Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5924 results about "Austenite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Austenite, also known as gamma-phase iron (γ-Fe), is a metallic, non-magnetic allotrope of iron or a solid solution of iron, with an alloying element. In plain-carbon steel, austenite exists above the critical eutectoid temperature of 1000 K (727 °C); other alloys of steel have different eutectoid temperatures. The austenite allotrope is named after Sir William Chandler Roberts-Austen (1843–1902); it exists at room temperature in stainless steel.

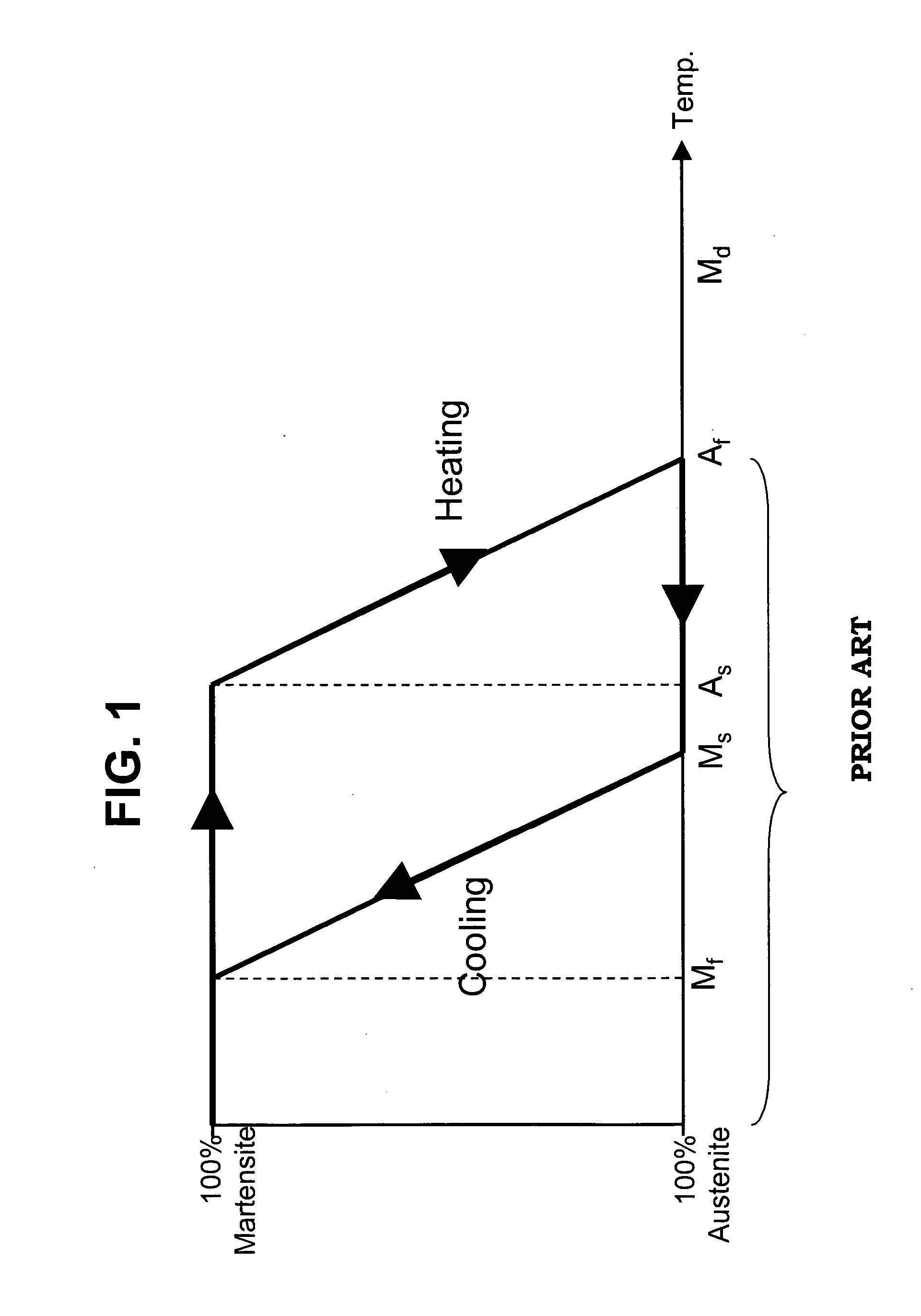

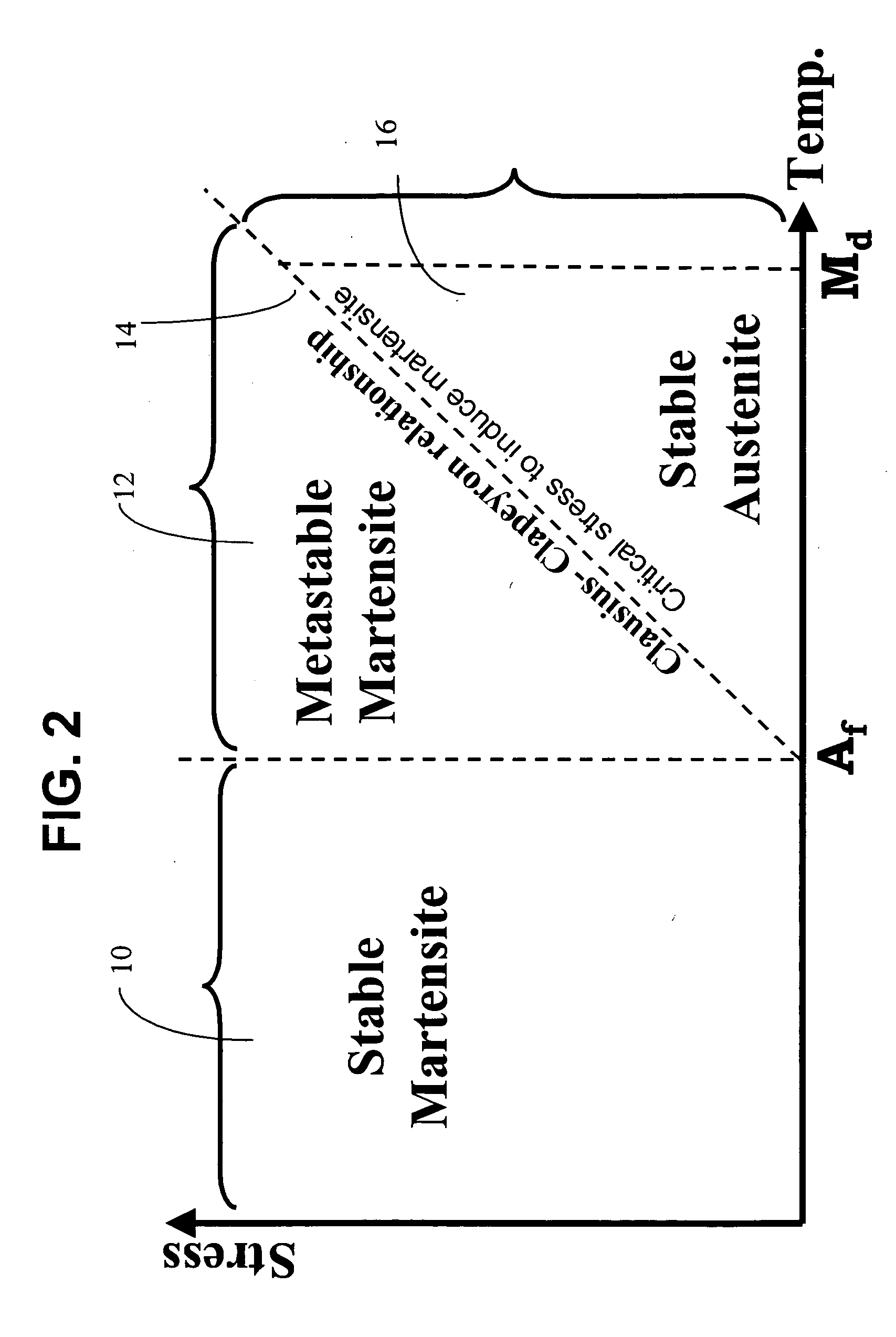

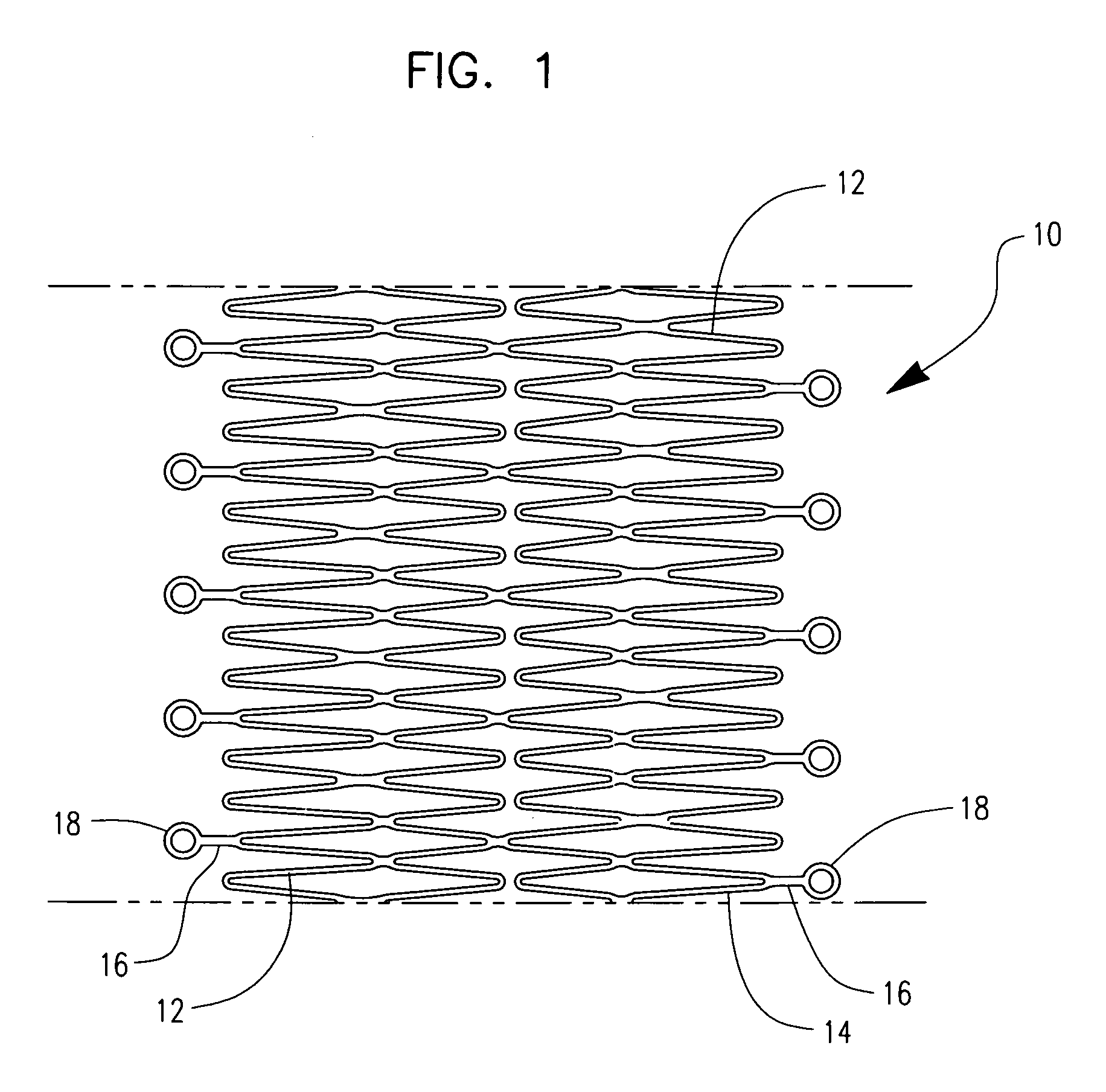

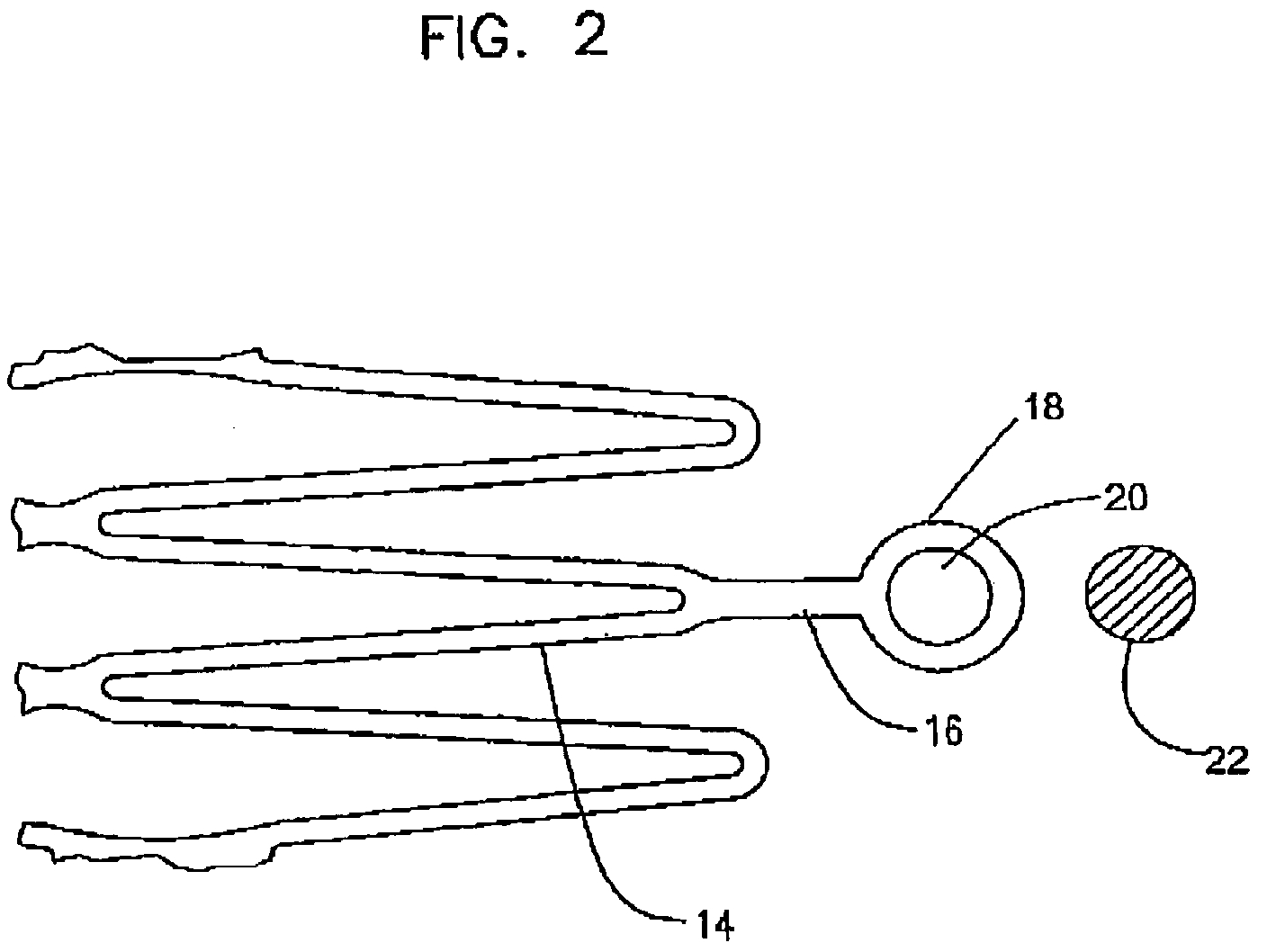

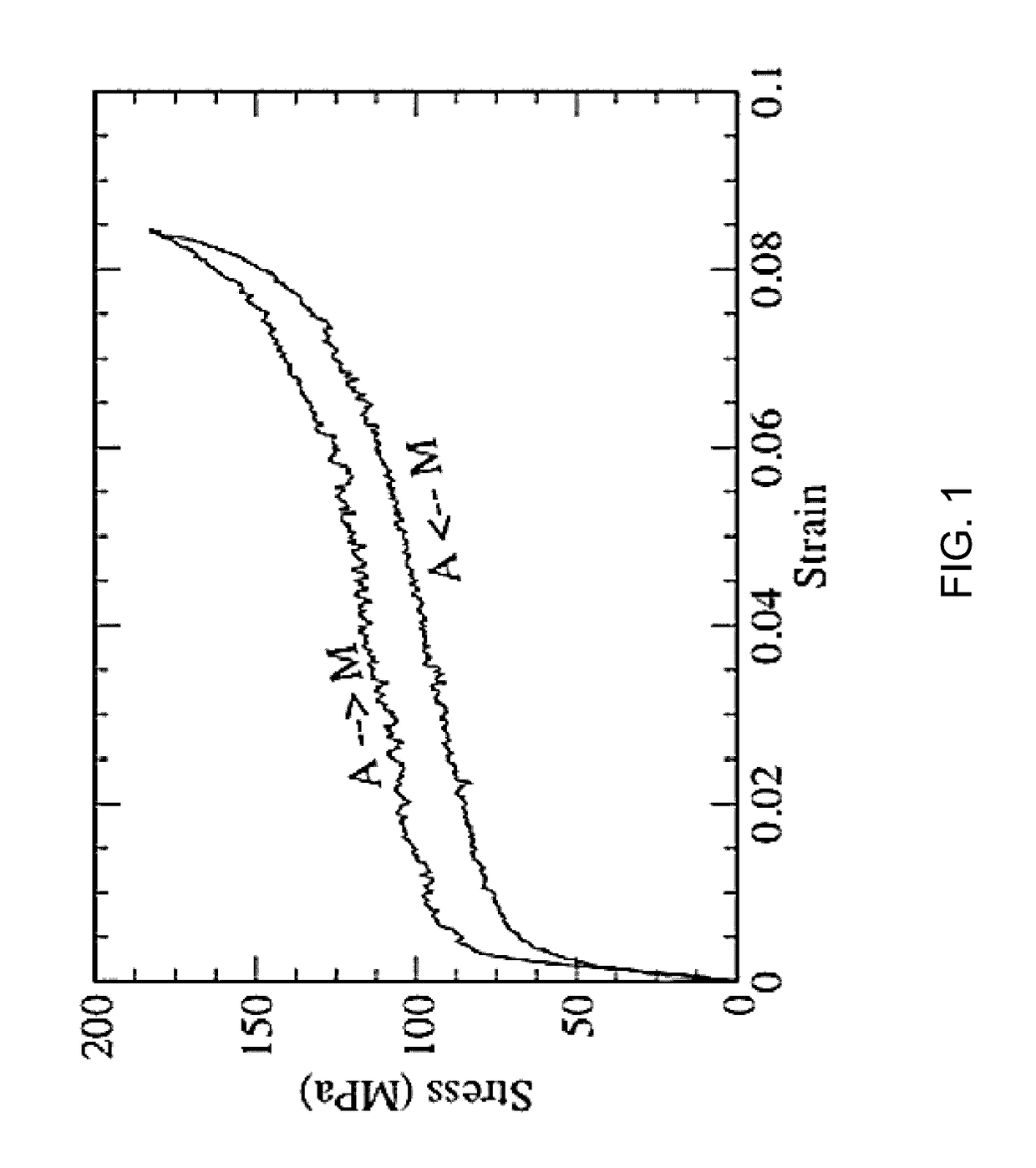

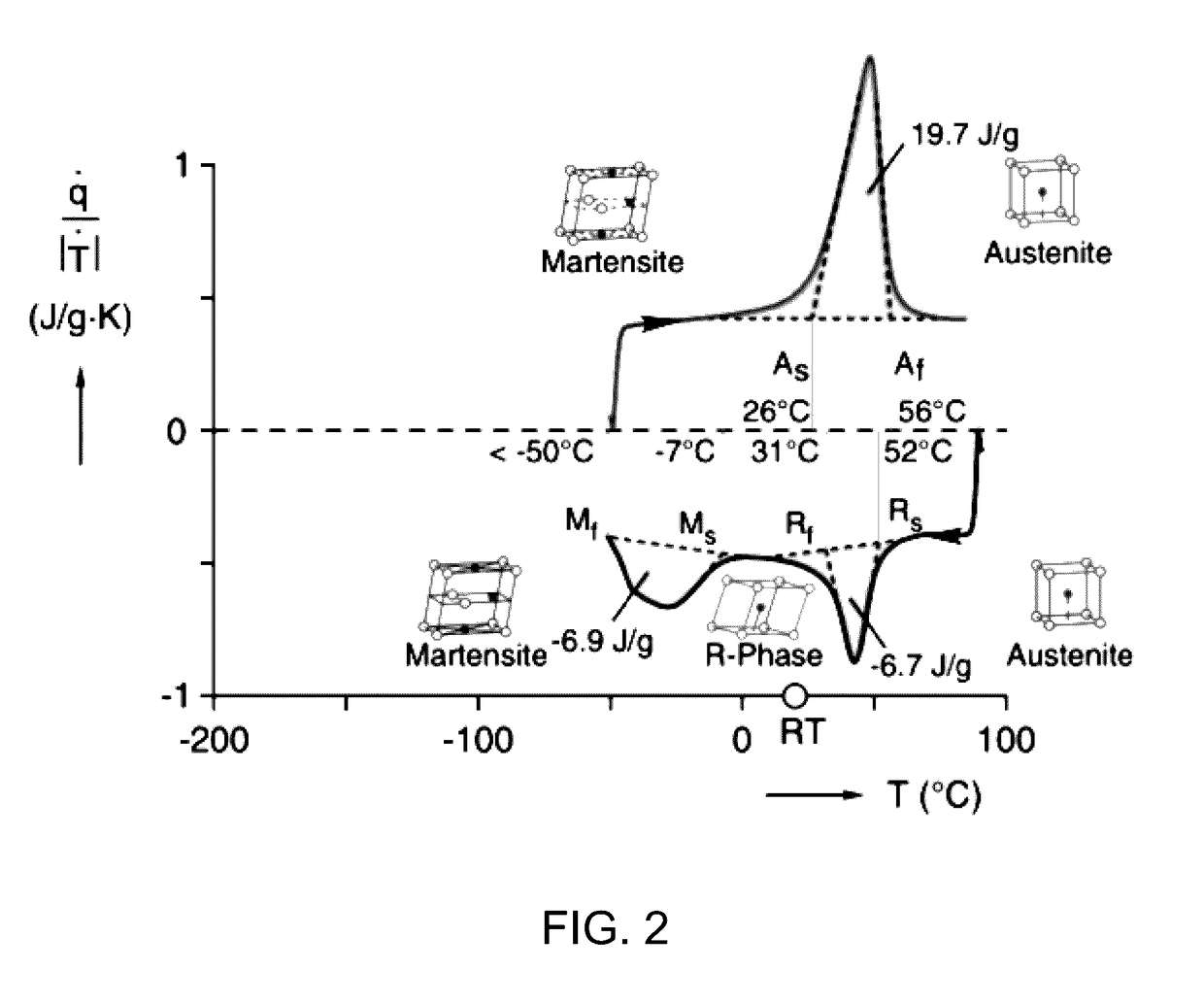

Medical devices formed from shape memory alloys displaying a stress-retained martensitic state and method for use thereof

InactiveUS20050043757A1Good body shapePromote recoverySuture equipmentsDental implantsManufactured formShape-memory alloy

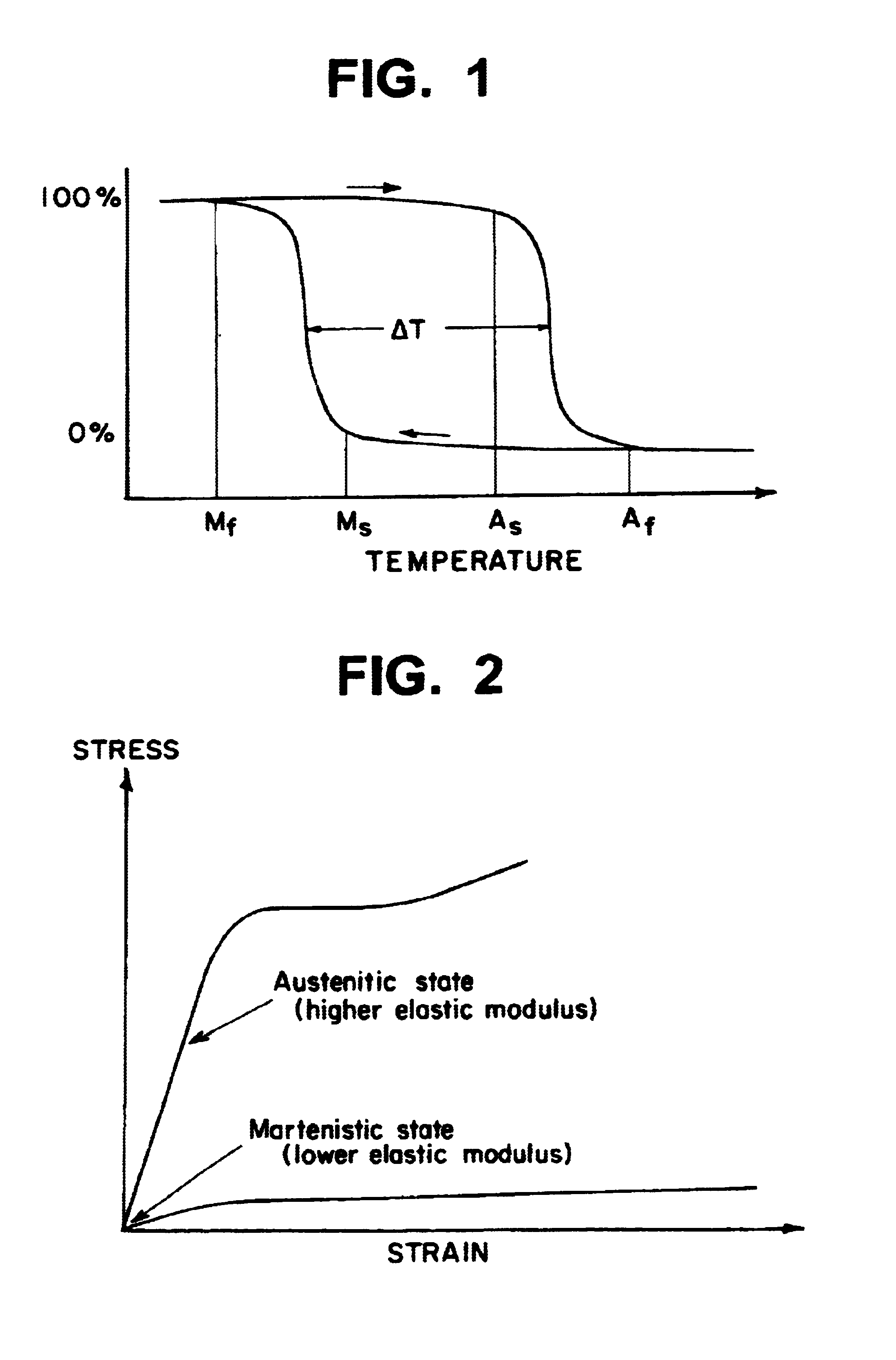

A method is disclosed for utilizing a deformable article of manufacture formed at least partly of a shape memory alloy. The method includes the steps of deforming the article from a first predetermined configuration to a second predetermined configuration while the shape memory alloy is, at least partially, in its stable martensitic state and at a first temperature. A resisting force is applied to the deformed article of manufacture using a restraining means and the article is heated from the first temperature to a second temperature in the presence of the resisting force. The stable martensitic state is transformed to a metastable stress-retained martensitic state. The resisting force is then removed allowing the alloy to transform to its austenitic state and the shape of the article to be restored substantially to its first configuration. Devices primarily medical devices operative by employing this method are also disclosed.

