Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3238 results about "Cooling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cooling rate. the rate at which temperature decreases with time (°C/min) immediately after the completion of hyperthermia treatment.

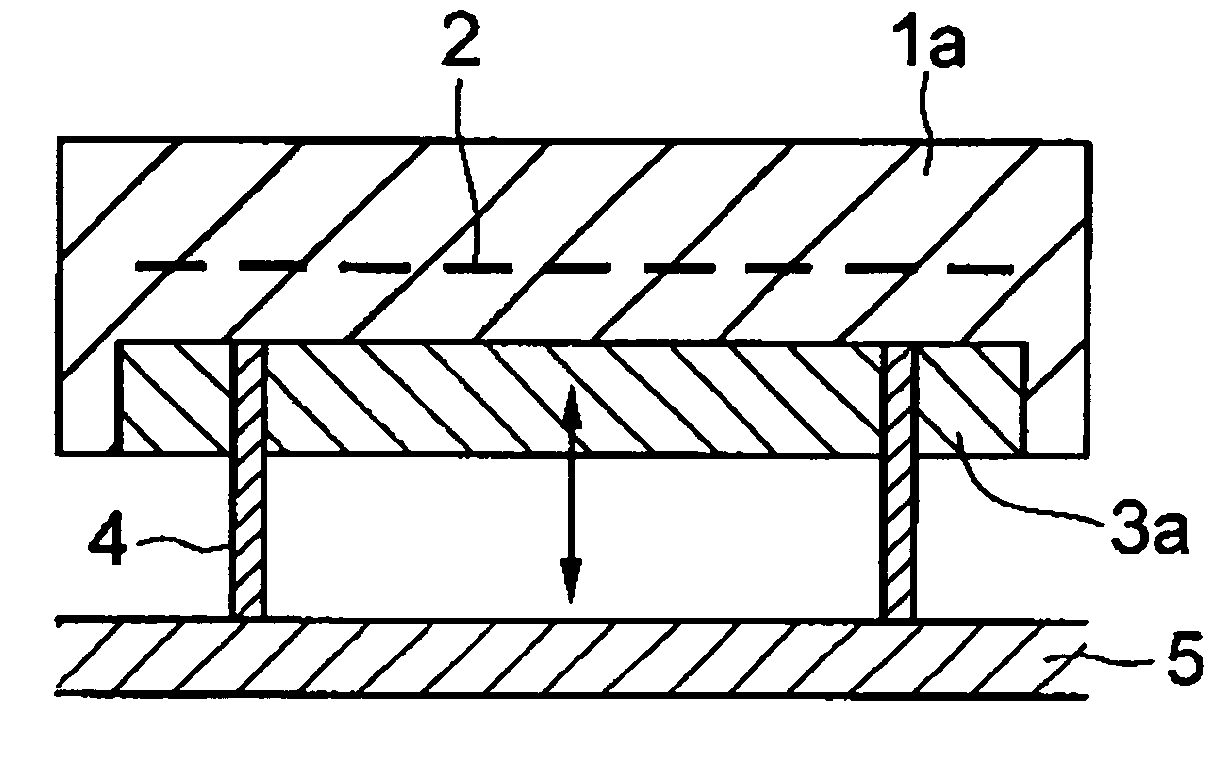

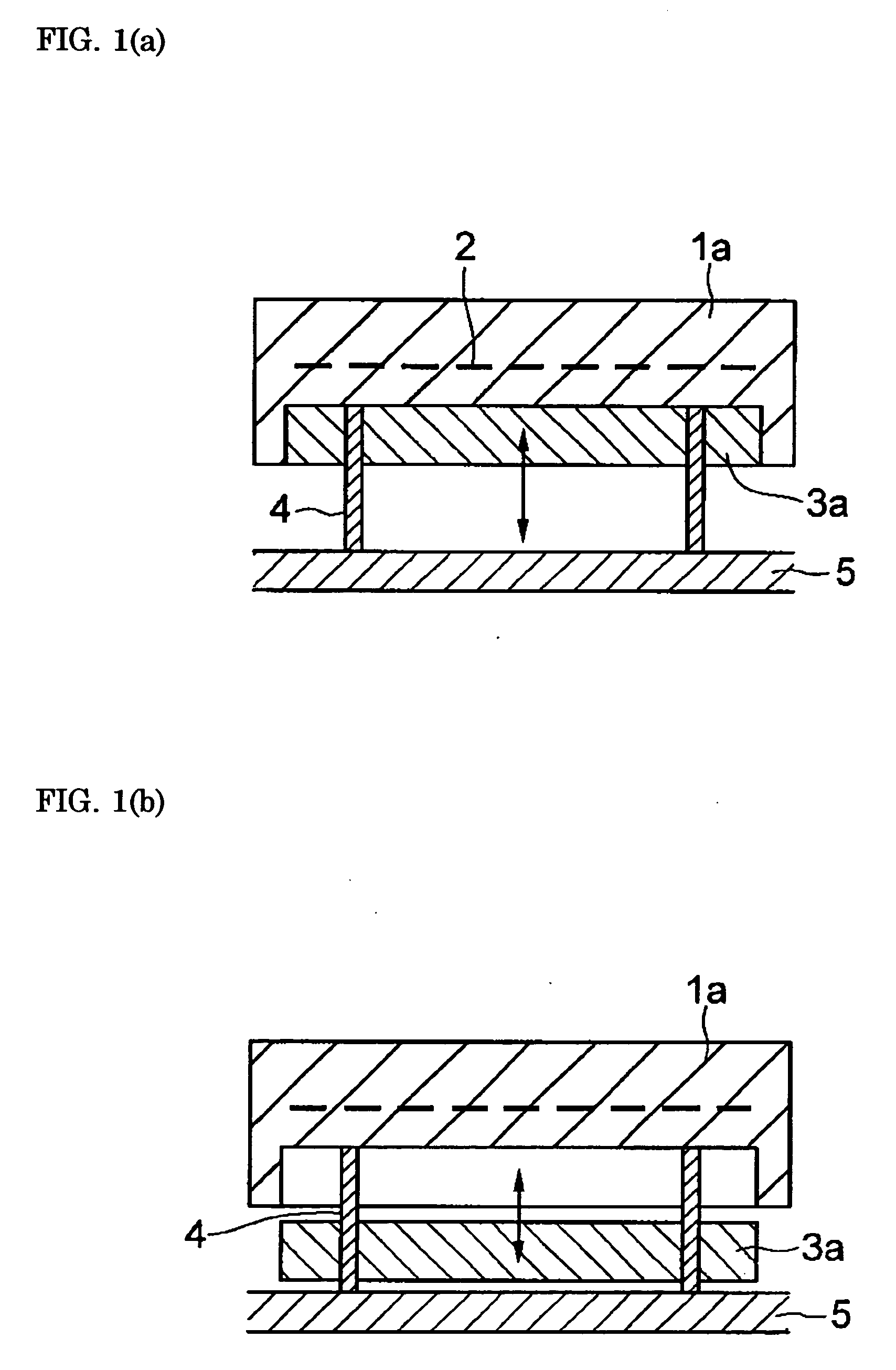

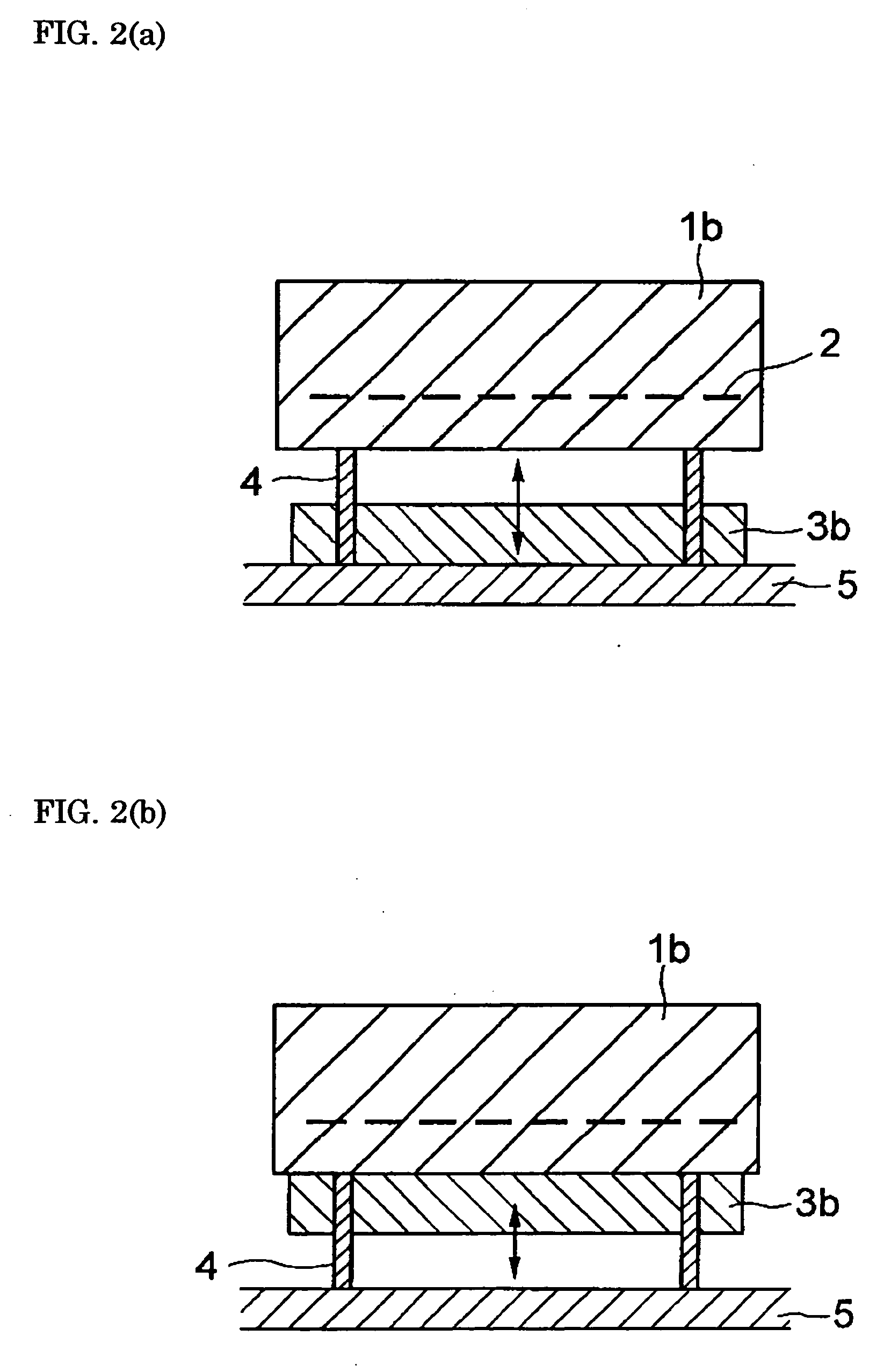

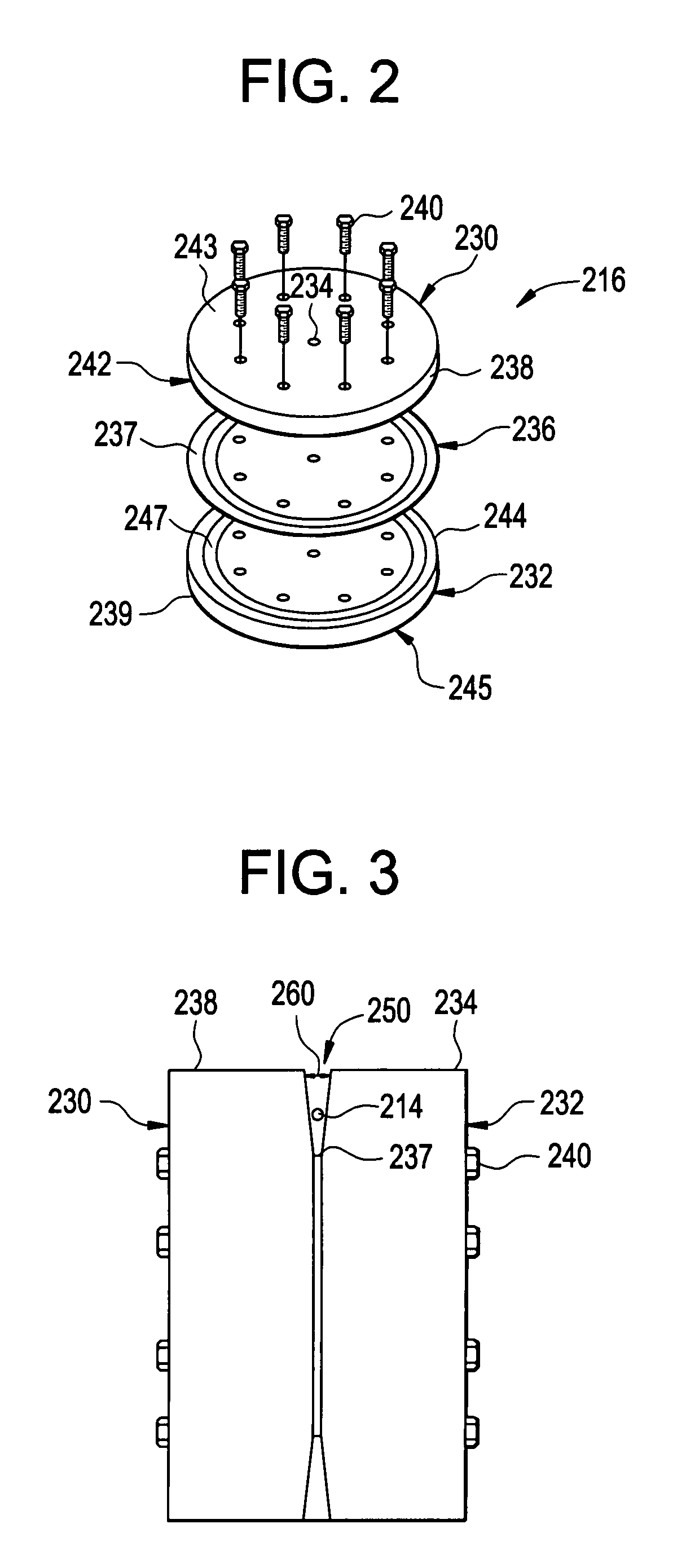

Heater module for semiconductor production system

InactiveUS20040238523A1Speed up coolingHigh bonding strengthSemiconductor/solid-state device manufacturingHot plates heating arrangementsProduction rateComputer module

Heater module, and semiconductor manufacturing equipment in which the heater module is utilized, for raising the cooling speed of a post-heating heater markedly more than conventional, and that can contribute toward bettering and improving productivity, without accompanying scaling-up of and cost increases in the semiconductor manufacturing equipment. The heater module is furnished with heater part 1a for controlled heating of a wafer placed on its top face, and block part 3a provided to be shiftable relative to said heater part, for varying heat capacity in total with heater part 1a by abutting on or separating from the reverse surface of heater part 1a. By having the heat capacity of block part 3a be 20% or more of the total heat capacity of heater part 1a and block part 3a, the heater cooling speed can be made 10° C. / min or more.

