Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1031 results about "Yield ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yield Ratio. A comparison of the expected yield of one bond to the expected yield of another. A yield ratio is important when deciding whether to invest in one bond or another; generally, the one with the higher yield wins out.

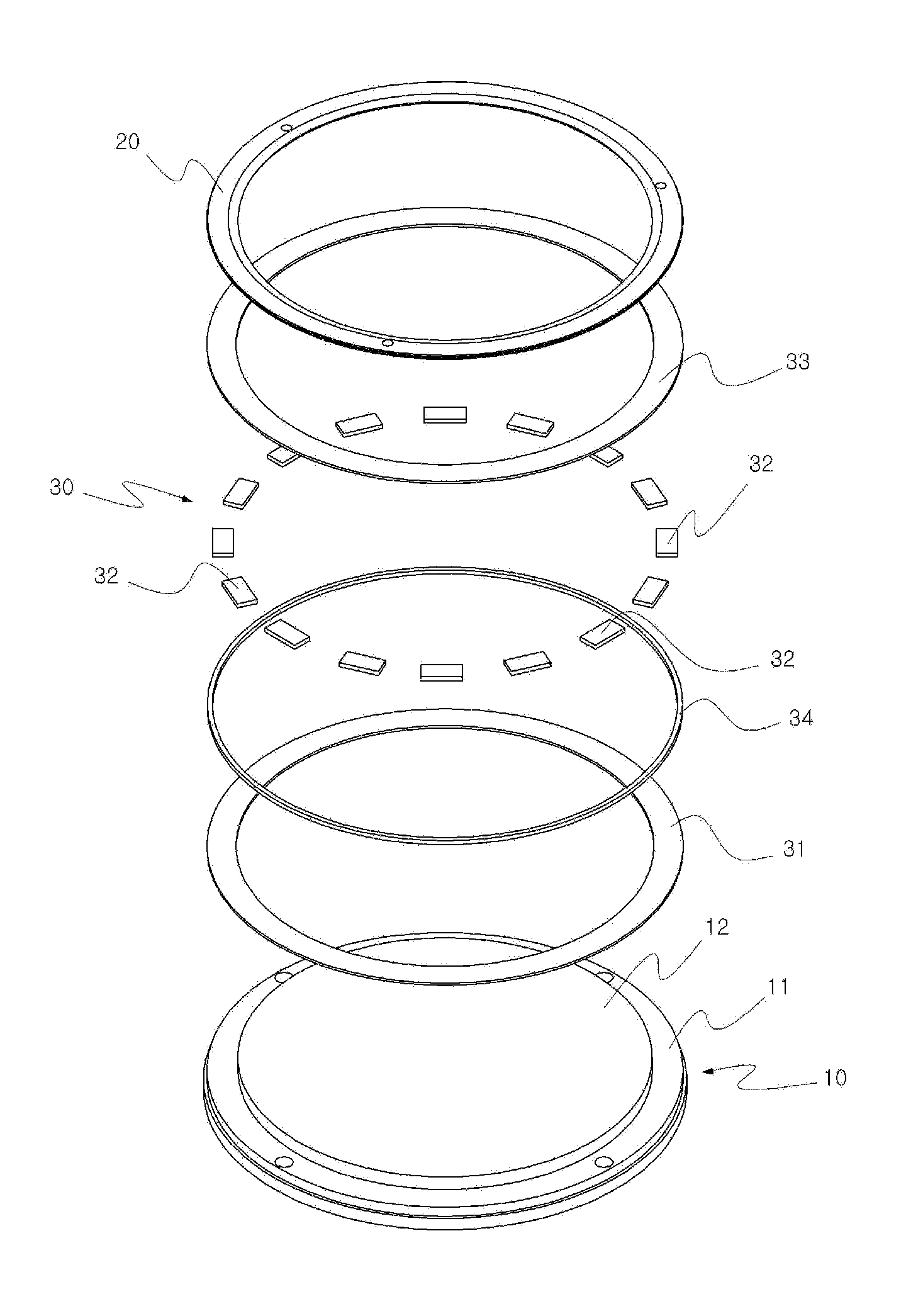

Edge ring cooling module for semi-conductor manufacture chuck

InactiveUS20140262193A1Yield ratio can be improvedLow failure rateSemiconductor/solid-state device manufacturingHeat exchange apparatusElectronics coolingYield ratio

An edge ring cooling module for semiconductor manufacturing chuck is provided which effectively cools the edge ring equipped in electrostatic chuck. The edge ring cooling module forcibly exhausts the heat of an edge ring (20) using an electronic cooling device (32) to top of a large-diameter portion (11) to effectively cool the edge ring (20) so that the temperature of the edge ring (20) is similar to that of top of a small-diameter portion (12) of a chuck body (10) to eventually improve the yield ratio while reducing the failure ratio.

Owner:TECHEST

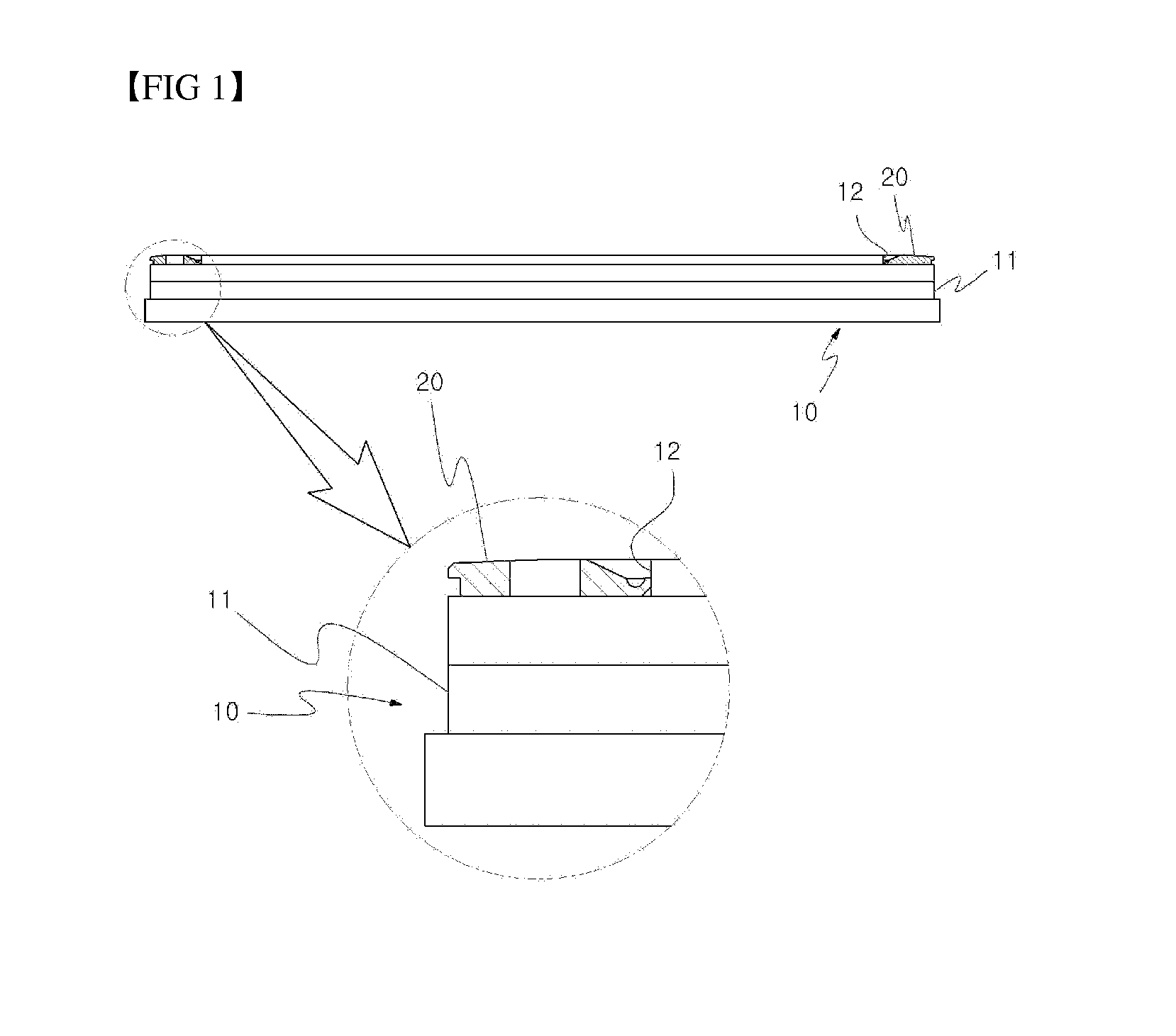

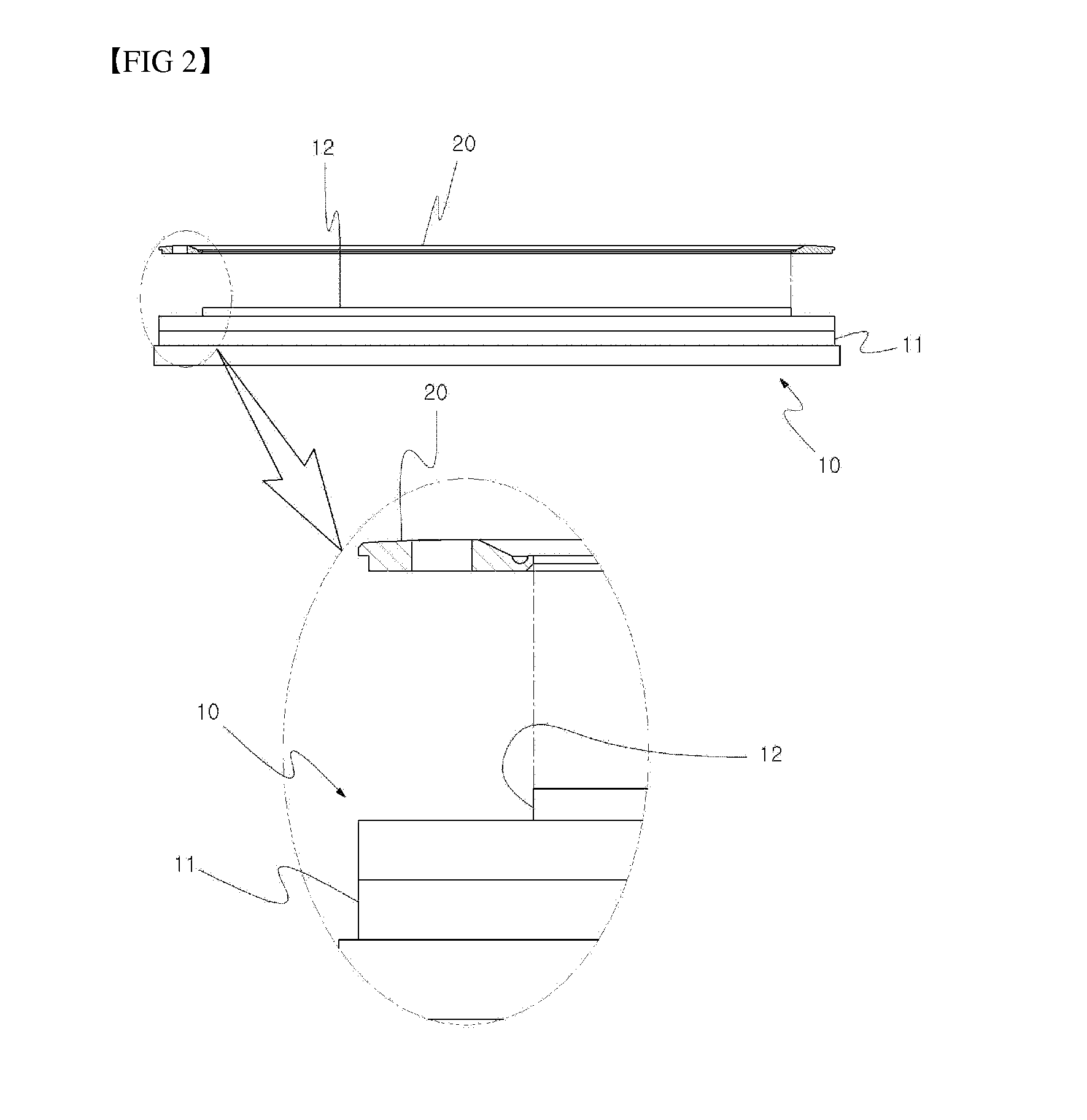

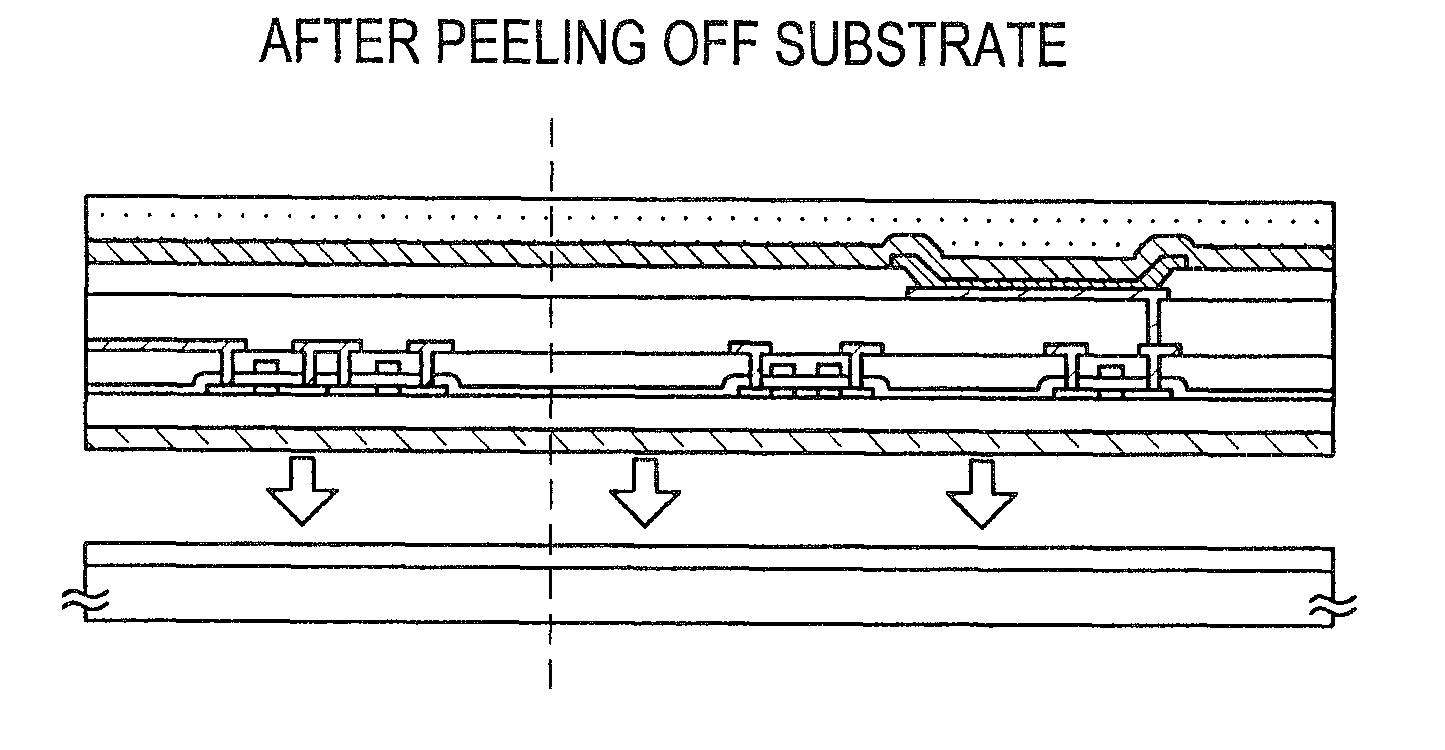

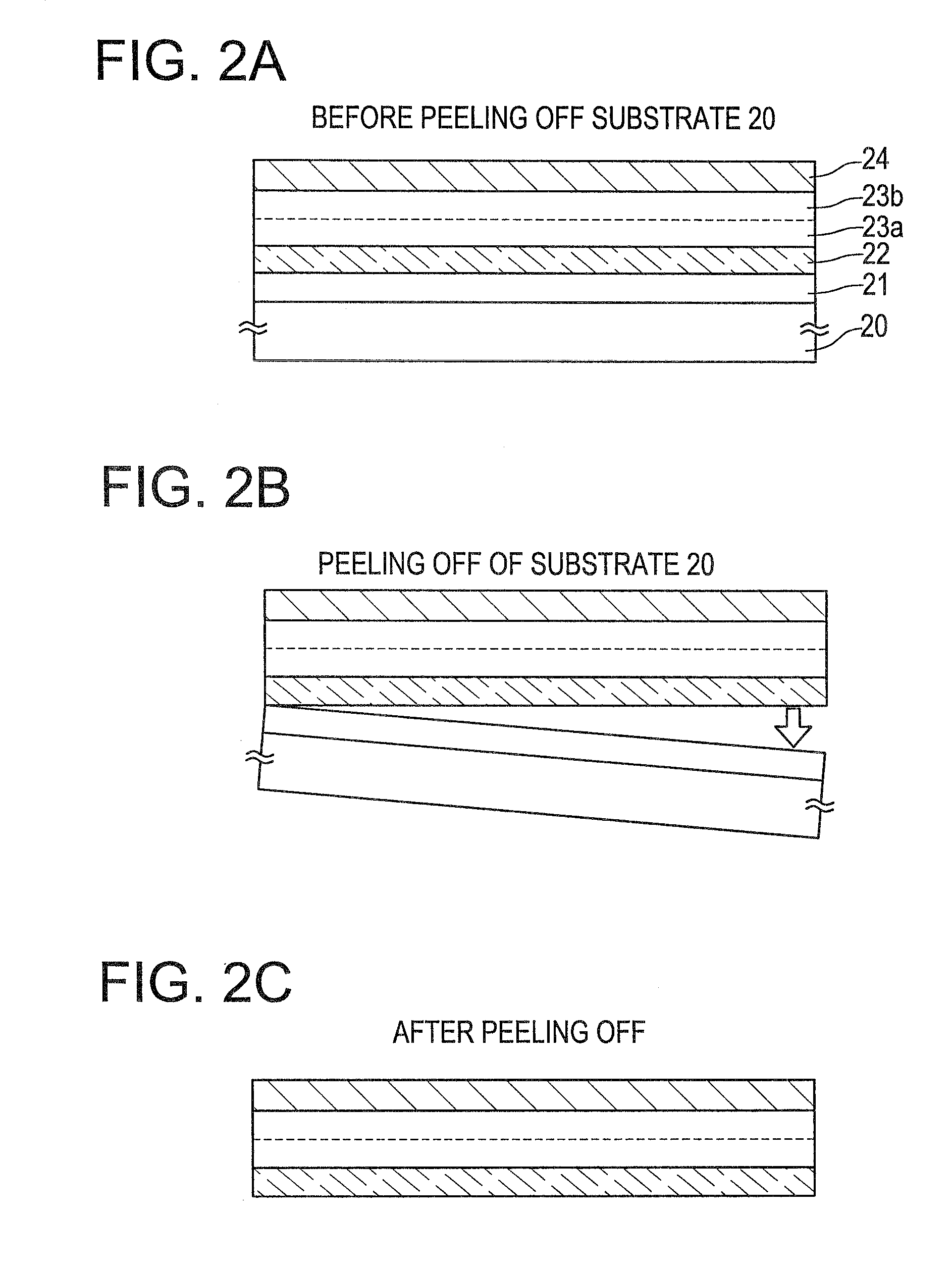

Semiconductor device and peeling off method and method of manufacturing semiconductor device

