Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3940 results about "High productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High Productivity. A nation being renown for the High Productivity of its citizens is a good situation, as it attracts global corporations and factories which will increase the nation's GDP by 6.1% to 7%. A nation usually becomes known for having high productivity when the average Productivity goes above 73%.

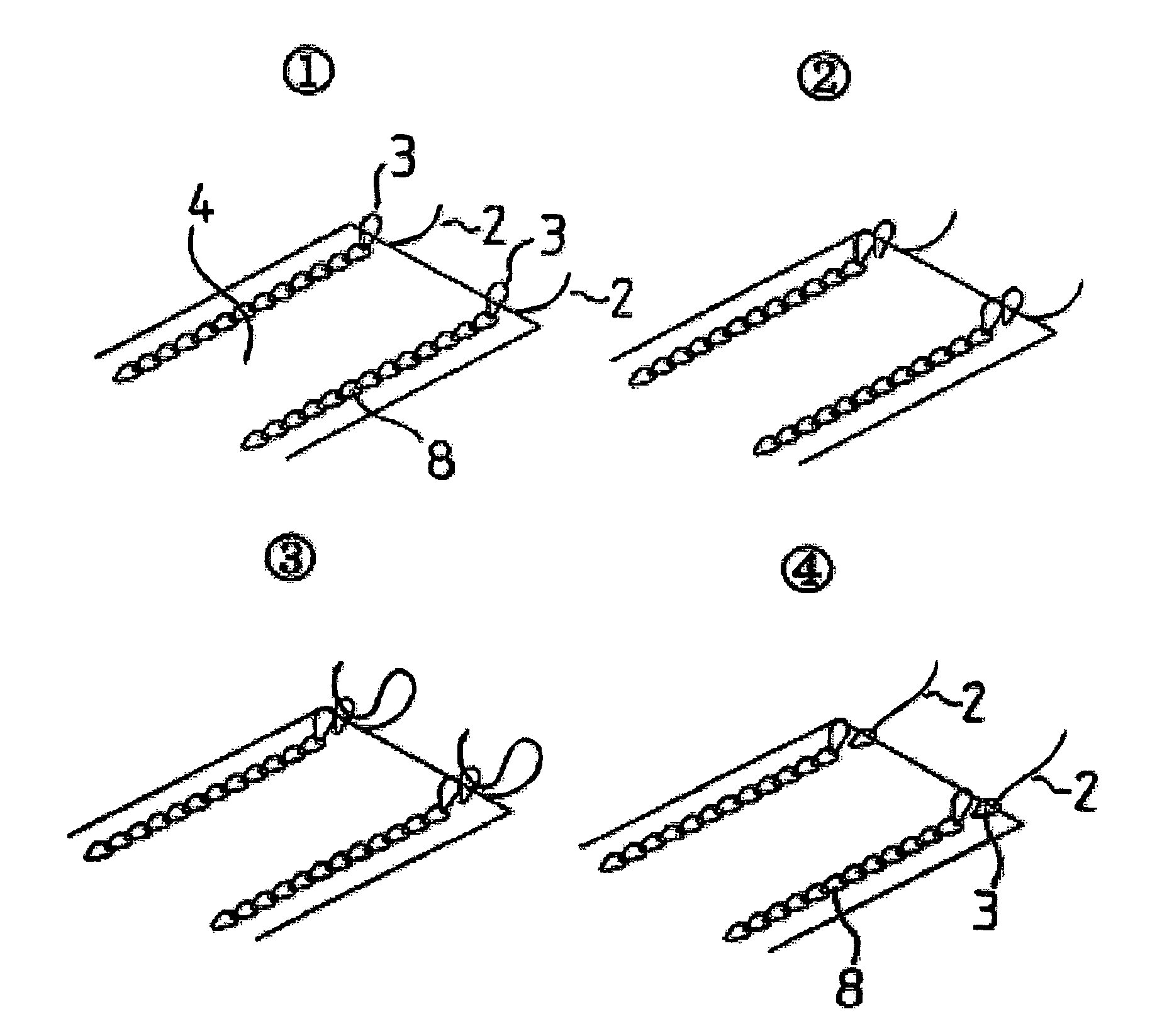

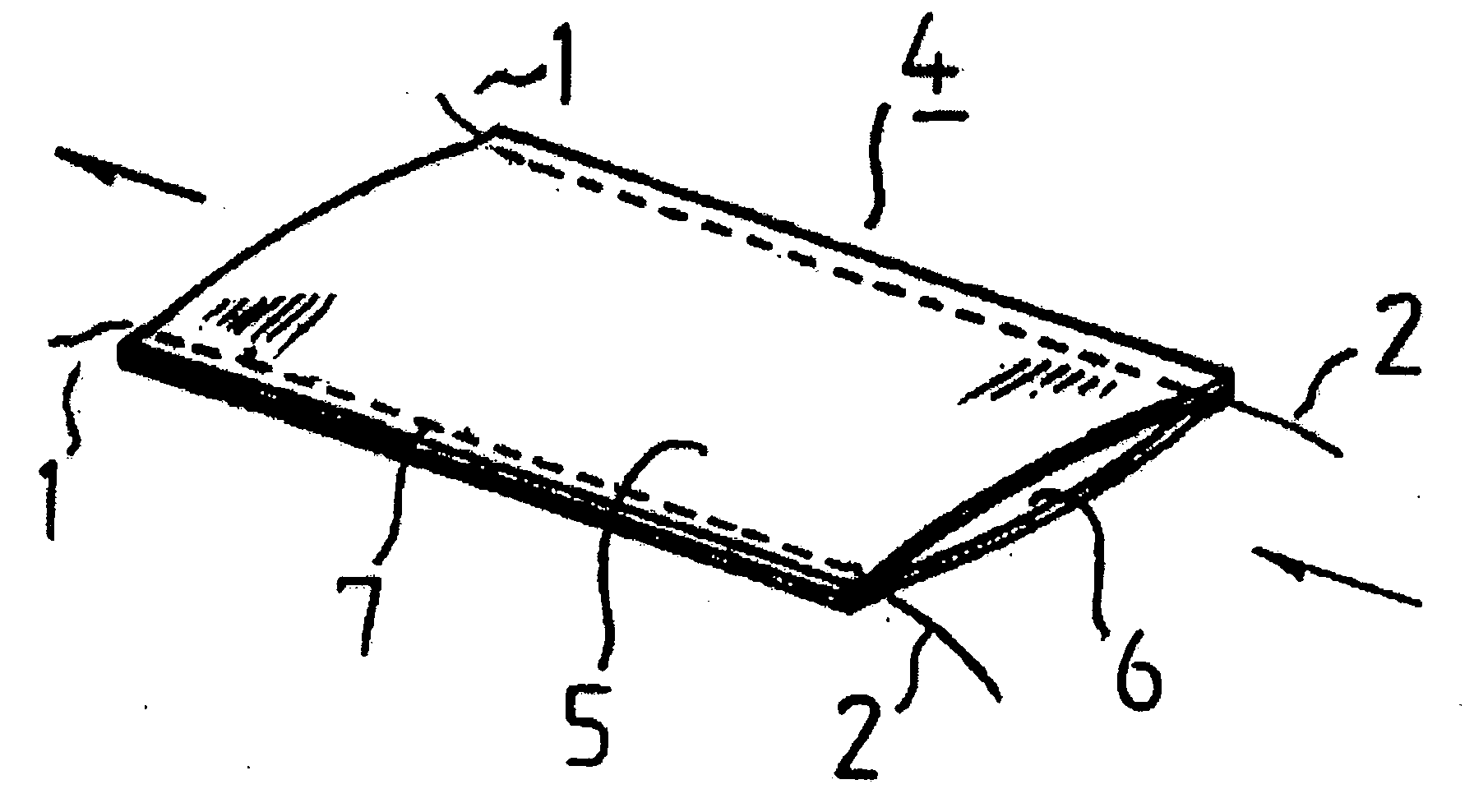

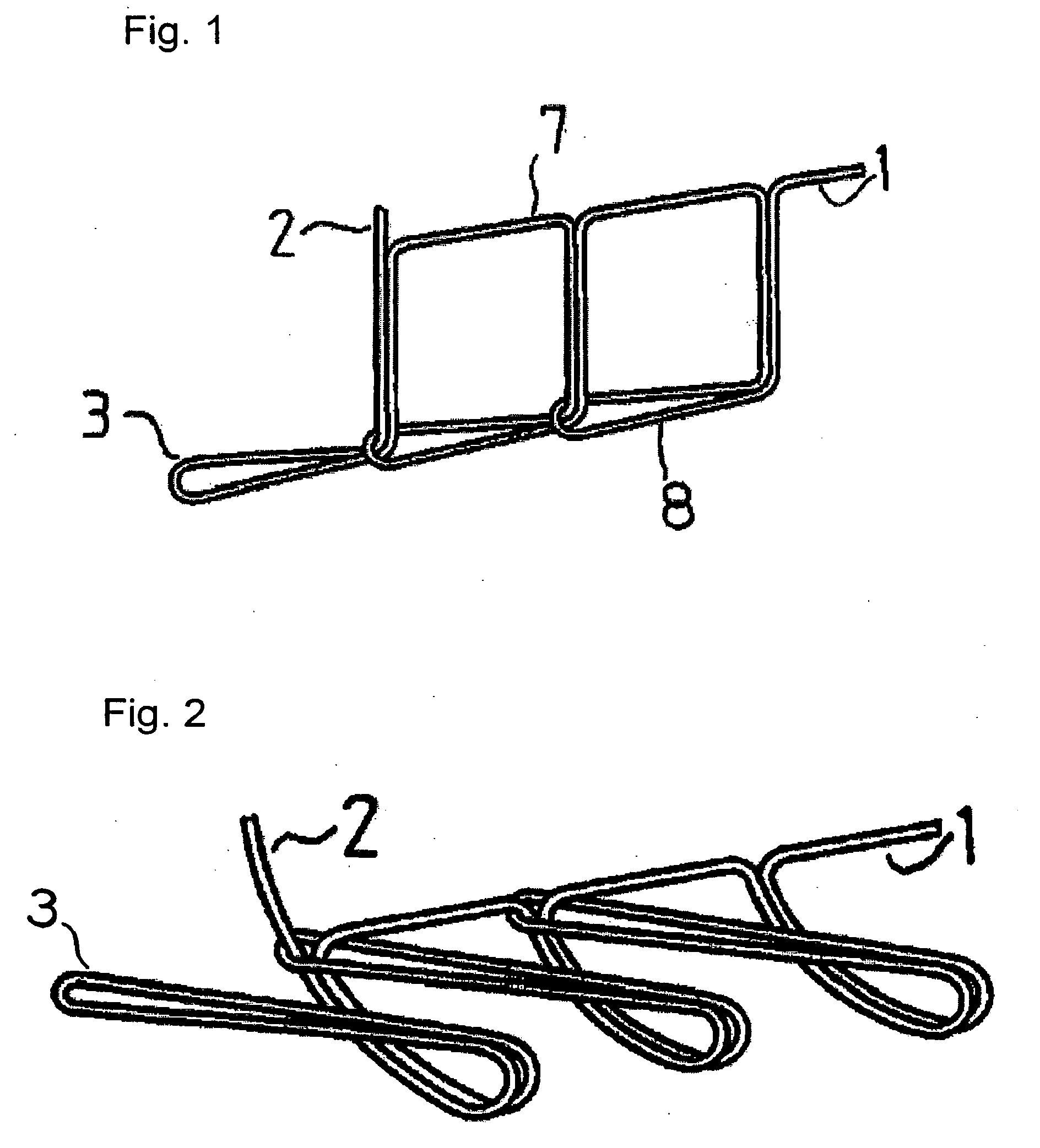

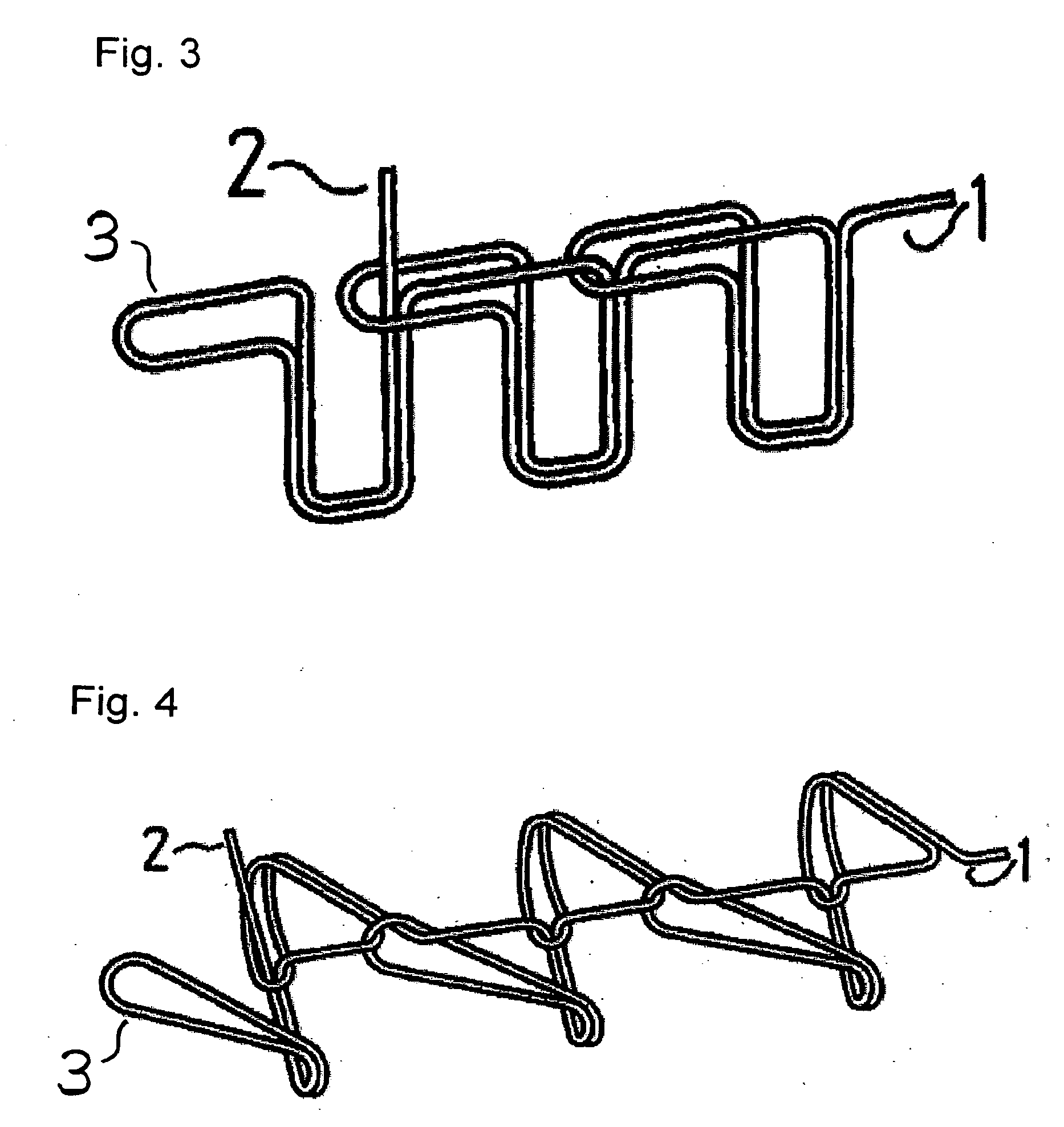

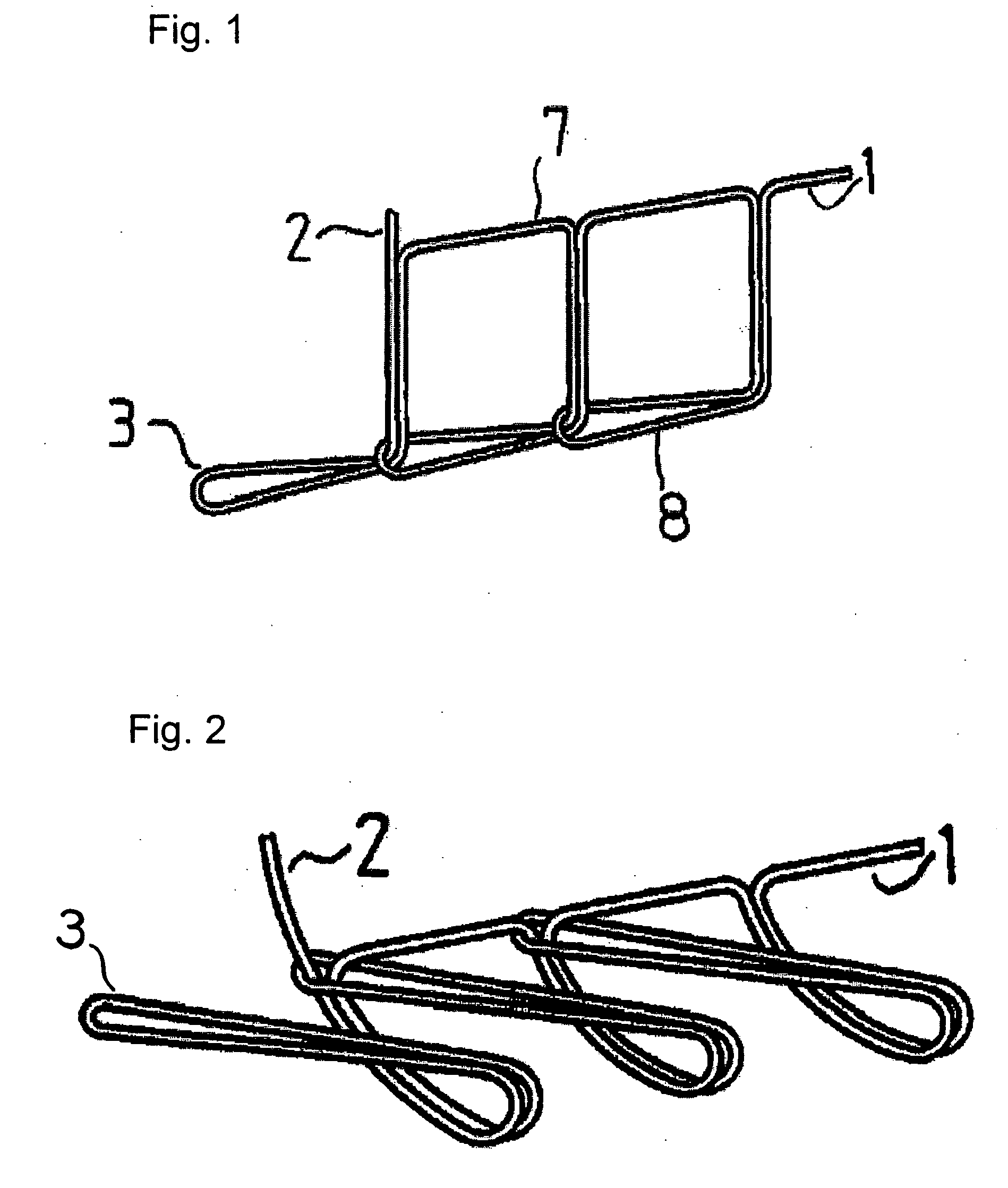

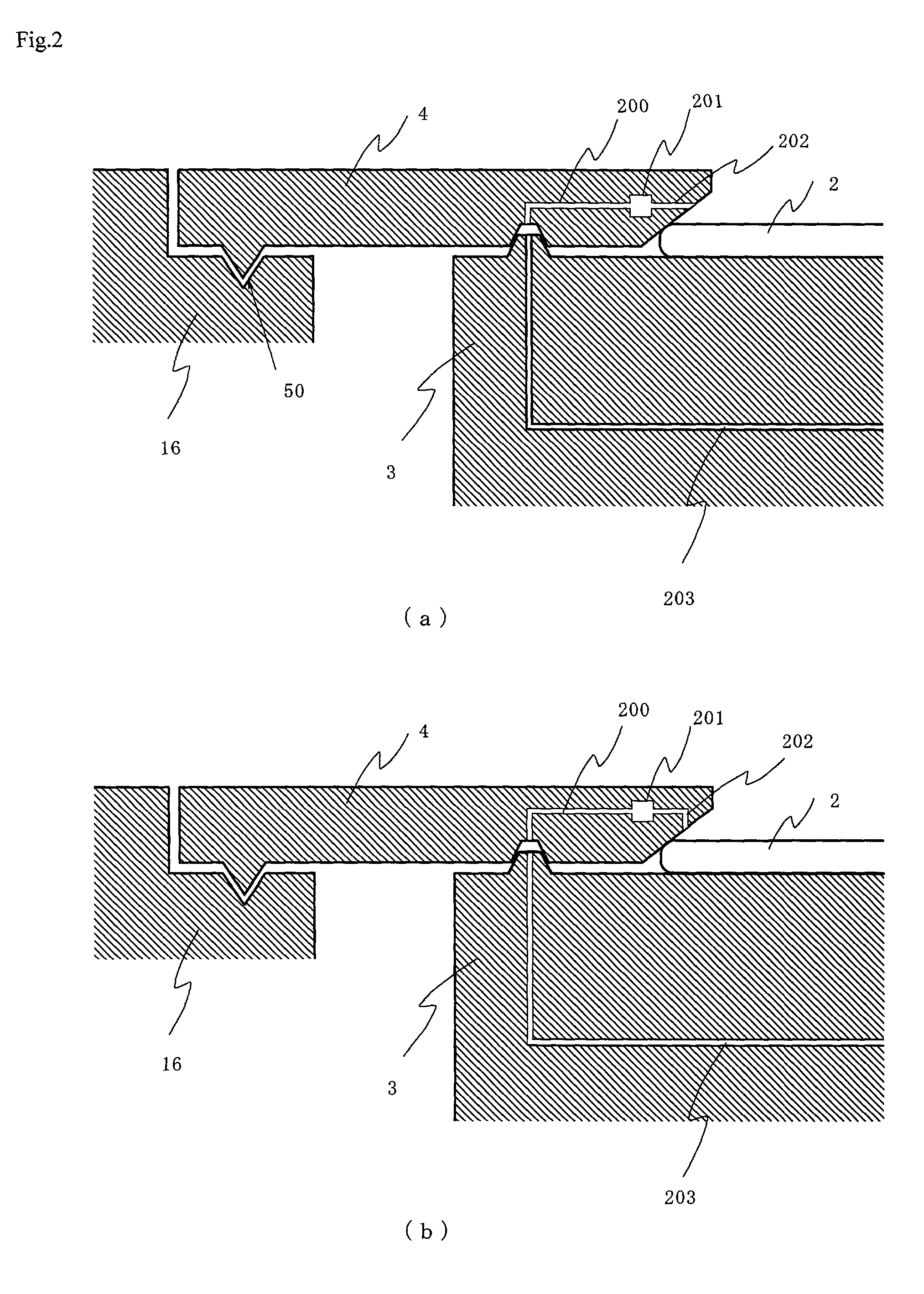

Suture reinforcement material for automatic suturing device

Owner:GUNZE LTD

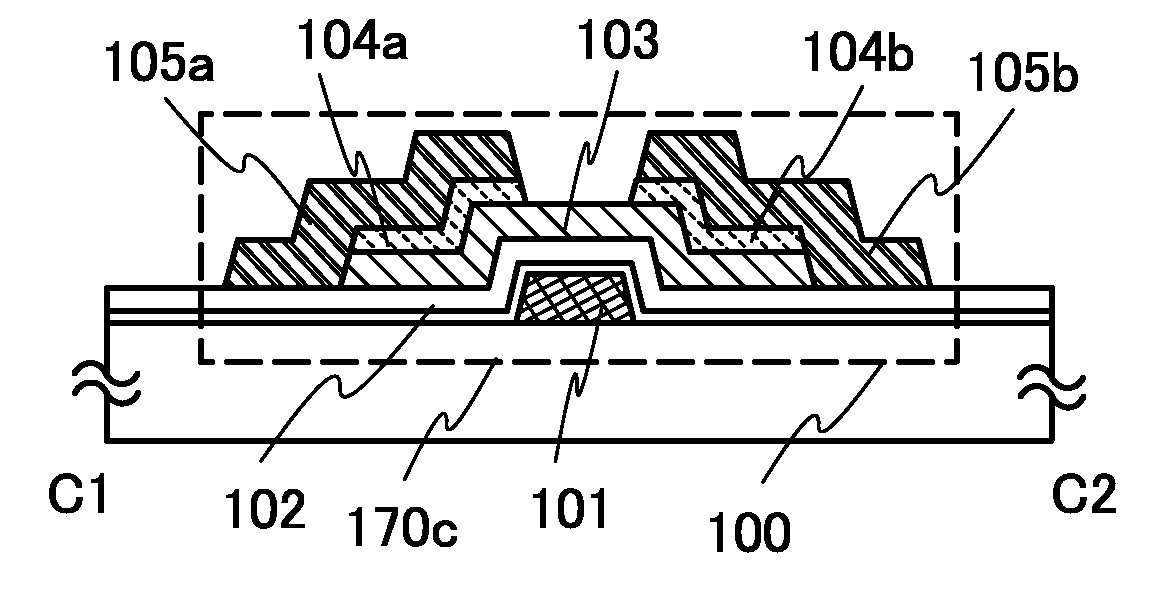

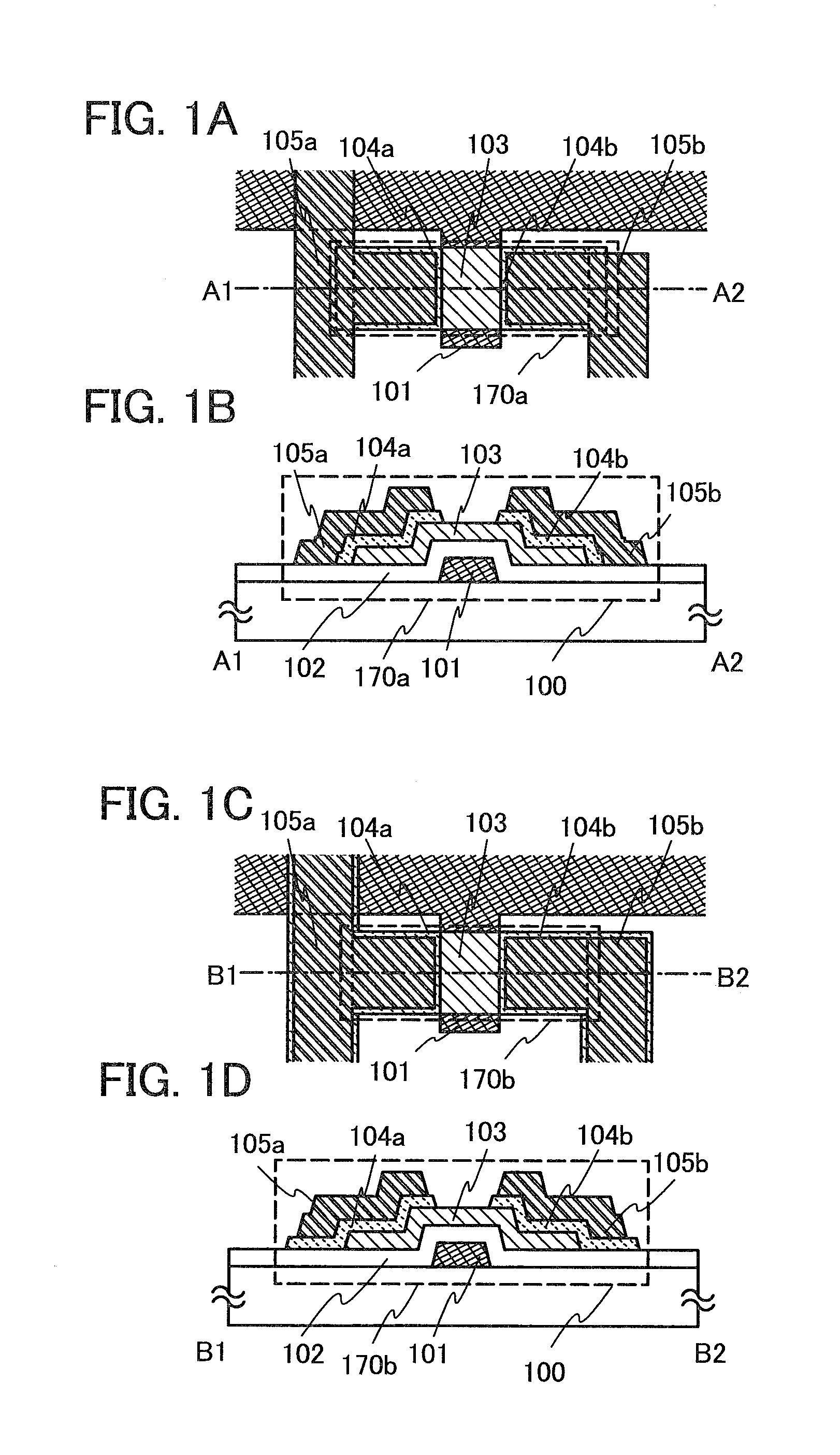

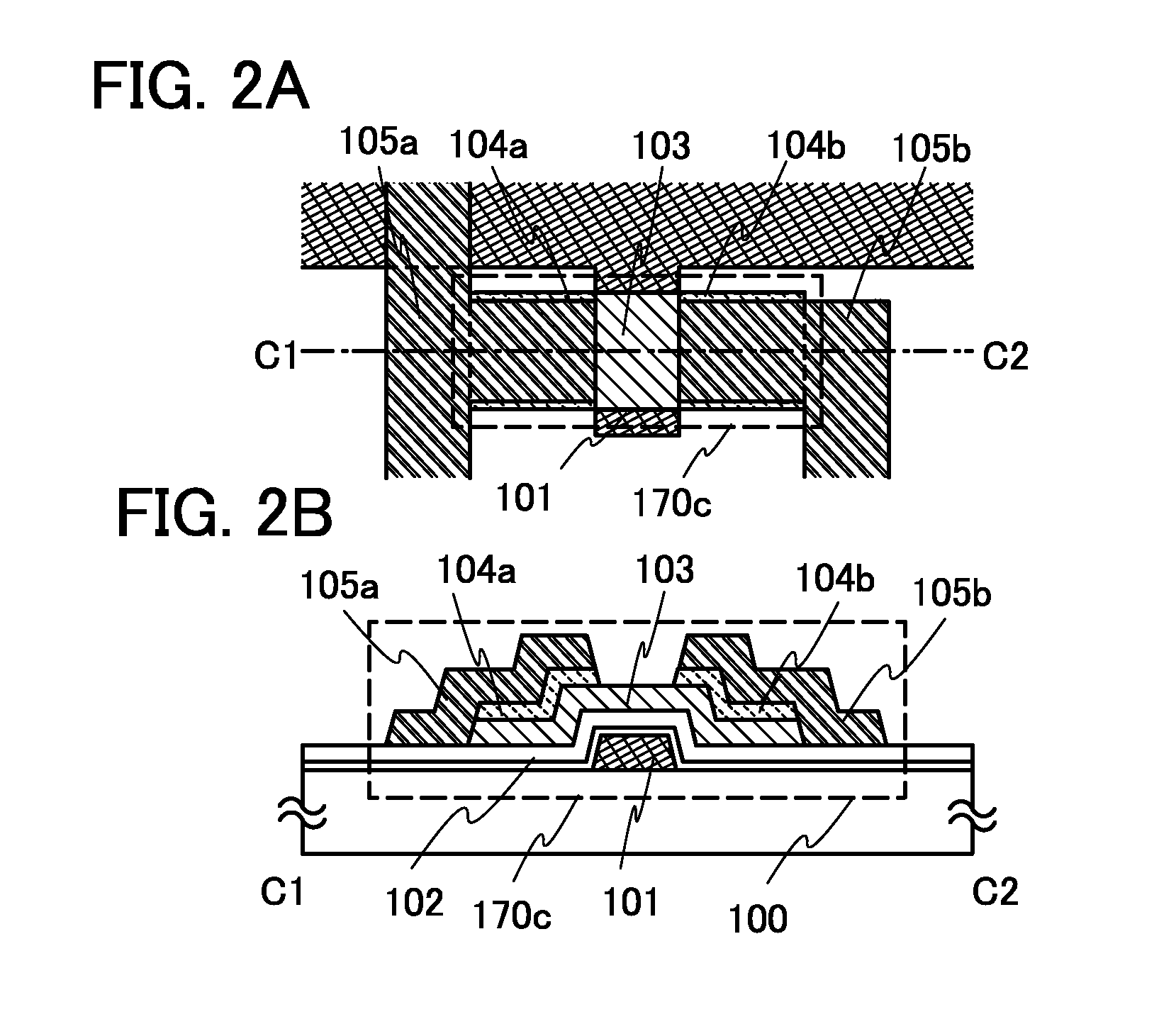

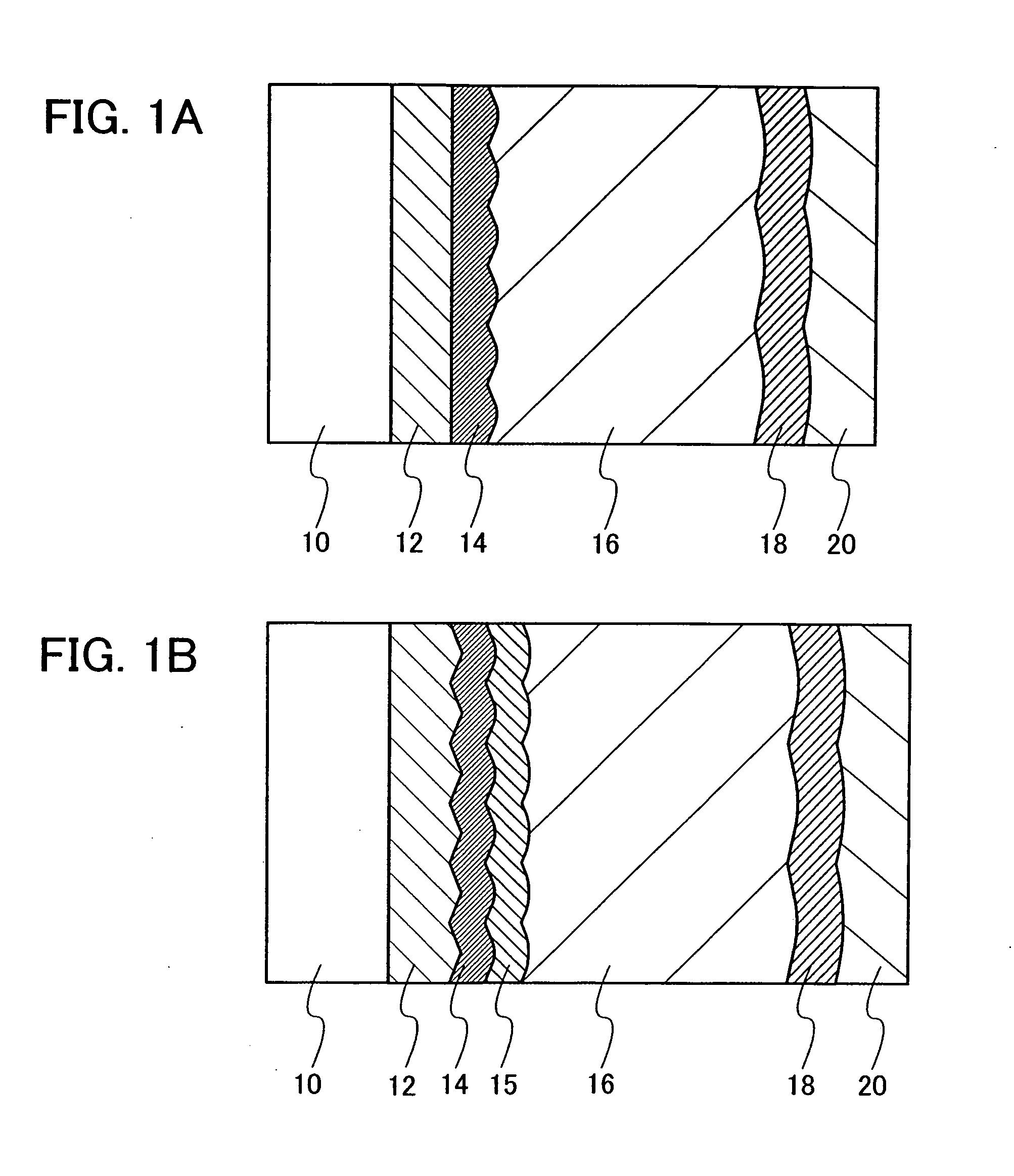

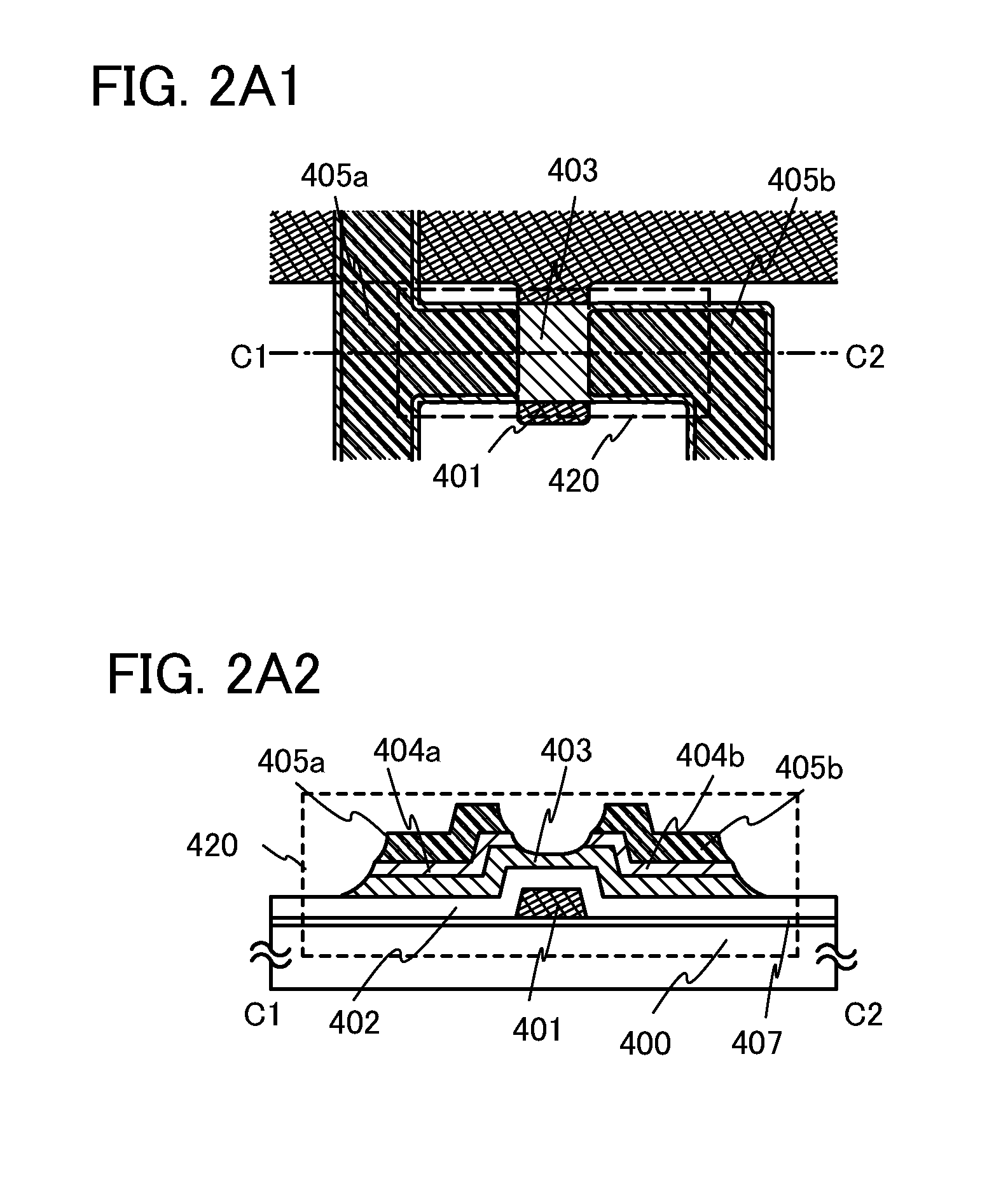

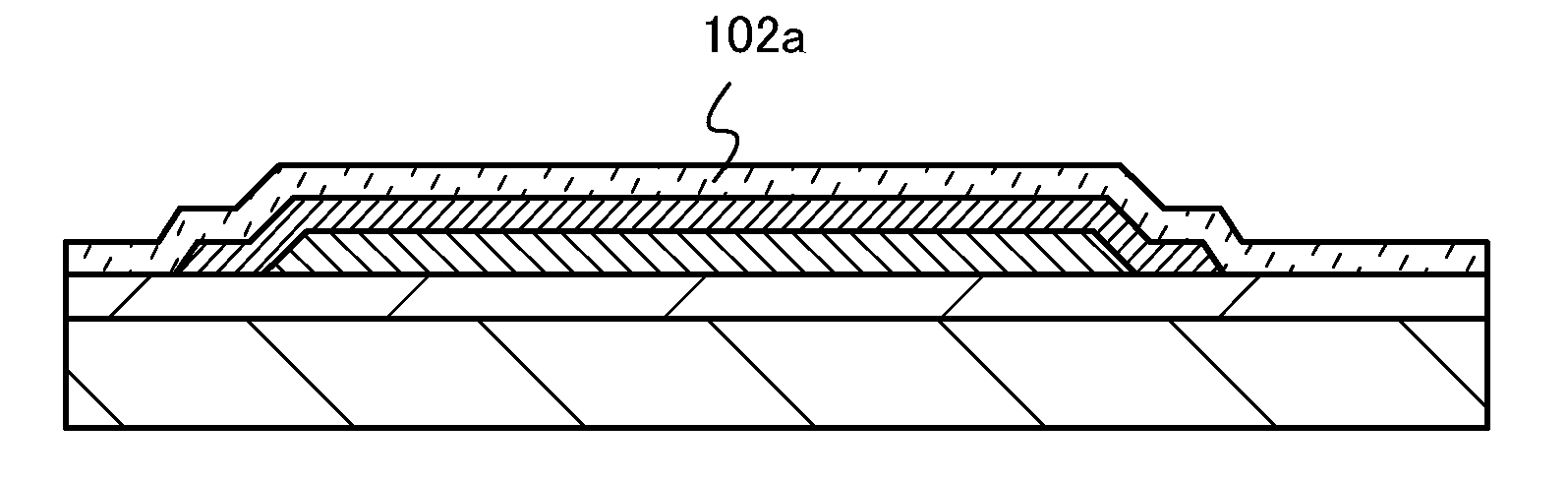

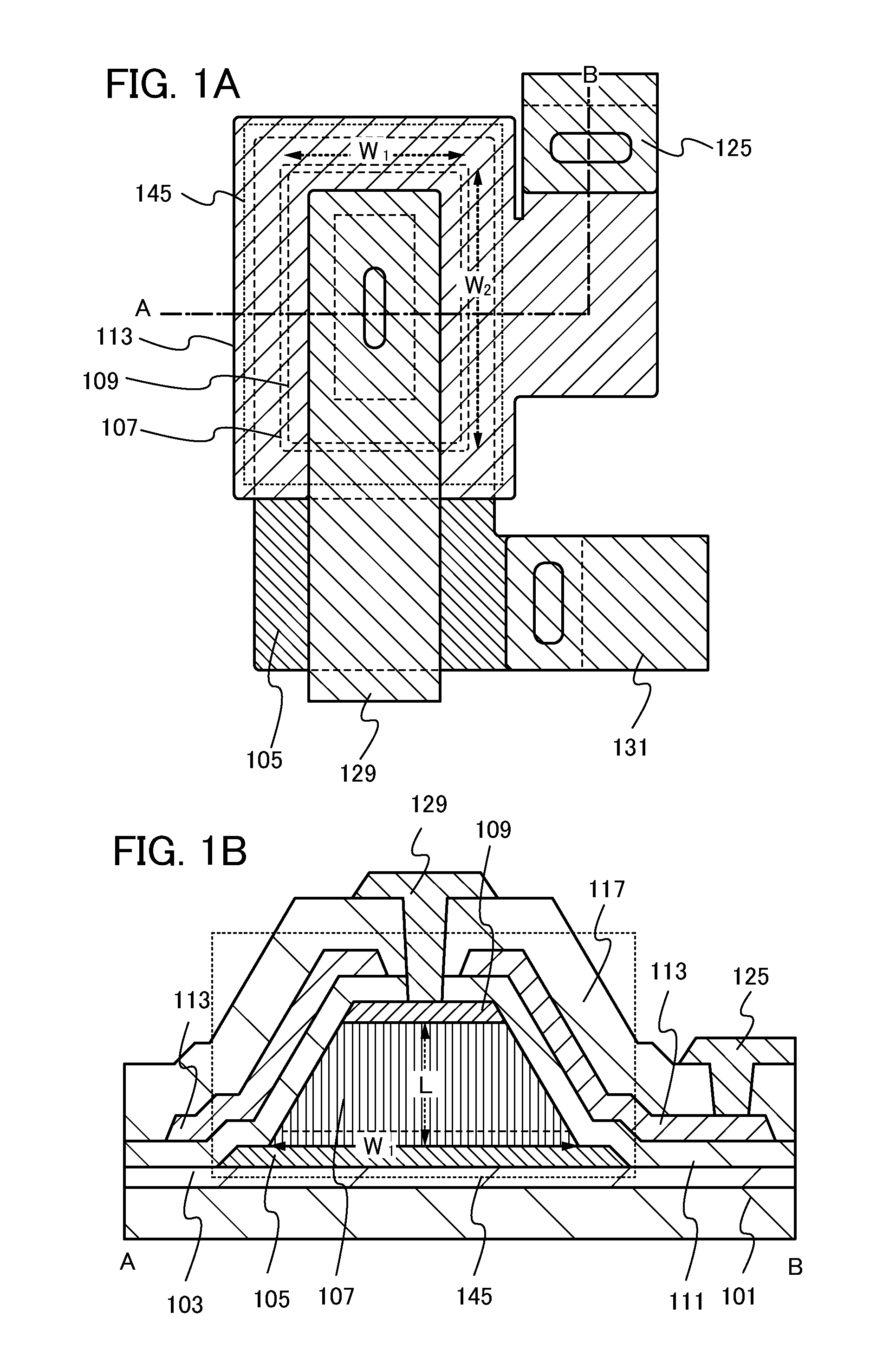

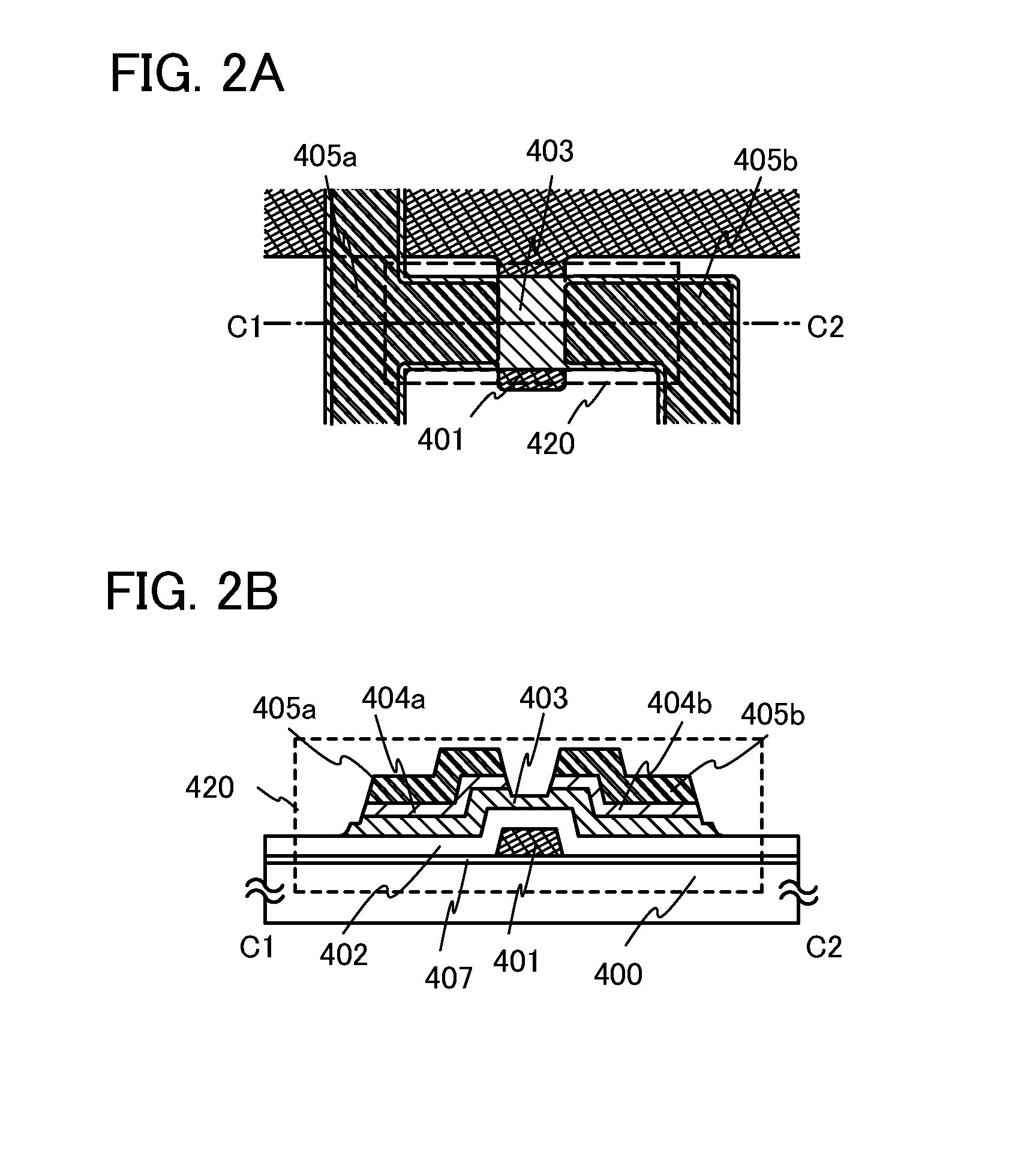

Semiconductor device and method for manufacturing the same

ActiveUS20100025678A1Comparatively-easy manufacturing processRun at high speedTransistorSolid-state devicesProduction rateOhmic contact

It is an object to provide a semiconductor device including a thin film transistor with favorable electric properties and high reliability, and a method for manufacturing the semiconductor device with high productivity. In an inverted staggered (bottom gate) thin film transistor, an oxide semiconductor film containing In, Ga, and Zn is used as a semiconductor layer, and a buffer layer formed using a metal