Owner:SUMITOMO ELECTRIC IND LTD

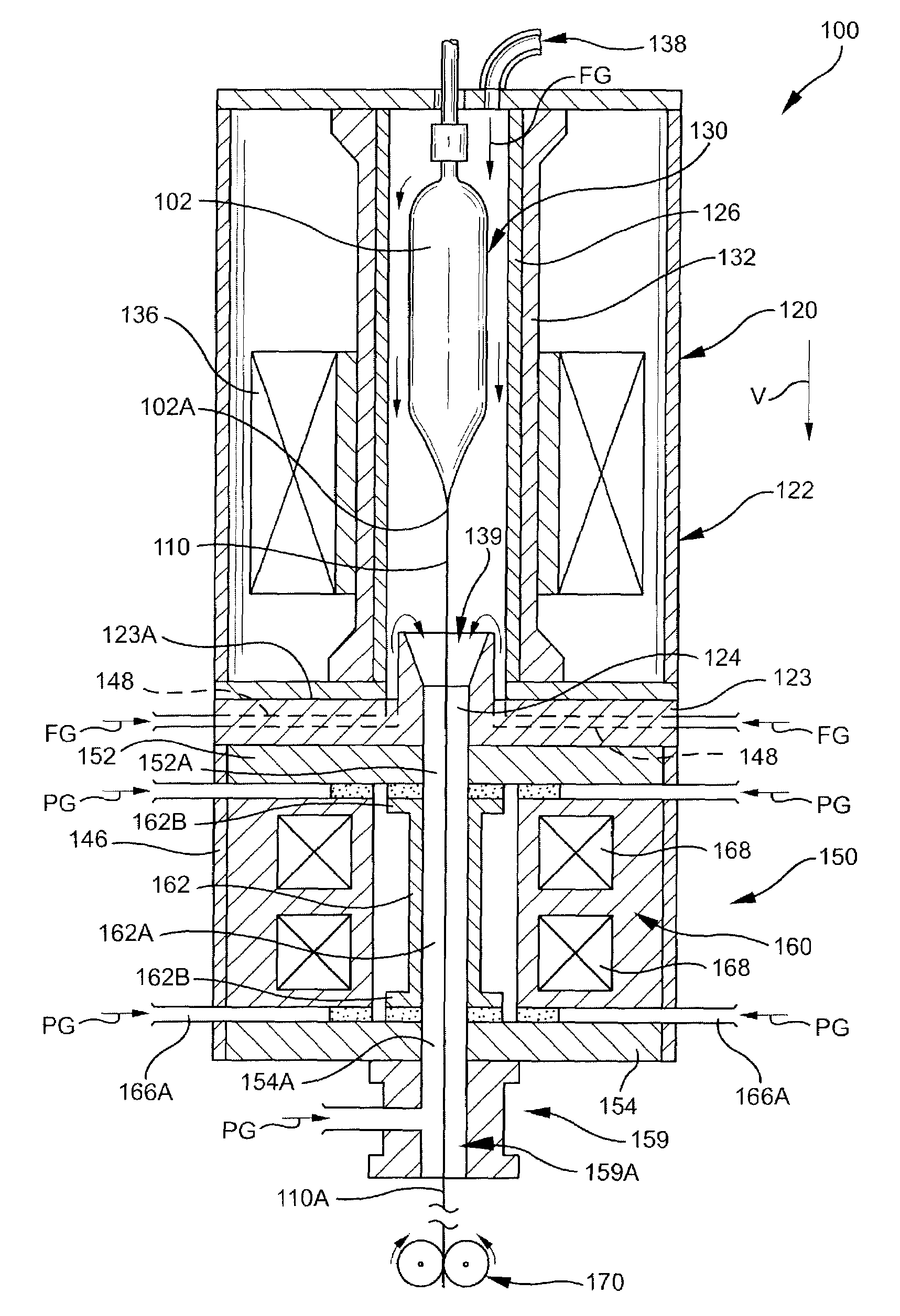

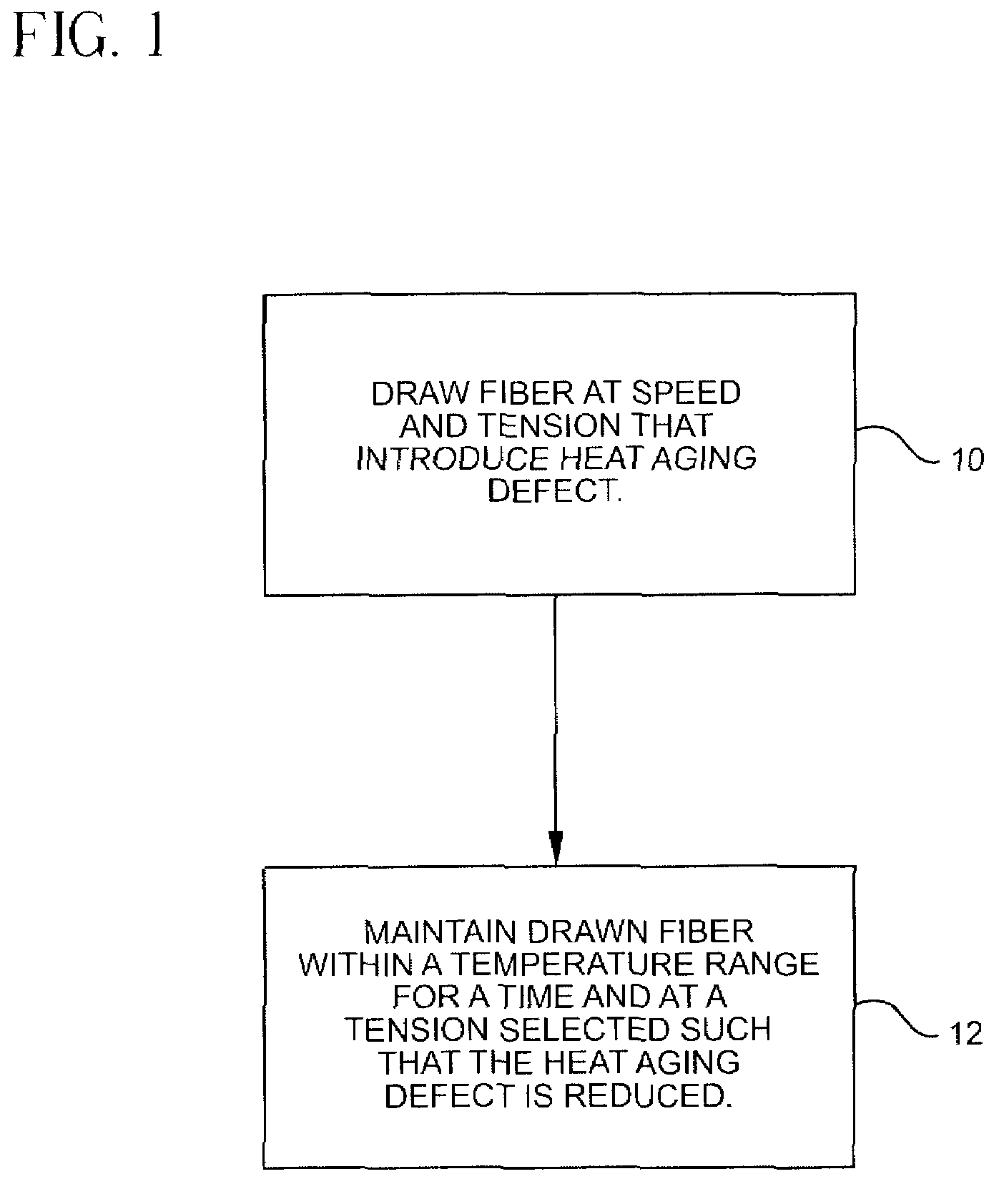

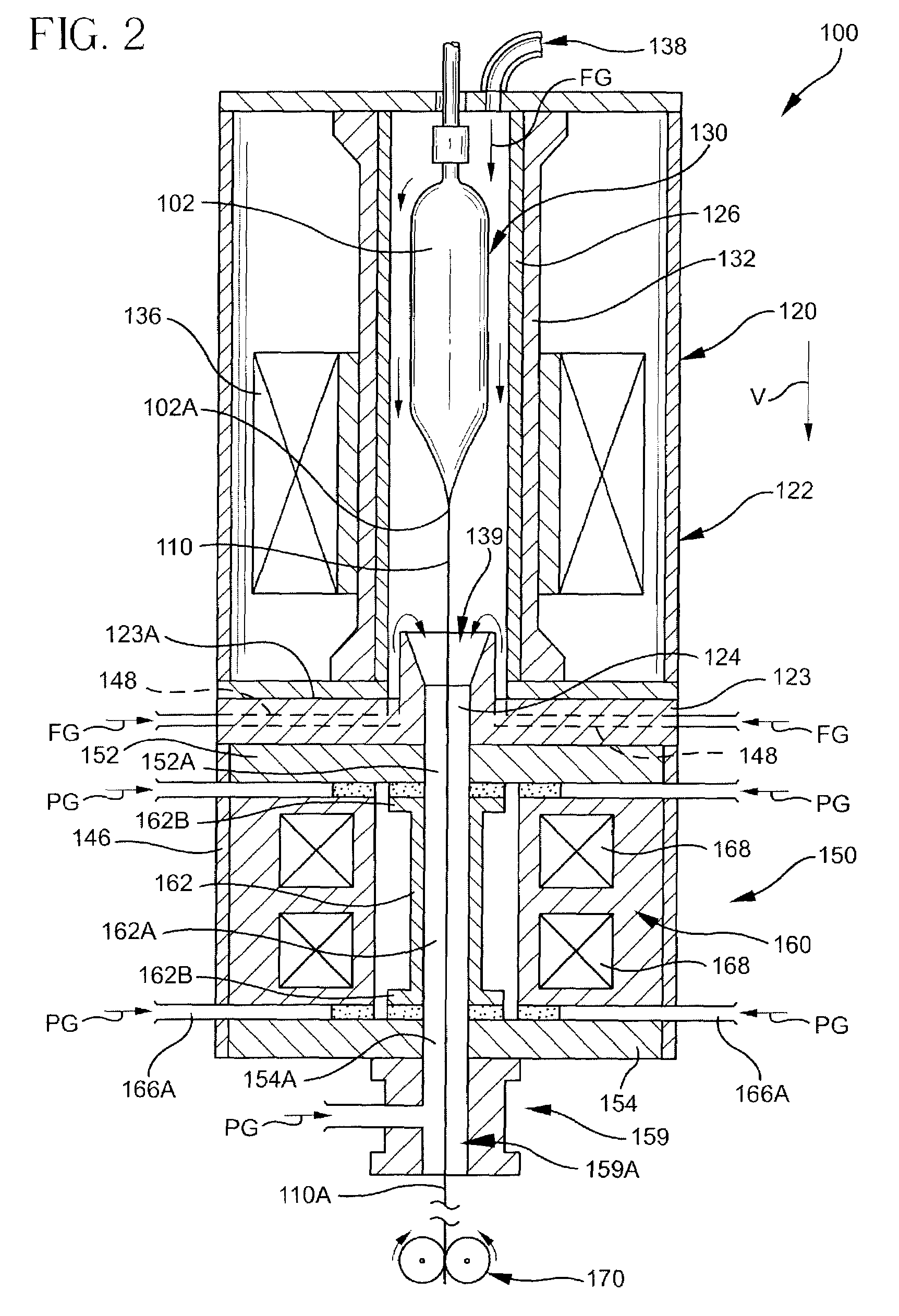

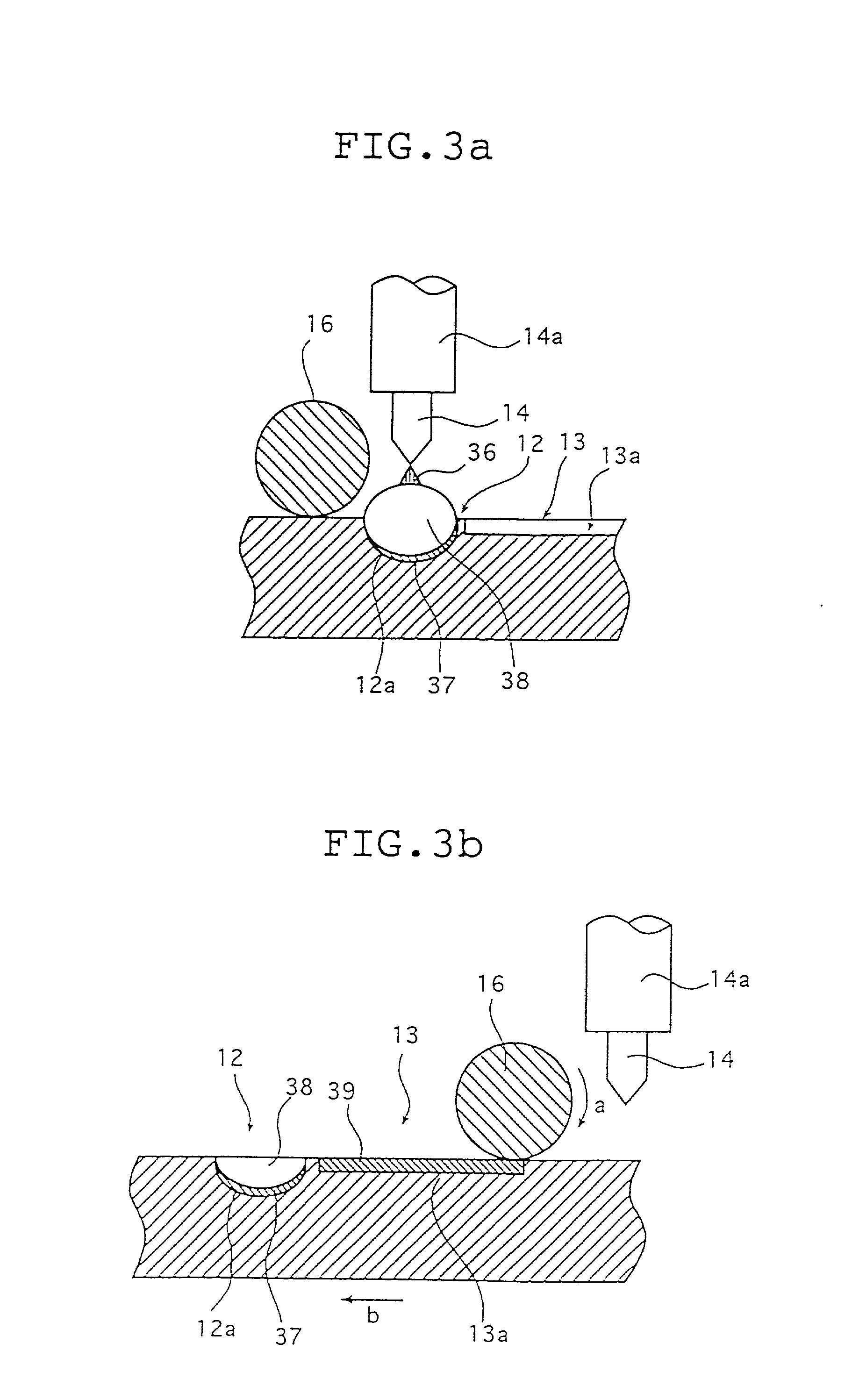

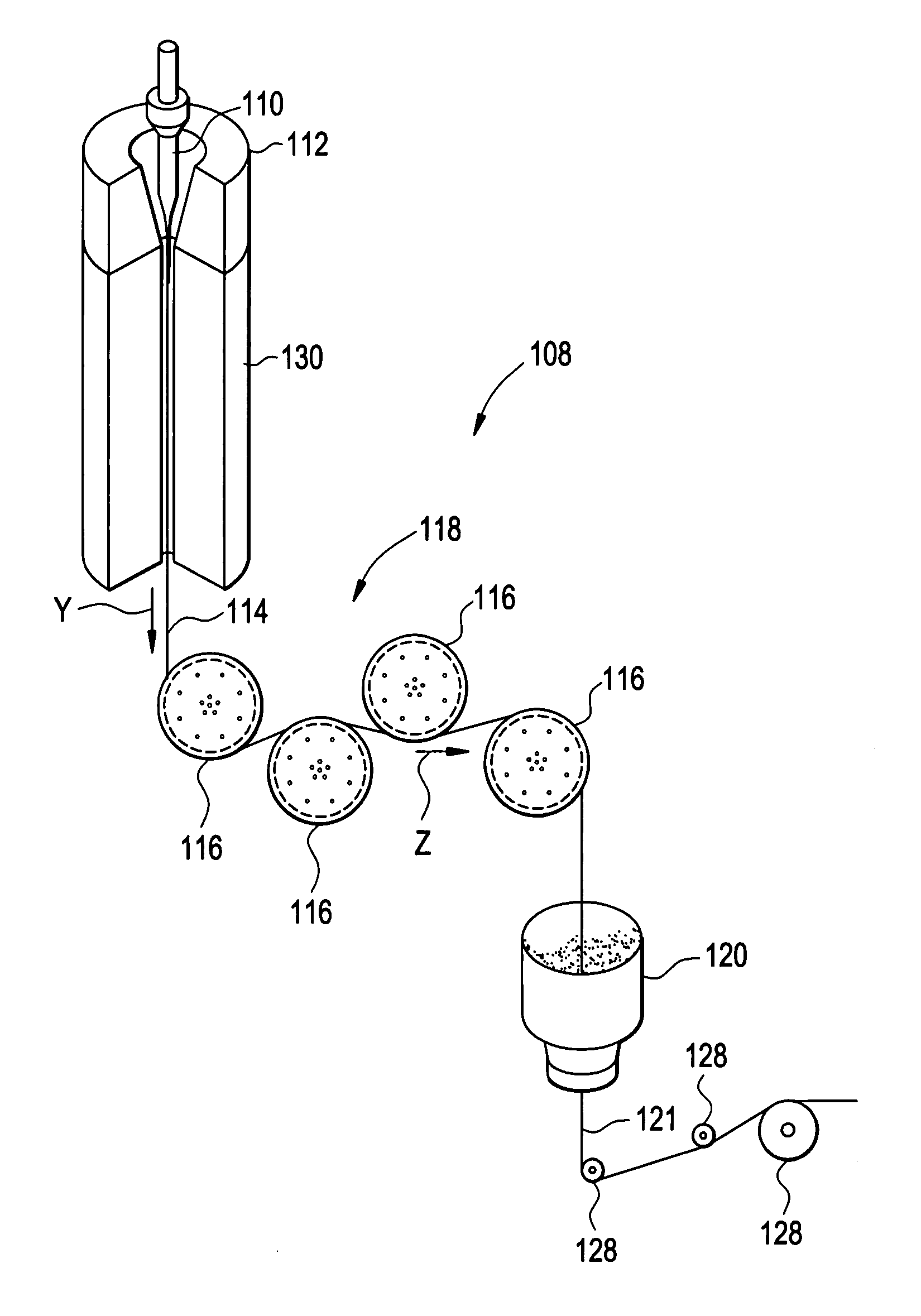

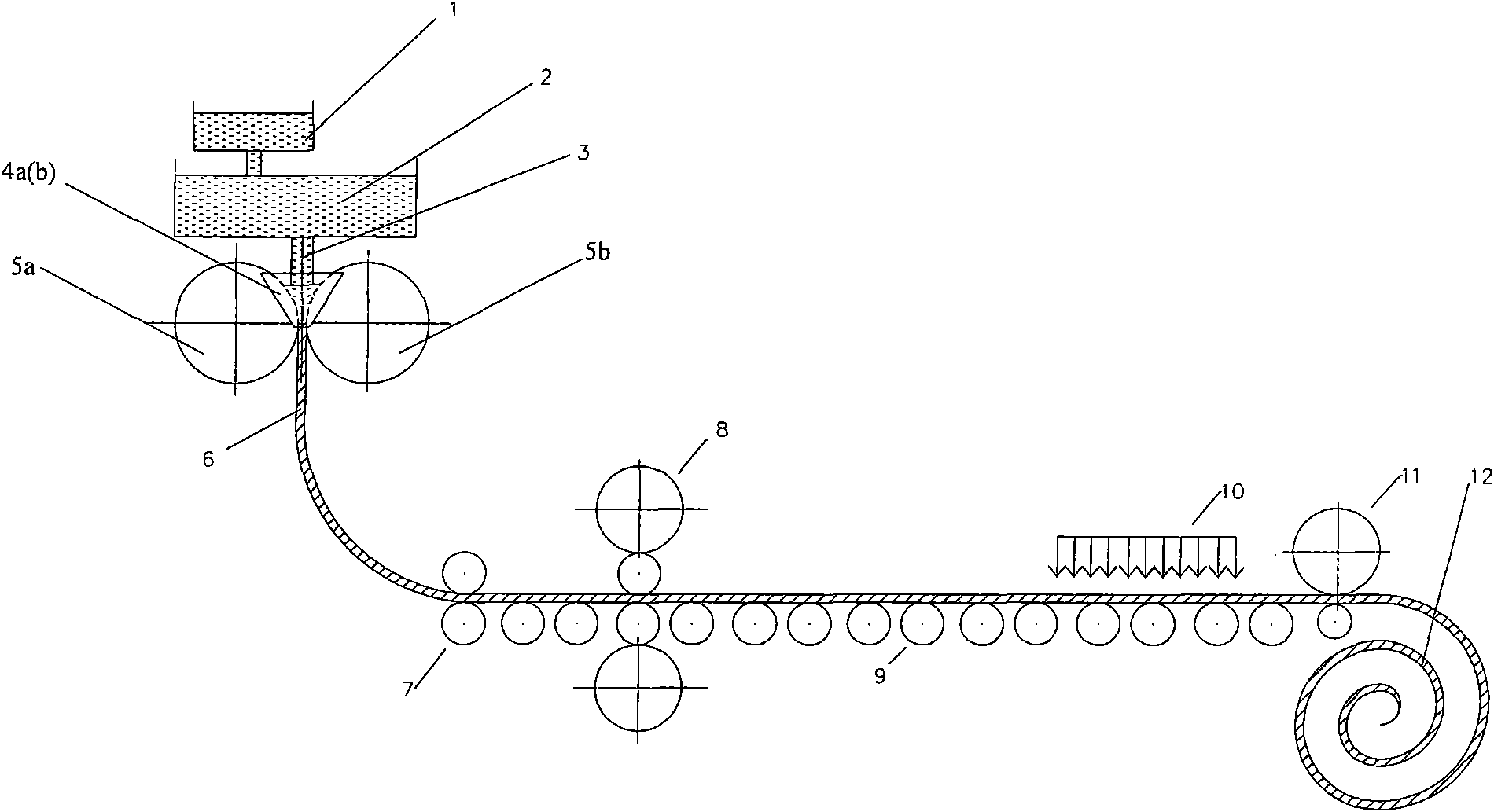

Methods and apparatus for forming heat treated optical fiber

InactiveUS7565820B2Trend downDecreases micro-density variationGlass fibre drawing apparatusNon-linear opticsUltrasound attenuationRayleigh scattering

A method for forming an optical fiber includes drawing the optical fiber from a glass supply and treating the fiber by maintaining the optical fiber within a treatment temperature range for a treatment time. Preferably also, the fiber is cooled at a specified cooling rate. The optical fiber treatment reduces the tendency of the optical fiber to increase in attenuation due to Rayleigh scattering, and / or over time following formation of the optical fiber due to heat aging. Apparatus are also provided.

Owner:CORNING INC

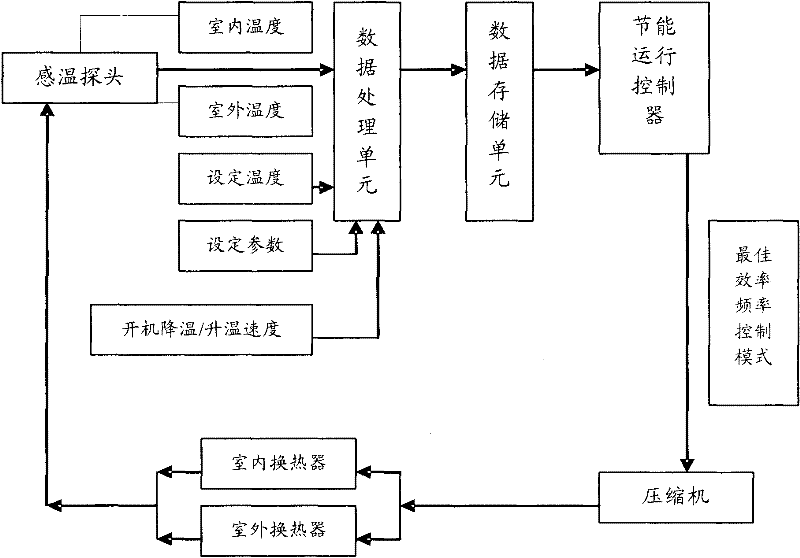

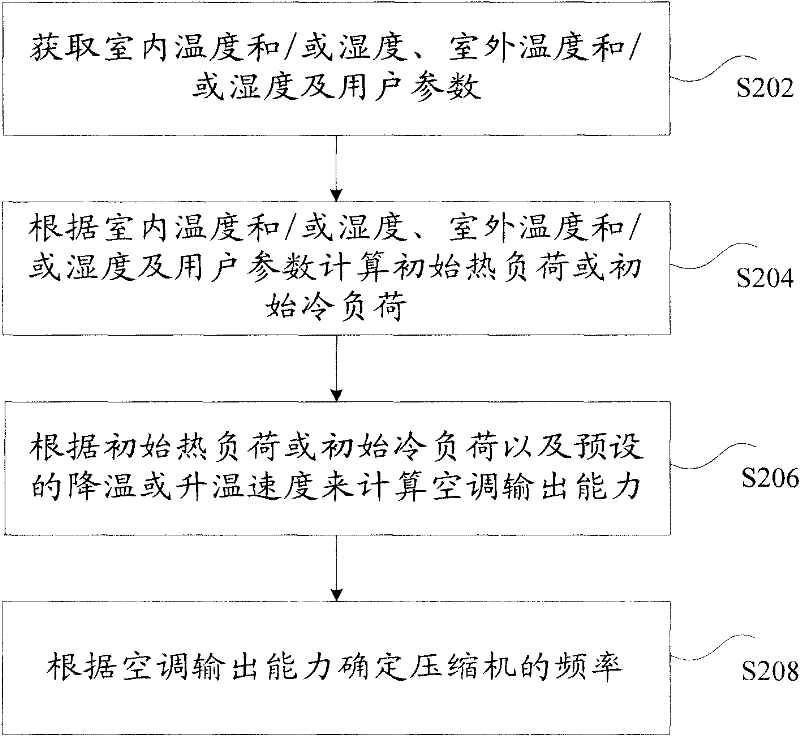

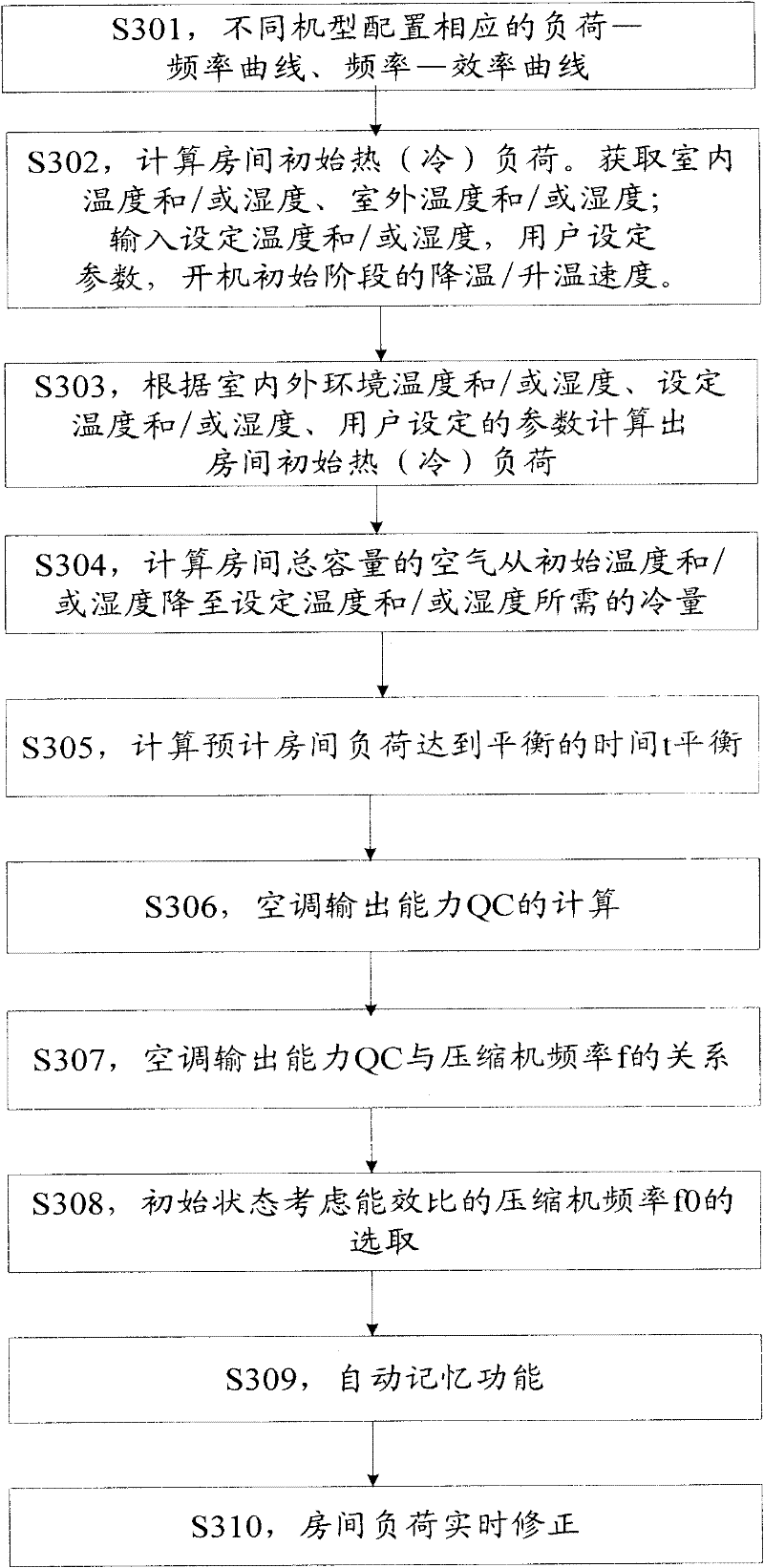

Air conditioner as well as control method and device thereof

ActiveCN102128481AOvercome the problem of relatively high power consumptionReduce power consumptionSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringOutdoor temperature

The invention provides an air conditioner as well as a control method and device thereof, wherein the method comprises the following steps: acquiring an indoor temperature / humidity, an outdoor temperature / humidity and user parameters; calculating an initial heat load or initial cold load according to the indoor temperature / humidity, the outdoor temperature / humidity and the user parameters; calculating the output capacity of the air conditioner according to the initial heat load or initial cold load and a preset cooling rate or heating rate; and determining the frequency of a compressor according to the output capacity of the air conditioner. Through the invention, the air conditioner can run with a frequency generated when the running efficiency of the air conditioner is the optimum efficiency, thereby reducing the power consumption.