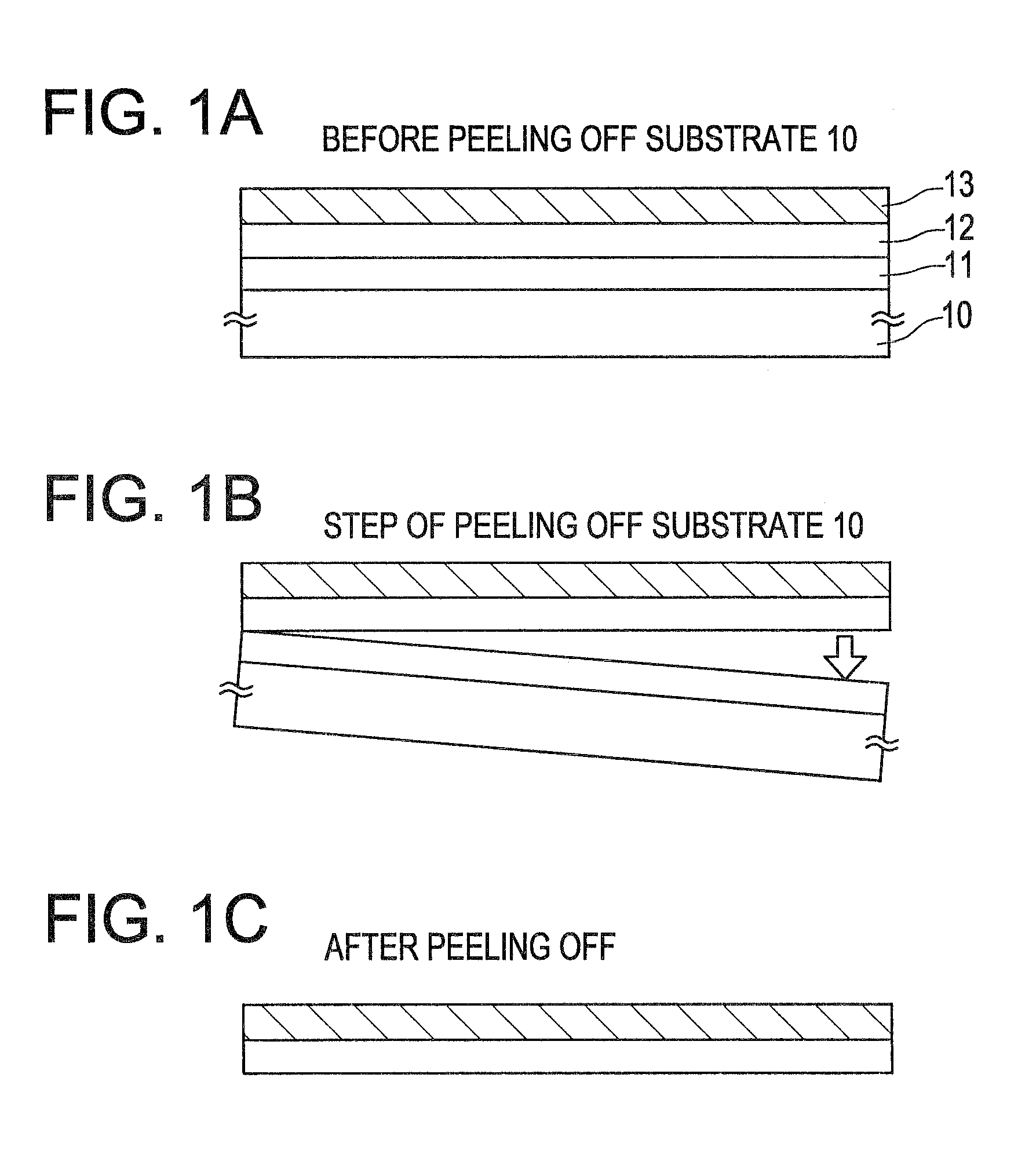

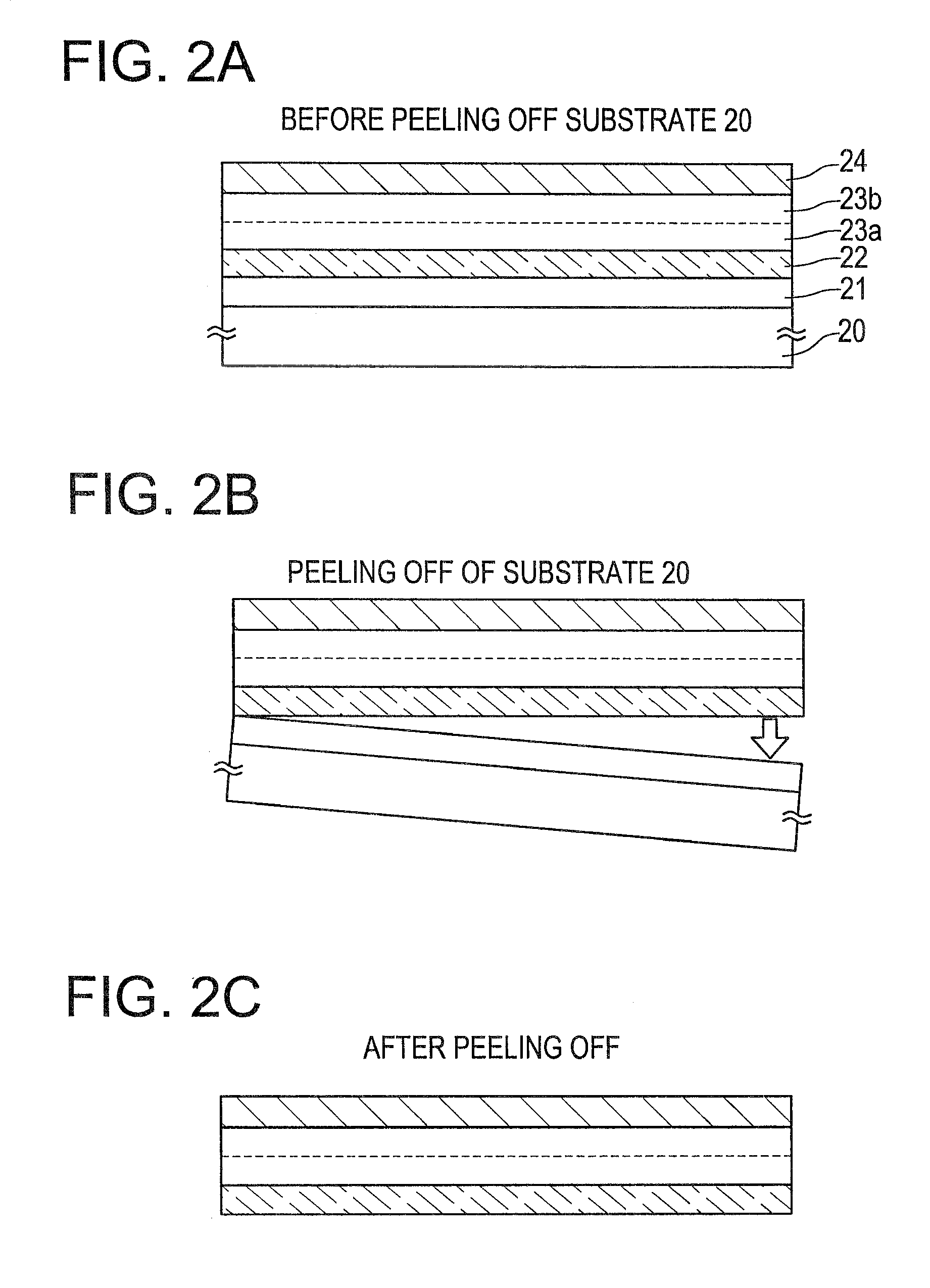

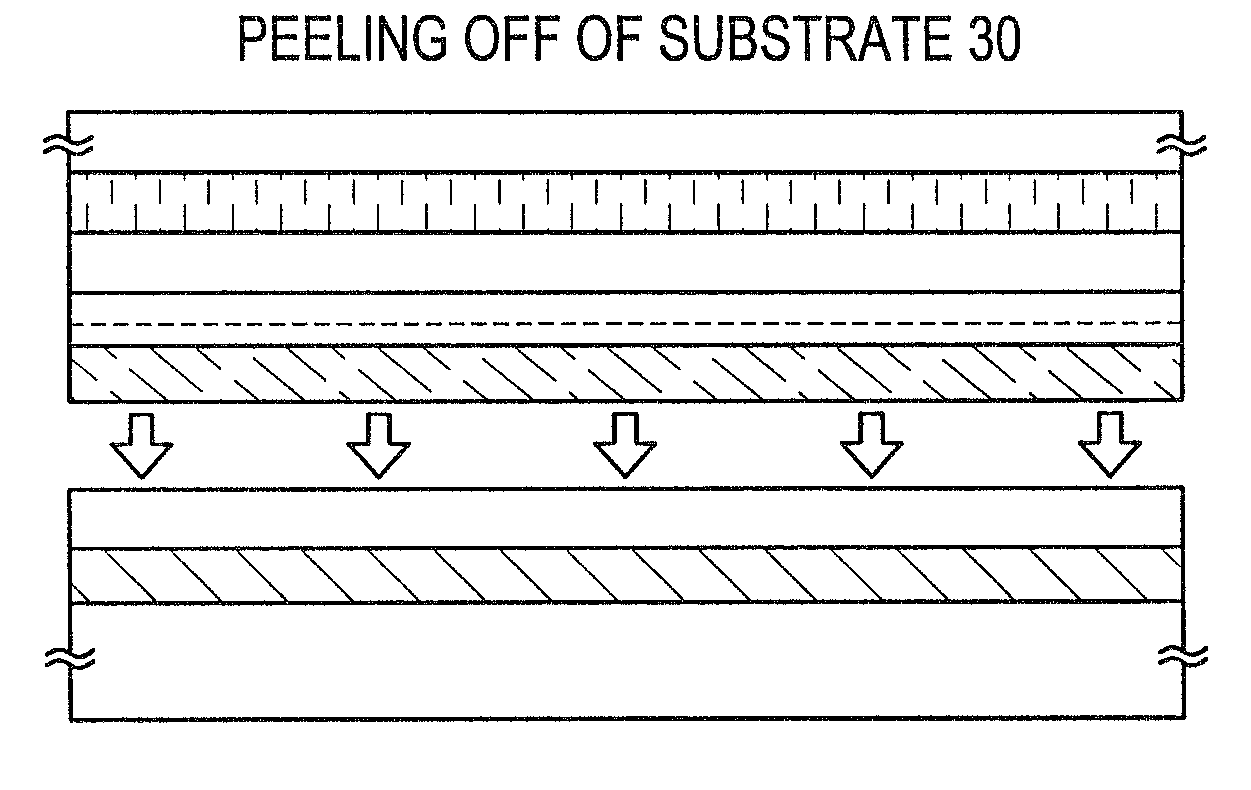

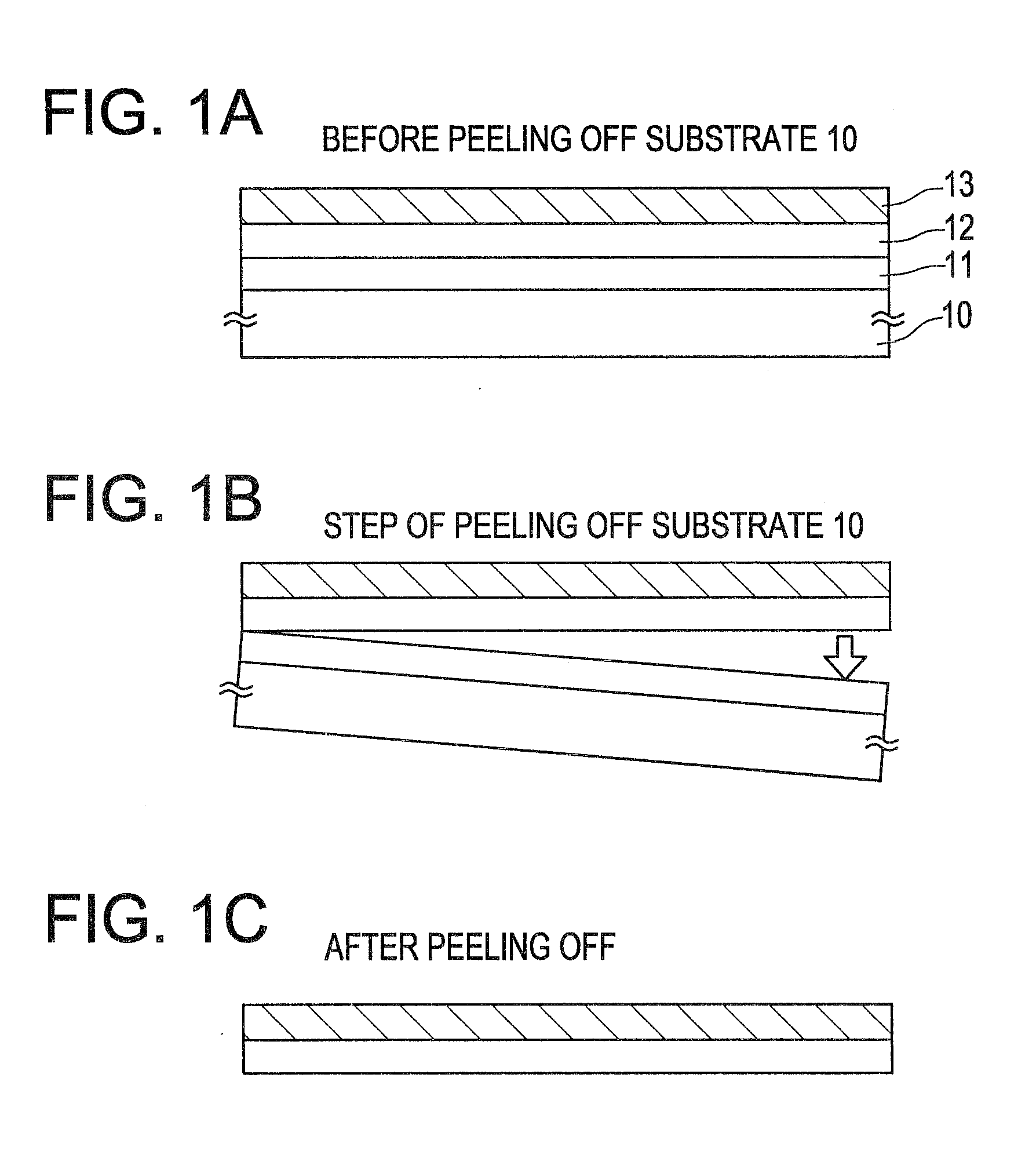

InactiveUS8367440B2Easily and clearly separatedReduce weightTransistorElectroluminescent light sourcesYield ratioNitride

The present invention provides a peeling off method without giving damage to the peeled off layer, and aims at being capable of peeling off not only a peeled off layer having a small area but also a peeled off layer having a large area over the entire surface at excellent yield ratio. The metal layer or nitride layer 11 is provided on the substrate, and further, the oxide layer 12 being contact with the foregoing metal layer or nitride layer 11 is provided, and furthermore, if the lamination film formation or the heat processing of 500° C. or more in temperature is carried out, it can be easily and clearly separated in the layer or on the interface with the oxide layer 12 by the physical means.

Owner:SEMICON ENERGY LAB CO LTD

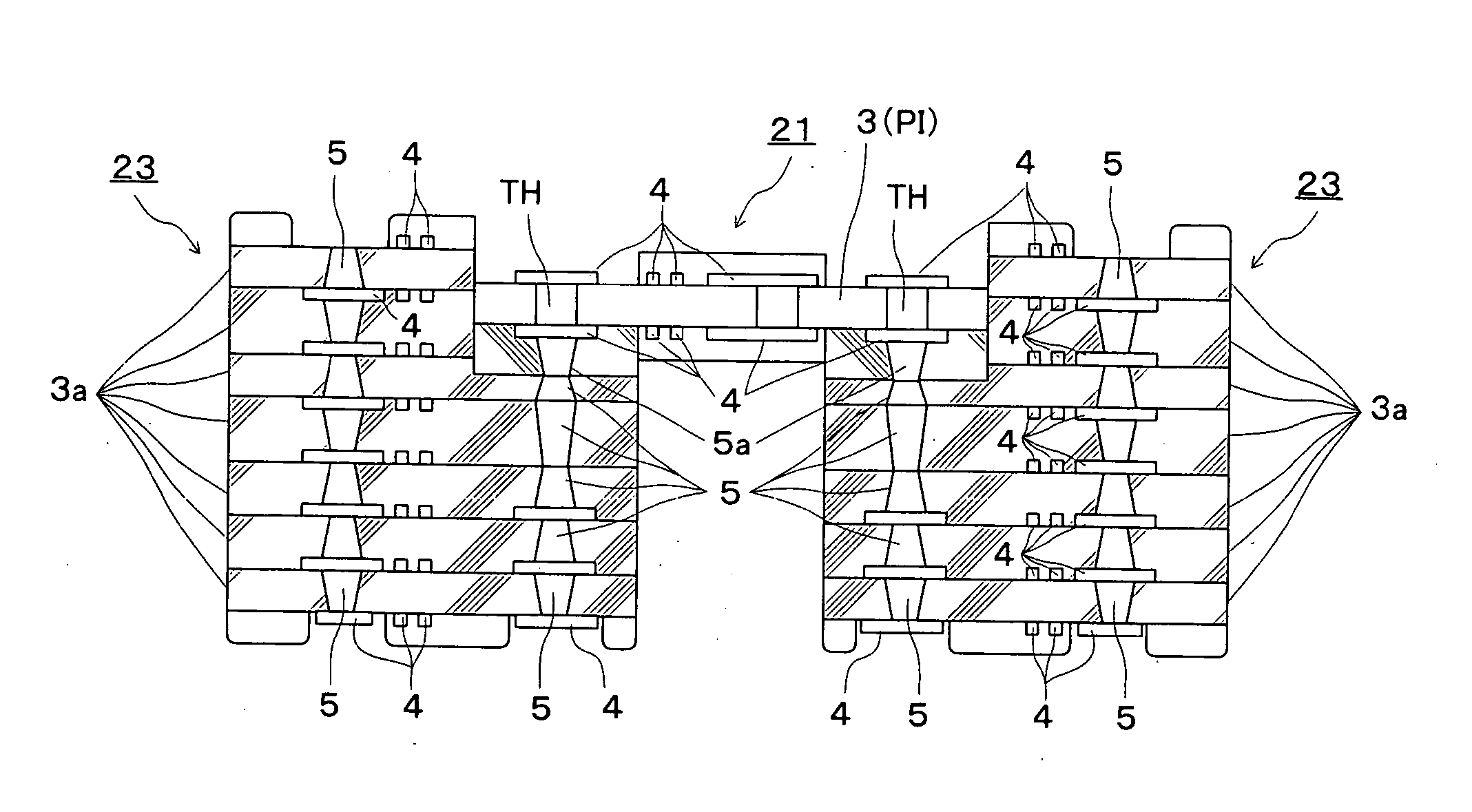

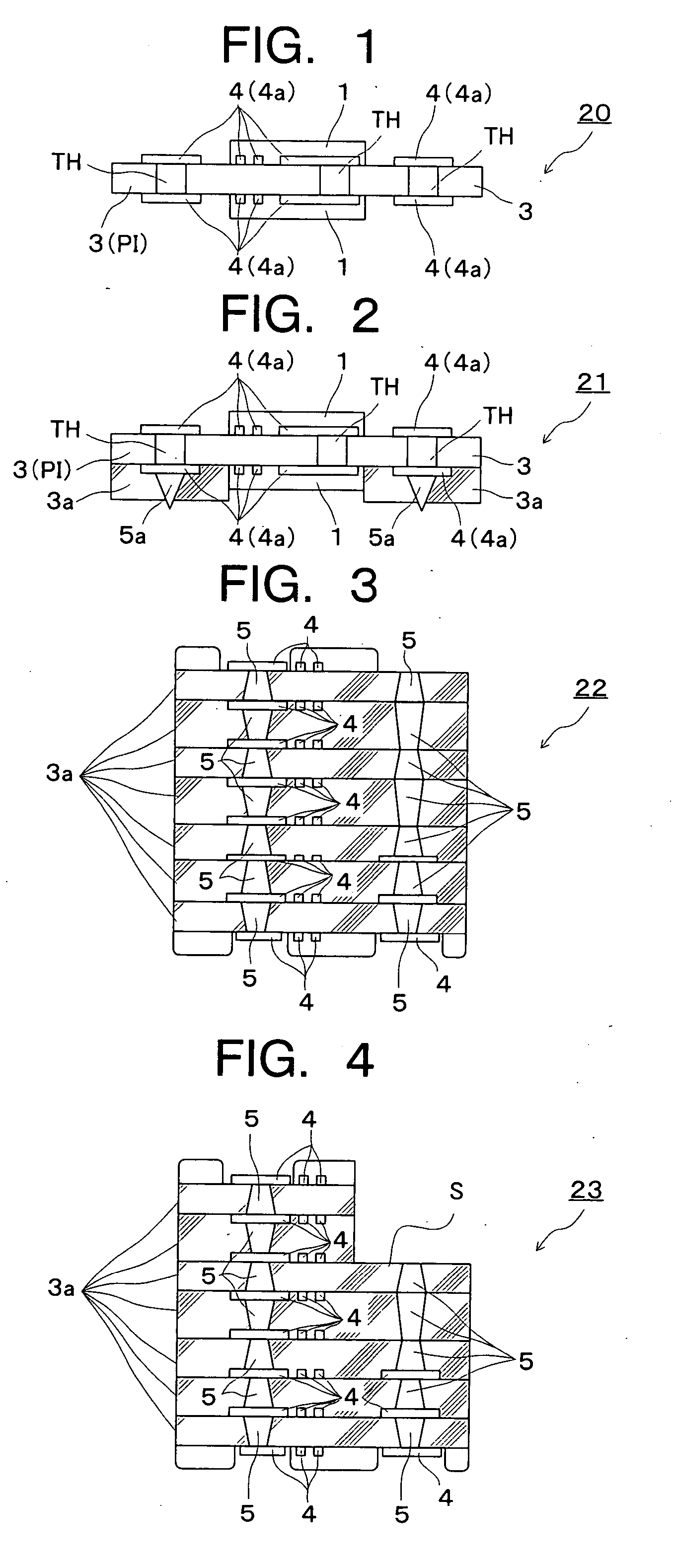

Semiconductor device and peeling off method and method of manufacturing semiconductor device

InactiveUS20090239320A1Reduce areaEasily and clearly separatedTransistorLamination ancillary operationsYield ratioNitride

The present invention provides a peeling off method without giving damage to the peeled off layer, and aims at being capable of peeling off not only a peeled off layer having a small area but also a peeled off layer having a large area over the entire surface at excellent yield ratio. The metal layer or nitride layer 11 is provided on the substrate, and further, the oxide layer 12 being contact with the foregoing metal layer or nitride layer 11 is provided, and furthermore, if the lamination film formation or the heat processing of 500° C. or more in temperature is carried out, it can be easily and clearly separated in the layer or on the interface with the oxide layer 12 by the physical means.

