Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

18102 results about "Water washing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital ink jet fabric-treating process

The present invention is digital ink jet fabric treating process, and belongs to the field of textile science and technology. The fabric pre-treating process for digital ink jetting and printing with water thinned pigment ink is suitable for fabric of cotton, hemp, silk, Dacron, polyester and cotton blend, acrylic fiber, etc.; and the treated fabric may be ink jetting printed with water thinned pigment ink in one digital ink jetting printer. After printing and proper heat treatment, may be produced printed product with clear pattern, bright color, and high fastness to resist water washing, friction and sunlight.

Owner:JIANGNAN UNIV

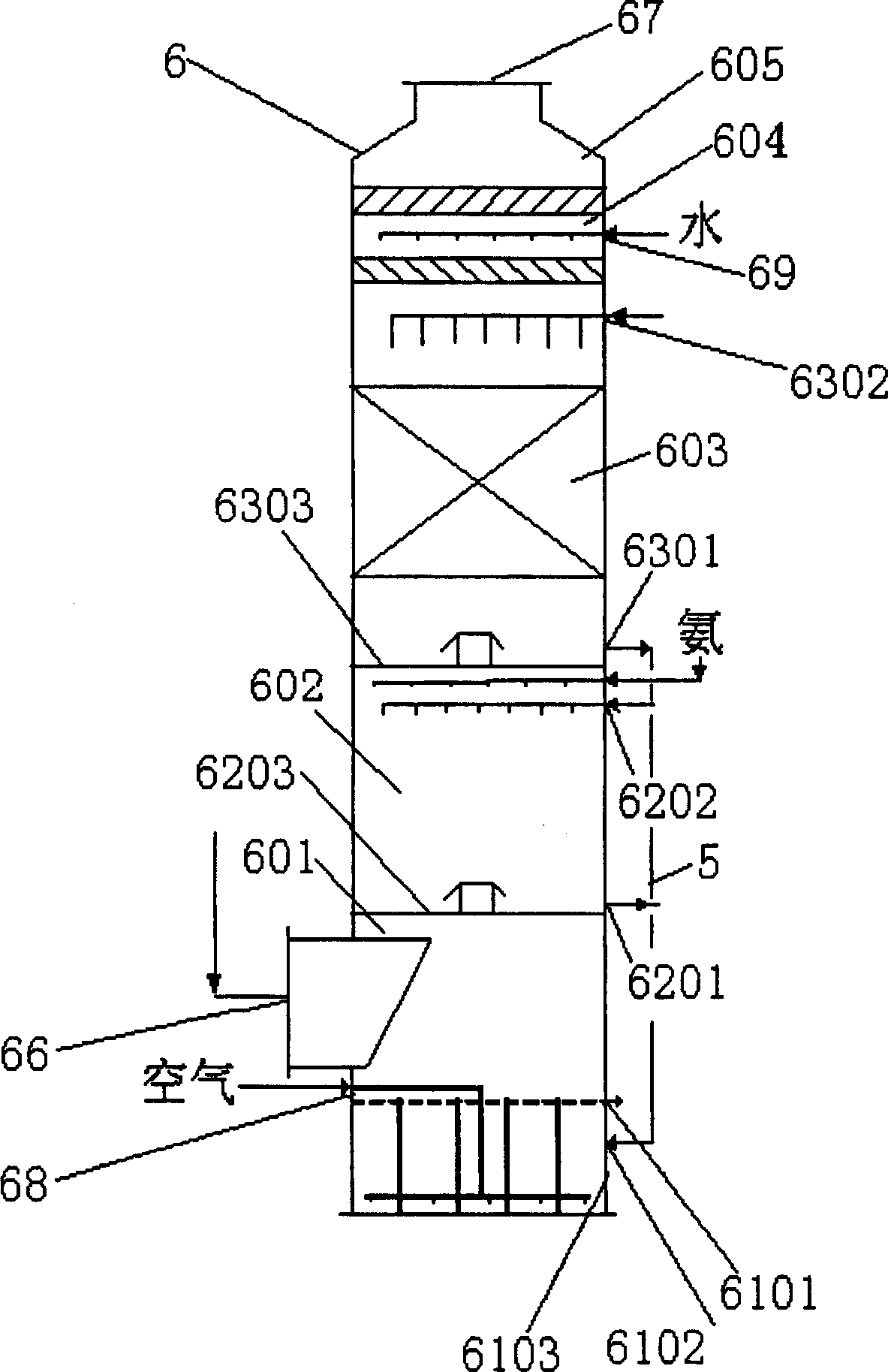

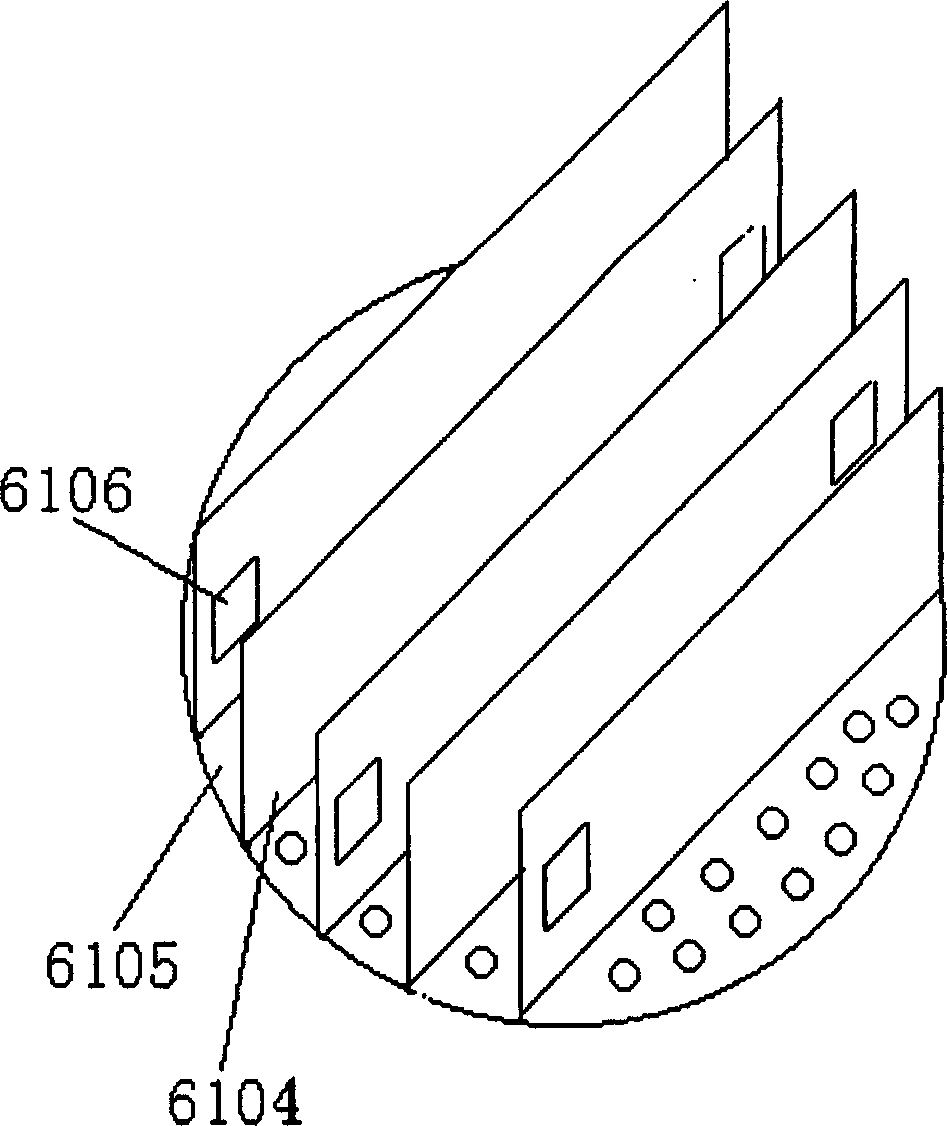

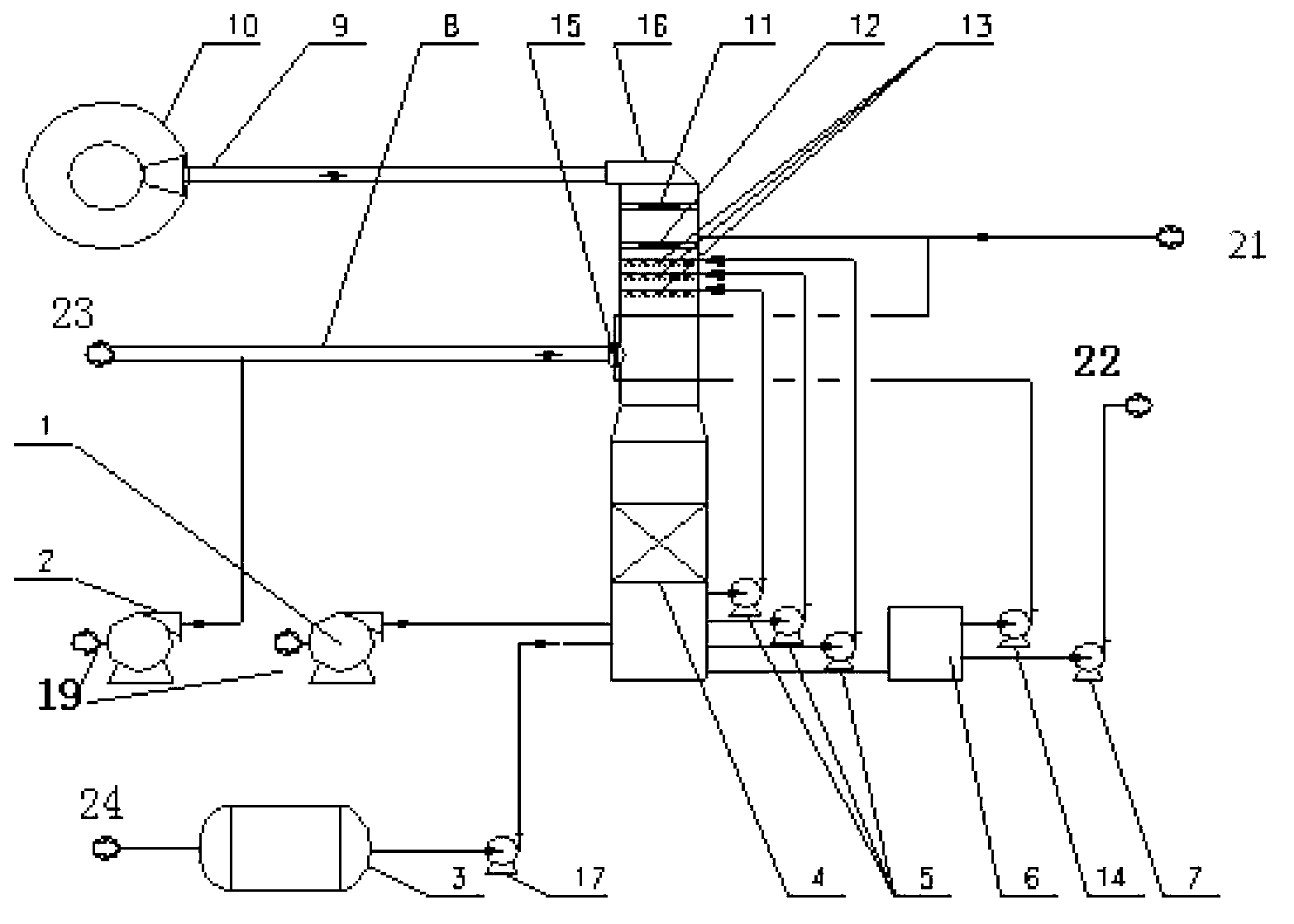

Removing and recovering process and device for SO2 in flue gas

InactiveCN1408464AReduce consumptionEasy to operateDispersed particle separationAmmonium sulfatesRecovery methodGas to liquids

The recovering process includes the steps of: the reaction of the S containing fume with water solution of ammonia, with ammonia-to-sulphur molar ratio of 1.3-1.8 and gas-to-liquid ratio of 2000-5000, to produce ammonium sulfite solution; the oxidation of ammonium sulfite solution with air to obtain ammonium sulfate solution; the contact of the ammonium sulfate solution with hot fume to evaporatewater and the crystallization of ammonium sulfate in a crystallizer to produce commercial ammonium sulfate fertilizer. The equipment includes one desulfurizing tower with SO2 absorbing section, one ammonium sulfite oxidizing section, ammonium sulfate solution concentration section, one water washing section and mist elimianting section. The present invention can lower cost and steam consumption, reduce fume density and produce ammonium sulfate fertilizer.

Owner:EAST CHINA UNIV OF SCI & TECH

Methods and compositions for on-line gas turbine cleaning

InactiveUS7185663B2Easy to cleanRestore powerInorganic/elemental detergent compounding agentsDetergent mixture composition preparationCombustion chamberAromatic solvent

Methods and compositions for on-line cleaning of internal surfaces of selected sections of a hydrocarbon fuel burning gas turbine and associated heat recovery equipment, during operation. Cleaning solutions containing graphite and / or molybdenum-based particles and oil soluble corrosion inhibitors, aromatic solvents, and surfactants are selectively introduced directly into the combustion chamber (combustor) of the gas turbine, into the fuel stream, water washing system, or the combustion air system (hot gas path). The cleaning process dislodges unwanted ash deposit buildup and, thereby restores the gas turbine to rated power. When introduced into the compressor section, the particles impinge on the metal surfaces, cleaning them prior to entering the hot gas section where the process may be repeated. They may also be carried through the exhaust to additionally clean attendant heat recovery equipment, if present.

Owner:LIQUID MINERALS GRP LTD

Method for preparing high purity vanadium pentoxide through using ammonium metavanadate

The invention which relates to a method for preparing high purity vanadium pentoxide through using ammonium metavanadate belongs to the wet metallurgy field. The method comprises the following steps: heating and dissolving crude ammonium metavanadate in water, adjusting the pH value to 8-10 with an alkali after dissolving, adding an impurity removing agent to remove impurities, filtering to obtain a sodium metavanadate solution, adding ammonia water or an ammonium salt to the sodium metavanadate solution to precipitate to obtain an ammonium metavanadate precipitate, dehydrating the ammonium metavanadate precipitate, carrying out water washing on the precipitate through using a dilute ammonium salt solution, dehydrating after the wash washing, and roasting to obtain the high purity vanadium pentoxide. Vanadium pentoxide produced through adopting the method of the invention has the advantages of high purity and less impurities, and completely satisfies production requirements of high-end products; and the method of the invention has the advantages of short process flow, simple equipment, low cost and high benefit, and is suitable for the large-scale industrial production.

Owner:崇阳县恒通工贸有限公司

Preparation of iron-managanese compounded oxide/diatomite adsorbant, its using and regenerating method

ActiveCN101024160AImprove adsorption capacityGood arsenic removal effectOther chemical processesWater/sewage treatment by sorptionSorbentManganese oxide

The invention supplies a new type adsorbent--mixed oxide of iron and manganese / diatomite preparation, use and regeneration method, belongs to the treatment of technology. The method used the soluble ferrous permanganate and salt as raw materials, respectively prepared the solutions, after adequate lye into permanganate solution, mixed two salt solutions, by adding diatomite particles, full oscillation, standing aging, neutralize, washing and drying to get the manganese oxide / silicon algae absorbent. The adsorbent is larger than the surface area and good adsorption properties can be used to remove arsenic in water pollutants (especially tervalence arsenic), and the adsorption surface activity of the saturated absorption of pollutants can be directly passed to load manganese oxide compound to regeneration.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