Owner:GREE ELECTRIC APPLIANCES INC

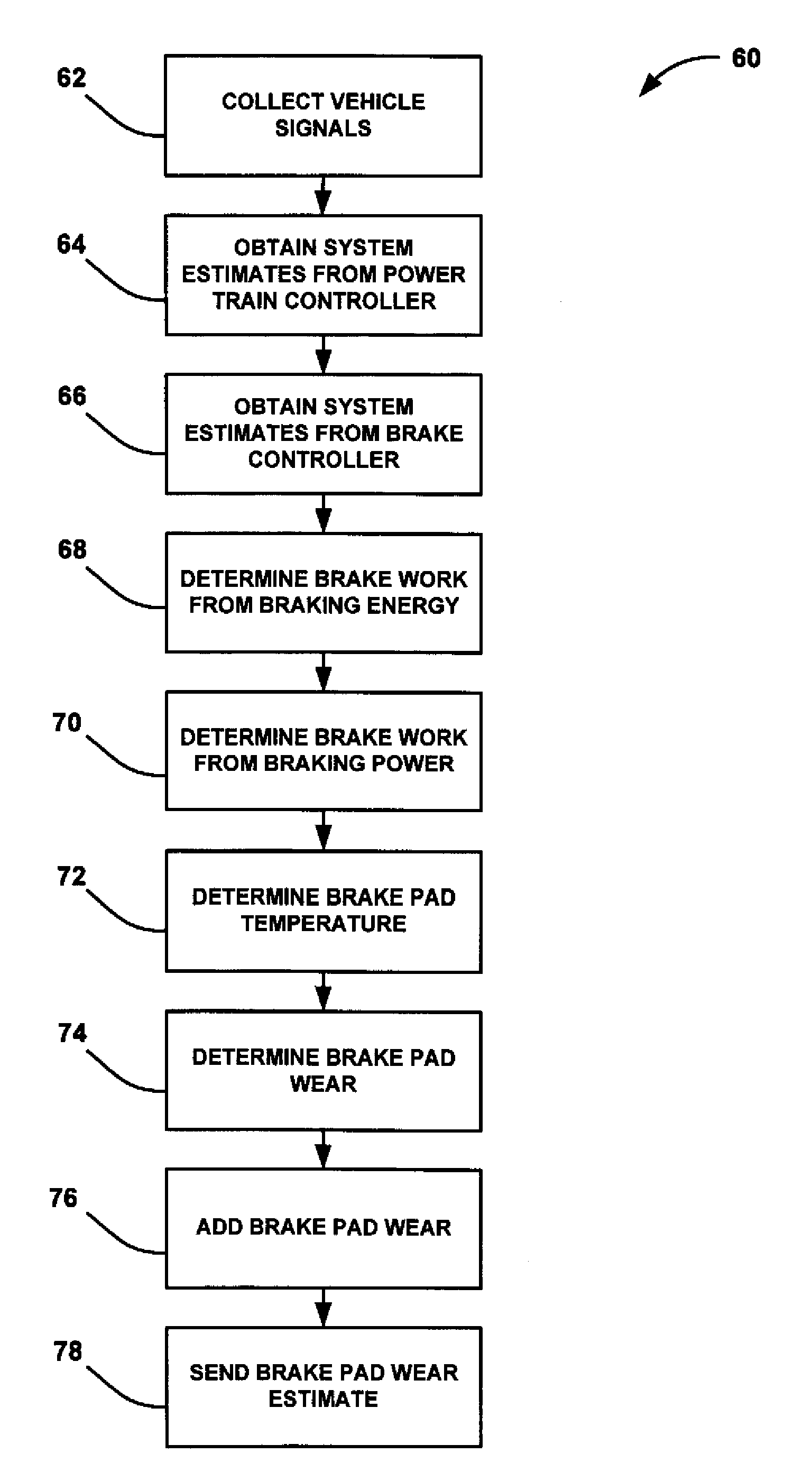

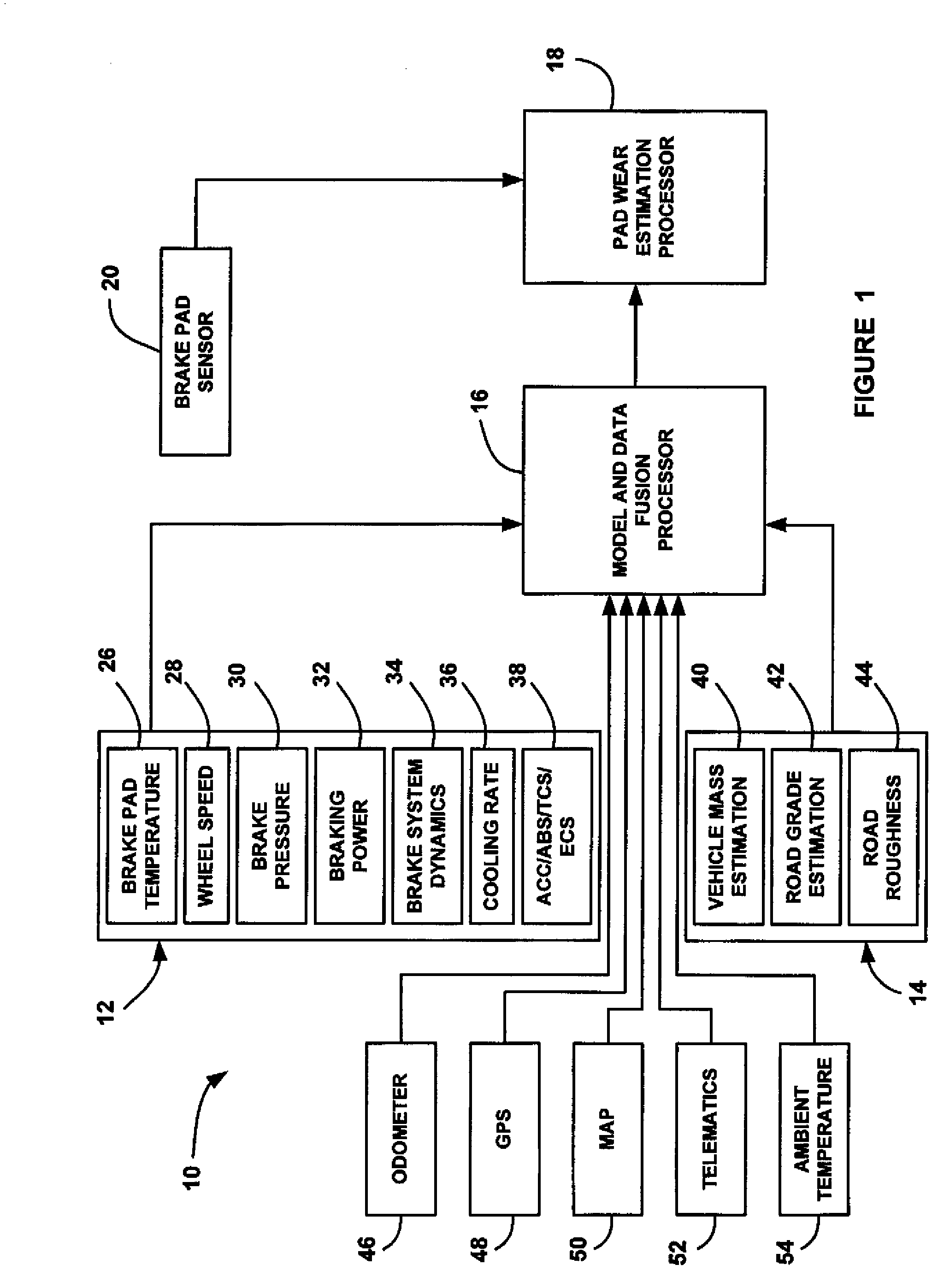

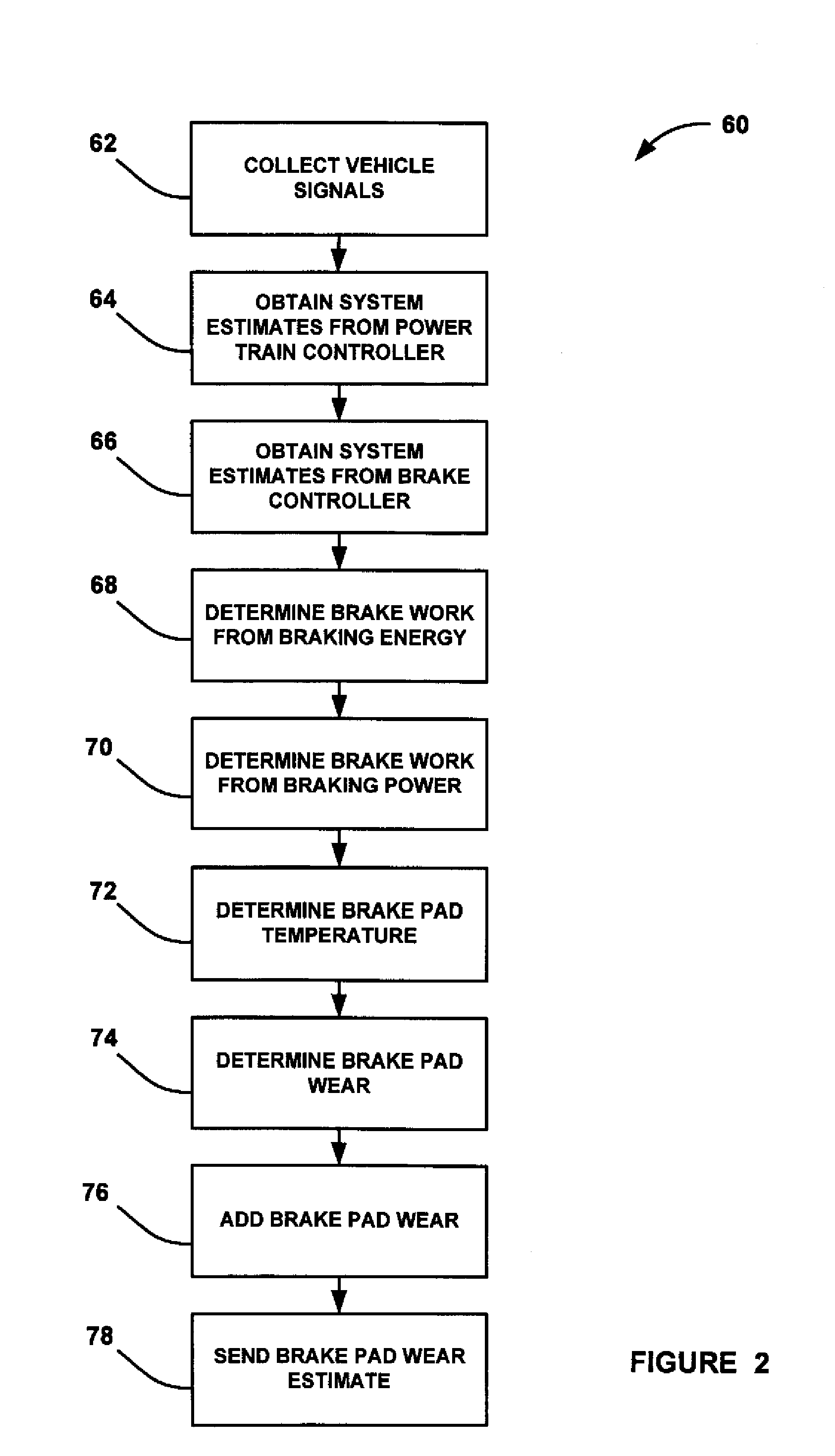

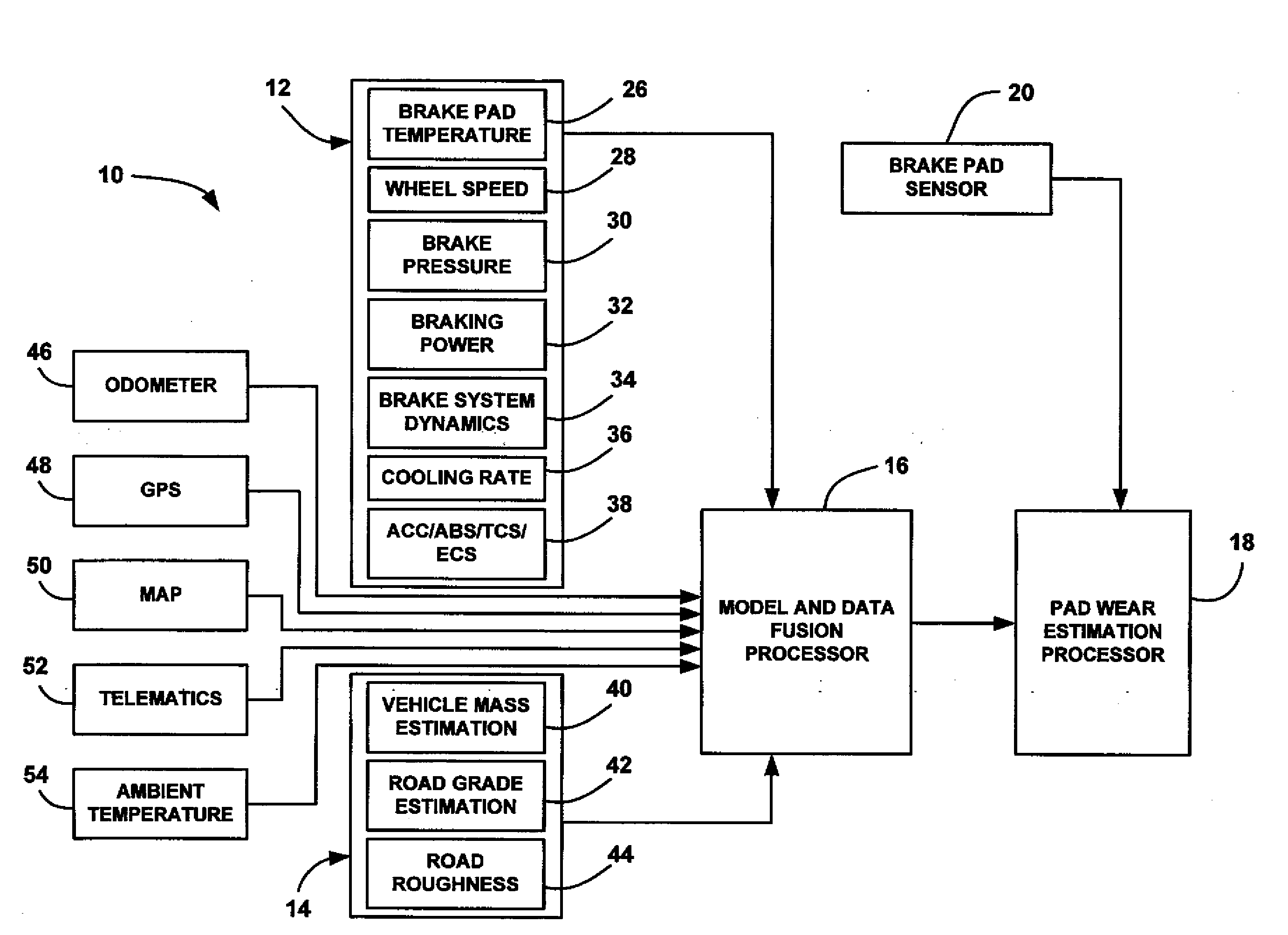

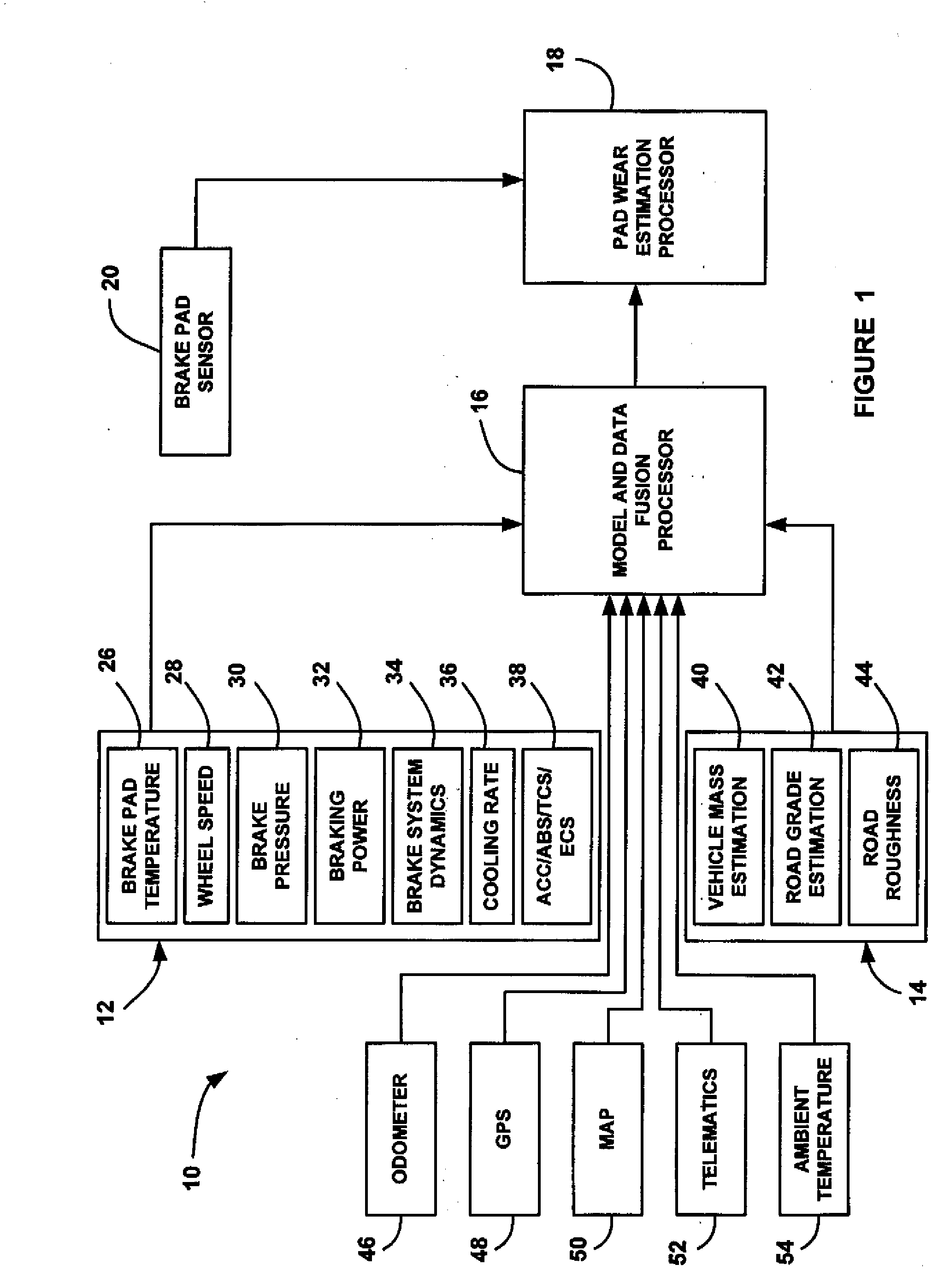

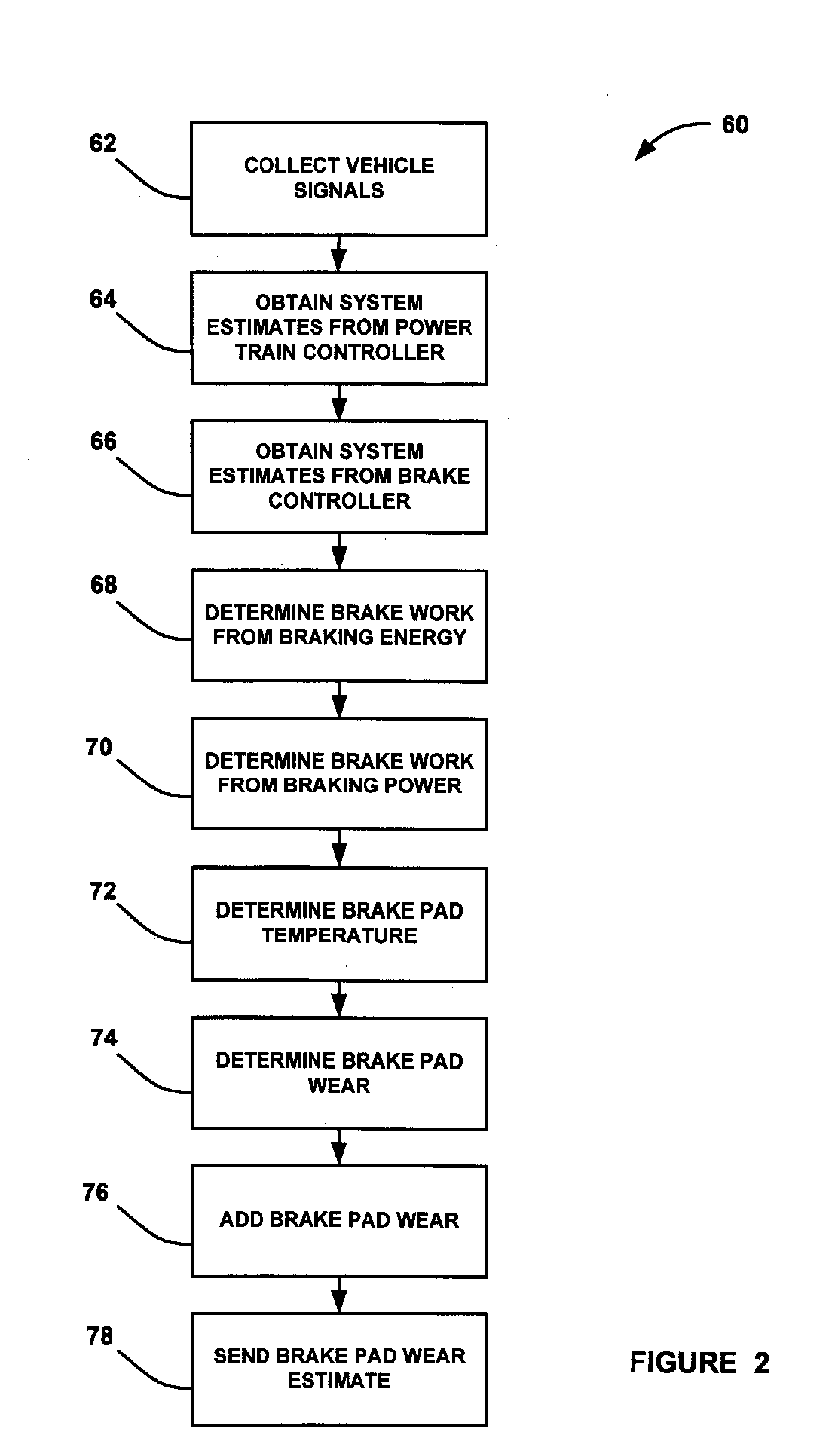

Brake pad prognosis system

A method for providing an estimate of brake pad thickness. The method employs fusion of sensors, if used, and driver brake modeling to predict the vehicle brake pad life. An algorithm is employed that uses various inputs, such as brake pad friction material properties, brake pad cooling rate, brake temperature, vehicle mass, road grade, weight distribution, brake pressure, brake energy, braking power, etc. to provide the estimation. The method calculates brake work using total work minus losses, such as aerodynamic drag resistance, engine braking and / or braking power as braking torque times velocity divided by rolling resistance to determine the brake rotor and lining temperature. The method then uses the brake temperature to determine the brake pad wear, where the wear is accumulated for each braking event. A brake pad sensor can be included to provide one or more indications of brake pad thickness from which the estimation can be revised.

Owner:GM GLOBAL TECH OPERATIONS LLC

Superhigh strength steel plate with yield strength more than 960Mpa and method for producing same

ActiveCN1840724AEasy to implementEasy to controlFurnace typesHeat treatment furnacesAusteniteForeign substance

The invention provides a super-strength steel plate comprising the following constituents (by weight percent): C 0.08-0.18%, Si<=0.6%, Mn 0.5-2.0%, Al <=0.018%, N<=0.008%, B<=0.0025%, Ca 0-0.006%, P<=0.015%, S<=0.005%, Ni <=1.0%, Cr<=0.8%, Cu<=0.5%, Mo<=0.6%, Ti 0.01-0.03%, V<=0.1%, Nb 0.01-0.1%, balancing Fe and unavoidable foreign substance. The invention also provides the preparing process.

Owner:BAOSHAN IRON & STEEL CO LTD

Leadless easy cutted brass ally material and its manufacturing method

An easily cutted lead-free brass alloy is prepared from Cu (60-62 wt.%), Bi (0.5-2.2), Al (0.01-0.1), Sn (0.5-1.6), P (0.04-0.15) and Zn (rest) through heat treating at 460-600 deg.C for 30 min-4 hr, and slow cooling at speed lower than 70 deg.C / hr.

Owner:SAN ETSU METALS

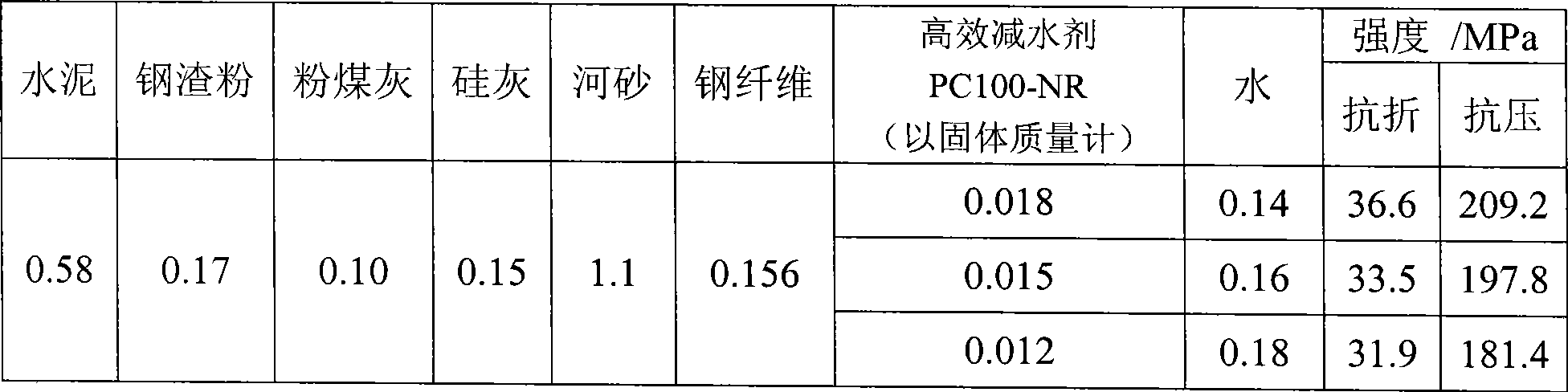

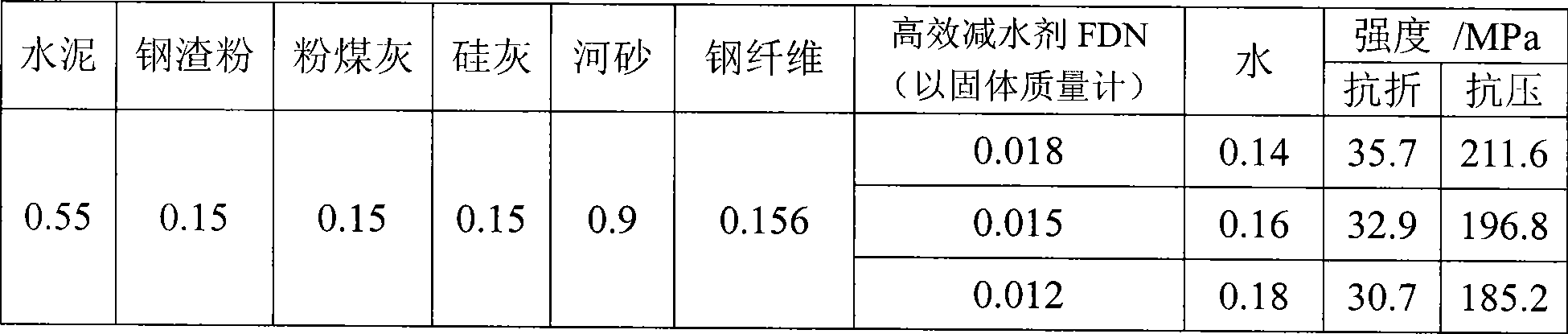

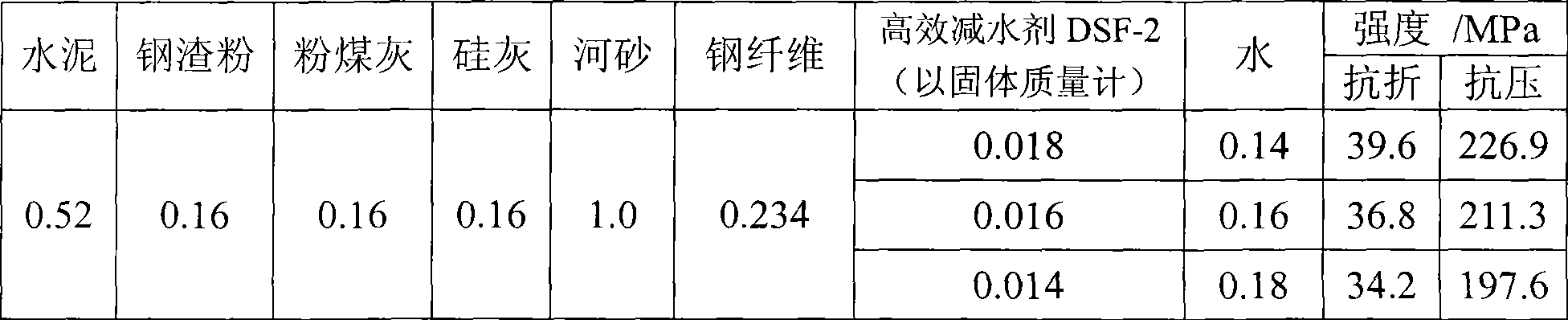

Low cost active powder concrete and preparation thereof

InactiveCN101486554ALow raw material costReduce maintenance costsSolid waste managementMixing operation control apparatusFiberSlag

The invention discloses active powder concrete which is prepared by Portland cement, steel slag powder, fly ash, silicon ash, effective water reducing agent, river sand, mixing water and steel fiber with the mass ratios of 0.52 to 0.58 : 0.16 to 0.18 : 0.10 to 0.16 : 0.13 to 0.16 : 0.012 to 0.018 : 0.9 to 1.1 : 0.14 to 0.18 : 0.156 to 0.234. The preparation method thereof is as follows: each component is sequentially added into a stirring machine for being uniformly stirred and shaped; then after the components are maintained, the temperature is raised to 80 to 90 DEG C at the temperature rising speed of 15 to 20 DEG C / h and then constant temperature maintaining is carried out for 72 to 96h; then, the components are cooled to room temperature at the cooling speed of not more than 20 DEG C / h to obtain the active powder concrete product. The invention employs the industrial wastes like steel slag powder and fly ash to replace quartz powder, partial cement and silicon ash, and employs thin river sand to replace quartz sand to prepare the active powder concrete of 200 grade under the maintaining conditions of normal pressure below 100 DEG C, thus not only being capable of remarkably reducing the material cost and the shaping maintaining cost, but also playing important roles on saving resources and energies, protecting the environment and promoting sustainable development as a large amount of industrial waste slag is used.

Owner:WUHAN UNIV OF TECH

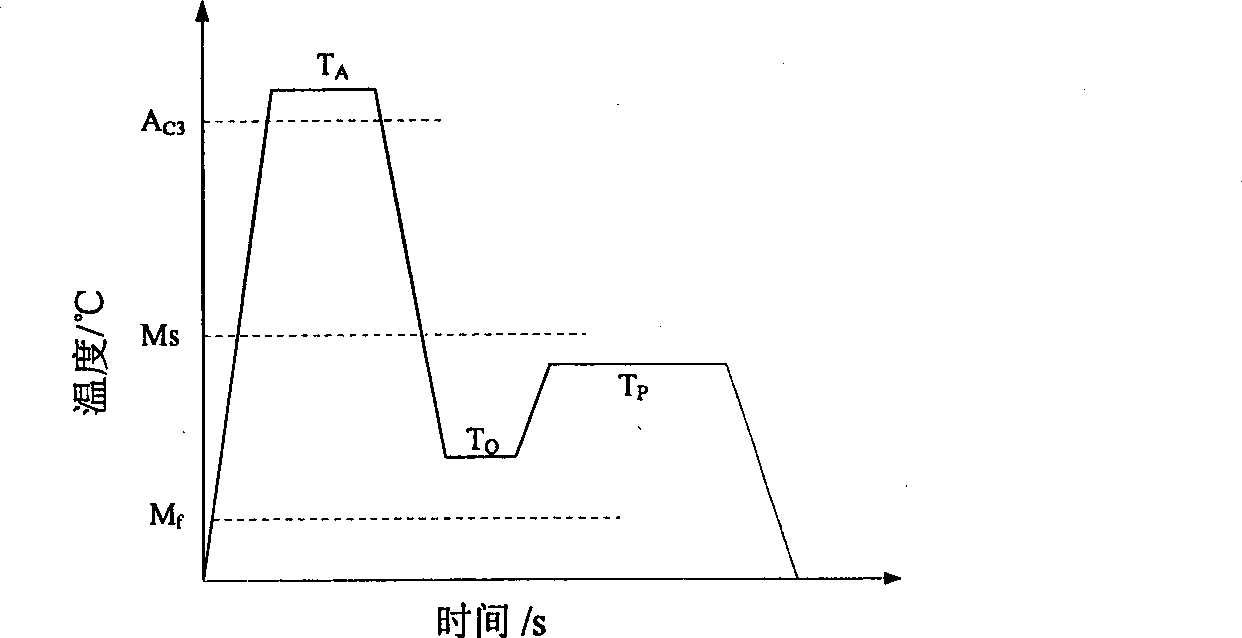

Low-alloy high-strength C-Mn-Al Q & P steel and method of manufacturing the same

The invention relates to a low-alloyed and high-strength Q and amp of a C-Mn-Al system; P steel; and a manufacturing method thereof, which belong to the technical field of metal materials. The method comprises the following processing steps of: (1) smelting and cast blocking: the mass percentages of the components are as follows: 0.16 percent to 0.25 percent of C, less than or equal to 0.40 percent of Si, 1.20 percent to 1.60 percent of Mn, 1.0 percent to 1.5 percent of Al, less than or equal to 0.02 percent of P, less than or equal to 0.008 percent of S and the balance of ferrite. (2) rolling: after the multi-pass hot-rolling of rough rolling and finish rolling, wherein, the deformation of roughing pass is 10 percent to 30 percent, the total deformation of the finish rolling is more than 60 percent, a hot rolled plate is subjected to multi-pass cold rolling, the deformation is 5 percent to 50 percent, and the plate is rolled to be a thin plate with the thickness being 0.6 to 2.0mm. (3) heat treating: firstly, austenitizing of 850 to 930 DEG C is carried out in a heating furnace, temperature is kept for 100 to 200 seconds and then rapid quenching is carried out to reach 230 to 250 DEG C, the temperature is kept for 20 to 40 seconds, after that the temperature is kept in 300 to 400 DEG C for 120 to 3600 seconds, at last fast cooling is carried out to room temperature (the speed of the cooling is not less than 10 DEG C / s). The Q and amp and the P steel have economic components, good quality of the surface, high strength and good shaping resistance. The strength and ductility product can reach over 37000MPa question mark percent.