Owner:SEMICON ENERGY LAB CO LTD

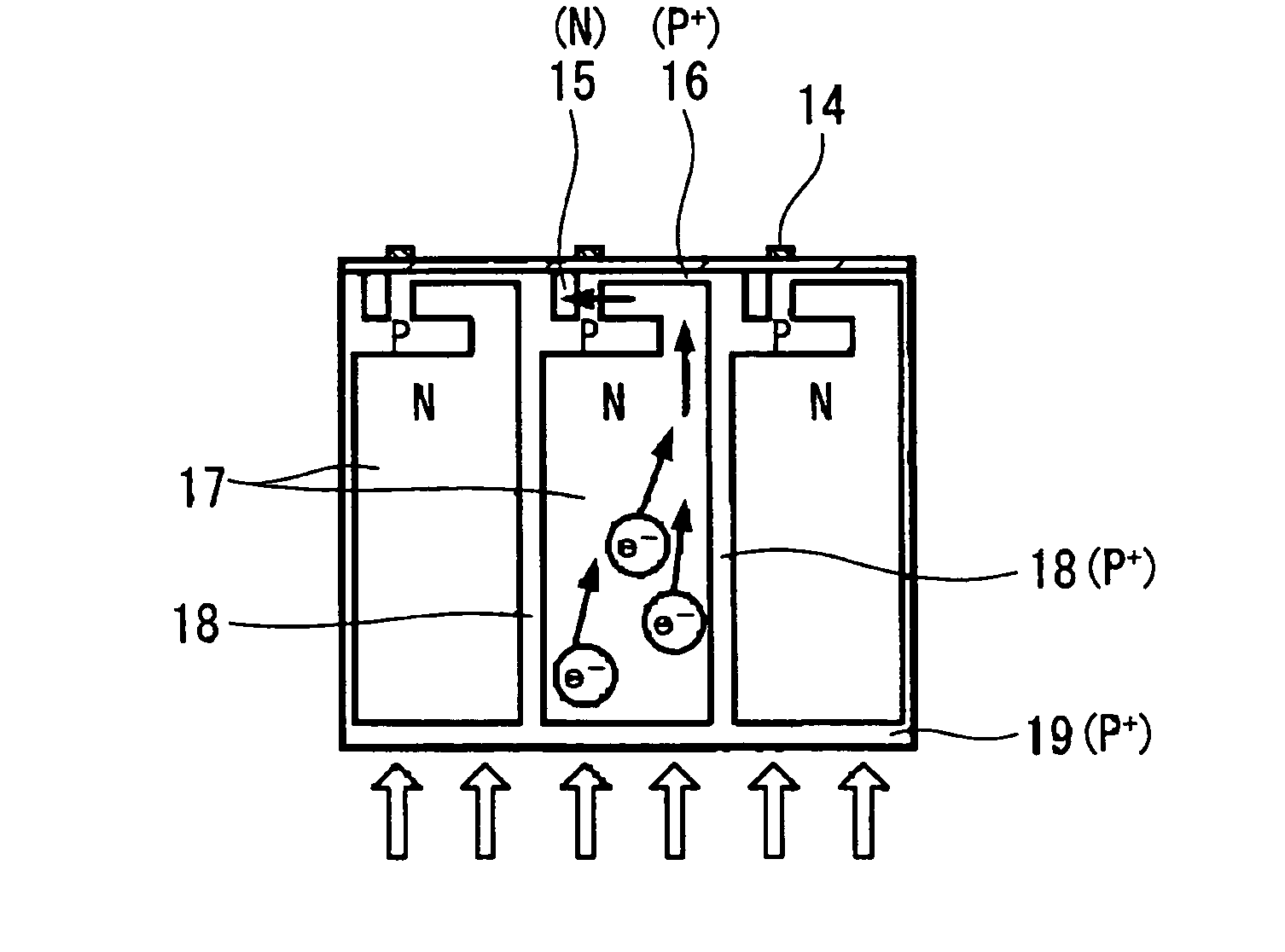

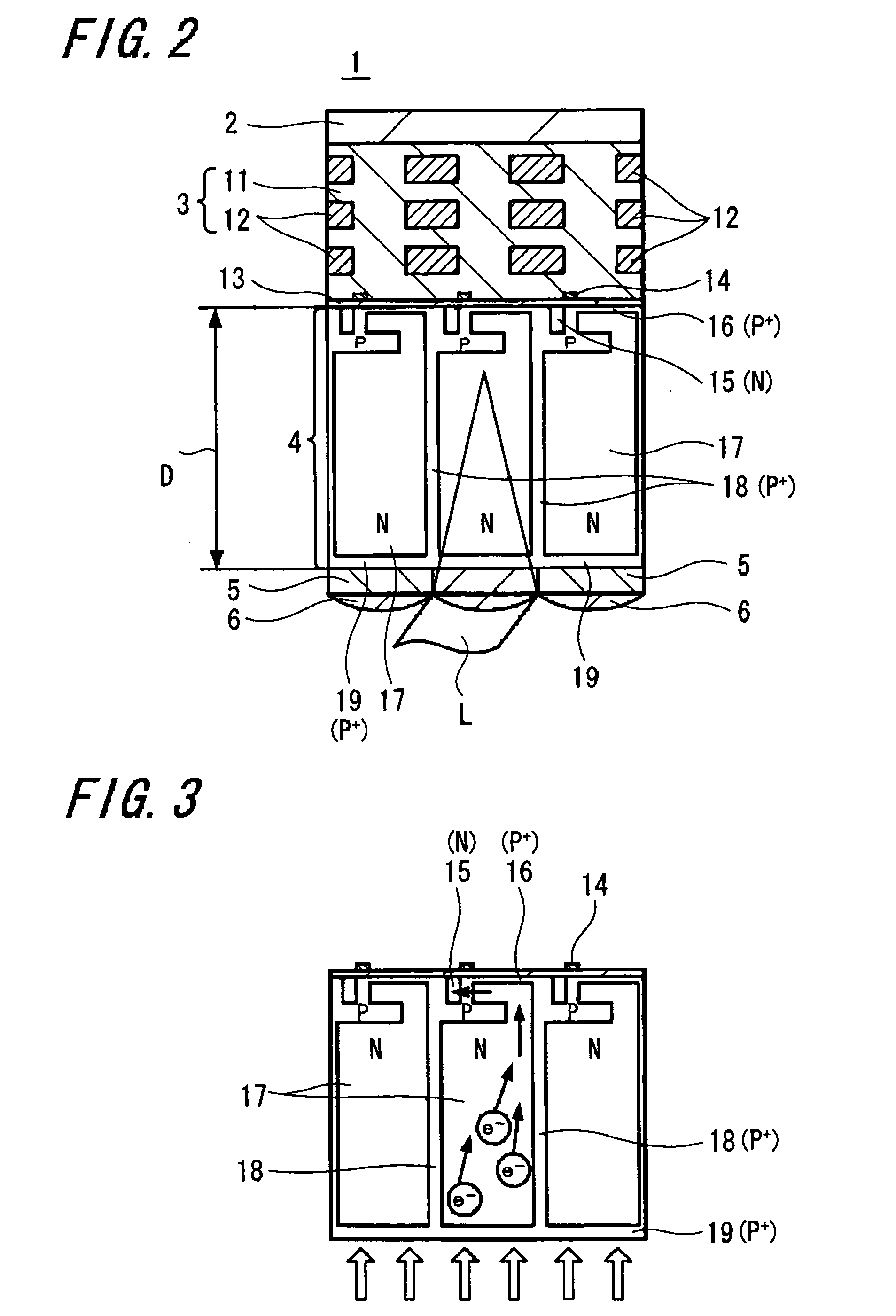

Solid-state imaging device and method for manufacturing the same

InactiveUS20050139828A1DistanceReduce distanceThyristorSemiconductor/solid-state device detailsInter layerYield ratio

Owner:SONY CORP

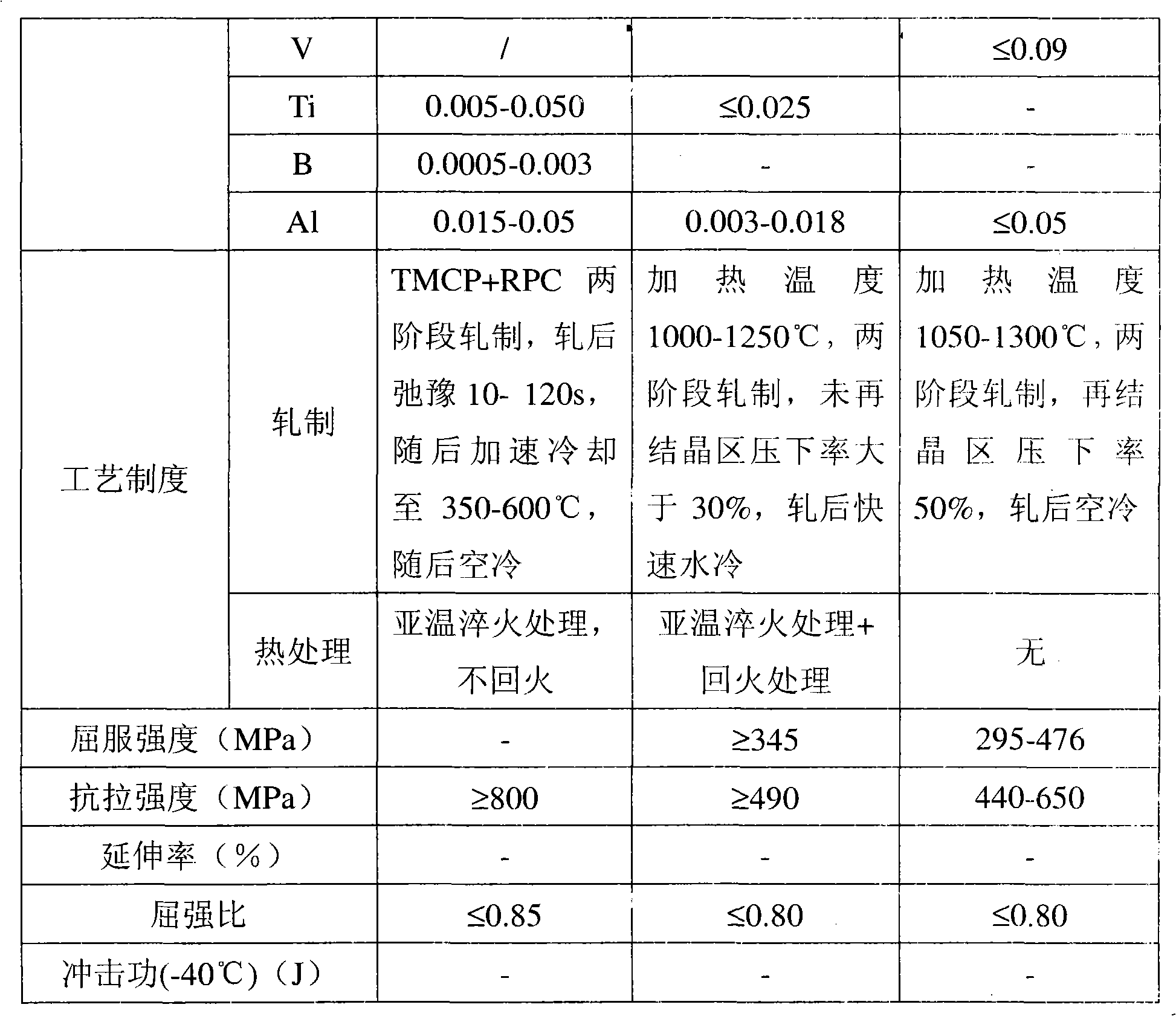

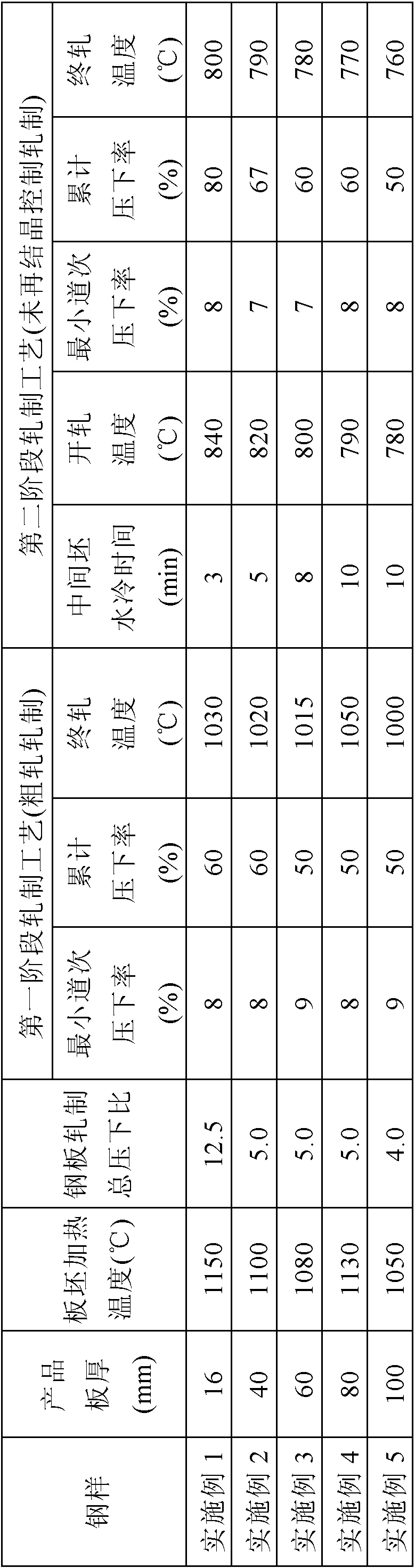

High strength steel plate for big thickness tall building structure and production method thereof

InactiveCN101323929AIncrease thickness specificationLow yield ratioMolten metal pouring equipmentsRoll mill control devicesSheet steelChemical composition

The invention relates to a steel plate with high intensity and used in construction structures of high buildings with large thickness and a production method thereof. The steel plate of the invention consists of the following components according to weight percentage: less than or equal to 0.20 percent of C, less than or equal to 0.55 percent of Si, 1.00 to 1.70 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.70 percent of Ni, less than or equal to 0.70 percent of Cr, less than or equal to 0.20 percent of V, more than or equal to 0.015 percent of Nb, less than or equal to 0.20 percent of Ti, 0.020 to 0.060 percent of Al, and the rest is Fe and inevitable impurity. The produced Q460E-Z35 steel plate with a thickness of 100 to 110 mm is capable of meeting the requirement of high intensity steel of large-thickness construction structure (Ceq is less than or equal to 0.50 percent); the steel plate of the invention can be applied to constructing the structure of high building, has good performance of welding and anti-layer tearing, can meet the requirement of on-site key stress points, has simple production process and is capable of realizing bulk production. The high intensity steel plate of the invention has the following advantages that (1) the steel quality of the invention is purer with less than or equal to 0.025 percent of P and less than or equal to 0.010 percent of S; (2) yield ratio of the invention is relatively low and less than 0.78 actually; (3) the anti-layer tearing performance is good, and Z is larger than or equal to 35 percent in whole thickness direction; (4) low-temperature toughness at the temperature of minus 40 DEG C is good; (5) maximum thickness of the steel plate can reach 110mm.

Owner:WUYANG IRON & STEEL

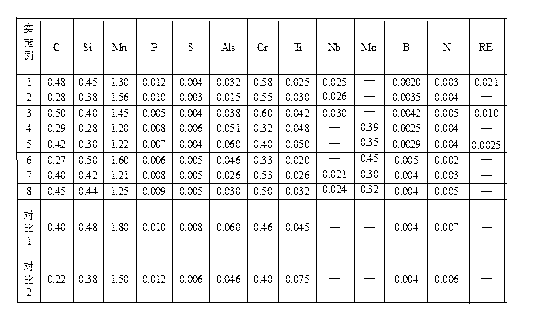

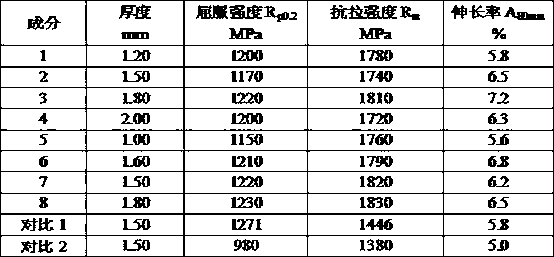

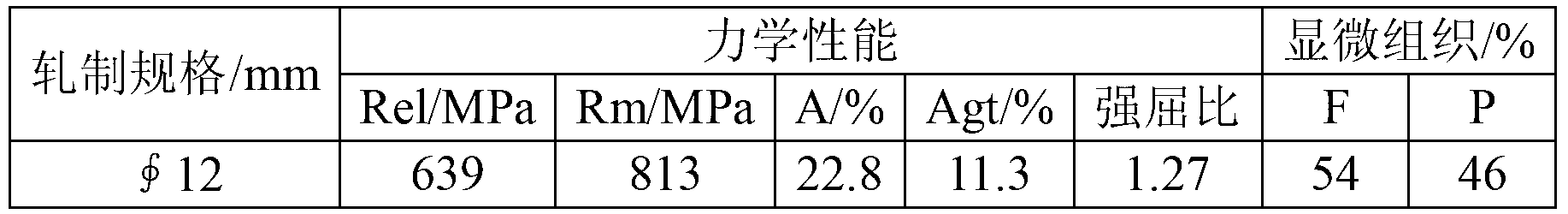

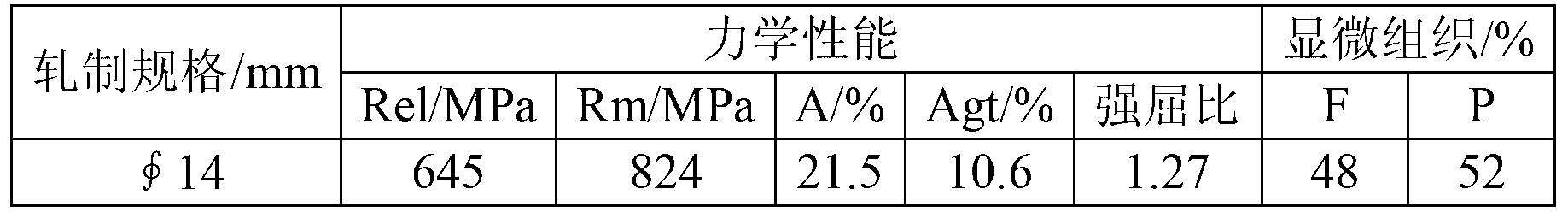

600MPa level quake-proof twisted steel and manufacturing method thereof

The invention discloses 600MPa level quake-proof twisted steel and a manufacturing method of the steel. The twisted steel comprises one or the combination of more than two of the following components in percentage by weight: 0.21-0.26% of C, 0.61-0.80% of Si, 1.30-1.60% of Mn, 0.15-0.21% of V, 0.001-0.050% of Nb, 0.001-0.050% of Ti, 0.10-0.50% of Cr, 0.0001-0.0050% of B, 0.001-0.010% of Mo and the balance of Fe and unavoidable impurities, wherein the components of C, Si, Mn and V are basic components, and the components of Nb, Ti, Cr, B and Mo are optional components. A short-flow process of converter or electric furnace smelting and small billet continuous casting and rolling and cold bed cooling is adopted by the manufacturing method of the twisted steel. The tensile strength of the twisted steel produced by adopting the components and the method is more than 730MPa, the yield strength is more than 600MPa, the percentage elongation after fracture is more than 14%, the maximum force percentage of total elongation is more than 9%, and the yield ratio is more than 1.25, so the international requirement of quake resistance on the twisted steel can be met.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

