Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

945 results about "Sandpaper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sandpaper and glasspaper are names used for a type of coated abrasive that consists of sheets of paper or cloth with abrasive material glued to one face. Despite the use of the names neither sand nor glass are now used in the manufacture of these products as they have been replaced by other abrasives such as aluminium oxide or silicon carbide. Sandpaper is produced in a range of grit sizes and is used to remove material from surfaces, either to make them smoother (for example, in painting and wood finishing), to remove a layer of material (such as old paint), or sometimes to make the surface rougher (for example, as a preparation for gluing). It is common to use the name of the abrasive when describing the paper, e.g. "aluminium oxide paper", or "silicon carbide paper".

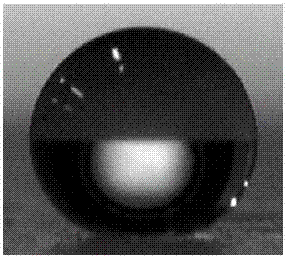

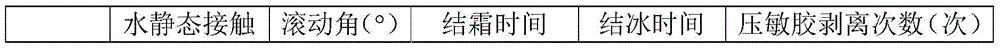

Processing method of aluminum and aluminum alloy super hydrophobic surface

InactiveCN101007304ASuperhydrophobicEasy to rollAntifouling/underwater paintsPretreated surfacesNickel saltCopper

The invention involves an aluminum or aluminum alloy super-hydrophobic surface preparation method. The method is: polishing the surface of aluminum or aluminum alloy using metallographic sandpaper or polishing paste, pure water washing, acetone ultrasonic cleaning, pure water washing and other clean treatment, handing it with chemical etching solution containing nitric acid and metal salts (copper or nickel salt) 30s-20min under 90 ~ 100 degree C, then coating low surface energy material on its surface to get super-hydrophobic property. The aluminum or aluminum alloy surface treated by the invention has excellent hydrophobicity, the contact angle of water and surface can be as high as 150-165 degree, droplets are easy to roll on the surface. The method of the invention need not complex equipment, cost is low, technology is simple and repeatability is good.

