Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Ellipsoidal particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enhanced LCD backlight

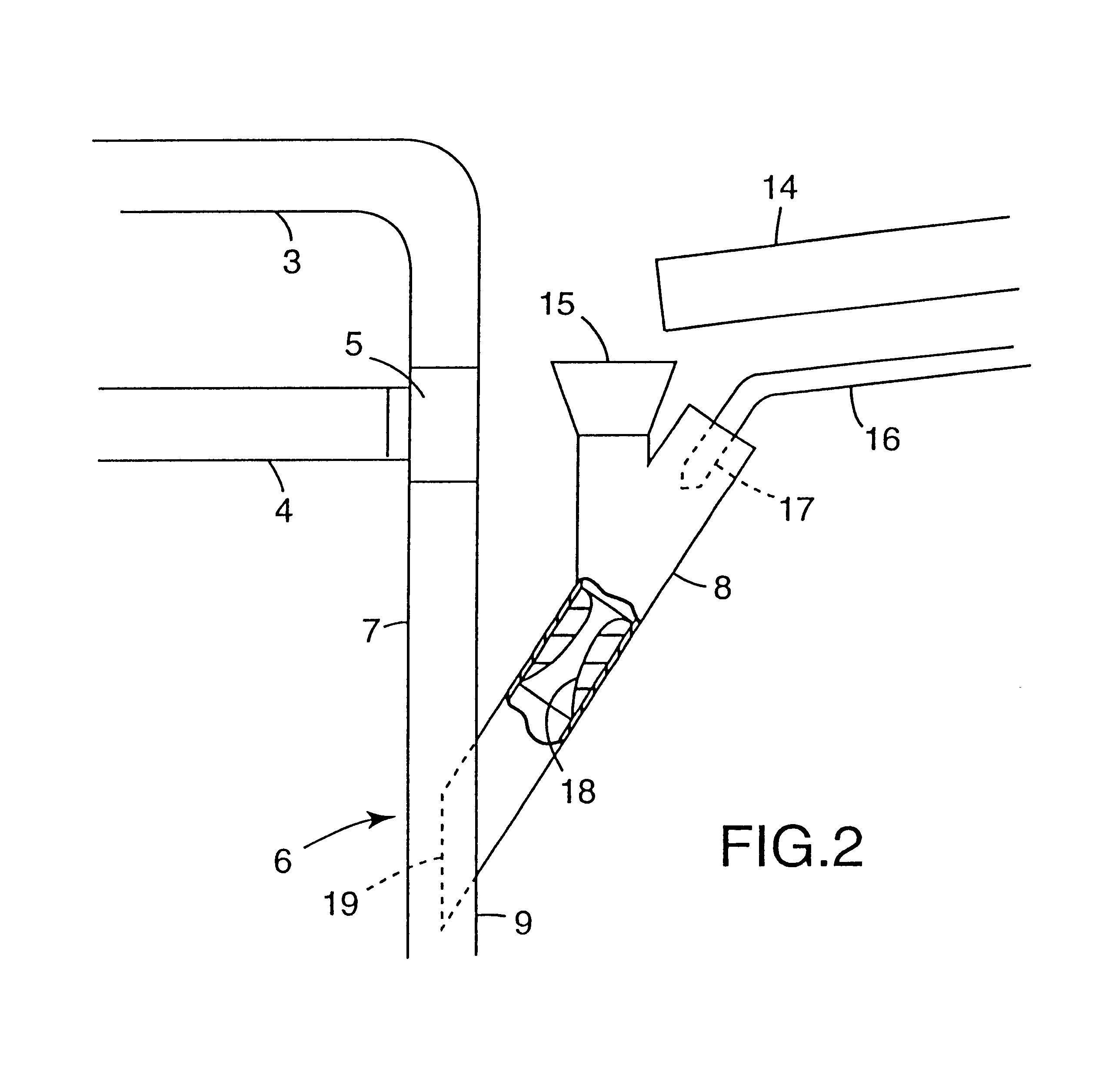

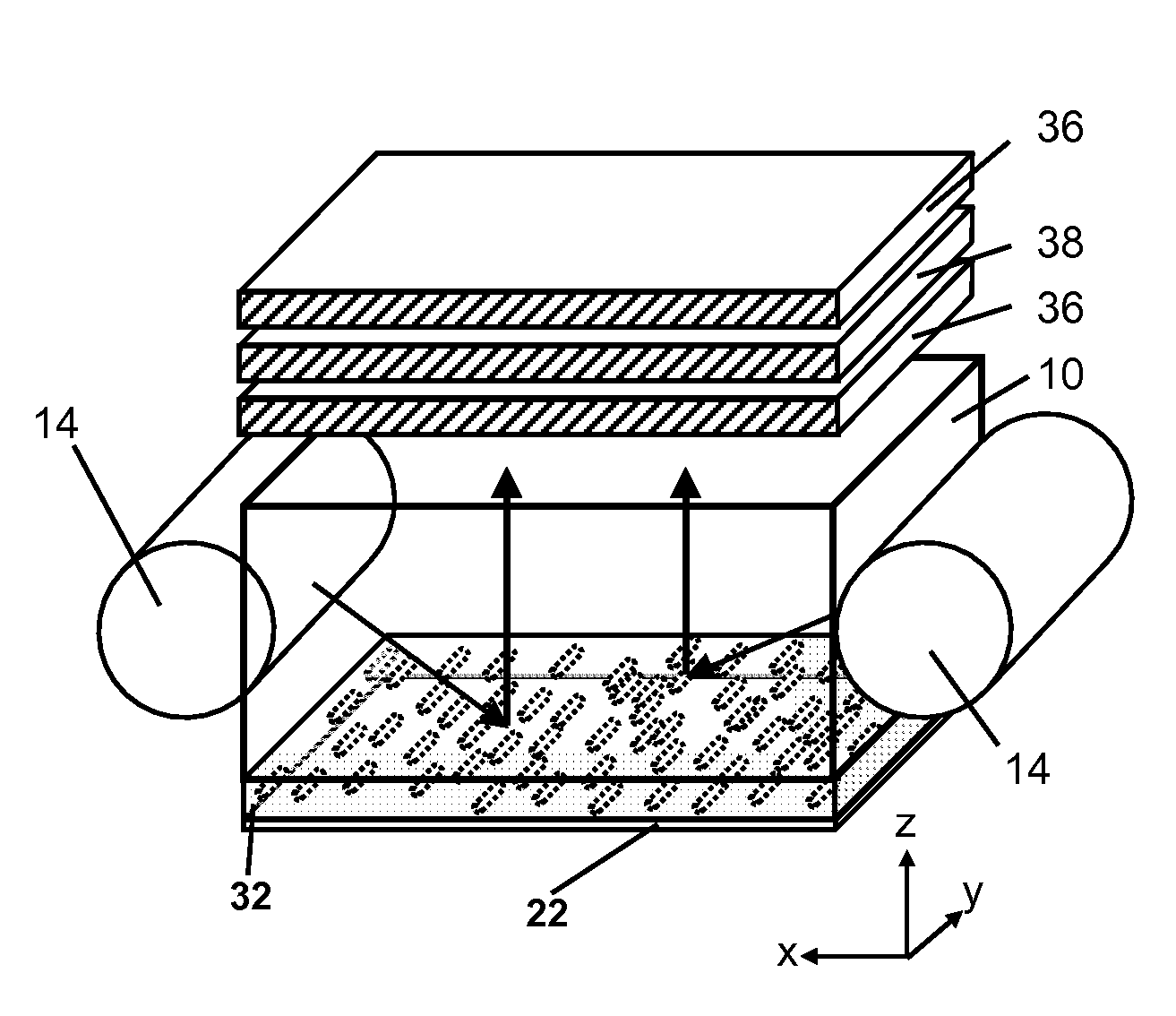

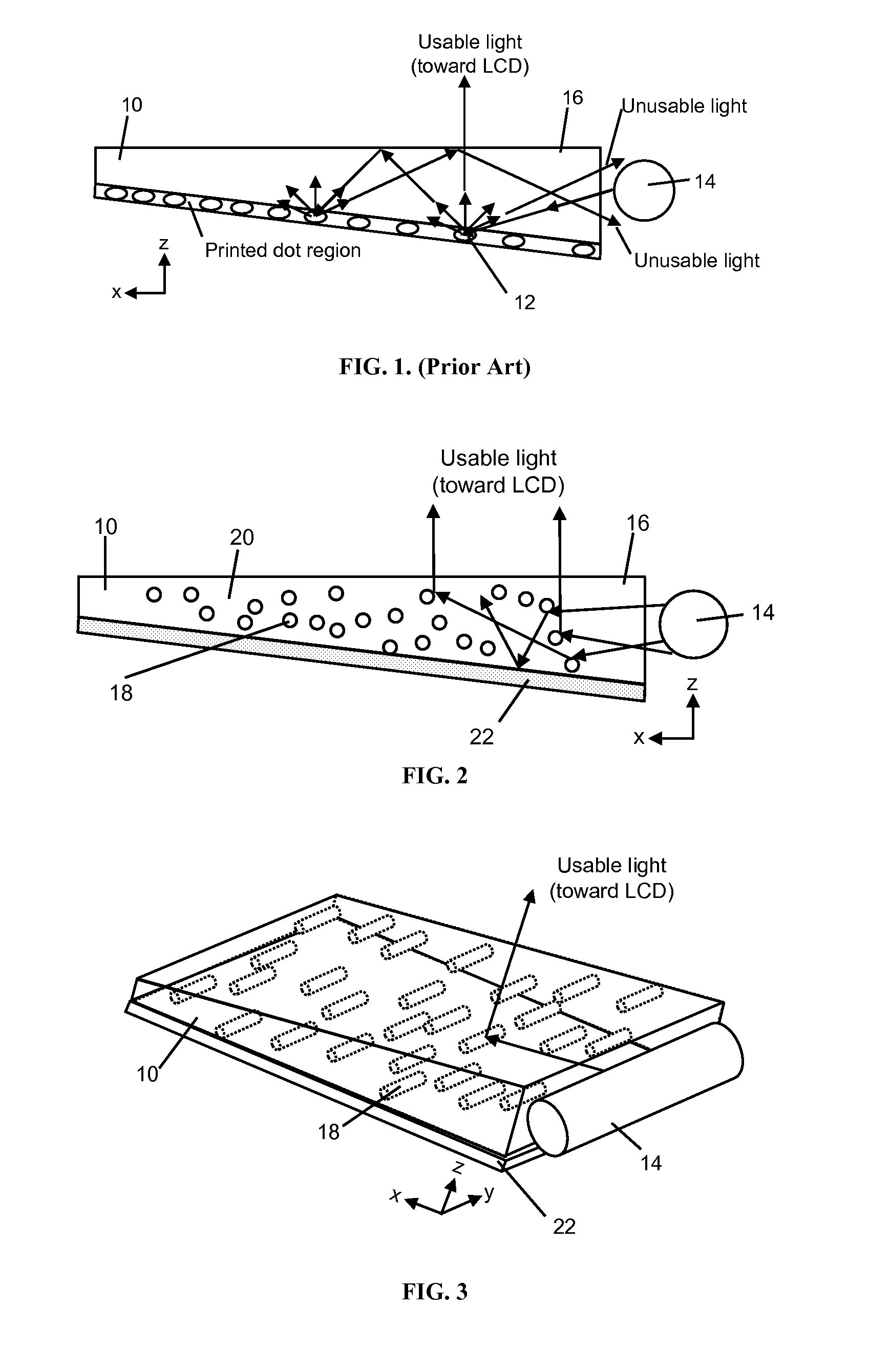

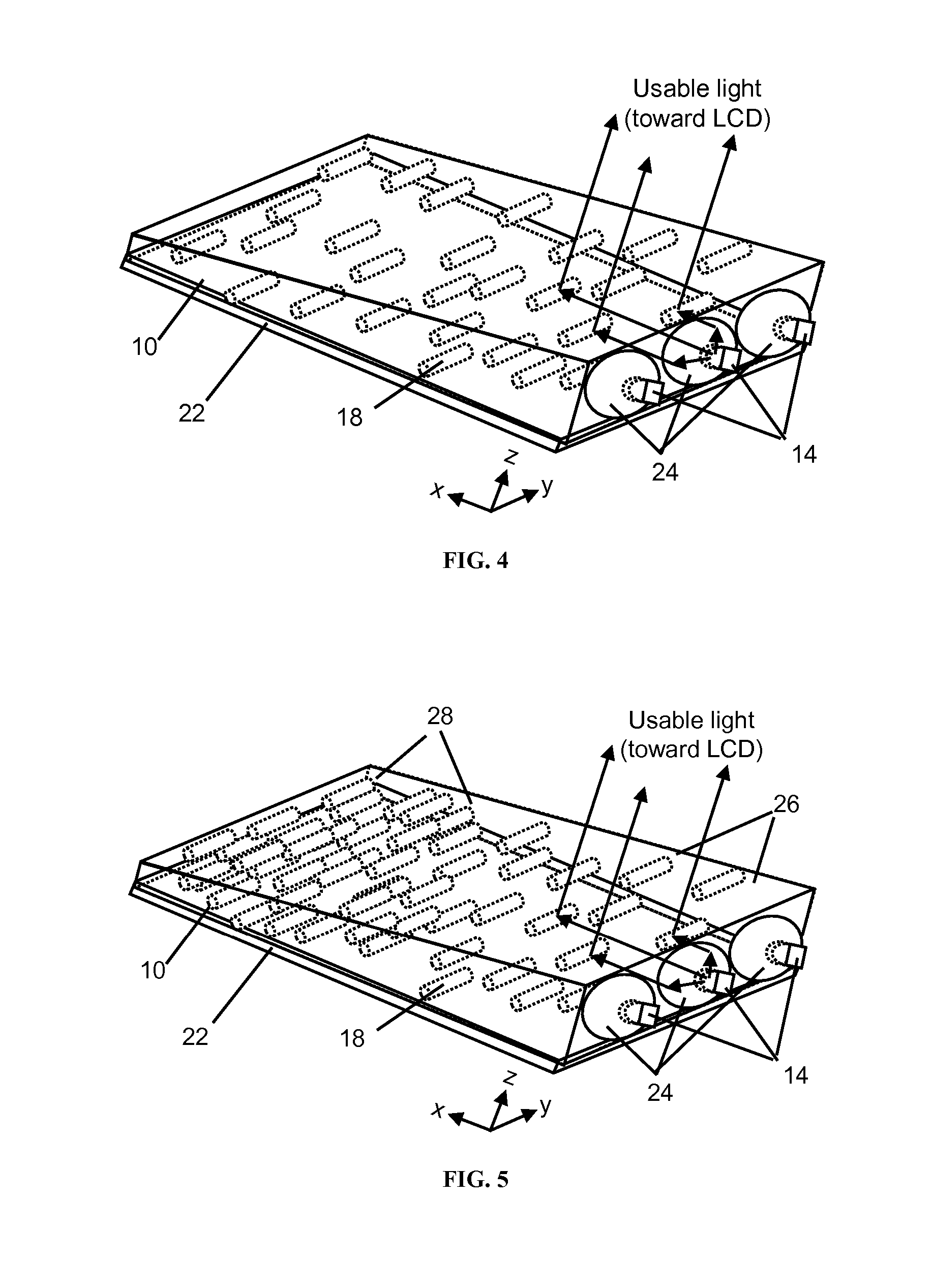

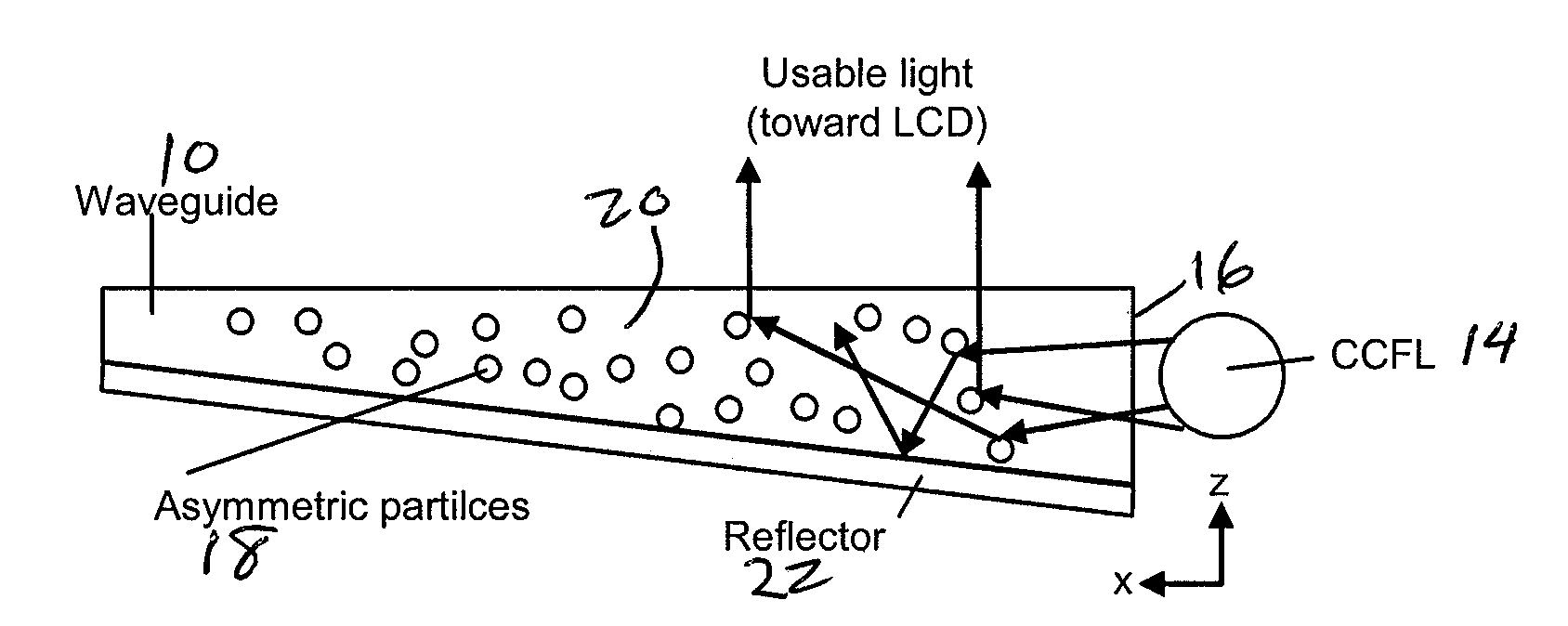

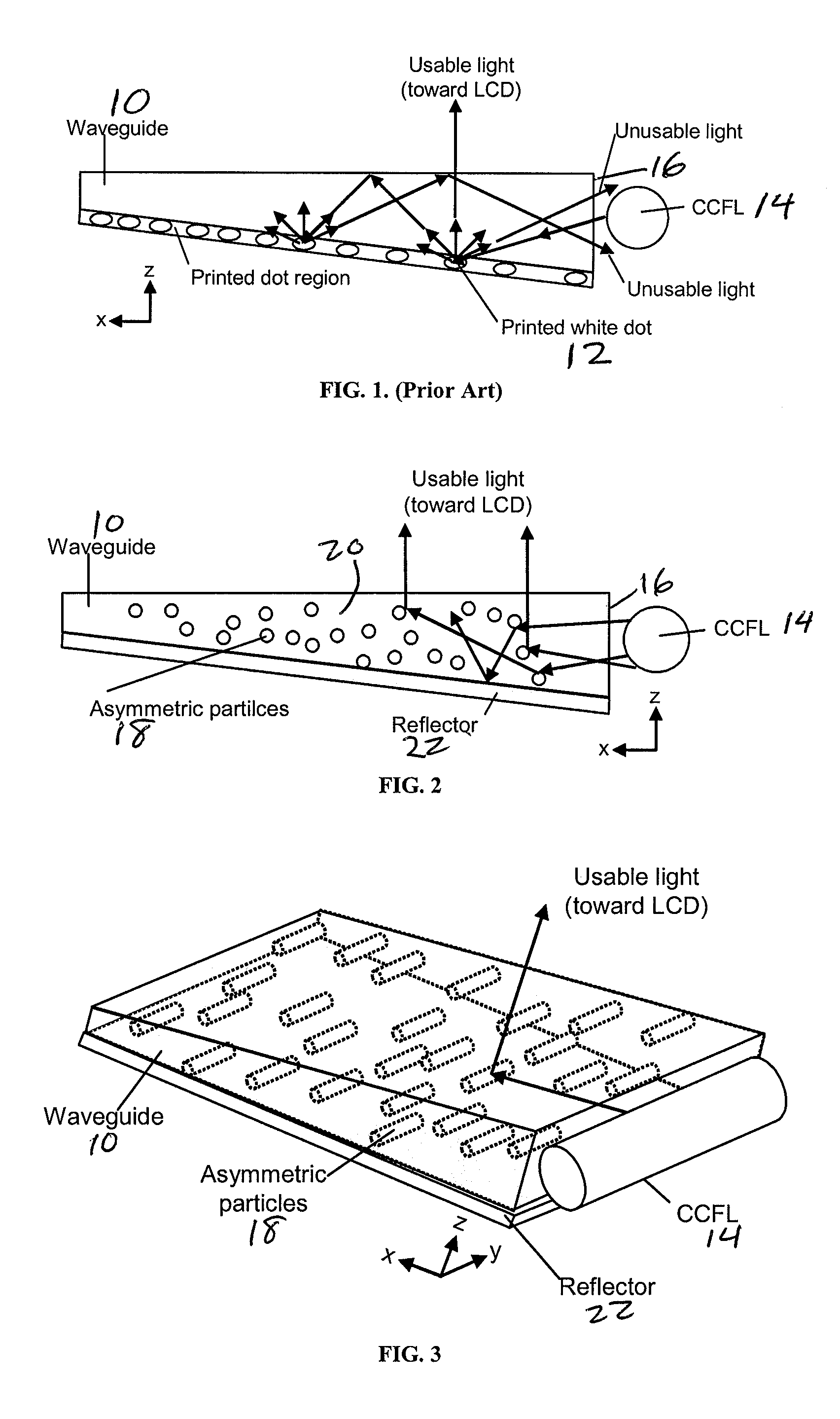

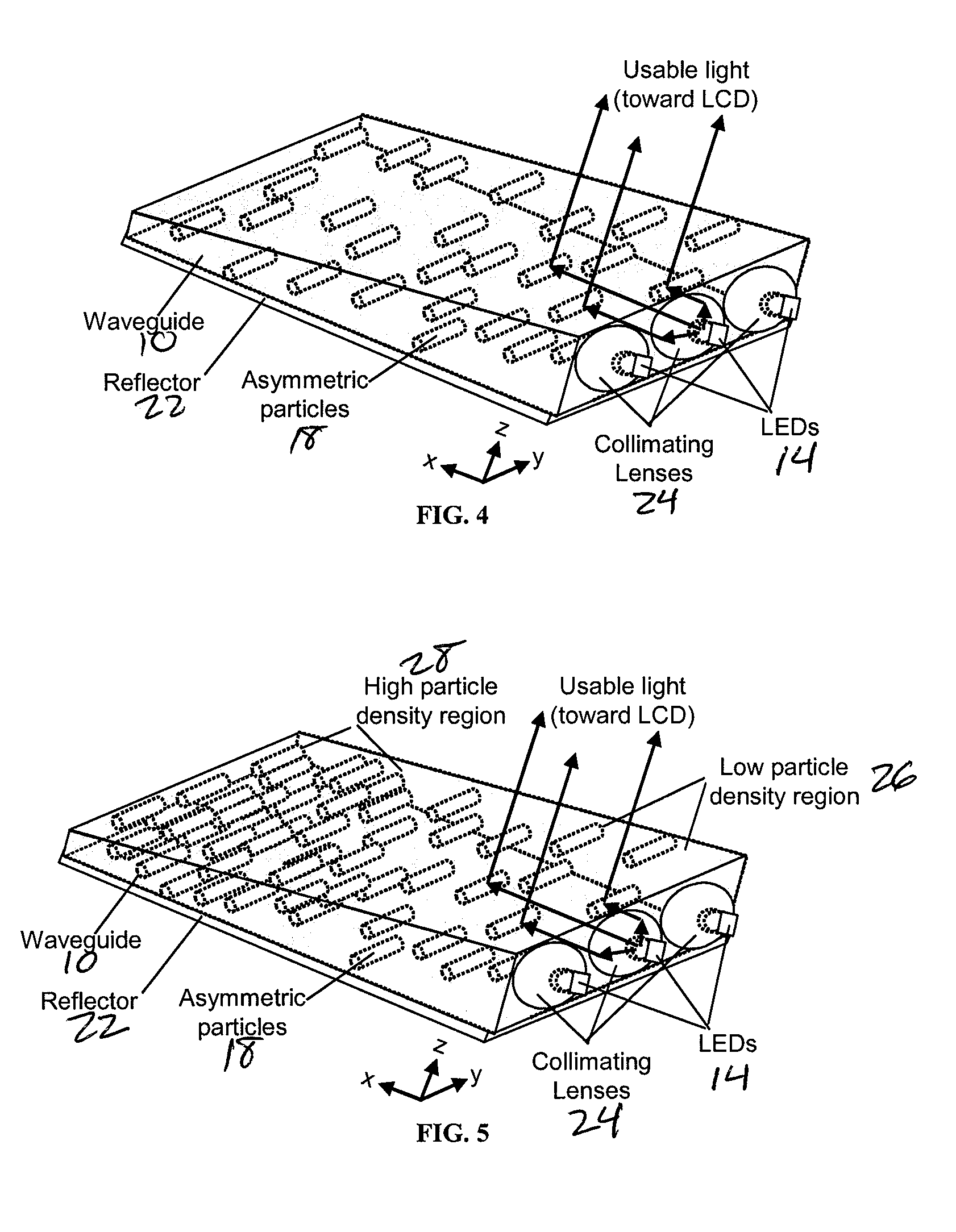

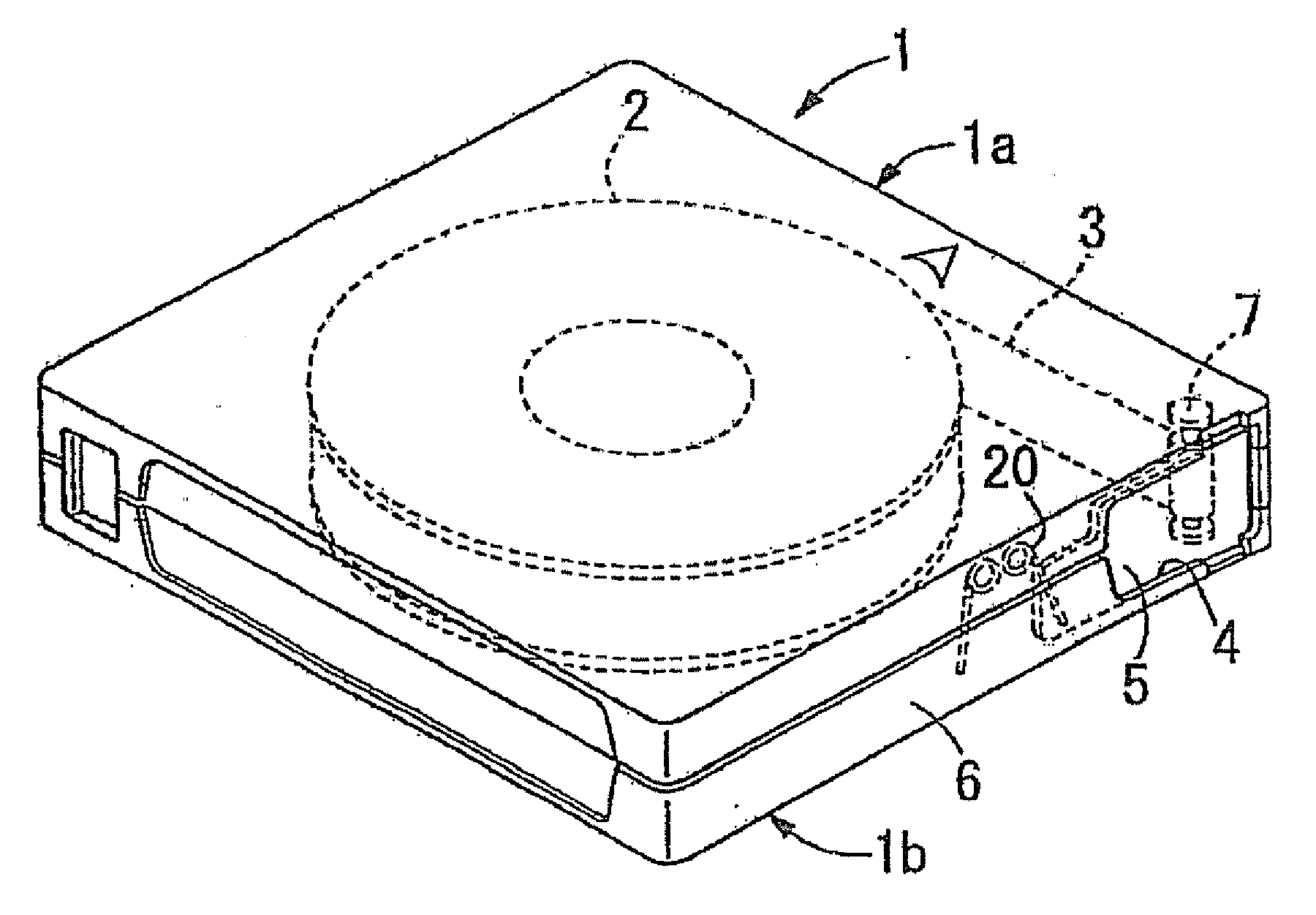

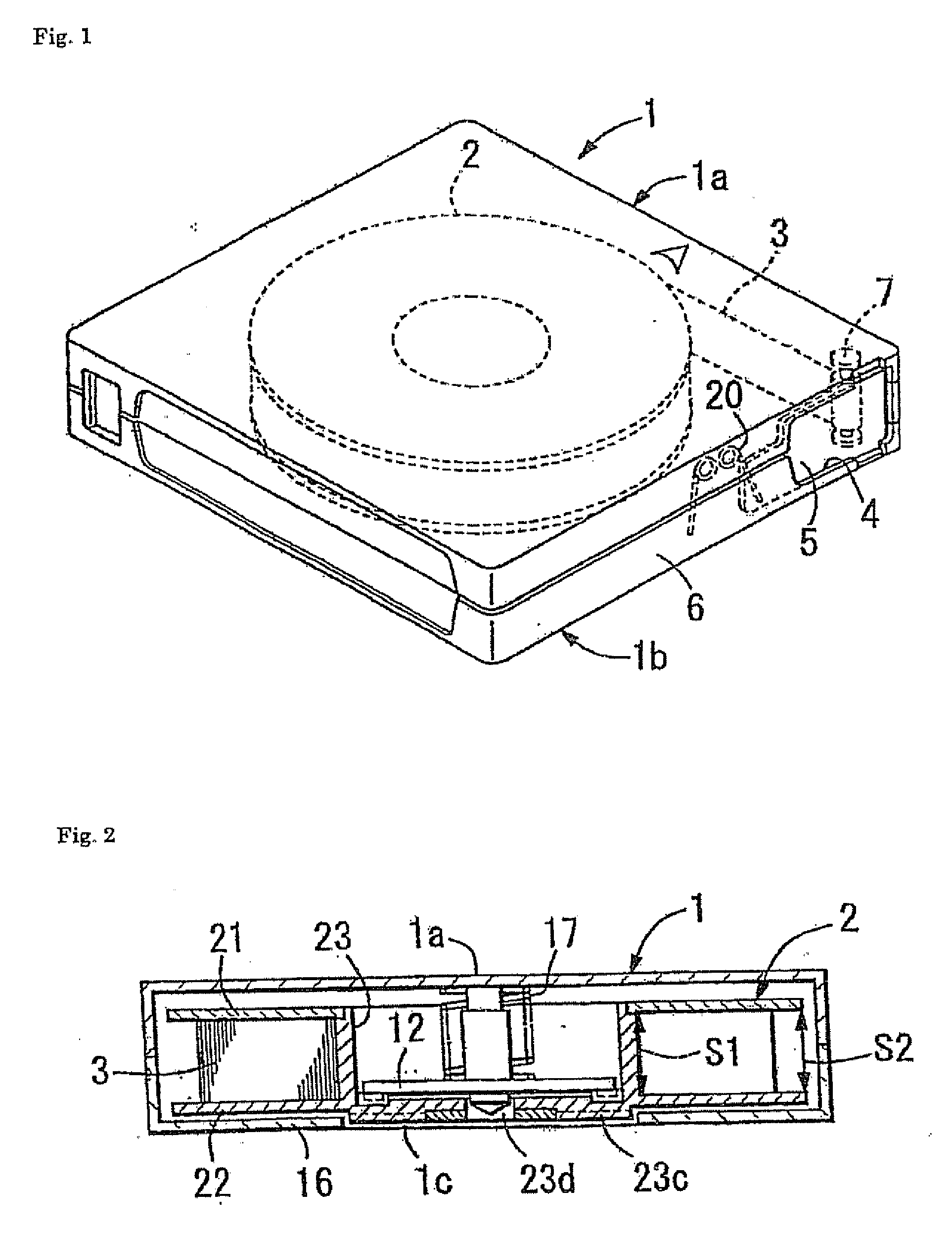

ActiveUS20060056166A1Improved backlight assemblyAvoid less flexibilityElectric discharge tubesDiffusing elementsCompression moldingEllipsoidal particle

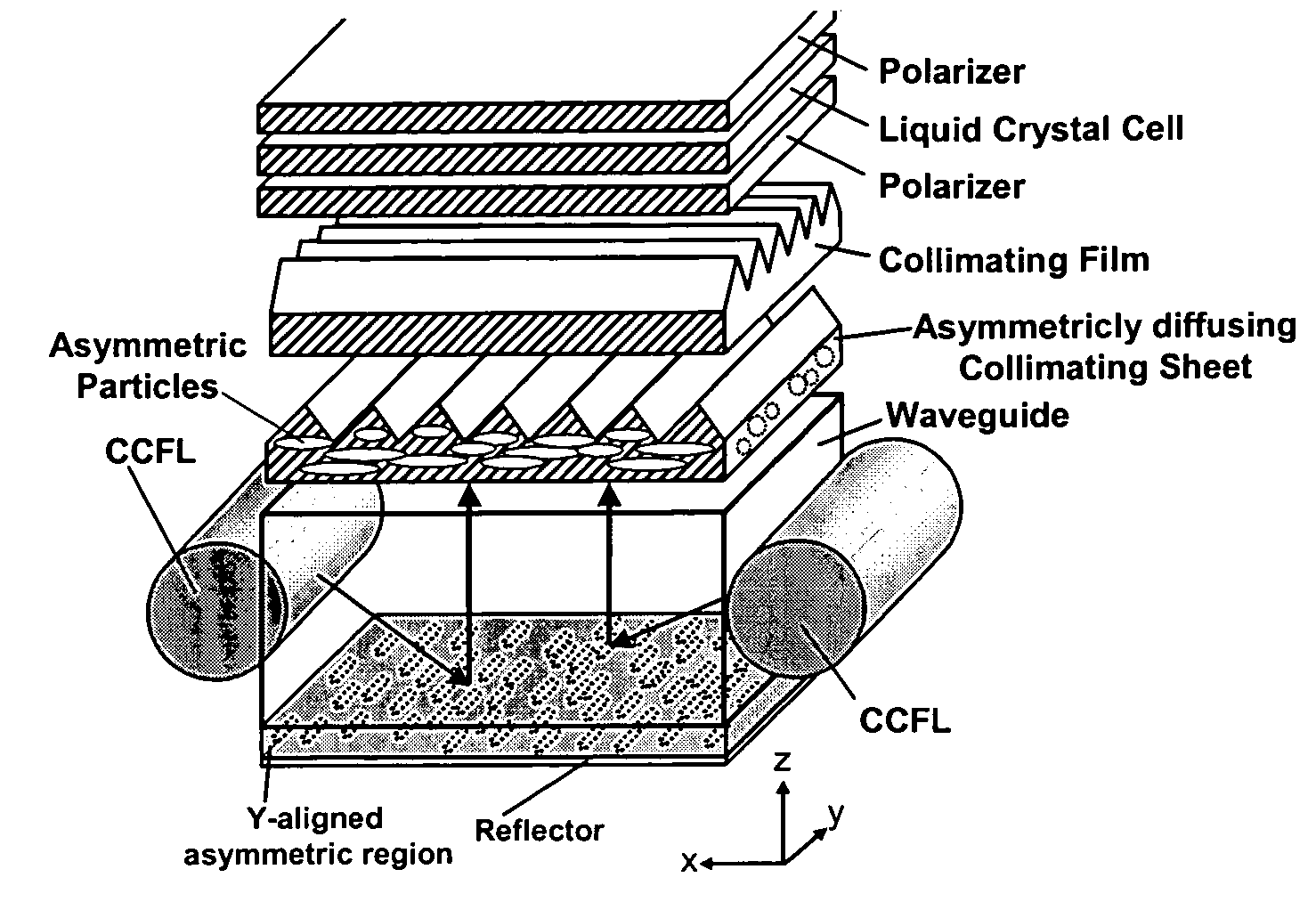

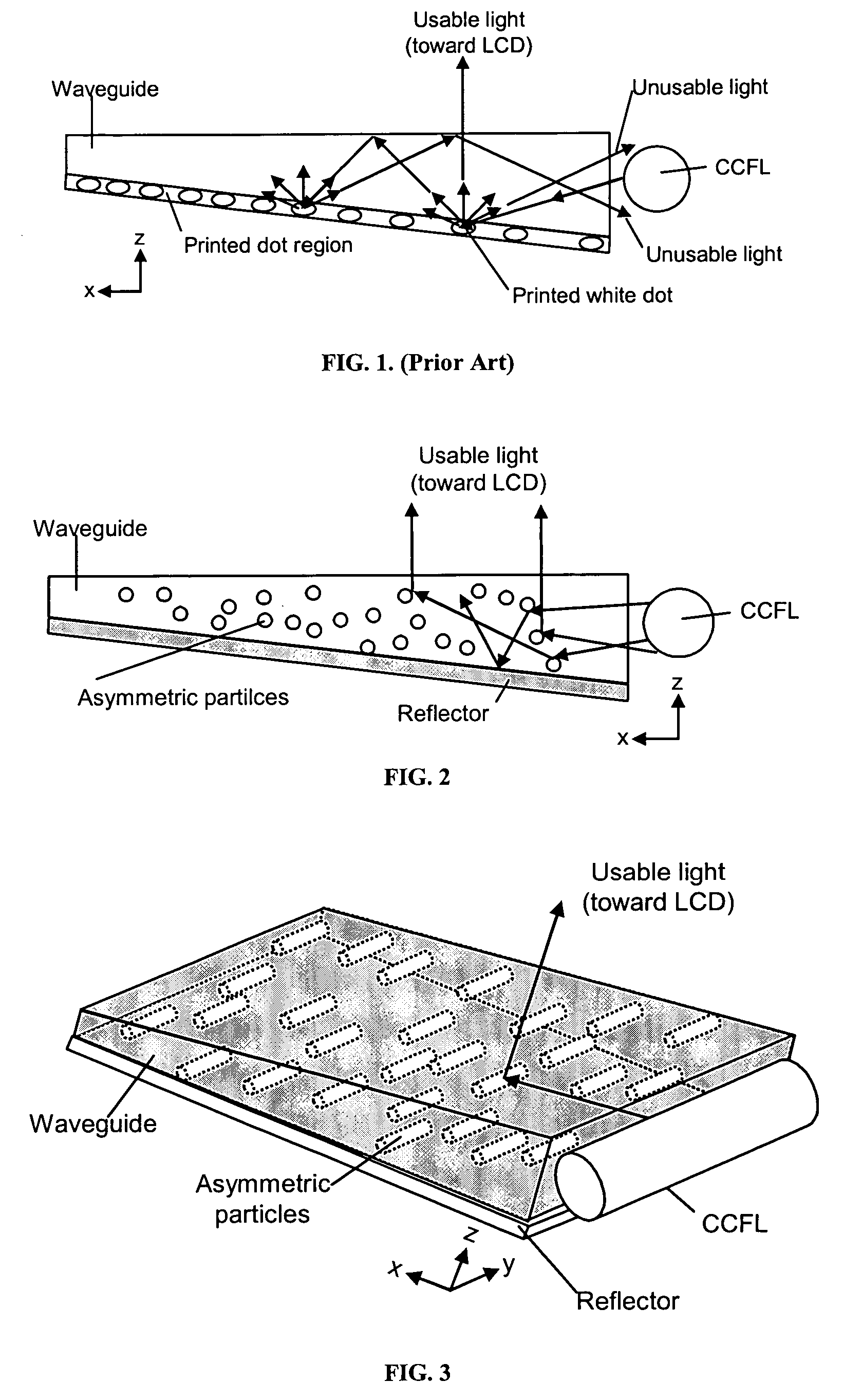

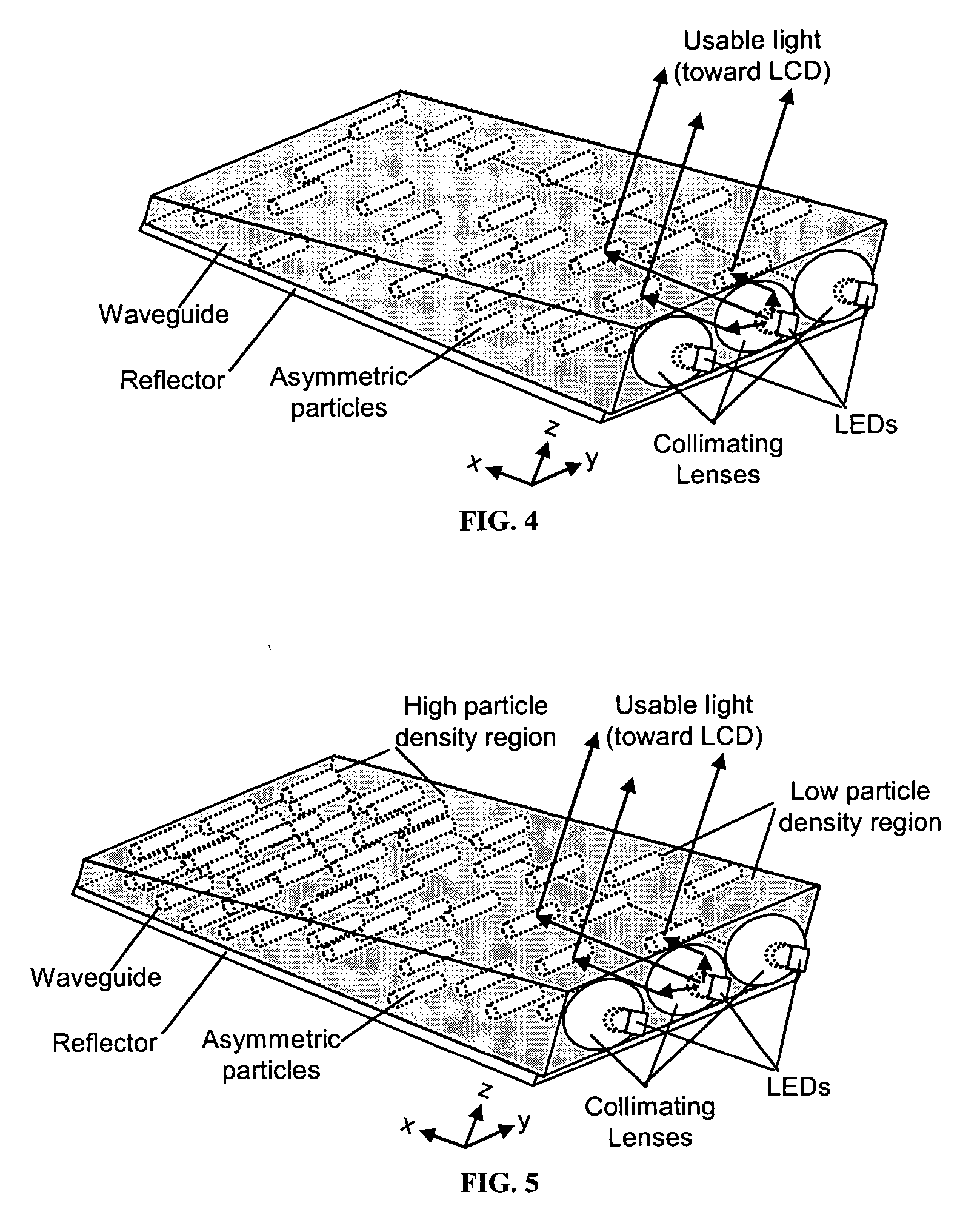

The present invention provides an improved light guide with inherently more flexibility for display system designers and higher optical efficiency. By using a light guide containing substantially aligned non-spherical particles, more efficient control of the light scattering can be achieved. One or more regions containing ellipsoidal particles may be used and the particle sizes may vary between 2 and 100 microns in the smaller dimension. The light scattering regions may be substantially orthogonal in their axis of alignment. Alternatively, one or more asymmetrically scattering films can be used in combination with a backlight light guide and a reflector to produce an efficient backlight system. The light guides may be manufactured by embossing, stamping, or compression molding a light guide in a suitable light guide material containing asymmetric particles substantially aligned in one direction. The light scattering light guide or non-scattering light guide may be used with one or more light sources, collimating films or symmetric or asymmetric scattering films to produce an efficient backlight that can be combined with a liquid crystal display or other transmissive display. By maintaining more control over the scattering, the efficiency of the recycling of light by using reflective polarizers can also be increased.

Owner:MASSACHUSETTS DEV FINANCE AGENCY

Fused glassy particulates obtained by flame fusion

InactiveUS6254981B1Efficient meltingFast heat transferSynthetic resin layered productsCellulosic plastic layered productsParticulatesSuspended particles

The disclosure describes methods for producing bulk, particulate material that includes solid, generally ellipsoidal particles. Irregularly shaped feed particles with average particle sizes of up to 25 microns on a volume basis are dispersed in at least a portion of a combustible gas mixture by application of force and / or fluidizing agents. The combustible mixture with particles in suspension is then delivered, while controlling agglomeration or re-agglomeration of the particles, to at least