Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

341 results about "Particle generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Particle generation is often performed with palladium dissolved into heavy water, where hydrogen is replaced with deuterium in order to generate more energy during fusion reactions. After decomposing heavy water into oxygen and deuterium, the deuterium molecules fuse, releasing energy and colliding with surrounding molecules.

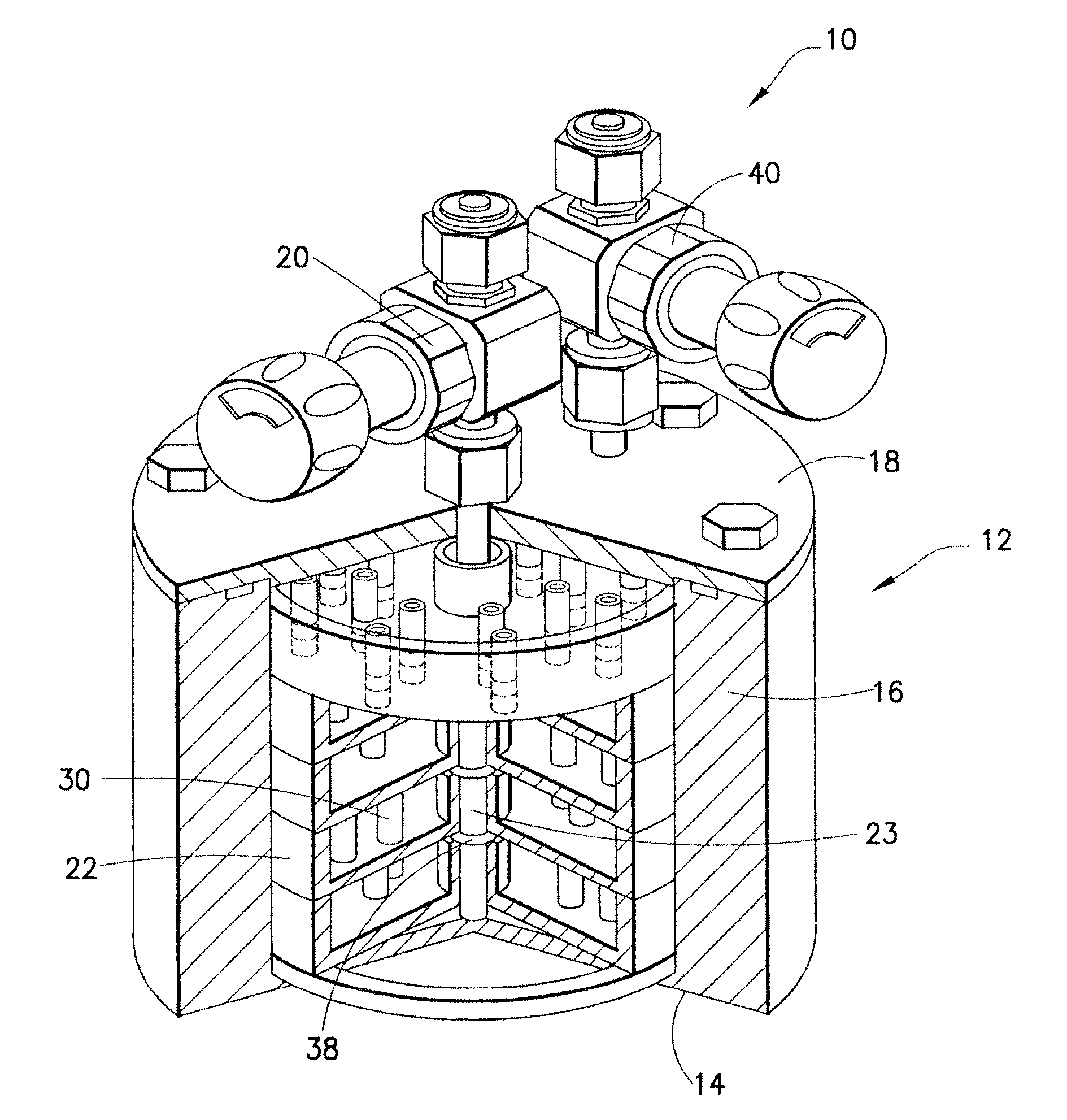

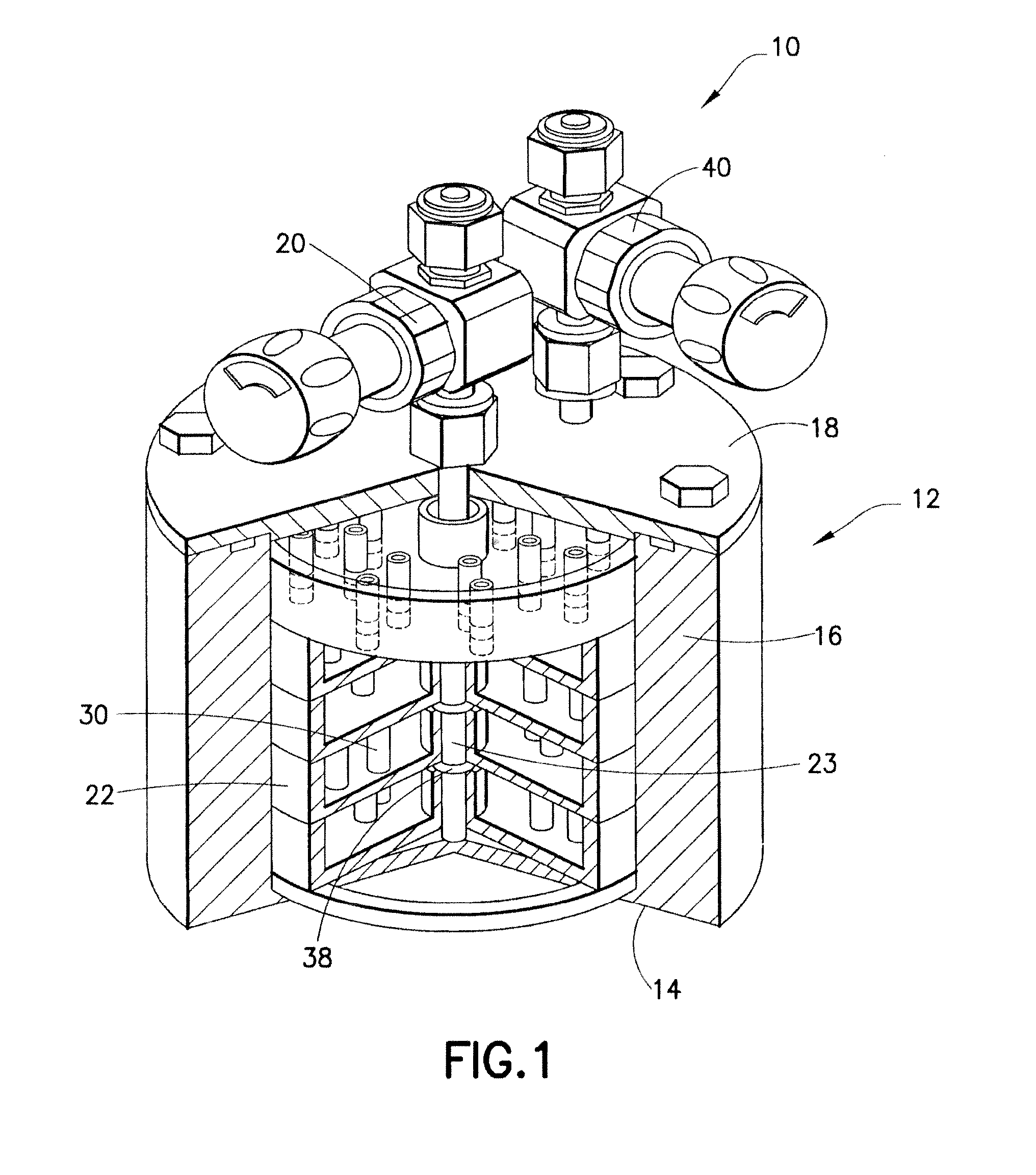

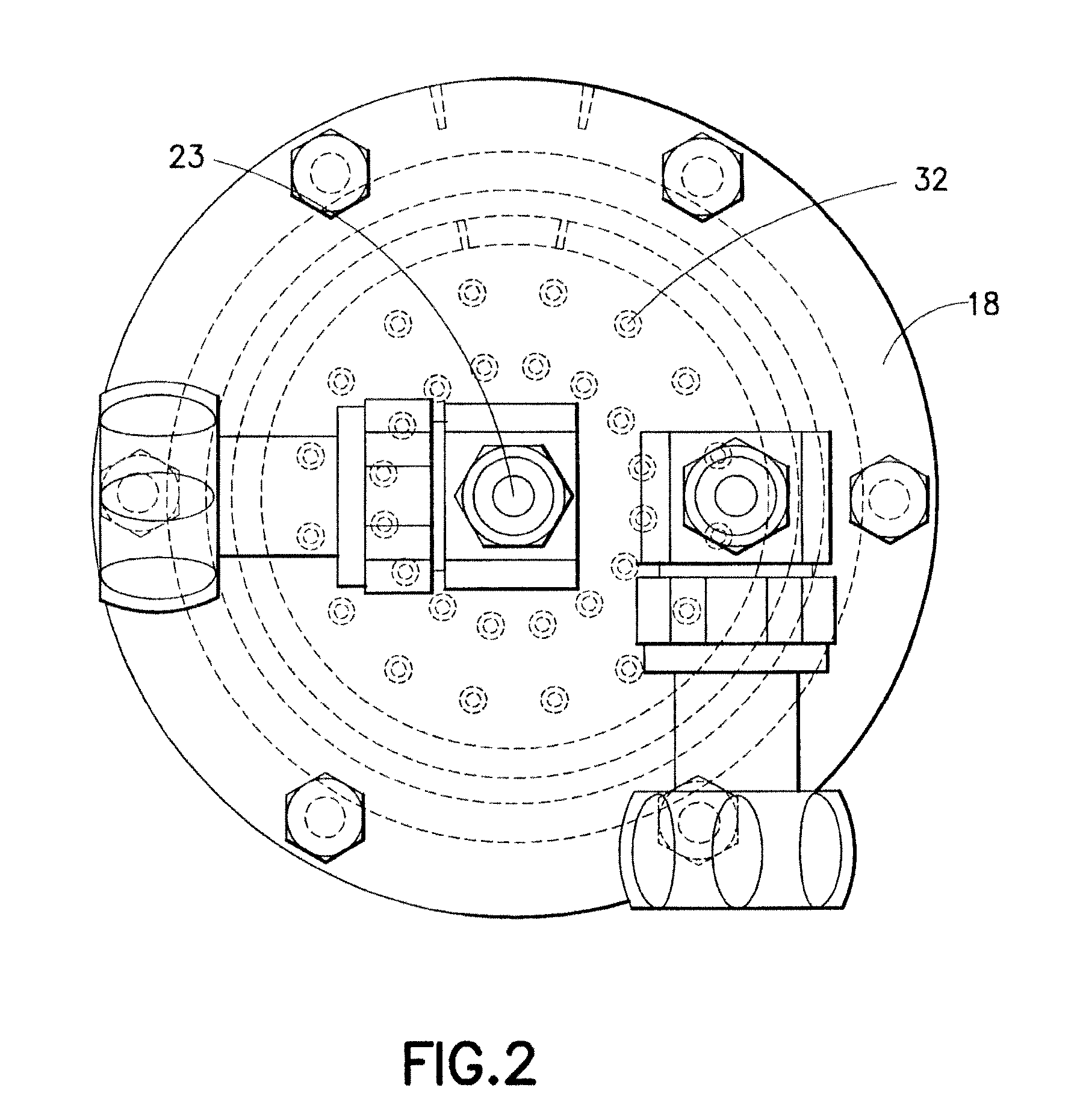

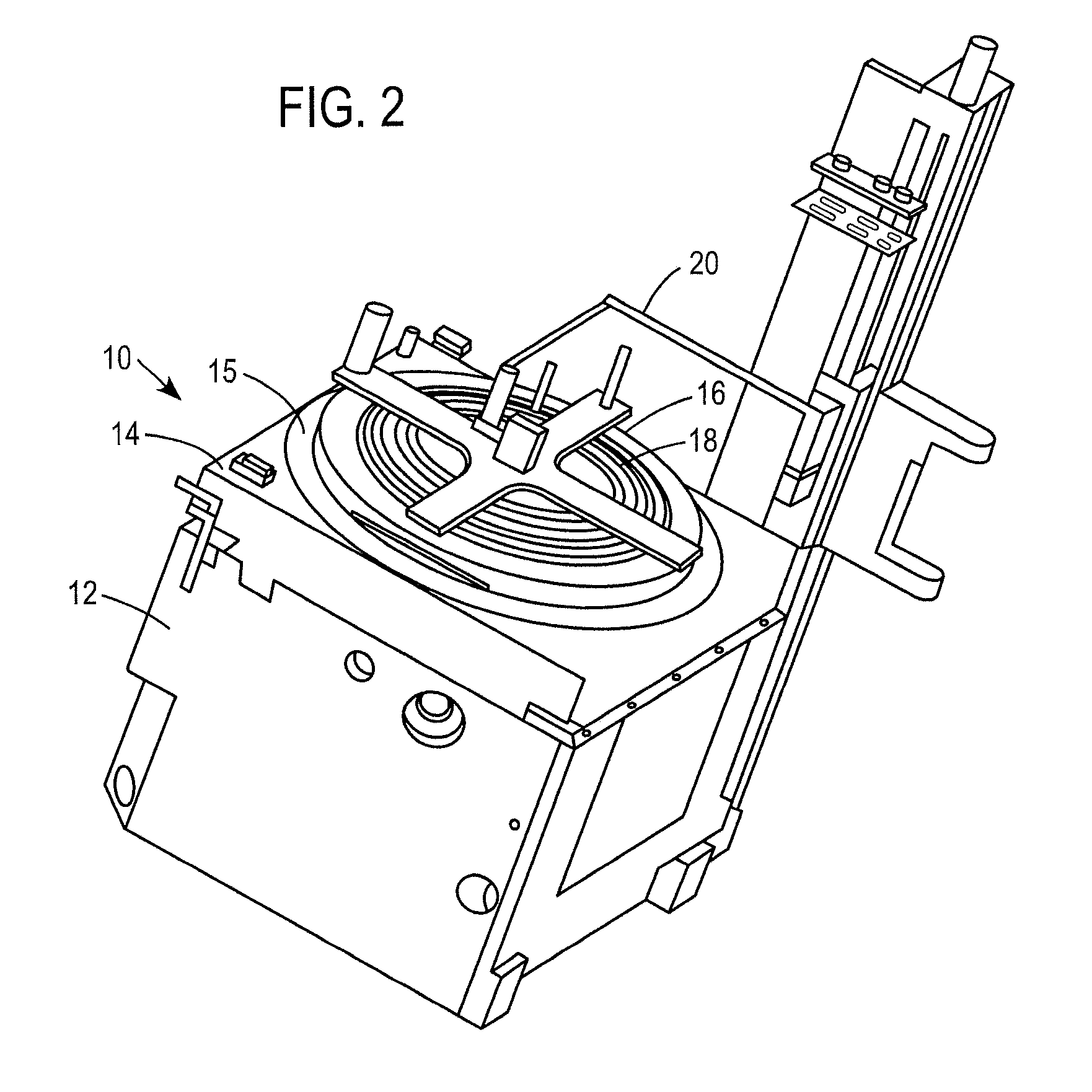

Solid precursor-based delivery of fluid utilizing controlled solids morphology

ActiveUS20100255198A1Vacuum evaporation coatingSputtering coatingMetal halidesAtomic layer deposition

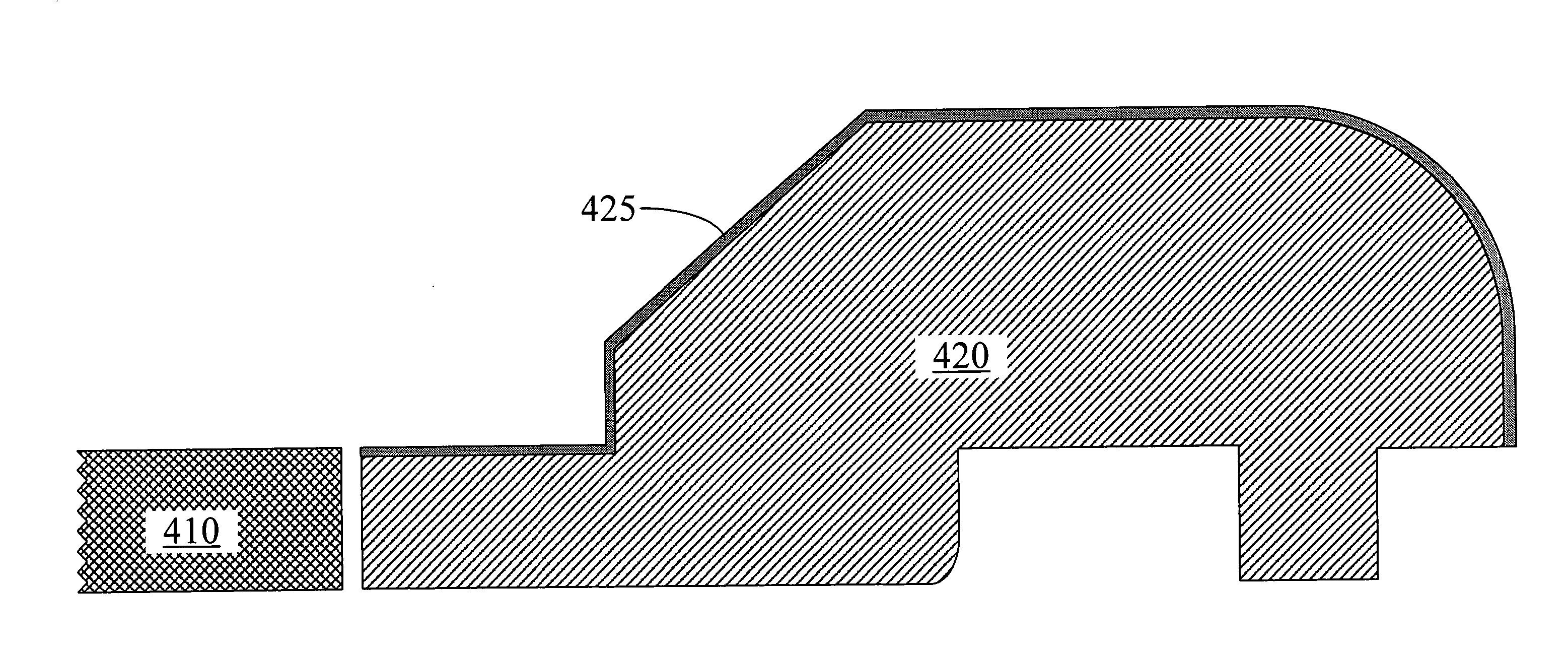

Apparatus and method for volatilizing a source reagent susceptible to particle generation or presence of particles in the corresponding source reagent vapor, in which such particle generation or presence is suppressed by structural or processing features of the vapor generation system. Such apparatus and method are applicable to liquid and solid source reagents, particularly solid source reagents such as metal halides, e.g., hafnium chloride. The source reagent in one specific implementation is constituted by a porous monolithic bulk form of the source reagent material. The apparatus and method of the invention are usefully employed to provide source reagent vapor for applications such as atomic layer deposition (ALD) and ion implantation.

