Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

19101results about How to "Improve machining accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

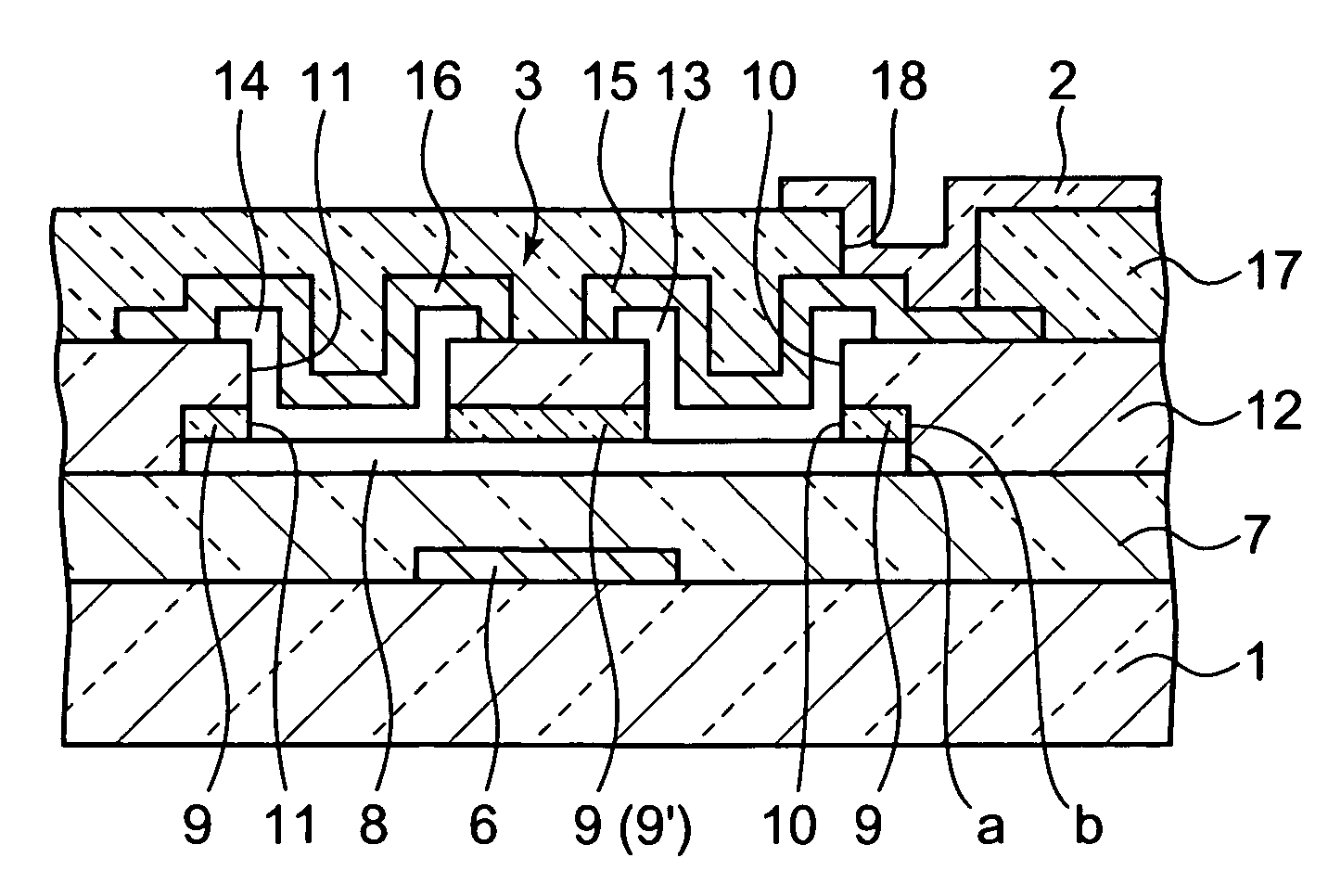

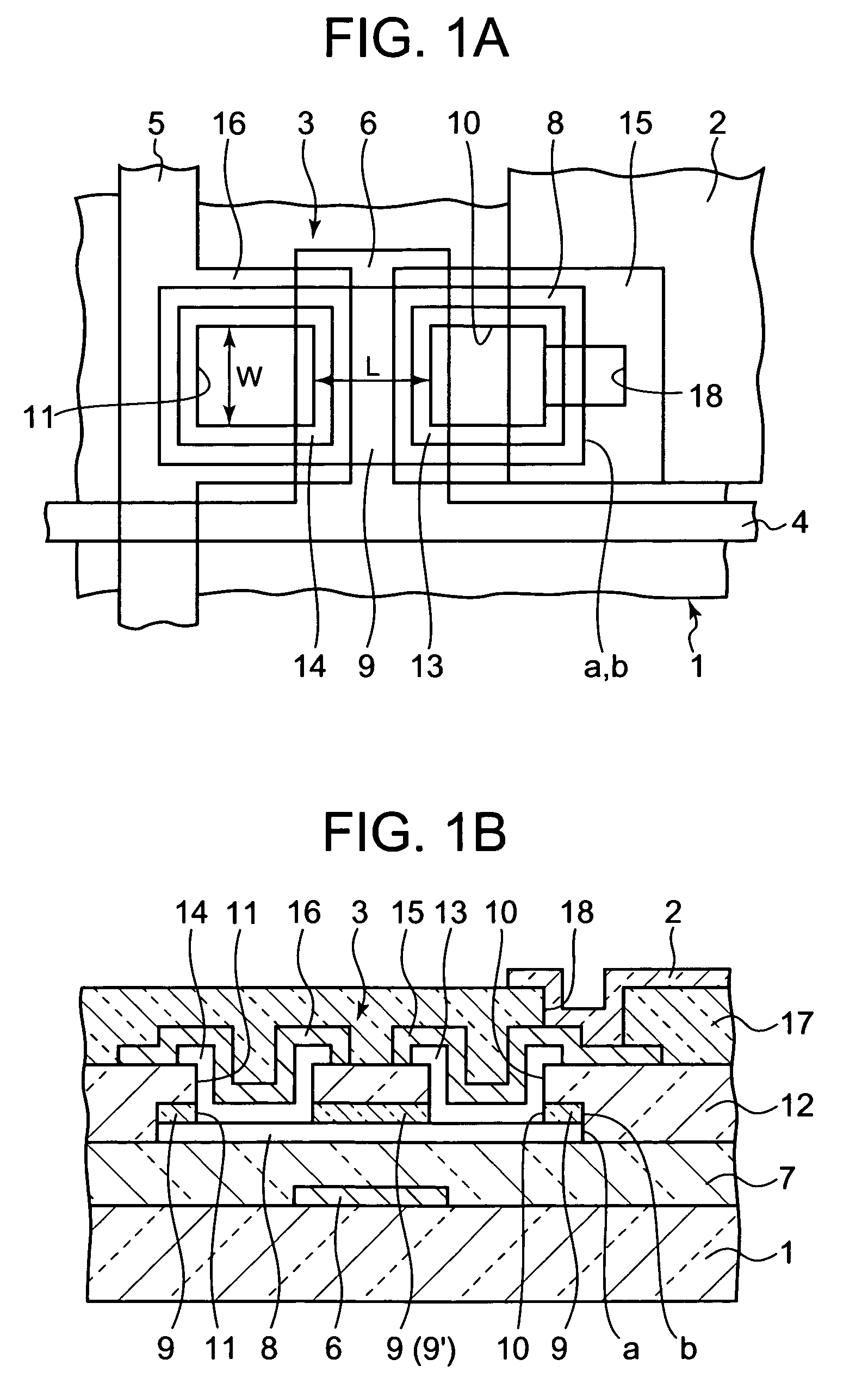

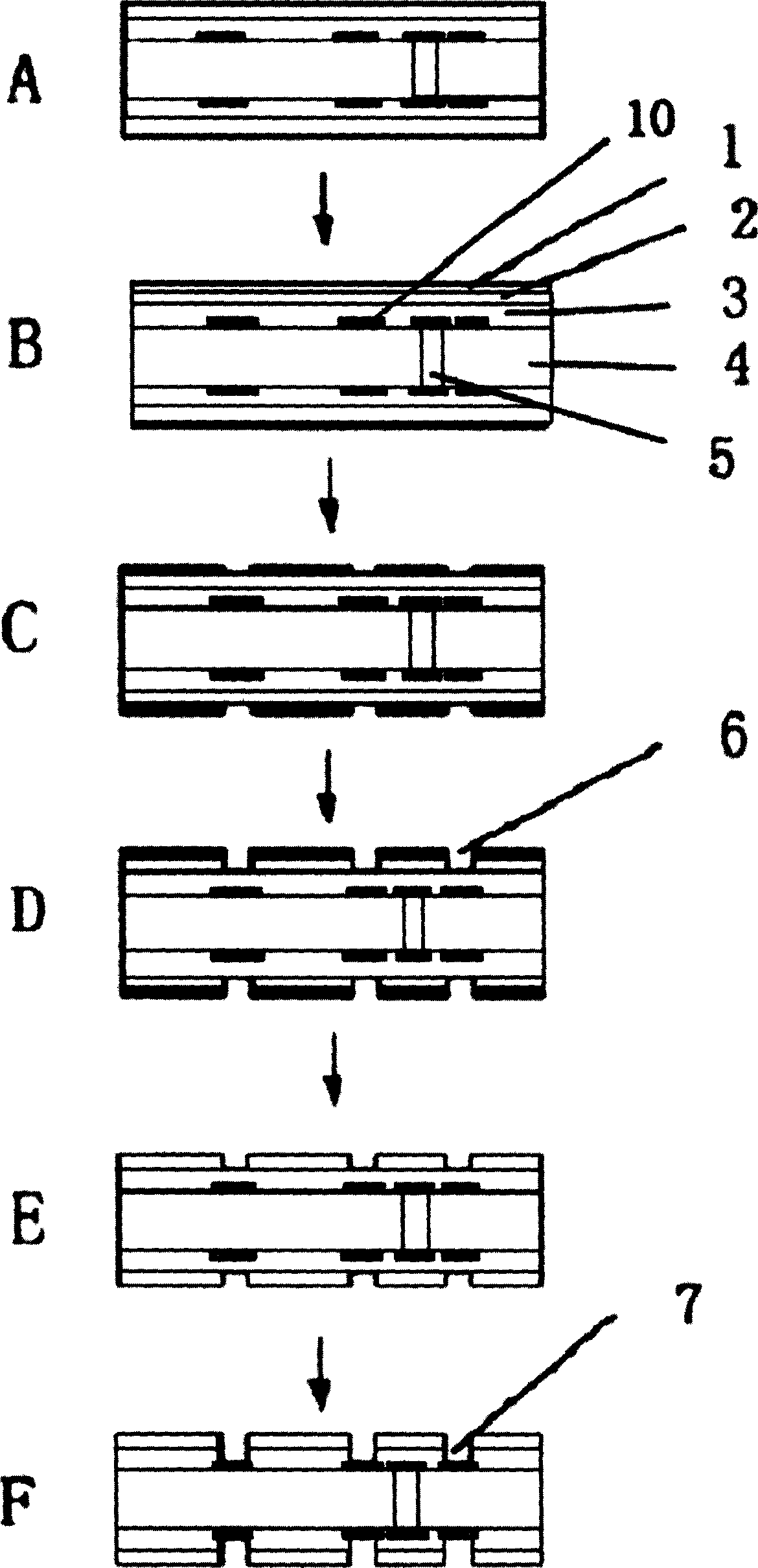

Thin film transistor having an etching protection film and manufacturing method thereof

InactiveUS7385224B2Improve machining accuracySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorSemiconductor thin films

A thin film transistor of the present invention includes a semiconductor thin film (8); a gate insulating film (7) formed on one surface of the semiconductor thin film (8); a gate electrode (6) formed to be opposite to the semiconductor thin film (8) through the gate insulating film (7); a source electrode (15) and a drain electrode (16) electrically connected to the semiconductor thin film (8); a source region; a drain region; and a channel region. The thin film transistor further includes an insulating film (9) formed on a peripheral portion corresponding to at least the source region and the drain region of the semiconductor thin film (8), and having a contact hole (10, 11) through which at least a part of each of the source region and the drain region is exposed wherein the source electrode (15) and the drain electrode (16) are connected to the semiconductor thin film (8) through the contact hole (10, 11).

Owner:CASIO COMPUTER CO LTD

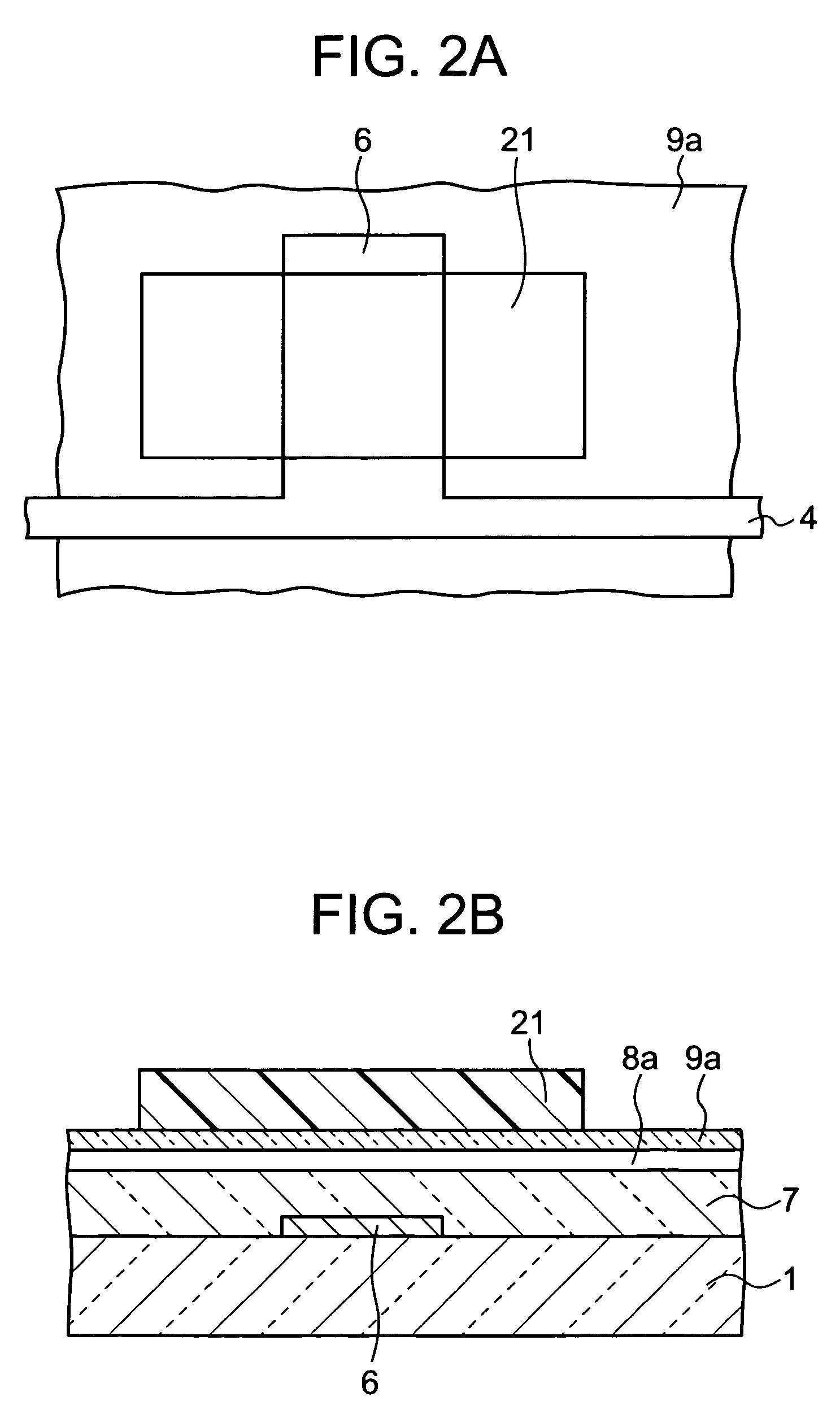

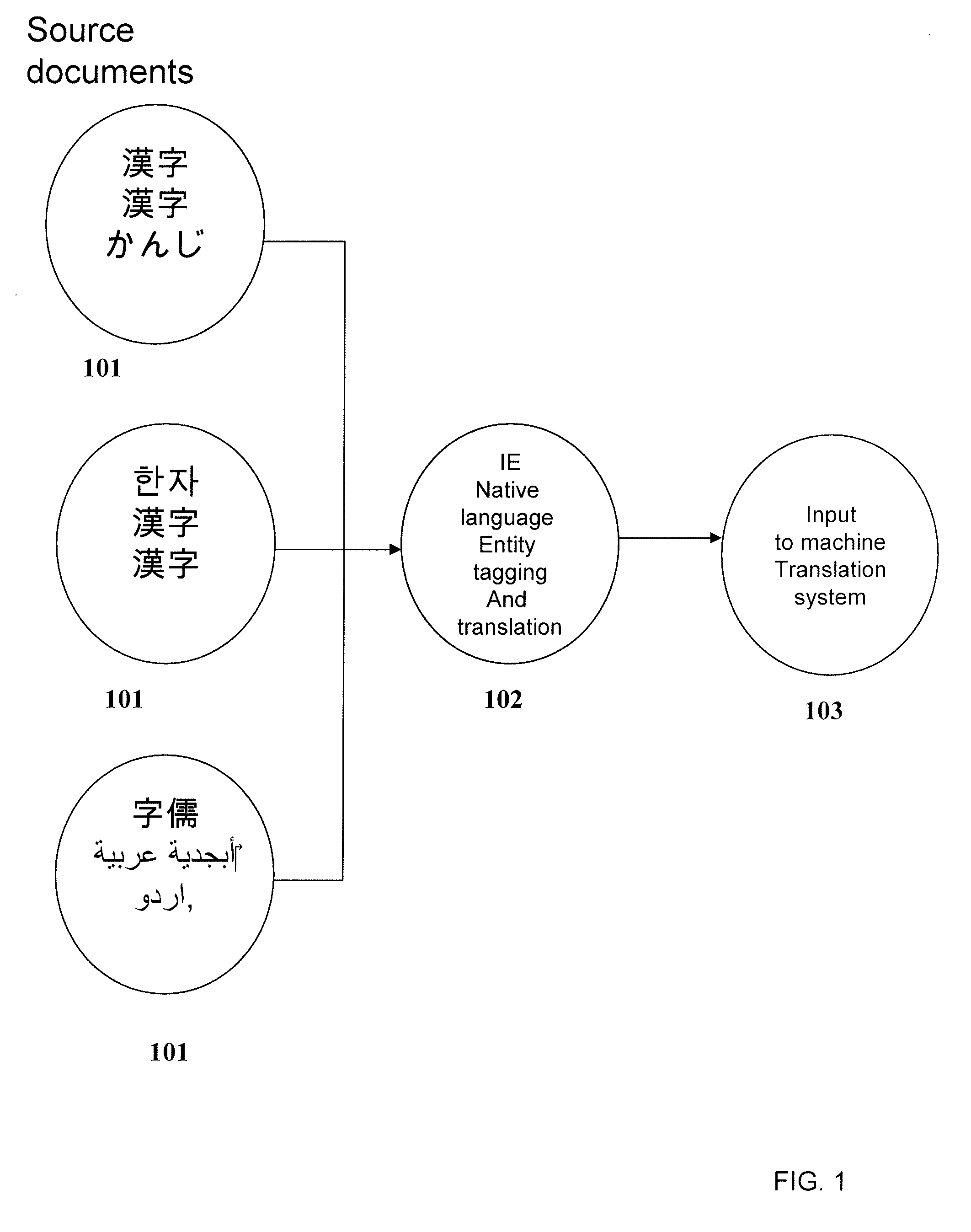

Context aware back-transliteration and translation of names and common phrases using web resources

InactiveUS20110137636A1Improve accuracyImprove machining accuracyNatural language translationSpecial data processing applicationsInformation retrievalData format

Described within are systems and methods for transliterating and translating source non-Romanized language text strings from a plurality of electronic sources to Romanized target language text strings by converting the source non-Romanized language text strings to a standard document encoding format, splitting the source non-Romanized language text strings into smaller units, transforming the smaller units into entity profiles, processing the entities profiles with data from external databases, translating the entities in the entity profiles into a Romanized target language, and outputting the entities into a plurality of data formats for external systems.

Owner:SMARTFOCUS HLDG

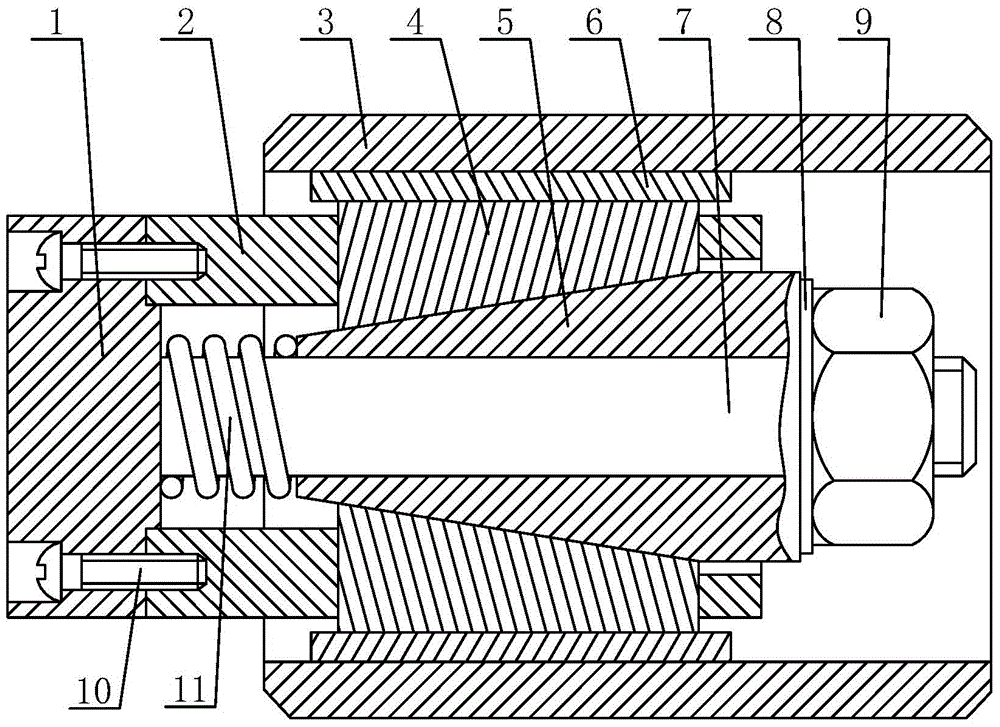

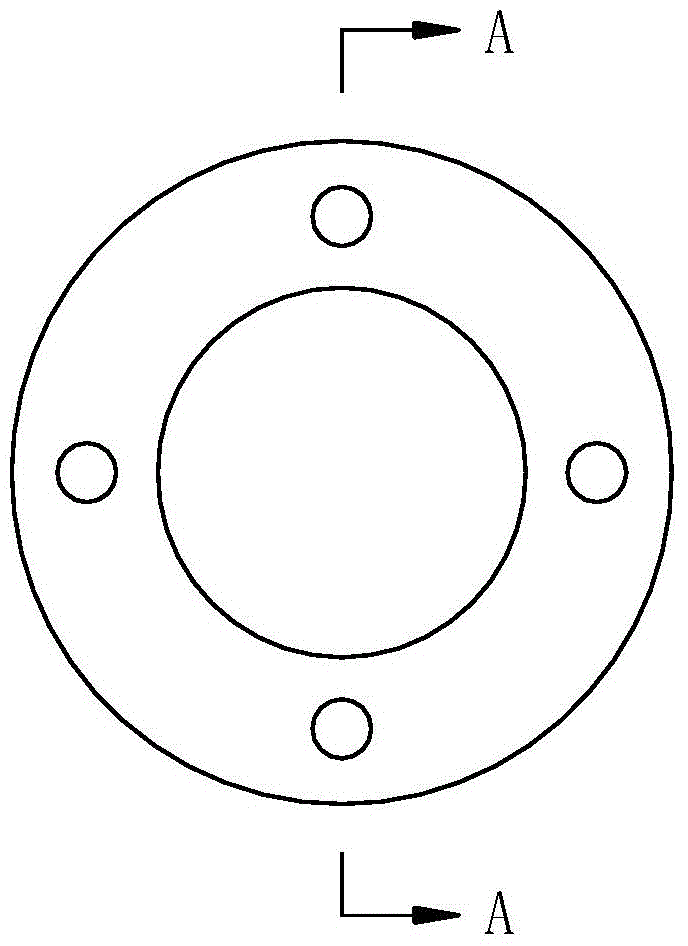

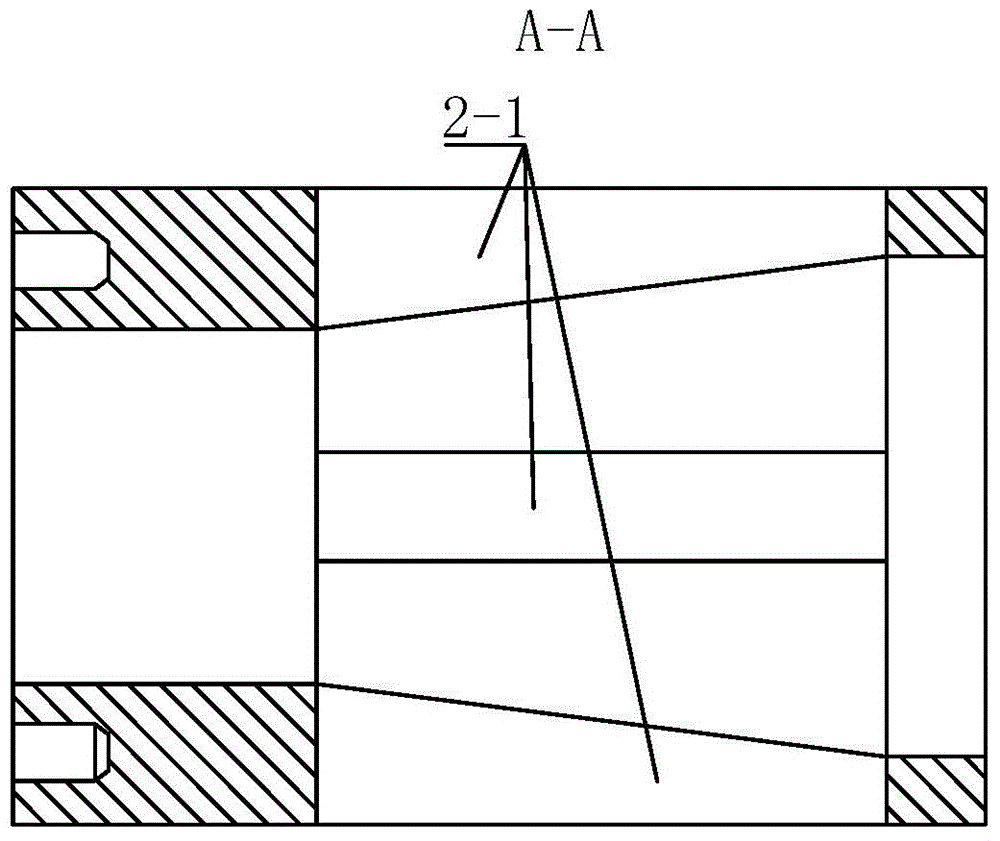

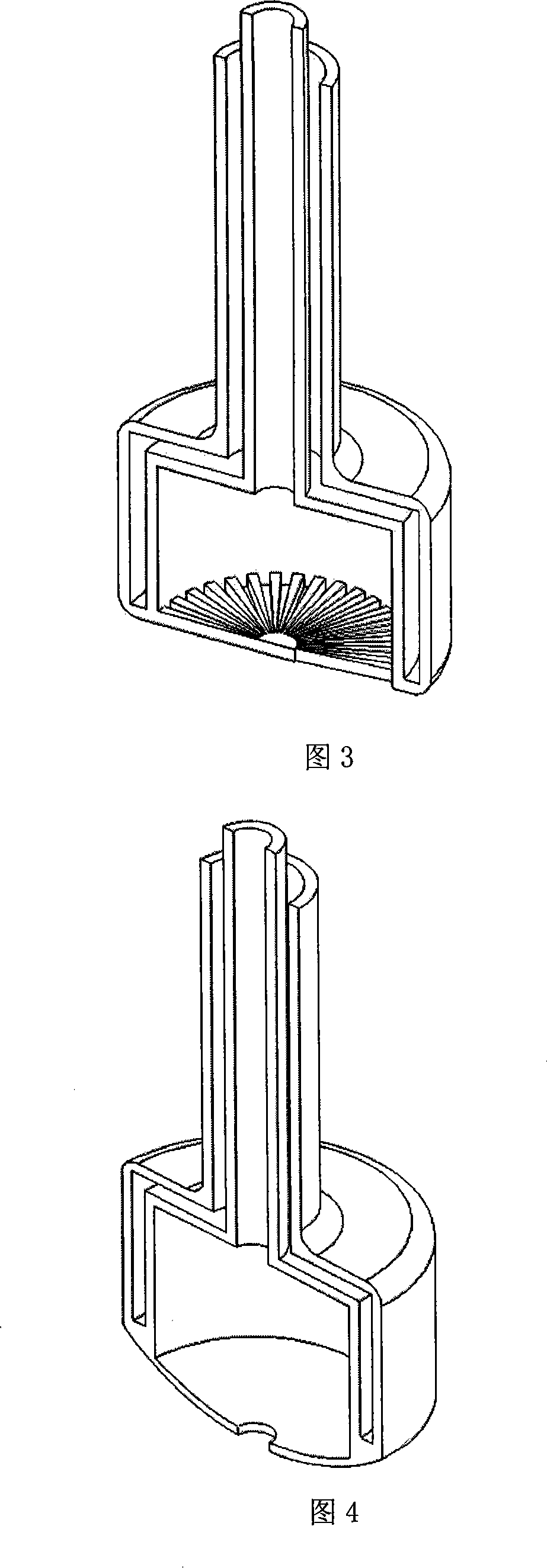

Thin-wall round pipe turning and clamping device

InactiveCN104607681AReasonable designCompact structureExpansion mandrelsEngineeringUltimate tensile strength

The invention discloses a thin-wall round pipe turning and clamping device. The thin-wall round pipe turning and clamping device comprises a slide block bracket for slidingly mounting inclined surface slide blocks, a screw rod for slidingly mounting and supporting taper sleeves, and a clamping base, wherein the slide block bracket and the screw rod are both fixedly mounted at one end of the clamping base; the taper sleeves are slidingly mounted on the screw rod; at least two inclined surface slide blocks fitting the taper sleeves to tightly eject workpieces from the inner sides are slidingly mounted on the slide block bracket; elastic cushion blocks are respectively arranged between all the inclined surface slide blocks and the workpieces; fastening nuts for tightly pressing the taper sleeves are arranged at the ends of the screw rod; and antiskid washers are arranged between the fastening nuts and the end surfaces of the taper sleeves. The thin-wall round pipe turning and clamping device has the characteristics of reasonable design, simple structure, good use effect, high machining precision, convenience for disassembly of the workpieces, low labor intensity, high production efficiency, low production cost and convenience for promotion and application.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