one flame front. There, the mixture and suspended particles are uniformly distributed across the surface(s) of and passed through the flame front(s) with a high concentration of particles in the mixture. This flame front and the resultant flame(s) with suspended particles are located in at least one "wall free" zone. In such zone(s) the flame(s) may expand while the particles are maintained in dispersion and heated, with controlled and highly efficient application of heating energy. At least partial fusion occurs within at least the surfaces of the particles at high thermal efficiencies, while agglomeration of particles during fusion is inhibited.

Owner:3M CO

Enhanced Light Guide

InactiveUS20080043490A1Improved backlight assemblyAvoid less flexibilityVehicle interior lightingProtective devices for lightingCompression moldingEllipsoidal particle

A light guide containing substantially aligned non-spherical particles provides more efficient control of light scattering. One or more regions containing ellipsoidal particles may be used and the particle sizes may vary between 2 and 100 microns in the smaller dimension. The light scattering regions may be substantially orthogonal in their axis of alignment. Alternatively, one or more asymmetrically scattering films can be used in combination with a backlight light guide and a reflector to produce an efficient backlight system. The light guides may be manufactured by embossing, stamping, or compression molding a light guide in a suitable light guide material containing asymmetric particles substantially aligned in one direction. The light scattering light guide or non-scattering light guide may be used with one or more light sources, collimating films or symmetric or asymmetric scattering films.

Owner:CREE LED LIGHTING SOLUTIONS INC

Enhanced LCD backlight

ActiveUS7278775B2Avoid less flexibilityReduce component countElectric discharge tubesDiffusing elementsCompression moldingEllipsoidal particle

A light guide containing substantially aligned non-spherical particles provides more efficient control of light scattering. One or more regions containing ellipsoidal particles may be used and the particle sizes may vary between 2 and 100 microns in the smaller dimension. The light scattering regions may be substantially orthogonal in their axis of alignment. Alternatively, one or more asymmetrically scattering films can be used in combination with a backlight light guide and a reflector to produce an efficient backlight system. The light guides may be manufactured by embossing, stamping, or compression molding a light guide in a suitable light guide material containing asymmetric particles substantially aligned in one direction. The light scattering light guide or non-scattering light guide may be used with one or more light sources, collimating films or symmetric or asymmetric scattering films.