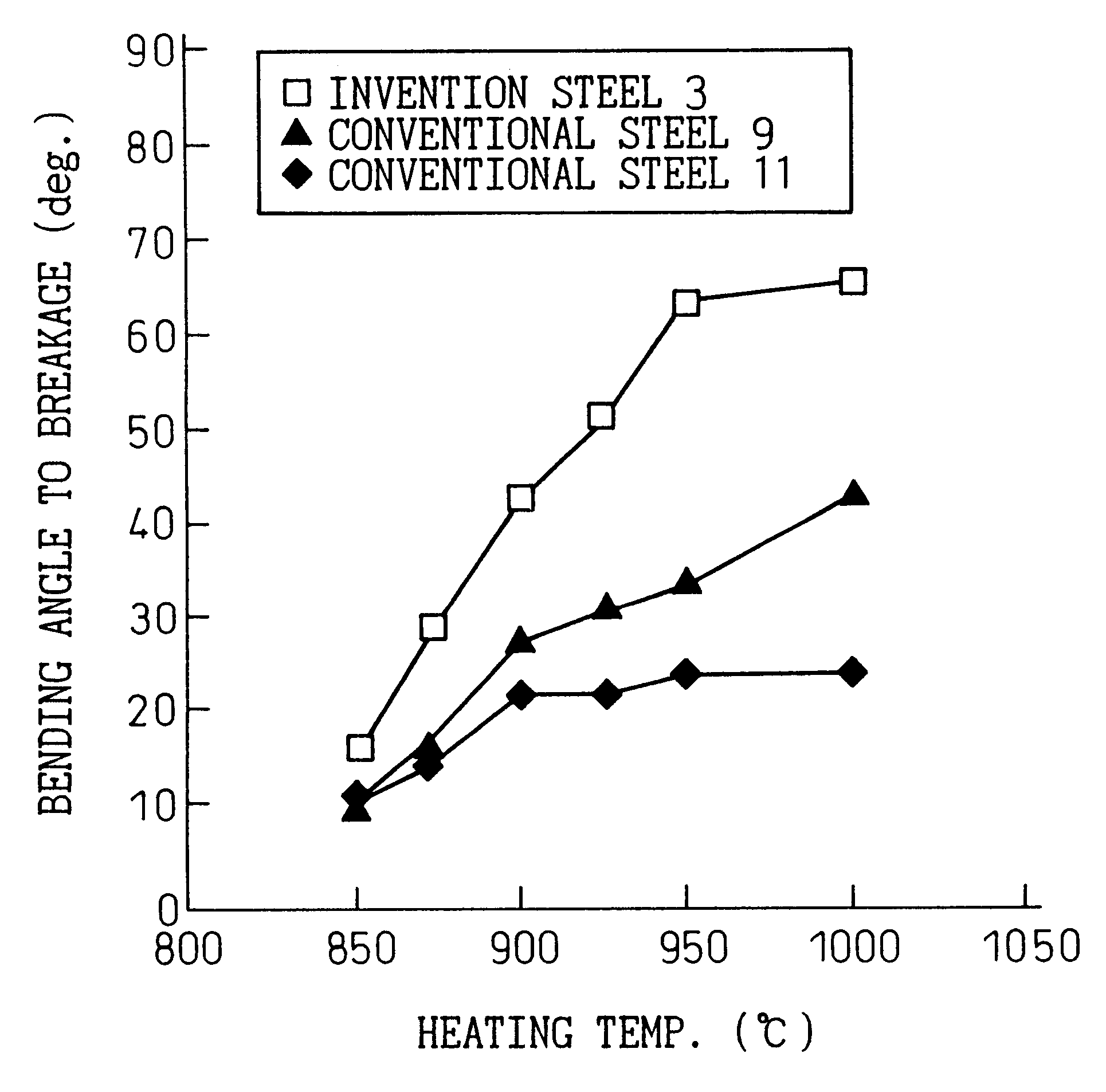

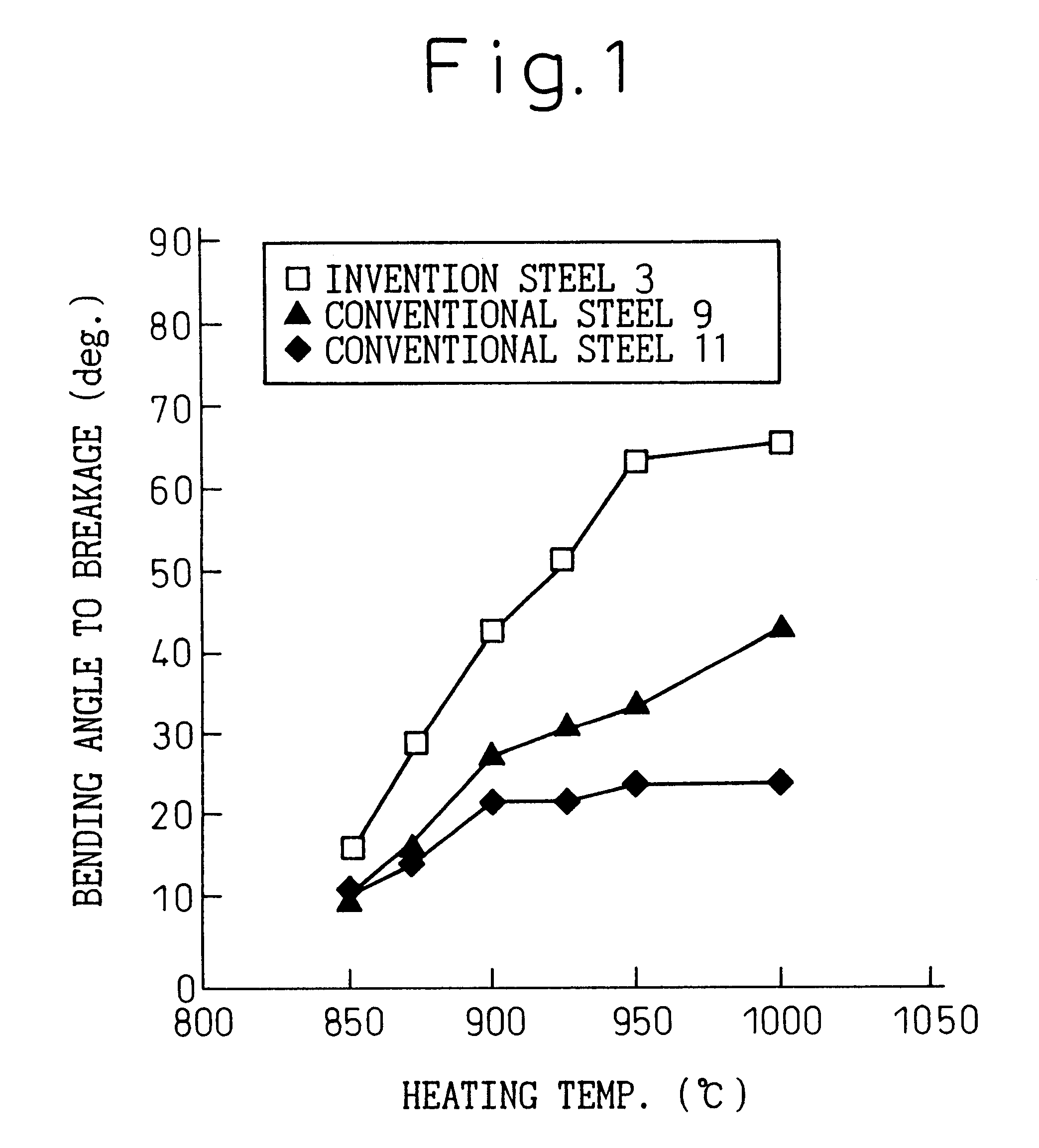

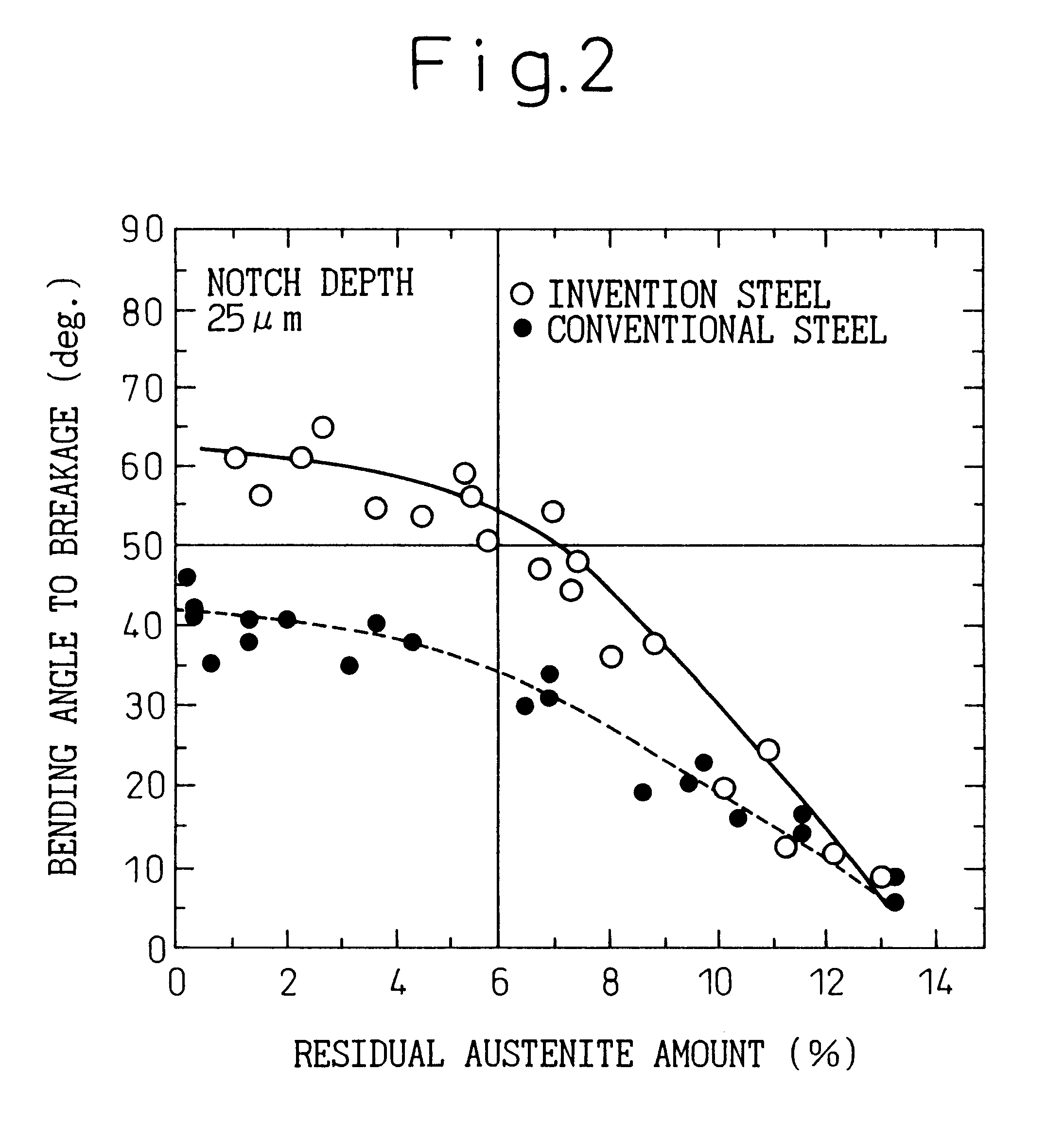

Steel wire for high-strength springs and method of producing the same

InactiveUS6338763B1Reduce contentReduce sizeFurnace typesHeat treatment furnacesNon-metallic inclusionsHigh intensity

This invention provides an oil-tempered wire having high strength (tensile strength of not less than 1960 MPa) and excellent workability and specifically provides a steel wire for high-strength springs comprising as steel components, in weight percent,the balance being Fe and unavoidable impurities, the steel wire having no nonmetallic inclusions of a size greater than 15 mum, a tensile strength of not less than 1960 MPa, and a yield ratio (sigma0.2 / sigmaB) of not less than 0.8 and not greater than 0.9 or a yield ratio (sigma0.2 / sigmaB) of not less than 0.8 and an amount of residual austenite of not greater than 6%. This invention also provides a method of producing the steel wire.

Owner:NIPPON STEEL CORP +1

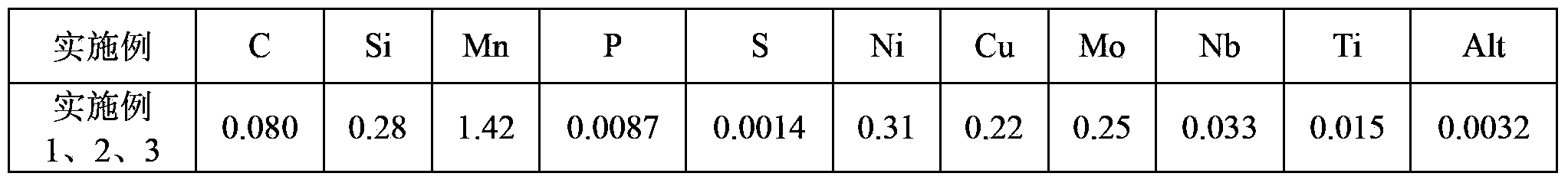

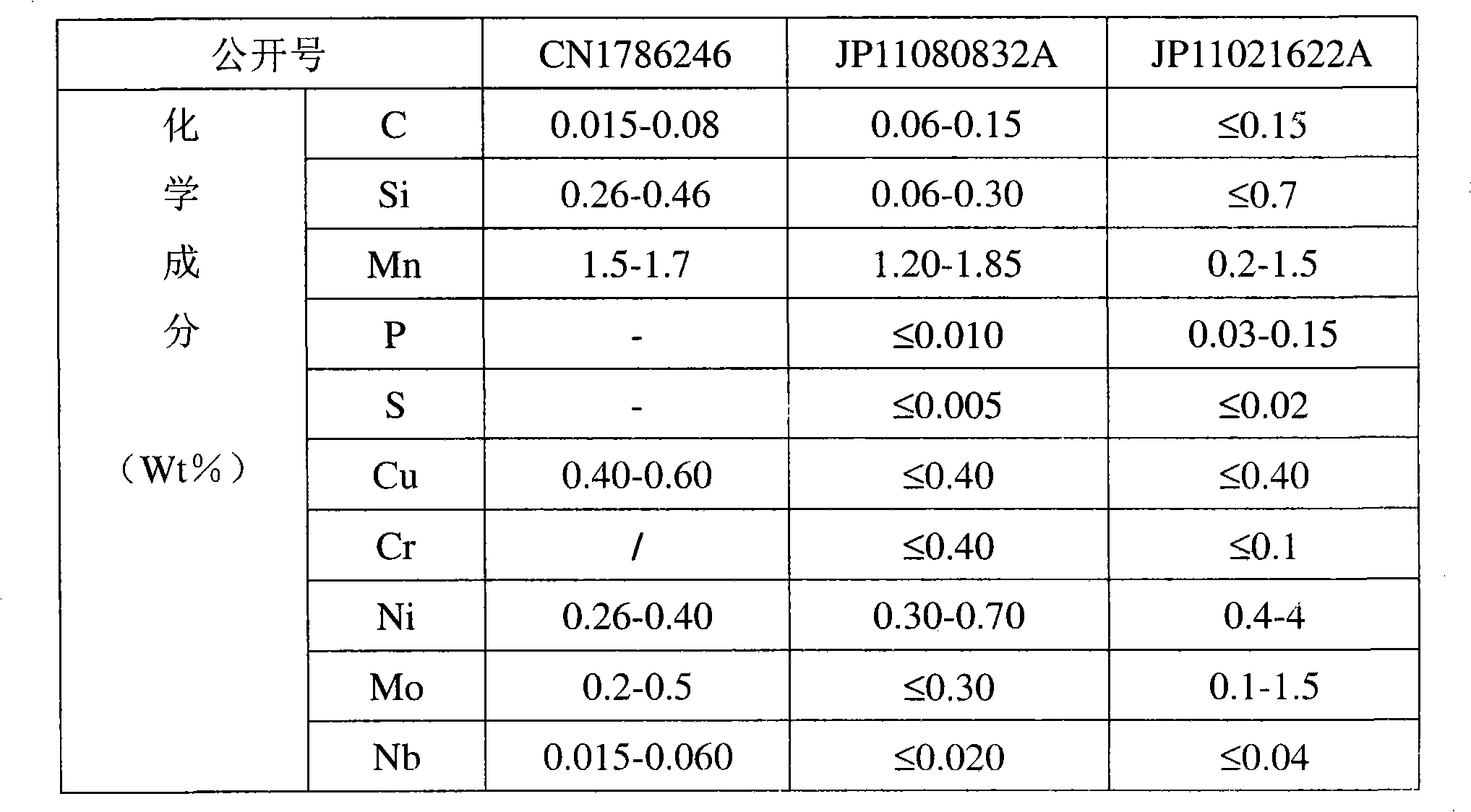

Low-yield ratio and high-strength steel for bridges and manufacturing method thereof

The invention discloses low-yield ratio and high-strength steel for bridges and a manufacturing method thereof. The steel comprises the following chemical components by weight percent : 0.06-0.10 percent of C, 0.20-0.45 percent of Si, 1.20-1.50 percent of Mn, no more than 0.010 percent of P, no more than 0.0020 percent of S, 0.30-.060 percent of Ni, 0.20-0.50 percent of Cu, 0.15-0.50 percent of Mo, 0.025-0.060 percent of Nb, no more than 0.035 percent of Ti, 0.020-0.040 percent of Alt, and Fe and unavoidable impurities in balancing amount. According to the invention, through smelting, refining, performing a reasonable thermo-mechanical control process (TMCP) and optimizing tempering heat treatment production, the tensile strength of the steel is 700-780 MPa, the yield strength is 530-600MPa, the extensibility is greater than or equal to 18 percent, the yield ratio is less than or equal to 0.80, and 40 below zero DEG C low-temperature longitudinal impact is greater than or equal to 100 J, so that the steel is good in obdurability matching and low in the yield ratio, is provided with excellent performance of shock prevention, and is stable in production process and strong in operability.

Owner:NANJING IRON & STEEL CO LTD

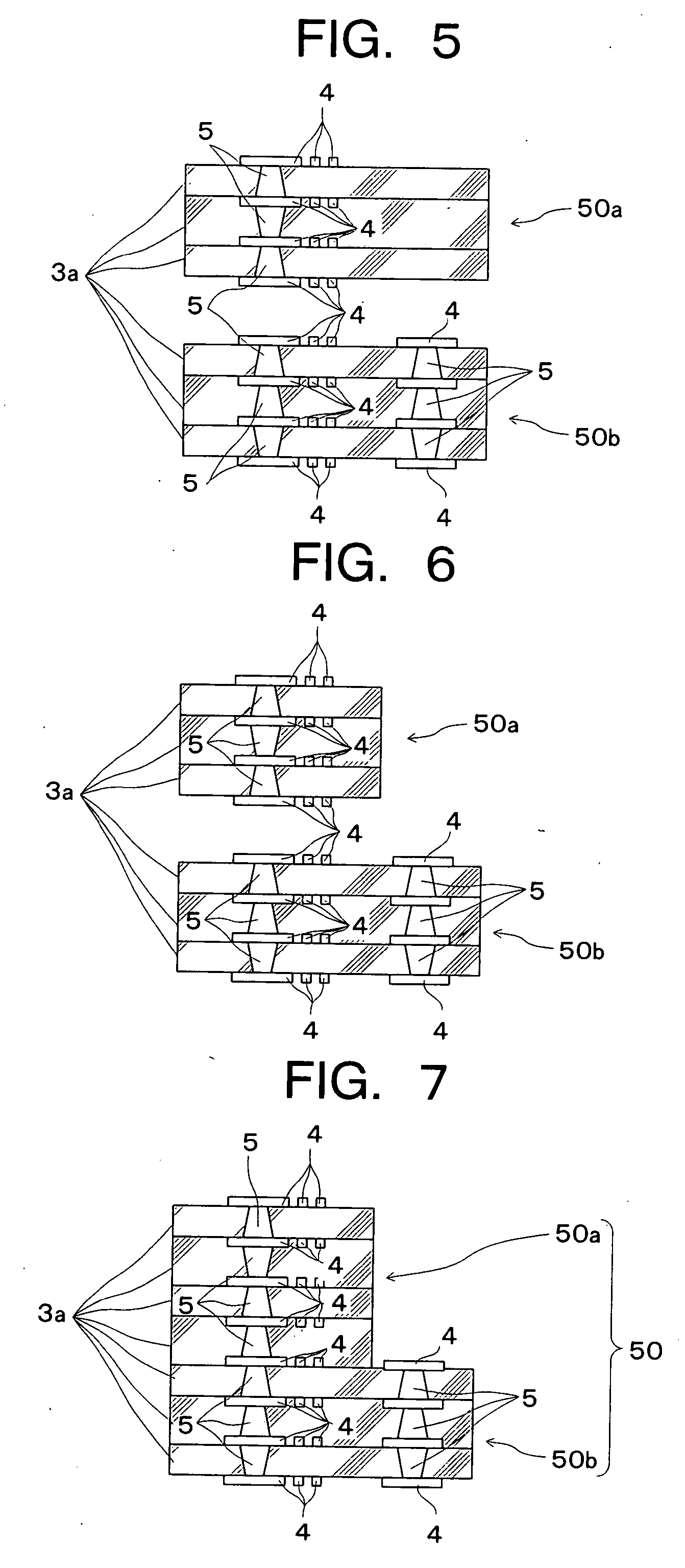

Rigid-Flexible Board and Method for Manufacturing the Same

InactiveUS20070281505A1High aspect ratioSimple molding processPrinted circuit assemblingLamination ancillary operationsEngineeringYield ratio

A rigid-flexible board and a method for manufacturing the same can be provided, whereby the material yield ratio can be enhanced and the productive yield can be also enhanced. A rigid board with a step for connection and a flexible board with a connector at the edge thereof are formed independently. Then, the connecting area is spot facing processed so that the depth of the thus obtained depressed portion is equal to or lower than the thickness of the flexible board. The connector of the flexible board is electrically connected to the vertical wiring area of the depressed portion.

Owner:DAI NIPPON PRINTING CO LTD

Trans free non-hydrogenated hard structural fat and non-hydrogenated hard palm oil fraction component

A trans free non hydrogenated high C-16 type palm fat suitable for the manufacture of trans free non hydrogenated hard structural fat that is being suitable for use in the manufacture of low SAFA (Saturated Fatty Acid) poly / mono unsaturated margarine and spreads and shortening and fat blends incorporating such hard Structural fat. The Structural fat is made from selectively fractionated non-hydrogenated high melting palm oil fraction with a C-16 fatty acid residue of at least 70%, which is subjected to chemical random interesterification using alkaline metal catalyst such as sodium methoxide / sodium methylate, with a dry fractionated non hydrogenated hard palm kernel stearin fraction. The structural fat that is produced has high yield ratios that can be economically and commercially incorporated in the oil blends for the manufacture of trans free margarine / spreads / shortening as well as other plastic W / O emulsions. Also described is a process for the manufacturing such structural fat as well as hard palm fraction including process for the manufacture of extra hard trans free structural fat by panning and pressing of above structural fat.

