Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

652results about How to "High expansion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

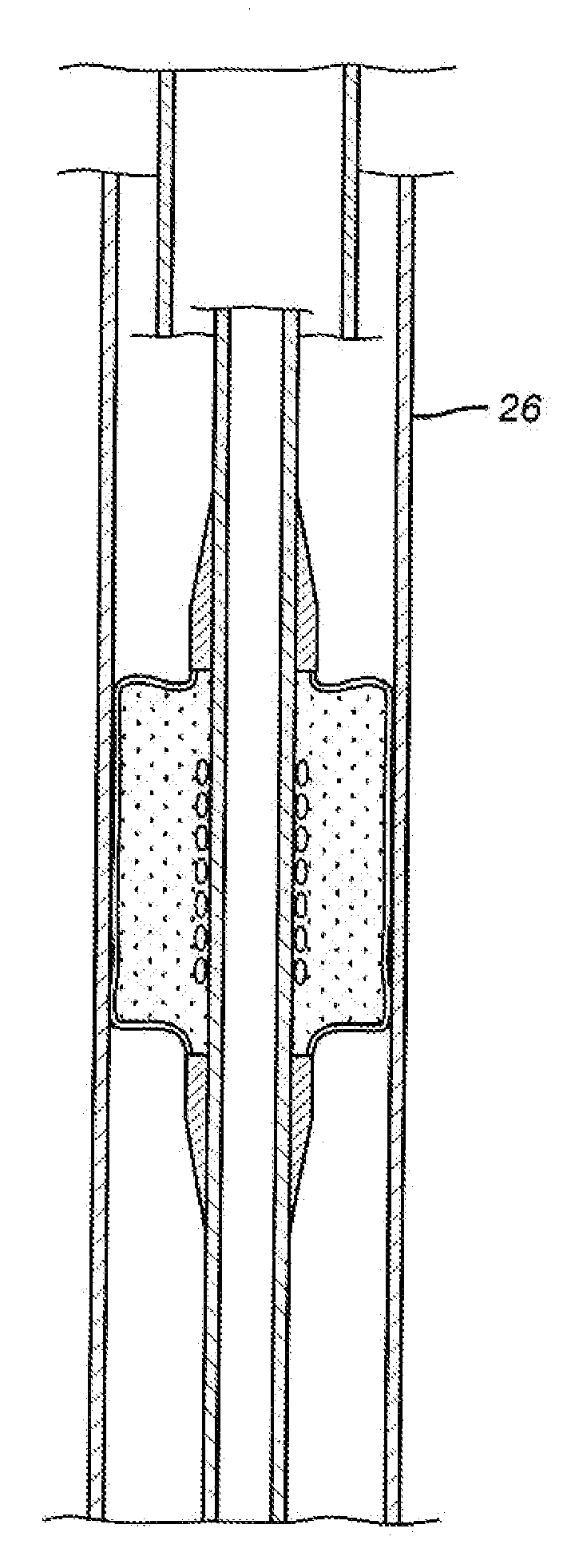

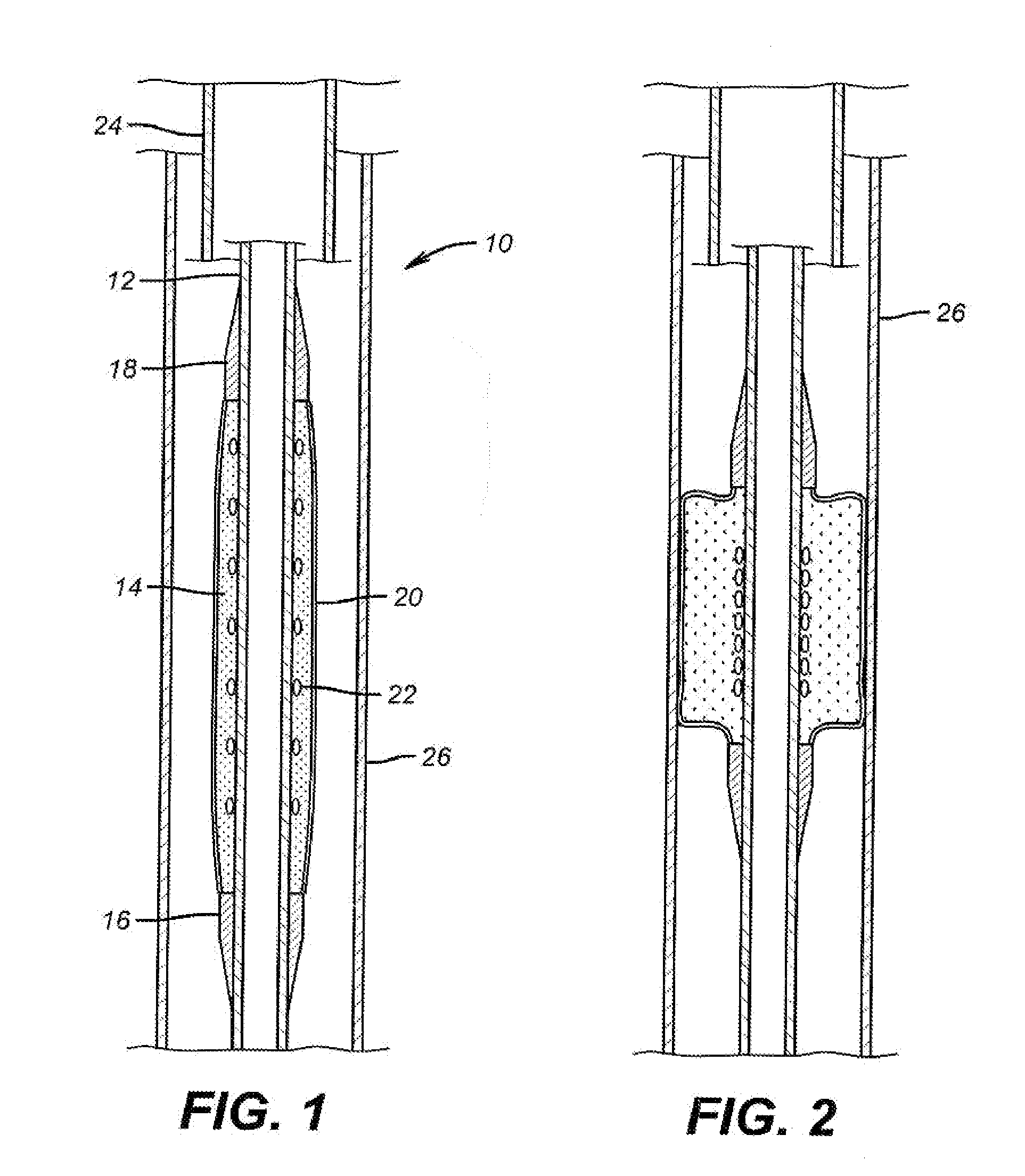

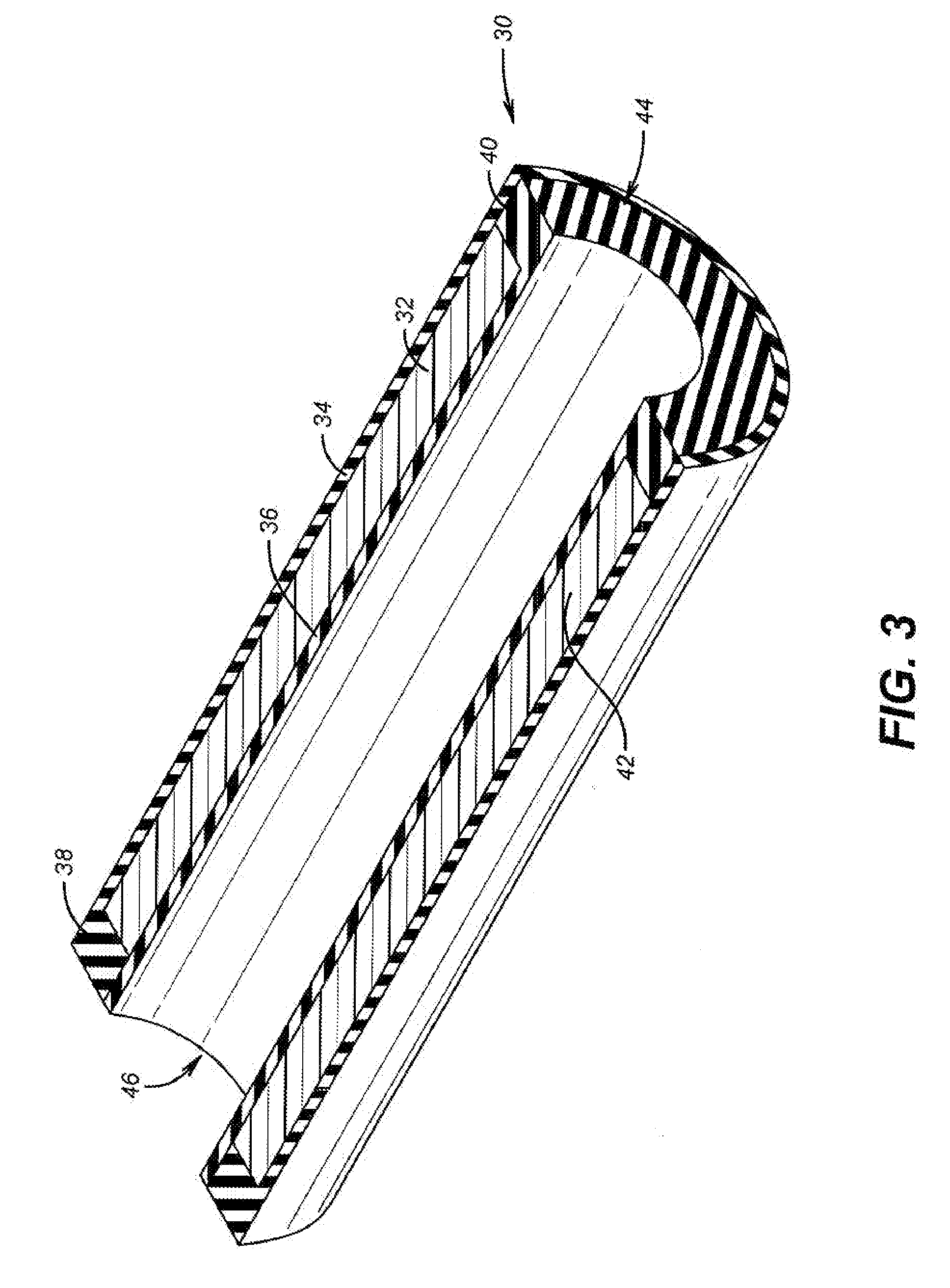

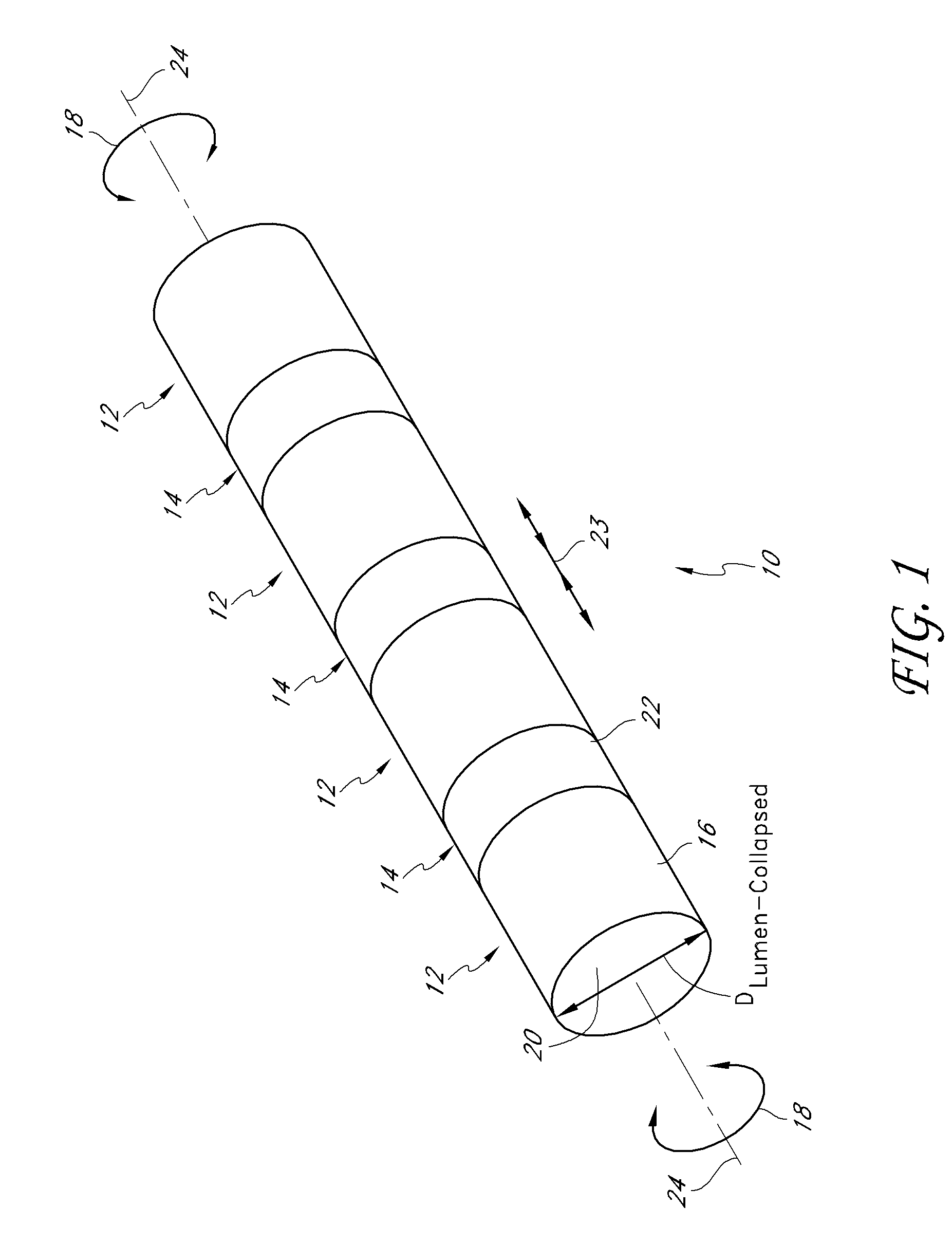

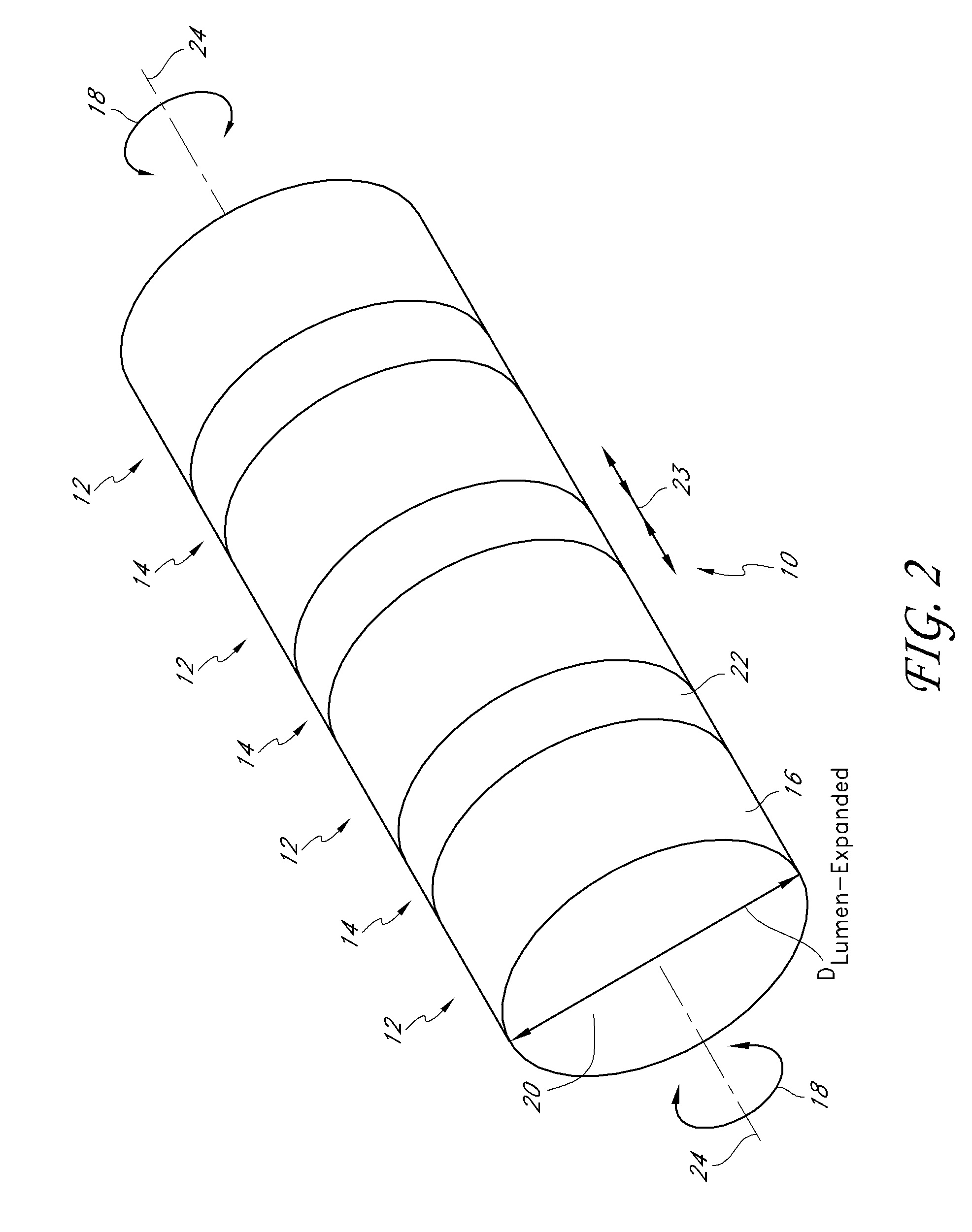

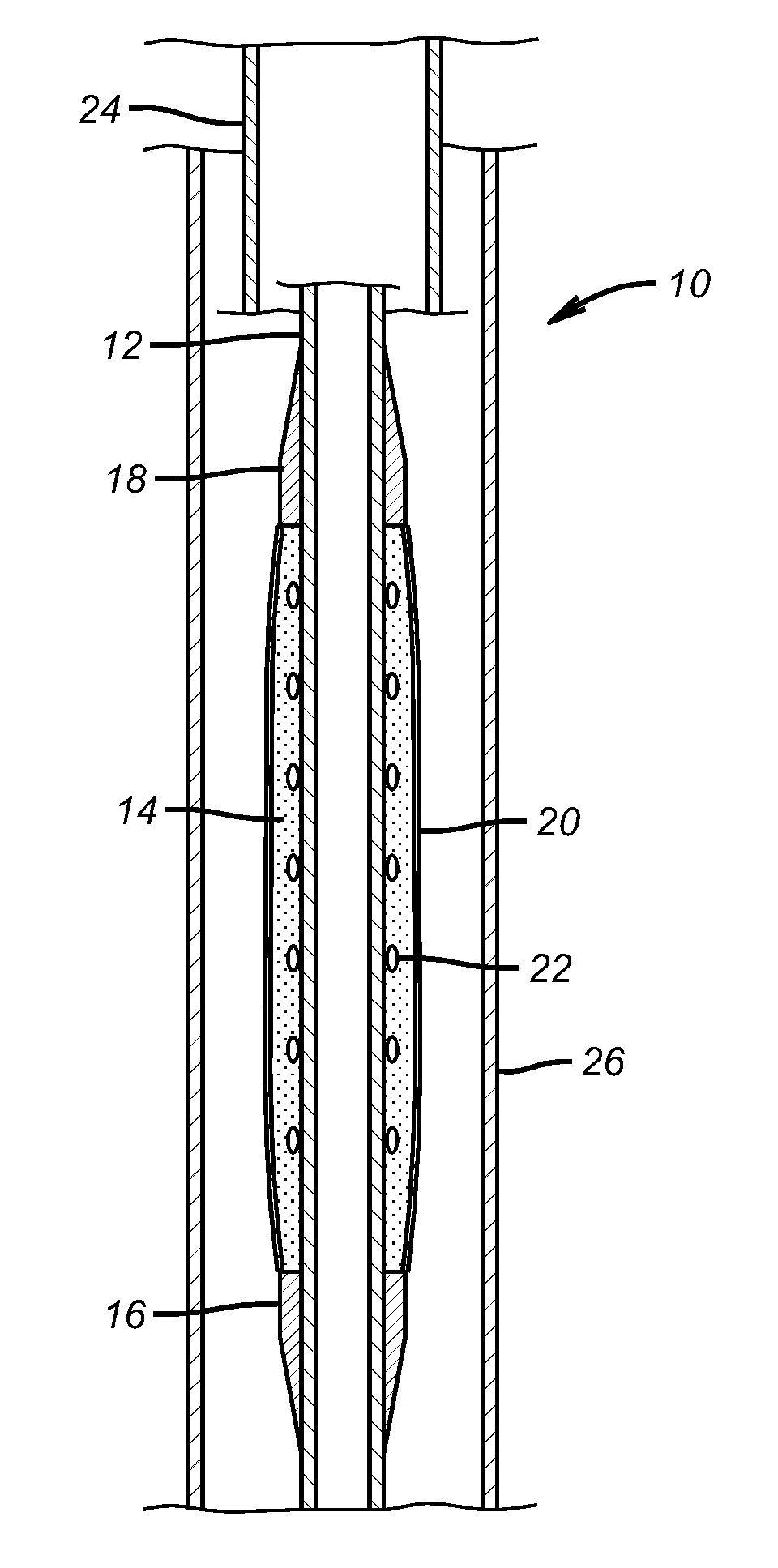

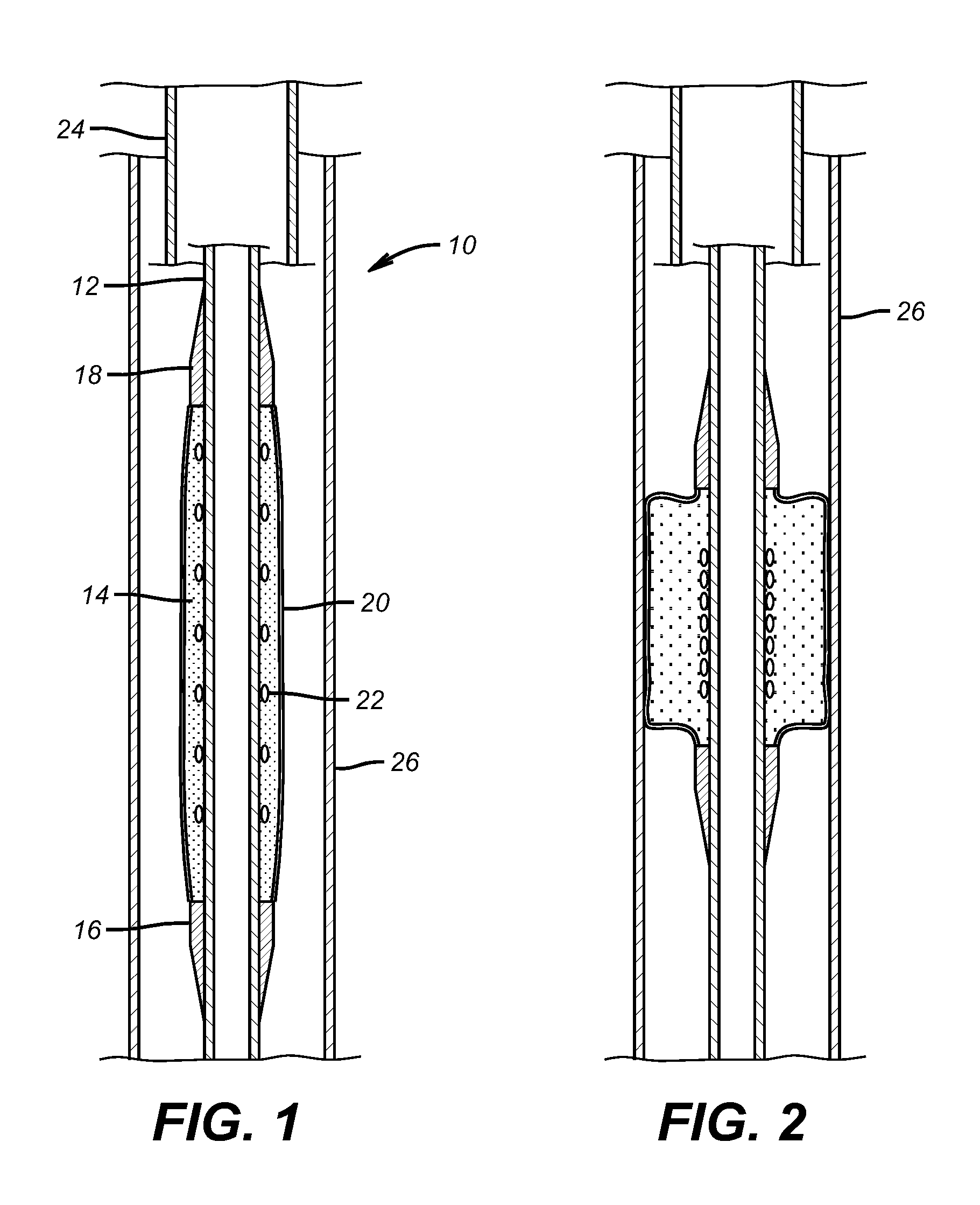

Packer sealing element with shape memory material

A packer or bridge plug uses a sealing element made from a shape memory polymer (SMP). The packer element receives heat or other stimulus to soften the SMP while the element is compressed and retained. While so retained, the heat or other stimulus is removed to allow the SMP to get stiff so that it effectively seals a surrounding tubular. High expansion rates are possible as the softness of the material under thermal input allows it to be reshaped to the surrounding tubular or to the surrounding open hole from a smaller size during run in and to effectively retain a sealed configuration after getting stiff on reduction in its core temperature while longitudinally compressed. The SMP or equivalent material whose modulus is changeable can be covered on the outside, the inside or both with an elastic material that protects the SMP and enhances the seal in the wellbore and against the mandrel.