Owner:MASSACHUSETTS DEV FINANCE AGENCY

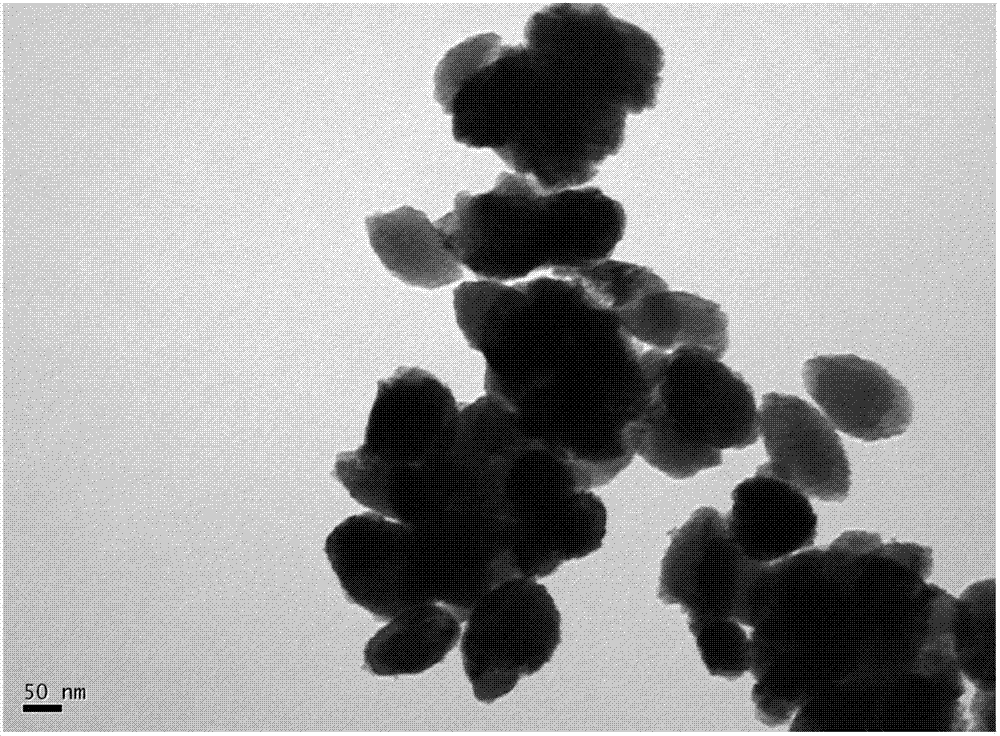

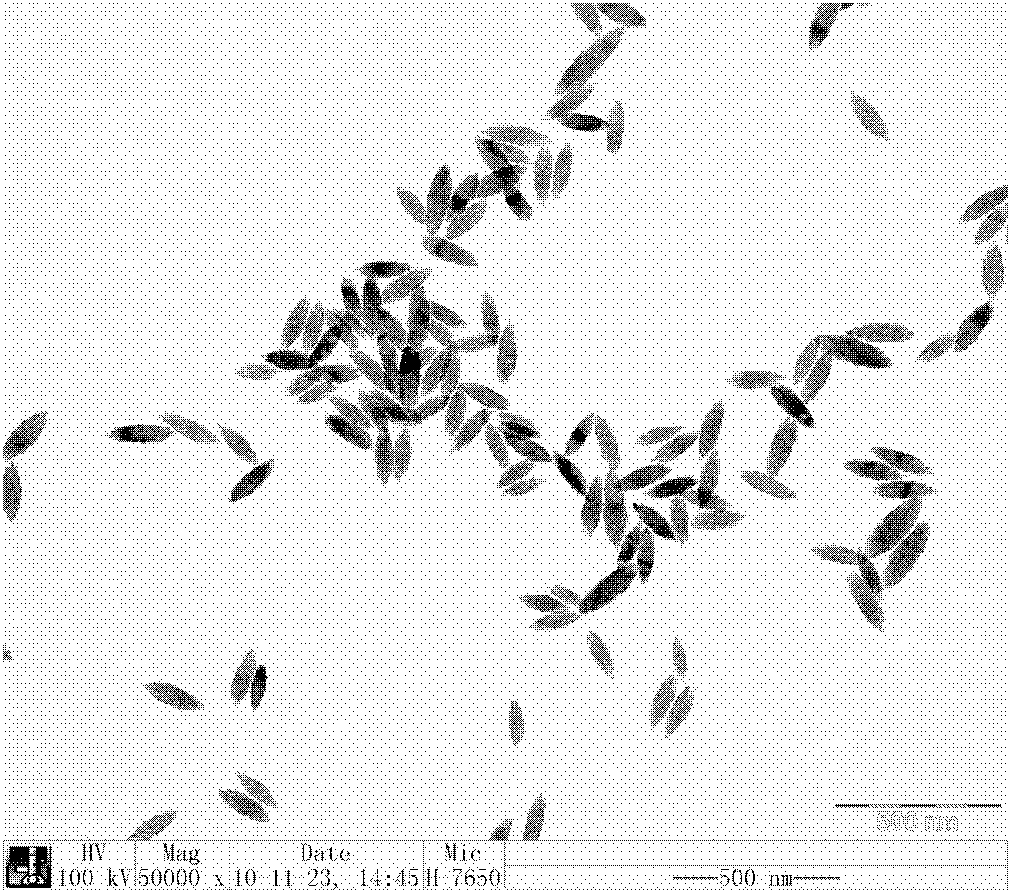

Preparation method of ellipsoidal particle size-controllable alpha-Fe2O3 nano particle

ActiveCN103043726ALarge controllable rangeLow costMaterial nanotechnologyFerric oxidesHydrogenEllipsoidal particle

The invention discloses a preparation method of an ellipsoidal particle size-controllable alpha-Fe2O3 nano particle. By adopting the raw material combination of trivalent iron salts and hydroxyl or / and carbonyl surfactant, the hydroxyl or the carbonyl and -OH of Fe(OH)3 for hydrogen bonds to be absorbed on the surfaces of crystals; the irregular motion of the surfactant molecules containing the hydroxyl or the carbonyl is intensified so as to form an ellipsoidal alpha-Fe2O3 seed crystal through induction; an obtained product is uniform in particle size; in the preparation process, the overall participation of the surfactant effectively suppresses hard agglomeration, the controllable range of the particle size is wide, raw materials are easily available and the cost is low, and the preparation process is simple and convenient; the particle size distribution of the prepared ellipsoidal alpha-Fe2O3 nano particle is 90-800nm + / -10 nanometers, the particle size can be regulated and controlled within the range of 90-800nm, the capacity is increased, and industrialization is realized.

Owner:CHONGQING YUNTIANHUA HIGH END NEW MATERIALS DEV CO LTD +1

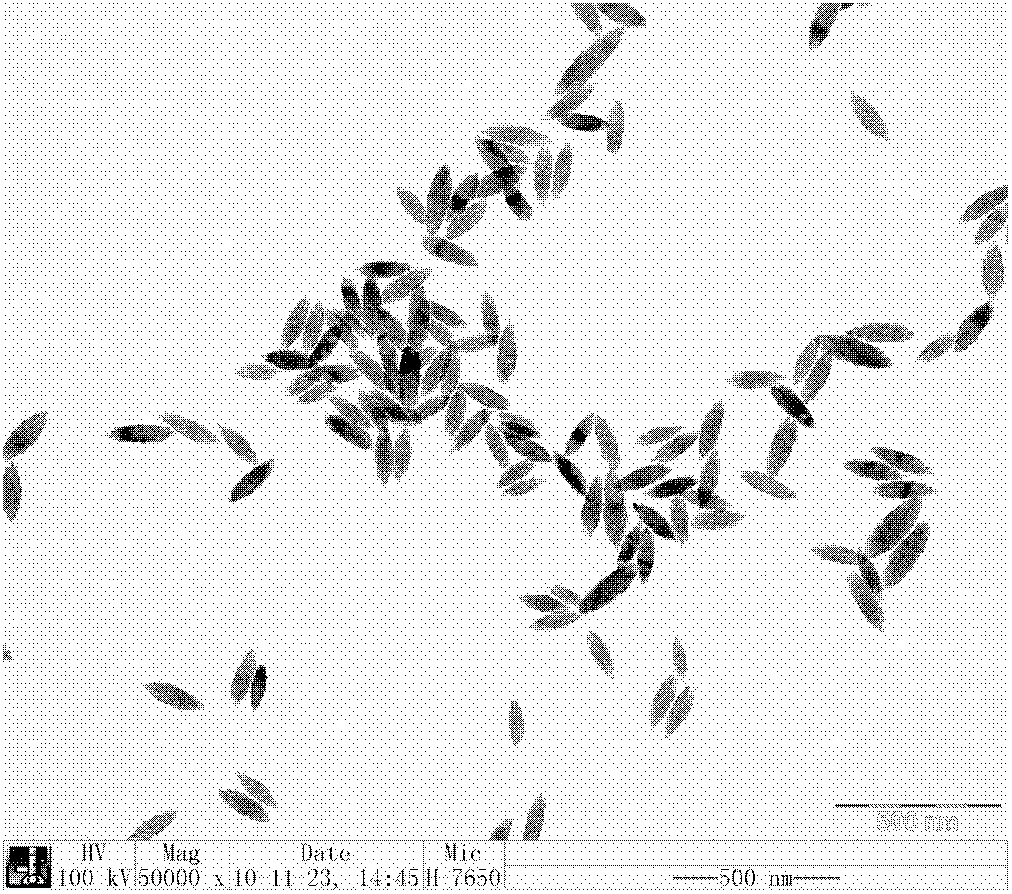

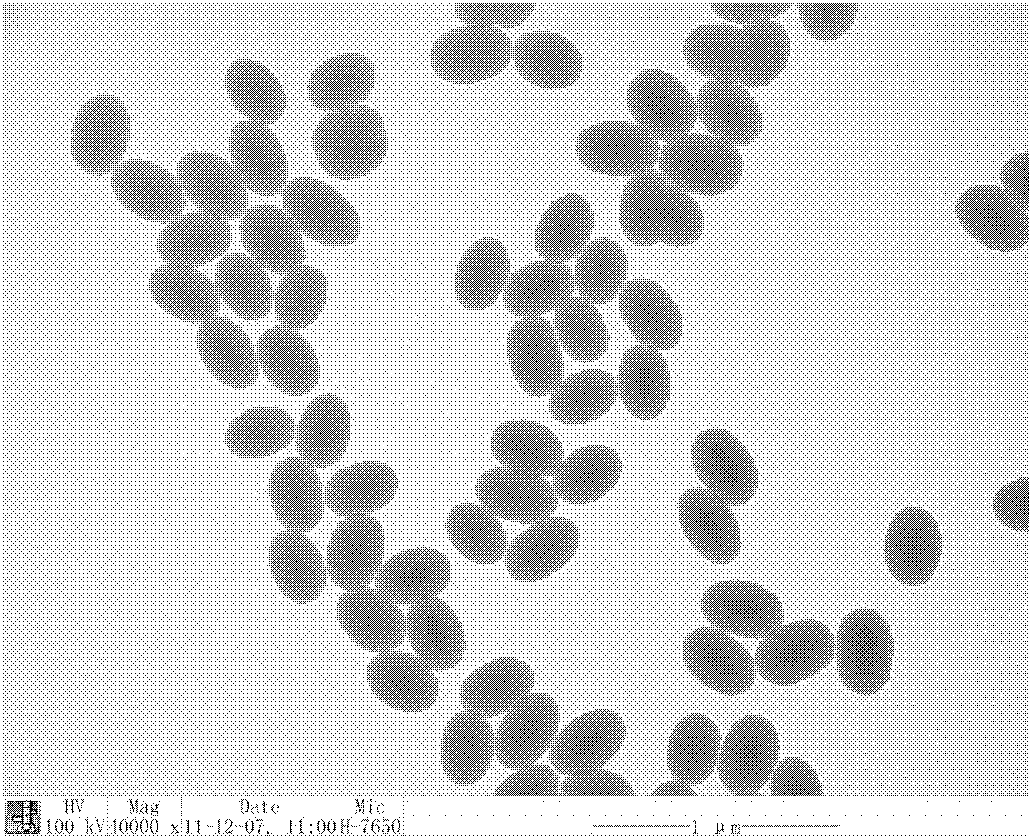

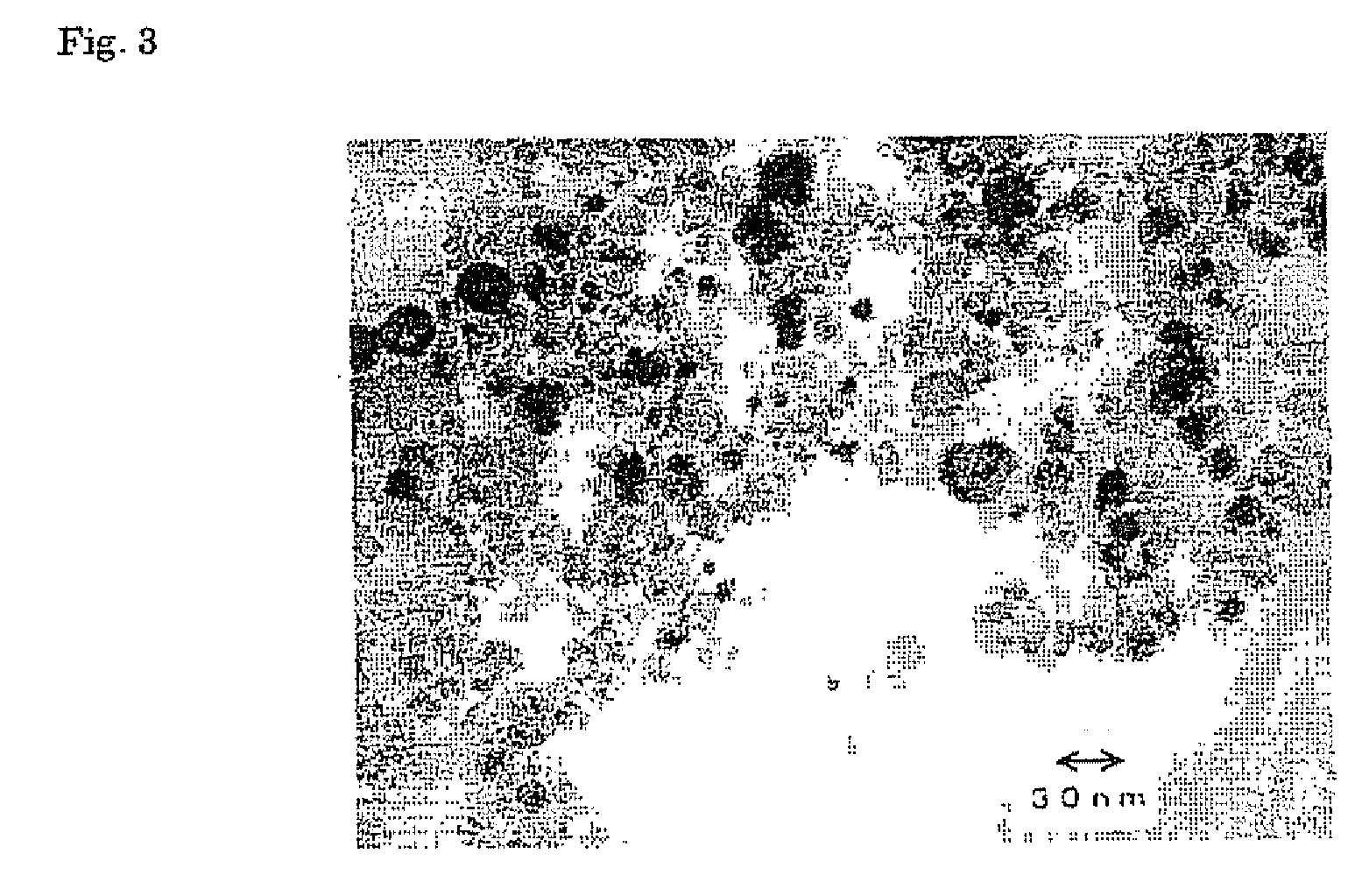

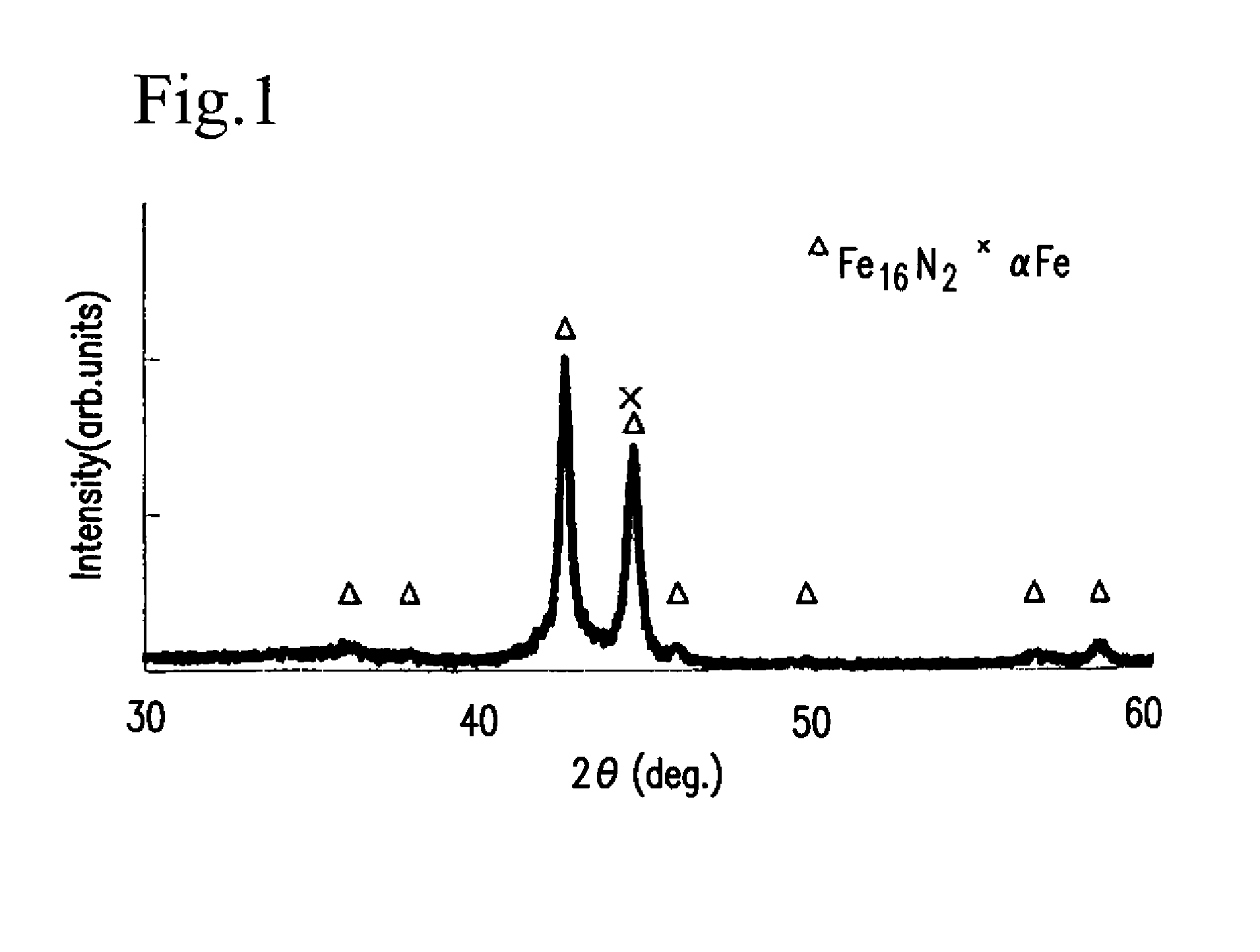

Magnetic powder, method for producing the same and magnetic recording medium comprising the same

InactiveUS6964811B2Recording characteristicImprove recording effectMaterials with ironNanomagnetismEllipsoidal particleMagnetization

A magnetic powder consisting of substantially spherical or ellipsoidal particles comprising a transition metal which comprises iron and a rear earth element which is mainly present in the outer layer of the magnetic powder particles, and having a particle size of 5 to 200 nm, a coercive force of 80 to 400 kA / m and a saturation magnetization of 10 to 25 uWb / g.