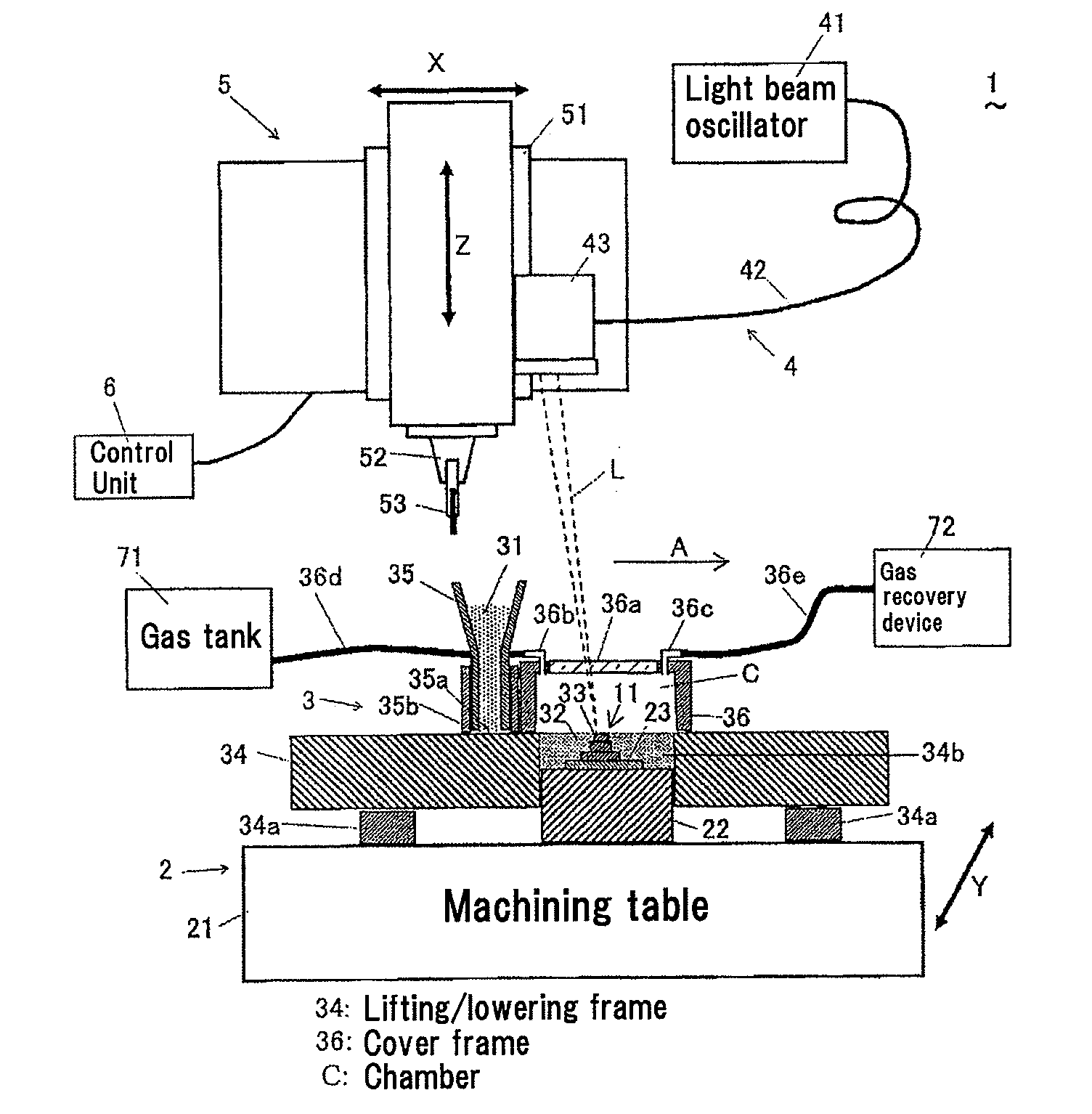

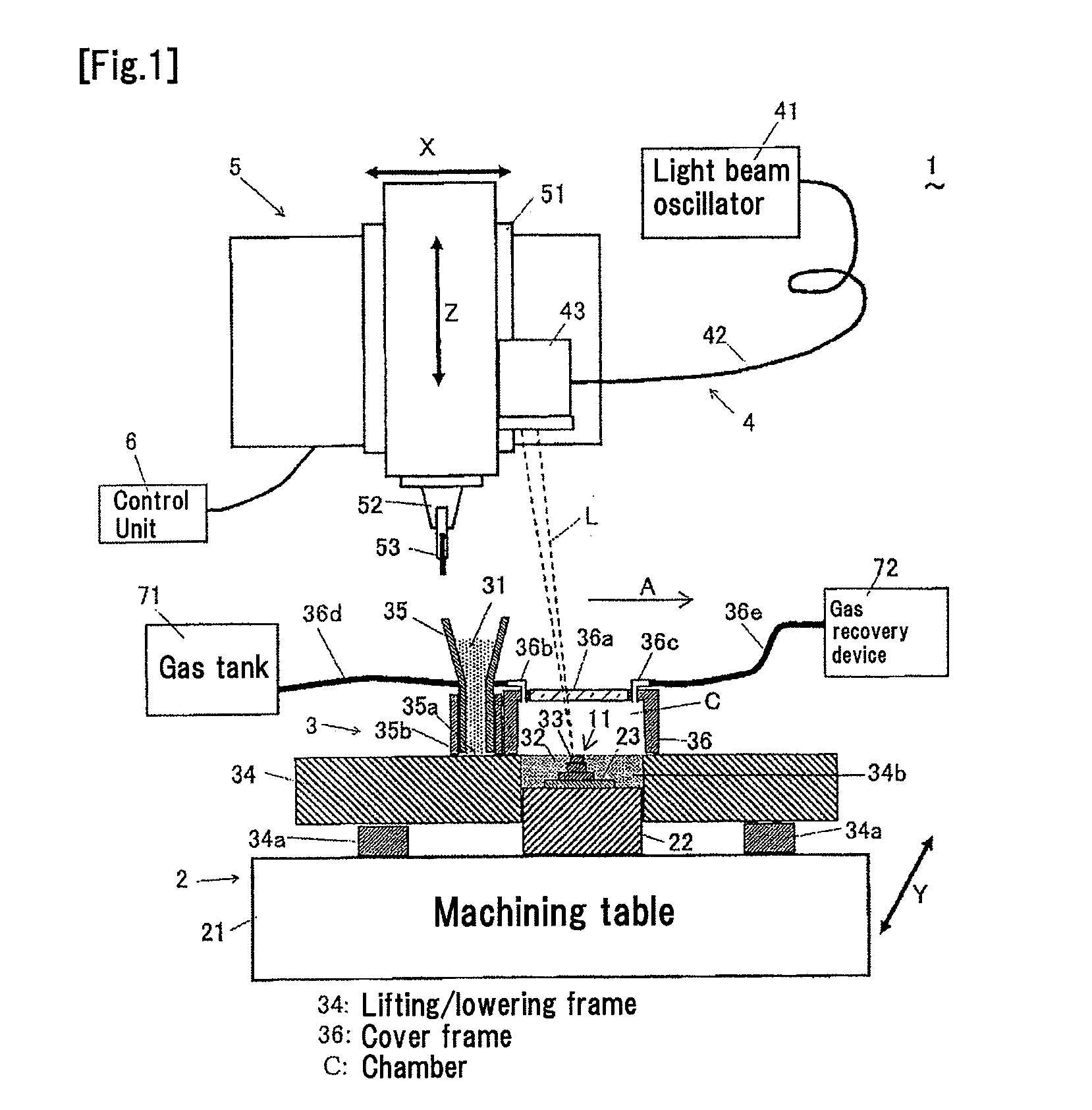

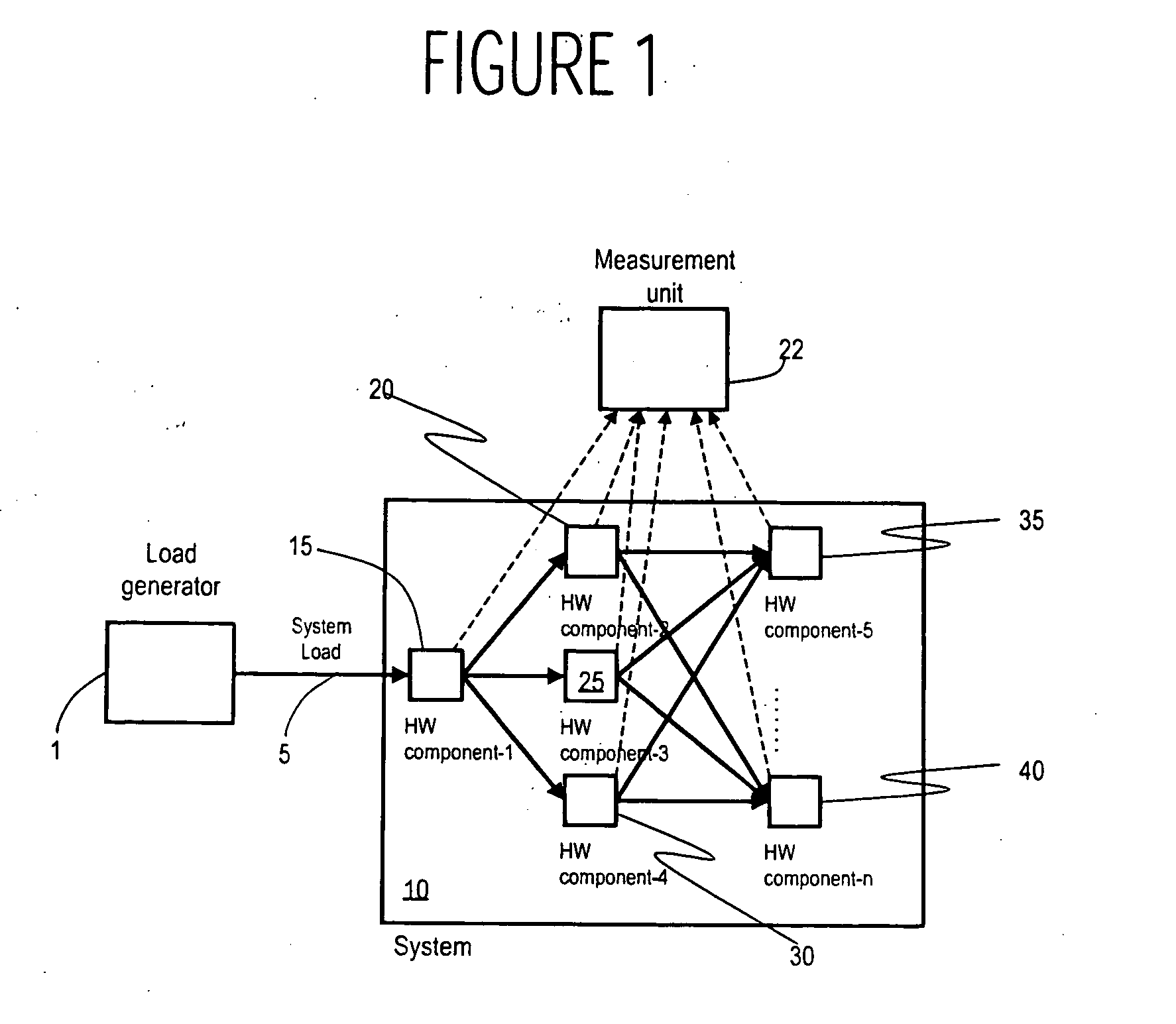

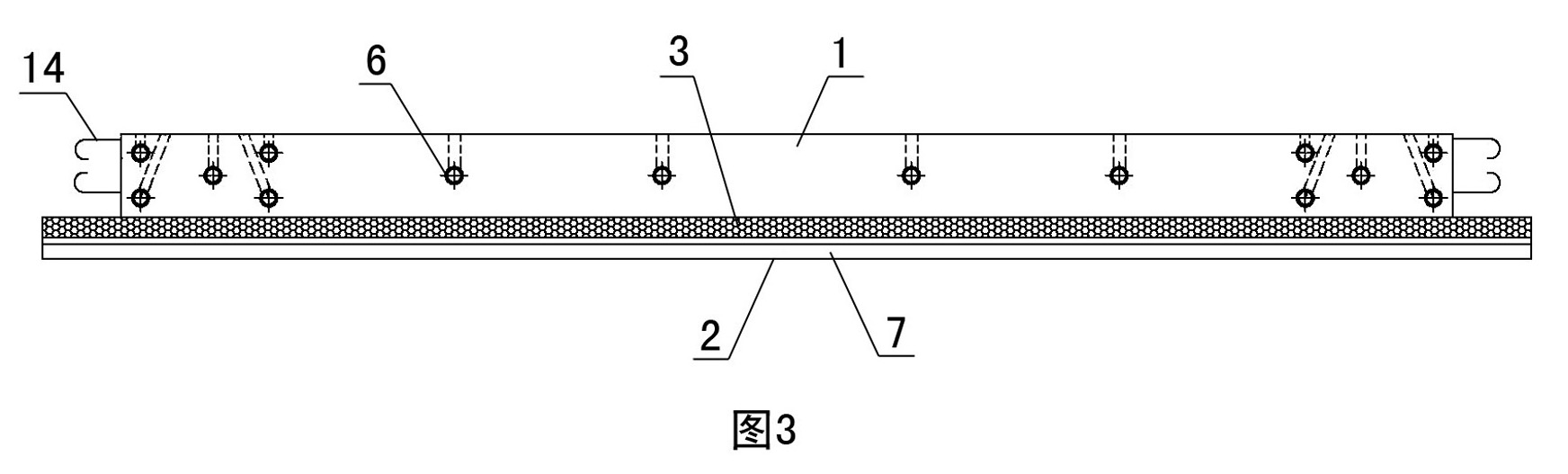

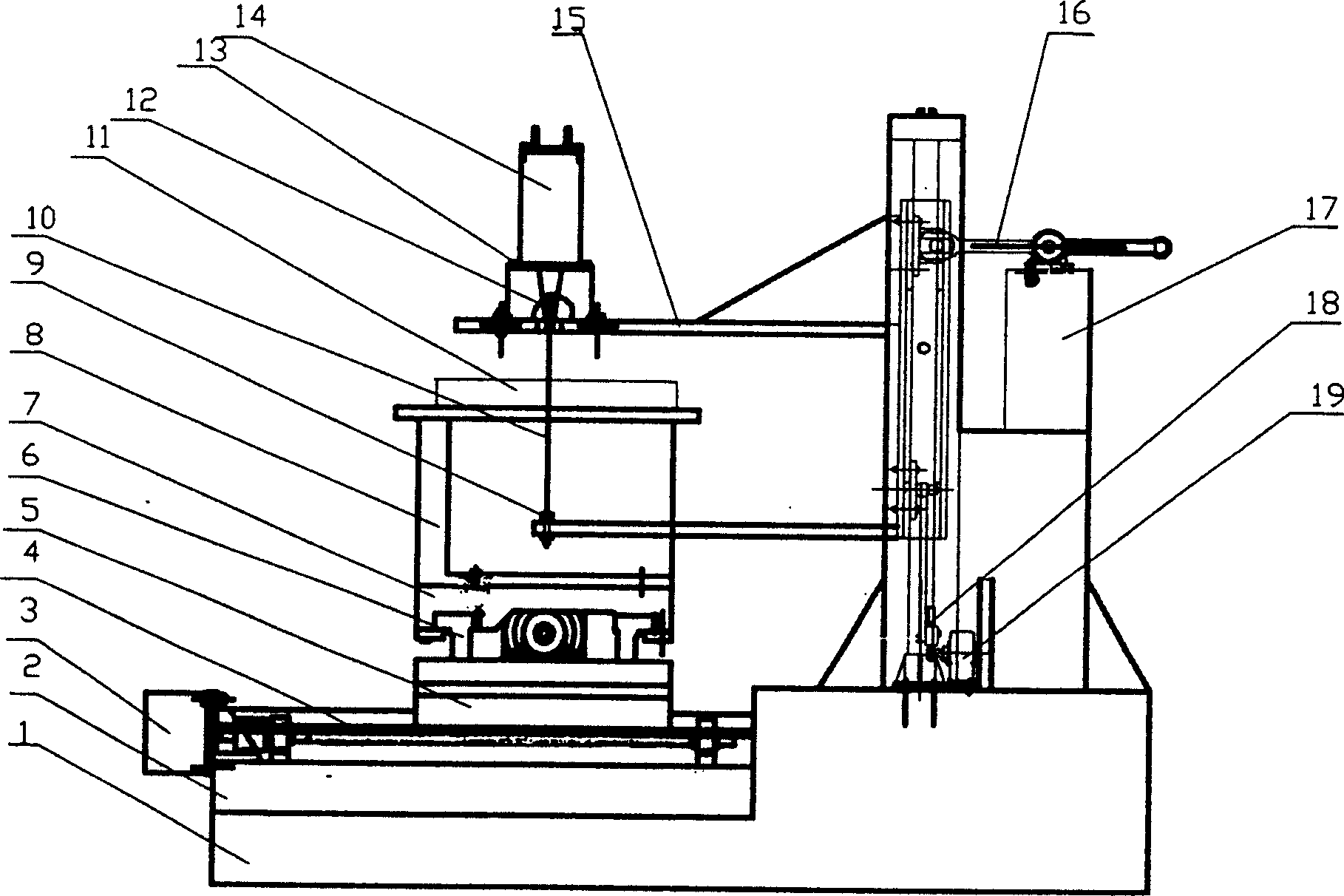

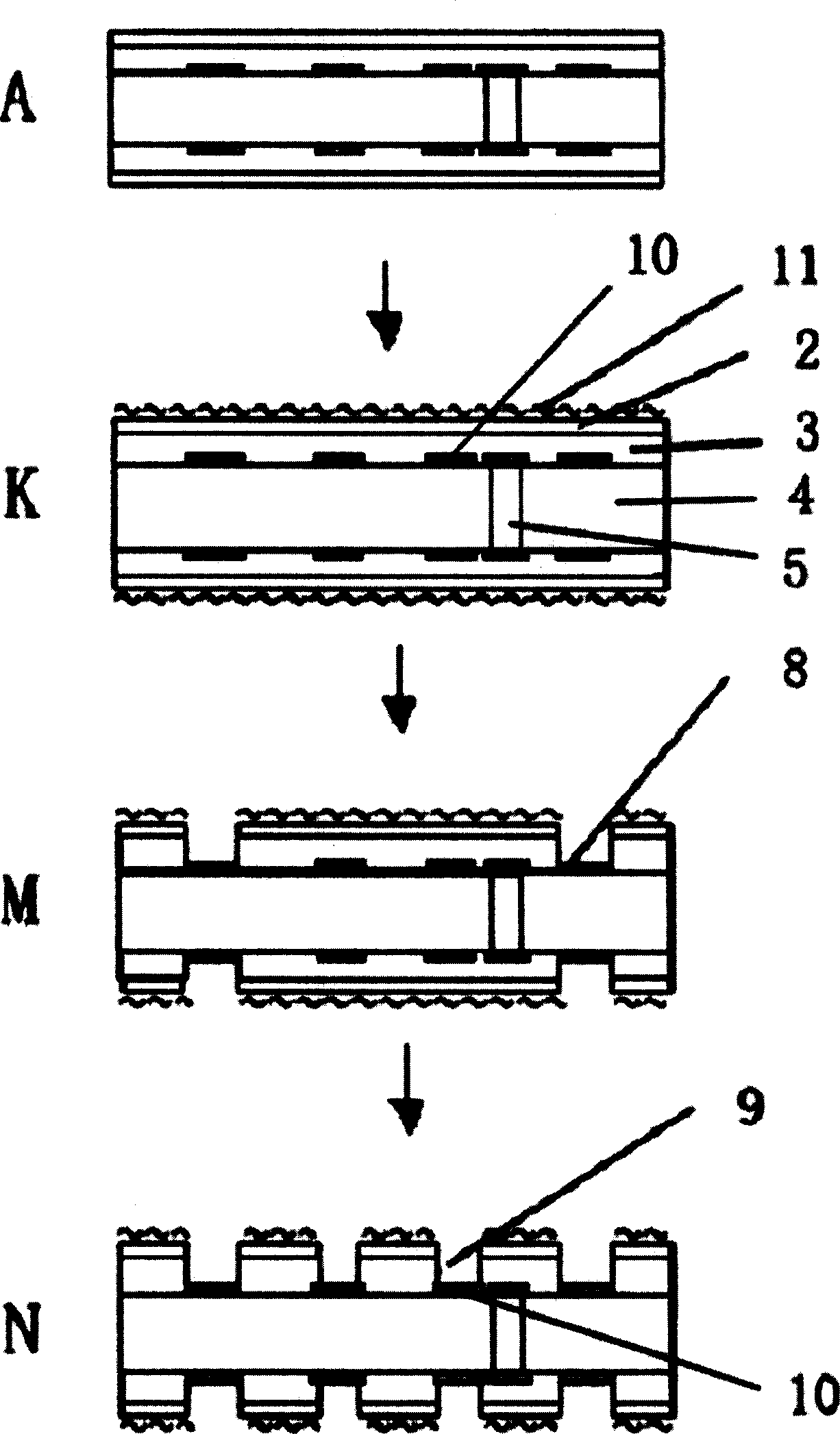

Layered-modeling device and method using said device for manufacturing three-dimensional objects

InactiveUS20120126457A1Easily eliminatingImprove machining accuracyAdditive manufacturing apparatusAuxillary shaping apparatusLayered modelLight beam

An object of the present invention is to easily eliminate fumes inside a chamber, so as to improve a positional accuracy of irradiation with a light beam and a machining accuracy in a method for manufacturing a three-dimensional shaped object. A stacked-layers forming device 1 includes a powder layer forming unit 3, a light beam irradiating unit 4, a base 22 which is fixed and on which a powder layer 32 is formed, a lifting / lowering frame 34 which surrounds the circumference of the base 22 and is freely capable of being lifted and lowered, a cover frame 36 which has a window 36a allowing transmission of light beam in its top surface, and whose bottom surface is opened, and which is disposed on the lifting / lowering frame 34 to form a chamber C, and a gas tank 71 for supplying an ambient gas. The lifting / lowering frame 34 is lowered to reduce the volume of the chamber C, so as to discharge fumes generated inside the cover frame 36, which performs replacement with the ambient gas. Since the volume of the chamber C is reduced, it is possible to easily eliminate the fumes, which makes it possible to improve the positional accuracy of irradiation with the light beam L, and the machining accuracy.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

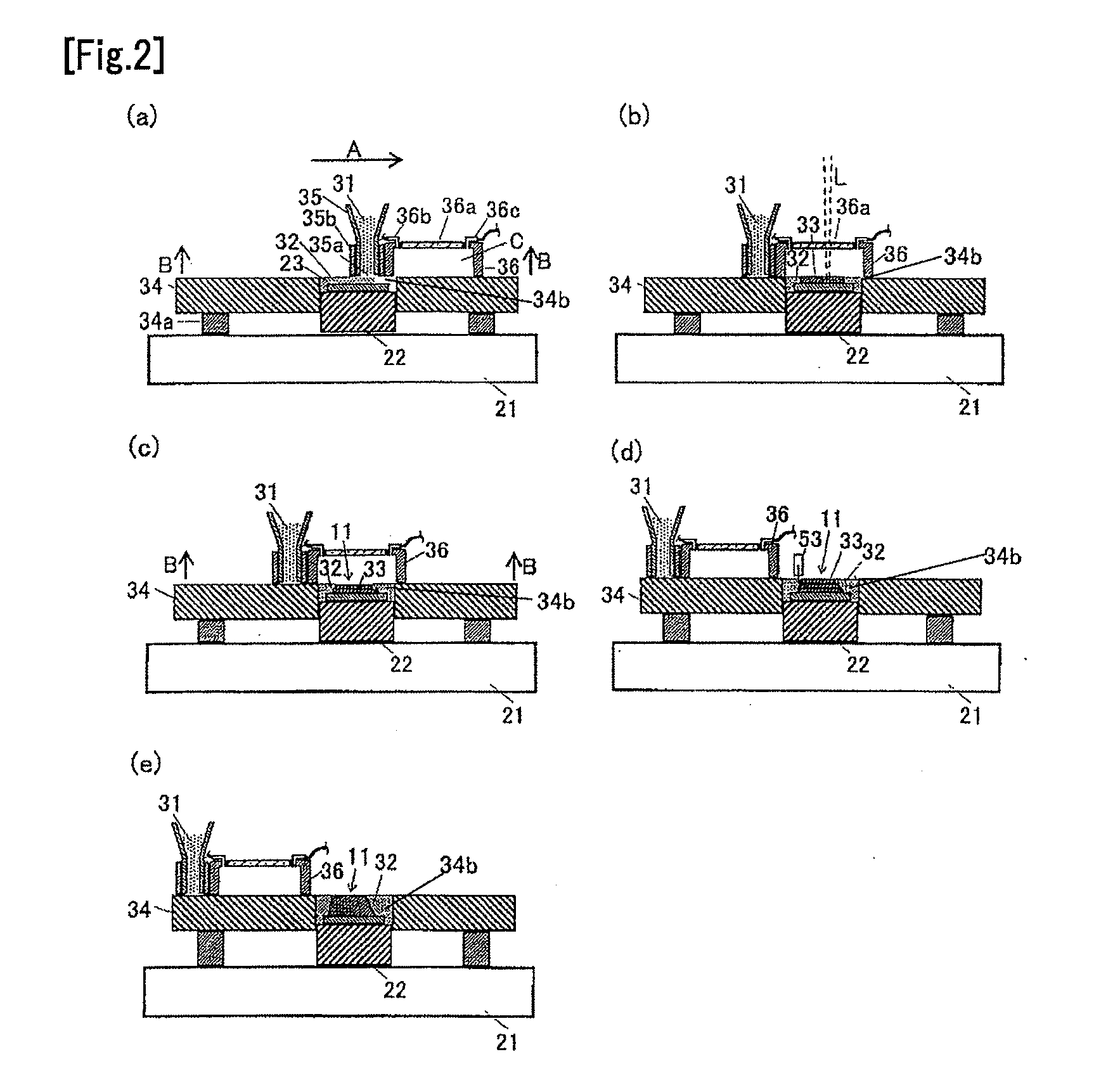

System for estimating processing requirements

InactiveUS20050228875A1Improve machining accuracyDigital computer detailsTransmissionCapacity limitComputer science

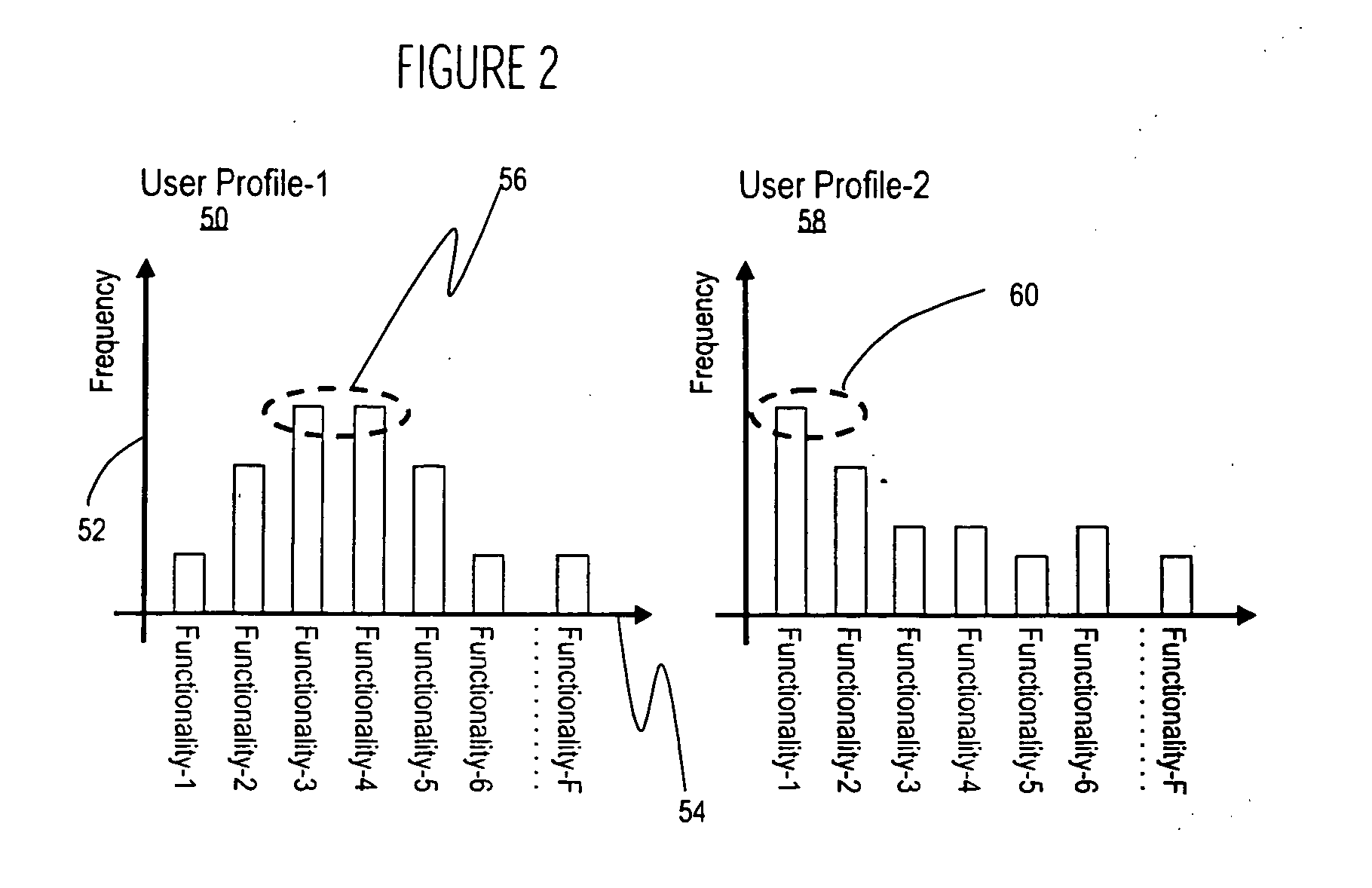

An application estimates sizing information and capacity limits for a processing system configuration using load data automatically provided by a load determination application. A system supports selection of processing devices for a particular user. At least one repository includes, usage information indicating distribution of usage of a plurality of functions supported by a particular configuration of processing devices and capacity information including data identifying a load limit associated with a particular usage distribution and a particular configuration of processing devices. An interface processor retrieves, from the at least one repository, data identifying a candidate particular configuration of processing devices in response to received data indicating a particular usage distribution.

Owner:SIEMENS MEDICAL SOLUTIONS HEALTH SERVICES CORPORAT

Speed control method used for numerical control machine

InactiveCN1971457AReduce shockImprove smoothnessComputer controlSimulator controlNumerical controlControl theory