Owner:ENTEGRIS INC

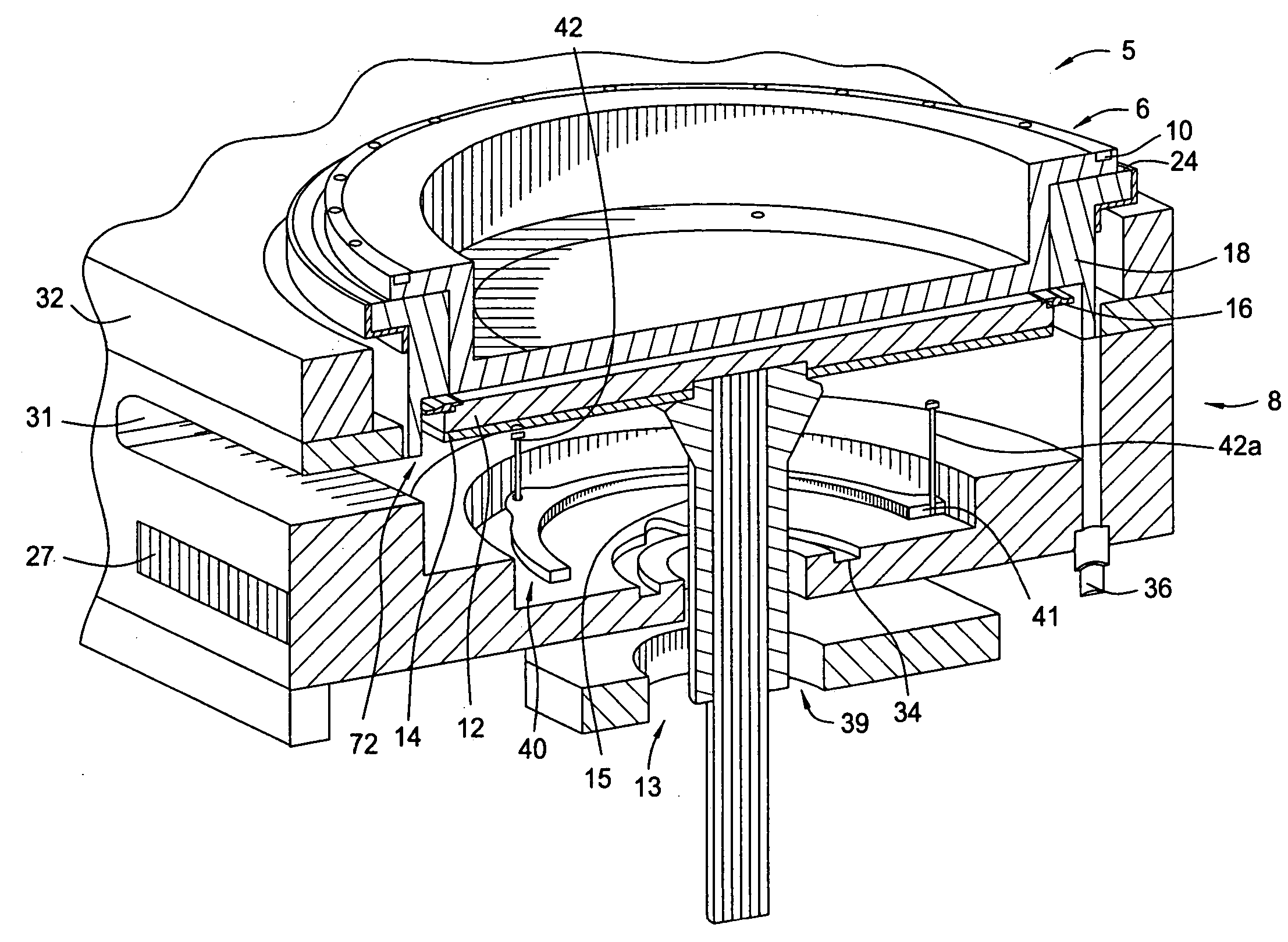

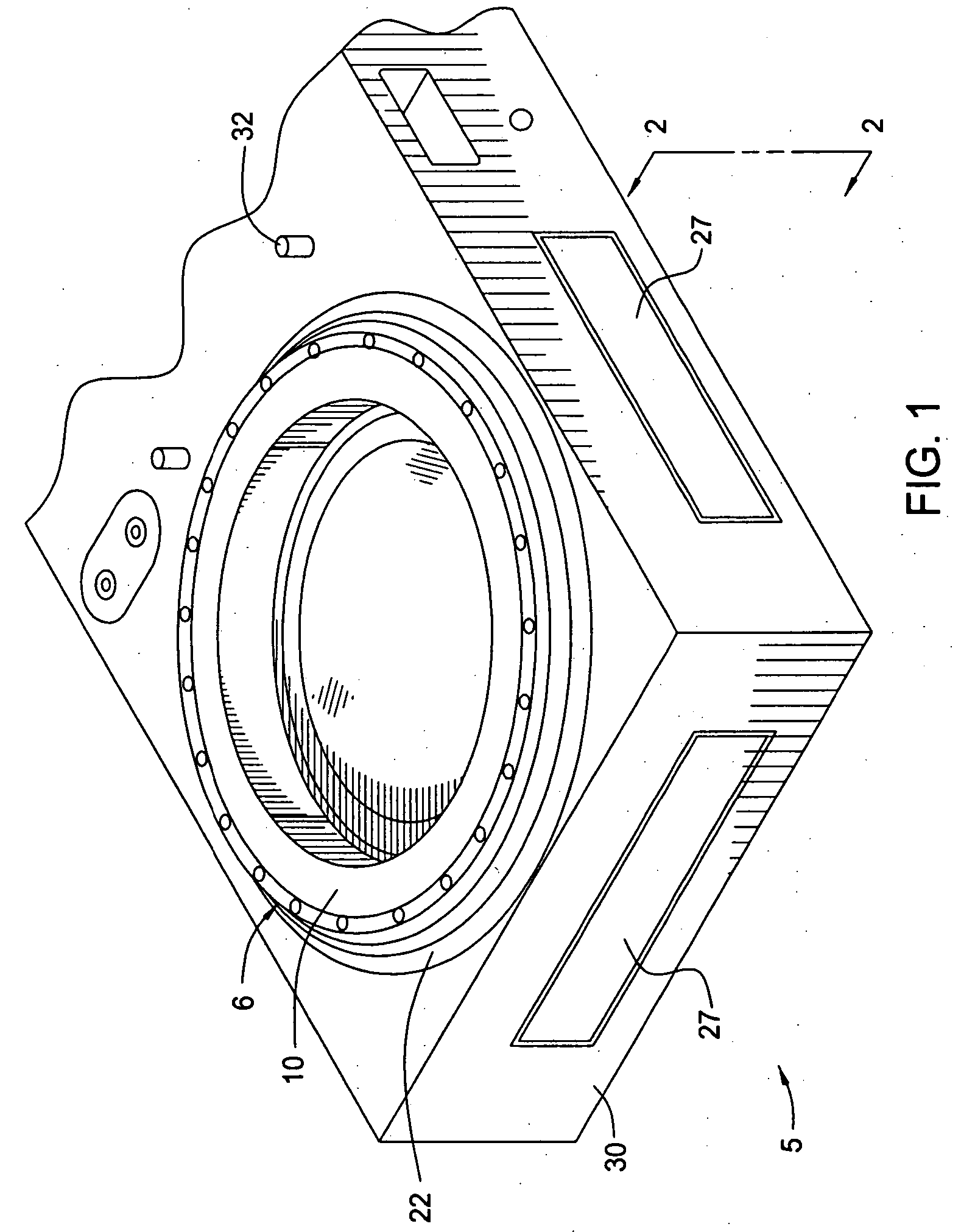

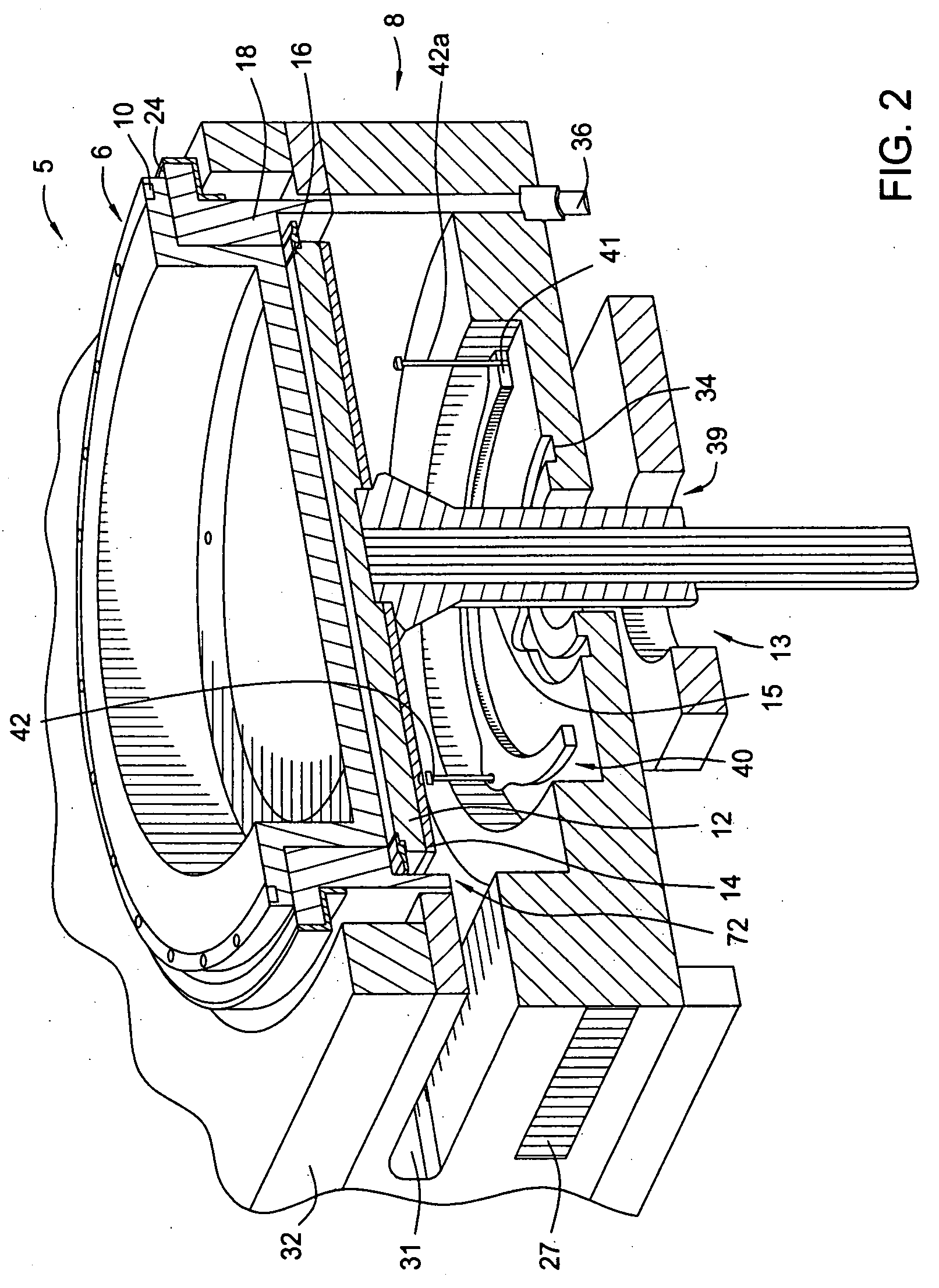

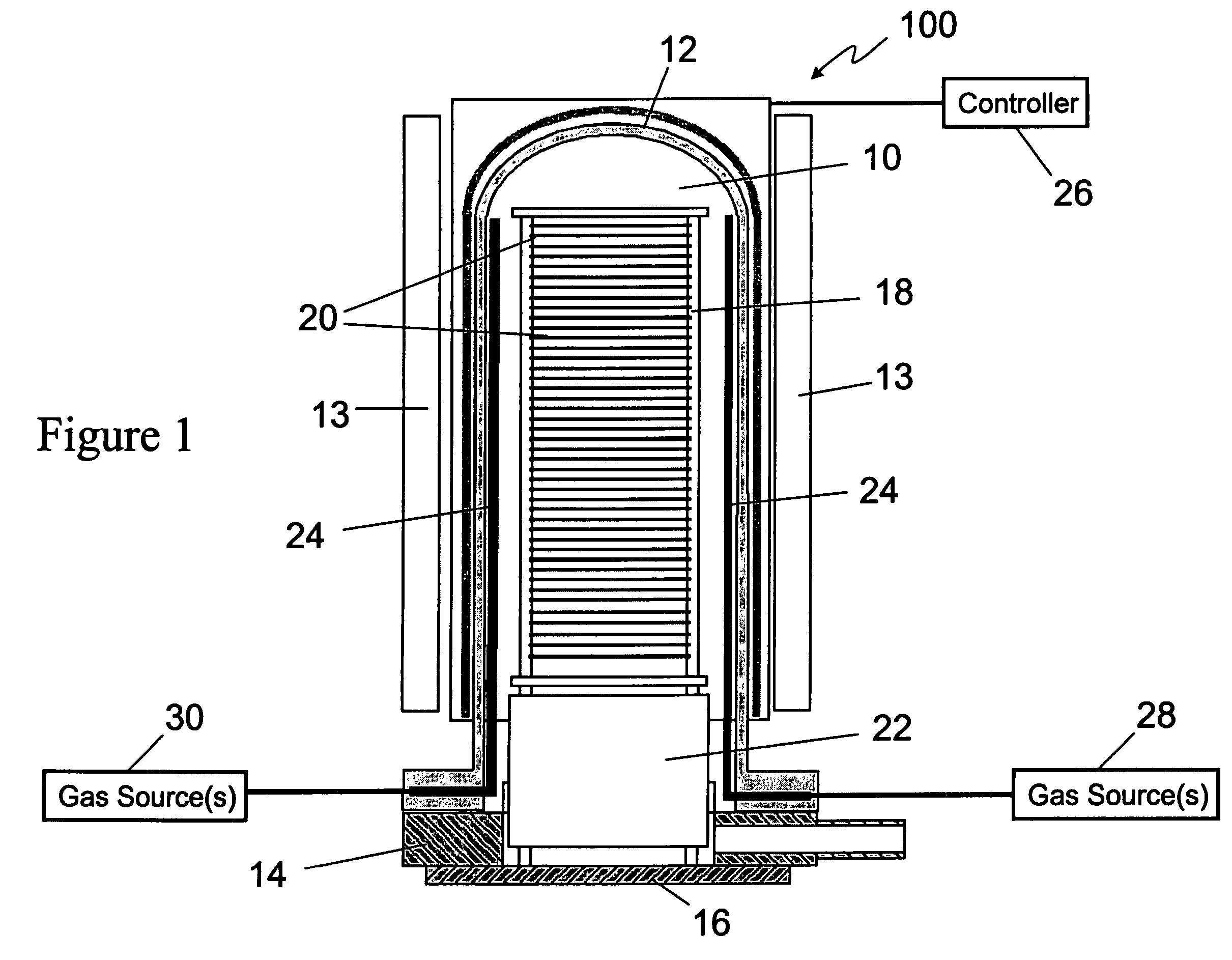

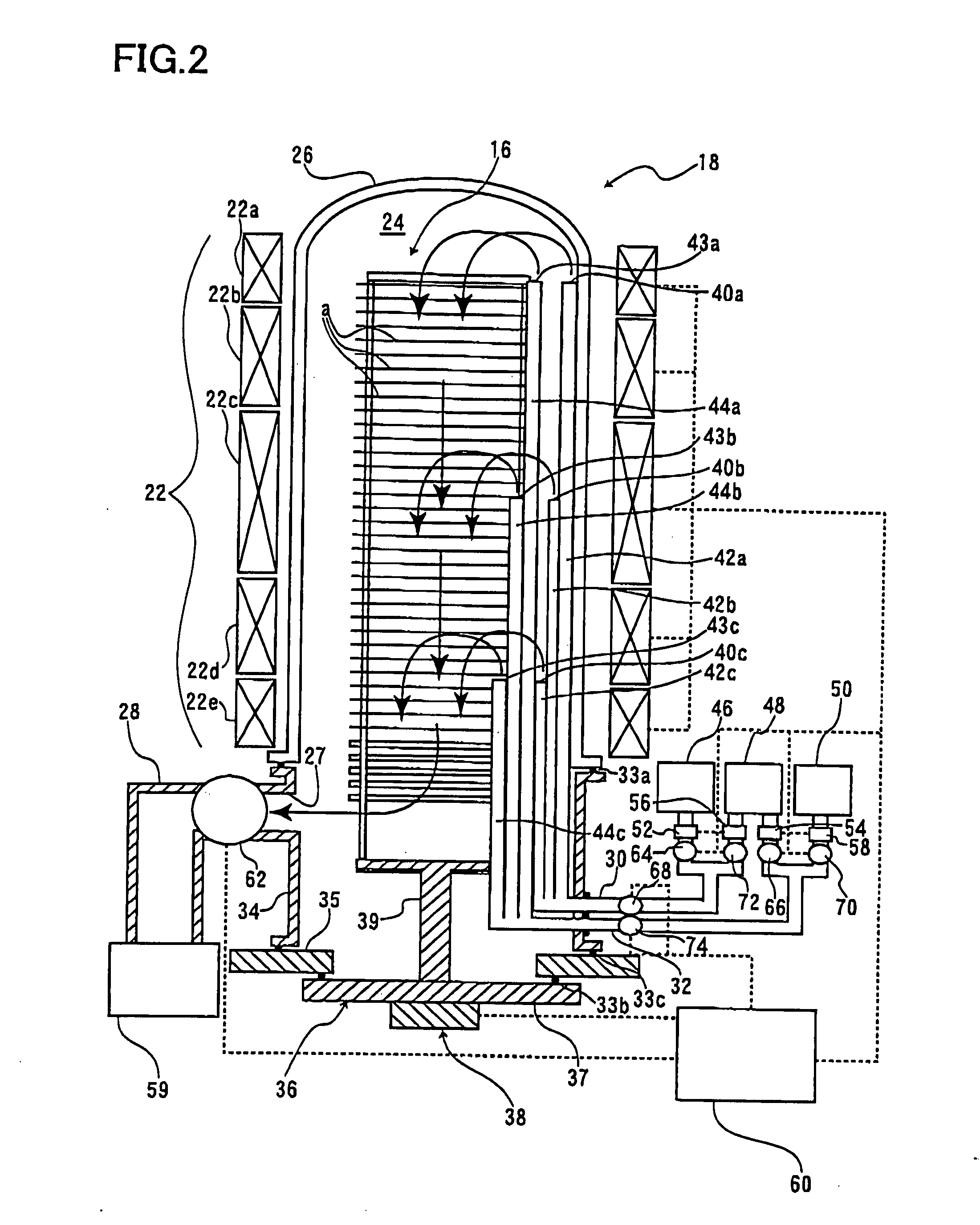

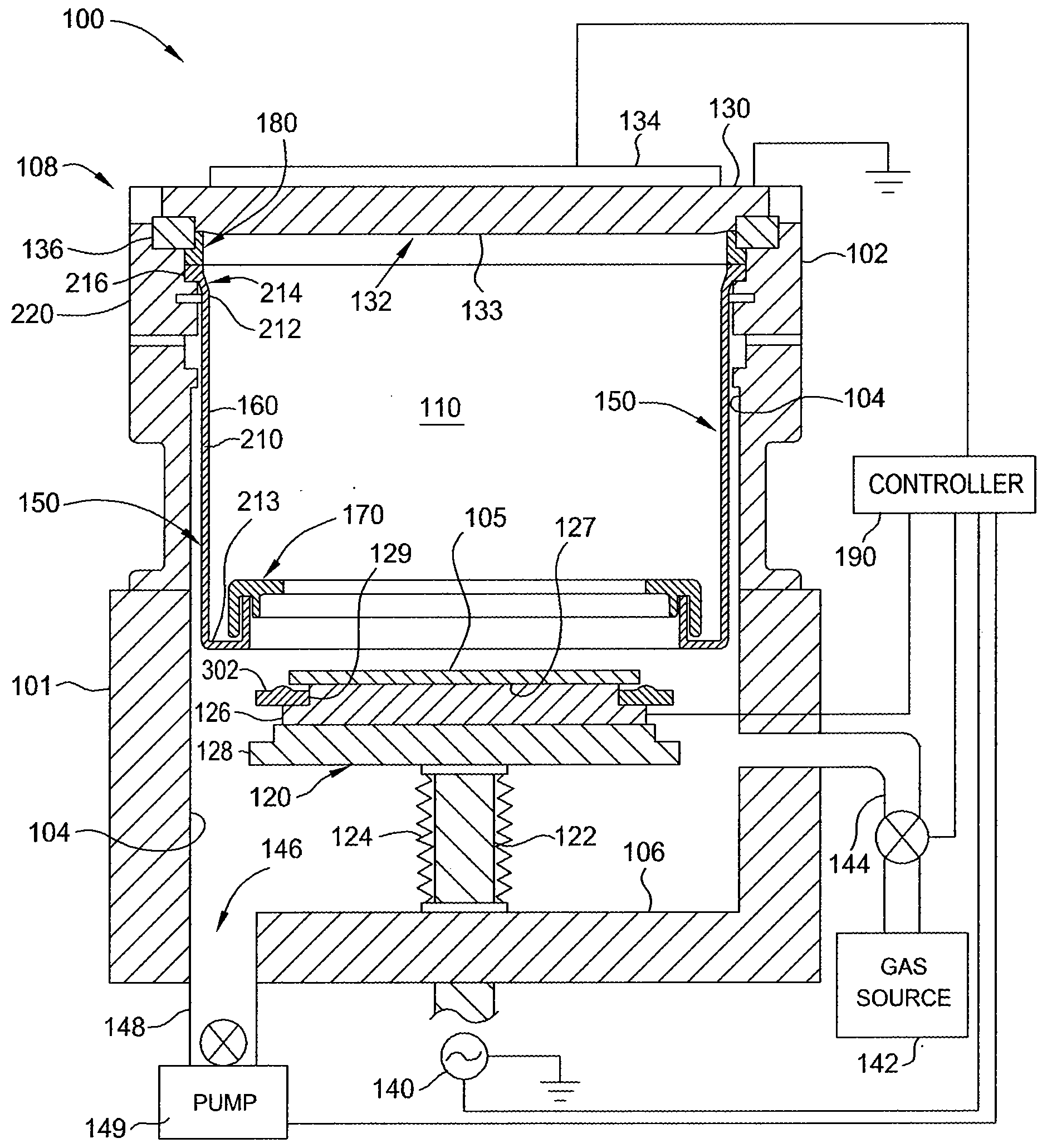

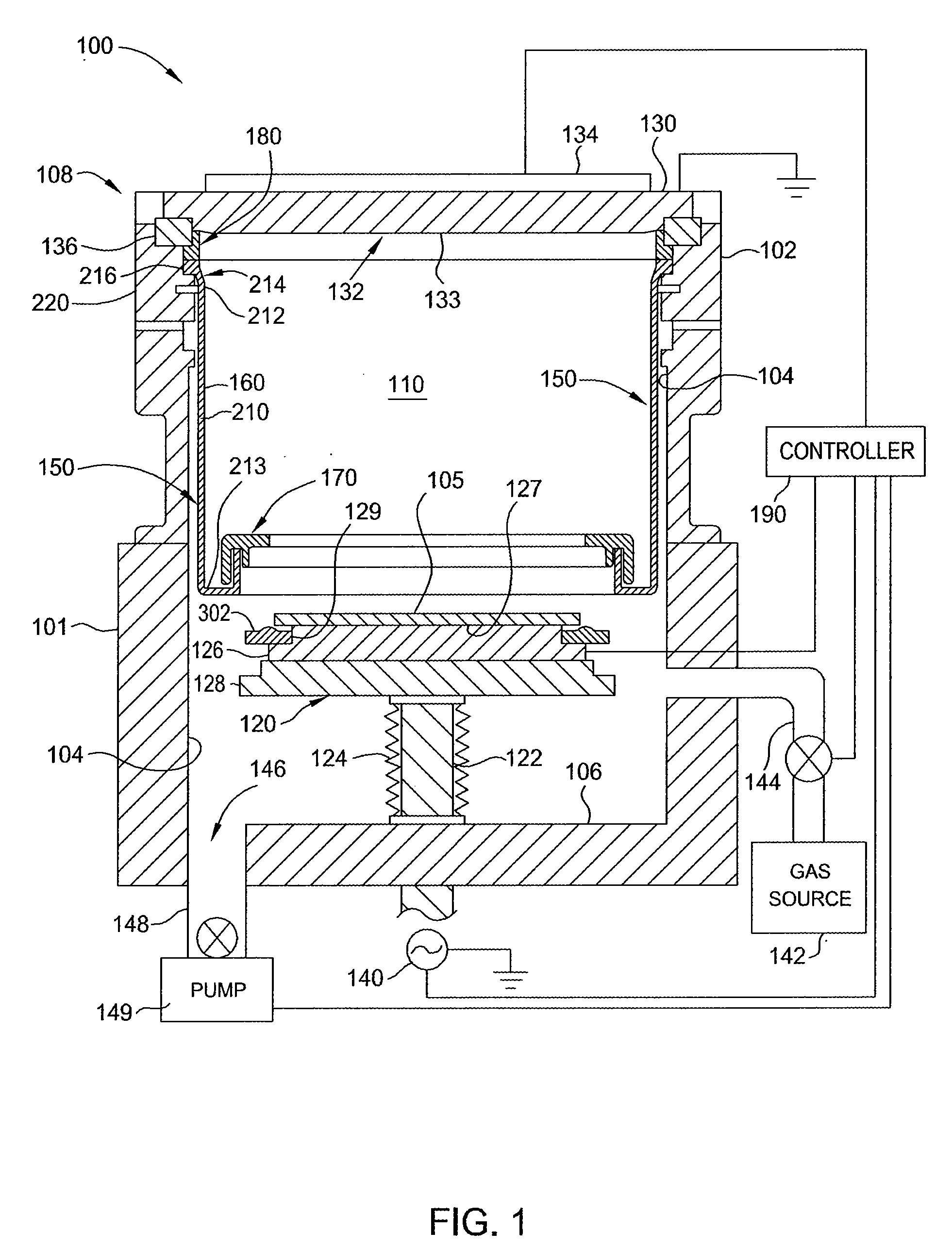

High productivity plasma processing chamber

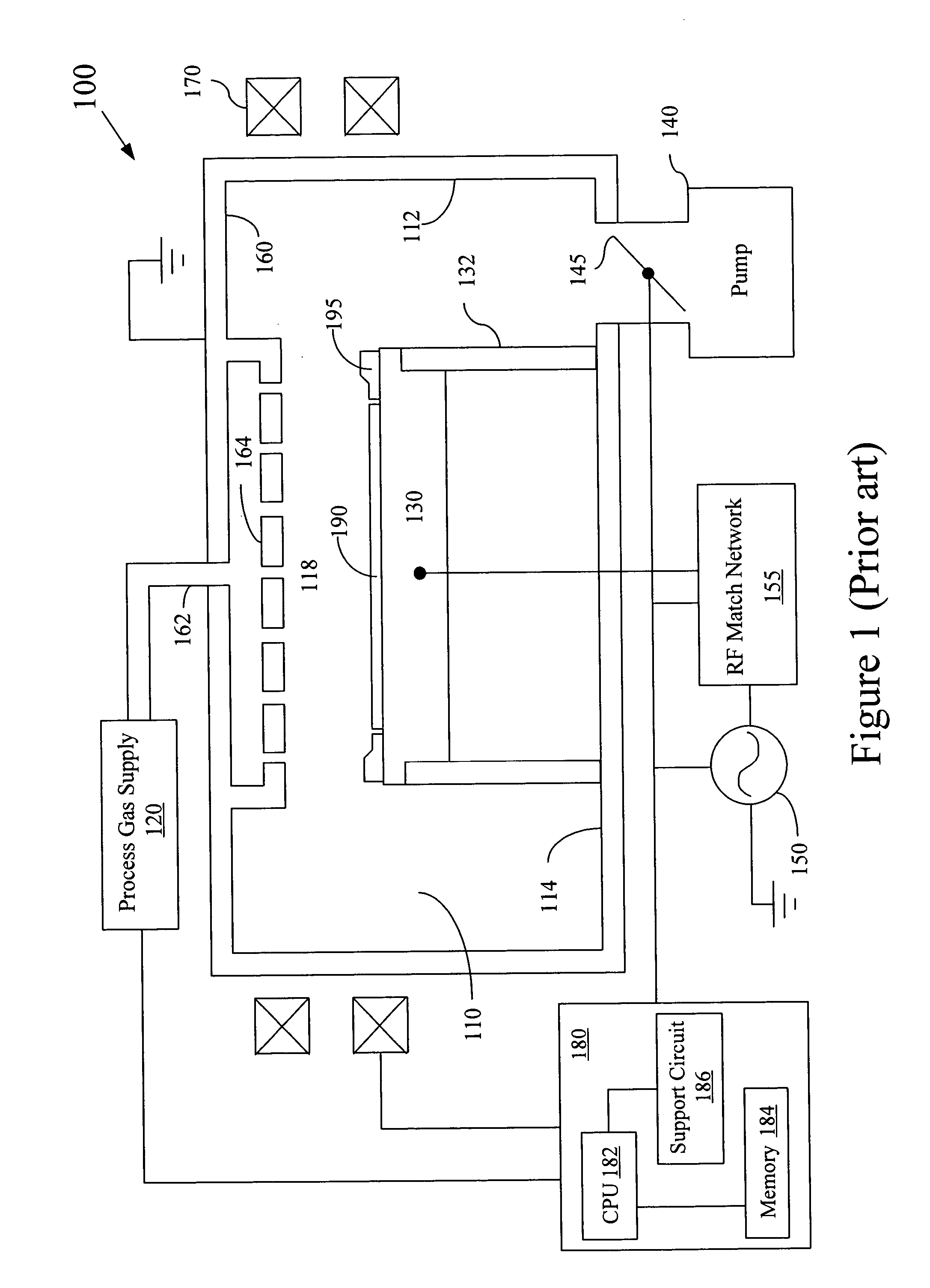

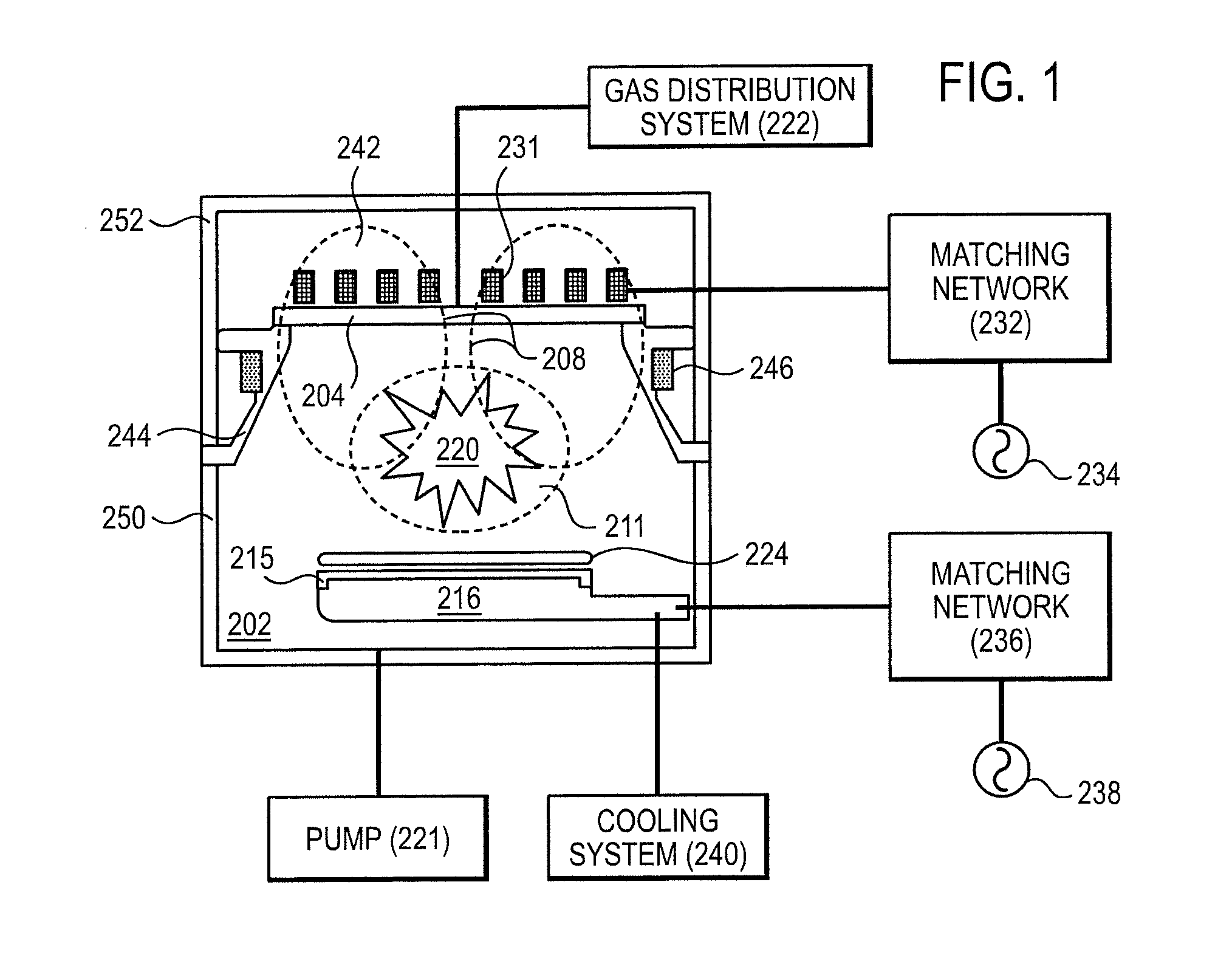

InactiveUS20050229849A1Maximizing allowable timeReduce probabilityElectric discharge tubesSemiconductor/solid-state device manufacturingTemperature controlProduction rate

Embodiments of the present invention are generally directed to apparatus and methods for a plasma-processing chamber requiring less maintenance and downtime and possessing improved reliability over the prior art. In one embodiment, the apparatus includes a substrate support resting on a ceramic shaft, an inner shaft allowing for electrical connections to the substrate support at atmospheric pressure, an aluminum substrate support resting on but not fixed to a ceramic support structure, sapphire rest points swaged into the substrate support, and a heating element inside the substrate support arranged in an Archimedes spiral to reduce warping of the substrate support and to increase its lifetime. Methods include increasing time between in-situ cleans of the chamber by reducing particle generation from chamber surfaces. Reduced particle generation occurs via temperature control of chamber components and pressurization of non-processing regions of the chamber relative to the processing region with a purge gas.

Owner:APPLIED MATERIALS INC

Method for reducing particle generation at bevel portion of substrate

ActiveUS9343343B2High mechanical strengthAvoid it happening againElectric discharge tubesSemiconductor/solid-state device detailsActuatorParticle generation

A method for transporting a substrate using an end effector which mechanically clamps a periphery of the substrate includes: before transporting the substrate, depositing a compressive film only on, at, or in a bevel portion of the substrate; and transporting the substrate whose bevel portion is covered by the compressive film as the outermost film, using an end effector while mechanically clamping the periphery of the substrate.

Owner:ASM IP HLDG BV

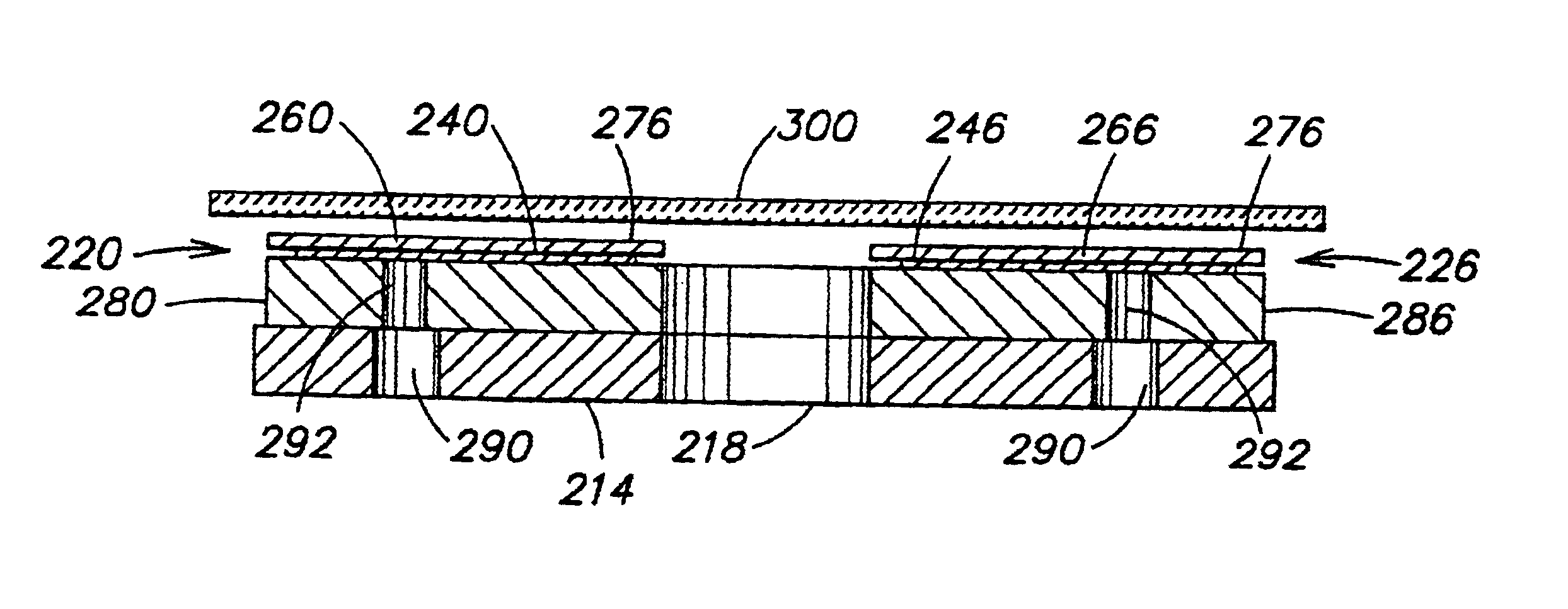

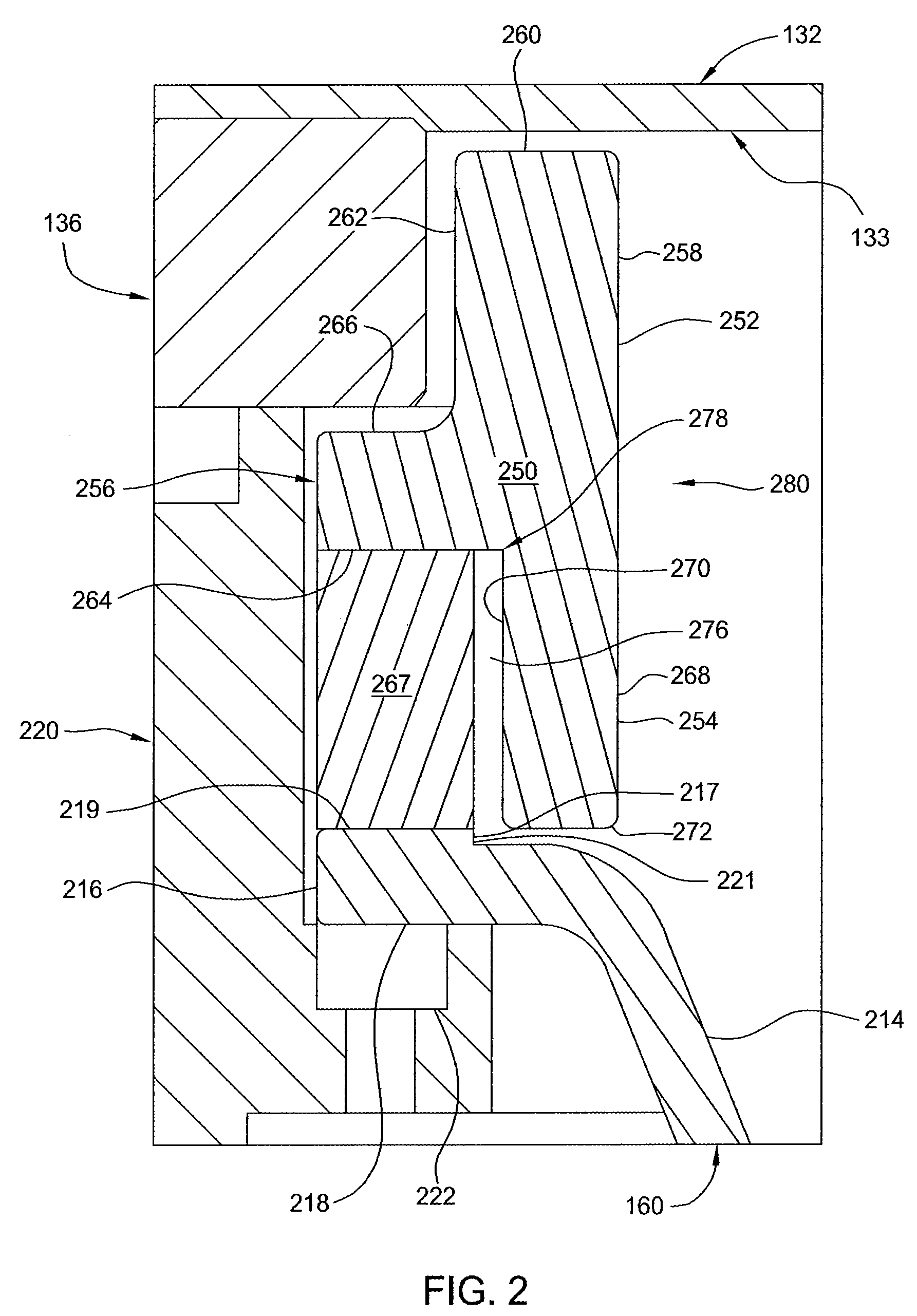

Magnetic susceptor to baseplate seal

ActiveUS20170011950A1Maintaining gapSolid-state devicesSemiconductor/solid-state device manufacturingSusceptorEngineering

A reaction system for processing semiconductor substrates is disclosed. In particular, the invention discloses an arrangement of a susceptor and a baseplate for when a substrate is placed into a reaction region. Magnets are embedded into the susceptor and the baseplate in order to create a gap between the two. As a result of the gap, the invention prevents an accumulation of gaseous materials that would exist in prior art systems as well as particle generation due to physical contact between parts.

Owner:ASM IP HLDG BV

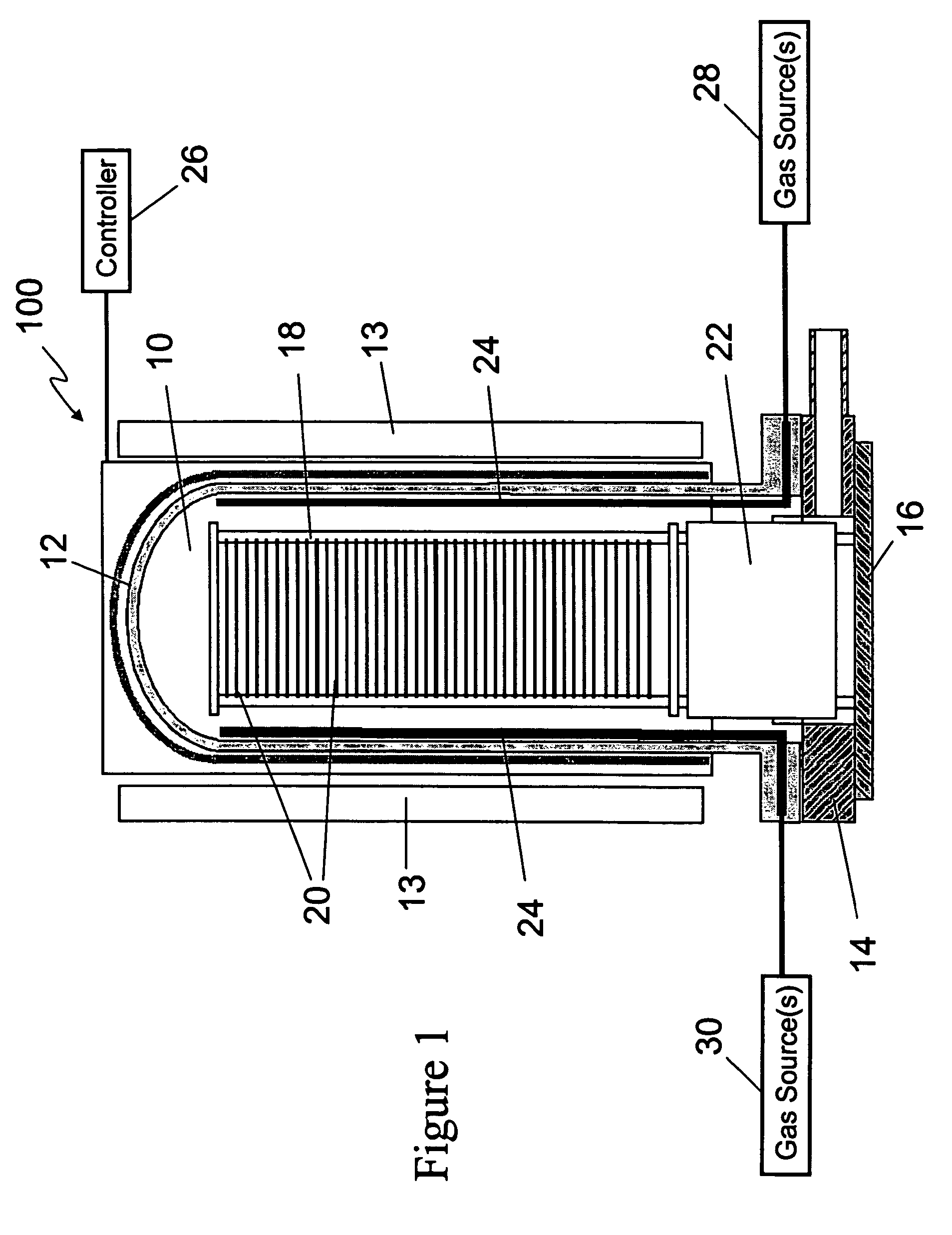

Parts for deposition reactors

ActiveUS7674726B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingThermal expansionSemiconductor

Processing methods and internal reactor parts avoid peeling and particle generation caused by differences in the coefficients of thermal expansion (CTE's) between reactor parts and films deposited on the reactor parts in hot wall CVD chambers. Conventional materials for reactor parts have relatively low CTE's, resulting in significant CTE differences with modem films, which can be deposited on the surfaces of reactor parts during semiconductor processing. Such CTE differences can cause cracking and flaking of the deposited films, thereby leading to particle generation. Reactor parts, such as boats and pedestals, which undergo large thermal cycles even in a hot wall chamber, are made of materials having a CTE greater than about 5×10−6 K−1, in order to more closely match the CTE of deposited materials, such TiN. The decreased CTE differences decrease differences between the expansion and contraction of the reactor parts and deposited films, leading to decreased cracking, flaking and, ultimately, decreased particle generation.

