Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1718 results about "Sander" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A sander is a power tool used to smooth surfaces by abrasion with sandpaper. Sanders have a means to attach the sandpaper and a mechanism to move it rapidly contained within a housing with means to hand-hold it or fix it to a workbench. Woodworking sanders are usually powered electrically, and those used in auto-body repair work by compressed air. There are many different types of sanders for different purposes. Multi-purpose power tools and electric drills may have sander attachments.

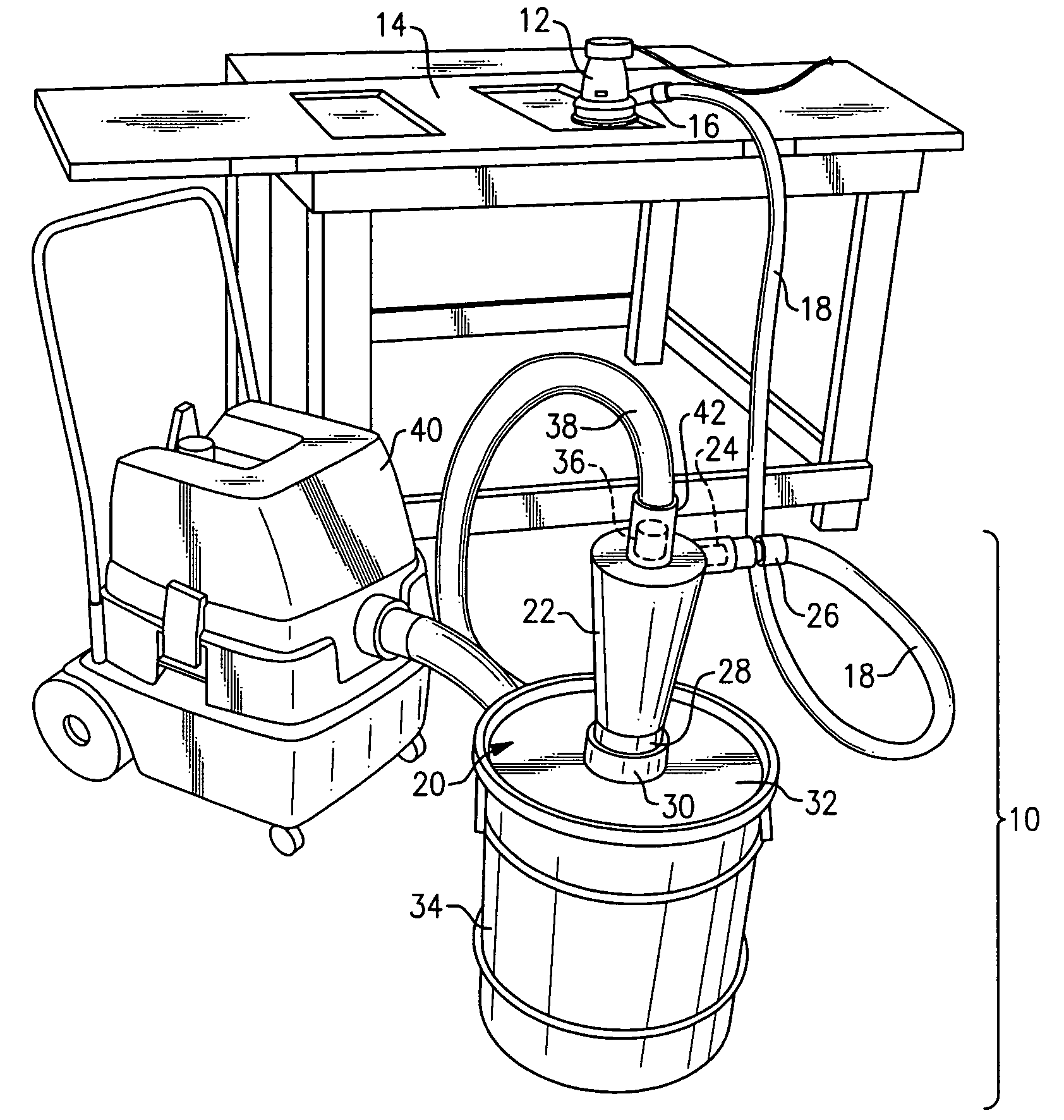

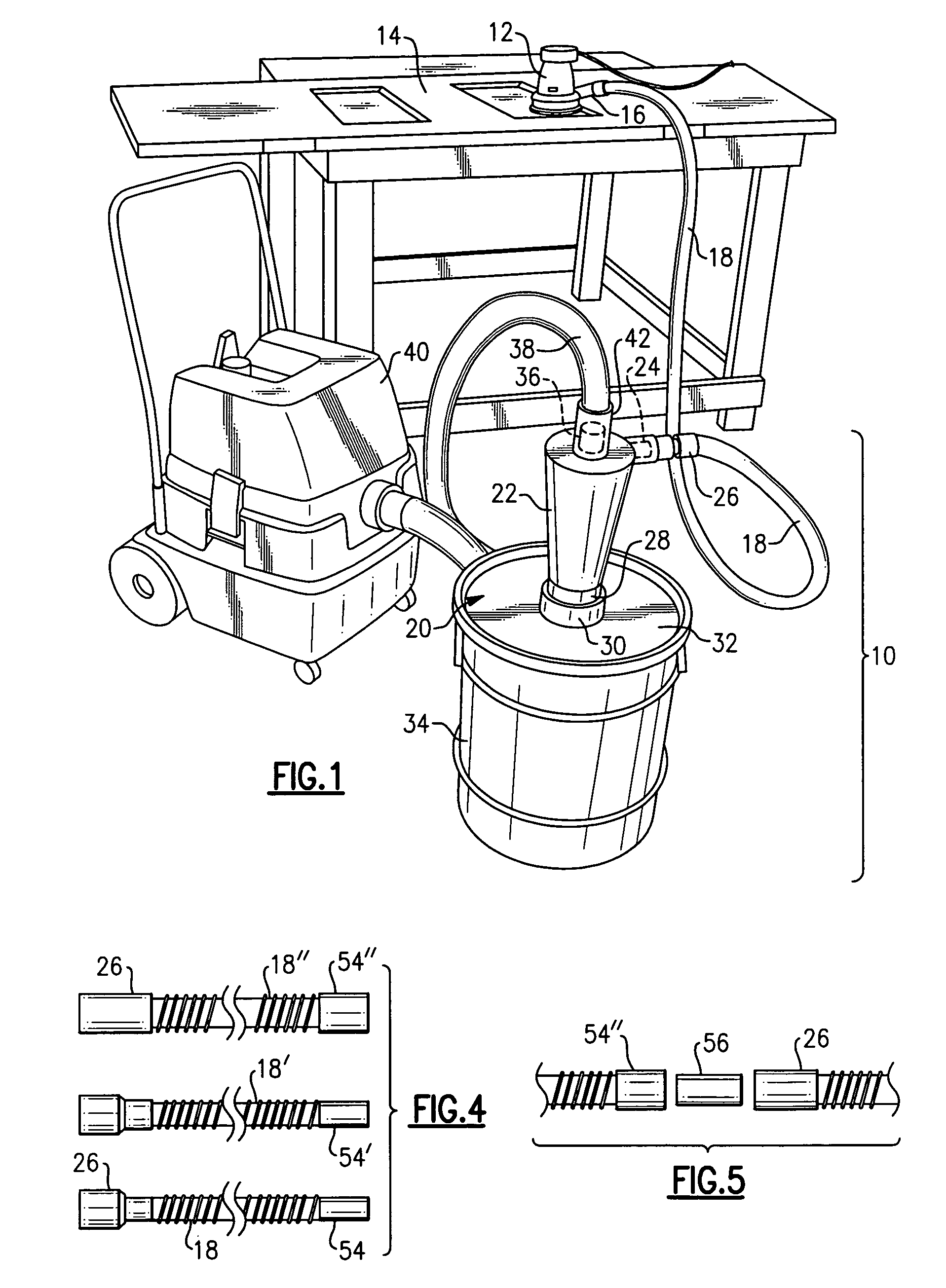

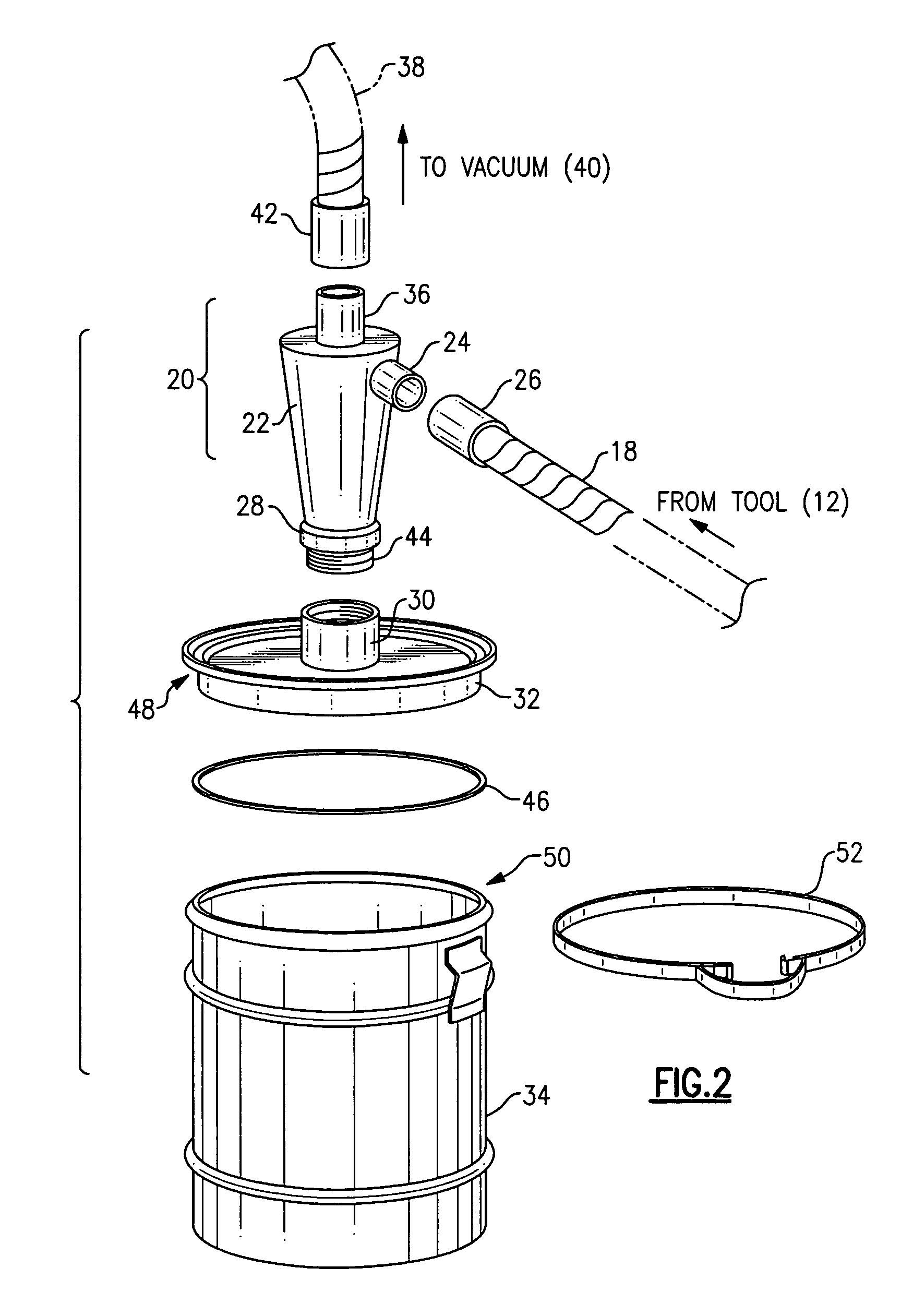

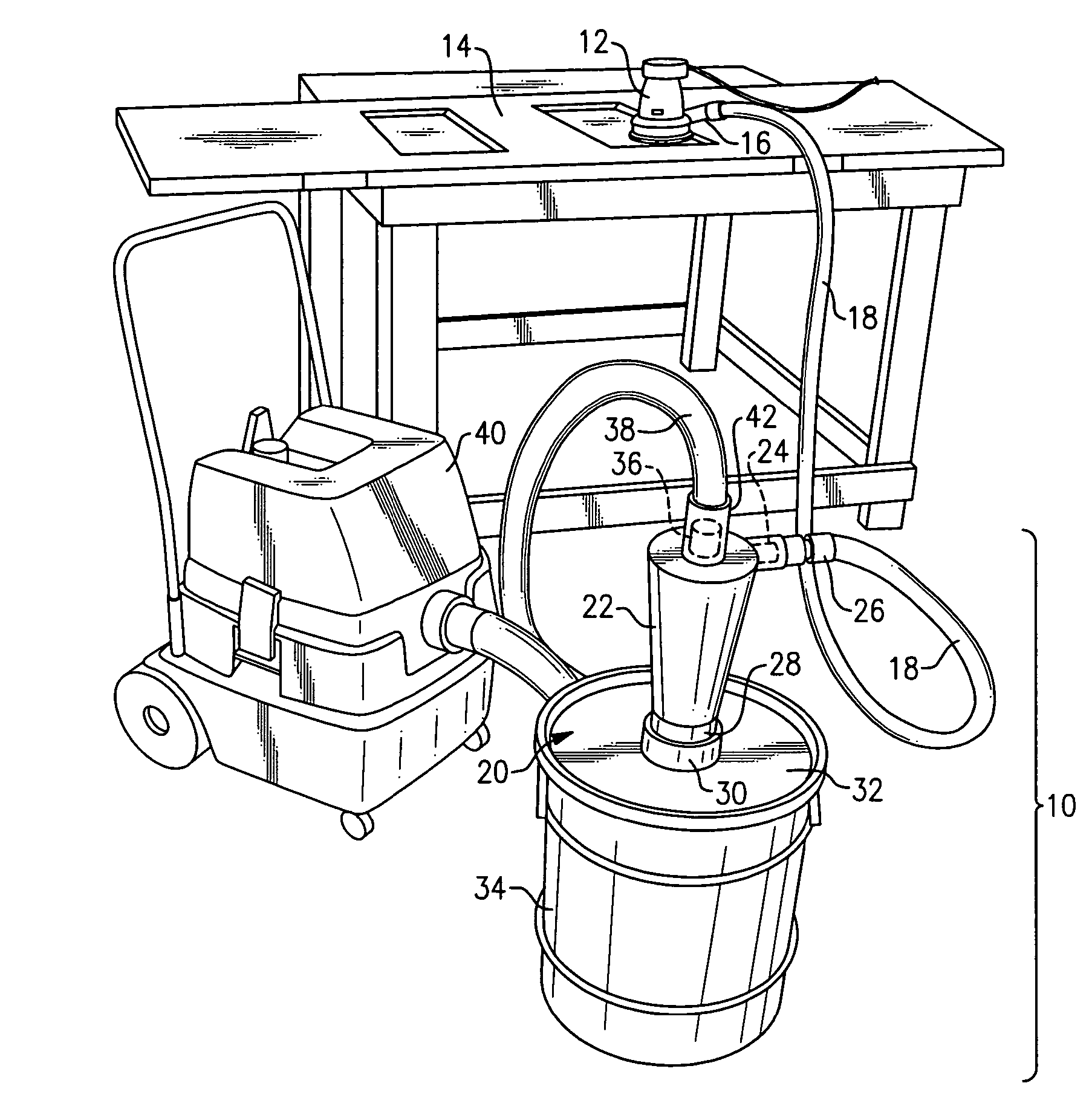

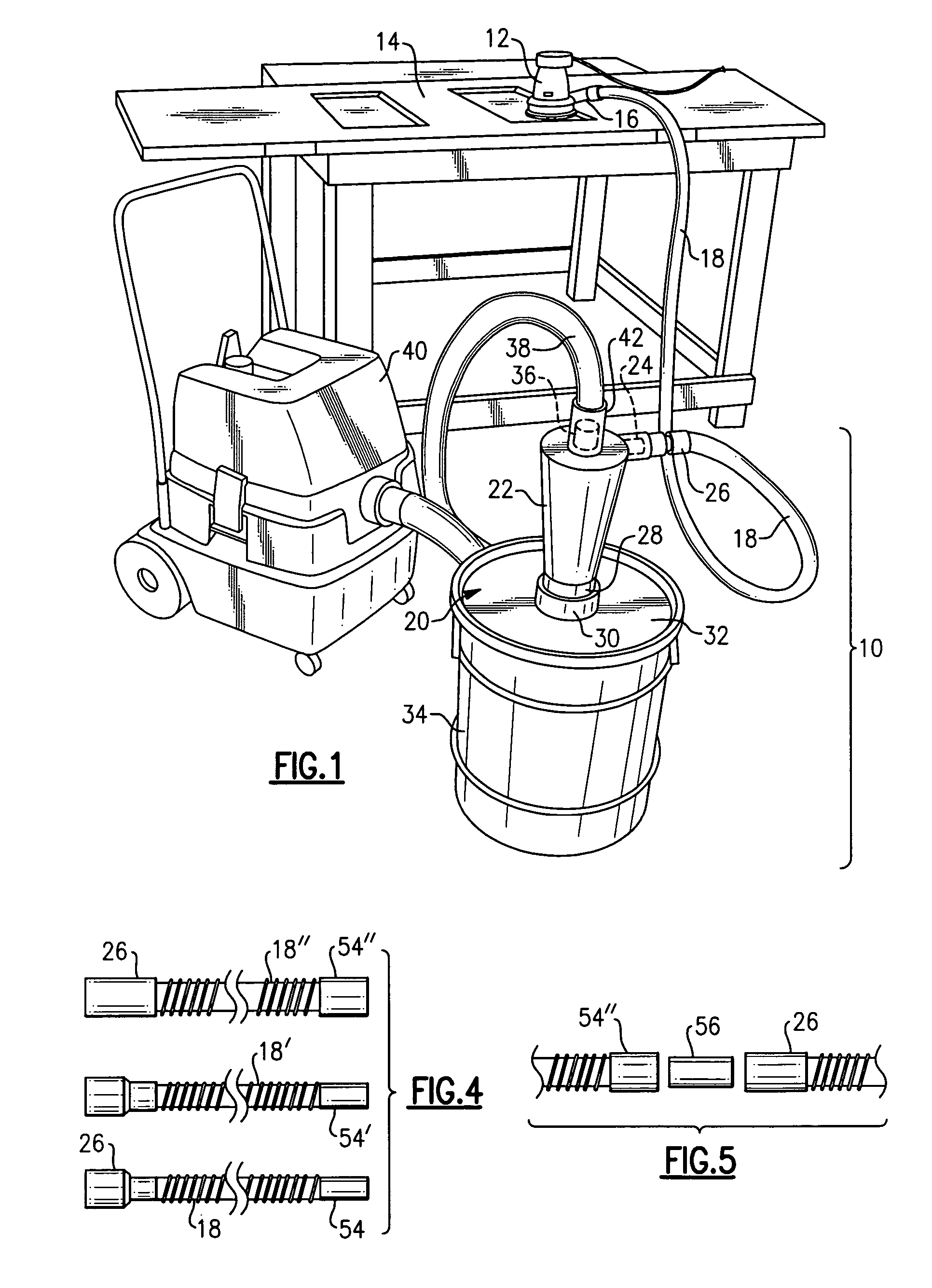

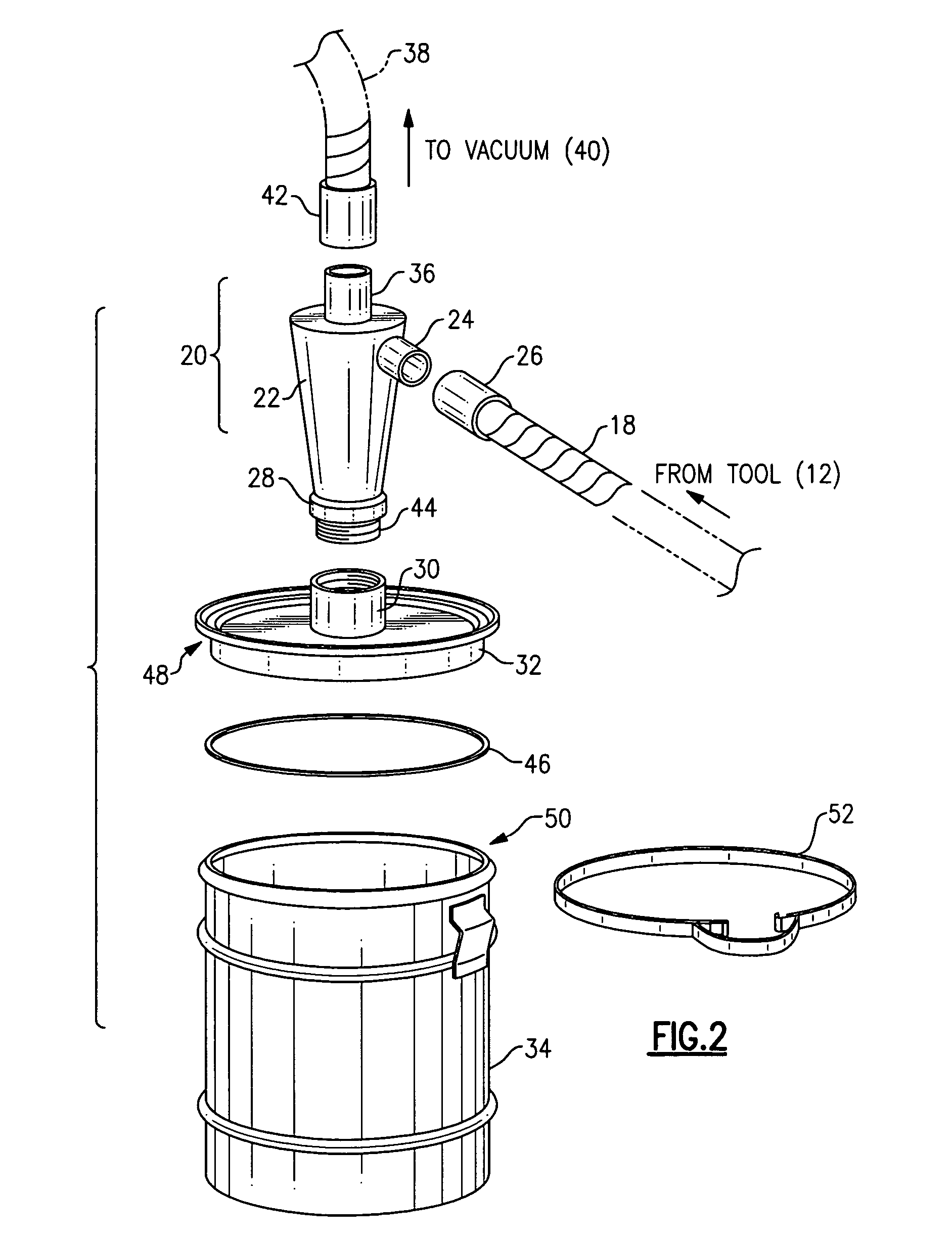

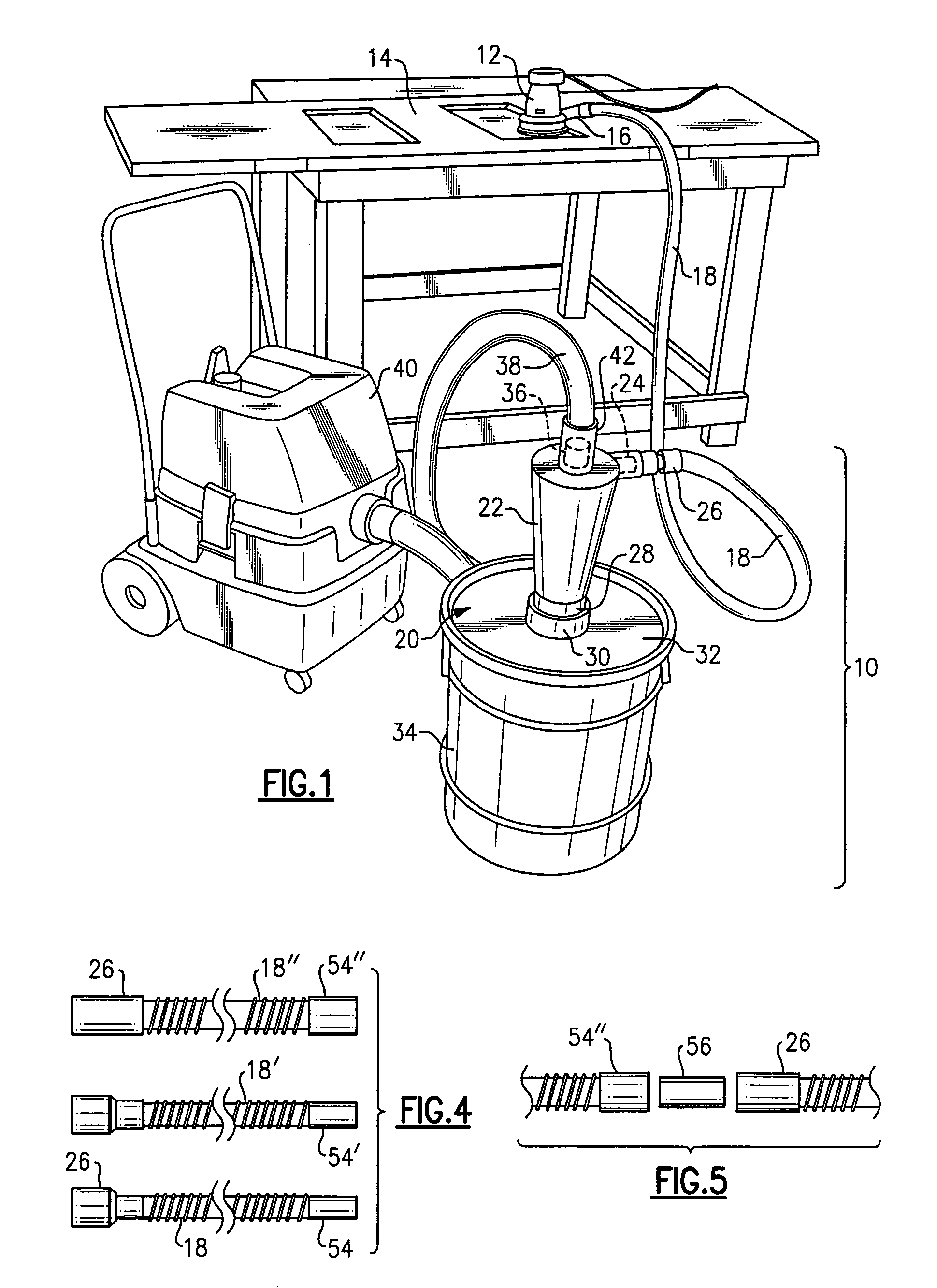

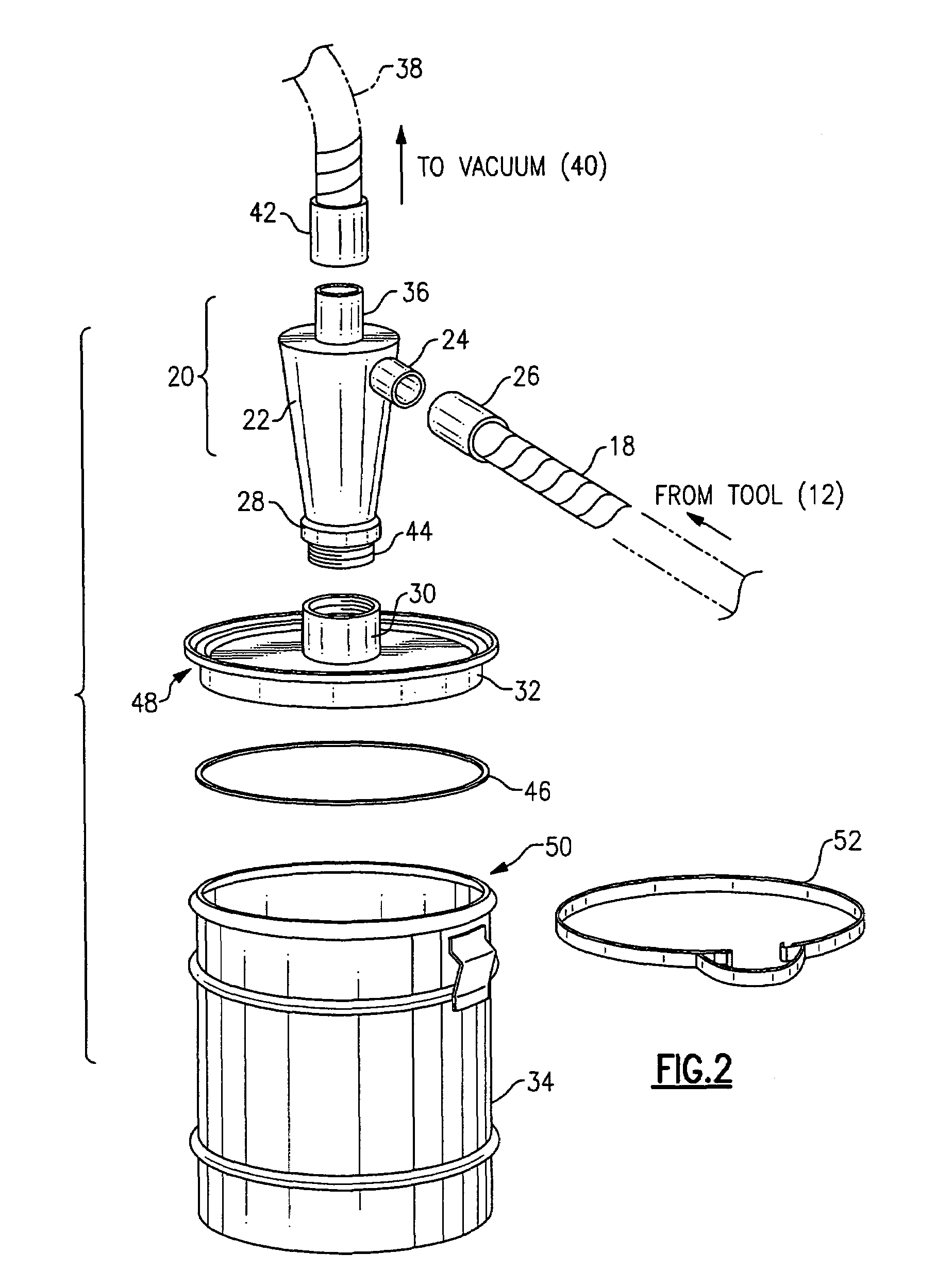

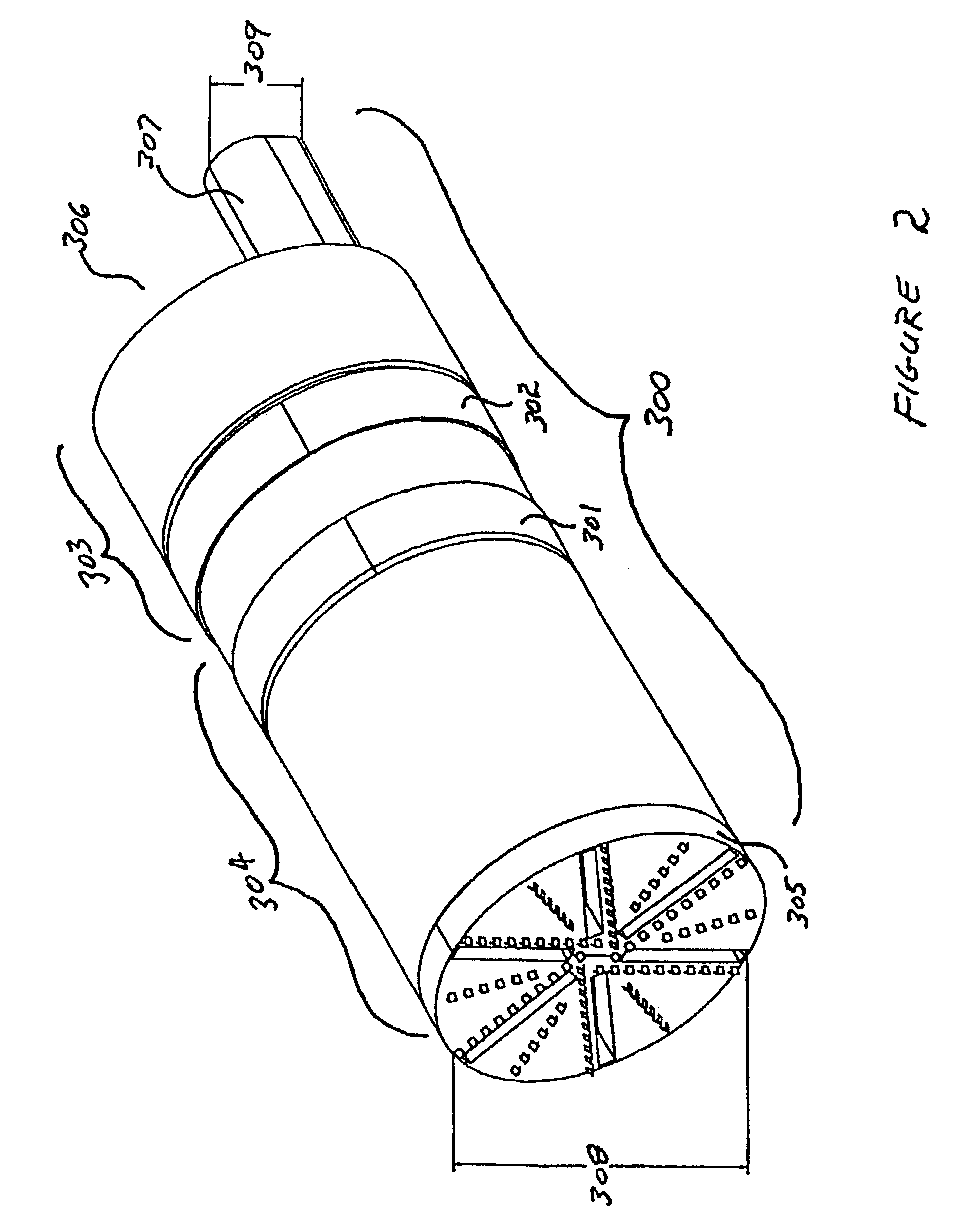

Auxiliary dust collection system

ActiveUS7282074B1Simple and straightforward in constructionImprove reliabilityCombination devicesReversed direction vortexSanderProcess noise

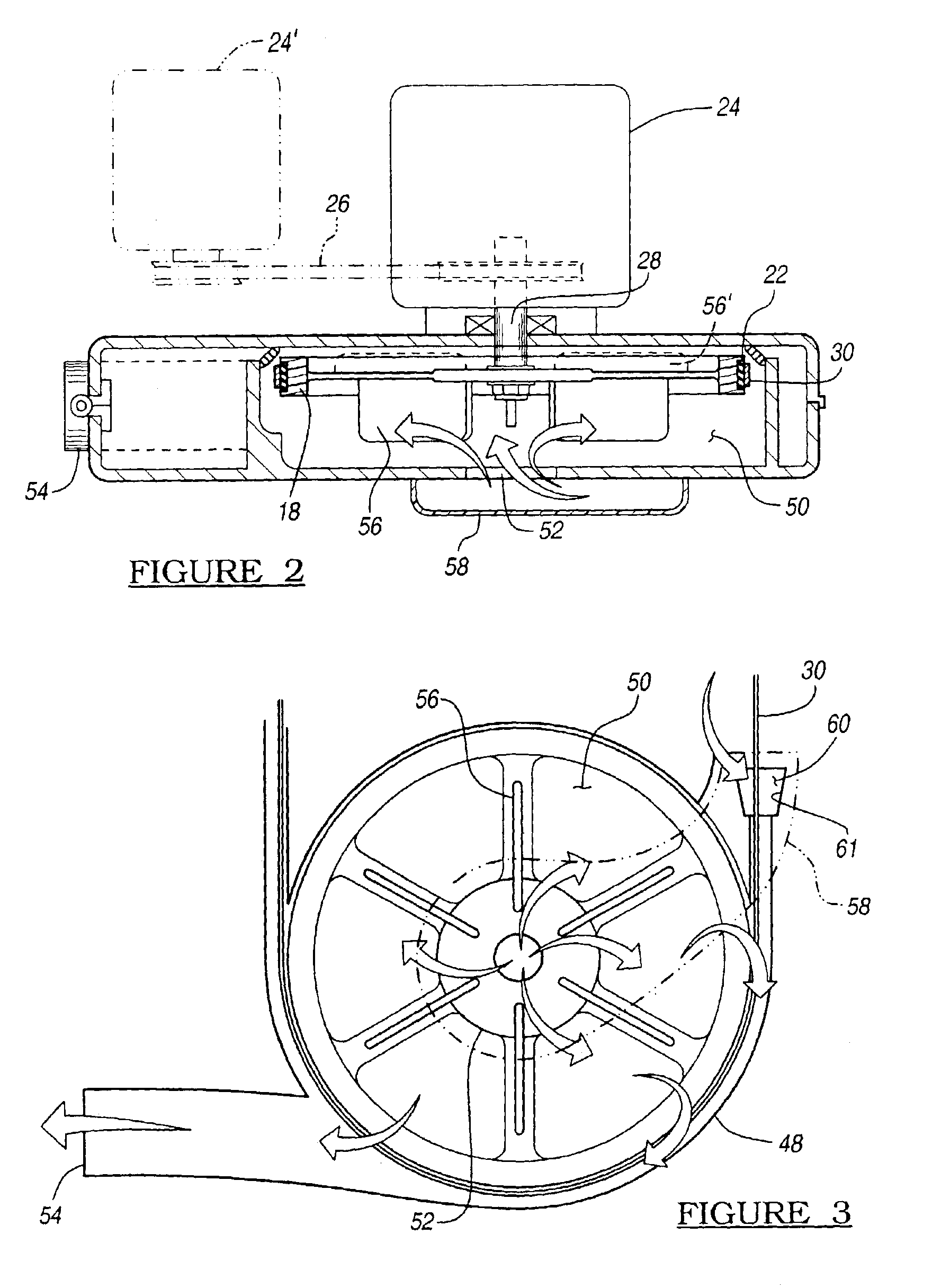

An auxiliary dust collection system can be interposed between a sander or other dust producing tool and a vacuum source, e.g., shop vacuum. This auxiliary system has a cyclonic separator connected by a flexible hose to the tool and by another hose to the vacuum source. The cone of the separator is mounted onto the lid of a drum into which the dust precipitates. For a tool that has its own blower, the vacuum source can be omitted, and the air leaving the outlet duct of the separator can be filtered and returned to the ambient. A drop in silencer formed of a sleeve or tube of acoustic foam can be positioned into the inlet side of a filter cartridge following a cyclonic separator. The silencer absorbs a significant fraction of the process noise.