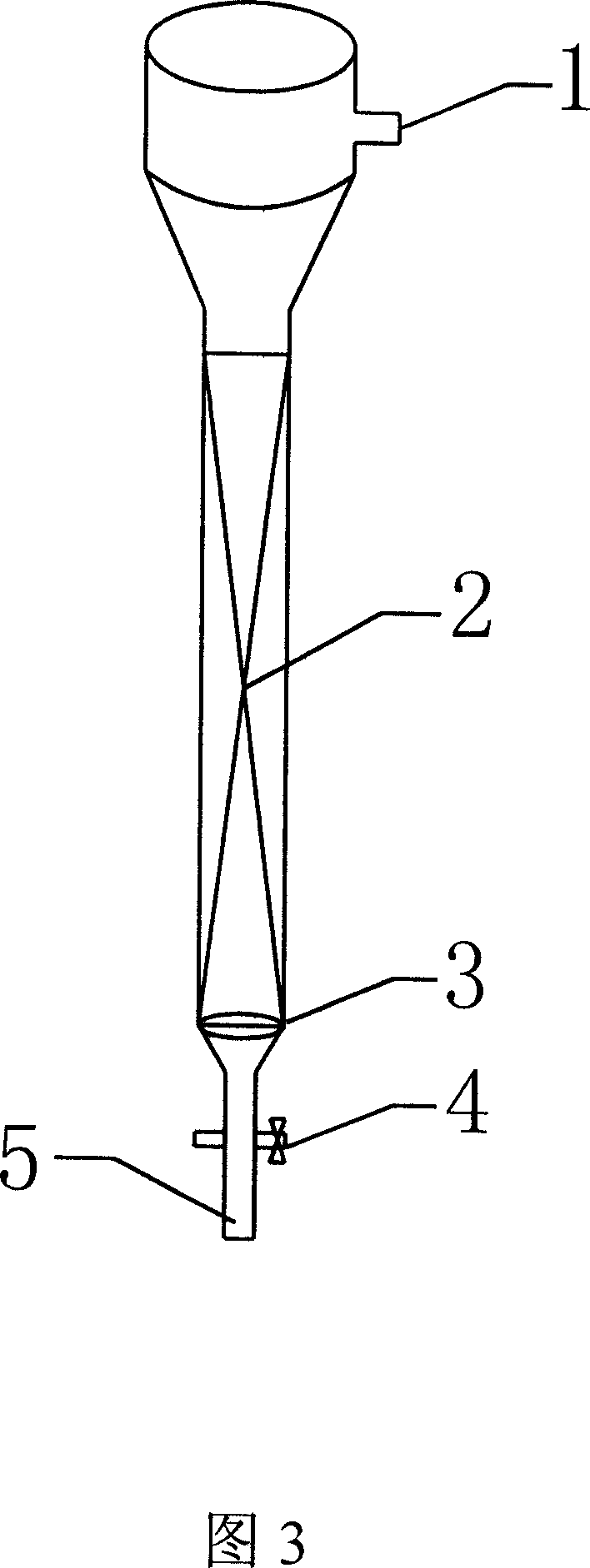

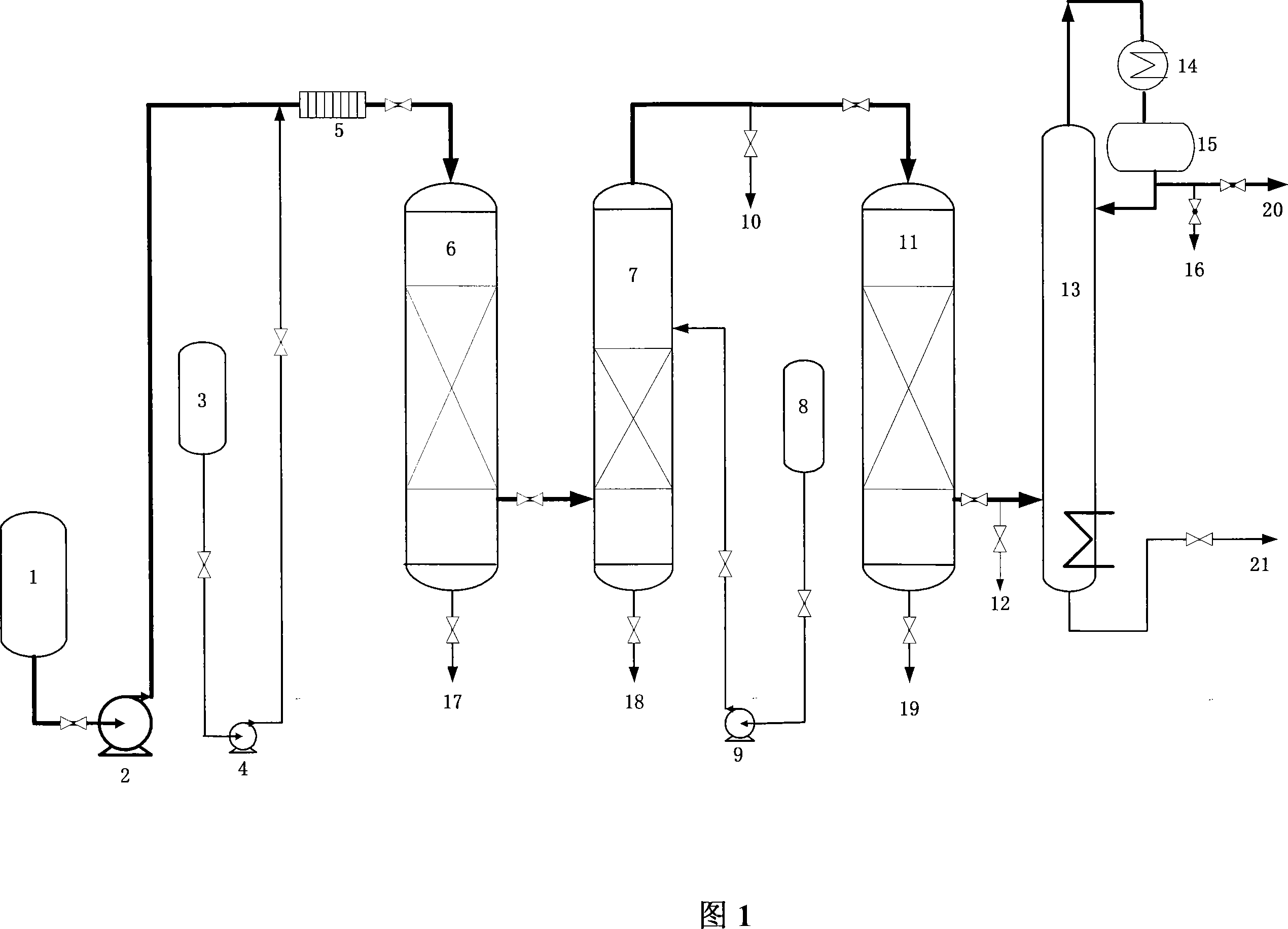

Deep desulfurization method for liquefied petroleum gas

The liquefied petroleum gas deep desulfurizing process includes the following steps: mixing alcohol amine treated liquefied petroleum gas with desulfurizer aqua, feeding the mixture into a reactor with carbonyl sulfide hydrolyzing catalyst for hydrolyzing carbonyl sulfide into hydrogen sulfide and CO2 and eliminating hydrogen sulfide, regenerating the used desulfurizer, water washing the liquefied petroleum gas to eliminate residual desulfurizer with water containing dissolved oxygen or hydrogen peroxide in a water washing tower with hydrogen peroxide decomposing catalyst in the stuffing layer, eliminating mercaptan from the liquefied petroleum gas through oxidizing mercaptan into disulfide in a mercaptan eliminating reactor with catalyst, and final rectifying in a rectifying tower to eliminate disulfide. The process is simple and practical, and can lower the total sulfide content in liquefied petroleum gas to below 5 ppm.

Owner:北京石大世通科技发展有限公司

Cold-rolling heap staining method for textile fabric

ActiveCN101016682AImprove solubilityGood compatibilityBiochemical fibre treatmentDyeing processSewageWater washing

The invention discloses a cold rolling stack dying method of face fabric, comprising immerging, stacking and water washing. The immerging step comprises cold rolling stack pretreatment, obtaining half finished product and drying rolling. The stacking step comprises coiling and stacking. The water washing step comprises washing with water, washing soap, washing with water and drying. The inventive method has advanced and reasonable process, with stable quality, energy-saving and environment friend functions, while the invention has simple process, low cost, and high fixation yield, or the like.

Owner:YUYUE HOME TEXTILE

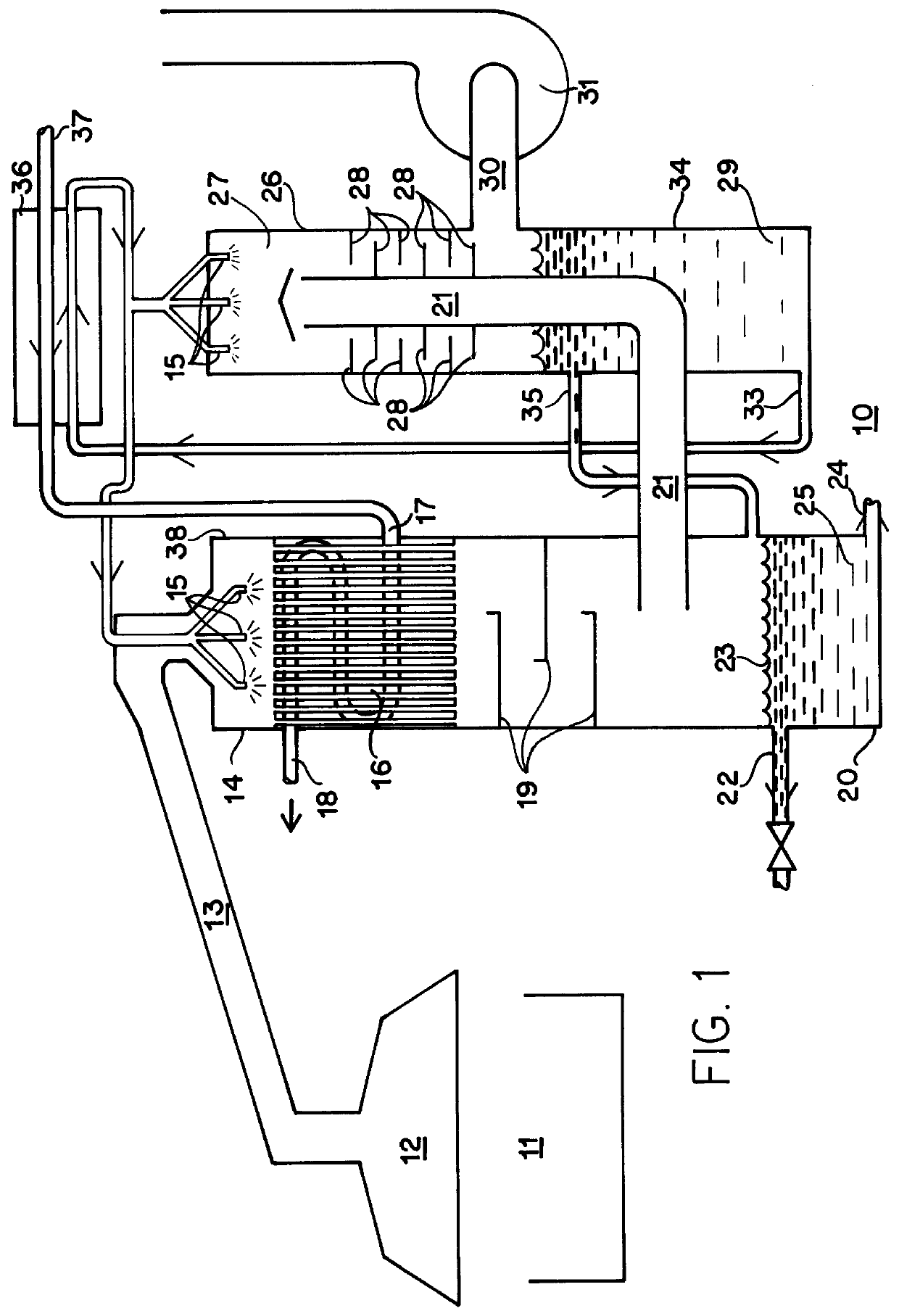

Apparatus and method for extracting heat from contaminated waste steam

InactiveUS6019819ALess energyHotter cooling water temperatureCombination devicesAuxillary pretreatmentAtmospheric airEngineering

Disclosed is a contaminated waste steam heat recovery apparatus 10 and method therefore which includes a primary condensing unit 38, a low pressure water washing unit 26, a liquid to liquid heat exchanger 36 and a vent fan 31. Waste gas is ducted from fryer 11 to a de-super-heating chamber 14 wherein superheated steam is converted to saturated steam by spraying water into the steam using spray nozzles 15. The gas is then introduced into a vertically disposed air to liquid heat exchanger 16 and is drafted downward therethrough. As heat is removed from the waste gas, water vapor in the steam condenses and in the process, collects some of the oil and hydrocarbons present. A plurality of condensate trays 19 are disposed below the bottom end of heat exchanger 16 in a cascading fashion to collect hold the condensate in the airflow path such that it will absorb some of the heat still present in the remaining waste gas. An oil outlet 22 is provided at the top of collection basin 22 for drawing off concentrated oil 23. The waste gas is pulled into a low pressure water washer 26 where it is washed by a second set of spray nozzles 15. Waste gas and water are sucked downward through a set of turbulence inducing baffles 28. The remaining waste gas is sucked out though exhaust tube 30, using vent fan 31, and vented to the atmosphere.

Owner:ALPHA ENGINEERS

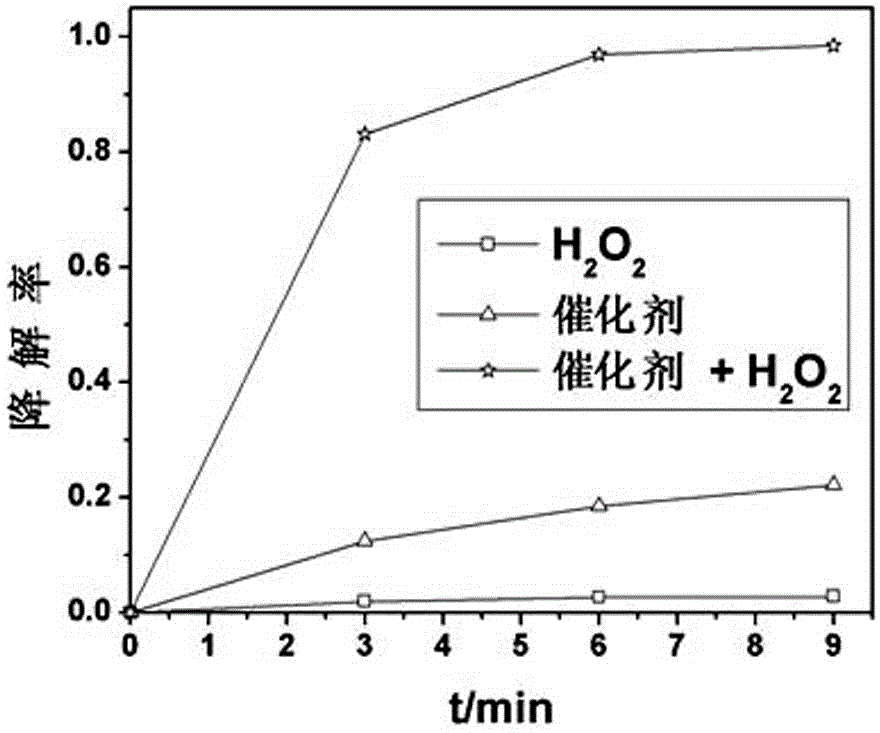

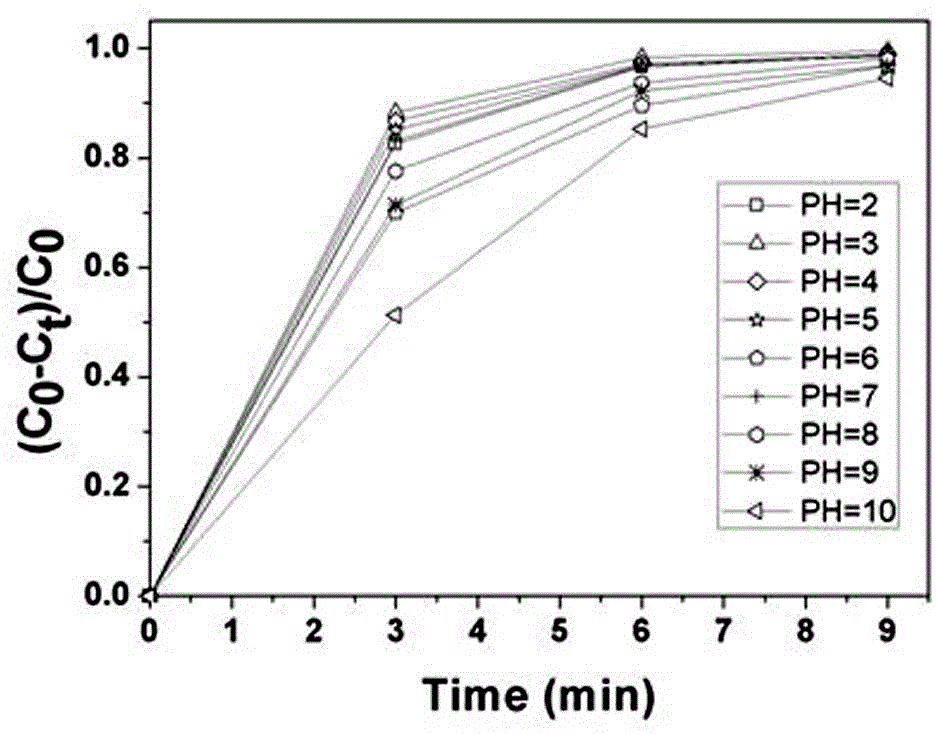

Preparation method and application of heterogeneous Fenton-like catalyst

InactiveCN102909073ALow costEfficient degradationOrganic-compounds/hydrides/coordination-complexes catalystsWaste water treatment from textile industryFiberCarbon fibers

Disclosed are a preparation method and application of heterogeneous Fenton-like catalyst. The preparation method includes the steps of firstly, dissolving complexing agent and metal salt in distilled water to respectively prepare complexing agent and metal salt solutions; secondly dropwise adding the metal salt solution into the complexing agent solution under the action of a magnetic mixer, and mixing for 20-60 after dropwise addition to obtain metal complex solution; and thirdly, impregnating activated carbon fiber in the metal complex solution for 1-24h, and subjecting taken-out activated carbon fiber to distilled water washing and drying to obtain the heterogeneous Fenton-like catalyst. The preparation method is simple, and conditions are mild. Environment-friendly hydrogen peroxide is used as oxidant, no extra ultraviolet light or even visible light is needed, and the heterogeneous Fenton-like catalyst is capable of efficiently degrading organic pollutants such as dye within a wide pH range of 2-10. The heterogeneous Fenton-like catalyst is well repeatable, and secondary pollution of the homogeneous Fenton reagent caused by iron ions is avoided.