Owner:ASM INTERNATIONAL

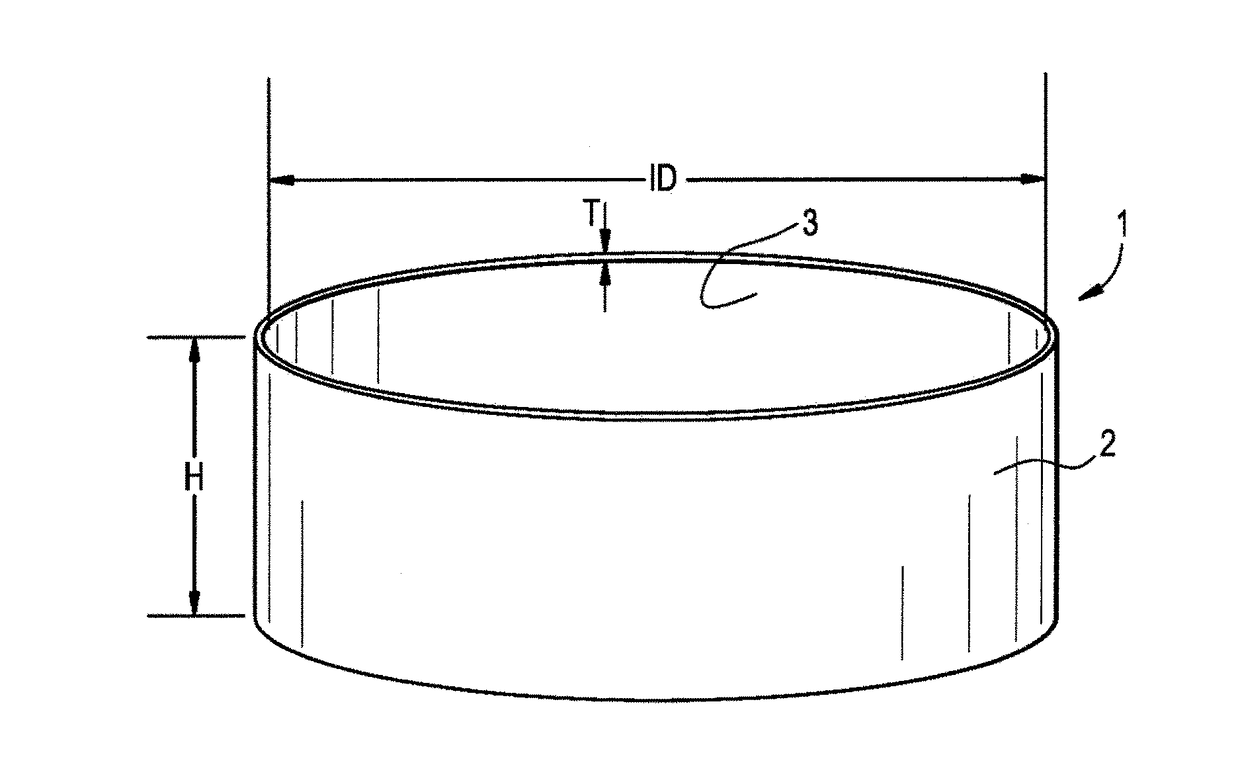

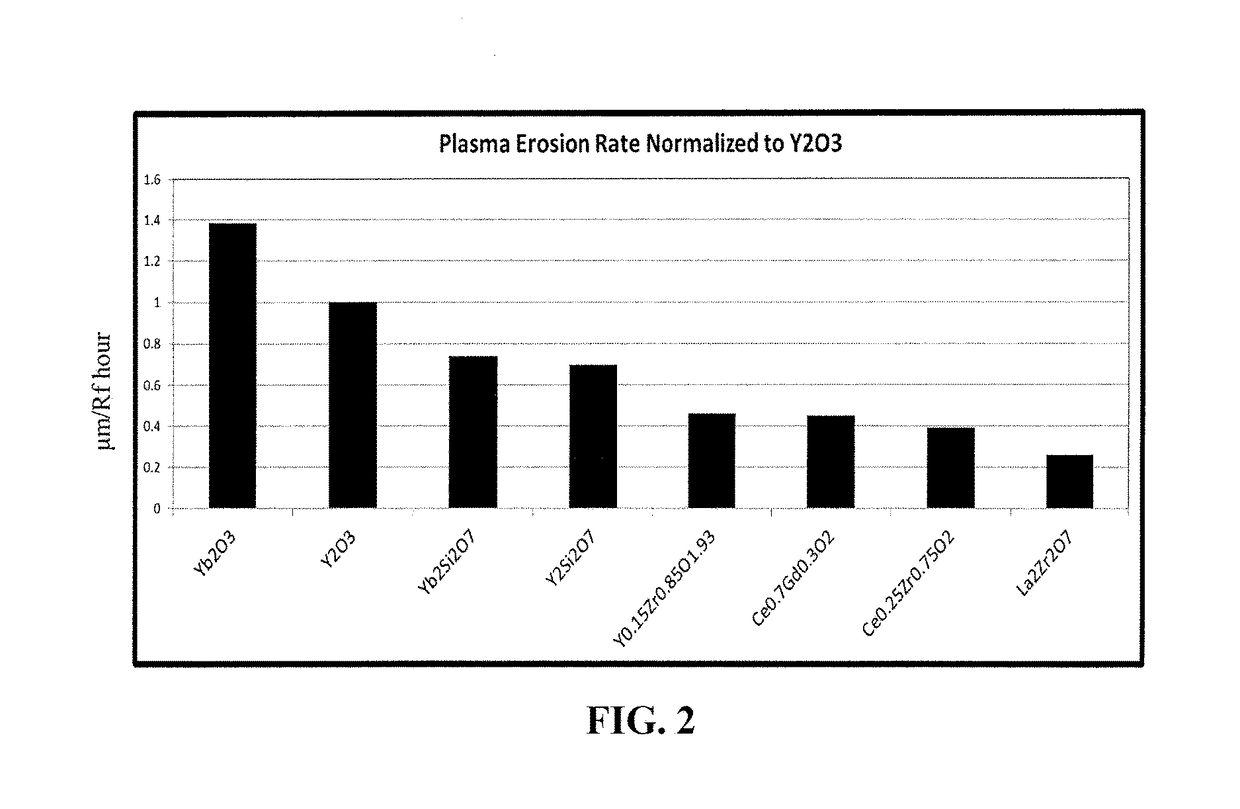

Coated semiconductor processing members having chlorine and fluorine plasma erosion resistance and complex oxide coatings therefor

ActiveUS20170301519A1High tensile bond strengthReduce pollutionMolten spray coatingElectric discharge tubesSolid solutionPlasma sprayed

A semiconductor processing member is provided, including a body and a plasma spray coating provided on the body. The coating is an ABO or ABCO complex oxide solid solution composition, where A, B and C are selected from the group consisting of La, Zr, Ce, Gd, Y, Yb and Si, and O is an oxide. The coating imparts both chlorine and fluorine plasma erosion resistance, reduces particle generation during plasma etching, and prevents spalling of the coating during wet cleaning of the semiconductor processing member.

Owner:FM INDS

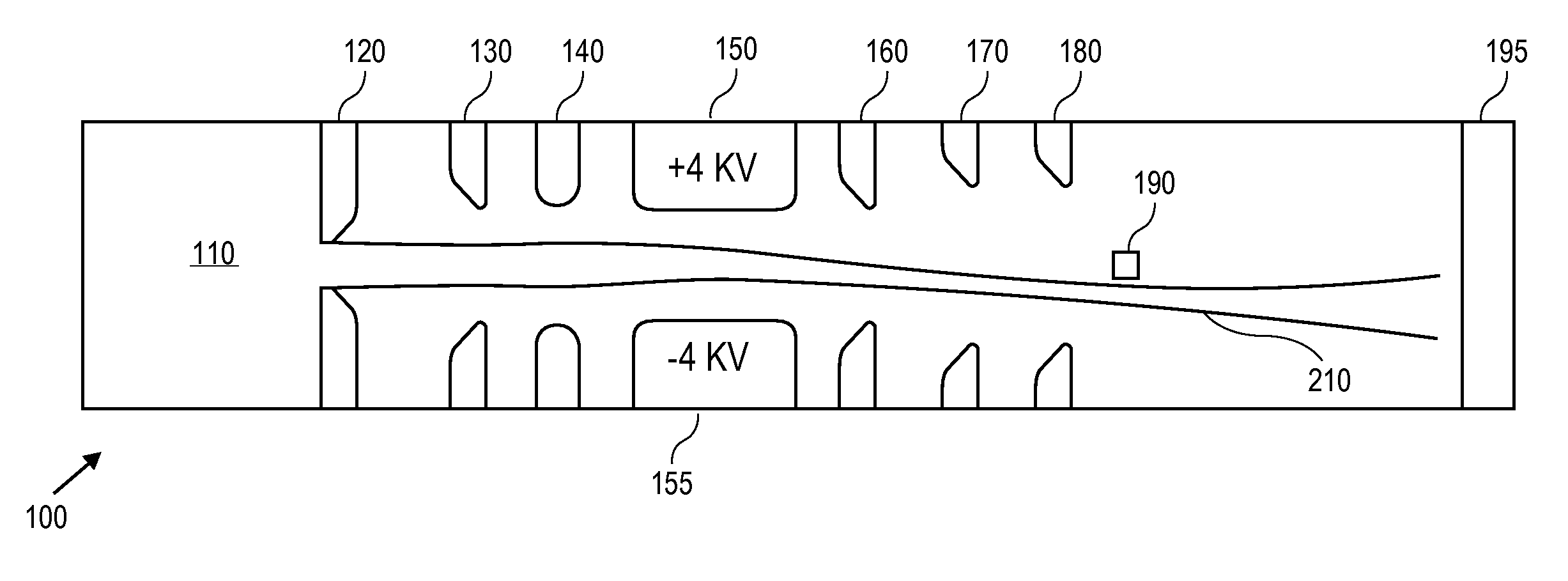

Method and apparatus for generating sequential beams of penetrating radiation

InactiveUS6421420B1Radiation/particle handlingCathode ray concentrating/focusing/directingLight beamElectromagnetic radiation

An apparatus and method for generating electronically steerable beams of sequential penetrating radiation. Charged particles from a source are formed into a beam and accelerated to a target. Electromagnetic radiation generated by the target is emitted with an angular distribution which is a function of the target thickness and the energy of the particles. A beam of particles is produced by allowing the radiation to exit from an apparatus through a collimator proximal to the target. The direction of the beam is determined by the point of radiation production and the corresponding array of transmission regions of the collimator.

Owner:SILICON VALLEY BANK

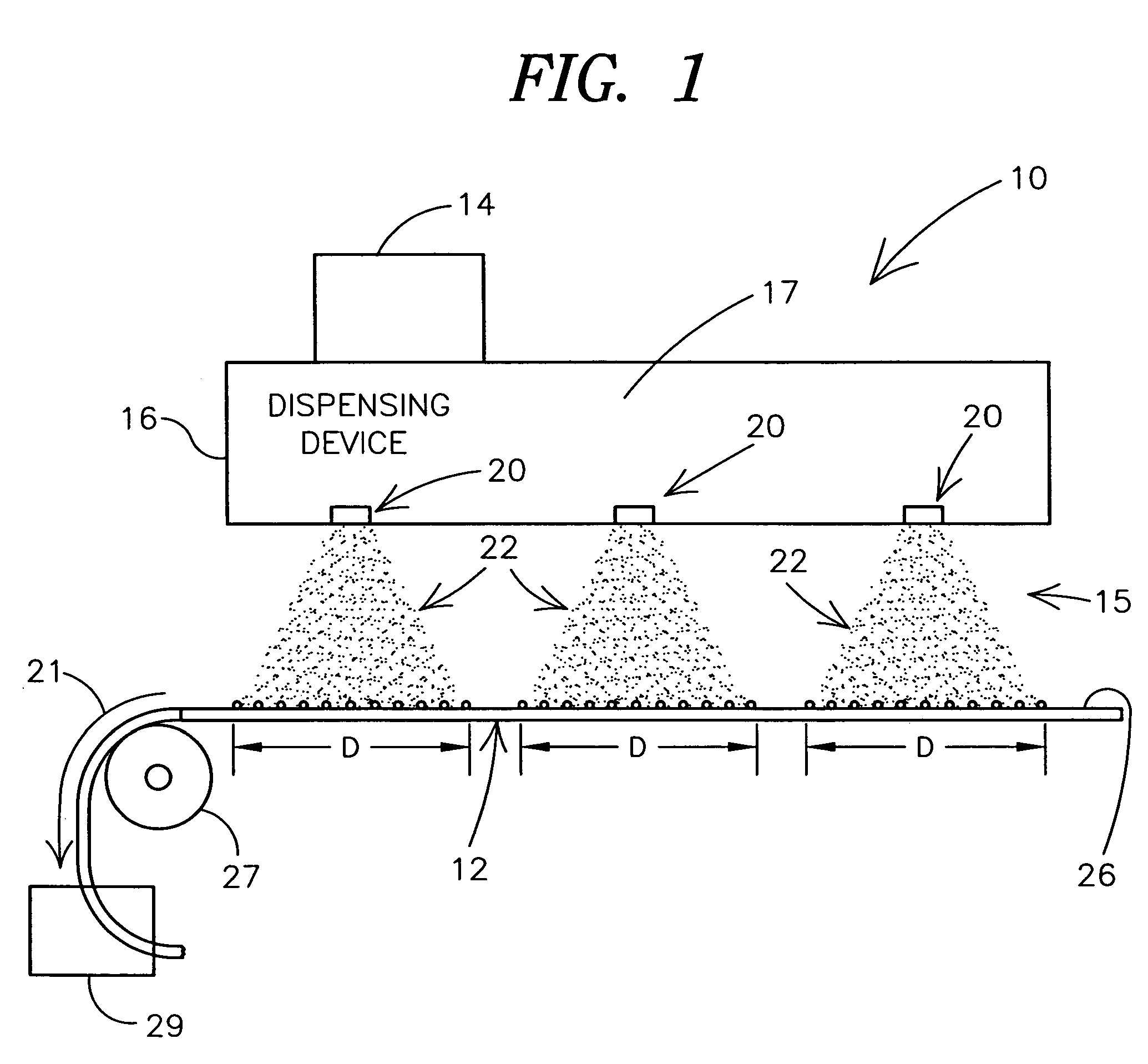

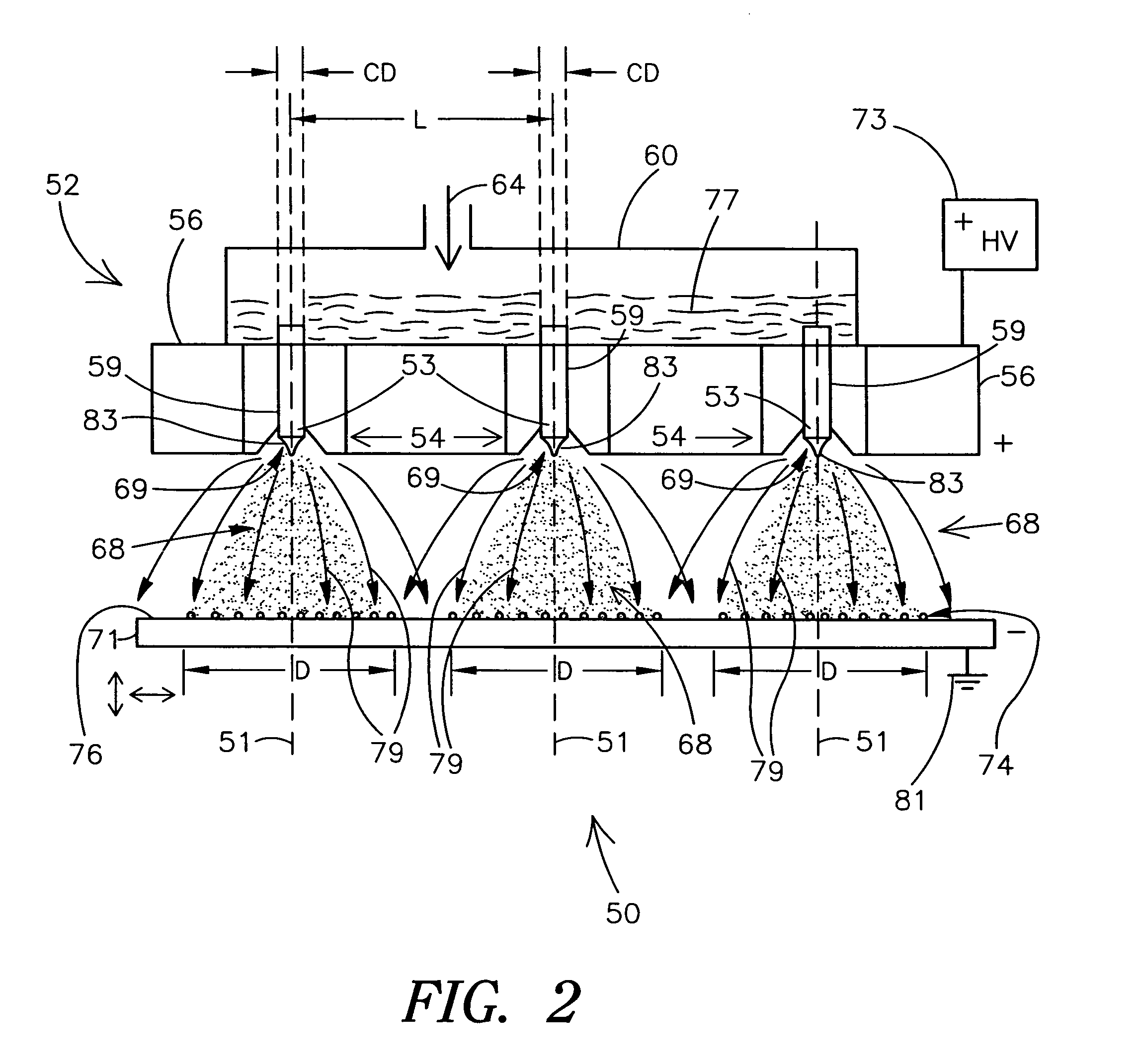

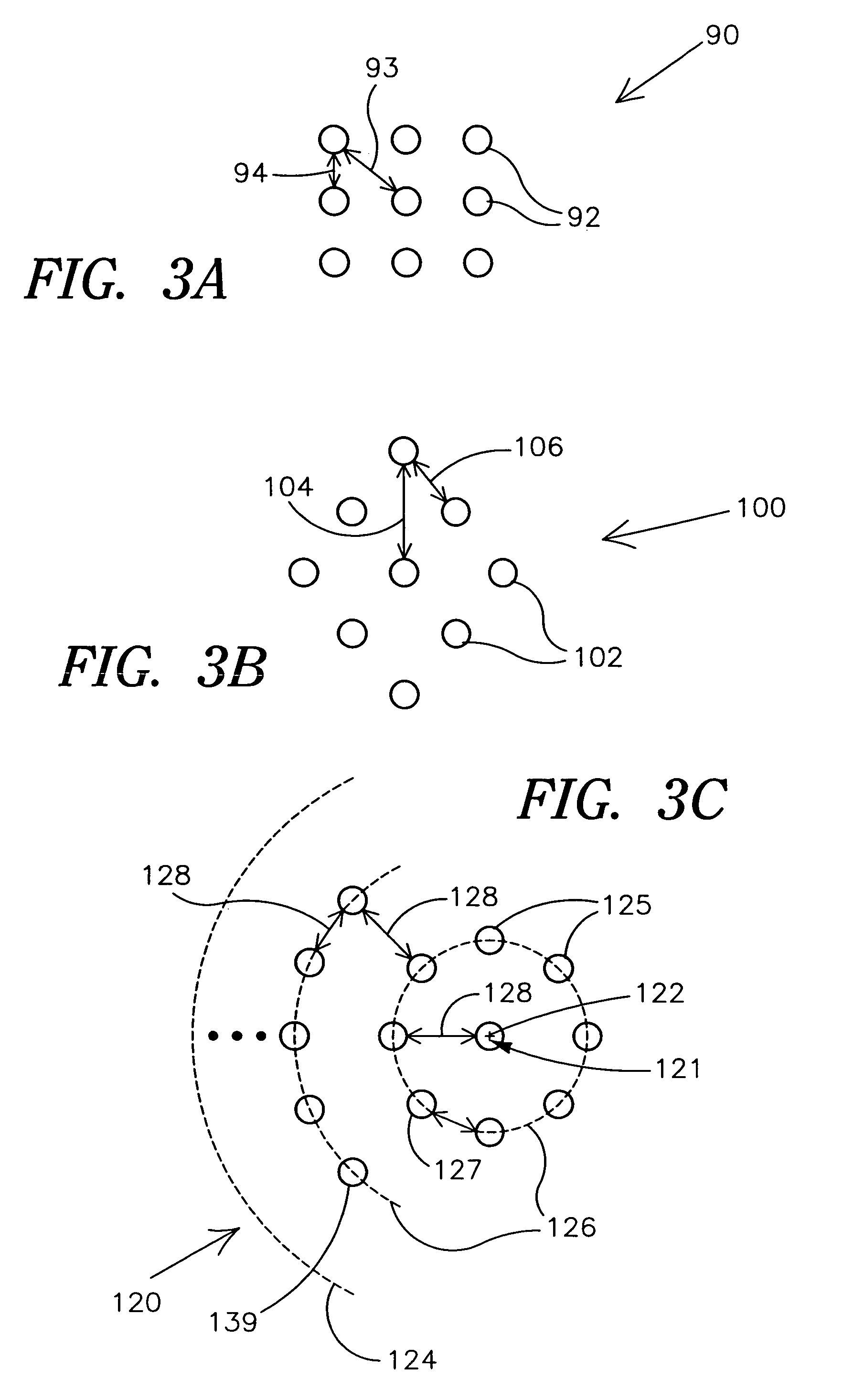

High mass throughput particle generation using multiple nozzle spraying

InactiveUS7498063B2High mass throughputImprove throughputSurgeryPretreated surfacesElectricityNanoparticle

Spraying apparatus and methods that employ multiple nozzle structures for producing multiple sprays of particles, e.g., nanoparticles, for various applications, e.g., pharmaceuticals, are provided. For example, an electrospray dispensing device may include a plurality of nozzle structures, wherein each nozzle structure is separated from adjacent nozzle structures by an internozzle distance. Sprays of particles are established from the nozzle structures by creating a nonuniform electrical field between the nozzle structures and an electrode electrically isolated therefrom.