Owner:BAKER HUGHES INC

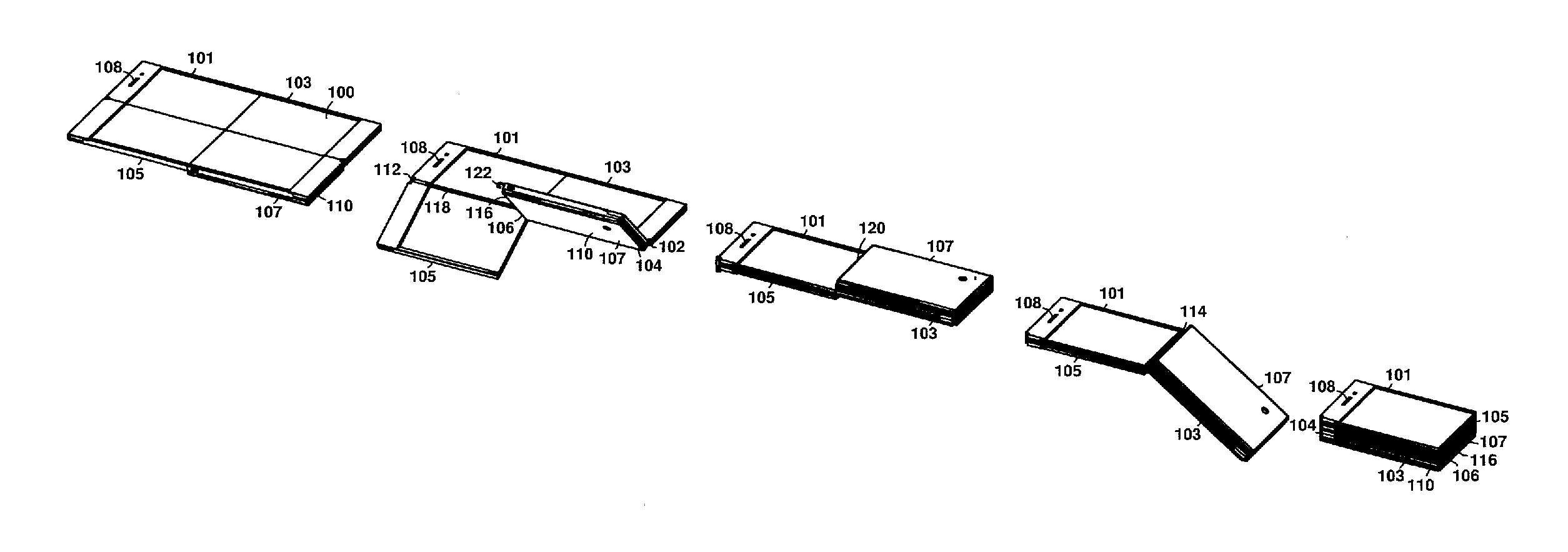

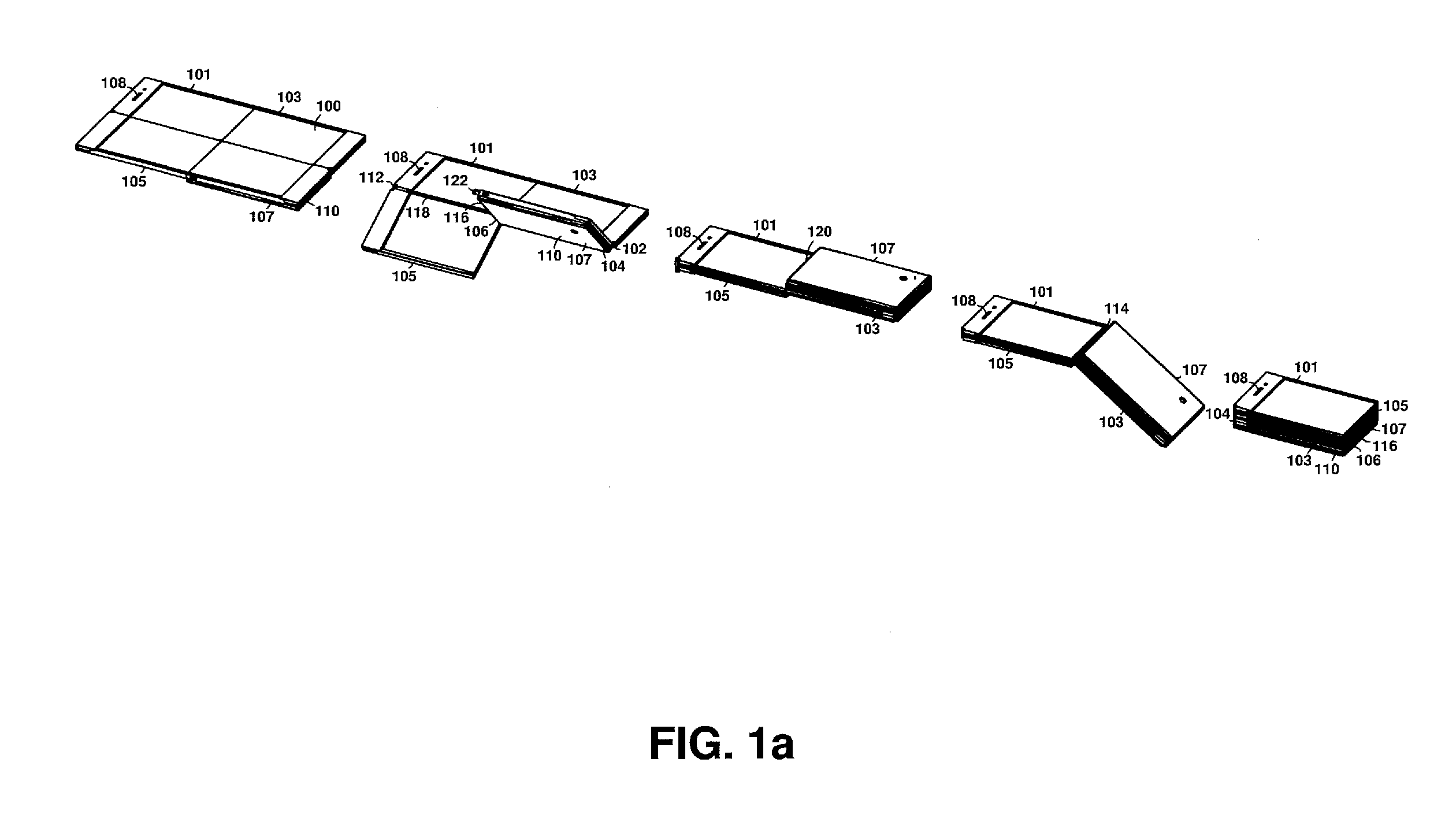

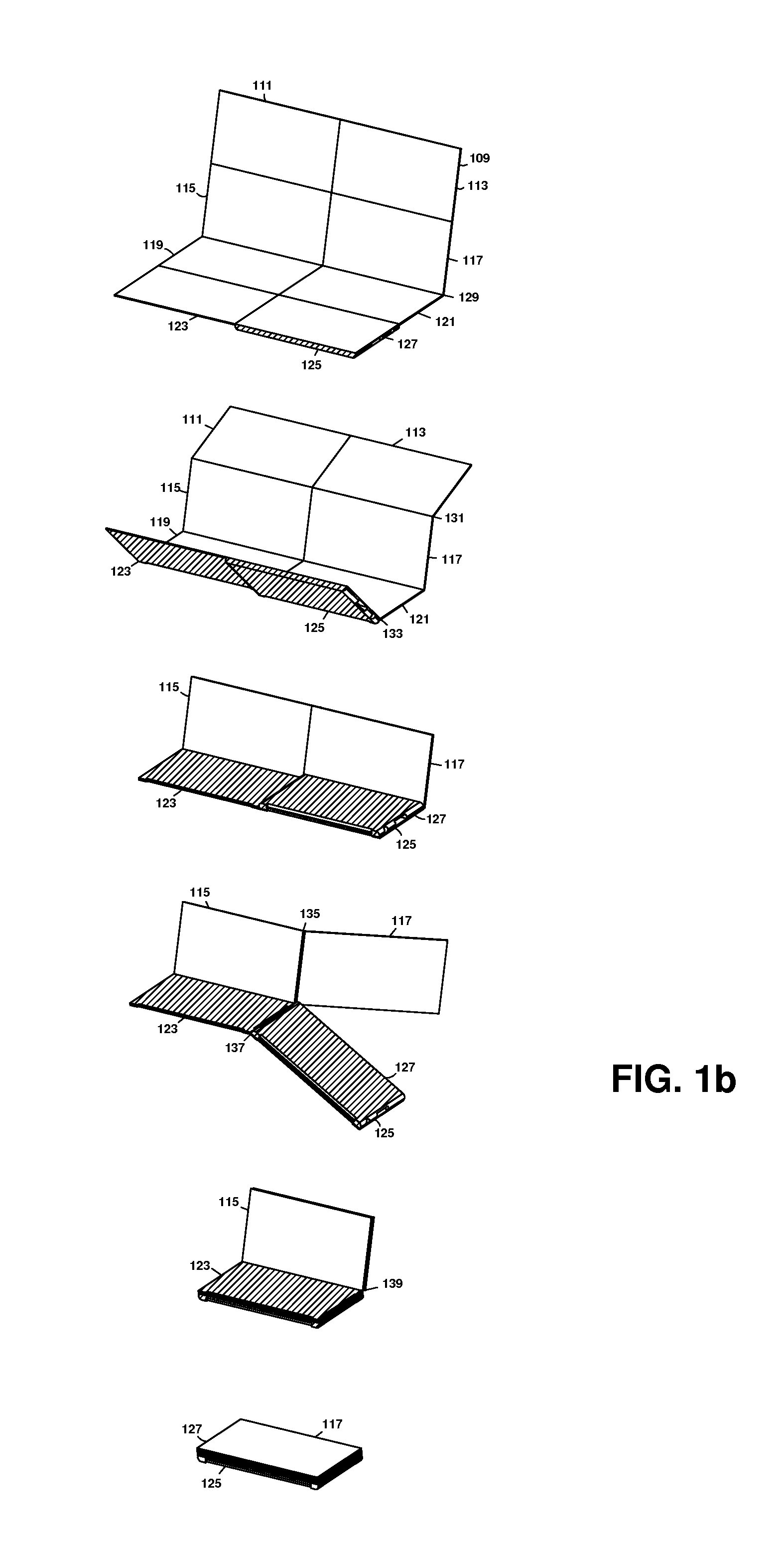

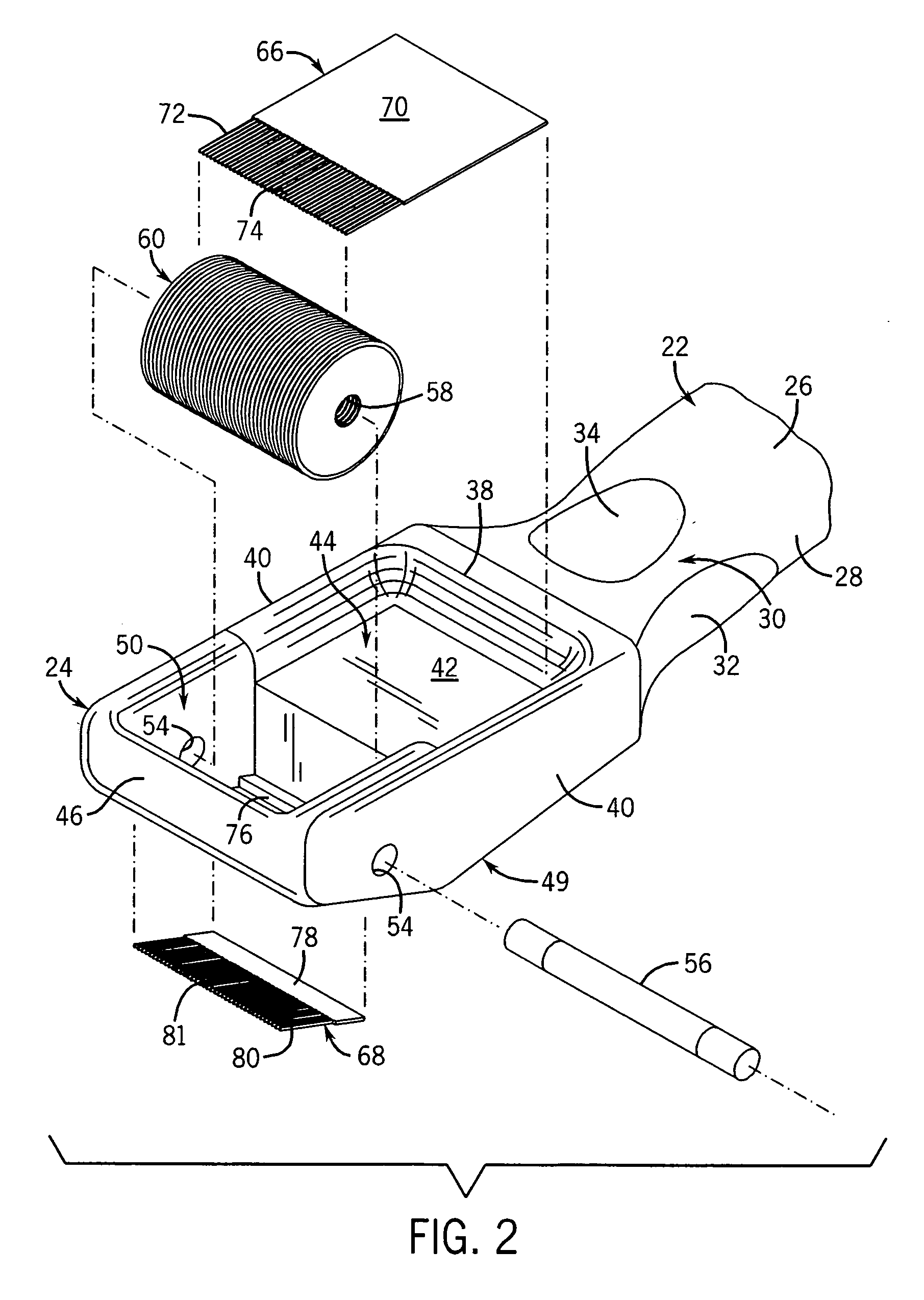

Reconfigurable touch screen computing device

ActiveUS20120038570A1Reduce difficultyHigh expansion rateDetails for portable computersInput/output processes for data processingTablet computerCommunications system

A reconfigurable touch screen computing device with folding configurations and an alignment locking mechanism. The touch screen display is made up of segments coupled to a flexible circuit and can be reconfigured from a compact state to an expanded state. The form factor of the compact state is roughly the size of a typical handheld phone, with an integrated speaker and microphone. The form factor of the expanded state is roughly the size of a tablet computer which may also include the mechanical functionality of a laptop. Both states provide a configuration which includes a touch screen display on a front side and a protective housing on a back side. The computing device may further include sensors to indicate the state of configuration. In one embodiment, a module attached to, situated within, or otherwise associated with at least one segment may contain all or substantially all processing and memory, along with a communications system, all of which may be used in either state.

Owner:LEPTON COMPUTING LLC

Chlorinated vinyl resin/cellulosic blends: composition, processes, composites, and articles therefrom

InactiveUS7030179B2High expansion rateEasy squeezeLavatory sanitoryRadiationCellulosePolymer science

Compositions and processes for preparing extrudable powder blends containing at least one vinyl chloride resin and a cellulosic material are provided. More specifically, compositions and processes for preparing extrudable free-flowing powder blends containing PVC and wood flour (WF) are also provided for preparing foamed or nonfoamed extrudates. The processes provided herein incorporate components which may contain up to a total of 25 weight percent water. Processes for preparing foamed extrudates are also provided wherein a cooling fluid is used to increase the expansion ratio of the foam. Finally provided are composites having an extrudable thermoplastic substrate and at least one capstock layer disposed thereon containing a PVC / WF composition.

Owner:ROHM & HAAS CO

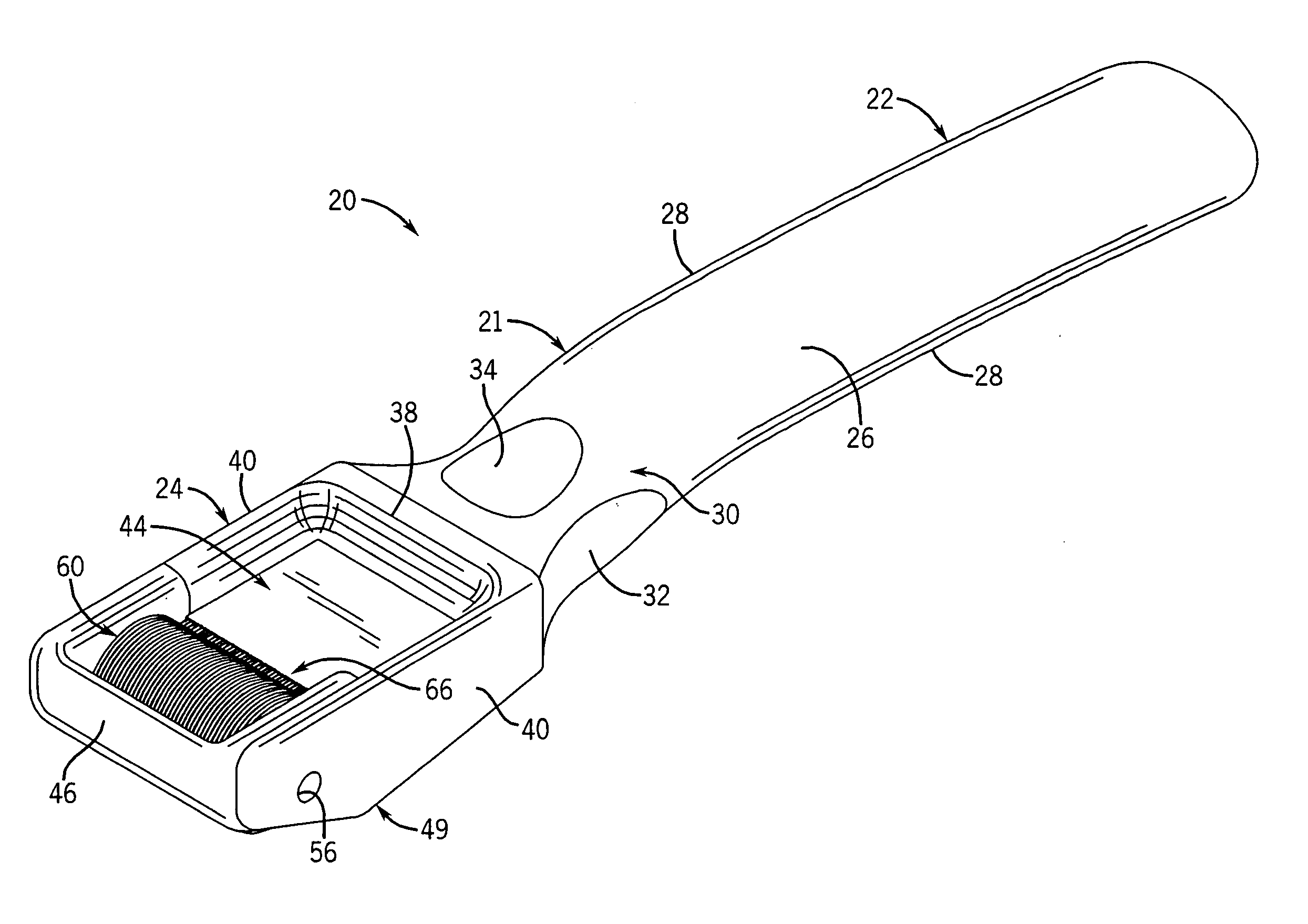

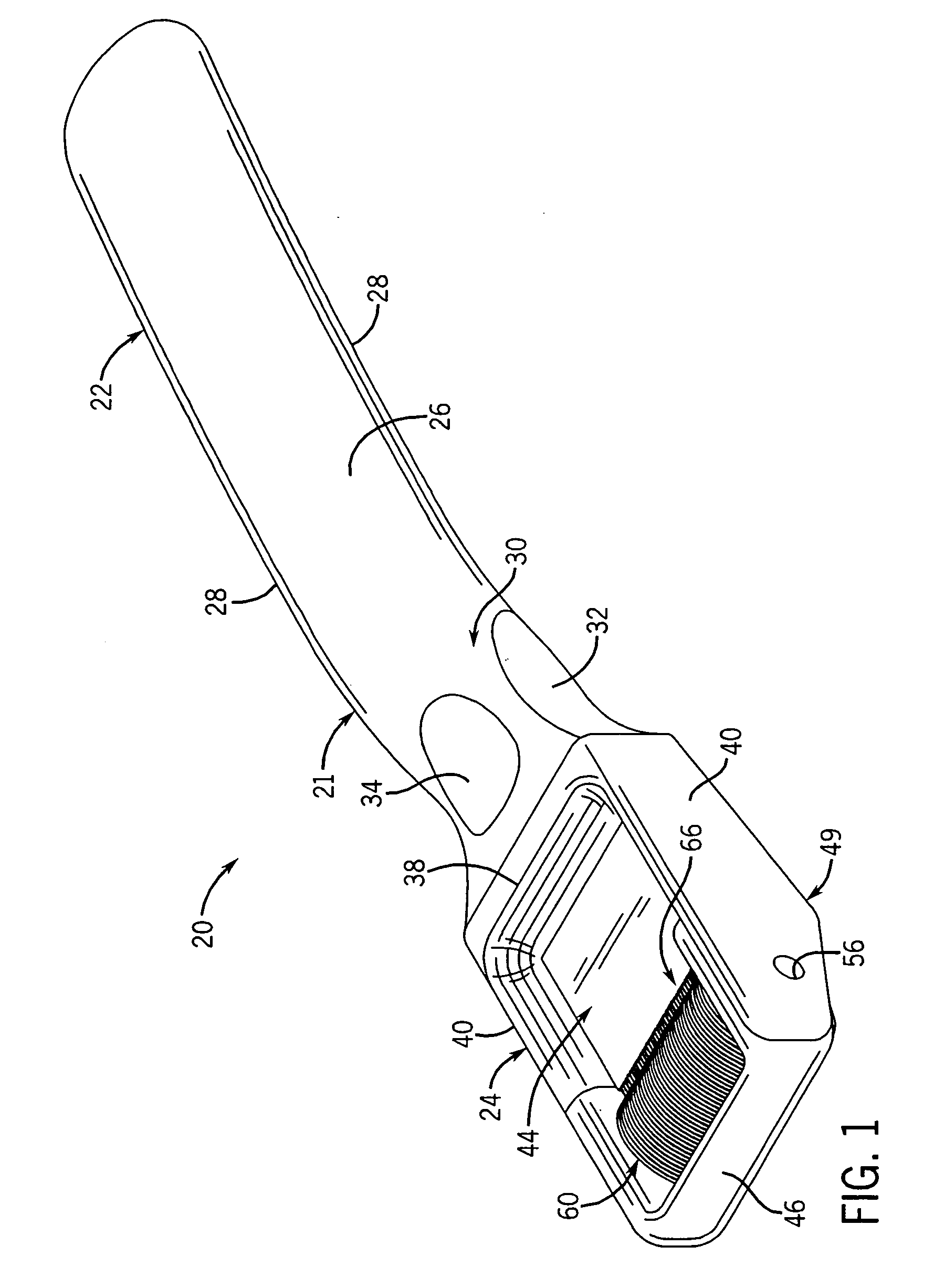

Method and apparatus for processing dermal tissue

ActiveUS20060271070A1Inexpensive and disposable and easy to useGood cosmetic effectDiagnosticsSurgerySingle-Use DeviceWound site

A portable and disposable device is provided for processing harvested dermal tissue. The device includes a housing presenting a handle having a gripping surface and a cutting head attached to the handle. A cutting assembly is supported by the cutting head and includes a plurality of spaced cutting blades that are rotatable with respect to the housing. A receptacle is disposed downstream of the cutting assembly and receives the sliced tissue from the cutting blades. The device is thus operable to slice harvested tissue into strips, and further into fine particles, that can be used for transplantation onto a wound site.