Owner:ZHEJIANG SCI-TECH UNIV

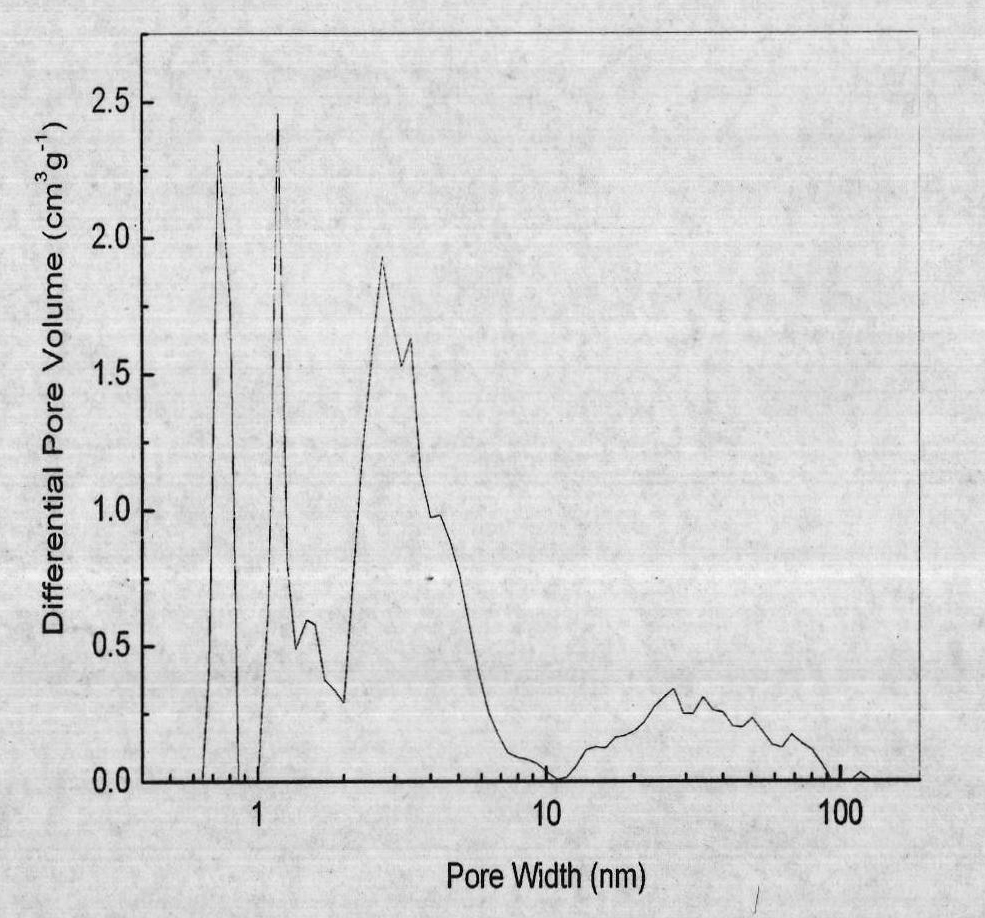

Preparation method of porous structured active carbon

The invention provides a preparation method of porous structured active carbon. The preparation method comprises the following steps of: drying animal bones serving as raw materials; pre-carbonizing at the temperature of 400 to 500 DEG C under the protection of an inert gas; crushing into powder; adding an activating agent into the powder; performing chemical activation under the protection of the inert gas; cooling and taking a product out; and performing aftertreatment process such as acid-washing, water-washing and drying to obtain the porous structured active carbon, wherein the product prepared at 850 DEG C has the specific surface area of 2,157 square meters per gram and the pore volume of 2.26 cubic centimeters per gram; the pores are in a three-dimensional distribution of micropores, mesopores and macropores. By taking organic substances and inorganic substances in the animal bones as a carbon source and a natural template with a special pore structure, the preparation method overcomes the defects of requirement on a template and difficulty in immersing pores in a template by using a carbon precursor, prepares the porous active carbon, and is low in cost and simple in process.

Owner:BEIJING UNIV OF CHEM TECH

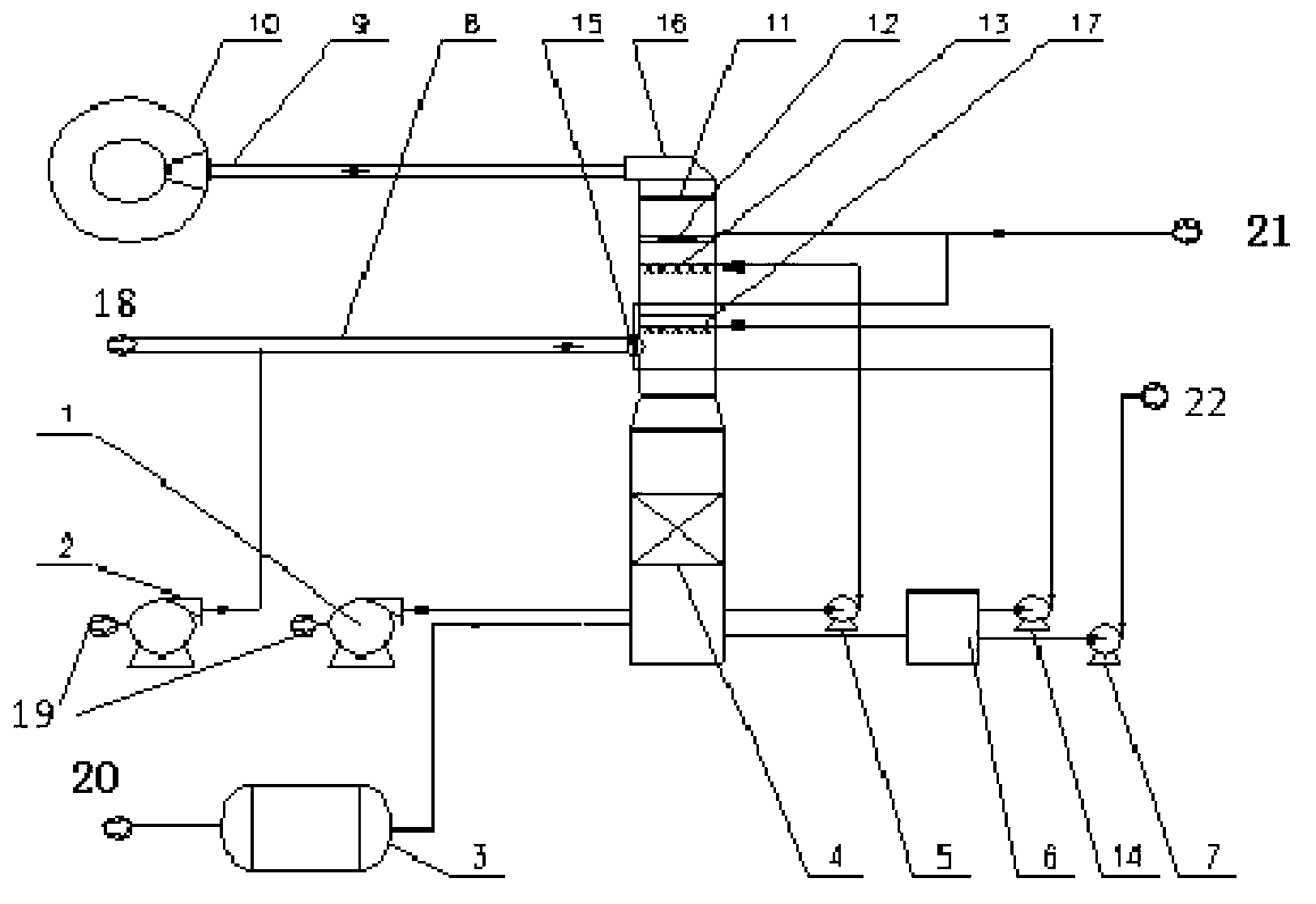

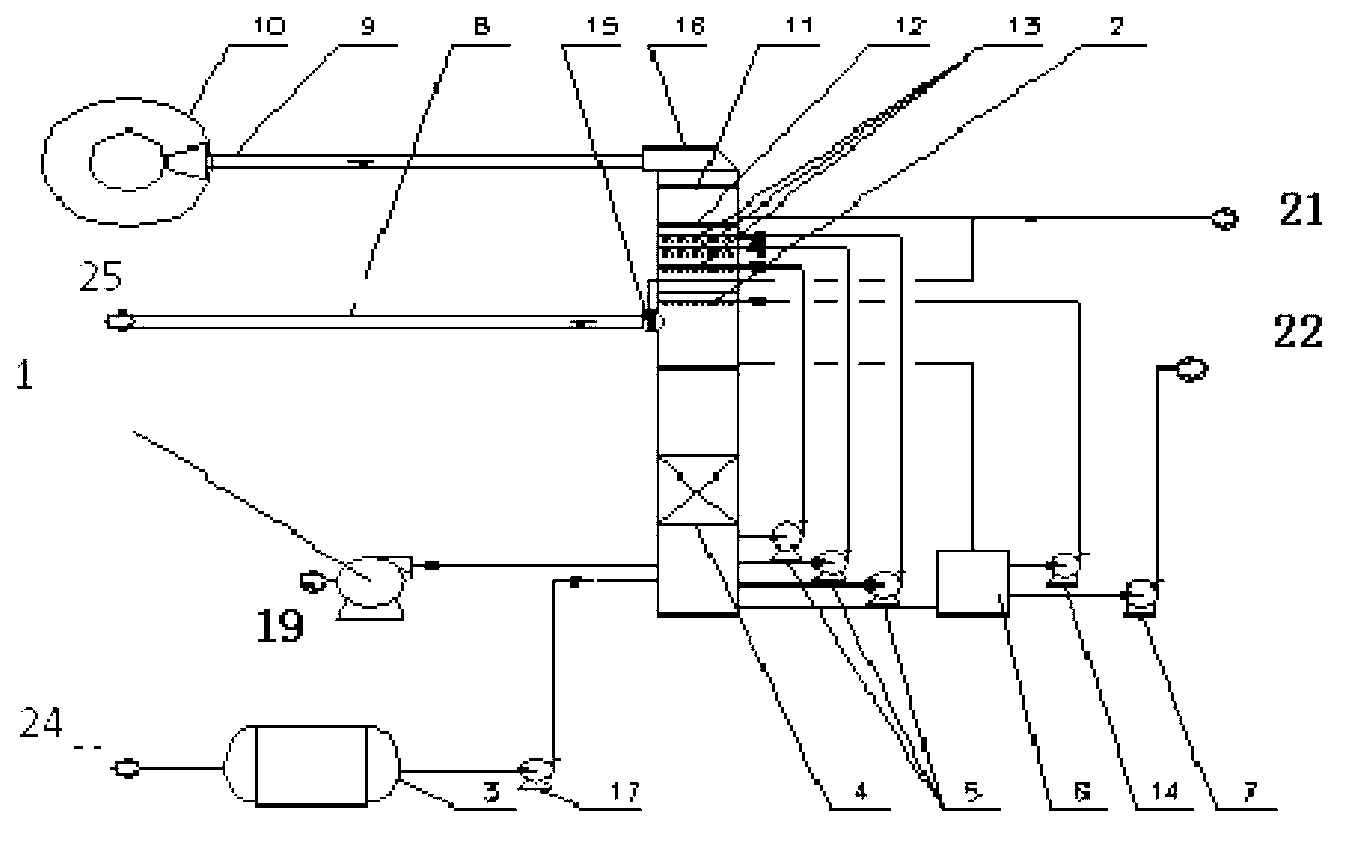

Ammonia process flue gas treatment method for acidic tail gas and device

ActiveCN103223292AIncreased self-concentrationGood desulfurization absorptionDispersed particle separationAmmonium sulfatesEnvironmental resistanceAmmonia storage

The invention relates to an ammonia process flue gas treatment method for acidic tail gas. The method includes the steps of: 1) controlling the sulfur dioxide concentration of tail gas entering an absorption tower at a level of less than or equal to 30000mg / Nm<3>; 2) arranging process water in an absorption tower entrance flue or in the absorption tower or cooperating with a ammonium sulphate solution to perform spray cooling; 3) disposing an oxidation section in the absorption tower, setting an oxidation distributor at the oxidation section to achieve oxidation of a desulfurized absorption liquid; 4) arranging an absorption section in the absorption tower, utilizing an absorption liquid distributor in the absorption section to realize desulfurization spray absorption by an ammonia-containing absorption liquid, which is fed through an ammonia storage groove; 5) arranging a water washing layer at an absorption section upper part in the absorption tower, washing the absorption liquid in the tail gas by the water washing layer and reducing the absorption liquid escape; and 6) setting a demister at the upper part of the water washing layer in the absorption tower to control the mist drop content in the purified tail gas. Employment of the Claus sulfur recovery and ammonia process desulfurization integrated desulfurization technology in the coal chemical industry can reduce the investment cost of after-treatment, the process can be simpler, and factory environmental protection treatment can form an intensive advantage.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Production method of biodiesel oil using high acid ralue animal and vegetable grease

InactiveCN1556174AAchieve cycleAchieve recyclingBiofuelsLiquid hydrocarbon mixture productionOil and greaseAlcohol

A process for preparing the biological diesel oil from the animal fat or vegetative oil with high acid number includes esterifying by glycerine under existance of strong acid catalyst, distilling in azeotropic solvent for removing water, mixing with methanol, transesterifying reacting to remove glycerine, water washing, and low-temp treating for removing high-smelting-point substances to obtain methyl ester of fatty acid, which is just the biological diesel oil.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

Process for preparing biological diesel oil from waste animal and plant oil

InactiveCN1382762AEliminate emissionsSimple production processLiquid hydrocarbon mixture productionBio-feedstockOil and greaseBiodiesel

A process for preparing biologic diesel oil from waste plant or animal oil includes alcoholysis and esterifying reactions under the existance of acidic catalyst, separating out the excessive non-product part to obtain coarse product, adding saturated equeous solution of edible salt containing sodium carbonate (10%), neutralizing reaction, adding industrial sodium carbonat4e, heating distillation and collecting the gas-phase fraction at 22-320 deg.C to obtain biologic diesel oil. Its advantages are high performance no pollution, and simple preparing process.

Owner:叶活动 +1

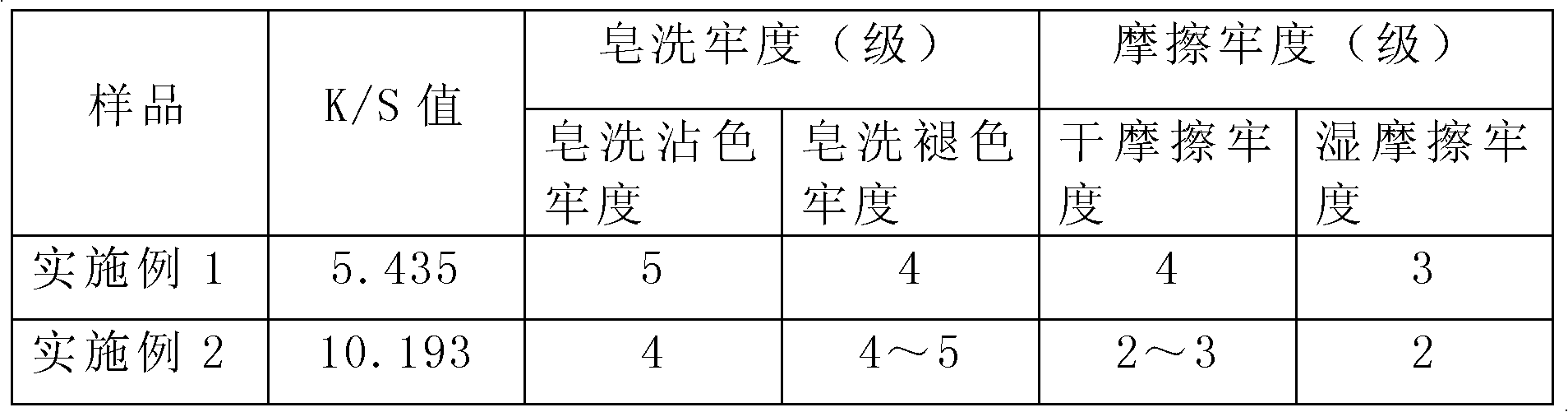

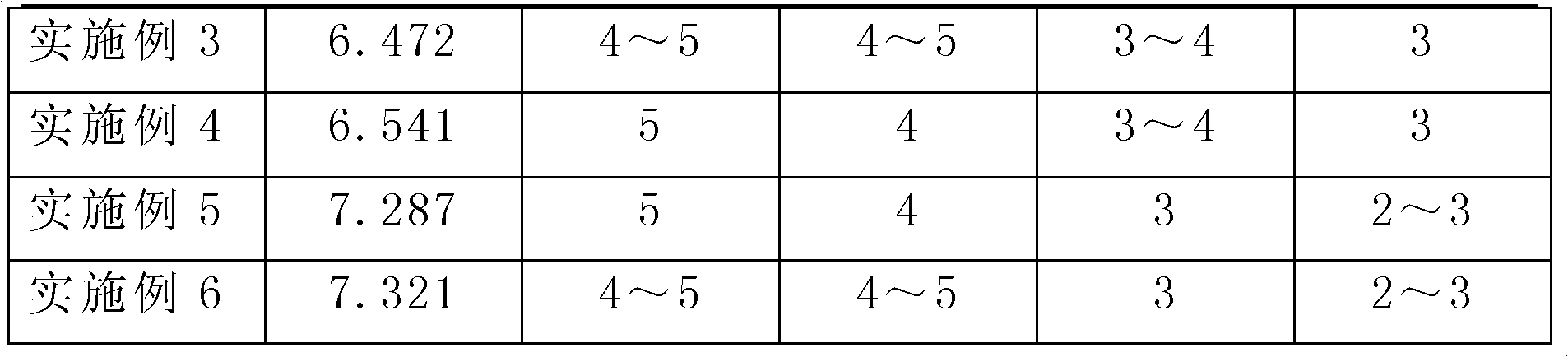

Method of dyeing fabric by using dye

ActiveCN102535194ASoft touchImprove washing fastnessBiochemical fibre treatmentDry-cleaning apparatus for textilesTextile printerEngineering

The invention provides a method for dyeing fabric by using a dye, belonging to the technical field of textile printing and dyeing and aiming to the solve the problems of complex process, low dyeing rate, poor dyeing uniformity and poor color fastness and hand feel of dyed fabric of the existing method for dyeing the fabric by using the dye. The method comprises the following steps of: desizing the fabric, scouring, bleaching and mercerizing; adding the dye, a cationic modifier, a leveling agent, a dispersant, an alkaline reagent and a wet rubbing fastness enhancer to water, and mixing uniformly to prepare a dyeing solution; soaking the fabric into the dyeing solution, and controlling temperature and liquor ratio to dye; steaming the dyed fabric for colour fixation, washing by water and drying to finish dyeing the fabric by using the dye. The method for dyeing the fabric by using the dye is simple, ensures the high dyeing rate and the uniform dyeing, and ensures that the dyed fabric has good washing fastness and rubbing fastness and a soft feel.