Owner:WITTER ROBERT M

Auxiliary dust collection system

ActiveUS20070251198A1Avoid disadvantagesSimple and straightforward in constructionCombination devicesReversed direction vortexSanderProcess noise

Owner:WITTER ROBERT M

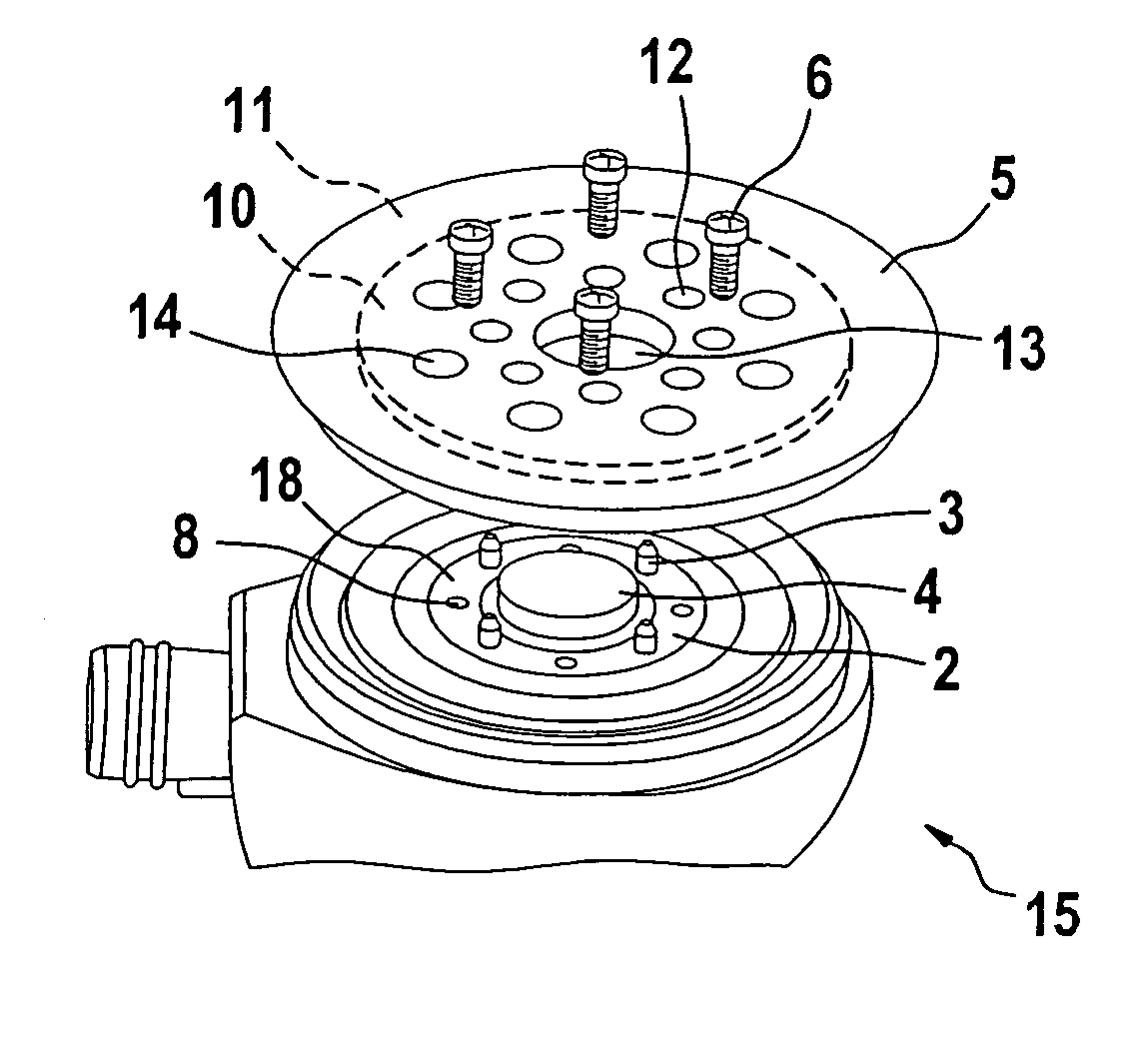

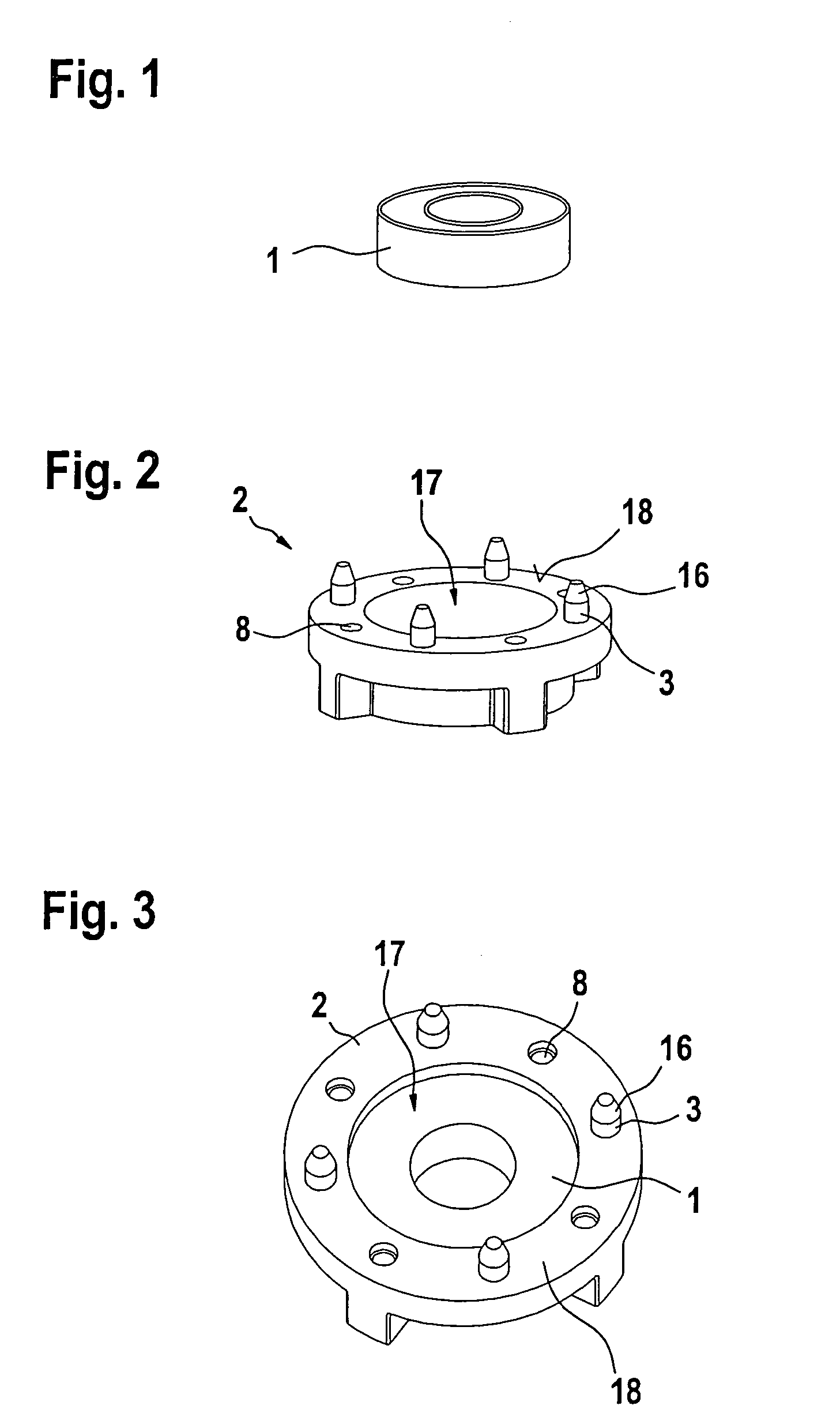

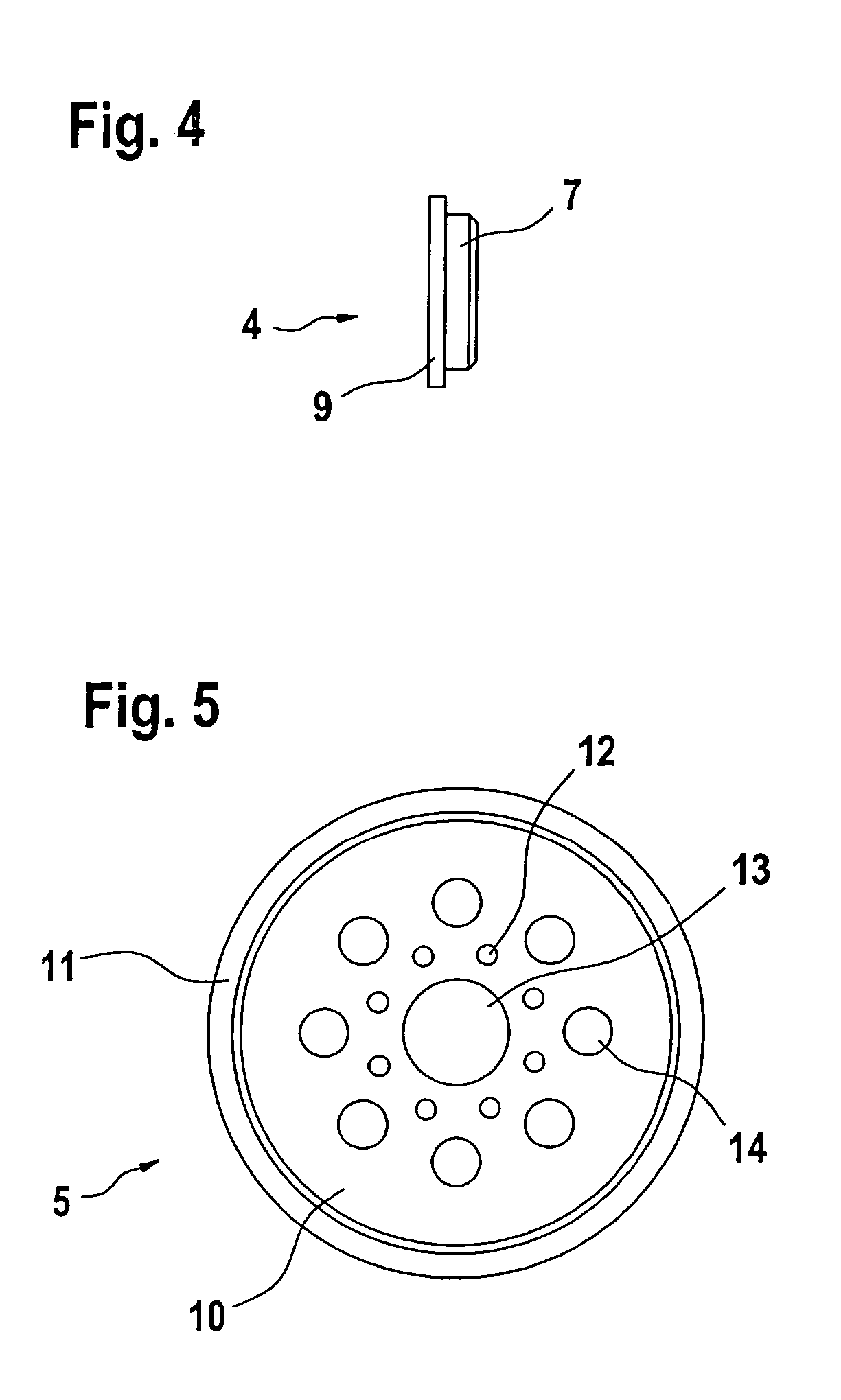

Grinding-disk receiving element especially for a hand-guided electric grinding tool

ActiveUS7217177B2Easy to installEasy to driveGrinding wheel securing apparatusSupport wheelsSanderEngineering

Owner:ROBERT BOSCH GMBH

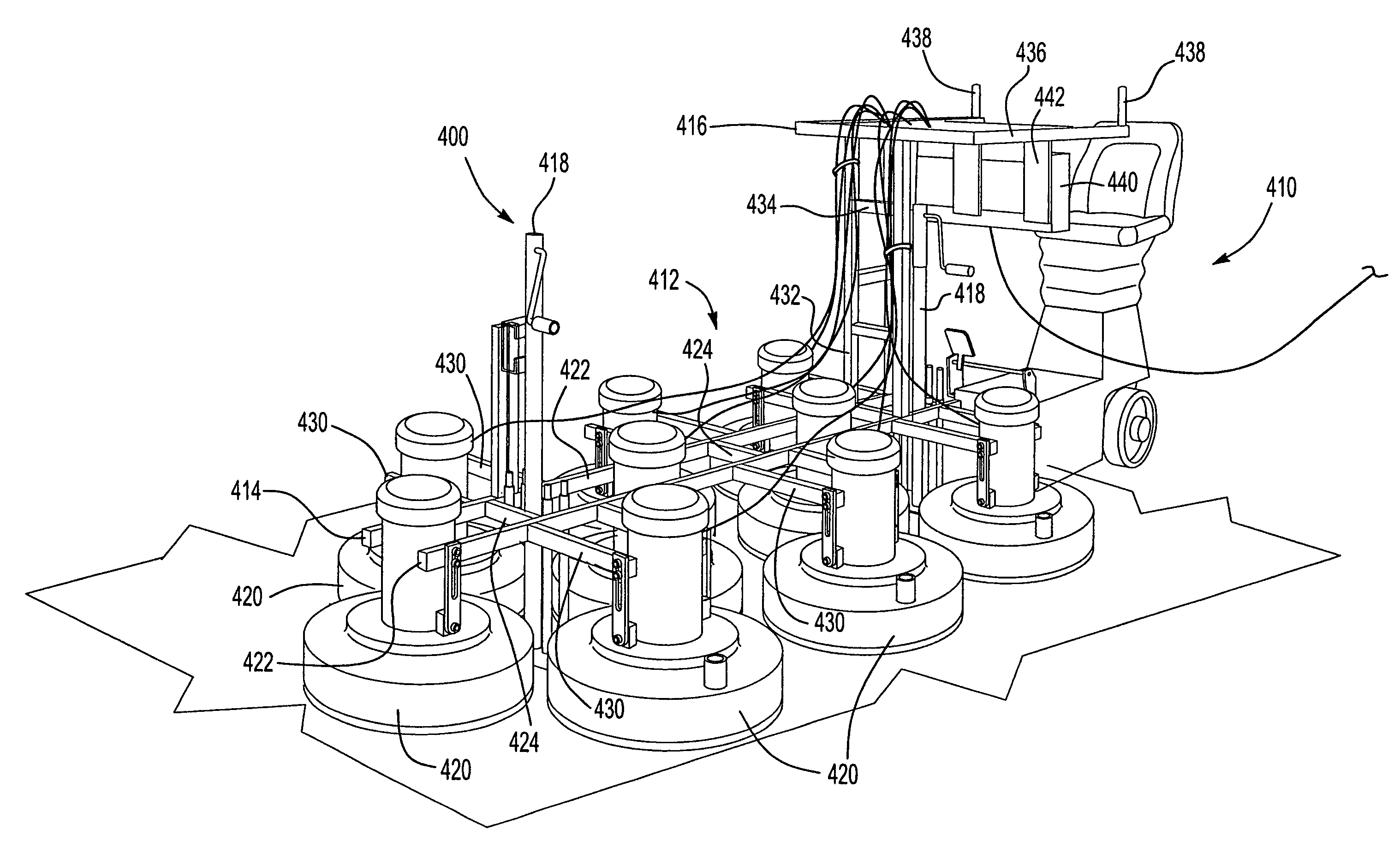

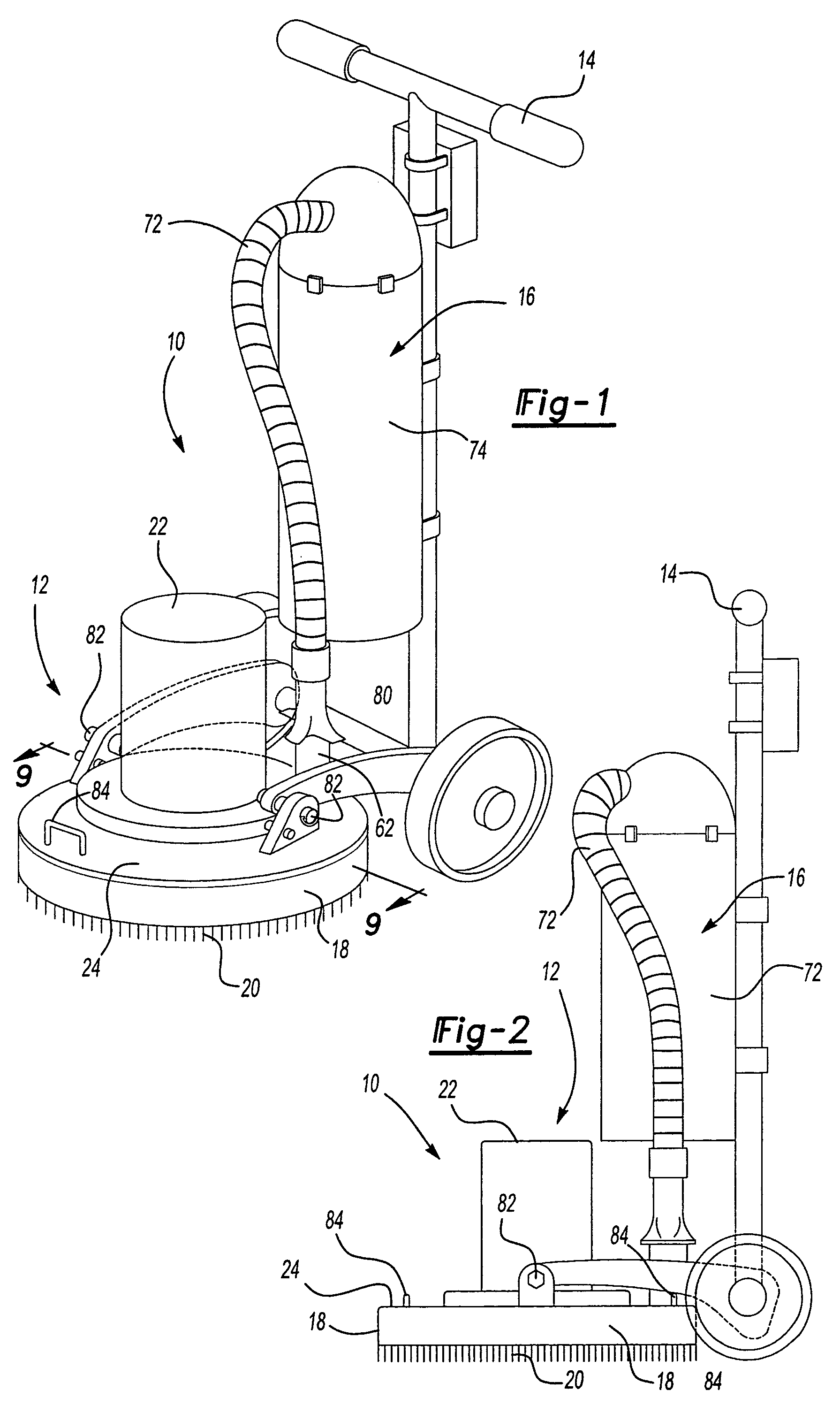

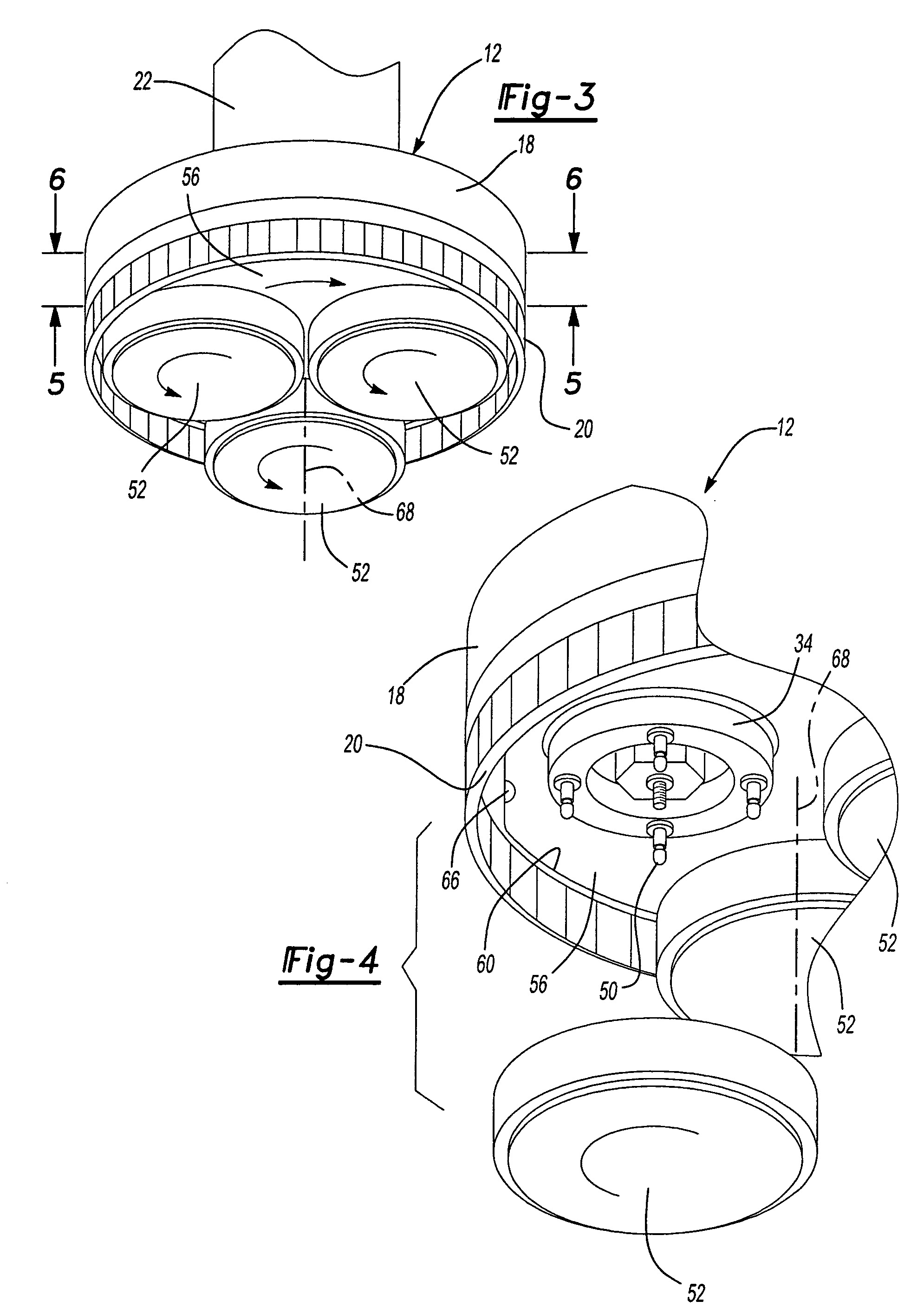

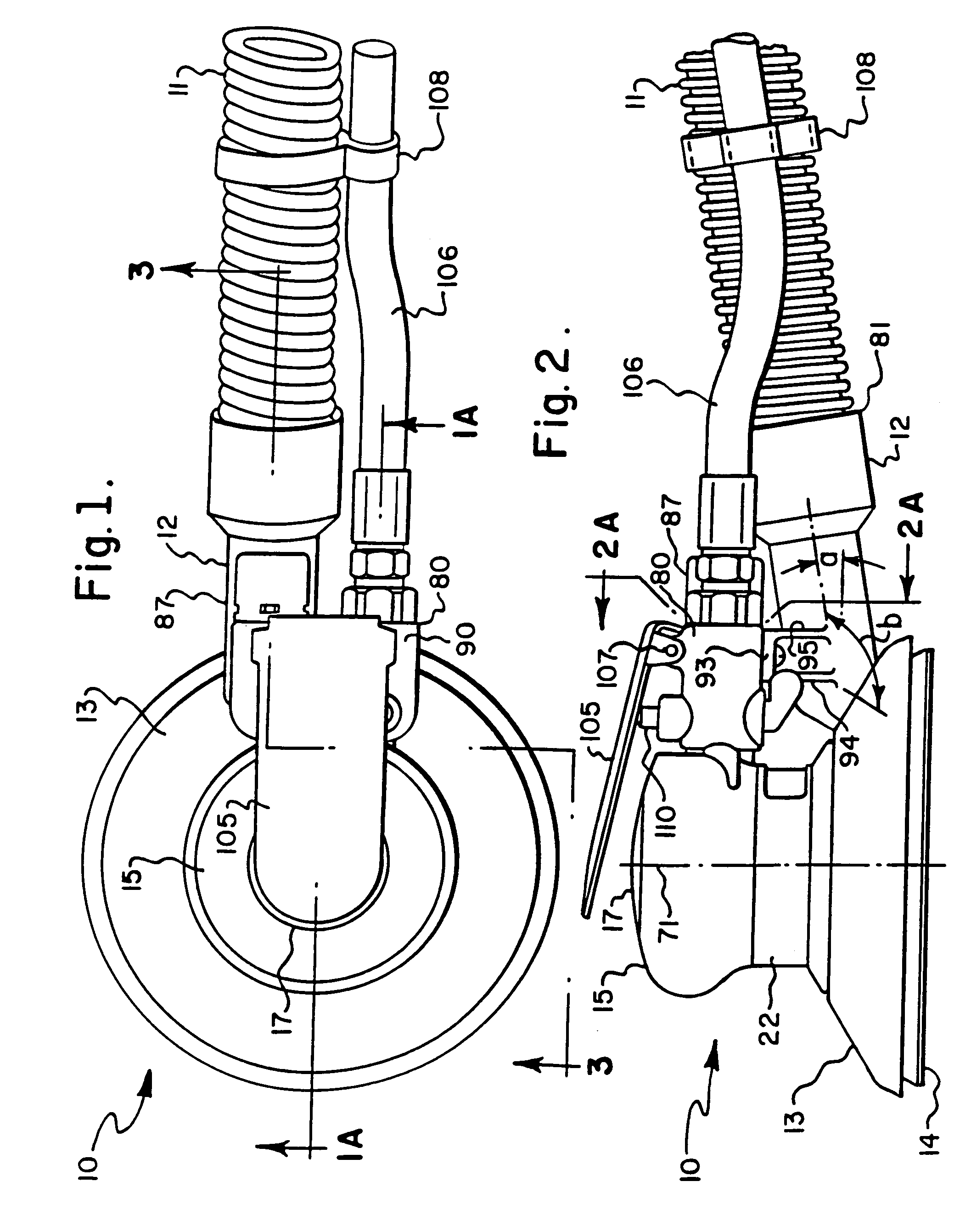

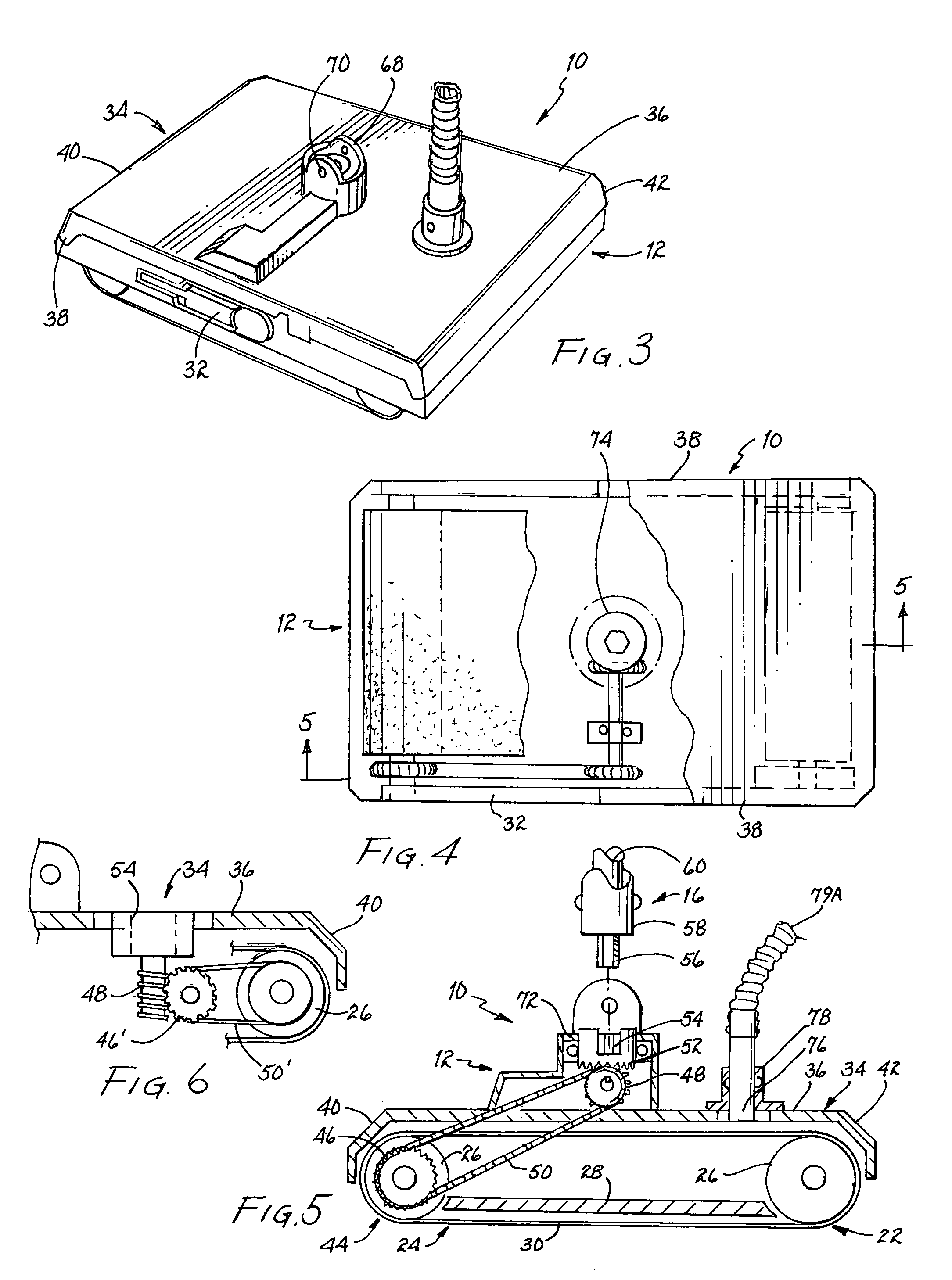

Wood floor sanding machine

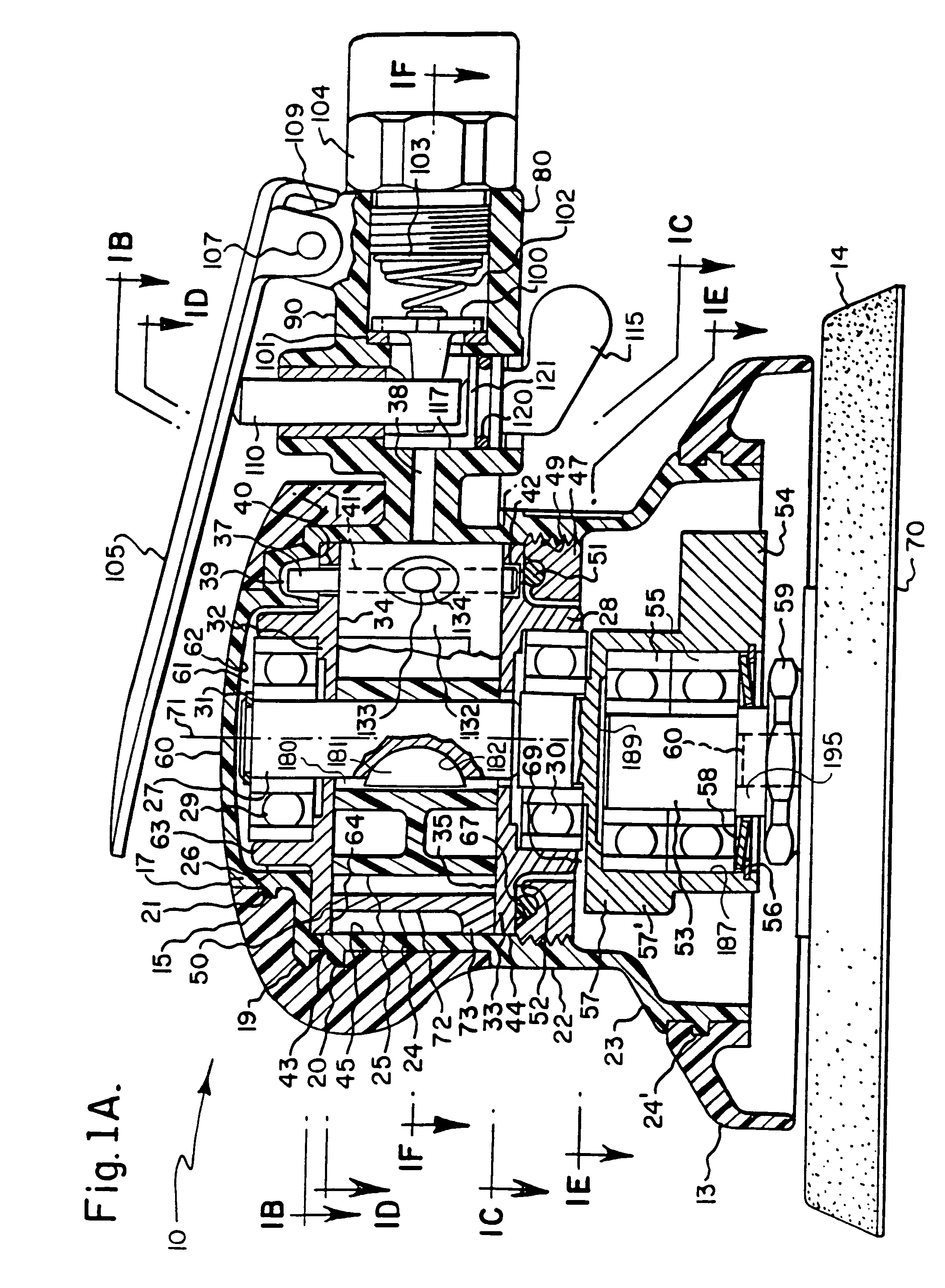

A power sanding machine (10) has three circumferentially spaced cogged belts (40) to drive three discs (52) rotatably mounted to an inner bowl (30) which is rotatably mounted to a housing (12), which in turn is connected to an operating handle (14). Mechanical lock can rotationally affix the inner bowl (30) to the housing to circumferentially position a pulley at the left or right edge (326, 322) of the sanding machine or at the front end (330) of the sanding machine. Power cleaning and sanding machines (412, 500, 600) incorporate the three disc (52) arrangement or a direct-drive one disc arrangement (572, 672). The machines (412, 500, 600) include multiple floor finishing units (420, 514, 614) ganged together in unique arrangements.

Owner:ONFLOOR TECH

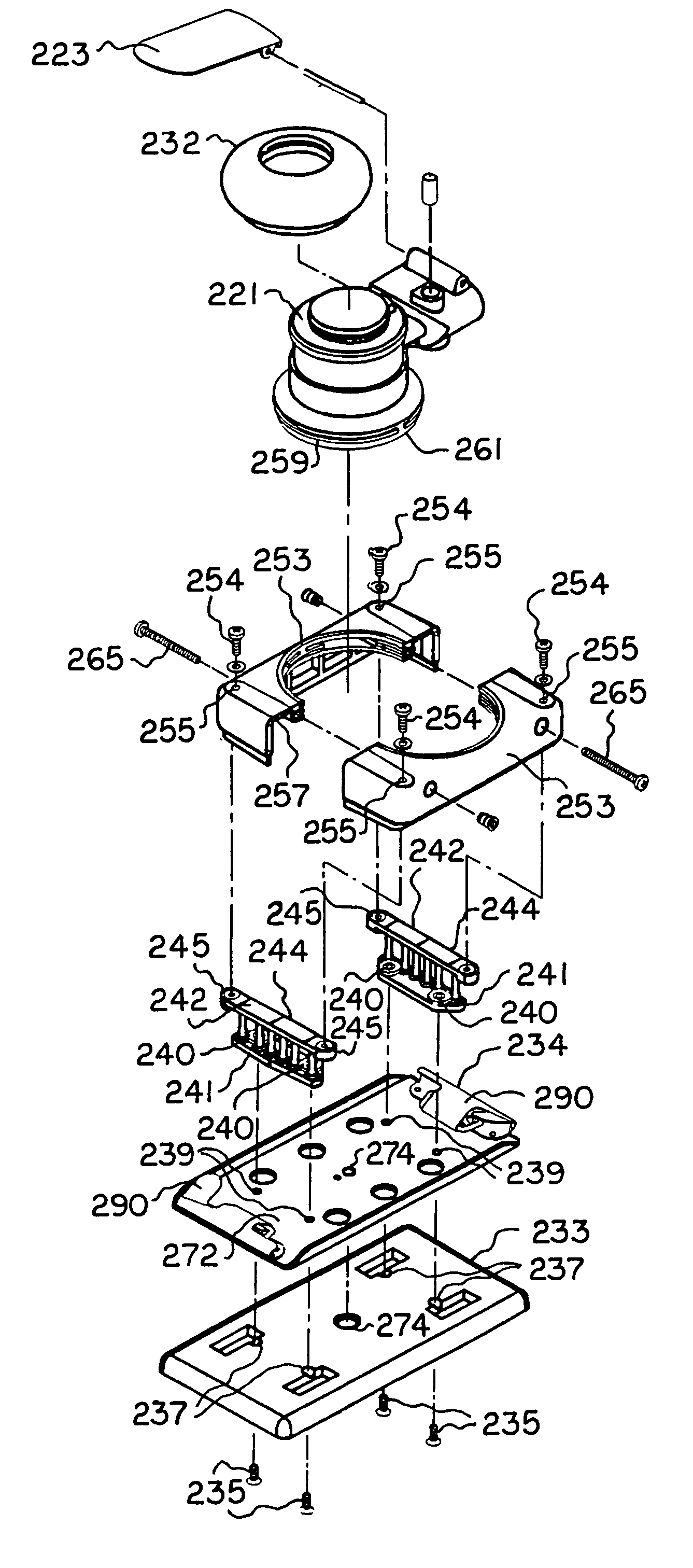

Electric sander and motor control therefor

ActiveUS20050245183A1More fatigueConvenient heightGrinding feed controlPortable grinding machinesSanderMotor speed

A hand held orbital sander has a housing having an electronically commutated motor disposed therein and an orbit mechanism disposed beneath the housing. A motor controller is coupled to the motor. The motor controller changes the speed of at which it runs the motor from an idle speed to a sanding speed upon the motor speed dropping from idle speed to an idle speed threshold value and changes the speed at which it runs the motor from sanding speed to idle speed upon the motor speed increasing from sanding speed to a sanding speed threshold value. The sander may have a mechanical brake that brakes the orbit mechanism and the motor controller also dynamically brakes the motor.

