Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2127results about How to "Shorten the manufacturing cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

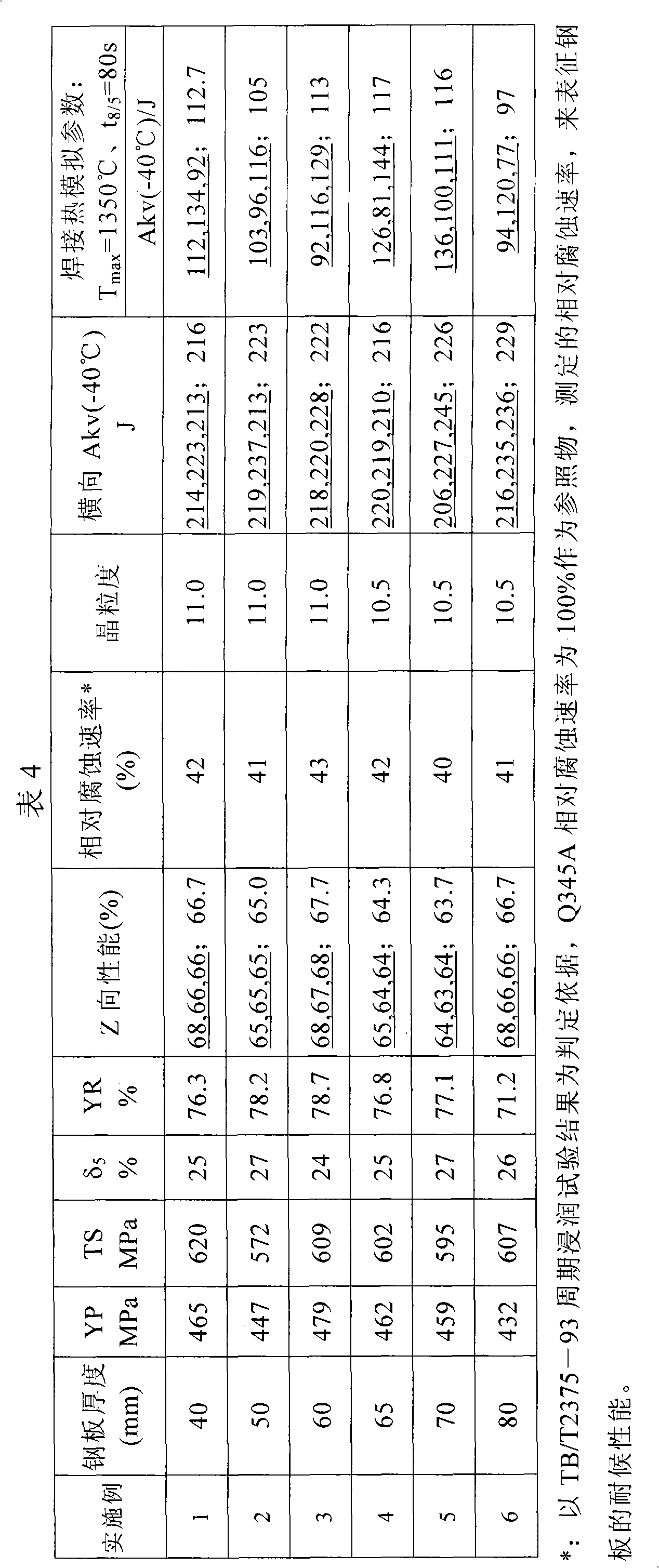

Weather resistant thick steel plate and manufacturing method thereof

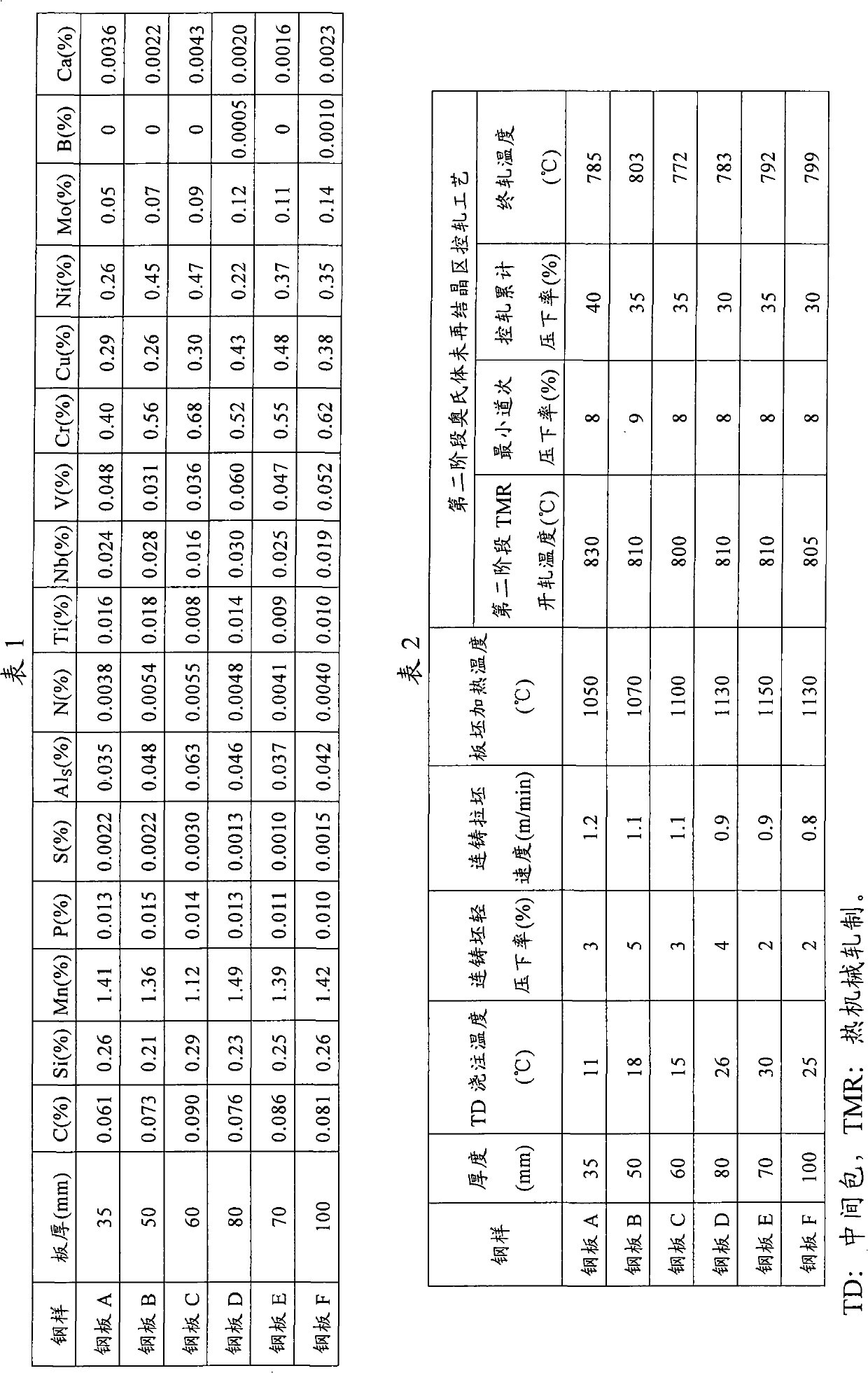

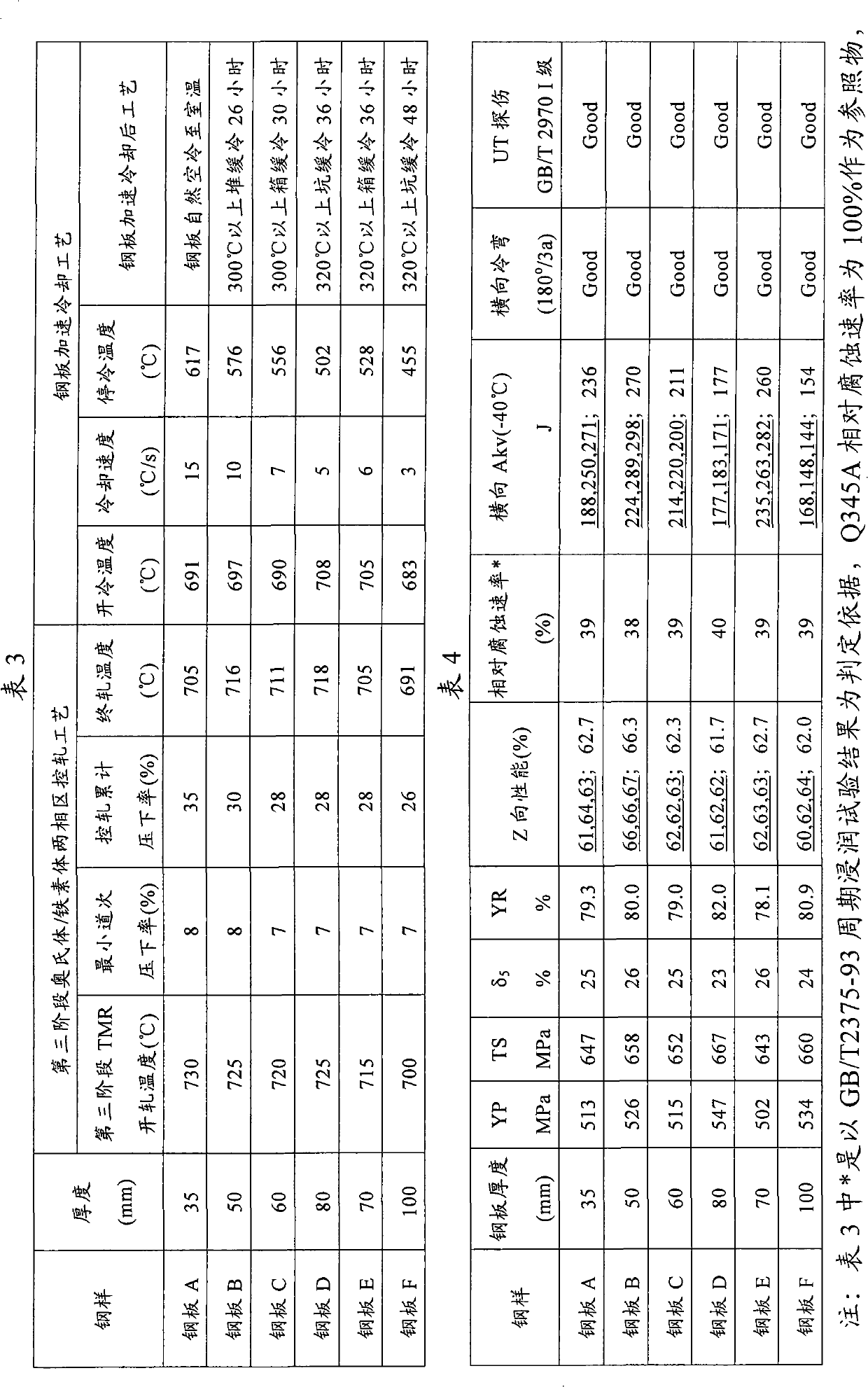

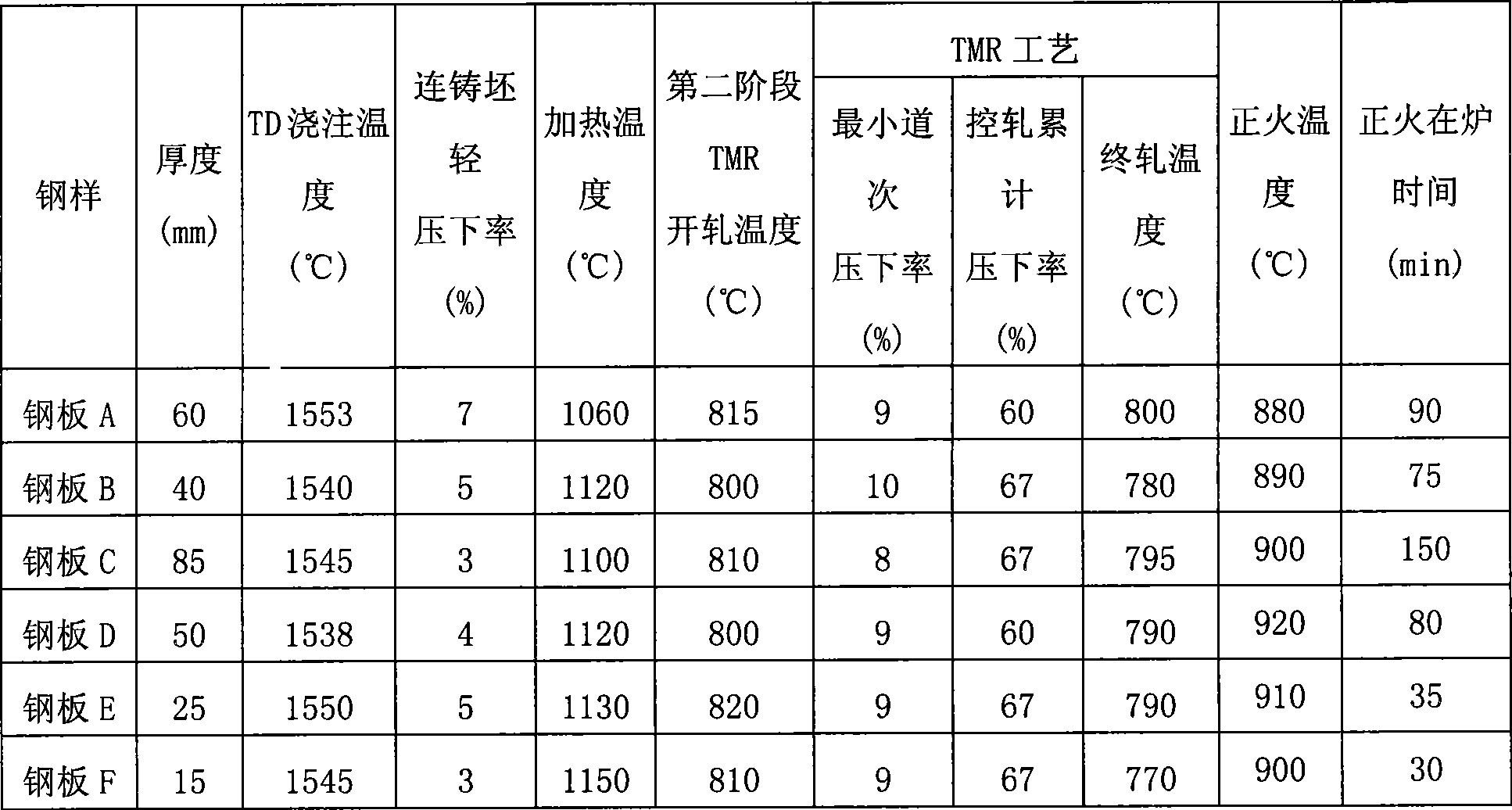

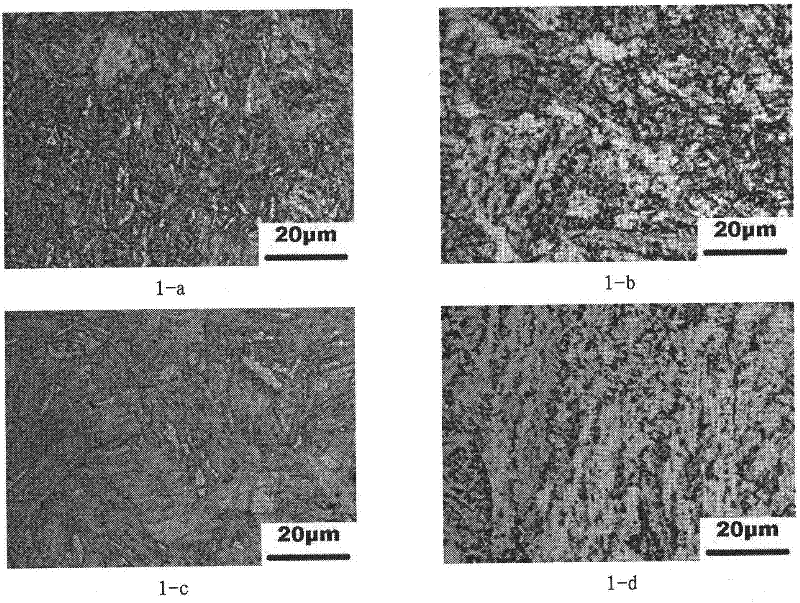

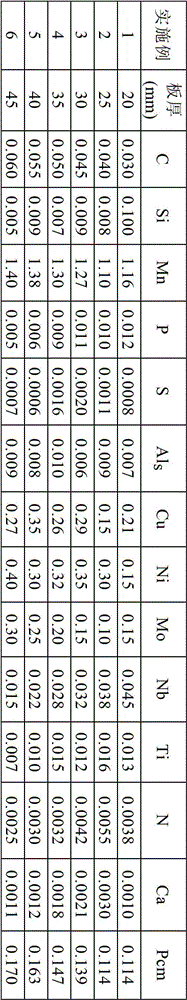

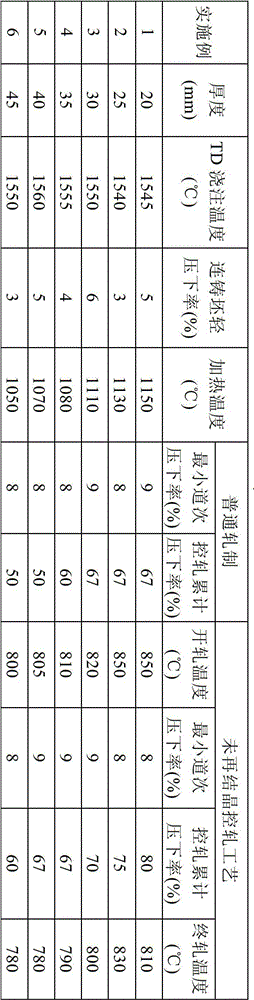

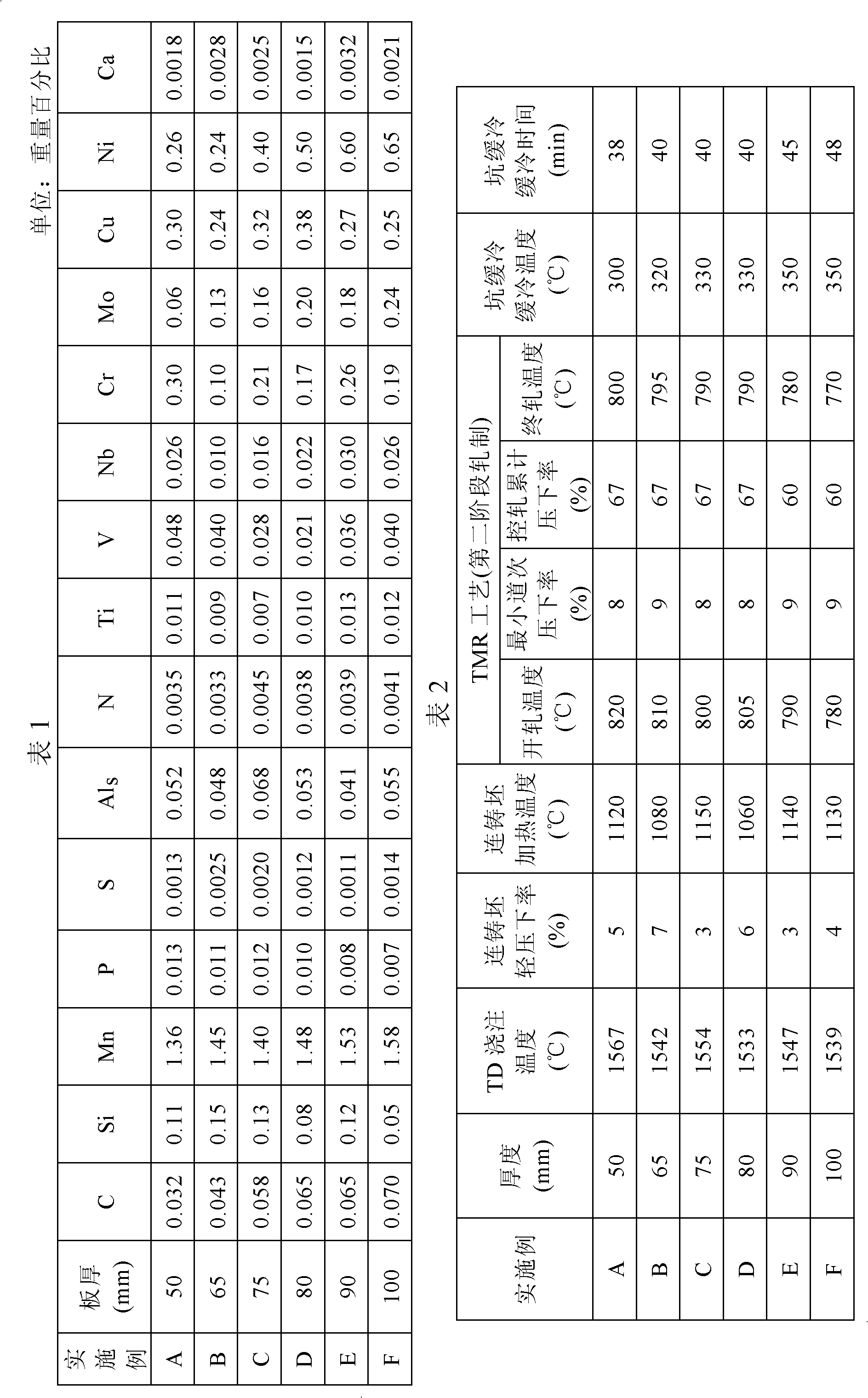

A weather resistant thick steel plate comprises, by weight, 0.06%-0.9% of C, not more than 0.30% of Si; 1.10%-1.50% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.035%-0.065% of Als, 0.25%-0.50% of Cu, 0.20%-0.50% of Ni, 0.40%-0.70% of Cr, 0.50%-0.15% of Mo, 0.008%-0.018% of Ti, 0.030%-0.060% of V, 0.015%-0.030% of Nb, not more than 0.0055% of N, 0.001%-0.004% of Ca, 0.0004%-0.0010% of selectively added B, and the balance of Fe and unavoidable impurities. The manufacturing method includes deep desulfurization of molten iron, converter smelting, LF, RH, continuous casting, on-line finishing of slabs, cut-to-length torch cutting of slabs, heating, TMCP, and slow cooling of steel plates. The obtained weather resistant thick steel plate has balanced strong toughness and strong plasticity, low yield ratio, atmospheric corrosion resistance, excellent weldability and fatigue resistance, and is especially applicable to non-coating high-rise building structures and bridge structures.

