enhanced Light Guide

InactiveUS20080043490A1Improved backlight assemblyAvoid less flexibilityVehicle interior lightingProtective devices for lightingCompression moldingEllipsoidal particle

A light guide containing substantially aligned non-spherical particles provides more efficient control of light scattering. One or more regions containing ellipsoidal particles may be used and the particle sizes may vary between 2 and 100 microns in the smaller dimension. The light scattering regions may be substantially orthogonal in their axis of alignment. Alternatively, one or more asymmetrically scattering films can be used in combination with a backlight light guide and a reflector to produce an efficient backlight system. The light guides may be manufactured by embossing, stamping, or compression molding a light guide in a suitable light guide material containing asymmetric particles substantially aligned in one direction. The light scattering light guide or non-scattering light guide may be used with one or more light sources, collimating films or symmetric or asymmetric scattering films.

Owner:CREE LED LIGHTING SOLUTIONS INC

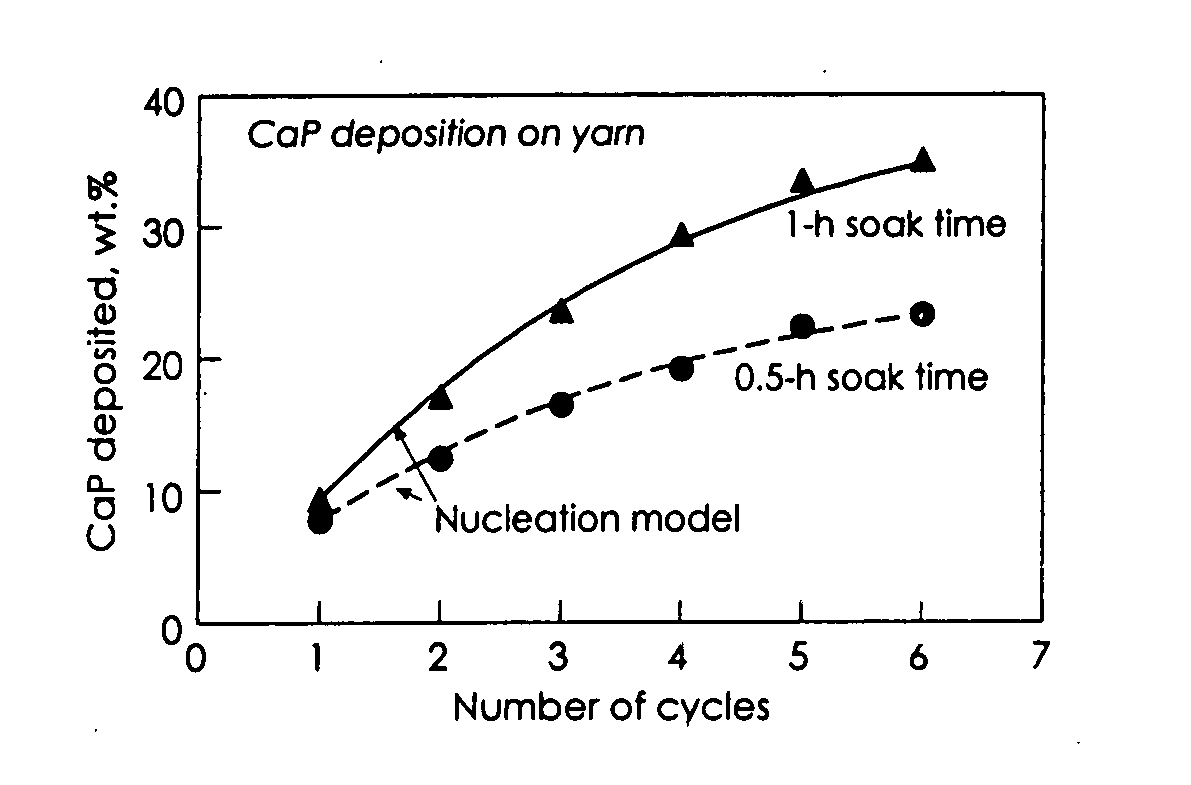

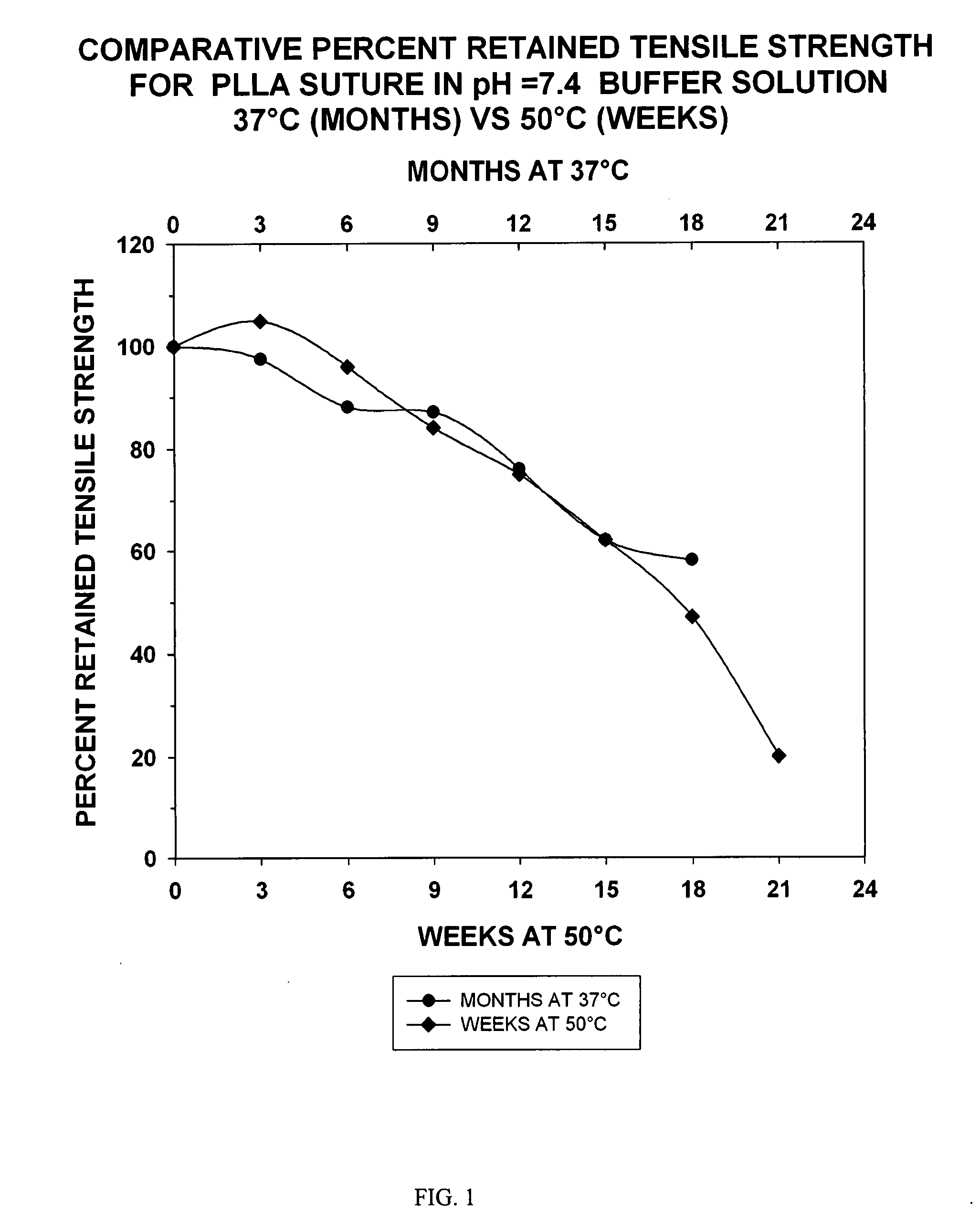

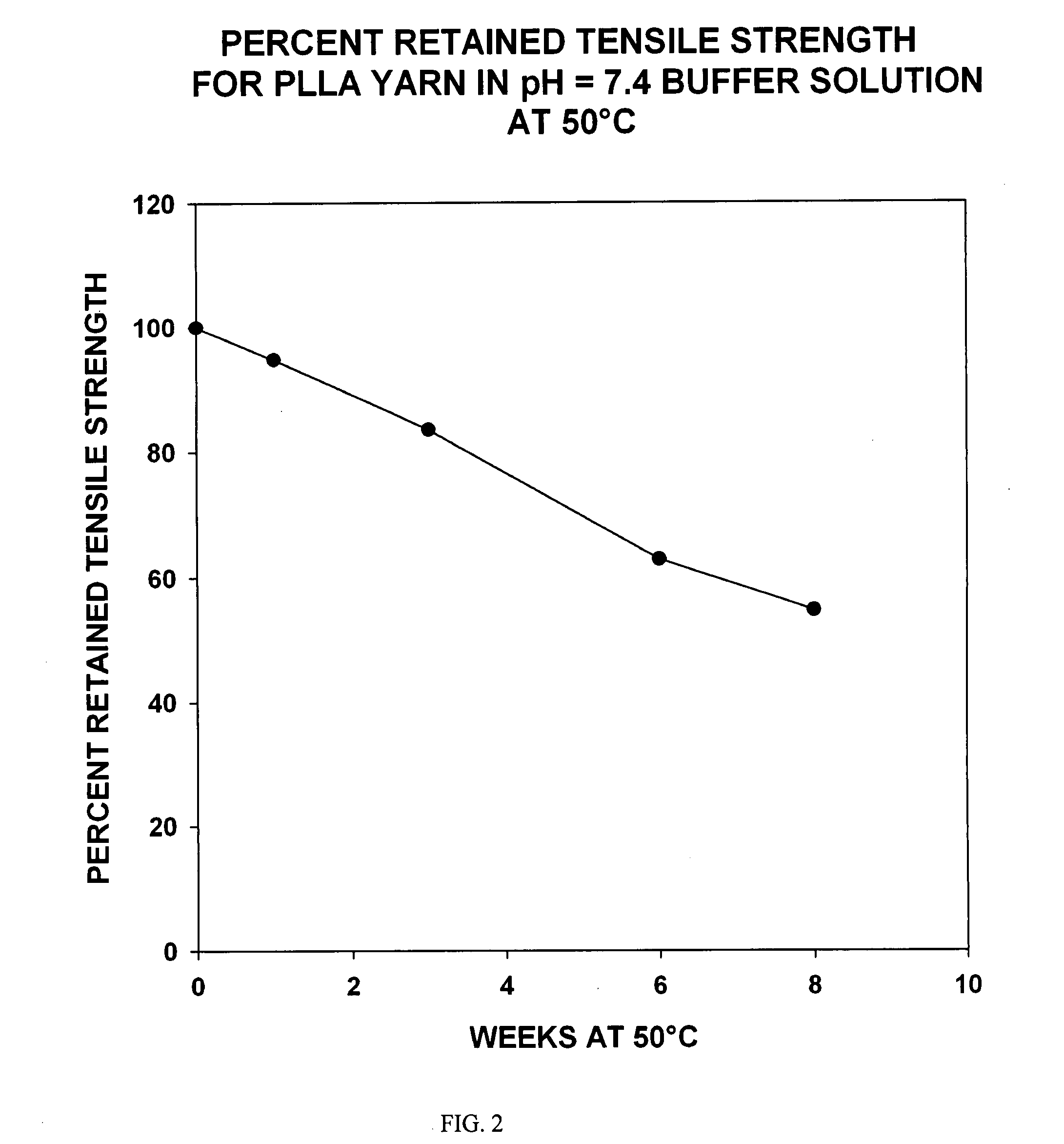

Calcium phosphate polymer composite and method

A bone-repair composite includes a core and a sheath. The core is a first primary unit including a combination of a first set of yarns coated with a calcium phosphate mineral layer. The first set of yarns being made from a first group of one ore more polymers. The sheath is a second primary unit a combination of a second set of yarns or one or more polymer coatings. The second set of yarns being made from a second group of one or more polymers, wherein the composite is made by covering the core with the sheath, and the composite is compression molded to allow the sheath to bond to the core. The bone-repair composite has a bending modulus comparable to that of a mammalian bone, such that the ratio of the core to the sheath is provided to maximize the mechanical strength of the bone-repair composite to mimic the mammalian bone.

Owner:TELEFLEX MEDICAL INC +1

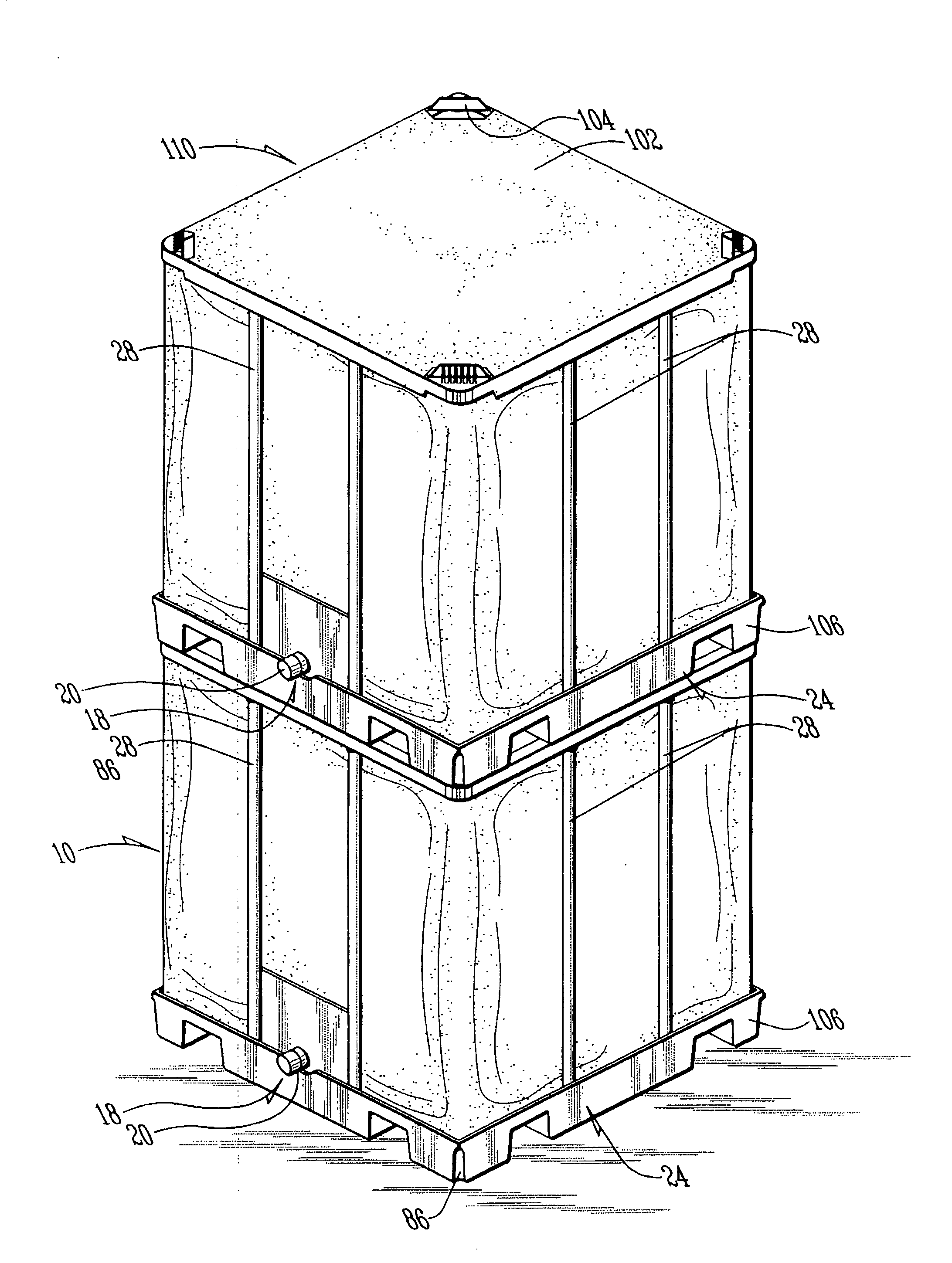

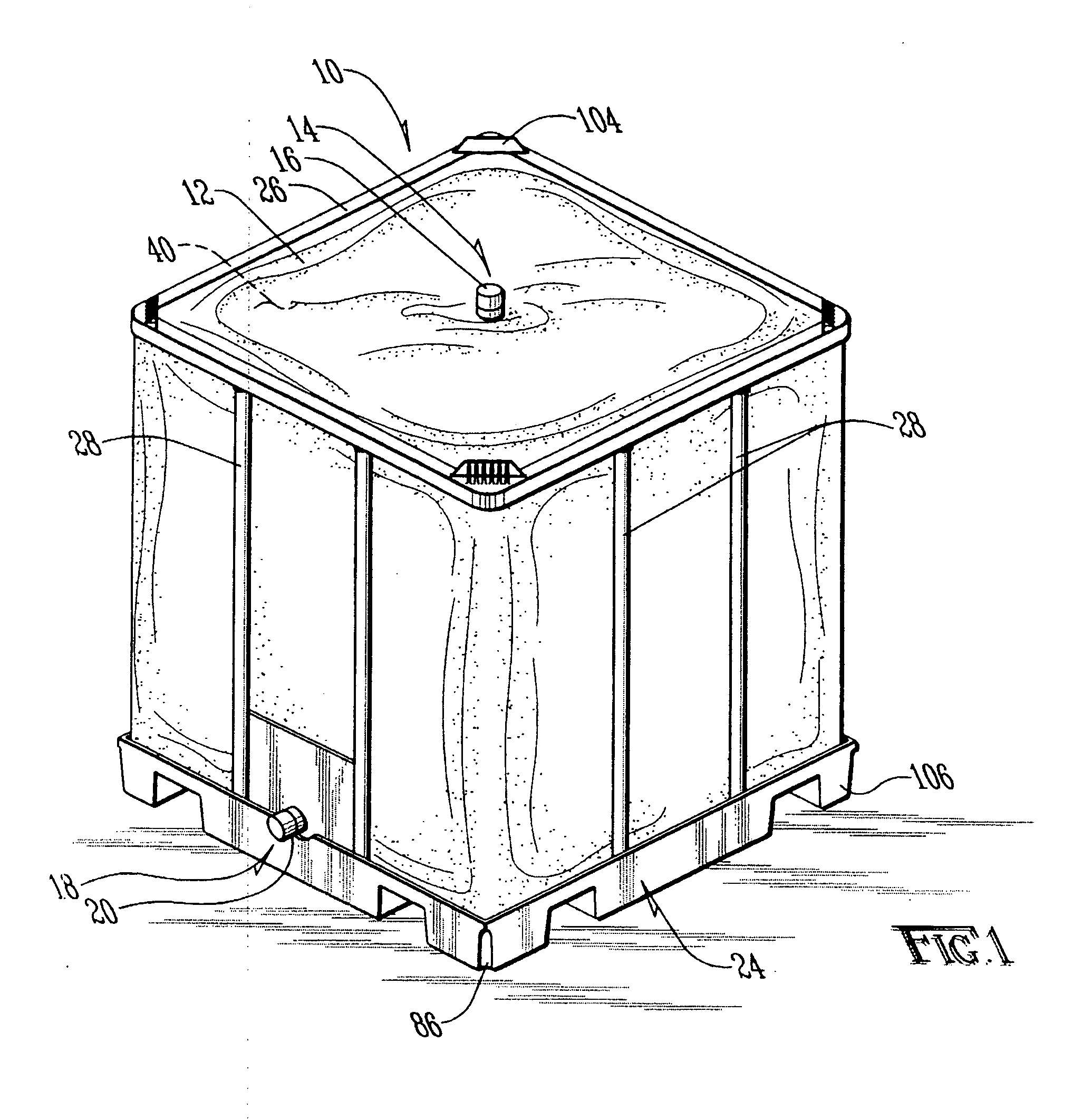

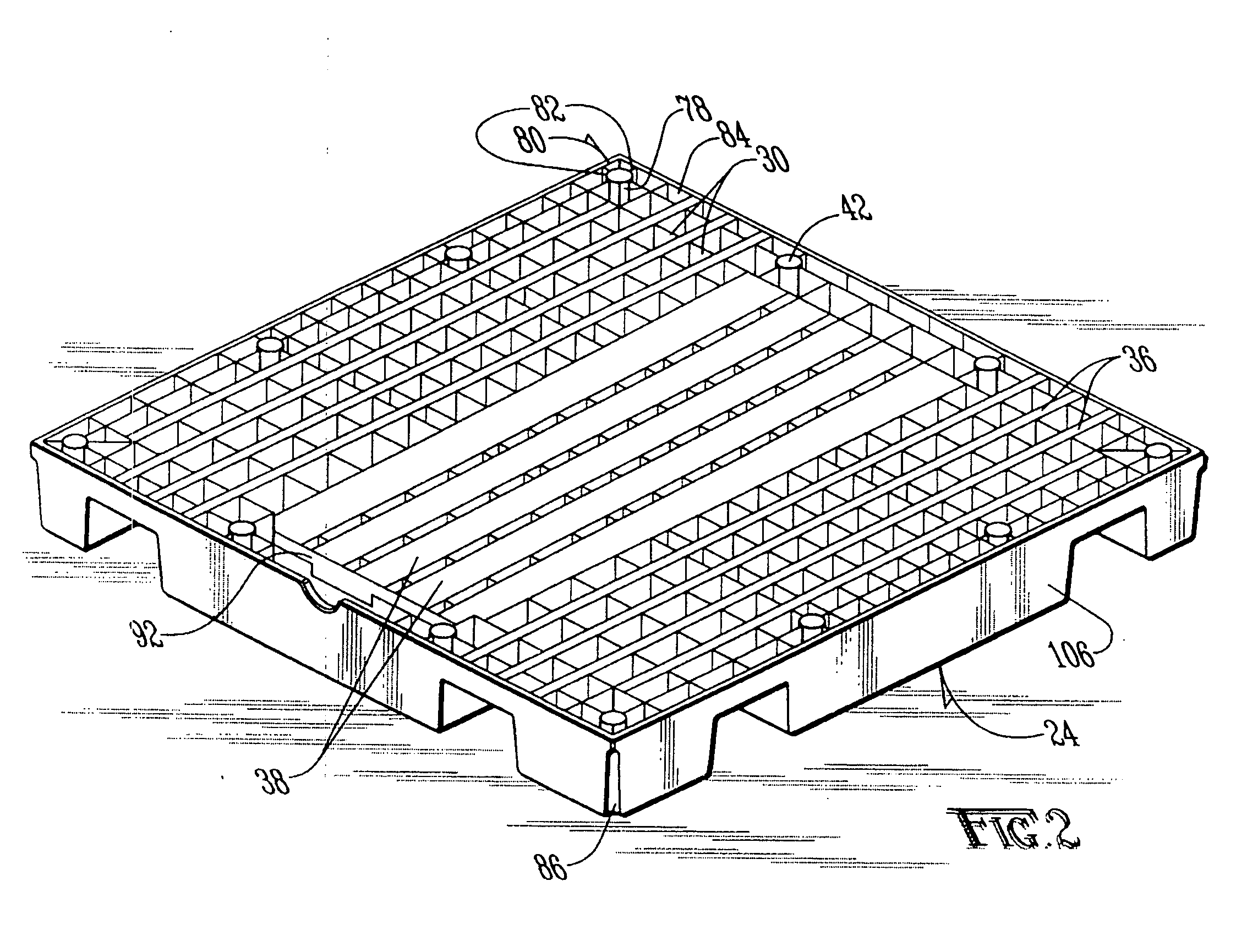

Stackable collapsible container

ActiveUS20100065466A1Low cost manufacturingEasy and low-cost maintenanceLarge containersOther accessoriesCompression moldingEngineering

A stackable, collapsible container for flowable materials. The container utilizes an outer container and a flexible inner liner retained by a base, a top and a plurality of support poles. The support poles are retained in a plurality of holes in the base provided with a plurality of wedges to secure the holes against lateral movement. Providing wedges within tapered holes facilitates the compression molding of the depth of holes required for adequately supporting the support poles.