Owner:BLACK & DECKER INC

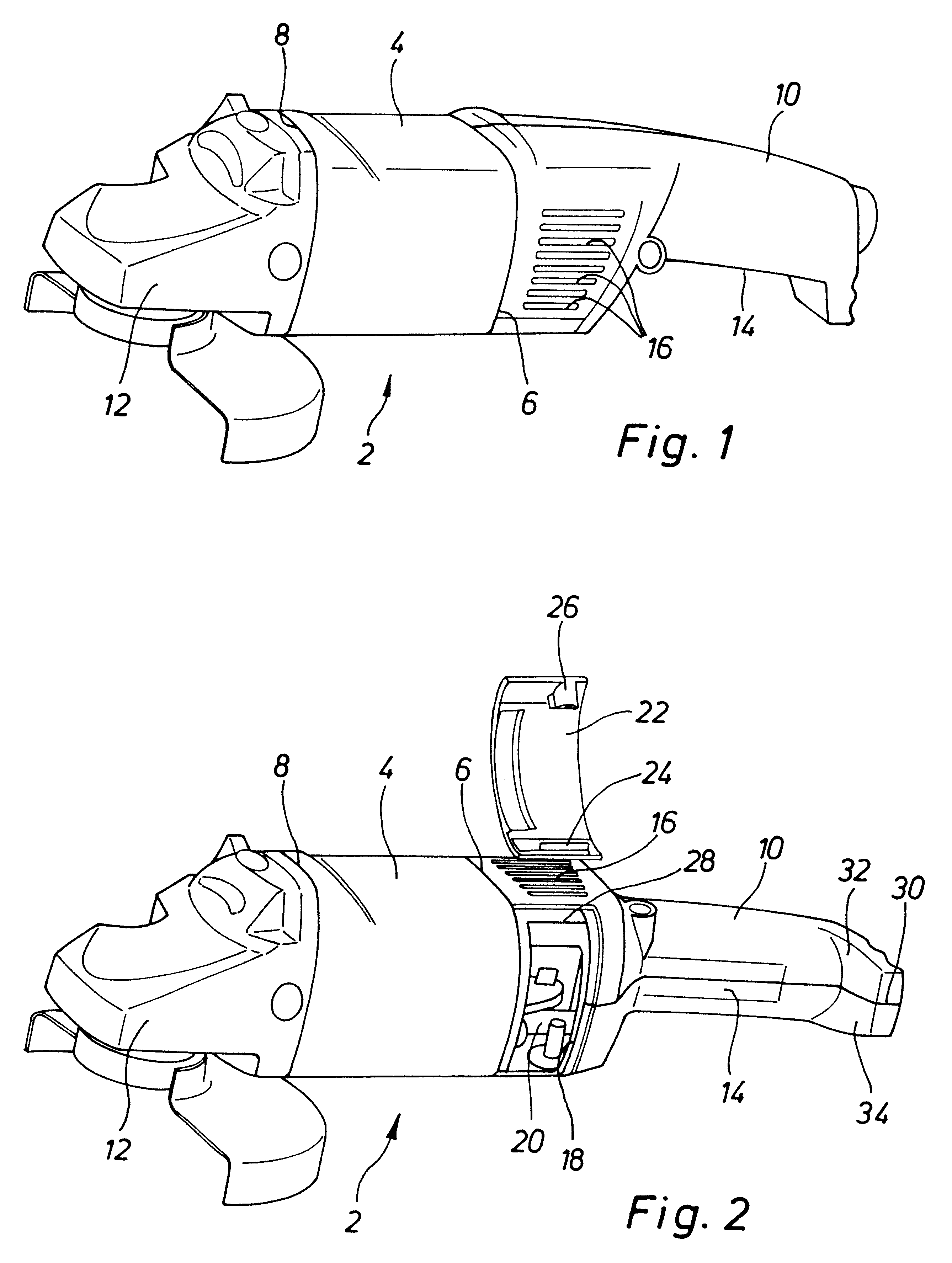

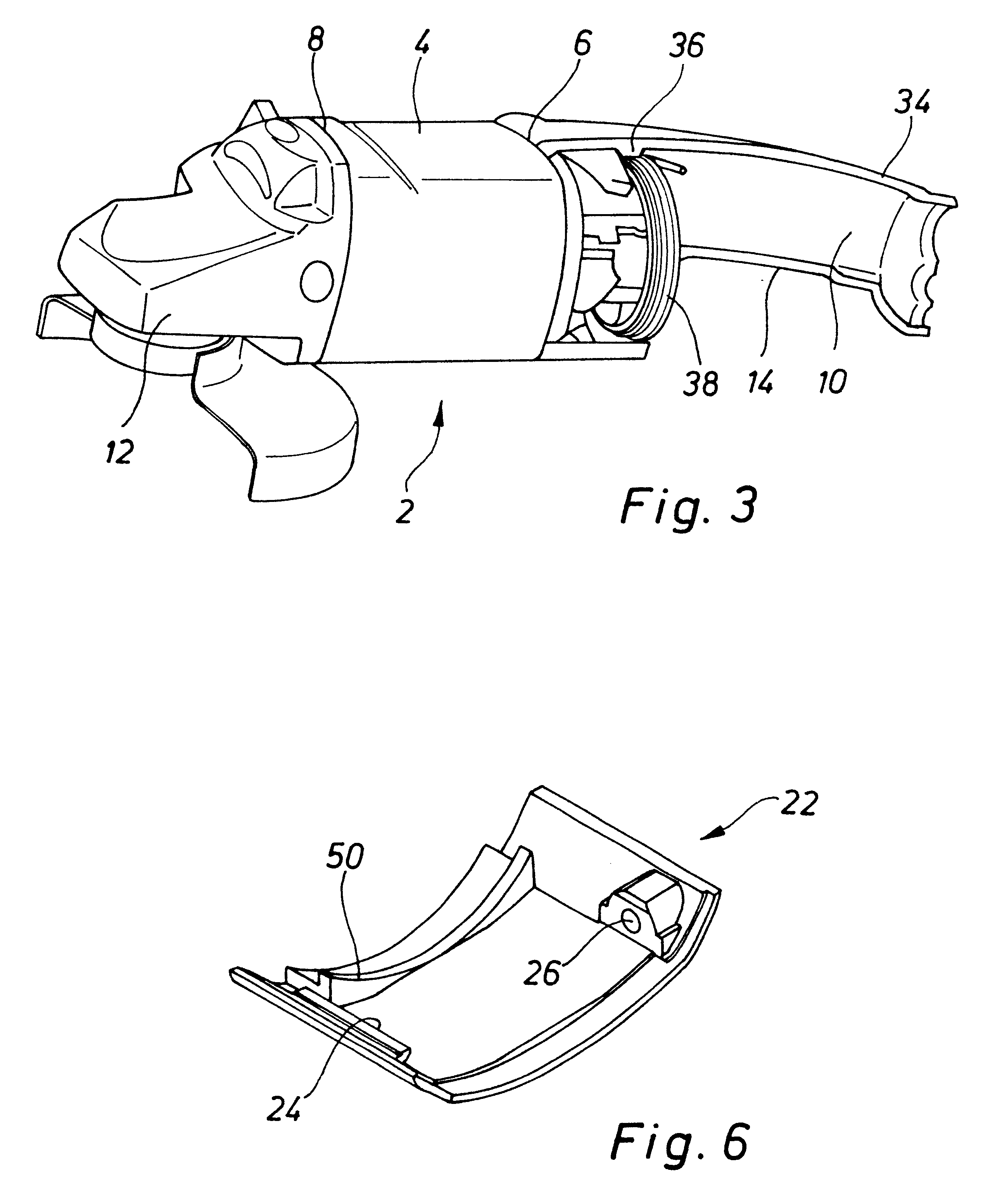

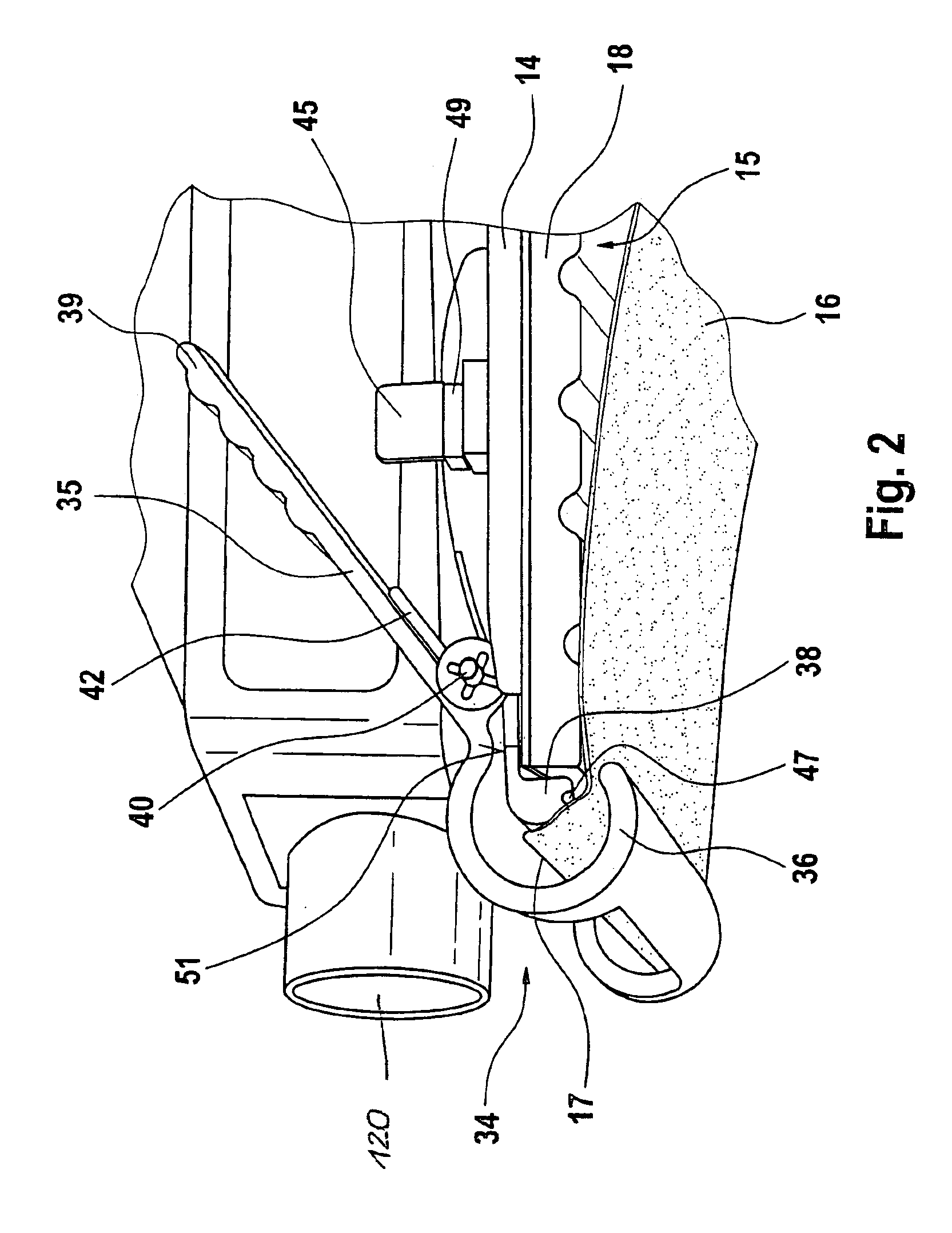

Electrical hand tool, in particular angle sander with rotatable maintenance opening

InactiveUS6527630B2Easy to operateReduce maintenanceEdge grinding machinesTransportation and packagingSanderHand tool

Owner:METABOWERKE

Electric sander and motor control therefor

ActiveUS7270591B2More fatigueConvenient heightGrinding feed controlPortable grinding machinesSanderMotor speed

A hand held orbital sander has a housing having an electronically commutated motor disposed therein and an orbit mechanism disposed beneath the housing. A motor controller is coupled to the motor. The motor controller changes the speed of at which it runs the motor from an idle speed to a sanding speed upon the motor speed dropping from idle speed to an idle speed threshold value and changes the speed at which it runs the motor from sanding speed to idle speed upon the motor speed increasing from sanding speed to a sanding speed threshold value. The sander may have a mechanical brake that brakes the orbit mechanism and the motor controller also dynamically brakes the motor.

Owner:BLACK & DECKER INC

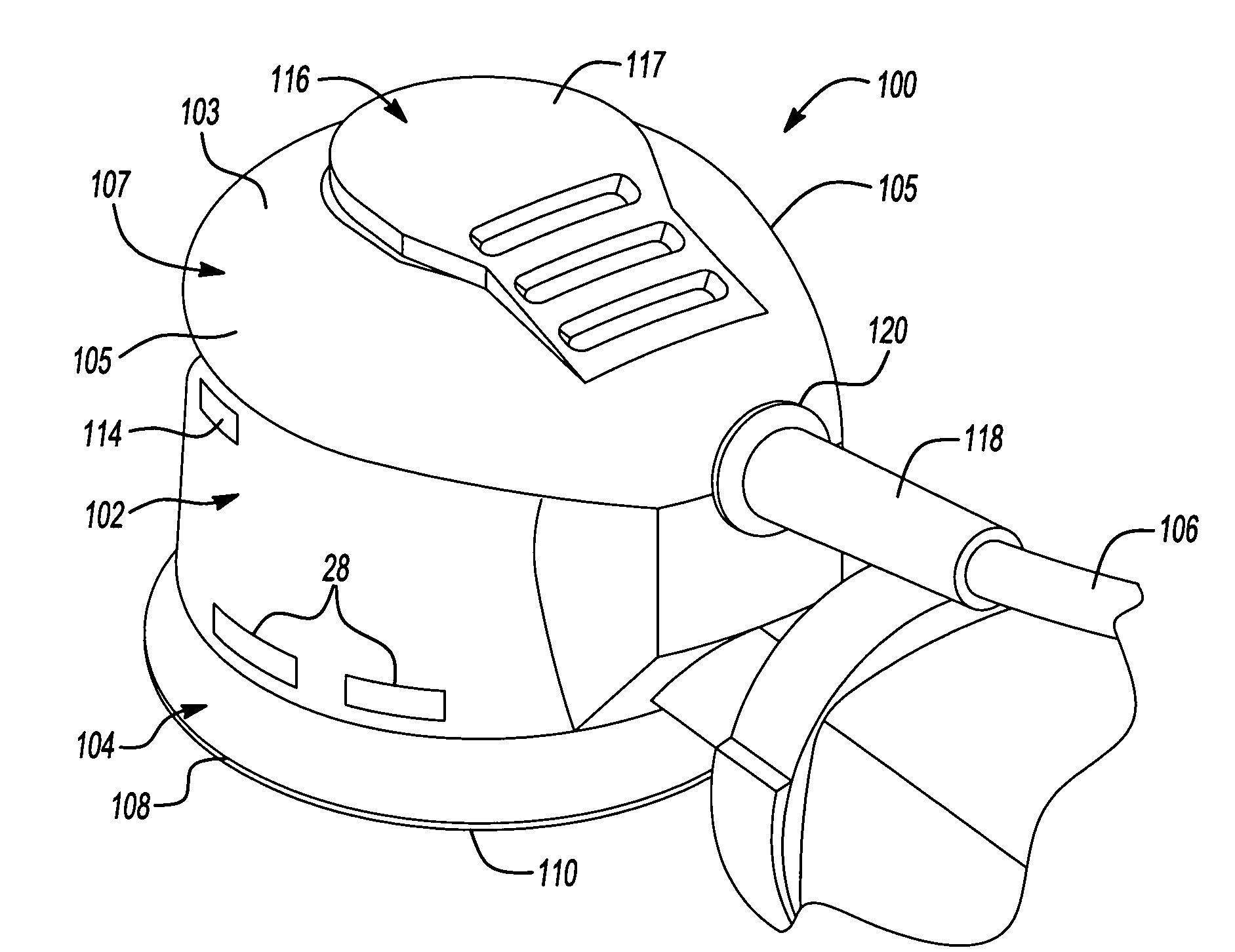

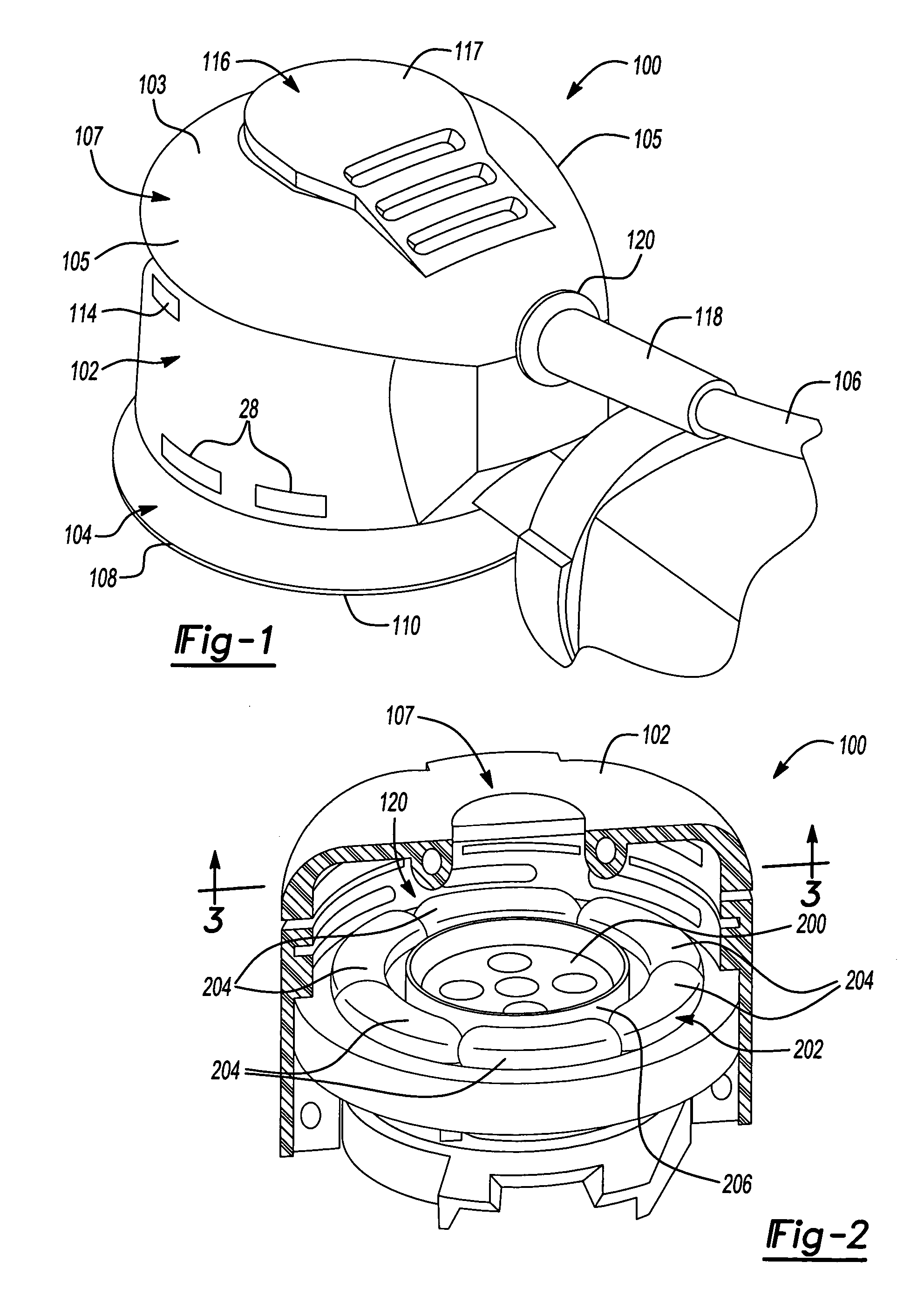

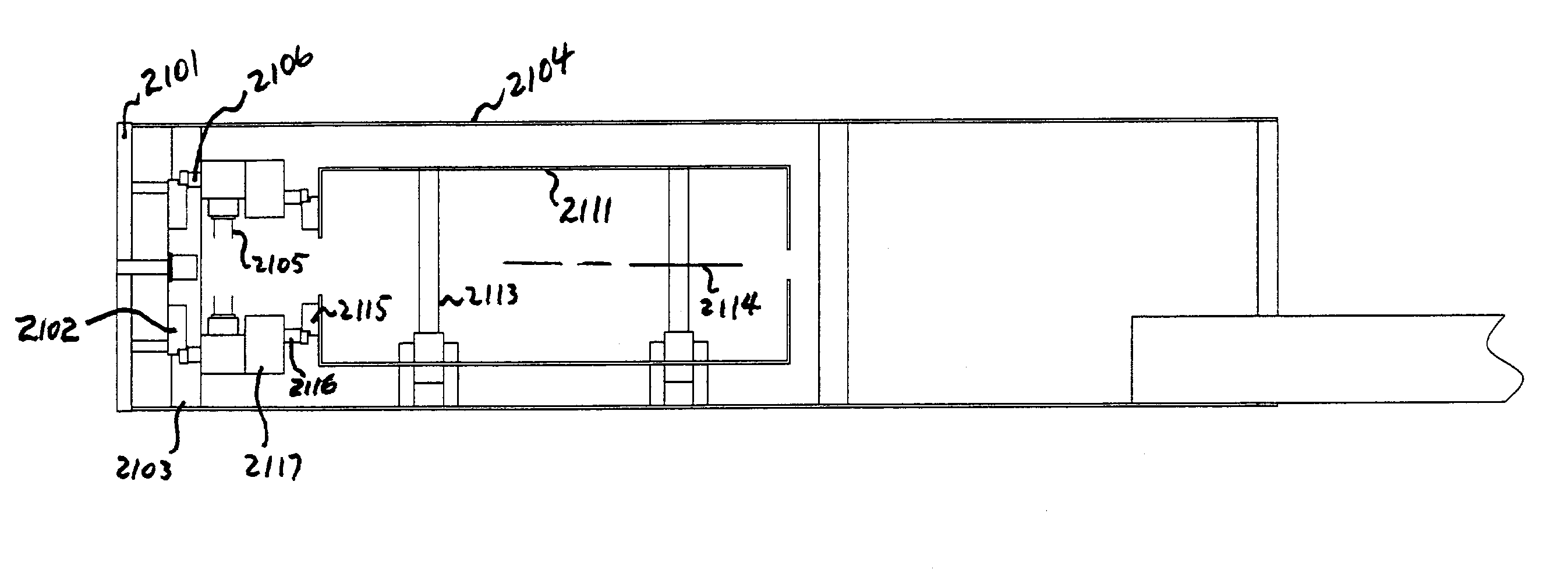

Low profile electric sander

InactiveUS20050245182A1Low profileSmall heightGrinding feed controlPortable grinding machinesSanderEngineering

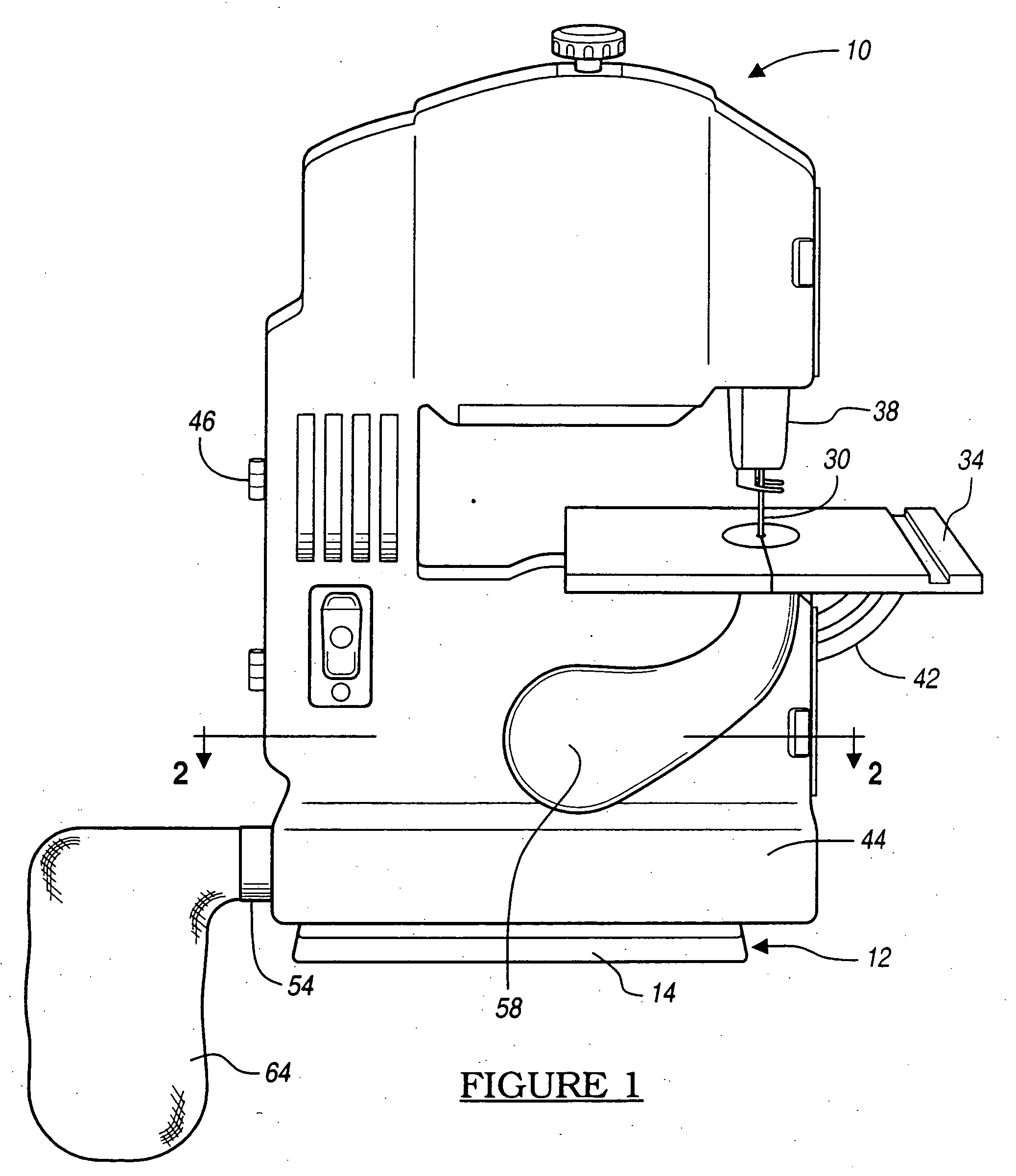

A power tool is a “low profile” power tool, that is the overall height of the power tool is sufficiently small that a user can grasp the top of the power tool with the user's hand and the hand will be positioned relative close to the bottom of the power tool compared with existing power tools. The low profile power tool uses a low profile motor having a diameter to lamination height ratio of at least 2:1. In an aspect of the invention, the motor is an electronically commutated “pancake” style motor. In an aspect of the invention, the power tool is a random orbital sander or an orbital sander having a motor that provides at least 40 watts of power. In an aspect of the invention, the sander has a mechanical brake that brakes the orbital mechanism and the motor is dynamically braked.