Owner:WRIGHT MEDICAL TECH

Halogen-free tin-bismuth-copper soldering paste and preparation method thereof

InactiveCN101695794AExtended shelf lifeExtended service lifeWelding/cutting media/materialsSoldering mediaAntioxidantExpansion rate

The invention relates to the technical field of soldering pastes, in particular to a halogen-free tin-bismuth-copper soldering paste and a preparation method thereof. A soldering flux of the halogen-free tin-bismuth-copper soldering paste consists of the following components in percentage by weight: 20 to 40 percent of polymerized rosin, 1 to 6 percent of rosin amine, 4 to 8 percent of thixotropic agent, 5 to 10 percent of organic acid, 5 to 10 percent of organic amine, 1 to 5 percent of antioxidant, 0.5 to 3 percent of surfactant and an organic solvent. The halogen-free tin-bismuth-copper soldering paste is mainly characterized by adopting the organic acid and the organic amine serving as activating agents and comprising no halogens at all, so not only the solderability is not reduced, but also the expansion rate and the insulation resistance value of the soldering paste are improved, and simultaneously the corrosivity of residues after soldering to a base material is reduced and the service life of the soldering paste is prolonged; and particularly, the peak temperature of the soldering paste during soldering is lower in favor of reducing the thermal damages to electronic components.

Owner:东莞市特尔佳电子有限公司

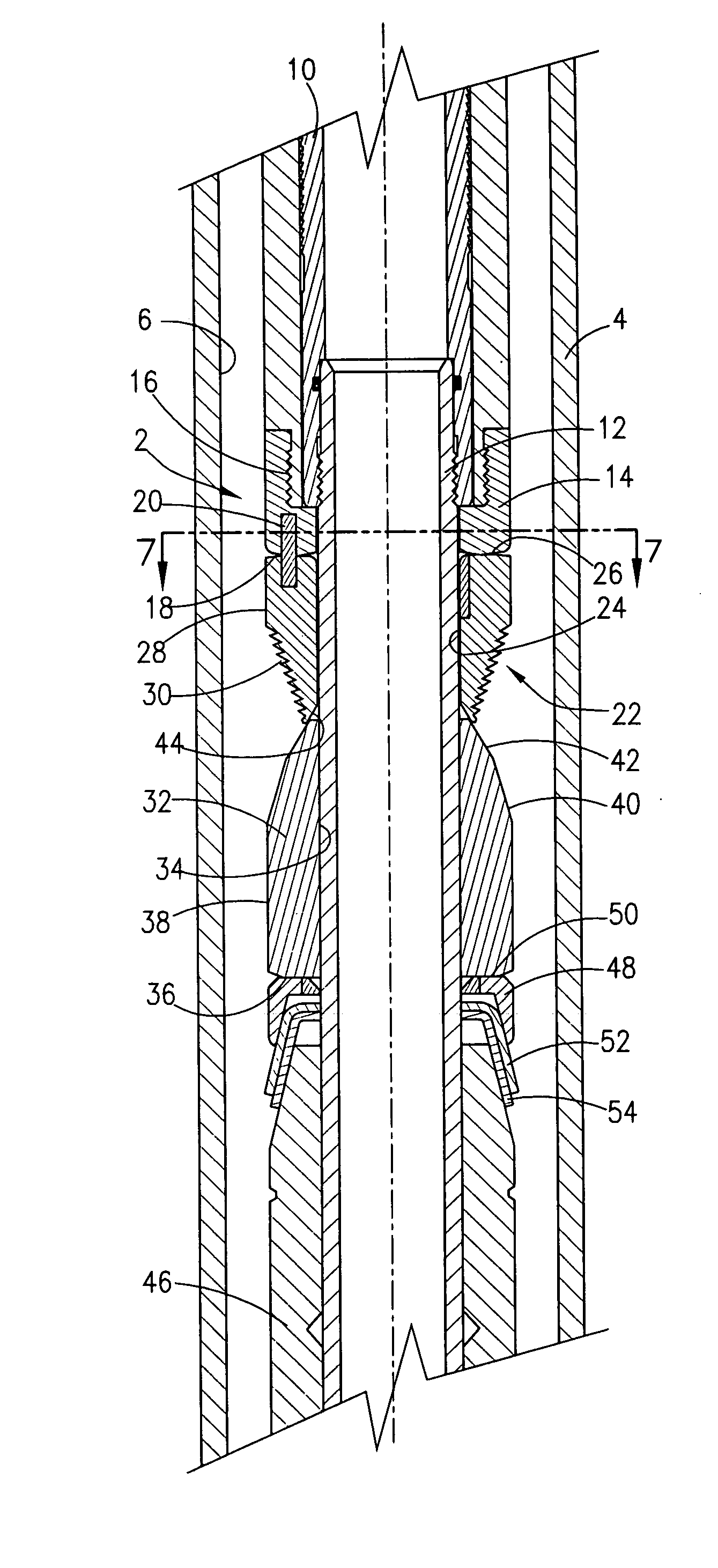

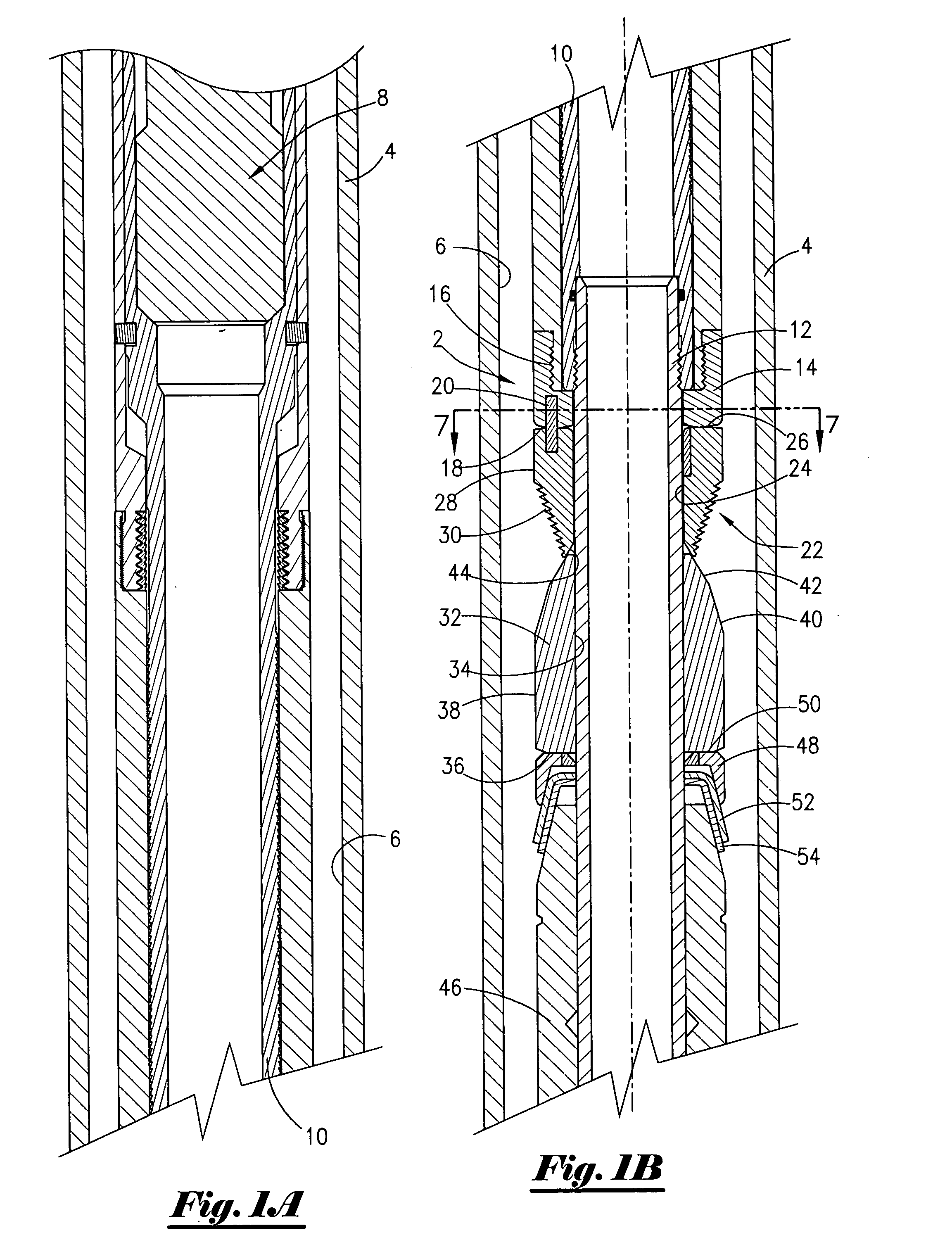

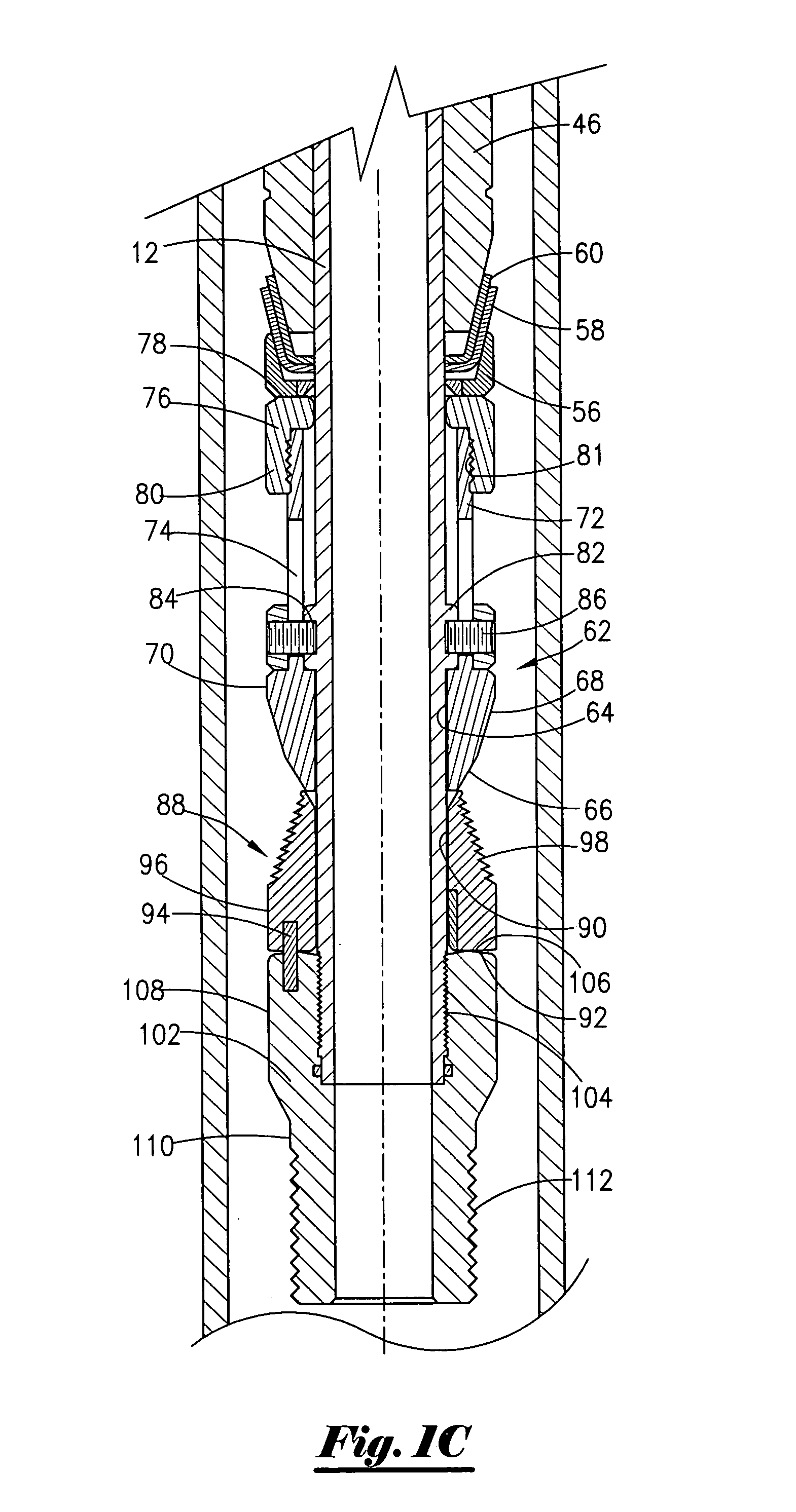

Apparatus for controlling slip deployment in a downhole device

ActiveUS20080073086A1Efficient and economically manufacturedEasy to disassembleFluid removalSealing/packingElastomerMechanical engineering

An apparatus for use in a well. The apparatus comprises a mandrel containing a radial shoulder, a sub member concentrically disposed about the mandrel, and an upper slip, concentrically disposed about the mandrel, for engaging the well. The apparatus further comprises an upper cone abutting an underside of the upper slip, and wherein the upper cone is disposed about the mandrel, and an elastomer operatively associated with the upper cone, and wherein the elastomer is disposed about the mandrel. The apparatus further includes a lower slip, concentrically disposed about the mandrel, for engaging with the internal portion of the well, and lower cone abutting an underside of the lower slip, and wherein the lower cone is disposed about the mandrel, and wherein the lower cone is operatively associated with the elastomer. The apparatus further contains a first alignment member selectively connecting the sub with the upper slip, and wherein the first alignment pin is selected to shear at a first predetermined force.

Owner:COOK ROBERT BRADLEY +1

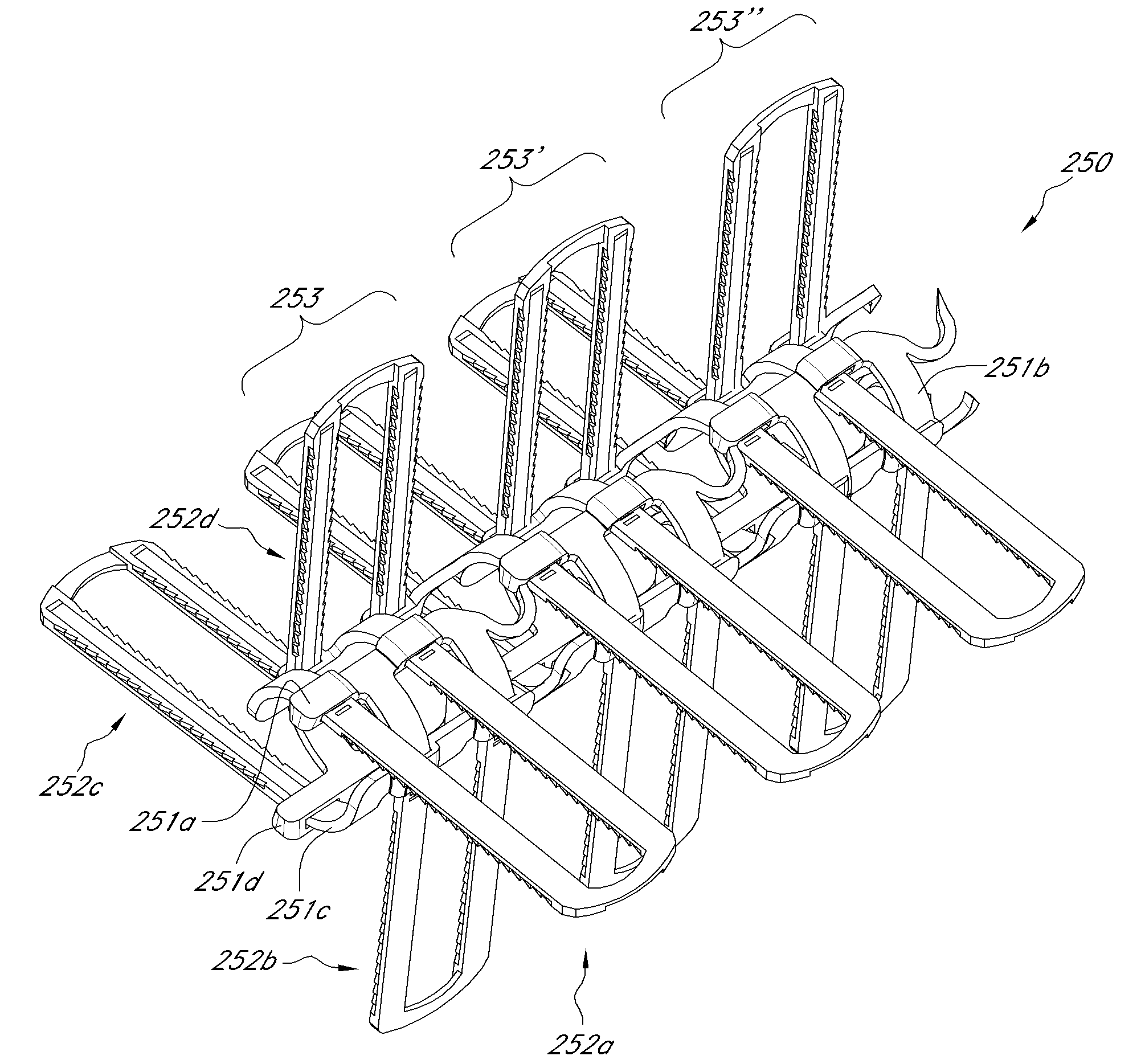

Axially-radially nested expandable device

InactiveUS20090143853A1Small non-deployed profileLow profileStentsAdditive manufacturing apparatusVascular deviceBlood vessel

Expandable medical implants for maintaining support of a body lumen are disclosed. These implants comprise an axially-radially nested, diametrically expandable, moveable vascular device for enlarging an occluded portion of a vessel. The device can be configured to allow for motion such as translating and / or slide and lock. One advantage of the axially-radially nested stent is that it maintains the expanded size, without significant recoil.

Owner:REVA MEDICAL

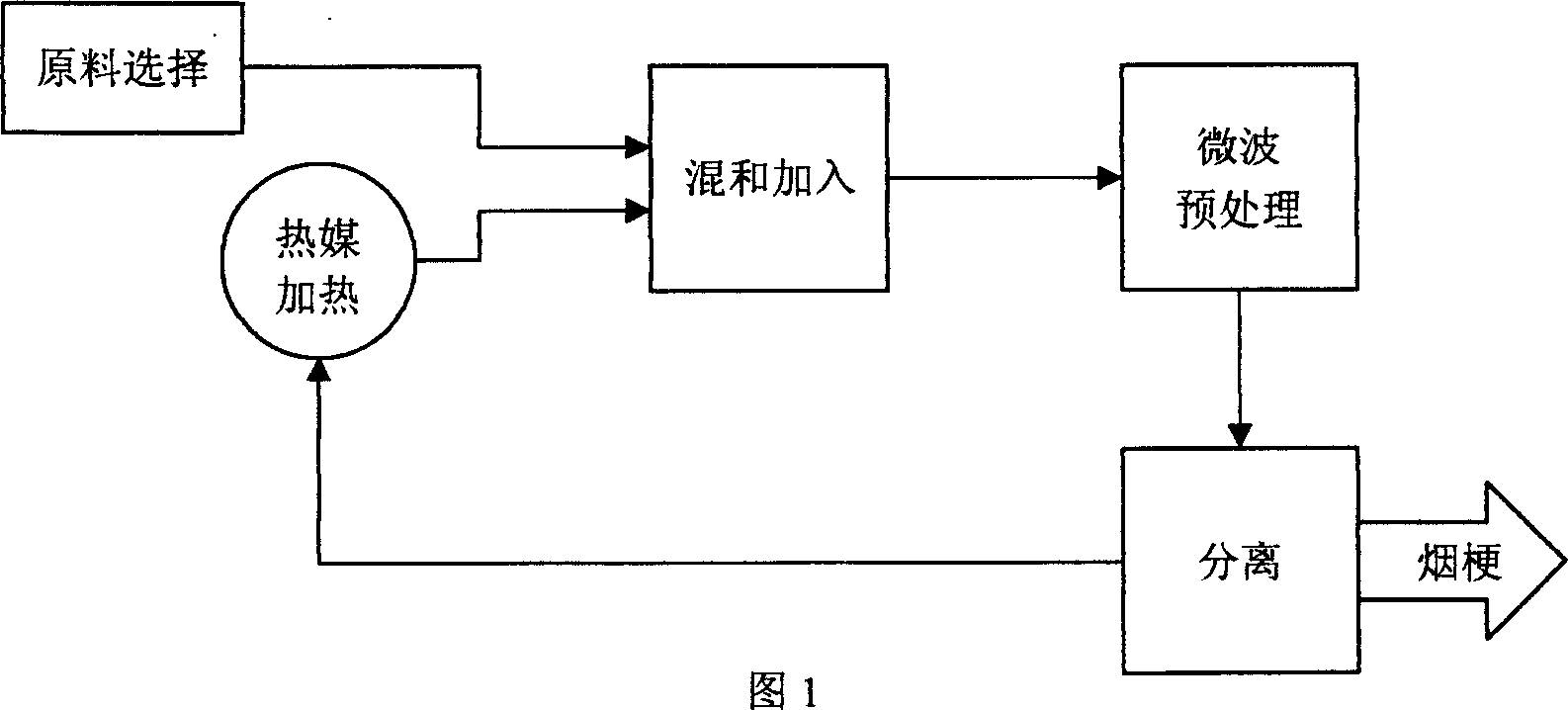

Technique for pretreating cabo

InactiveCN1518906AReduce energy consumptionGood smokeTobacco preparationPretreatment methodMicrowave

A technology for pre-processing the stems of tobacco leaves includes heating the low-loss granular solid microwave medium as thermal medium to 100-200 deg.c, mixing said stems with said thermal medium, heating in microwaven over for puffing the stems, and separating the tobacco stems from thermal medium. The pre-processed stems feature high loseness and elasticity, and good smell.