Owner:BAOSHAN IRON & STEEL CO LTD

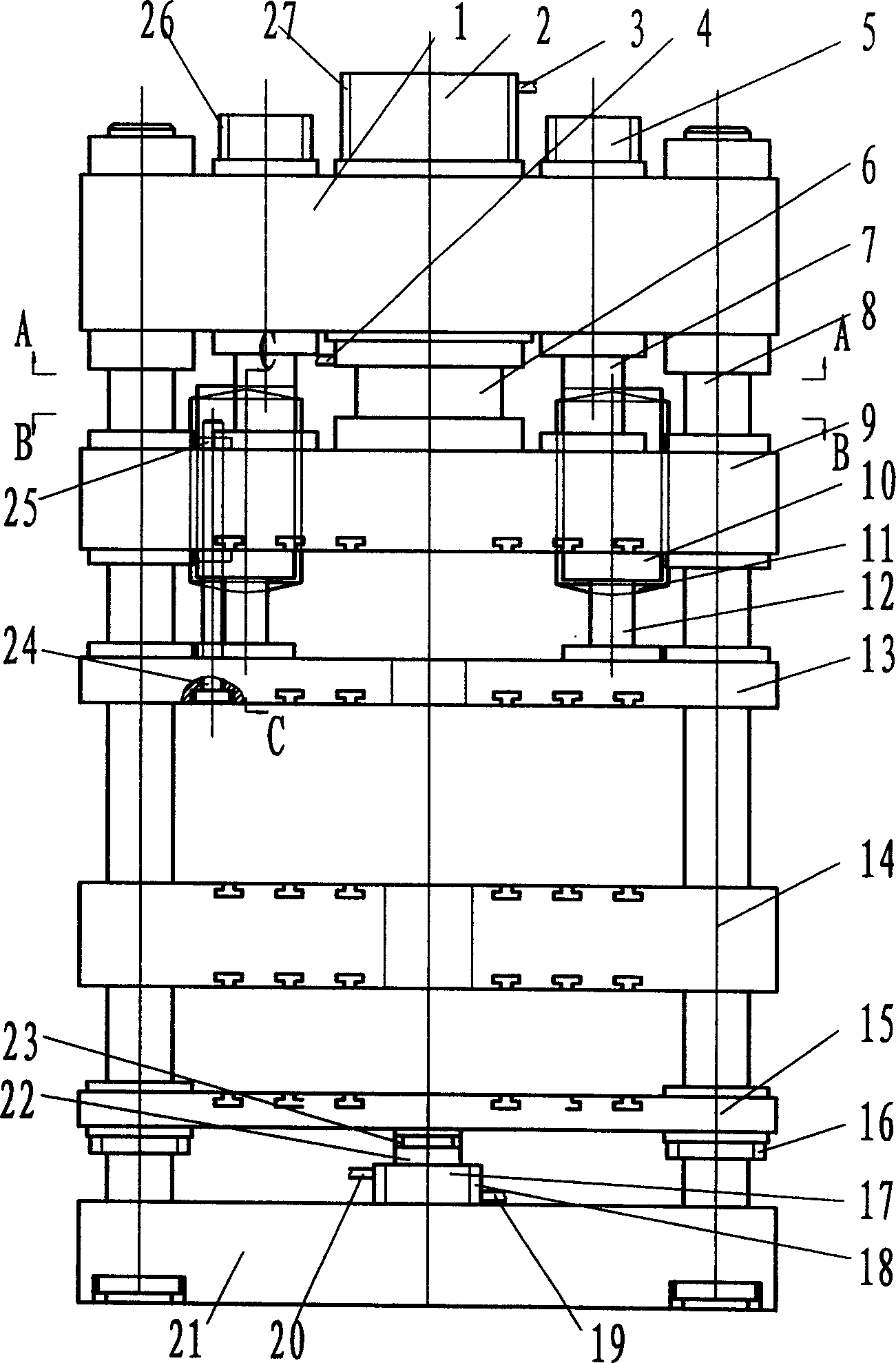

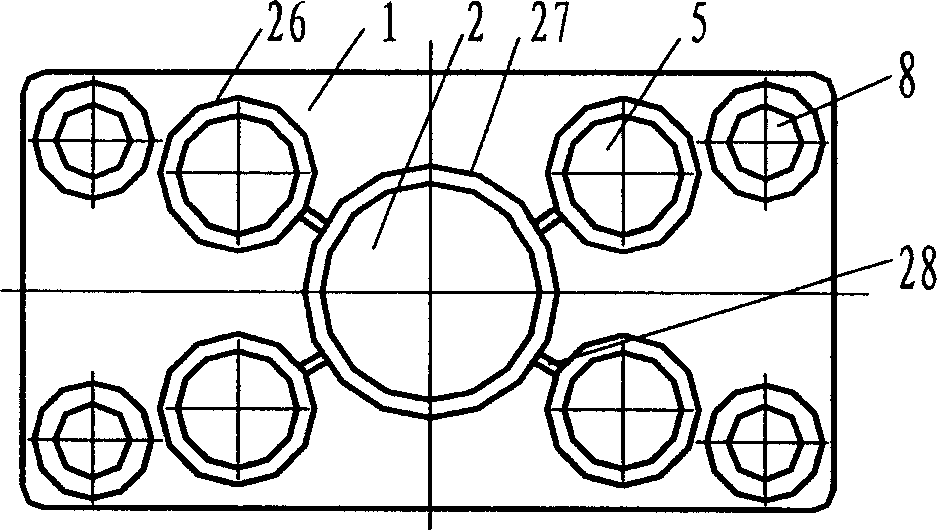

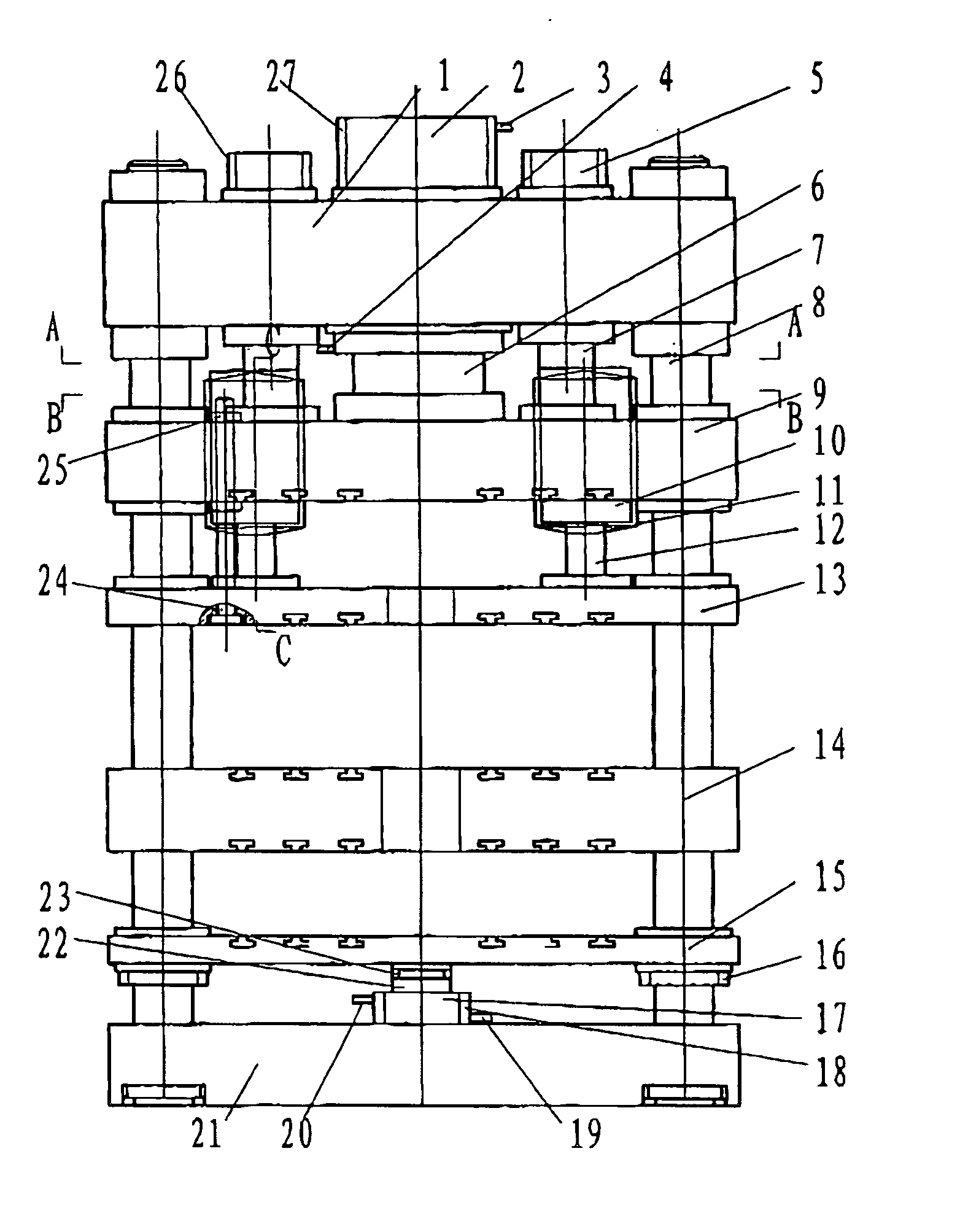

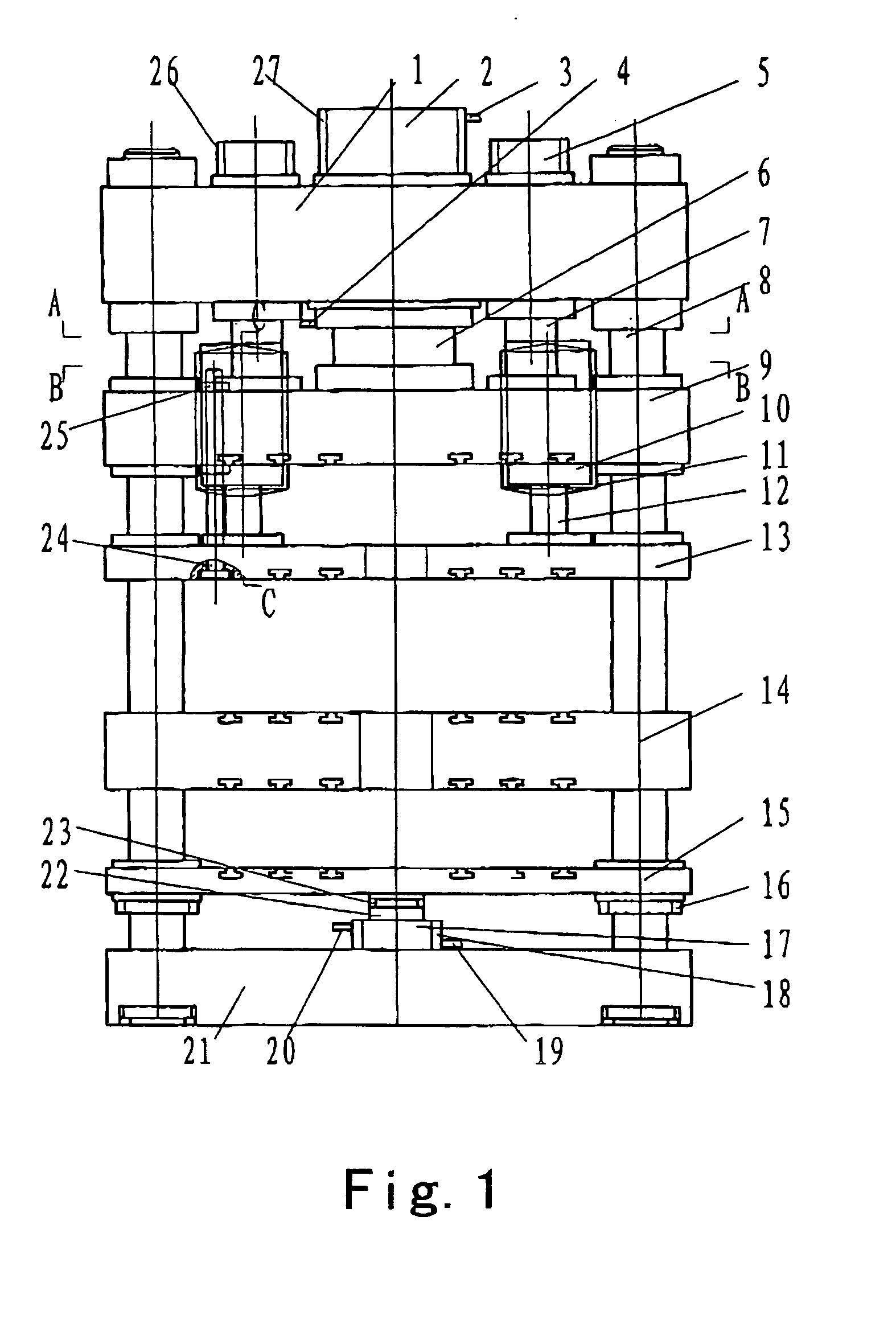

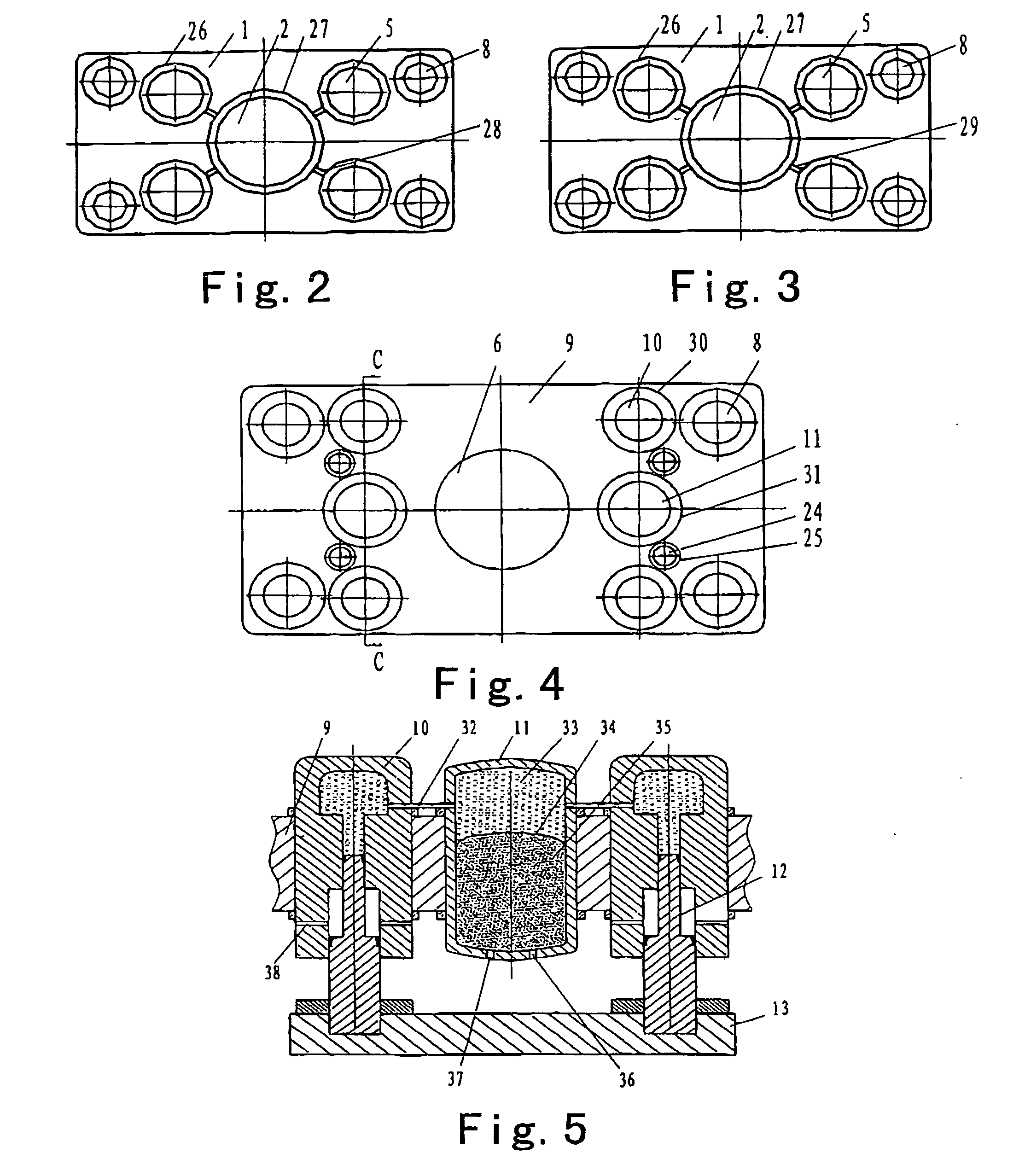

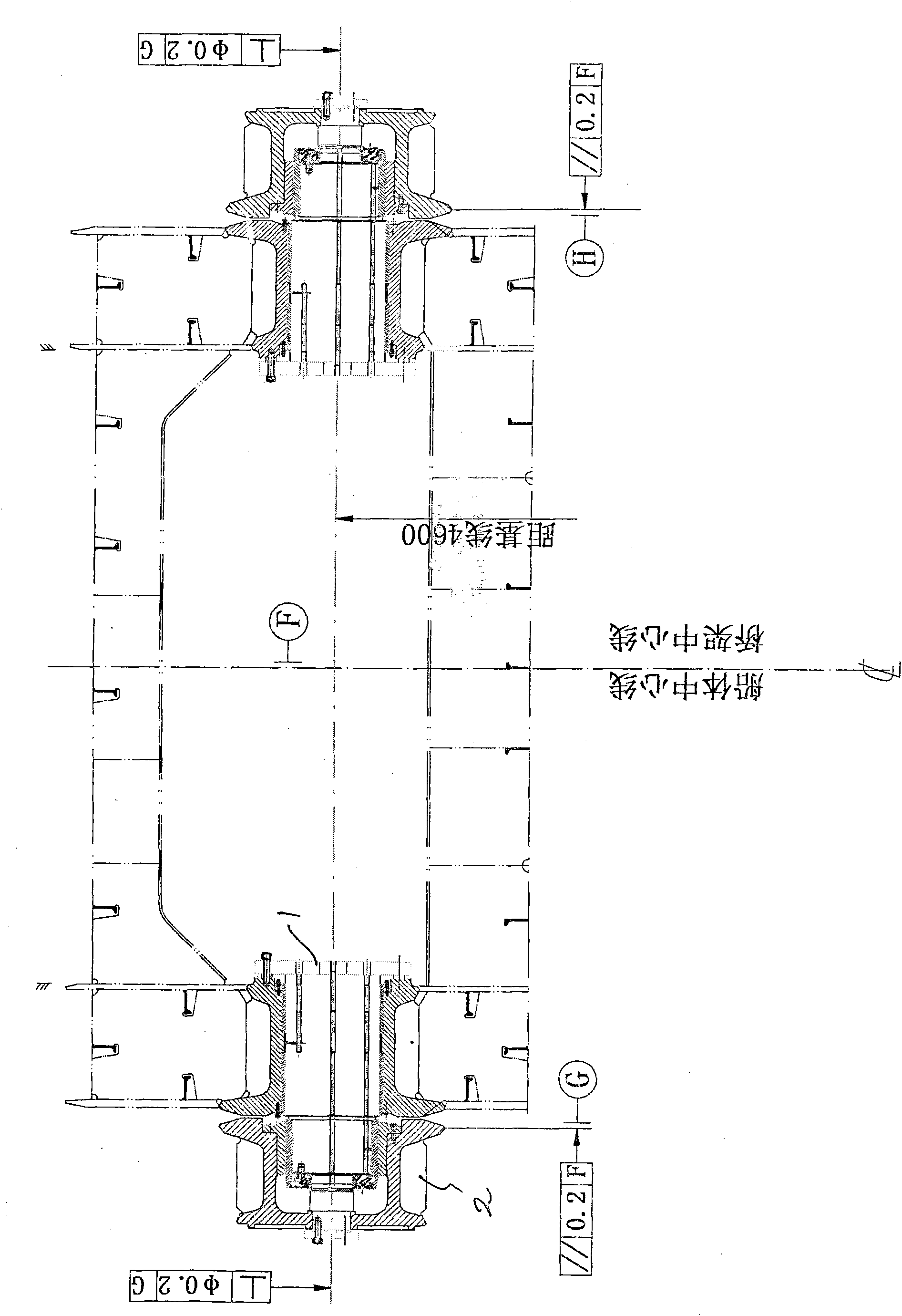

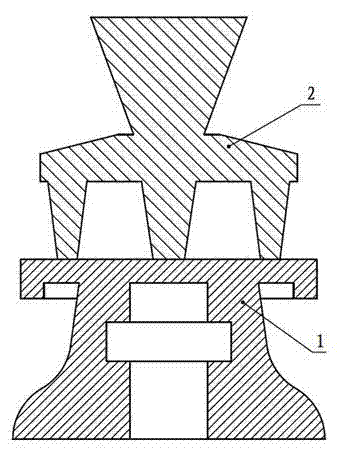

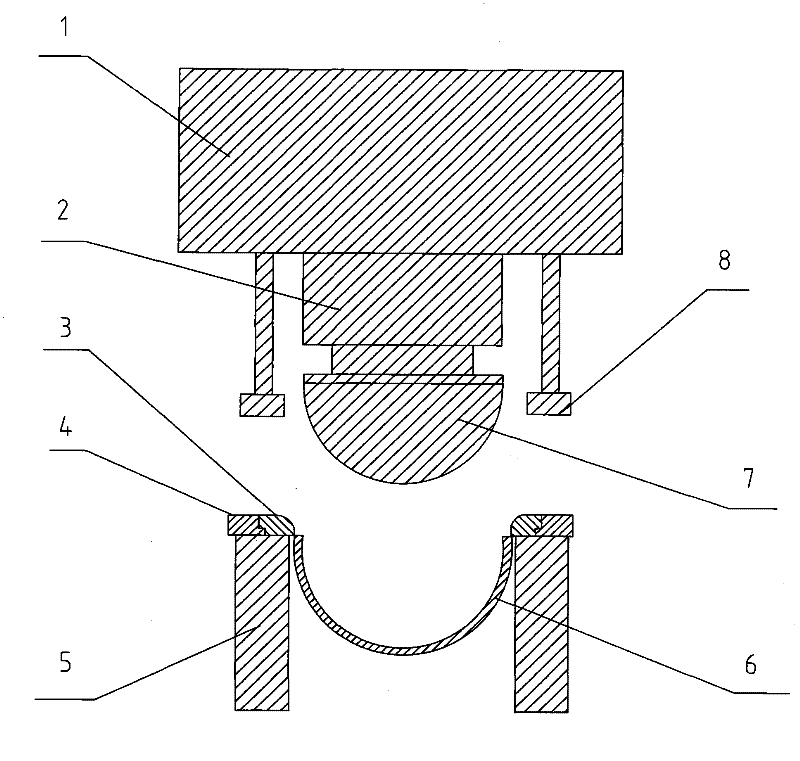

Regulatable hydraulic machine with up and down both double moving

InactiveCN1559792AInnovative designSimple structureForging press drivesPress ramMarine engineeringMaster cylinder

An adjustable hydraulic press with movable upper and lower units is composed of vertical columns, upper transverse beam, primary slide block, the slide block for pressing edge, bench, floating bench, lower transverse beam, the primary and secondary cylinders fixed to upper transverse beam, and a push-up cylinder fixed to lower transverse beam for driving said floating bench.

Owner:JILIN UNIV

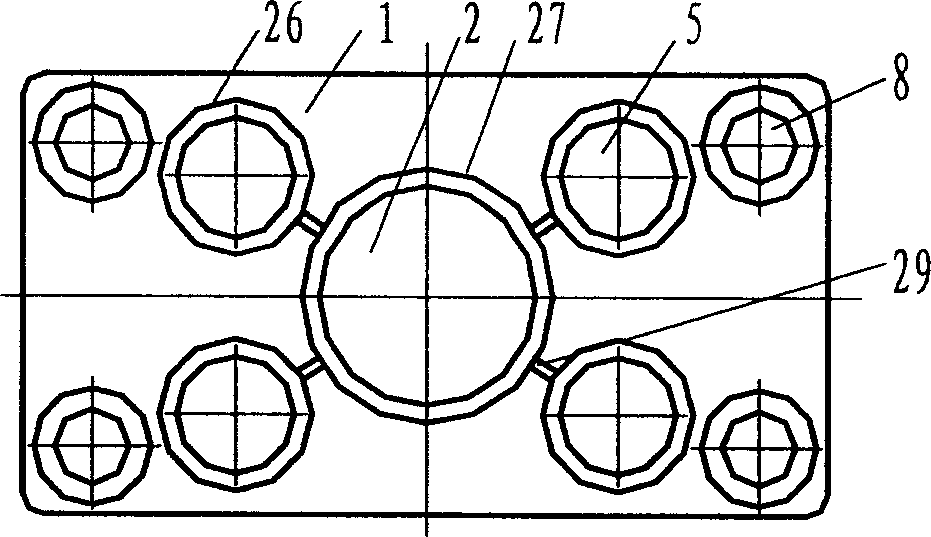

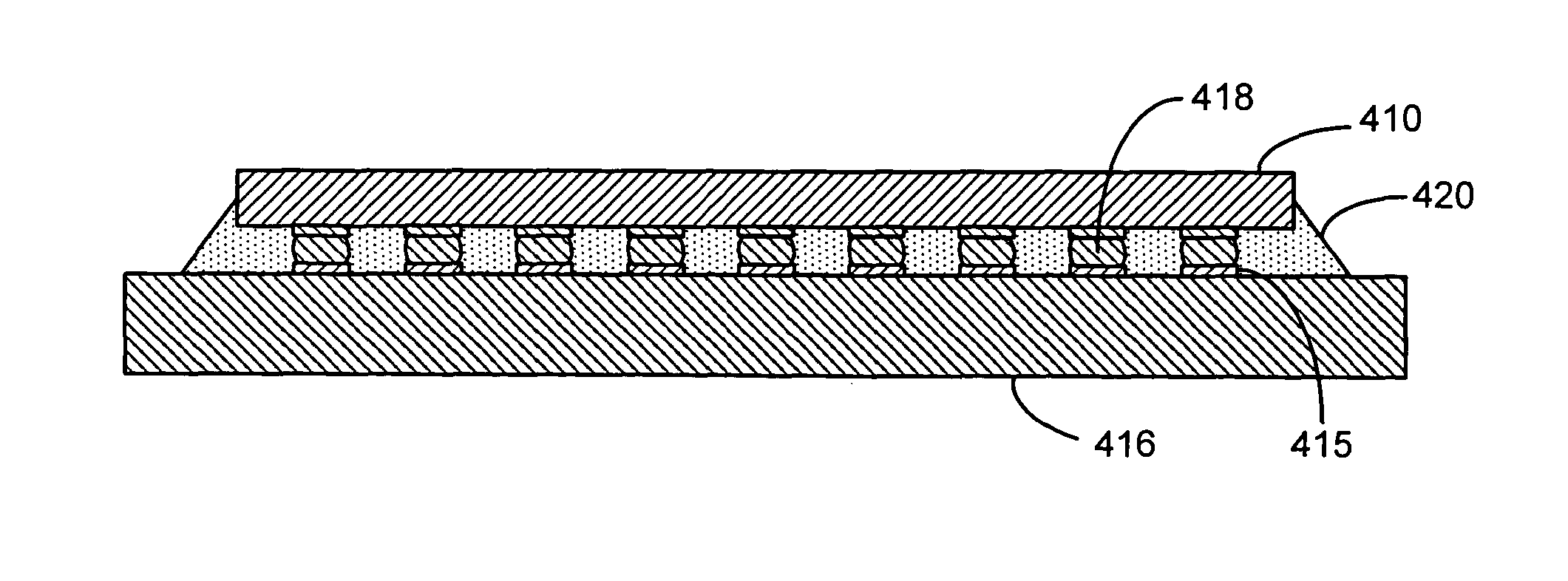

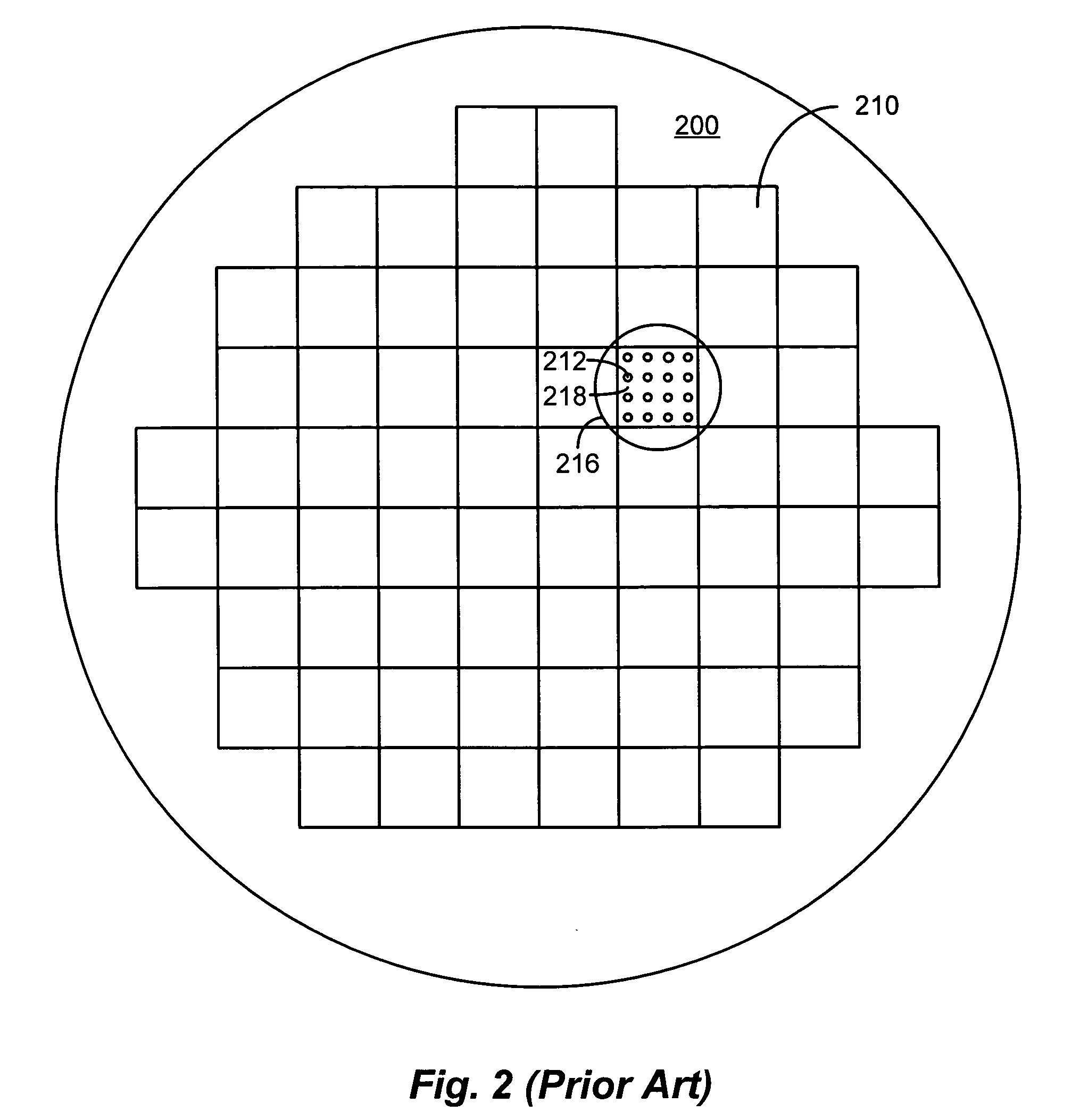

Integrated underfill process for bumped chip assembly

InactiveUS20050028361A1High yieldWeight increasePrinted circuit assemblingSemiconductor/solid-state device detailsEngineeringThermal expansion

An integrated underfilling process for attaching a chip / die having conductive solder bump contacts to a substrate. The process involves B-staging filled underfill on the chip / die, depositing a fluxing unfilled underfill onto the surface of the substrate, mating the chip / die with the B-staged underfill to the substrate and reflowing the assembled chip / substrate. The B-staged filled underfill reduces the coefficient of thermal expansion of the underfill fillet and the fluxing unfilled underfill removes metal oxide from the surface of the solder bump contacts and bond pads to promote the formation of reliable metallurgical joints.