Owner:BLACK & DECKER INC

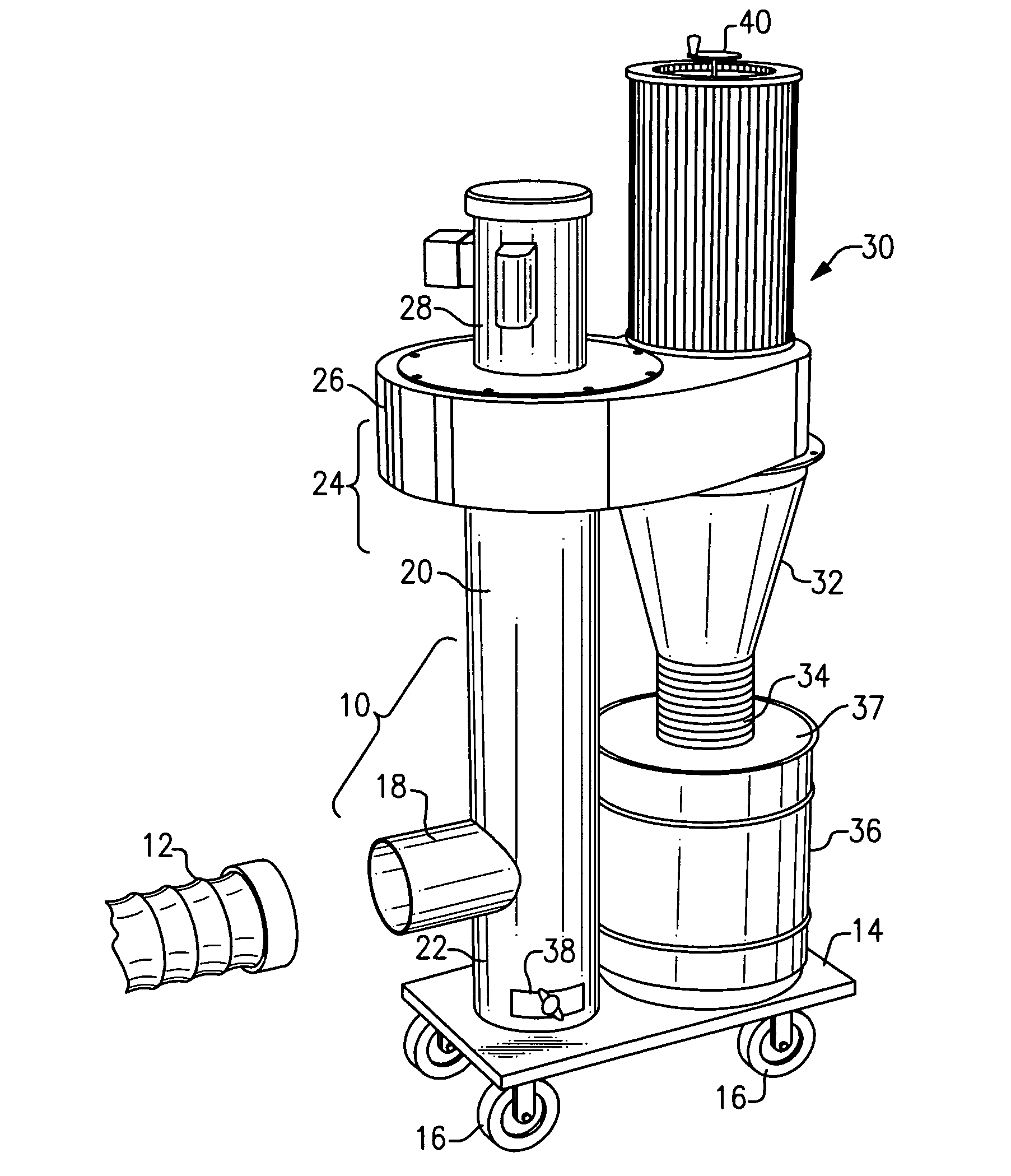

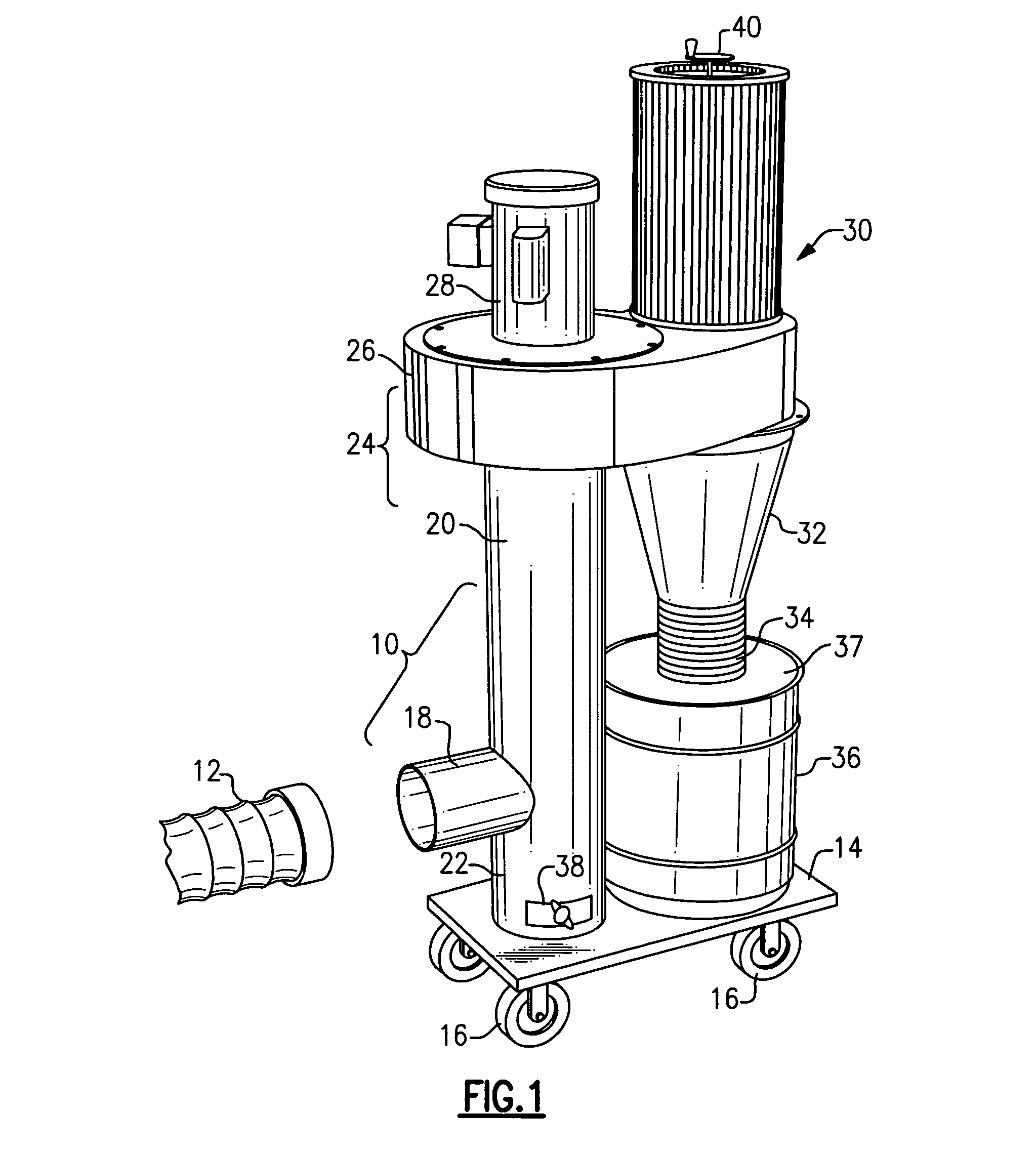

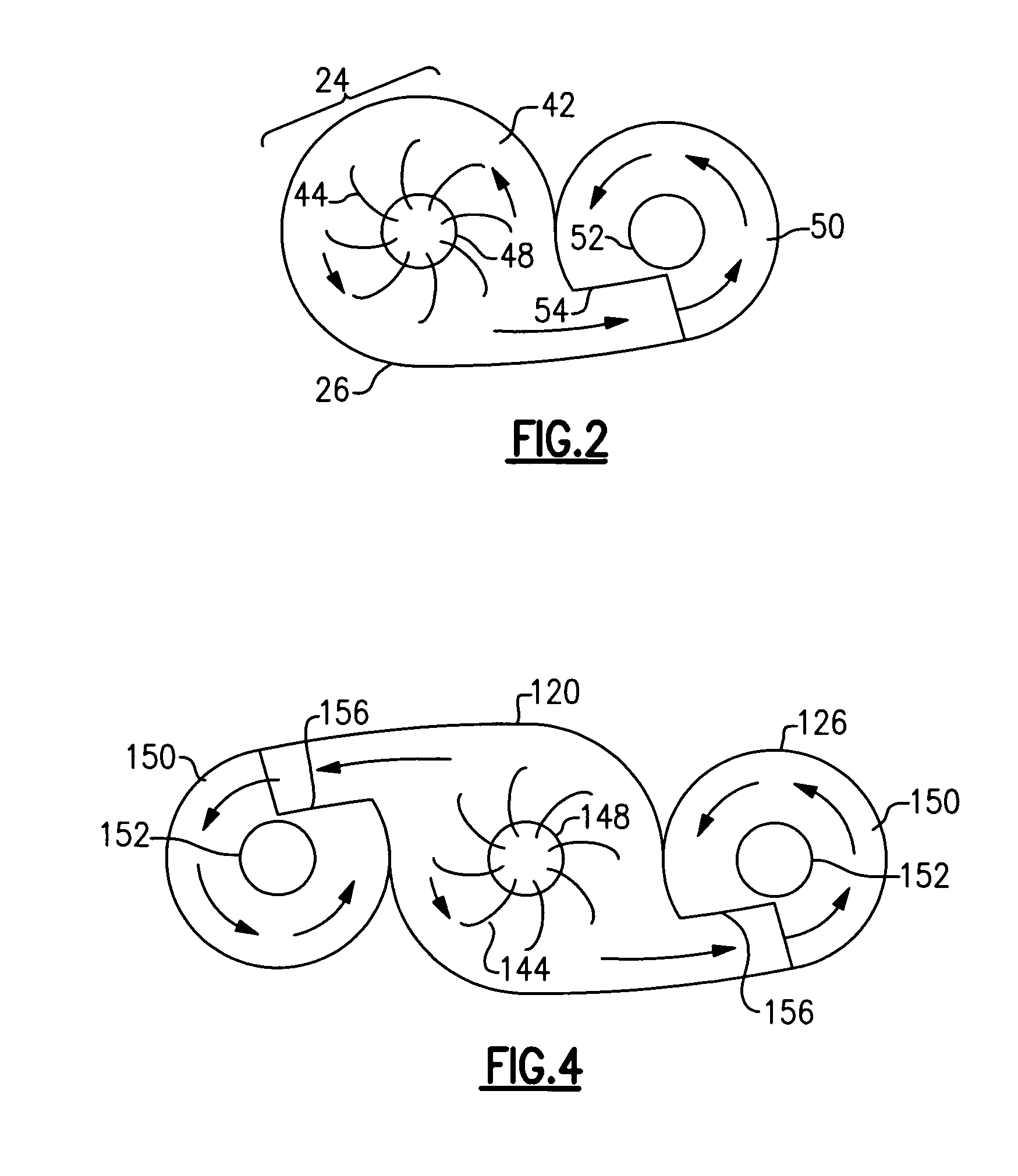

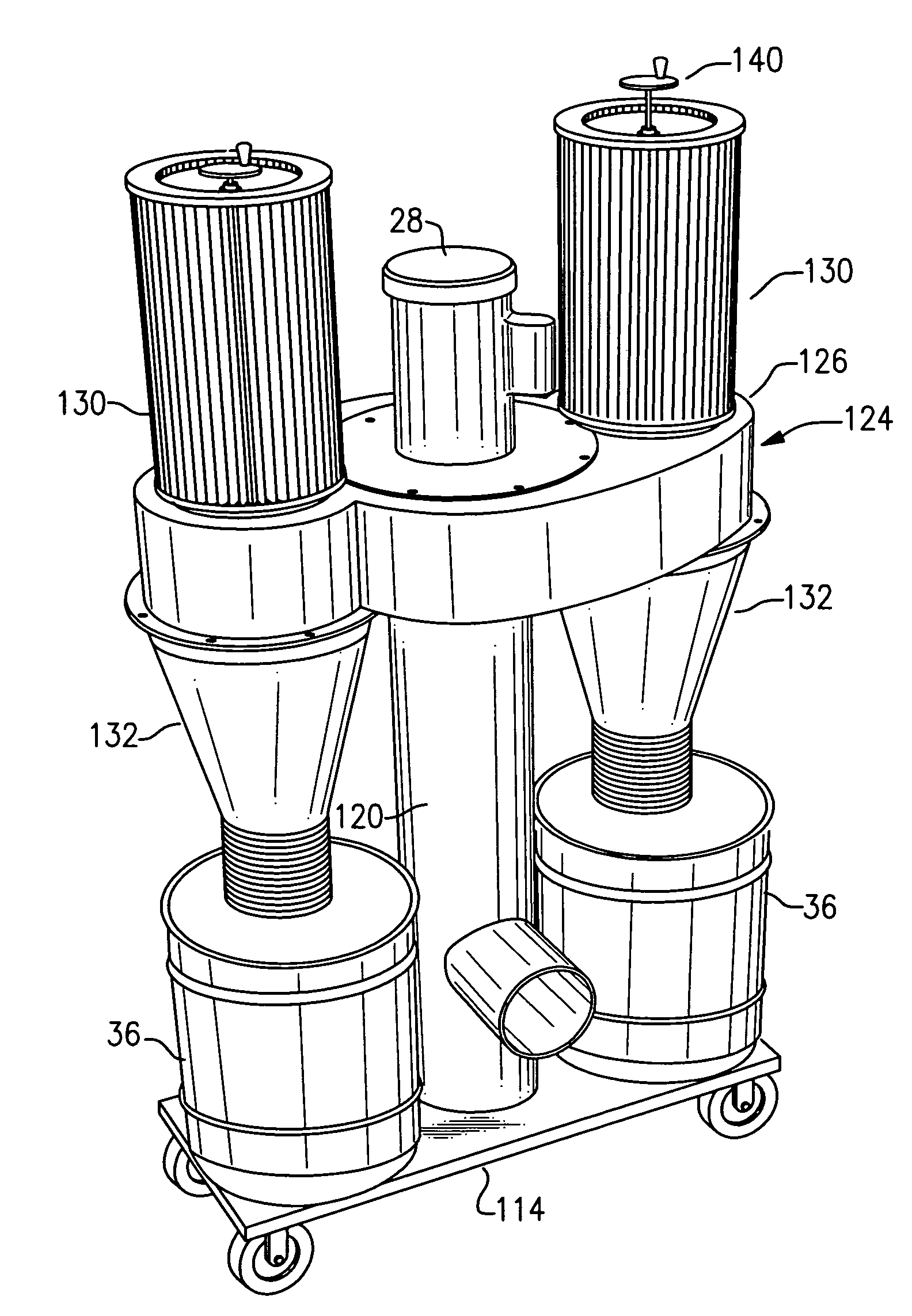

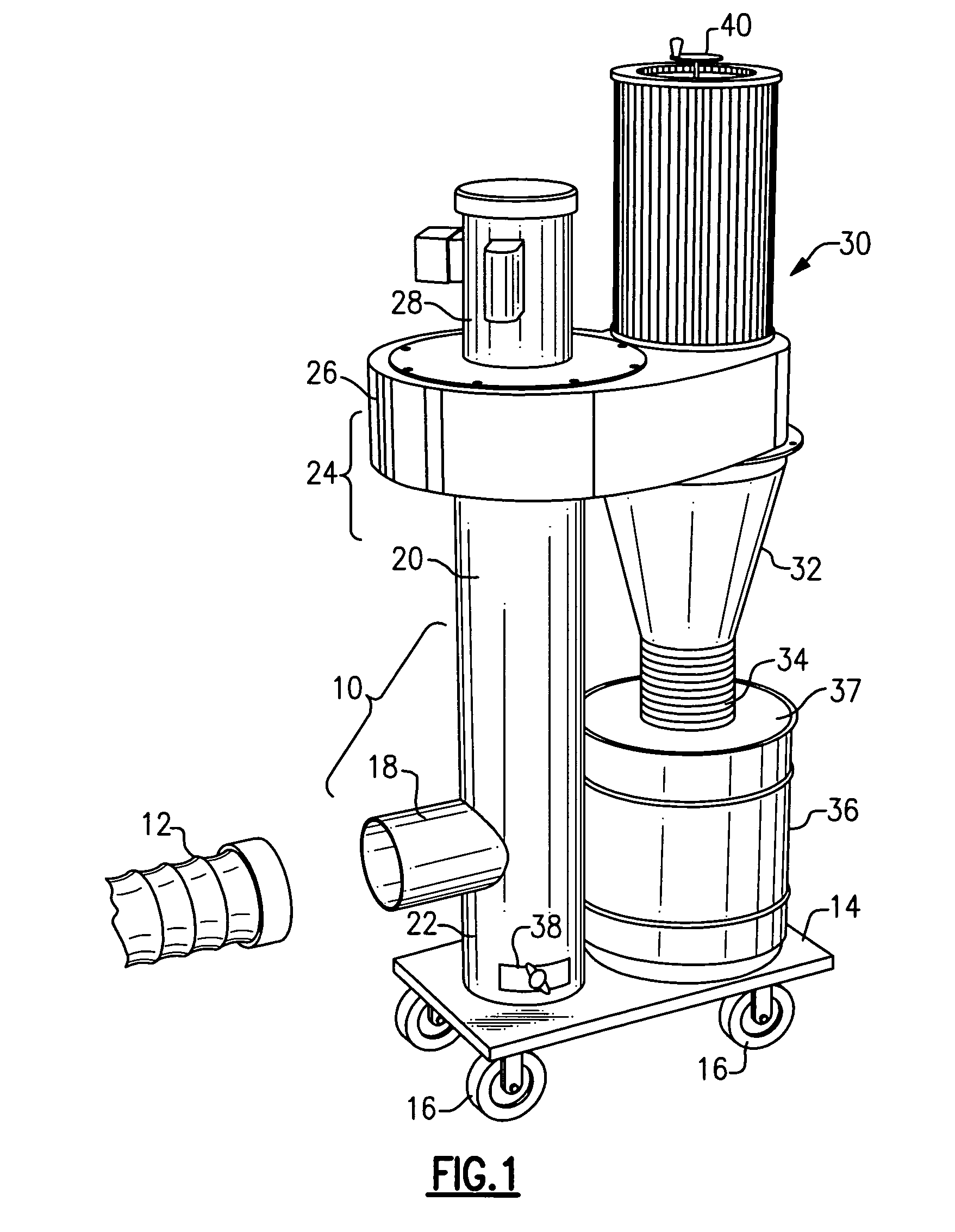

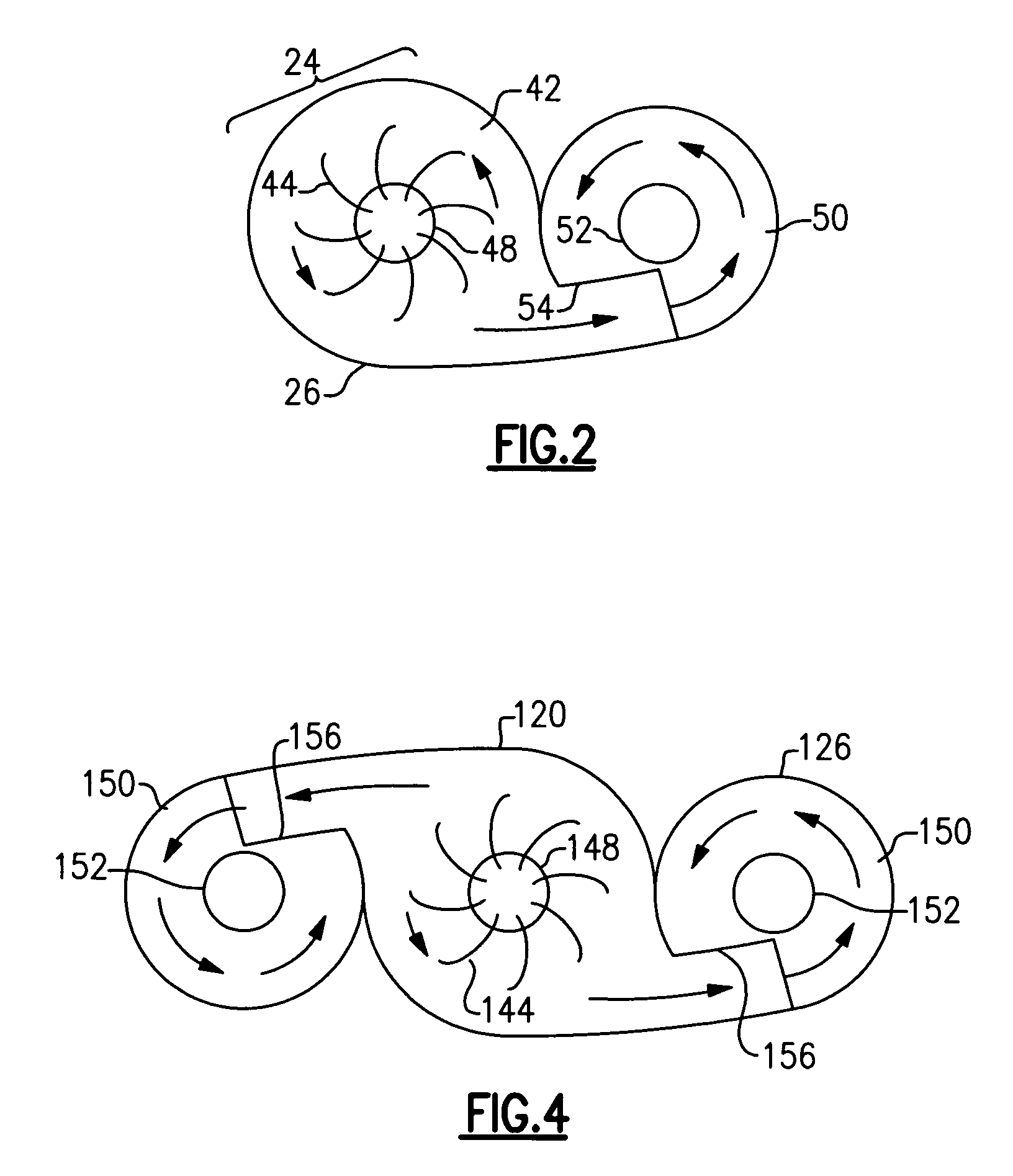

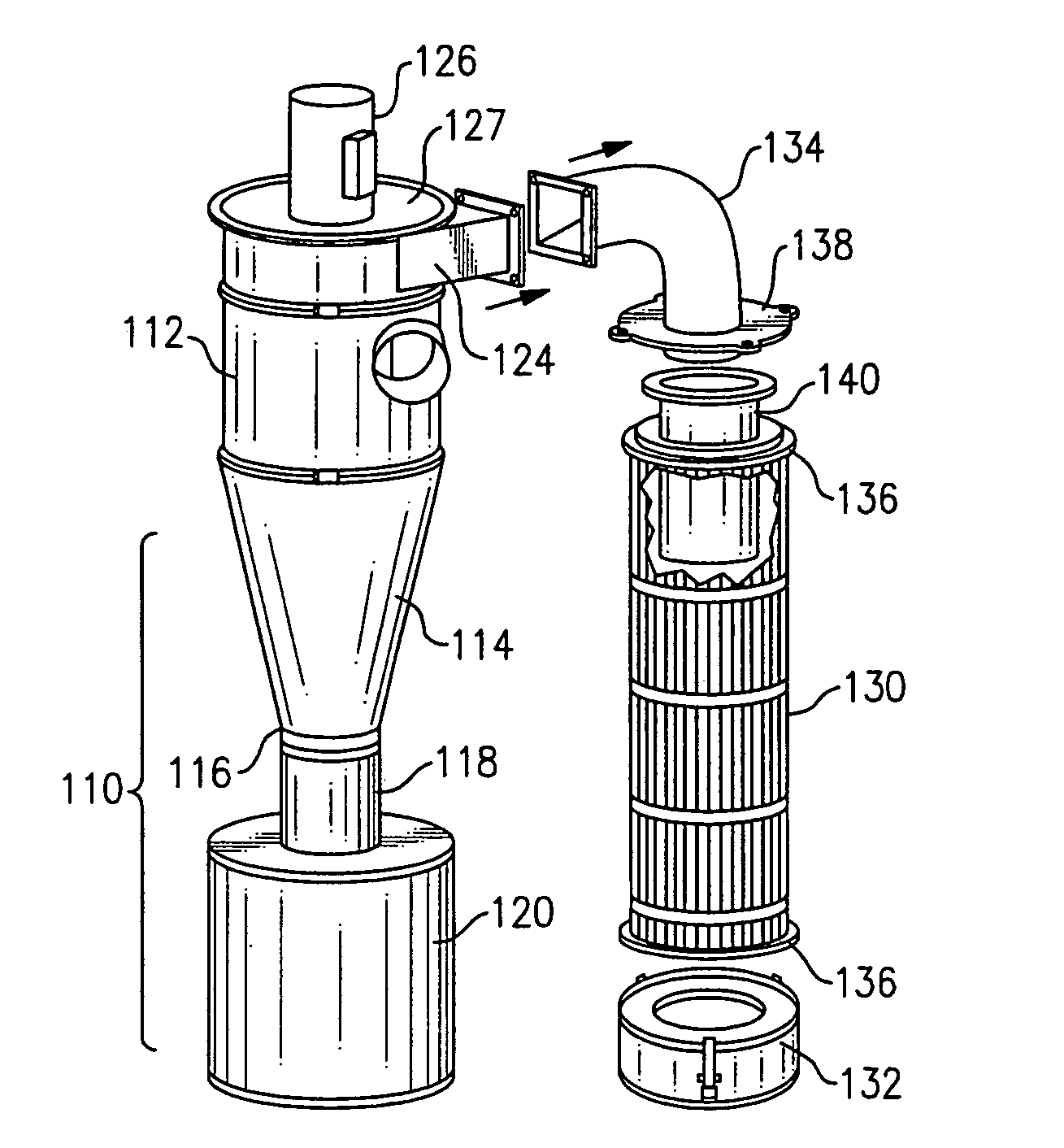

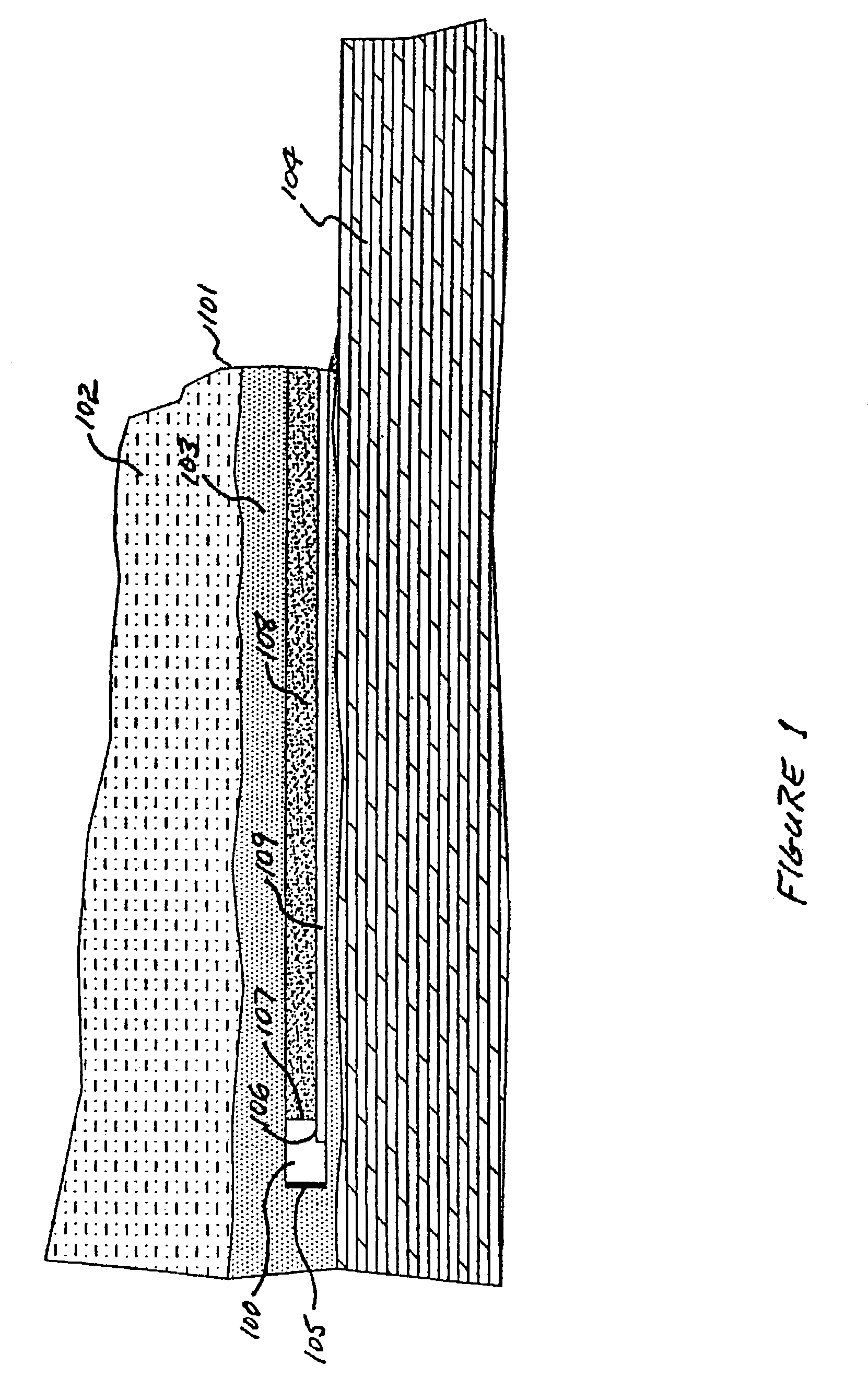

Portable cyclonic dust collection system

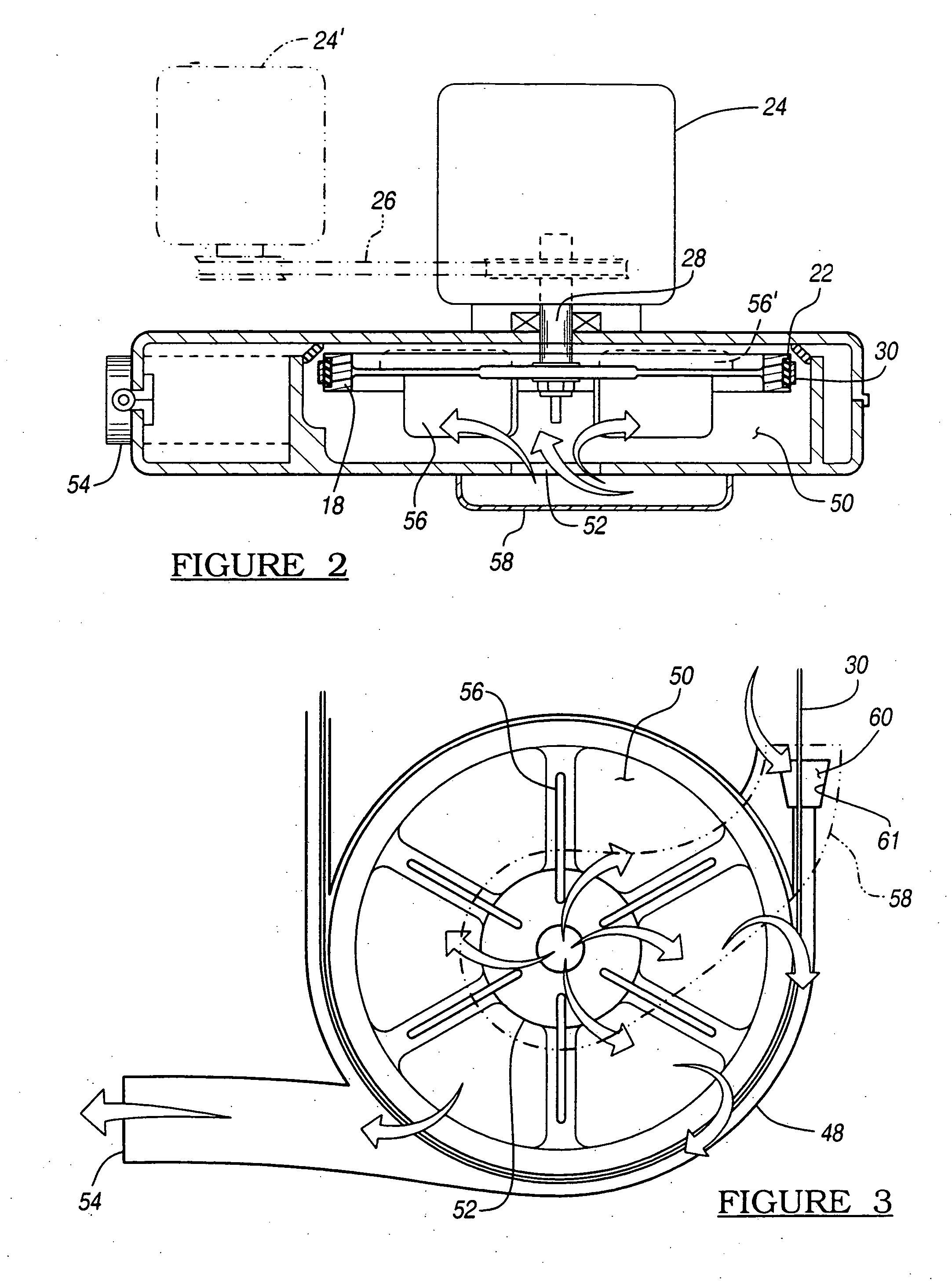

A portable dust collection system for a wood shop or other dust producing environment is employed with a sander, power saw, router or other dust-producing tool such as a woodworking tool. A movable platform has a vertical intake pipe supporting a head portion formed with a shroud. A centrifugal impeller drives the intake air stream plus any entrained particles into one or more cyclonic separators, which deposit the dust in a respective drum supported on the platform beneath the cyclone. The air inlet from the tool enters the vertical pipe at a point partway up the pipe, so that large particles drop to the bottom end of the pipe, where a clean-out door is provided. The exhaust or discharge air from the cyclonic separator(s) passes out through a filter cartridge to the ambient. A deflector plate prevents the dust from eddying back into the separator.

Owner:WITTER ROBERT M

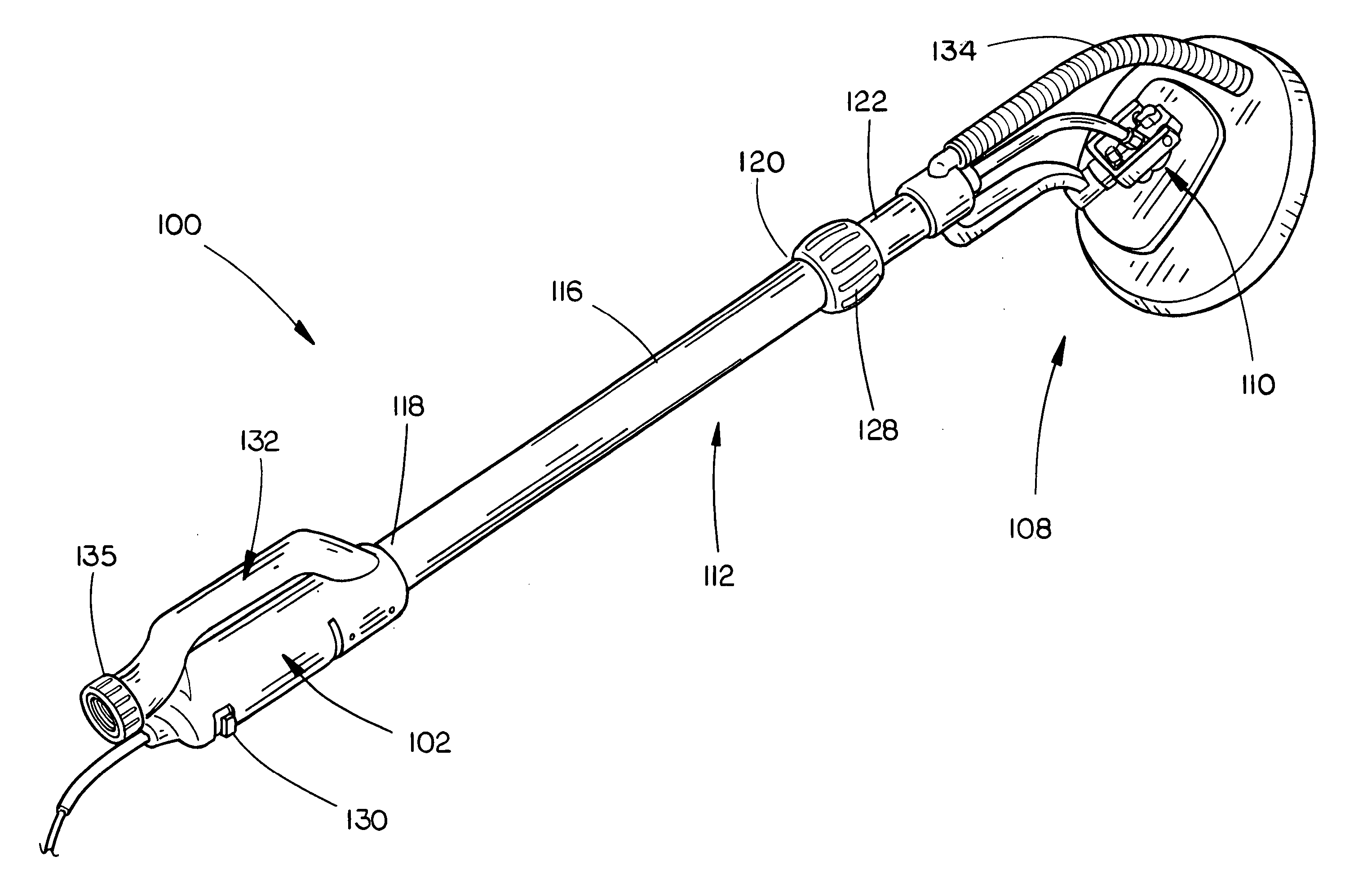

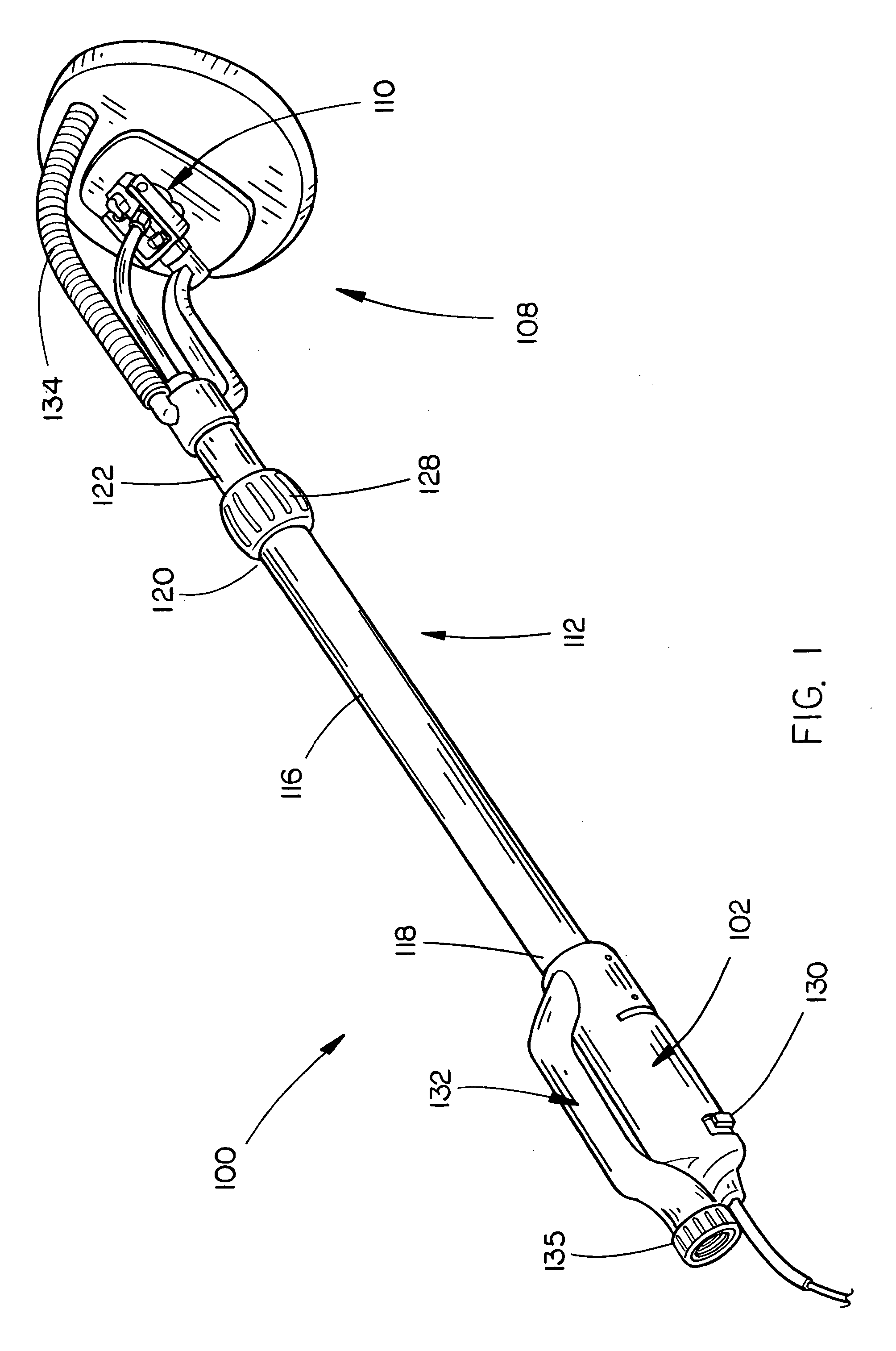

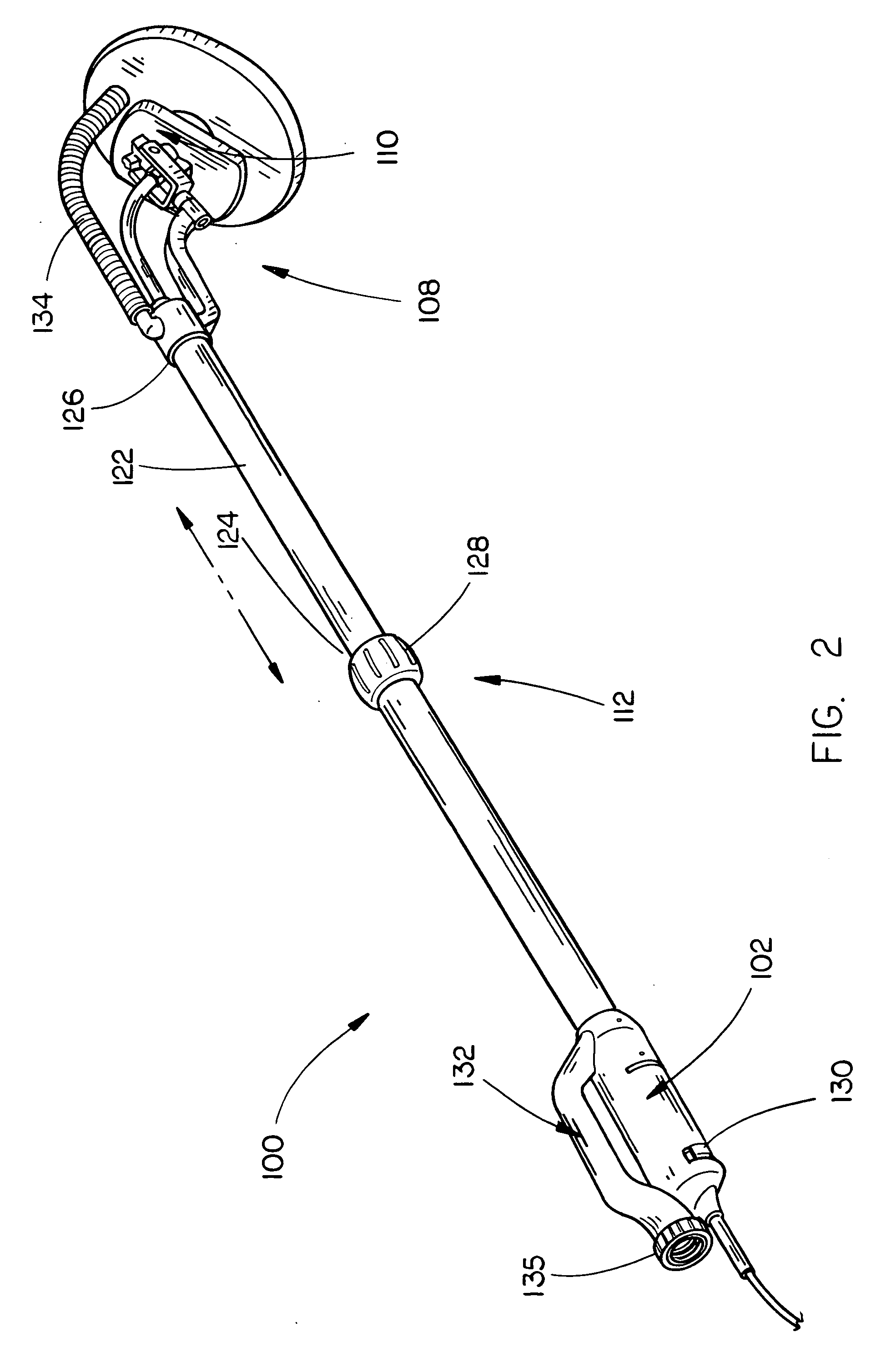

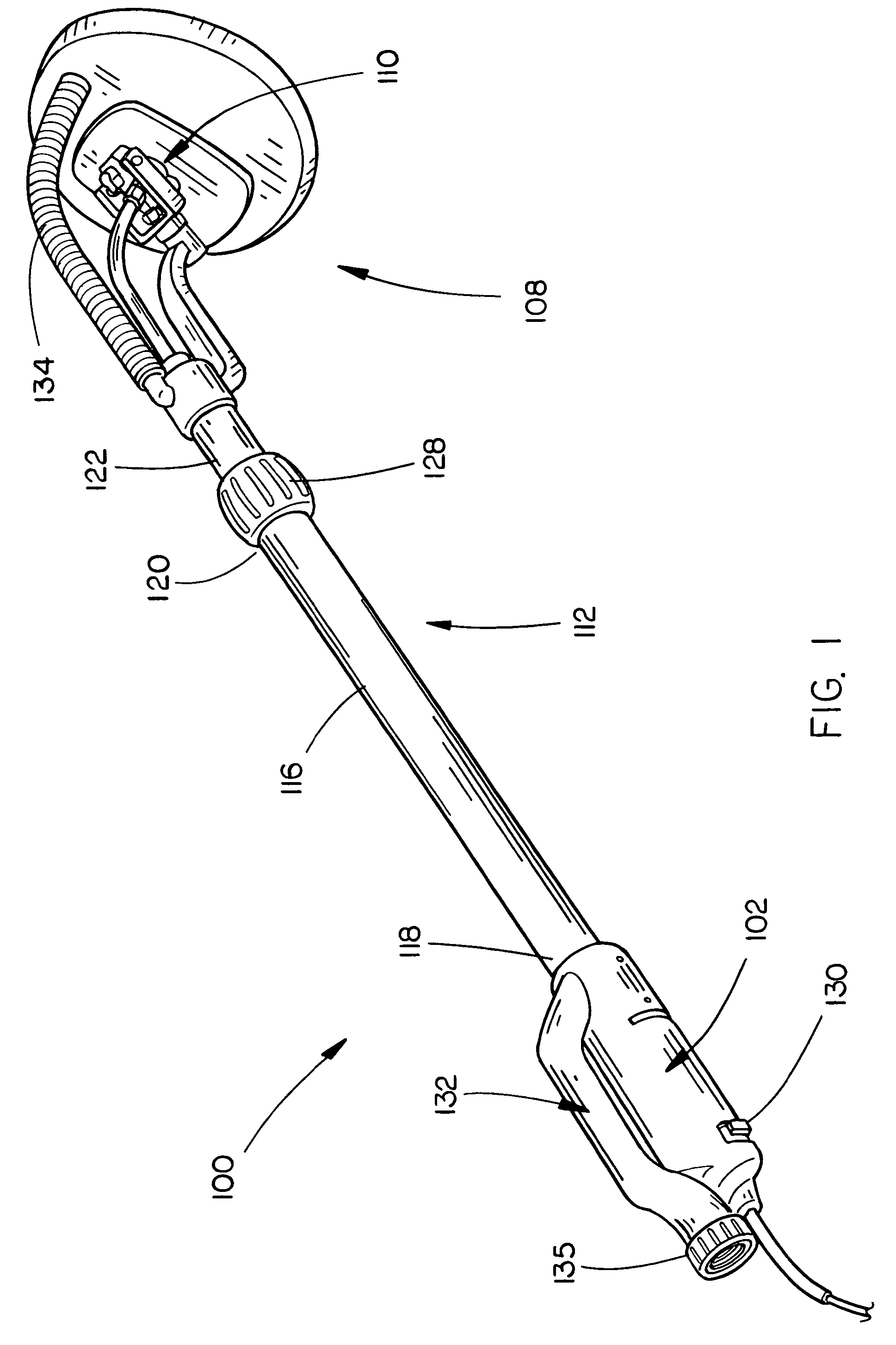

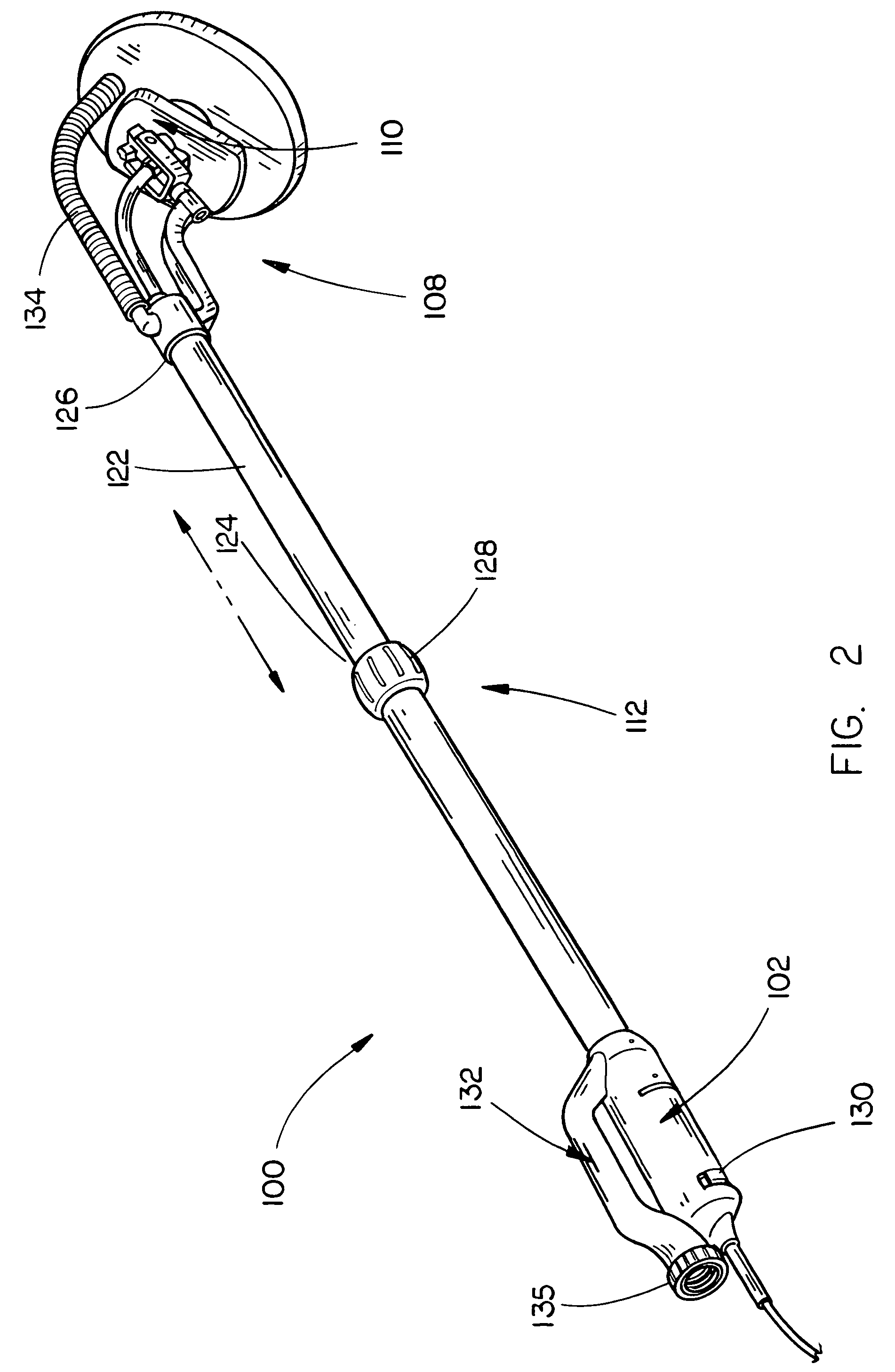

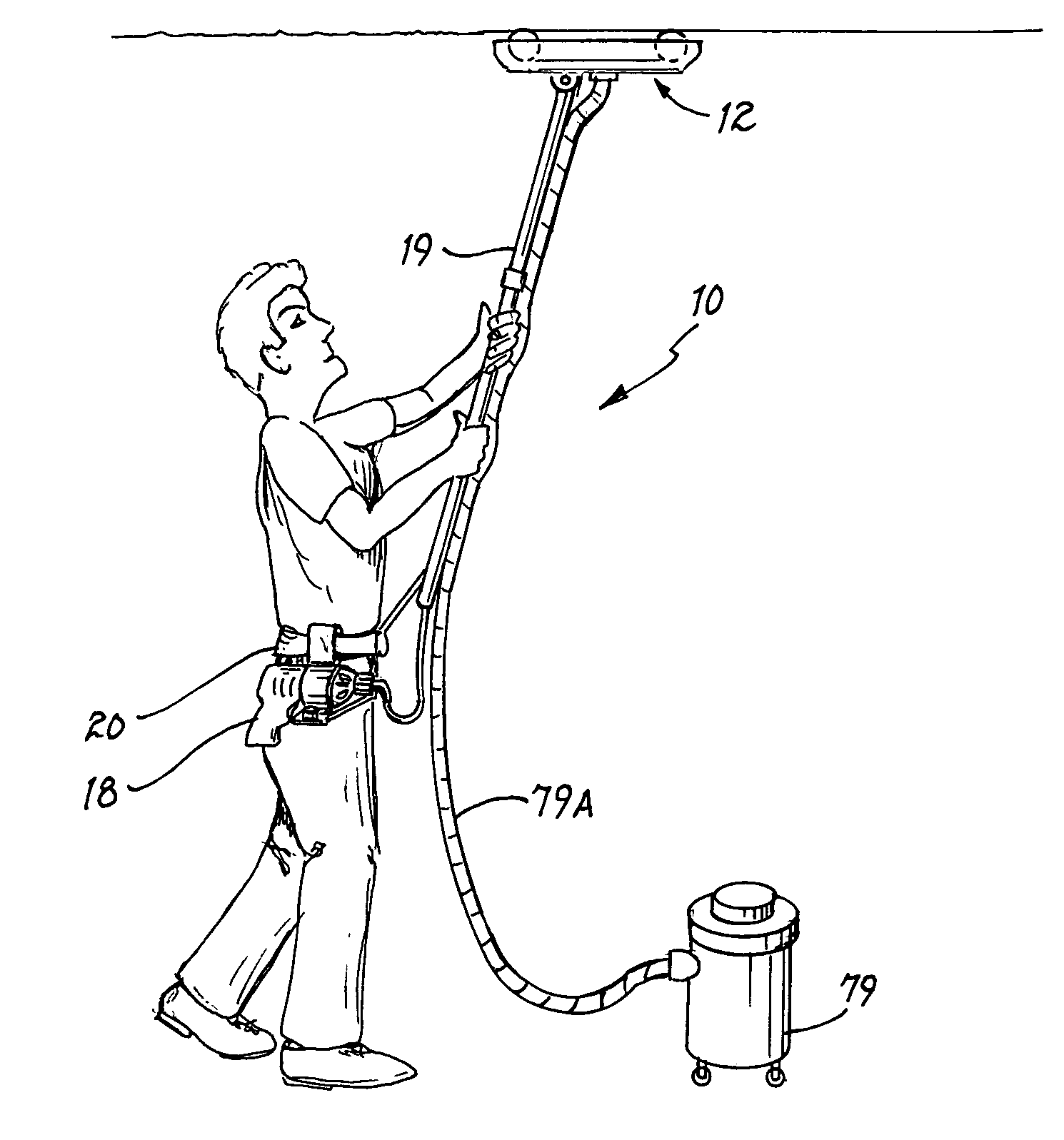

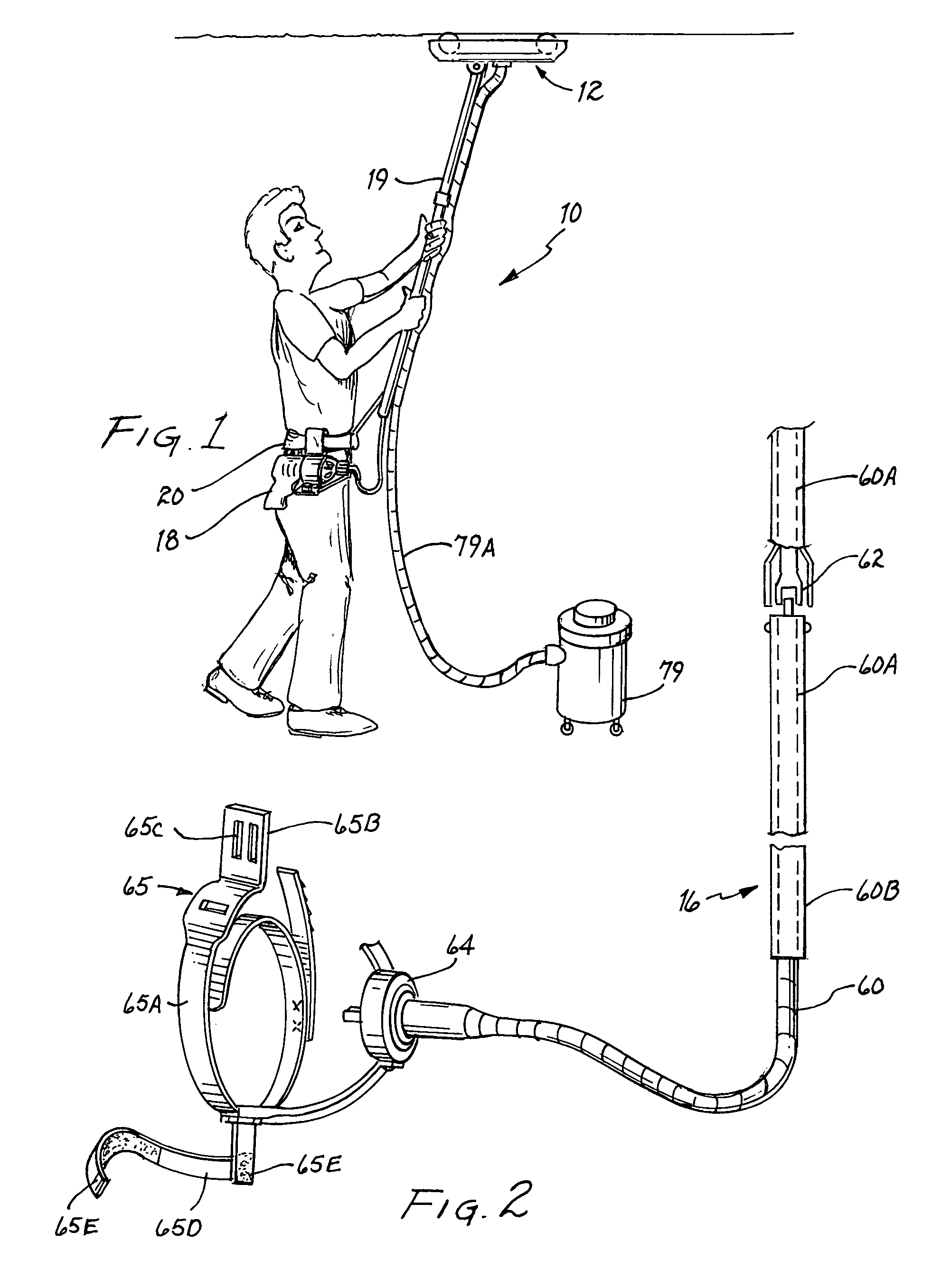

Drywall sander

ActiveUS20060073778A1Adjustable lengthRevolution surface grinding machinesGrinding drivesSanderDrive shaft

The present invention provides an adjustable drywall sander capable of imparting more than one type of motion. In an exemplary embodiment, the sander includes a power unit with a motor and a sanding assembly coupled to the power unit. A telescopic support arm assembly is coupled to the sanding assembly and the power unit for supporting the sanding assembly. The telescopic support arm assembly includes a first support arm with a first and a second end and a second support arm with a first and second end. The first end of the first support arm being coupled to the power unit and the second end of the second support arm being coupled to the sanding assembly. A collapsible drive shaft is substantially enclosed by the telescopic support arm assembly. The telescopic support arm assembly and the collapsible drive shaft allow the length of the telescopic assembly to be adjusted.