Owner:NITI SURGICAL SOLUTIONS

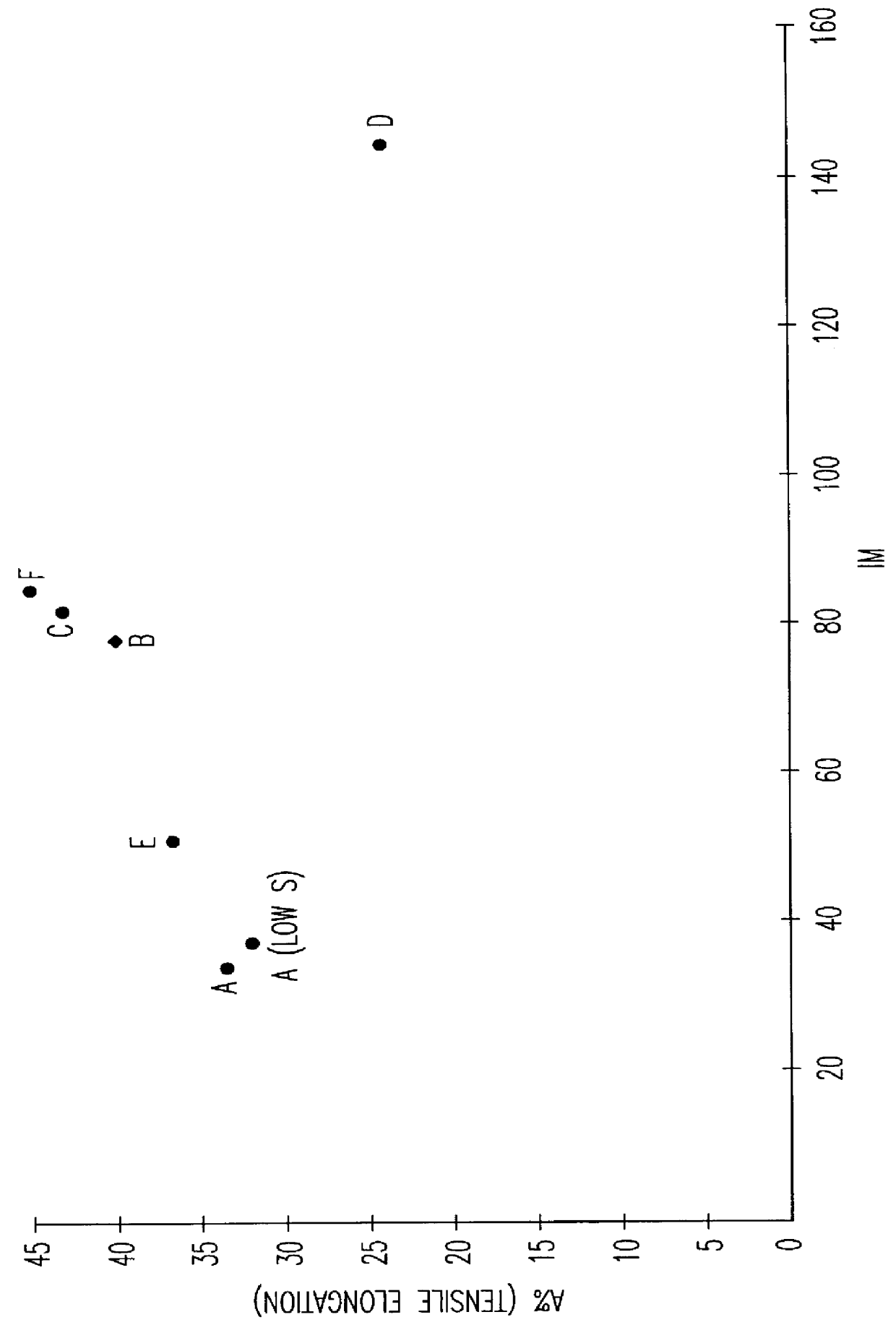

Austenoferritic stainless steel having a very low nickel content and a high tensile elongation

InactiveUS6096441ALow nickel contentImproved general propertyHeat treatment process controlElectric furnaceSulfurManganese

An austenoferritic stainless steel with high tensile elongation includes iron and the following elements in the indicated weight amounts based on total weight: carbon<0.04% 0.4%<silicon<1.2% 2%<manganese<4% 0.1%<nickel<1% 18%<chromium<22% 0.05%<copper<4% sulfur<0.03% phosphorus<0.1% 0.1%<nitrogen<0.3% molybdenum<3% the steel having a two-phase structure of austenite and ferrite and comprising between 30% and 70% of austenite, wherein Creq=Cr %+Mo %+1.5 Si % Nieq=Ni %+0.33 Cu %+0.5 Mn %+30 C %+30 N % and Creq / Nieq is from 2.3 to 2.75, and wherein IM=551-805(C+N)%-8.52 Si %-8.57 Mn %-12.51 Cr %-36 Ni %-34.5 Cu %-14 Mo %, IM being from 40 to 115.

Owner:UGITECH

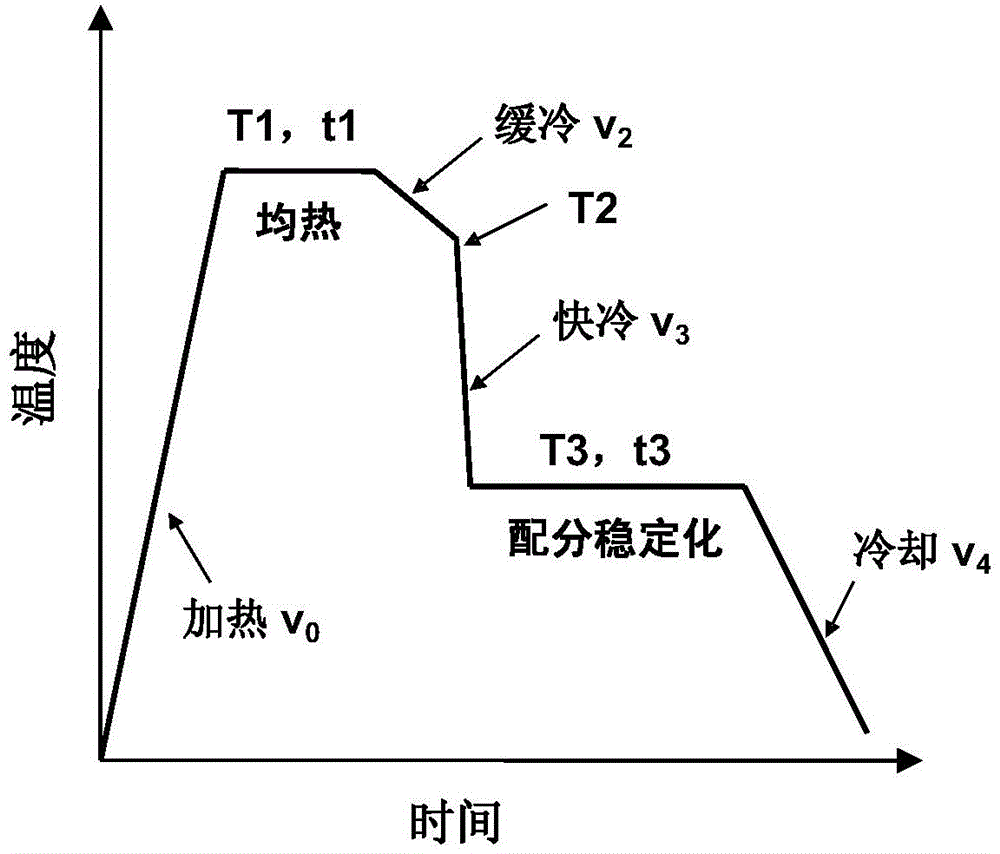

Method for producing steel with retained austenite

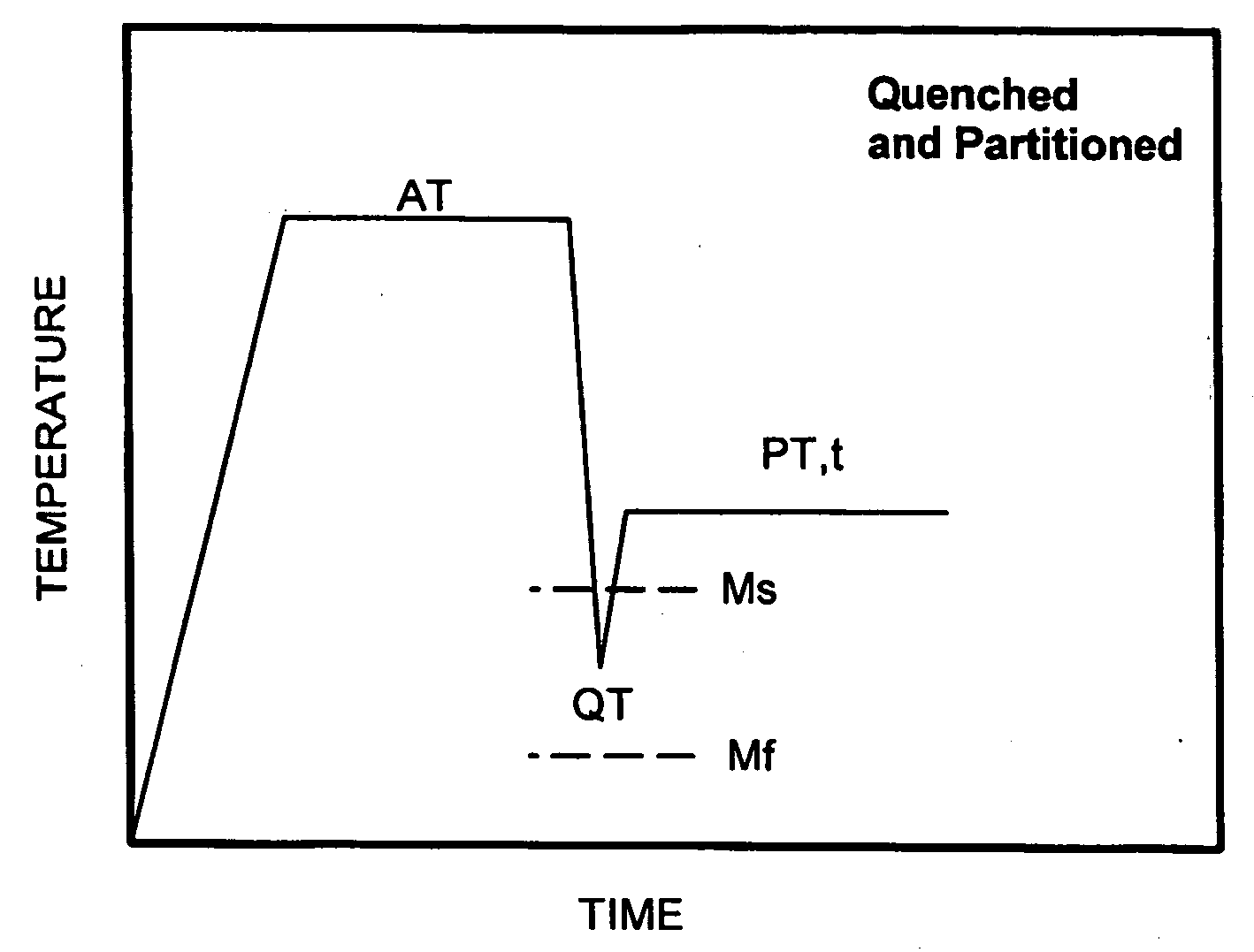

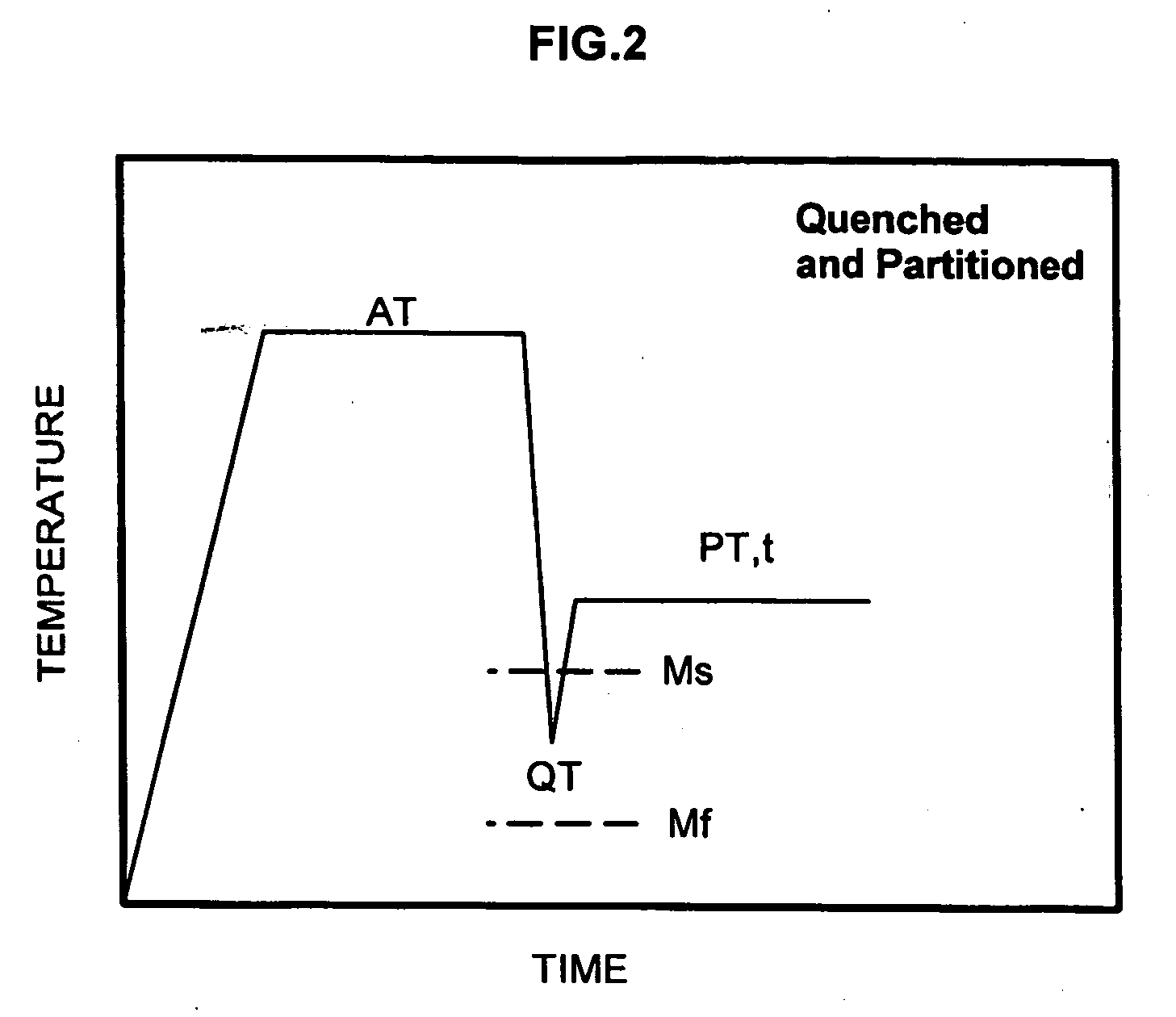

The present invention relates to a process for producing steel with retained austenite. In one embodiment, the process comprises the steps of heating a steel alloy to produce austenite, quenching the steel to produce martensite, and carbon partitioning to transfer carbon from the martensite to the austenite.

Owner:COLORADO SCHOOL OF MINES

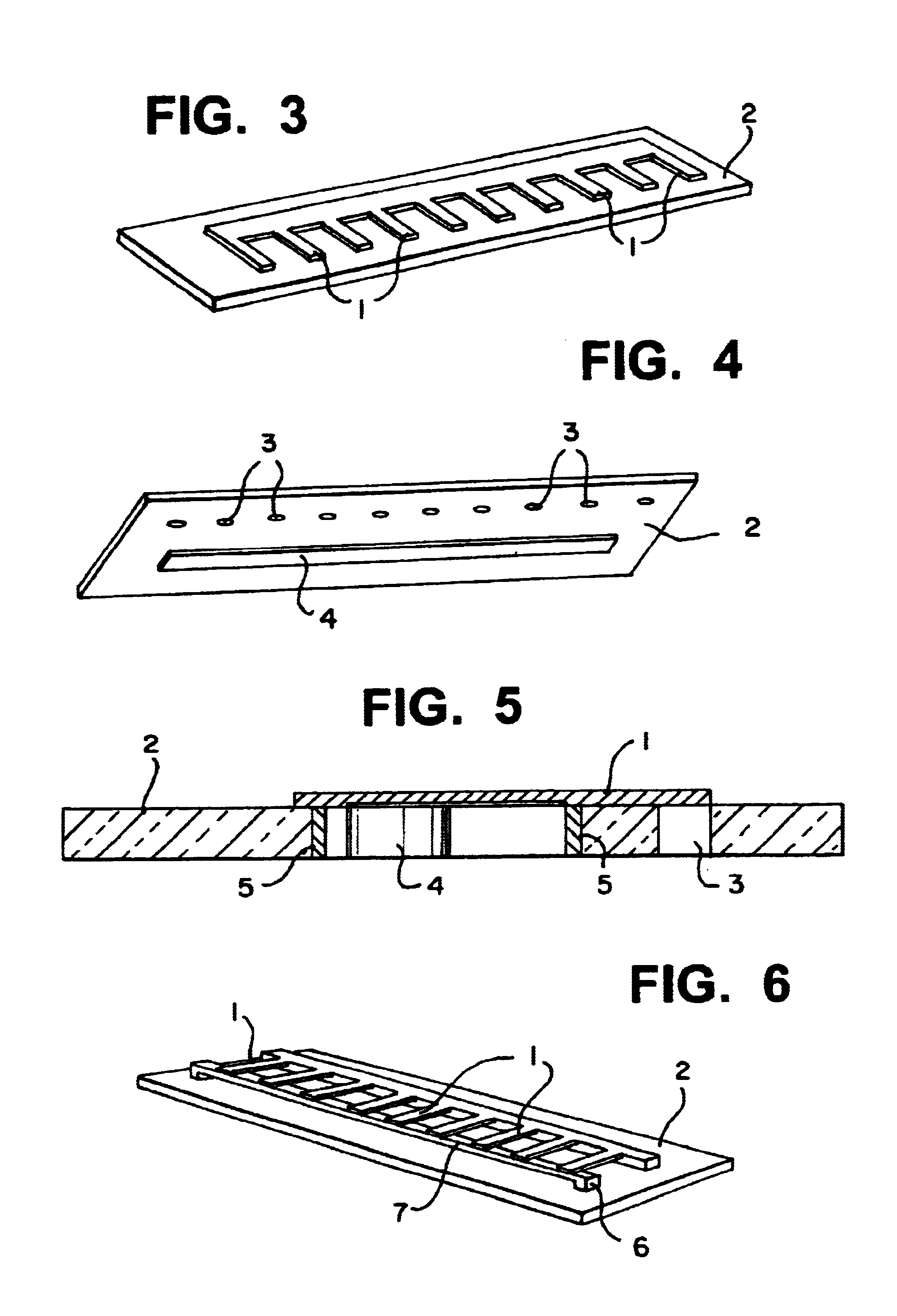

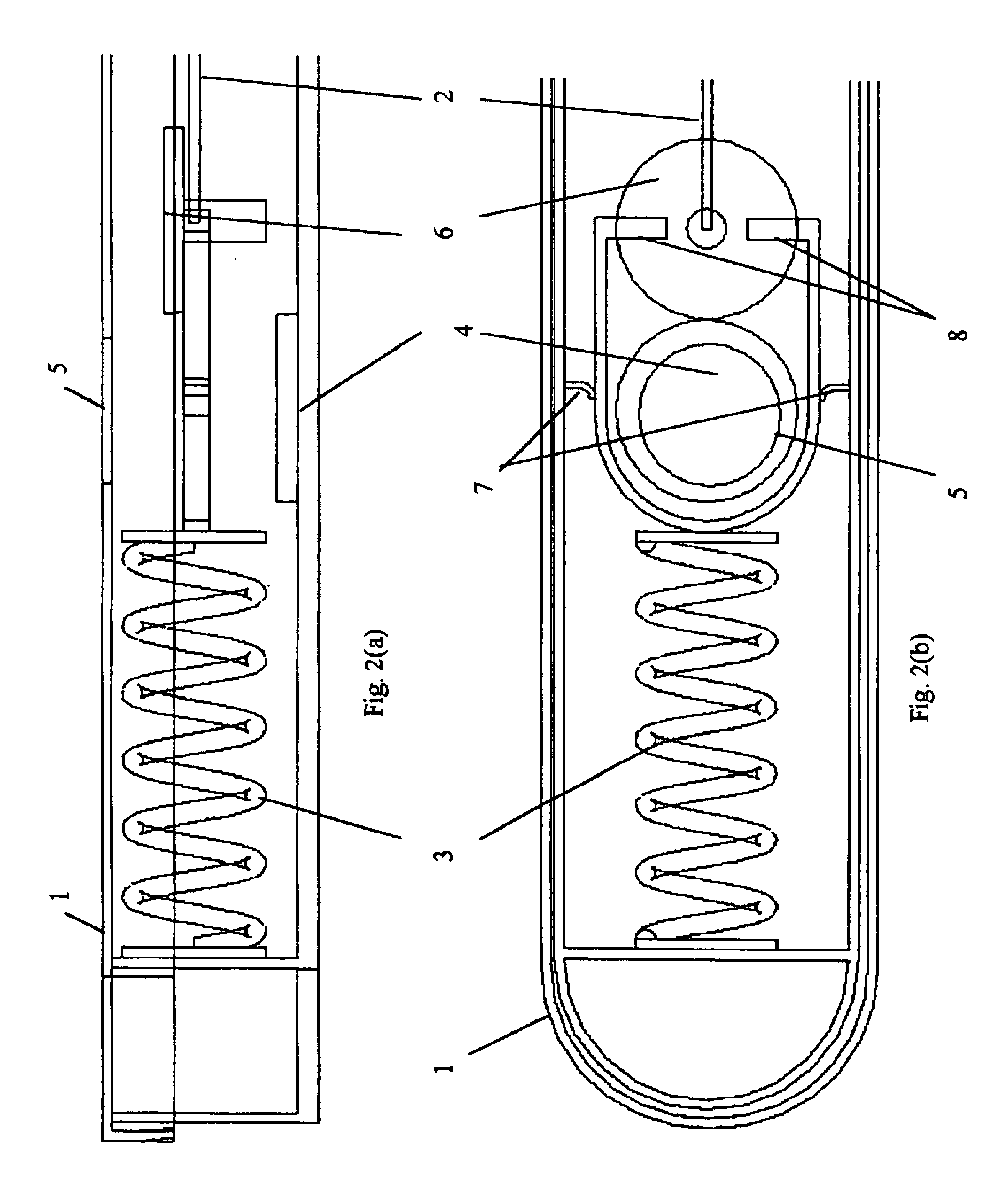

Method of setting and actuating a multi-stable micro valve and adjustable micro valve

InactiveUS6926246B2Less sensitive to blockageOperating means/releasing devices for valvesCircuit elementsShape-memory alloyEngineering

A micro valve and a method for setting or actuating a micro valve for use in fluidic applications includes cooling an array of actuating members made of Shape Memory Alloy (SMA) material. The SMA material is cooled to a temperature equal to or below the temperature at which a transformation from austenitic to martensitic state occurs so that the entire array of SMA actuating members is either fully or partially in the martensitic state. At least one of the actuating member is selected to correspond to a pre-determined opening pressure or flow resistance. Each of the actuating members are heated individually, except the previously selected one, to a temperature equal to or above the temperature at which a transformation from the martensitic state to the austensitic state occurs.