Owner:PAPER SYST

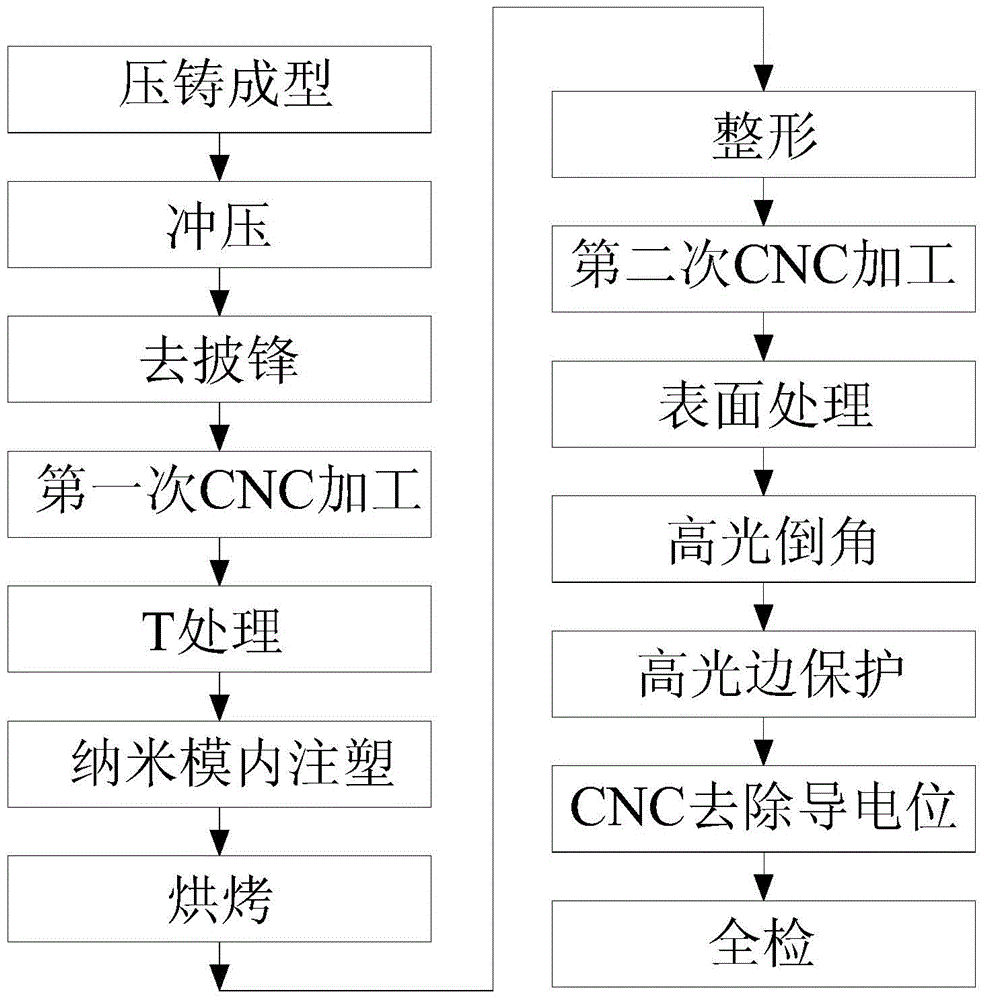

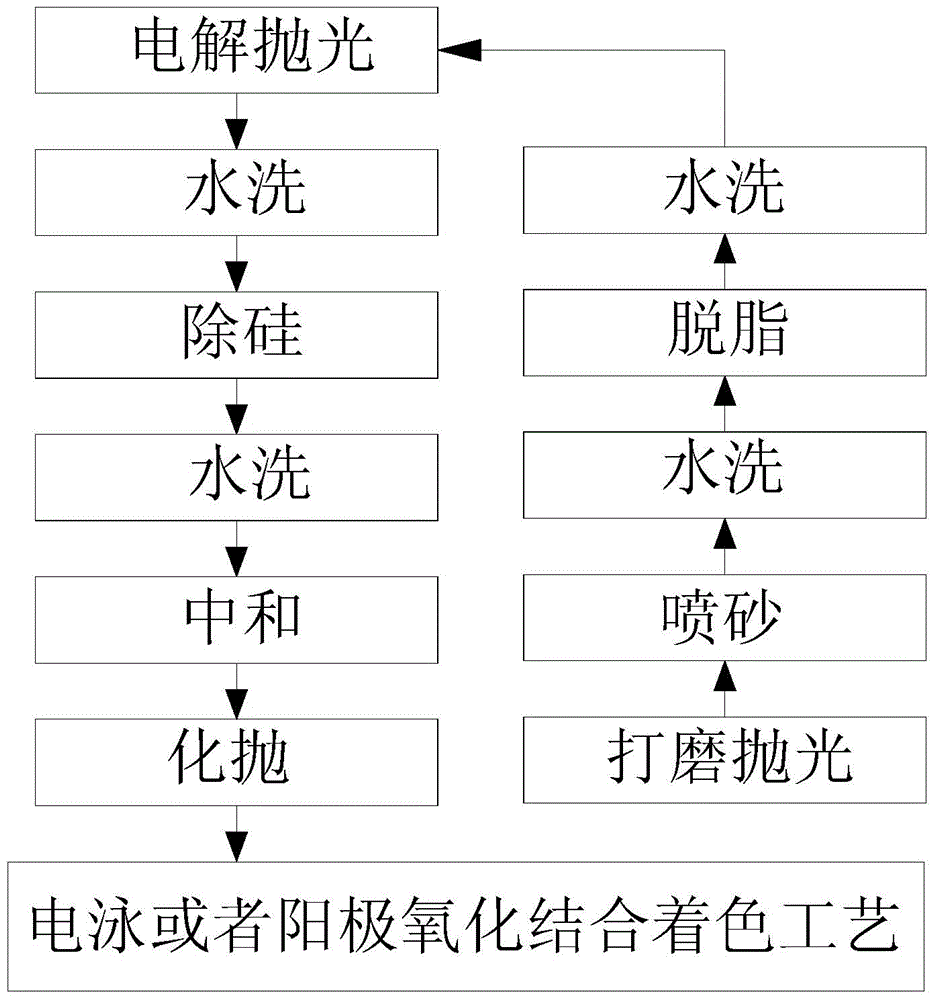

Processing technique of cellphone shell with metal luster

ActiveCN104607884AGuaranteed StrengthReduce processing costsCoatingsNumerical controlAbrasive blasting

The invention provides a processing technique of a cellphone shell with metal luster. The processing technique includes the steps of S1, performing compression molding; S2, performing stamping; S3, performing primary CNC (computer numerical control) machining; S4, performing T treatment; S5, performing injection molding in a nano mold; S6, performing secondary CNC machining; S7, performing surface treatment, to be specific, performing a, polishing, b, shot-blasting, c, degreasing, d, washing, e, electrolytic polishing, f, washing, g, silicon removal aiming to decrease silicon content of the polished surface of the cellphone shell, h, neutralizing, i, chemical polishing, and j, electrophoresis or combination of anodic oxidation and coloring, aiming to impart metal luster to the polished surface of the cellphone shell. The compete cellphone shell is made through the steps S1 to S6, the silicon content of the polished surface of the cellphone shell is processed, the cellphone shell never produces compounds of intervals such as Al-Mg-Si-Fe during following anodic oxidation, defects such as oxide film darkening, bluing or milky-whiting are avoided, and the metal-lustered cellphone shell is manufactured through the complete process.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Closures for bottles

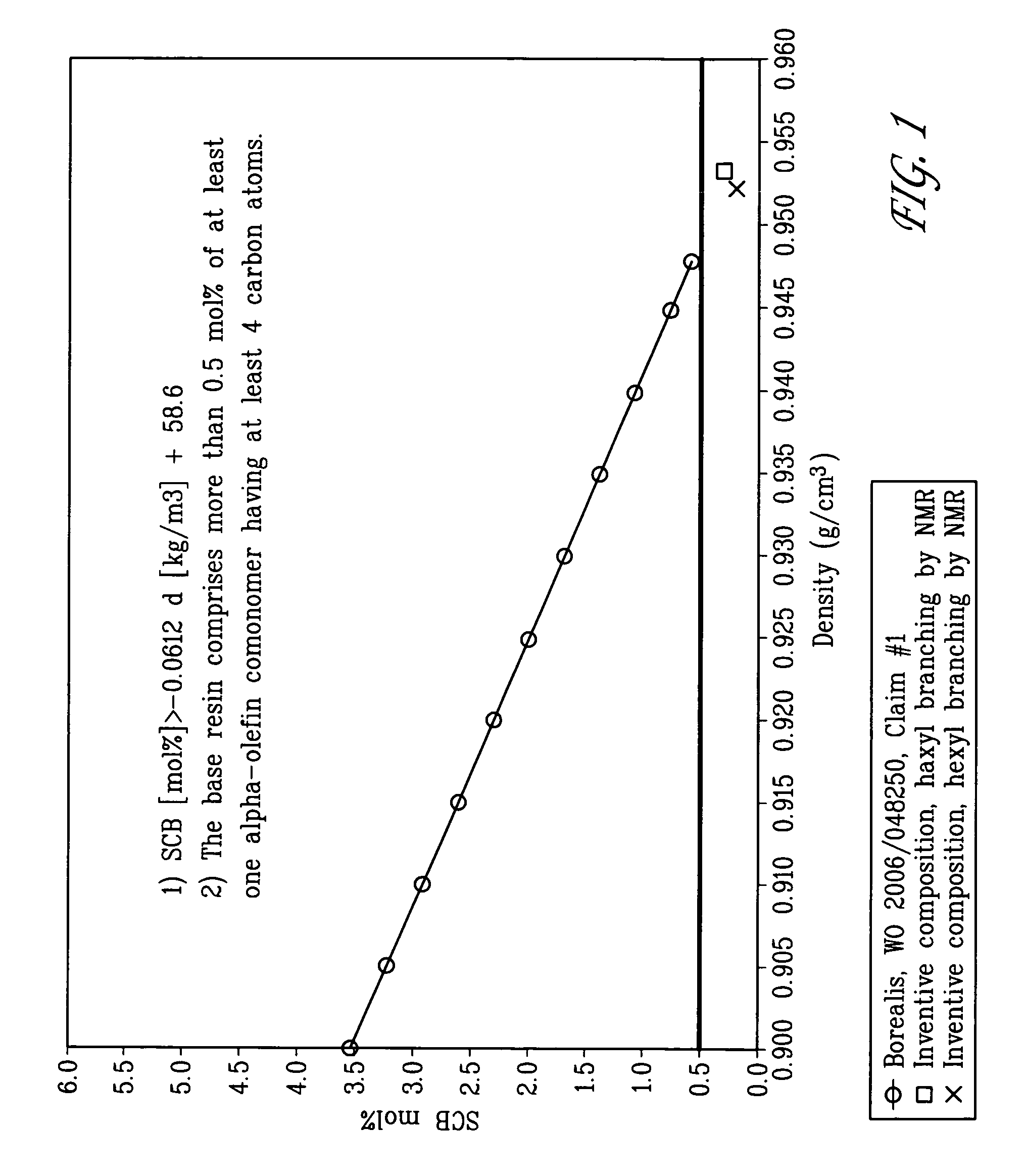

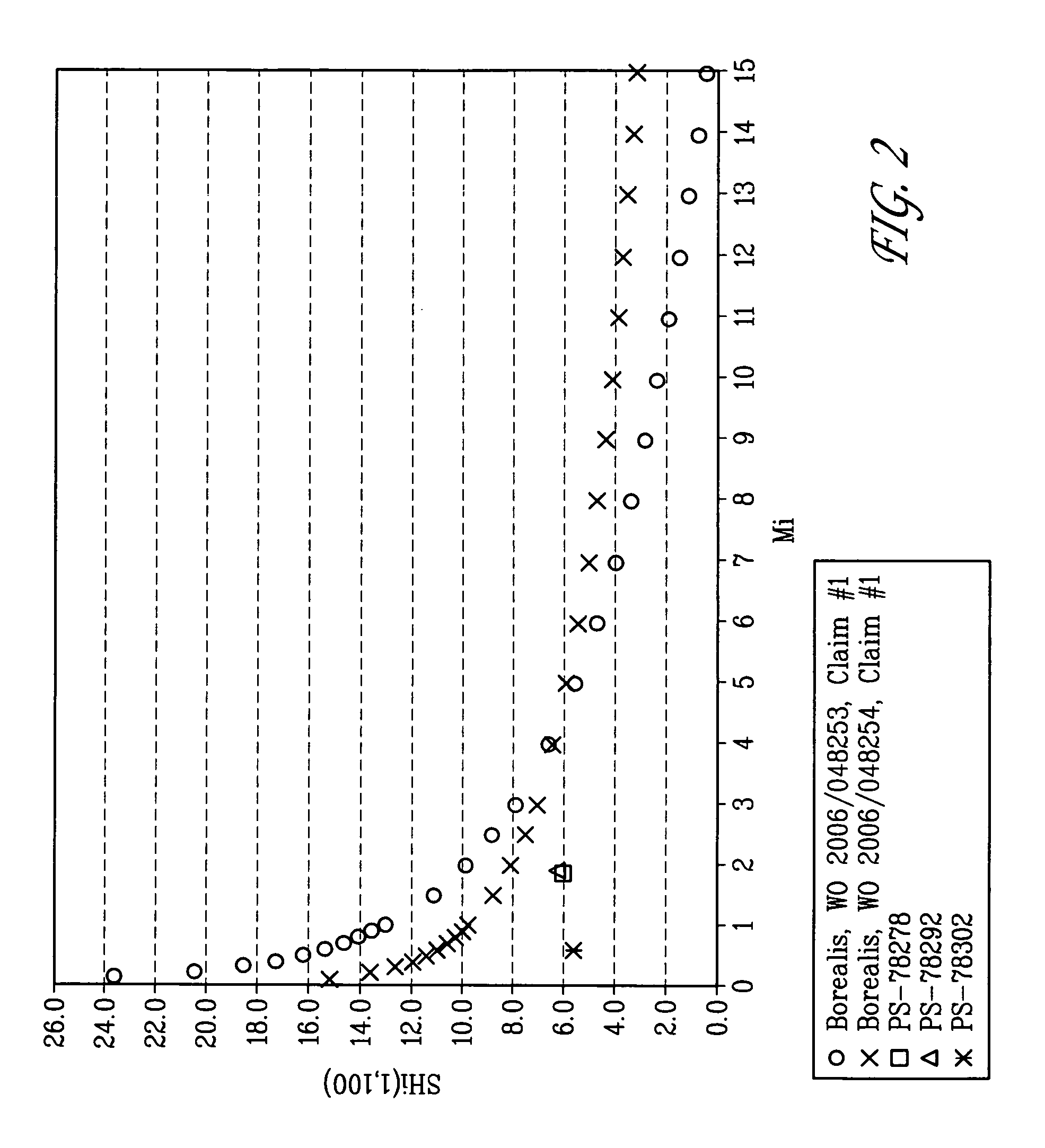

ActiveUS8022143B2Improved balance of Theological and processing and organoleptic propertyCompression moldingPolymer science

A dual reactor solution process gives high density polyethylene compositions containing a first ethylene polymer and a second ethylene polymer which have a good balance of processability, toughness, and environmental stress crack resistance combined with good organoleptic properties. The polyethylene compositions are suitable for compression molding or injection molding applications and are particularly useful in the manufacture of caps and closures for bottles.

Owner:NOVA CHEM (INT) SA

Method of forming a mold and molding a micro-device

A method of forming a device including a plurality of micron or sub-micron sized features is provided. A master having a surface contour defining a plurality of features is provided. The surface contour of the master is coated with at least one layer of material to form a shell. The master is removed from the shell to form a negative image of the surface contour in the shell. The negative image in the shell is filled with material, for example, polycarbonate, polyacrylic, or polystyrene, to form a device having features substantially the same as the master. The negative image may be filled using injection molding, compression molding, embossing or any other compatible technique.