Owner:FUJIFILM CORP

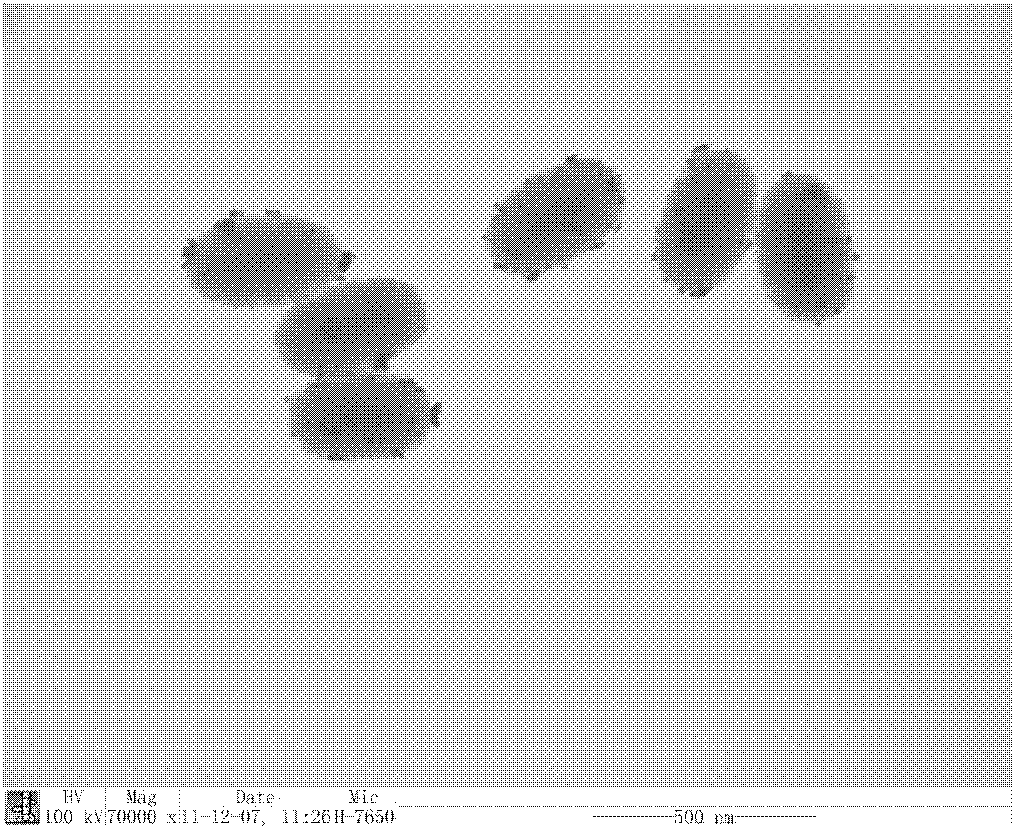

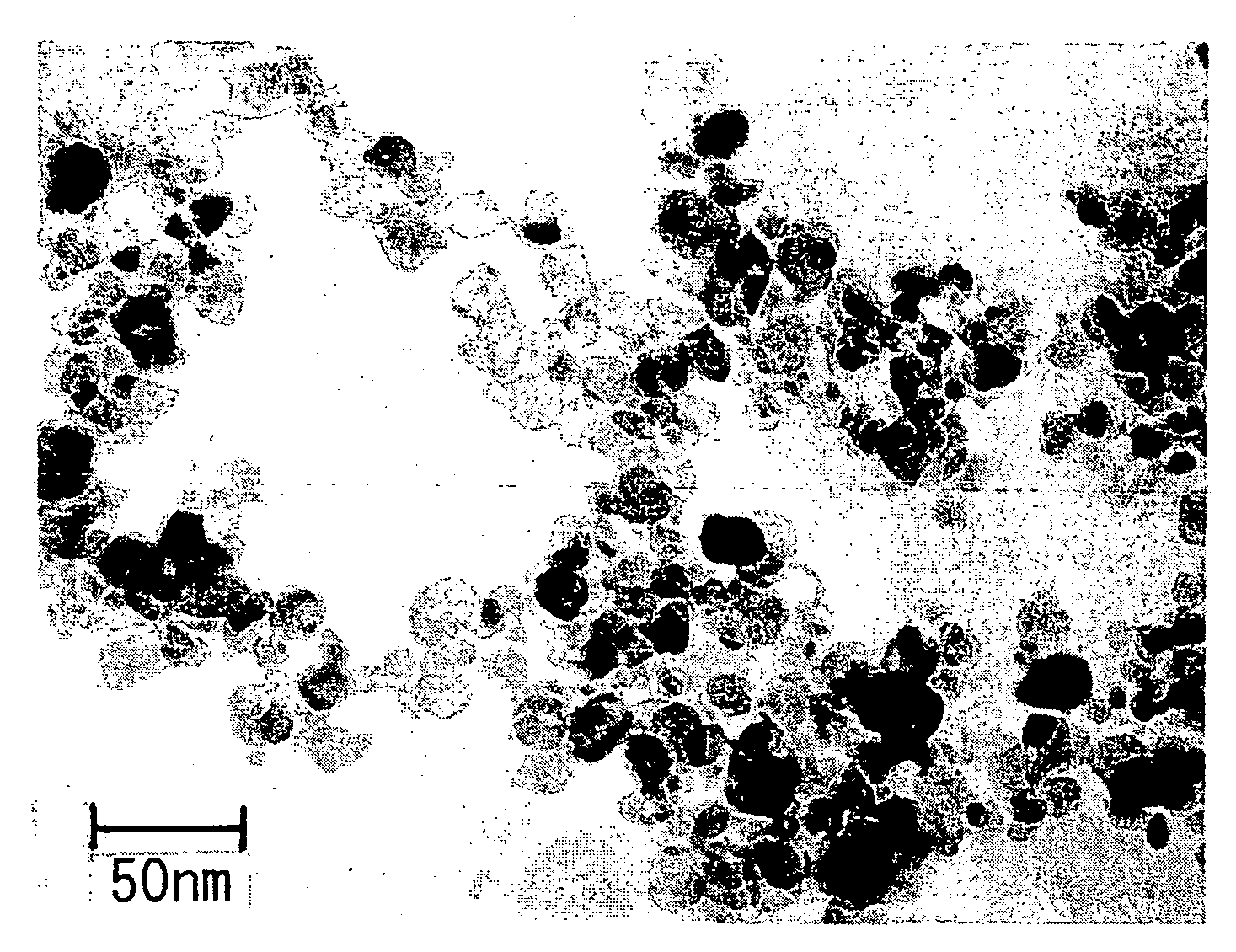

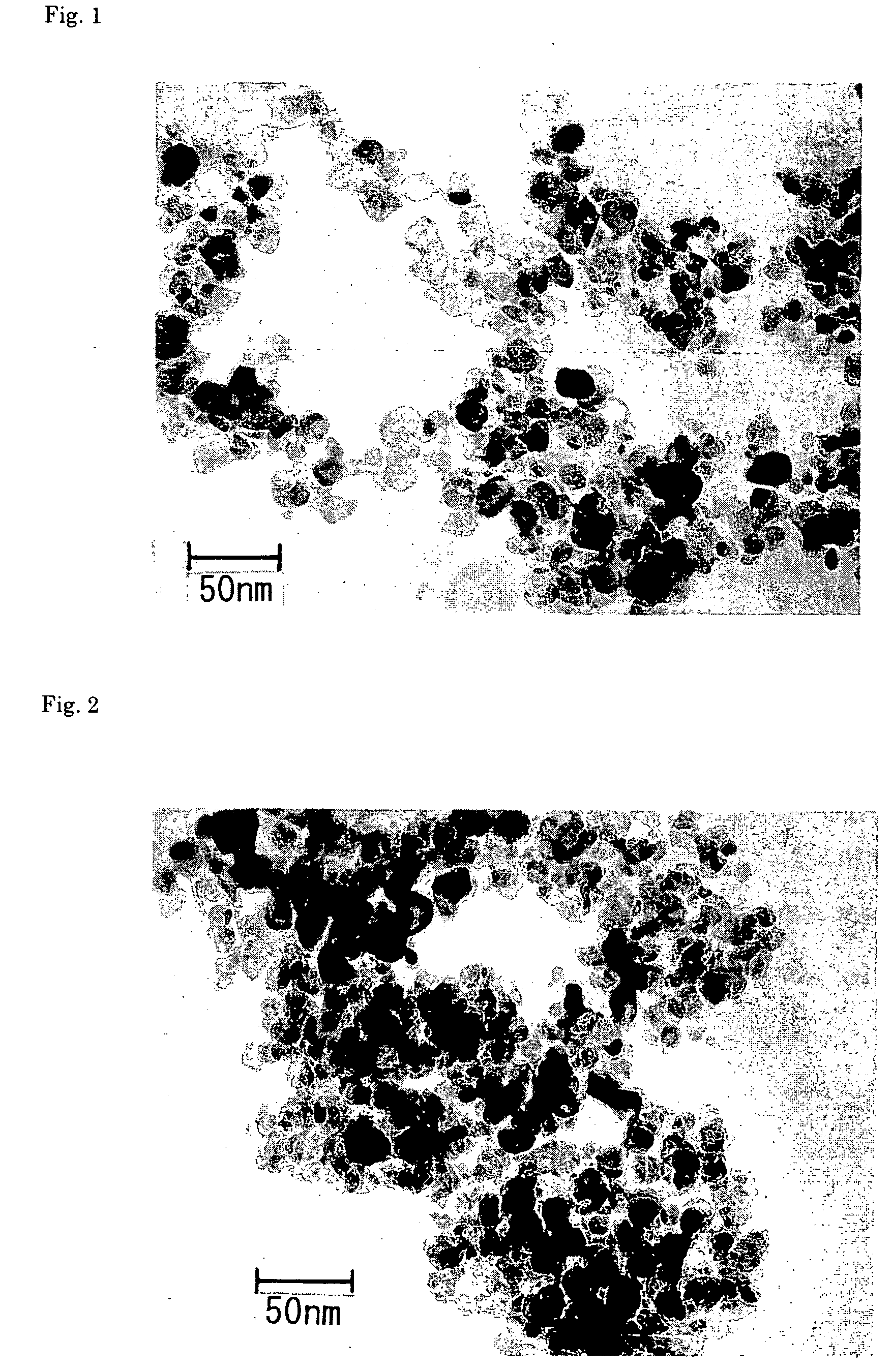

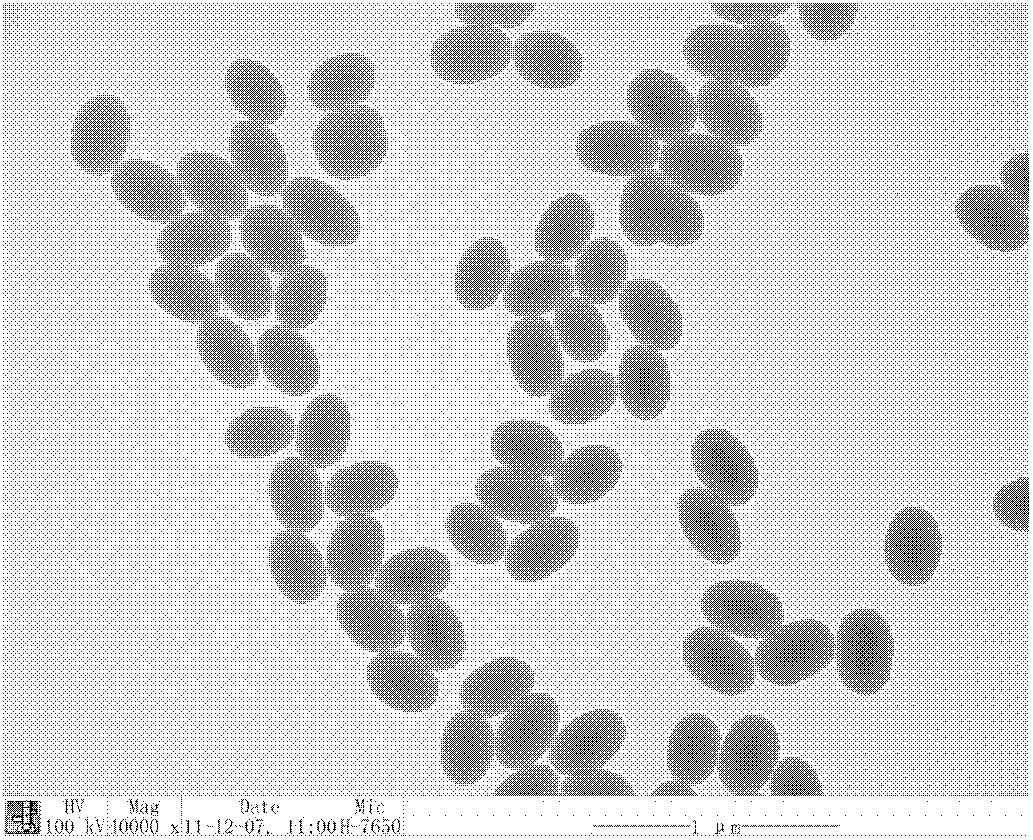

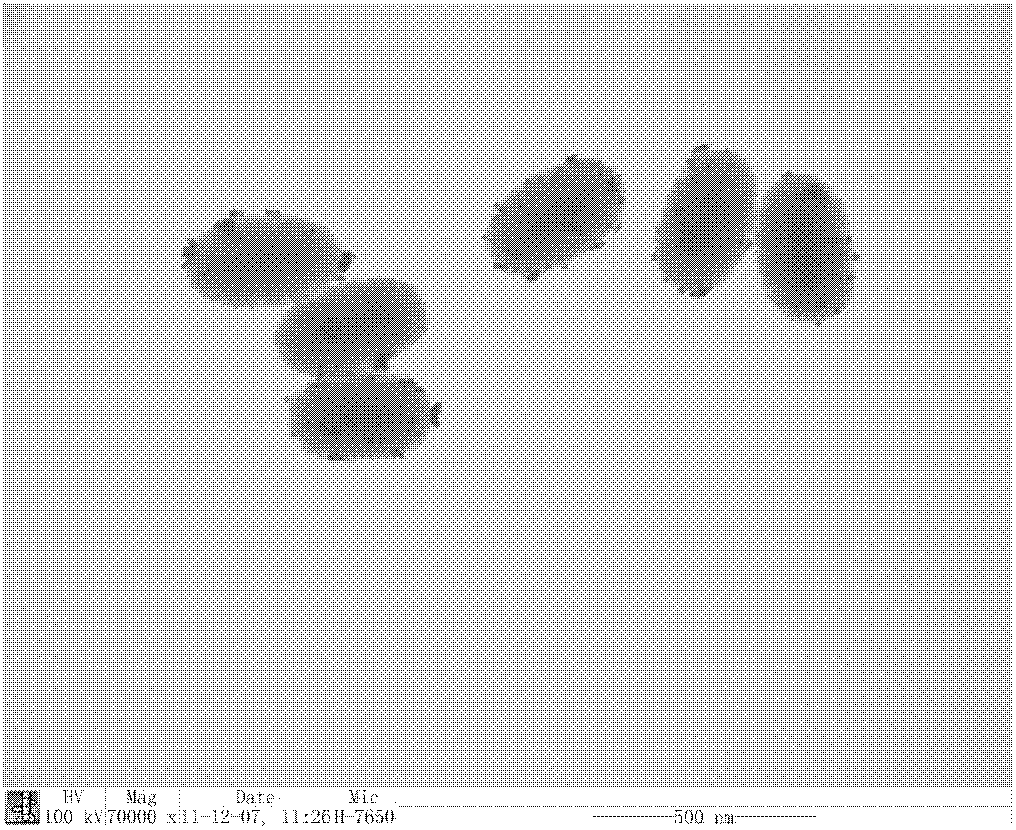

Preparation method for gold-shell magnetic ellipsoid

ActiveCN102528027AHigh crystallinityImprove uniformityFerroso-ferric oxidesFerric oxidesPolyelectrolyteEllipsoidal particle

The invention discloses a preparation method for a gold-shell magnetic ellipsoid and relates to a preparation method for a multi-layer nuclear shell structure ellipsoid. The preparation method is used for solving the problem that a photonic crystal assembled by the existing magnetic ellipsoid with the nuclear shell structure is low in photo-thermal conversion efficiency and photoelectric conversion efficiency. The preparation method comprises the following steps: 1. preparing a spindly alpha-Fe2O3 particle; 2. firstly obtaining alpha-Fe2O3 particle dispersing solution, and then adding polyvinylpyrrolidone for modification; 3. carrying out silicon dioxide coating to obtain a silicon dioxide coated ellipsoidal particle; 4. adding a poly dimethyl diallyl ammonium chloride aqueous solution and NaCl to prepare a silicon dioxide coated ellipsoidal aqueous solution adsorbing polyelectrolyte; 5. preparing a gold solution; 6. adding the gold solution into the silicon dioxide coated ellipsoidalaqueous solution adsorbing polyelectrolyte to obtain alpha-Fe2O3 / SiO2 / Au ellipsoidal particles; and 7. carrying out hydrogen reduction to obtain the Fe3O4 / SiO2 / Au ellipsoid. The preparation method ismainly used for preparing the gold-shell magnetic ellipsoid.

Owner:HARBIN INST OF TECH

Magnetic powder, method for producing the same and magnetic recording medium comprising the same

InactiveUS20060008645A1Quick reversalRecording characteristicMaterials with ironNanomagnetismEllipsoidal particleMagnetization

A magnetic powder consisting of substantially spherical or ellipsoidal particles comprising a transition metal which comprises iron and a rear earth element which is mainly present in the outer layer of the magnetic powder particles, and having a particle size of 5 to 200 nm, a coercive force of 80 to 400 kA / m and a saturation magnetization of 10 to 25 μWb / g.