Owner:MEDOS

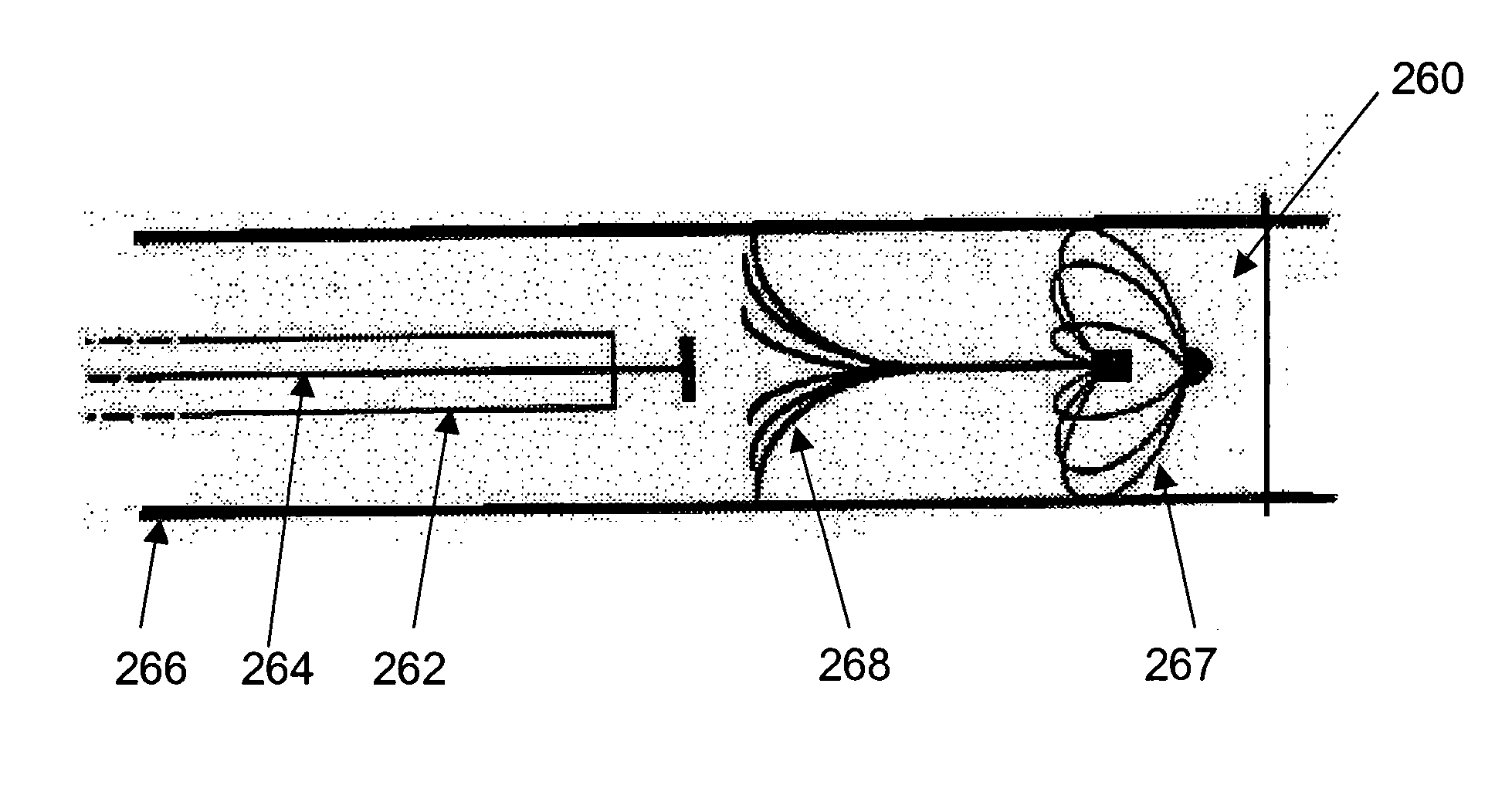

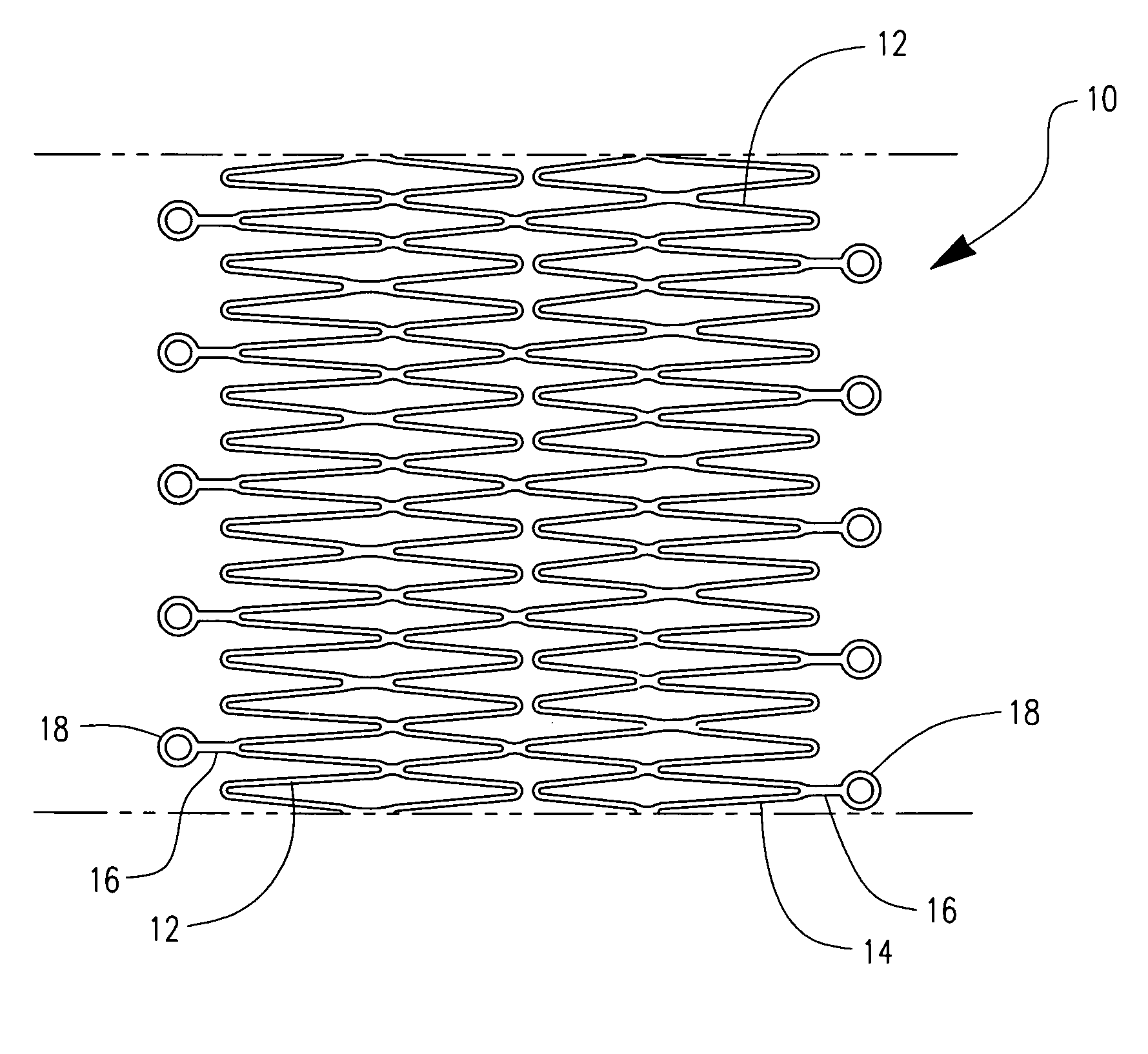

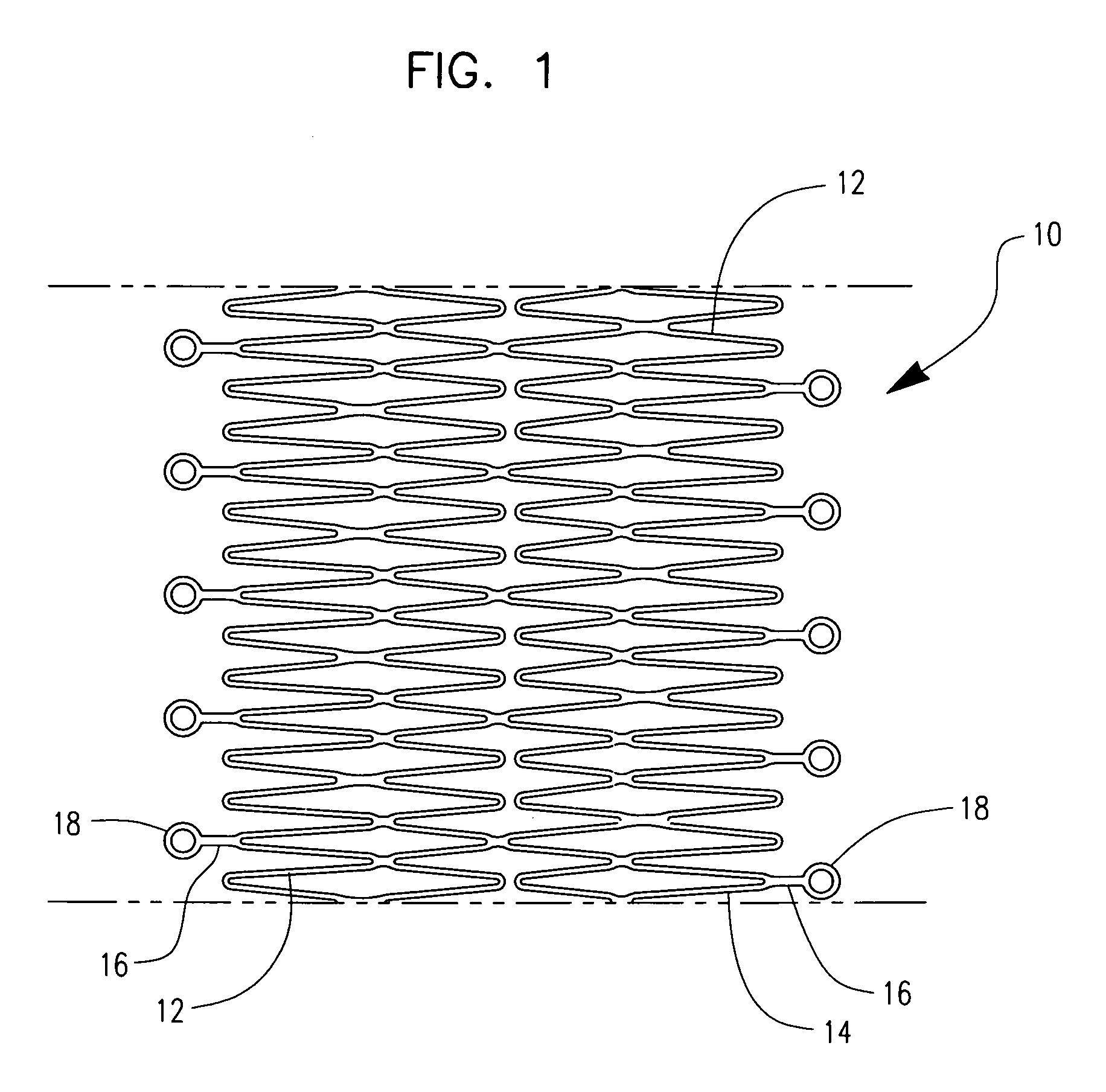

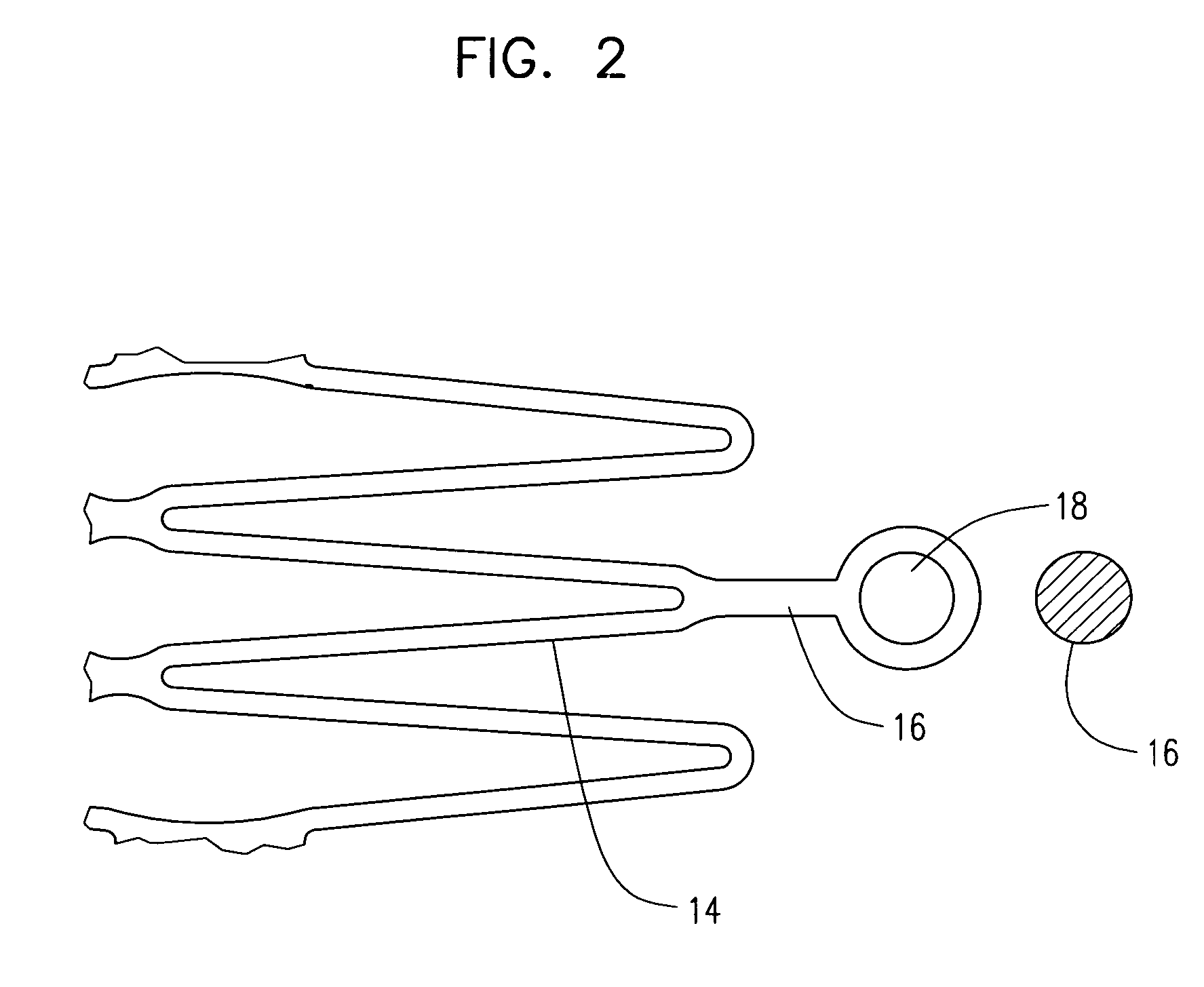

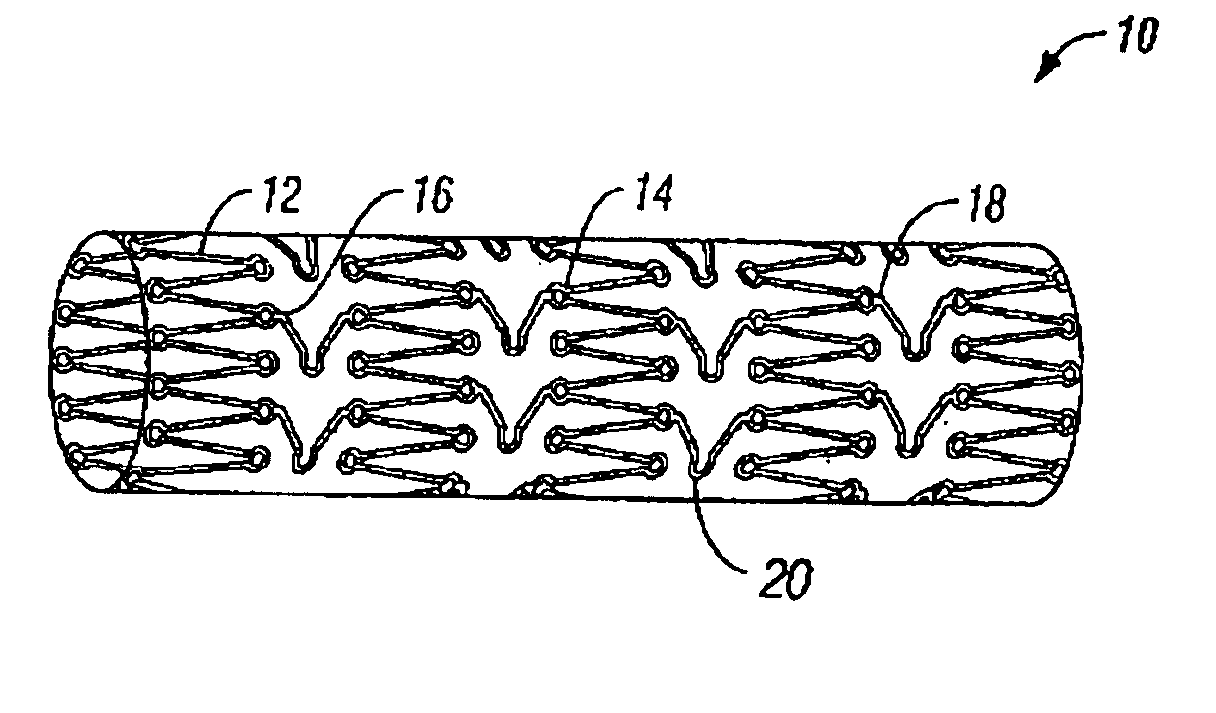

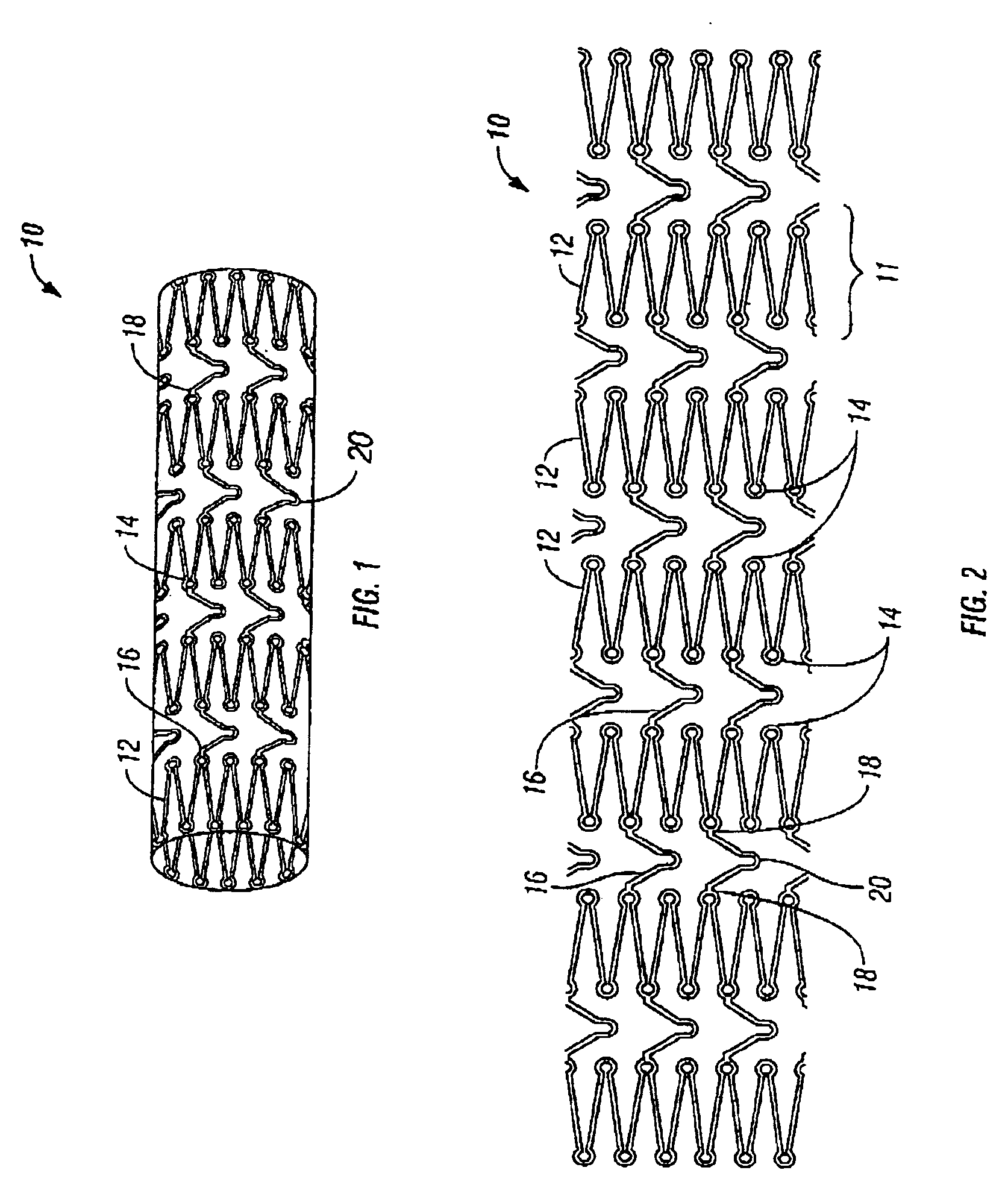

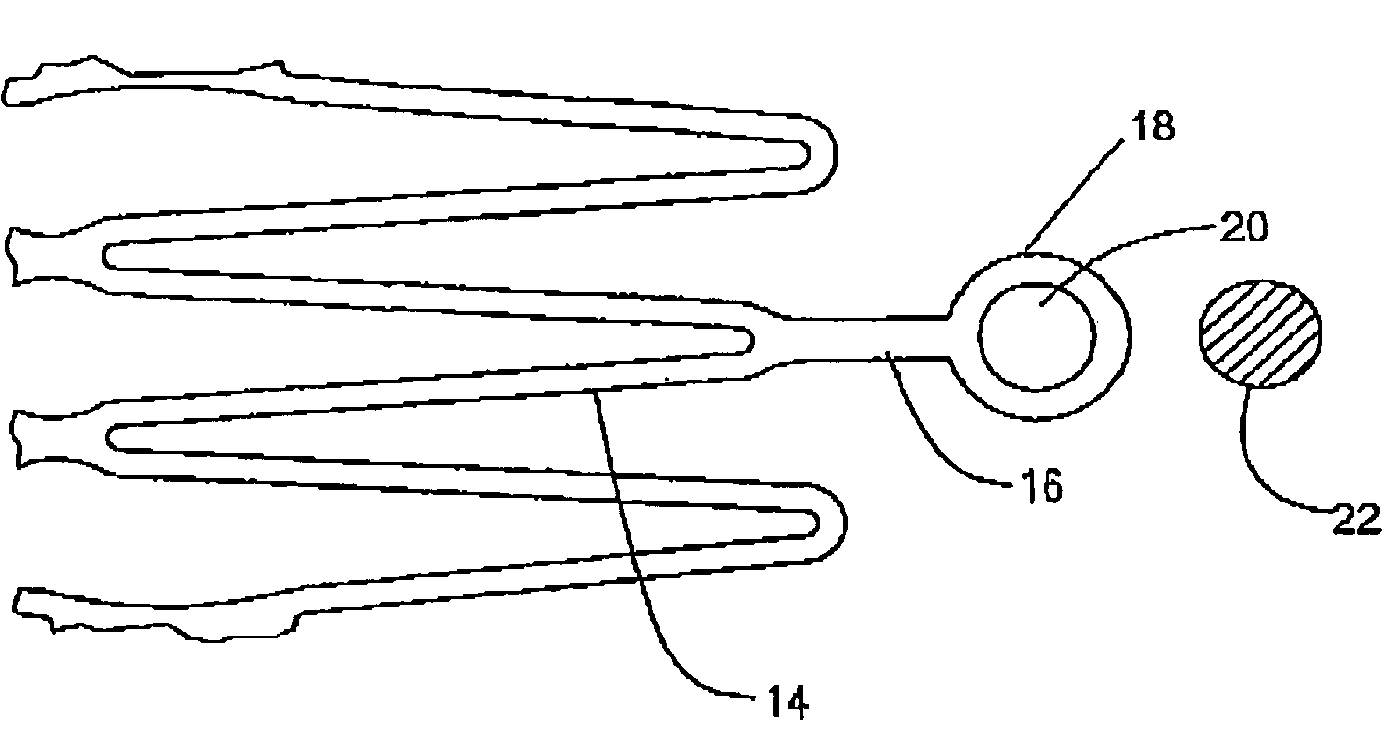

Process method for attaching radio opaque markers to shape memory stent

A process comprising the steps of providing a precursor for an implantable medical device, at least a portion of the precursor made of a shape memory material, the shape memory material having a receptacle for receiving a marker therein, the shape memory material having an austenitic and a martensitic phase; enlarging the receptacle while the shape memory material is in the martensitic phase; inserting a marker in the receptacle while the shape memory material is in the martensitic phase; and thereafter transforming the precursor to the austenitic phase.

Owner:BOSTON SCI SCIMED INC

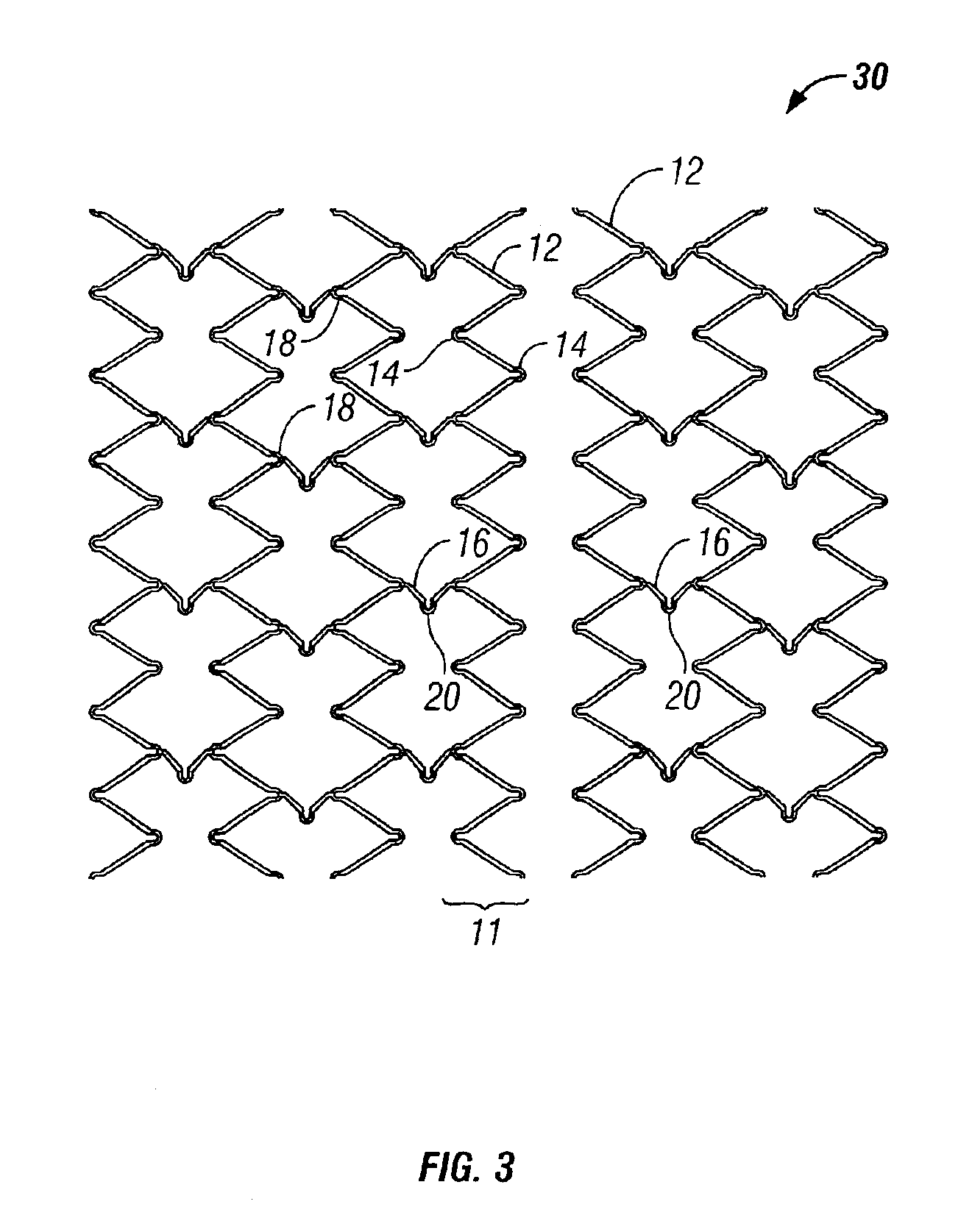

Implantable expandable medical devices having regions of differential mechanical properties and methods of making same

InactiveUS6923829B2Minimizing unwanted vascular injuryMinimizing vascular injuryStentsSurgeryIn vivoMartensite

An implantable expandable medical device in which selected regions of the device are in a martensite phase and selected regions are in an austenite phase. The martensitic regions exhibit pseudoplastic behavior in vivo and may be deformed without recovery under in vivo body conditions. In contrast the austenitic regions exhibit superelastic behavior in vivo and will recover their pre-programmed configuration upon deformation or release of an applied strain

Owner:VACTRONIX SCI LLC

Superhigh strength steel plate with yield strength more than 1100Mpa and method for producing same

The invention provides a super-strength steel plate comprising the following constituents (by weight percent): C 0.10-0.20%, Si<=0.6%, Mn 0.5-2.5%, Al <=0.03%, N 0.001-0.006%, B 0-0.0025%, Ca 0-0.006%, P<=0.015%, S<=0.005%, Ni 0.2-1.2%, Cr 0-0.8%, Cu 0-0.5% and Mo 0-0.6%, Ti 0.01-0.03%, V 0-0.1%, Nb 0.01-0.1%, balancing Fe and unavoidable foreign substance.