Owner:BECTON DICKINSON & CO

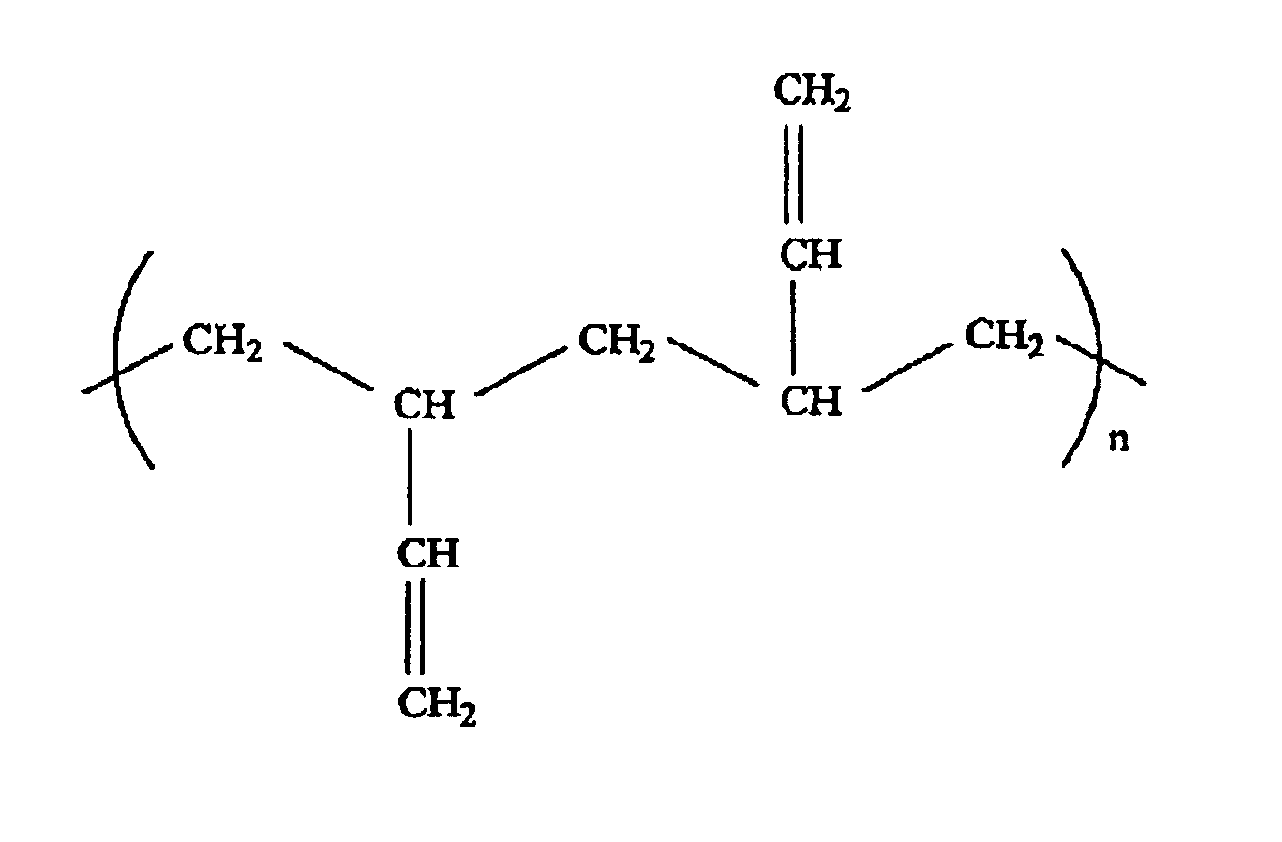

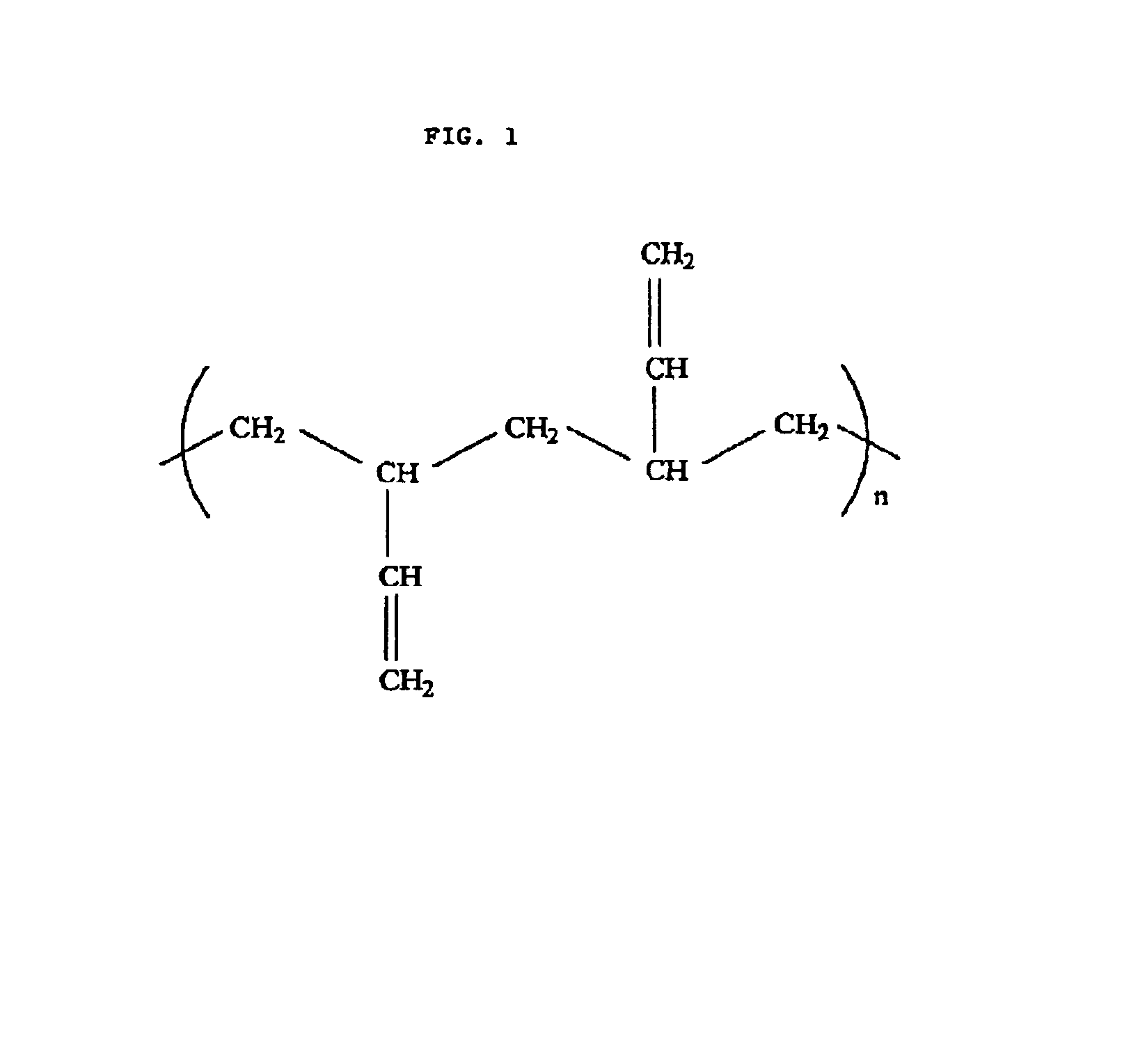

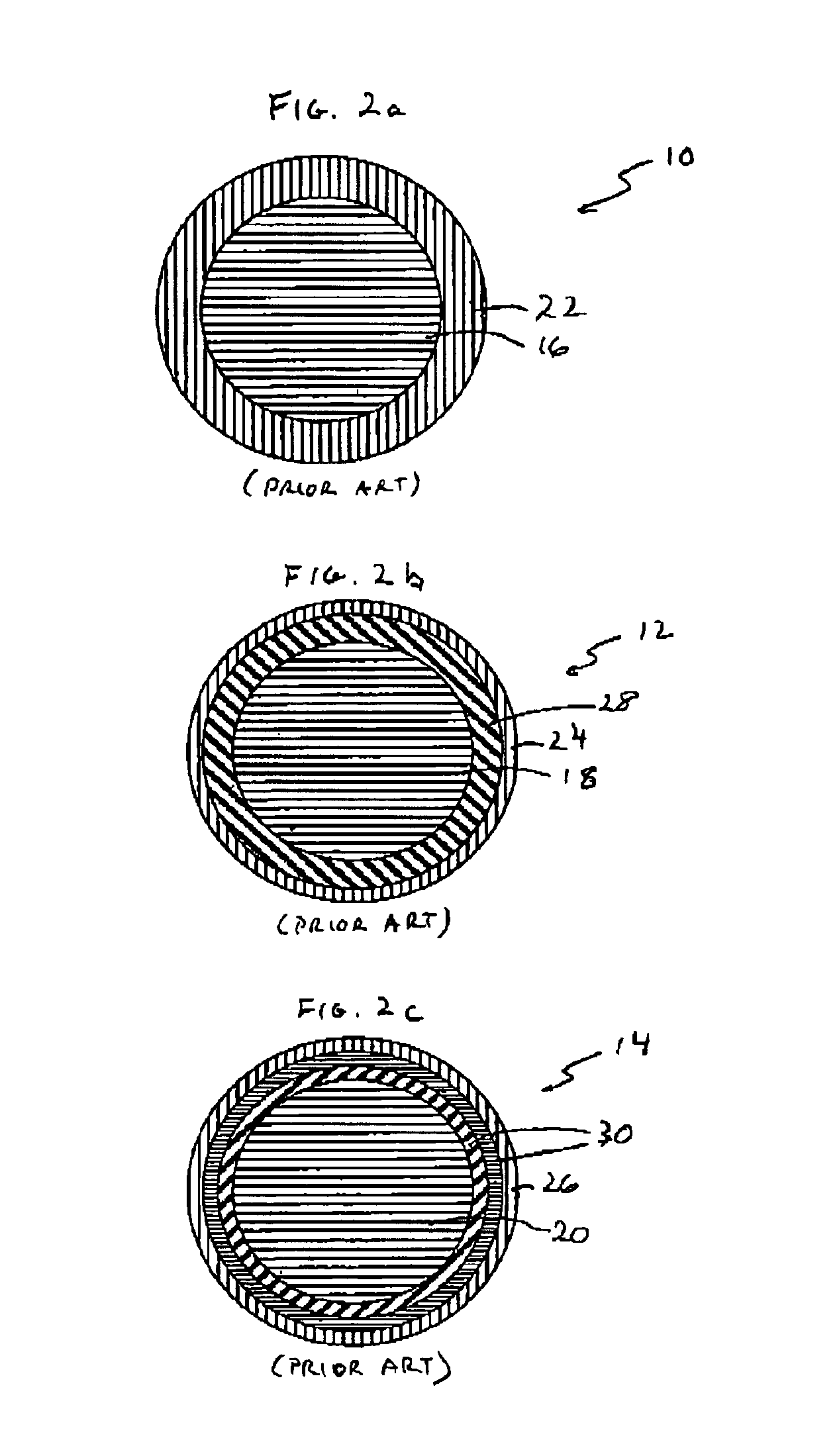

Golf balls, golf ball compositions, and methods of manufacture

Golf balls and compositions for use in ball cores, covers and intermediate layers incorporate syndiotactic 1,2-polybutadiene having crystallinity and other specified physical properties. Golf balls incorporating the compositions of the present invention provide flexibility in golf ball design to improve ball performance, such as hit feel and spin rate, without adversely affecting shear-cut resistance of the ball. Also, methods for making golf balls include preparing a composition comprising syndiotactic 1,2-polybutadiene having crystallinity, and then incorporating the composition into a golf ball. The methods can include injection molding only, or injection and compression molding. When the composition being molded incorporates crosslinking agents, co-crosslinking agents, or crosslinking accelerators, preferred methods include inducing partial or total crosslinking of the composition at preferred steps of making the golf balls.