Owner:INDIUM CORPORATION

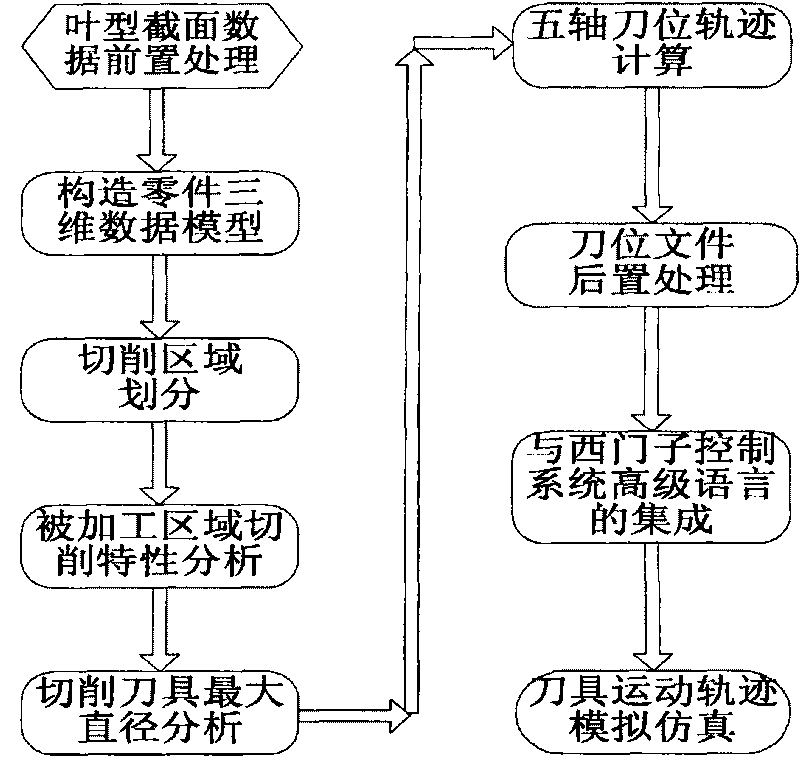

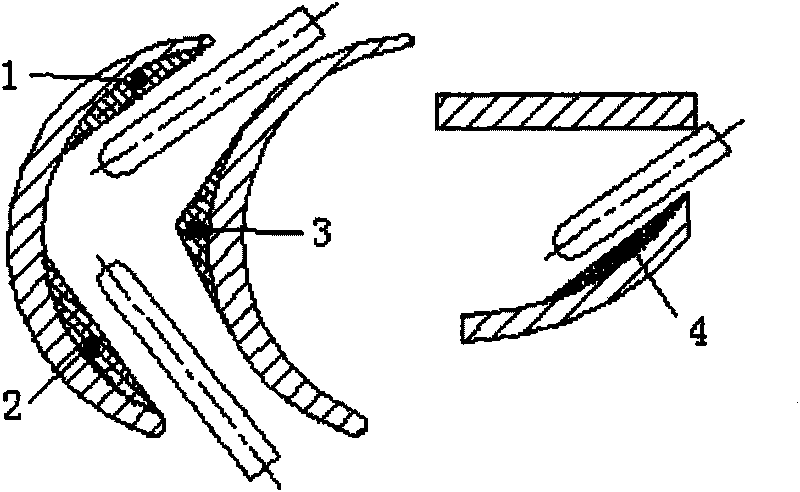

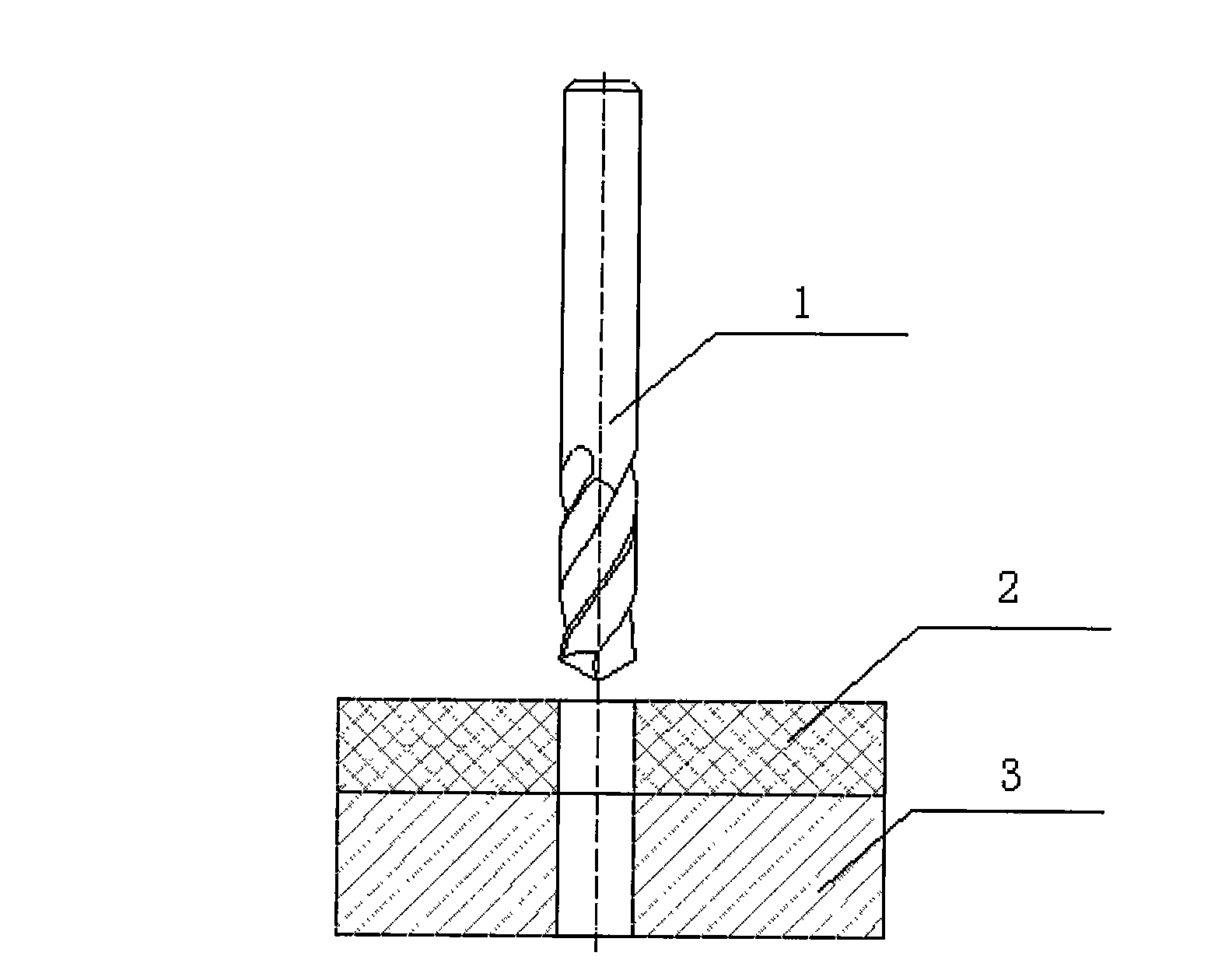

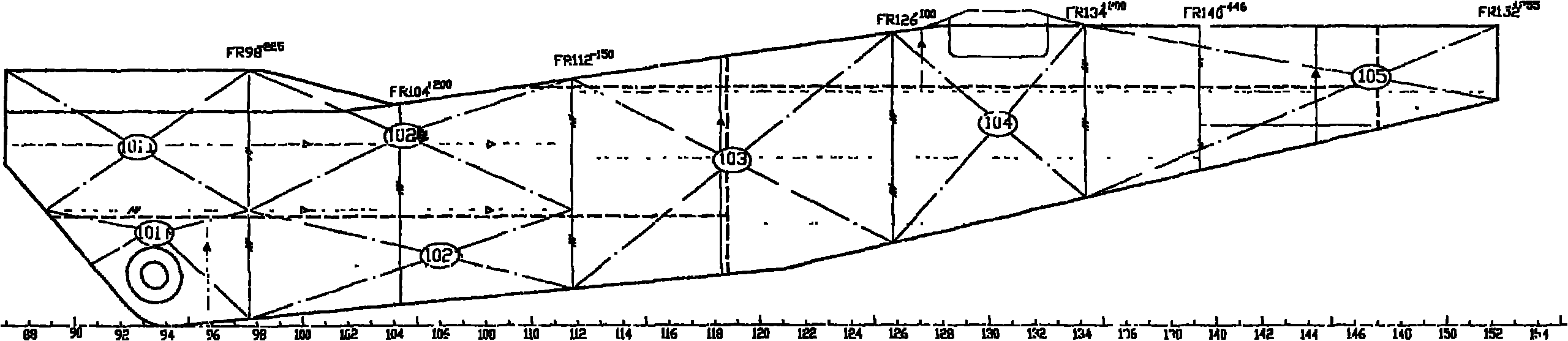

Numerically controlled drilling and milling processing method for runner of blisk of engine

InactiveCN101733618AImprove processing efficiencyShorten the manufacturing cyclePositioning apparatusNumerical controlAngular degreesEngineering

The invention provides a numerically controlled drilling and milling processing method for a runner of a blisk of an engine. The main technical flow before drilling and milling the runner comprises the following steps: lathing each surface of a blank, performing nondestructive testing, lathing inner and outer cavities of the blisk, finely milling a needed periphery and an axial benchmark, drilling and boring an angular datum hole, drilling and milling the runner and inspecting. A part and a fixture are in peripheral seam allowance fit to limit a radial degree of freedom of the part; an end face gland and a central pull bar axially limit an axial degree of freedom of the part; and a precise positioning pin angularly limits an angular degree of freedom of the part. The method has the advantages that: by applying the drilling and milling processing method to a part machining process of the blisk of the engine having the material removing rate of over 90 percent, the method improves the processing efficiency, shortens the manufacturing period of the product, and provides a new technical means for removing a large amount of remainder materials of the blisk; and the processing of a high-temperature alloy, a titanium alloy and other difficult-to-process materials shows that the material is more difficult to process, the removing rate is bigger and the effect is more obvious.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Preparation method of silicon carbide and silicon carbide composite material member

ActiveCN103387405AStrong process matchingShorten the manufacturing cycleCeramic matrix compositeNanotechnology

The invention relates to a preparation method of silicon carbide and silicon carbide composite material member, especially relates to a preparation method of deformed silicon carbide and silicon carbide composite material member, and belongs to the technology field of ceramic matrix composite material. The impregnation phase and the precursor used in the preparation method not only comprise the solid PCS, but also comprise the liquid PCS, which is more cheap, so the technology matching property of the member is stronger, the densification efficiency of the member is improved to some degree, the cost is reduced and the preparation period of the member is shortened. The impregnation phase has little harm to the environment and the operators, and only a general type ventilation device is needed.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Steel used at lower temperature and method for manufacturing same

ActiveCN101545077AIncrease the content of acid-soluble AlsEliminate Recycling DifficultiesMetal rolling arrangementsSheet steelChemical composition

The invention discloses a steel used at a lower temperature and a method for manufacturing the same. The steel comprises the following chemical components by weight percentage: 0.060 to 0.090 percent of C, less than or equal to 0.20 percent of Si, 1.10 to 1.50 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.003 percent of S, 0.040 to 0.070 percent of Als, 0.05 to 0.45 percent of Cu, 0.05 to 0.35 percent of Ni, 0.05 to 0.30 percent of Cr, 0.007 to 0.011 percent of Ti, 0.007 to 0.020 percent of Nb, less than or equal to 0.0040 percent of N, 0.001 to 0.011 percent of Ca, and the balance of Fe and inevitable impurities. The manufacturing process comprises of the steps: making the steel plate obtain excellent low-temperature toughness and making the steel plate bear the big line energy welding. The steel and the method can be widely applied to petroleum natural gas pipelines, low-temperature gas tank bodies LPG, low temperature steel plates of LNG.

Owner:BAOSHAN IRON & STEEL CO LTD

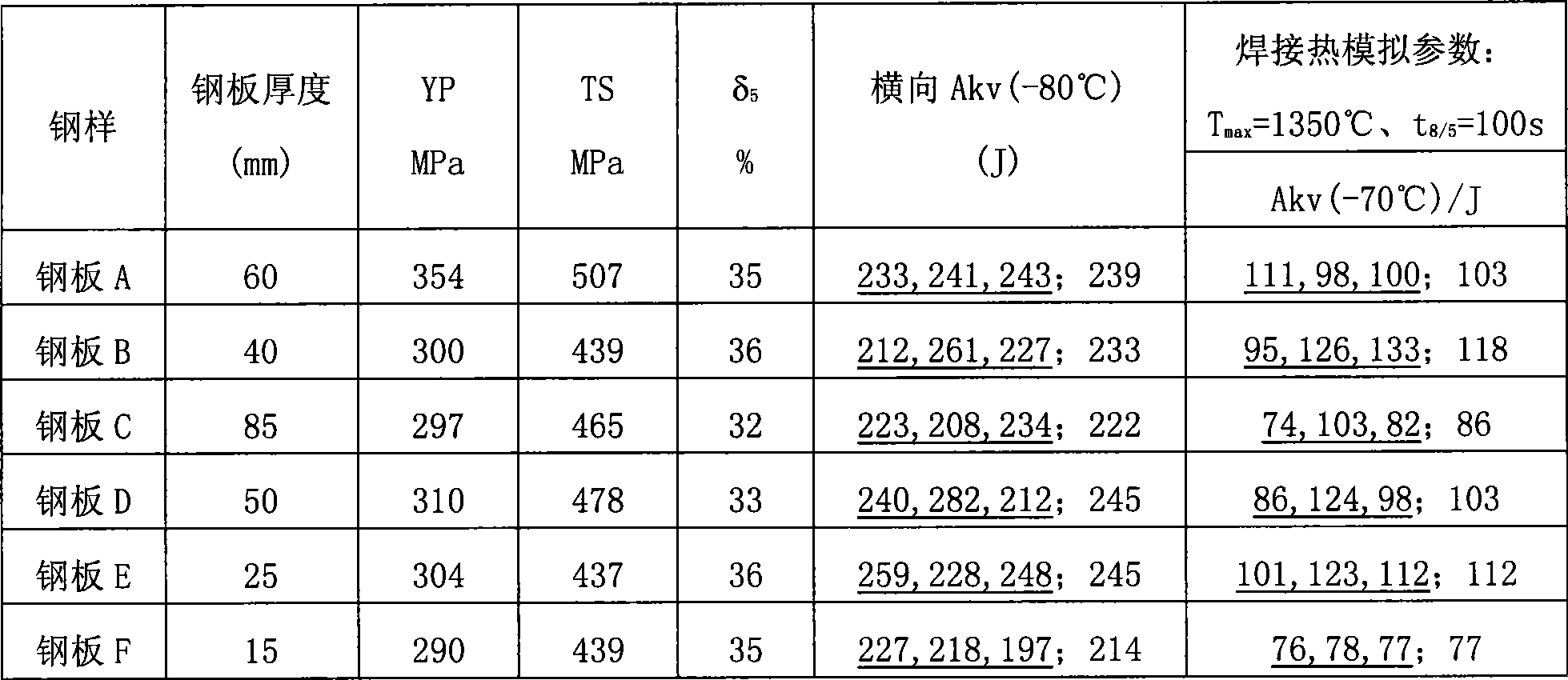

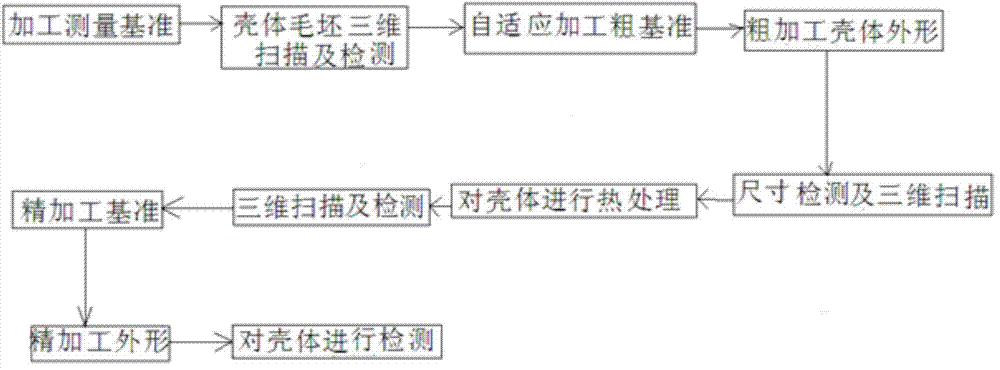

Machining method for large cast titanium alloy diamond-shaped cabin shell

ActiveCN103753124AQuality assuranceControl Wall Thickness UniformityAircraft componentsMachining deformationTitanium alloy

The invention discloses a machining method for a large cast titanium alloy diamond-shaped cabin shell and belongs to the machining method for a complex piece. The machining method for the large cast titanium alloy diamond-shaped cabin shell includes the following steps: step 1, machining a base and measuring; step 2, carrying out three-dimensional scanning on a blank and detecting; step 3, carrying out self-adaption machining on a rough base; step 4, roughly machining the shape; step 5, detecting the size and performing three-dimensional scanning; step 6, performing heat treatment; step 7, performing three-dimensional scanning and detecting; step 8, finishing the base; step 9, finishing the shape; step 10, detecting the shell. The machining method for the large cast titanium alloy diamond-shaped cabin shell is capable of comprehensively analyzing the cast size precision and allowance, quickly determining the machining base, controlling the wall thickness uniformity and guaranteeing the shell quality, has small machining deformation, and enables the manufacturing cycle to be shortened.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