Owner:BAOSHAN IRON & STEEL CO LTD

Process method for attaching radio opaque markers to shape memory stent

Owner:BOSTON SCI SCIMED INC

Low-alloy super-strength multiphase steel and heat treatment method thereof

The invention discloses a low-alloy superhigh-intensity diphase steel and the heat treatment method, which is characterized in that: the components of the diphase steel (wt %) are C of 0.3 to 0.7, Si of 0.01 to 3.0, Al of 0.0 to 2.0, Nb of 0.0 to 0.25, V of 0.0 to 0.3, Mo of 0.0 to 2.0, Ni of 0.0 to 4.0, Mn of 0.05 to 3.0, Cr of 0.00 to 3.0, Co of 0.00 to 2.0, W of 0.0 to 2.0, S less than 0.04, P less than 0.04 and Fe of balance; the heat treatment method is that: a workpiece is first heated to 800 to 1000 degree centigrade to process the austenite treatment, and then the workpiece is quickly quenched into a liquid quenching medium of 50 to 250 degree centigrade, and then the workpiece is partitioned in a liquid quenching medium of 250 to 450 degree centigrade, and then the workpiece is quickly quenched into a liquid quenching medium of 100 to 250 degree centigrade for holding, finally the workpiece is quenched into water, and then the workpiece has a three-phase organization with martensite, nanometer ferrito martensite and remaining austenite with rich carbon. The low-alloy superhigh-intensity diphase steel and the heat treatment method has an advantage of increasing the intensity and plasticity of workpieces.

Owner:SHANGHAI JIAO TONG UNIV

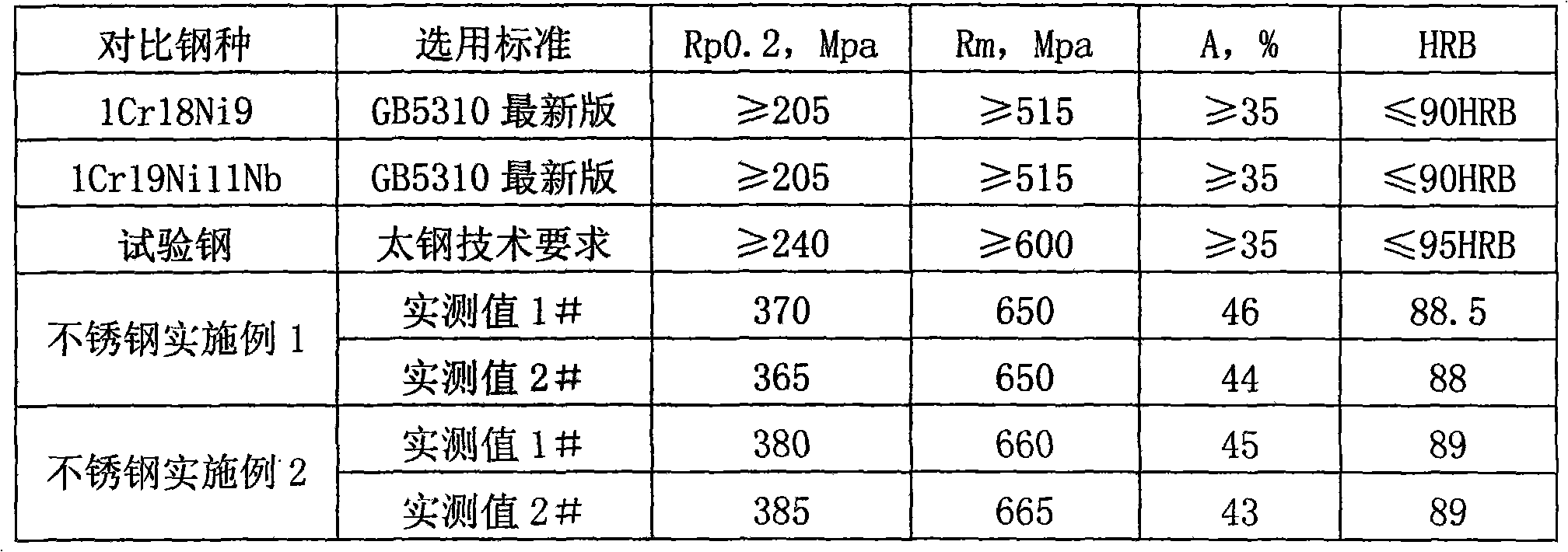

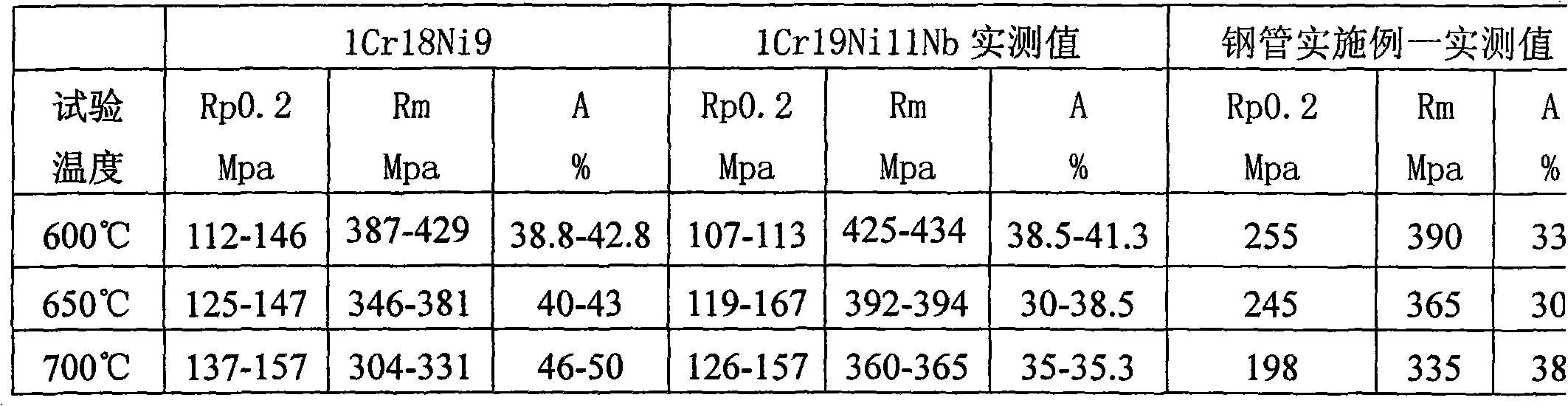

Austenitic stainless steel, steel tube thereof and manufacturing method thereof

ActiveCN101633999AImprove high temperature creep resistanceExcellent resistance to high temperature steam corrosionTemperature control deviceManufacturing convertersSS - Stainless steelIngot

The invention relates to an austenitic stainless steel, a steel tube thereof and a manufacturing method thereof, wherein the austenitic stainless steel and the stainless steel tube comprise the components by mass percent: 0.060-0.14% of C, more than 0 and less than or equal to 0.50% of Si, more than 0 and less than or equal to 1.00% of Mn, less than 0.040% of P, less than 0.015% of S, 17.00-20.00% of Cr, 8.00-11.00% of Ni, 2.50-4.00% of Cu, 0.30-0.60% of Nb, 0.15-0.50% of Mo, 0.15-0.50% of Co, 0.05-0.14% of N, 0.001-0.01% of B, the rest of Fe and unavoidable impurity. The manufacturing method of the steel tube comprises: smelting and pouring to form steel ingots or continuously cast bloom, processing bar material, preparing tubular billet and further processing the steel tube; the method comprises the steps: the heating temperature of processing the bar material is 1250-1270 DEG C, heating temperature of preparing the tubular billet is 1100-1220 DEG C, and the finished product solid solution temperature is 1120-1190 DEG C. The austenitic stainless steel tube has high temperature creep strength and corrosion resisting performance at the high temperature.

Owner:SHANXI TAIGANG ENG TECH +1

Superhigh strength steel plate with yield strength more than 960Mpa and method for producing same

ActiveCN1840724AEasy to implementEasy to controlFurnace typesHeat treatment furnacesAusteniteForeign substance

The invention provides a super-strength steel plate comprising the following constituents (by weight percent): C 0.08-0.18%, Si<=0.6%, Mn 0.5-2.0%, Al <=0.018%, N<=0.008%, B<=0.0025%, Ca 0-0.006%, P<=0.015%, S<=0.005%, Ni <=1.0%, Cr<=0.8%, Cu<=0.5%, Mo<=0.6%, Ti 0.01-0.03%, V<=0.1%, Nb 0.01-0.1%, balancing Fe and unavoidable foreign substance. The invention also provides the preparing process.

Owner:BAOSHAN IRON & STEEL CO LTD

Steel plate for stamping and quenching and thermoforming method of steel plate

ActiveCN102031456ASimple compositionPlay the effect of weight reduction and energy savingHot stampingSimple component

The invention discloses a steel plate for stamping and quenching and a thermoforming method of the steel plate. The steel plate comprises the following chemical components in percentage by weight: 0.14-0.28% of C, less than 0.40% of Si, 0.4-2.0% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.016-0.040% of Al, 0.15-0.8% of Cr, 0.015-0.12% of Ti, 0.0001-0.005% of B, less than or equal to 0.005% of N, and the balance of Fe and inevitable impurities. The thermoforming method comprises the following steps: blanking by shearing the steel plate, and heating at Ac3 to (Ac3+80) DEG C to carry out austenization; after insulating for 5-10 minutes in the heating furnace, immediately transferring the steel plate to a metal mold the inside of which is cooled by introducing water, and stamping at the high temperature of 650-850 DEG C; cooling the formed workpiece in the closed mold, and cooling the mold by water circulation in the mold, wherein the cooling rate is greater than the critical cooling rate when austenite forms martensite, and the temperature of the workpiece leaving the hot stamping production line is below 150 DEG C; and carrying out air-cooling to room temperature. The steel plate has the advantages of simple component system and favorable hardenability; and the substrate tissues, which are ferrite and pearlite, are processed by hot stamping andquenching to obtain the all martensitic structure. The tensile strength of the steel plate can be higher than 1300 N / mm<2>.

Owner:ANGANG STEEL CO LTD

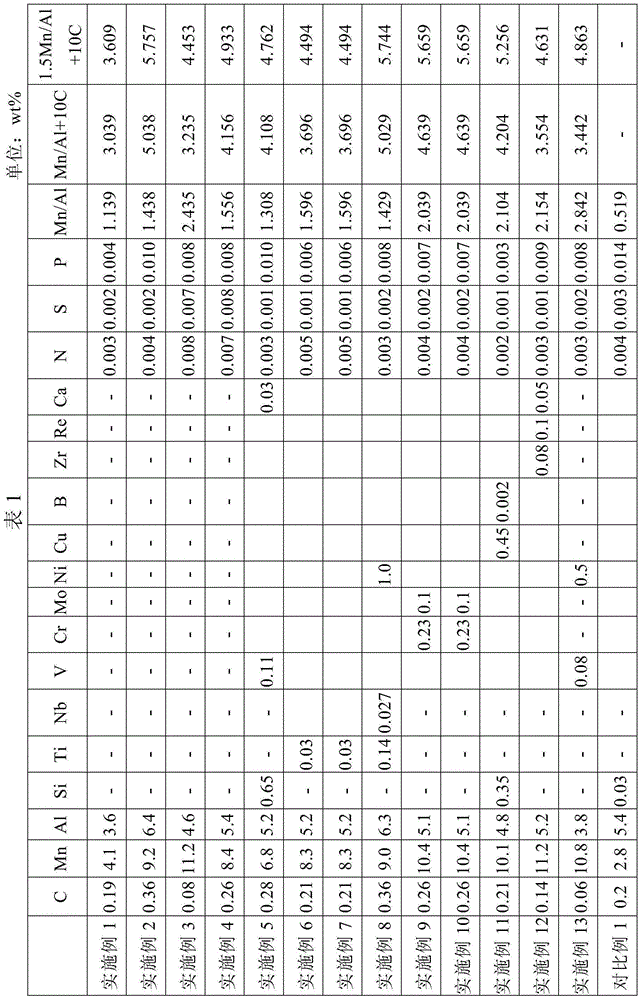

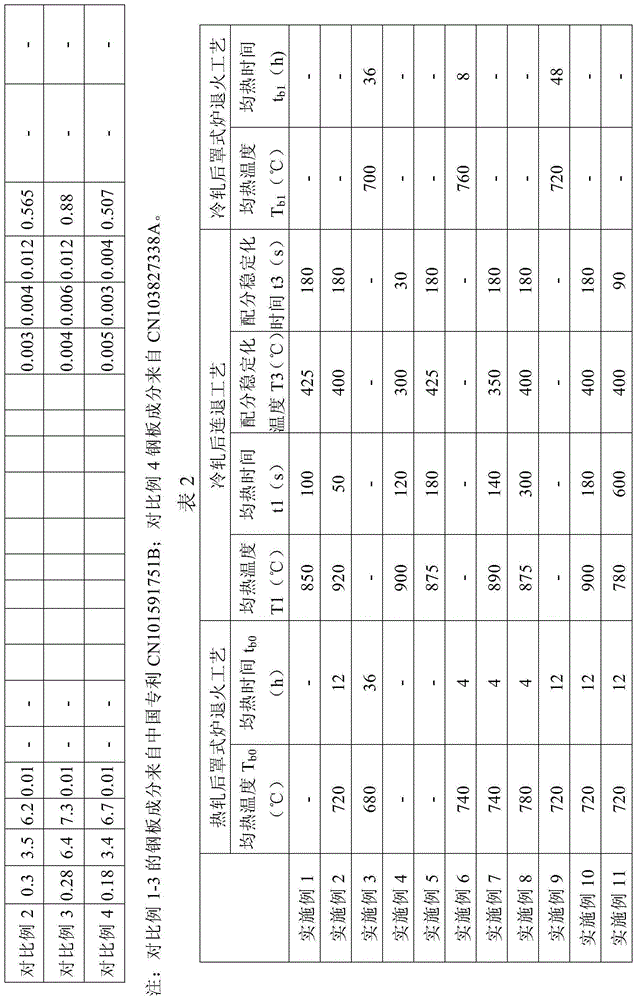

Ferrite low-density high-strength steel and manufacturing method thereof

A ferrite low-density high-strength steel and manufacturing method thereof. The ferrite low-density high-strength steel chemical comprises the following chemical components composition by mass percentage: 0.05-0.40% of C, 4.0-12.0% of Mn, 3.0-7.0% of Al, no more than 0.02% of P, no more than 0.01% of S, no more than 0.01% of N, and the balance of Fe and inevitable impurity elements. The above elements satisfy the following relationship: 1.0<Mn / Al, 3.5 <1.5Mn / Al+10C, and Mn / Al + 10C <5.2 The manufacturing method comprises hot rolling, annealing, pickling, cold rolling and annealing to prepare the low-density high-strength steel plate. In addition to ferrite, the microstructure of the steel plate also contains 6-40% of residual austenite. The low-density high-strength steel plate has tensile strength no less than 800MPa, elongation no less than 25%, and density less than 7500kg / m<3>.

Owner:BAOSHAN IRON & STEEL CO LTD

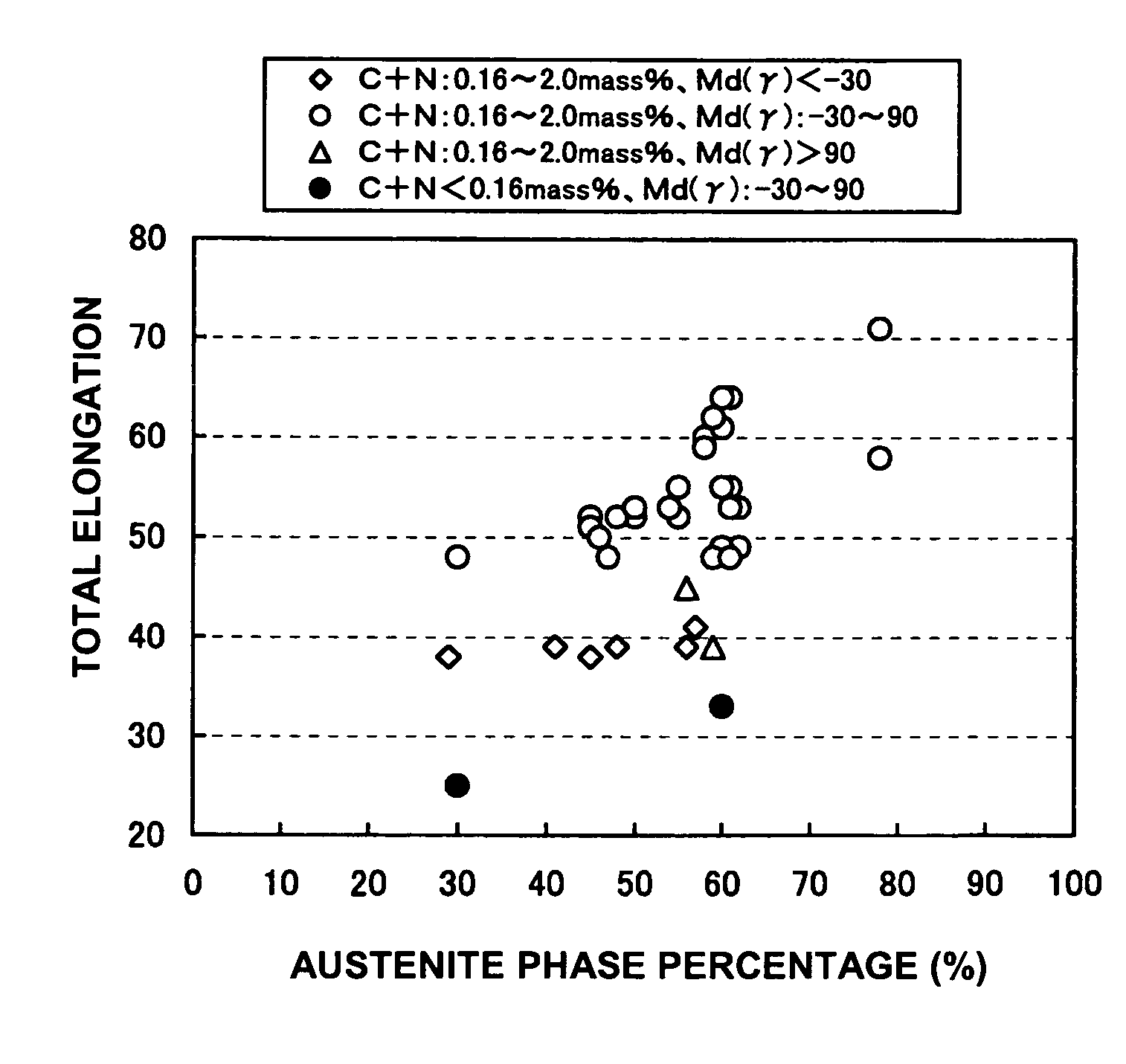

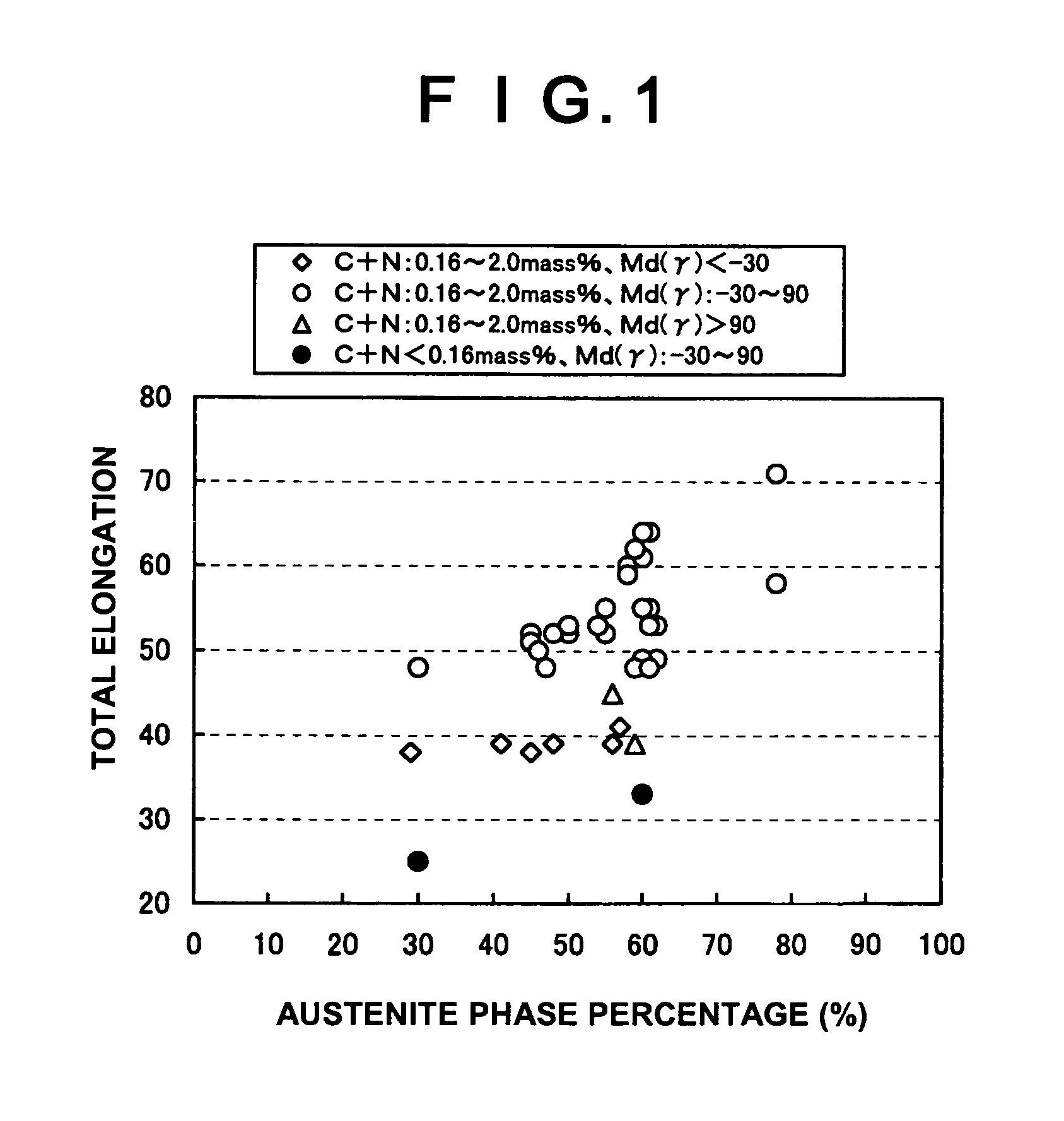

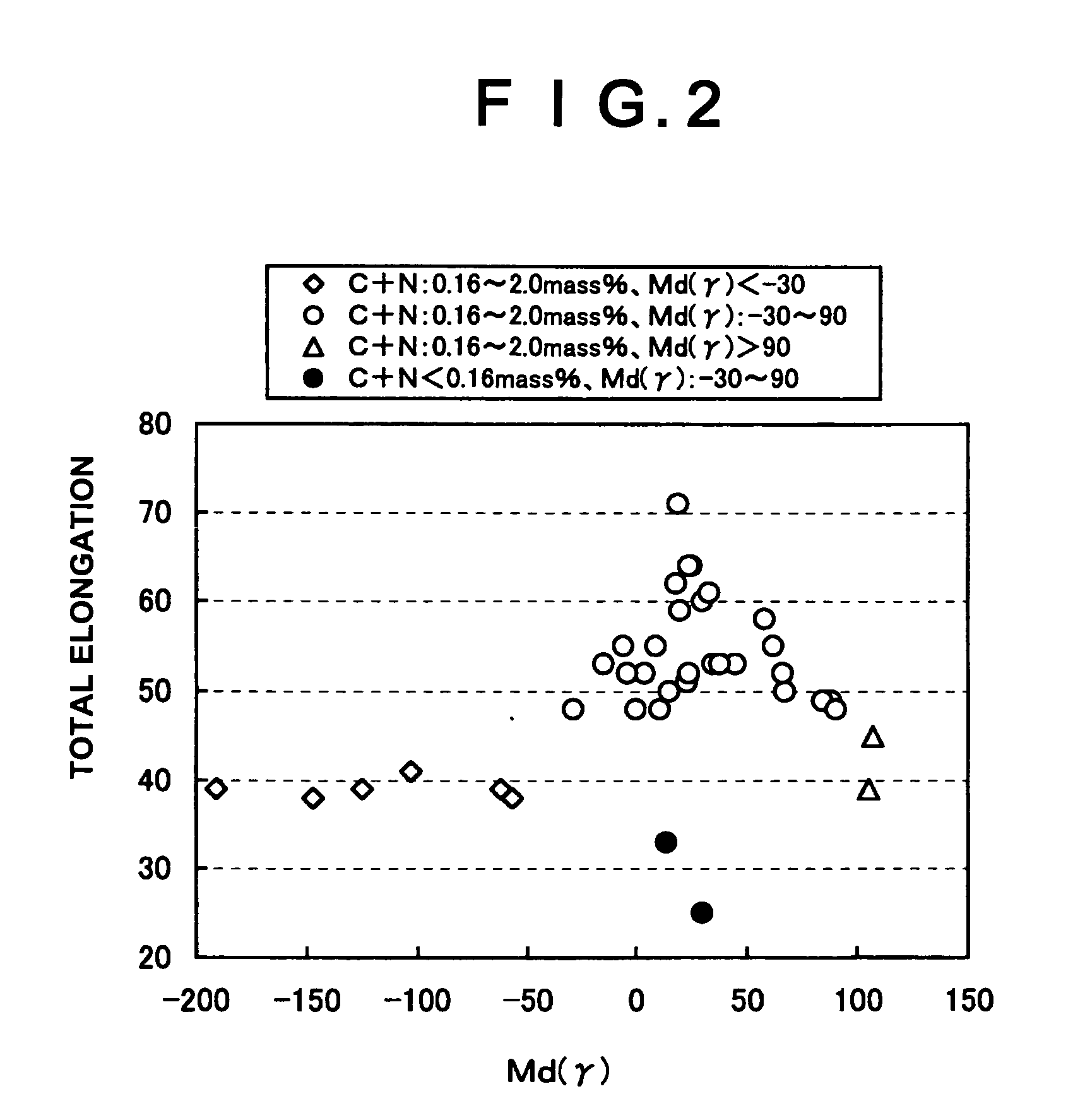

Austenitic-ferritic stainless steel

A low Ni and high N austenitic-ferritic stainless steel is disclosed. It includes an austenitic-ferritic stainless steel having high formability and punch stretchability, crevice corrosion resistance, corrosion resistance at welded part, or excellent intergranular corrosion resistance, from a stainless steel structured by mainly austenite phase and ferrite phase, and consisting essentially of 0.2% or less C, 4% or less Si, 12% or less Mn, 0.1% or less P, 0.03% or less S, 15 to 35% Cr, 3% or less Ni, and 0.05 to 0.6% N, by mass, by adjusting the percentage of the austenite phase in a range from 10 to 85%, by volume. Furthermore, it includes an austenitic-ferritic stainless steel having higher formability by adjusting the amount of (C+N) in the austenite phase to a range from 0.16 to 2% by mass.