Owner:TAYLOR MADE GOLF

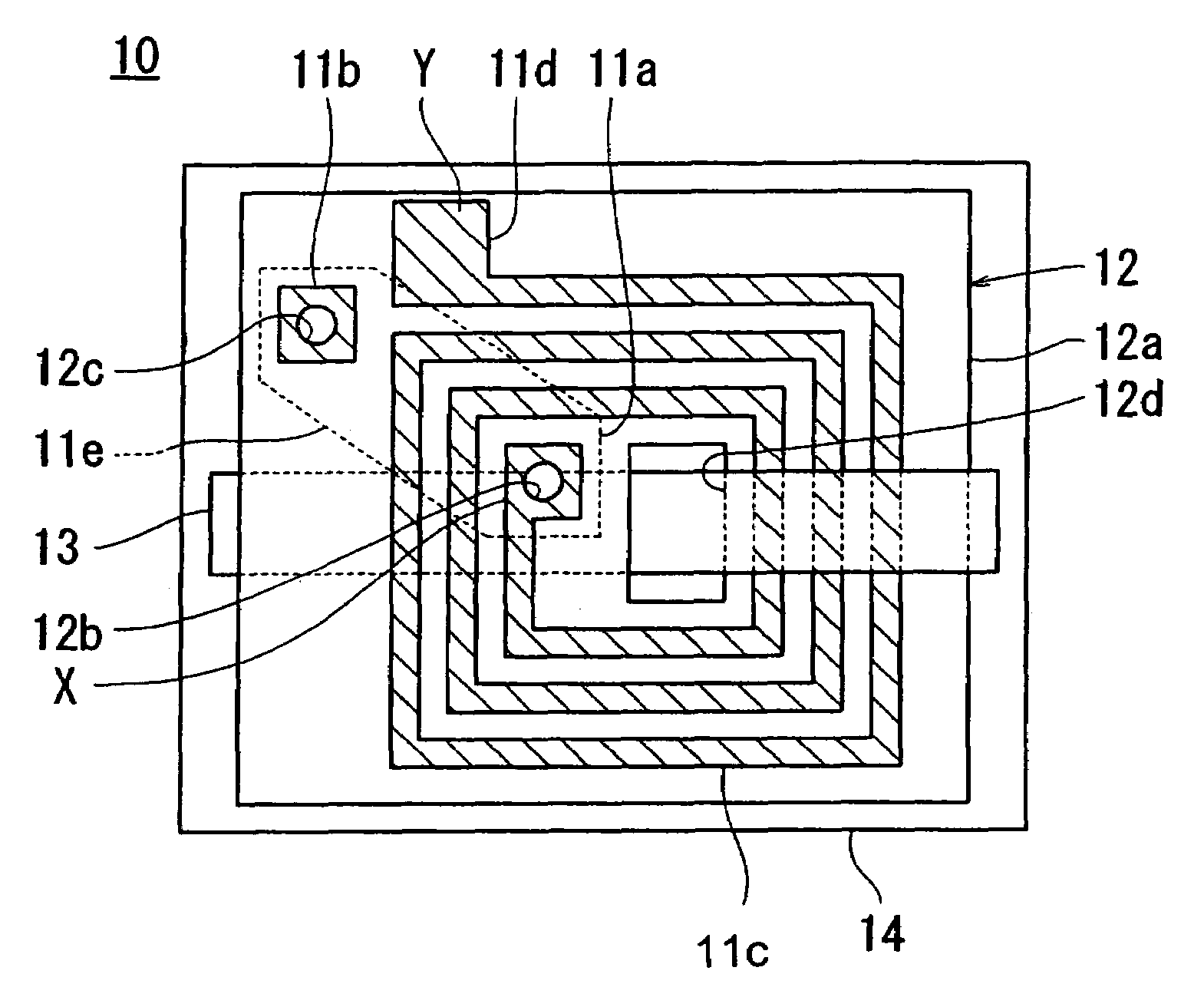

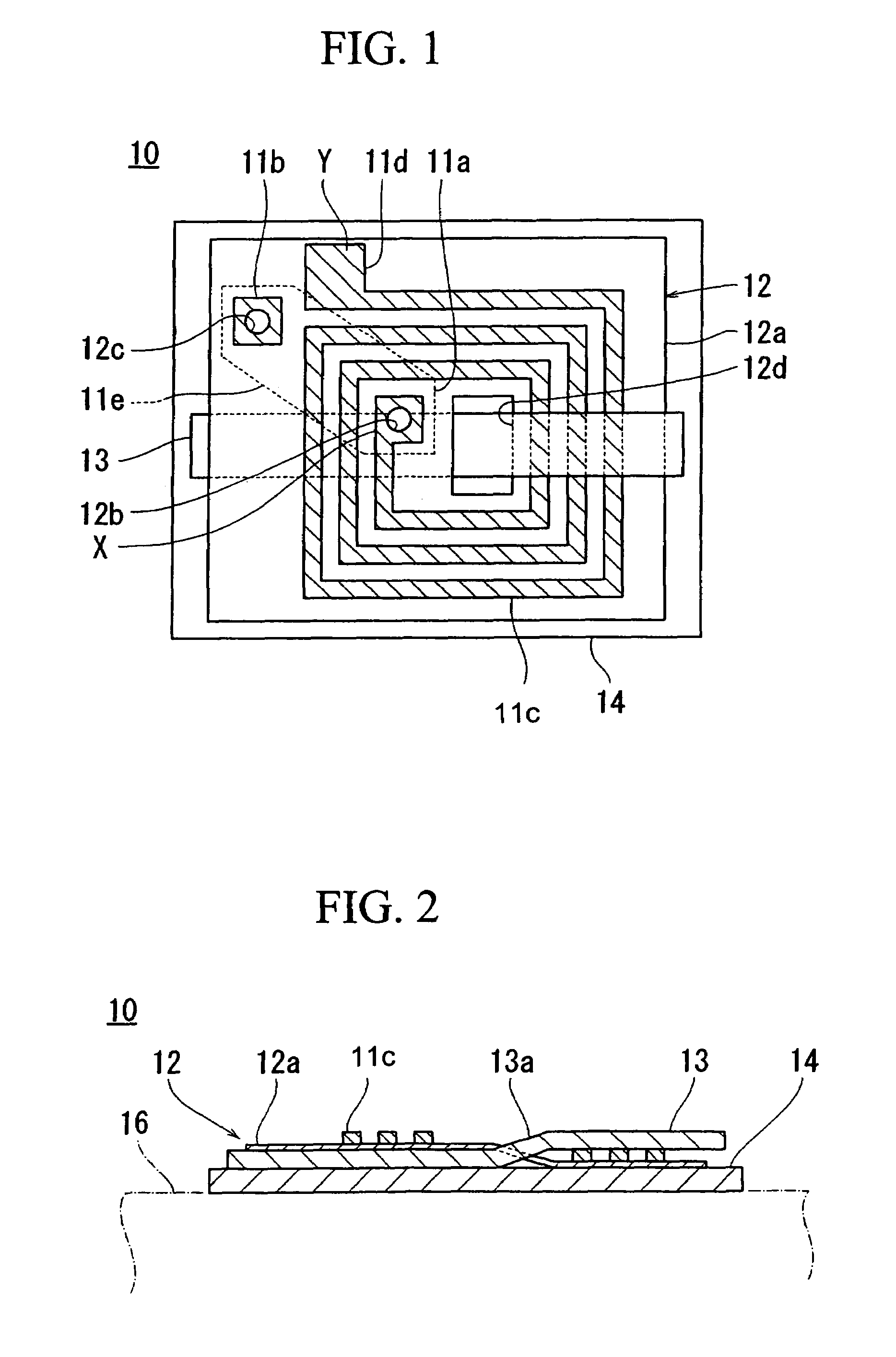

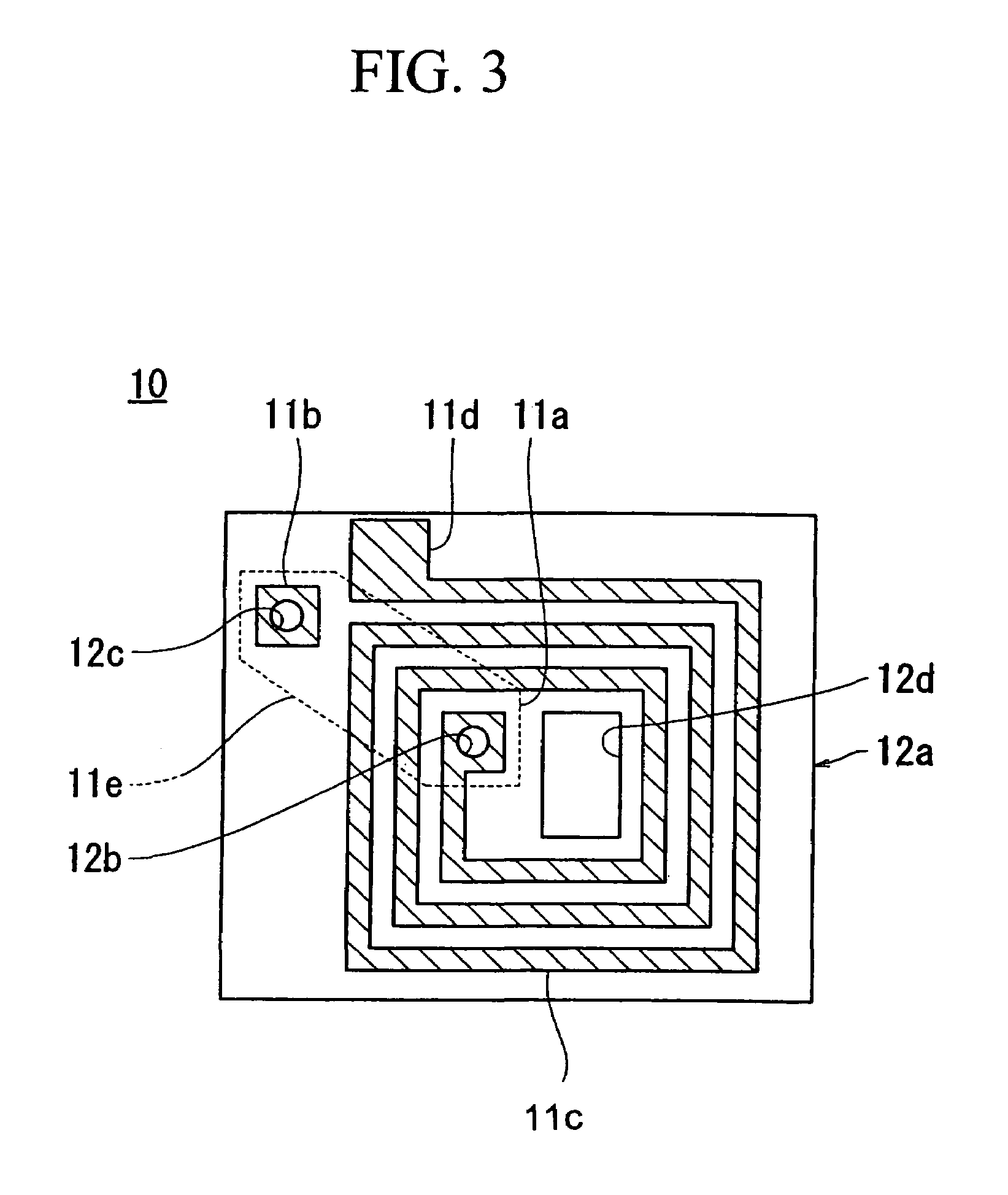

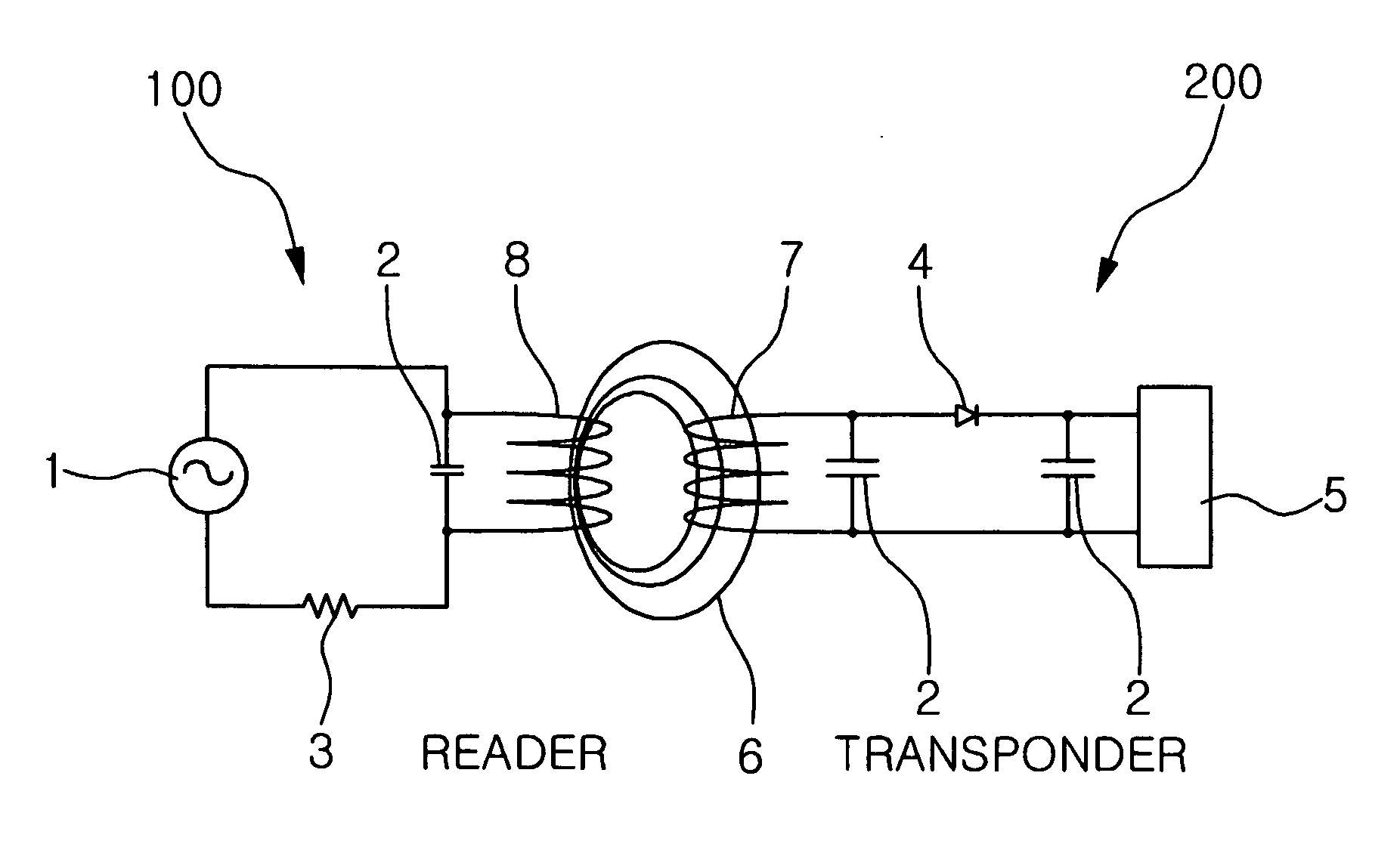

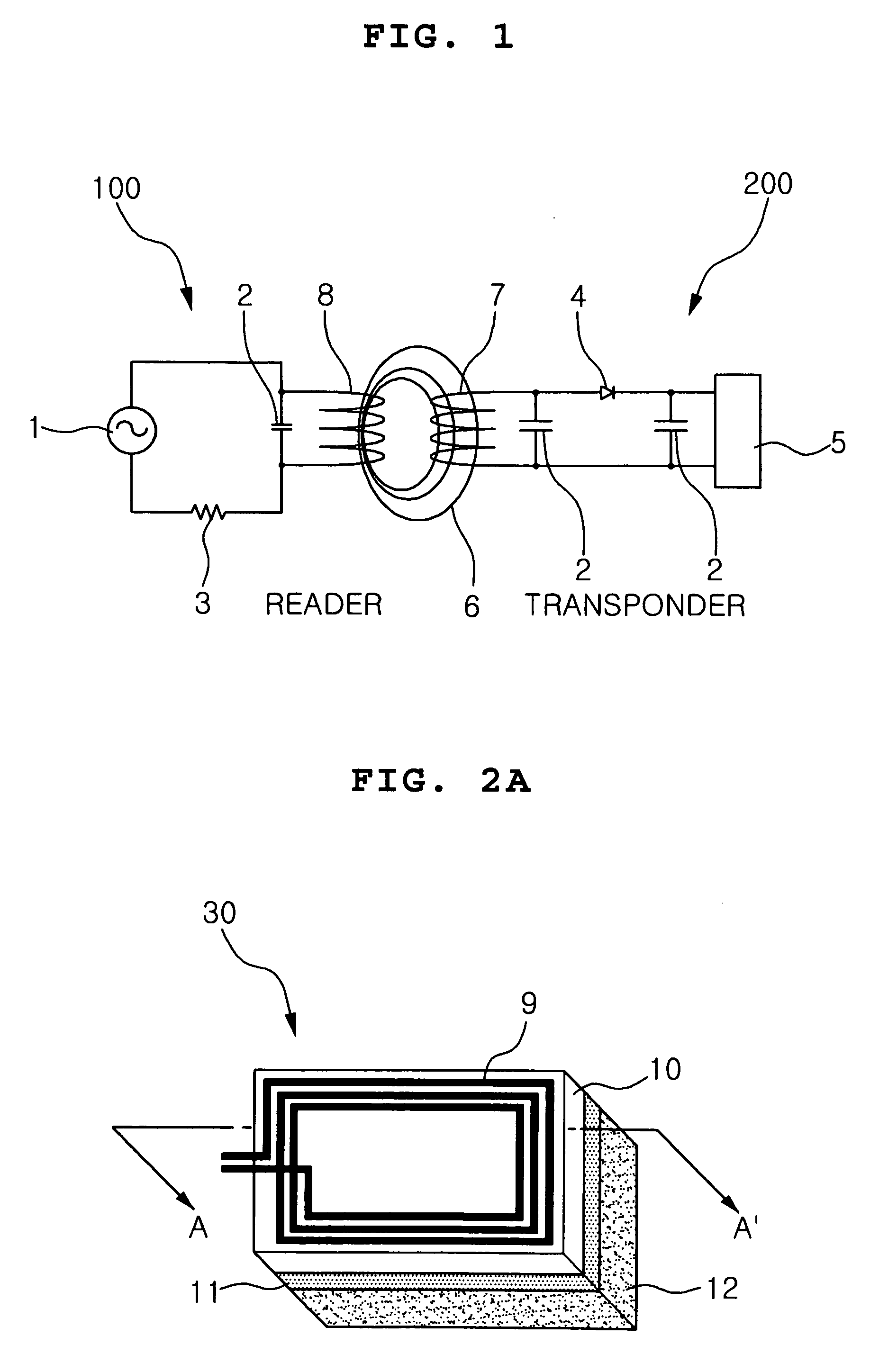

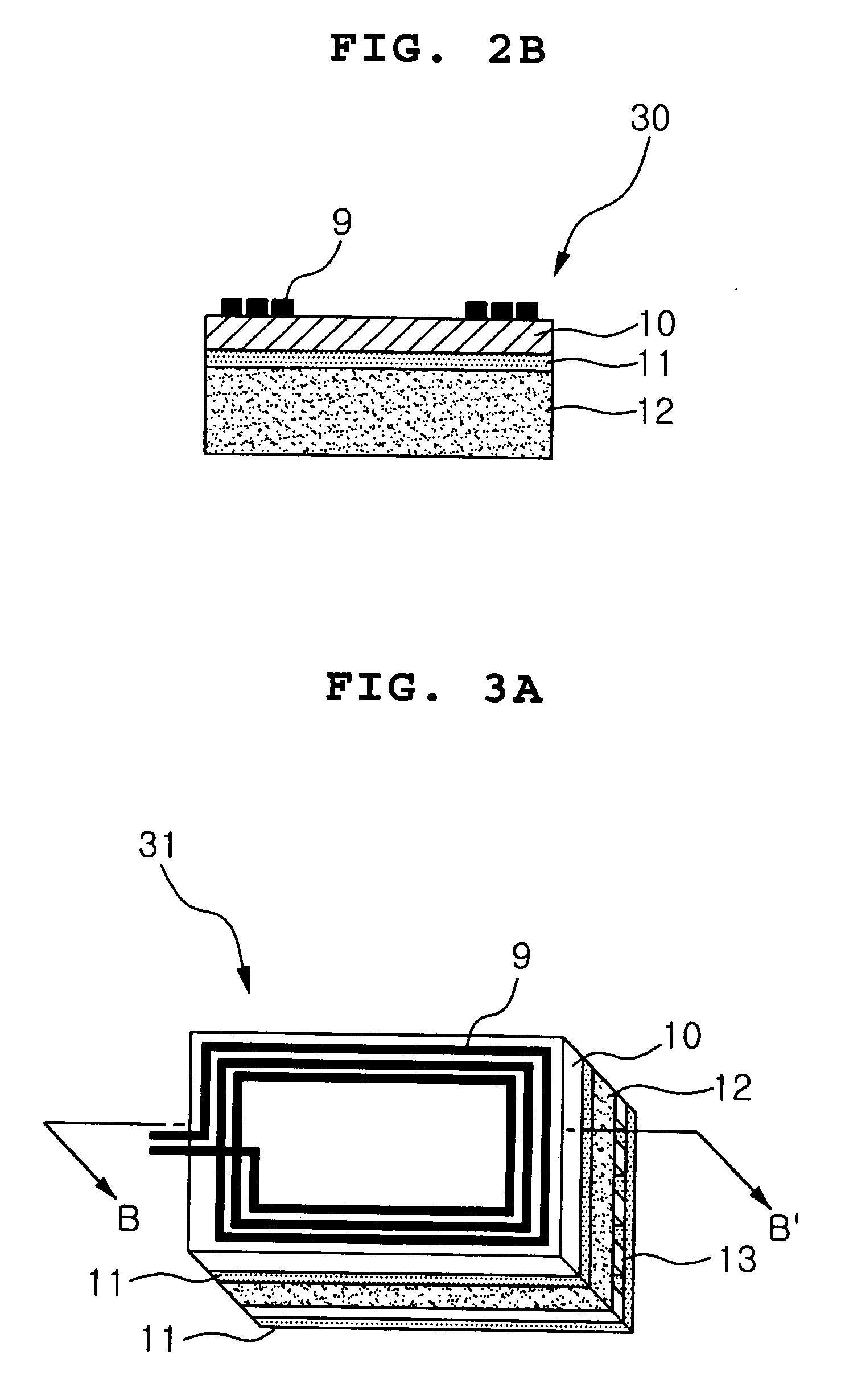

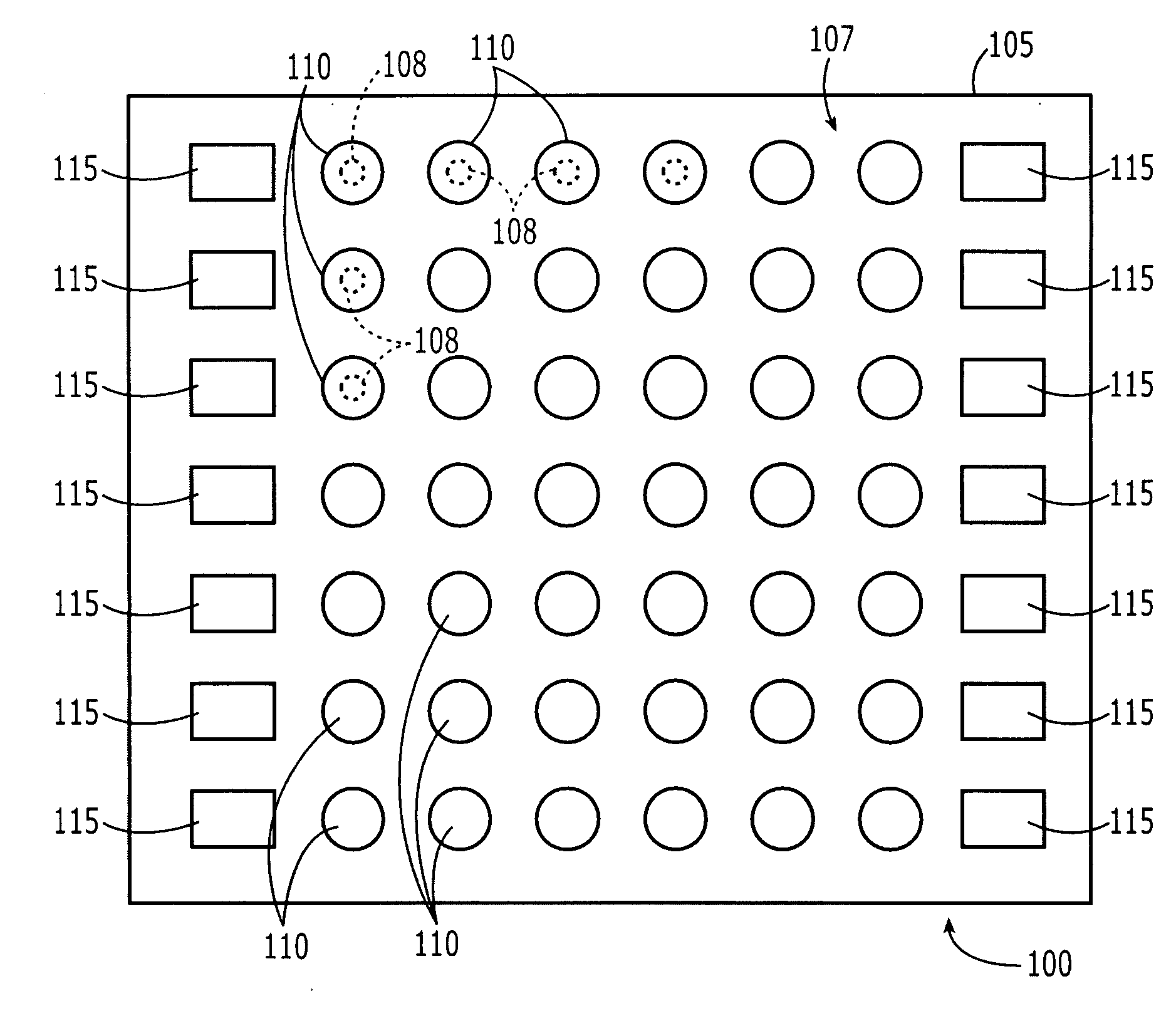

Antenna coil, and RFID-use tag using it, transponder-use antenna

InactiveUS7088304B2Improve rigidityHigh frequencyLoop antennas with ferromagnetic coreOther printing matterEngineeringNon magnetic

An antenna coil includes an air-core coil wound helically in a plane and a plate magnetic core member inserted in the air-core coil to be approximately parallel with a plane of the air-core coil. The magnetic core member is formed by a soft magnetic metal, an amorphous or ferrite, or a composite member of a powder, flake and plastic, or rubber. The magnetic core member is formed by performing an injection molding operation or a compressing molding operation of the composite member. Alternatively, the magnetic core member is a magnetic coating formed by applying and drying the composite member. A non-magnetic conductive plate that has a conductivity is layered on a surface of the air-core coil through which the magnetic core member is inserted. The conductive plate is made of a copper, a copper alloy, an aluminum or an aluminum alloy having 0.01 to 2 mm thickness. The antenna coil is operated by relatively high frequency while it is rigid relatively.

Owner:MITSUBISHI MATERIALS CORP

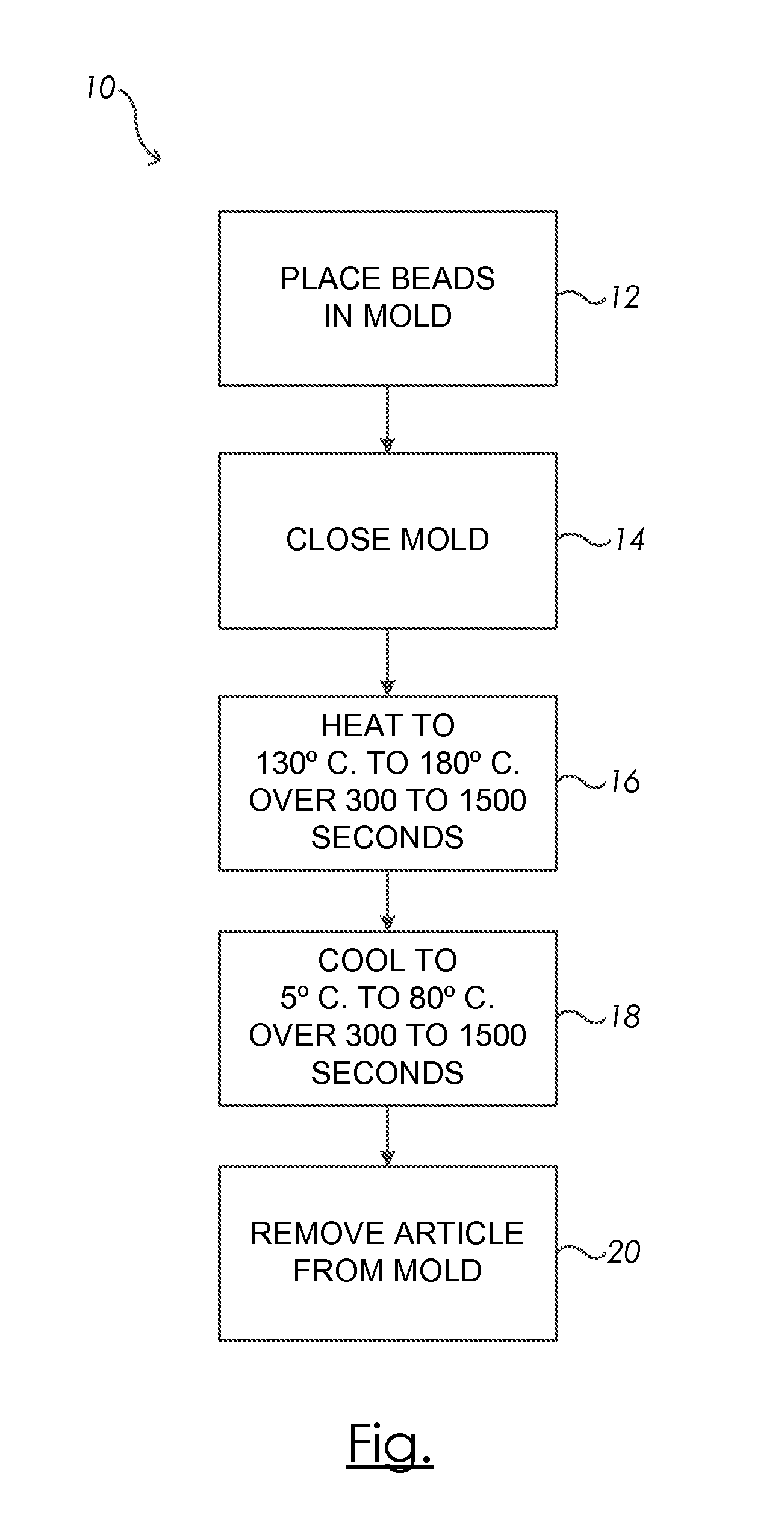

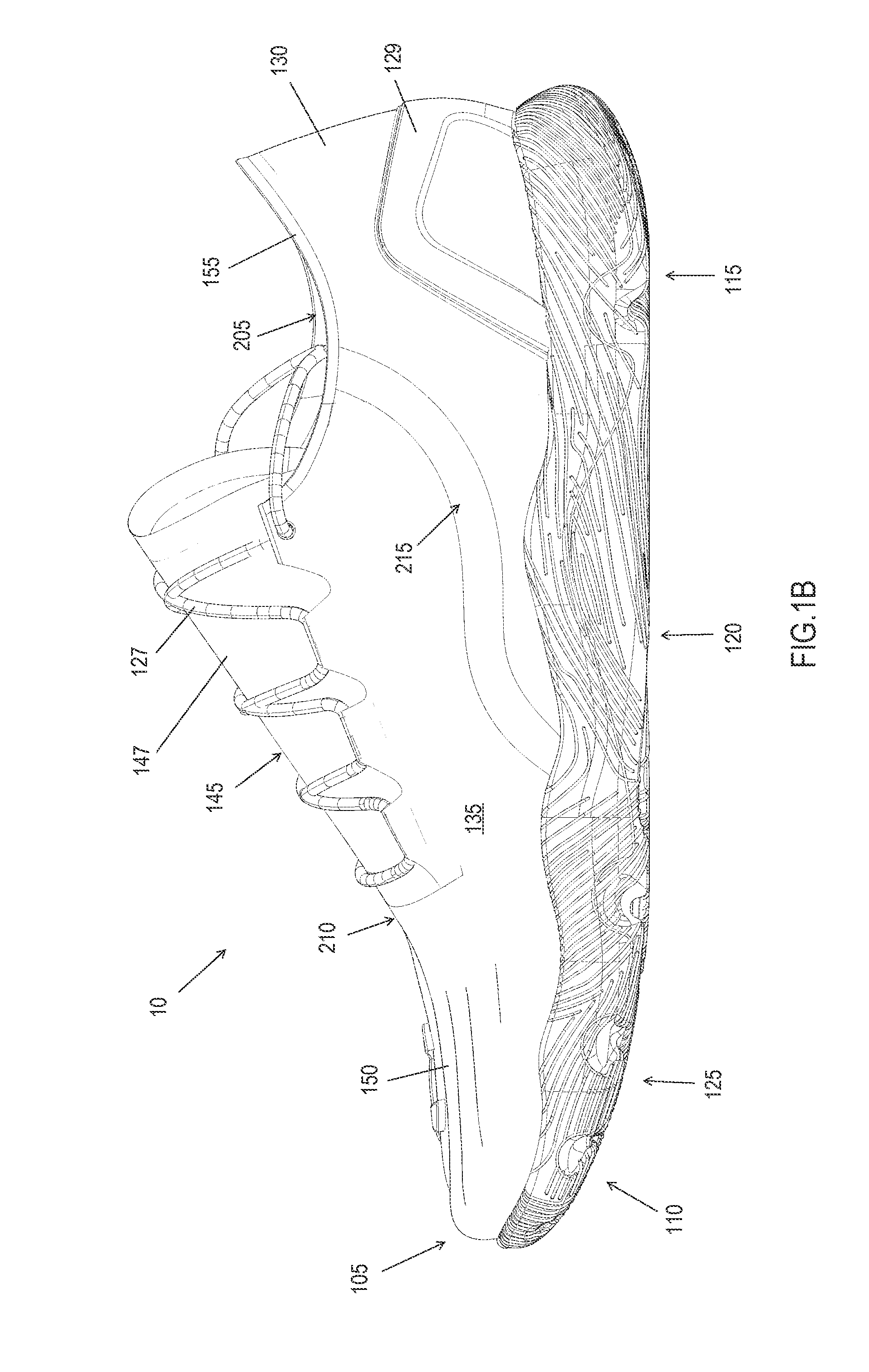

Bead Foam Compression Molding Method for Low Density Product

ActiveUS20140017450A1Low densityOptimization definitionSolesLayered productsCompression moldingThermoplastic polyurethane

Disclosed is a method for molding a foamed article, such as a midsole or outsole for footwear, in which a desired amount of thermoplastic polyurethane foam beads are placed in a compression mold in the shape of the article and the mold is brought to a peak temperature of from about 130° C. to about 180° C. over a period of from about 300 to about 1500 seconds, then cooled to from about 5° C. to about 80° C. over a period of from about 300 to about 1500 seconds within about 30 seconds after the peak temperature is reached. The foamed article made by the method has a density of from about 0.1 to about 0.45 g / cm3.

Owner:NIKE INTERNATIONAL LTD

Fiber-Reinforced Thermoplastic Resin Molded Article, Molding Material, and Method for Production of the Molded Article

ActiveUS20090004453A1Improve mechanical propertiesEasy to operateSynthetic resin layered productsSpecial tyresCompression moldingCarbon fibers

According to the present invention, a fiber-reinforced thermoplastic resin molded article in which monofilamentous carbon fibers are contained in a thermoplastic resin in a high content, such fibers having long fiber lengths and being randomly arranged, is provided. Also, a molding material comprising monofilamentous carbon fibers and monofilamentous thermoplastic resin fibers, in which the carbon fibers are contained in a high content, such fibers having long fiber lengths and being randomly arranged, is provided. In addition, a method for producing a fiber-reinforced thermoplastic resin molded article, comprising molding the molding material by compression molding, is provided.

Owner:TORAY IND INC

Magnetic sheet for radio frequency identification antenna, method of manufacturing the same, and radio frequency identification antenna using the same

InactiveUS20060266435A1Thickness can be thin and uniformLow costAntenna supports/mountingsInorganic material magnetismCompression moldingAlloy

Provided are a magnetic sheet for use in a radio frequency identification (RFID) antenna, an RFID antenna including the magnetic sheet, and a method of manufacturing the magnetic sheet, in which the magnetic sheet includes an amorphous alloy selected from the group consisting of Fe—Si—B, Fe—Si—B—Cu—Nb, Fe—Zr—B and Co—Fe—Si—B. The magnetic sheet is made by laminating amorphous alloy ribbons made of an amorphous alloy between magnetic sheet layers formed of alloy powder including at least one amorphous alloy and then compression-molding the amorphous alloy ribbons, to thereby control microcrack of the amorphous alloy ribbons and enhance characteristic of an end-product. The magnetic sheet is also thin, and has an excellent magnetic permeability, and a simple manufacturing process.