Owner:FUJIFILM CORP

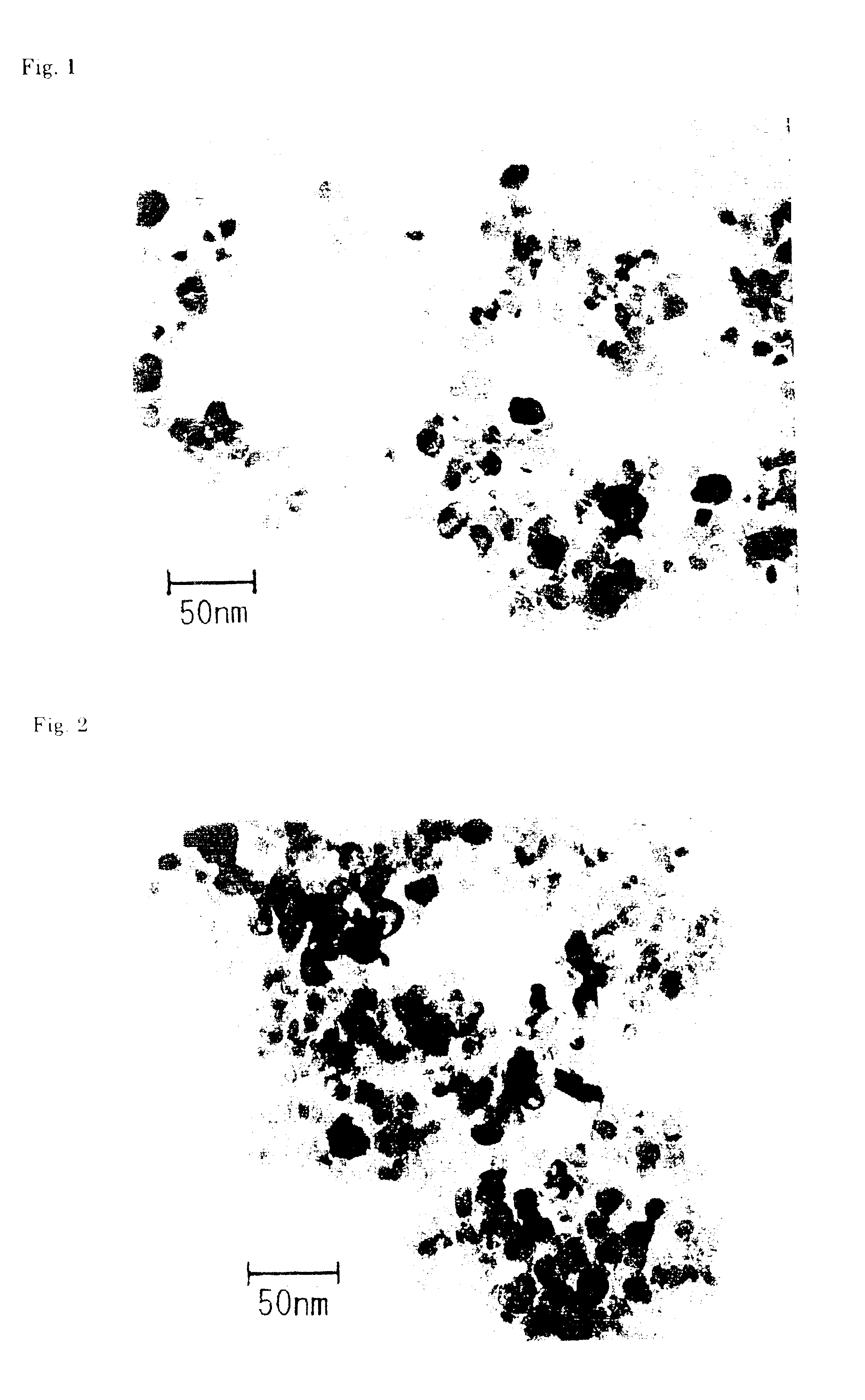

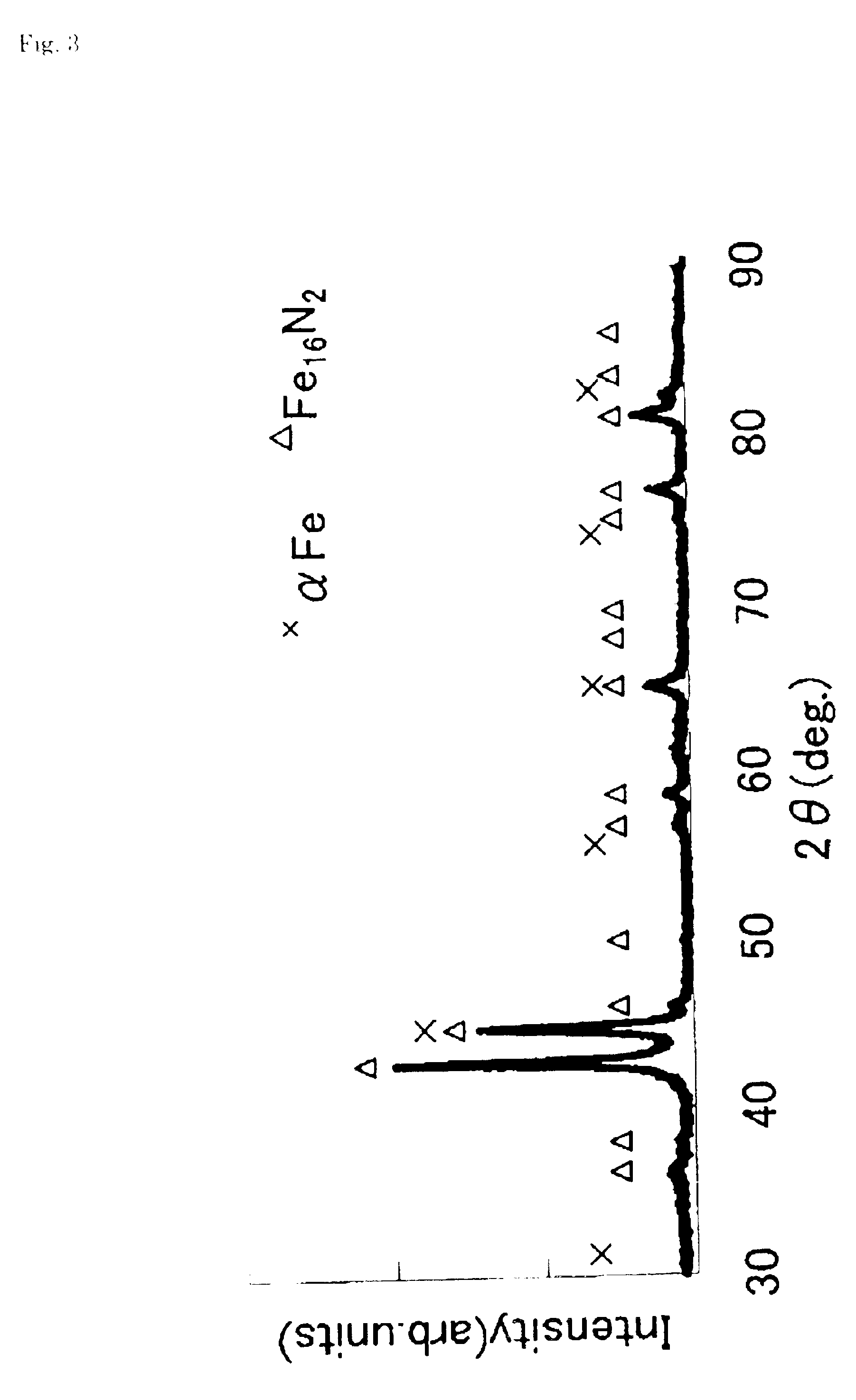

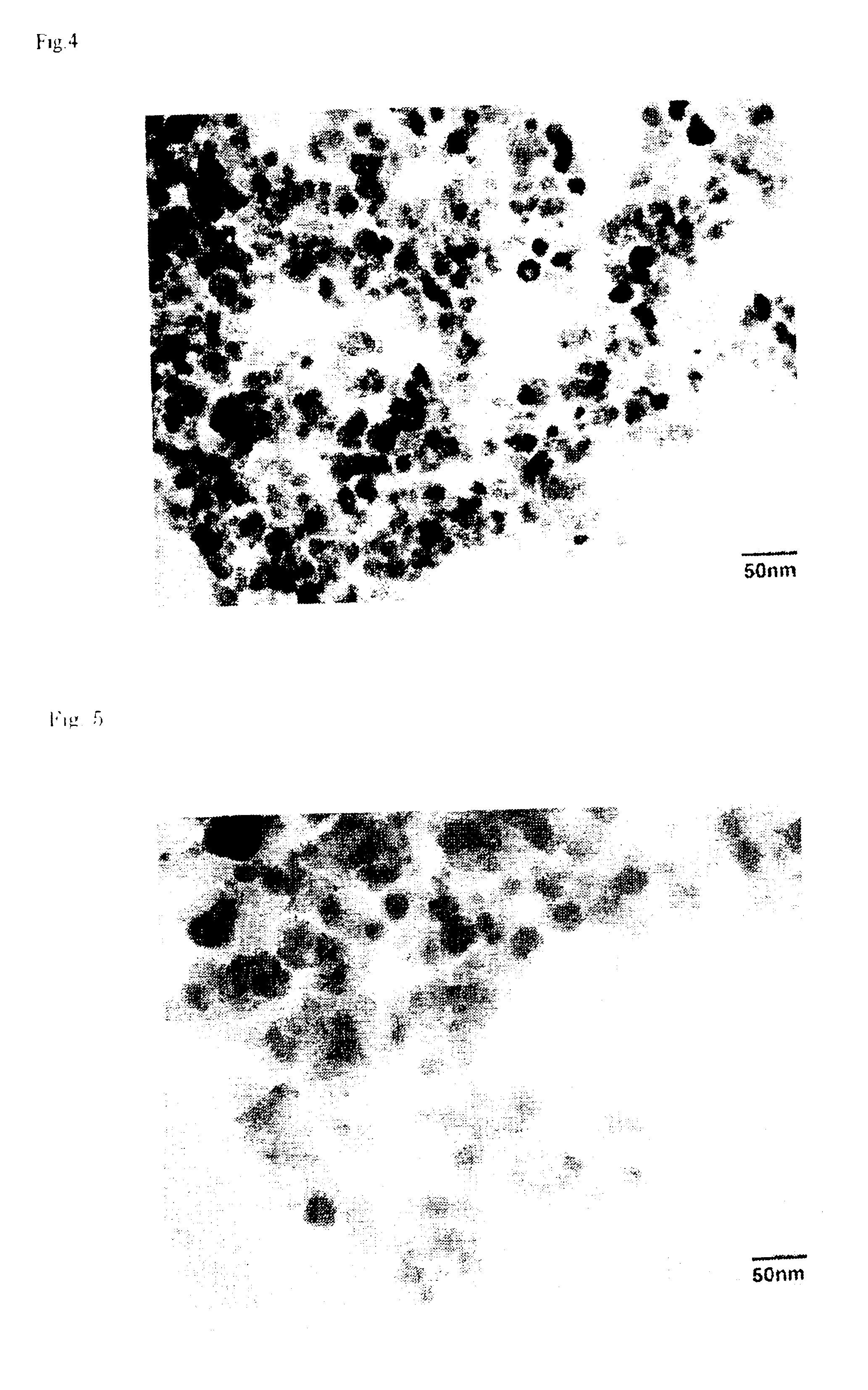

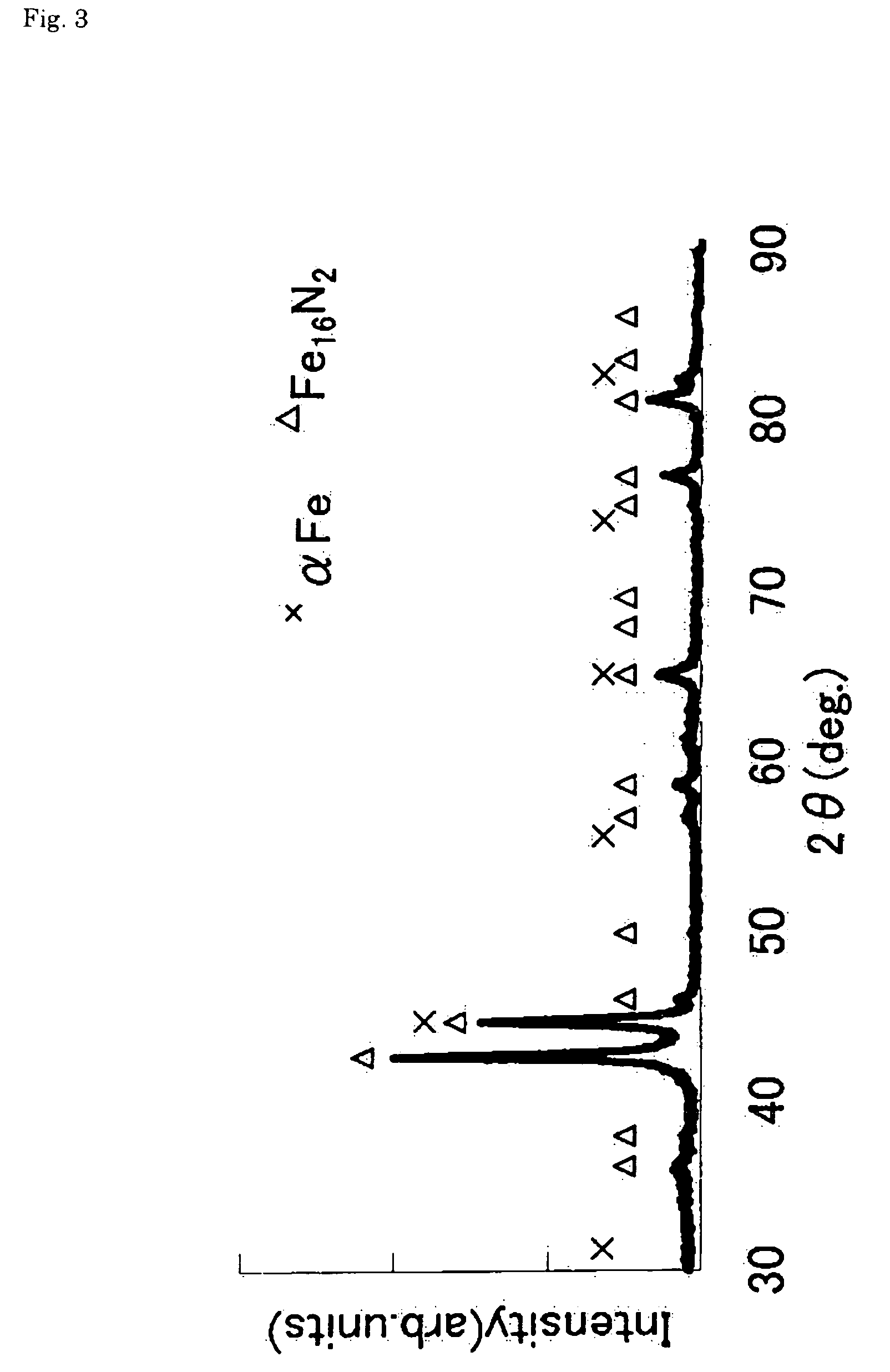

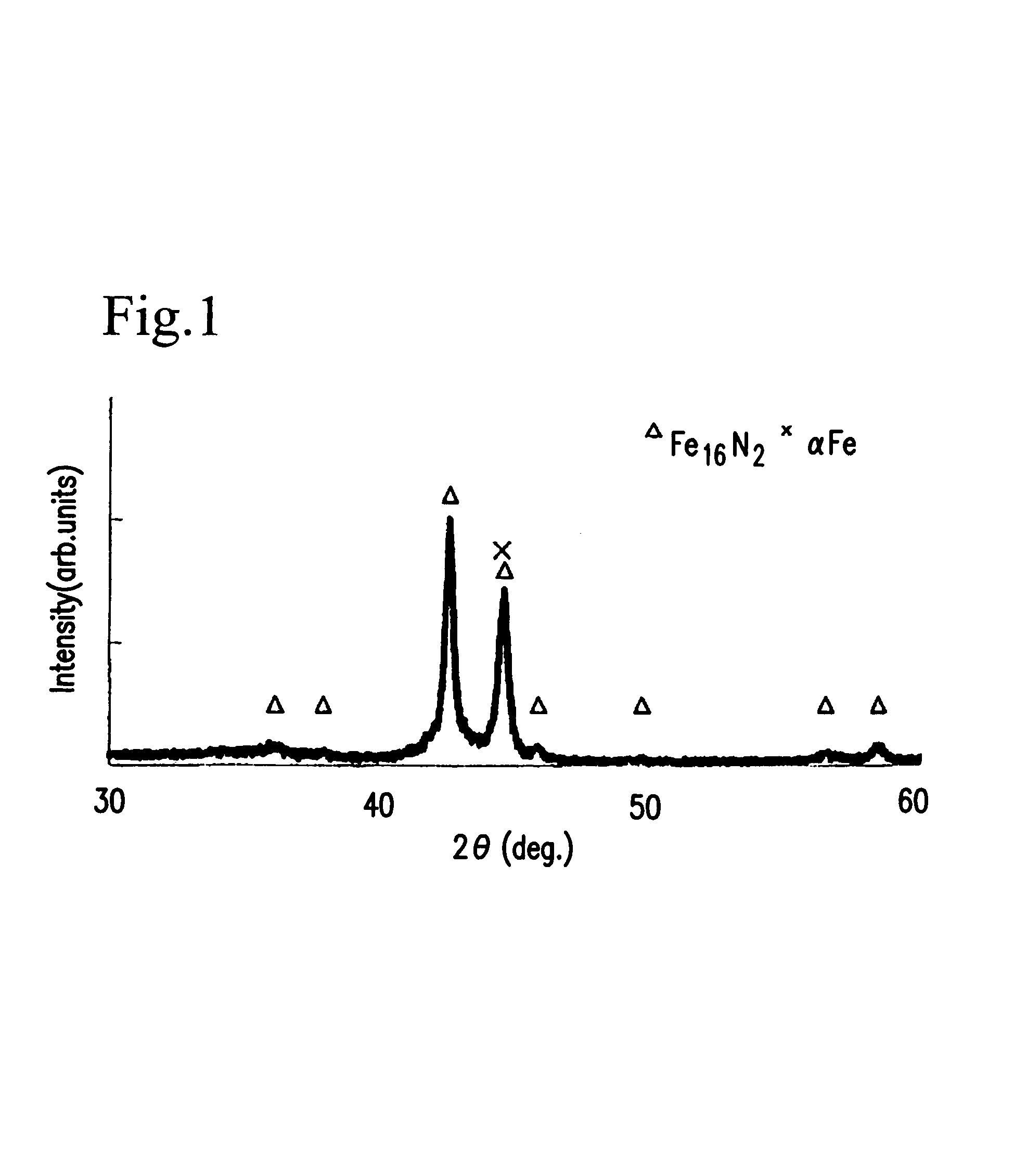

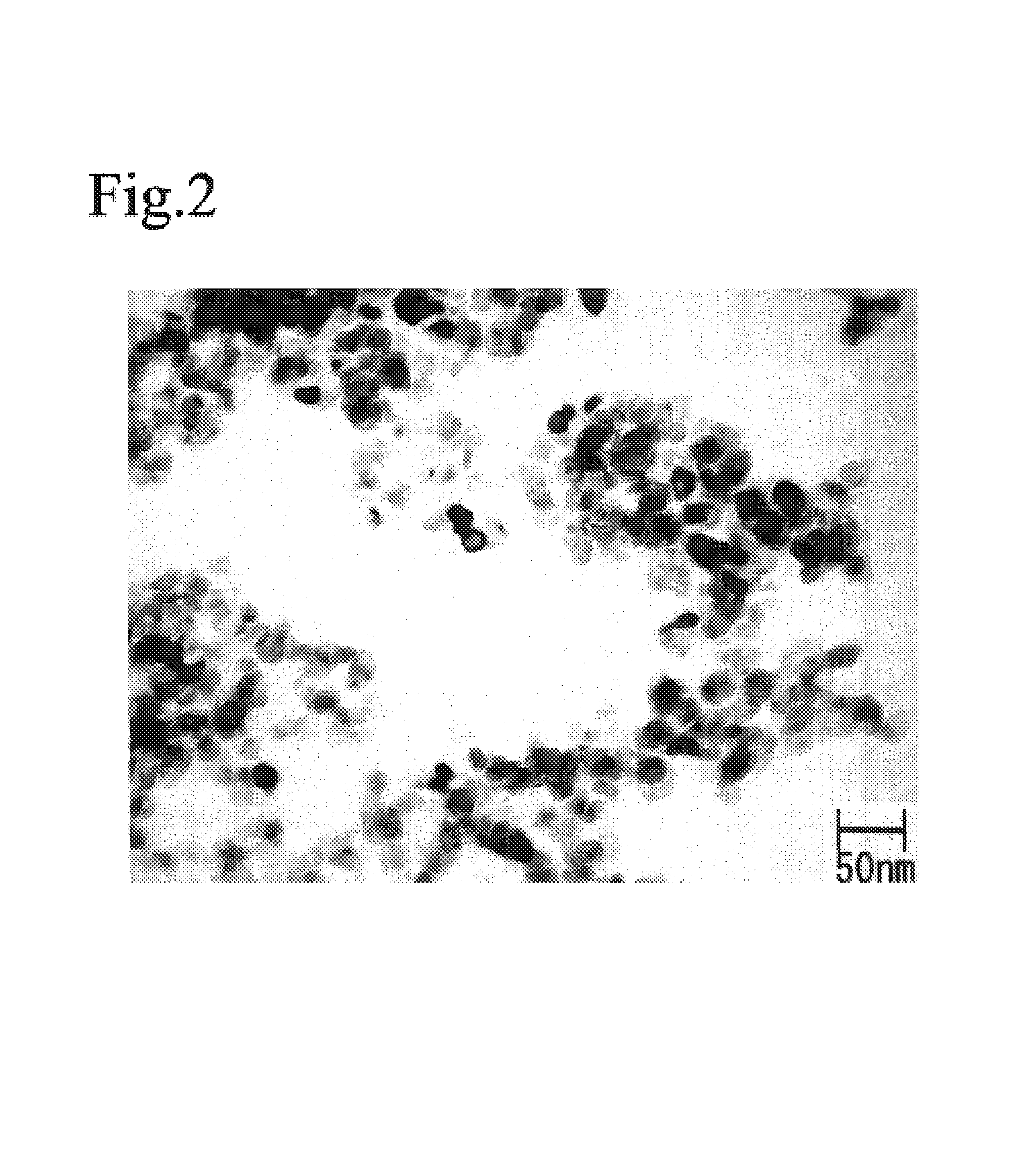

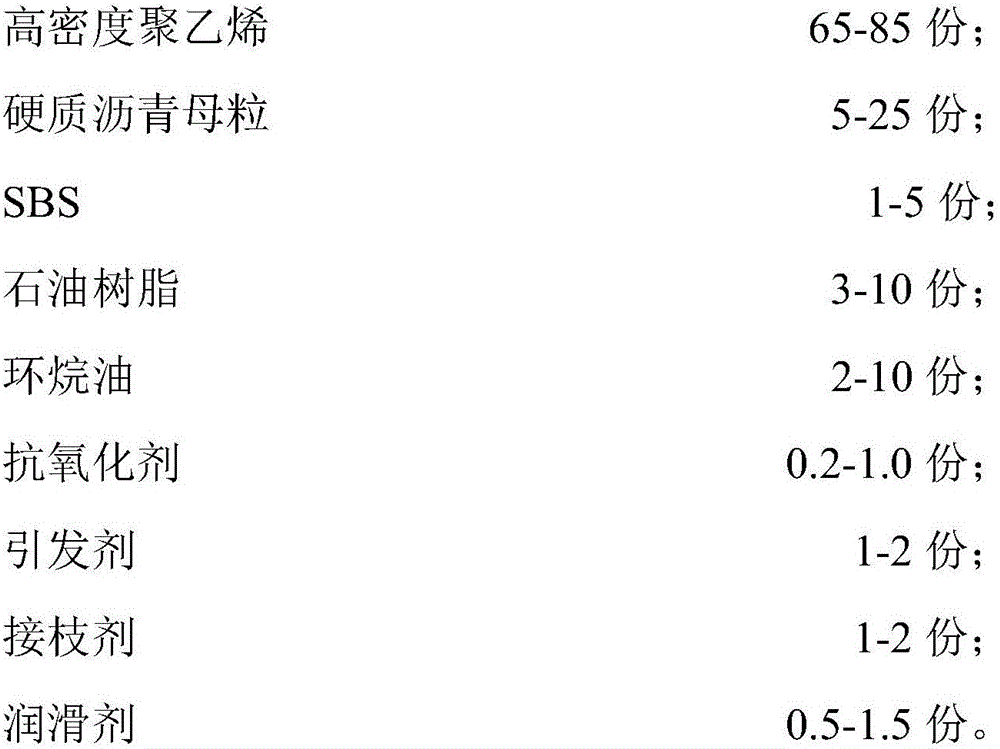

Magnetic recording medium containing particles with a core containing a Fe16N2 phase

ActiveUS7238439B2Increase productionExcellent short wavelength recording propertyMaterials with ironBase layers for recording layersRare-earth elementEllipsoidal particle

A magnetic recording medium comprising a nonmagnetic support and a magnetic layer formed on the support and containing a magnetic powder and a binder, wherein said magnetic powder comprises substantially spherical or ellipsoidal particles and at least one element selected from the group consisting of rare earth elements, silicon and aluminum, and has a Fe16N2 phase, an average particle size of 5 to 30 nm and an axis ratio (a ratio of a major axis to a minor axis) of 1 to 2. This magnetic recording medium achieves a high output and has excellent short wavelength recording properties, since it uses a magnetic powder having a very small particle size and has a very high coercive force and a saturation magnetization suitable for high density recording.

Owner:FUJIFILM CORP

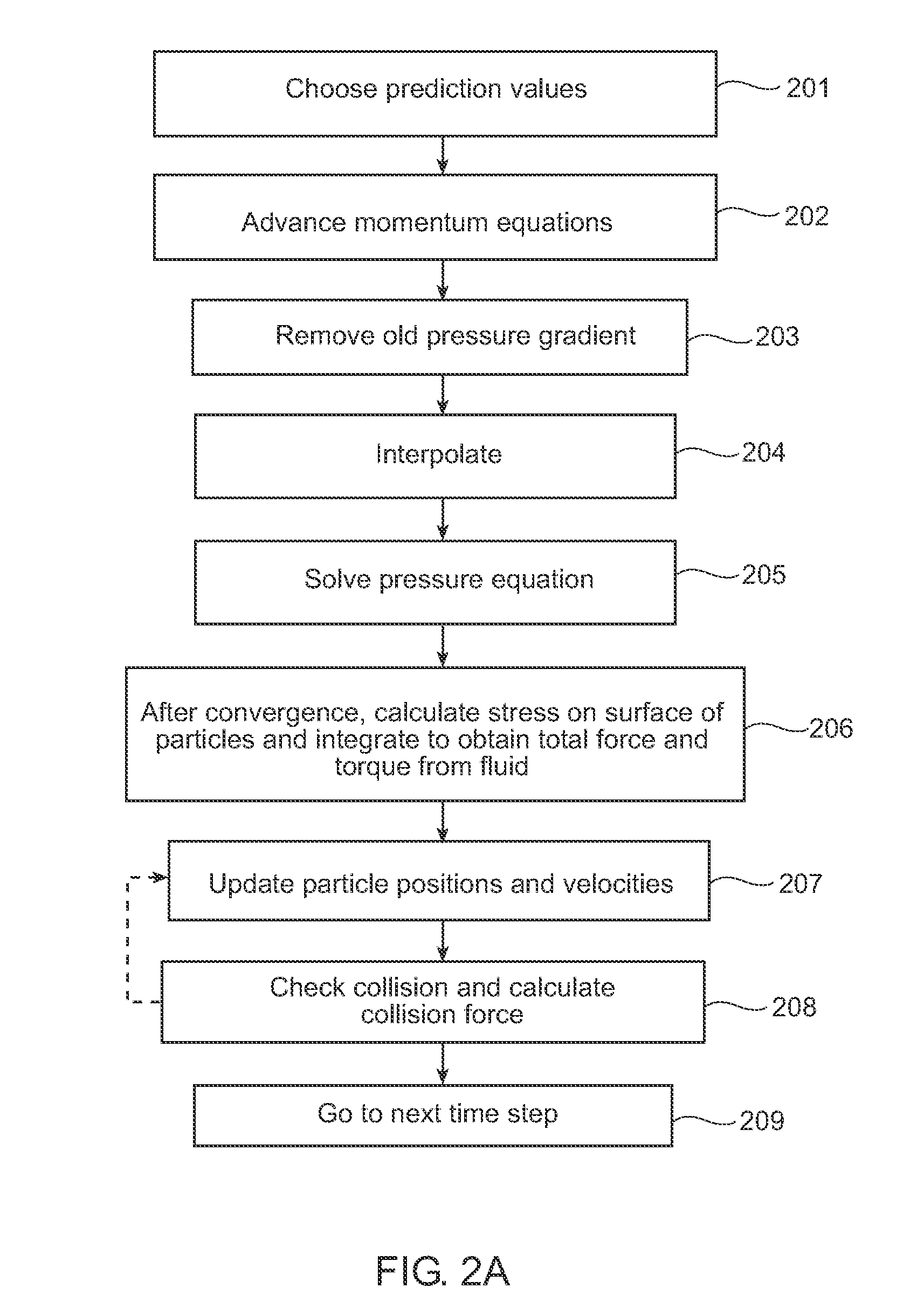

Collision Effect And Particle Information Update In Particulate Fluid Flow Simulations

InactiveUS20120065947A1Computation using non-denominational number representationDesign optimisation/simulationParticulatesEllipsoidal particle

Owner:SEIKO EPSON CORP

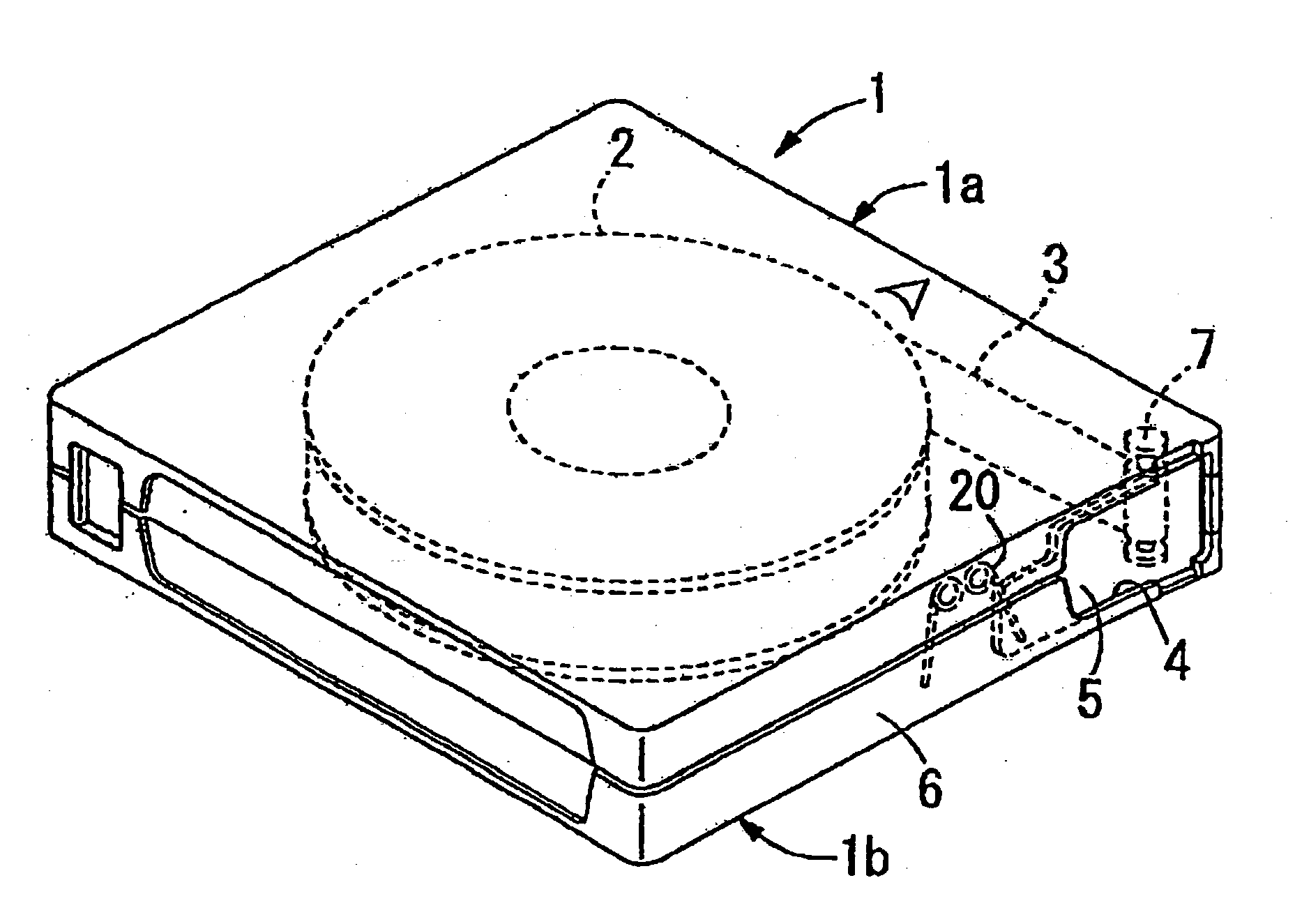

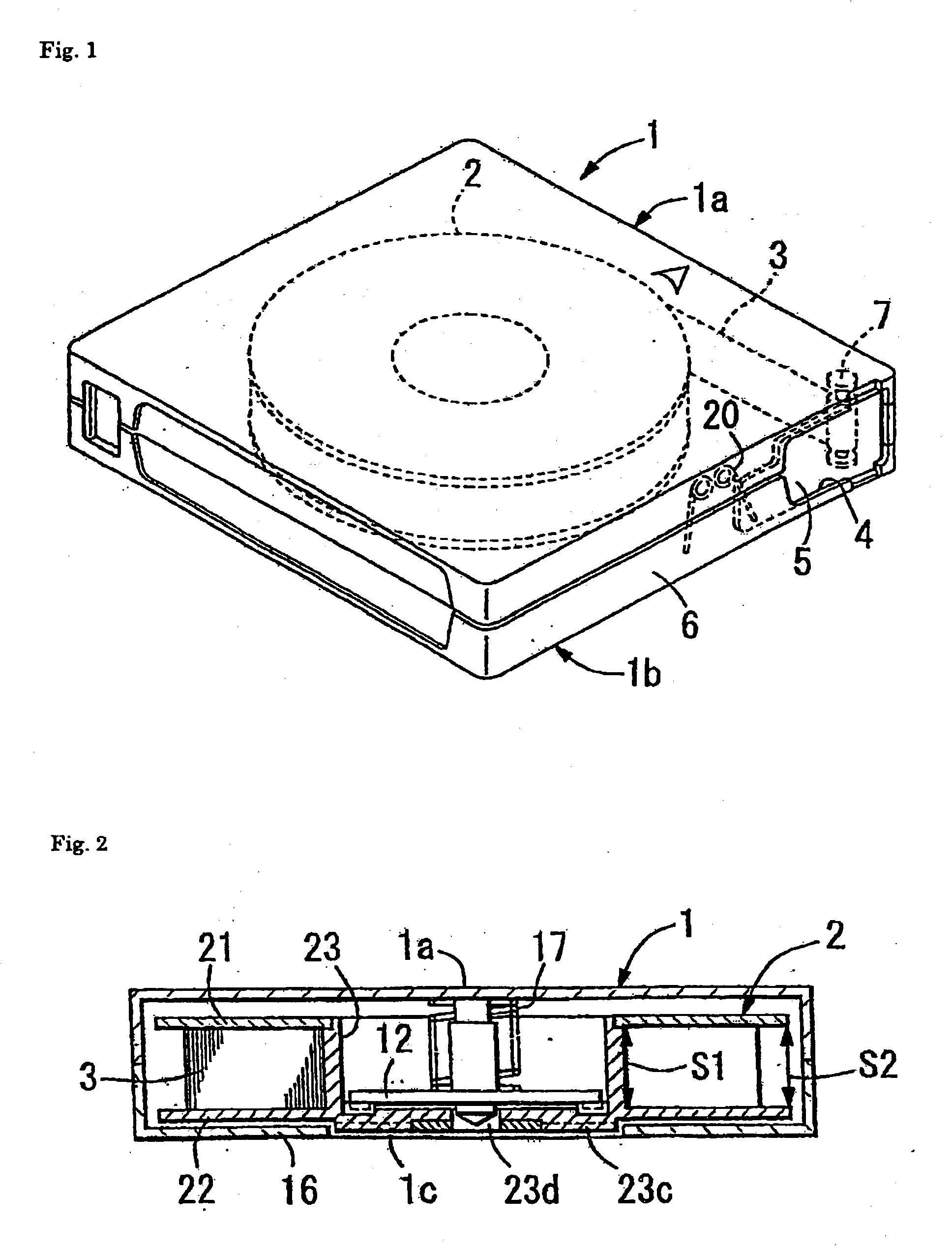

Magnetic recording medium and magnetic recording cassette

InactiveUS20050276999A1Improve recording densityMaterials with ironNanomagnetismRare-earth elementEllipsoidal particle

A magnetic recording medium comprising a non-magnetic support, at least one primer layer formed on one surface of the non-magnetic support, comprising a non-magnetic powder and a binder resin, at least one magnetic layer formed on the primer layer, comprising a magnetic powder and a binder resin, and a back layer formed on the other surface of the non-magnetic support, wherein the magnetic powder contained in the uppermost layer of the magnetic layer is a rare earth metal-iron type magnetic powder of substantially spherical or ellipsoidal particles comprising a rare earth element and iron or a transition metal which comprises iron, and has a number average particle size 5 to 50 nm and an average axis ratio of 1 to 2, and the total thickness of the magnetic recording medium is less than 6 μm. This magnetic recording medium can achieve an excellent block error rate, which cannot be realized with magnetic recording media comprising conventional acicular magnetic powders.