Owner:RGT UNIV OF MINNESOTA

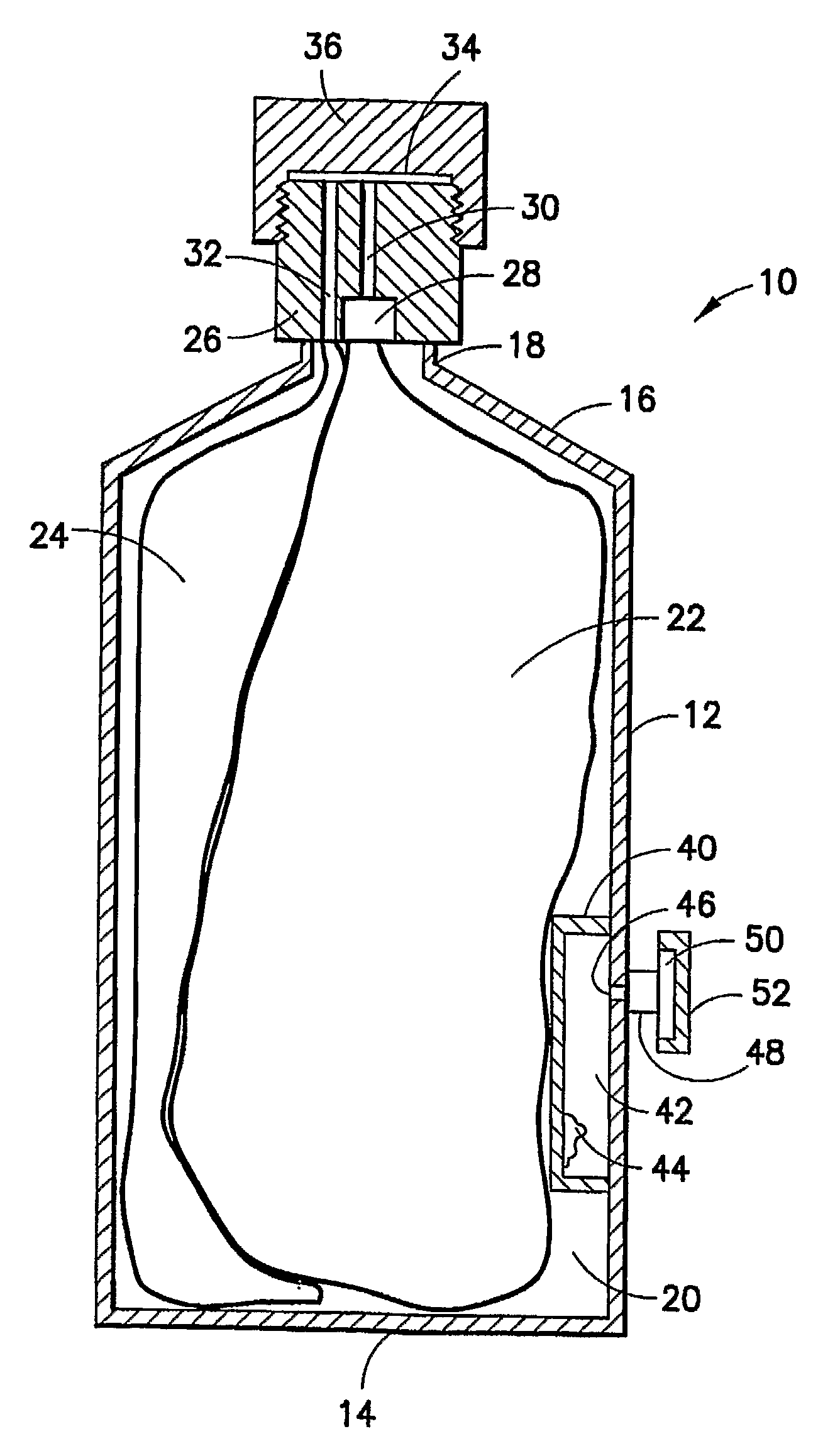

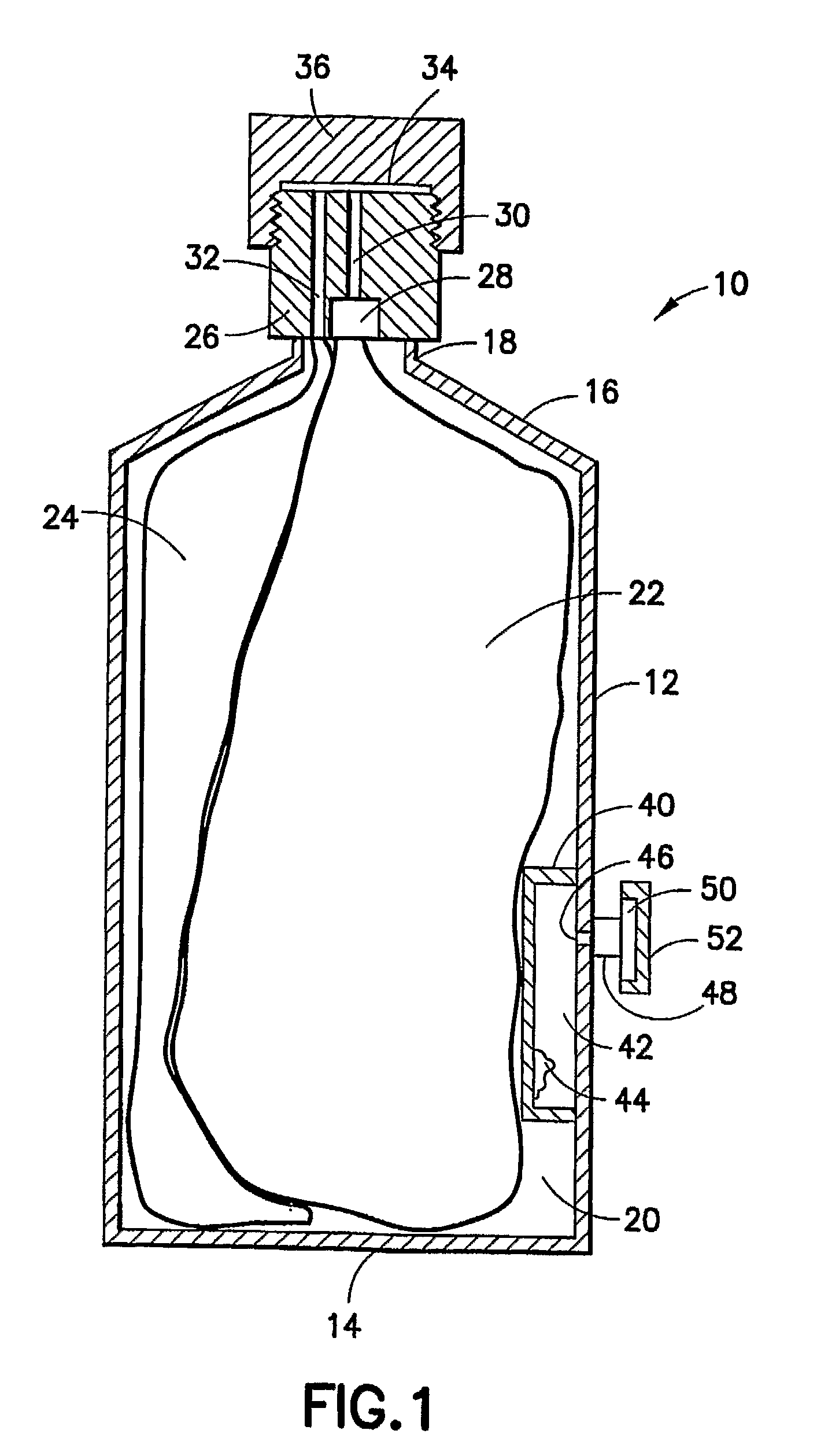

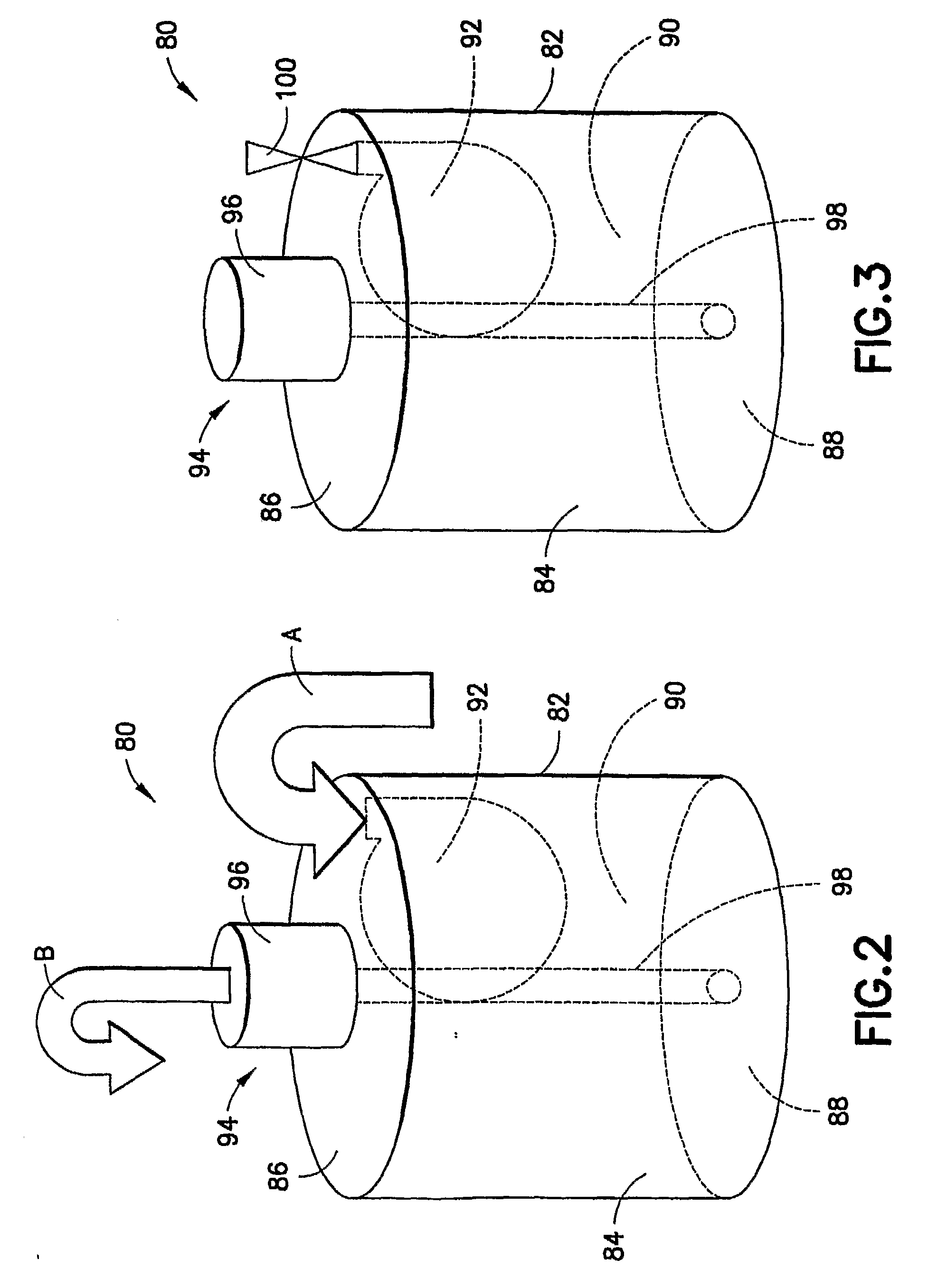

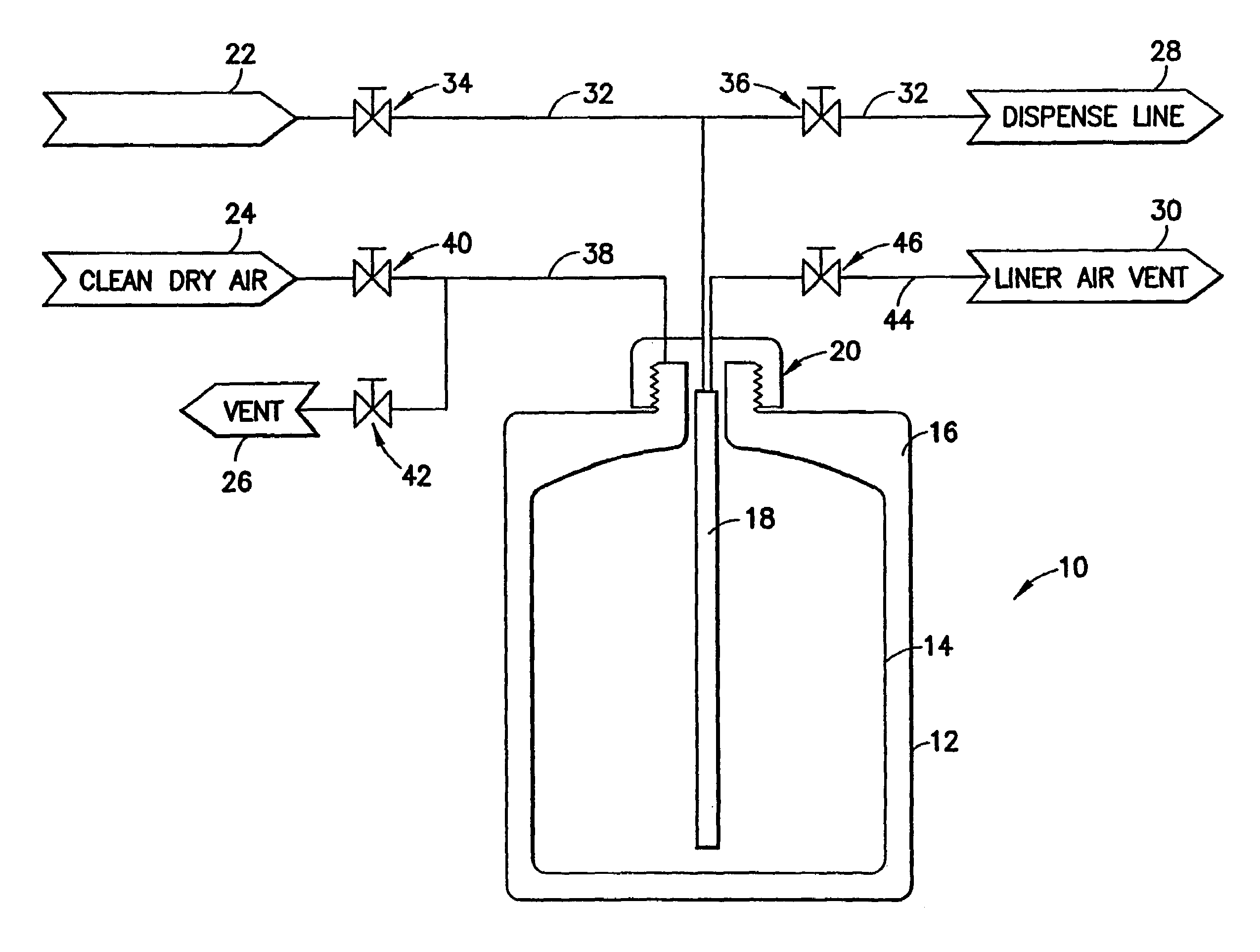

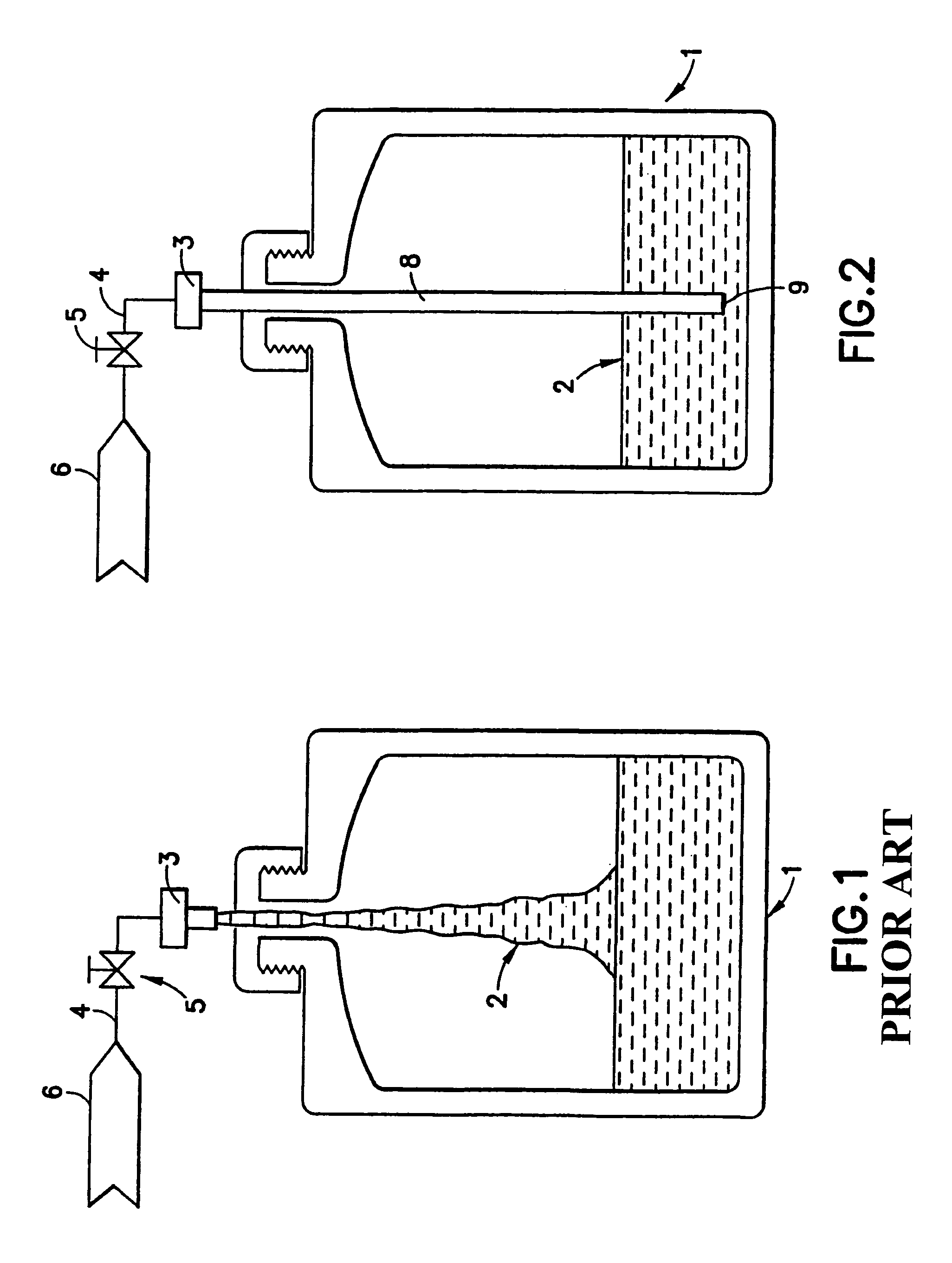

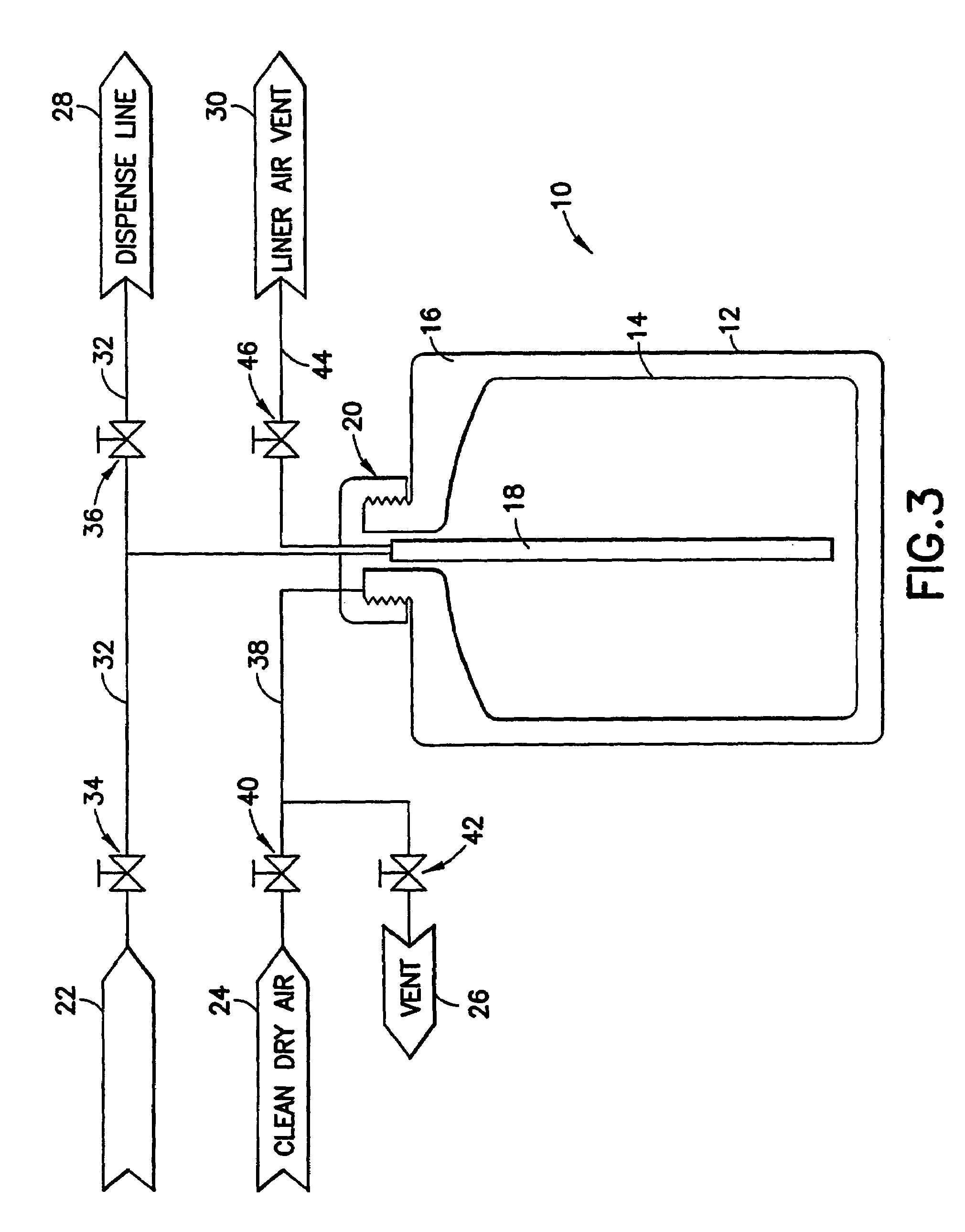

Material storage and dispensing packages and methods

InactiveUS20090212071A1Solve the lack of spaceInhibit productionPower operated devicesShock-sensitive articlesEngineeringParticle generation

Packages and methods for storage and dispensing of materials, e.g., high purity liquid reagents and chemical mechanical polishing compositions used in the manufacture of microelectronic device products, including containment structures and methods adapted for pressure-dispensing of high-purity liquids. Liner packaging of liquid or liquid-containing media is described, in which zero or near-zero head space conformations are employed to minimize adverse effects of particle generation, formation of bubbles and degradation of contained material.

Owner:ADVANCED TECH MATERIALS INC

Apparatus and method for minimizing the generation of particles in ultrapure liquids

ActiveUS7188644B2Reduce Particle GenerationLess particle generationSpraying apparatusLiquid transferring devicesAir liquid interfaceEngineering

A system and method of reducing particle generation in packaging containers used to transport ultra pure liquids. Particle generation in the containers is reduced by reducing the air-liquid interface present during filling, transport, and dispensing of the liquid.

Owner:ADVANCED TECH MATERIALS INC

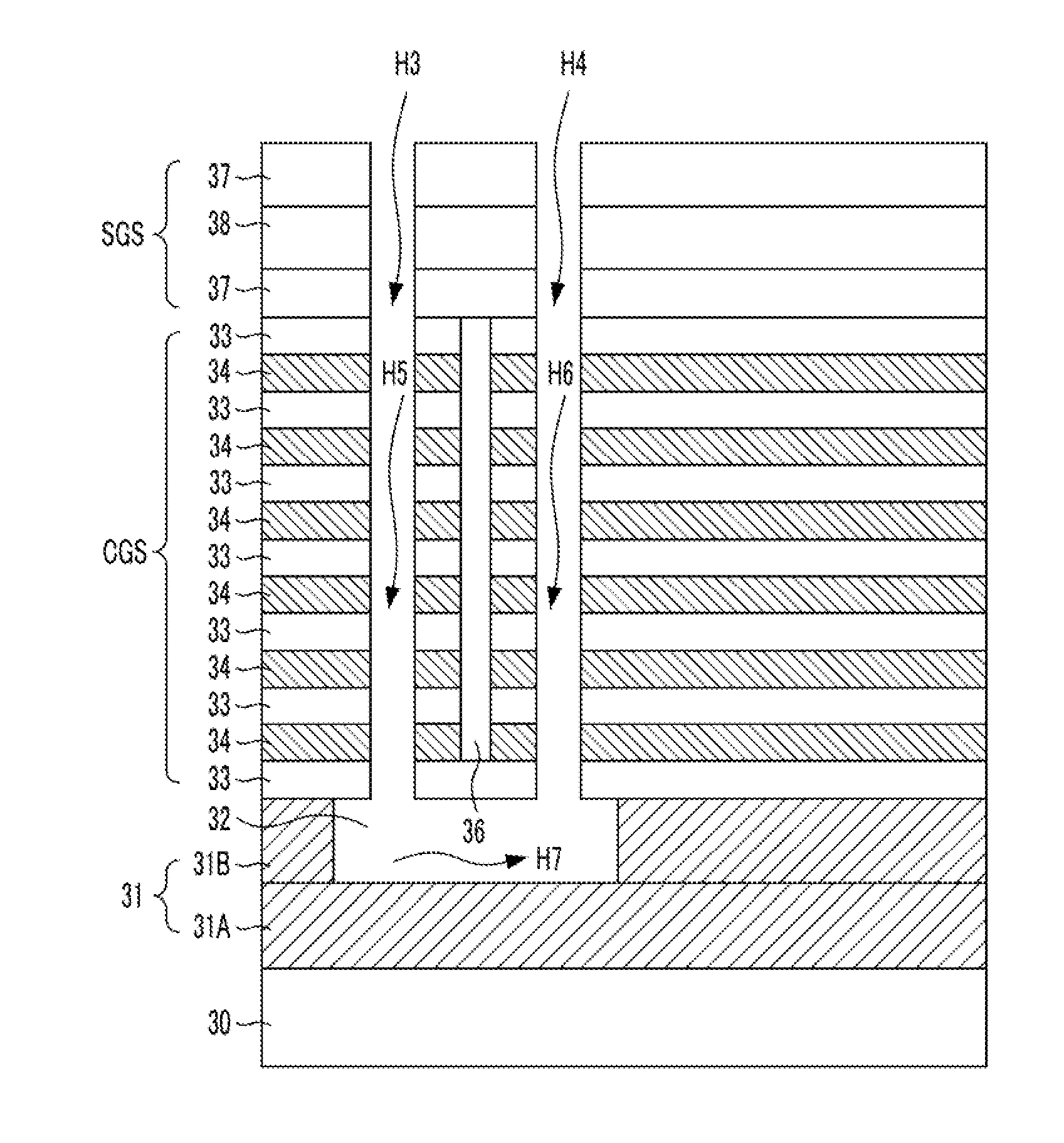

Substrate treatment device

InactiveUS20080135516A1Prevent particle generationExcellent etching propertiesAfter-treatment apparatusPolycrystalline material growthSpray nozzleProduct gas

It is intended to provide a substrate treatment device capable of adjusting both of a growth speed and an etching speed in a selective epitaxial growth, avoiding particle generation from nozzles, and achieving good etching characteristics. A substrate treatment device for selectively growing an epitaxial film on a surface of a substrate by alternately supplying a raw material gas containing silicon and an etching gas to a treatment chamber, the substrate treatment device being provided with a substrate support member for supporting the substrate in the treatment chamber, a heating member provided outside the treatment chamber for heating the substrate and an atmosphere of the treatment chamber, a gas supply system provided inside the treatment chamber, and a discharge port opened on the treatment chamber, wherein the gas supply system comprises first gas supply nozzles for supplying the raw material gas and second gas supply nozzles for supplying the etching gas.