Owner:AMOTECH

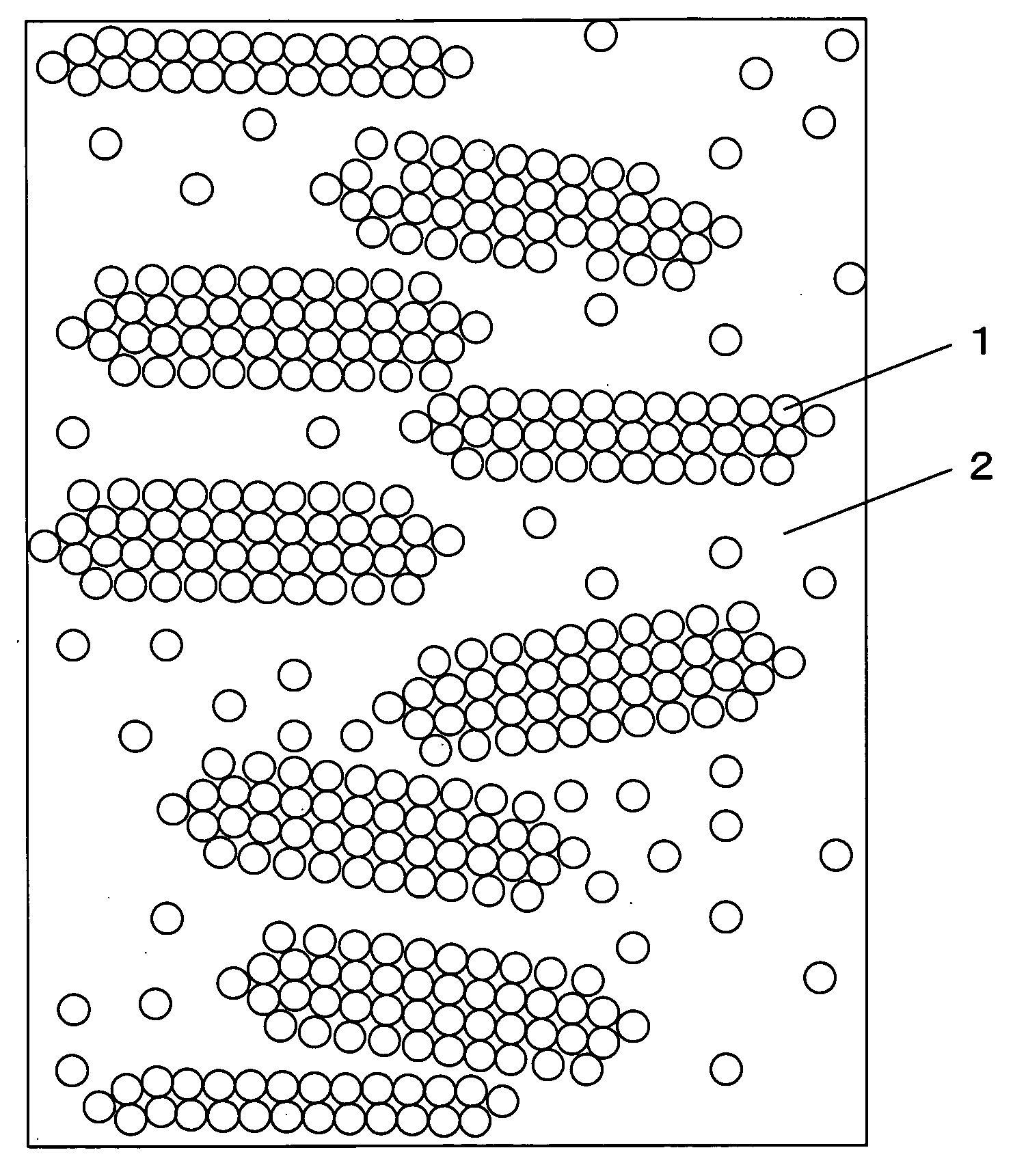

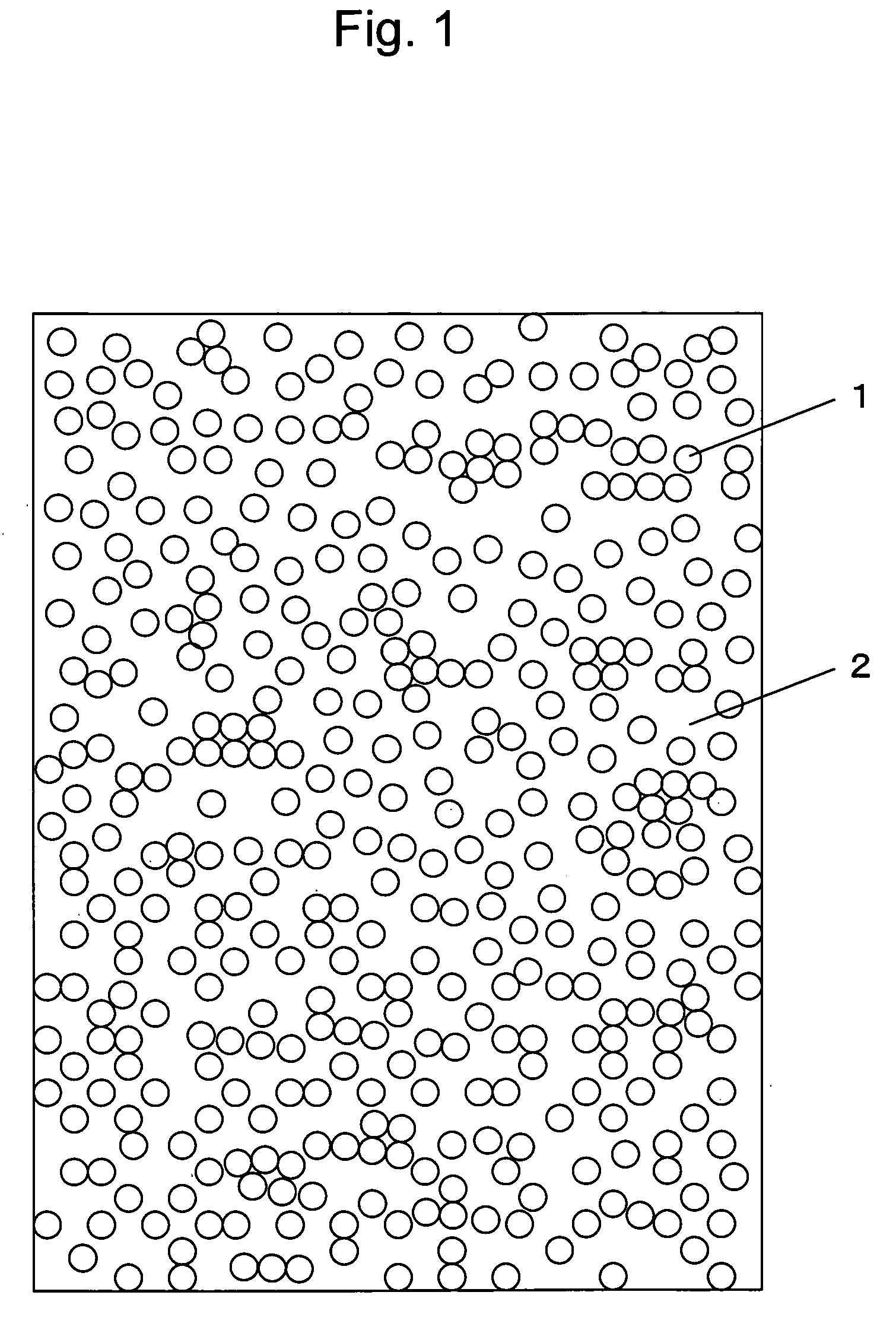

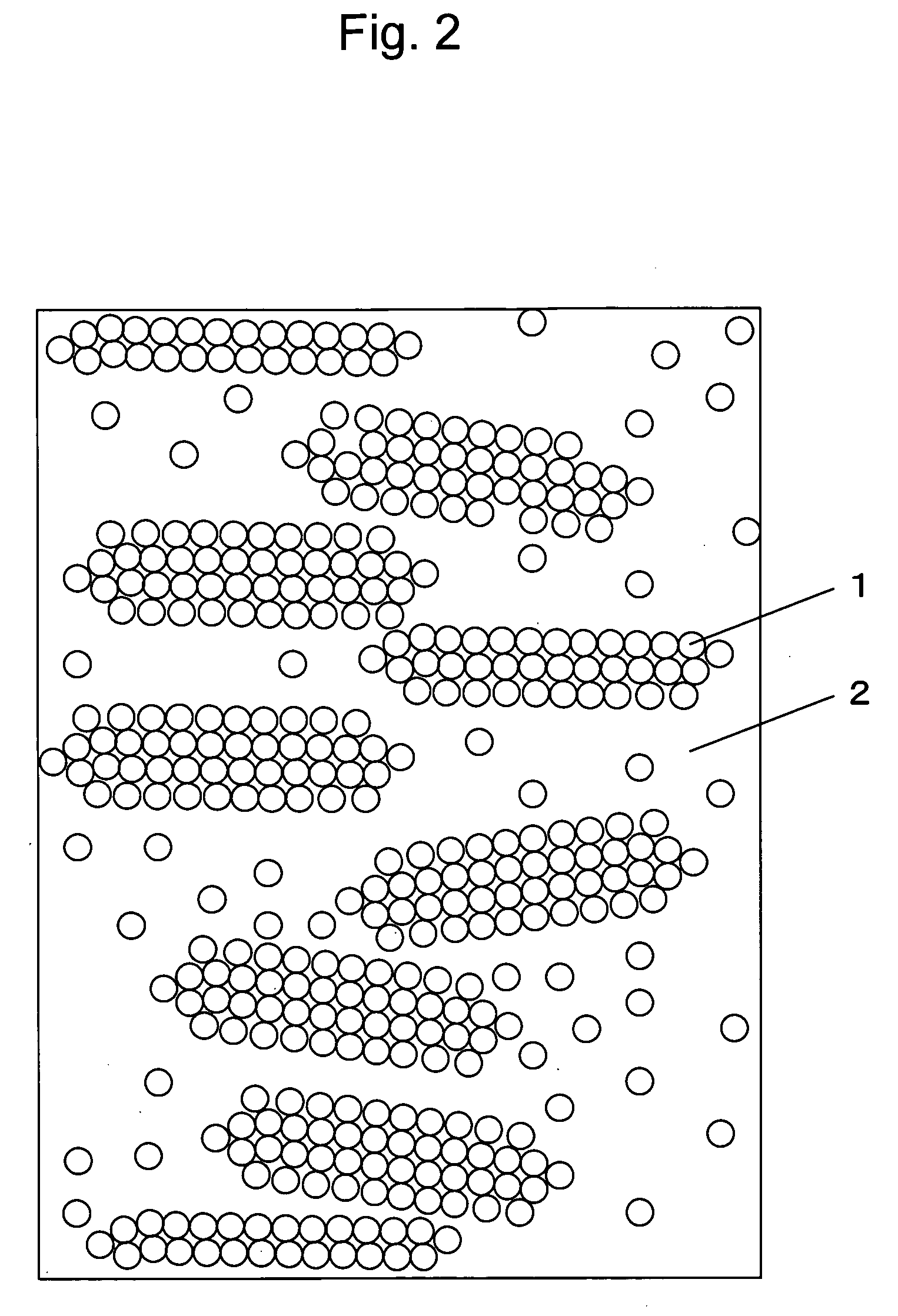

Enhanced LCD backlight

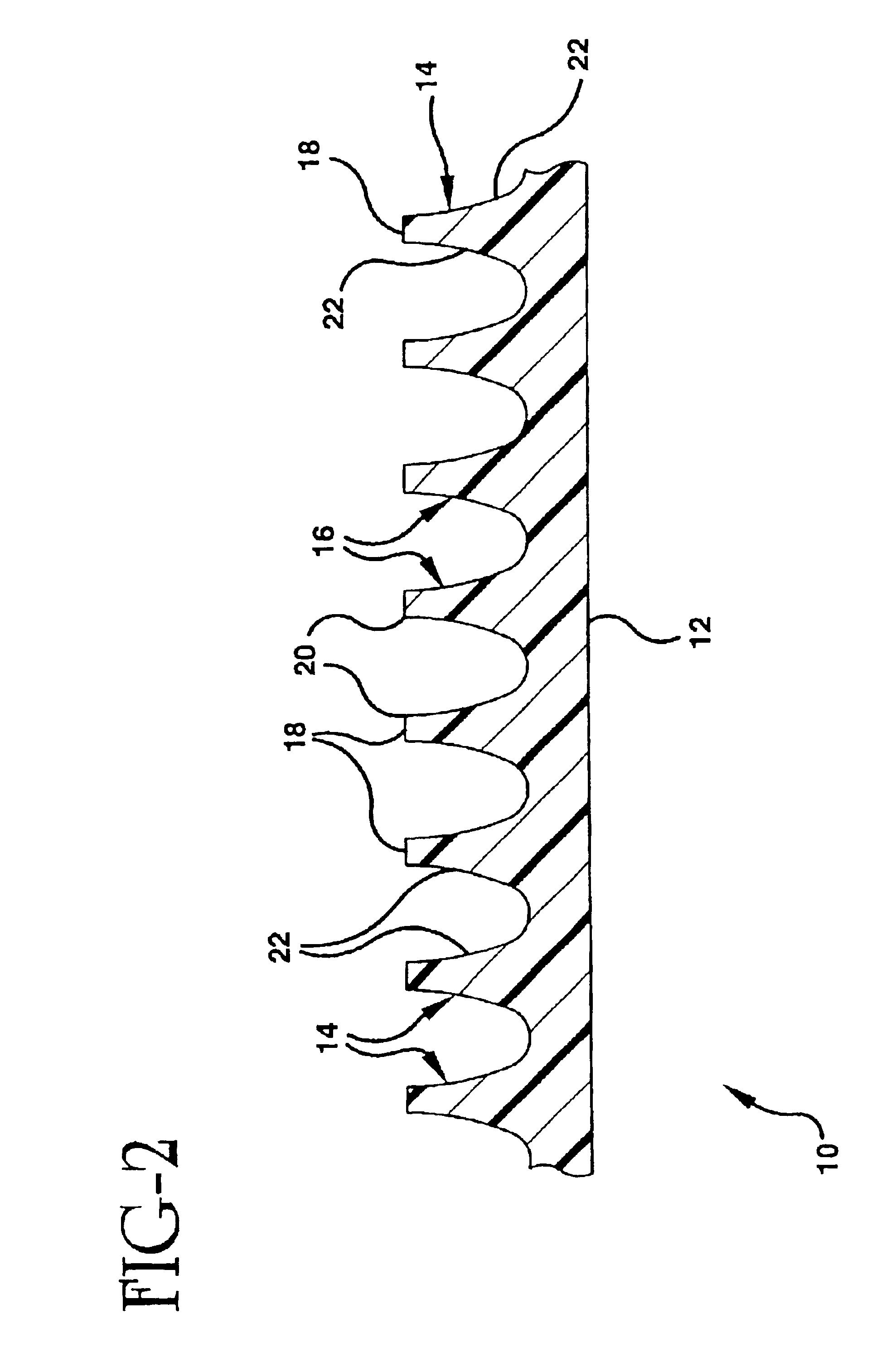

ActiveUS7278775B2Avoid less flexibilityReduce component countElectric discharge tubesDiffusing elementsCompression moldingEllipsoidal particle

A light guide containing substantially aligned non-spherical particles provides more efficient control of light scattering. One or more regions containing ellipsoidal particles may be used and the particle sizes may vary between 2 and 100 microns in the smaller dimension. The light scattering regions may be substantially orthogonal in their axis of alignment. Alternatively, one or more asymmetrically scattering films can be used in combination with a backlight light guide and a reflector to produce an efficient backlight system. The light guides may be manufactured by embossing, stamping, or compression molding a light guide in a suitable light guide material containing asymmetric particles substantially aligned in one direction. The light scattering light guide or non-scattering light guide may be used with one or more light sources, collimating films or symmetric or asymmetric scattering films.

Owner:MASSACHUSETTS DEV FINANCE AGENCY

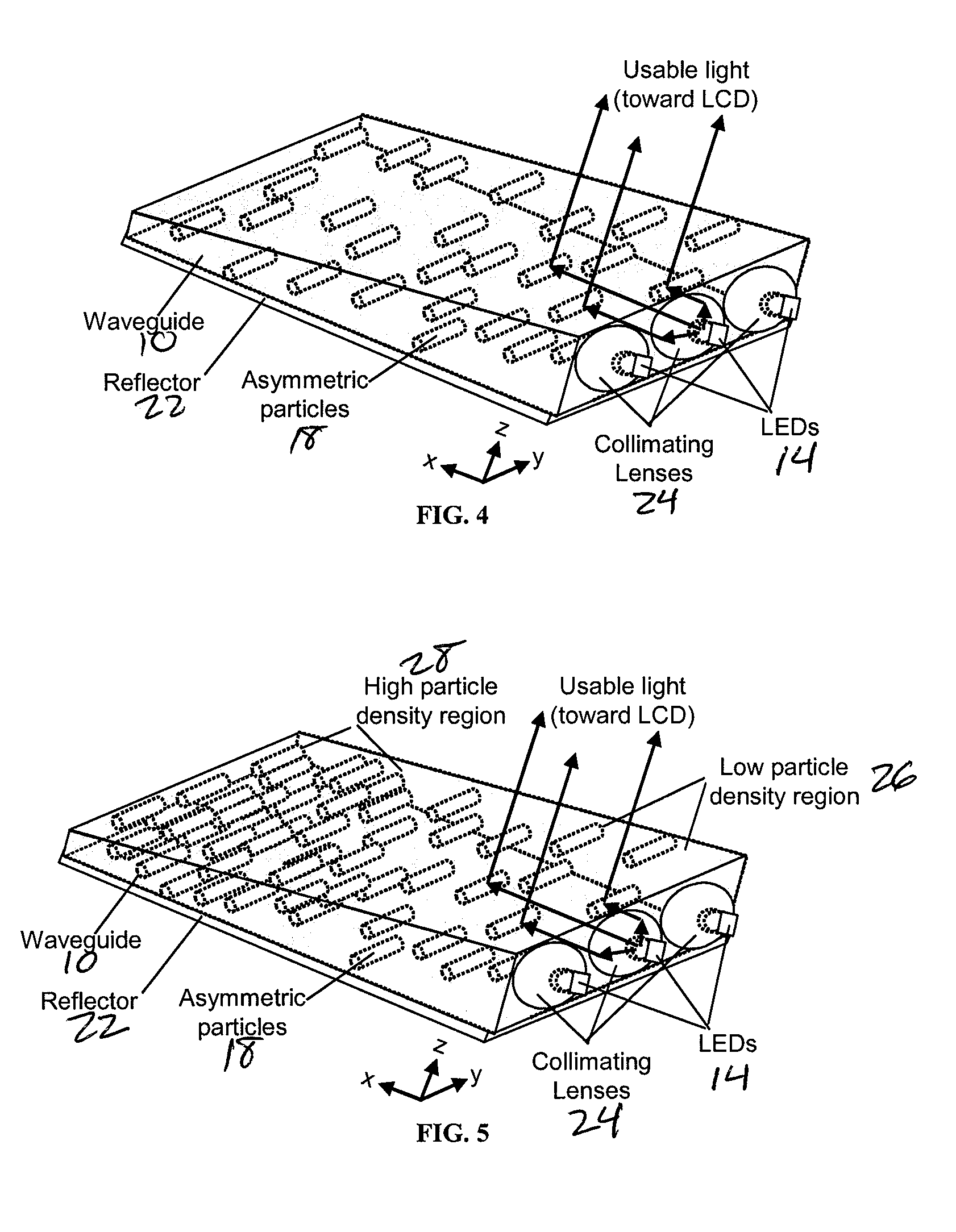

I-Section automotive bumper formed from mineral-filled glass mat thermoplastic (GMT) composite

InactiveUS6286879B1Improve flow characteristicsIncrease modulusBumpersCompression moldingShell molding

The invention is a fiber reinforced thermoplastic automotive bumper wherein the reduced fiber additions consist of a long, chopped glass mat with the addition of mineral fillers such as mica, talc or clay. The modified thermoplastic is used to produce I-section bumpers. The improved reinforced thermoplastic material has favorable flow characteristics which enable the material to substantially fill the deep ribs and mounting stay structures used in I-section bumpers during compression molding while improving the modulus or cross-face stiffness of the finished part. For the first time, improved flow characteristics during molding permit the material to flow evenly into small ribs, bosses and other features. The invention makes it possible to increase part integration, molding pencil braces, fascia supports, mounting holes and mounting stays. The front surface of the bumper may be covered with a conformal energy absorber made of plastic foarn. Moreover, the absorber serves to mount appearance fascia. The result is a cost-reduced, weight-reduced bumper with improved impact resistance.