Owner:BLACK & DECKER INC

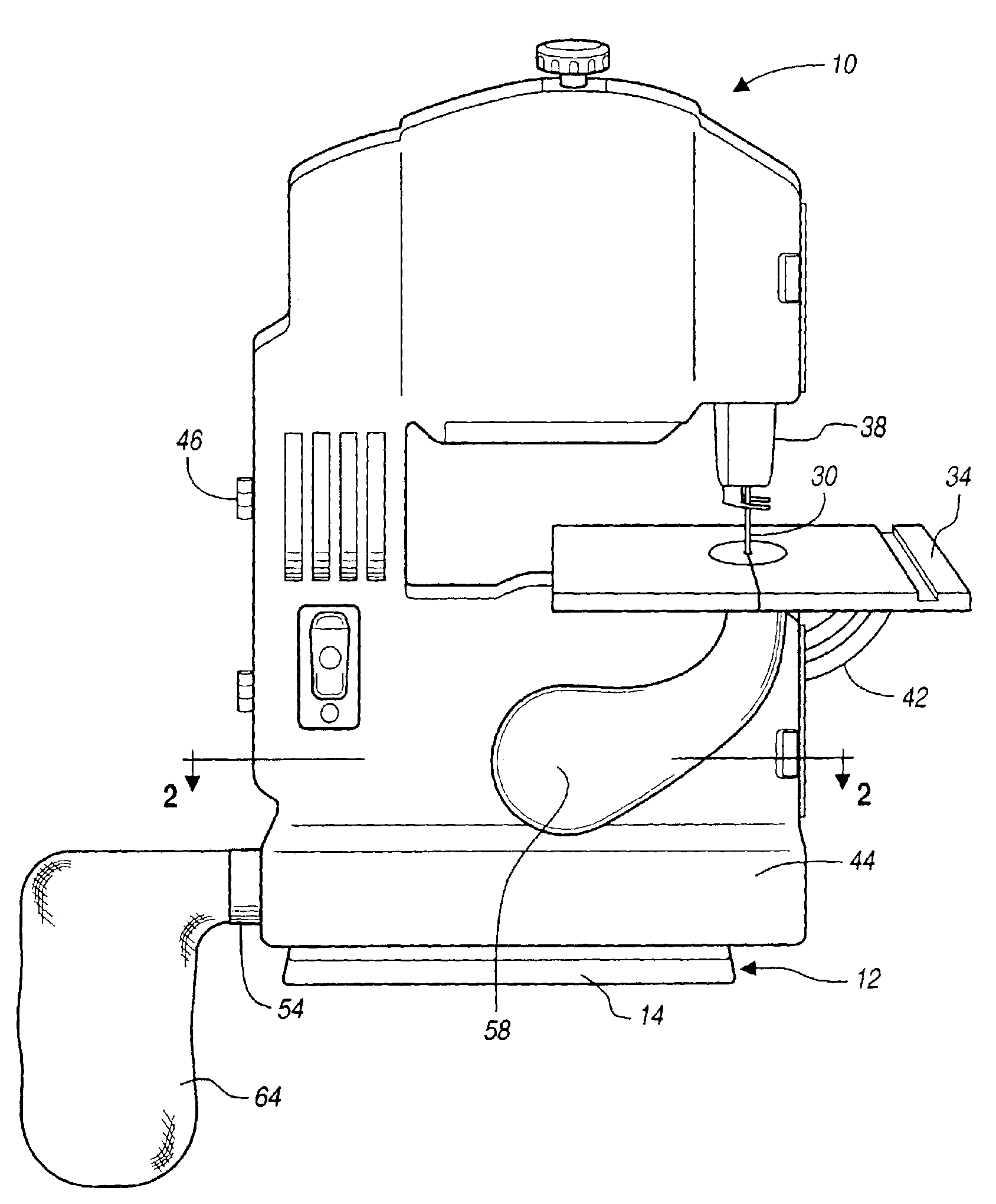

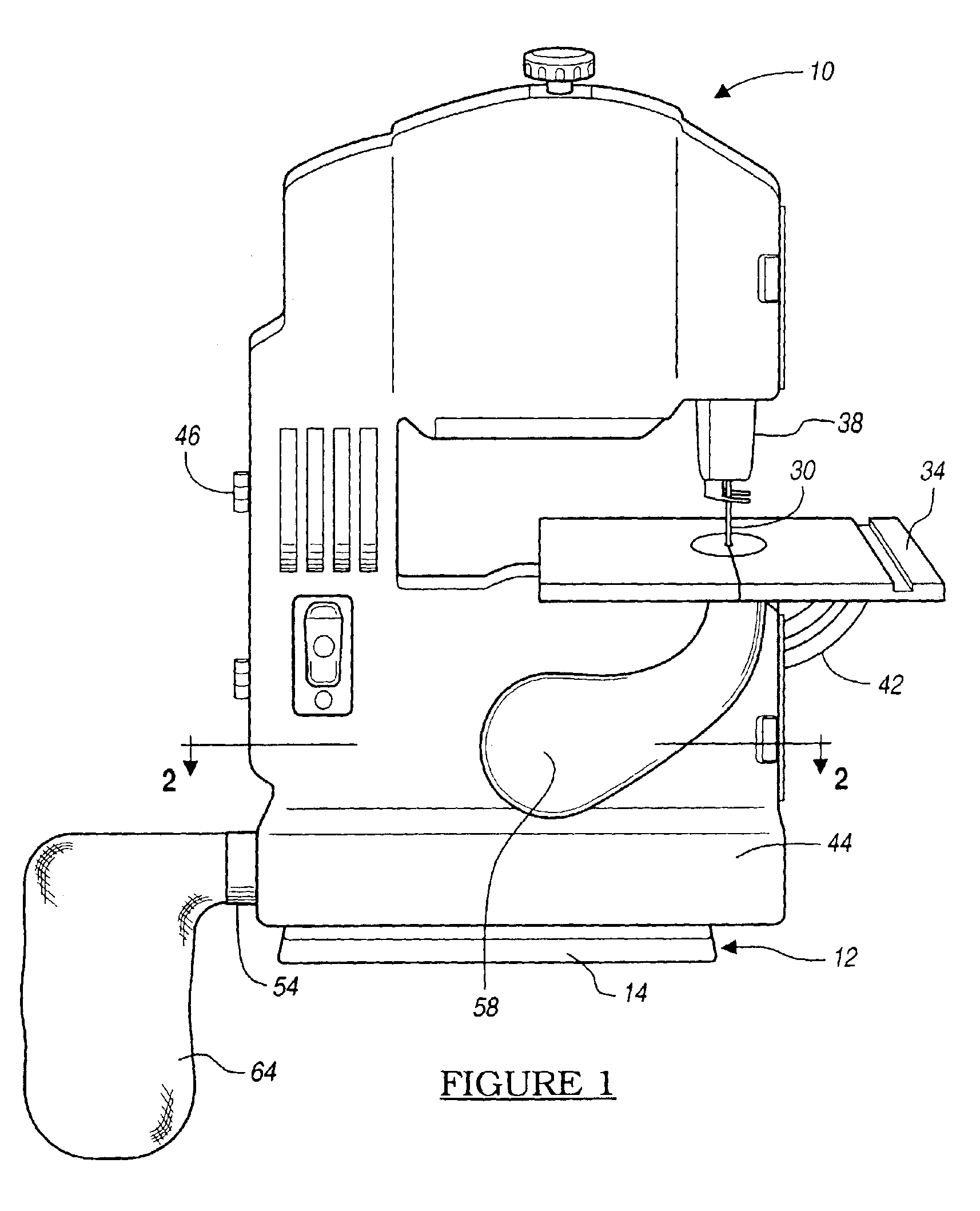

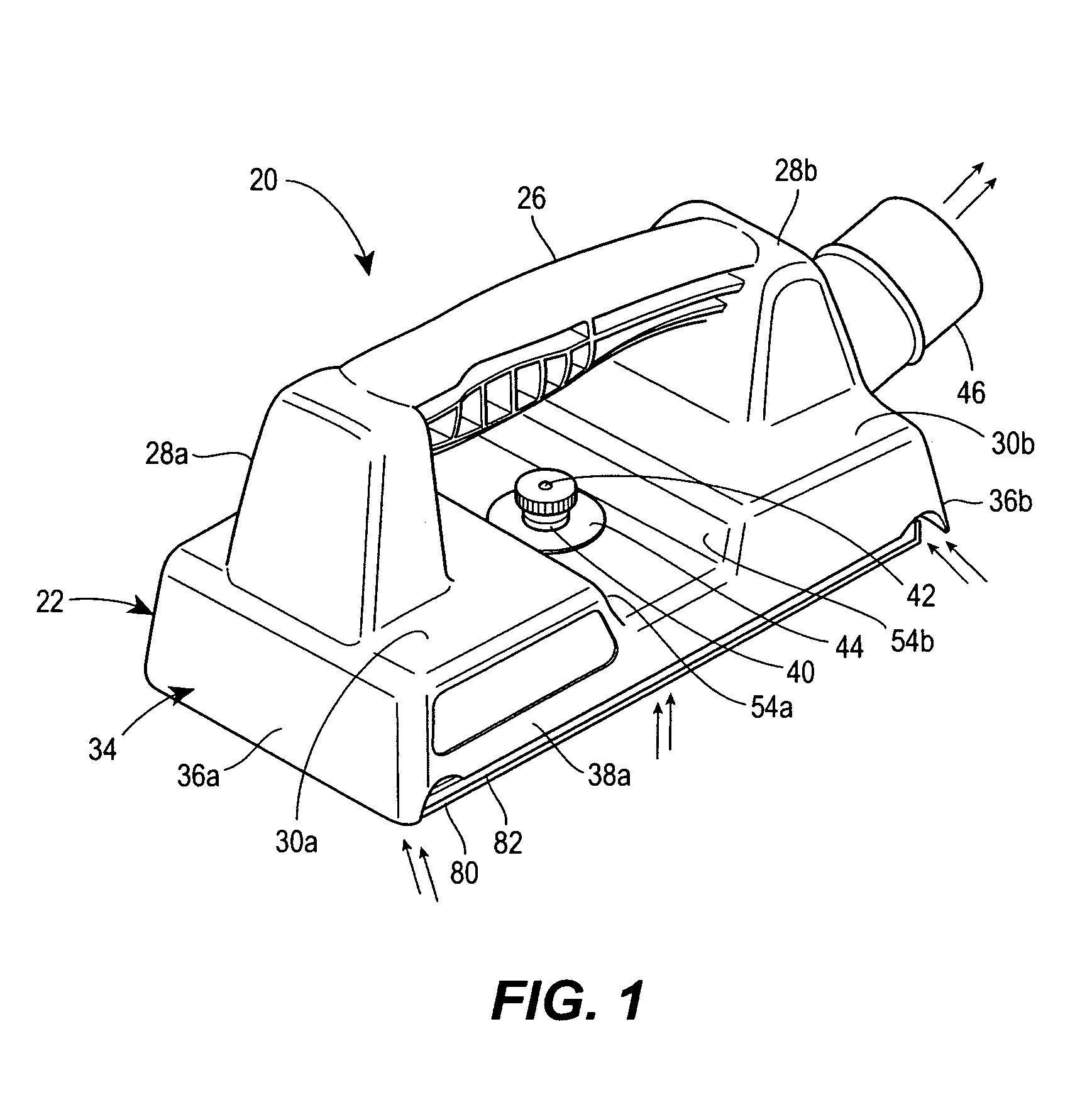

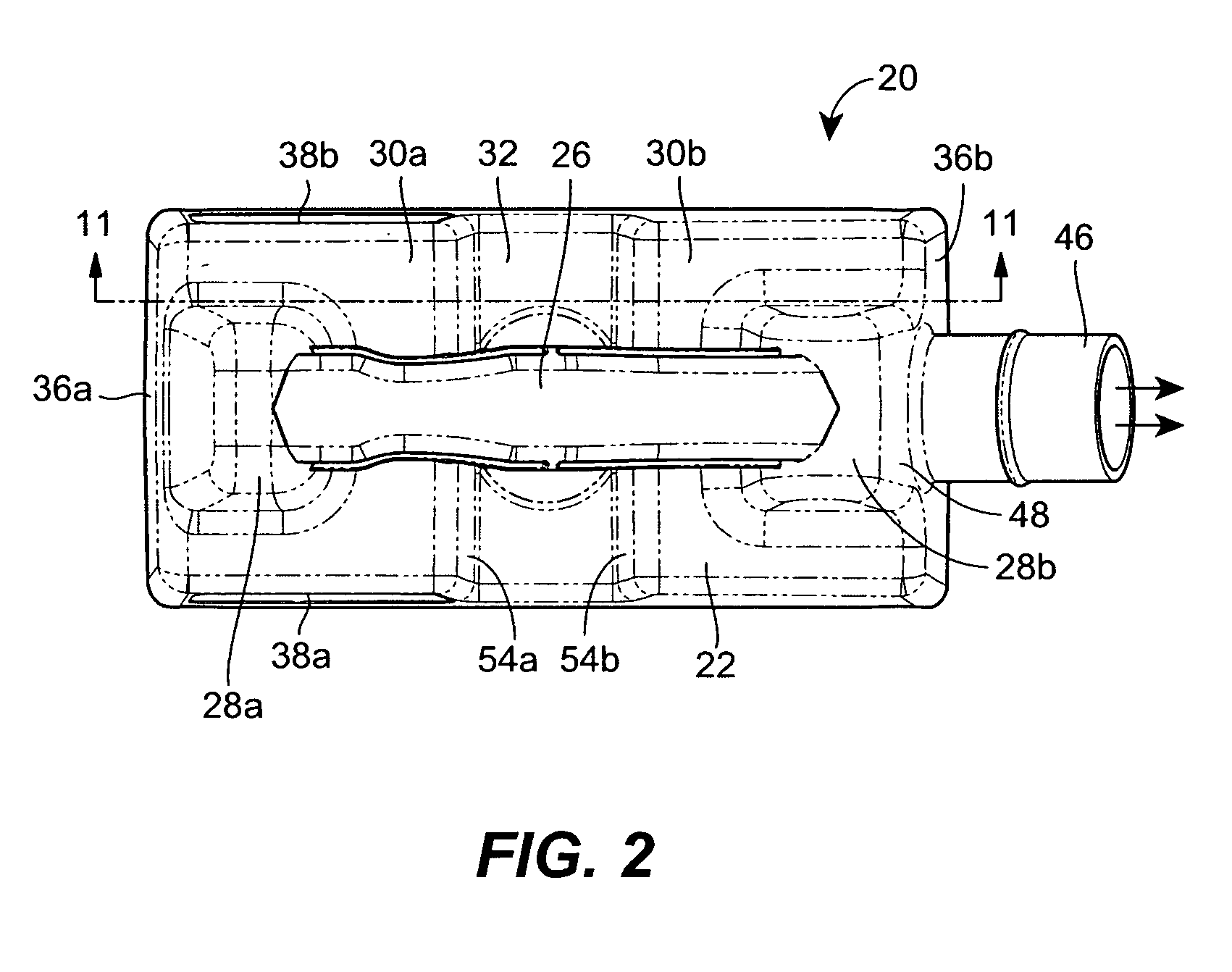

Motor driven wood working tool with vacuum feature

InactiveUS6948412B2Efficient collectionMetal sawing devicesMetal sawing accessoriesSanderMotor drive

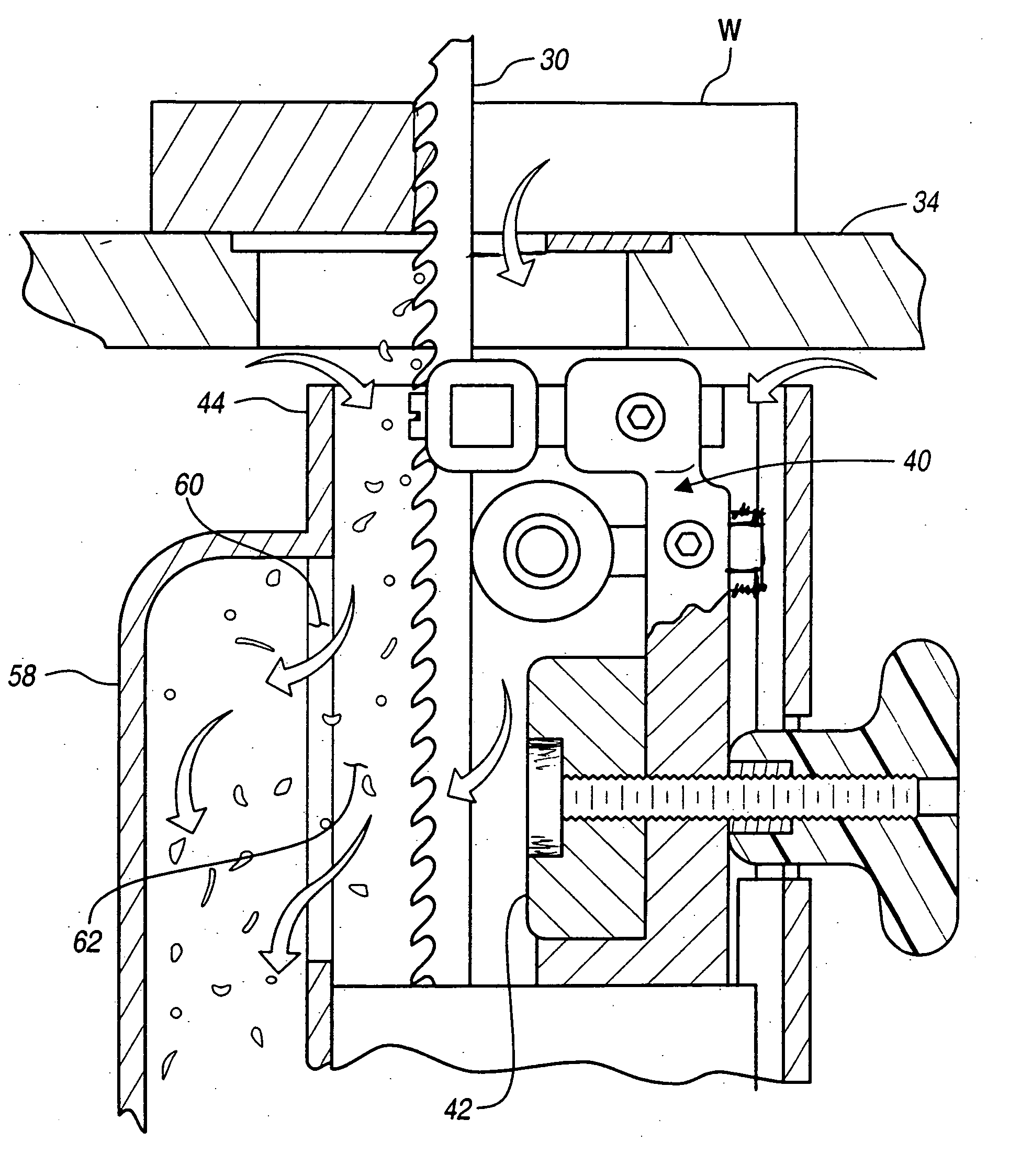

A motor driven power tool is provided having an internal dust collection system. A single electric motor drives the working member such as a saw or sander and simultaneously drives an air pump which acts as a collector vacuum for debris created when the power tool is in use. A dust collector shroud surrounds a portion of the cutting member and forms an outlet connected to the air pump inlet.

Owner:ONE WORLD TECH

Plane abrasive belt glazing machine

InactiveCN101181779AImprove polishing efficiencySimple structureBelt grinding machinesSanderDrive wheel

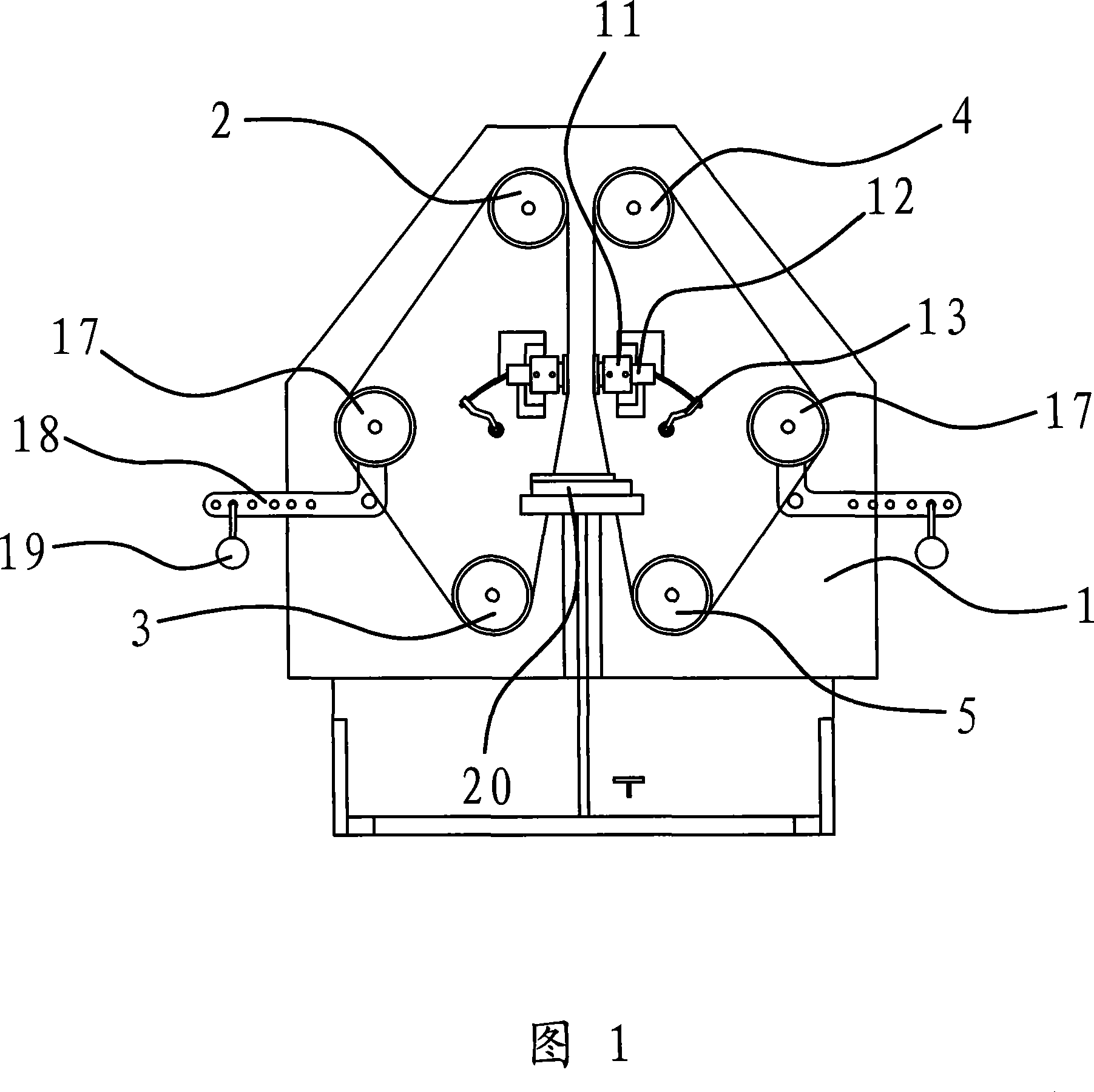

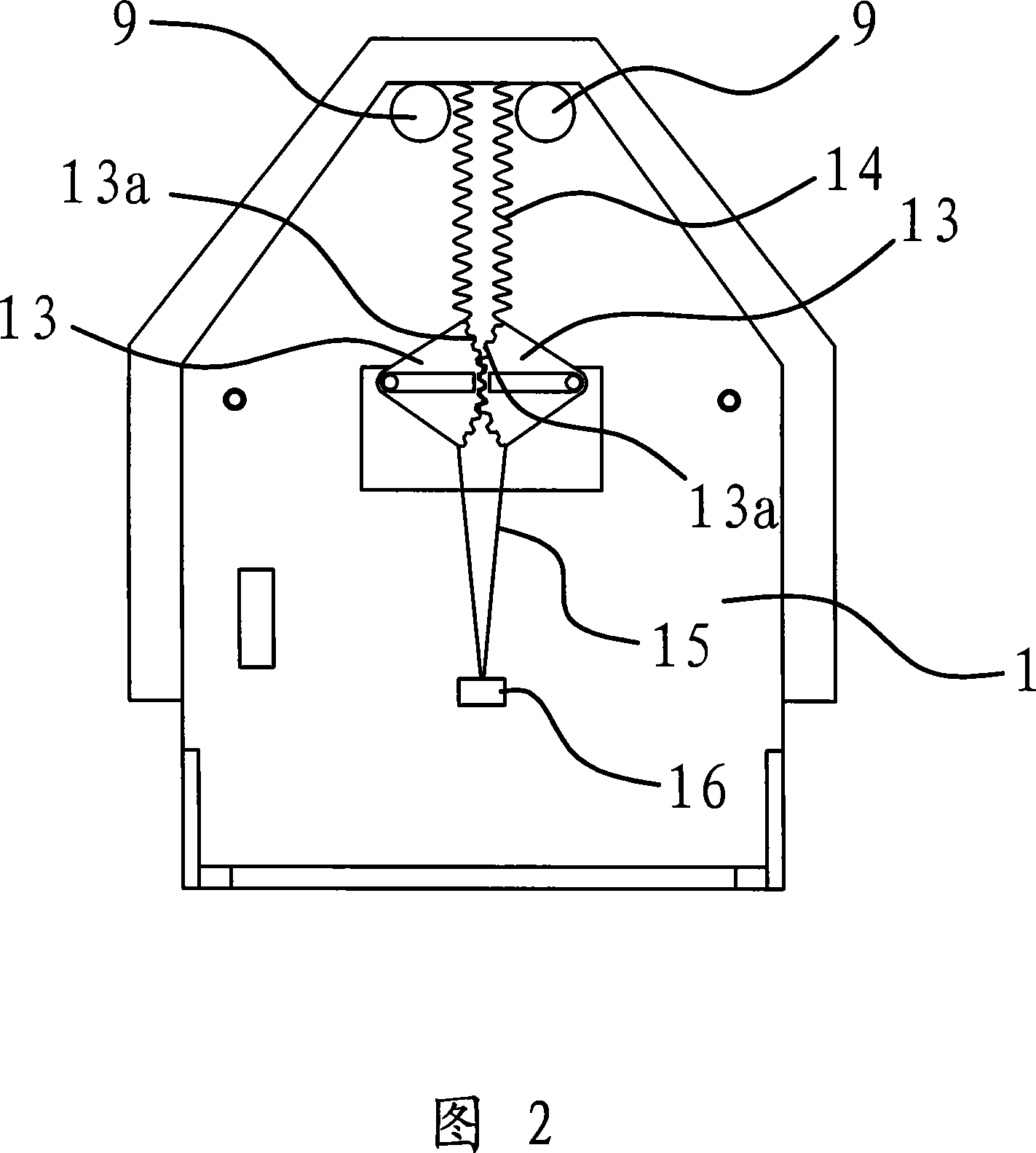

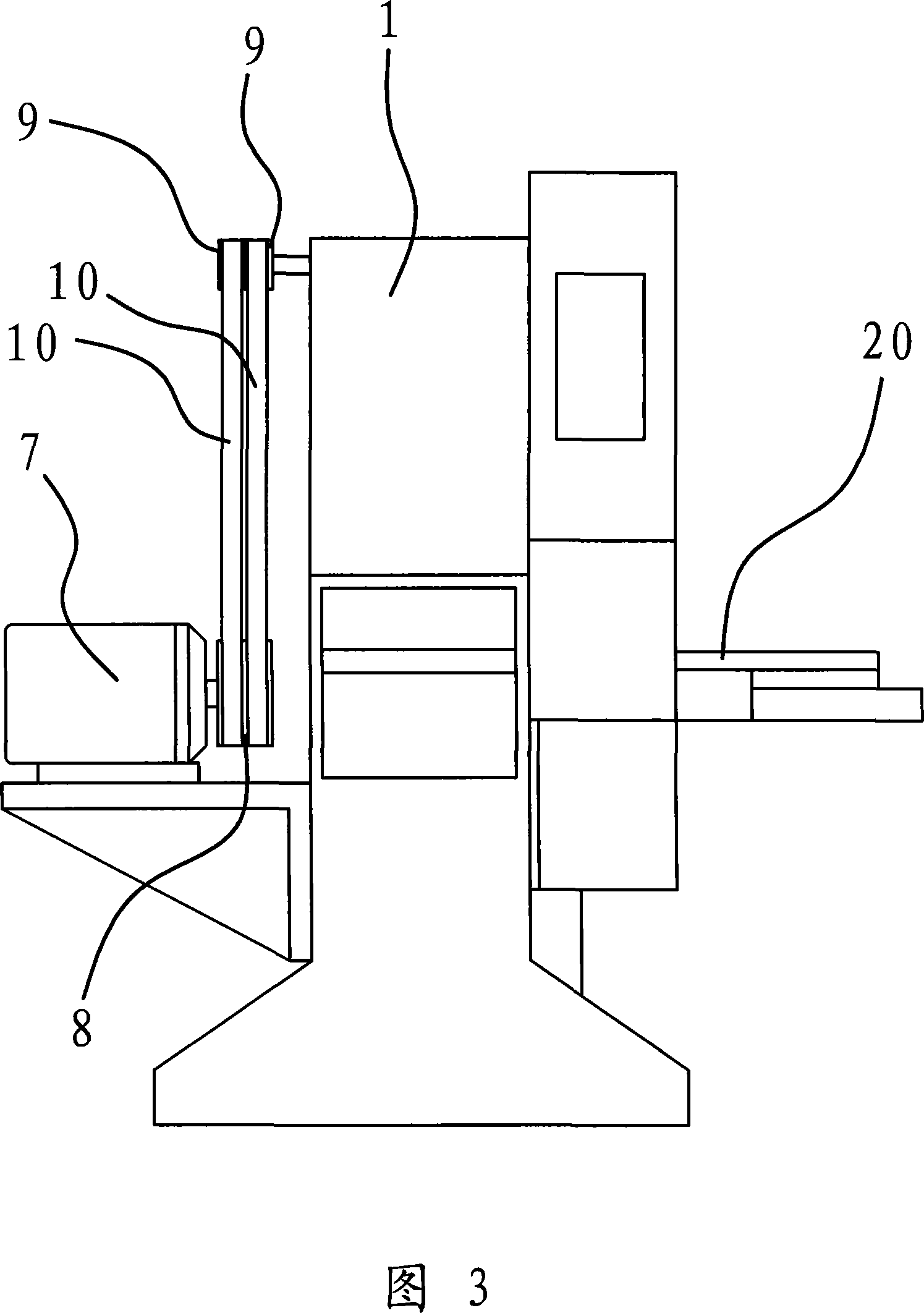

The invention provides a plane abrasive belt grinder, which belongs to the technical field of machinery. The utility model solves the problems of low work efficiency and the like when the existing polishing machine polishes the workpiece surface. The flat belt sander includes a frame, and the frame is provided with a driving wheel 1, a driven wheel 1, a driving wheel 2, a driven wheel 2 and two abrasive belts, one of which is covered by the driving wheel 1. and the driven wheel one, another abrasive belt is set on the driving wheel two and the driven wheel two, the two abrasive belts are adjacent and the polishing working surfaces of the two abrasive belts are in the opposite position, the two abrasive belts The abrasive belts are equipped with a pressing mechanism capable of pressing the inner side of the polishing surface of the abrasive belt, and the two pressing mechanisms are in the opposite position, and the first driving wheel and the second driving wheel are connected with the power device. Because it has two abrasive belts, it can polish both surfaces of the workpiece at the same time when polishing the workpiece, so its polishing efficiency is high. In addition, its structure is simple and its cost is low.

Owner:江苏优氟防腐科技有限公司

Skin treatment device and method for exfoliation and cellulite reduction

A novel device and method for use in providing multiple cosmetic treatments is disclosed, where a sanding tool is provided with sanding surfaces for use in imparting exfoliation, depilation, and cellulite treatments on the skin of a person. Select sanding surfaces are use for each of the exfoliation, depilation and cellulite treatments with the sanding action being generated by the orbital sanding effects of a palm sander. Specifically, a 100 grit (CAMI) sanding paper is used for exfoliation, a 180 grit (AMI) sanding paper is used for depilation, and the sander pad of the sanding tool of the present invention is used directly on the skin for cellulite reduction.