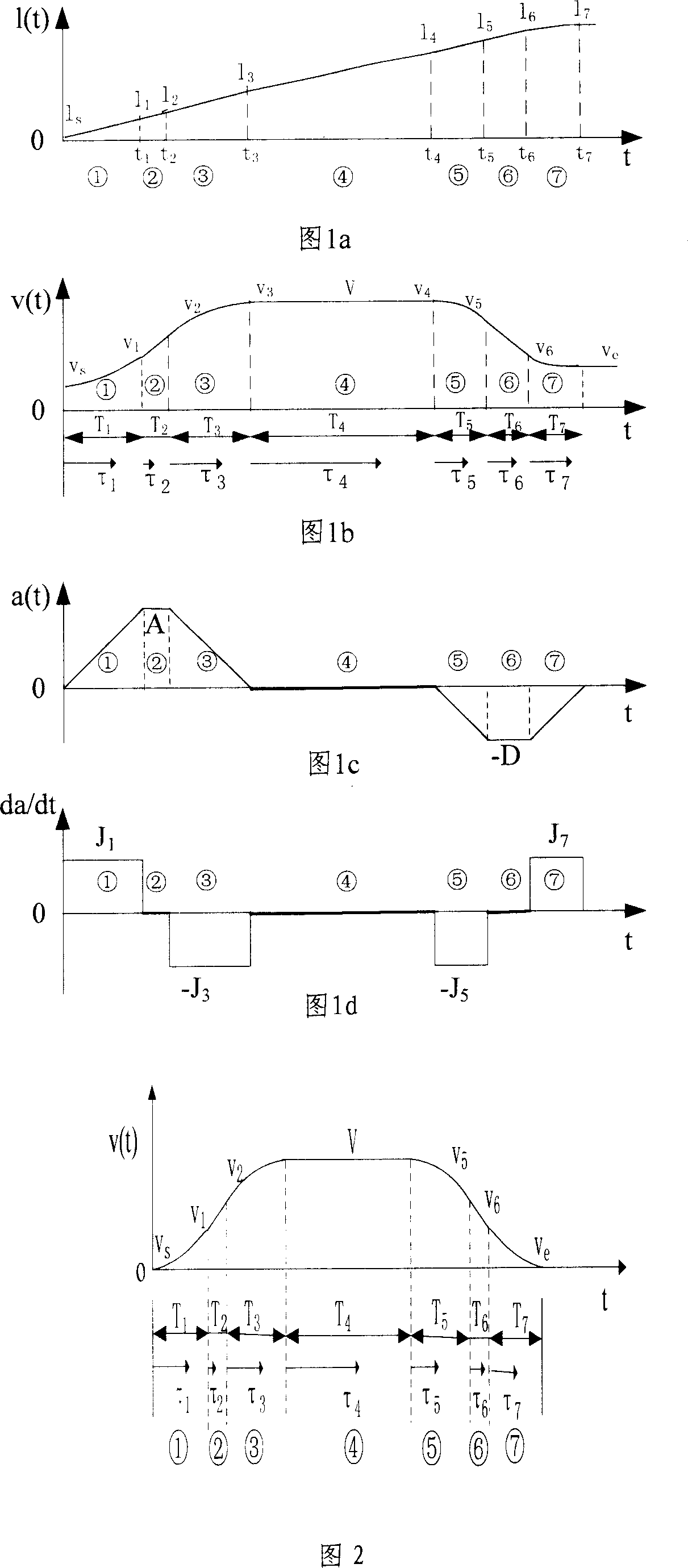

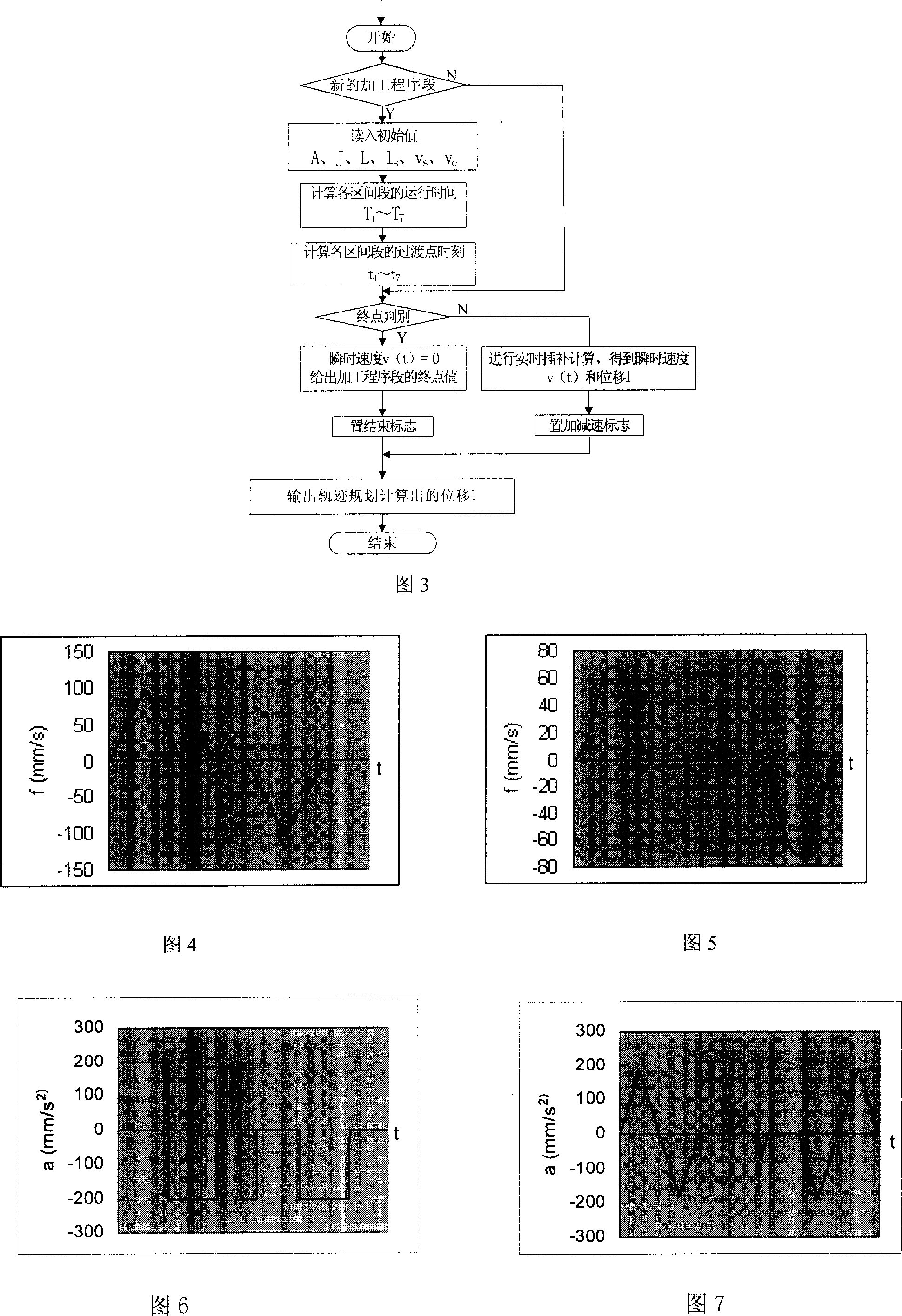

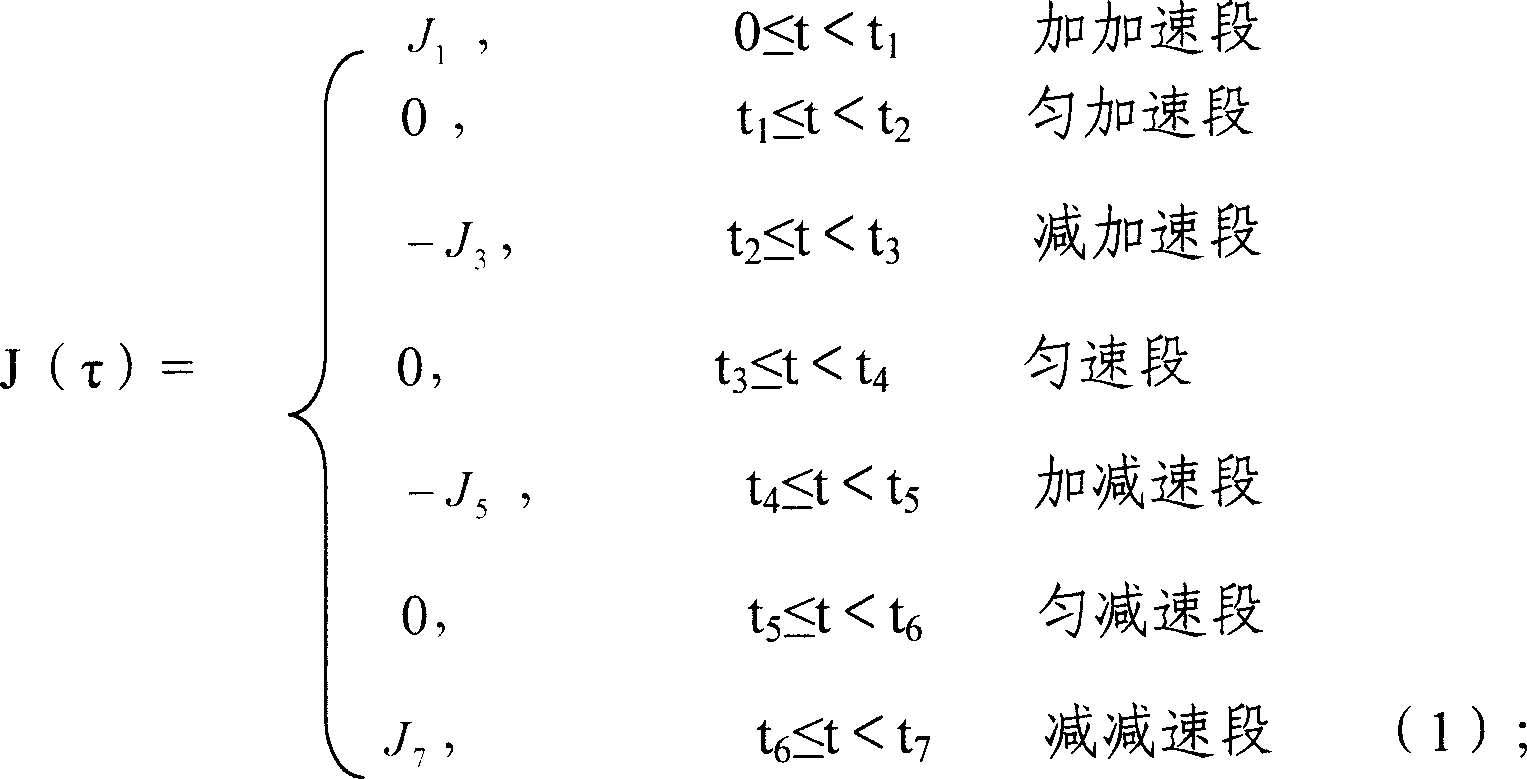

The invention discloses acceleration and deceleration controlling means used in numerical control machine, the concept of 'add-acceleration' is introduced against the dynamic property of the controlled member, the add-acceleration is constant in stage of acceleration and deceleration, the two physical quantities of acceleration and add-acceleration are setting; the segmented handling method of add-accelerating sections, uniform accelerating sections, decelerated accelerating sections, uniform speed sections, add-decelerating sections, uniformly-retarded sections and decelerated deceleration sections is adopted, after the interval discrimination, the real-time interpolating calculation in every interval is exceeded based on the integral relation between the add-acceleration, acceleration, speed and displacement, the S type velocity curve is formed to realize the flexible acceleration and deceleration control; the destination discrimination process is proceeded before the interpolating calculation can increase the machining precision of the acceleration and deceleration control. The method is simple, the impact is small, the speed is smooth, the machining precision is high and the flexible control can be realized.

Owner:中国科学院沈阳计算技术研究所有限公司 +1

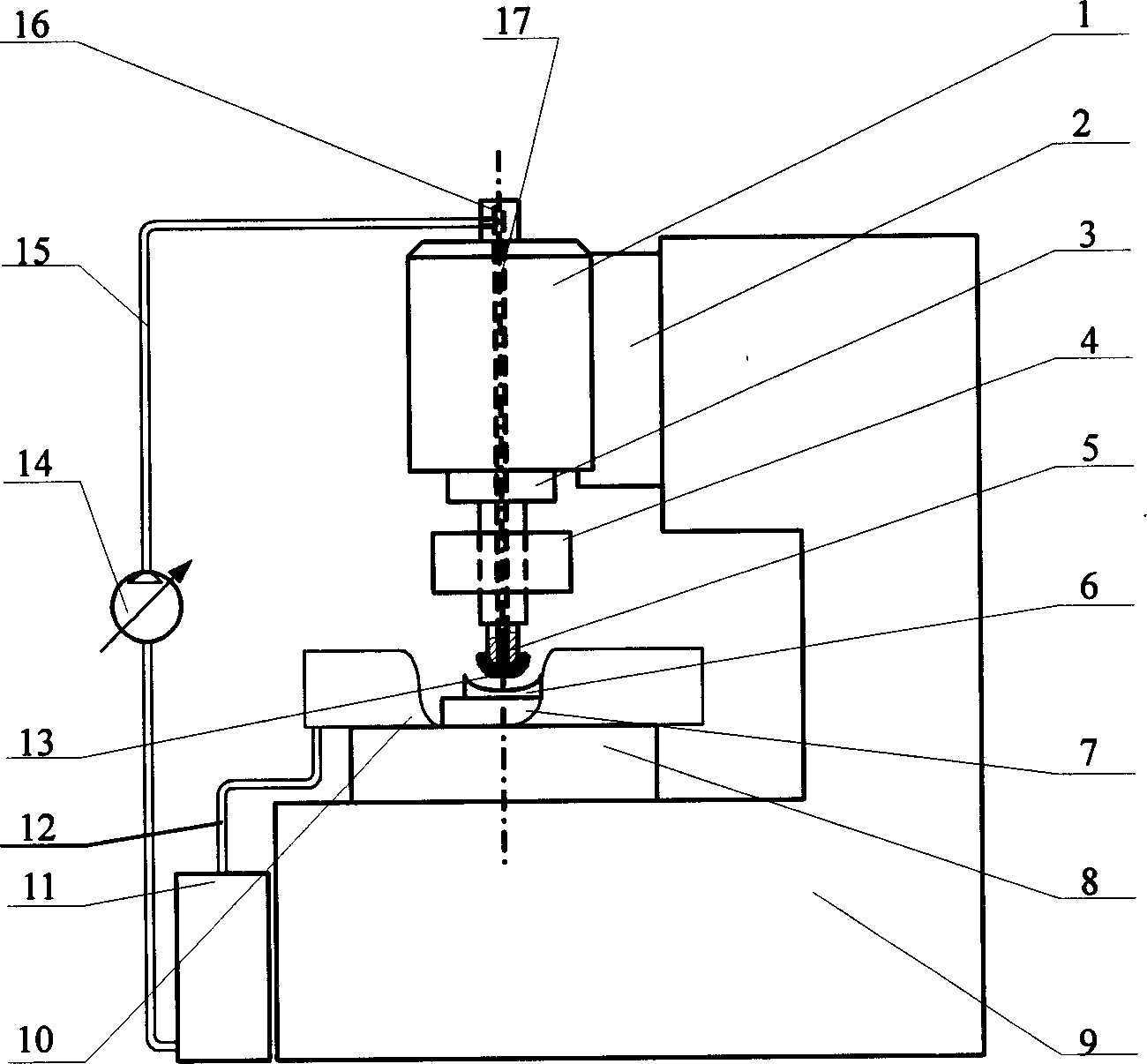

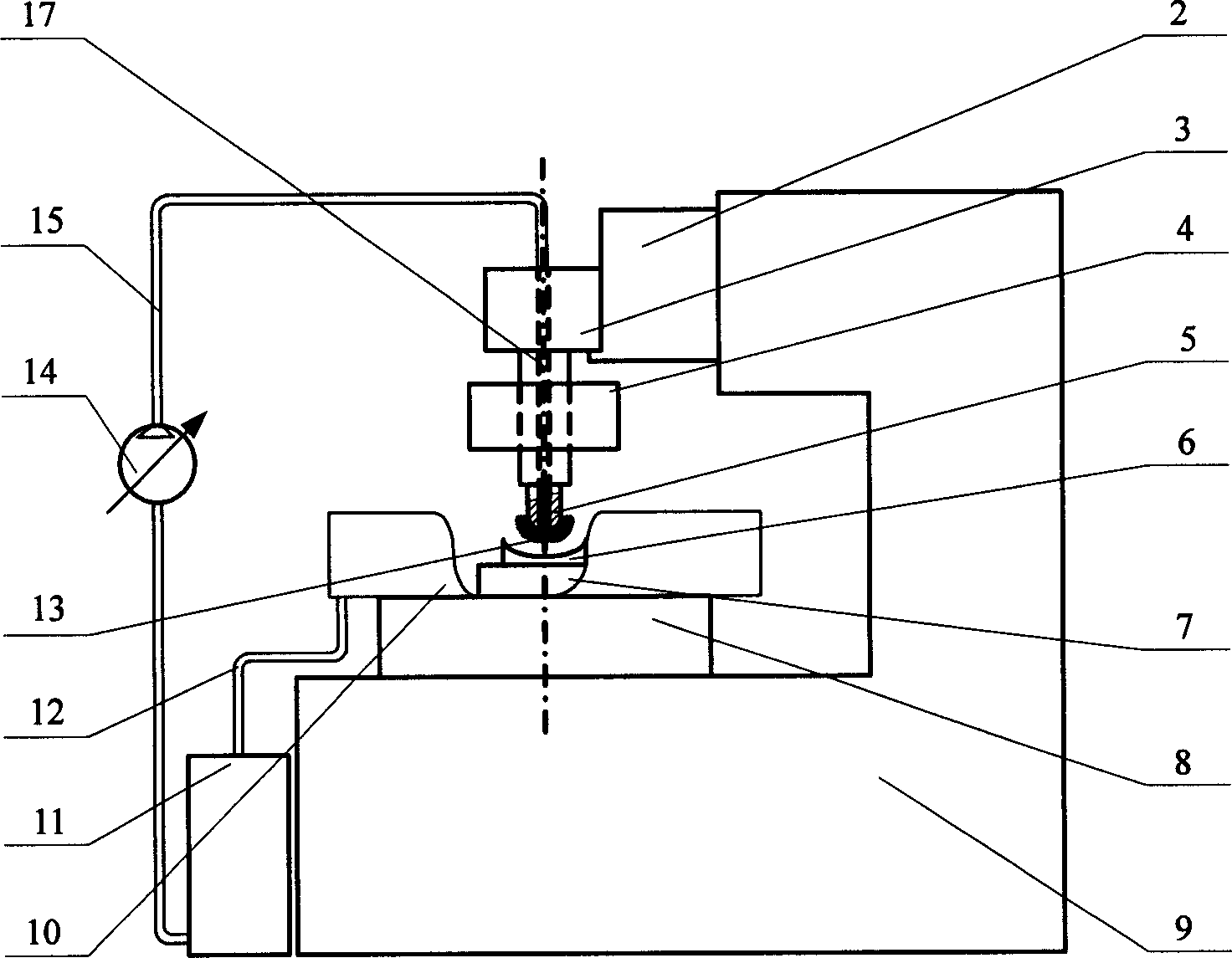

Ultrasonic magnetic rheological composite polishing method and polisher thereof

InactiveCN1613605AAchieve recyclingStable Polishing PropertiesOptical surface grinding machinesUltrasonic vibrationEngineering

An ultrasonic-magnetorheologic polishing method features that the mixture of abrasive material and magnetorheologic liquid is filled in a small-diameter rotary hollow polishing head and a magnetic field is applied to it to make the magnetorheologic liquid become flexible polishing liquid on the polishing head while the ultrasonic vibration is applied to it for higher polishing effect. Its apparatus is composed of polishing head, ultrasonic generator, and electromagnet.

Owner:HARBIN INST OF TECH

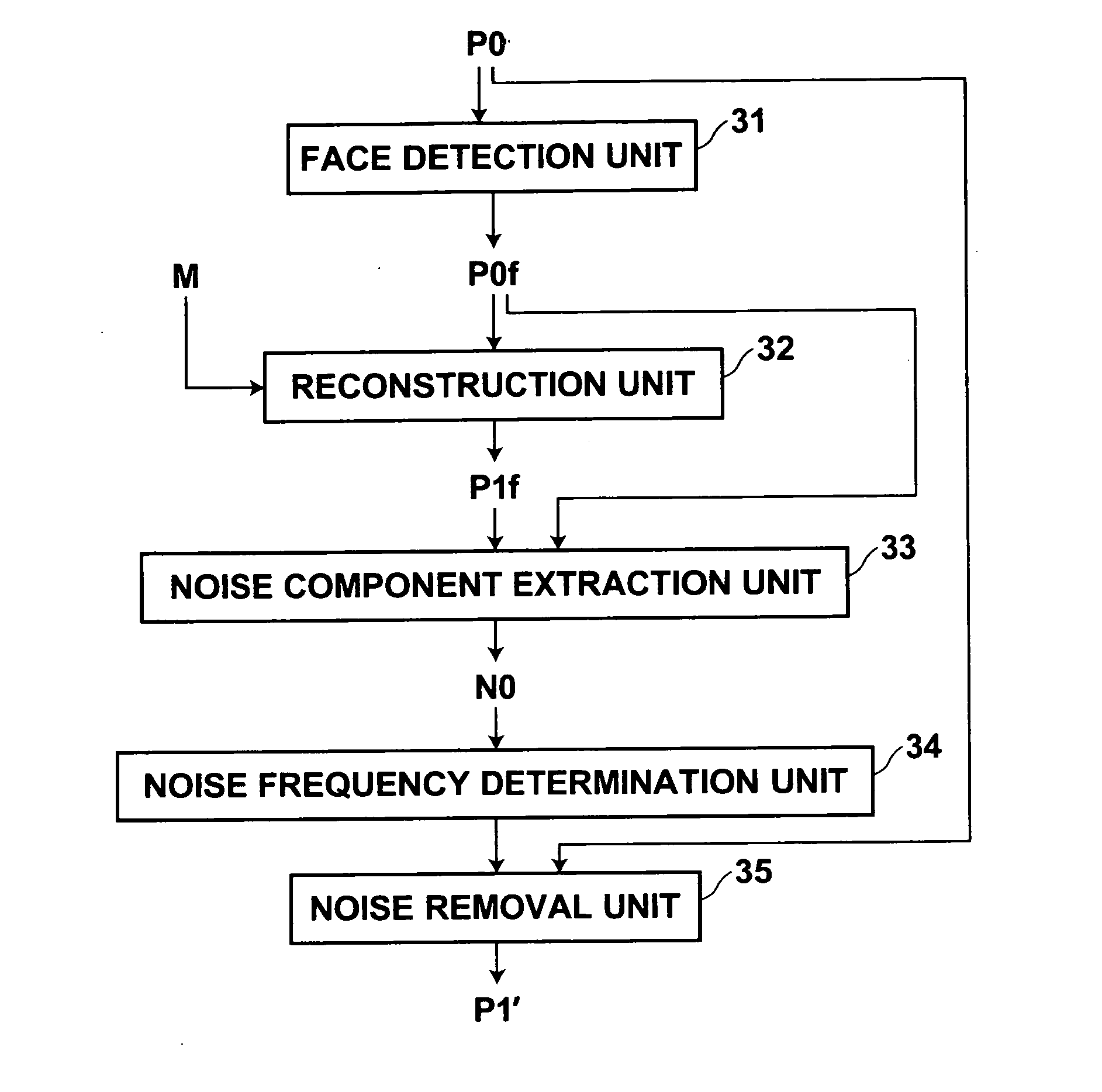

Image processing apparatus, image processing method, and image processing program

ActiveUS20060257047A1Quality improvementGood removal effectCharacter and pattern recognitionFace detectionImaging processing

In order to accurately remove an unnecessary periodic noise component from an image, a reconstruction unit generates a reconstructed image without a periodic noise component by fitting to a face region detected in an image by a face detection unit a mathematical model generated according a method of AAM using a plurality of sample images representing human faces without a periodic noise component. The periodic noise component is extracted by a difference between the face region and the reconstructed image, and a frequency of the noise component is determined. The noise component of the determined frequency is then removed from the image.

Owner:FUJIFILM HLDG CORP +1

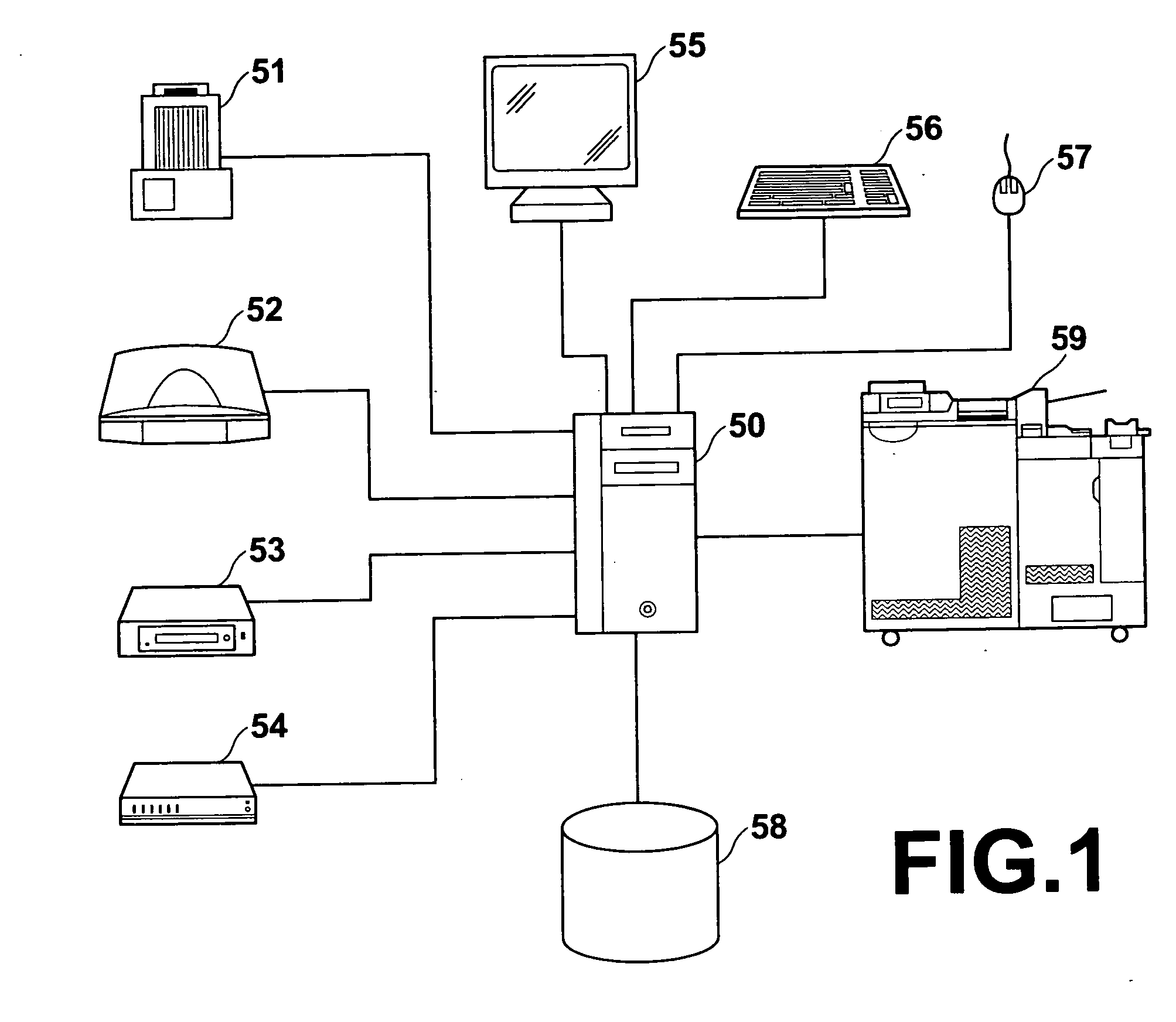

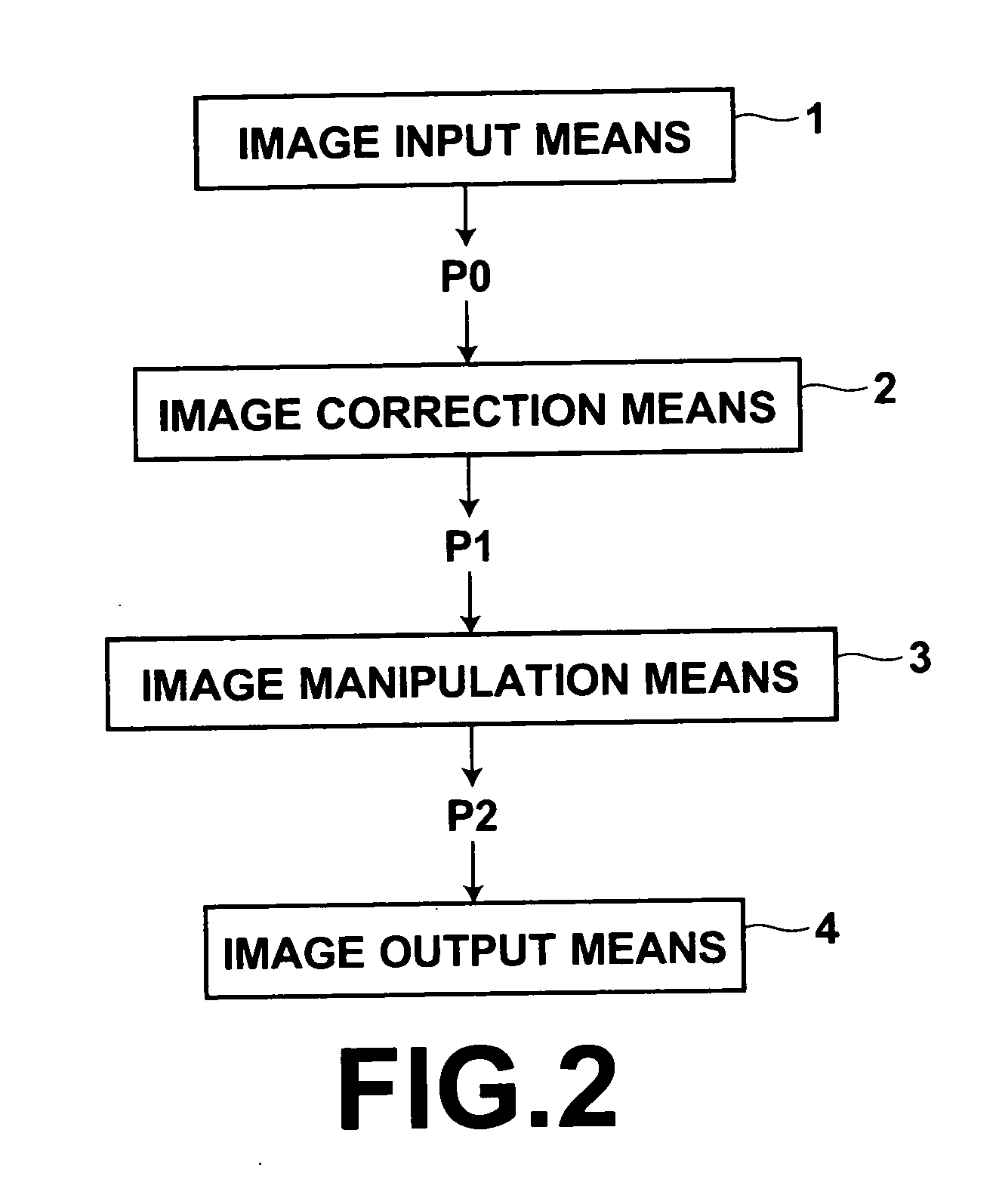

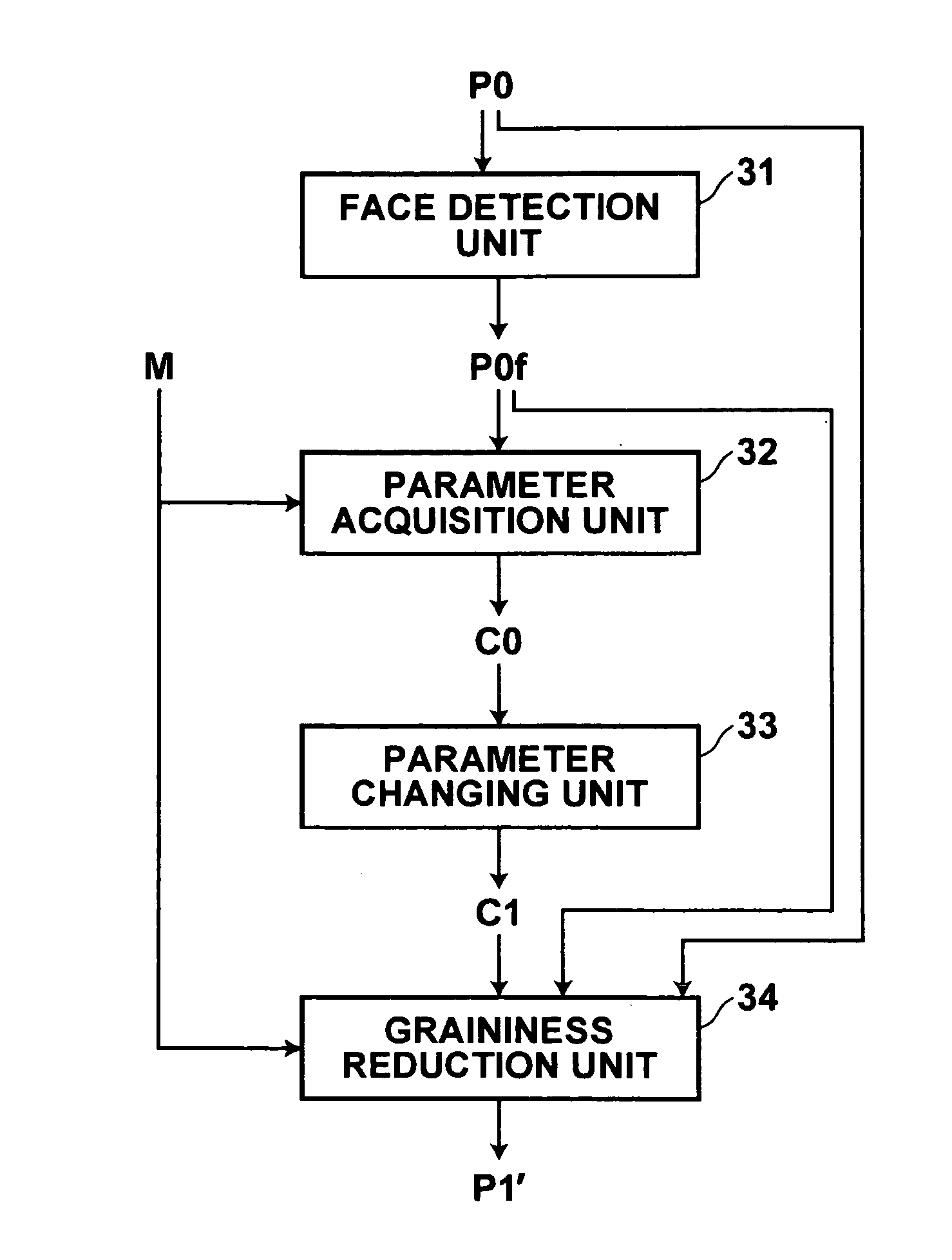

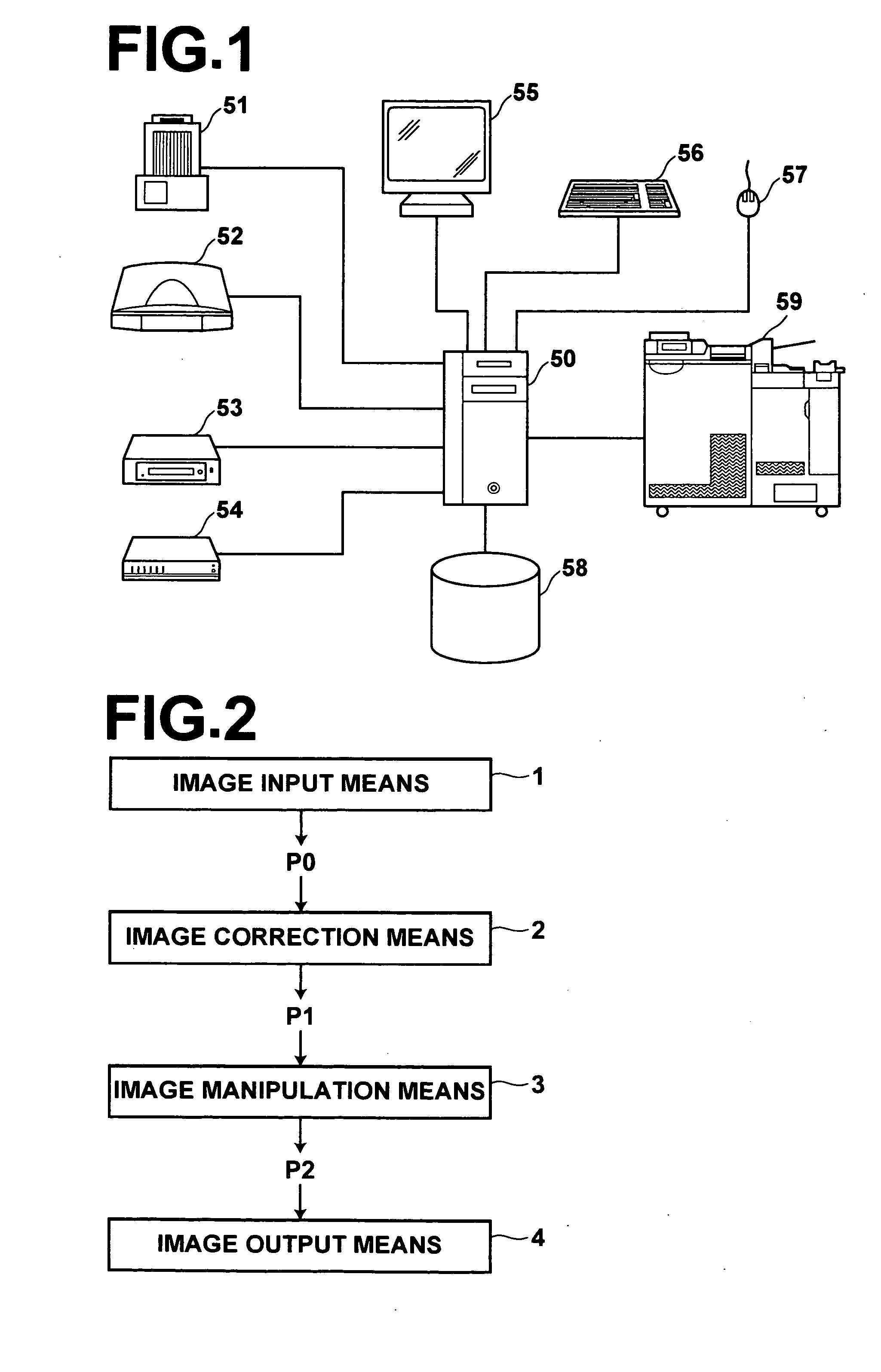

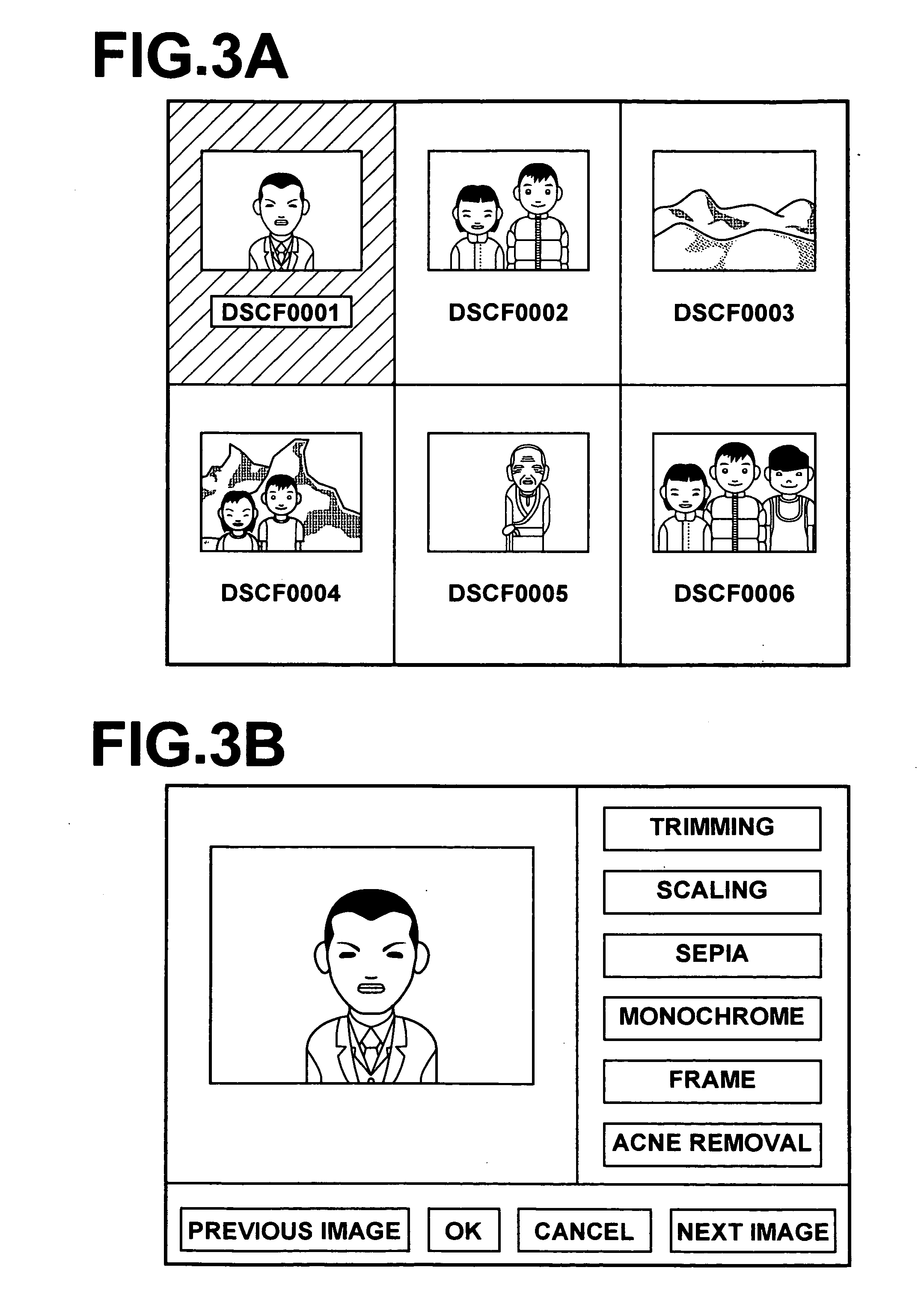

Apparatus, method and program for image processing

InactiveUS20060291739A1Reduce graininessImprove machining accuracyCharacter and pattern recognitionFace detectionImaging processing

Graininess reduction processing is carried out with accuracy by finding a degree of graininess in an image. For this purpose, a parameter acquisition unit obtains a weighting parameter for a principal component representing the degree of graininess in a face region found in the image by a face detection unit, by fitting to the face region a mathematical model generated by a method of AAM using a plurality of sample images representing human faces in different degrees of graininess. A parameter changing unit changes the parameter to have a desired value. A graininess reduction unit reduces graininess of the face region according to the parameter having been changed.