Owner:UNIV OF SCI & TECH BEIJING

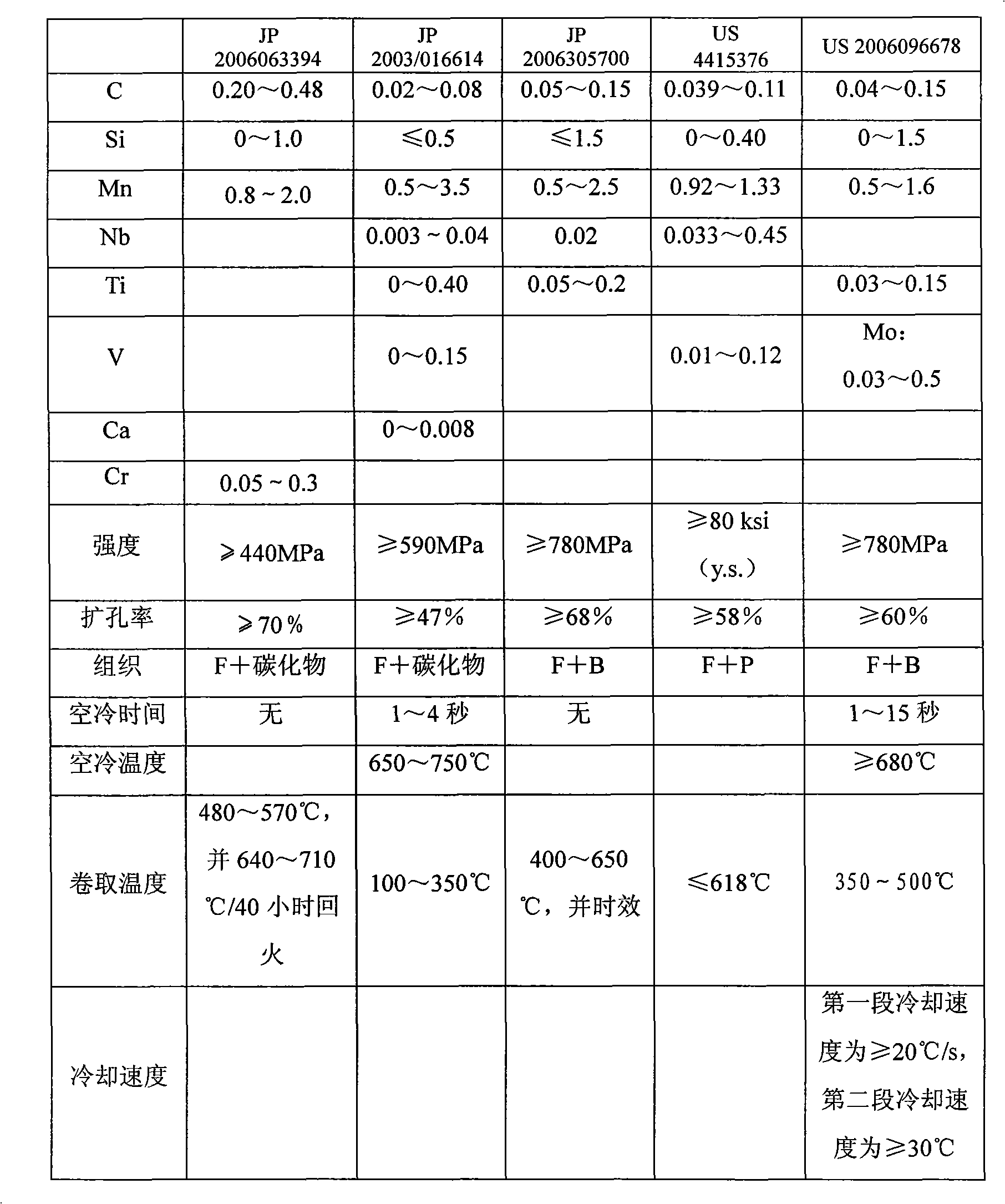

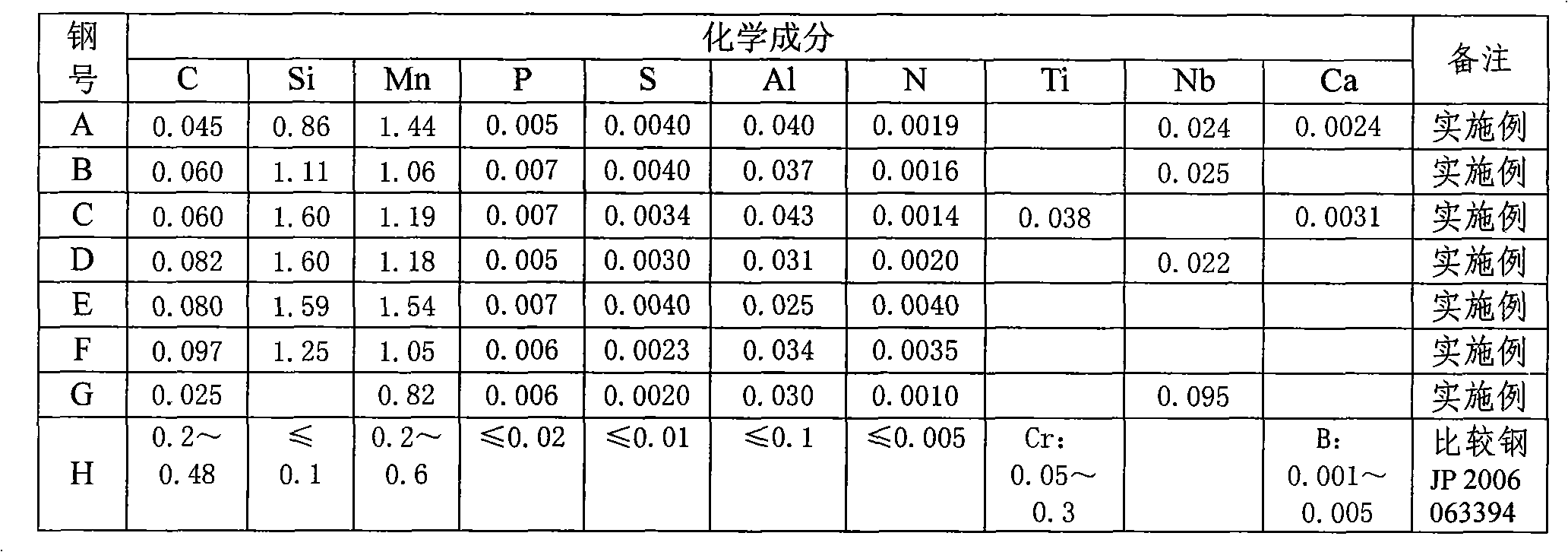

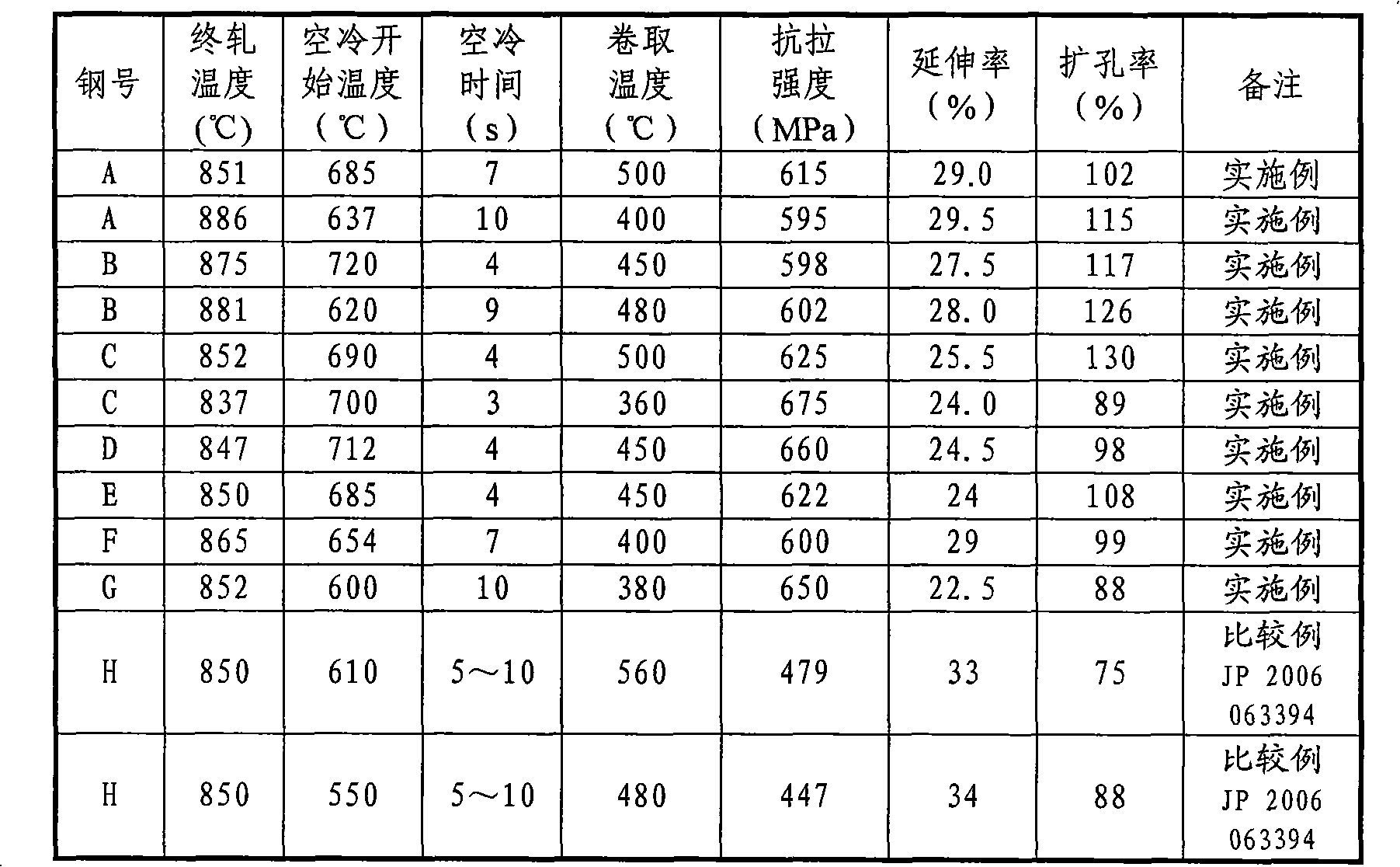

Hot rolling high-chambering steel plate with tensile strength of 590 MPa and manufacturing process thereof

The invention discloses a hot rolling high-chambering steel plate with the tensile strength of 590 MPa. The steel plate comprises the following chemical compositions in percentage by weight: 0.02-0.10 percent of C, 0-1.6 percent of Si, 0.8-2.0 percent of Mn, smaller than or equal to 0.035 percent of P, smaller than or equal to 0.010 percent of S, 0.025-0.060 percent of Al, smaller than or equal to 0.0060 percent of N, 0-0.10 percent of Nb, 0-0.04 percent of Ti, 0-0.0050 percent of Ca and the balance of Fe and unavoidable impurities. The manufacturing process of the hot rolling high-chambering steel plate comprises the following steps of: heating a steel billet at 1,150-1,250 DEG C, and then rolling in an austenitic area, wherein the rolling deformation is larger than 80 percent, and the finish rolling temperature is 830-900 DEG C; cooling the steel plate after finish rolling to 600-750 DEG C at a cooling speed of 50-100 DEG C / s; cooling for 3-10 seconds in the air at a cooling speed of 5-15 DEG C / s; then cooling the steel plate to 350-500 DEG C at a cooling speed of 70 DEG C / s and reeling; and then cooling in the air to room temperature. The steel plate is particularly suitable for manufacturing a chassis component of a car.

Owner:BAOSHAN IRON & STEEL CO LTD

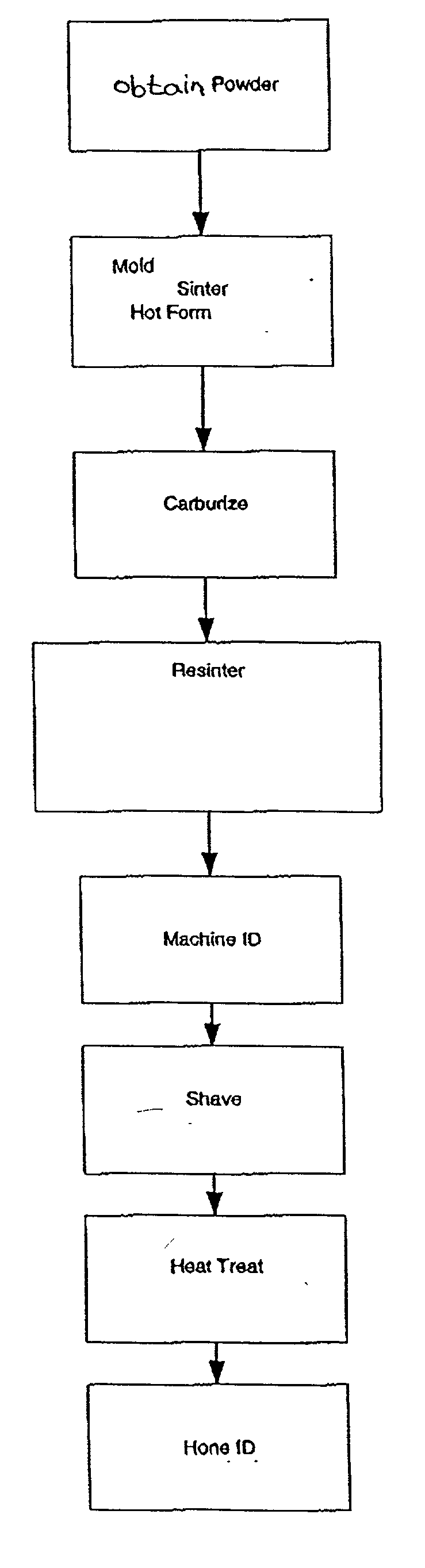

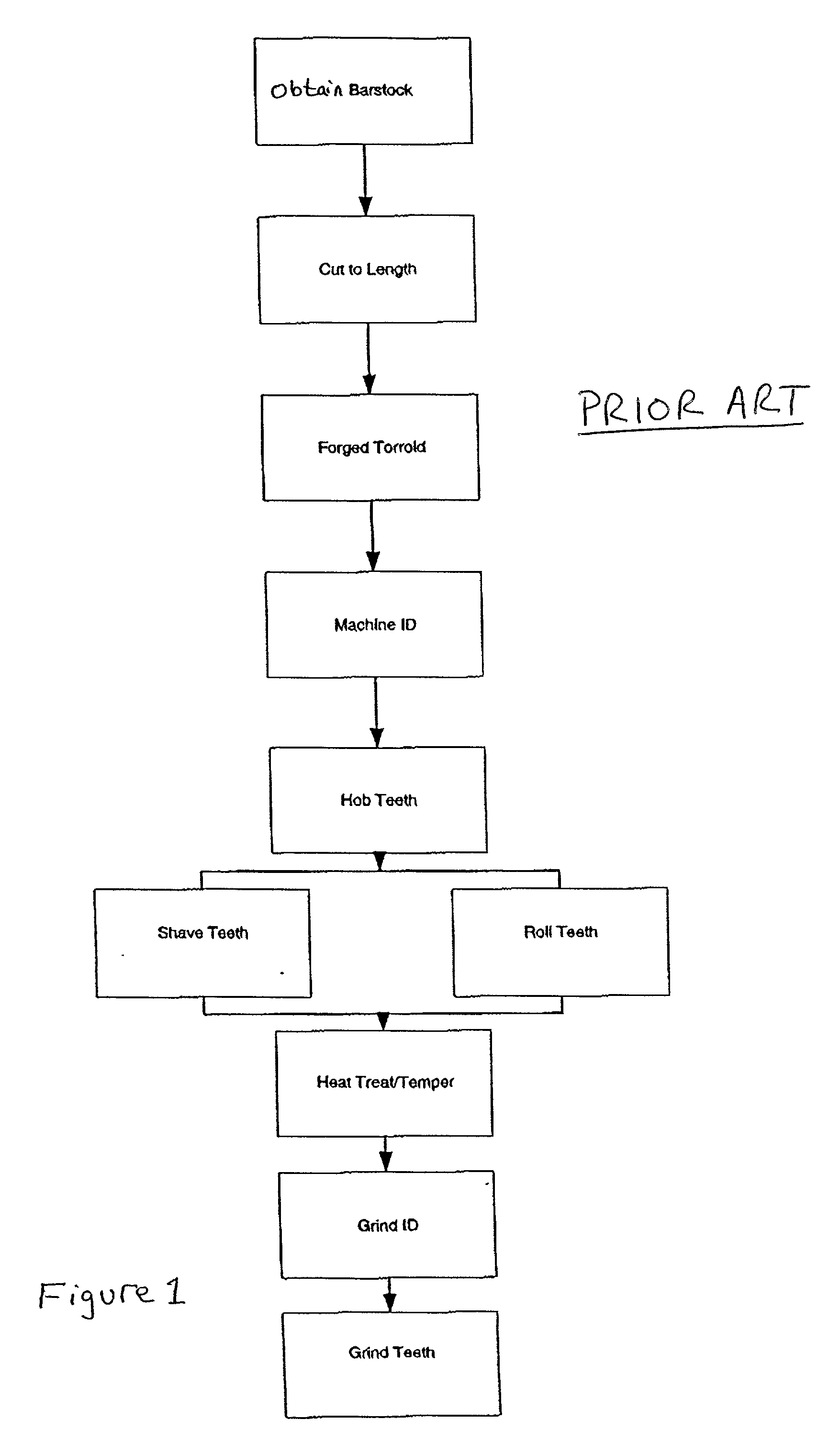

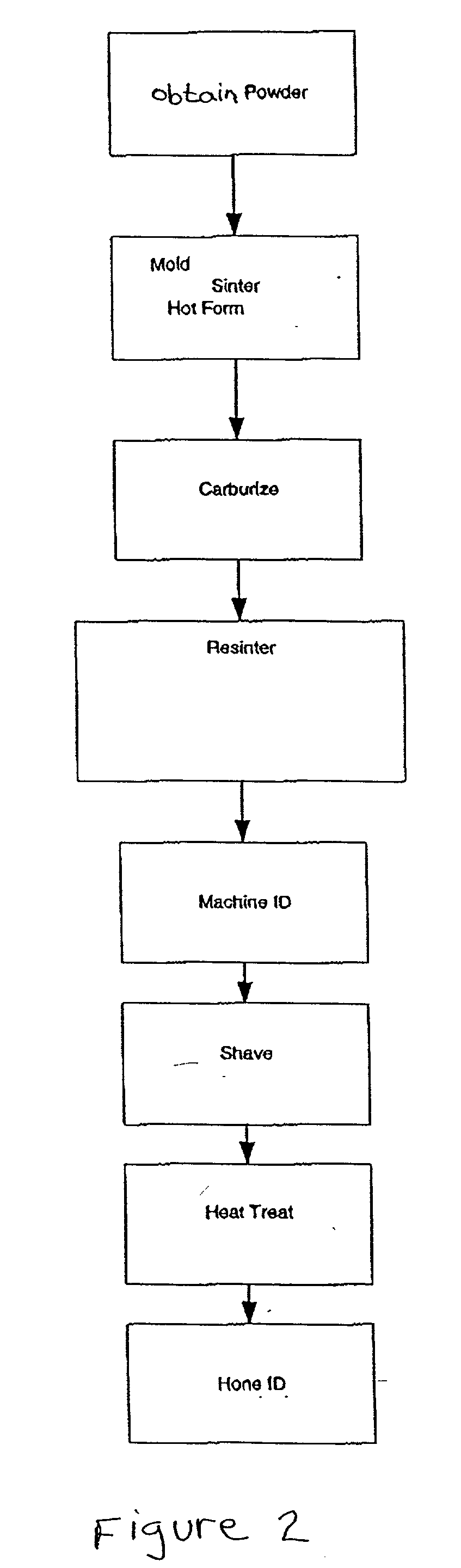

Method for producing powder metal gears

InactiveUS20030035747A1Improve uniformityHigh hardnessFurnace typesHeat treatment furnacesGear toothMetal

A method of producing a gear from a metallurgical powder includes molding at least a portion of the powder to provide a gear preform. The gear preform is sintered and hot formed, and subsequently may be carburized. The gear preform is resintered and cooled at a cooling rate suitable to provide a bainitic microstructure in at least a surface region of the preform. The gear teeth of the preform may be shaved to, for example, adjust dimensions, and enhance dimensional uniformity.

Owner:KEYSTONE INVESTMENT CORP

Brake Pad Prognosis System

A method for providing an estimate of brake pad thickness. The method employs fusion of sensors, if used, and driver brake modeling to predict the vehicle brake pad life. An algorithm is employed that uses various inputs, such as brake pad friction material properties, brake pad cooling rate, brake temperature, vehicle mass, road grade, weight distribution, brake pressure, brake energy, braking power, etc. to provide the estimation. The method calculates brake work using total work minus losses, such as aerodynamic drag resistance, engine braking and / or braking power as braking torque times velocity divided by rolling resistance to determine the brake rotor and lining temperature. The method then uses the brake temperature to determine the brake pad wear, where the wear is accumulated for each braking event. A brake pad sensor can be included to provide one or more indications of brake pad thickness from which the estimation can be revised.

Owner:GM GLOBAL TECH OPERATIONS LLC

Diphase stainless steel and manufacturing method thereof

The invention discloses a diphase stainless steel, which comprises the following components in percentage by weight: less than or equal to 0.05 percent of C, 0.2 to 1.0 percent of Si, 0 to 2.0 percent of Mn, 22 to 27 percent of Cr, 0 to 2.0 percent of W, less than or equal to 0.1 percent of S, less than or equal to 0.03 percent of P, 0 to 0.003 percent of B, more than 0 and less than or equal to 0.2 percent rare earth of which the Ce content is more than 50 percent, and the balance of Fe and inevitable impurities, wherein a casting blank of the diphase stainless steel comprises over 60 percent of isometric crystal. A method for manufacturing the diphase stainless steel comprises the following steps of: performing smelting, die casting or continuous casting to form the casting blank, wherein the thickness of a steel die is more than 30 mm during the die casting to ensure that the cooling velocity of the steel is more than 10 DEG C per minute, and in the process of the continuous casting, the degree of superheating of the casting is between 30 and 100 DEG C, and the casting speed is over 1.2 meters per minute; putting the casting blank into a heating furnace, heating the casting blank to the temperature of between 1,100 and 1,250 DEG C, performing heat preservation on the casting blank, and then forging or hot-rolling the casting blank to a required thickness; and annealing and pickling a steel plate or a plate coil after forging or hot-rolling, and controlling the annealing temperature to be between 1,000 and 1,100 DEG C. The diphase stainless steel has high corrosion resistance and high hot-working performance, and can be widely applied in the fields of petroleum, chemical industry, papermaking, marine engineering and the like in rigorous corrosion environments.

Owner:BAOSTEEL SPECIAL STEEL CO LTD +1

Super-thick non-hardening plastic mold steel and method for manufacturing the same

ActiveCN101096743ARealize non-temperedEliminate quenching and temperingHeat treatment process controlHardnessImpurity

The invention discloses a hyper-thick non-modified plastic die steel, which comprises the following parts: 0.20-0.32% C , 0.20-0.80% Si , 1.80-2.50% Mn, 0.80-1.50% Cr, 0.20-0.60% Mo, 0.08-0.20% V, 0.0010-0.0030% B, 0.02-0.06% Ti , not more than 0.035% P, not more than 0.035% S, ferric and inevitable impurity, wherein the structure condition is bainite. The invention ensures the hardness HRC30-36 of bainite structure and pre-hardening plastic die steel, which controls the cooling speed after forging with thickness over 300mm.

Owner:宝武特种冶金有限公司

Thick steel plate with great line energy and low welding crack sensitivity and its production process

The present invention discloses one kind of thick steel plate with great line energy and low welding crack sensitivity and its production process. The chemical composition includes C 0.06-0.10 wt%, Si 0.15-0.40 wt%, Mn 1.20-1.60 wt%, P not more than 0.015 wt%, S not more than 0.007 wt%, Ni 0.15-0.40 wt%, Cr not more than 0.30 wt%, Mo 0.15-0.30 wt%, V 0.02-0.06 wt%, Al 0.015-0.045 wt%, Ti 0.010-0.034 wt%, except Fe and inevitable impurities; and meets Pcm not higher than 0.20 %. The production process includes pre-treatment of molten iron, smelting in converter, LF furnace plus VD furnace vacuum treatment, two stage controlled rolling, on-line laminar flow cooling, tempering at 600-680 deg.c and other steps. The produced steel plate has no need of quenching and tempering treatment.