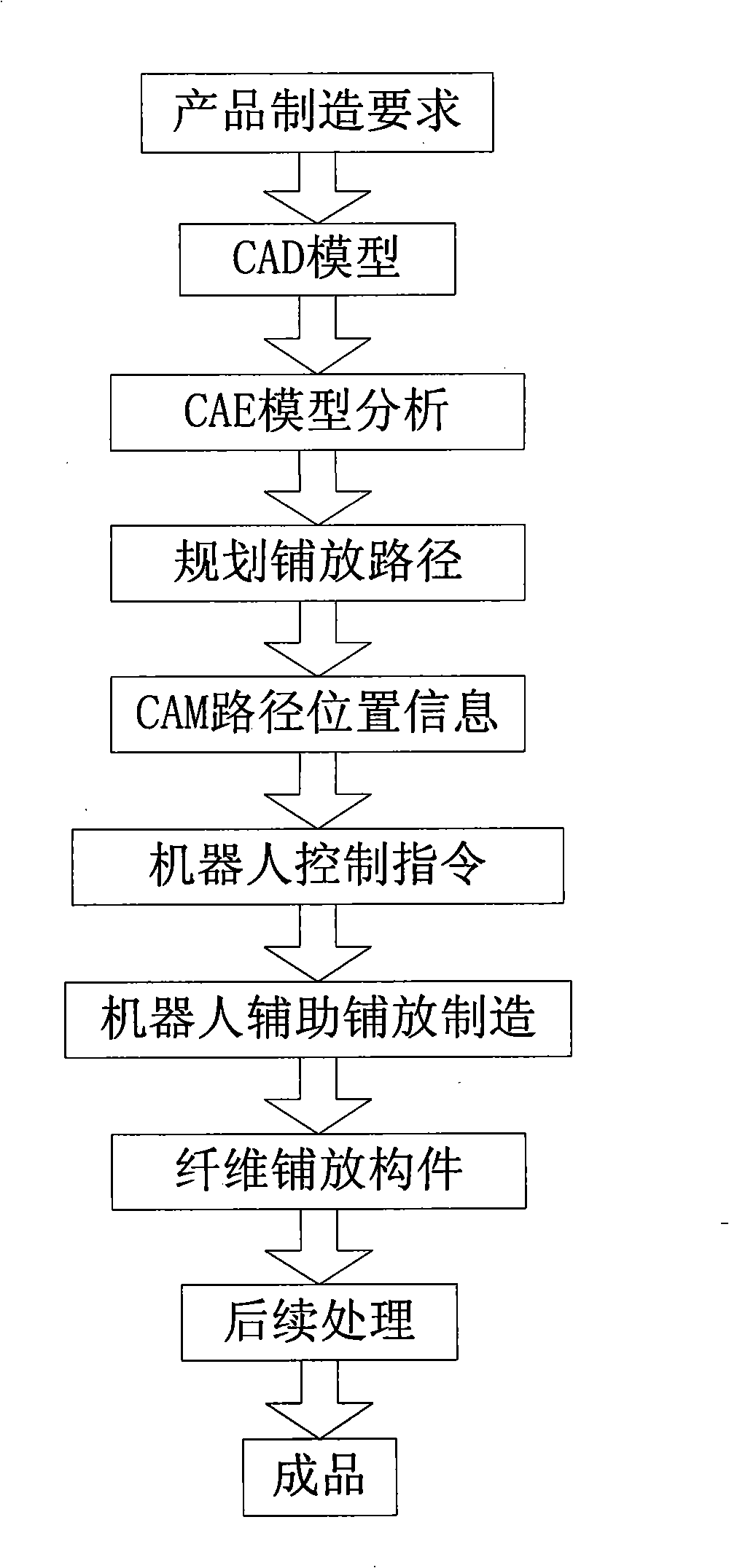

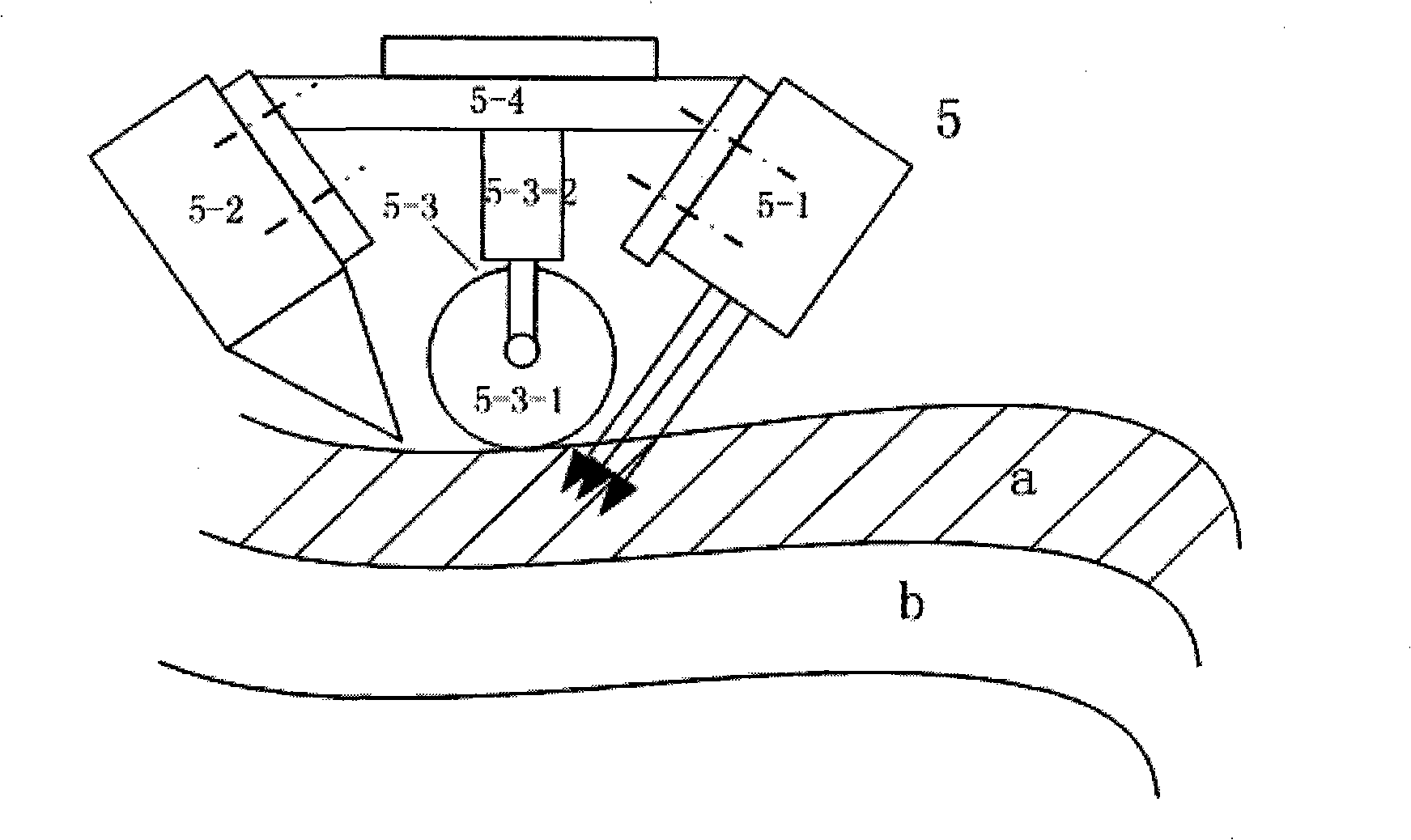

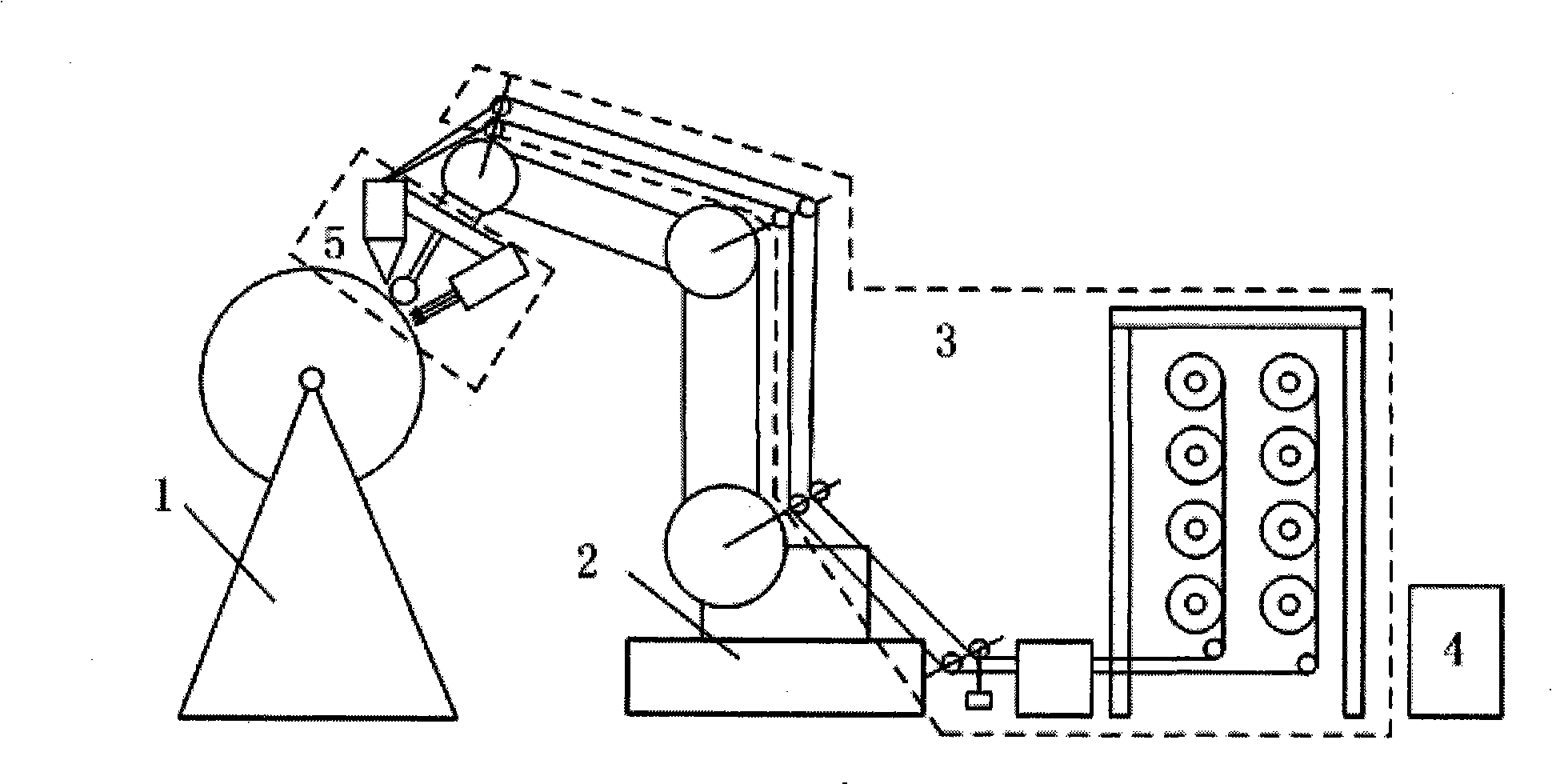

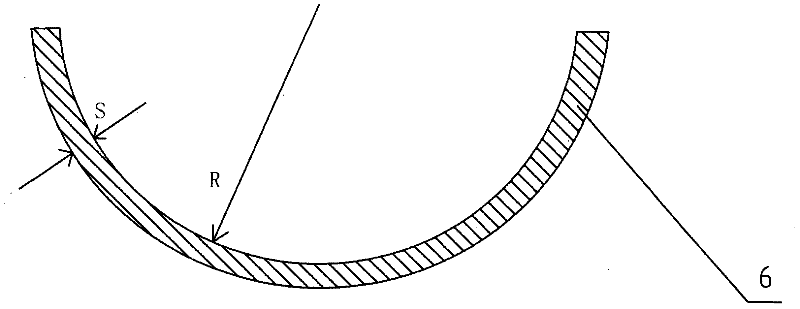

In-situ consolidation fibre laying method and device for producing resin-based compound material component

InactiveCN101254652ASimple manufacturing processShorten the manufacturing cycleCrazingThermal deformation

The invention discloses a method and a device for manufacturing resin-based composite material component by using fiber placement technology. By adopting fiber placement technology, the method and the device can place a fiber placement layer on the surface of a core die by a compaction mechanism to solve the problem of conventional winding equipment that is incapable of manufacturing surface component with negative curvature and non-gyrorotor component. Meanwhile, in-situ instantaneous stratified radiation curing is adopted to eliminate the influence of a tensile force in the fiber placement layer on the shape of the product and to solve the problems and disadvantages of large thermal deformation and easy generation of cracks due to autoclave curing treatment, the restriction of the autoclave volume on the component size, high production cost, and long production period. Based on industrial robot as the manufacture body, the device can improve the problems of prior placement equipment such as the deficiency of the flexibility in manufacturing more complex surface and complex structure.

Owner:XI AN JIAOTONG UNIV

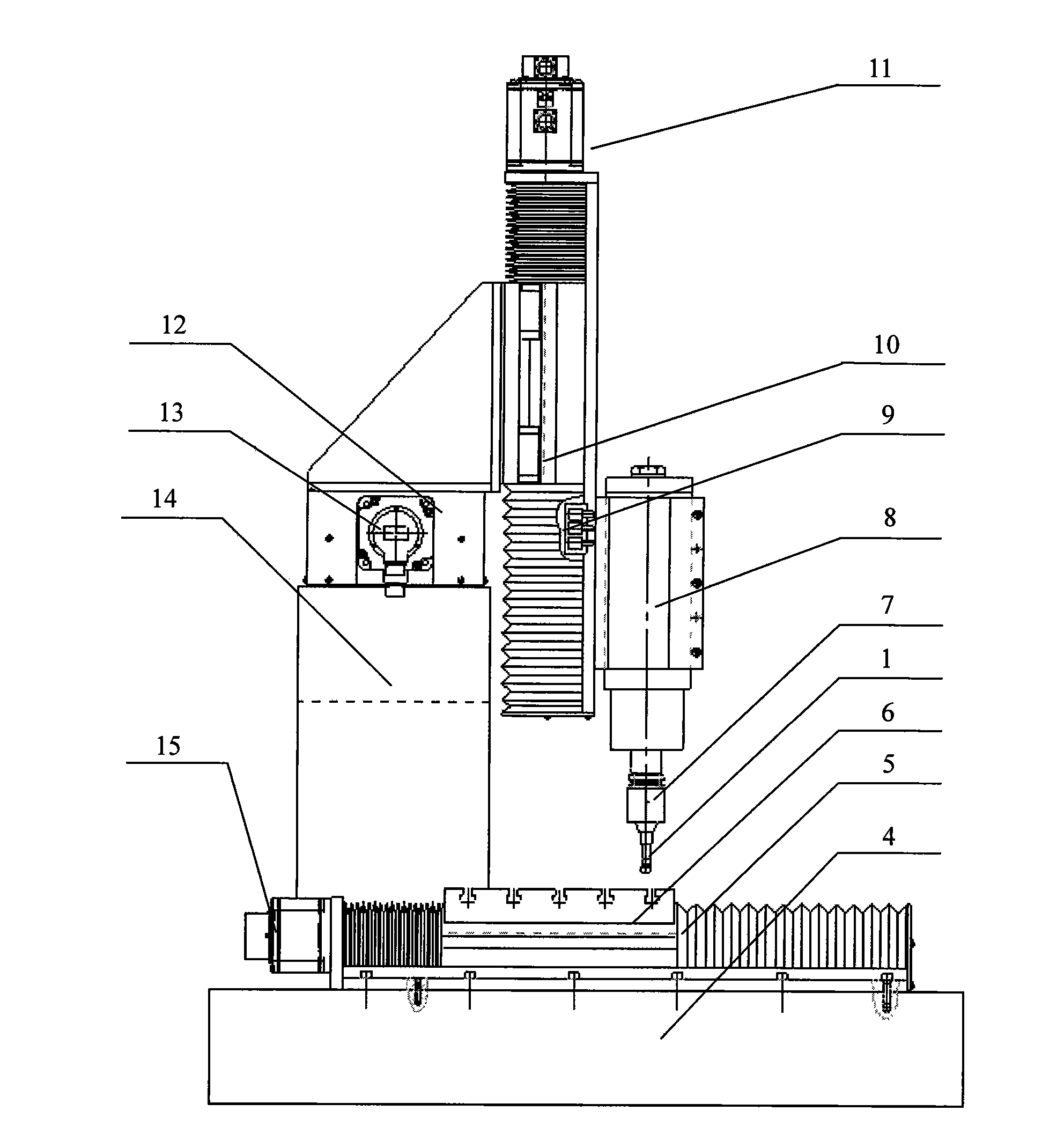

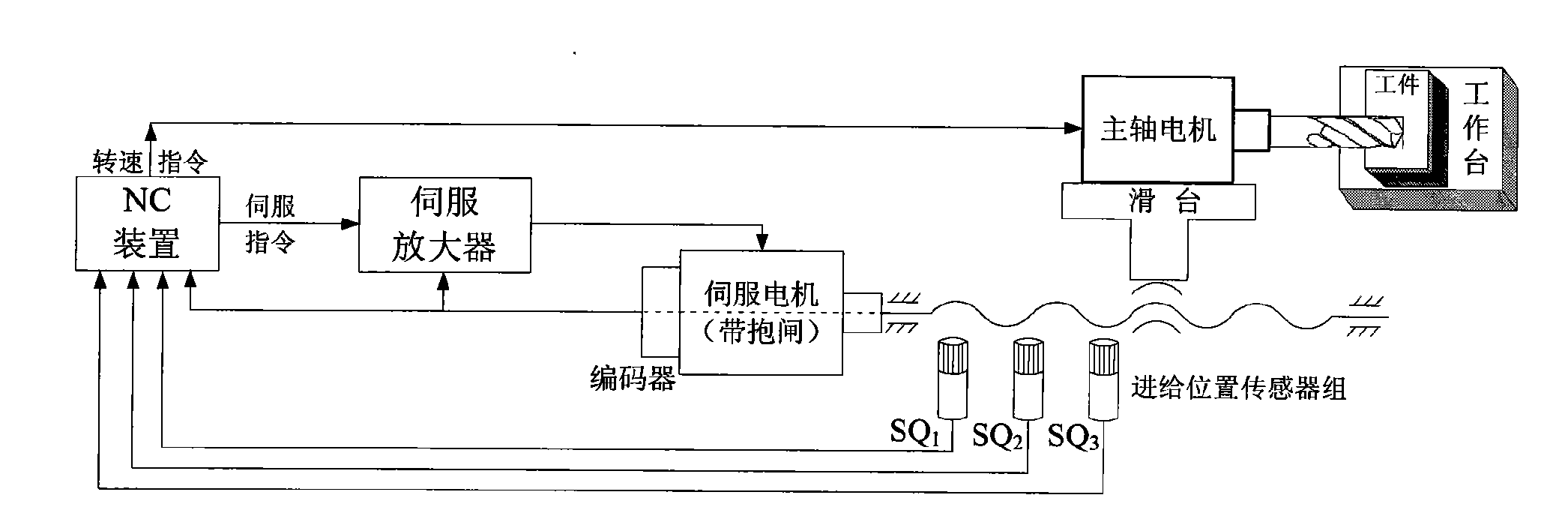

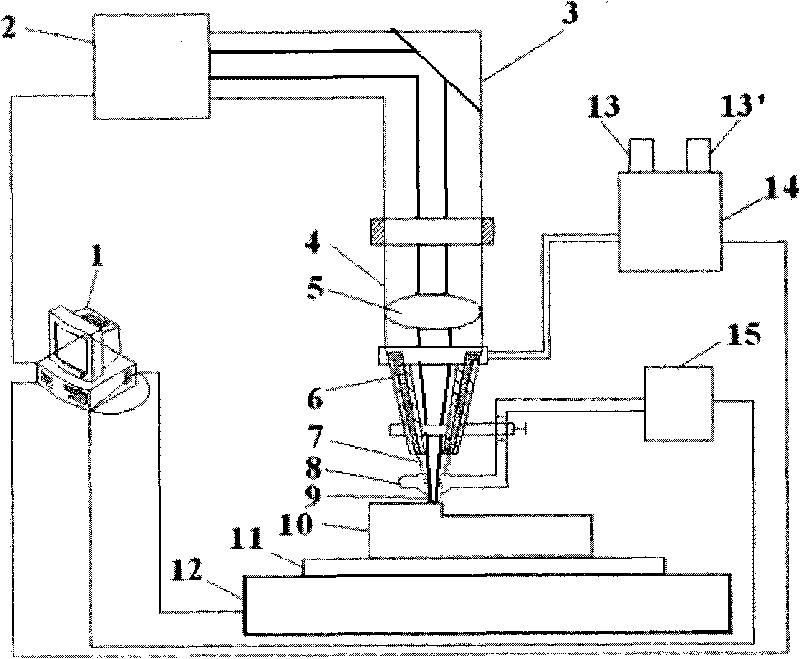

Method and device of disposing holes on carbon fiber composite material and meal material which are overlapped

InactiveCN101670448AHigh degree of automationGuaranteed stabilityAutomatic control devicesTransportation and packagingManufacturing technologyControl manner

The invention relates to a method and device of disposing high-quality holes on carbon fiber composite material and meal material which are overlapped, belonging to the field of the mechanical processing and manufacturing technology. The method of disposing high-quality holes on the carbon fiber composite material and the meal material which are overlapped is characterized in that in the process of disposing holes on the carbon fiber composite material and the meal material which are overlapped by a device of disposing holes, such as a polycrystalline diamond (PCD), a coating, a cemented carbide bit and a diamond grinding rod, the rotating speed and the feeding speed of a cutter are automatically changed according to the materials on which holes are to be disposed by the hardware triggering or software numerical-control programming control mode of a feeding position sensor set so that the cutter can be in the optical process parameter state. The device of disposing high-quality holes on the carbon fiber composite material and the meal material which are overlapped is characterized by comprising a body, the cutter the handle of the cutter, an electric main shaft, the feeding position sensor set, a vertical feeding sliding-platform, a main shaft variable-frequency speed-regulating system and a hole disposing device numerical control system. The invention realizes the adaptive continuous processing, obviously improves the quality and the processing efficiency of holes disposed integrally on different overlapped materials and lowers the production cost.

Owner:DALIAN UNIV OF TECH

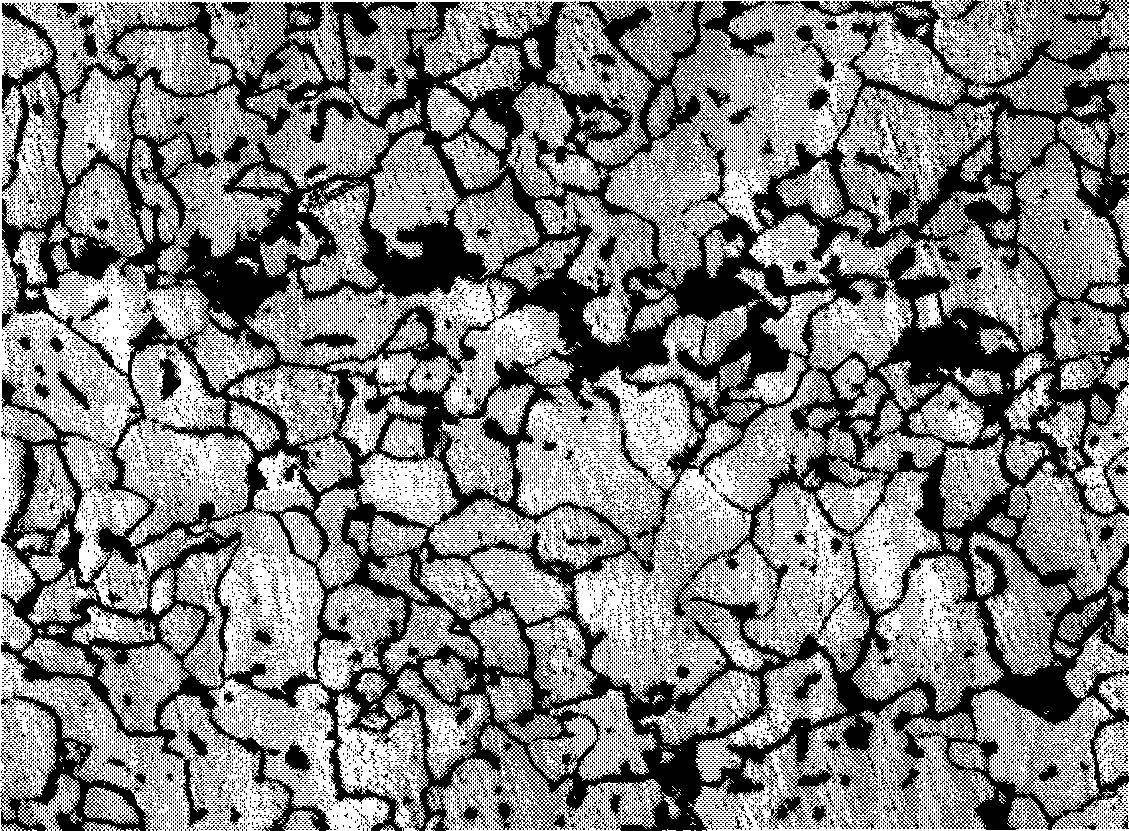

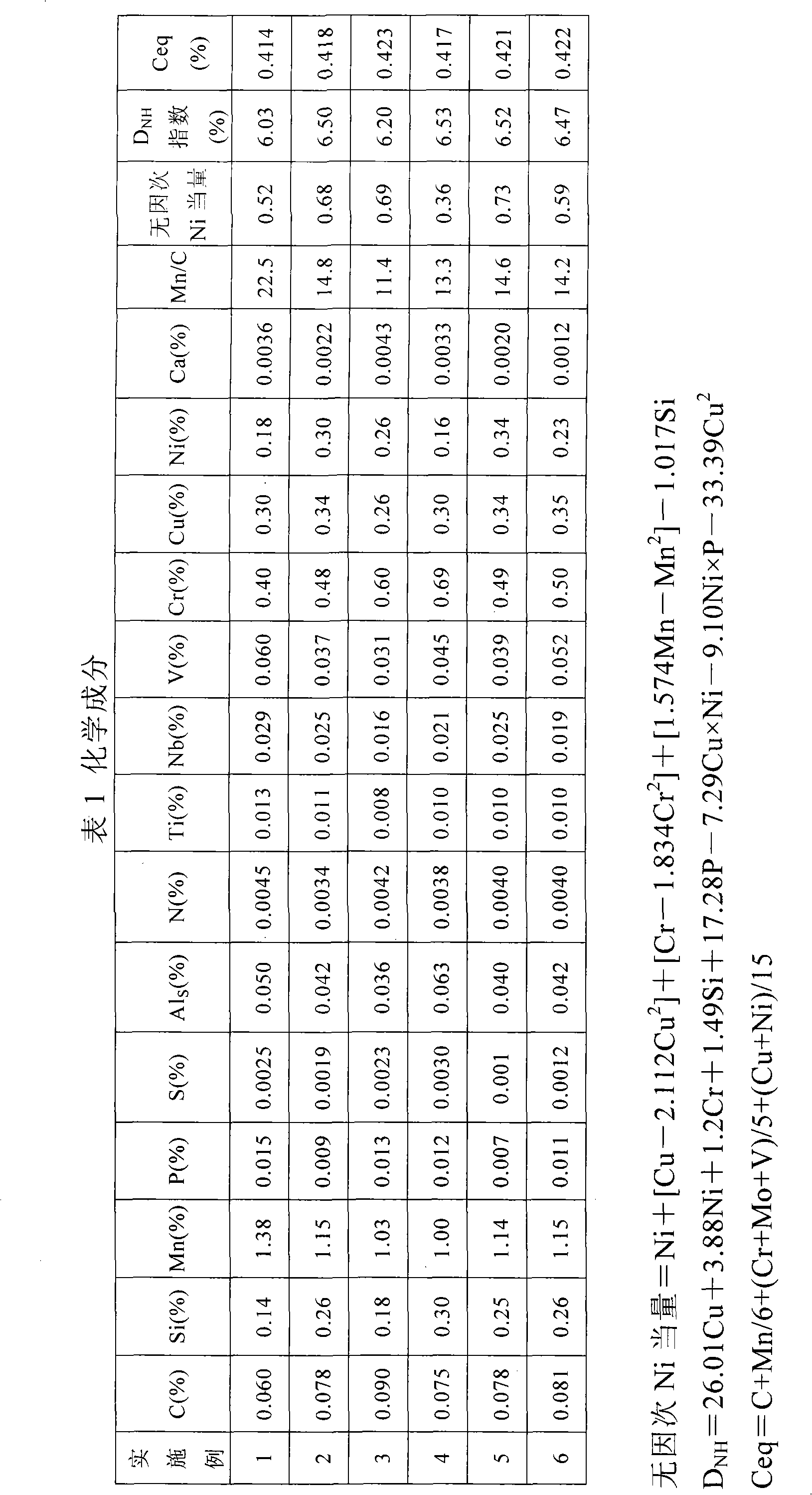

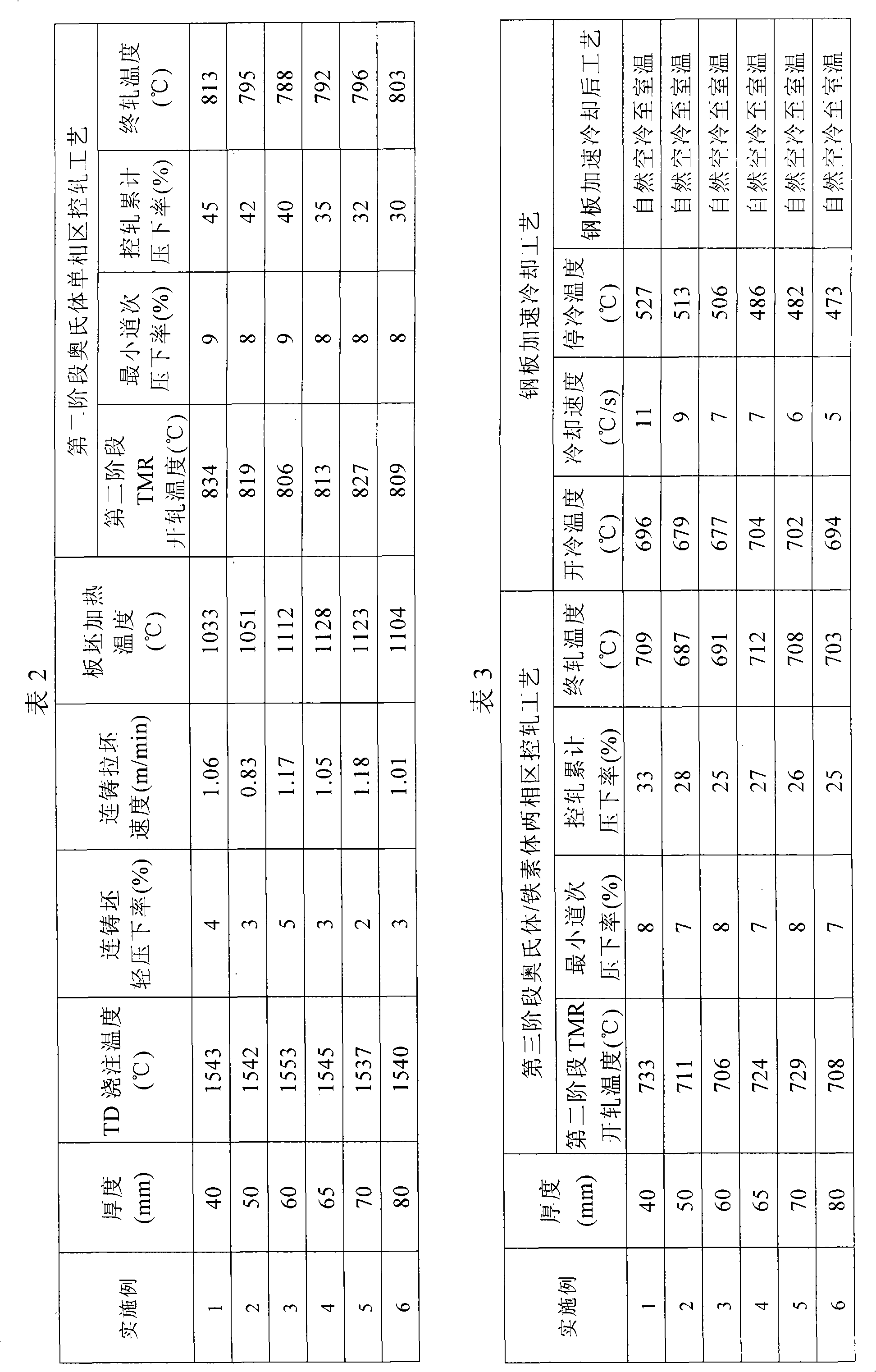

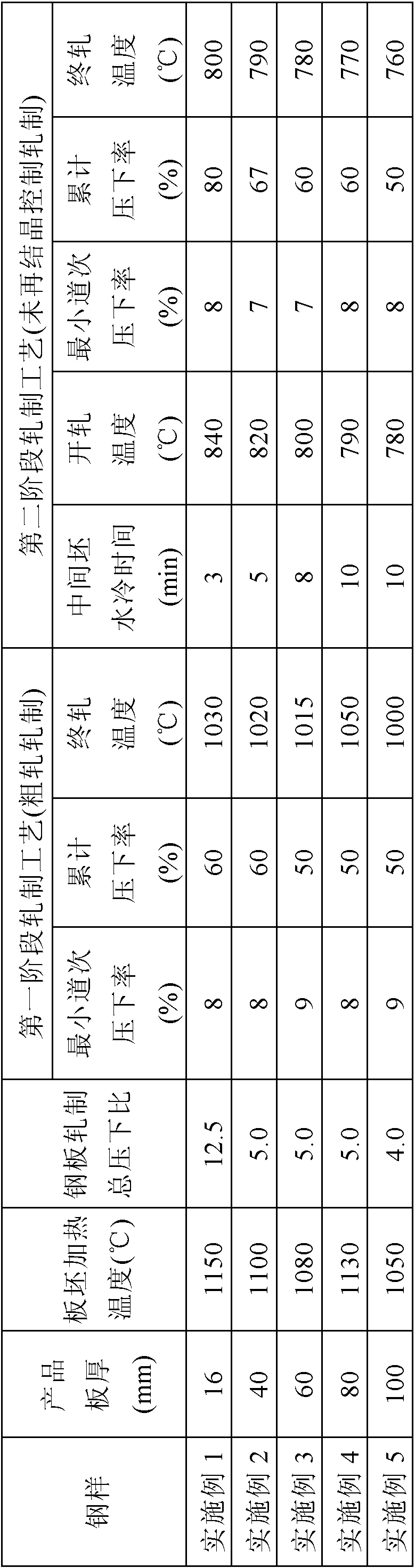

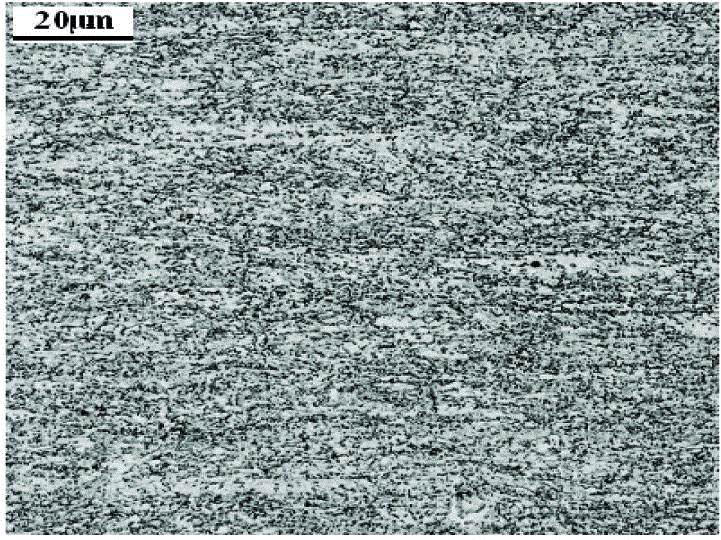

High-performance weather-proof building structural steel and manufacturing method thereof