Owner:FUJIFILM HLDG CORP +1

Water-based cutting fluid used in slice machining of hard brittle crystal material and preparation method of water-based cutting fluid

InactiveCN102618374AGuaranteed lubrication effectGuaranteed anti-rust performanceAdditivesWater basedTool wear

The invention discloses a water-based cutting fluid used in slice machining of a hard brittle crystal material, comprising the following compositions: base oil, organic amine, organic acid, synthetic ester, emulsifier, rust and corrosion inhibitor, dispersion flocculation and hard-water resisting agent, antiseptic bactericide, antifoaming agent, coupling agent, adjuvant and a proper amount of water. Aiming at the machining techniques of inner circle slicing and outer circle slicing, the water-based cutting fluid has good generality, lubricity, strong antirust property and a long service life; when the cutting fluid is used, the machining situation can be observed easily, the cooling property is good, the cleaning and the permeability are strong, cuttings subside easily, and the machining problems of machining error, crack and the like caused by cutter blocking, abrasion and the like are solved; according to the invention, the problems that cuttings are easy to adhere and suspend, a cutter is seriously abraded, a machined product cracks easily, the accuracy is not high, the machining efficiency is low, the later period cleaning is complex and the like existing in the current slice machining of the hard brittle crystal material are solved, and further, a machine bed is protected, and the cost is reduced.

Owner:AMER TECH CO LTD

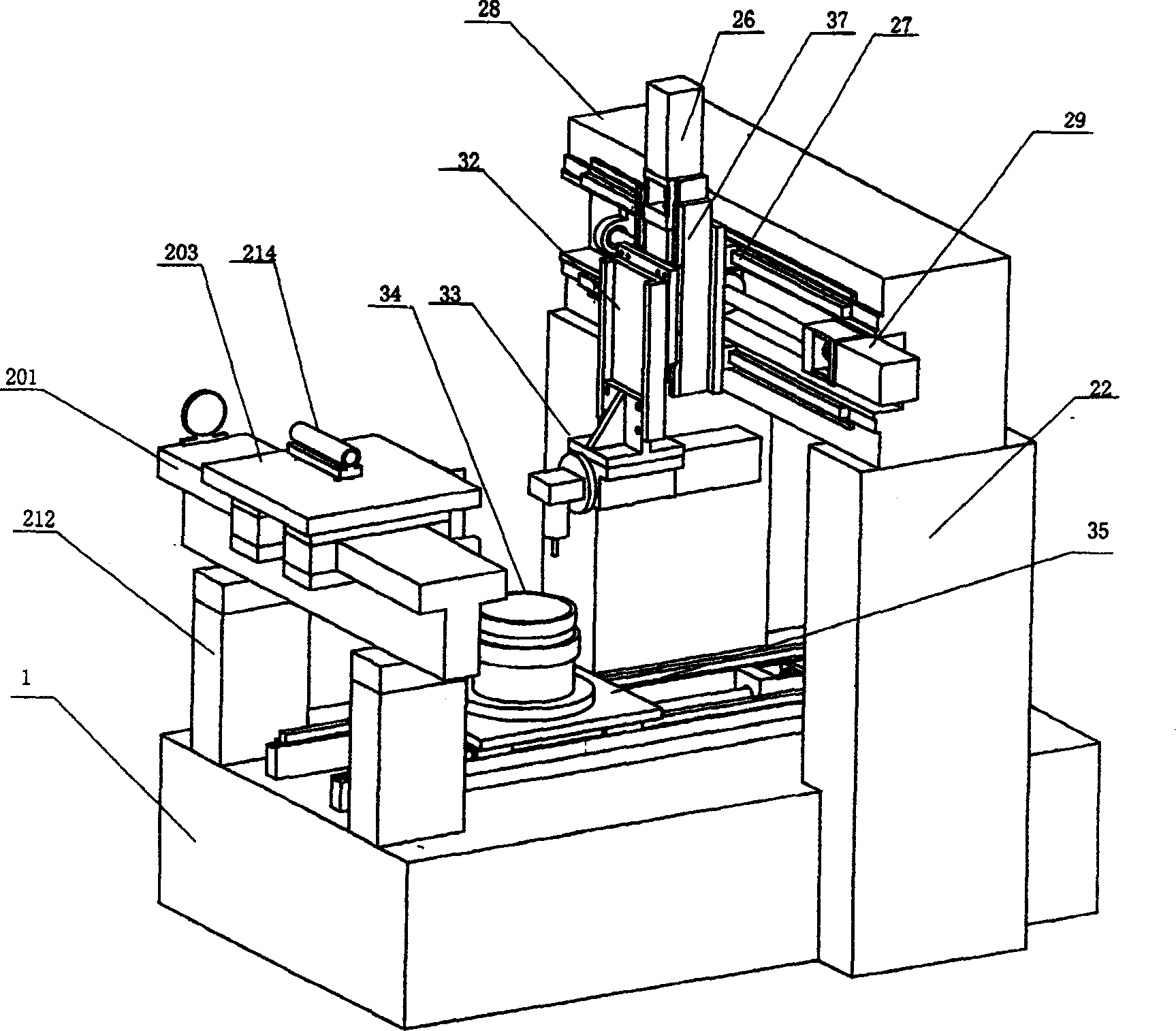

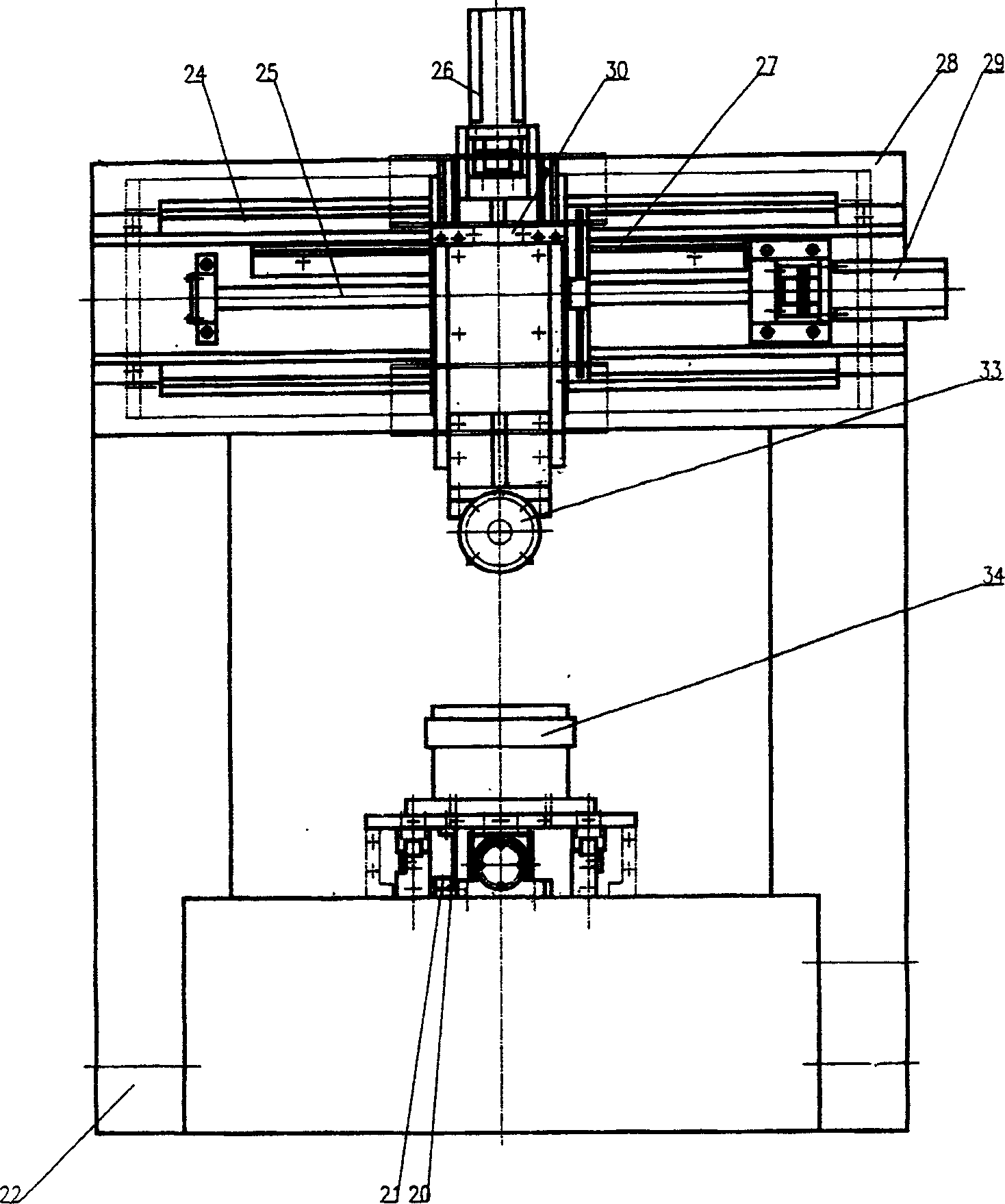

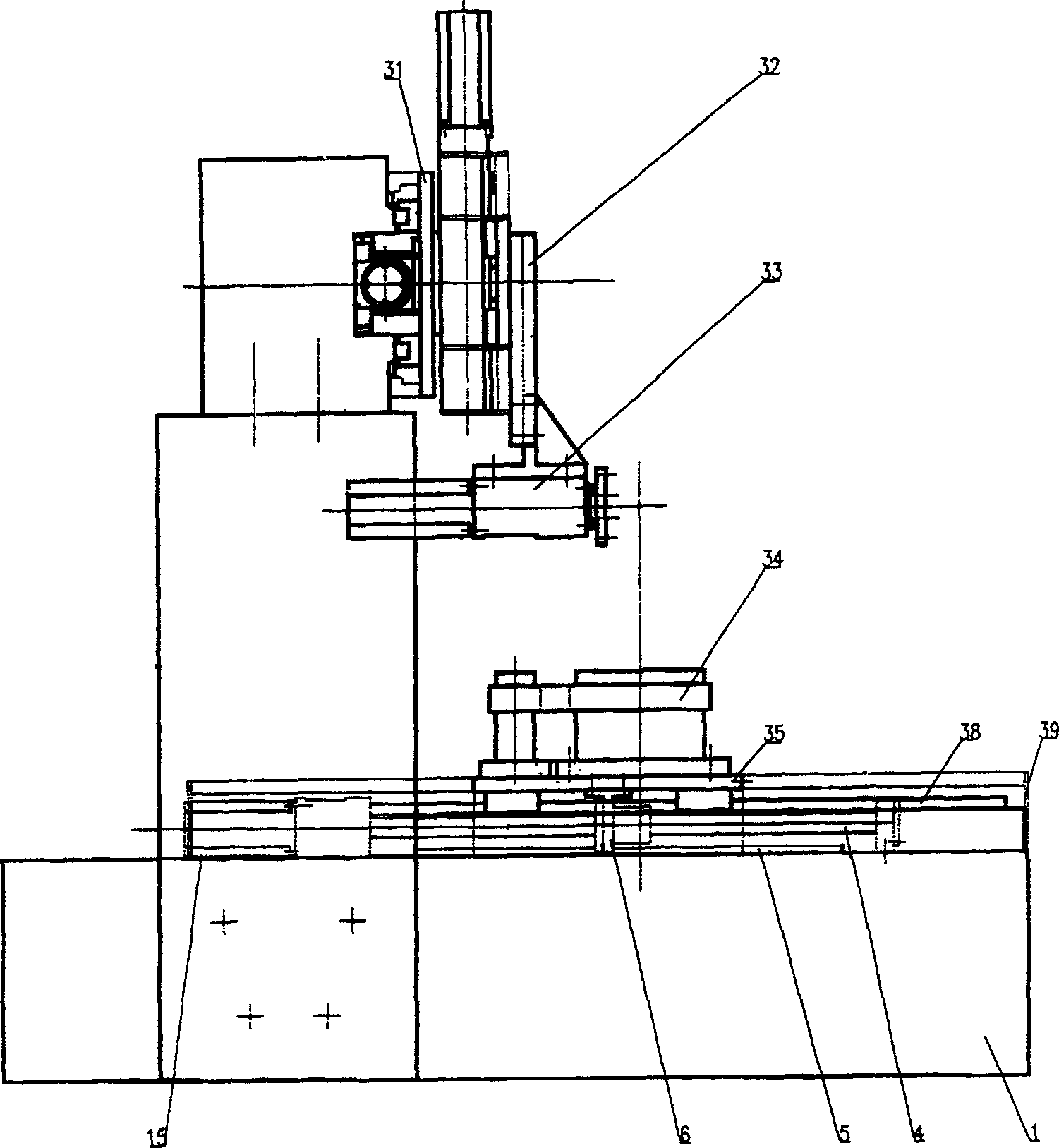

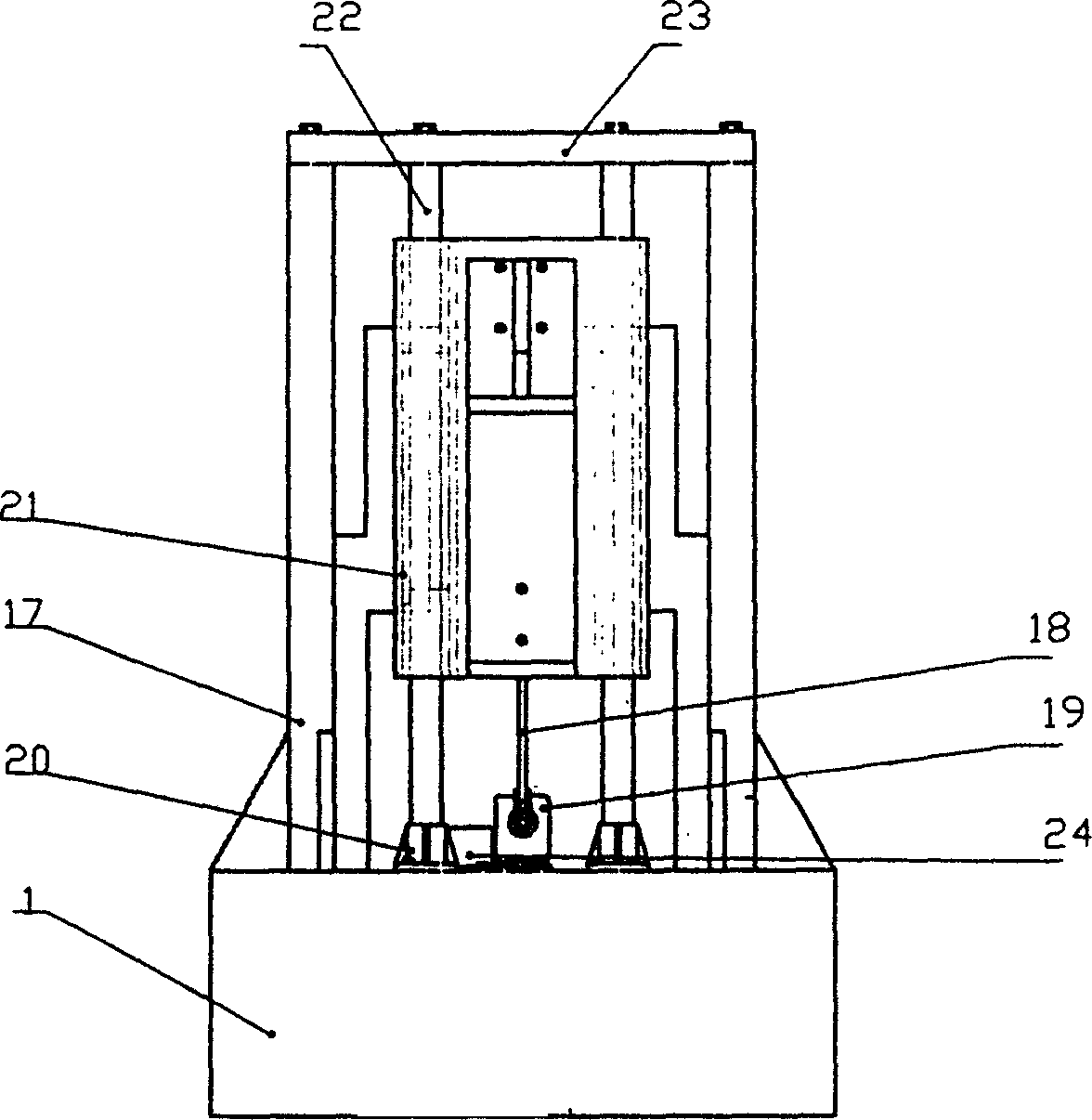

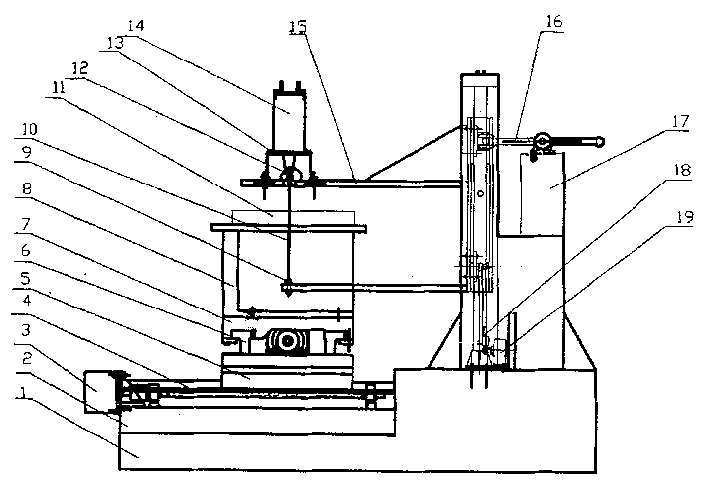

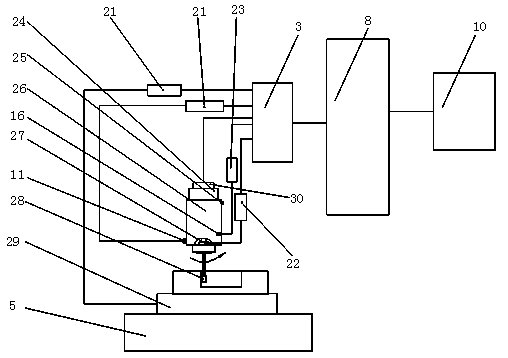

Non-spherical optical component composite machining and testing machine tools

InactiveCN1490125AImprove processing efficiencyOvercome the disadvantage that the revolution speed is difficult to increaseAutomatic control devicesFeeding apparatusEngineeringFloating platform

A machine tool for machining and testing the non-spherical optical part features that its main body has the symmetrical gantry frame structure with X, Y, Z and C axises designed modularly, the milling head or polishing mechanism is installed to the Z-axis bench, and the floating platform equipped with the in-line measuring and error-measuring unit for plane and parallel to Y axis is arranged on main body. Its advantage is high machining precision.

Owner:NAT UNIV OF DEFENSE TECH

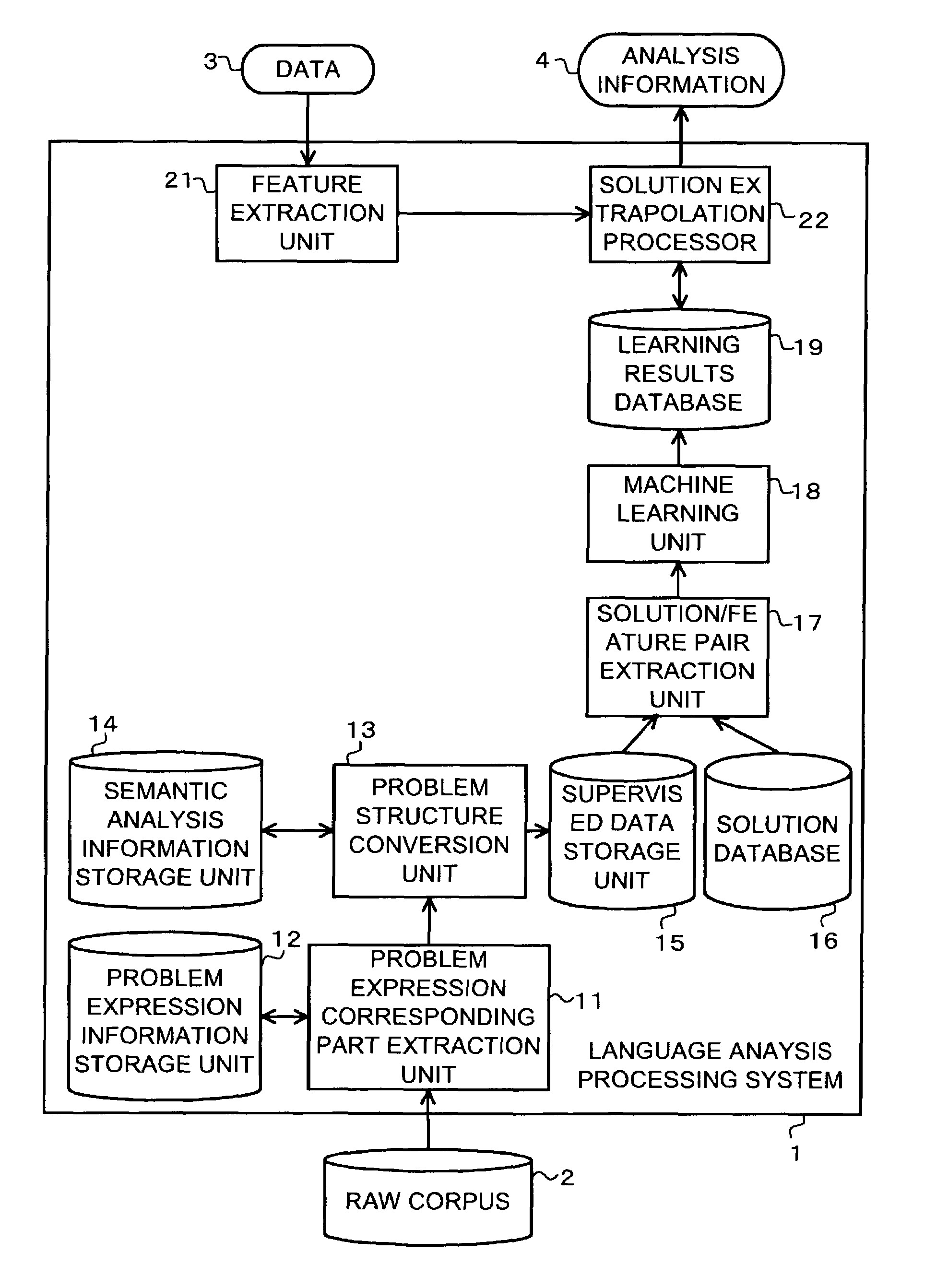

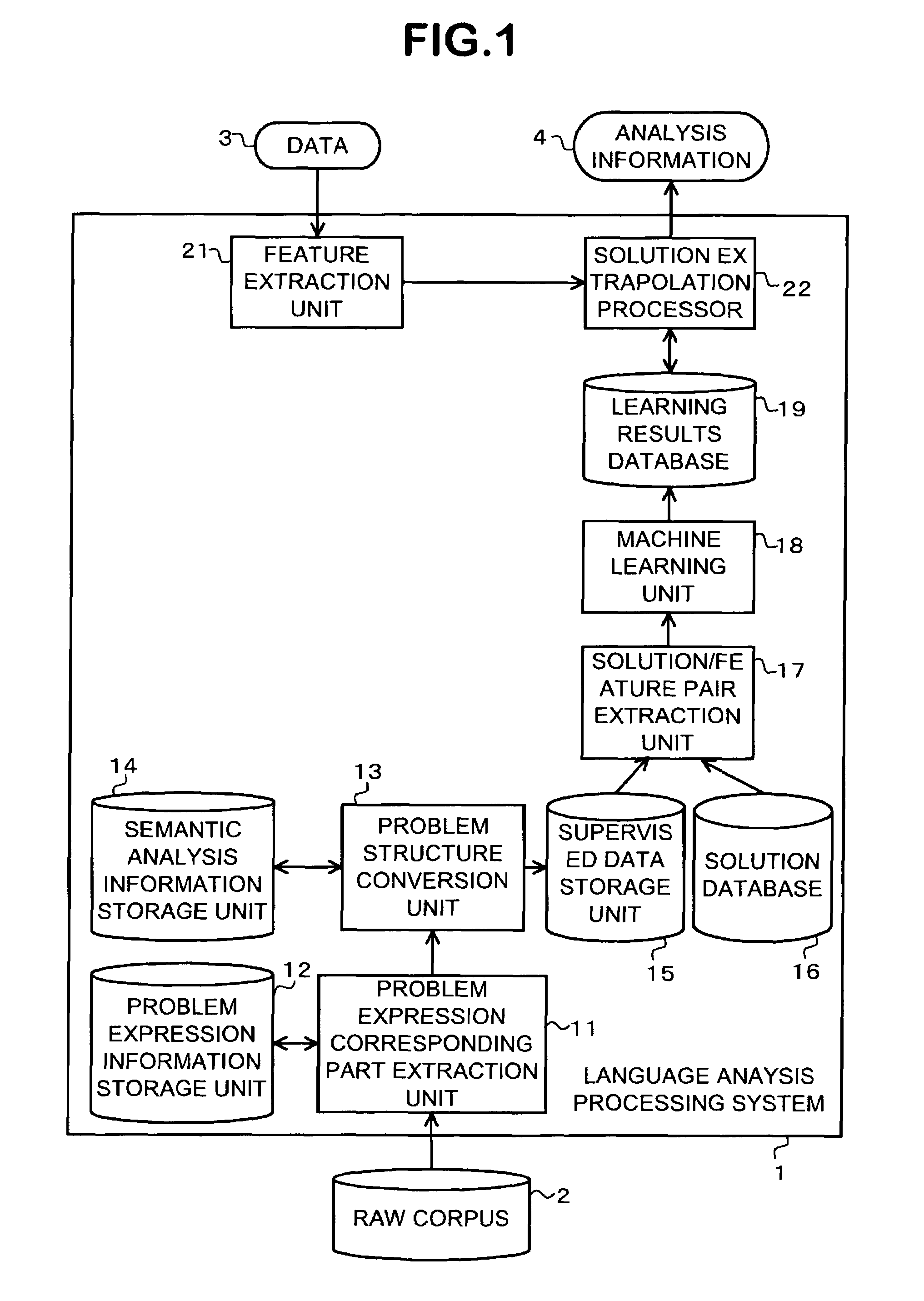

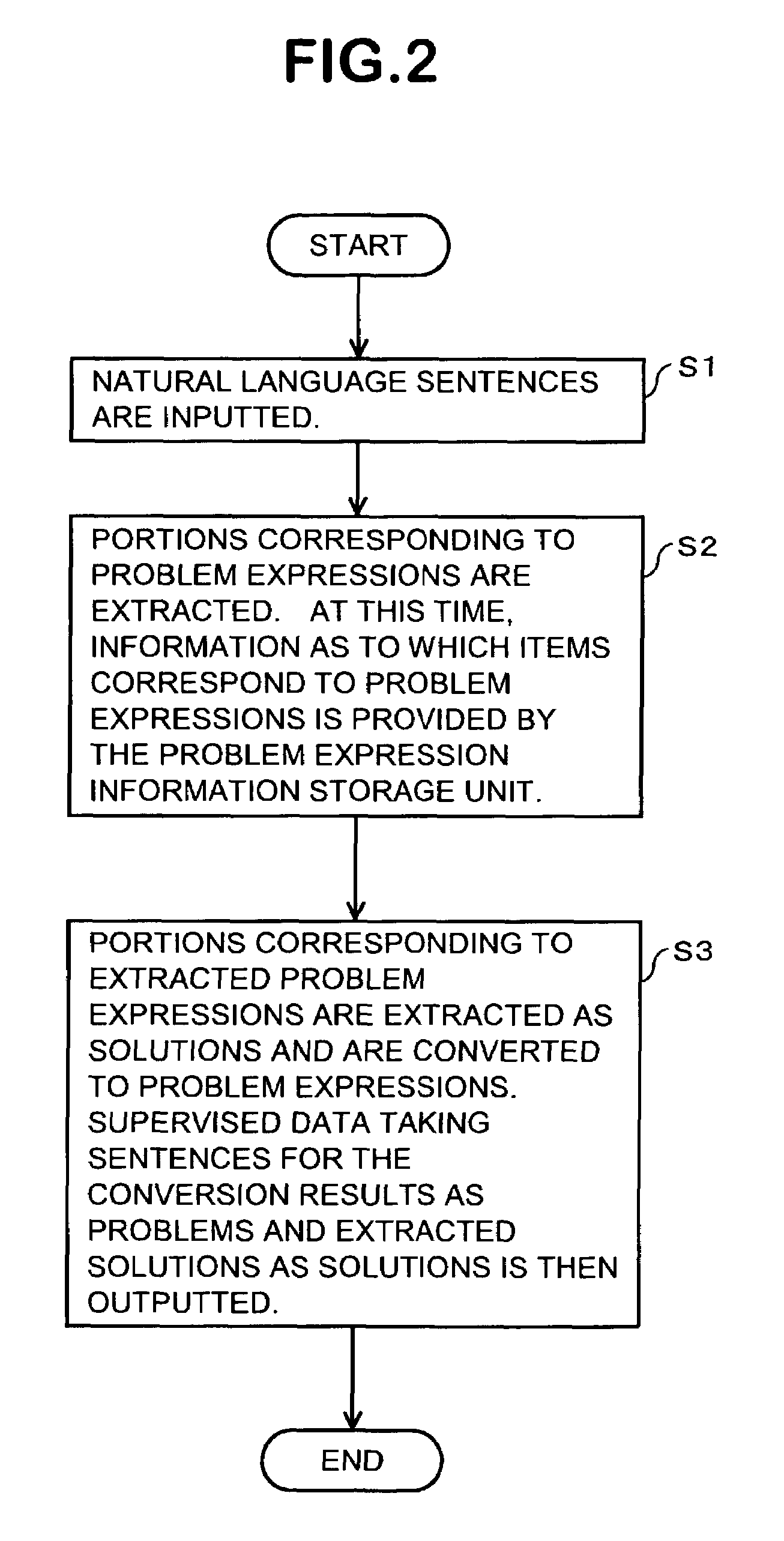

System and method for analyzing language using supervised machine learning method

InactiveUS7542894B2Increase the number ofImprove learning accuracyNatural language analysisSpecial data processing applicationsAlgorithmData memory

A system for analyzing language using supervised learning method. The system extracts portions matching the structures of problem expressions from a raw corpus that is not supplemented with analysis information, then converts the extracted portions corresponding to the problem expressions into supervised data including problems and solutions and stores in the data storage. The system extracts sets of solutions and features from the supervised data stored in the data storage, carries out machine learning processing using the sets and stores learned results as to what kind of solution is the most straightforward for which feature in the learning results database. The system then extracts sets of features from the inputting object data, extrapolates analysis information showing the most optimum for a certain feature, from the sets of features based on the learning results database.

