Preparation method for gold-shell magnetic ellipsoid

An ellipsoid and magnetic technology, which is applied in the field of preparation of multi-layer core-shell structure ellipsoids, can solve the problems of low photothermal and photoelectric conversion efficiency, and achieve the effects of good conversion effect, improved monodispersity, and increased reaction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

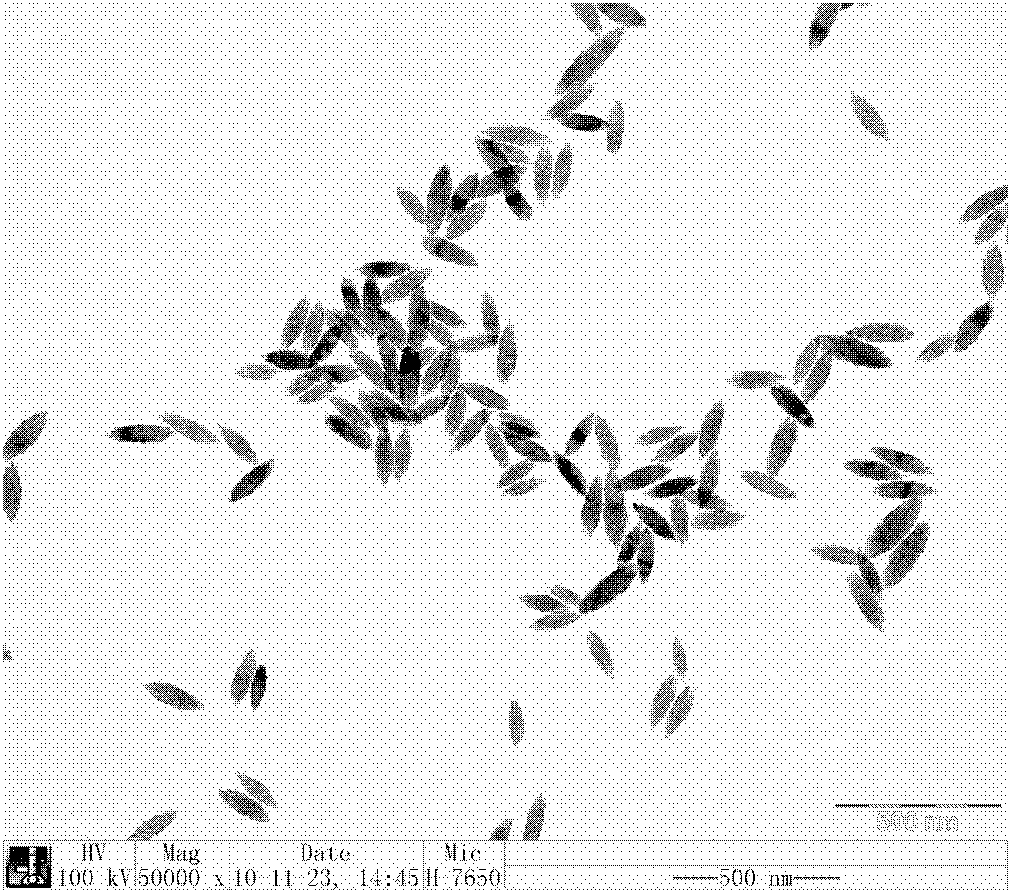

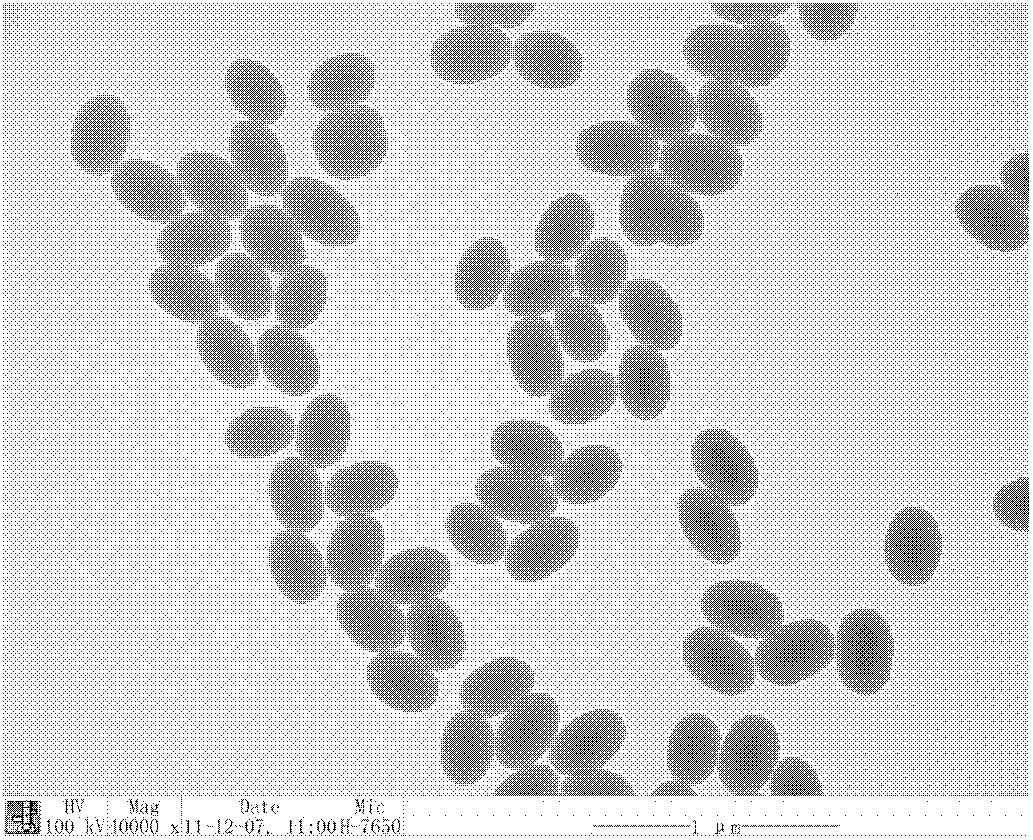

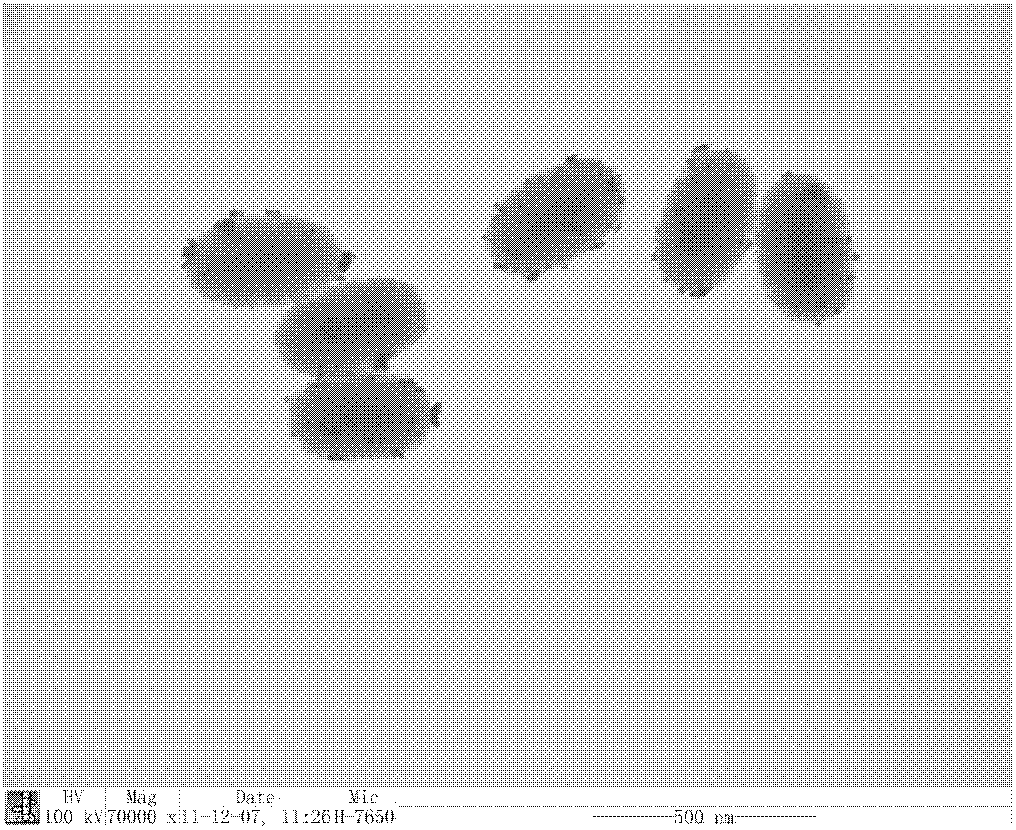

[0024] Specific embodiment 1: This embodiment is a method for preparing a gold shell magnetic ellipsoid, which is specifically completed according to the following steps:

[0025] 1. First, completely dissolve iron perchlorate, sodium dihydrogen phosphate and urea in deionized water to obtain a homogeneous mixture, and then transfer the homogeneous mixture to a polytetrafluoroethylene reactor and seal it at a temperature of 100℃~140 Reaction at ℃ for 8h-16h, and then centrifuged at 5000r / min~7000r / min for 8min~12min, and the solid obtained by centrifugation is washed with deionized water at a centrifugal speed of 5000r / min~7000r / min 2 to 5 times, a single centrifugal washing time is 5min to 10min, and finally drying at a temperature of 40℃~60℃ until constant weight, that is, spindle-shaped α-Fe is obtained 2 O 3 Particles; the molar ratio of iron perchlorate and sodium dihydrogen phosphate described in step one is (20-25):1; the concentration of iron perchlorate in the uniform mix...

specific Embodiment approach 2