Owner:SHENZHEN HONGXIANG YISHENG TECH CO LTD

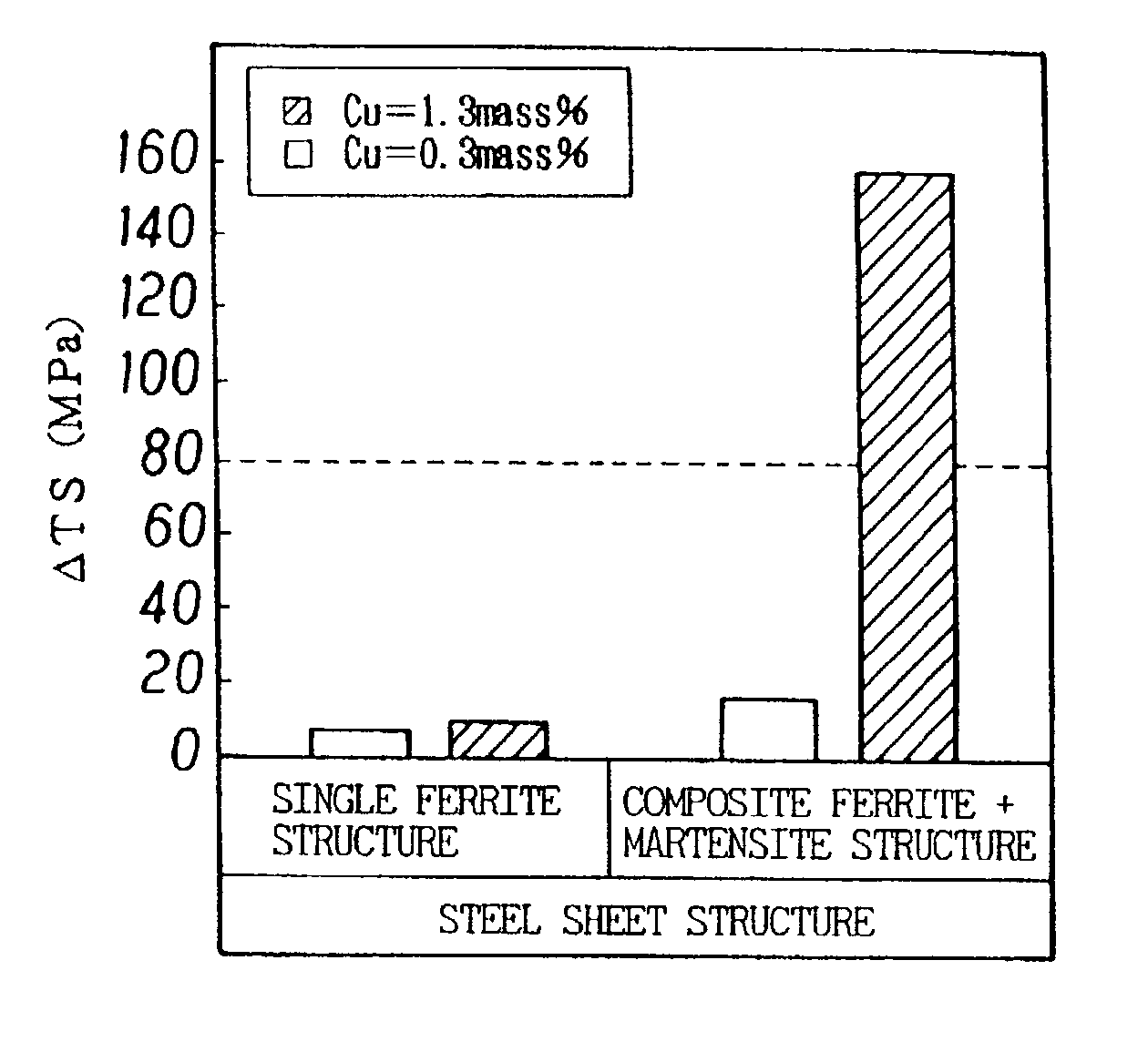

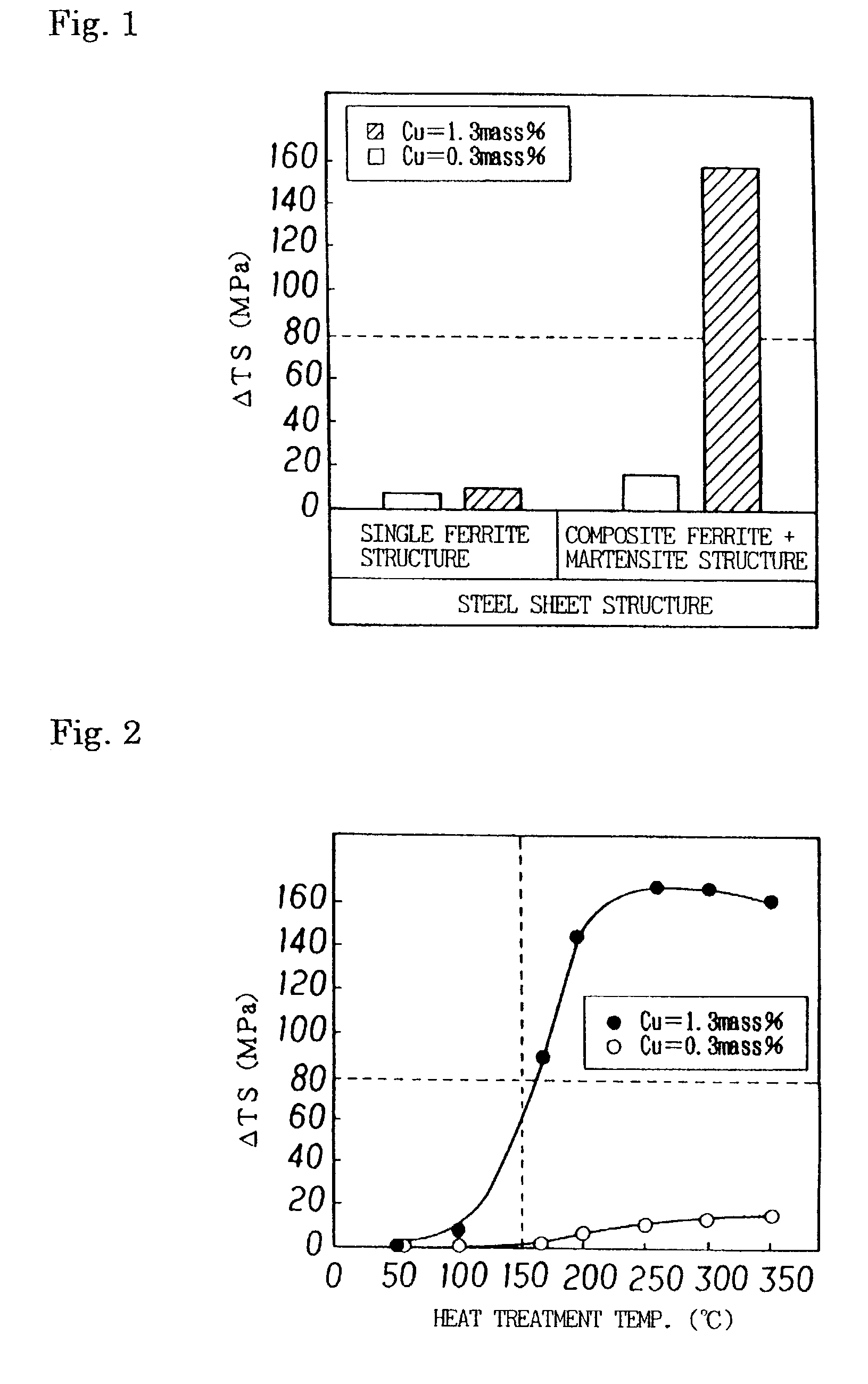

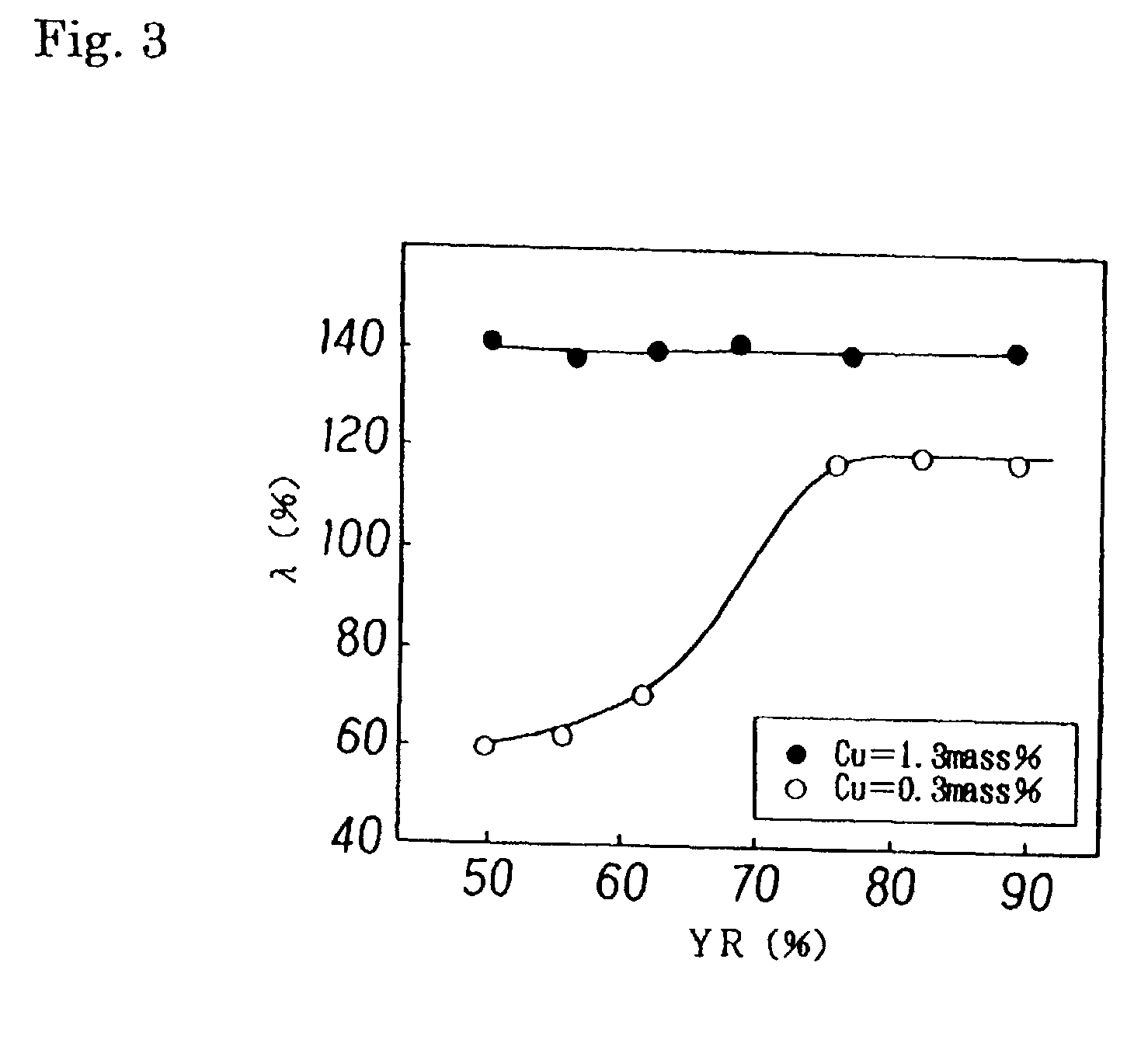

Hot rolled steel plate, cold rolled steel plate and hot dip galvanized steel plate being excellent in strain aging hardening characteristics, and method for their production

InactiveUS20030111144A1Improve stamping formabilityGood strainHot-dipping/immersion processesFurnace typesSheet steelChemical composition

The present invention provides a steel sheet having a chemical composition comprising 0.15% or less C, 2.0% or less Si, 3.0% or less Mn, P, S, Al and N in adjusted amounts, from 0.5 to 3.0% Cu, or one or more of Cr, Mo and W in a total amount of 2.0% or less, and having a composite structure comprising ferrite and martensite having an area ratio of 2% or more. The steel sheet is in the form of a high-strength hot-rolled steel sheet, a high-strength cold-rolled steel sheet, or a hot-dip galvanized steel sheet. There is thus available a steel sheet excellent in press-formability and in strain age hardening property as represented by a DELTATS of 80 MPa or more.

Owner:JFE STEEL CORP

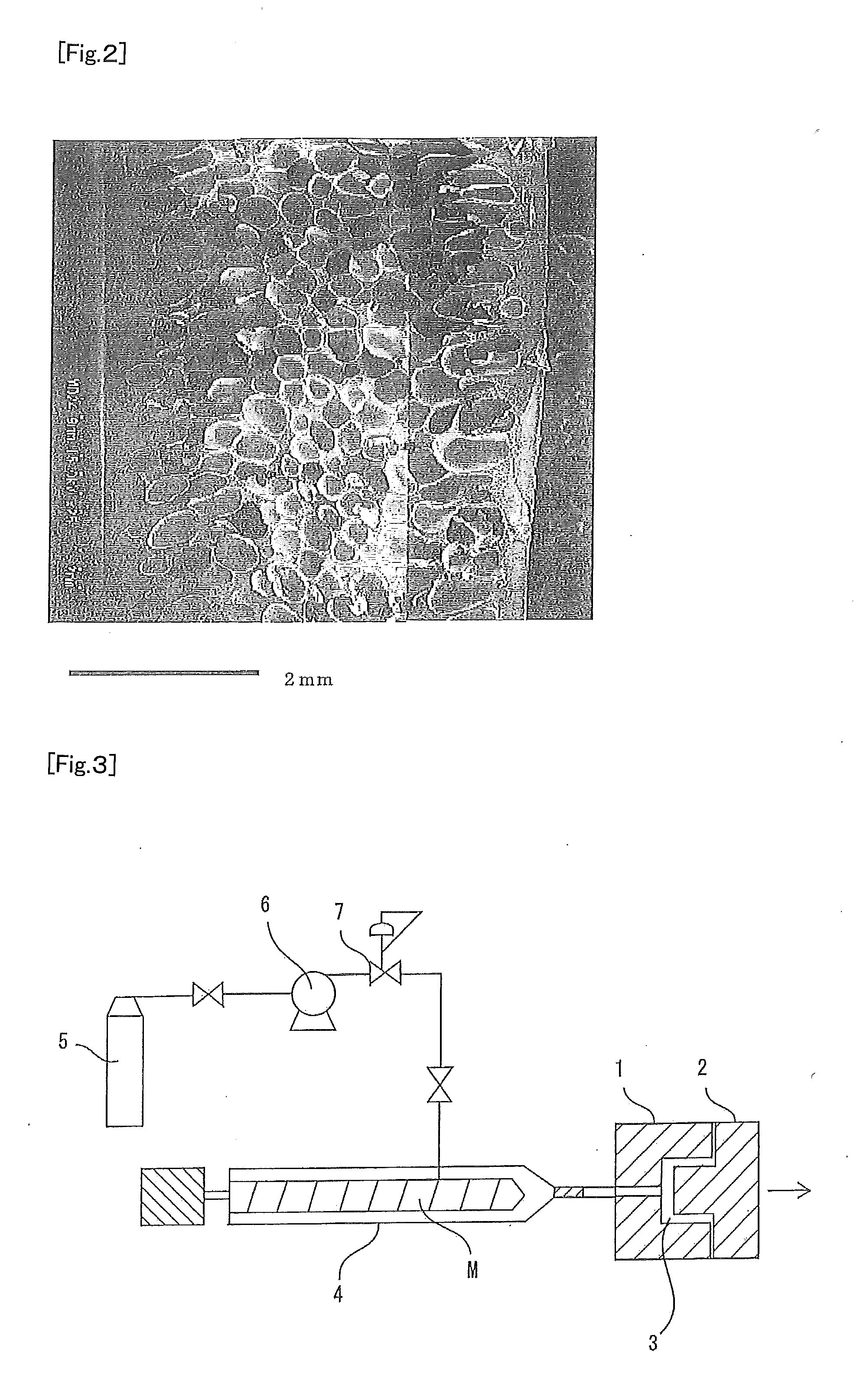

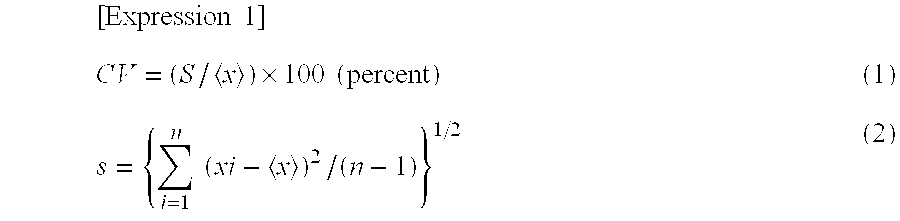

Polypropylene based resin composition, expanded moldings comprising the same and method for production thereof

ActiveUS7423071B2Good fluidityHigh in in tensionLayered productsThin material handlingPolymer scienceFoaming agent

A polypropylene-based resin composition for injection foam molding, containing (A) 50 to 95 parts by weight of a linear polypropylene-based resin having a melt flow rate of from 10 g / 10 min. to 100 g / 10 min. and a melt tension of 2 cN or less and (B) 5 to 50 parts by weight of a modified polypropylene having a melt flow rate of from 0.1 g / 10 min. to less than 10 g / 10 min. and a melt tension of 5 cN or more and exhibiting a strain hardening property (provided that a total of the resin (A) and the resin (B) is 100 parts by weight) and a foaming agent are supplied to an injection molding machine to be injected into a die, thereby achieving a foam molding. It is thus possible to obtain a injection foamed molded article which has a satisfactory injection foam moldability, a skin layer having little silver streaks or the like on its surface, and an internal core layer having a foam of high expansion ratio and uniformly fine and a excellent appearance glossiness, lightweightness, and rigidity at a low cost.

Owner:KANEKA CORP

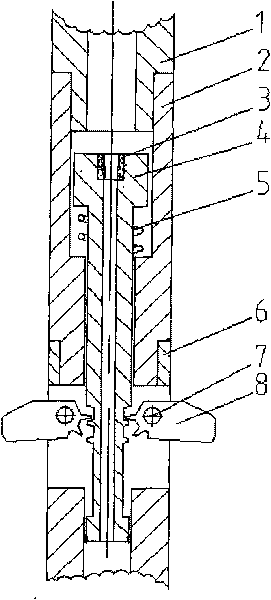

Drill-following reamer

A drill-following reamer comprises an upper joint, a reamer body, a piston nozzle, a piston, a compression spring, a blade, a pin shaft and a limit stop. The upper part of the whole set of device is connected with a drilling tool through the upper joint, while the lower part is connected with a drill bit through a screw thread. During drill-following reaming operation, the liquid piston nozzle pumped on the ground produces pressure drop to push the piston to move downwards, a groove on the piston pushes a gear structure on the blade to rotate the blade outwards by using the pin shaft as the center when the piston moves downwards till the blade is limited by the limit stop, and then the blade is expanded to reach the maximum outside diameter to start the drill-following reaming operation. 78.6 percent of drill hole expansion rate can be achieved by using the drill-following reamer, so the drill hole expansion rate is high; the blade has the mechanical locking function and is not retracted due to the extrusion of the well wall, so the diameter of the reamed drill hole is regular; and because the drilling and the reaming are carried out at the same time, the drilling cost is saved.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

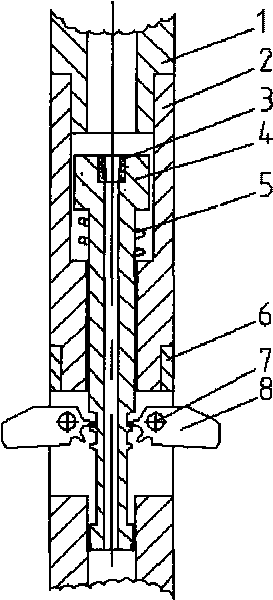

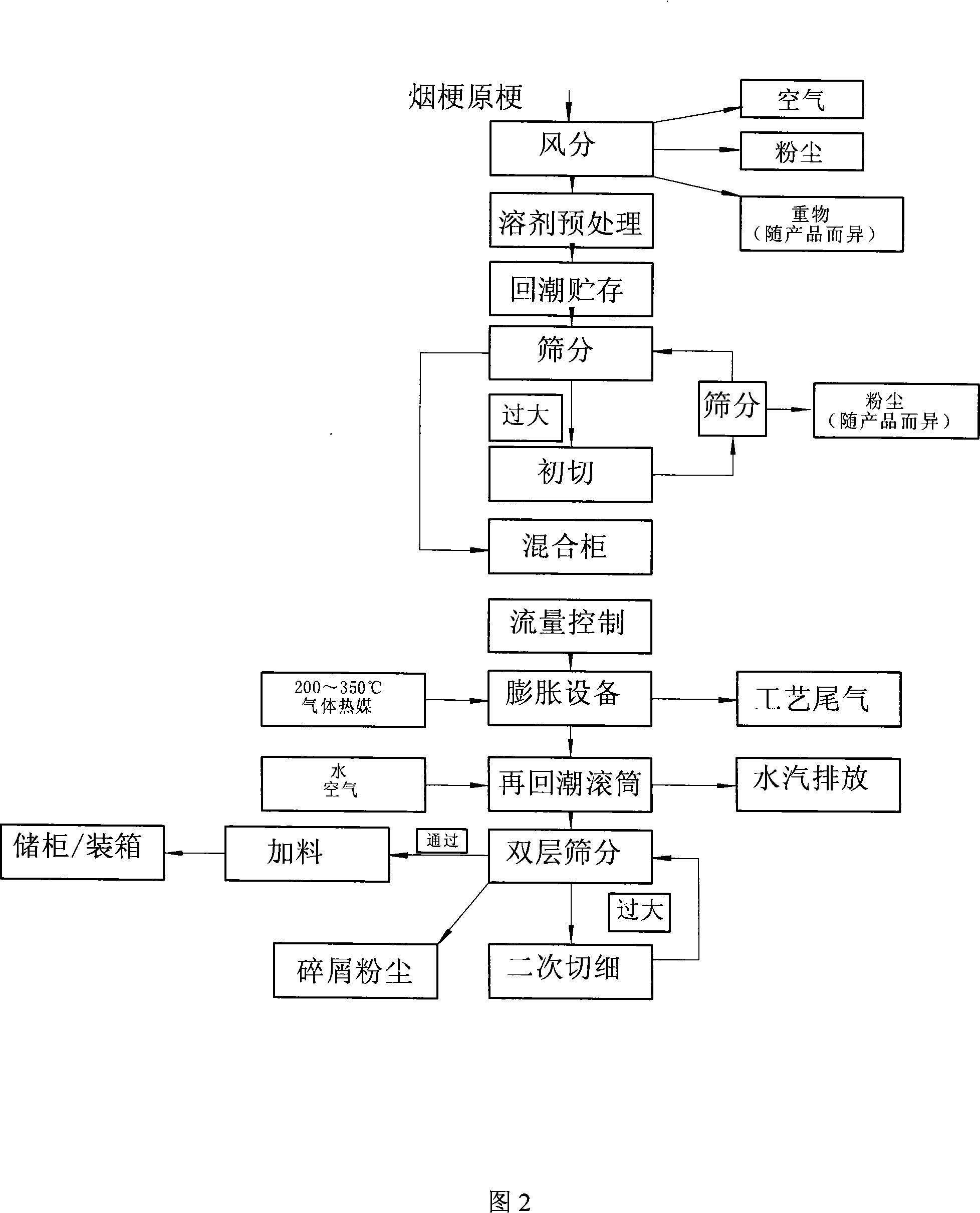

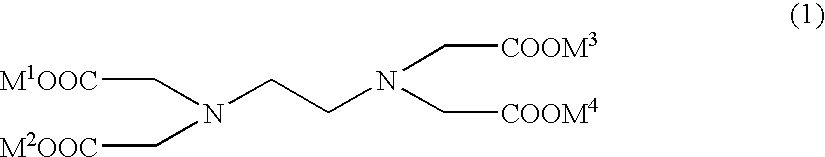

Method and equipment for pretreatment cabo

ActiveCN101214086AImprove uniformityHigh expansion rateTobacco preparationTobacco treatmentGas solidPretreatment method

The invention relates to a pretreatment method of tobacco stem which is preheated through gas heat medium and is treated with microwaves in the gas heat medium environment and equipment which adopts the method. The tobacco stem which is required to be processed is treated: preheating the raw materials to be 100-170 DEG C; heating the gas heat medium to be 150-350 DEG C; mixing the tobacco stem and the gas heat medium and implementing the gas-solid separation after the microwave field action to obtain solid expanded tobacco stem which is treated completely. Then,granular expanded tobacco stem is obtained after the moisture regaining, the screening, the fine shearing, etc. The equipment includes a gas heat medium preheating mechanism, a microwave complex expansion treatment mechanism, etc. With the process and the equipment of the invention, the breakage during the expansion process is small; the pressure used by the process is close to the normal pressure; the pressure resistance requirement for the equipment is not high; the production process is simple and easy; the most fundament lies in that through the gas heat medium with low oxygen content used for preheating the tobacco stem, the evenness and the expansion ration of the tobacco stem and the aspiration quality of the tobacco stem materials are obviously improved.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

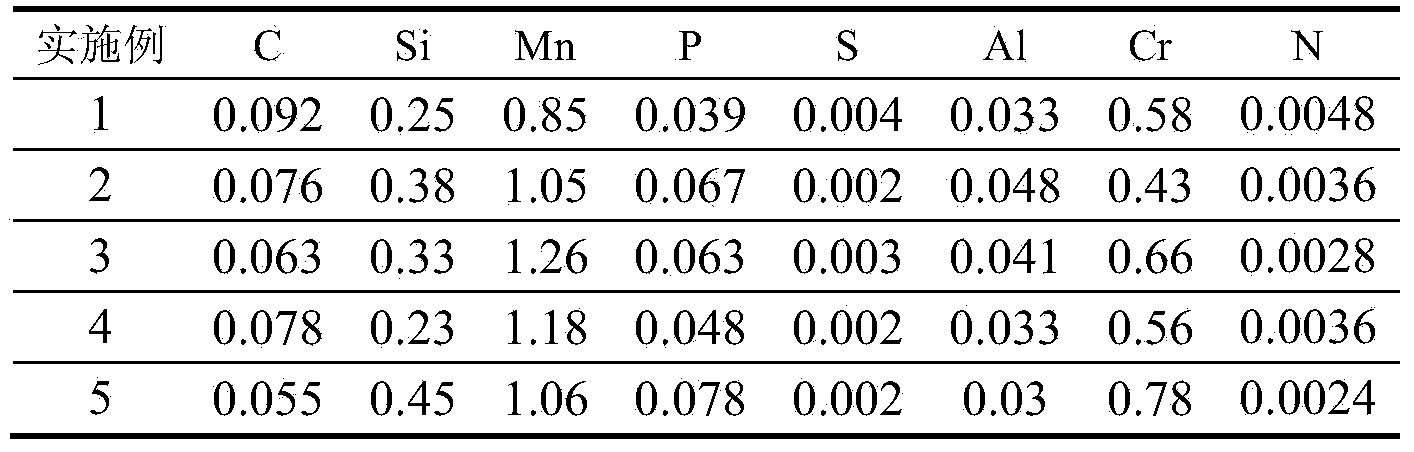

Hot rolling ferrite/bainite high strength steel plate and manufacturing method thereof

The invention relates to hot rolling ferrite / bainite high strength steel and a manufacturing method thereof. The hot rolling ferrite / bainite high strength steel comprises the following main chemical components by mass percentage: 0.05-0.10% of C, 0.20-0.50% of Si, 0.80-1.30% of Mn, 0.02-0.06% of Alt, 0.40-0.8% of Cr, less than or equal to 0.09% of P, less than or equal to 0.010% of S, less than or equal to 0.006% of N, and the balance of Fe and unavoidable impurities. The manufacturing method of the hot rolling ferrite / bainite high strength steel comprises the steps of molten iron pretreatment, converter smelting, alloy fine adjustment and argon blowing, LF (ladle furnace) refining, a continuous casting heating technology, a rolling technology, a cooling technology and a rolling technology. According to the steel and the method, C and Mn contents are strictly controlled based on the composition of C-Mn steel, an Si content is reduced, Cr and P are added appropriately, Nb, V and Ti microalloy elements are not added, noble alloys such as Mo and Ni are not added, the cost is lowered greatly, the hot rolling ferrite / bainite dual phase steel with the tensile strength reaching 550-650MPa is obtained by adopting an appropriate rolling and cooling control technology, a hole expansion rate is high, and the forming property is excellent.