Owner:NAT INST OF INFORMATION & COMM TECH

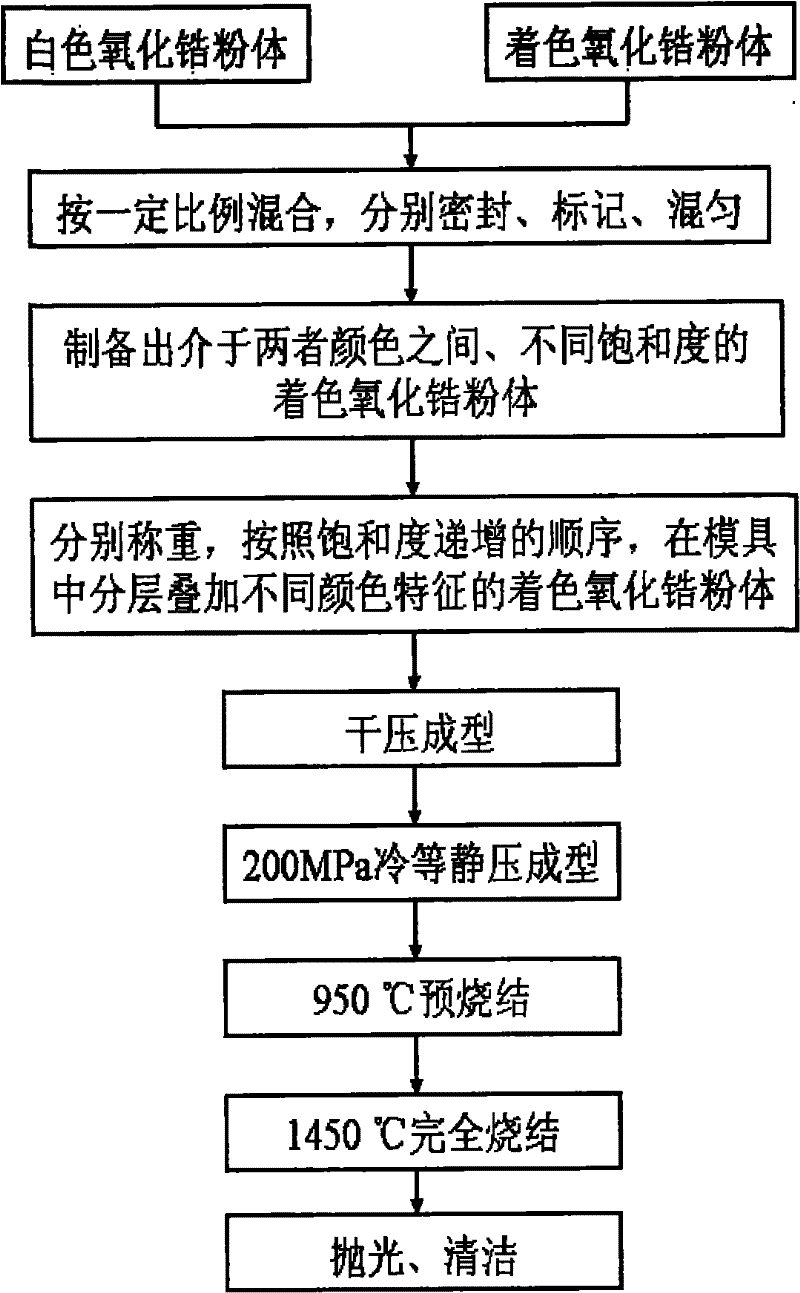

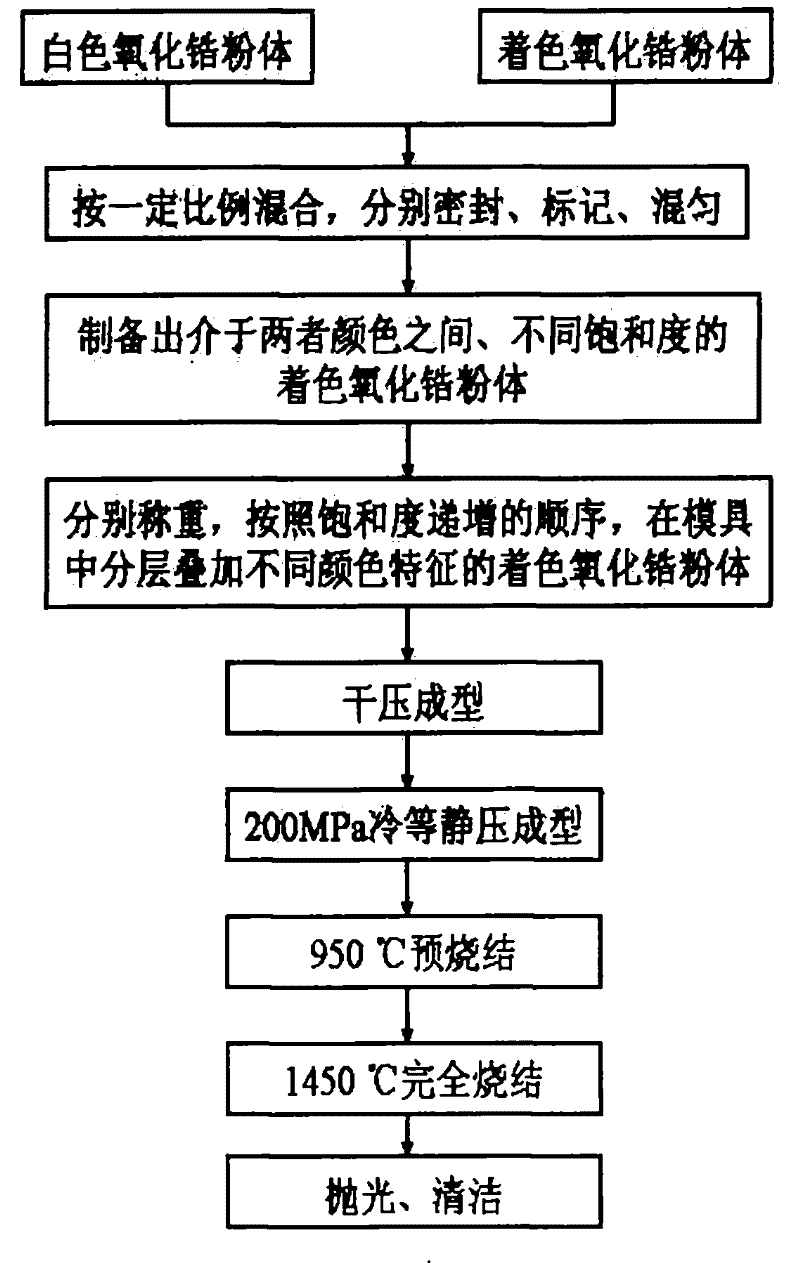

Dental complex color machinable zirconia ceramics and preparation method

InactiveCN102285795AHigh simulationFull aestheticsImpression capsDentistry preparationsAll ceramicAbutment

A dental multi-color machinable zirconia ceramic and its preparation method. The zirconia ceramic has the characteristics of translucence and color gradient, and contains more than five porcelain layers with the same hue and different saturation. The lightness gradually decreases from the top of the ceramic to the bottom layer, and the saturation The density gradually increases, and the color transitions naturally with a sense of hierarchy; the pre-sintered porous ceramic body of the zirconia ceramic is easy to cut and shape, and can be used to make personalized and beautiful dental zirconia all-ceramic restorations through the CAD / CAM system, which is conducive to preserving the abutment teeth. Improve the repair success rate. The preparation method of the dental complex color machinable zirconia ceramic is simple, effective and easy to popularize.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY +1

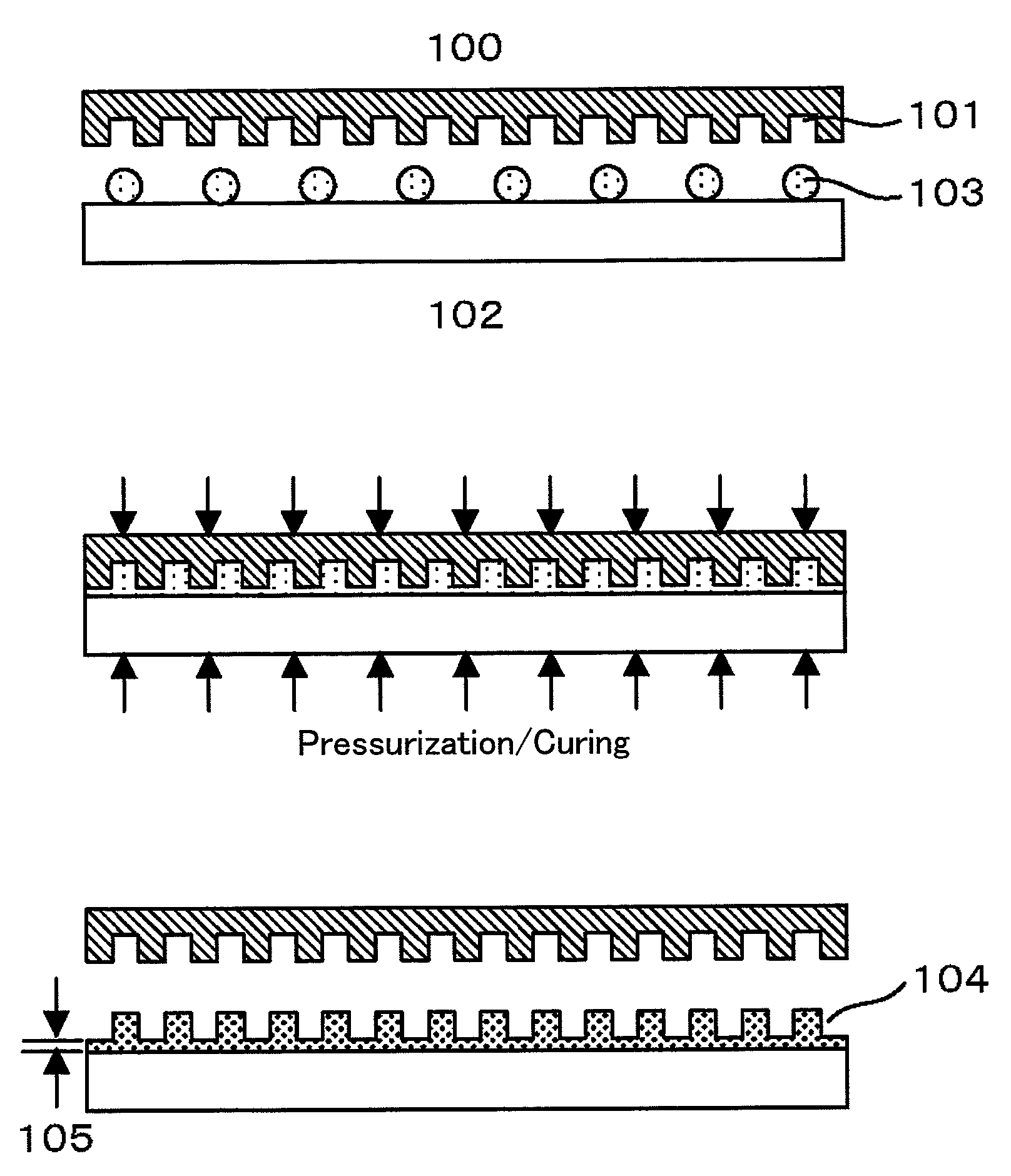

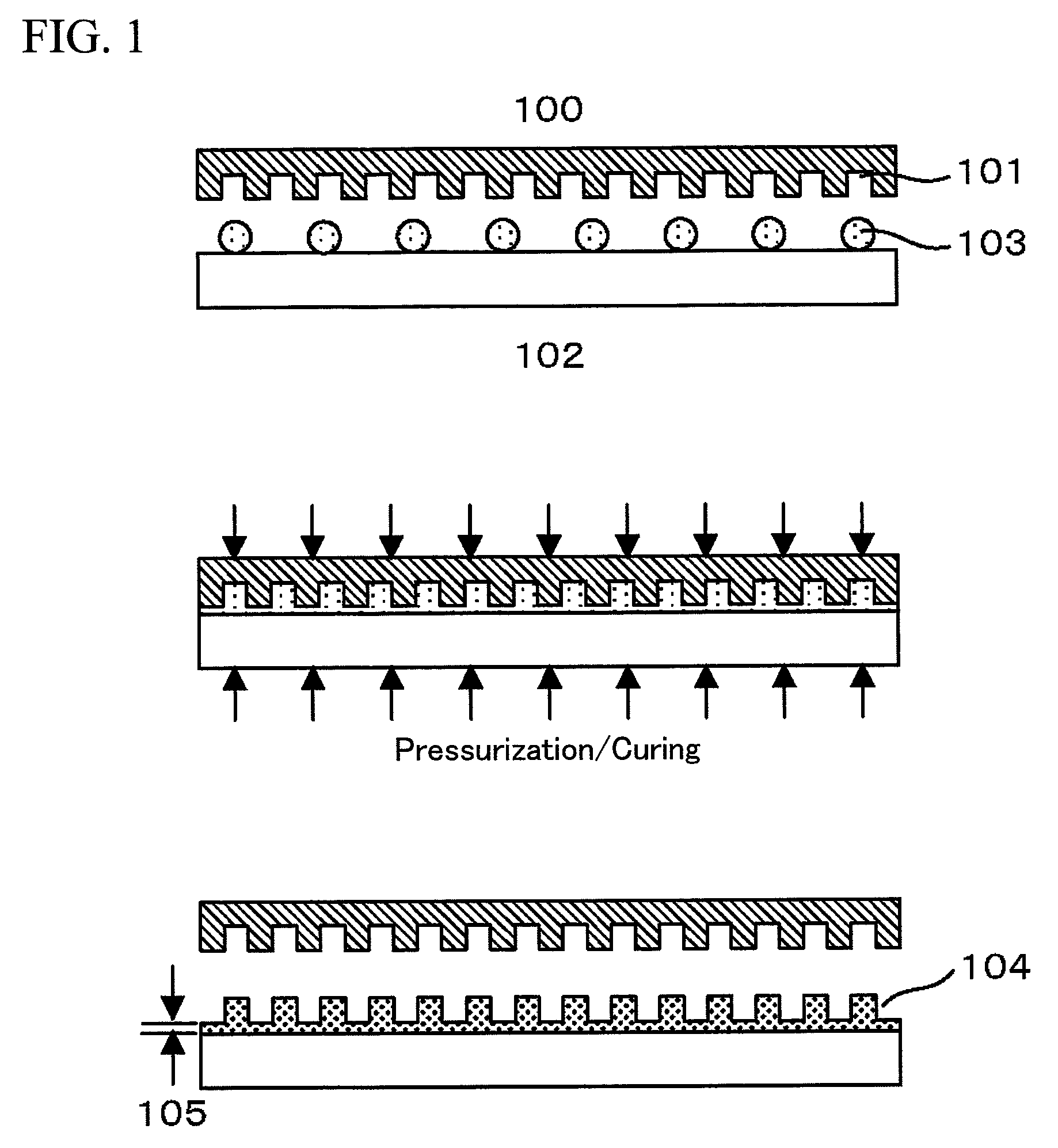

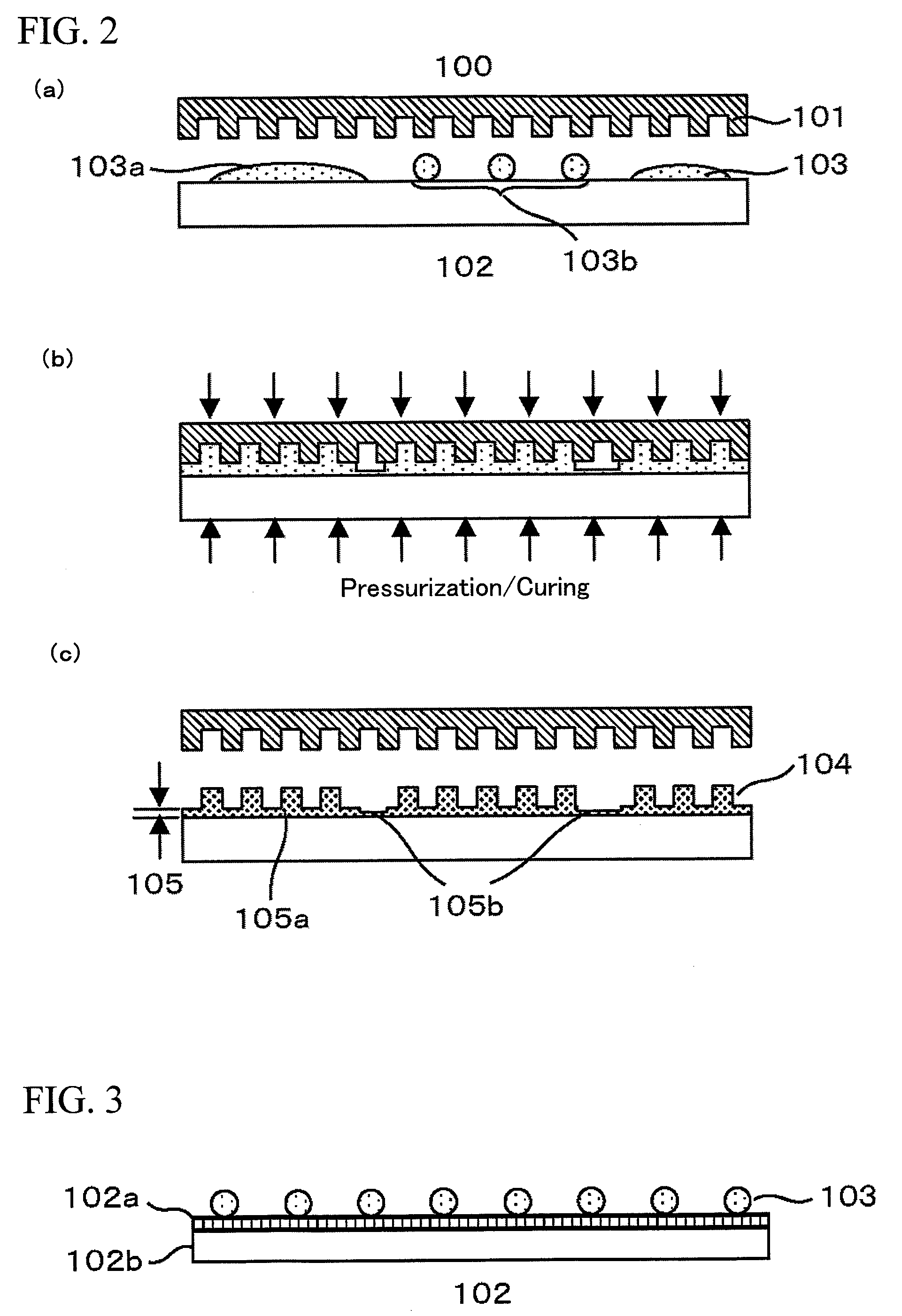

Photo nanoimprint lithography

InactiveUS20090085255A1Improve machining accuracyImprove positioning characteristicNanoinformaticsPhotomechanical apparatusResistNanoimprint lithography

The present invention is directed to providing a photo nanoimprint lithography which can form a more uniform base layer. A photo nanoimprint lithography according to the present invention includes the steps of discretely applying a photo-curable resist drop-wise onto a substrate, filling an asperity pattern of a mold with the photo-curable resist by bringing the mold having the asperity pattern formed therein into contact with the photo-curable resist, curing the photo-curable resist by irradiating the resist with a light and releasing from the mold the photo-curable resist which has been photo-cured, wherein an intermediary layer is formed on a surface of the substrate for maintaining a discrete placement of the photo-curable resist that has been instilled drop-wise on the substrate until the mold is brought into contact with the photo-curable resist that has been instilled drop-wise on the substrate.

Owner:HITACHI LTD

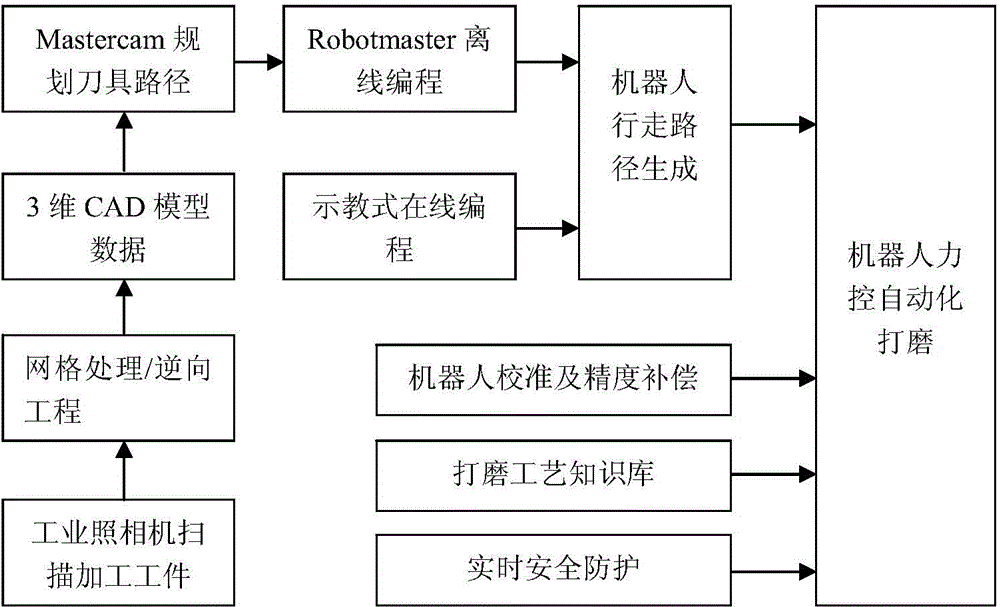

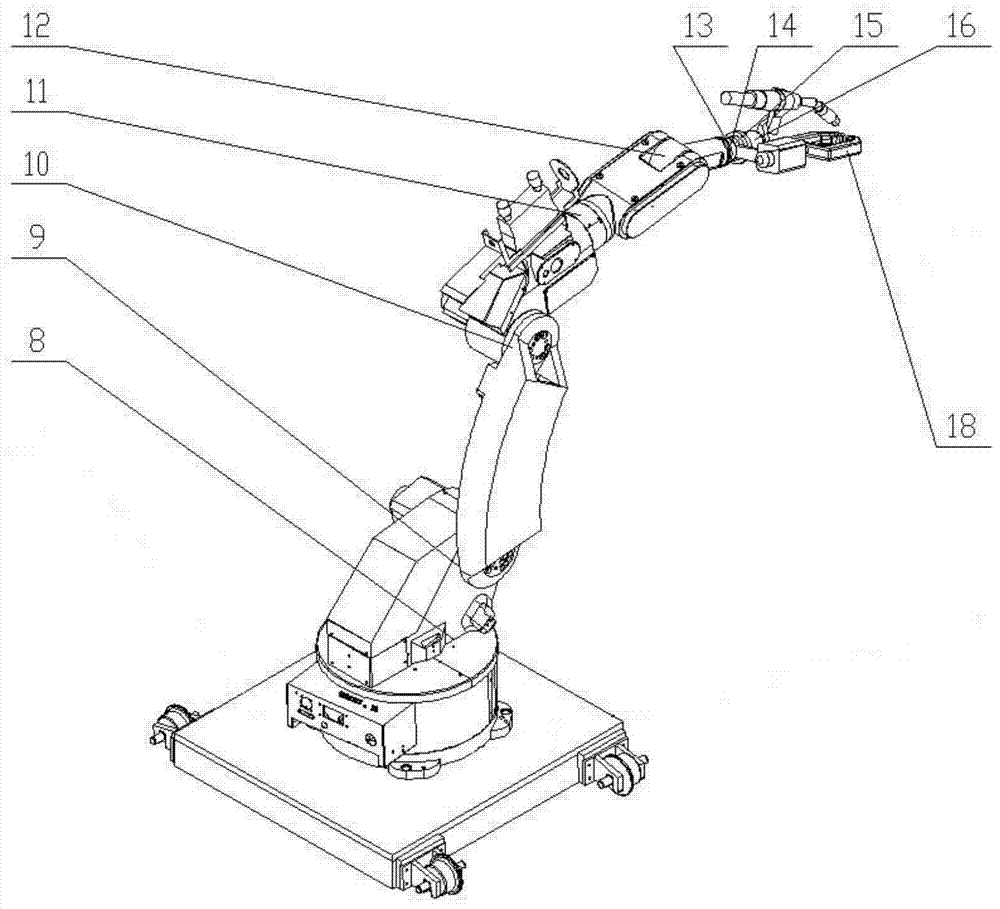

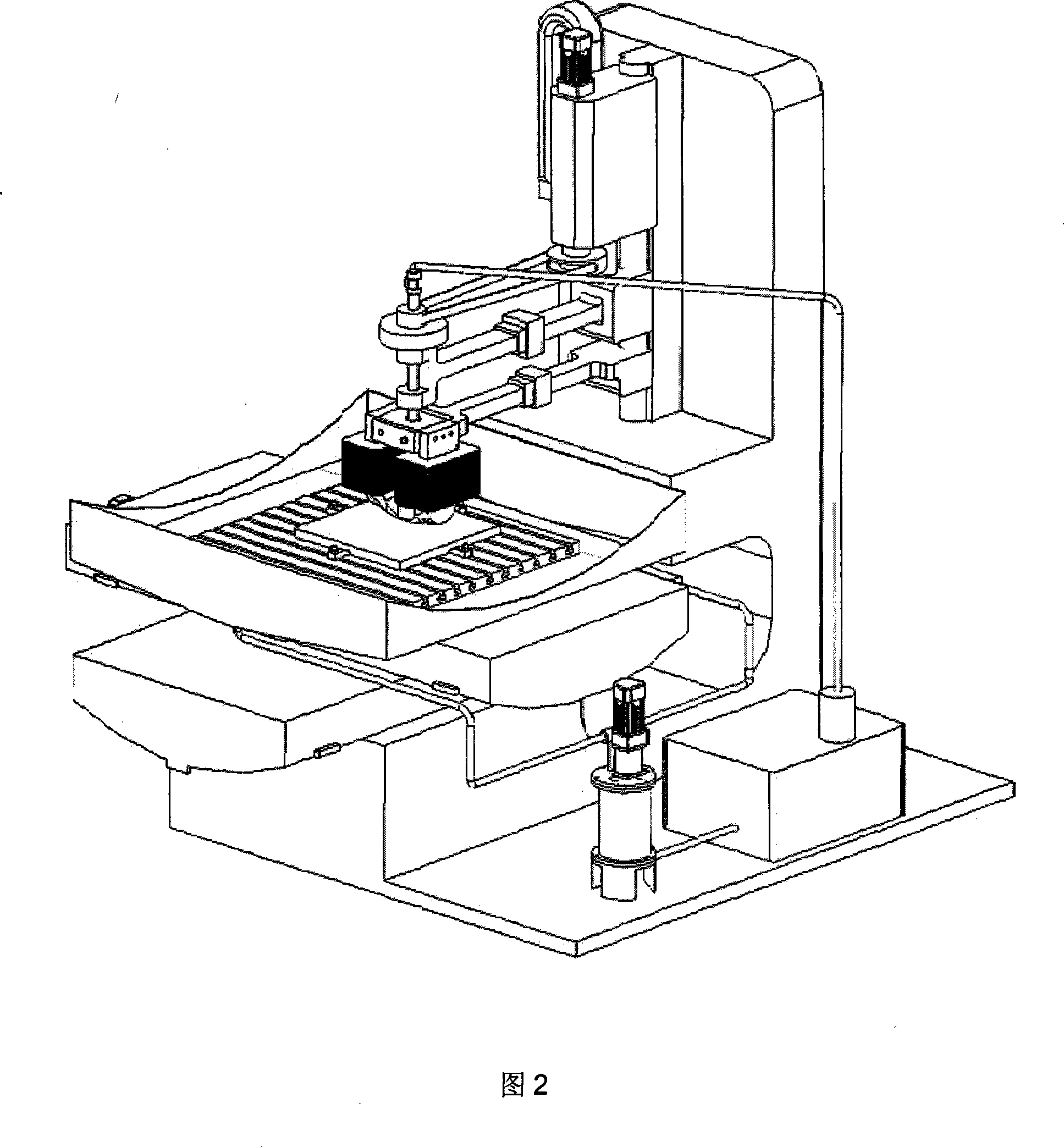

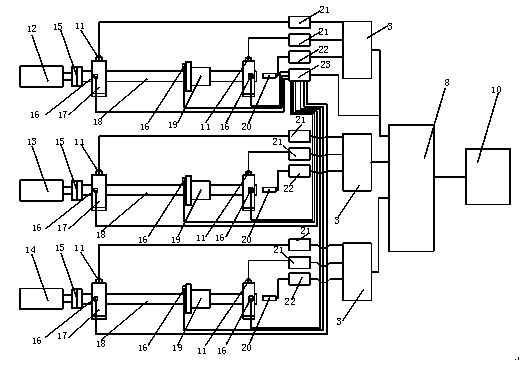

Intelligent force control robot grinding system and method

ActiveCN104972362ARealize automatic processingImprove machining accuracyAutomatic grinding controlSurface finishControl theory

The invention relates to an intelligent force control robot grinding system. The intelligent force control robot grinding system comprises a computer, an industrial camera, a robot, a robot controller, a calibration and compensation system, a safety protection unit, a force sensor and an automatic knife changing system. The computer is connected with the industrial camera. The robot controller is connected with the computer, the robot, the calibration and compensation system, the safety protection unit, the force sensor and the automatic knife changing system. A method comprises the steps that the computer receives workpiece scanning data collected by the industrial camera, generates a knife path and converts the knife path into the robot posture and the tail end path; calibration and compensation are carried out; the robot controller controls all joints to move while the robot posture and the tail end path are adjusted. Hardware of a high-precision force control grinding system is achieved, the path self-calibration and online compensation technology is adopted, and the machining of a complex hook face with the high requirements for machining precision and surface smoothness can be finished.

Owner:宏阔(南通)智能装备有限公司

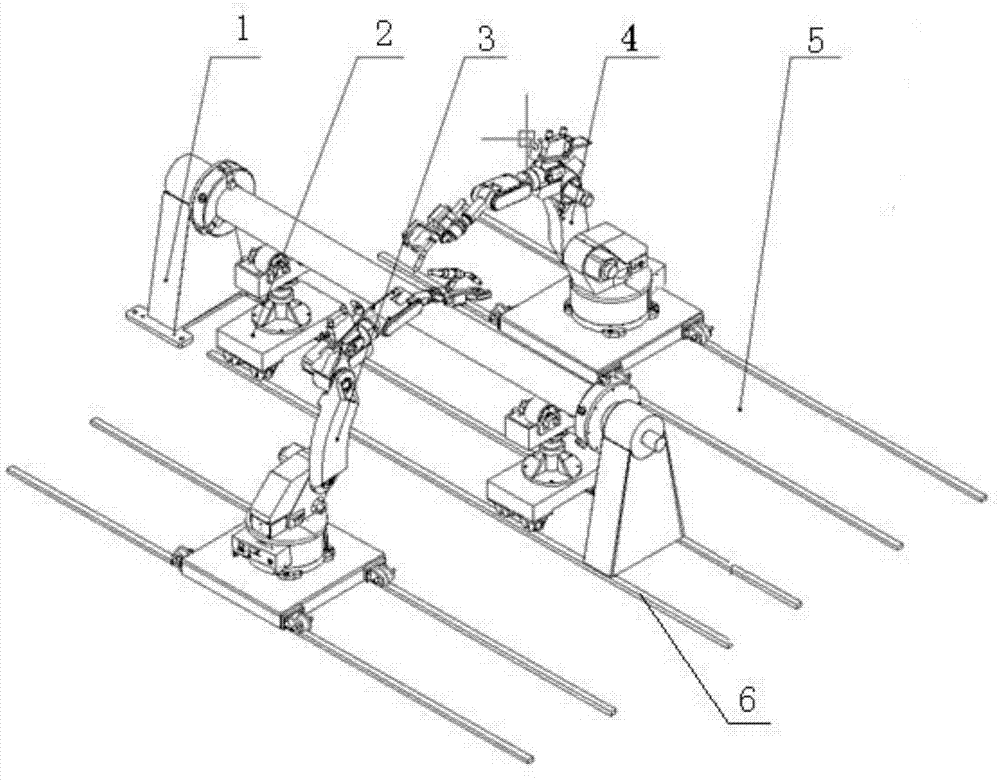

Integrated workstation based on robot cutting, welding and carrying in pipe processing

ActiveCN103567677AImprove processing qualityImprove machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSmall footprint

The invention discloses an integrated workstation based on robot cutting, welding and carrying in pipe processing. The integrated workstation comprises a headstock and tailstock position changer, a movable support, a welding robot, a cutting robot, a middle sliding rail and two side sliding rails, wherein the headstock and tailstock position changer comprises a headstock base and a tailstock base; a pipe workpiece is clamped between clamping and fixing devices on the headstock base and the tailstock base; a lifting driving device is installed on a sliding base of the movable support; a roller is installed on the lifting driving device and is tangent with the pipe workpiece; the welding robot and the cutting robot are slidably installed on the two side sliding rails on the two sides of the pipe workpiec respectively to finish carrying, cutting and welding operation and the like. The integrated workstation based on the robot cutting, welding and carrying in pipe processing is an integrated working system, can ensure good consistency in pipe processing, improves the processing quality and the processing precision of the whole pipe workpiece, and is simple in structure, less in equipment and small in occupied area.

