Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1833 results about "Wood flour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood flour is finely pulverized wood that has a consistency fairly equal to sand or sawdust, but can vary considerably, with particles ranging in dimensions from a fine powder to roughly that of a grain of rice. Most wood flour manufacturers are able to create batches of wood flour that have the same consistency throughout. All high quality wood flour is made from hardwoods because of its durability and strength. Very low grade wood flour is occasionally made from sapless softwoods such as pine or fir.

Elastomeric material compositions obtained from castor oil and epoxidized soybean oil

Elastomers are formed from castor oil and / or ricinoleic acid estolides and a polyester formed from an epoxidized vegetable oil such as ESO and a polycarboxylic acid such as sebacic acid, optionally in the presence of a peroxide initiator, or include crosslinked reaction products derived from ricinoleic acid or castor oil estolides, epoxy group-containing compounds such as epoxy resins and / or epoxidized vegetable oil, epoxy hardeners such as polyamine and polycarboxylic acid hardeners, thermally activated free radical initiators such as peroxides, and optionally but preferably include fillers such as limestone or wood flour. The elastomers can be prepared using a two-step, solvent-less procedure at elevated or ambient temperatures. These predominantly “all-natural” elastomers have physical properties comparable to conventional petroleum-based elastomers and composites and exhibit good flexibility, resiliency, abrasion resistance and inertness to hydrolysis. The resulting elastomers display good mechanical strength and resiliency, are resistant to abrasion and hydrolysis, and can be processed into sheet materials, which makes them attractive as floor covering components.

Owner:AFI LICENSING +1

Preparation of multifunctional wood-plastic composite material

The invention relates to a wood-plastic composite material which can be applied to the floor, tableware, daily necessities, Profile, automotive, and other fields. In the invention, it adds the anion additives, nano-photocatalyst, nano-fillers into the composite material to make the wood-plastic composite material achieves the function such as release negative ions, antibacterial bacteriostasis, removing odor, clean air, flame retardant.

Owner:卓玉国

Wood plastic composite material composection and formed board thereof and their preparation process

The present invention provides one kind of wood-plastic composition, which contains wood powder and resin as well as nanometer particle of size below 100 nm. The wood-plastic composition with nanometer particle has hardness greater than 56HRR and heat distortion temperature higher than 105 deg.c. It may be produced into plate used widely for building, transportation, packing, household decoration and daily use article.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Wood plastic composite material

The invention relates to a wood plastic composite material comprising the following materials in parts by weight: 100 parts of wood meals, 20-80 parts of waste plastics, 5-50 parts of waste rubbers, 10-60 parts of high-melt index thermoplastic resins, 1-12 parts of surface active agents, 2-8 parts of lubricating agents, 0.1-4 parts of cross-linking agents, 0.1-4 parts of antioxygens and 0.05-1.5 parts of processing agents, wherein the grain diameter of the wood meals ranges from 10 meshes to 325 meshes; the flow velocity of the high-melt index thermoplastic resins is higher than 20 g / 10 minutes; the cross-linking agents are peroxides, thus the invention improves the dispersibility and the flowability of the wood meals contained in the composite and the compatibility of plastics by adding the high-melt index thermoplastic resins, can not only better utilize the resources, but also enhances the mechanical strength (such as tensile strength, bending strength, impact strength, and the like) of the composite material by adding the waste rubbers, has the advantages of good processing property, low water absorption rate, good stability of products, and the like and is suitable for injection moulding and beneficial to market promotion.

Owner:东莞市启原实业有限公司

PVC foaming wood plastic composite material

The invention discloses a PVC foaming wood plastic composite material which is produced by processing the raw materials based on the parts by weight: 100 parts of polyvinyl chloride (PVC), 40-50 parts of lignified plant fiber, 10-20 parts of active light calcium, 3-6 parts of calcium zinc complex stabilizer, 1-3 parts of compound-type foaming agent, 0.5-1.5 parts of lubricating agent OPE wax, 0.5-1 part of compound lubricating agent and 3-8 parts of foaming conditioning agent; the raw materials are evenly mixed by a mixing machine and then are directly put into a screw extruder to be extruded and molded at the temperature of 160-170 DEG C. The PVC foaming wood plastic composite material is added with full dose of heat stabilizer in the process of blending and processing, so that the degradation temperature of plastics can be increased, thermal degradation of the plastics and carbonization of wood powder in the process of mixing and forming can be prevented, and the operation of extruding and molding can be completed in one step, thus greatly simplifying the production technique and reducing the production cost.

Owner:石河子市森力新材料科技有限公司

Chlorinated vinyl resin/cellulosic blends: composition, processes, composites, and articles therefrom

InactiveUS7030179B2High expansion rateEasy squeezeLavatory sanitoryRadiationCellulosePolymer science

Compositions and processes for preparing extrudable powder blends containing at least one vinyl chloride resin and a cellulosic material are provided. More specifically, compositions and processes for preparing extrudable free-flowing powder blends containing PVC and wood flour (WF) are also provided for preparing foamed or nonfoamed extrudates. The processes provided herein incorporate components which may contain up to a total of 25 weight percent water. Processes for preparing foamed extrudates are also provided wherein a cooling fluid is used to increase the expansion ratio of the foam. Finally provided are composites having an extrudable thermoplastic substrate and at least one capstock layer disposed thereon containing a PVC / WF composition.

Owner:ROHM & HAAS CO

PVC foam wood/plastic composite material and manufacturing method thereof

The invention discloses a PVC foam wood / plastic composite material and relates to the technical field of composite materials. The PVC foam wood / plastic composite material is made from the following raw materials in parts by weight: 20-70 parts of PVC resin powder, 0-55 parts of wood flour, 5-40 parts of calcium carbonate powder, 0.1-0.5 part of sodium bicarbonate, 0.3-0.6 part of an azo-compound or hydrazine derivative, semicarbazide compound or nitroso-compound, 2-10 parts of a foaming regulator, 1.5-6 parts of a composite stabilizer, 0.7-2.1 parts of a lubricant, 0.5-1.2 part of soybean oil, 2.5-5.5 parts of an impact modifier, and 0.5-3 parts of a processing agent. The PVC foam wood / plastic composite material provided by the invention has the advantages of strong chemical stability, high strength, resistance to acid / alkaline corrosion, resistance to water seepage, flame retardancy and low cost.

Owner:山东宜群木塑科技有限公司

Elastomeric material compositions obtained from castor oil and epoxidized soybean oil

Elastomers are formed from castor oil and / or ricinoleic acid estolides and a polyester formed from an epoxidized vegetable oil such as ESO and a polycarboxylic acid such as sebacic acid, optionally in the presence of a peroxide initiator, or include crosslinked reaction products derived from ricinoleic acid or castor oil estolides, epoxy group-containing compounds such as epoxy resins and / or epoxidized vegetable oil, epoxy hardeners such as polyamine and polycarboxylic acid hardeners, thermally activated free radical initiators such as peroxides, and optionally but preferably include fillers such as limestone or wood flour. The elastomers can be prepared using a two-step, solvent-less procedure at elevated or ambient temperatures. These predominantly "all-natural" elastomers have physical properties comparable to conventional petroleum-based elastomers and composites and exhibit good flexibility, resiliency, abrasion resistance and inertness to hydrolysis. The resulting elastomers display good mechanical strength and resiliency, are resistant to abrasion and hydrolysis, and can be processed into sheet materials, which makes them attractive as floor covering components.