Owner:ANGANG STEEL CO LTD

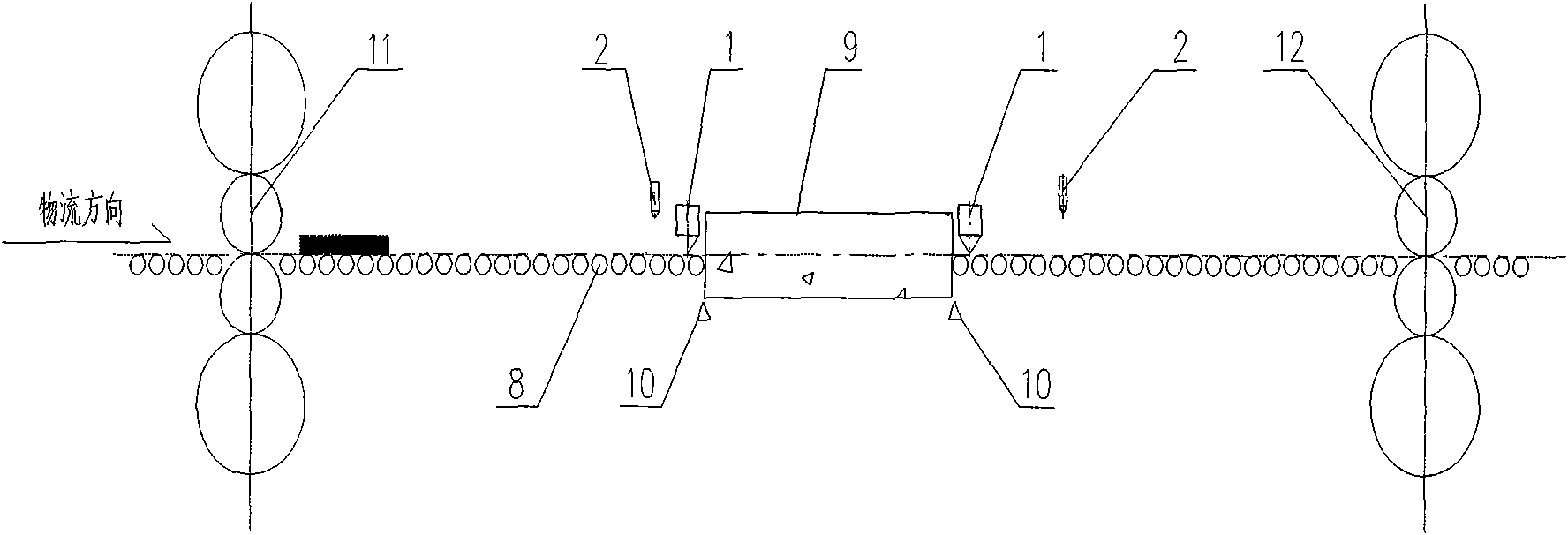

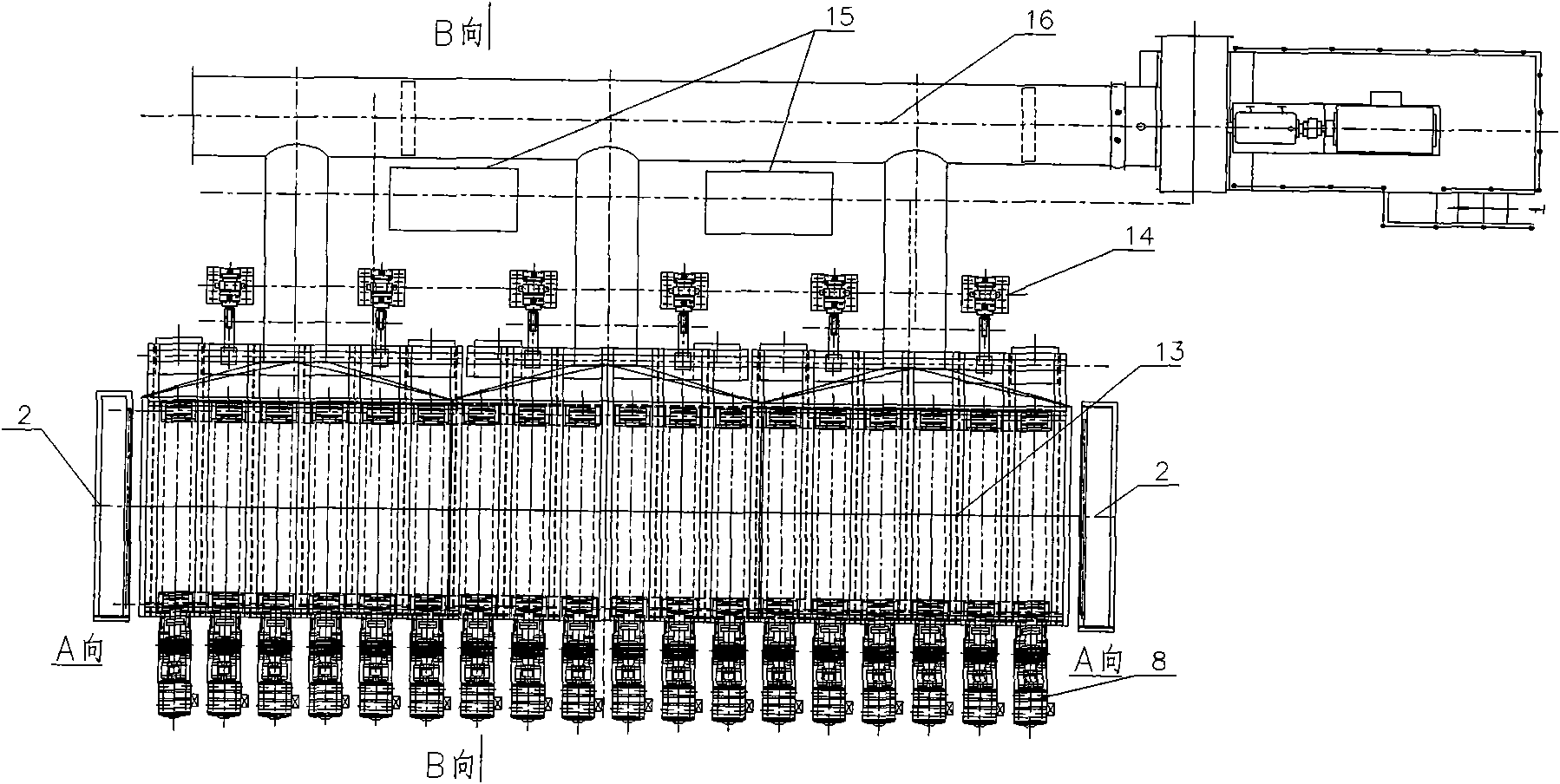

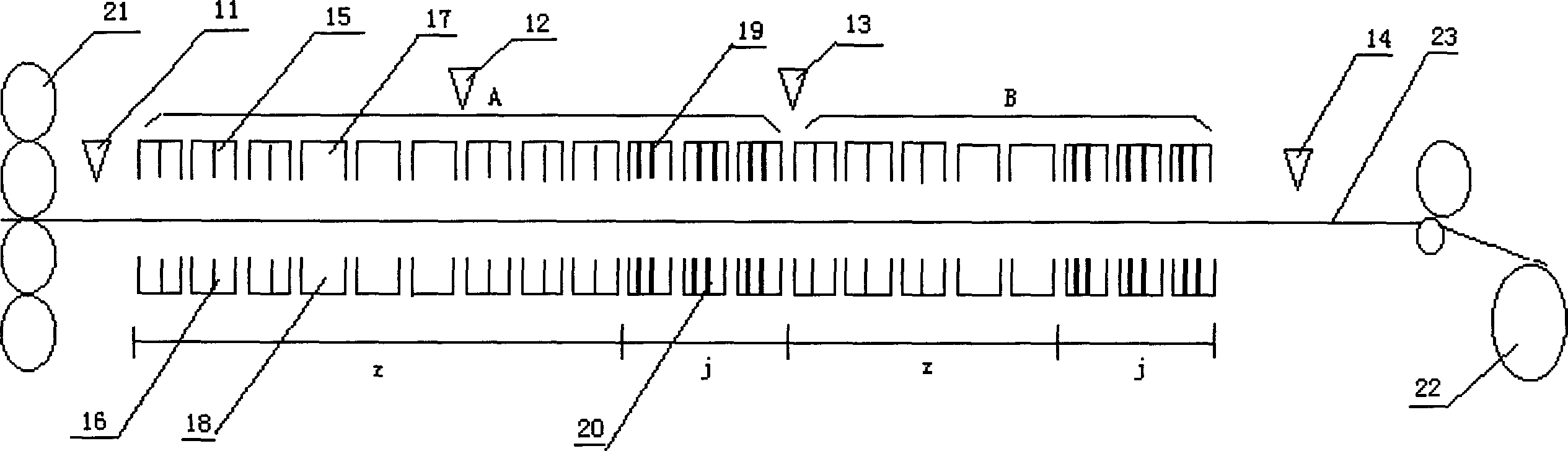

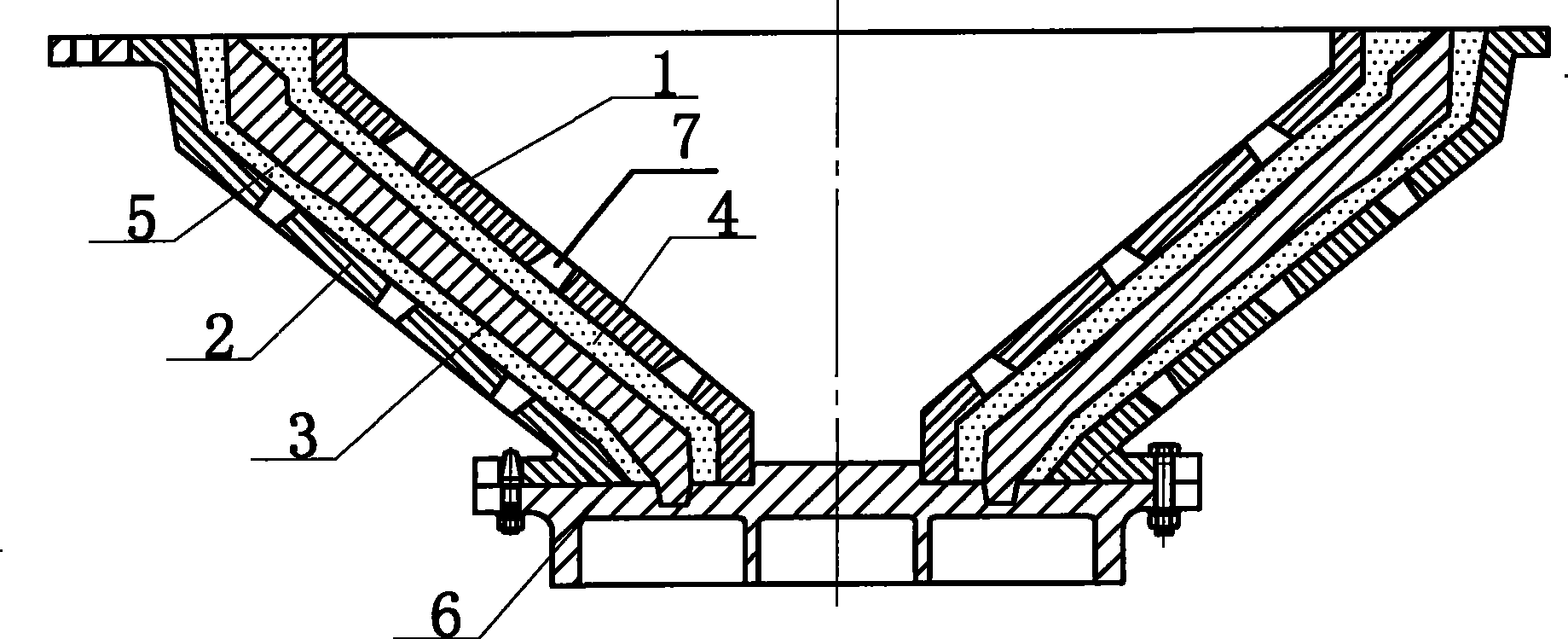

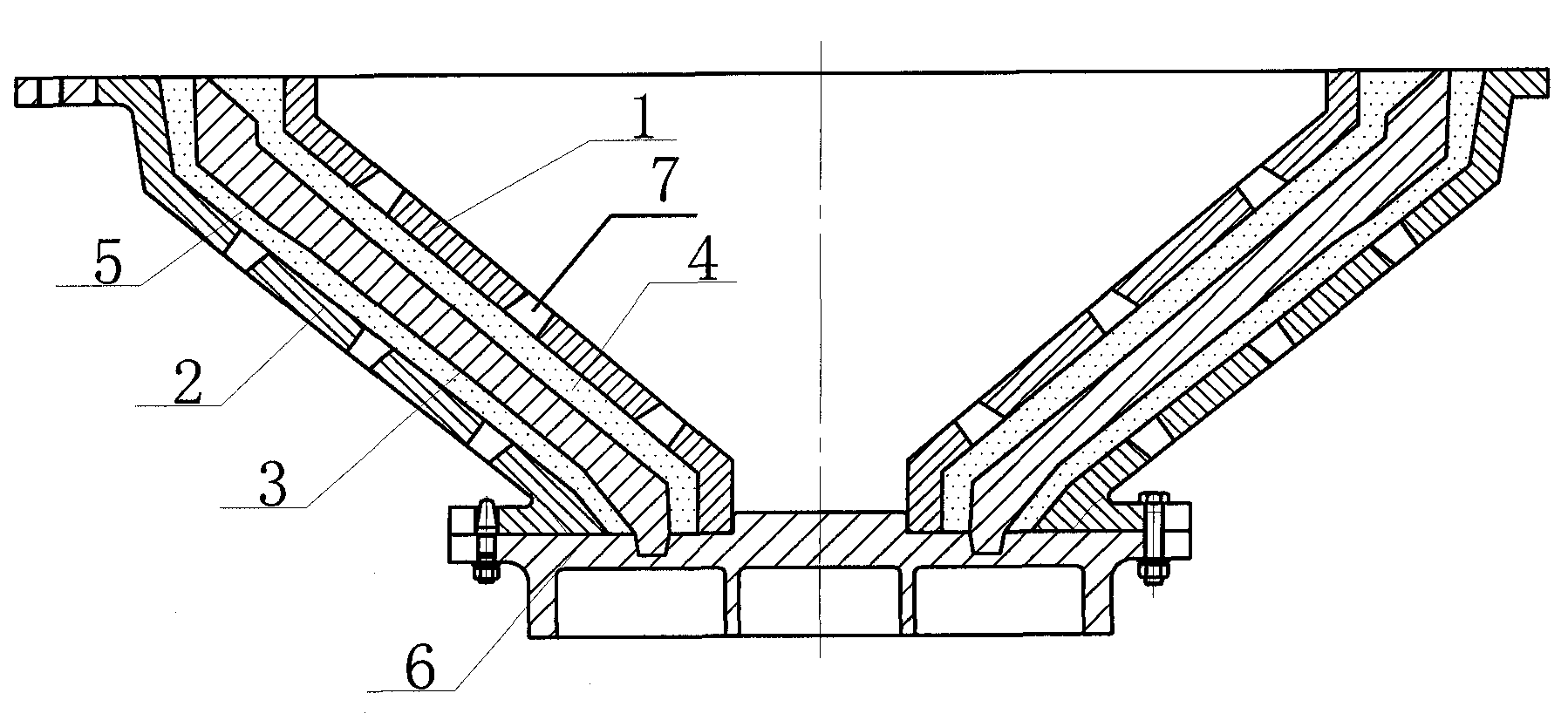

Intermediate blank cooling system and cooling control technology

ActiveCN101642780ADoes not change metal propertiesReduce difficultyTemperature control deviceWork treatment devicesProduction lineEngineering

The invention belongs to the metallurgy technical field and in particular relates to an intermediate blank cooling system and cooling control technology. The intermediate blank cooling system is characterized in that an aerial fog cooling device body is arranged between a rough mill and a finishing mill. The aerial fog cooling device body is composed of an upper cooling header and a lower coolingheader, and an aerial fog nozzle and a compression air pipe are arranged on the cooling water pipe of the upper cooling header and the lower cooling header; and the on / off control valve and flow control valve of the cooling water pipe and the compression air pipe are connected with a control valve station. The intermediate blank aerial fog cooling technology is controlled by the aerial fog controltechnology sprayed on the cooling header arranged near roller ways at the front and rear of the mills. The invention has fast cooling speed without changing metal performance, water yield regulatingrange is wide and the water yield can be regulated continuously, the cooling speed of the intermediate blank can be precisely controlled, and the invention can be widely applicable to middle and thickplate production line.

Owner:CISDI ENG CO LTD

Device and method for continuous block metal glass shaping

InactiveCN101543885ASolve the vacuum problemIncrease cooling intensityMetallic materialsPressure difference

The invention relates to a device and method for continuous block metal glass shaping, belonging to the technical field of metal material preparation. A heat insulating ring is arranged between a graphite casting mould and a water cooling copper mould which are arranged in a first vacuum chamber, an air cooler is arranged in a second vacuum chamber, and a traction rod enters the graphite casting mould and horizontally moves by a traction device. The method uses the graphite casting mould and the water cooling copper mould for primary main cooling and the air cooling mode for secondary auxiliary cooling, and the two vacuum chambers have a certain air-pressure difference. The device and the method have a high cooling speed, satisfy the requirements of the amorphous phase change of the block metal glass material. The shaping pressure of a metal melting body can be easily controlled, and the good shaping performance of the metal melting body is ensured by adjusting the pressure in the vacuum chambers. The metal passes through the graphite casting mould in a liquid state and is solidified in the water cooling copper mould, and the casting graphite casting mould has long service. The composite casting mould and the traction device have exchangeability to be convenient for realizing the continuous shaping of rod wires, boards, pipes and abnormal-shaped materials of different section sizes.