Owner:PREMIUM VEGETABLE OILS

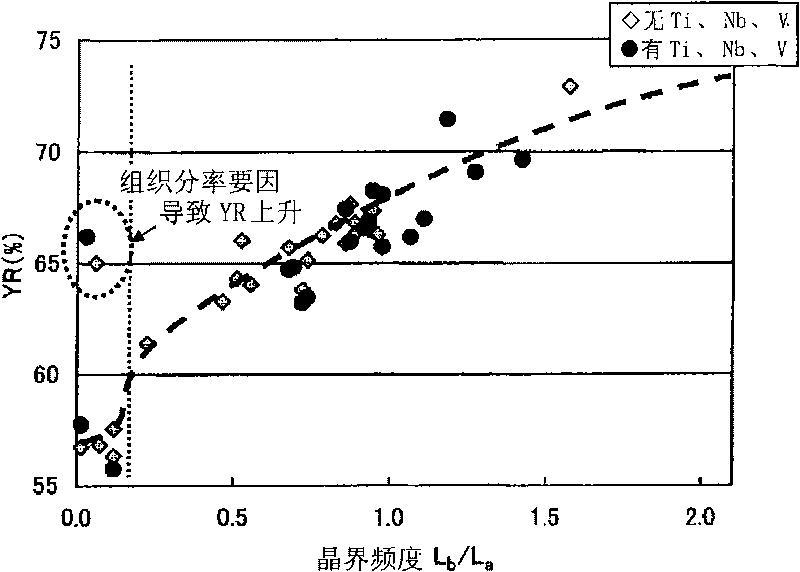

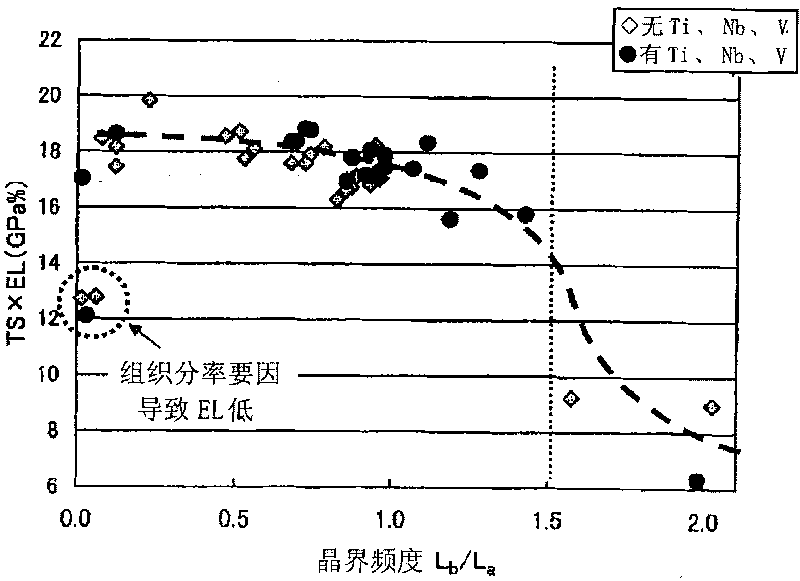

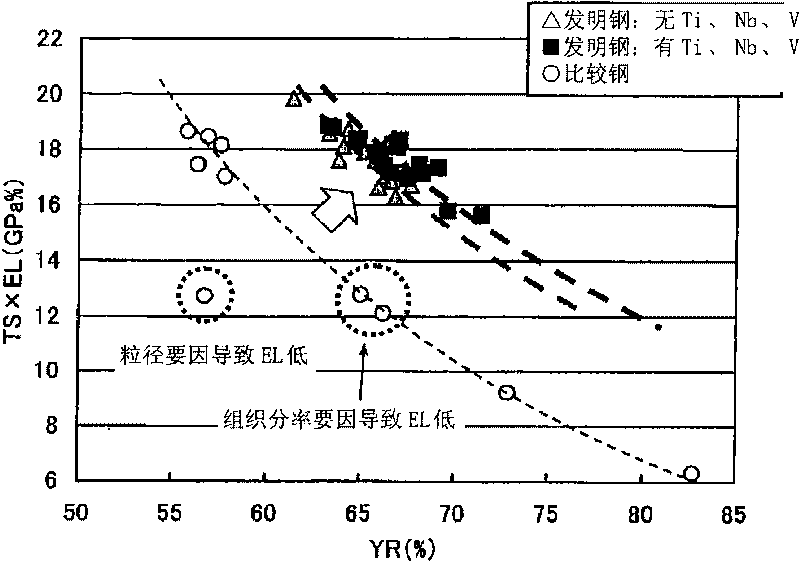

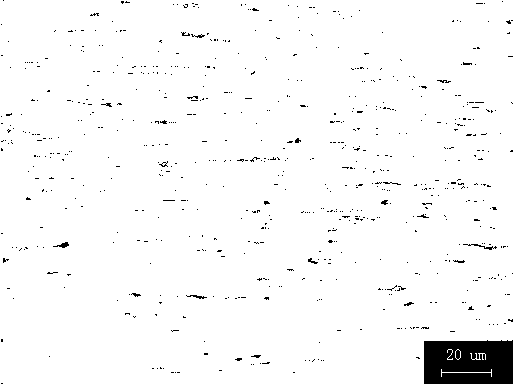

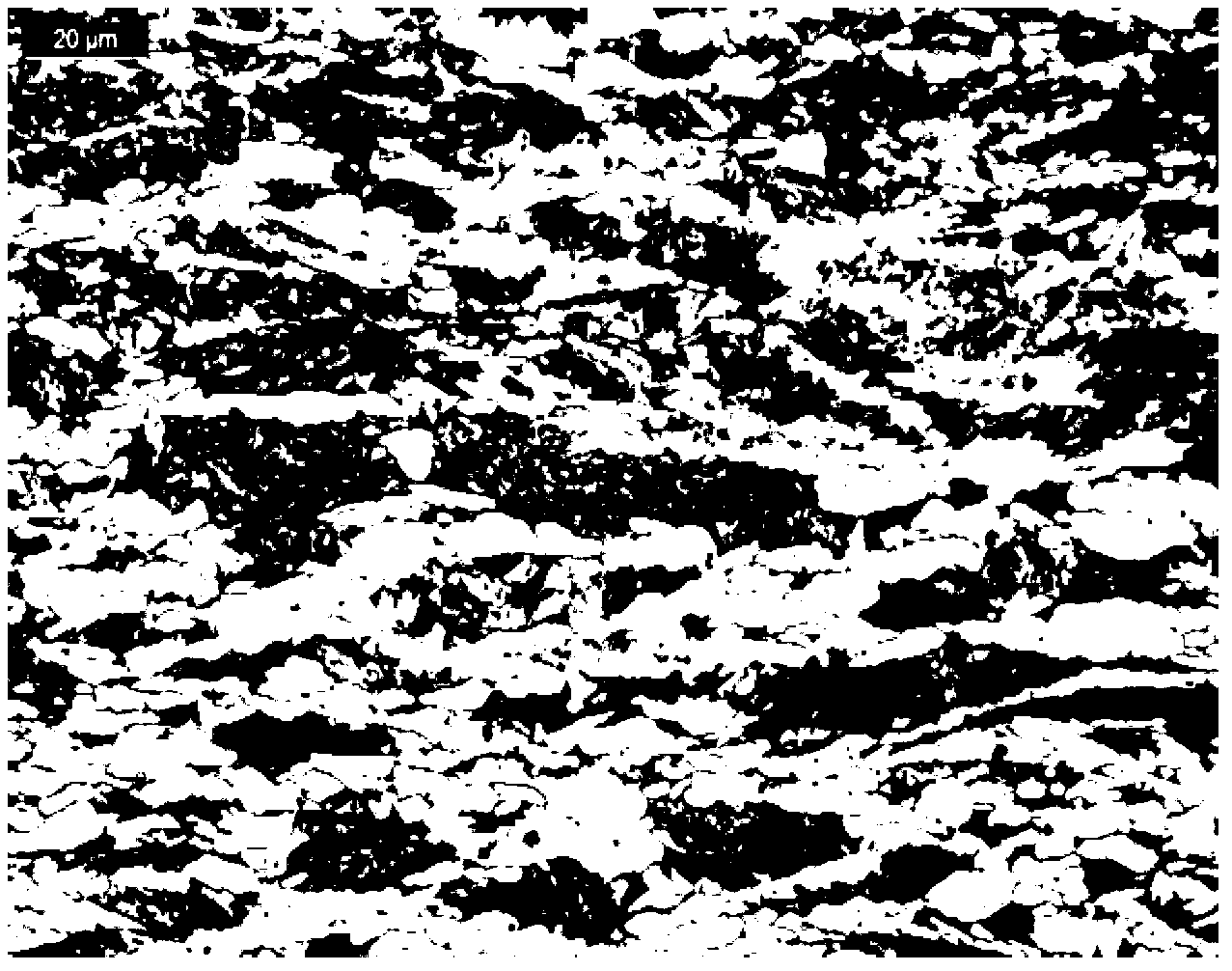

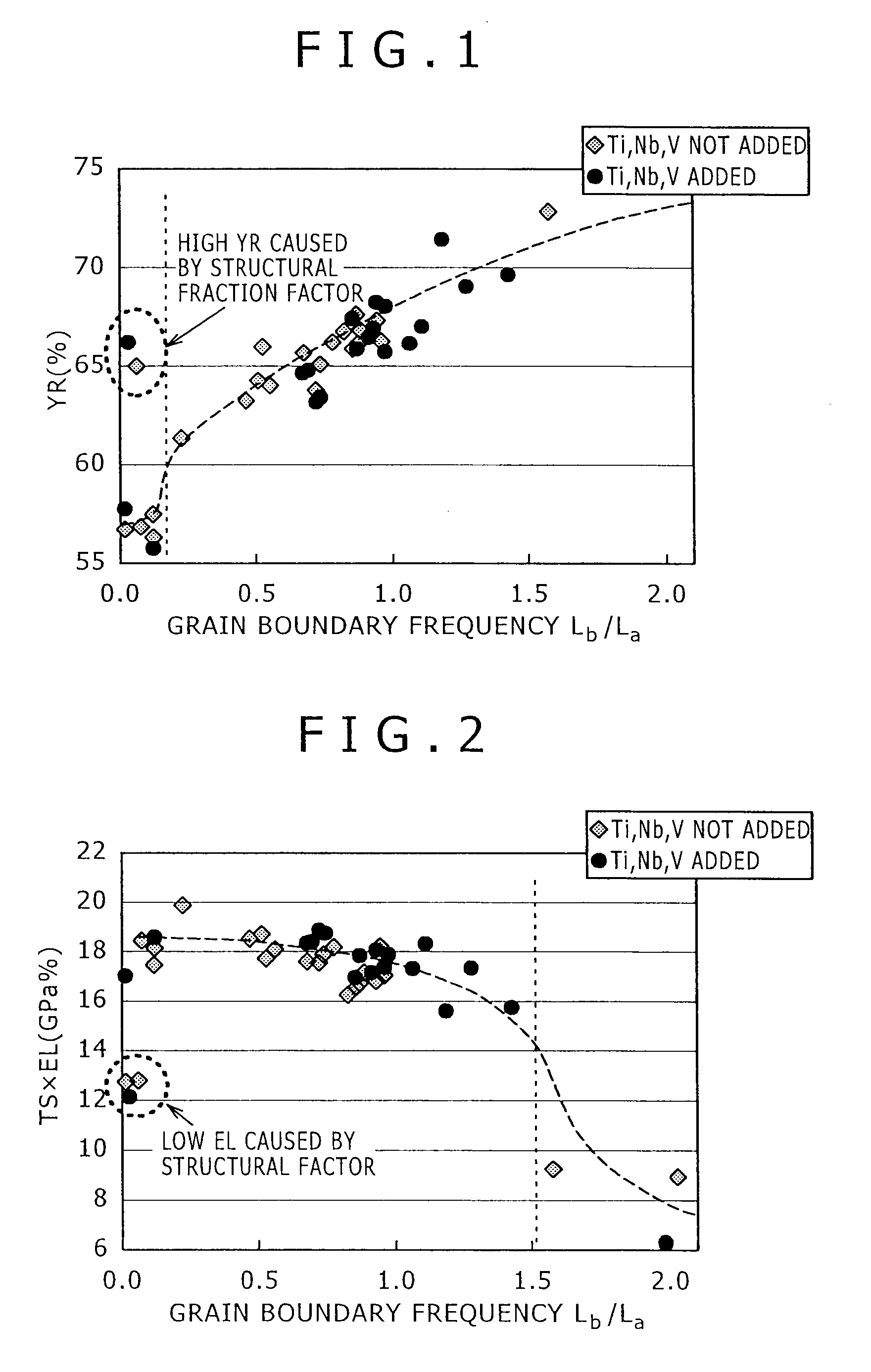

High yield ratio and high-strength hot-dip galvanized steel sheet excellent in workability and production method thereof

InactiveCN101724776AHigh yield ratioHigh elongationHot-dipping/immersion processesFurnace typesSheet steelCrystal orientation

A high-strength hot-dip galvanized steel sheet excellent in workability according to the present invention: contains C, Si, Mn and other elements; has a dual phase structure containing ferrite and martensite as the metallographic structure; and, in the ferrite structure, satisfies the expression 0.2<=(Lb / La)<=1.5 when the length per unit area of the grain boundaries of crystal grains the crystal orientation differences of which are 10 degrees or more is defined as La and the length per unit area of the grain boundaries of crystal grains the crystal orientation differences of which are less than 10 degrees is defined as Lb and further satisfies the requirements that the average value of D is 25 [mu]m or less and the area ratio of crystal grains satisfying the expression D<=30 [mu]m in the ferrite grains surrounded by the grain boundaries of crystal grains the crystal orientation differences of which are 10 degrees or more is 50% or more when the circle equivalent diameter of each of ferrite grains surrounded by the grain boundaries of crystal grains the crystal orientation differences of which are 10 degrees or more is defined as D; and has a tensile strength of 980 MPa or more.

Owner:KOBE STEEL LTD

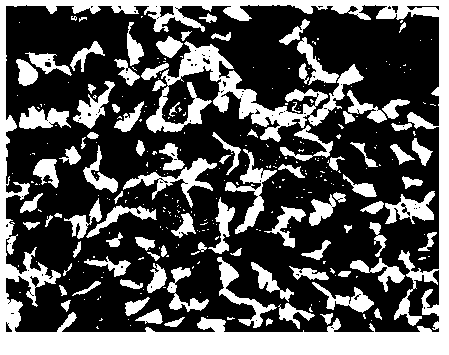

X80 level large-deformation resistance pipe line steel medium and heavy plate production method

InactiveCN101456034AReduce manufacturing costGrain refinementTemperature control deviceWork treatment devicesDouble phaseYield ratio

The invention relates to a method for producing an X80 grade large deformation resistant pipeline steel medium plate. The economic component design with low carbon is adopted to perform controlling and rolling stages on ingot, namely rolling the grain refined zone and the non grain refined zone. The method comprises: firstly, air cooling and relaxing after finished rolling is performed so that the temperature of a steel plate before entering water and cooled is reduced below the phase change point Ar3 between 30 and 50 DEG C, and 50 to 70 percent of austenite in the relaxing process is converted into proeutectoid ferrite; and secondly, laminar flow cooling is performed on the steel plate within the range of the cooling speed between 20 and 35 DEG C per second, the finished cooling temperature is controlled within the range of between 250 and 400 DEG C; and in the water cooling process, the remaining austenite is converted into bainite structure, and proeutectoid ferrite + bainite double-phase structure is obtained. The intensity and the plasticity index of the finished product satisfy the following requirements: the yield strength Rt0.5 is 530 to 630MPa, the intensity of tension Rm is 625 to 825 MPa, the yield ratio Rt0.5 / Rm is less than or equal to 0.80, and the homogeneous deformation tensile stretch UEL is more than or equal to 10 percent.

Owner:UNIV OF SCI & TECH BEIJING

Austenitic, lightweight, high-strength steel sheet of which the yield ratio and flexibility are outstanding and a production method therefor

ActiveCN103370434AHigh yield ratioImprove ductilityHot-dipping/immersion processesThin material handlingPliabilityManganese

The present invention relates to an austenitic, lightweight, high-strength steel sheet having a high yield ratio and ductility and a method for producing the same, and more particularly, to a high-strength steel sheet for automotive interior panels, exterior panels, and structural parts, and a method for producing the steel sheet. An aspect of the present invention provides austenitic, lightweight, high-strength hot rolled steel sheet , cold rolled steel sheet and coated steel sheet having a high yield ratio and ductility and a method for producing thereof including appropriate concentrations of alloying elements such as Mn, Si, and Al to obtain a tensile strength of 800 MPa or greater, an elongation of 30% or greater, and a yield ratio of 60% or greater that are difficult to obtain from high-carbon, high-manganese steel sheets or high-manganese, lightweight steel sheets of the related art. The present invention provides a steel sheet having a low specific gravity, a high yield ratio, and high ductility as compared to high-strength steel sheets of the related art such as advanced high strength steels (AHSS). The steel sheet of the present invention is effective in maintaining the rigidity of a structural member and have good press processing characteristics so that the steel sheet can be used for manufacturing automotive parts to reduce the weight of automobiles and combining a plurality of parts into a single module or as one part to simplify machining or assembly processes.

Owner:POSCO CO LTD

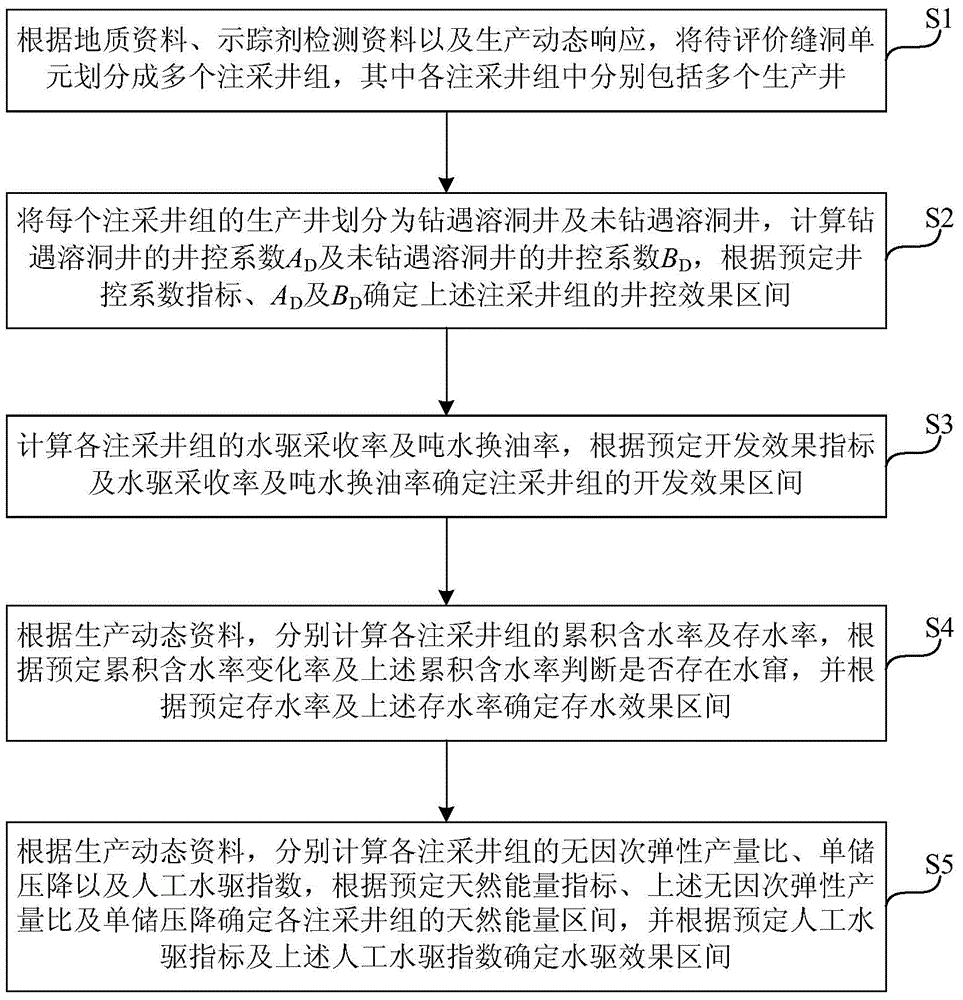

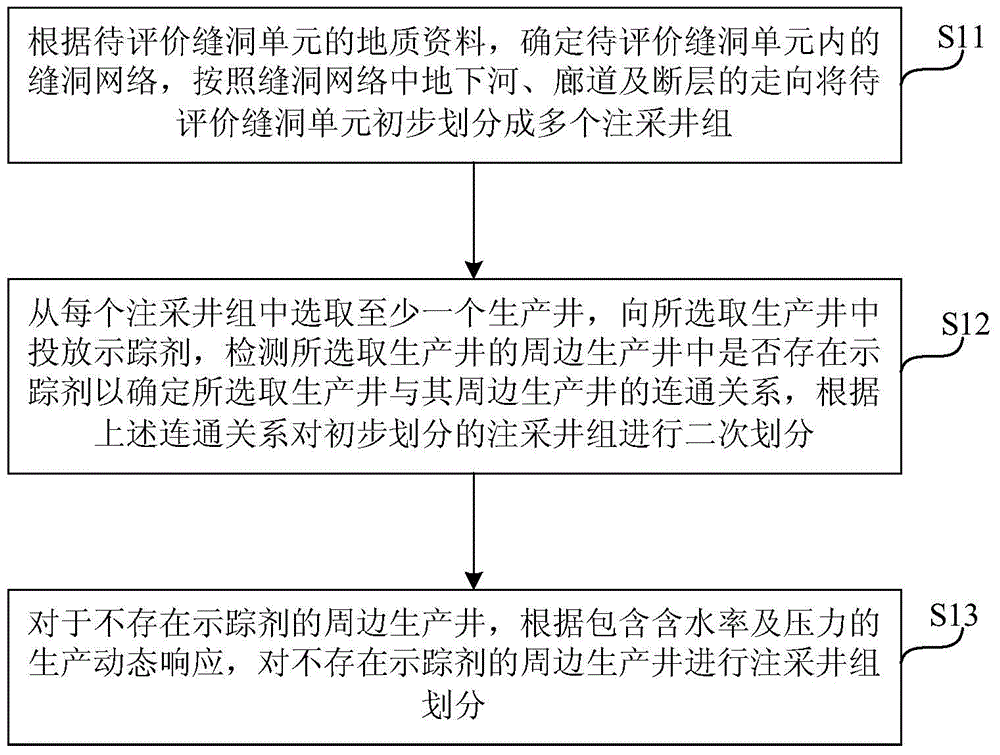

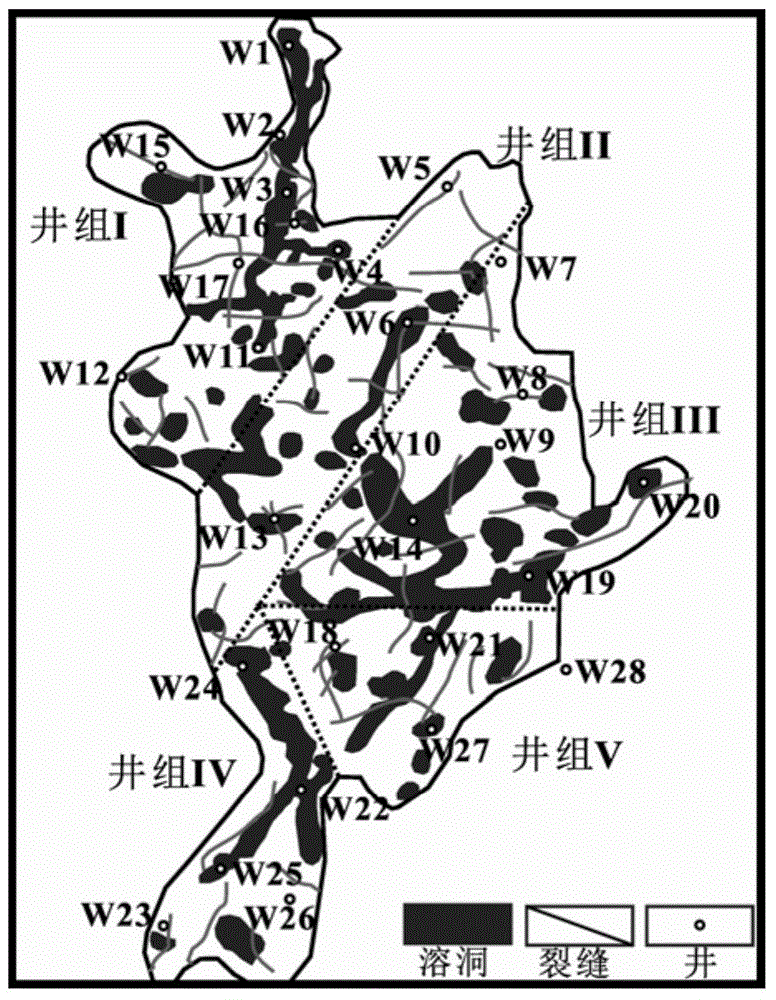

Fracture-vug type oil reservoir water-flooding development effect evaluation method