Owner:AFI LICENSING +1

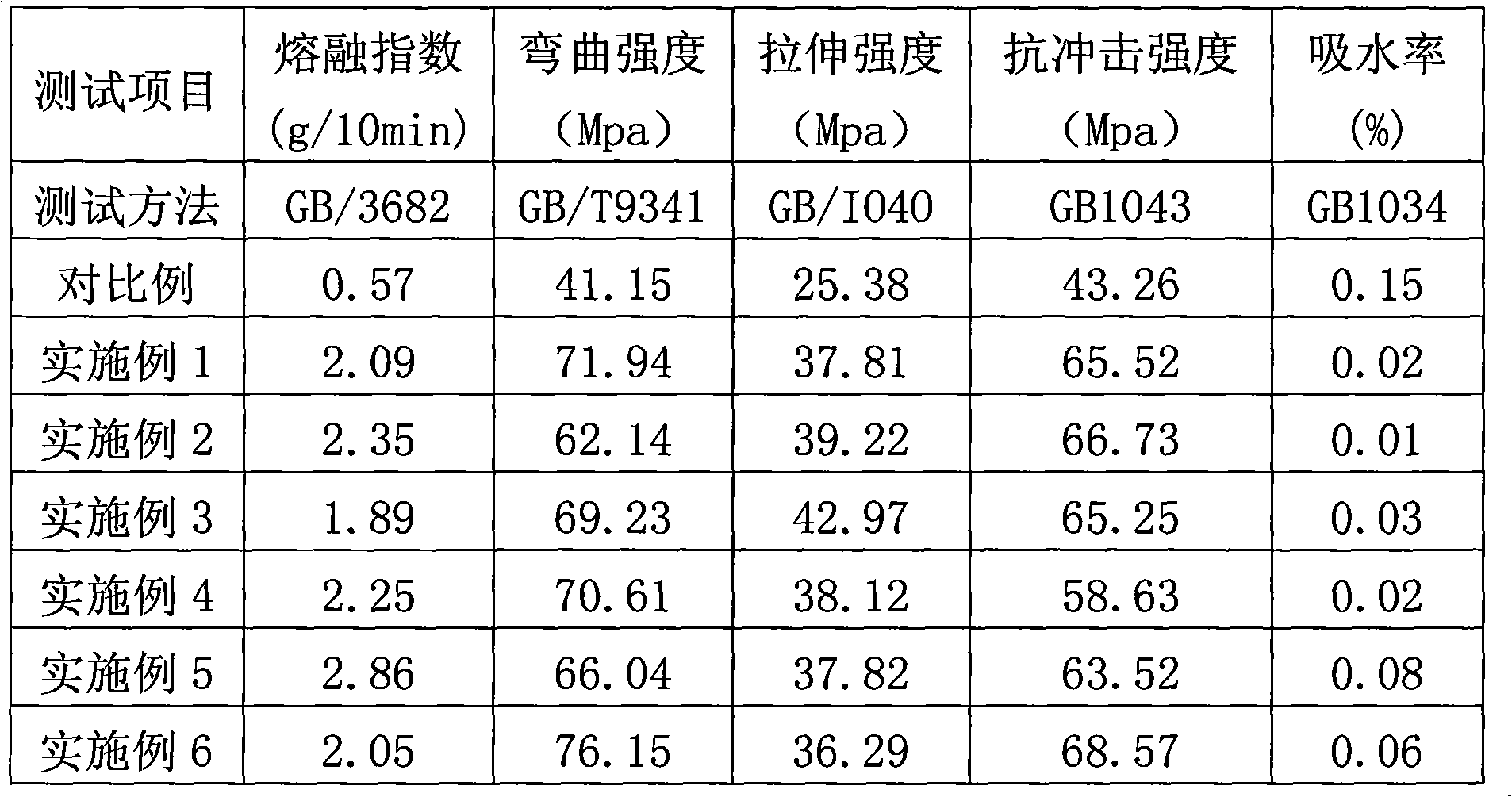

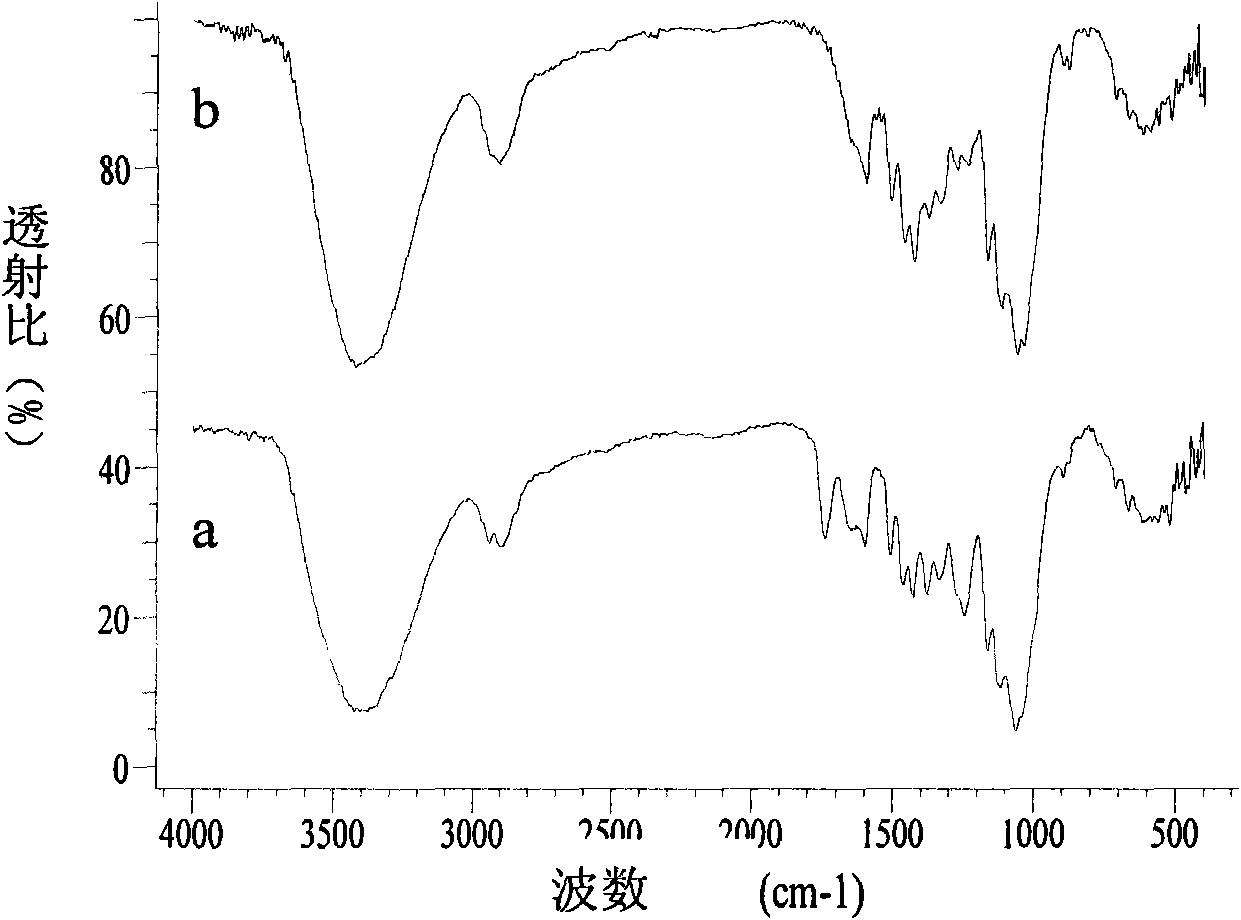

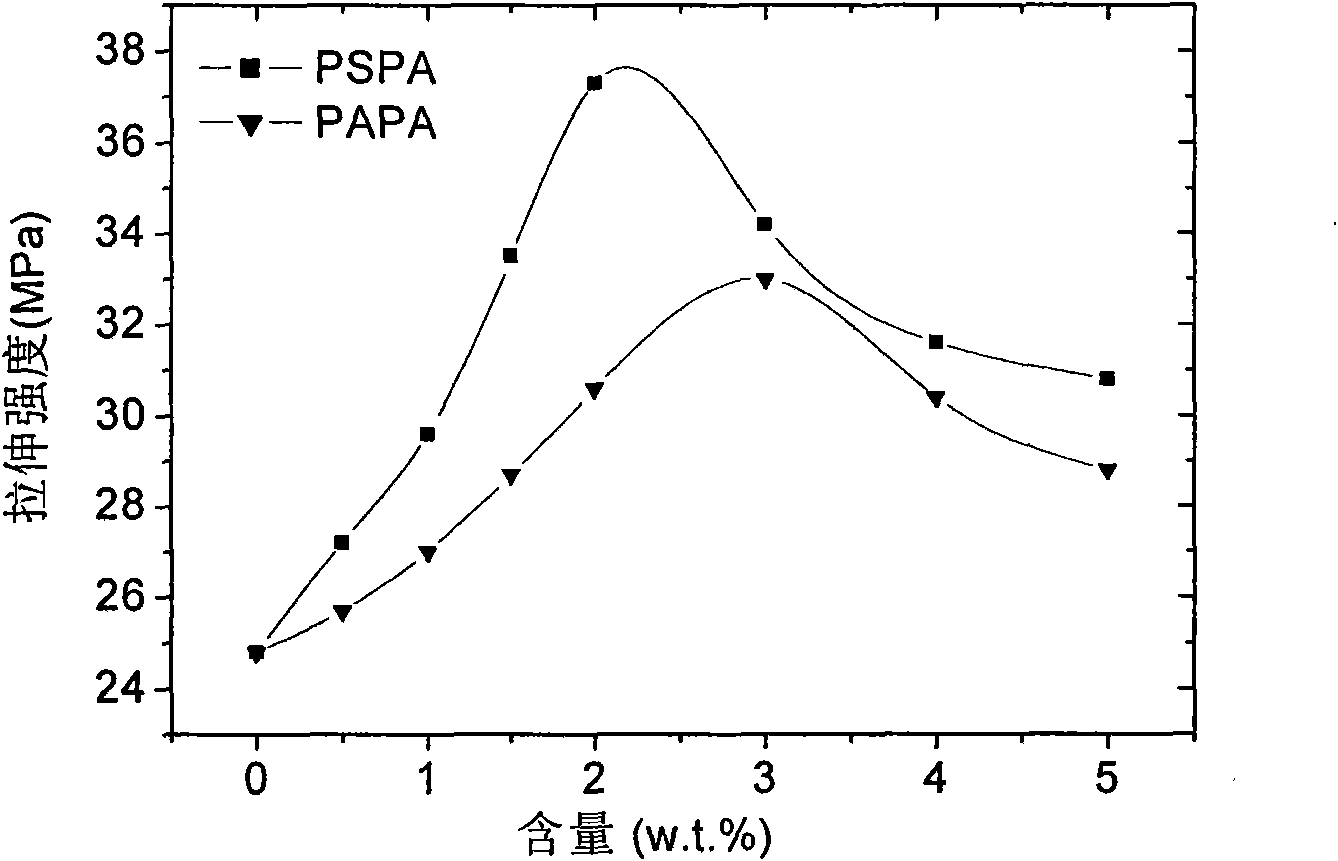

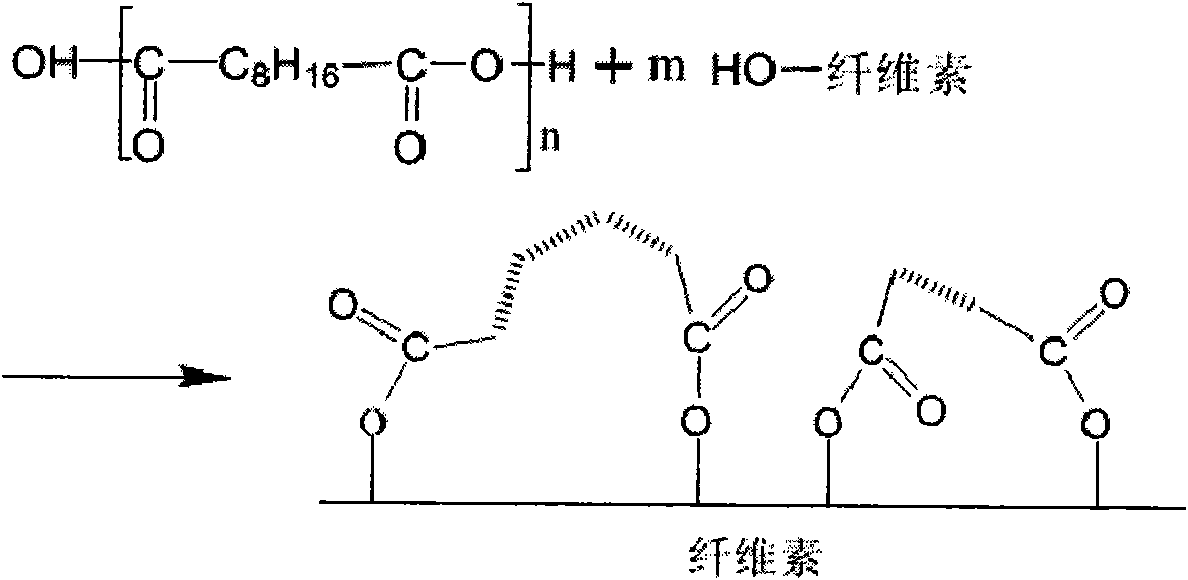

Water-resistant wood-plastic composite material and preparation method thereof

InactiveCN101613503AImprove interface compatibilityImprove composite effectPolyolefinPolymer substrate

The invention discloses a water-resistant wood-plastic composite material, which is prepared from the following raw materials in percentage by weight: 1-65% modified wood powder, 25-98% of polyolefin matrix and 1-10% compatilizer; wherein, the compatilizer is one of polysebacic polyanhydride (PSPA) and polyazelaic polyanhydride (PAPA) or both the two. The invention also discloses a preparation method of the water-resistant wood-plastic composite material. The method is as follows: PSPA and / or PAPA are / is utilized to carry out segmented surface grafting on the wood powder to improve the interface compatibility between the wood powder and polyethylene, and the wood powder is pretreated by alkali liquor to removing unstable substances, such as semi-cellulose and esters with small molecules, in the wood powder, thus enhancing the composite effect and the mechanical property of lignocellulose to the polyolefin matrix and obtaining the wood-plastic composite material with excellent mechanical property, low water absorption capacity and good dimensional stability; in addition, the operation of the preparation method is simple, and the method is applicable to industrial production.

Owner:ZHEJIANG UNIV +1

Polymer wood composite material and method of making same

A polymer wood composite material comprises a polymeric component, wood flour, a coupling agent, a thermal stabilizer component, a plasticizer, a foaming agent, and a pigment. Preferably, the composite material exhibits better hardness than natural wood, as well as less water absorption (<5% by weight) and less thickness swelling (<1%) than natural wood when submerged in water for at least 24 hours, wherein the thickness swelling is measured as a percentage of original thickness. The composite material may be used to form a building component for use in the production of furniture and buildings, such as a doorjamb. In addition, a method of producing an extrudable mixture for an extrusion process to produce a polymer wood composite material is disclosed, wherein the method preferably does not include any pre-drying, pre-treatment or pelletizing processes.