Owner:SOUTH CHINA UNIV OF TECH

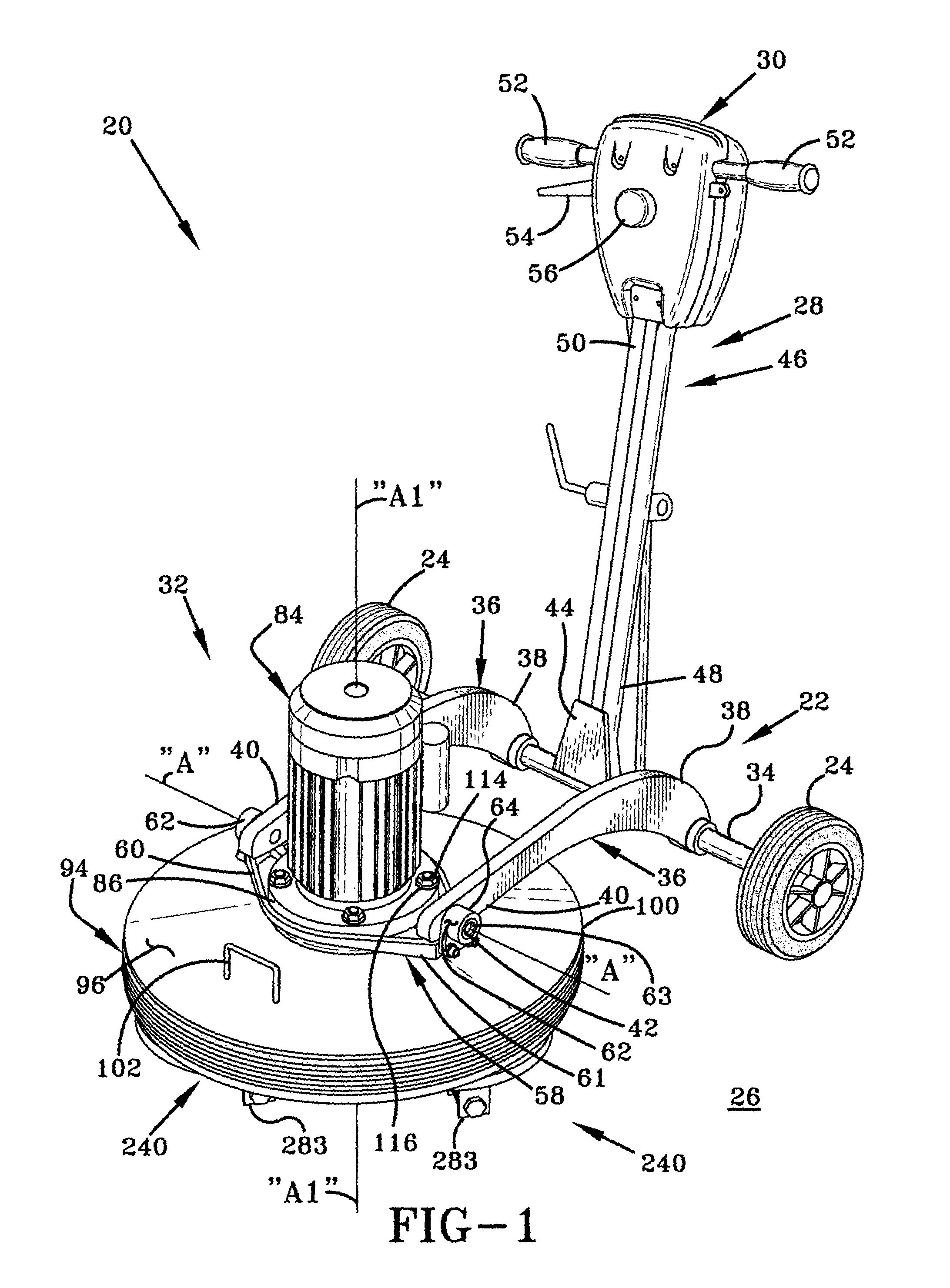

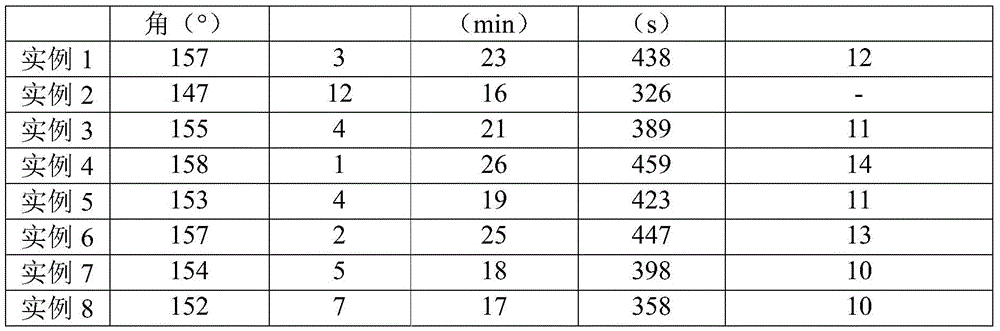

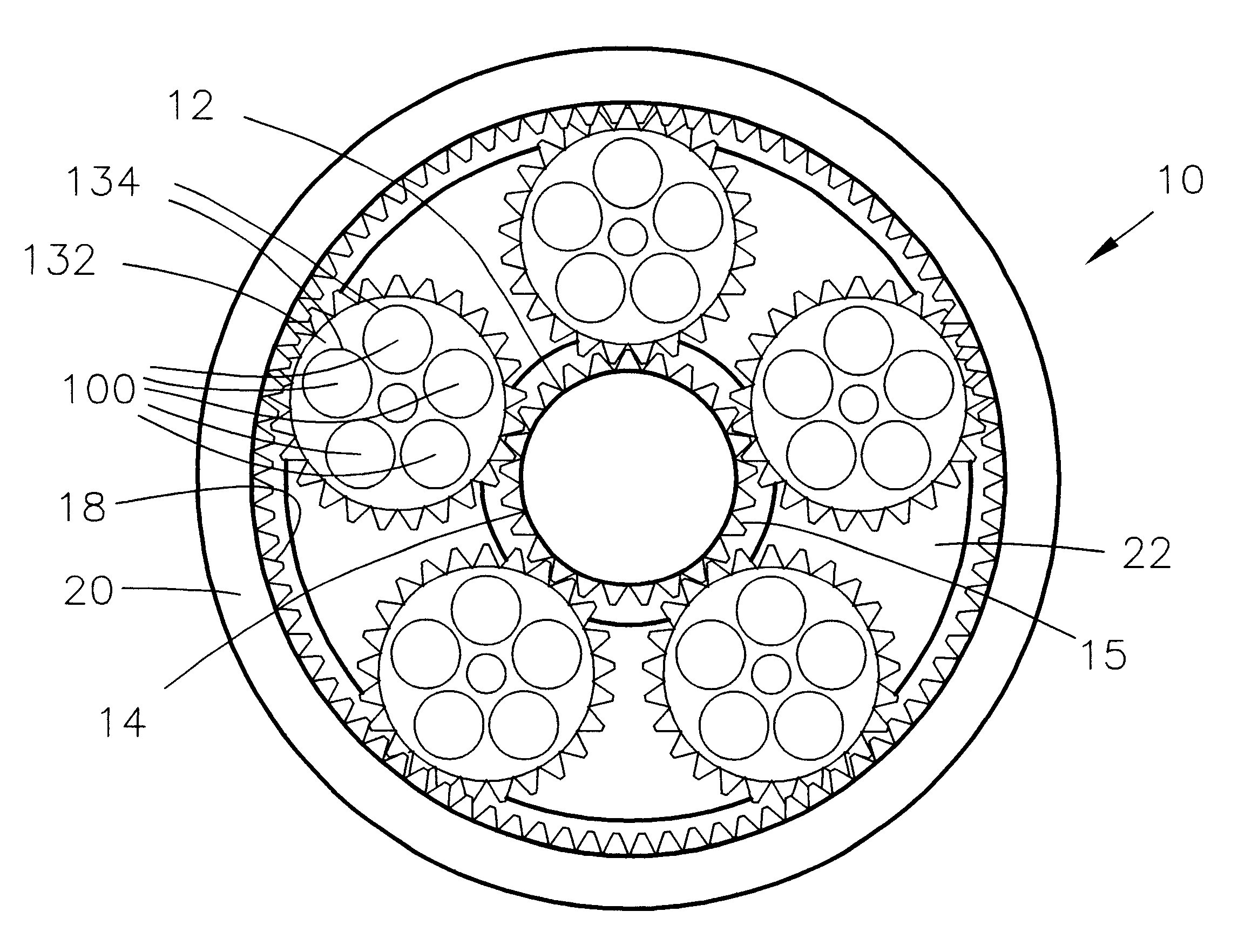

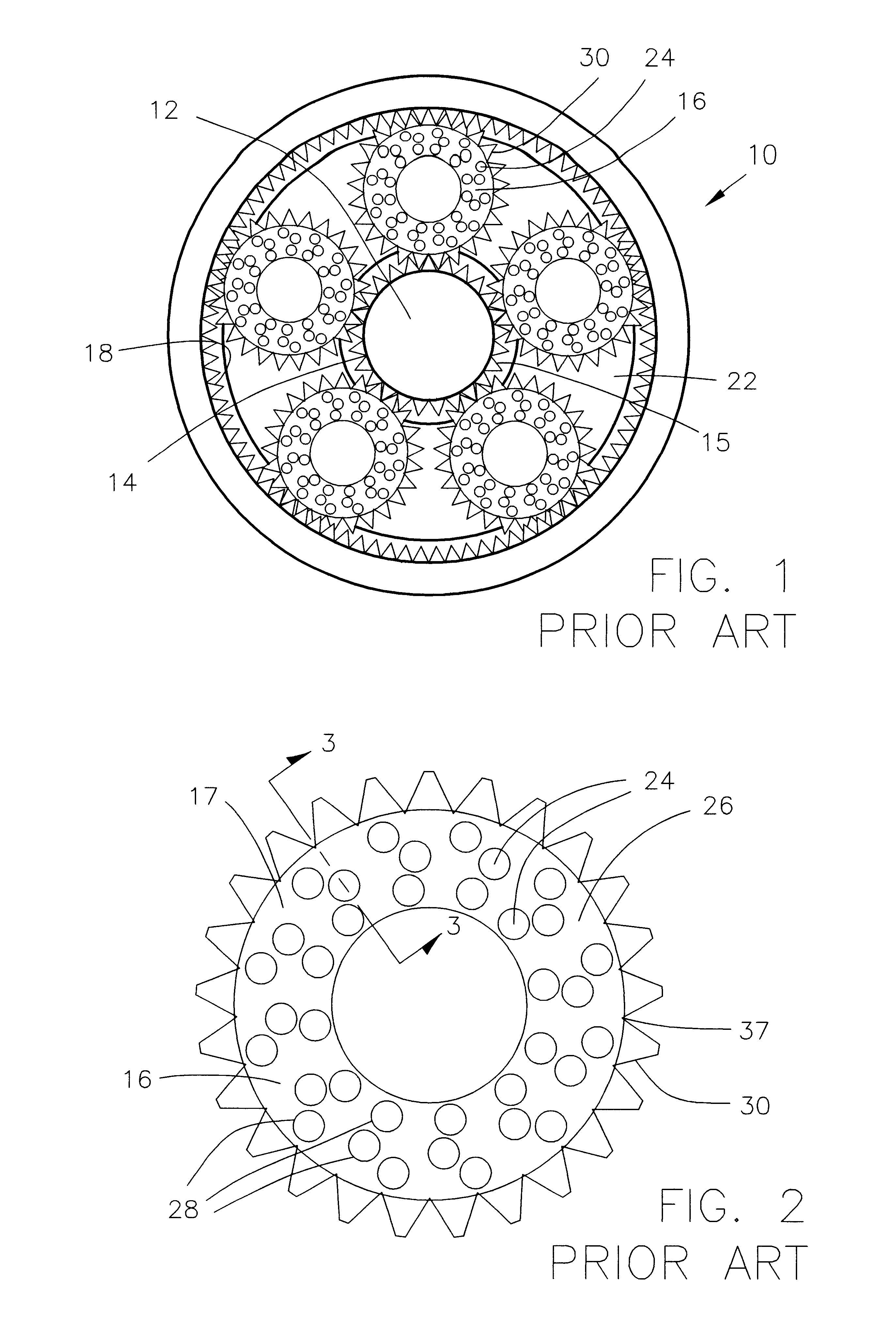

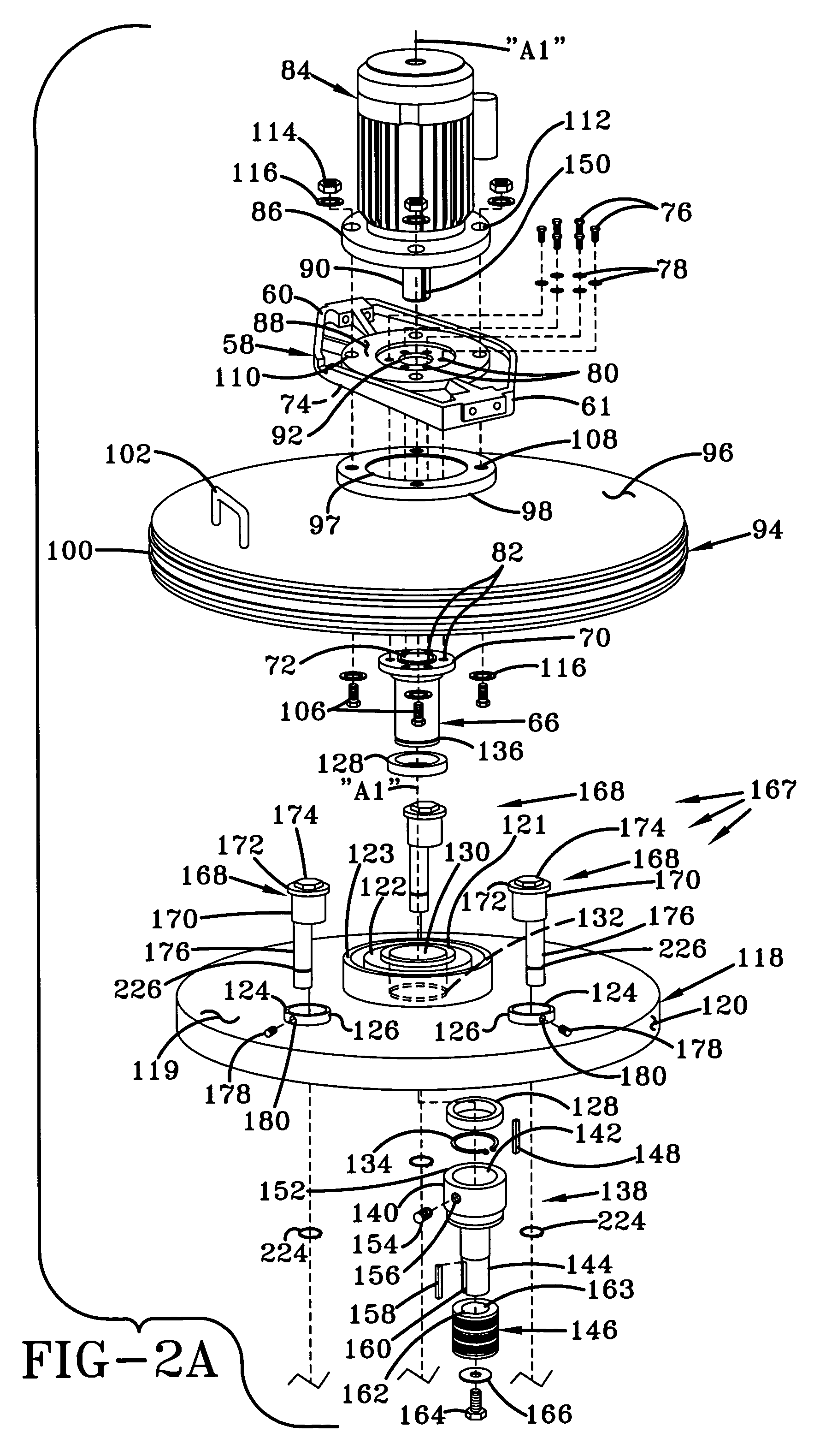

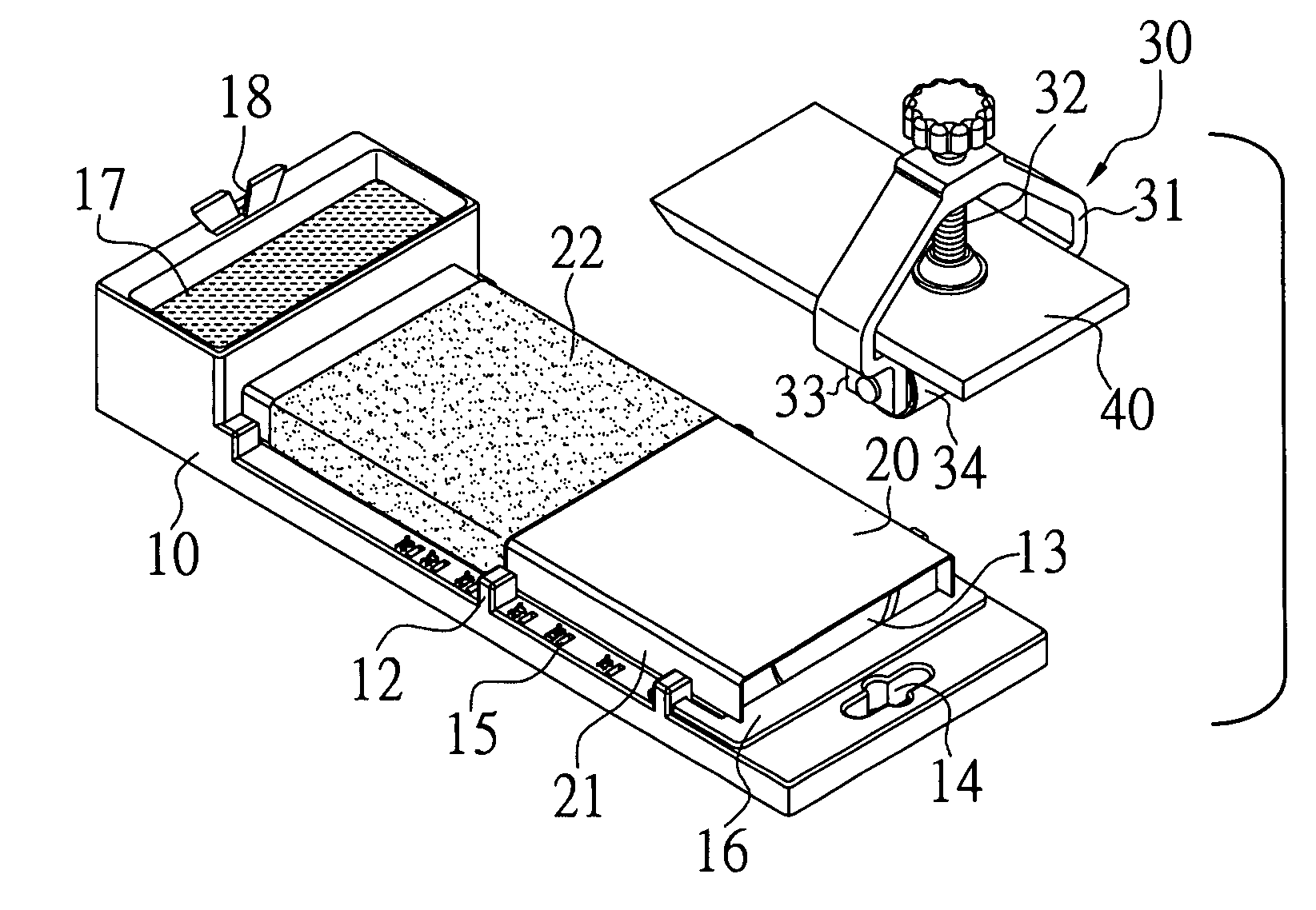

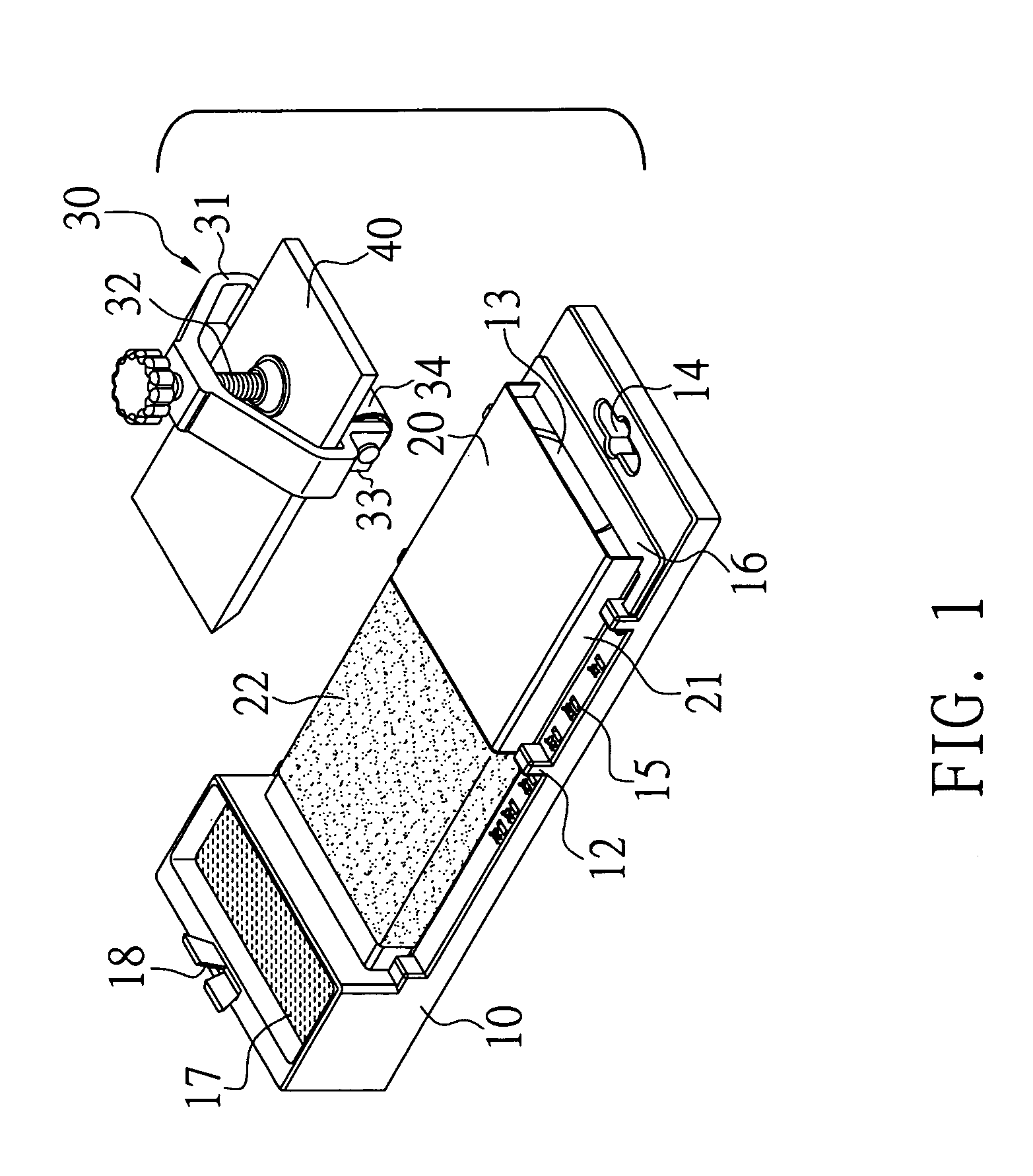

Floor resurfacing disks for rotary floor resurfacing machines

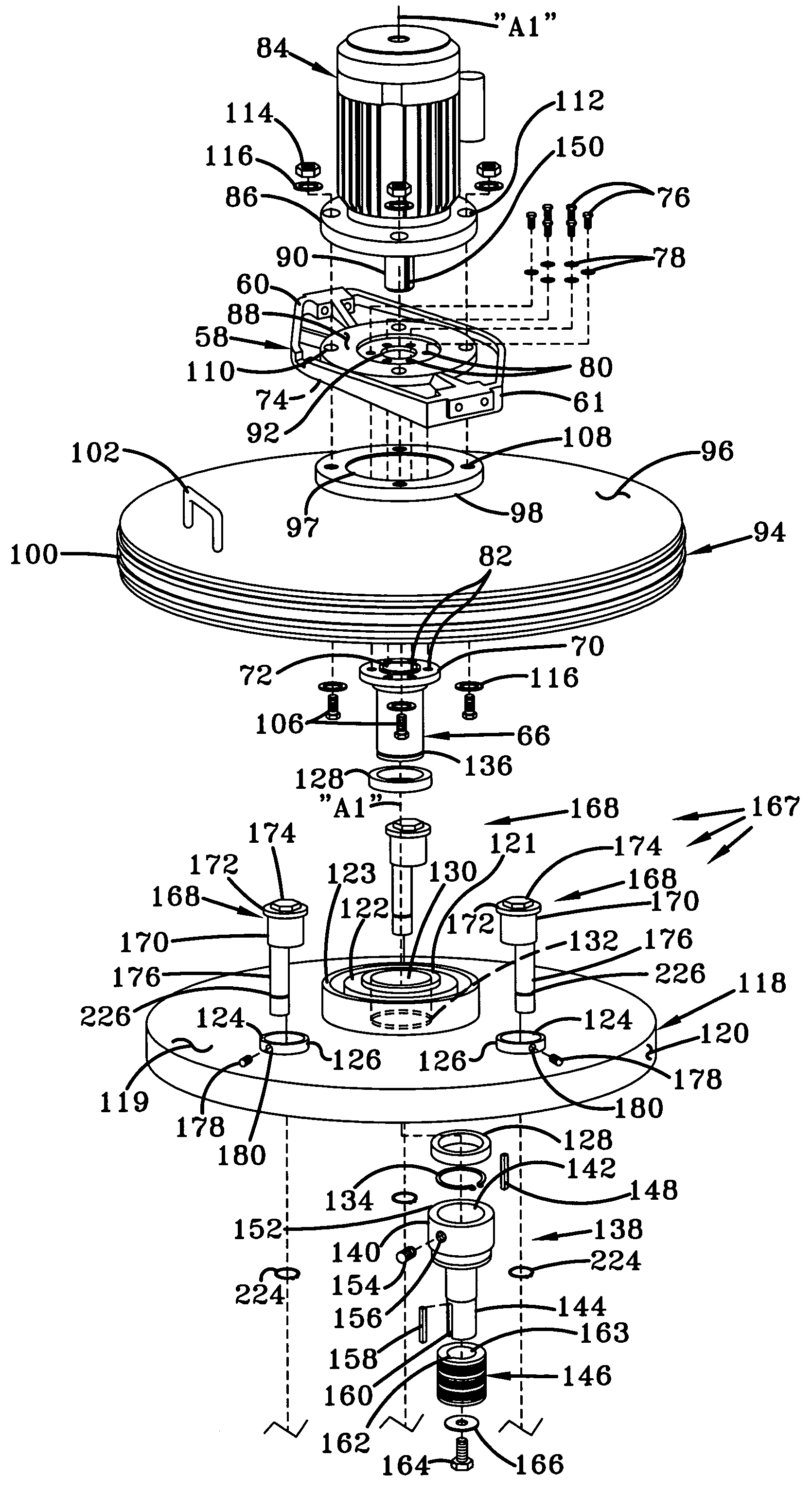

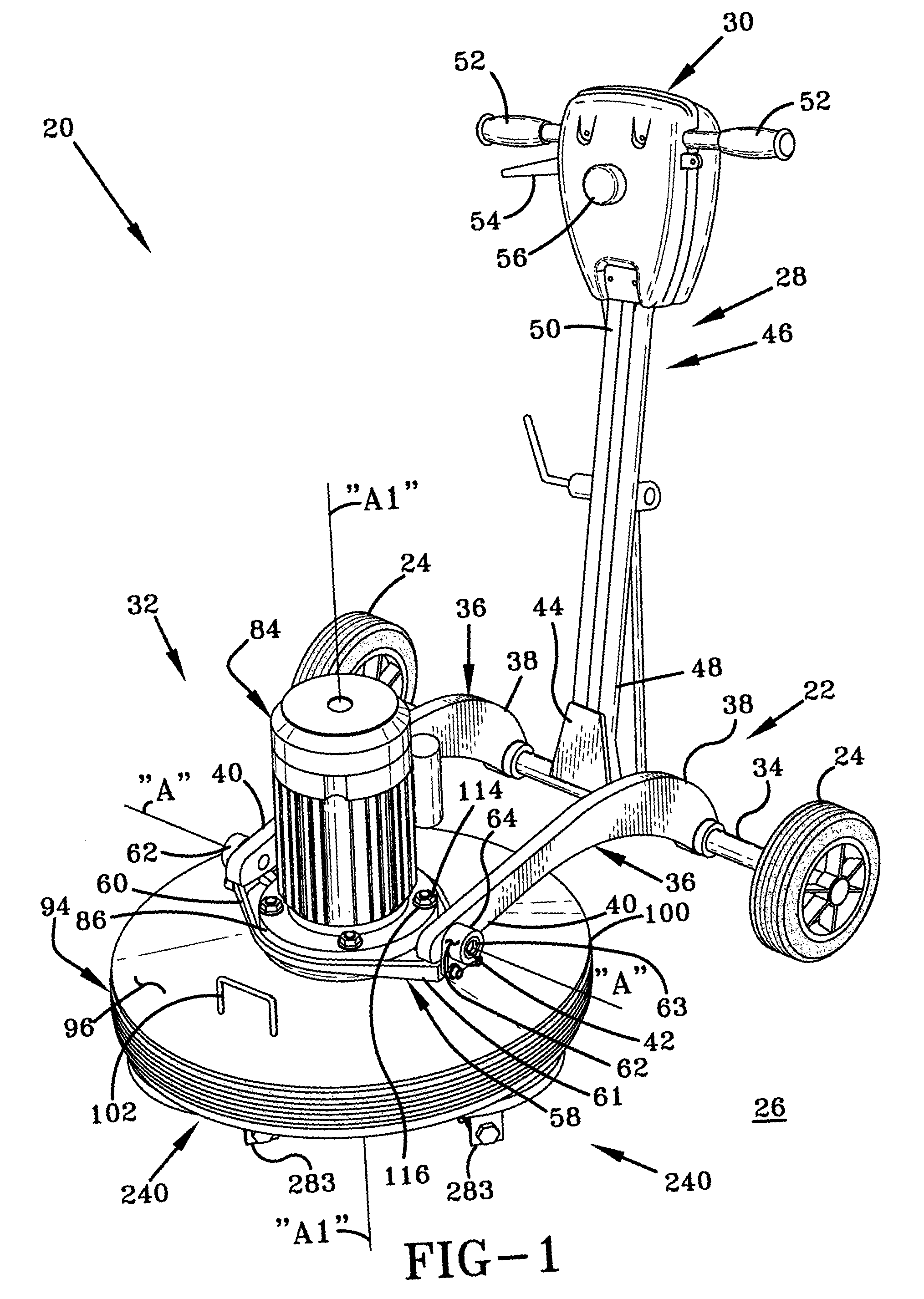

InactiveUS7033258B2Improve consistencyShorten the timePortable grinding machinesGrinding headsEngineeringGrommet

A resurfacing disk which mounts to a rotatable disk mount of a conventional rotary floor resurfacing machine. The resurfacing disk includes a rigid upper disk with four counterbored holes through an upper surface corresponding to four downwardly open holes of each disk mount. A resilient, flanged grommet is retained extending through corresponding holes of a retaining plate mounted to the upper surface. The grommets include respective vertically oriented longitudinal bores closely receive a mounting pin which extends from a corresponding hole of the disk mount. A plurality of rotary cutters each include a bracket which mounts to the upper disk opposite the grommets and an externally toothed cutter rotatably mounted thereto. The rotatable toothed cutters are oriented radially outwardly of the resurfacing disk so as to rotate while engaging the floor as the resurfacing disk spins with the disk mount. A resiliently deformable lower disk may be mounted in place of the rotary cutters and a sandpaper disk is removably affixed thereto using sheets interconnectable hook and a loop fastener material. The grommets and the lower disk deform to permit the floor resurfacing device to more closely follow contours of the floor surface and are easily replaceable if damaged or worn out.

Owner:LITE PREP SURFACE PREPARATION EQUIP

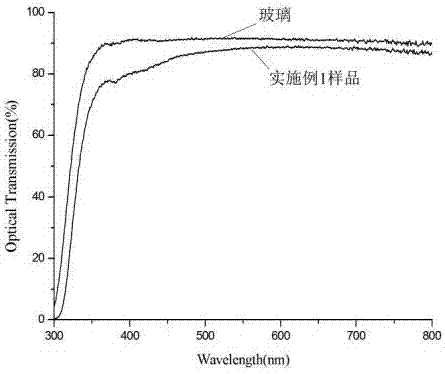

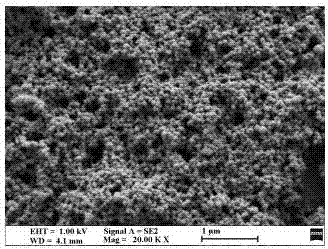

Preparation method of highly transparent wear-resistant superhydrophobic composite coating

ActiveCN107022279AEasy to prepareWide applicabilityEpoxy resin coatingsWear resistantSuperhydrophobic coating

The invention belongs to the technical field of superhydrophobic materials, and particularly relates to a preparation method of a highly transparent wear-resistant superhydrophobic composite coating. Surface-modified nano-silica powder prepared by a sol-gel method is dispersed in anhydrous ethanol to obtain a superhydrophobic coating solution. The surface of a substrate of stone, metal, glass and the like is coated with reactive-diluent-modified E-51 epoxy resin glue, standing is carried out for 1 to 2 hours at room temperature, the superhydrophobic coating solution is used for brushing to obtain the highly transparent wear-resistant superhydrophobic coating. The contact angle between the coating and water is 165 to 175 DEG, a rolling angle is 2 to 5 DEG, the light transmittance of coating glass in the 500 to 650nm is greater than 84%, and at pressure intensity of 2500 Pa, the contact angle between the coating and water is greater than 90 DEG after the coating is rubbed with 320-mesh sandpaper along a line. The preparation method of the coating is simple, environmentally friendly and low in cost, is suitable for the surface of glass, stone, ceramics, wood, metal and the like, and has a wide application prospect.

Owner:FUZHOU UNIV

Preparation method of super-hydrophobic coating layer on aluminum surface

ActiveCN105521934AImprove hydrophobicityGood anti-fogPretreated surfacesLiquid/solution decomposition chemical coatingAcid etchingSilanes

The invention discloses a preparation method of a super-hydrophobic coating layer on an aluminum surface. The preparation method mainly comprises the following steps: (1) an aluminum piece is polished by an abrasive paper, is ultrasonically cleaned for 10 minutes by acetone and ethanol, is washed by distilled water to remove oil stains on the surface, and is dried in an oven; (2) the aluminum piece is dip in an acid etching agent for etching to obtain the aluminum surface with a micron rough structure; (3) the micron rough aluminum piece is dip in nanometer TiO2 particle solution, and is treated at high temperature to obtain the aluminum surface with a micron-nanometer composite rough structure; and (4) the aluminum surface with the micron-nanometer composite rough structure is treated by fluorine silane with low surface energy to obtain the aluminum surface with super-hydrophobic performance. The prepared super-hydrophobic aluminum piece is excellent in self-cleaning performance, fog resistance and ice covering resistance, and can be applied to field of ice covering prevention.

Owner:ZHEJIANG UNIV

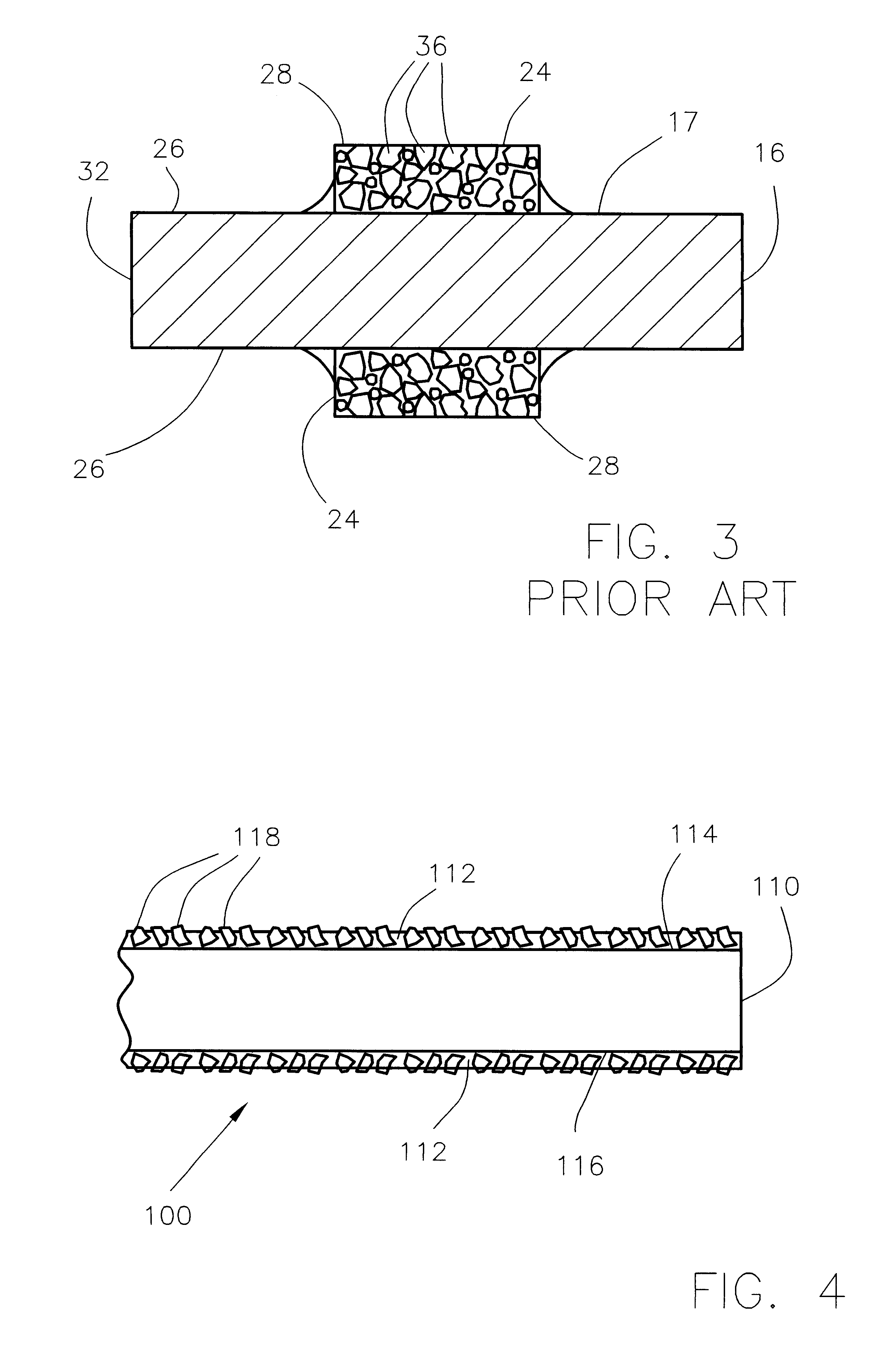

Process of dressing glass disk polishing pads using diamond-coated dressing disks

InactiveUS6254461B1Rapidly but accurately removeEasy to takePolishing machinesGrinding drivesMagnetic memoryCerium

A dressing disk for dressing and reconditioning the polishing pad of a planetary disk polishing machine is fabricated by plating a nickel / diamond matrix layer onto a stainless steel disk wherein the matrix layer thickness is developed or plated to a thickness which leaves exposed about 25 percent of the fine diamond particles, thereby forming a surface that has the look and feel of medium to coarse sandpaper. The dressing disks are inserted into the holes in a disk carrier of a planetary polishing machine and driven by its central rotary drive. While being so driven under a flow of water to carry away abraded particles, a pair of polishing pads are engaged with the disk surfaces and forced together with a loading or down force to cause the disks to abrade or grind away a thin surface layer of the polishing pad, thereby removing glazing and exposing cerium particles embedded in the urethane matrix of the polishing pad to engage the glass disks to be polished to a very smooth surface for use as substrates for magnetic memory disks useable in disk drives.