[0035] Embodiment 2: The difference between this embodiment and Embodiment 1 is: in step 1, ferric perchlorate, sodium dihydrogen phosphate and urea are completely dissolved in deionized water to obtain a homogeneous mixed solution, and then the homogeneous mixed solution Transfer to a Teflon reactor and seal, and react at 110℃~130℃ for 10h~14h, then centrifuge at 5500r / min~6500r / min for 9min~11min, and centrifuge the obtained solid Use deionized water at a centrifugal speed of 5500r / min~6500r / min for centrifugal water washing 2~5 times, a single centrifugal water washing time is 6min~9min, and finally drying at a temperature of 45℃~55℃ until constant weight, that is Get spindle-shaped α-Fe 2 O 3 particle. Others are the same as the first embodiment.

specific Embodiment approach 3

[0036] Specific embodiment three: this embodiment is different from specific embodiment one or two in that: in step two, the spindle-shaped α-Fe 2 O 3 The particles are dispersed in deionized water to obtain spindle-shaped α-Fe 2 O 3 Particle dispersion, then add polyvinylpyrrolidone at a stirring speed of 250r / min~350r / min, and react at a stirring speed of 250r / min~350r / min for 20h~28h, and then centrifuge at a speed of 6500r / min~7500r Centrifuge for 7min-9min at 1 / min, and centrifuge the solid obtained by centrifugation with deionized water at a centrifugal rotation speed of 6500r / min-7500r / min for 3-6 times, and the washing time for a single centrifugation is 7min-9min. Others are the same as the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com