Owner:NANJING PANDA ELECTRONICS +1

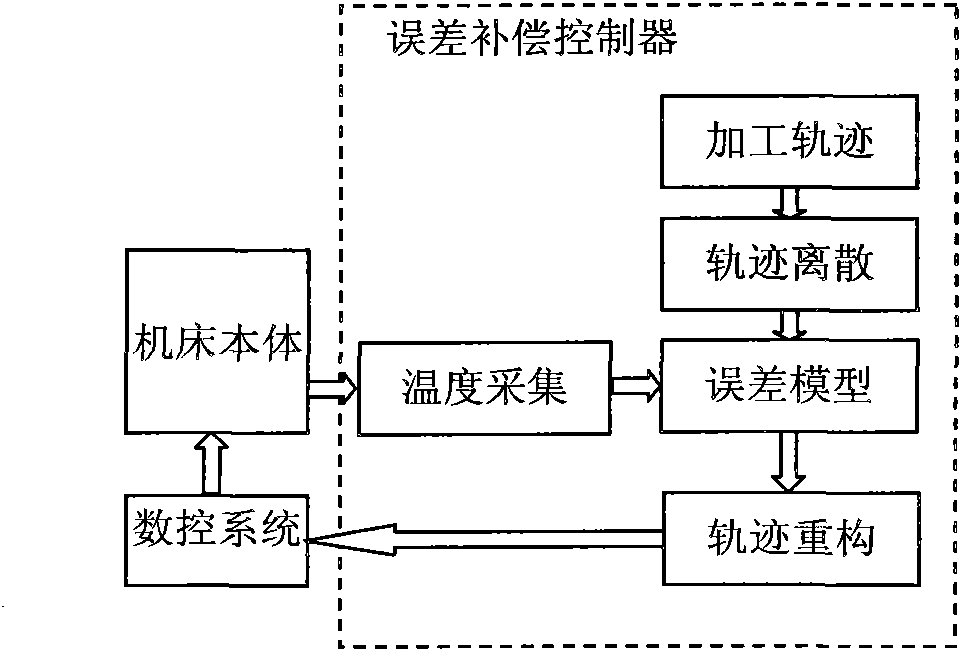

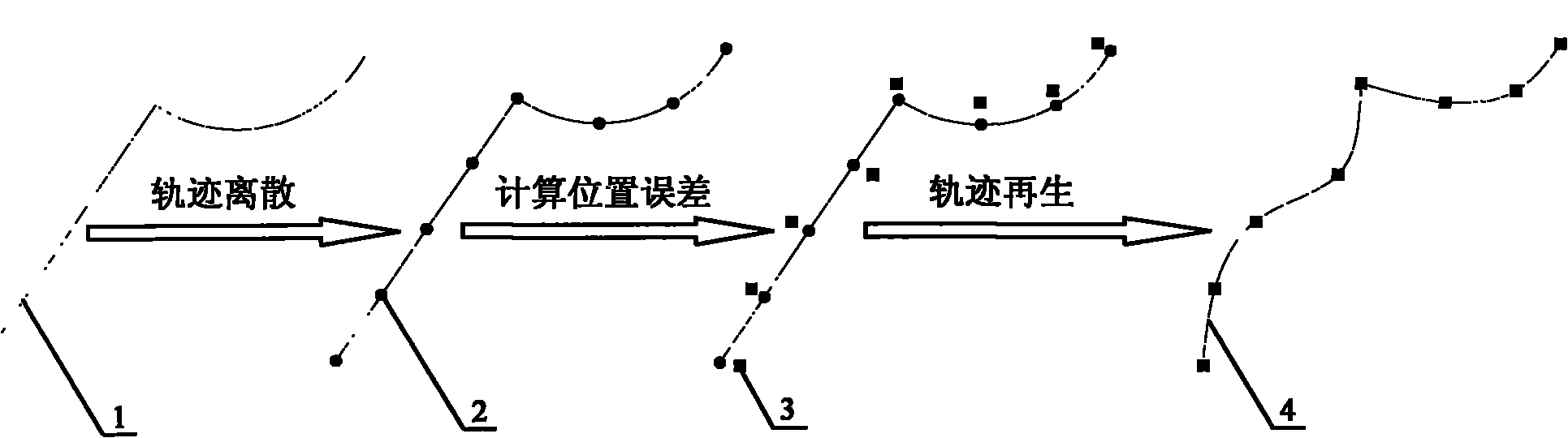

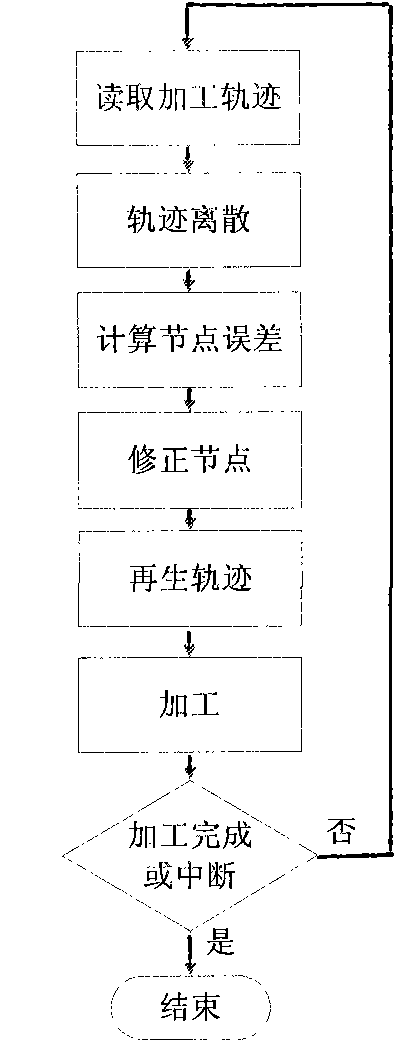

Trajectory regeneration compensation method of numerical control machine error

InactiveCN101943896AImprove machining accuracySimple structureProgramme controlComputer controlEngineeringControl theory

The invention discloses a trajectory regeneration compensation method of numerical control machine error. The method comprises the steps that: at first, a temperature sensor is arranged on a numerical control machine to measure geometrical error and thermal error of the machine, and then a machine error model is established; second, an error compensation controller diverges a numerical control trajectory to be processed and reads data from the temperature sensor; afterwards, the error compensation controller substitutes a node coordinate subsequent to divergence and temperature data in the machine error model to obtain an error to which the coordinate is corresponding, the error is then superposed on the coordinate of the node, and the numerical trajectory is reconstructed according to the corrected coordinate; and finally, the error compensation controller transfers the reconstructed trajectory to numerical control system for being processed, so as to realize the compensation for numerical control machine error. Compared with other compensation methods, the method according to the invention has the advantages of great flexibility and convenience, strong adaptability and no need of changing numerical control system, etc.

Owner:ZHEJIANG UNIV

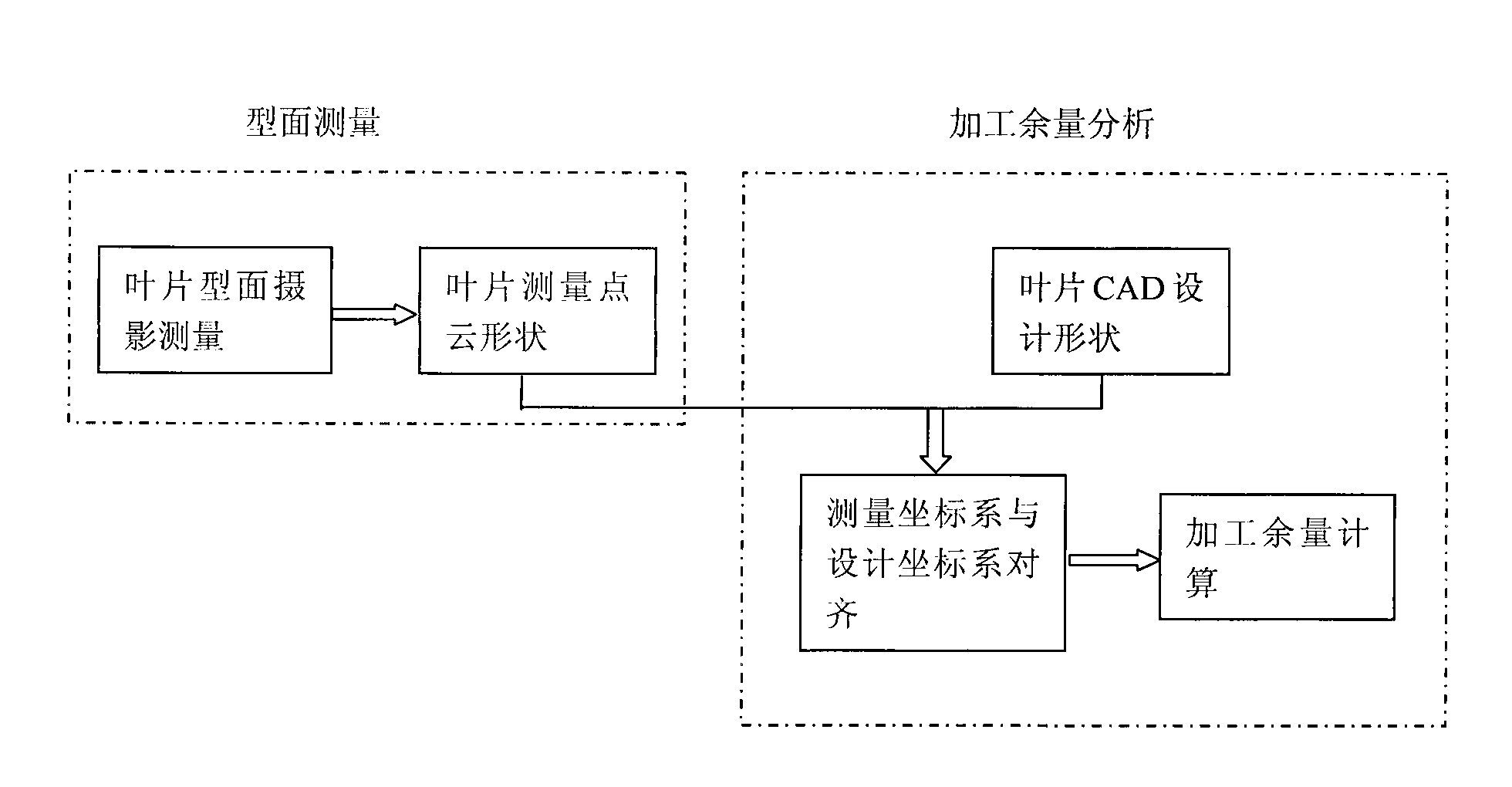

Water turbine blade blank profile measuring and machining allowance analyzing method

InactiveCN101634544AHigh speedImprove machining accuracyUsing optical meansCavitationMeasurement point

The invention relates to a water turbine blade blank profile measuring and machining allowance analyzing method capable of effectively solving the problem of water turbine blade blank profile measurement and machining allowance analysis to ensure the manufacturing quality and precision of the water turbine blades, comprising the following technical solutions: measuring the blade blanks by using a digital close range photogrammetry to obtain the measuring point cloud data shapes of the blank profiles consequently, aligning a measuring coordinate system where the measuring point clouds are located to a design coordinate system where a CAD design model is located, establishing a differential relation of free-form surface parameters with respect to rigid rotation parameters by using an analytic method derived by the multivariate of Newton iteration method to obtain a Jacobian matrix and Hessian matrix which are available for a target equation; then performing the numerical optimization calculation based on the LM method and Newton iteration method, and performing report or graphical output and print on the result. The inventive method is scientific, advanced, stable and reliable, and has high accuracy, thereby ensuring the hydraulic stability, production efficiency and cavitation property, and bringing enormous economic and social benefits.

Owner:郑州辰维科技股份有限公司

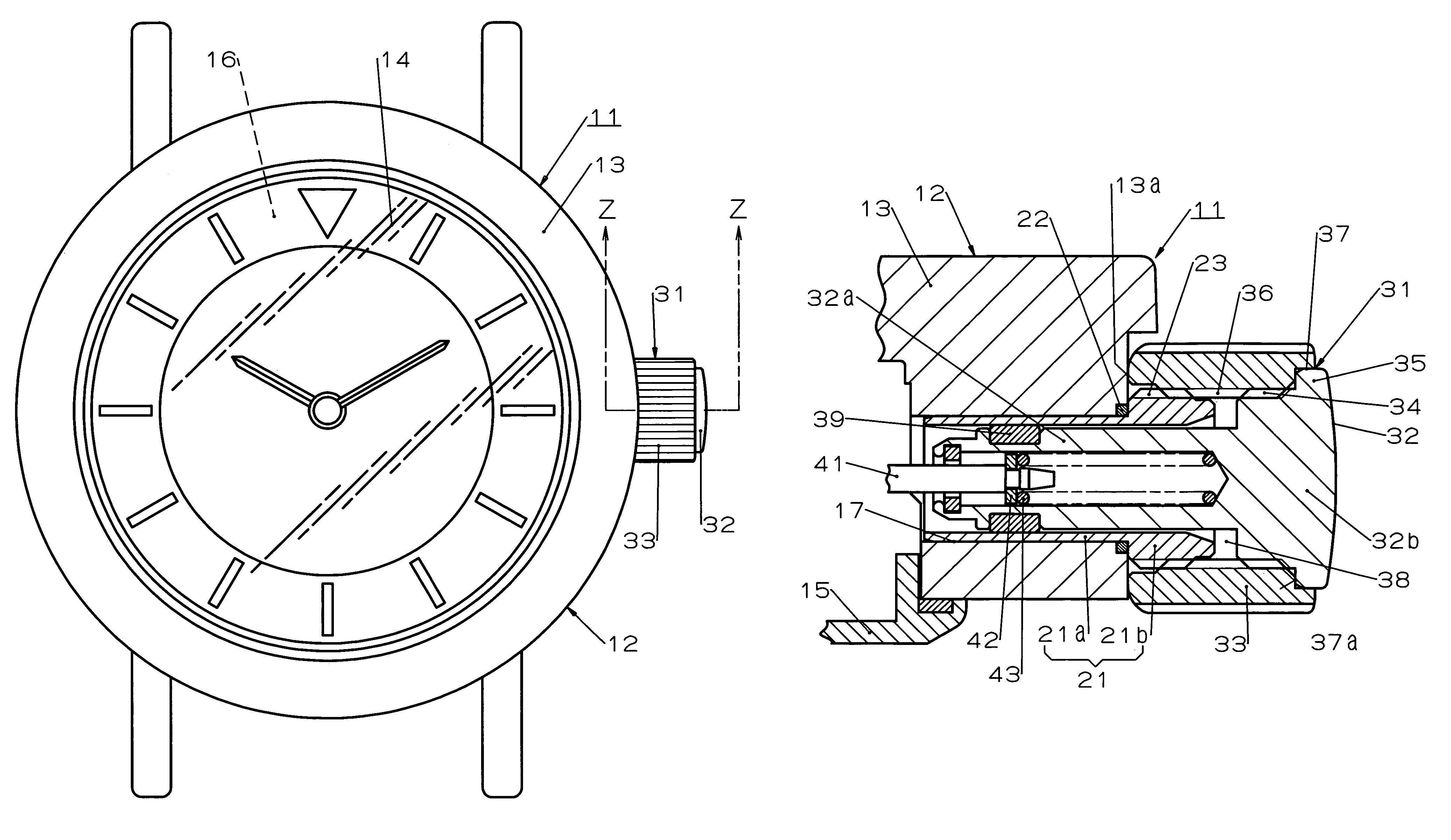

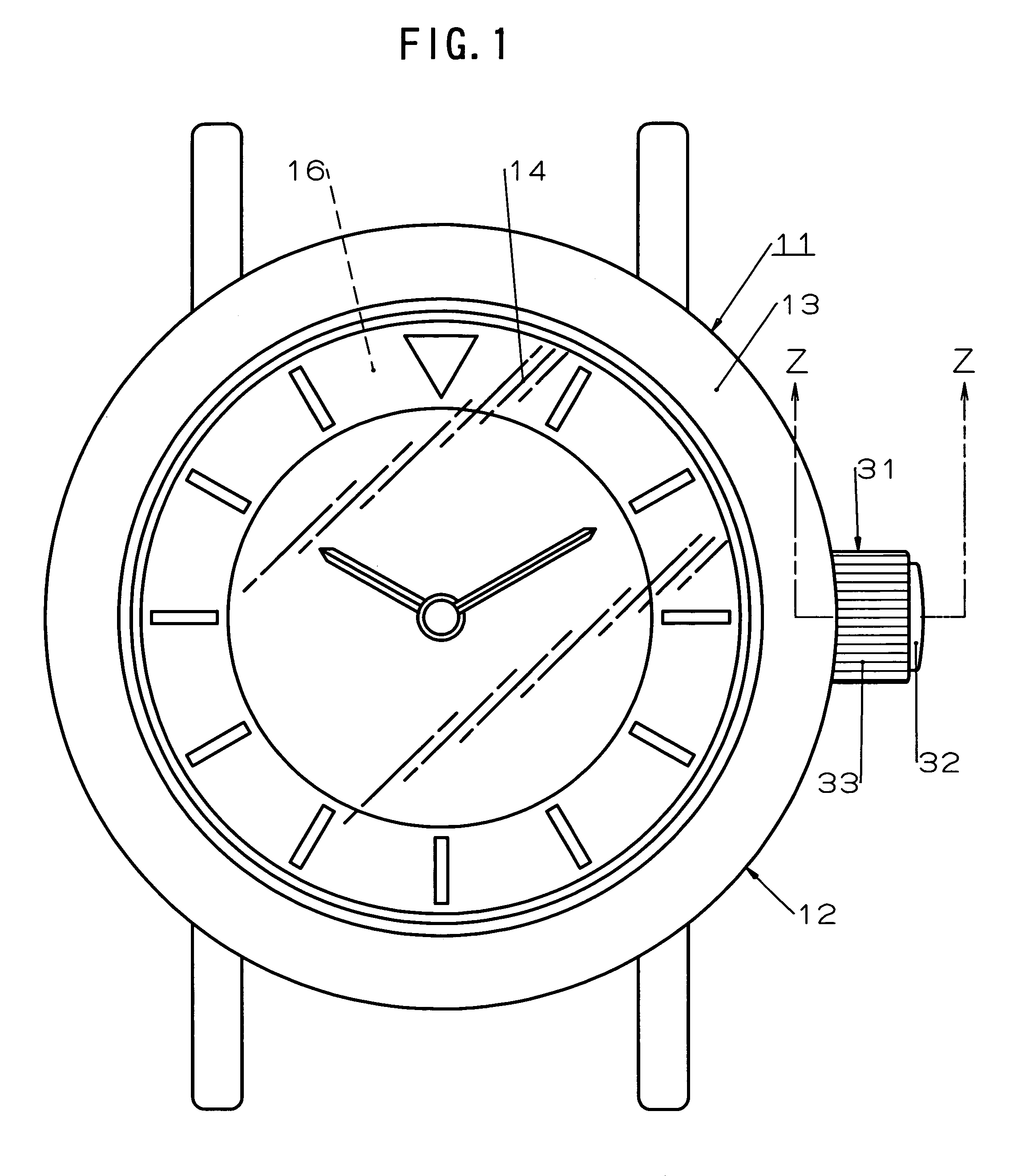

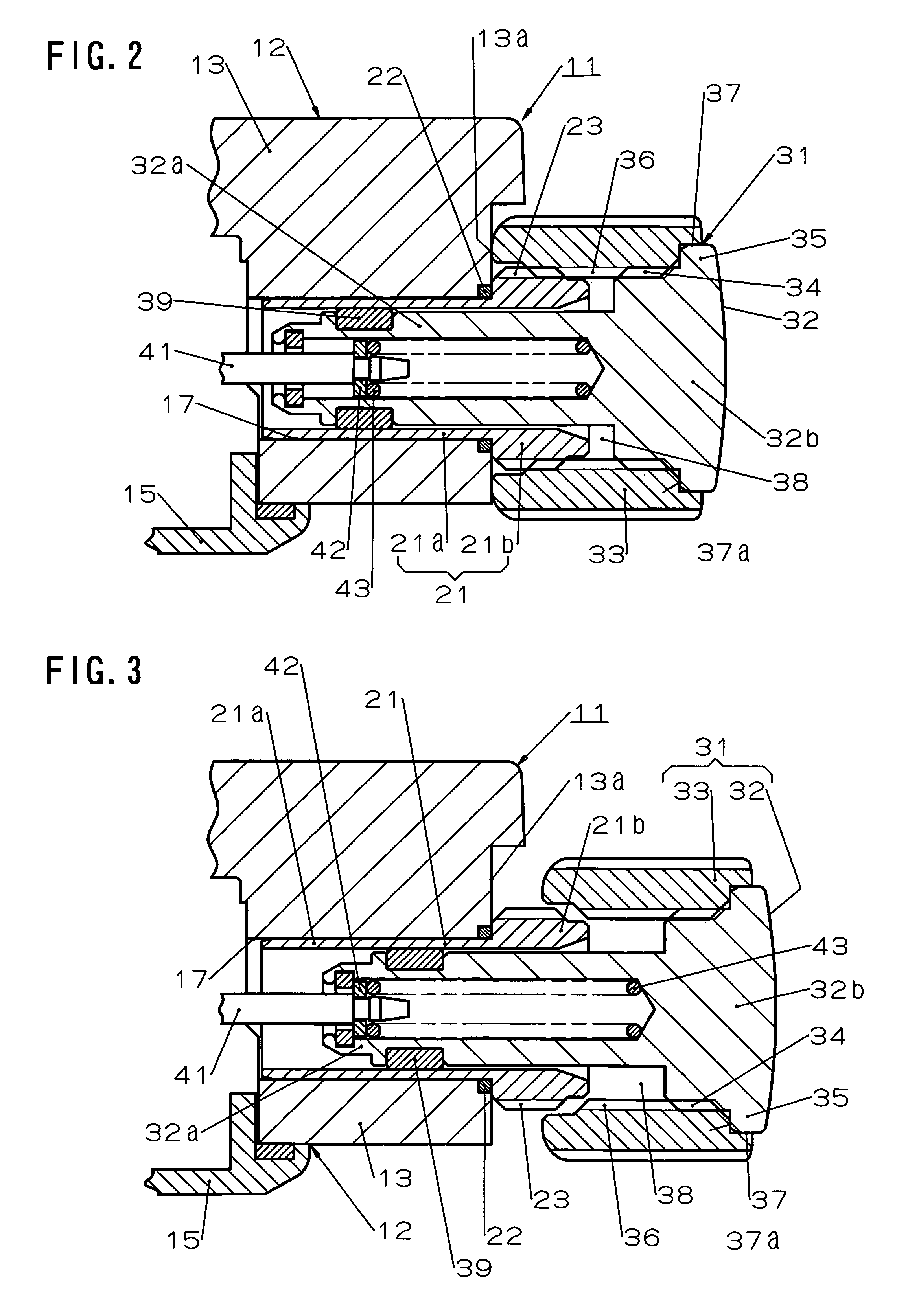

Watch and crown used in this watch

ActiveUS7591582B2Easy to processImprove machining accuracyNormal windingClockwork casesEngineeringScrew thread

A watch is offered in which the life of the threadedly engaged portion between the stem pipe and the crown can be improved and which has an internal thread capable of being machined relative to the crown easily and accurately. The watch is based on a watch in which the crown is threadedly locked to a stem pipe mounted to a barrel. The stem pipe has a barrel outside protruding portion provided with an external thread. The crown has a crown shaft and a crown ring having an internal thread removably threaded to the external thread, the ring being connected to the crown shaft. The crown shaft has a barrel insertion cylindrical portion which is smaller in diameter than the crown ring and inserted in the stem pipe and a ring connection portion mounted integrally with this cylindrical portion and connected to one end portion of the crown ring.

Owner:SEIKO INSTR INC

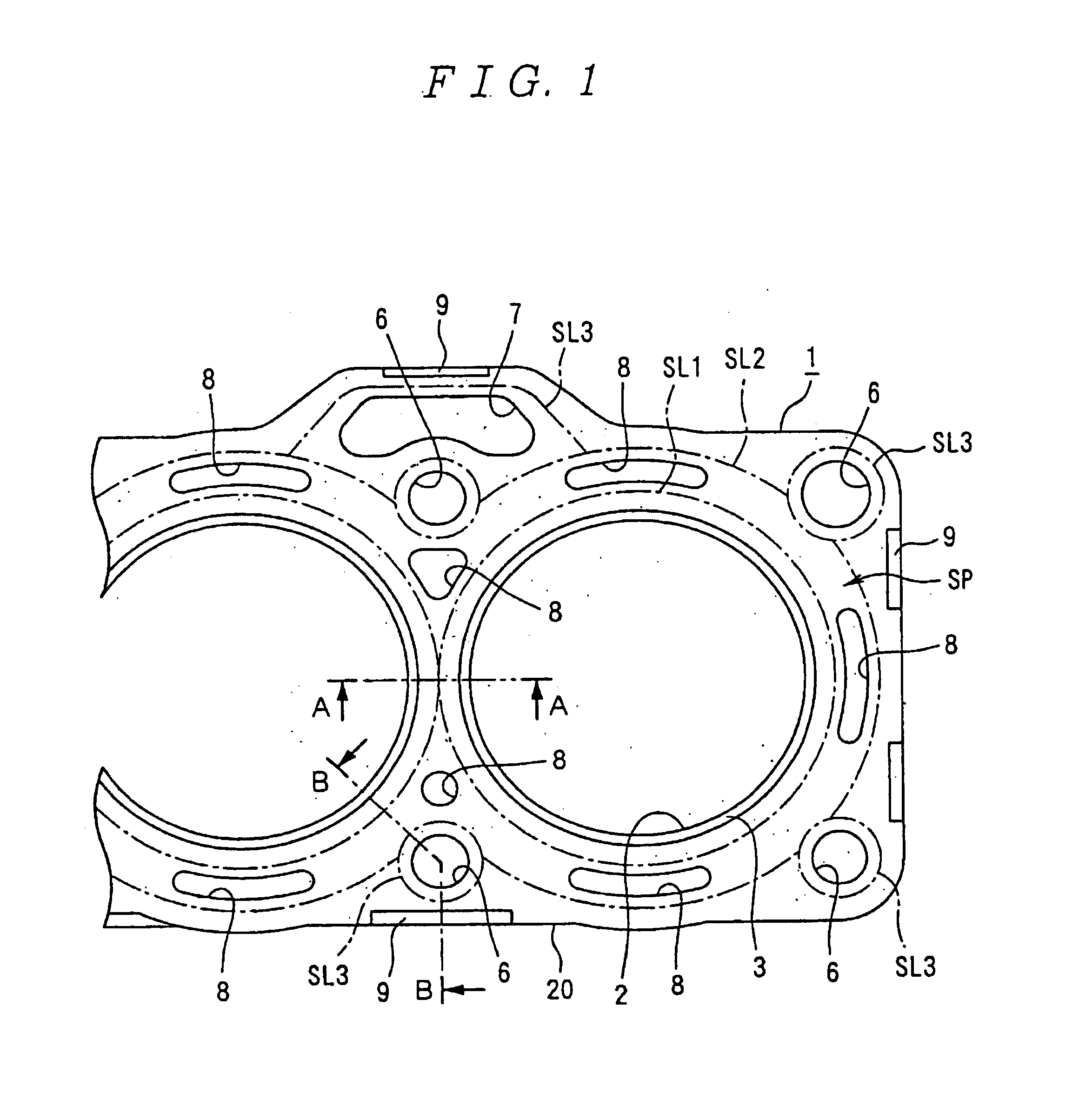

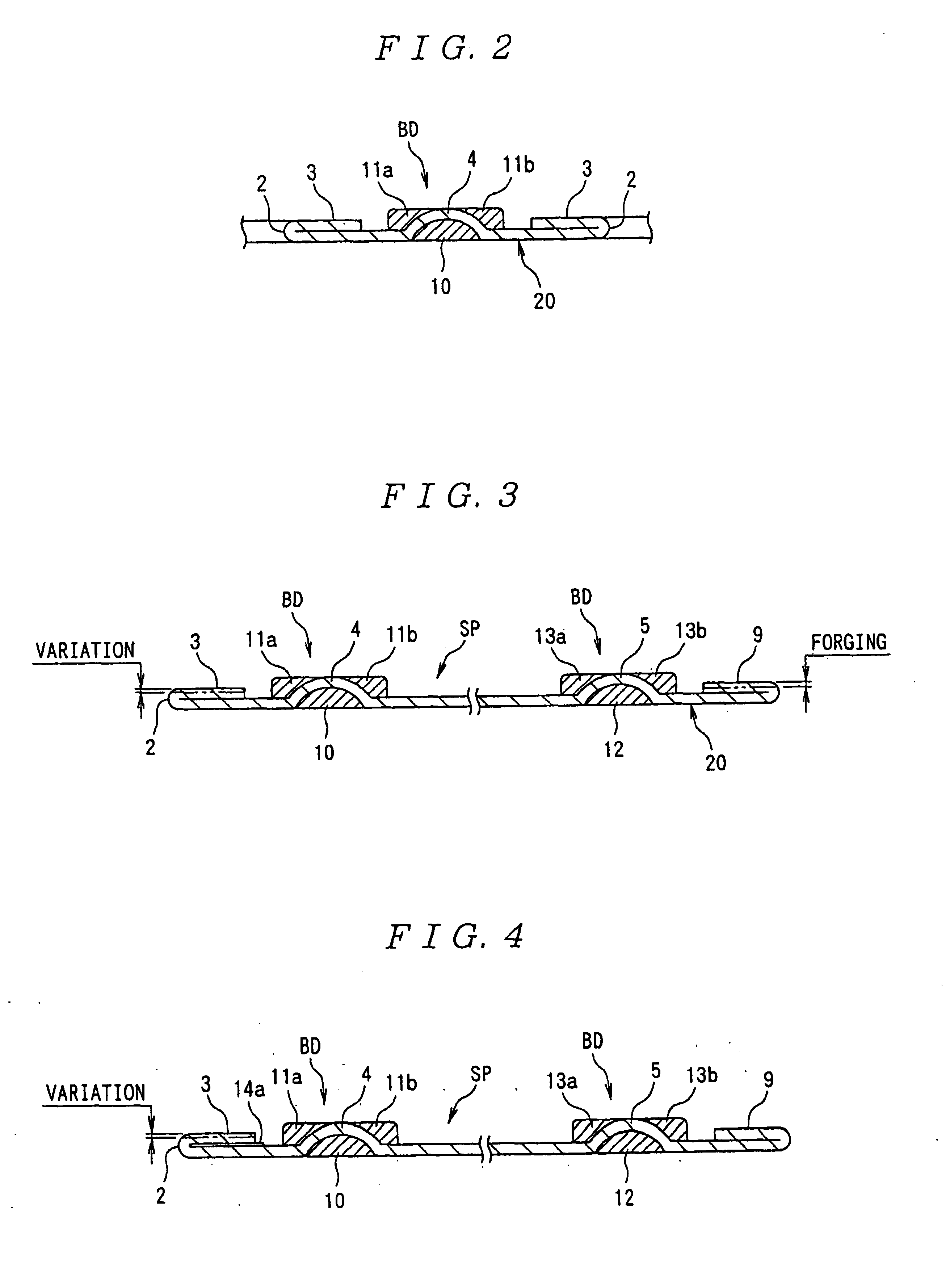

Metallic gasket

InactiveUS7025358B2Improve machining accuracyImprove cooling effectEngine sealsSealing arrangements for enginesCombustion chamberCooling effect

A metallic gasket comprising a base plate having a first thickness-increased portion 3 formed at a peripheral edge on a combustion chamber opening 3 side of a base plate, and a first seal line SL1 and a second seal line SL2 arranged on the outer side of said first thickness-increased portion 3. No openings other than a cooling water hole 8 exist between said two seal lines. Beads formed along said seal lines SL1 and SL2 each consist of a convex metal bead raised only upward from an upper surface of said base plate and a rubber bead made of an elastic sealing material fixed to a convex portion and a concave portion of said metal bead. This structure of said metallic gasket can improve a processing accuracy of said metal bead and also enhance cooling effects on said metallic gasket itself and said joint surfaces of an engine, between which said metallic gasket is disposed.