Owner:FERRARA JOELLA ANN

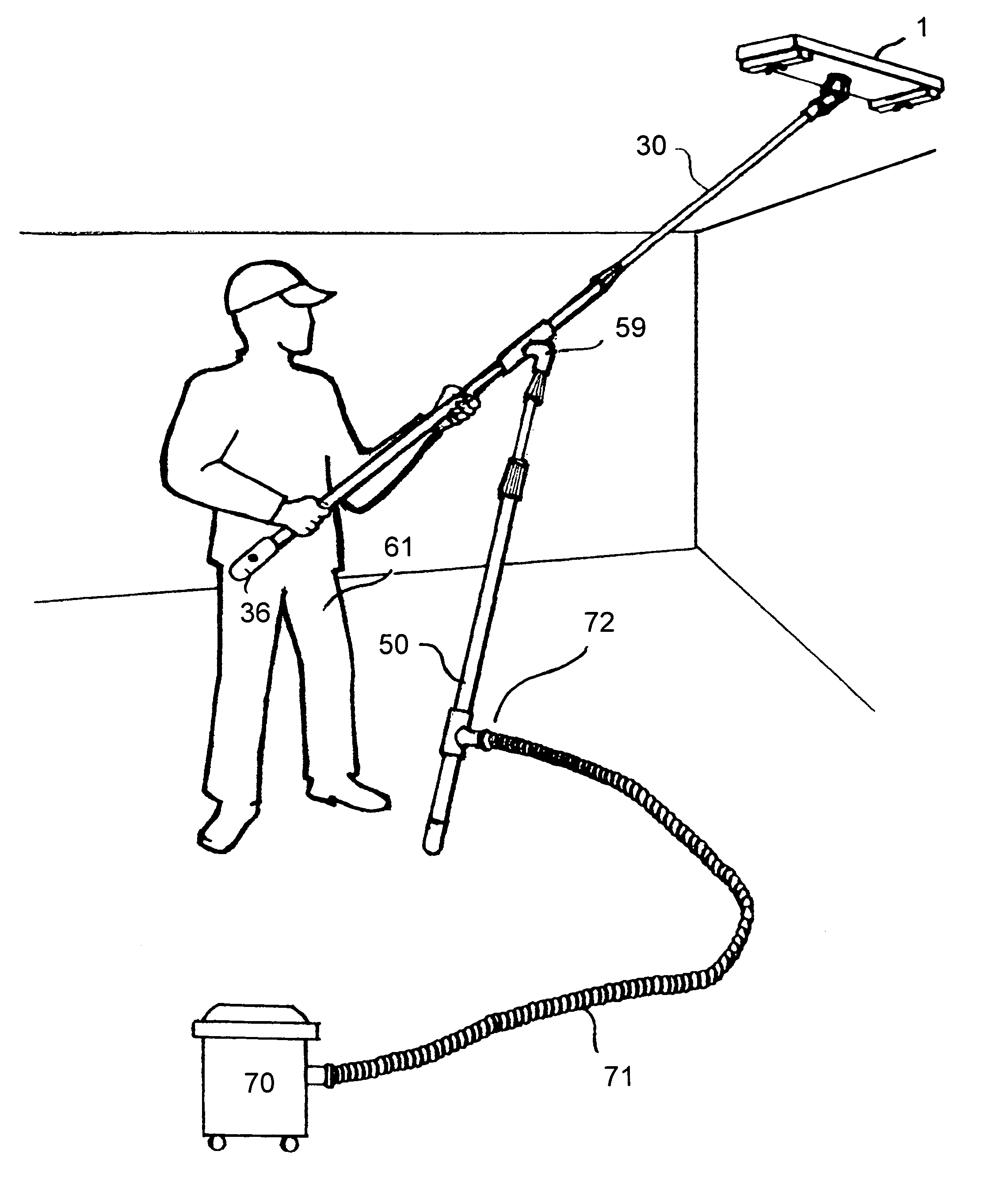

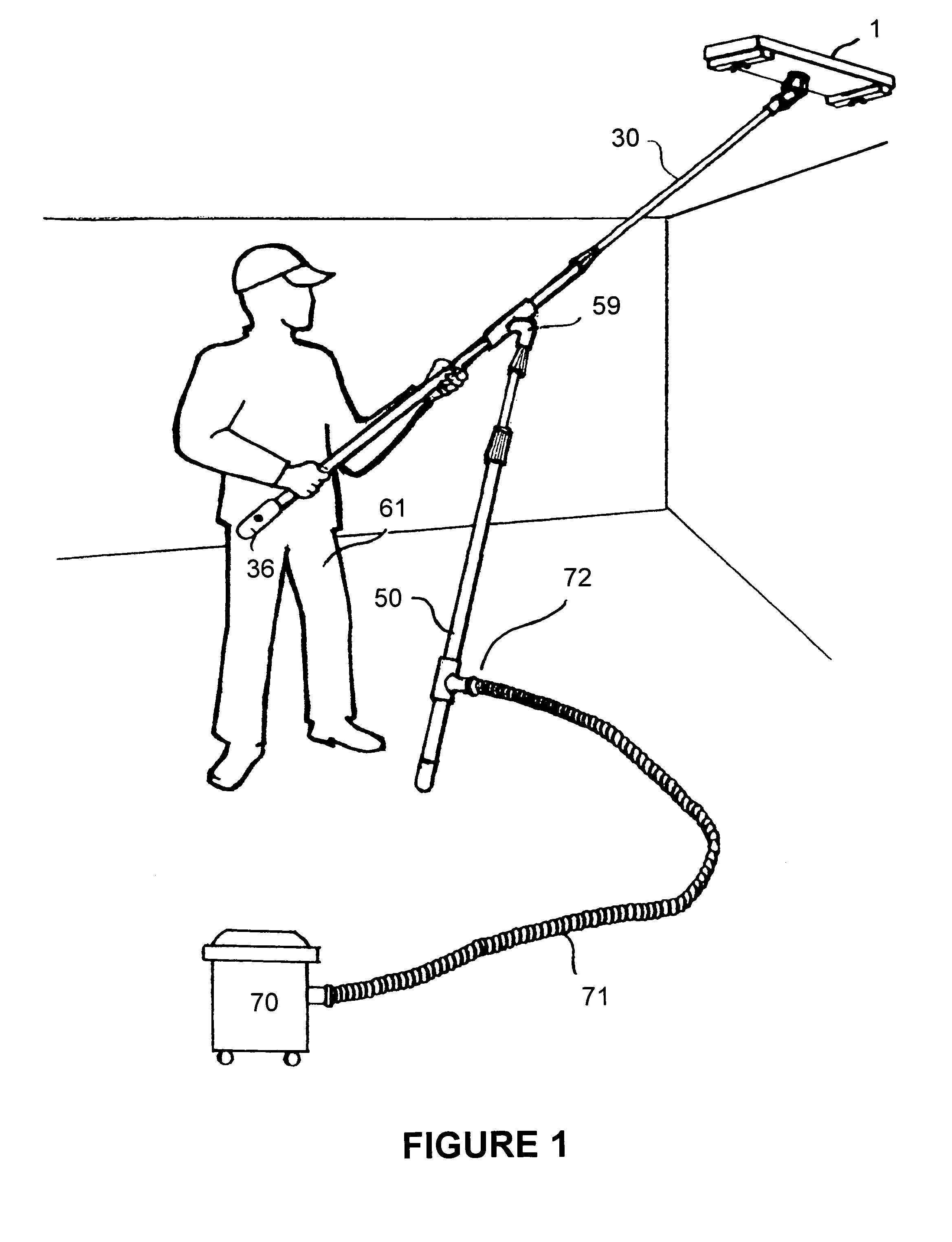

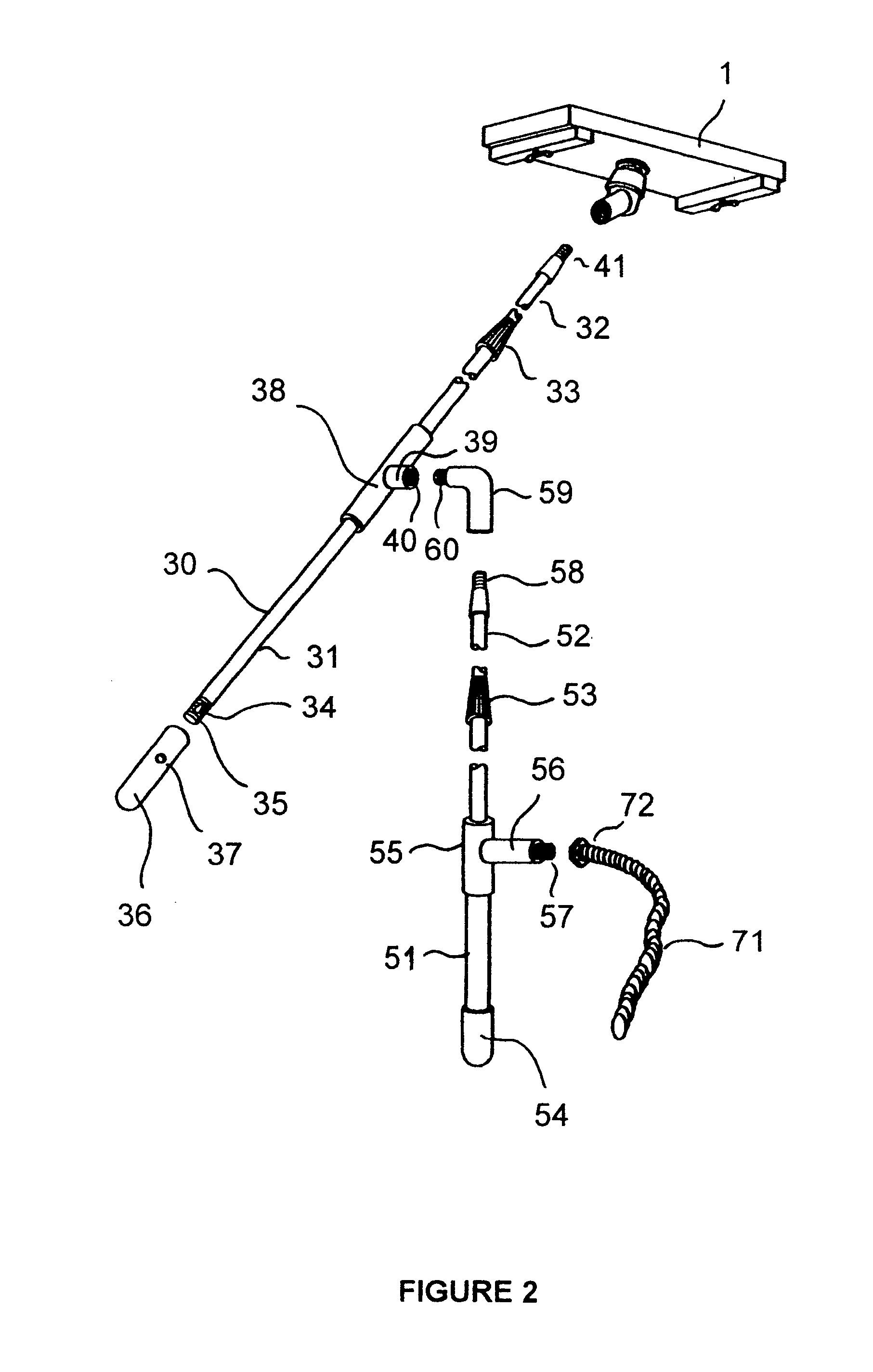

Vacuum sander

InactiveUS7249996B1Quality improvementEasy to usePortable grinding machinesGrinding/polishing hand toolsSanderVacuum assisted

A vacuum-assisted pole sander includes a sanding means attached at the end of the main pole, which in turn is supported in its middle section by a support pole. Both the support pole and the main pole are hollow and adjustable in length. The vacuum is transmitted from the sanding means of the device through the main pole to the vacuum connector in the supporting pole such that a vacuum can be attached on to ensure dust removal during operation. The combination of the support pole and the main pole is designed in such a way that the entire device is supported on the floor of the building under construction while allowing the operator to move it easily back and forth to achieve sanding of the ceiling. The support pole has a non-slip cap on its lower end and an angle connector on the other end. The angle connector is rotatably attached to the main pole such that it ensures the ability to swivel and at the same time provides a fluid communication between the inside portions of both the main pole and the support pole. The support pole is equipped with a vacuum attached for connecting to the suction means. The lower end of the main pole is equipped with vacuum strength adjustment means.

Owner:VOLYAR MYKHAYLO

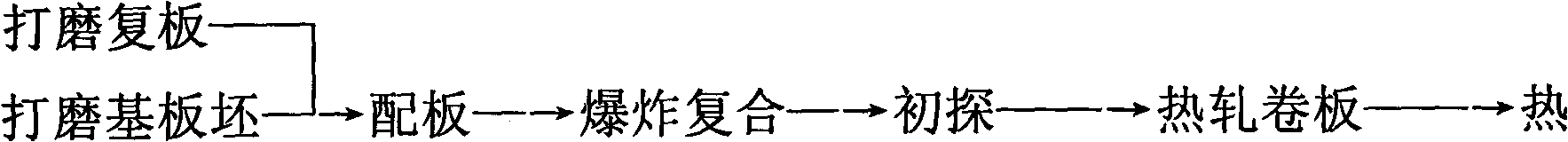

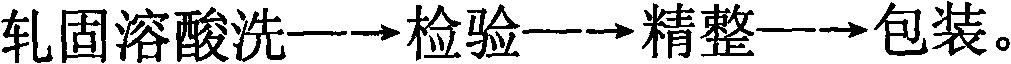

Method for producing stainless steel composite steel plate

ActiveCN101352805AUniform thicknessIncrease binding rateMetal rolling arrangementsNon-electric welding apparatusSanderSheet steel

A method for manufacturing a compound steel plate of stainless steel includes the following steps in turn: I, matching two stainless steel plates with a common carbon steel plate and carrying out fitting up according to the demands of a final finished product and rolling; II, welding carbon steel strips on the surrounding of the compound plate: welding the common carbon steel strips with a thickness of 6-8mm and a width of 60mm on the surrounding of the non-junction surface of the compound plate; III, polishing: using a sander to remove the impurities like oxide on the junction surface; IV, explosion welding: welding the compound plate of A surface on a basic plate firstly, and then welding the compound plate of B surface in an explosion way; V, fault detection: using an ultrasonic defectoscope to carry out fault detection; the area junction rate between the compound plate and the basic plate is not less than 99 percent; VI, carrying out defected weldseams on the surrounding fault; VII, carrying out hot rolling on the compound steel plate; feeding the compound steel plate into a hot milling roll to be rolled into a hot rolling compound steel bend with a thickness not more than 3mm; VIII, carrying out hot rolling, solid solution and acid cleaning on the steel plate and finally finishing the steel plate. The manufacture method of the invention can be used for manufacturing the compound steel plate of stainless steel with a total thickness of 0.8mm to 2mm.

Owner:TAIYUAN IRON & STEEL GROUP

Portable cyclonic dust collection system

A portable dust collection system for a wood shop or other dust producing environment is employed with a sander, power saw, router or other dust-producing tool such as a woodworking tool. A movable platform has a vertical intake pipe supporting a head portion formed with a shroud. A centrifugal impeller drives the intake air stream plus any entrained particles into one or more cyclonic separators, which deposit the dust in a respective drum supported on the platform beneath the cyclone. The air inlet from the tool enters the vertical pipe at a point partway up the pipe, so that large particles drop to the bottom end of the pipe, where a clean-out door is provided. The exhaust or discharge air from the cyclonic separator(s) passes out through a filter cartridge to the ambient. A deflector plate prevents the dust from eddying back into the separator.

Owner:WITTER ROBERT M

Silencer for dust collection system

ActiveUS7247180B1Simple and straightforward in constructionImprove reliabilityCombination devicesAuxillary pretreatmentProcess noiseSander

An auxiliary dust collection system can be interposed between a sander or other dust producing tool and a vacuum source, e.g., shop vacuum. A cyclonic separator is connected by a flexible hose to the tool and by another hose to the vacuum source. The cone of the separator is mounted onto the lid of a drum into which the dust precipitates. For a tool that has its own blower, the vacuum source can be omitted, and the air leaving the outlet duct of the separator can be filtered and returned to the ambient. A drop in silencer formed of a sleeve or tube of acoustic foam can be positioned into the inlet side of a filter cartridge following a cyclonic separator. The silencer absorbs a significant fraction of the process noise. The acoustic foam can have a textured surface on the sound-facing side.