Owner:AZDEL INC

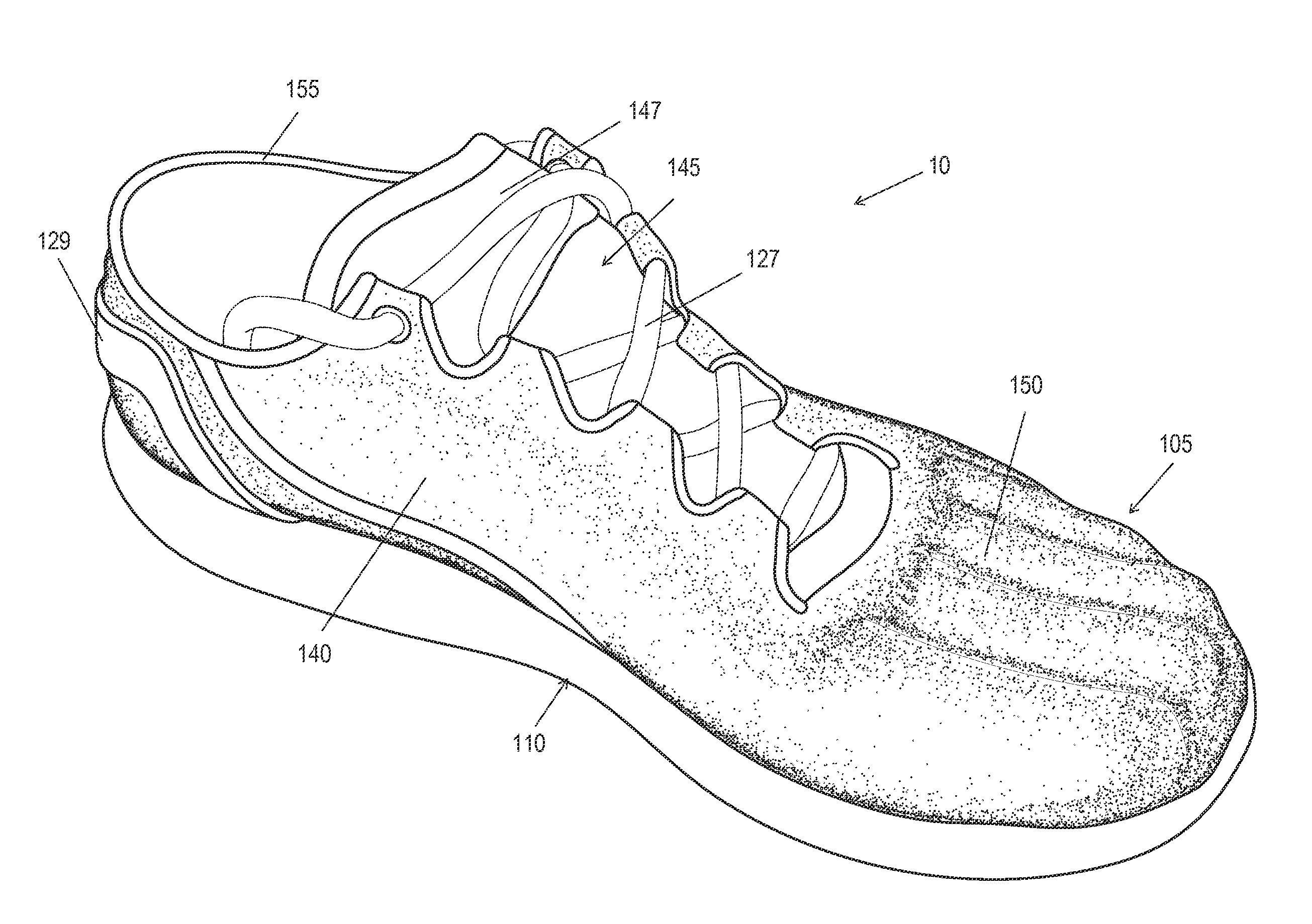

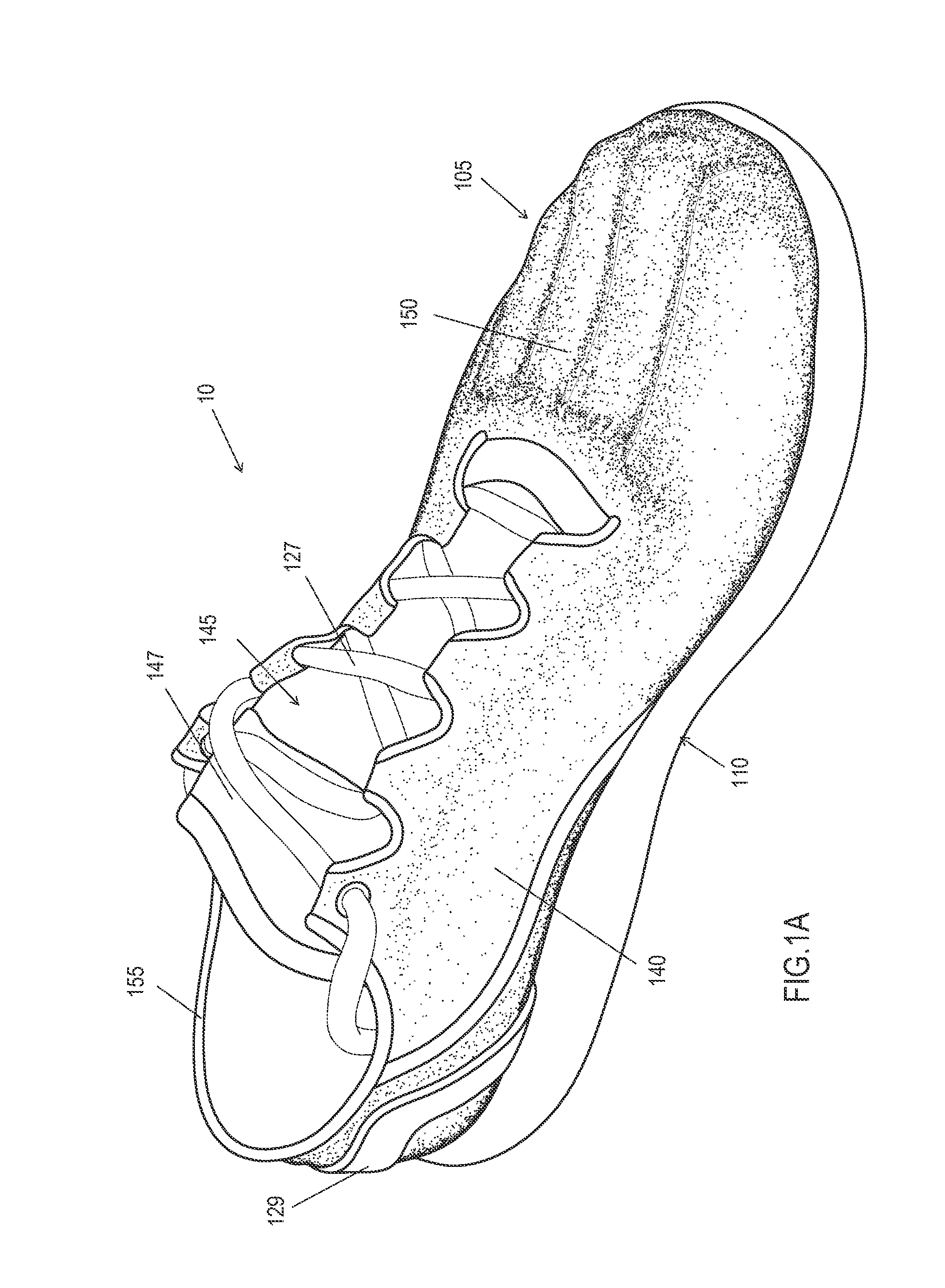

Performance footwear

The present invention is directed toward footwear including an upper connected to a sole structure. The upper includes two portions formed via compression molding in which textile layers are compressed to form a fabric laminate. One of the upper portions generally defines a seamless heel cup. The other upper portion generally defines a toe cage. The toe cage includes one or more integrated toe guides operable to position a toe of a wearer in a predetermined position within the cavity.

Owner:UNDER ARMOUR

Pet toys incorporating multiple hardness sections

A molded pet toy includes sections or layers of various hardnesses. The pet toy may be constructed through known injection molding, transfer, or compression molding processes. The layers and sections typically have varying hardnesses which facilitates use of the pet toy for a specific purpose. For use as a pet toy, an optimal arrangement provides that the outermost section or layer is of a lower hardness, while the inner sections or layers have a higher hardness. Durability of the pet toy is increased through the molding process which prevents separation between the layers. The pet toy is preferably shaped aerodynamically so it may be easily thrown by a user.

Owner:MARKHAM JOSEPH P

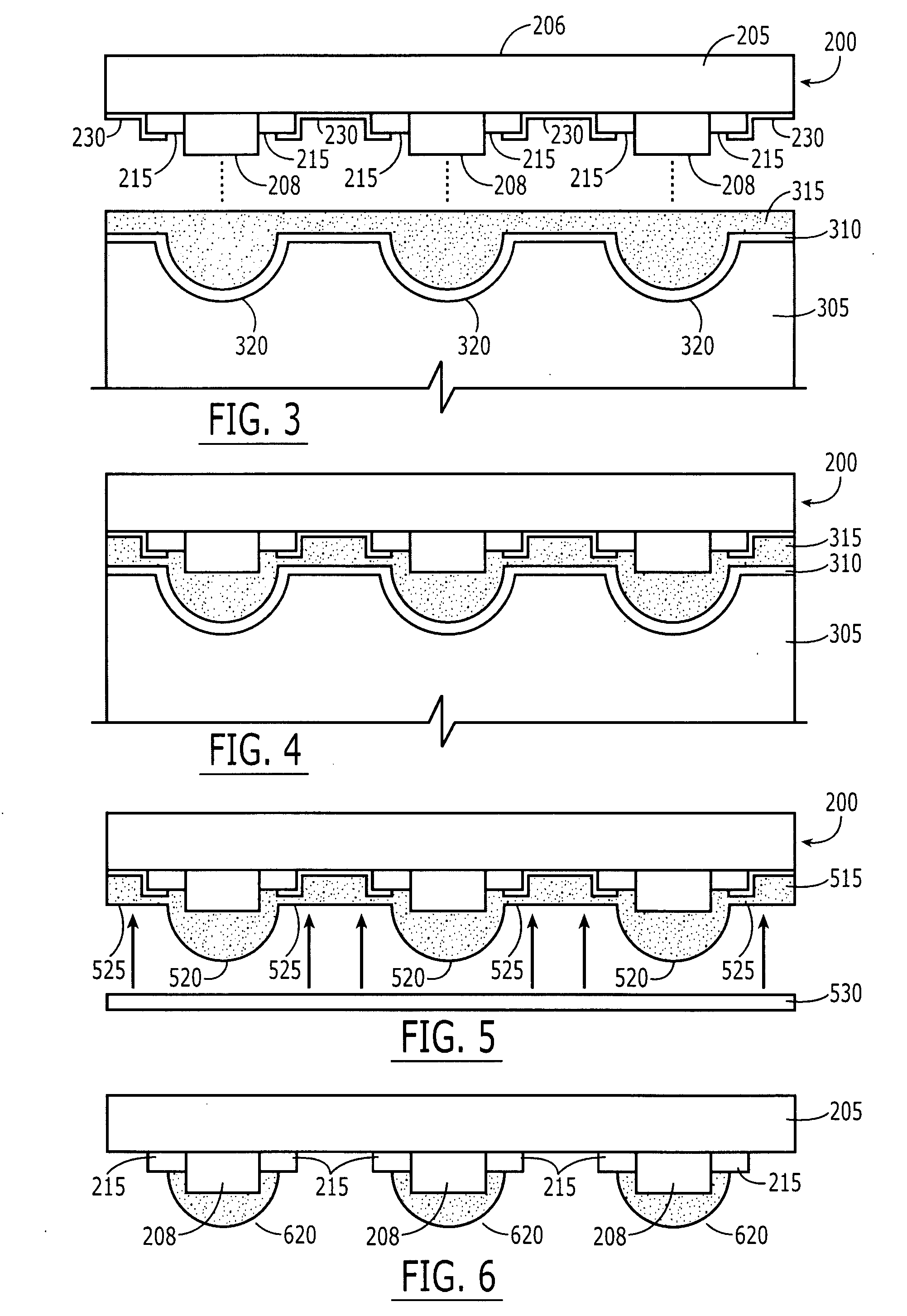

Methods of forming packaged semiconductor light emitting devices having front contacts by compression molding

ActiveUS20080191225A1Solid-state devicesSemiconductor/solid-state device manufacturingCompression moldingEngineering

Methods of packaging a semiconductor light emitting device include providing a substrate having the semiconductor light emitting device on a front face thereof and a contact on a front face thereof, wherein the light emitting device is electrically connected to the contact on the front face of the substrate. The substrate is compression molded to form an optical element on the front face of the substrate over the semiconductor light emitting device and a residual coating over a region of the front face of the substrate including the contact. The residual coating over the contact may be removed without damaging the contact. Packaged semiconductor light emitting devices are also provided.

Owner:CREELED INC

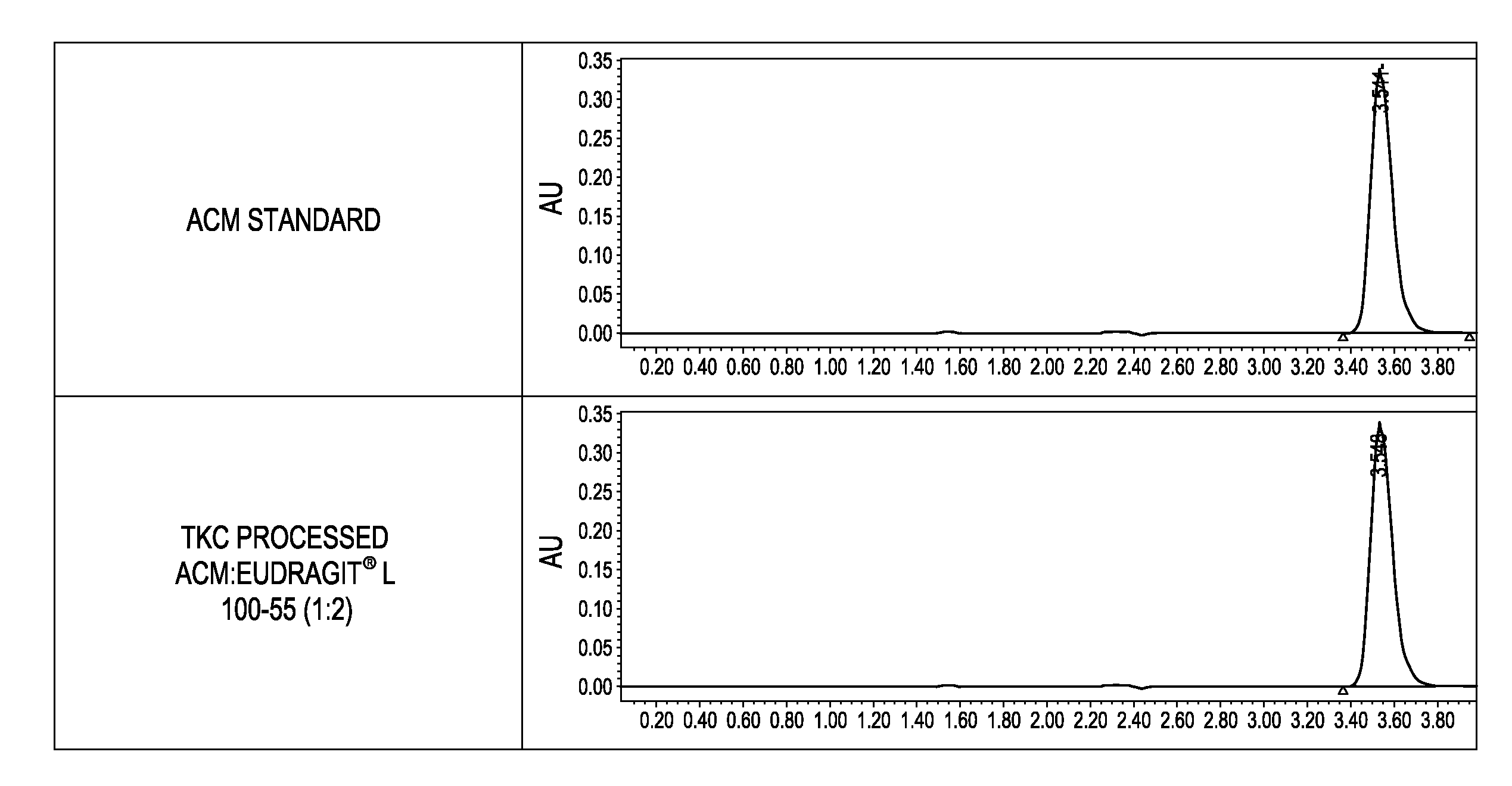

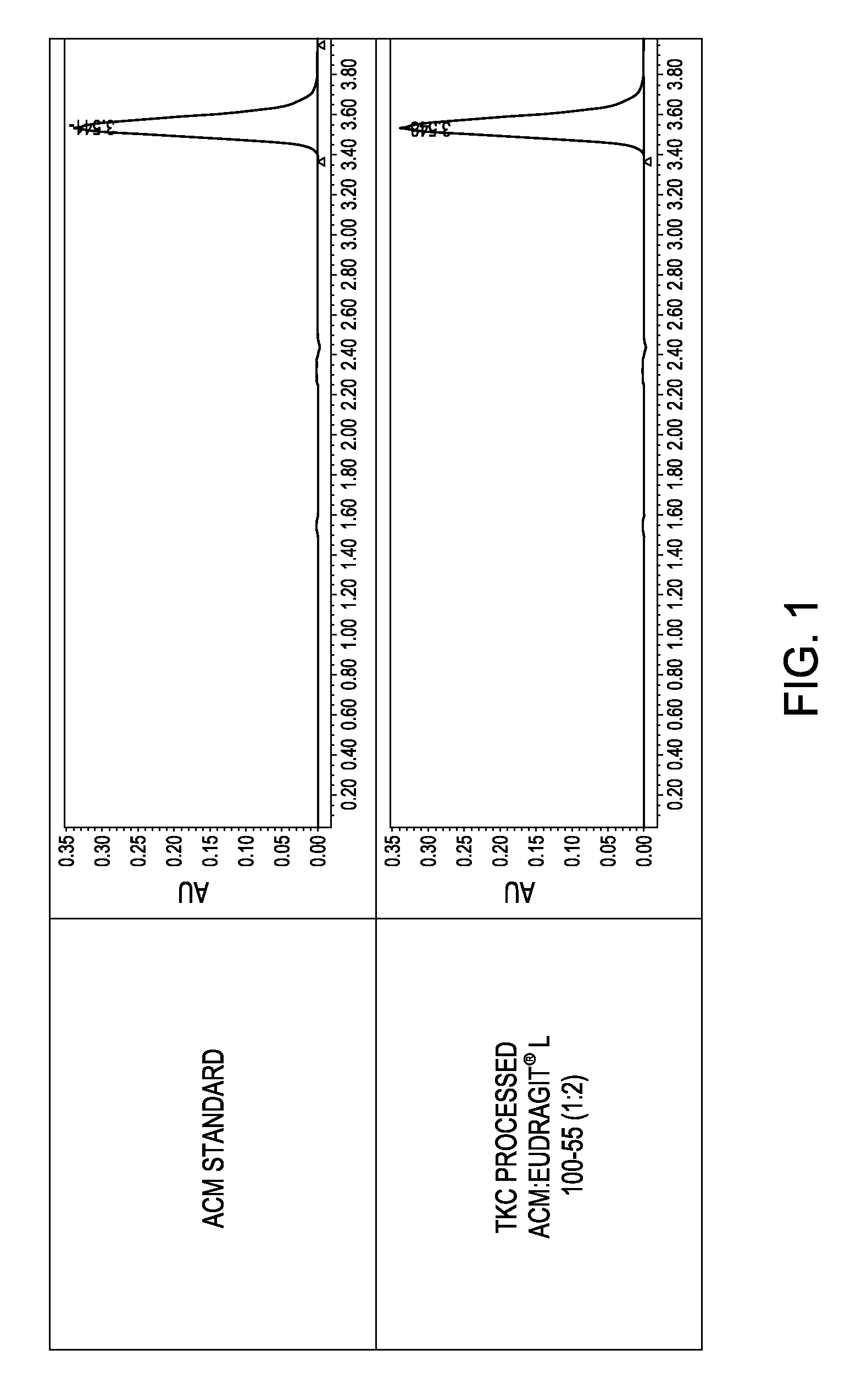

Thermo-Kinetic Mixing for Pharmaceutical Applications

ActiveUS20090053315A1Low process temperatureIncrease shear ratePowder deliveryOrganic active ingredientsCompression moldingAdditive ingredient

Compositions and methods for making a pharmaceutical dosage form include making a pharmaceutical composition that includes one or more active pharmaceutical ingredients (API) with one or more pharmaceutically acceptable excipients by thermokinetic compounding into a composite. Compositions and methods of preprocessing a composite comprising one or more APIs with one or more excipients include thermokinetic compounding, comprising thermokinetic processing the APIs with the excipients into a composite, wherein the composite can be further processed by conventional methods known in the art, such as hot melt extrusion, melt granulation, compression molding, tablet compression, capsule filling, film-coating, or injection molding.

Owner:AUSTINPX LLC +1

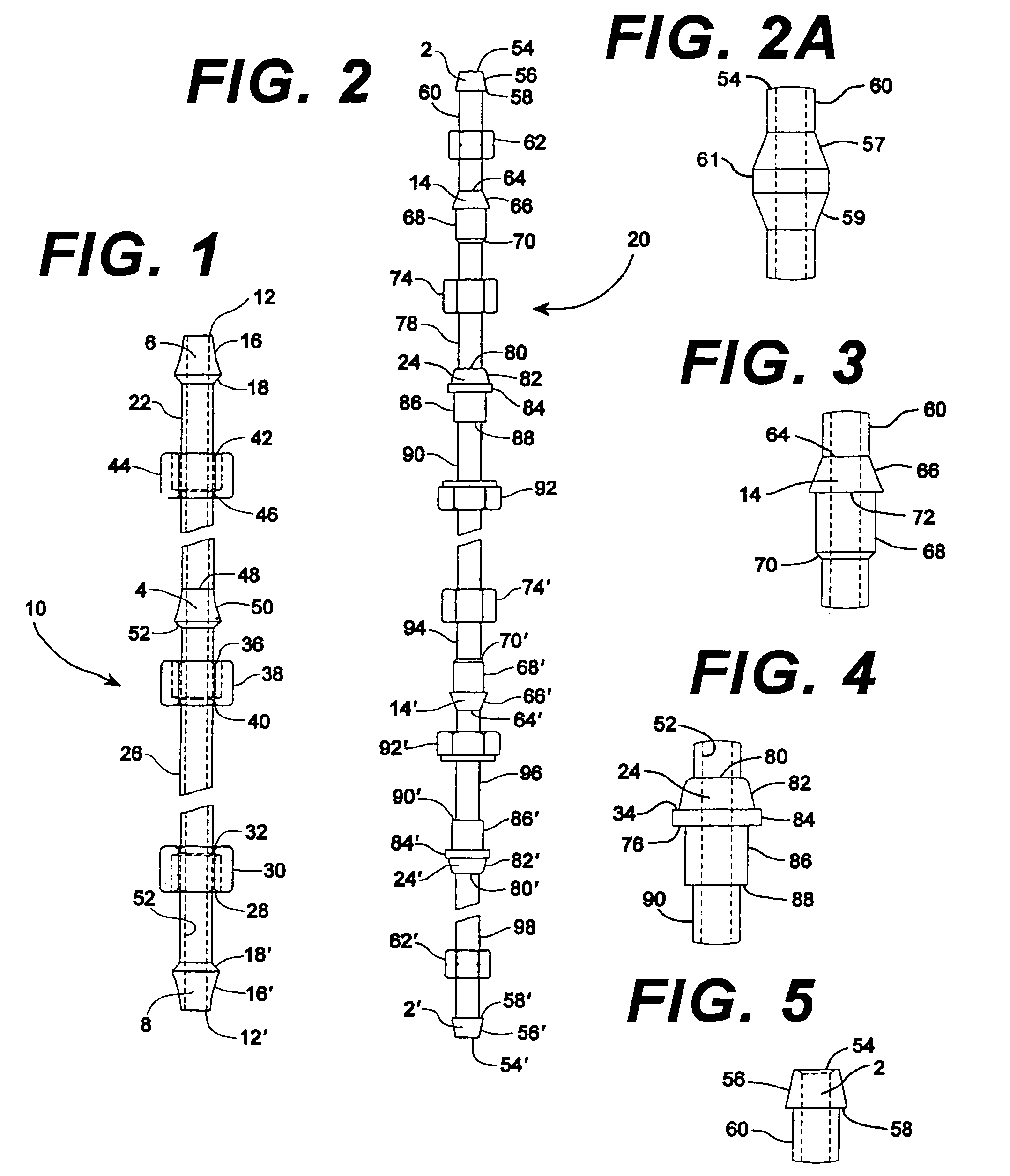

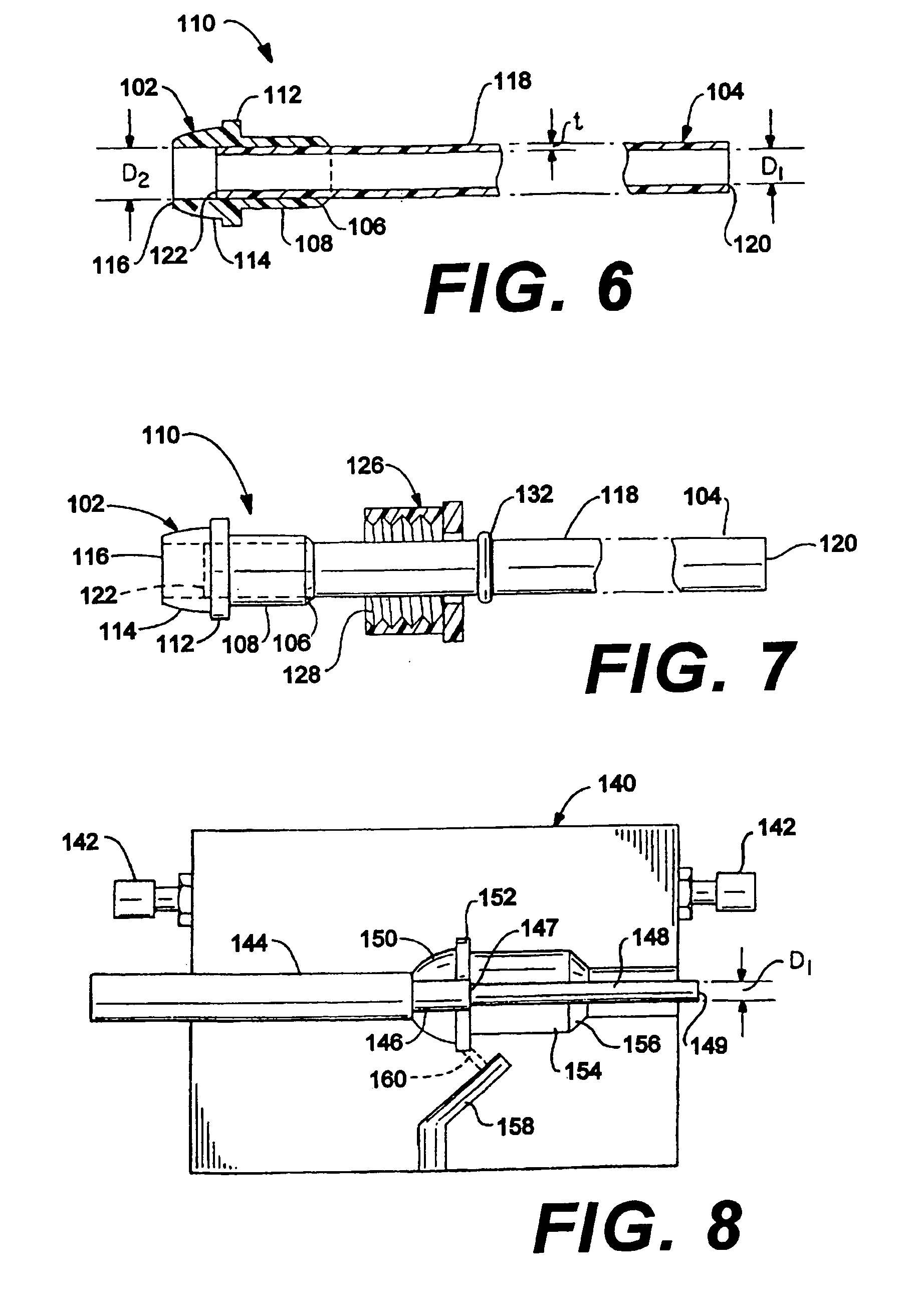

Universal connector tubing

The invention is a universal connector which is useful with a variety of differently configured and shaped fittings as well as for applications when the fittings are identical. The connectors provided at either end of the tube may be formed by either compression molding or injection overmolding whereas the connections which are provided internal of either end connection, are positioned on the tube by injection overmolding.