Owner:JIGANG GRP

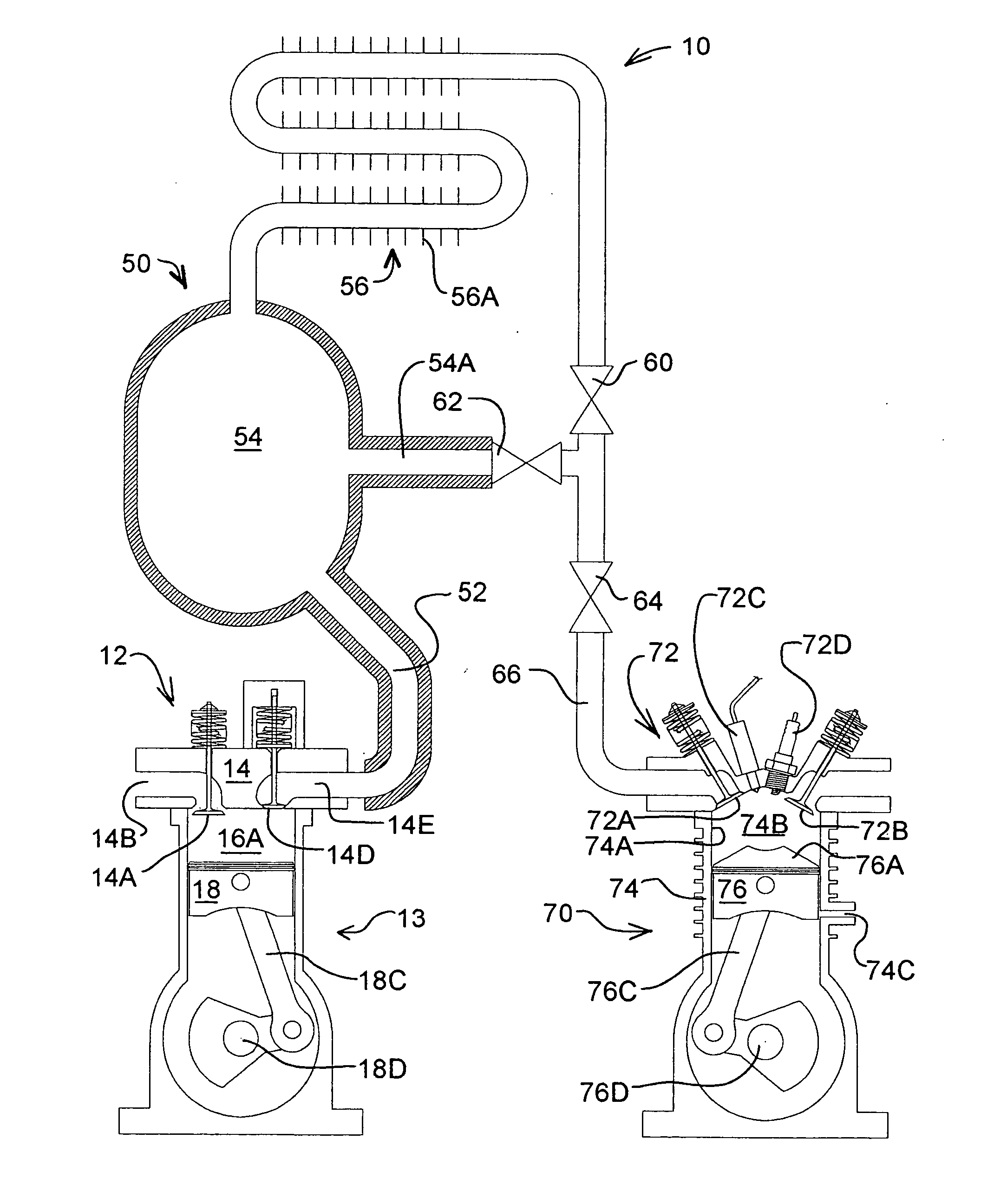

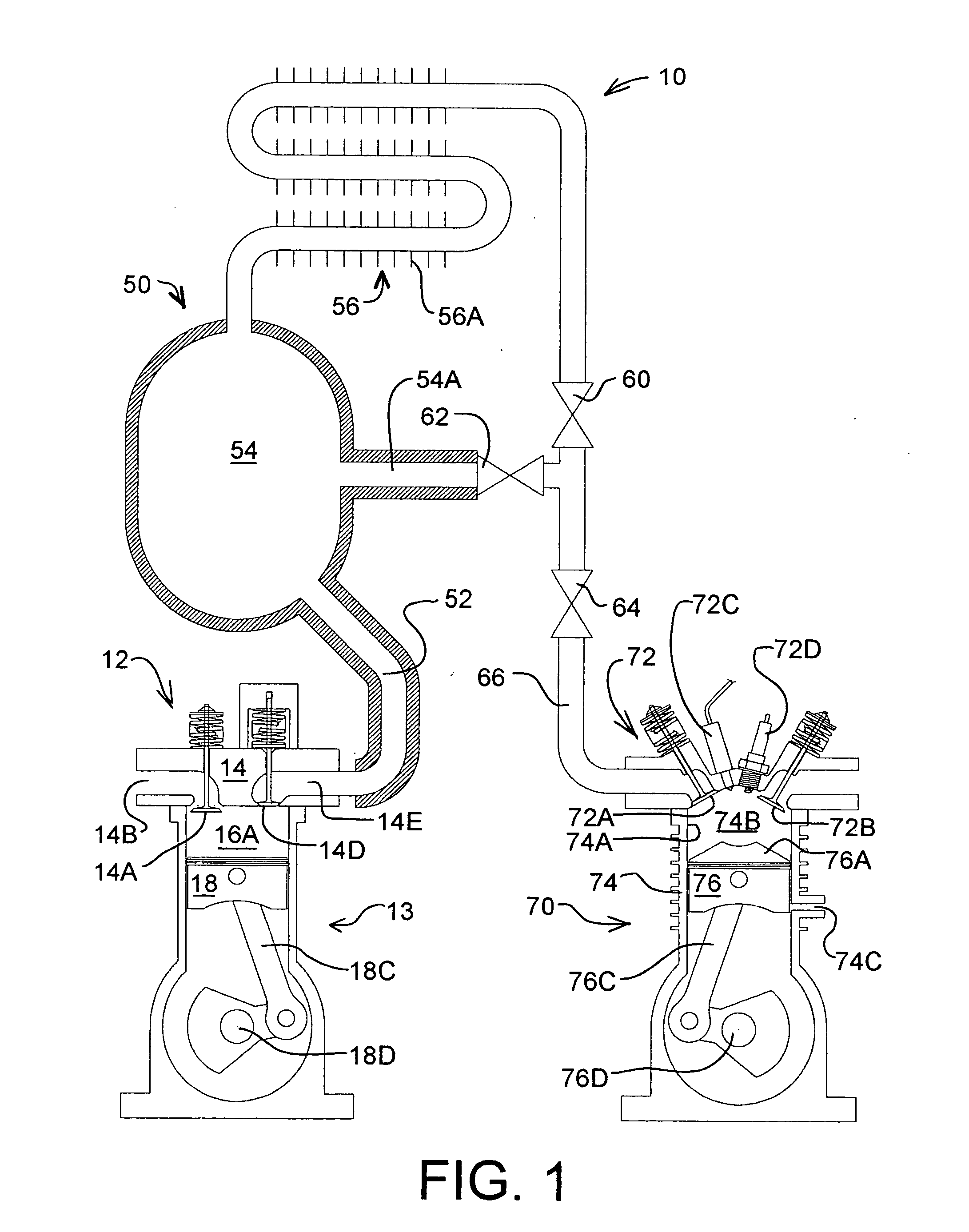

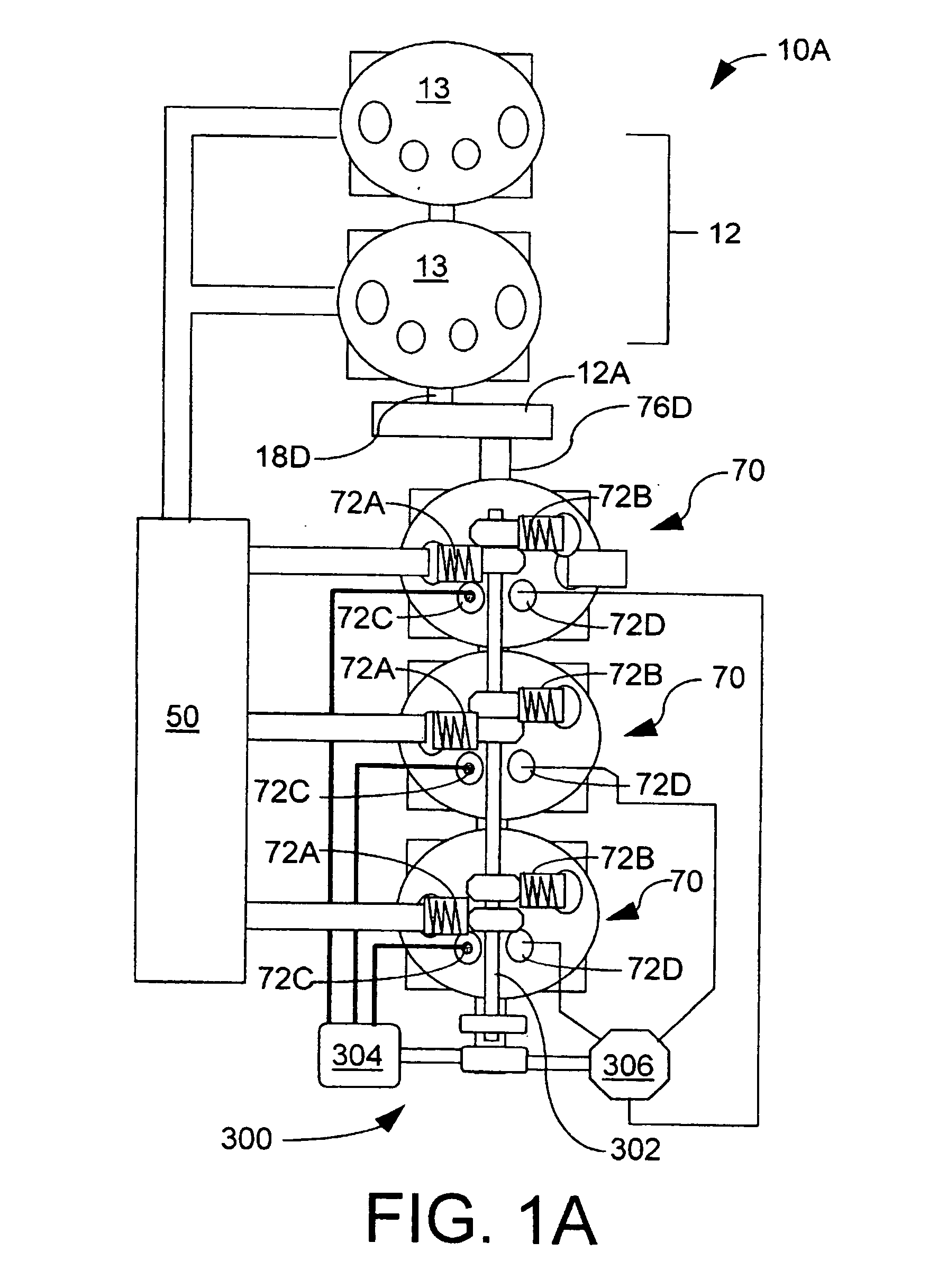

Air injection engine

InactiveUS20060124085A1Ratio of compression can be significantly higher or lowerHigh expansion rateInternal combustion piston enginesOutput powerInjection airCylinder (engine)

An internal combustion engine of the present invention features separate compression and expansion cycles. The engine includes a separate compressor device which pressurizes air by a ratio greater than 15 to 1, at least one two stroke combustion cylinder and a compressed air conduit for transferring compressed air from the compressor to the at least one combustion cylinder. An air injection valve injects the compressed air into the combustion cylinder during the second half portion of the return stroke of the combustion cylinder. The compressed air is mixed with fuel and combusted for expansion during a power stroke. In this engine compression occurs only to a minor degree in the combustion cylinder. Accordingly, the compression ratio of the present engine may be significantly higher or lower than the volumetric expansion ratio of the combustion cylinder thus resulting in corresponding increases in either power density or thermodynamic efficiency respectively.

Owner:D J ENG

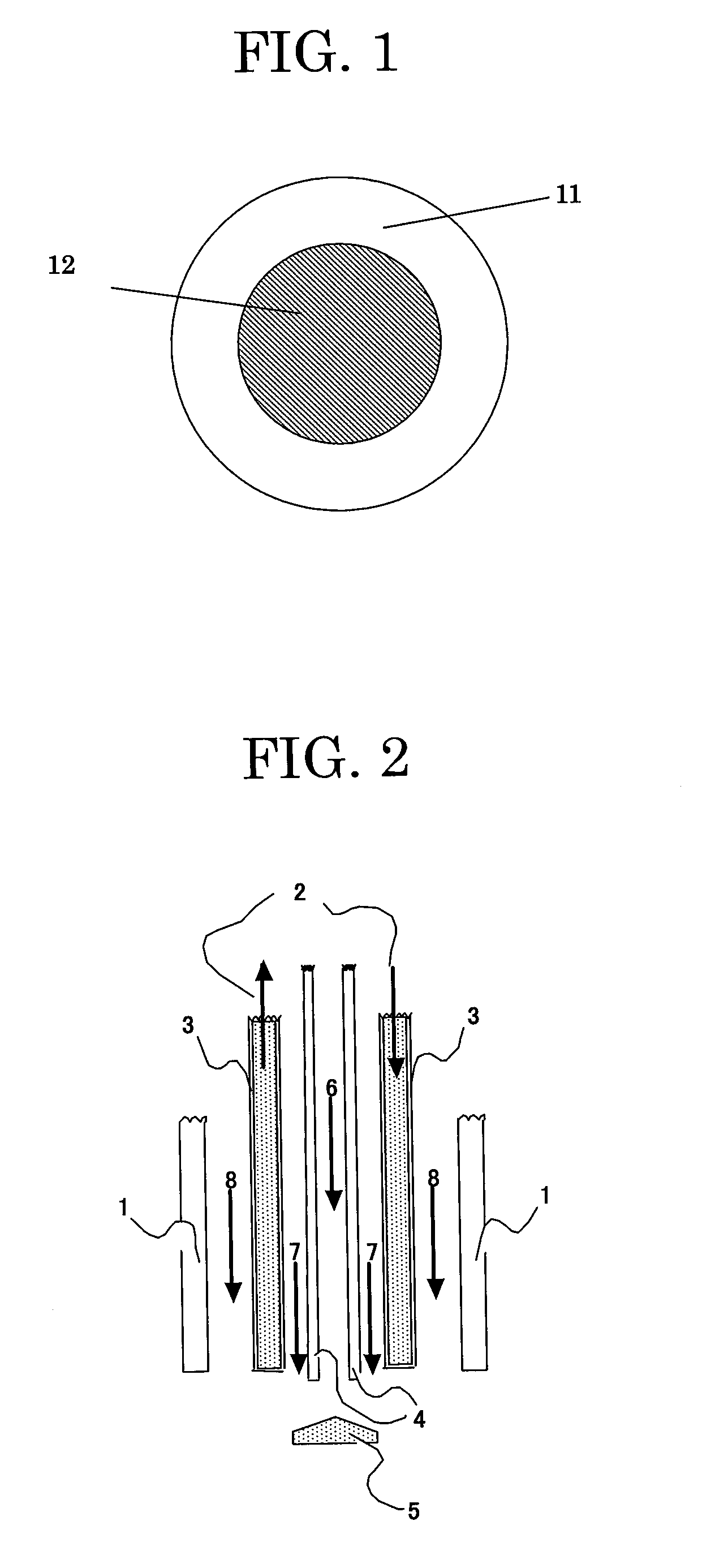

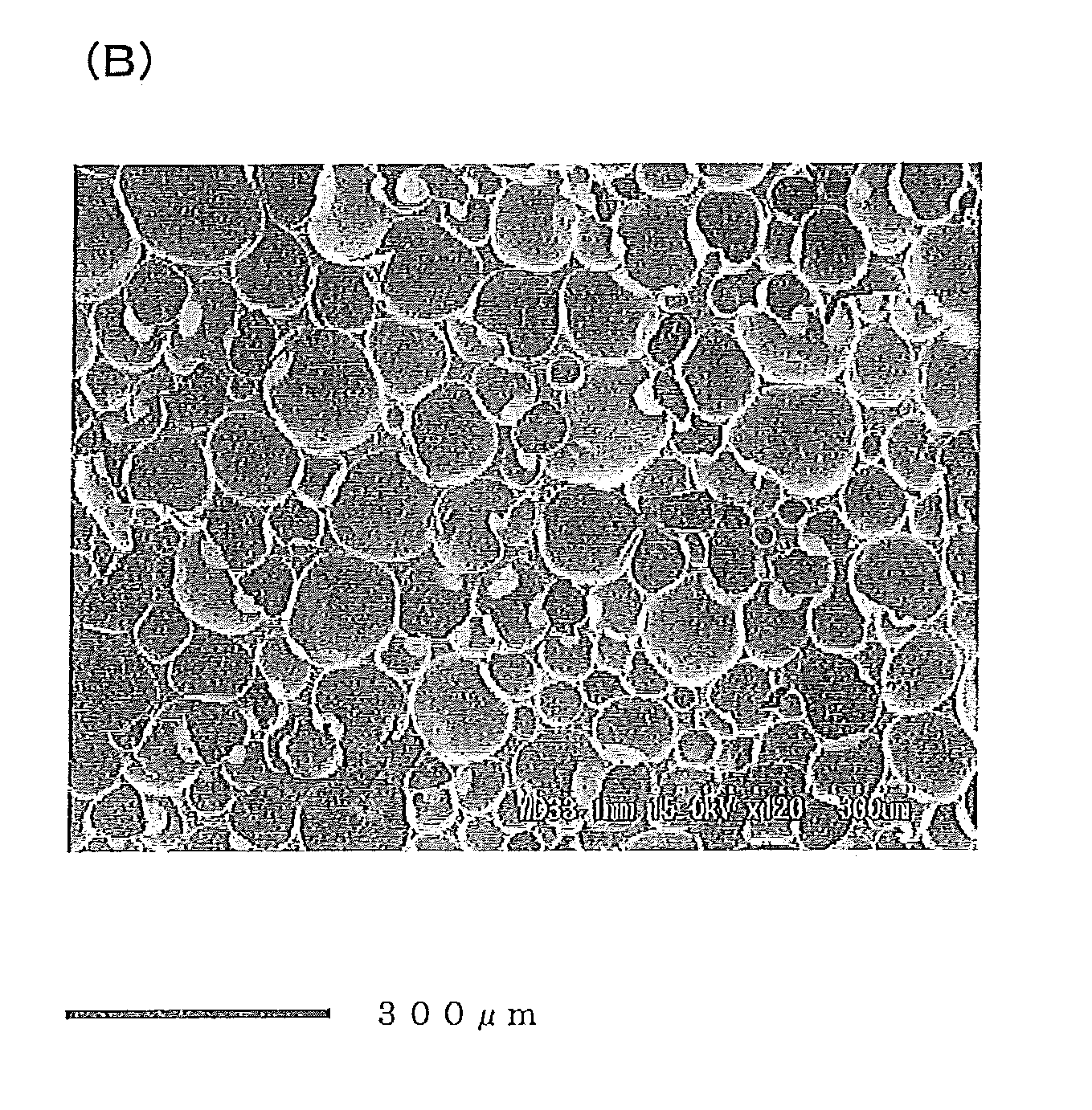

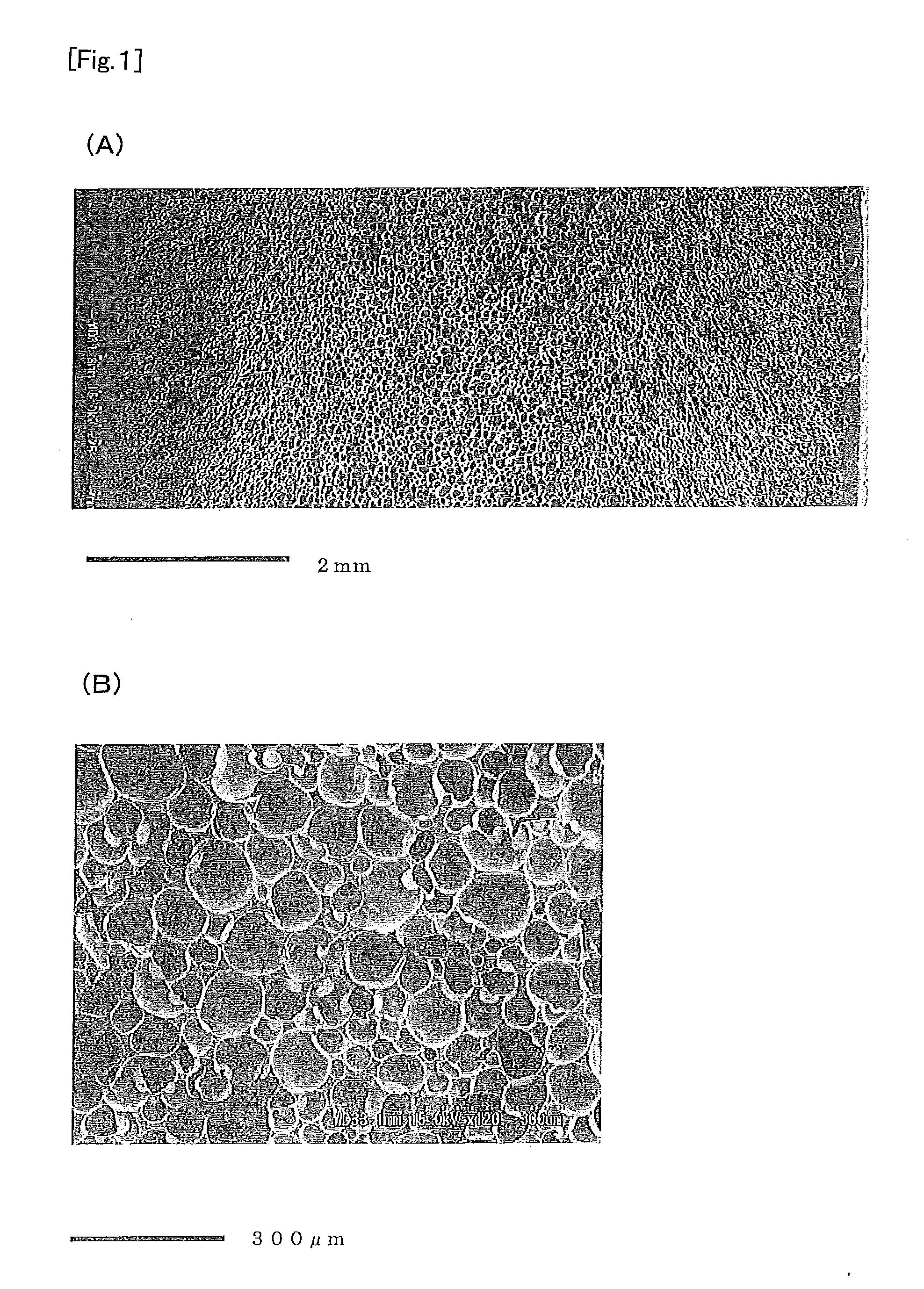

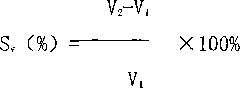

Heat-expandable microspheres, method for producing the same, and application thereof

ActiveUS20090149559A1High expansion rateIncreased durabilitySynthetic resin layered productsCellulosic plastic layered productsParticulatesFoaming agent

Heat-expandable microspheres include a shell of thermoplastic resin and a blowing agent encapsulated therein having a boiling point not higher than the softening point of the thermoplastic resin, have a maximum expanding ratio not lower than 50 times, and are thermally expanded into hollow particulates having a repeated-compression durability not lower than 75 percent. The method of producing the heat-expandable microspheres includes the steps of dispersing an oily mixture containing a polymerizable component and the blowing agent in an aqueous dispersing medium containing a specific water-soluble compound and polymerizing the polymerizable component contained in the oily mixture.