Owner:IBM CORP

Hand sander vacuum attachment

A manual sander vacuum attachment, providing edge sanding and multiple positioning capabilities, having a lower sanding backer plate member, which carries a soft sanding pad and secures the sandpaper sheet, and an upper housing portion, having a generally horizontal platform with two vertically-extending stanchion supporting a handle therebetween, with a vacuum fitting for connection to a hose for a vacuum air source, and a peripheral skirt surrounding the backer plate member, whereby all vacuum air flow of sanded debris travels about periphery of sander backing plate up into interior of the housing portion.

Owner:SHOP VAC

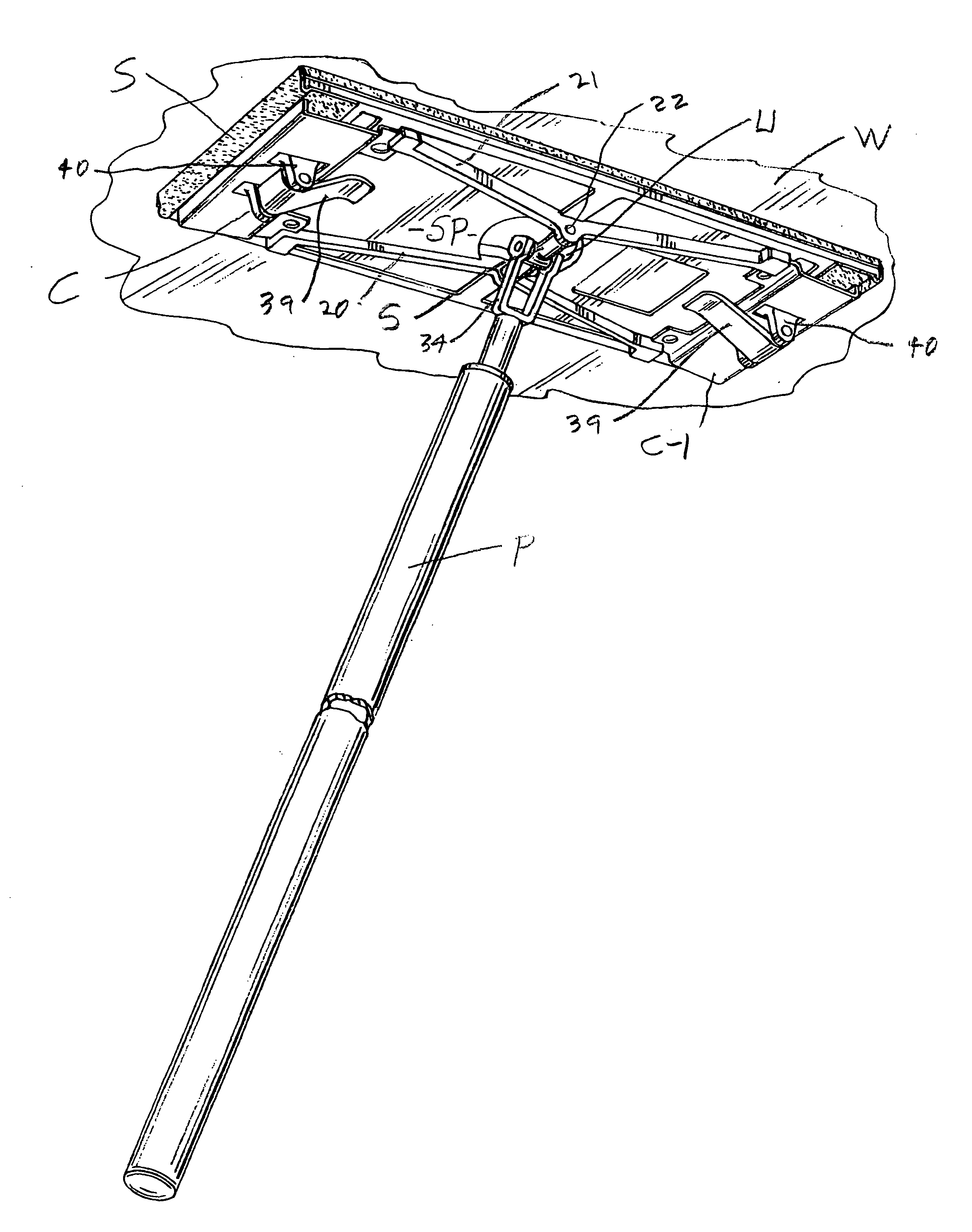

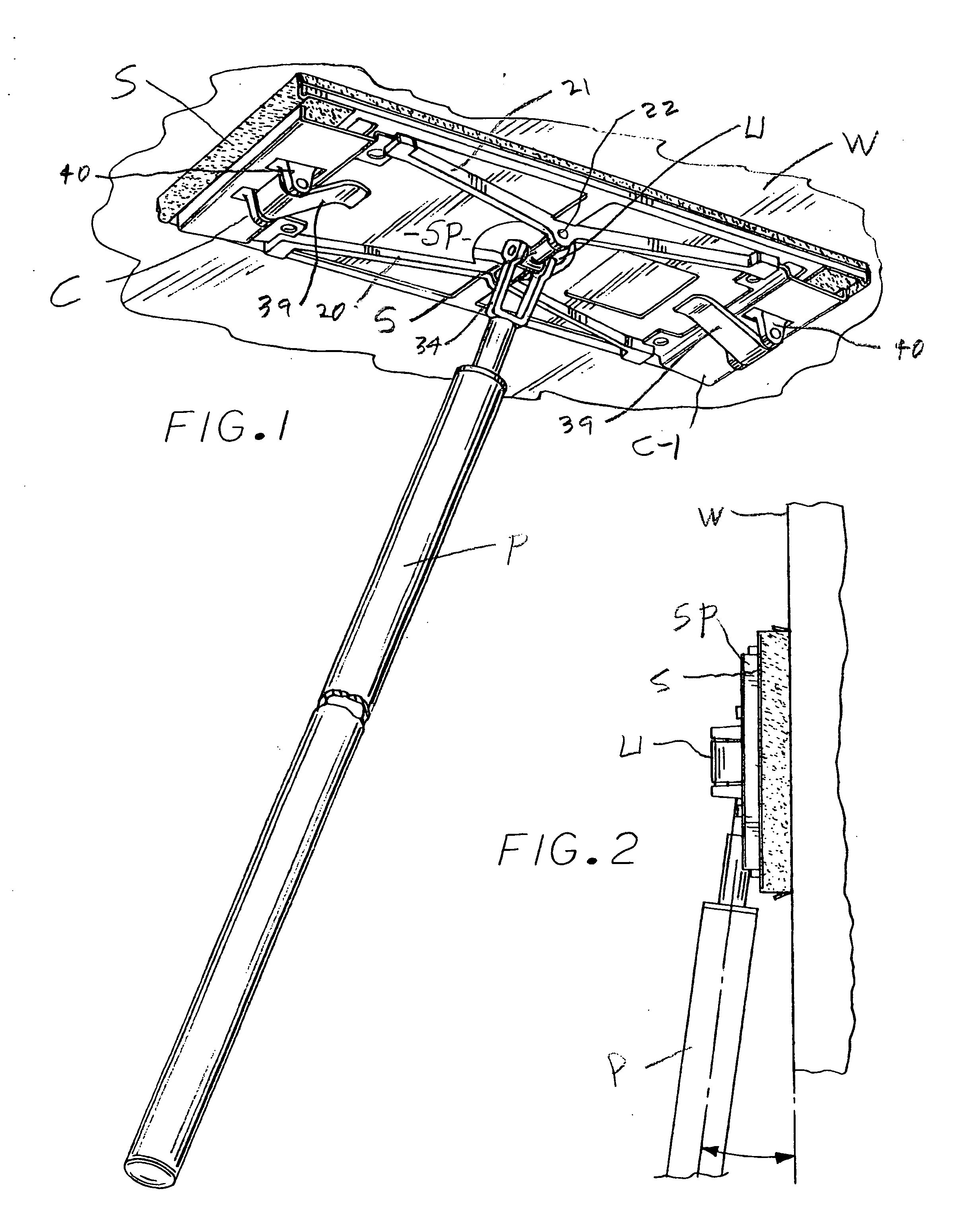

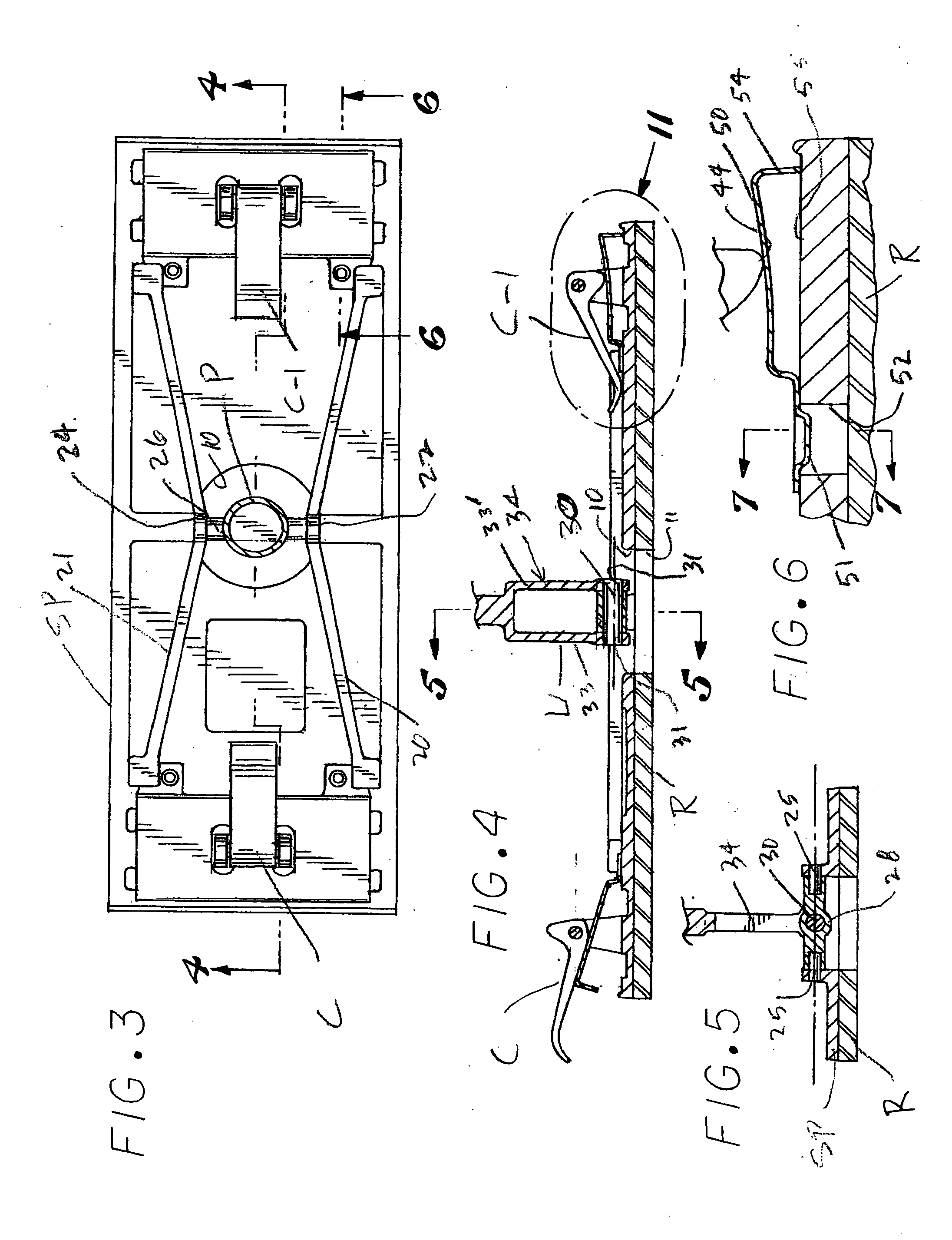

Pole sander

InactiveUS20050287937A1Shorten the timeOvercome disadvantagesPortable grinding machinesBuilding constructionsSanderUniversal joint

A pole sander having a rectangular sander plate which removeably holds one or more sheets of sandpaper by a pair of clamp assemblies positioned at opposite ends of the sander plate. The sander plate is attached to the upper end of a pole by a universal joint having elements arranged to permit the pole to assume a position close to parallel with the drywall surface being sanded.

Owner:WALLBOARD TOOL

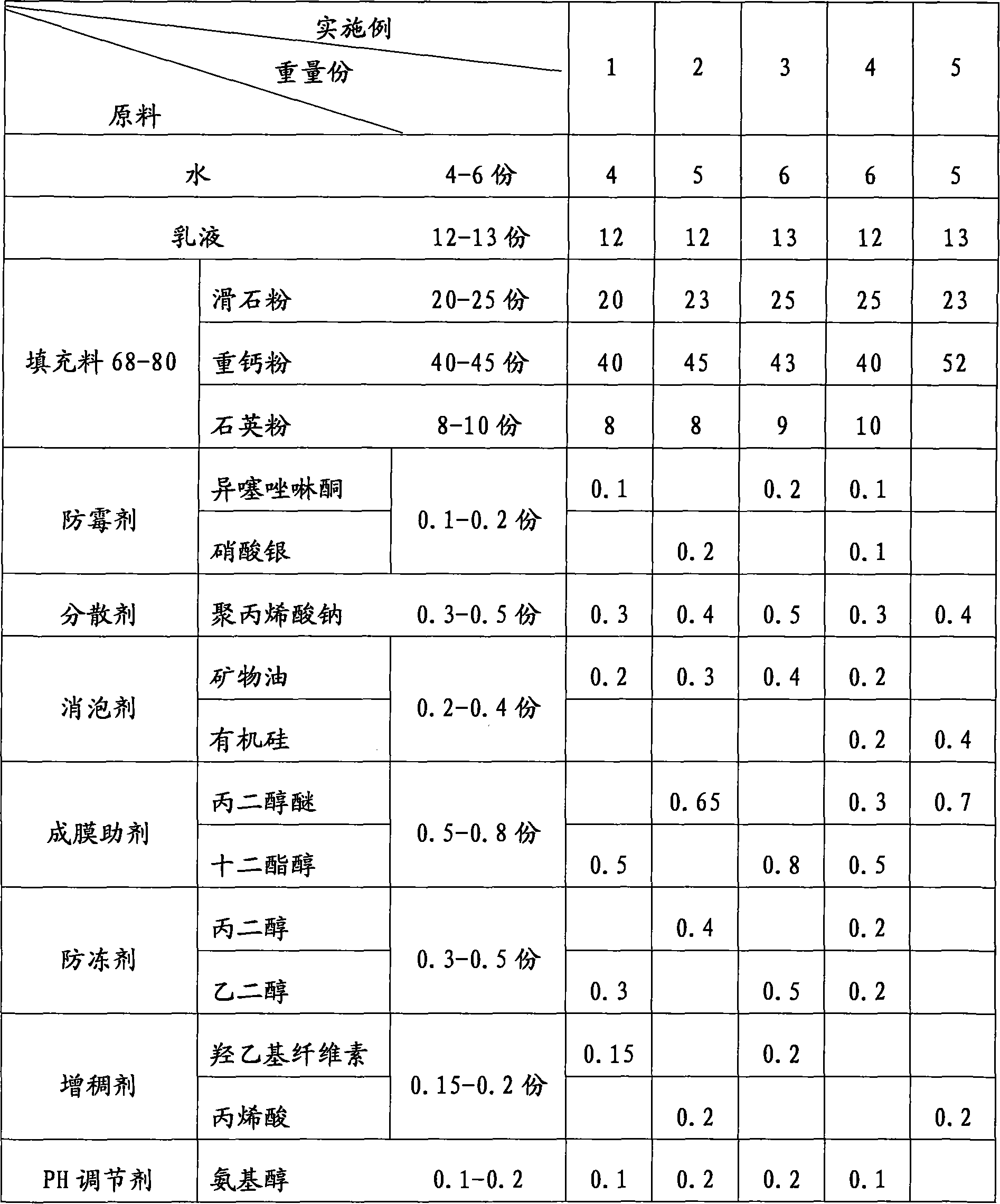

Method of producing and painting stone similar paint for flexible flat surface

InactiveCN101108943ANot easy to accumulate dustLow costLiquid surface applicatorsCoatingsEmulsionLacquer

A production method of a flexible stone-like paint is provided, which consists of the following raw materials and weight portion mixture ratios: 4 to 6 of water, 12 to 13 of waterborne pure acrylic acid emulsion, 68 to 80 of fillers and 0.65 to 2.8 addition agents. The method is that water, emulsion and addition agents are mixed first and are dispersed for 5min to 10min at medium speed, and are dispersed for 20min to 30min at low speed after adding the fillers; each half of antifoamers are added into the above two procedures respectively and are mixed with color and stirred evenly to form the stone-like paint. The wall is neatened first when painting and then sprayed by primer or rendered by roller coat, and tackiness paper tapes are stuck in grids; the stone-like paint is adopted to spray spots which are polished by abrasive paper after drying; the stone-like paint is adopted to level and polish twice until the spots are completely set off, to remove the dust and rip off the tackiness paper tapes and spray finishing varnish finally. The stone-like paint is applied in the decoration of the walls of construction or the table-board of the kitchens and toilets, and is beneficial for environment protection, light in quality and strong in toughness, which can be directly coated on the wall with surface low cost and energy-saving, therefore, the wall surface is not easy to store dust and the shapes and colors of the plane-imitating marble slab and the granite slab are lifelike.

Owner:浙江华特新材料有限公司

Fine abrasive paper backing material and method of making thereof

In one embodiment is provided a method of making an abrasive backing having a smooth surface comprising the steps of providing a paper having a first paper surface and a second paper surface; applying a first synthetic polymeric layer comprising a first synthetic polymeric composition to the first paper surface; and applying a second synthetic polymeric layer comprising a second synthetic polymeric composition to the first synthetic polymeric layer. The method is used to prepare fine abrasive backings having a smooth exterior surface for preparation of fine abrasive papers.