Owner:台州东海翔染整有限公司

Processing method of aluminum and aluminum alloy super hydrophobic surface

InactiveCN101007304ASuperhydrophobicEasy to rollAntifouling/underwater paintsPretreated surfacesNickel saltCopper

The invention involves an aluminum or aluminum alloy super-hydrophobic surface preparation method. The method is: polishing the surface of aluminum or aluminum alloy using metallographic sandpaper or polishing paste, pure water washing, acetone ultrasonic cleaning, pure water washing and other clean treatment, handing it with chemical etching solution containing nitric acid and metal salts (copper or nickel salt) 30s-20min under 90 ~ 100 degree C, then coating low surface energy material on its surface to get super-hydrophobic property. The aluminum or aluminum alloy surface treated by the invention has excellent hydrophobicity, the contact angle of water and surface can be as high as 150-165 degree, droplets are easy to roll on the surface. The method of the invention need not complex equipment, cost is low, technology is simple and repeatability is good.

Owner:SOUTH CHINA UNIV OF TECH

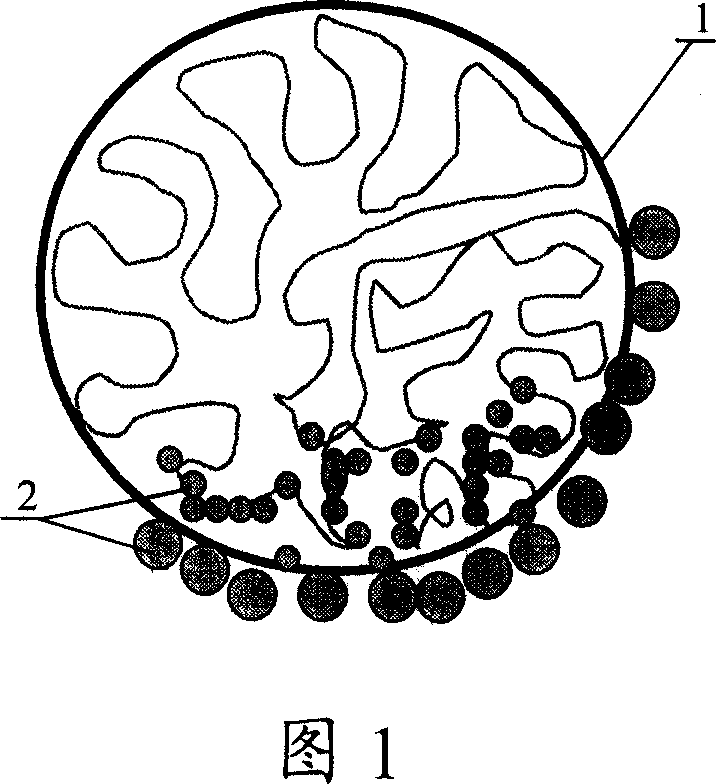

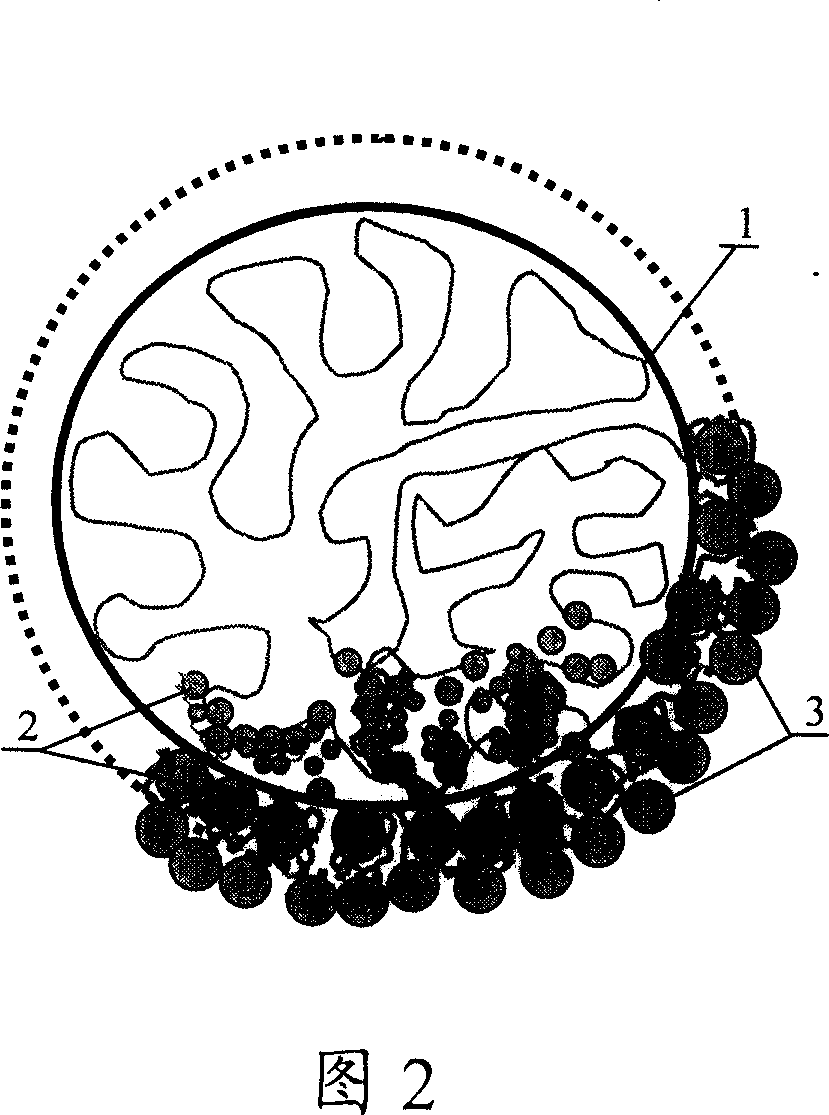

Encapsulates

The present application relates to perfume compositions, delivery systems comprising such perfumes products comprising such perfumes and / or delivery systems, and processes for making and using same. Such perfumes and delivery systems provide improved perfume performance under high soil conditions and in cold water washing and a shell that at least partially surrounds said core.

Owner:THE PROCTER & GAMBLE COMPANY

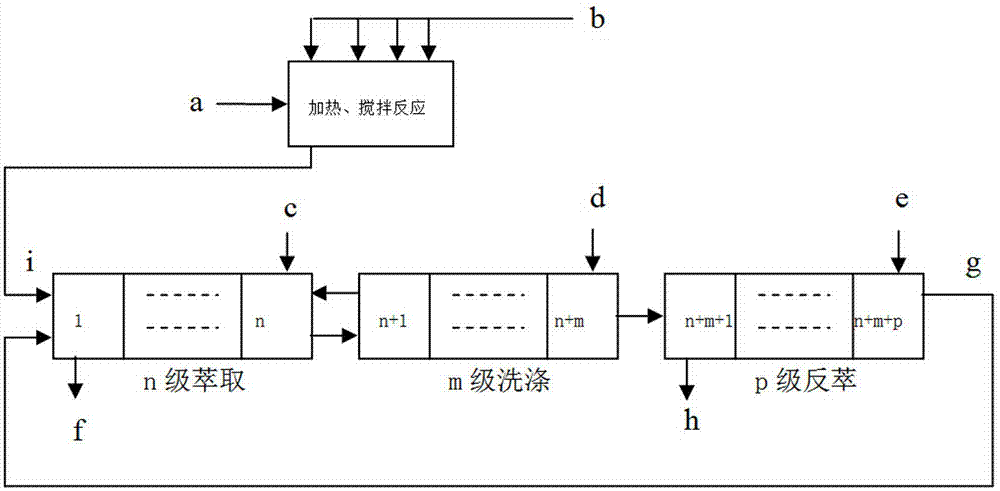

Method for non-saponification extraction and separation of light rare earth elements

ActiveCN104120258ALow viscosityImprove liquidityProcess efficiency improvementRare-earth elementPhosphate

The invention discloses a method for non-saponification extraction and separation of light rare earth elements. After a compound extraction agent consisting of acid phosphorus type extraction agent, alkaline amine type extraction agent and solvent oil is mixed with phosphate solvent or organic alcohol solvent at 30-70 DEG C, chlorinated light rare earth liquid is extracted and separated; and the water washing and the hydrochloric acid reverse extraction are performed to finally realize the separation of La, Ce, Pr and Nd; and a mixed organic phase after the reverse extraction is returned to an extraction tank for recycling. The method pretreats the mixed organic phase consisting of the compound extraction agent and the solvent, so that such defects as high viscosity, weak mobility, easy emulsification and long phase splitting time are overcome; the method has no need to saponify the acid phosphorus type extraction agent, so that no alkali liquor consumption and no waste water emission in the extraction process are realized, but the separation capacity of a saponification extracting agent system is achieved, and the extraction grade is reduced compared with that needed by the saponification extracting agent system; and the method is a rare earth element separation process with economy and high efficiency.

Owner:GUANGXI NORMAL UNIV

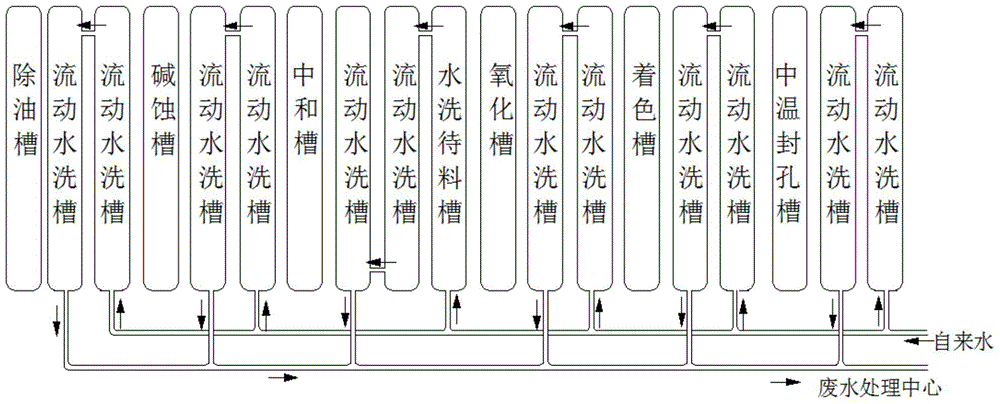

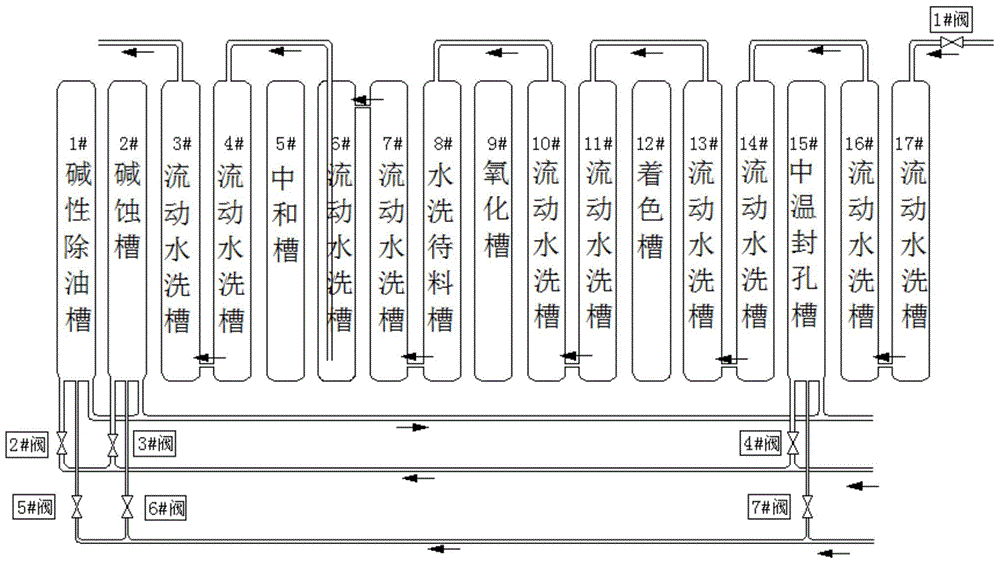

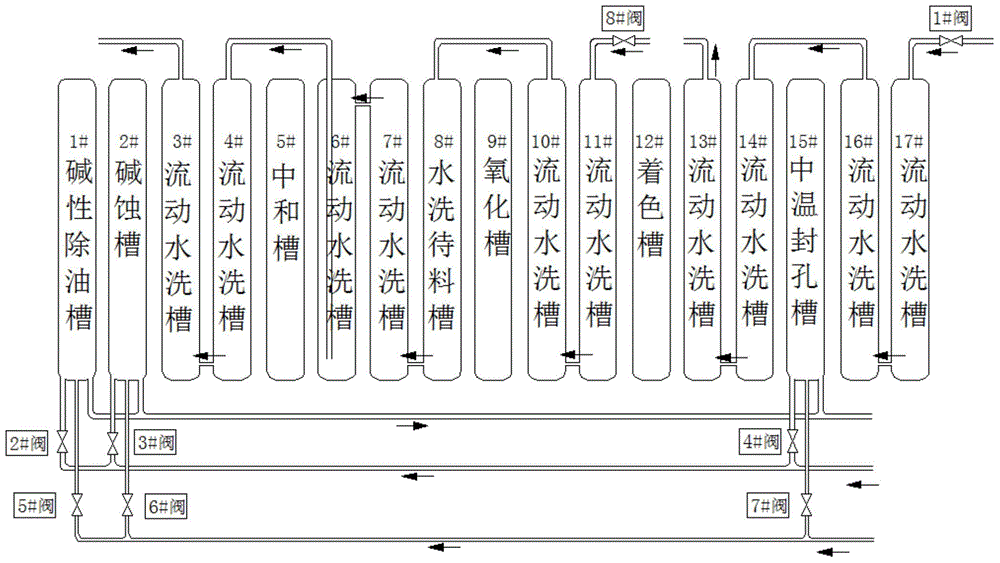

Aluminum alloy anodizing line treatment process

ActiveCN103952741AAchieve large-scale water conservationAvoid pollutionAnodisationAnodizingMaterials science

The invention relates to an aluminum alloy anodizing line treatment process. The aluminum alloy anodizing line treatment process comprises a functional trough system and water washing trough systems arranged between functional troughs. The functional trough system is arranged along the flow direction of washing water in a manner that an upstream functional trough is compatible with a downstream functional trough, and the water washing trough systems are arranged in an overall phase-reversing in-series-connection manner. According to the aluminum alloy anodizing line treatment process, a mode in which a flowing water washing tank is separately configured for each functional trough in the traditional anodizing line is changed. Since all water washing troughs are connected in series in a phase-reversing manner, the number of the water inlets and outlets is greatly reduced and the water consumption is decreased from 25.0-35.0 tons per ton material to 5.0-6.0 tons per ton material and the water is saved by more than 80%. The treatment process disclosed by the invention has the advantages of low production cost, high efficiency and environmental friendliness and is suitable for industrial application.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