Owner:MATSUMOTO YUSHI SEIYAKU

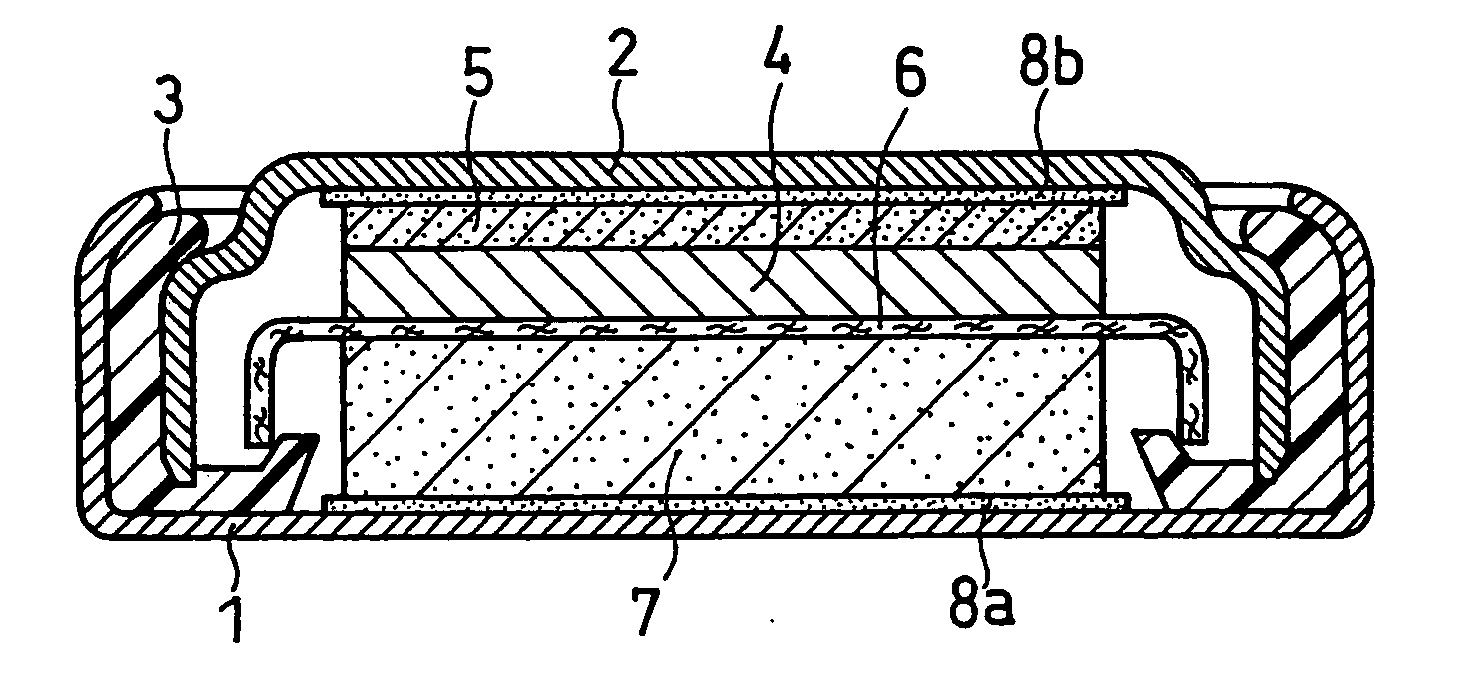

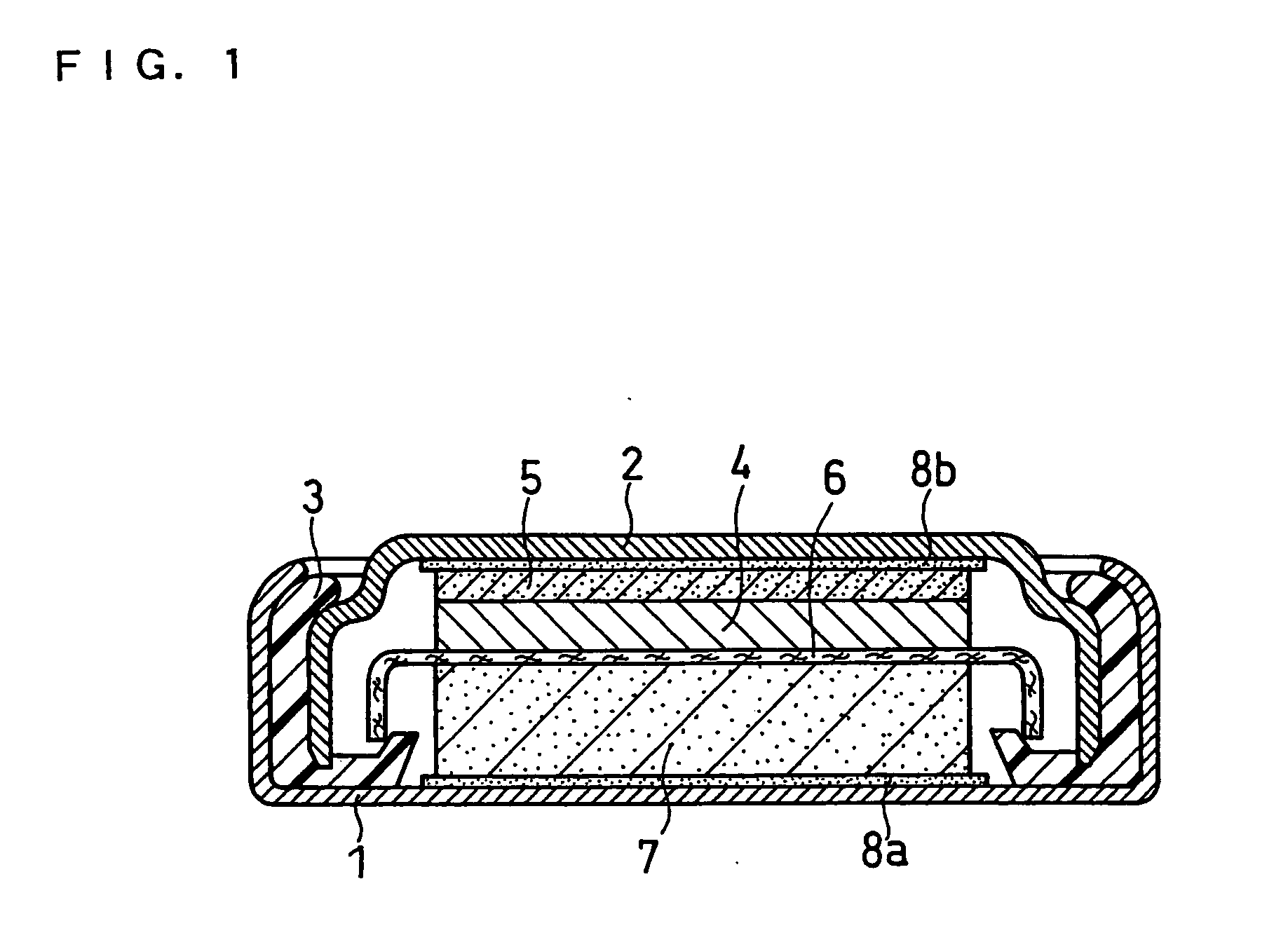

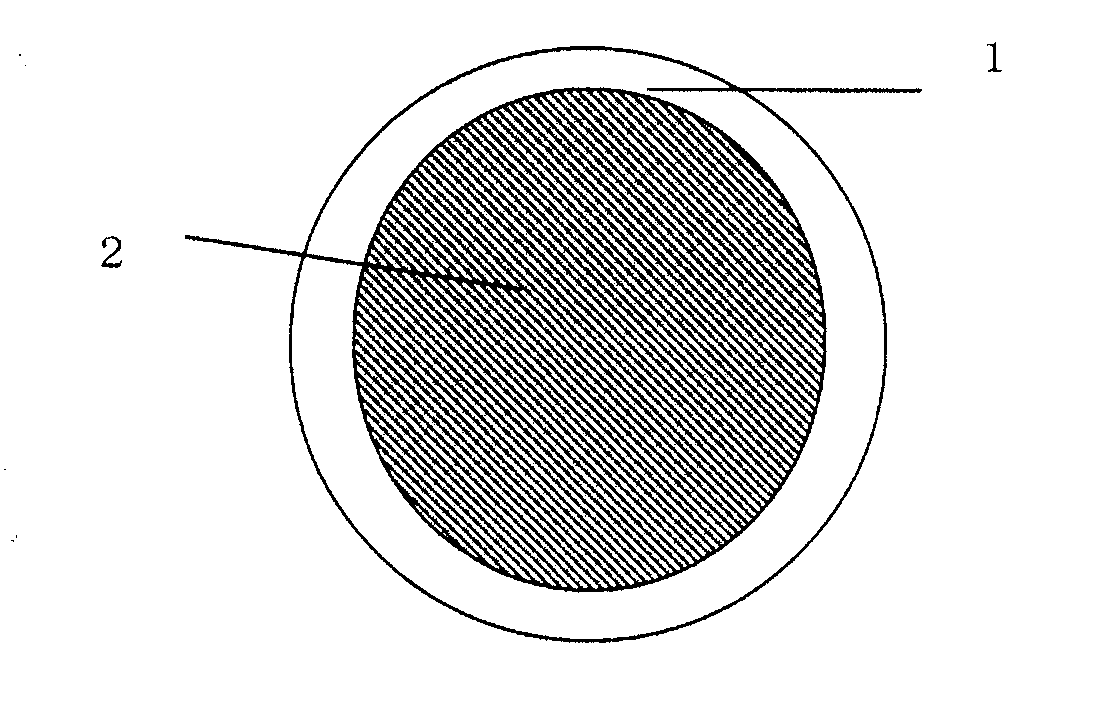

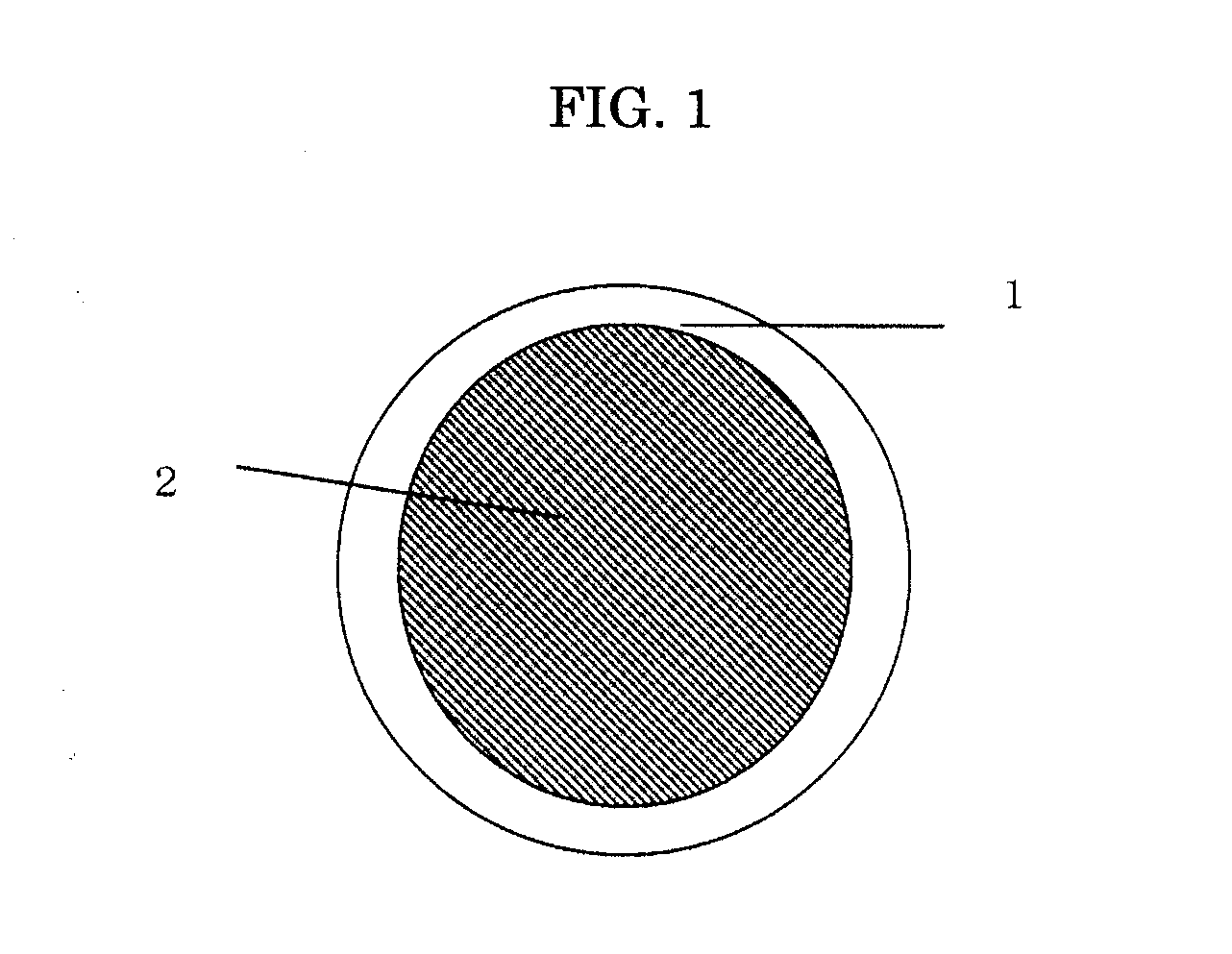

Non-aqueous electrolyte secondary battery

ActiveUS20060102473A1Large capacityImprove featuresFinal product manufactureActive material electrodesAlloyMaterials science

A non-aqueous electrolyte secondary battery that has a high electrical capacity and exhibits excellent cycle characteristics even when the battery is rapidly charged and discharged at a large current includes: a positive electrode capable of reversibly absorbing and desorbing Li; a negative electrode; and a non-aqueous electrolyte. The negative electrode includes an alloying material that is capable of electrochemically absorbing and desorbing Li, and includes an A phase composed mainly of Si and a B phase including an intermetallic compound of at least one transition metal element and Si. The transition metal element is selected from the group consisting of Ti, Zr, Ni, Cu, and Fe. At least one of the A phase and the B phase includes a microcrystalline or amorphous region. The weight percent of the A phase relative to the total weight of the A phase and the B phase is greater than 40% and not greater than 95%.

Owner:PANASONIC CORP

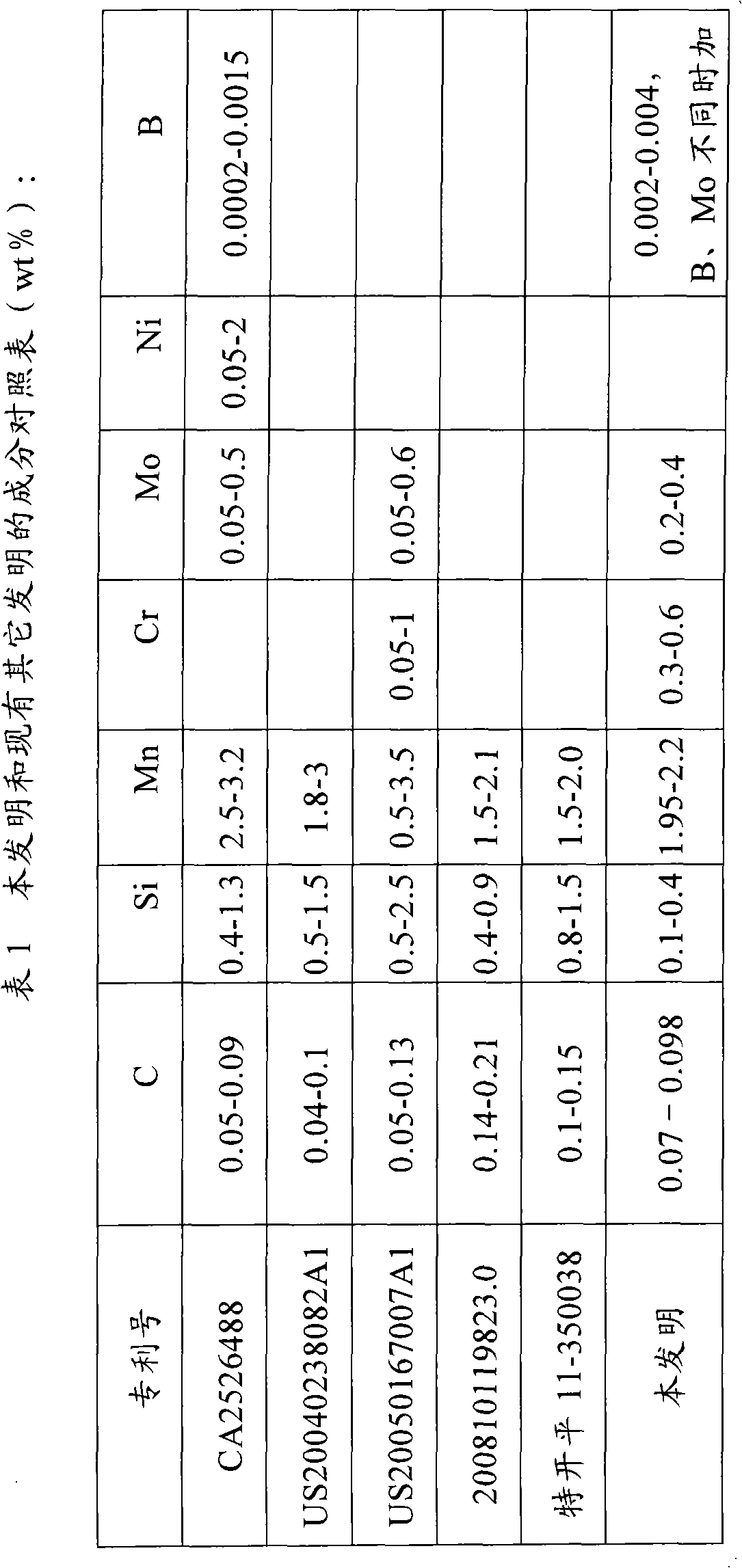

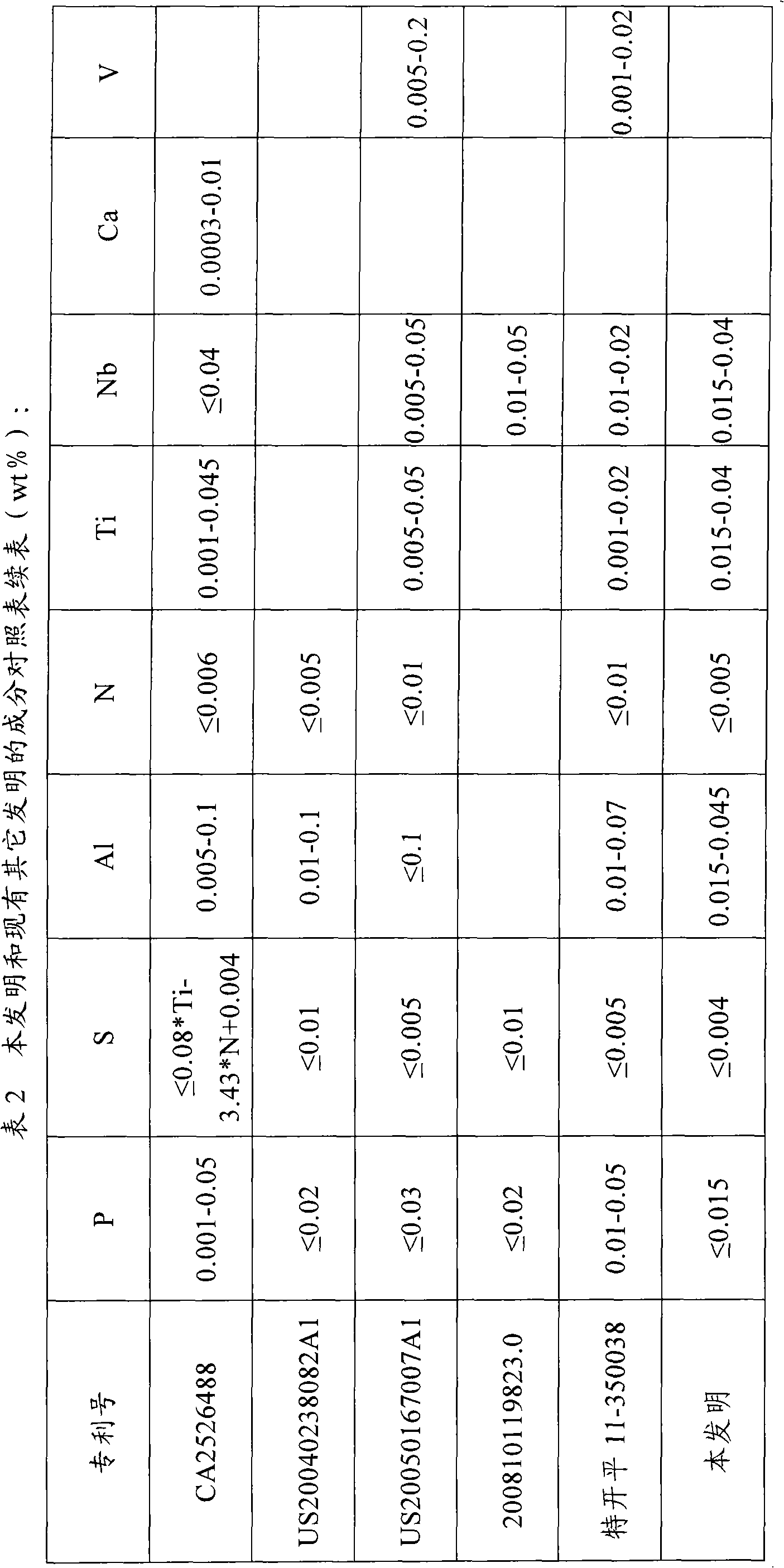

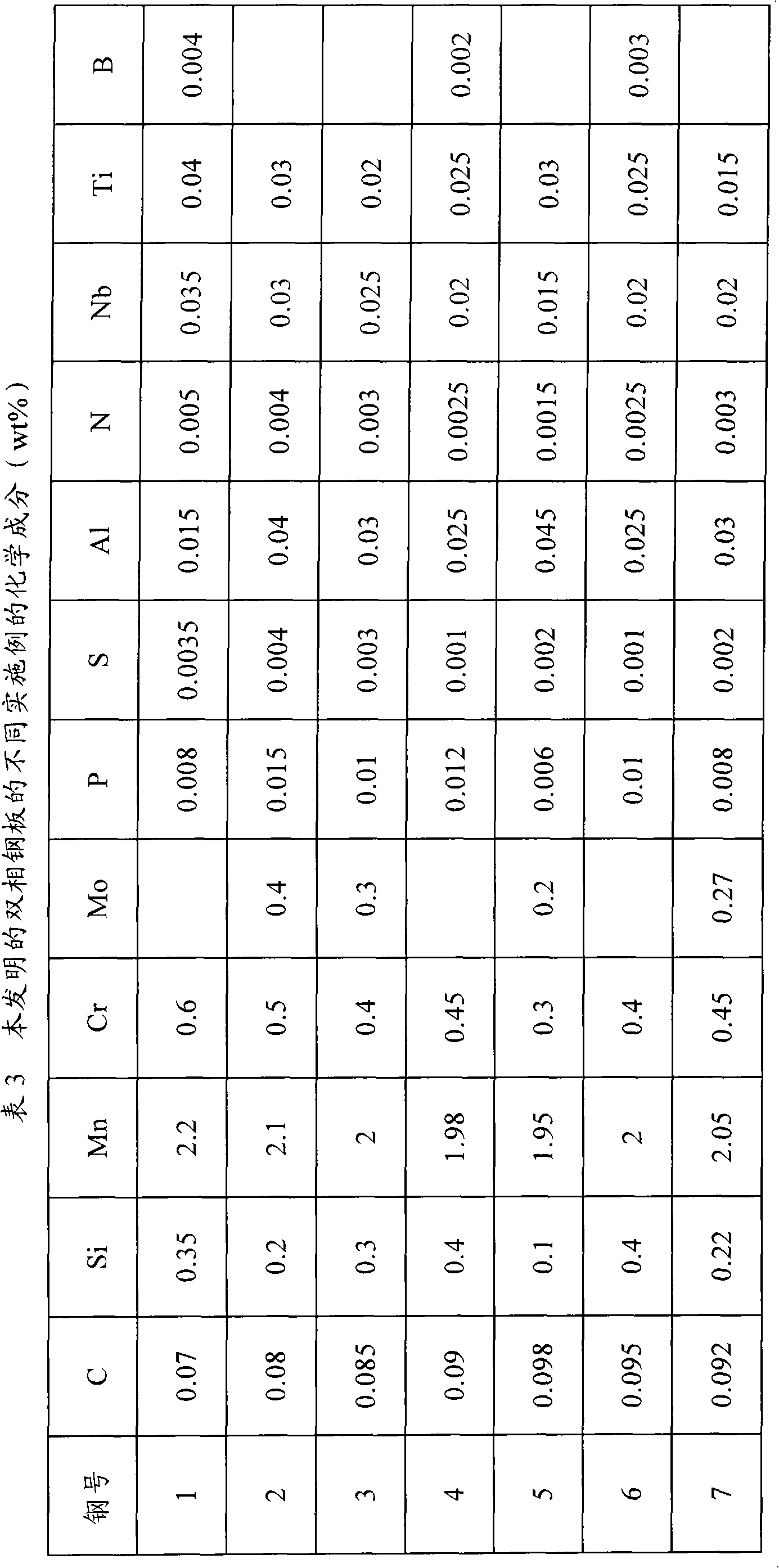

Double-phase steel plate and manufacturing method thereof

ActiveCN102586688AReduce the degree of enrichmentReduce defects such as red rustManufacturing technologyDouble phase

The invention provides a double-phase steel plate which comprises 0.07-0.098 of C, 0.1-0.4 of Si, 1.95-2.2 of Mn, 0.3-0.6 of Cr, less than or equal to 0.015 of P, less than or equal to 0.004 of S, less than or equal to 0.005 of N, 0.015-0.04 of Nb, 0.015-0.04 of Ti, 0.015-0.045 of Al, and 0.002-0.004 of B or 0.2-0.4 or Mo, wherein Pcm equals to C+Si / 30+Mn / 20+2P+4S which is less than or equals to 0.24; and the double-phase steel plate also comprises the balance of Fe and unavoidable impurities. The invention also provides a manufacturing method of the double-phase steel plate. The high-strength uniform-performance double-phase steel plate can be obtained by the proper composition design and manufacturing technology, and the manufacturing requirements on parts of a high-strength automobile body can be better met.