Owner:J & M MANUFACTURING CO INC

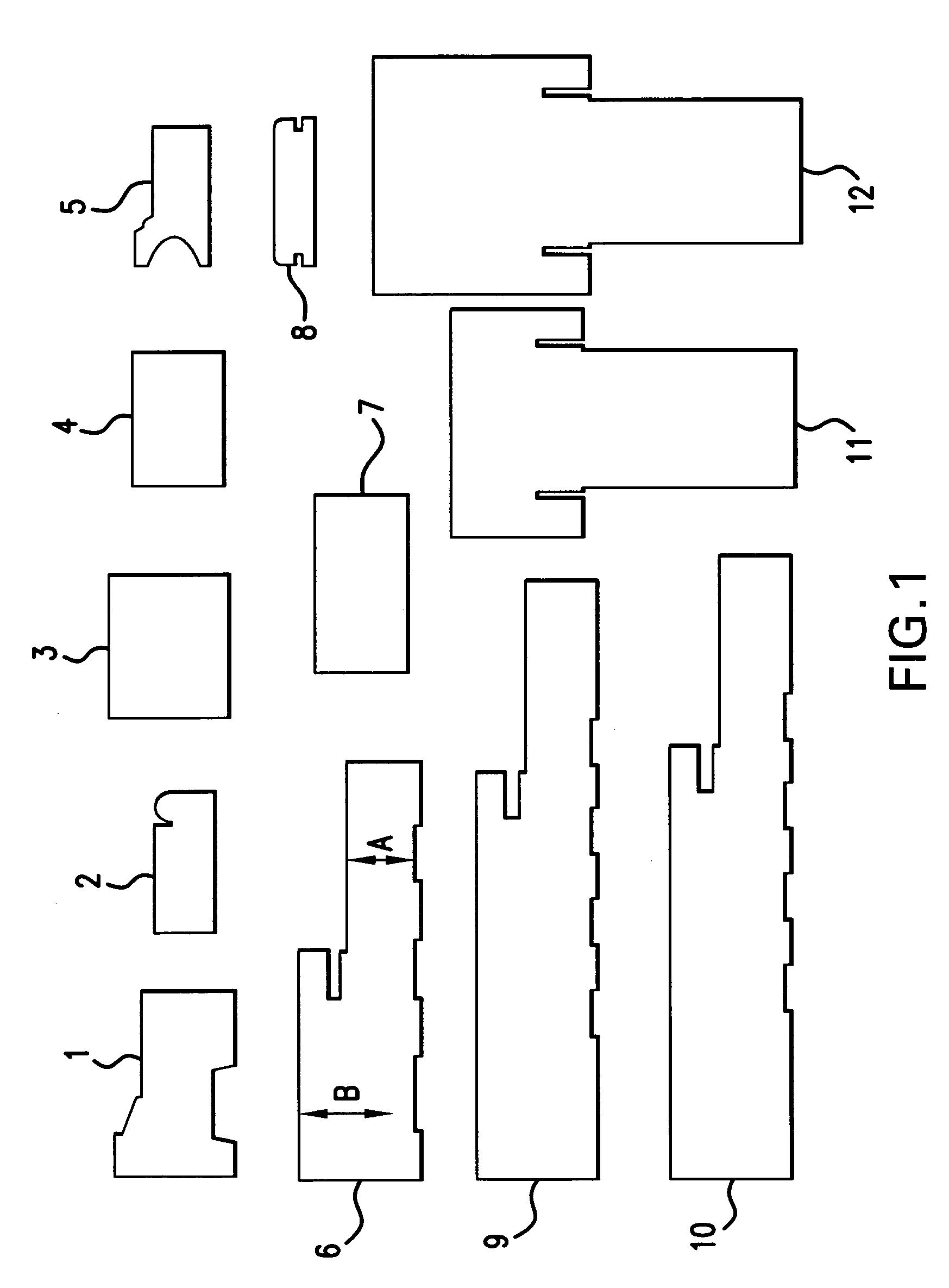

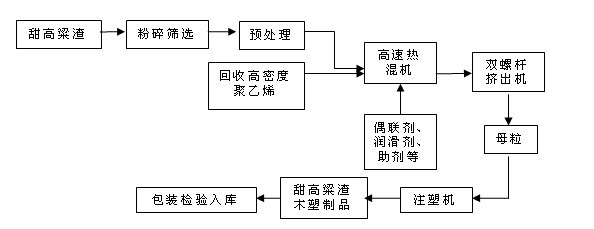

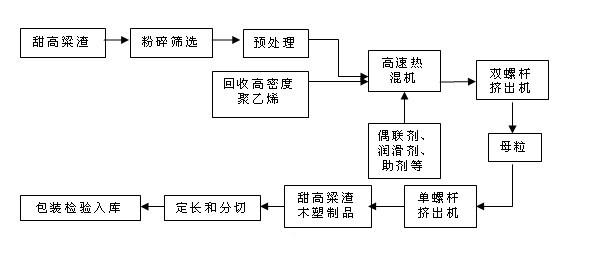

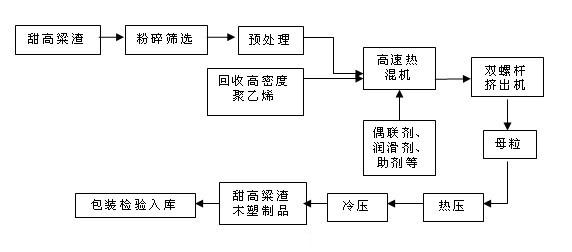

Wood-plastic composite material using sweet sorghum slag as enhanced phase and preparation method for wood-plastic composite material

InactiveCN102690525AGood mechanical propertiesImprove performanceCoatingsAgricultural engineeringMoisture resistance

The invention discloses a wood-plastic composite material using sweet sorghum slag as an enhanced phase and a preparation method for the wood-plastic composite material. The wood-plastic composite material comprises 10 to 80 parts of sweet sorghum slag and 20 to 90 parts of recycled plastic, wherein the sweet sorghum slag and the recycled plastic serve as a matrix phase; and the sweet sorghum slag is subjected to combined pretreatment by an alkali-oxygen method and a steam explosion method. Sectional materials such as a sweet sorghum slag wood-plastic four-pore board, a sauna board, garden protective process, walls and the like are manufactured by extruding a fixed die and forming, or sweet sorghum slag wood-plastic products are manufactured by formation such as injection molding, pressing and the like. The sweet sorghum slag wood-plastic products can be suitable for large-scale continuous batch production and has the advantages of high performance, low cost, moth resistance, moisture resistance, no formaldehyde and the like. Compared with the conventional wood powder fillings, the wood-plastic composite material has the advantages of light weight, high performance, low cost, high extrusion speed, low processing temperature and the like, wherein the mechanical performance of the sweet sorghum slag subjected to treatment is superior to that of wood powder. The sweet sorghum slag wood-plastic composite material has good economic benefits, social benefits and ecological benefits of reducing environmental pollution, protecting forest resource and promoting economic development.