Owner:JFE STEEL CORP

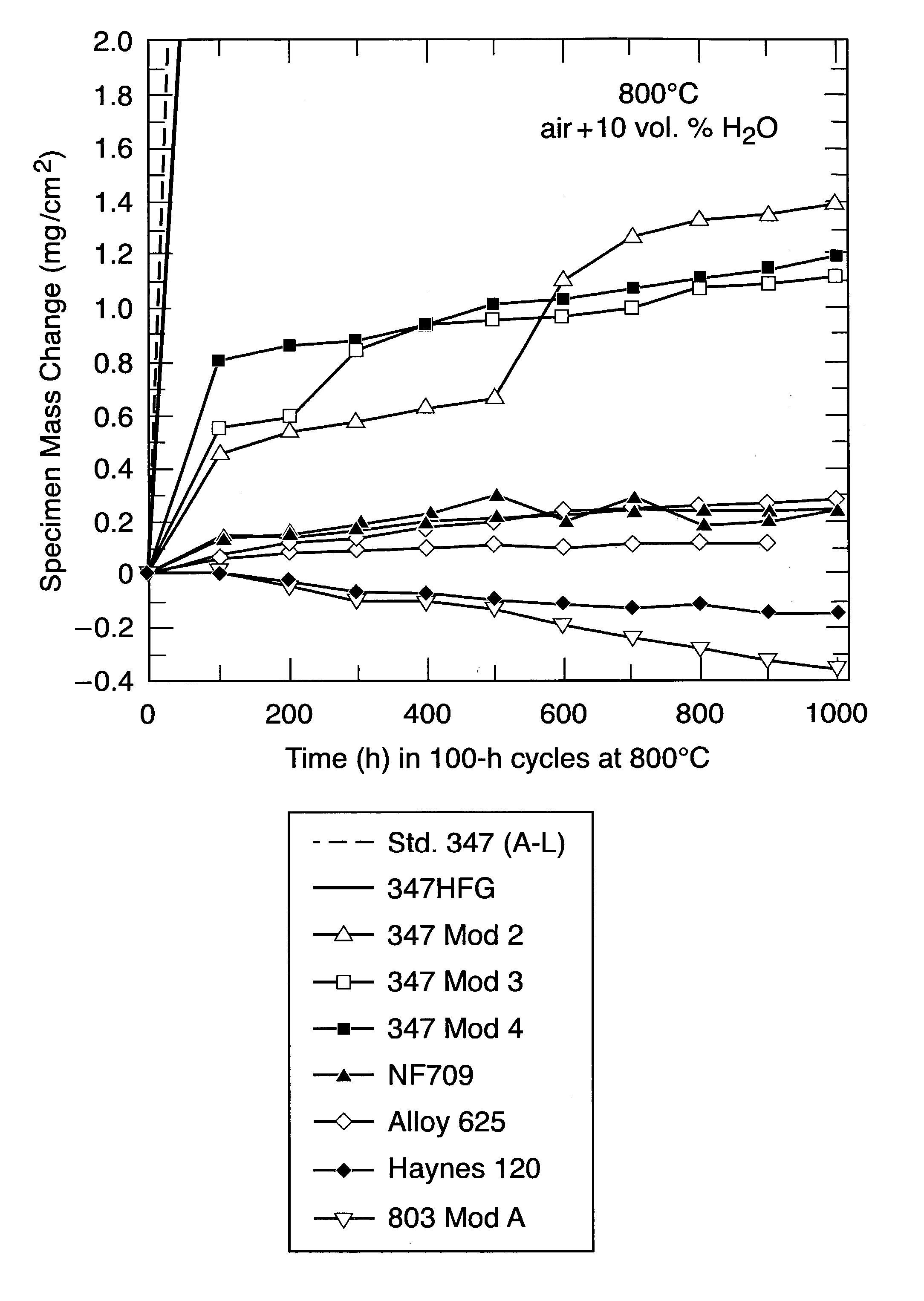

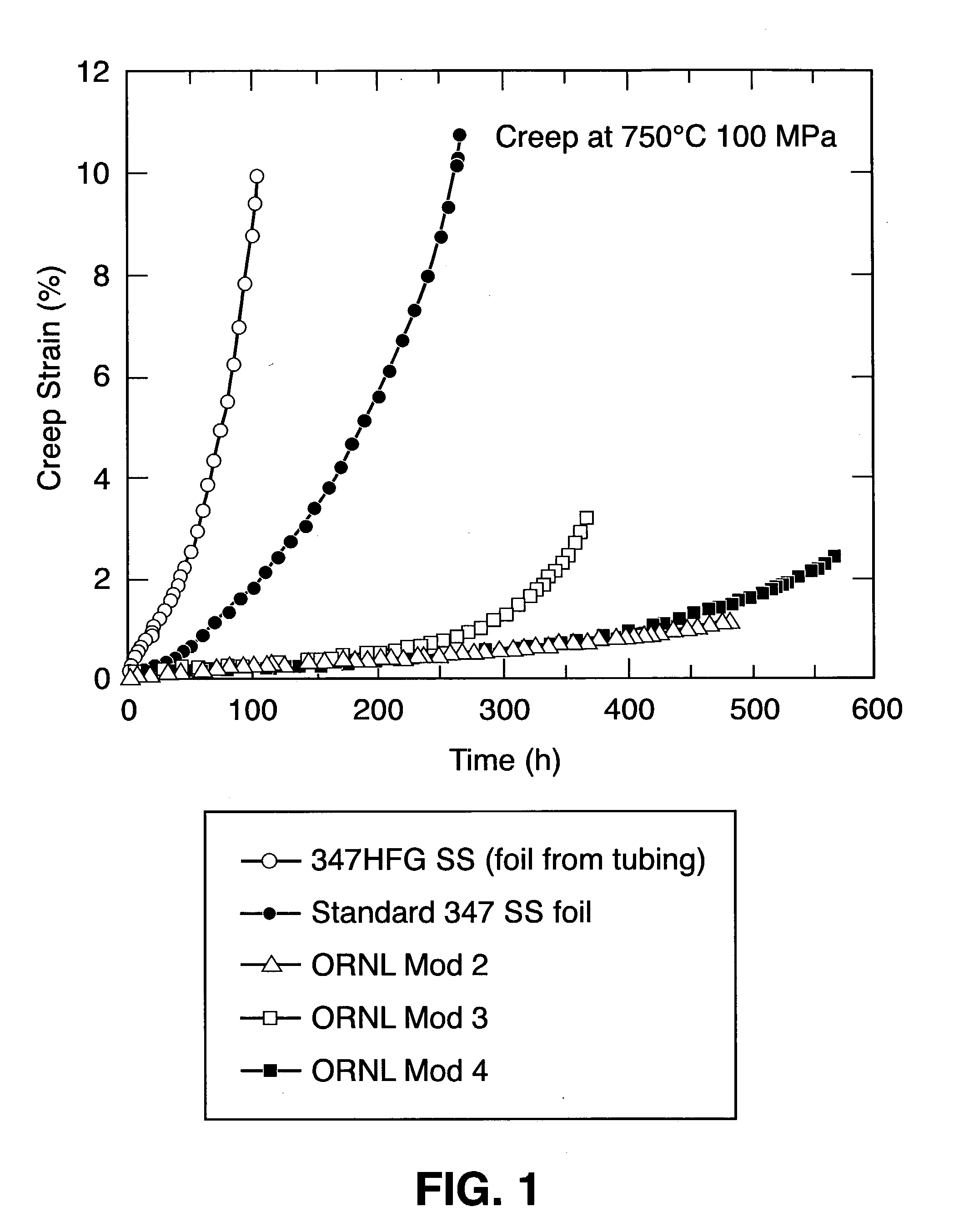

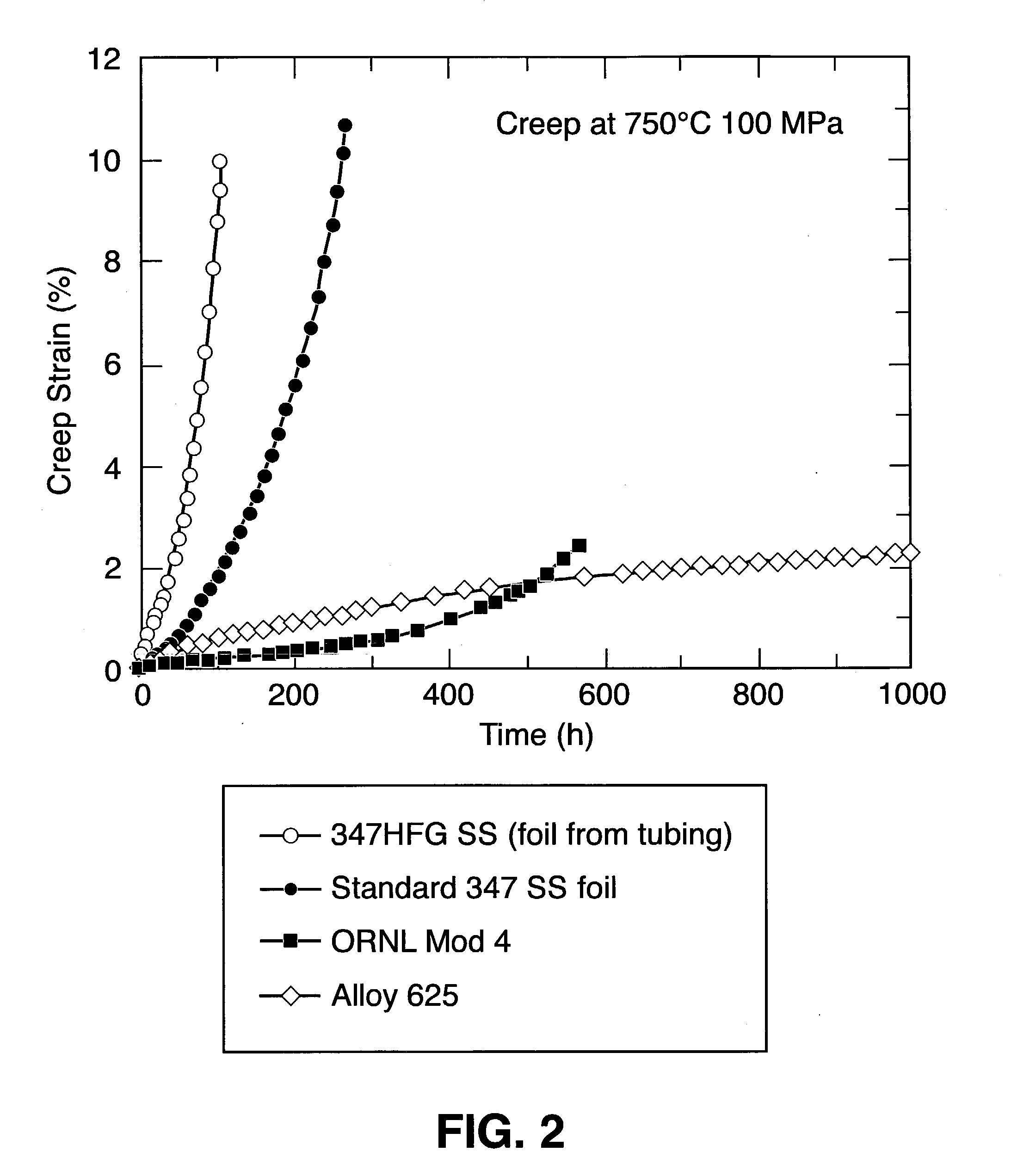

Wrought stainless steel compositions having engineered microstructures for improved heat resistance

InactiveUS20040191109A1Increase heatIncrease resistanceHeat exchange apparatusHeat resistanceAustenite

A wrought stainless steel alloy composition includes 12% to 25% Cr, 8% to 25% Ni, 0.05% to 1% Nb, 0.05% to 10% Mn, 0.02% to 0.15% C, 0.02% to 0.5% N, with the balance iron, the composition having the capability of developing an engineered microstructure at a temperature above 550° C. The engineered microstructure includes an austenite matrix having therein a dispersion of intragranular NbC precipitates in a concentration in the range of 10<10 >to 10<17 >precipitates per cm<3>.

Owner:UT BATTELLE LLC

1000MPa grade cold rolling hot dip galvanizing two-phase steel and manufacturing method thereof

The invention provides 1,000 MPa cold-rolled hot-dip galvanized dual-phase steel and a manufacturing method thereof, belonging to the technical field of cold-rolled hot-dip galvanized high-strength steel plates. The chemical components in mass percentage of the cold-rolled hot-dip galvanized dual-phase steel are: 0.06 to 0.18 percent of C, less than or equal to 0.1 percent of Si, 1.2 to 2.5 percent of Mn,0.05 to 0.5 percent of Mo, 0.05 to 0.6 percent of Cr, 0.005 to 0.05 percent of Al, 0.01 to 0.06 percent of Nb, 0.01 to 0.05 percent of Ti, less than or equal to 0.02 percent of P, less than or equal to 0.01 percent of S, less than or equal to 0.005 percent of N, the balance being Fe and inevitable impurities. The manufacturing method adopts Cr or Mo to replace Si, so as to enlarge an austenitic and ferritic two-phase region and improve the hardenability of the dual-phase steel, and meanwhile, the manufacturing method improves the strength of toughness of the steel by adding Nb or Ti refined grains, so as to ensure that the steel has good weldability and usability, and the strength grade of the steel can reach over 1,000 Mpa.

Owner:UNIV OF SCI & TECH BEIJING +1

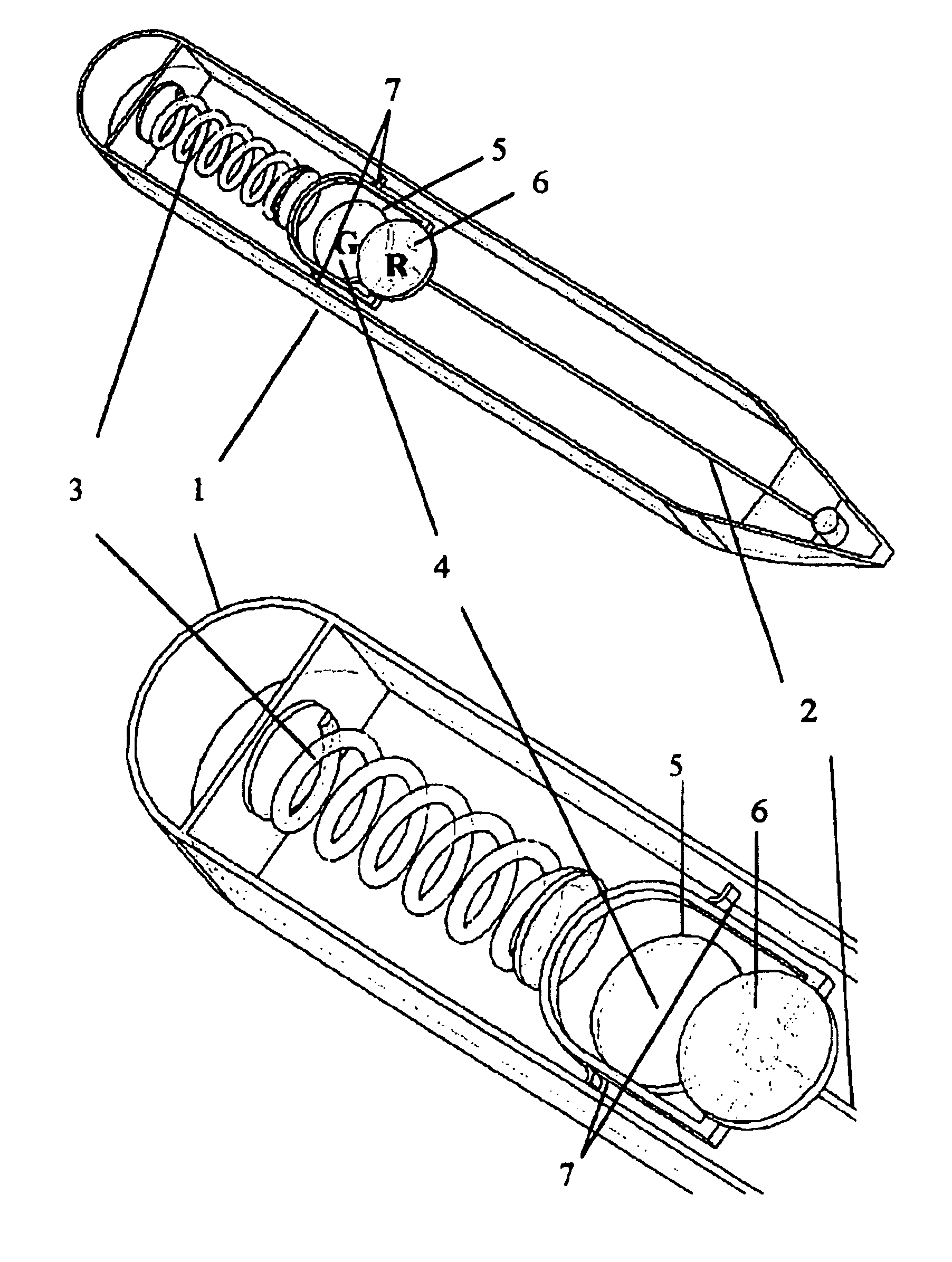

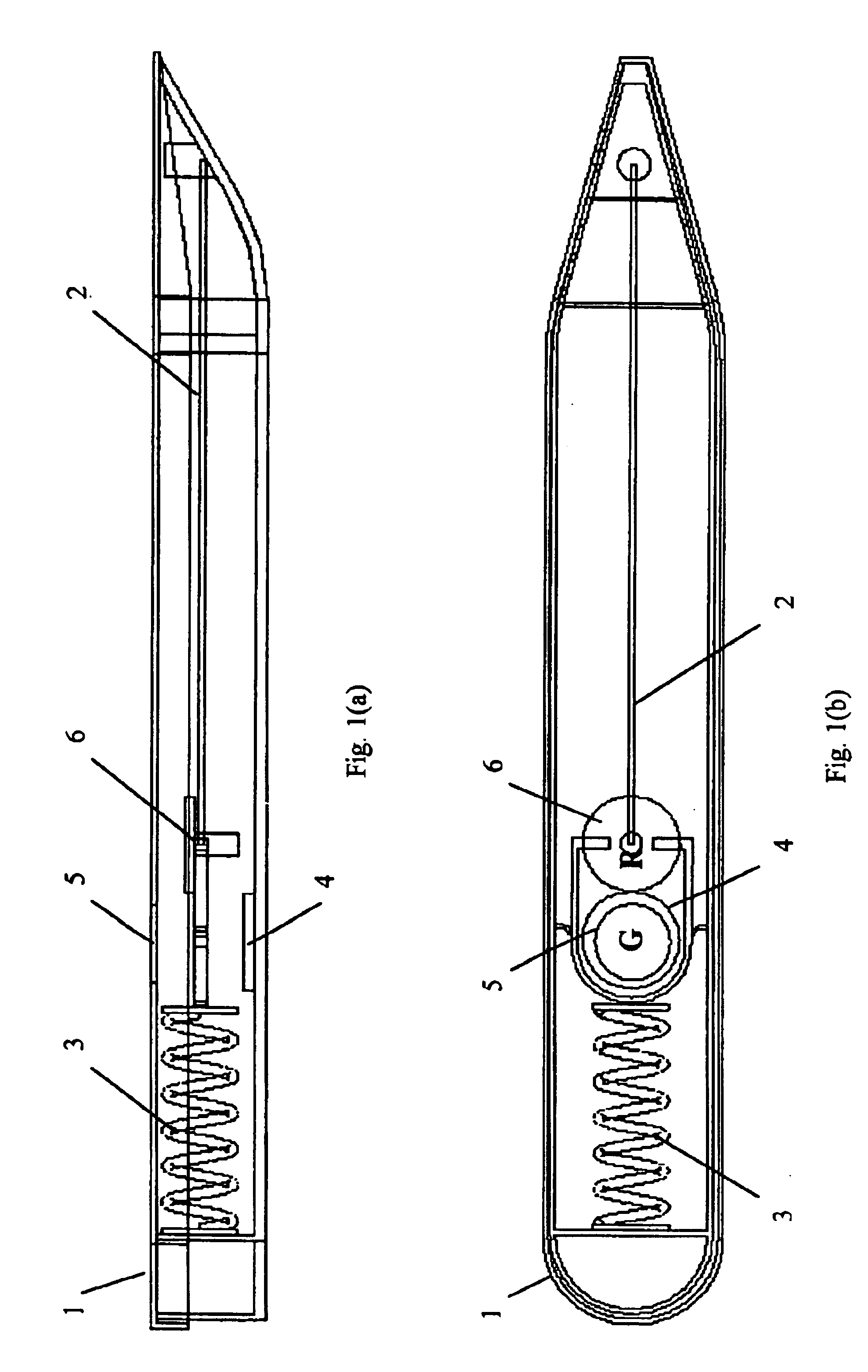

Shape memory alloy temperature sensor

InactiveUS6837620B2Avoid attenuationInhibition of contractionThermometers using material expansion/contactionThermometers using weight distributionShape changeShape-memory alloy

A sensor provides a persistent indication that it has been exposed to temperatures below a certain critical temperature for a predetermined time period. An element of the sensor made from shape memory alloy changes shape when exposed, even temporarily, to temperatures below the Austenitic start temperature As and well into Martensite finish temperature Mf off the shape memory alloy. The shape change of the SMA element causes the sensor to change between two readily distinguishable states. The sensor includes a one-way stop element that creates a persistent indication of the temperature history, allowing the sensor to be manufactured and stored at temperatures above the Austenitic temperature without causing the indication of an over-temperature event.