Owner:BAOSHAN IRON & STEEL CO LTD

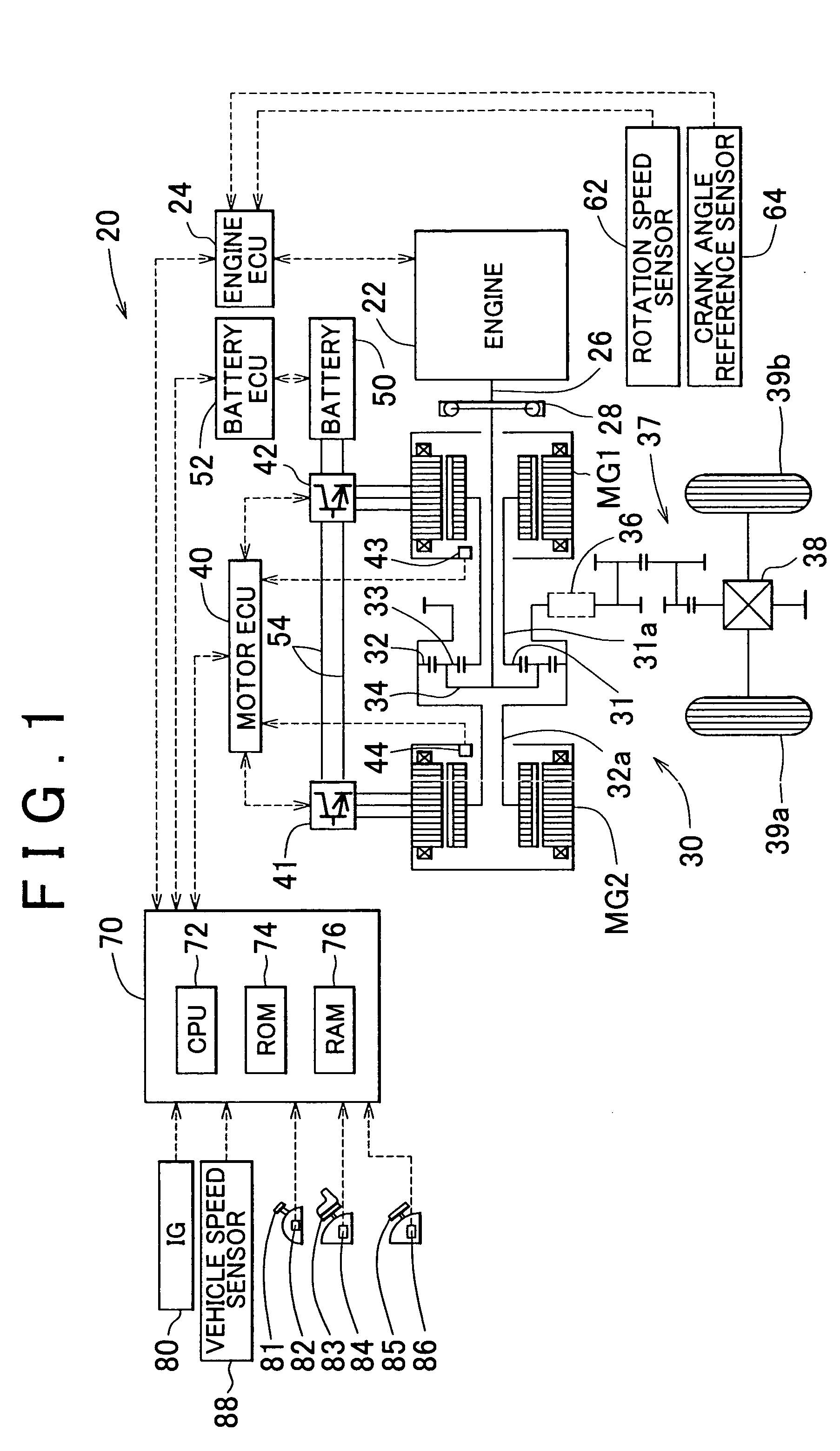

Drive apparatus, control method thereof, and motor vehicle equipped with the apparatus and the method

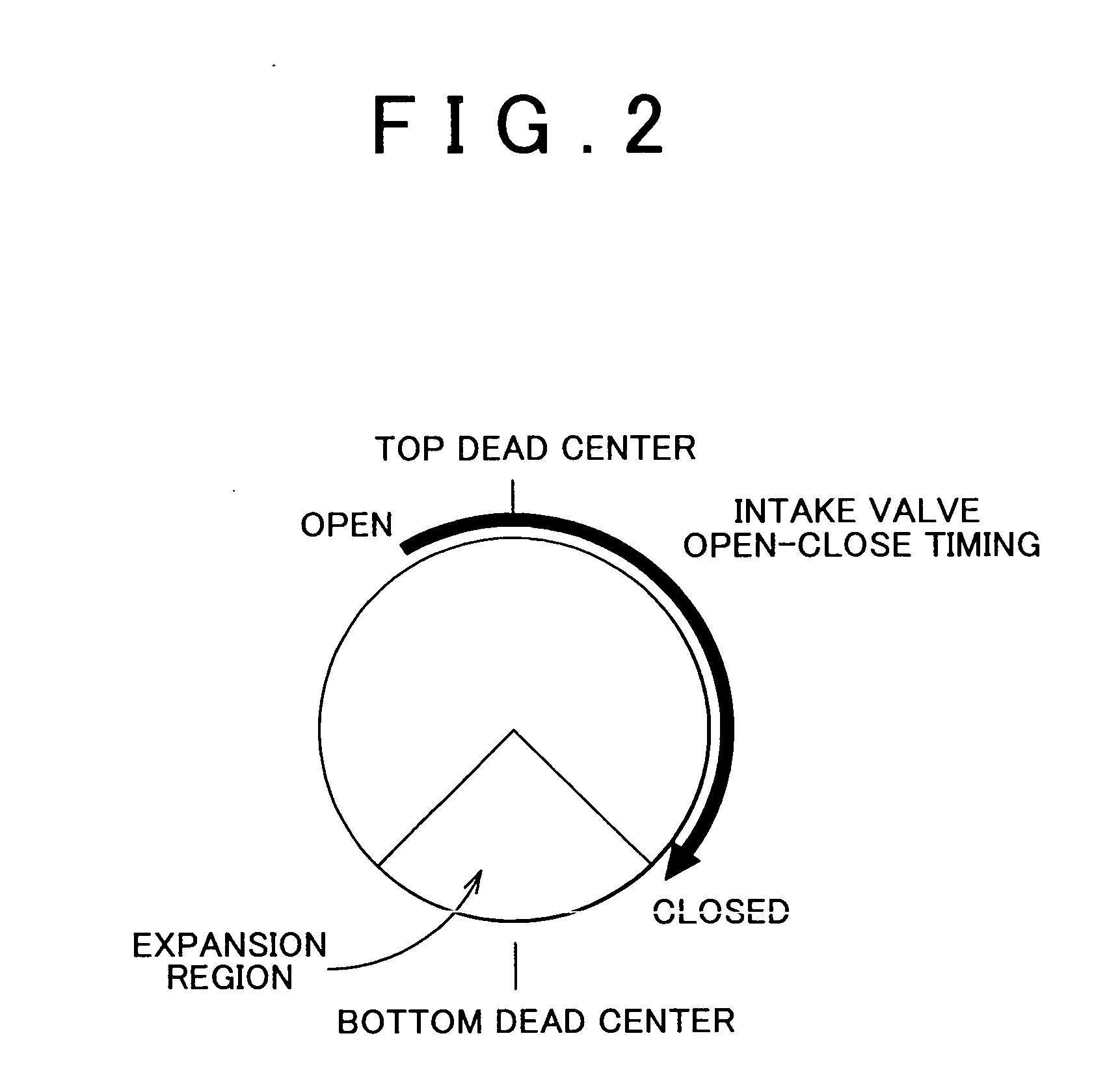

ActiveUS20050066933A1High expansion rateEffective compression ratioHybrid vehiclesValve arrangementsOutput deviceControl theory

Provided herein are a drive apparatus that includes an internal combustion engine capable of operating with a high expansion ratio by reducing an effective compression ratio through advancement of an intake valve closing timing, and a control method of the drive apparatus, and a motor vehicle equipped with the apparatus and method. The drive apparatus further includes a torque output device capable of outputting a torque to an output shaft of the internal combustion engine. Upon a command to stop operation of the internal combustion engine, the apparatus controls the driving of the torque output device so that the internal combustion engine stops at a target stop position which is set outside a region that leads to an increased compression ration in an initial compression stroke when the internal combustion engine is next stated.

Owner:TOYOTA JIDOSHA KK

Polyamide resin composition, expanded polyamide resin molding, and automotive resin molding

Provided is a polyamide resin composition which can provide an expanded molding being superior in heat resistance and sufficiently reduced in weight and having high load resistance by a simple molding process. The polyamide resin composition is characterized by comprising a polyamide resin (A), a glycidyl-group-containing styrene copolymer (B) having two or more glycidyl groups per molecule, a weight average molecular weight of 4000 to 25000 and an epoxy value of 400 to 2500 Eq / 1×106 g and an inorganic reinforcing material (C) in a proportion such that the content of the glycidyl-group-containing styrene copolymer (B) is 0.2 to 25 parts by mass and the content of the inorganic reinforcing material (C) is 0 to 350 parts by mass relative to 100 parts by mass of the polyamide resin (A).

Owner:TOYO TOYOBO CO LTD

Crosslinked olefin elastomer foam and elastomer composition therefor

A crosslinked olefin elastomer foam has a specific gravity of 0.05 to 0.2, an expansion ratio of 8 to 15, a compression set of 30 to 60% and a tear strength of 1.5 to 2.5 kg / cm. The crosslinked foam is obtained by heating an elastomer composition comprising a specific ethylene / alpha-olefin copolymer, an organic peroxide, a crosslinking auxiliary and a foaming agent. The crosslinked foam has a high expansion ratio, is free from surface roughening attributed to defoaming, realizes a soft touch, exhibits a low compression set and is excellent in mechanical strength (particularly tear strength) and heat resistance.

Owner:MITSUI CHEM INC

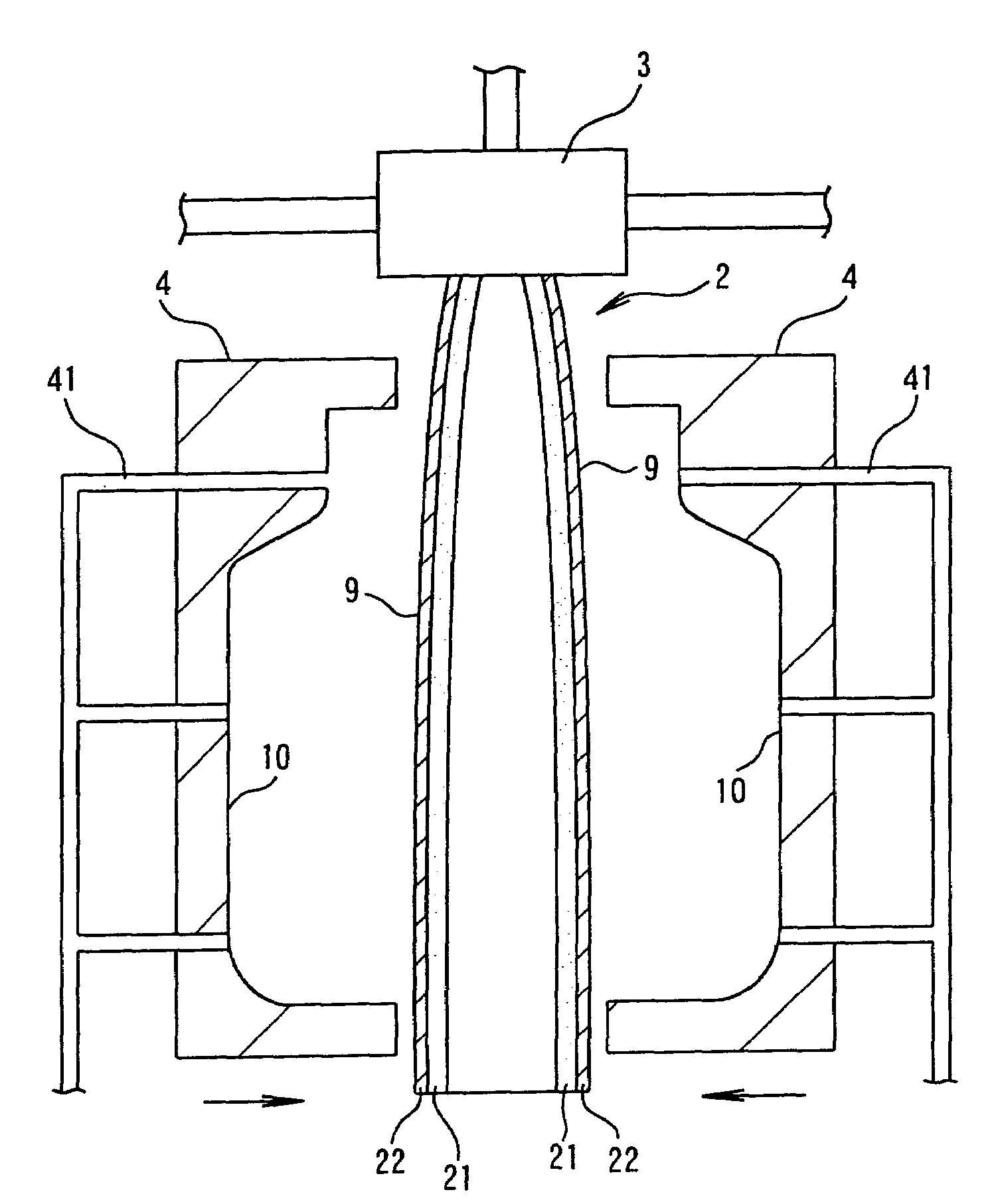

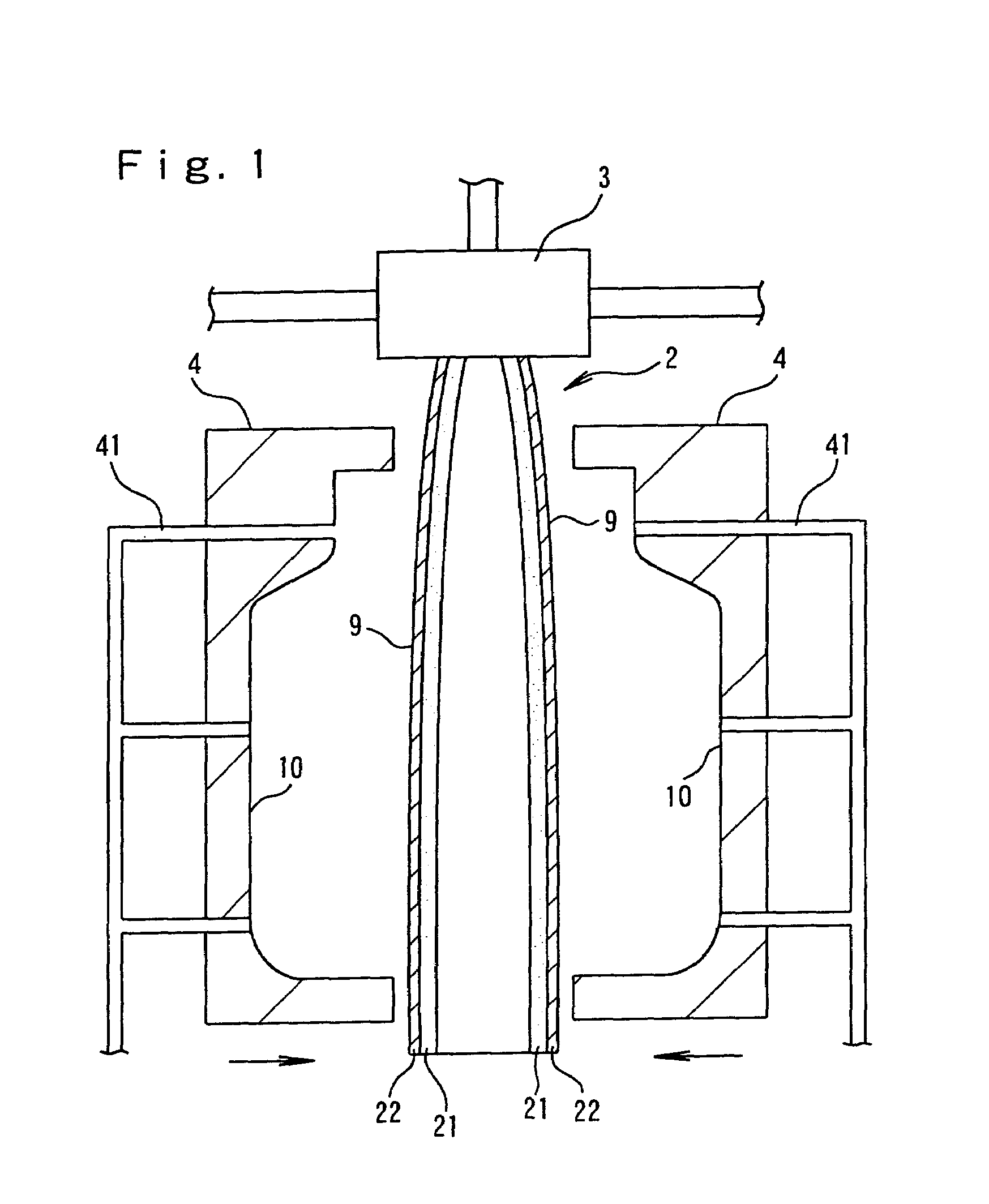

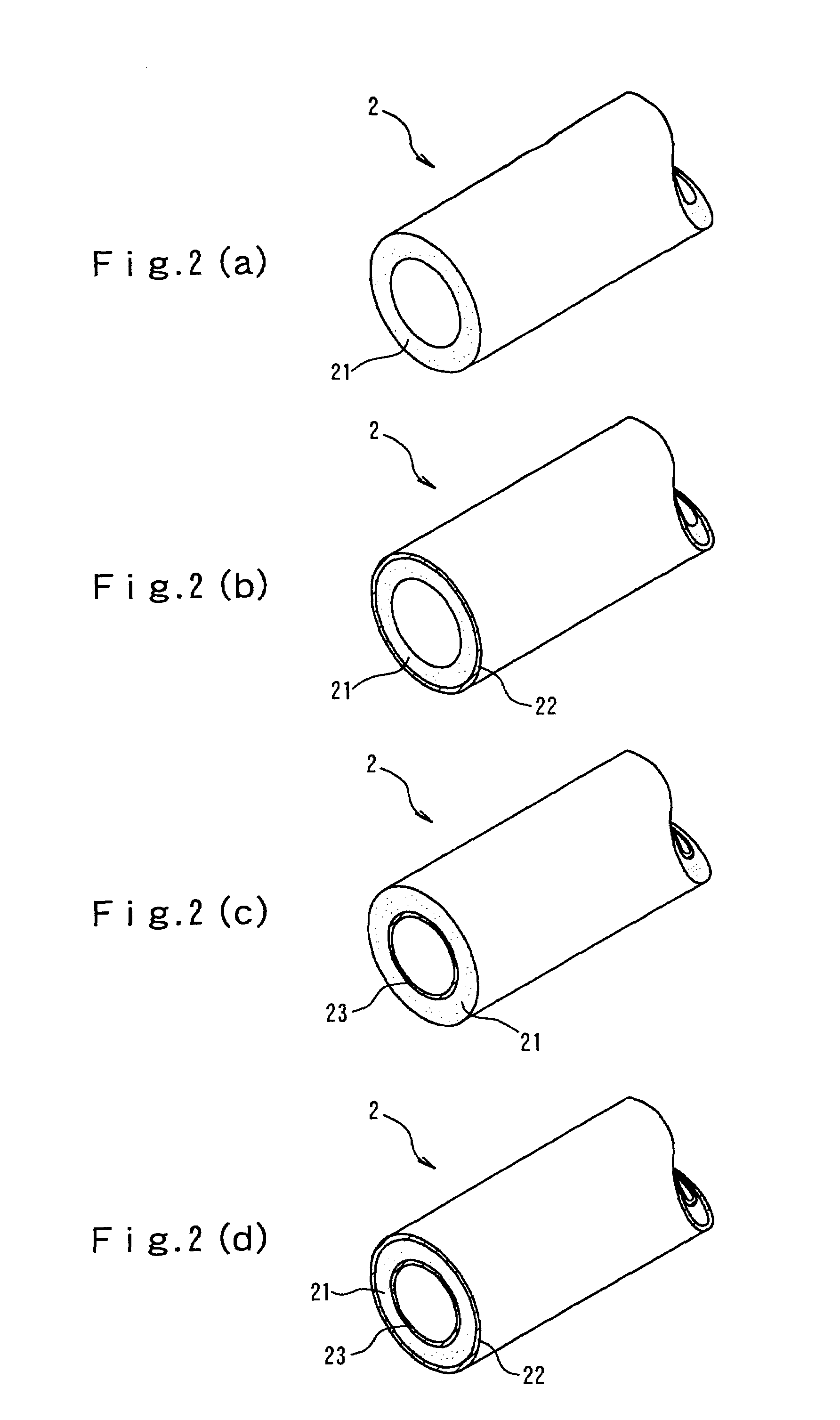

Polypropylene resin hollow molded foam article and a process for the production thereof

ActiveUS7014801B2Low production costHigh expansion rateDomestic articlesFlat articlesApparent densityPolymer science

The present invention relates to a hollow molded foam article in which a plurality of polypropylene resins are used as the base resin, and to a process for the production of this hollow molded foam article. More particularly, the present invention relates to a polypropylene resin hollow molded foam article having a foam layer, in which the base resin comprises (a) a polypropylene resin with a melt tension of at least 98 mN and a melt flow rate of 0.5 to 15 g / 10 minutes, (b) a polypropylene resin with a melt tension of less than 30 mN (excluding O) and a melt flow rate of 2 to 30 g / 10 minutes, and (c) a polypropylene resin with a melt tension of at least 30 mN and less than 98 mN and a melt flow rate of 2 to 15 g / 10 minutes, formed by positioning in a mold a softened cylindrical foam having a foam layer obtained by extruding from the die of an extruder a foamable molten resin composition containing a foaming agent, wherein the melt tension at 230° C. of the polypropylene resin that forms the foam layer is at least 10 mN and less than 49 mN, and the apparent density of the foam layer is no more than 0.3 g / cm3.