Owner:FUJIFILM CORP

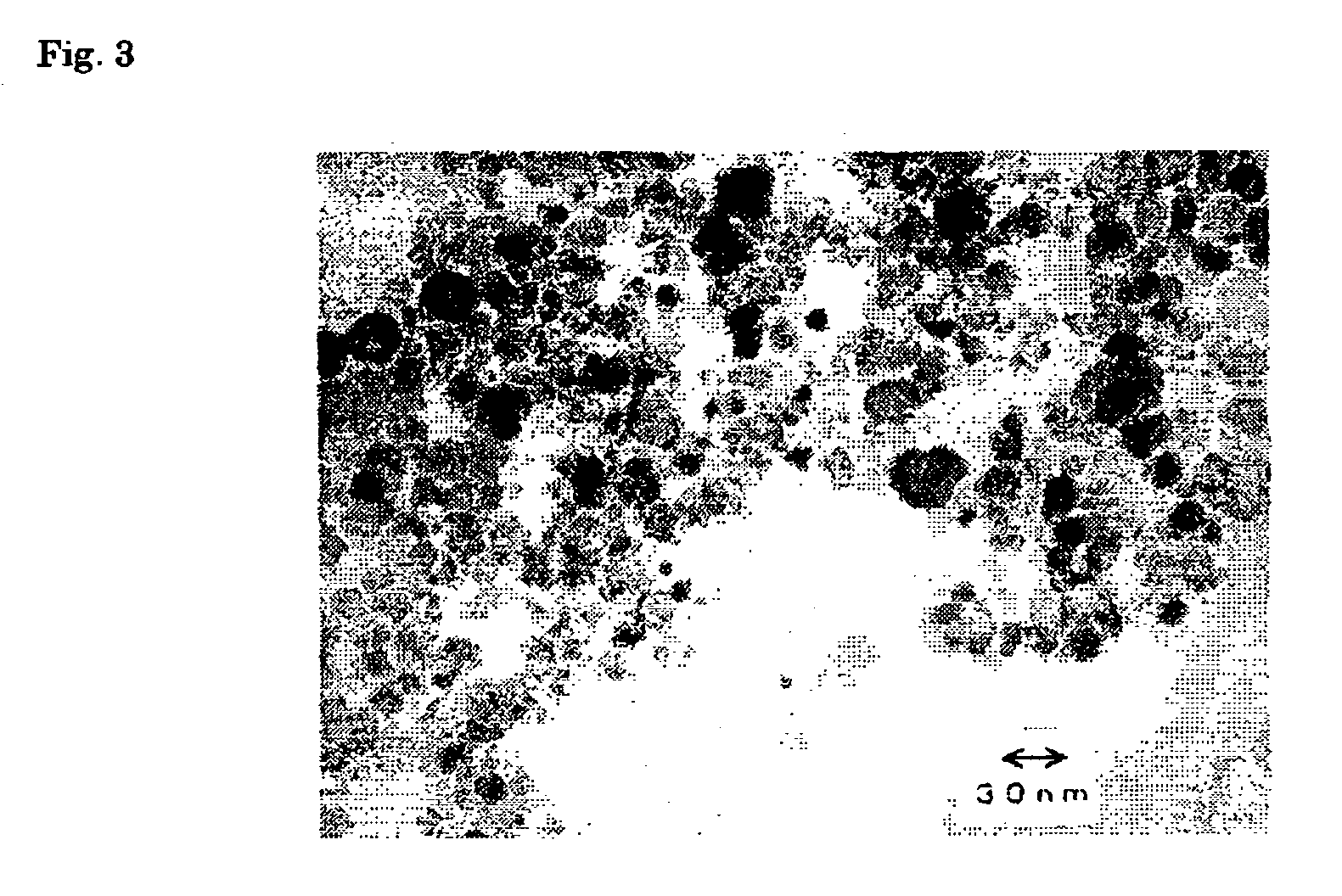

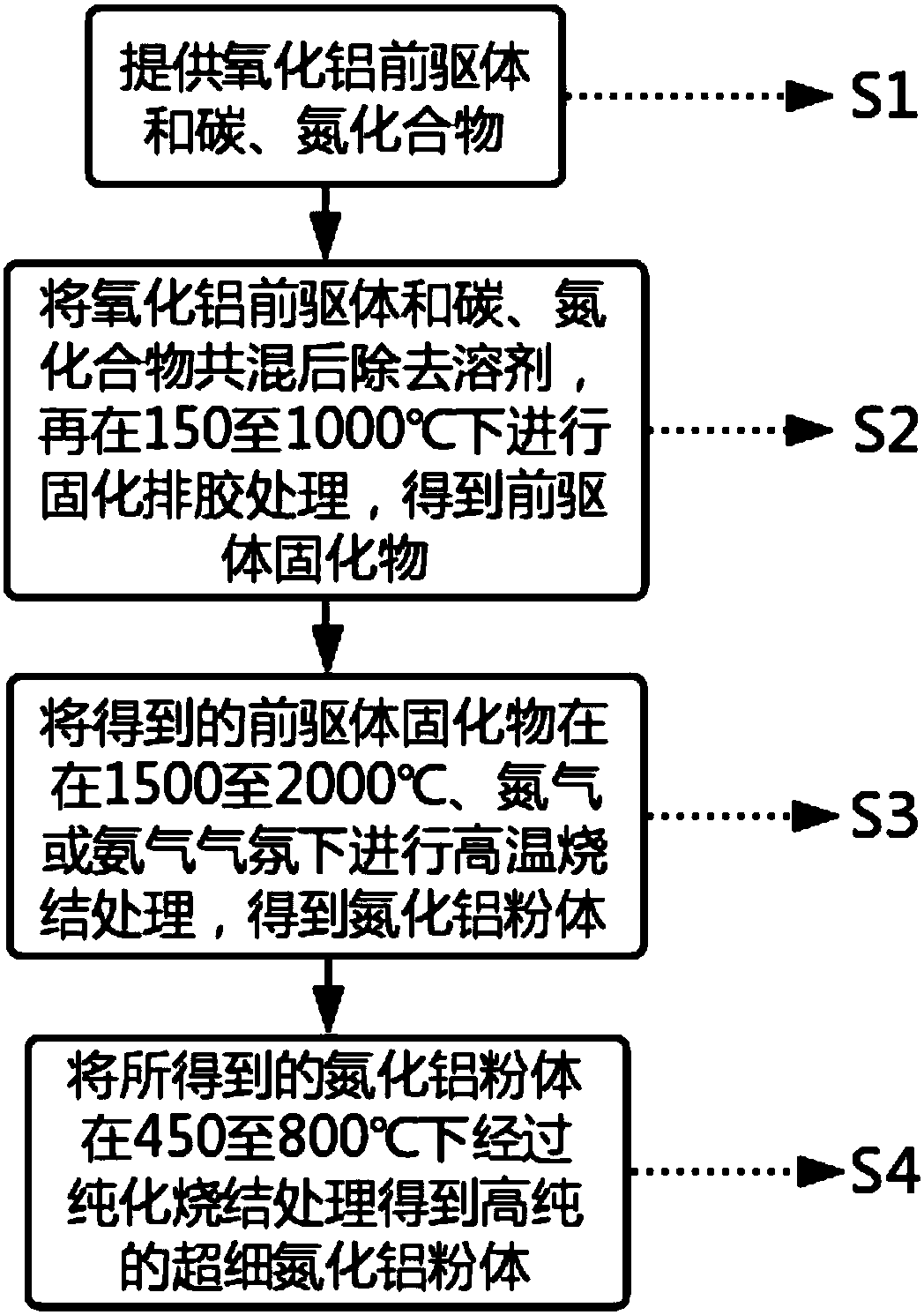

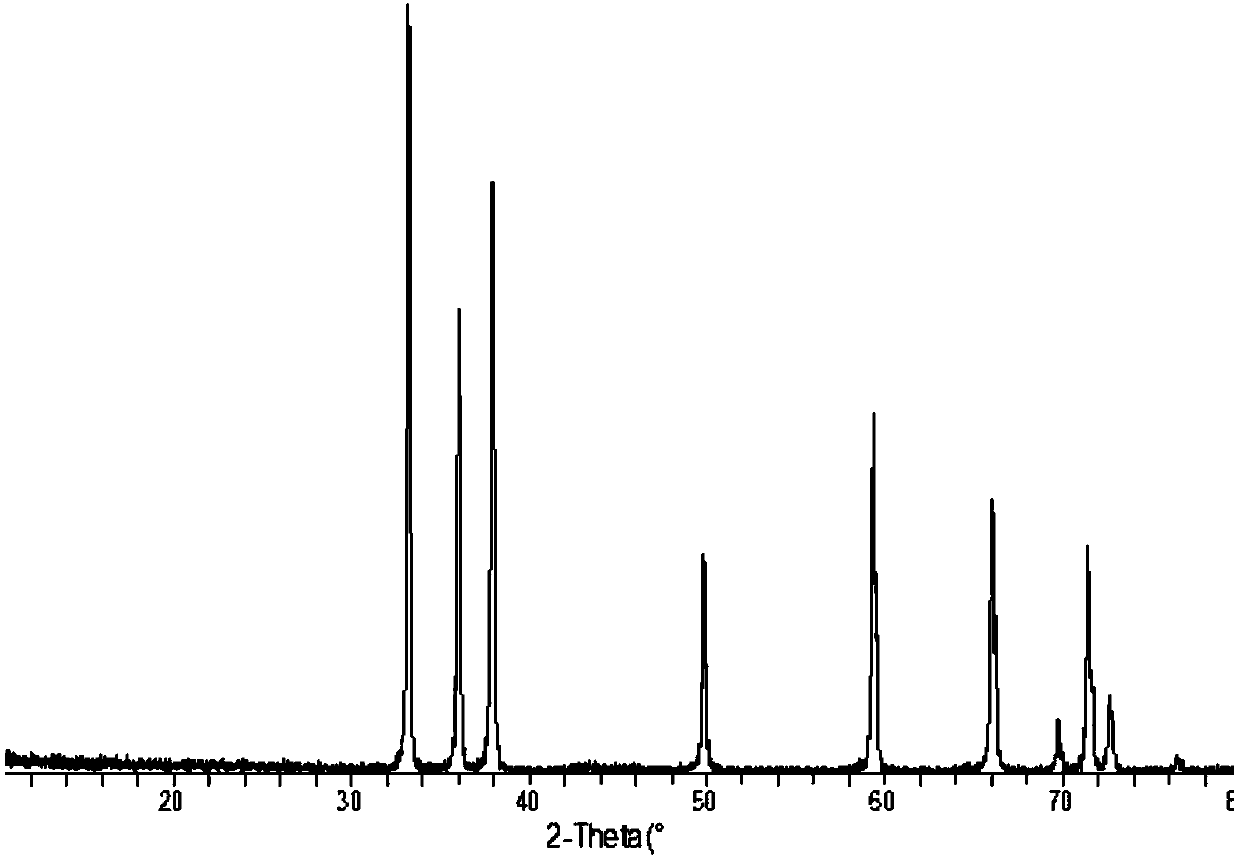

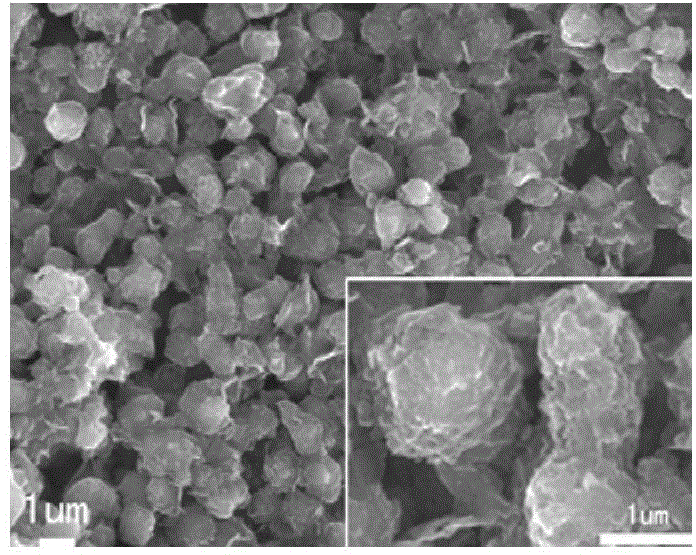

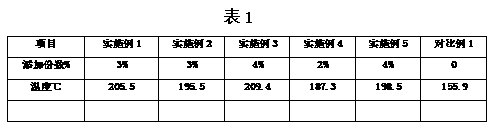

Aluminum nitride powder and preparation method thereof

The invention relates to aluminum nitride powder and a preparation method thereof. The preparation method comprises the following steps: S1, providing an aluminum oxide precursor and a carbon-nitrogencompound; S2, mixing the aluminum oxide precursor and the carbon-nitrogen compound to prepare a uniform mixed solution, curing and discharging glue under 150-1000 DEG C to obtain a precursor cured material; S3, sintering the precursor cured material at high temperature of 1500-2000 DEG C to obtain the aluminum nitride powder; and S4, purifying and sintering the obtained aluminum nitride powder for 1-72 hours under 450-800 DEG C to obtain high-purity aluminum nitride powder. The preparation method is used for mixing the aluminum oxide precursor with the carbon-nitrogen compound, then curing and discharging glue under certain temperature, then carrying out carbon-nitrogen reduction reaction and purification reaction under high temperature to prepare high-purity superfine aluminum nitride powder. The preparation method is simple in process high in efficiency and low in requirement on equipment; the prepared aluminum nitride powder can be prepared into submicron-sized ellipsoidal particles and is uniform in size distribution and high in dispersity; meanwhile, the content of aluminum nitride in the aluminum nitride powder is greater than 96%; the requirements of industrialization can be met.

Owner:SUZHOU TUNABLE MATERIALS TECH CO LTD

Magnetic recording medium and magnetic recording cassette

InactiveUS20070159722A1Improve recording densityMaterials with ironNanomagnetismRare-earth elementEllipsoidal particle

A magnetic recording medium comprising a non-magnetic support, at least one primer layer formed on one surface of the non-magnetic support, comprising a non-magnetic powder and a binder resin, at least one magnetic layer formed on the primer layer, comprising a magnetic powder and a binder resin, and a back layer formed on the other surface of the non-magnetic support, wherein the magnetic powder contained in the uppermost layer of the magnetic layer is a rare earth metal-iron type magnetic powder of substantially spherical or ellipsoidal particles comprising a rare earth element and iron or a transition metal which comprises iron, and has a number average particle size of 5 to 50 nm and an average axis ratio of 1 to 2, and the total thickness of the magnetic recording medium is less than 6 μm. This magnetic recording medium can achieve an excellent block error rate, which cannot be realized with magnetic recording media comprising conventional acicular magnetic powders.

Owner:HITACHT MAXELL LTD

Modified urea formaldehyde resin and preparation method thereof

The present invention relates to a modified urea formaldehyde resin preparation method, which comprises: adding a modified layered silicate to a urea formaldehyde resin prepolymer, and polymerizing to obtain the layered silicate-modified urea formaldehyde resin, wherein the modified layered silicate is the layered silicate with the amino functional group on the surface. According to the present invention, the provided urea formaldehyde resin can contain up to 40% of the layered silicate so as to substantially reduce the cost of the urea formaldehyde resin; the morphology is the regular spherical particles, the irregular columnar particles or the irregular ellipsoidal particles, and the thermal stability is good; and the ideal of the preparation method is ingenious, the operation is simple, and the platform is provided for the modification of the urea formaldehyde resin.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method of monodisperse alpha-Fe2O3@TiO2 ellipsoids

PendingCN111013587ASolve highGood dispersionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsEllipsoidal particlePtru catalyst

The invention discloses a preparation method of monodisperse alpha-Fe2O3@TiO2 ellipsoids, and relates to a preparation method of a functional microsphere. The method comprises the following steps: 1,uniformly mixing an aqueous ferric trichloride solution and an aqueous ammonium dihydrogen phosphate solution which are respectively prepared, and reacting by adopting a hydrothermal synthesis technology to obtain alpha-Fe2O3 spindle-shaped particles; 2, modifying the surfaces of the alpha-Fe2O3 particles with polyvinylpyrrolidone, and synthesizing monodisperse alpha-Fe2O3@TiO2 core-shell ellipsoidal particles in the same reaction system by using a technology of dynamically controlling the instantaneous addition amount of a catalyst ammonia water; and 3, carrying out high-temperature calcination treatment. The alpha-Fe2O3@TiO2 ellipsoidal particles obtained in the invention are good in monodispersity, few titanium dioxide byproducts exist in the product, and the operation method is simple,convenient and repeatable.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

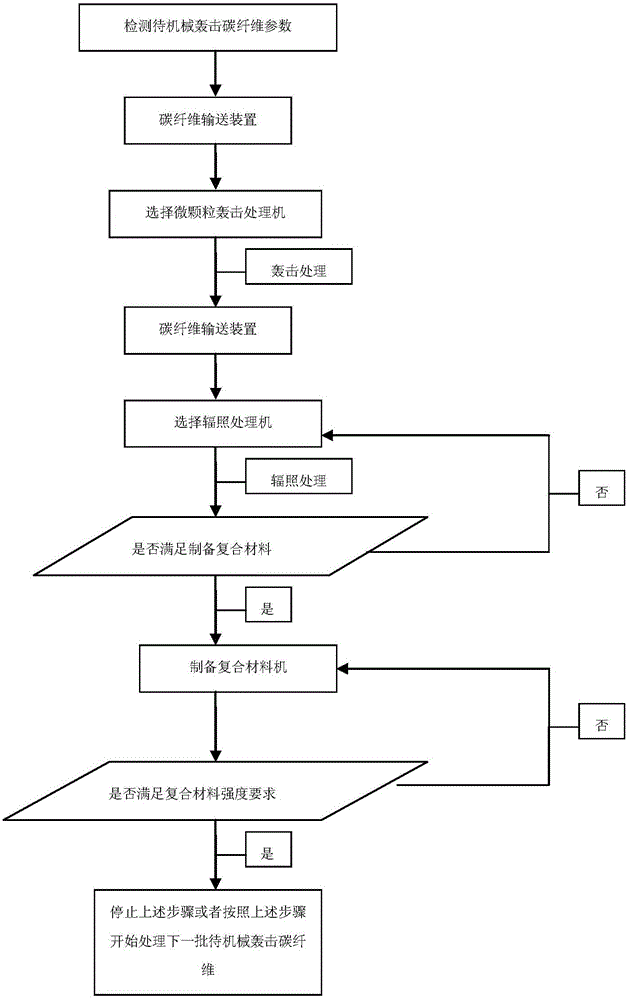

Carbon fiber surface quick composite reinforcing treatment method

ActiveCN106192360AIncrease production speedIncrease production capacityCarbon fibresLaser beam fibre treatmentAdhesion forceFiber

The invention relates to a carbon fiber surface quick composite reinforcing treatment method including the steps of: 1) detecting parameters of carbon fibers; 2) selecting the type of a micro-particle bombardment processing machine; 3) selecting the type of micro-particles, wherein the micro-particles may be spherical or ellipsoidal particles; 4) controlling the operation parameters of processing the carbon fibers by the micro-particle bombardment processing machine; 5) selecting an irradiation processing machine; 6) controlling the operation parameters of the irradiation processing machine; 7) bombarding and irradiating the carbon fibers; 8) performing performance detection to the irradiated carbon fibers; and 9) preparing a composite material. The method is quick and high-effectively and can reinforce the surface of the carbon fibers and improve the adhesion force between the carbon fibers and a resin base body; and furthermore, the method can be used for quickly preparing the carbon fiber reinforced composite material and also can be applied for preparing the composite material on site, thus effectively increasing production speed and improving productivity, and ensuring that the mechanical performance of the composite material satisfies use demand.

Owner:绵阳三阳智造科技有限公司

Heat conduction sheet, method of manufacturing heat conduction sheet, and heat dissipating device

ActiveUS20200247963A1Reduce thermal resistanceSemiconductor/solid-state device detailsSolid-state devicesElastomerPolymer science

A heat conduction sheet, includes at least one kind of graphite particle (A) selected from the group consisting of scale-like particles, ellipsoidal particles and rod-like particles; a polymer (B) having an isobutylene structure; an ethylene-propylene copolymer (C); and an ethylene octene elastomer (D), in which, in a case of scale-like particles, a plane direction of the particle is oriented in a thickness direction of the heat conduction sheet, and in a case of ellipsoidal particles or rod-like particles, a long axis direction of the particle is oriented in the thickness direction of the heat conduction sheet.

Owner:RESONAC CORP

A numerical simulation method for uniaxial compressive strength test of porous cement concrete

ActiveCN109033503ADesign optimisation/simulationSpecial data processing applicationsEllipsoidal particleStress–strain curve

The invention discloses a numerical simulation method for uniaxial compressive strength test of porous cement concrete, which comprises the following steps: generating an initial space area of a numerical sample by using a wall command in PFC3D software; generating ellipsoidal particles representative of the aggregate according to the gradation of the aggregate; compacting the numerical specimen to the required height of the final numerical specimen by setting the gravity field and controlling the effect of wall. The meso-mechanics model is selected for the contact between particles. The walllocated on the top and bottom of the final numerical specimen is used to simulate the indenter and end ferrule of uniaxial compressive strength test in laboratory. Based on the stress-strain curve derived from laboratory uniaxial compressive strength tests, the parameters are determined and calibrated by simulation, so as to realize the numerical simulation of uniaxial compressive strength test ofporous cement concrete. This method solves the problems of large dispersion, high cost and long period in laboratory test of porous cement concrete, and provides a basis for the study of meso-structure of porous cement concrete.

Owner:JIANGSU UNIV OF SCI & TECH

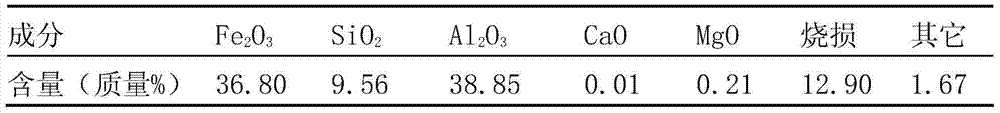

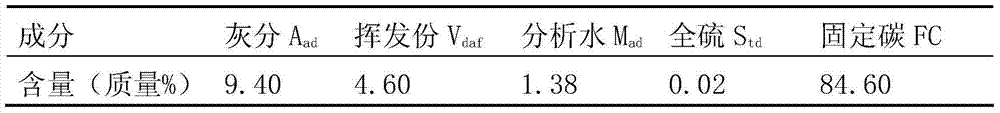

Method for preparing Al-Si-Fe alloy by using high-ferrum and high-silicon bauxite

The invention relates to a method for preparing an Al-Si-Fe alloy by using high-silicon and high-iron bauxite. The method comprises the steps of breaking a high-ferrum and high-silicon bauxite raw ore and a reducing agent thoroughly; adding an organic adhesive and water; mixing thoroughly; making the above mixture into ellipsoidal particles and drying; adding the dried ellipsoidal particles into an electrothermal furnace; smelting at a reducing atmosphere, a smelting temperature being controlled at 2,000-2,300 DEG C; tapping of the obtained molten iron; directly sending to a casting ingot mold for casting; and cooling to obtain primary Al-Si-Fe alloy. The method provided by the invention has the advantages of high utilization rate of raw materials and low energy consumption.

Owner:NORTHEASTERN UNIV

Weather-resistant urea formaldehyde resin preparation method

The invention relates to a weather-resistant urea formaldehyde resin preparation method. The method comprises the steps that a modifier is added into urea formaldehyde resin prepolymer, polymerizationis conducted, and urea formaldehyde resin good in weather resistance is obtained, wherein the modifier is acrylate emulsion polymer. The service life of the urea formaldehyde resin is greatly prolonged; the urea formaldehyde resin is shaped like regular spherical particles or irregular cylindrical particles or irregular ellipsoidal particles, and the thermal stability and weather resistance are good; the preparation method is ingenious in idea and easy to operate, and the usage environment of the urea formaldehyde resin is expanded.