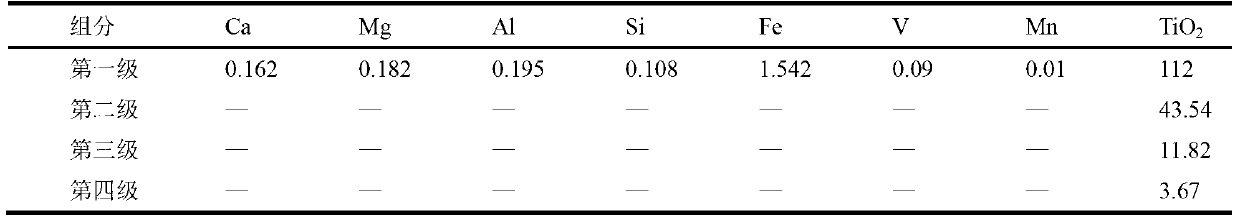

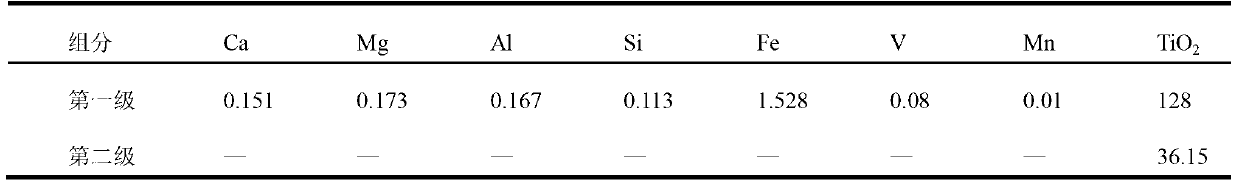

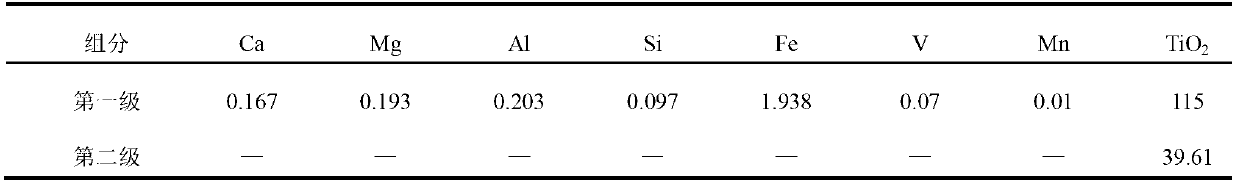

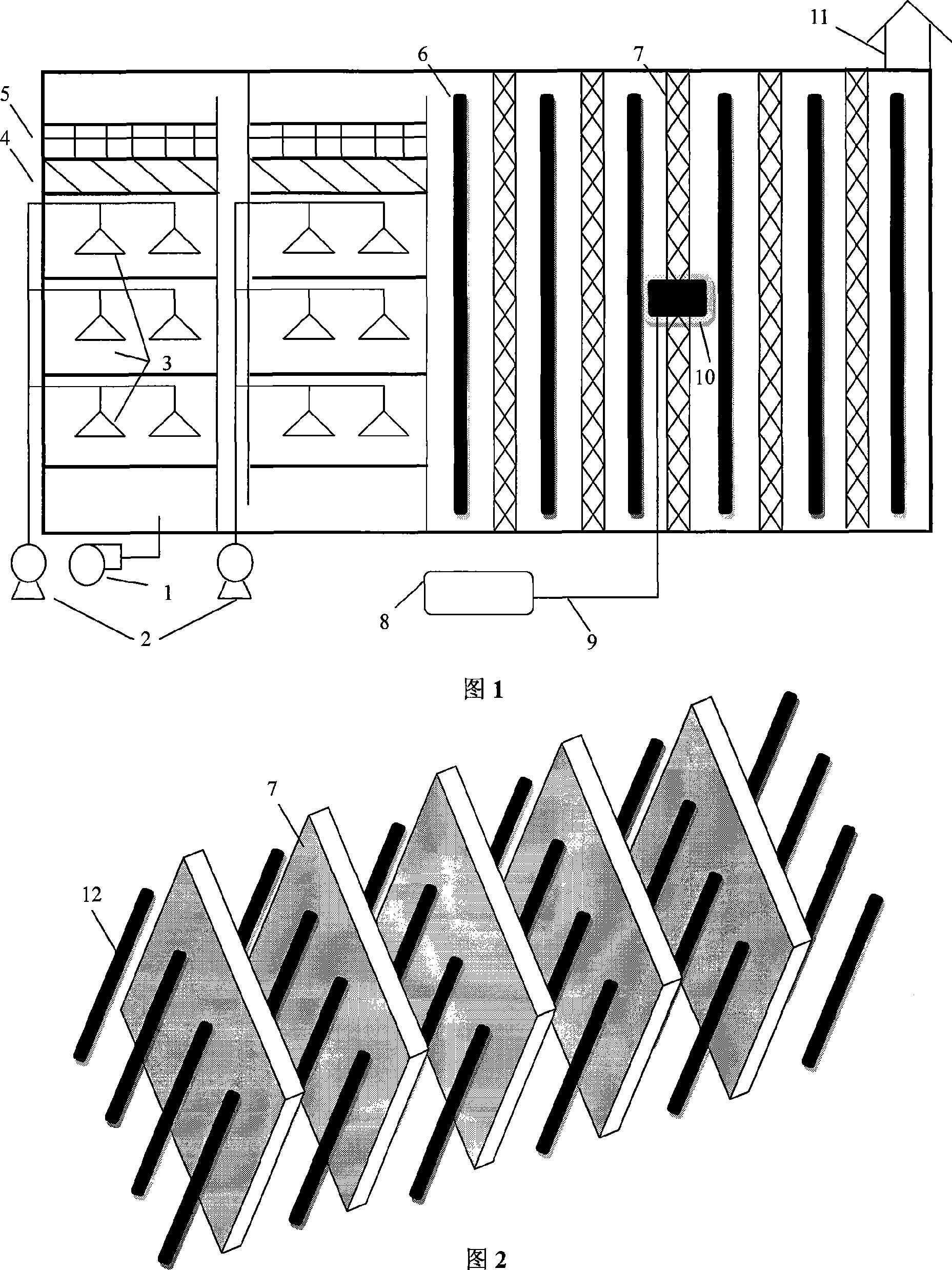

Method for preparing titanium solution by wet-processing on vanadium-titanium magnetite concentrates

ActiveCN103276207ASolve unexploitable puzzlesImprove resource utilizationProcess efficiency improvementSlagResource utilization

The invention belongs to the wet-process metallurgical filed and in particular relates to a method for preparing titanium solution by wet-processing on vanadium-titanium magnetite concentrates. The method for preparing titanium solution by wet-processing on vanadium-titanium magnetite concentrates comprises the following steps of: (1), mixing the vanadium-titanium magnetite concentrate with hydrochloric acid, and leaching to obtain an intermediate sizing agent; (2), filtering the intermediate sizing agent to obtain leaching liquor and leaching residues; (3), carrying out water-washing on the leaching slag to obtain washing water and washing slag; (4), carrying out fused-salt reaction on the washing slag to obtain fused-salt reaction materials; (5), carrying out water-washing and filtering on the fused-salt reaction materials to obtain water-washing materials; (6), carrying out acid pickling on the water-washing materials to obtain sizing agent, and filtering to obtain the acid-pickled sizing agent; (7), carrying out acid dissolving on the acid-pickled materials by using a sulfuric acid solution to obtain acid-dissolved materials; and (8), adding the acid-dissolved materials to the sulfuric acid solution for extracting, and filtering to obtain extracting solution which is the titanium solution. According to the method for preparing titanium solution by wet-processing on vanadium-titanium magnetite concentrates disclosed by the invention, the titanium in the iron concentrate is sufficiently utilized, so that the titanium resource utilization rate is high and the recovery rate of the titanium in the titanium concrete is higher than 90%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Cleaning treatment method and apparatus for malodorous gas

InactiveCN101366966AStrong oxidation abilityImprove processing efficiencyGaseous substancesDeodrantsAdditive ingredientUltraviolet lights

The invention relates to a method for performing purification treatment on malodorous gases and a device carrying out the same. The ultraviolet light catalysis and ozone oxygenation technologies are optimally integrated to adapt to the treatment of the obnoxious gases with different concentrations and ingredients. Waste gas enters a spraying system to be washed by water or drugs, then is filtered and dried by a demisting device, enters an ultraviolet light catalysis and ozone oxygenation system, and finally is discharged at the top. The method for performing purification treatment on the malodorous gases and the device carrying out the same have the characteristics of less investment, low operation cost, small occupied area, high treatment efficiency, wide application scope and simple operation and management.

Owner:ZHEJIANG UNIV

Production process of paste attapulgite clay

The invention provides a process of preparing paste formed attapulgite clay. The key points of the technical proposal include: the process of preparing paste formed attapulgite clay comprises the steps of pulping, sodium treatment, acidizing treatment, water washing and impurity screening out, and the mud obtained is subjected to precipitation to obtain the paste formed attapulgite clay. The attapulgite ore mud is subjected to the steps of sodium treatment, acidizing treatment, water washing and impurity screening out, and become natural gel with good thixotropy and stickiness, and the pH value is neutral. The attapulgite clay obtained by the preparation process of the invention has viscosity, expansion capacity, colloid value, whiteness degree, specific surface area, adsorbability and dirt removing power greatly improved, and the invention is suitably applied to the production of the paste formed attapulgite clay.

