High-strength hot-dip zinc plated steel sheet excellent in workability and process for manufacturing the same

A hot-dip galvanized steel sheet with excellent workability. It is used in manufacturing tools, chemical instruments and methods, heat treatment furnaces, etc. It can solve problems such as poor workability and poor impact resistance, and achieve lightweight, improved corrosion resistance, and safety. Improved performance and excellent workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

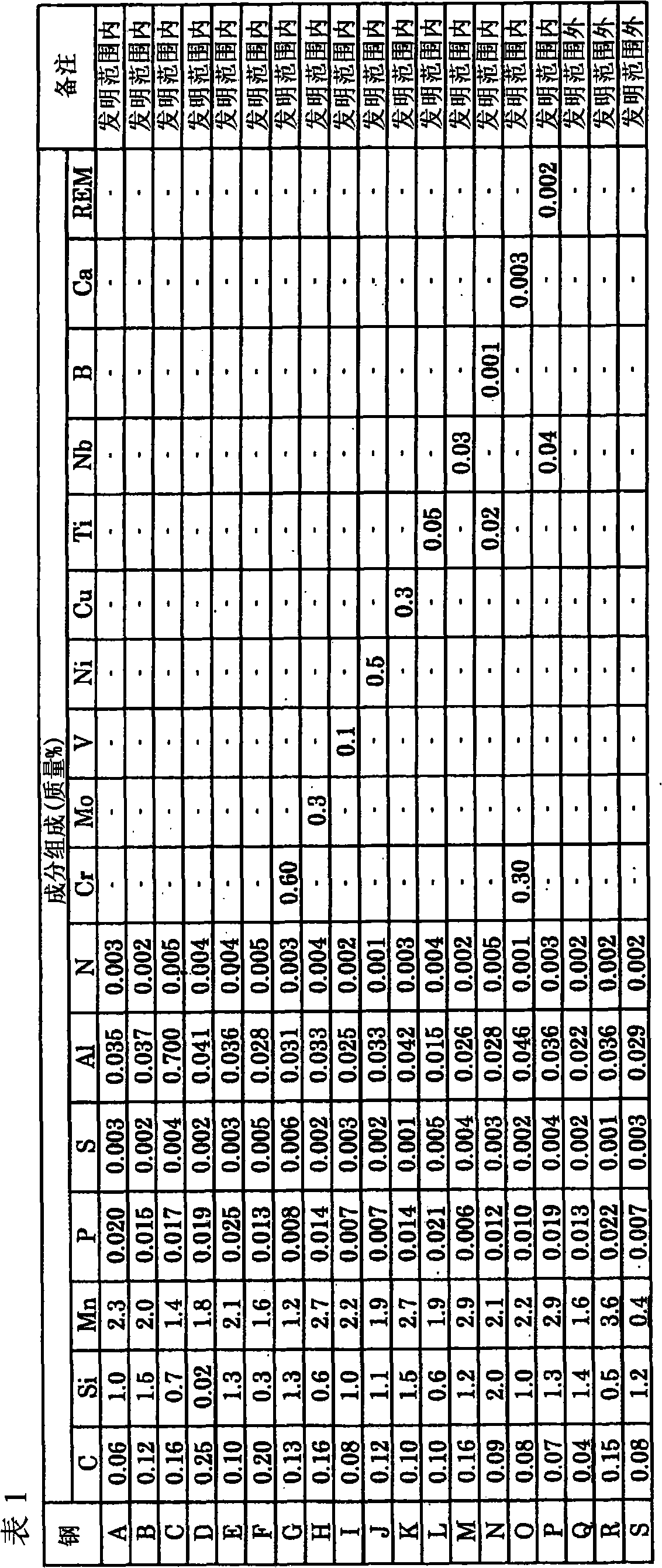

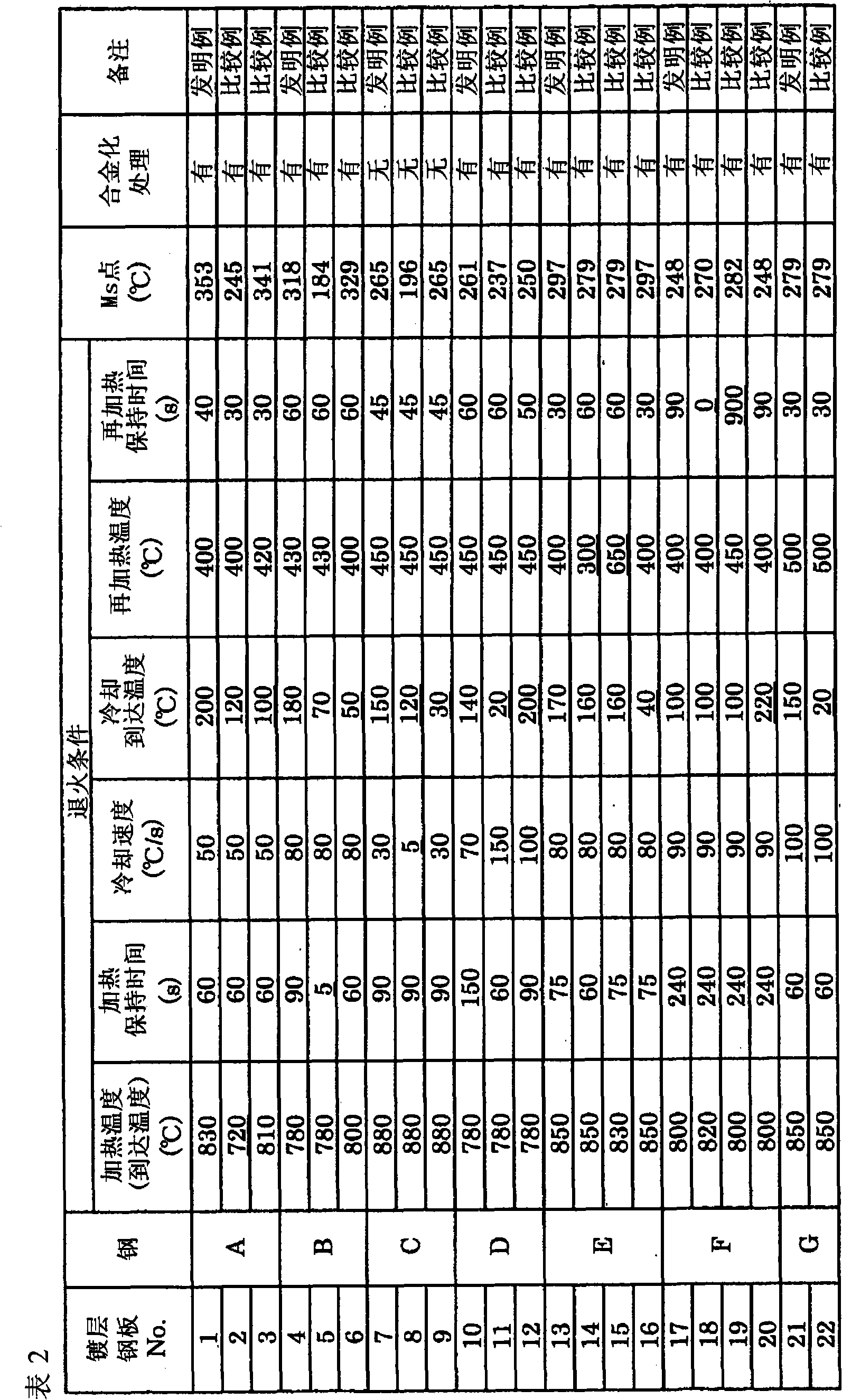

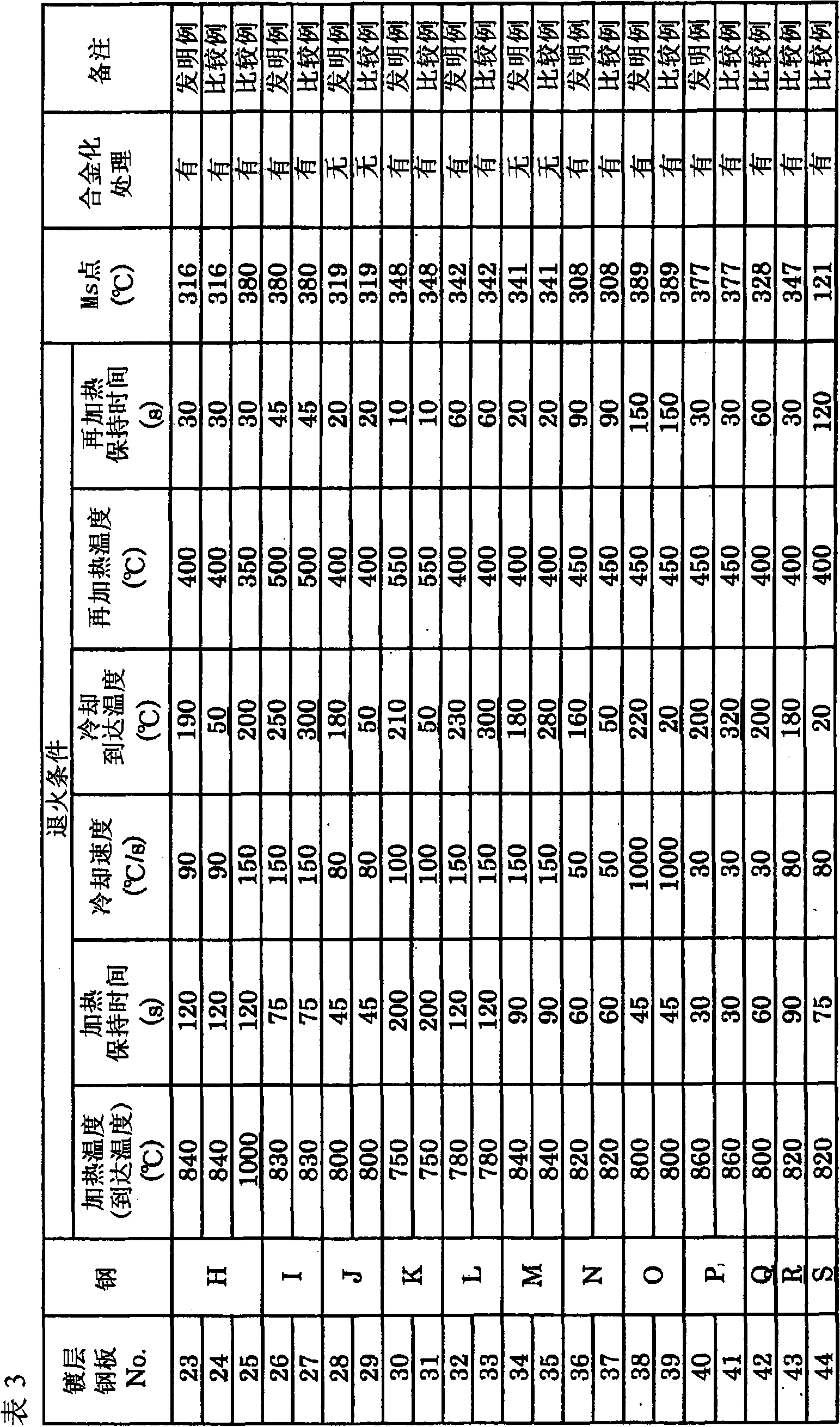

[0103] Use a converter to smelt the steels A to S with the composition shown in Table 1, and make billets by continuous casting, then hot-roll them at a final rolling temperature of 900°C to a plate thickness of 3.0mm, and cool them at a cooling rate of 10°C / s after