Owner:BEIJING UNIV OF CHEM TECH

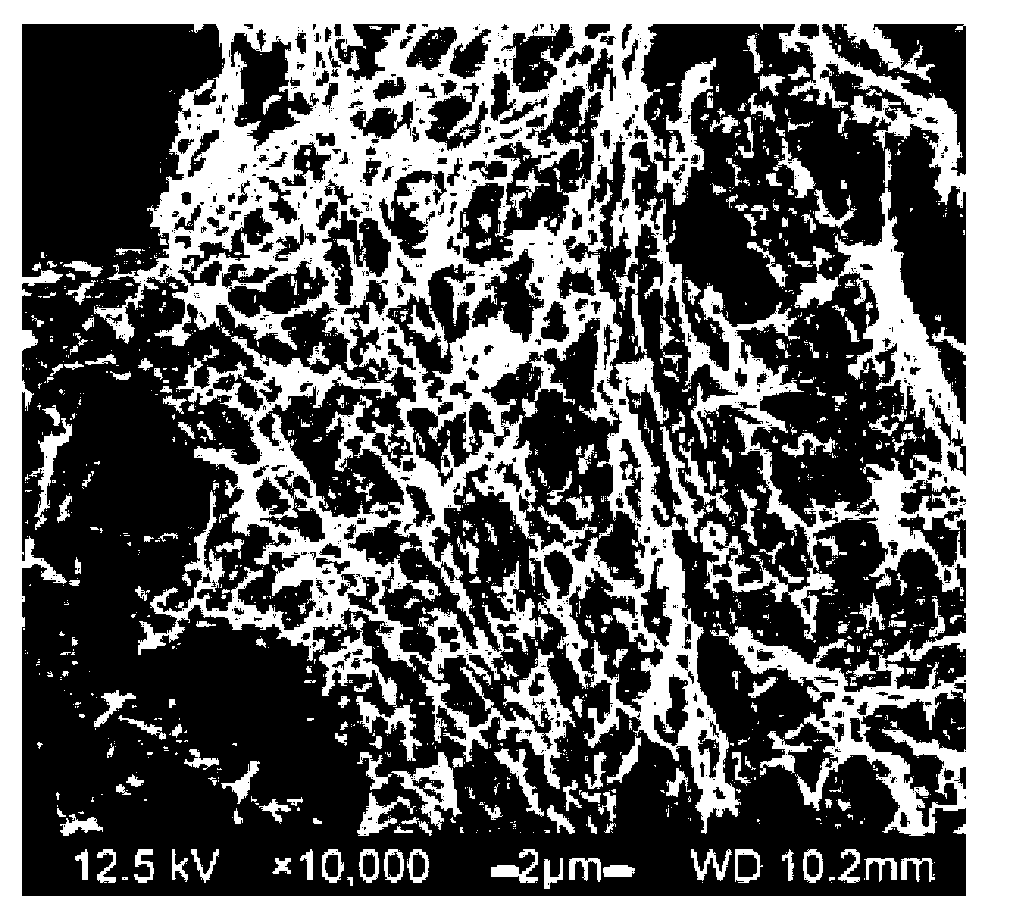

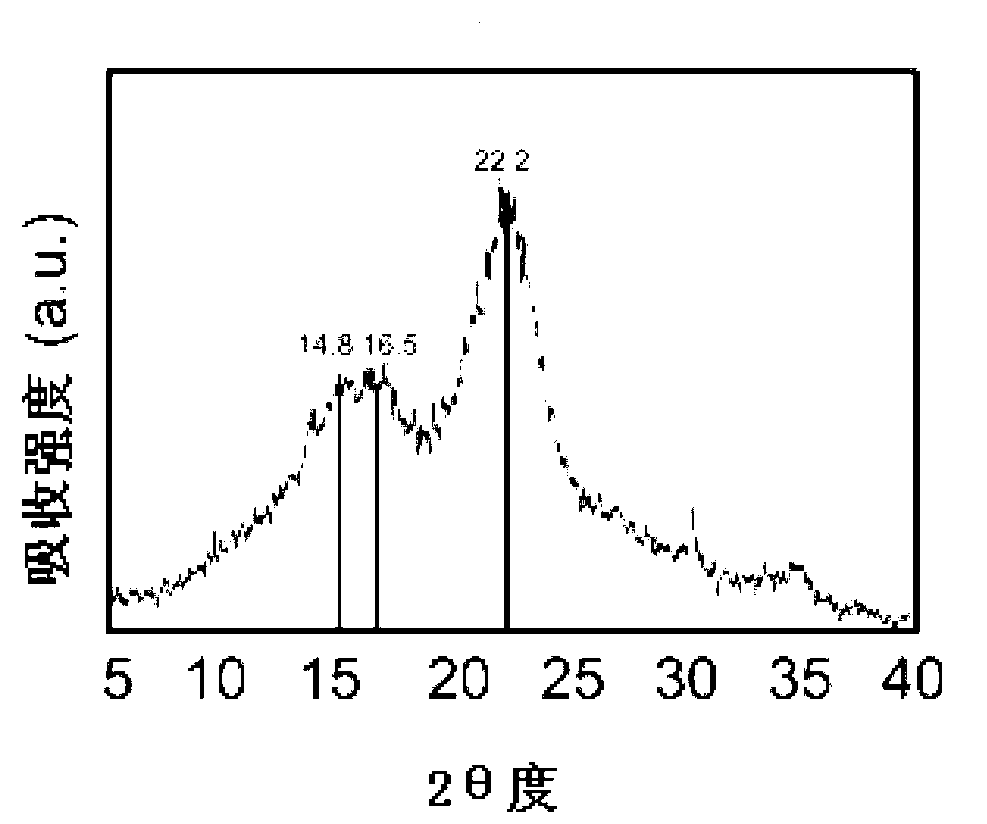

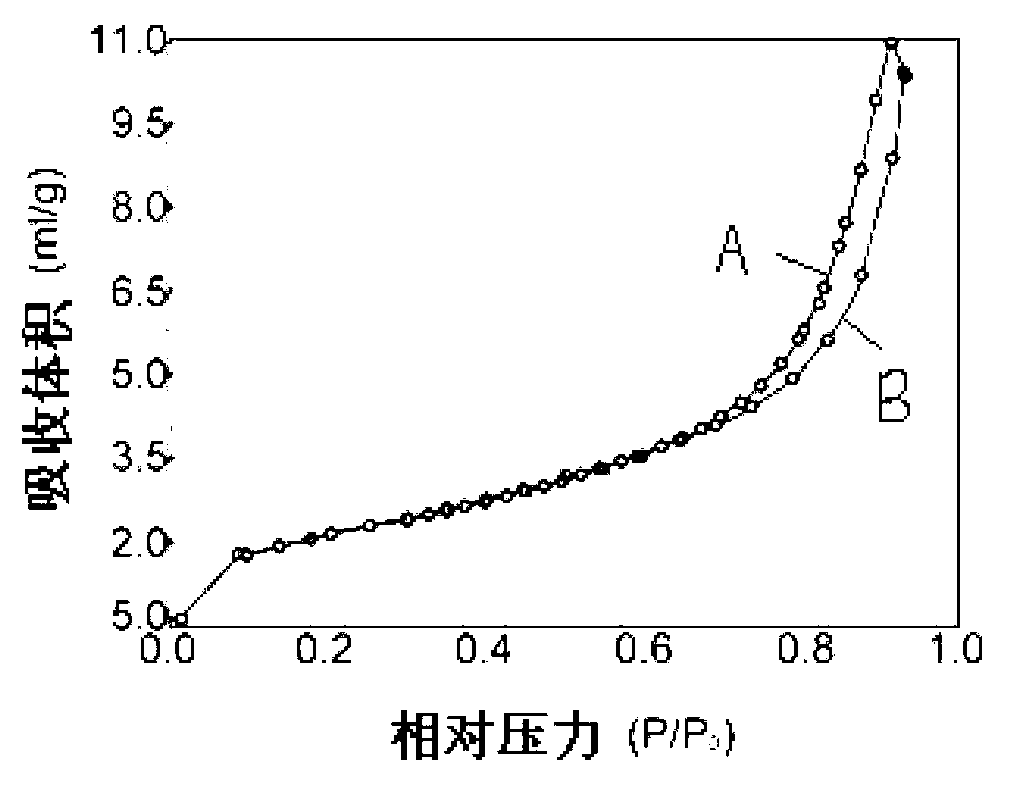

Method for preparing lignocellulose aerogel by using ionic liquid

A method for preparing lignocellulose aerogel by using ionic liquid relates to a method for preparing lignocellulose aerogel, and aims to solve the problems of the prior art that during the preparation of aerogel by directly using woods, macroscopic gommures can not be shaped, and treatment of the raw material is complicated. The method is realized through the following steps: step I, timbers are smashed and then sieved to obtain wood flour, the wood flour and the ionic liquid are dried and mixed, and the mixture is heated to 80-130 degree C and stirred to obtain a mixed solution; step II, the mixed solution is refrigerated and thawed; step III, the step II is repeated for 1 to 9 times, and then displacement liquid I is added, so that lignocellulose gel is obtained; and step IV, the lignocellulose gel is treated by means of critical point drying or freeze drying, so that the lignocellulose aerogel can be obtained.

Owner:NORTHEAST FORESTRY UNIVERSITY

Moulding-grade wood-plastic composite and processing process

InactiveCN101024709AImprove high temperature fluidityExcellent formabilityCoatingsMoulding gradeStearic acid

The invention relates to an injection moulding wood plastic compound material and the process technology. It is made up from recycled P or HDPE or PVC 100 portions, wood flour 80-130 portions, chlorinated polyethylene 5-10 portions, polyethylene wax 0.5-5.0 portions, geoceric acid or stearate 1.0-5.0 portions, nanometer reinforcing agent 4.0-8.0 portions, organic esters flexibilizer 5.0-15.0 portions, and PE grafted by maleic anhydride 5.0-20 portions. Mixing the materials at low speed (300-600round / min), high speed (1500-2500 round / min), low speed (300-600 round / min) for 5-10min, 25-40min, and 5-10min, the premixed material would be gained. After being extruded from extruder, the moulding wood plastic compound material would be gained. It could be widely used in producing complex shaped products.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Modified composite material of woods and plastics as well as its usage and manufacturing method

A modified wood-plastics composition is prepared from wood flour, plastic, assistant, and grafting agent through graft modifying of wood flour and plastics, and continuous extruding out. Its advantage is high tension strength, bending strength and impact strength.

Owner:BEI JING NEW BUILDING MATERIALGRP

High-intensity wood plastic composite board and fabrication method thereof

InactiveCN101708614AEasy to produceHigh strengthWood veneer joiningFlat articlesMechanical propertyWhite oil

The invention relates to a wood plastic composite, in particular to a high-intensity wood plastic composite board and a fabrication method thereof. The method for fabricating the high-intensity wood plastic composite board comprises the following steps: treating nano titanium dioxide with silane coupling agent to obtain modified nano titanium dioxide; mechanically stirring the modified nano titanium dioxide, plastic particles, maleic anhydride grafted plastic particles, calcium stearate and the like, and extruding and pelleting all the materials to obtain modified plastic particles; mechanically stirring the modified plastic particles, wood flour, terpene resin, chopped glass fiber, white oil, antioxidant and the like, and extruding, melt-blending and pelleting all the materials to obtain high-intensity wood plastic composite particles; and finally extruding the high-intensity wood plastic composite particles with a machine to mold the high-intensity wood plastic composite board. The high-intensity wood plastic composite board has extremely wide application range, and is applied to the fields such as transportation, construction, decoration, ornament, municipal works, garden and park, packaging and the like. The high-intensity wood plastic composite board has the advantages of reproducibility, low cost and higher mechanical properties such as static bending strength and the like, thereby being an ideal material for replacing wood. Compared with traditional wood plastic composites, the high-intensity wood plastic composite board has longer service life, and is a novel upgrade product of the present wood plastic composites.

Owner:江苏森诺塑胶科技有限公司

Polyethylene wood plastic and preparation method thereof

The invention relates to a polyethylene wood plastic and a preparation method thereof and belongs to the technical field of plastic compound modifying processing. The invention provides a formula of the polyethylene wood plastic and a preparation method for a section bar; extruding temperature and extruding speed are increased; a polyethylene wood plastic section bar produced according to the preparation method has excellent high-temperature resistance; and according to the technical scheme, the polyethylene wood plastic comprises the following raw materials in parts by weight: 30-40 parts of polyethylene, 50-70 parts of wood flour, 0.5-2 parts of maleic anhydride grafted polyethylene, 0.8-1.5 parts of polyethylene wax, 1-3 parts of zinc stearate, 2-6 parts of toner, 0.5-1 part of antioxidant, 0.4-0.9 part of anti-ultraviolet light absorber UV-531 and 0.5-1.2 parts of stearic acids. The preparation method provided by the invention is suitable for the extruding molding of the polyethylene wood plastic section bar.

Owner:山西峰岩新型建材股份有限公司

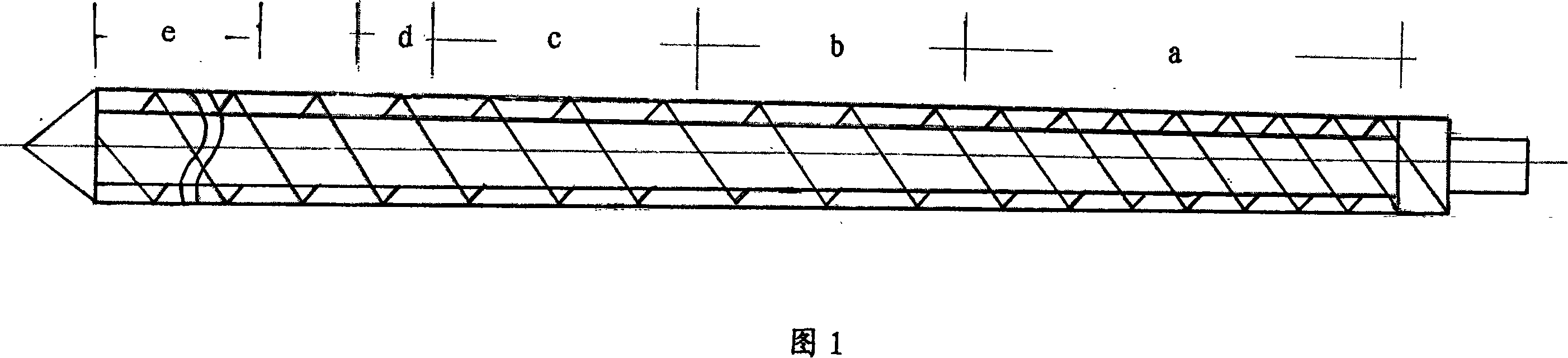

Wood plastic plank stuff production technology and equipment thereof

InactiveCN101138857AChange compatibilityImprove wettabilityFlat articlesDomestic articlesSocial benefitsGranularity

The present invention discloses a production process for a wood-plastic board and equipment thereof. The production process includes the following steps: (1). Plastic bags and similar waste are collected and crushed uniformly by a special equipment and then mixed non-quantitatively with saw dusts or plant straw powders with granularities from 10 to 30 mesh as a standby; (2). The surfaces of the saw powders or plant straw powders go through a containment treatment. (3). A recycled plastic PE broken piece is modified, (4) mixed, (5) plasticized in an extruder, (6) and formed by pressure. (7) The product is tested and dressed. To complete the process, the special equipments needed are (1) a wood flour drier and (2) a feeding screw of a large-scale extruder. The present product is mainly used for a construction template, a rural sanitary latrine, a detachable mobile simple building, a baffle plate and an enclosing wall in a construction site. The product which is nonpoisonous, unharmful, anti-aging, resistant to shock and source-saving has a strong toughness, a good physical and mechanical property, protects the natural ecology, reduces environmental pollution and makes waste profitable, thus possessing, good social benefits as well as significant economic benefits.