oxide layer is provided between the semiconductor layer and a source and drain electrode layers. The metal oxide layer is intentionally provided as the buffer layer between the semiconductor layer and the source and drain electrode layers, whereby ohmic contact is obtained.

Owner:SEMICON ENERGY LAB CO LTD

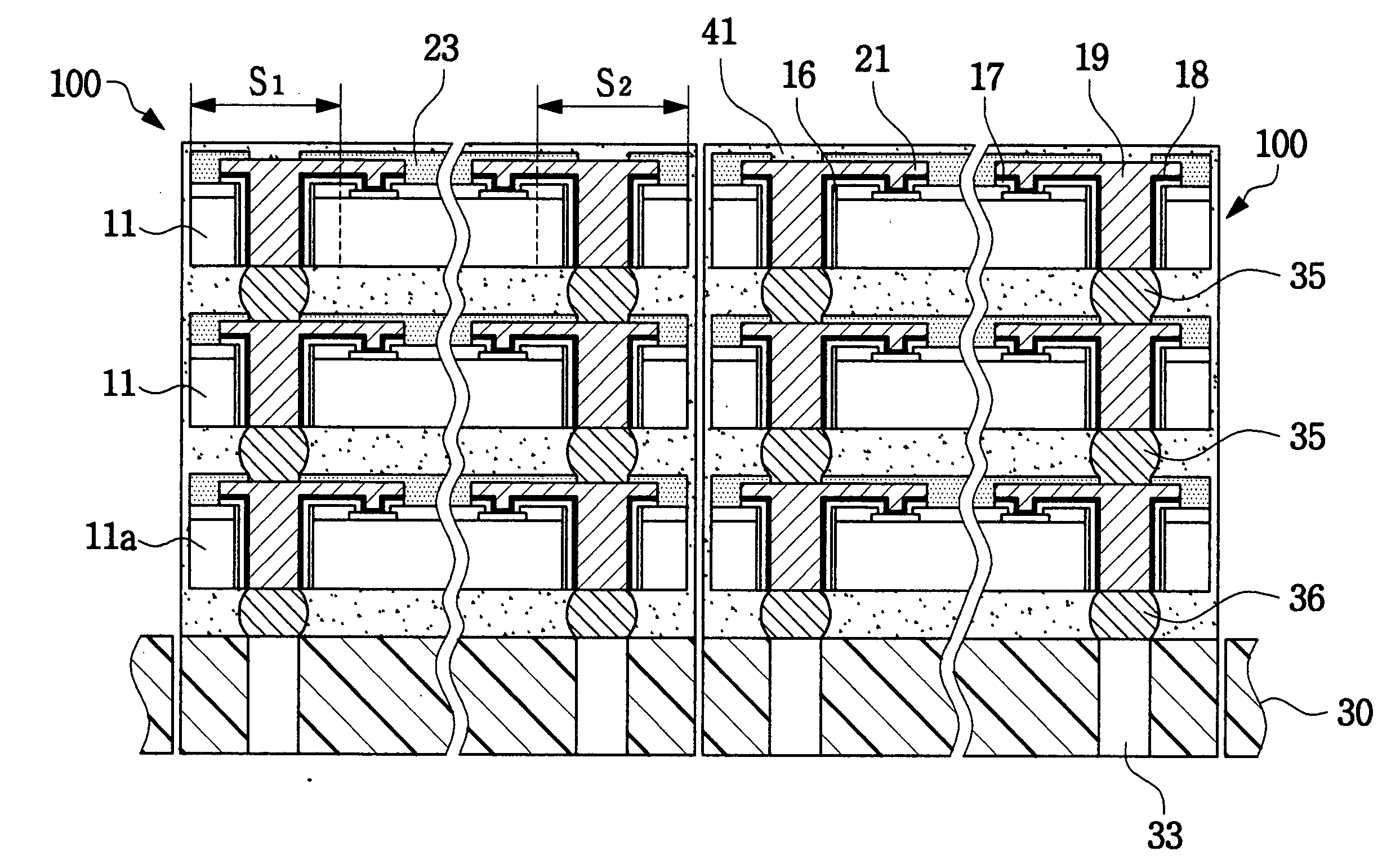

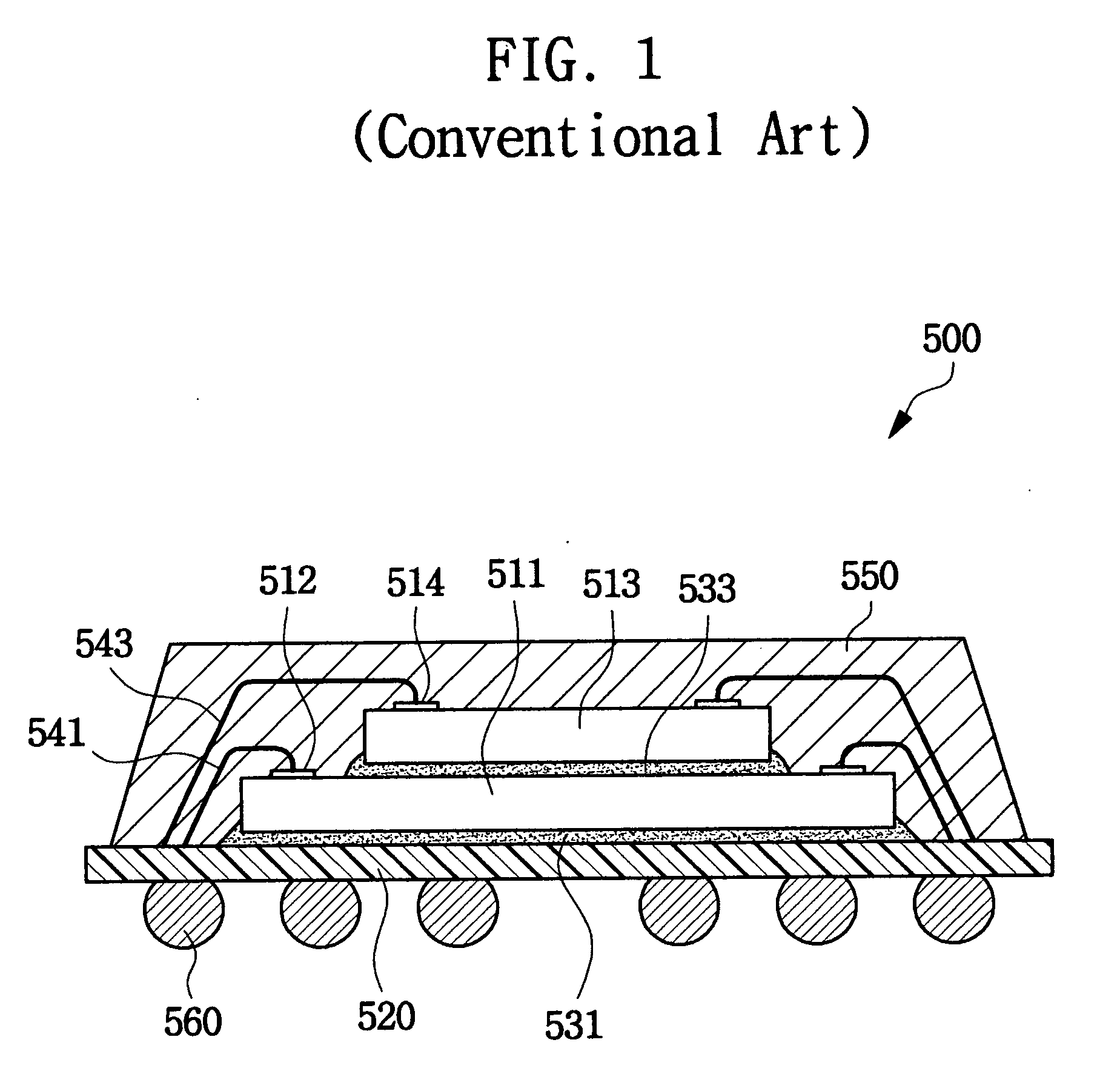

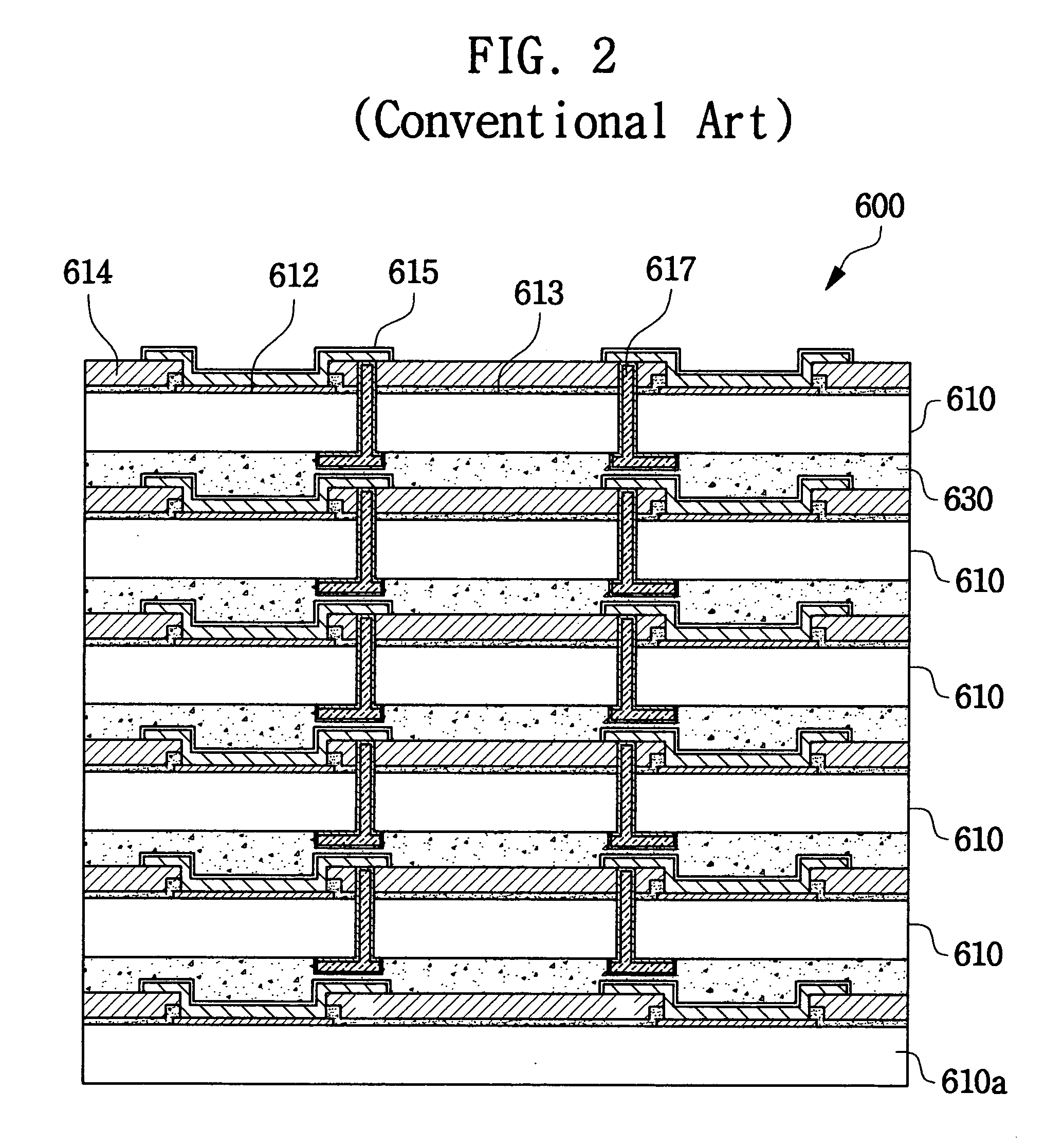

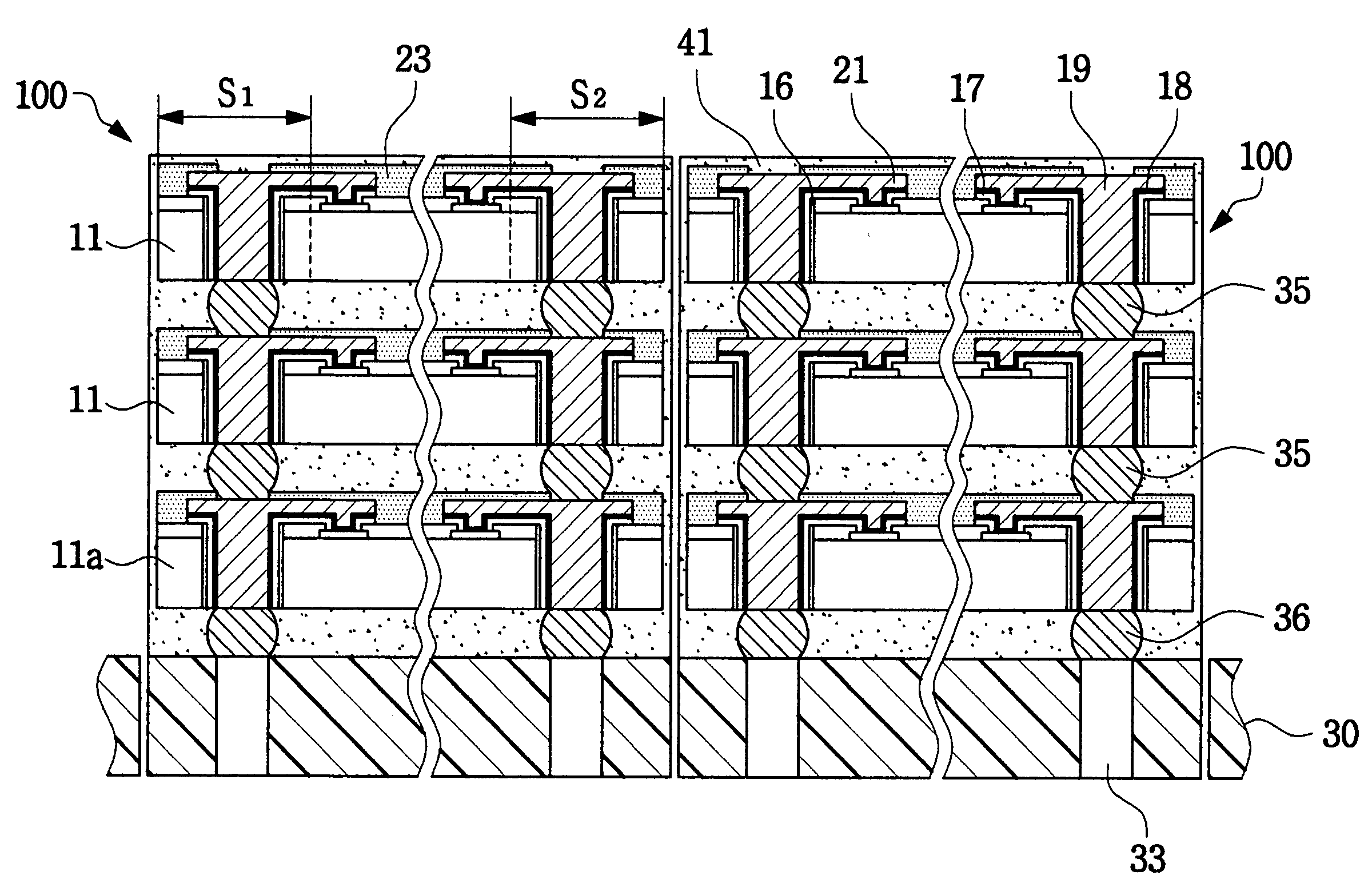

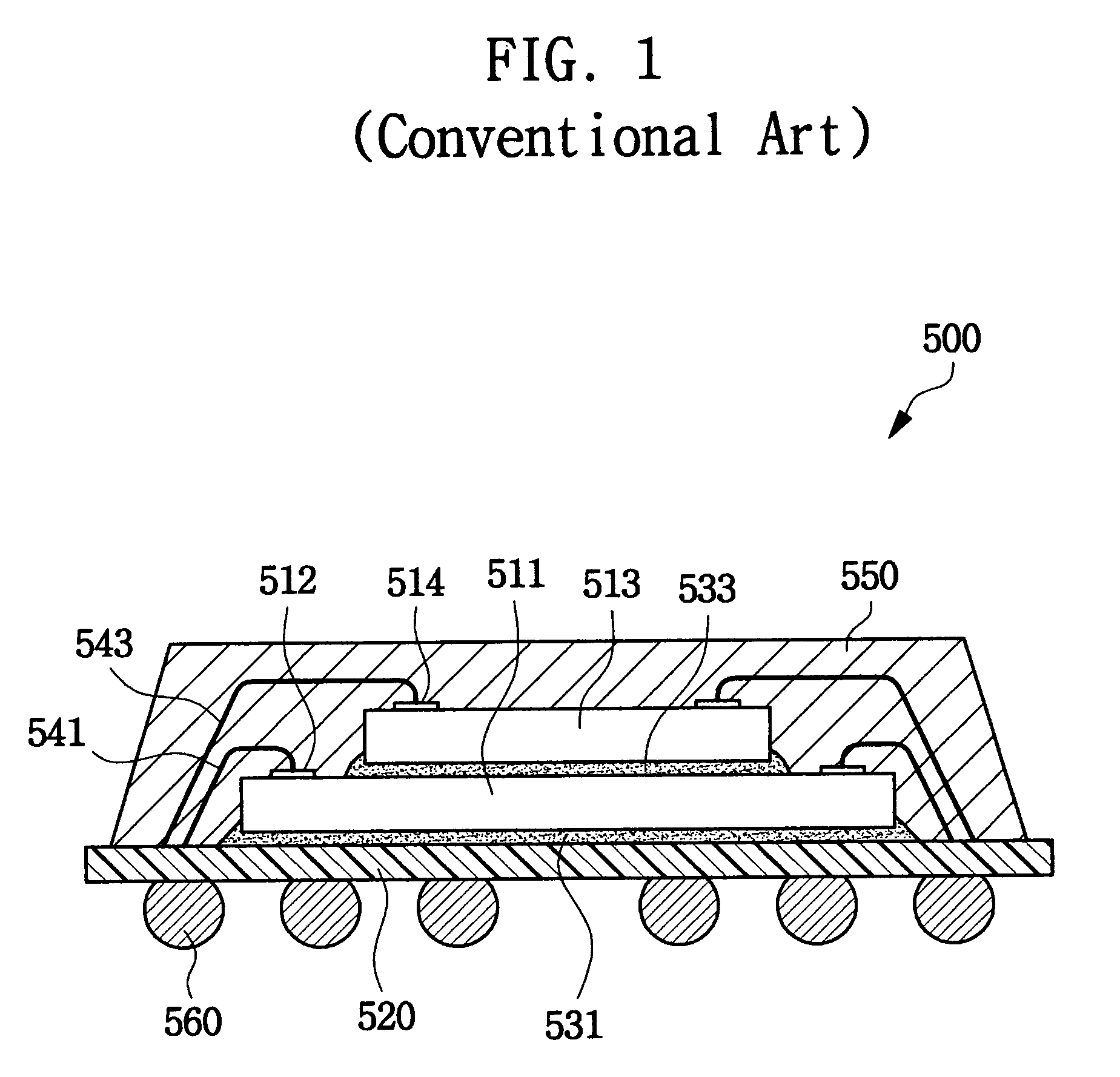

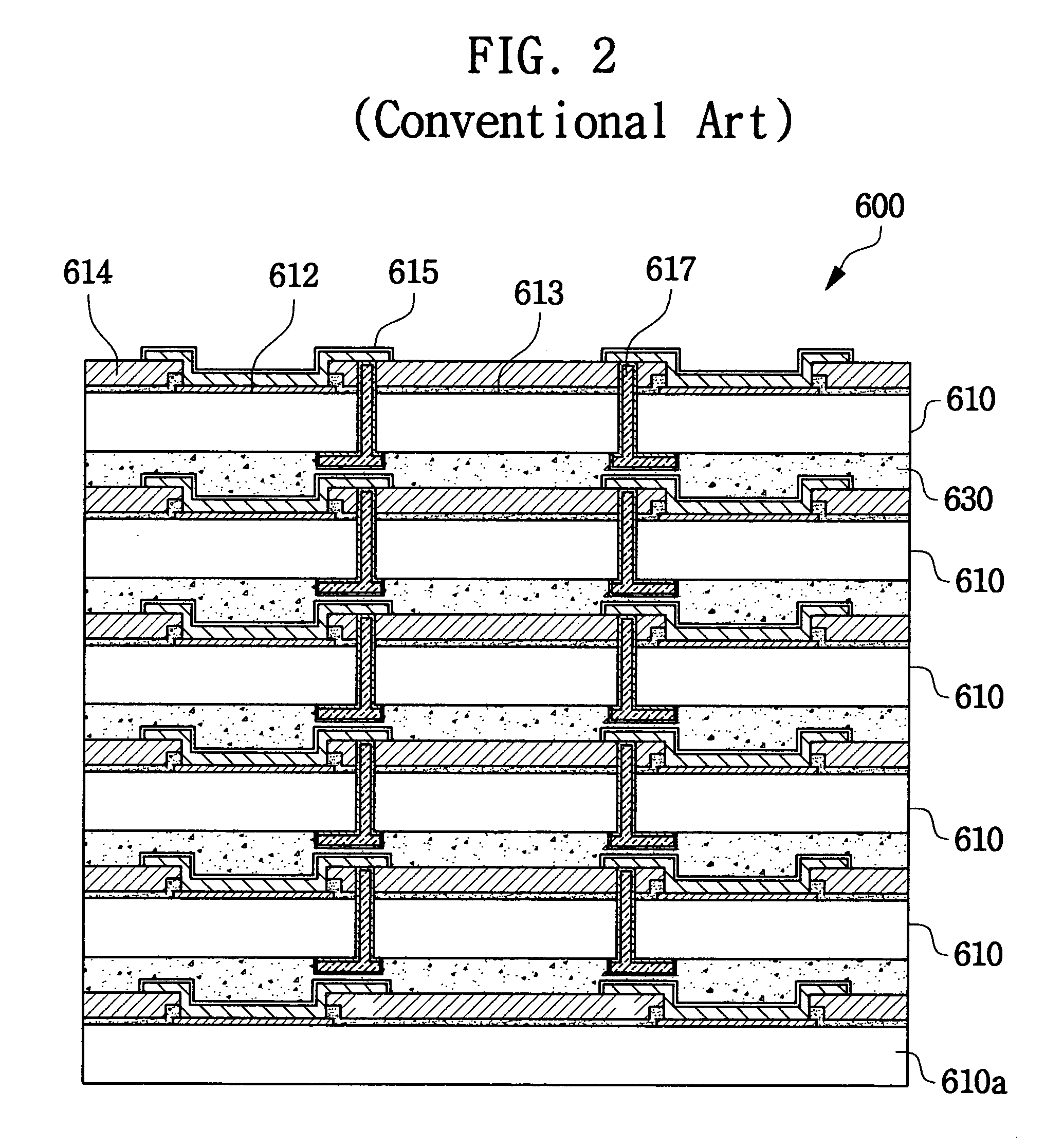

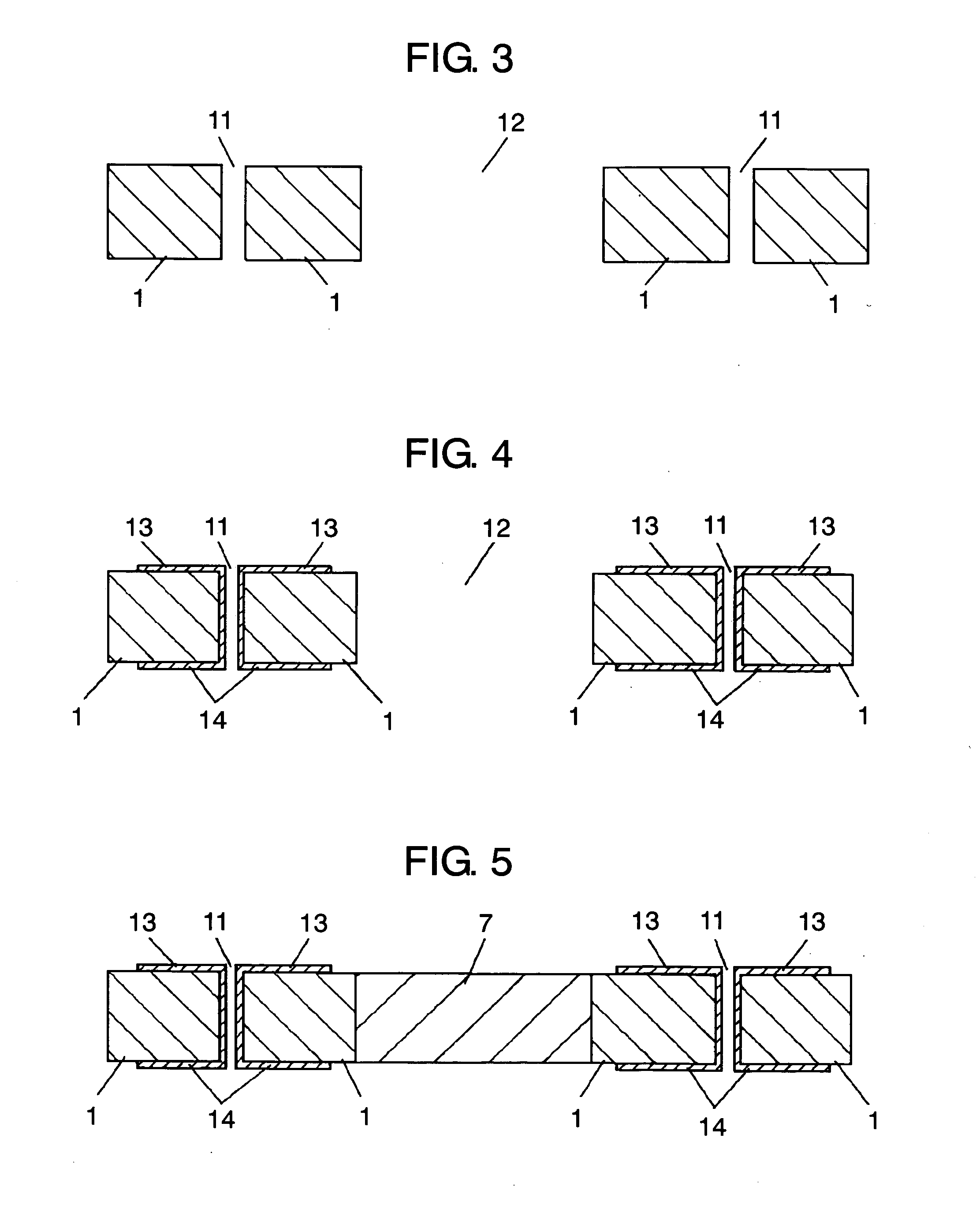

Chip stack package and manufacturing method thereof

ActiveUS20050046002A1Reduce manufacturing costReduce time costSemiconductor/solid-state device detailsSolid-state devicesProduction rateElectrical connection

A chip stack package is manufactured at a wafer level by forming connection vias in the scribe lanes adjacent the chips and connecting the device chip pads to the connection vias using rerouting lines. A lower chip is then attached and connected to a substrate, which may be a test wafer, and an upper chip is attached and connected to the lower chip, the electrical connections being achieved through their respective connection vias. In addition to the connection vias, the chip stack package may include connection bumps formed between vertically adjacent chips and / or the lower chip and the substrate. The preferred substrate is a test wafer that allows the attached chips to be tested, and replaced if faulty, thereby ensuring that each layer of stacked chips includes only “known-good die” before the next layer of chips is attached thereby increasing the production rate and improving the yield.