Owner:JAPAN METAL GASKET CO LTD

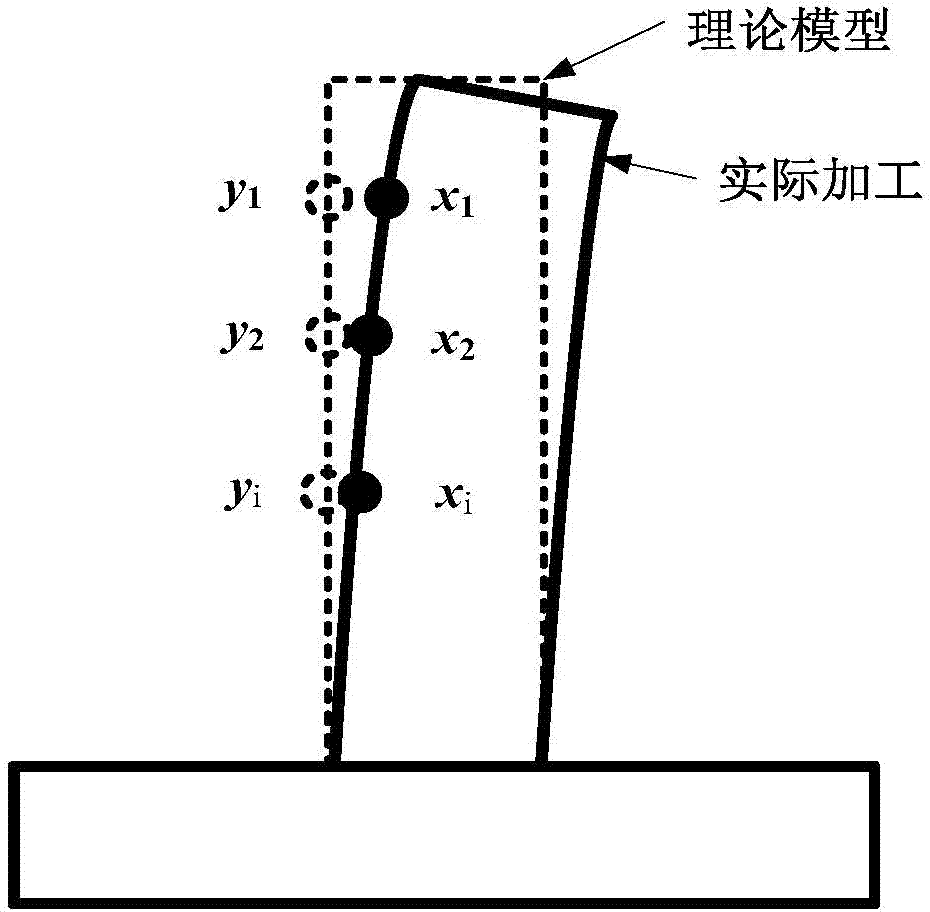

Online milling deformation measurement and complementation machining method for thin-walled part

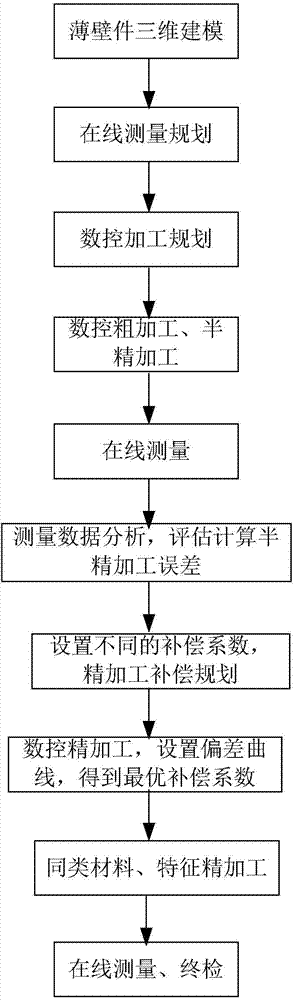

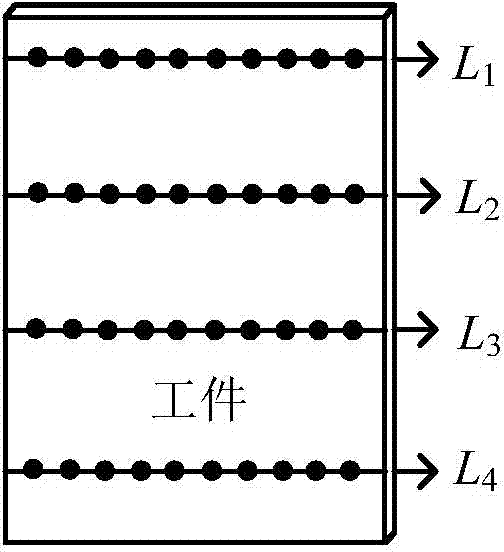

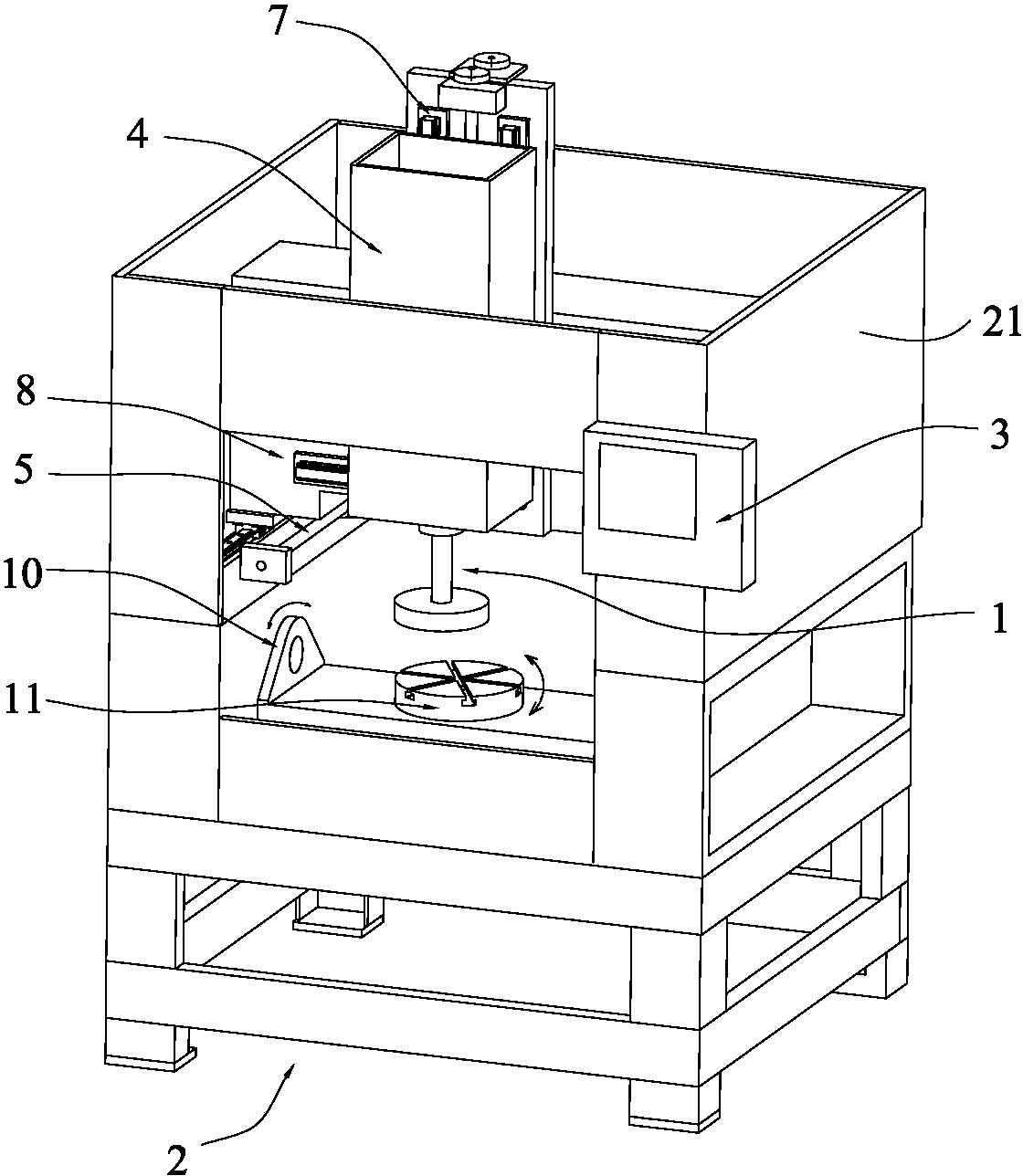

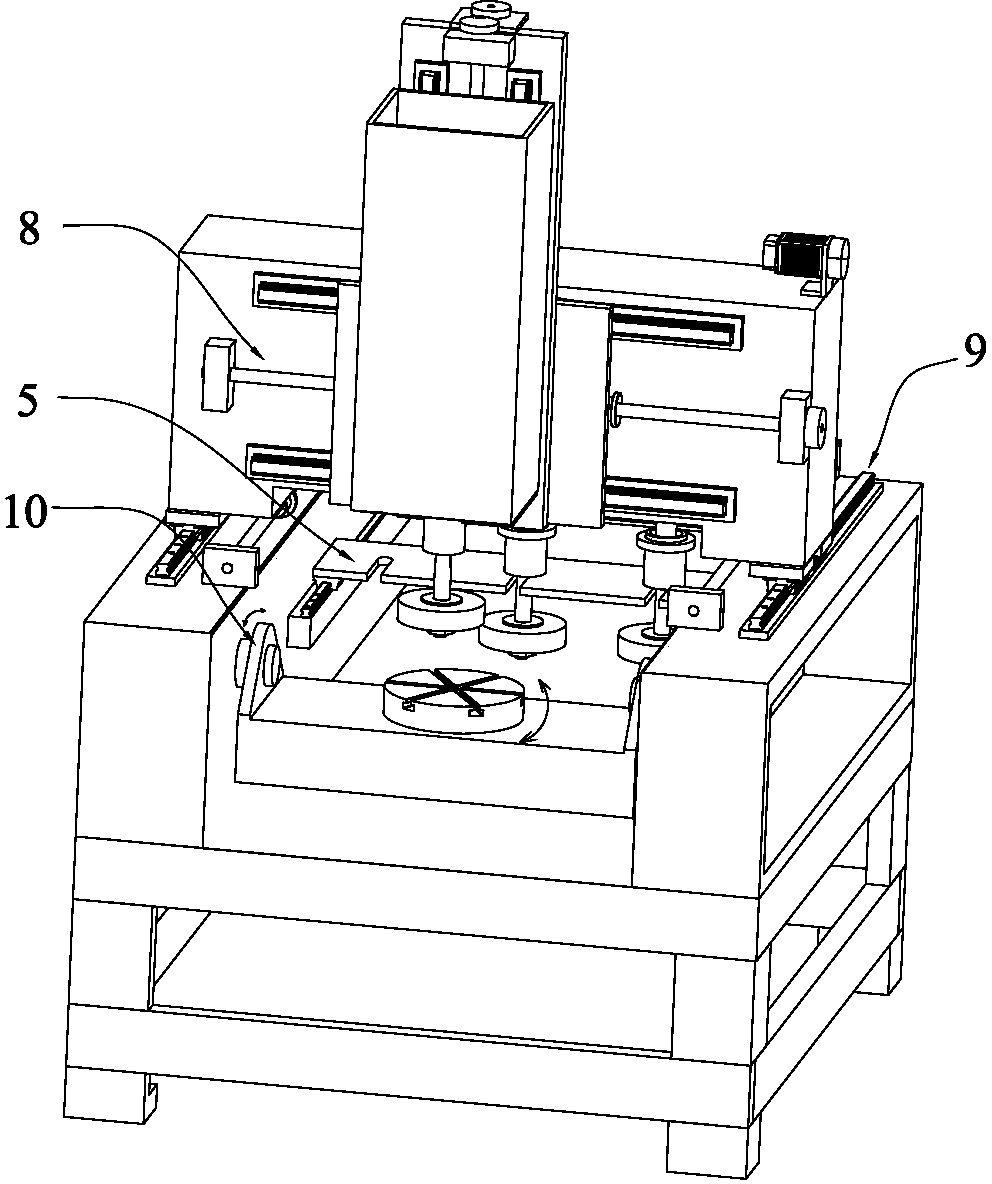

ActiveCN104759942AAvoid insufficient boundary conditionsGood compensationGeometric CADMachine tool componentsNumerical controlMeasurement point

The invention discloses an online milling deformation measurement and complementation machining method for a thin-walled part. The online milling deformation measurement and complementation machining method for the thin-walled part comprises the steps that 1, a three-dimensional model of the thin-walled part is established, and a numerical control code is obtained; 2, measurement point locations are extracted from the three-dimensional model; 3, based on the model, a measurement path is planned; 4, rough machining and semi-precise machining are conducted on a workpiece blank; 5, online measurement is conducted, and the coordinate values of all the planed measurement point locations are obtained; 6, the obtained coordinate values of the planed measurement point locations are compared with those of the corresponding point locations on the three-dimensional model of the thin-walled part, and the difference between the coordinates of each point location of the actually machined workpiece and those of the corresponding point location on the three-dimensional model is calculated; 7, according to the machining differences, a complementation factor optimal machining path is generated according to the machining differences, precise machining is conducted according to the path, and then the final deformation deviation and the compensation values are obtained. By the adoption of the online milling deformation measurement and complementation machining method, semi-precise machining and precise machining are adopted, the identical machining parameters are adopted by the semi-precise machining and the precise machining, and the best precise machining compensation effect of the thin-walled parts which are made of the same materials and have the same characteristics can be achieved to the greatest extent through only one group of tests.

Owner:HUAZHONG UNIV OF SCI & TECH

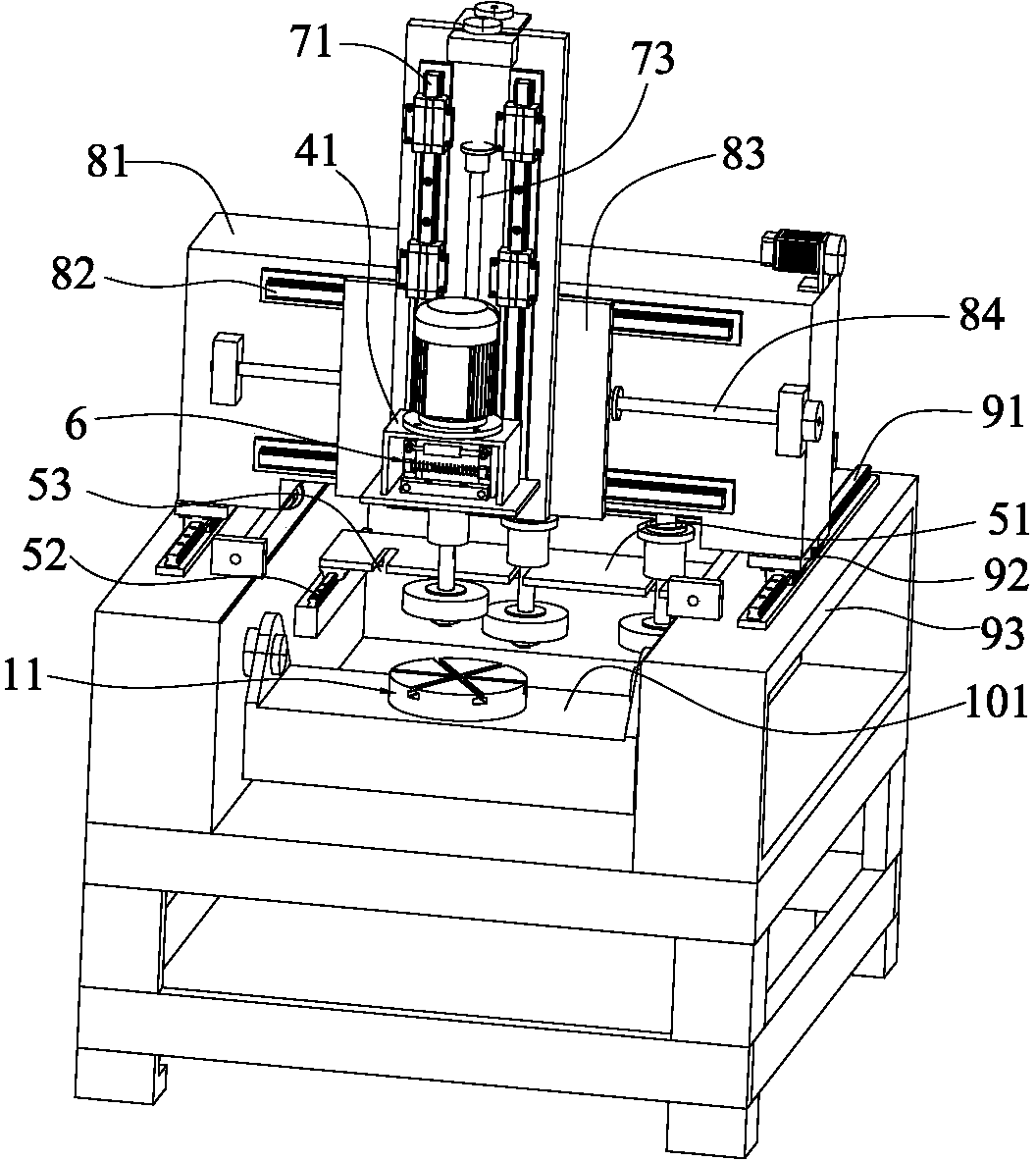

Five-axis numerical control polishing machine capable of changing grinding heads automatically

InactiveCN103465145AAutomatic replacementReduce labor intensityPolishing machinesNumerical controlCurve shape

The invention discloses a five-axis numerical control polishing machine capable of changing grinding heads automatically. The five-axis numerical control polishing machine comprises a plurality of semi-axis grinding heads, a machine body frame, a controller, a polishing head, a grinding head supply mechanism, a spindle clamping device, a Z-axis drive mechanism, an X-axis drive mechanism, a Y-axis drive mechanism, an A-axis rotary workbench and a C-axis rotating mechanism. The polishing head, the grinding head supply mechanism, the spindle clamping device, the Z-axis drive mechanism, the X-axis drive mechanism, the Y-axis drive mechanism, the A-axis rotary workbench and the C-axis rotating mechanism are respectively connected with the controlled and controlled by the same. The five-axis numerical control polishing machine capable of changing grinding heads automatically has the advantages that the polishing machine is ingenious and reasonable in structural design, high in automation level, convenient and fast to operate, high in flexibility by the five-axis linkage structure, and widely applicable; multiple polishing procedures such as rough polishing, fine polishing and mirror polishing can be completed at one-step clamping, clamping time is saved, machining efficiency and precision are increased greatly, polishing effect is guaranteed, work efficiency is increased, labor intensity of workers is lowered, enterprise competitiveness is increased effectively, and polishing of surfaces of complex curve shapes can be achieved.

Owner:东莞市钜铧机械有限公司

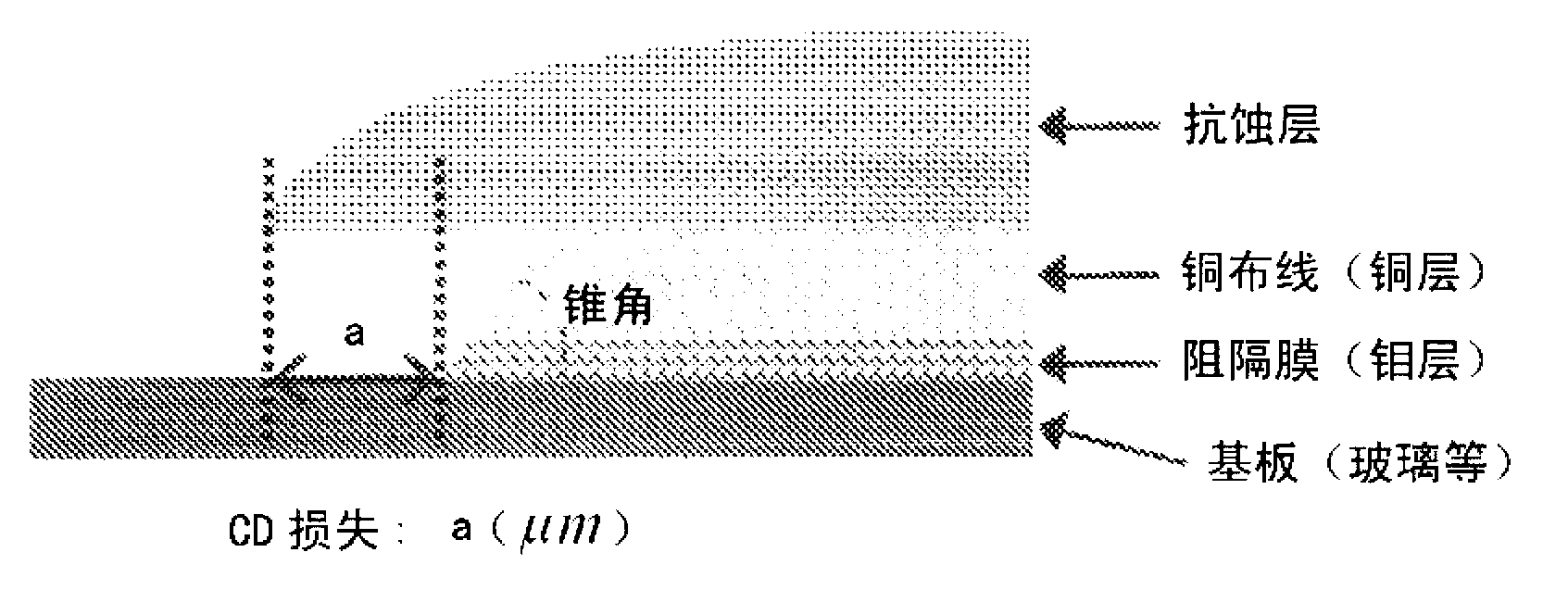

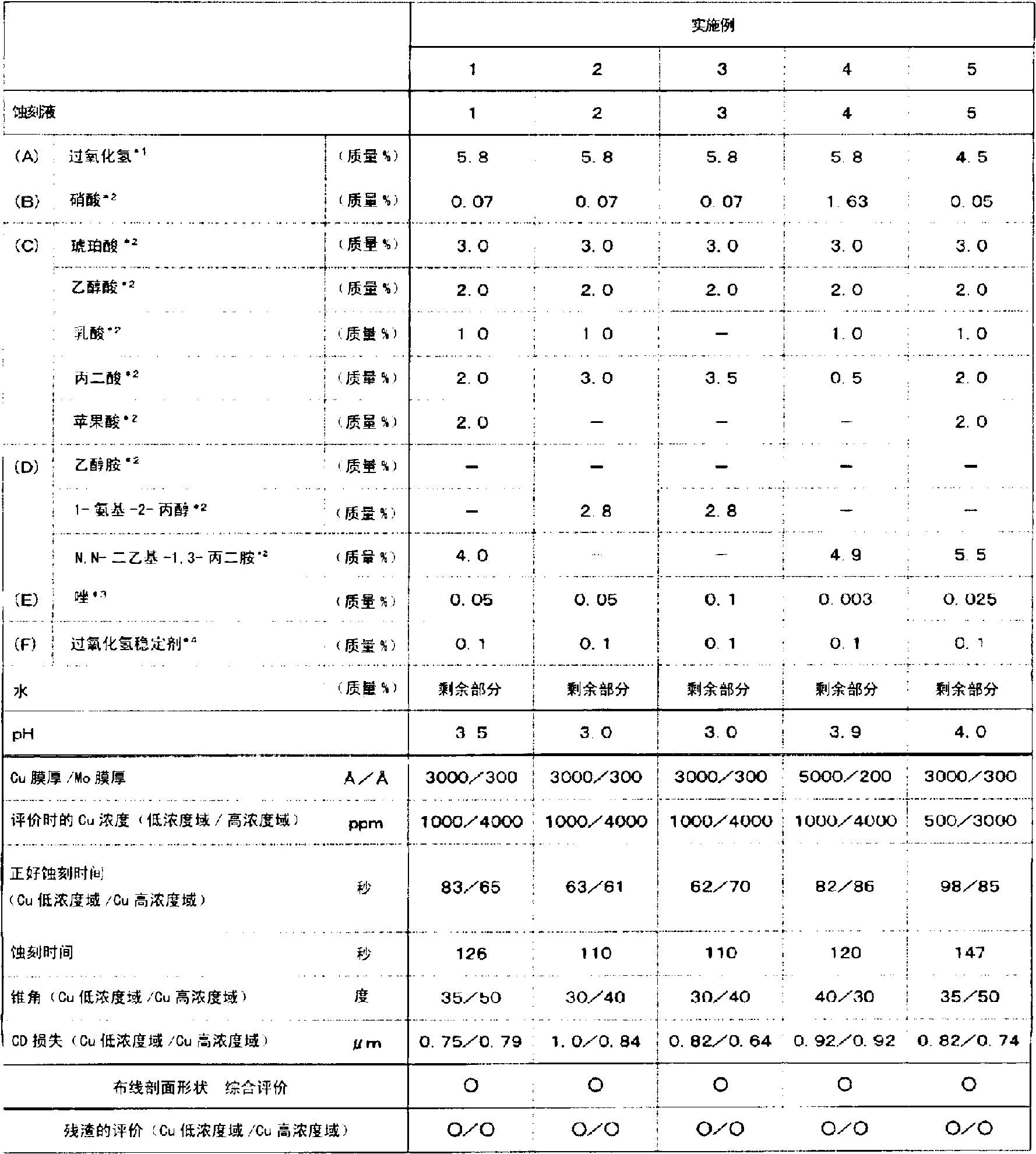

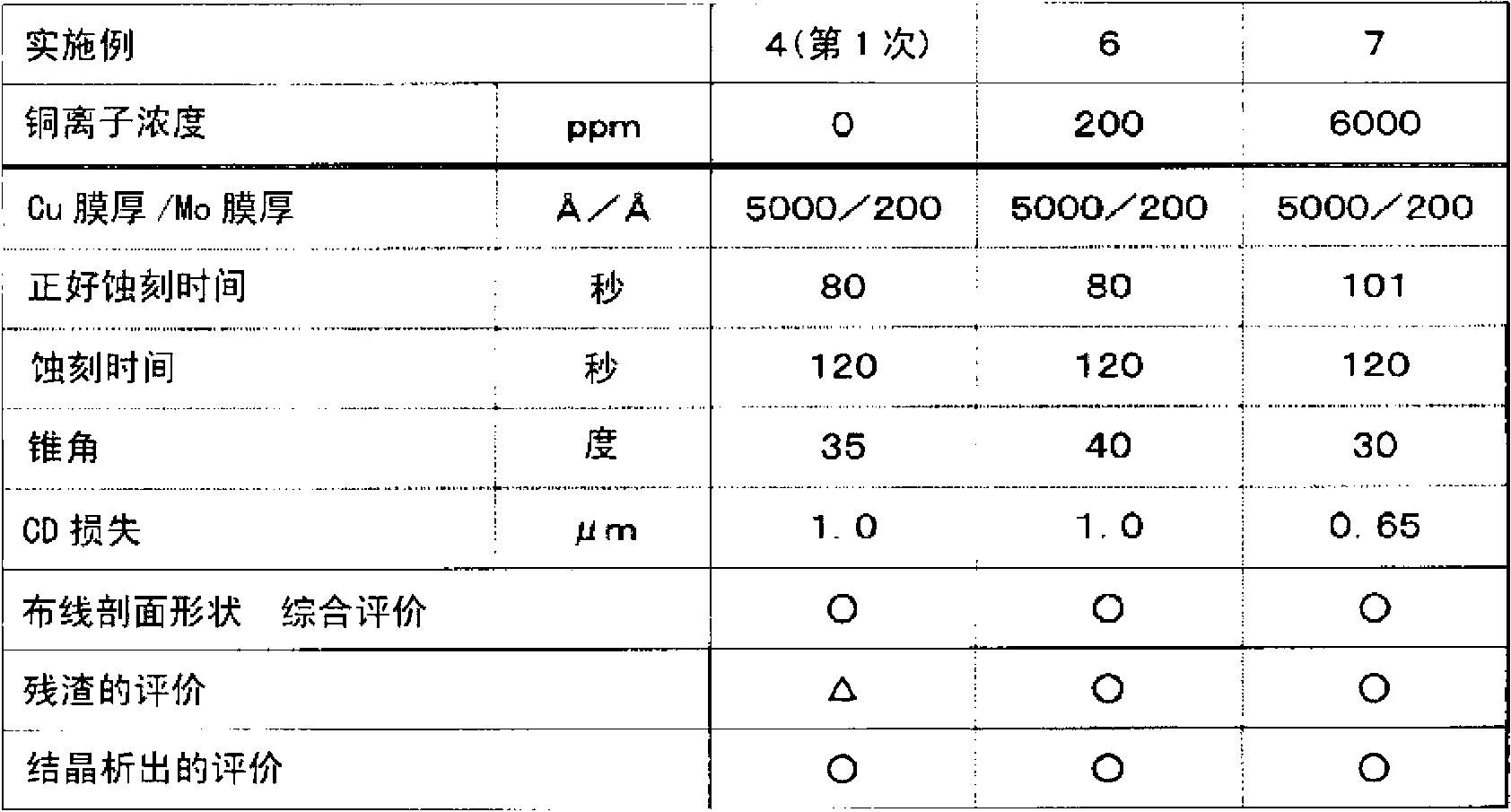

Etching solution for multilayer thin film having copper layer and molybdenum layer contained therein

ActiveCN102762770AExtend your lifeImprove machining accuracySemiconductor/solid-state device detailsSolid-state devicesOrganic acidCopper

Disclosed are: an etching solution for a multilayer thin film having a copper layer and a molybdenum layer contained therein; and a method for etching a multilayer thin film having a copper layer and a molybdenum layer contained therein using the etching solution. Specifically disclosed are: an etching solution for a multilayer thin film having a copper layer and a molybdenum layer contained therein, which comprises (A) hydrogen peroxide, (B) an inorganic acid having no fluorine atom, (C) an organic acid, (D) an amine compound having 2 to 10 carbon atoms and also having an amino group and a hydroxy group in the total number of two or more, (E) an azole, and (F) a hydrogen peroxide stabilizer, and which has a pH value of 2.5 to 5; and an etching method using the etching solution.

Owner:MITSUBISHI GAS CHEM CO INC

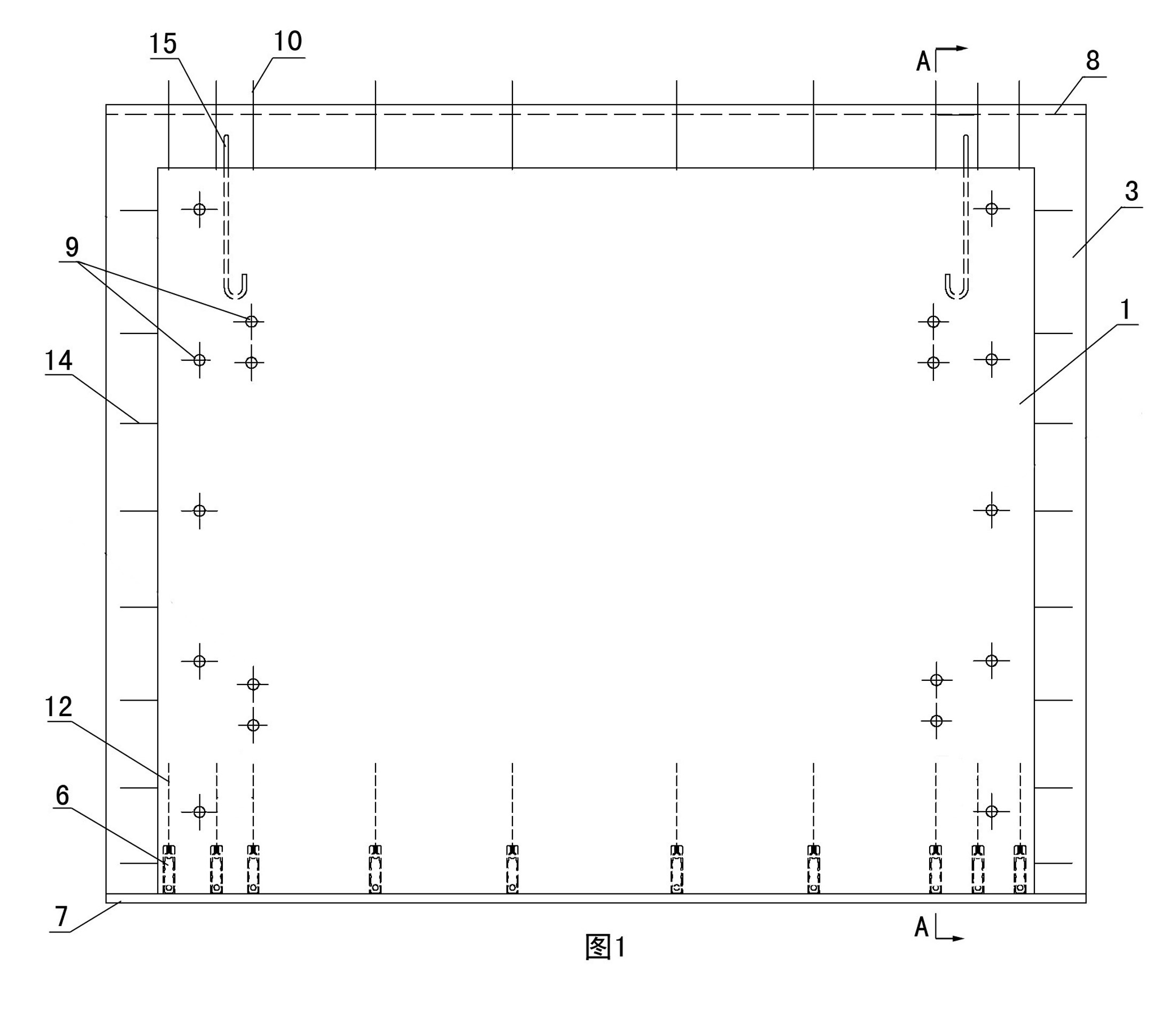

Assembled integral building and construction method thereof

ActiveCN101818539AGuarantee the construction qualityLow costBuilding componentsBuilding material handlingFloor slabReinforced concrete

The invention discloses an assembled integral building and a construction method thereof. The assembled integral building comprises a reinforced concrete wall and floor slabs, wherein the reinforced concrete wall is formed by hoisting and assembling prefabricated composite insulating wallboards integrally at a construction site; a board body of each prefabricated composite insulating wallboard comprises a structure layer, an insulating layer and a protective layer from the inside to the outside in turn; a reinforcement cage is arranged in the structural layer; steel meshes are arranged in the concrete of the protective layer; the structural layer, the insulating layer and the protective layer are anchored together by inserting connecting members in a dotted distribution; the left and right edges of the protective layer and the insulating layer protrude out of the structural layer; a lower edge of the protective layer extends downward to form a bulged opening; the top parts of the protective layer and the insulating layer upward protrude out of the structural layer; and an upper edge of the protective layer is provided with a notch which corresponds to the bulged opening of the prefabricated composite insulating wallboard adjacent to an upper layer. The building overcomes the defects of erecting shuttering on site, binding steel bars and concreting in a traditional construction method, speeds up the construction, and lowers the construction cost; and the construction quality of the building structure can be sufficiently guaranteed.