Owner:孔繁诚

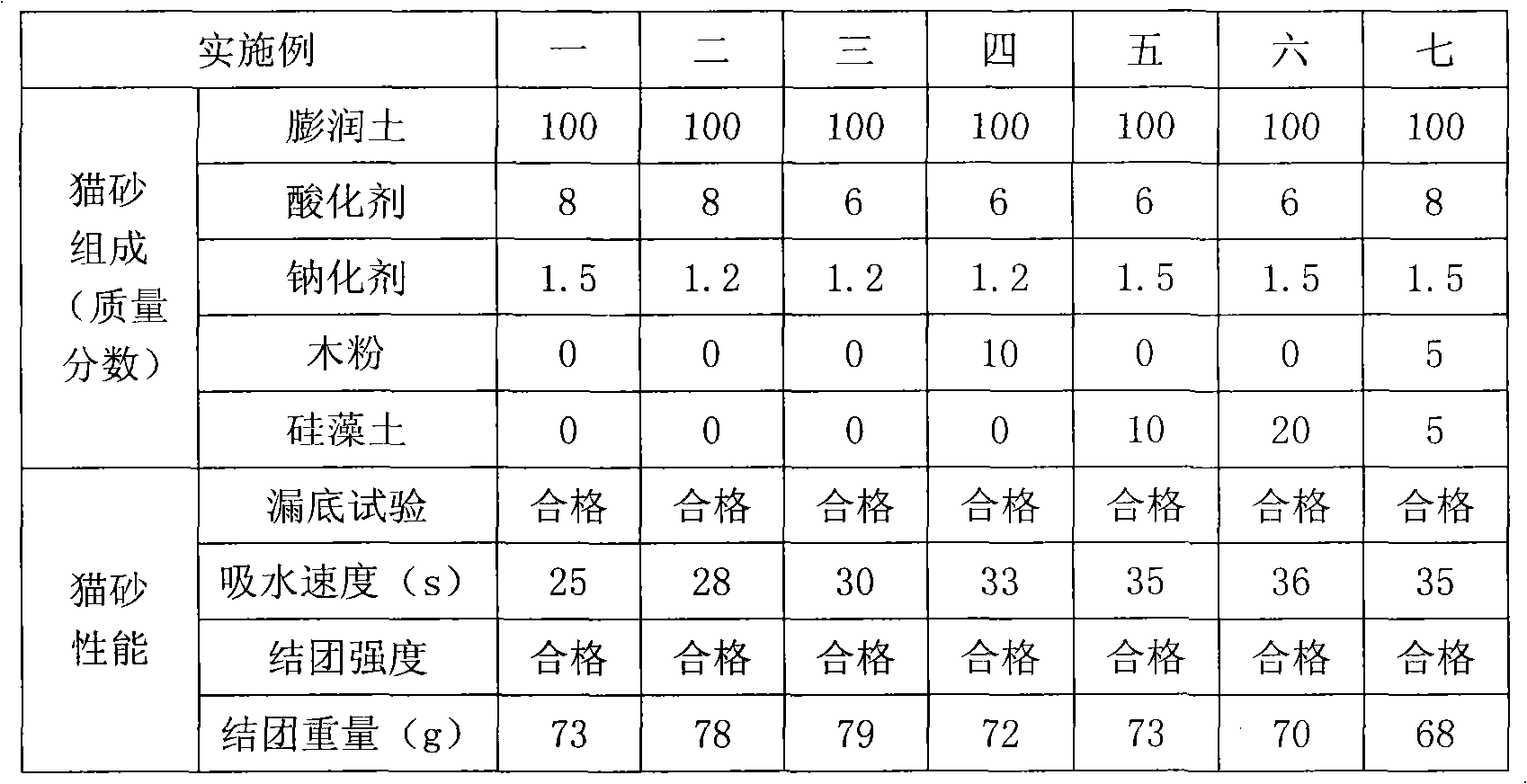

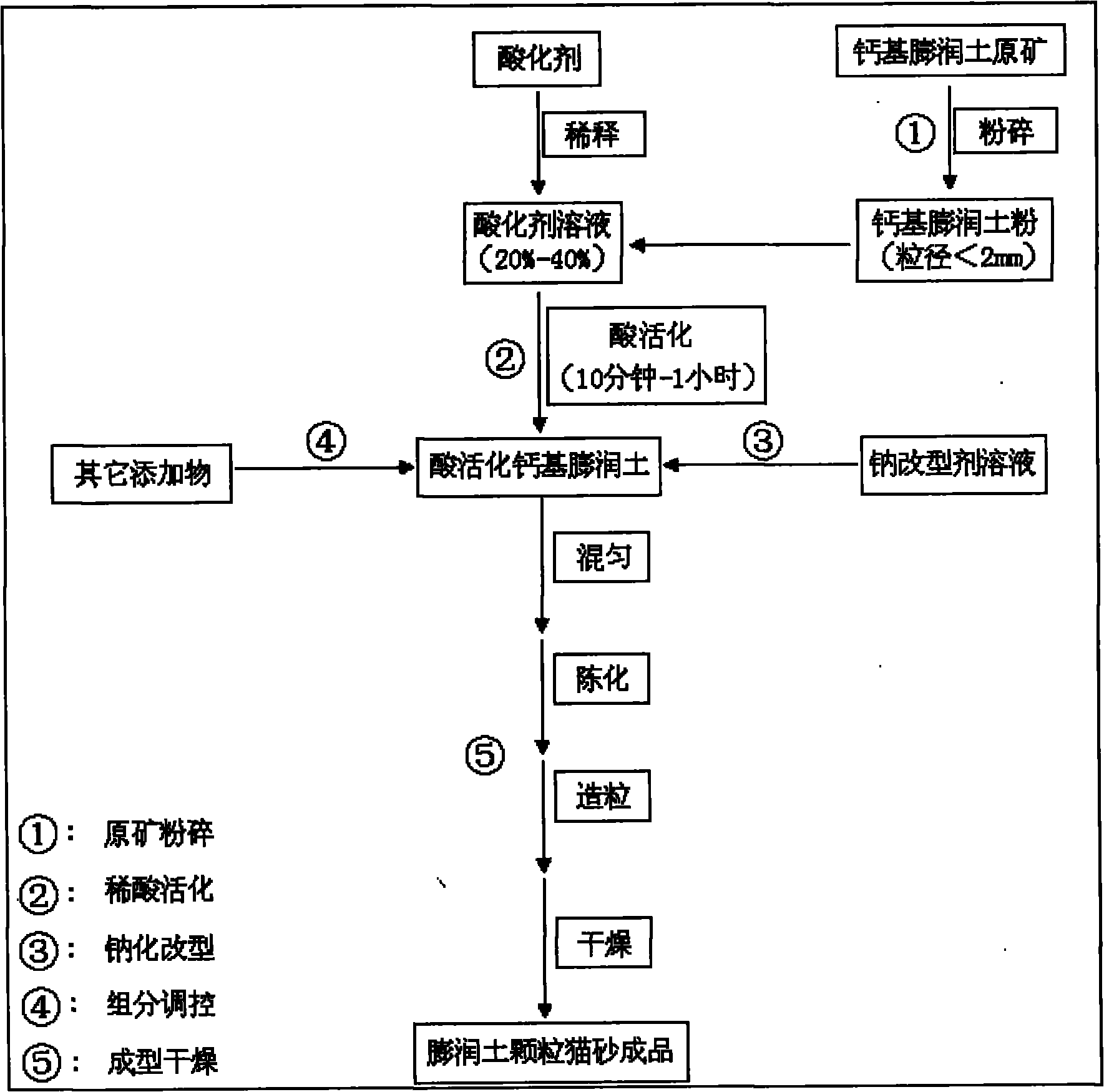

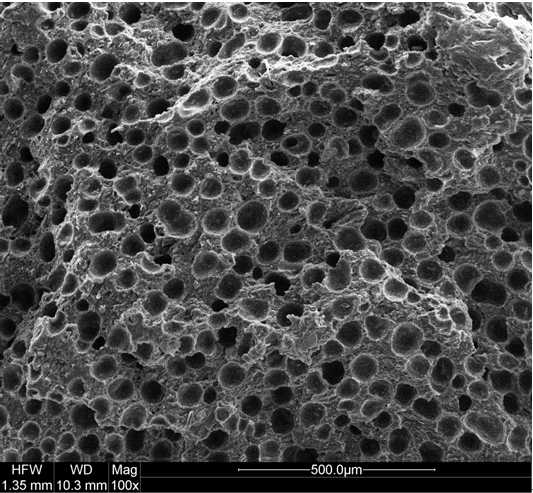

Method for producing bentonite cat litter

The invention discloses a method for producing bentonite cat litter by calcium-based bentonite. The method comprises the following steps of: grinding, acidification, sodium-modification, forming, drying and the like. In method, the calcium-based bentonite crude ores are used as a starting point, the bentonite slices are acidified and corroded by an acidifier so as to greatly increase a specific surface area of the bentonite, a sodium-modification agent is used for sodium-modification of the acidified calcium-based bentonite so as to improve a water absorption rate and bonding property of the bentonite, other additives such as wood flour and diatomite are added so as to adjust indexes, such as density and whiteness, of the cat litter, and finally the bentonite undergoes granulation, drying, screening and the like to form the bentonite cat litter having the advantages of quick water absorption, large amount of water absorption, high whiteness and high strength. The method has the advantages of good quality of the bentonite cat litter prepared by the method, simple process and low cost.

Owner:INNER MONGOLIA UNIVERSITY

Micro-foaming wood plastic composite material plate for building template and preparation method thereof

The invention discloses a micro-foaming wood plastic composite material plate for a building template and a preparation method thereof. The wood plastic composite material consists of polrvinyl chloride, wood powder, lightweight active calcium carbonate, a foaming agent, a foaming stabilizer, polyethylene wax, a titanate coupling agent, chlorinated polyethylene, an adsorbent nano calcium oxide, an auxiliary foaming agent nano zinc oxide, a silicone processing adjuvant and reinforced fiber alkali-free glass fiber. The preparation method comprises the following steps of: mixing the wood powder and the nano calcium oxide powder at a high speed; adding the titanate coupling agent and then mixing at the high speed; adding the rest materials; mixing at the high speed and then mixing at a low speed to obtain a premix; extruding the premixing by using an extruder; and cooling very quickly to obtain the product. The micro-foaming wood plastic composite material plate has the characteristics ofhigh surface hardness, high flowability, high strength, high toughness, high dimensional stability, long service life and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

3D (three dimensional) wood printing supply and preparation method thereof

The invention provides a 3D (three dimensional) wood printing supply which comprises components in percentage by mass as follows: 60%-90% of wood meal, 3%-15% of ABS (acrylonitrile butadiene styrene) plastics, 4%-15% of PLA (poly lactic acid), 2%-10% of PHA (polyhydroxyalkanoate), 1%-2% of PP (polypropylene) and 1%-2% of a compatilizer. The 3D wood printing supply has the characteristics such as water proofing, corrosion resistance, moisture resistance, freeness of worm damage, mildew and toxicity, acid and alkali resistance, environment protection and the like, the real flavor of wood is diffused; the wood printing supply is fused and deposited by a 3D printer at the temperature of 190-230 GDE C to form various different 3D models, the 3D models have the hand feel, the impression and the fragrance of natural wood and have an effect approaching to a solid wood effect and wood properties, and the printing supply can be nailed, drilled, planed, carved, adhered and painted as wood; and the comprehensive physical properties and chemical properties can be well improved and optimized, the performance requirement of the 3D printer can be effectively reduced, and accordingly, the printing supply is suitable for both high-end printers and low and medium-end 3D printers and has a wider application range.