Owner:SAMSUNG ELECTRONICS CO LTD

Chip stack package and manufacturing method thereof

ActiveUS7276799B2Low costShorten the timeSemiconductor/solid-state device detailsSolid-state devicesProduction rateElectrical connection

A chip stack package is manufactured at a wafer level by forming connection vias in the scribe lanes adjacent the chips and connecting the device chip pads to the connection vias using rerouting lines. A lower chip is then attached and connected to a substrate, which may be a test wafer, and an upper chip is attached and connected to the lower chip, the electrical connections being achieved through their respective connection vias. In addition to the connection vias, the chip stack package may include connection bumps formed between vertically adjacent chips and / or the lower chip and the substrate. The preferred substrate is a test wafer that allows the attached chips to be tested, and replaced if faulty, thereby ensuring that each layer of stacked chips includes only “known-good die” before the next layer of chips is attached thereby increasing the production rate and improving the yield.

Owner:SAMSUNG ELECTRONICS CO LTD

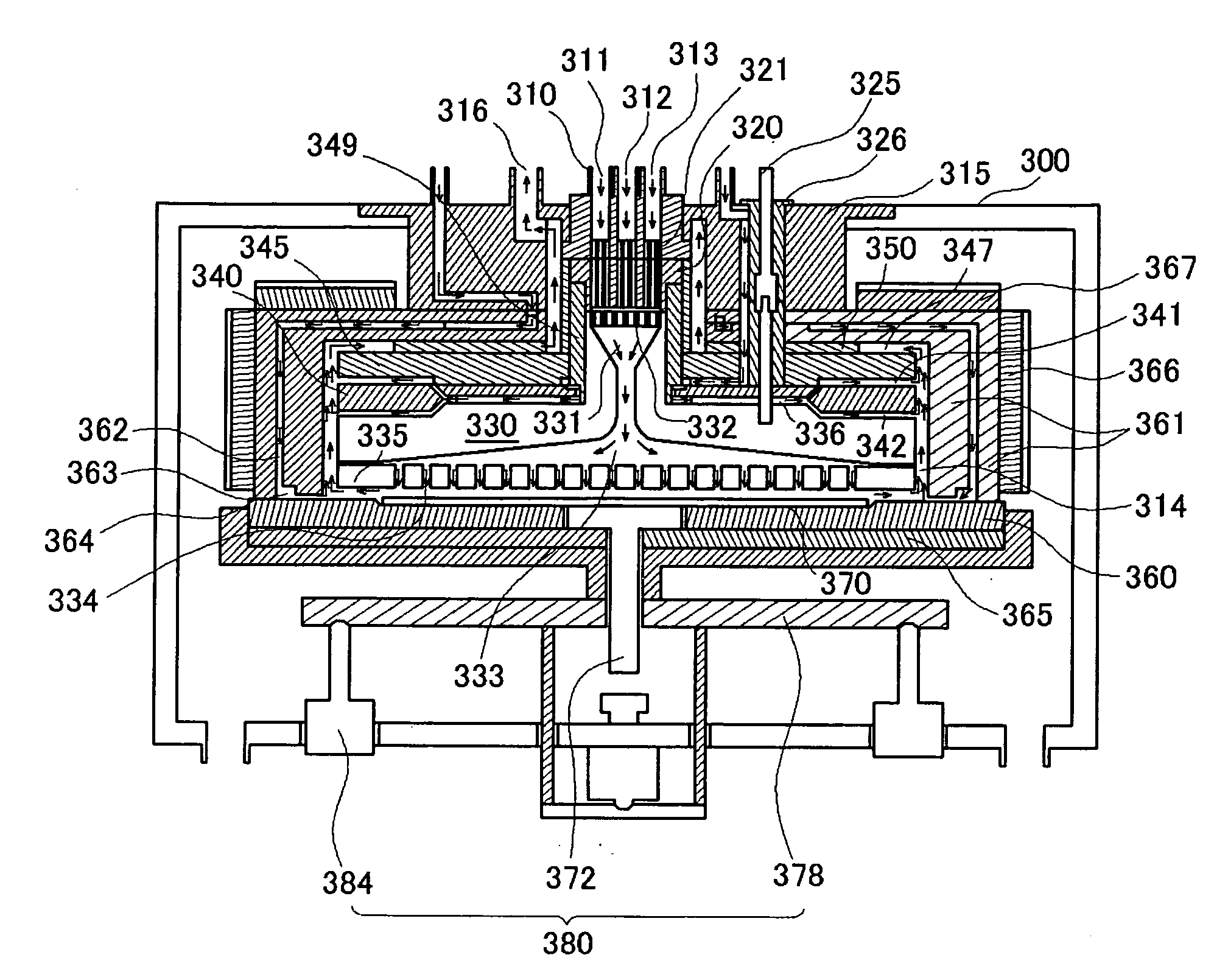

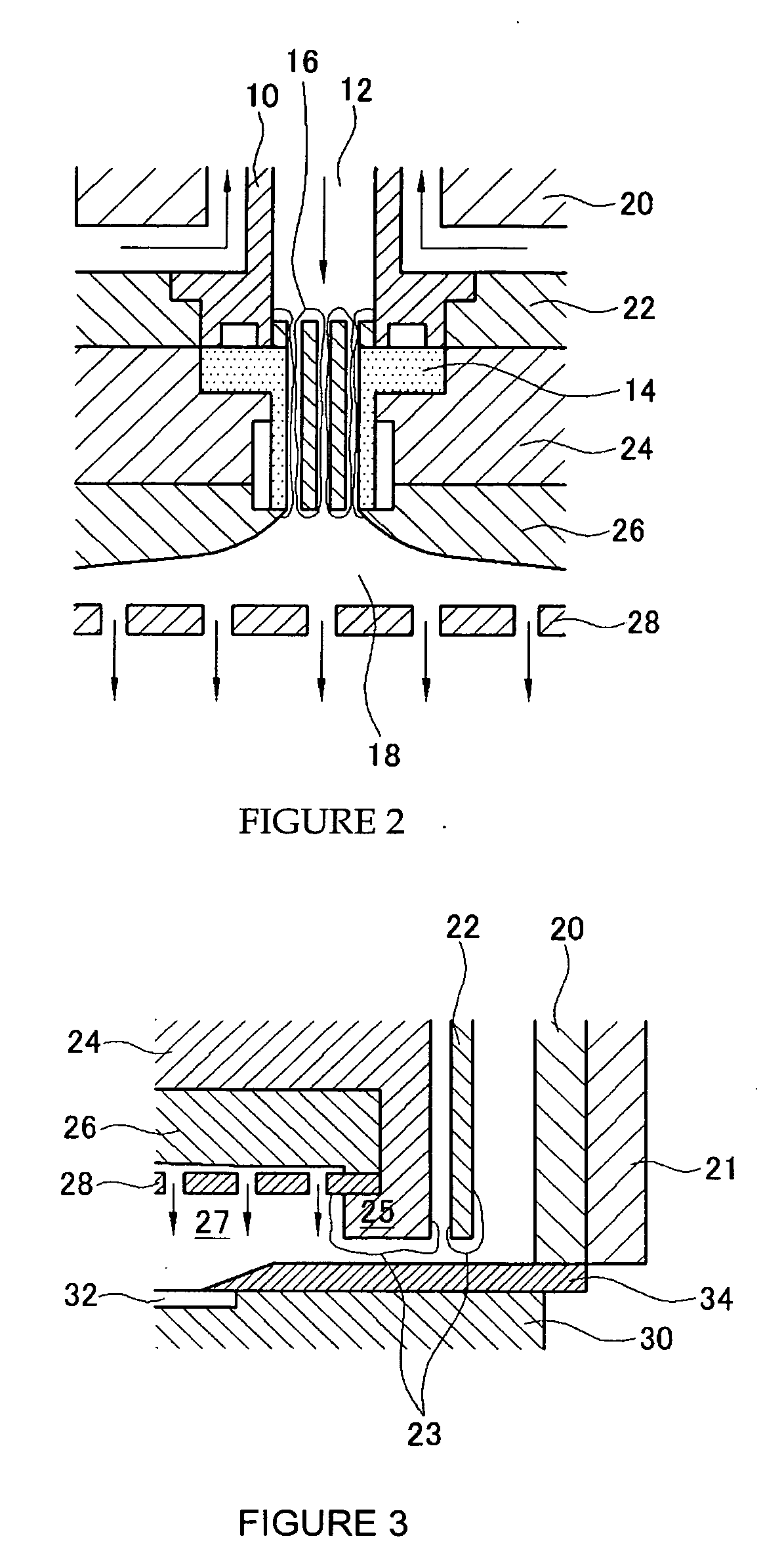

Atomic layer deposition apparatus

InactiveUS20060137608A1Uniform thicknessEasy to controlChemical vapor deposition coatingEngineeringAtomic layer deposition

An atomic layer deposition (ALD) apparatus is, suitable for thermal ALD and plasma-enhanced ALD of conductive and non-conductive films. The ALD apparatus can maintain electrical insulation of a gas dispersion structure, such as a showerhead assembly, which acts as an RF electrode to generate plasma inside a reaction chamber while depositing electrically conductive films in the reaction chamber. Fine tubules of micro-feeding tube assembly prevents plasma generation in them and reactive gases each have separate flow paths through the micro-feeding tube assembly. Process gases out of the micro-feeding tube assembly enter narrow grooves of a helical flow inducing plate and form helical flows which mix well each other. Symmetrically mounted pads on showerhead assembly and flow guiding plate maintain a symmetrical gap through which an inert gas flows continuously to keep reactive gases outside the gap and unwanted film deposition in the gap. Longer operating time before maintenance (cleaning) and thus higher productivity can be achieved.

Owner:ASM GENITECH KOREA

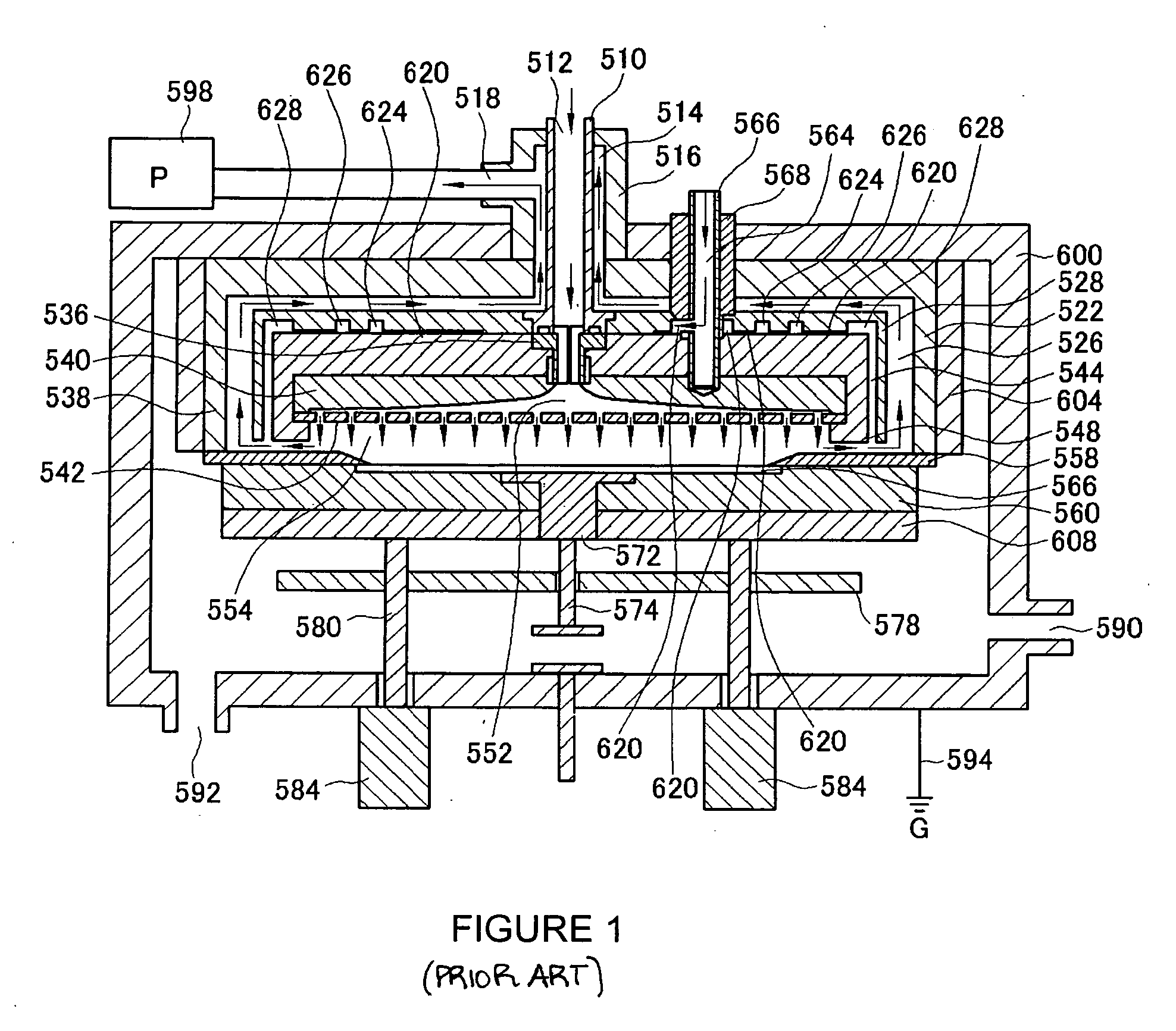

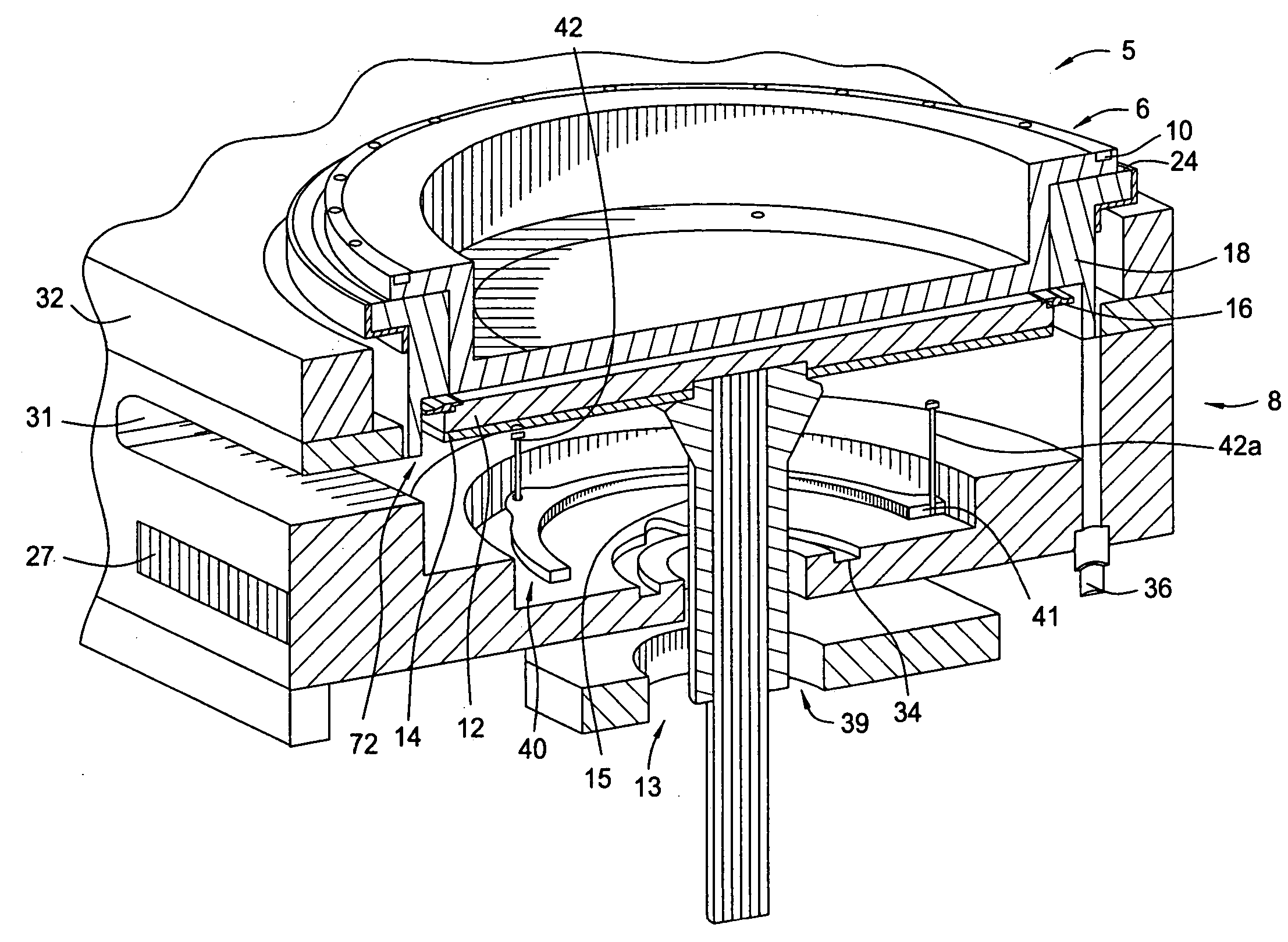

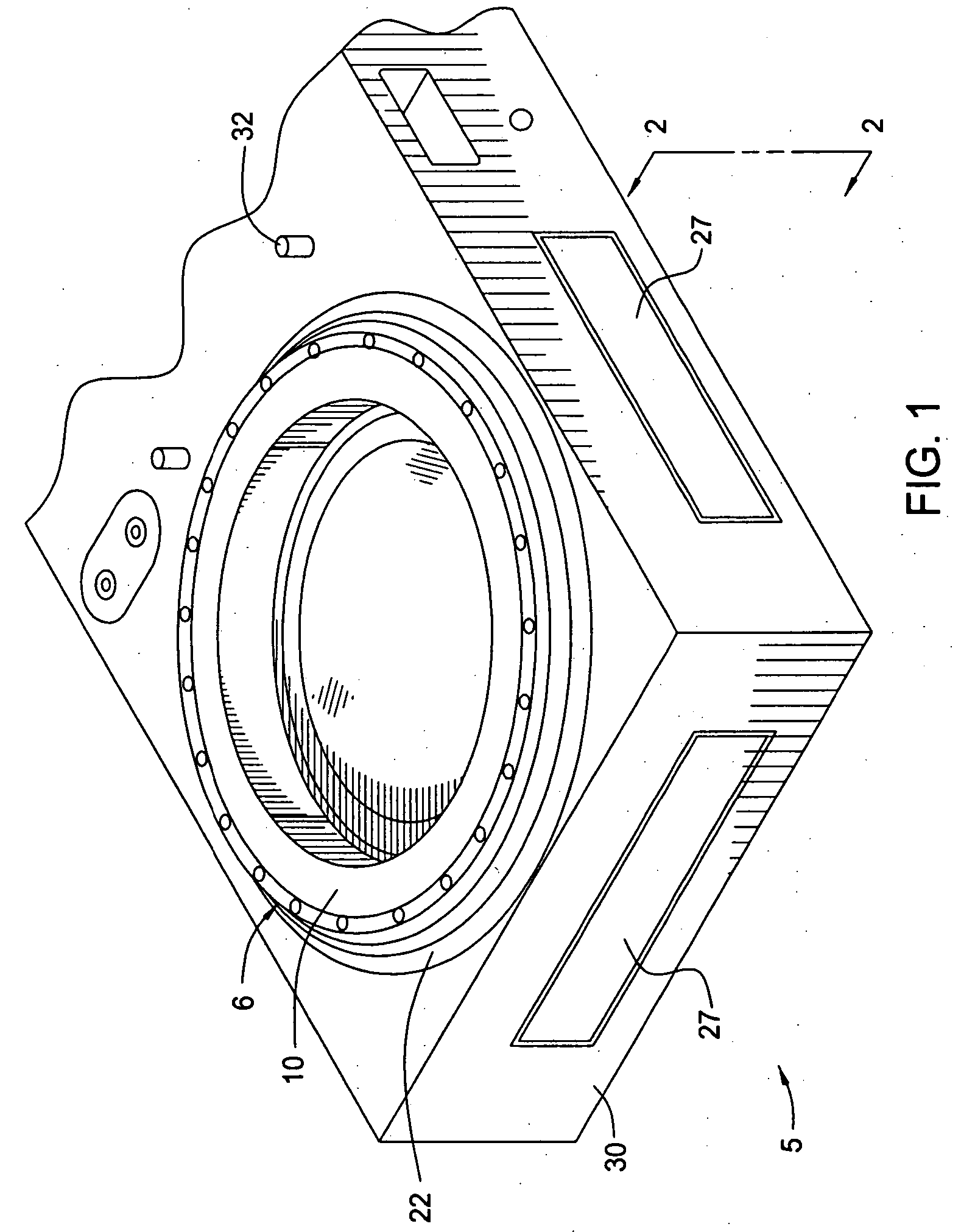

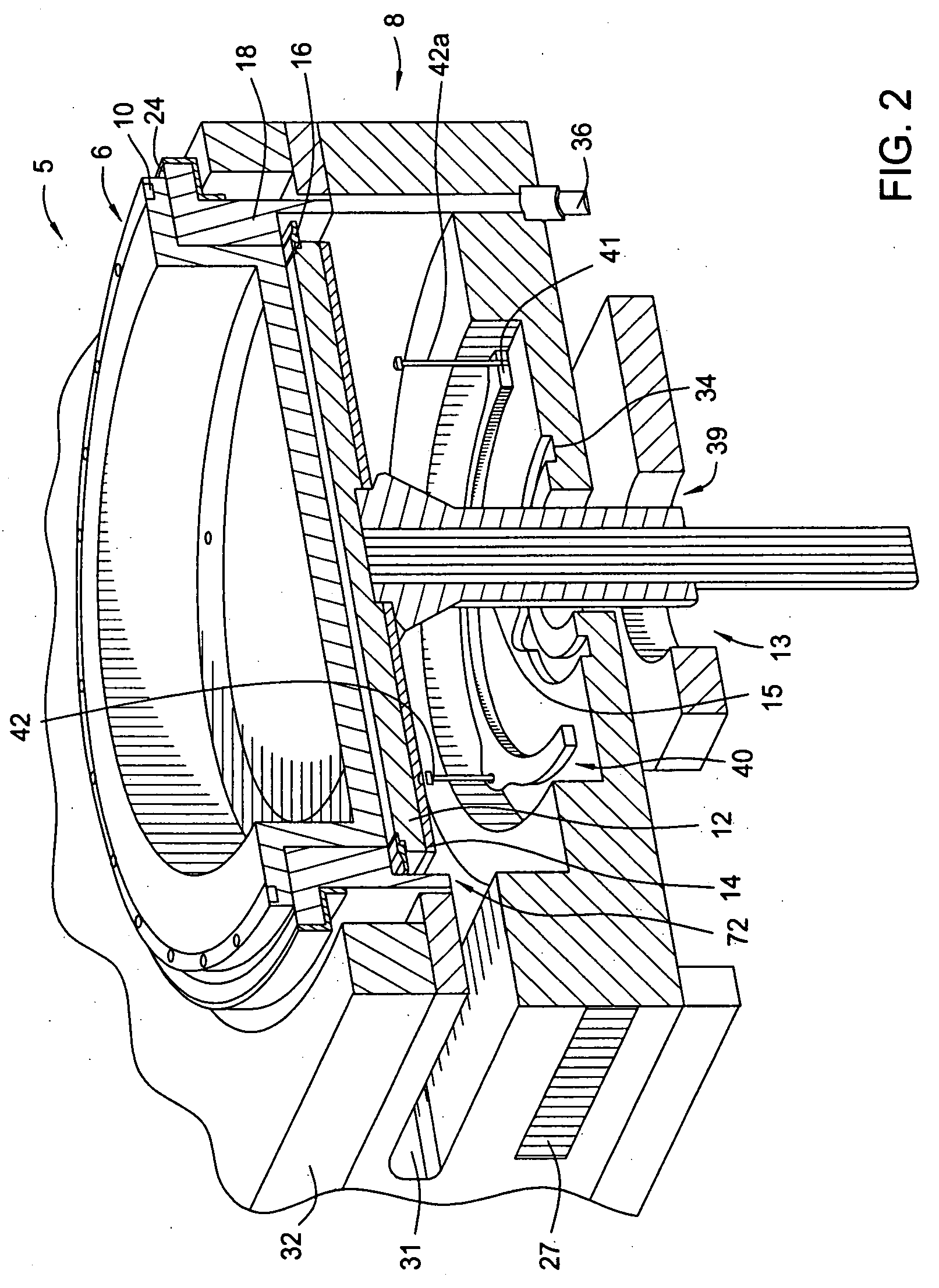

High productivity plasma processing chamber

InactiveUS20050229849A1Maximizing allowable timeReduce probabilityElectric discharge tubesSemiconductor/solid-state device manufacturingTemperature controlProduction rate

Embodiments of the present invention are generally directed to apparatus and methods for a plasma-processing chamber requiring less maintenance and downtime and possessing improved reliability over the prior art. In one embodiment, the apparatus includes a substrate support resting on a ceramic shaft, an inner shaft allowing for electrical connections to the substrate support at atmospheric pressure, an aluminum substrate support resting on but not fixed to a ceramic support structure, sapphire rest points swaged into the substrate support, and a heating element inside the substrate support arranged in an Archimedes spiral to reduce warping of the substrate support and to increase its lifetime. Methods include increasing time between in-situ cleans of the chamber by reducing particle generation from chamber surfaces. Reduced particle generation occurs via temperature control of chamber components and pressurization of non-processing regions of the chamber relative to the processing region with a purge gas.

Owner:APPLIED MATERIALS INC

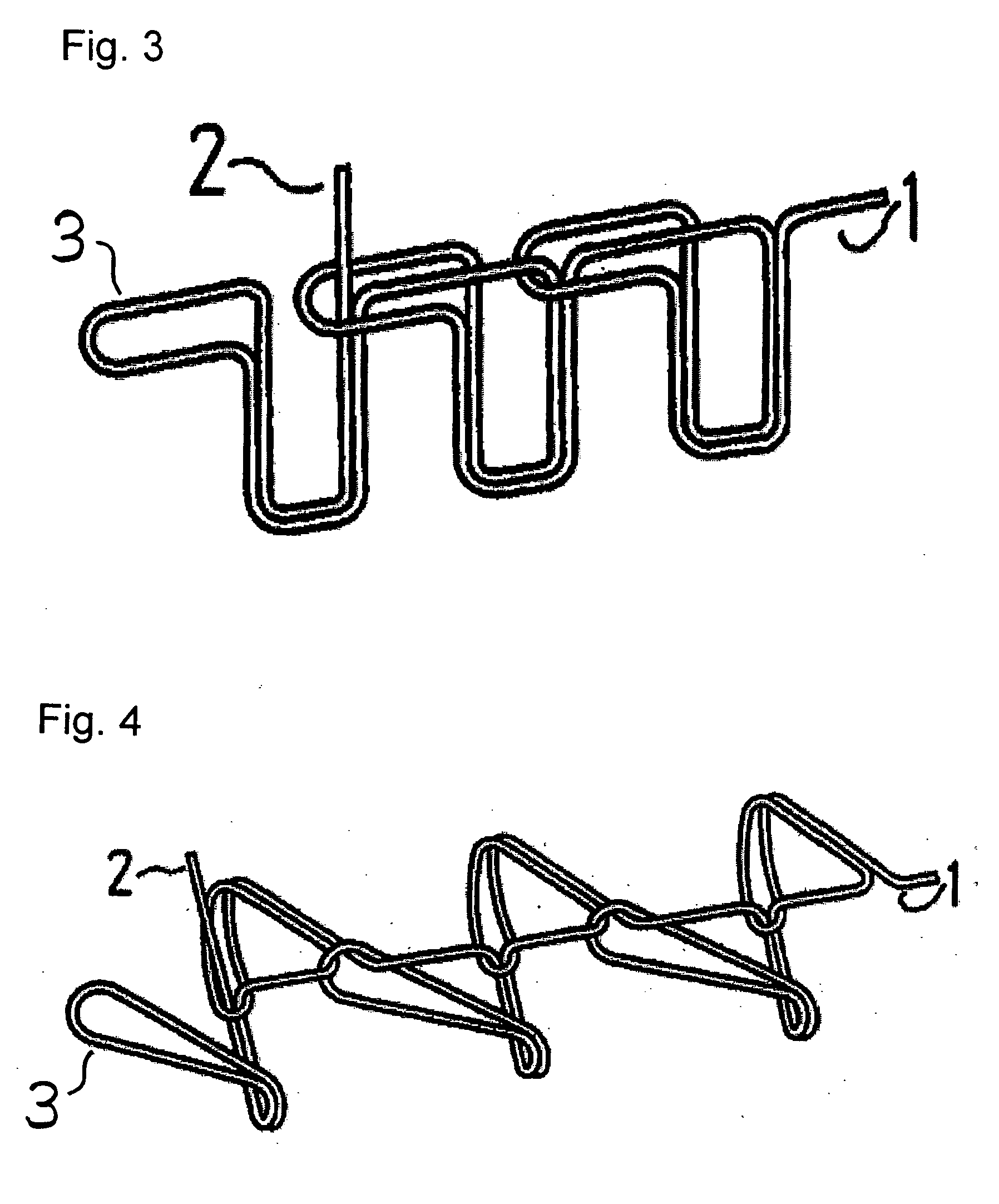

Suture reinforcement material for automatic suturing device

ActiveUS20070049953A2Smoothly removedPreventing a thread from unravelingSuture equipmentsSurgical needlesProduction rateSurgical operation

The present invention relates to a tubular suture reinforcement material suitable for use in automatic suturing devices that are widely used in surgical operations, etc. More specifically, the present invention relates to a tubular suture reinforcement material with which a tubular shape is easily obtained to thereby increase its productivity, and removal of thread is easily achieved. The present invention aims to overcome drawbacks such that sheet-like materials joined by the conventional temporary adhesion easily separate from each other, and the tubular suture reinforcement material manufactured using a running stitch requires a lot of time and skill, and removal of the thread is difficult depending on the kind of sheet-like material, sewing pitch, etc. More specifically, the present invention relates to a tubular suture reinforcement material for an automatic suturing device, wherein both ends of one or two sheet-like materials are sewed using a chain stitch (intralooping stitch) with a single thread to form a tubular shape, and one or two thread ends at one or two sewing ends are suitably extended.

Owner:GUNZE LTD

Method for manufacturing photoelectric conversion device

InactiveUS20090029503A1Quality improvementReduce deterioration rateFinal product manufactureSemiconductor/solid-state device manufacturingProduction rateMicrowave

To form a microcrystalline semiconductor with high quality which can be directly formed at equal to or less than 500° C. over a large substrate with high productivity without decreasing a deposition rate. In addition, to provide a photoelectric conversion device which employs the microcrystalline semiconductor as a photoelectric conversion layer. A reactive gas containing helium is supplied to a treatment chamber which is surrounded by a plurality of juxtaposed waveguides and a wall, the pressure in the treatment chamber is maintained at an atmospheric pressure or a subatmospheric pressure, microwave is supplied to a space sandwiched between the juxtaposed waveguides to generate plasma, and a photoelectric conversion layer of a microcrystalline semiconductor is deposited over a substrate which is placed in the treatment chamber.

Owner:SEMICON ENERGY LAB CO LTD

Suture prosthetic material for automatic sewing device

ActiveUS20060178683A1Stable removalOvercomes drawbackSuture equipmentsSurgical needlesProduction rateSurgical operation

The present invention relates to a tubular suture reinforcement material suitable for use in automatic suturing devices that are widely used in surgical operations, etc. More specifically, the present invention relates to a tubular suture reinforcement material with which a tubular shape is easily obtained to thereby increase its productivity, and removal of thread is easily achieved. The present invention aims to overcome drawbacks such that sheet-like materials joined by the conventional temporary adhesion easily separate from each other, and the tubular suture reinforcement material manufactured using a running stitch requires a lot of time and skill, and removal of the thread is difficult depending on the kind of sheet-like material, sewing pitch, etc. More specifically, the present invention relates to a tubular suture reinforcement material for an automatic suturing device, wherein both ends of one or two sheet-like materials are sewed using a chain stitch (intralooping stitch) with a single thread to form a tubular shape, and one or two thread ends at one or two sewing ends are suitably extended.