Owner:任会平

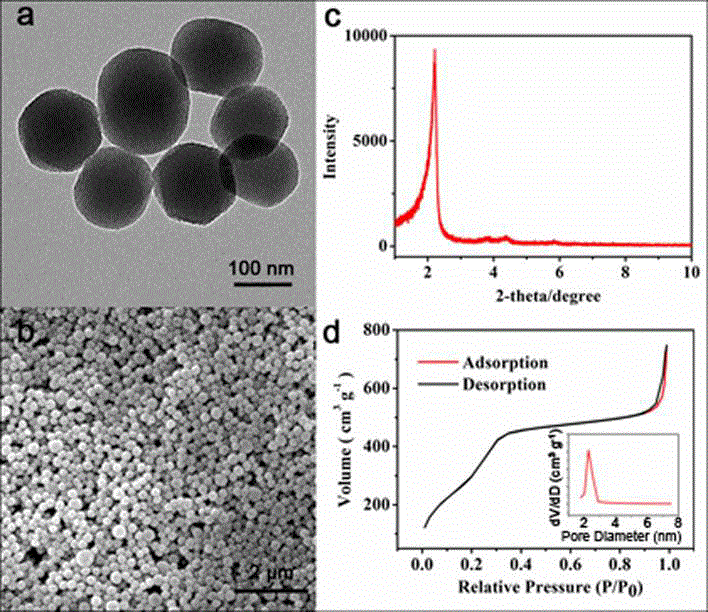

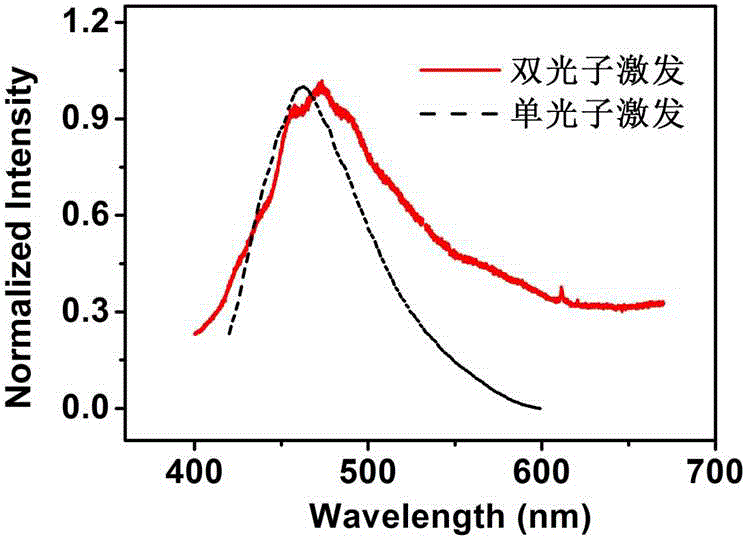

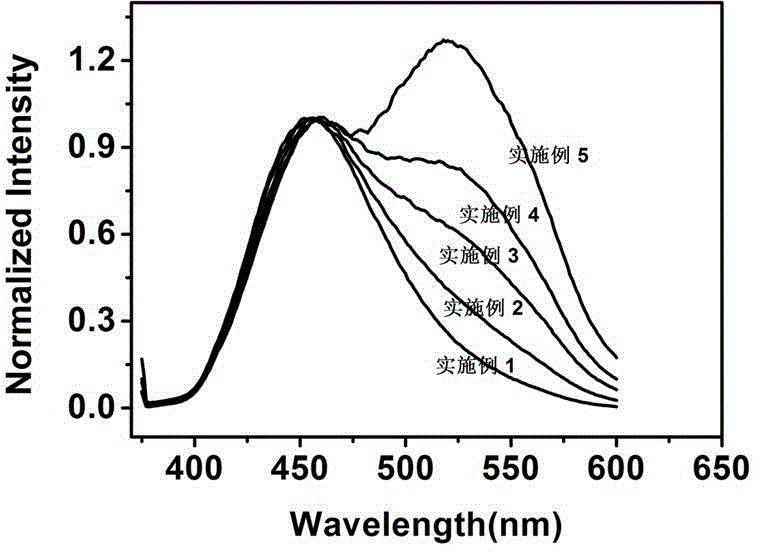

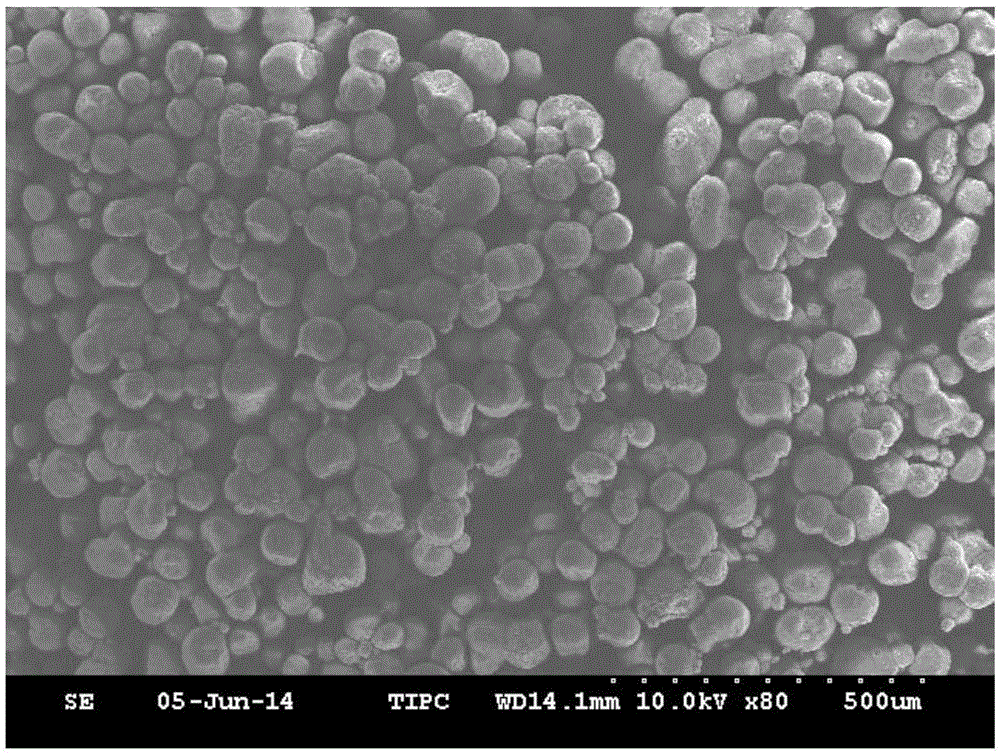

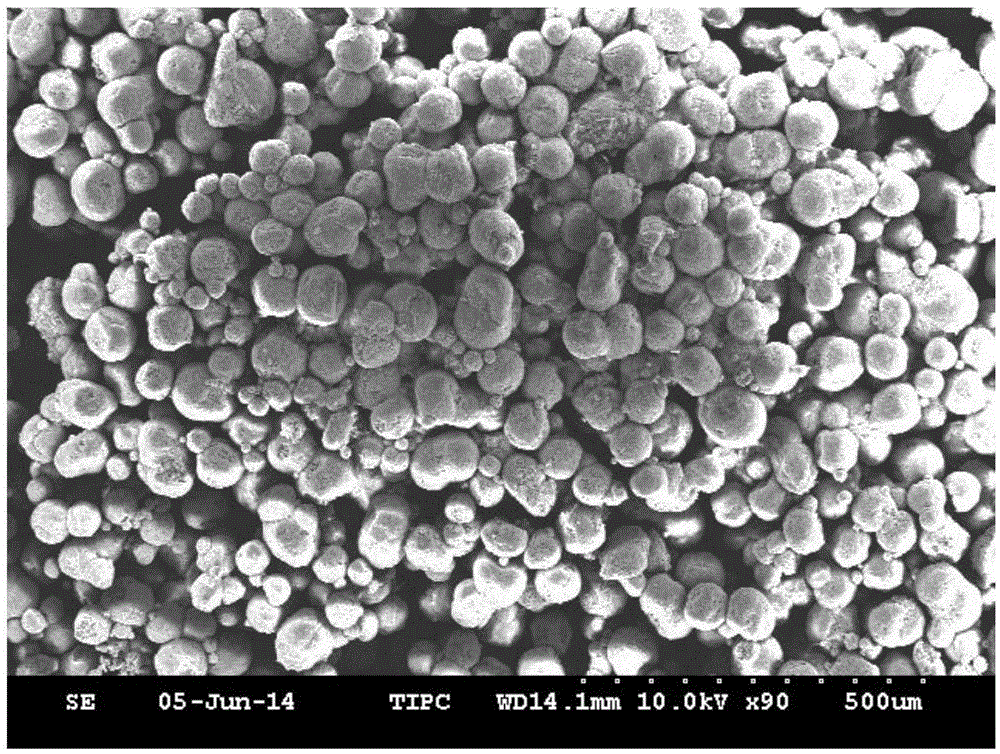

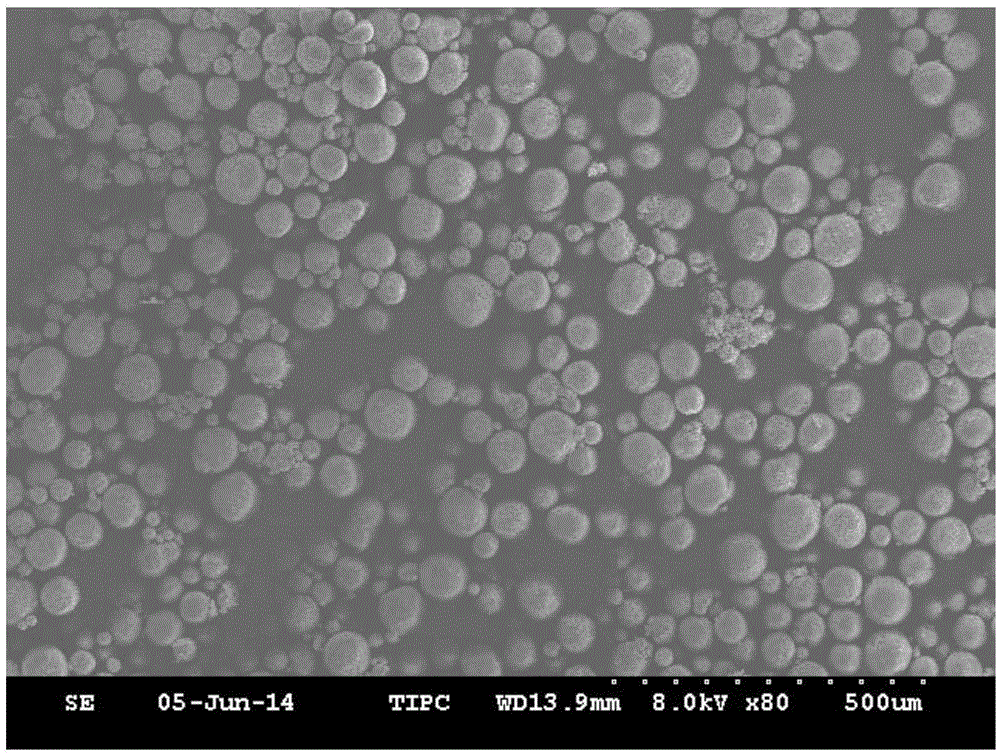

Ordered mesoporous organosilicon fluorescent nanometer material and preparation method thereof

InactiveCN105419790ANot affected by mesoporous structureSmall particle sizeLuminescent compositionsEllipsoidal particleModified carbon

The present invention discloses a mesoporous silicon fluorescent nanometer material preparation method, which comprises that: (1) organic silane-modified carbon quantum dots are obtained by using a high temperature cracking method; and (2) with the hydrolysis condensation polymerization of tetraethyl orthosilicate and the modified carbon quantum dots under an alkaline condition, the ordered mesoporous organosilicon fluorescent nanometer material is obtained through a one-step method. Compared to the fluorescent nanometer material in the prior art, the fluorescent nanometer material of the present invention has the following characteristics that the carbon quantum dots are doped in the pore walls instead of the pore channels, the material has smooth and ordered mesoporous pore channels, can be subjected to two-photon excitation, has adjustable fluorescence emission, is monodispersed spherical or ellipsoidal particles, and has small particle size, and the silicon-based material has advantages of low toxicity, good biocompatibility and the like, such that the material of the present invention has wide application prospects in the fields of traceable drug delivery, multi-channel fluorescent biological imaging, and the like.

Owner:EAST CHINA UNIV OF SCI & TECH

Nylon alloy composite micro-powder for selective laser sintering, and preparation method thereof

The present invention discloses nylon alloy micro-powder for selective laser sintering, wherein the nylon alloy composite micro-powder comprises regular and irregular spherical or ellipsoidal particles having a diameter of 10-300 [mu]m, and the particles comprise the following raw materials by weight: 1-99% of short chain nylon, 1-99% of long chain nylon, 0.1-2% of an antioxidant, and 0.1-5% of a flowing aid. According to the present invention, the alloy micro-powder is prepared under the action of the PVP aid through the improved dissolving precipitation method, has the size of 10-300 [mu]m, has god fluidity, and does not contain the compatibilizer; the two materials have good compatibility and complement the advantages to each other, wherein the flexibility of the nylon 6 is increased while the price is much lower than the commercial nylon 12 micr-powder so as to provide a certain economic significance; and the product is expected to be adopted as the SLS selective laser sintering technology material, and the application range of the SLS technology in the fields of aviation, vehicles, medical devices, electronic instruments, mechanical molds, artworks and the like can be broadened.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

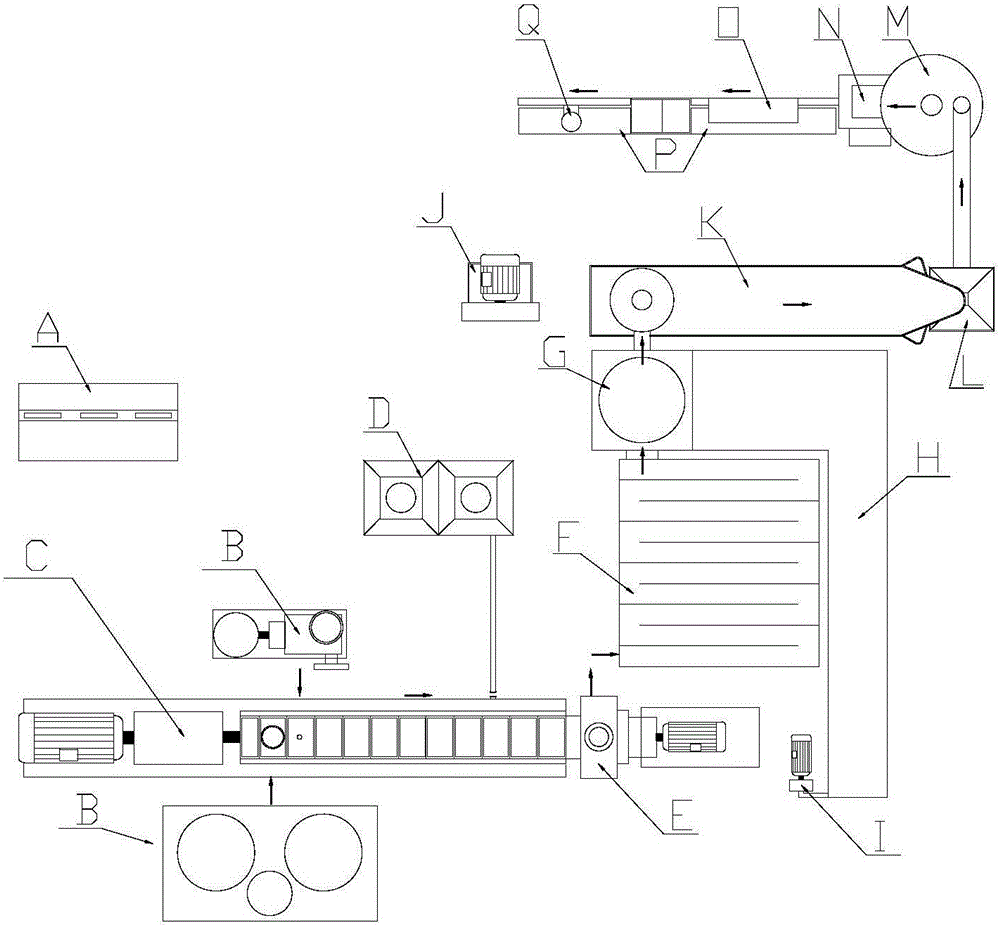

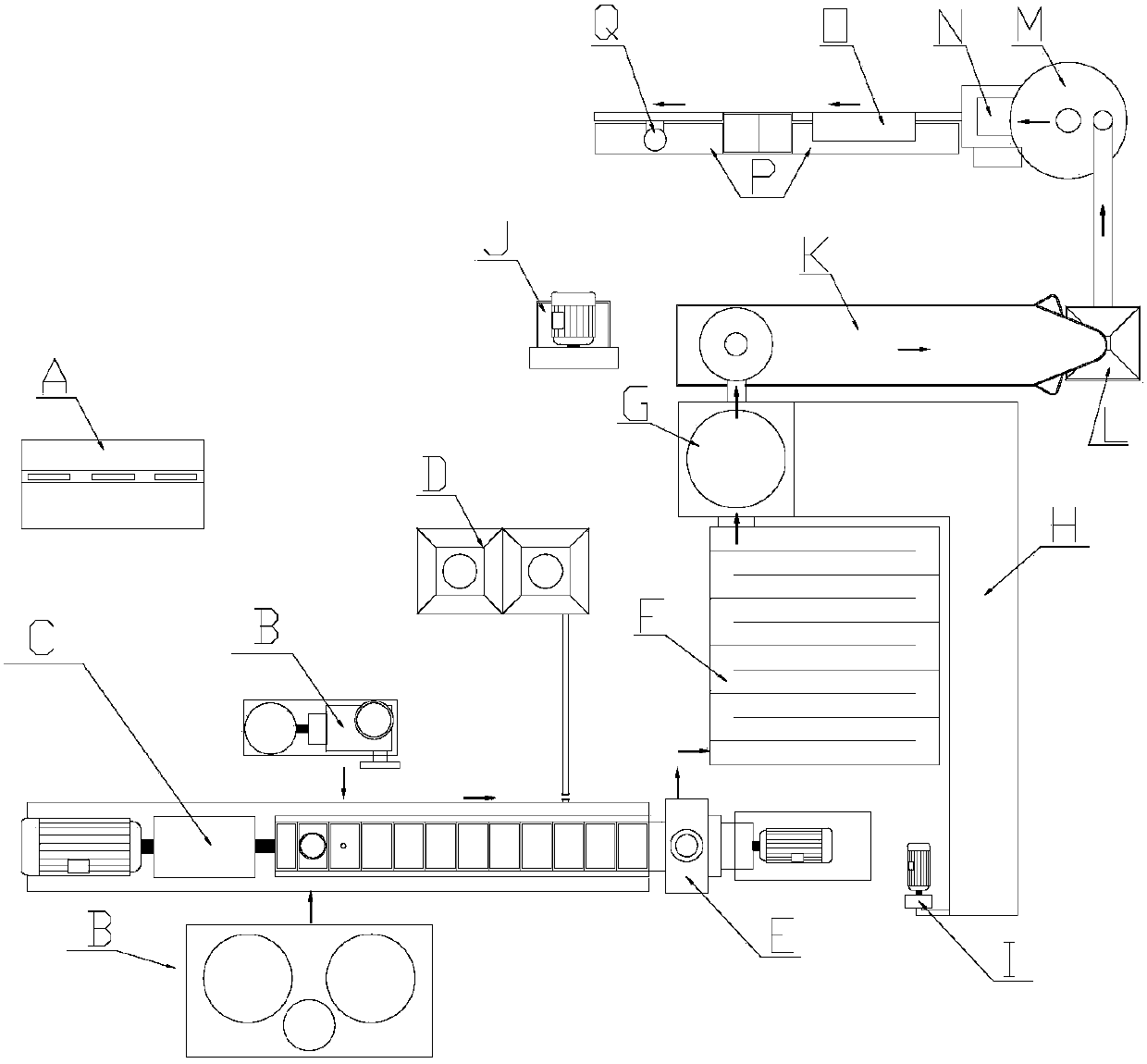

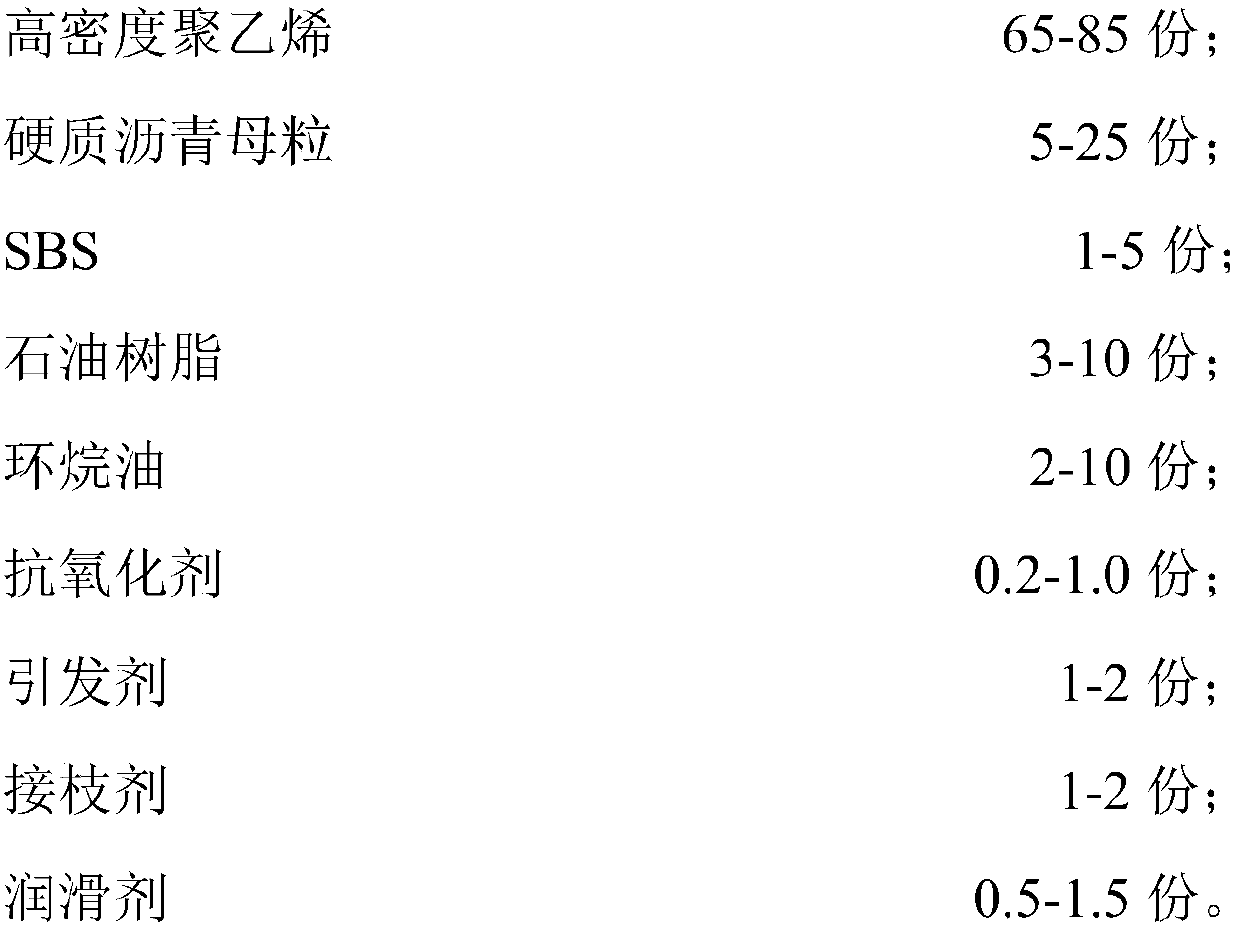

Direct-vat type environment-friendly anti-rutting agent and production device and method thereof

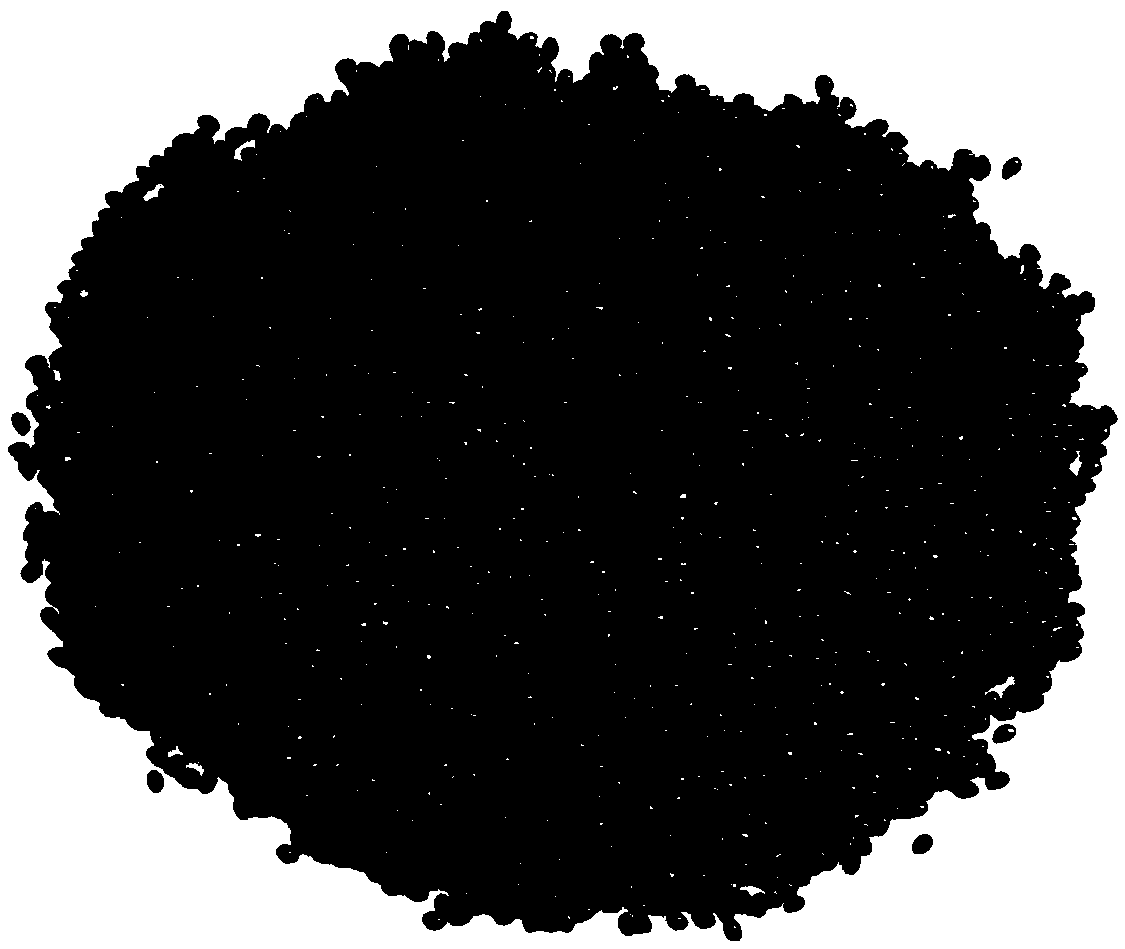

ActiveCN106117710AImproves rutting resistanceLow costBuilding insulationsEllipsoidal particleRoad surface

The invention provides a direct-vat type environment-friendly anti-rutting agent. The anti-rutting agent is prepared from materials shown in the description. The direct-vat type environment-friendly anti-rutting agent is ellipsoidal particles and can be directly put into an asphalt and concrete stirring machine, stirring and contact of the anti-rutting agent and asphalt are more sufficient, and dispersion is more sufficient. Product storage, transportation and use are very convenient, and product quality completely meets the requirement of heavy-load pavements.