Owner:NEENAH PAPER INC

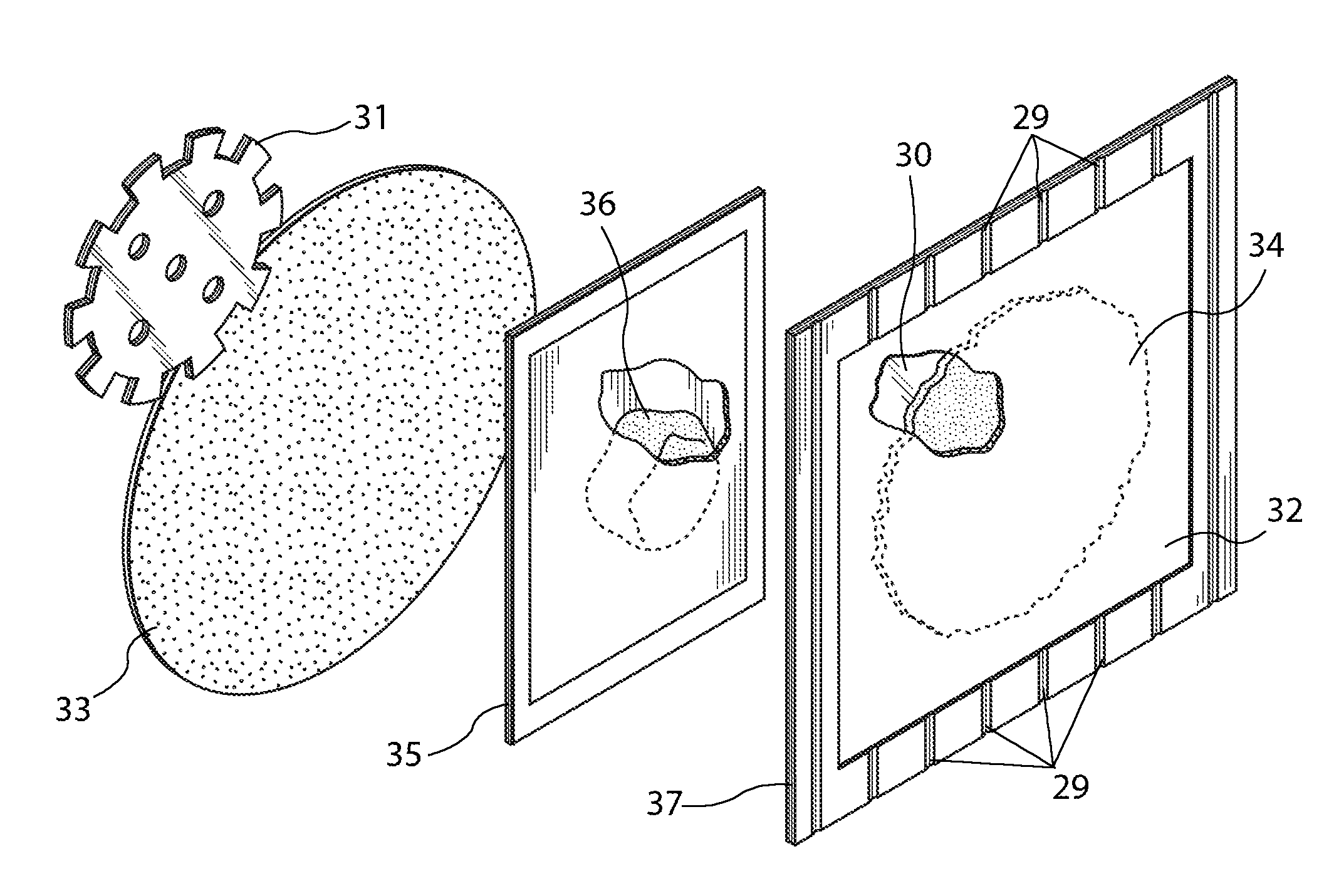

Floor resurfacing disks for rotary floor resurfacing machines

InactiveUS20050054279A1Improve consistencyShorten the timePortable grinding machinesGrinding headsEngineeringGrommet

A resurfacing disk which mounts to a rotatable disk mount of a conventional rotary floor resurfacing machine. The resurfacing disk includes a rigid upper disk with four counterbored holes through an upper surface corresponding to four downwardly open holes of each disk mount. A resilient, flanged grommet is retained extending through corresponding holes of a retaining plate mounted to the upper surface. The grommets include respective vertically oriented longitudinal bores closely receive a mounting pin which extends from a corresponding hole of the disk mount. A plurality of rotary cutters each include a bracket which mounts to the upper disk opposite the grommets and an externally toothed cutter rotatably mounted thereto. The rotatable toothed cutters are oriented radially outwardly of the resurfacing disk so as to rotate while engaging the floor as the resurfacing disk spins with the disk mount. A resiliently deformable lower disk may be mounted in place of the rotary cutters and a sandpaper disk is removably affixed thereto using sheets interconnectable hook and a loop fastener material. The grommets and the lower disk deform to permit the floor resurfacing device to more closely follow contours of the floor surface and are easily replaceable if damaged or worn out.