Owner:GUNZE LTD

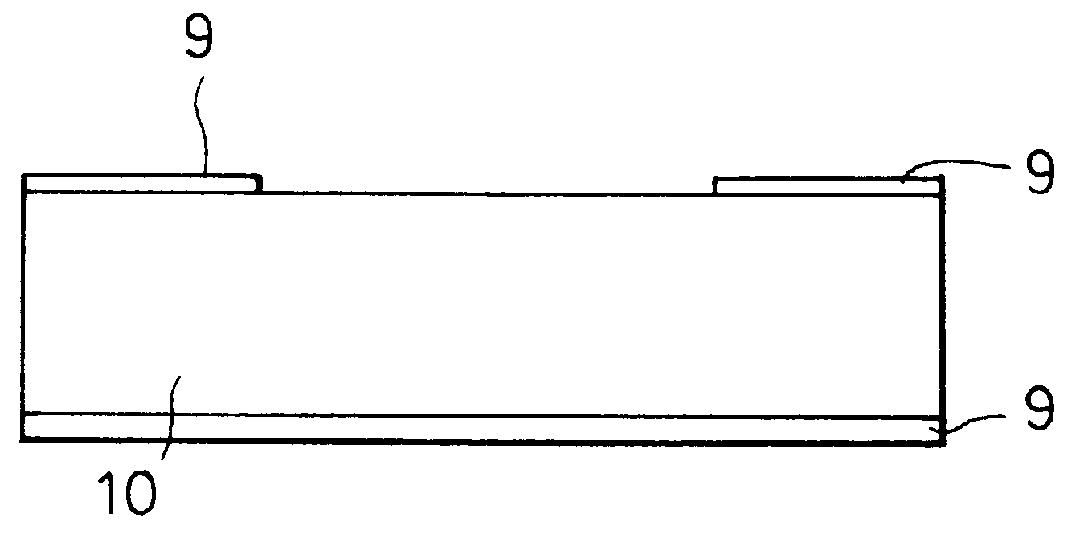

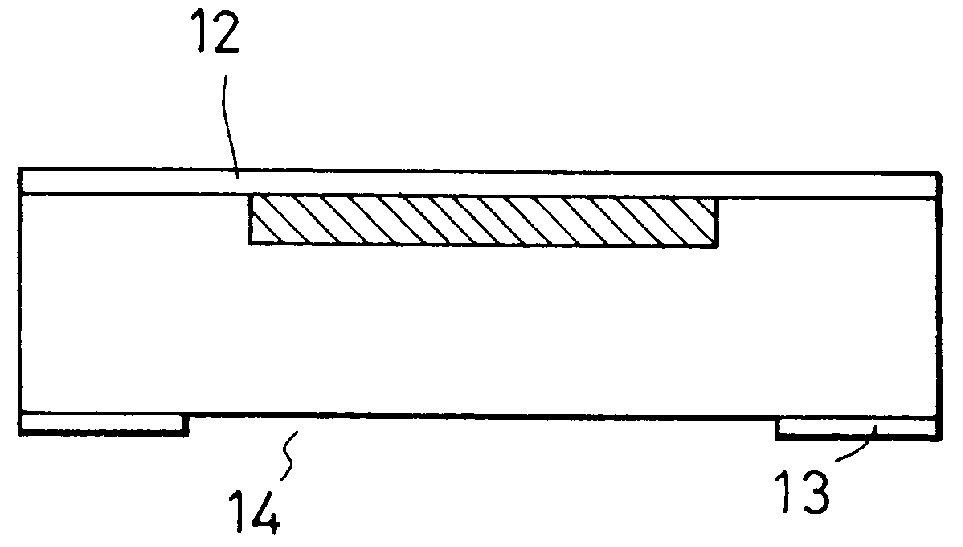

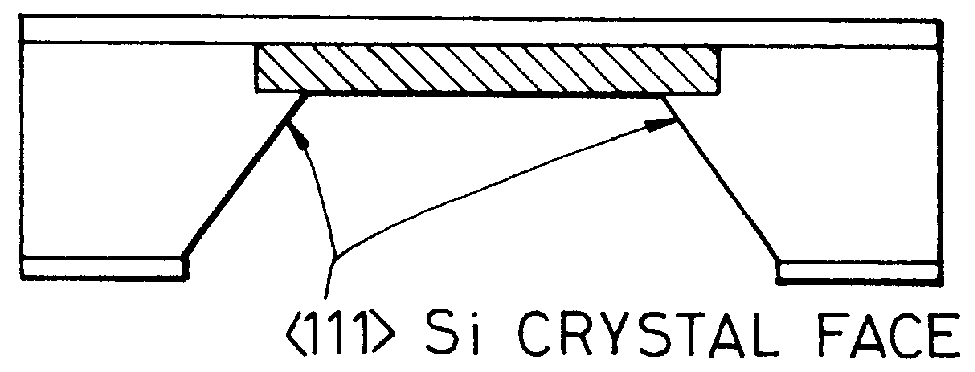

Method of producing a through-hole, silicon substrate having a through-hole, device using such a substrate, method of producing an ink-jet print head, and ink-jet print head

The invention provides a method of producing a through-hole, a substrate used to produce a through-hole, a substrate having a through-hole, and a device using such a through-hole or a substrate having such a through-hole, which are characterized in that: a through-hole can be produced only by etching a silicon substrate from its back side; the opening length d can be precisely controlled to a desired value regardless of the variations in the silicon wafer thickness, and the orientation flat angle, and also regardless of the type of a silicon crystal orientation-dependent anisotropic etchant employed; high productivity, high production reproducibility, and ease of production can be achieved; a high-liberality can be achieved in the shape of the opening end even if temperature treatment is performed at a high temperature for a long time; and a high-precision through-hole can be produced regardless of the shape of a device formed on the surface of a substrate.

Owner:CANON KK

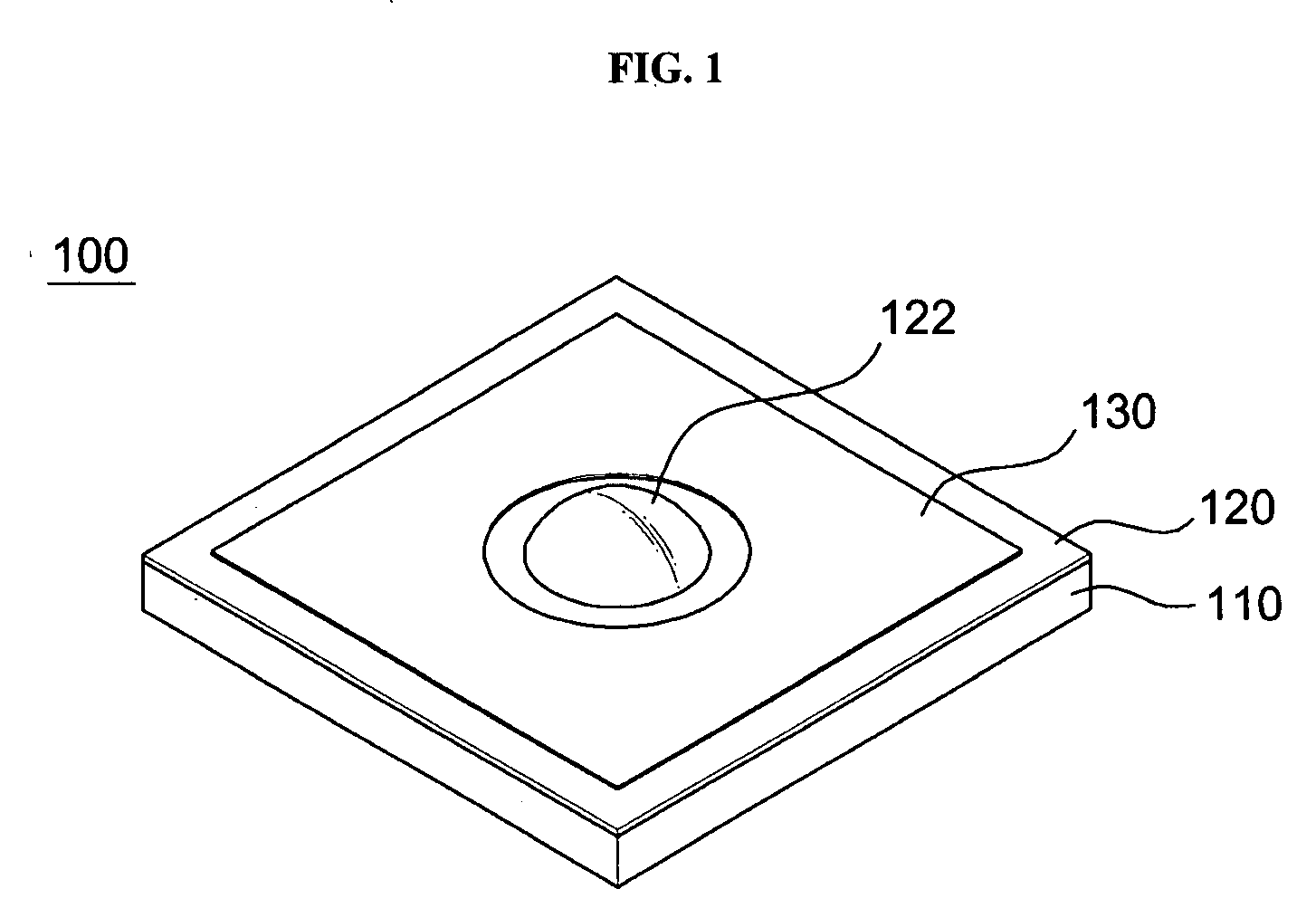

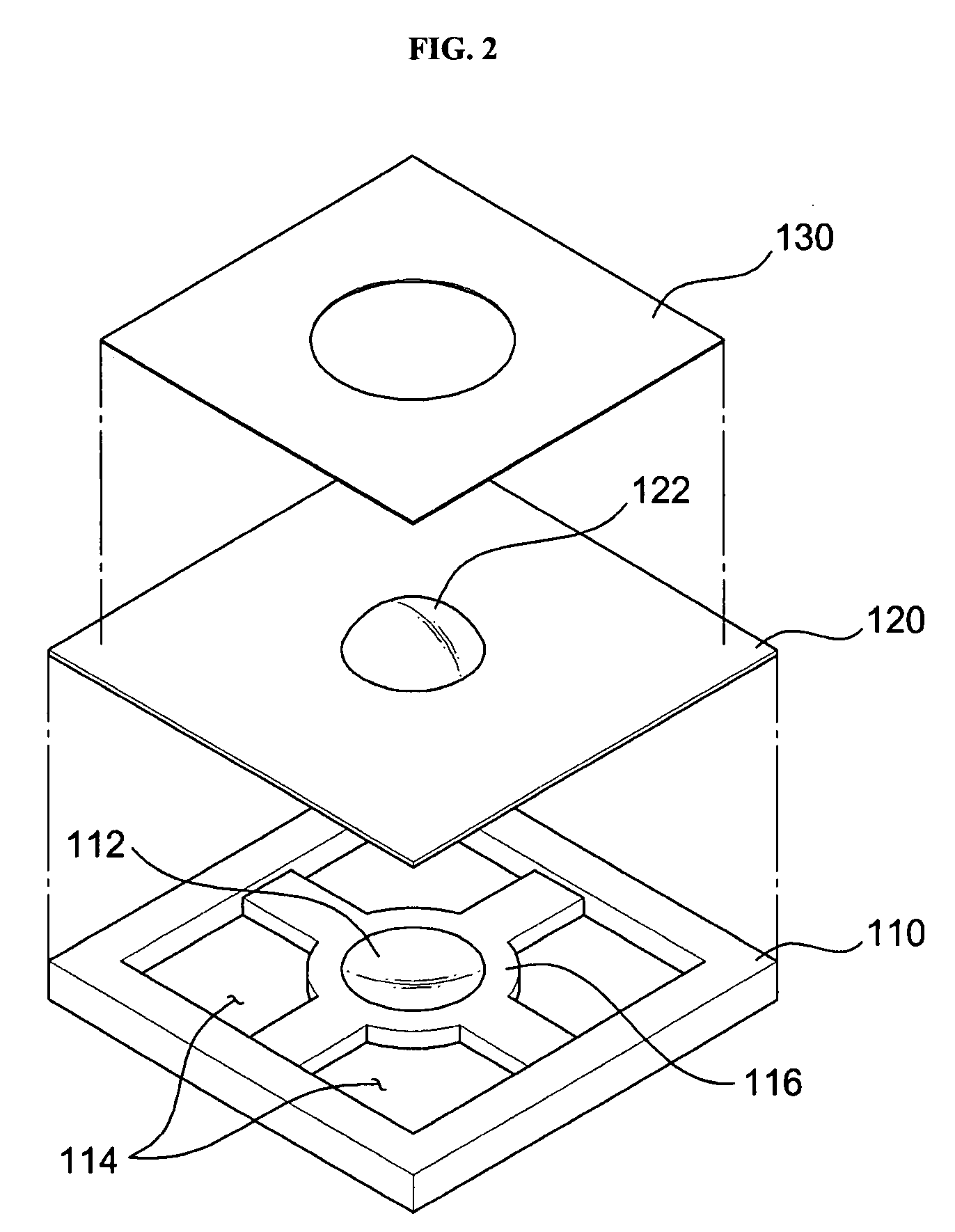

Optical lens and method of manufacturing the same

InactiveUS20080112059A1Improve efficiencyLower performance requirementsOptical articlesMountingsProduction rateManufacturing technology

An optical lens is provided. The optical lens provides miniaturization and thin size, and reduces the cost and improves productivity by simplifying the structure and manufacturing process. The optical lens includes a light-transmitting substrate with a lens chamber and a fluidic chamber that are connected with each other. The optical lens also includes a light-transmitting elastic film which seals the lens chamber, a buffer elastic film which seals the fluidic chamber, and an actuator on the buffer elastic film which corresponds to the fluidic chamber, and varies the volume of the fluidic chamber to vary a pressure acting on the light-transmitting elastic film.

Owner:SAMSUNG ELECTRONICS CO LTD

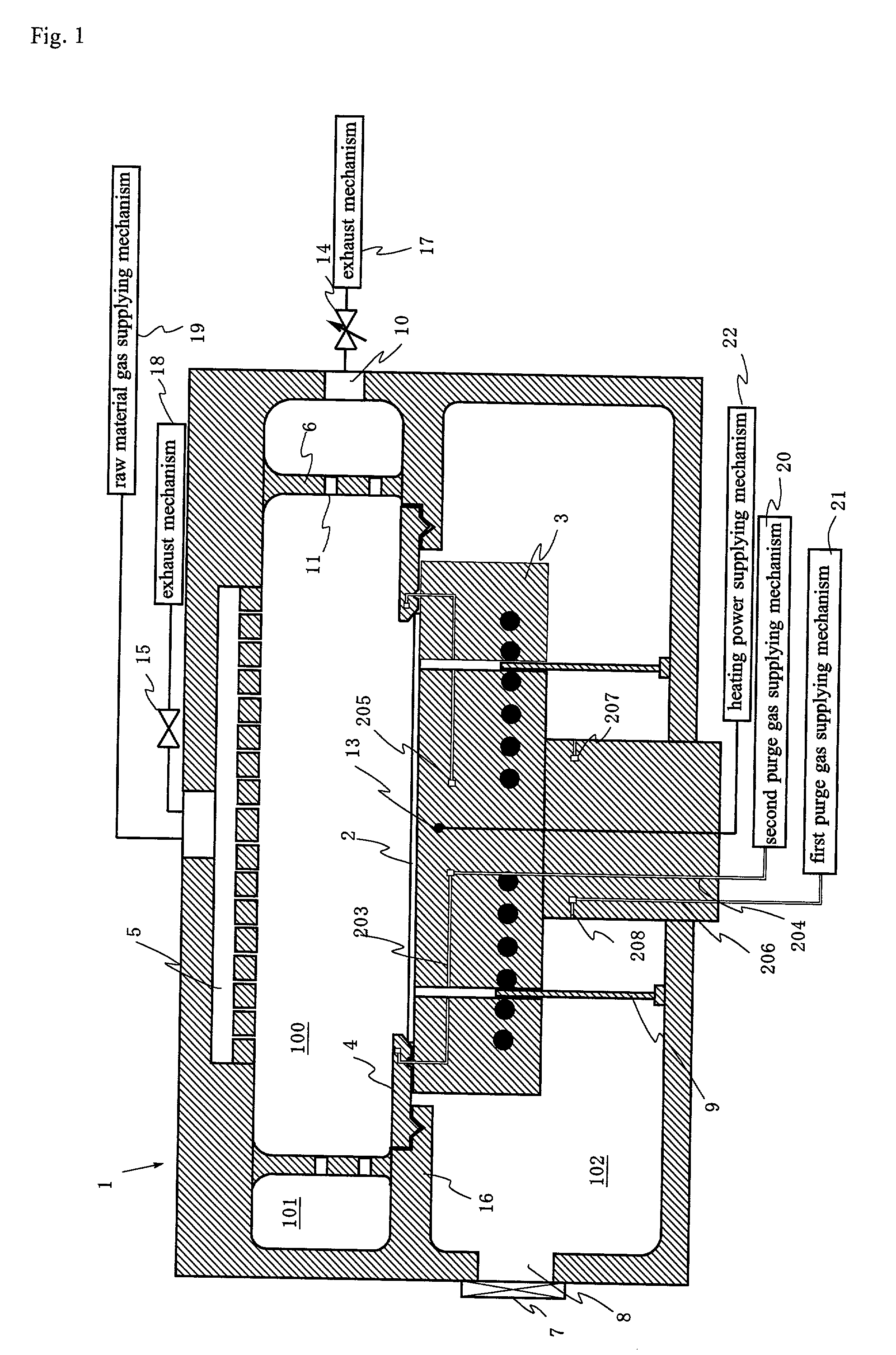

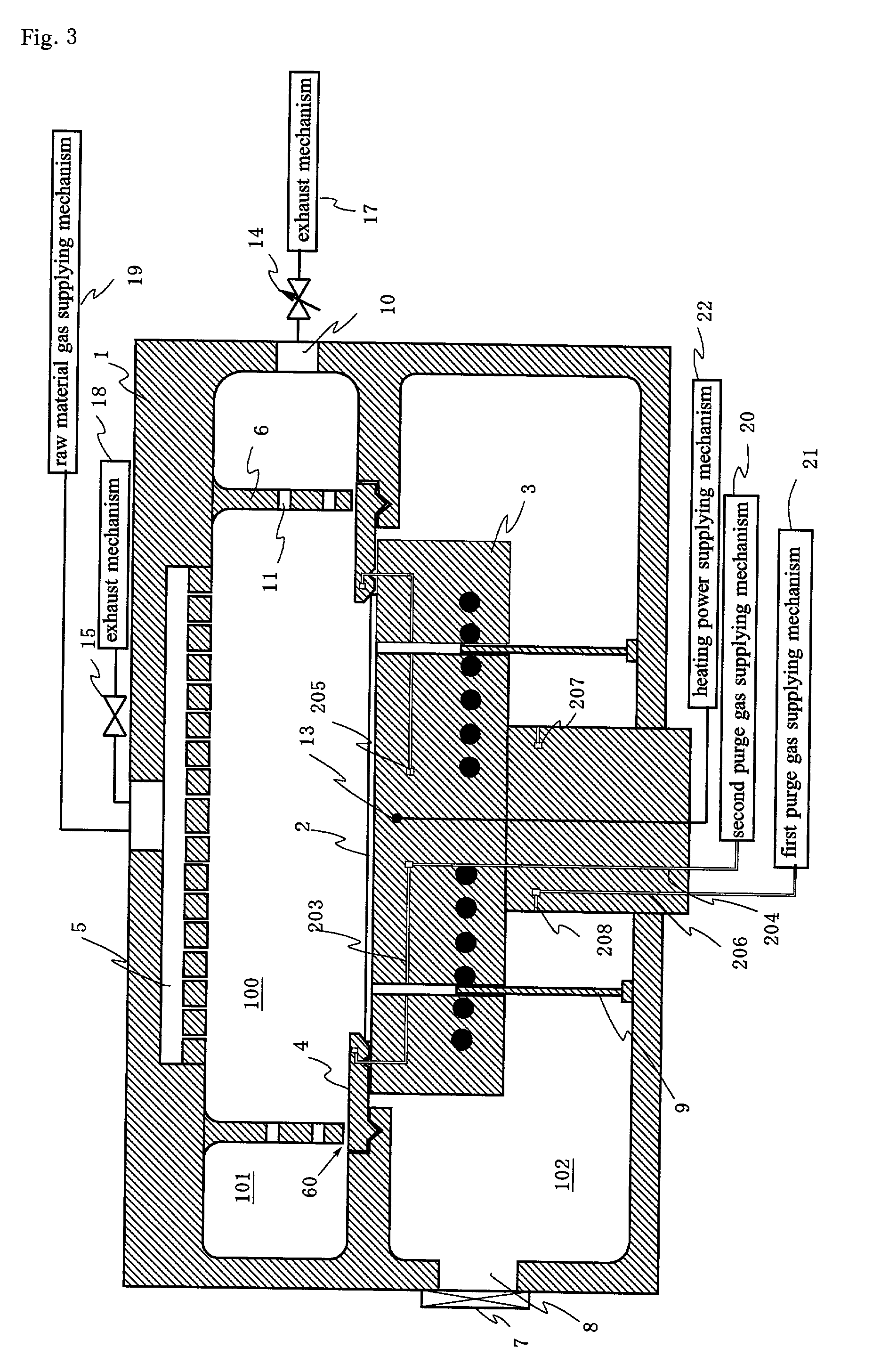

CVD apparatus

InactiveUS20010042514A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingProduction rateEngineering

The present invention is to provide a CVD apparatus having a high productivity, involving less contamination on the back surface of a substrate and having a high yield. A CVD apparatus for forming a thin film is characterized in that the interior of the vessel is divided into a upper portion and a lower portion (transfer chamber) by a support member for holding the ring chuck and the upper portion is further divide by inner wall into a deposition chamber and an exhaust chamber in axial symmetry around the same central axis. The deposition chamber communicated to the exhaust chamber through a gap between the inner wall and the ring chuck and / or holes provided in the inner wall. The transfer chamber is communicated to the deposition chamber or exhaust chamber through a gap formed between the ring chuck and the support member.