The invention relates to high-performance weather-proof building structural steel and a manufacturing method thereof. The composition system of low C-medium Mn-low N-micro Nb alloying-ultramicro Ti processing low content alloy weather-proof steel is taken as foundation, the acid solution Als content in the steel is increased properly, and the range of the acid solution Als content is controlled; the zero dimension Ni equivalent weight is controlled to be more than or equal to 0.35, the Ceq is less than or equal to 0.425%, and the Mn / C is more than or equal to 10; the weather-proof property index DNH is more than or equal to 6.0%; and the Ca is processed, the Ca / S is controlled within the range of 1.0-3.0, and Ca*S 0.28 is less than or equal to 1.0*10<-3>. By adopting a TMCP technique, a weather-proof steel plate with good toughness, strong plasticity matching, low yield ratio, atmosphere corrosion resistance, excellent weldability and anti-fatigue performance can be obtained, is especially suitable for non-coating high-rise building structure and bridge structure, and can realize stable batch industrialized production with low cost.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

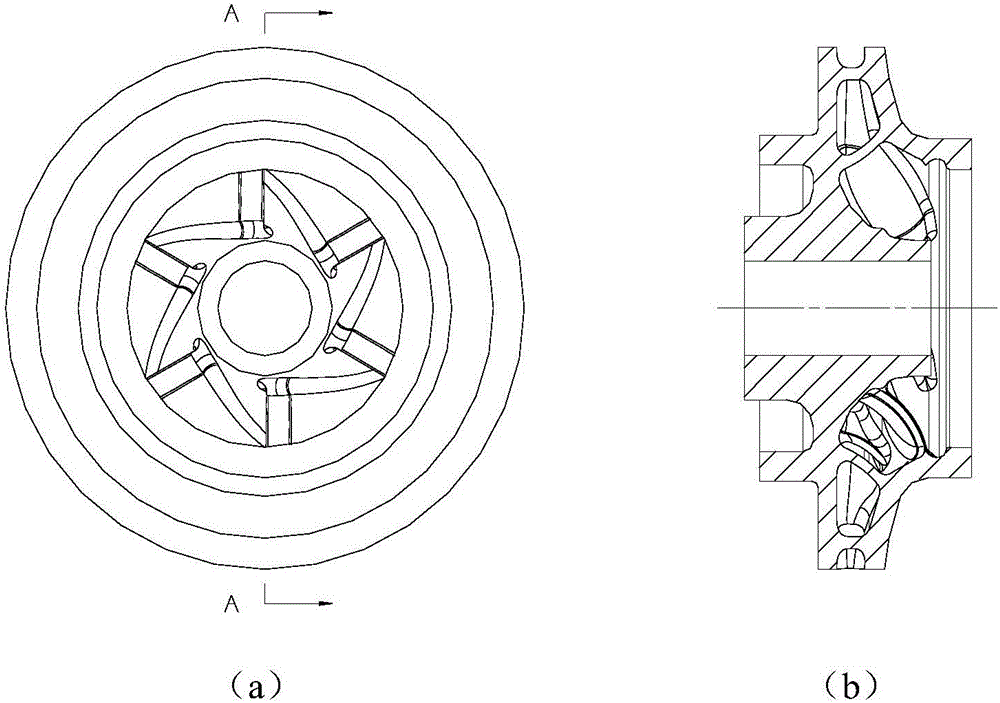

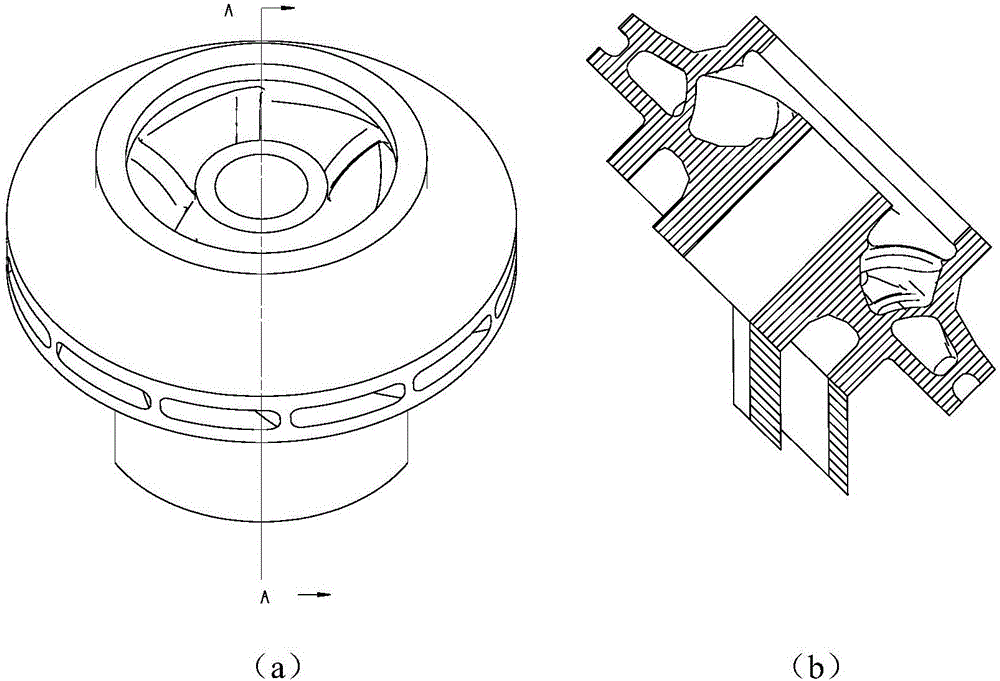

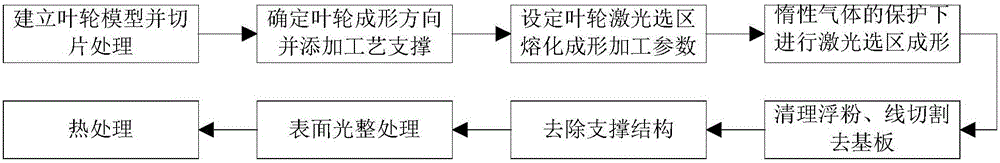

Integral manufacturing method of S-04/S-08 high-strength stainless steel three-dimensional flow shrouded impeller

ActiveCN106077643AShorten the manufacturing cycleCompact structureAdditive manufacturing apparatusEngine manufactureMaterials scienceAustenitic stainless steel

The invention provides an integral manufacturing method of an S-04 / S-08 high-strength stainless steel three-dimensional flow shrouded impeller. The integral manufacturing method comprises the steps of firstly, establishing an impeller three-dimensional model, and carrying out slicing treatment; determining the forming direction and support adding positions according to structural characteristics of the impeller; setting parameters of a laser selective melting forming processing technology according to characteristics of a high-strength stainless steel material; forming under protection of an inert gas; after forming, cleaning floating powder, removing a base plate through linear cutting, and removing supports; and finally, carrying out follow-up treatment such as surface treatment and thermal treatment on the impeller. According to the integral manufacturing method, complex cutters or fixtures do not need to be designed, materials can be directly added for part manufacturing only through the three-dimensional model of the impeller, the manufacturing cycle is greatly shortened, and the integral manufacturing method is applicable to trial manufacturing and middle and small-batch production in the development stage.

Owner:XIAN SPACE ENGINE CO LTD

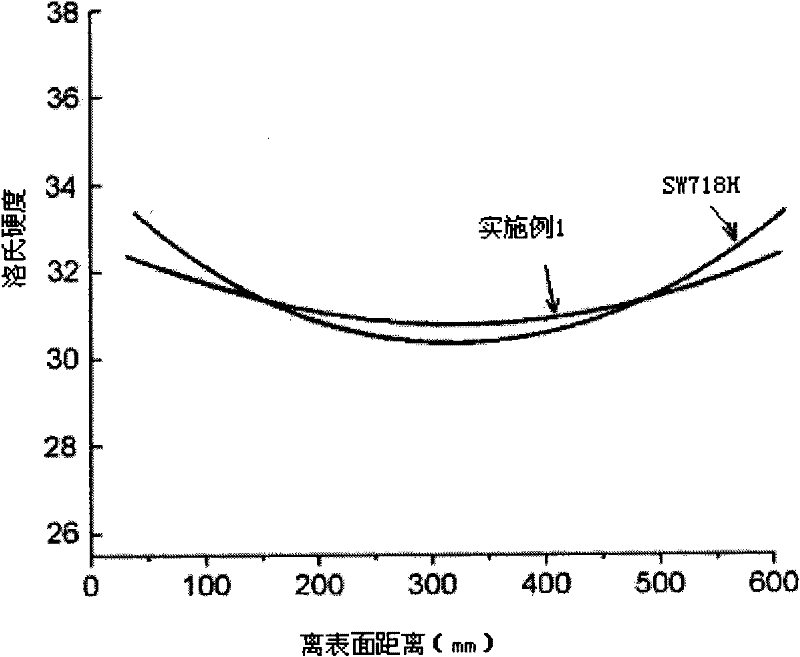

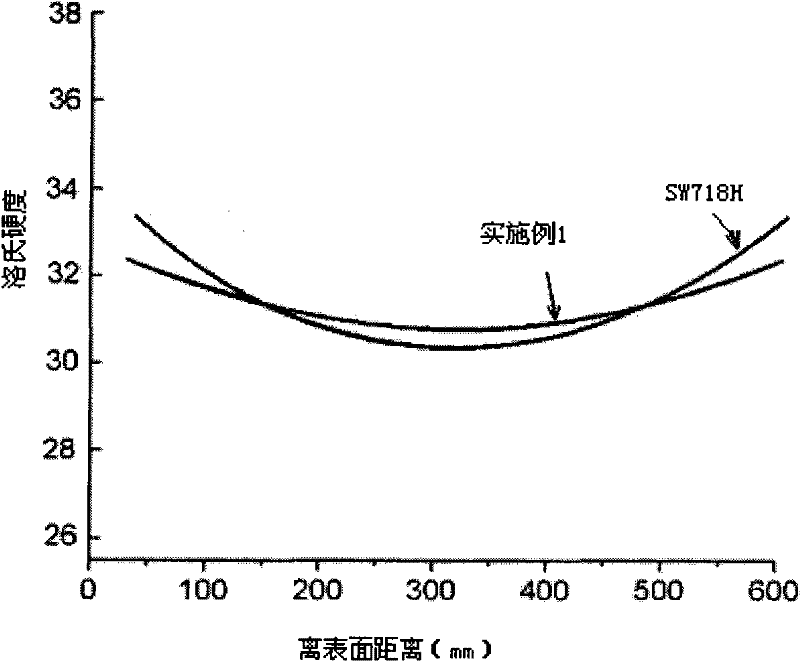

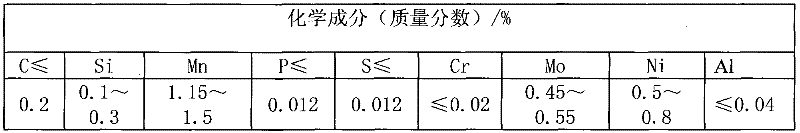

A kind of plastic mold steel and its manufacturing method

The invention discloses a plastic mold steel which comprises the following chemical components in percentage by weight: 0.25-0.29% of C, 1.30-1.50% of Mn, 0.40-0.60% of Si, 1.20-1.50% of Cr, 0.40-0.50% of Mo, 0.02-0.05% of Nb, less than or equal to 0.15% of Ni, less than or equal to 0.15% of Cu, less than or equal to 0.020% of P, less than or equal to 0.015% of S, less than or equal to 0.012% of N and the balance of iron and inevitable impurities. In the manufacture method of the plastic mold steel, a quenching and tempering heat treatment process is not used, and direct air cooling after forging is carried out, thus prehardened plastic mold steel with thickness above 600 mm and uniform hardness from core to surface is manufactured. According to the plastic mold steel disclosed by the invention, the limit that the existing non-quenched and tempered mold steel has thickness smaller than 400 mm is overcome, and the requirements of mold industries on low-cost high-quality large-sized prehardened plastic mold steel are reached.

Owner:宝武特种冶金有限公司

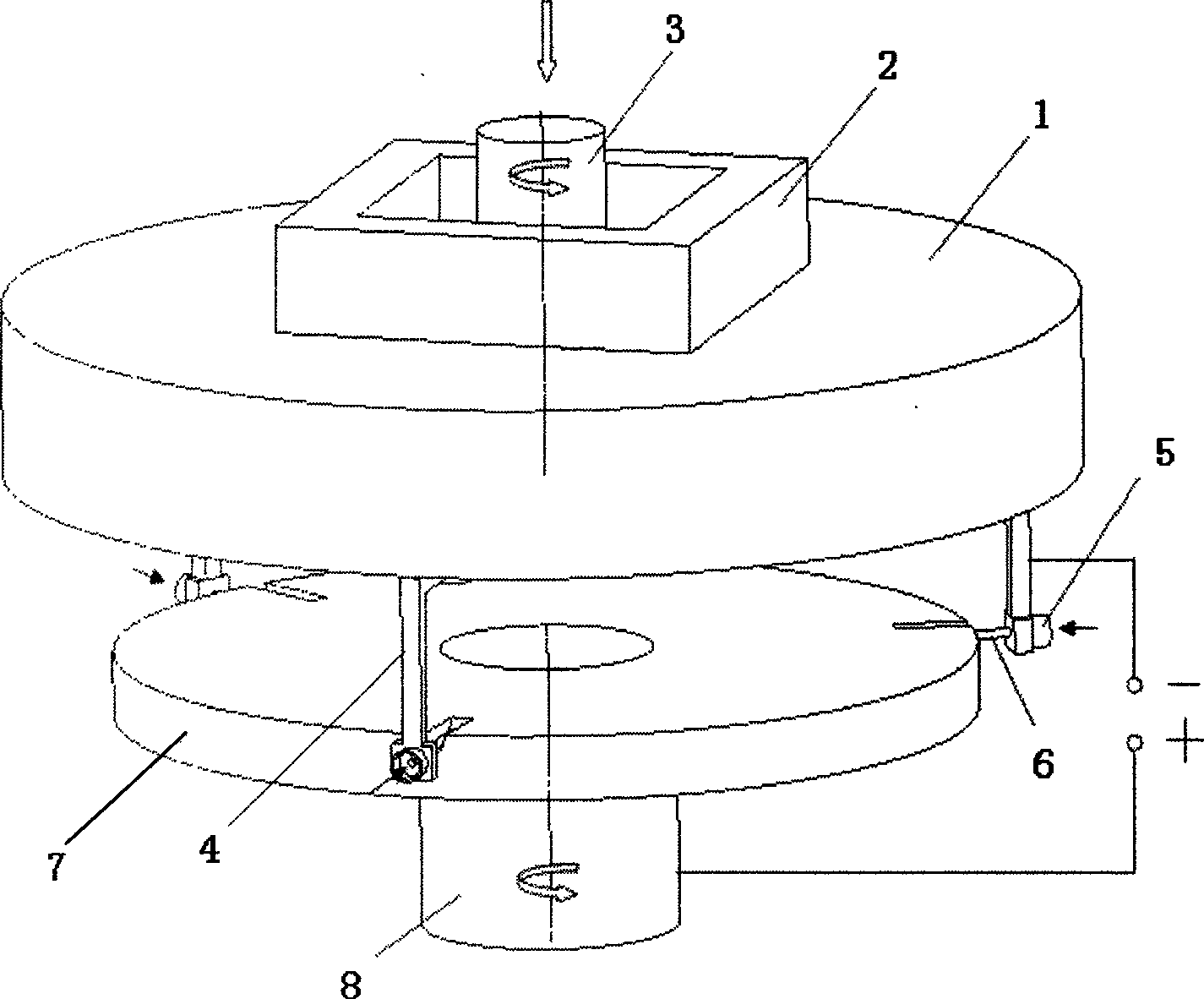

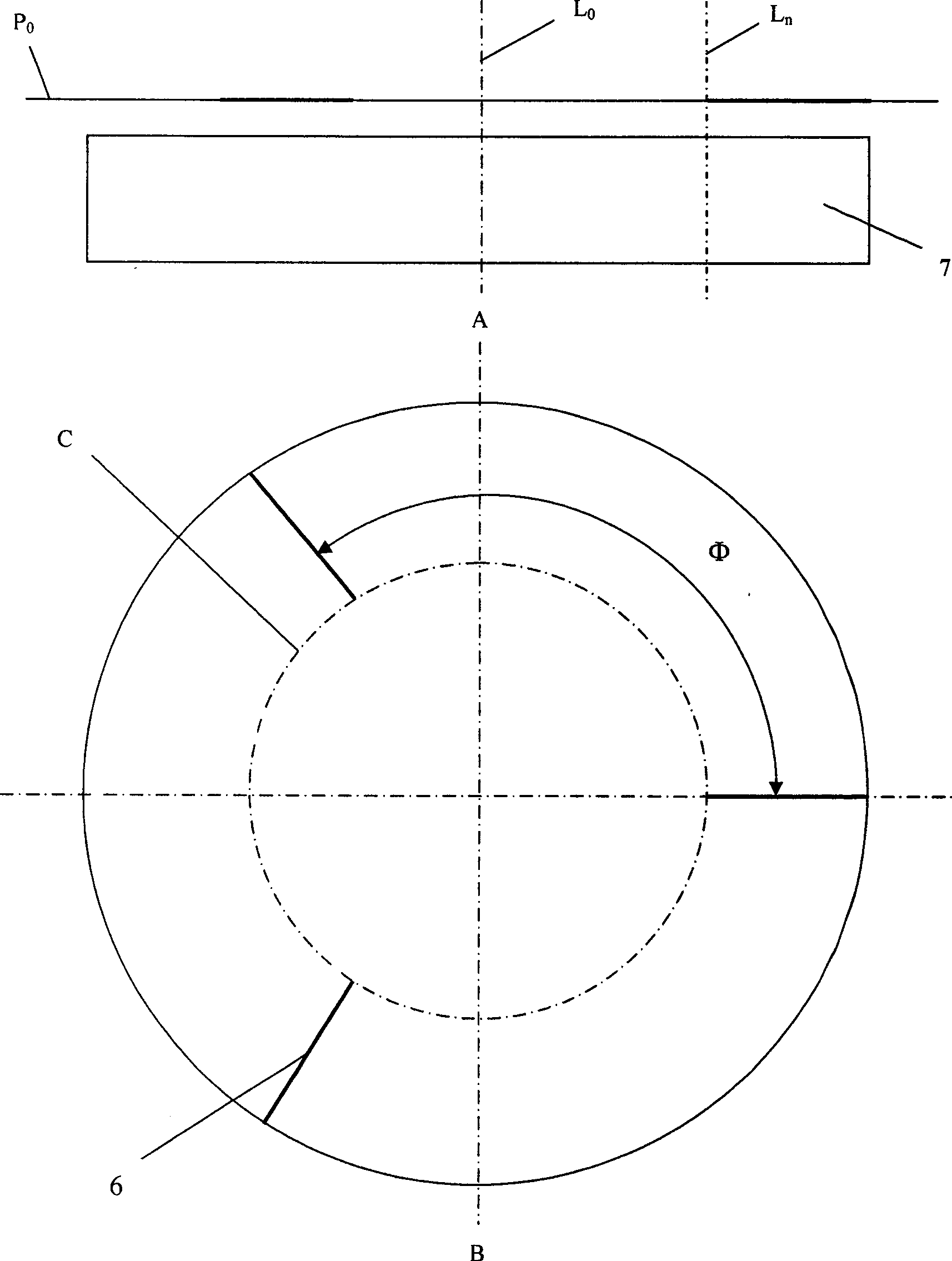

Adjustable Hydraulic Press With Both Upper And Lower Double Action

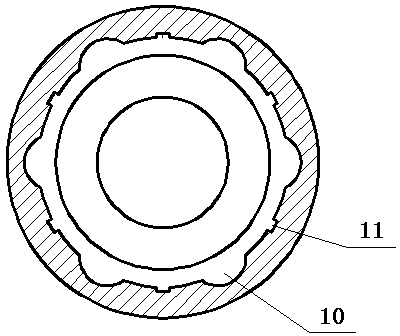

ActiveUS20080098908A1Innovative designSimple structureShaping toolsForging/hammering/pressing machinesMetal formingGear wheel

The present invention discloses an adjustable hydraulic press with both upper and lower double action, specially suitable for the cylindrical gear formed by stamping or expanding, closed forging and the metal cold forming or metal hot forming of punching, finishing, flanging and drawing of sheet materials. The press comprises four columns, an upper beam, a main slide block, a hold down slide block, a fixing worktable, a floating worktable and a lower beam. The hydraulic chamber of master cylinder fixed in the upper beam communicates to the hydraulic chamber of the auxiliary cylinder, the plunger of master cylinder is connected to the main slide block and drives it. The hydraulic chamber of gas-liquid power accumulator fixed in the main slide block communicates to the hydraulic chamber of hold down cylinder, the plunger of hold down cylinder is connected to the hold down slide block and drives it. The plunger of ejecting cylinder fixed in the lower beam is connected to the floating worktable and drives it. The hydraulic press of the invention simplifies the hydraulic system of the existing hydraulic, improves utilization rate of energy, production efficiency and working accuracy of workpiece.

Owner:JILIN UNIV

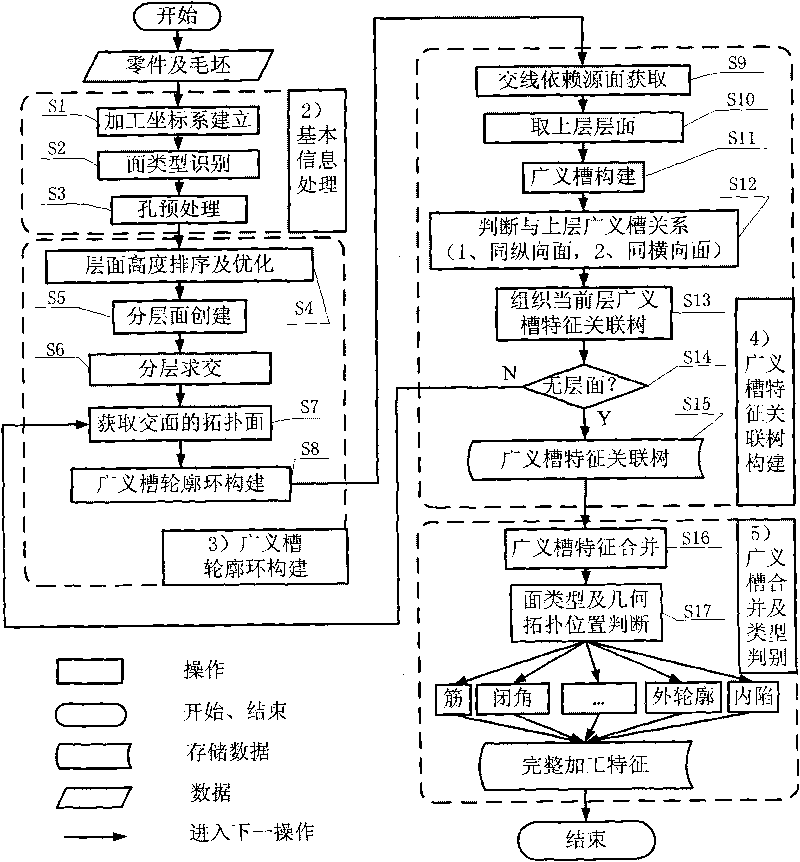

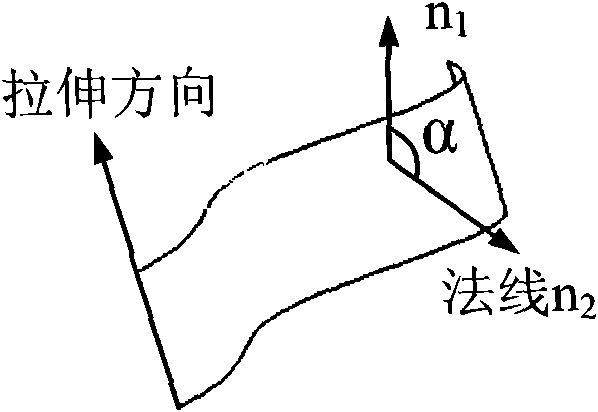

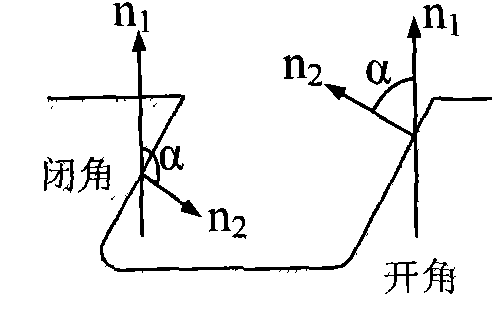

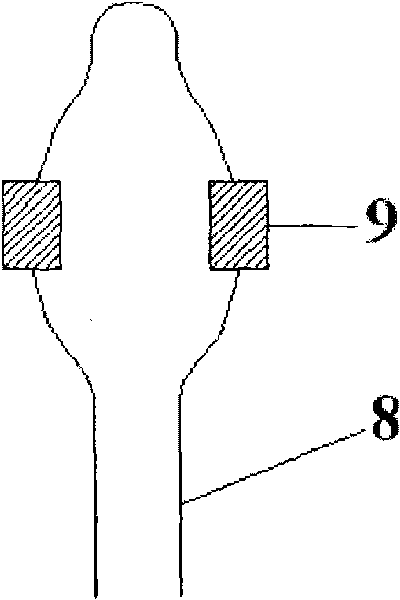

Identification method of machining characteristics of complex parts of airplane

InactiveCN101763069AShorten the manufacturing cycleReduce workloadProgramme controlComputer controlNumerical controlCharacteristic type

The invention provides an identification method of the machining characteristics of complex parts of an airplane, which comprises steps of: firstly, setting a machining coordinate system, identifying a machining surface and preprocessing a hole to complete basic information process; secondly, layering and intersecting to obtain intersecting line rings in each layer of intersecting result and relationships among the intersecting line rings to complete the construction of outline rings of generalized grooves; building the generalized grooves according to the outlines of the generalized grooves and the source surface depended by the intersecting lines; building the characteristics relevance tree of the generalized grooves according to the lengthways relationship of the outlines of the generalized grooves; and emerging the generalized grooves and identifying the characteristics types to complete the identification of the machining characteristics of a whole part. The method has the characteristics of high identification accuracy rate, high speed and small space usage, and the like; can be used for designing and developing systems for programming the complex parts of the airplane by means of intelligent numerical control, analyzing a machining technical scheme, and automatically generating blanks, and the like; and has good application foreground.