Owner:LITE PREP SURFACE PREPARATION EQUIP

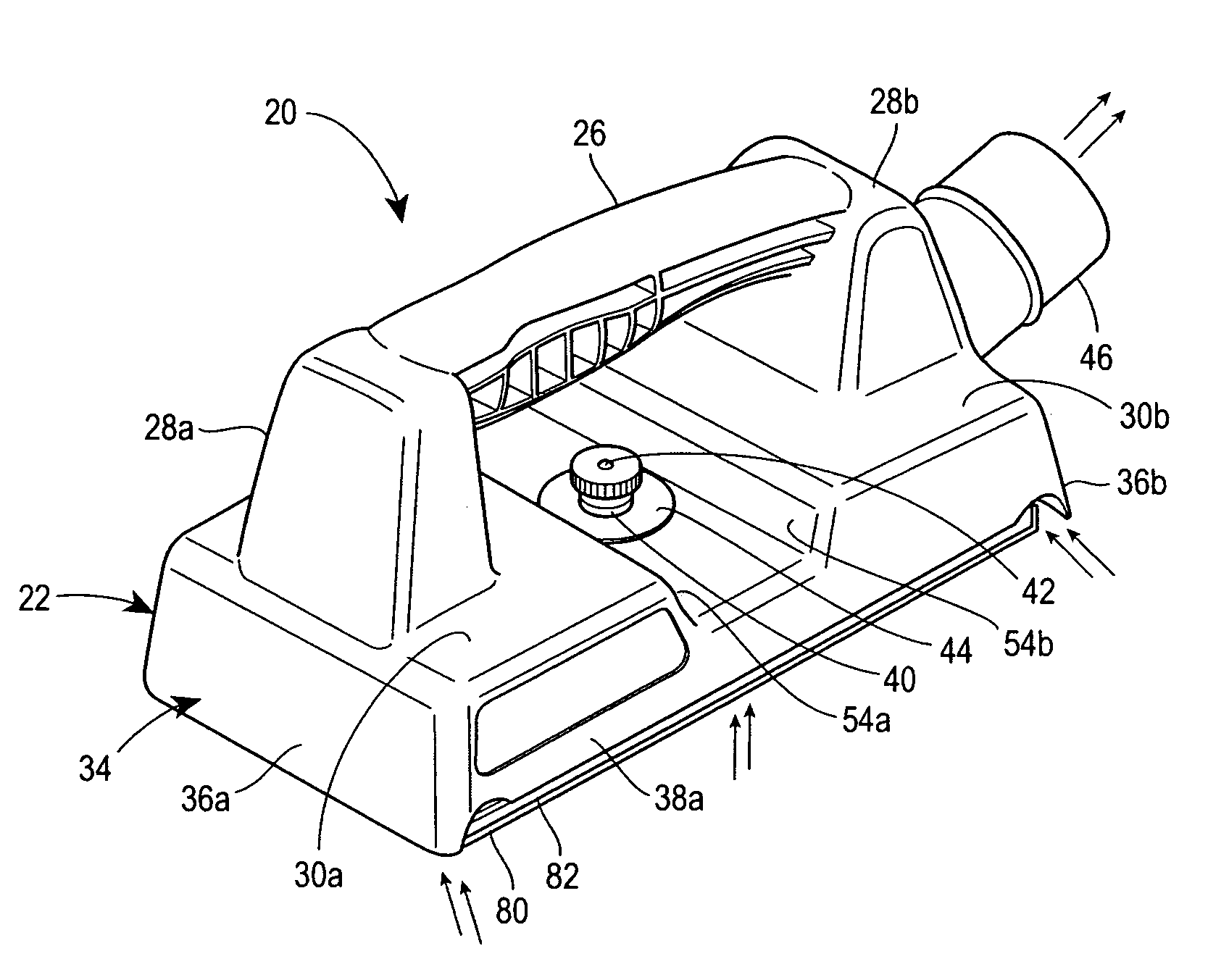

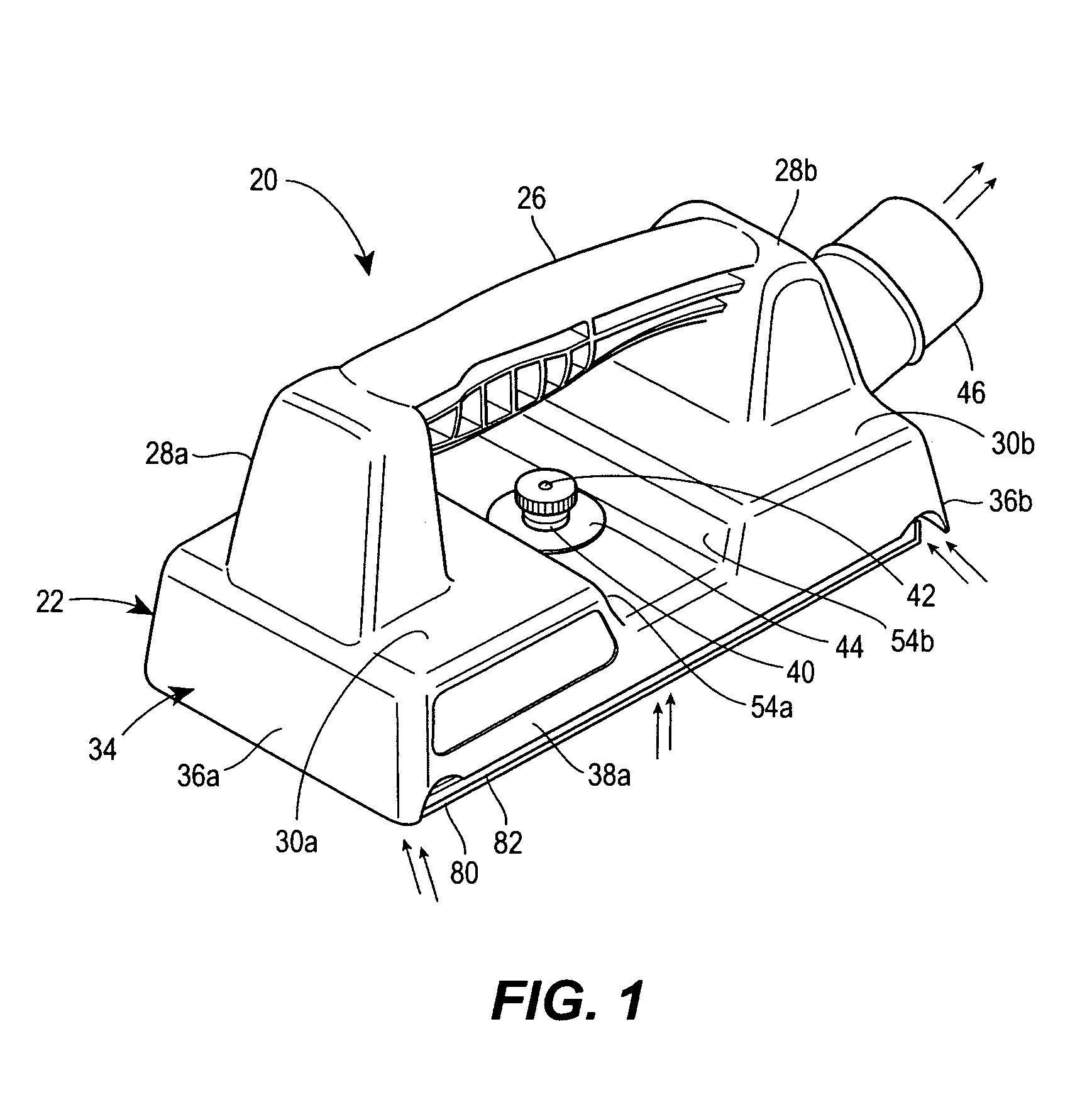

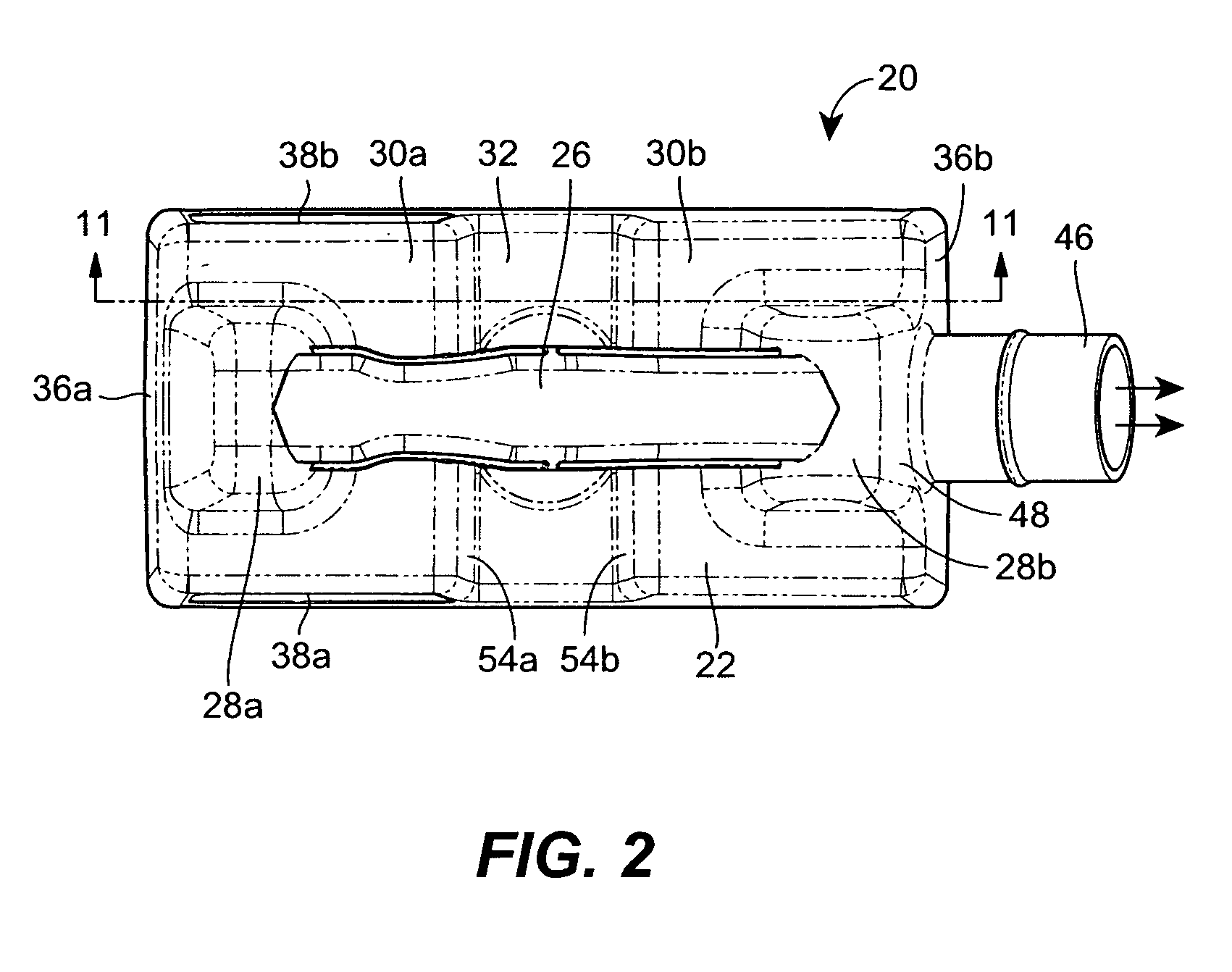

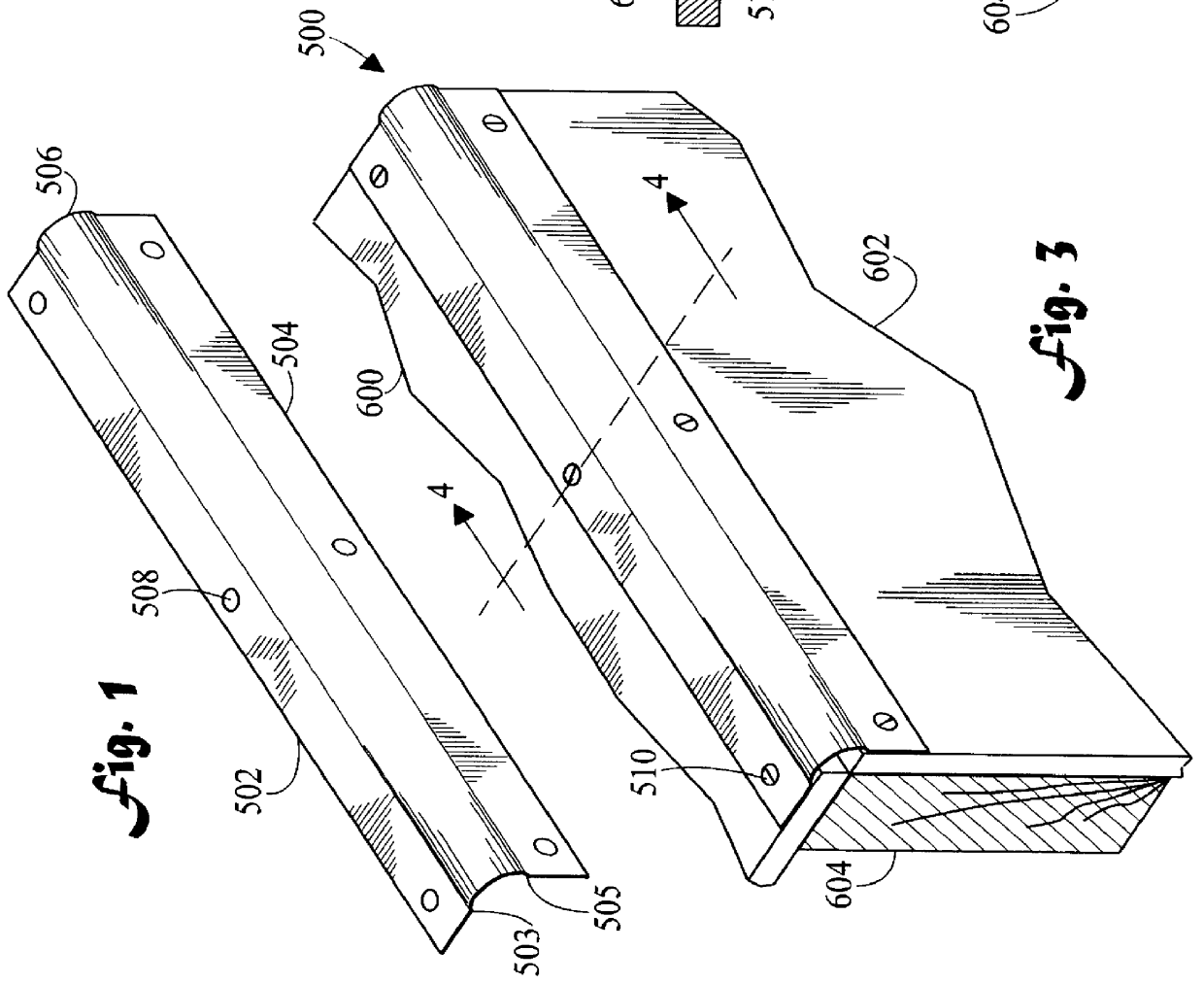

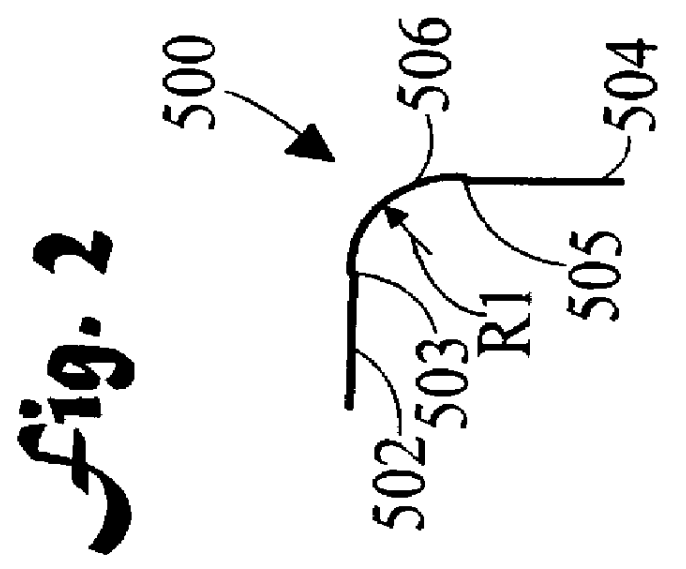

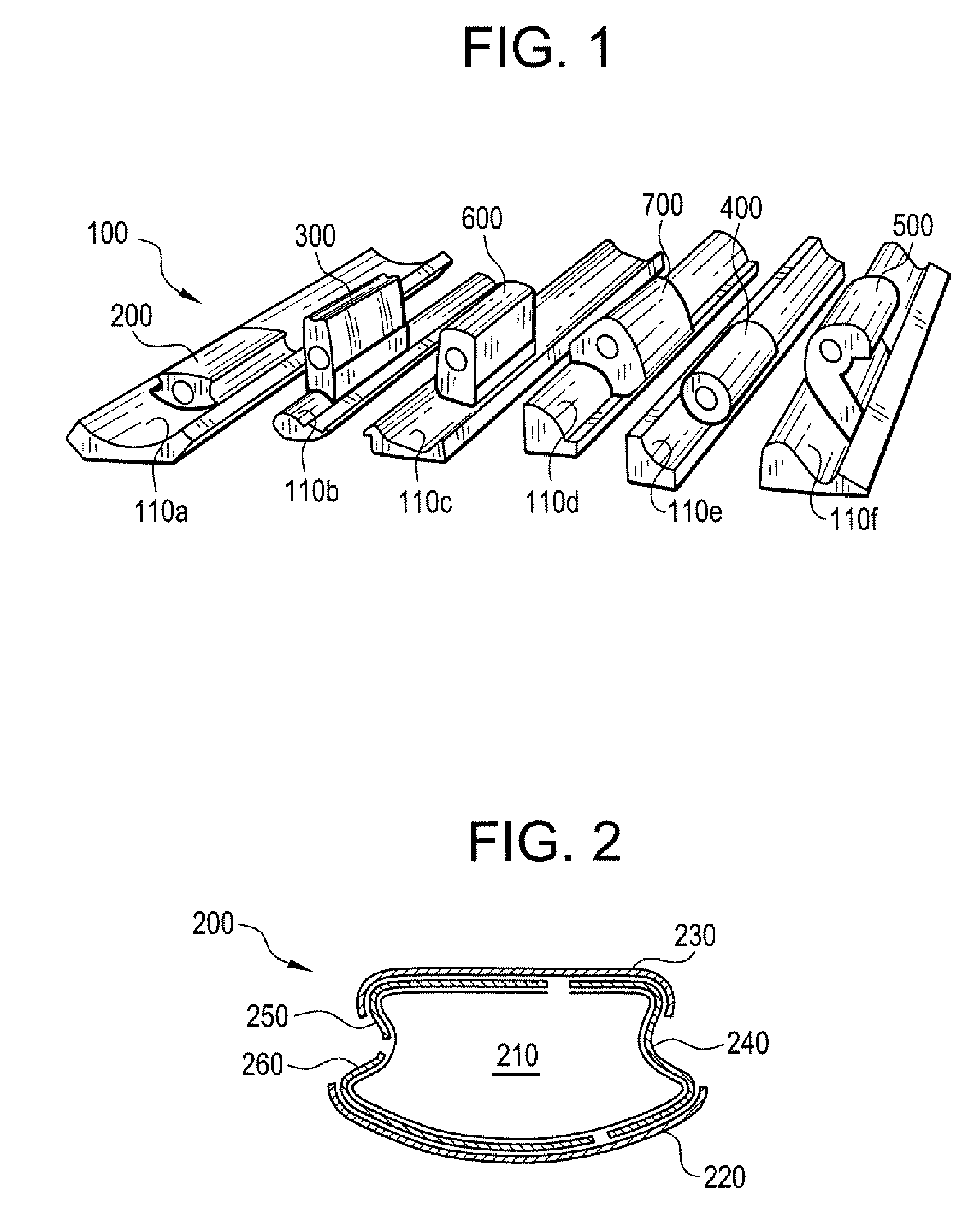

Sander for a bullnose cornerbead and method of use

A sander (20) for a bullnose cornerbead (500) includes a body (22) having a bullnose-shaped concave surface (24) having a second radius of curvature (R2) greater than the first radius of curvature (R1) of the bullnose cornerbead (500). A flexible pad (26) is disposed on concave surface (24), and forms a third radius of curvature (R3) which is greater than first radius of curvature (R1), and less than second radius of curvature (R2). Pad (26) does not fully extend to the edges (34) and (36) of sander (20), thereby leaving two gaps (38) and (40). A sheet of abrading material (700) such as sandpaper or emery cloth is clamped adjacent to flexible pad (26) and around concave surface (24) of sander (20). A handle (800) is connected to a pivotable connector (48) which only pivots in one plane (50).

Owner:MONTROSS CHRISTOPHER G

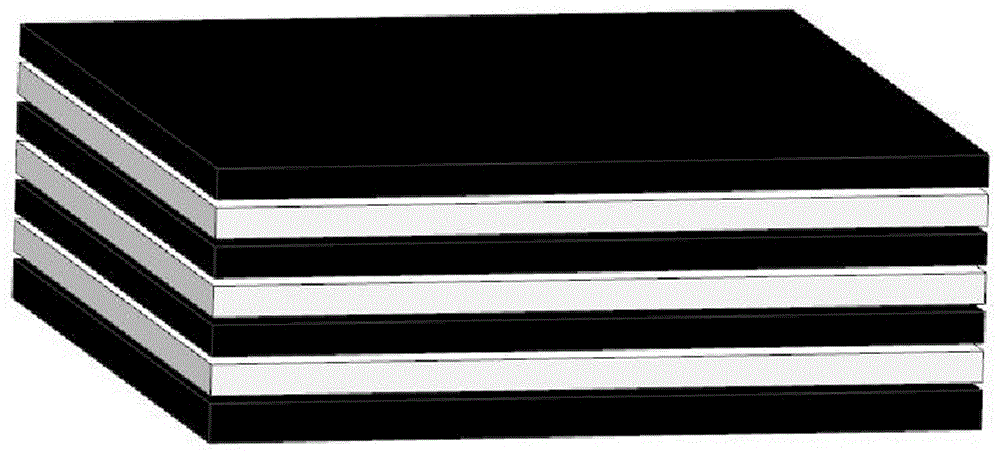

Method for preparing metal sealed intermetallic compound base lamination composite amour

The invention discloses a method for preparing a metal sealed intermetallic compound base lamination composite amour. The method comprises the following steps: (1) abrasive paper grinding and acetone ultrasonic cleaning surface treatment: a Ti foil and an Al foil are polished by an abrasive paper to remove surface impurities and oxide layers; and acetone is used for ultrasonically cleaning the Ti foil and the Al foil by 20 minutes for drying; (2) alternate lamination and rolling: a gap between rollers is adjusted, so that a sample alternately laminated by the Ti foil and the Al foil is rolled by two times for compaction, and is molded; (3) sealing and vacuumizing: the cold-rolled Ti foil and the Al foil are sealed by metal foils of 0.01 mm, and are vacuumized; and (4) sintering: the Ti foil and the Al foil are put in a hot pressing furnace for sintering after metal sealing, and are cooled along with a furnace. The method combines cold rolling, vacuum sealing and hot-pressed sintering to prepare the novel metal sealed intermetallic compound base lamination composite amour, and is unique in process circuit, simple, low in production cost and suitable for commercial production.

Owner:ZHONGBEI UNIV

Preparation method of superhydrophobic self-cleaning material

InactiveCN101982490AHas superhydrophobic propertiesCompliant with self-cleaning material requirementsInorganic pigment treatmentPolymer scienceGlycerol

The invention relates to a preparation method of superhydrophobic self-cleaning material. Firstly silicon rubber and vulcanizer are mixed by weight proportion of 100: (0.5-3), refining is carried out, and pre-mixed glue is prepared; then graphite is fluoridized, polypropylene (100phr), graphite fluoride (1-50phr), pre-mixed glue (1-50phr), antioxidant (0.5-3phr), stearic acid (0.5-3phr) and glycerol (0.5-3phr) are mixed based on weight part, a double screw extrusion machine is used for extrusion, then a pelleting machine is used for pelleting, thus obtaining blended particle; the blended particle is pressed into plates by virtue of a flat high temperature pressing machine, and chips on the surface of plates are removed by adopting 80#-600# sand paper, thus obtaining the required superhydrophobic self-cleaning material. The superhydrophobic self-cleaning material obtained by adopting the method provided by the invention can realize good superhydrophobic and self-cleaning effects, and meanwhile processing method is simple, and application prospect and economic value are good.

Owner:EAST CHINA UNIV OF SCI & TECH

Sanding blocks for use with adhesive-backed sandpaper

A sanding block and a kit for sanding curved surfaces are provided. The sanding block includes an elongated body which has a first sanding surface; and a sandpaper removably affixed to the first sanding surfaces wherein the body is elastically deformable such that the block can conform against a curved surface to be sanded.

Owner:STYLE LINE CORP INT

Construction method for water-based texture wallpaper paint and special-purpose tool for the same

InactiveCN101168988AEasy to coverImprove crack resistanceCovering/liningsNatural patternsWater basedScreen printing

The invention relates to a construction method for aqueous texture wallpaper paint, and a special tool thereof. The invention is characterized in that the construction method comprises the following steps: firstly, the water seepage and leakage phenomena of a wall is treated, then the wall is filled up, flattened, and struck off integrally; secondly, after the base course is fundamentally dry, the scratching on the wall surface is burnished to be flat, and is roller coated or brush coated with priming paint; thirdly, after priming is performed, the aqueous texture wallpaper paint with well matched colors is rolled thinly for bottoming; fourthly, after the surface of the ground color is dry, the aqueous texture wallpaper paint is coated thickly, with the thickness of 0.6 to 0.8 mm, then a special texture roller is used for vertically rolling texture of various shapes, so as to form a texture surface; fifthly, after the texture surface is dry, No.180 waterproof abrasive paper is used for burnishing the texture surface to be smooth, when the texture surface feels soft by being touched by a hand, the steps of finish paint applying, shining spot spraying, silk screen printing, rubber roller coating, etc. can be performed. The special texture roller comprises a roller and a handle articulated with the middle part of the roller, and texture surfaces with various different patterns and shapes are arranged on the surface of the outer circle of the roller. The invention saves the working steps for filling up minor cracks on the wall surface, thereby saving the working time and improving the working efficiency.

Owner:李望龙

Grinding, cleaning and drying integrated machine for baseball bats

ActiveCN106737053AAutomate operationsReduce labor costsRevolution surface grinding machinesDrying machines with progressive movementsEngineeringCleaning station

The invention discloses a grinding, cleaning and drying integrated machine for baseball bats. An automatic feeding device, a grinding device, a cleaning device and a drying device are arranged. The automatic feeding device is used for feeding the baseball bats into the grinding device; the surfaces of the baseball bats are ground with abrasive paper after the baseball bats reach the grinding station; after the surfaces are ground, the baseball bats are conveyed to the cleaning station of the cleaning device, and water is sprayed to the baseball bats so as to remove impurities generated on the surfaces after grinding; and finally, the baseball bats are conveyed to the drying station of the drying device for drying treatment and then discharged. The whole process does not require manual intervention, automatic operation is achieved, and the purposes of reducing labor cost and improving production efficiency are achieved.

Owner:QUEST COMPOSITE TECH CORP

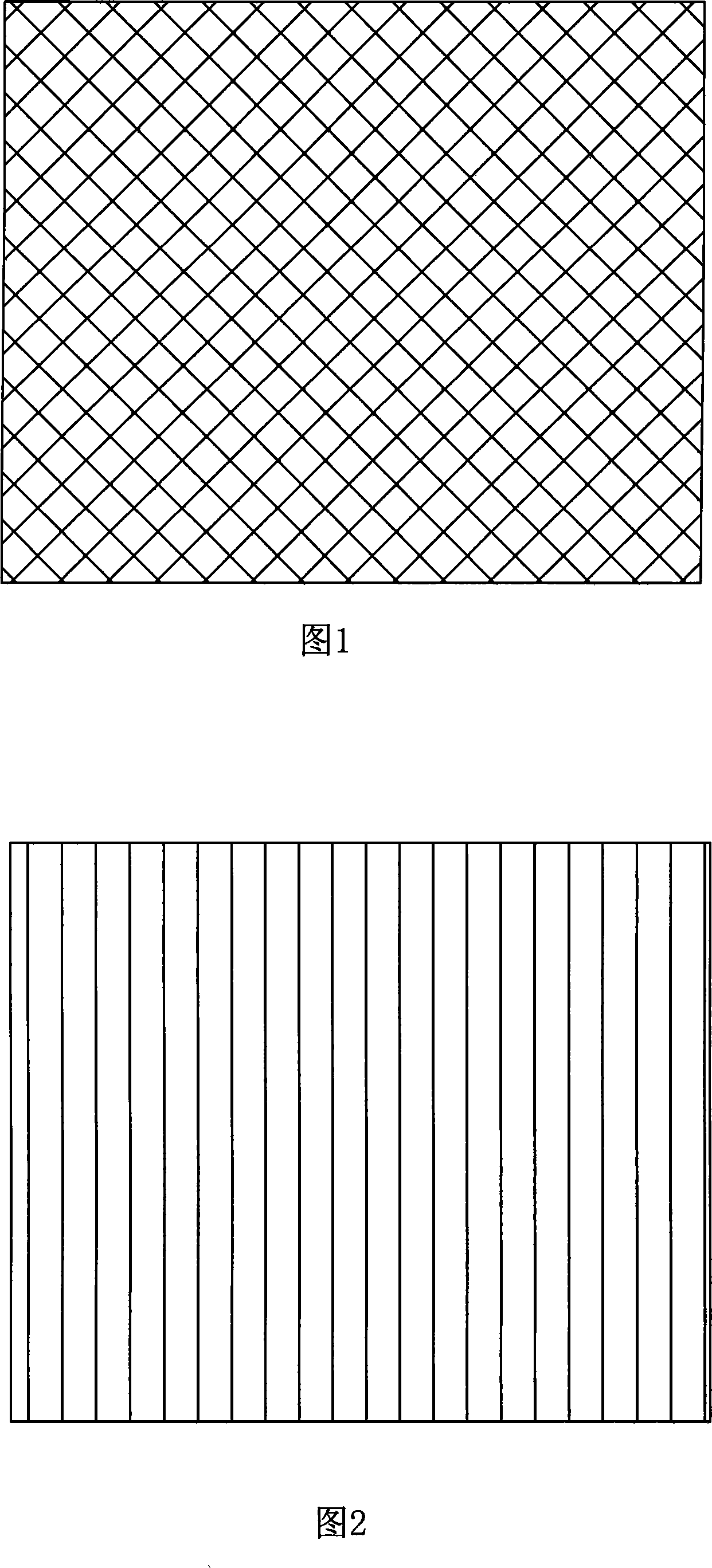

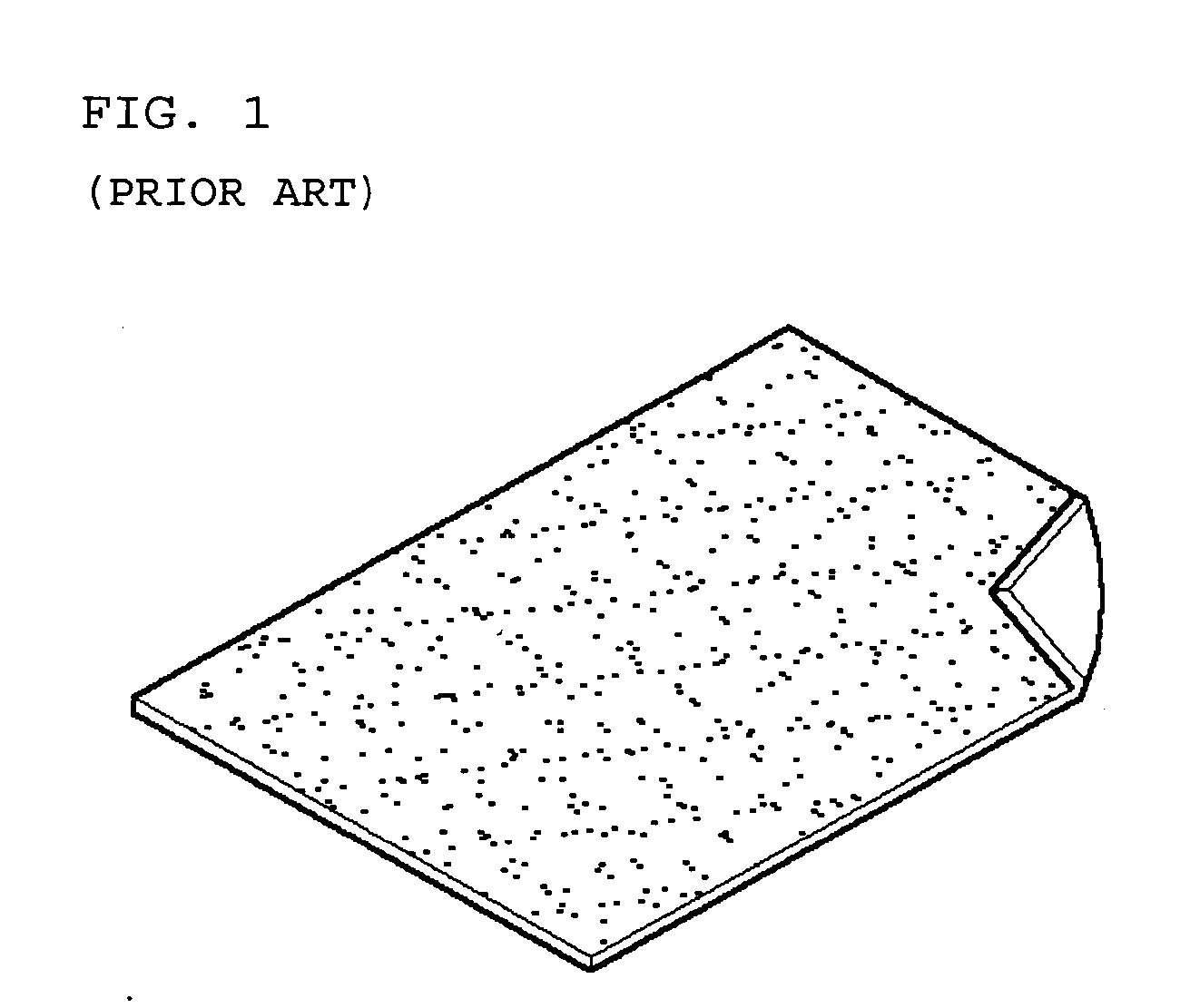

Roll-type sandpaper with cutting lines and apparatus for manufacturing cutting lines

InactiveUS20050107019A1Small storage volumeEasy to cutAbrasion apparatusMetal working apparatusEconomic benefitsEngineering

Disclosed is a roll-type sandpaper, including a base sheet formed of paper or fabric and an abrasive coated to a front surface of the base sheet. Further, the roll-type sandpaper is wound many times, and has a plurality of cutting lines formed in parallel with predetermined intervals and barcodes between the cutting lines on a back surface of the base sheet. Thus, the roll-type sandpaper is advantageous in terms of a small storage volume, and easy cutting by the cutting line even without an additional cutting tool. Moreover, the sandpaper can be purchased in quantities required for abrasion by the barcode, thereby increasing work efficiencies and generating economic benefits. In addition, an apparatus for forming the cutting lines of the sandpaper is provided.