Owner:ANELVA CORP

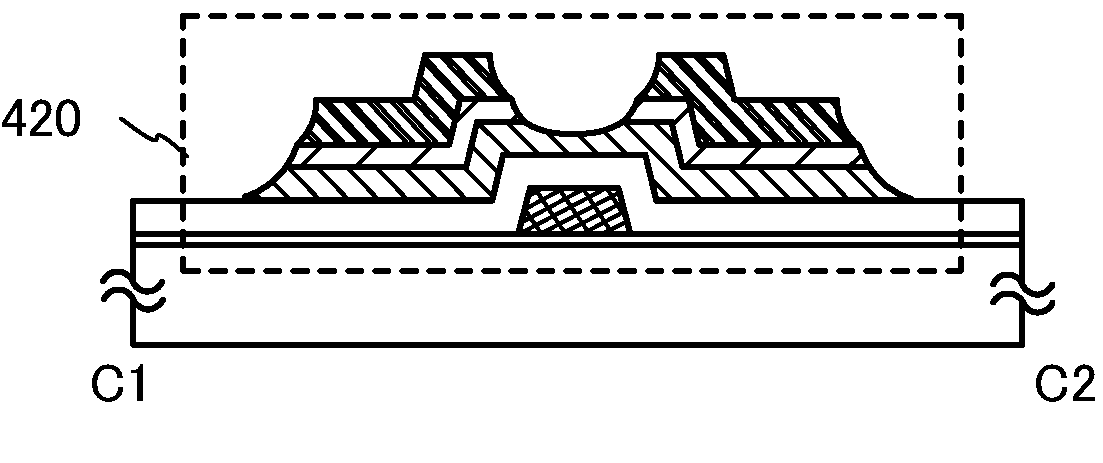

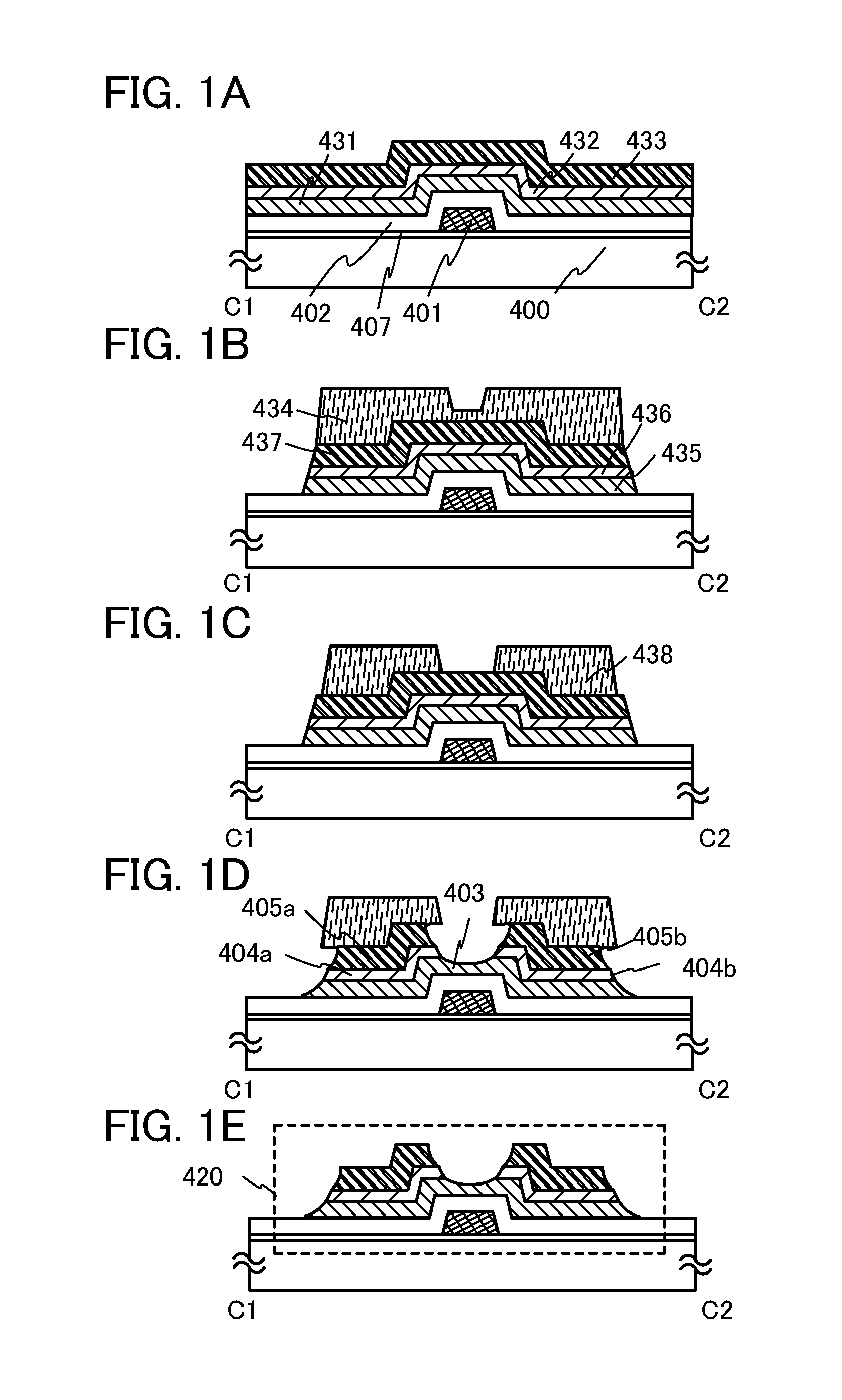

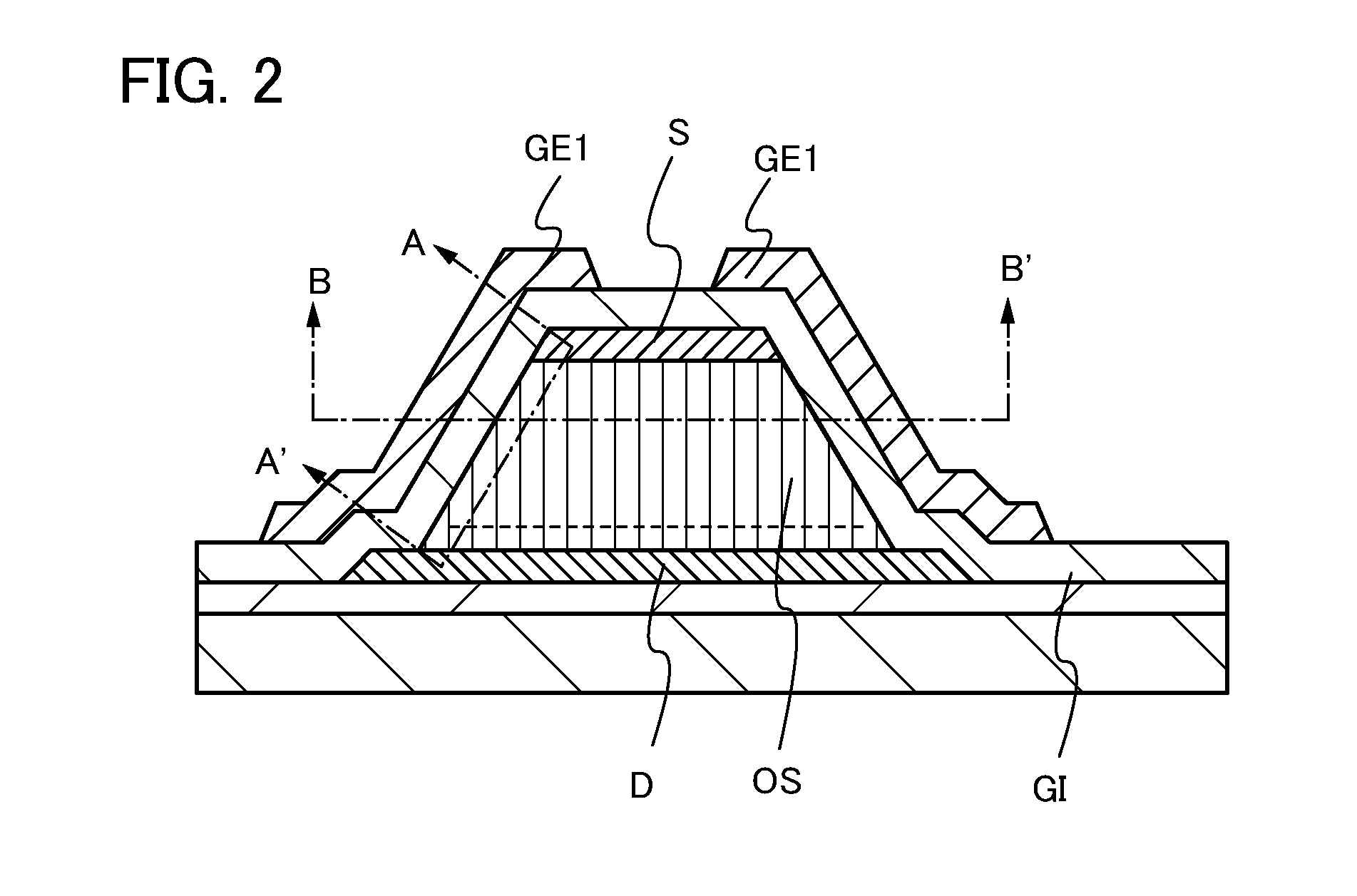

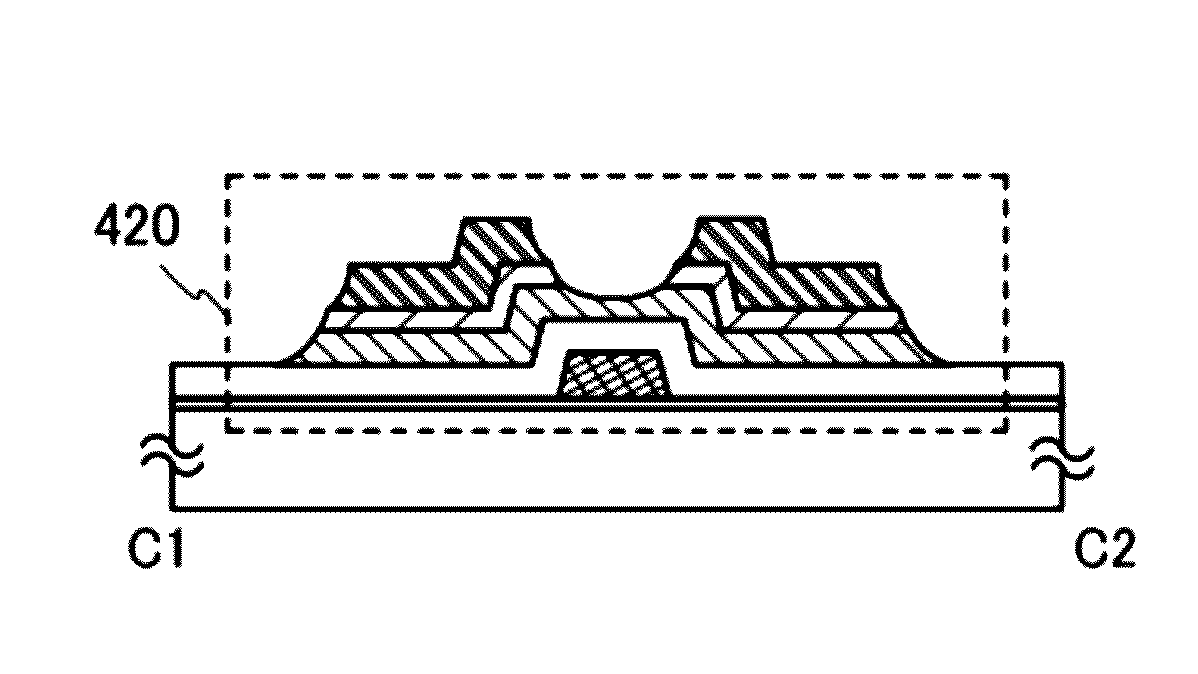

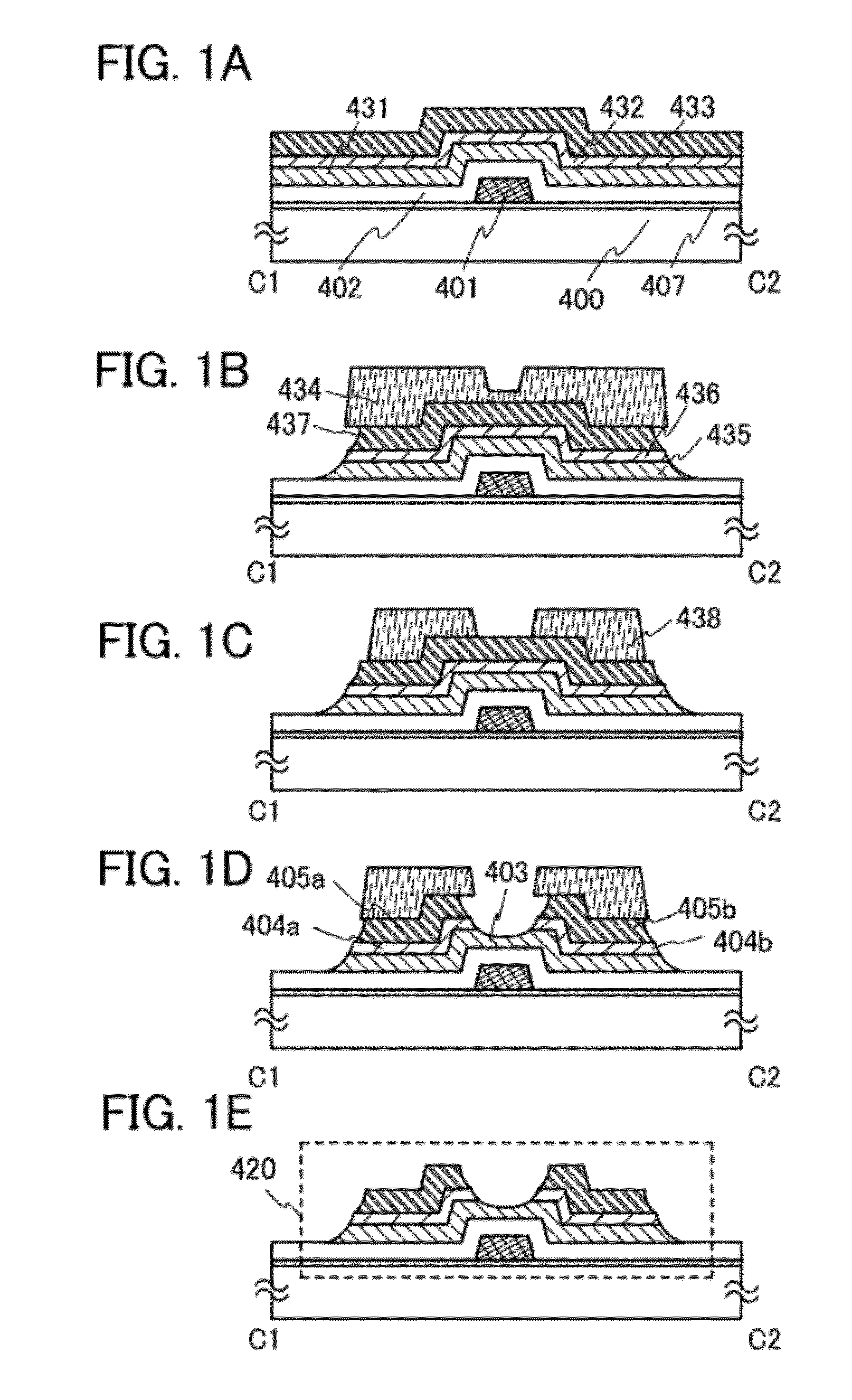

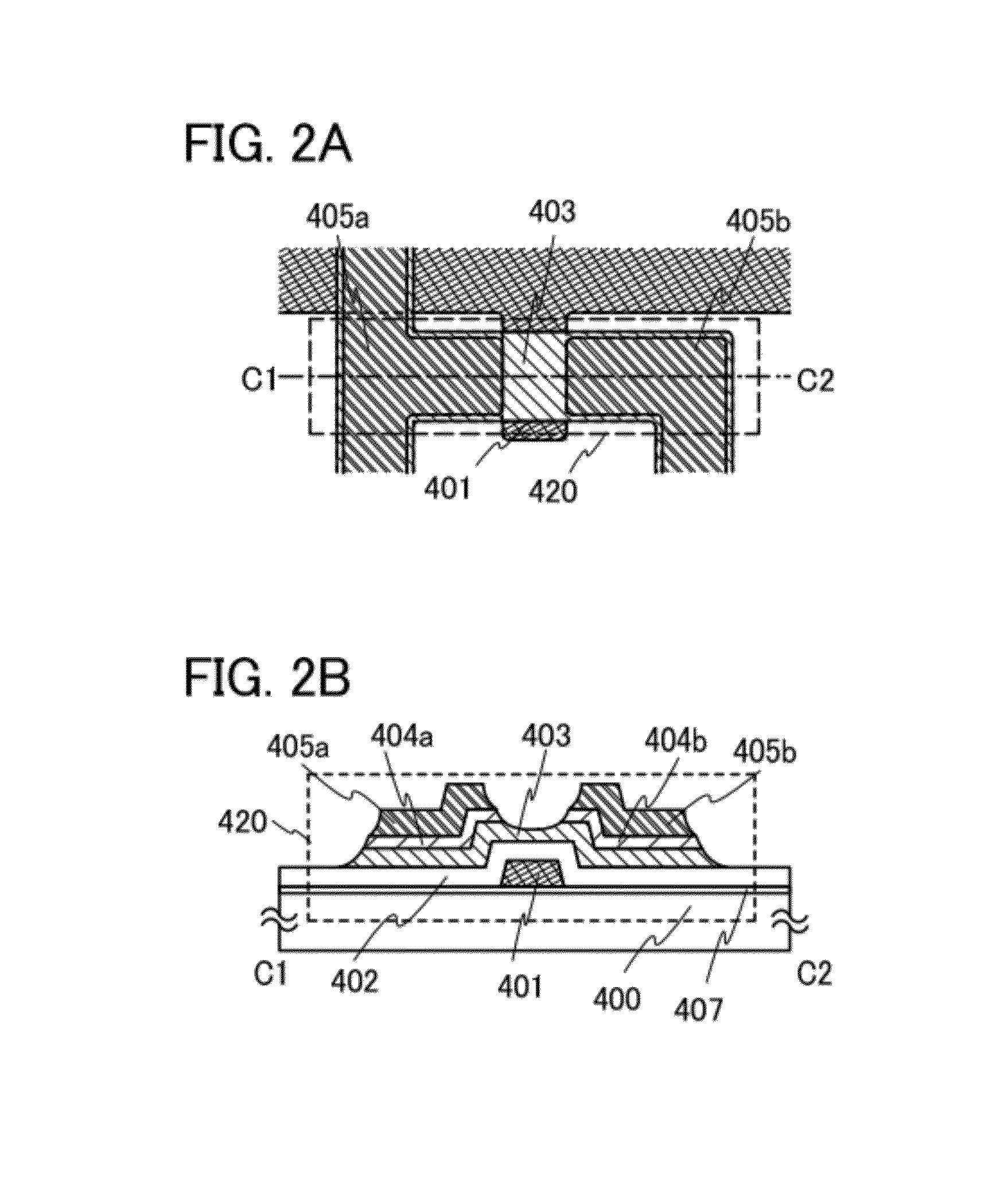

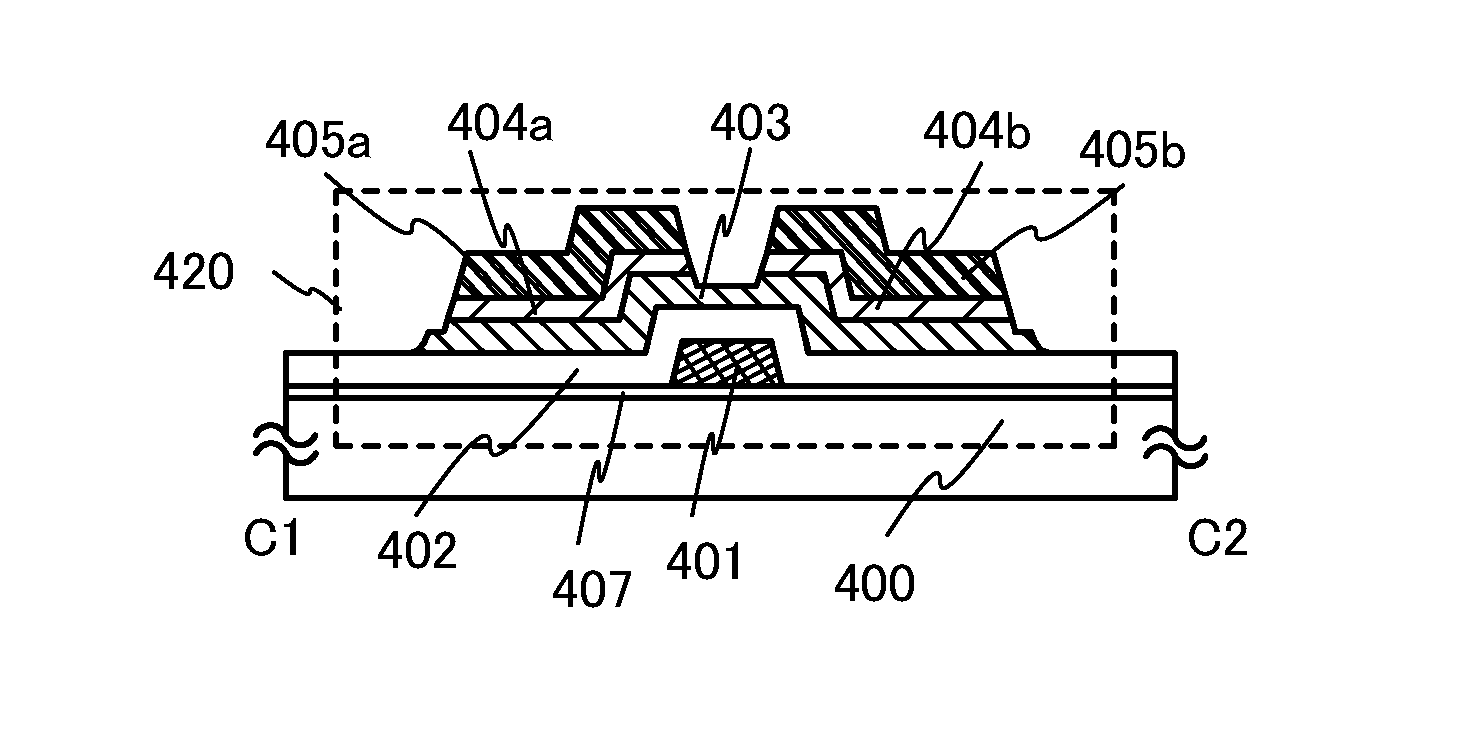

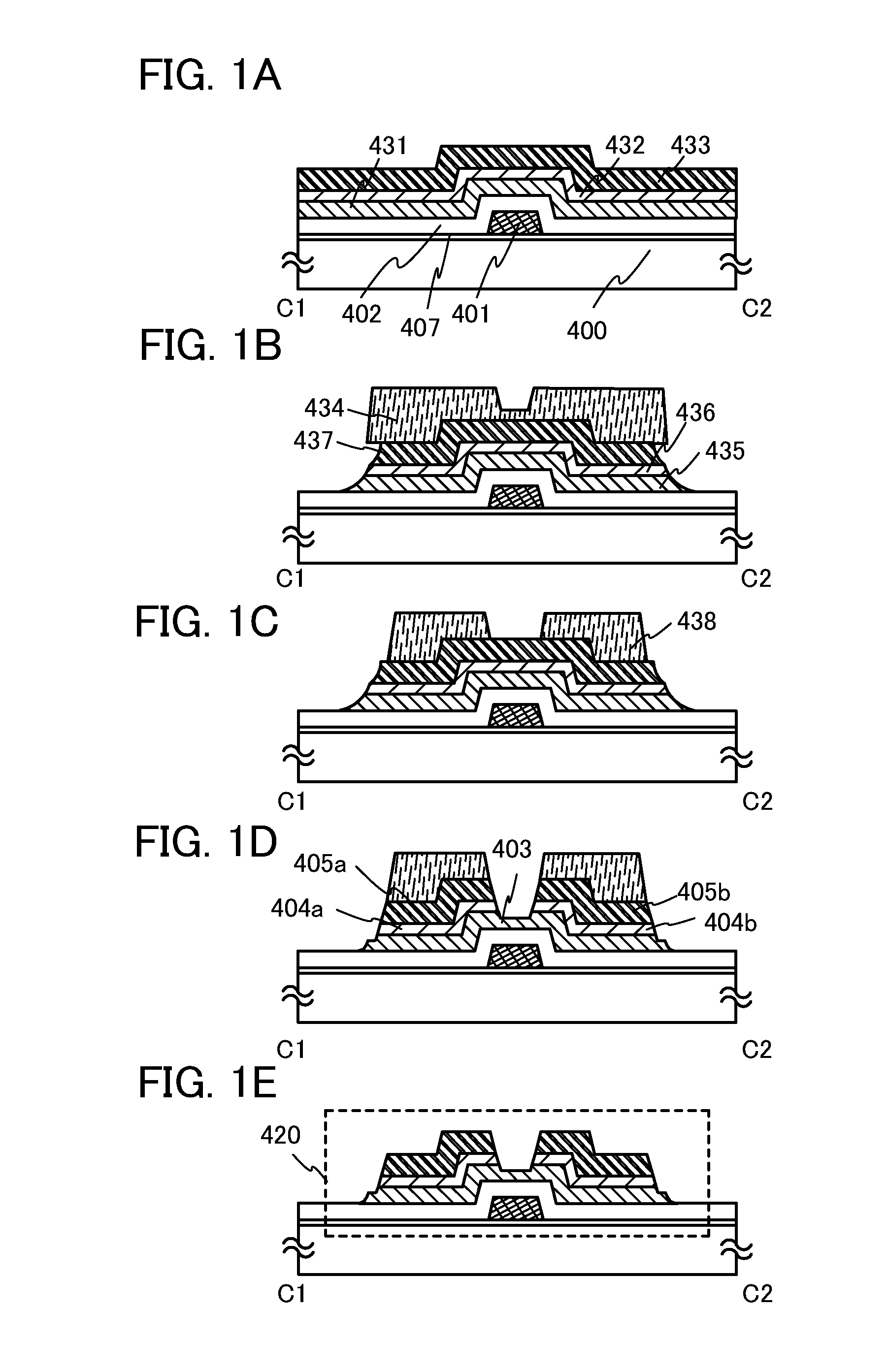

Method for manufacturing semiconductor device

ActiveUS20100105163A1Reduce manufacturing costImprove productivityTransistorElectroluminescent light sourcesProduction rateLight exposure

An object is to manufacture a semiconductor device including an oxide semiconductor at low cost with high productivity in such a manner that a photolithography process is simplified by reducing the number of light-exposure masks. In a method for manufacturing a semiconductor device including a channel-etched inverted-staggered thin film transistor, an oxide semiconductor film and a conductive film are etched using a mask layer formed with the use of a multi-tone mask which is a light-exposure mask through which light is transmitted so as to have a plurality of intensities. In etching steps, a first etching step is performed by dry etching in which an etching gas is used, and a second etching step is performed by wet etching in which an etchant is used.

Owner:SEMICON ENERGY LAB CO LTD

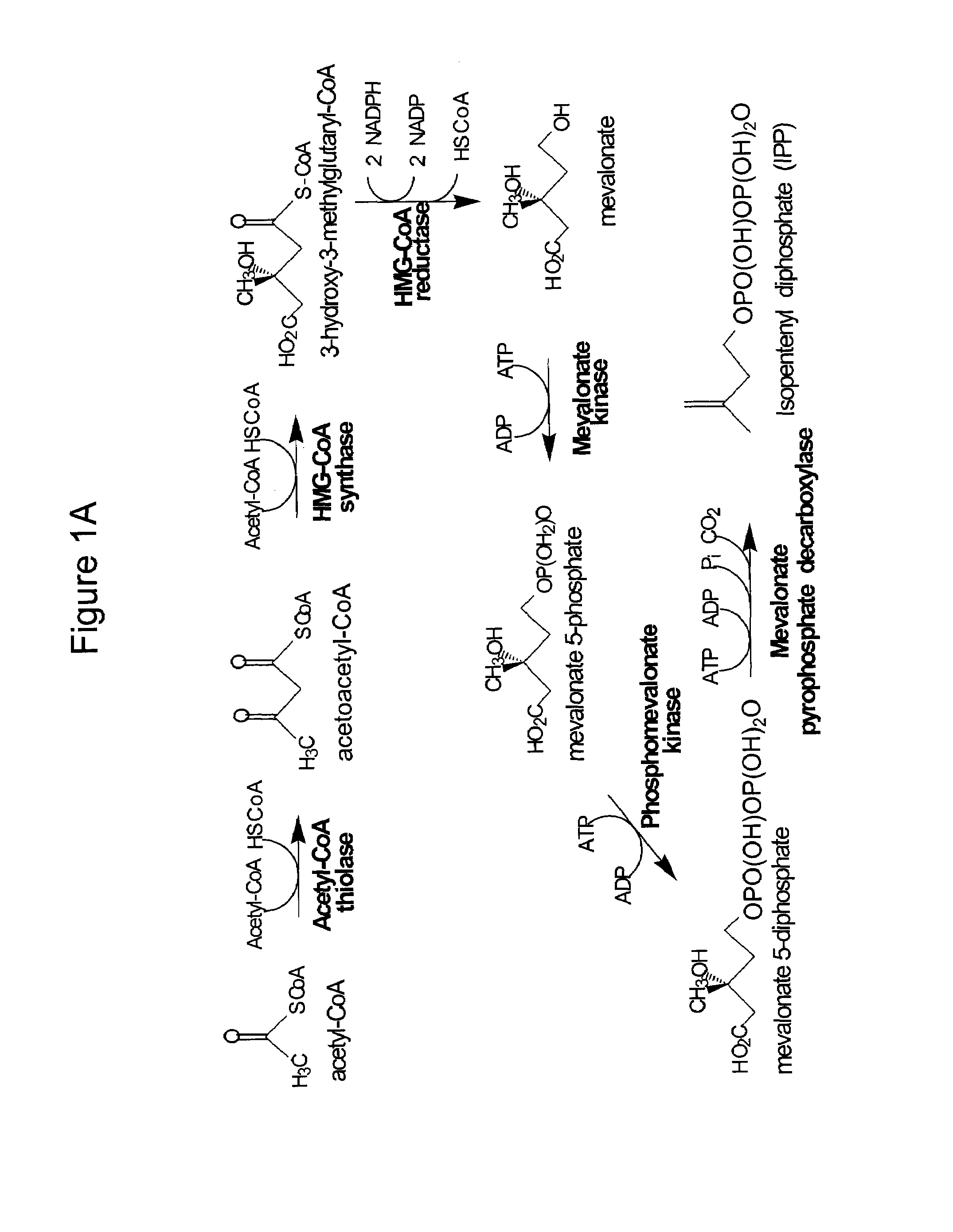

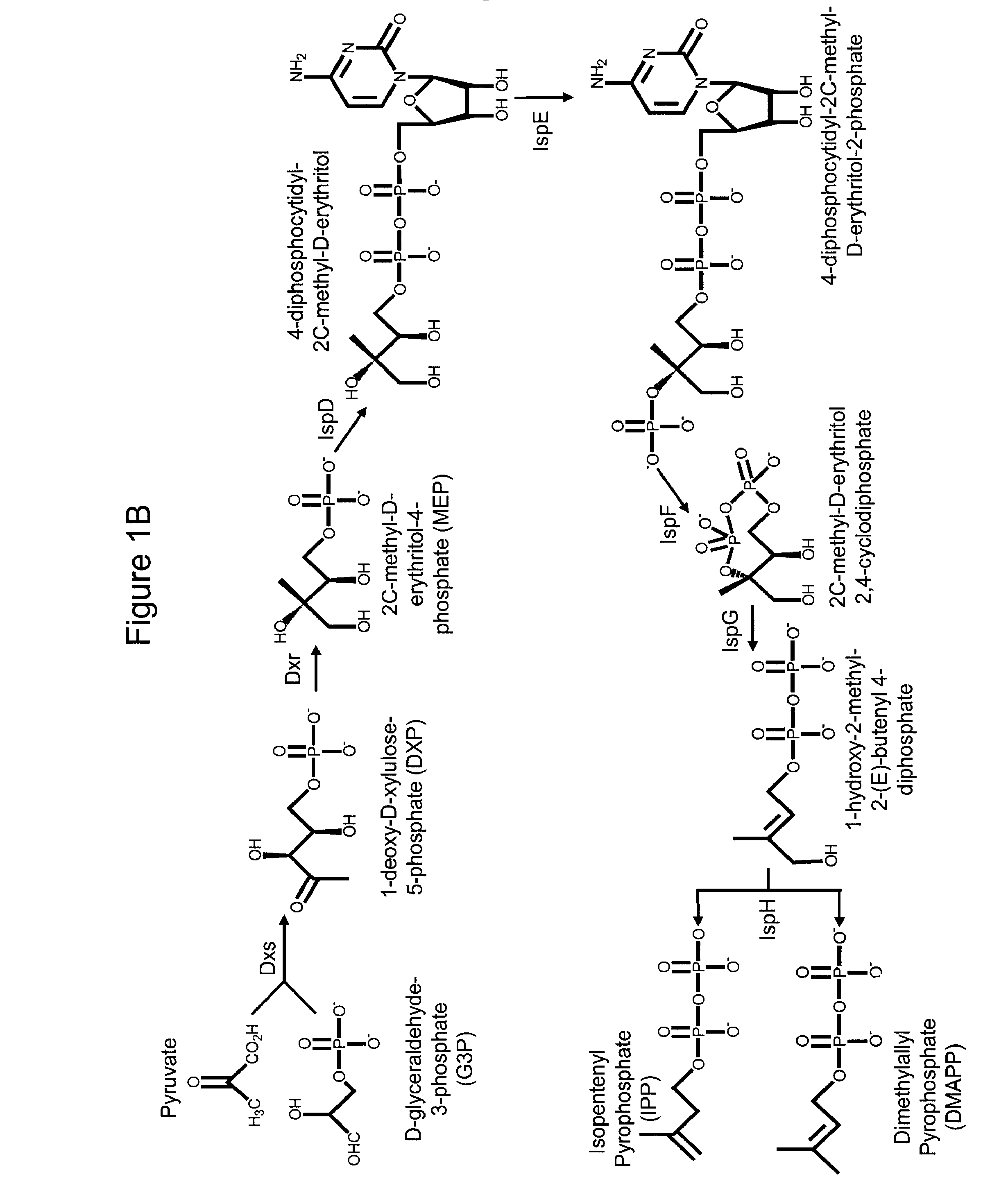

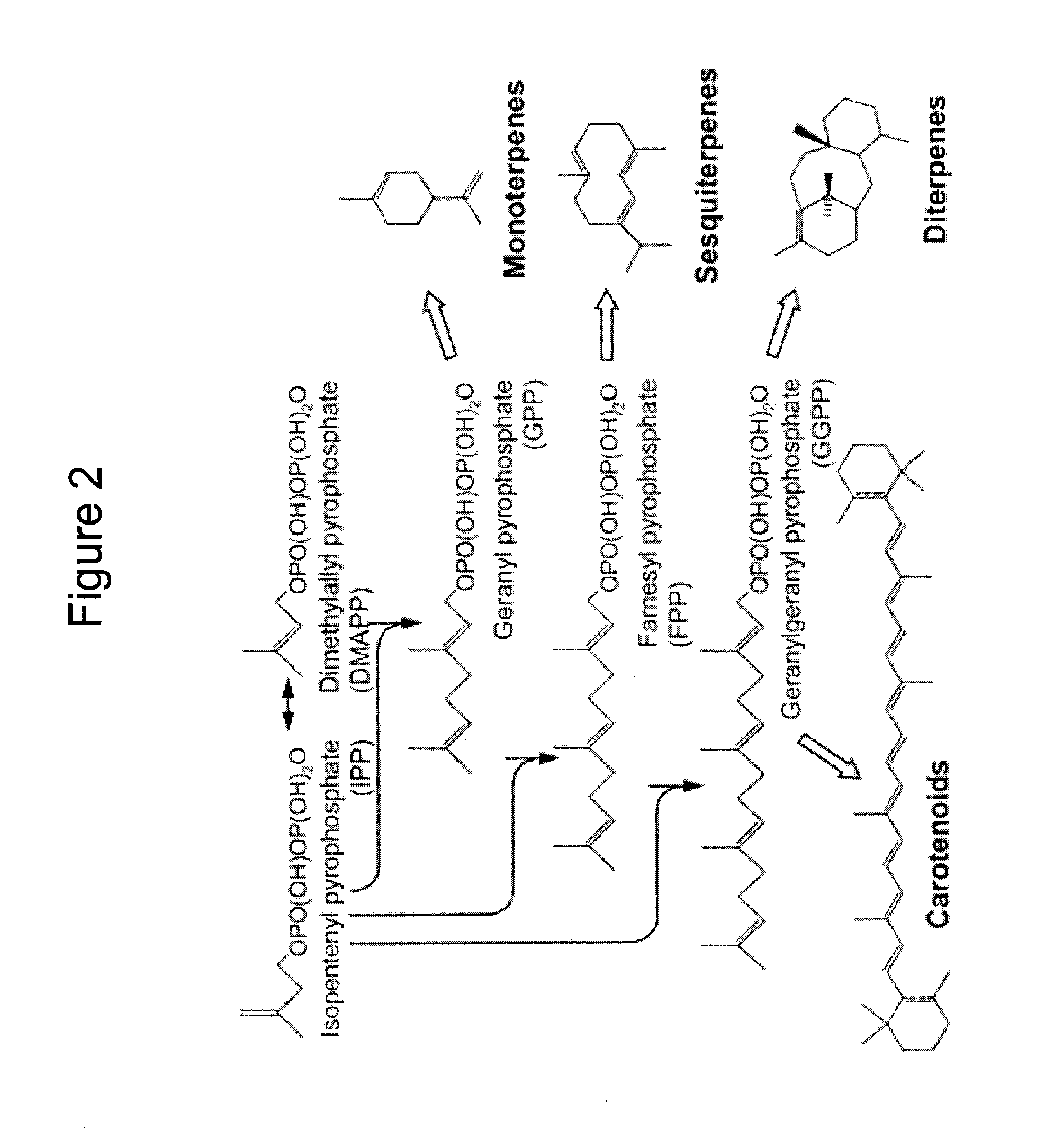

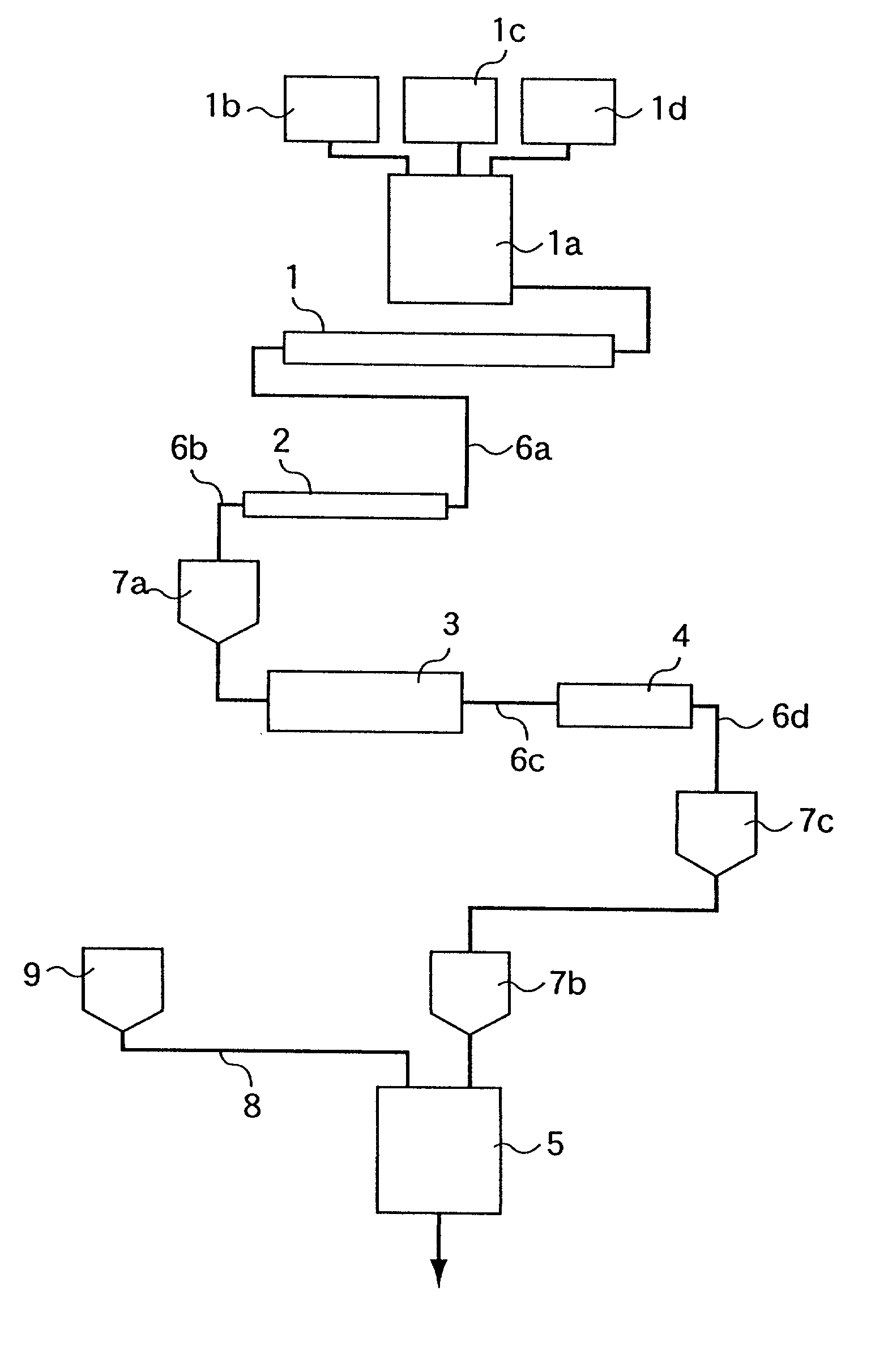

Production of isoprenoids

The present invention provides methods for a robust production of isoprenoids via one or more biosynthetic pathways. The invention also provides nucleic acids, enzymes, expression vectors, and genetically modified host cells for carrying out the subject methods. The invention also provides fermentation methods for high productivity of isoprenoids from genetically modified host cells.

Owner:AMYRIS INC

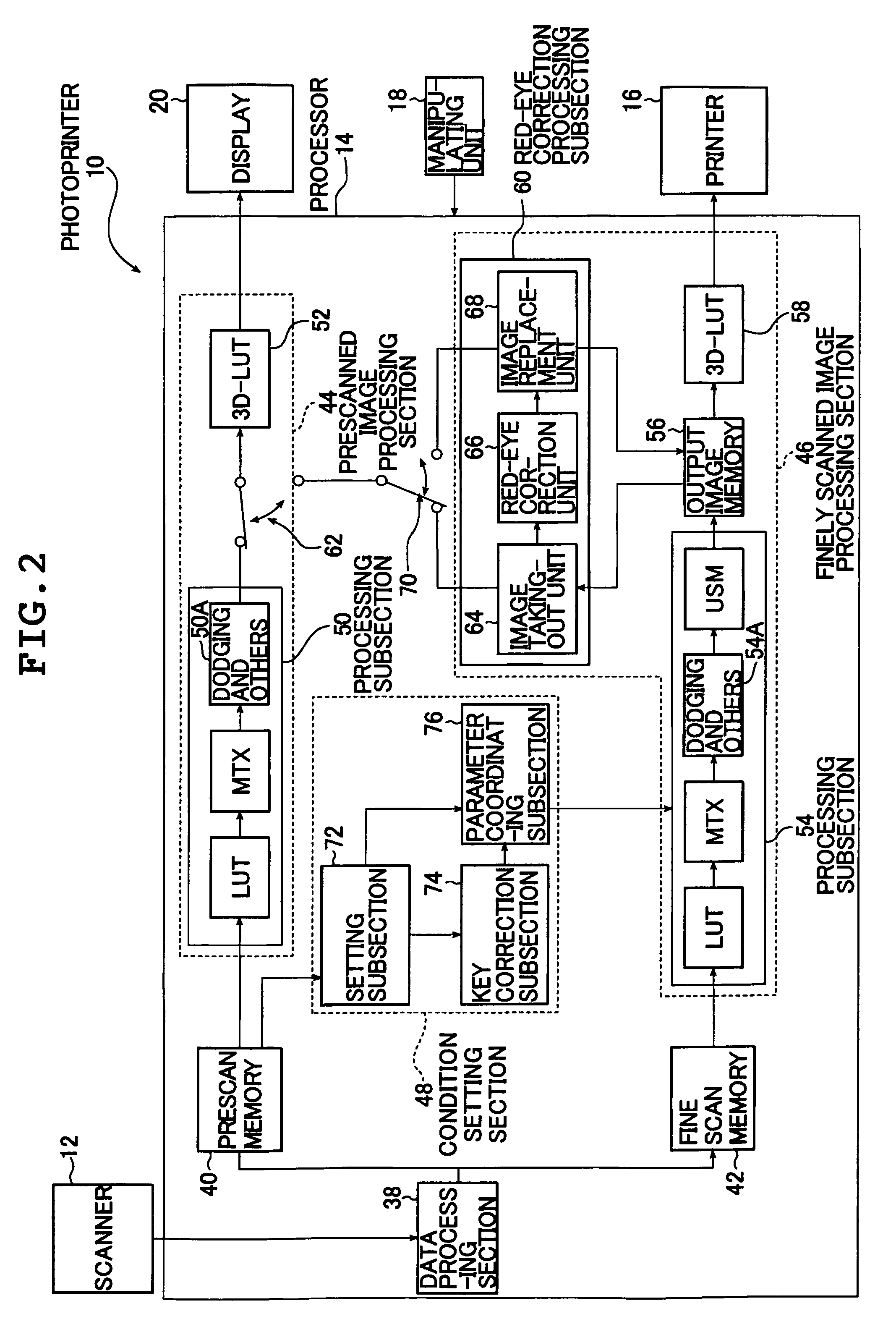

Image processing apparatus

InactiveUS7042501B1Precise processingSecuring productivityTelevision system detailsColor television detailsProduction rateImaging processing

There is provided an image processing apparatus comprising a display, a display switching section, a designation section and a red eye correction section, wherein the display switching section switches in such a way that at least a region designated by the designation section in an image is displayed on the display at high resolution before or after, or both before and after the region is processed by the red eye correction section. The image processing apparatus is capable of effectively performing the red eye correction processing by simple manipulation and outputting an image of high quality without a red eye effect in high productivity.

Owner:FUJIFILM CORP

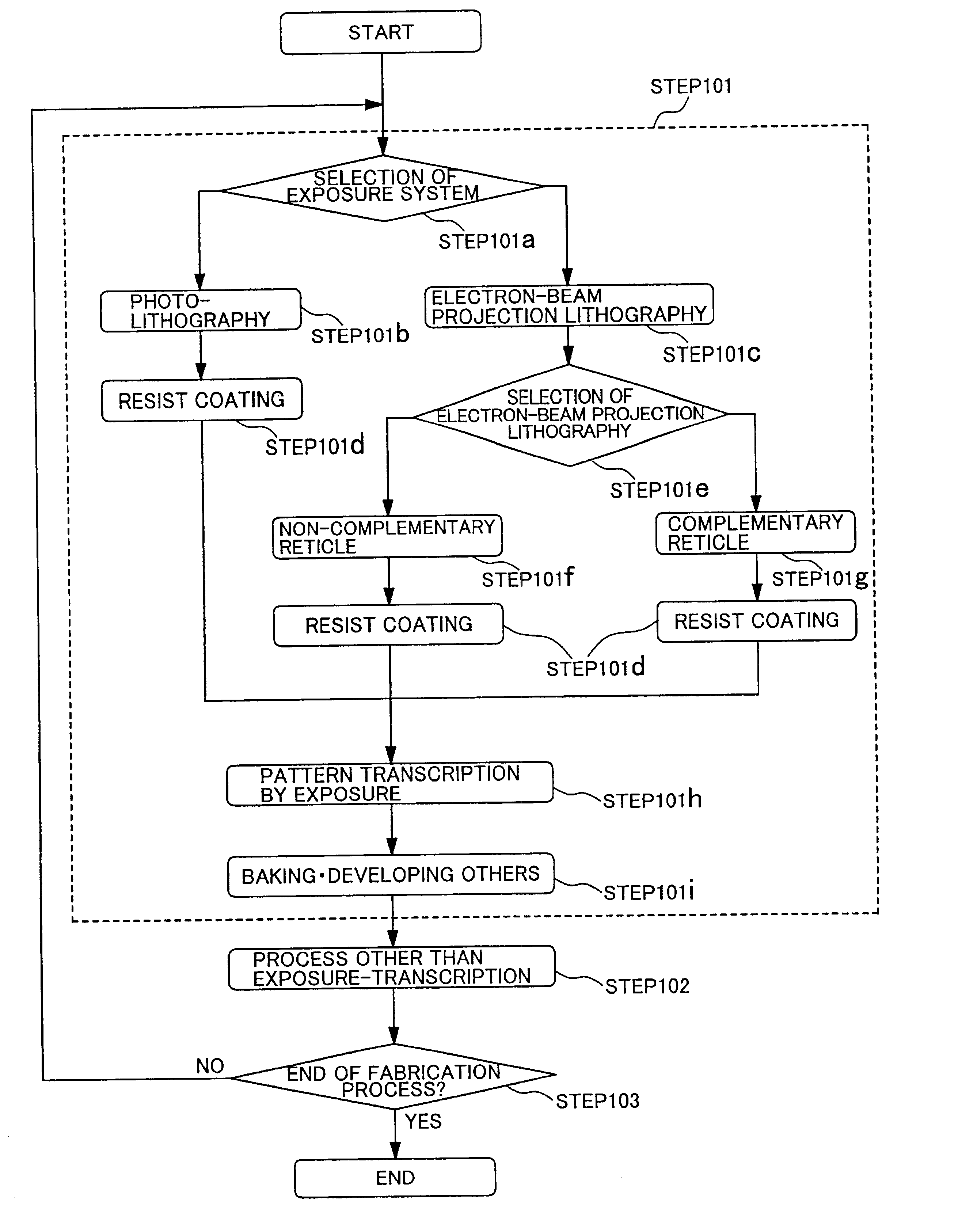

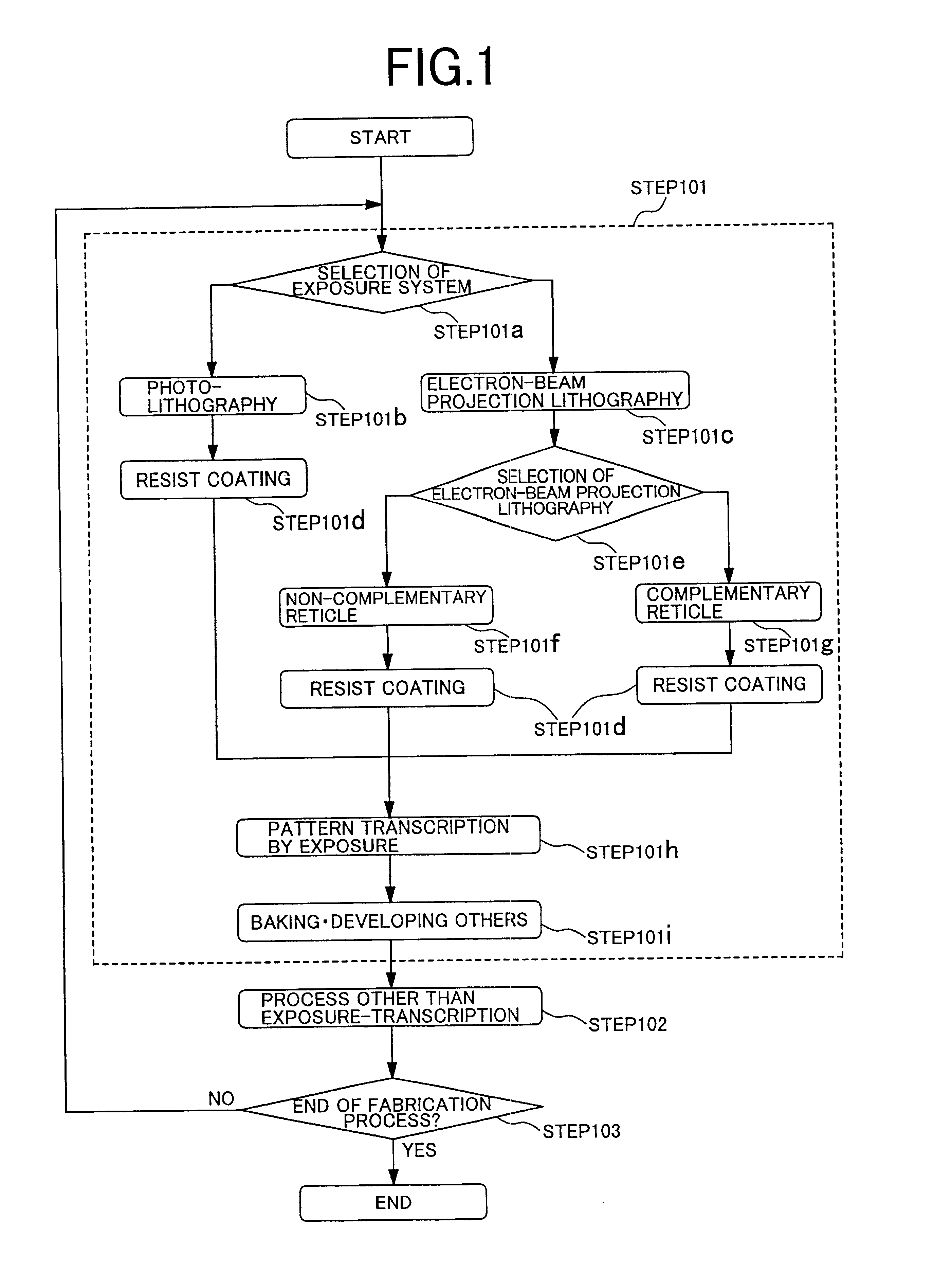

Semiconductor device and a manufacturing method of the same

There is disclosed a method for forming micro patterns in a semiconductor integrated circuit device with high productivity and high accuracy. A photolithography having high throughput and electron beam lithography using a reticle and having relatively high throughput and high resolution are selectively used so as to obtain highest throughput while satisfying accuracy and resolution required for each product / layer. In the case of using the electron beam lithography, a non-complementary reticle and a complementary reticle are selectively used so as to obtain highest throughput while satisfying required accuracy and resolution. Thus, productivity and integration can be improved for the semiconductor integrated circuit device.