Owner:KOKUSA ELECTRIC CO LTD

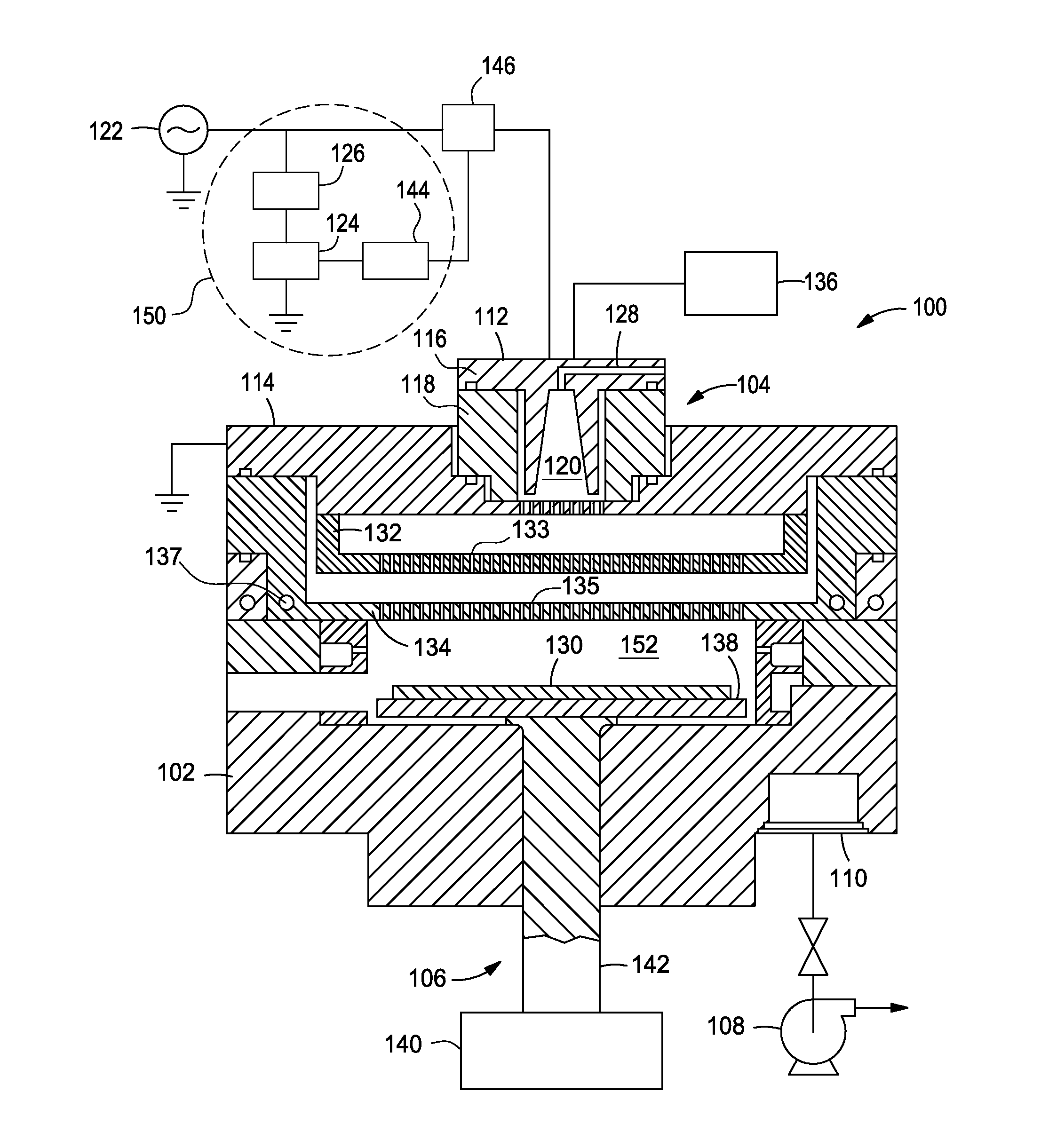

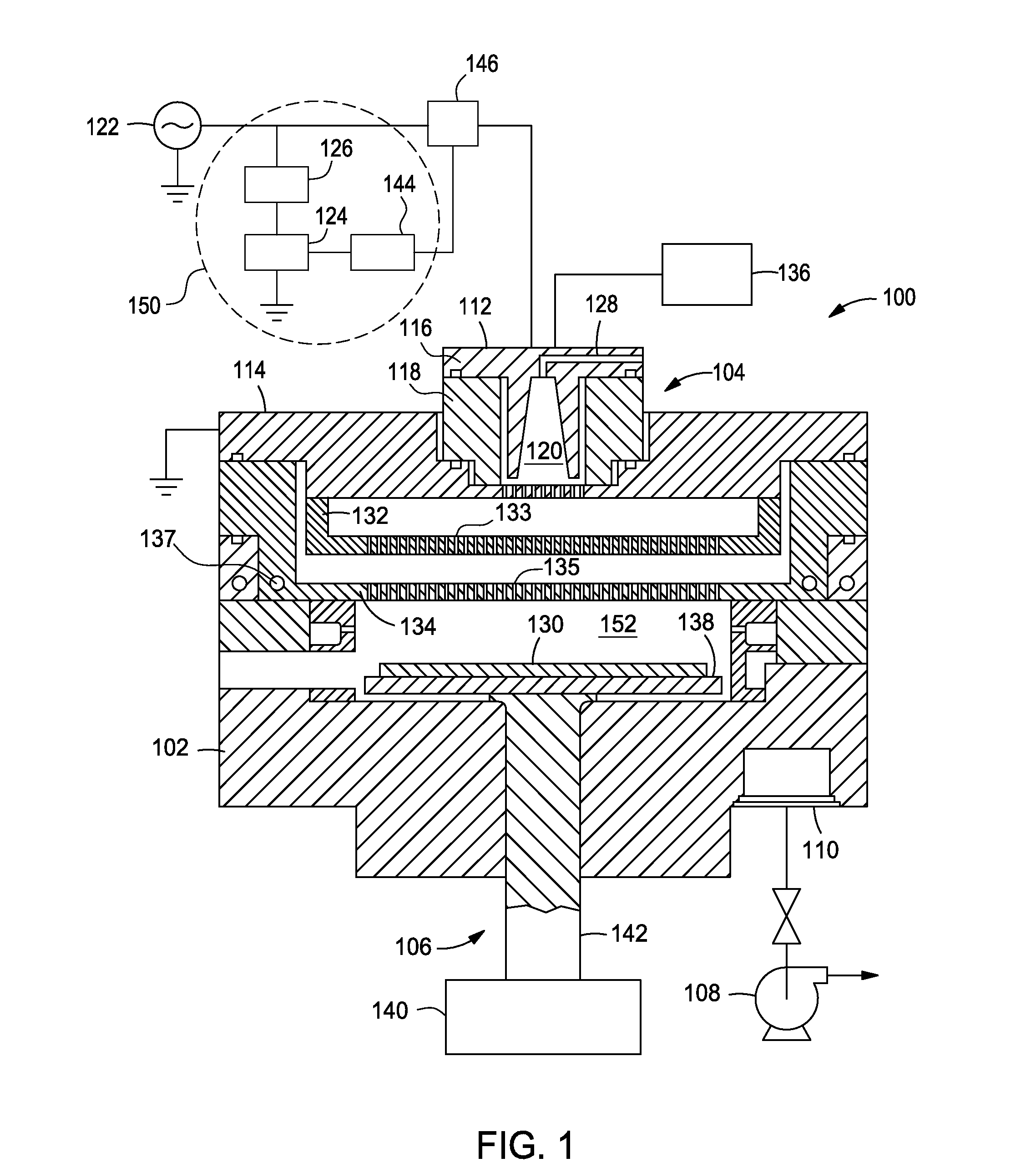

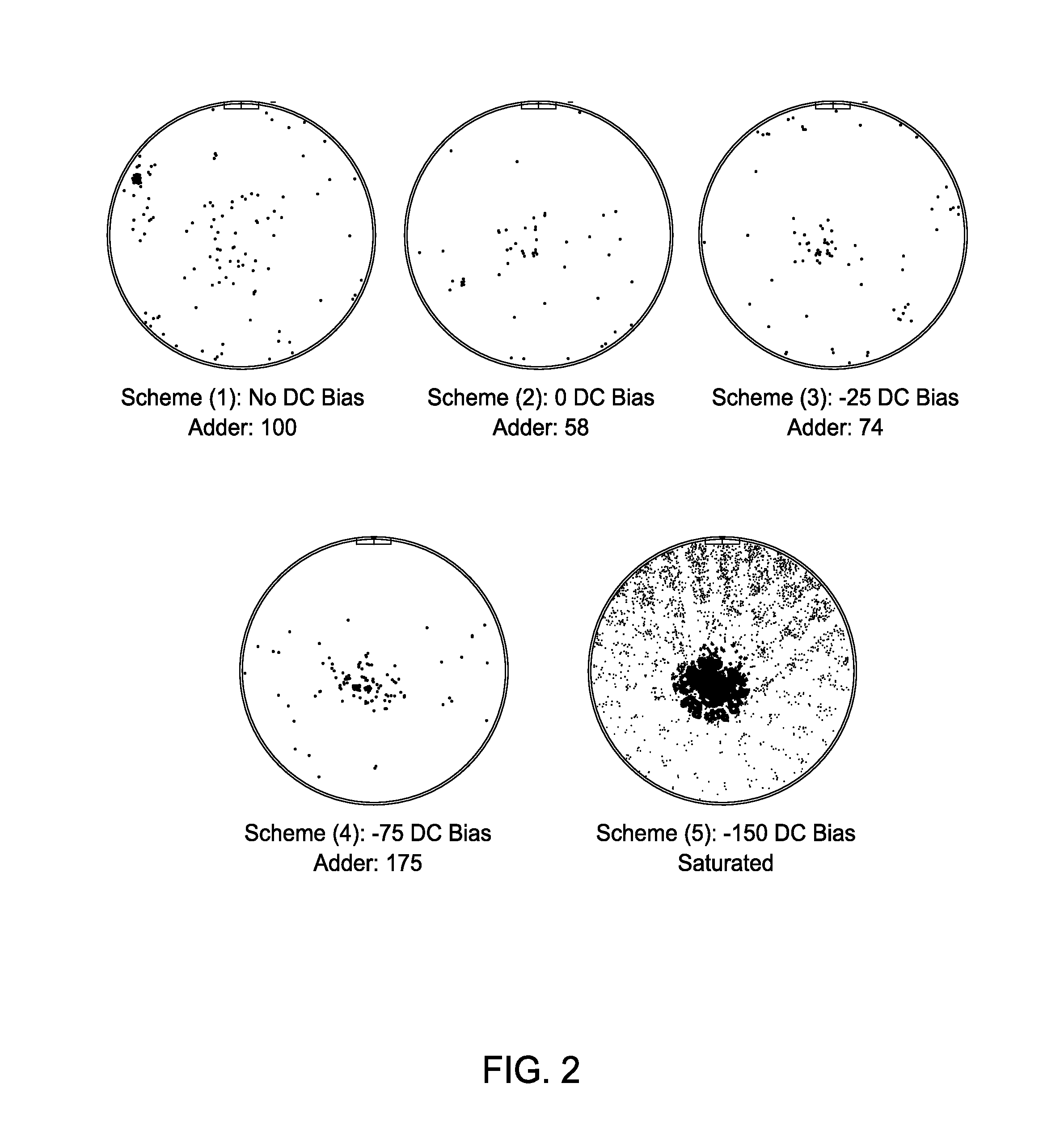

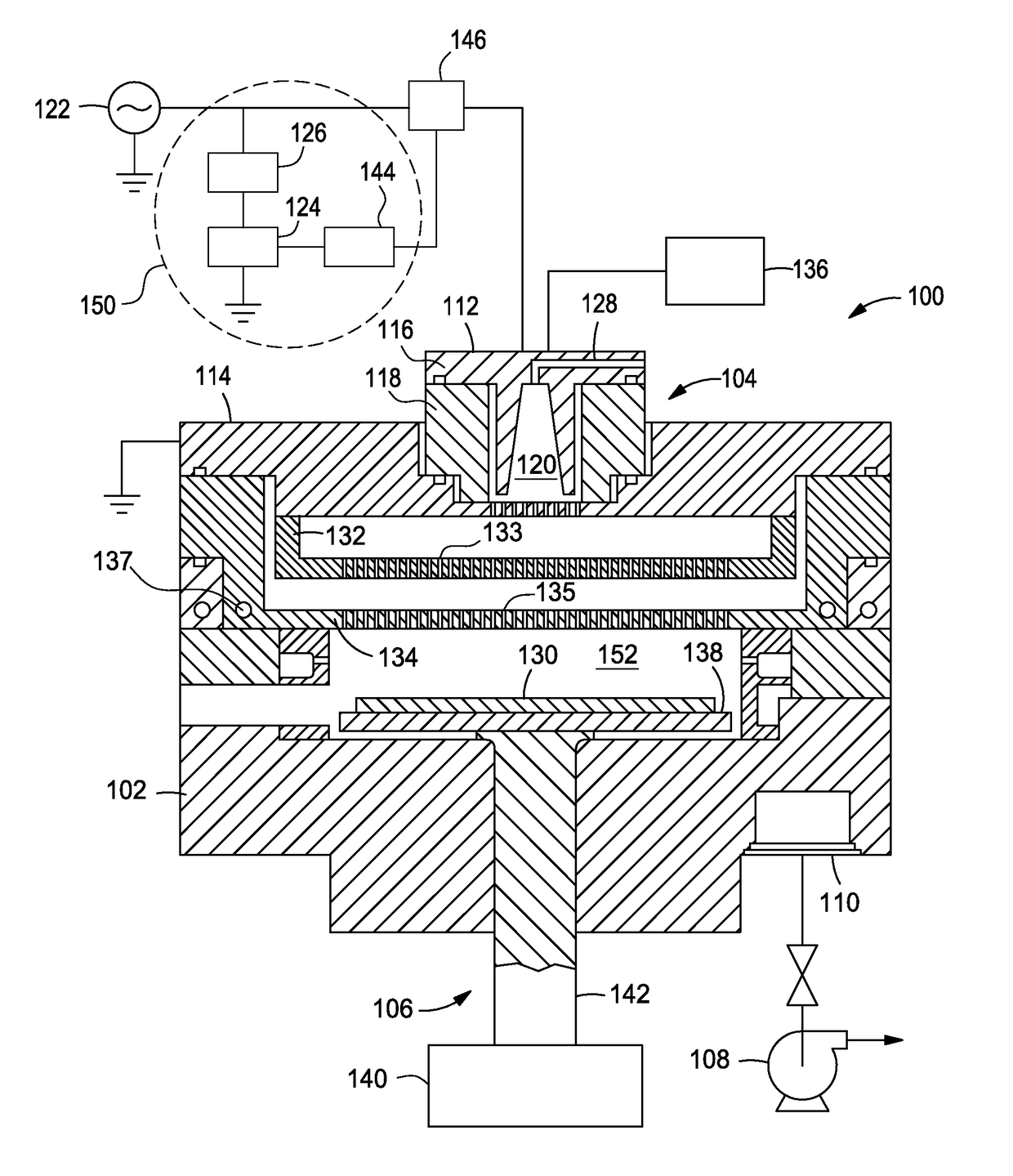

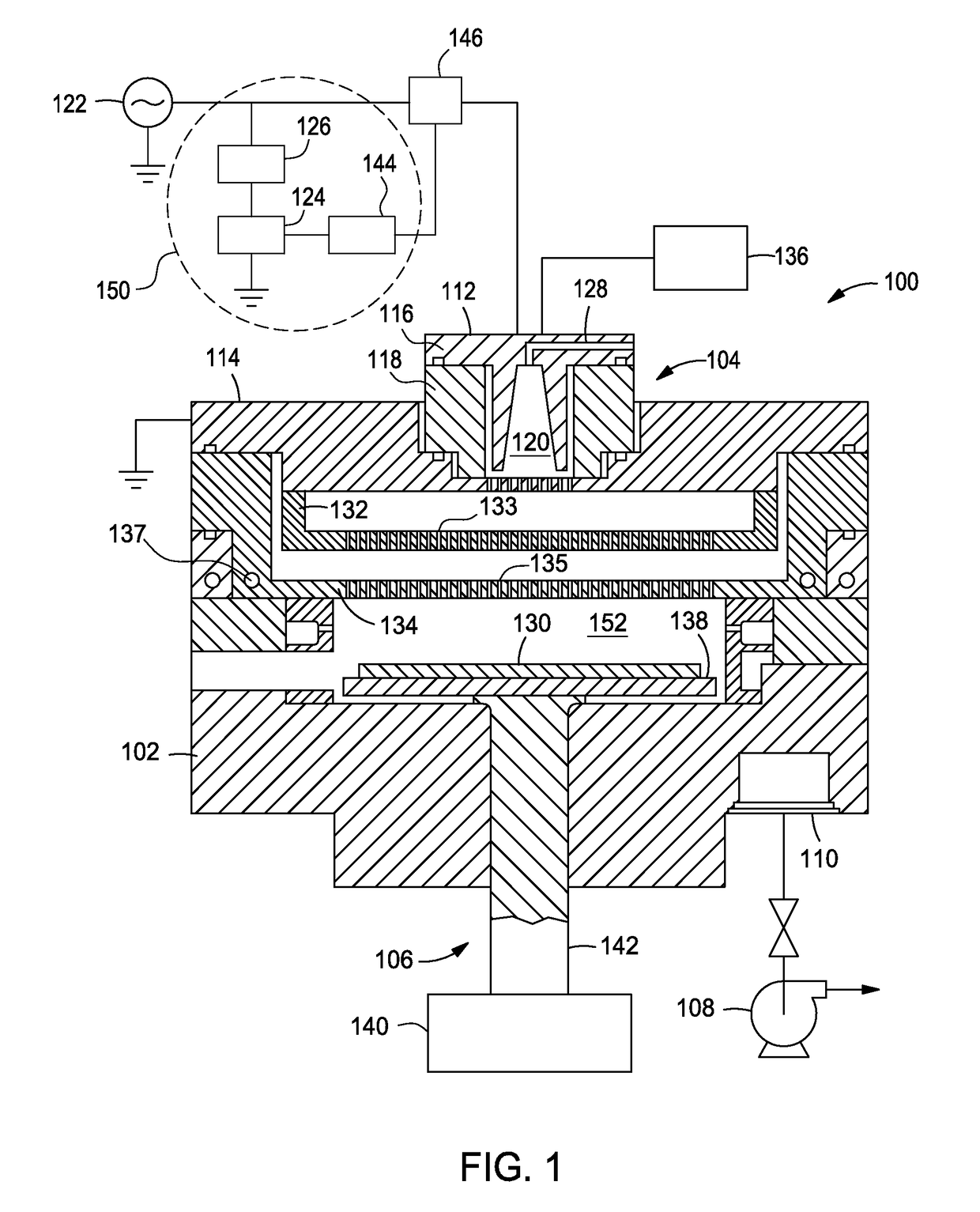

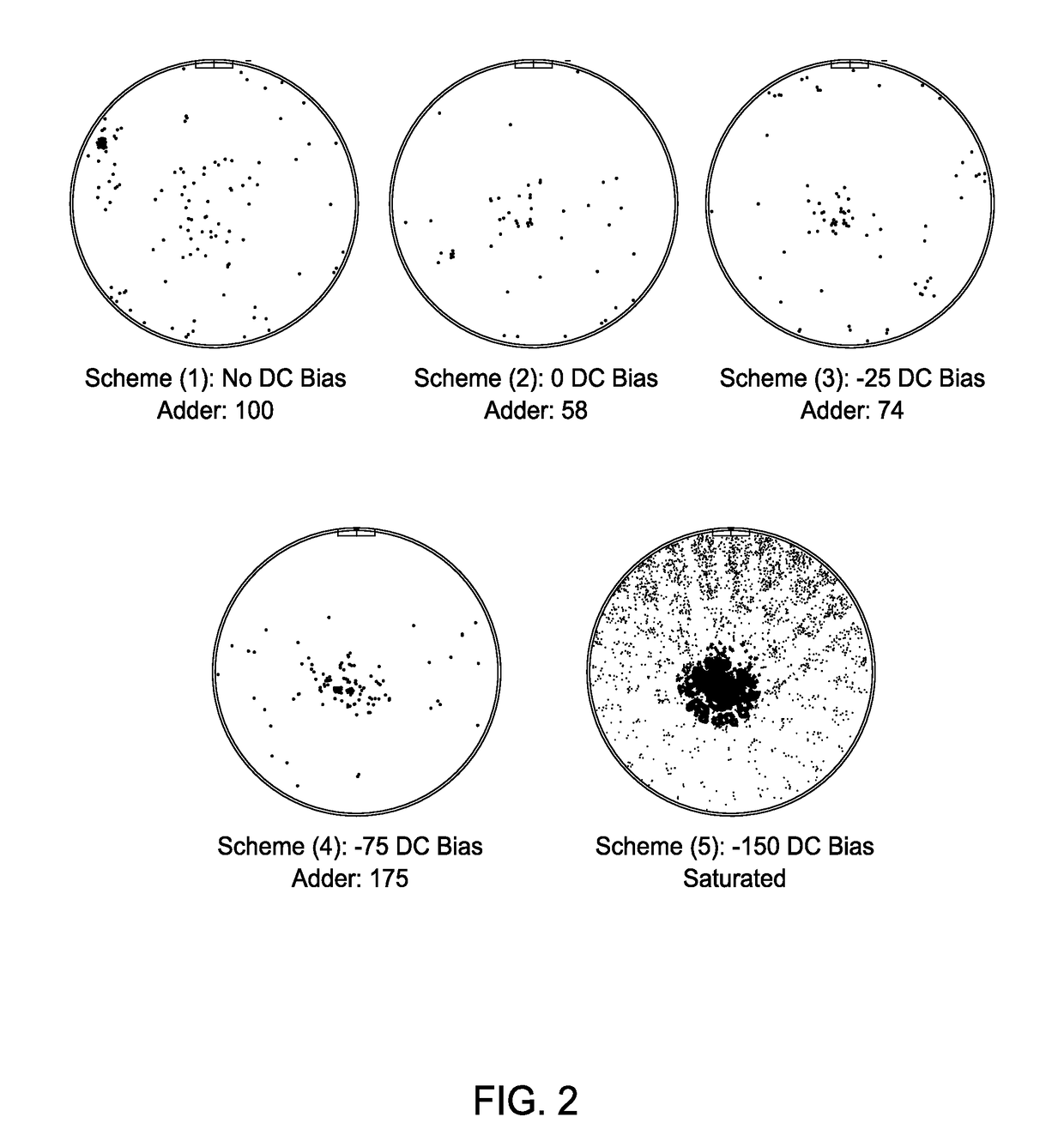

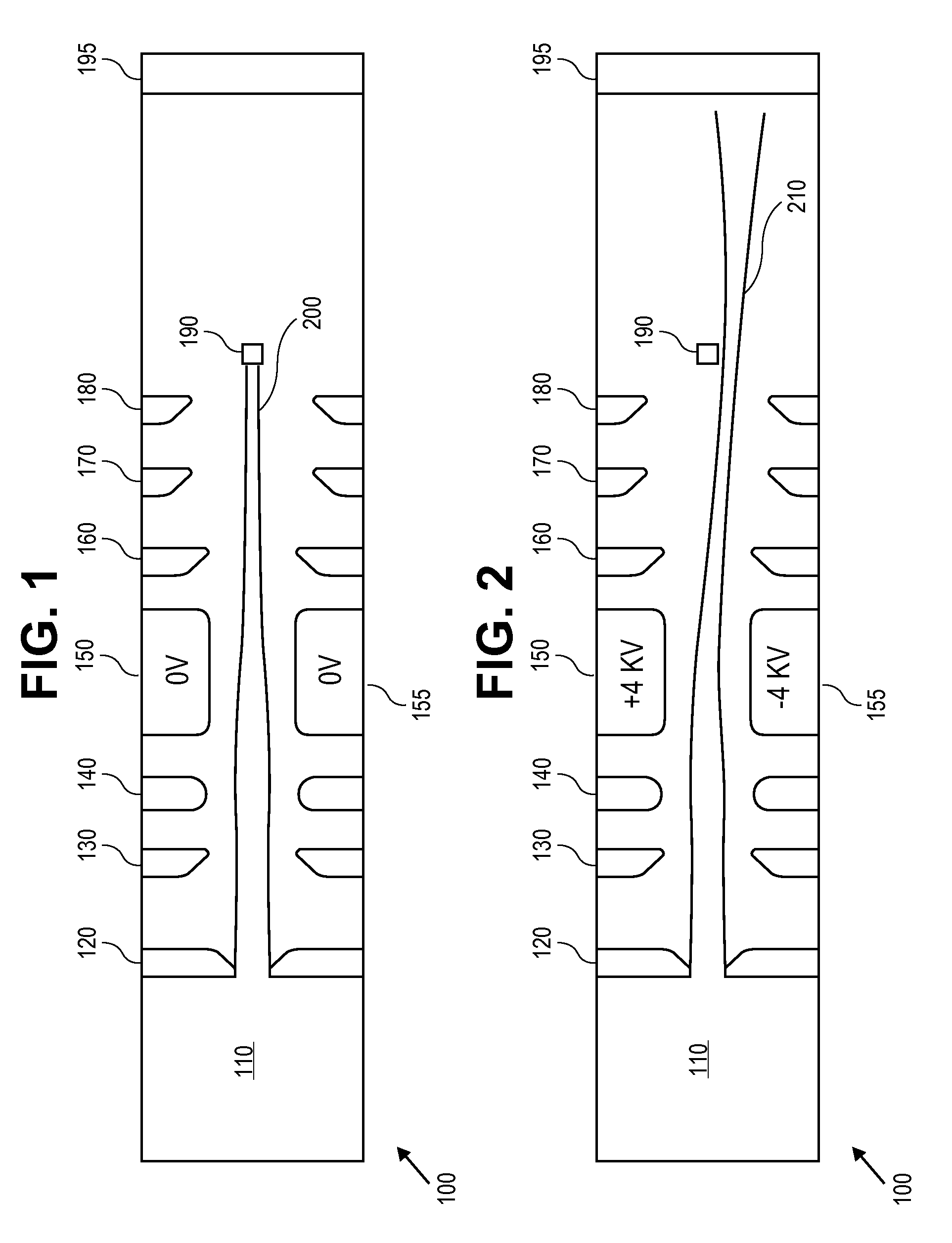

Particle generation suppresspr by DC bias modulation

Embodiments of the present disclosure generally relate to an apparatus and method for reducing particle generation in a processing chamber. In one embodiment, the methods generally includes generating a plasma between a powered top electrode and a grounded bottom electrode, wherein the top electrode is parallel to the bottom electrode, and applying a constant zero DC bias voltage to the powered top electrode during a film deposition process to minimize the electrical potential difference between the powered top electrode and the plasma and / or the electrical potential difference between the grounded bottom electrode and the plasma. Minimizing the electrical potential difference between the plasma and the electrodes reduces particle generation because the acceleration of the ions in the sheath region of the electrodes is reduced and the collision force of the ions with the protective coating layer on the electrodes is minimized. Therefore, particle generation on the substrate surface is reduced.

Owner:APPLIED MATERIALS INC

Process kit for erosion resistance enhancement

InactiveUS20050016684A1Minimize impactExtended service lifeElectric discharge tubesSemiconductor/solid-state device manufacturingPolymer sciencePermittivity

A process kit is described that resists plasma erosion, preserves the spatial uniformity of plasma properties, reduces particle generation in the chamber, and significantly enhances the lifetime of the process kit. A layer of polymer material covers the top surface of the process kit. The polymer material is fluorocarbon-based and not reactive with the species in the plasma. The polymer material not only protects the process kit from progressive erosion, but also prevents the generation of particles in the chamber. The polymer material has similar permittivity to that of the process kit and therefore maintains the spatial uniformity of plasma properties, e.g., etch rate, near the wafer perimeter. The thickness of the layer is controlled between 0.5 and 1.5 mm such that the difference between its coefficient of thermal expansion and that of the process kit will not cause the layer to peel off the process kit's top surface.

Owner:APPLIED MATERIALS INC

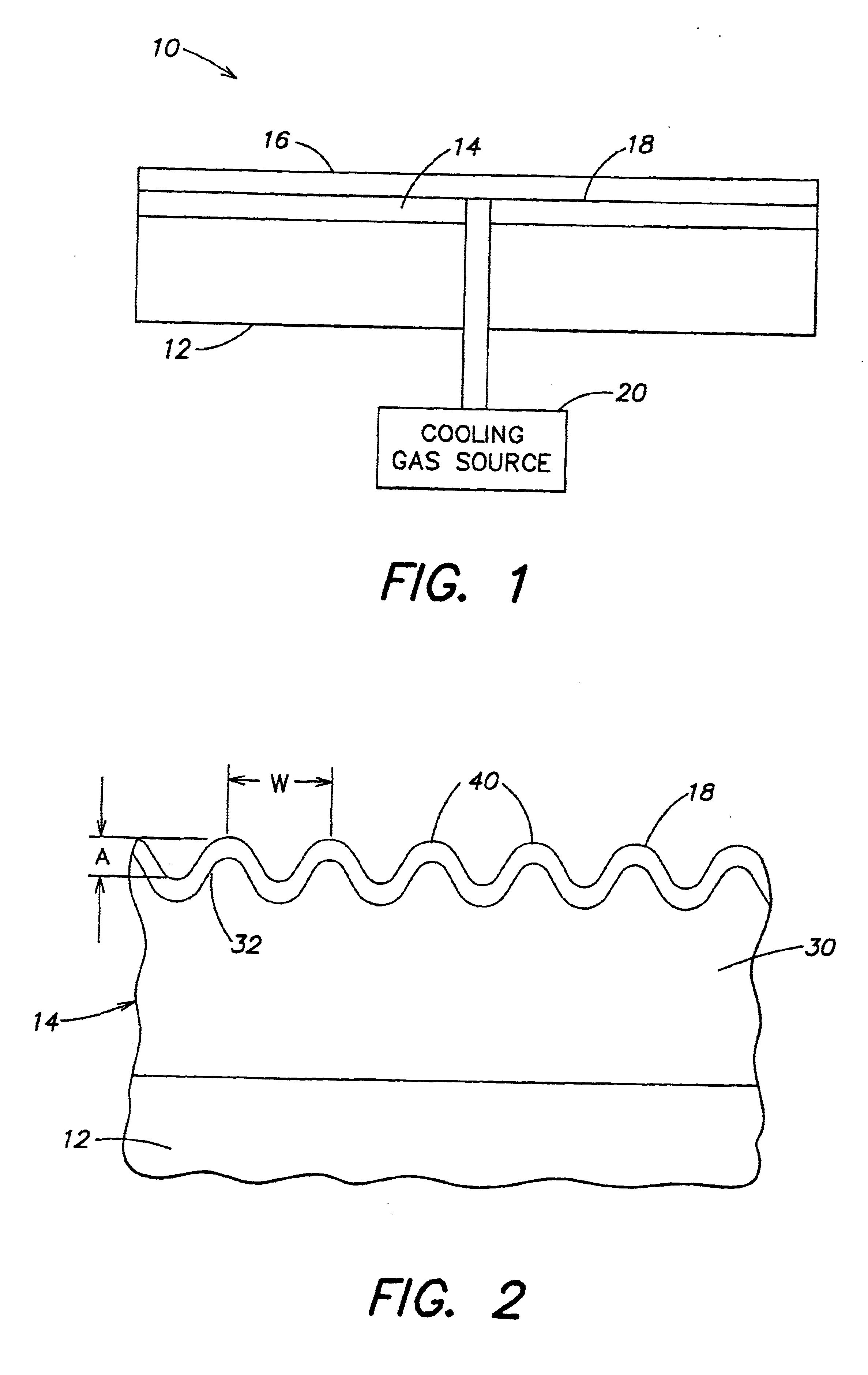

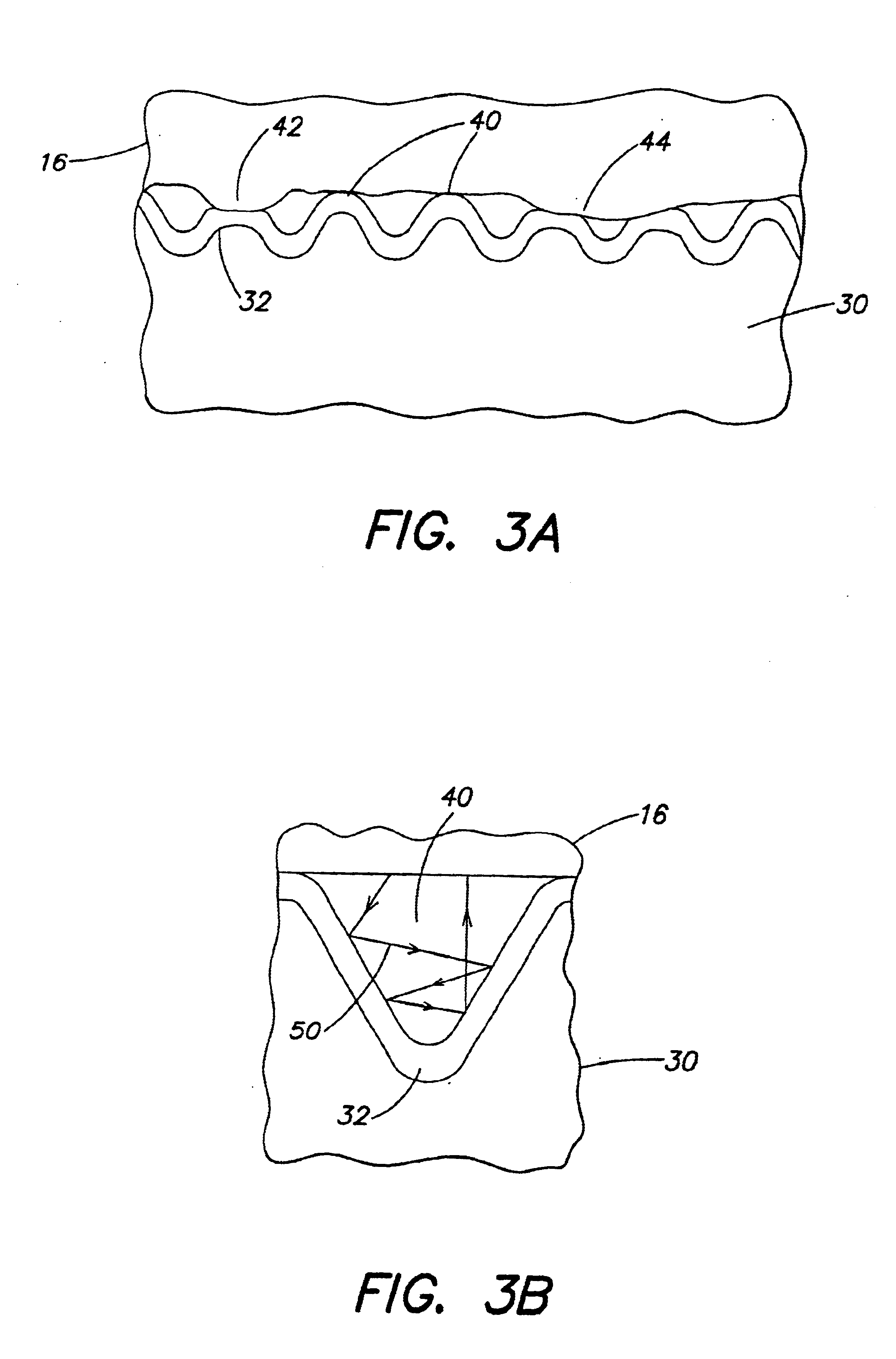

Surface structure and method of making, and electrostatic wafer clamp incorporating surface structure

InactiveUS6839217B1Increased shear strengthEfficient thermal transferSemiconductor/solid-state device manufacturingElectretsCoated surfaceEngineering

A surface structure for contacting a workpiece includes a flexible layer adhered to a support element and a coating on the flexible layer. The coating has ripples on its surface. The flexible layer may be thermally conductive. The ripples on the surface enhance thermal transfer from the workpiece and are characterized by low particle generation and low particulate contamination of the workpiece. The ripples in the coating may be formed by expanding the flexible layer, applying the coating to the expanded flexible layer and then contracting the flexible layer. In one application, the surface structure is utilized in an electrostatic wafer clamp. The surface structure provides high efficiency thermal transfer in a vacuum processing system when utilized in conjunction with a low pressure cooling gas between the workpiece and the surface structure.

Owner:VARIAN SEMICON EQUIP ASSOC INC

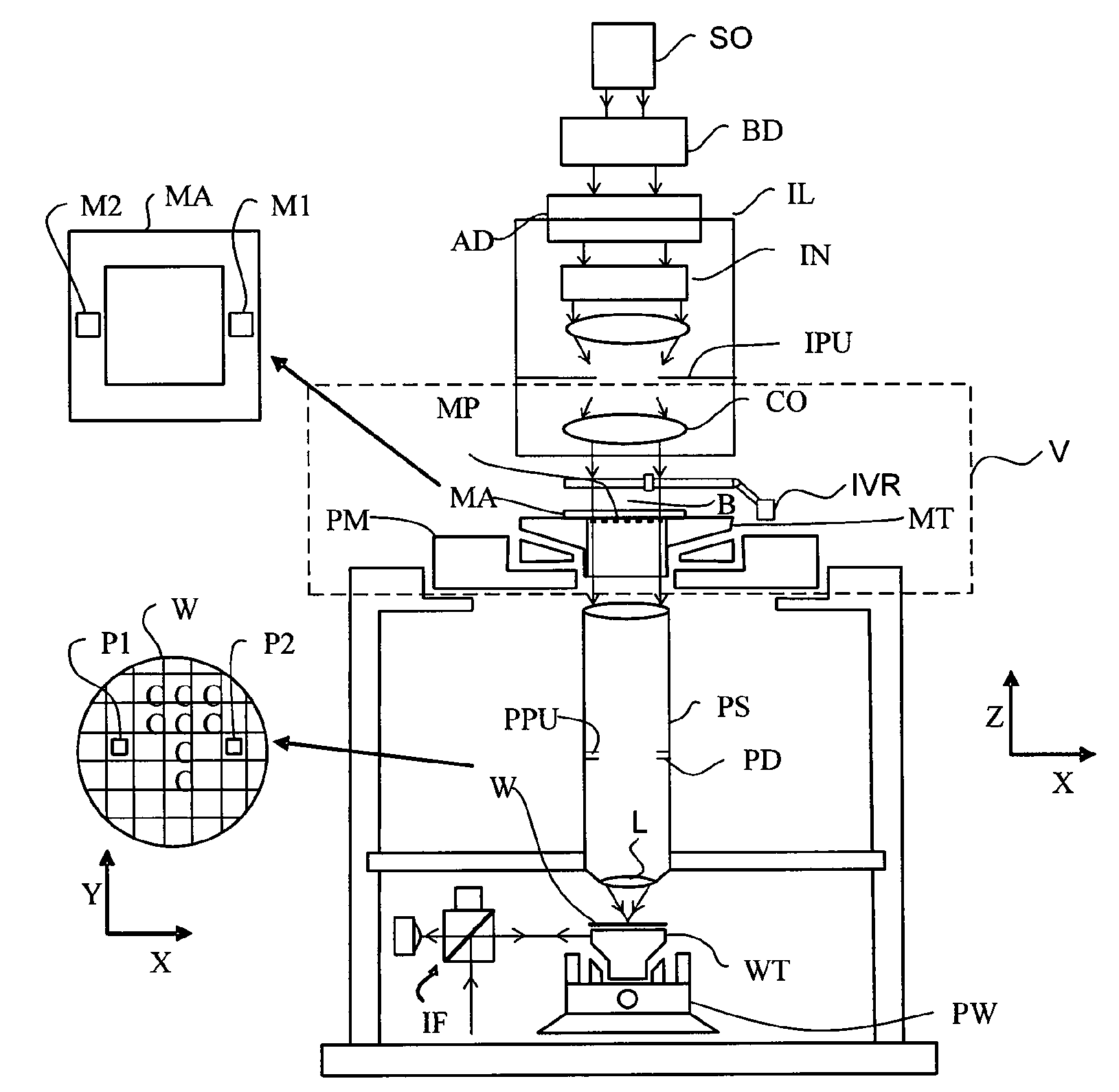

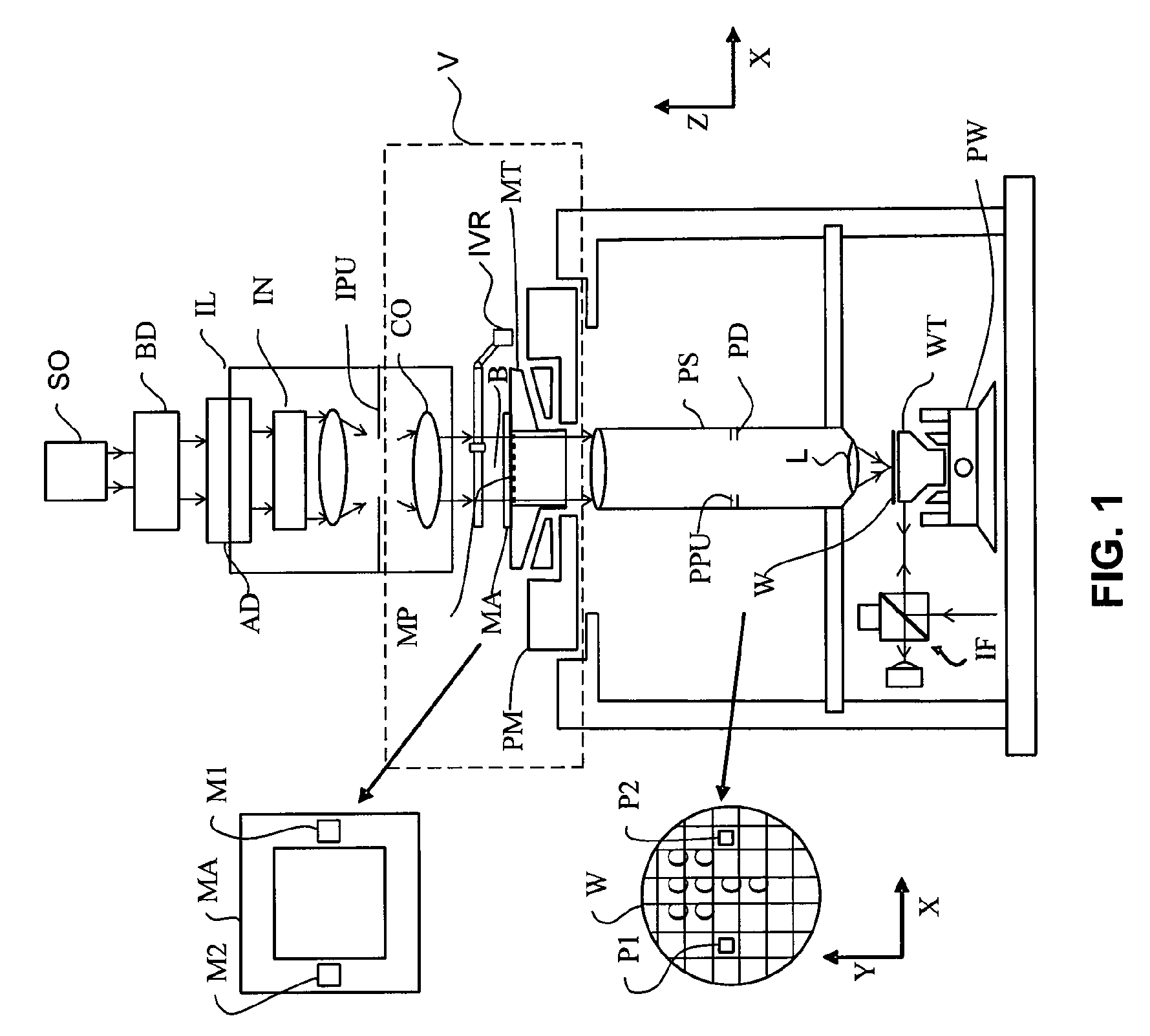

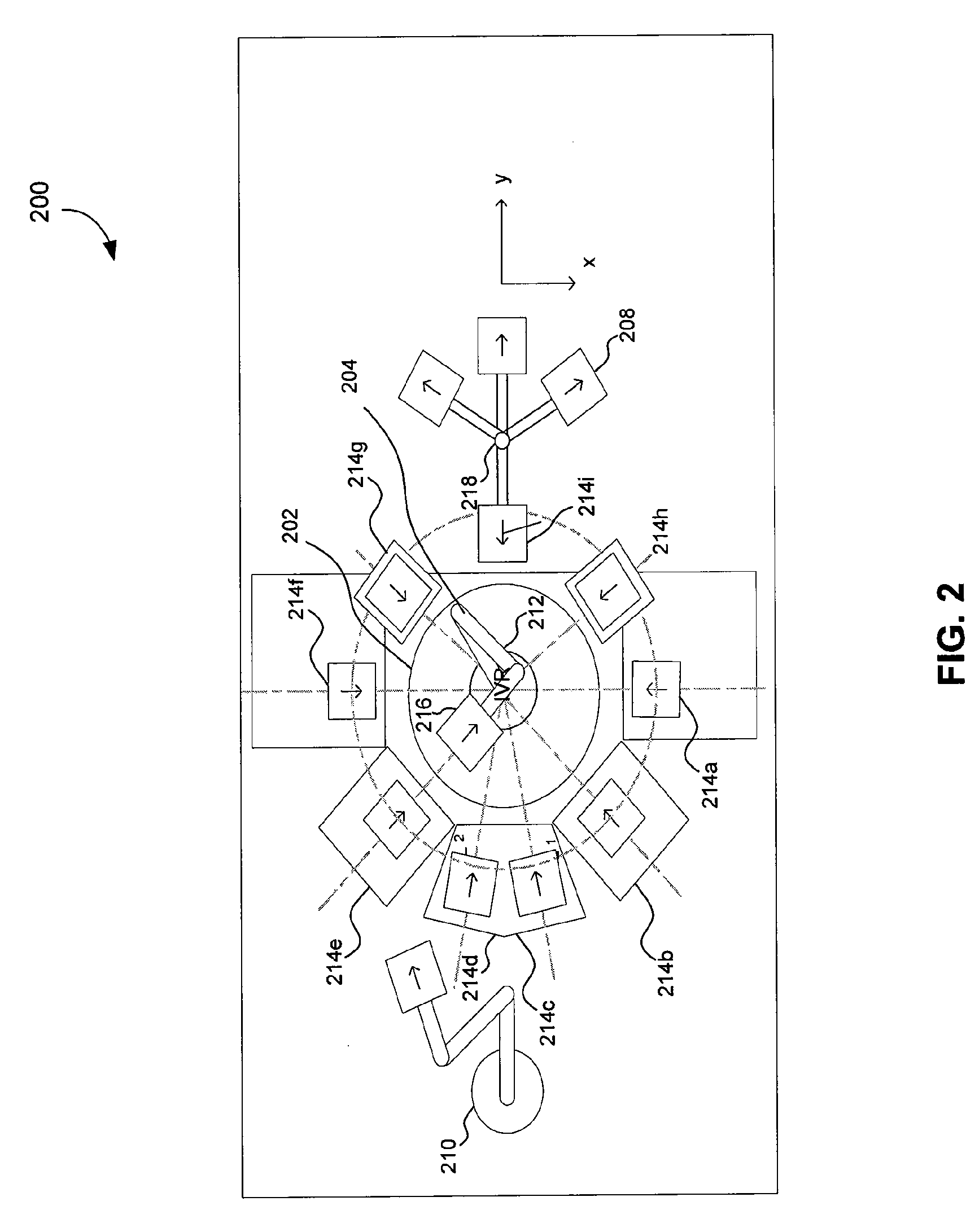

Robot Position Calibration Tool (RPCT)