Owner:上海砼仁环保技术发展有限公司

Magnetic recording medium

InactiveUS20070224457A1Increase productionExcellent short wavelength recording propertyMaterials with ironBase layers for recording layersRare-earth elementEllipsoidal particle

A magnetic recording medium comprising a nonmagnetic support and a magnetic layer formed on the support and containing a magnetic powder and a binder, wherein said magnetic powder comprises substantially spherical or ellipsoidal particles and at least one element selected from the group consisting of rare earth elements, silicon and aluminum, and has a Fe16N2 phase, an average particle size of 5 to 30 nm and an axis ratio (a ratio of a major axis to a minor axis) of 1 to 2. This magnetic recording medium achieves a high output and has excellent short wavelength recording properties, since it uses a magnetic powder having a very small particle size and has a very high coercive force and a saturation magnetization suitable for high density recording.

Owner:FUJIFILM CORP

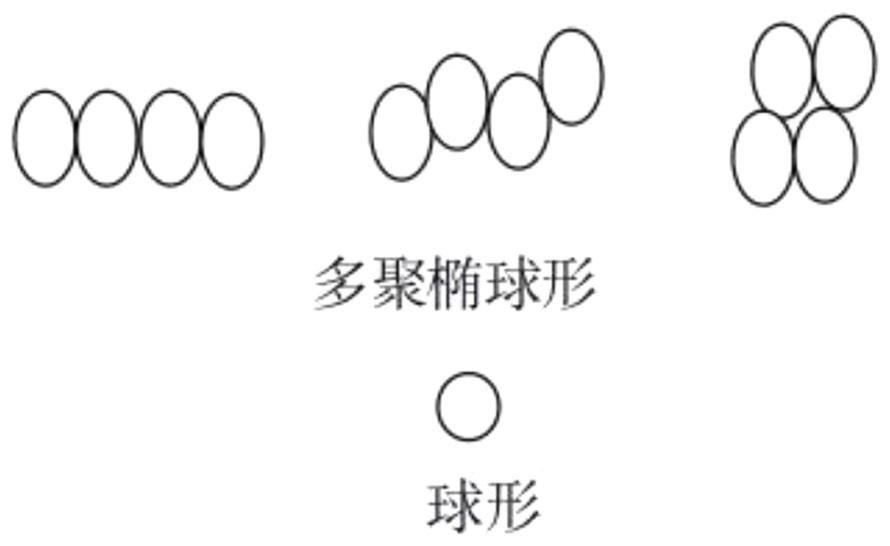

Chemical mechanical fine polishing liquid for silicon wafer

ActiveCN113881347APrecision control introductionMeet fine polishing requirementsPolishing compositions with abrasivesEllipsoidal particleActive agent

The invention provides chemical mechanical fine polishing liquid for a silicon wafer. The fine polishing liquid is specifically prepared by the following steps: mixing 2-30wt% of high-purity ellipsoidal silicon dioxide large particles A, 2-15wt% of high-purity silicon dioxide spherical small particles B, 0.01-1wt% of a pH regulator, 0.01-2wt% of a chelating agent, 0.001-0.1 wt% of a surfactant, 0.01-1wt% of a dispersing agent, 0.1-2wt% of an oxidizing agent and the balance of ultrapure deionized water of more than 18 megohms in a fluorine coating reaction kettle, and performing uniform stirring to obtain the fine polishing liquid. According to the polishing liquid disclosed by the invention, in an alkaline environment with the pH value of 8-11, the silicon dioxide grinding particles with different forms and particle sizes are matched and used, the friction area is increased and the polishing rate of a silicon wafer is increased in the grinding process by the large poly-ellipsoidal particles, and the scratch of the silicon wafer is reduced by the lubricating effect of the small spherical particles in the grinding process.

Owner:深圳市科玺化工有限公司

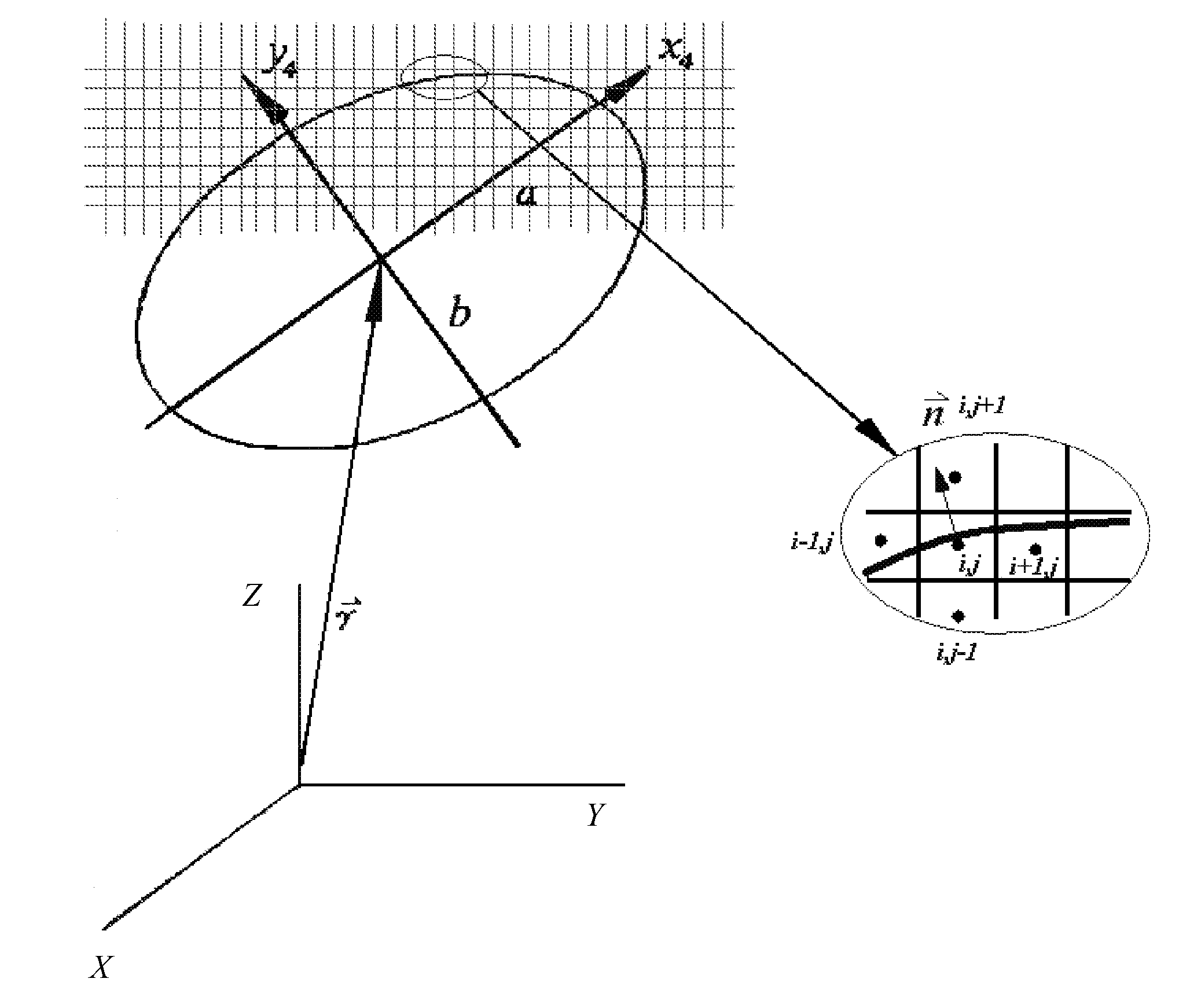

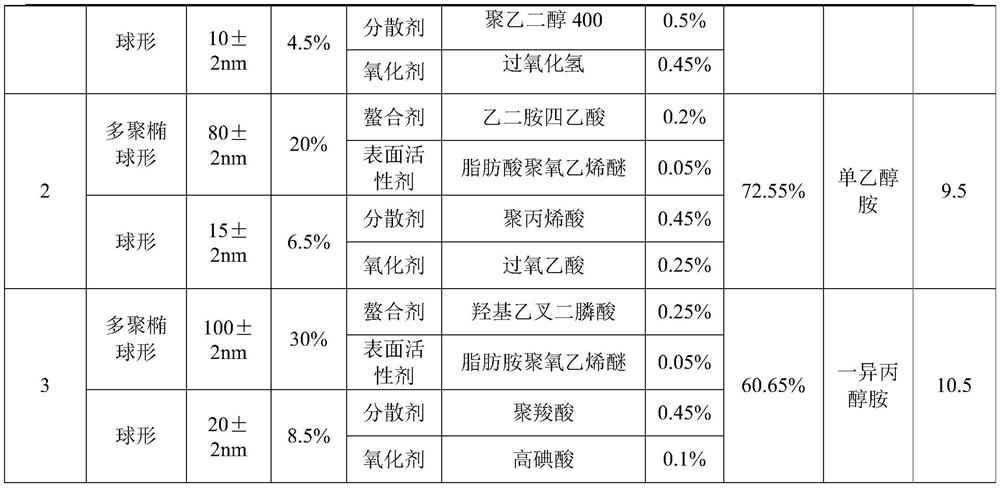

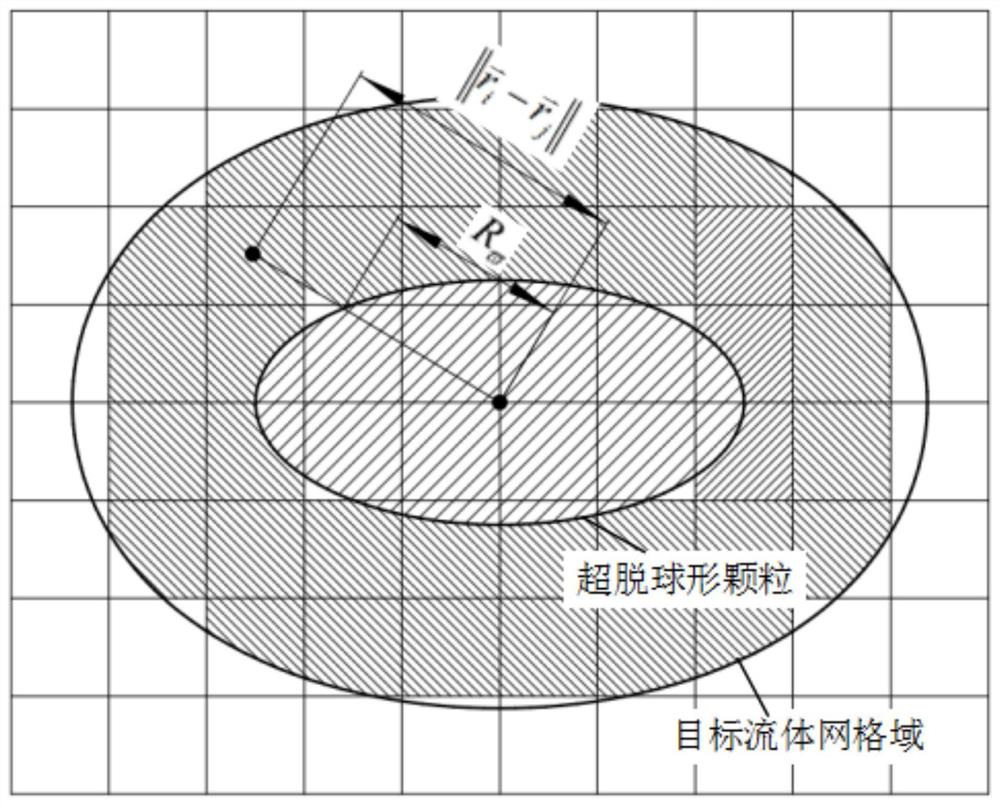

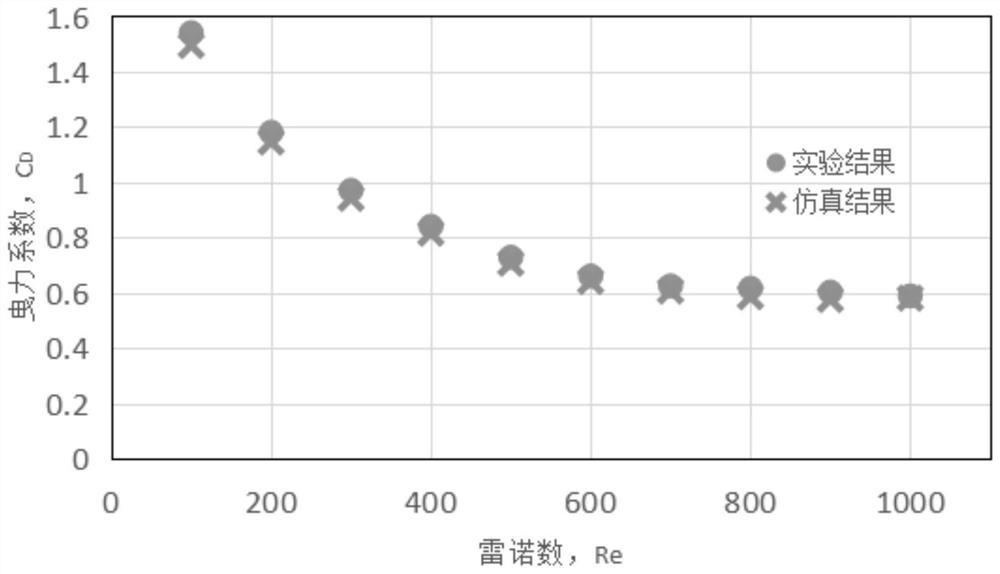

Semi-analytical calculation method for bidirectional coupling of hyper-ellipsoidal particles and flow field

ActiveCN112380788ADetailed simulationAccurate predictionDesign optimisation/simulationEllipsoidal particleEngineering

The invention discloses a hyper-ellipsoidal particle and flow field bidirectional coupling semi-analytical calculation method, and aims to provide an analytical method for improving the applicabilityof a hyper-ellipsoidal particle and flow field coupling simulation technology. The method comprises the following steps: setting initial positions and motion parameters of particles, and setting initial information of a flow field; determining a target fluid domain of the hyper-ellipsoidal particle coupling force; establishing a target fluid domain grid flow field information index; and establishing a hyper-ellipsoidal particle coupling force solving model, solving the hyper-ellipsoidal particle and fluid coupling force and coupling torque to calculate the hyper-ellipsoidal particle resultantforce and velocity gradient and the hyper-ellipsoidal particle resultant torque and angular velocity gradient, and realizing bidirectional coupling calculation of the hyper-ellipsoidal particles and the flow field. According to the invention, the coupling calculation of the fluid grid unit scale and the particle size of the hyper-ellipsoidal particles in the same magnitude can be realized, and theapplicability of the hyper-ellipsoidal particle and flow field coupling simulation technology is improved.

Owner:TIANJIN UNIV

Preparation method of urea-formaldehyde resin with high thermal stability

The invention relates to a urea-formaldehyde resin with high thermal stability, and a preparation method thereof. The preparation method comprises: adding an appropriate thermal stabilizer to a urea-formaldehyde resin prepolymer, and polymerizing to obtain the urea-formaldehyde resin with high thermal stability, wherein the thermal stabilizer is a composite rare earth stabilizer. According to thepresent invention, the modified urea-formaldehyde resin has the substantially-improved heat resistance, the morphology of the urea-formaldehyde resin is regular spherical particles, irregular cylindrical particles or irregular ellipsoidal particles, and the thermal stability is good; and the preparation method has advantages of clever design and simple operation, and provides the platform for themodification of urea-formaldehyde resin.

Owner:广东晨晖新材料科技有限公司

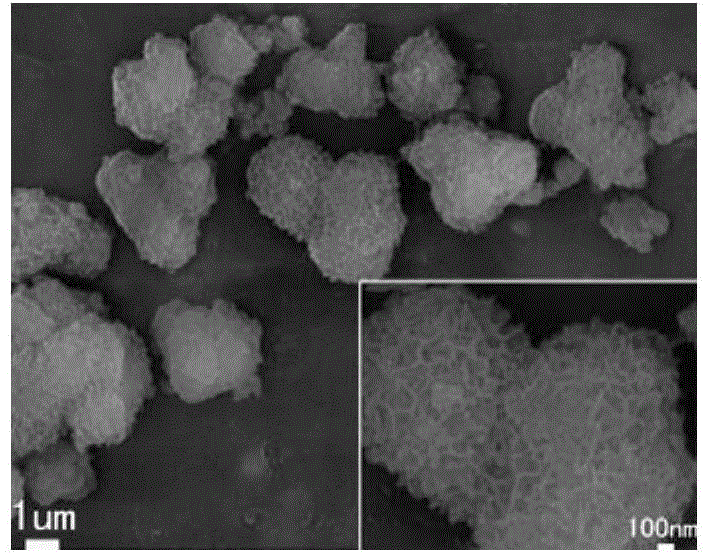

Preparation method for gold-shell magnetic ellipsoid

ActiveCN102528027BHigh crystallinityImprove uniformityFerroso-ferric oxidesFerric oxidesPolyelectrolyteEllipsoidal particle

The invention discloses a preparation method for a gold-shell magnetic ellipsoid and relates to a preparation method for a multi-layer nuclear shell structure ellipsoid. The preparation method is used for solving the problem that a photonic crystal assembled by the existing magnetic ellipsoid with the nuclear shell structure is low in photo-thermal conversion efficiency and photoelectric conversion efficiency. The preparation method comprises the following steps: 1. preparing a spindly alpha-Fe2O3 particle; 2. firstly obtaining alpha-Fe2O3 particle dispersing solution, and then adding polyvinylpyrrolidone for modification; 3. carrying out silicon dioxide coating to obtain a silicon dioxide coated ellipsoidal particle; 4. adding a poly dimethyl diallyl ammonium chloride aqueous solution and NaCl to prepare a silicon dioxide coated ellipsoidal aqueous solution adsorbing polyelectrolyte; 5. preparing a gold solution; 6. adding the gold solution into the silicon dioxide coated ellipsoidalaqueous solution adsorbing polyelectrolyte to obtain alpha-Fe2O3 / SiO2 / Au ellipsoidal particles; and 7. carrying out hydrogen reduction to obtain the Fe3O4 / SiO2 / Au ellipsoid. The preparation method ismainly used for preparing the gold-shell magnetic ellipsoid.

Owner:HARBIN INST OF TECH

A direct-throwing environment-friendly anti-rutting agent and its production device and method

ActiveCN106117710BImproves rutting resistanceLow costBuilding insulationsEllipsoidal particleProcess engineering

Owner:上海砼仁环保技术发展有限公司

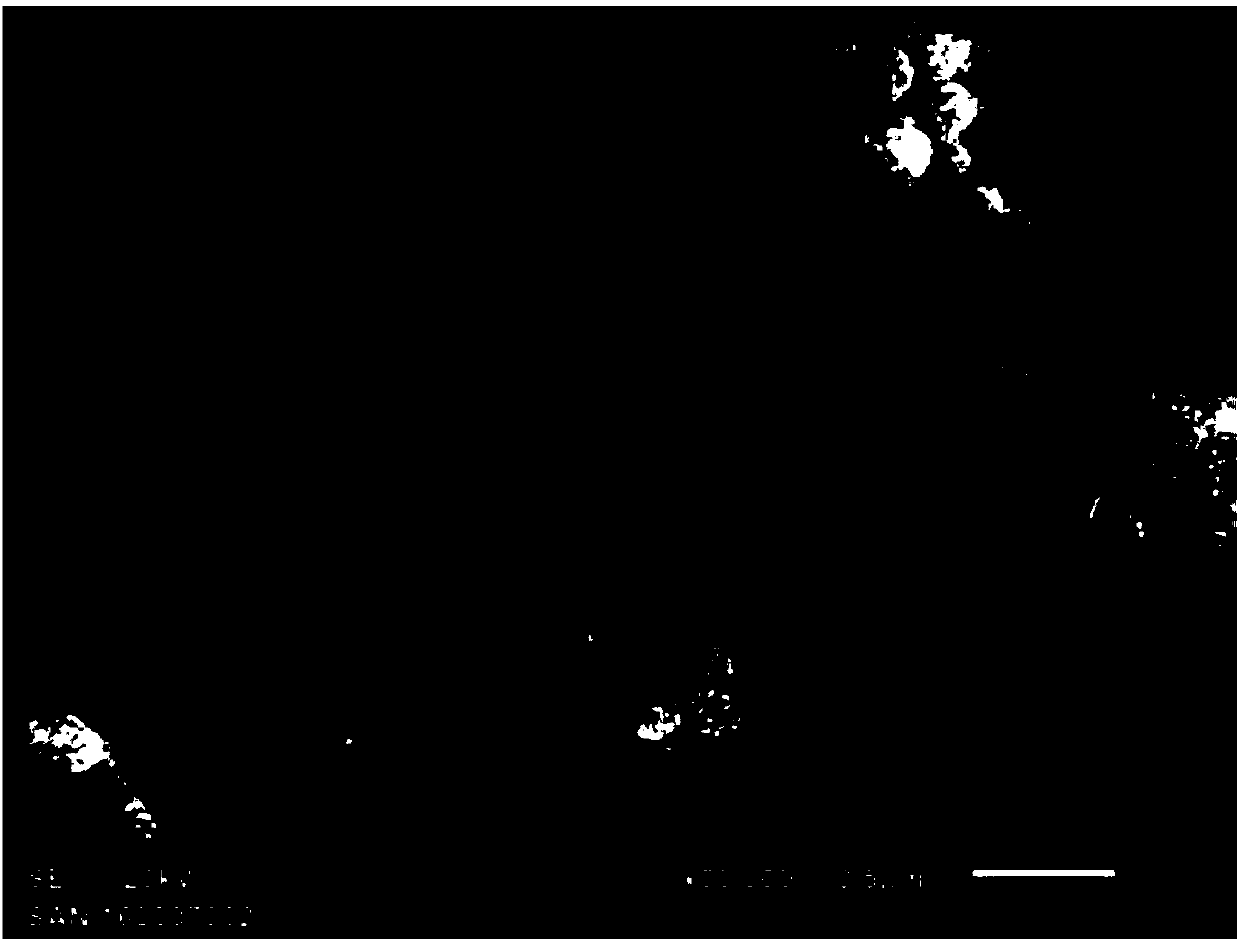

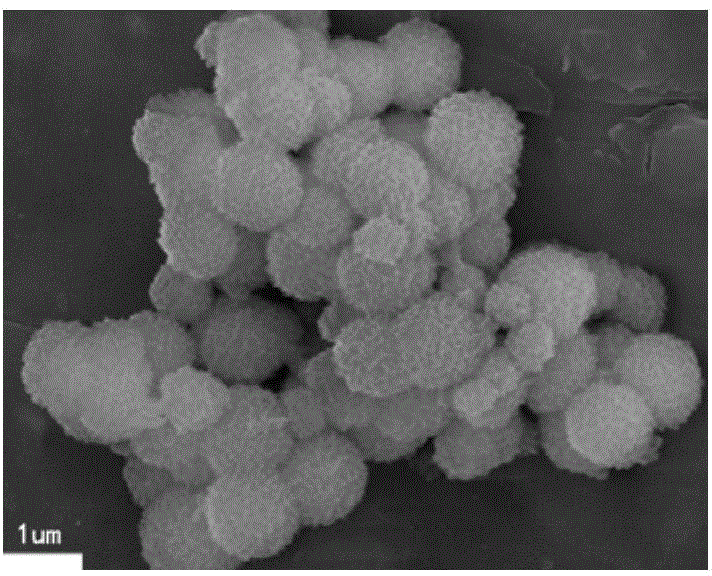

Ellipsoidal milk substitute milk powder for suckling pigs and preparation method thereof

InactiveCN108669328AImprove feeding safetyEasy to useFood processingAnimal feeding stuffPig farmsEllipsoidal particle

The invention discloses ellipsoidal milk substitute milk powder for suckling pigs and a preparation method thereof. The ellipsoidal milk substitute milk powder comprises the following raw materials: concentrated whey protein, whey powder, whole milk powder, white sugar, cheese, sodium alginate, sodium carboxymethylcellulose, lysine, methionine, tryptophan and multi-vitamin; the particle diameter of the ellipsoidal milk substitute milk powder is 2.0 to 12.0mm; the ball height is 1.4 to 6.0mm. The method comprises the following steps: adding and sufficiently mixing the raw materials in proportion, so as to form a powder semi-finished product, then ensuring that the semi-finished product passes a compaction rolling-granulating system, so as to obtain a mixture of ellipsoidal particles and powder, and ensuring that the mixture passes a classifying screen, so as to obtain the ellipsoidal milk substitute milk powder (as shown in Figure 3). The method solves the problem that the necessary circular mould-press roll granulating system in the current feed industry cannot manufacture substitute milk powder into powder particles, successfully manufactures the formula milk substitute milk powder semi-finished product into ellipsoidal particles through the compaction rolling-granulating system, and realizes the convenience operation that the milk substitute milk powder can be used for directly feeding the suckling pigs in pig farms.

Owner:CONTI FEED CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com