Owner:江苏苏州洲盛非晶科技有限公司

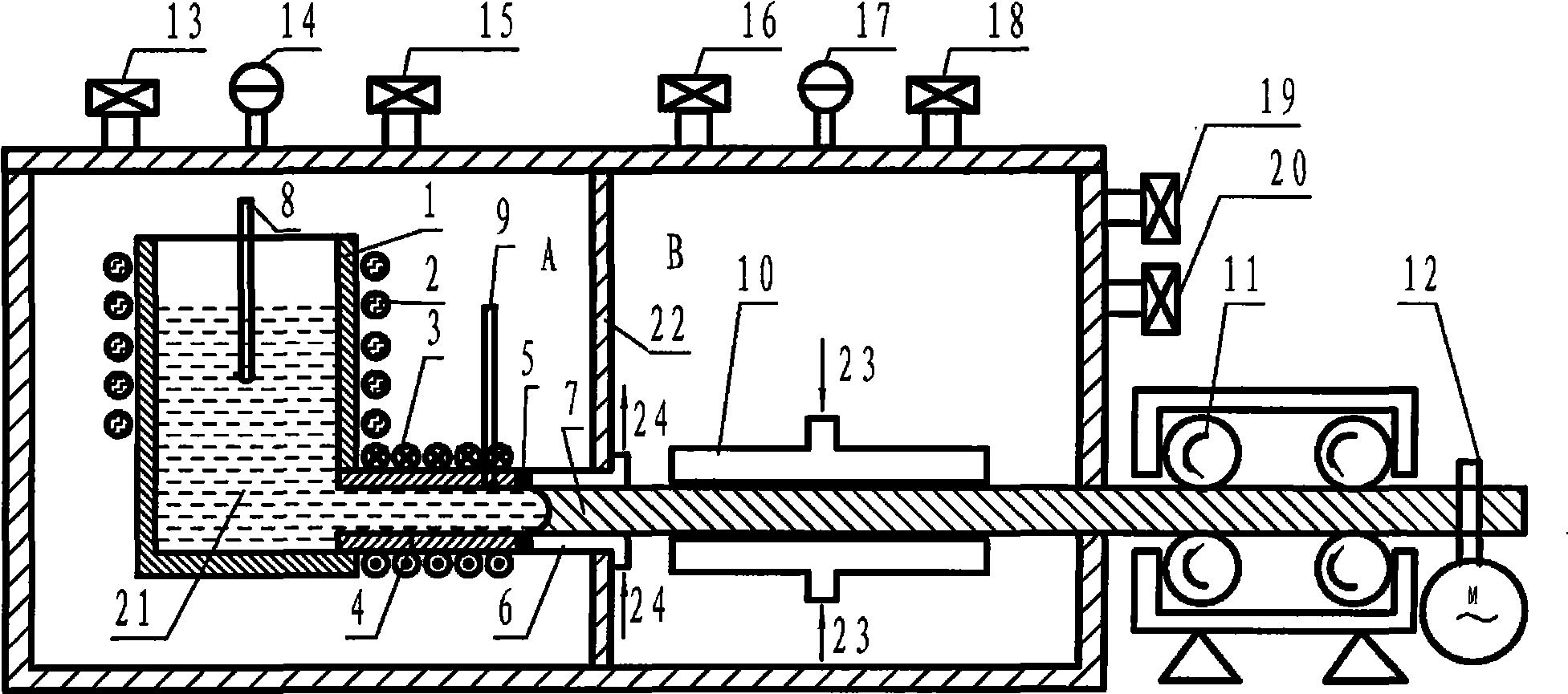

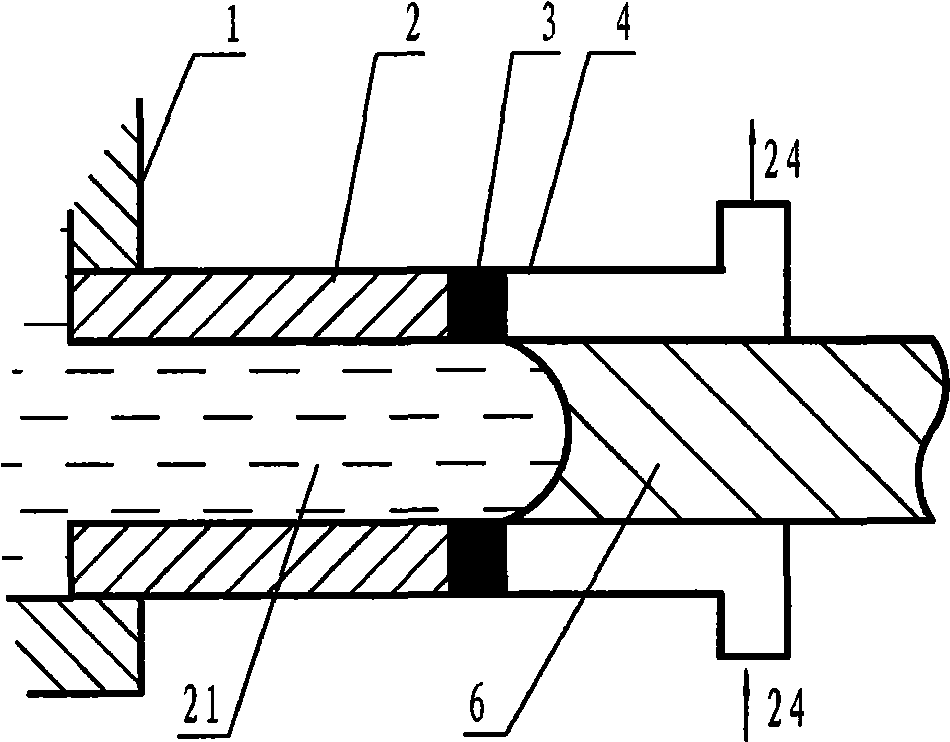

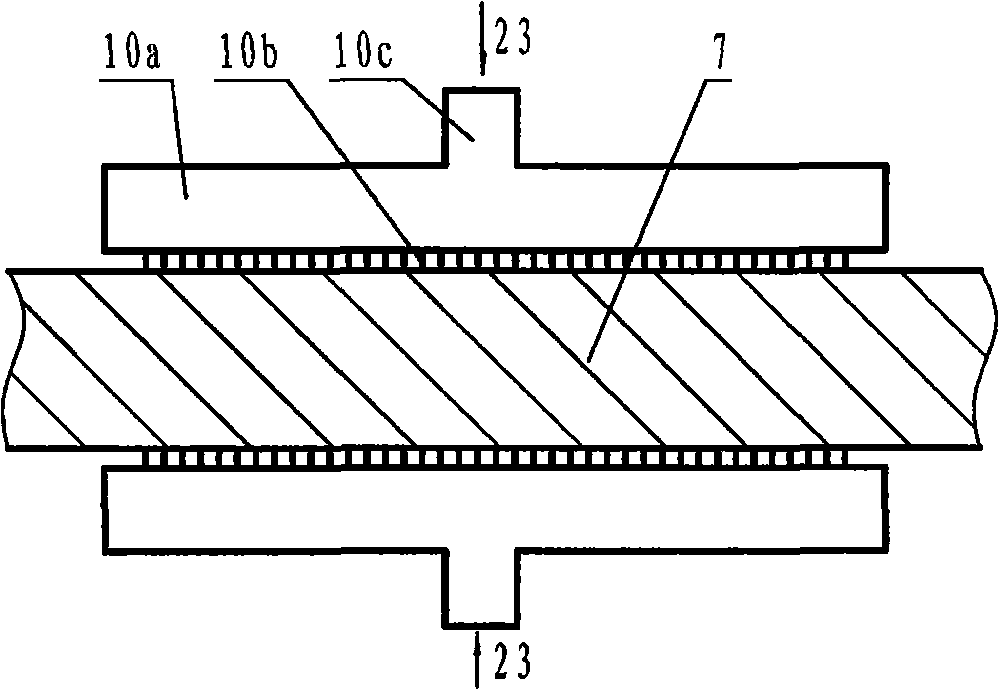

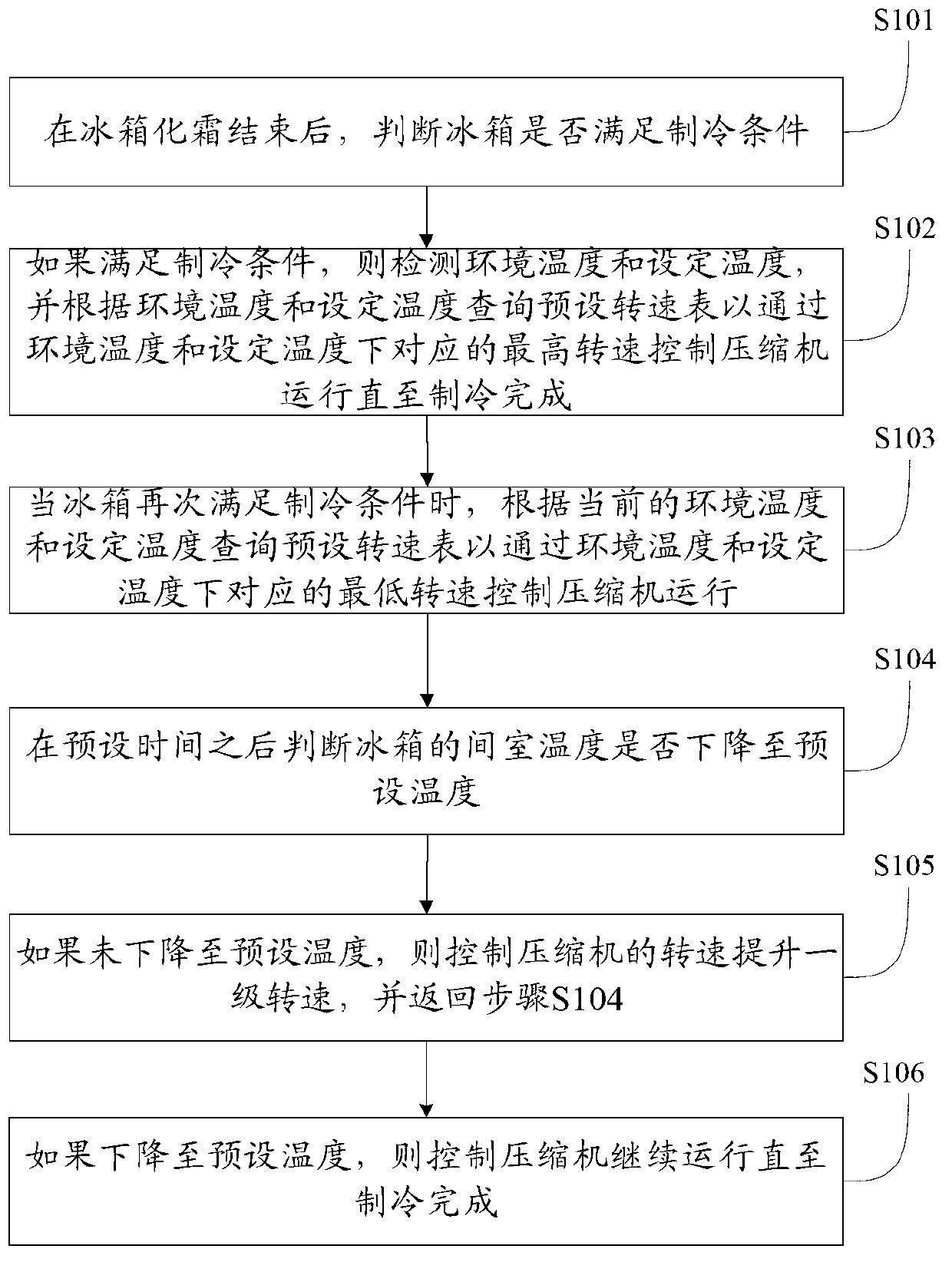

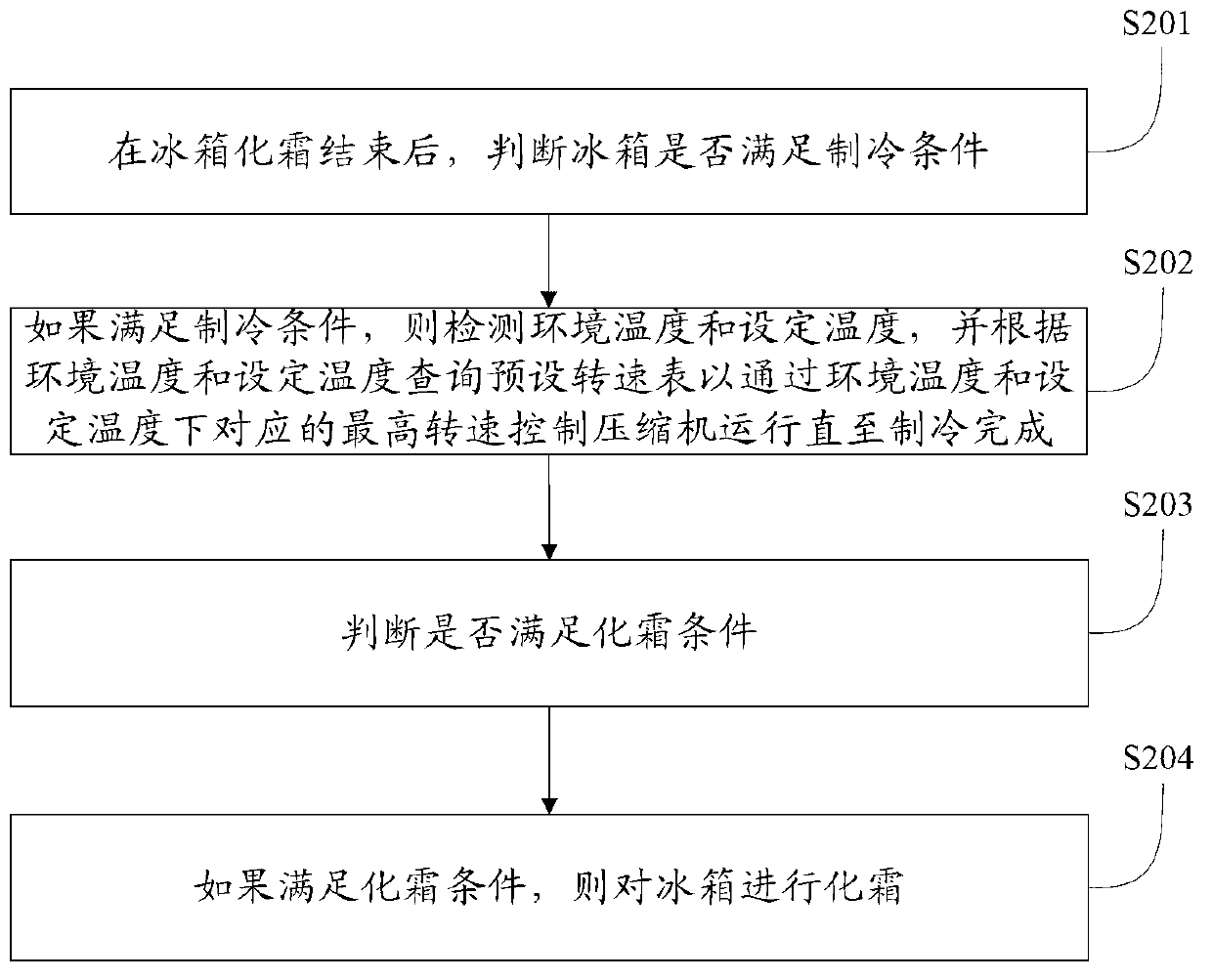

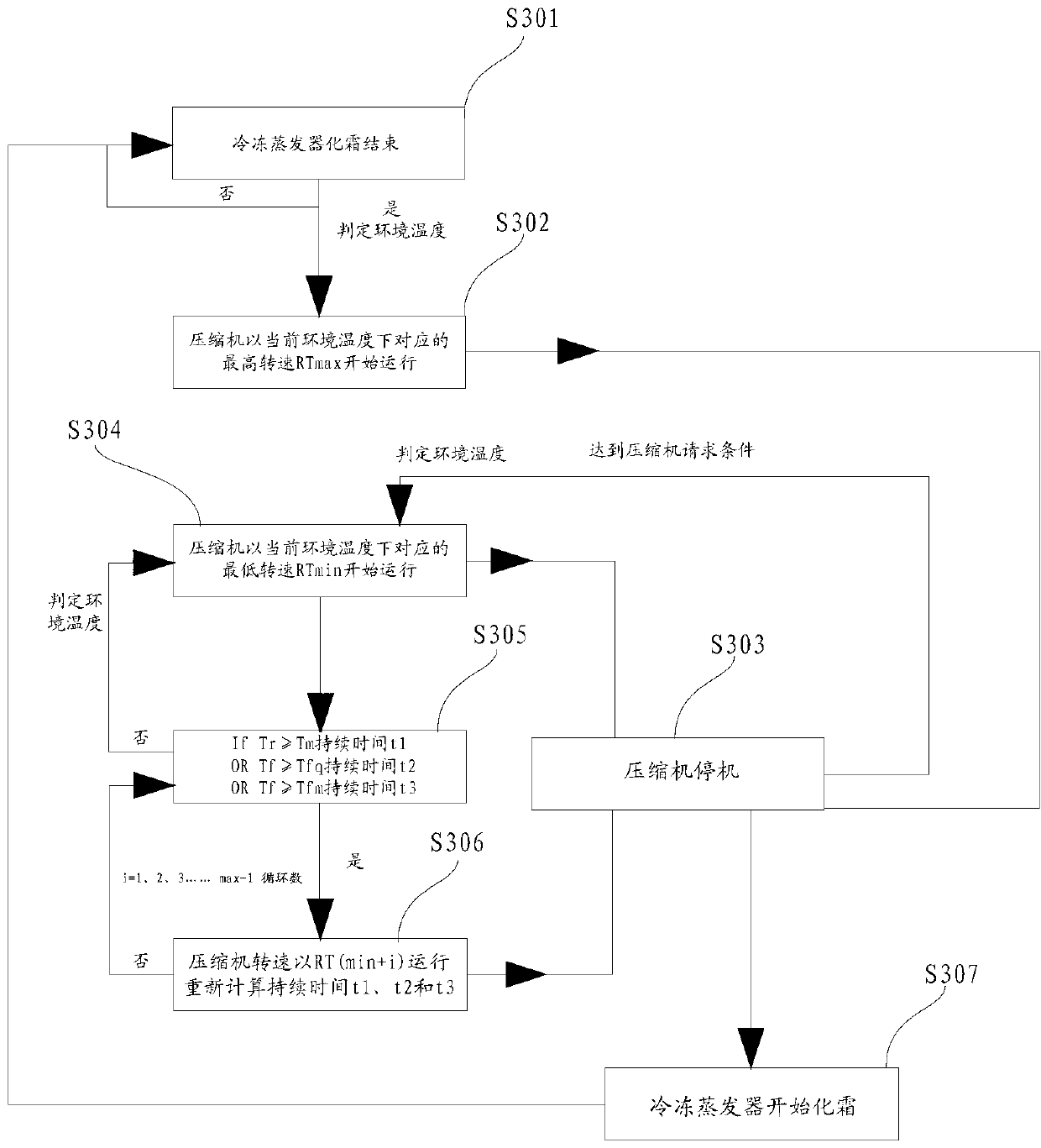

Frequency converting control method for refrigerator

ActiveCN102997609ASpeed up coolingReduce wasteDomestic cooling apparatusLighting and heating apparatusFrequency conversionEngineering

The invention provides a frequency converting control method for a refrigerator. The method includes that (1) whether the refrigerator meets a refrigeration condition or not is determined after defrosting of the refrigerator is finished; (2) if the refrigerator meets the refrigeration condition, an environment temperature and a setting temperature are detected, and a preset revolution meter is inquired so as to control the operation of a compressor at a corresponding maximum revolution speed until the refrigeration is completed; (3) when the refrigerator meets the refrigeration condition again, the operation of the compressor is controlled at a corresponding minimum revolution speed; (4) whether the compartment temperature of the refrigerator decreases to a preset temperature or not after preset time is determined; (5) if the compartment temperature of the refrigerator does not decrease to the preset temperature, the revolving speed of the compressor is increased by one level, and the step (4) is returned; and (6) if the compartment temperature of the refrigerator decreases to the preset temperature, the compressor is controlled to continue operating until the refrigeration is finished. According to the frequency converting control method for the refrigerator, the revolving speed of the compressor is continuously adjusted according to the environment temperature, interior temperatures of compartments and the like, so that the frequency conversion is achieved, the cooling speed of the refrigerator is improved, waste of cooling capacity of the compressor is reduced, and the energy consumption is lowered.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

High strength non-quenched and tempered free machining steel for automobile connecting bar and technological process thereof

The invention discloses a high-intensity non-quenching and tempering easy-cutting steel used for a vehicle connection rod and a technical method thereof. The invention starts from the principle of improving the intensity of the non-quenching and tempering easy-cutting steel and leads the anti-tension intensity of the non-quenching and tempering easy-cutting steel containing 0.30 to 0.40 percent of carbon to be 1000MPa and the yield strength to be 750MPa by adjusting the components. The technical scheme of the invention is: the high-intensity non-quenching and tempering easy-cutting steel used for a vehicle connection rod consists of the elements of C, Si, Mn, Al, P, S, Cr, V, N and Fe; the weight percentages of the component elements are: 0.30 to 0.4 percent of C, 0. 50 to 0.70 percent of Si, 0.80 to 1.20 percent of Mn, equal to or less than 0.040 percent of P, 0.030 to 0.060 percent of S, 0.010 to 0.040 percent of Al, 0.10 to 0.40 percent of Cr, 0.10 to 0.30 percent of V, 010 to 0.015 percent of N and the rest is Fe and unavoidable impurities. The heating temperature of a continuous casting blank is 1200 DEG C; the heating time is 160min; the start rolling temperature is 1100 DEG C; the final rolling temperature is 900 DEG C; the pressing volume is 16; the cooling speed after rolling is 40 DEG C / min; after bundling, the components are thrown in a pit and slowly cooled.

Owner:WUHAN IRON & STEEL (GROUP) CORP

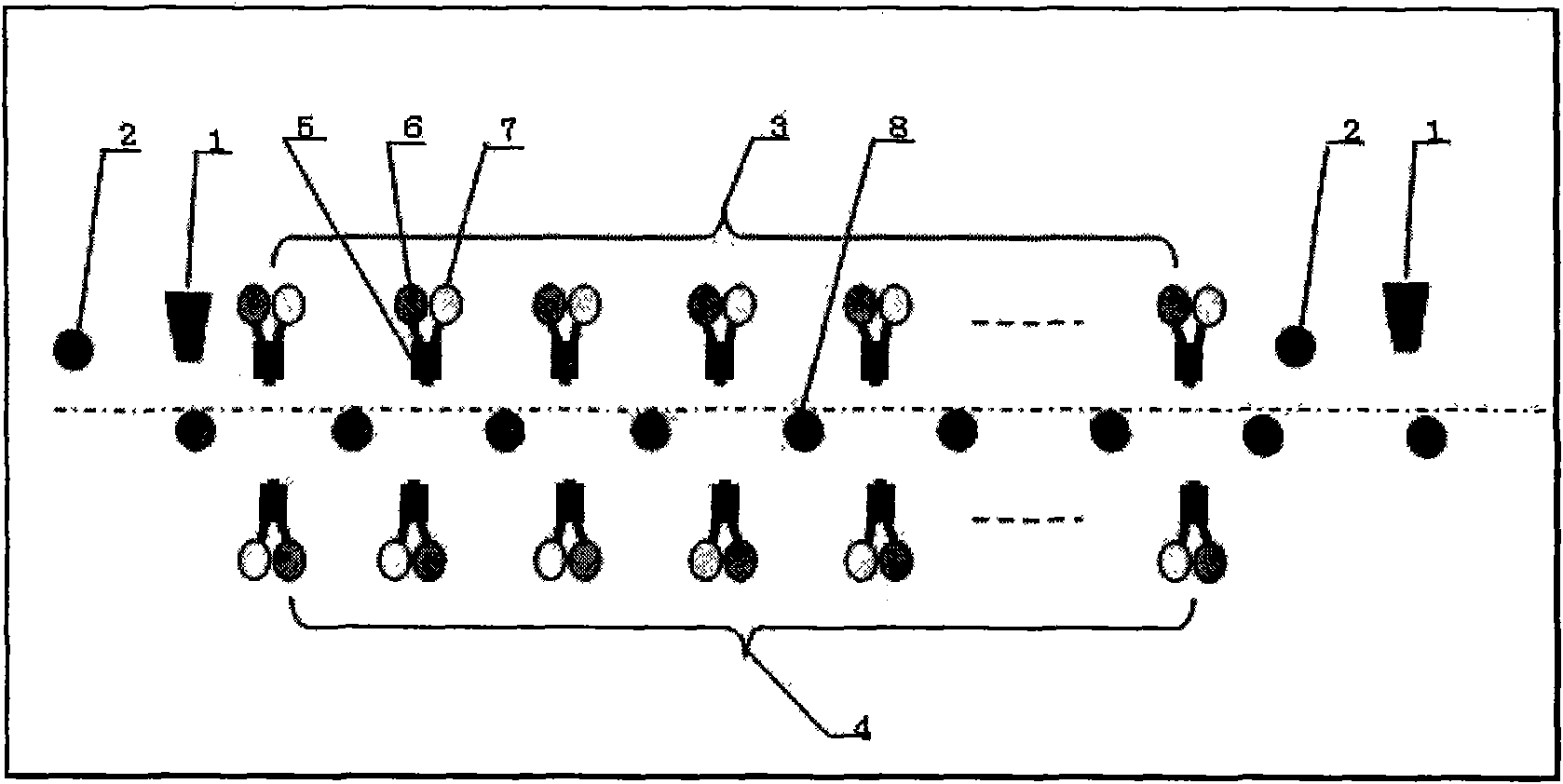

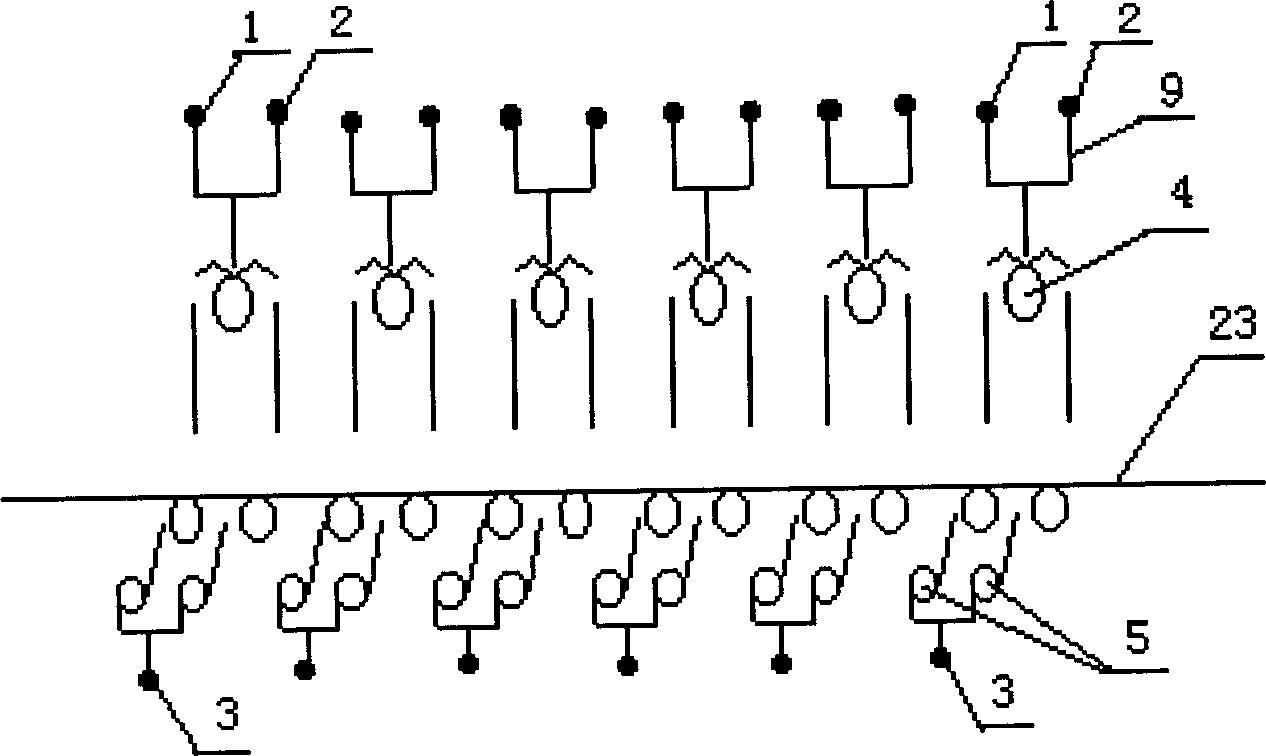

Band-steel laminar-flow cooling device and its cooling control method

InactiveCN1640575ALong cooling areaImprove cooling effectWork treatment devicesMetal rolling arrangementsTemperature controlEngineering

The present invention provides a strip steel laminar flow cooling device which has two cooling zones and has strong cooling function and its controlled cooling method. Said device is formed from cooling zone consisting of upper laminar flow manifold and lower jet manifold, and said cooling zone includes two portions of main cooling section and fine cooling section which are formed from several upper laminar flow manifold groups and correspondent number of lower jet manifold groups. Its controlled cooling method is implemented by using computer to make setting computation, feedback computation and feedforward computation.