Owner:MERCURY PLASTICS LLC

Semiaromatic polyamide composite article and processes for its preparation

ActiveUS20080008879A1Synthetic resin layered productsGlass/slag layered productsCompression moldingPolyamide

A semiaromatic polyamide composite article comprising a first component comprising a fiber-reinforced material comprising a polyamide composition and reinforcing fibers and having a tensile modulus of at least about 16 GPa as measured by ISO method 527-2:1993 at a rate of 5 mm / min on test specimens having a thickness of 4 mm, a second component comprising a polyamide composition, and an optional tie layer therebetween. The polyamide composition of first component and / or the second component is a semiaromatic polyamide compositions. The second component is prepared by injection molding and / or injection-compression molding the semiaromatic polyamide composition onto the first component.

Owner:DUPONT POLYMERS INC

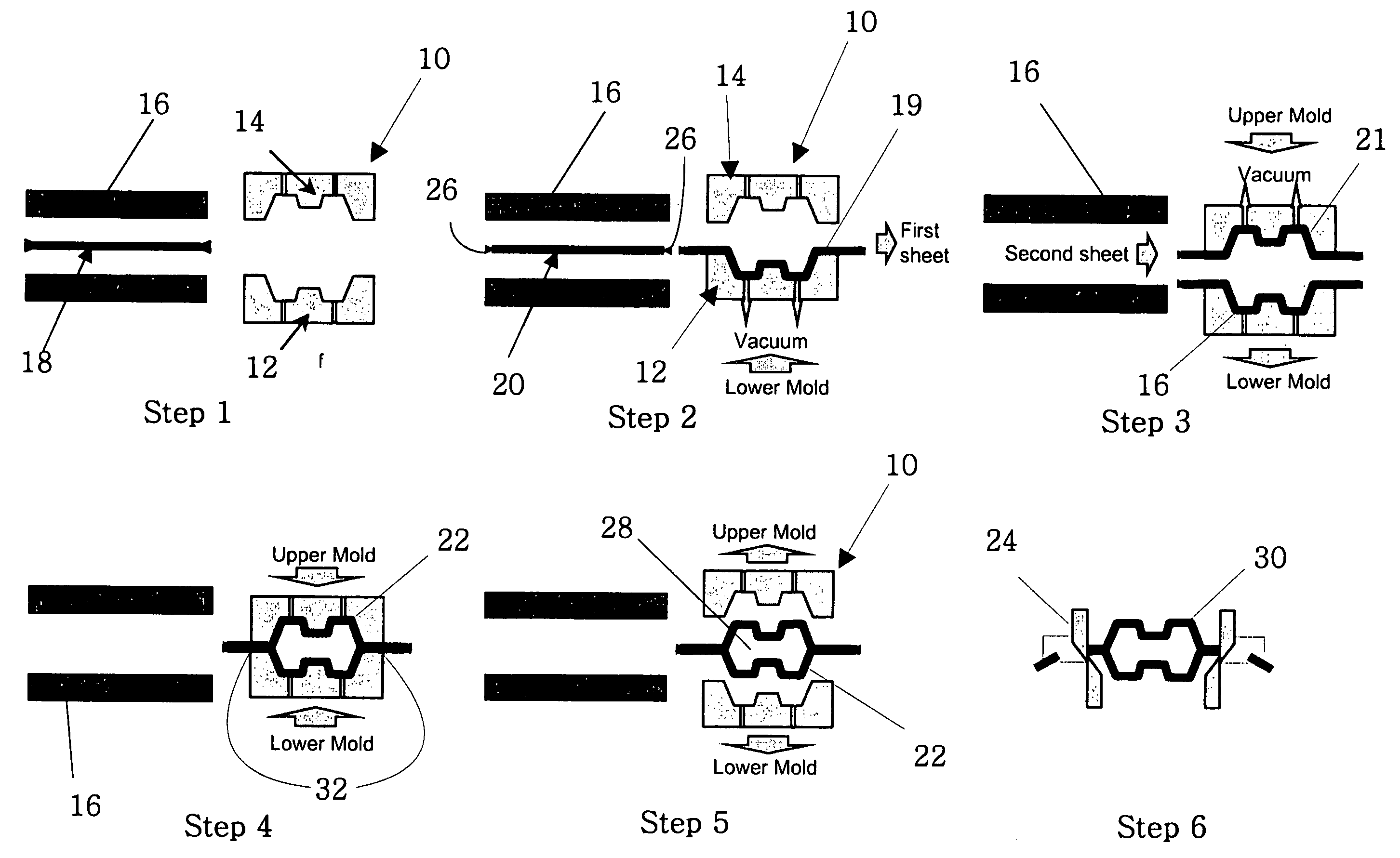

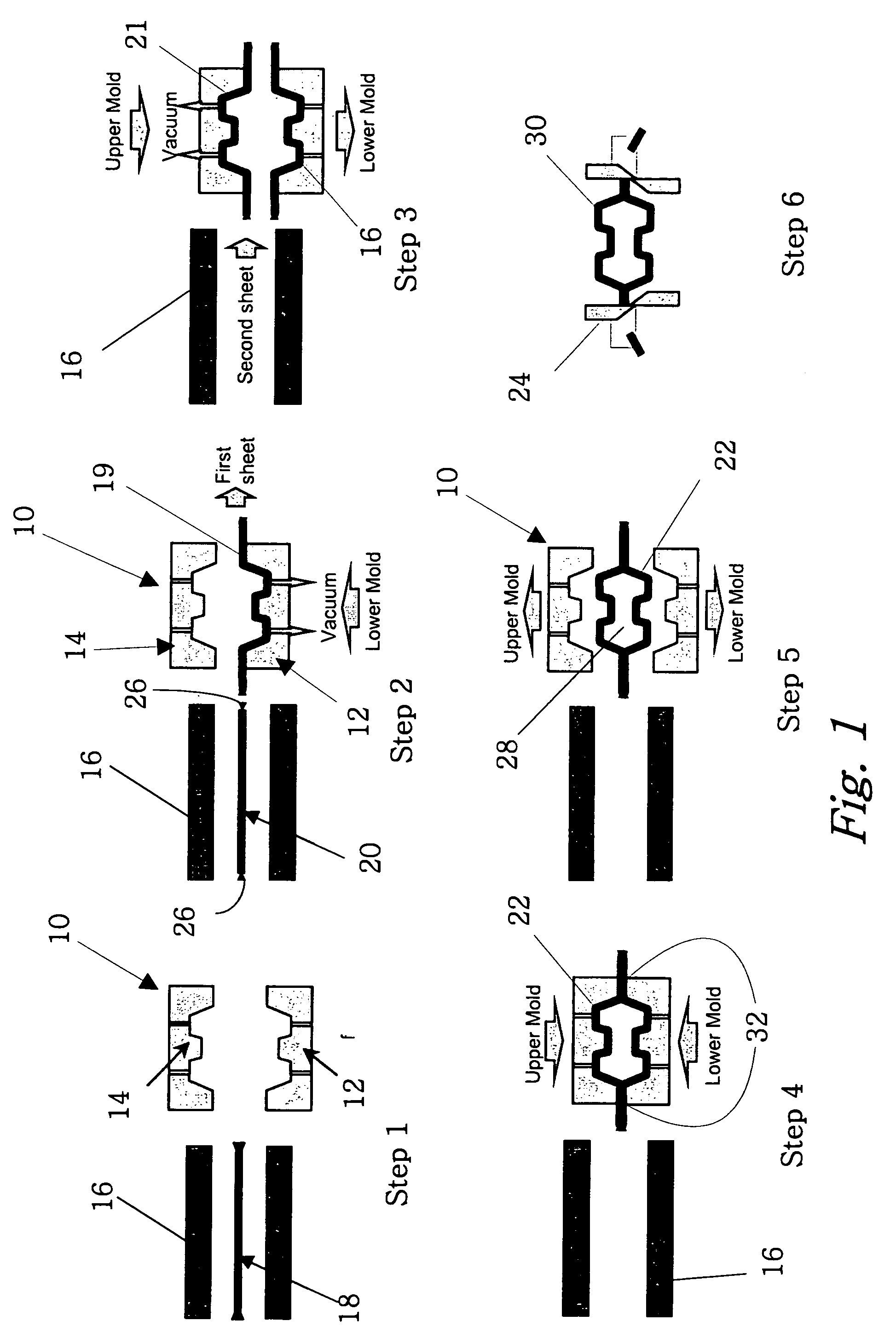

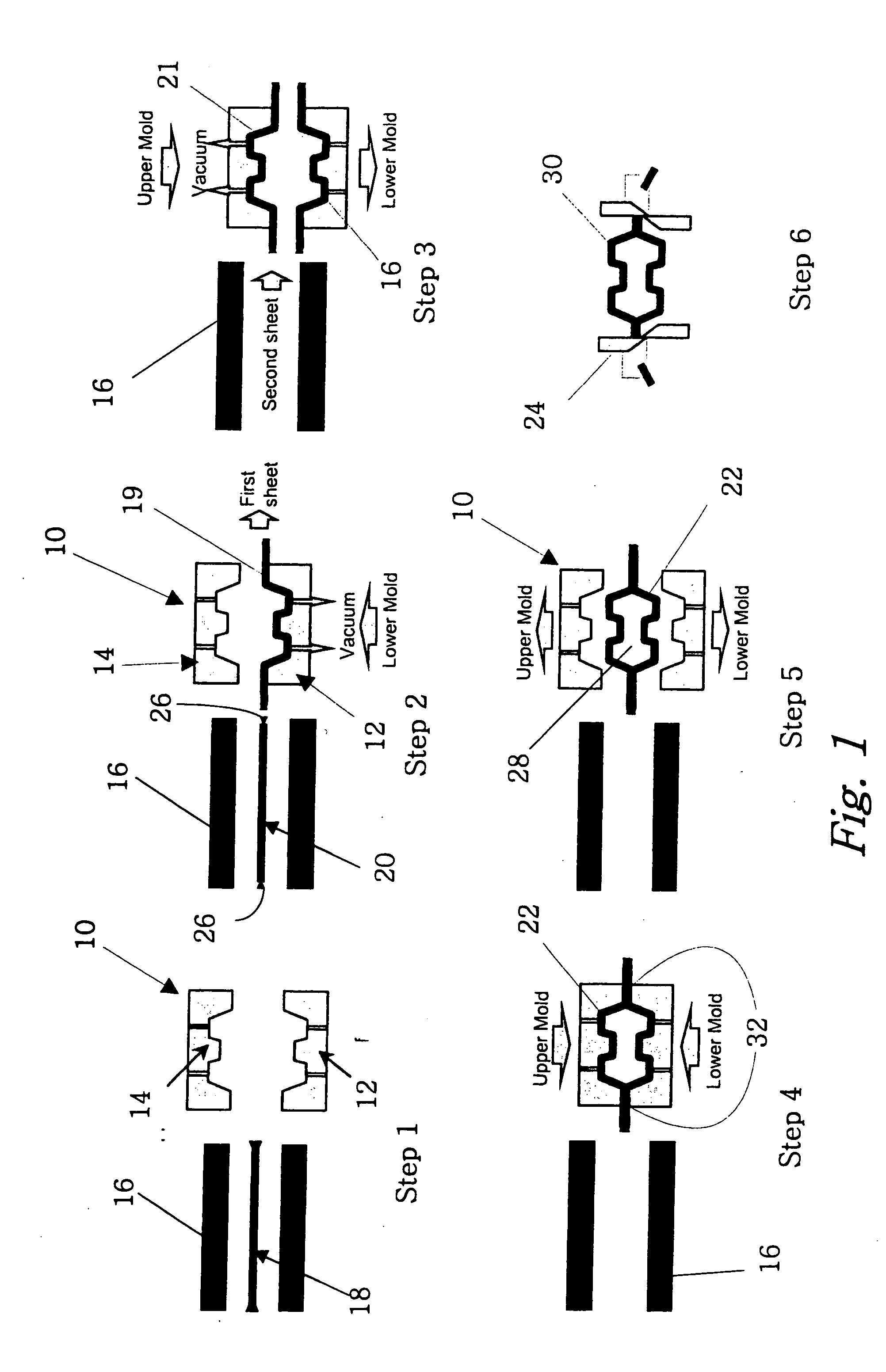

Twin-sheet thermoforming process

A twin-sheet thermoforming process for the manufacture of vehicle headliners. In the process a first sheet and second sheet of SuperLite material are mounted onto respective frames. The frames transfer the sheets into an oven, where they are heated to a desired temperature using IR. The first sheet is combined with a cover-stock material using compression molding forming a covered first headliner part. The covered first headliner part is then transferred to a second mold station. The second sheet is heated and then transferred from the oven to the second mold station where it is vacuum-formed on the upper half mold, forming a second headliner part. The upper and lower mold halves are pressed together fusing and sealing the first and second headliner parts into a unified part. The unified part is then unloaded and trimmed as necessary forming a headliner. The SuperLite material used to form the headliner is a sheet of low pressure, thermoformable, thermoplastic composite comprised of polypropylene and long chopped glass fibers.

Owner:AZDEL INC

Inorganic matrix composition and composites incorporating the matrix composition

InactiveUS6969422B2Good physical and mechanical propertiesIncrease loadAlkali metal silicate coatingsCement productionSlurryOragene

A modified alkali silicate composition for forming an inorganic network matrix. The modified alkali silicate matrix is made by reacting an alkali silicate (or its precursors such as an alkali hydroxide, a SiO2 source and water), an acidic inorganic composition, such as a reactive glass, water and optional fillers, additives and processing aids. An inorganic matrix composite can be prepared by applying a slurry of the modified aqueous alkali silicate composition to a reinforcing medium and applying the temperature and pressure necessary to consolidate the desired form. The composite can be shaped by compression molding as well as other known fabrication methods. A notable aspect of the invention is that, although composite and neat resin components prepared from the invention can exhibit excellent dimensional stability to 1000° C. and higher, they can be prepared at the lower temperatures and pressures typical to organic polymer processing.

