Hot rolling ferrite/bainite high strength steel plate and manufacturing method thereof

A high-strength steel plate and a manufacturing method technology, applied in the field of steel material engineering, can solve the problems of high cost, high manganese content, high requirements, etc., and achieve the effects of excellent formability, high hole expansion rate, and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

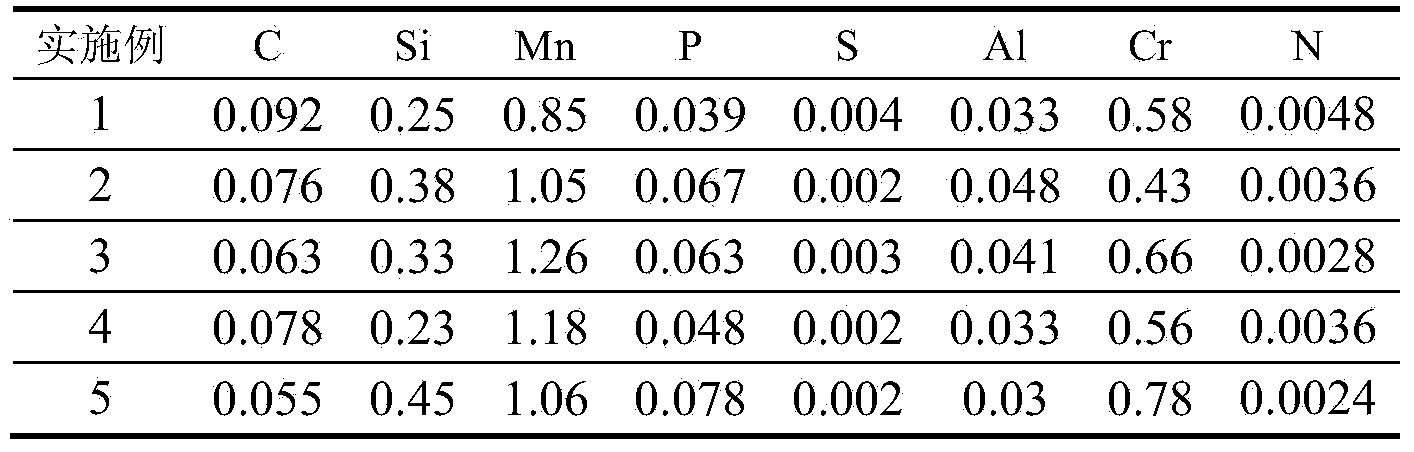

[0035] A hot-rolled ferritic bainite high-strength steel, the chemical composition of which is shown in Table 1.

[0036] A production method of hot-rolled ferritic bainite high-strength steel, comprising molten iron pretreatment-converter smelting-alloy fine-tuning argon blowing-LF-continuous casting-hot continuous rolling. The hot continuous rolling process is as follows: slab thickness 135mm, heating temperature 1180°C, holding time 2h, rough rolling start temperature 1130°C, finish rolling temperature 1070°C, 3-pass rolling to 33mm intermediate billet, finish rolling stage The rolling start temperature is 1020°C, the final rolling temperature is 880°C, then cooled to 729°C at a cooling rate of 64°C / S, air-cooled for 3S, and then water-cooled to the target coiling temperature at 56°C / S, and the coiling temperature is 496°C. The thickness of the finished steel plate is 4mm.

Embodiment 2

[0038] A hot-rolled ferritic bainite high-strength steel, the chemical composition of which is shown in Table 1.

[0039] A production method of hot-rolled ferritic bainite high-strength steel, comprising molten iron pretreatment-converter smelting-alloy fine-tuning argon blowing-LF-continuous casting-hot continuous rolling. Described continuous hot rolling process is:

[0040] The thickness of the slab is 135mm, the heating temperature is 1160°C, the holding time is 2.5h, the rough rolling start temperature is 1110°C, the final rolling temperature is 1060°C, and the intermediate billet of 33mm is rolled in 3 passes. The rolling temperature is 880°C, then cooled to 708°C at a cooling rate of 58°C / S, air-cooled for 3.5S, and then water-cooled to the target coiling temperature at 52°C / S, the coiling temperature is 462°C, and the thickness of the finished steel plate is 4.5mm.

Embodiment 3

[0042] A hot-rolled ferritic bainite high-strength steel, the chemical composition of which is shown in Table 1.

[0043] A production method of hot-rolled ferritic bainite high-strength steel, comprising molten iron pretreatment-converter smelting-alloy fine-tuning argon blowing-LF-continuous casting-hot continuous rolling. The hot continuous rolling process is as follows: slab thickness 135mm, heating temperature 1230°C, holding time 1.5h, rough rolling start temperature 1140°C, finish rolling temperature 1070°C, 3-pass rolling to a 35mm intermediate billet, finish rolling Stage rolling temperature is 1020°C, final rolling temperature is 840°C, then cooled to 668°C at a cooling rate of 37°C / S, air-cooled for 4S, then water-cooled to the target coiling temperature at 28°C / S, the coiling temperature is 413°C, The thickness of the finished steel plate is 6.0mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com