Owner:SHENYANG AIRCRAFT CORP +1

Method for rapidly preparing gradient metal ceramic composite material by laser induction hybrid cladding

InactiveCN101709468AIncrease profitImprove efficiencyMetallic material coating processesStrength of materialsMechanical property

The invention relates to a method for rapidly preparing a gradient metal ceramic composite material by laser induction hybrid cladding, which is characterized by comprising the following steps of: (1) generating a 3-D CAD solid model of a gradient metal ceramic composite material component by utilizing special CAD software or a reverse technology in a computer; (2) generating a processing program; (3) controlling the distance between the surface of a base material surface and an induction coil within the range of 2-10 mm; (4) locating a focused CO2 laser beam in an induction heating area; and (5) lifting a laser induction hybrid cladding processing head to the distance equal to the thickness of a CAD 2-D sheet. The invention has the advantages that: (1) a bulk metal ceramic composite material part the ceramic phase of which is continuously tunable along the material thickness direction within 0-100percent by weight is obtained; (2) the use ratio of laser energy and laser cladding efficiency are greatly improved; (3) the metal ceramic composite material with compact tissue but without cracks is obtained; (4) special tools and fixtures are not needed in the manufacturing process, and the flexibility is high; and (5) the mechanical property, the abrasive resistance and the corrosion resistance of the gradient metal ceramic composite material are greatly improved.

Owner:NANCHANG HANGKONG UNIVERSITY

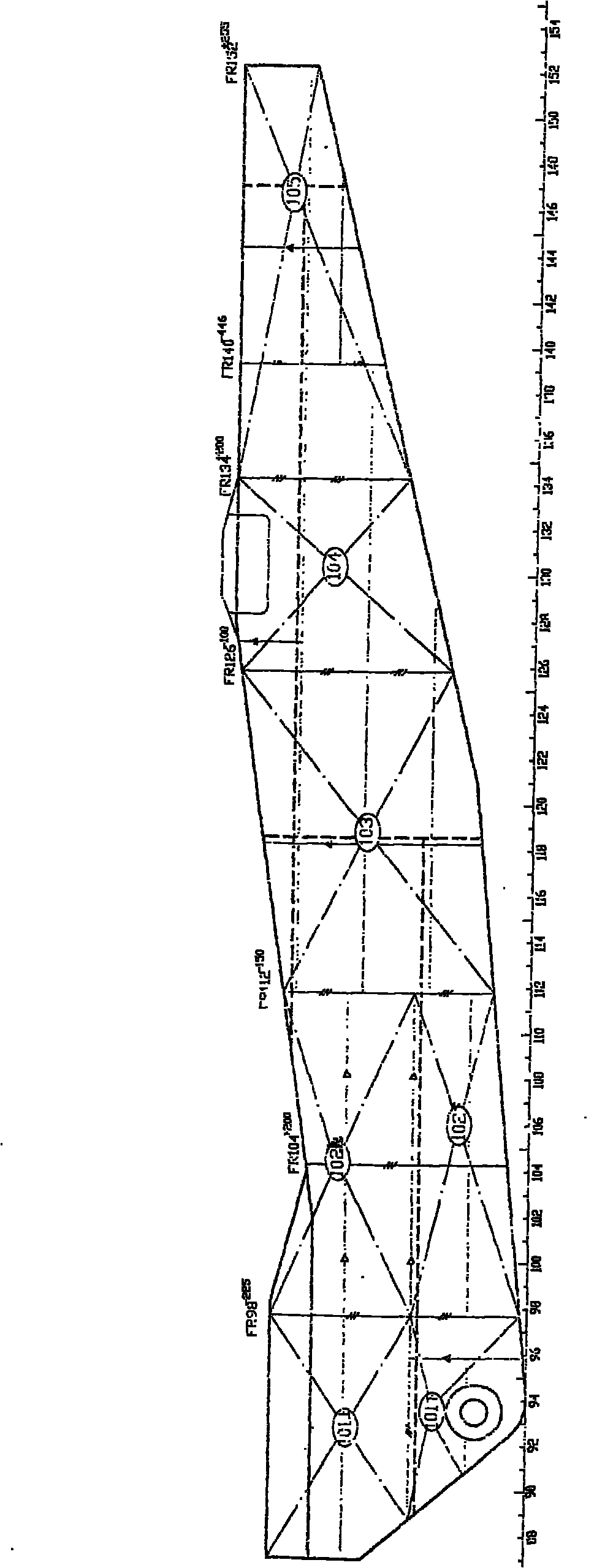

Preparation and on-board installation process of crane span of cutter suction dredger

InactiveCN101811553ASave installation timeShorten the manufacturing cycleVessel partsOn boardEngineering

The invention discloses a preparation and on-board installation process of crane span of cutter suction dredger. The process comprises the following steps: preparing the jig of a crane span, performing sectionalized assembly of the crane span, performing wire-drawing to the trunnion of the crane span, performing wire-drawing to the trunnion of a hull, closing shipways, fixing the crane span, installing bolts, etc. The process of the invention has the advantages of convenient construction and good construction effect; and the installation time of the crane span is fully reduced, and the total cycle time for the preparation of ships is shortened.

Owner:南通港闸船舶制造有限公司

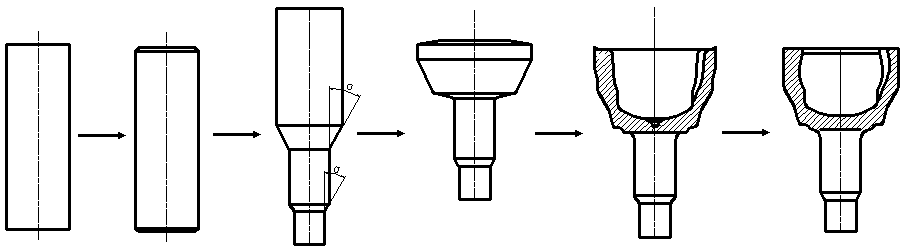

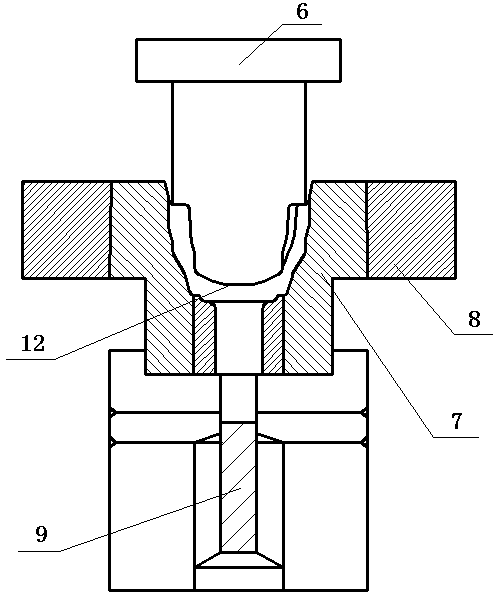

Precision-forging plastic molding technology of bell shell of ball-cage type universal joint

InactiveCN102861861AReduce workloadImprove product qualityRailway componentsForging/hammering/pressing machinesSand blastingUniversal joint

The invention discloses a precision-forging plastic molding technology of a bell shell of a ball-cage type universal joint, comprising steps of warm-forging plastic molding and cold-forging plastic molding. The warm-forging plastic molding technology comprises the following steps: a. blanking; b. manufacturing a blank; c. coating; d. heating; e. directly extruding; f. upsetting; g. extruding reversely; h. normalizing, shaping, sand blasting, parkerising, and treating the surface by a manner of saponification; and adopting the forging plastic molding technology of combining the warm-forging plastic molding technology with the cold-forging plastic molding technology, firstly upsetting to obtain the pre-molding blanking material, secondly, extruding reversely in the chamber of the molding mold to form a ball channel and finally forming the inner spherical surface by using the cold-forging plastic molding technology. The product quality is steady, the production efficiency is improved, the production period is short, the method for adopting the machine tool after the hot-forging is replaced, the workload of the machine tool process is reduced, the precision requirements are met, the manufacturing cost and the period are reduced, and the development trend of the manufacturing field in the world is met.

Owner:张太良

HT550 steel plate with ultrahigh toughness and excellent weldability and manufacture method thereof

ActiveCN103320692AImprove performanceShorten the manufacturing cycleFurnace typesQuenching agentsSheet steelYield ratio

Owner:BAOSHAN IRON & STEEL CO LTD

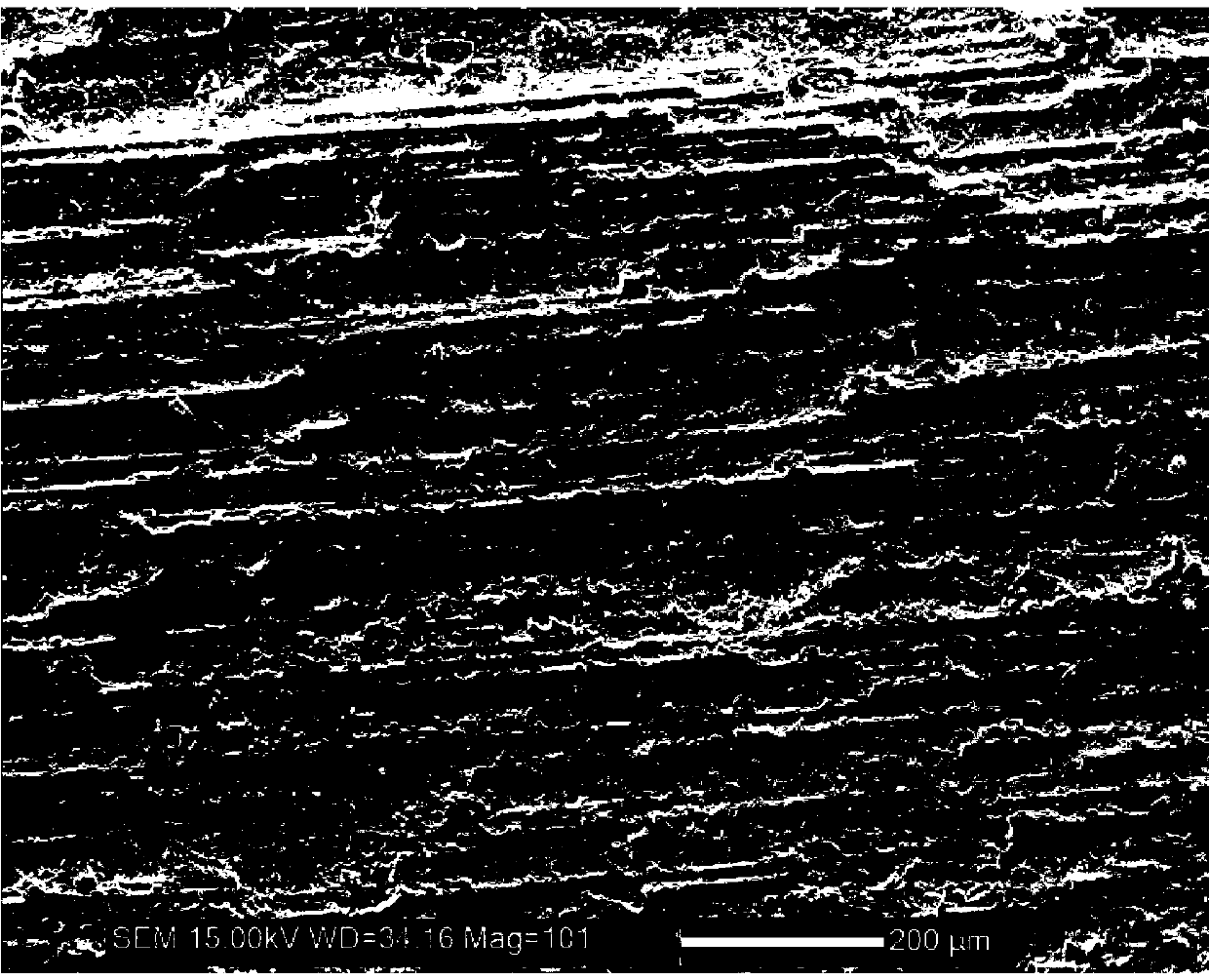

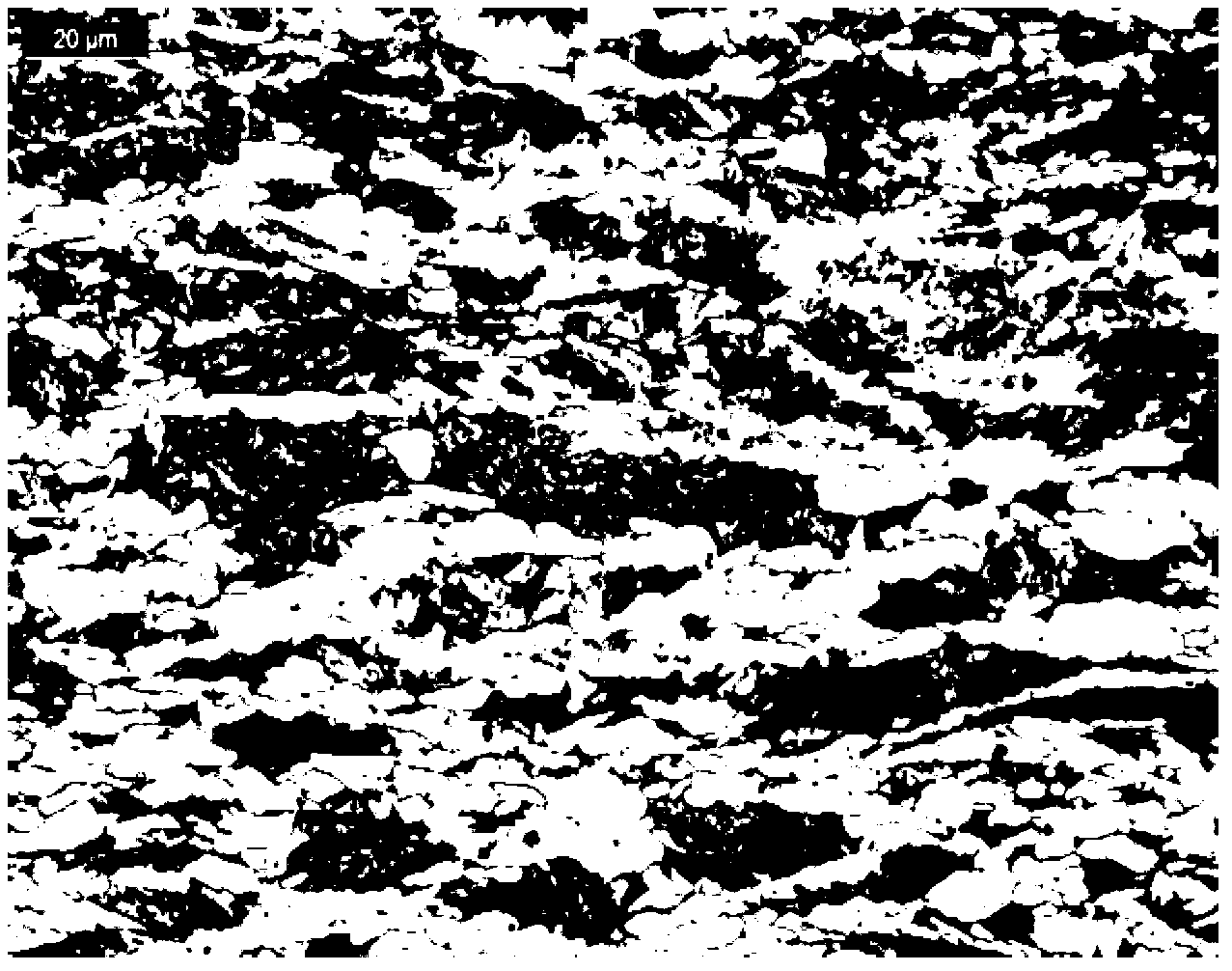

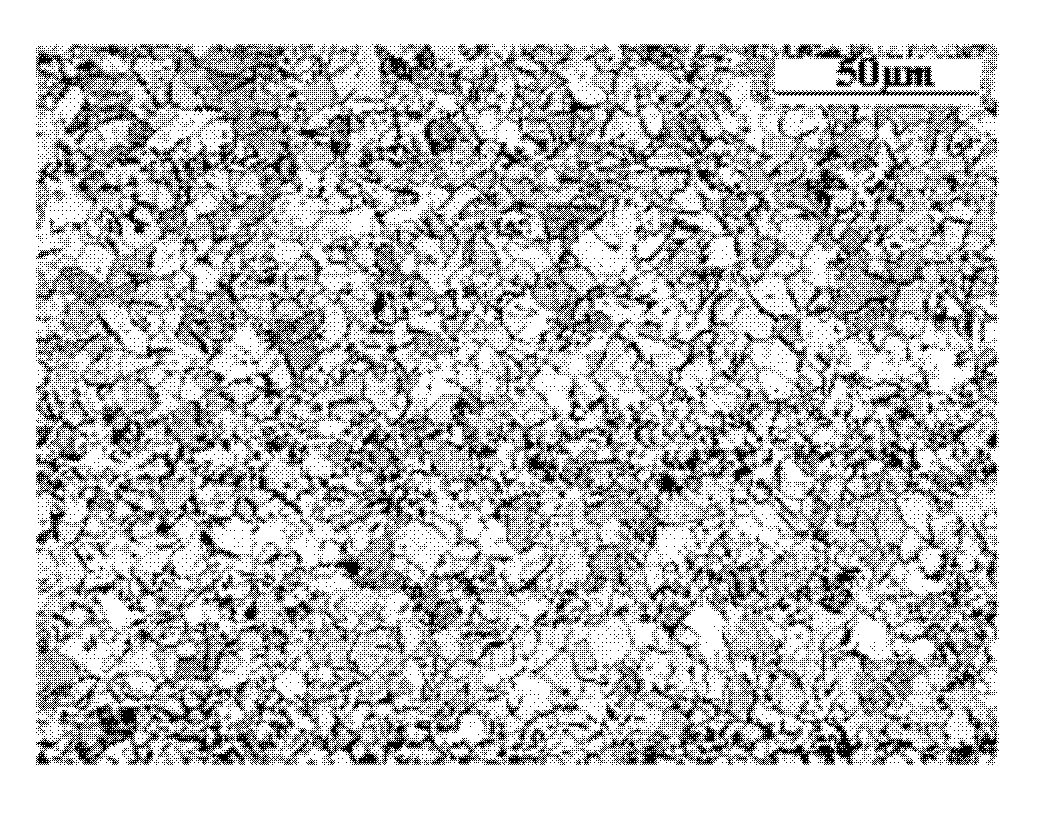

High-strength low-temperature steel with high hydrogen induced cracking (HIC) and sulfide stress corrosion cracking (SSC) resistance and manufacturing method thereof

ActiveCN102719745AReduce consumptionReduce difficultyHeat treatment process controlStress corrosion crackingSteel tube

The invention relates to high-strength low-temperature steel with high hydrogen induced cracking (HIC) and sulfide stress corrosion cracking (SSC) resistance and a manufacturing method thereof. A low alloy steel component system with ultra-low C content, low Si content, medium Mn content, low Als content, low N content, a little alloyed Ni and Mo and trace Ti and Nb is adopted, Mn / C is more than or equal to 22, the segregation index 1.32 (percent C)*[(1.53 (percent Mn)+1.37 (percent Si)+1.15 (percent Mo)+1.06 (percent Cr)+(percent Cu)+0.86 (percent Ni)]*[(30 (percent P)+10 (percent S)] is less than or equal to 0.060, [(percent Si)+(percent Als)]*(percent C) is less than or equal to 0.0035, Pcm is less than or equal to 0.018 percent, Nib / Ti is 1.5 to 3.5, Ca treatment is performed, Ca / S is 0.80 to 3.00, the microstructure of a finished steel plate product consists of uniform and fine acicular ferrites and a few upper bainites by optimizing a thermal mechanical control processing (TMCP) technology, and the average particle size is less than 10mu m; and the characteristics of high strength, toughness and HIC and SSC resistance are achieved, high heat input welding can be performed, and the steel is particularly suitable for manufacturing a low temperature storage tank, a low temperature pressure steel pipe, an ocean platform in an ice sea area, and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

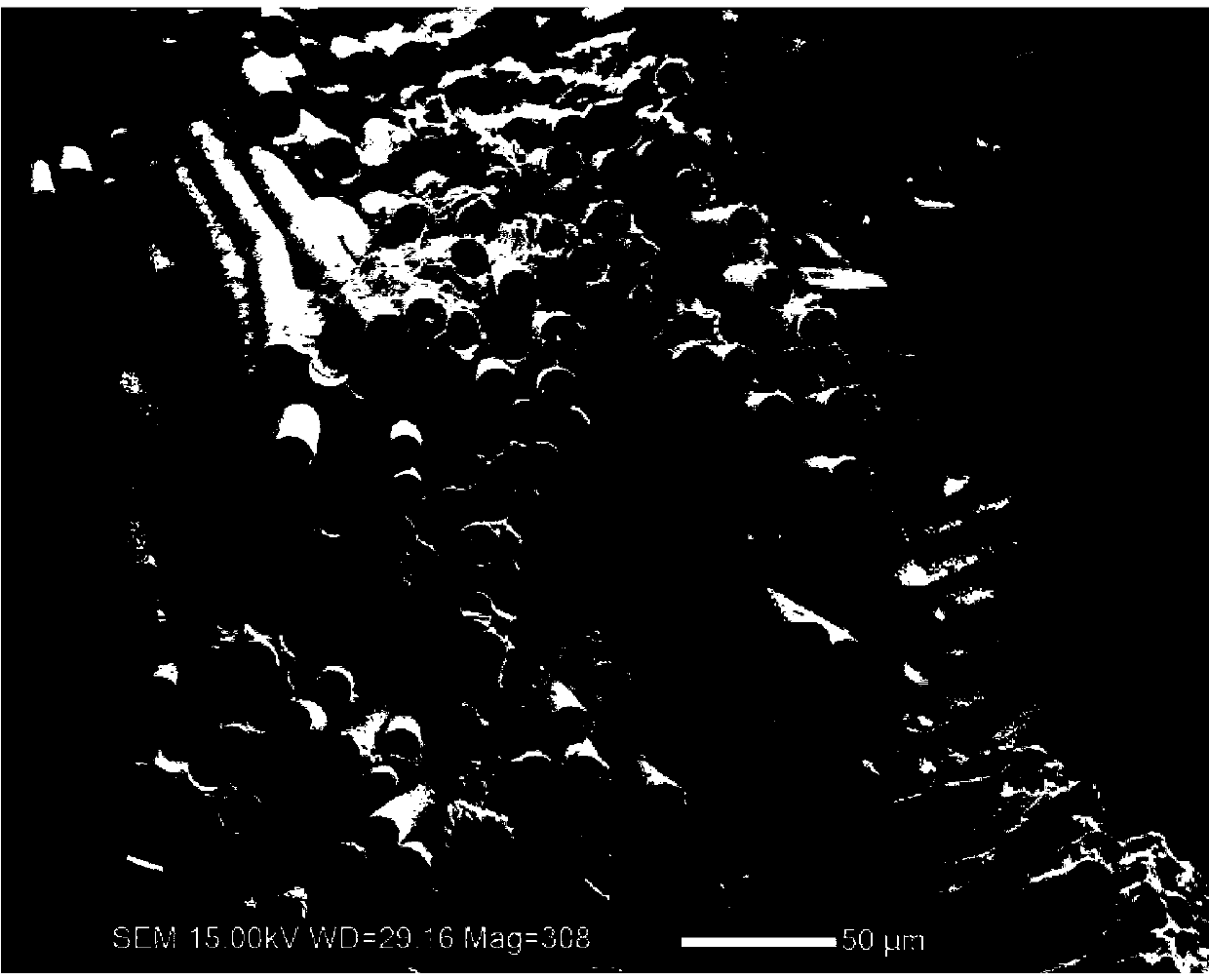

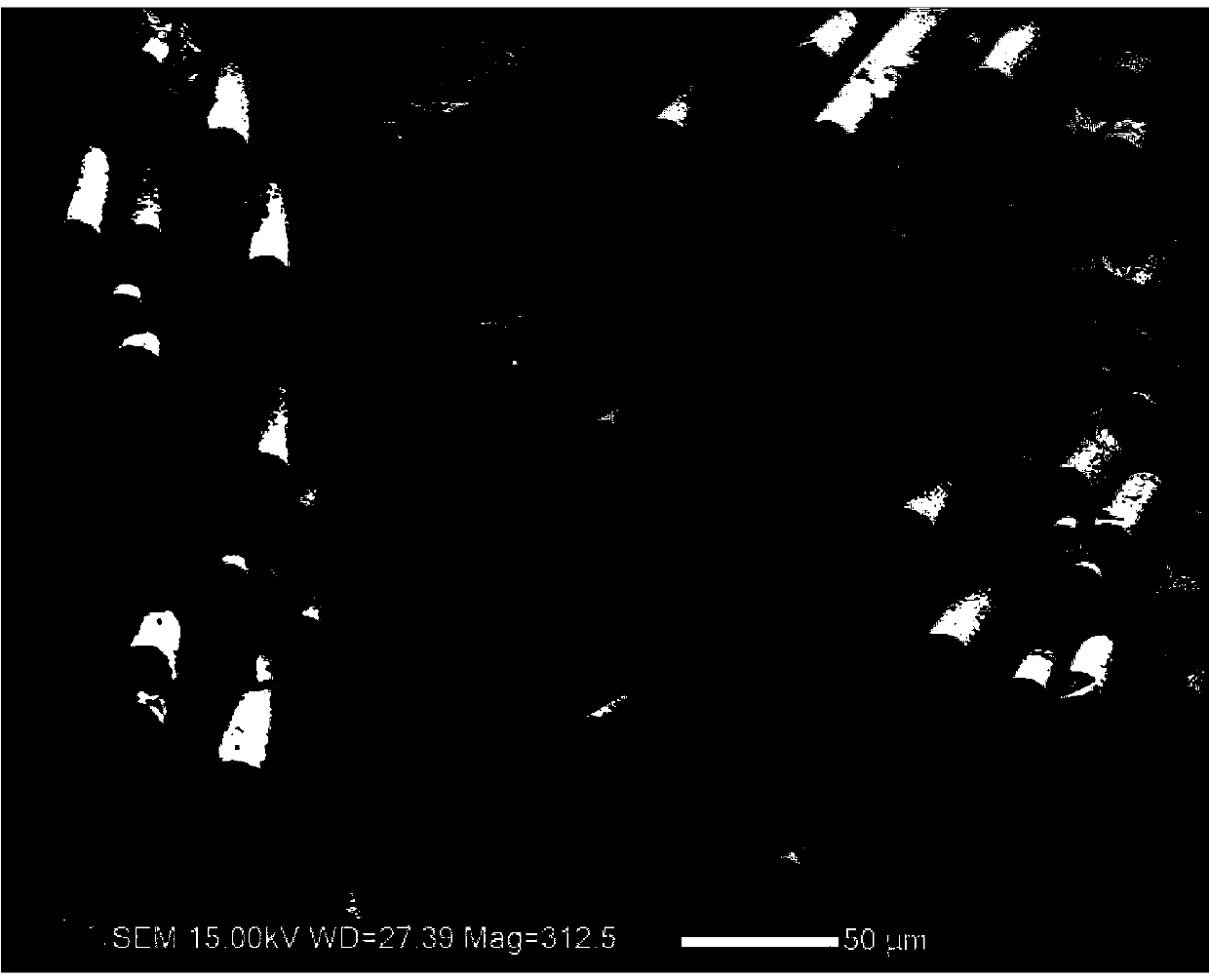

Powder metallurgy preparation method for high-strengthening-toughening metal-based composite material