Owner:许盛英

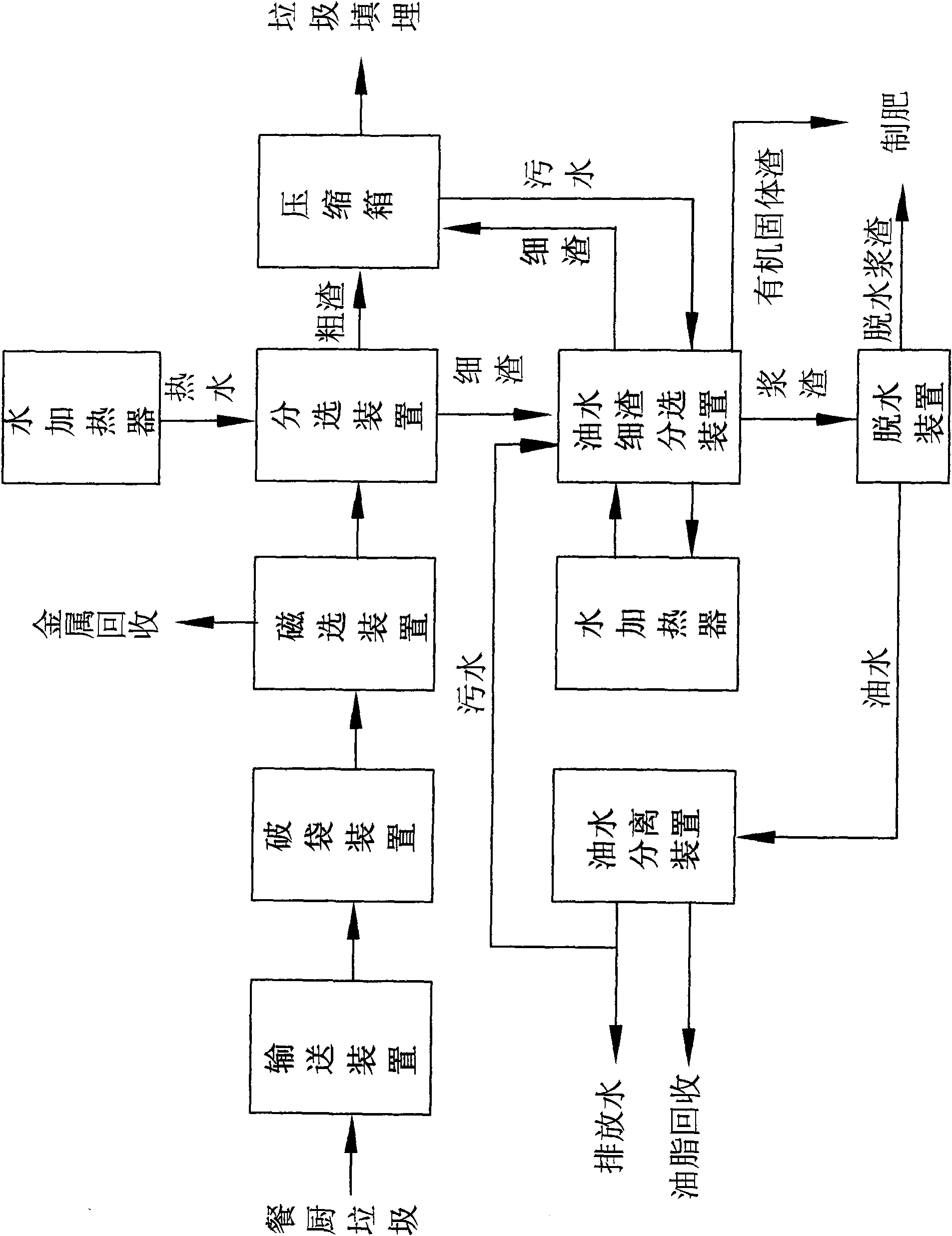

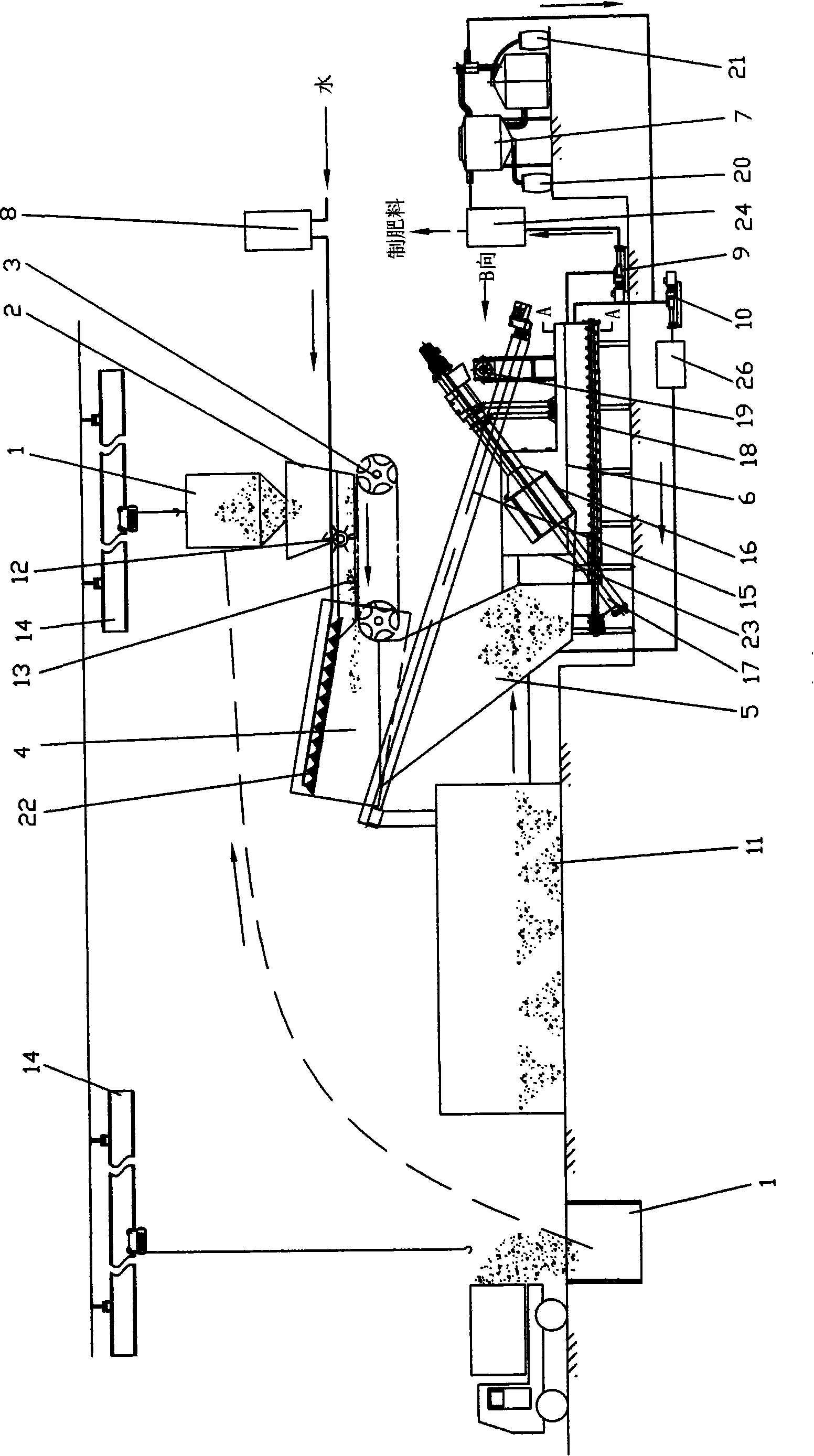

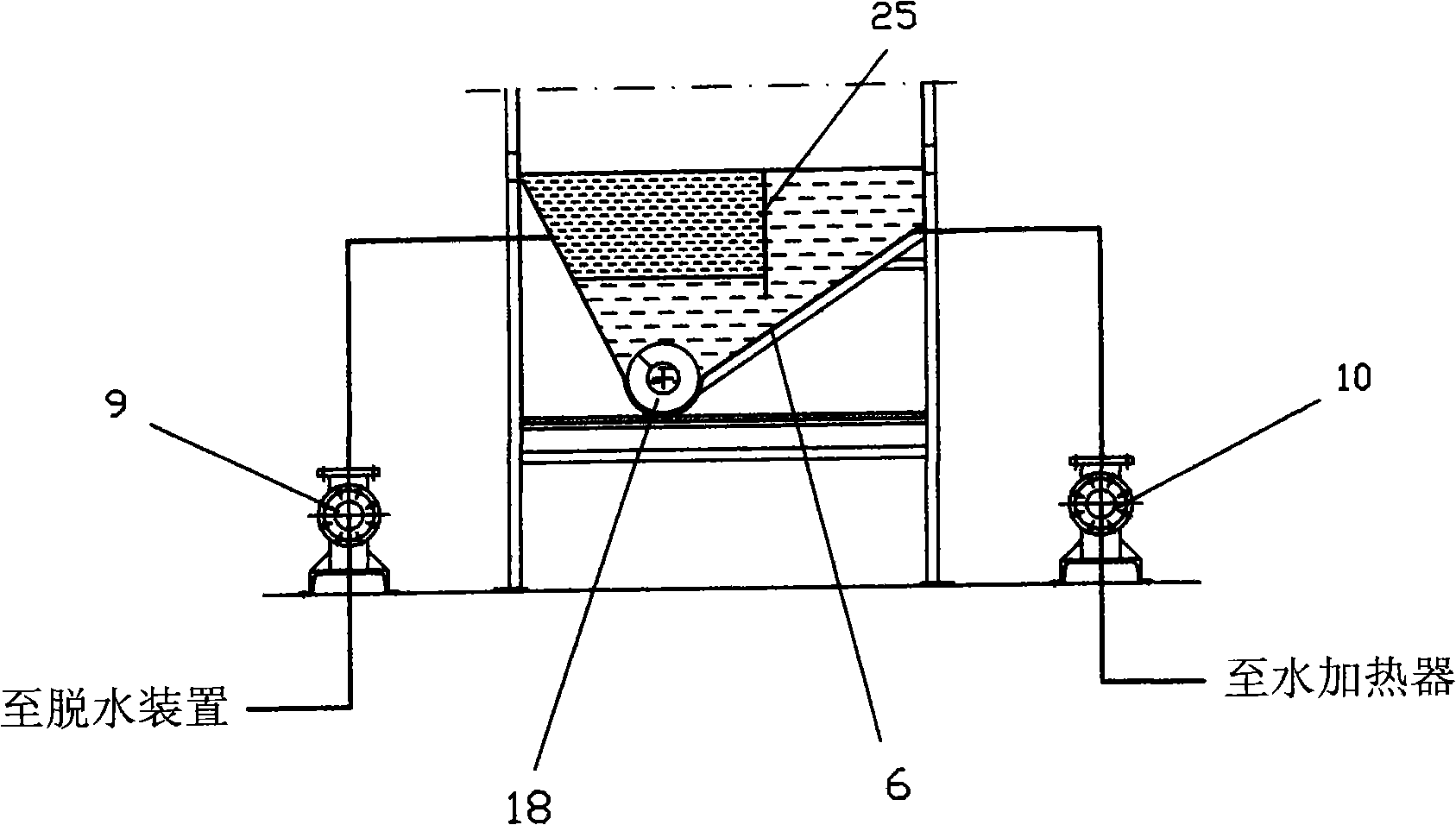

Treating technical method for food wastes and treating equipment

InactiveCN101524700AHarmlessReduce consumptionSolid waste disposalMagnetic separatorEnvironmental engineering

The invention discloses a treating technical method for food wastes and treating equipment, which relate to the technical field of screening and oil water separation in food waste treatment; the technique method comprises the following steps: the food waste is recycled by bag crushing, magnetic separation, coarse residue screening, hot water washing, solid-liquid separation of fine residue and secondary oil water separation with water in a separator of oil, water and fine residue. The treating equipment of food wastes for realizing the technique method mainly comprises a charging part, a conveying part, a bag-crushing device, a magnetic separator, a coarse residue separating part, a solid-liquid separator, a dehydrating unit, an oil water separator and the like. The invention can carry out grading screening, solid-liquid separation, oil water separation and resource recycling on food wastes, has continuous operation in use, thorough treatment and high efficiency and can protect environment.

Owner:BEIJING CENTURY GREEN ENVIRONMENTAL ENG &TECH +1

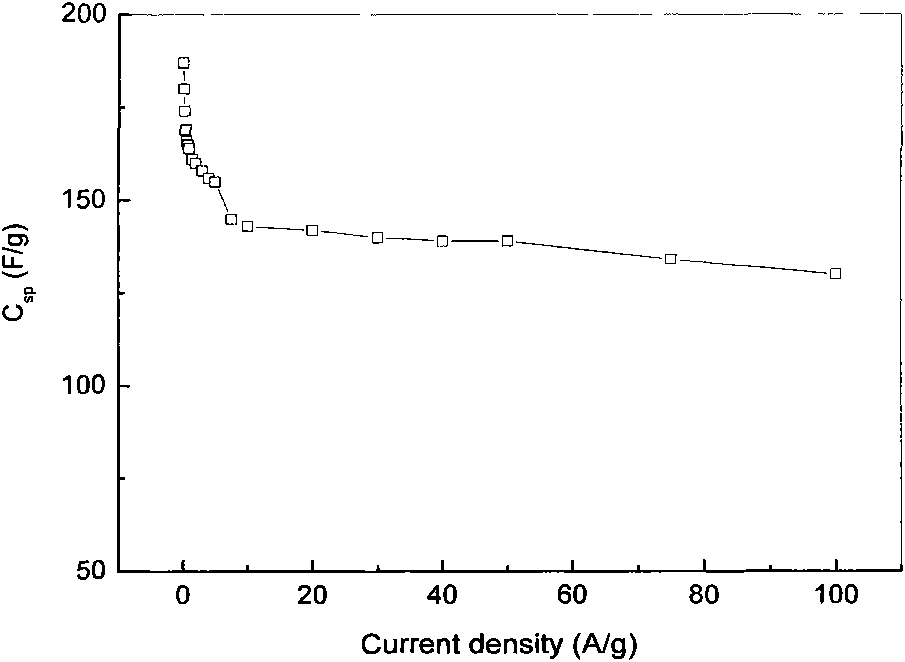

Ozone catalyst and preparation method

InactiveCN104646020ASolve the defect that it is difficult to access the active site of its poreHigh activityMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationDissolutionSodium hydroxide

The invention discloses an ozone catalyst and a preparation method. The catalyst comprises the following components by weight: 70 to 80% of a modified active carbon carrier and active components, namely, 10 to 20% of Fe2O3 and 10 to 20% of MnO2. The modified active carbon carrier is prepared by cleaning active carbon with a sodium hydroxide solution, then dipping the cleaned active carbon with dilute nitric acid, cleaning the dipped active carbon with deionized water and carrying out drying. The preparation method comprises the following steps: loading the active components on the modified active carbon carrier according to the above-mentioned amounts; and carrying out drying and roasting so as to prepare the ozone catalyst. The catalyst provided by the invention has good stability, overcomes the problems of dissolution and loss of metal oxide active components and exerts good effect on COD removal, decolorization, deodorization, degradation of toxic pollutants and improvement of biodegradability of wastewater.

Owner:北京天灏柯润环境科技有限公司

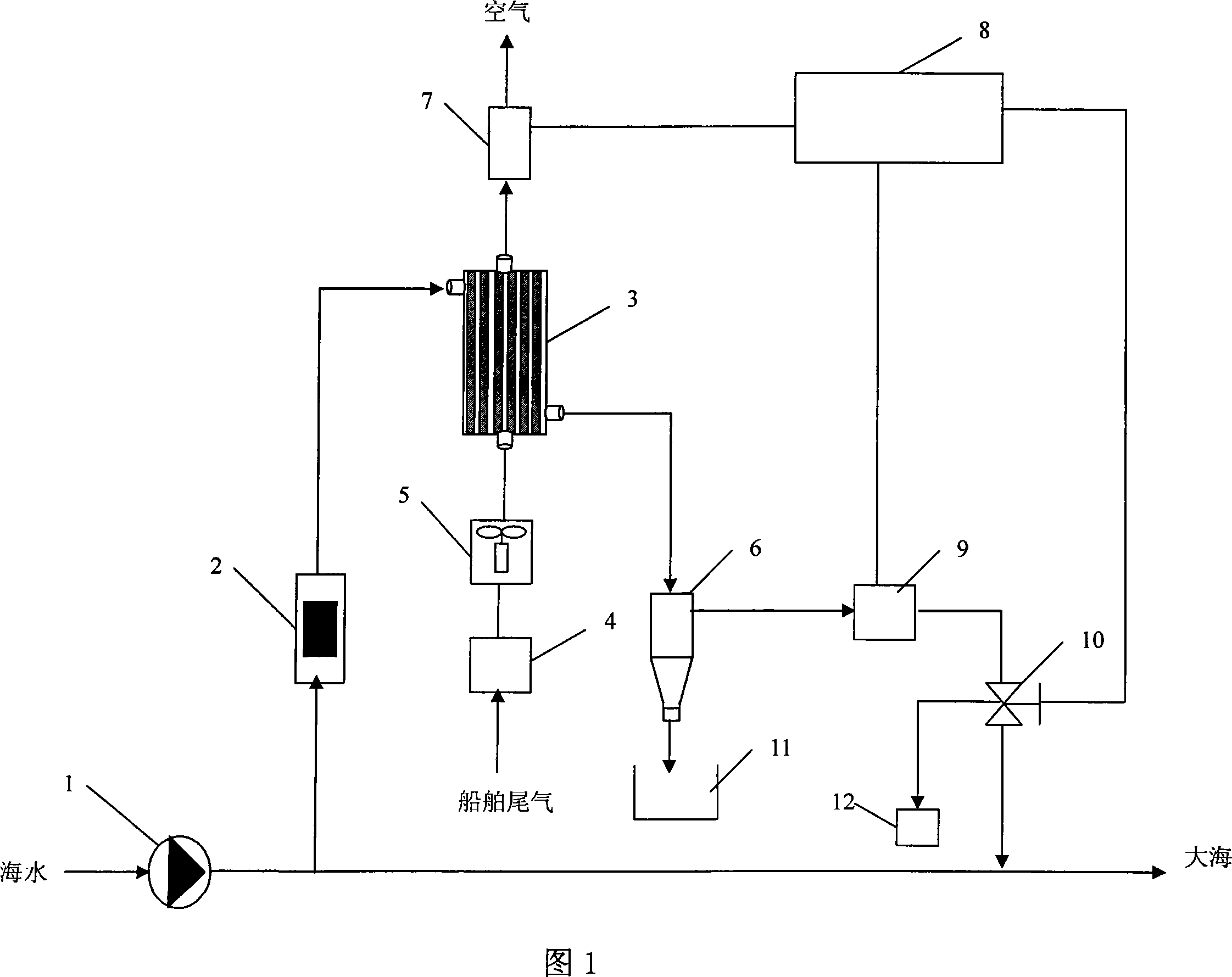

Device and method for treating ship tail gas with sea water washing

InactiveCN101104130AEfficient removalEasy to checkDispersed particle separationWater dischargeWater quality

The invention is a device and the method conducting seawater washing treatment to the ship exhaust gas which belongs to the ship exhaust gas treatment technical field. The ship exhaust gas after the dust-removing pretreatment is treated by seawater washing in a hollow fiber membrane contactor which serves as a syringe, a control system comprising an SO2 density monitor, a water quality monitor and a PLC programmable controller conducts real-time detection and storage to the SO2 density and waste water quality in the ship exhaust gas after treatment, as well as the control to the water discharging. The invention has beneficial effects that: water requirement is little by adopting the hollow fiber membrane contactor as the syringe, and the oxysulfide and particle substances in the ship exhaust gas can be effectively eliminated; and real-time monitoring, collection and storage of treatment effects of the ship exhaust gas and the seawater by adopting the PLC programmable controller facilitate the inspections of port states.

Owner:DALIAN MARITIME UNIVERSITY

Method for extracting and separating 1-deoxynojirimycin with high purity from natural products