Owner:广东傲趣三维科技有限公司

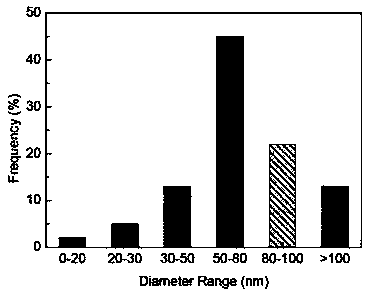

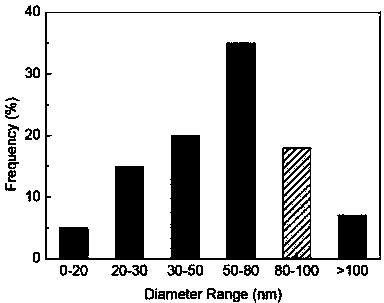

Preparation method for composite material of cellulose nanofiber and reinforced polyurethane

InactiveCN103436002AHigh strengthReduce forcePaper recyclingWaste paper working-upCelluloseChemical treatment

The invention discloses a preparation method for a composite material of cellulose nanofiber and reinforced polyurethane. The method comprises the following steps: 1) pretreating in a chemical method; 2) unfastening fibers in a mechanical method. According to the invention, chemical treatment and mechanical treatment are adopted to separate the cellulose nanofiber, which has a high length diameter ratio and is used for reinforced polyurethane, from newspaper; the transparent nano composite material with high-intensity is prepared; wood meal and newspaper are adopted as raw materials to prepare cellulose nanofiber through the chemical treatment combined with the mechanical treatment; the diameter range of the cellulose nanofiber is 30-100 nm, and the length diameter ratio is higher than 1000.

Owner:NANJING FORESTRY UNIV

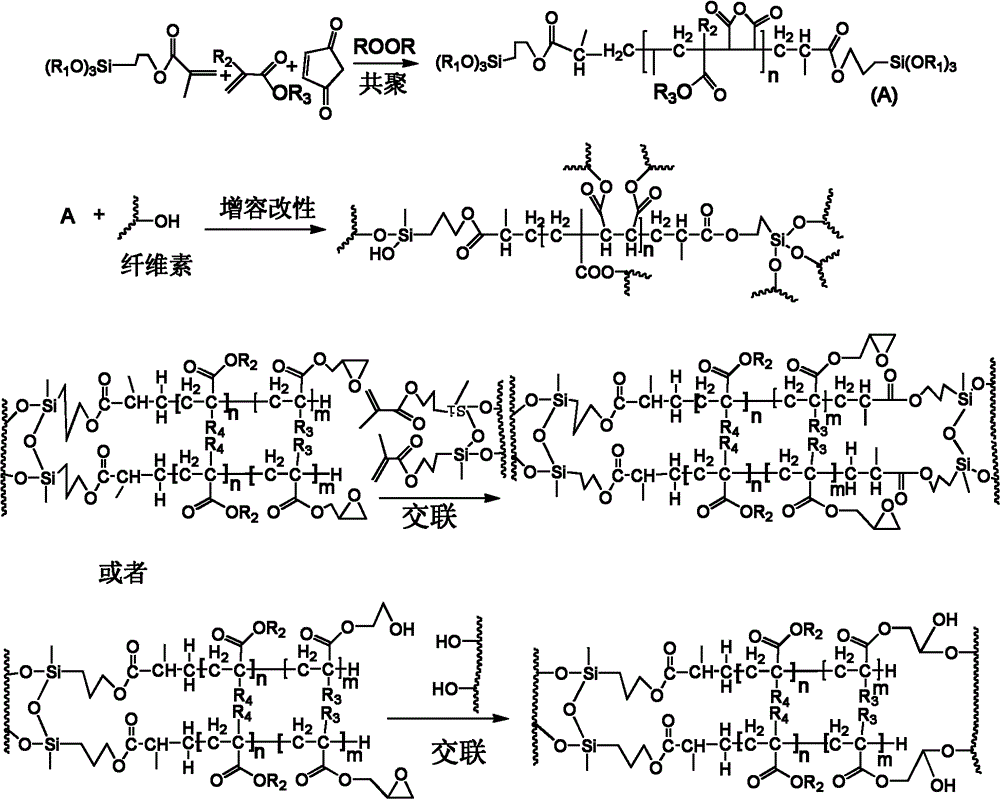

Preparation method and application of acrylate wood-plastic composite compatibilization modifier

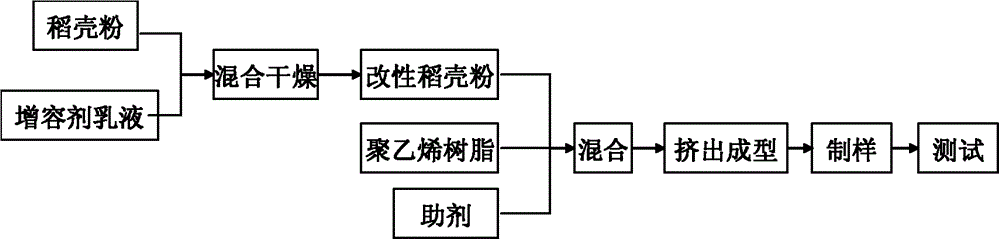

The invention relates to a preparation method and application of an acrylate wood-plastic composite compatibilization modifier. According to the method and the application, alkene monomers of polyacrylate, vinyl acetate, maleic anhydride or the like are subjected to free radical polymerization under the action of a persulfate or azoamidine initiator by using an emulsion polymerization method so as to obtain an acrylate copolymer emulsion, an organosilane coupling agent, a titanate coupling agent, a lubricant, an anti-aging agent and the like are compounded in the emulsion so as to obtain the wood-plastic composite compatibilization modifier, and a wood-plastic composite material is prepared through uniformly mixing the emulsion with wood flour or plant stalk powder, drying a mixture after full infiltration, mixing the mixture with plastics, such as polyethylene, polypropylene, polyvinyl chloride or polystyrene, and carrying out blending and extruding or compression molding. The usage amount of the composite compatibilization modifier is small, the infiltration with the wood flour is uniform, and the matrix compatibility is high; the prepared composite material is smooth and beautiful in surface and strong in internal interface interphase toughness; and the prepared wood-plastic composite material has the advantages of low cost, high aging resistance and high impact resistance and tensile strength.

Owner:SHANDONG UNIV OF TECH

Wood liquefied carbide fiber, protofilament and preparation method thereof

InactiveCN101135075AIncrease profitIncrease added valueFibre chemical featuresPhosphoric acidAldehyde

The present invention discloses one kind of wood fibril and carbon fiber prepared therewith. The wood fibril for preparing carbon fiber is prepared through crushing wood into wood powder, phosphoric acid catalyzed phenol liquefaction of wood powder to obtain wood fluid, mixing with synthesizing agent in certain amount, heating the mixture to react to obtain wood spinning fluid and spinning to obtain wood fibril. The wood fibril is then prepared into carbon fiber through soaking into acid solution of aldehyde and heating to cure to obtain fibril with enhanced mechanical performance, and carbonizing to obtain carbon fiber with performances similar to that of other universal carbon fiber.

Owner:BEIJING FORESTRY UNIVERSITY

Self-heated type thermal paste

InactiveCN102715978AImprove insulation effectImprove water retentionHeat-exchange elementsTherapeutic coolingActivated carbonTap water

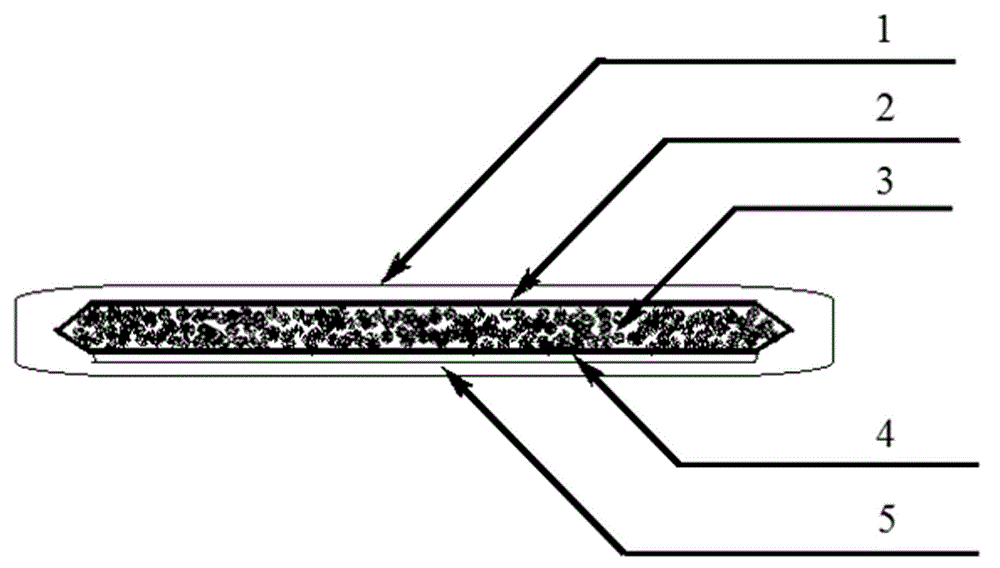

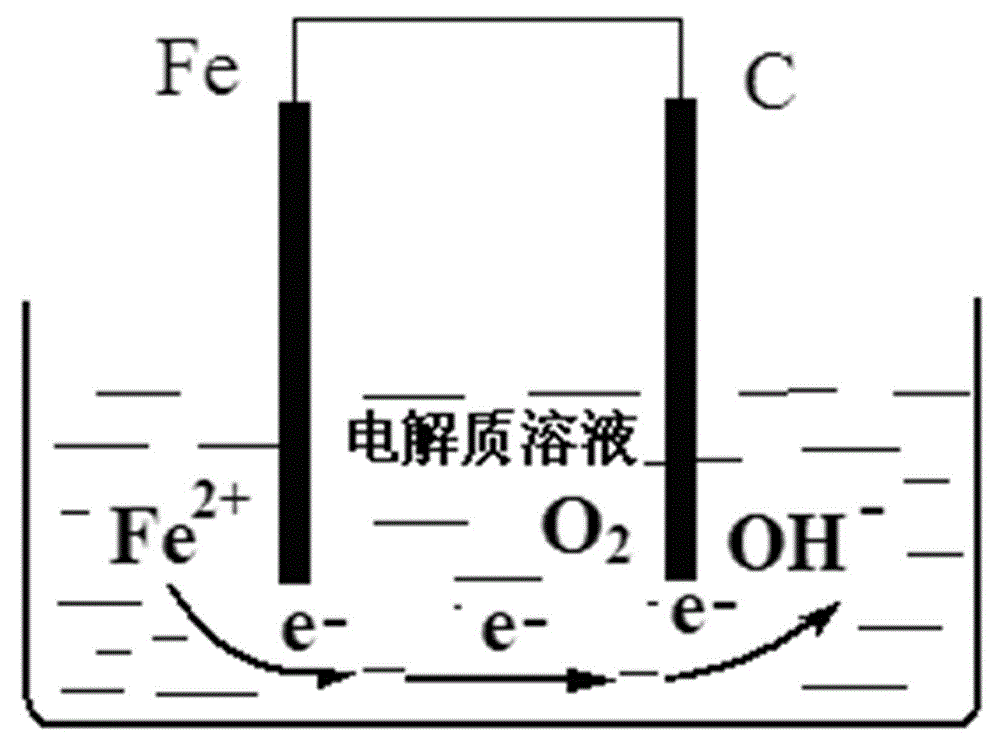

The invention provides a self-heated type thermal paste which comprises a vacuum external packaging bag and a breathable internal packaging bag. The internal packaging bag is filled with a heating material; one side of the internal packaging bag is provided with a gelatin layer; the gelatin layer is provided with a protecting film; the heating material is prepared from secondarily-reduced iron powder, sodium chloride, vermiculite, wood powder, active carbon powder and tap water at a certain proportion. Because the vermiculite is used as the heat preserving and insulating material of the self-heated type thermal paste, the heating time of the self-heated type thermal paste is prolonged greatly, and because the wood powder is used to prepare the self-heated type thermal paste, the heat preserving performance and the water retaining performance of the self-heated type thermal paste are improved effectively. A large number of experiments show that the self-heated type thermal paste can be heated to 40-50 DEG C, and the heat can be preserved for about 20 hours. In addition, the self-heated type thermal paste has the characteristics of low cost, easily-available raw materials, simple formula, quick long-time heating and balanced heat and can be used by people who can not tolerate cold and people who work or do activities outdoors in cold winter to keep warm.