Owner:ANGANG STEEL CO LTD

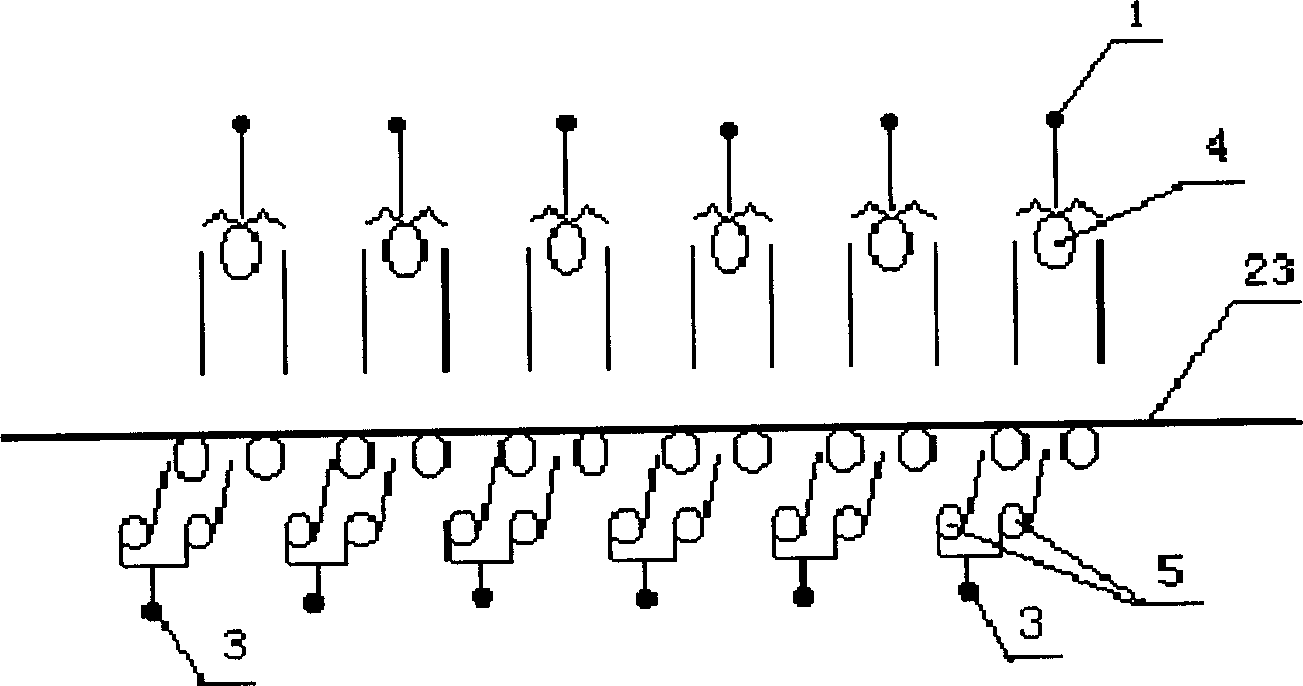

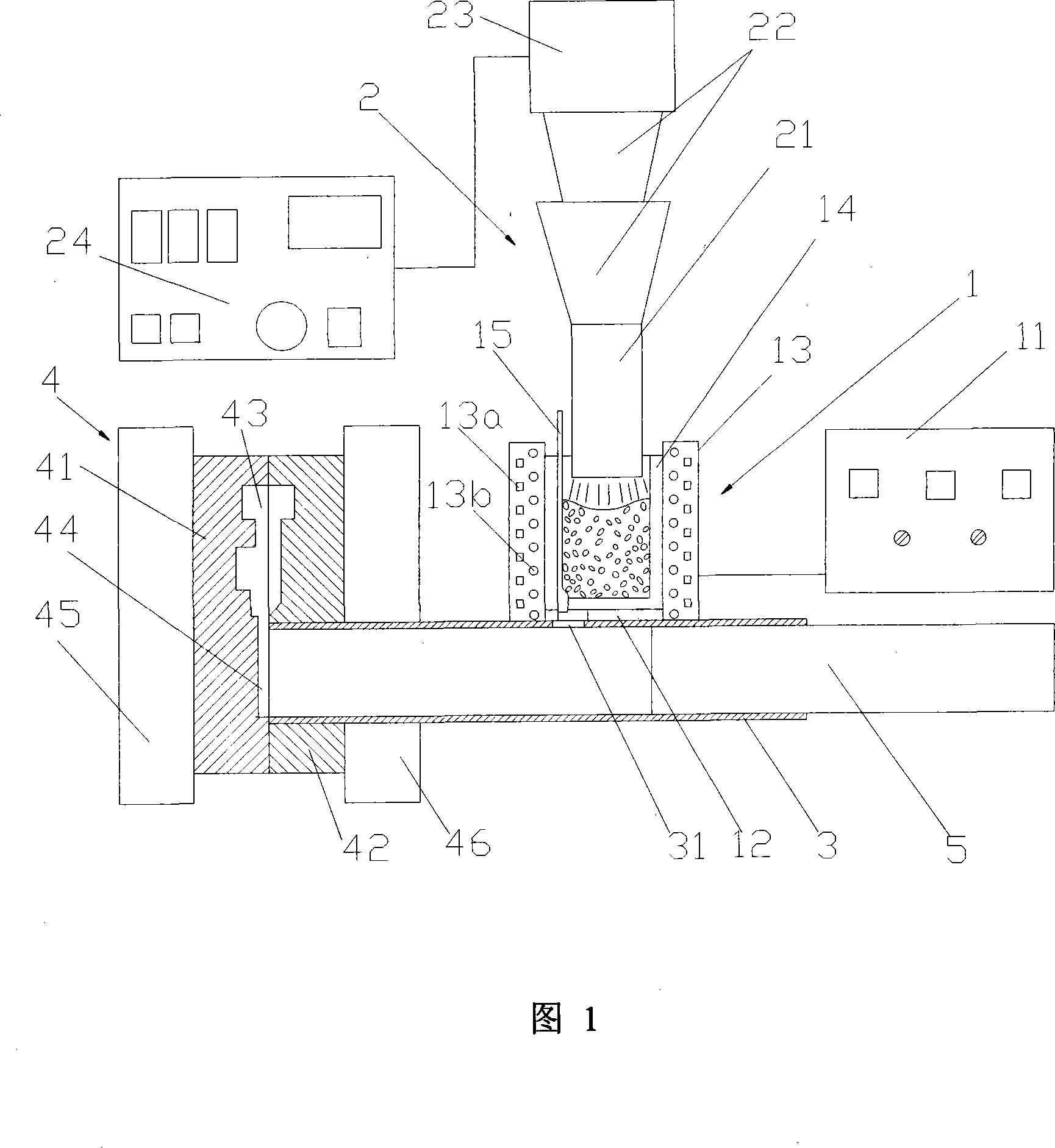

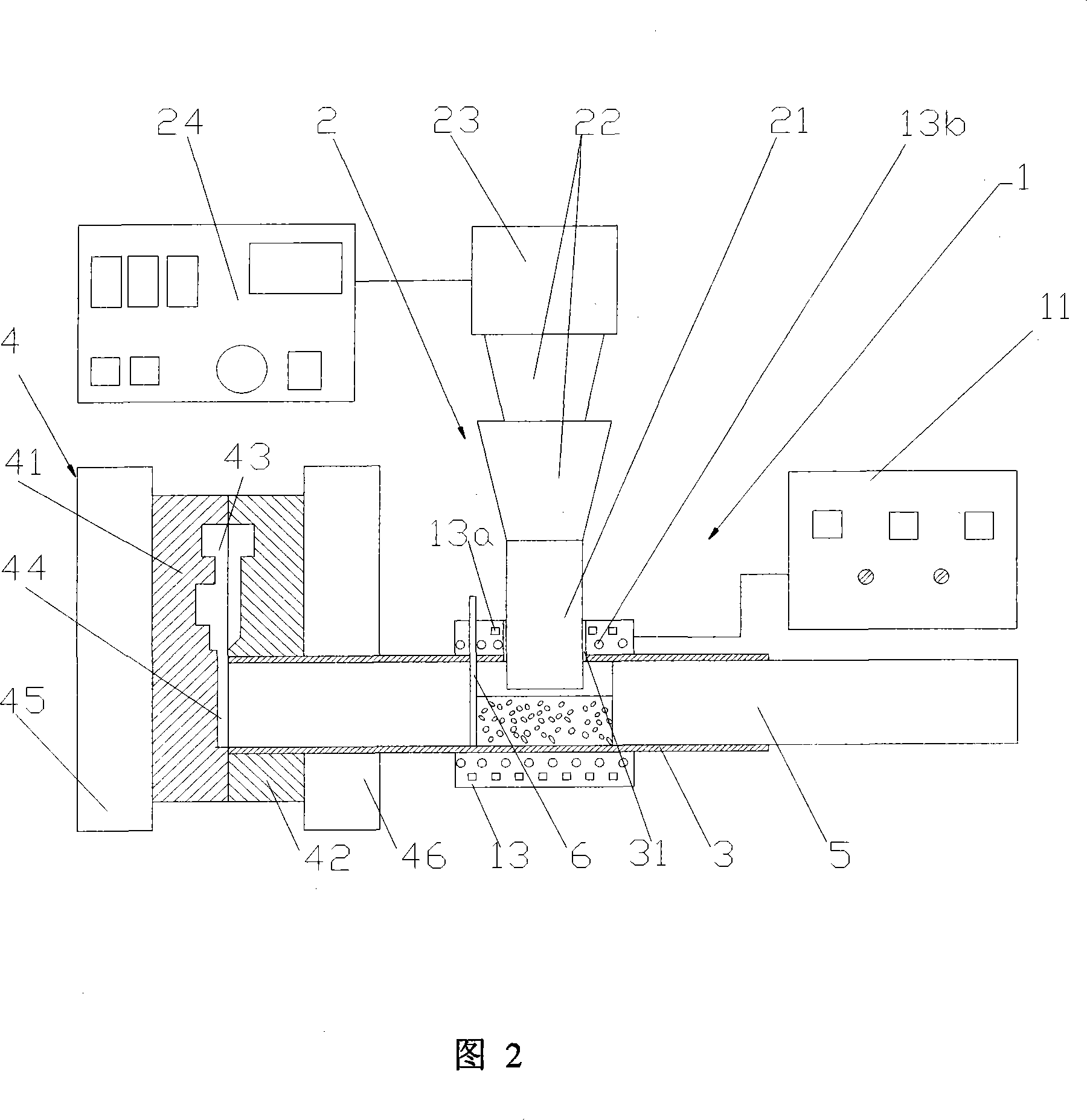

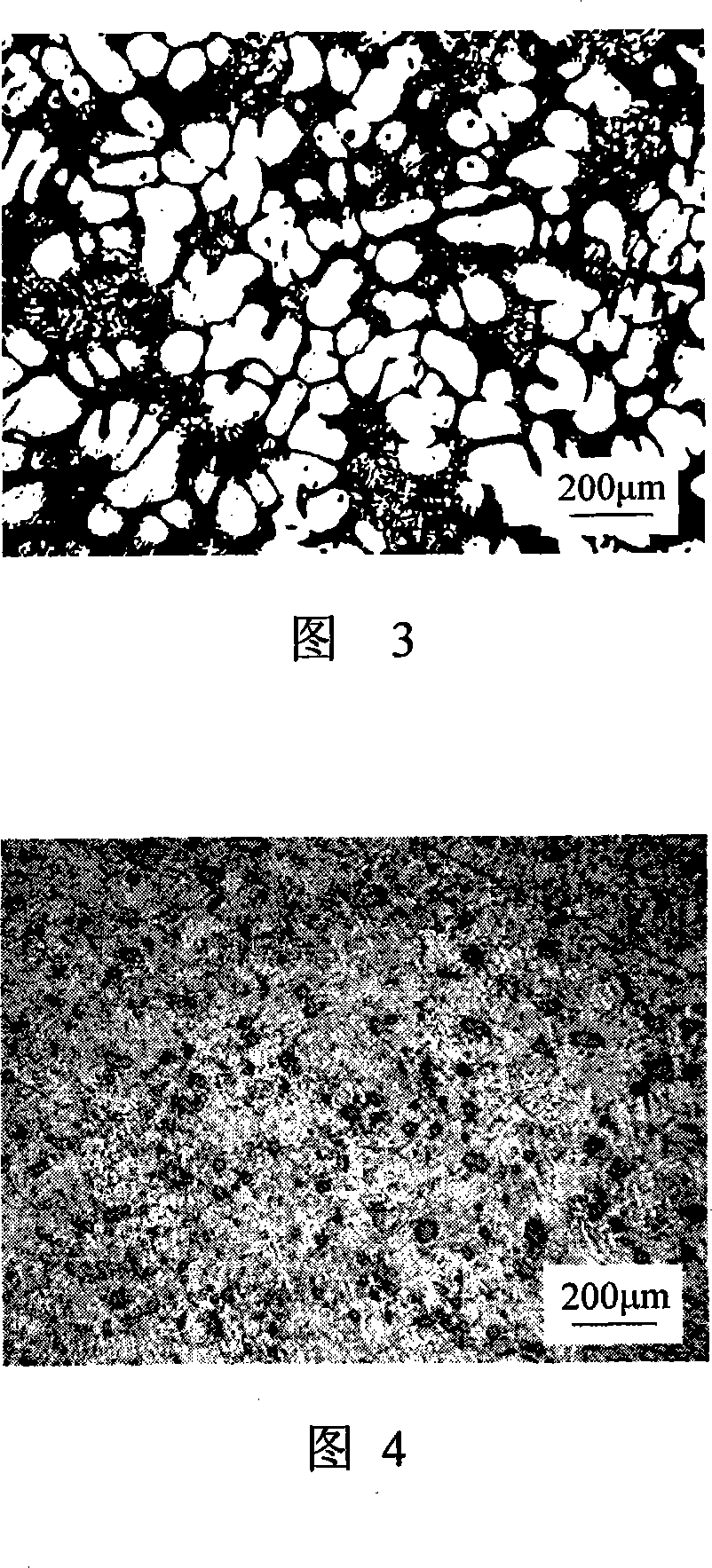

Semi solid rheoforming method for metal parts and device therefor

The invention relates to a semi-solid fluidized molding method and a device for metal parts. Liquid metal with the temperature from 0 to 40 DEG C above liquid phase is guided into a pulp container, and then an ultrasonic radiation is lowered down to 1 to 30mm above the liquid surface, ultrasonic radiation is started, and the slurry is cooled at the speed ranging from 0.1 DEG C per second to 3 DEG C per second. The ultrasonic radiation can be pulse radiation or non-radiation pulse with ultrasonic frequency ranging from 12kHz to 80kHz, radiation volume power 5W / cm<3> to 100W / cm<3>, and radiation time from 15s to 1000s; the slurry is poured into molding equipment to be molded into parts after the radiation. The molded part has dense organization, fine and equally distributed grains. The device of the invention comprises a pulp container, a thermostat, an ultrasonic generation and a control unit, a sleeve, and a mold and an injection rod and a molding device. The fluidized molding method and device can be used for fluidized molding of various alloy parts made from aluminum, magnesium, tin, copper and iron etc. The method has the advantages of non-contaminated pulp, long service life of ultrasonic equipment and high part production efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

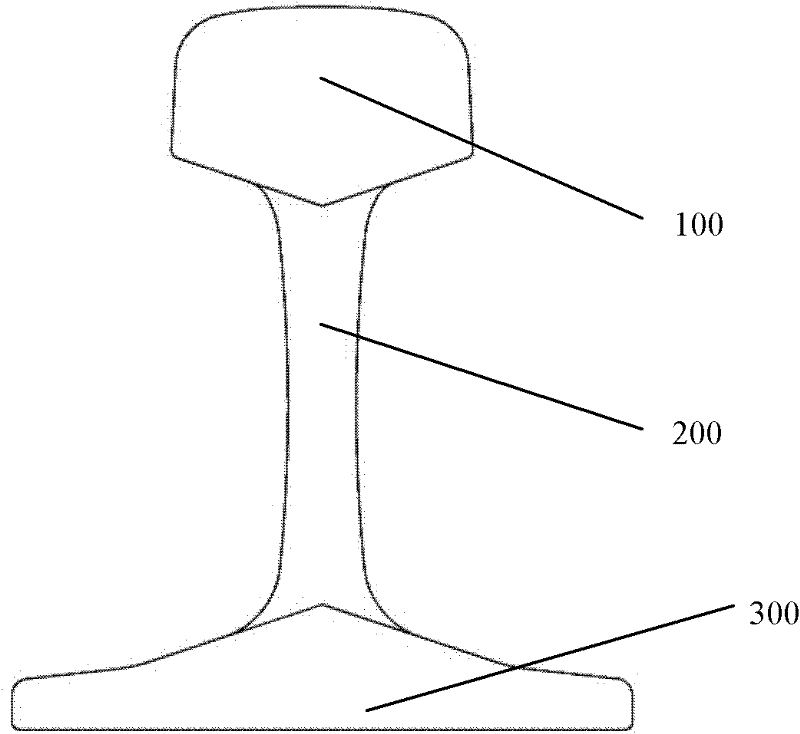

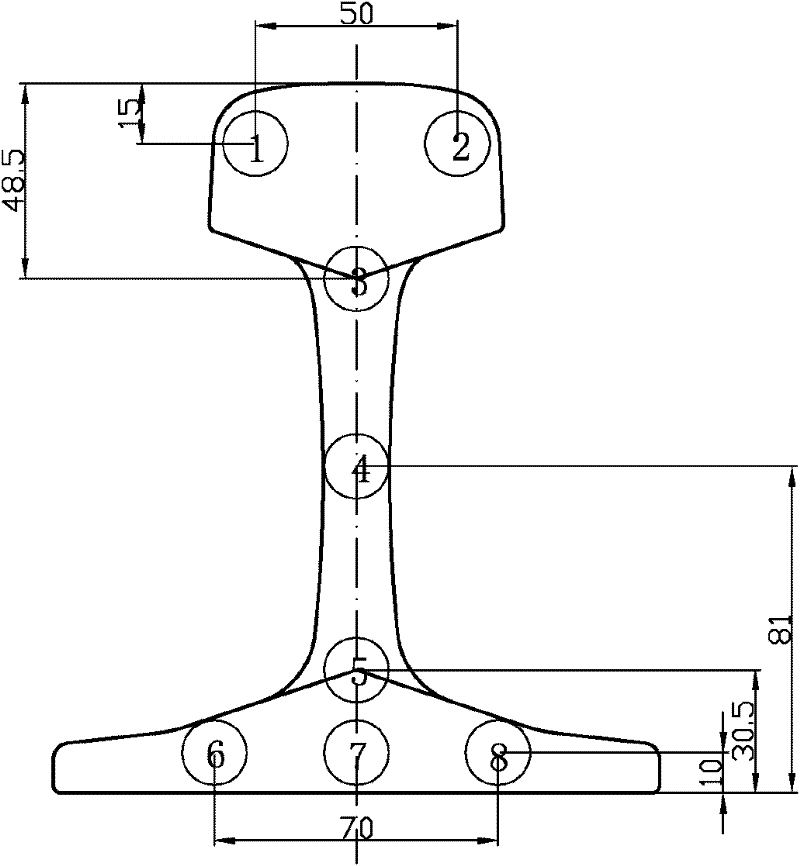

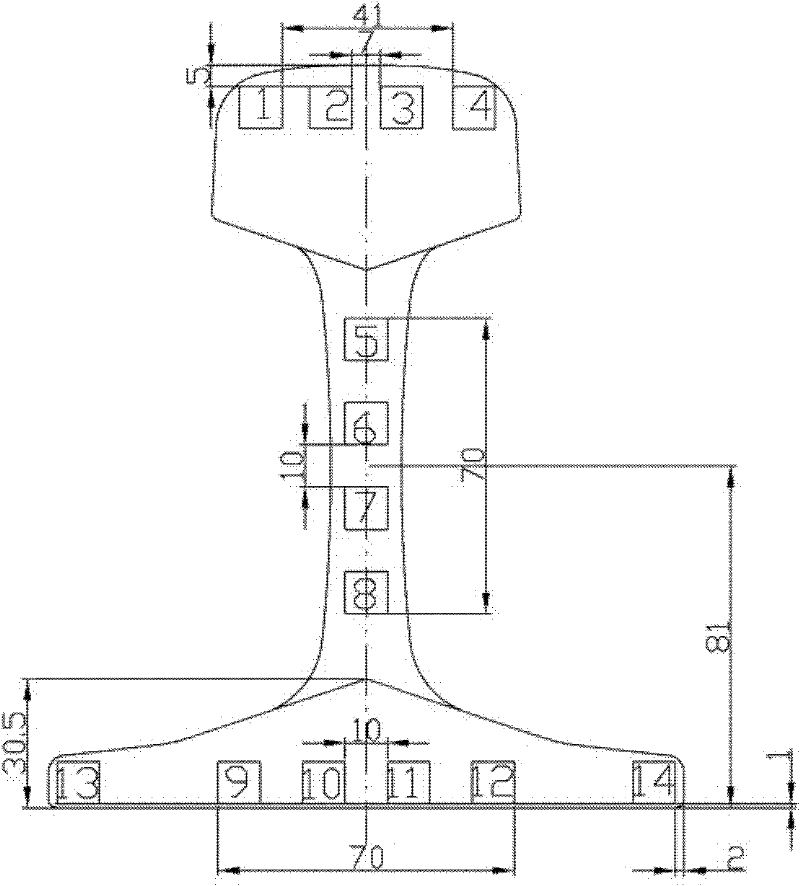

Bainite/martensite steel rail with 1,500 Mpa level of high toughness and manufacturing method thereof

The invention provides a bainite / martensite steel rail and a manufacturing method thereof. The steel rail is formed by performing steel hot rolling on the following components in percentage by weight: 0.10 to 0.40 percent of C, 0.80 to 2.00 percent of Si, 1.20 to 2.40 percent of Mn, 0.50 to 1.20 percent of Cr, 0.20 to 0.60 percent of Mo, and the balance of Fe and inevitable impurities. The steel rail comprises a rail head, a rail waist and a rail bottom, wherein the rail head is subjected to accelerated cooling at a cooling speed of higher than 1 DEG C / s and lower than and equal to 5 DEG C / s to an accelerated cooling stop temperature of lower than 300 DEG C and higher than 200 DEG C.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI

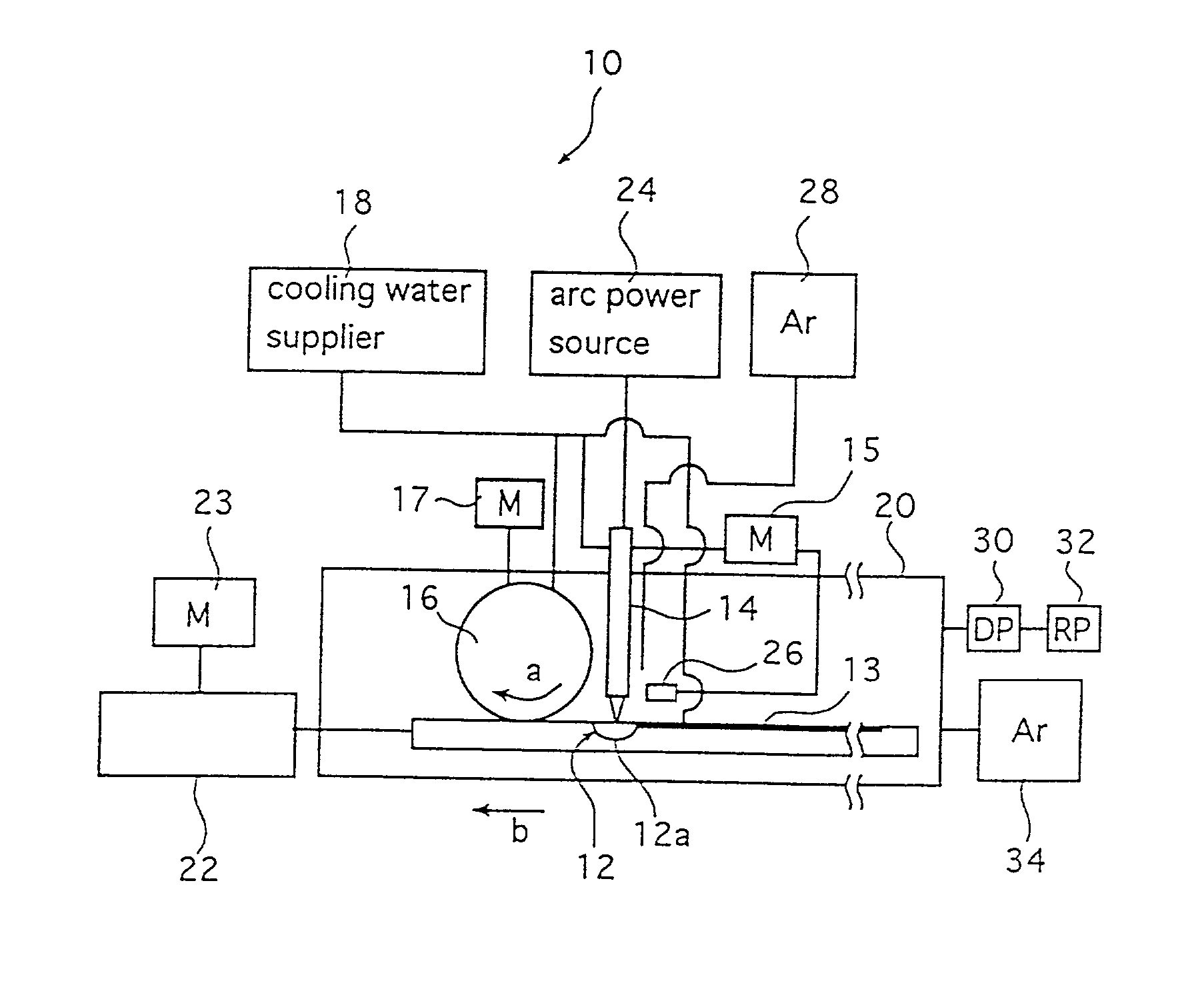

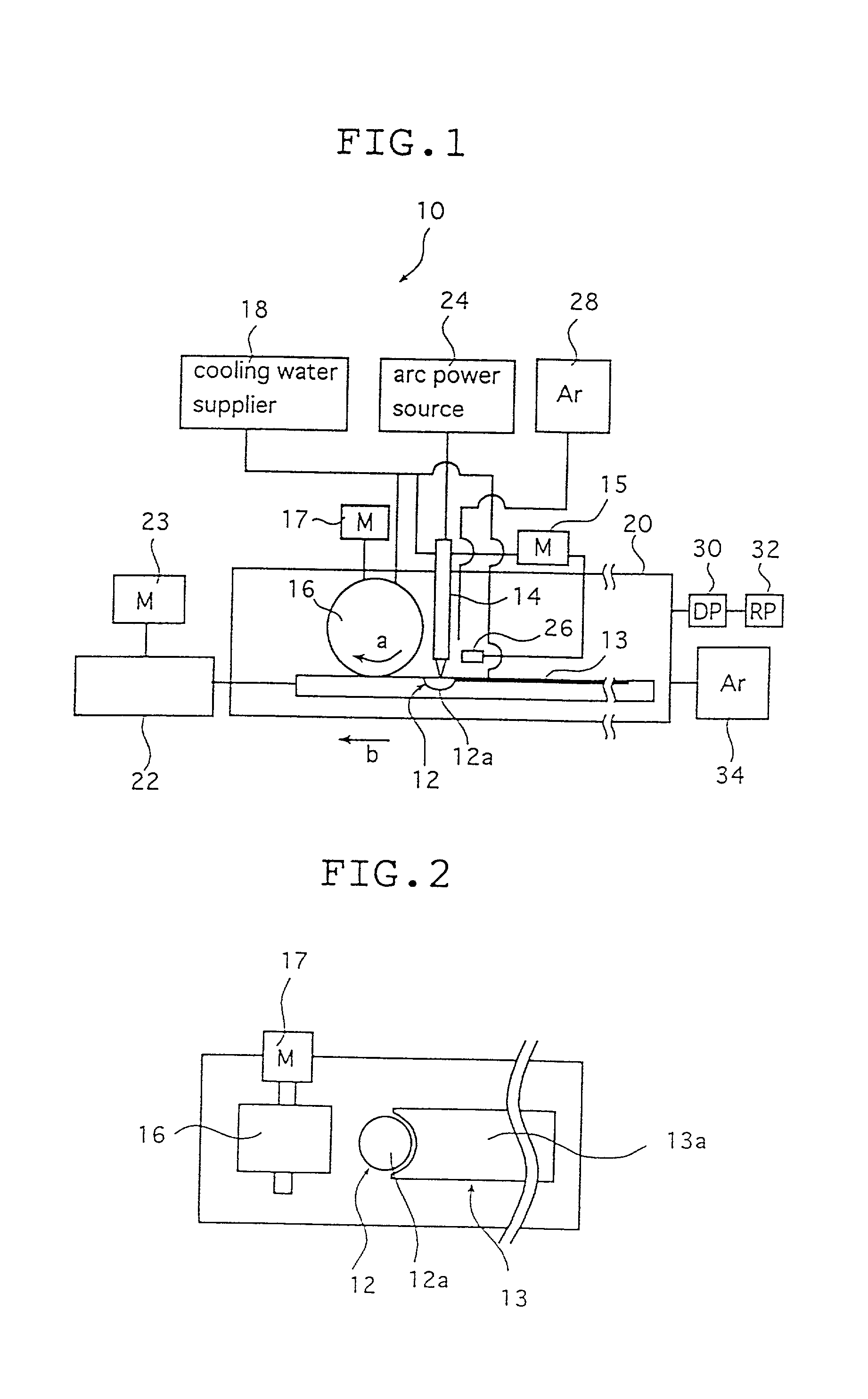

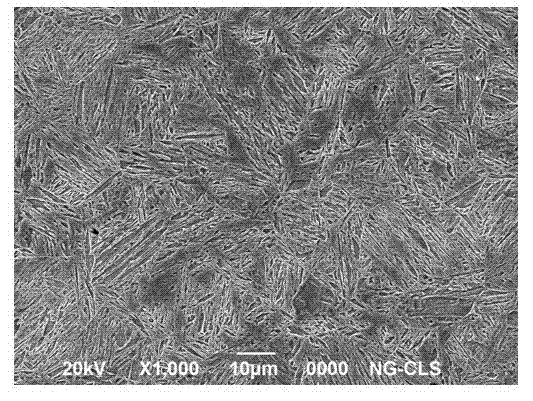

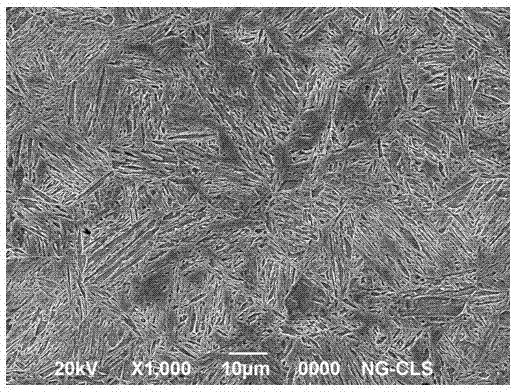

Process and apparatus for producing metallic glass

InactiveUS20020100573A1Simple processGood strength performanceFoundry mouldsFoundry coresHigh energyAlloy

A process and an apparatus for producing metallic glass which are capable of producing a bulk amorphous alloy of desired shape, in particular, a bulk amorphous alloy of desired final shape are provided. In the present invention, the molten metal at a temperature above the melting point is selectively cooled at a rate higher than the critical cooling rate, and the product comprises single amorphous phase which is free from the crystalline phase formed by the development of crystal nuclei through nonuniform nucleation. The present invention is capable of producing the bulk amorphous alloy which is free from casting defects such as cold shuts and which has excellent strength properties in a simple process at a high reproducibility. Accordingly, a bulk metallic glass of desired shape is produced by filling a metal material in a hearth; melting the metal material by using a high-energy heat source which is capable of melting the metal material; pressing the molten metal at a temperature above the melting point of the metal material to deform the molten metal into the desired shape by at least one of compressive stress and shear stress at a temperature above the melting point, while avoiding the surfaces of the molten metal cooled to a temperature below the melting point of the metal material from meeting with each other during the pressing; and cooling the molten metal at a cooling rate higher than the critical cooling rate of the metal material simultaneously with or after the deformation to produce the bulk metallic glass of desired form.

Owner:MAKABE GIKEN

Fiber air turn for low attenuation fiber

A method for forming an optical fiber includes drawing the optical fiber from a glass supply and treating the fiber by maintaining the optical fiber in a treatment zone wherein the fiber is cooled at a specified cooling rate. The optical fiber treatment reduces the tendency of the optical fiber to increase in attenuation due to Rayleigh scattering, and / or over time following formation of the optical fiber due to heat aging. Methods for producing optical fibers along nonlinear paths incorporating fluid bearings are also provided thereby allowing for increased vertical space for the fiber treatment zone.

Owner:CORNING INC

Manufacturing method of HB500 grade low-manganese wear-resistant steel plate

The invention discloses a manufacturing method of a HB500 grade low-manganese wear-resistant steel plate. The manufacturing method comprises the specific steps as follows: continuous casting billets meeting the requirements are selected; the rolling process is conducted: the heating temperature is 1100 to 1200 DEG C, the rolling is conducted at a crystallization region and an austenite non-recrystallization region by adopting austenite, the final rolling temperature is 1000 to 1050 DEG C, and the billets are roughly rolled into intermediate billets of 1.7 to 2.0 times the thickness; the finish rolling starting temperature is 850 to 920 DEG C, a laminar cooling manner is adopted, the final cooling temperature is 600 to 700 DEG C, and the cooling rate is 10 to 20 DEG C / S; the quenching process is conducted: the steel plate heating temperature is 860 to 940 DEG C, the heat preservation time is 10 to 30min, and the billets are cooled to a normal temperature at a cooling speed of 40 DEG C / S; and the tempering process is conducted: the quenching steel plate heating temperature is 150 to 300 DEG C, the billets are loaded to a cooling bed to be air-cooled after the heat of the billets is preserved for 1 to 3 hours, and then the HB500 grade low-manganese wear-resistant steel plate is obtained. The HB500 grade low-manganese wear-resistant steel plate has the advantages of high hardness, high strength and high toughness, and is suitable for being used in bulldozers, loaders, excavators, dump trucks and various mining machines.