Owner:HITACHI LTD +1

Semiconductor device and method for manufacturing the same

ActiveUS20110127522A1High on-off ratioHigh puritySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsElectron donor

Objects are to provide a semiconductor device for high power application in which a novel semiconductor material having high productivity is used and to provide a semiconductor device having a novel structure in which a novel semiconductor material is used. The present invention is a vertical transistor and a vertical diode each of which has a stacked body of an oxide semiconductor in which a first oxide semiconductor film having crystallinity and a second oxide semiconductor film having crystallinity are stacked. An impurity serving as an electron donor (donor) which is contained in the stacked body of an oxide semiconductor is removed in a step of crystal growth; therefore, the stacked body of an oxide semiconductor is highly purified and is an intrinsic semiconductor or a substantially intrinsic semiconductor whose carrier density is low. The stacked body of an oxide semiconductor has a wider band gap than a silicon semiconductor.

Owner:SEMICON ENERGY LAB CO LTD

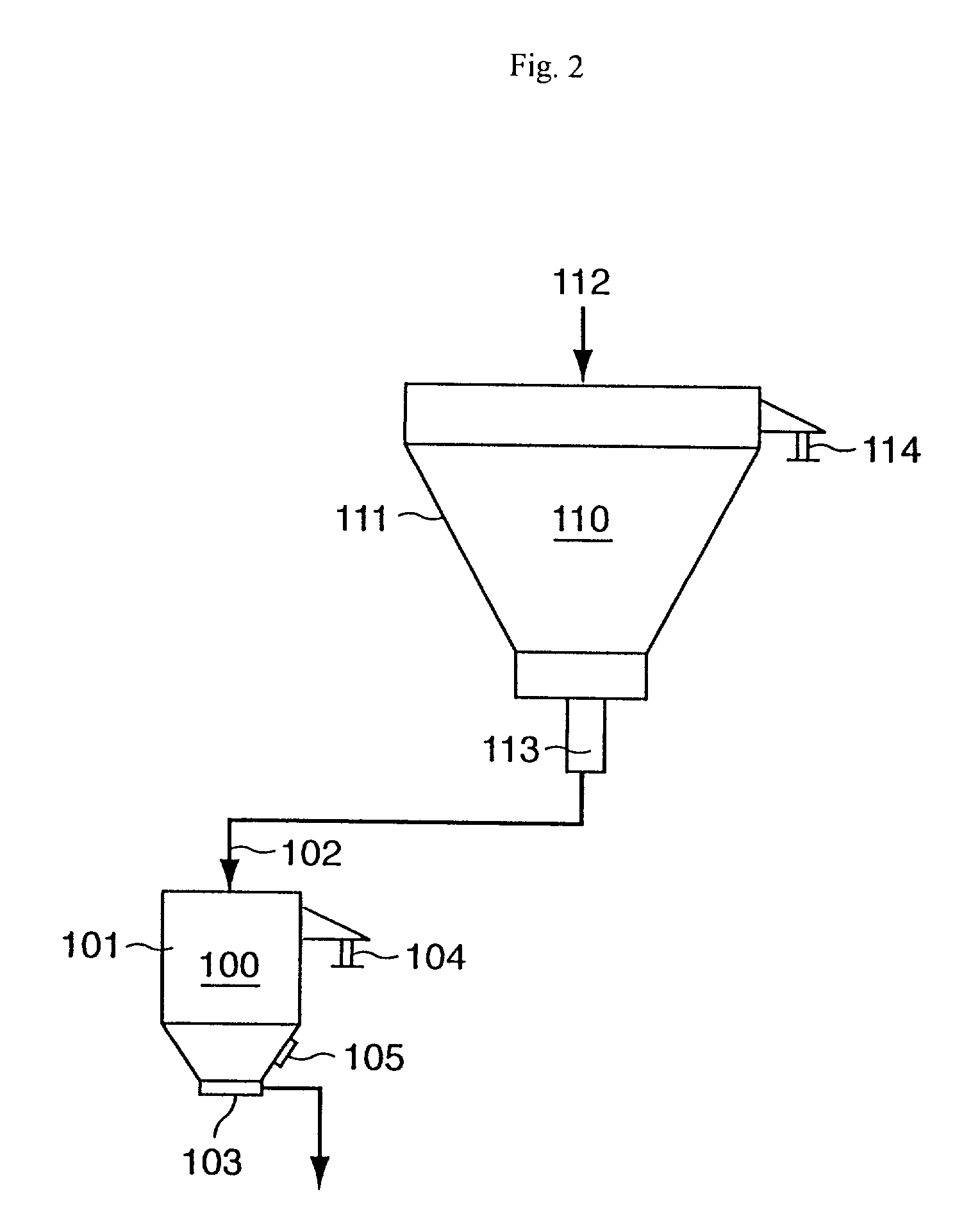

Continuous production process for water-absorbent resin powder and powder surface detector used therefor

InactiveUS20030020199A1Quality improvementImprove productivityFilament/thread formingMachines/enginesProduction rateMaterials science

A surface-modified water-absorbent resin powder is produced continuously with high productivity in a state where the particle diameter distribution is narrow and where the properties are high by a process comprising a polymerizing step, a drying step, a pulverizing step, a classifying step, and a surface-modifying step, and further, conveying steps of connecting them, wherein the conveying steps include at least two hoppers for storing the water-absorbent resin powder. A powder surface detector used favorably for this process includes a float hung down by a hanging line.

Owner:NIPPON SHOKUBAI CO LTD

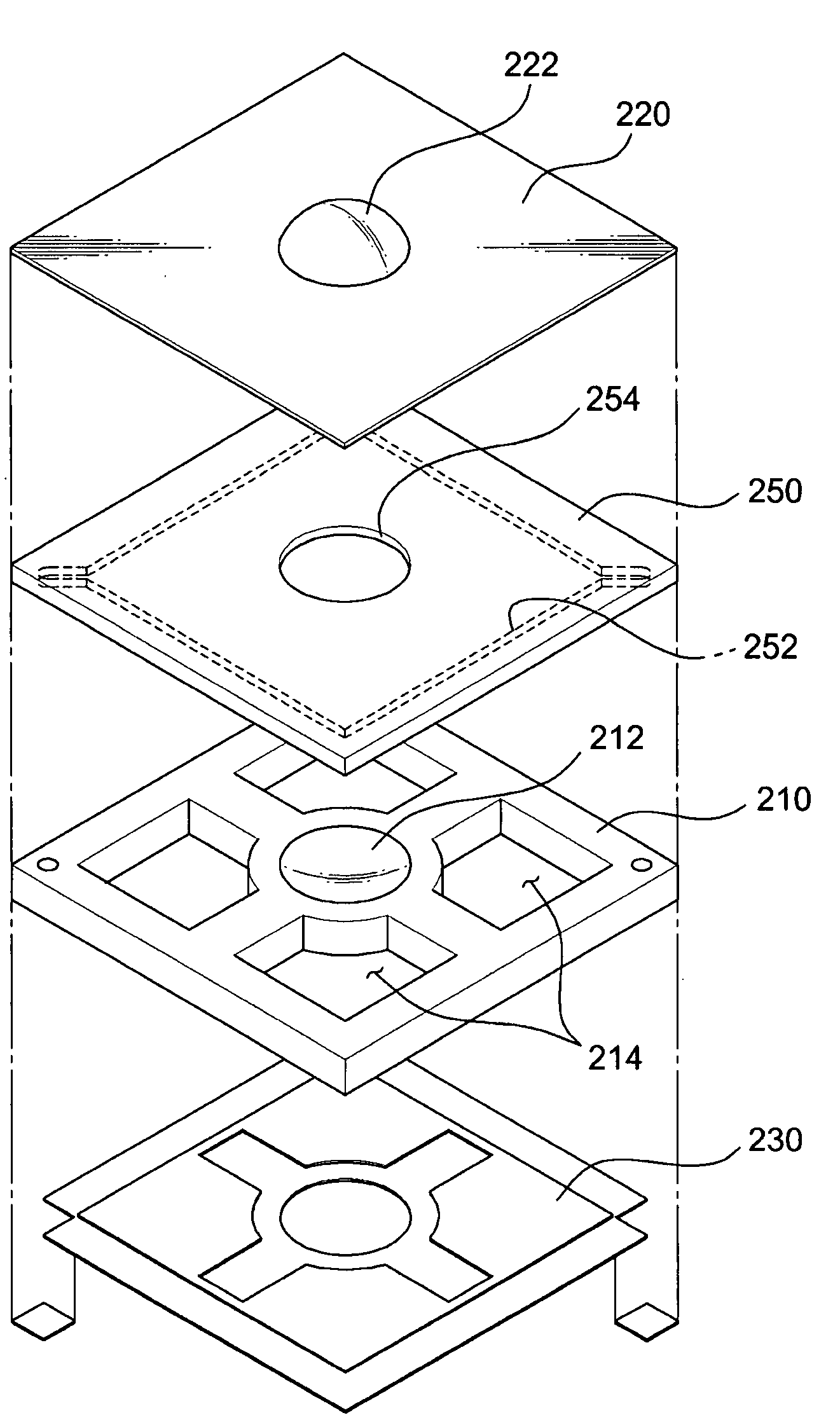

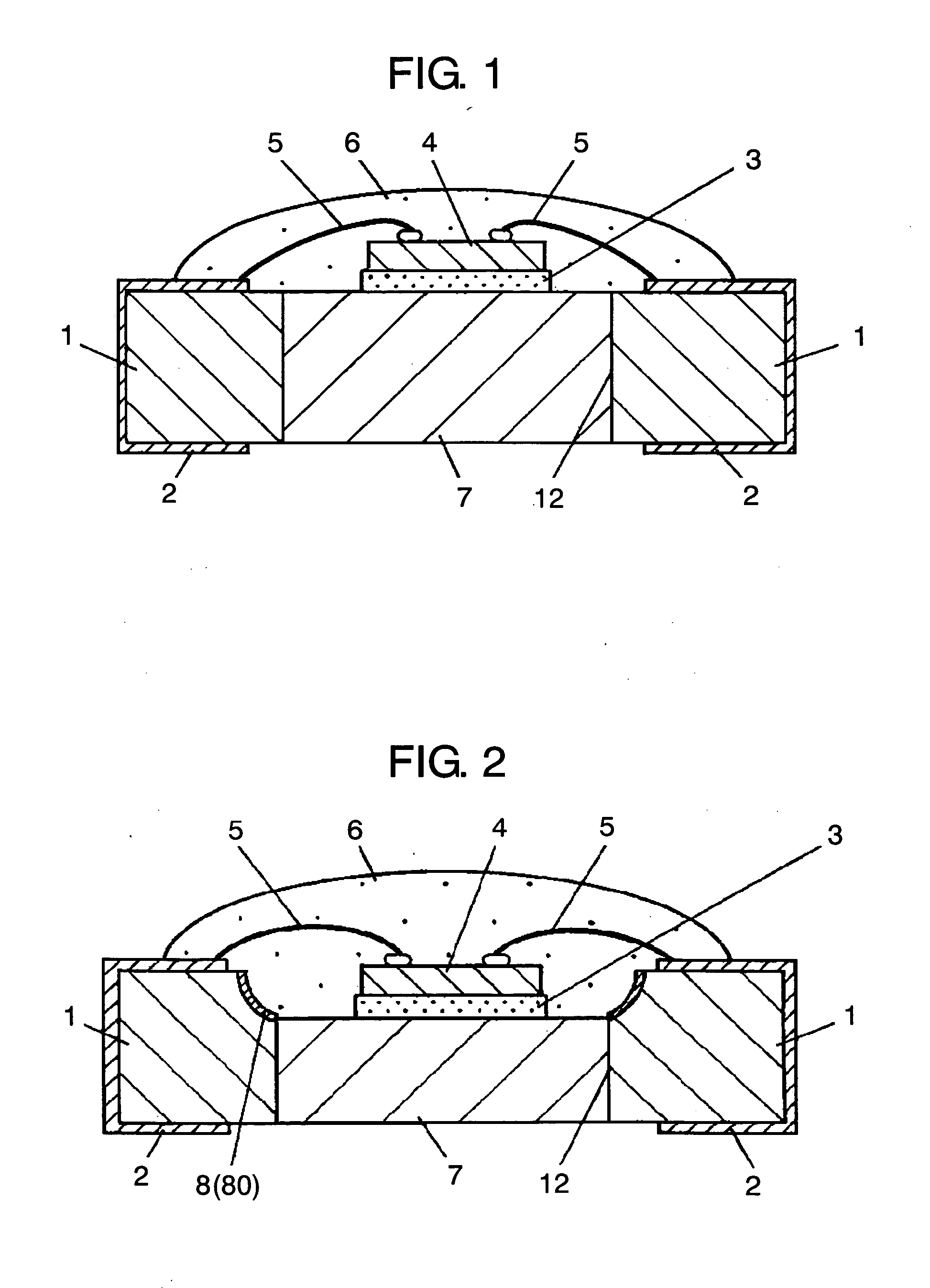

LED assembly and manufacturing method

InactiveUS20070200133A1Effective coolingImprove antistatic propertiesCoupling device detailsSolid-state devicesProduction rateEngineering

An LED assembly including a wiring substrate with an opening at its center; a heat sink housed inside the opening; an LED chip mounted on the heat sink; a connecting section for electrically coupling the LED chip and wiring substrate; and a transparent resin covering the LED chip and connecting section. Heat generated from the LED chip is efficiently dissipated, and high productivity is also achievable.

Owner:PANASONIC CORP

Method for manufacturing semiconductor device

ActiveUS8343799B2High field-effect mobilityThin film transistorElectroluminescent light sourcesSolid-state devicesProduction rateDevice material

An object is to manufacture a semiconductor device including an oxide semiconductor at low cost with high productivity in such a manner that a photolithography process is simplified by reducing the number of light-exposure masks. In a method for manufacturing a semiconductor device including a channel-etched inverted-stagger thin film transistor, an oxide semiconductor film and a conductive film are etched using a mask layer formed with the use of a multi-tone mask which is a light-exposure mask through which light is transmitted so as to have a plurality of intensities. The etching step is performed by wet etching in which an etching solution is used.

Owner:SEMICON ENERGY LAB CO LTD

Method for manufacturing thin film transistor using multi-tone mask

ActiveUS8242494B2Improve mobilityThin film transistorTransistorElectroluminescent light sourcesProduction rateLight exposure

An object is to manufacture a semiconductor device including an oxide semiconductor at low cost with high productivity in such a manner that a photolithography process is simplified by reducing the number of light-exposure masks. In a method for manufacturing a semiconductor device including a channel-etched inverted-staggered thin film transistor, an oxide semiconductor film and a conductive film are etched using a mask layer formed with the use of a multi-tone mask which is a light-exposure mask through which light is transmitted so as to have a plurality of intensities. In etching steps, a first etching step is performed by wet etching in which an etchant is used, and a second etching step is performed by dry etching in which an etching gas is used.

Owner:SEMICON ENERGY LAB CO LTD

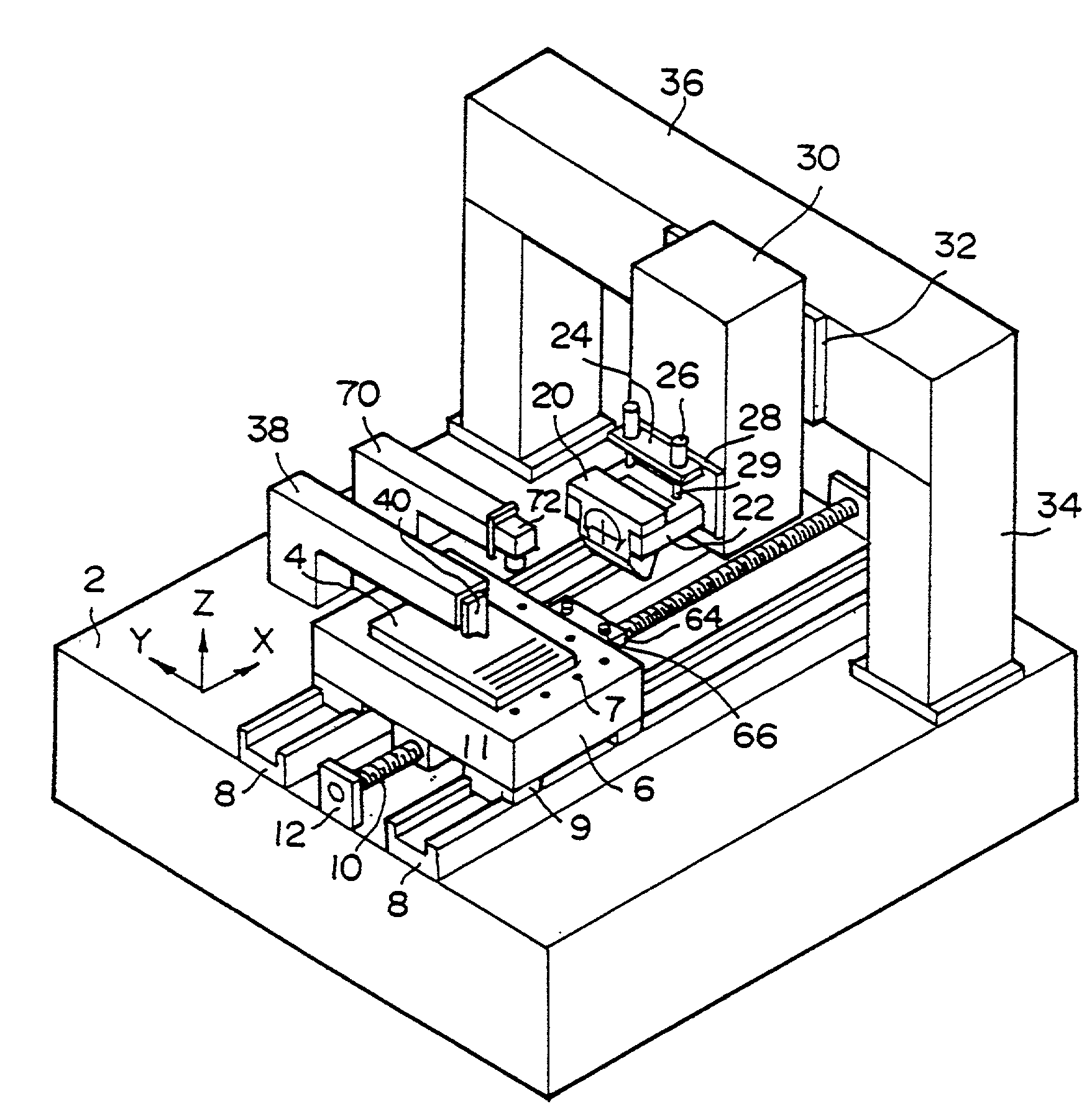

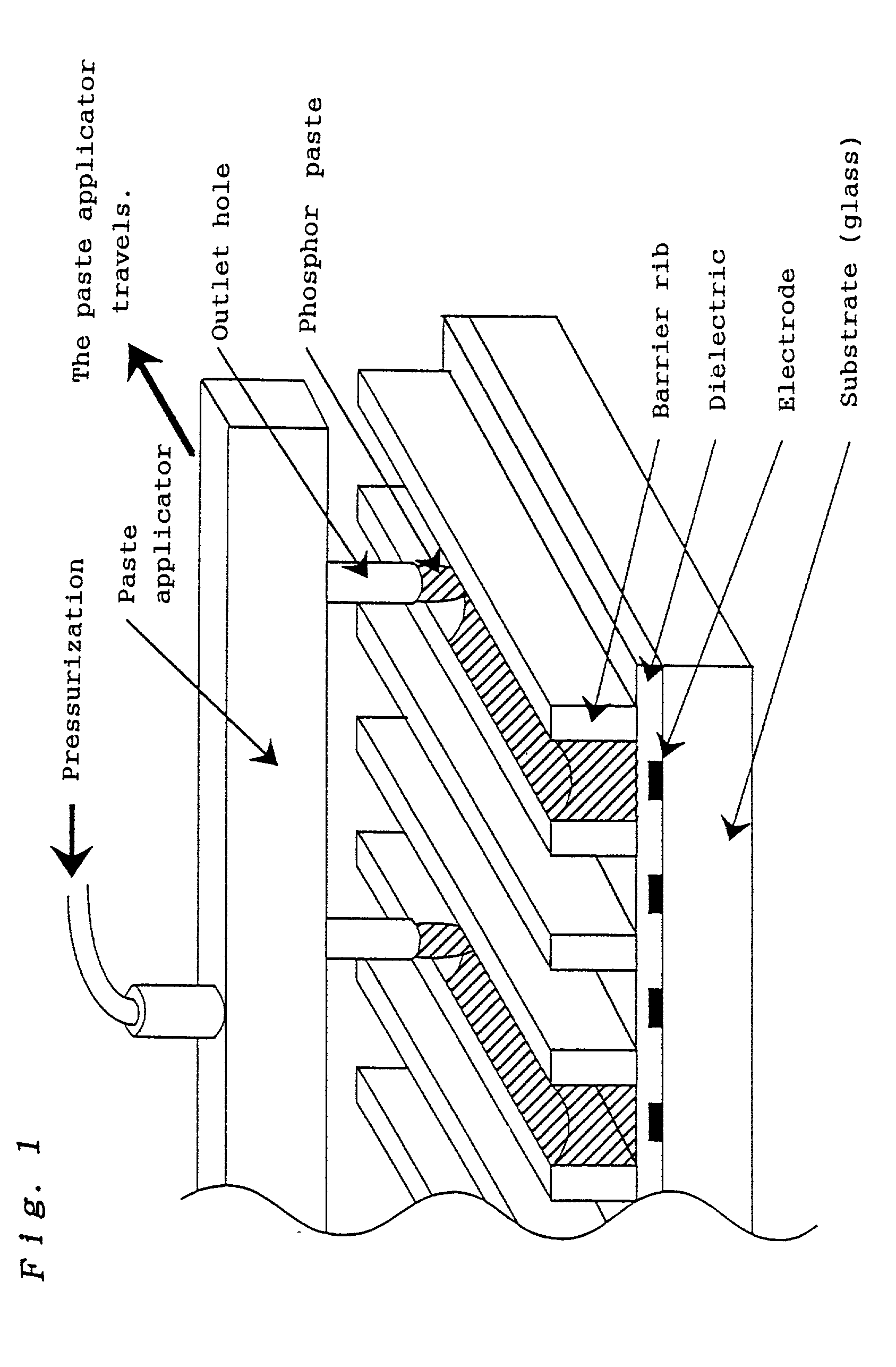

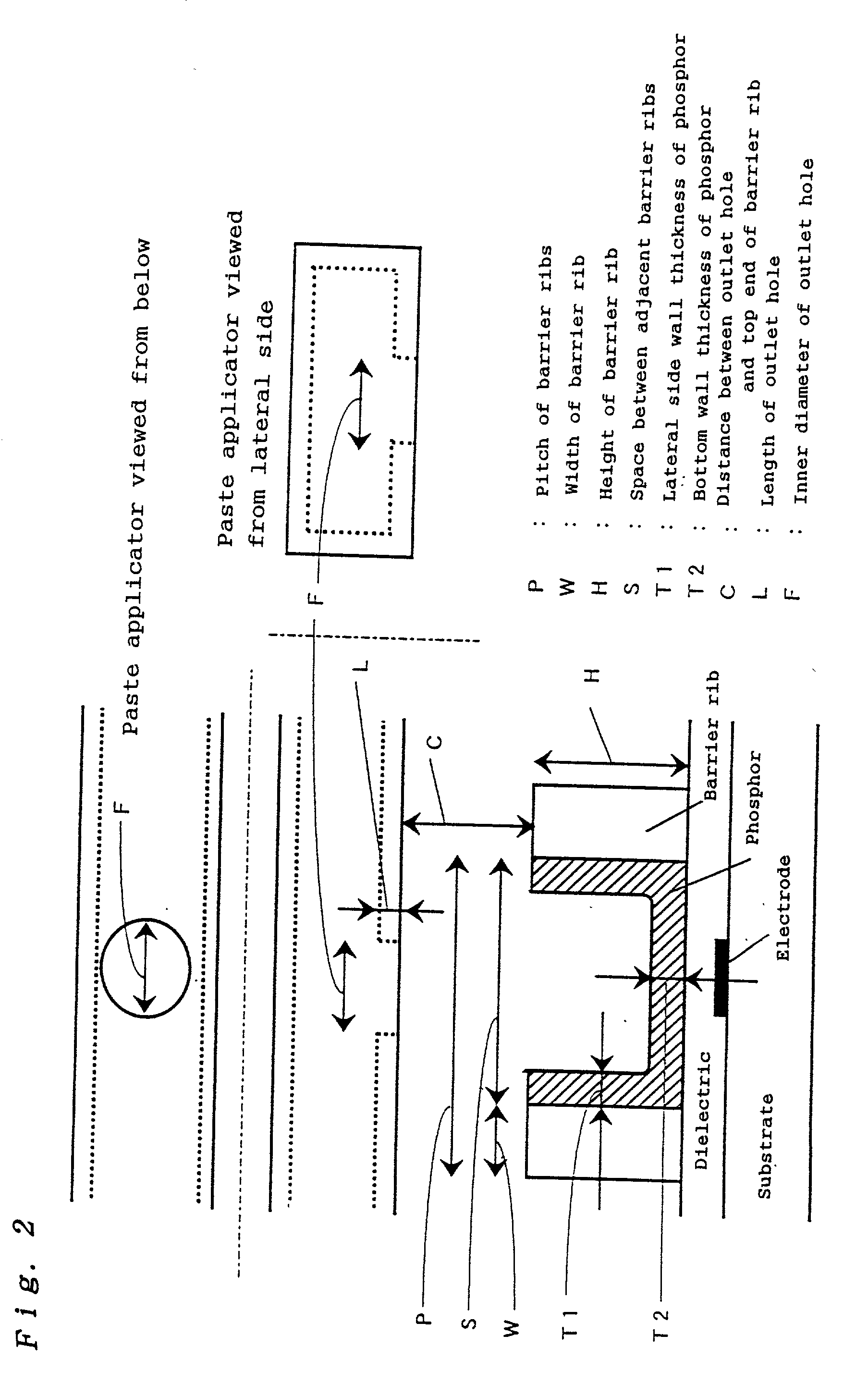

Method and apparatus for producing a plasma display

InactiveUS20020009536A1High levelElectric discharge tubesVacuum evaporation coatingProduction rateFluorescence

Since a widely applicable high quality plasma display equipped with a phosphor layer suitable as a highly precise plasma display can be produced continuously at a high productivity level, an industrially advantageous method and apparatus for producing a plasma display can be provided. The highly precise plasma display obtained in the present invention can be widely used in the display field, for example, for wall mounted television sets, information displays, etc. The method for producing a plasma display of the present invention comprises the step of continuously applying a phosphor paste containing a phosphor powder and an organic compound onto a substrate with a plurality of barrier ribs from a paste applicator with a plurality of outlet holes. Furthermore, the present invention comprises the steps of coating a substrate with a plurality of barrier ribs, with three phosphor pastes respectively containing a phosphor powder emitting light of red, green or blue, as stripes in the spaces between the respectively adjacent barrier ribs on the substrate, from a paste applicator with outlet holes, and heating to form a phosphor layer. Moreover, the apparatus for producing a plasma display of the present invention comprises a table for fixing a substrate with a plurality of barrier ribs, a paste applicator with a plurality of outlet holes to face the barrier ribs of the substrate, a supply means for supplying a phosphor paste to the paste applicator, and a moving means for three-dimensionally moving the table and the paste applicator relatively each other.

Owner:PANASONIC CORP +1

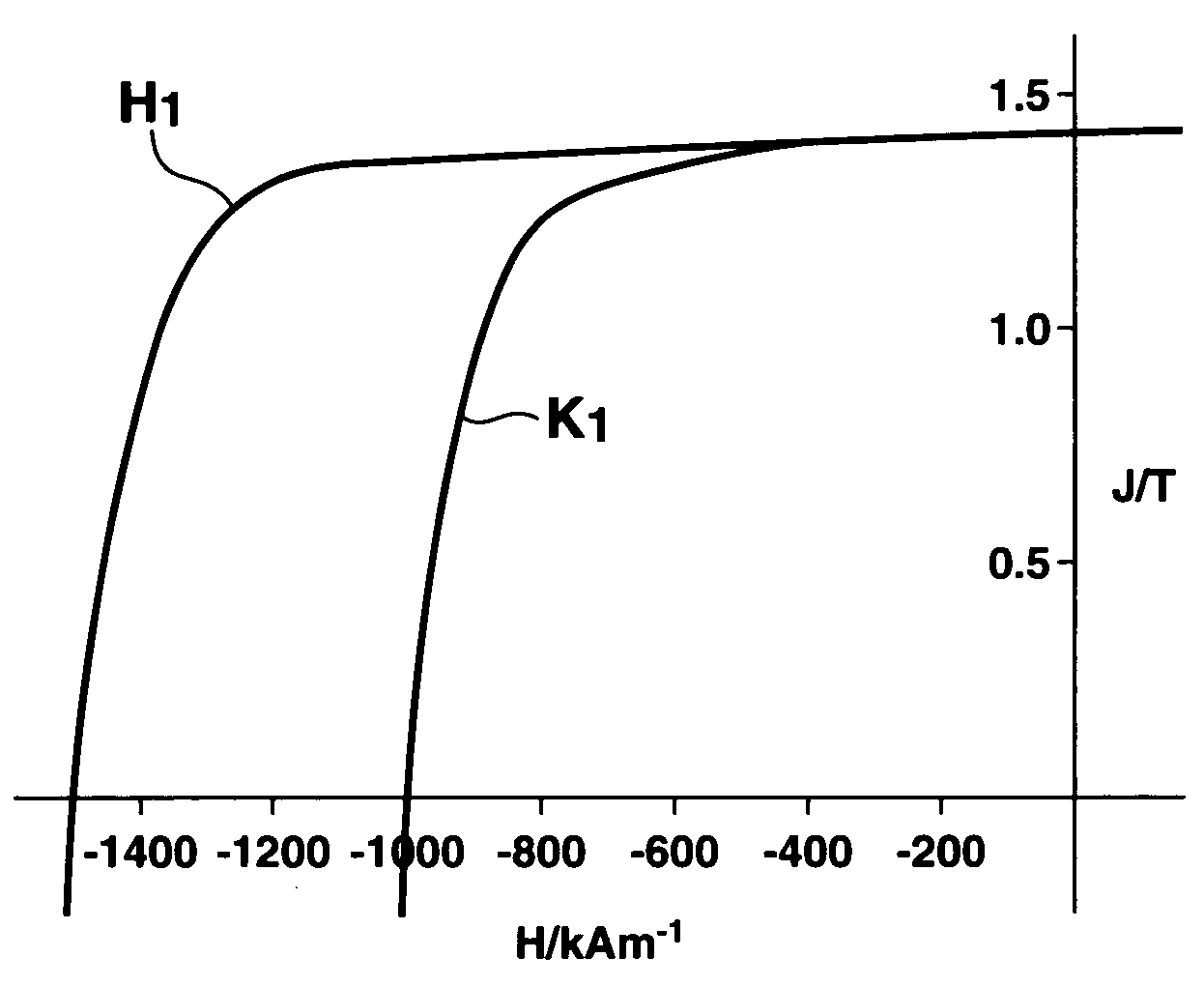

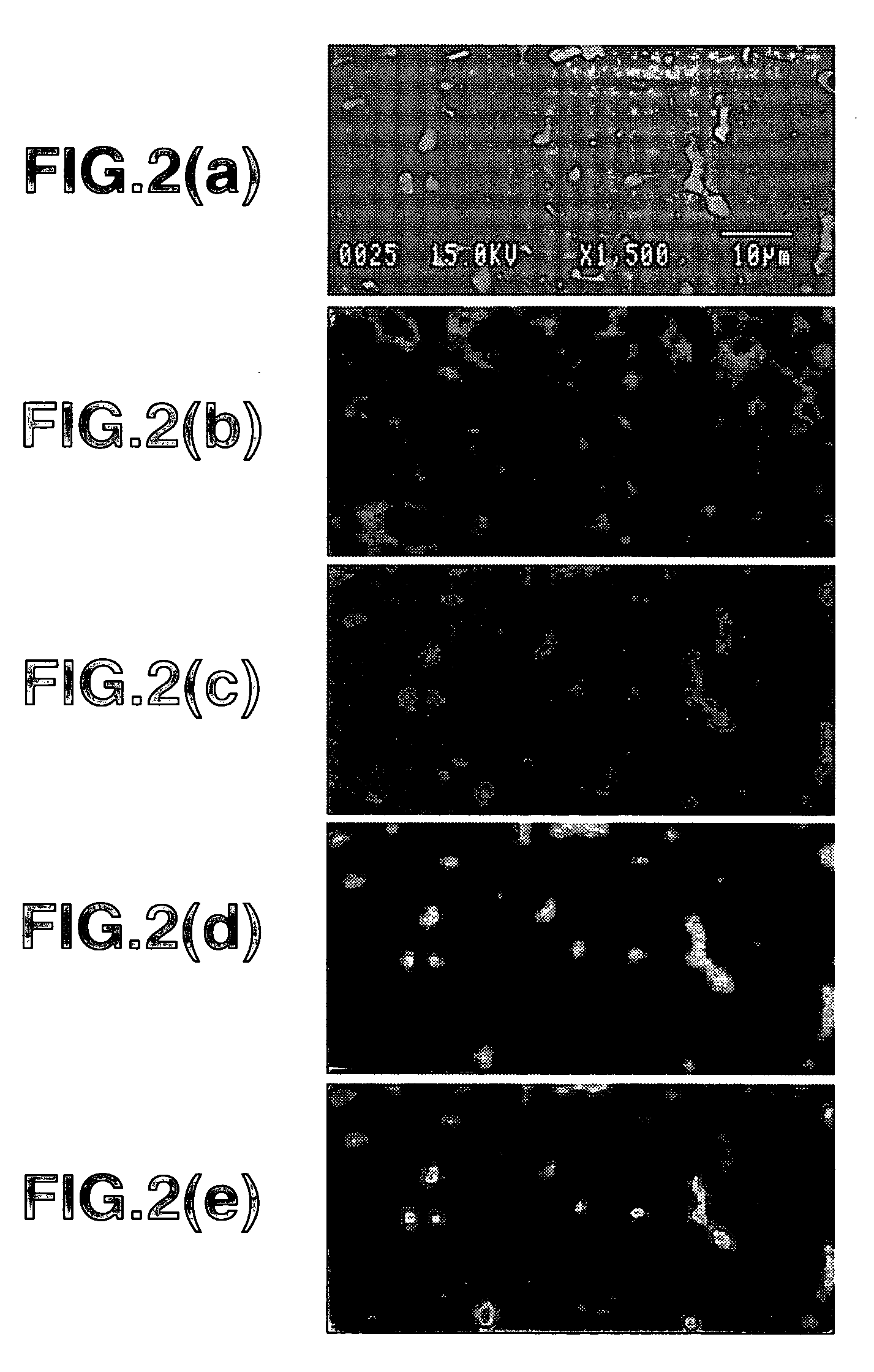

Preparation of Rare Earth Permanent Magnet Material

ActiveUS20080245442A1Improve remanenceImprove coercive forceElectric discharge tubesPermanent magnetsRare-earth elementRemanence

A method for preparing a rare earth permanent magnet material comprising the steps of:disposing a powder comprising one or more members selected from an oxide of R2, a fluoride of R3, and an oxyfluoride of R4 wherein R2, R3 and R4 each are one or more elements selected from among rare earth elements inclusive of Y and Sc on a sintered magnet form of a R1—Fe—B composition wherein R1 is one or more elements selected from among rare earth elements inclusive of Y and Sc, andheat treating the magnet form and the powder at a temperature equal to or below the sintering temperature of the magnet in vacuum or in an inert gas.The invention offers a high performance, compact or thin permanent magnet having a high remanence and coercivity at a high productivity.