Owner:雄安万科绿色研发有限公司

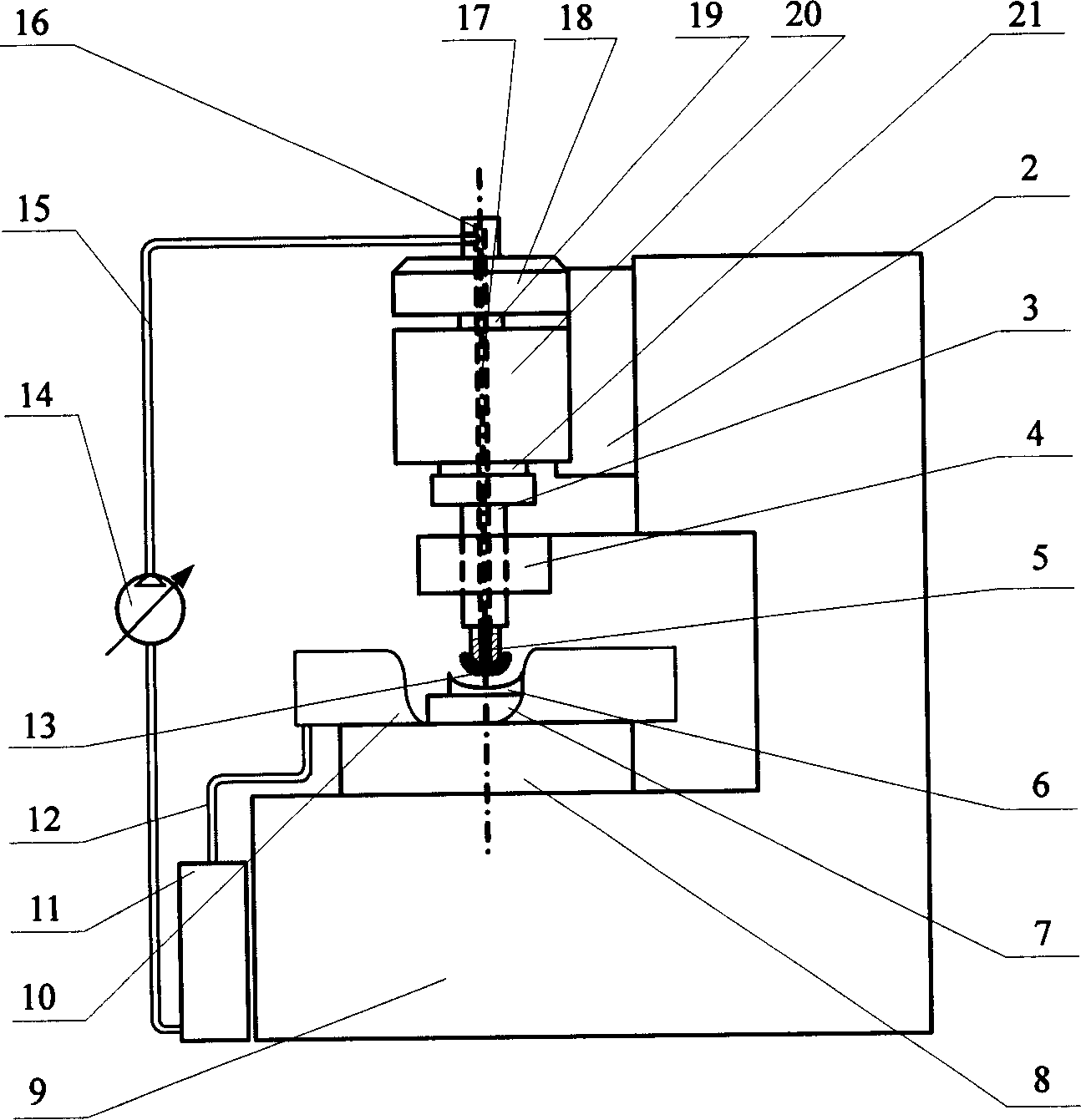

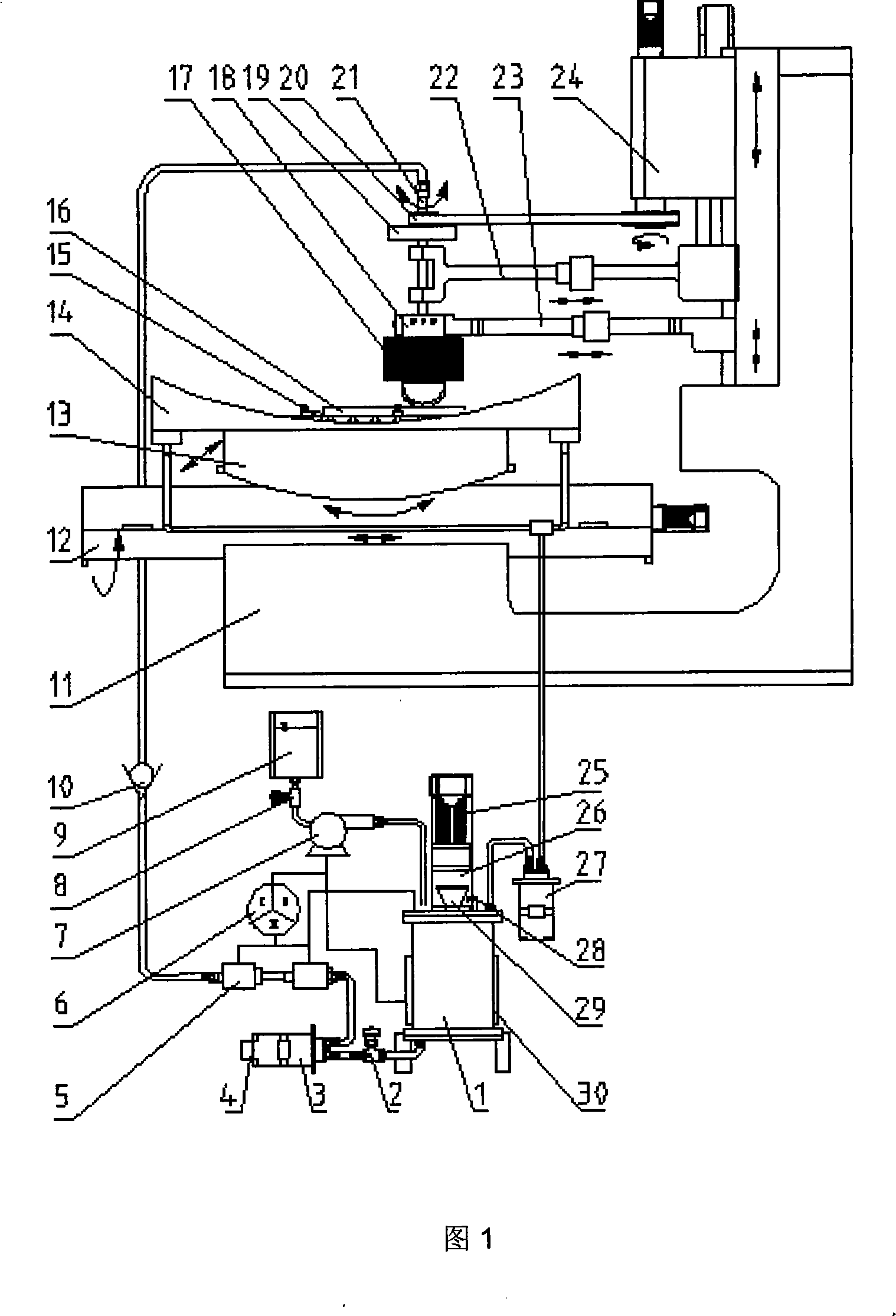

Precise magnetic flowage polishing system for optics parts and method thereof

InactiveCN101224556AImprove processing efficiencyEasy clampingOptical surface grinding machinesPeristaltic pumpTemperature control

The invention relates to an optical part magnetic rheologic precise polishing system and a method; magnetic rheologic liquid which flows out of a liquid storage cylinder is pressurized by a peristaltic pump and then enters a polishing head through a rotating connector and a guide pipe; the clearance between a workpiece and the polishing head is fully filled by the magnetic rheologic liquid; under the action of electromagnetic field, the magnetic rheologic liquid is transformed from the liquid state to the half-solid state so as to form a flexible grinding head used for polishing. The polishing head of the invention is not directly contacted with the workpiece; the polishing heads with different shapes and specifications can be replaced according to the processed workpiece; a computer automatic control device can realize the viscousity control and the temperature control of the magnetic rheologic liquid, and different polishing efficiency and precisions can be obtained by changing the factors such as magnetic field and rotation speed, etc.; the method of the invention can process the curved workpieces and plane workpieces with different shapes, more particularly the ultra-precise polishing of the large plane optical parts; the system has the advantages of high processing efficiency, wide applicable range, high processing precision and convenient operation.

Owner:DONGHUA UNIV

Ultrasonic wire cutting saw for hard-fragile material processing

InactiveCN1488480ASimple structureIncrease productivityStone-like material working toolsWire cuttingEngineering

The invention is a kind of supersonic wave tangent line saw for hard and crisp material, which comprises the bed, longitudinal working slide flat, transversal work slide flat, piece bracket, diamond line saw, supersonic wave vibrating device, saw reciprocating motion mechanism and electricity control device, the supersonic vibrating device is fixed on the upper arm of the C type work bracket through screw, the electrical signal is transformed into mechanical vibration, and enlarges the amplitude through a pole, the diamond saw vibrates as wave, it generates reciprocating motion through cranked rod, C type work bracket, slide flat seat. The saw is in linear high frequency vibration state and reciprocating motion; the invention is simple and has a high productivity.

Owner:沈阳工业学院

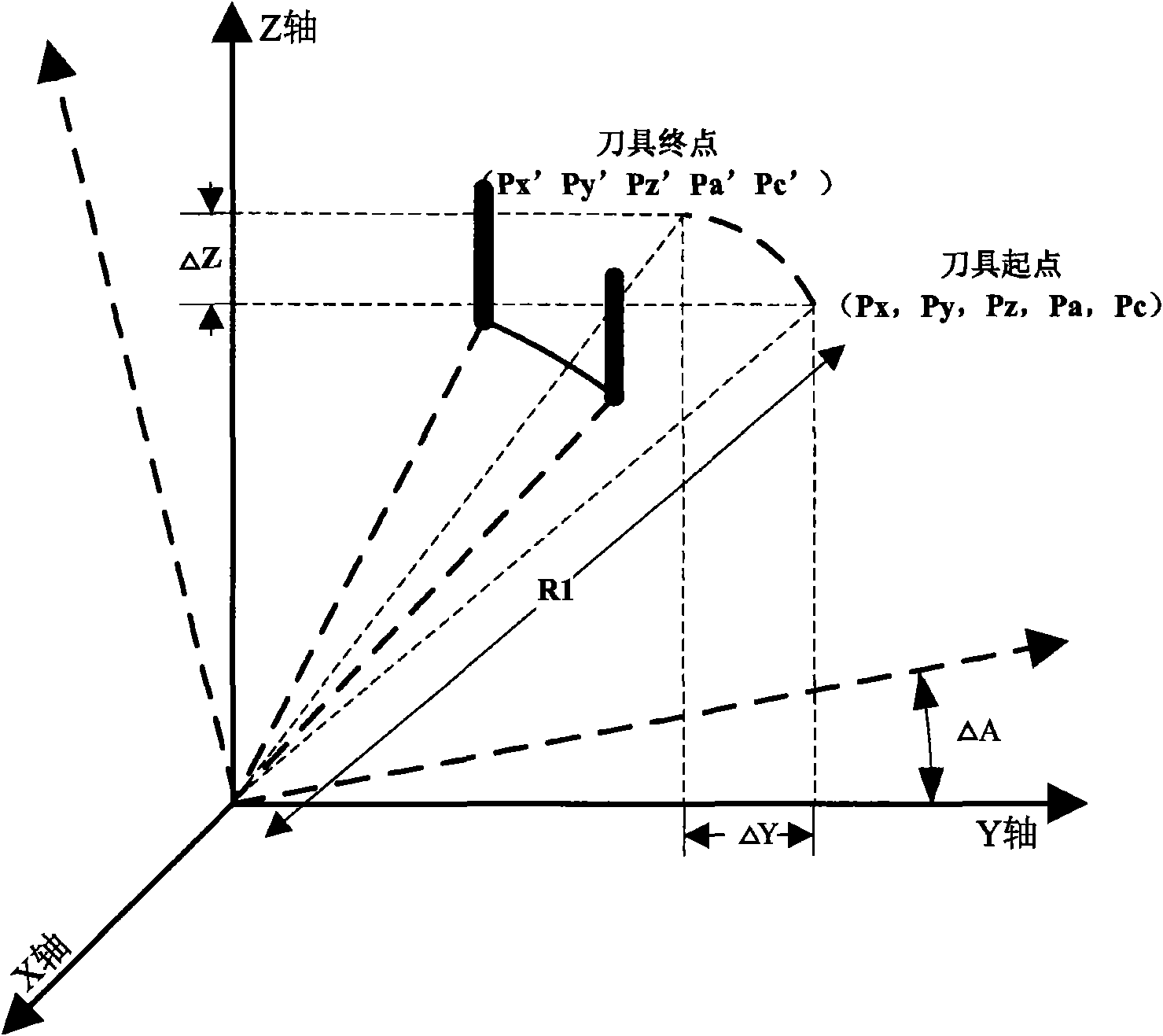

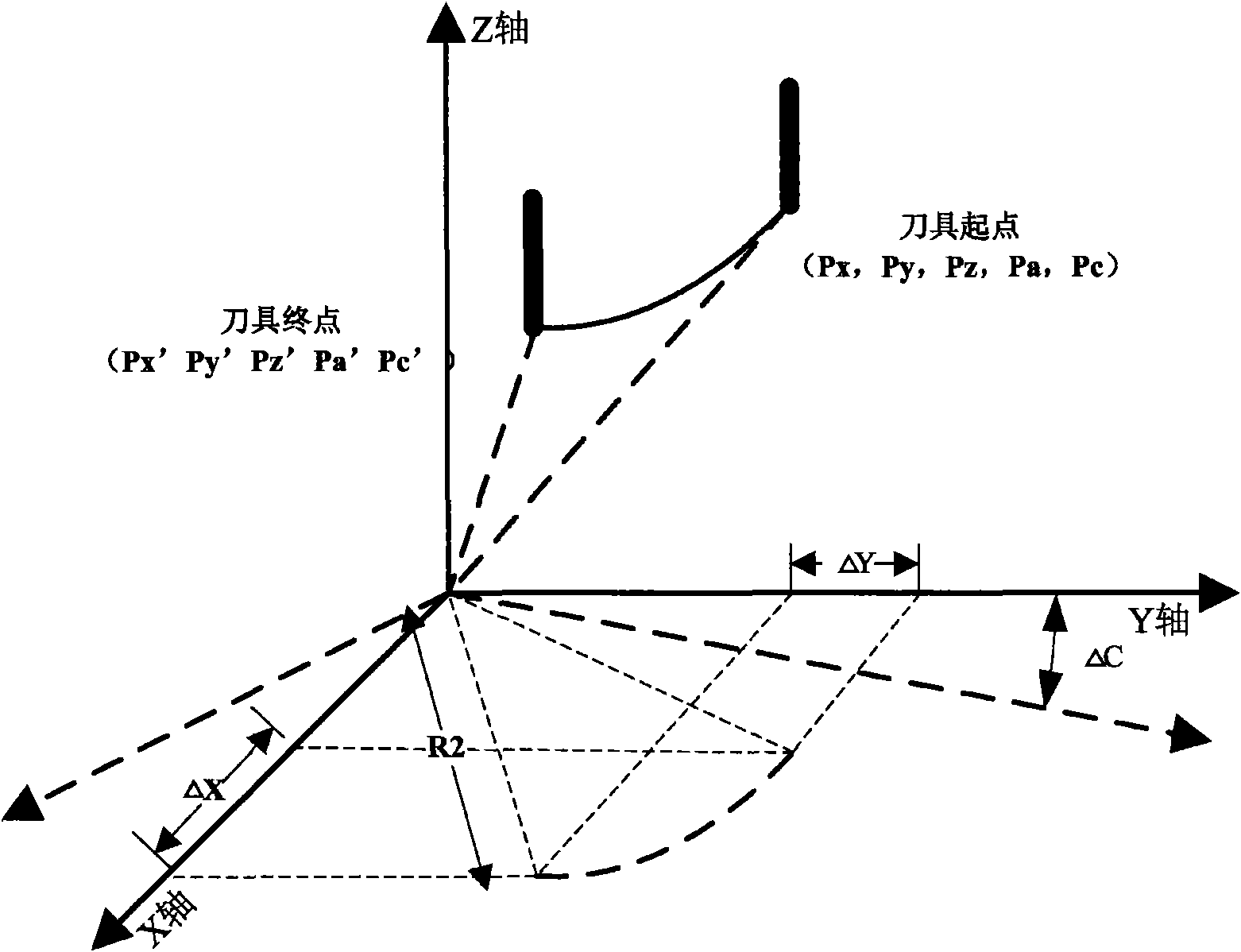

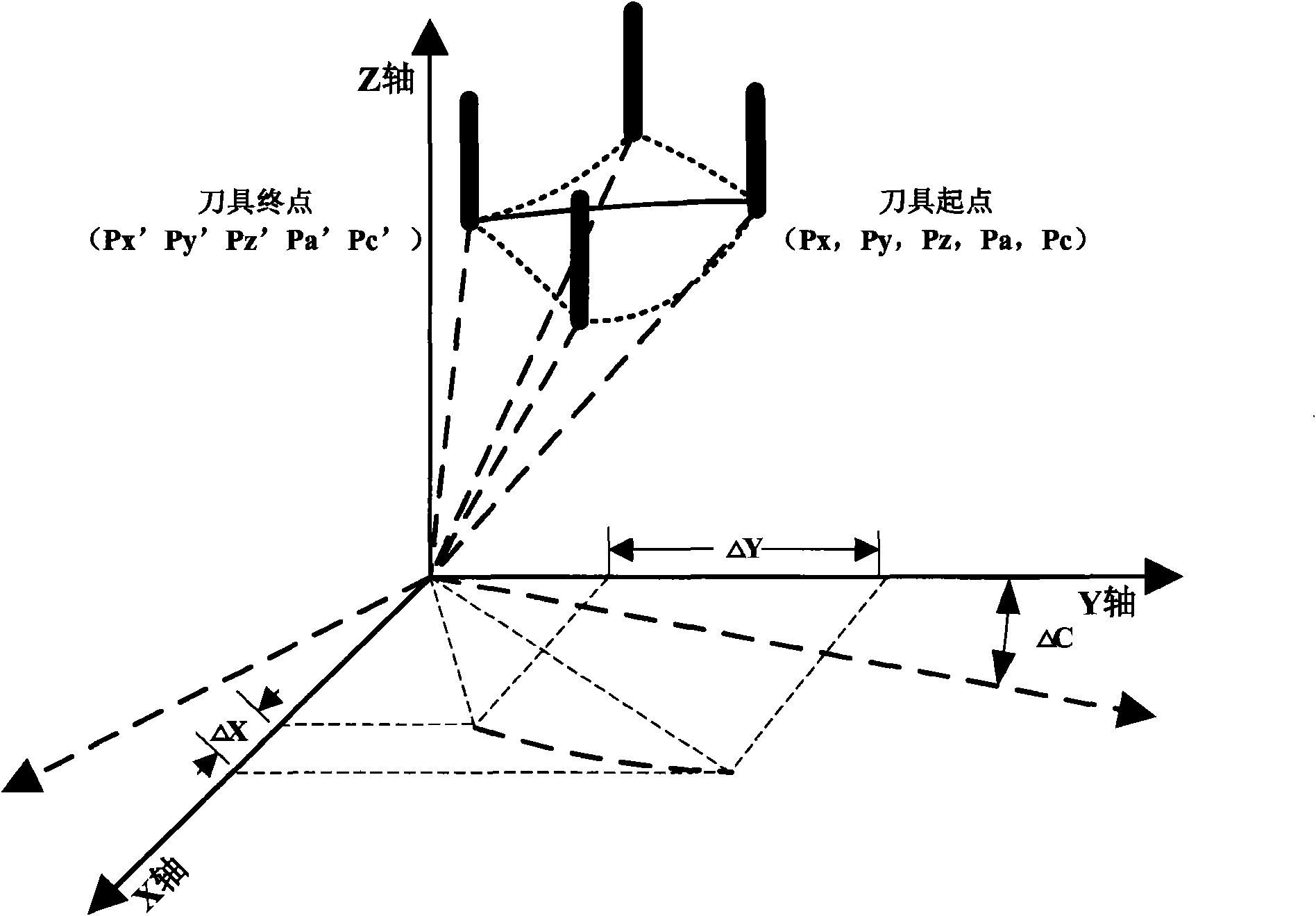

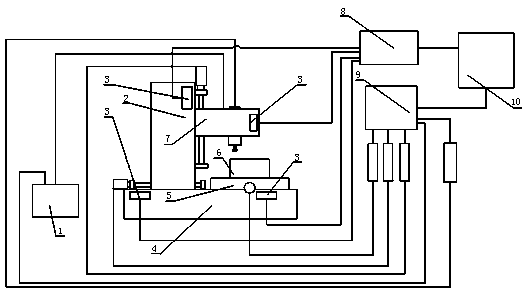

Method for compensating central point of double-turntable five-axis linked numerical control machining rotary tool

InactiveCN101980091ASolve the problem of nonlinear motion errorImprove performanceProgramme controlComputer controlLinear motionNonlinear motion

The invention discloses a method for compensating a central point of a double-turntable five-axis linked numerical control machining rotary tool. The method is characterized by comprising the following steps of: when a tool trace of a double-turntable five-axis linked numerical control system which machines a spatial complex curved surface is a straight line, discretely approximating the movement trace of the central point of the tool through line interpolation, starting a real time control protocol (RTCP) module, obtaining a normal plane compensation vector and performing projection to obtain a central point compensation vector and output displacement by using the RTCP module, and inputting a number axis center distance parameter to realize the compensation of a nonlinear movement error during the machining of the double-turntable five-axis linked numerical control system. The method can well inhibit the nonlinear movement error, so that the running efficiency of the numerical control machining equipment is improved, the numerical control equipment can perform high-precision and high-efficiency machining, the machining quality of parts can be remarkably improved, and the method has excellent application prospect in the field of mechanical engineering.

Owner:RES INST OF XIAN JIAOTONG UNIV & SUZHOU

Numerical machine tool machining state multi-parameter online active monitoring system and implement method thereof

ActiveCN103823409AImprove processing qualityImprove processing efficiencyProgramme controlComputer controlActive monitoringState parameter

The invention discloses a numerical machine tool machining state multi-parameter online active monitoring system and an implement method thereof. The system and the method mainly solve the problems that state detection performance indexes of an existing numerical control machine tool are not comprehensive, and closed-loop control during the machining process can not be achieved. The numerical machine tool machining state multi-parameter online active monitoring system comprises a first sensor assembly arranged on a numerical control machine tool servo feeding unit, a second sensor assembly arranged on a main shaft unit, a third sensor assembly disposed on a cooling liquid circulating unit and a multi-channel synchronous data collecting PXI box used for receiving information of collected data. The multi-channel synchronous data collecting PXI box sends related collected state signals to a monitoring computer in real time for analysis, calculation, display and storage, the monitoring computer generates related control instructions according to abnormal or optimized machining state parameters, transmits the related control instructions to a numerical control system of the numerical control machine tool through an Ethernet bus and executes related active control instruments, and accordingly real-time adjustment and control of numerical control machining process states are finished.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method of drilling a hole through Co2 laser directly

InactiveCN1761378AHigh precisionGuaranteed alignmentConductive material chemical/electrolytical removalLaser beam welding apparatusEtchingCopper foil

Drilling method of carbon dioxide laser includes steps: preparing locating point on layer next to the outer layer; before pressfitting added layer, browning oxidizing surface of target bonding pad; after pressfitting added layer, milling location hole / polishing edge, washing surface under high pressure; browning front surface of copper, thinning and coursing the surface before drilling hole by layer; first time to drill hole by laser; positioning film perforation by using plate location hole in original etching method for making window of copper, burning through copper foil and resin above the locating point on layer next to the outer layer so as to expose the locating point; second time to drill hole by laser; using the exposed locating point as position fixing to make micro hole inplate; washing surface under high pressure to remove browning layer after drill hole. The invention saves dry film and etching liquid, and raises process precision.

Owner:WUS PRINTED CIRCUIT (KUNSHAN) CO LTD

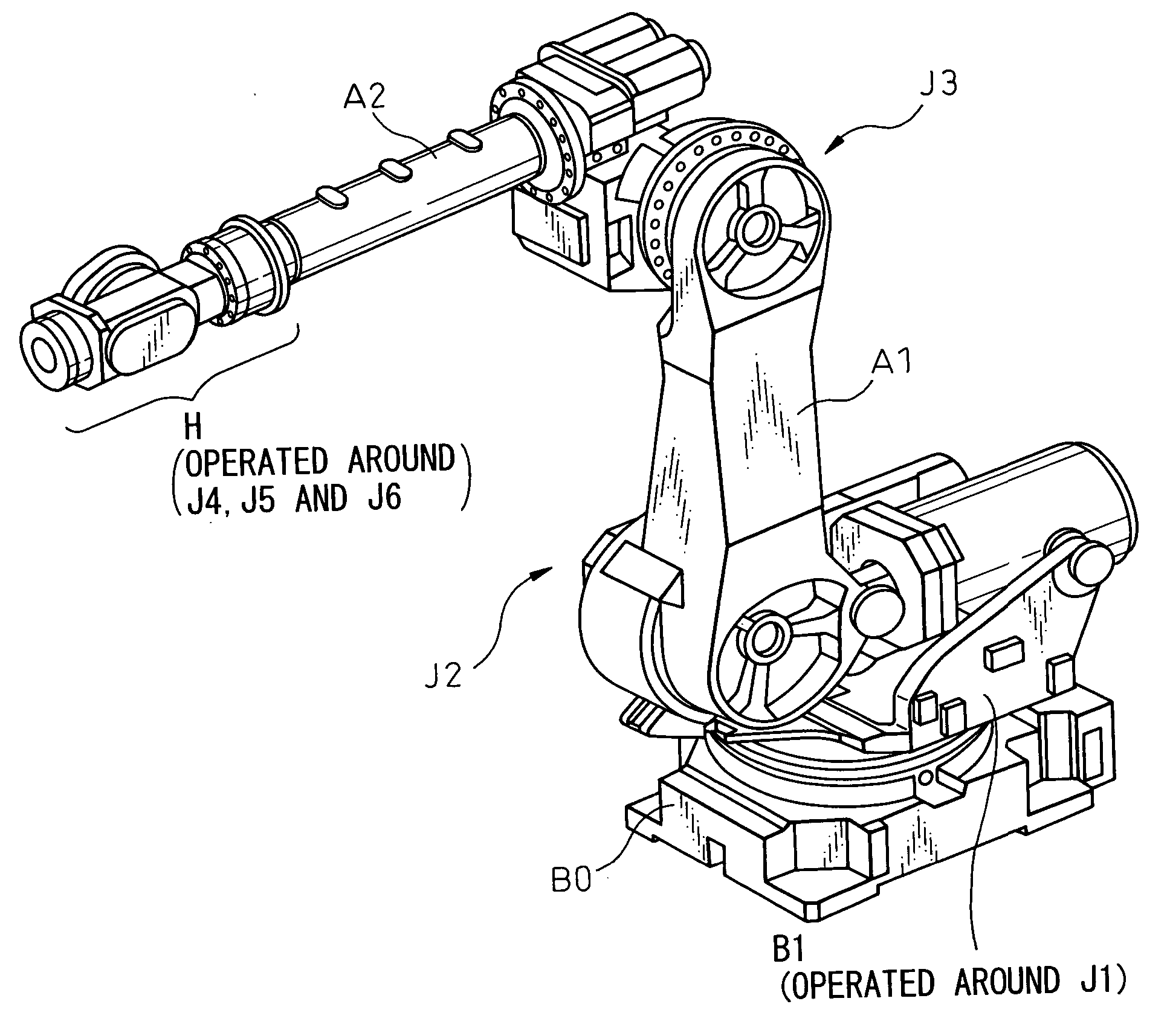

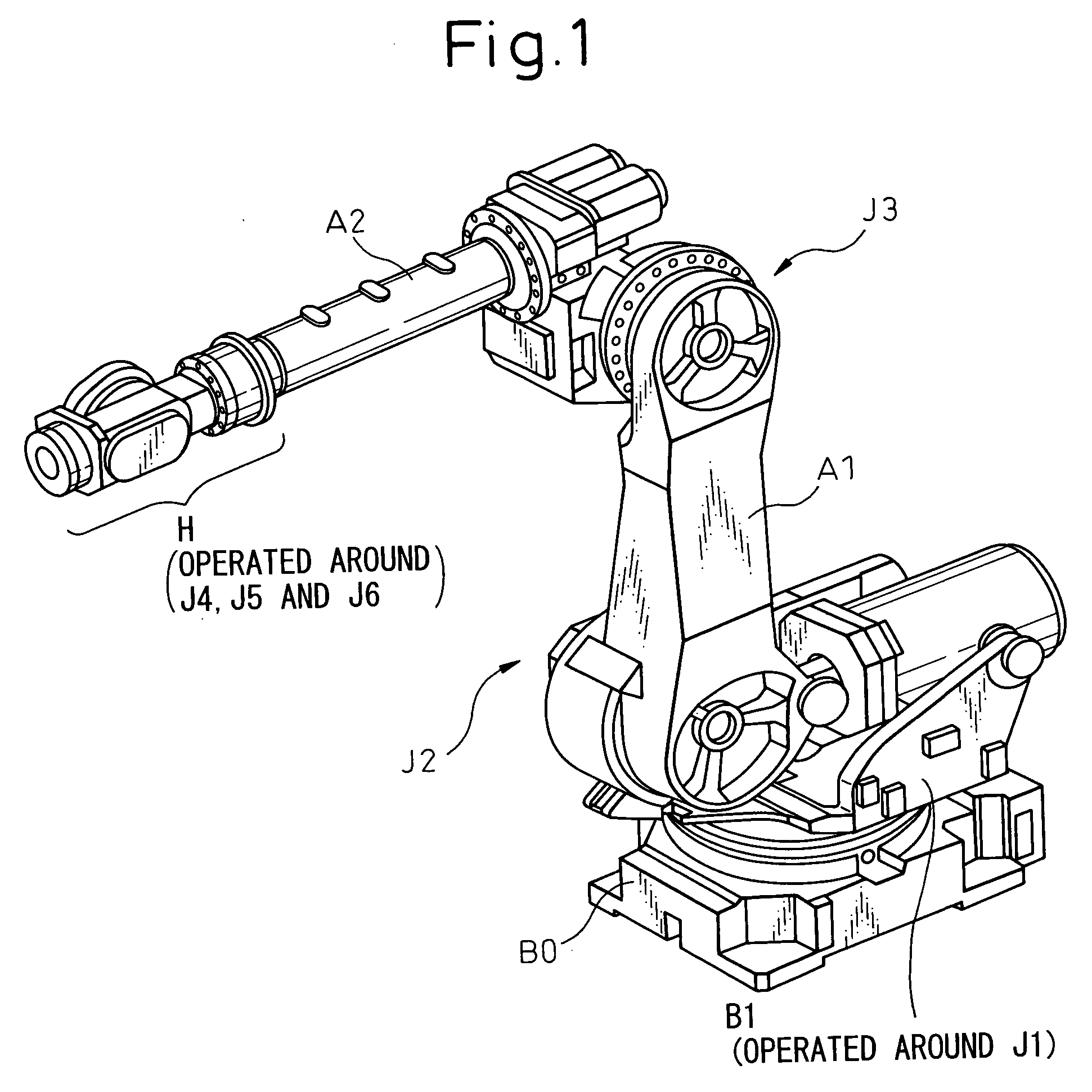

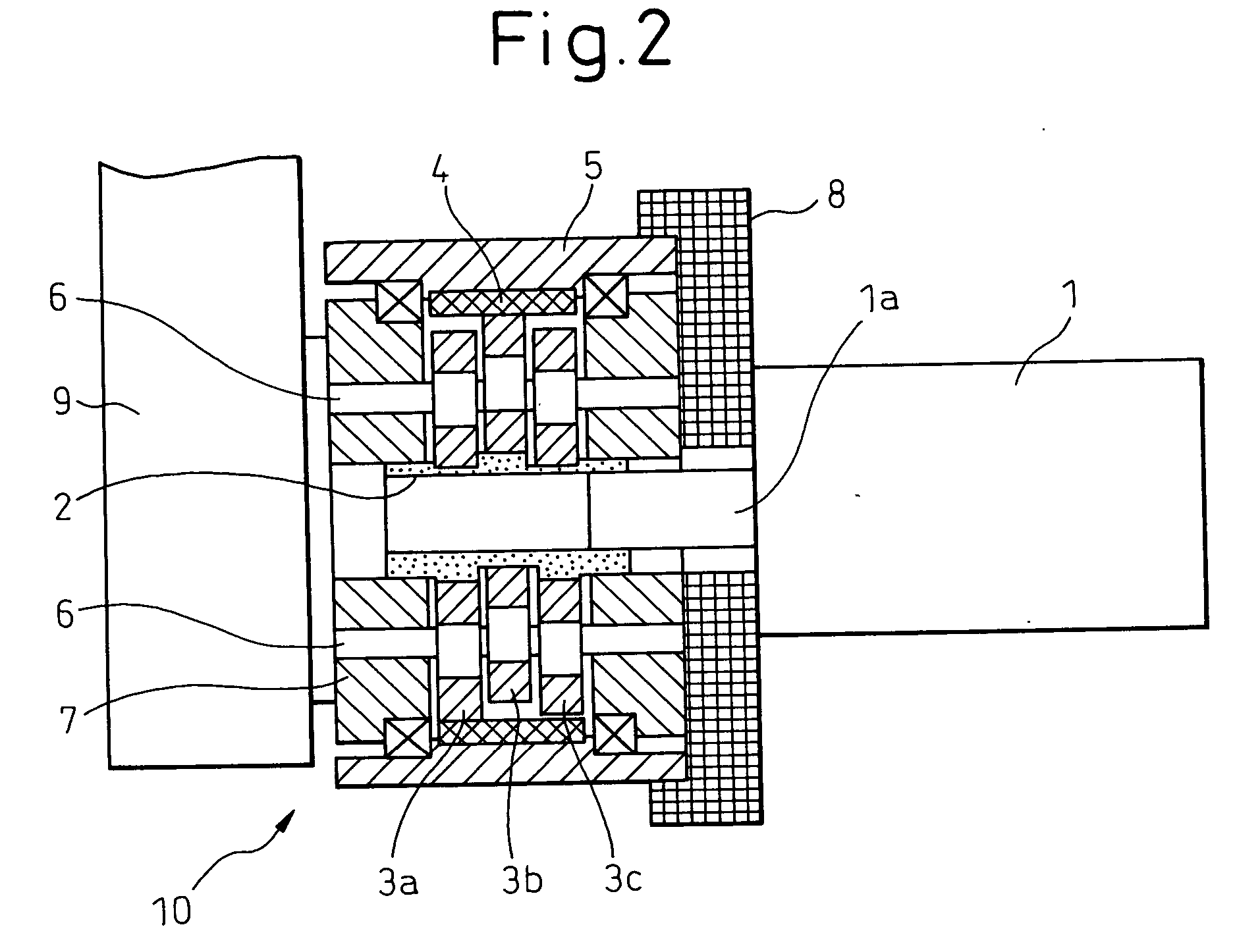

Industrial robot

InactiveUS20050204850A1Simple structureImprove machining accuracyProgramme-controlled manipulatorJointsEngineeringControl theory

A joint structure is employed for an articulated type robot in which a speed reducer of one-stage speed reducing structure and a servo motor are directly connected to each other for the joint of the rotary base B1 and the lower arm A1 and for the joint of the lower arm A1 and the upper arm A2. The input shaft 2 of the speed reducer 10 directly connected to the output shaft of the servo motor 1 attached to the first member 8 (B1 / A2) is a crank shaft composing a cam, and the external gears 3a, 3b, 3c are meshed with the cam surfaces. When the servo motor 1 is driven and the input shaft 2 is rotated, the external gears 3a, 3b, 3c are eccentrically revolved and rotated while the external gears 3a, 3b, 3c are meshed with the internal gear 4 provided inside the case 5 of the speed reducer 10. The rotation is taken out by a plurality of pin members 6 engaged to the external gears 3a, 3b, 3c and transmitted to the output shaft 7 of the speed reducer 10. Therefore, the second member 9 (A1) is relatively pivoted with respect to the first member 8. Due to the foregoing, the robot structure in which a plurality of joint devices for connecting the adjoining links via the speed reducer are connected in series to each other can be simplified.

Owner:FANUC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com