Owner:SHAHINPOOR MOHSEN

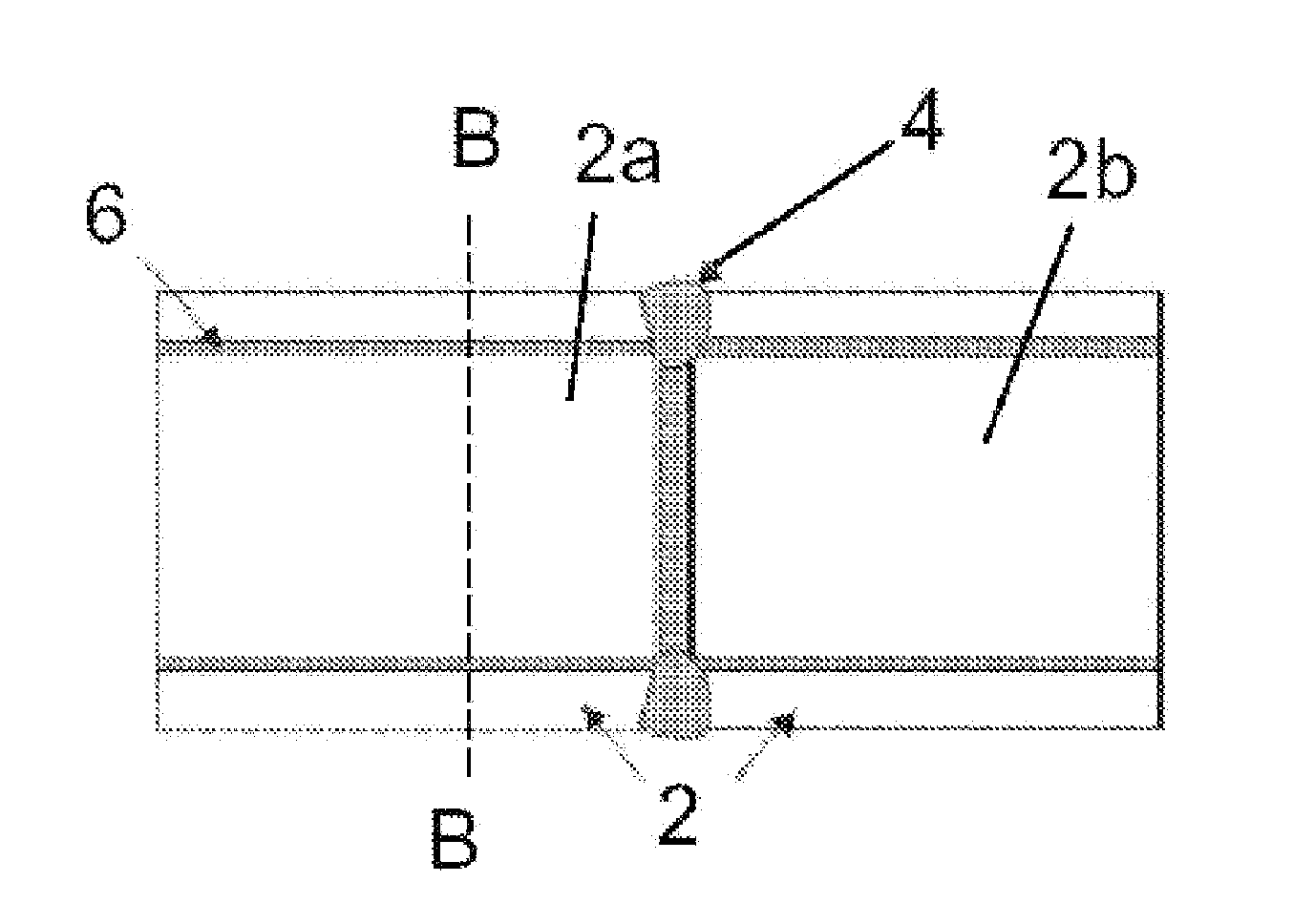

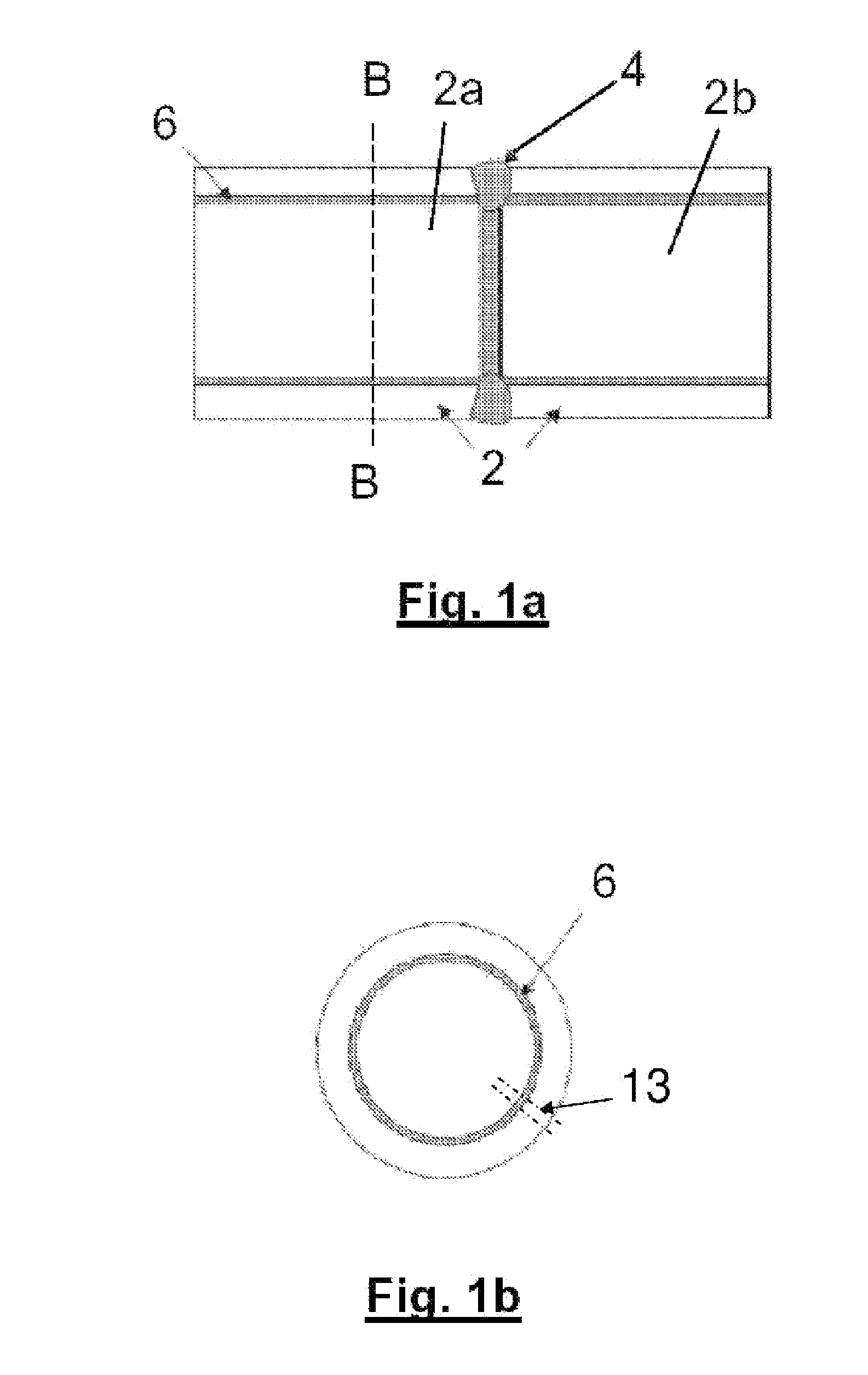

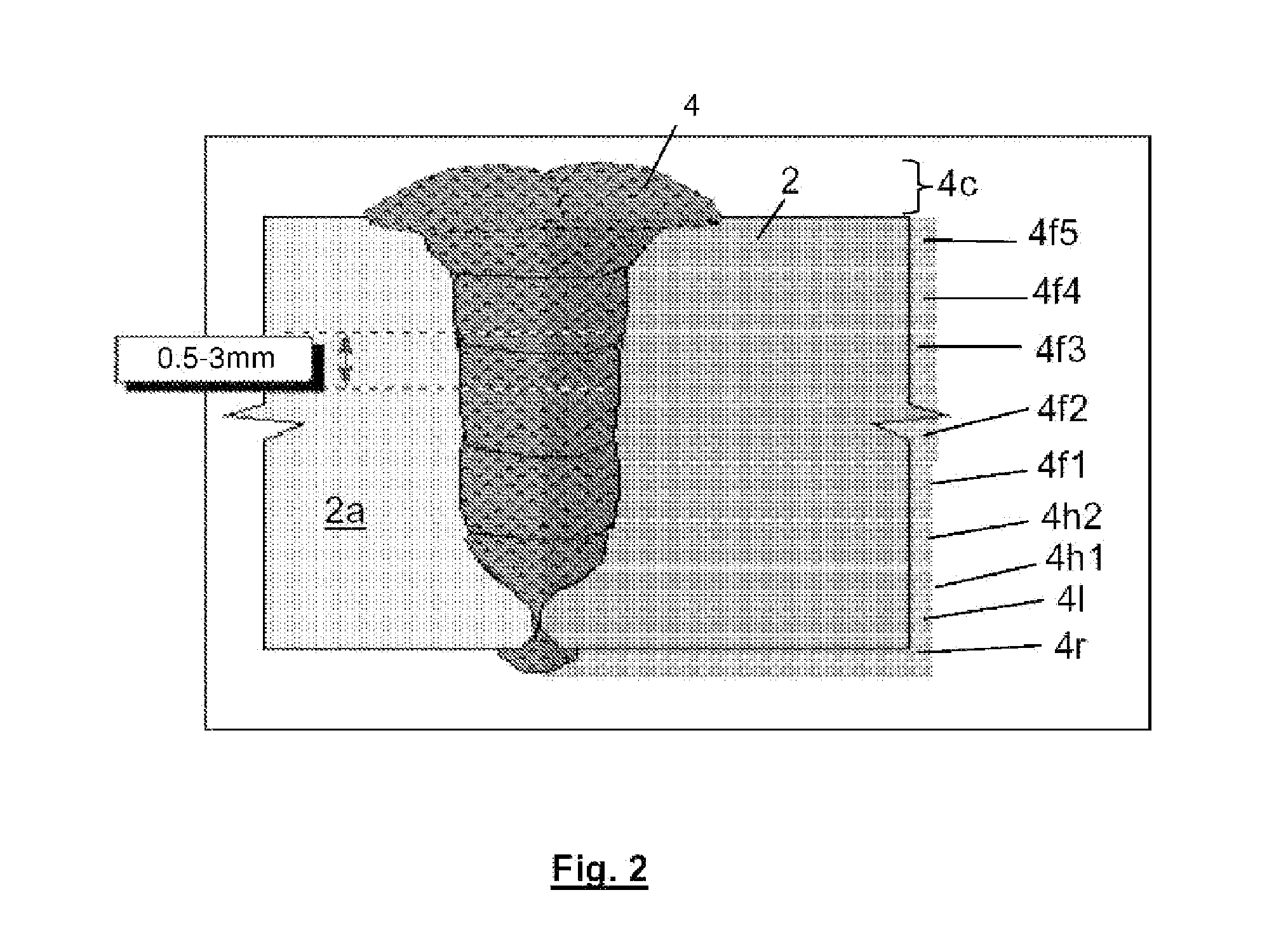

Method for testing pipeline welds using ultrasonic phased arrays

ActiveUS20110296923A1Great advantageAccurate detection and classificationMaterial analysis using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsTemporal informationLongitudinal wave

NDT inspection of an austenitic weld between two CRA Clad pipes using a phased ultrasonic transducer array system is described. The method may be performed during laying of gas / oil fatigue sensitive pipelines, for example, at sea. Two types of UT inspection may be generated simultaneously by a Phased Array on each side (Upstream and Downstream) of a girth weld. Firstly, mode converted longitudinal waves are used. These waves have properties that they propagate well. Shear waves are also used. The combination of these two ultrasonic waves, with the addition of surface waves, enables 100% of the girth weld to be inspected to the standard required in fatigue sensitive welds, such as Steel Catenary Risers. Shear waves and compression waves are emitted substantially contemporaneously. Defects may be detected and measured using time of flight information and amplitudes of radiation detected on reflection and on diffraction from the defect.

Owner:SAIPEM SPA

Production method of ultrahigh strength steel plate for cold forming and steel plate

The invention provides a production method of an ultrahigh strength steel plate for cold forming and the steel plate. The method comprises the steps of smelting, casting, hot rolling, cold rolling, heating the cold-rolled steel plate through a continuous annealing production line with rapid cooling treatment to the austenite temperature, holding the temperature for a certain time, carrying out quenching treatment, obtaining a steel plate with the main structure of M+A and carrying out distribution treatment in a bell type annealing furnace. The steel plate comprises the following components in percentage by mass: 0.02-0.60% of C, 0.05-3.5% of Si, 0.20-3.50% of Mn, P more than or equal to 0.005 but less than or equal to 0.50%, S not more than 0.05%, 0.02-3.00% of Al, Cr not more than 0.50%, Ni not more than 3.00%, Cu not more than 0.50%, Mo not more than 1.50%, V not more than 0.50%, Ti not more than 0.20%, Nb not more than 0.20% and the balance of Fe and unavoidable impurities. The steel plate produced by adopting the method provided by the invention has the advantages of high strength and capability of cold forming and the process route of Q&P steel industrial production is effectively solved.

Owner:ANGANG STEEL CO LTD

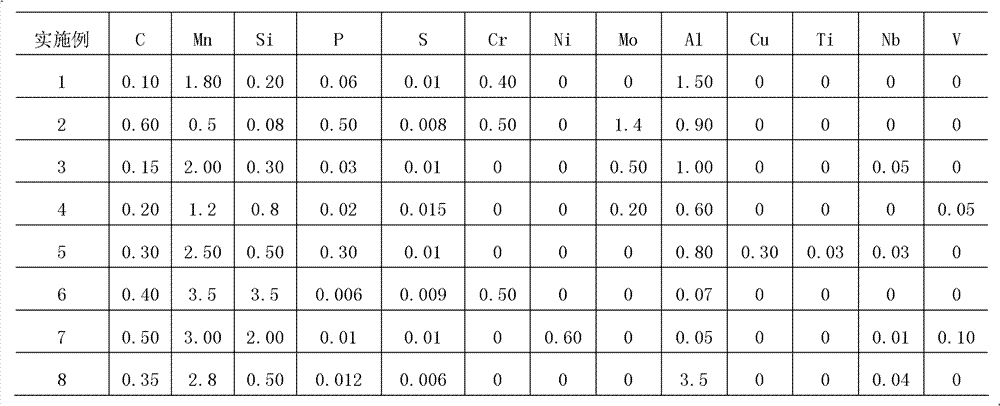

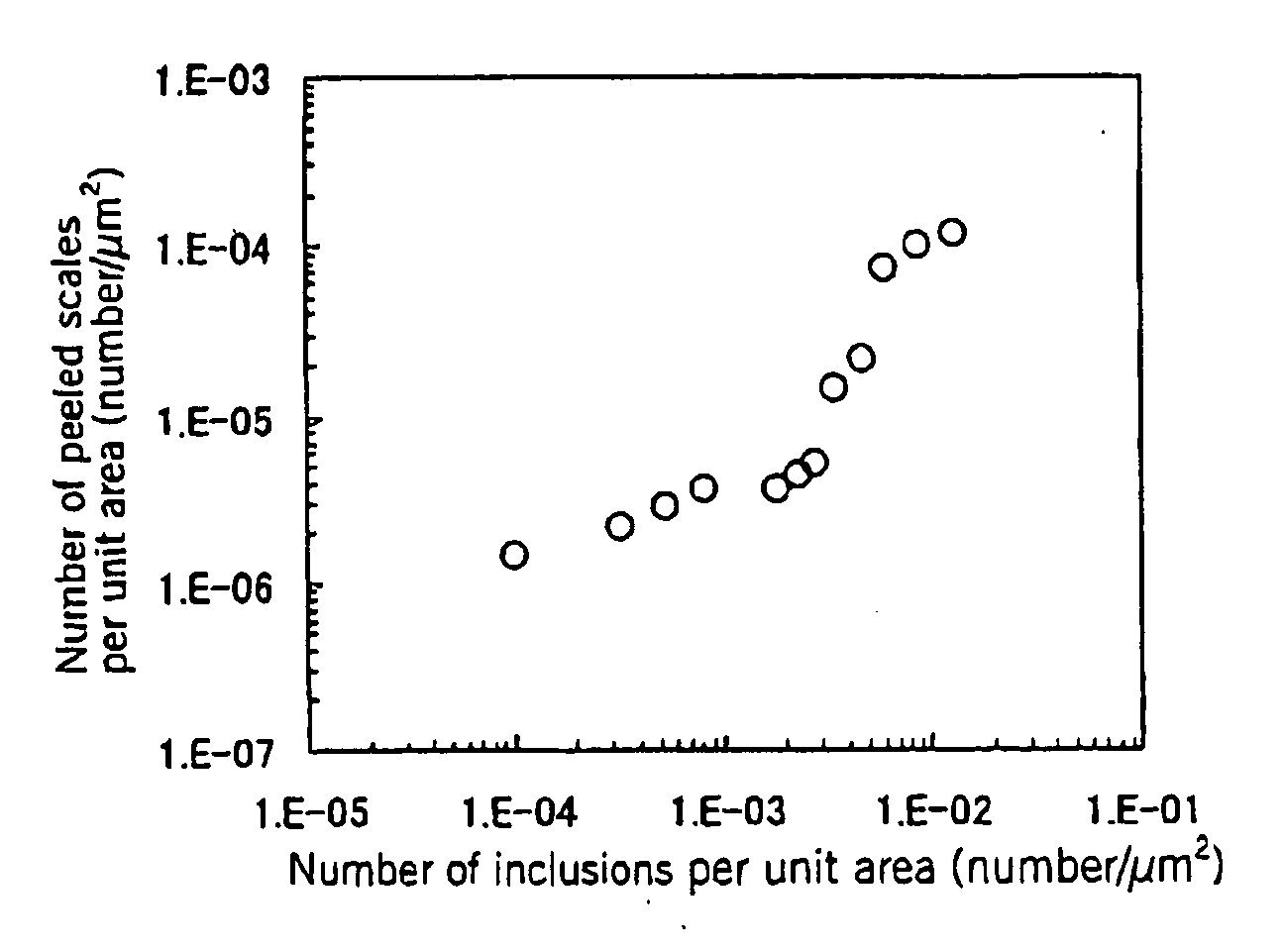

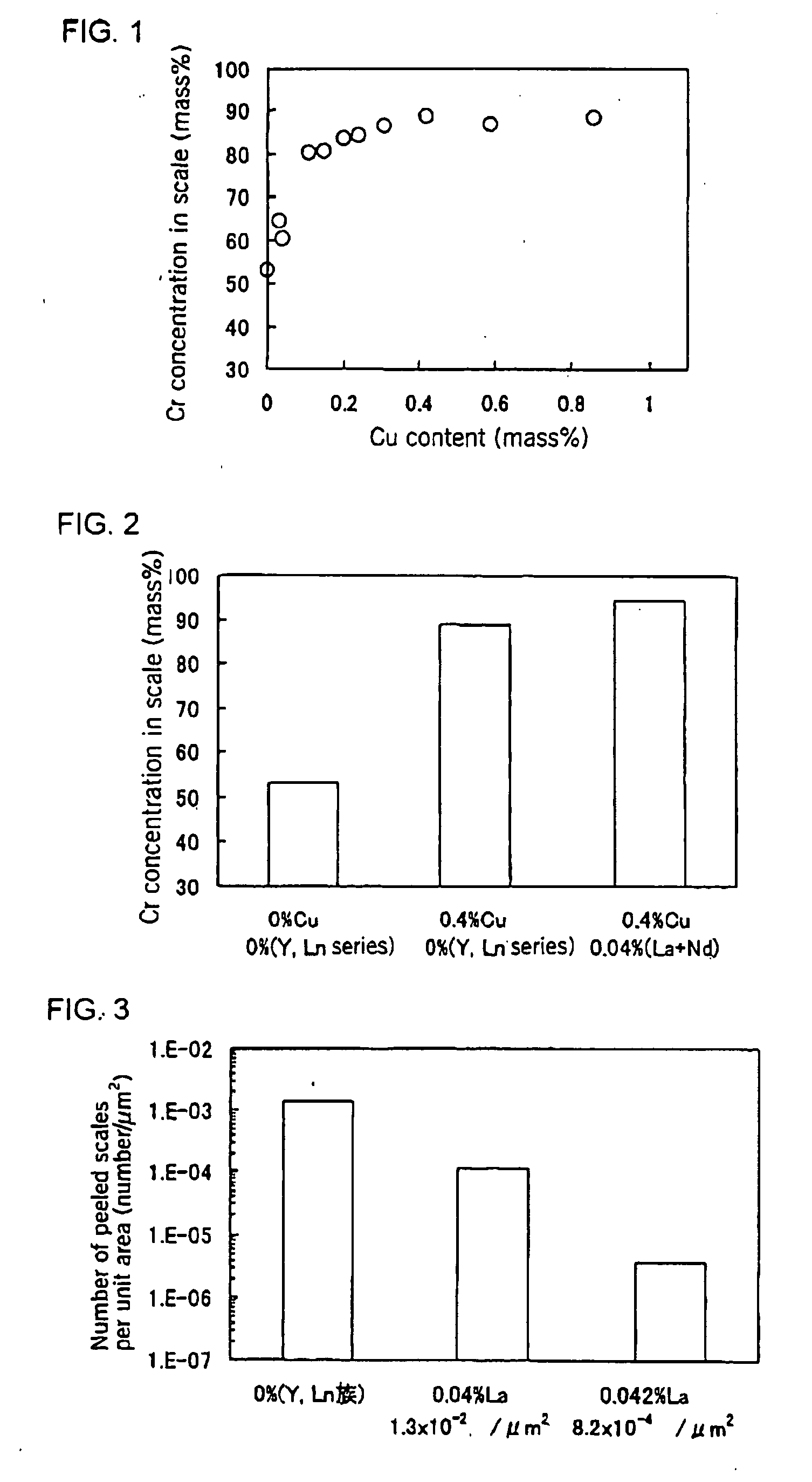

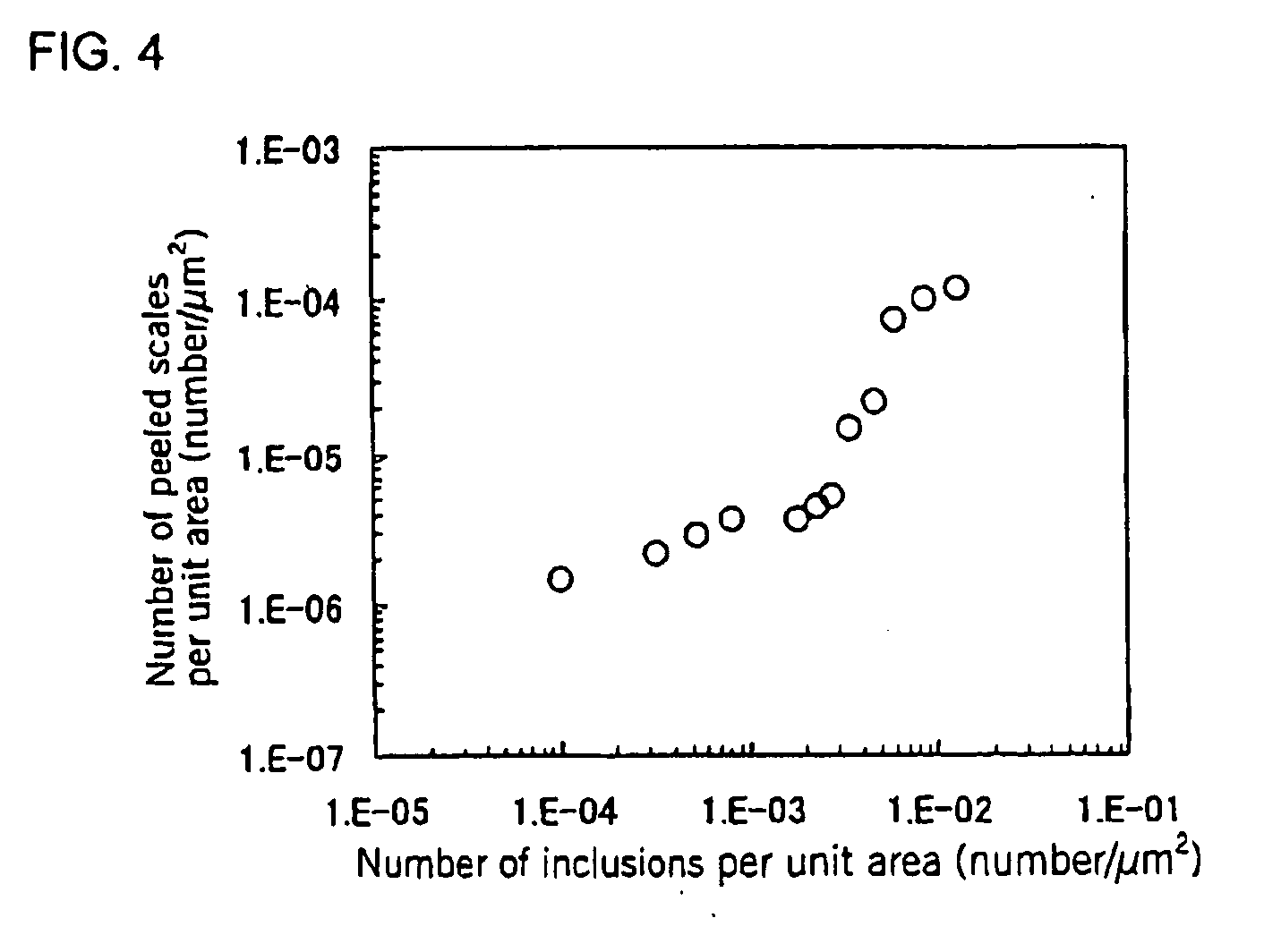

Austenitic stainless steel

ActiveUS20080107559A1Careful analysisAvoid dissociationHeat exchange apparatusMetallurgyProtective oxide

An austenitic stainless steel having excellent resistance to scale peeling which can suppress peeling of a protective oxide scale which is formed on the steel surface even when the steel undergoes repeated cycles of high temperature heating and cooling and which is suitable for use in a high temperature, humidified gas environment at a high temperature and particularly at 1023 K or above has a steel composition consisting essentially of C: 0.01-0.15%, Si: 0.01-3%, Mn: 0.01-2%, Cu: 0.1-2.5%, Cr: 23-30%, Ni: 16-25%, Al: 0.005-0.20%, N: 0.001-0.40%, P: at most 0.04%, S: at most 0.01%, at least one of Y and Ln series elements: a total of 0.005-0.1%, and a balance of Fe and unavoidable impurities, with the number of inclusions containing Y and Ln series elements in the steel surface being at most 5×10−3 / μm2.