ActiveCN108080644AImproved deformation coordinationAchieve toughnessMetal matrix compositeMetal powder

The invention discloses a powder metallurgy preparation method for a high-strengthening-toughening metal-based composite material and belongs to the field of metal-based composite materials. The method comprises the steps that (1), mixed powder of metal powder and part reinforcing phase is subjected to ball-milling treatment, and ball-milling is stopped before all crystal particles in the metal powder reach ultrafine crystal; (2), the rest reinforcing phase is added to the powder after ball-milling in the step (1), the ball-milling is continued, and the ball-milling is stopped until the reinforcing phase is completely dispersed; (3), after the powder after the ball-milling in the step (2) is treated by powder metallurgy sintering process, then the high-strengthening-toughening metal-basedcomposite material is obtained. According to the powder metallurgy preparation method for the high-strengthening-toughening metal-based composite material, the reinforcing phase is made to be orderlydistributed in a base body by adding the reinforcing phase step by step; crystal particle distribution is adjusted and controlled utilizing the crystal particle refining effect of the reinforcing phase on the base body, a coarse and fine crystal gradient grading structure is formed, thus the strengthening-toughening of materials is realized; and by means of the powder metallurgy preparation methodfor the high-strengthening-toughening metal-based composite material, the process procedure can be simplified, and the strong plasticity of the materials can be improved at the same time.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

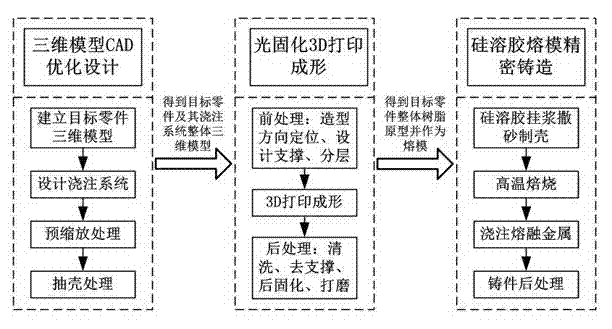

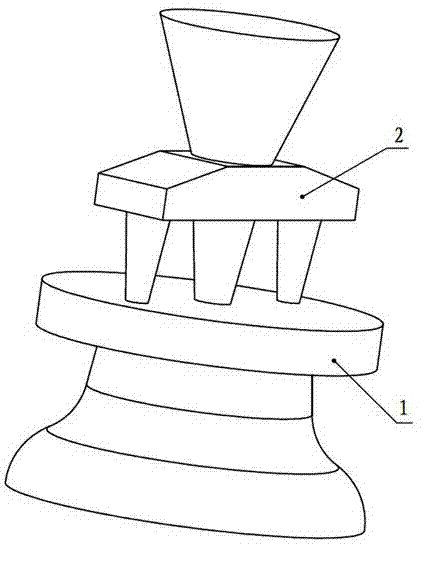

Rapid precise casting technology based on photocuring 3D printing technique

ActiveCN104493094AEliminate processing and manufacturing linksShorten the manufacturing cycleFoundry mouldsFoundry coresInvestment casting3D modeling

The invention relates to a rapid precise casting technology based on a photocuring 3D printing technique, and belongs to the technical field of a melted module precise casting. The rapid precise casting technology comprises the following steps: firstly, carrying out a CAD optimization design on an objective part based on 3D modeling software, mainly including establishing a 3D model of the objective part, designing a pouring system, carrying out prescale treatment and carrying out shell drawing treatment; secondly, carrying out photocuring 3D printing and forming on an integral model of the objective part so as to obtain an integral resin prototype of the objective part and a pouring system of the objective part; carrying out silica sol investment casting by taking the integral resin prototype of the objective part as a melted mold, including the working procedures of manufacturing a shell, roasting, pouring, removing the shell, carrying out aftertreatment and the like sequentially; and finally preparing the precise metal casting of the objective part. According to the rapid precise casting technology, the mold manufacturing cost is reduced; the part manufacturing cycle is shortened; the product development efficiency is improved; parts with complex shapes can be rapidly and precisely cast.

Owner:浙江省机电设计研究院有限公司 +1

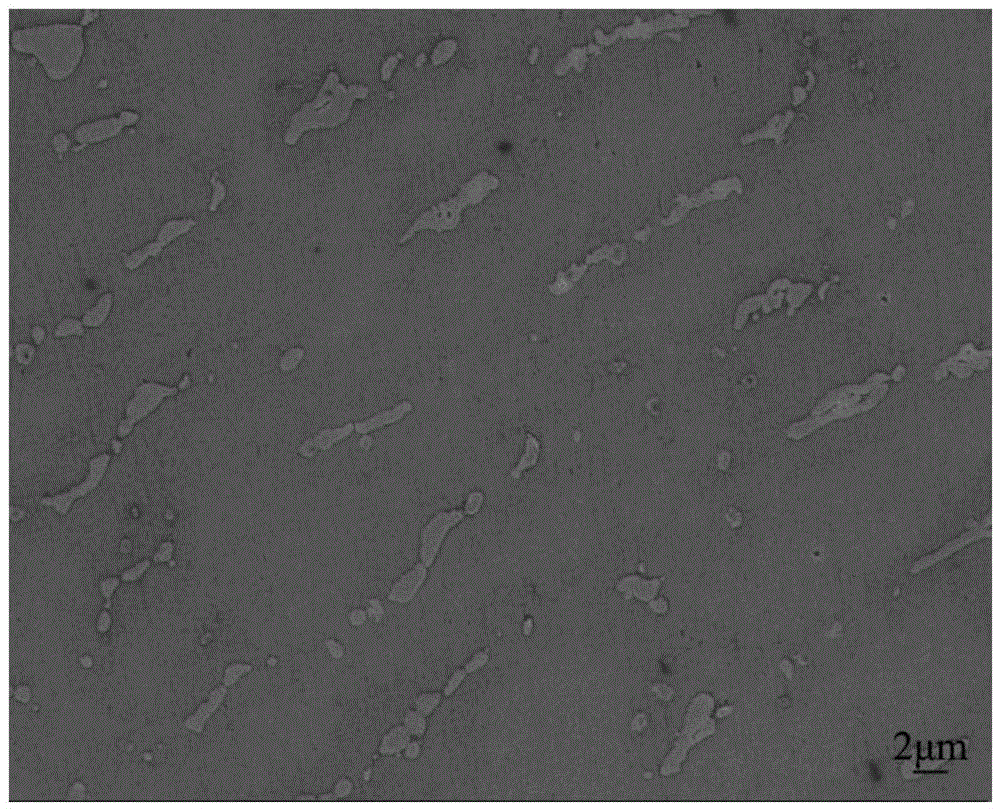

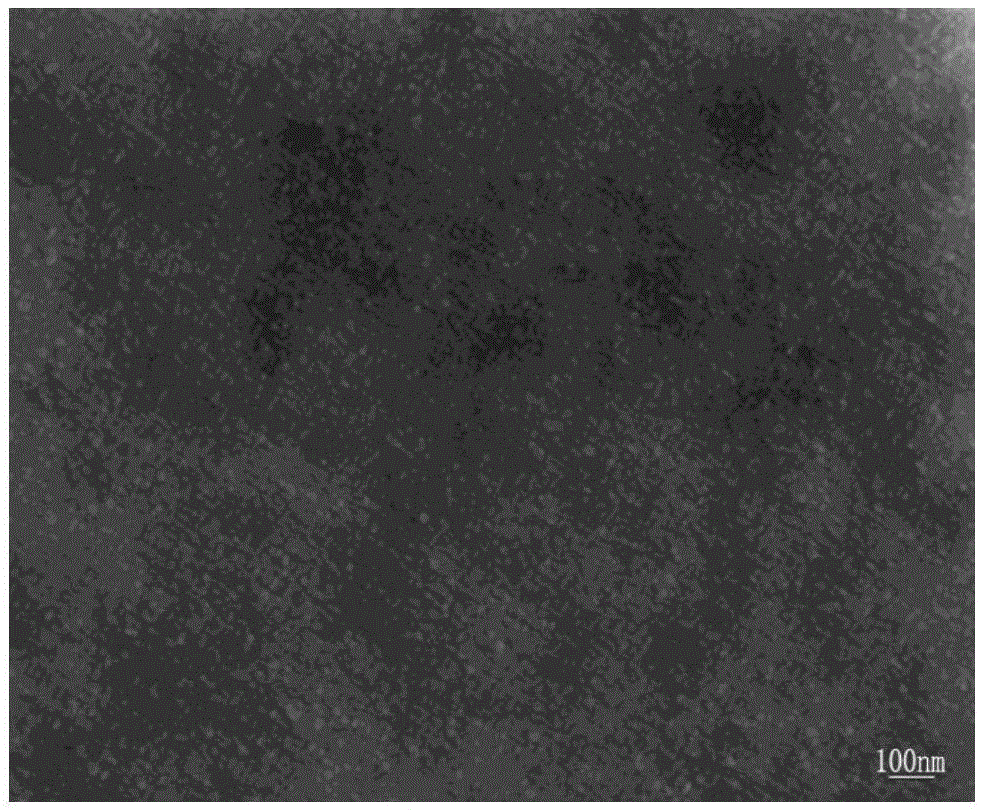

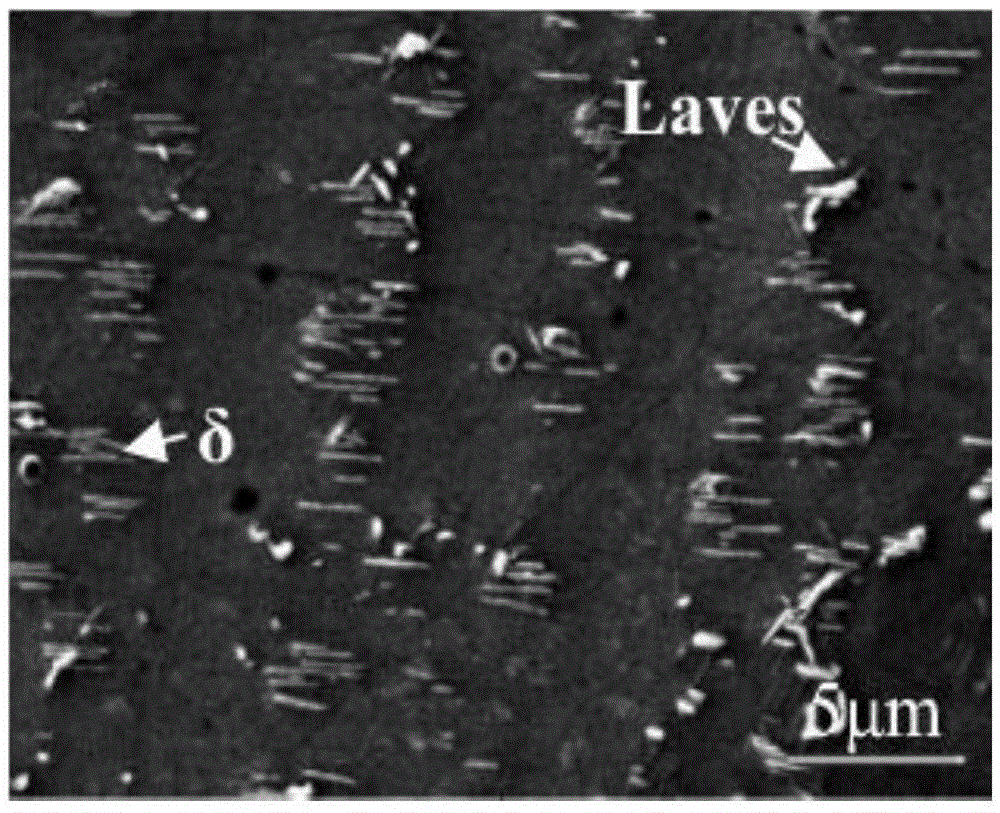

Preparation method of material increase manufactured nickel-based high-temperature alloy reserved with Laves phase

ActiveCN105543747AShorten the manufacturing cycleFast preparationMetallic material coating processesFree coolingSuperalloy

The invention provides a preparation method of a material increase manufactured nickel-based high-temperature alloy reserved with the Laves phase. GH4169 high-temperature alloy with the Laves phase distributed in a dispersed particle shape is prepared through the preparation method, and compared with industrial forged and cast isometric crystal high-temperature alloy, the high-temperature mechanical properties, especially the high-temperature creep property, the high-temperature endurance life and the like are greatly improved. The preparation method comprises the following steps that firstly, in a processing rood, GH4160 high-temperature alloy powder or wire materials are processed through a high-energy beam heat source to be continuously melted and deposited on a base plate, so that the GH4169 high-temperature alloy reserved with the Laves phase is prepared; secondly, the prepared GH4169 high-temperature alloy reserved with the Laves phase is naturally cooled in the processing room and taken out after the temperature of the GH4169 high-temperature alloy is below 100 DEG C; and thirdly, two stages of heat treatment is conducted on the GH4169 high-temperature alloy which is taken out of the processing and reserved with the Laves phase in sequence, the first stage is completed by conducting heat preservation for 8-24 hours under the condition that the GH4169 high-temperature alloy is heated to the temperature of 700-740 DEG C, then the second stage is completed by cooling the GH4169 high-temperature alloy to the temperature below 600-640 DEG C along with a heat preservation furnace and then conducting heat preservation for eight hours, and finally air cooling is conducted till the indoor temperature is reached, so that the material increase manufactured nickel-based high-temperature alloy reserved with the Laves phase is obtained.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Polyolefine sheathing compound for coaxial cable and preparation method thereof

ActiveCN102153812AShorten the manufacturing cycleHarm reductionPlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePolyolefin

The invention discloses a polyolefine sheathing compound for a coaxial cable and a preparation method thereof. The sheathing compound consists of the following components in parts by weight: 60-90 parts of ethylene-propylene-diene rubber, 5-25 parts of high-density polyethylene, 5-15 parts of functional polyolefin resin, 180-200 parts of flame retardant, 1-3 parts of surface modifier, 0.01-0.05 part of crosslinking agent, 0.5-2 parts of antioxidant and 1.5-9 parts of processing aid. The preparation method comprises the following steps of: putting the flame retardant into a high-speed stirrer for stirring at a high speed at the temperature of not lower than 80 DEG C; adding organosilane and stirring for 3-5 minutes; putting the remaining materials into the high-speed stirrer for continually stirring for 3-5 minutes; adding into a double-screw mixing extruder set by using a feeder for pelletizing; and drying. The sheathing compound has the advantages of flame retardance, low smoke, freeness from halogen, low toxicity, freeness from harmful heavy metals such as lead, cadmium and the like, freeness from phosphorus, difficulty in burning and small smog harm in case of fire, environmental friendliness, high temperature resistance level of 105 DEG C, high extruding performance, excellent electric performance, no need of subsequent crosslinking after stranding, saving in a large amount of manpower and materials and great reduction in the manufacturing period of the cable.

Owner:KINGFA SCI & TECH CO LTD +2

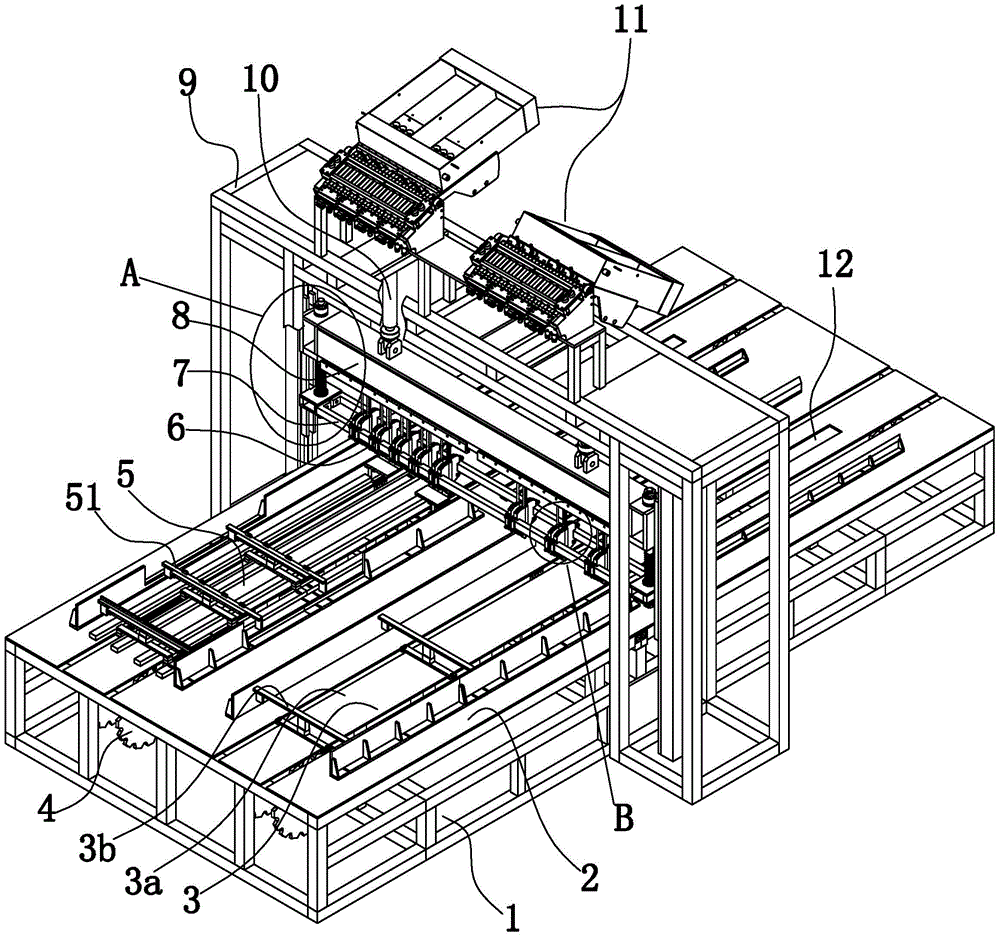

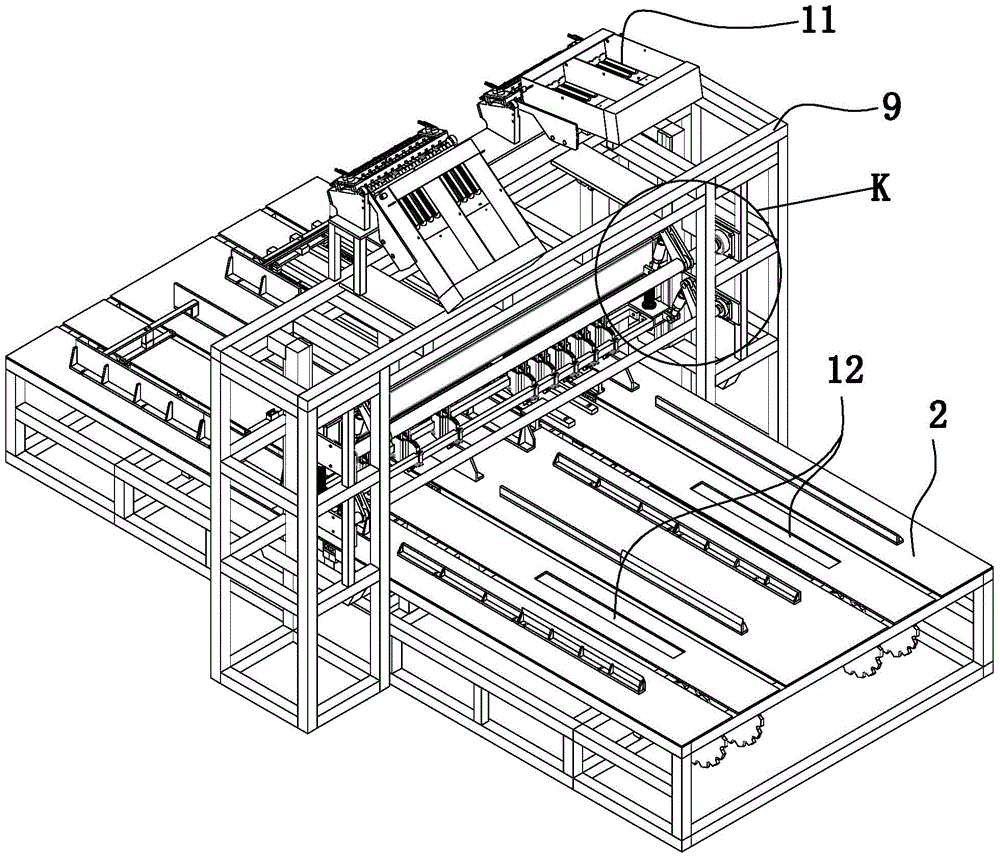

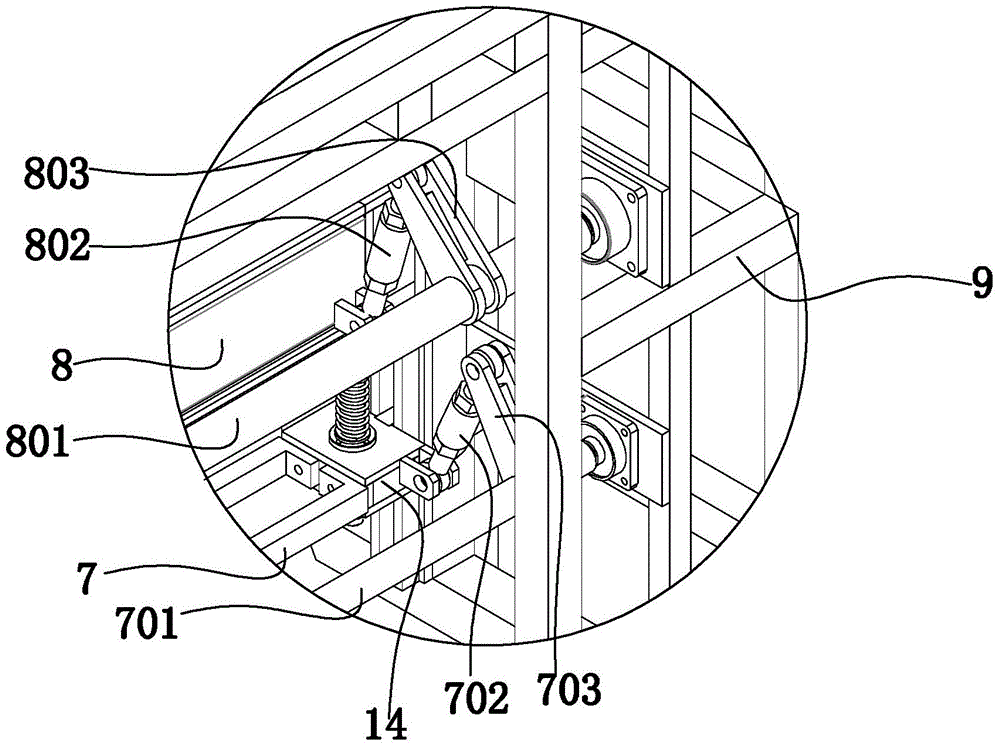

Production line for wood pallets

ActiveCN103600401AImprove production efficiencyImprove product qualityWood working apparatusProduction linePulp and paper industry

The invention discloses a production line for wood pallets and aims at providing the production line for wood pallets, which is capable of improving the wood pallet production efficiency and the product quality effectively and reducing labor costs. The production line comprises a rack, a wood pallet delivery device arranged on the rack and a nailing device which is arranged above the wood pallet delivery device. A material holding platform is arranged on the rack, and the wood pallet delivery device comprises a first wood pallet delivery line and a second wood pallet delivery line which are arranged in parallel on the material holding platform. The first wood pallet delivery line comprises a plurality of wood pier guide grooves formed in the material holding platform, a plurality of wood pier push rods perpendicular to the wood pier guide grooves and a first driving device for driving the wood pier push rods to move along the direction of the wood pier guide grooves. The second wood pallet delivery line comprises a plurality of wood pallet guide grooves formed in the material holding platform, a plurality of wood pallet push rods perpendicular to the wood pallet guide grooves and a second driving device for driving the wood pallet push rods to move along the direction of the wood pallet guide grooves.