Owner:THE BF GOODRICH CO

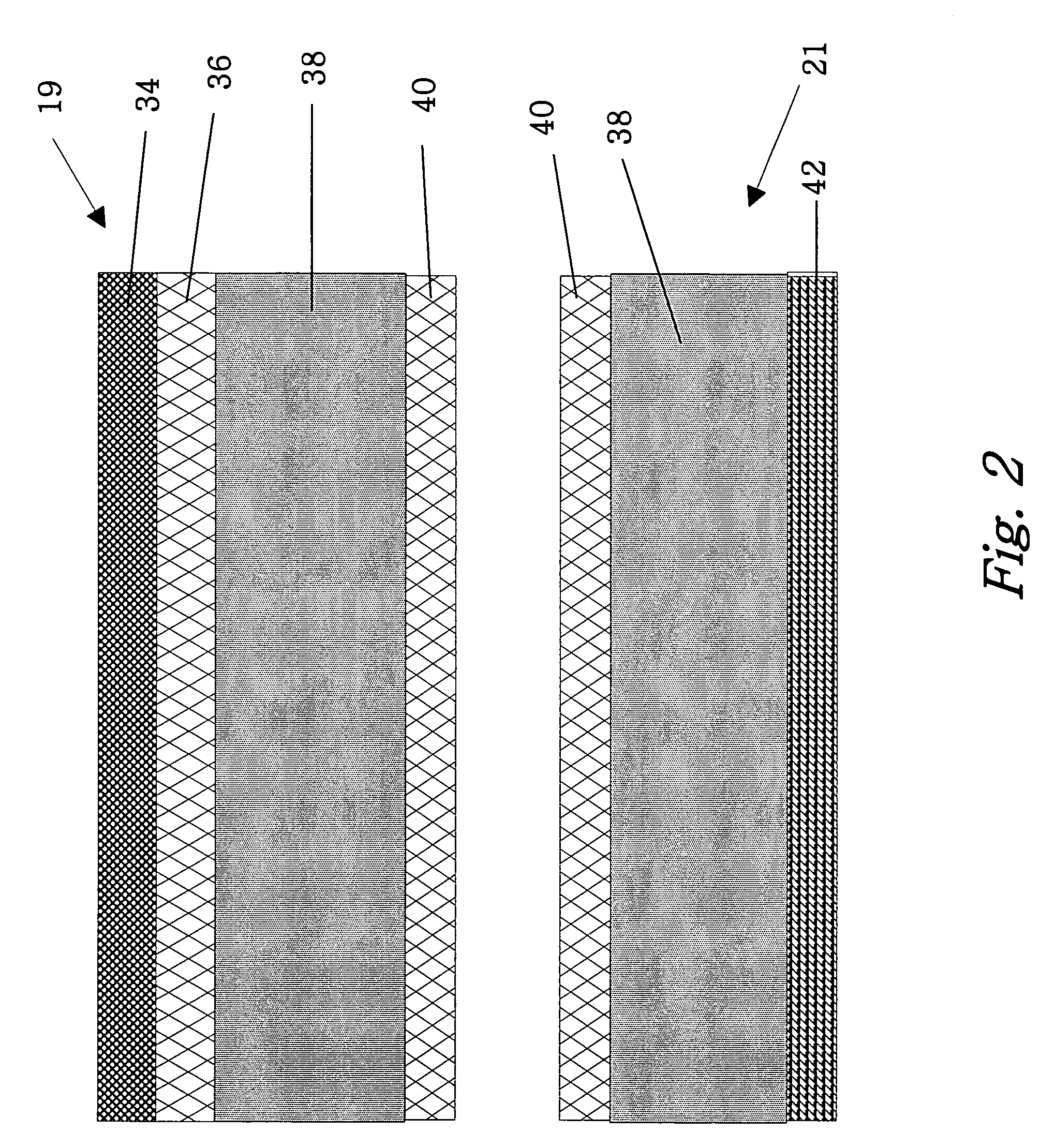

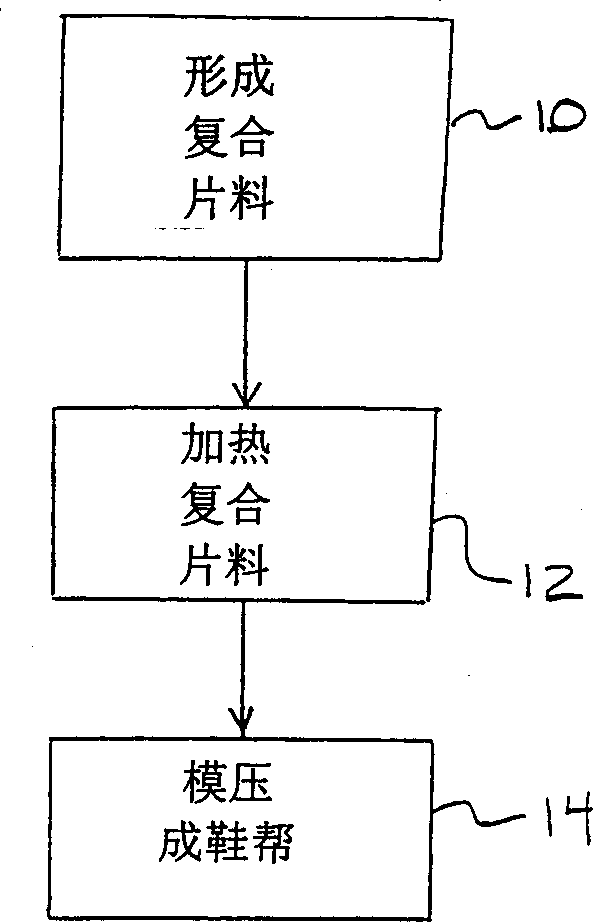

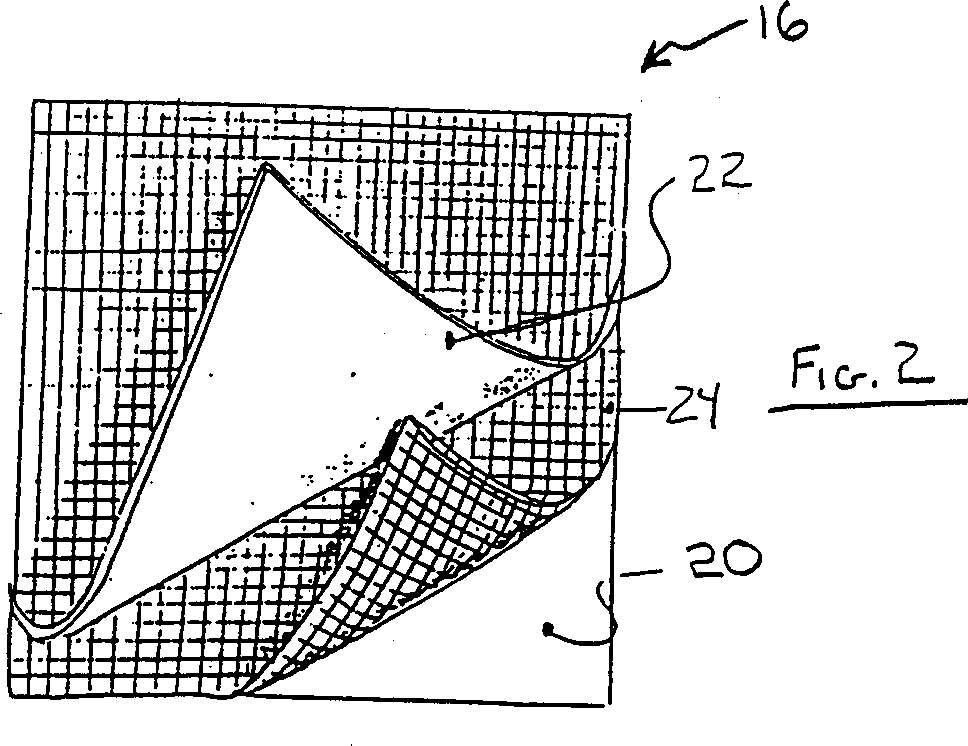

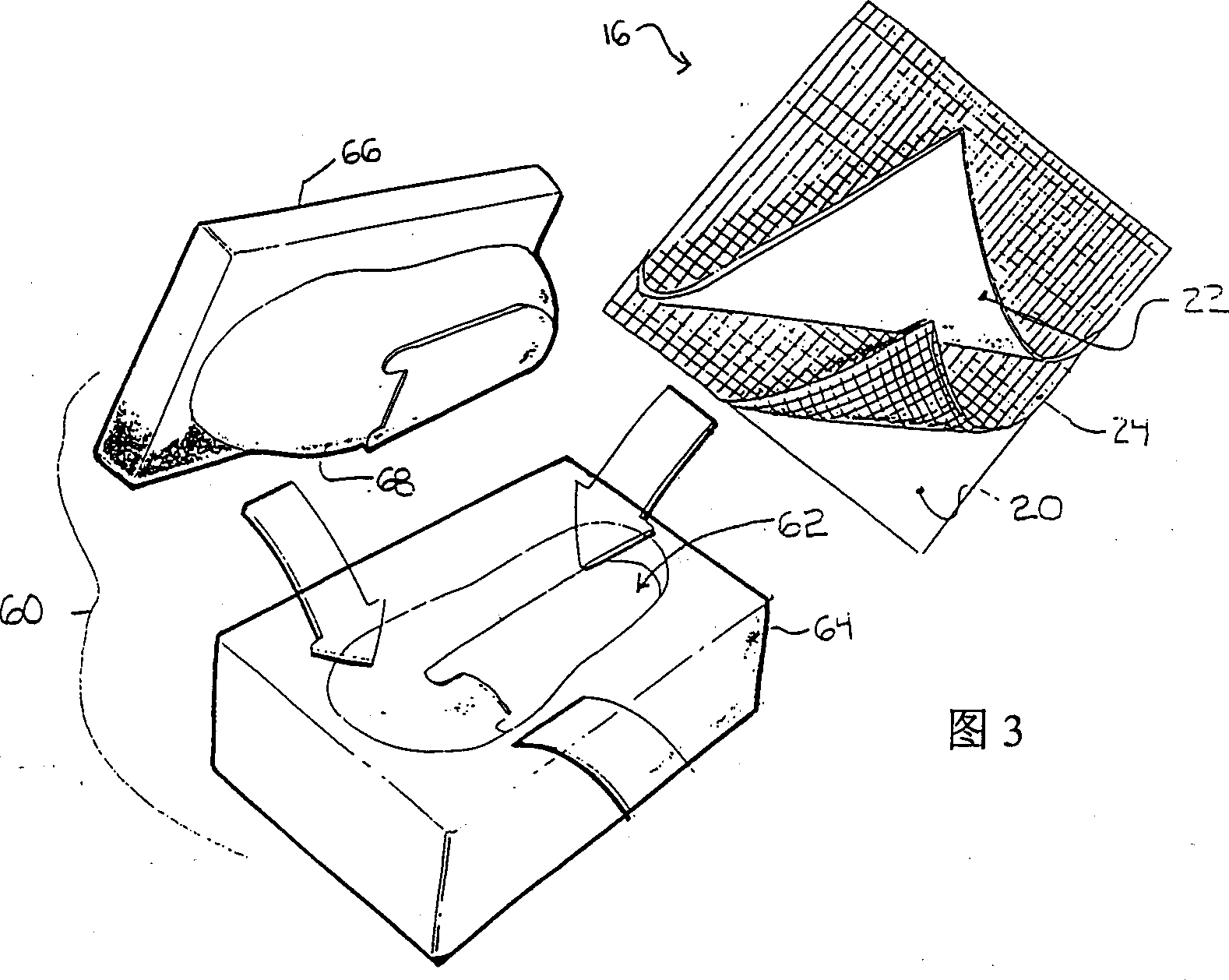

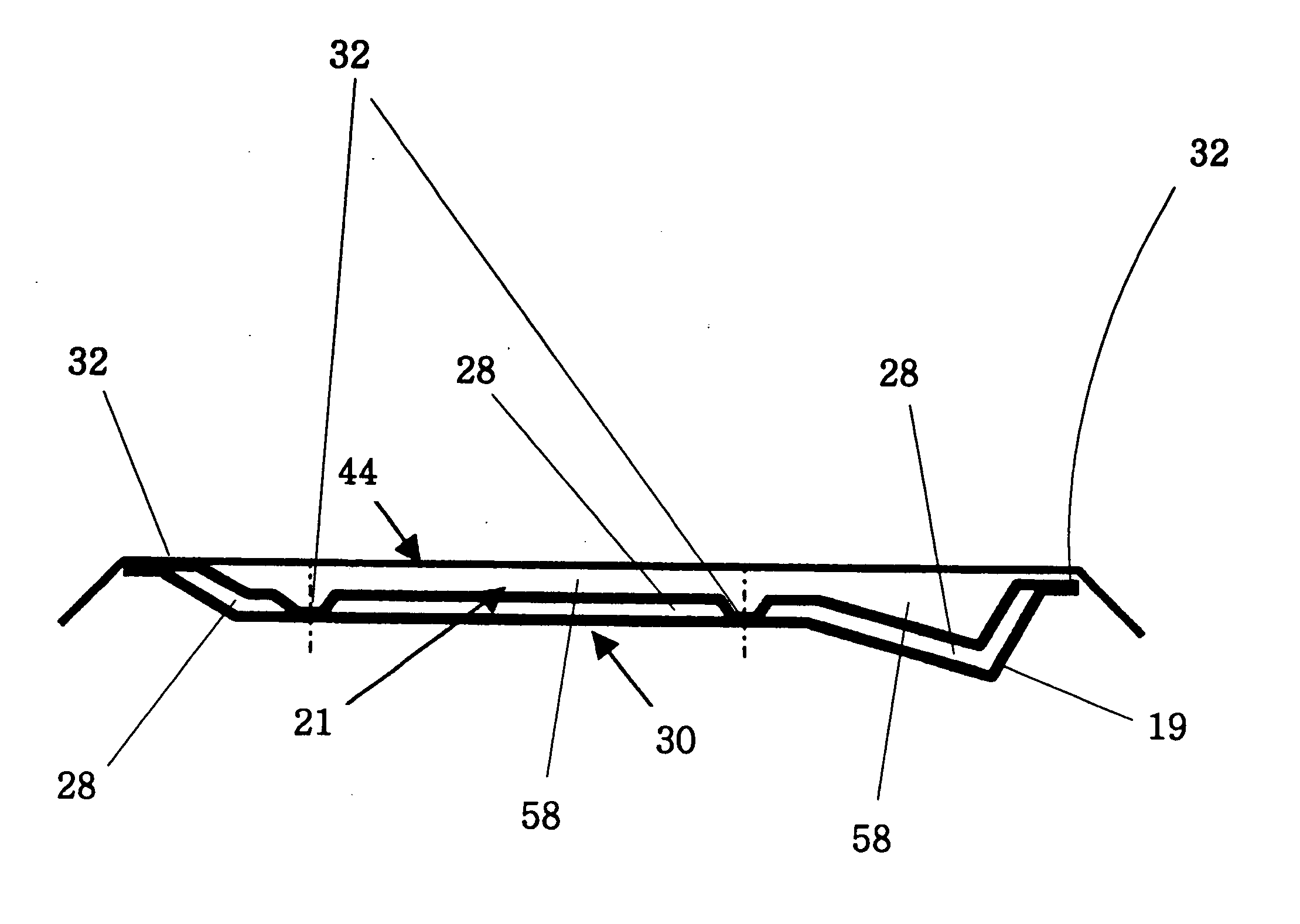

Composite footwear upper and manufacturing method thereof

InactiveCN1342046AEasy to processChange propertiesDomestic footwearUpperCompression moldingEngineering

A method of manufacturing a multi-layer, composite footwear upper having a three-dimensional geometry includes the steps of forming a substantially planar composite sheet from two or more layers, heating the composite sheet, and compression molding the composite sheet into the three-dimensional geometry of the footwear upper. The composite sheet is formed by laminating a first layer of thermoplastic foam to a second layer of thermoplastic urethane (TPU), preferably in the form of a TPU film. A third layer of mesh fabric can be interposed between the first and second layers. The composite sheet is compressed after heating in a mold cavity to achieve the desired three-dimensional geometry. The composite sheet can be compression molded into separate sections which are assembled after molding to form the footwear upper. Alternatively, the composite sheet can be compression molded into a seamless, unitary footwear upper that requires minimal, if any, assembly for completion. The multi-layer composite upper can be applied to a sole to form performance footwear suitable for use in a wide range of conditions.

Owner:爱德华·J·诺顿 +1

Twin-sheet thermoformed products

A twin-sheet thermoforming process for the manufacture of vehicle headliners. In the process a first sheet and second sheet of SuperLite material are mounted onto respective frames. The frames transfer the sheets into an oven, where they are heated to a desired temperature using IR. The first sheet is combined with a cover-stock material using compression molding forming a covered first headliner part. The covered first headliner part is then transferred to a second mold station. The second sheet is heated and then transferred from the oven to the second mold station where it is vacuum-formed on the upper half mold, forming a second headliner part. The upper and lower mold halves are pressed together fusing and sealing the first and second headliner parts into a unified part. The unified part is then unloaded and trimmed as necessary forming a headliner. The SuperLite material used to form the headliner is a sheet of low pressure, thermoformable, thermoplastic composite comprised of polypropylene and long chopped glass fibers.

Owner:AZDEL INC

Compression-molded vegetable wax-based candle

InactiveUS20070144058A1Burn cleanSuperior compressed candle productSolid fuelsCandle ingredientsParaffin waxCompression molding

Prilled wax particles are formed from a vegetable wax-based composition. After compression, a predominantly paraffin wax-based composition is optionally poured over the vegetable wax-based composition to form an encased candle. The method of the present invention offers the possibility to incorporate a high fragrance load to the candle.

Owner:CHEN QIN +4

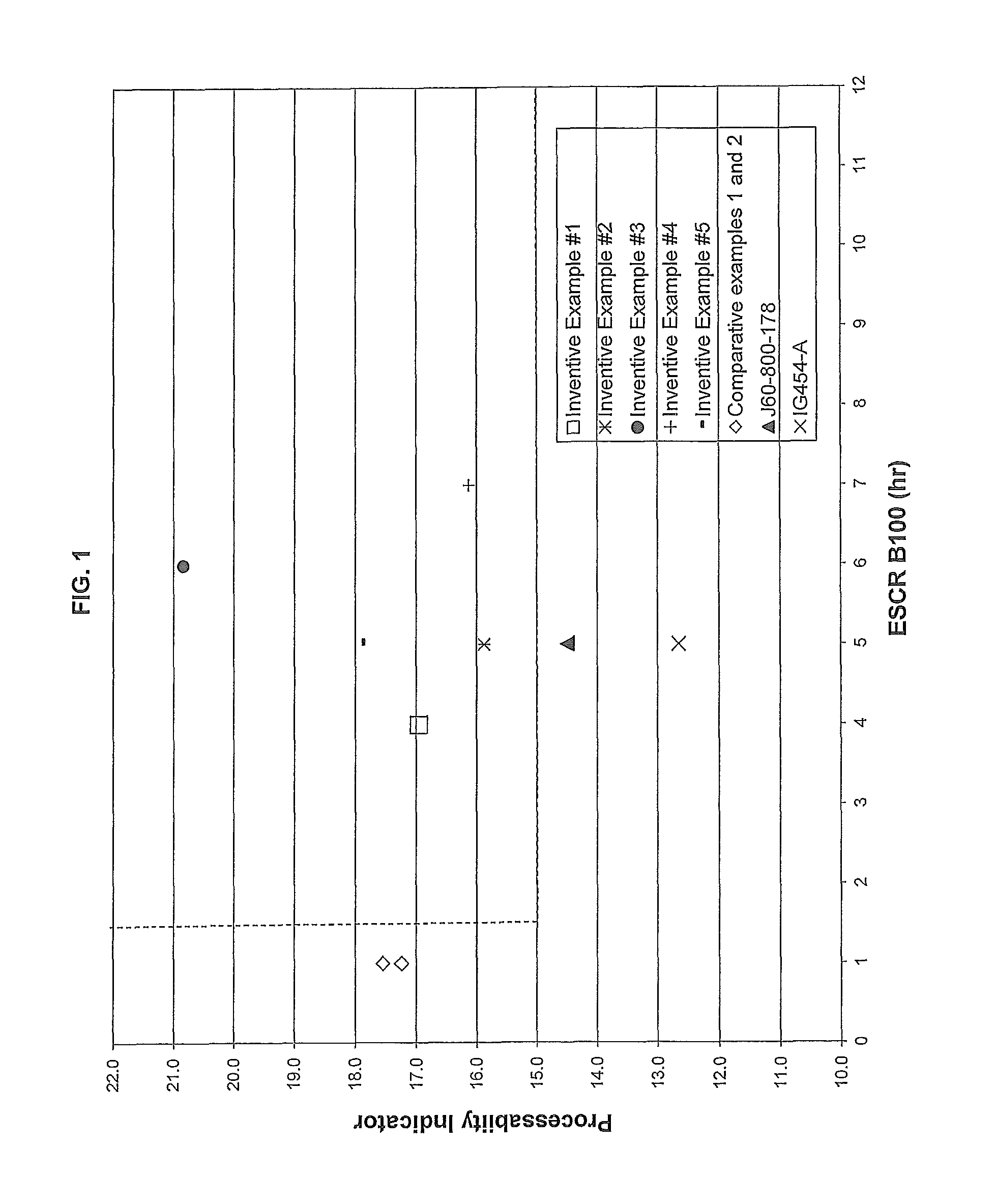

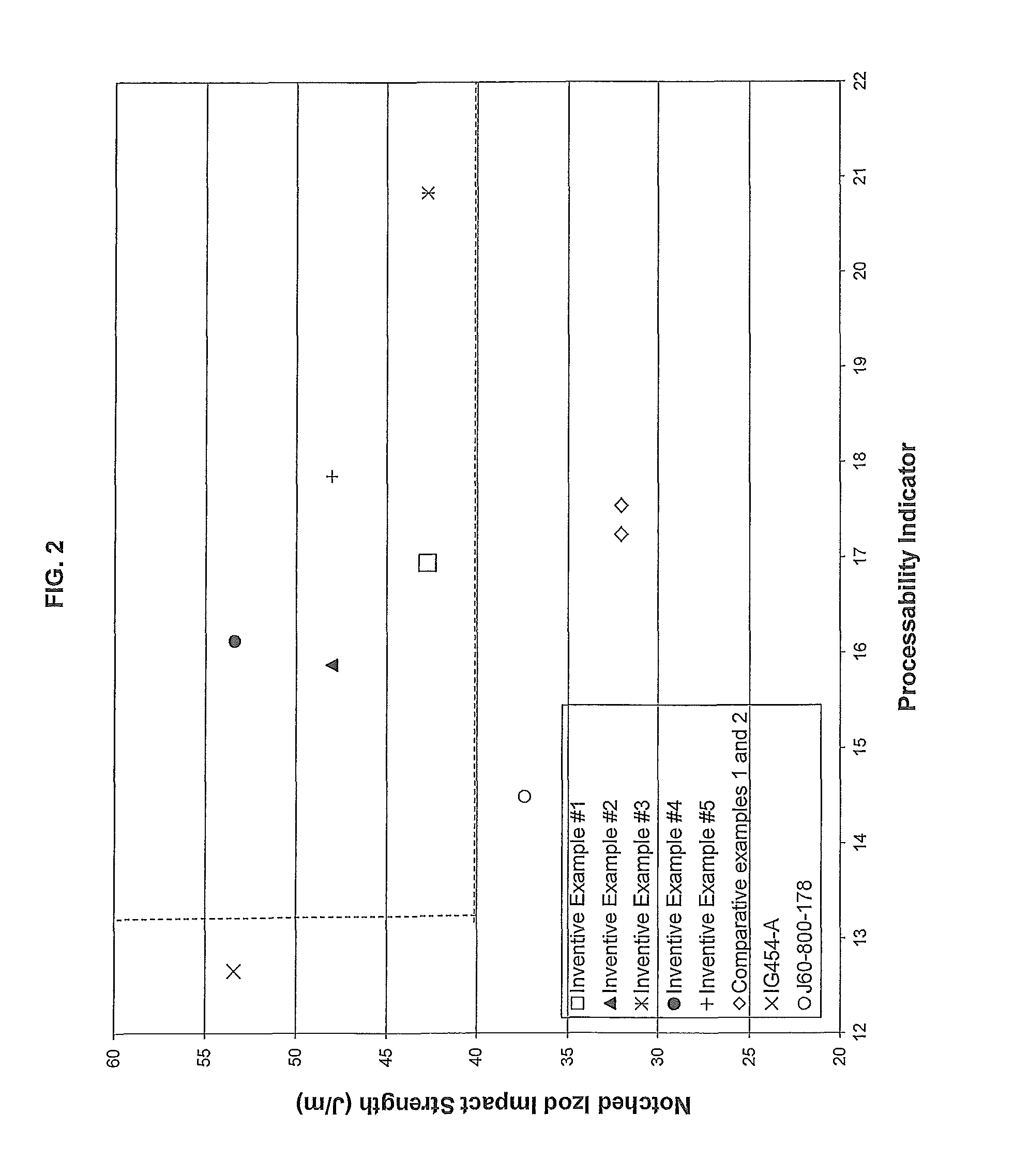

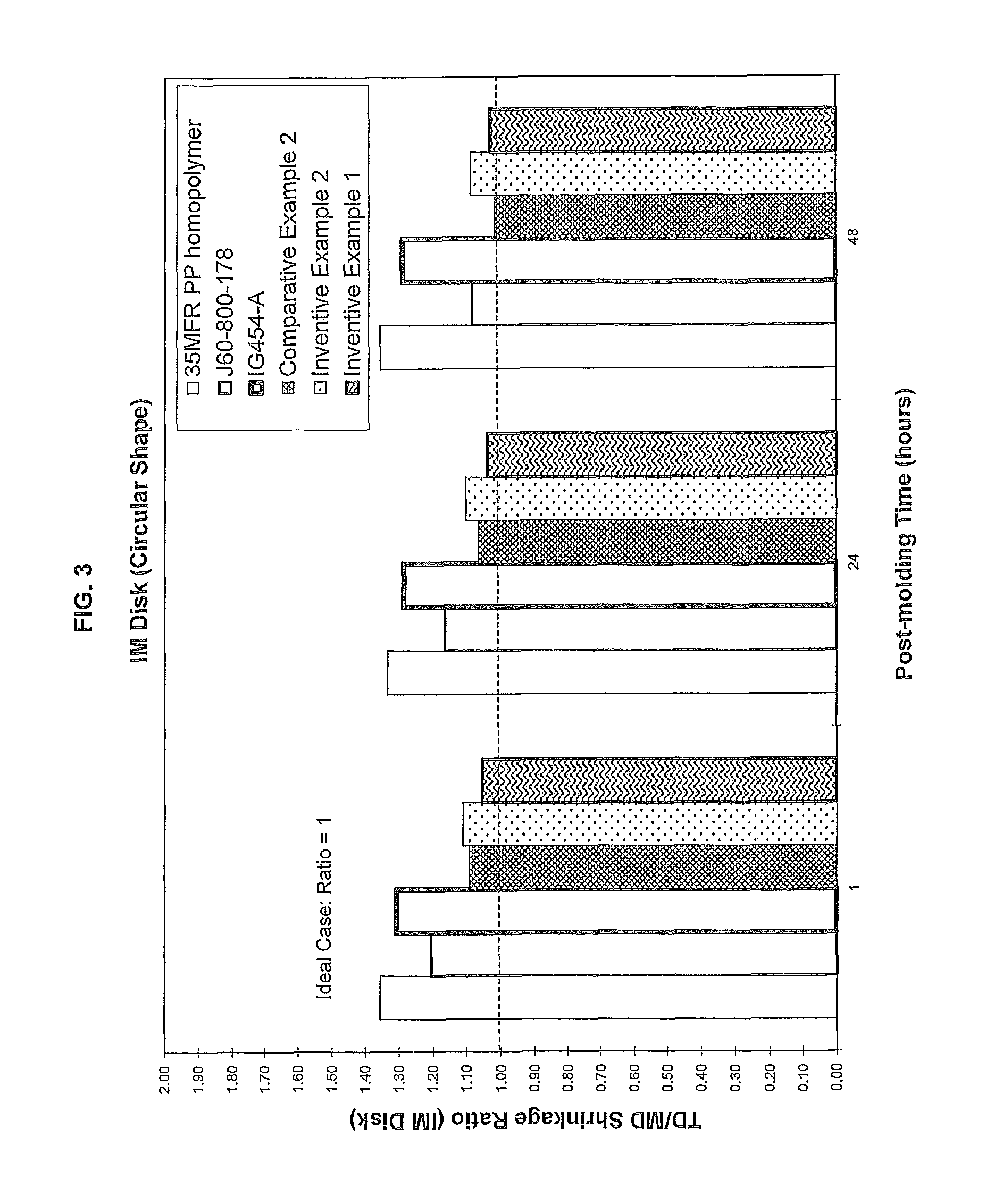

Polyethylene compositions having high dimensional stability and excellent processability for caps and closures

ActiveUS9074082B2Isotropic shrinkage ratioShrinkage differentialCapsClosure capsCompression moldingPolymer science

A dual reactor solution polymerization process gives high density polyethylene compositions containing a first ethylene copolymer and a second ethylene copolymer and which have high dimensional stability, excellent processability as well as good organoleptic properties and reasonable stress cracking resistance. The polyethylene compositions are suitable for compression molding or injection molding applications and are useful, for example, in the manufacture of caps and closures for bottles, and for example, in bottles containing non-pressurized liquids.

Owner:NOVA CHEM (INT) SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com