Owner:SHIN ETSU CHEM IND CO LTD

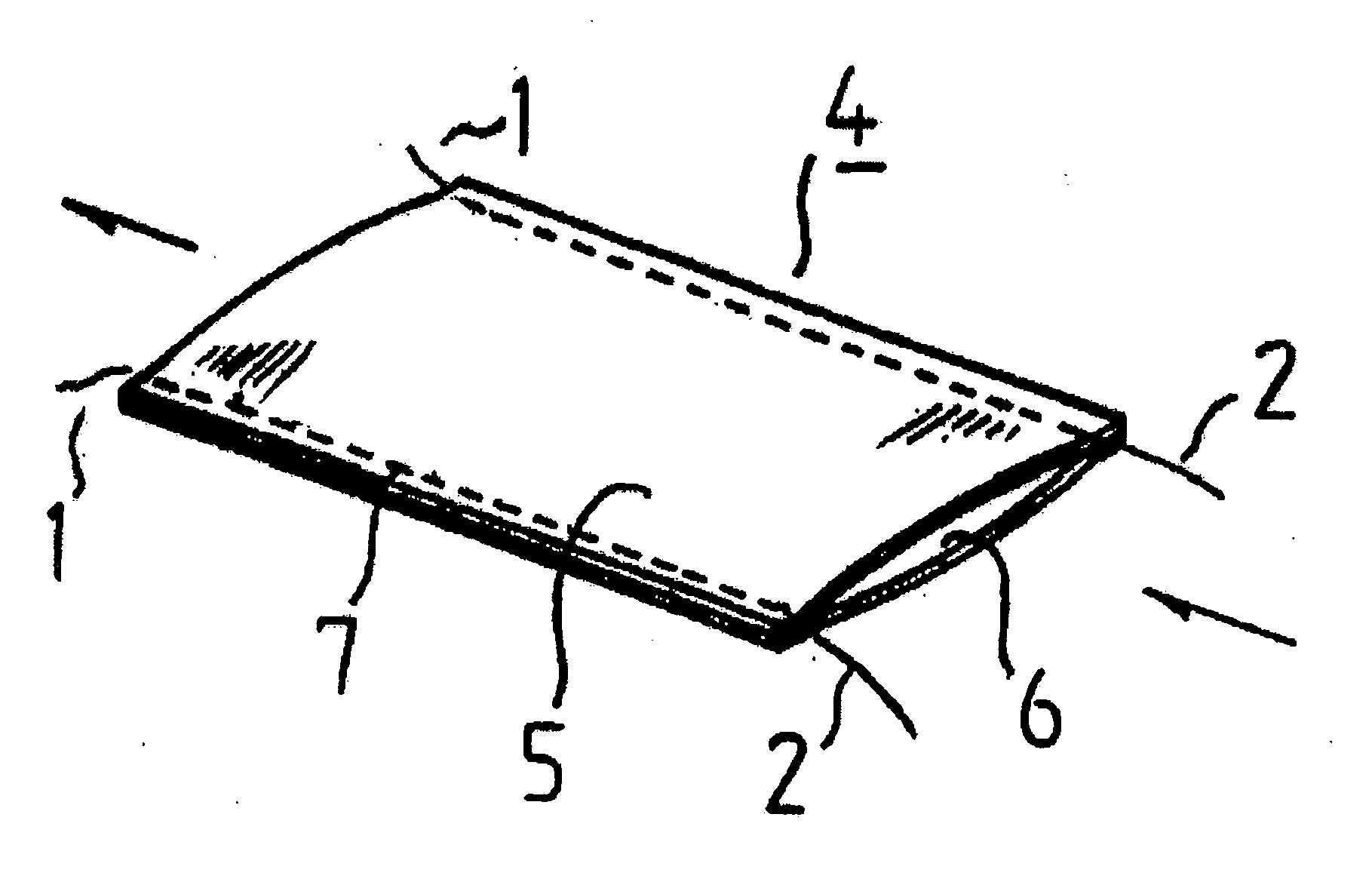

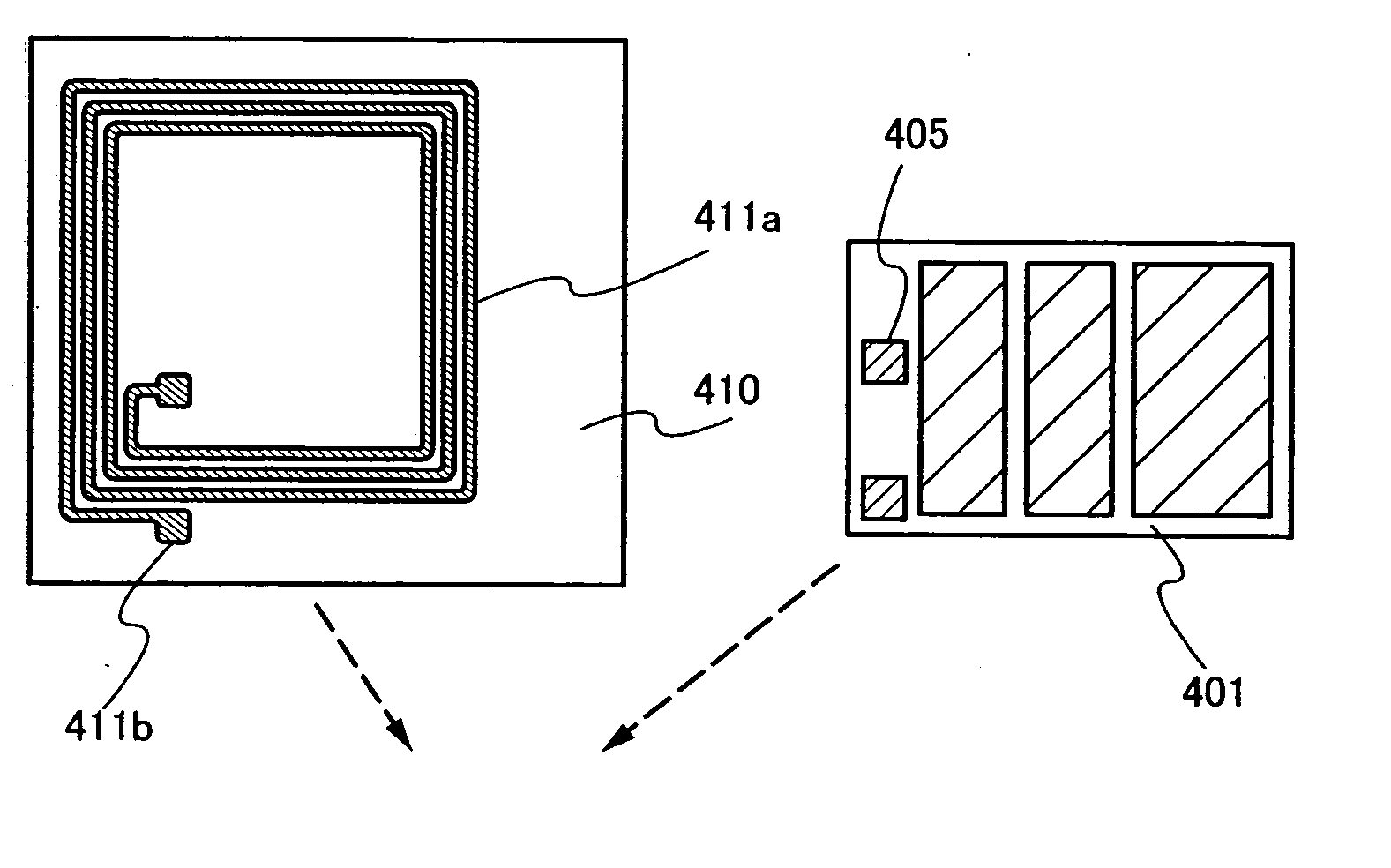

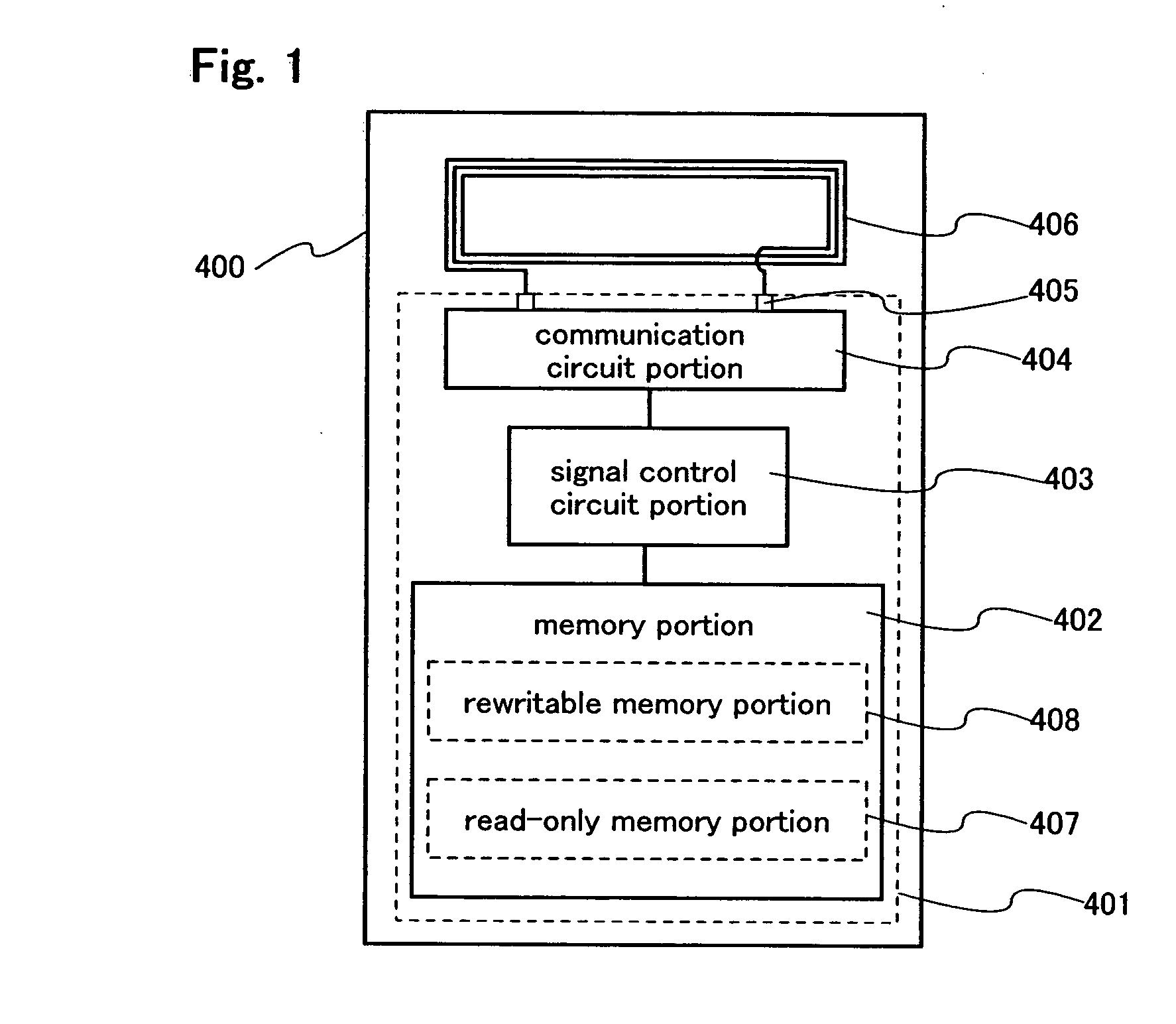

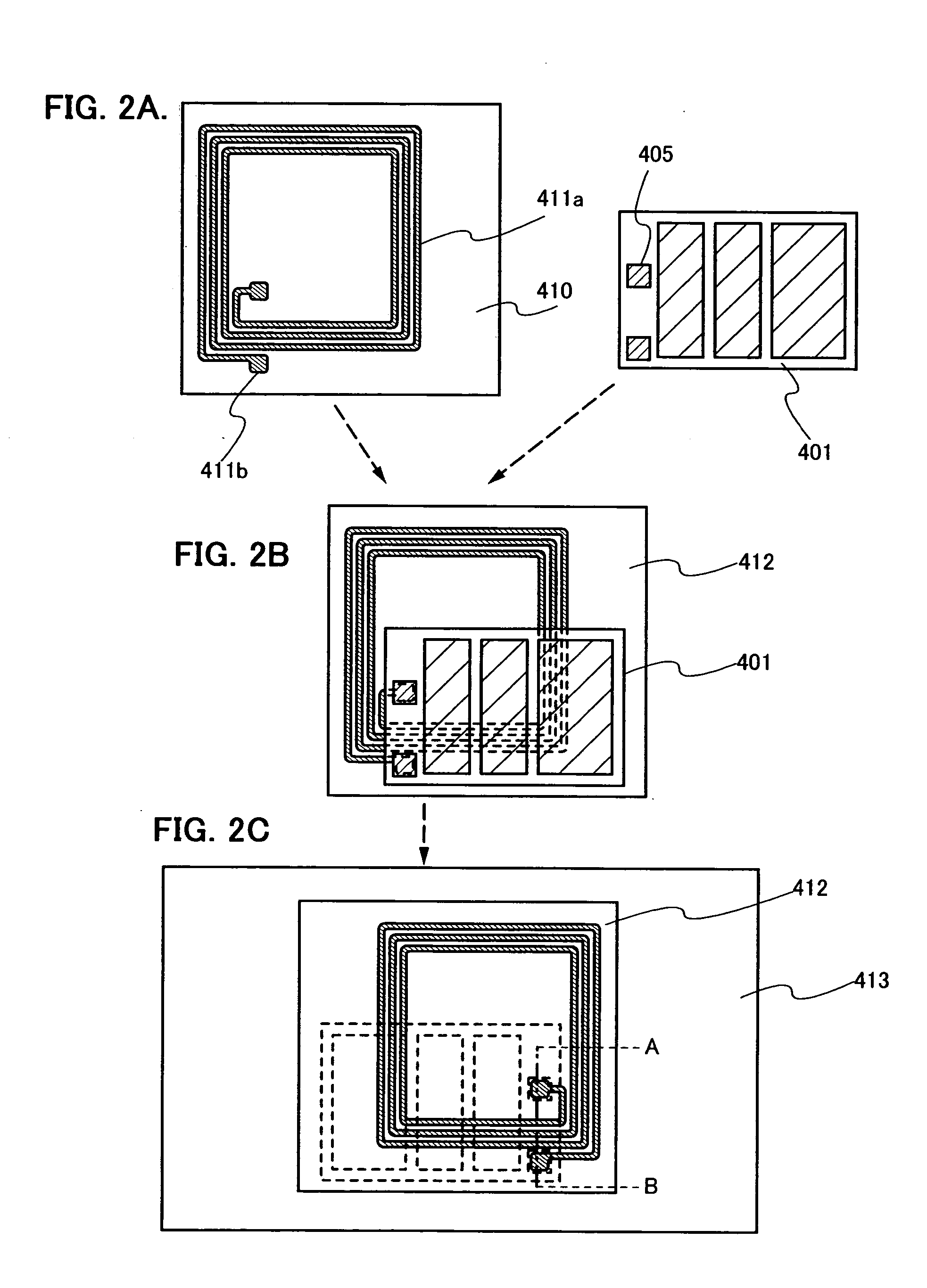

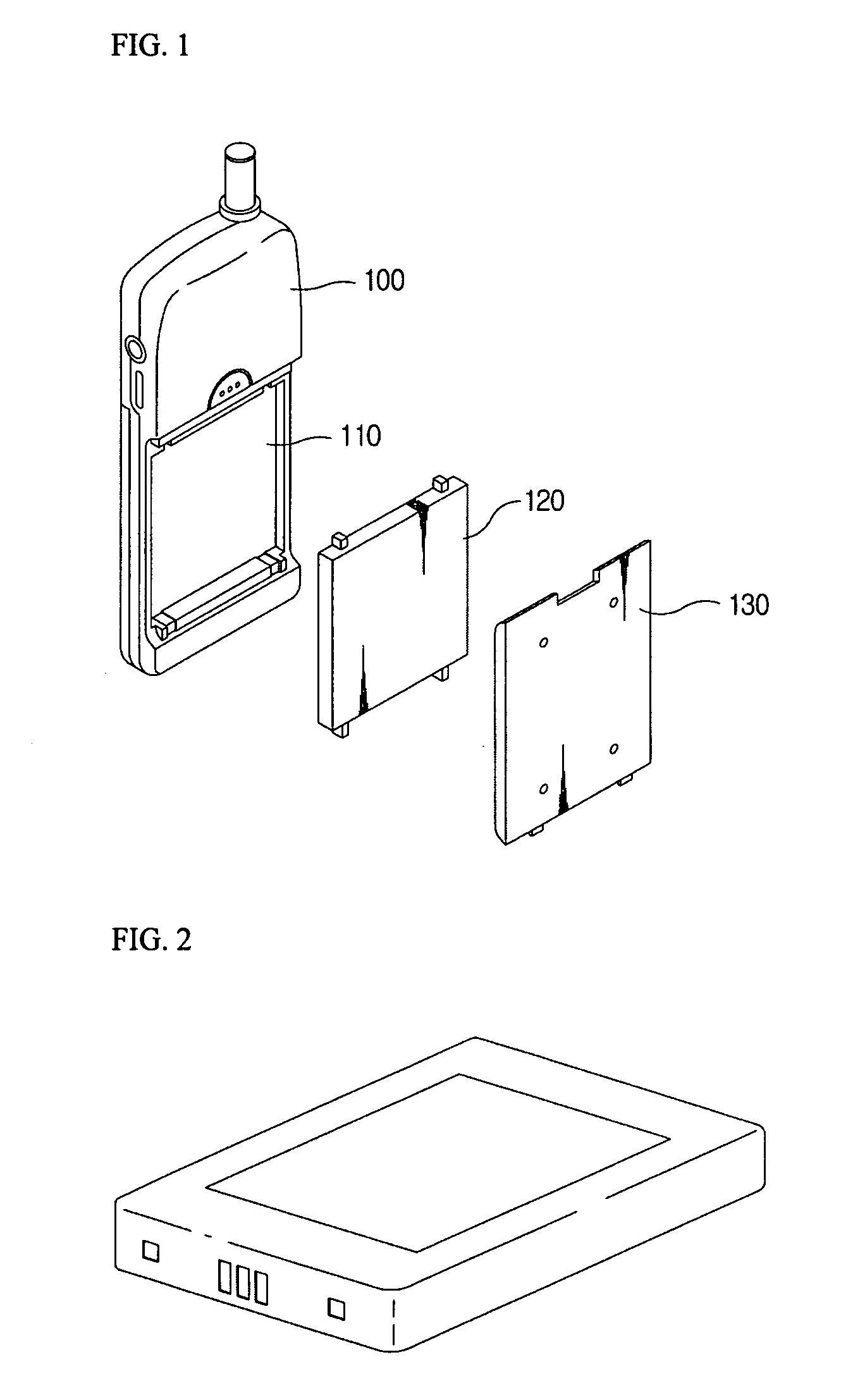

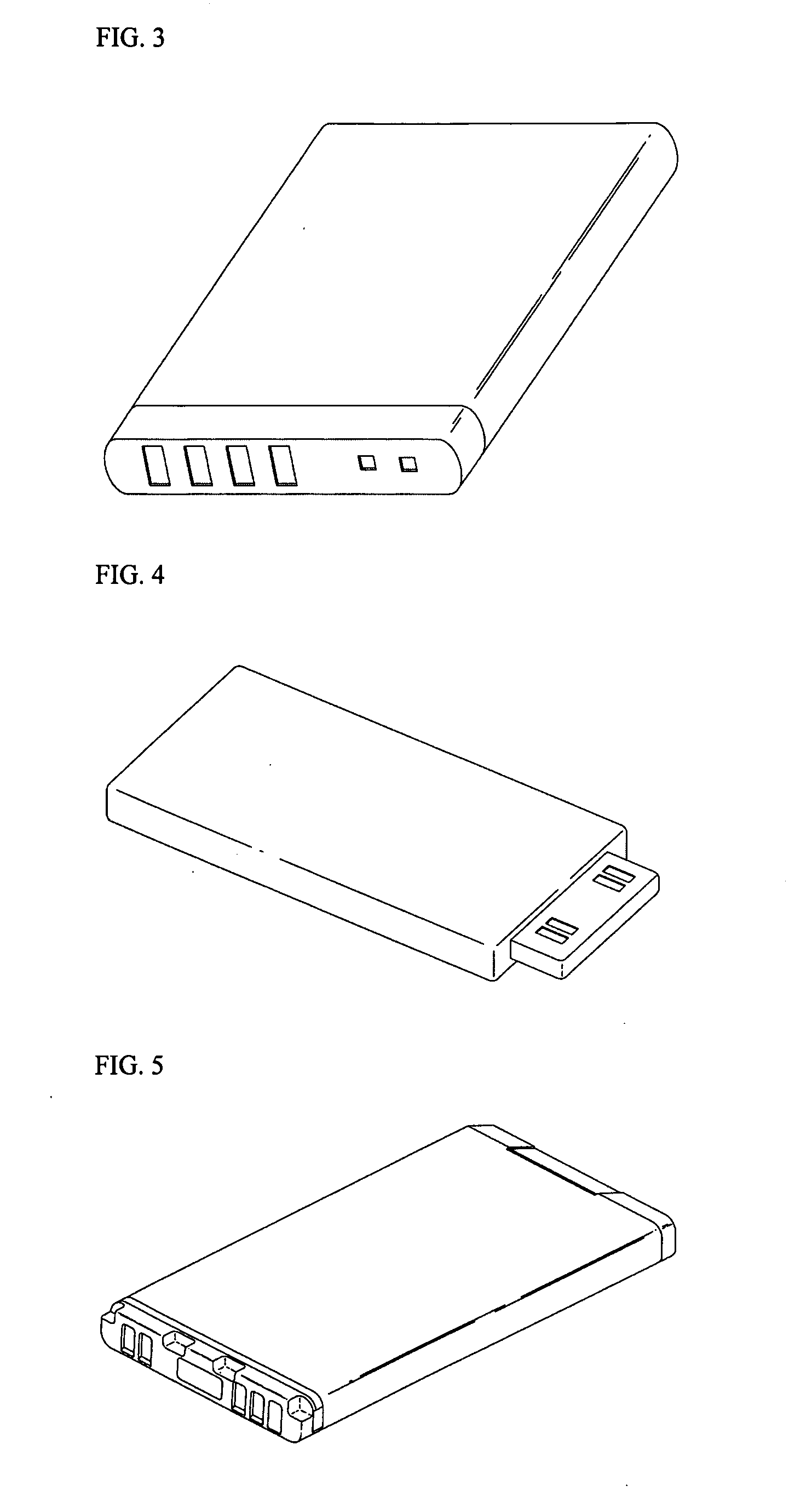

Semiconductor device, RFID tag and label-like object

ActiveUS20050134463A1Improve productivityLow costLine/current collector detailsSemiconductor/solid-state device detailsProduction rateData storing

An object of the present invention is to supply a semiconductor device capable of communicating data through radio communication, such as an RFID tag or a label-like object, with high productivity at low cost. In the invention, a memory portion, a signal control circuit portion and a communication circuit portion are formed with the use of a TFT formed over an insulating substrate, and the insulating substrate is fixed opposite to a support provided with an antenna so that the antenna is connected to a terminal portion connected to a communication circuit. The invention is an RFID tag and a label-like object including an ID chip whose memory portion, signal control portion and communication circuit portion are formed with the use of TFTs formed over an insulating substrate and an antenna formed to connect to a terminal portion of the ID chip, in which data stored in a memory portion or data to be stored in a memory portion can be communicated through a communication circuit by radio communication.

Owner:SEMICON ENERGY LAB CO LTD

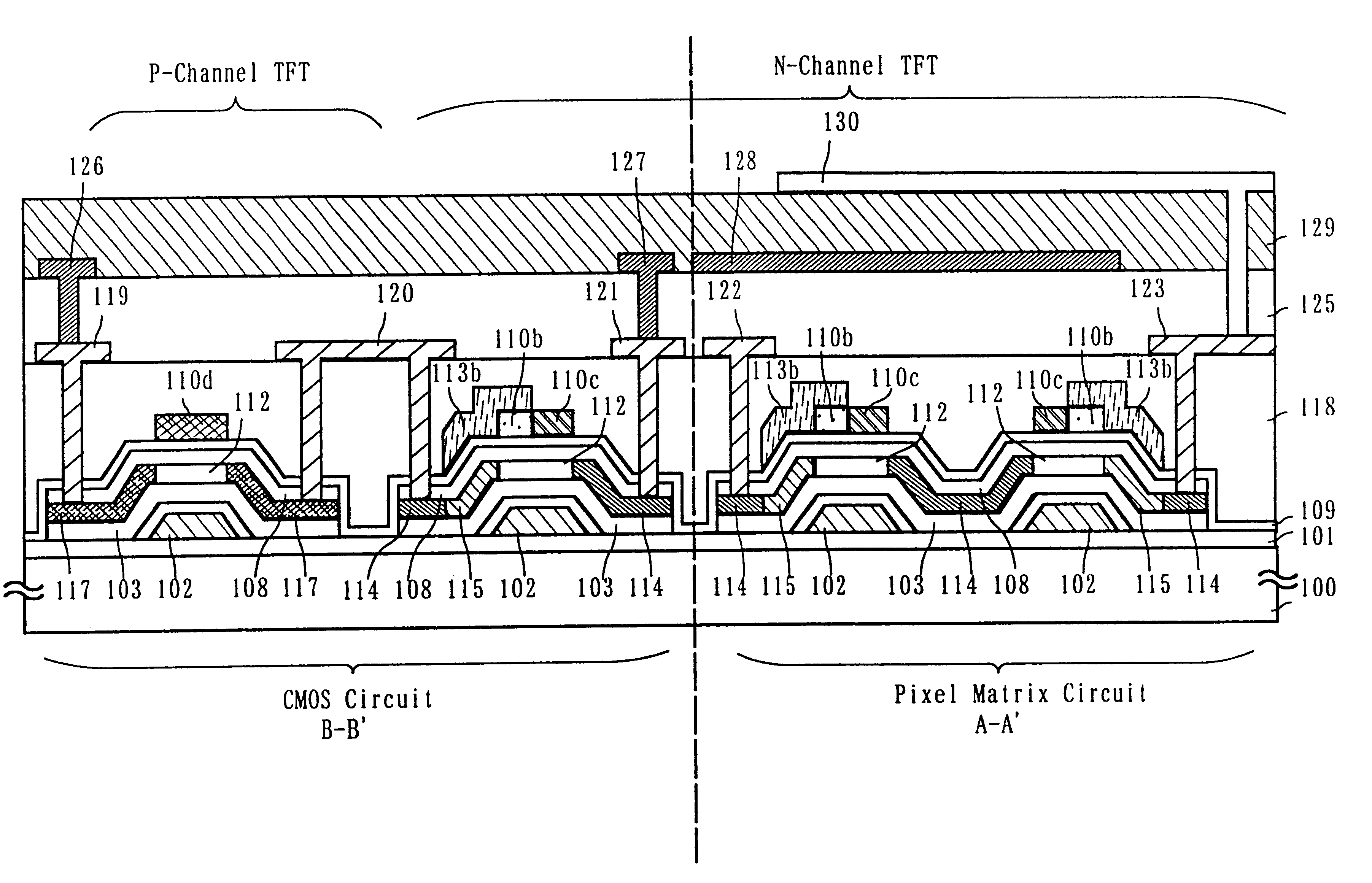

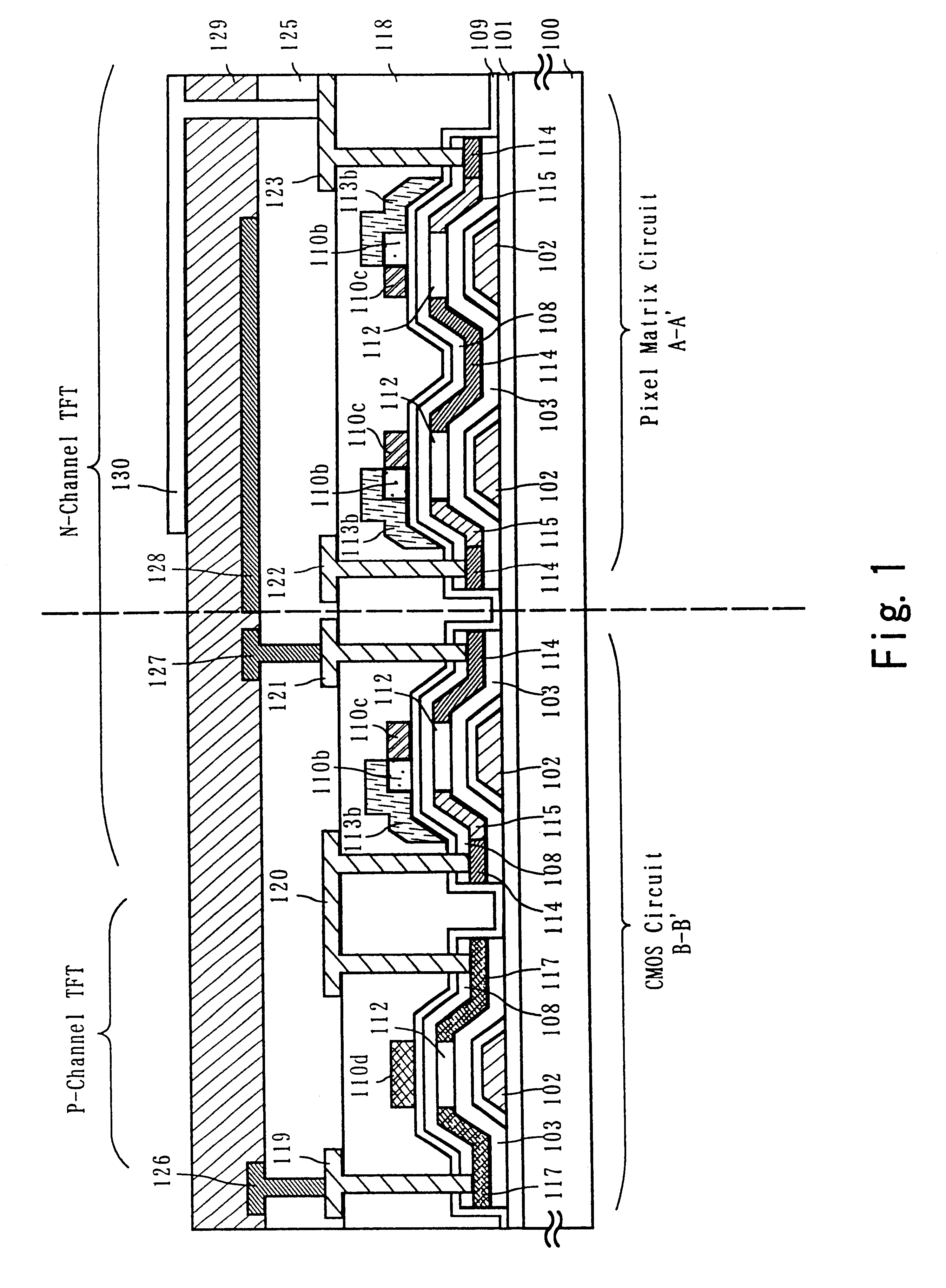

Thin-film transistor with lightly-doped drain

There is provided a semiconductor device including a semiconductor circuit formed by semiconductor elements having an LDD structure which has high reproducibility, improves the stability of TFTs and provides high productivity and a method for manufacturing the same.In order to achieve the object, the design of a second mask is appropriately determined in accordance with requirements associated with the circuit configuration to make it possible to form a desired LDD region on both sides or one side of the channel formation region of a TFT.

Owner:SEMICON ENERGY LAB CO LTD

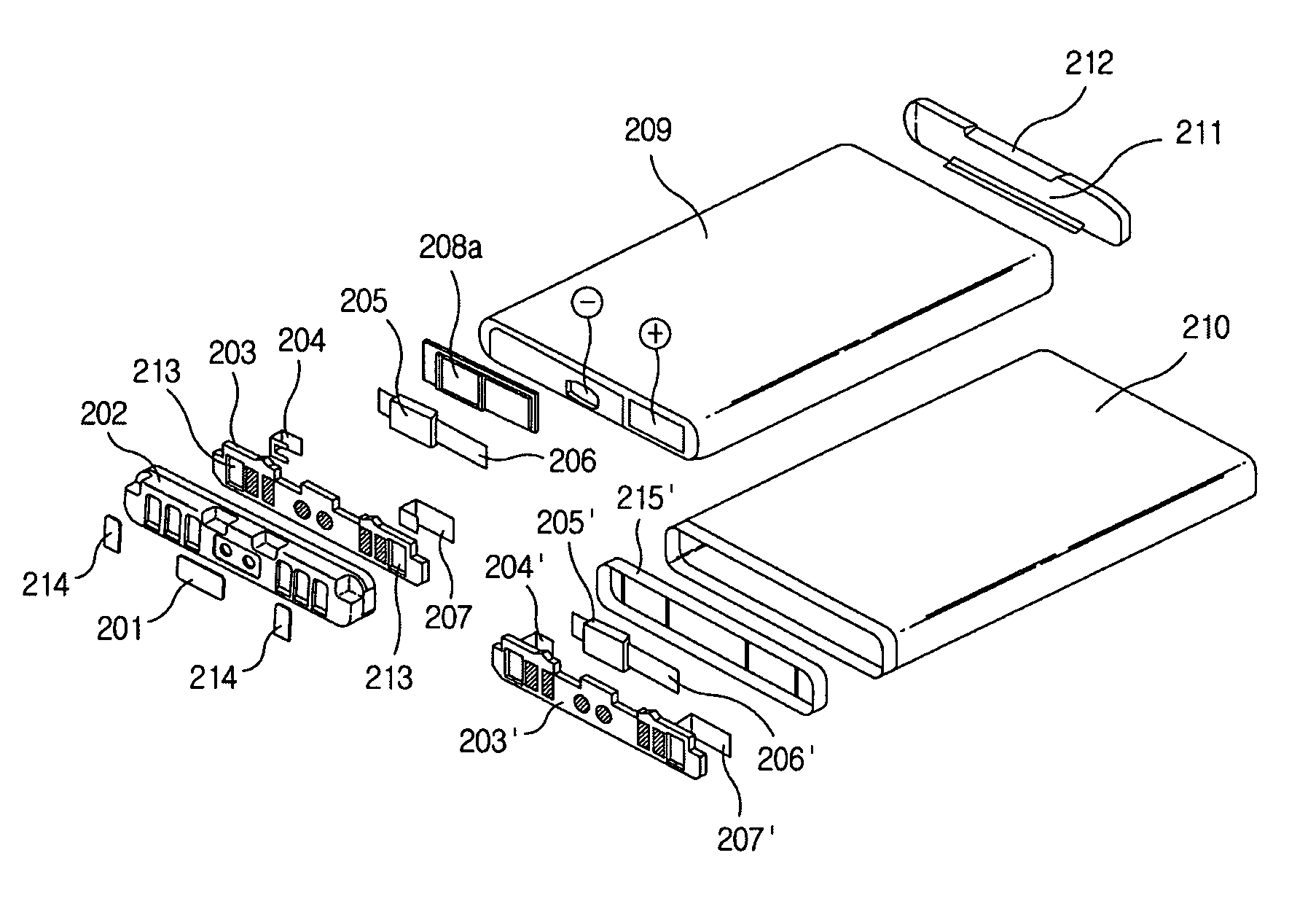

Battery pack of improved structure

ActiveUS20050208346A1Small sizeImprove workabilitySmall-sized cells cases/jacketsCells structural combinationManufacturing cost reductionProduction rate

A battery pack comprising a battery cell having electrode terminals formed on an upper surface of the battery cell, and a protective circuit module (PCM) block mounted on the battery cell, wherein one or more connecting holes for electrical connection between the battery cell and the PCM block are perforated through the PCM block such that a connecting portion between the battery cell and the PCM block is exposed to the outside of the upper surface of the battery cell. The battery pack is lighter, compacter and miniaturized, thereby allowing an electronic device employing the battery pack to be reduced in an overall size, enhancing workability through a simplified assembling process, reducing manufacturing costs through reduction of the number of components, and enhancing productivity through reduction of the number of operating steps by eliminating additional installation steps.