ActiveCN104790926AIncreased reliability of divisionHigh degree of fitData processing applicationsFluid removalWater storageWater flooding

The invention provides a fracture-vug type oil reservoir water-flooding development effect evaluation method. The fracture-vug type oil reservoir water-flooding development effect evaluation method comprises the steps that fracture-vug units to be evaluated are divided into a plurality of injection and production well sets; the well control coefficient of each injection and production well set is calculated, and the well control effect interval of each well set is determined combined with a corresponding preset well control coefficient index; the water-flooding recovery efficiency and the oil exchange rate of per ton water of each injection and production well set are calculated, and the development effect interval of each well set is determined combined with a corresponding preset development coefficient index; the cumulative water content and the water storage rate of each injection and production well set are calculated, the judging that whether water channeling exists or not is performed according to the cumulative water content, a water storage effect interval is determined combined with a preset water storage rate index; the non-dimensional flexible yield ratio, the single reservoir pressure drop and the artificial water-flooding index of each injection and production well set are calculated, the natural energy interval of each well set is determined combined with a corresponding preset natural energy index, a water-flooding effect interval is determined combined with a preset artificial water-flooding index. The fracture-cavern type oil reservoir water-flooding development effect evaluation method fully reflects the water injection effect of the injection and production well sets and the reason of achieving the effects, and therefore the foundation and the basis and the pertinence of the provided adjustment measure are better achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

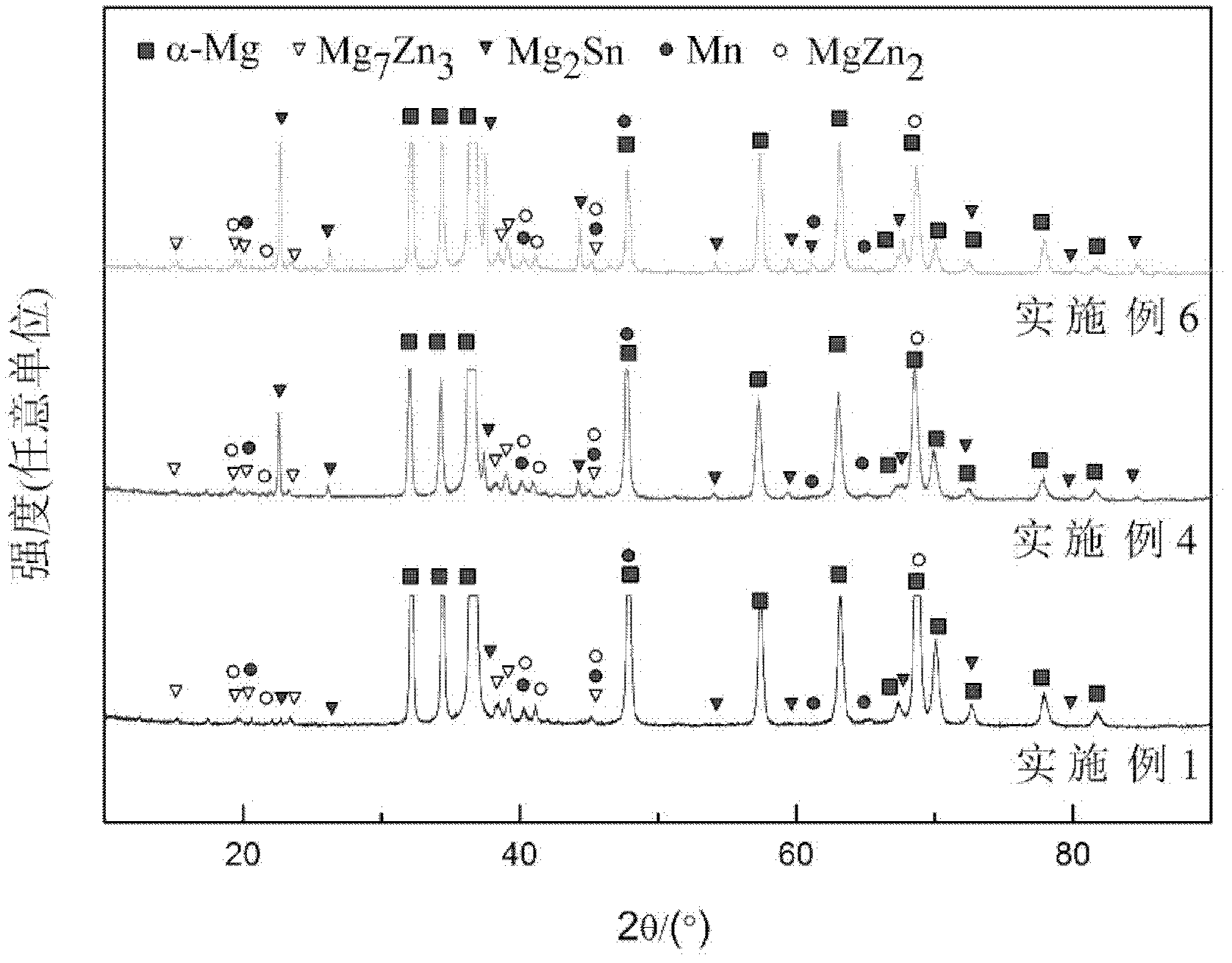

Magnesium alloy of high intensity and high yield ratio and preparation method thereof

The invention provides a magnesium alloy material of high intensity and high yield ratio. The alloy comprises the following components by mass: 5.0-9.0% of Zn; 0.5-1.5% of Mn; 1-10% of Sn; less than 0.15% of inevitable impurities; and the balance magnesium. By means of plastic forming and a choice of reasonable technological conditions for heat treatment after forming, the magnesium alloy material of the invention can be of high intensity and high yield ratio, and is higher than the high-strength wrought magnesium alloy ZK60 in terms of yield strength and tensile strength. With low cost, good extrudability and formability at a low temperature, the magnesium alloy material provided in the invention boasts substantial application potential, thus being able to partly replace the magnesium alloy material ZK60.

Owner:QINGHAI SUNGLOW MAGNESIUM

800 MPa-grade low-yield-ratio structural steel plate and production method thereof

ActiveCN102011068AGood welding performanceGood low temperature impact propertiesYield ratioHeat treated

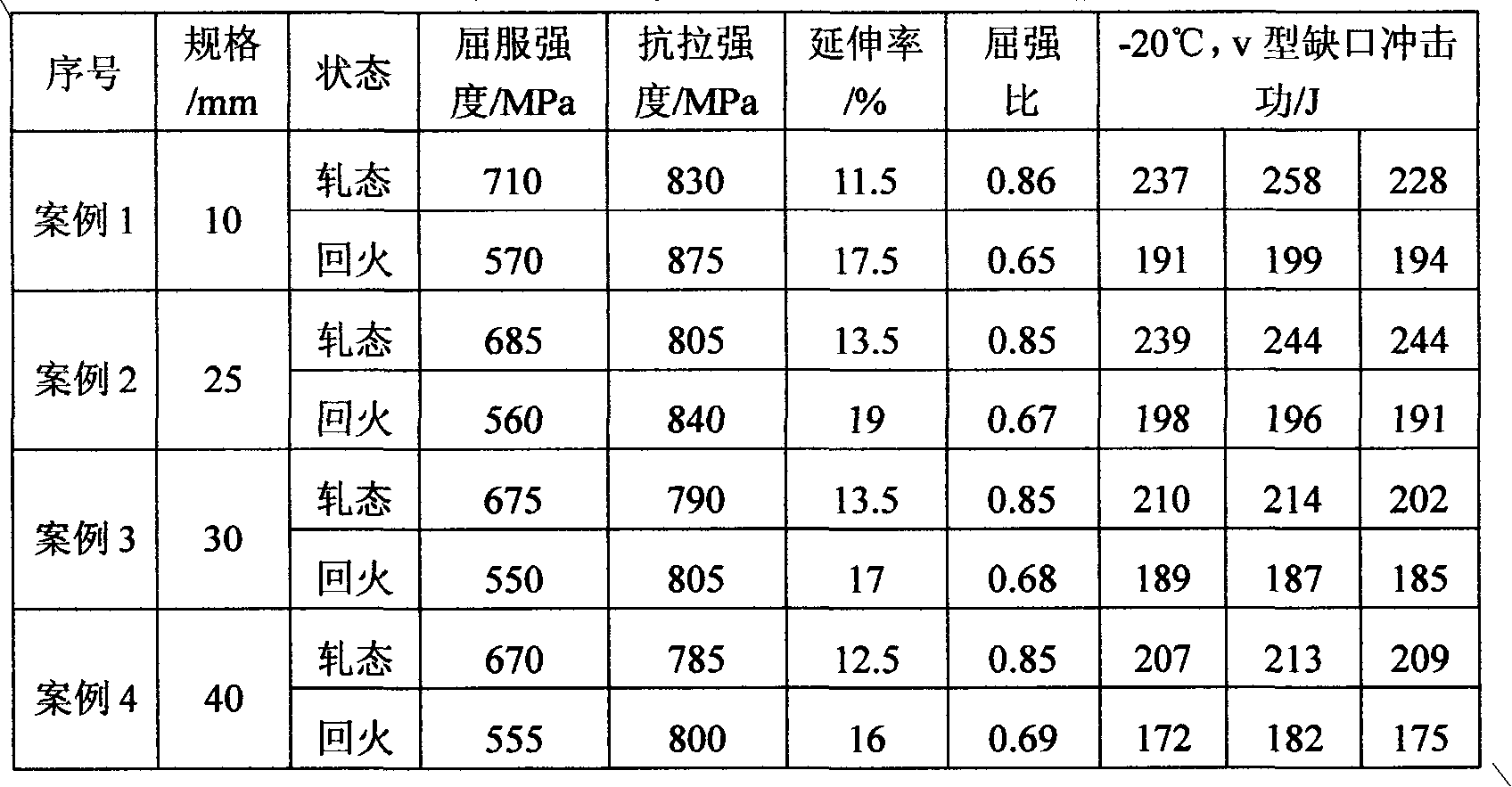

The method relates to an 800 MPa-grade low-yield-ratio structural steel plate and a production method thereof. The steel comprises the chemical components in percentage by weight: 0.045 to 0.075 percent of C, 0.30 to 0.55 percent of Si, 1.55 to 1.95 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.0025 percent of S, 0.012 to 0.035 percent of Al, 0.15 to 0.25 percent of Cr, 0.15 to 0.3 percent of Mo, 0.2 to 0.4 percent of Cu, 0.2 to 0.4 percent of Ni, 0.008 to 0.04 percent of Nb, 0.008 to 0.04 percent of V, 0.008 to 0.03 percent of Ti, 0.0008 to 0.0015 percent of B, and the balance of Fe and inevitable impurities. The steel is subjected to RH vacuum treatment, ladle furnace (LF) external refining, full protection casting, a thermo mechanical control process (TMCP), and tempering heat treatment to form the steel plate with low yield ratio, high strength and high work hardening rate. The steel plate has the thickness specification of between 10 and 40 mm, the yield strength of more than or equal to 550MPa, the tensile strength of more than or equal to 800 MPa and the yield ratio of less than 0.70, and has excellent low temperature compact performance, cold forming performance and welding performance.

Owner:SHOUGANG CORPORATION

Ti microalloyed ultra-fine grained cold rolling dual-phase steel of 1,000MPa level and preparation method thereof

InactiveCN101768695ALow priceInhibit growthTemperature control deviceFurnace typesChemical compositionMicrometer

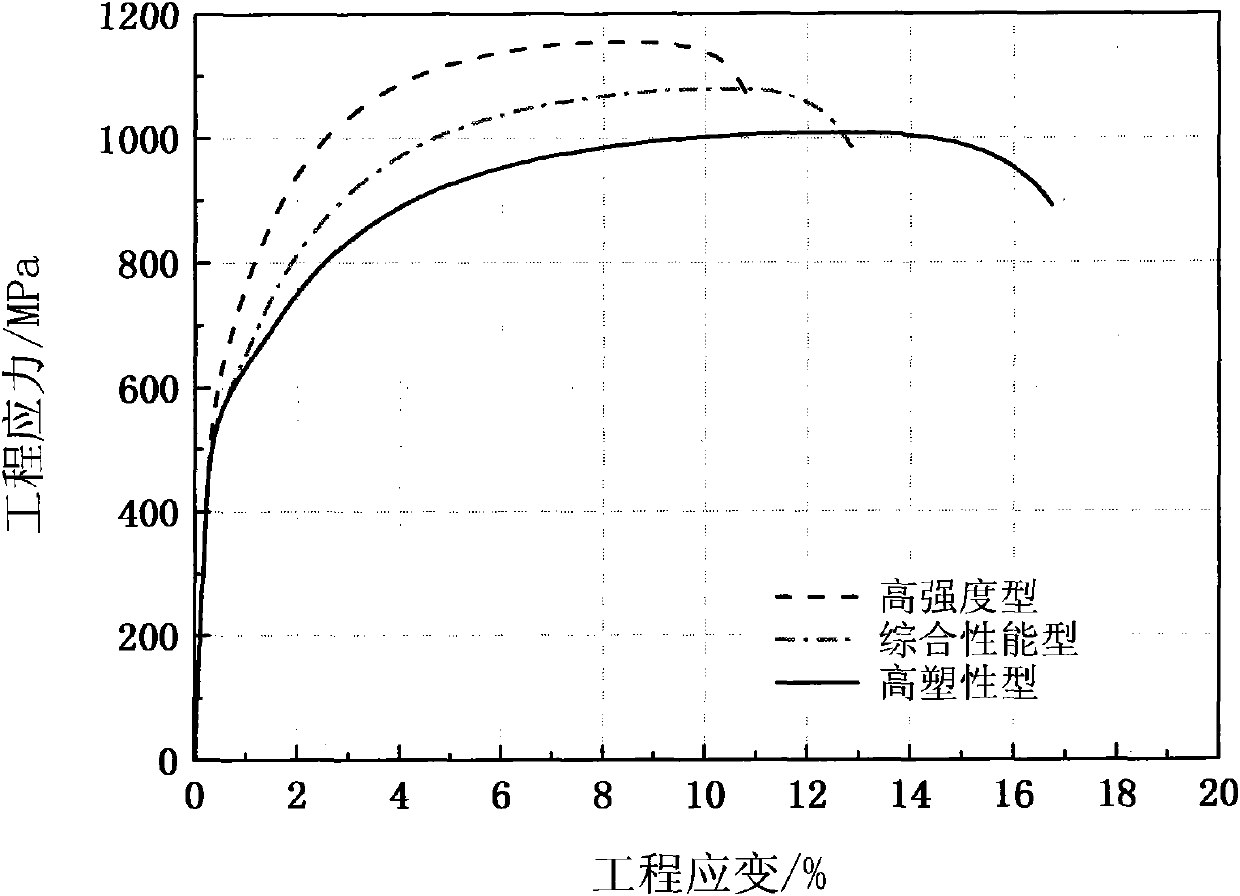

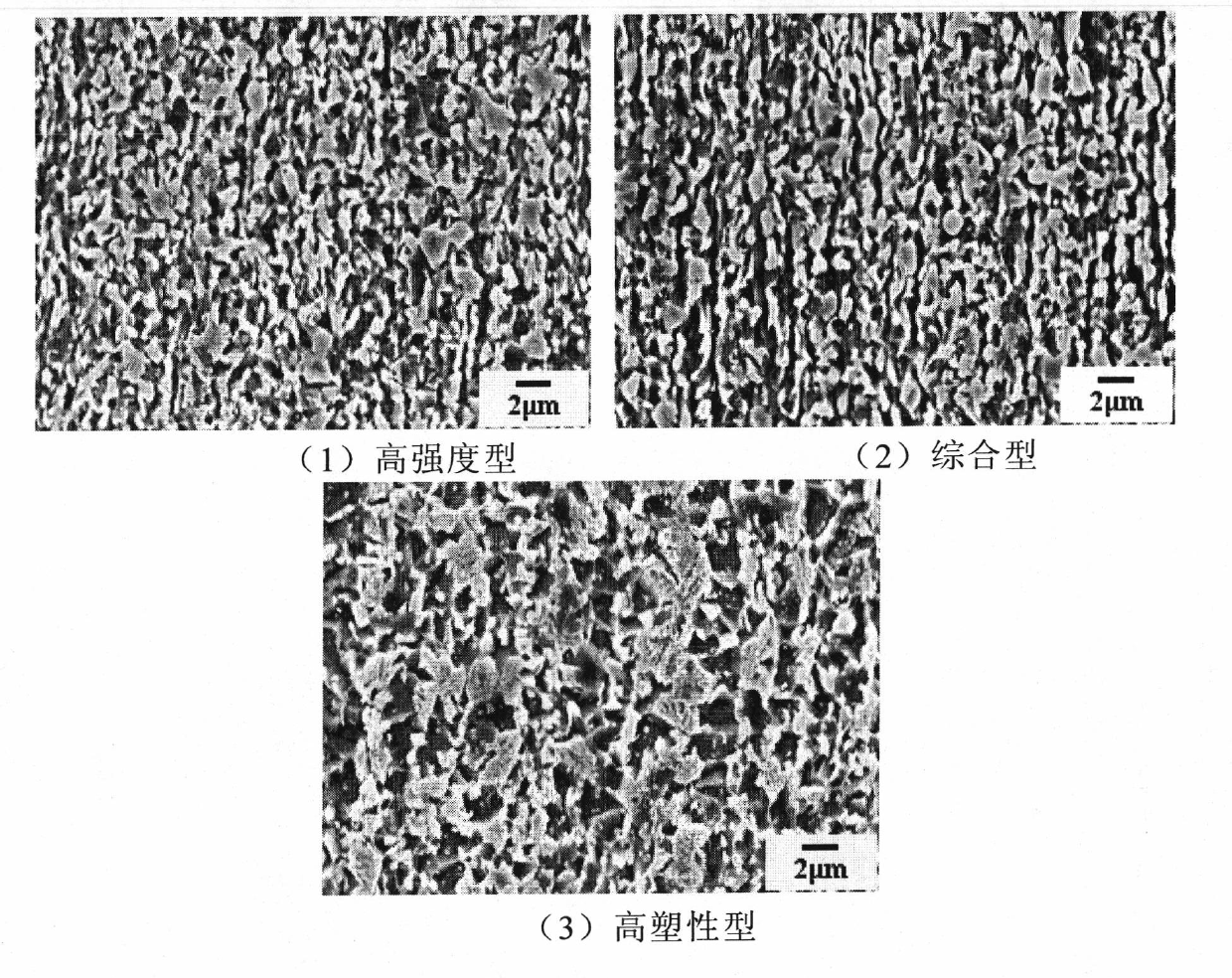

The invention relates to Ti microalloyed ultra-fine grained cold rolling dual-phase steel of a 1,000MPa level and a preparation method thereof, belonging to the technical field of cold rolling ultra-high strength steel for automobiles. The steel comprises the following chemical compositions in percentage by weight: 0.03-0.20 percent of C, 0.20-0.80 percent of Si, 1.2-2.0 percent of Mn, 0.03-0.15 percent of Ti, less than 0.15 percent of S, less than 0.020 percent of P, 0.02-0.15 percent of Als and the balance of Fe. In the invention, C-Si-Mn-Ti is used as a basic alloy system, low-price Ti is adopted, and alloy elements such as Cr, Mo, Nb, V, and the like are not added, thereby reducing the production cost; through a flexible continuous annealing process, the size of a martensite island can be controlled to be 1-2 micrometers or increased to about 5 micrometers under the condition that the quick cooling speed is lower than 50 DEG C / s in continuous annealing so as to obtain the following three different types of dual-phase steel: a high strength type (Rm is 980-1,200MPa, and A50 is 10-13 percent), a high plasticity type (Rm is 980-1,100MPa, and A50 is 14-18 percent) and a synthesizing type (Rm is 980-1,150MPa, and A50 is 12-15 percent); and the yield ratio is 0.47-0.65.