Owner:NIPPON STEEL CORP

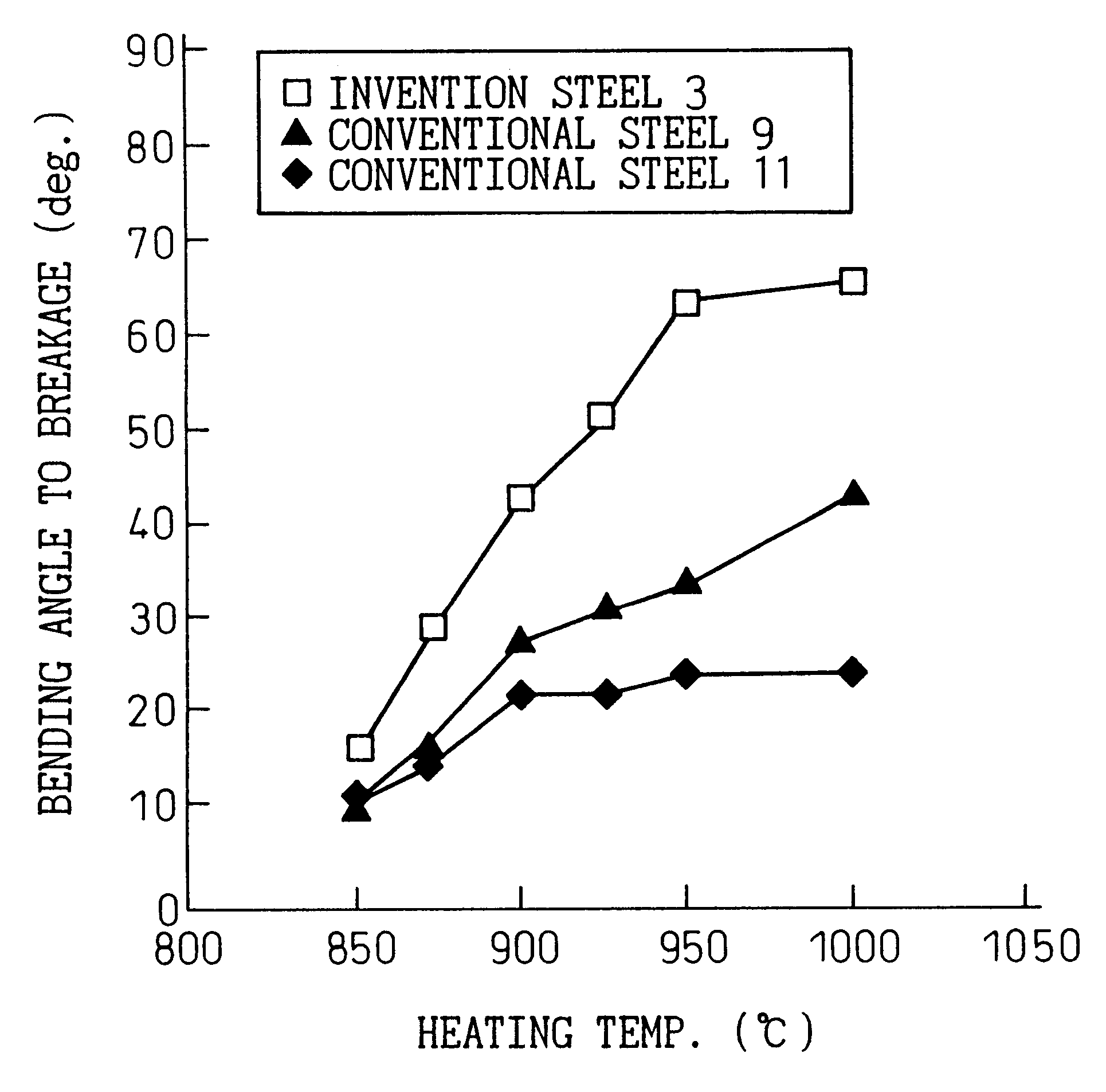

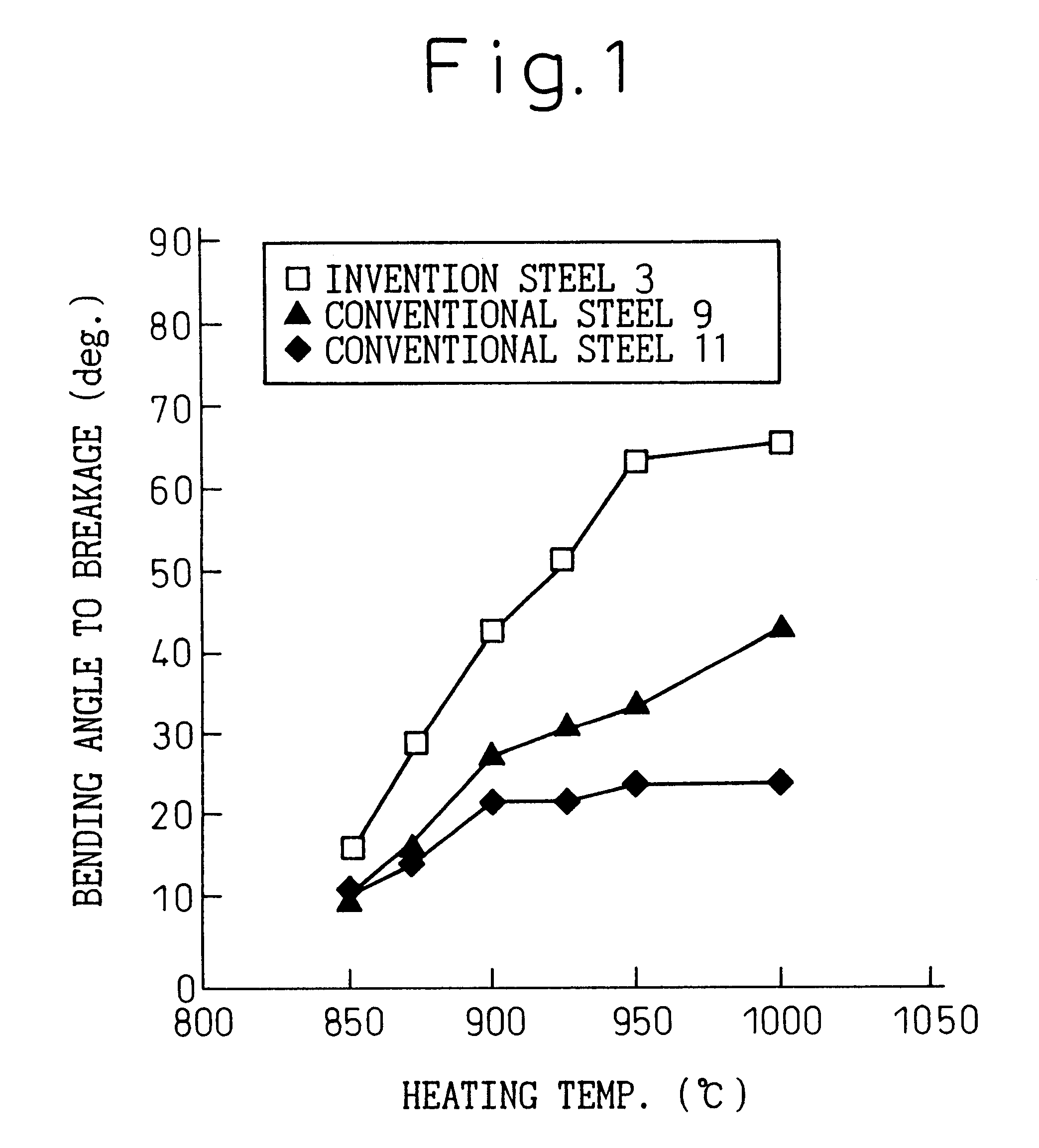

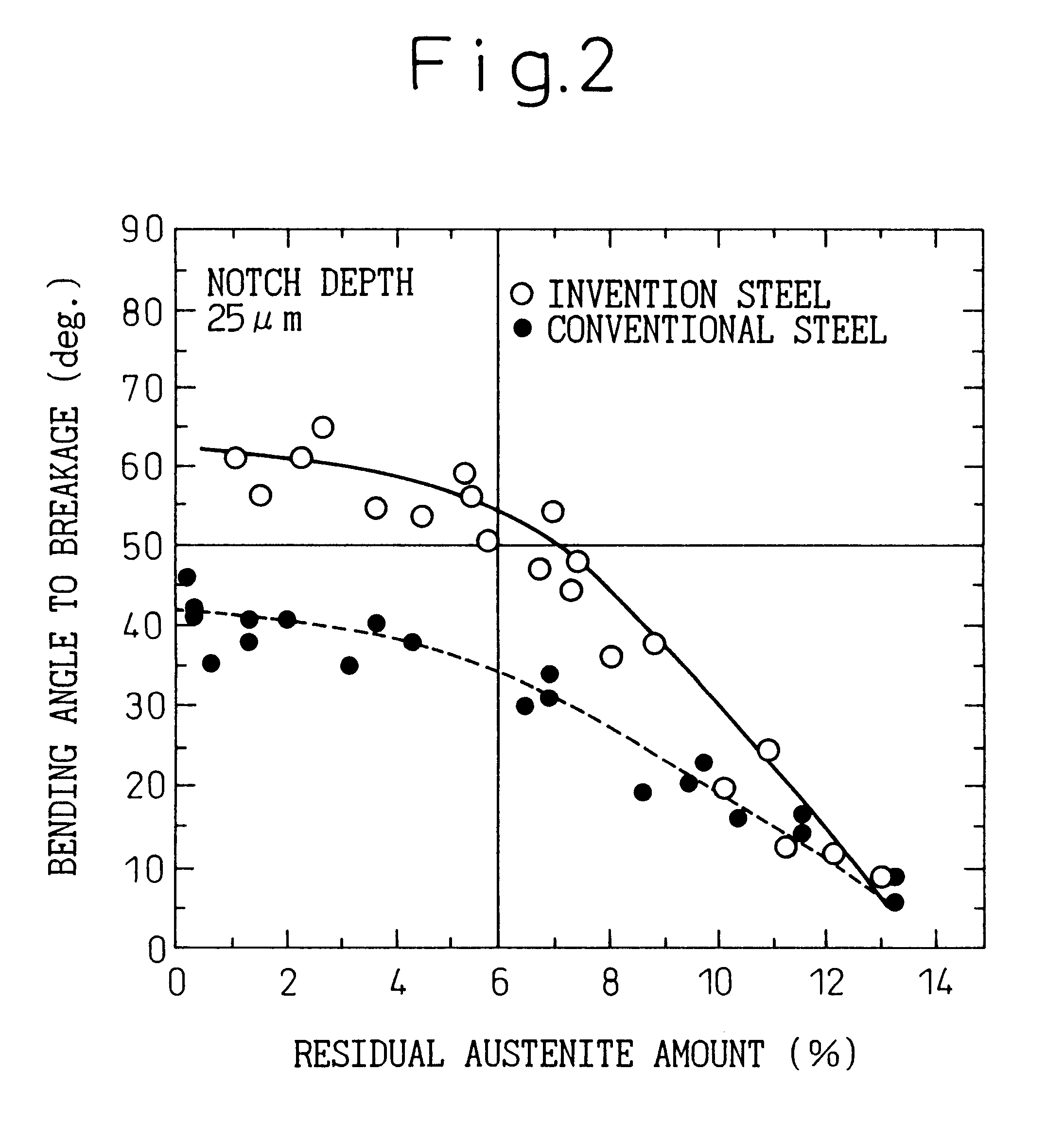

Steel wire for high-strength springs and method of producing the same

InactiveUS6338763B1Reduce contentReduce sizeFurnace typesHeat treatment furnacesNon-metallic inclusionsHigh intensity

This invention provides an oil-tempered wire having high strength (tensile strength of not less than 1960 MPa) and excellent workability and specifically provides a steel wire for high-strength springs comprising as steel components, in weight percent,the balance being Fe and unavoidable impurities, the steel wire having no nonmetallic inclusions of a size greater than 15 mum, a tensile strength of not less than 1960 MPa, and a yield ratio (sigma0.2 / sigmaB) of not less than 0.8 and not greater than 0.9 or a yield ratio (sigma0.2 / sigmaB) of not less than 0.8 and an amount of residual austenite of not greater than 6%. This invention also provides a method of producing the steel wire.

Owner:NIPPON STEEL CORP +1

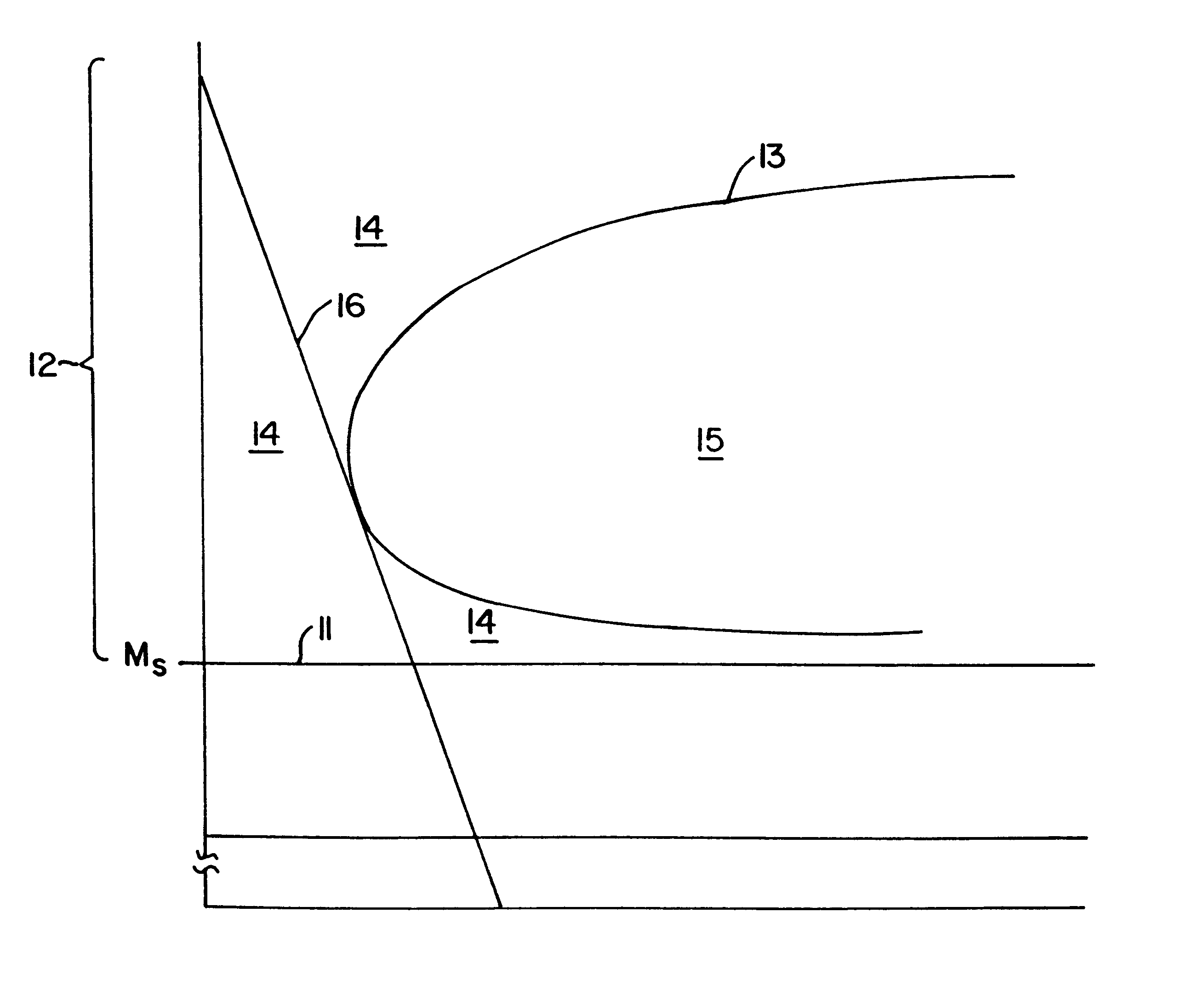

Low-carbon steels of superior mechanical and corrosion properties and process of making thereof

InactiveUS6273968B1Simple structureAccelerated corrosionFurnace typesHeat treatment furnacesCrystal twinningCarbide

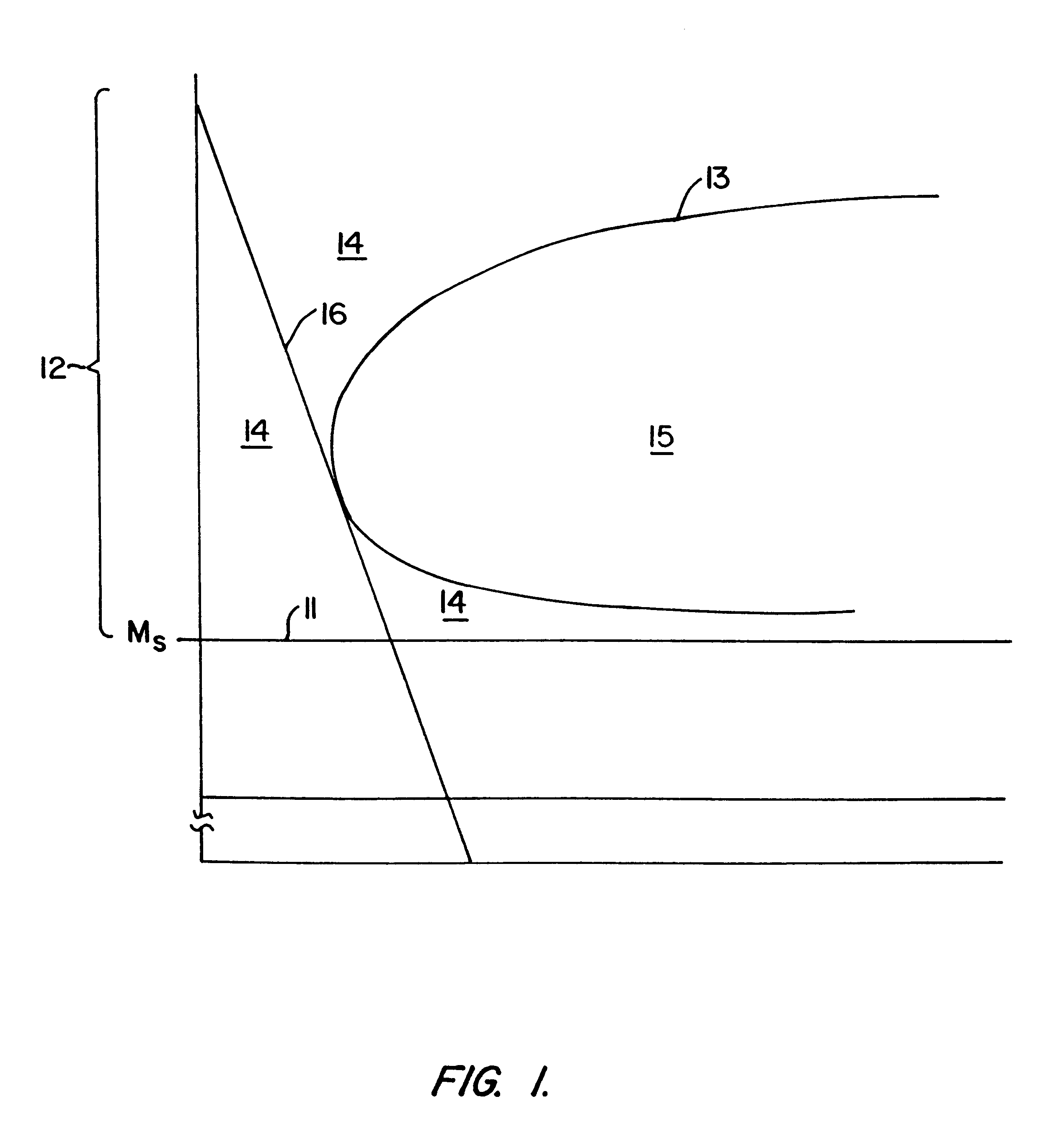

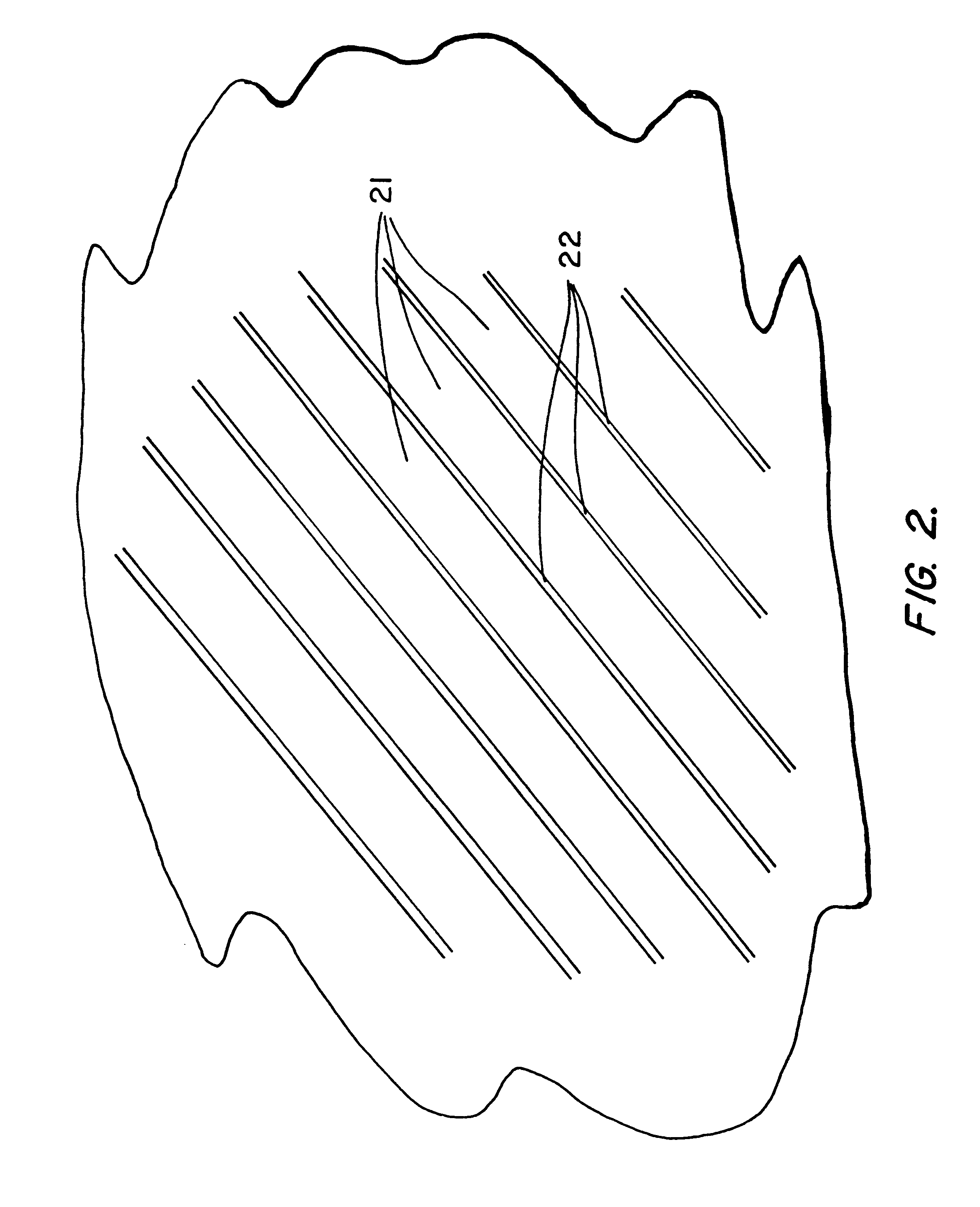

Alloy steels that combine high strength and toughness with high corrosion resistance are achieved by a dislocated lath microstructure, in which dislocated martensite laths that are substantially free of twinning alternate with thin films of retained austenite, with an absence of autotempered carbides, nitrides and carbonitrides in both the dislocated martensite laths and the retained austenite films. This microstructure is achieved by selecting an alloy composition whose martensite start temperature is 350° C. or greater, and by selecting a cooling regime from the austenite phase through the martensite transition region that avoids regions in which autotempering occurs.