InactiveUS20090259337A1Minimizes repeated particle generationQuick calibrationProgramme controlProgramme-controlled manipulatorLithographic artistOutgassing

A Robot Position Calibration Tool (RPCT) is used to accurately calibrate a robot position for a reticle hand-off to a transfer station in a lithography tool with minimized particle generation and outgassing. Method(s), system(s) and computer program product(s) are described to calibrate the robot with minimal sensor usage and minimal slippage of a payload leading to minimized particle generation and outgassing inside a vacuum chamber of a lithography tool.

Owner:ASML HLDG NV

Film of yttria-alumina complex oxide, a method of producing the same, a sprayed film, a corrosion resistant member, and a member effective for reducing particle generation

InactiveUS7138192B2Improve abilitiesReduce Particle GenerationMolten spray coatingSemiconductor/solid-state device manufacturingPrillCorrosion resistant

The invention provides a film of an yttria-alumina complex oxide having a high peel strength with respect to a substrate. A mixed powder of powdery materials of yttria and alumina is sprayed on a substrate to form a sprayed film made of an yttria-alumina complex oxide. Preferably, the powdery material of yttria has a 50 percent mean particle diameter of not smaller than 0.1 μm and not larger than 100 μm, and the powdery material of alumina has a 50 percent mean particle diameter of not smaller than 0.1 μm and not larger than 100 μm. Preferably, the yttria-alumina complex oxide contains at least a garnet phase, and may further contain a perovskite phase.

Owner:NGK INSULATORS LTD

Process kit for RF physical vapor deposition

Embodiments of the invention generally relate to a process kit for a semiconductor processing chamber, and a semiconductor processing chamber having a kit. More specifically, embodiments described herein relate to a process kit including a cover ring, a shield, and an isolator for use in a physical deposition chamber. The components of the process kit work alone and in combination to significantly reduce particle generation and stray plasmas. In comparison with existing multiple part shields, which provide an extended RF return path contributing to RF harmonics causing stray plasma outside the process cavity, the components of the process kit reduce the RF return path thus providing improved plasma containment in the interior processing region.

Owner:APPLIED MATERIALS INC

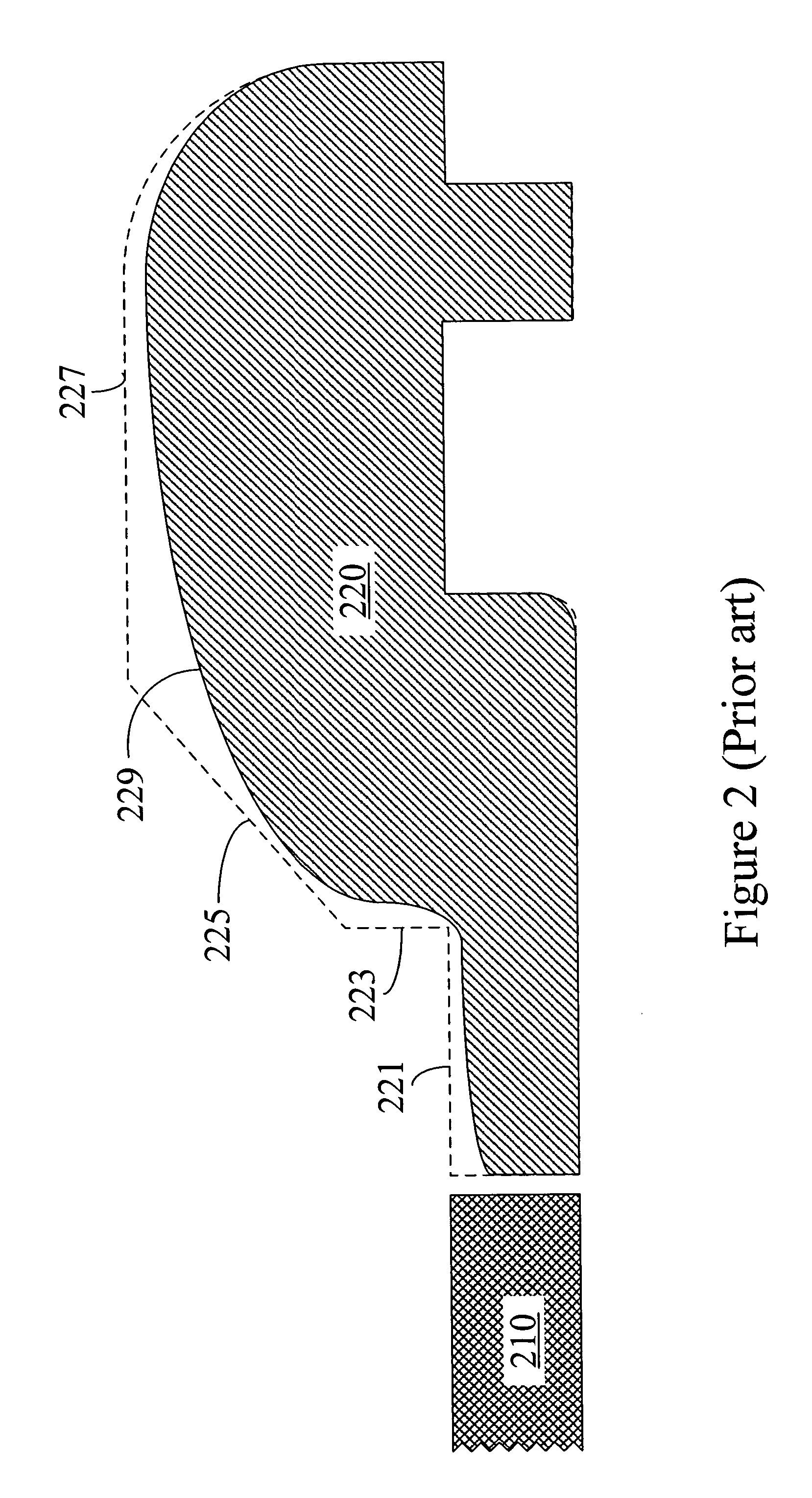

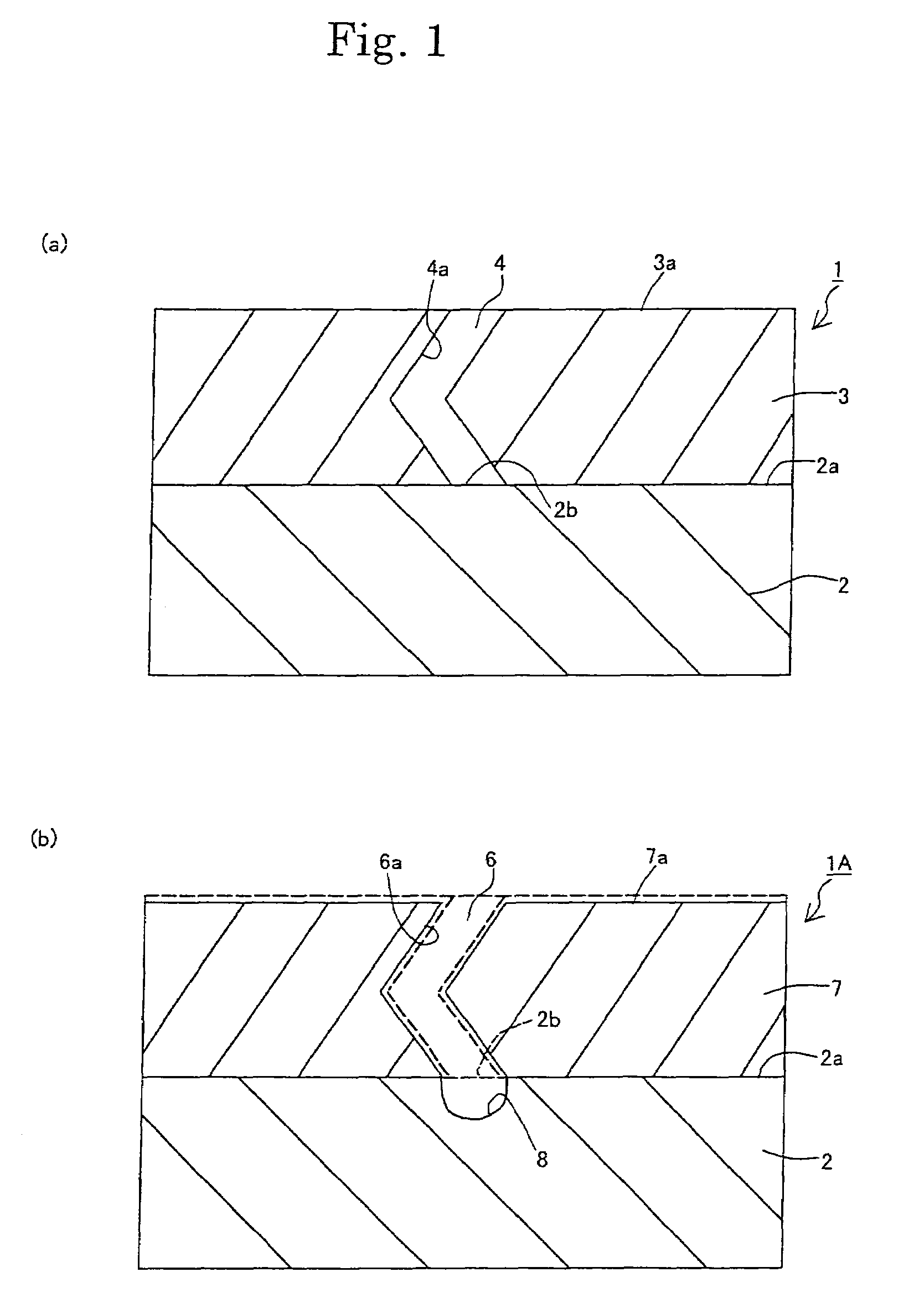

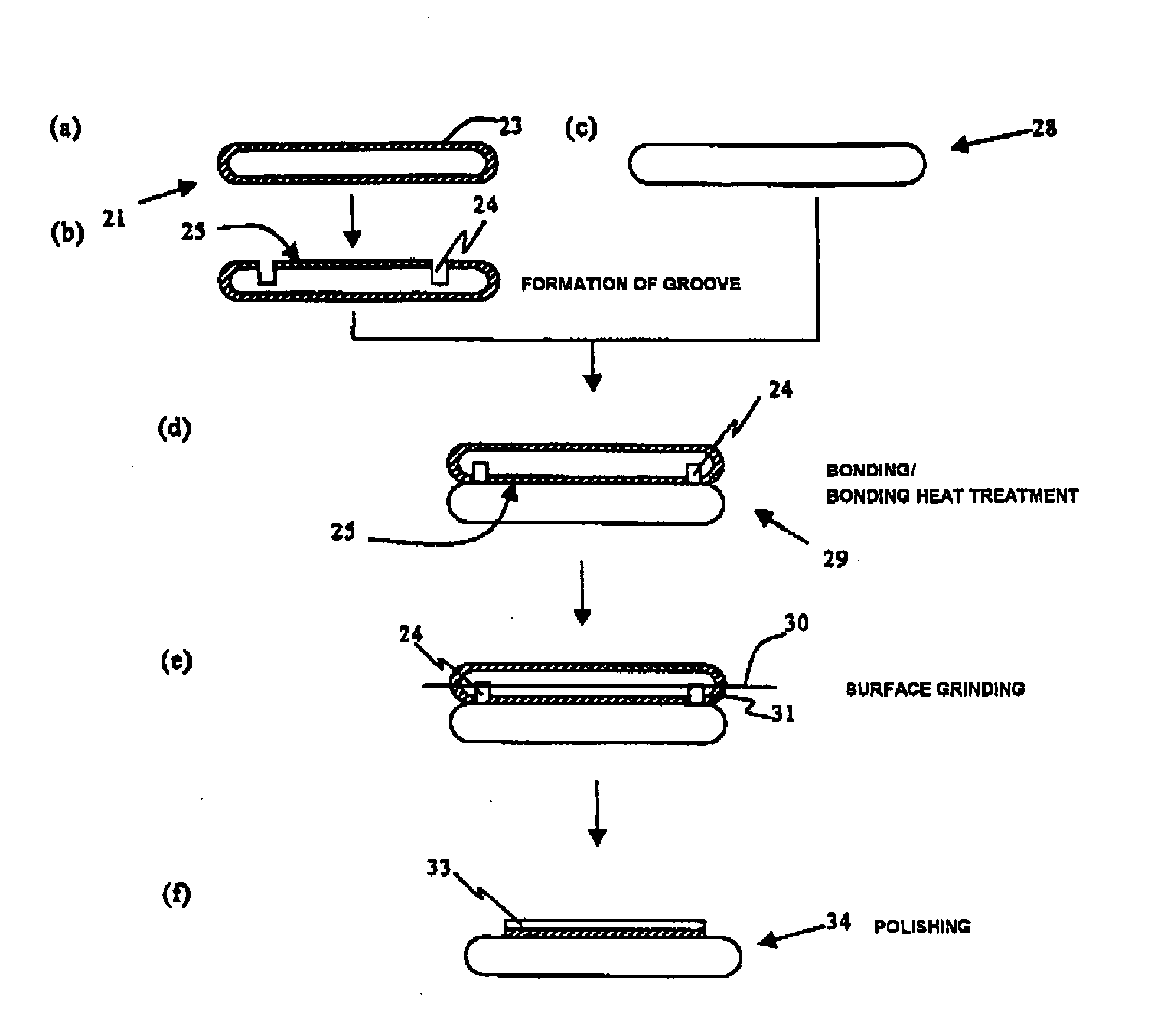

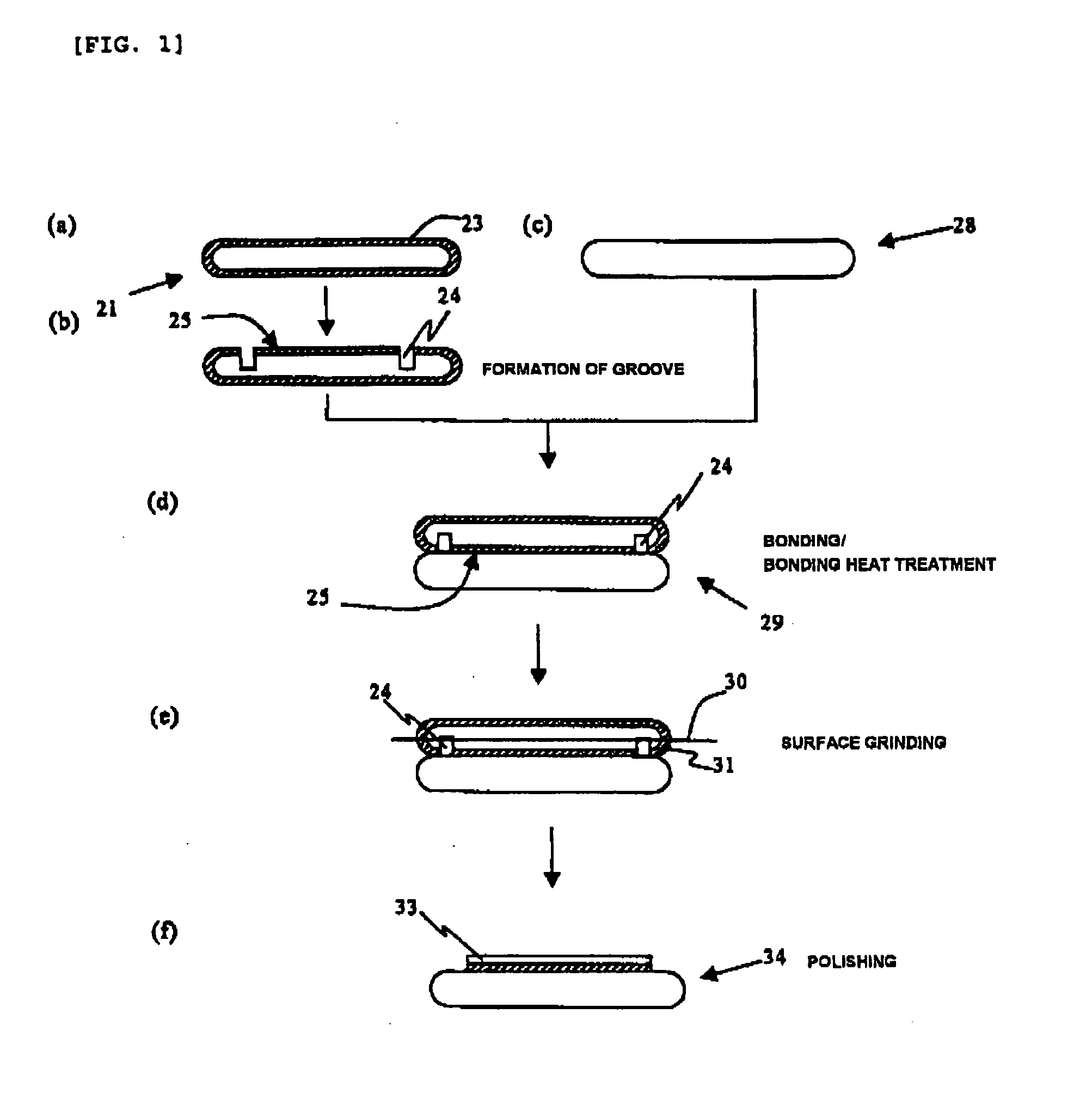

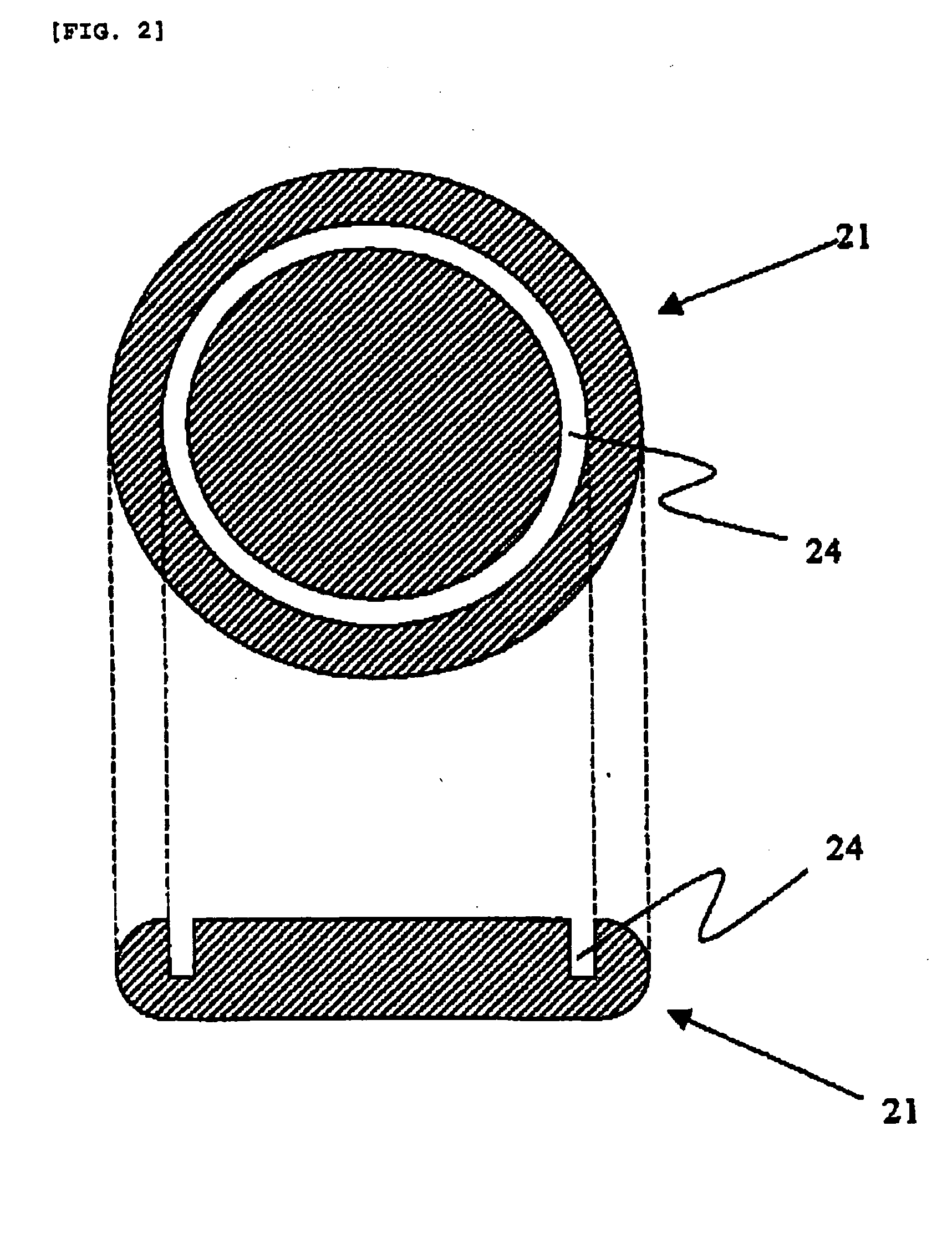

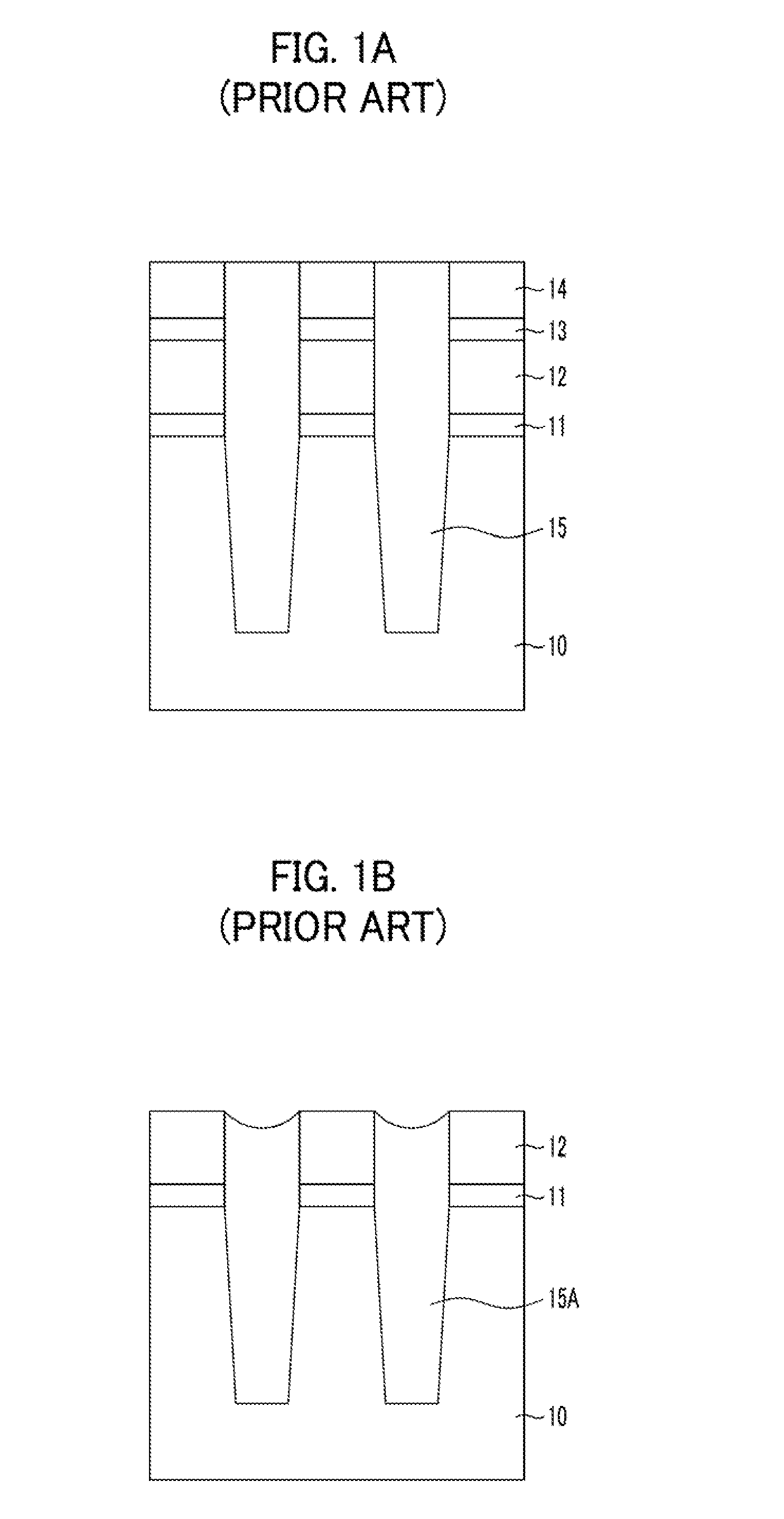

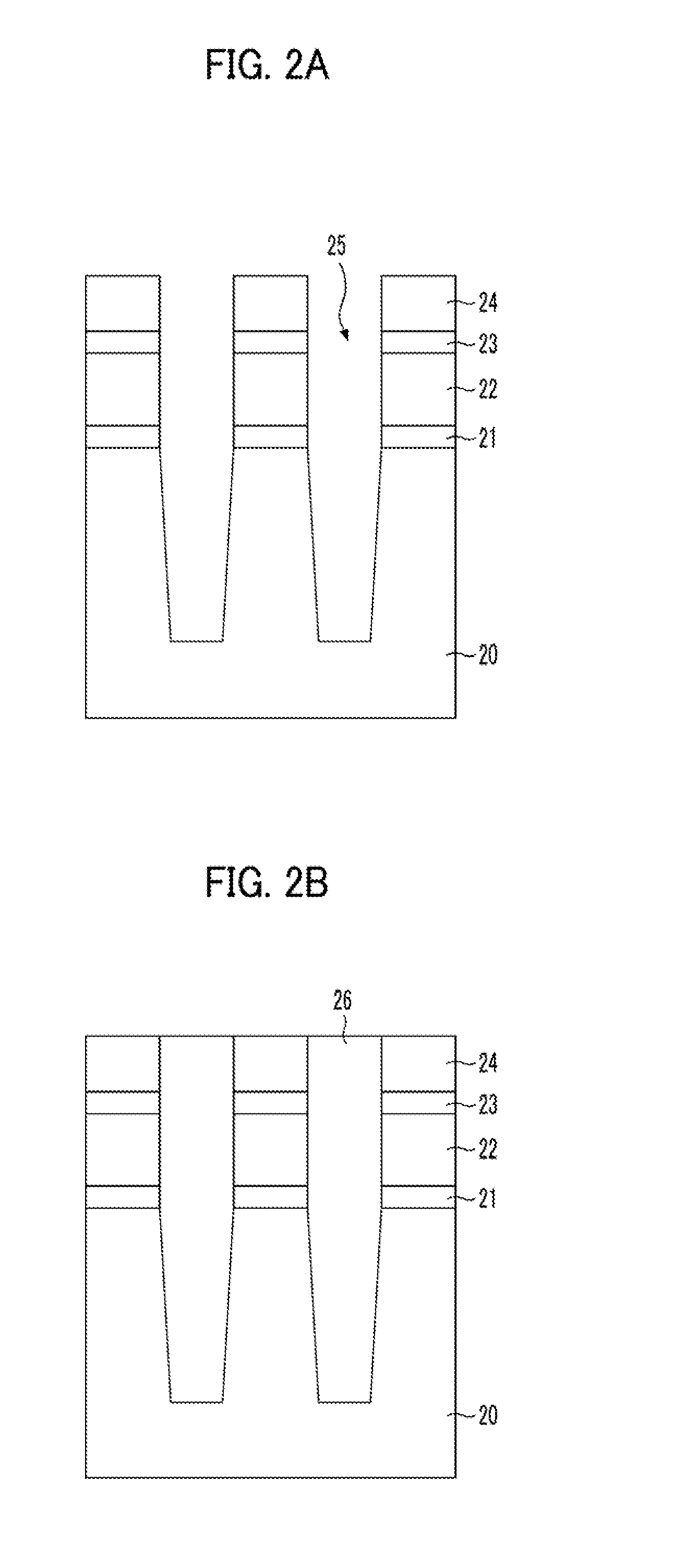

Method for Manufacturing Bonded Substrate

InactiveUS20090203167A1Reduce film thicknessGood edge shapeSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringWafer bonding

The present invention provides a method for manufacturing a bonded substrate that is a method for manufacturing a bonded substrate where an active layer wafer is bonded to a support substrate wafer, comprising: a first step of providing a groove on an inner side on a surface of the active layer wafer along an outer peripheral portion over an entire circumference; a second step of determining a surface where the groove is formed as a bonding surface and bonding the active layer wafer to the support substrate wafer; and a third step of reducing a film thickness of the active layer wafer and removing an unbonded portion on an outer side of the groove of the active layer wafer. As a result, there is provided the method for manufacturing a bonded substrate that can simplify processes, avoid breakage, cracks, or particle generation, and manage a shape of an edge portion of an active layer wafer when reducing a film thickness of the active layer wafer.