Owner:UNIV OF SCI & TECH BEIJING

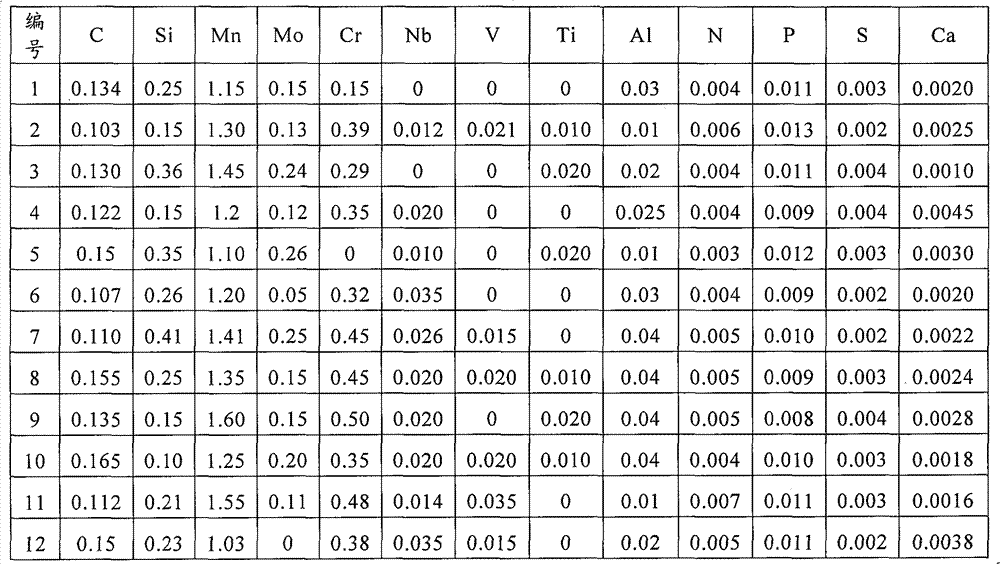

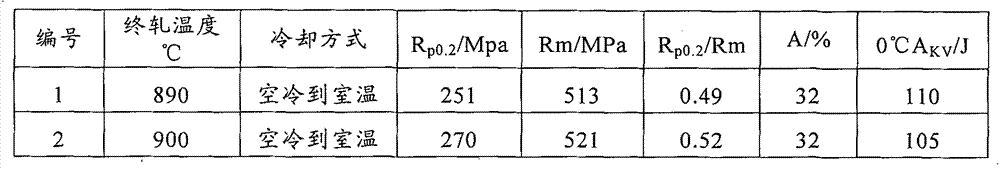

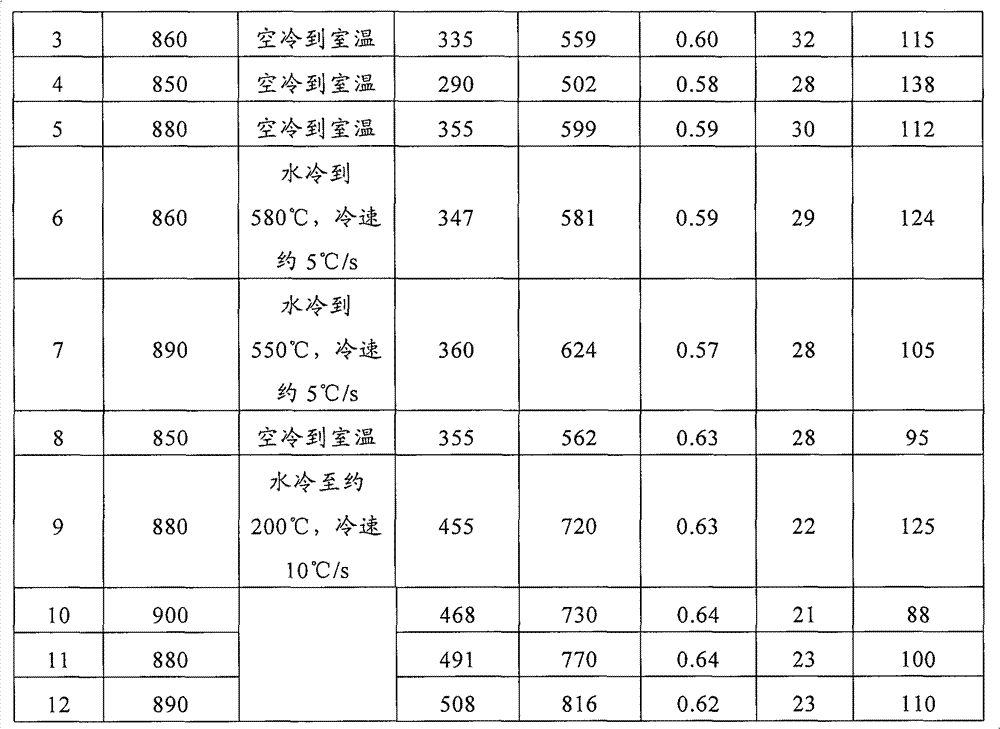

Fire-resistant and earthquake-resistant steel for construction and production method thereof

ActiveCN102952994AImprove fire resistanceSimple mechanical propertiesReduction rateEarthquake resistance

The invention relates to a fire-resistant and earthquake-resistant steel for construction. The steel comprises the following components by weight percent: 0.1-0.18 % of C, 0.1-0.50 % of Si, 1-1.80 % of Mn, less than or equal to 0.025 % of P, less than or equal to 0.015 % of S, less than or equal to 0.50 % of Cr, less than or equal to 0.30 % of Mo, less than or equal to 0.04 % of Al, less than or equal to 0.007 % of N, less than or equal to 0.006 % of Ca, one or two or more of less than or equal to 0.050 % of Nb, less than or equal to 0.055 % of V and less than or equal to 0.035 % of Ti, with Nb+V+Ti being <= 0.055 %, and the balance being Fe and unavoidable impurities. A production method comprises heating under a temperature of 1180 DEG C, insulating for 3 hours, rolling with a starting temperature of not less than 1180 DEG C, an accumulated reduction rate of last three controlled rolling being not less than 35 %, and a terminating temperature of 860 to 900 DEG C, and then directly air-cooling to a room temperature or cooling with a rate of 5 to 15 DEG C per second to the room temperature. The obtained steel is excellent in fire resistance, low in yield ratio (Rp0.2 / Rm <= 0.75), and good in earthquake-resistance performance, with Rp0.2 (yield strength at 600 DEG C) / Rp0.2 (yield strength at the room temperature) >= 2 / 3.

Owner:BAOSHAN IRON & STEEL CO LTD +1

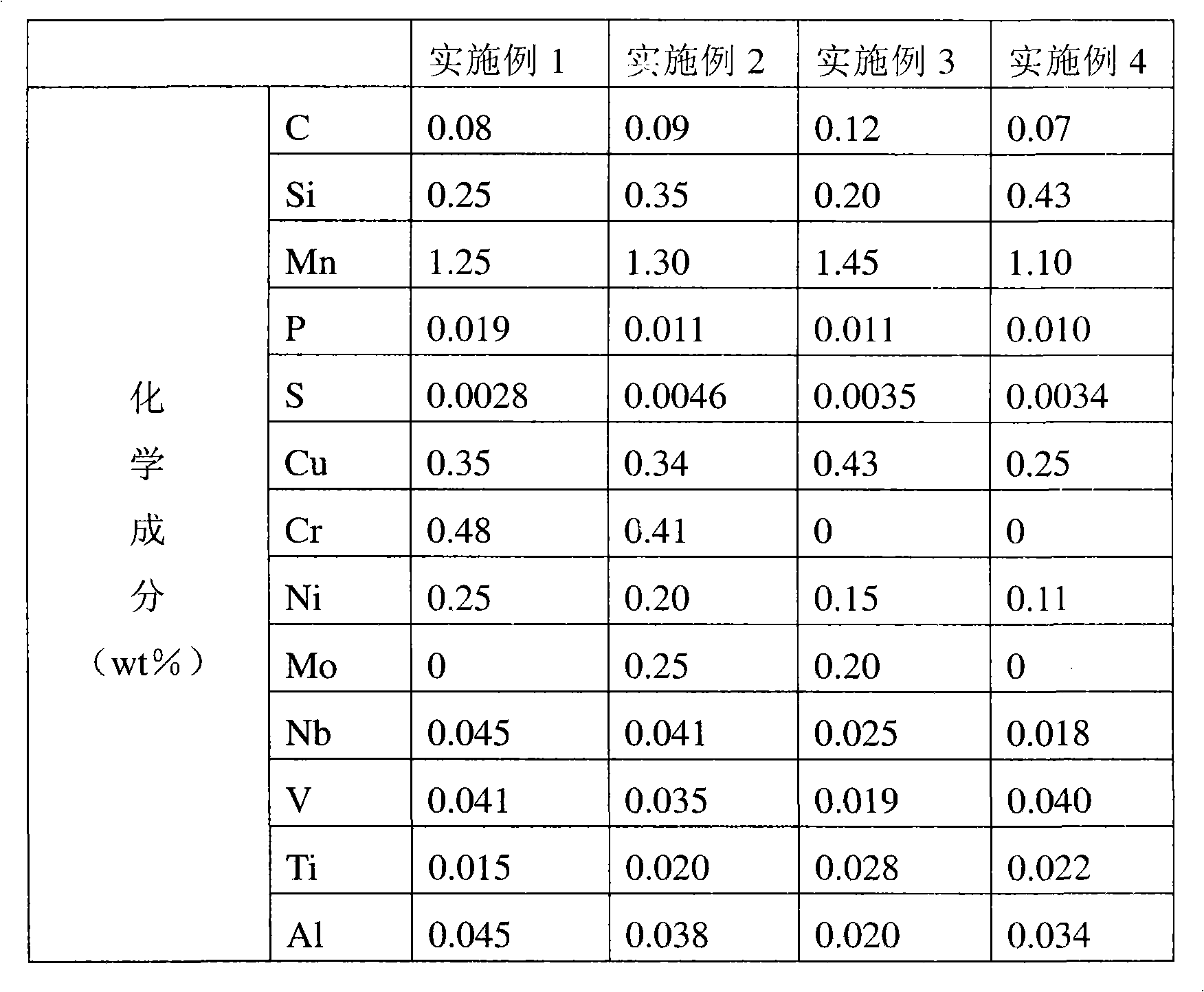

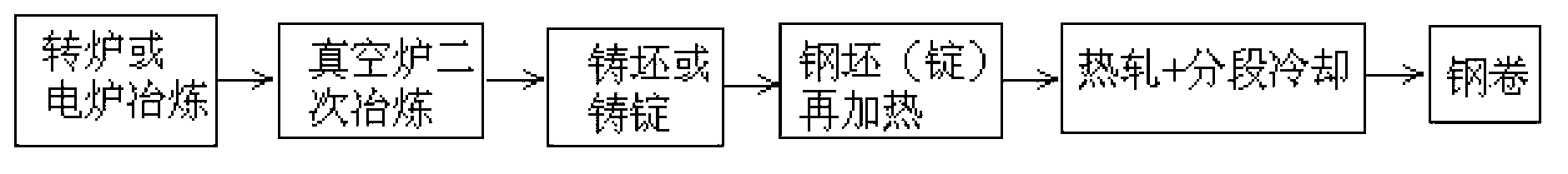

Ultra-strength, high toughness and low yield ratio steel and steel plate and manufacturing method thereof

The invention provides ultra-strength, high toughness and low yield ratio steel, which comprises the following chemical components: 0.05 to 0.12 weight percent of C, 0.15 to 0.50 weight percent of Si,1.0 to 1.5 weight percent of Mn, less than or equal to 0.025 weight percent of P, less than or equal to 0.015 weight percent of S, 0.20 to 0.50 weight percent of Cu, less than or equal to 0.25 weightpercent of Ni, 0.015 to 0.05 weight percent of Nb, 0.015 to 0.045 weight percent of V, 0.010 to 0.050 weight percent of Ti, less than or equal to 0.55 weight percent of Cr, less than or equal to 0.30weight percent of Mo, 0.015 to 0.05 weight percent of Al and the balance of Fe and inevitable impurities. The invention also provides a steel plate manufactured by using the ultra-strength, high toughness and low yield ratio steel and a manufacturing method thereof. The steel plate has excellent mechanical property, has a yield strength of more than or equal to 460 Pa and a yield ratio of less than or equal to 0.80. Moreover, the steel plate has good low-temperature impact toughness and weldability, and is suitable for high steel-structure buildings and other large-scale steel structure fields with low yield ratio requirements.

Owner:BAOSHAN IRON & STEEL CO LTD

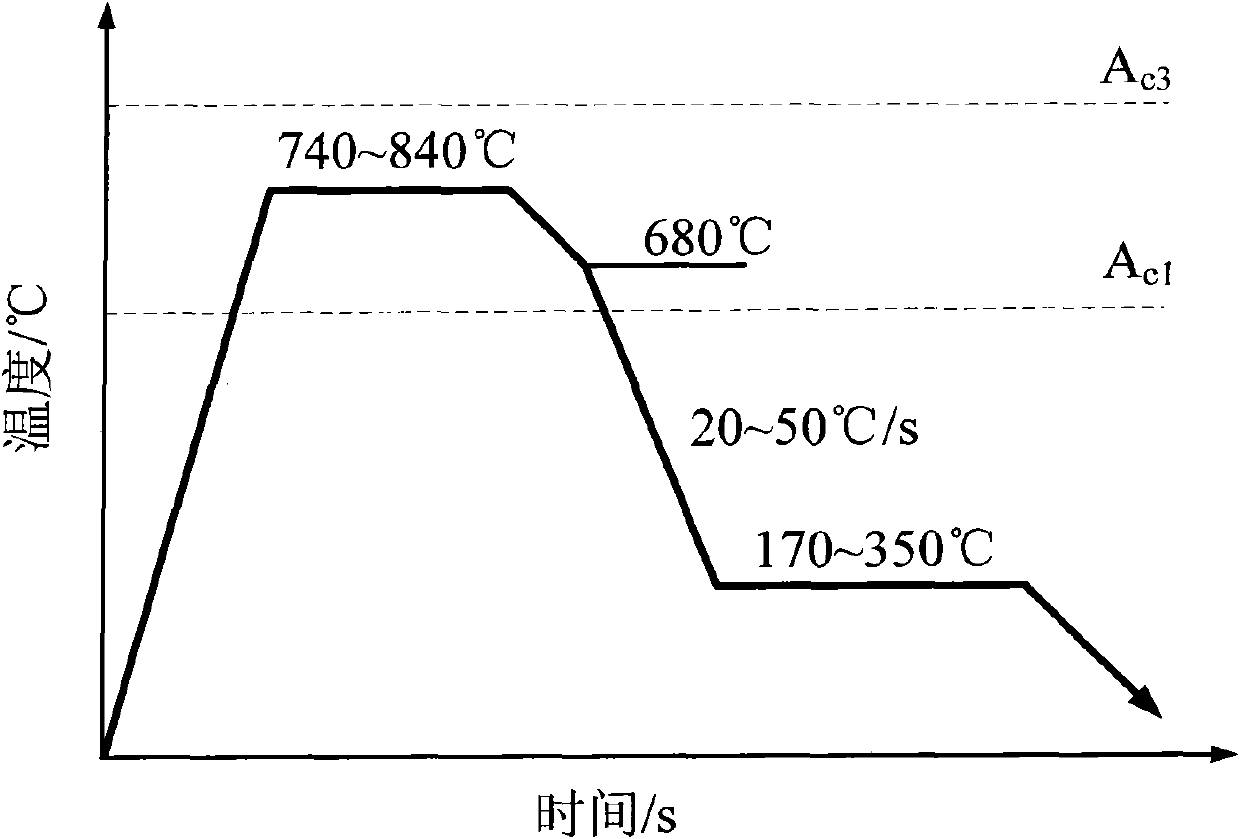

Low-yield-ratio high-strength hot-rolled Q&P steel and manufacturing method thereof

The invention relates to low-yield-ratio high-strength hot-rolled Q&P steel and a manufacturing method thereof. The steel comprises the chemical components of 0.20-0.40% of C, 1.0-2.0% of Si, 1.5-3.0% of Mn, no more than 0.015% of P, no more than 0.005% of S, 0.02-0.08% of Al, no more than 0.006% of N, 0.005-0.015% of Ti, and balance of Fe and unavoidable impurities. According to the invention, through low-cost component design, on a basis of common C-Mn steel, Si content is increased such that cementite precipitation is inhibited, and austenite grains are micronized through micro-Ti treatment. Also, with a combination of hot continuous rolling process and sectioned cooling process, a structure comprising proeutectoid ferrite, martensite, and residual austenite is obtained. The yield strength is lower than 700MPa, a tensile strength is higher than 1000MPa, a yield ratio is 0.50-0.60, and alloy cost is greatly reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Low-cost steel plate for building structure and manufacturing method thereof

InactiveCN101705423ALow costGood welding performanceTemperature control deviceFurnace typesYield ratioHigh rise

The invention discloses a low-cost steel plate for a building structure and a manufacturing method thereof. The steel plate comprises the following chemical components: C accounts for 0.14 percent to 0.17 percent, Si accounts for 0.20 percent to 0.50 percent, Mn accounts for 1.30 percent to 1.50 percent, P is equal to or less than 0.012 percent, S is equal to or less than 0.005 percent, Alt accounts for 0.020 percent to 0.060 percent, and the balances are Fe and unavoidable foreign impurities. (1) No noble metal elements such as Nb, V, Ti, Ni, Cr, Mo and the like, are added in the steel, the requirement of Q345GJ strength level is met completely though the chemical components C-Si-Mn-Al, and the cost is low; (2) the steel is purer, P is equal to or less than 0.012 percent, and S is equal to or less than 0.005 percent; (3) the impact toughness is good at the temperature of minus 40 DEG C, and the Charpy impact energy of a V-shaped notch is equal to or higher than 80 J; (4) the earthquake resistance is good, and the actual yield ratio is respectively smaller than 0.78; and (5) the lamellar tearing resistance is excellent, and the actual Z-direction section shrinkage ratio in the total-thickness direction is equal to or higher than 38 percent. The hot-rolling Q345GJEZ35 steel plate used for the building structure and provided with thickness of 20-90 mm can be produced, and the steel plate and the manufacturing method can be applied to the manufacture of the steel structure of the high-rise building, have good comprehensive performance and simple production process, can realize the batch production and have low cost.