Owner:CMC STEEL FABTORS

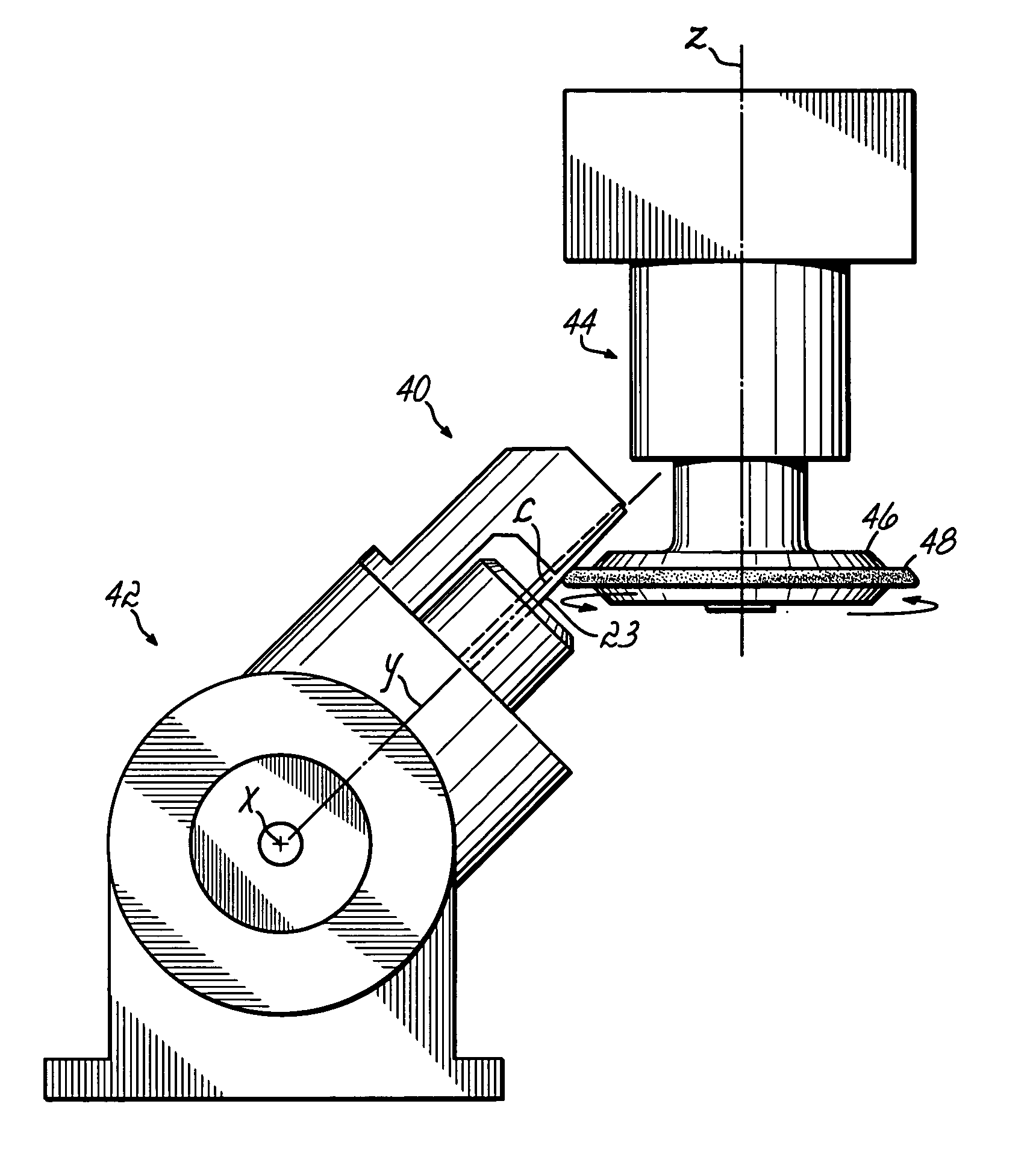

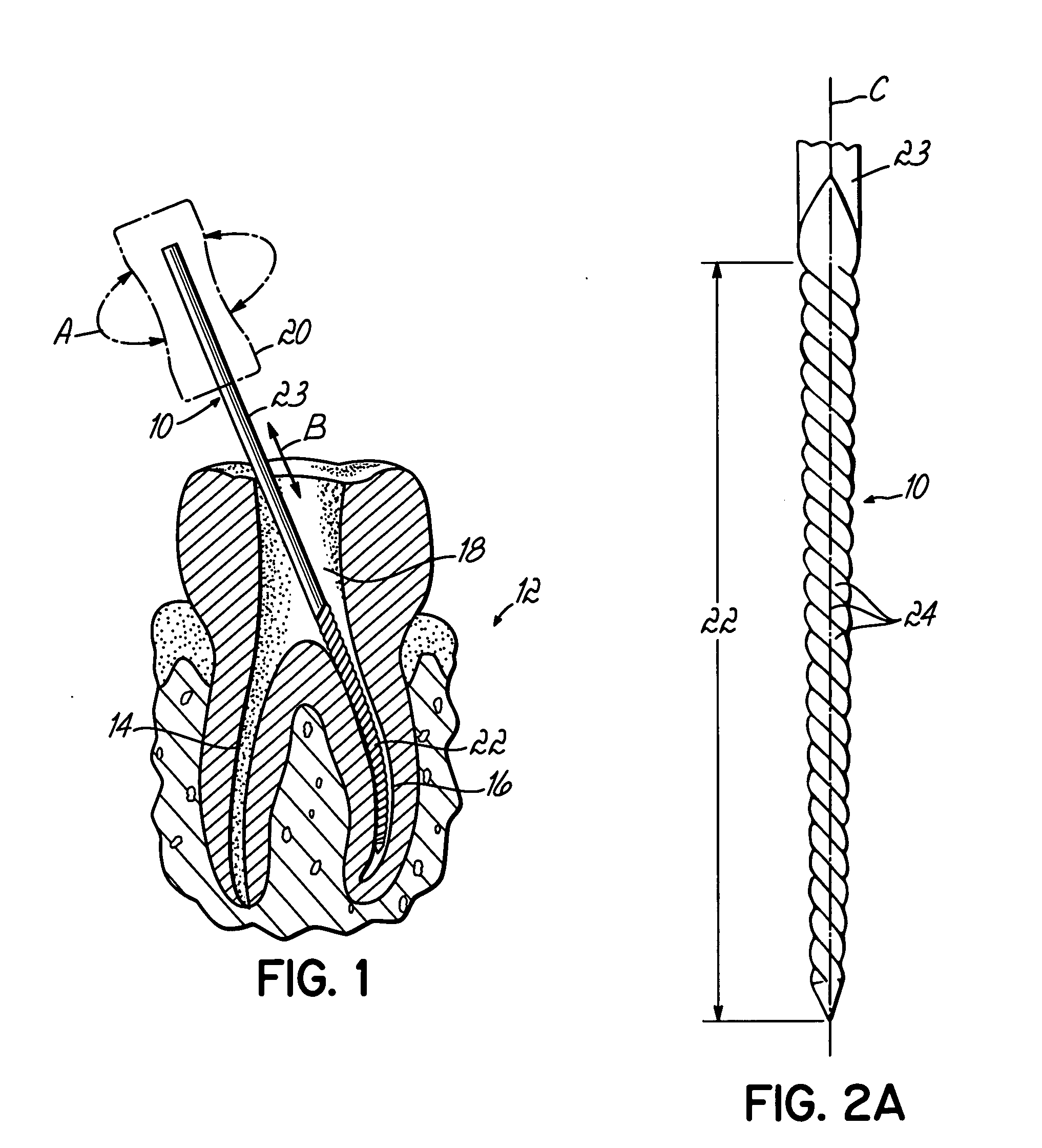

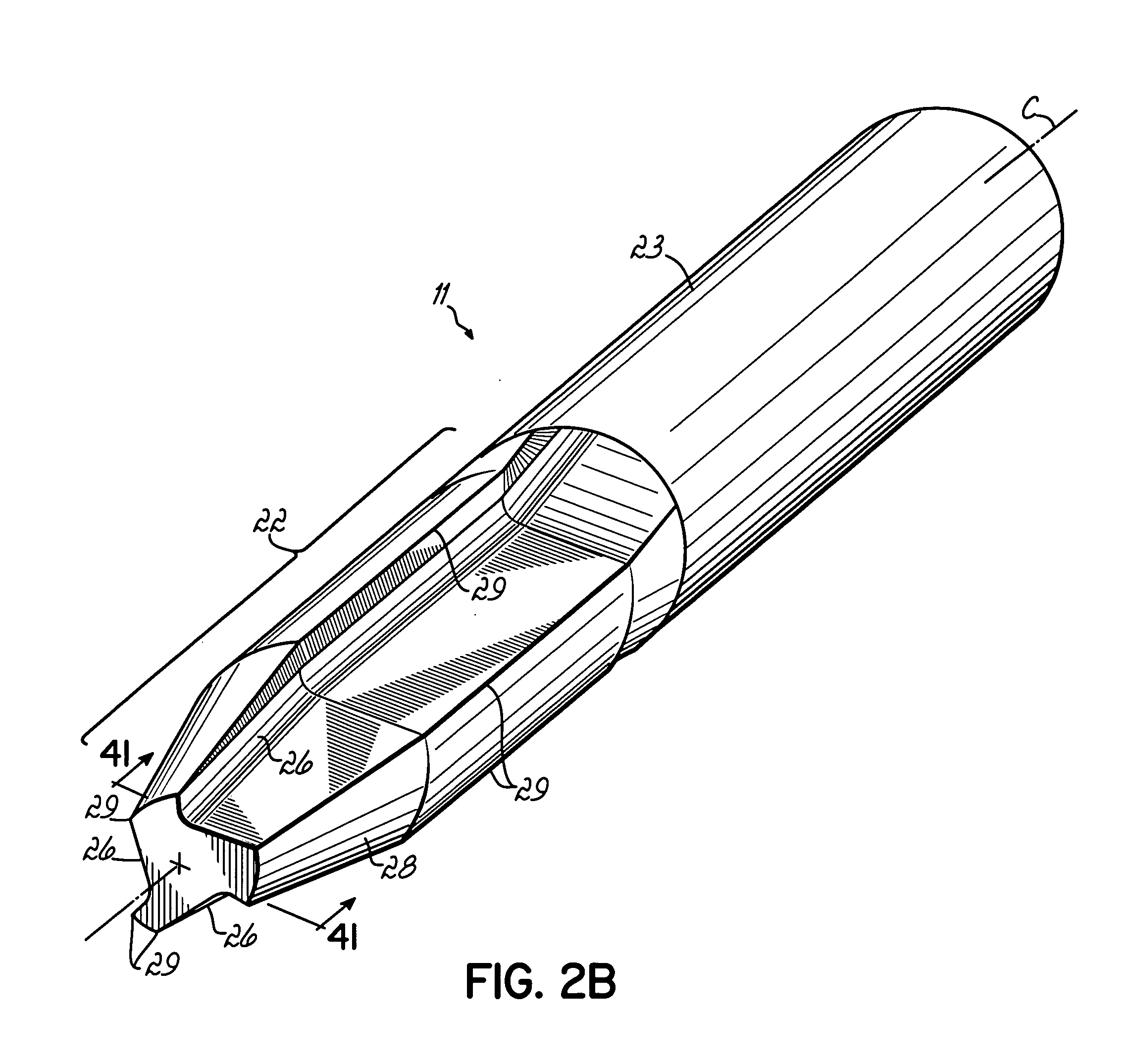

Method of manufacturing a dental instrument

Method for manufacturing a dental instrument having a desired machined configuration, without twisting the instrument. A blank of superelastic material is brought to an annealed state comprising a phase structure including a rhombohedral phase alone or in combination with austenite and / or martensite, or a combination of martensite and austenite. In this annealed state, a portion of the annealed material is removed at low temperature, for example less than about 100° C., and advantageously at ambient temperature, to form a final machined configuration for the instrument. The instrument is then heat treated and rapidly quenched to a superelastic condition.

Owner:ORMCO CORP

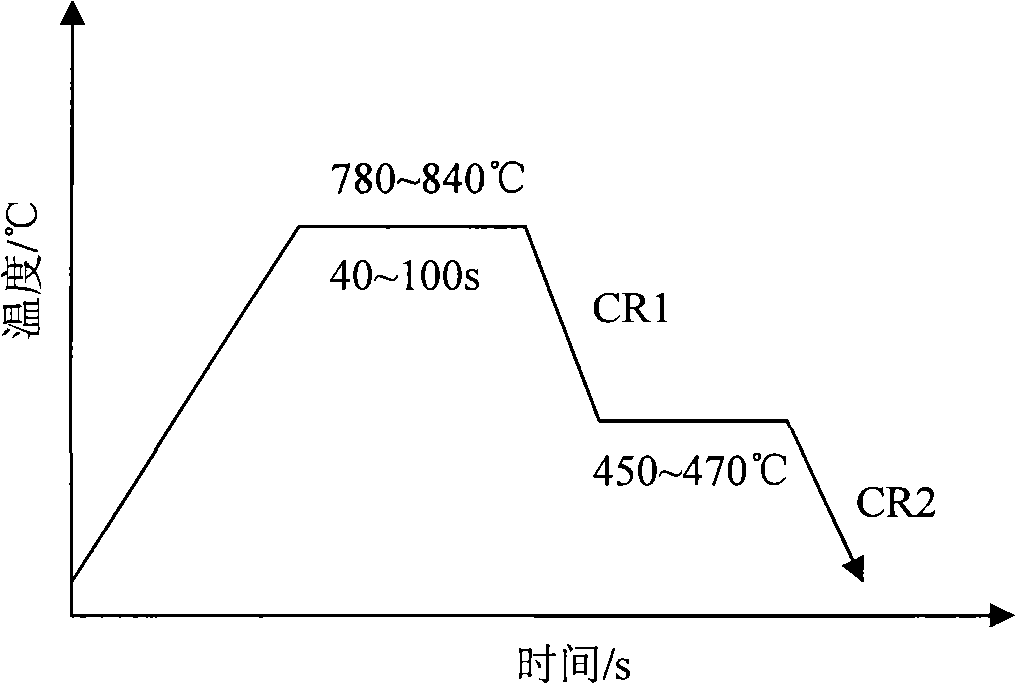

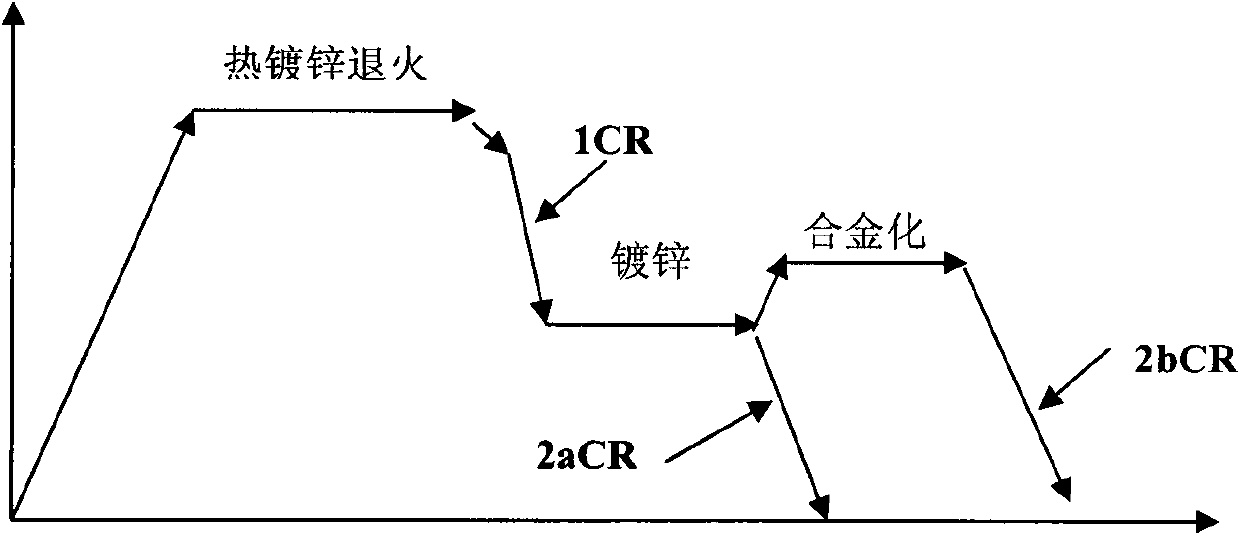

Cold-rolled galvanized duplex steel and manufacturing method thereof

ActiveCN102021482APlatability EliminationHigh strengthHot-dipping/immersion processesManufacturing convertersHigh rateOxygen

The invention relates to a cold-rolled galvanized duplex steel, wherein the substrate thereof comprises the following components by weight percentage: 0.08 to 0.18 wt.% of C, 0.50 to 1.50 wt.% of Si, 1.50 to 2.5 wt.% of Mn, 0.10 to 1.0 wt.% of Cr, 0.02 to 0.5 wt.% of Mo, 0.005 to 0.05 wt.% of Nb, 0.005 to 0.05 wt.% of Ti, 0.002 to 0.05 wt.% of T.Al, less than or equal to 0.02 wt.% of P, less thanor equal to 0.01 wt.% of S and less than or equal to 0.006 wt.% of N, and the balance of Fe. The manufacturing method thereof comprises the steps of: smelting in an oxygen top-blown convertor, refining in a heating steel ladle, continuously casting into a slab, and then conventionally hot rolling, pickling tandem rolling, galvanizing and annealing, wherein the critical annealing temperature is between 760 and 840 DEG C; the annealing is finished in the two-phase area of ferrite and austenite; 1CR section cooling has a cooling speed of 1 to 40 DEG C / S from the annealing temperature to the zincpool, putting the substrate into the zinc pool having a temperature of 450 to 465 DEG C so as to galvanize; and 2a CR section cooling has a cooling speed more than 3 DEG C / S. The steel of the invention has the advantages of high tensile strength, low yield ratio, capable of being press formed, excellent matching between strength and toughness, high rate of initially work-hardening and being free from yield extending.

Owner:BAOSHAN IRON & STEEL CO LTD

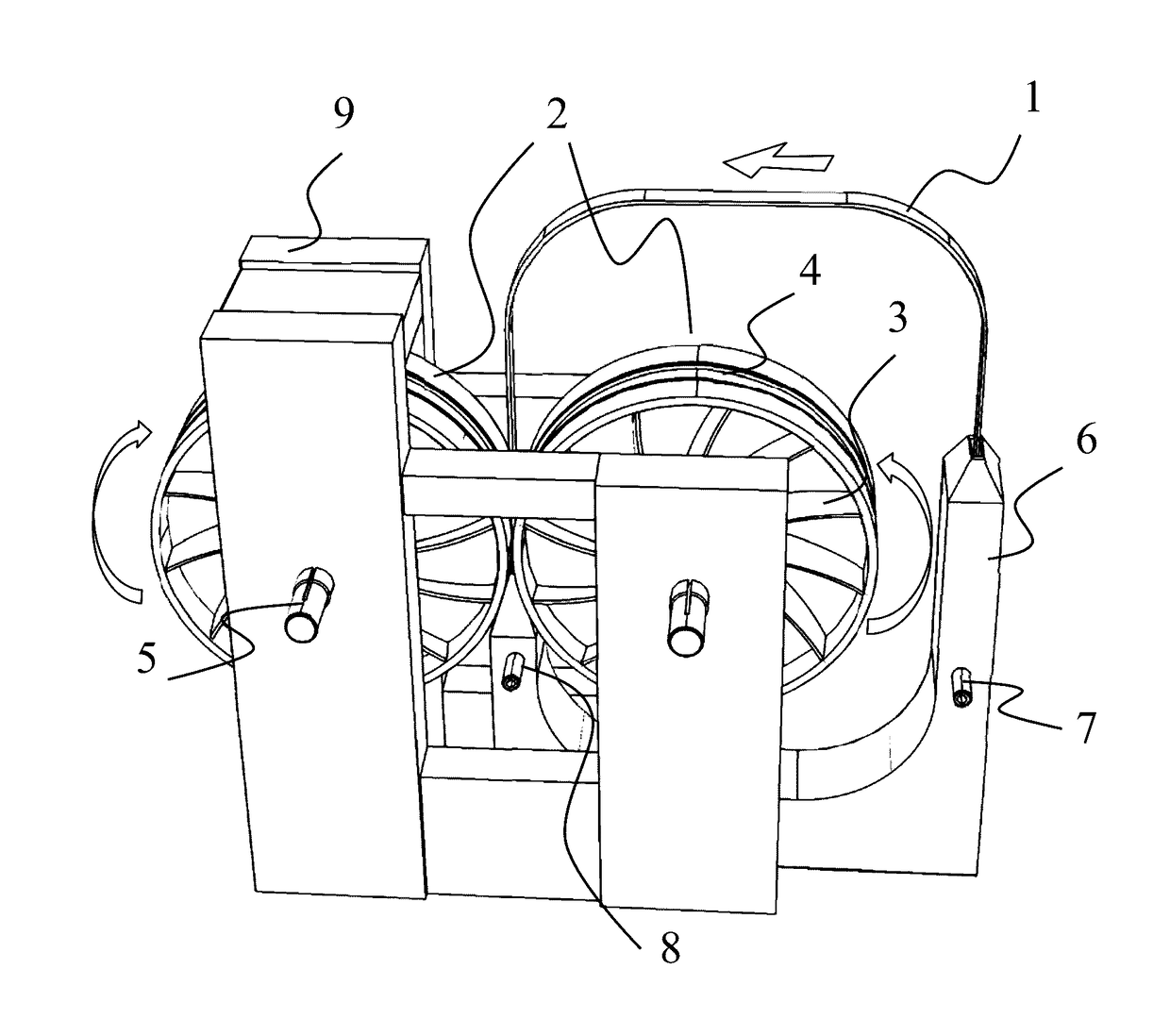

Compact thermoelastic cooling system

ActiveUS20170138648A1Increase contact areaHeat-exchange elementsRegenerative heat exchangersEngineeringRefrigerant

A compact cooling system based on thermoelastic effect is provided. In one embodiment, the system comprises a pair of rollers serving as a heat sink, stress applicator and belt drive, a cold reservoir and a solid refrigerant belt coupled to the cold reservoir and to the heat sinks to pump heat from the cold reservoir to the heat sink. The refrigerant belt comprises solid thermoelastic materials capable of thermoelastic effect. The refrigerant material is mechanically compressed when entering the gap of the roller and subsequently released after passing through. When compressed the refrigerant material transforms to martensite phase and releases heat to the roller and neighboring materials. After released by the rollers, the refrigerant material transforms back to austenite and absorbs heat from the ambient atmosphere.

Owner:CUI JUN +1

Nitrogen-containing nickel-free stainless steel and metallurgy forming process for powder thereof

The invention provides a nitrogenous nickel-free stainless steel and a powder-metallurgical molding technology, relating to the field of stainless steel production. Nitrogenous stainless steel powder and a prepared cementing agent are mixed evenly in a mixing machine and then crashed to injection molding feedstock; injection molding blanks with smooth surfaces and without macro defects are obtained by an injection molder under appropriate injection temperature and injection pressure; after degreasing by chlorylene solvent, thermal degreasing and presintering are carried out to the injection molding blanks, thermal degreasing blanks with certain strength and without defects are obtained; the thermal degreasing blanks are sintered and densified in nitrogen based atmosphere, therefore, products with higher density and more excellent performance can be obtained. The nitrogenous nickel-free stainless steel of the invention can solve the problems that resource price of the nickel-contained stainless steel is expensive and the contained nickel thereof is harmful to human health and the like, extends the application scope of nitrogenous austenitic stainless steel. The materials prepared by using the nitrogenous nickel-free stainless steel of the invention are better than traditionally smelted austenitic stainless steel in terms of performance and the nitrogenous nickel-free stainless steel of the invention is resource saving and environmentally friendly.

Owner:UNIV OF SCI & TECH BEIJING

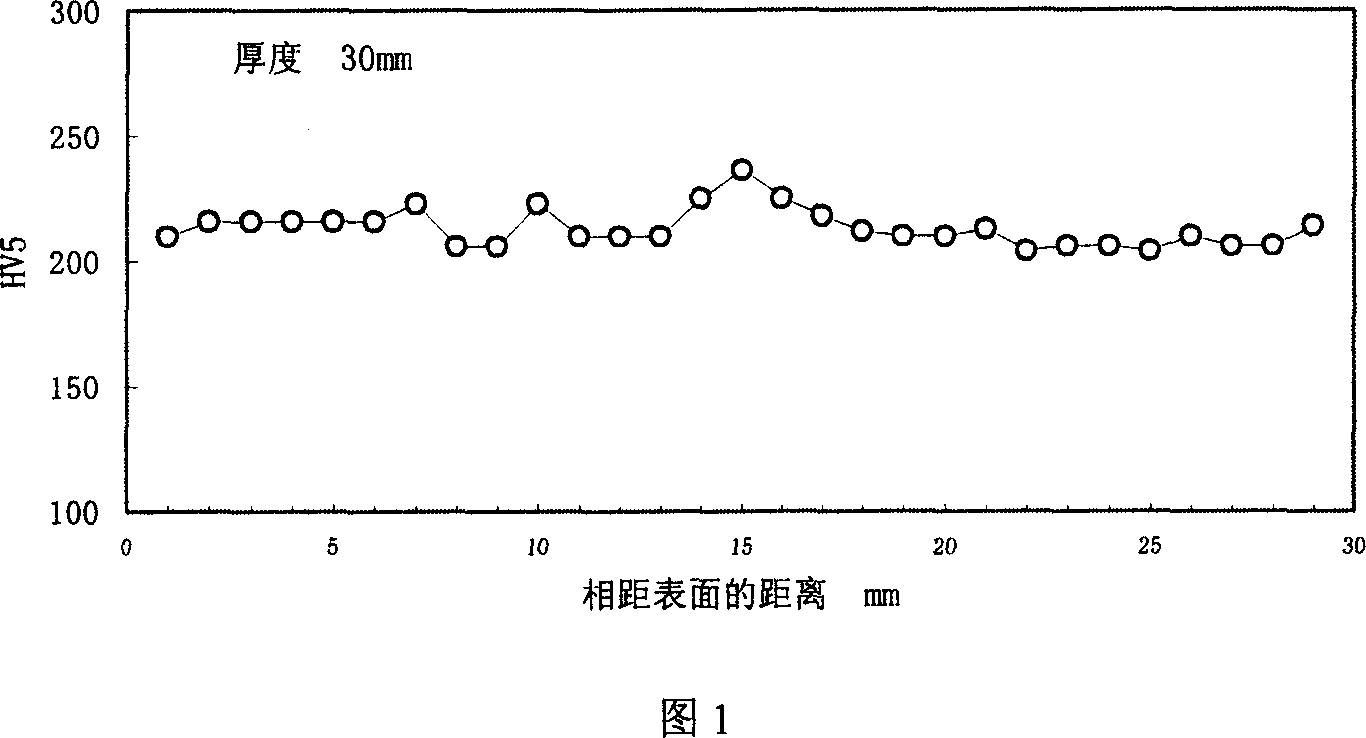

Thick steel plate with high strength and low welding crack sensitivity and its production process

InactiveCN1932063ASimple designGuaranteed performanceTemperature control deviceSheet steelChemical composition

The present invention discloses one kind of thick steel plate with high strength and low welding crack sensitivity and its production process. The chemical composition includes C 0.06-0.09 wt%, Si 0.15-0.55 wt%, Mn 1.00-1.60 wt%, P not more than 0.015 wt%, S not more than 0.006 wt%, Ni 0.15-0.40 wt%, Cr not more than 0.30 wt%, Mo not more than 0.30 wt%, Cu not more than 0.30 wt%, V 0.02-0.06 wt%, Nb 0.005-0.05 wt% and Als 0.010-0.04 wt%, except Fe and inevitable impurities; and meets Pcm not higher than 0.20 % and Ceq not higher than 0.42 %. The production process includes two stage controlled rolling, on-line laminar flow cooling, off-line tempering and other steps. The produced steel plate has thickness up to 75mm, tensile strength not lower than 610 MPa and very low welding crack sensitivity.

Owner:ANGANG STEEL CO LTD

High-strength hot-dip zinc plated steel sheet excellent in workability and process for manufacturing the same

ActiveCN101821419AImprove balanceExcellent stretch flangeabilityHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

The invention provides a high-strength hot-dip zinc plated steel sheet which exhibits high TS-El balance, excellent stretch frangeability, excellent workability due to low YR, and excellent impact characteristics, and a process for manufacturing the same. A high-strength hot-dip zinc plated steel sheet excellent in workability and impact characteristics, having a composition which contains by mass C: 0.05 to 0.3%, Si: 0.01 to 2.5%, Mn: 0.5 to 3.5%, P: 0.003 to 0.100%, S: 0.02% or below, Al: 0.010 to 1.5%, and N: 0.007% or below and further contains at least one element selected from among Ti, Nb and V in a total amount of 0.01 to 0.2% with the balance being Fe and unavoidable impurities and a microstructure which comprises, in terms of area fraction, 20 to 87% of ferrite, 3 to 10% (in total) of martensite and retained austenite, and 10 to 60% of tempered martensite and in which the average grain diameter of the second phase consisting of the martensite, retained austenite, and tempered martensite is 3[mu]m or below.

Owner:JFE STEEL CORP

High boron wear-resisting casting steel and preparation process thereof

InactiveCN100999803ASufficient sourceReduce manufacturing costFurnace typesHeat treatment process controlFerromanganeseAluminium

The present invention discloses one kind of antiwear high-boron cast steel and its preparation process. The antiwear high-boron cast steel has the chemical components including C 0.10-0.50 wt%, B 0.8-5.0 wt%, Cu 0.3-0.6 wt%, Mn 0.8-2.0 wt%, Cr 1.0-2.5 wt%, Si less than 1.5 wt%, Ti 0.08-0.20 wt%, Ce 0.04-0.12 wt%, Mg 0.02-0.18 wt%, N 0.06-0.18 wt%, S less than 0.05 wt%, P less than 0.05 wt%, and Fe and inevitable impurity for the rest. Its preparation process includes smelting in an electric furnace while adding ferromanganese, frrroboron and Al to deoxidize, composite modification of molten steel, fast cooling, and low temperature tempering to eliminate stress. The present invention has simple production process, low production cost and other advantages.

Owner:XI AN JIAOTONG UNIV

Super-thick steel plate for low yield ratio buildings with 460 MPa grade yield strength and manufacturing method

The invention relates to a super-thick steel plate for low yield ratio buildings with 460 MPa grade yield strength and a manufacturing method, which belongs to the technical field of high strength low alloy construction steel. The steel pipe comprises the following components by weight percent: 0.14 to 0.18 percent of C, 0.35 to 0.45 percent of Si, 1.40 to 1.50 percent of Mn, 0.025 to 0.035 percent of Nb, 0.040 to 0.050 percent of V, 0.010 to 0.020 percent of Ti, smaller than 0.020 percent of P, and the balance Fe. The rolling technology is as follows: the heating temperature is 1220 to 1250 DEG C, the tapping temperature is 1200 to 1230 DEG C, and two stages (ausrenitic recrystallization region and ausrenitic non-recrystailization region) are used for controlling rolling. The heat treatment technology is as follows: steel plates, the thickness of which is larger than or equal to 80 mm, are obtained after controlled rolling and cooling are carried out on continuously cast bloom, a two-phase region is heated up to 800 to 850 DEG C and insulated for 10 to 20 minutes, and then water quenching is adopted and the final cooling temperature is controlled to be less than or equal to 100 DEG C; 450 to 600 DEG C tempering treatment is carried out on the quenched steel plates, and finally the high strength low alloy construction steel plates are obtained. The steel plate not only has excellent comprehensive mechanical properties, but also lowers the cost and reduces the waste of resources.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com