Owner:GANSU RES INSTION OF CHEM IND GRICI

Method for separating lignin and cellulose from lignocellulose by using ionic liquid solvent

InactiveCN101580522AReduce stressImprove thermal stabilityLignin derivativesPaper material treatmentAlkaneSolvent

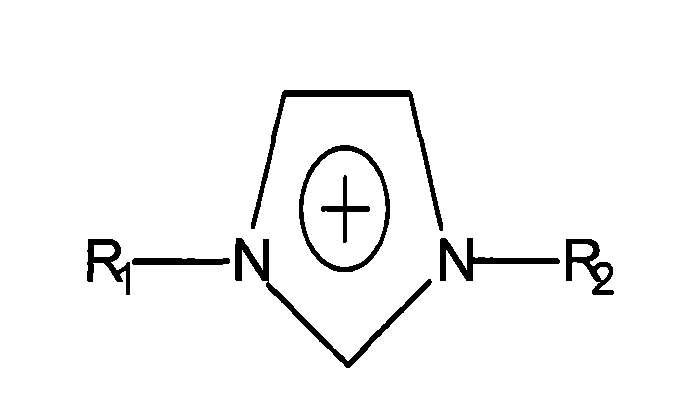

The invention relates to a method for separating lignin and cellulose from lignocellulose by using ionic liquid solvent, which comprises the following steps: adopting ionic liquid synthesized from an imidazole compound and halogenated alkane and water to form a liquid phase system which is added with wood flour, wood chips or vegetation plants to separate the lignin and the cellulose in a high-pressure autoclave at certain pressure and temperature, wherein the lignin is dissolved in ionic liquid water solution; filtering, separating, cleaning and drying the solid phase to obtain a cellulose product; and diluting, filtering, separating and drying the liquid phase to obtain a lignin product, wherein the ionic liquid can be recycled. The method achieves the separation of the lignin and the cellulose, the prepared cellulose product can be used as a raw material for papermaking directly and also can be used for preparing cellulose derivatives applied to the fields of daily use chemicals, medicaments, biology and the like; and the lignin can be used for preparing lignin modified products. The method does not volatile organic solvents and causes no environmental pollution, the used solvent can be recycled, and the production cost is low, thus the method has strong industrial application prospect.