Owner:JS

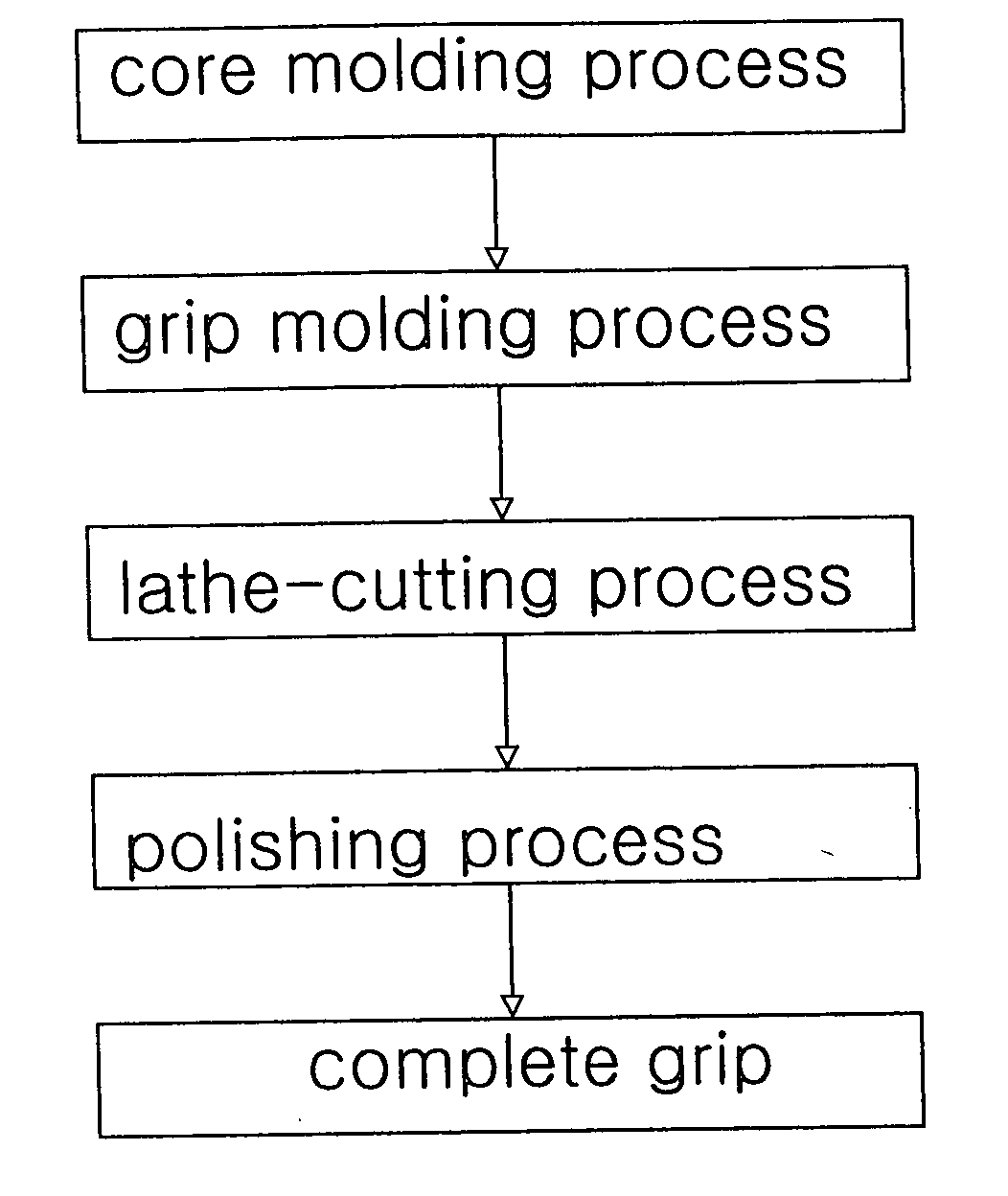

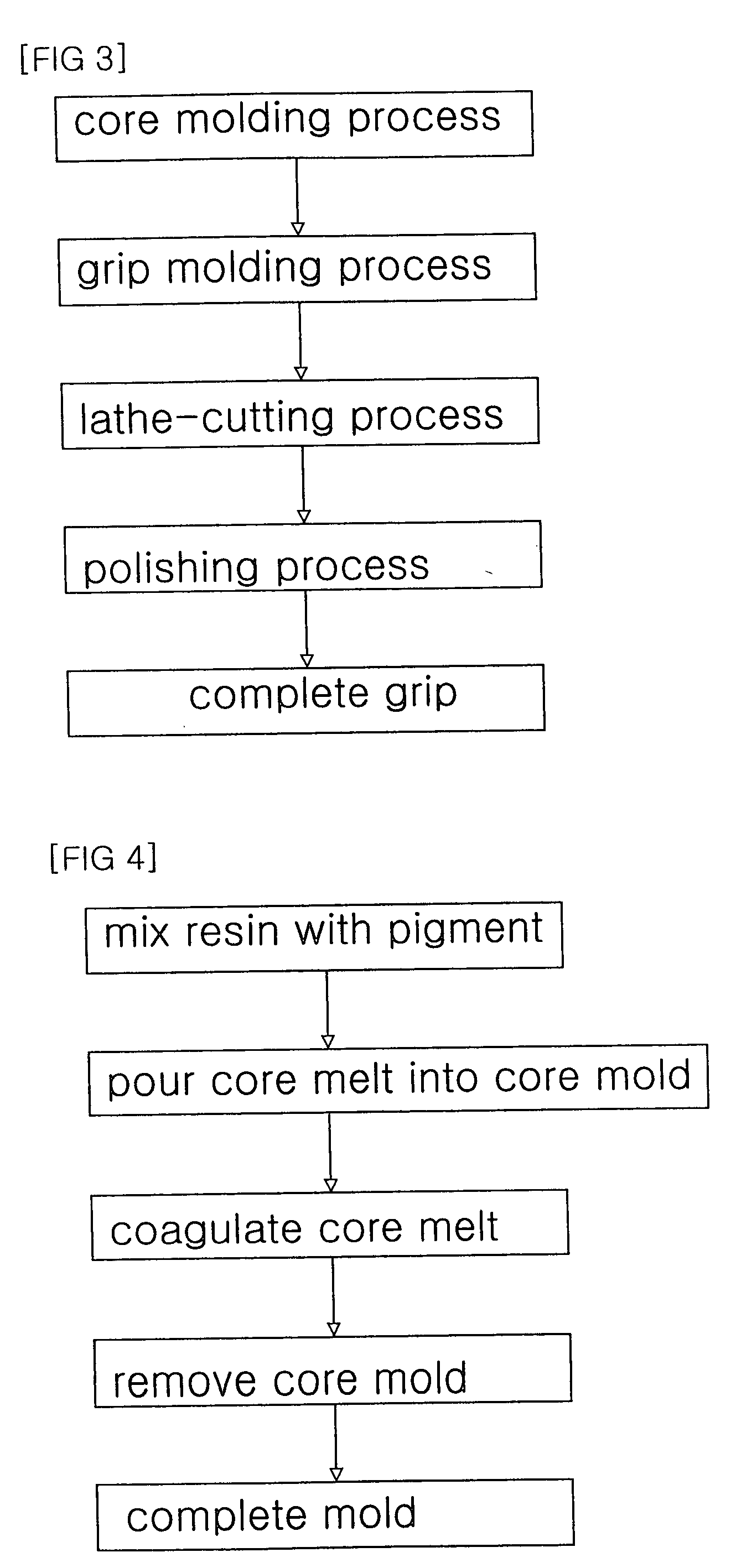

Grip for makeup brush and method of manufacturing the same

InactiveUS20050133947A1High strengthGood beauty appearanceBrush bodiesMouldsRough surfaceSynthetic resin

A grip for a makeup brush having the grip, hair and a combining unit includes a synthetic resin core inside and a brilliant transparent resin layer on an outer surface of the core, and manufactured through the steps of molding a core by pouring core melt containing resin and pigment into a core mold and removing the core mold after coagulation; molding a grip by pouring transparent resin melt into a grip mold with the molded core fixed at the center of the grip mold and removing the grip mold after coagulation; cutting an outer surface of the molded grip smooth and cutting an end of the grip, which is combined with a combining unit, to have a rough surface with a reduced diameter by a lathe; and polishing the outer surface of the cut grip by using a sandpaper. This grip has better appearance and improved durability.

Owner:SAMSUNG GROUP

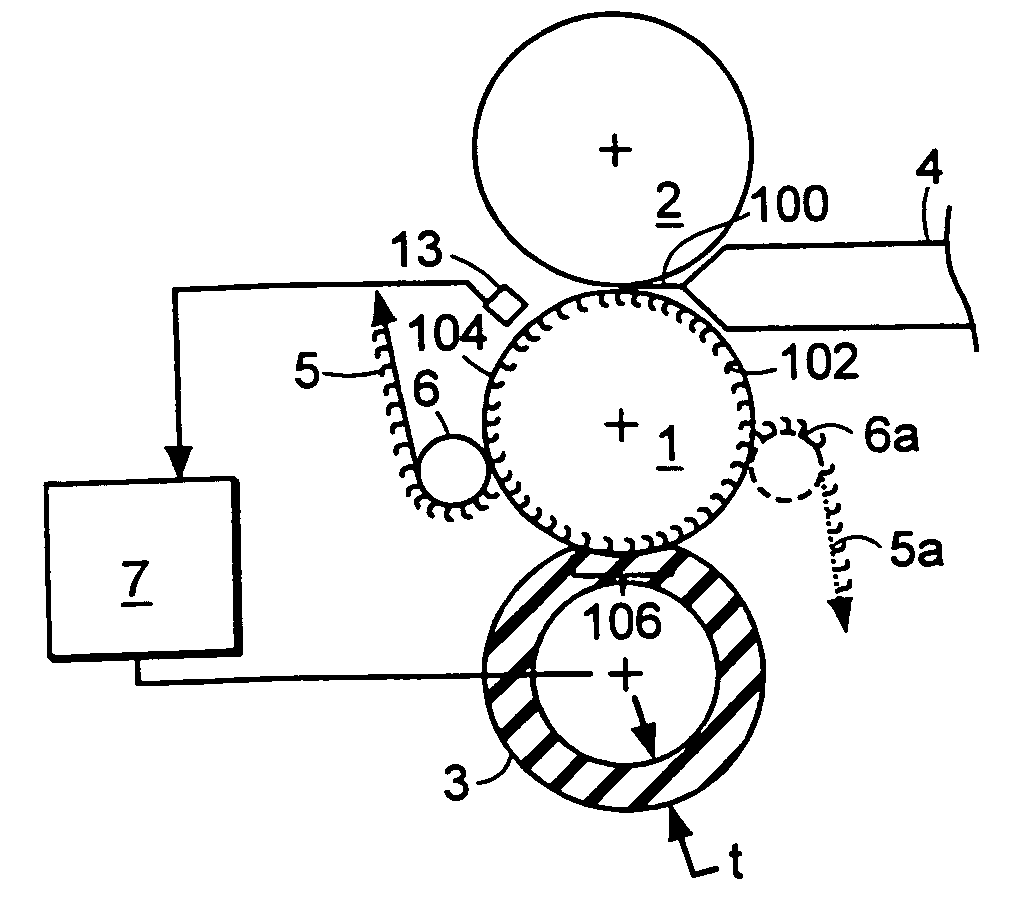

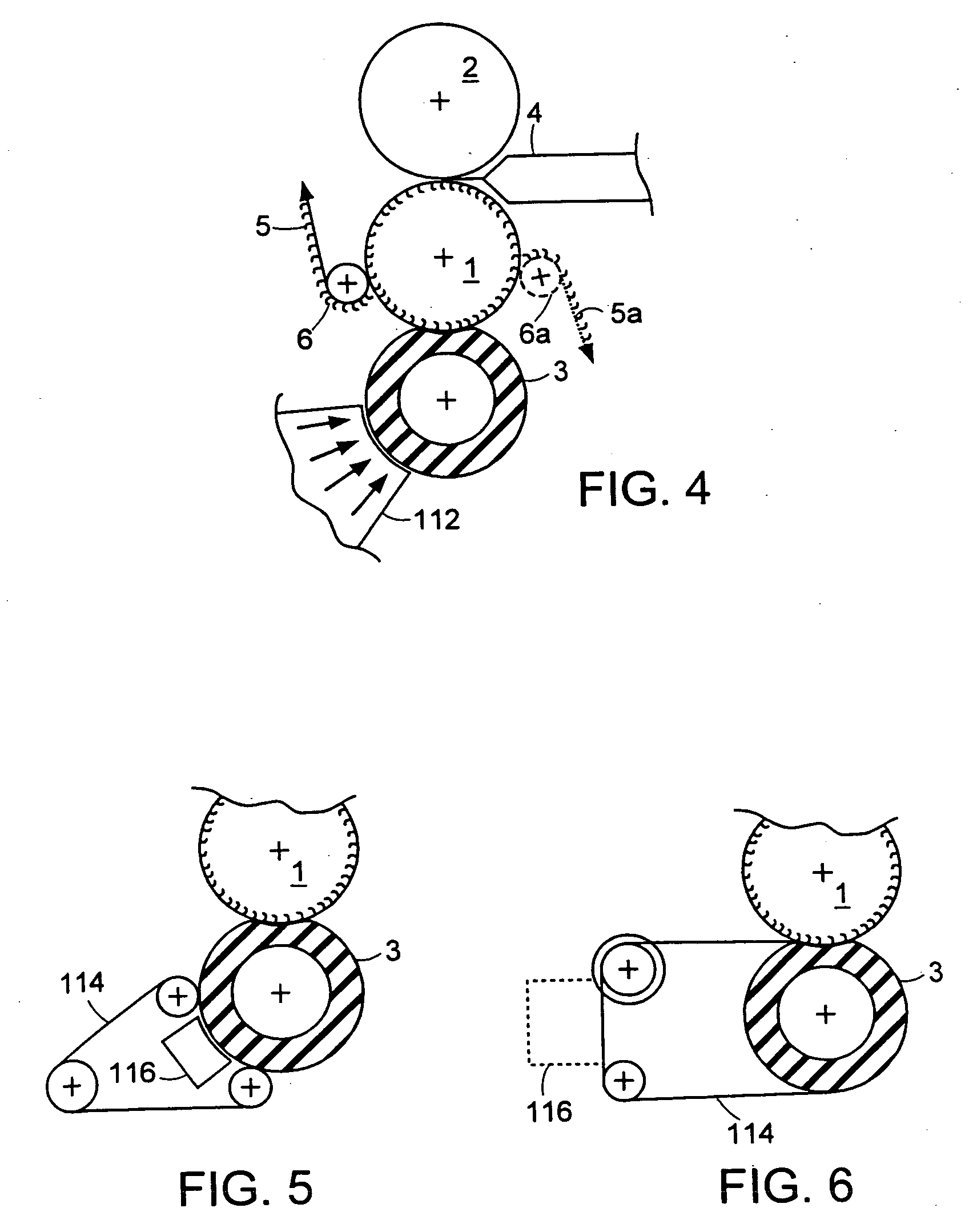

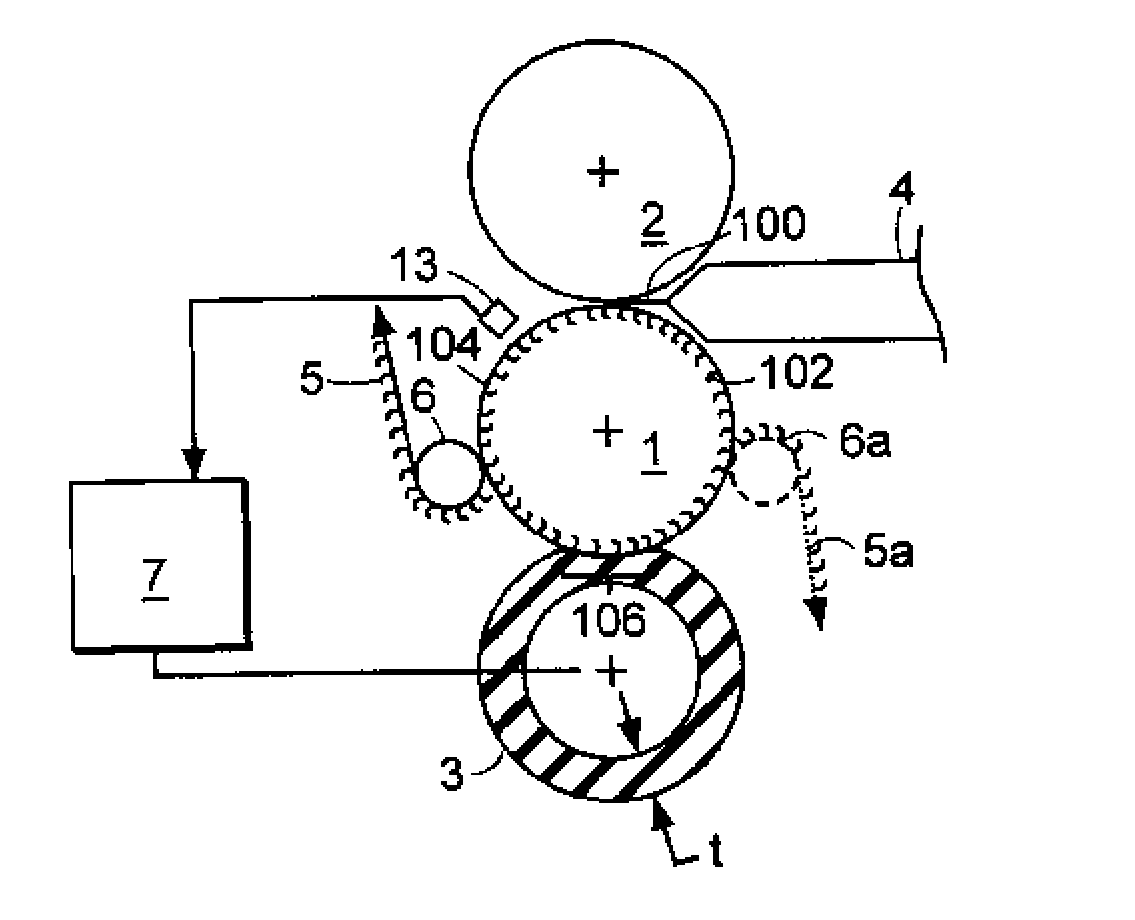

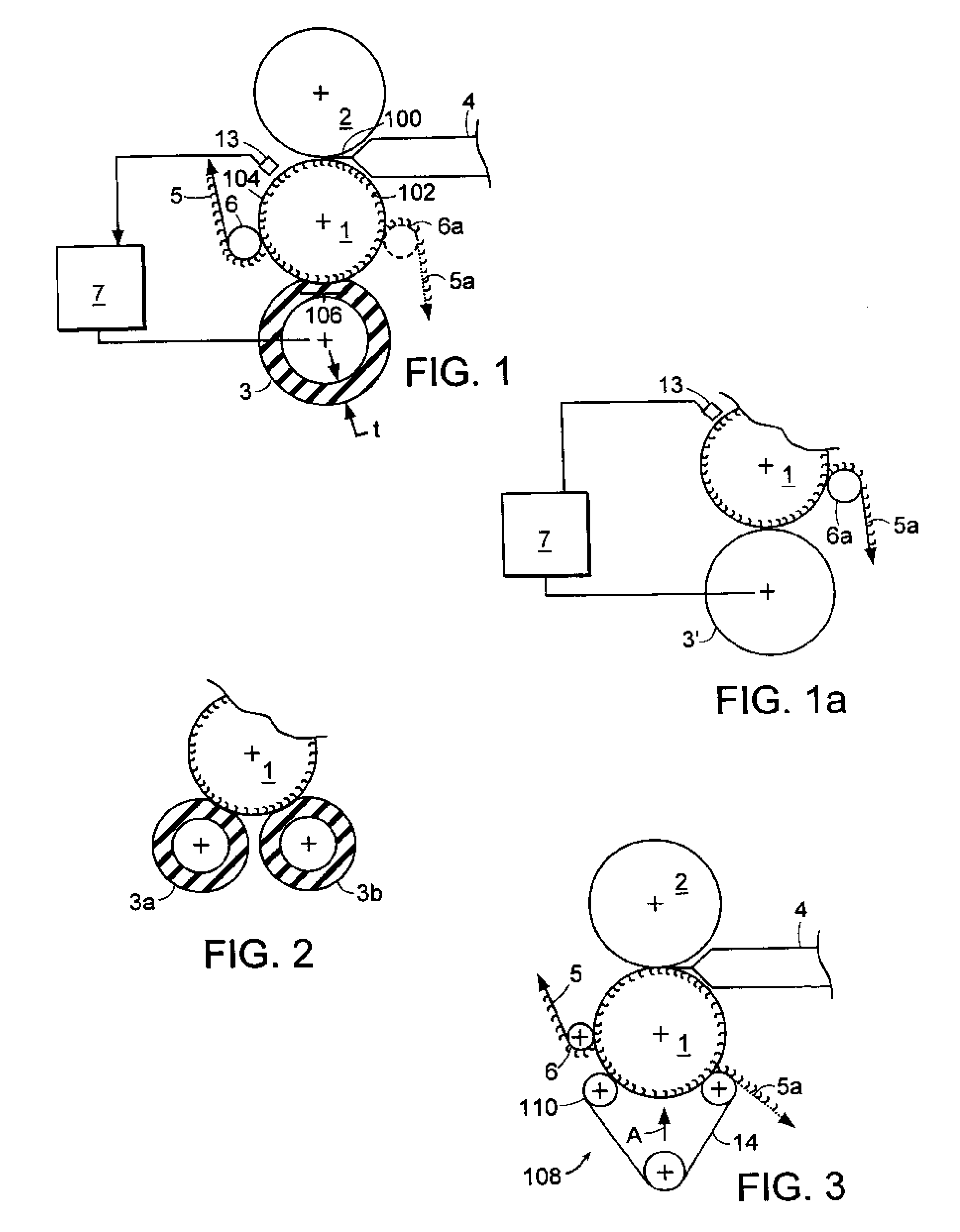

Continuous molding of fastener products and the like and products produced thereby

InactiveUS20070035060A1Uniform thicknessCost-effective commercializationLayered productsFilament/thread formingEngineeringFiberboard

Owner:VELCRO IND BV

Preparation method for forming second-level porous active surface structure on titanium material surface through mixed alkali

InactiveCN104451685AIncrease mechanical locking forceIncrease surface areaTitanium alloyDrug biological activity

The invention relates to a preparation method for forming a second-level porous active surface structure on a titanium material surface through mixed alkali. The preparation method mainly solves the problems that the biological activity of existing titanium and titanium alloy is low, and the combination strength with bone tissue is low. The preparation method comprises the steps that firstly, a titanium material is ground level by level through 200# metallographic abrasive paper, 400# metallographic abrasive paper, 600# metallographic abrasive paper and 1000# metallographic abrasive paper, and then ultrasonic cleaning is conducted on the titanium material through acetone and ethyl alcohol in sequence and then dried under the room temperature; secondly, sand blasting is conducted on the preprocessed titanium material through aluminum oxide particles; thirdly, the titanium material obtained after the sanding blasting is steeped with the sulfuric acid solution; fourthly, the acid etched titanium material is placed in a mixed alkali solution to be processed; fifthly, the titanium material obtained after alkali-heat treatment is cleaned through deionized water and absolute ethyl alcohol in sequence and then dried; sixthly, heat treatment is conducted on the titanium material obtained after alkali treatment for 60 min under 600 DEG C, the titanium material is cooled along with a furnace, and the preparation is completed. The preparation method is applied to the biological medical field.