Owner:WUHU ASIA PACIFIC GENERAL TRAY PACKING CO LTD

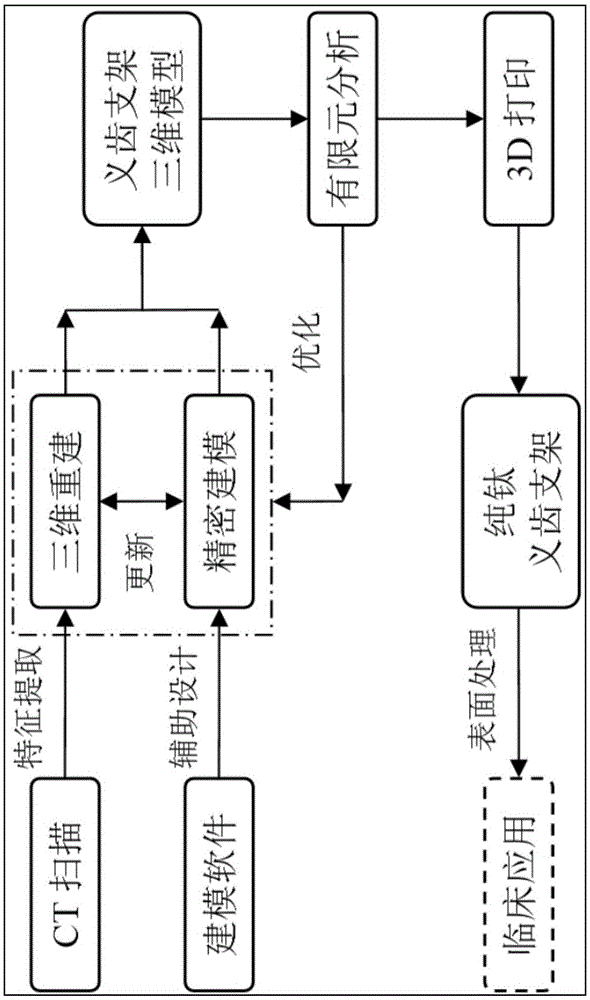

Method for preparing false tooth support through 3D printing laser stereo-lithography technology

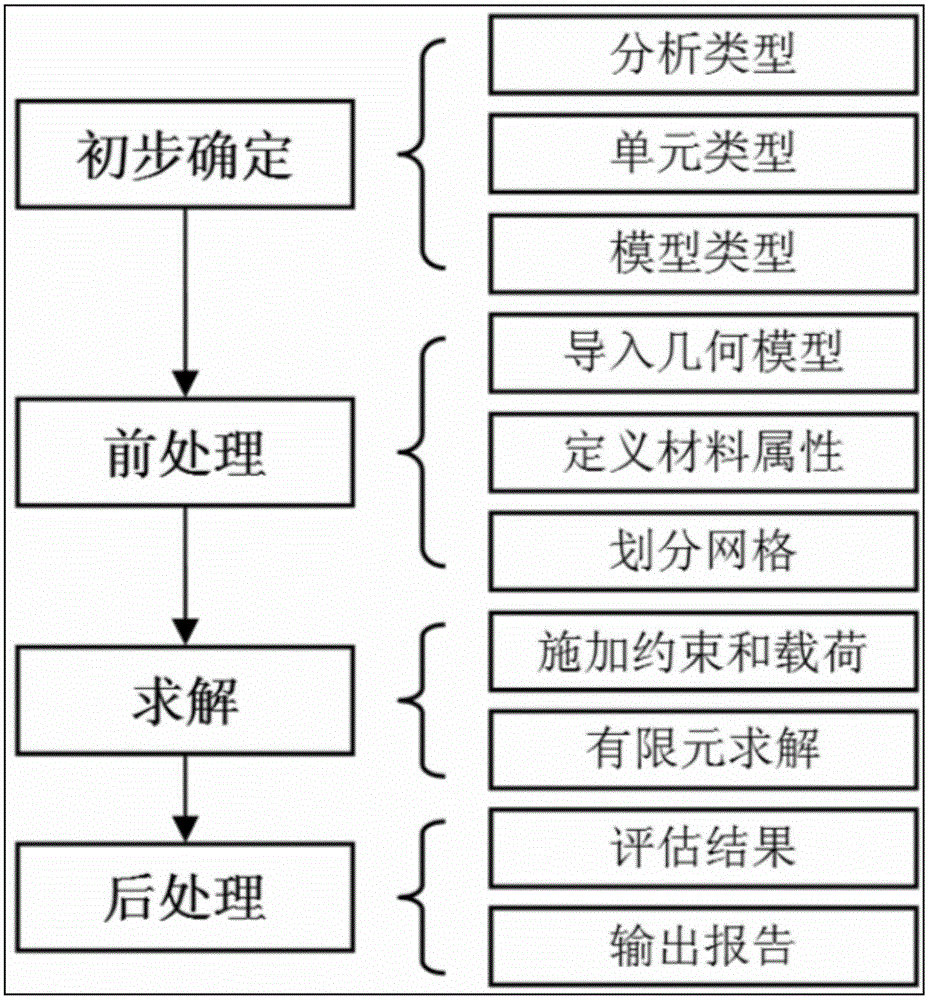

InactiveCN104999078AGuaranteed comfortGuaranteed service lifeAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing cost reductionFinite element technique

The invention discloses a method for preparing a false tooth support through a 3D printing laser stereo-lithography technology. According to the method for preparing the false tooth support through the 3D printing laser stereo-lithography technology, the individual false tooth support most suitable for a patient is printed through the 3D printing laser stereo-lithography technology; the comfort level and the service life of the false tooth support are ensured by means of a finite element technology; the operation difficulty of a physician is lowered; the manufacturing cost is reduced; the manufacturing period is shortened. The surface of the false tooth support is processed through an anodizing and / or electrochemical deposition method so that the surface of the false tooth support can have more excellent synosteosis features and biology activity, osteoblast growth and surface calcification are facilitated, and the satisfaction of the patient is improved. The method is suitable for the field of medical devices.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Method for manufacturing end socket of voltage stabilizer for nuclear power

ActiveCN102248362ASize qualifiedQualified shapeFurnace typesHeat treatment furnacesHot stampingNuclear power

The invention discloses a method for manufacturing an end socket of a voltage stabilizer for nuclear power. The integral end socket is subjected to hot stamping deep drawing by a 16MND5 low-alloy steel plate, and is subjected to heat treatment of normalizing and tempering to form the end socket, which is reliable in quality, accurate in size and high in mechanical property, of the voltage stabilizer for nuclear power. In the method, the weight of the end socket manufactured by the low-alloy steel plate can be reduced by about half compared with that of the end socket manufactured by forging piece materials, the manufacturing period is short and the cost is reduced greatly.

Owner:泰安东润核电装备有限公司

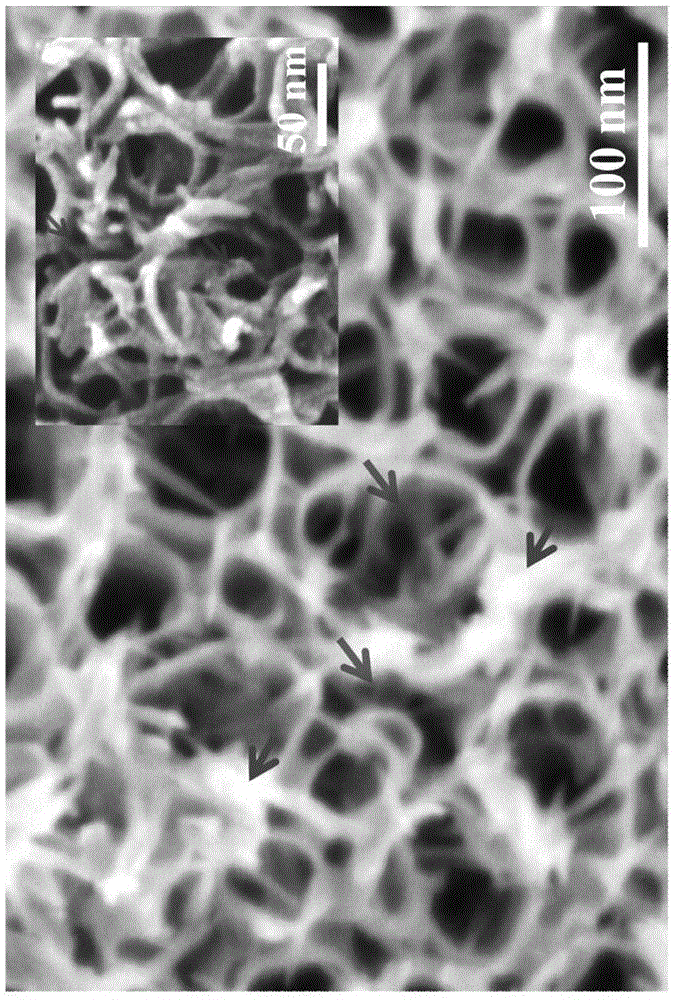

Nano ceramic particle reinforced nickel-based superalloy composite material and laser 3D printing forming method thereof

InactiveCN104745887AGood high temperature corrosion resistanceImprove wear resistanceAlloy compositeHigh energy laser

The invention discloses a nano ceramic particle reinforced nickel-based superalloy composite material and a laser 3D printing forming method thereof. A nickel-based superalloy with the particle size of 15-45mu m is taken as a matrix, CrC with the particle size of 40-100nm is taken as a reinforced phase, and the addition amount of CrC is 2.0-8.0% by weight of the composite material matrix; a nano CrC particle hybrid reinforced nickel-based superalloy composite material part has the advantages of good high-temperature anti-corrosion property, abrasion resistance, high temperature creep and the like and can meet special performance requirements of an aero-engine hot end component at high temperature; a high-energy laser forming method is applicable to preparation of a difficult-to-process material and forming of a complex part; and a forming die is not needed, so that a manufacturing cycle is shortened, and the cost is reduced.

Owner:JIANGSU SILAIMU INTELLIGENT TECH CO LTD

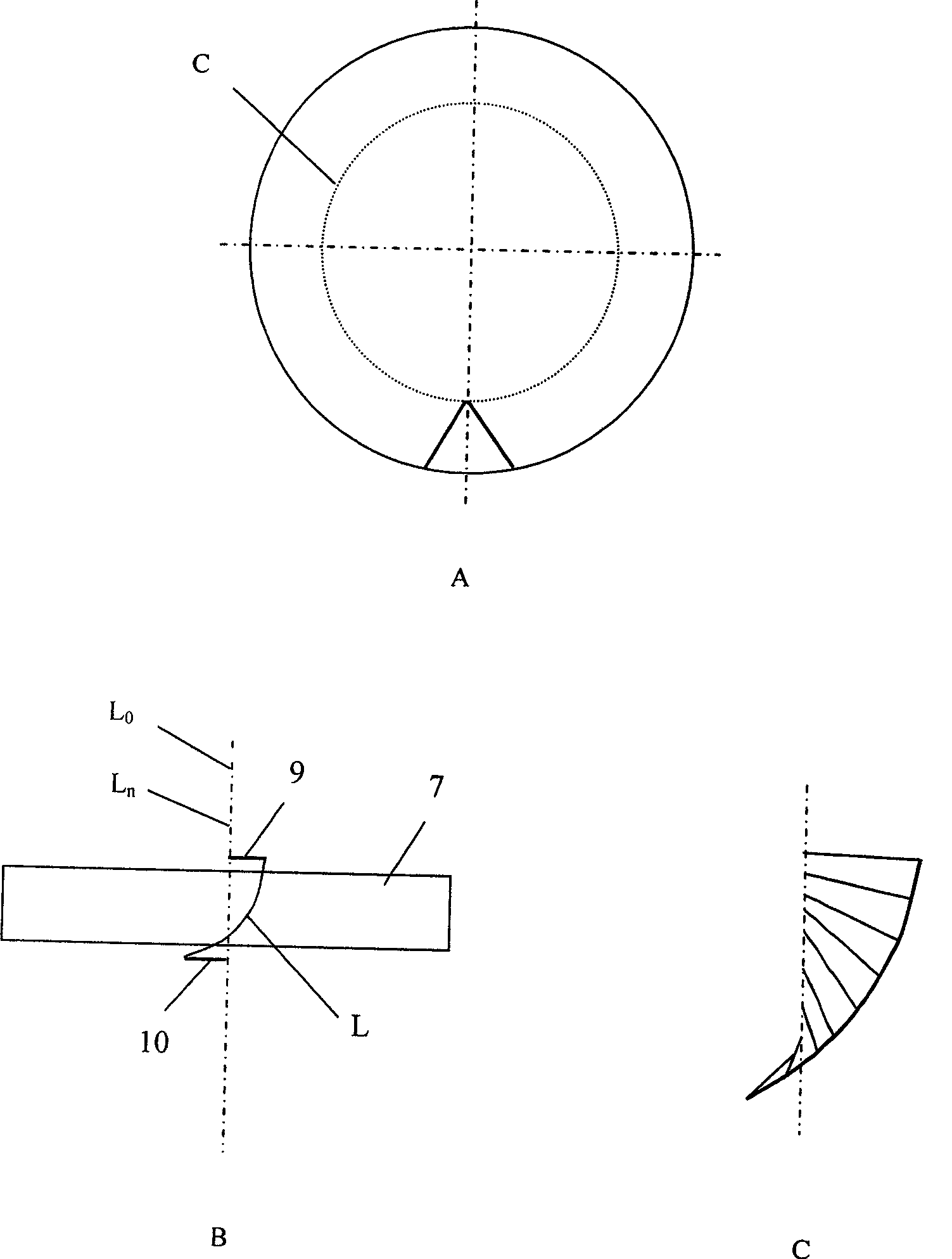

Multi-electrode spiral feeding integral blade wheel inter-blade passage electrolytic machining method

InactiveCN101508047AImprove processing efficiencyShorten the manufacturing cycleImpellerMachining process

The invention relates to an electrolytic machining method for multi-electrode screw feeding integral impeller flow passages, and belongs to the technical field of electrolytic machining. The method adopts a plurality of tool electrodes which are positioned on the same plane and arranged on an electrolytic machining clamp. In the machining process, a translation stage of a machine tool drives the plurality of the tool electrodes to simultaneously feed linearly along the axes direction of an impeller blank, and a turn table on the translation stage drives the plurality of the tool electrodes to rotate; meanwhile, the impeller blank rotates around the axes of the impeller blank, and the tool electrodes perform electrolytic machining along a motion trail determined by the resultant motion. The electrodes and the impeller blank keep a small clearance; electrolyte flows out at a high speed from gaps of the tool electrodes to continuously take away products of electrolysis; and a plurality of impeller flow passages are machined finally. The number and distribution positions of the tool electrodes can be adjusted to meet machining requirements of integral impellers in different types. Because the plurality of the electrodes are adopted to perform machining simultaneously, the machining efficiency for the integral impeller is greatly improved, and the rotation of the electrodes makes machining allowance more even at the same time.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

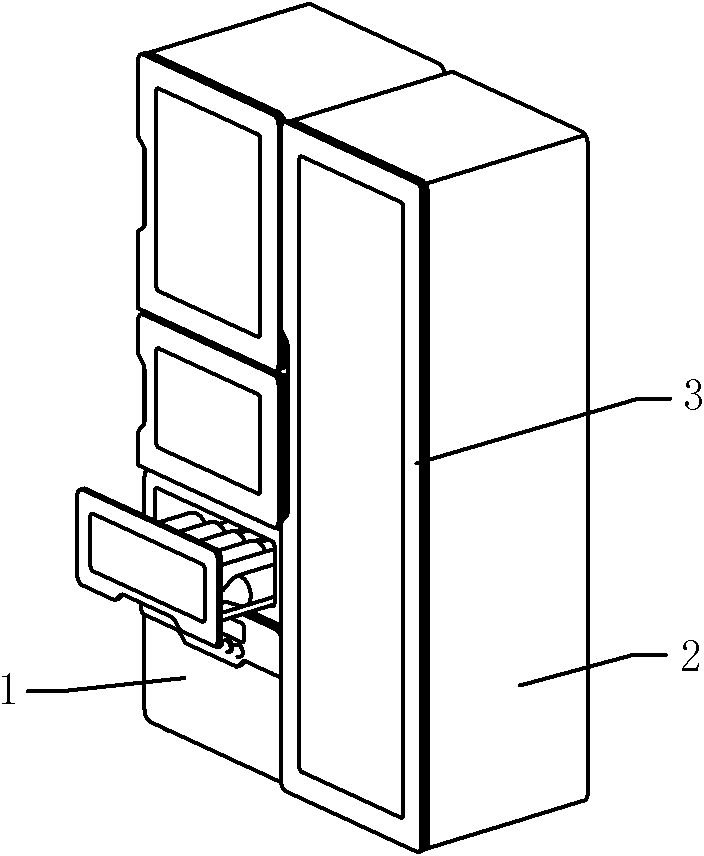

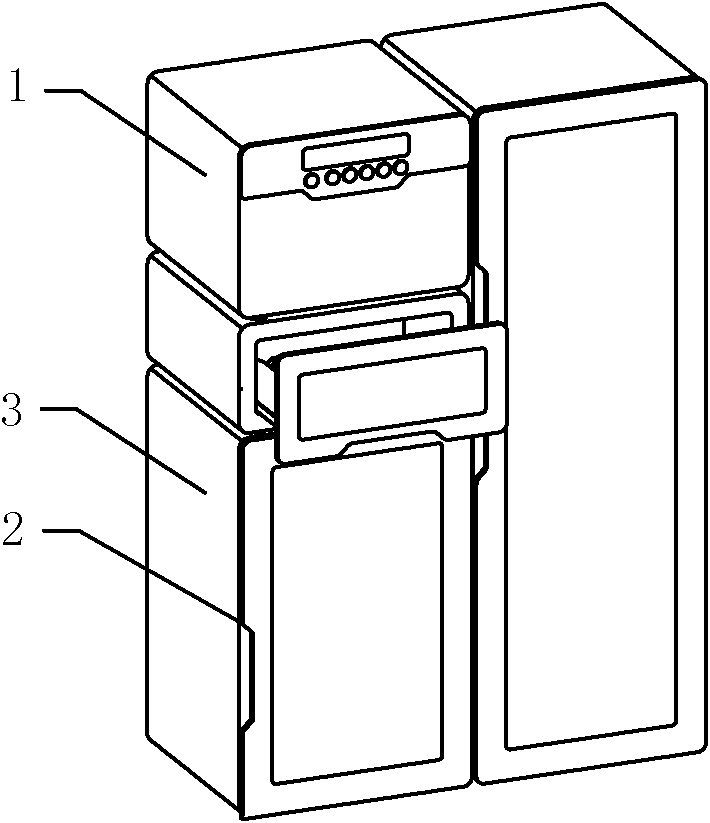

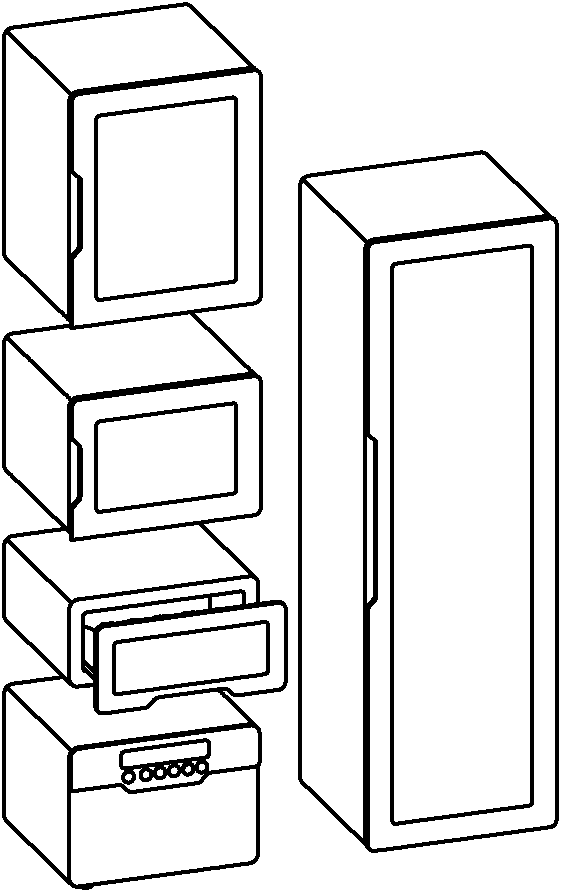

Module combined refrigerator

InactiveCN101915487AMeet usabilityMeet needsLighting and heating apparatusDomestic refrigeratorsComputer moduleElectric control

The invention provides a module combined refrigerator which comprises a refrigeration system and an electric control system, wherein, the refrigerator is composed of a mainframe room and two or more cold rooms, and the mainframe room and the cold rooms are independent and separated from each other; the cold rooms comprise door bodies and insulation boxes; the mainframe room is internally equipped with two or more refrigeration system interfaces and electric control system interfaces, and the cold rooms are internally equipped with refrigeration system joints and electric control system joints which are correspondingly connected with the refrigeration system interfaces and the electric control system interfaces in the mainframe room; and the mainframe room is equipped with a compressor, a condenser, a capillary tube and a main controller, and the cold rooms are equipped with evaporators. By means of a plurality of combined module units in the mainframe room, the module combined refrigerator can simultaneously meet the combined use requirements for a refrigerating room, a cold room, a soft-freezing room, a wine cabinet and the like, thus meeting the personalized need of customers, reducing development expense, shortening design and production cycle, saving warehousing floor space, and facilitating storage and transportation.

Owner:广东安博基业电器有限公司

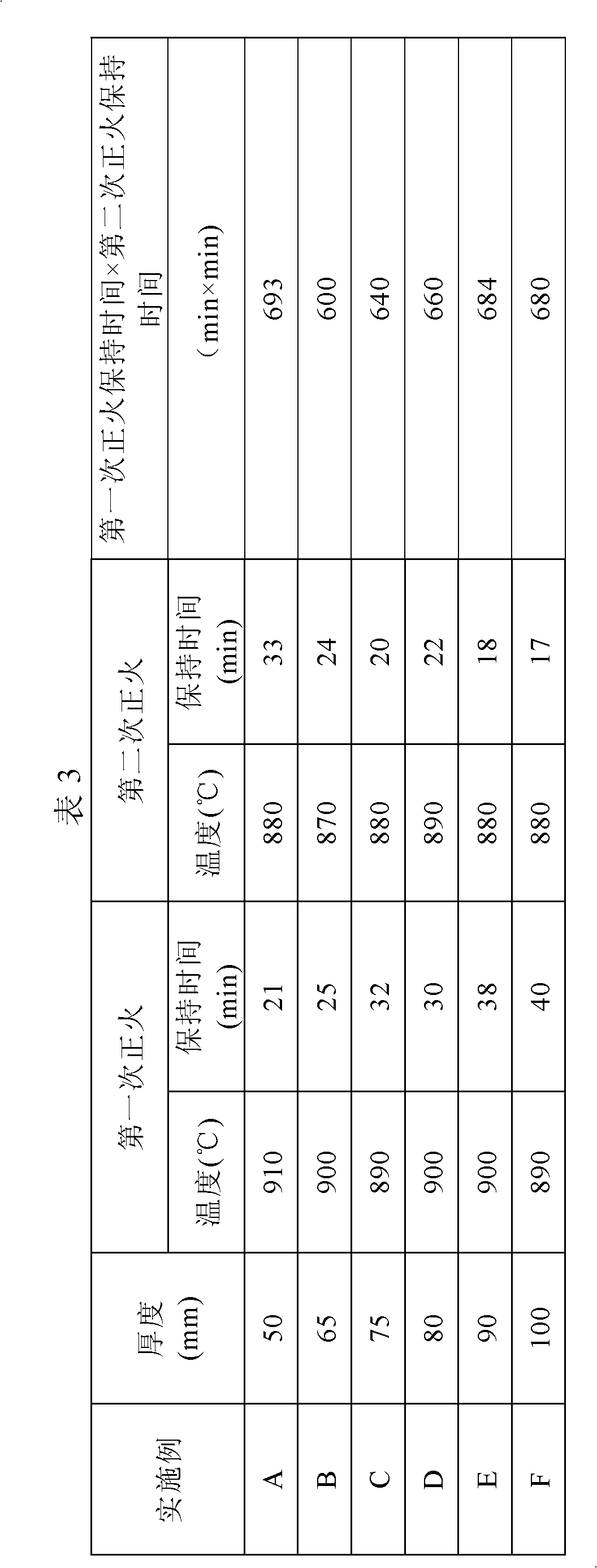

High tempering parameter PWHT embrittlement resistant, extra thick cryogenic steel plate and manufacture method thereof

ActiveCN102691007AIncrease the content of acid-soluble AlsExcellent anti-HICToughnessMaterials science

A high tempering parameter PWHT embrittlement resistant, extra thick cryogenic steel plate and a manufacture method thereof. The steel plate comprises, by weight, 0.030%-0.070% of C, Si no more than 0.15%, 1.30%-1.60% of Mn, P no more than 0.013%, S no more than 0.0025%, 0.040%-0.070% of Als, 0.10%-0.40% of Cu, 0.25-0.65% of Ni, 0.10%-0.30% of Cr, 0.05%-0.25% of Mo, 0.007%-0.013% of Ti, 0.010%-0.030% of Nb, 0.020%-0.050% of V, N no more than 0.0045%, 0.001%-0.004% of Ca, residual iron and unavoidable inclusions. According to optimized controlled rolling and two times of normalizing technology, the steel plate gains extremely high ultralow temperature toughness, excellent HIC / SCC resistance, weldability and bearing capacity of high heat input welding; and more importantly, the steel plate has excellent high tempering parameter PWHT embrittlement resistance characteristic, and is especially suitable for manufacture of large-scale LPG low temperature storage tank, low temperature storage tank for ship and ocean platform for ice ocean.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com