Owner:ONEIDA AIR SYST

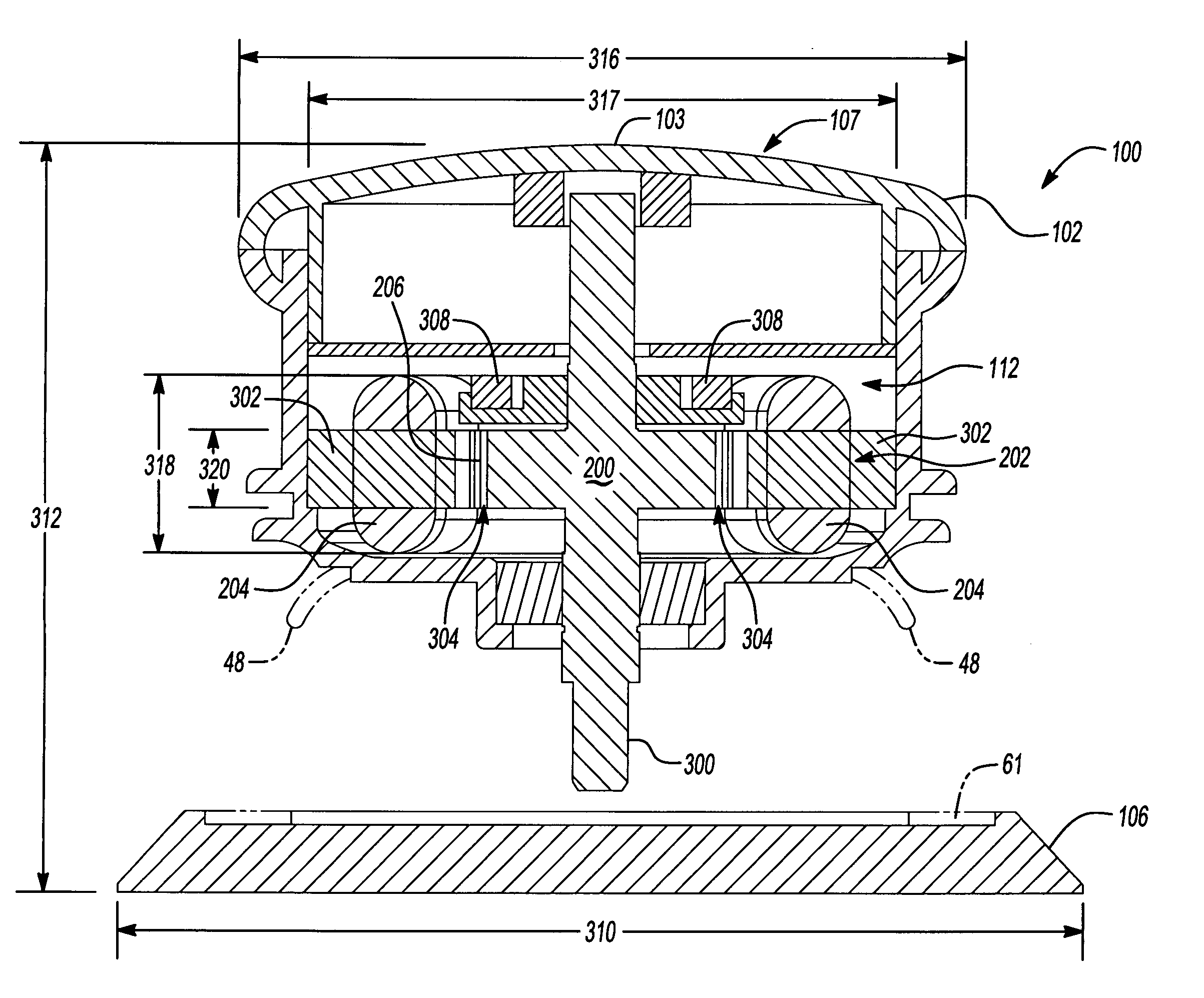

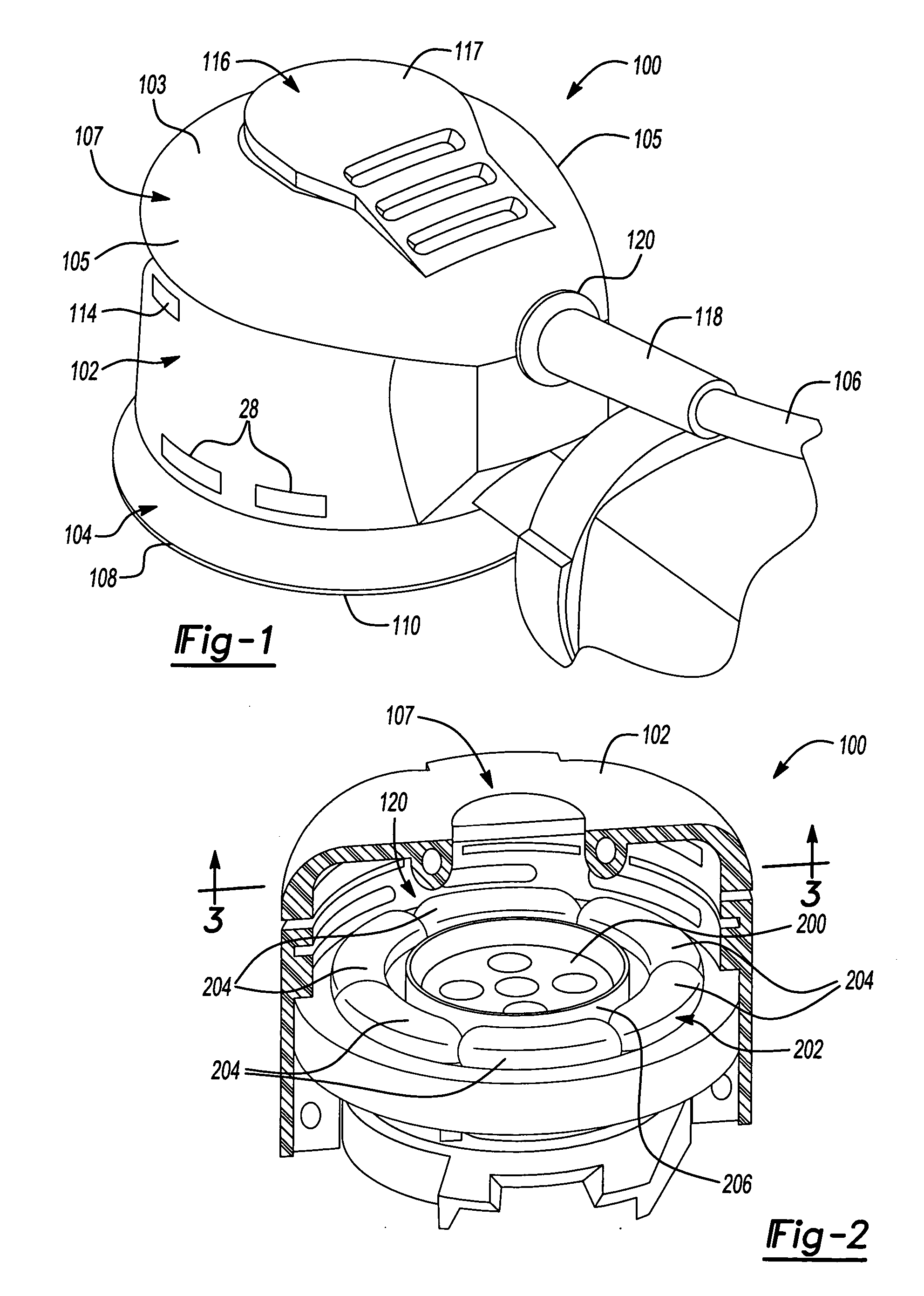

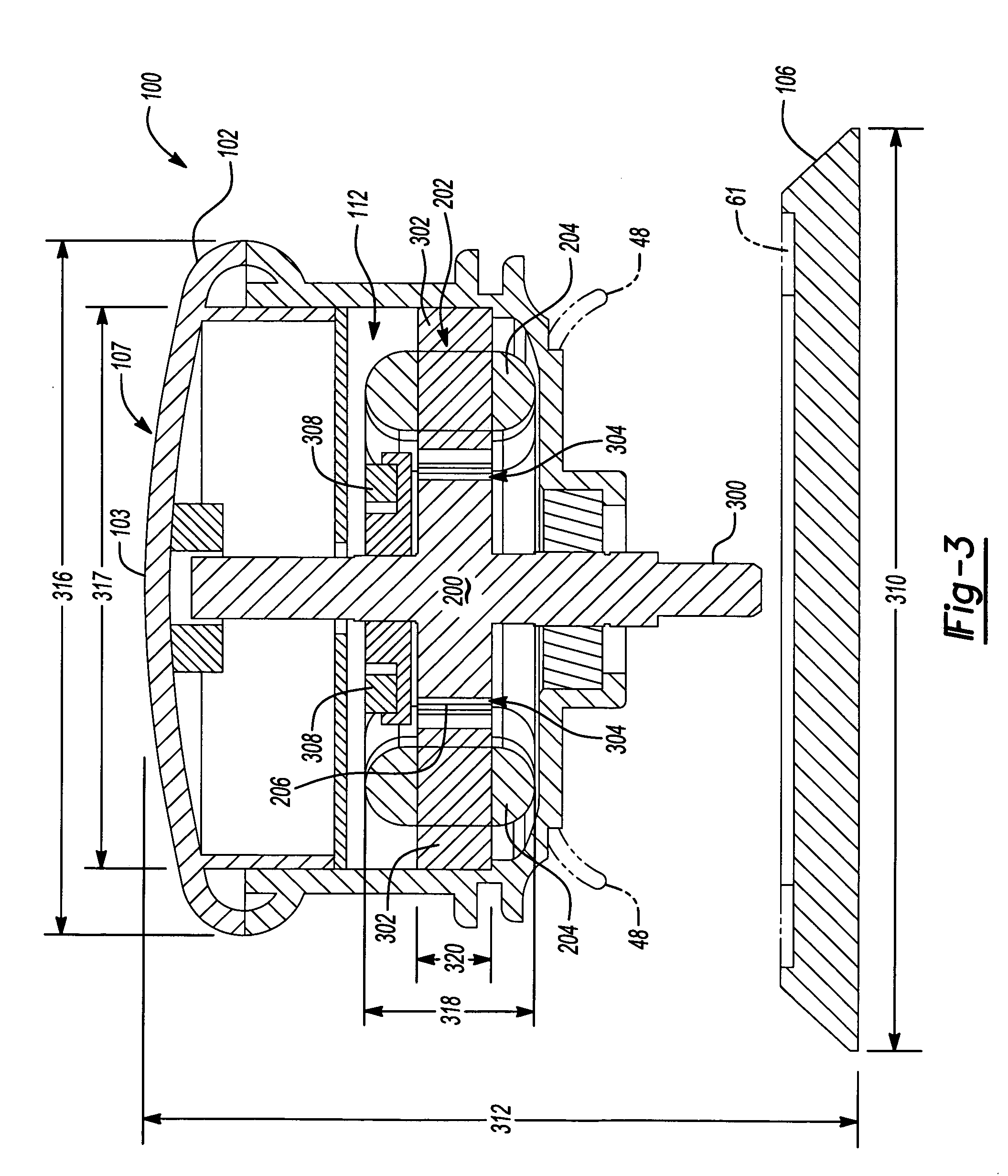

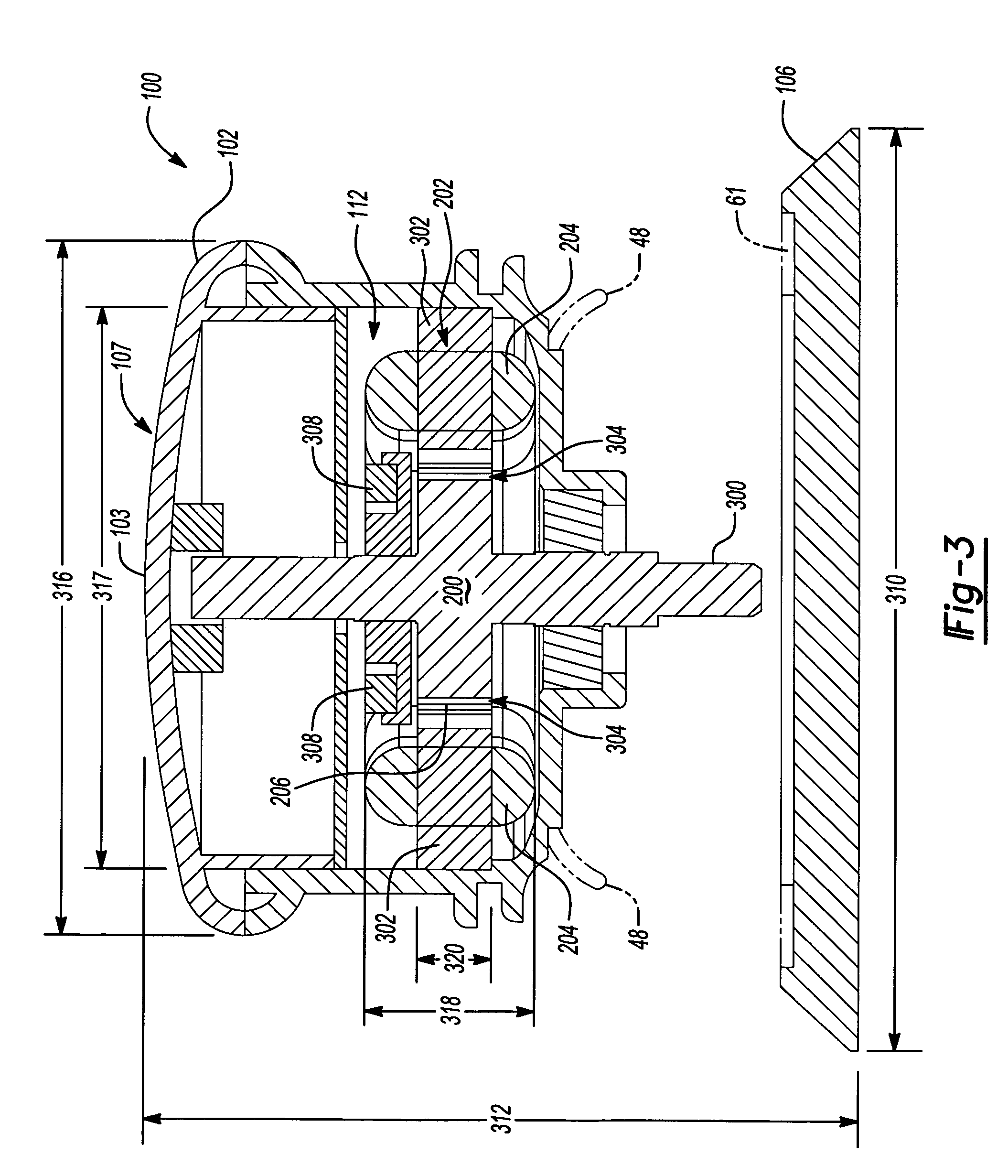

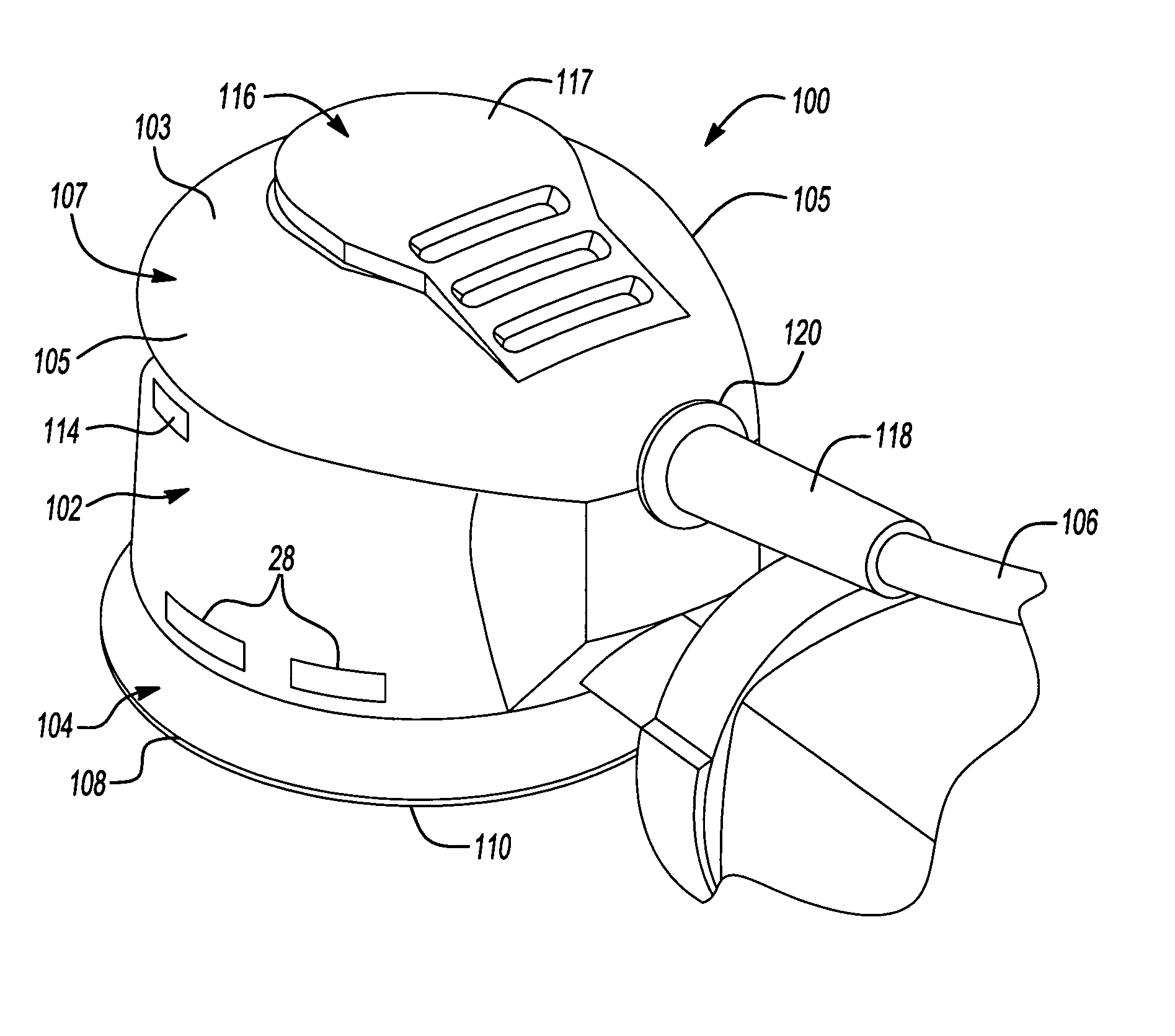

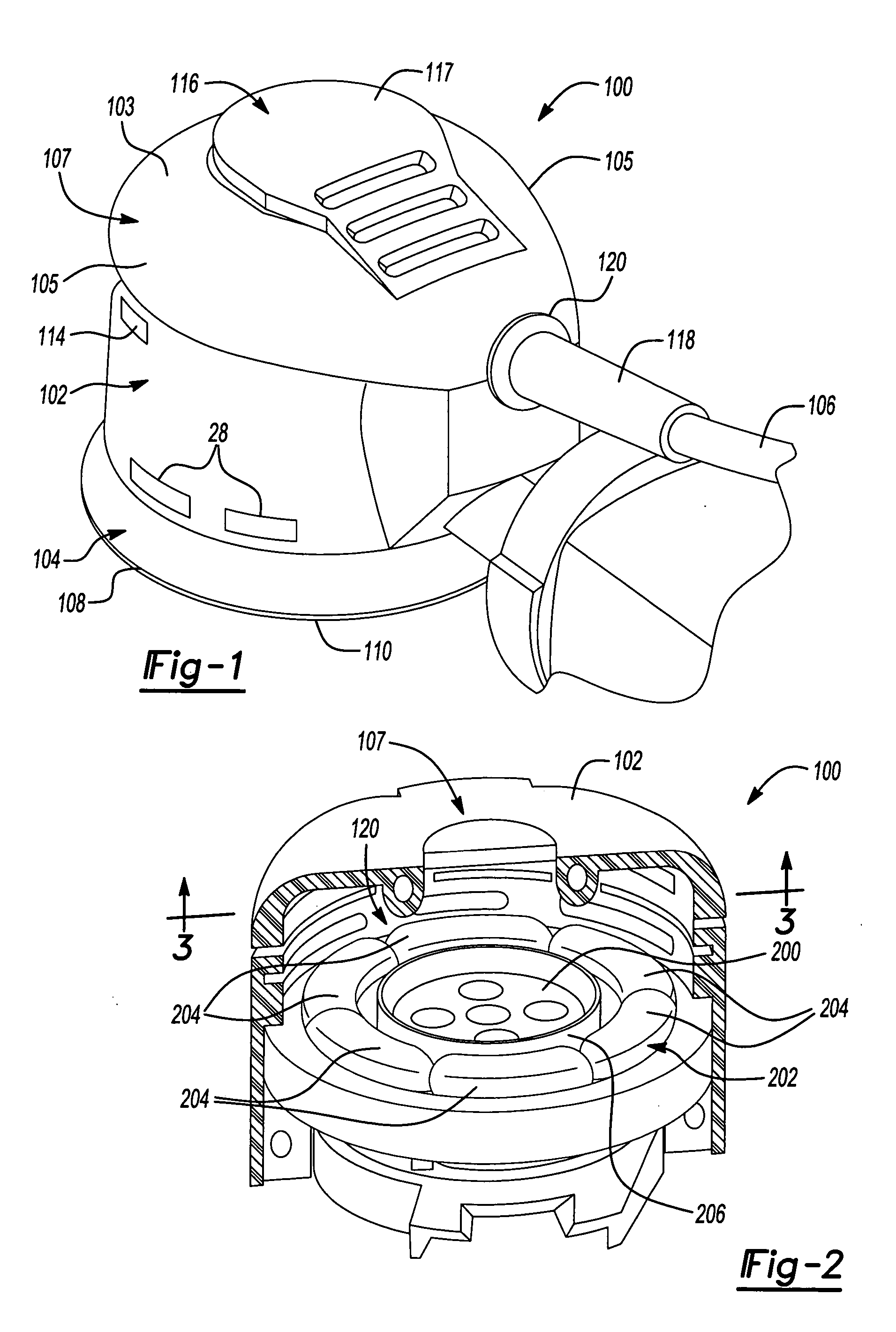

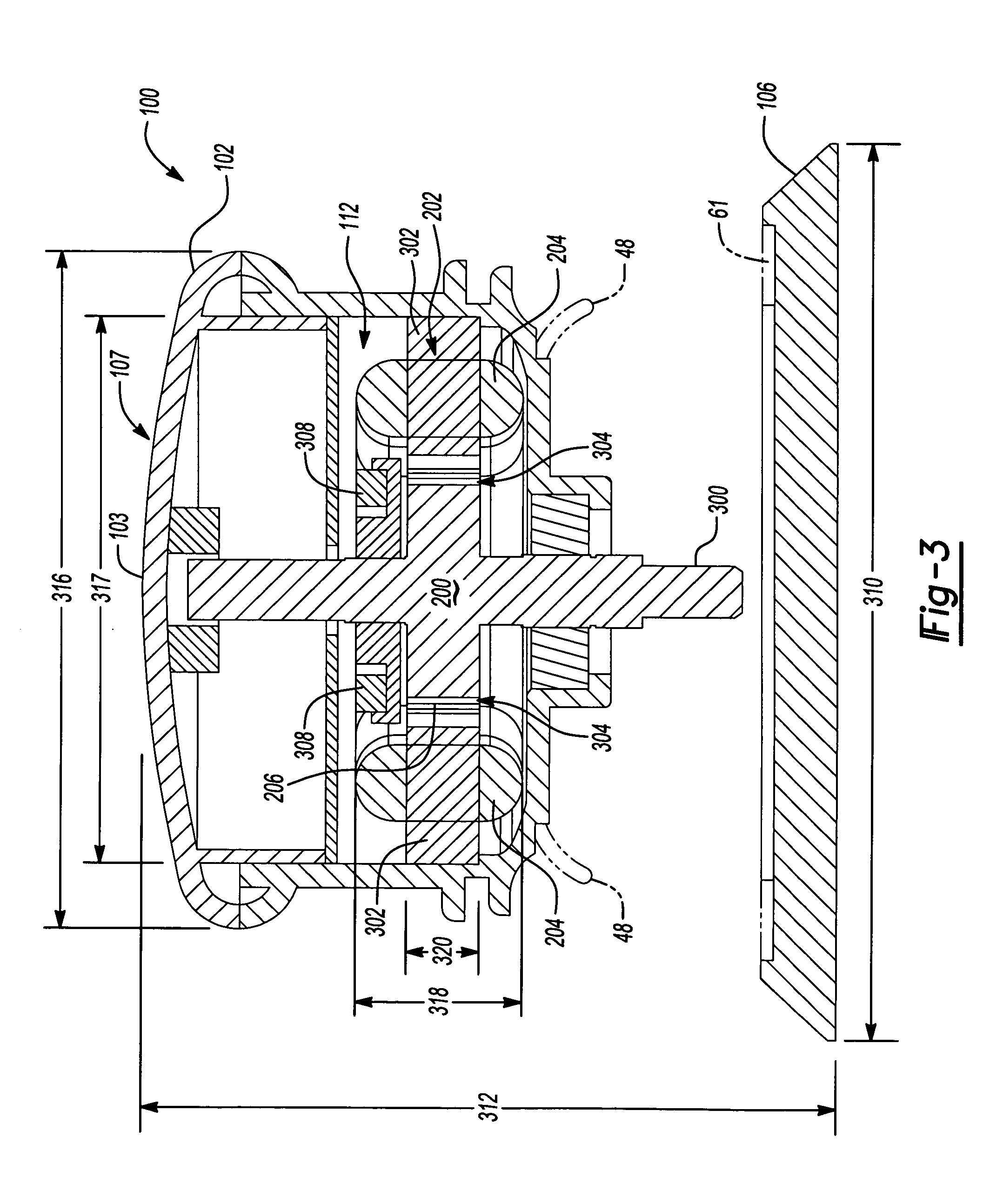

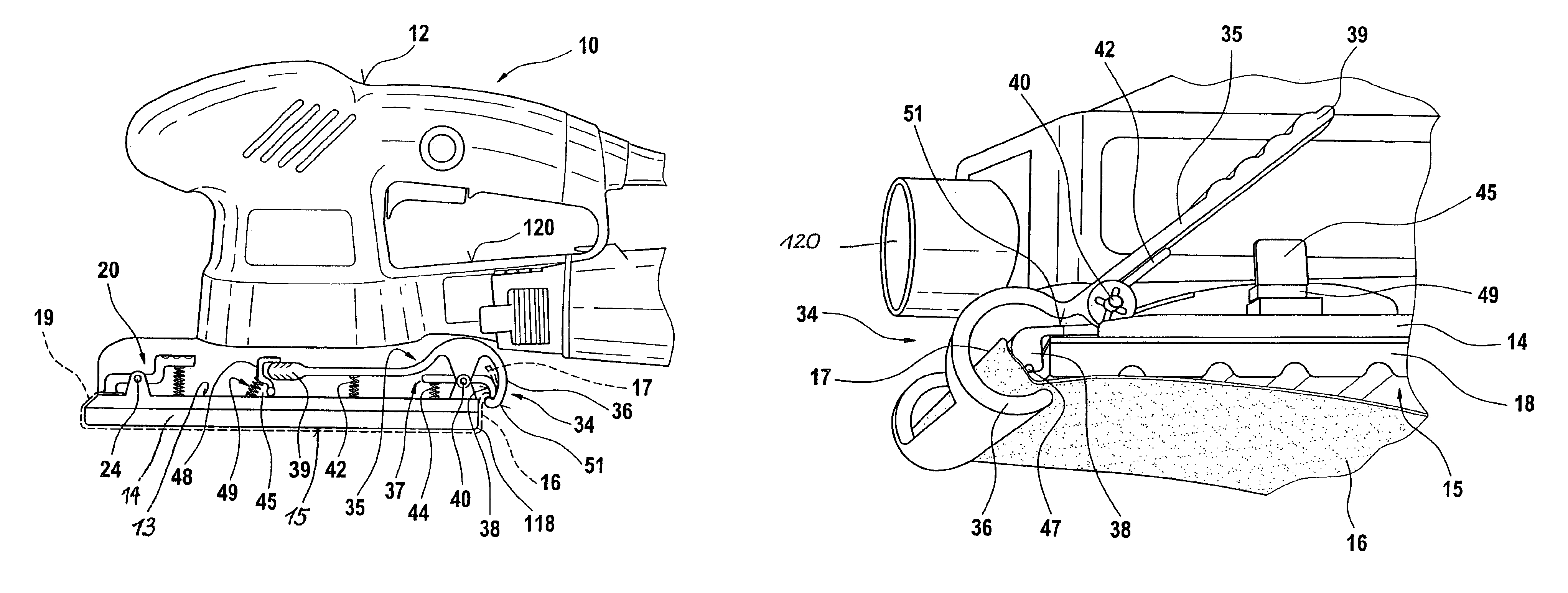

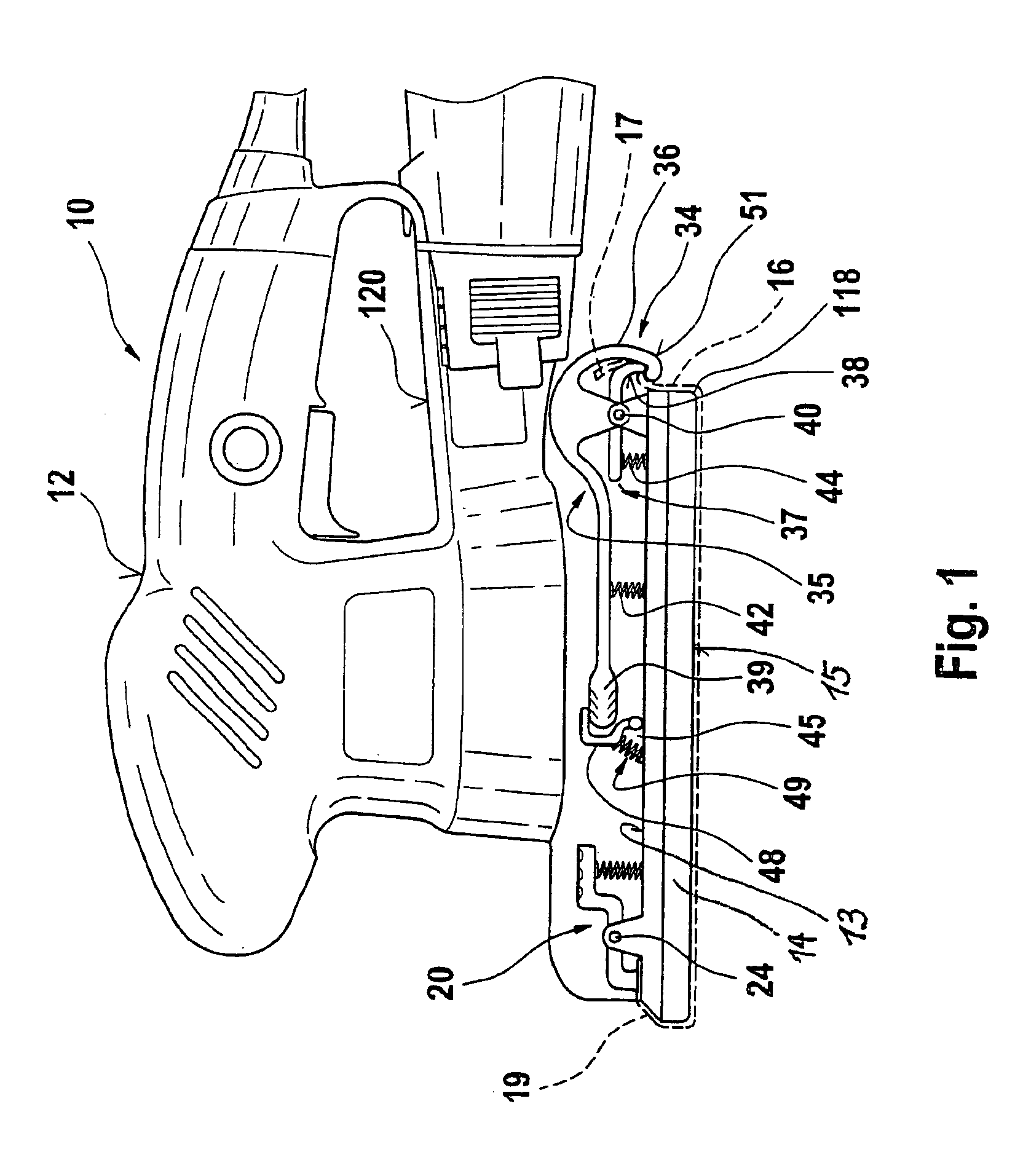

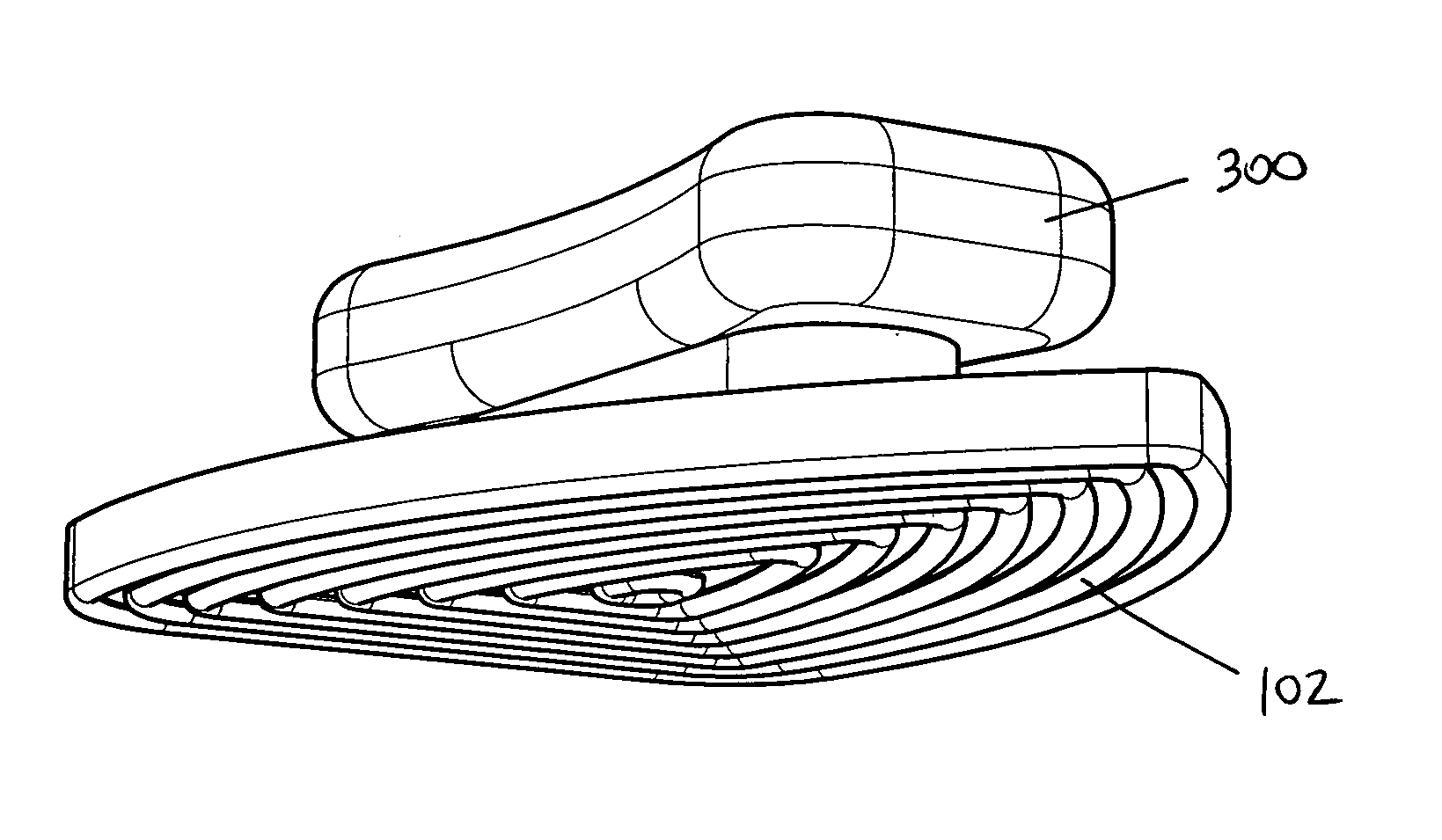

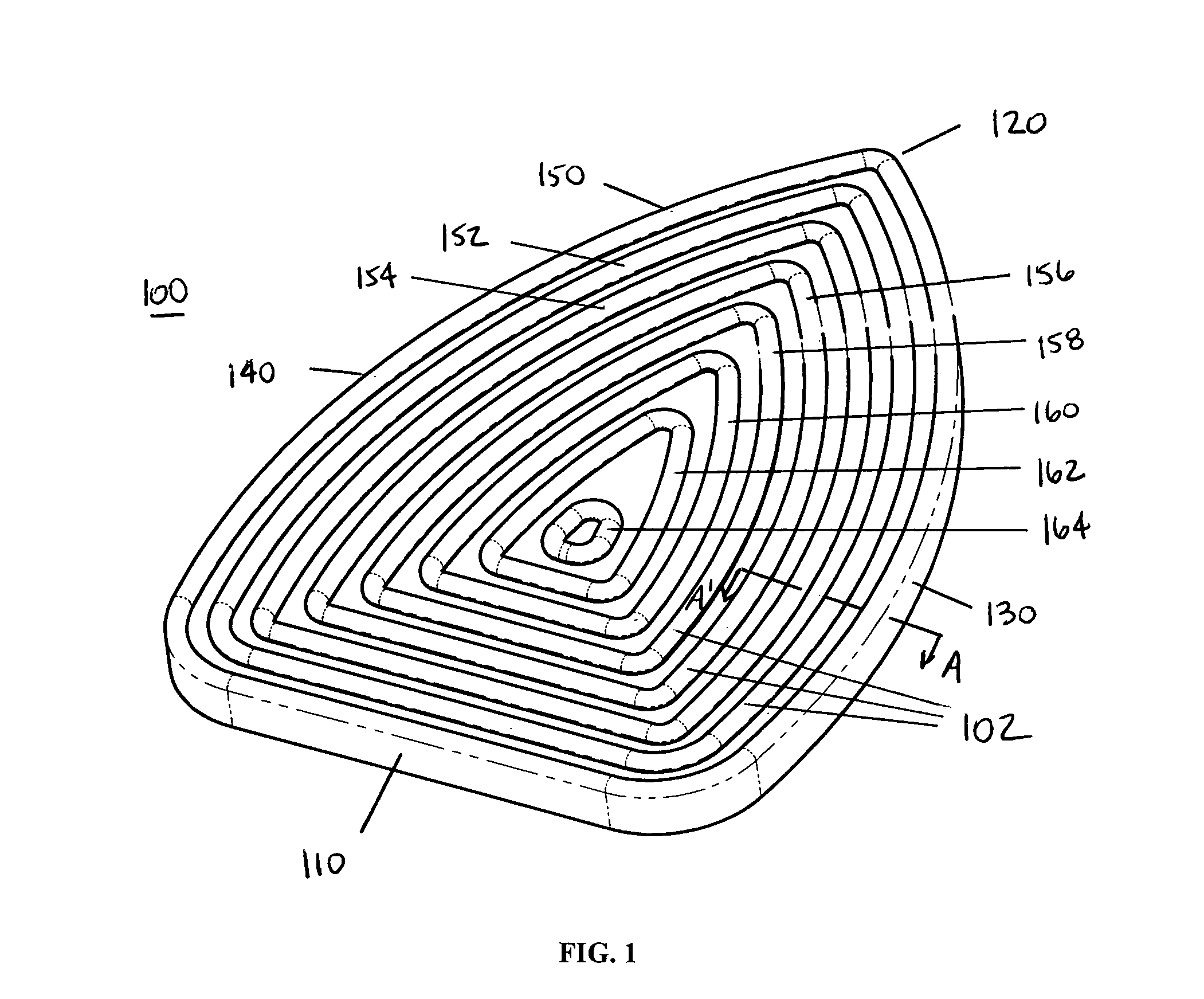

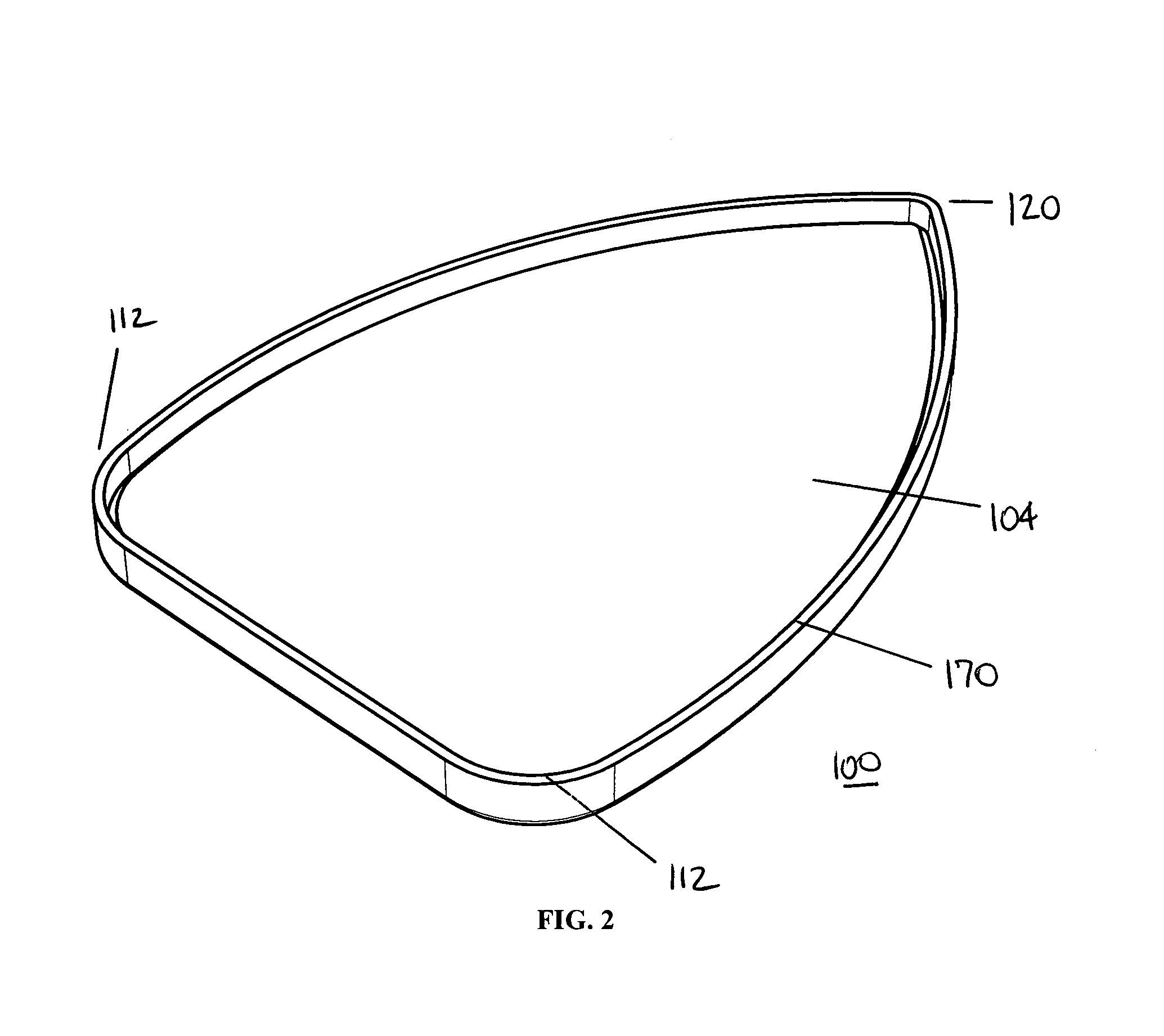

Ergonomically friendly orbital sander construction

InactiveUS6979254B1High strengthSufficient lateral flexibilityRotary piston pumpsPortable grinding machinesSanderAcute angle

A random orbital sander including a housing, a motor having a vertical axis in the housing, a pad coupled to the motor, a face on the pad extending substantially perpendicularly to the vertical axis, a shroud surrounding the pad, an opening in the shroud, and a dust discharge tube having an inner end in communication with the opening and an outer end on the dust discharge tube end extending at an acute angle to the face of the pad. An orbital sander wherein the pad is supported from the sander housing by columnar units located on opposite sides of the motor. A bore in the motor shaft conducts compressed air through the chamber housing the bearings which support the spindle which mounts the pad.

Owner:CHAO HAO CHIEN

Motor driven wood working tool with vacuum feature

InactiveUS20070044609A1Efficient collectionMetal sawing devicesMetal sawing accessoriesSanderMotor drive

A motor driven power tool is provided having an internal dust collection system. A single electric motor drives the working member such as a saw or sander and simultaneously drives an air pump which acts as a collector vacuum for debris created when the power tool is in use. A dust collector shroud surrounds a portion of the cutting member and forms an outlet connected to the air pump inlet.

Owner:BRAZELL KENNETH M +1

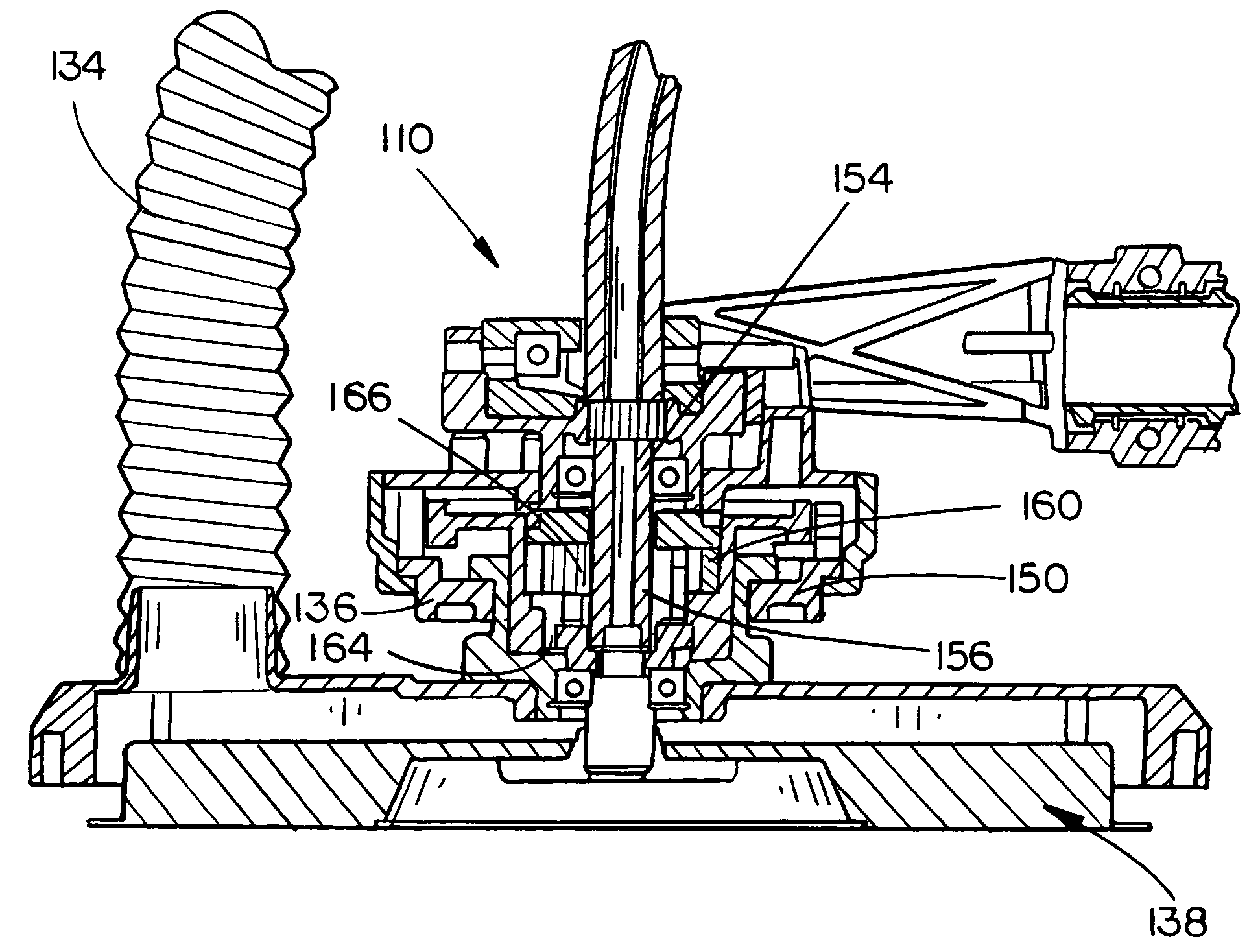

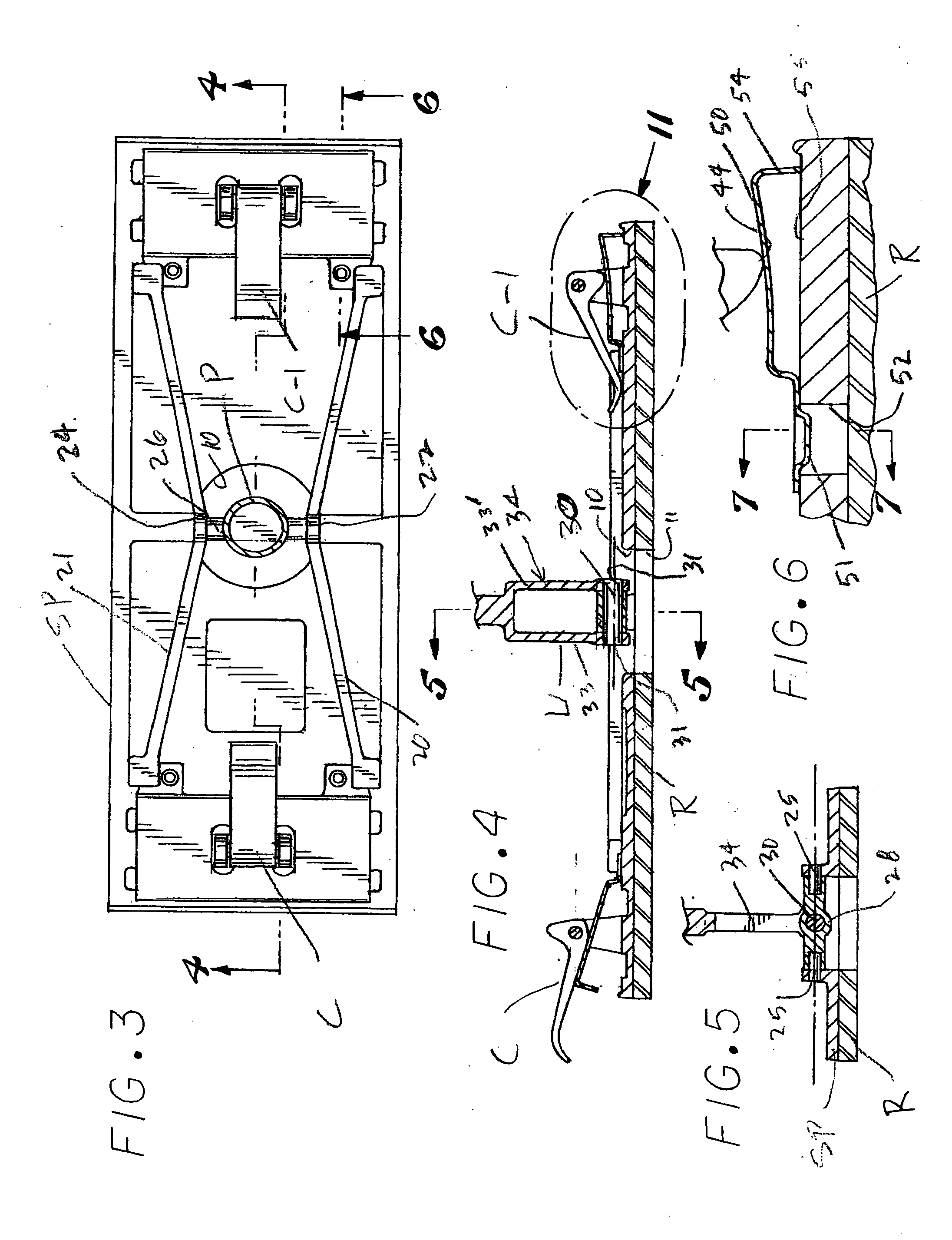

Drywall sander

ActiveUS7220174B2Adjustable lengthRevolution surface grinding machinesGrinding drivesSanderDrive shaft

The present invention provides an adjustable drywall sander capable of imparting more than one type of motion. In an exemplary embodiment, the sander includes a power unit with a motor and a sanding assembly coupled to the power unit. A telescopic support arm assembly is coupled to the sanding assembly and the power unit for supporting the sanding assembly. The telescopic support arm assembly includes a first support arm with a first and a second end and a second support arm with a first and second end. The first end of the first support arm being coupled to the power unit and the second end of the second support arm being coupled to the sanding assembly. A collapsible drive shaft is substantially enclosed by the telescopic support arm assembly. The telescopic support arm assembly and the collapsible drive shaft allow the length of the telescopic assembly to be adjusted.

Owner:BLACK & DECKER INC

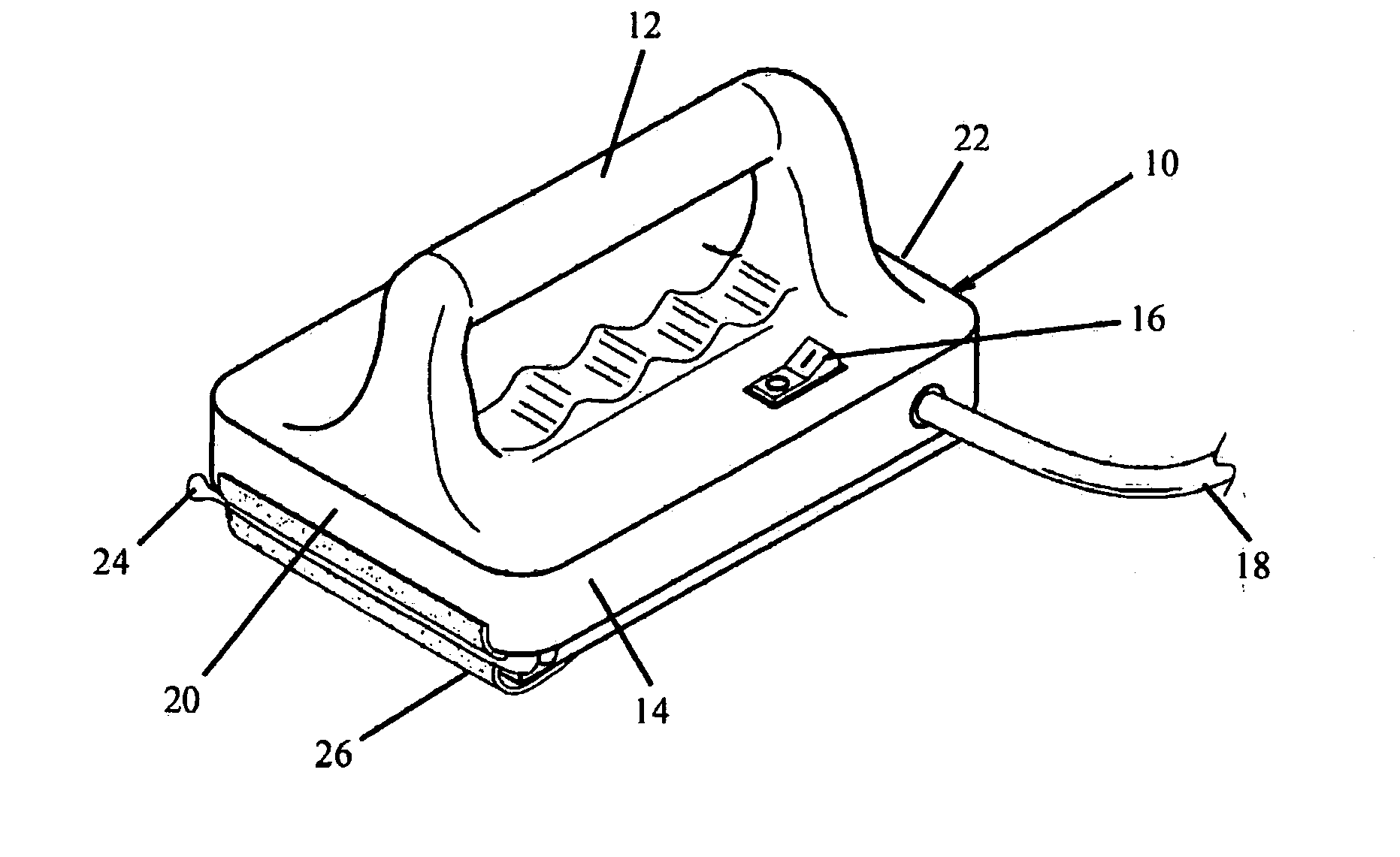

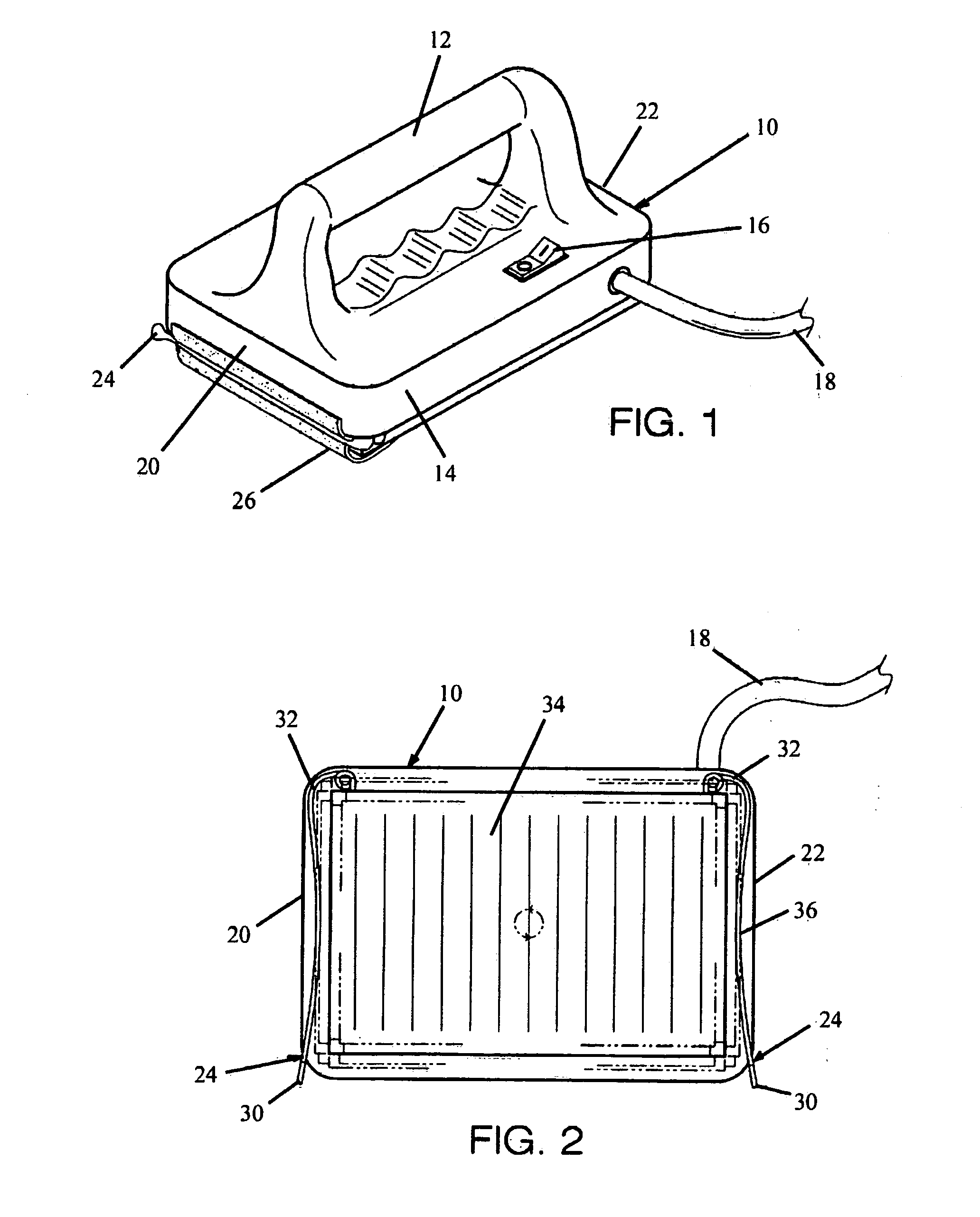

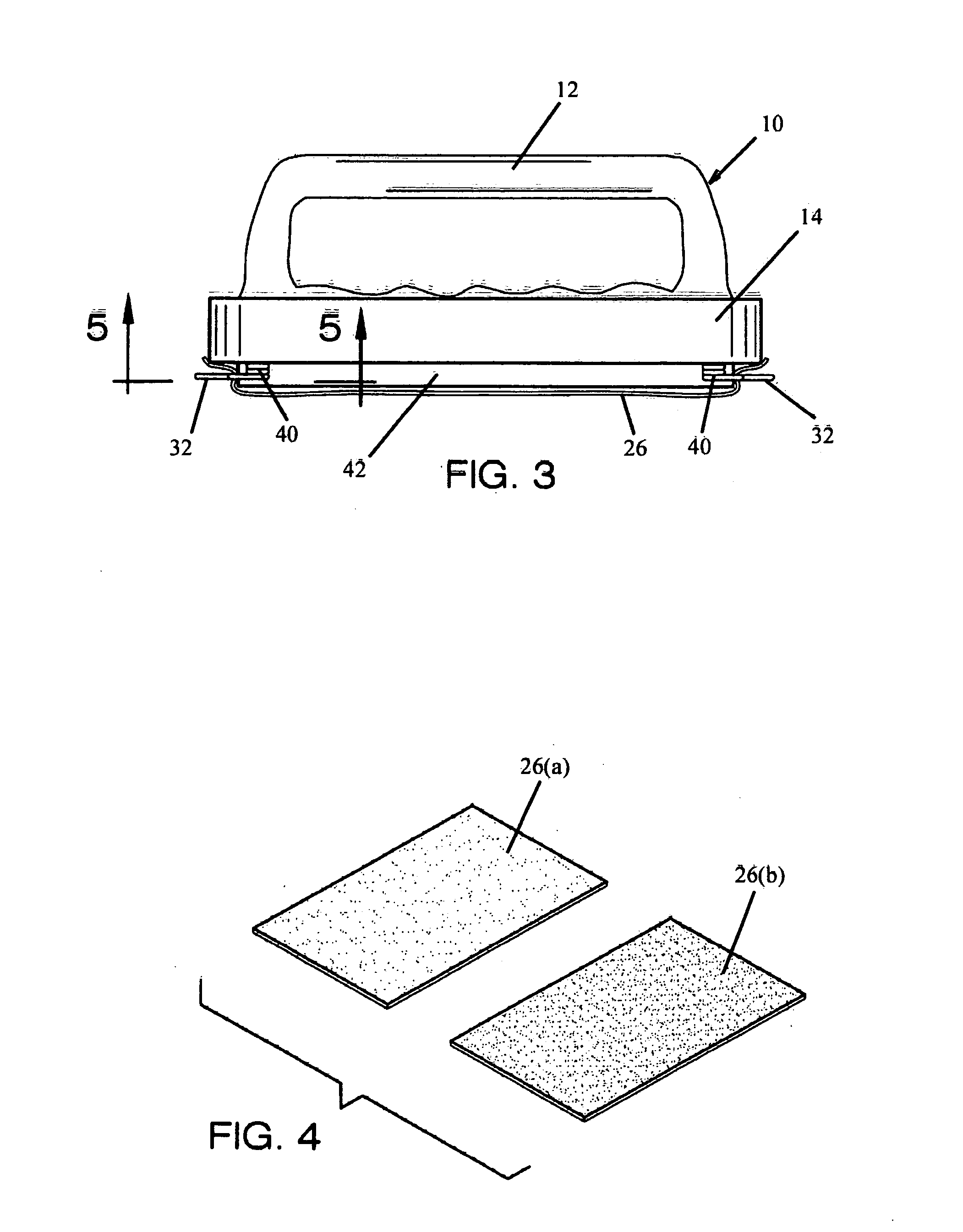

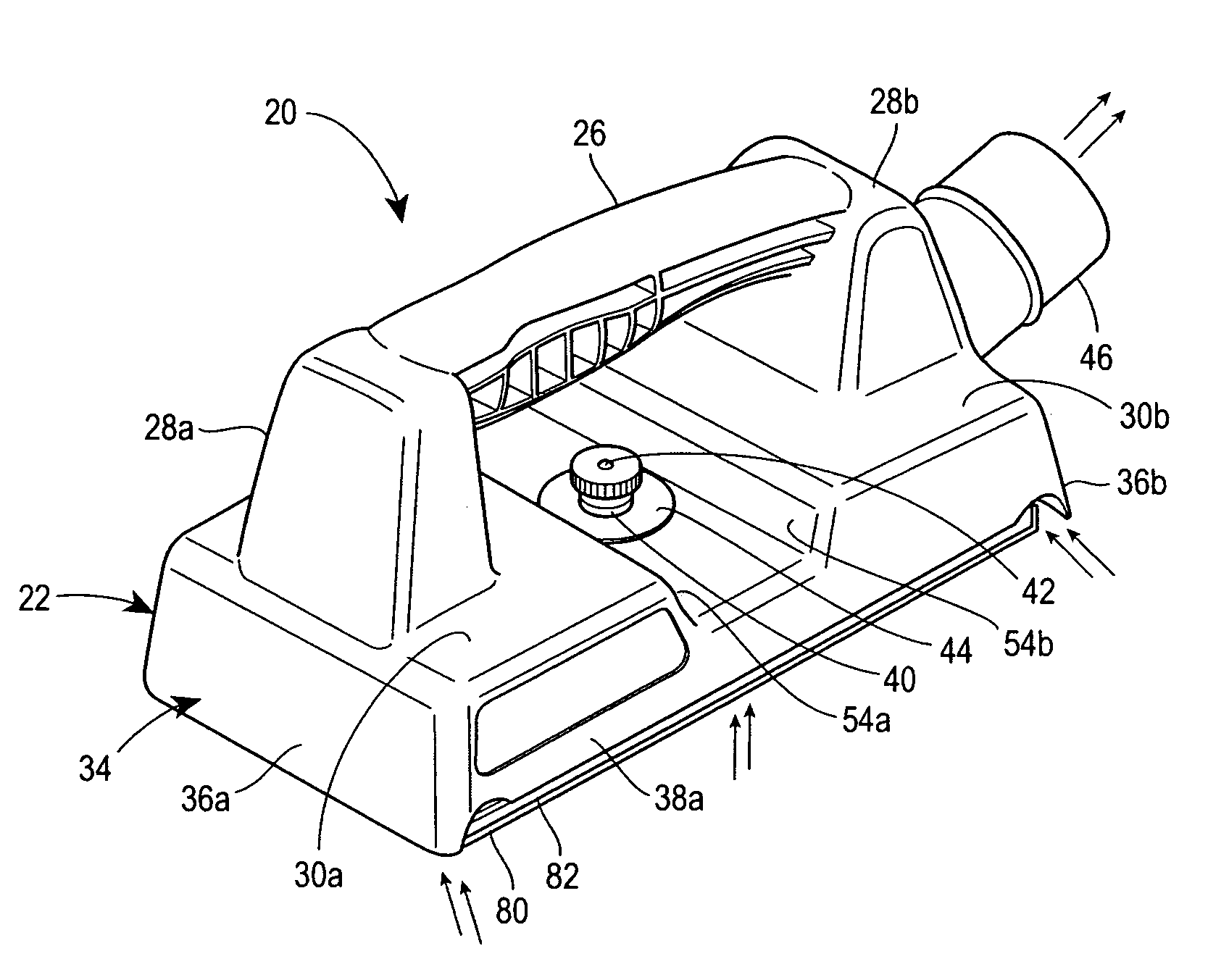

Hand sander vacuum attachment

A manual sander vacuum attachment, providing edge sanding and multiple positioning capabilities, having a lower sanding backer plate member, which carries a soft sanding pad and secures the sandpaper sheet, and an upper housing portion, having a generally horizontal platform with two vertically-extending stanchion supporting a handle therebetween, with a vacuum fitting for connection to a hose for a vacuum air source, and a peripheral skirt surrounding the backer plate member, whereby all vacuum air flow of sanded debris travels about periphery of sander backing plate up into interior of the housing portion.