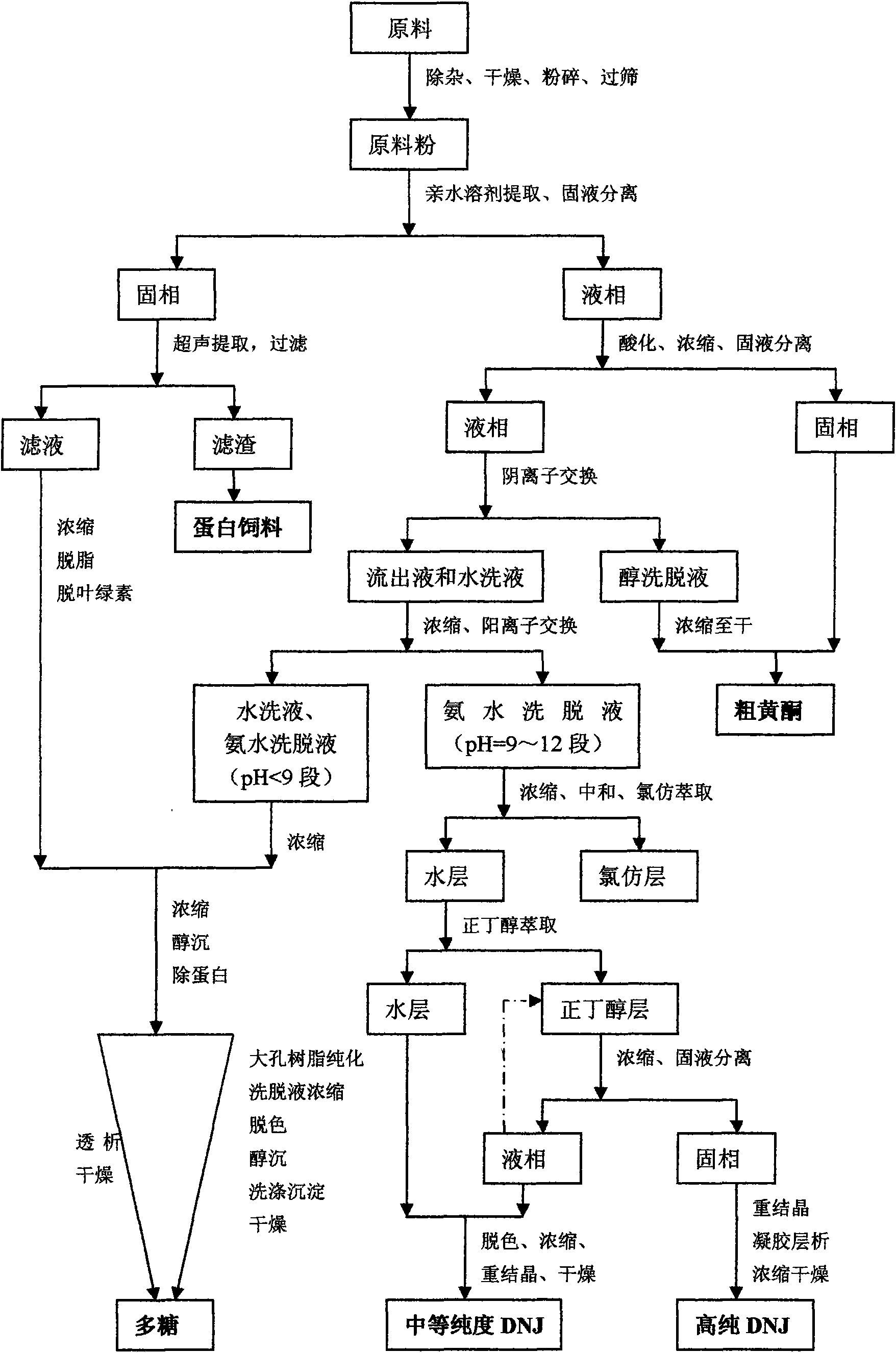

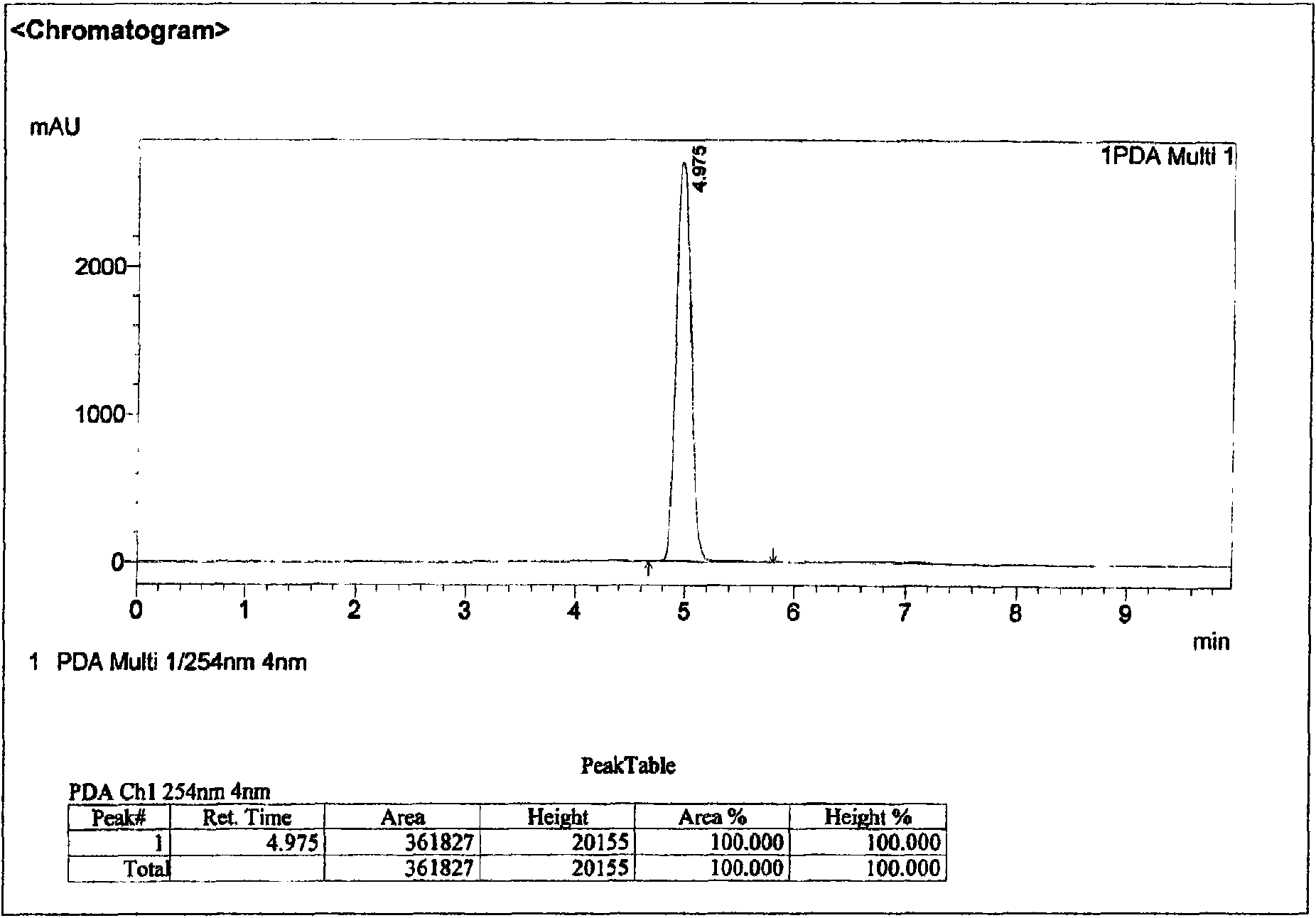

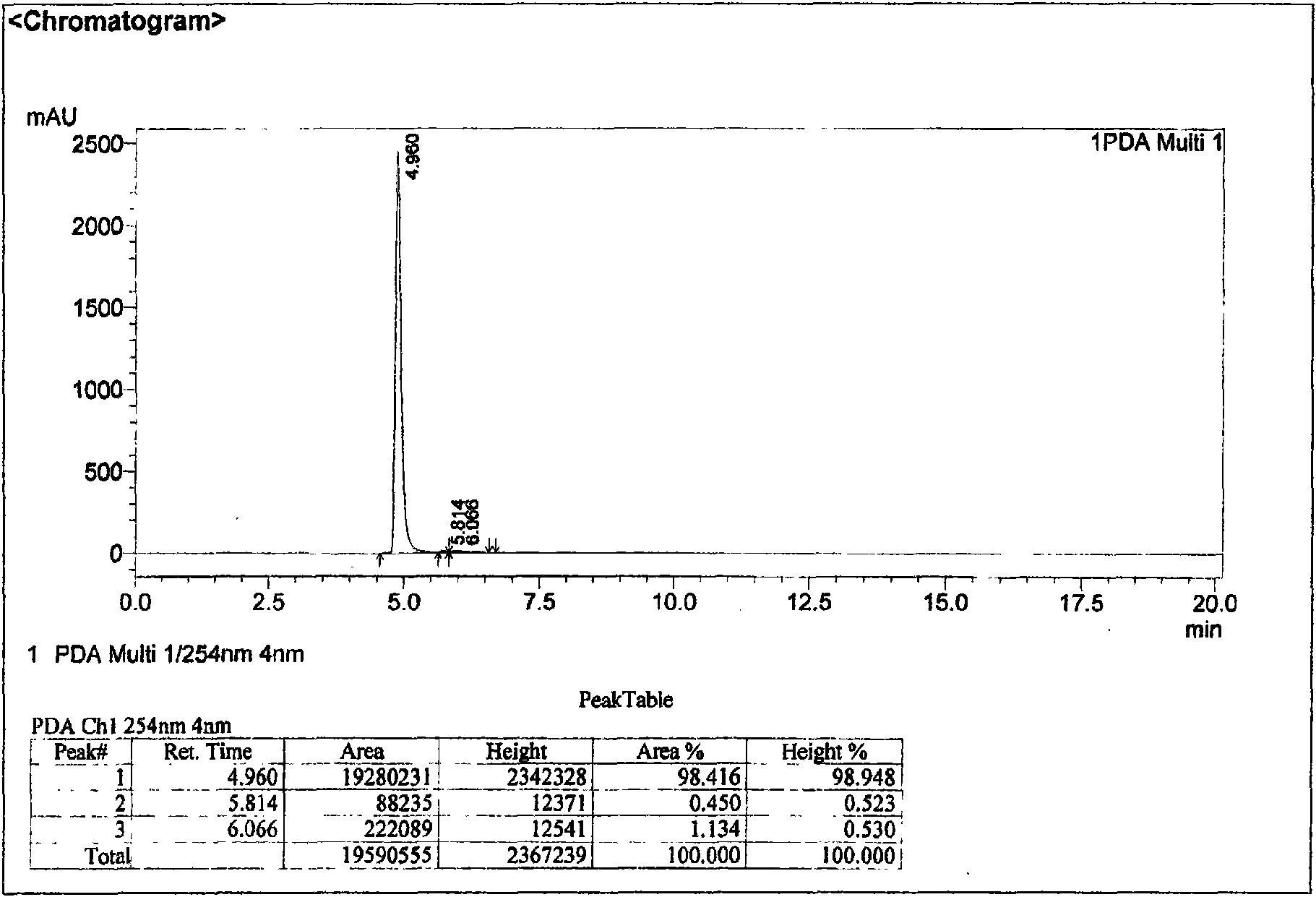

InactiveCN101654428AConducive to in-depth development and utilizationLow costOrganic chemistryAnimal feeding stuffSolventIon-exchange resin

The invention relates to the field of the traditional Chinese medicine, in particular to a method for extracting and separating 1-deoxynojirimycin (DNJ) with the purity higher than 98% from natural products comprising mulberry leaves, mulberry twigs, white mulberry root-bark, mulberry fruit and silkworm litter and also preparing a 1-deoxynojirimycin crude product (with the purity more than 35%), protein feeds, crude flavone and refined polysaccharide (with the purity more than 90%). The method mainly comprises the following steps: extracting a raw material of dry powder by a hydrophilic solvent, soaking by anion exchange resin after acidizing and concentrating extracting liquid, carrying out chromatography by a cation exchange column after concentrating effluent liquid and water washing liquid, extracting by an organic solvent, recrystallizing, carrying out chromatography by a gel column and purifying. The content of the 1-deoxynojirimycin in the obtained product is not less than 98%,and the concrete execution already enters intermediate test.

Owner:CHENGDU GOLD DOCTOR TECH HEALTH IND +2

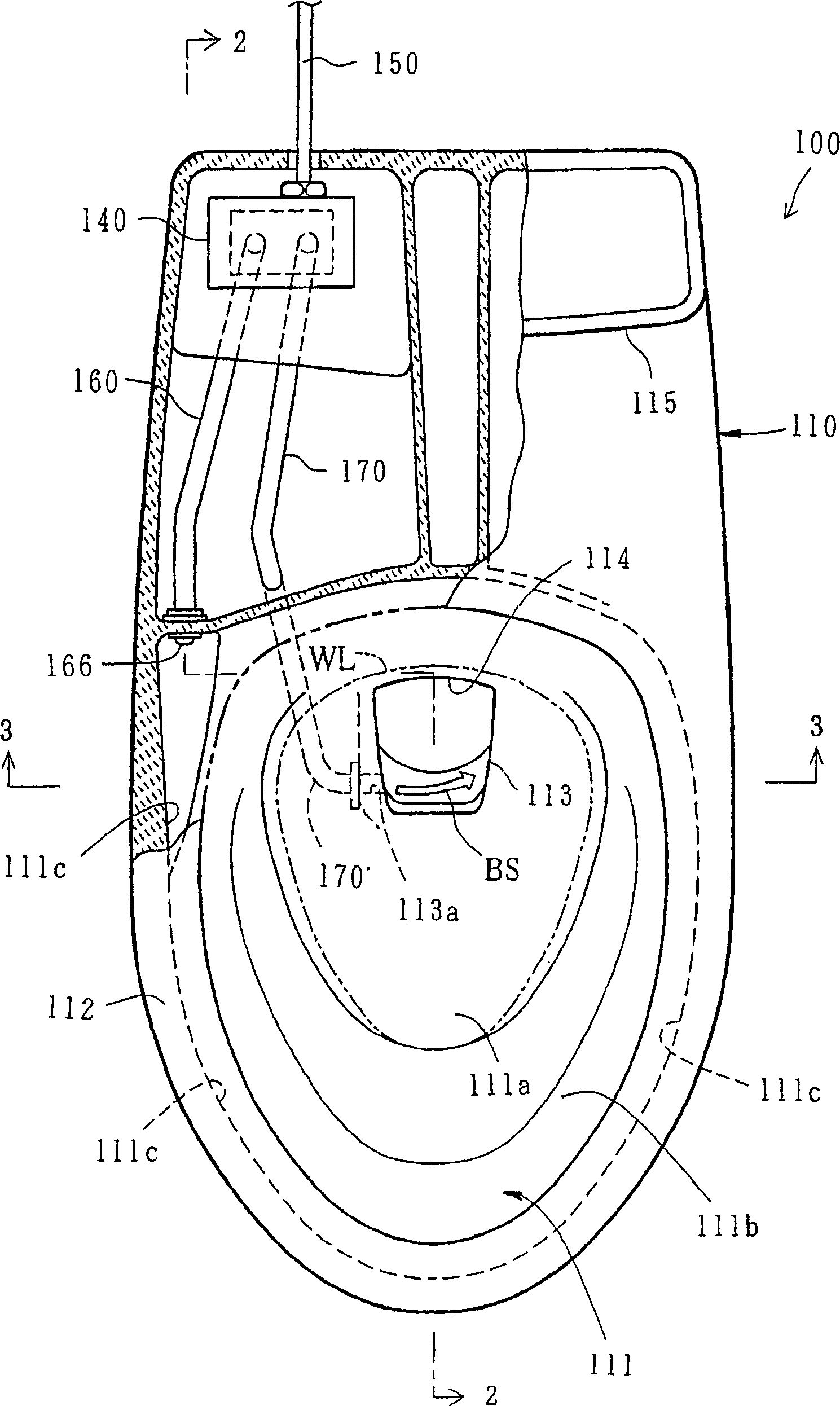

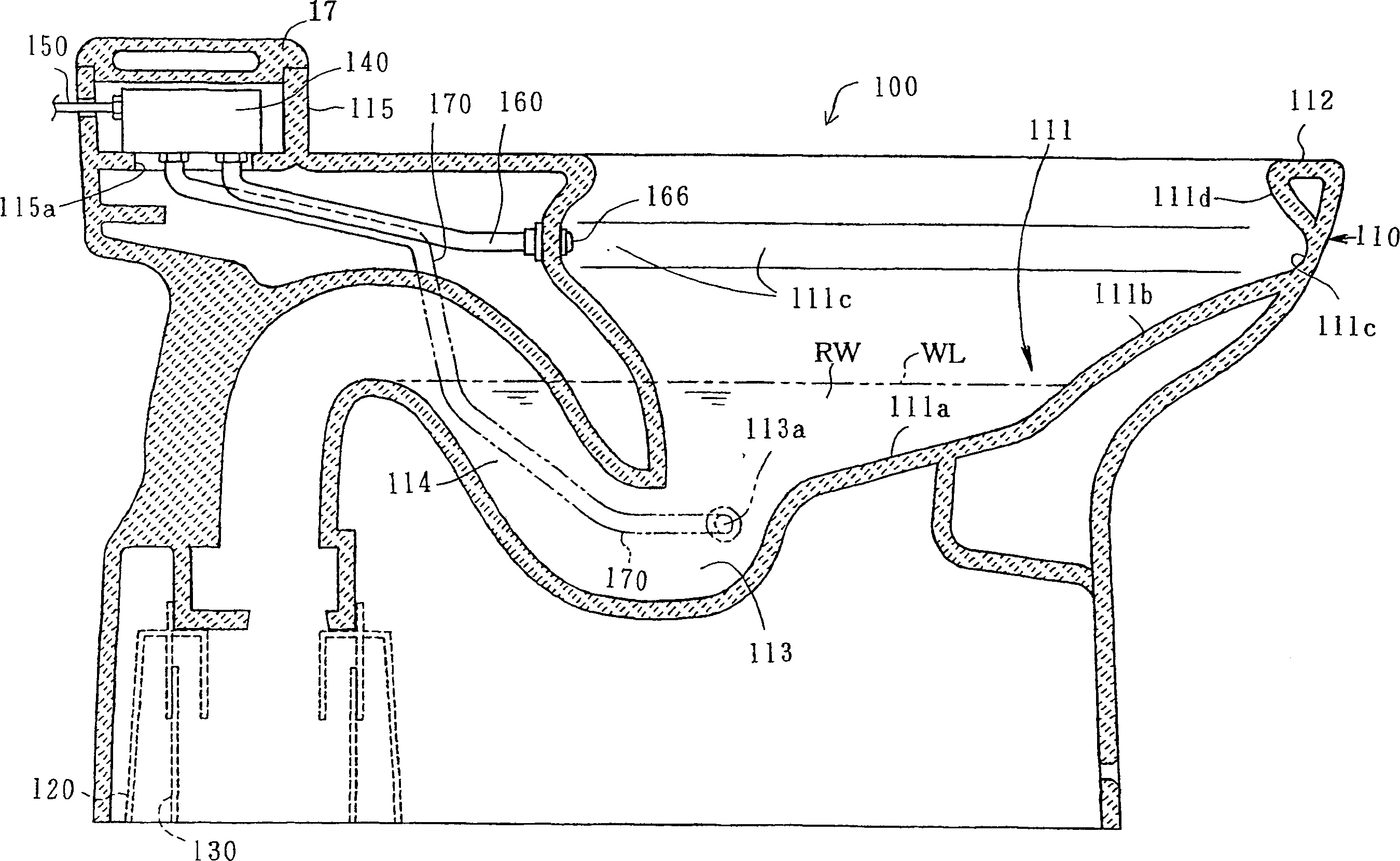

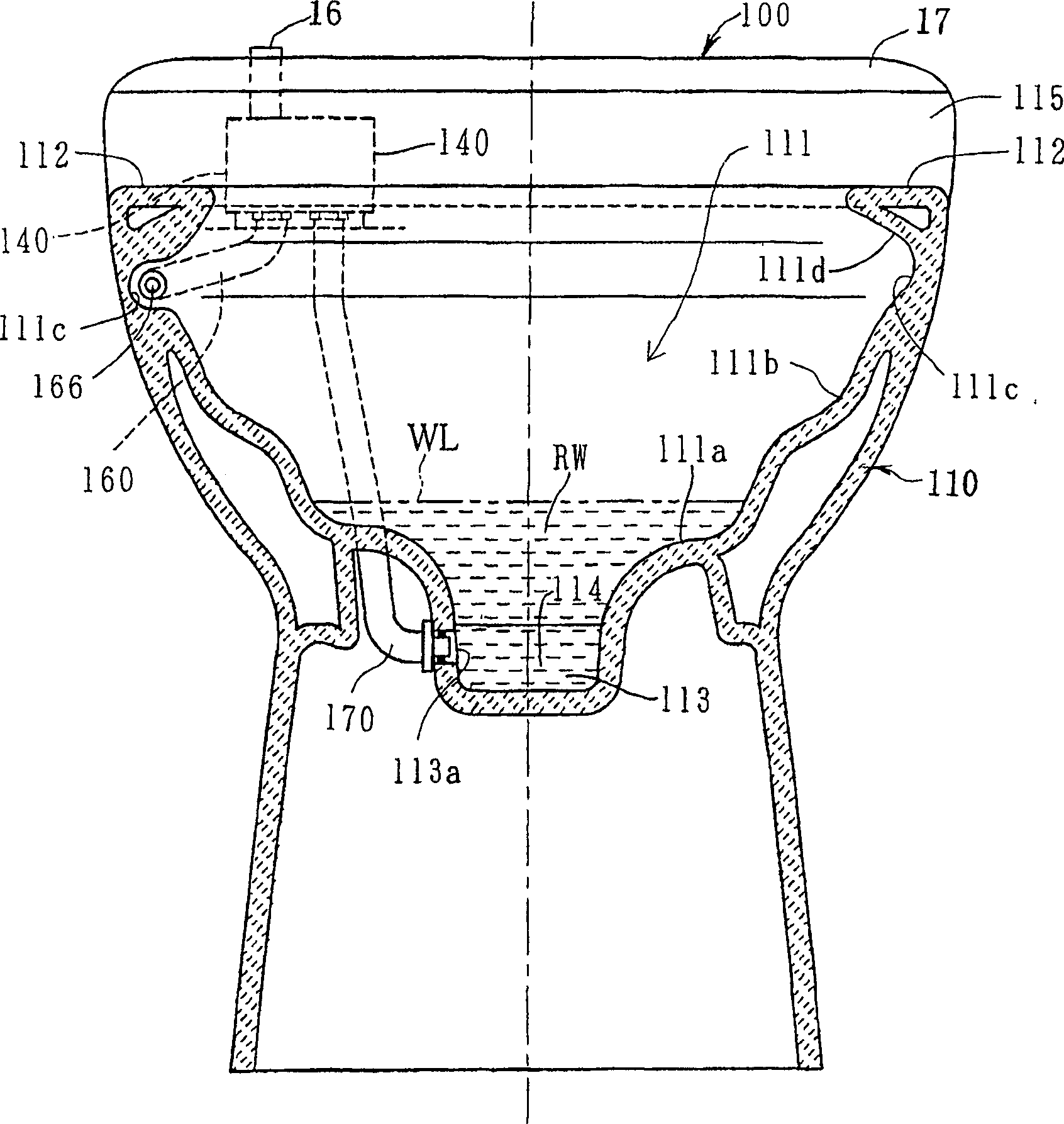

Water closet

A flush toilet comprises a toilet body having a bowl for storing wash water as water seal, first means for supplying the toilet body with pressurized wash water and second means for discharging the wash water substantially horizontally along the upper peripheral portion of the inner surface of the bowl to swirl it along the inner surface of the bowl.

