Preparation and on-board installation process of crane span of cutter suction dredger

A cutter suction dredger and installation process technology, which is applied to ship components, ship construction, transportation and packaging, etc., can solve the problems of difficulty, long installation process period, and long bridge length of cutter suction dredger, etc. To achieve convenient construction, shorten the overall cycle, and good construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

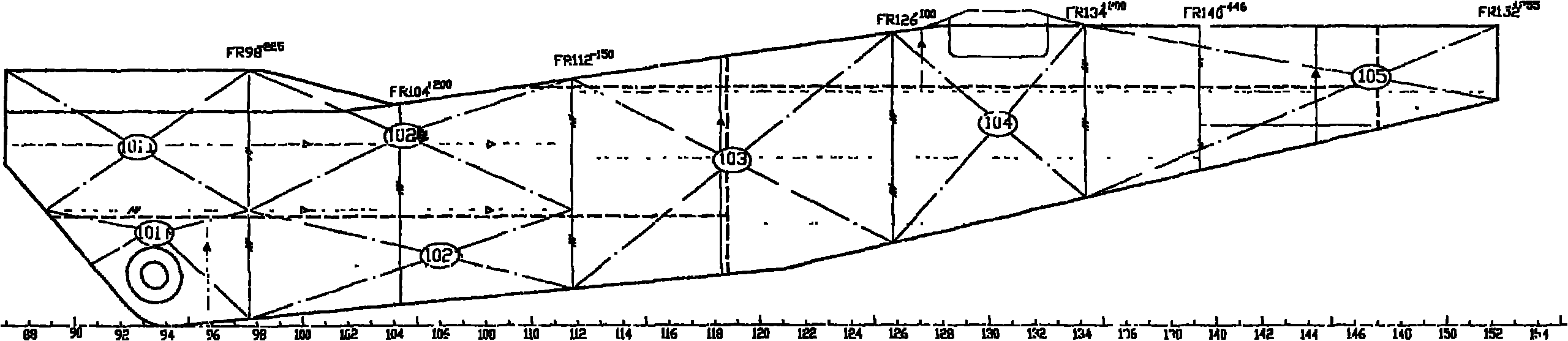

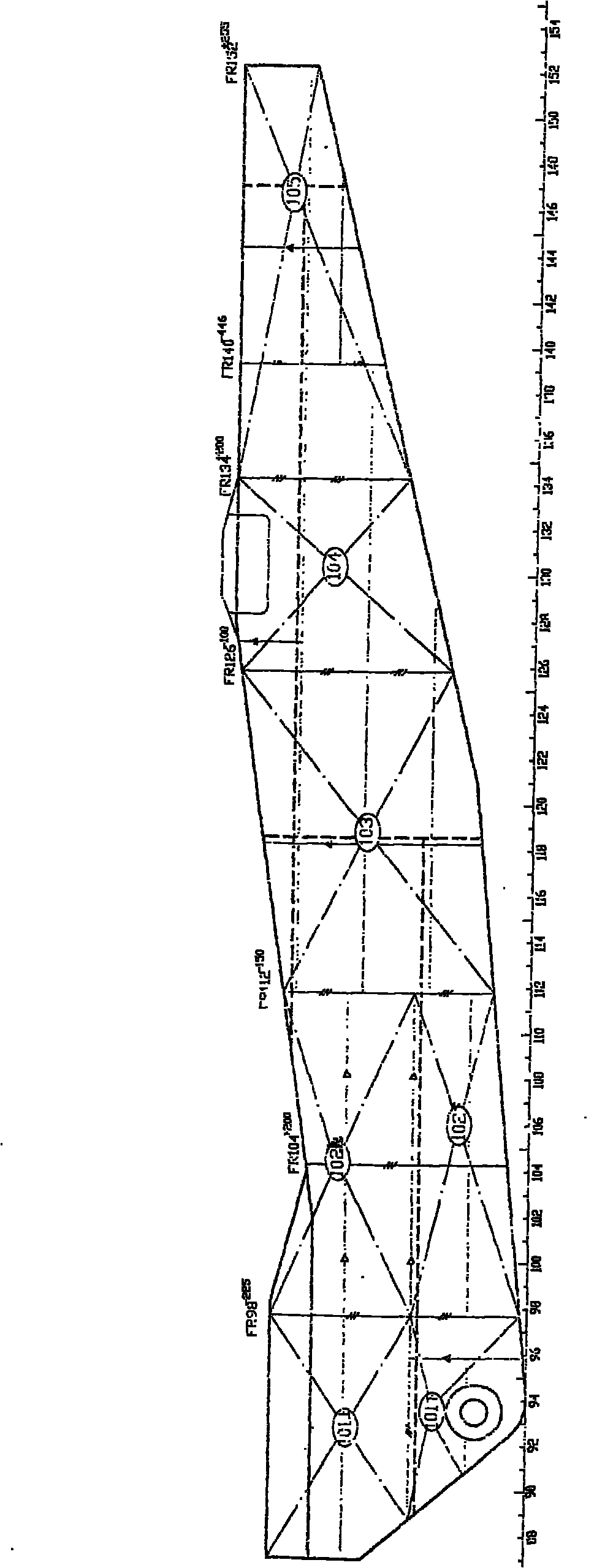

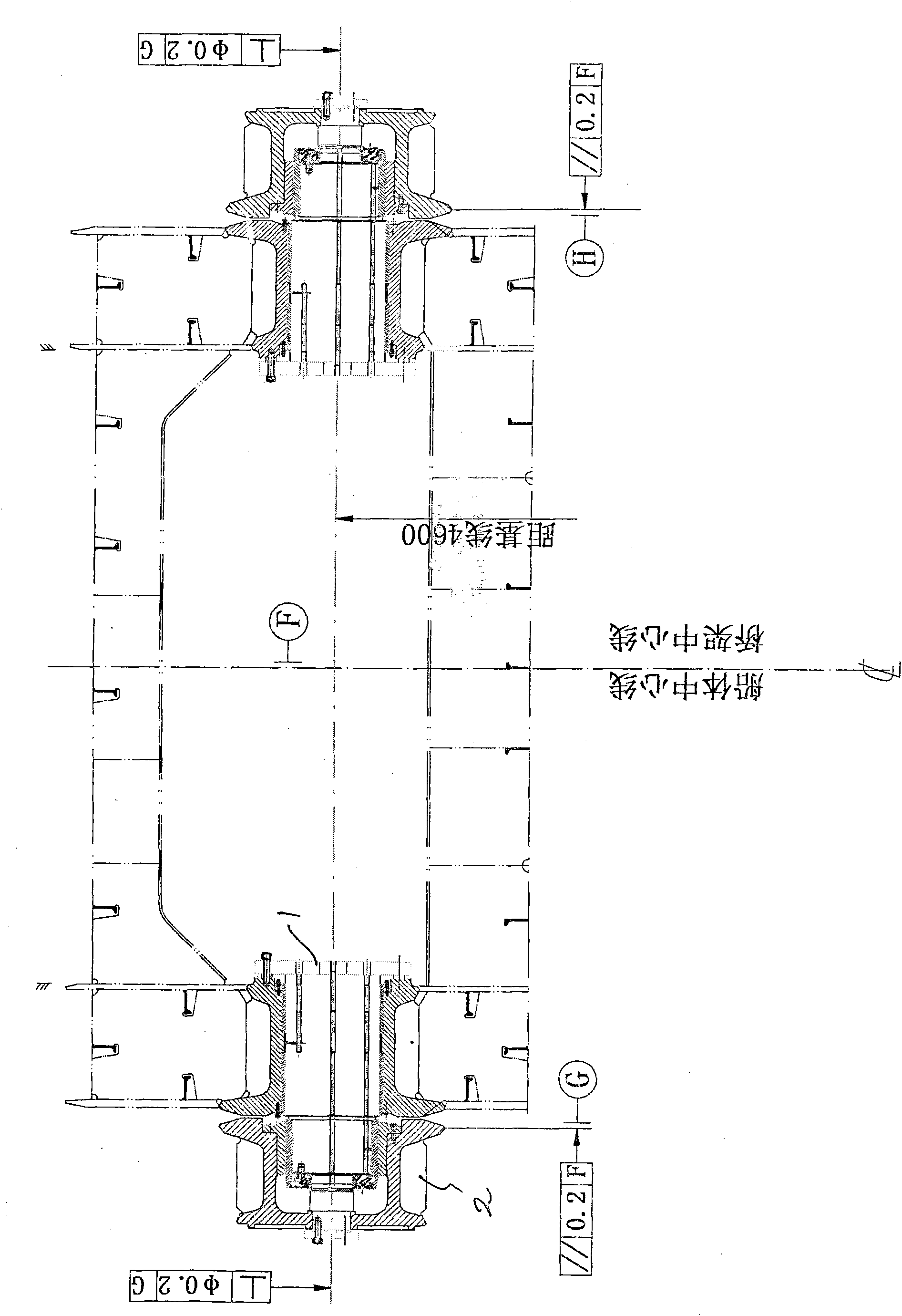

[0058] A bridge frame manufacturing and on-board installation process of a cutter suction dredger, comprising the following steps:

[0059] (1) Fabrication of the bridge tire frame: according to the line shape of the bottom of the bridge frame, it is manufactured with the body tire frame, and the tire frame type value is provided by the numerical control stakeout to provide the accurate type value table or the raised data value; the section with a large change in the shape line is provided by the stakeout Tire mold, submitted for construction after CNC cutting;

[0060] The tire frame is marked by laser theodolite to draw the bridge center line, bridge width line, large seam line, middle rib position line and horizontal inspection line, and make a hard mark;

[0061] After the tire frame is completed and submitted to the quality inspection department for acceptance, the segmental planking and structural marking can be carried out, and the precision of the tire frame production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com