Owner:LG ENERGY SOLUTION LTD

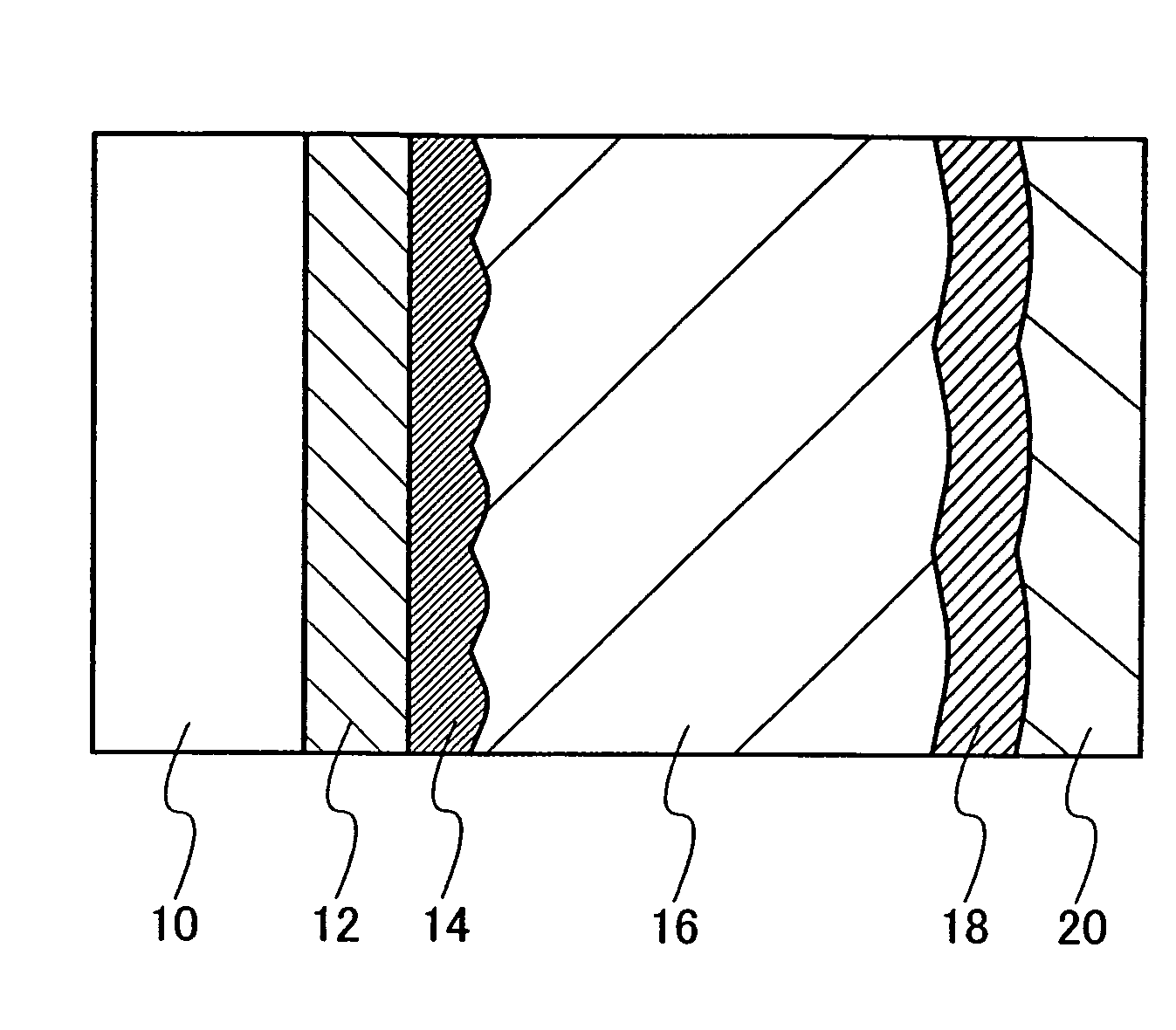

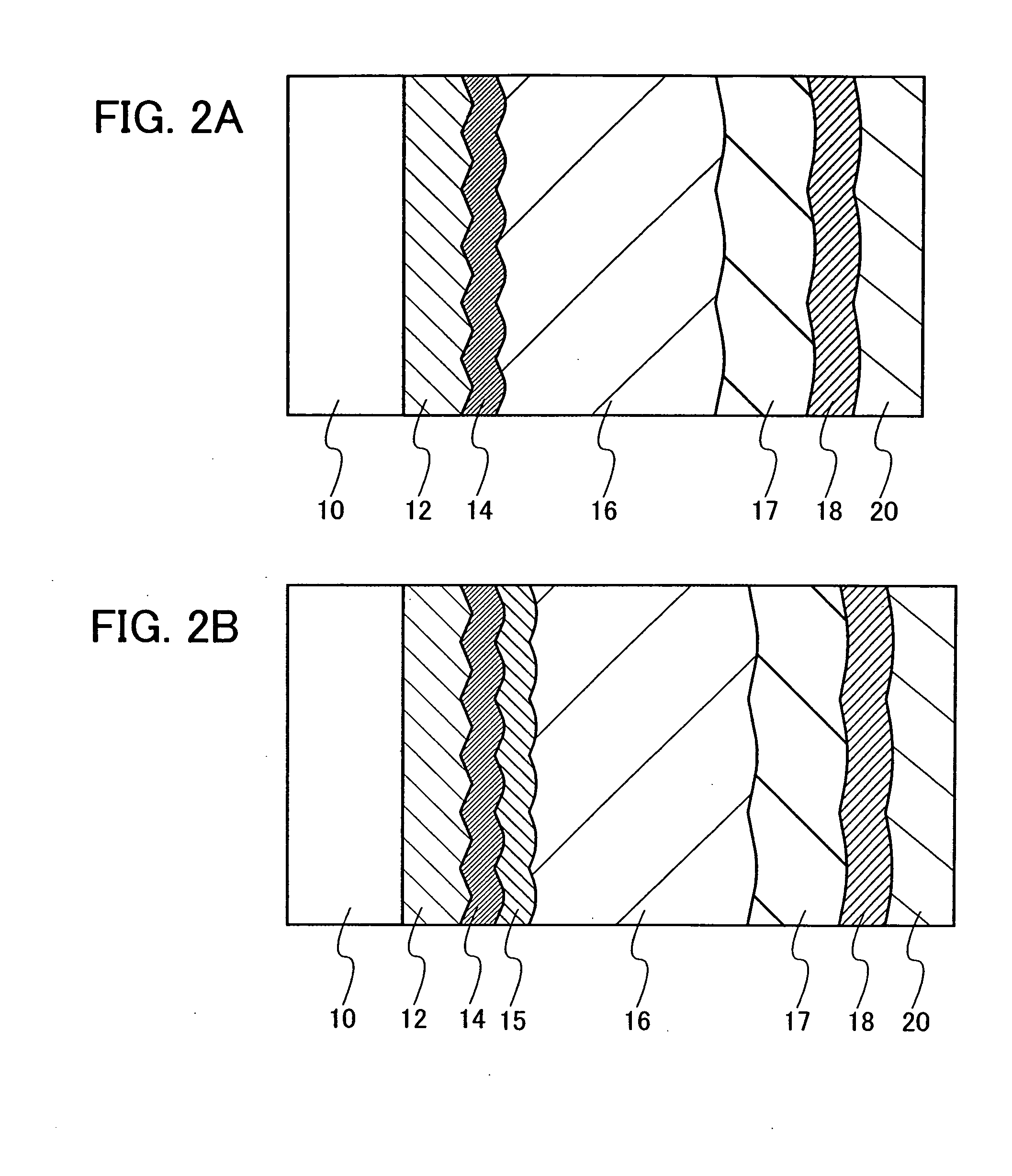

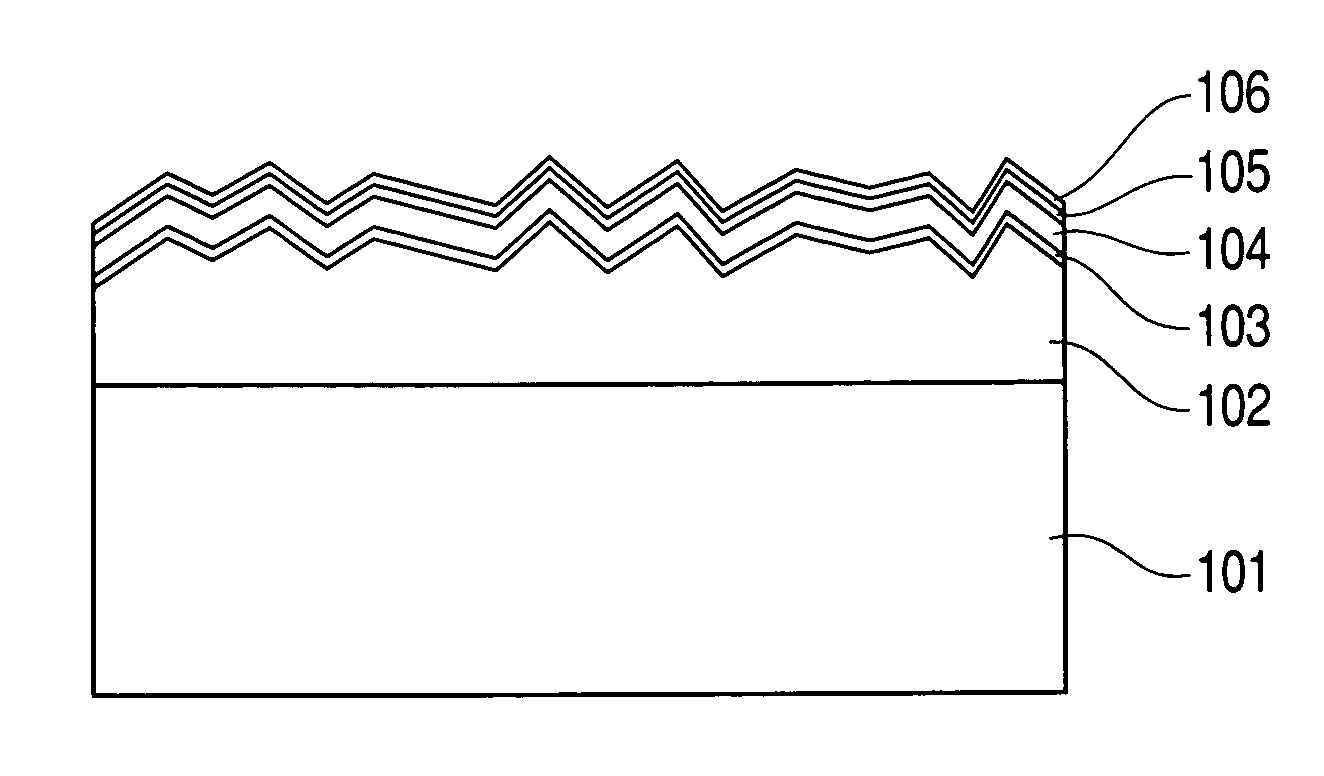

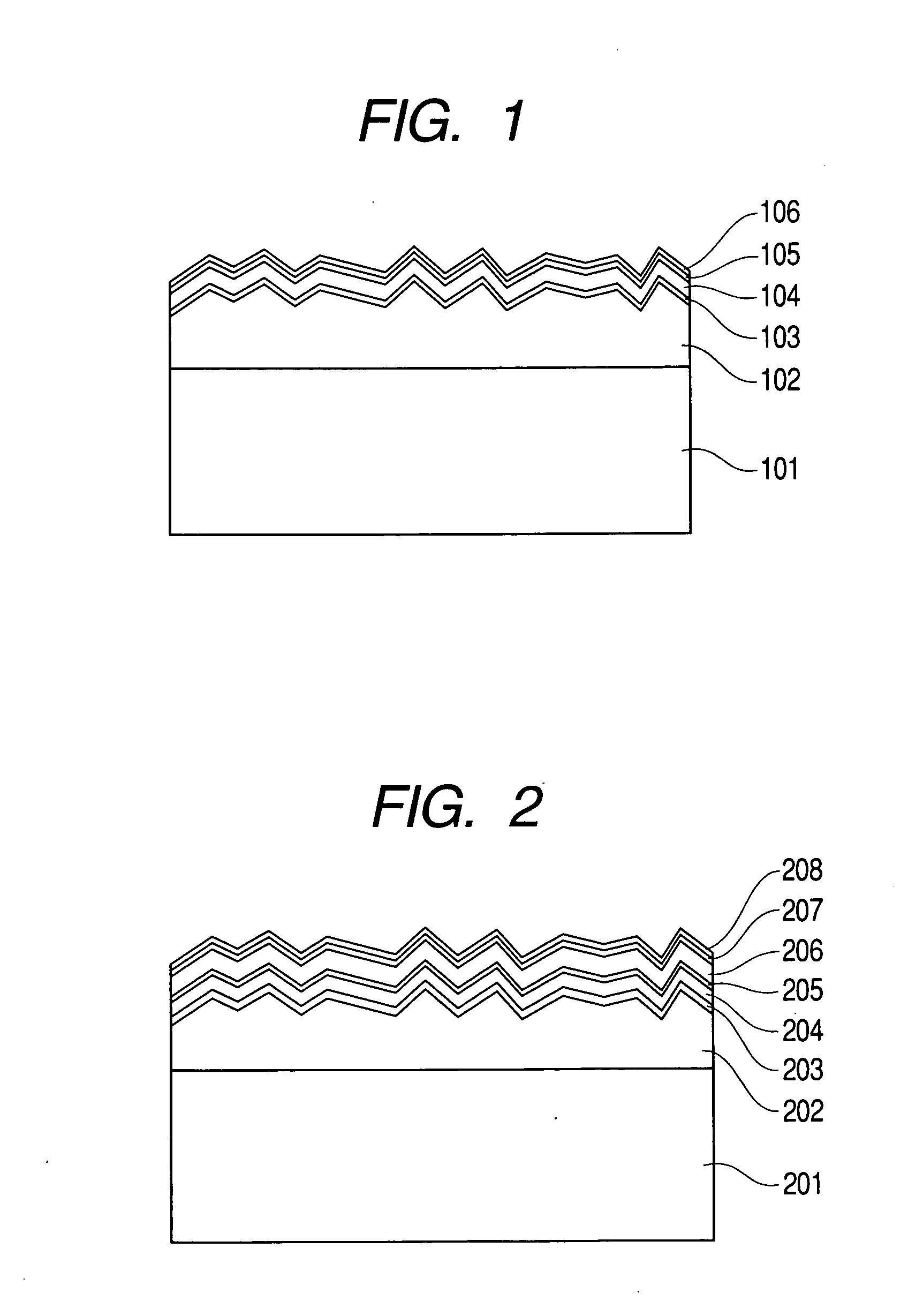

Photovoltaic device and manufacturing method thereof

InactiveUS20050109388A1Increase costLow costFinal product manufacturePhotovoltaic energy generationProduction ratePolycrystalline silicon

There is provided a photovoltaic device in which at least one pin-junction is formed in a thin film semiconductor deposited on a substrate, the substrate including: a base including polycrystalline silicon; and a polycrystalline silicon layer formed on the base by liquid phase growth, in which at least a part of a surface of the polycrystalline silicon layer has unevenness composed of facet surfaces. The photovoltaic device prevents a reduction in photoelectric conversion efficiency due to the absence of preferable unevenness, an increase in cost due to the use of an expensive material, and a reduction in throughput in the photovoltaic device, and has a preferable characteristic and high productivity.

Owner:CANON KK

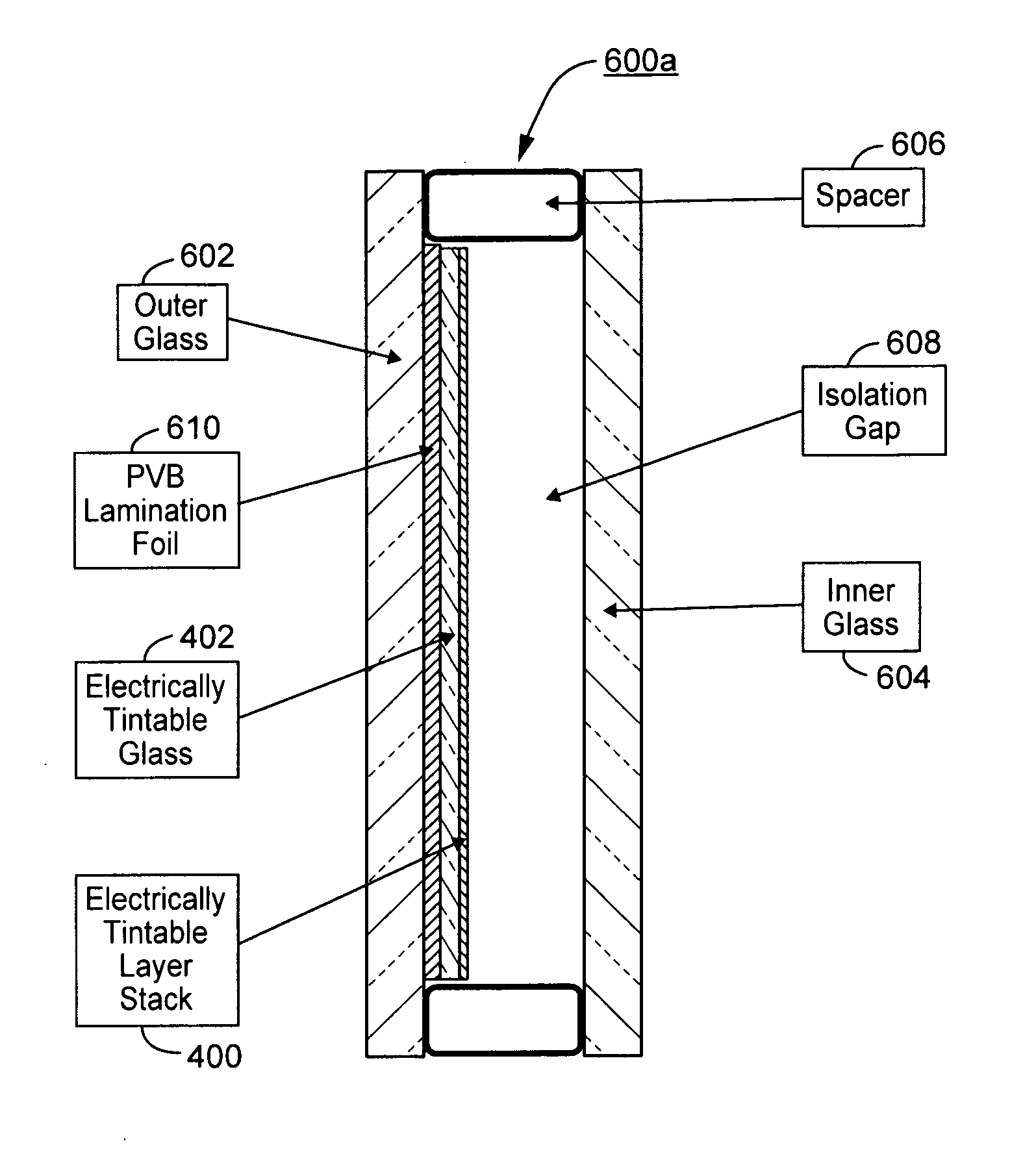

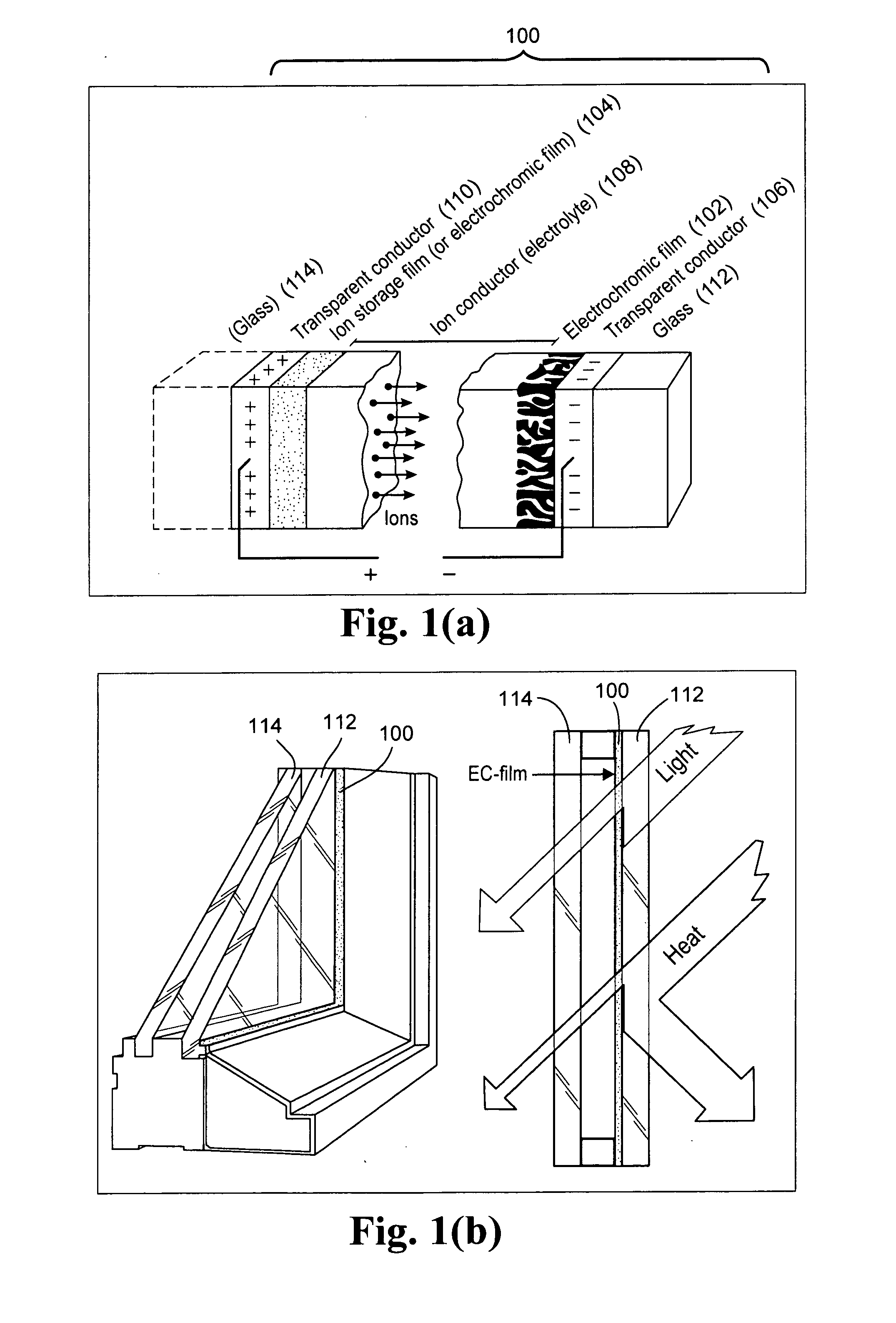

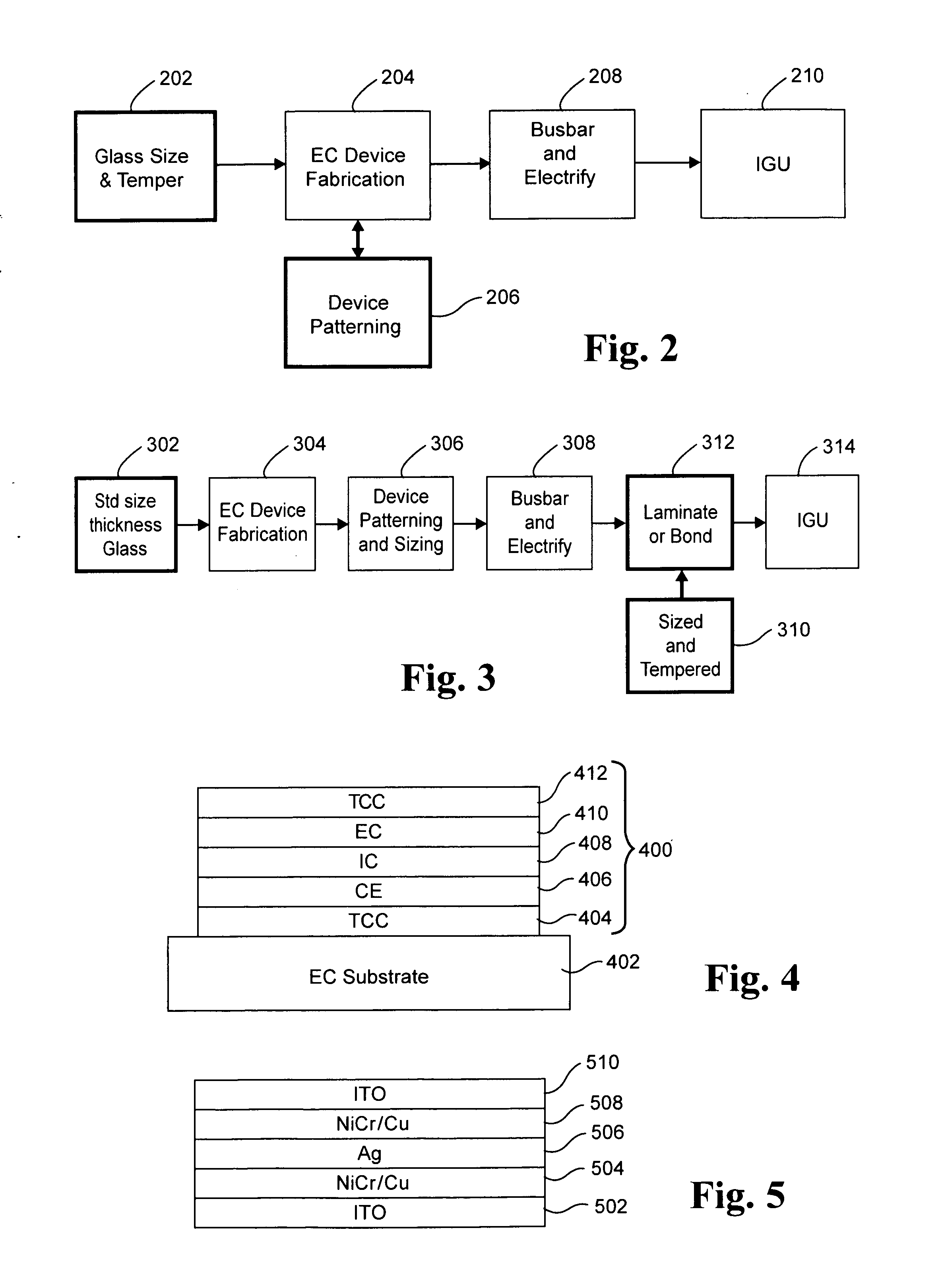

Electrochromic devices, assemblies incorporating electrochromic devices, and/or methods of making the same

ActiveUS20110051221A1Great visible transmissionGood lookingLight protection screensGlass/slag layered productsElectricityProduction rate

Certain example embodiments of this invention relate to electrochromic (EC) devices, assemblies incorporating electrochromic devices, and / or methods of making the same. More particularly, certain example embodiments of this invention relate to improved EC materials, EC device stacks, high-volume manufacturing (HVM) compatible process integration schemes, and / or high-throughput low cost deposition sources, equipment, and factories.

Owner:GUARDIAN GLASS LLC

Hydrocarbon-Producing Catalyst, Process for Producing the Same, and Process for Producing Hydrocarbons Using the Catalyst

InactiveUS20080064769A1Increase probabilityStably and smoothly promoteHydrocarbon from carbon oxidesOrganic compound preparationRutheniumLiquid hydrocarbons

An object of the present invention is to provide a catalyst which, in the FT process, exhibits a high chain growth probability, and a high catalytic activity, can stably and smoothly promote the reaction, exhibits a high productivity of C5+, and can efficiently produce liquid hydrocarbons, and a process therefor.The invention relates to a hydrocarbon-producing catalyst obtainable by supporting a ruthenium compound on a support composed of a manganese oxide and an aluminum oxide, and which satisfies at least one of characteristics (1) and (2): (1) the catalyst being treated with an aqueous alkaline solution and subsequently subjected to calcination treatment in the air at 150 to 500° C., (2) the aluminum oxide being an aluminum oxide wherein pore volume formed by pores having a pore diameter of 8 nm or more accounts for 50% or more of total pore volume.

Owner:JAPAN OIL GAS & METALS NAT CORP +1

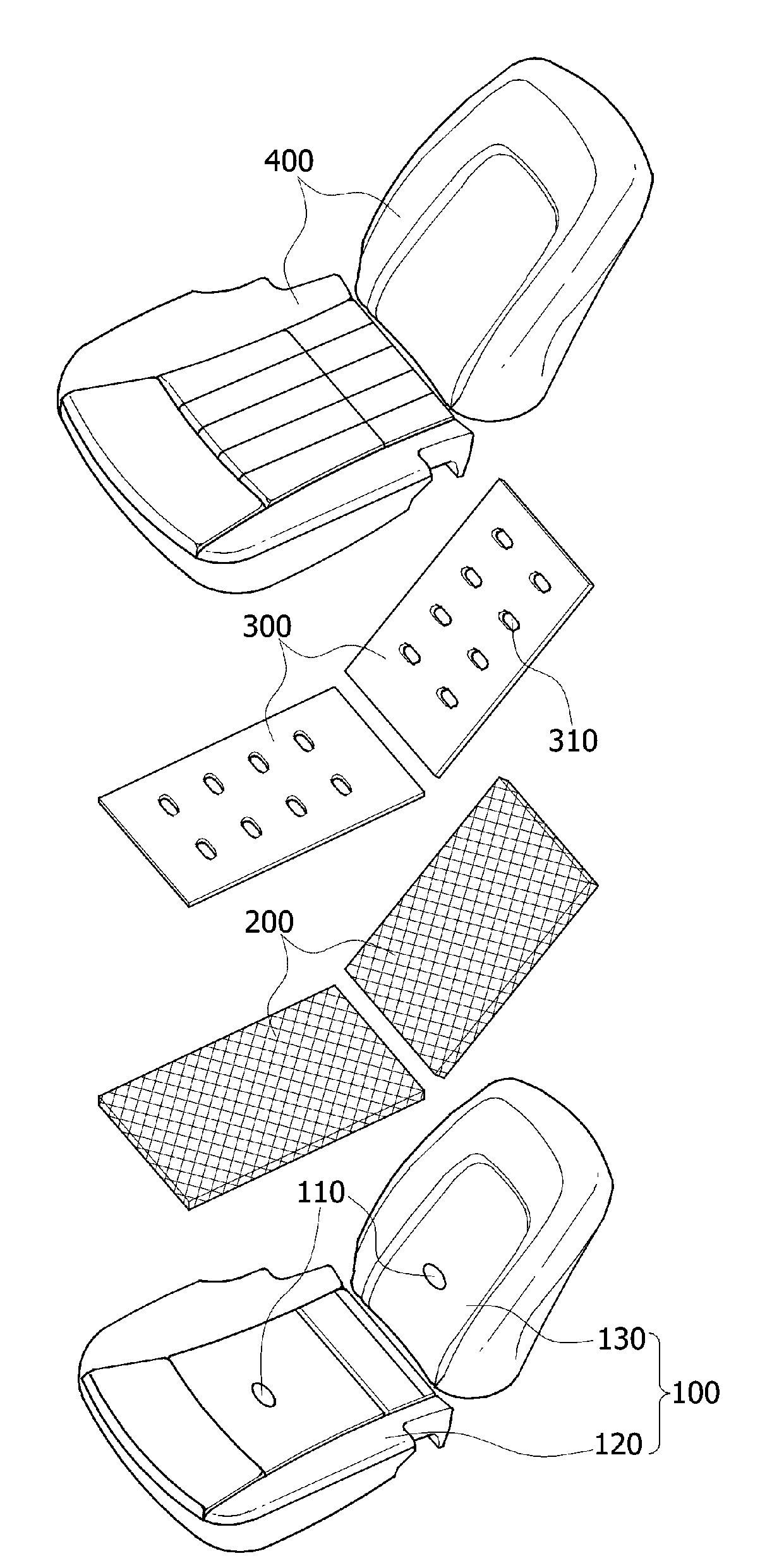

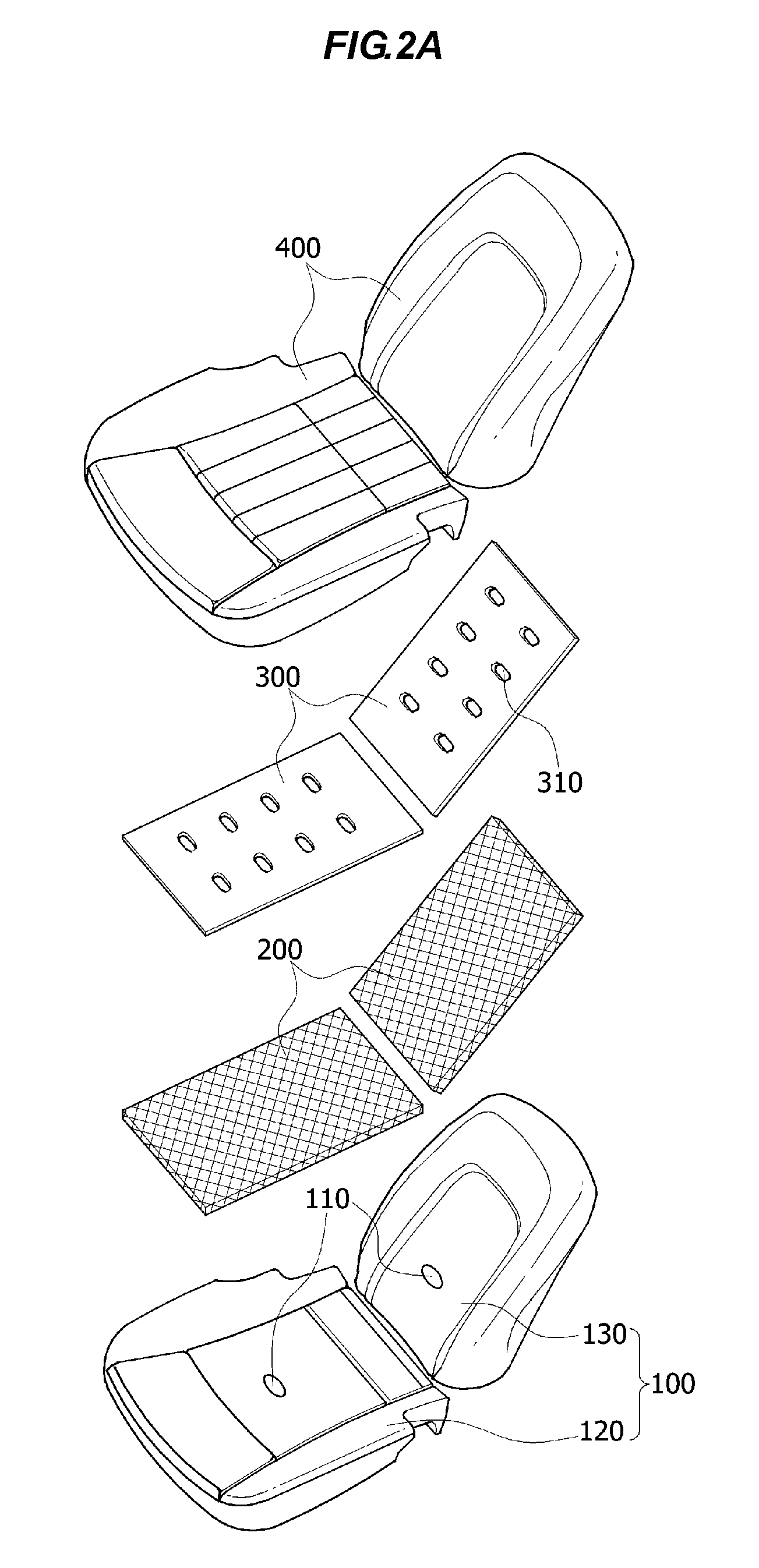

Vehicle seat for cooling and heating

ActiveUS20110109127A1Maximize blowing performanceSimple structureSeat heating/ventillating devicesVehicle heating/cooling devicesManufacturing cost reductionProduction rate

A vehicle seat for cooling and heating may include a seat pad, a mesh sheet having a certain thickness, a first film, and a porous seat cover, which are arranged sequentially in the direction in which air is introduced to flow. The seat pad has a pad hole, which allows air to pass through, and includes one or both of a seat cushion pad, which supports the buttocks of a user, and a seatback pad, which supports the upper body of the user. The mesh sheet has a porous network structure, through which air easily passes. The first film has a first film hole, which allows air to pass through. Air passages are maintained stable to maximize blowing performance, seating comfort is improved, and a ventilation structure is simplified to reduce manufacturing costs while improving productivity.

Owner:HYUNDAI TRANSYS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com