Owner:SHOP VAC

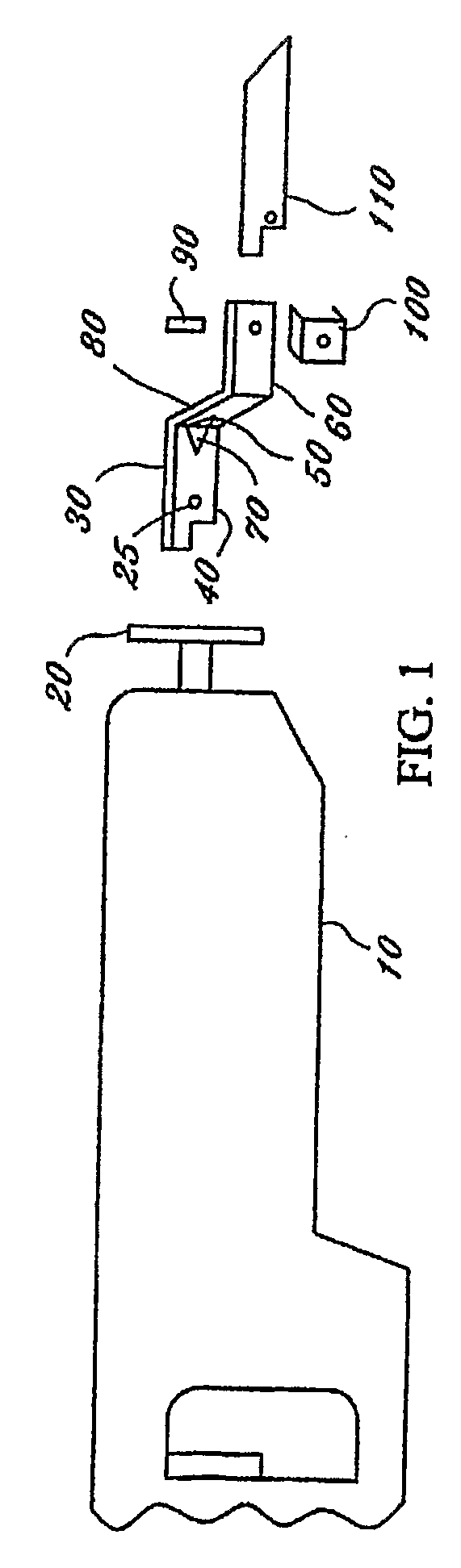

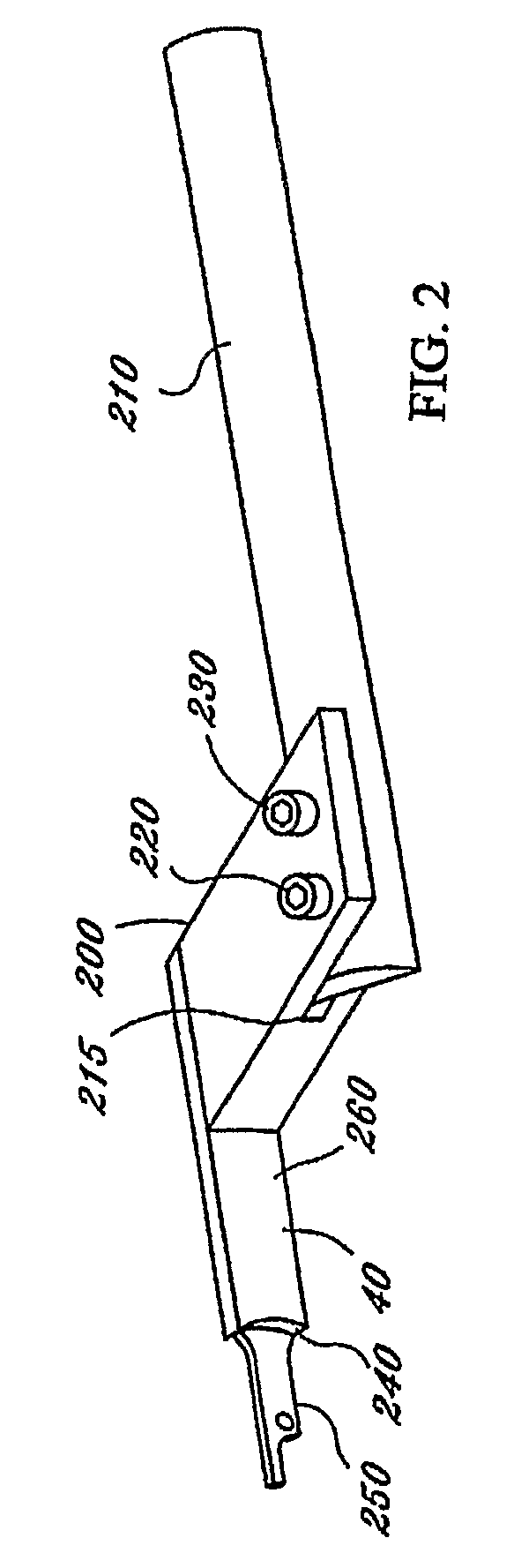

Extendable remote motored sander and method therefor

A remote powered extendable sander has a sanding unit having a sanding surface. A drive system is coupled to the sanding unit. The drive system is used to move the sanding surface. A drive transfer unit is provided for transferring rotational motion from a small motorized construction tool to the drive system for powering the sanding unit. A housing is coupled to the sanding unit. An extension member is removably coupled to the housing for raising the remote powered extendable sander.

Owner:BIRK JOHN

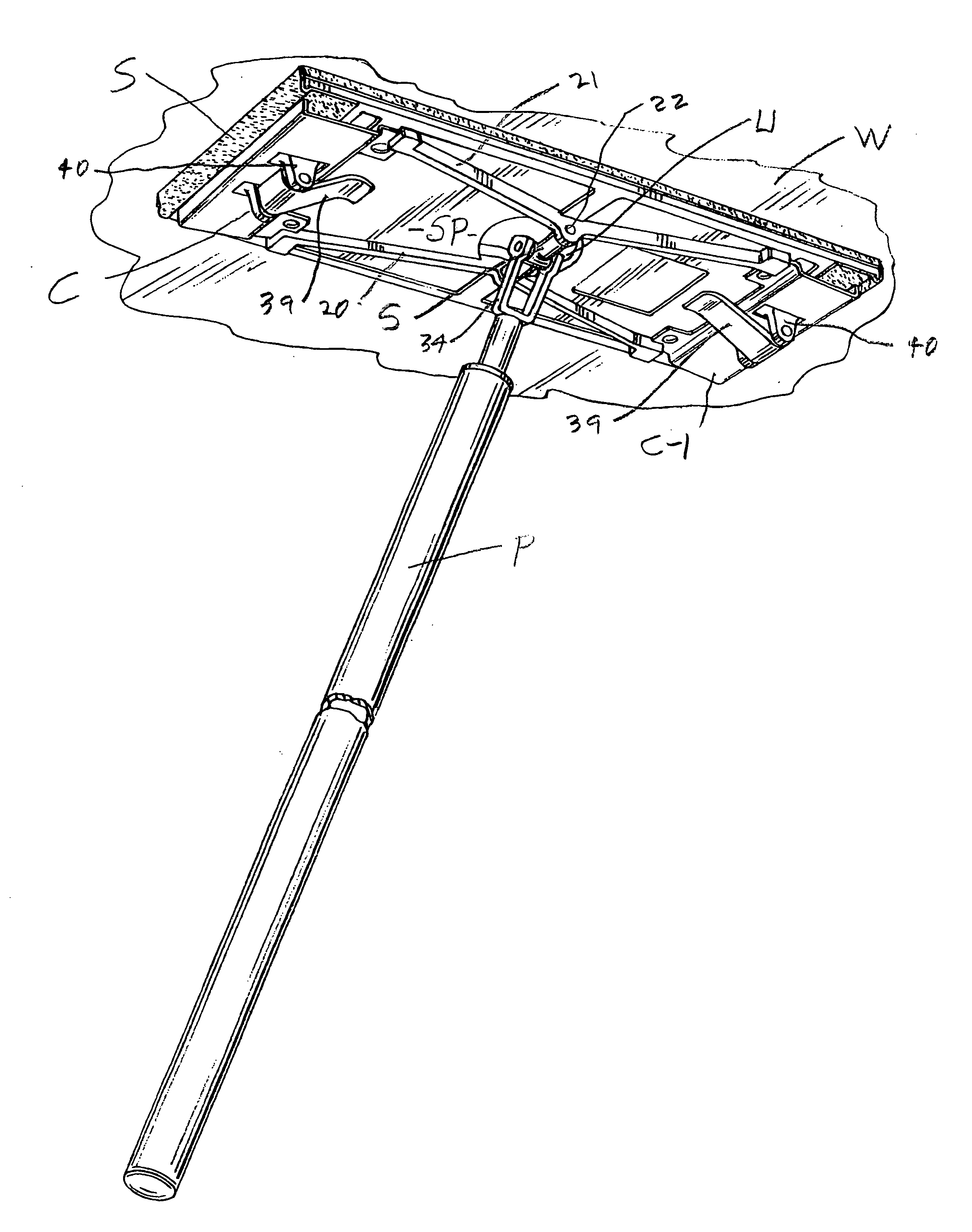

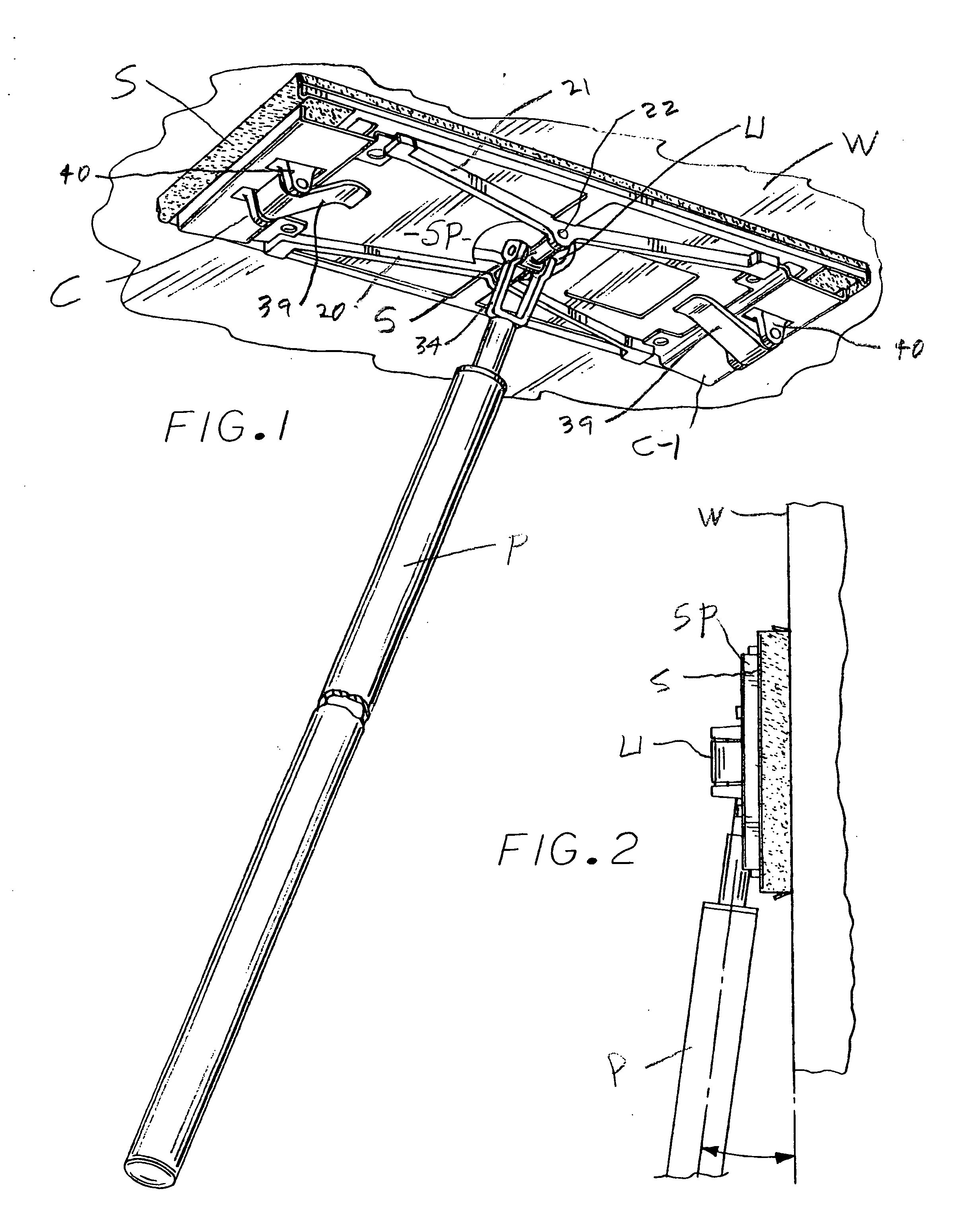

Pole sander

InactiveUS20050287937A1Shorten the timeOvercome disadvantagesPortable grinding machinesBuilding constructionsSanderUniversal joint

A pole sander having a rectangular sander plate which removeably holds one or more sheets of sandpaper by a pair of clamp assemblies positioned at opposite ends of the sander plate. The sander plate is attached to the upper end of a pole by a universal joint having elements arranged to permit the pole to assume a position close to parallel with the drywall surface being sanded.

Owner:WALLBOARD TOOL

Method and means for processing oil sands while excavating

InactiveUS7097255B2Easy to separateReciprocating drilling machinesUnderground miningSanderTunnel boring machine

The present invention is directed to the separation of bitumen, such as by the Clark process or by a countercurrent de-sander, in an underground excavation machine, such as a tunnel boring machine.

Owner:OSUM OIL SANDS CORP

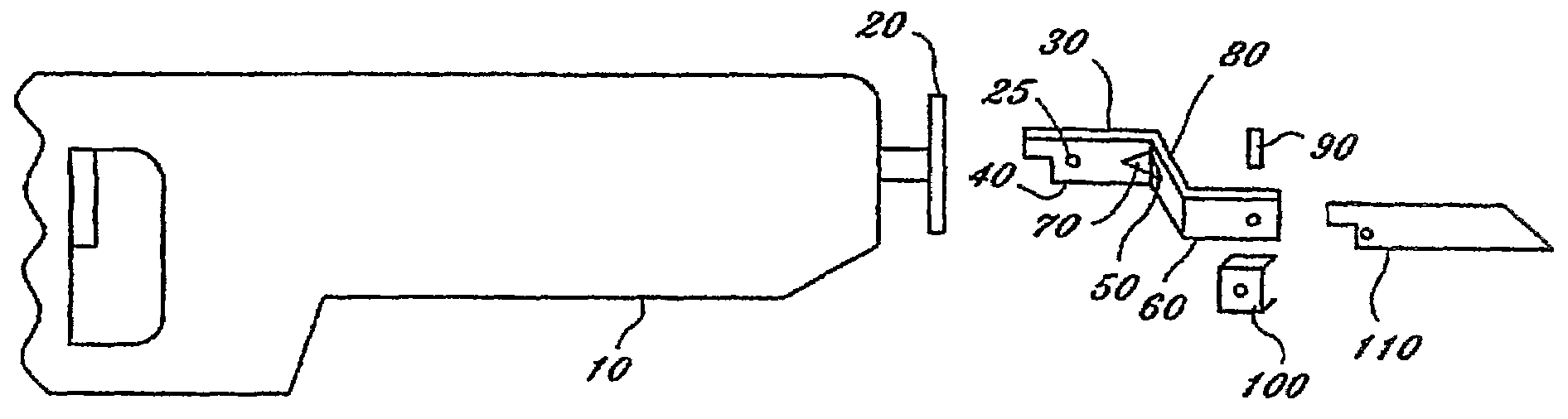

Reciprocating Saw and Attachments

InactiveUS20080276470A1Quick swapIncrease reachMetal sawing devicesNon-rotary toothed toolsSanderEngineering

A simple attachment for a reciprocating tool that will effectuate the ability to do a flush cut in an inexpensive and simple manner which is neither' too ligid, nor not rigid enough. This is effectuated by providing an insert, which fits into the reciprocating tool in the same fashion as a regular' blade. The present invention then offsets the placement of a blade, sander, file, or' other 1 tool by as many inches as wished by the user 1. The blade, sander, file, or other tool is held rigid through the use of a 45 degree bracket spanning the distance from the original plane to the offset plane, or via a single or compound trapezoid design.

Owner:RITTER JON +1

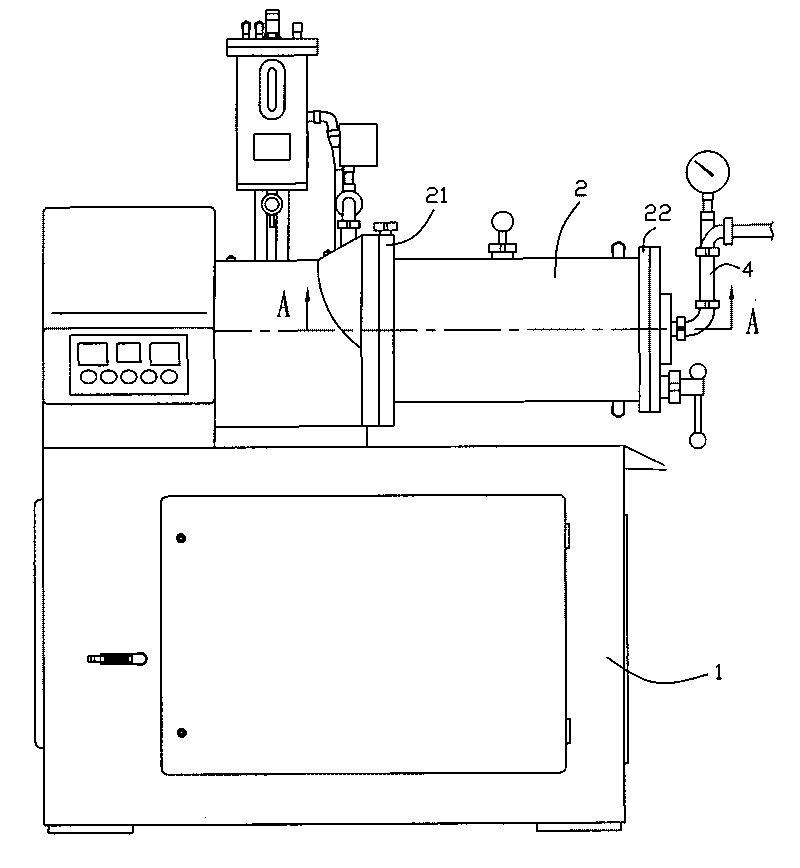

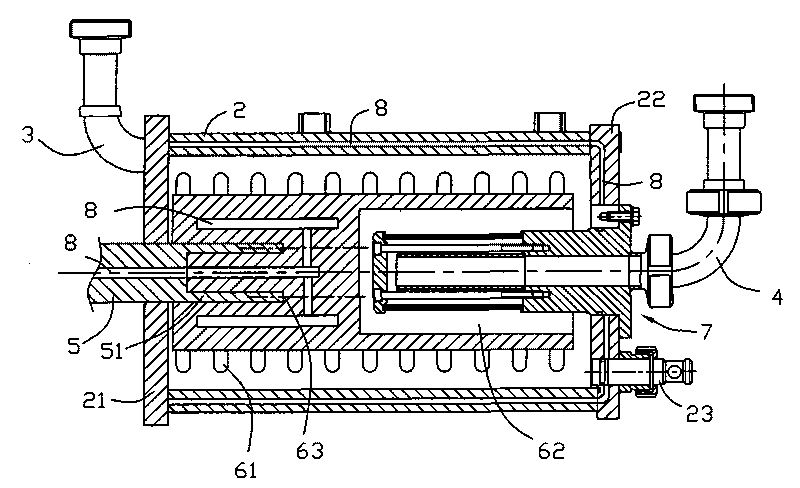

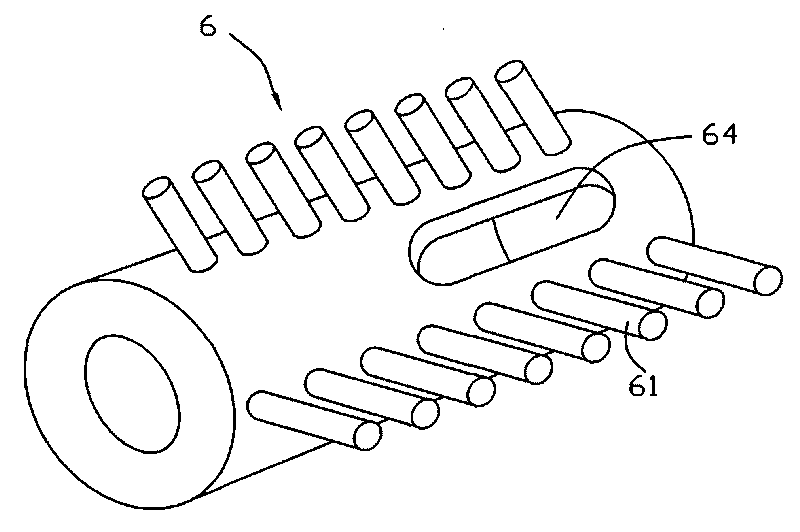

Nanoscale high-flow pin-type sand mill

The invention relates to a nanoscale high-flow pin-type sand mill comprising a rack and a sand cylinder which is arranged on the rack and is sealed by a left cover and a right cover, wherein a feed pipe and a discharging pipe are respectively arranged on the two sides of the sand cylinder; a spindle passes through the left end cover to extend into the sand cylinder and is fixedly provided with a rotor; the surrounding wall of the rotor is axially provided with a plurality of rows of pins; a separator is installed on the sand cylinder and is communicated with the discharging pipe; one end of the rotor is installed on the spindle, and the other end of the rotor is axially provided with a groove; one end of the separator is fixed on the right end cover; and the other end of the separator passes through the right end cover to extend into the groove. In this way, the length of the sand cylinder can be effectively shortened to increase the diameter thereof, thus the spindle can be designed to be short and thick so as to improve the rotational speed of the spindle and increase the linear speed of the material and grinding medium in the sand cylinder; and the material is fully dispersed and ground to ensure grinding precision and improve grinding efficiency.

Owner:PUHLER GUANGDONG SMART NANO TECH CO LTD

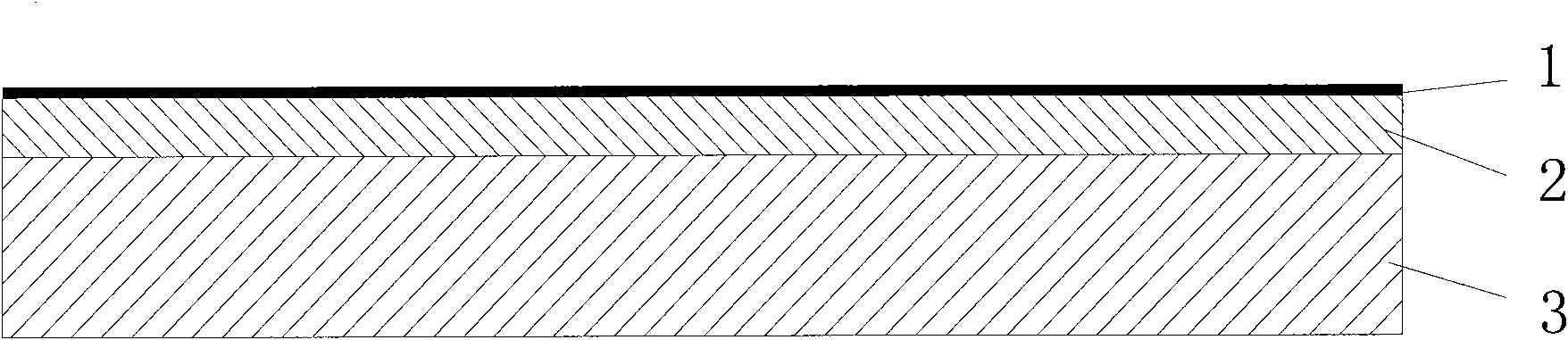

Manufacturing method of flame retardant solid composite floor

InactiveCN102114656AImprove flame retardant performanceSimple production processLiquid surface applicatorsPressure impregnationEnvironmental resistanceSander

The invention discloses a manufacturing method of flame retardant solid composite floors. The method comprises steps of: performing flame retardant treatment on a natural rare tree veneer with the thickness of 0.5mm to 5mm by a vacuum pressure impregnation method, adhering the dried veneer to a glued floor substrate, and performing the processes of assembling, cold pressing, thermal pressing, health preserving, edge cutting, sanding, mortising and the like to obtain the solid composite floor blank; and then performing painting treatment on the surface of the solid composite plate blank, wherein the painting treatment adopts a process of twelve bottoms and two surfaces and the painting is performed according to the order: water primer, putty, elastic primer, wear resistant primer, transparent primer, sander, wear resistant primer, hardening primer, transparent primer, wear resistant primer, hardening primer, transparent primer, sander, finishing paint and finishing paint, and the wear resistant primer, the hardening primer and the sander are added with flame retardant agent. The flame retardant solid composite floor manufactured by the method has excellent flame retardant and fireproof performance and eco-friendly performance, and has excellent physics mechanical properties.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

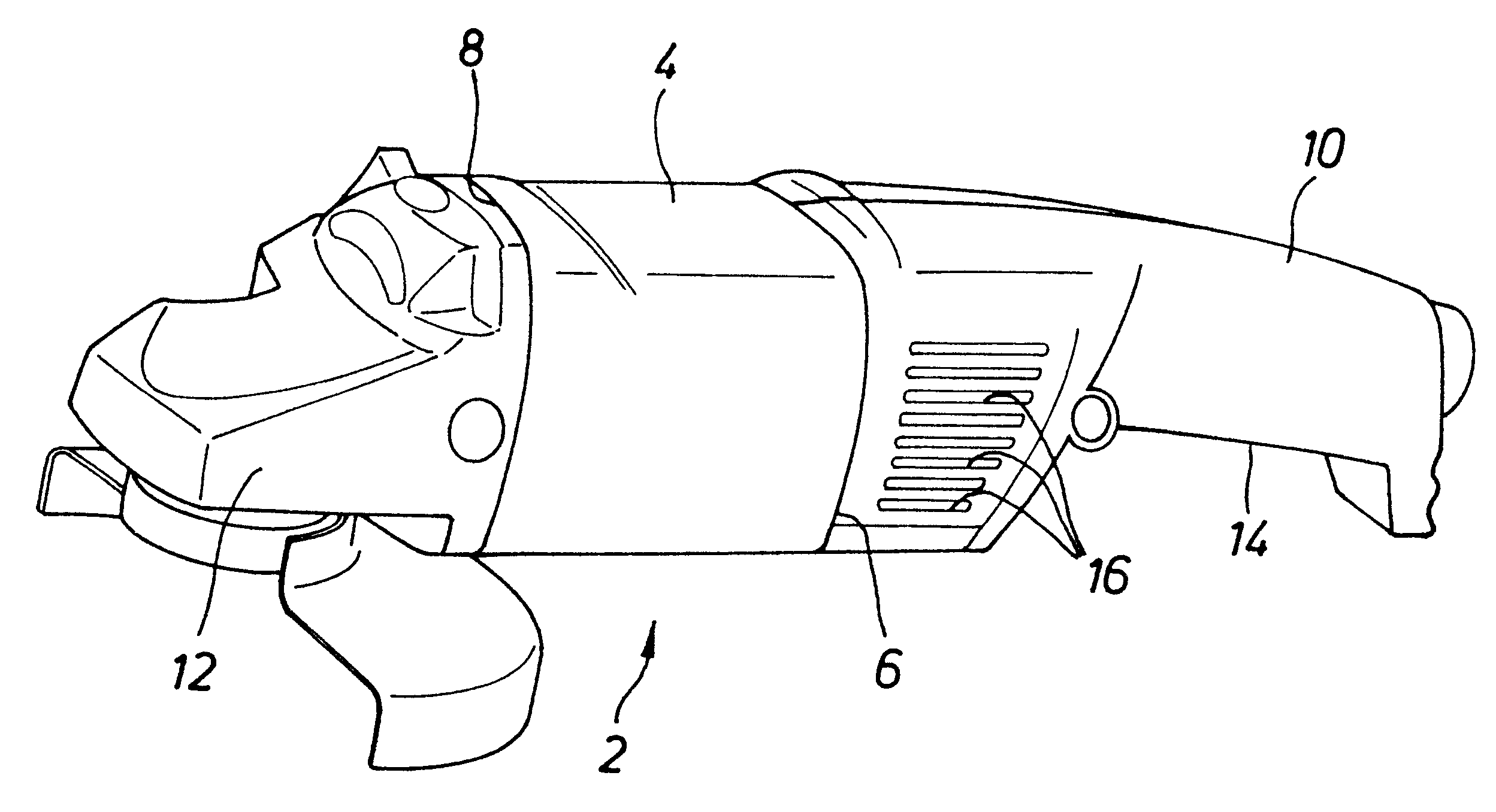

Abrasive strip carrier and hand sander

InactiveUS6857948B2Improve grinding effectImprove efficiencyPortable grinding machinesGrinding/polishing hand toolsSanderEngineering

A power grinder, in particular an oscillating grinder (10), having a housing (12) and a grinding sheet holder (14), on whose working face (15) a grinding sheet (16) to be received is braced, and its reception is effected by means of clamping means (20, 23) that lock opposite grinding sheet ends (17, 19) to the grinding sheet holder (14), is made easier to operate, and its machining capacity is improved, by providing that for equipping it with the grinding sheet, the clamping means (20, 23) are movable jointly with a grinding sheet end (17) clamped to them away from the opposite, likewise clamped grinding sheet end (19), so that the latter is locked, while under tensile stress.

Owner:ROBERT BOSCH GMBH

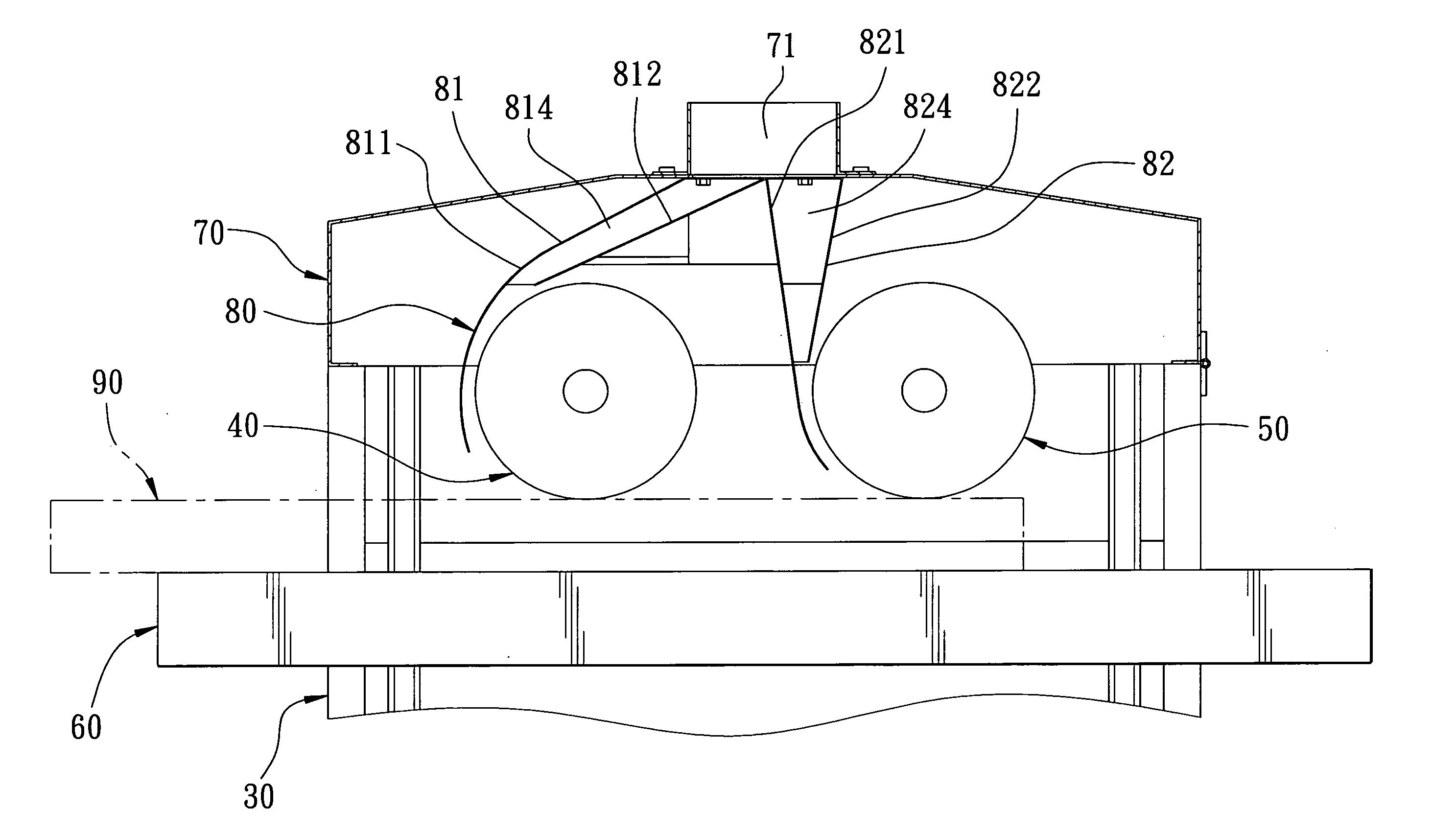

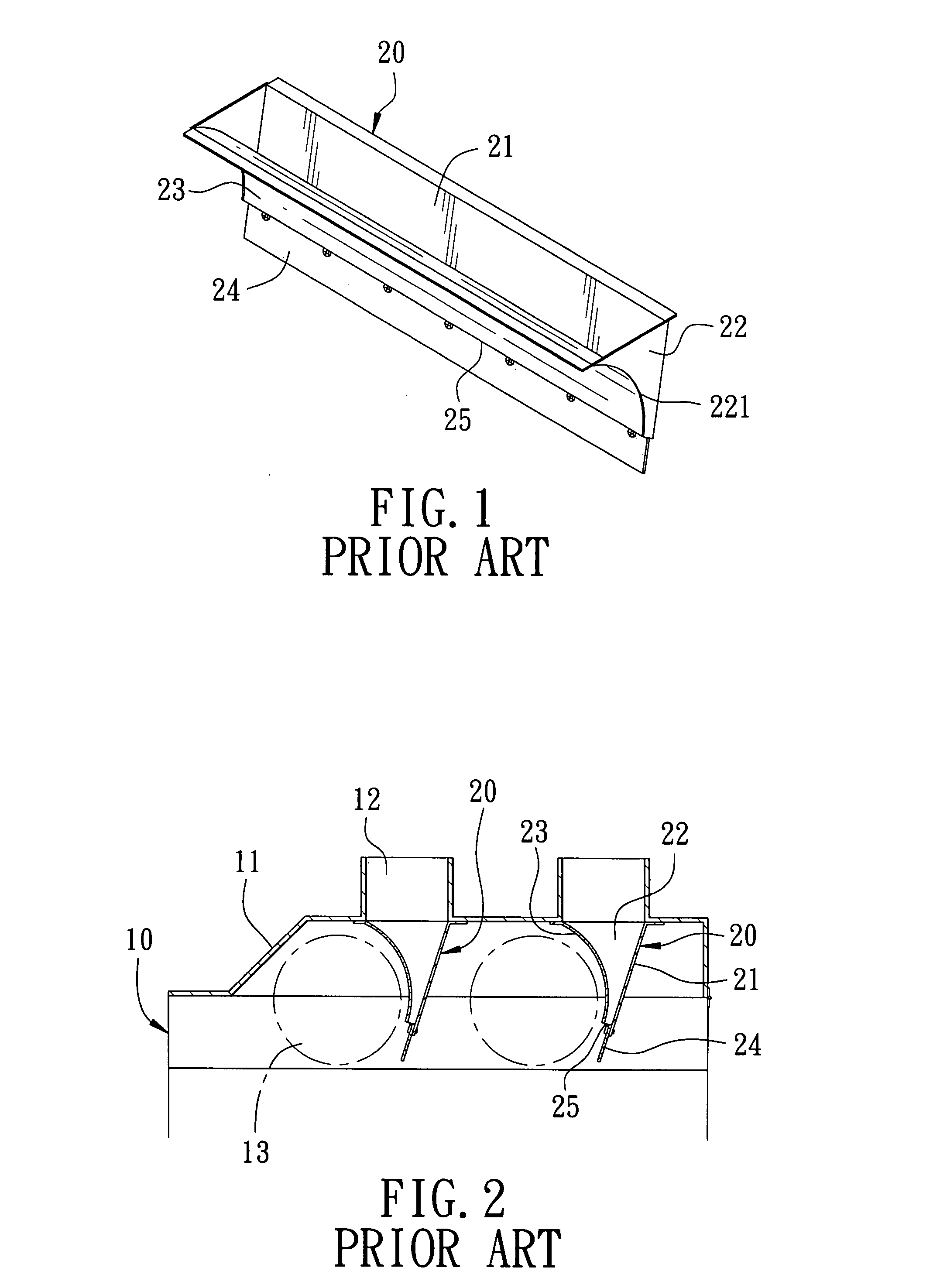

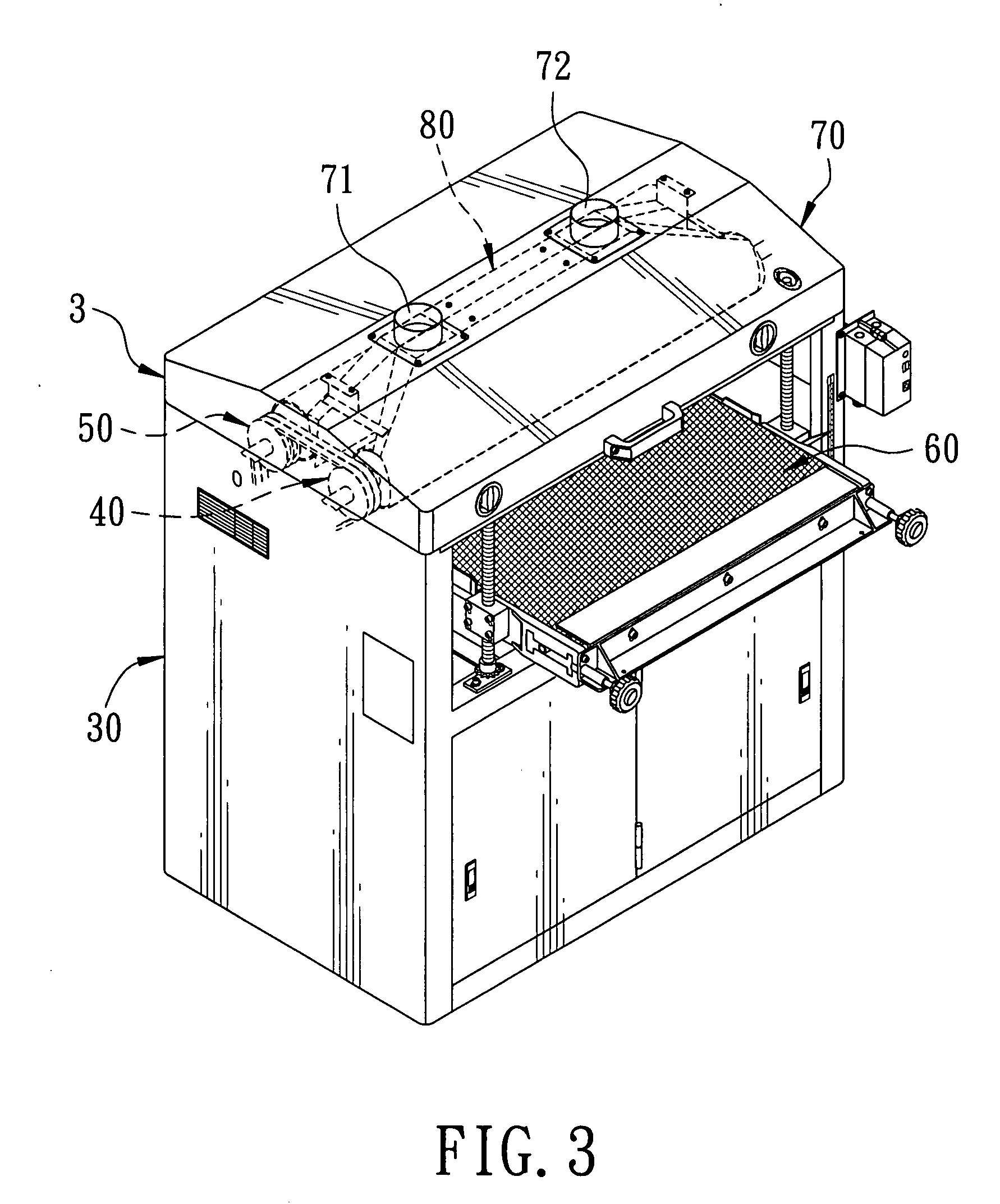

High-efficiency dust collecting device with two gateways

InactiveUS20080200104A1Extended service lifeSimple processGrinding/polishing safety devicesSanderElectrical and Electronics engineering

A high-efficiency dust collecting device with two gateways is connected with exits of a cover of a sand grinder and above two sanding belt rollers., composed of a first gateway set and a second gateway set, which are both formed integrally with a metallic panel and provided respectively with a first and a second arc-like panel, a first and a second blocking plate, and two first and two second dust-guiding plates. A first and a second gateway are respectively formed between the arc-like panel and the blocking plate so as to suck in the dust or the wood flour generated while grinding a workpiece. The dust or the wood flour is then sucked further to pass through the exits to the collecting device, favored by the dust-guiding plates.

Owner:CHUANG PO CHANG

Method and apparatus for plaster burnishing tool

ActiveUS7115172B1High glossTedious and expensive processLiquid surface applicatorsCeramic shaping apparatusSanderEngineering

An Advanced Burnishing Tool for burnishing Venetian plaster surfaces comprises a base with a working surface with a plurality of concentric ribs. The tool may be used manually or may be mounted on a power tool such as an oscillating sander. Each rib has a rounded upper portion for contacting the surface, so that each rib acts in a manner similar to the rounded edge of conventional burnishing tools. The plurality of ribs provide a simultaneous working of multiple points in the plaster surface. Efficiency is further improved when a power tool is used to reduce the manual effort required for burnishing.

Owner:TEODOROVICH MISHKO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com