Owner:SHIN-ETSU HANDOTAI CO LTD

Fe-Pt-Based Ferromagnetic Material Sputtering Target

An Fe—Pt-based ferromagnetic material sputtering target comprising a metal and a metal oxide, wherein the metal has a composition in which Pt is contained in an amount of 5 mol % or more and 60 mol % or less and the remainder is Fe. An object of the present invention is to provide a ferromagnetic material sputtering target, which enables to form a magnetic recording layer composed of a magnetic phase such as an Fe—Pt alloy, and a non-magnetic phase to isolate the magnetic phase, and in which a metal oxide is used as one of the materials for the non-magnetic phase. Provided is a ferromagnetic material sputtering target wherein an inadvertent release of the metal oxide during sputtering and particle generation due to abnormal electrical discharge starting at a void inherently included in the target are suppressed, the adherence between the metal oxide and the matrix alloy is enhanced, and its density is increased.

Owner:JX NIPPON MINING& METALS CORP

Particle generation suppressor by DC bias modulation

Methods for reducing particle generation in a processing chamber are disclosed. The methods generally include generating a plasma between a powered top electrode and a grounded bottom electrode, wherein the top electrode is parallel to the bottom electrode, and applying a constant zero DC bias voltage to the powered top electrode during a film deposition process to minimize the electrical potential difference between the powered top electrode and the plasma and / or the electrical potential difference between the grounded bottom electrode and the plasma.

Owner:APPLIED MATERIALS INC

5 ns or less neutron and gamma pulse generator

InactiveUS20100025573A1Improve scanning rateLaser detailsDirect voltage acceleratorsBeam dumpParticle beam

A fast nuclear particle generator is described, useful for highly penetrating particle beam inspection equipment, that is capable of generating pulses of 5 ns or less, which pulses may comprise neutrons of various energies, gammas of various energies, or a mixture of neutron and gammas of various energies. The nuclear particle generator includes means for decelerating an incident swept beam so that nuclear particles are generated only during that small time interval that a beam strikes a target. This eliminates spurious background nuclear particle generation, and decreases beam dump cooling requirements.

Owner:RGT UNIV OF CALIFORNIA

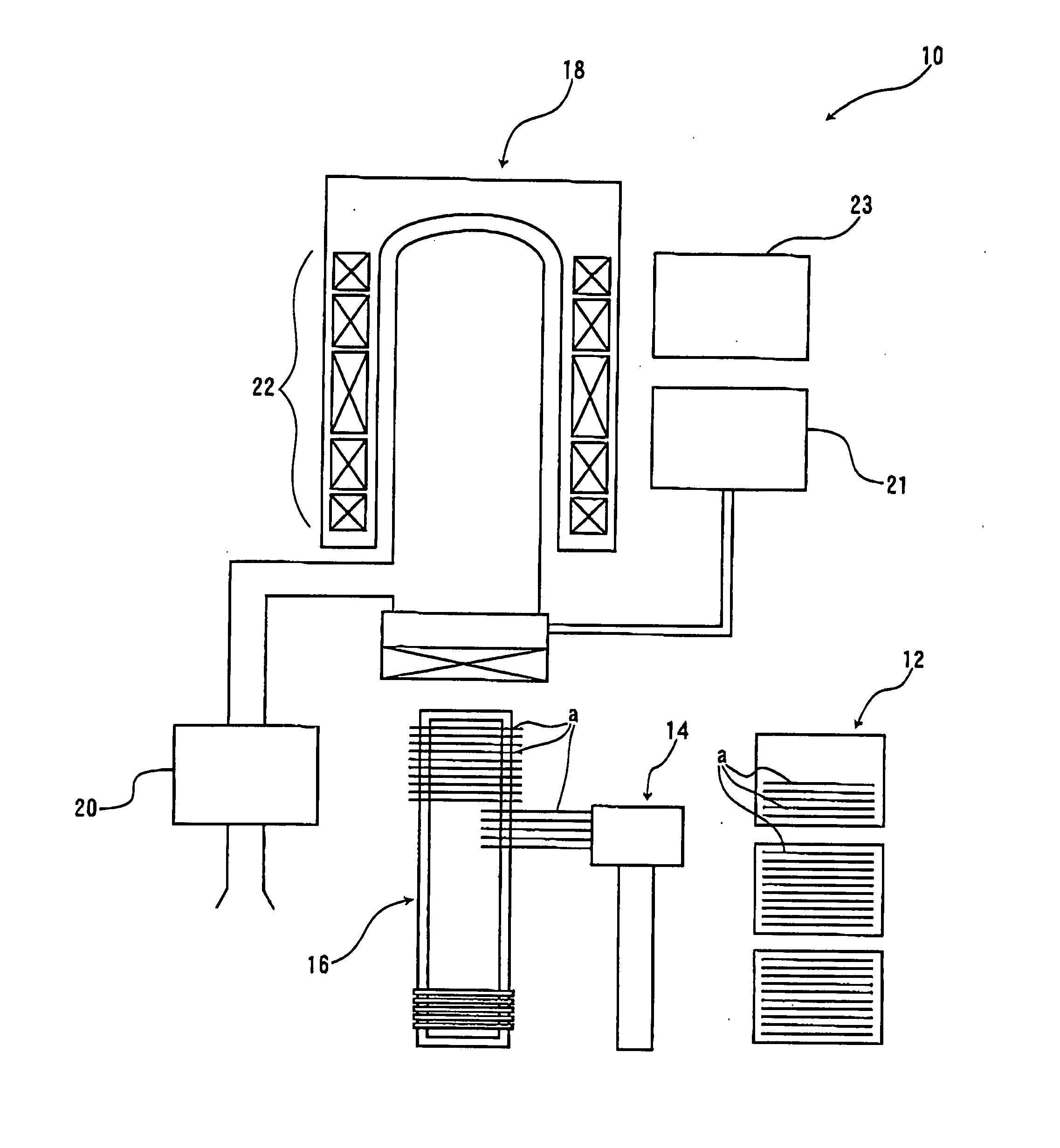

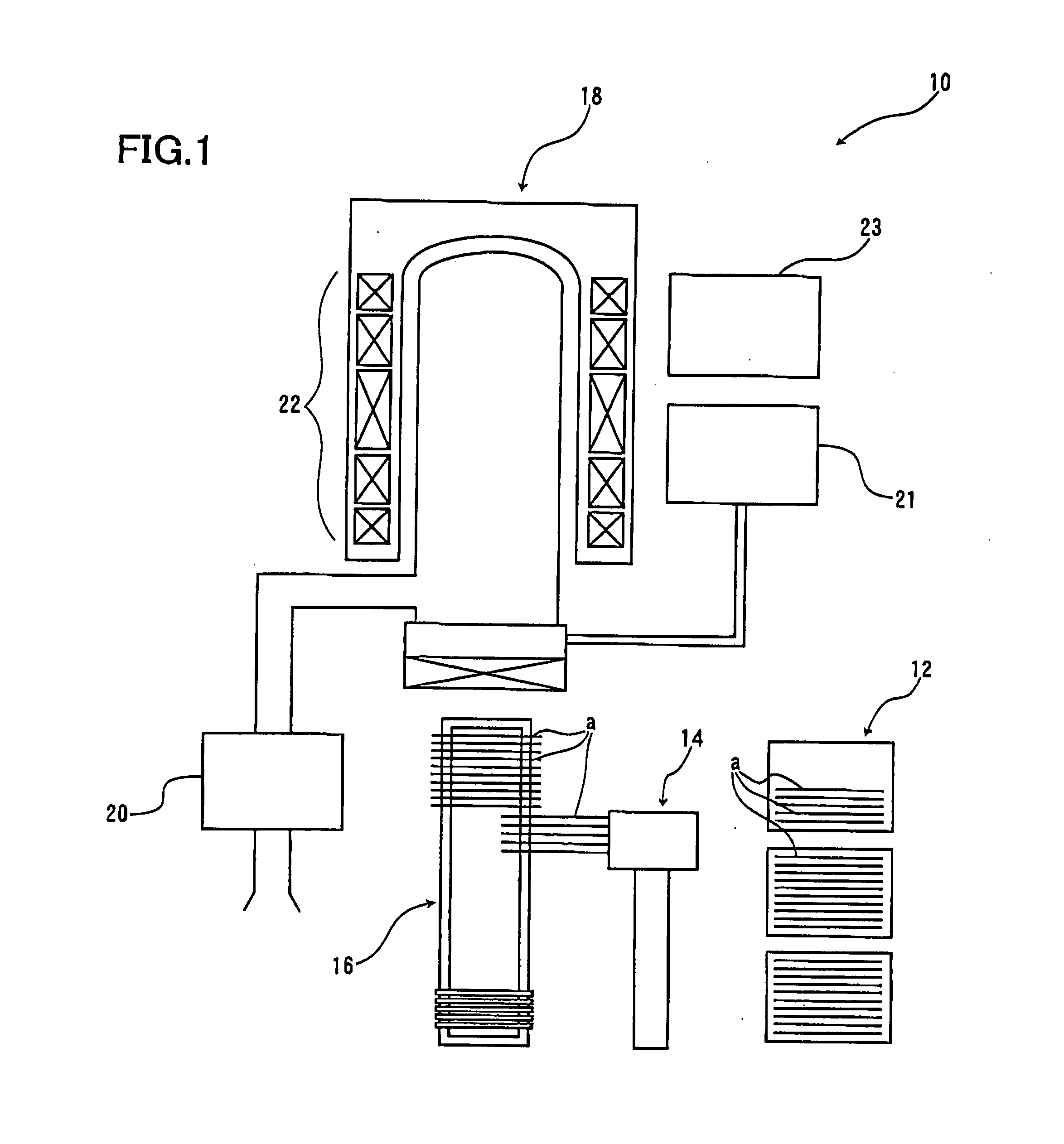

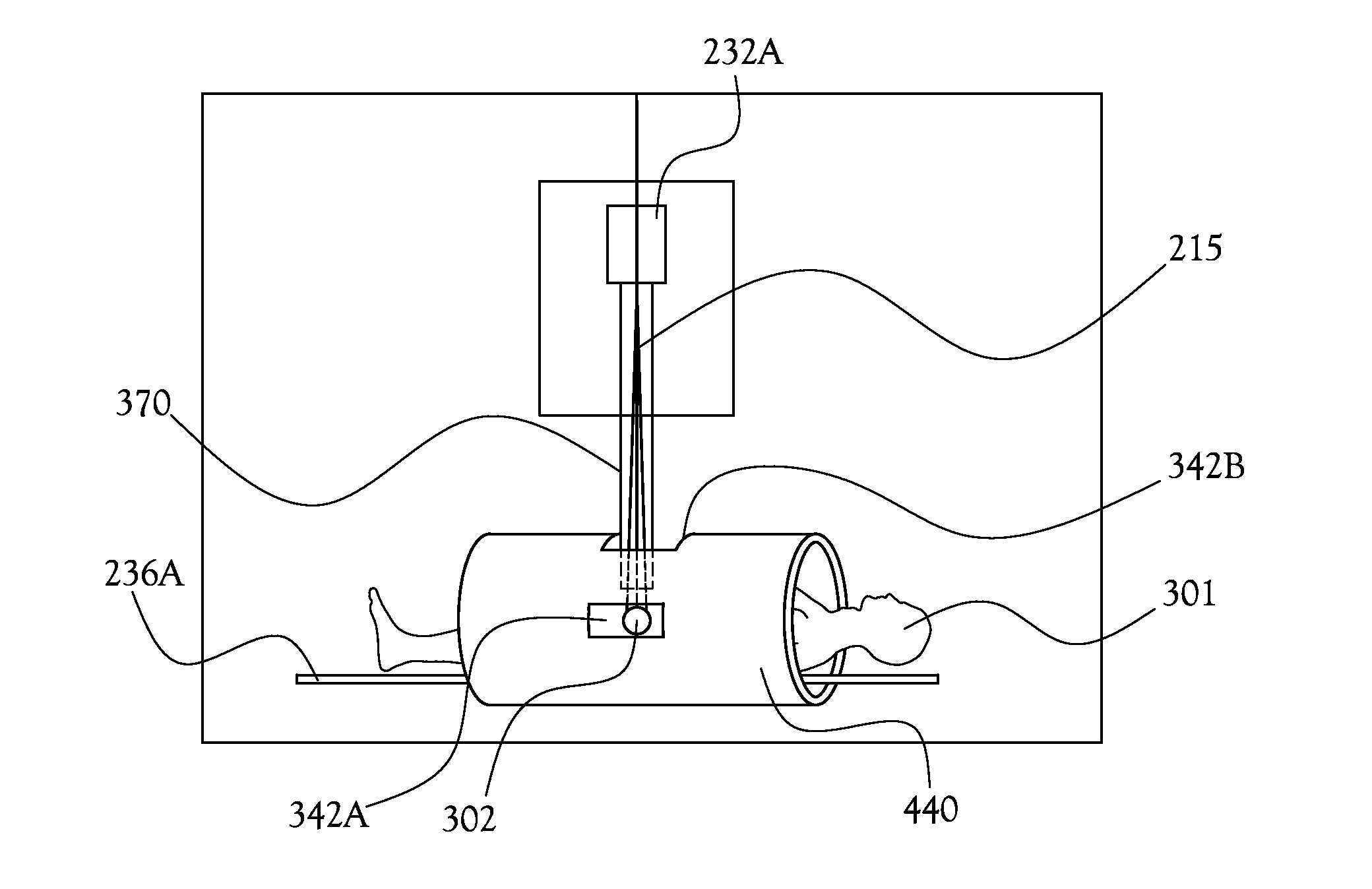

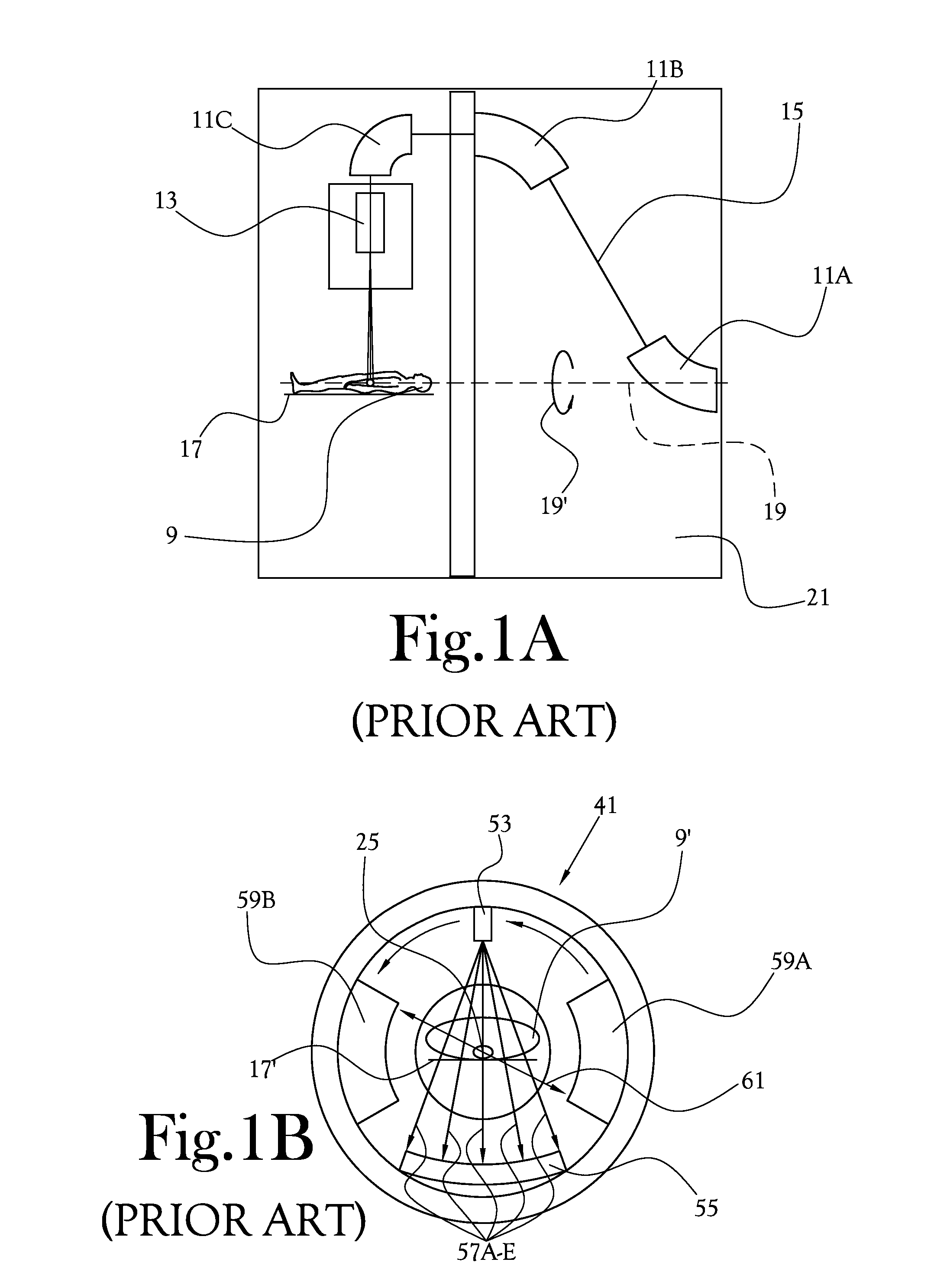

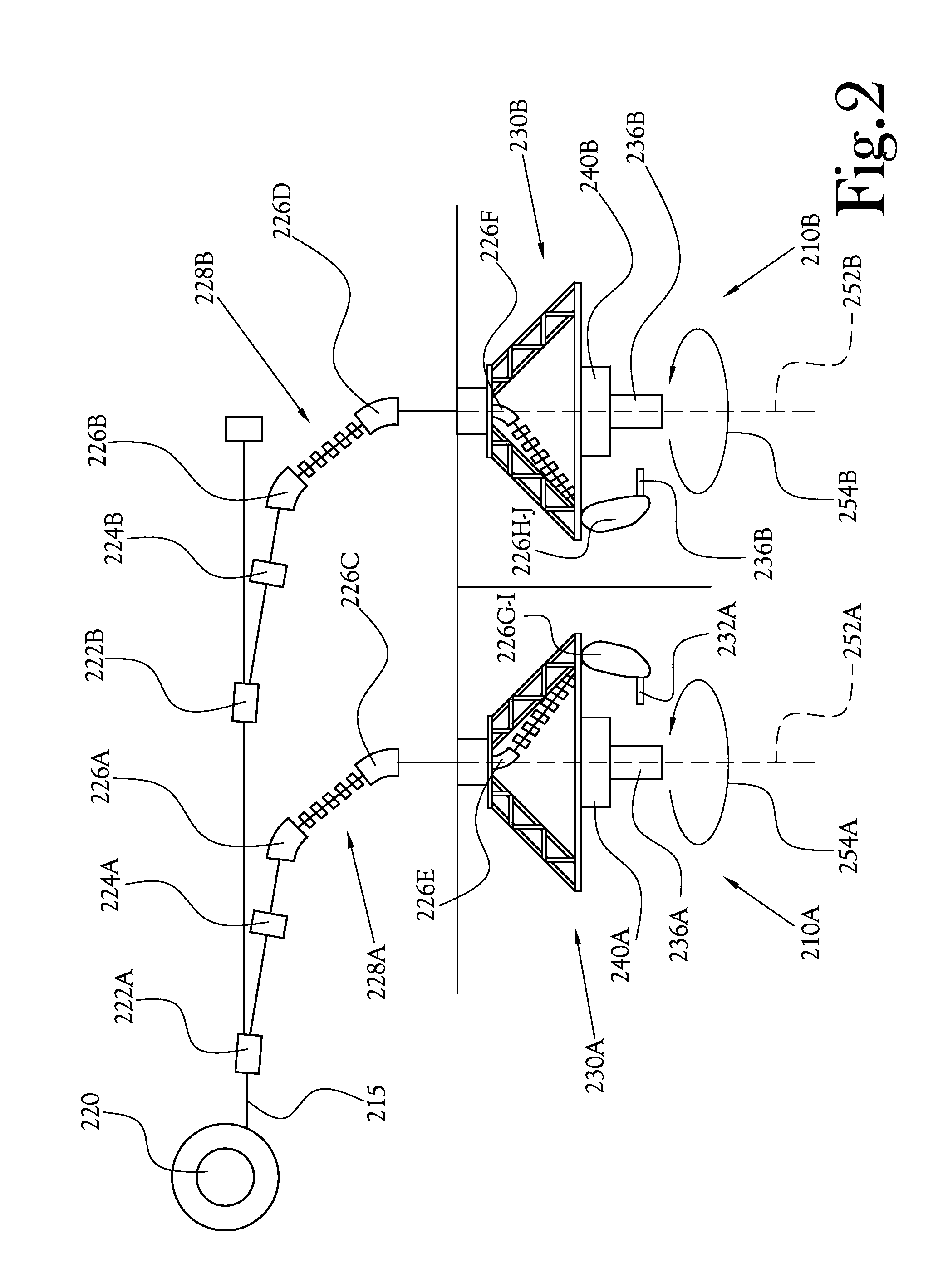

Simultaneous Imaging and Particle Therapy Treatment system and Method

InactiveUS20140066755A1Computerised tomographsDiagnostic recording/measuringNuclear medicineParticle generation

A simultaneous imaging and particle therapy treatment system including a means for generating a particle beamline, a treatment bed to receive and support a patient having a treatment volume, a gantry to receive the particle beamline from the generating means and to redirect the beamline to the patient's treatment volume, the gantry rotating about the treatment bed with an axis of rotation substantially coplanar with the treatment bed and redirecting the beamline to encounter the treatment volume substantially perpendicular to the gantry's axis of rotation, and an image scanner having a plurality of detector arrays radially positioned around the treatment bed to capture images of the treatment volume; whereby the scanner and gantry simultaneously capture images of and treat the treatment volume with particle therapy.

Owner:PRONOVA SOLUTIONS

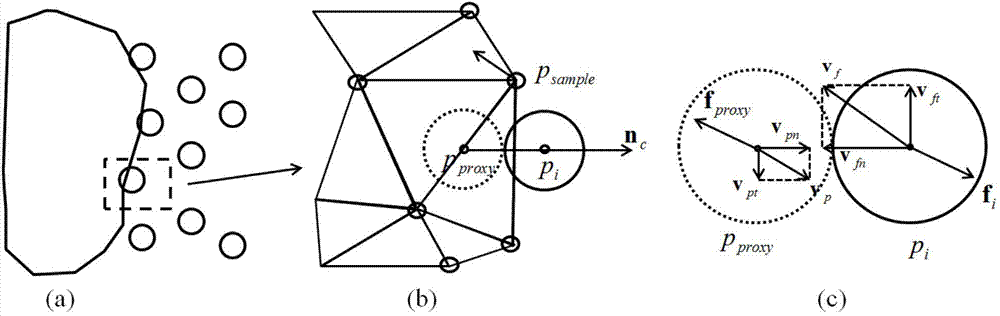

Fluid-solid coupling method based on smoothed-particle hydrodynamics (SPH) and nonlinear finite elements

InactiveCN103699715ASolve problems that are difficult to directly coupleEasy to implement in parallelSpecial data processing applicationsSmoothed-particle hydrodynamicsElement model

The invention provides a fluid-solid coupling method based on smoothed-particle hydrodynamics (SPH) and nonlinear finite elements. The method comprises the following six steps: at a collision detection stage, detecting collision information of fluid particles with a finite element network; at an agent particle generation stage, generating collision agent particles presenting a finite element model according to the collision information for processing the collision between a fluid and a solid; at a coupling force calculation stage, calculating force generated by collision between agent particles and fluid particles according to the position and speed relations of the agent particles and the fluid particles; at a coupling force allocation stage, controlling the position relation of the agent particles and the finite element model and allocating the coupling force to a finite element stress model; at a position and speed updating stage, driving the position and speed update of the finite element model and a fluid particle model according to the calculated coupling force; at a non-penetration modification stage, modifying penetration fluid particles according to an updated position.

Owner:BEIHANG UNIV

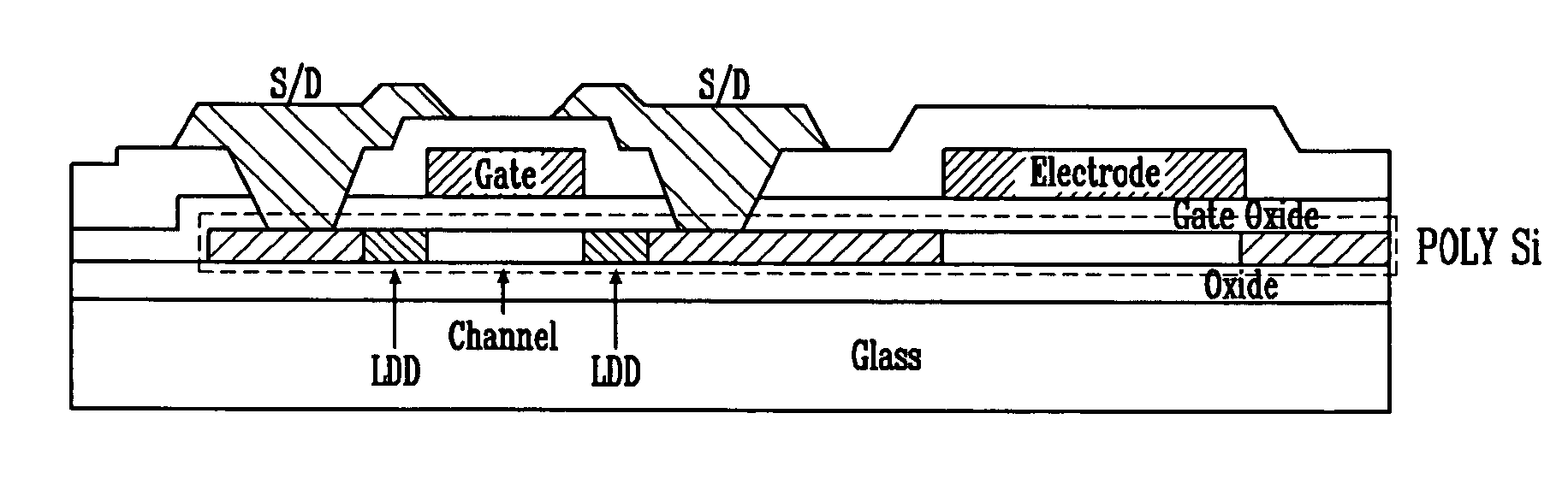

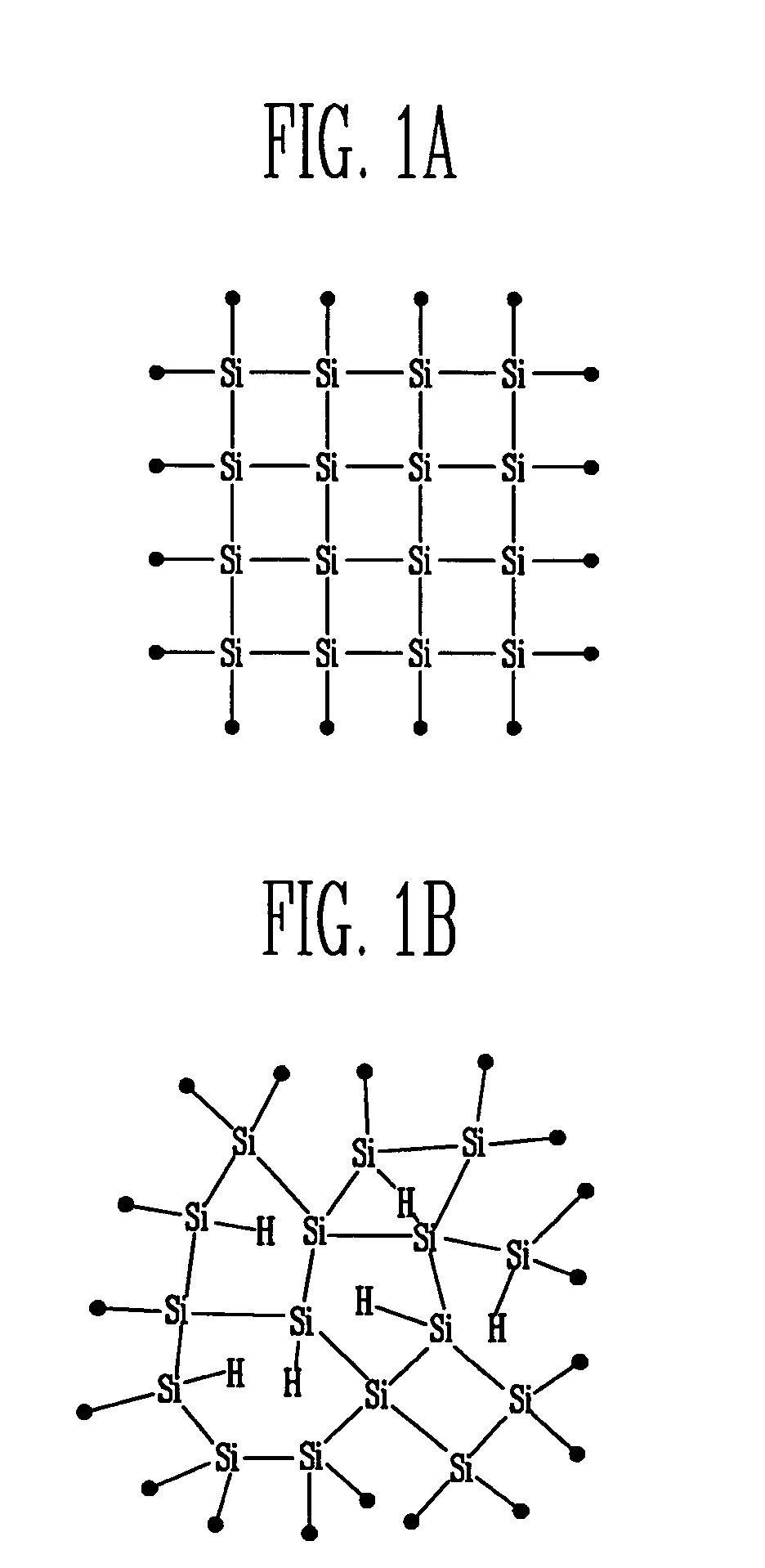

CVD apparatus for depositing polysilicon

InactiveUS20070128861A1Minimizes particle generationInhibit deteriorationSolid-state devicesSemiconductor/solid-state device manufacturingHydrogen contentEngineering

Disclosed is a CVD apparatus for depositing polysilicon without a separate following annealing process, the CVD apparatus comprising: a chamber to form a thin film on a substrate; a showerhead placed in an upper part of the chamber to inject reaction gas onto the substrate; a distributor formed with distributing holes to uniformly distribute the reaction gas; a catalyst hot wire unit to heat and dissolve the reaction gas injected through the distributing holes of the distributor; a chuck on which the substrate is mounted; a discharging hole to discharge the reaction gas; and a shielding wall provided as a lateral wall of the chamber and formed with a heater to suppress particle generation. With this configuration, the particle generation is minimized and thus the yield is enhanced. Also, the thin film has good crystallinity, and decreased hydrogen content.