Owner:NANJING IRON & STEEL CO LTD +1

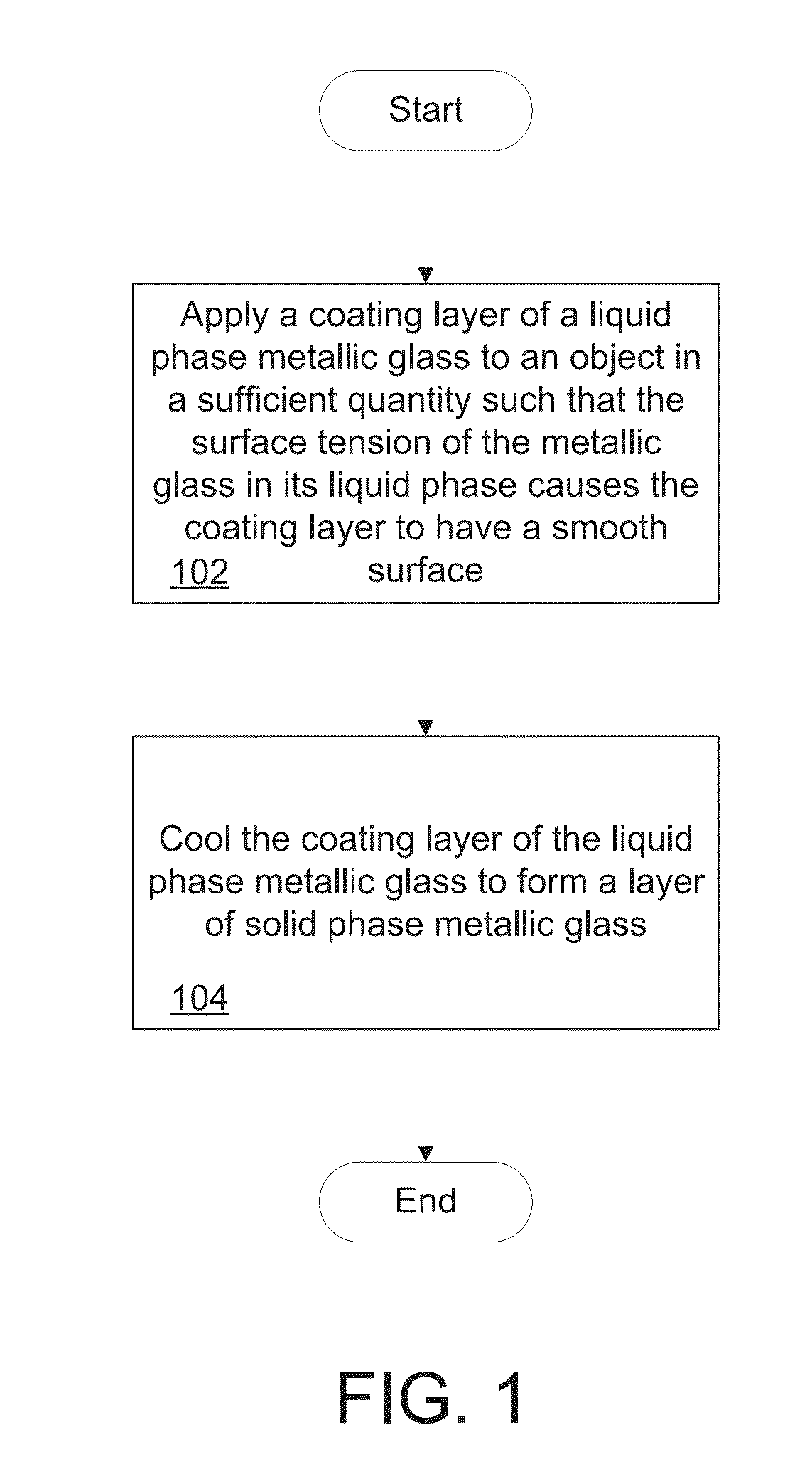

Systems and Methods Implementing Layers of Metallic Glass-Based Materials

ActiveUS20140141164A1Eliminate excessLower melting temperatureHot-dipping/immersion processesMolten spray coatingMetalMaterial system

Systems and methods in accordance with embodiments of the invention implement layers of metallic glass-based materials. In one embodiment, a method of fabricating a layer of metallic glass includes: applying a coating layer of liquid phase metallic glass to an object, the coating layer being applied in a sufficient quantity such that the surface tension of the liquid phase metallic glass causes the coating layer to have a smooth surface; where the metallic glass has a critical cooling rate less than 1000 K / s; and cooling the coating layer of liquid phase metallic glass to form a layer of solid phase metallic glass.

Owner:CALIFORNIA INST OF TECH

Method for manufacturing metal molds used for casting manganese steel crushing walls or rolling motor walls of cone crushers

ActiveCN101954456ARealize the mechanization of modelingStandardize workFoundry mouldsFoundry coresCasting moldCrusher

The invention discloses a method for manufacturing metal molds used for casting manganese steel crushing walls or rolling motor walls of cone crushers. The method is characterized by comprising the following steps of: (1) manufacturing cast molds according to different sizes, specifications and models of the manganese steel crushing walls or the rolling motor walls of the cone crushers; (2) respectively designing and manufacturing near inner metal molds and near outer metal molds which have corresponding thicknesses and overall structures according to the shapes of the cast molds; and (3) distributing trumpet-shaped vent holes on the near inner metal molds and the near outer metal molds. Castings produced by using the method do not produce fragmentation; the metal molds can accelerate the cooling speed of the castings so that the surfaces of the castings have fine grain structures; and the mold cavities have the characteristics of high size precision, bright and clean surface and no distortion.

Owner:广西长城机械股份有限公司

Weathering steel and manufacturing method thereof

The invention discloses weathering steel, which comprises the following chemical compositions in percentage by weight: 0.06 to 0.12 percent of C, 0.20 to 0.40 percent of Si, less than or equal to 1.6 percent of Mn, 0.08 to 0.22 percent of P, less than or equal to 0.008 percent of S, 0.01 to 0.06 percent of Al, 0.20 to 0.80 percent of Cu, 0.40 to 0.75 percent of Cr, 0.12 to 0.40 percent of Ni, 0.001 to 0.006 percent of Ca and the balance of iron and inevitable impurity elements. The weathering steel is manufactured by a thin strip continuous casting process. The manufacturing process comprises the following steps of: performing deep desulfurization on molten steel, performing composite blowing on the top and bottom of a converter, performing RH vacuum circular degassing process, and simultaneously performing calcium treatment; performing twin-roll continuous casting, and making the temperature of the molten steel in a molten bath not lower than 1,535DEG C; controlling rolling in the reduction ratio of not less than 30 percent; controlling cooling at the speed 30 to 50 DEG C / s; and coiling at the temperature of between 600 and 650 DEG C. The weathering steel of which the texture is acicular ferrite has good weatherability and can be widely applied to structural materials.

Owner:BAOSHAN IRON & STEEL CO LTD

Secondary cooling method for reducing transverse cracks of corners of microalloy sheet billet

The invention relates to a secondary cooling method for reducing transverse cracks of corners of a microalloy sheet billet, which is characterized in that the cooling temperature of a casting blank is facilitated to reach a temperature for starting the transformation from gamma to alpha by controlling the secondary cooling speed at an earlier stage when the casting blank passes through a vertical section after being delivered out of a crystallizer; at the later stage, the cooling water quantity of the casting blank is reduced, potential heat produced by the solidification of the casting piece is used for reheating the casting piece, and the reheating temperature is controlled to make the casting blank reach more than an austenite phase changing temperature when the casting piece is delivered out of the vertical section; the entire process is under the transformation of gamma to alpha to gamma, so that crystal grains of a final transformation product are smaller; and after the casting blank leaves the vertical section, the casting blank enters the subsequent secondary cooling area in a slowly cooling mode. By optimizing the continuous-casting billet cooling mode, the crystal grains are refined, and second-phase particles in the steel are controlled, so that the high-temperature mechanical property of the casting blank can be improved, simpleness in operation is realized, and the transverse cranks on the surface of the casting blank can be effectively reduced.

Owner:WISDRI ENG & RES INC LTD

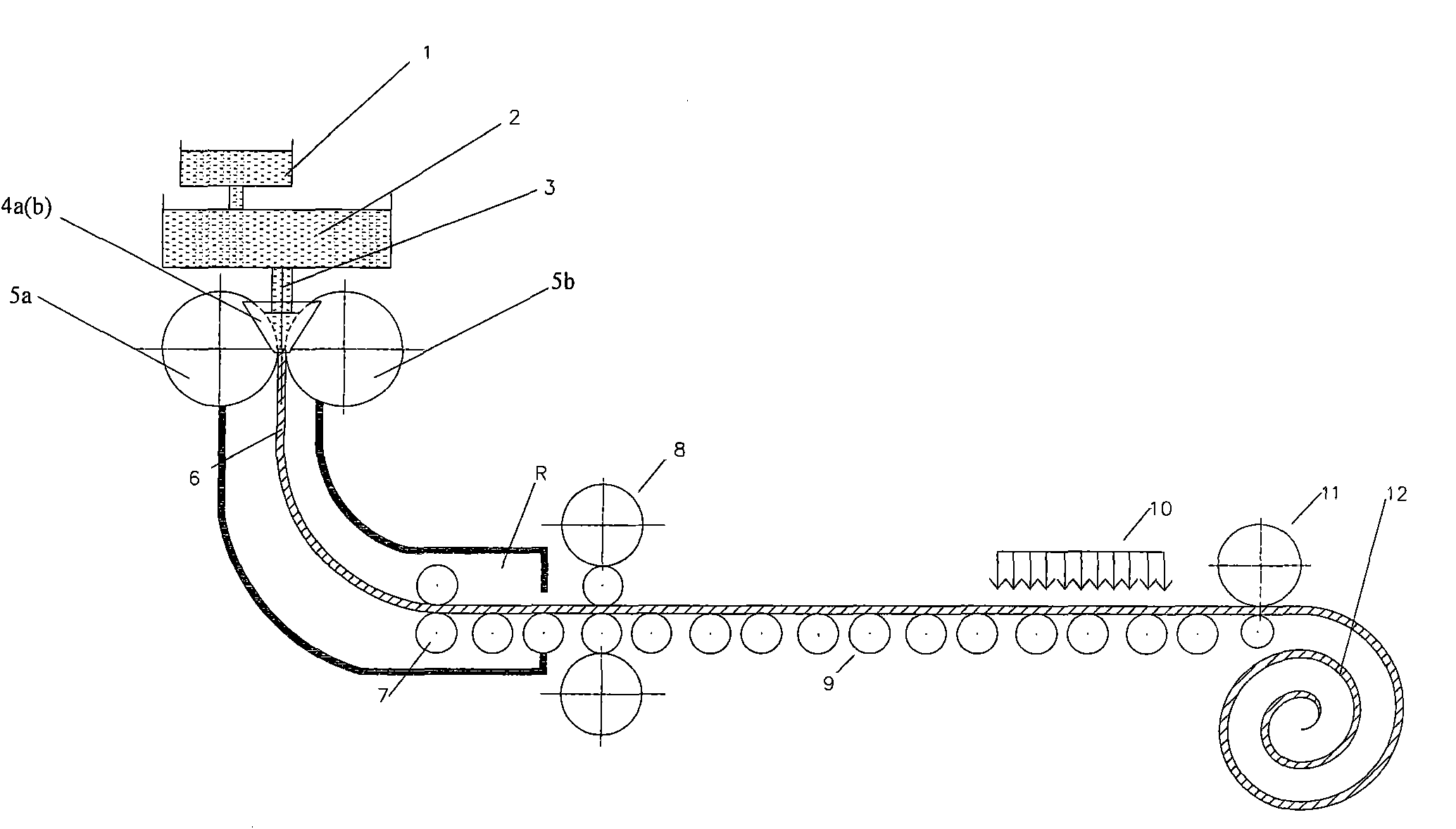

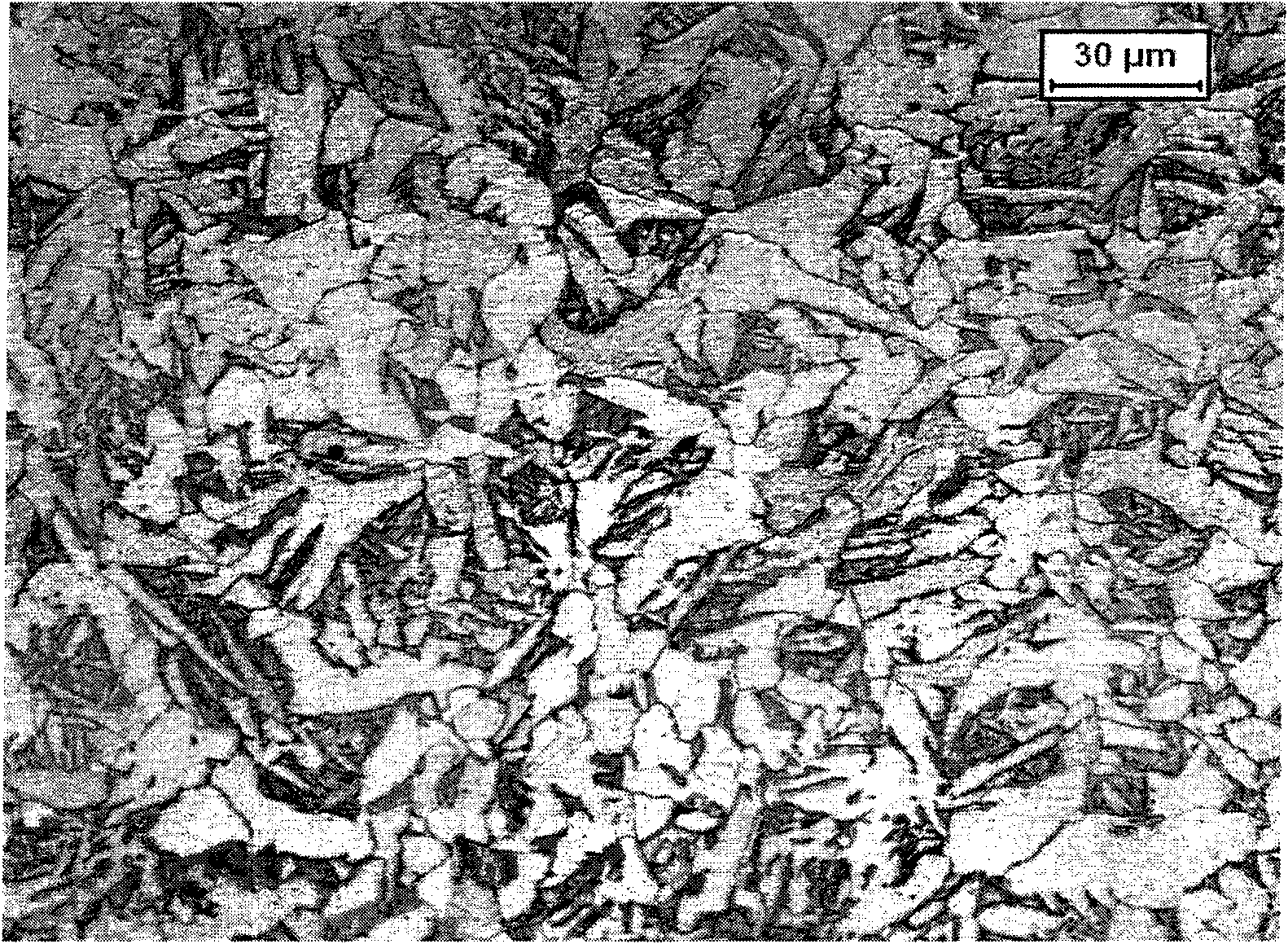

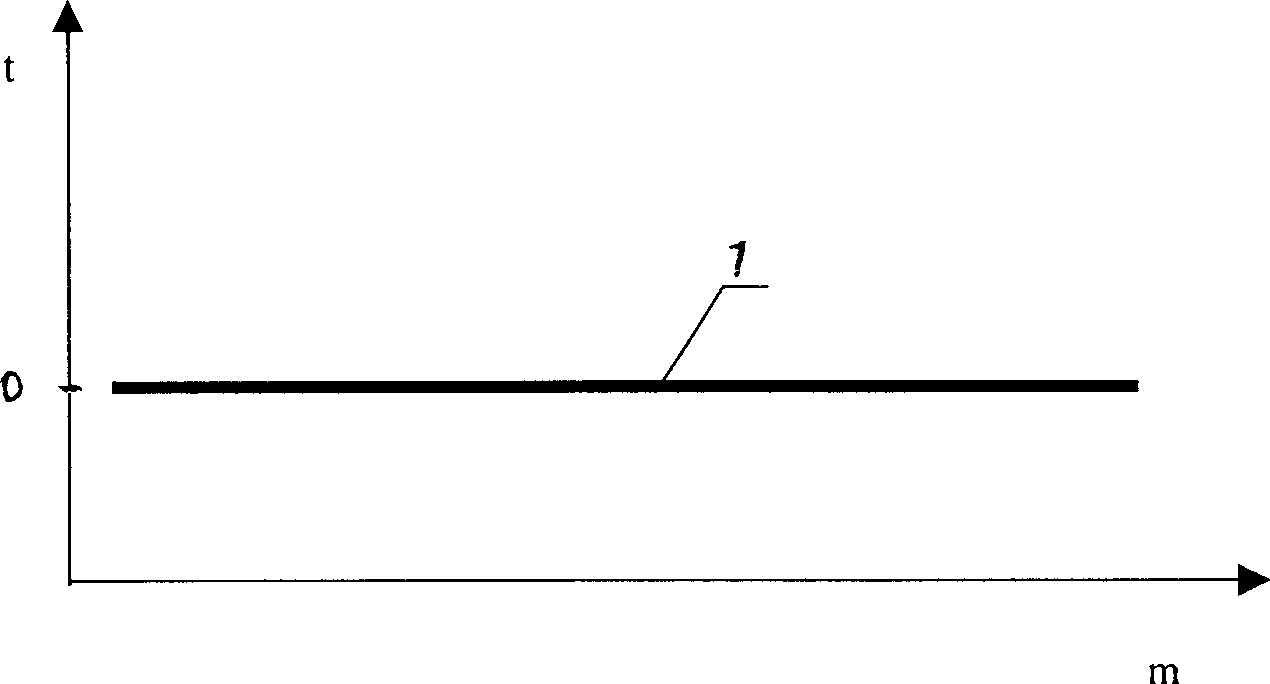

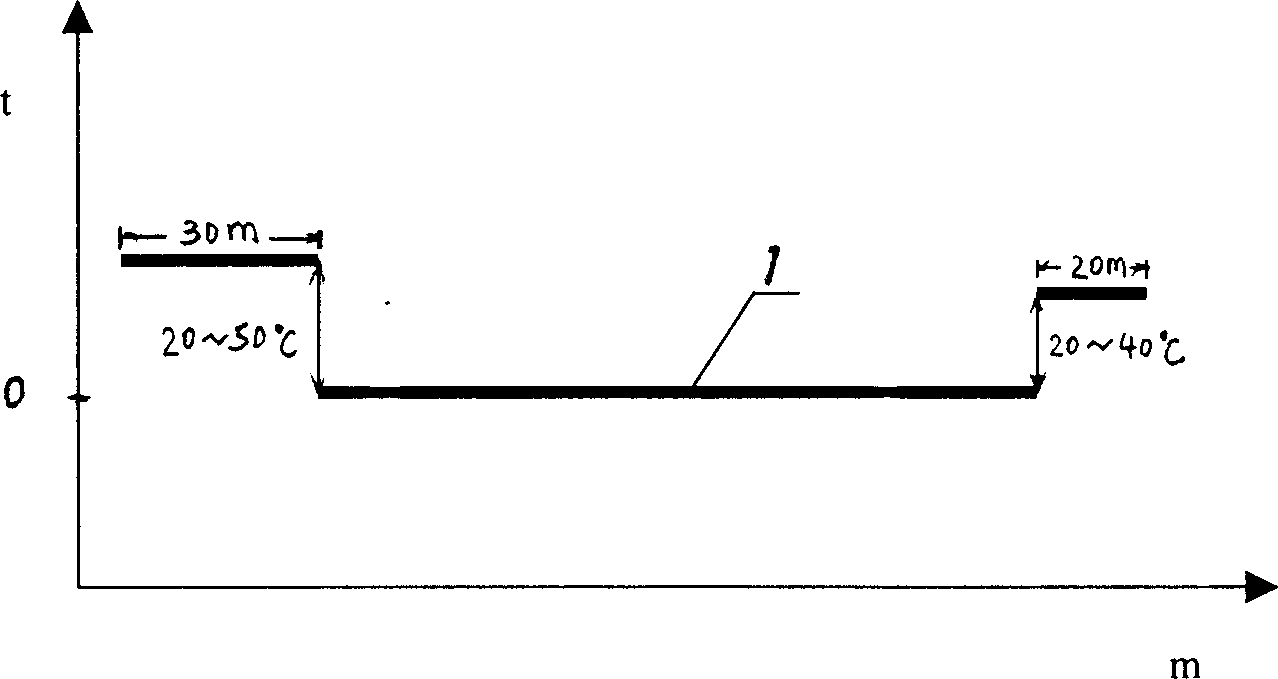

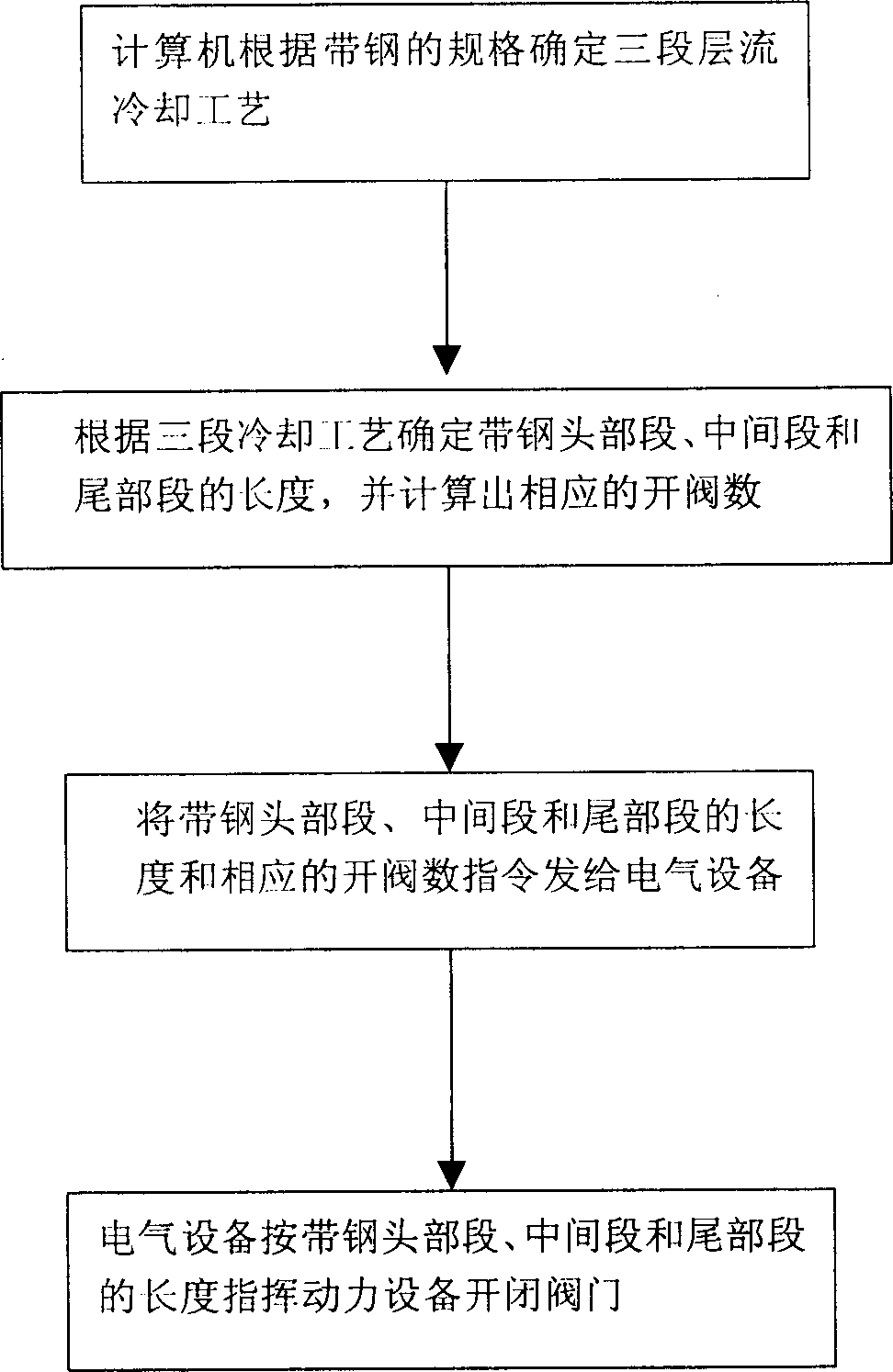

Three section laminar flow cooling technology for hot rolling band steel

InactiveCN1483528AImprove performance uniformitySolve productivityTemperature control deviceWork treatment devicesEngineeringStrip steel

The present invention provides a three-section cooling process by laminar flow for hot-rolled steel strip. Said process adopts the computer laminar flow cooling control, and is characterized by that the steel strip can be divided into three sections for cooling, first section is head portion section whose length is 30 m, second section is intermediate section of the steel strip, and third section is the tail portion section whose length is 20 m, and the cooling temperatures of said three sections are respectively controlled in that its intermediate section temp. is equal to the objective coiling temp., its head portion section temp. is 20-50 deg.C higher than that of objective coiling section, and its tail portion section temp. is 20-40 deg.C higher than objective coiling temp. Said invention can improve the performance uniformity of steel strip.

Owner:ANGANG STEEL CO LTD

Method for processing metastable beta-type titanium alloy plate

The invention relates to a method for processing a metastable beta-type titanium alloy plate and belongs to the technical field of titanium alloy processing. The invention aims to overcome defects in the prior art, provides technology for processing a Ti-15-3 alloy plate and improves the cold working performance of alloy. The method for processing the metastable beta-type titanium alloy plate comprises the following steps of: smelting the titanium alloy plate into an ingot, charging at the temperature of between 800 and 850 DEG C and keeping the temperature for 100 to 150 minutes, raising the temperature to between 1,100 and 1,150 DEG C and keeping the temperature for 240 to 360 minutes, and finishing the first fire by repeatedly upsetting and drawing; drawing unidirectionally until cogging is finished so as to obtain a blank; sawing and rolling the plate blank into a hot-rolled plate blank with the thickness of 4 to 10 mm at the temperature of between 850 and 1,000 DEG C; and cold rolling to obtain a plate with the thickness of 1 to 3 mm after annealing and alkaline and acid washing. By controlling the rolling temperature, the deformation degree and the cooling speed after deformation, the method controls the structure of a forging stock to fully break the forging stock, and effectively suppresses phase precipitation resulting in a brittle alloy. Therefore, the cold working plasticity and cold working performance are improved.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com