Owner:DALIAN POLYTECHNIC UNIVERSITY

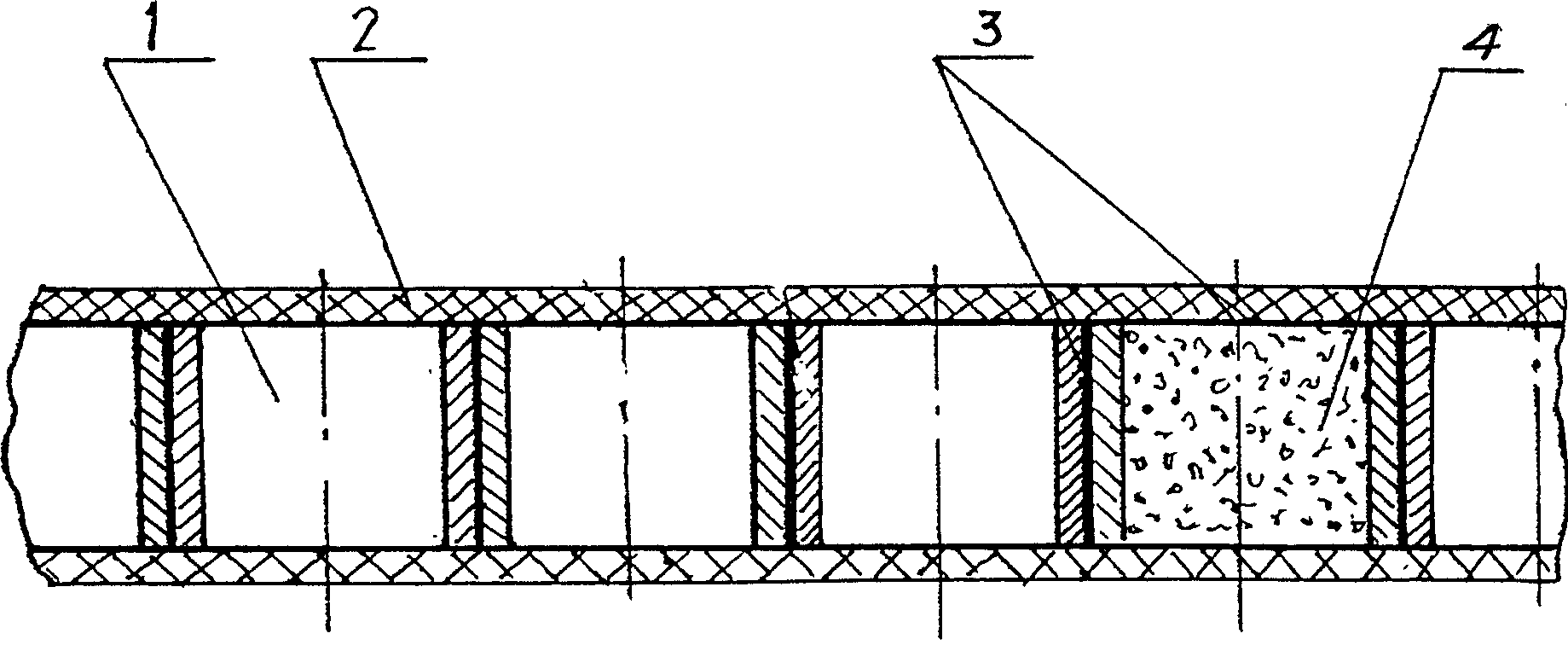

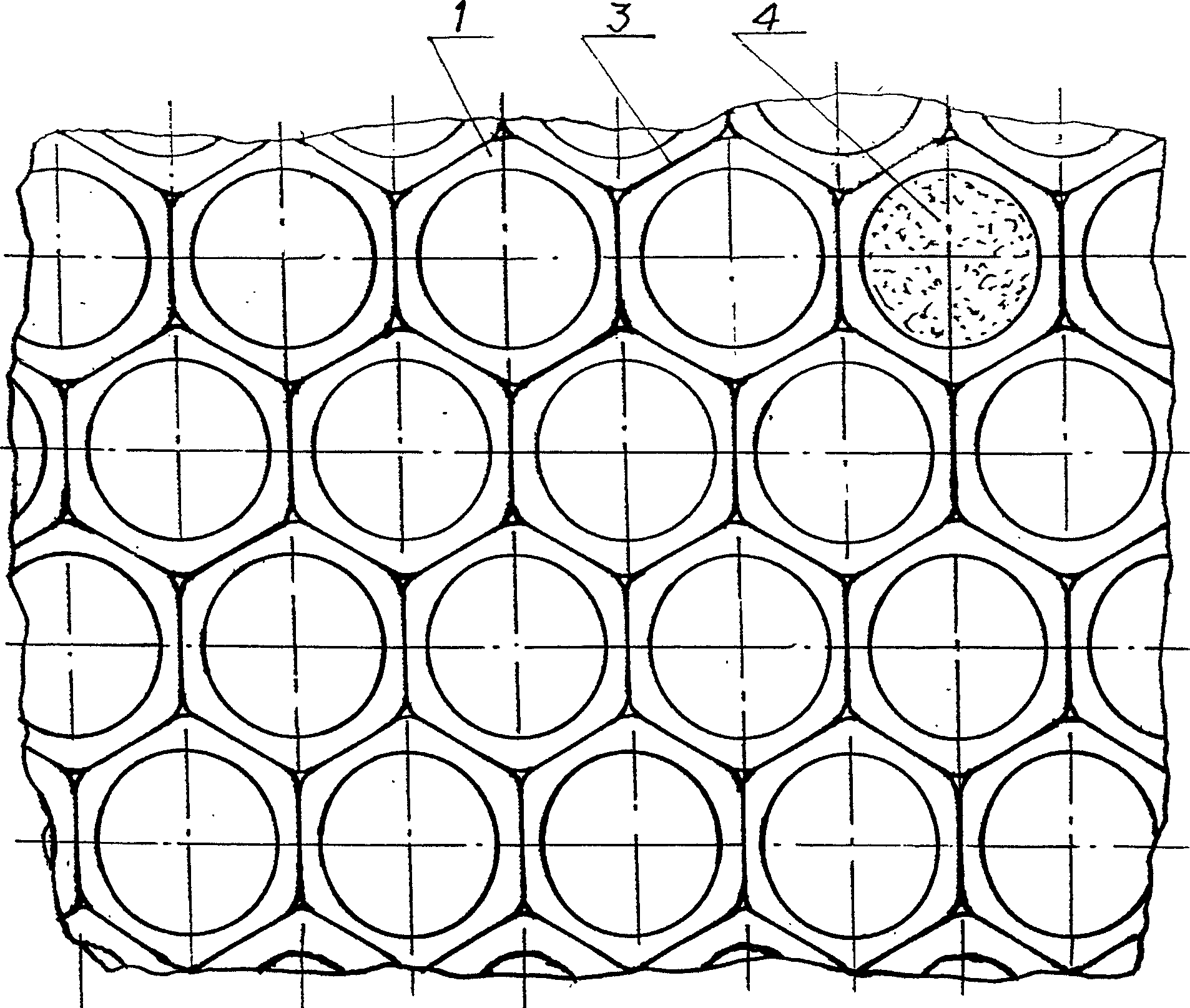

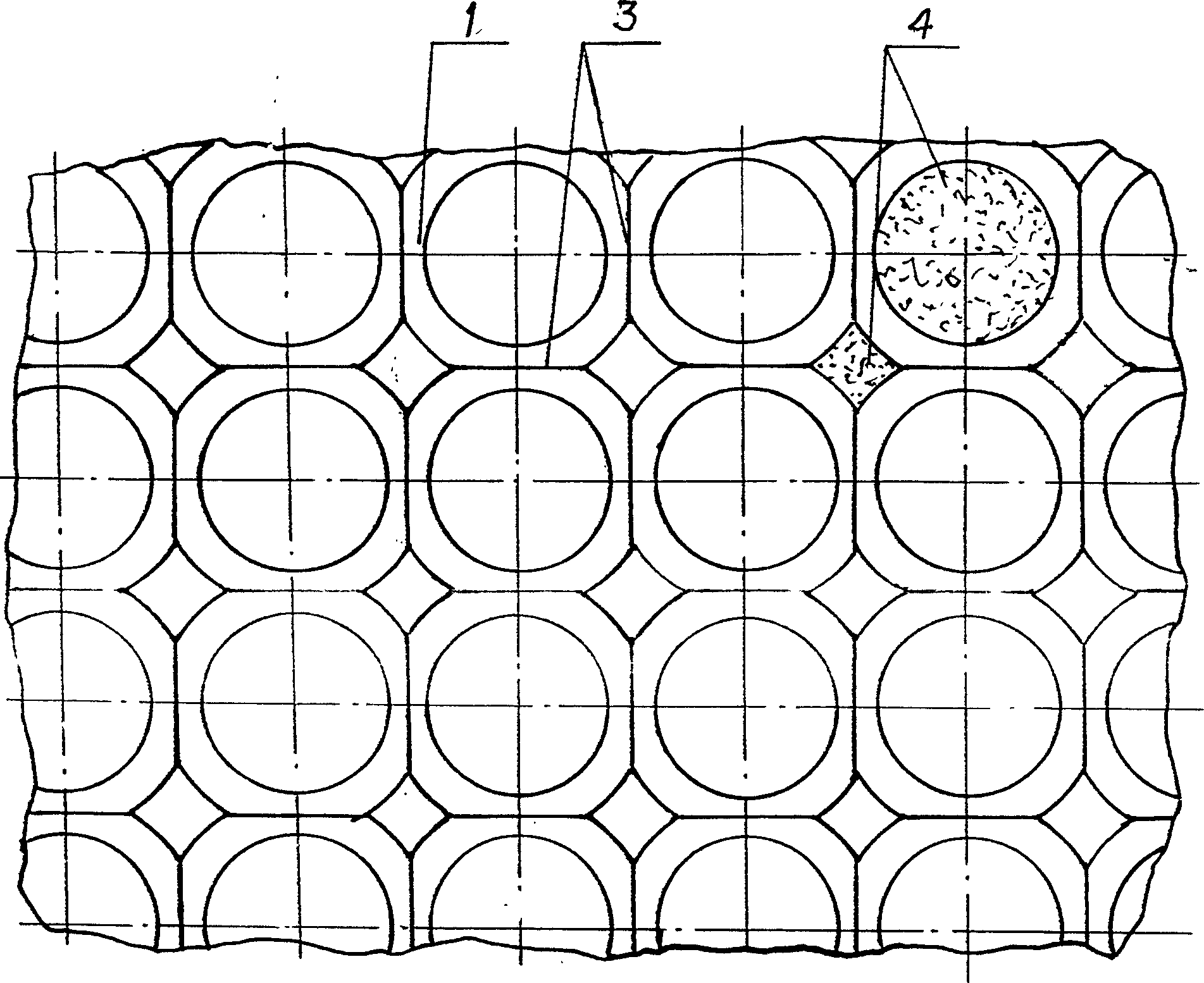

Bamboo-made wallboard

InactiveCN1743598AReduce weightEasy constructionConstruction materialLayered productsFiberWood shavings

A bamboo wall board is composed of bamboo tubes with adhesive peripheral faces, in which, the outer shapes of multiple bamboo tubes are the same, they are orthohexagonal post, die-square or cylindrical and an adhesive agent for connecting bamboo tubes is set at the contact places of the peripheral faces, the tubes are filled with fillers of bamboo bits, wood flour, wood shavings, fibers, crushed plant stovers, cement slurry, gypsum powder or foamed plastics, all of which are doped with adhesives. The bamboo wallboard is adhered with coats of bamboo boards, wood plywood, fiberboard, plastics, metallic board, gypsum boards or asbestos boards.

Owner:天津市朗明通信科技有限公司

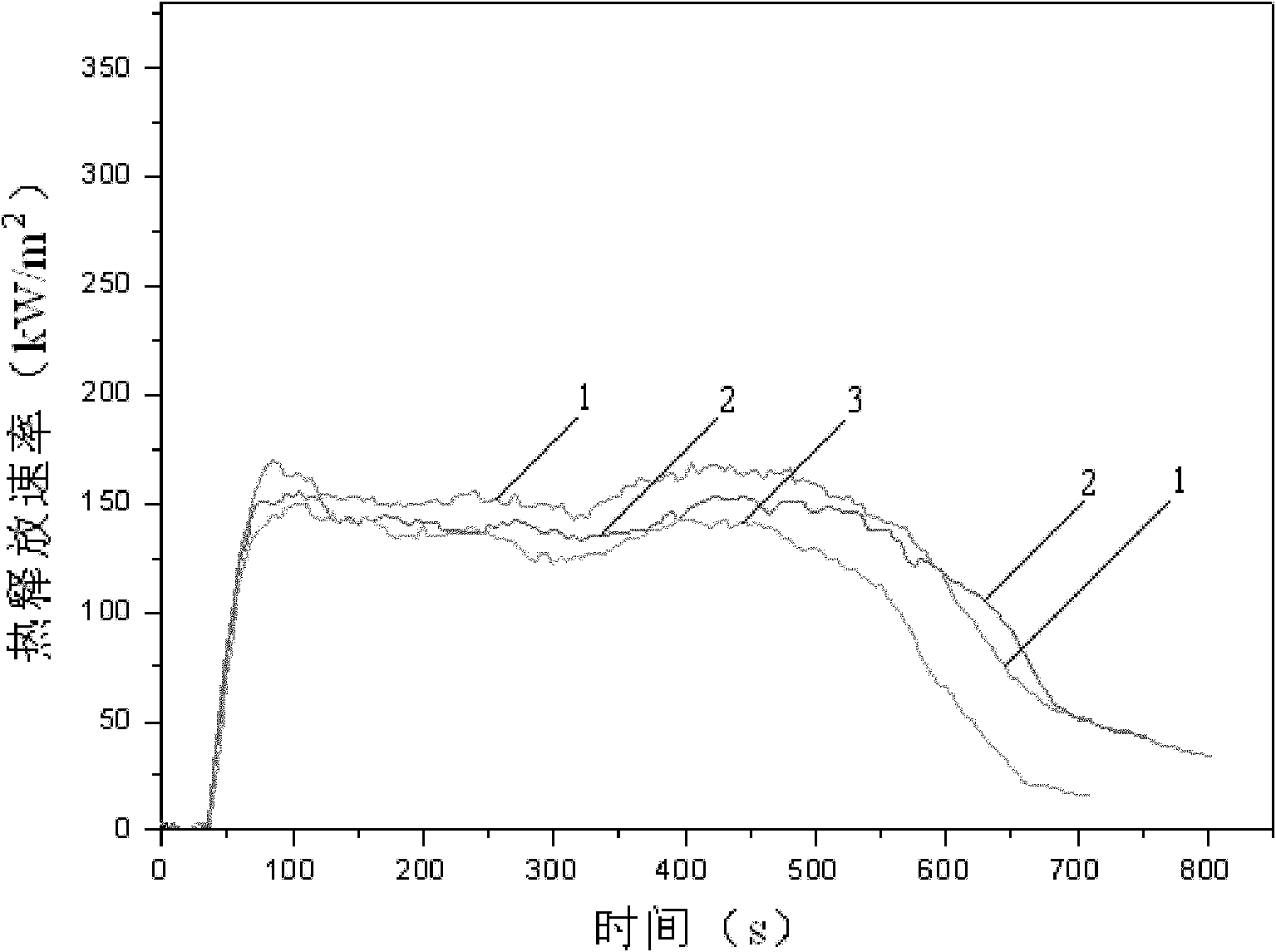

Wood flour/polypropylene wood-plastic composite material using silane modified ammonium polyphosphate as fire retardant and preparation method thereof

InactiveCN102093735AImprove flame retardant performanceImprove mechanical propertiesHeat resistancePolypropylene

The invention relates to a wood flour / polypropylene wood-plastic composite material and a preparation method thereof, in particular to a wood flour / polypropylene wood-plastic composite material using silane modified ammonium polyphosphate as a fire retardant and a preparation method thereof. The invention solves the problems of poor compatibility, low mechanical properties, poor fire retardance and poor heat resistance of the existing wood flour / polypropylene wood-plastic composite material using ammonium polyphosphate as a fire retardant. The wood-plastic composite material is prepared from wood flour, polypropylene, silane modified ammonium polyphosphate, m-TMI-g-PP coupling agent and antioxidant, wherein the silane modified ammonium polyphosphate is prepared from ammonium polyphosphate and gamma-methacryloxypropyltrimethoxysilane. The preparation method comprises the following steps: preparing the silane modified ammonium polyphosphate; then, mixing the wood flour, polypropylene, silane modified ammonium polyphosphate, m-TMI-g-PP coupling agent and antioxidant; and finally, extruding by using a double screw extruder. The wood-plastic composite material provided by the invention has fine fire retardance, high mechanical properties and good heat resistance; and the process is simple.

Owner:NORTHEAST FORESTRY UNIVERSITY

Wood composite alloy composition having a compatibilizer that improves the ability to process and compress cellulosic fiber

A crystalline polyamide 6 in a compounding extrusion process to make wood flour-polyolefin composite. The wood plastic composite pellet and can be post-blended with reinforced polyolefin pellets in an injection molding step to produce hybrid fibrous composites. The resulting compatibilization in the hybrid fibrous composites gives molded parts having enhanced mechanical properties at greatly reduced temperatures. There is wide variety of molded parts that can be made by varying the blend ratio of the wood plastic compounded product with or without and glass fiber reinforced pellets in the injection molding step.

Owner:INNOVATIVE PLASTICS & MOLDING +1

Wood-plastic composite for walls and preparation method thereof

The invention discloses a wood-plastic composite for walls, comprising the following components by mass: 68-78 parts of wood flour, 20-25 parts of PE plastics, 2-4 parts of coupling agents, 0.1-0.2 part of antioxidant and 2-5 parts of precipitated calcium carbonate-silicone oil. The invention also discloses a preparation method of the wood-plastic composite for walls. The quantity of the PE plastics in the formula of the wood-plastic composite is 20-25%, which is half as much as 50% of plastics in the common wood-plastic material, thus greatly saving the plastics and lowering the production cost, meanwhile, the prepared wood-plastic composite has the characteristics of high strength, creep resistance, good processability, low moisture rate and high weatherability.

Owner:姚喜智

Wood powder reinforced polyurethane wood-imitation material for furniture and production method thereof

The invention discloses a wood powder reinforced polyurethane wood-imitation material for furniture and a production method thereof. The mixture of polyether glycol, foaming agent, catalyst, stabilizing agent and fire retardant serves as a white material, polyisocyanate serves as black material, and wood powder filler with 80-100 meshes serves as the stabilizing agent, wherein, the mass ratio of white material to black material to wood powder is 112:112:7. The production method is as follows: respectively mixing the white material according to ratio to prepare composite polyether; adding wood powder to prepare wood powder / composite polyether mixture; then, adding the black material to prepare foaming mixture; and after injection molding and curing for 20 minutes, demolding to prepare the wood powder reinforced polyurethane wood-imitation material. The invention has the advantages that the compression strength and the shock resistance of the produced wood-imitation material and products are strengthened, wood texture effect is obvious, and density distribution is improved; the produced wood-imitation material and the product have stable size, small deformation and favorable heat insulation and sound insulation performance and are hard and ageing-resistant; flame retardant property can reach construction B2 grade, the product is environmentally-friendly and has low cost as well as favorable handling characteristics, such as sawing, digging, drilling, nailing, rubbing, sticking, coloring, coating and the like.

Owner:德华兔宝宝装饰新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com