Owner:SHOUGANG CORPORATION

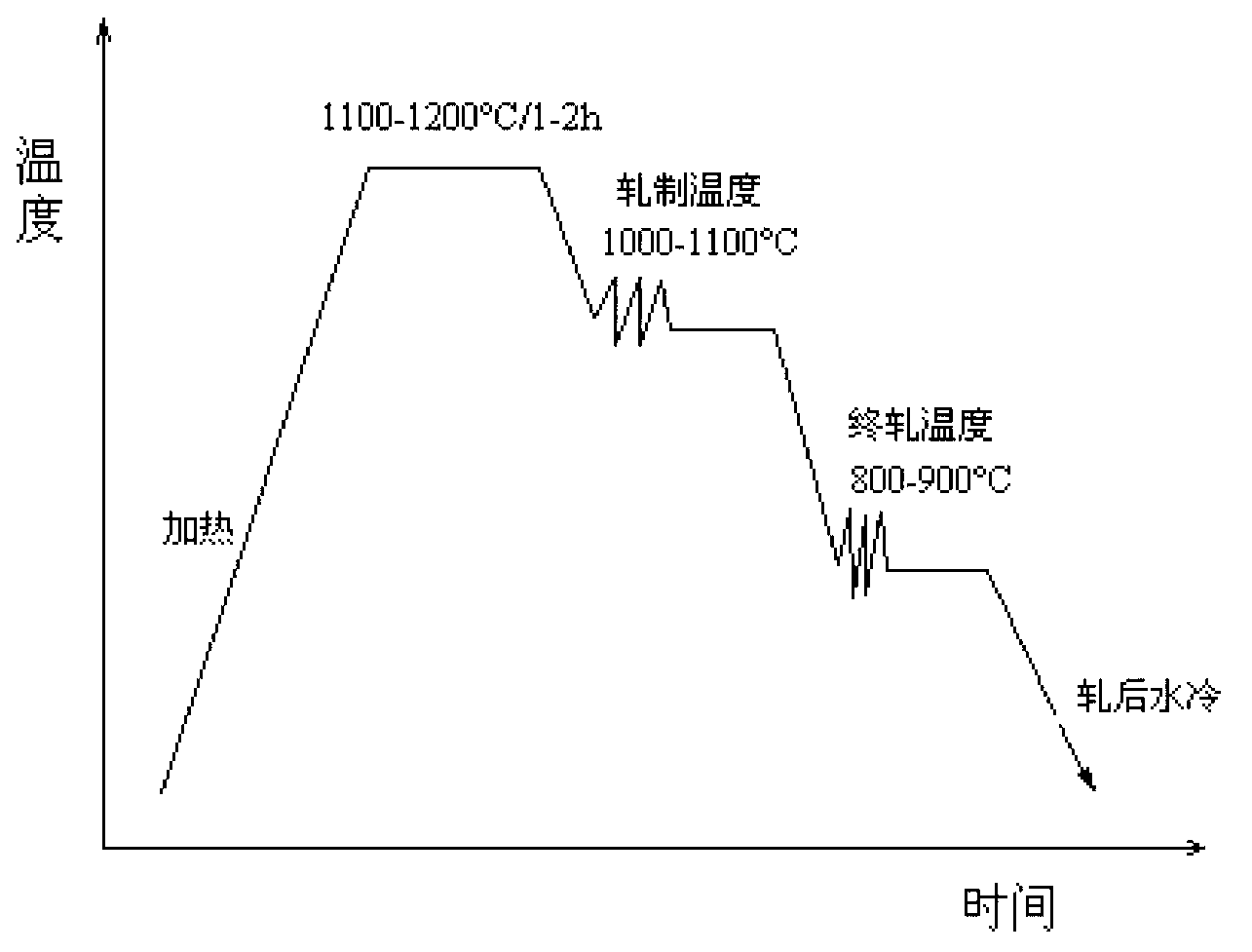

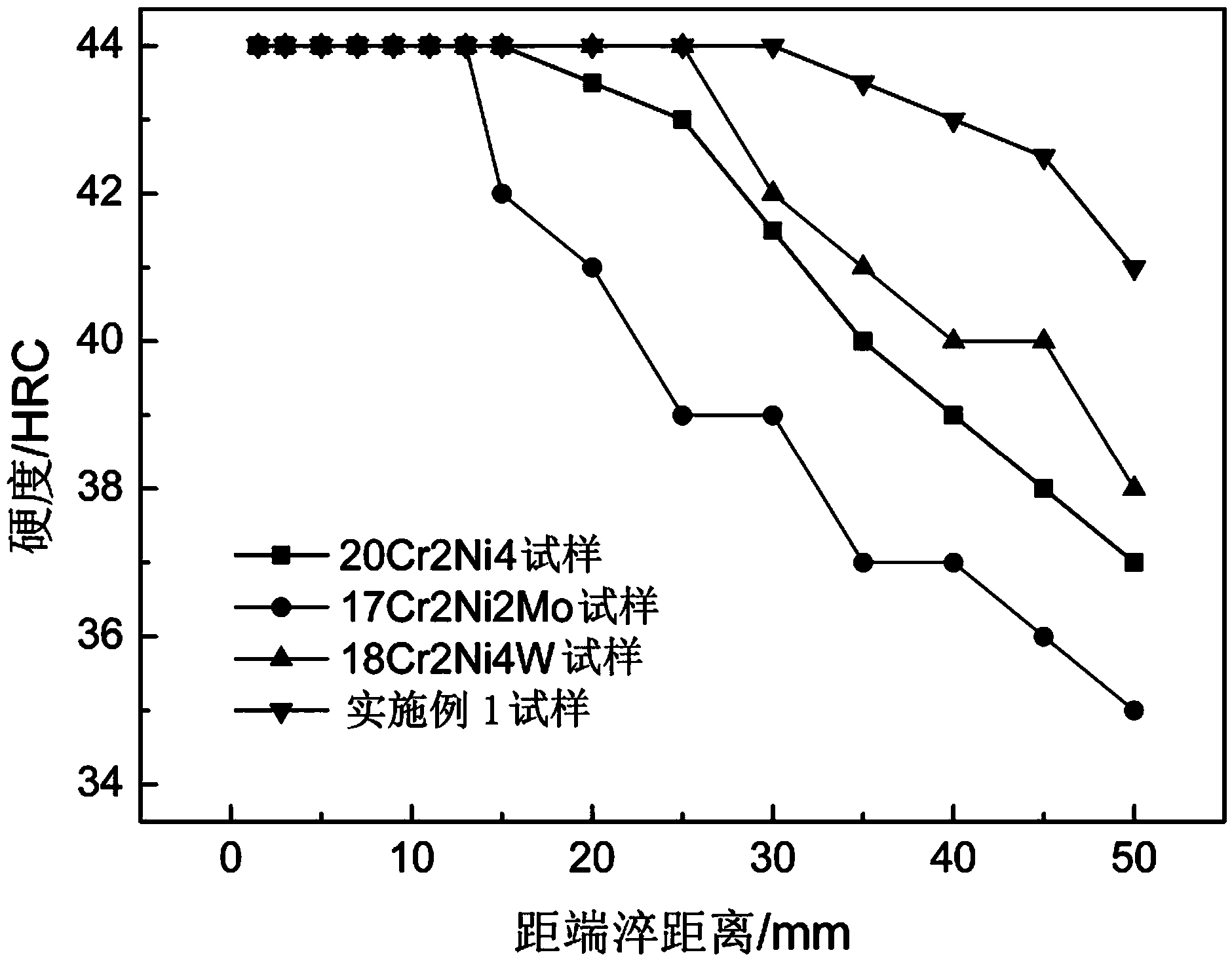

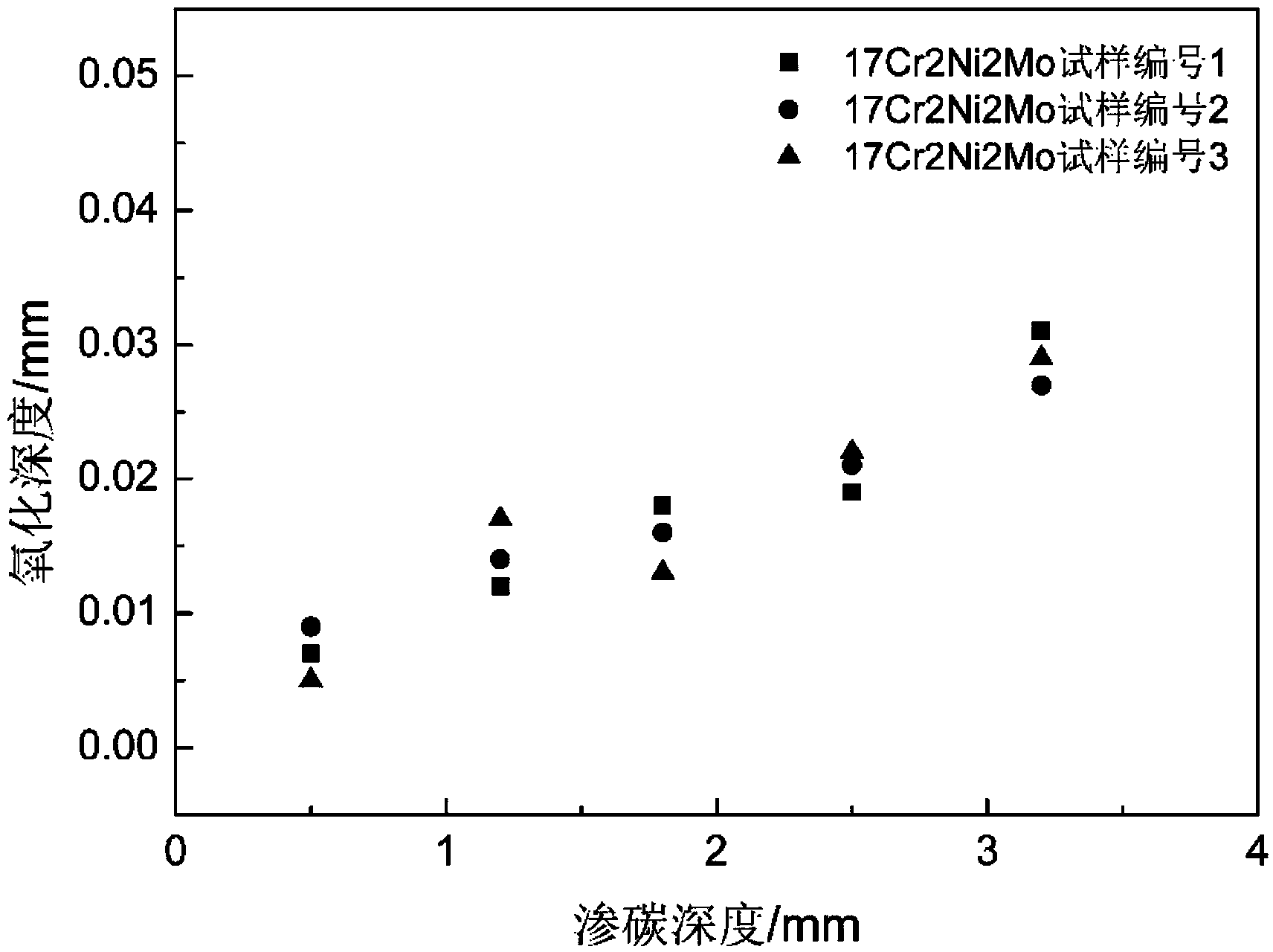

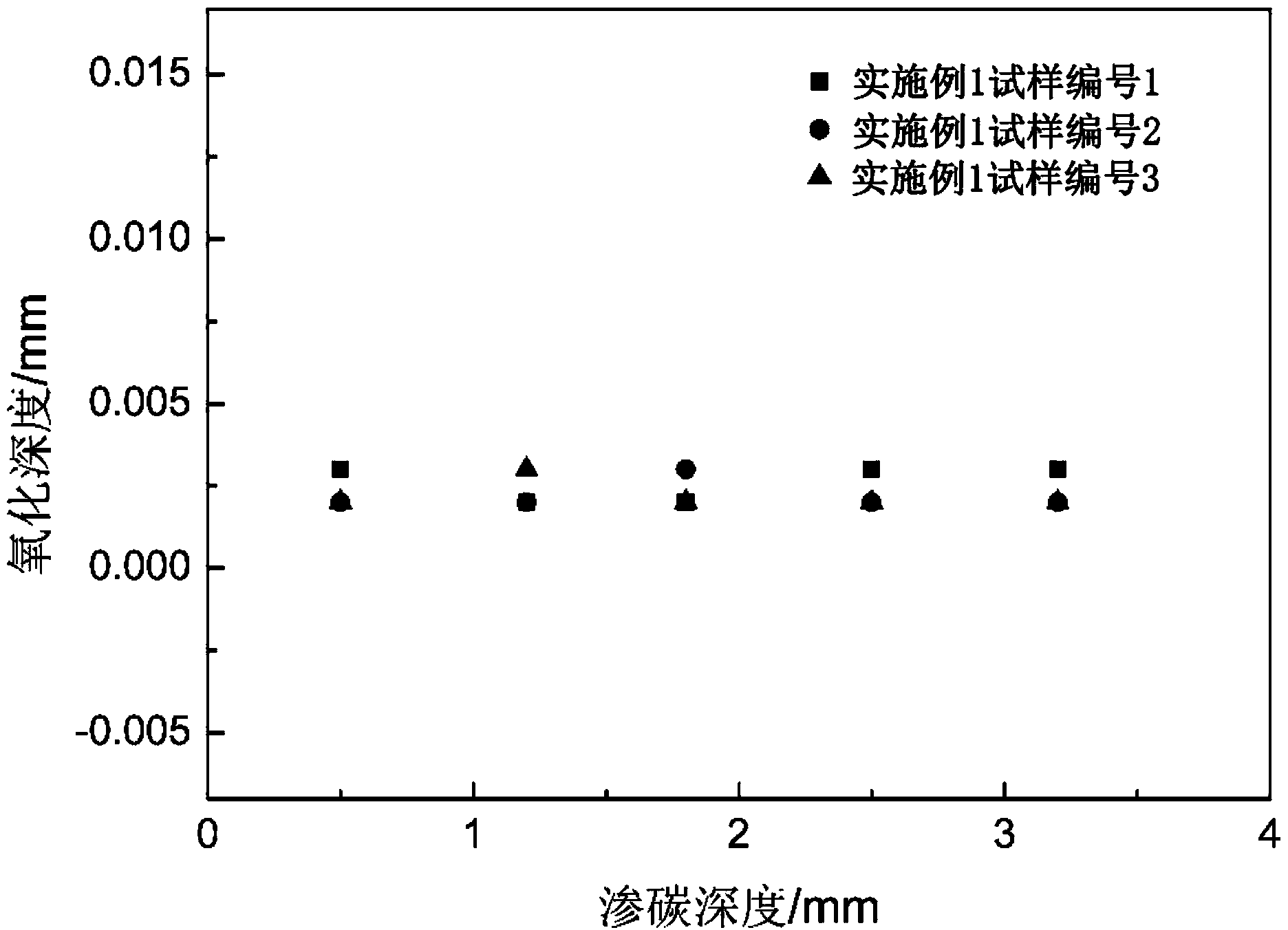

Carburizing alloy steel, and preparation method and application thereof

The invention relates to carburizing alloy steel, and a preparation method thereof. The alloy of the carburizing alloy steel comprises, by mass, 0.15%-0.25% of C, less than or equal to 0.30% of Si, 0.30%-1.20% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30%-1.50% of Cr, 2.80%-3.80% of Ni, 0.30%-1.00% of Mo, 0.01%-0.08% of Al, at least one selected from 0.05%-0.15% of V and 0.025-0.10% of Nb, and the balance being Fe and inevitable impurities. A mass percentage of V, Nb and Al meets an equation of V+Nb+Al <= 0.30%. The carburizing alloy steel provided by the invention has good anti-fatigue performance, excellent comprehensive properties, good hardenability, high yield ratio, extremely small internal oxidation and the characteristic of resisting grain growth at a high temperature, and is suitable for manufacturing heavy-duty gears.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

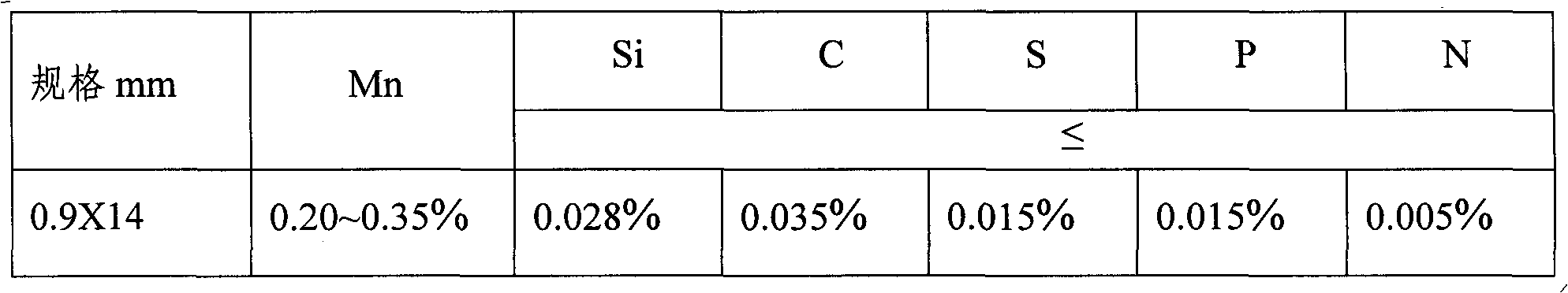

Hard tinned sheet steel and its production method

The invention relates to a hard tinned sheet steel produced from low carbon aluminium killed steel so as to solve the technical problems of easy appearance of local edge waves during current pickling rolling production of tinned sheet steel, high incidence of surface iron oxide scale during continuous annealing production, high yield ratio of tin plates, undesirable stamping processing and the like. The hard tinned sheet steel and its raw sheet comprise the following chemical components (by weight): 0.05-0.07% of C, less than or equal to 0.1% of Si, 0.20-0.30% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, 0.010-0.060% of Alt, less than or equal to 0.0060% of N, and the balance Fe and some inevitable impurity elements. The production method of the hard tinned sheet steel includes: steelmaking, continuous casting, hot rolling, combined pickling rolling, continuous annealing, double-stand tempering, and electrotinning. The hard tinned sheet steel produced in the invention has the advantages of small production control difficulty, excellent appearance quality, thin specification, stable hardness, and good stamping processing performance, etc., can meet the use requirements of high-speed canning, and can be widely used as a food cans, beverage cans, aerosol cans and other packaging materials.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

HT550 steel plate with ultrahigh toughness and excellent weldability and manufacture method thereof

ActiveCN103320692AImprove performanceShorten the manufacturing cycleFurnace typesQuenching agentsSheet steelYield ratio

Owner:BAOSHAN IRON & STEEL CO LTD

High yield ratio and high-strength hot-dip galvanized steel sheet excellent in workability and production method thereof

ActiveUS20100108200A1High elongationHigh yieldHot-dipping/immersion processesFurnace typesCrystal orientationHigh intensity

A high-strength hot-dip galvanized steel sheet excellent in workability according to the present invention: contains C, Si, Mn and other elements; has a dual phase structure containing ferrite and martensite as the metallographic structure; and, in the ferrite structure, satisfies the expression 0.2≦(Lb / La)≦1.5 when the length per unit area of the grain boundaries of crystal grains the crystal orientation differences of which are 10 degrees or more is defined as La and the length per unit area of the grain boundaries of crystal grains the crystal orientation differences of which are less than 10 degrees is defined as Lb and further satisfies the requirements that the average value of D is 25 μm or less and the area ratio of crystal grains satisfying the expression D≦30 μm in the ferrite grains surrounded by the grain boundaries of crystal grains the crystal orientation differences of which are 10 degrees or more is 50% or more when the circle equivalent diameter of each of ferrite grains surrounded by the grain boundaries of crystal grains the crystal orientation differences of which are 10 degrees or more is defined as D; and has a tensile strength of 980 MPa or more.

Owner:KOBE STEEL LTD

High-yield-ratio high-strength thin steel sheet and high-yield-ratio high-strength hot-dip galvanized thin steel sheet excelling in weldability and ductility as well as high-yield ratio high-strength alloyed hot-dip galvanized thin steel sheet and process for producing the same

ActiveUS20070029015A1Good weldabilityImprove ductilityHot-dipping/immersion processesFurnace typesSheet steelHigh intensity

Owner:NIPPON STEEL CORP

High-strength high-tensile ratio cold-rolled steel sheet and manufacturing method thereof

ActiveCN101376944AAdd lessReduce the impactRoll mill control devicesMetal rolling arrangementsChemical compositionSheet steel

The invention provides a high-strength and high-yield ratio cold-rolled steel sheet and a manufacturing method thereof. The high-strength and high-yield ratio cold-rolled steel sheet comprises the following chemical components by the weight percentage: C: 0.08 percent to 0.14 percent, Si: 0.4 percent to 1.0 percent, Mn: 1.2 percent to 2.0 percent, P: less than or equal to 0.03 percent, S: less than or equal to 0.02 percent, N: less than or equal to 0.008 percent, Al: 0.02 percent to 0.06 percent, Nb: 0.01 percent to 0.03 percent, and the rest are Fe and inevitable impurities. The high-strength and high-yield ratio cold-rolled steel sheet is manufactured through processes, such as final rolling at normal temperature, coiling at low temperature, heating and heat preservation at quite high temperature, quick cooling and the like. The yield strength of the cold-rolled steel sheet is more than or equal to 500Mpa, the tensile strength is more than or equal to 600Mpa and the yield ratio is more than or equal to 0.80; therefore, the steel sheet can meet the requirements of the automobile manufacturing industry for high-yield ratio steel sheets with higher strength.

Owner:BAOSHAN IRON & STEEL CO LTD

Thermoforming steel with tensile strength of 1,700MPa level and production method thereof

The invention discloses thermoforming steel with tensile strength of 1,700MPa level, which consists of the following components in percentage by weight: 0.27-0.50% of C, 0.28-0.50% of Si, 1.20-1.60% of Mn, 0.32-0.60% of Cr, 0.025-0.055% of Ti, 0.002-0.005% of B, 0.010-0.06% of Als, less than or equal to 0.012% of P, 0.010-0.035% of Nb or 0.30-0.45% of Mo or less than or equal to 0.50% of the mixture of Nb and Mo, less than or equal to 0.008% of S, less than or equal to 0.005% of N and less than or equal to 0.005% of O. A production method comprises the following steps of: molten iron desulphurization, converter smelting and blank casting; heating of the cast blank; rough rolling; finish rolling; laminar cooling; reeling; acid pickling and cold rolling; annealing; flattening; finishing and shearing; heating in protective atmosphere; moulding; quenching; and low-temperature tempering for later use. According to the thermoforming steel disclosed by the invention, the tensile strength is greater than 1,700MPa, and the yield ratio is not over 0.70; when used for manufacturing structural parts and safety parts of an automobile, the thermoforming steel not only can reduce the body weight of the automobile, but also can realize yield deformation in the case of automobile accidents to absorb energy and impact force; and therefore, the thermoforming steel is not broken immediately, and the safety of a driver and passengers is effectively protected.

Owner:武汉钢铁有限公司

Small-size 600MPa-level aseimatic twisted steel and manufacturing method thereof

ActiveCN103255349ASolve the problem of low yield ratioStrong Yield Ratio GuaranteeManufacturing convertersProcess efficiency improvementYield ratioRebar

The invention discloses small-size 600MPa-level aseimatic twisted steel, comprising the following components by weight percent: 0.23-0.28% of C, 0.60-0.80% of Si, 1.00-1.60% of Mn, 0.12-0.14% of V, 0.010-0.030% of N, 0.55-0.60% of Cr, the balance of Fe and inevitable impurities, and also comprising any one or combination of more than two of 0.001-0.040% of Nb, 0.001-0.020% of Ti, 0.001-0.010% of Al, and 0.001-0.050% of Cu. The manufacturing method comprises the short flow technologies of smelting by a converter or an electric furnace; continuously casting and rolling a billet, and cooling a cooling bed. The small-size twisted steel produced by the components and the method has high tensile strength, high yield strength, high percentage elongation after fracture, and over 1.25 of yield ratio, and can meet the requirements of the aseimatic steel.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

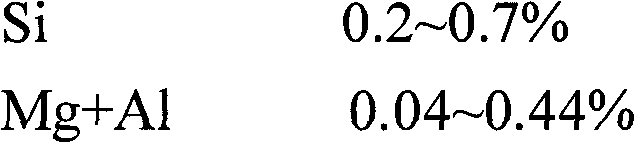

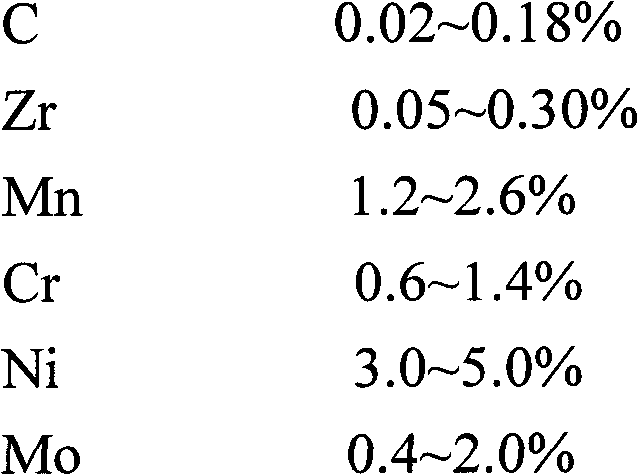

High-strength and high-toughness metal powder flux-cored wire

InactiveCN102179640AGood welding process adaptabilityStable mechanical propertiesArc welding apparatusWelding/cutting media/materialsFillet weldHydrogen

The invention relates to a high-strength and high-toughness metal powder flux-cored wire which comprises a carbon steel sheath (weight percentage: 78-84%) and a flux core (weight percentage: 16-22%), wherein the flux core comprises the following components in percentage by weight: 0.10-1.5% of TiO2, 0.10-0.5% of SiO2, 0.02-0.20% of Na2O+K2O, 0.2-0.7% of Si, 0.04-0.44% of Mg+Al, 0.02-0.18% of C, 0.05-0.30% of Zr, 1.2-2.6% of Mn, 0.6-1.4% of Cr, 3.0-5.0% of Ni, 0.4-2.0% of Mo, 0.2-1.0% of one or two of NaF or CaF2 and the balance of Fe and inevitable impurities. Through adopting a metal powder cored slag system and cooperating with the protection of argon-rich mixed gas (consisting of 80% of Ar and 20% of CO2), the high-strength and high-toughness metal powder flux-cored wire provided by the invention is mainly applicable to downward welding and horizontal fillet welding. In addition, the high-strength and high-toughness metal powder flux-cored wire is good in welding process adaptability, stable in mechanical performance, good in cold cracking resistance, fine in seawater corrosion resistance and excellent in anti-explosion performance; and meanwhile, the yield ratio of weld metalsis below 0.87, and the diffusible hydrogen in deposited metals reaches an ultra-low hydrogen level.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com