Owner:SAMSUNG MOBILE DISPLAY CO LTD +1

A kind of preparation method of cermet coating with intermetallic compound as bonding phase

InactiveCN102296289ASimple structureAccelerated corrosionMetallic material coating processesCeramic compositeCeramic coating

The invention discloses a structure design and preparation method of a metal-ceramic coating with an intermetallic compound as a binding phase, which adopts a mechanical alloying process to prepare a metastable structure metal / ceramic composite powder with a high volume fraction of a ceramic hard phase. By cold spraying the precipitation coating and heat treatment process, the in-situ generation of the intermetallic compound binder phase and the control of the interface between the particle interface, the ceramic hard phase and the binder phase interface are used to obtain the intermetallic compound-based metal with controllable interface bonding. Ceramic coating. The intermetallic compound-based cermet coating prepared by the method has the structural characteristics of high volume fraction of ceramic hard phase, good dispersibility, in-situ generation of intermetallic compound binding phase and controllable bonding of particle interface.

Owner:JIUJIANG UNIVERSITY

Etching composition and method for fabricating semiconductor device using the same

ActiveUS20130157427A1Minimizing etch rateSolid-state devicesSemiconductor/solid-state device manufacturingPower semiconductor devicePhosphate

The present invention provides an etching composition, comprising a silyl phosphate compound, phosphoric acid and deionized water, and a method for fabricating a semiconductor, which includes an etching process employing the etching composition. The etching composition of the invention shows a high etching selectivity for a nitride film with respect to an oxide film. Thus, when the etching composition of the present invention is used to remove a nitride film, the effective field oxide height (EEH) may be easily controlled by controlling the etch rate of the oxide film. In addition, the deterioration in electrical characteristics caused by damage to an oxide film or etching of the oxide film may be prevented, and particle generation may be prevented, thereby ensuring the stability and reliability of the etching process.

Owner:SK HYNIX INC

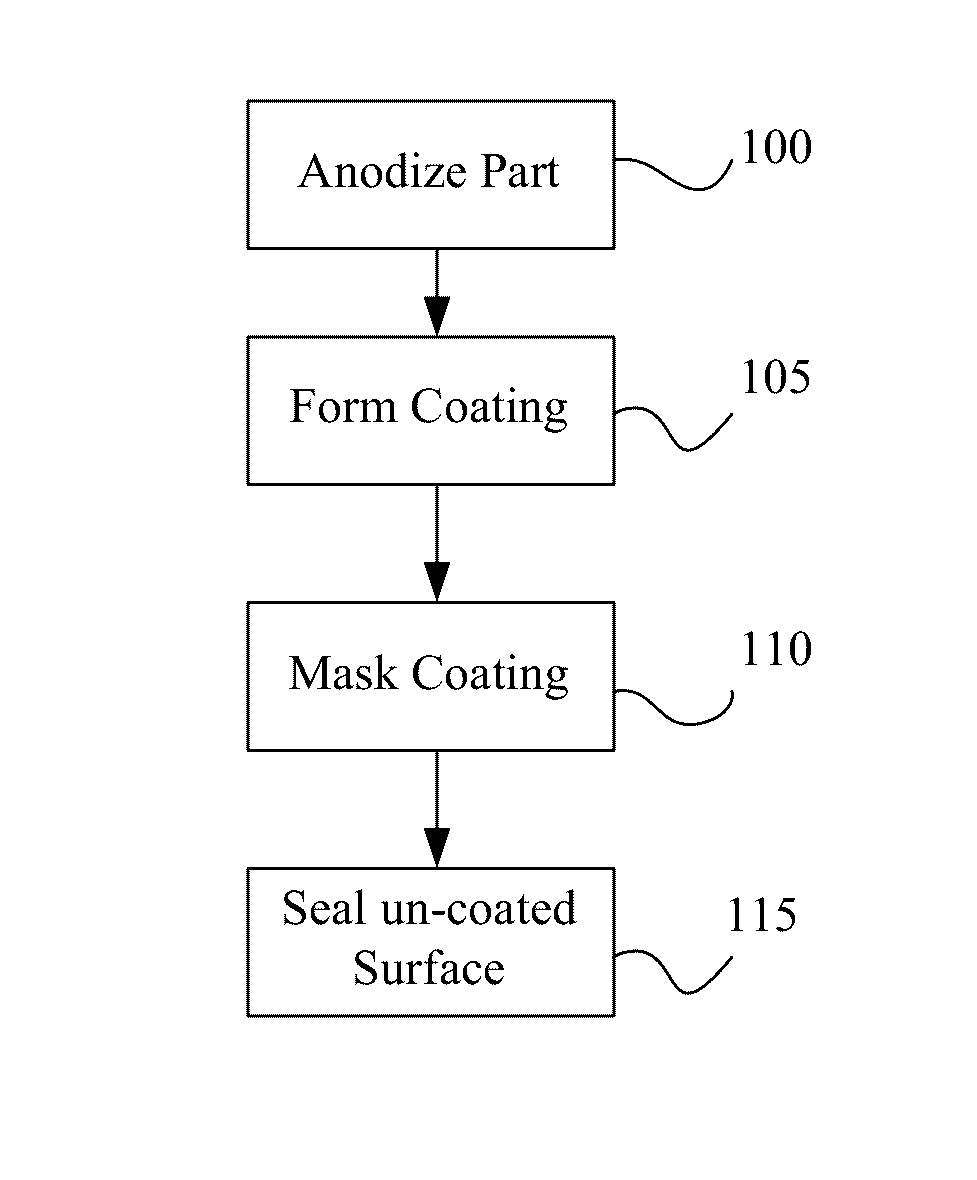

Coating packaged chamber parts for semiconductor plasma apparatus

ActiveUS9617633B2Improve service performanceImprove processing qualityAnodisationVacuum evaporation coatingSemiconductor plasmaParticle generation

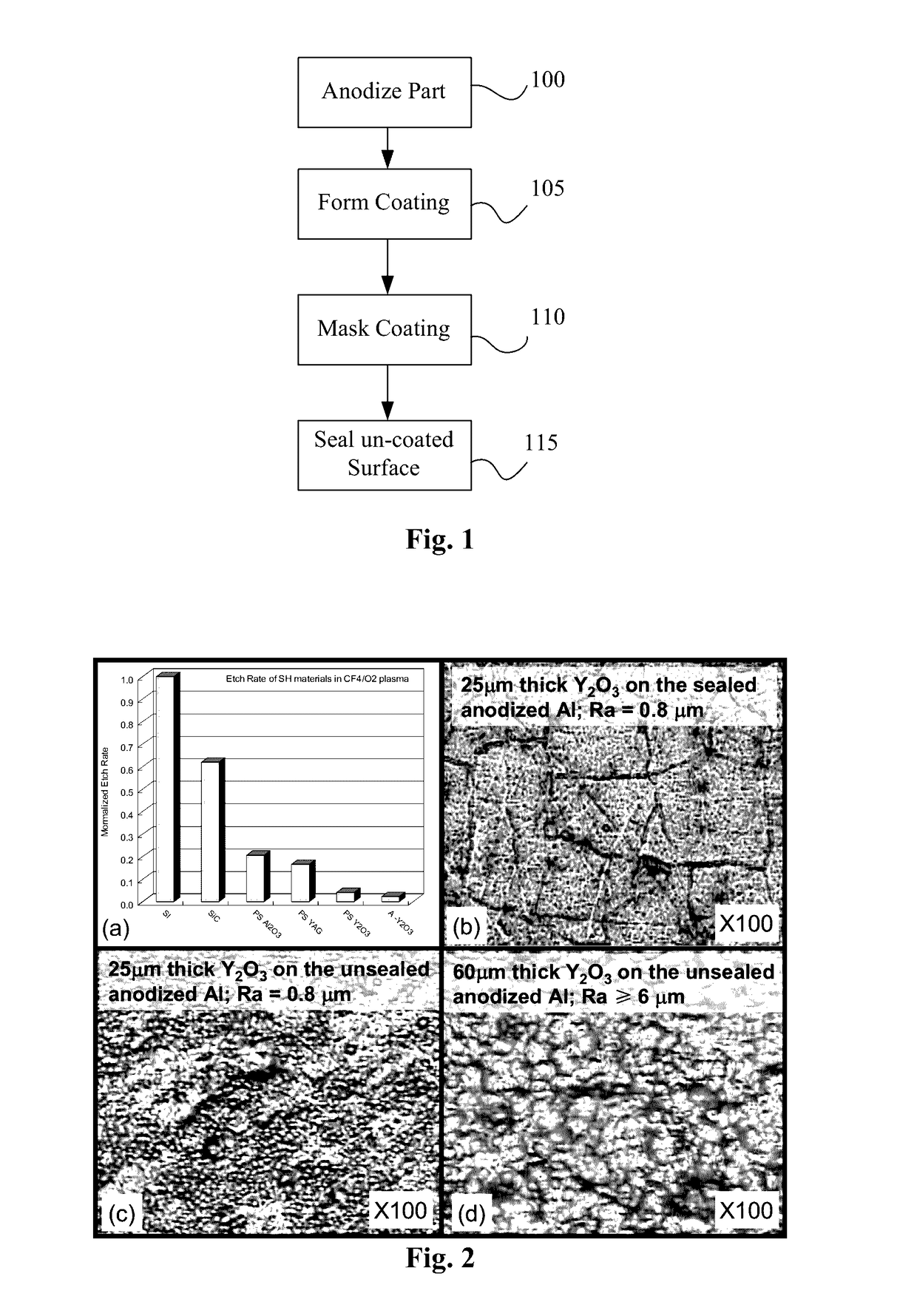

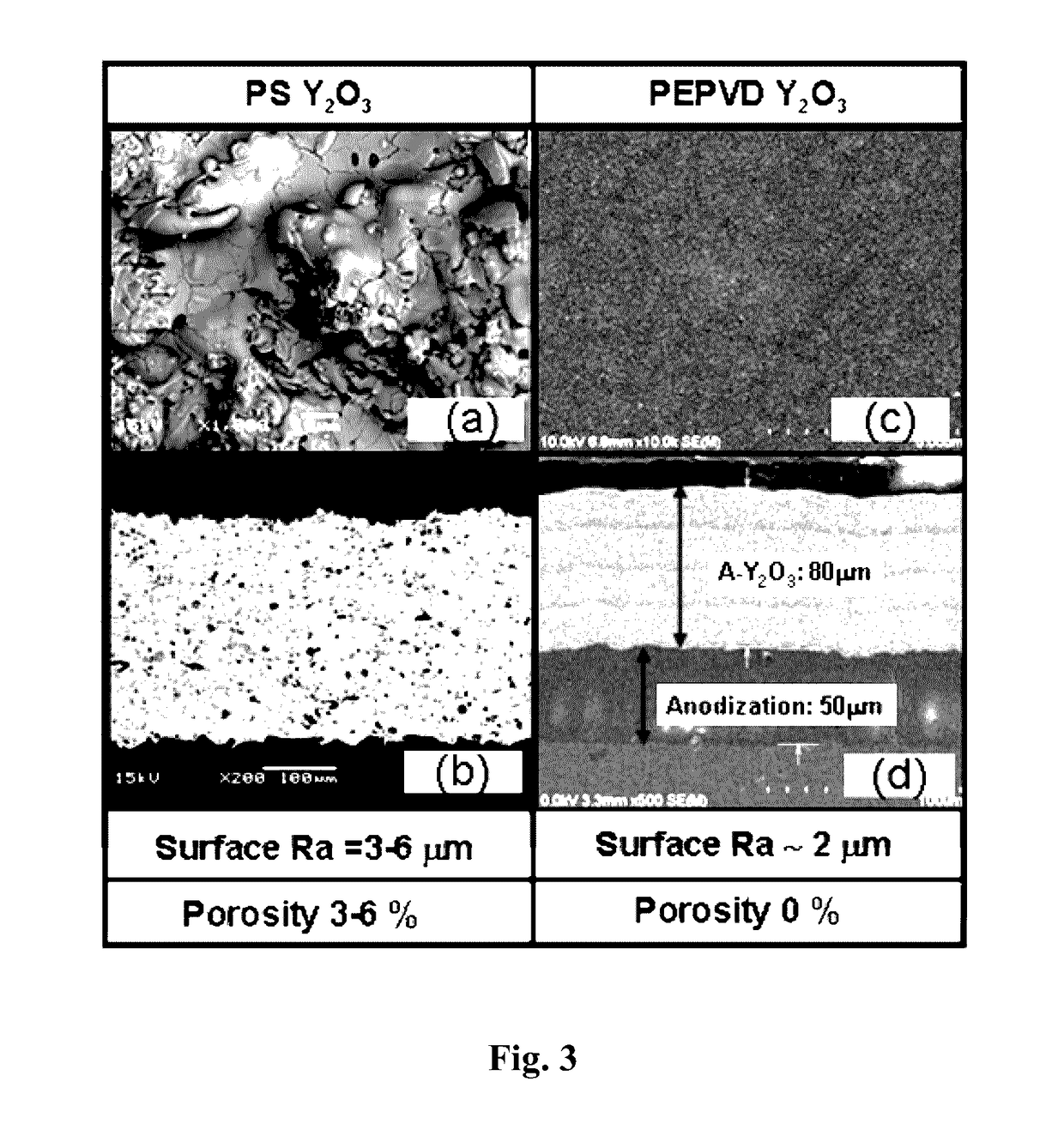

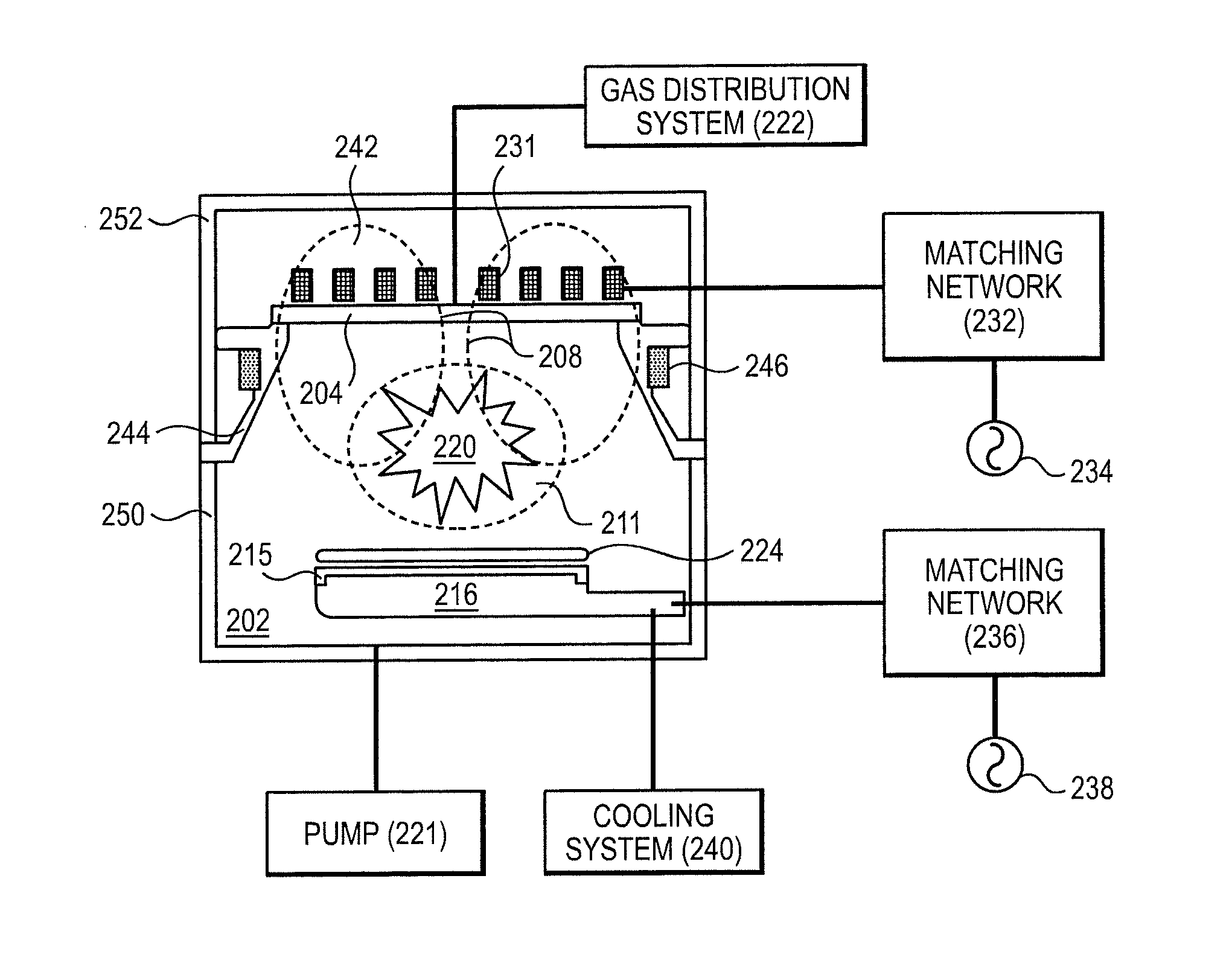

An advanced coating for parts used in plasma processing chamber. The advanced coating is formed over an anodized surface that has not been sealed. After the coating is formed, the coated area is masked, and the remaining anodized surface is sealed. The porous and rough structure of the anodized but un-sealed aluminum enhances adhesion of the coating. However, to prevent particle generation, the exposed anodized surface is sealed after formation of the coating. The coating can be of yttria, formed by plasma enhanced atomic deposition techniques which results in a dense and smooth coating.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Components of plasma processing chambers having textured plasma resistant coatings

InactiveUS20130102156A1Electric discharge tubesLayered productsPlasma coatingInductively coupled plasma

A component of a plasma processing chamber includes a three dimensional body having a highly dense plasma resistant coating thereon wherein a plasma exposed surface of the coating has a texture which inhibits particle generation from film buildup on the plasma exposed surface. The component can be a window of an inductively coupled plasma reactor wherein the window includes a textured yttria coating. The texture can be provided by contacting the plasma exposed surface with a polishing pad having a grit size effective to provide intersecting scratches with a depth of 1 to 2 microns.

Owner:LAM RES CORP

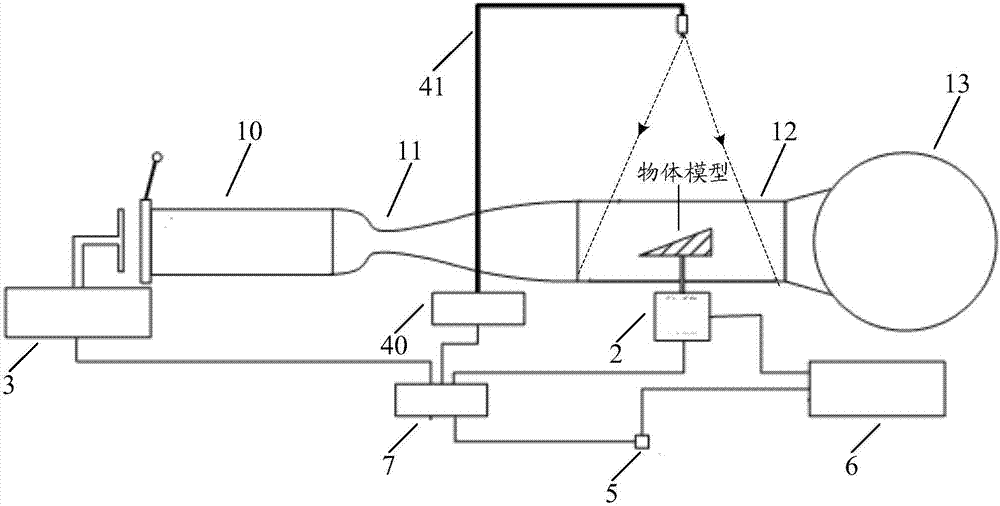

Wind tunnel flow field observation system

The invention discloses a wind tunnel flow field observation system which comprises a wind tunnel device, a displacement control device used for controlling the position movement of an object model in the wind tunnel device, a tracer particle generation device used for adding tracer particles to the wind tunnel device, a light source device used for shining light to the wind tunnel device, a shooting device used for shooting images of the flow field in the wind tunnel device, and an image processing device used for constructing a three-dimensional flow field structure image according to a sequence of flow field images shot by the shooting device and the position information of the object model recorded by the displacement control device. According to the wind tunnel flow field observation system of the invention, the position movement of the object model in the wind tunnel device is controlled by the displacement control device, a sequence of flow field images of the wind tunnel device are shot, a three-dimensional flow field structure image is constructed according to a sequence of flow field images shot and the position information of the object model recorded by the displacement control device, and therefore, the three-dimensional flow field structure of the flow field in the wind tunnel is obtained.

Owner:NAT UNIV OF DEFENSE TECH

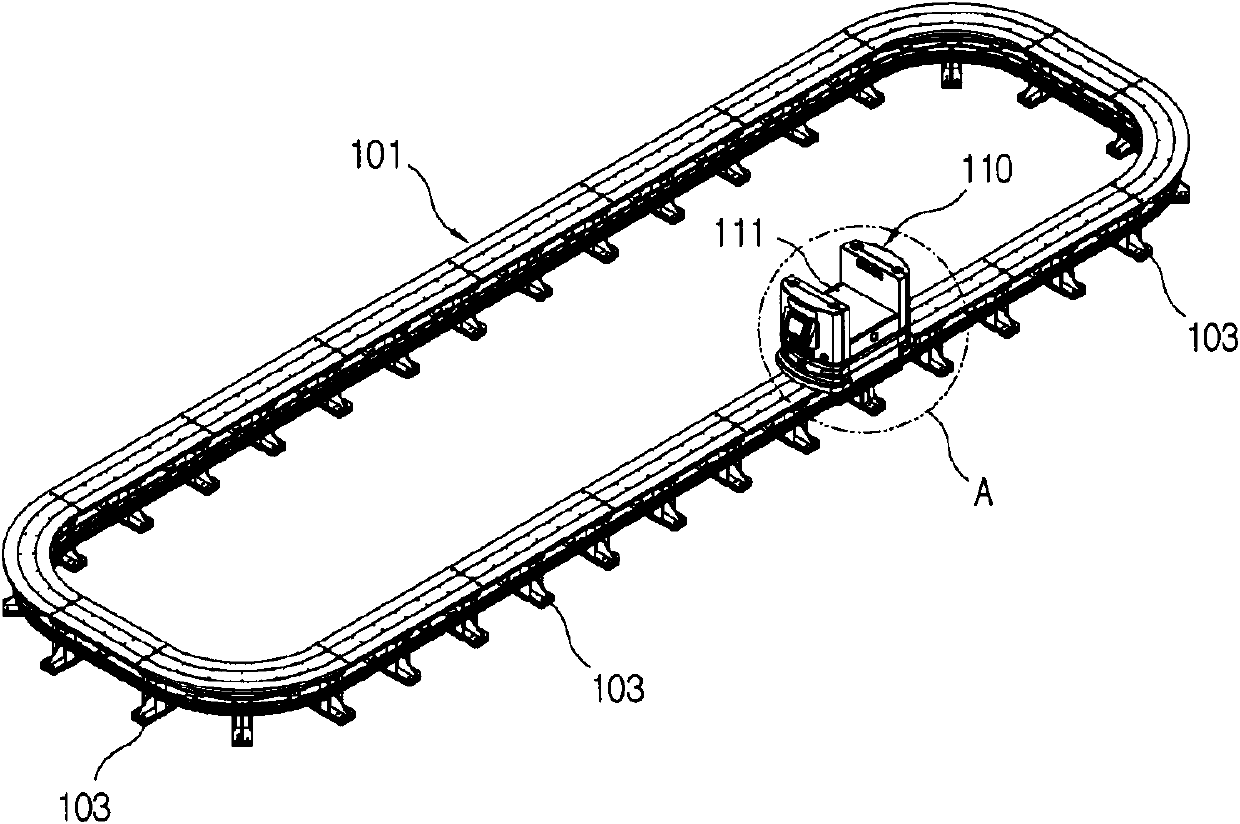

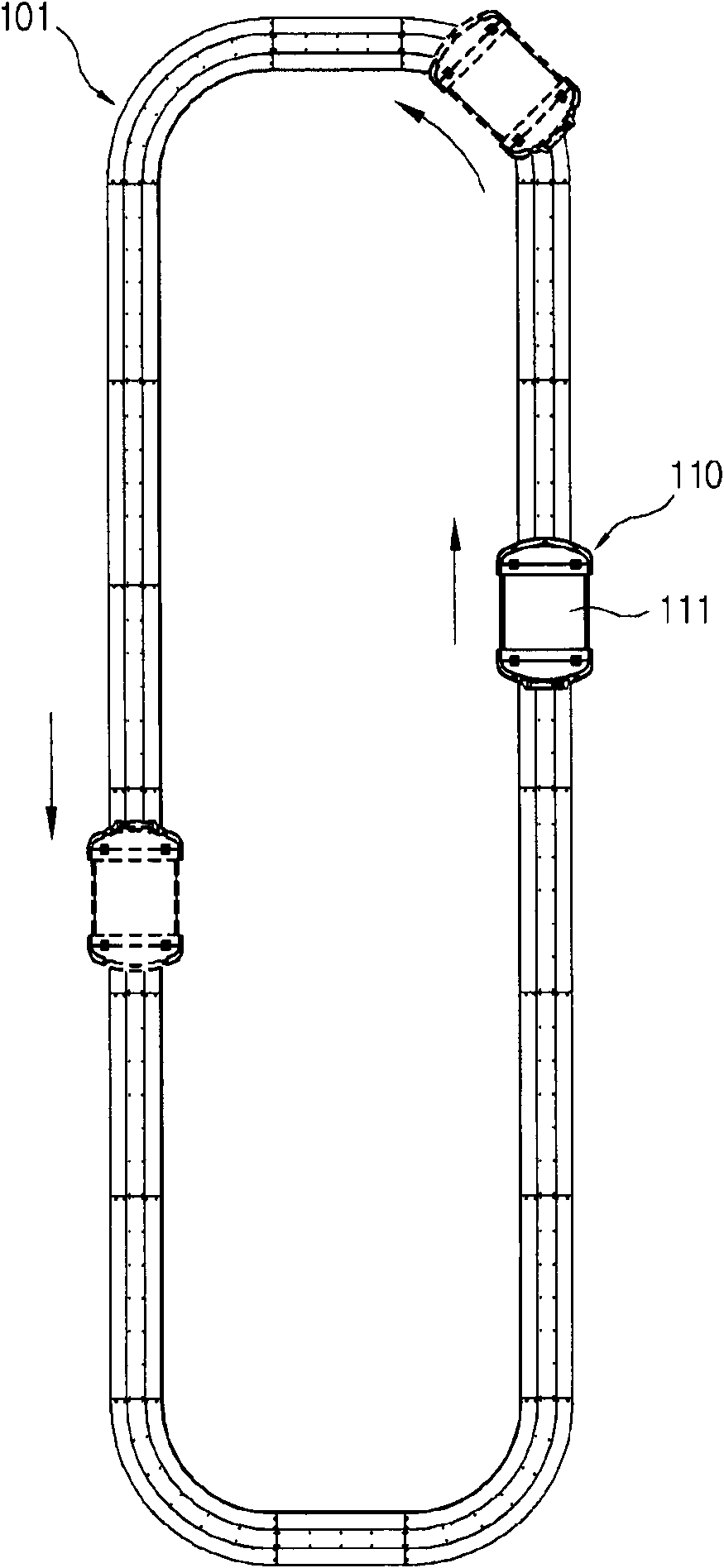

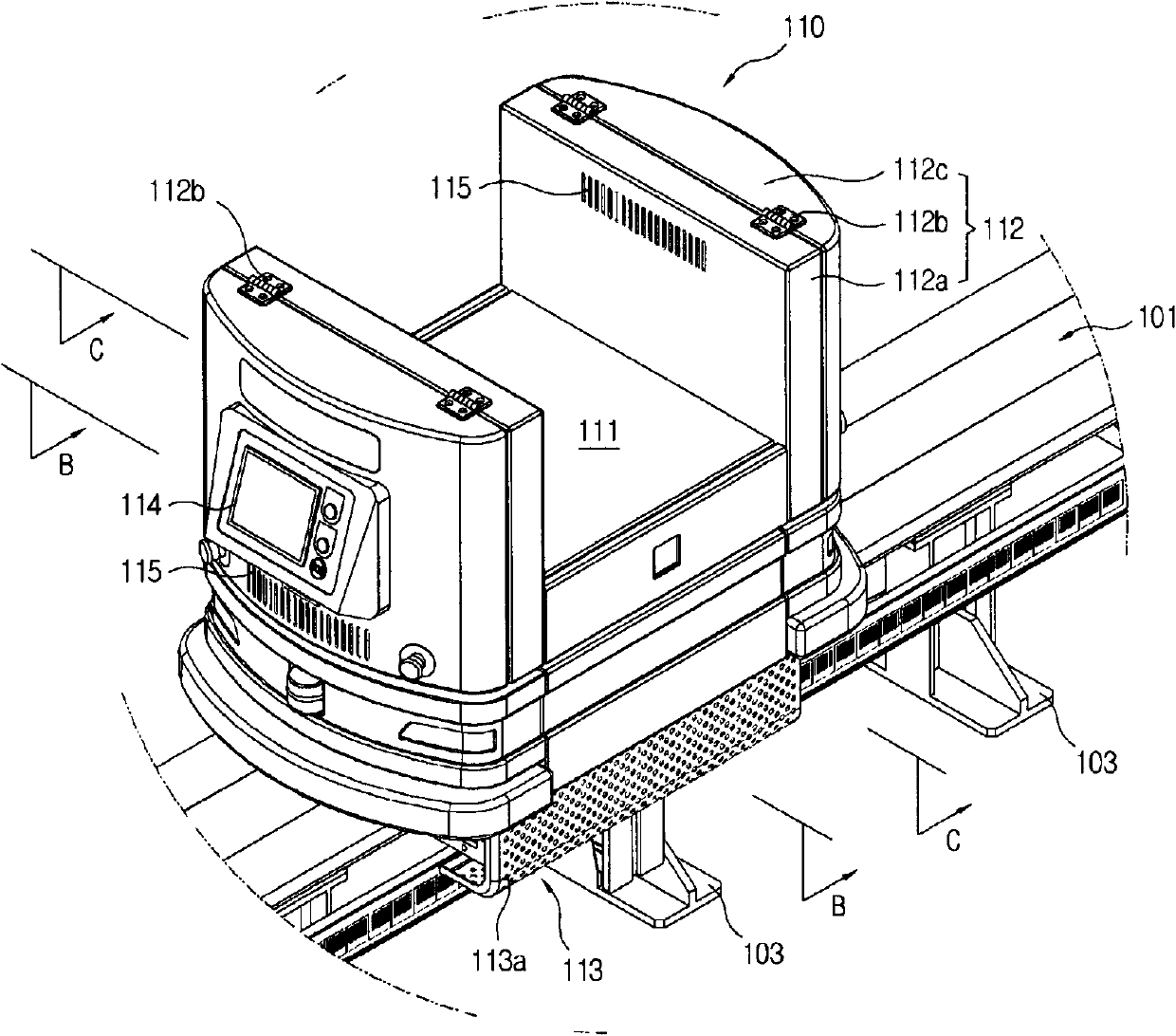

Magnetic levitation transferring system

InactiveCN102030192AStable structureAvoid vibrationNon-mechanical conveyorsNoise generationTransfer system

The present invention provides a magnetic levitation transferring system which comprises the following components: a loading unit which is loaded with object; a body transferring unit while the loading unit is coupled to the body transferring unit at one side; a rail which forms a line for transferring the body transferring unit; a levitating unit which is connected with the body transferring unit and causes the body transferring unit to levitate to a preset height relatively to the rail; a pushing unit which is connected with the body transferring unit and provides a pushing force for transferring the body transferring unit levitated by the levitating unit along the line of the rail; and a non-contact power source which receives power through a non-contact mode and supplies power for at least one in the levitating unit and the pushing unit. Through the configuration, a magnetic levitation technique is adopted in transferring object as one of the non-contact techniques thereby settling the problems of assembly damage caused by wearing and abrasion, noise generation and particle generation. Furthermore the power is supplied stably and safely while the object is transferred with a high speed.

Owner:SFA ENG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com