Owner:JSP CORP

Lead-free solder solder paste for electronic industry and method for manufacturing soldering fluid

InactiveCN101244491AHigh expansion rateImprove wettabilityWelding/cutting media/materialsSoldering mediaSolventSolder paste

The invention relates to a welding material, in particular to a preparation method of electronic industry-used lead-free solder paste and flux; wherein, the welding material comprises 85 to 90% lead-free solder powder and 10 to 15% flux; the lead-free solder powder is a 25 to 45 micrometer lead-free solder made by tin, copper, silver and titanium; the flux comprises a high viscosity rosin, an organic acid activator, a thixotropic agent, a wetting agent and a solvent. The welding material has the advantages of green environmental protection of lead-free solder, resolving the drawbacks of lead-free solder of high melting point and low fluidity, high expansion rate, no- halogen, low post-weld residue and corrosive property, high insulation resistance, and good protection performance.

Owner:TIANJIN QINGHE TECH DEV

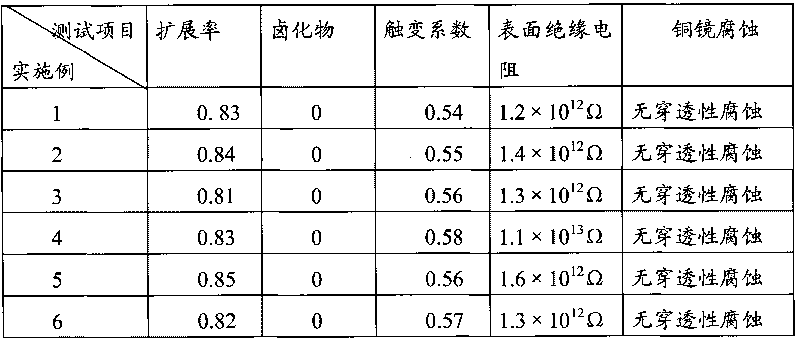

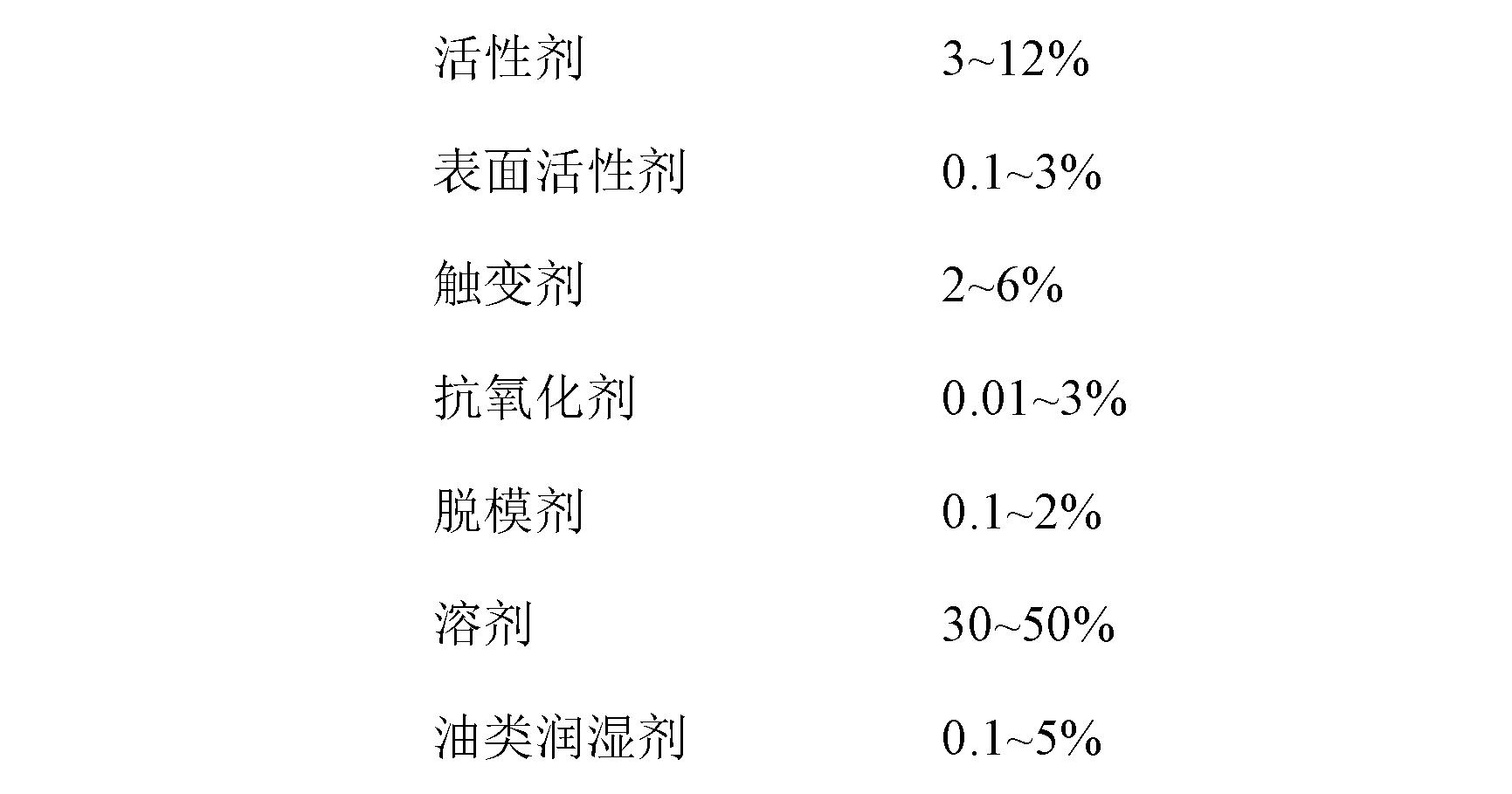

Halogen-free scaling powder used for lead-free solder paste and preparation method thereof

ActiveCN103008921AHigh surface insulation resistanceNo penetrating corrosionWelding/cutting media/materialsSoldering mediaAntioxidantActive agent

The invention relates to a halogen-free scaling powder used for a lead-free solder paste and a preparation method thereof. The halogen-free scaling powder used for the lead-free solder paste is characterized by being composed of the following components by weight percent: 25-55% of modified rosin, 3-12% of active agent, 0.1-3% of surface active agent, 2-6% of thixotropic agent, 0.01-3% of antioxidant, 0.1-2% of release agent, 30-50% of solvent and 0.1-5% of oil wetting agent, wherein the scaling powder does not contain halogen; the activity of the scaling powder can be obviously improved through adding organic carboxylic acid and hydroxy carboxylic acid as the active agent, and combining the active agent with the surface active agent; and in addition, the oil wetting agent is used, so that a layer of thin continuous oil membrane is enabled to cover the surface of a welding spot in a whole reflow soldering technological process of the solder paste, thereby playing an oxygen insulating function, and greatly improving the expansibility and the wetting property. The solder paste prepared by the scaling powder provided by the invention and a tin-silver-copper lead-free solder has the advantages of being good in printing performance, clean in demoulding, good in solderability and strong in wettability, having no penetrability corrosion in a bronze mirror after soldering, being high in soldering spot reliability and excellent in mechanical property, and capability of satisfying the high reliability requirements of high-end electronic products.

Owner:广东中实金属有限公司 +1

Preparation method of high-diffusivity water-absorbent resin

The invention discloses a preparation method of a high-diffusivity water-absorbent resin. The preparation method comprises the following steps: adding acrylic acid, a 50% sodium hydroxide solution, a compound cross-linker, sodium bicarbonate, ethanol, silicon dioxide and deionized water to a reactor, mixing evenly, and then introducing nitrogen for 20 min to remove oxygen; next, adding an initiator at a temperature within the range of 5-10 DEG C to initiate a polymerization reaction, terminating the reaction when the temperature stops rising, and preserving heat for 2 hours at a temperature above 80 DEG C, thereby obtaining polymeric colloid; pelleting the colloid to obtain resin particles and drying at 180 DEG C until the moisture content is lower than 3%; and finally, evenly spraying a surface treating fluid to the particles for surface treatment, and preserving heat at 180 DEG C for 40 minutes, thereby obtaining the product. According to the preparation method of the high-diffusivity water-absorbent resin, the resin particles are of a loose porous structure, numerous pore passages are formed inside the resin particles and the contact area is greatly increased, and therefore, the high-diffusivity water-absorbent resin has an instantaneous absorption effect; and the pore passages are in contact and connected in series with each other, and due to the capillary action, moisture can be transferred among the particles smoothly.

Owner:诺宸股份有限公司

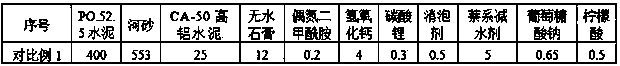

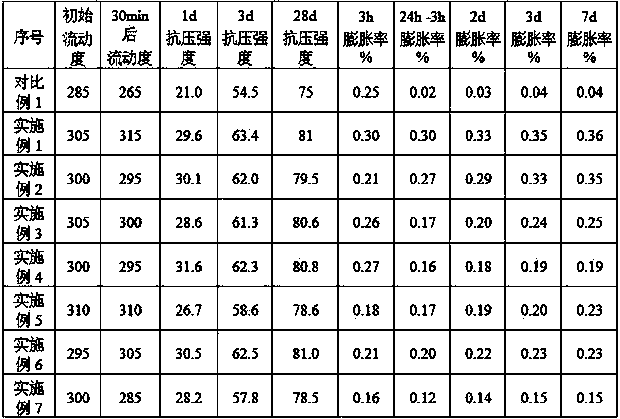

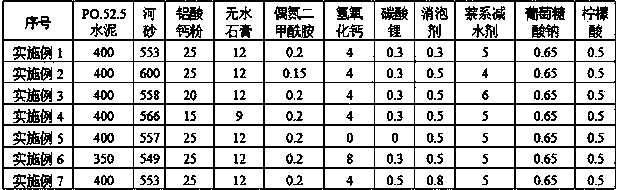

Cement-based no-shrinkage grouting material

The invention discloses a cement-based no-shrinkage grouting material which is prepared by carrying out dry mixing on the following raw materials in parts by weight: 350-400 parts of cement, 550-600 parts of sand, 4-6 parts of water reducing agent, 20-40 parts of rigid expanding agent, 0.1-0.25 part of plastic expanding agent, 0.3-0.8 part of defoaming agent, 0.8-1.6 parts of retarder and 0-8 parts of property regulator. The grouting material disclosed by the invention has the advantages of low consumption of expanded components, high plastic expansion ratio, high rigid expansion ratio, short stabilization time, low dependence on wet curing, excellent flowability and excellent strength property, and can be used for large-scale equipment installation, bolt anchorage and structure reinforcement.

Owner:SUZHOU UNIV OF SCI & TECH +1

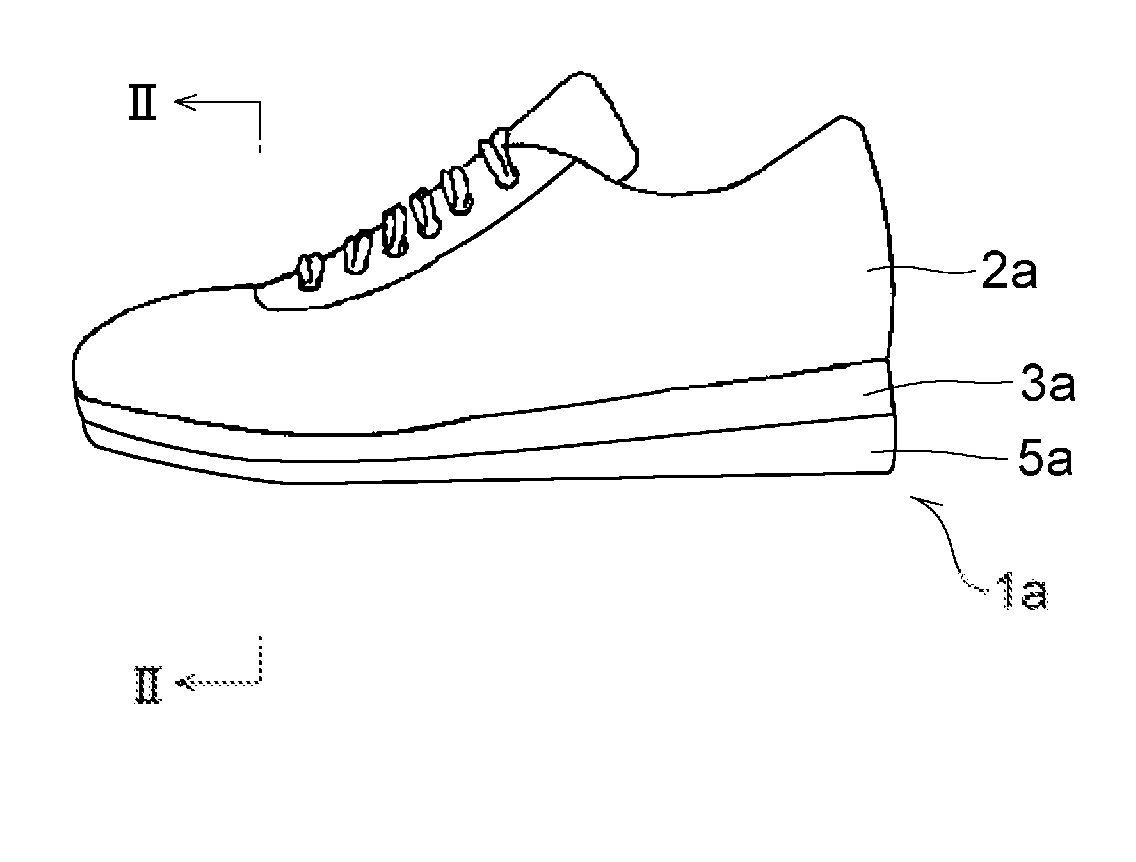

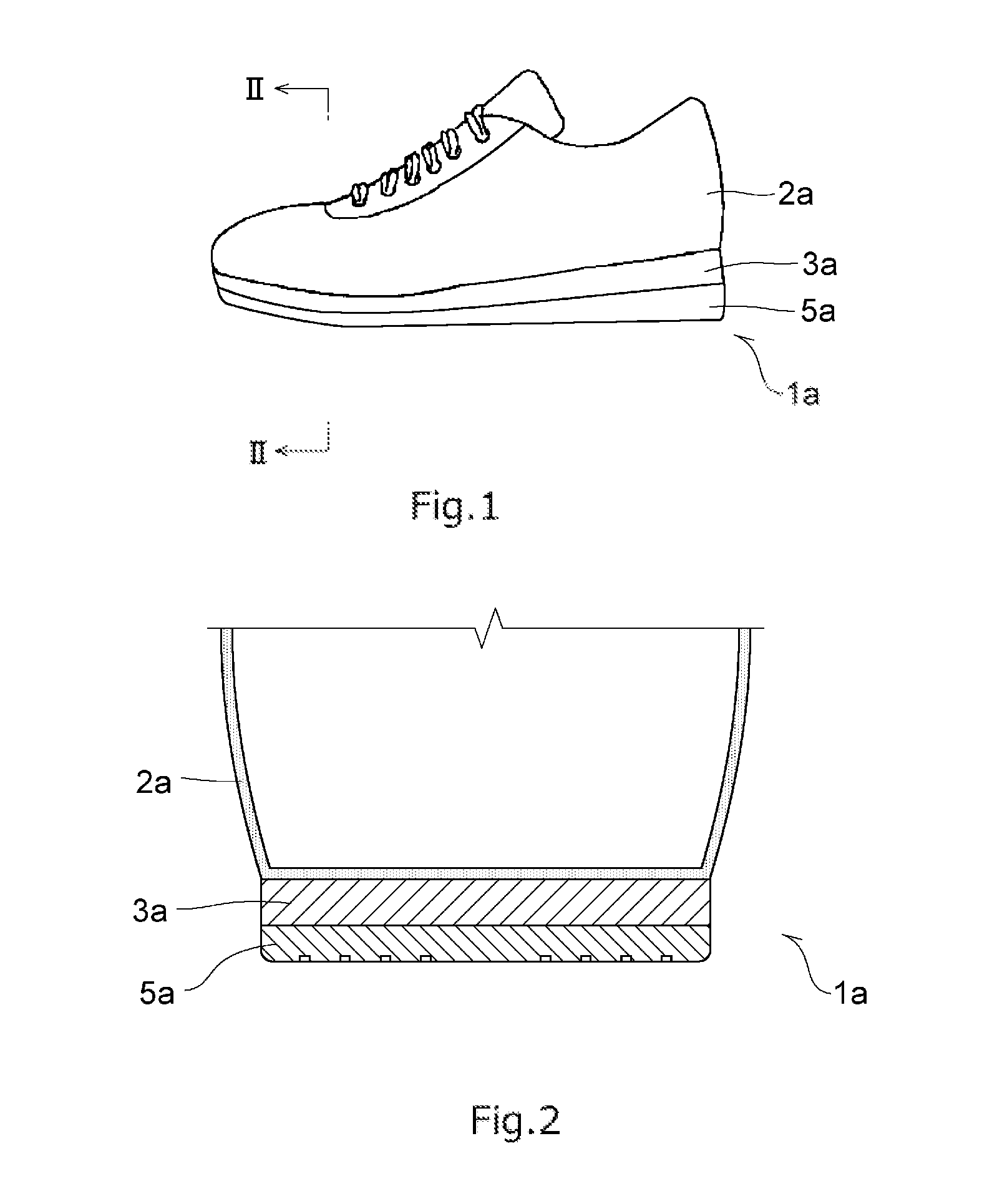

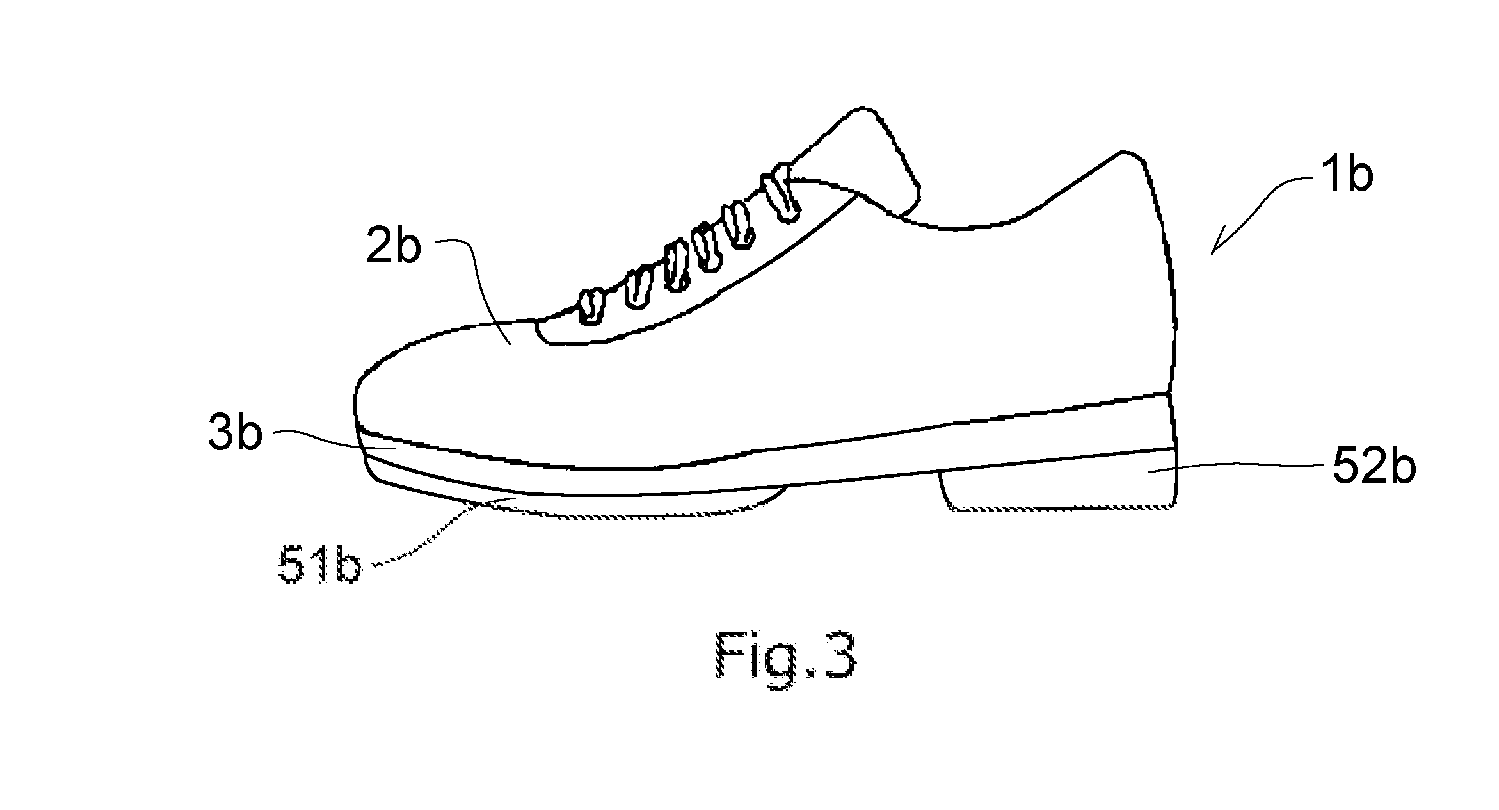

Foamed Sole and Shoe

A foamed sole according to the present invention includes a foam molding containing a rubber component and a resin component, wherein the maximum value of a loss factor [tan δ] at a frequency of 10 Hz and at 30° C. to 80° C. of the foam molding is 0.18 or less, and a peak of a loss factor [tan δ] at a frequency of 10 Hz of the foam molding lies within the range of 100° C. or higher. The foamed sole has a feature that it hardly shrinks when it is heated.

Owner:ASICS CORP

Method for preparing hydrated adhesive

InactiveCN101654602AHigh sticky surface cleanlinessEasy to storeNatural rubber adhesivesAlginic acid adhesivesAdhesiveWater soluble

The invention provides a method for preparing hydrated adhesive, which solves the problems of disposable usage, difficultly-controlled pasting position, difficult removal and the like in the traditional tackifier fundamentally. The technical key points of the invention are as follows: the hydrated adhesive is prepared by mixedly stirring the following raw materials by weight percent at normal temperature and pressure: 10%-35% of sodium alga acid (C6H7O8Na), 5%-30% of competed hydrate, 20%-50% of water-soluble adhesive and 5%-65% of water. The hydrated adhesive in the invention has the advantages of controllable viscosity, stable physicochemical property, environment protection, capability of repeated use, no residual and the like, and is suitable for caking of solid materials such as various paper, plastic and the like.

Owner:梁跃飞

Packer sealing element with shape memory material and associated method

A packer or bridge plug uses a sealing element made from a shape memory polymer (SMP). The packer element receives heat to soften the SMP while the element is compressed and retained. While so retained, the heat is removed to allow the SMP to get stiff so that it effectively seals a surrounding tubular. High expansion rates are possible as the softness of the material under thermal input allows it to be reshaped to the surrounding tubular from a smaller size during run in and to effectively retain a sealed configuration after getting stiff on reduction in its core temperature while longitudinally compressed.

Owner:BAKER HUGHES HLDG LLC

Method for preparing water-expandable polyurethane elastomer

InactiveCN101798376AWide adjustable range of hardnessHigh strengthOther chemical processesPolyurethane elastomerWater leakage

The invention relates to a method for preparing water-expandable polyurethane elastomer, comprising the following steps: adding polyether glycol, isocyanate, plasticizer and nano-filler at a weight ratio of 70-90: 10-20: 10-25: 3-5 to a reaction kettle; heating, stirring; preparing polyurethane prepolymer having free isocyano-content after vacuum dehydration and reaction; uniformly mixing the prepolymer, chain extendor or crosslinking agent and catalyst; vulcanizing at controlled temperature or vulcanizing at room temperature and then secondarily vulcanizing at controlled temperature to prepare high-performance water-expandable polyurethane elastomer. The prepared elastomer has wide adjustable range of rigidity, high strength, and small loss of weight after expansion; the expansivity is high with many times of repeated expansion, and the expansion magnification is adjustable; with simple production technology, the prepared expandable polyurethane elastomer is widely applied to engineering fields such as bridge, subway, tunnel, water supply and drainage, mine water prevention and water leakage prevention.

Owner:QINGDAO UNIV OF SCI & TECH

Heat-expandable microspheres, process for producing the same, and application thereof

ActiveUS20100204349A1Improve good performanceHigh expansion rateSynthetic resin layered productsCellulosic plastic layered productsBoiling pointMicrosphere

Heat-expandable microspheres include a shell of thermoplastic resin and core material encapsulated in the shell. The core material include a blowing agent having a boiling point not higher than the softening point of the thermoplastic resin and a gas migration inhibitor having a boiling point higher than the softening point of the thermoplastic resin. The ratio of the gas migration inhibitor to the core material is at least 1 weight percent and below 30 weight percent. The average particle size of the heat-expandable microspheres ranges from 1 to 100 micrometers.

Owner:MATSUMOTO YUSHI SEIYAKU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com