Owner:TOTO LTD

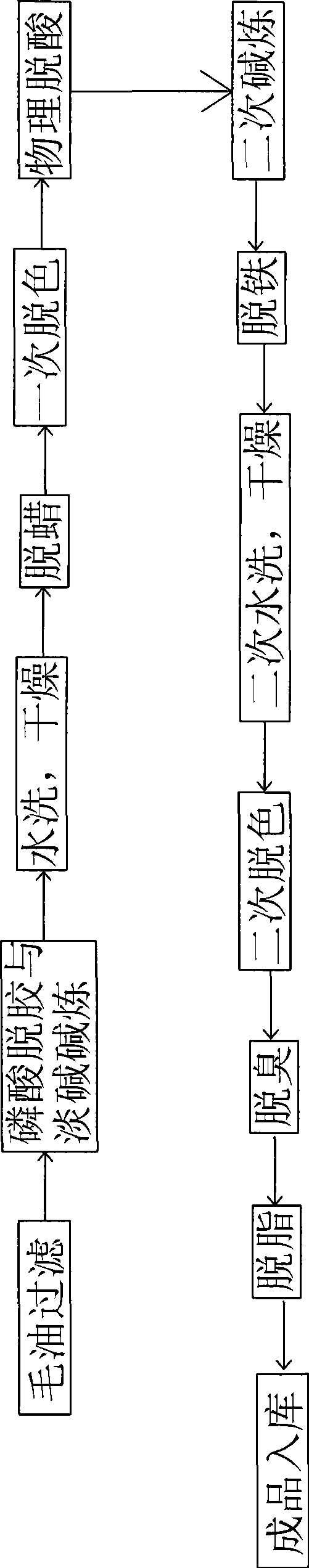

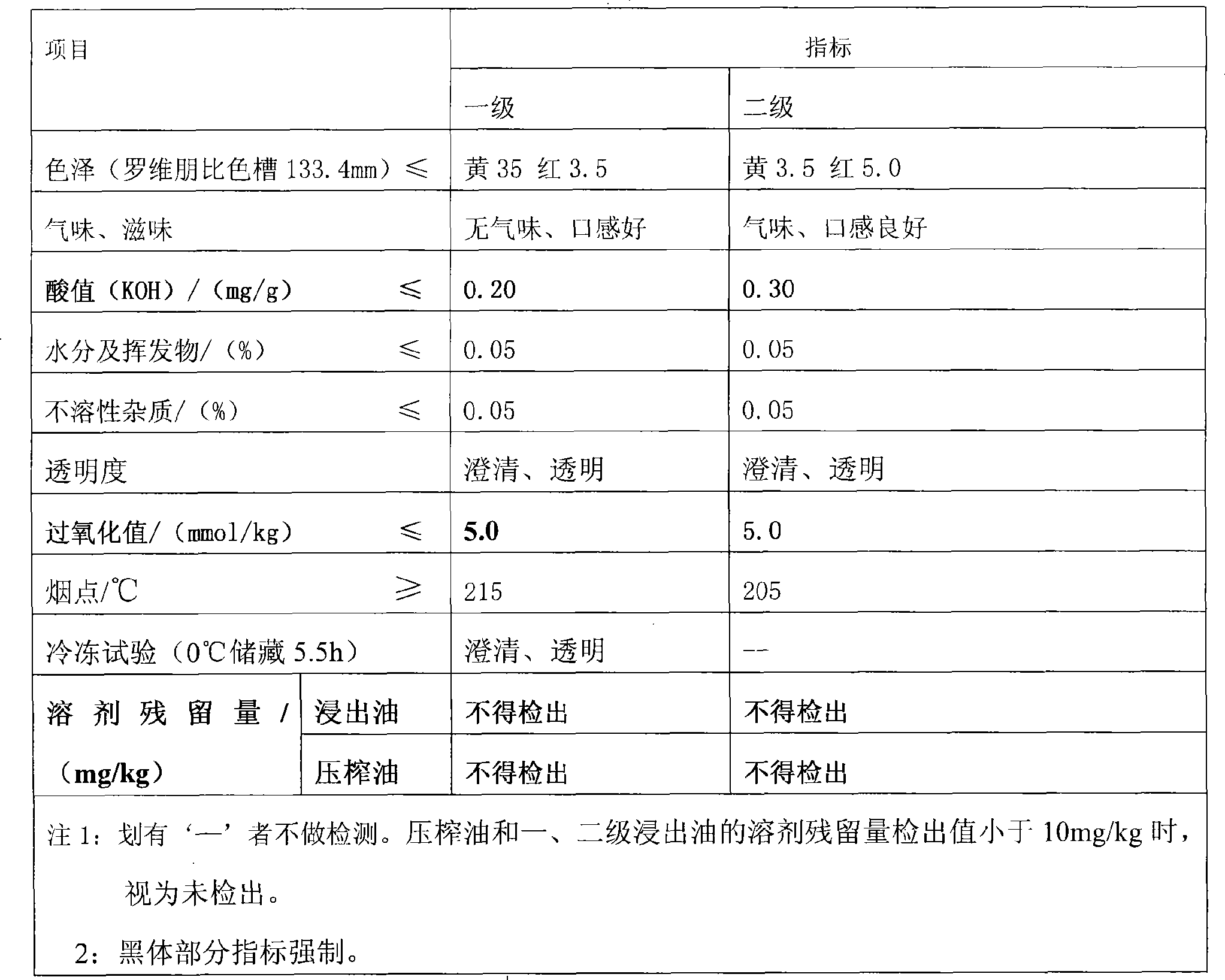

Rice bran first-level oil refinement production method

ActiveCN101455242ARealize large-scale productionReduce pollutionEdible oils/fatsFood preparationSocial benefitsO-Phosphoric Acid

The present invention relates to a manufacturing method of refining rice bran top oil, which can effectively refining top oil from the rice bran and satisfy the people requirement to the health dieting. The invention includes the following steps: (1) crude oil filtering; (2) phosphoric acid degumming and light alkali alkali refining; (3) washing, drying; (4) dewaxing; (5) a primary decolorizing; (6) physical deacidification; (7) secondary alkali refining; (8) iron removing; (9) washing; (10) drying; (11) secondary decolorizing; (12) deodorization; (13) degreasing. The invention adopts a mode of combining the physical refining and chemical refining to realize a large-scale production of the rice bran top oil, provides a favorable technique to the rice bran deep-processing, improves the extraction rate from traditionally 55-60% to 75-80%, saves materials and reduces environmental pollution, has huge economic and social benefits. The invention is a major innovation to the edible rice bran oil production.

Owner:河南华泰粮油机械股份有限公司

Fabric pre-treating method for digital ink-jet printing of dispersed dye

The invention relates to a fabric pre-treating method for digital ink-jet printing of a dispersed dye, which comprises the following steps of: (1) uniformly mixing 1 to 5 percent of water-soluble organic polymer, 2 to 3 percent of porous inorganic nano particle, 0.1 to 2 percent of surfactant and water to form a pre-treating agent; and (2) dipping, padding and coating a fabric dyed by a dispersed dye or sparing the pre-treating agent on the fabric dyed by the dispersed dye, wherein the fabric carrying liquid rate is 50 to 90 percent, drying the fabric, and heating the fabric at 180 to 220 DEG C for 0.5 to 20 minutes. The method of the invention is simple, low in cost and suitable for industrial production; the direct ink-jet printing of the fabric with the pre-treating agent has the advantages of uniform color, inhibited penetration phenomenon, high printing precision, sharp boundaries of patterns, clear detail and bright color; and the fabric offers a soft hand feel and has very good washing, friction and color fastness to light.

Owner:DONGHUA UNIV +1

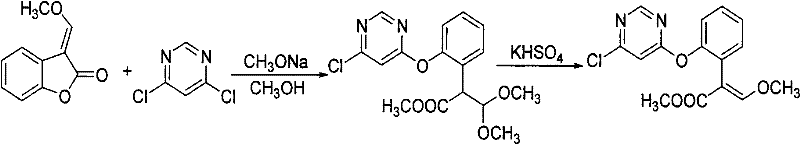

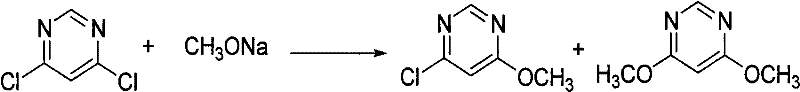

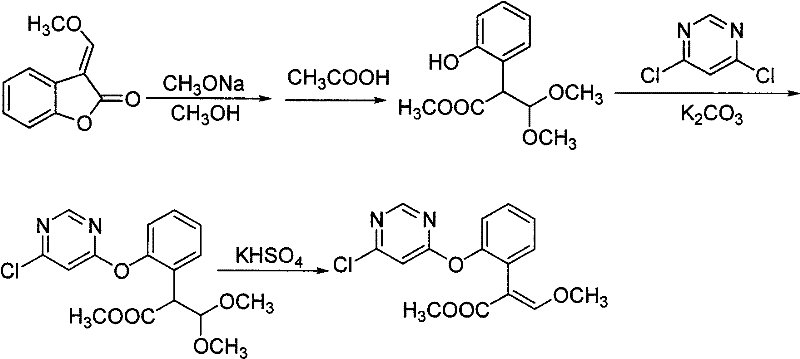

Synthetic method of azoxystrobin and special intermediate for synthesis

The invention relates to a synthetic process of a chemical substance, and particularly relates to a synthetic method for synthesizing (E)-2-[2-(6-chloro pyrimidine-4-yloxy)phenyl]-3-methoxy methacrylate and azoxystrobin; the method comprises the following steps: mixing a raw material of 3-(alpha-methoxy)methylene benzofuran-2-(3H)-ketone and potassium carbonate in a toluene solvent, cooling to 0-10 DEG C, adding sodium methoxide, reacting for 0.4-0.6 hours; adding 4,6-dichloropyrimidine and a catalyst of DABCO, reacting for 1-2 hours, filtering to remove inorganic salts, washing the filtrate with water, performing distillation to recover toluene; adding a catalyst of potassium bisulfate into the distillation residues of the above reaction, heating to 132-145 DEG C in a reduced-pressure condition for reaction; directly adding salicylonitrile to synthesize azoxystrobin or performing toluene dissolution, water washing, solvent recovery, recrystallization and filtration to obtain an intermediate. The production and synthesis of (E)-2-[2-(6-chloro pyrimidine-4-yloxy)phenyl]-3-methoxy methacrylate by the production process of the invention has high yield, and simple operations, and the used raw materials and processes are routine reagents and methods.

Owner:CHONGQING UNISPLENDOUR CHEM

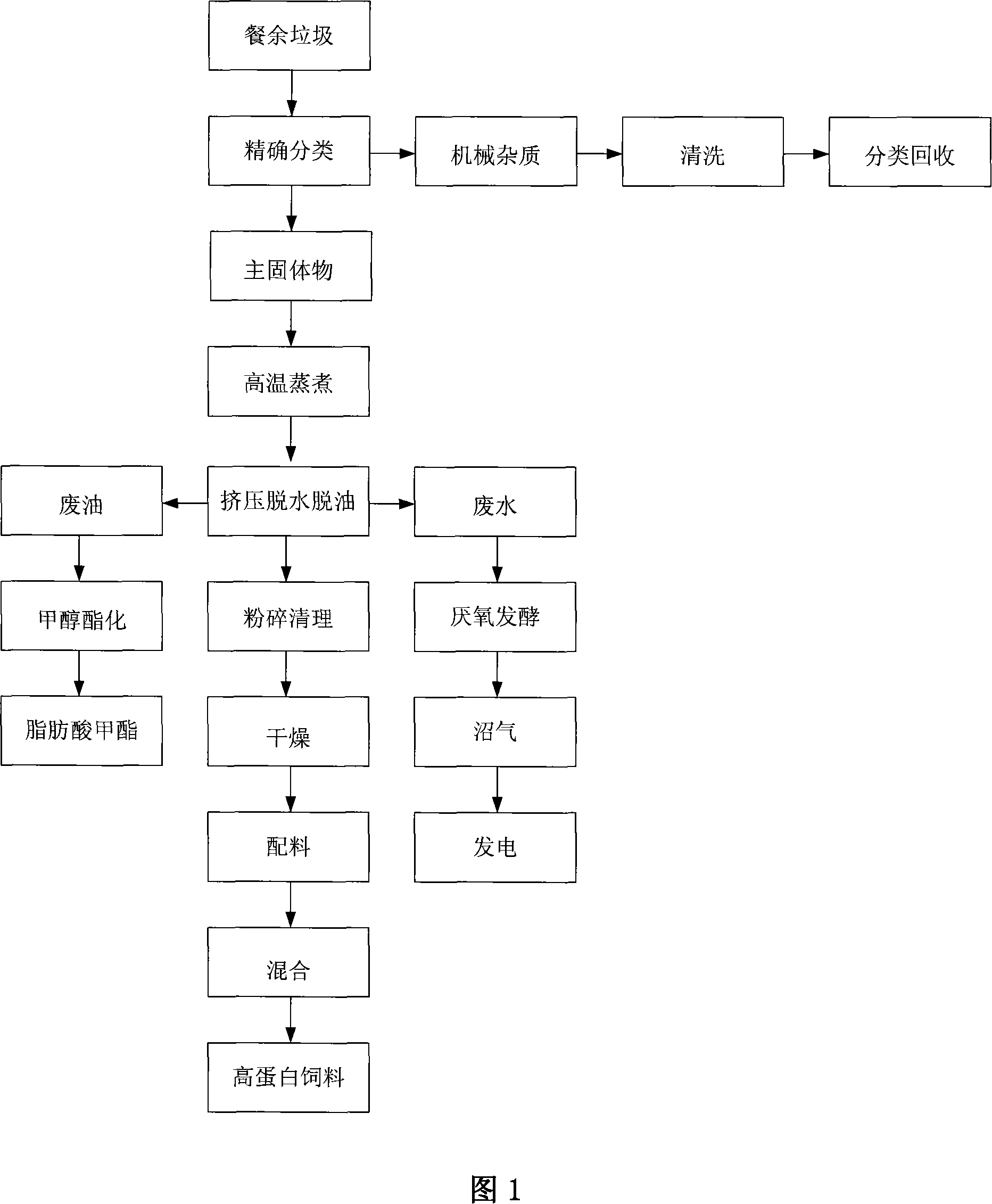

Method for comprehensive processing garbage of food and recycling to use

ActiveCN101130194AAccurate classificationRealize resource processingFood processingSolid waste disposalWaste oilFatty acid methyl ester

The invention discloses a synthetic processing recycling reusing method of residual dining rubbish, which comprises the following steps: cutting to remove package bag, waste table cloth and plastic bag; vibrating and sieving to pick chopstick; using magnet to attract bottle cap; washing the separated materials mechanically; collecting splitly; boiling main solid material under 130-150 deg. c for 30-60 min; squeezing the boiled material to separate solid from liquid; proceeding oil-water separation for the squeezed water and oil through centrifuging; doing anaerobic ferment for the waste water to produce methane; esterifying waste oil and carbinol to prepare fatty acid methyl ester. The invention eliminates secondary pollution during environmental protection and disposal, which is a reasonable, industrial, scaling, non-harmful, resourcing disposing pattern for the dining rubbish with good applying prospect.

Owner:鲁控环保(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com