Owner:HARBIN INST OF TECH

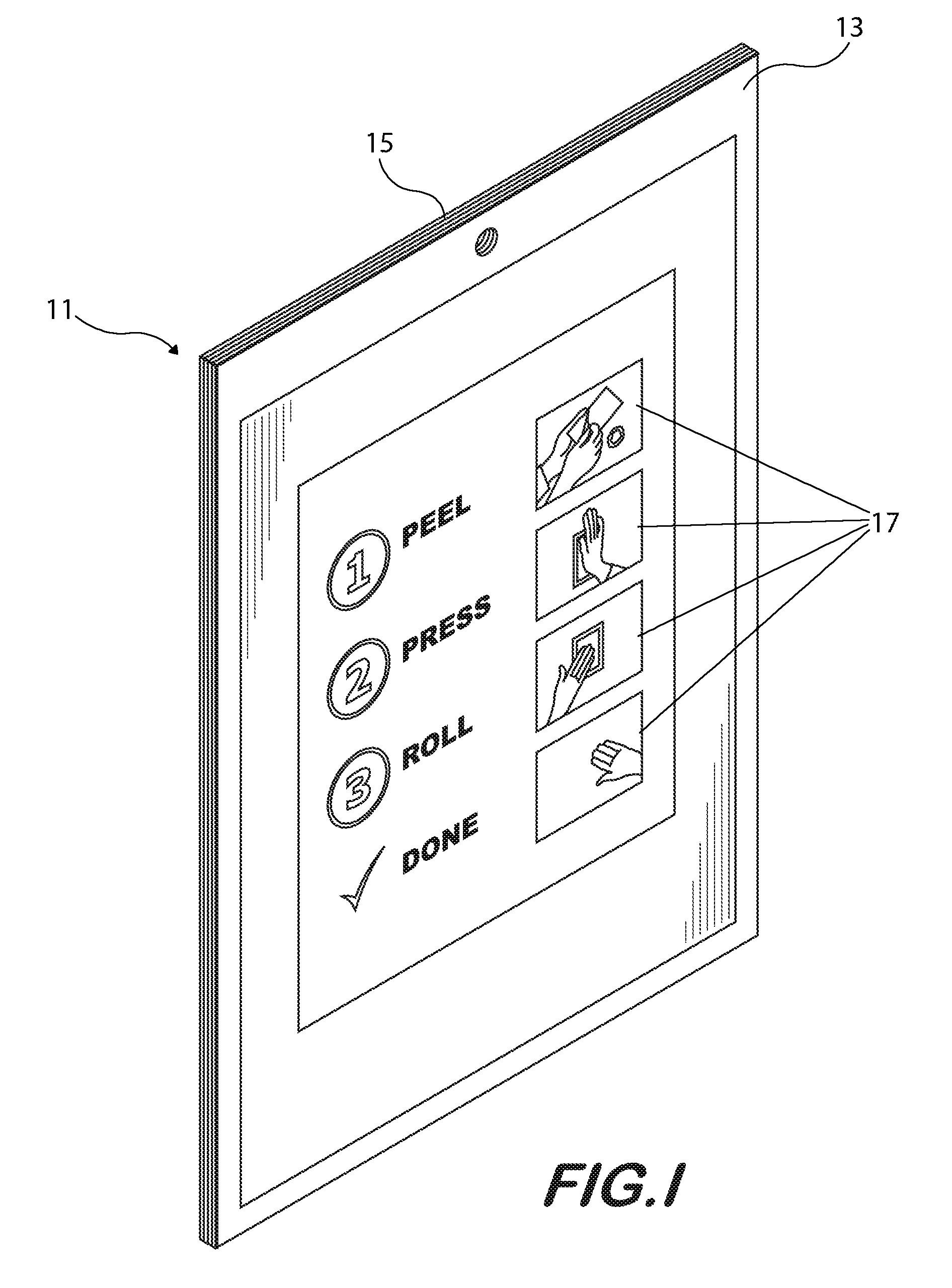

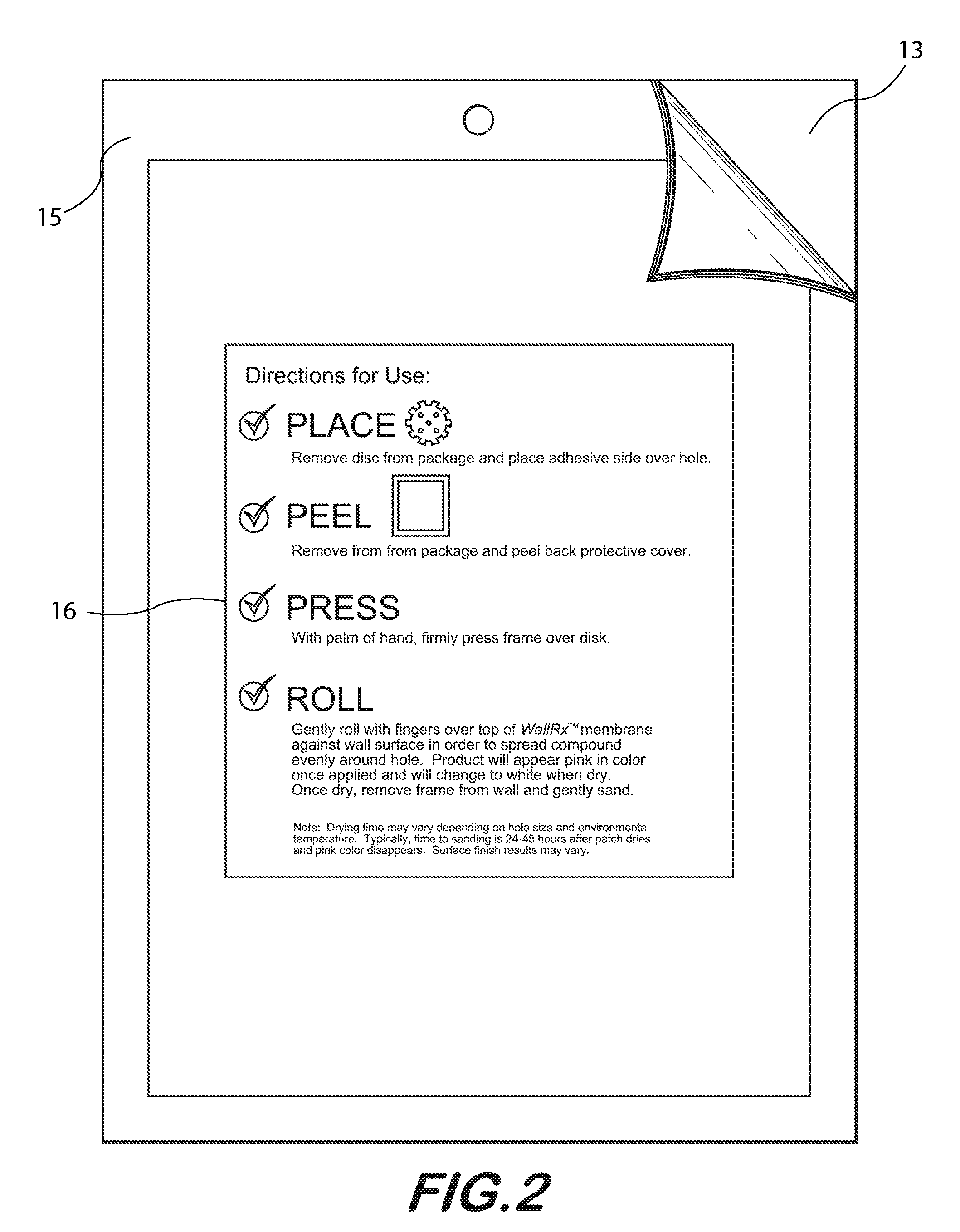

Drywall repair kit

InactiveUS8381474B2Ease and convenienceEasy to useBuilding repairsFoundation repairJoint compoundEngineering

Owner:THE WALL DOCTORX

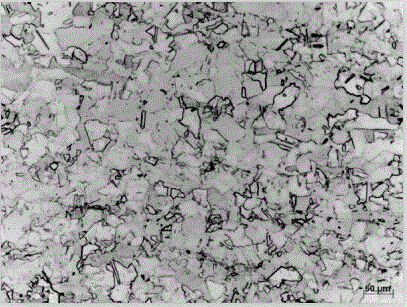

Metallographic structure etching solution of high-nitrogen stainless steel and metallographic etching method

ActiveCN104404520AEasy to prepareErosion effect is goodPreparing sample for investigationEtchingMaterials science

The invention discloses metallographic structure etching solution of high-nitrogen stainless steel. The metallographic structure etching solution comprises the following constituents in percent by volume: 35 to 40 percent of hydrochloric acid, 25 to 30 percent of acetic acid, 25 to 30 percent of nitric acid, and 5 to 10 percent of glycerinum. An etching method comprises the following steps: firstly, preparing the etching solution, secondly, sanding and polishing an embedded sample, thirdly, immersing the polished sample into the etching solution to etch the sample till the surface of the sample becomes silver gray, or repeatedly wiping the surface of the sample with degreasing cotton dipped with the etching solution till the surface of the sample becomes silver gray; fourthly, washing the surface of the sample through deionized water immediately after etching, then washing the surface of the sample through absolute ethyl alcohol, finally drying the surface of the sample through compressed air, and observing a microstructure through a microscope. The etching solution is easy to prepare, nontoxic and harmless, good in etching effect and clear in crystal boundary; the etching method is simple to operate, the etching process is controllable, and the display effect of a metallographic structure is good.

Owner:HEBEI IRON AND STEEL

Cutter-grinder

InactiveUS7104876B1Heat dissipationWash awayBelt grinding machinesPortable grinding machinesEngineeringKnife blades

An innovative cutter-grinder comprised of a base, a cutter holder, and a mobile base plate; the base plate being mounted with emery cloth before being placed on a deck of the frame to secure the emery cloth and allow easy replacement of the emery cloth; the cutter holder adapted with a roller at bottom retaining a blade for the user to hold the cutter holder to roll back and forth on the base plate to grind the cutter against the emery cloth; and an angle set plate being inserted onto slots respectively provided on both sides of the deck allowing the adjustment of the grinding angle.

Owner:LIN KUN MENG

Transferring drawing baking lacquer panel and its production method

InactiveCN1876403ABeautiful colorNot easy to fall offDecorative surface effectsOrnamental structuresPolyesterWax

Owner:杨春雷

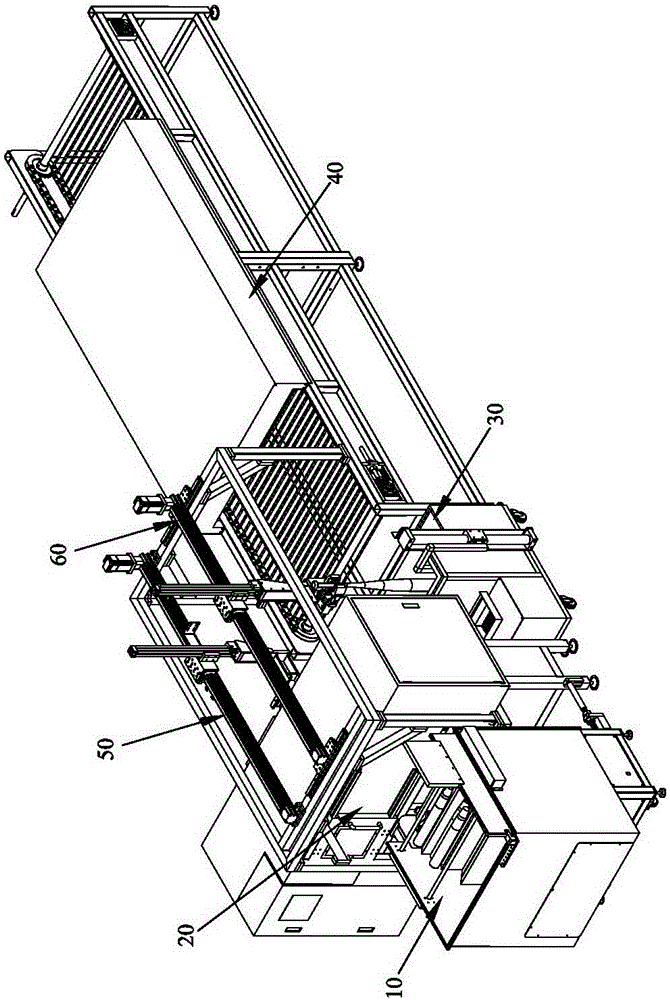

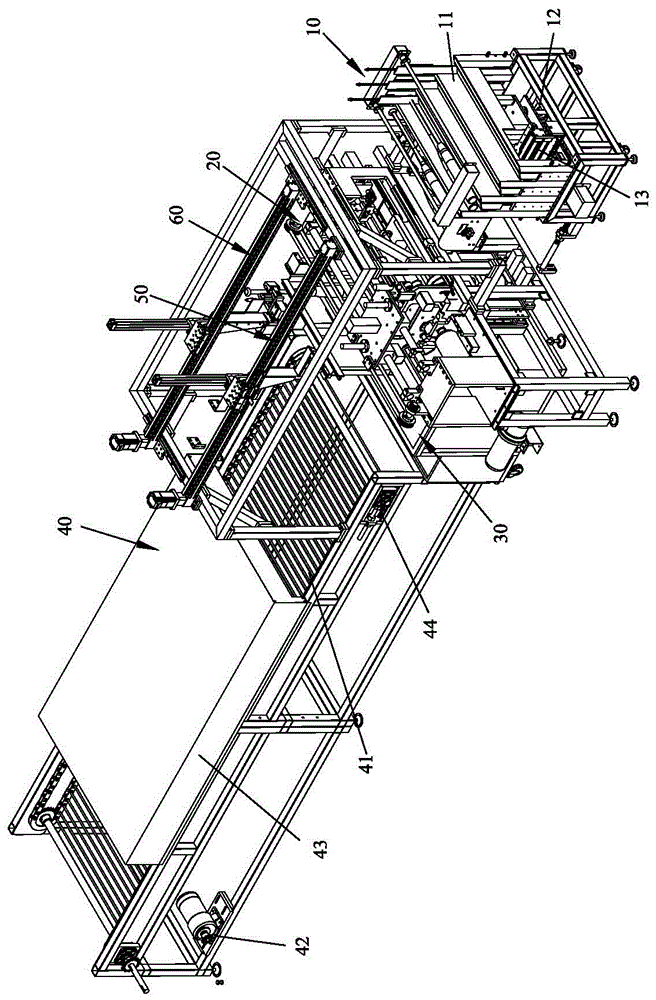

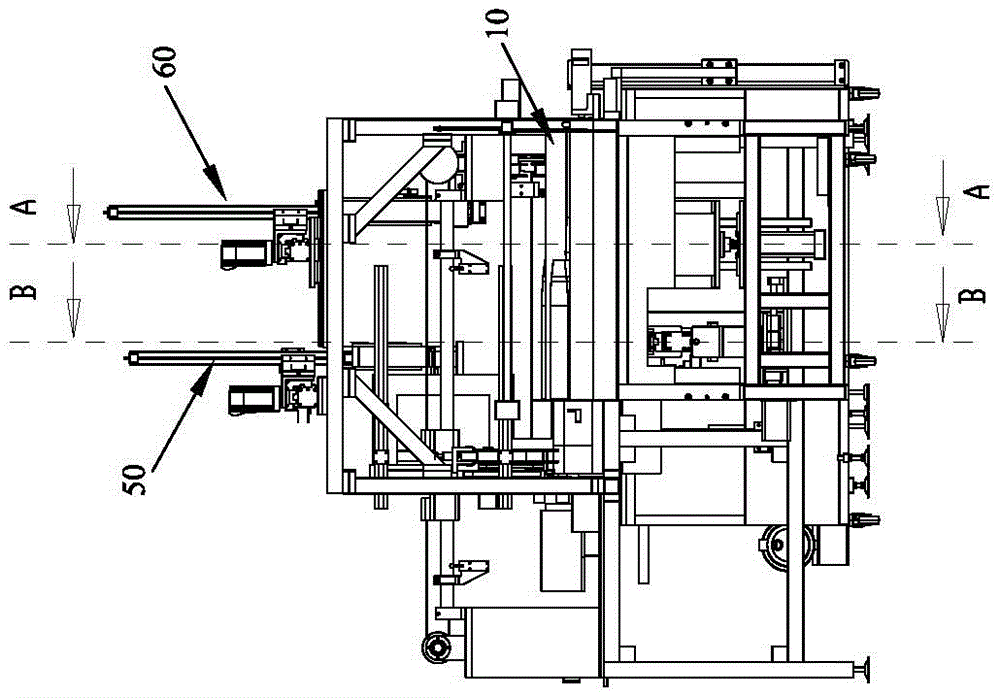

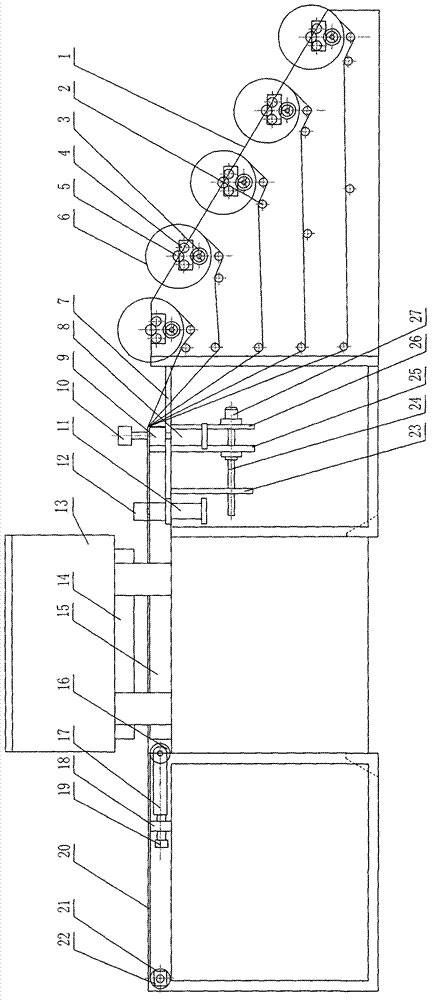

Die-cutting process and die-cutting production equipment for abrasive paper and cloth

ActiveCN103586935ARealize automatic feedingOperational securityMetal working apparatusBiochemical engineeringMachining process

The invention discloses a die-cutting process and die-cutting production equipment for abrasive paper and cloth. The die-cutting production equipment comprises feeding devices, a conveying and pressing device, a cutting device and a finished product discharging device. An integral framework is a cuboid, steel structures are connected with one another to form the framework, the feeding devices are arranged on one side of the framework, the conveying and pressing device is arranged on the left side of the corresponding feeding device, the cutting device is arranged on the left side of the conveying and pressing device, and the finished product discharging device is arranged on the left side of the cutting device. The die-cutting process and the die-cutting production equipment have the advantages that an outdated manual and mechanical combined machining process is changed, and the abrasive paper and cloth can be automatically fed, cut and formed by the aid of the die-cutting production equipment; the die-cutting production equipment can be operated safely and conveniently and is high in work efficiency and good in product quality, the abrasive paper and cloth can be accurately positioned, and raw materials and energy can be saved.

Owner:YANCHENG XIEHE MACHINERY

Method for carving colored drawing on surface of musical instrument

InactiveCN101279566AClear colorStrong three-dimensional senseDecorative surface effectsArtistic surface treatmentPolyesterEngineering

The invention relates to a method for decorating the surface of a musical instrument with carved colored drawing, which comprises the following technology steps that: 1) a board with a thickness of no less than 0.8mm is selected as the carving material, and then pasted on the decoration surface of the musical instrument after being neatly scrapped and polished; 2) a pattern is pasted on the board, and the carving is artificially completed,; then burrs are removed and the board is neatly scrapped and polished, pinholes are filled and leveled up by a putty the board is smoothly polished and dedusted by using crocus paper; 3) polyester is sprayed and coated and the board is polished with primer, and then is put in a paint drying room in a dustless environment so as to be dried in the shade for 24 hours; afterwards, the previously processed board is smoothly polished and dedusted by the crocus paper; 4) the pattern is defined with colored drawing coatings and then the colored board is dried in the shade in a paint drying room in the dustless environment; 5) the board is sprayed and coated with polyester topcoat and dried in the shade in the dustless environment. The method has the advantages that the musical instrument has discernible color, strong stereoscopic sensation and vivid picture after going through the treatment of the carving colored drawing process and gives delightful visual impact to the executant and the audience, thereby being suitable for the decoration of the surfaces of musical instruments such as koto, cymbalo, lute, etc.