rolling. Cool and coil at a coiling temperature of 600°C. Next, after pickling, cold rolling to a plate thickness of 1.2 mm, passing through a continuous hot-dip galvanizing production line, annealing under the annealing conditions shown in Tables 2 and 3, and then immersing in a plating bath at 460°C to form a plate with an adhesion of 35~ 45g / m 2 The coated layer was alloyed at 520°C and cooled at a cooling rate of 10°C / sec to manufacture coated steel sheets 1-44. In addition, as shown in Tables 2 and 3, the alloying treatment was performed on the partially plated steel sheet. Then, with respect to the obtained plated steel sheet, the area ratios of ferrite, martensite, retained austenite, and tempered martensi...

Embodiment 2

[0111] The steels AA~AL with the composition shown in Table 6 were smelted in a converter, made into slabs by continuous casting, hot rolled at a final rolling temperature of 900°C to a plate thickness of 3.0mm, and cooled at a cooling rate of 10°C / s after rolling Cool and coil at a coiling temperature of 600°C. Next, after pickling, cold rolling to a plate thickness of 1.2 mm, passing through a continuous hot-dip galvanizing production line, annealing under the annealing conditions shown in Table 7, and then immersing in a plating bath at 460°C to form a plate with an adhesion weight of 35-45g / m 2 The coated layer was alloyed at 520°C and cooled at a cooling rate of 10°C / sec to manufacture coated steel sheets 101-130. In addition, as shown in Table 7, the alloying treatment was performed on the partially plated steel sheet. Then, for the obtained coated steel sheet, the area ratio of ferrite, martensite, retained austenite and tempered martensite and the area ratio of mart...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com