Owner:张立君

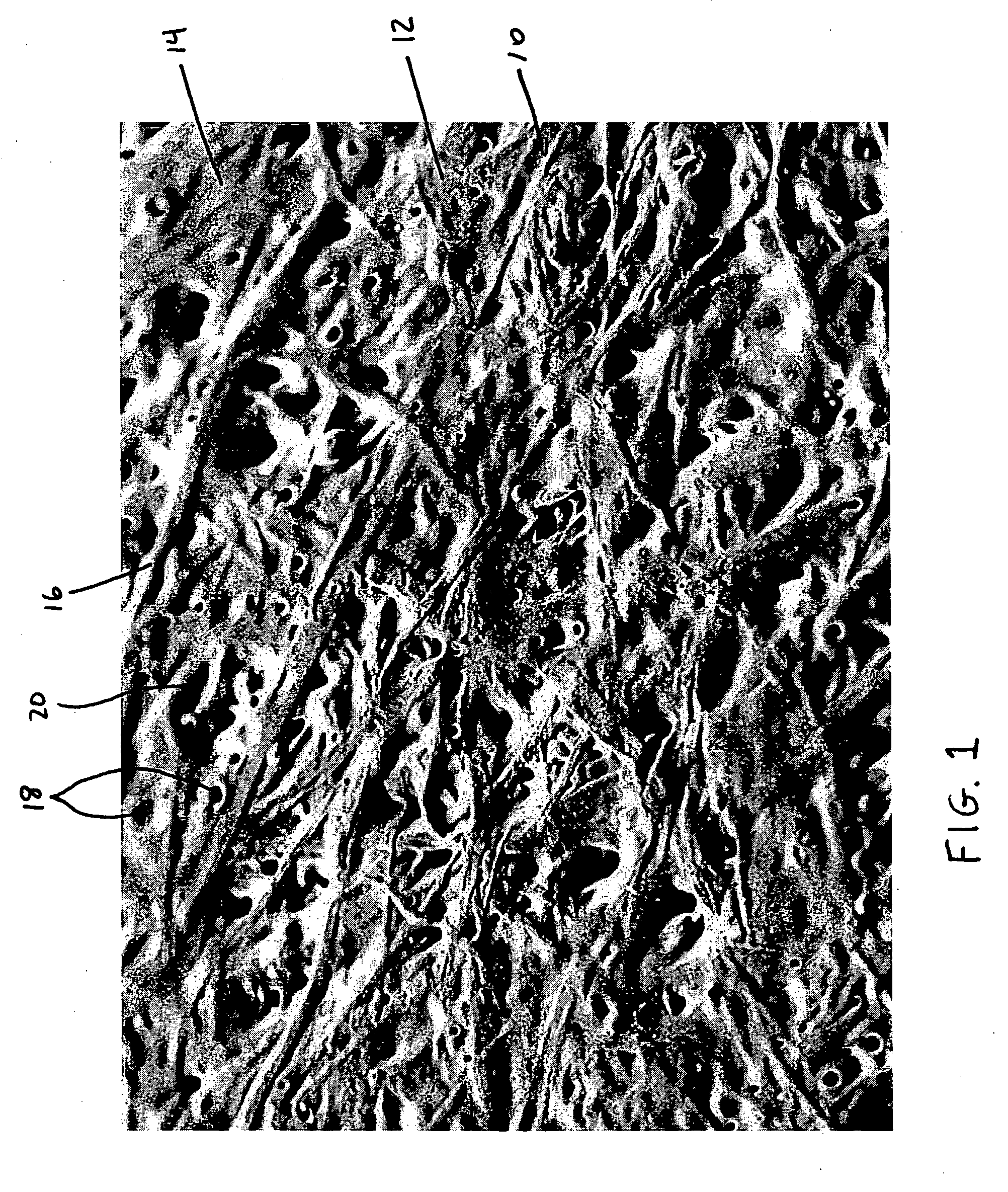

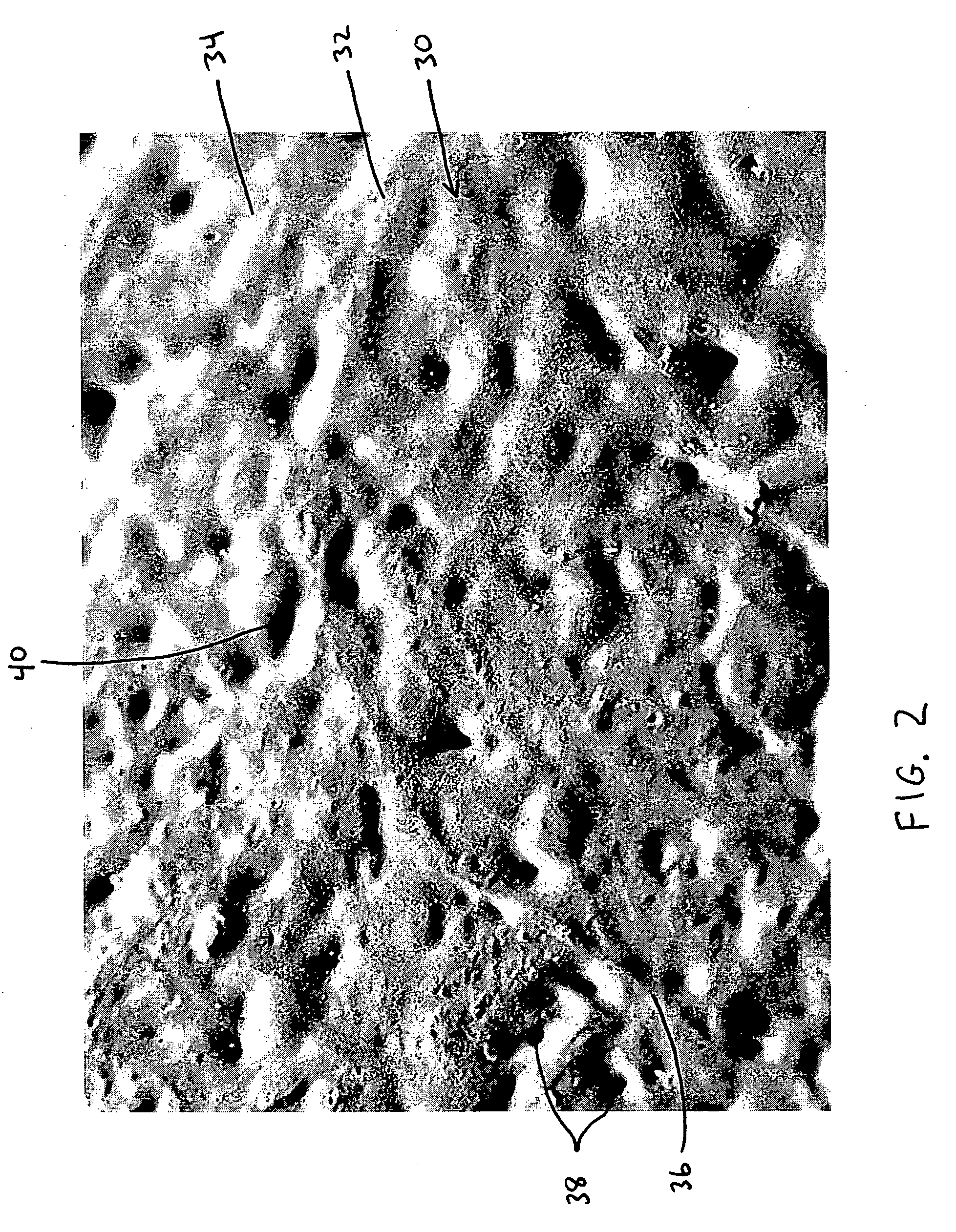

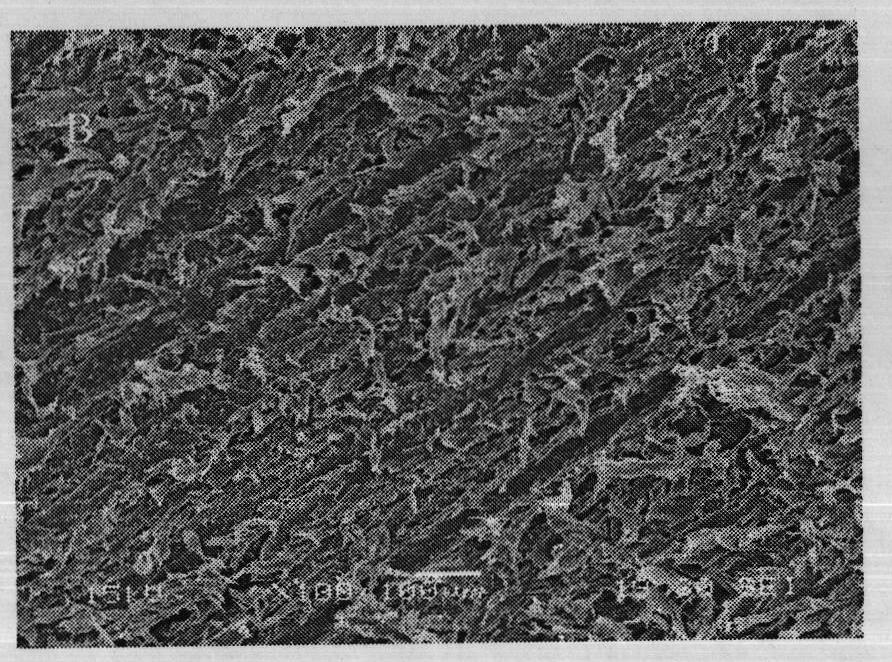

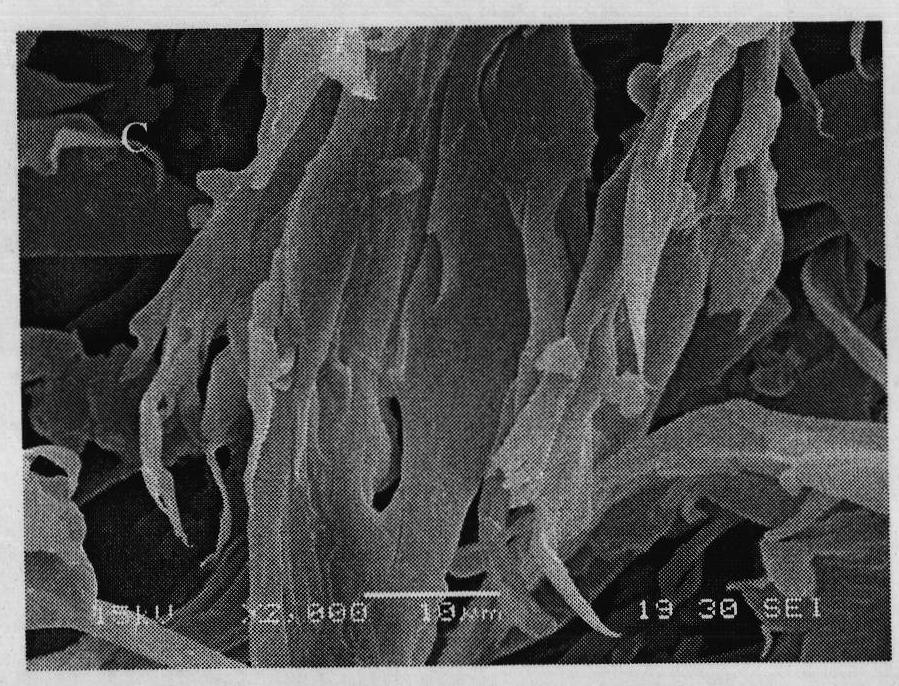

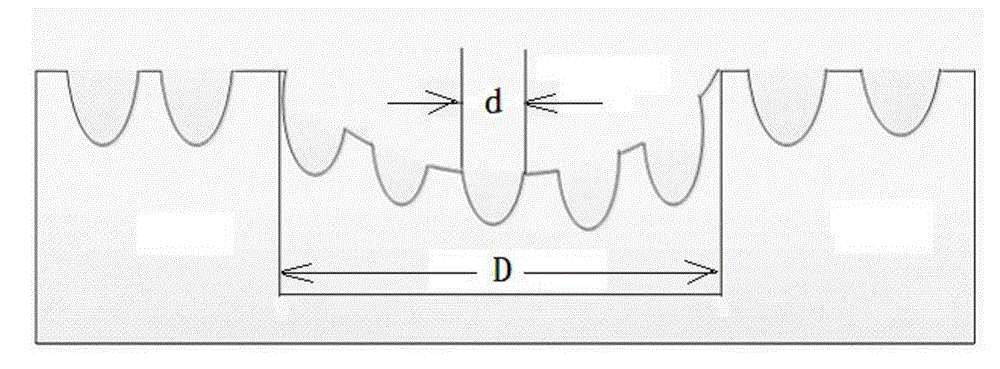

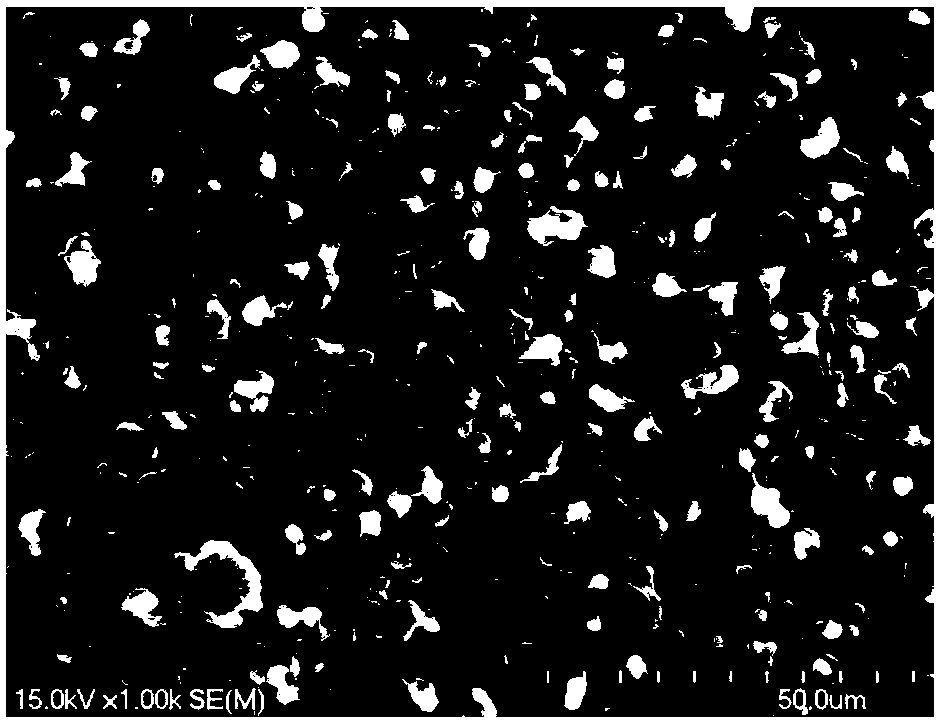

Agreement structure for friction nano generator-used friction layer material surface roughness and manufacturing method thereof

The invention belongs to the field of material micro surface processing, and particularly relates to an agreement structure for friction nano generator-used friction layer material surface roughness and a manufacturing method thereof. The method uses a simple sand paper template, spin coating of PDMS onto the rough surface of the sand paper is carried out, and after stripping, a PDMS film with a pattern surface complementary with the shape of the sand paper is manufactured; and on the other hand, a copper film with a small thickness is directly evaporated on the sand paper surface through a thermal evaporation and film coating mode, and thus, a copper friction material with a rough surface and a reproduced sand paper shape is manufactured. The two positive and negative friction layer materials used by the friction nano generator are manufactured, and the material has a surface with a pattern complementary with the shape of the sand paper and also has a surface with the sand paper shapepattern. More importantly, templates with the same specifications are adopted for manufacturing, the sizes of the surface shape patterns are almost the same, the shapes are complementary and can completely agree, and the actual contact area during the friction process is larger.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Continuous molding of fastener products and the like and products produced thereby

InactiveUS20040201124A2Uniform product thicknessUniform thicknessLayered productsFilament/thread formingFiberShell molding

Abstract of the Disclosure Improvements are disclosed for an apparatus for continuously molding small fastener elements integral with a base web from a flowable resin. The apparatus comprises a cylindrical mold roll rotatable about an axis and defining small fastener element-shaped mold cavities in the surface thereof, and pressure-applying means to apply operating pressure to force the resin into the cavities at a pressure zone. The pressure-applying means and mold roll define a mold gap therebetween for forming the base web. The advantageous use of relatively long mold rolls, to produce a correspondingly wide web, and the use of higher molding pressures, e.g. to form very small fastener elements, is enabled by various improvements, including means to maintain the mold gap at a desired thickness profile across the length of the molding region of the mold roll under operating pressure. In some cases the pressure-applying means includes a pressure roll, in other cases it includes a resin nozzle assembly or pressure head. In some other cases it includes a belt. Various control schemes are also disclosed, as are means to provide cooling. In some particularly useful embodiments, at least one of the rolls of the apparatus has a resiliently deformable surface. Methods of molding fastener elements directly on a sheet material, such as sandpaper, are also disclosed, as well as methods for laminating.

Owner:VELCRO IND BV

Wear-resistant super-hydrophobic coating layer and preparation method thereof

InactiveCN110862756AWide applicabilityExcellent superhydrophobic propertiesPolyurea/polyurethane coatingsPolyurethane dispersionCoated surface

The invention discloses a wear-resistant super-hydrophobic coating layer and a preparation method thereof. An absolute ethyl alcohol dispersion liquid of hydrophobic silicon dioxide nanoparticles is uniformly mixed with a single-component waterborne polyurethane aqueous solution to obtain a hydrophobic silicon dioxide nanoparticle / single-component waterborne polyurethane dispersion liquid, then the dispersion liquid is brushed or sprayed on a base material, and cured at room temperature for 5 h to obtain the wear-resistant super-hydrophobic coating layer. The prepared super-hydrophobic aqueoussolution can be stored in a sealed manner for a long time, can be coated as required, can be cured at room temperature, and is quite convenient. The base material can be any one of glass, metals, plastics, ceramics and stone. The static water contact angle of the surface of the wear-resistant super-hydrophobic coating layer is 151 DEG-153 DEG, the rolling angle of the surface of the wear-resistant super-hydrophobic coating layer is 4 DEG-6 DEG, and the wear-resistant super-hydrophobic coating layer can rub 1800 cm on 320-mesh abrasive paper along a straight line under the pressure of 2500 Pa.The method has the advantages of being simple in preparation process, convenient to operate, green, environmentally friendly, low in cost and the like, has high practical value and application prospects, and can be applied to various fields.

Owner:FUZHOU UNIV

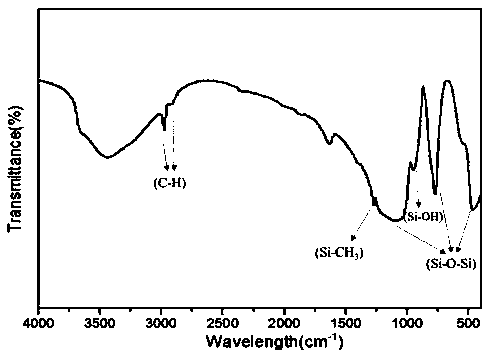

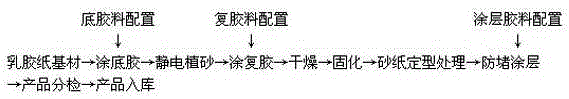

Abrasive paper production process and coating adhesive formula

The invention discloses an abrasive paper production process and a coating adhesive formula. The abrasive paper production process includes the following steps: a, after a base material is coated with primer, electrostatic sand planting and drying are carried out on the base material; b, after the base material is coated with composite cement, drying and curing are carried out; c, abrasive paper is subjected to sizing treatment; d, the base material is coated with anti-blocking coating adhesive, and drying is carried out; and e, products are put in storage after being sorted. The coating adhesive formula comprises, by weight percentage, 60% of lubrication padding, 10% of a cementing compound, 2% of an anti-electrostatic agent and 28% of a solution. The base material is latex paper with high surface smoothness. The abrasive paper has the beneficial effects that the higher strength and the higher excellent softening property are achieved, the surface smoothness is high, the abrasive paper is particularly suitable for polishing irregular surfaces of surfboards and snowboards, the polishing effect is good, and the degree of finish is high.

Owner:DONGGUAN GOLDEN SUN ABRASIVES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com